Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1582 results about "Refractory metals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Refractory metals are a class of metals that are extraordinarily resistant to heat and wear. The expression is mostly used in the context of materials science, metallurgy and engineering. The definition of which elements belong to this group differs. The most common definition includes five elements: two of the fifth period (niobium and molybdenum) and three of the sixth period (tantalum, tungsten, and rhenium). They all share some properties, including a melting point above 2000 °C and high hardness at room temperature. They are chemically inert and have a relatively high density. Their high melting points make powder metallurgy the method of choice for fabricating components from these metals. Some of their applications include tools to work metals at high temperatures, wire filaments, casting molds, and chemical reaction vessels in corrosive environments. Partly due to the high melting point, refractory metals are stable against creep deformation to very high temperatures.

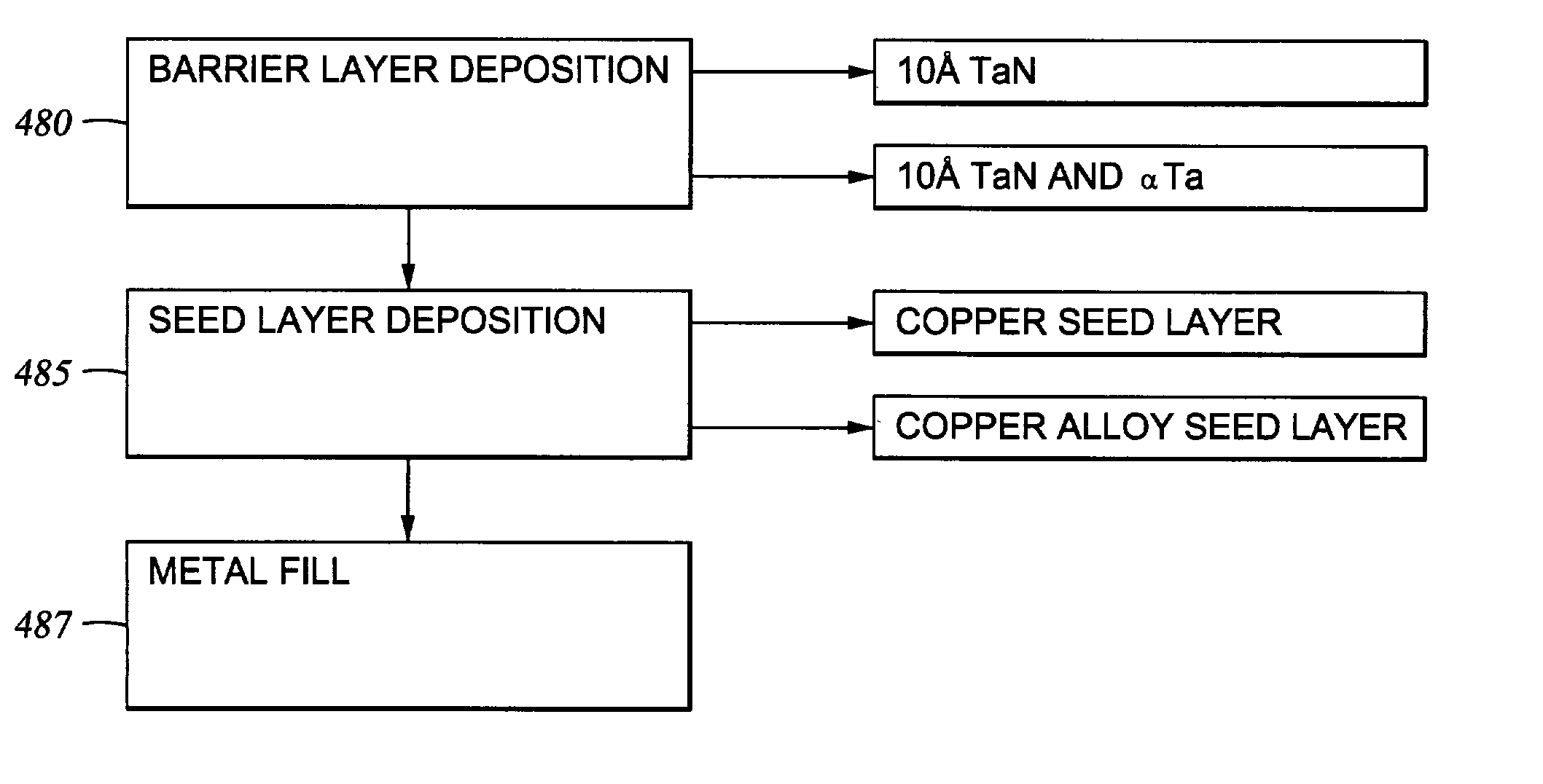

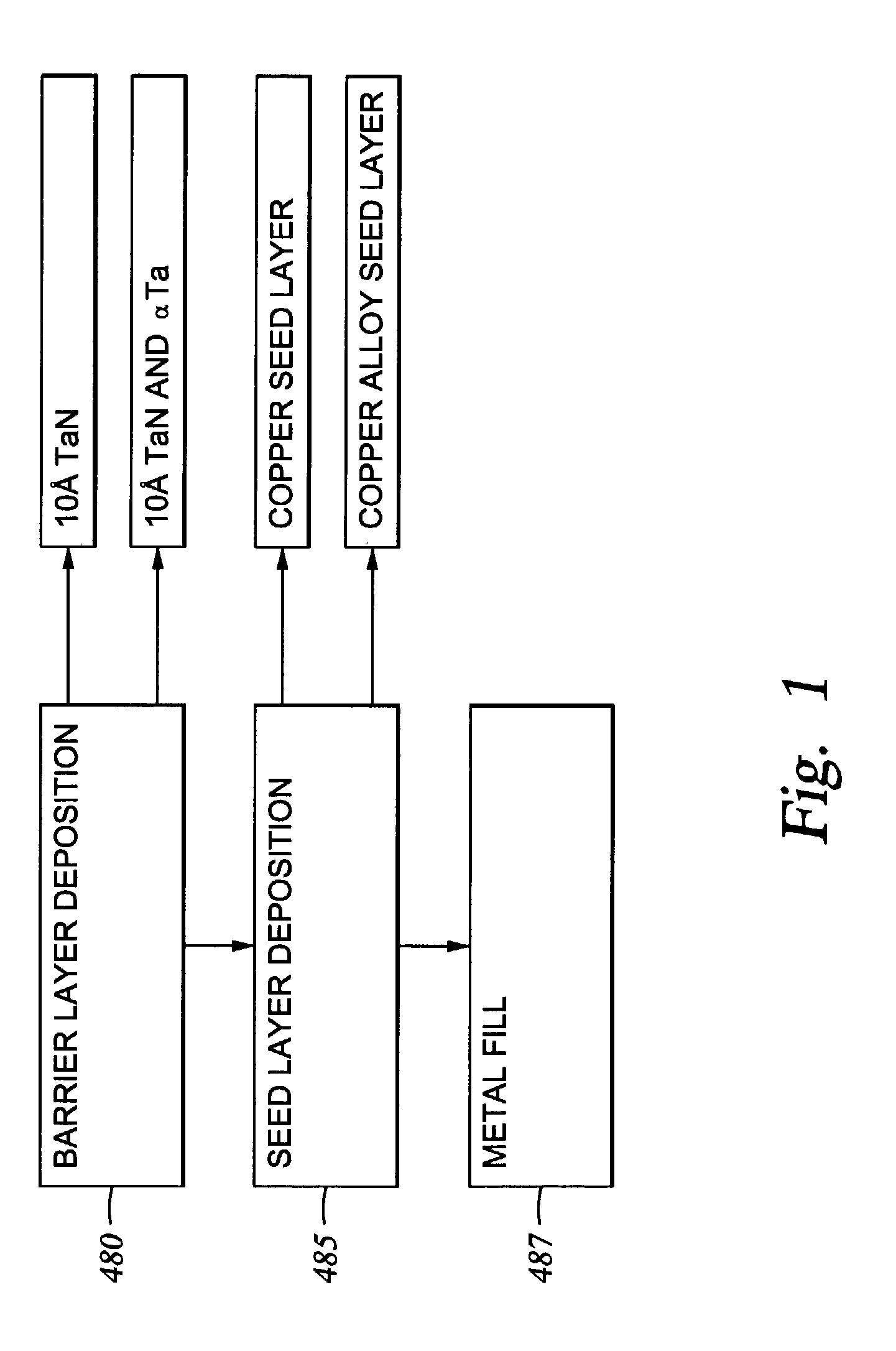

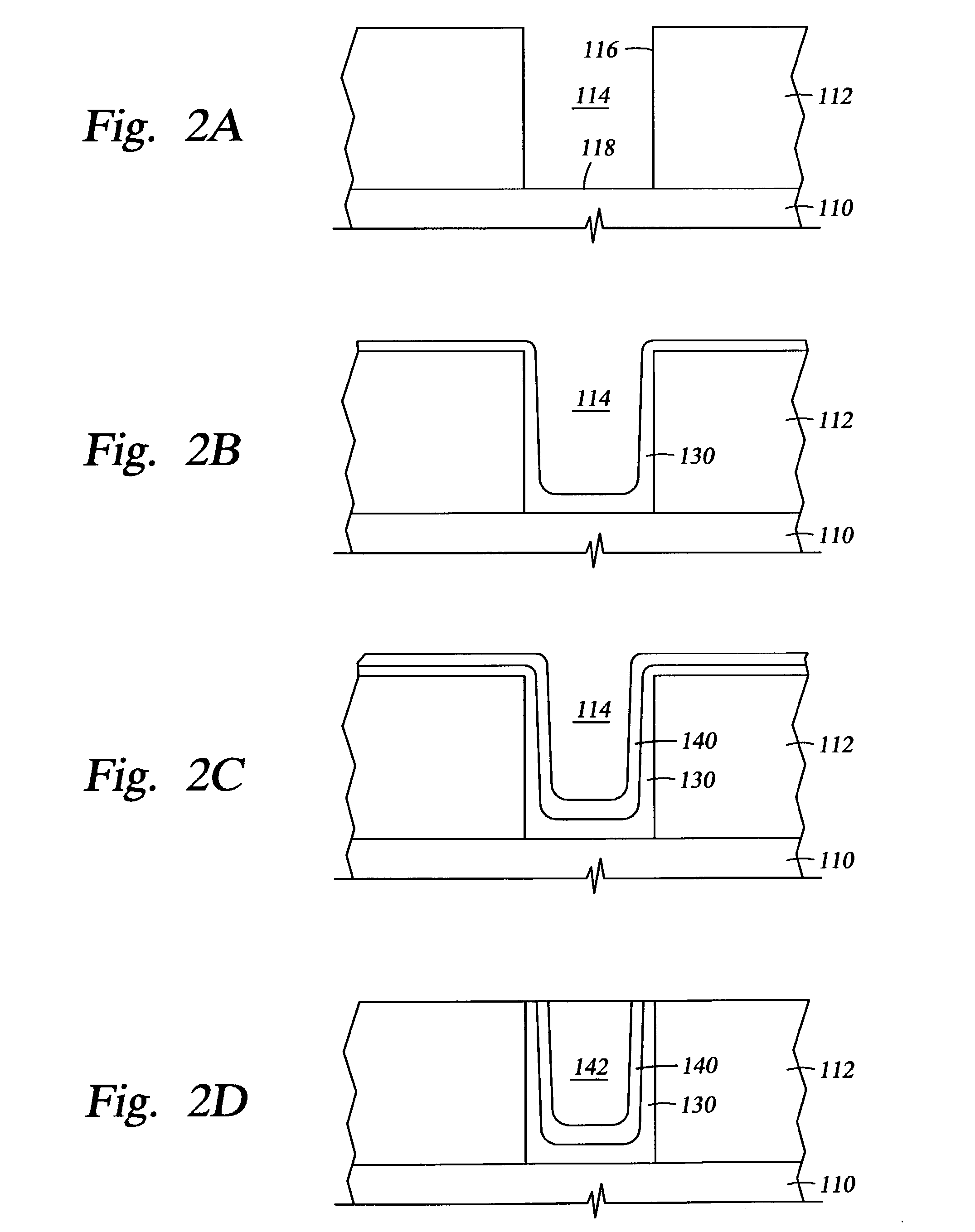

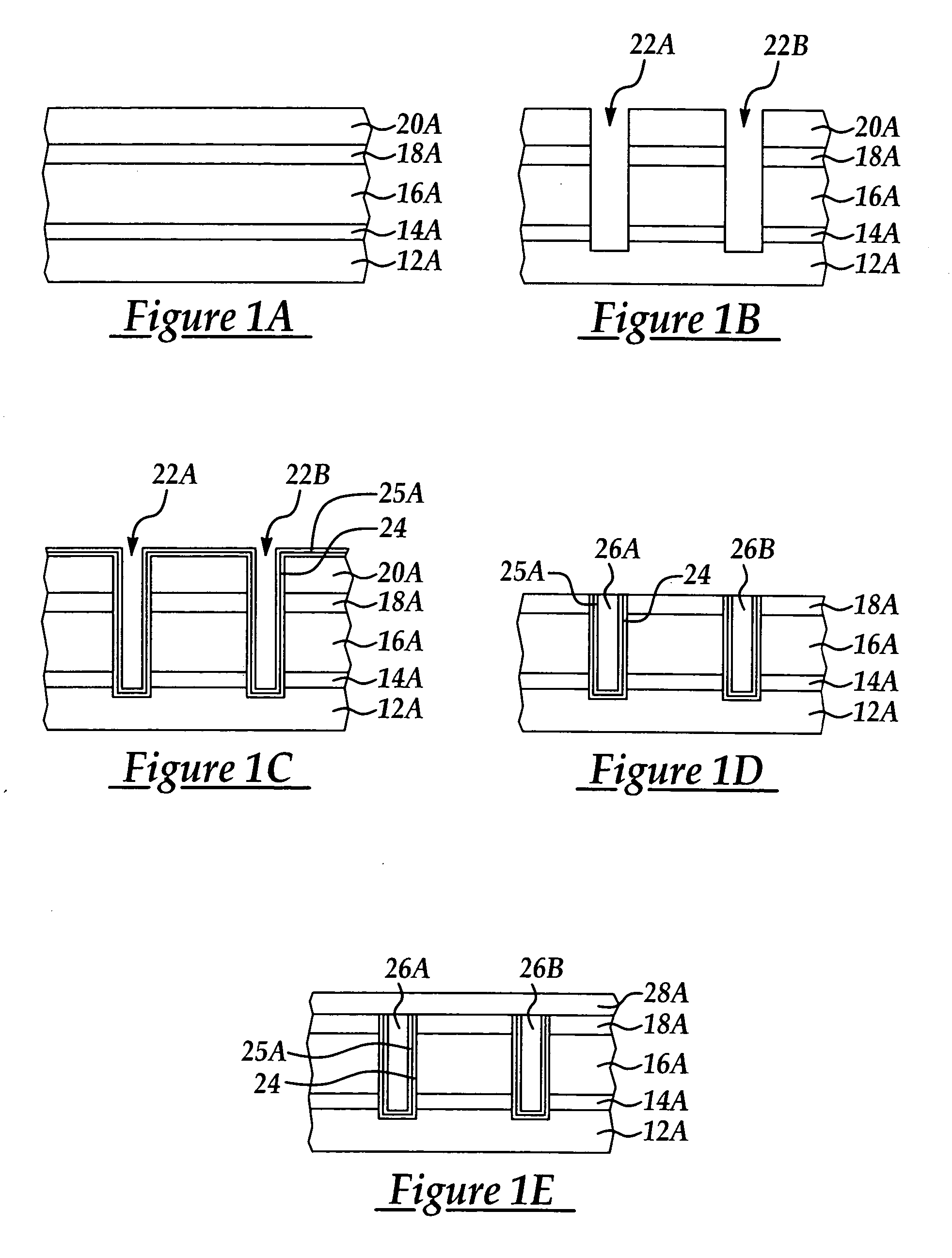

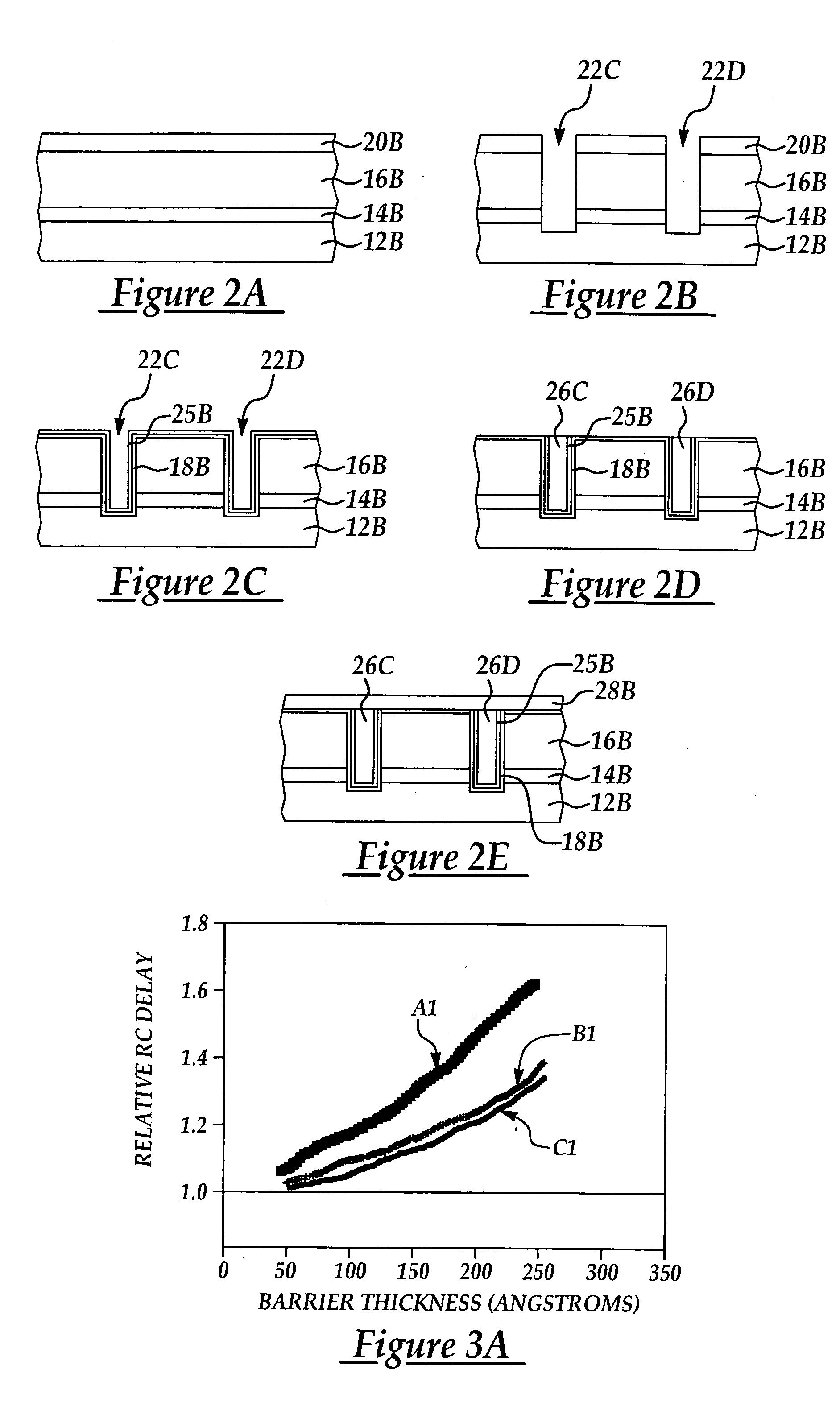

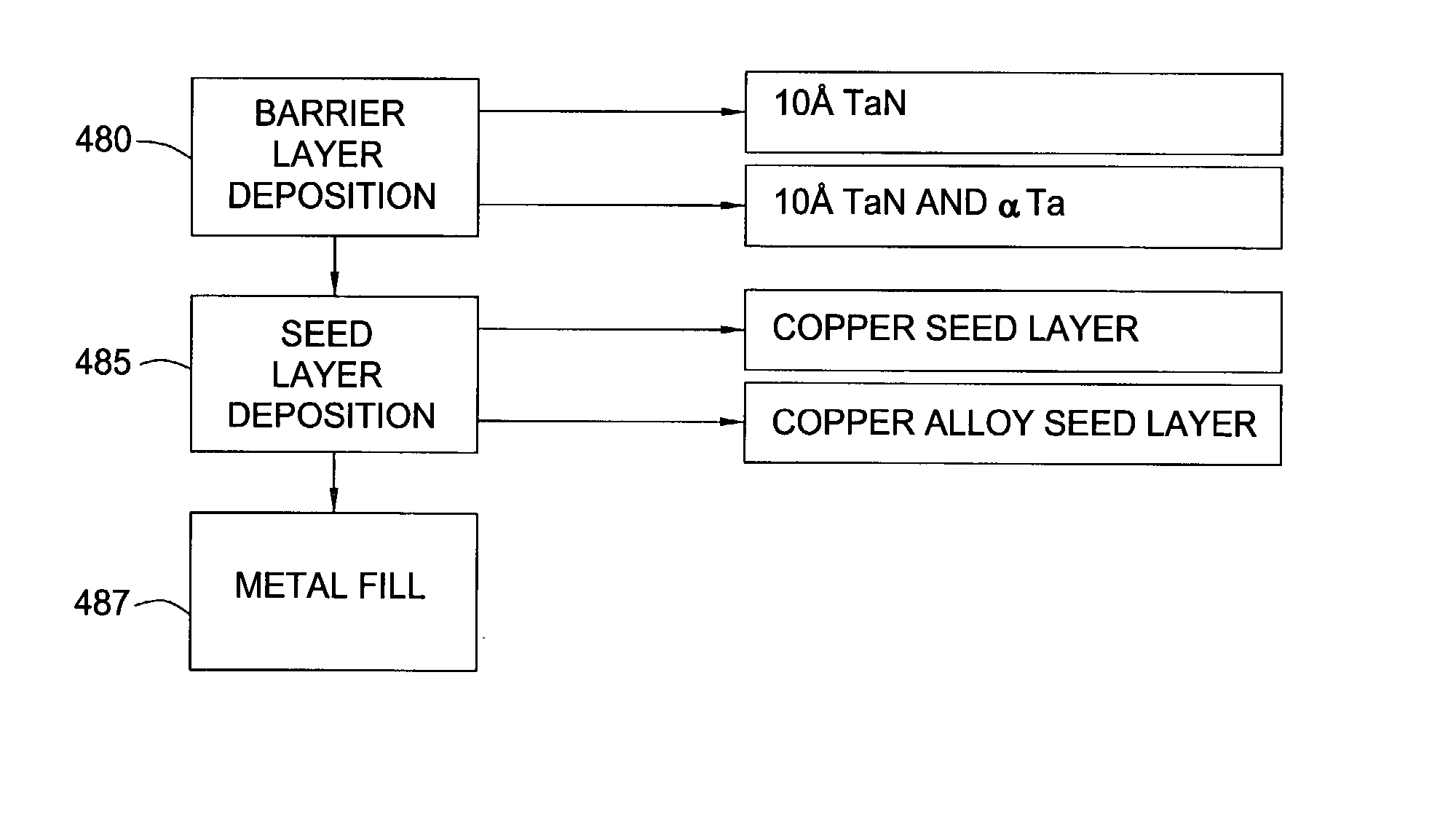

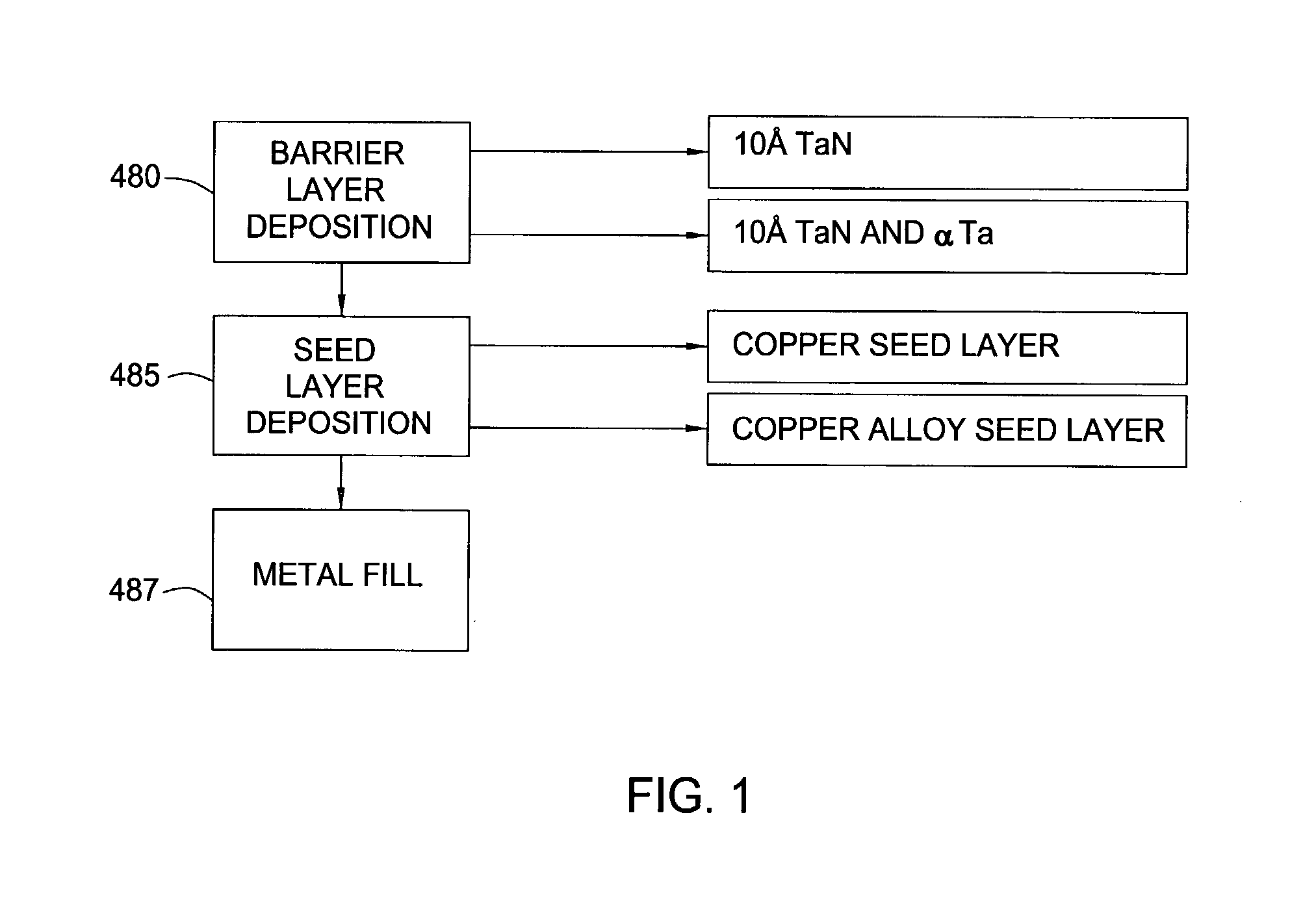

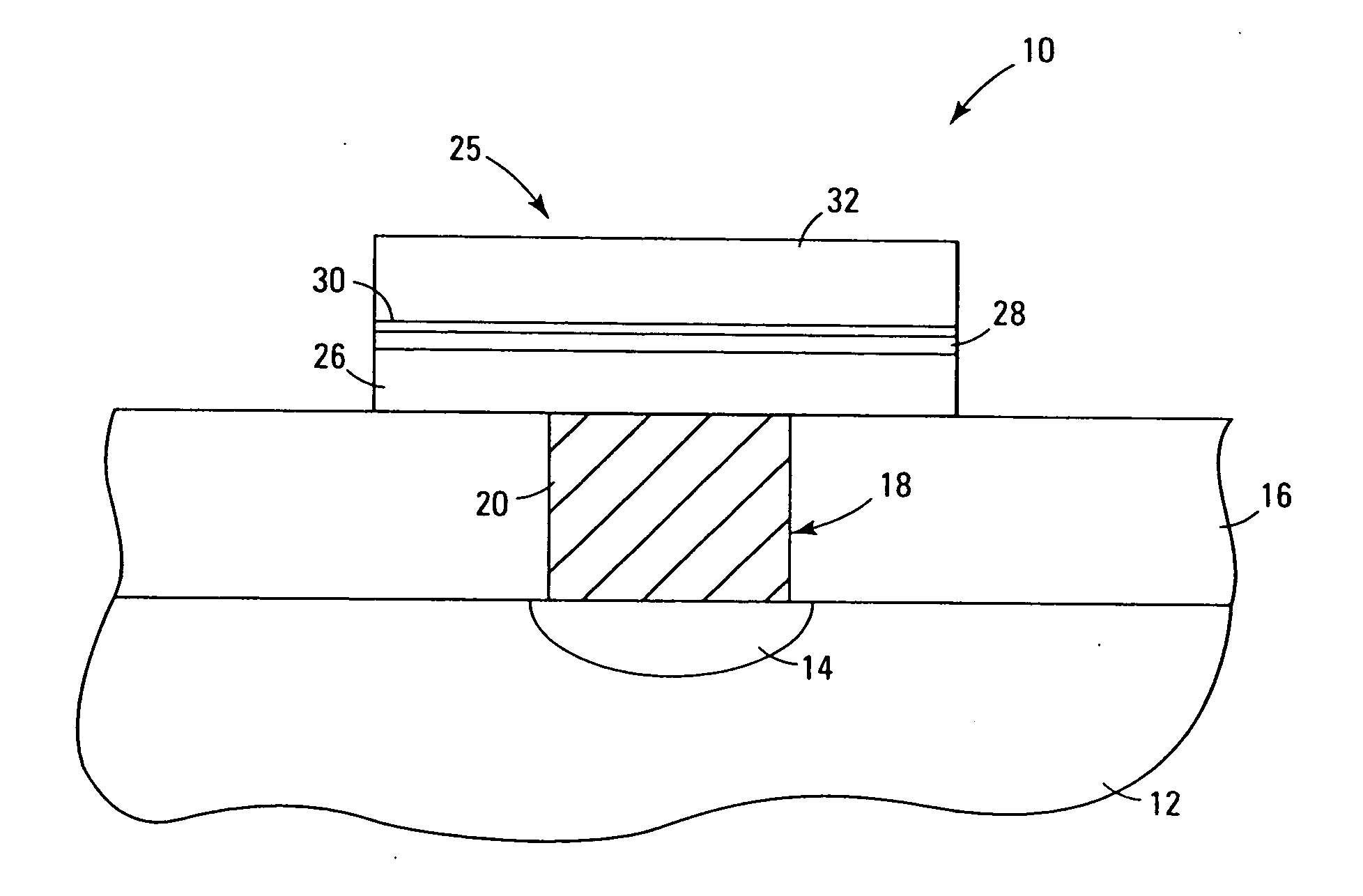

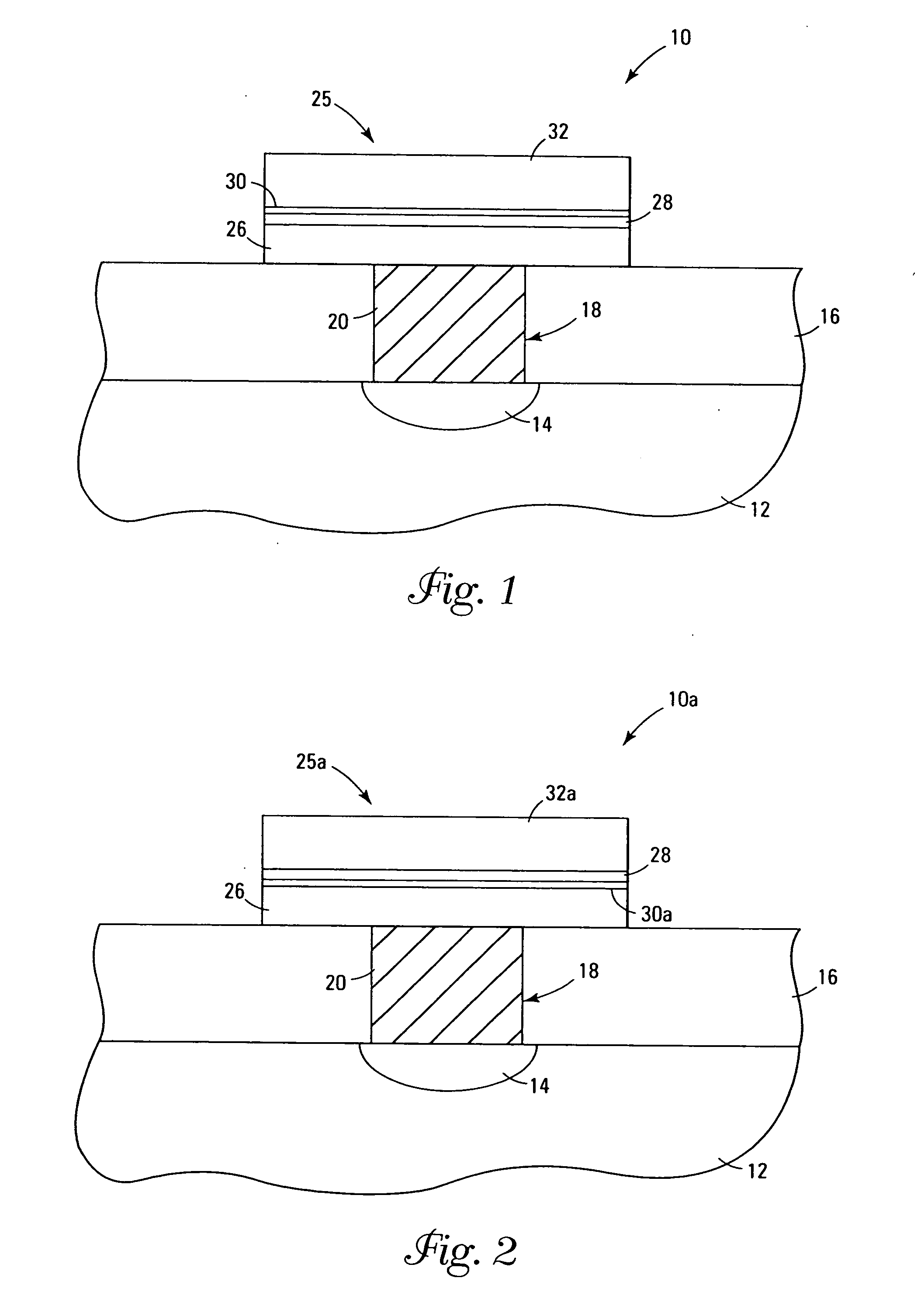

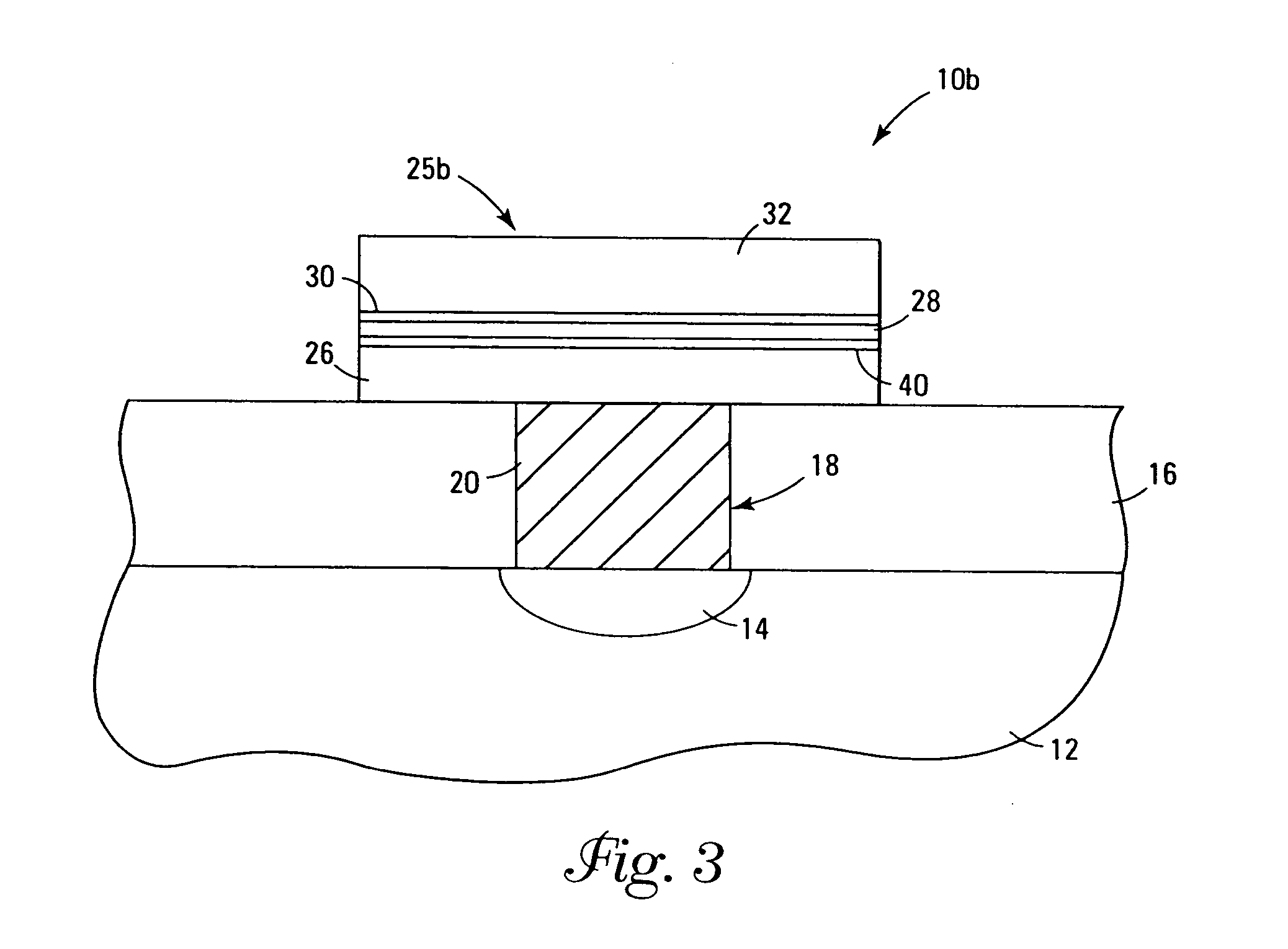

Integration of ALD tantalum nitride and alpha-phase tantalum for copper metallization application

InactiveUS20030082307A1Pretreated surfacesSemiconductor/solid-state device manufacturingMetal interconnectTantalum nitride

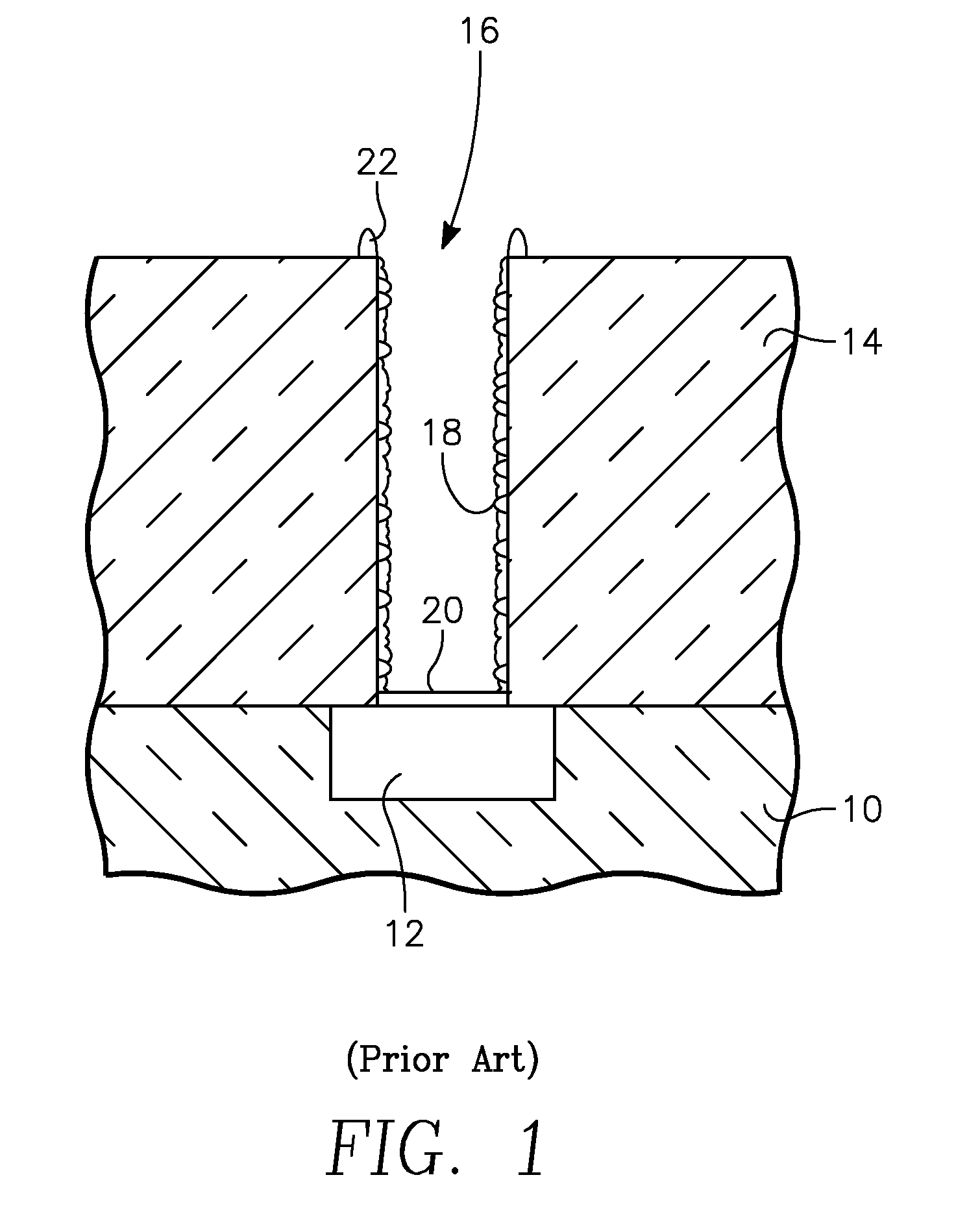

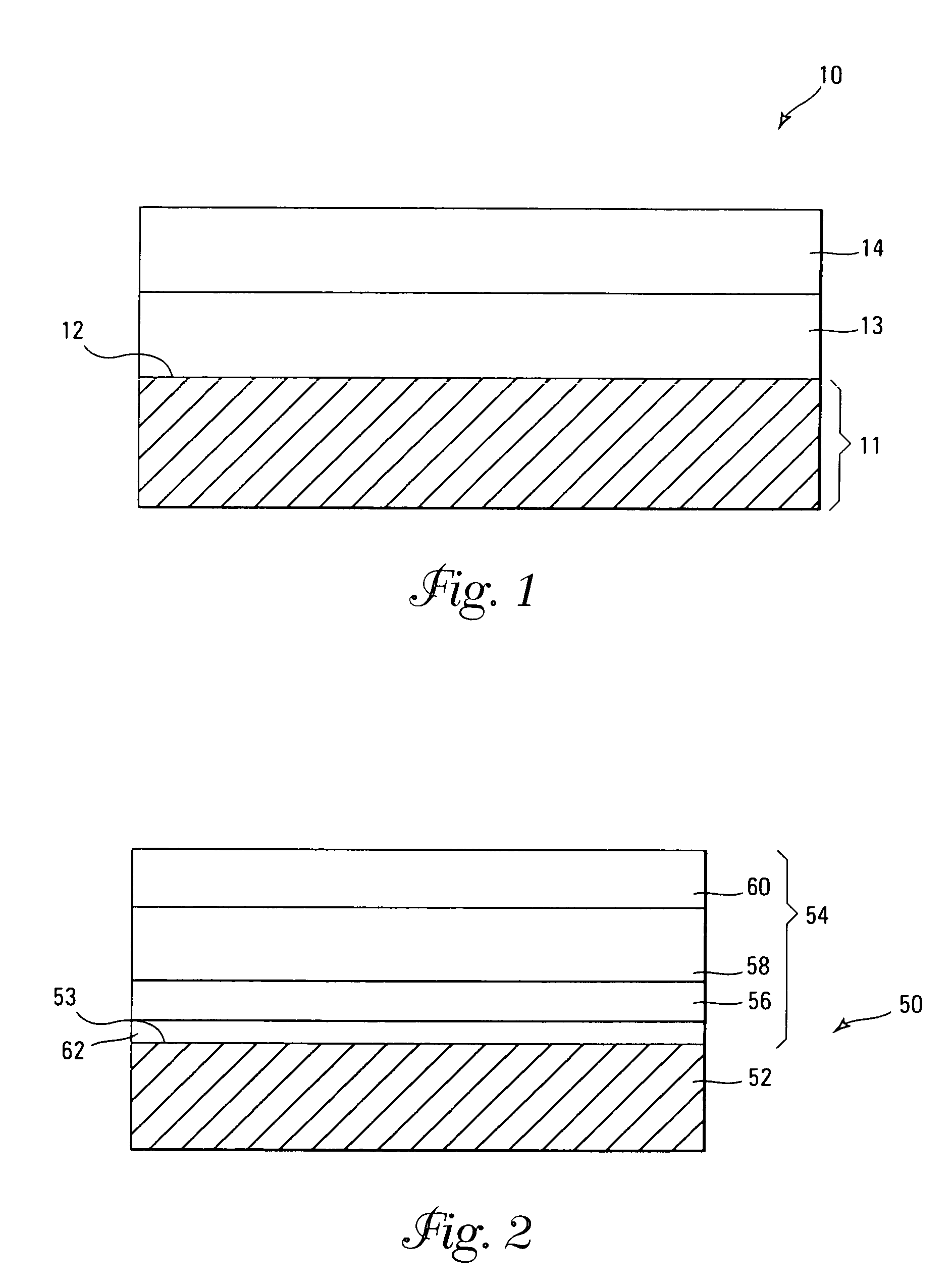

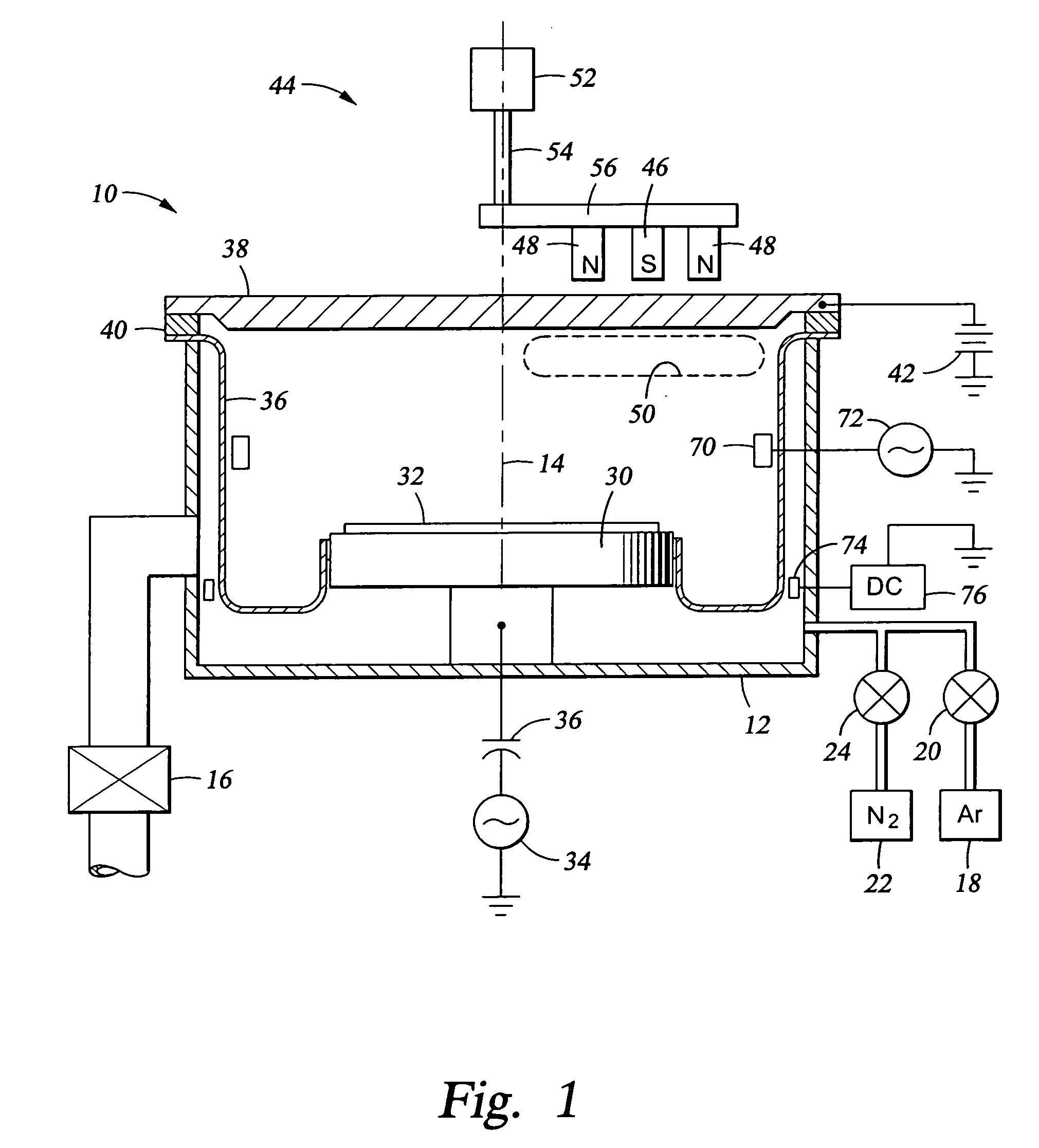

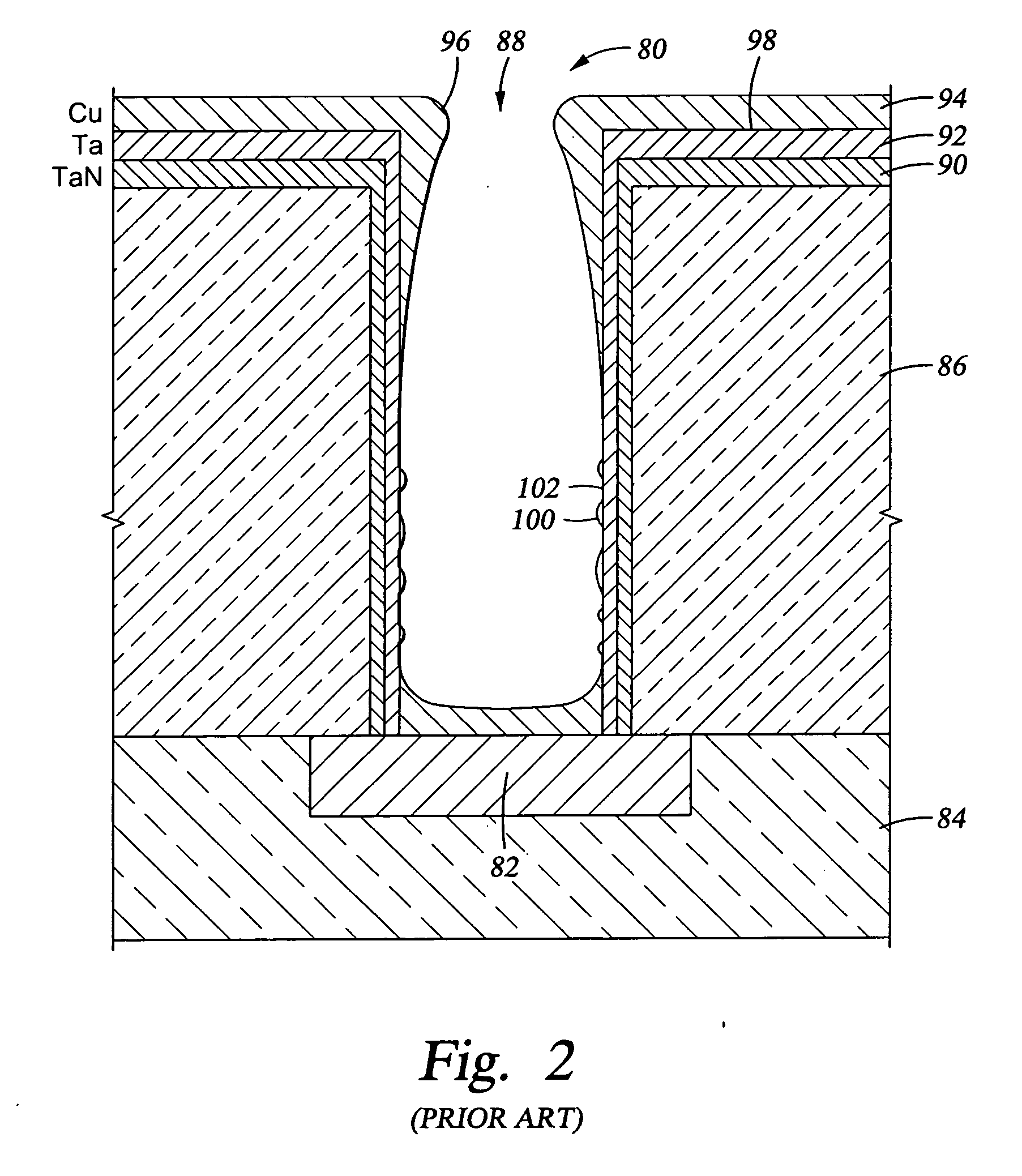

A method for forming a metal interconnect on a substrate is provided. The method includes depositing a refractory metal-containing barrier layer having a thickness less than about 20 angstroms on at least a portion of a metal layer by alternately introducing one or more pulses of a metal-containing compound and one or more pulses of a nitrogen-containing compound. The method also includes depositing a seed layer on at least a portion of the barrier layer, and depositing a second metal layer on at least a portion of the seed layer. The barrier layer provides adequate barrier properties and allows the grain growth of the metal layer to continue across the barrier layer into the second metal layer thereby enhancing the electrical performance of the interconnect.

Owner:APPLIED MATERIALS INC

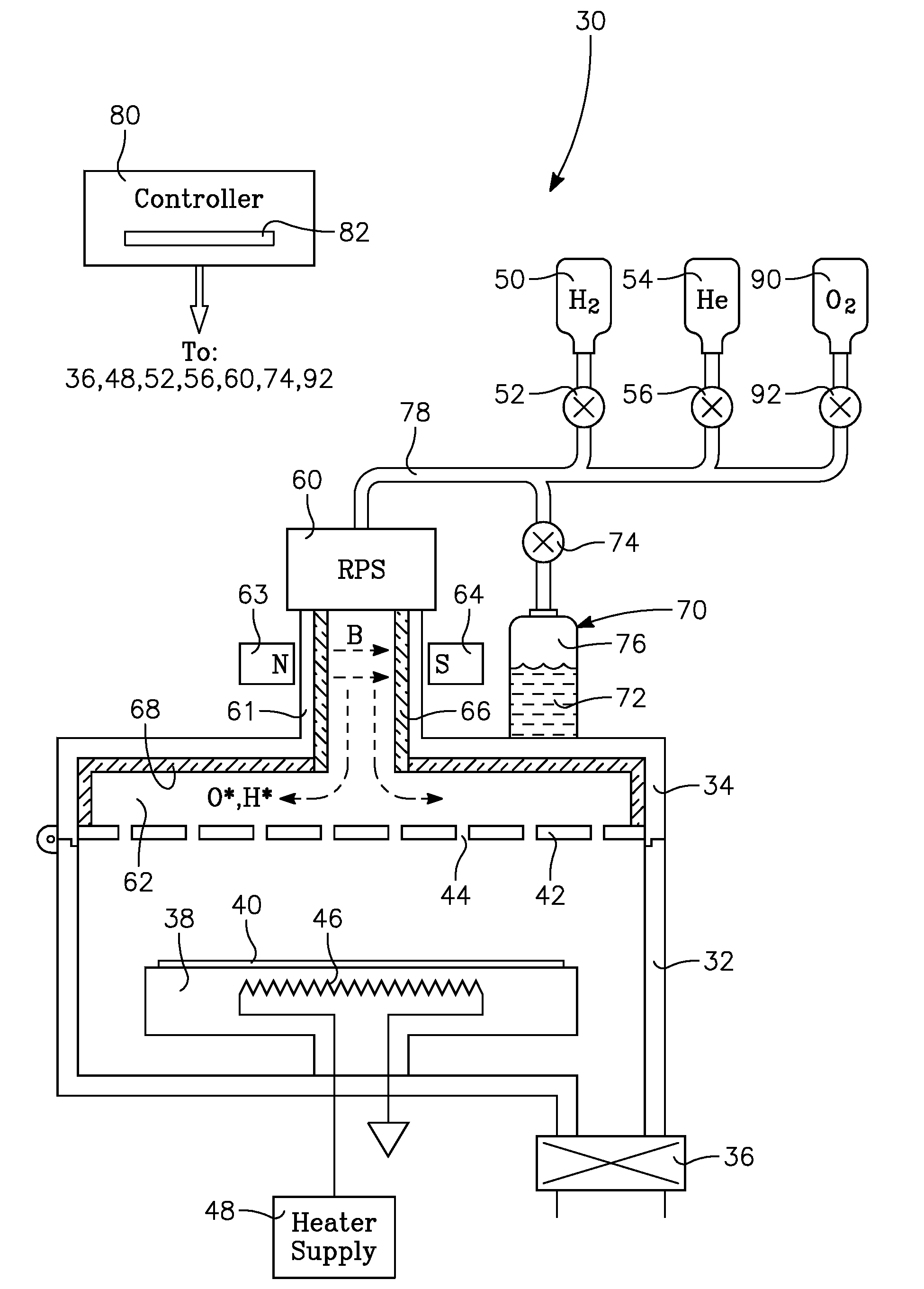

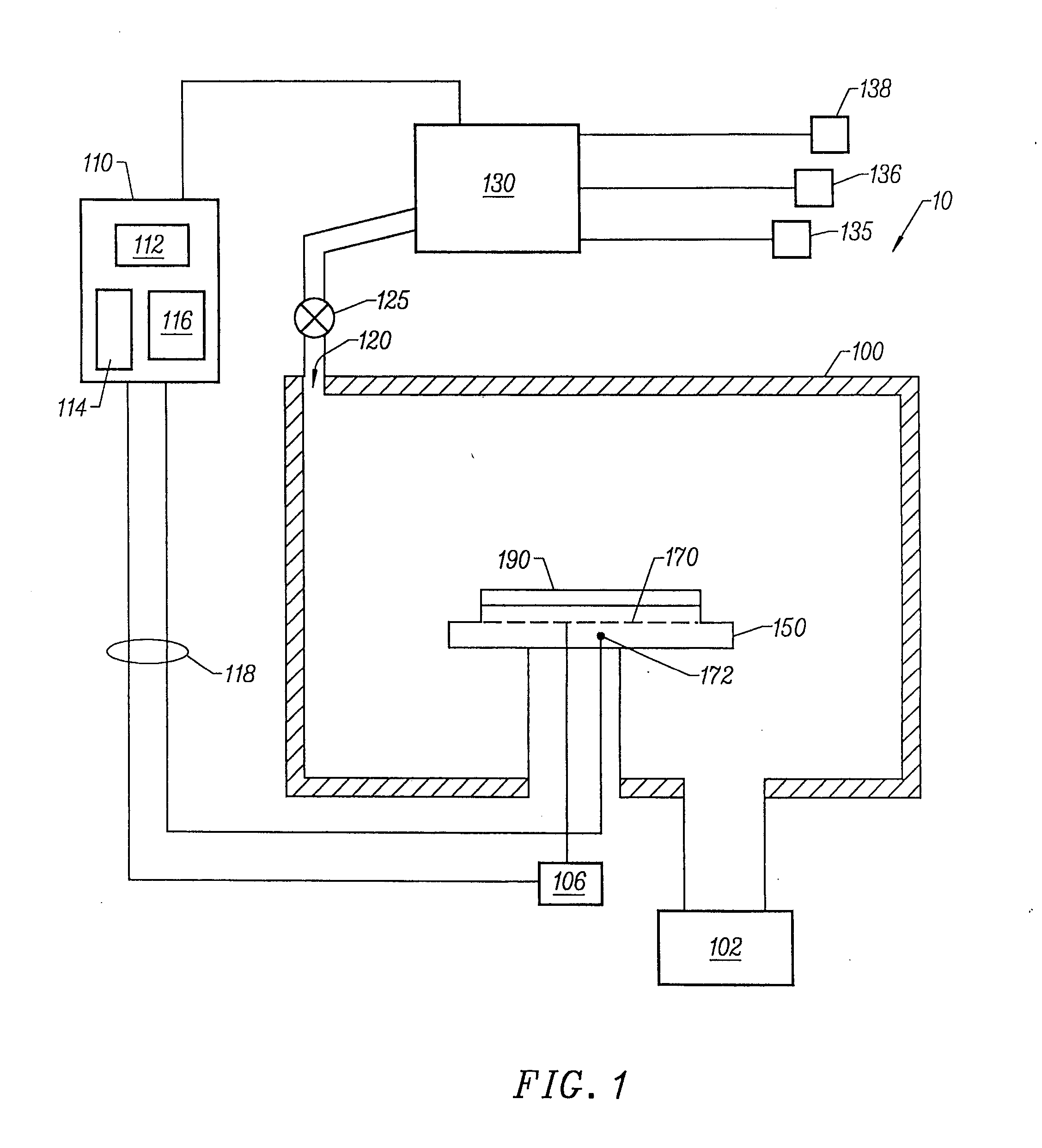

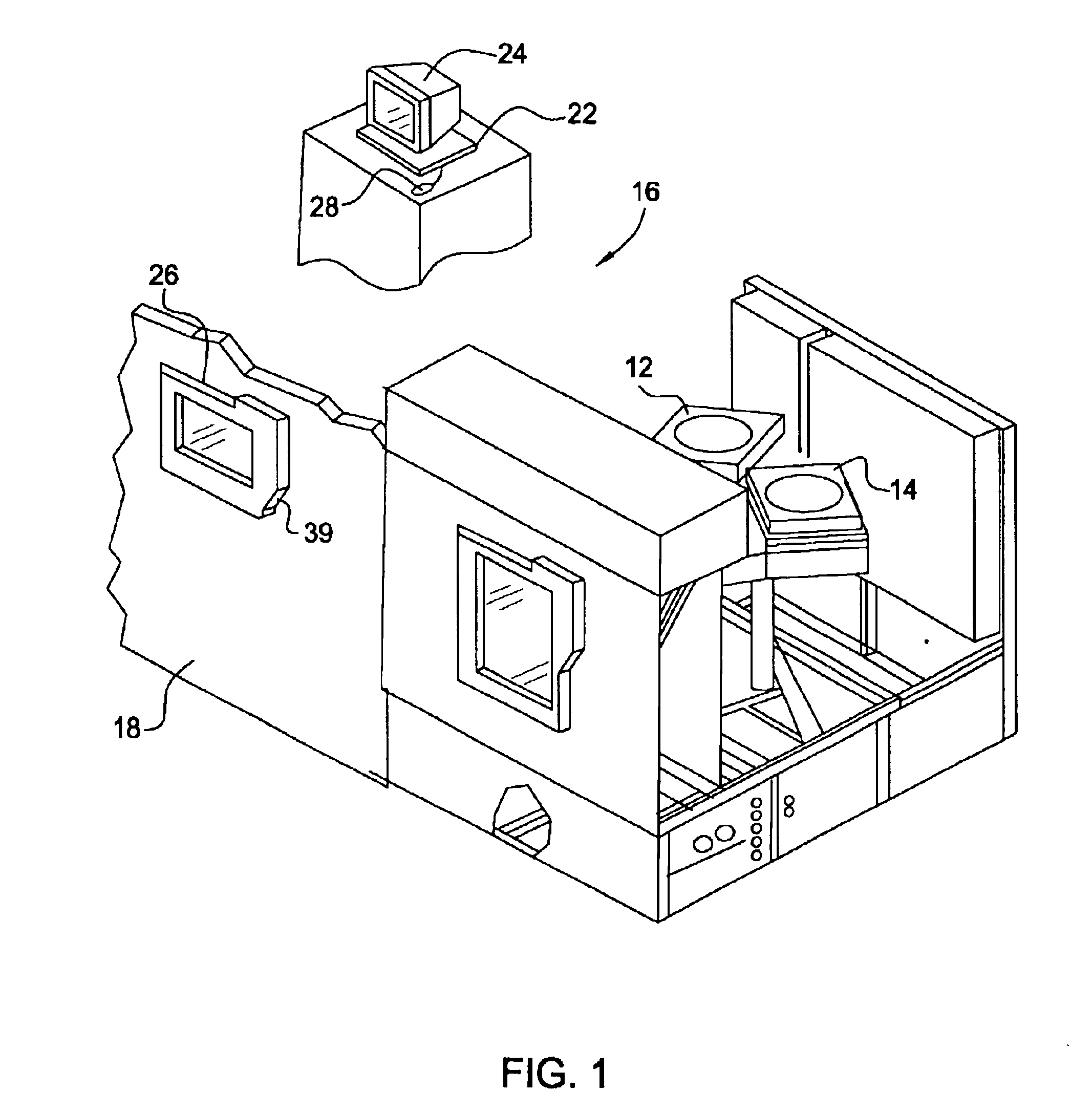

Remote Plasma Source for Pre-Treatment of Substrates Prior to Deposition

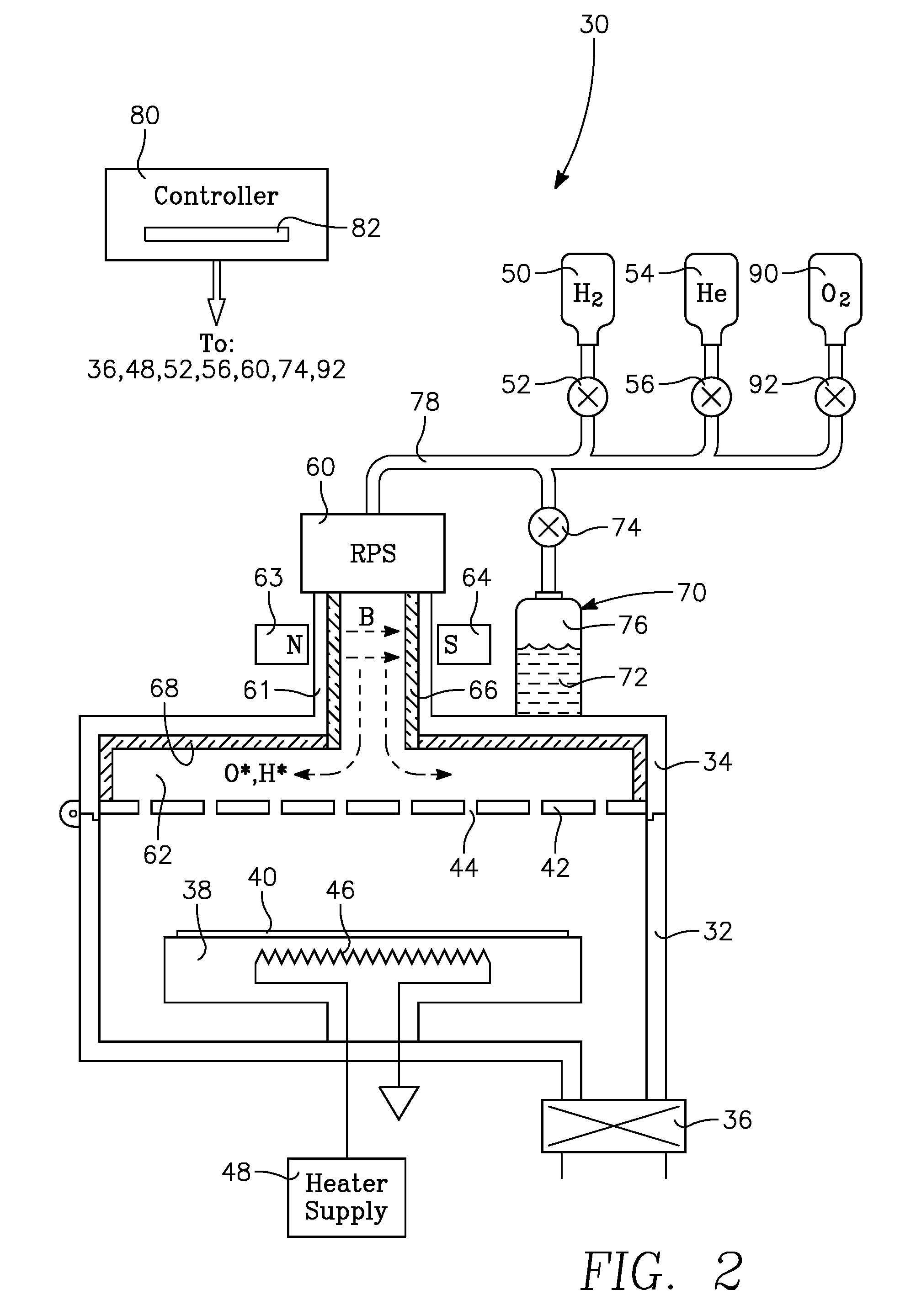

ActiveUS20090017227A1Electric discharge tubesSemiconductor/solid-state device manufacturingOxygenRefractory metals

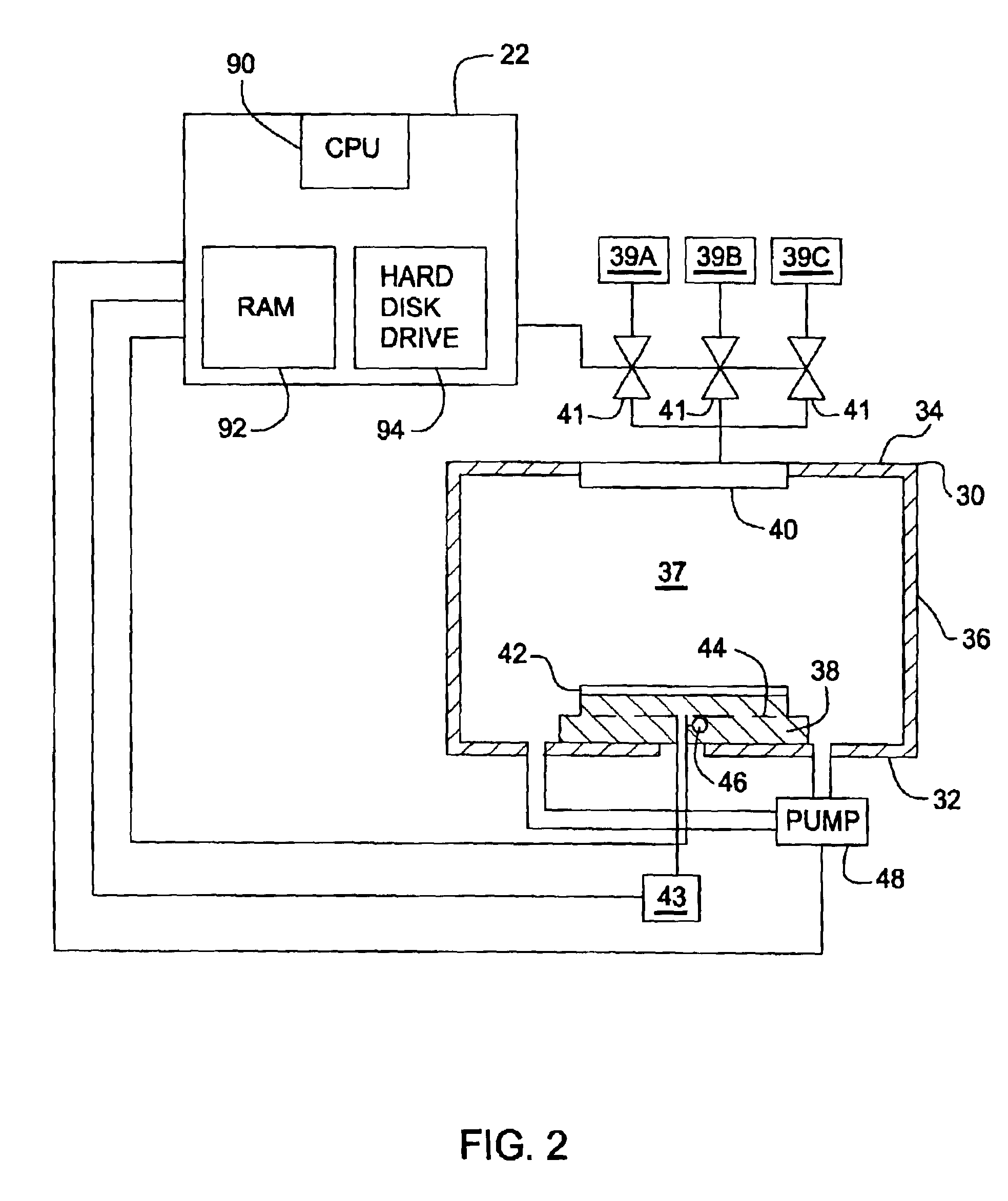

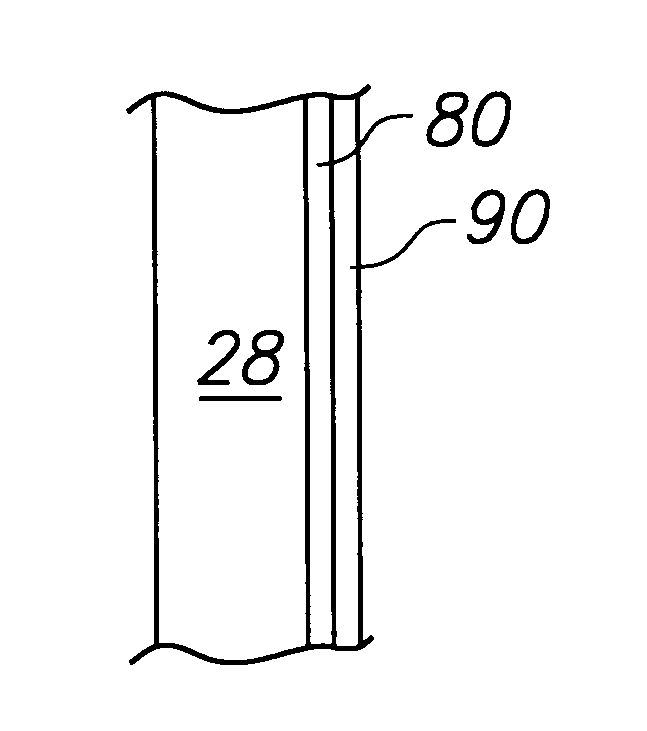

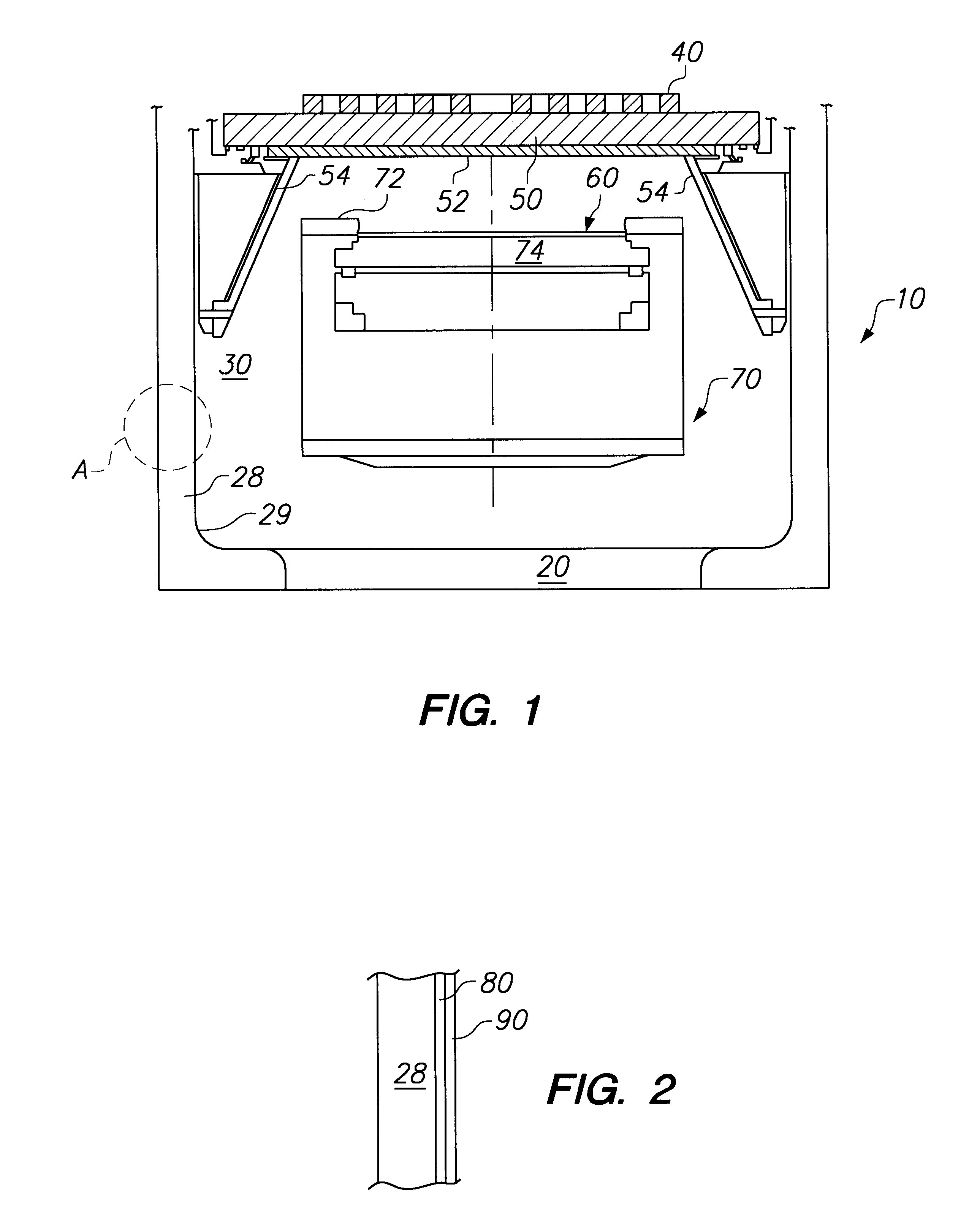

A plasma processing chamber particularly useful for pre-treating low-k dielectric films and refractory metal films subject to oxidation prior to deposition of other layers. A remote plasma source (RPS) excites a processing gas into a plasma and delivers it through a supply tube to a manifold in back of a showerhead faceplate. The chamber is configured for oxidizing and reducing plasmas in the same or different processes when oxygen and hydrogen are selectively supplied to the RPS. The supply tube and showerhead may be formed of dielectric oxides which may be passivated by a water vapor plasma from the remote plasma source. In one novel process, a protective hydroxide coating is formed on refractory metals by alternating neutral plasmas of hydrogen and oxygen.

Owner:APPLIED MATERIALS INC

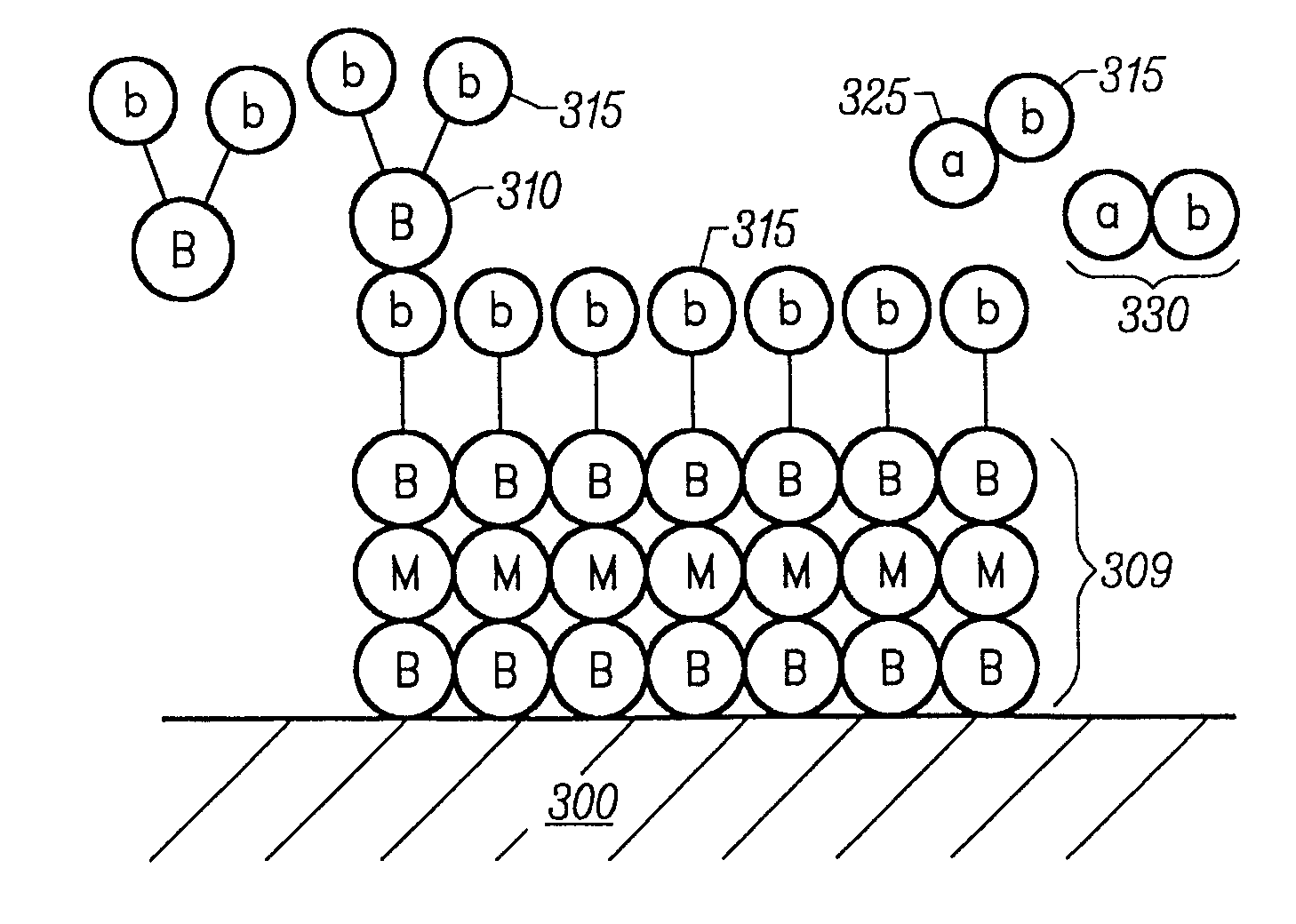

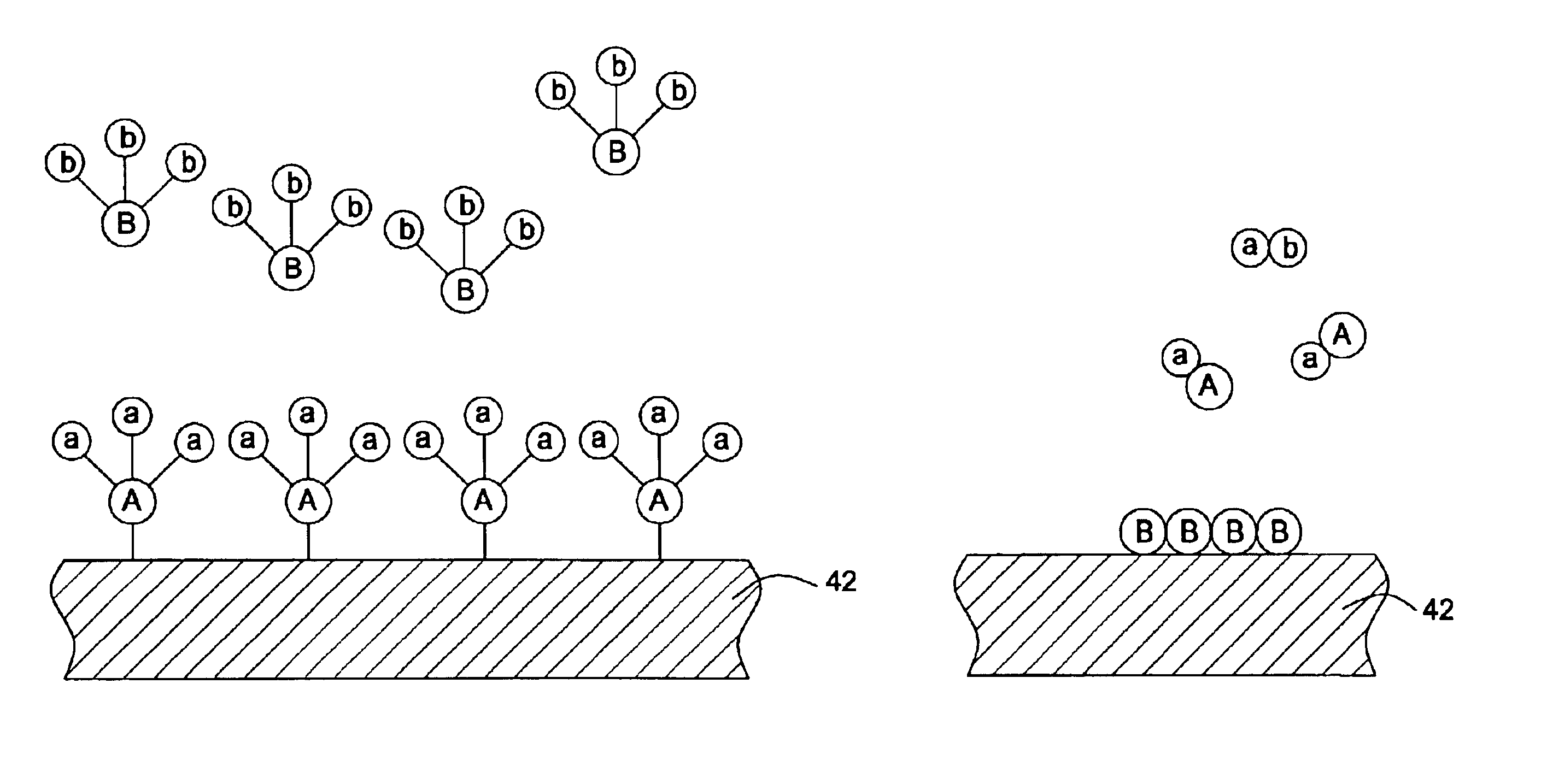

Formation of boride barrier layers using chemisorption techniques

InactiveUS7208413B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingBorideBoron containing

A method of forming a boride layer for integrated circuit fabrication is disclosed. In one embodiment, the boride layer is formed by chemisorbing monolayers of a boron-containing compound and one refractory metal compound onto a substrate. In an alternate embodiment, the boride layer has a composite structure. The composite boride layer structure comprises two or more refractory metals. The composite boride layer is formed by sequentially chemisorbing monolayers of a boron compound and two or more refractory metal compounds on a substrate.

Owner:APPLIED MATERIALS INC

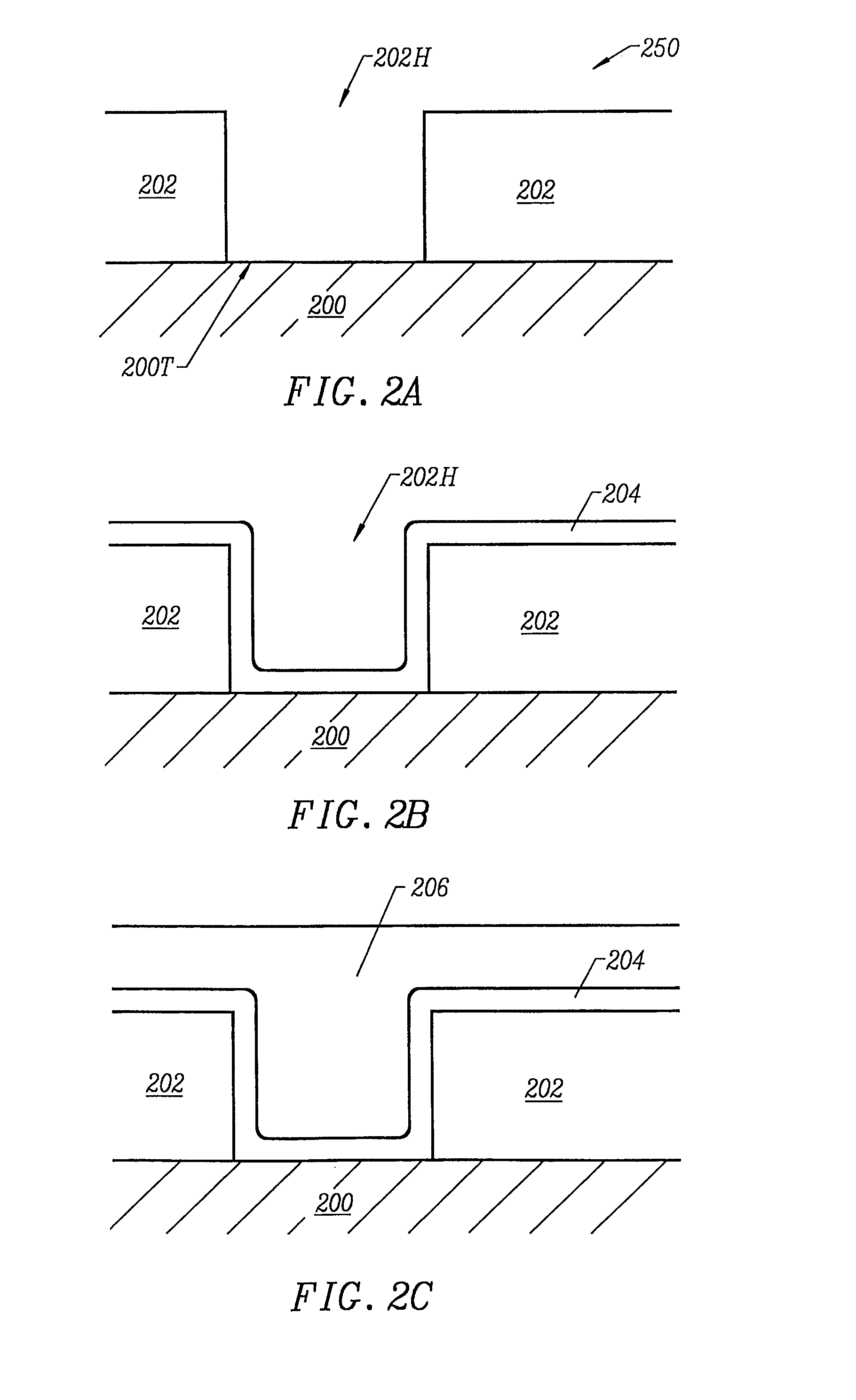

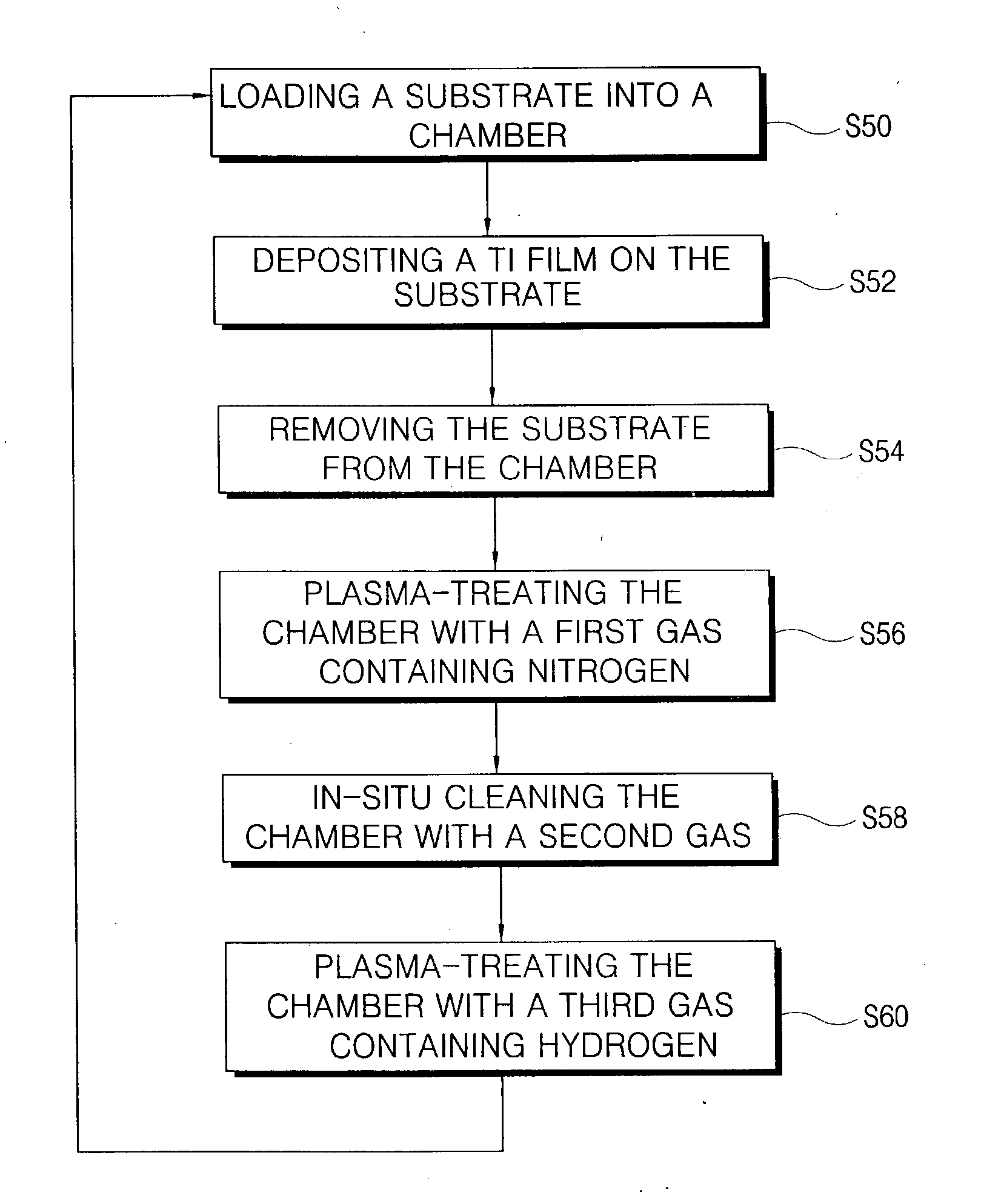

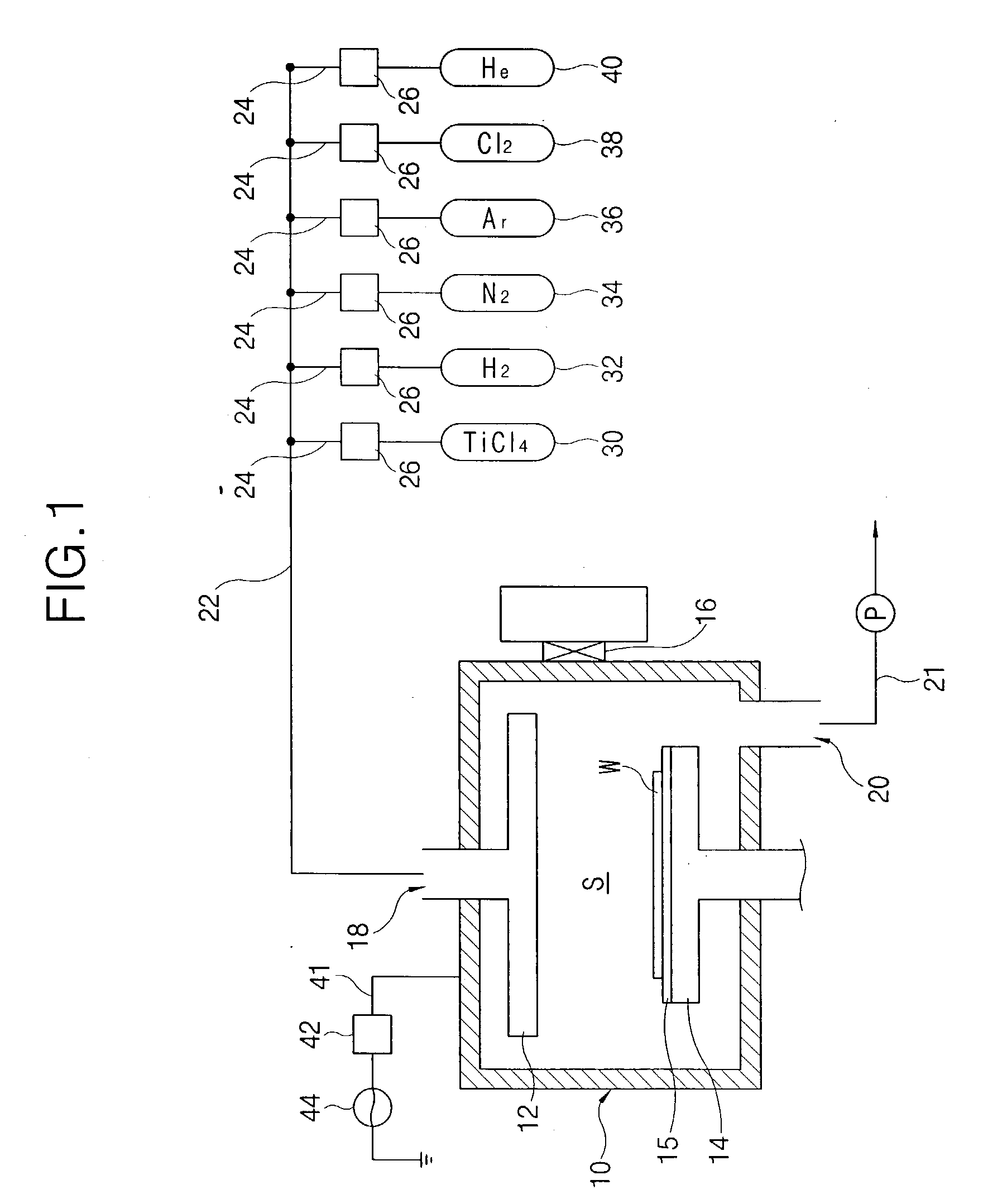

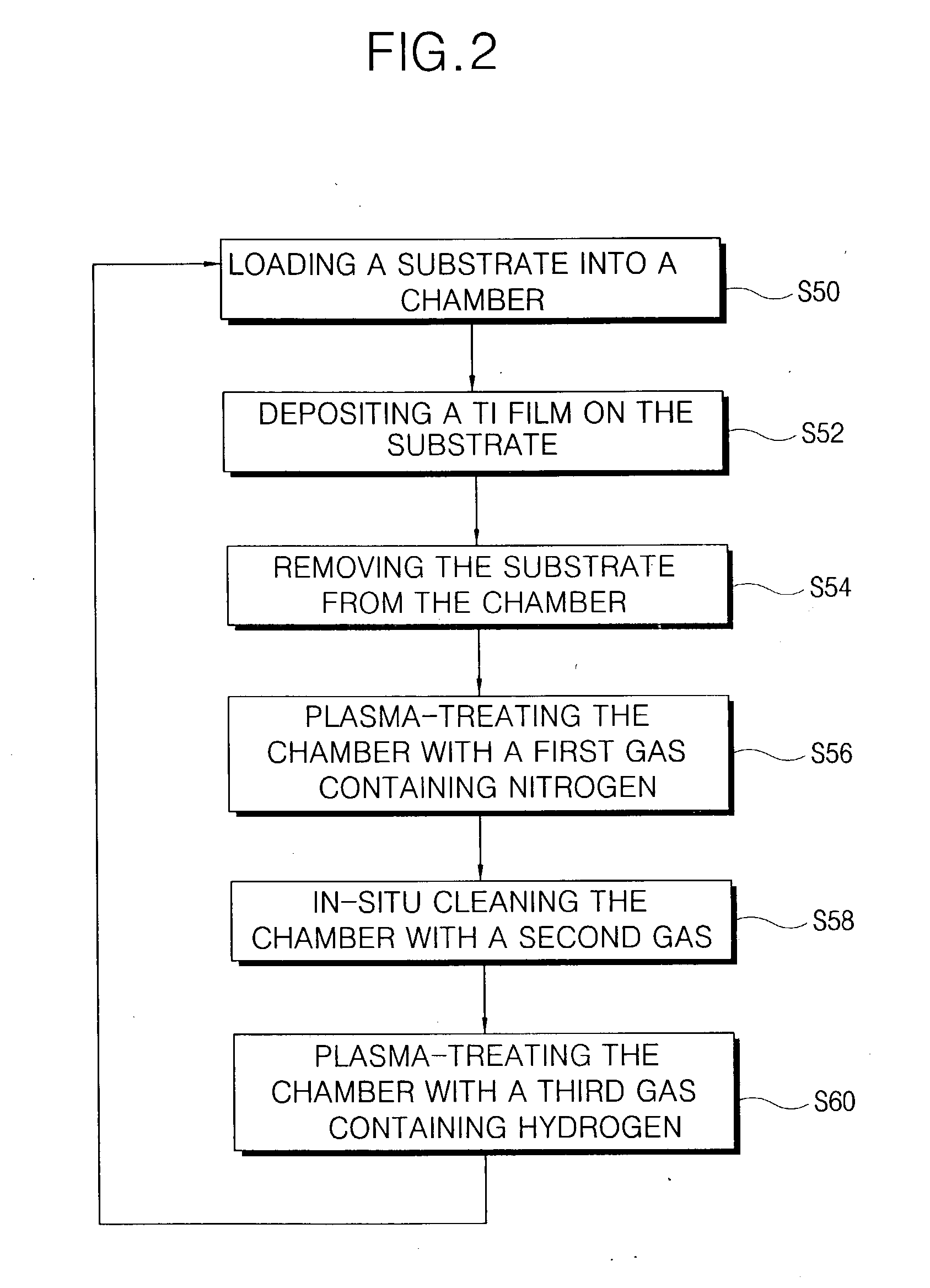

Method of cleaning a chemical vapor deposition chamber

InactiveUS20040013818A1Reduce the amount requiredIncrease resistanceHollow article cleaningElectrostatic cleaningHydrogenNitrogen

After a processing chamber is used to deposit a refractory metal film on a substrate, the chamber is plasma-treated with a gas including either nitrogen and / or hydrogen and in-situ cleaned. By plasma-treating the chamber with a gas including nitrogen, the refractory metal film that forms on interior surfaces of the chamber during substrate processing is nitrided. The nitrided refractory metal film can be removed from the chamber during the in-situ cleaning. By plasma-treating the chamber with a gas including hydrogen, reaction by-products generated in the chamber is diluted and removed. The chamber may be plasma-treated in a gas ambient including both nitrogen and hydrogen. Also, the plasma treatment may be performed before and after the in-situ cleaning.

Owner:SAMSUNG ELECTRONICS CO LTD

Formation of boride barrier layers using chemisorption techniques

InactiveUS20050118804A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingBorideChemisorption

A method of forming a boride layer for integrated circuit fabrication is disclosed. In one embodiment, the boride layer is formed by chemisorbing monolayers of a boron-containing compound and one refractory metal compound onto a substrate. In an alternate embodiment, the boride layer has a composite structure. The composite boride layer structure comprises two or more refractory metals. The composite boride layer is formed by sequentially chemisorbing monolayers of a boron compound and two or more refractory metal compounds on a substrate.

Owner:APPLIED MATERIALS INC

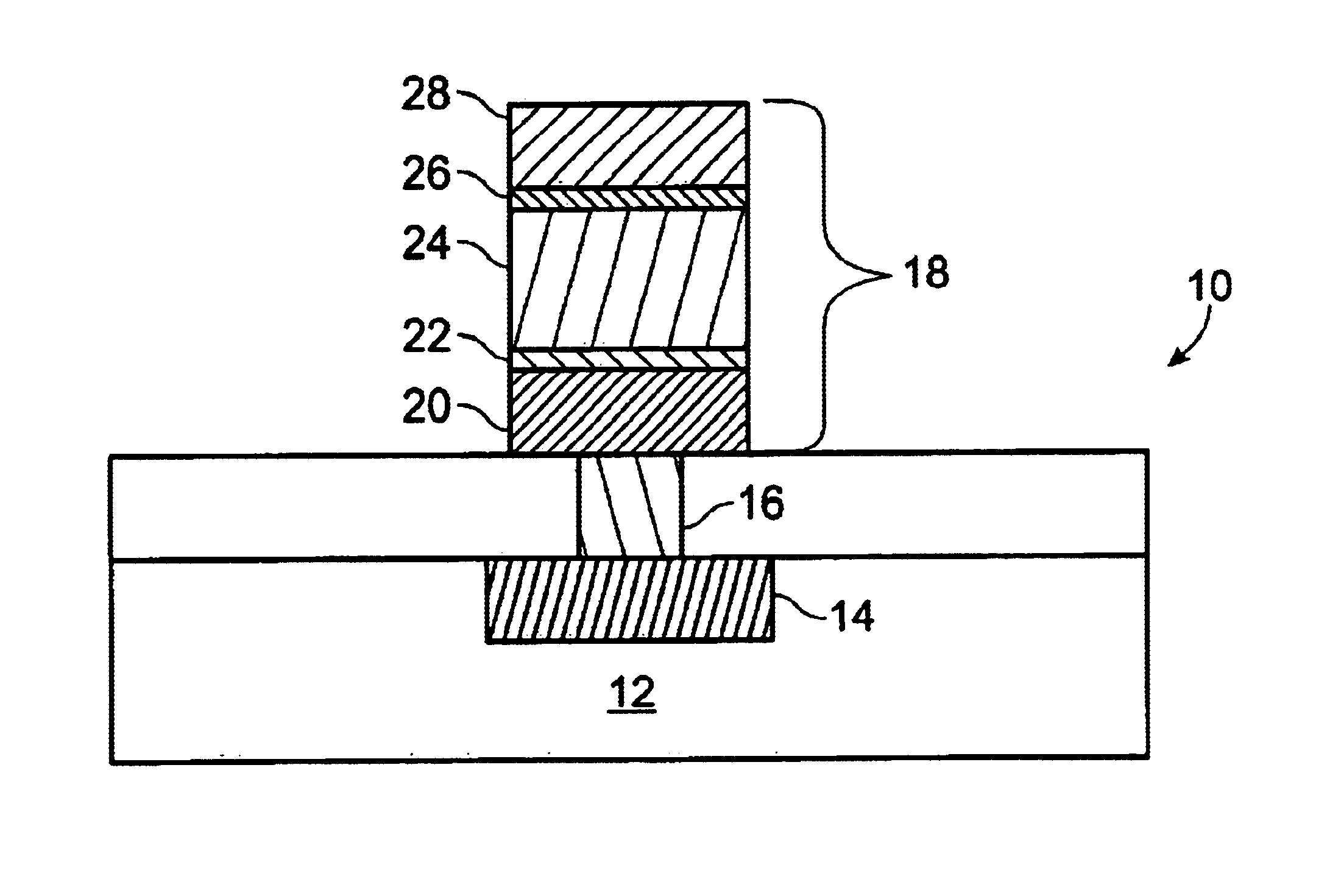

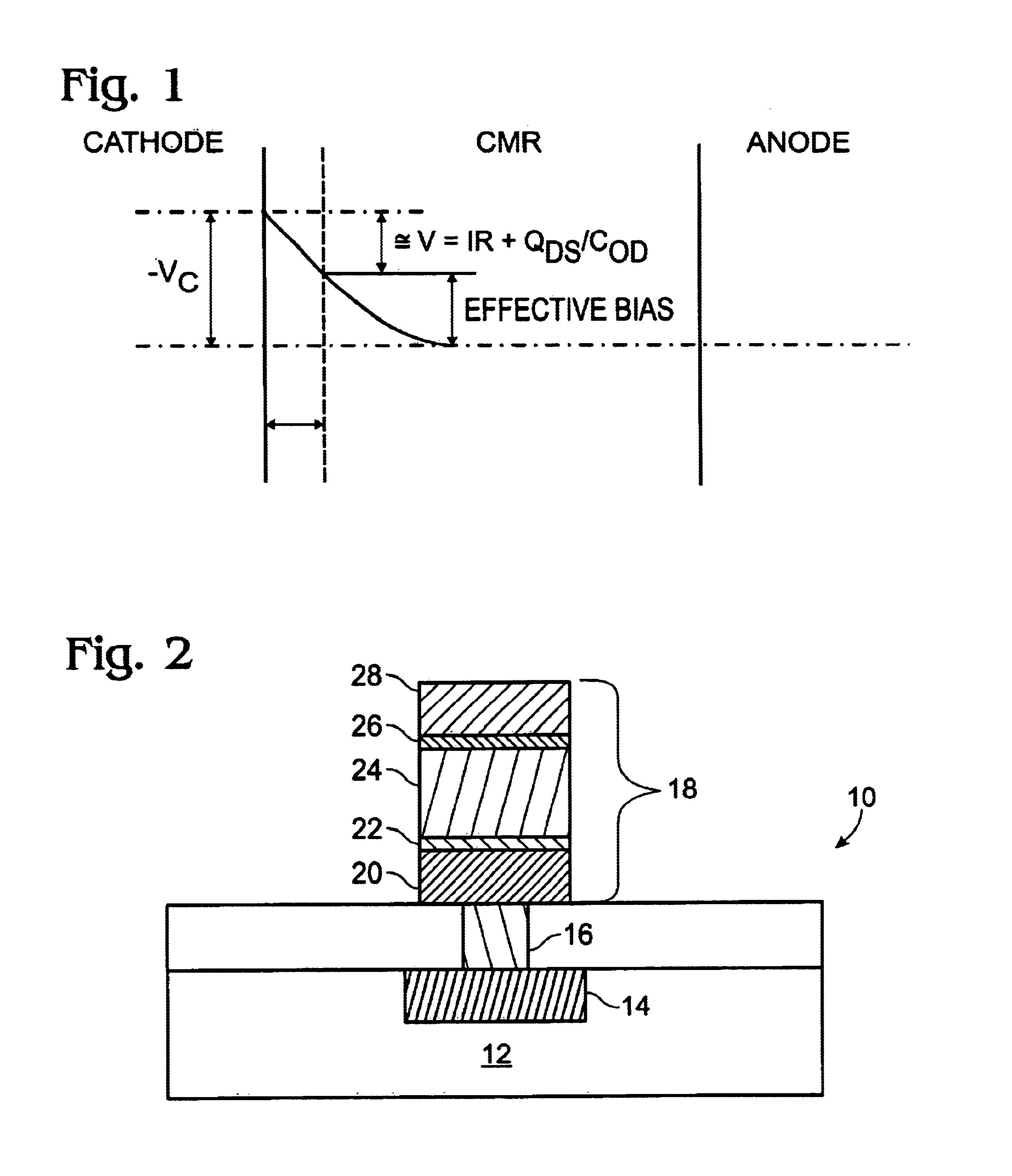

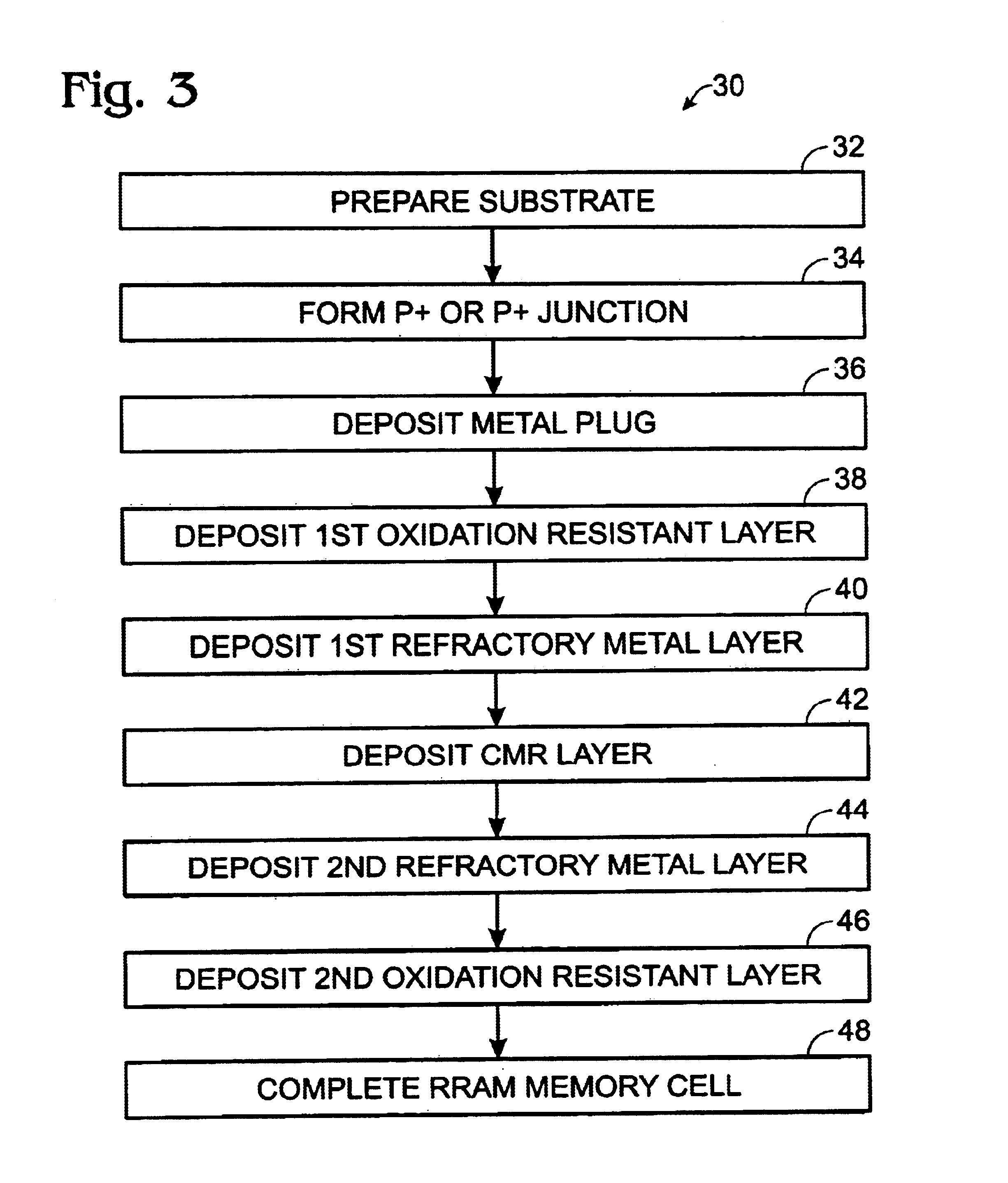

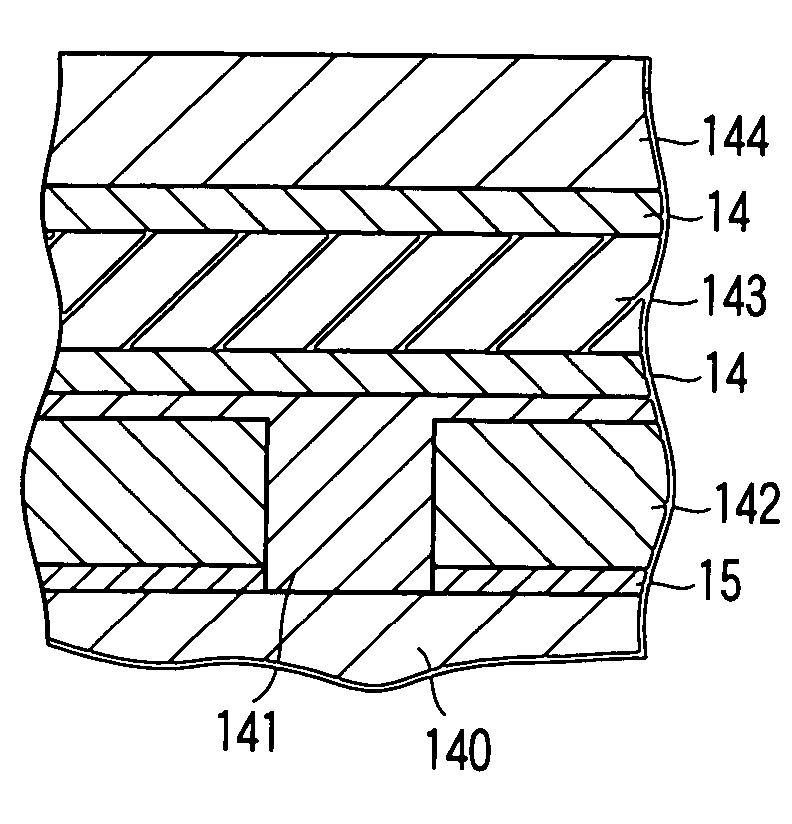

RRAM memory cell electrodes

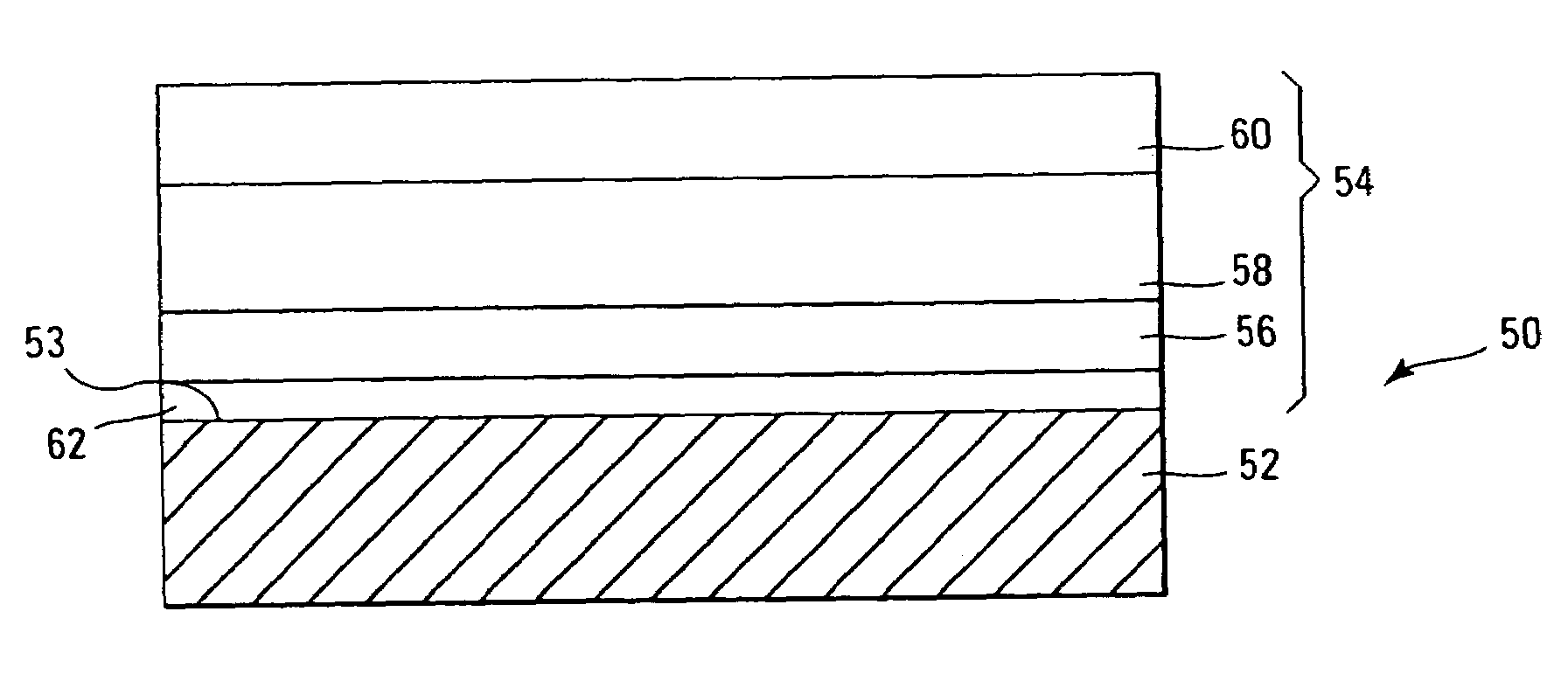

ActiveUS6849891B1Improve device reliabilityImprove device device enduranceTransistorMagnetic-field-controlled resistorsOxidation resistantSilicon

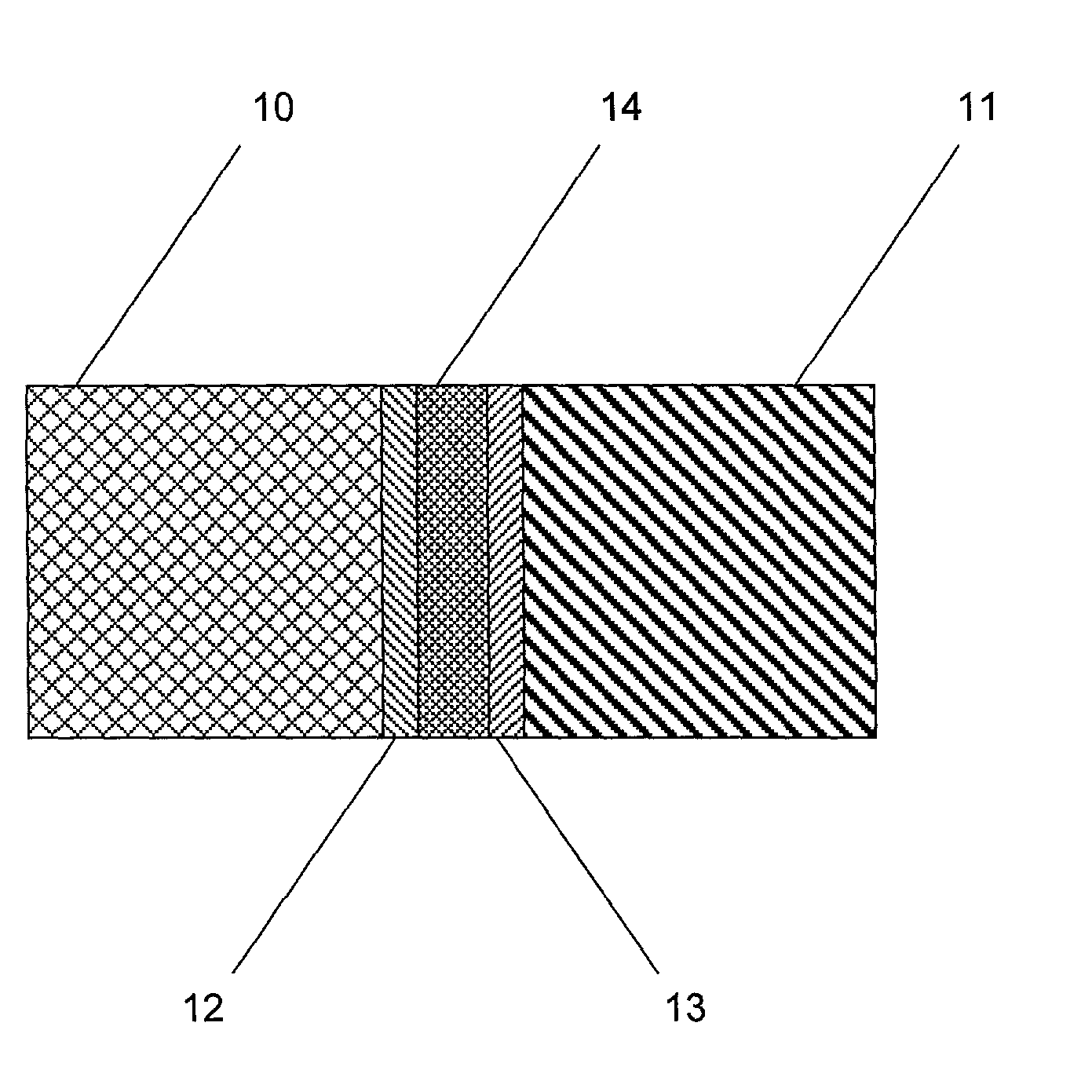

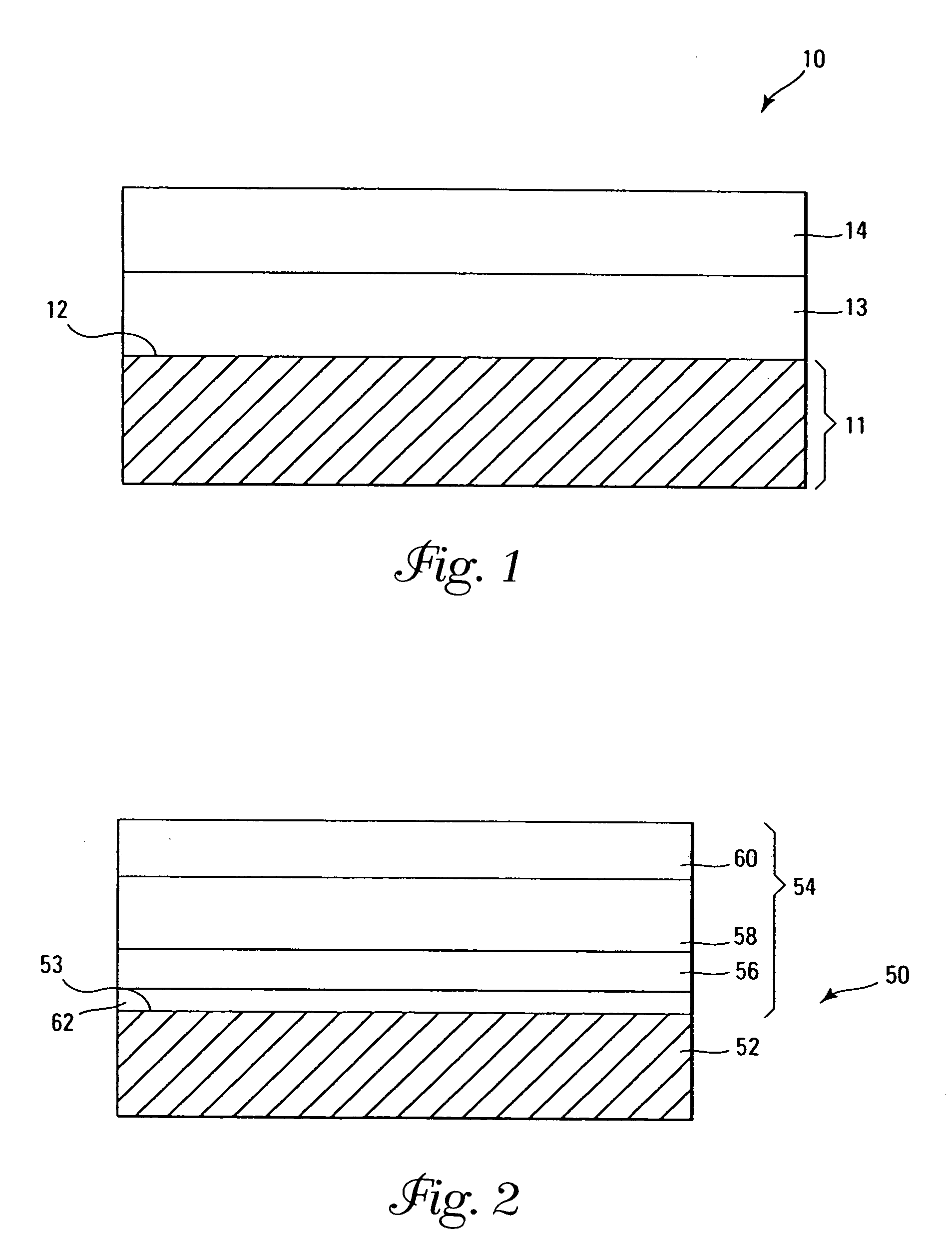

A RRAM memory cell is formed on a silicon substrate having a operative junction therein and a metal plug formed thereon, includes a first oxidation resistive layer; a first refractory metal layer; a CMR layer; a second refractory metal layer; and a second oxidation resistive layer. A method of fabricating a multi-layer electrode RRAM memory cell includes preparing a silicon substrate; forming a junction in the substrate taken from the group of junctions consisting of N+ junctions and P+ junctions; depositing a metal plug on the junction; depositing a first oxidation resistant layer on the metal plug; depositing a first refractory metal layer on the first oxidation resistant layer; depositing a CMR layer on the first refractory metal layer; depositing a second refractory metal layer on the CMR layer; depositing a second oxidation resistant layer on the second refractory metal layer; and completing the RRAM memory cell.

Owner:XENOGENIC DEV LLC

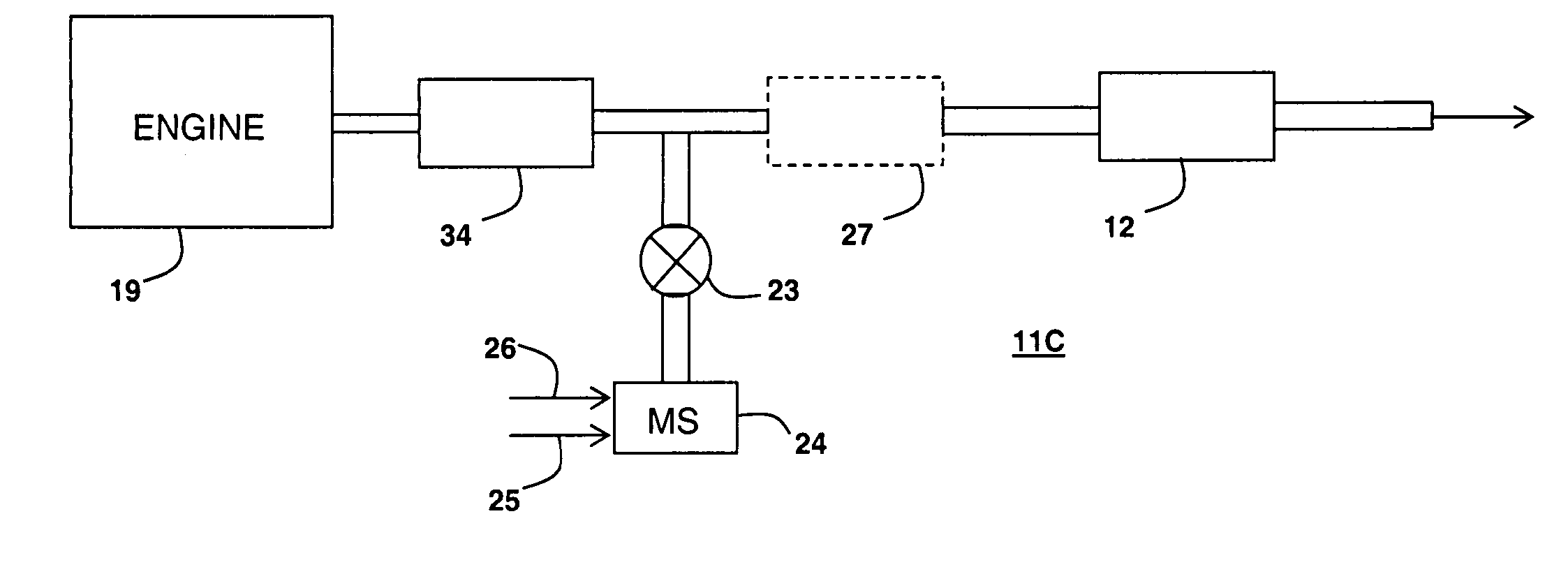

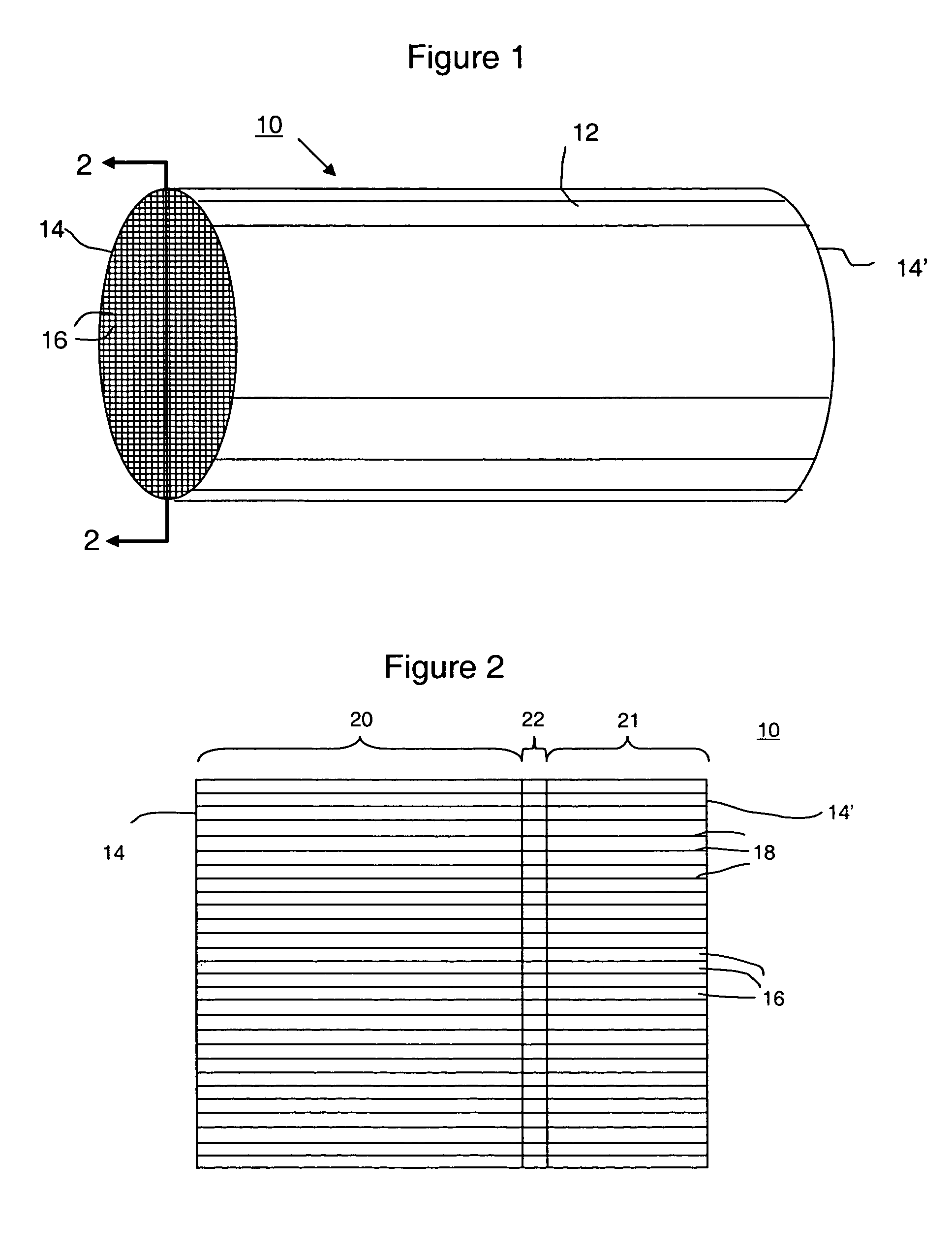

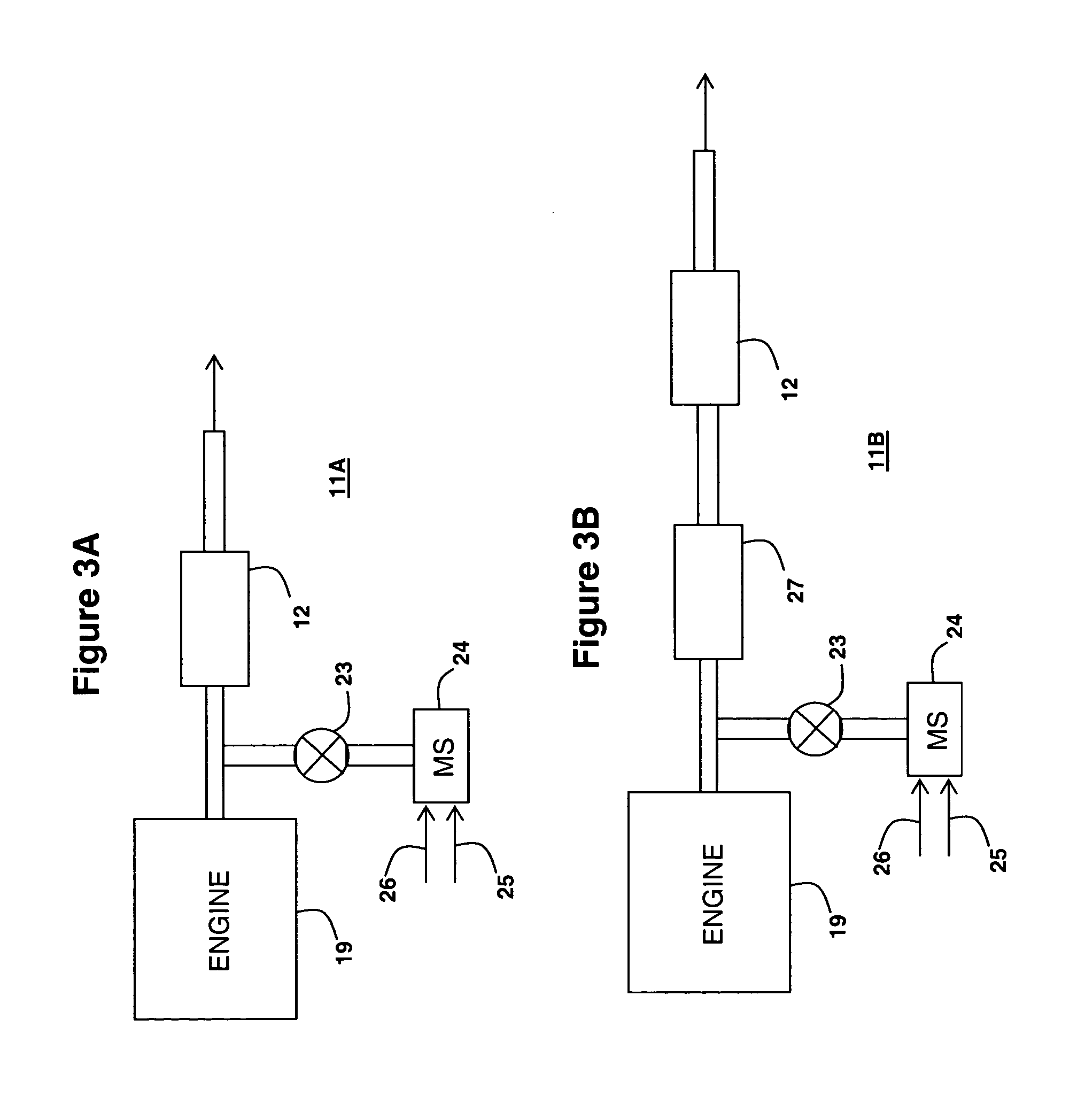

Zone coated catalyst to simultaneously reduce NOx and unreacted ammonia

ActiveUS20060039843A1Efficient conversionReduce riskCombination devicesNitrogen compoundsEngineeringInternal combustion engine

Provided is an emissions treatment system and method for reducing NOx emissions in the exhaust stream produced from an internal combustion engine. The system has an injector for periodically metering ammonia or an ammonia precursor into an exhaust stream; and a first substrate with a first SCR catalyst composition, downstream of the injector. The first substrate has an inlet end, an outlet end, a length extending between the inlet end to the outlet end, wall elements and a plurality of passages defined by the wall elements. The first SCR catalyst composition is disposed on the wall elements from the inlet end toward the outlet end to a length that is less than the substrate's axial length to form an inlet zone. The first substrate also has an NH3 destruction catalyst composition with a platinum group metal component dispersed on a refractory metal oxide. The NH3 destruction catalyst is disposed on the wall elements from the outlet end toward the inlet end to a length that is less than the substrate's axial length to form an outlet zone. Generally, there is from 0.1 to 10 g / ft3 of platinum group metal component in the outlet zone.

Owner:BASF CATALYSTS LLC

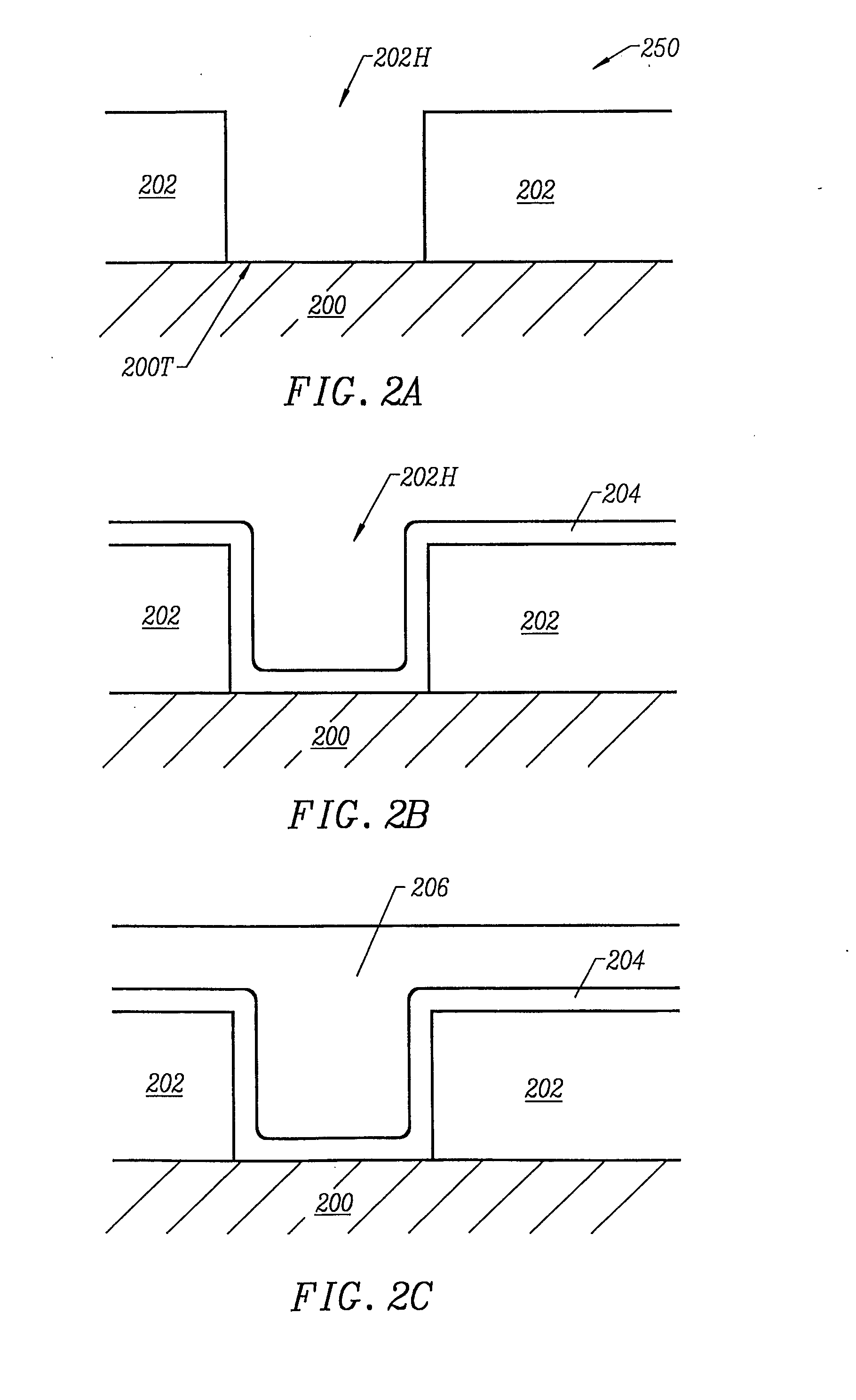

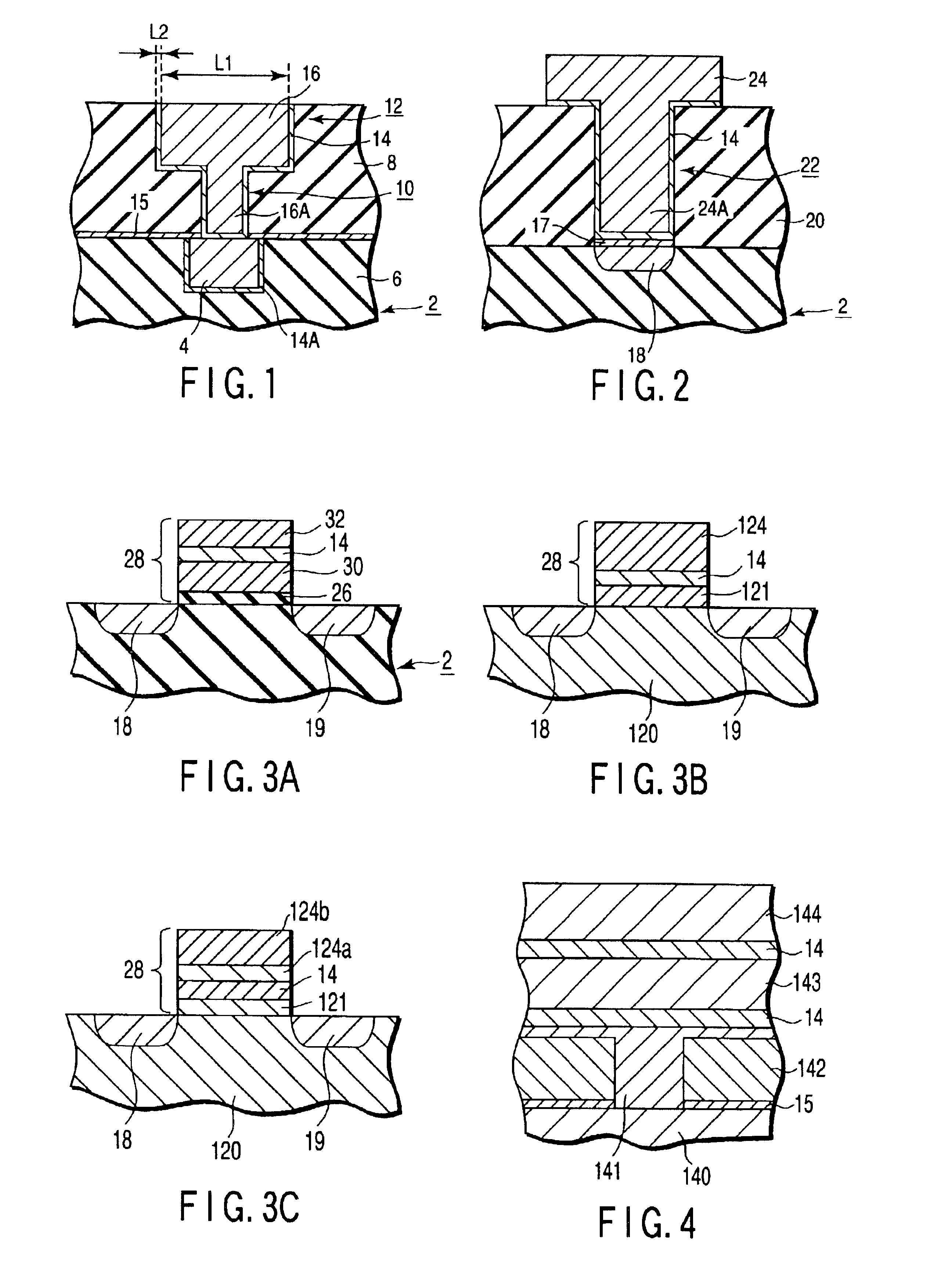

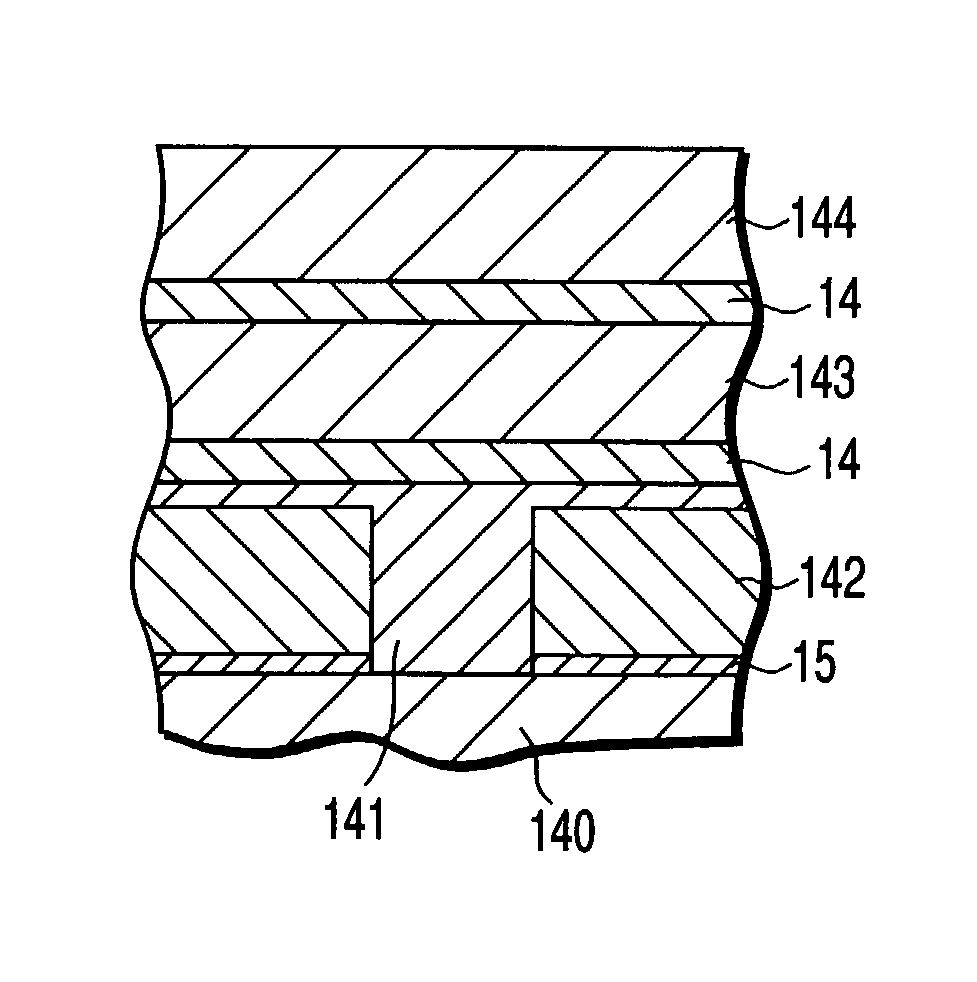

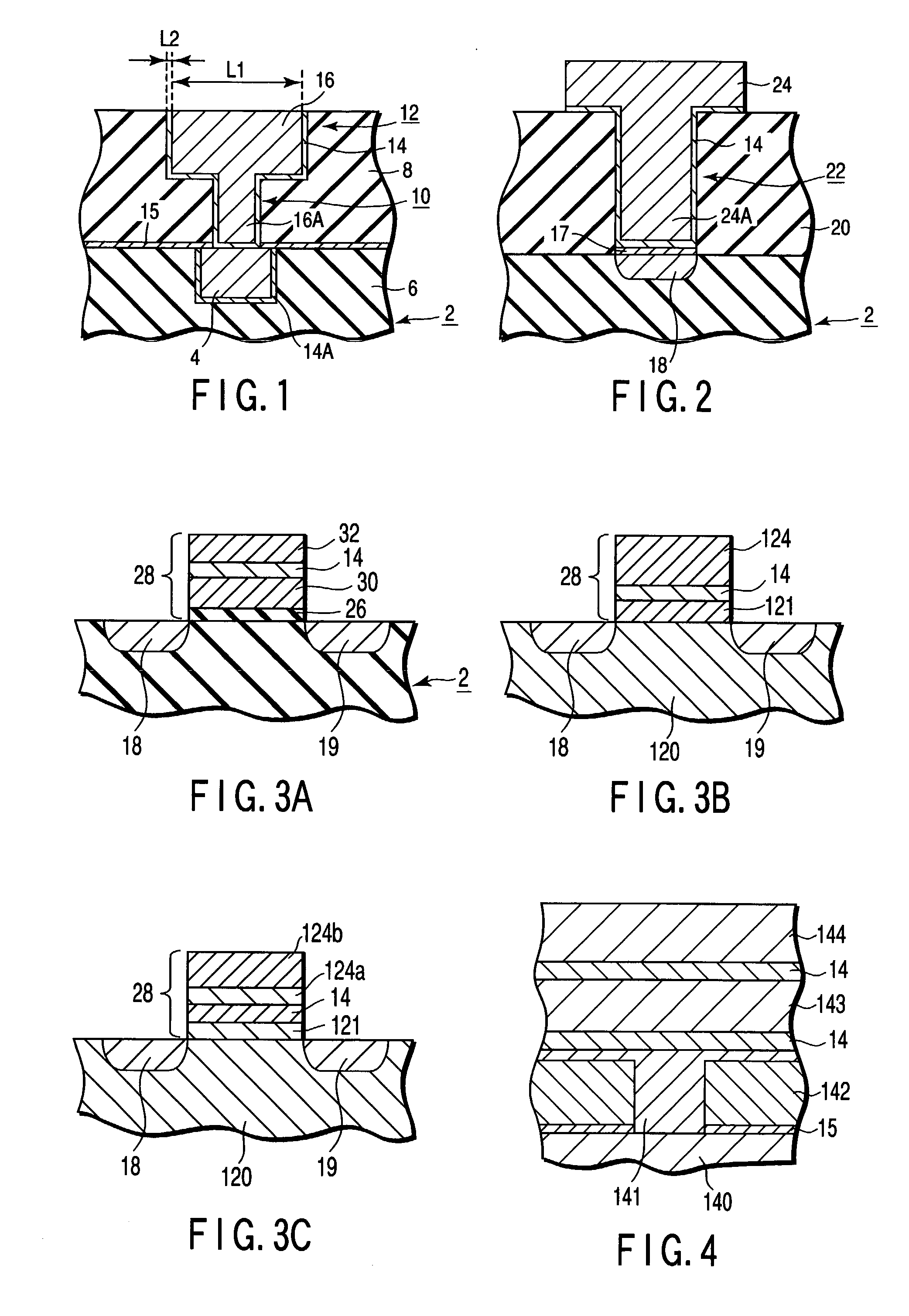

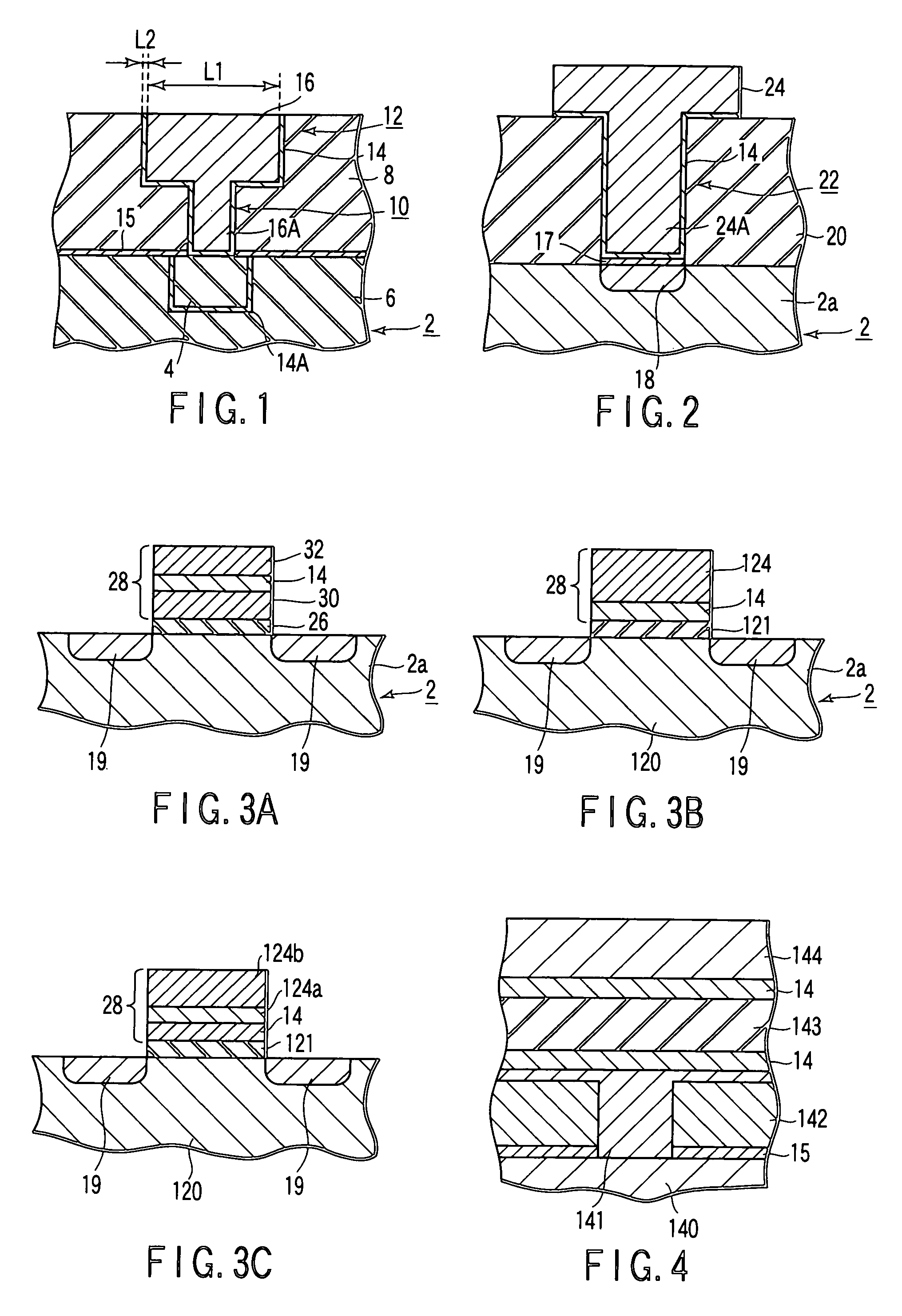

Method of forming a barrier film and method of forming wiring structure and electrodes of semiconductor device having a barrier film

InactiveUS6861356B2Maintain good propertiesSemiconductor/solid-state device detailsSolid-state devicesDevice materialPhysical chemistry

There is provided a method of forming a barrier metal which is designed to be interposed between a metal layer and an insulating layer, both constituting a multi-layered structure of semiconductor device, the method comprising the steps of positioning a substrate having the insulating layer formed thereon at a predetermined position inside a processing vessel forming a processing space, and alternately introducing a gas containing a refractory metallic atom, a gas containing Si atom and a gas containing N atom into the processing vessel under a predetermined processing pressure, thereby allowing a refractory metal nitride or a refractory metal silicon nitride to be deposited on the insulating layer by way of atomic layer deposition.

Owner:TOKYO ELECTRON LTD

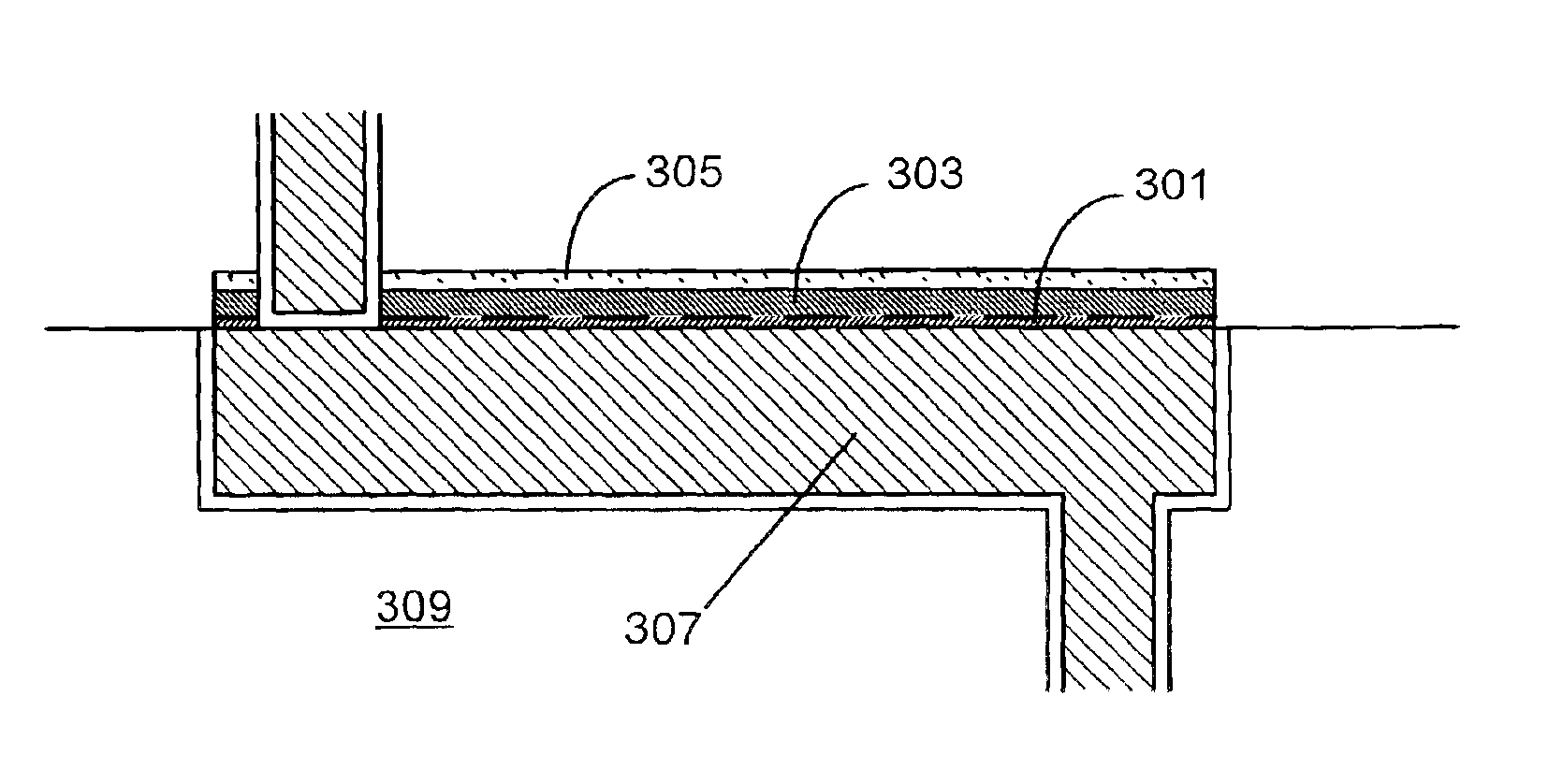

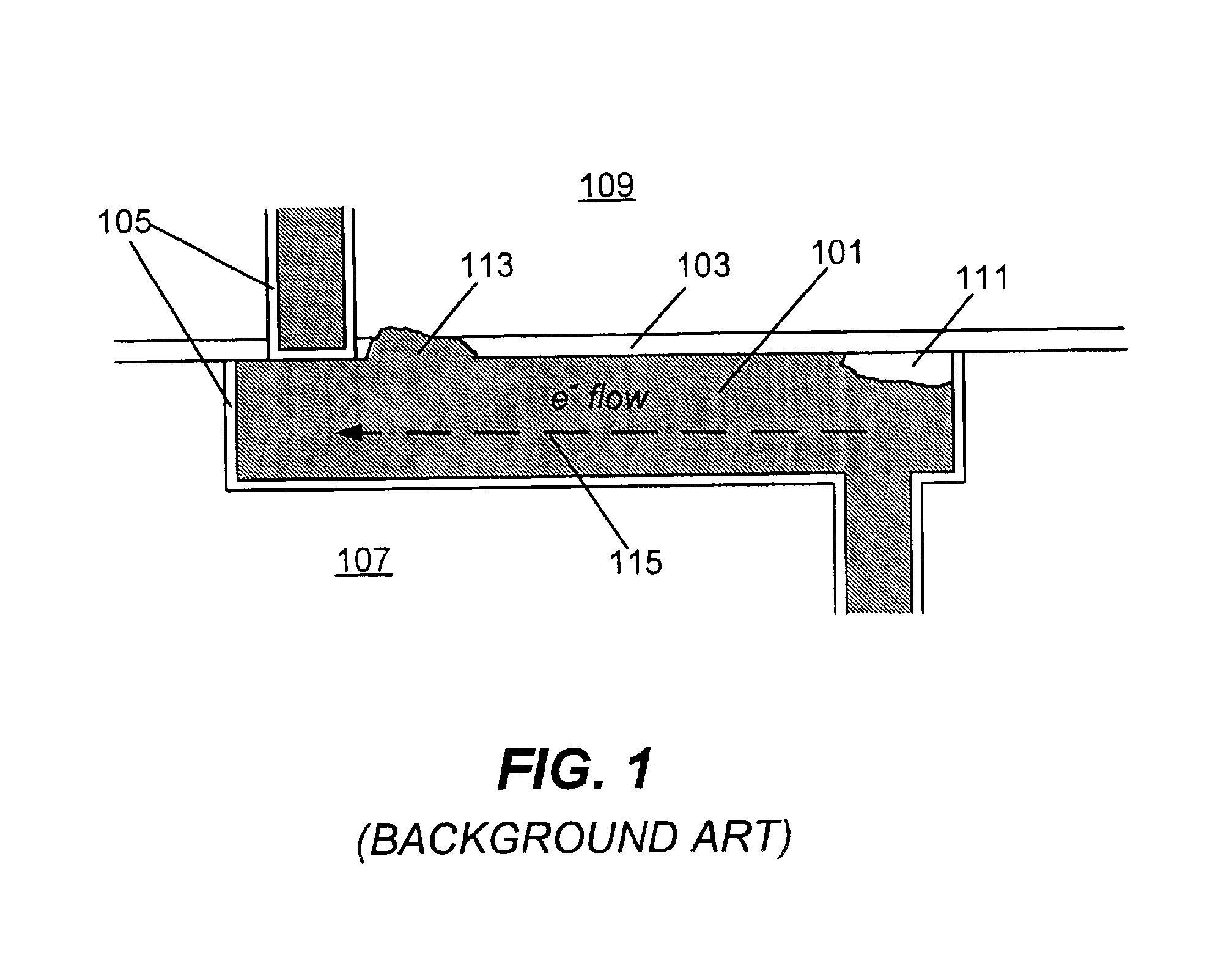

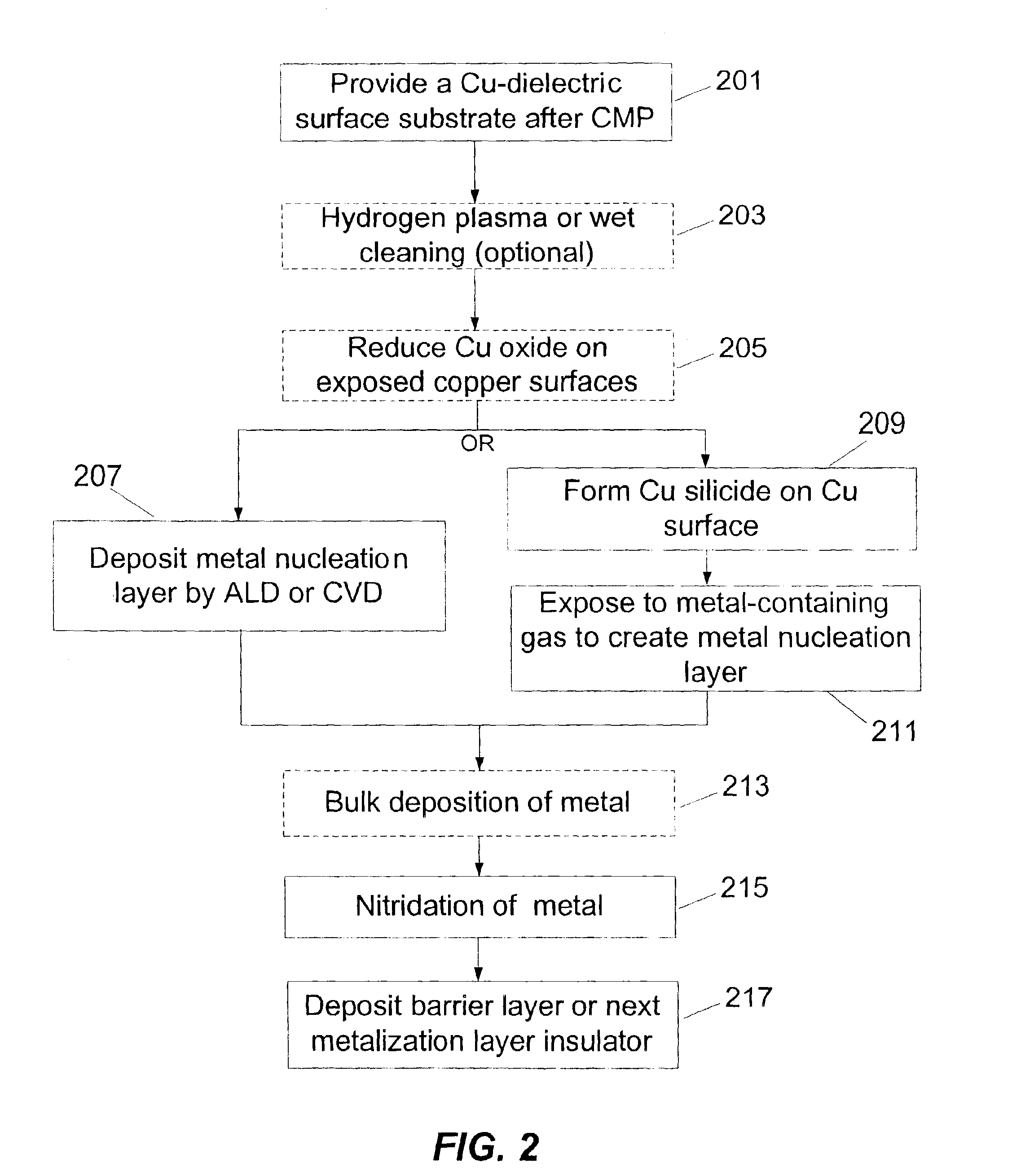

Selective refractory metal and nitride capping

InactiveUS6844258B1Inhibited DiffusionPrevent electromigrationSemiconductor/solid-state device detailsSolid-state devicesCopperNucleation

A method for creating a refractory metal and refractory metal nitride cap effective for reducing copper electromigration and copper diffusion is described. The method includes depositing a refractory metal nucleation layer and nitriding at least the upper portion of the refractory metal layer to form a refractory metal nitride. Methods to reduce and clean the copper lines before refractory metal deposition are also described. Methods to form a thicker refractory metal layer using bulk deposition are also described.

Owner:NOVELLUS SYSTEMS

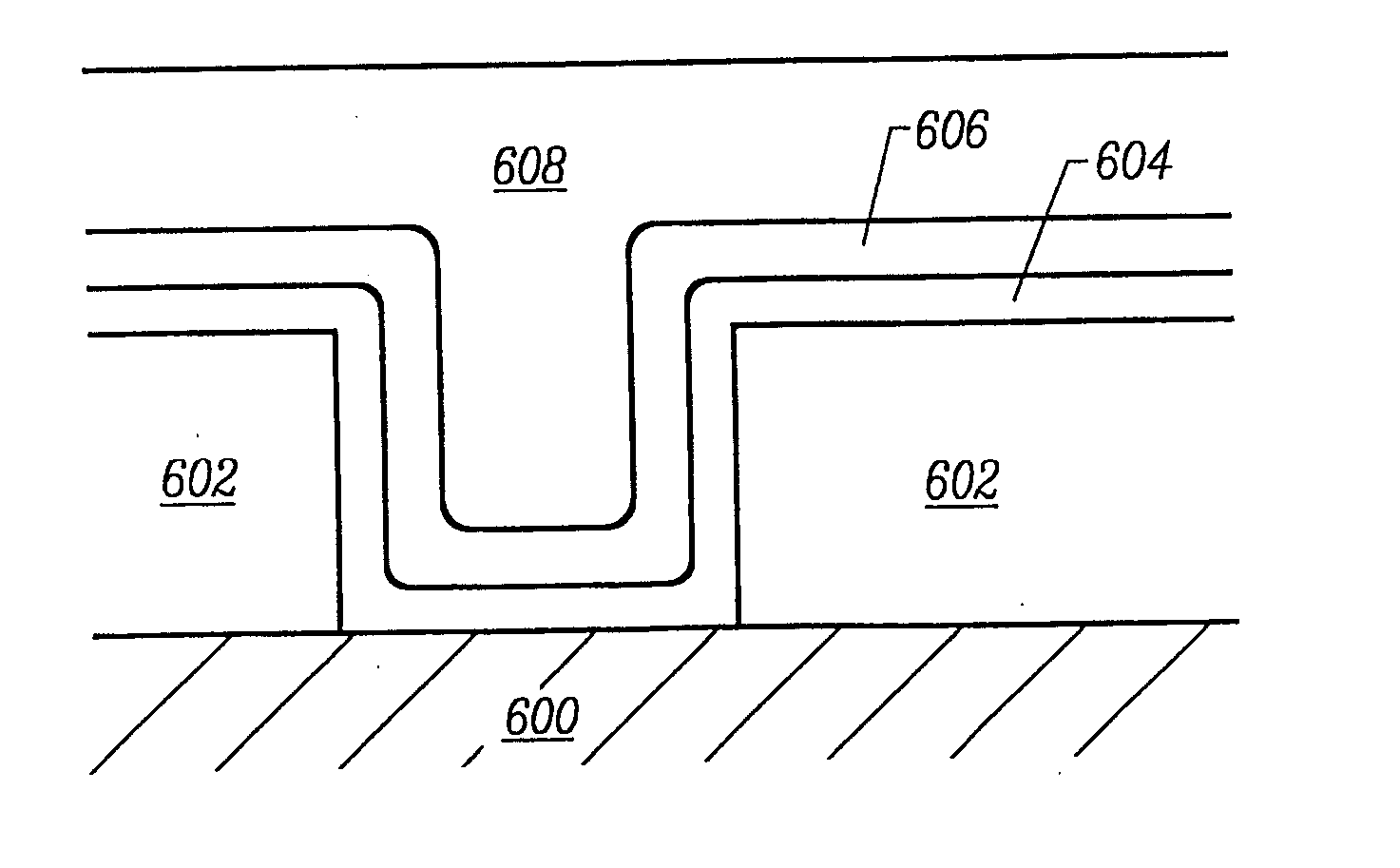

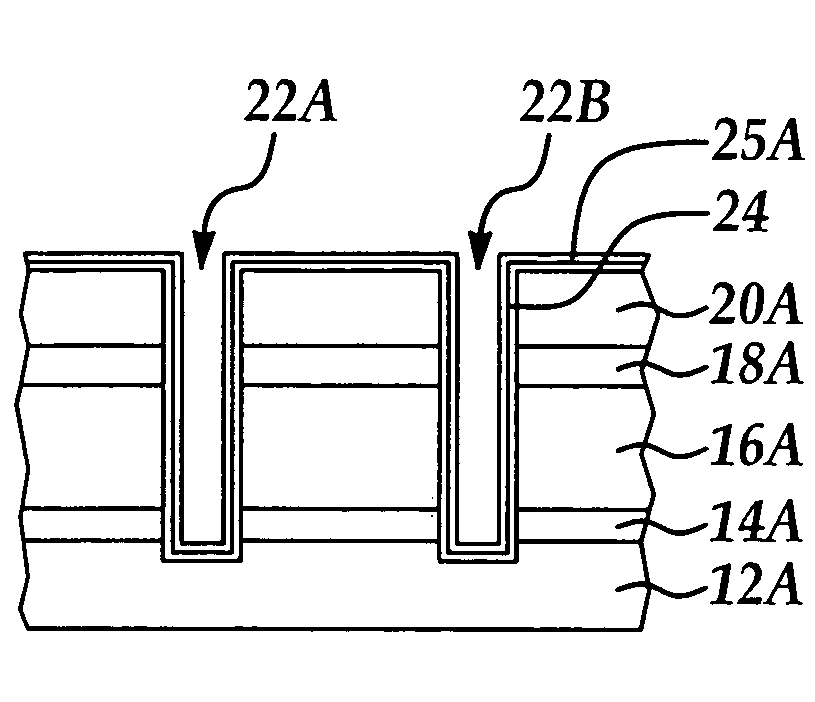

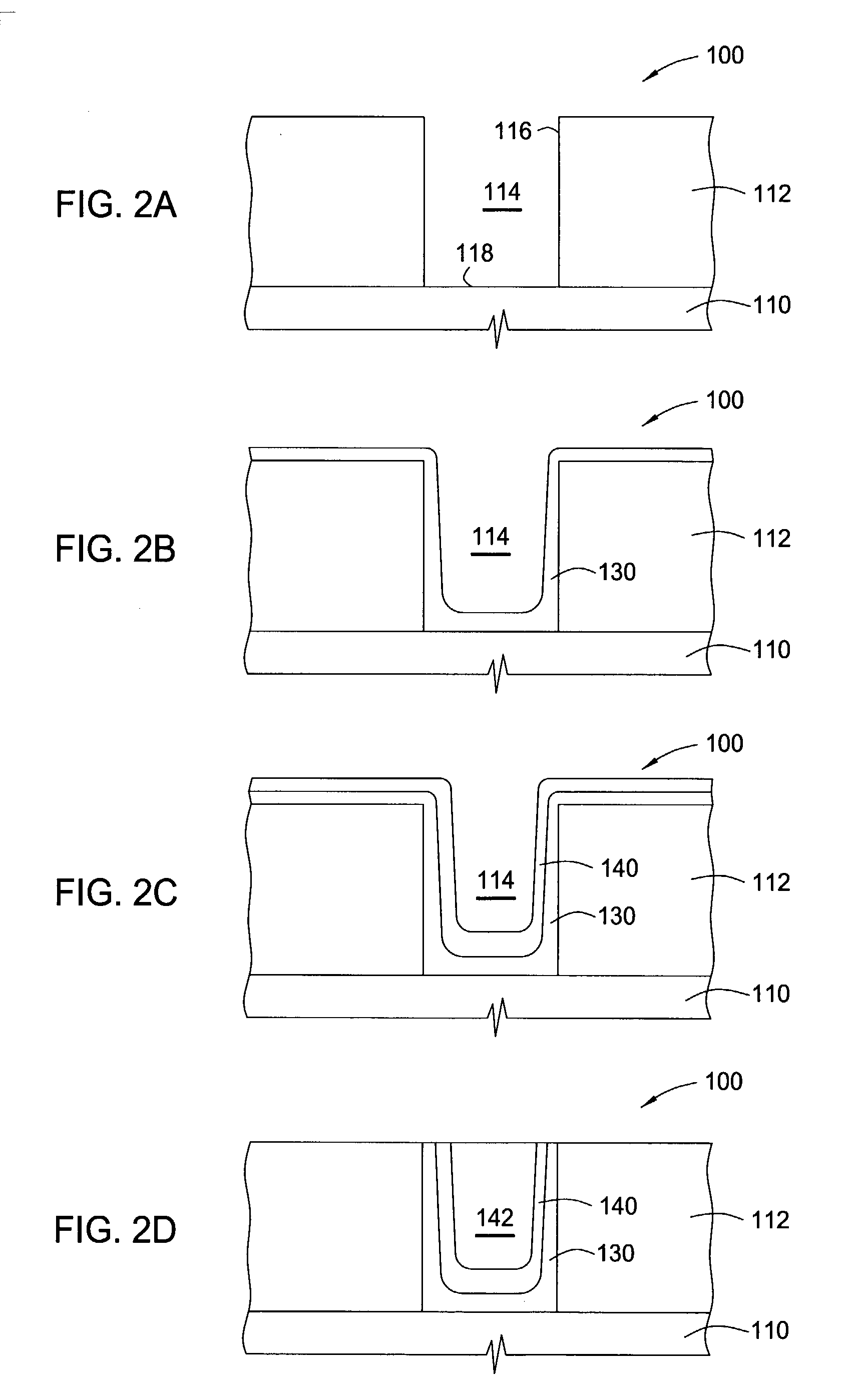

Copper damascene barrier and capping layer

InactiveUS20060024954A1Improve electrical performanceSemiconductor/solid-state device manufacturingAnti-reflective coatingEngineering

A method for forming a damascene with improved electrical properties and resulting structure thereof including providing at least one dielectric insulating layer overlying a first etch stop layer; forming an anti-reflectance coating (ARC) layer prior to a photolithographic patterning process; forming at least one opening extending through a thickness portion of the at least one dielectric insulating layer and first etch stop layer according to said photolithographic patterning and an etching process; blanket depositing a barrier layer including material selected from the group consisting of silicon carbide and silicon oxycarbide to line the at least one opening; blanket depositing a refractory metal liner over the barrier layer; blanket depositing at least one metal layer to fill the at least one opening; and, removing at least the at least one metal layer overlying the at least one opening level according to a chemical mechanical polish (CMP) process.

Owner:WU ZHEN CHENG +3

Integration of ALD tantalum nitride and alpha-phase tantalum for copper metallization application

InactiveUS20030124262A1Pretreated surfacesSemiconductor/solid-state device manufacturingMetal interconnectTantalum nitride

Owner:APPLIED MATERIALS INC

Two-dimensional fiber cloth reinforced composite material and preparation method thereof

InactiveCN101224989AImprove fracture toughnessImprove use reliabilityMetal powderStructural stability

The invention discloses a two-dimensional fiber cloth reinforced ceramics based composite material and the preparation technique, which adopts the two-dimensional fiber cloth as the reinforcing phase and the ceramic powder or the refractory metal powder as the stuffing, and the carbon and the carborundum as the base. The process steps are following: first the sizing agent with different ceramic powder and metal powder is coated on the two-dimensional fiber cloth, and then overlapping, puncturing and repeated densification are carried out. The preparation method has the advantages of lowering preparation cost and shortening preparation cycle, and the two-dimensional fiber cloth reinforced ceramics based composite material has the advantages of high shear strength between layers, structural stability and high reliability. The types of fiber cloth and the base can be adjusted and optimized in a wider range according to the applications, so as to be applicable for different fields.

Owner:NAT UNIV OF DEFENSE TECH

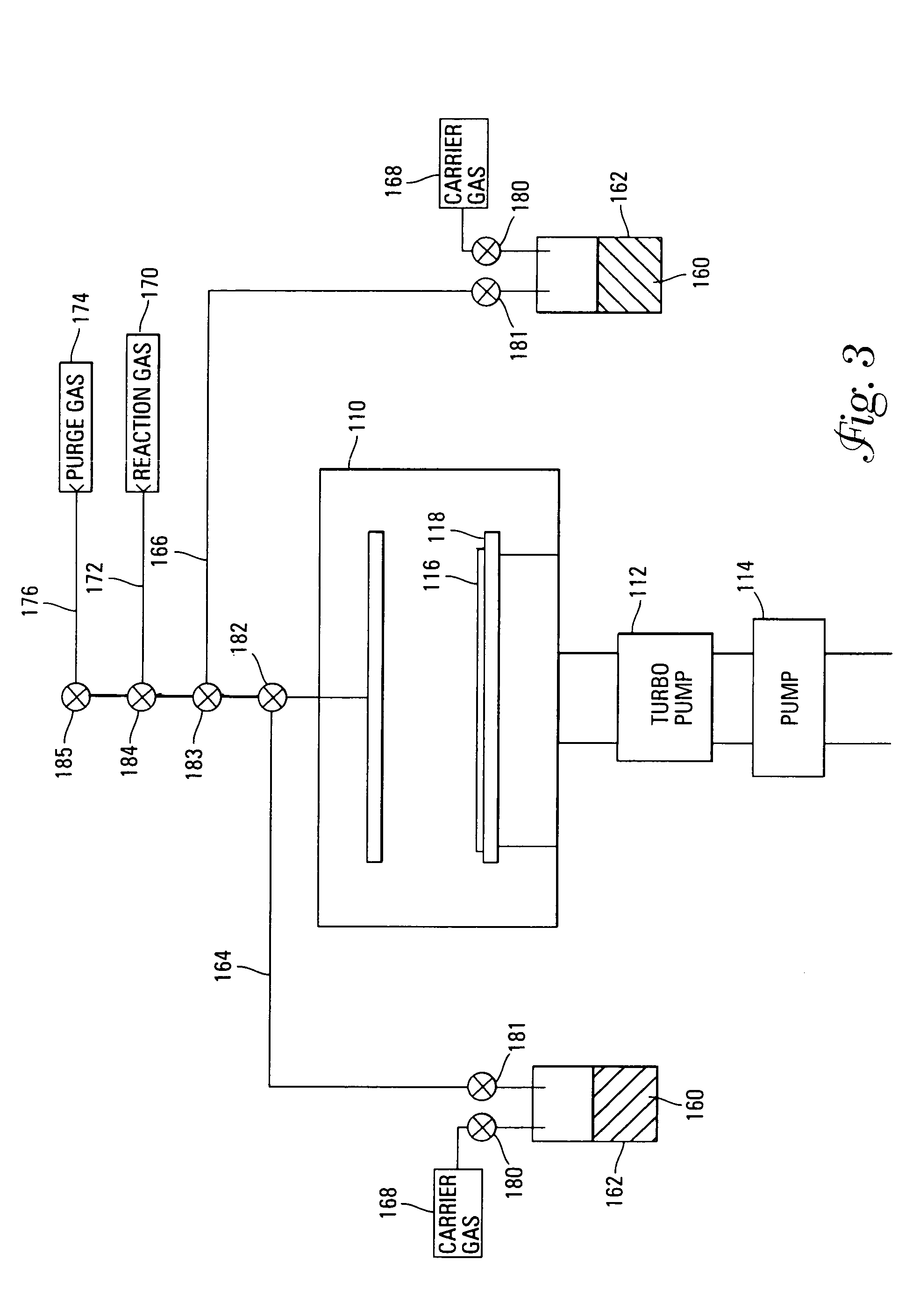

Systems and methods of forming refractory metal nitride layers using disilazanes

InactiveUS7122464B2Reduce diffuseReduce layeringSemiconductor/solid-state device manufacturingCapacitorsGas phaseDeposition process

A method of forming (and apparatus for forming) refractory metal nitride layers (including silicon nitride layers), such as a tantalum (silicon) nitride barrier layer, on a substrate by using a vapor deposition process with a refractory metal precursor compound, a disilazane, and an optional silicon precursor compound.

Owner:MICRON TECH INC

Investment casting cores

Owner:RTX CORP

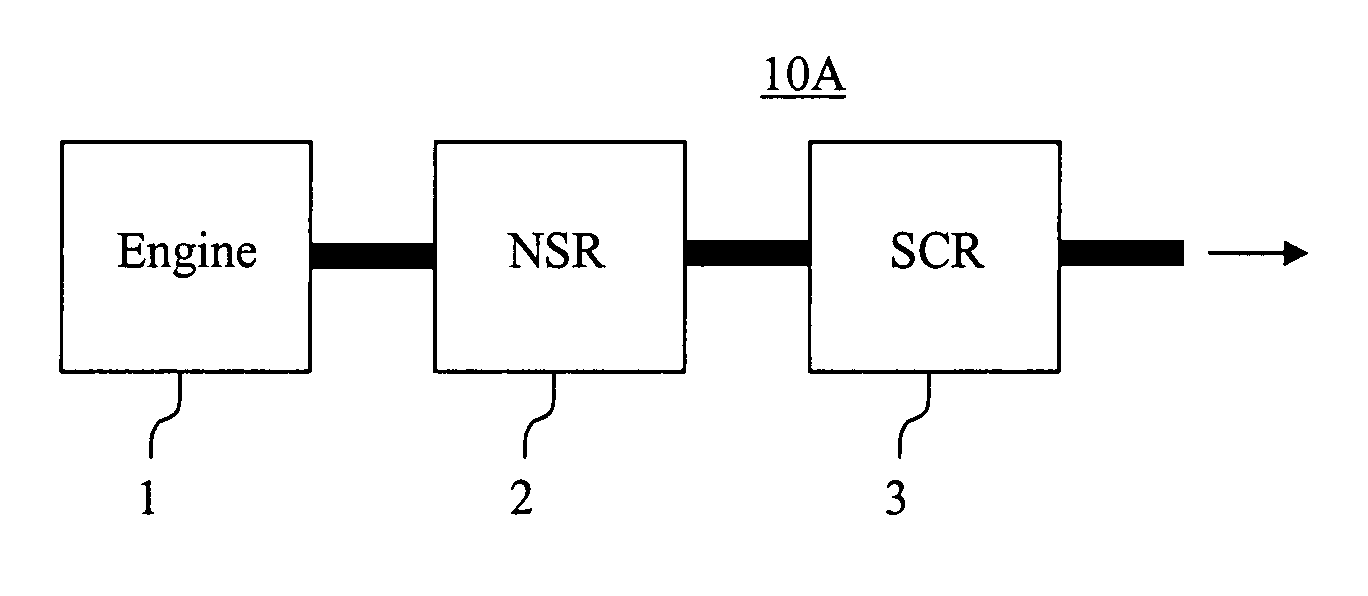

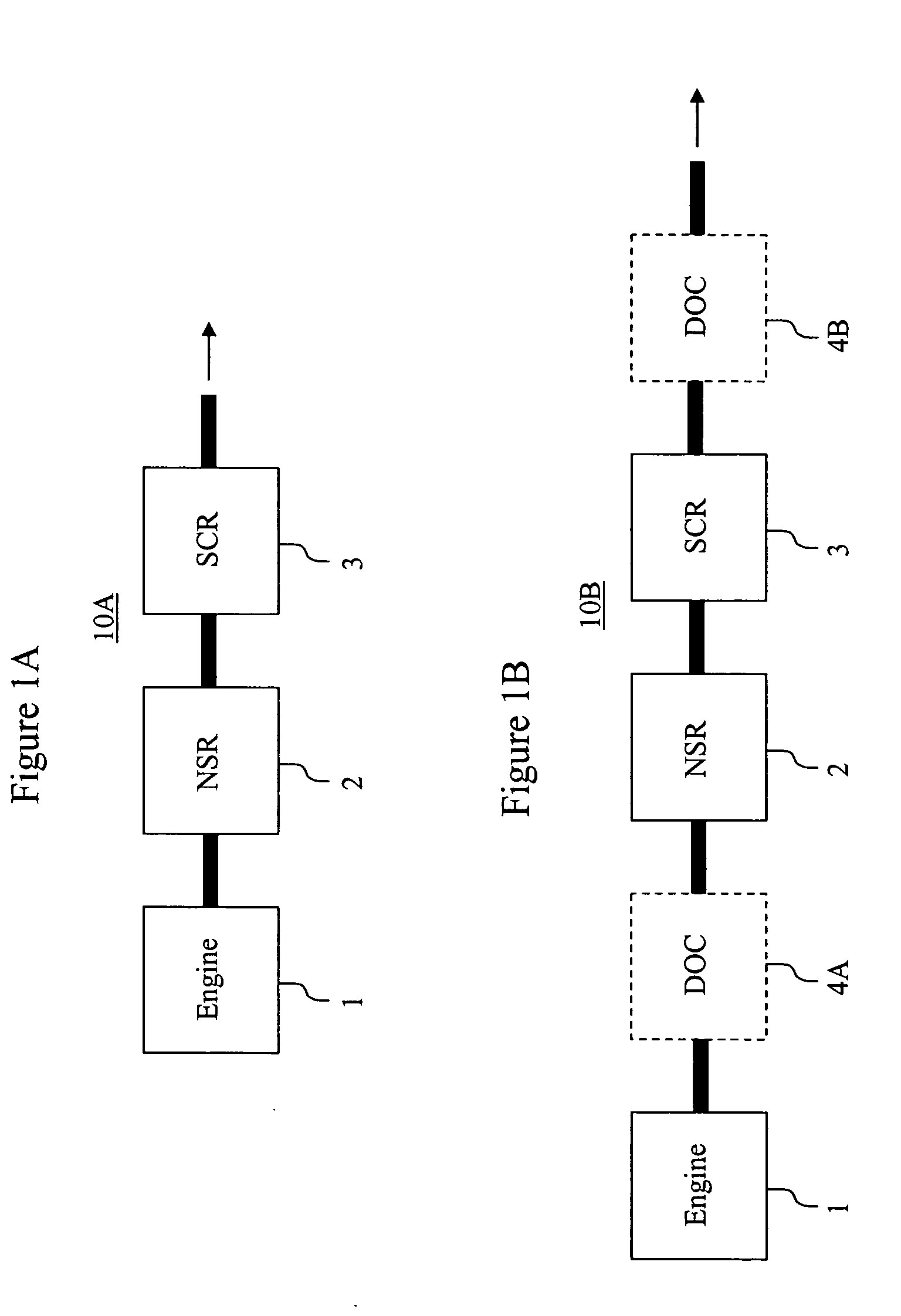

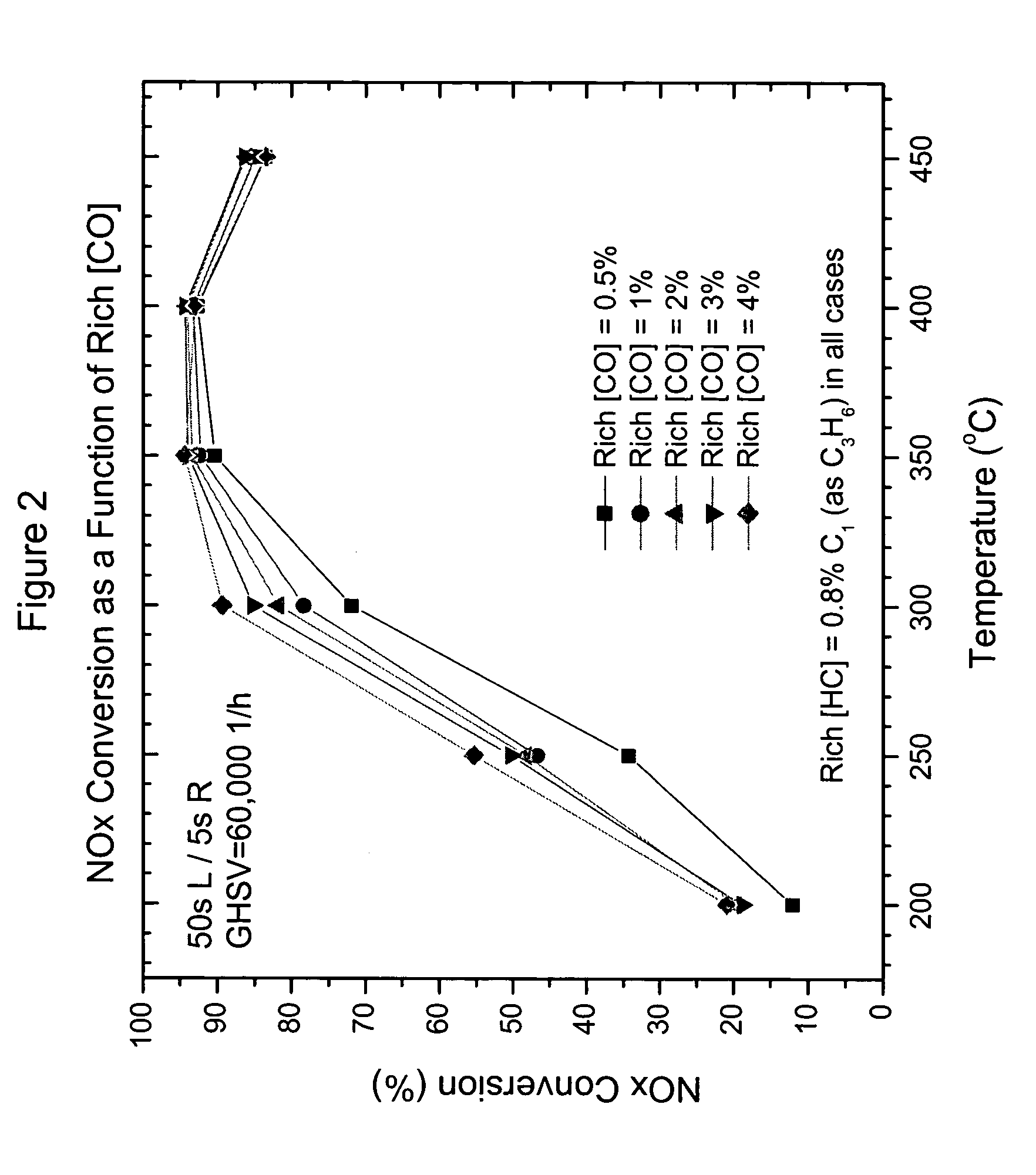

Emissions treatment system with NSR and SCR catalysts

ActiveUS20050129601A1Small sizeReduce amount particulate matterGas treatmentNitrogen compoundsSorbentGasoline

Provided is an emissions treatment system for an exhaust stream, having a NOx storage reduction (NSR) catalyst with a NOx sorbent at a concentration of at least 0.1 g / in3 and a platinum group metal component dispersed on a refractory metal oxide support; and, an SCR catalyst disposed downstream of the NSR catalyst. The emissions treatment system is advantageously used for the treatment of exhaust streams from diesel engines and lean burn gasoline engines.

Owner:BASF CATALYSTS LLC

Systems and methods for forming refractory metal nitride layers using organic amines

InactiveUS6967159B2Reduce diffuseReduce layeringSemiconductor/solid-state device manufacturingCapacitorsTantalum nitrideDeposition process

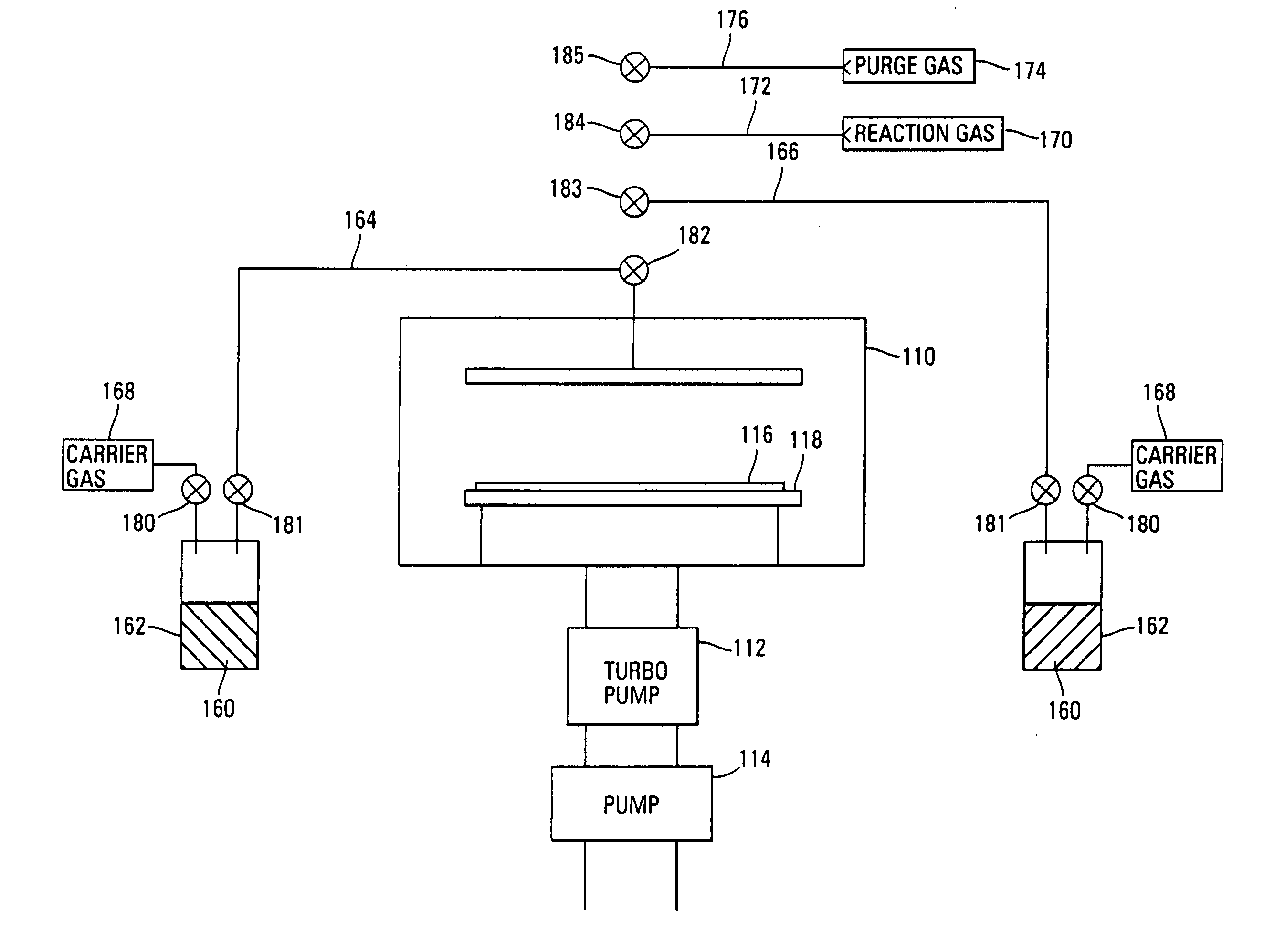

A method of forming (and apparatus for forming) refractory metal nitride layers (including silicon nitride layers), such as a tantalum nitride barrier layer, on a substrate by using an atomic layer deposition process (a vapor deposition process that includes a plurality of deposition cycles) with a refractory metal precursor compound, an organic amine, and an optional silicon precursor compound.

Owner:MICRON TECH INC

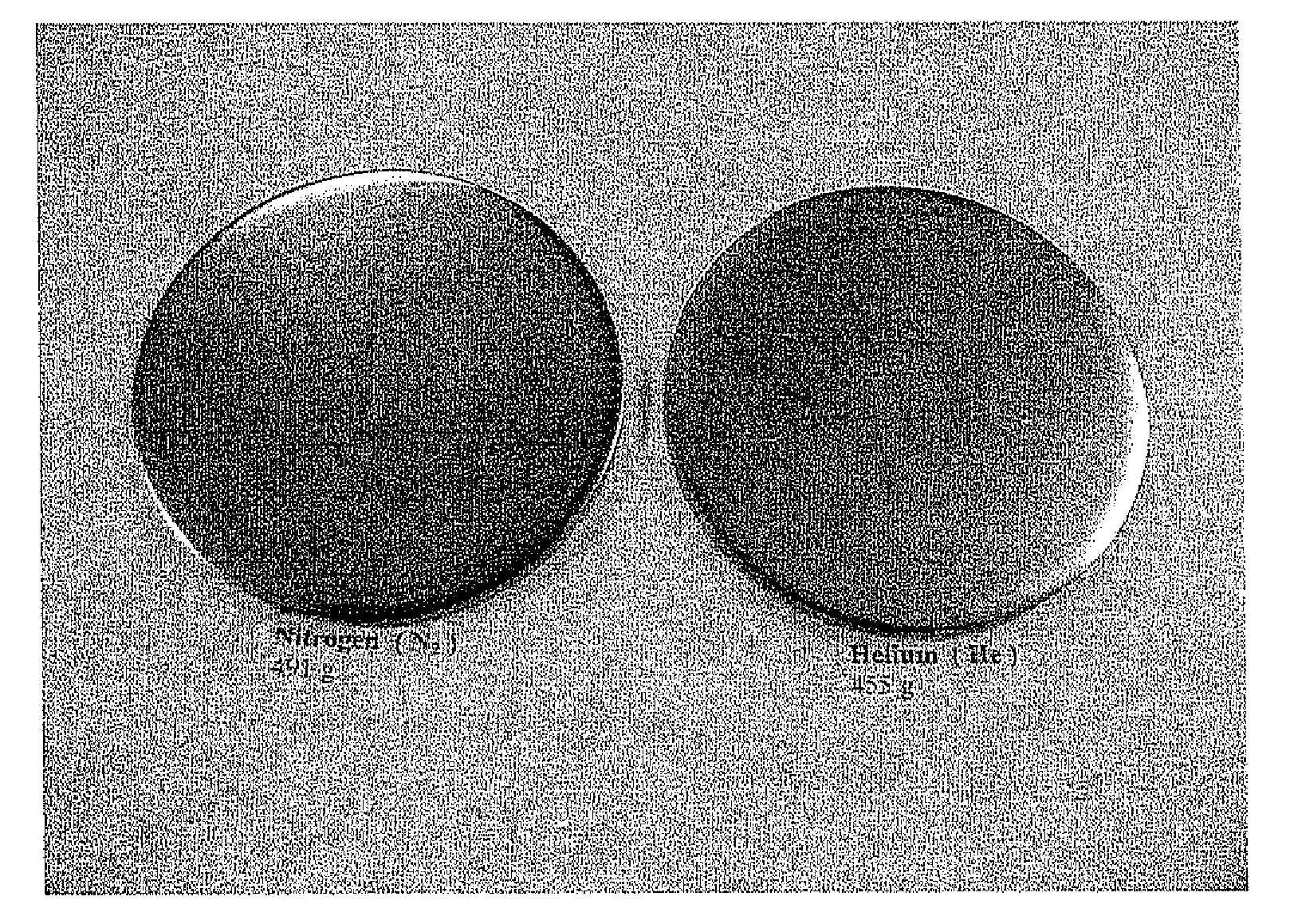

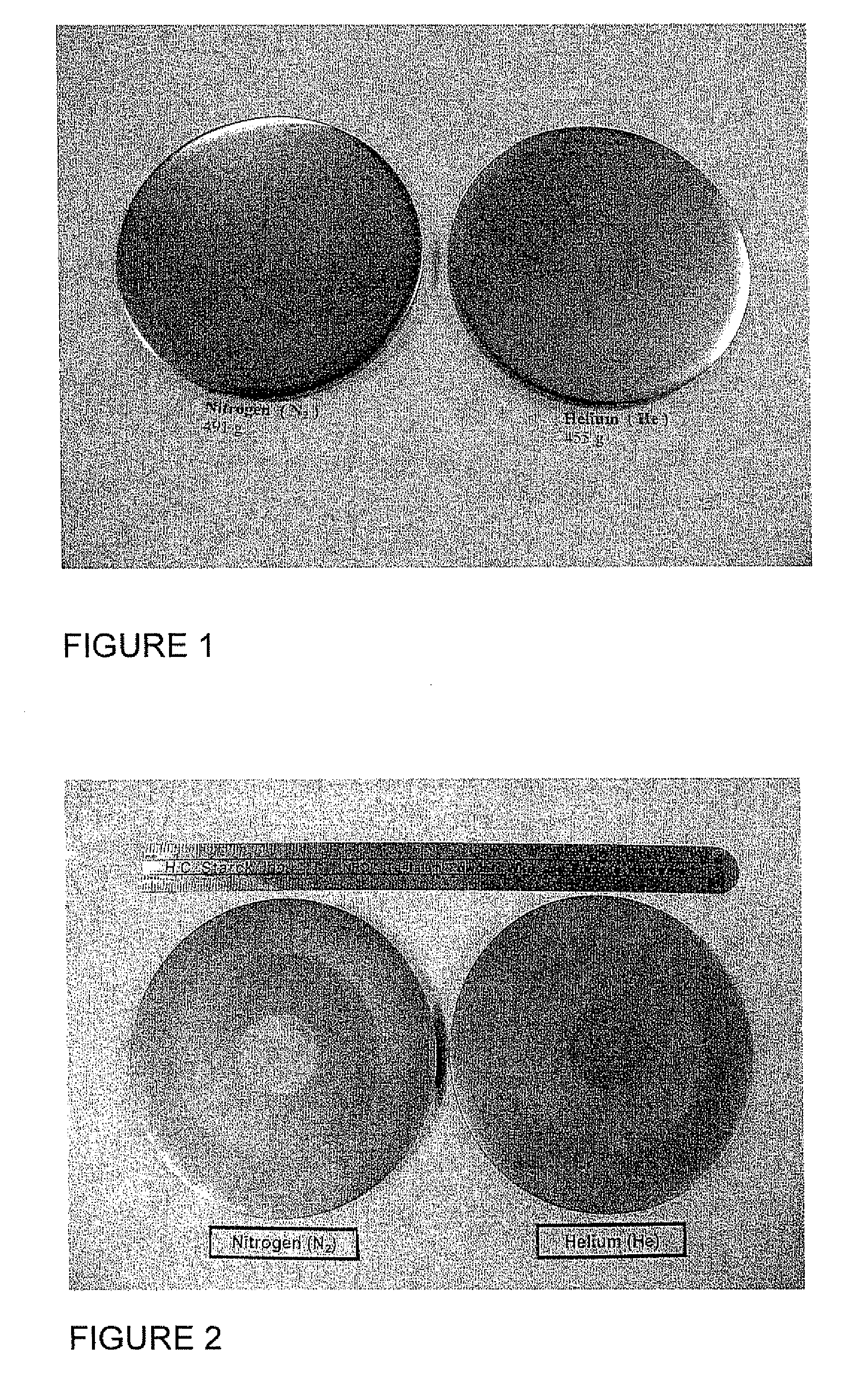

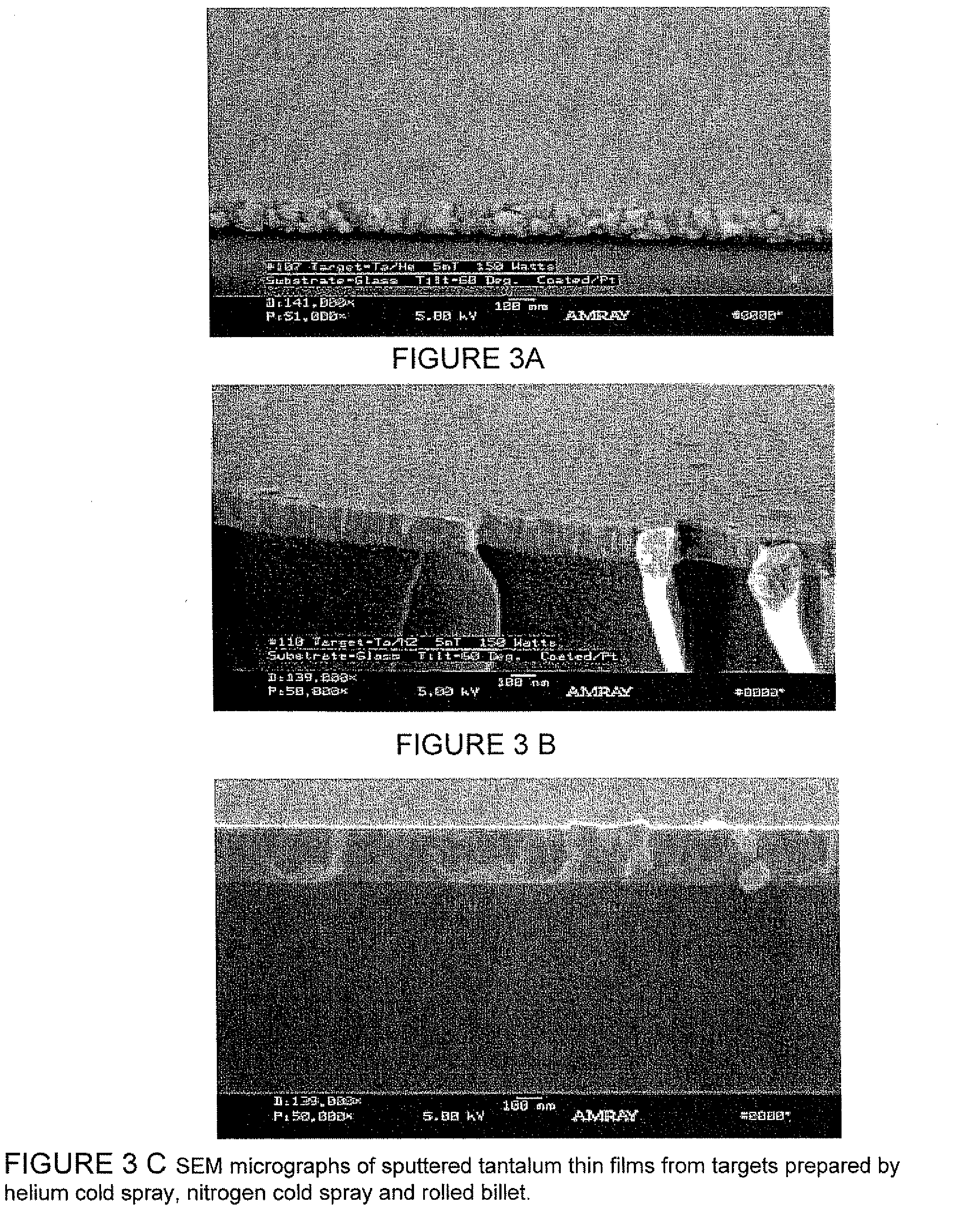

Fine Grained, Non Banded, Refractory Metal Sputtering Targets with a Uniformly Random Crystallographic Orientation, Method for Making Such Film, and Thin Film Based Devices and Products Made Therefrom

ActiveUS20080271779A1Cost-effectively createCost effectiveLiquid surface applicatorsMolten spray coatingFilm baseThermal expansion

The invention relates to a sputtering target which has a fine uniform equiaxed grain structure of less than 44 microns, no preferred texture orientation as measured by electron back scattered diffraction (“EBSD”) and that displays no grain size banding or texture banding throughout the body of the target. The invention relates a sputtering target with a lenticular or flattened grain structure, no preferred texture orientation as measured by EBSD and that displays no grain size or texture banding throughout the body of the target and where the target has a layered structure incorporating a layer of the sputtering material and at least one additional layer at the backing plate interface, said layer has a coefficient of thermal expansion (“CTE”) value between the CTE of the backing plate and the CTE of the layer of sputtering material. The invention also relates to thin films and their use of using the sputtering target and other applications, such as coatings, solar devices, semiconductor devices etc. The invention further relates to a process to repair or rejuvenate a sputtering target.

Owner:H C STARCK GMBH +1

Systems and methods for forming refractory metal oxide layers

InactiveUS20050009266A1Easy to controlMinimizing detrimental gas phase reactionSemiconductor/solid-state device manufacturingCapacitorsGas phaseEther

A method of forming (and apparatus for forming) refractory metal oxide layers, such as tantalum pentoxide layers, on substrates by using vapor deposition processes with refractory metal precursor compounds and ethers.

Owner:MICRON TECH INC

Method of forming a barrier film and method of forming wiring structure and electrodes of semiconductor device having a barrier film

There is provided a method of forming a barrier metal which is designed to be interposed between a metal layer and an insulating layer, both constituting a multi-layered structure of semiconductor device, the method comprising the steps of positioning a substrate having the insulating layer formed thereon at a predetermined position inside a processing vessel forming a processing space, and alternately introducing a gas containing a refractory metallic atom, a gas containing Si atom and a gas containing N atom into the processing vessel under a predetermined processing pressure, thereby allowing a refractory metal nitride or a refractory metal silicon nitride to be deposited on the insulating layer by way of atomic layer deposition.

Owner:TOKYO ELECTRON LTD

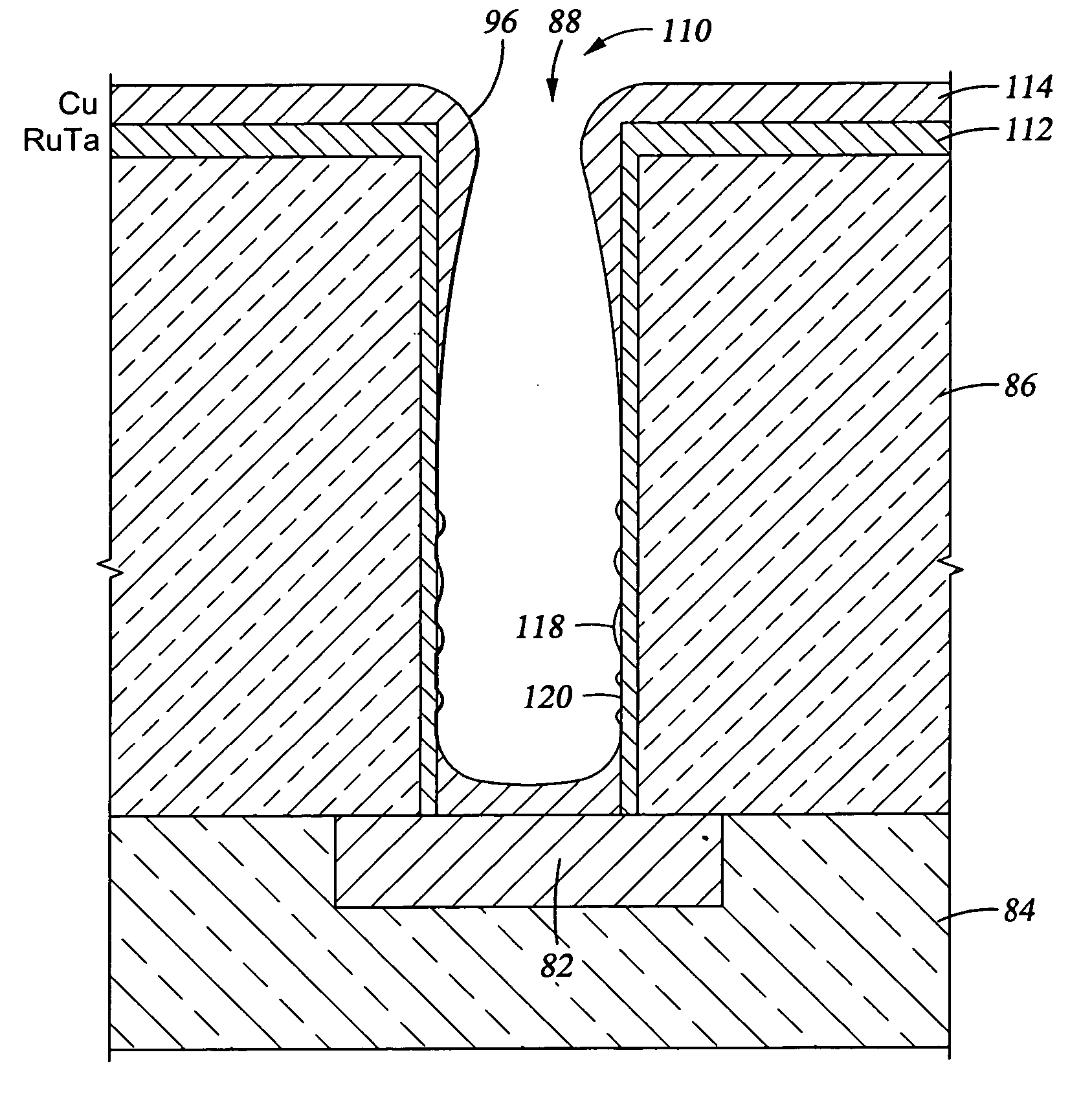

Integrated process for sputter deposition of a conductive barrier layer, especially an alloy of ruthenium and tantalum, underlying copper or copper alloy seed layer

InactiveUS20070059502A1Effective interfacial barrierGood suitSemiconductor/solid-state device detailsVacuum evaporation coatingMoisture barrierRefractory metals

A fabrication method and a product for the deposition of a conductive barrier or other liner layer in a vertical electrical interconnect structure. One embodiment includes within a a hole through a dielectric layer a barrier layer of RuTaN, an adhesion layer of RuTa, and a copper seed layer forming a liner for electroplating of copper. The ruthenium content is preferably greater than 50 at % and more preferably at least 80 at % but less than 95 at %. The barrier and adhesion layers may both be sputter deposited. Other platinum-group elements substitute for the ruthenium and other refractory metals substitute for the tantalum. Aluminum alloying into RuTa when annealed presents a moisture barrier. Copper contacts include different alloying fractions of RuTa to shift the work function to the doping type.

Owner:APPLIED MATERIALS INC

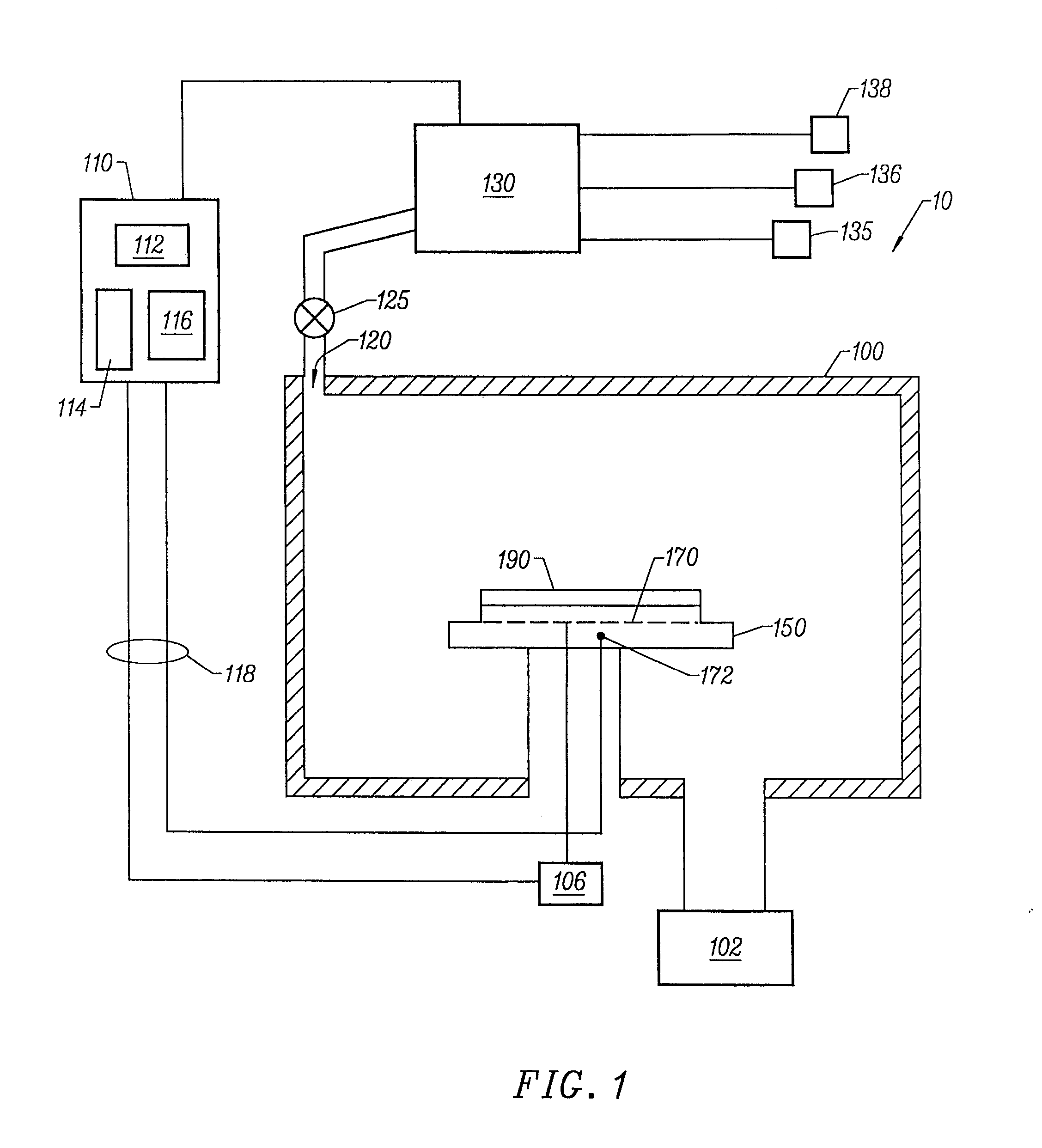

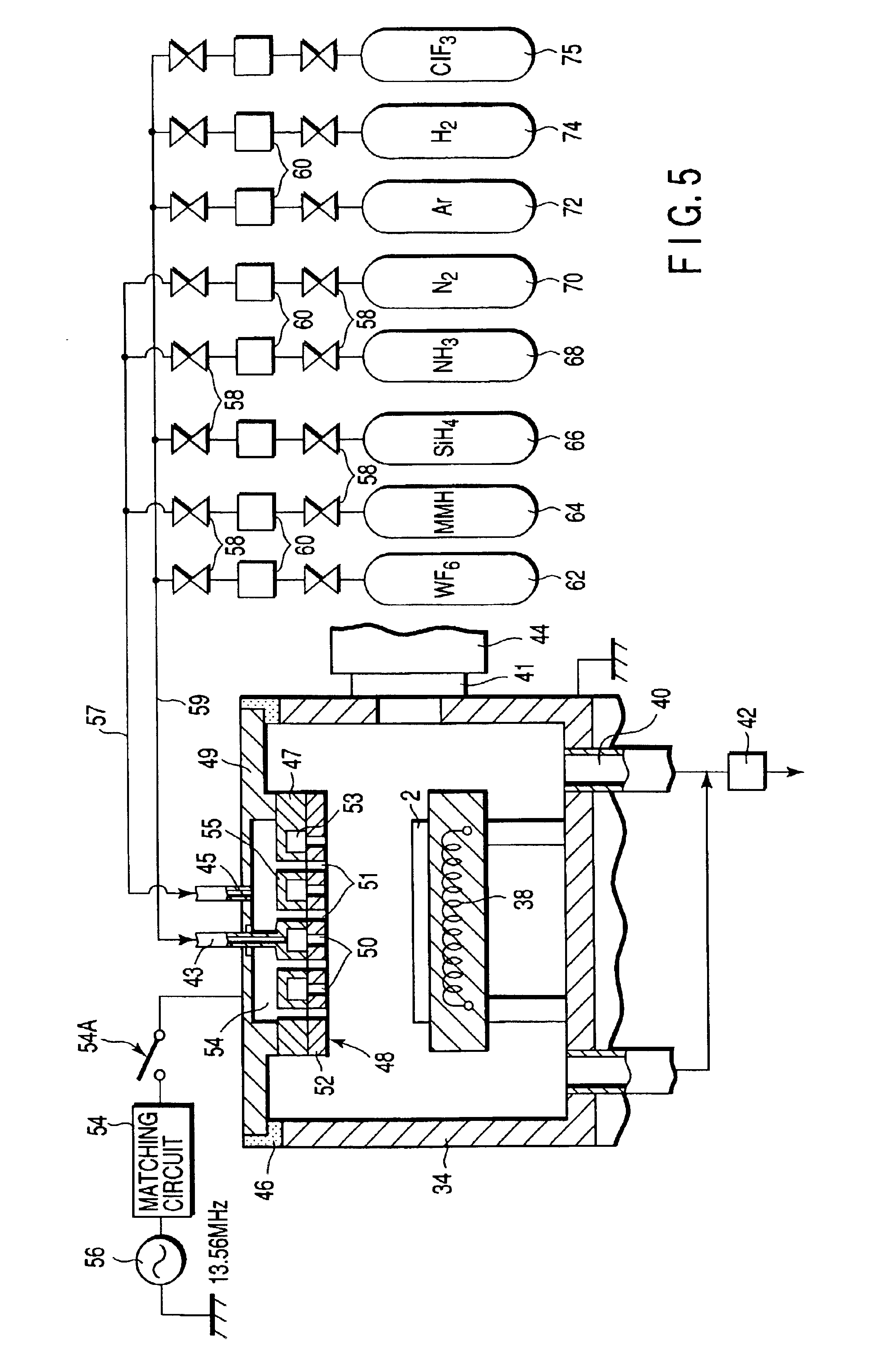

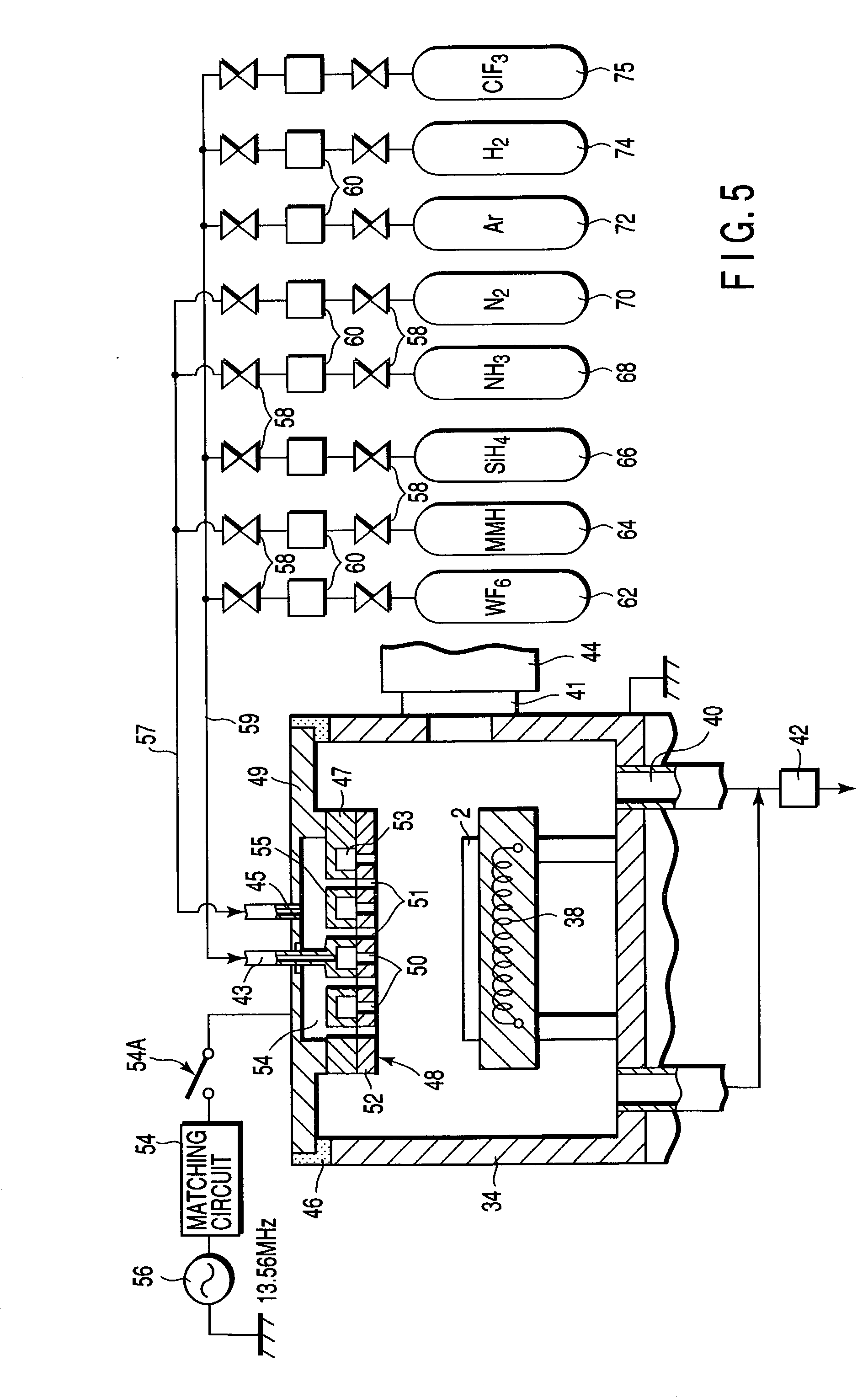

Method and apparatus for depositing tungsten after surface treatment to improve film characteristics

InactiveUS6936538B2Reduce fluorine contentHigh resistivitySolid-state devicesSemiconductor/solid-state device manufacturingChemical speciesNucleation

A method and system to form a refractory metal layer over a substrate includes introduction of a reductant, such as PH3 or B2H6, followed by introduction of a tungsten containing compound, such as WF6, to form a tungsten layer. It is believed that the reductant reduces the fluorine content of the tungsten layer while improving the step coverage and resistivity of the tungsten layer. It is believed that the improved characteristics of the tungsten film are attributable to the chemical affinity between the reductants and the tungsten containing compound. The chemical affinity provides better surface mobility of the adsorbed chemical species and better reduction of WF6 at the nucleation stage of the tungsten layer. The method can further include sequentially introducing a reductant, such as PH3 or B2H6, and a tungsten containing compound to deposit a tungsten layer. The formed tungsten layer can be used as a nucleation layer followed by bulk deposition of a tungsten layer utilizing standard CVD techniques. Alternatively, the formed tungsten layer can be used to fill an aperture.

Owner:APPLIED MATERIALS INC

Corrosion resistant component of semiconductor processing equipment and method of manufacturing thereof

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber includes a metal surface such as aluminum or aluminum alloy, stainless steel, or refractory metal coated with a phosphorus nickel plating and an outer ceramic coating such as alumina, silicon carbide, silicon nitride, boron carbide or aluminum nitride. The phosphorus nickel plating can be deposited by electroless plating and the ceramic coating can be deposited by thermal spraying. To promote adhesion of the ceramic coating, the phosphorus nickel plating can be subjected to a surface roughening treatment prior to depositing the ceramic coating.

Owner:LAM RES CORP

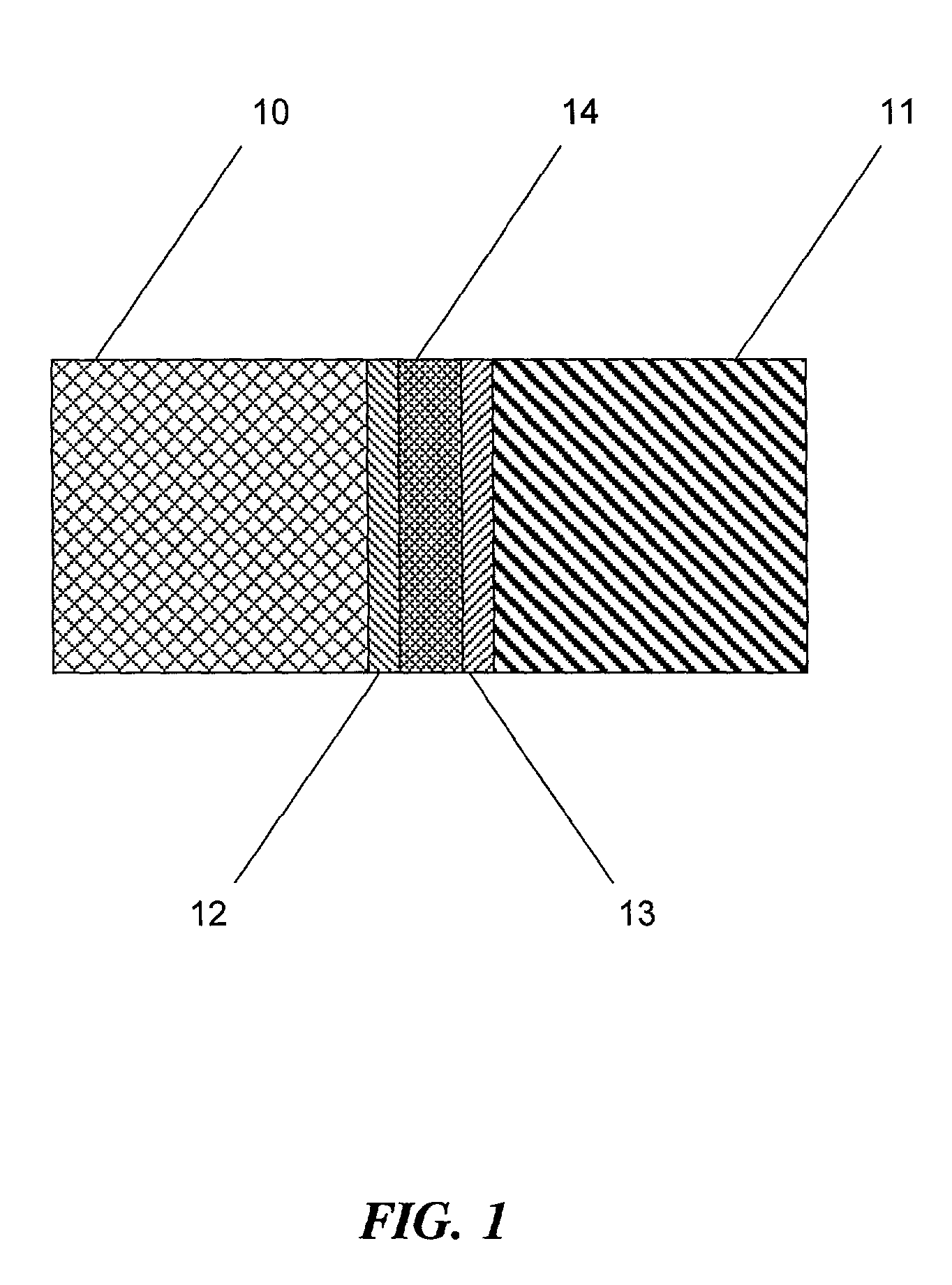

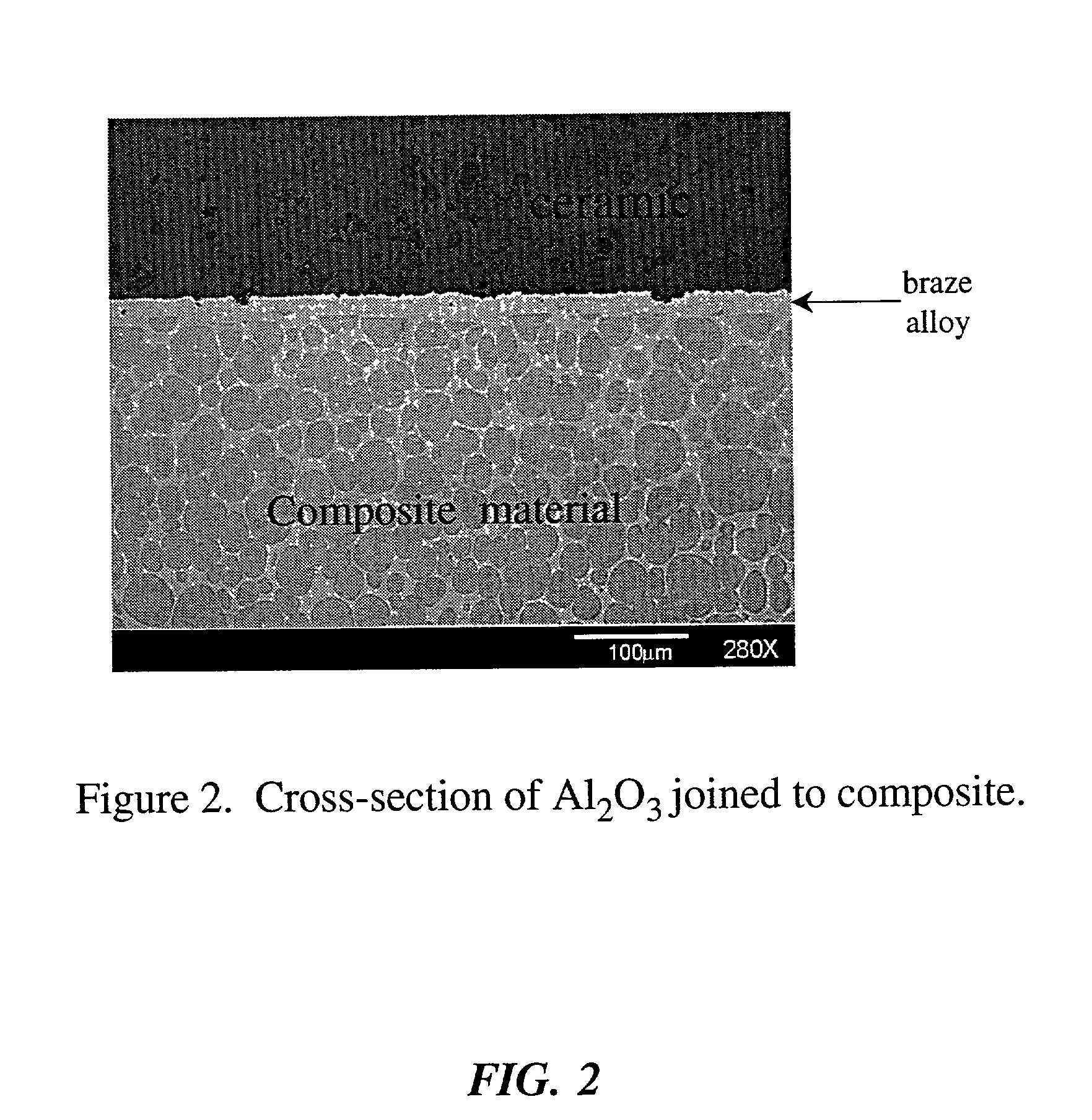

Braze system and method for reducing strain in a braze joint

A system for joining a pair of structural members having widely differing coefficients of thermal expansion is disclosed. A mechanically "thick" foil is made by dispersing a refractory metal powder, such as molybdenum, niobium, tantalum, or tungsten into a quantity of a liquid, high expansion metal such as copper, silver, or gold, casting an ingot of the mixture, and then cutting sections of the ingot about 1 mm thick to provide the foil member. These foil members are shaped, and assembled between surfaces of structural members for joining, together with a layer of a braze alloy on either side of the foil member capable of wetting both the surfaces of the structural members and the foil. The assembled body is then heated to melt the braze alloy and join the assembled structure. The foil member subsequently absorbs the mechanical strain generated by the differential contraction of the cooling members that results from the difference in the coefficients of thermal expansion of the members.

Owner:SANDIA NAT LAB

Systems and methods of forming refractory metal nitride layers using disilazanes

InactiveUS20050028733A1Easy to controlMinimizing detrimental gas phase reactionPolycrystalline material growthSemiconductor/solid-state device manufacturingGas phaseDeposition process

A method of forming (and apparatus for forming) refractory metal nitride layers (including silicon nitride layers), such as a tantalum (silicon) nitride barrier layer, on a substrate by using a vapor deposition process with a refractory metal precursor compound, a disilazane, and an optional silicon precursor compound.

Owner:MICRON TECH INC

Systems and methods of forming refractory metal nitride layers using disilazanes

InactiveUS20050032360A1Easy to controlMinimizing detrimental gas phase reactionSemiconductor/solid-state device manufacturingCapacitorsGas phaseDeposition process

Owner:MICRON TECH INC

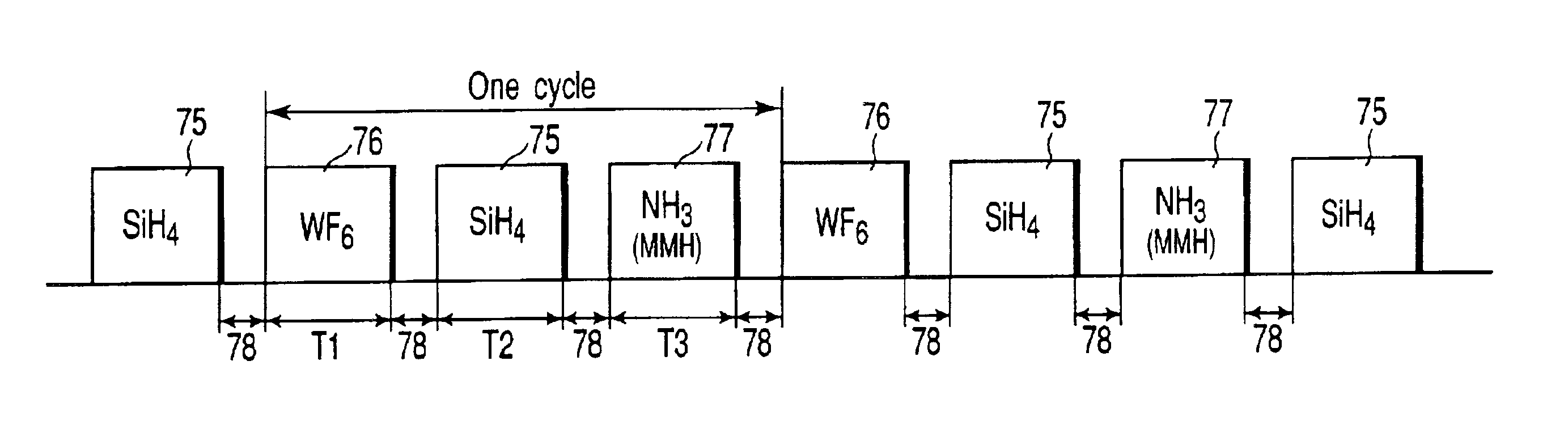

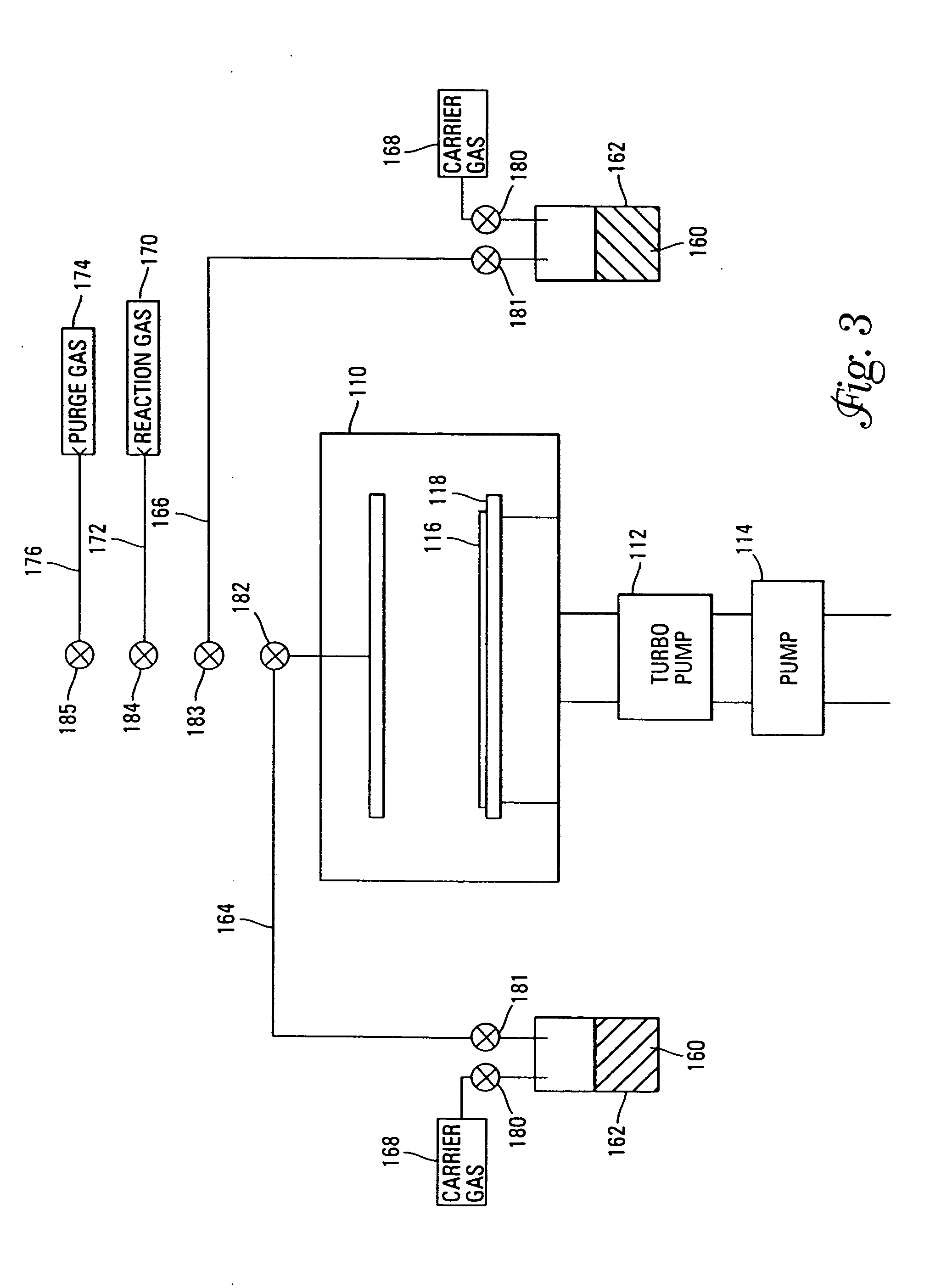

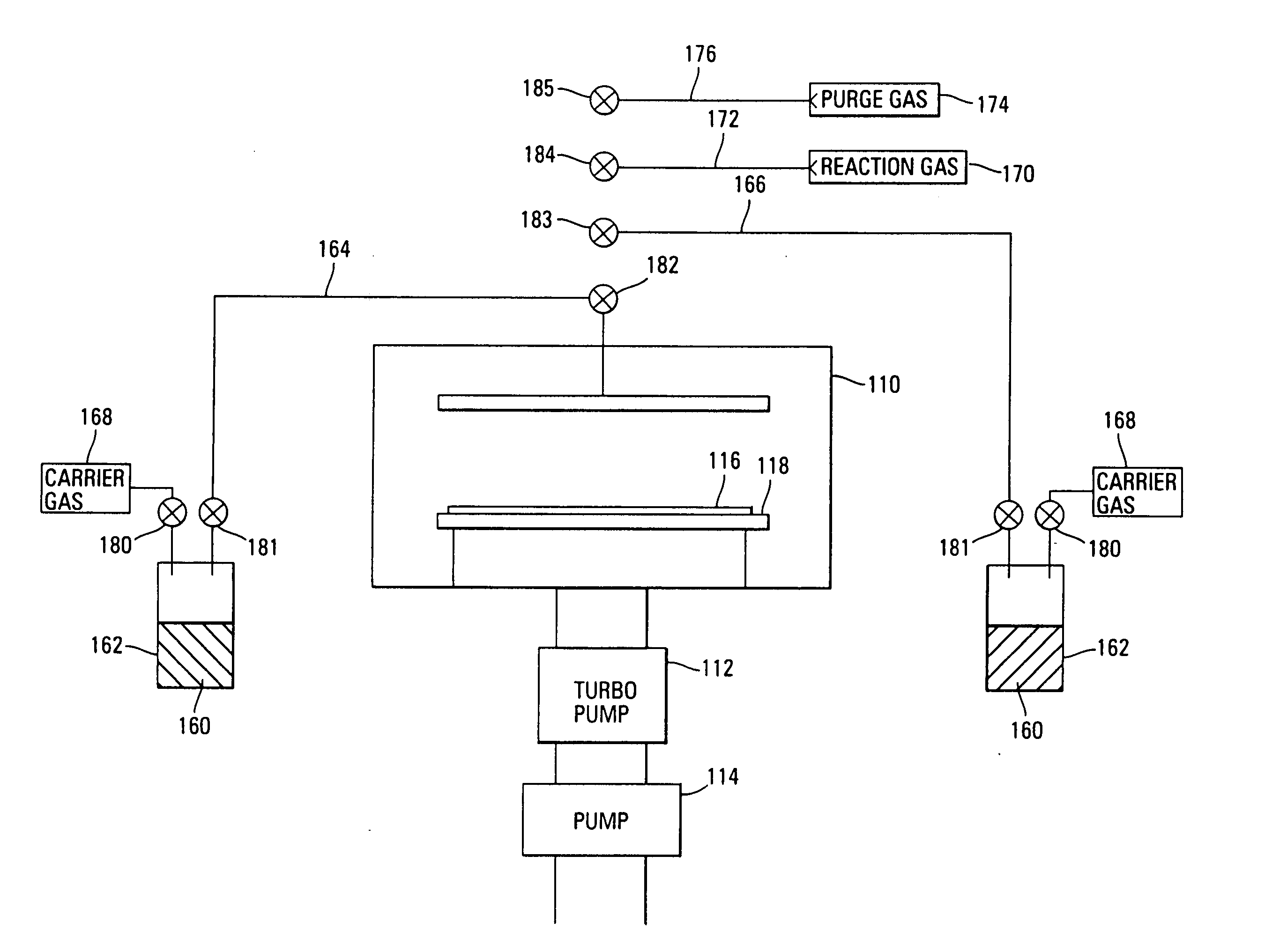

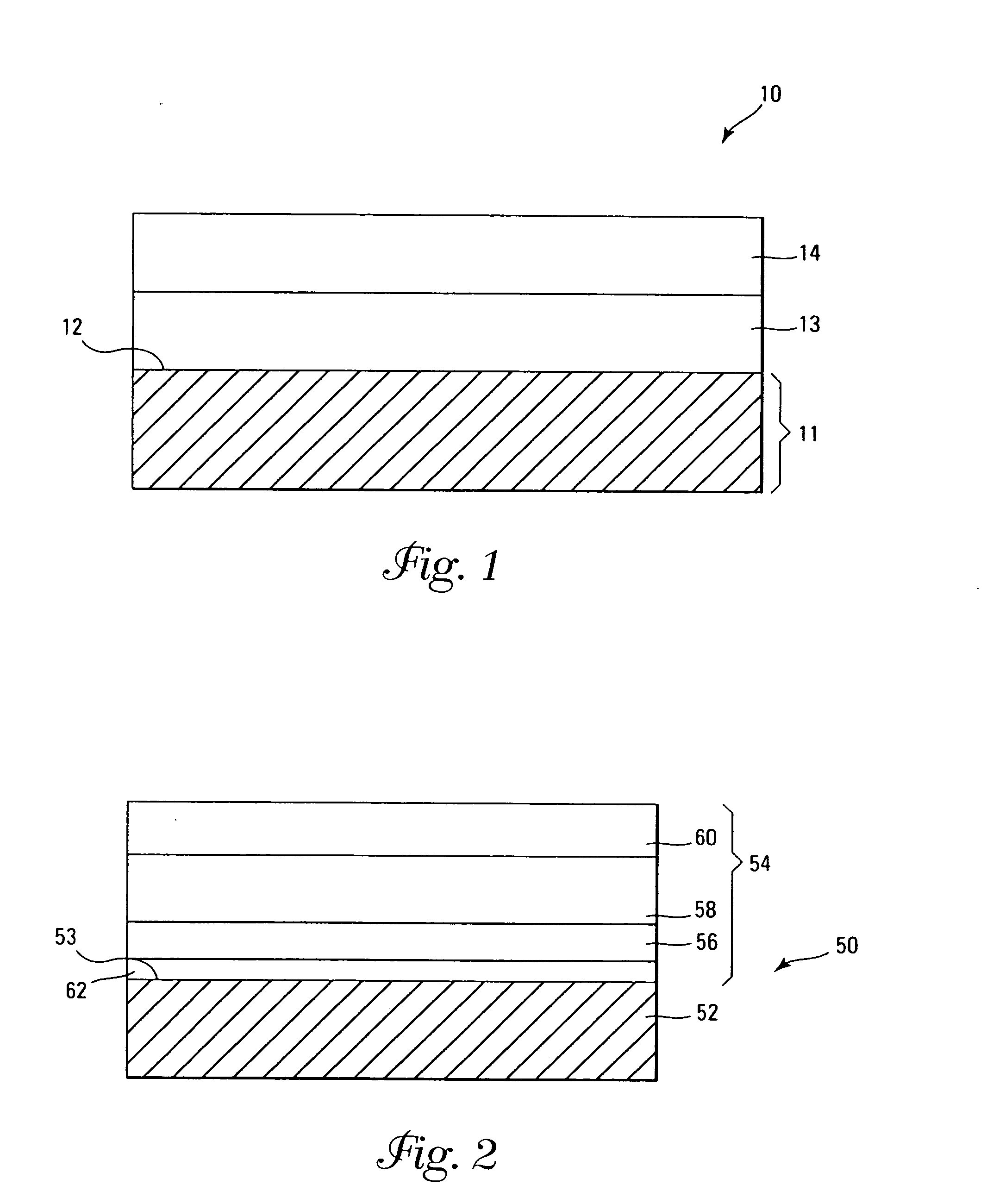

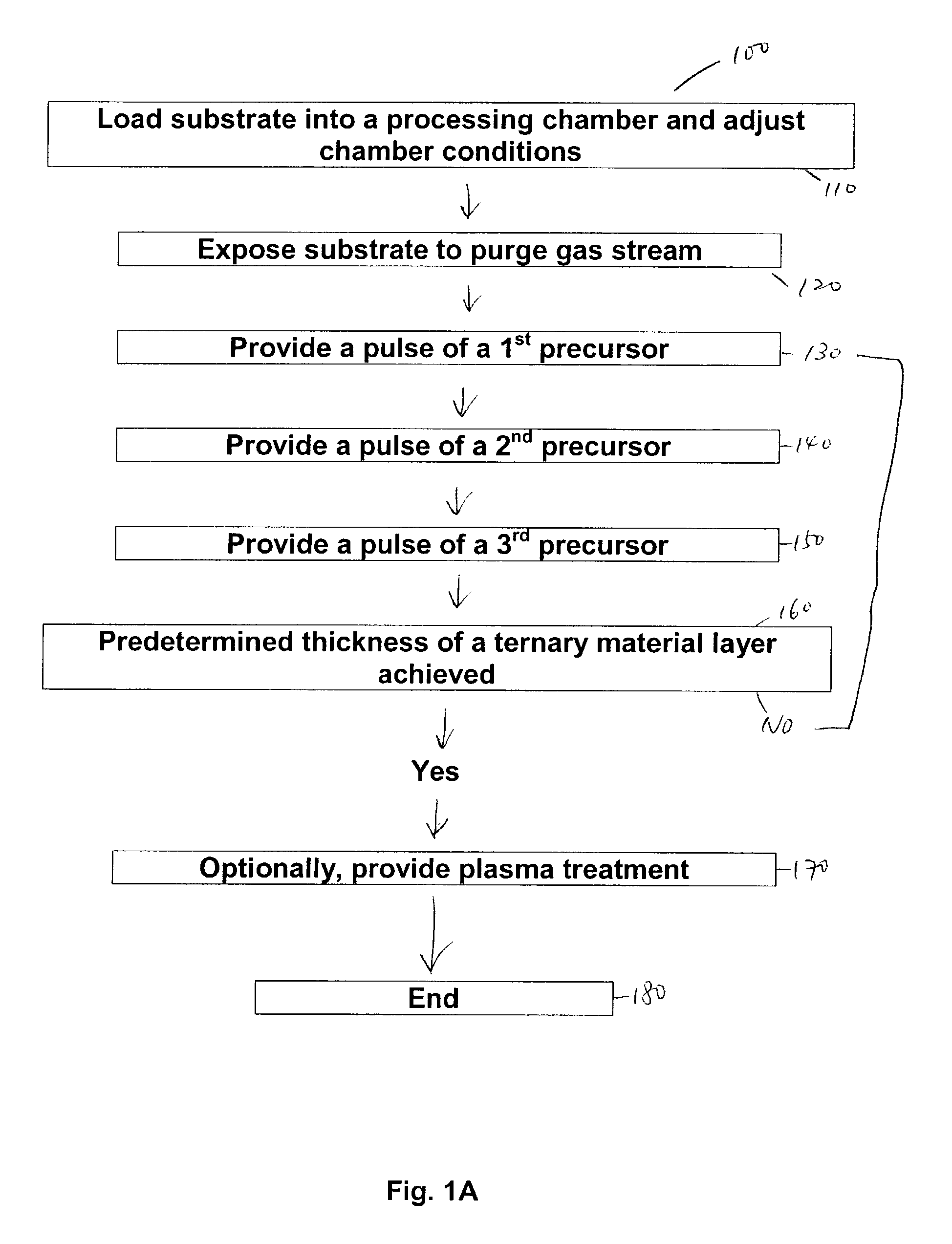

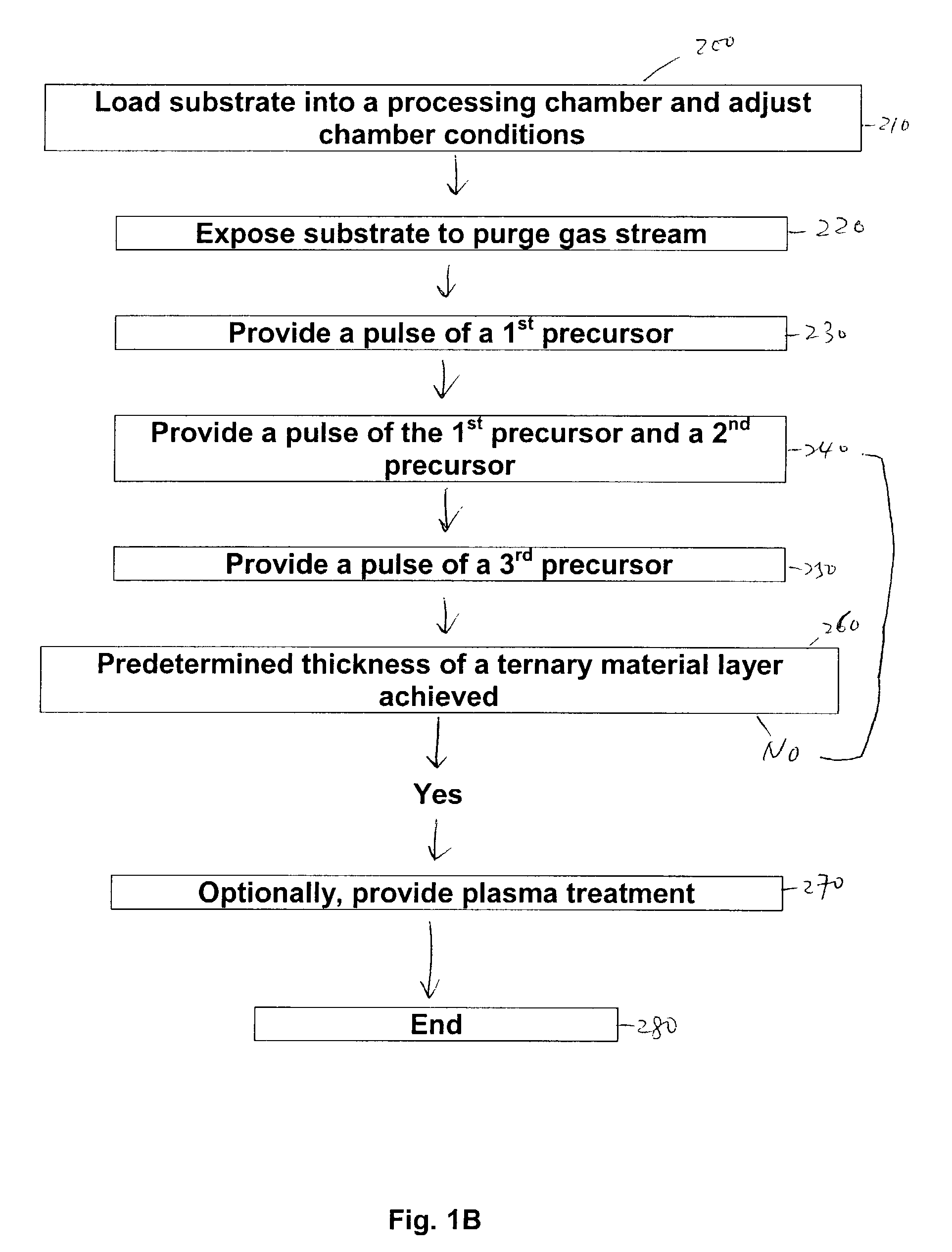

Cyclical deposition of refractory metal silicon nitride

InactiveUS7081271B2Prevent proliferationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSubstrate surfaceMaterials science

Embodiments of the invention relate to an apparatus and method of cyclical layer deposition utilizing three or more precursors. In one embodiment, the method includes providing at least one cycle of precursors to form a ternary material layer. Providing at least one cycle of precursors includes introducing a pulse of a first precursor, introducing a pulse of a second precursor, and introducing a pulse of a third precursor, wherein the pulses of two of the three precursors are introduced simultaneously or sequentially. In another embodiment, the method includes introducing a pulse of a first precursor, introducing a pulse of a second precursor, repeating the introduction of the first and the second precursors at least one time to form a binary material layer on the substrate surface, and introducing a pulse of a third precursor to form the ternary material layer.

Owner:APPLIED MATERIALS INC

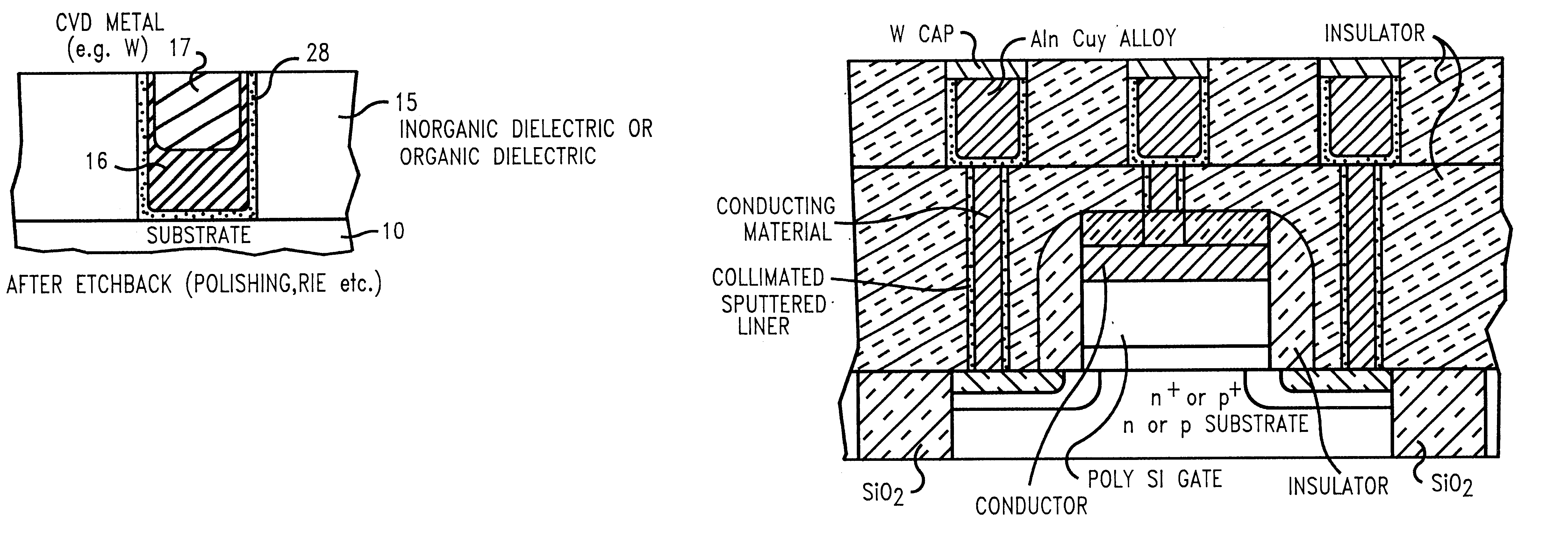

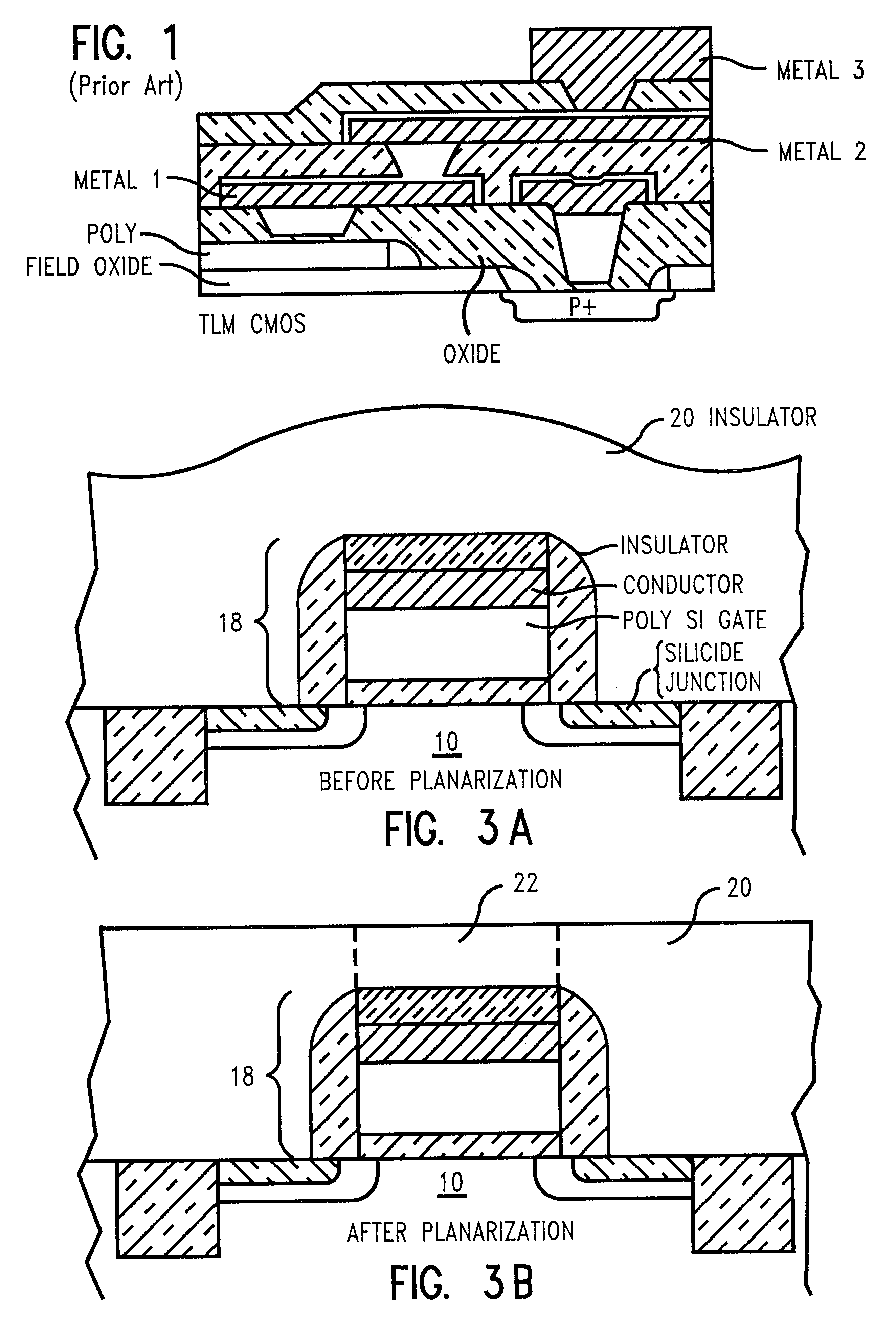

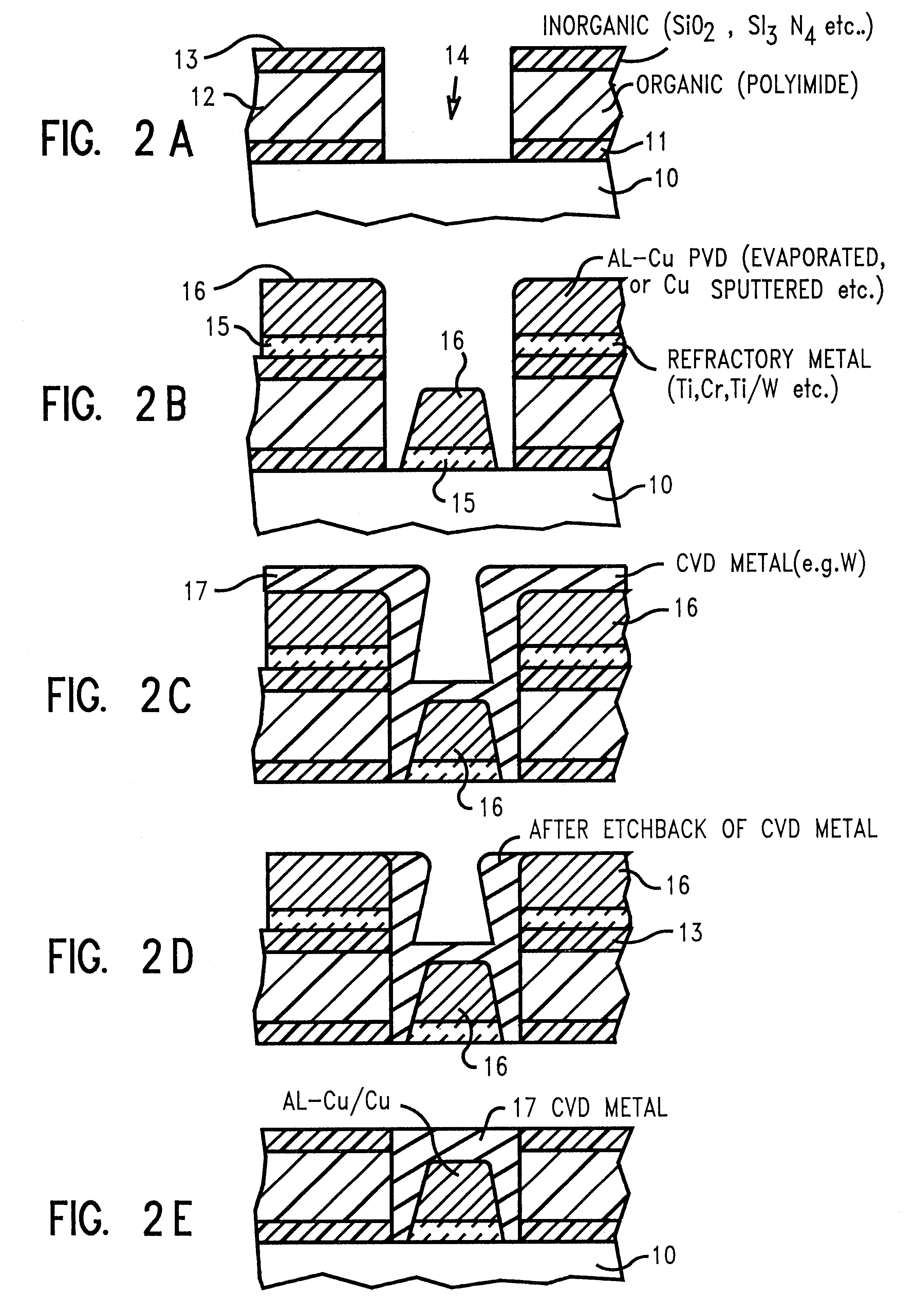

Refractory metal capped low resistivity metal conductor lines and vias formed using PVD and CVD

InactiveUS6323554B1High process yieldSemiconductor/solid-state device detailsSolid-state devicesDielectricGas phase

Capping a low resistivity metal conductor line or via with a refractory metal allows for effectively using chemical-mechanical polishing techniques because the hard, reduced wear, properties of the refractory metal do not scratch, corrode, or smear during chemical-mechanical polishing. Conductive lines and vias are created using a combination of both physical vapor deposition (e.g., evaporation or collimated sputtering) of a low resistivity metal or alloy followed by chemical vapor deposition (CVD) of a refractory metal and subsequent planarization. Altering a ratio of SiH4 to WF6 during application of the refractory metal cap by CVD allows for controlled incorporation of silicon into the tungsten capping layer. Collimated sputtering allows for creating a refractory metal liner in an opening in a dielectric which is suitable as a diffusion barrier to copper based metalizations as well as CVD tungsten. Ideally, for faster diffusing metals like copper, liners are created by a two step collimated sputtering process wherein a first layer is deposited under relatively low vacuum pressure where directional deposition dominates (e.g., below 1 mTorr) and a second layer is deposited under relatively high vacuum pressure where scattering deposition dominates (e.g., above 1 mTorr). For refractory metals like CVD tungsten, the liner can be created in one step using collimated sputtering at higher vacuum pressures.

Owner:GLOBALFOUNDRIES INC

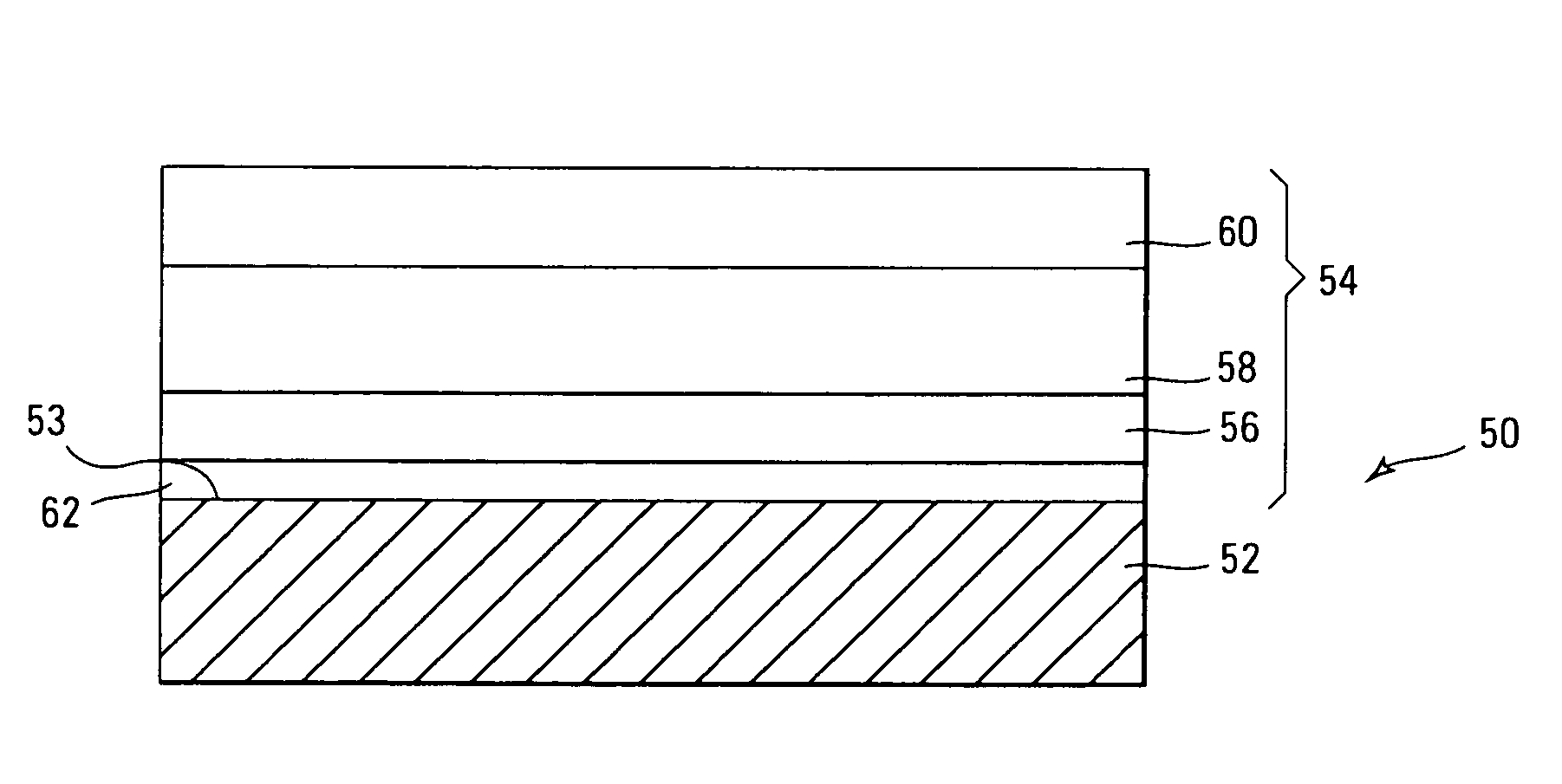

Exhaust gas treatment catalyst

InactiveUS7374729B2Improved coating architectureSacrificing TWC catalyst performanceCombination devicesInternal combustion piston enginesSorbentMetal

Provided are an exhaust treatment catalyst and an exhaust article containing the catalyst. The catalyst comprises:(a) a carrier;(b) a first layer deposited on the carrier, said first layer comprising substantially only at least one refractive metal oxide;(c) a second layer deposited on the first layer, said second layer comprising substantially only at least one oxygen storage component and at least one binder therefor; and(d) a third layer deposited on the second layer, said third layer comprising at least one layer of one or more platinum group metal components supported on a refractory metal oxide support.Optionally, a fourth layer is deposited on the third layer wherein the fourth layer comprises one or more platinum group metal components supported on a refractory metal oxide support. As a further option, an overcoat layer may be deposited on the third or fourth layer wherein the overcoat layer comprises a catalyst poison sorbent. Also provided are methods for preparing the catalyst and methods for monitoring the exhaust storage capacity of an exhaust article containing the catalyst.

Owner:BASF CATALYSTS LLC

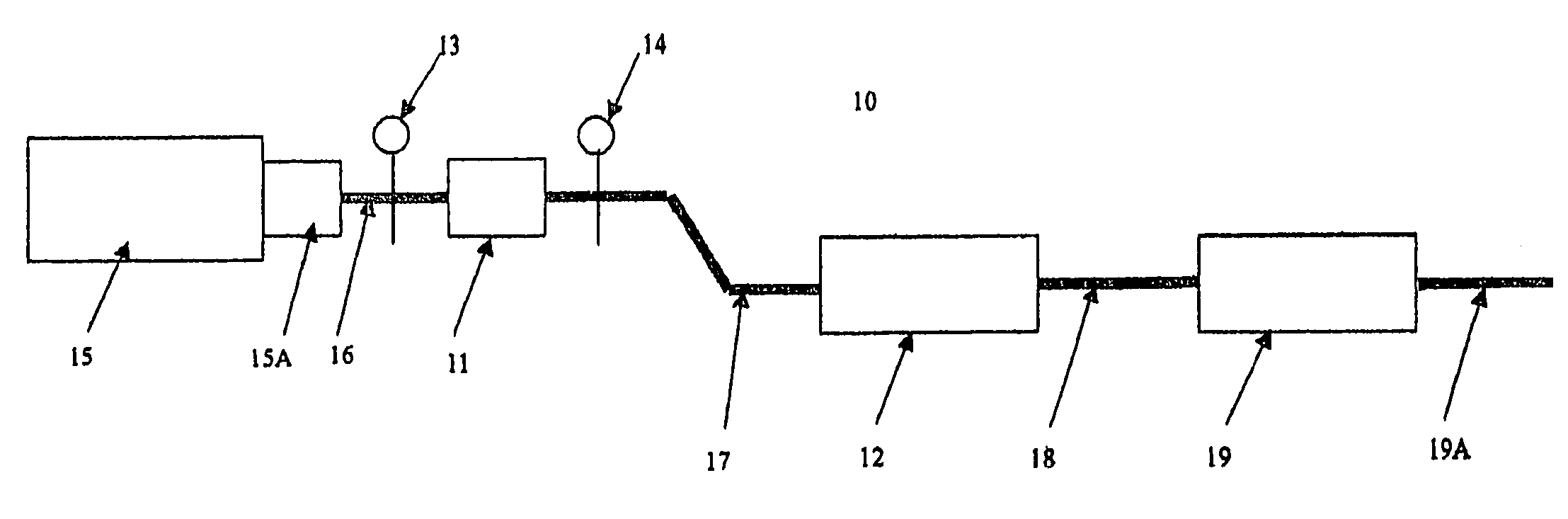

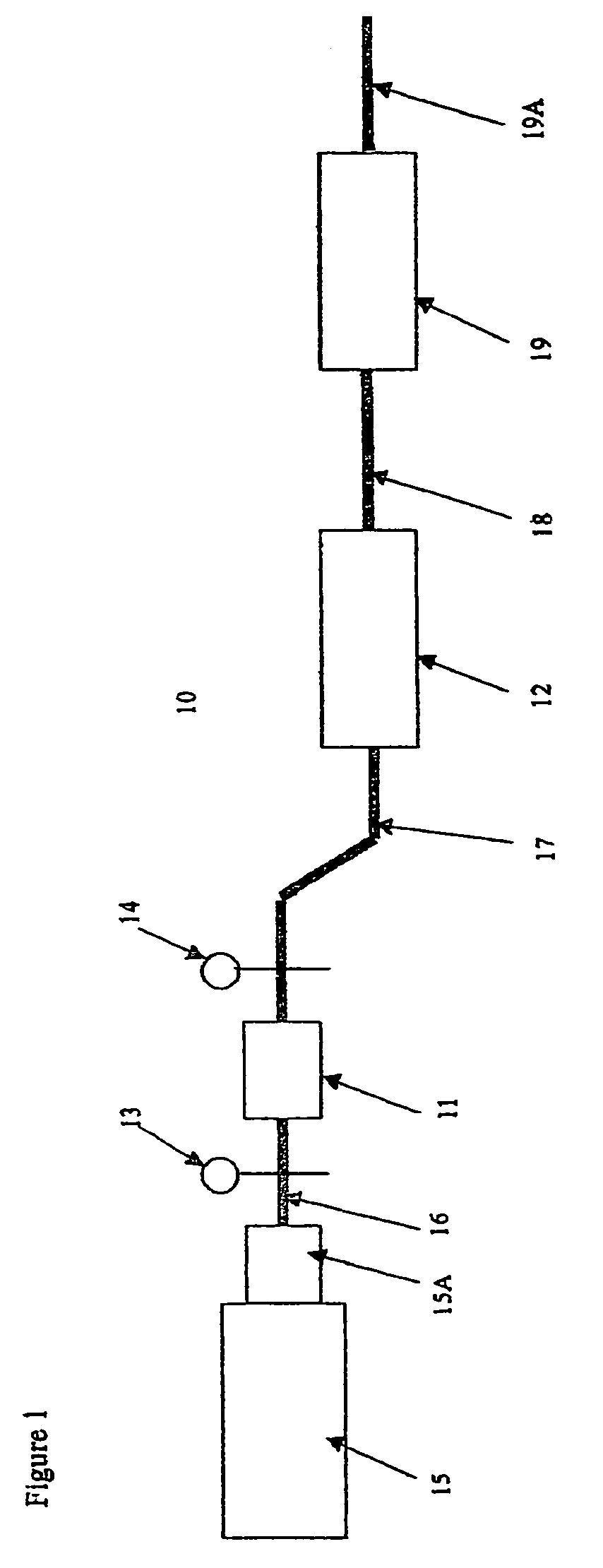

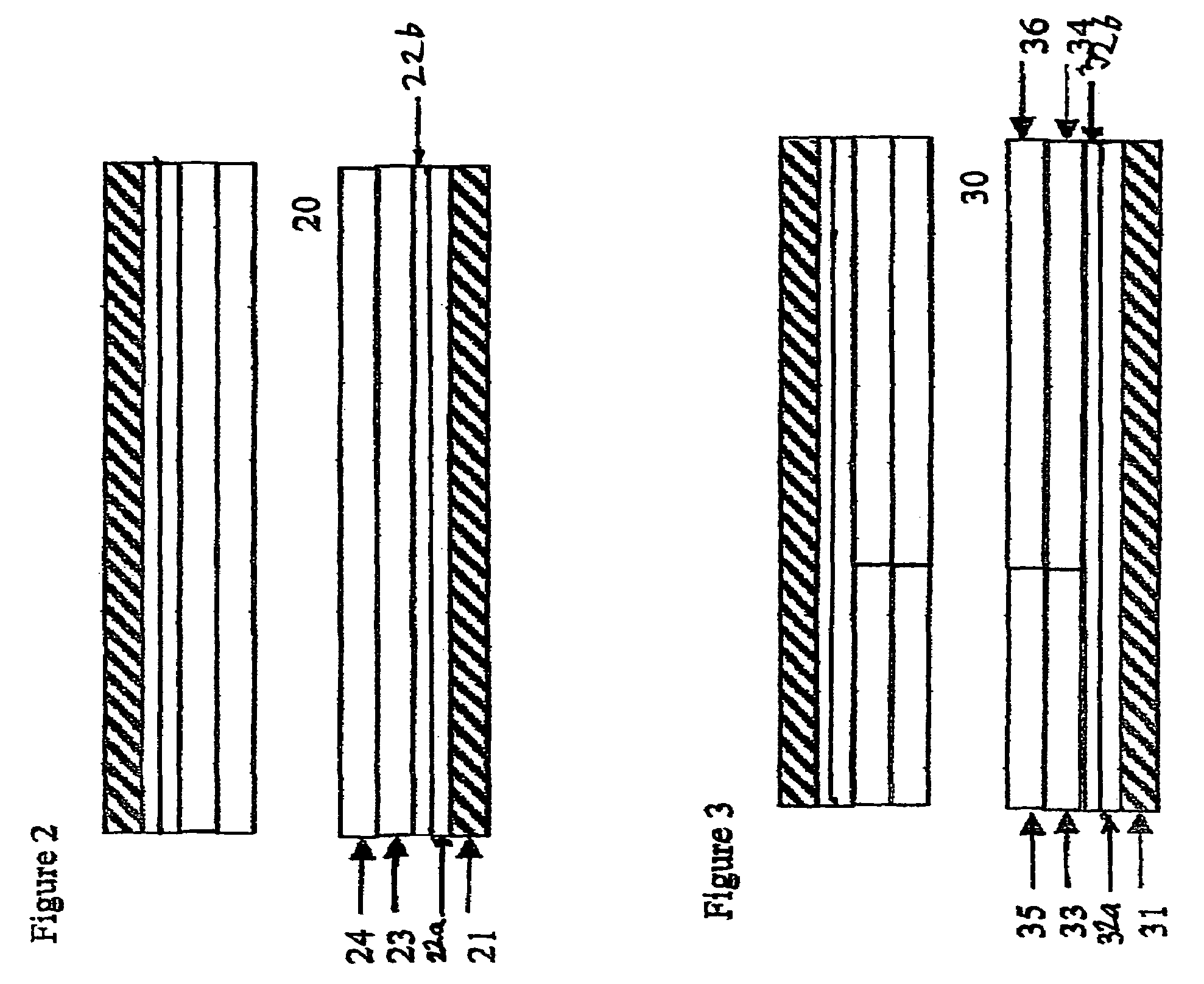

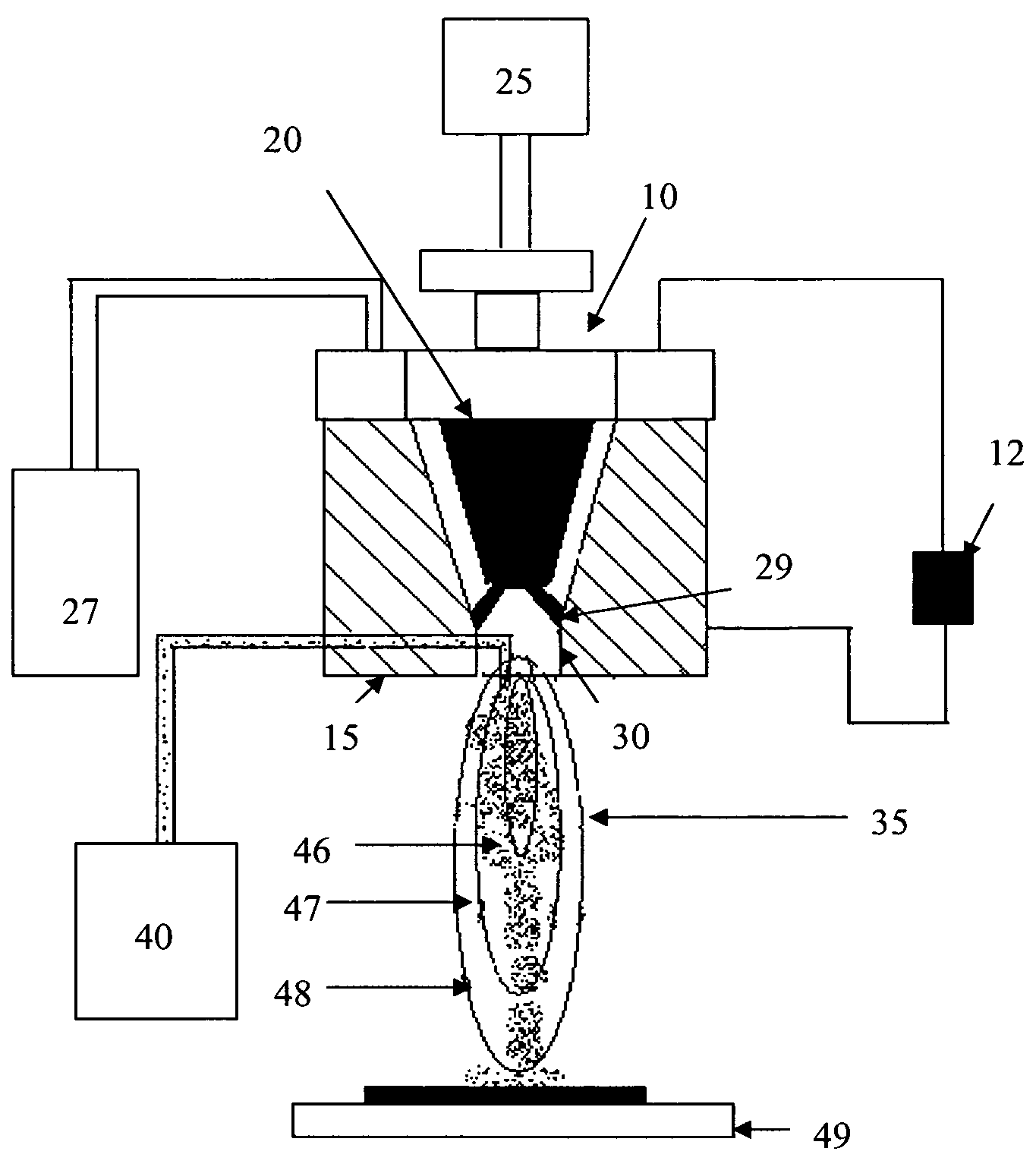

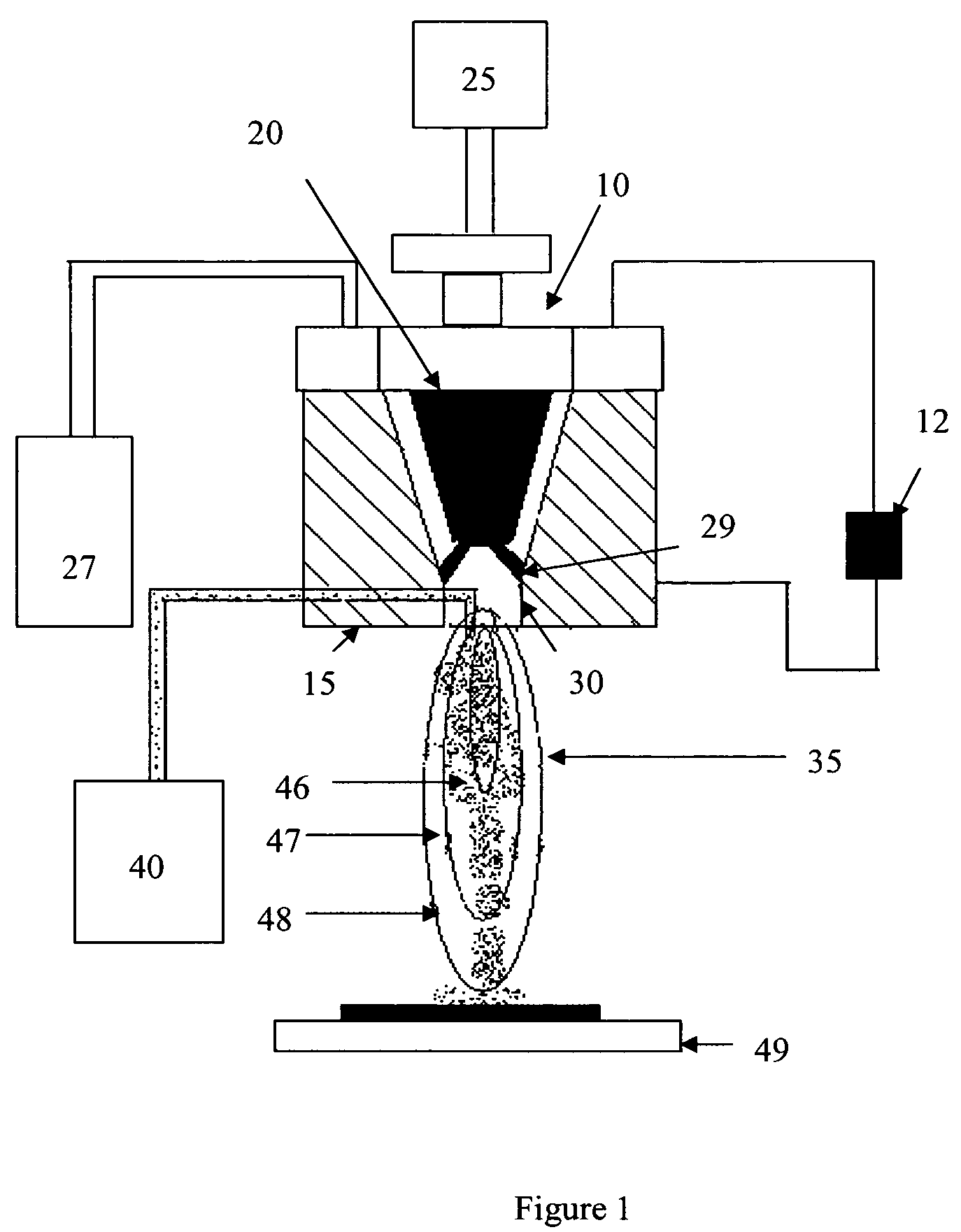

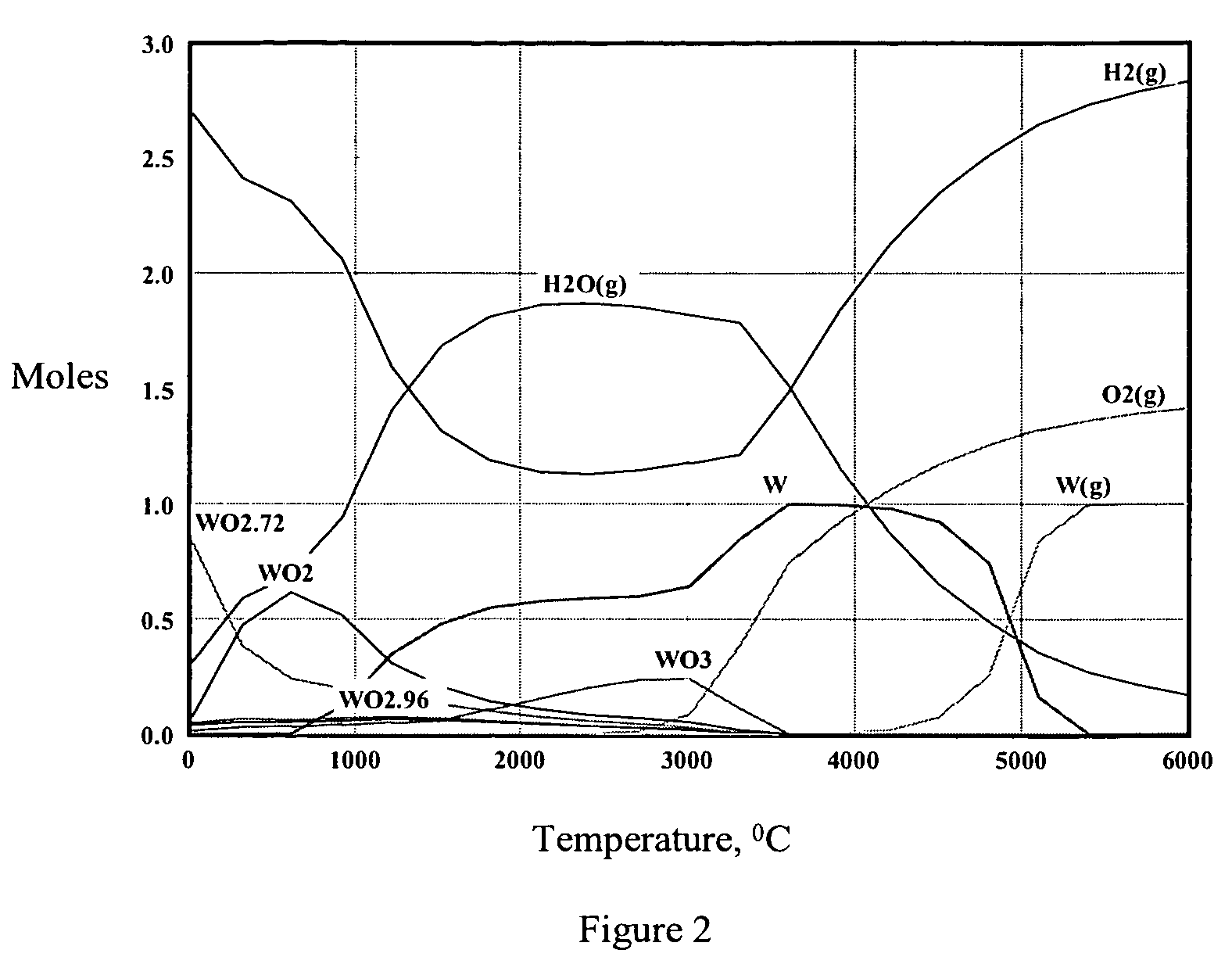

Nano powders, components and coatings by plasma technique

ActiveUS7615097B2Rapid quenching and generationHigh materialLiquid surface applicatorsMolten spray coatingRheniumChemical reaction

Ultra fine and nanometer powders and a method of producing same are provided, preferably refractory metal and ceramic nanopowders. When certain precursors are injected into the plasma flame in a reactor chamber, the materials are heated, melted and vaporized and the chemical reaction is induced in the vapor phase. The vapor phase is quenched rapidly to solid phase to yield the ultra pure, ultra fine and nano product. With this technique, powders have been made 20 nanometers in size in a system capable of a bulk production rate of more than 10 lbs / hr. The process is particularly applicable to tungsten, molybdenum, rhenium, tungsten carbide, molybdenum carbide and other related materials.

Owner:PLASMA PROCESSES

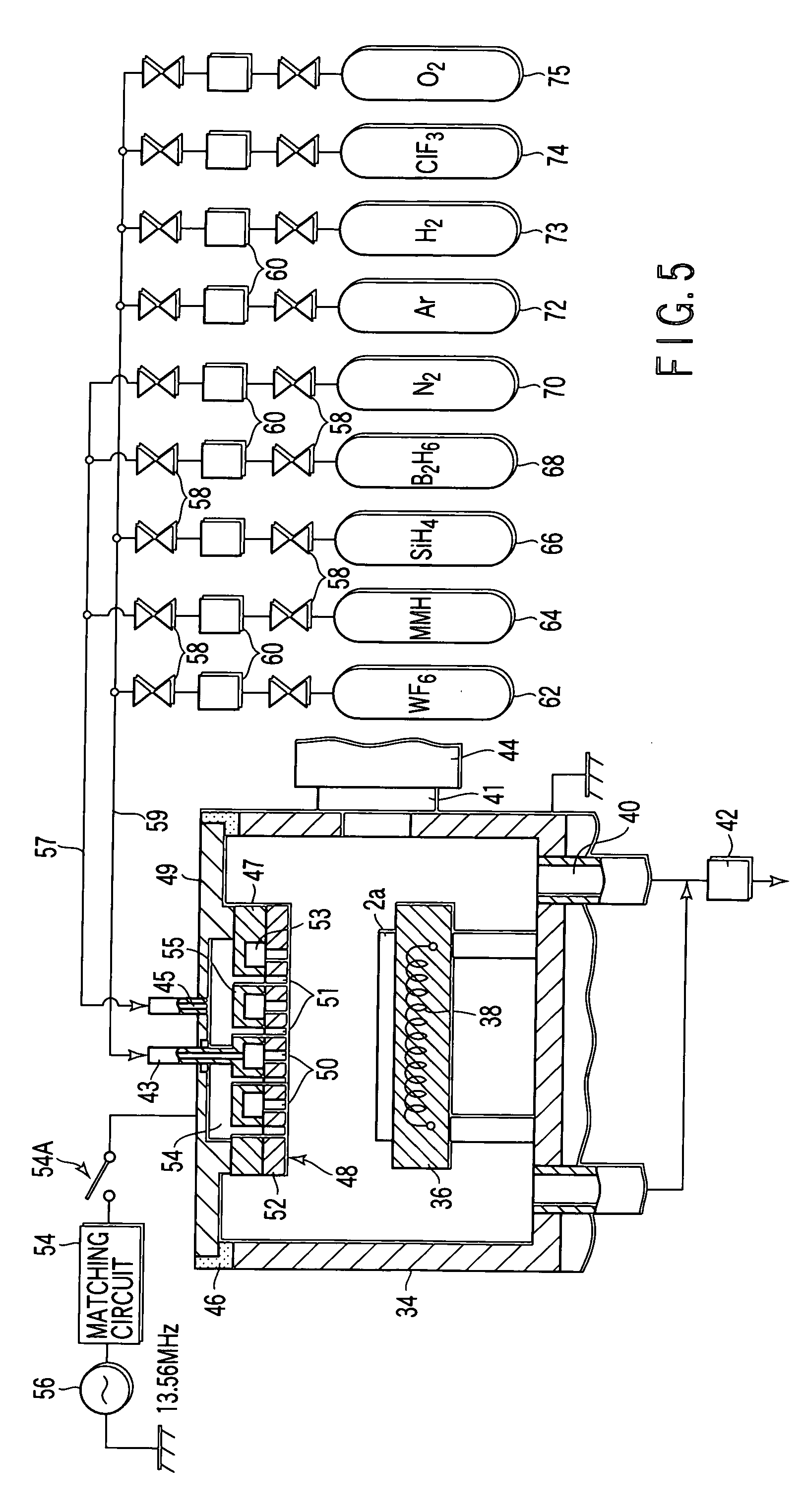

Method of forming a metal film for electrode

InactiveUS20050191803A1Semiconductor/solid-state device detailsSolid-state devicesGroup elementProcess engineering

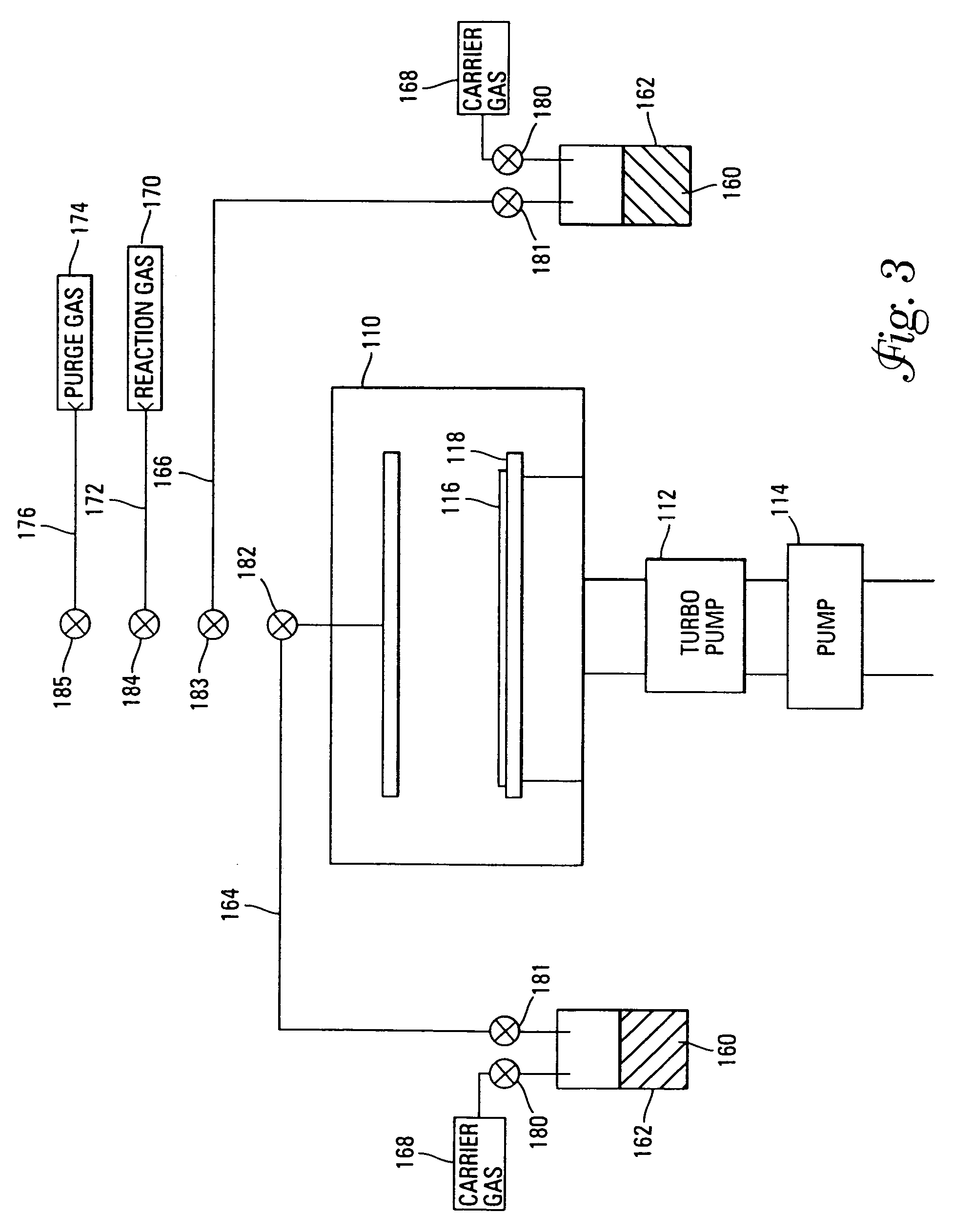

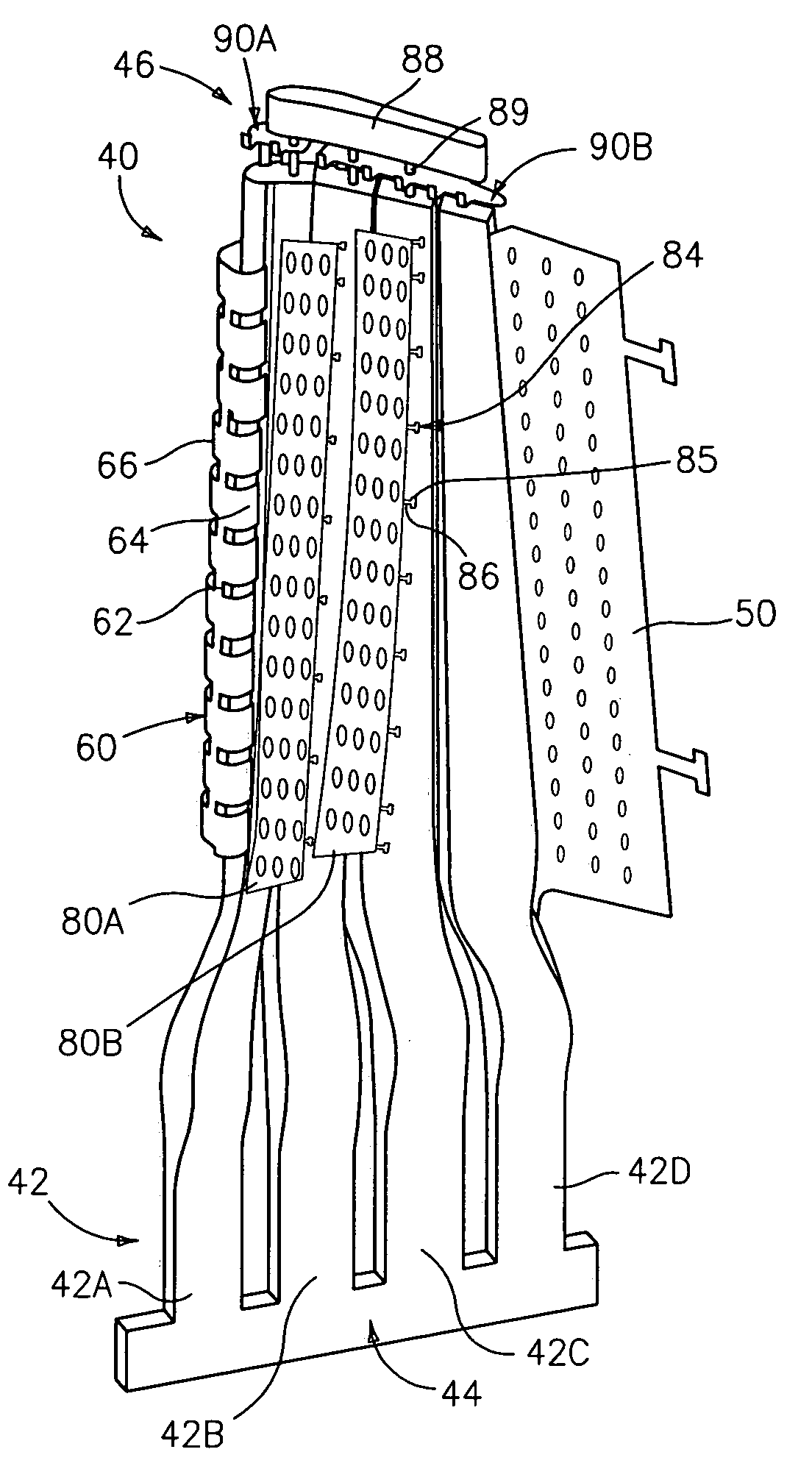

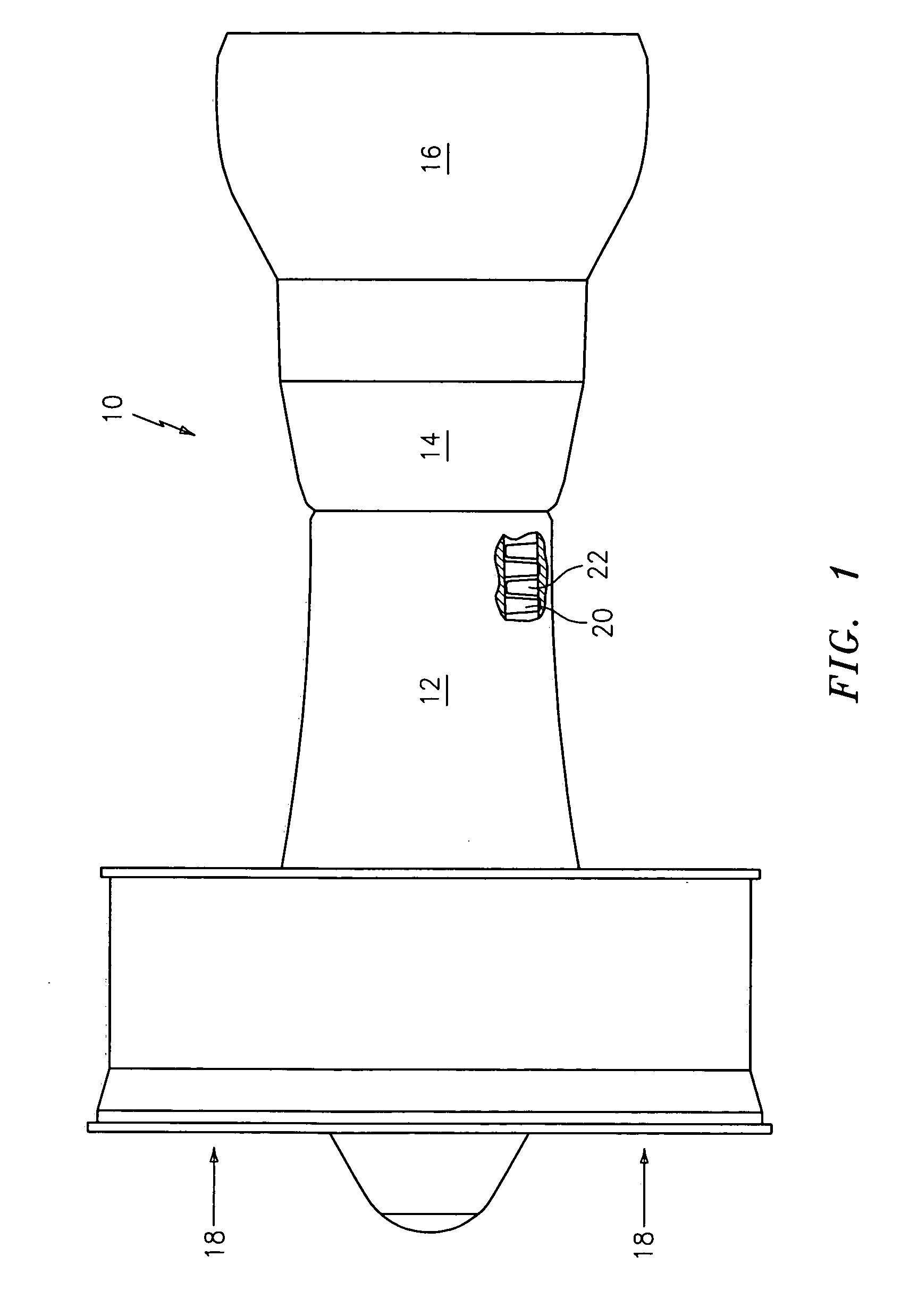

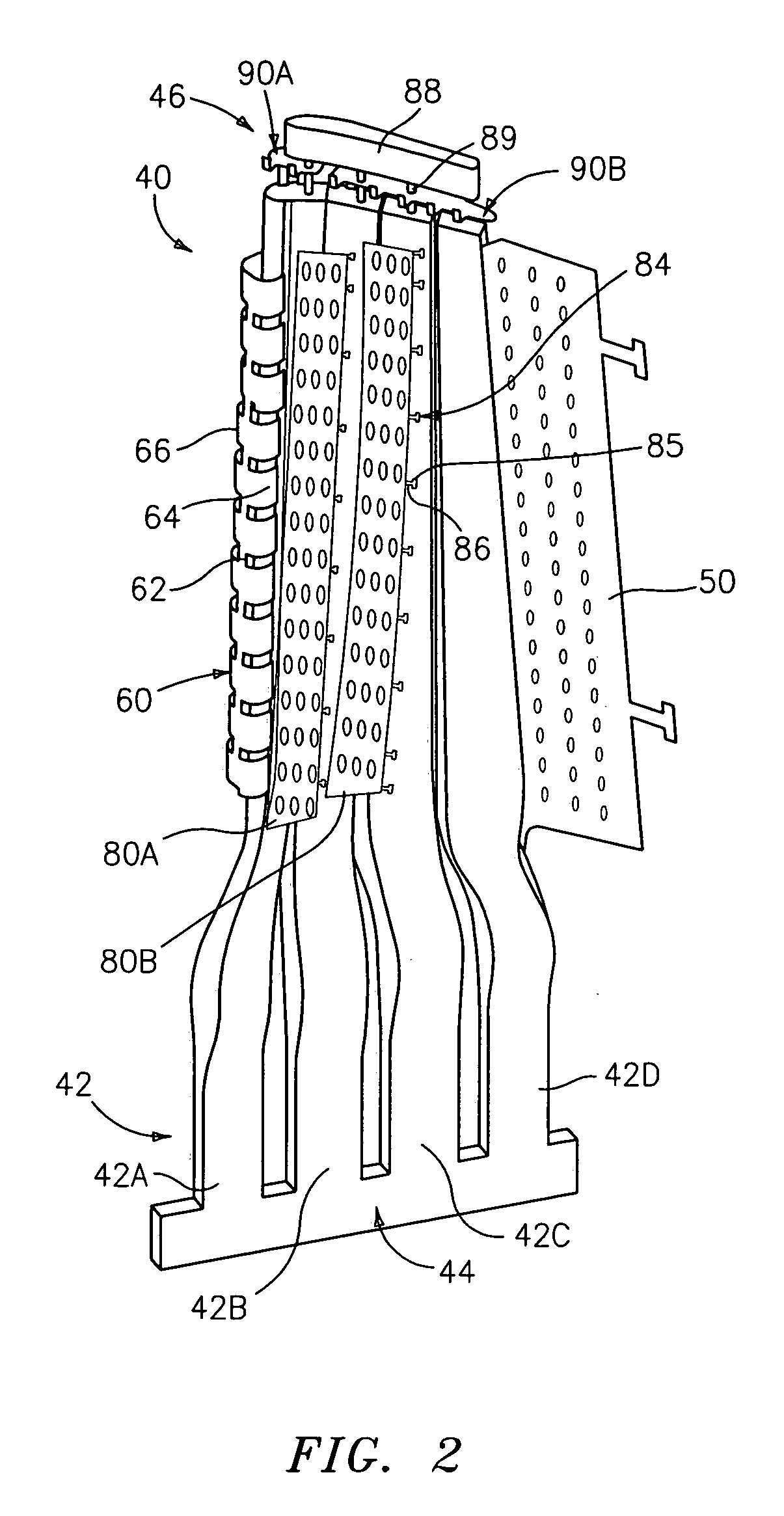

A method of forming a refractory metal film doped with III or V group elements. The first process gas is supplied from a first gas source through a first gas introducing member to and through a gas supply mechanism toward a substrate within a processing vessel. The second process gas is supplied from a second gas source through a second gas introducing member to and through the gas supply mechanism toward the substrate within the processing vessel. The processing vessel is purged by evacuating the processing vessel by an evacuating mechanism, while supplying the inert gas from a third source through a third gas introducing member to and through the gas supply mechanism into the processing vessel. The supplying the first process gas and the supplying the second process gas are repeated with the supplying the purging gas being carried out between supplying the first and second gases performed so that residual gas present in the processing vessel after performing the supplying of the first and second process gases is reduced to a level of 1 to 30% based on the entire capacity of the processing vessel.

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com