Thermoplastic elastomer capable of coating and bonding with nylon

A thermoplastic elastomer and nylon technology, applied in the field of thermoplastic elastomer materials, can solve problems such as defects in the physical properties of thermoplastic elastomers, affecting material market development, low material physical properties, etc., and achieve industrial production convenience and mechanical properties Excellent, compatibility-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

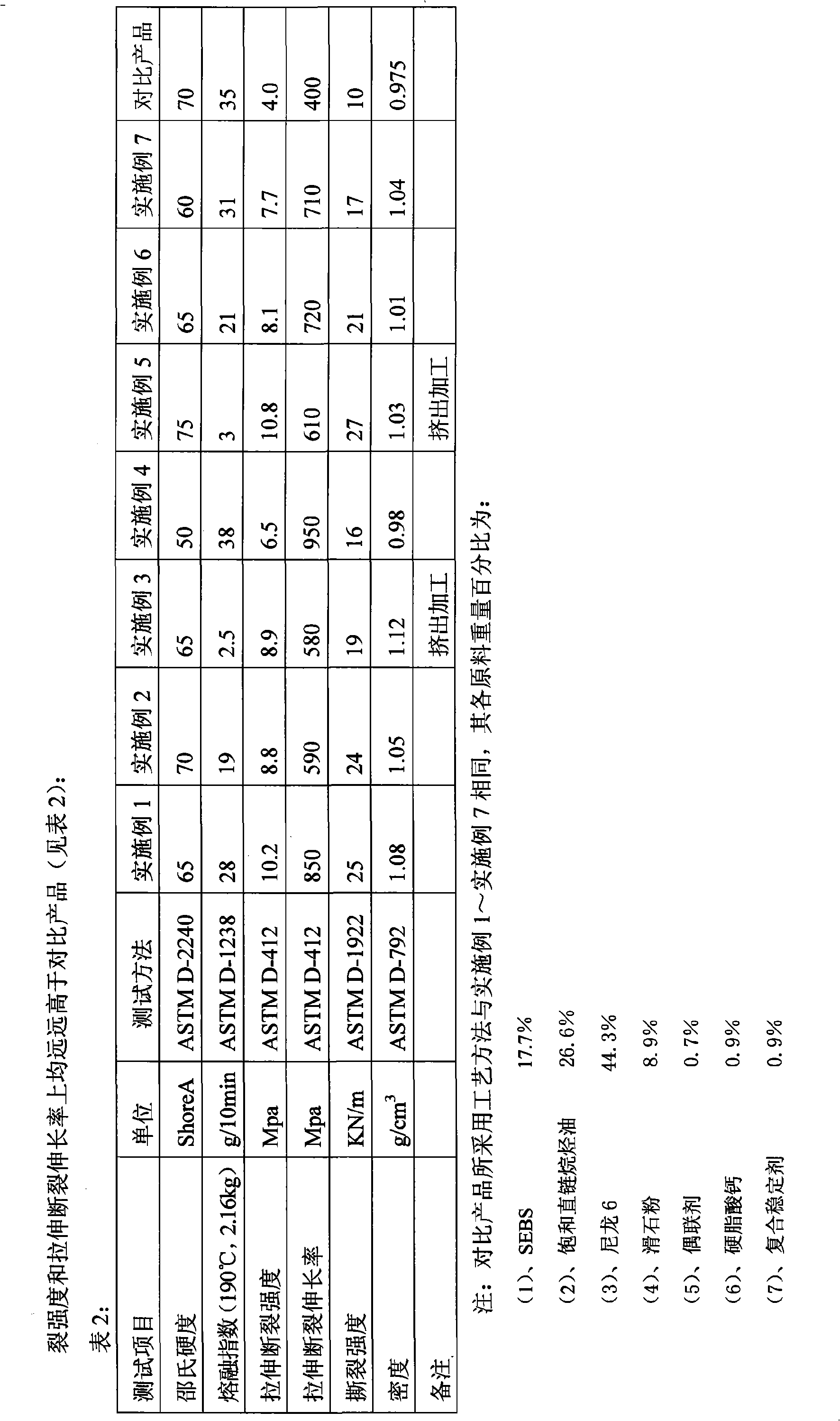

Examples

Embodiment Construction

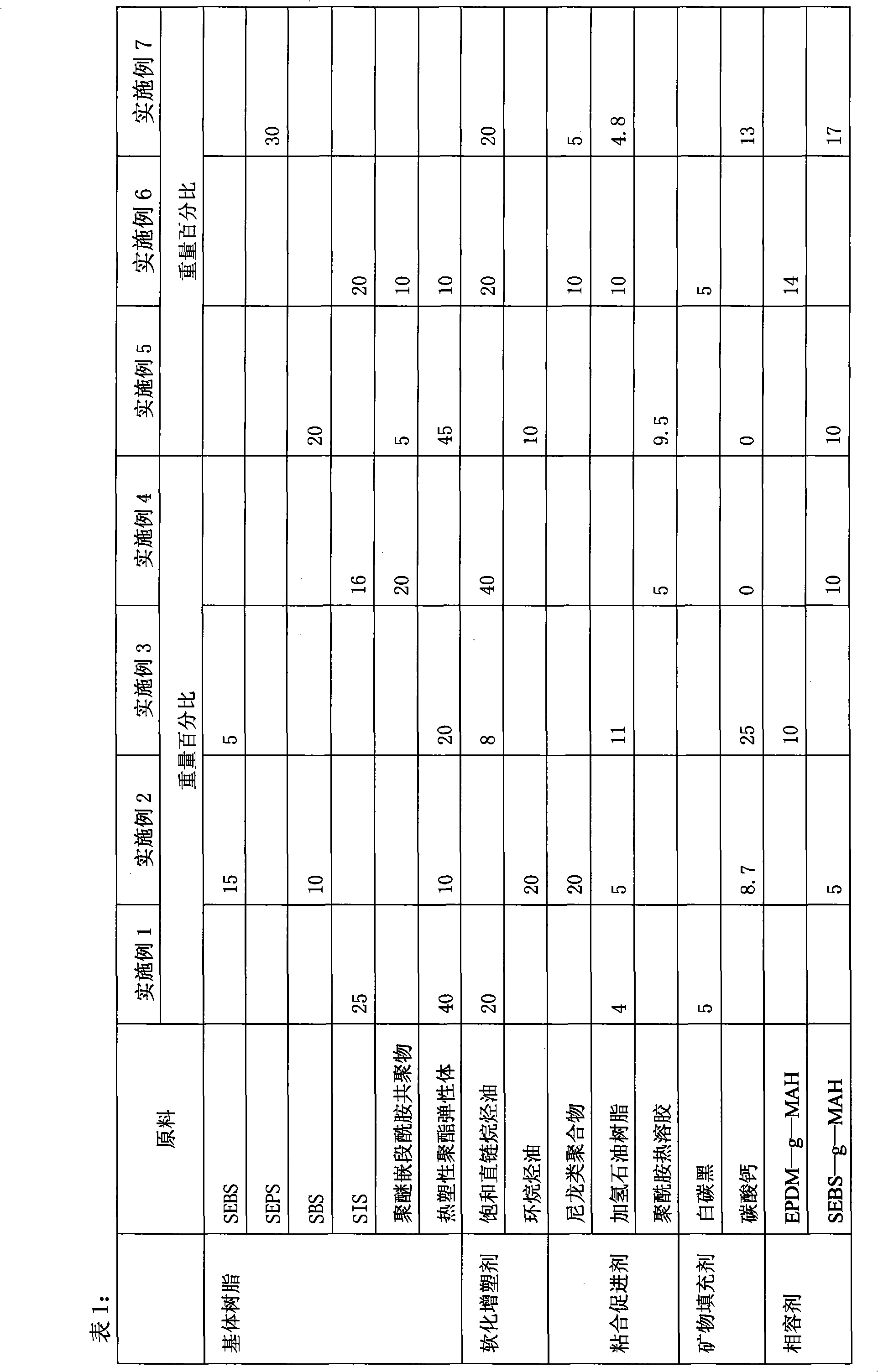

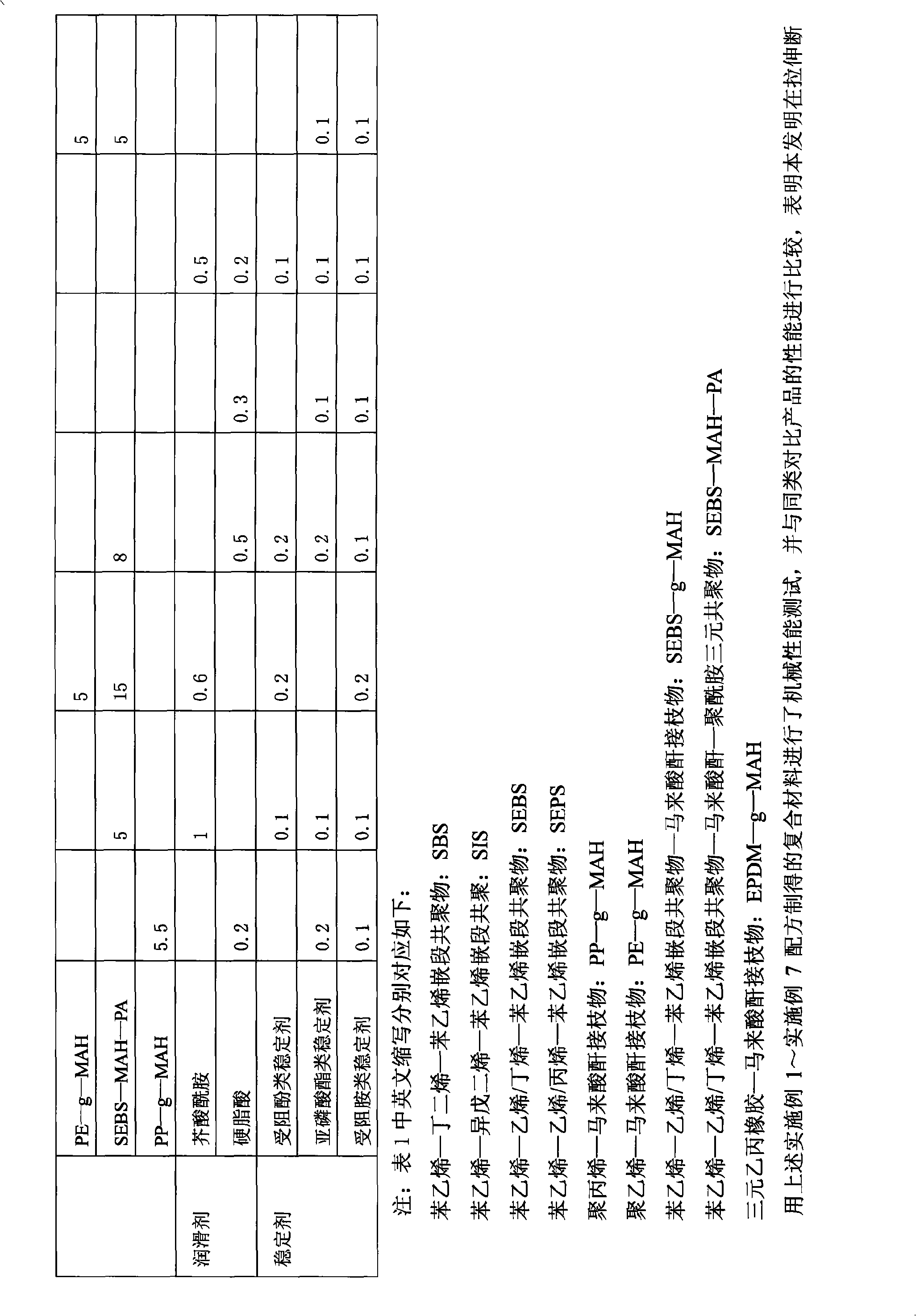

[0016] The thermoplastic elastomer that can be covered and bonded with nylon according to the weight percentage of raw material of the present invention:

[0017] (1) Matrix resin: 20% to 75%;

[0018] (2) Softening plasticizer: 5% to 45%;

[0019] (3) Adhesion promoter: 1% to 30%;

[0020] (4) Mineral filler: 0% to 3%;

[0021] (5) Compatibilizer: 5% to 35%;

[0022] (6) Lubricant: 0% to 2%;

[0023] (7) Stabilizer: 0% to 2%.

[0024] Wherein (1) matrix resin comprises:

[0025] Styrene-butadiene-styrene block copolymer (SBS), such as LG501S and LG411S of Korean LG Company; KTR101 and KTR401 of Han Jinhu Company; YH792 of Yueyang Petrochemical Co., Ltd.;

[0026] Styrene-isoprene-styrene block copolymer (SIS), such as Kraton D1114, D1124;

[0027] Styrene-ethylene / butylene-styrene block copolymer (SEBS), such as American Kraton G-1650, G-1651, G-1654, Taiwan Taiwan Rubber Company 3150, 3151, 3154, Yueyang Petrochemical YH-502 , YH-503, etc.;

[0028] Styrene-ethylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com