Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1572 results about "Surface roughening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

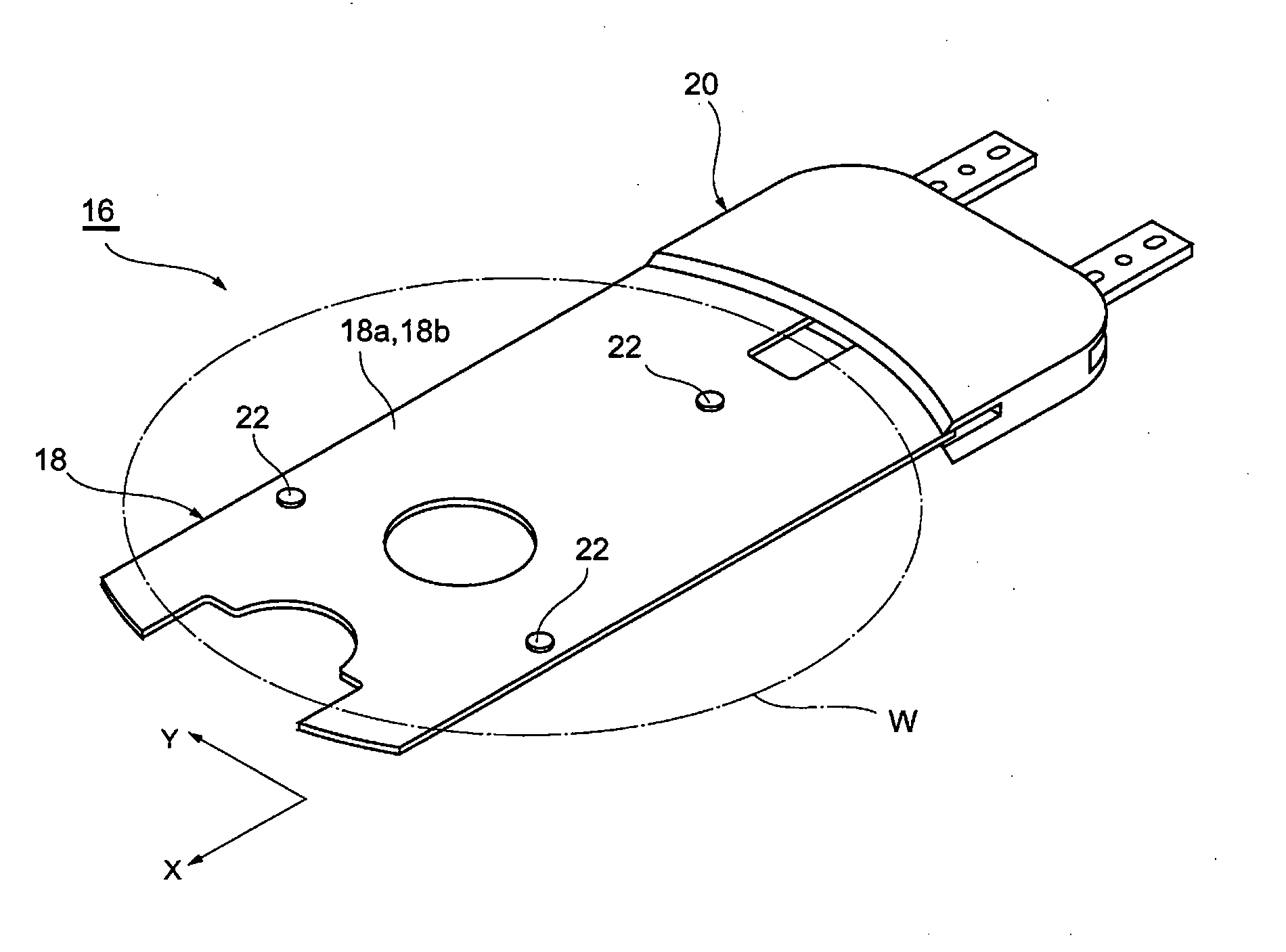

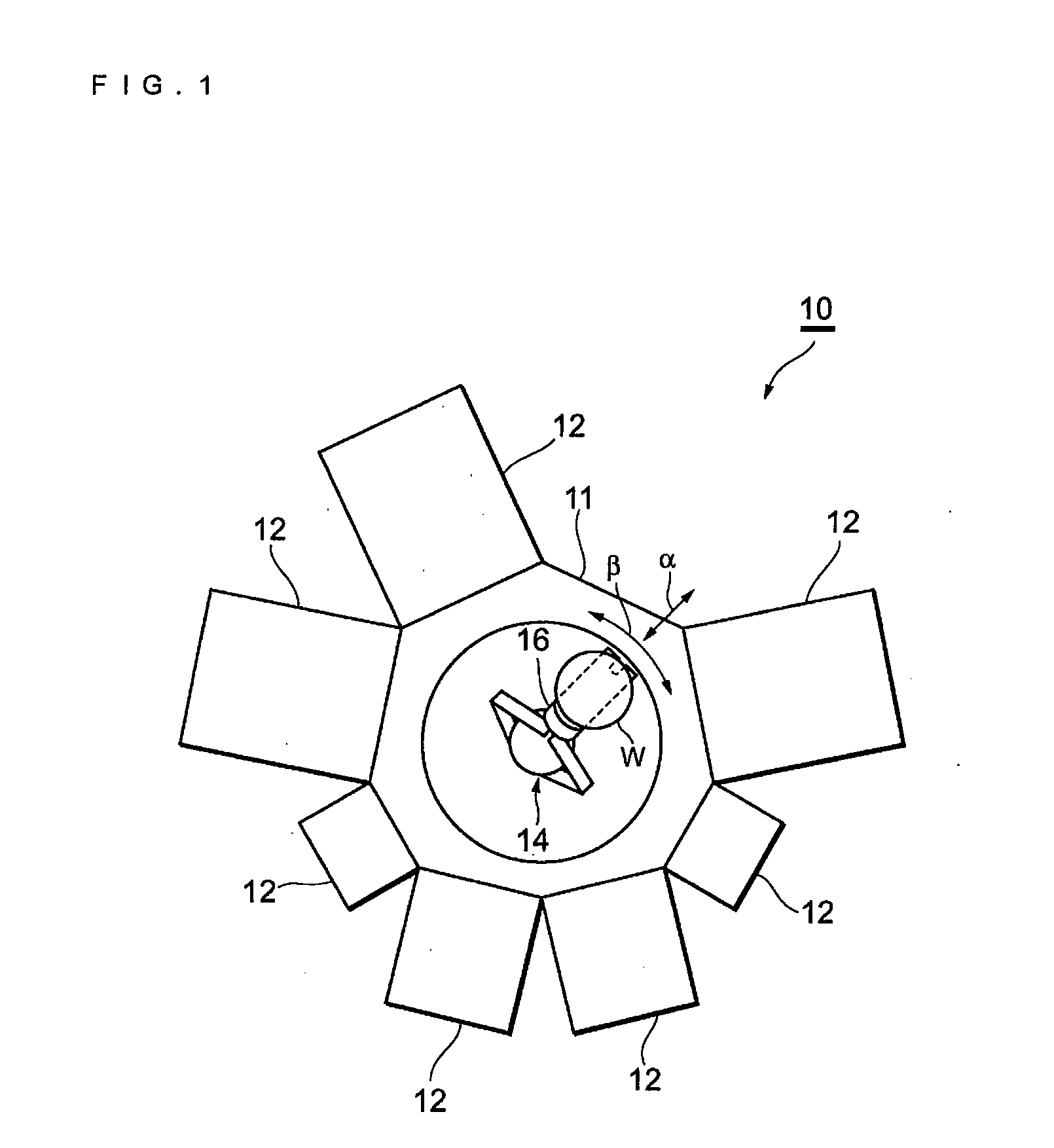

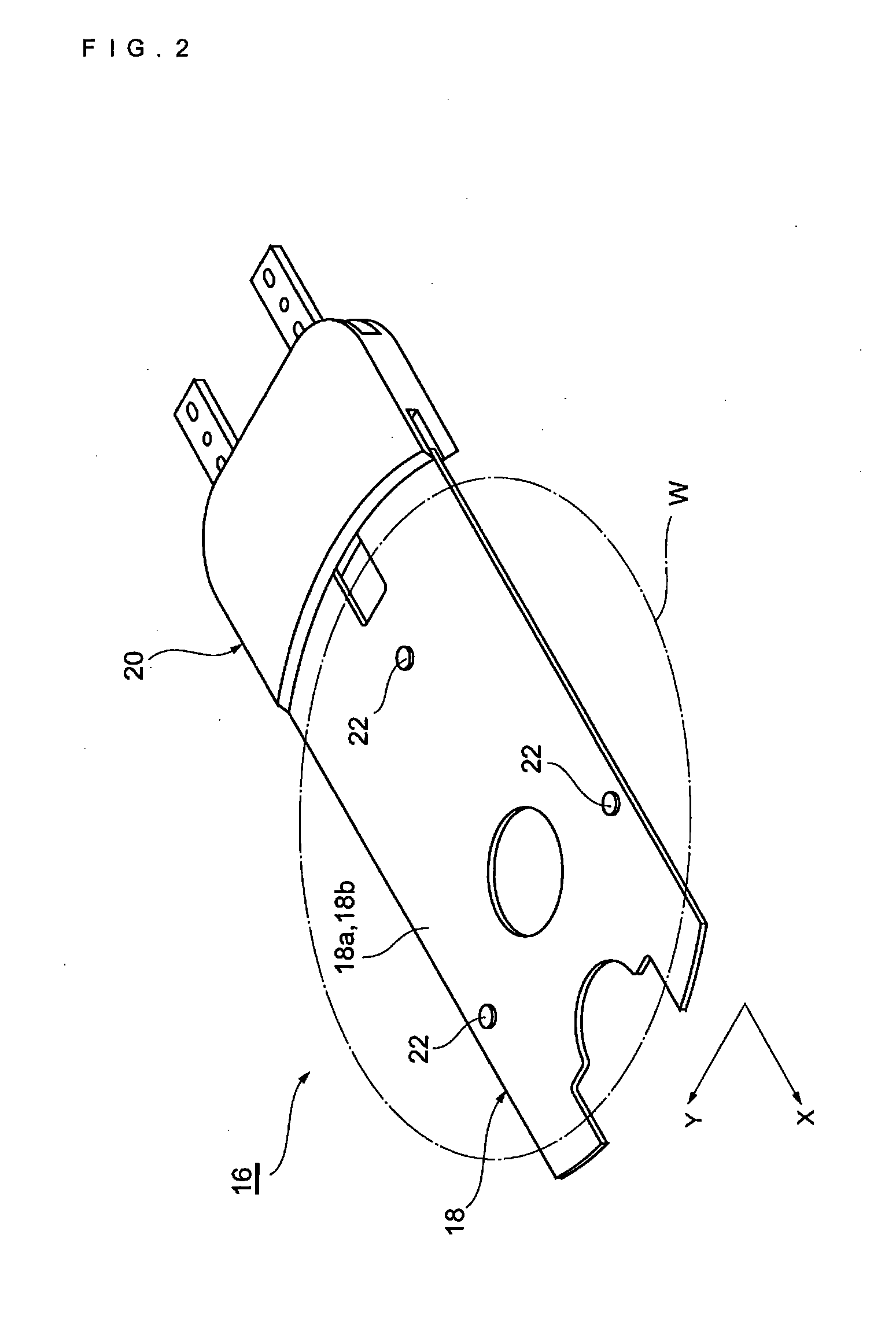

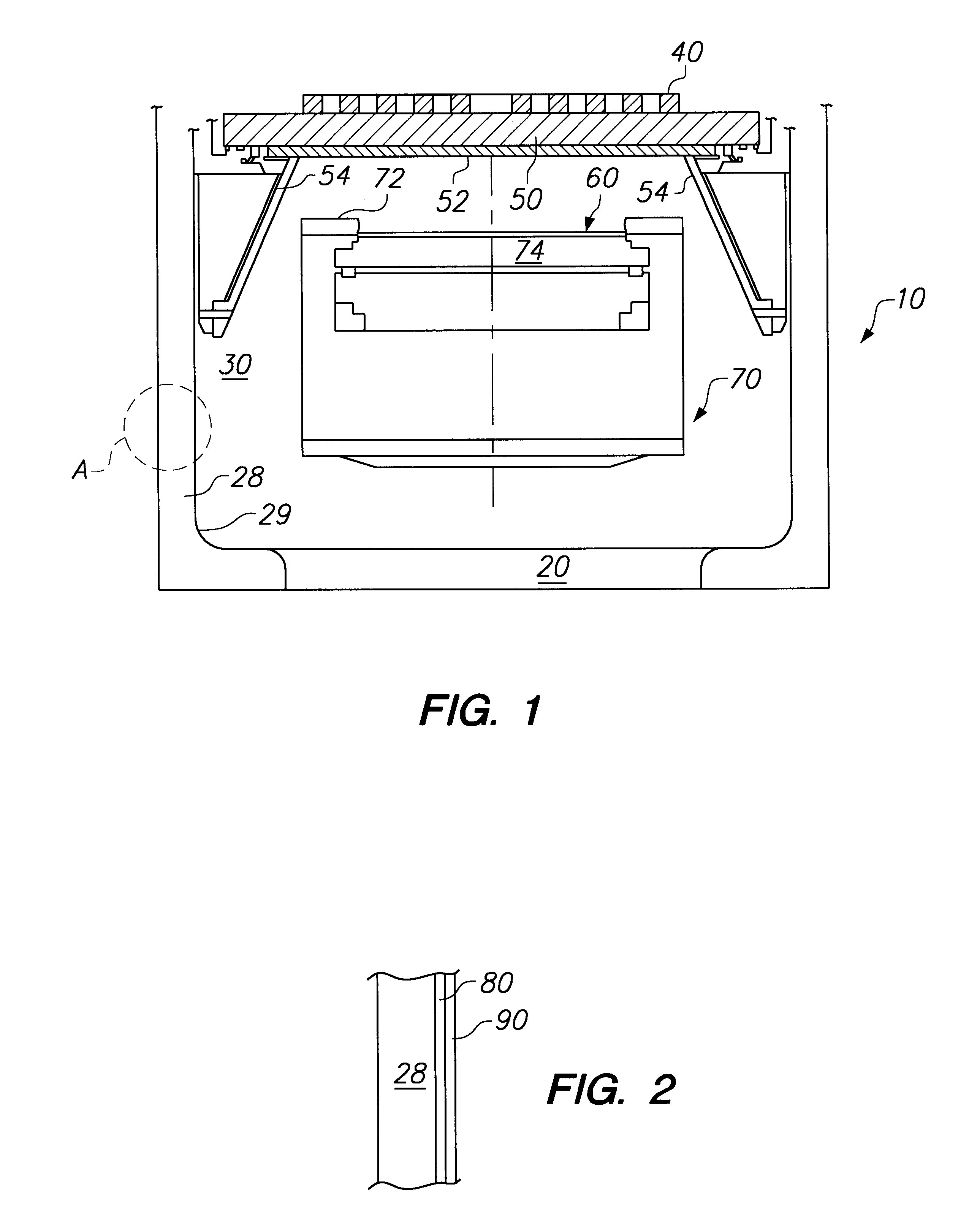

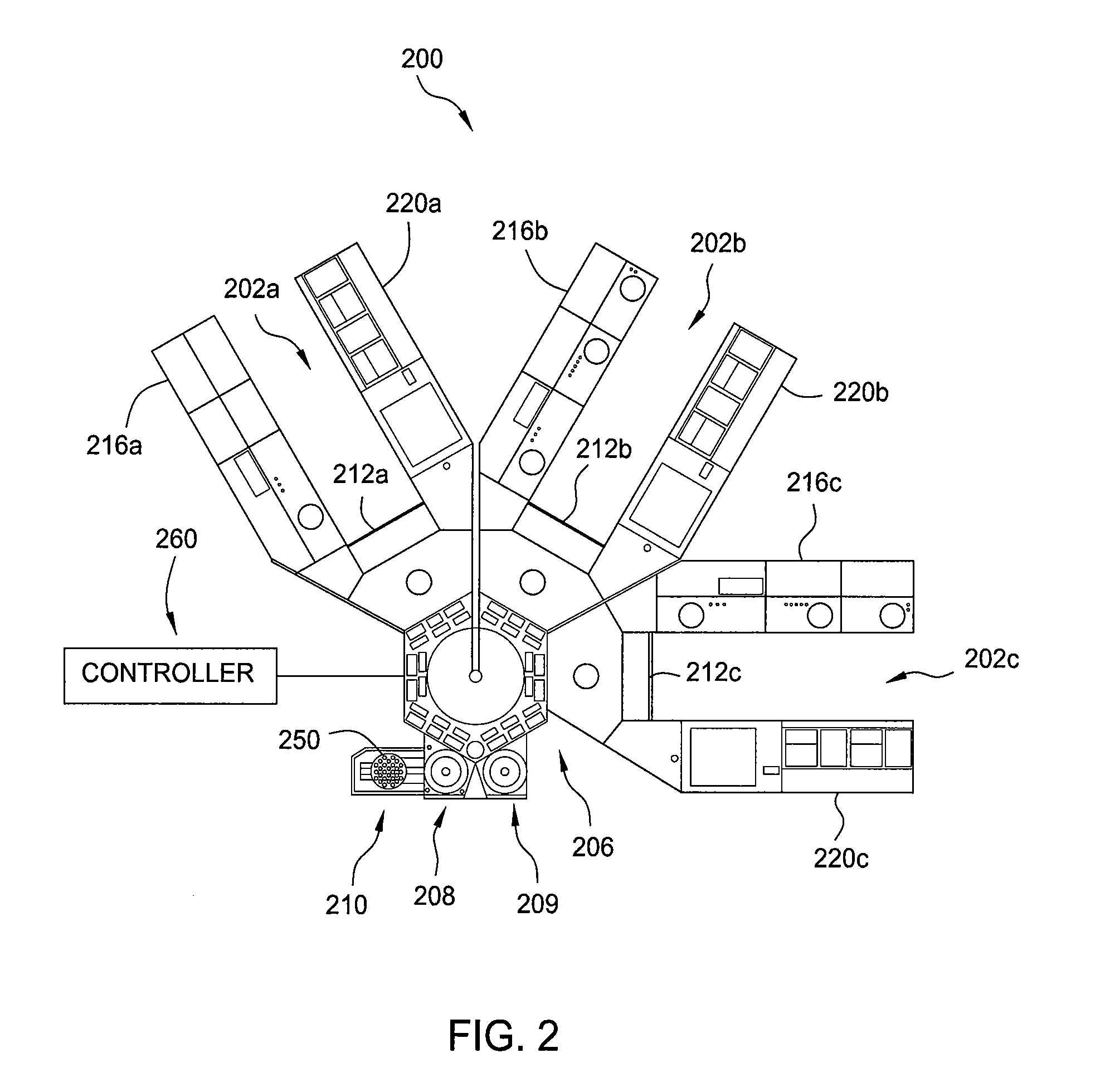

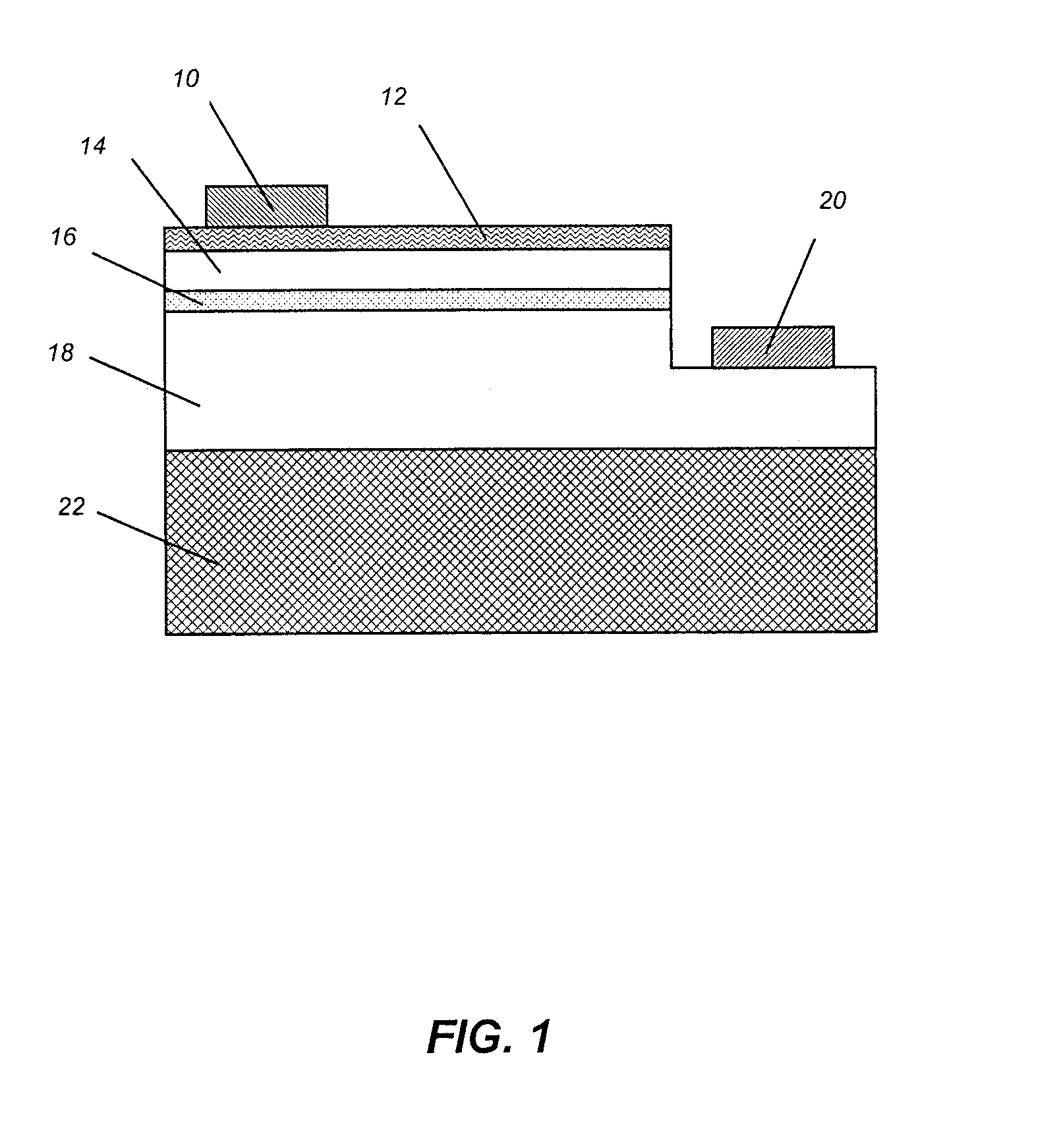

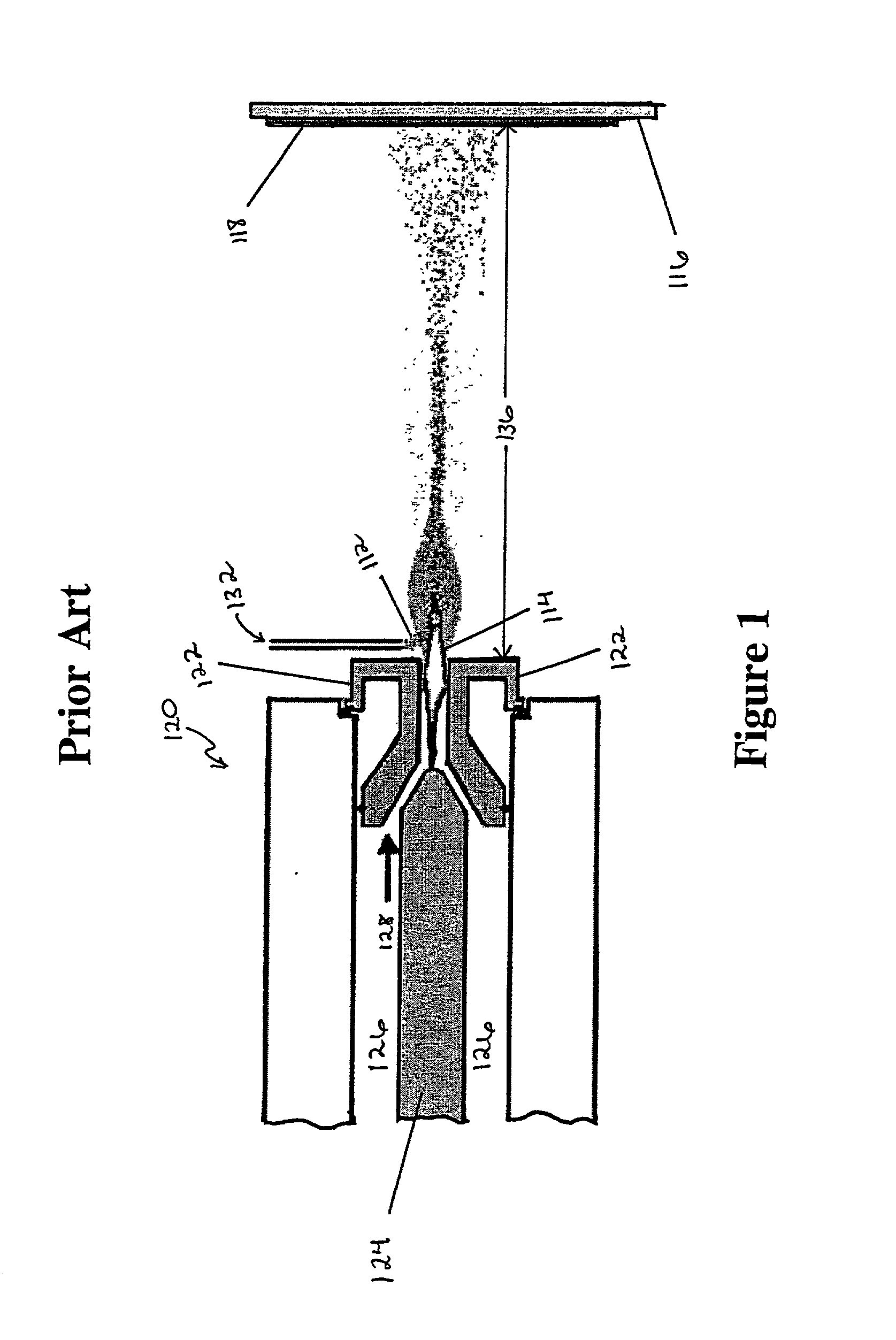

Wafer transfer blade

InactiveUS20090250955A1Reduce defectsSimple structureSemiconductor/solid-state device manufacturingLifting devicesEngineeringSurface roughening

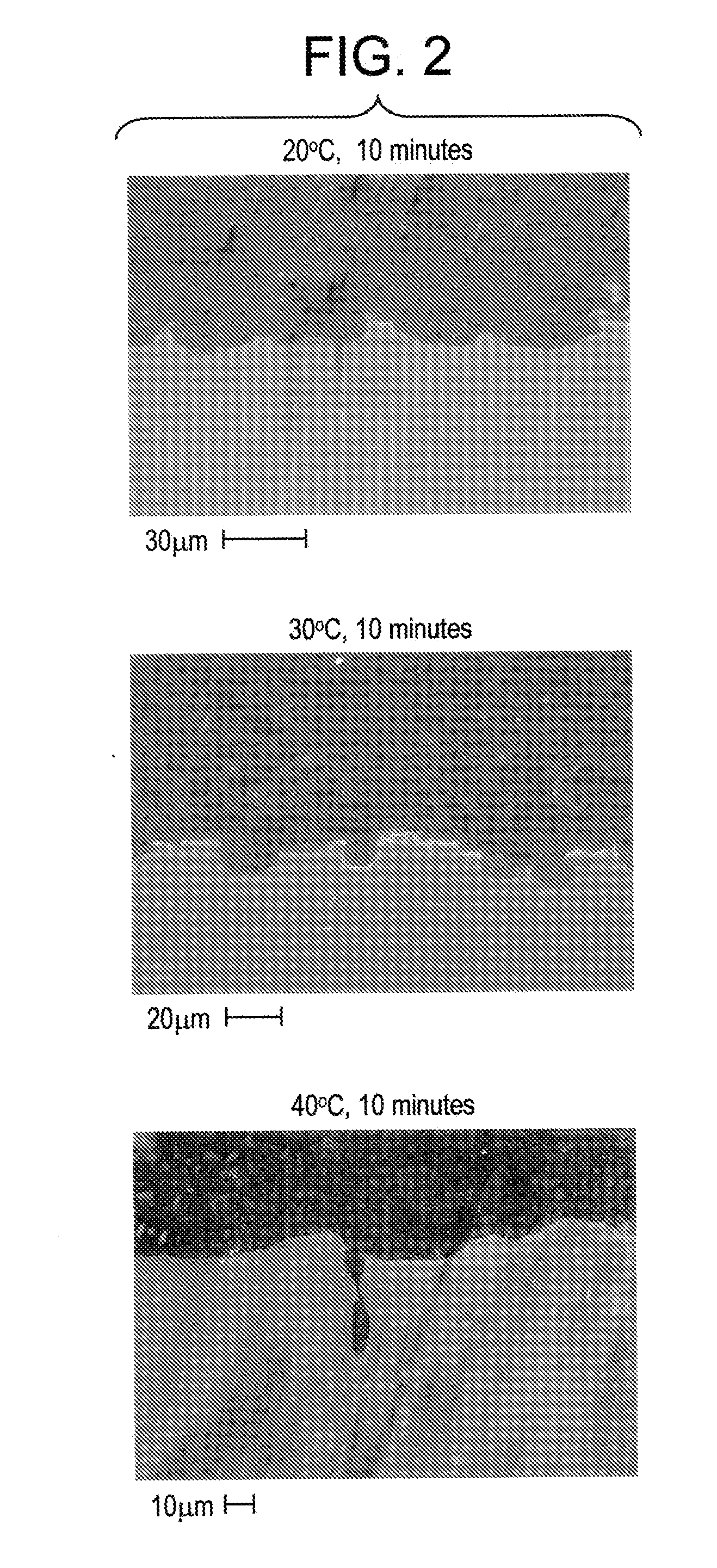

Projections 22 of the blade 16 provided on a blade surface in a wafer-loading region 18b of a body 18 support a wafer W loaded on the blade surface 18a. Since the projections 22 have microgrooves formed by surface roughening the wafer W is retained on the projections 22 with a suppressed displacement. The blade 16 has a simple structure that retains the wafer W without vacuum suction and has no receiving hole to retain the wafer W in the body 18 of the blade 16. This can effectively prevent formation of defects on the wafer W.

Owner:APPLIED MATERIALS INC

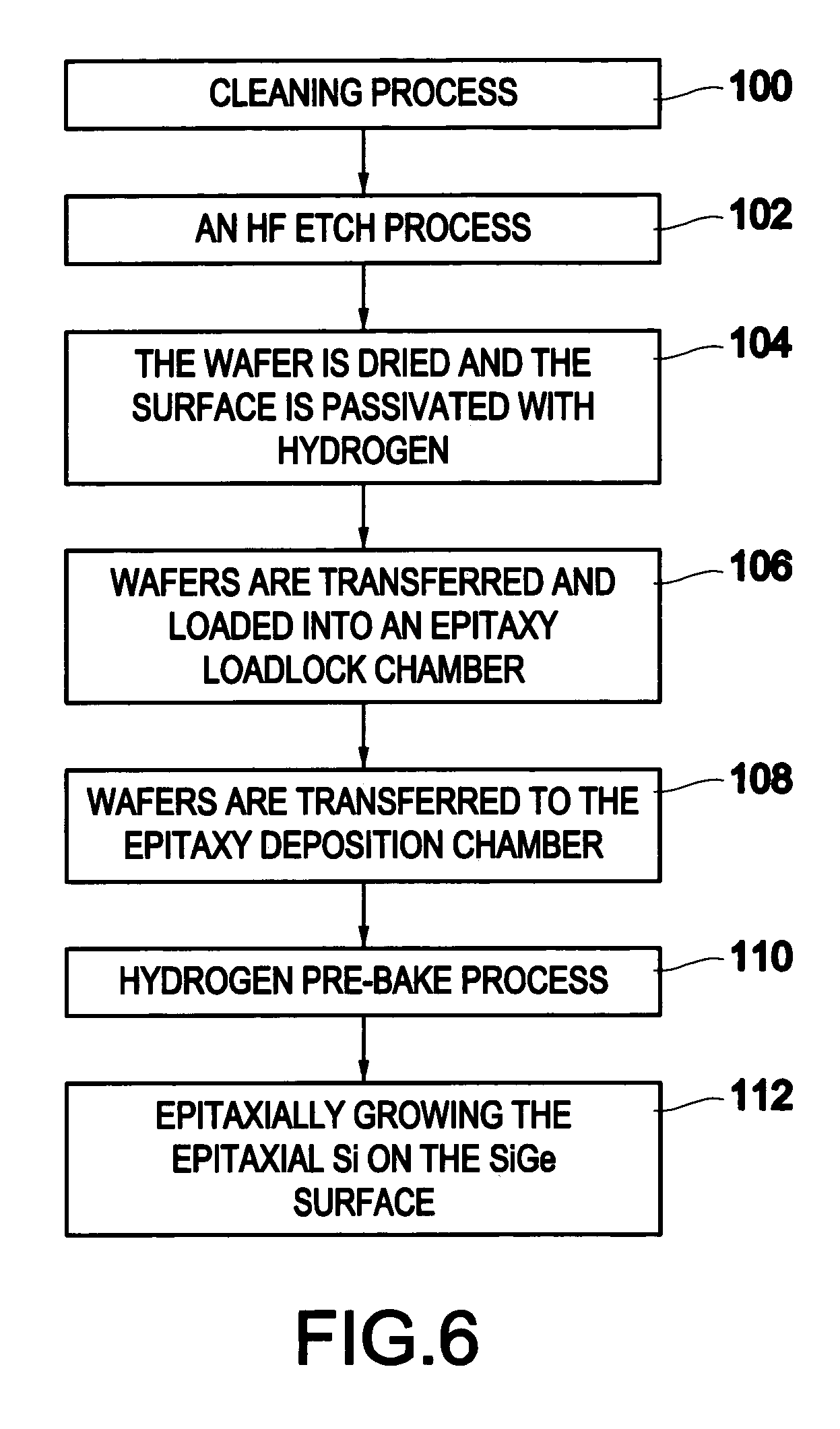

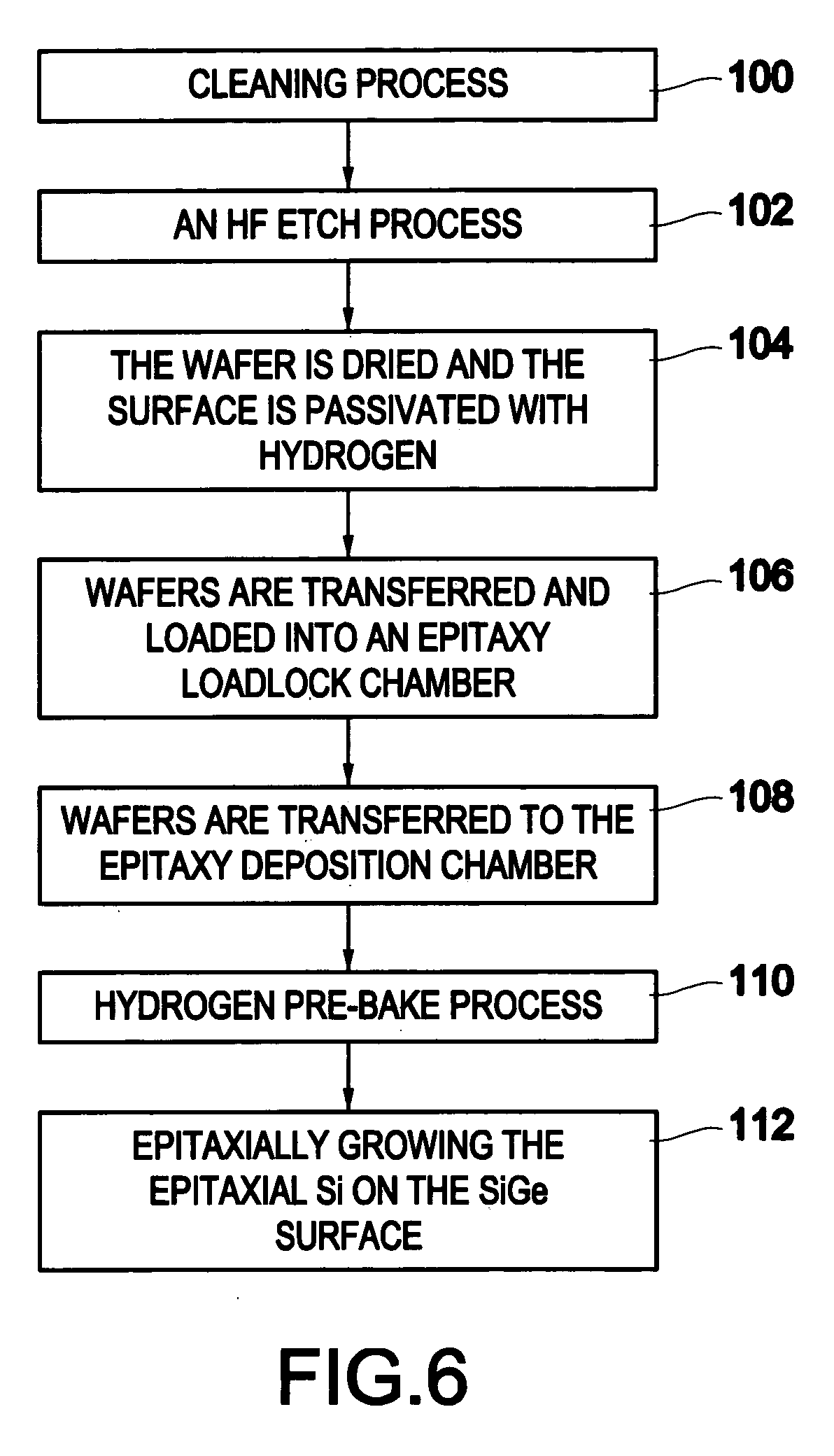

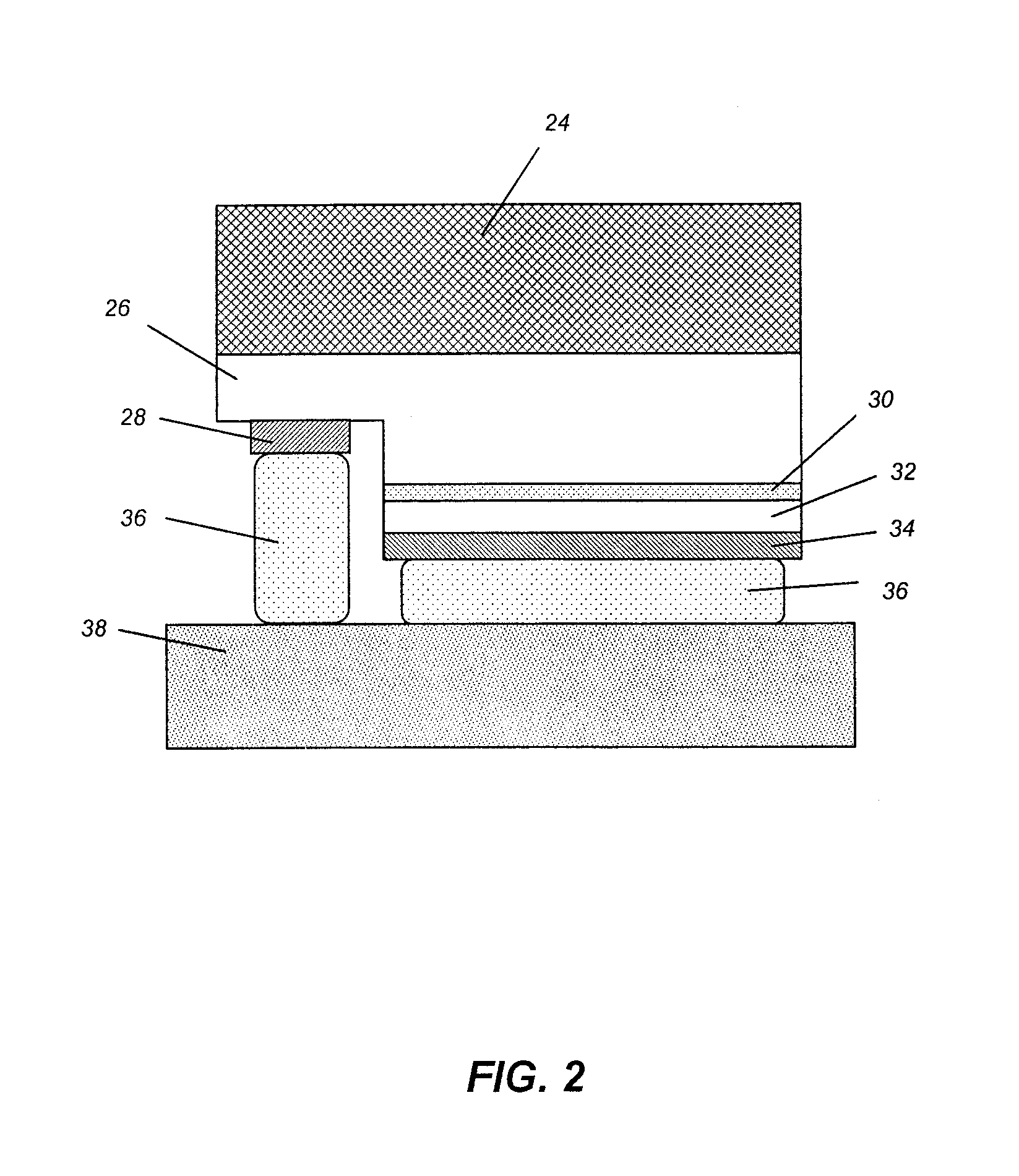

Method of preventing surface roughening during hydrogen pre-bake of SiGe substrates using chlorine containing gases

InactiveUS20050148162A1Prevent surfaceAvoid creatingPolycrystalline material growthSemiconductor/solid-state device manufacturingPartial oxidationSilicon on insulator

The invention forms an epitaxial silicon-containing layer on a silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface and avoids creating a rough surface upon which the epitaxial silicon-containing layer is grown. In order to avoid creating the rough surface, the invention first performs a hydrofluoric acid etching process on the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. This etching process removes most of oxide from the surface, and leaves only a sub-monolayer of oxygen (typically 1×1013-1×1015 / cm2 of oxygen) at the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. The invention then performs a hydrogen pre-bake process in a chlorine containing environment which heats the silicon germanium, strained silicon, or thin silicon-on-insulator surface sufficiently to remove the remaining oxygen from the surface. By introducing a small amount of chlorine containing gases, the heating processes avoid changing the roughness of the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. Then the process of epitaxially growing the epitaxial silicon-containing layer on the silicon germanium, patterned strained silicon, or patterned silicon-on-insulator surface is performed.

Owner:IBM CORP

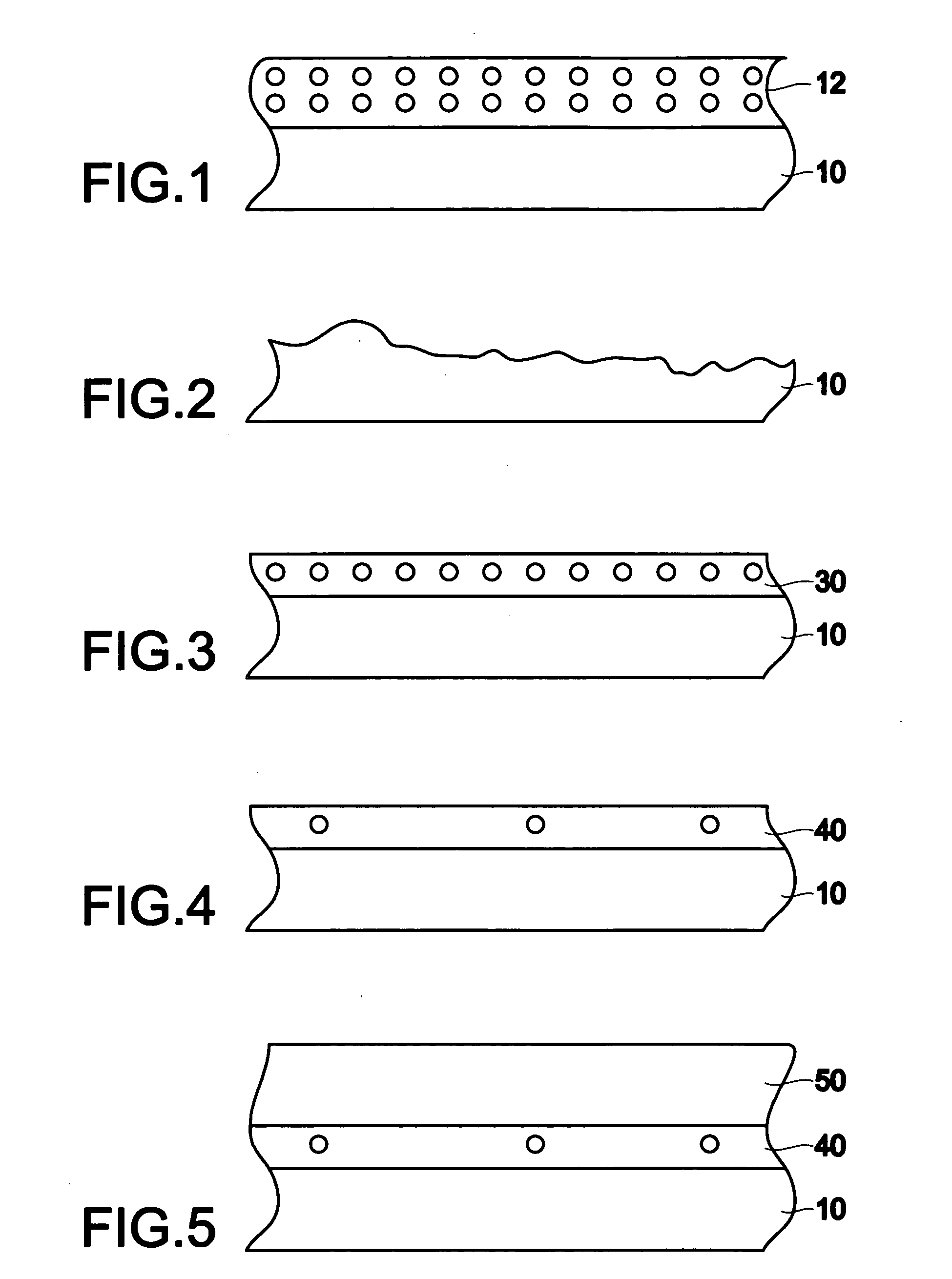

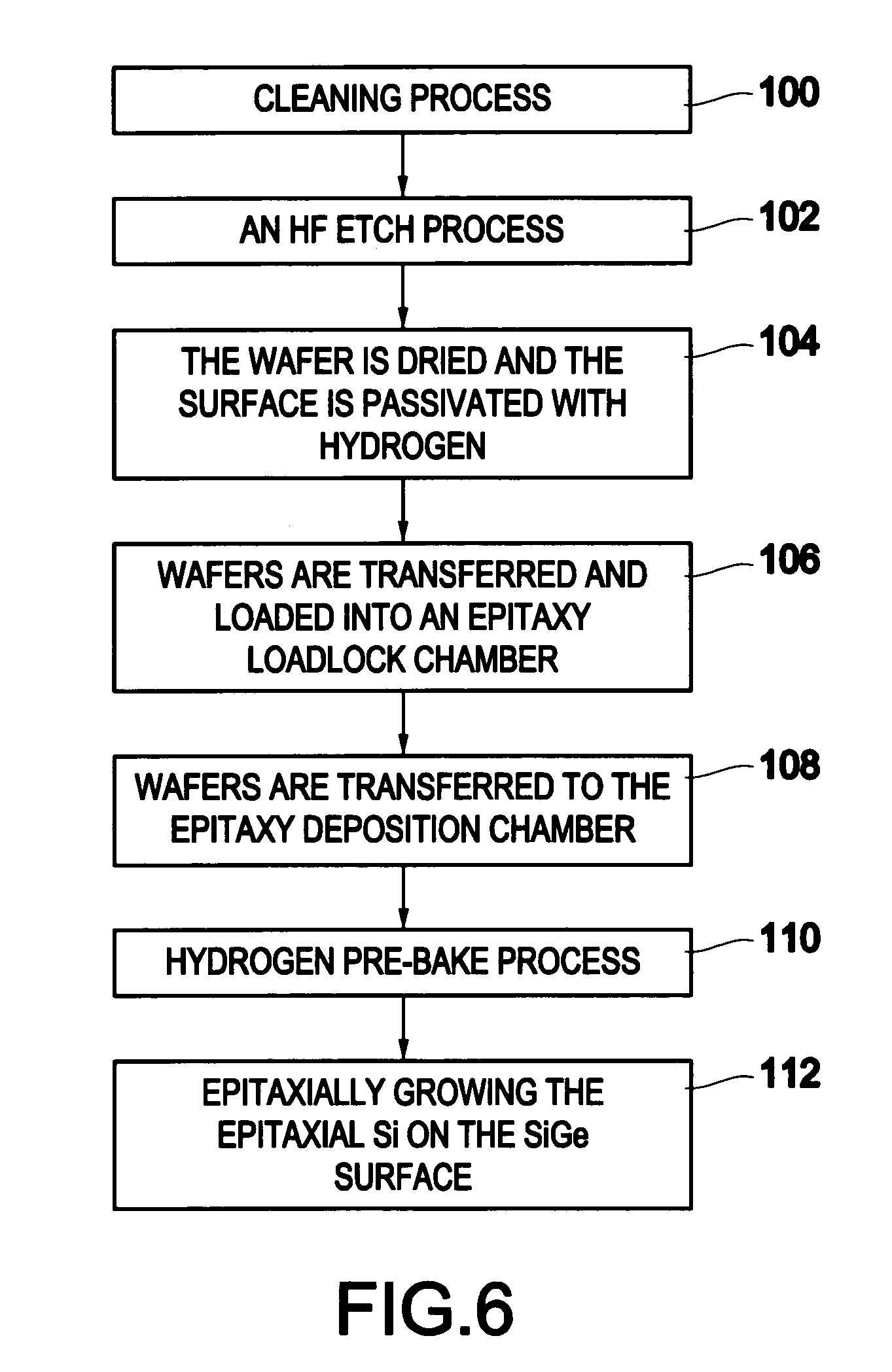

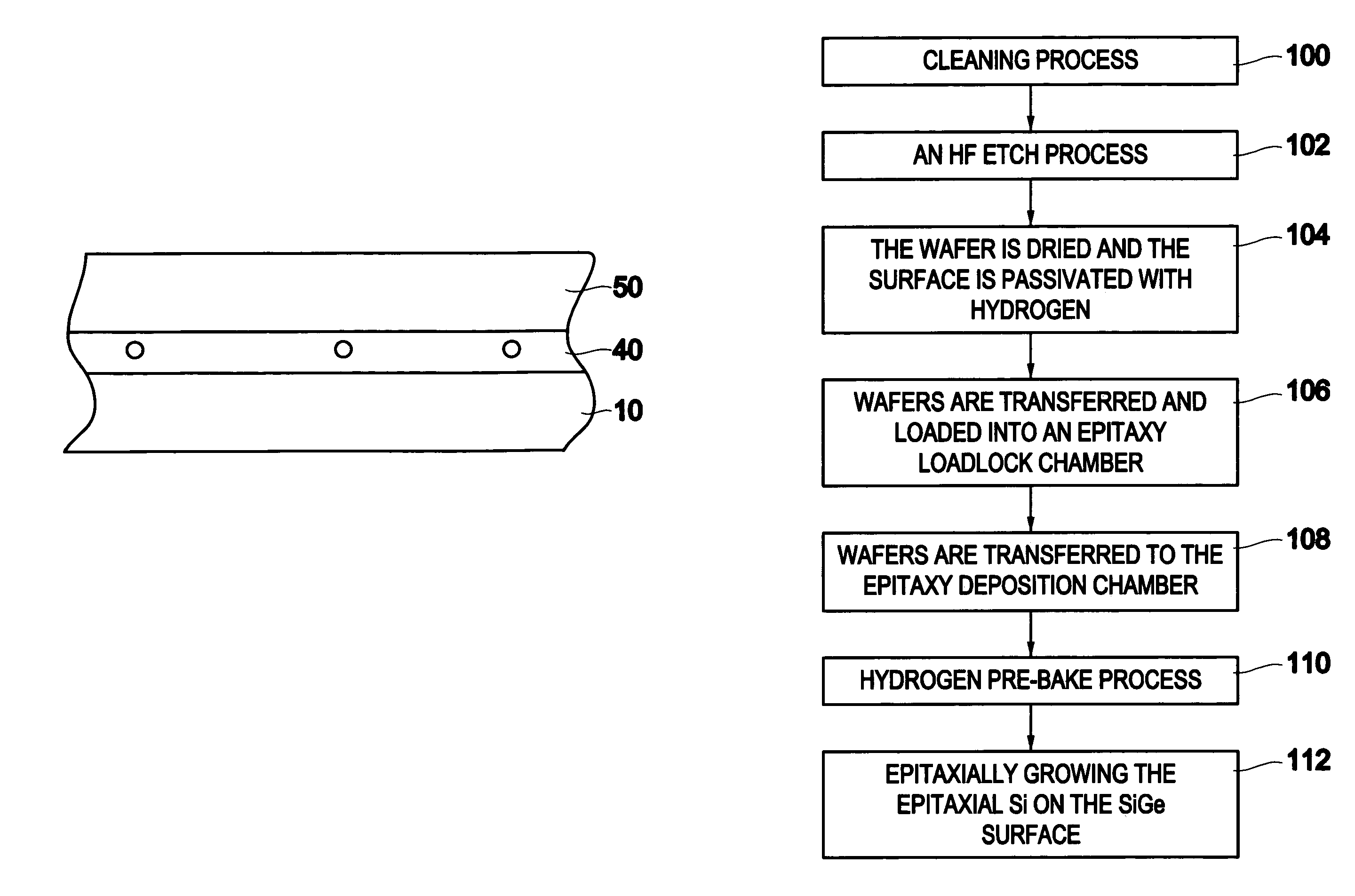

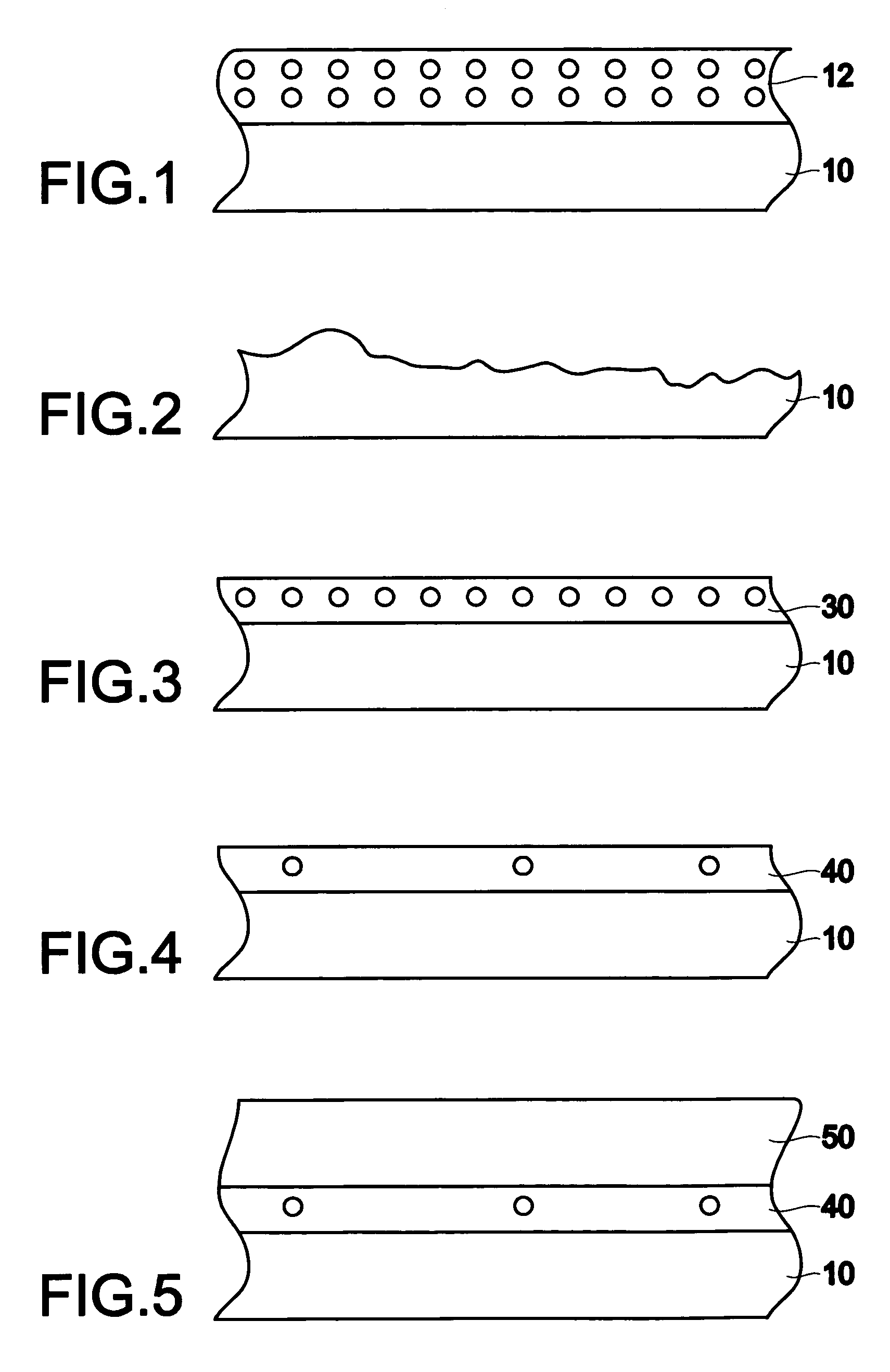

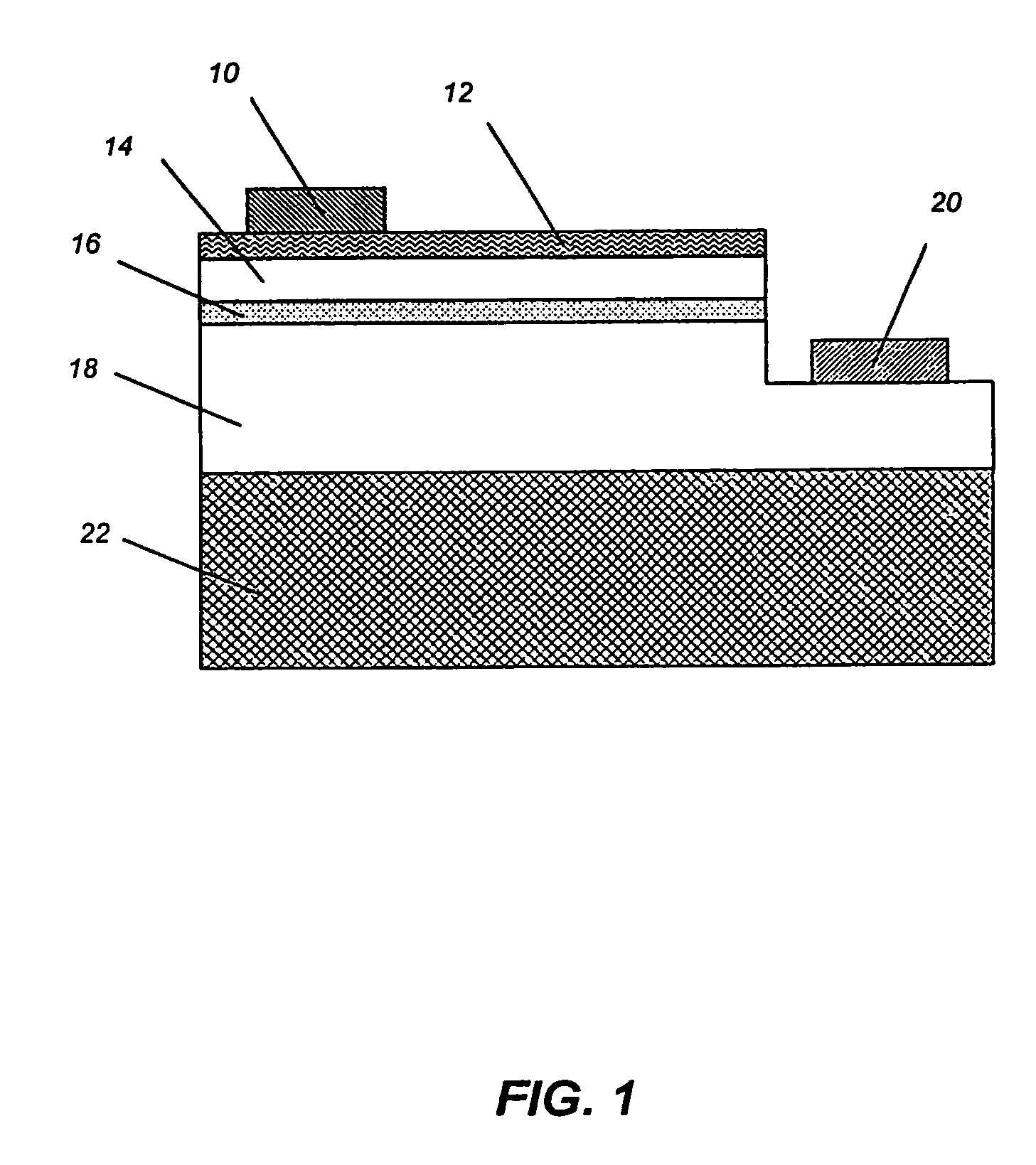

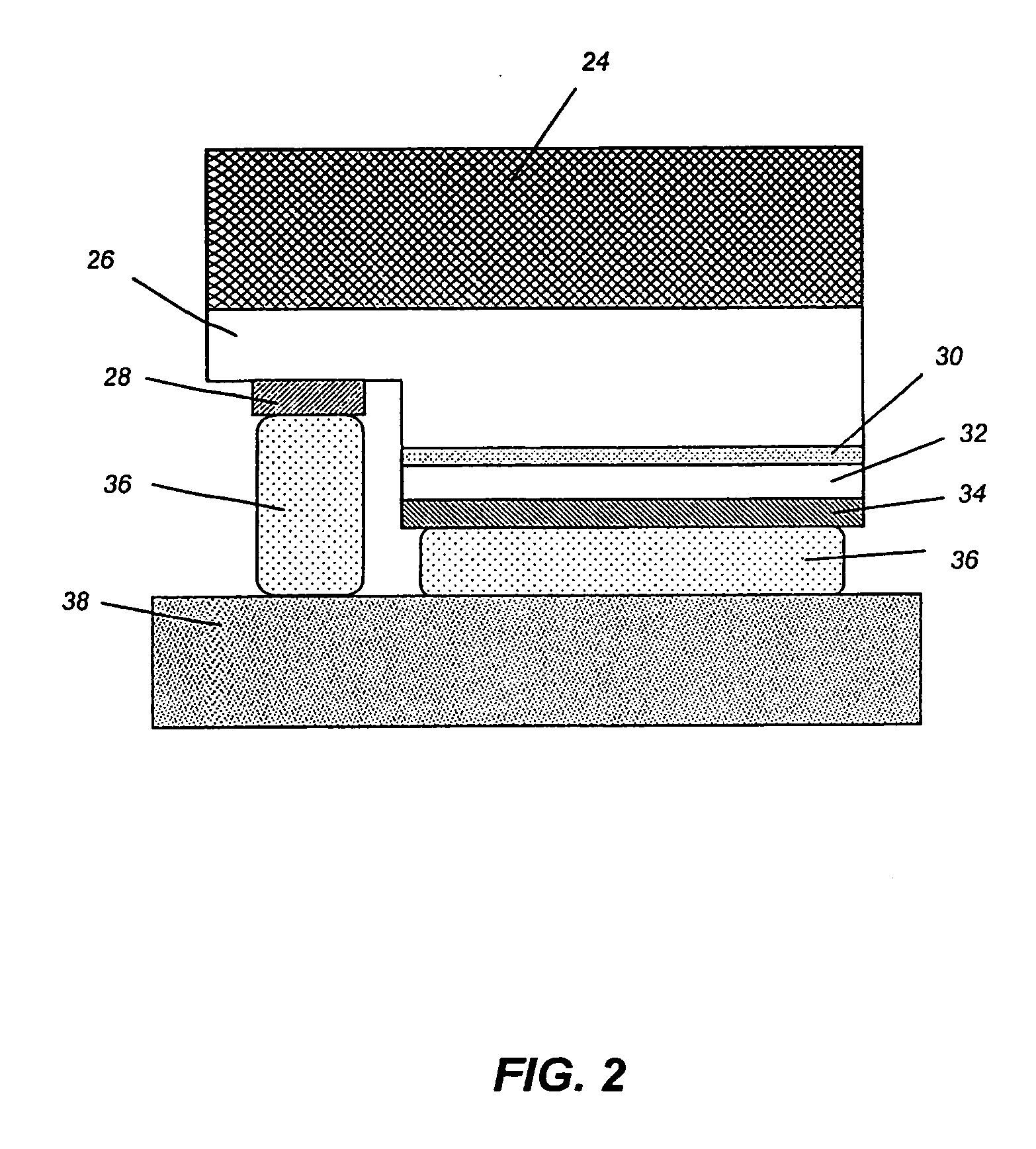

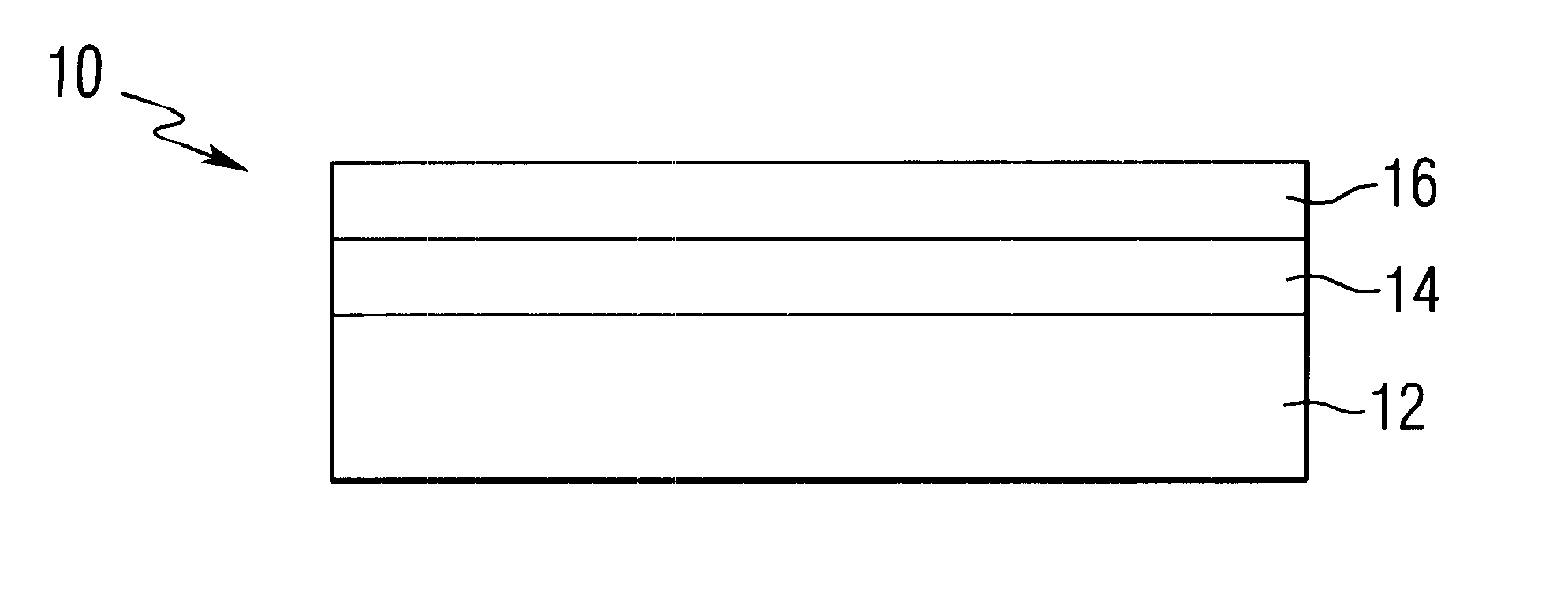

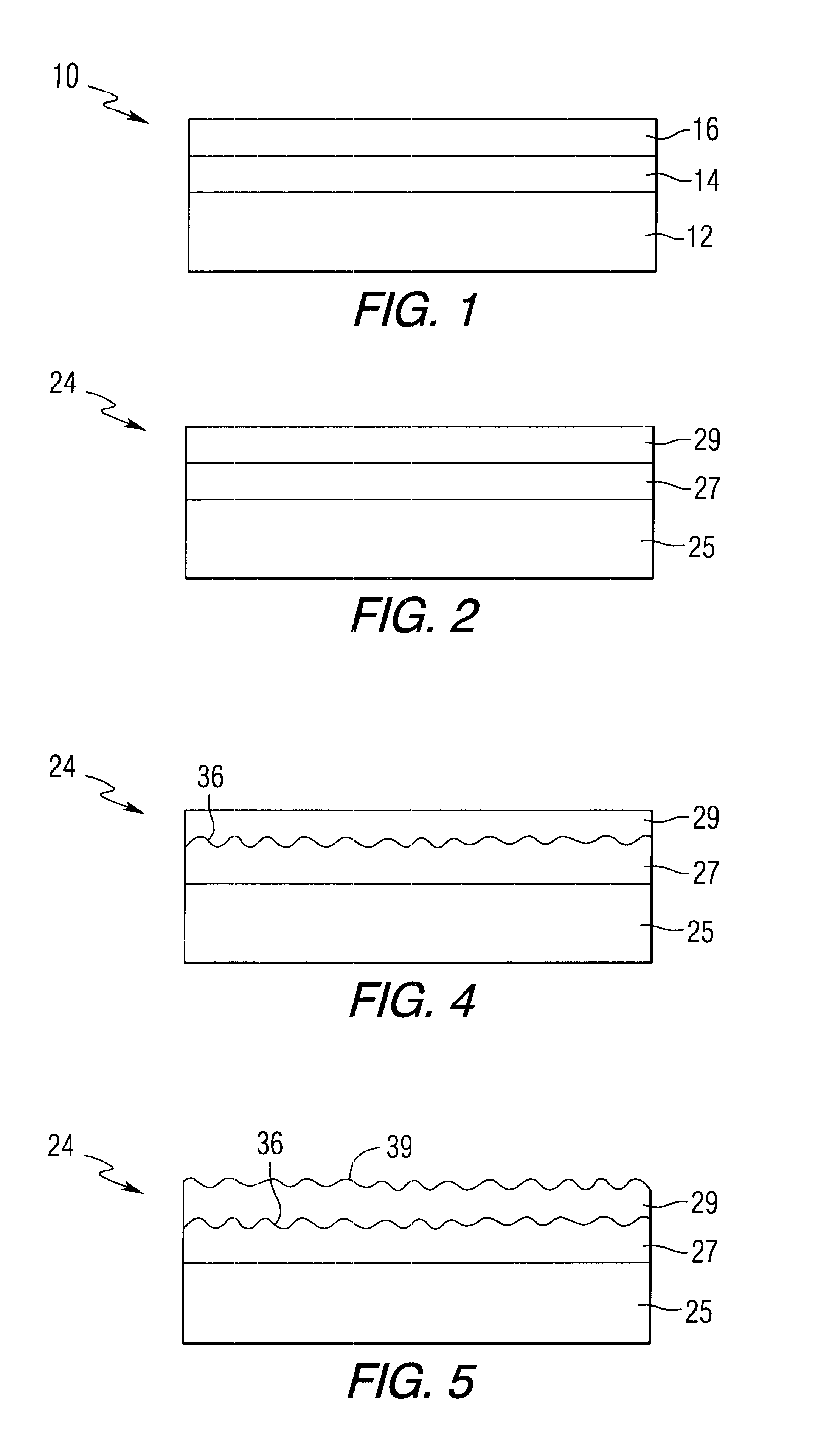

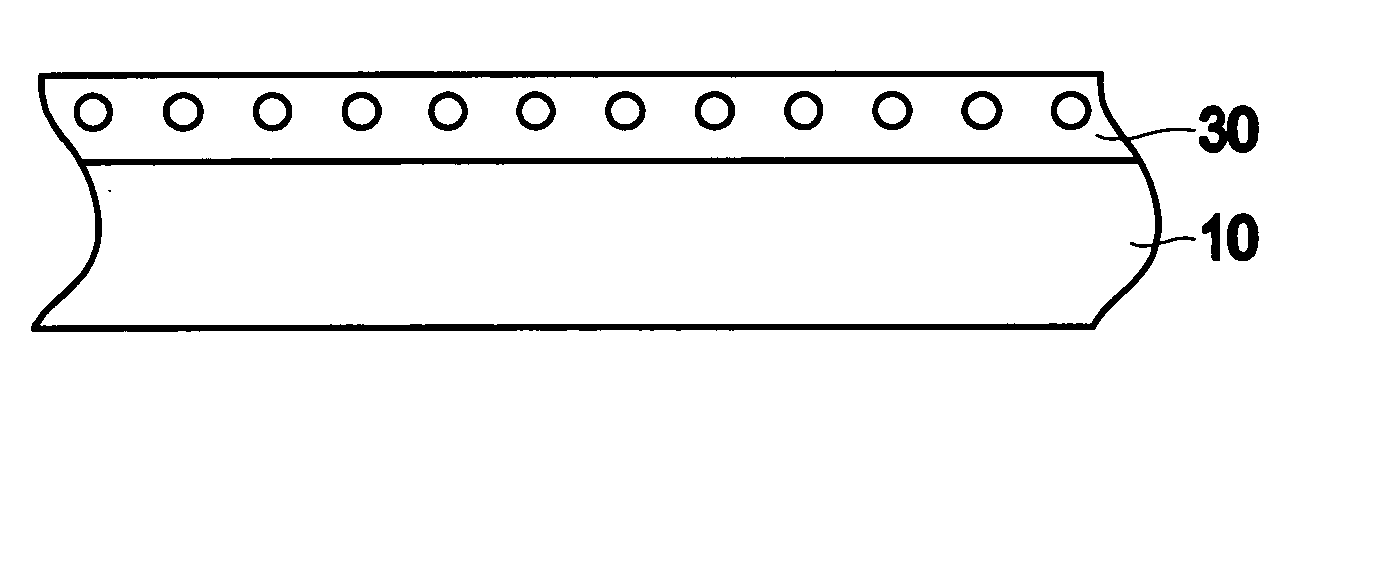

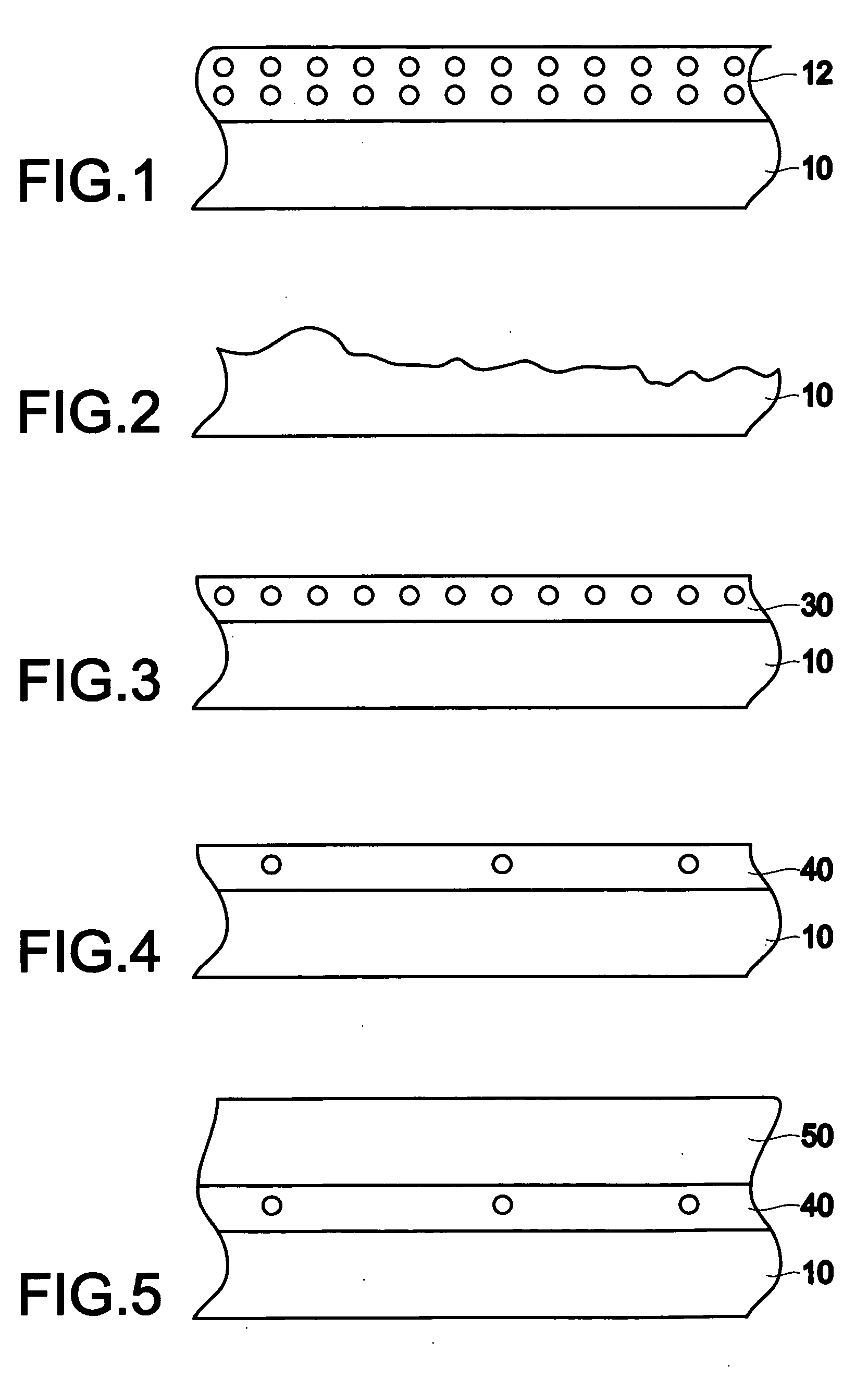

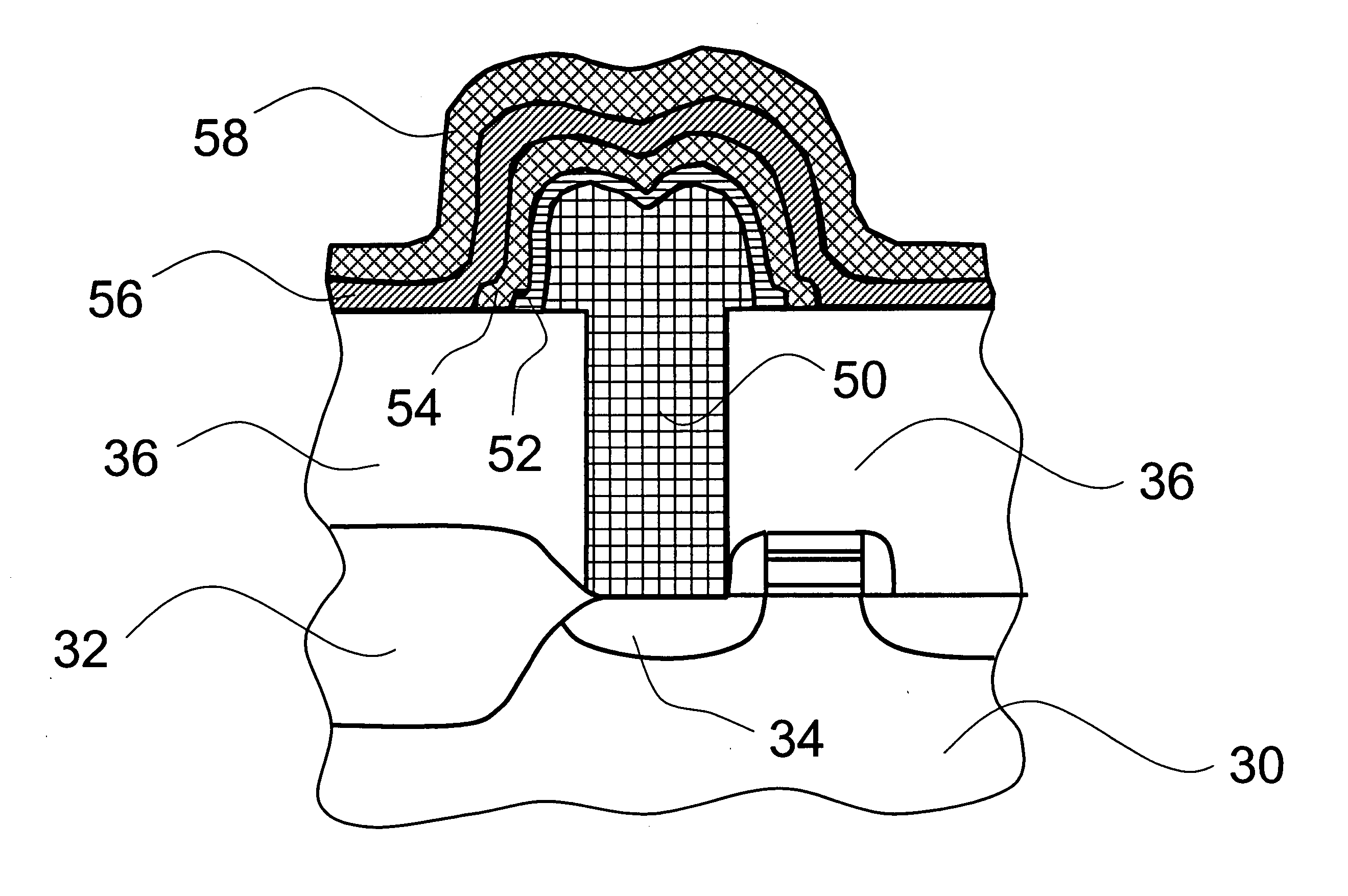

Method of preventing surface roughening during hydrogen prebake of SiGe substrates

InactiveUS6958286B2Polycrystalline material growthSemiconductor/solid-state device manufacturingRough surfaceHydrofluoric acid

The invention forms an epitaxial silicon-containing layer on a silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface and avoids creating a rough surface upon which the epitaxial silicon-containing layer is grown. In order to avoid creating the rough surface, the invention first performs a hydrofluoric acid etching process on the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. This etching process removes most of oxide from the surface, and leaves a first amount of oxygen (typically 1×1013−1×1015 / cm2 of oxygen) on the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. The invention then performs a hydrogen pre-bake process which heats the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface sufficiently to remove additional oxygen from the surface and leave a second amount of oxygen, less than the first amount, on the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. The heating process leaves an amount of at least 5×1012 / cm2 of oxygen (typically, between approximately 1×1013 / cm2 and approximately 5×1013 / cm2 of oxygen) on the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. By leaving a small amount of oxygen on the silicon germanium, patterned strained silicon, or patterned silicon-on-insulator surface, the heating processes avoid changing the roughness of the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. Then the process of epitaxially growing the epitaxial silicon-containing layer on the silicon germanium, patterned strained silicon, or patterned silicon-on-insulator surface is performed.

Owner:INT BUSINESS MASCH CORP

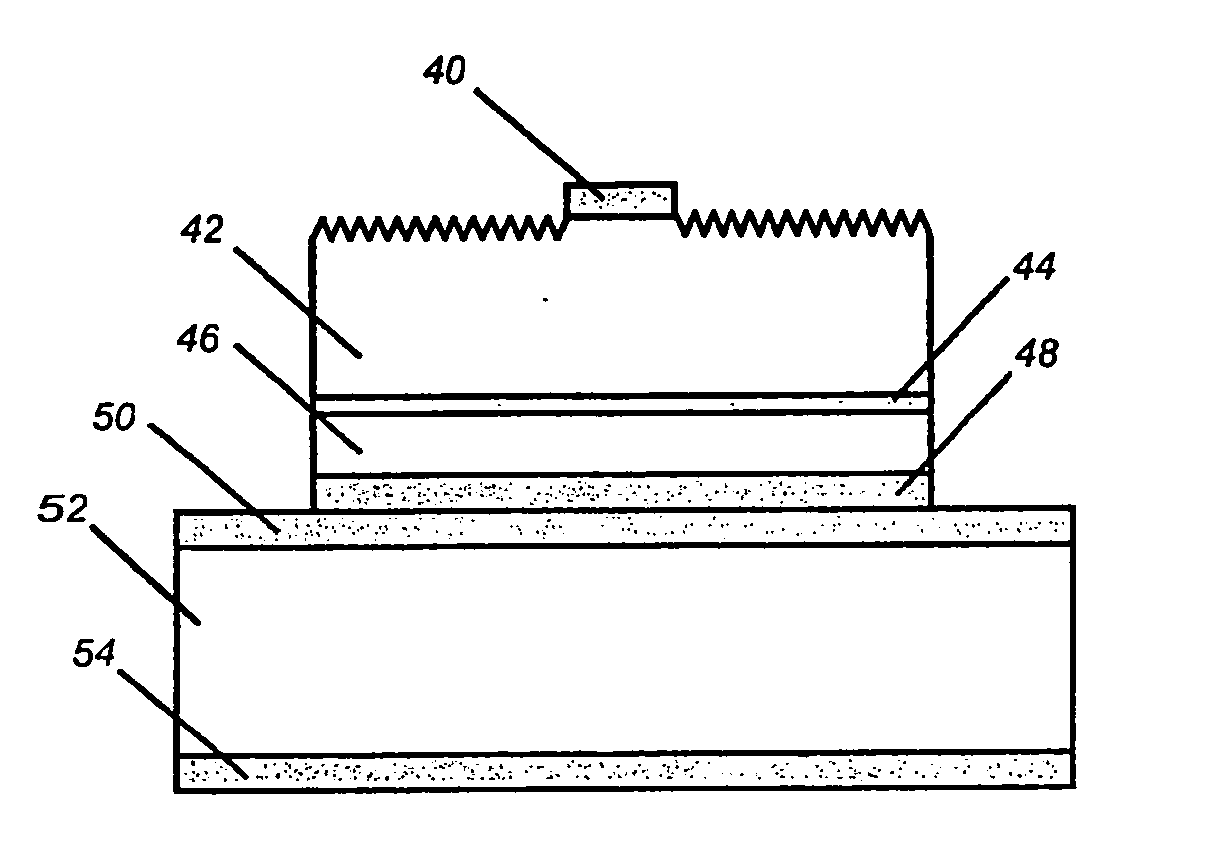

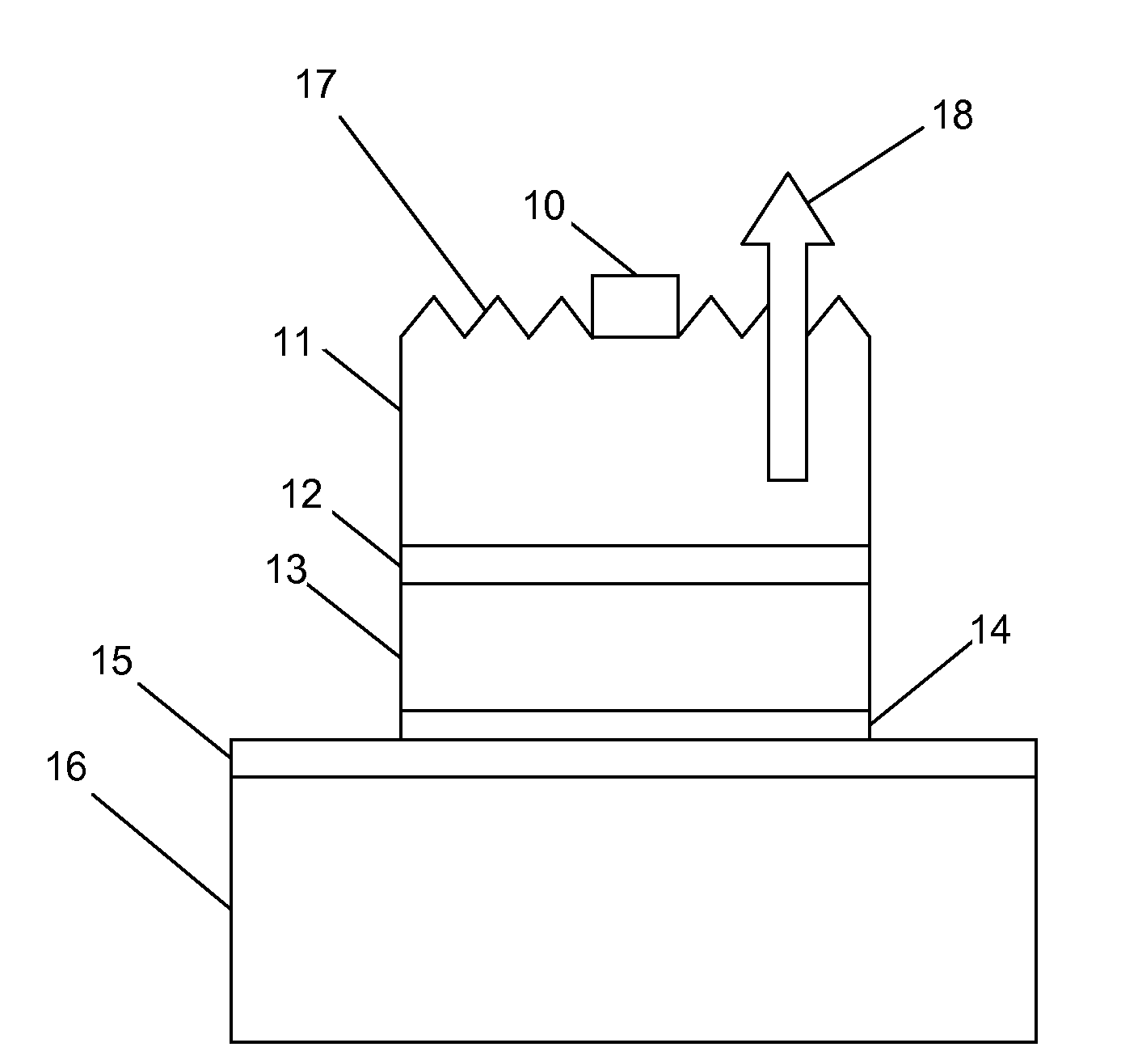

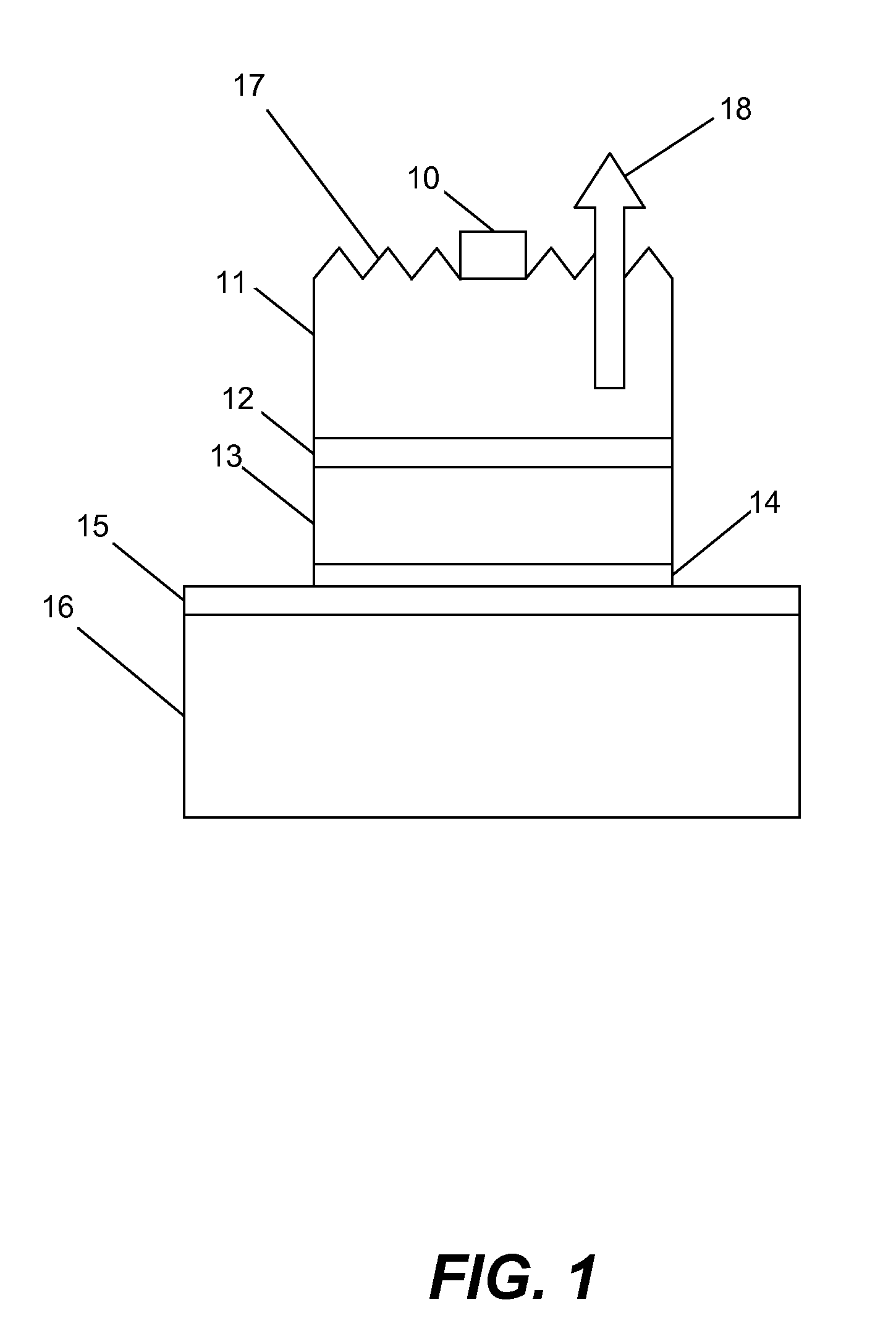

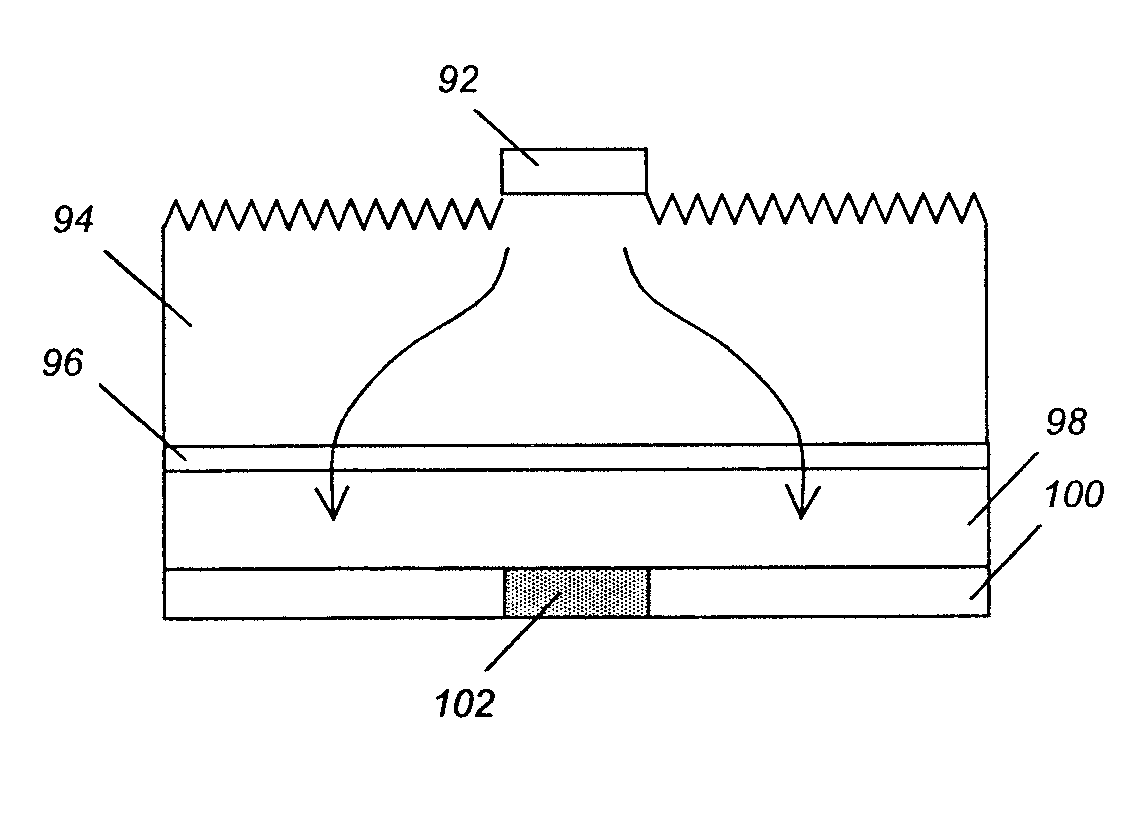

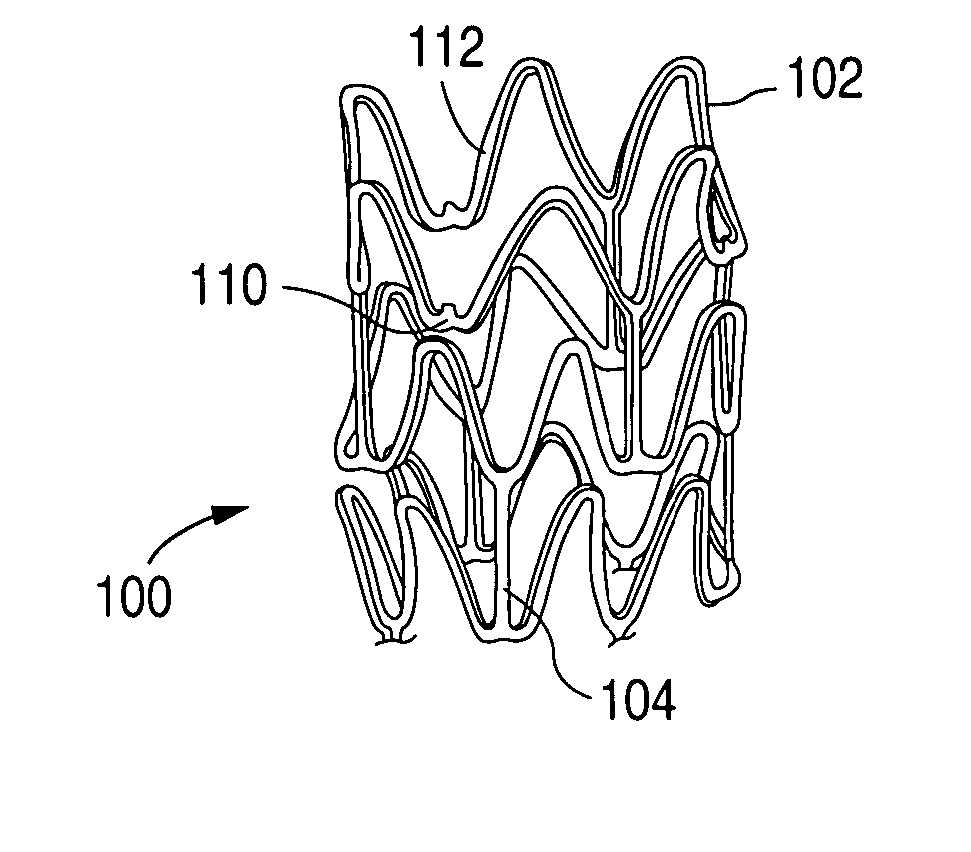

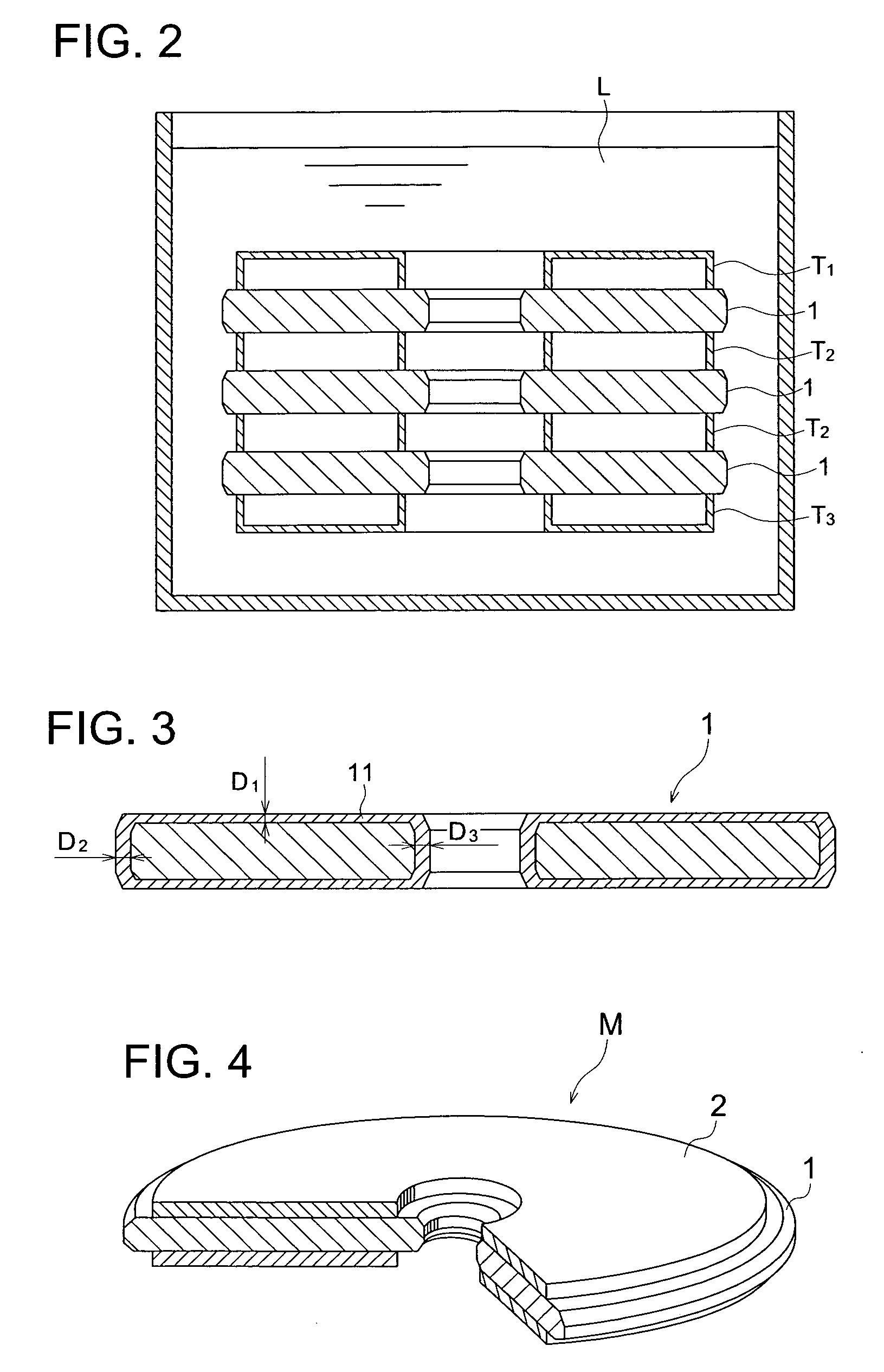

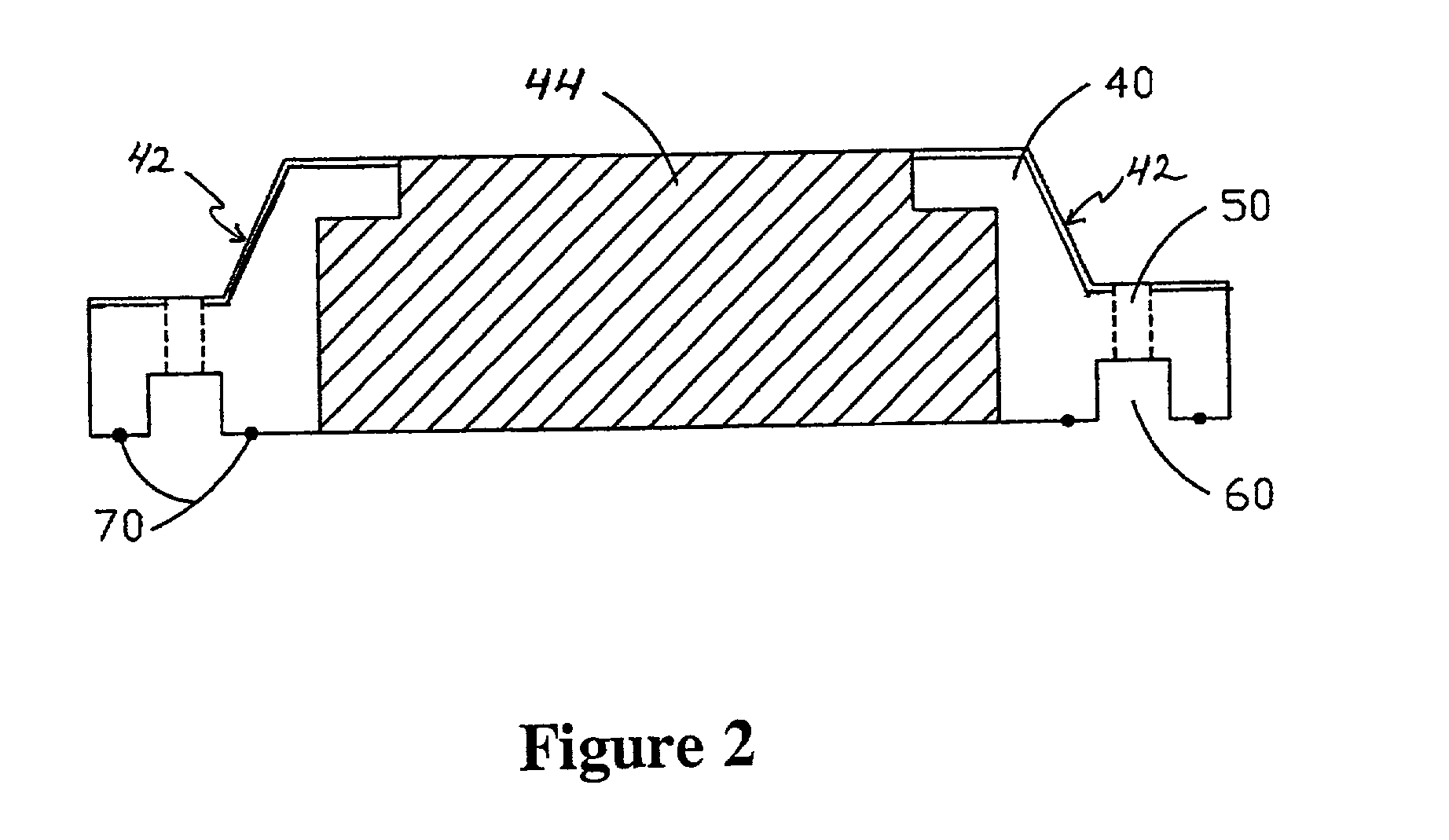

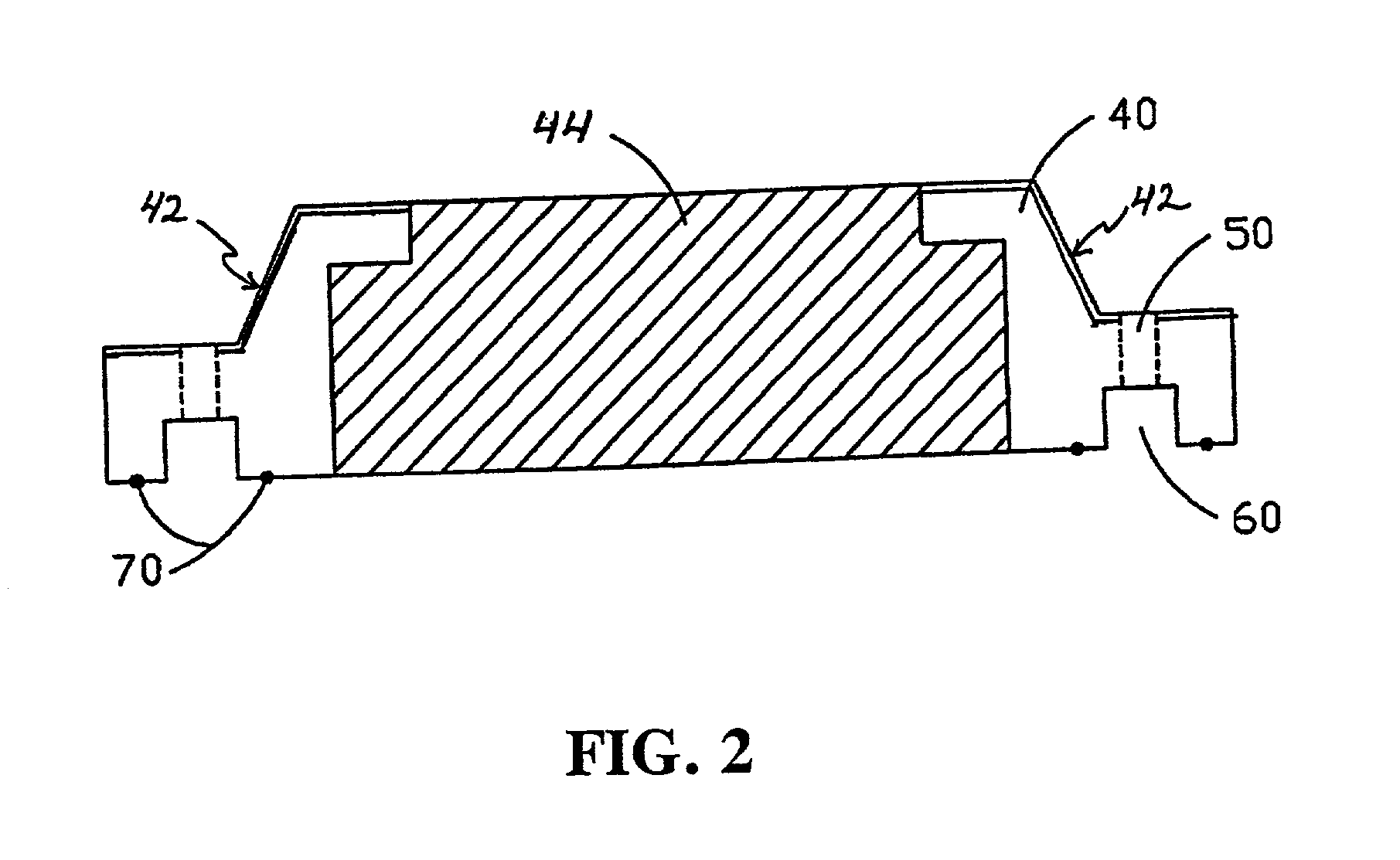

Highly efficient gallium nitride based light emitting diodes via surface roughening

ActiveUS20070121690A1Solid-state devicesSemiconductor/solid-state device manufacturingNitrogenLight reflection

A gallium nitride (GaN) based light emitting diode (LED), wherein light is extracted through a nitrogen face (N-face) (42) of the LED and a surface of the N-face (42) is roughened into one or more hexagonal shaped cones. The roughened surface reduces light reflections occurring repeatedly inside the LED, and thus extracts more light out of the LED. The surface of the N-face (42) is roughened by an anisotropic etching, which may comprise a dry etching or a photo-enhanced chemical (PEC) etching.

Owner:JAPAN SCI & TECH CORP

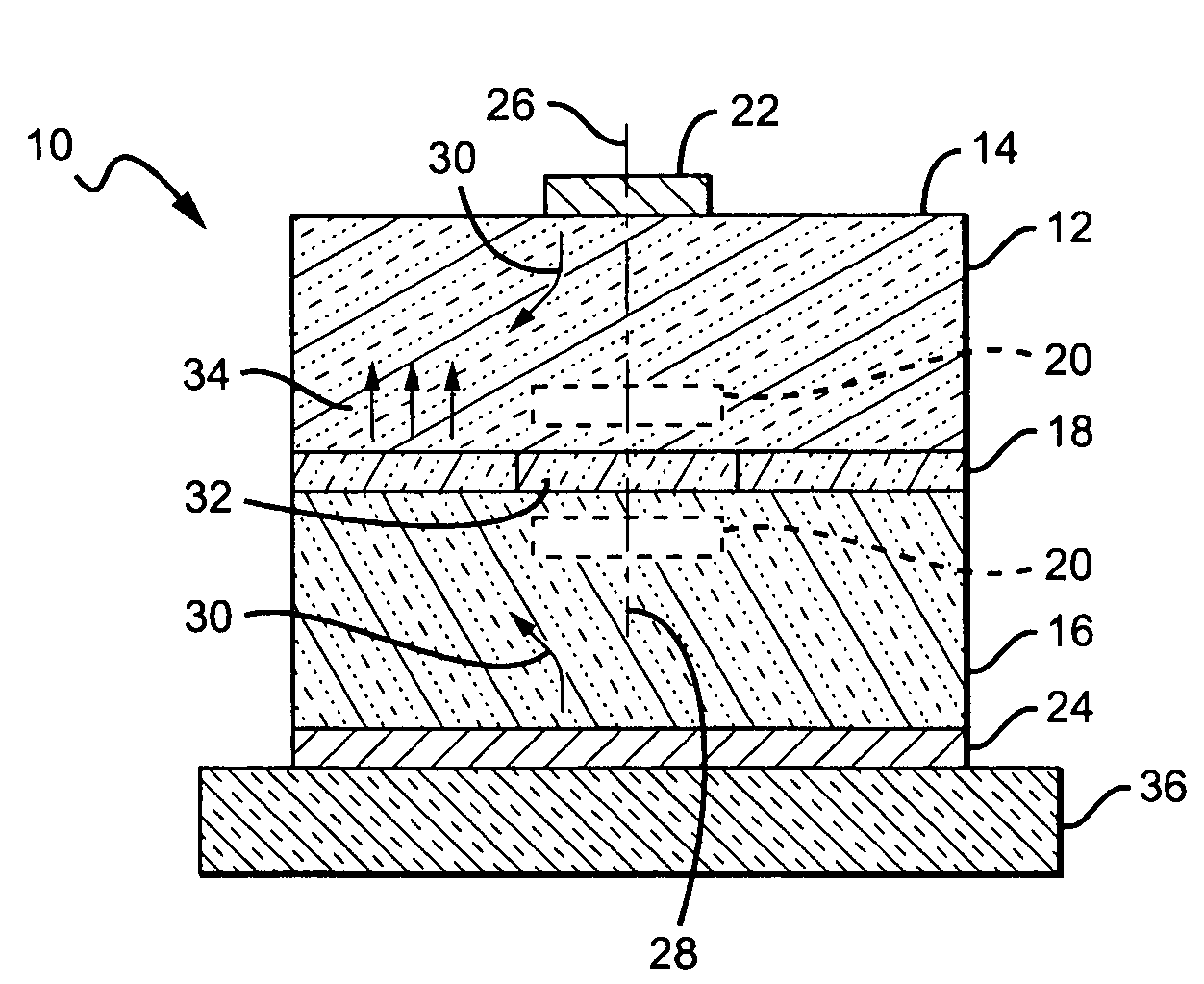

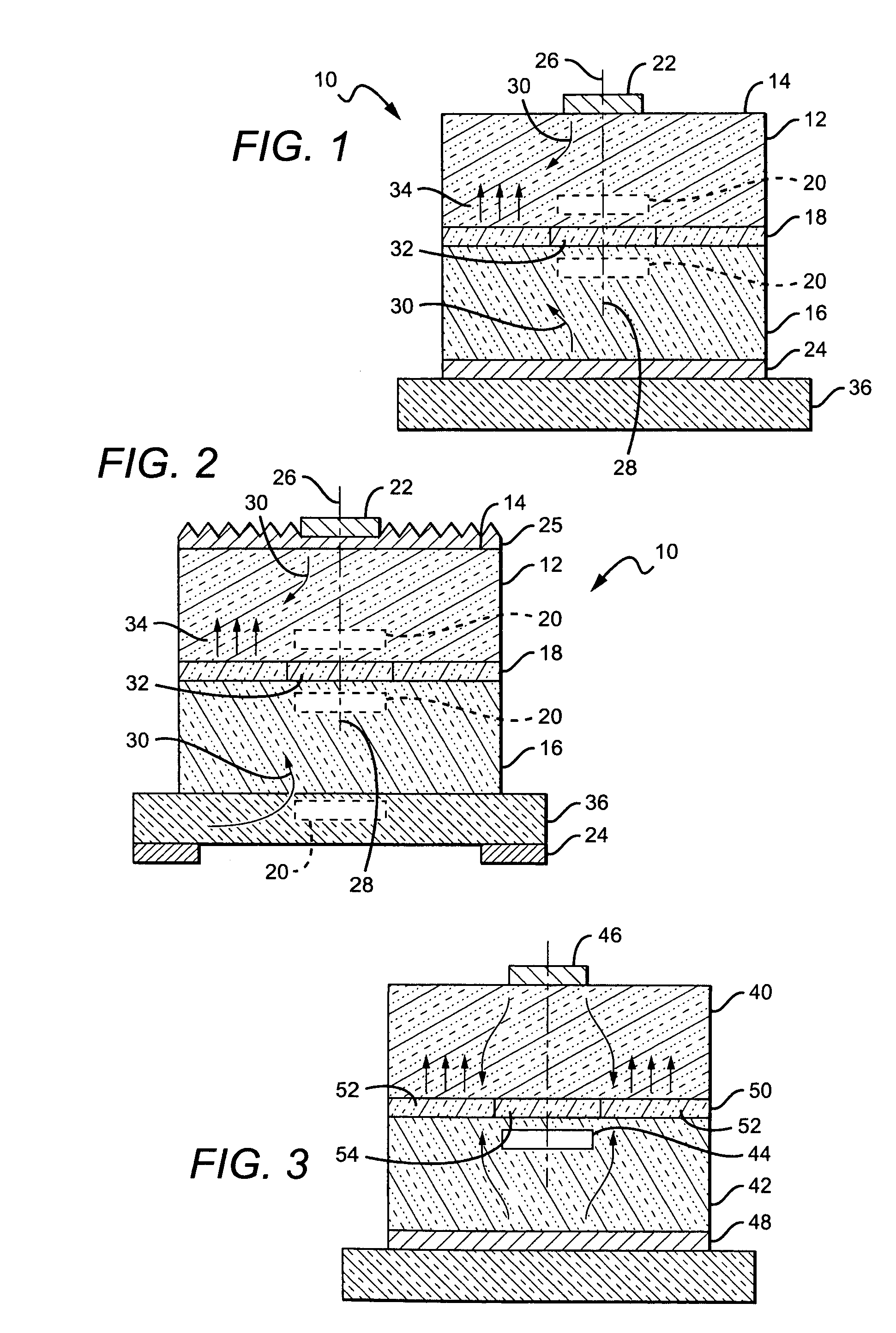

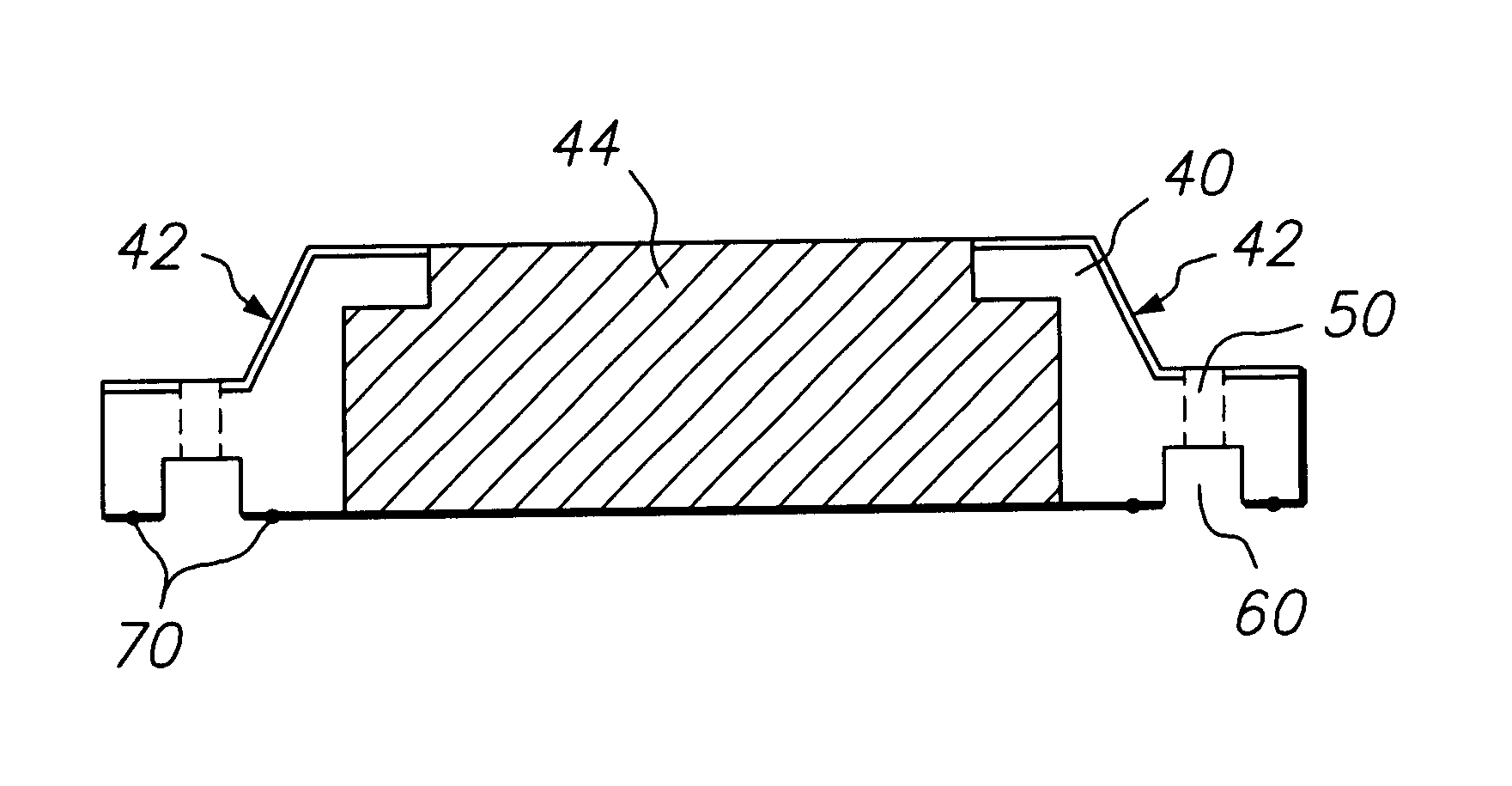

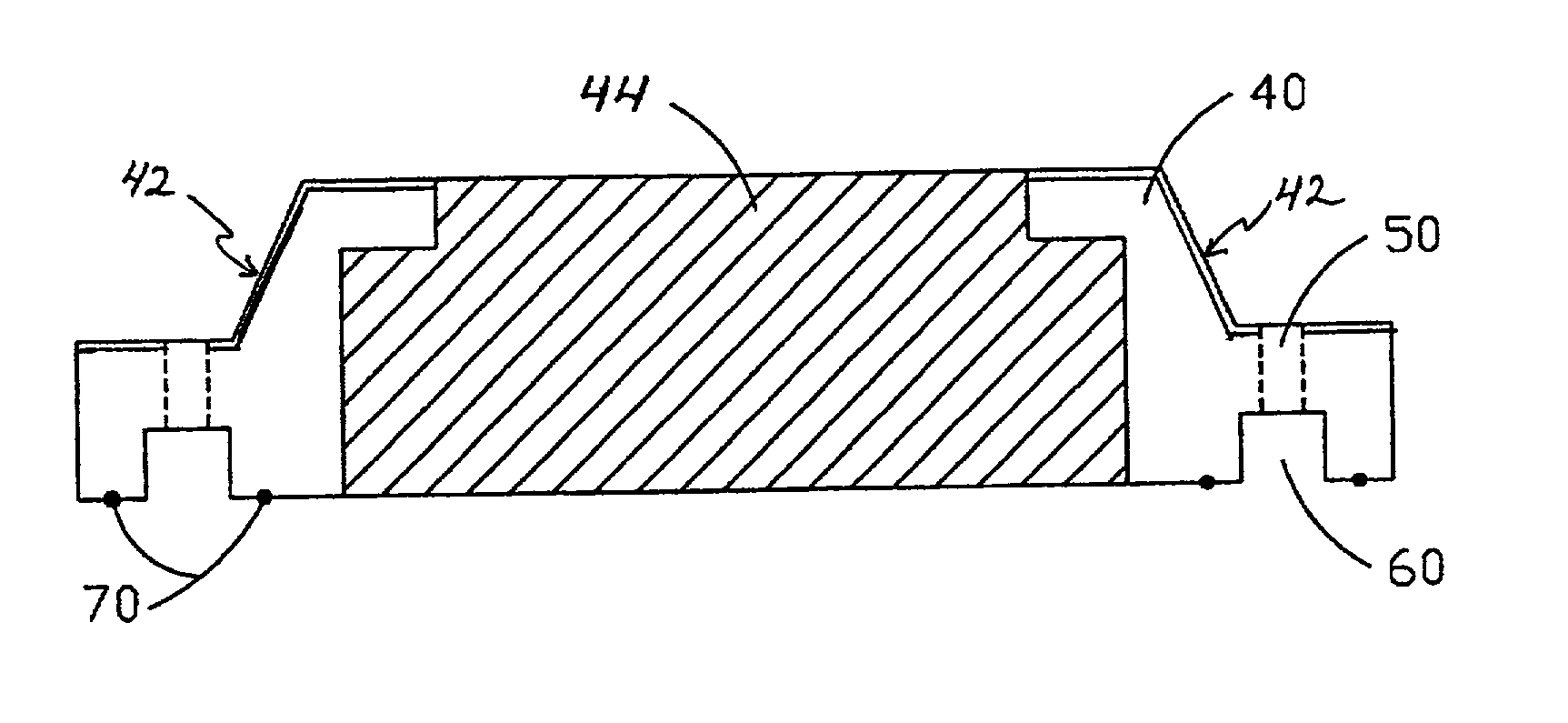

LED with current confinement structure and surface roughening

ActiveUS7335920B2Add featureAvoid emissionsSolid-state devicesSemiconductor devicesCurrent limitingSurface roughness

Owner:CREELED INC

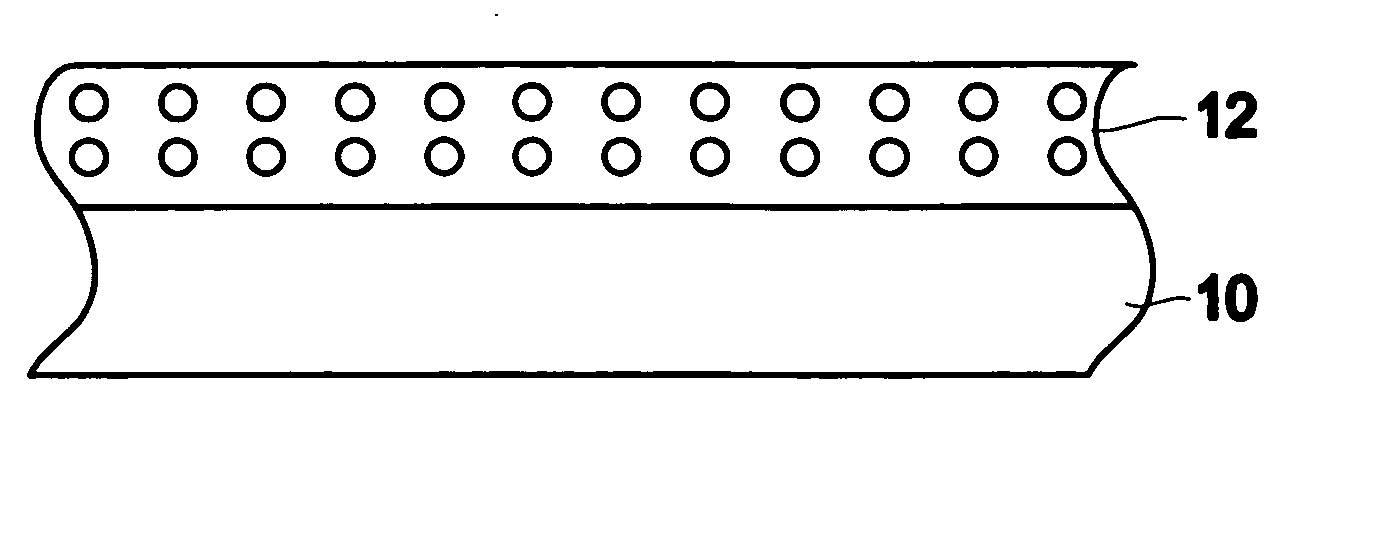

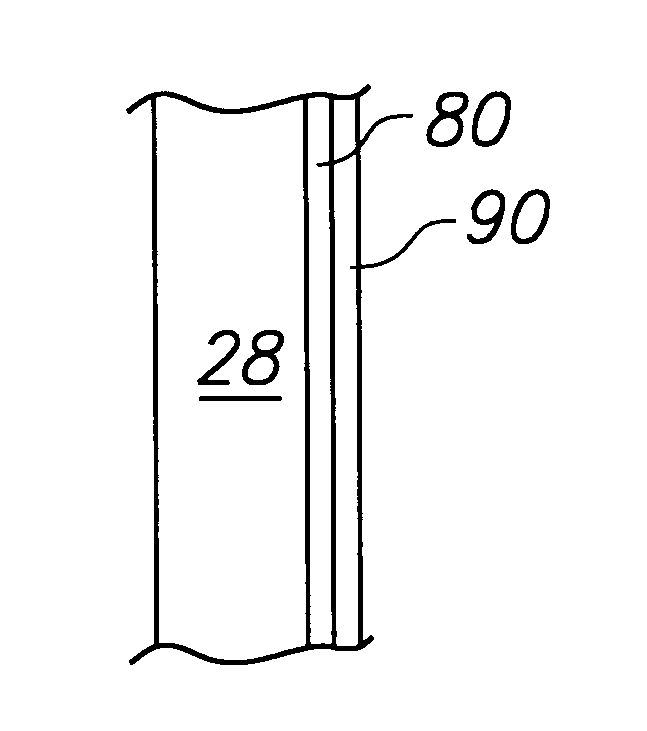

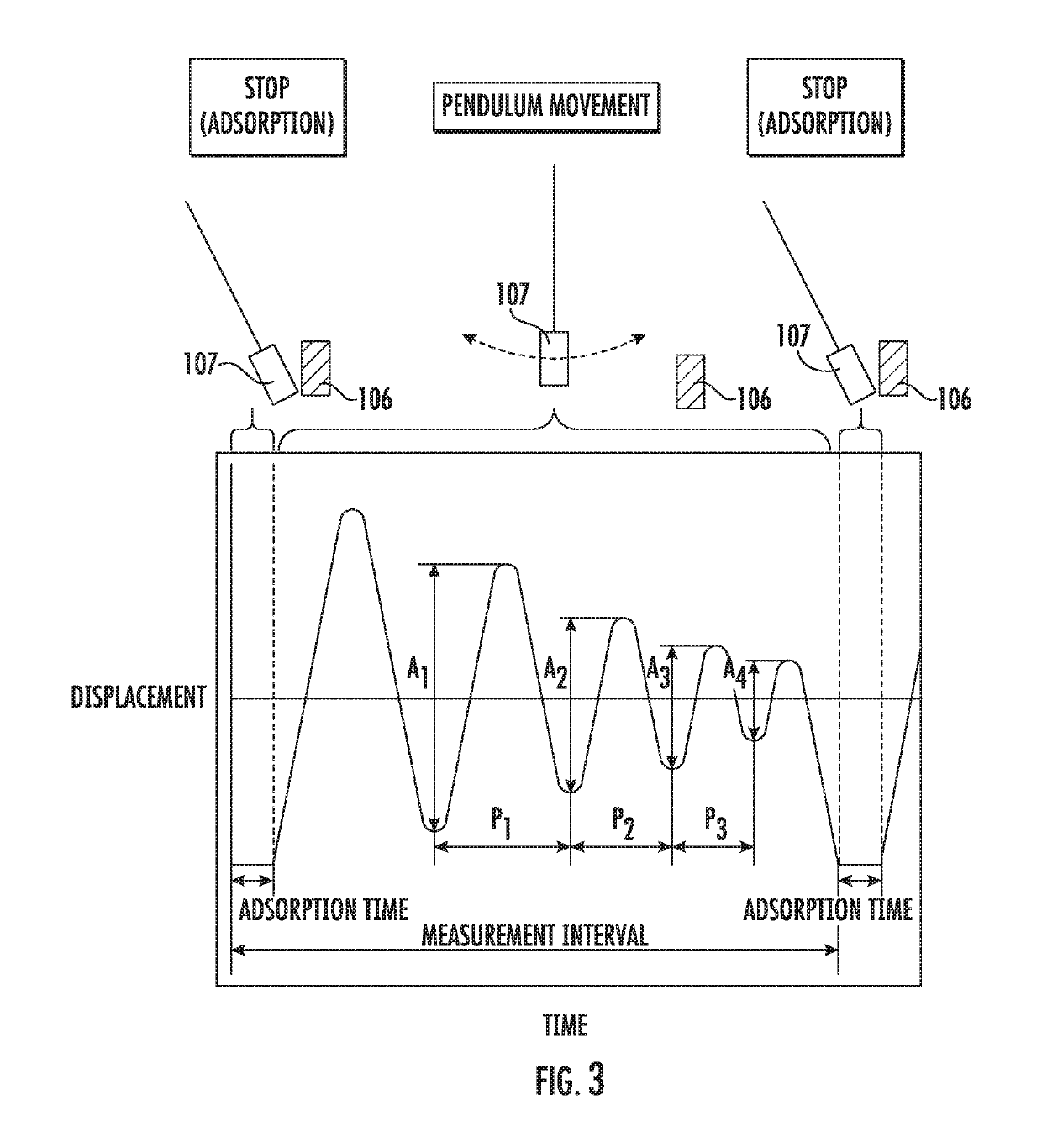

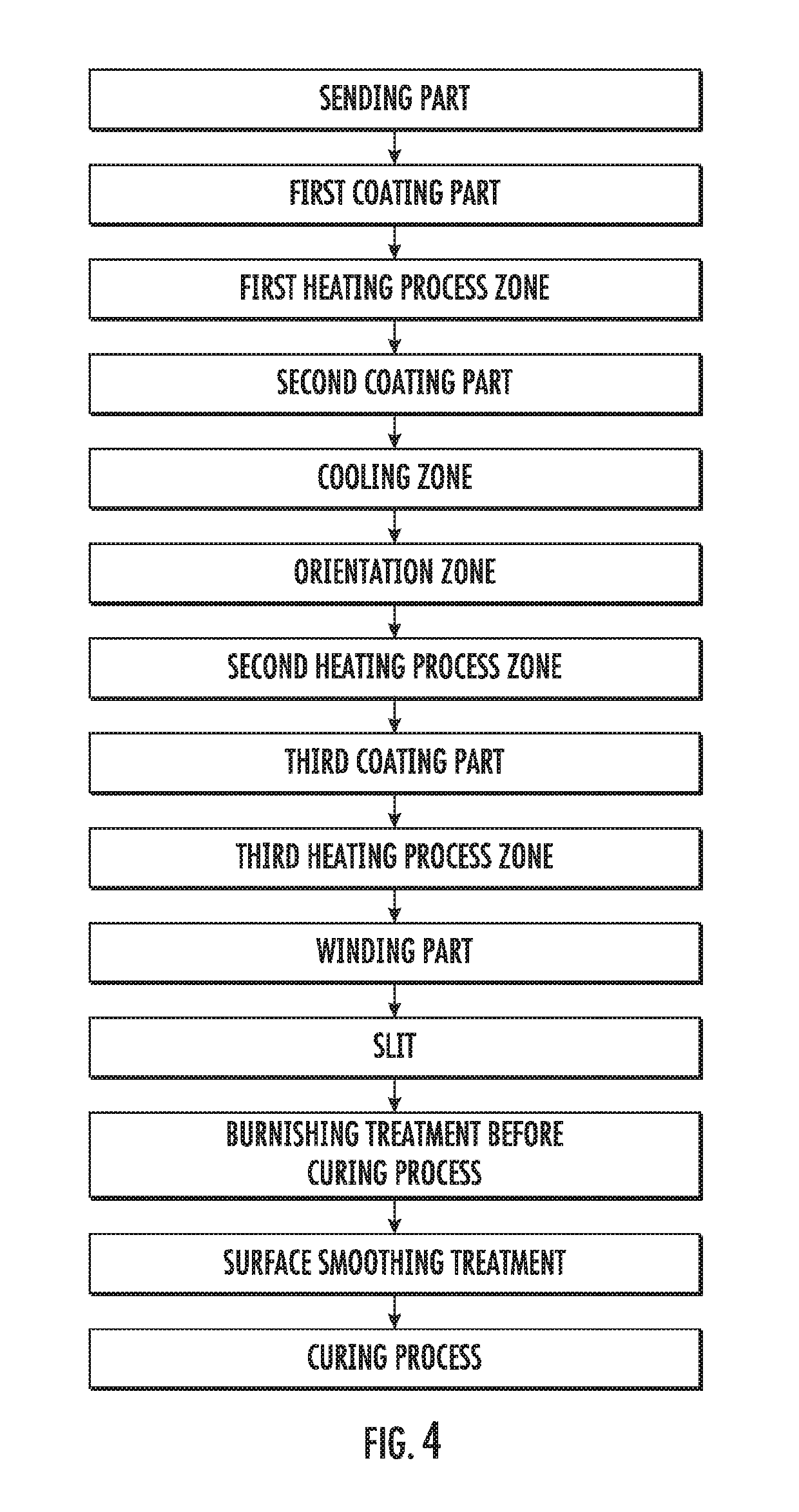

Magnetic tape

InactiveUS20120196156A1Good electromagnetic characteristicGood characteristic frictionMagnetic materials for record carriersRecord information storageMagnetic tapeNon magnetic

An aspect of the present invention relates to a magnetic tape comprising, on one surface of a nonmagnetic support, a nonmagnetic layer containing a nonmagnetic powder and a binder, and thereon, a magnetic layer containing a ferromagnetic powder and a binder, whereinthe magnetic layer contains a nonmagnetic filler the average particle diameter φ of which satisfies relation (I) below with a thickness t of the magnetic layer:1.0≦φ / t≦2.0 (I);the thickness t of the magnetic layer ranges from 30 to 200 nm;the nonmagnetic layer has a thickness ranging from 30 to 200 nm;a composite elastic modulus as measured on a surface of the magnetic layer ranges from 6.0 to 8.0 GPa; anda centerline average surface roughness Ra of the surface of the magnetic layer, as measured by an optical three-dimensional profilometer, ranges from 0.2 to 1.5 nm.

Owner:FUJIFILM CORP

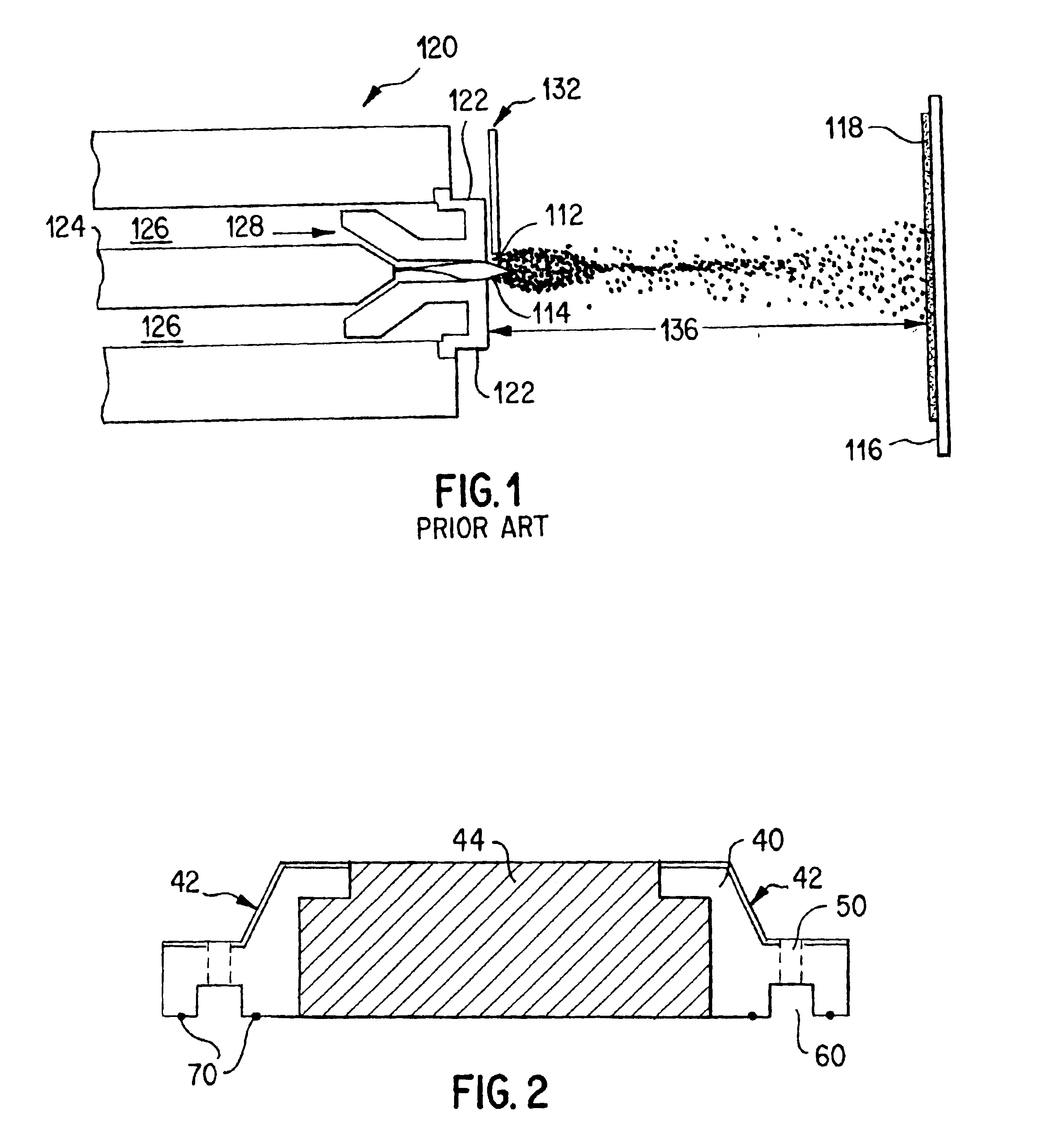

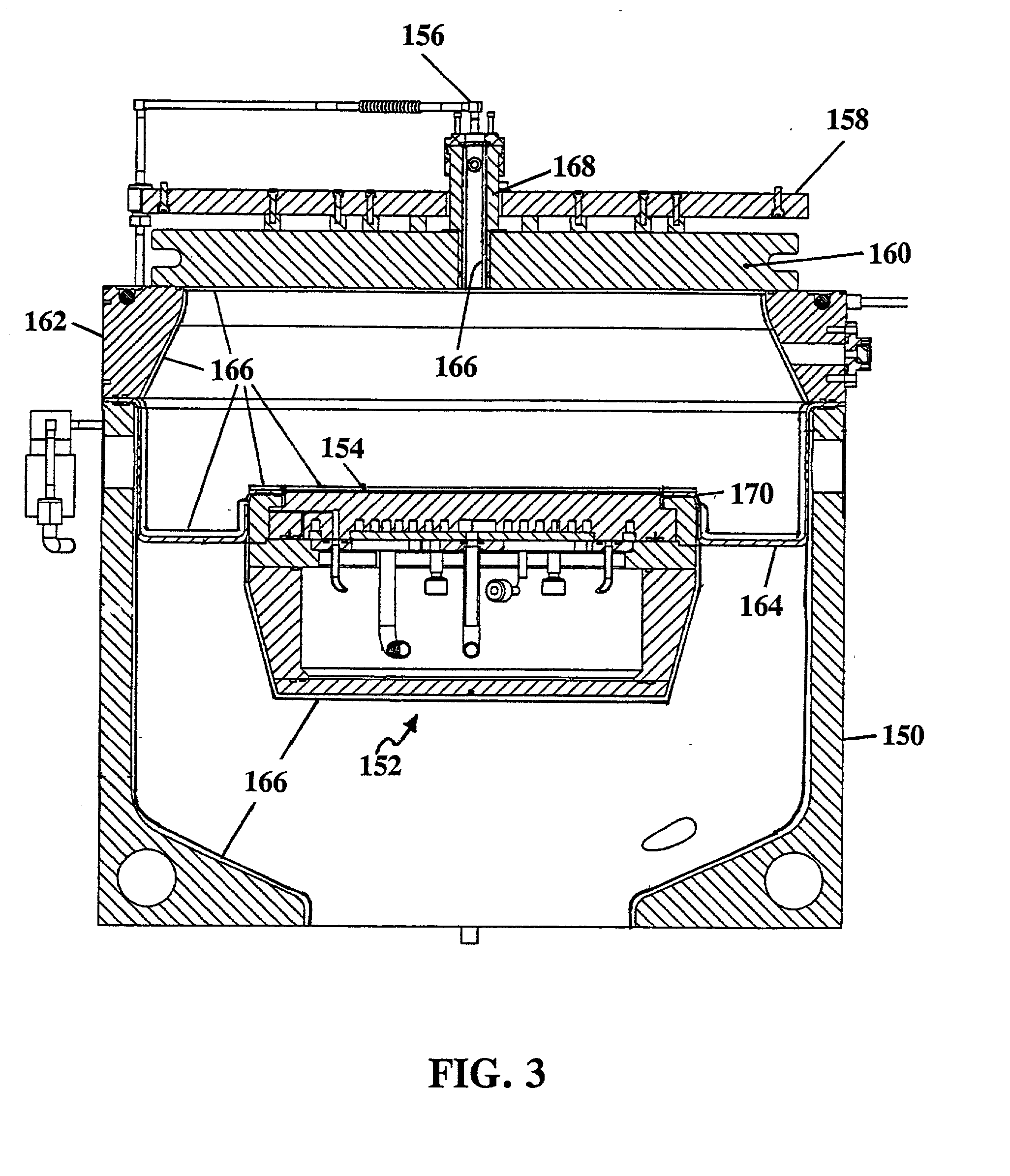

Corrosion resistant component of semiconductor processing equipment and method of manufacturing thereof

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber includes a metal surface such as aluminum or aluminum alloy, stainless steel, or refractory metal coated with a phosphorus nickel plating and an outer ceramic coating such as alumina, silicon carbide, silicon nitride, boron carbide or aluminum nitride. The phosphorus nickel plating can be deposited by electroless plating and the ceramic coating can be deposited by thermal spraying. To promote adhesion of the ceramic coating, the phosphorus nickel plating can be subjected to a surface roughening treatment prior to depositing the ceramic coating.

Owner:LAM RES CORP

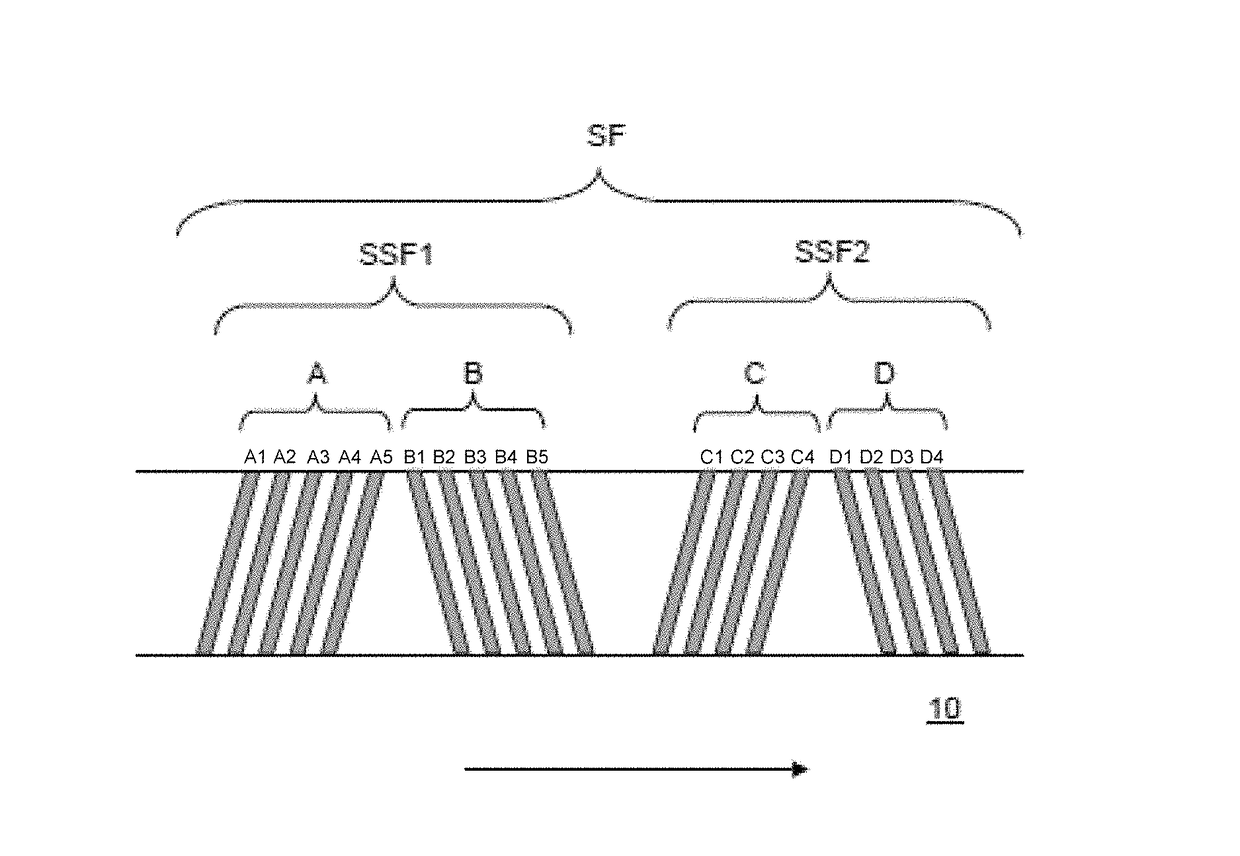

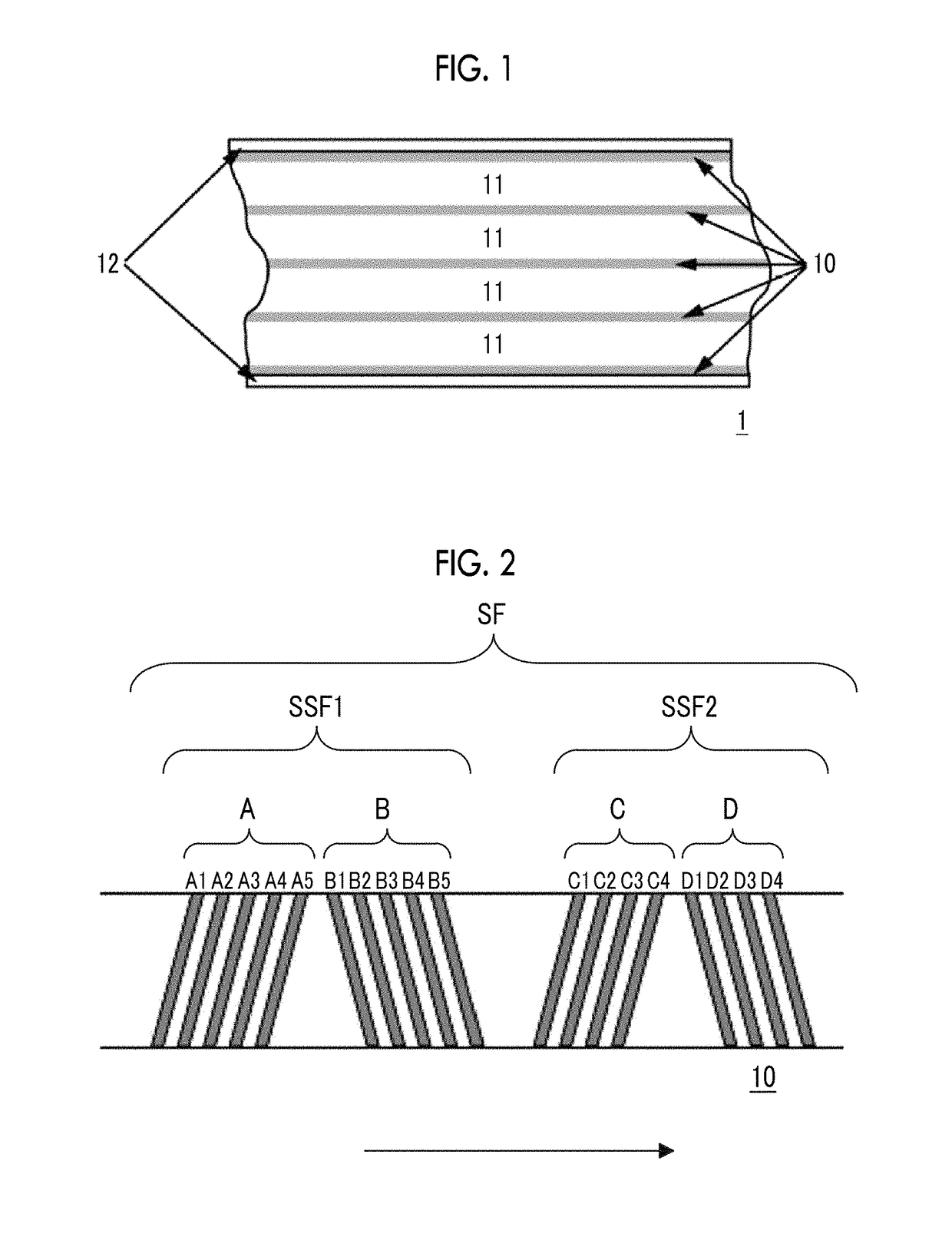

Magnetic tape and magnetic tape device

ActiveUS9837116B2Increase the number ofIncrease recording capacityAlignment for track following on tapesRecord information storageMagnetic tapeSurface roughness

Owner:FUJIFILM CORP

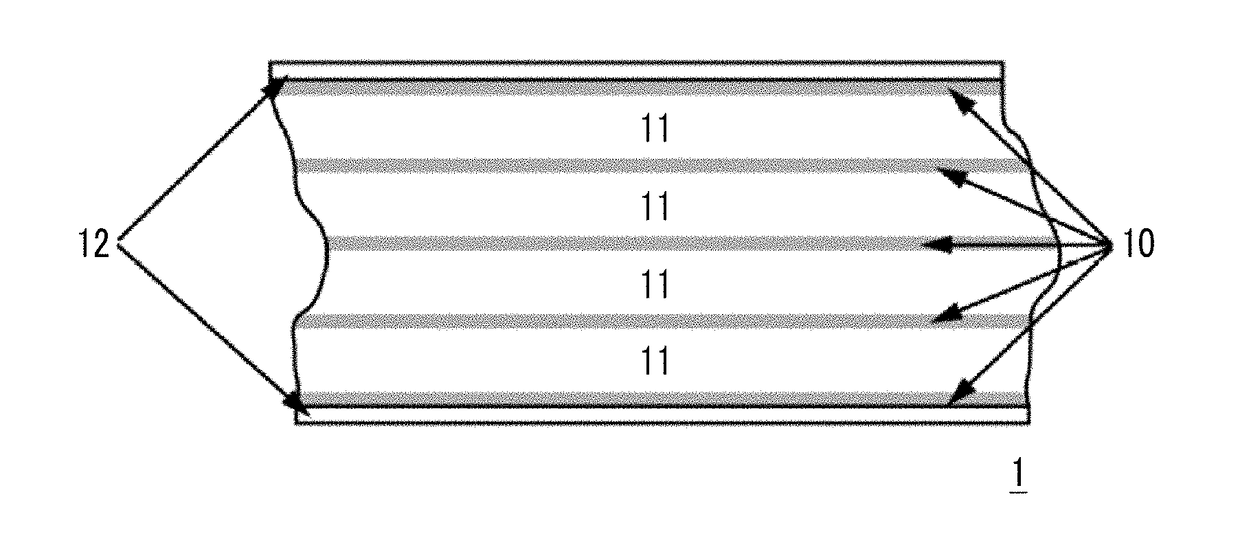

High light extraction efficiency nitride based light emitting diode by surface roughening

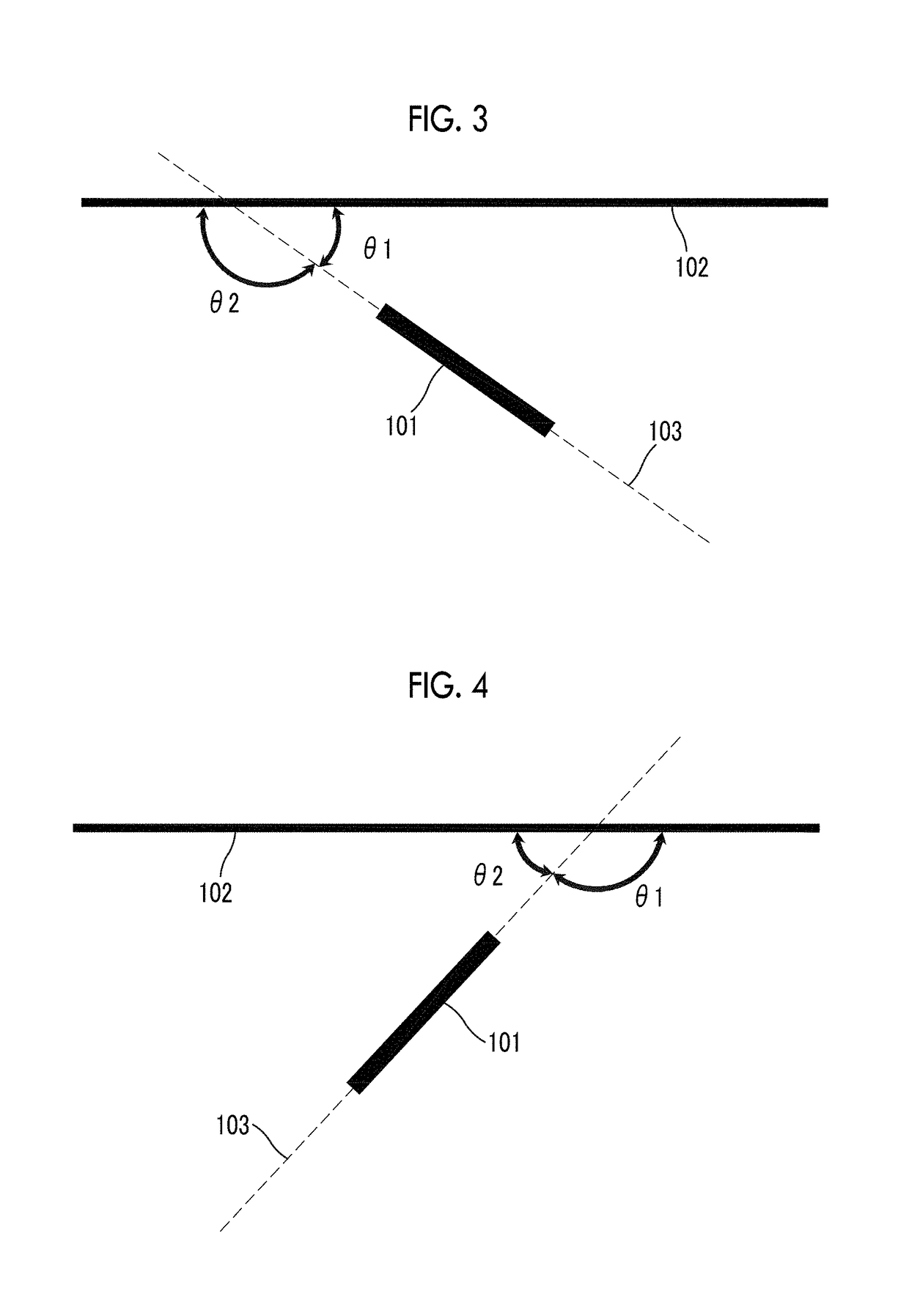

ActiveUS20090146170A1Reduce the angle of incidenceIncrease the angle of incidenceSemiconductor/solid-state device manufacturingSemiconductor devicesEtchingNitride

A III-nitride light emitting diode (LED) and method of fabricating the same, wherein at least one surface of a semipolar or nonpolar plane of a III-nitride layer of the LED is textured, thereby forming a textured surface in order to increase light extraction. The texturing may be performed by plasma assisted chemical etching, photolithography followed by etching, or nano-imprinting followed by etching.

Owner:RGT UNIV OF CALIFORNIA

Magnetic tape and magnetic tape device

ActiveUS20170372736A1Improve surface smoothnessDefect signalAlignment for track following on tapesTape carriersMagnetic tapeSurface roughness

The magnetic tape includes a non-magnetic support; and a magnetic layer including ferromagnetic powder and a binder on the non-magnetic support, in which the total thickness of the magnetic tape is equal to or smaller than 5.30 μm, the magnetic layer includes a timing-based servo pattern, a center line average surface roughness Ra measured regarding a surface of the magnetic layer is equal to or smaller than 1.8 nm, the ferromagnetic powder is ferromagnetic hexagonal ferrite powder, the magnetic layer includes an abrasive, and a tilt cos θ of the ferromagnetic hexagonal ferrite powder with respect to a surface of the magnetic layer acquired by cross section observation performed by using a scanning transmission electron microscope is 0.85 to 1.00.

Owner:FUJIFILM CORP

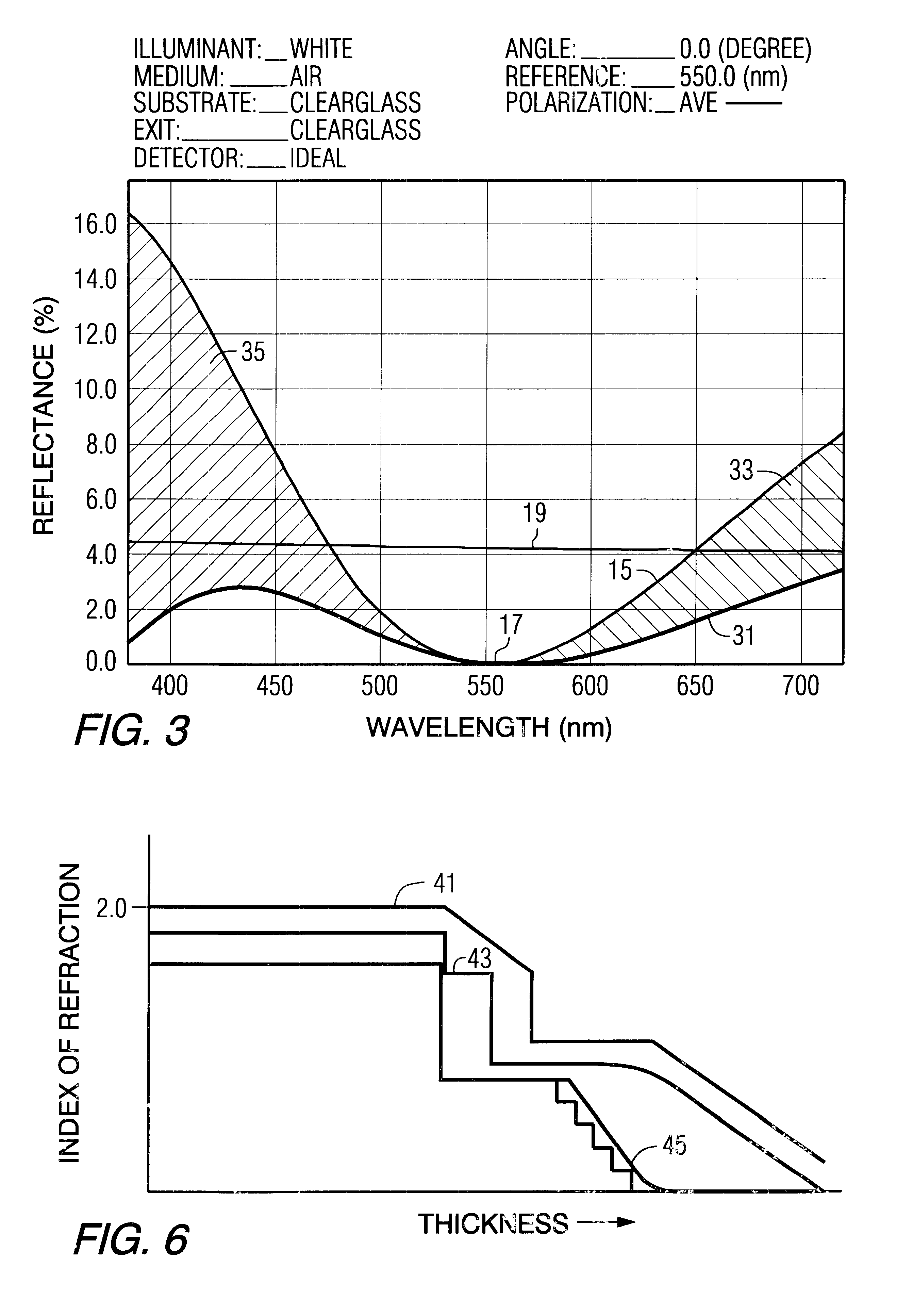

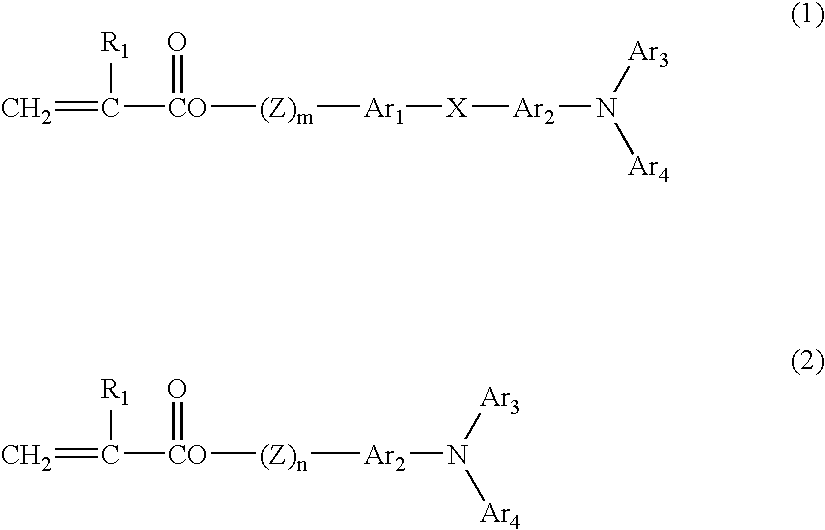

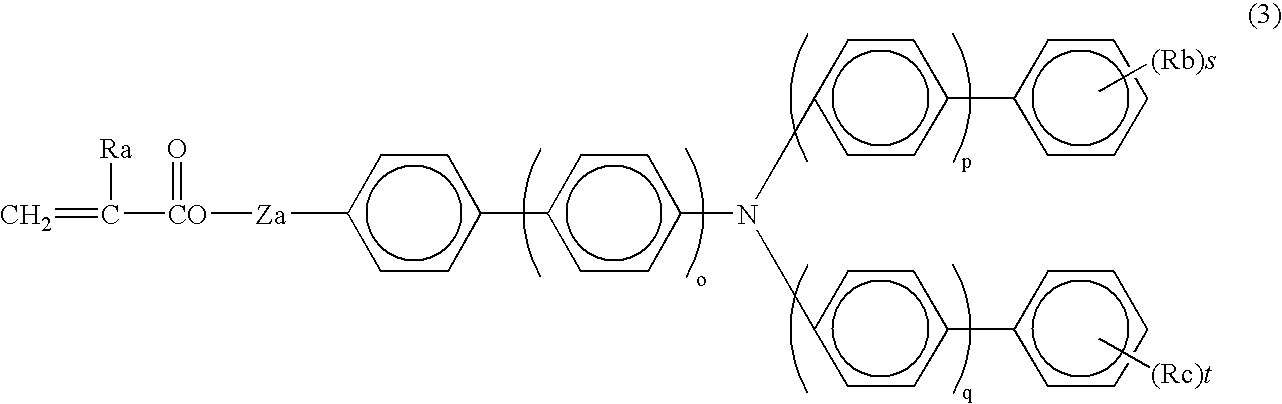

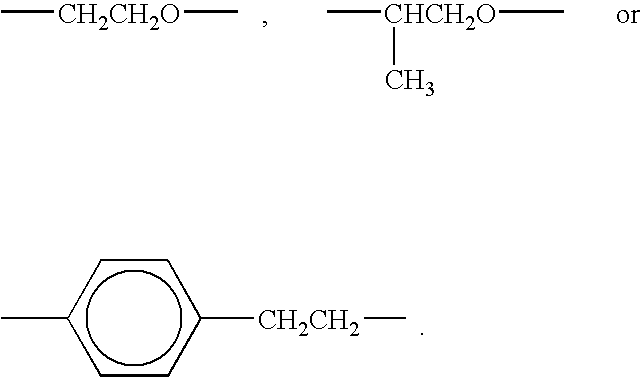

Conductive antireflective coatings and methods of producing same

This invention relates to a two layers or more anti-static film coating deposited on a substrate. Selected layers of the films may have anti-static and / or electromagnetic properties. In one embodiment, the film farthest from the substrate has an index of refraction lower than the underlying film. In another embodiment, the surface of the film is roughened to provide a graded index of refraction.

Owner:VITRO FLAT GLASS LLC

Electrophotographic photoconductor, and image forming process, image forming apparatus and process cartridge for an image forming apparatus using the same

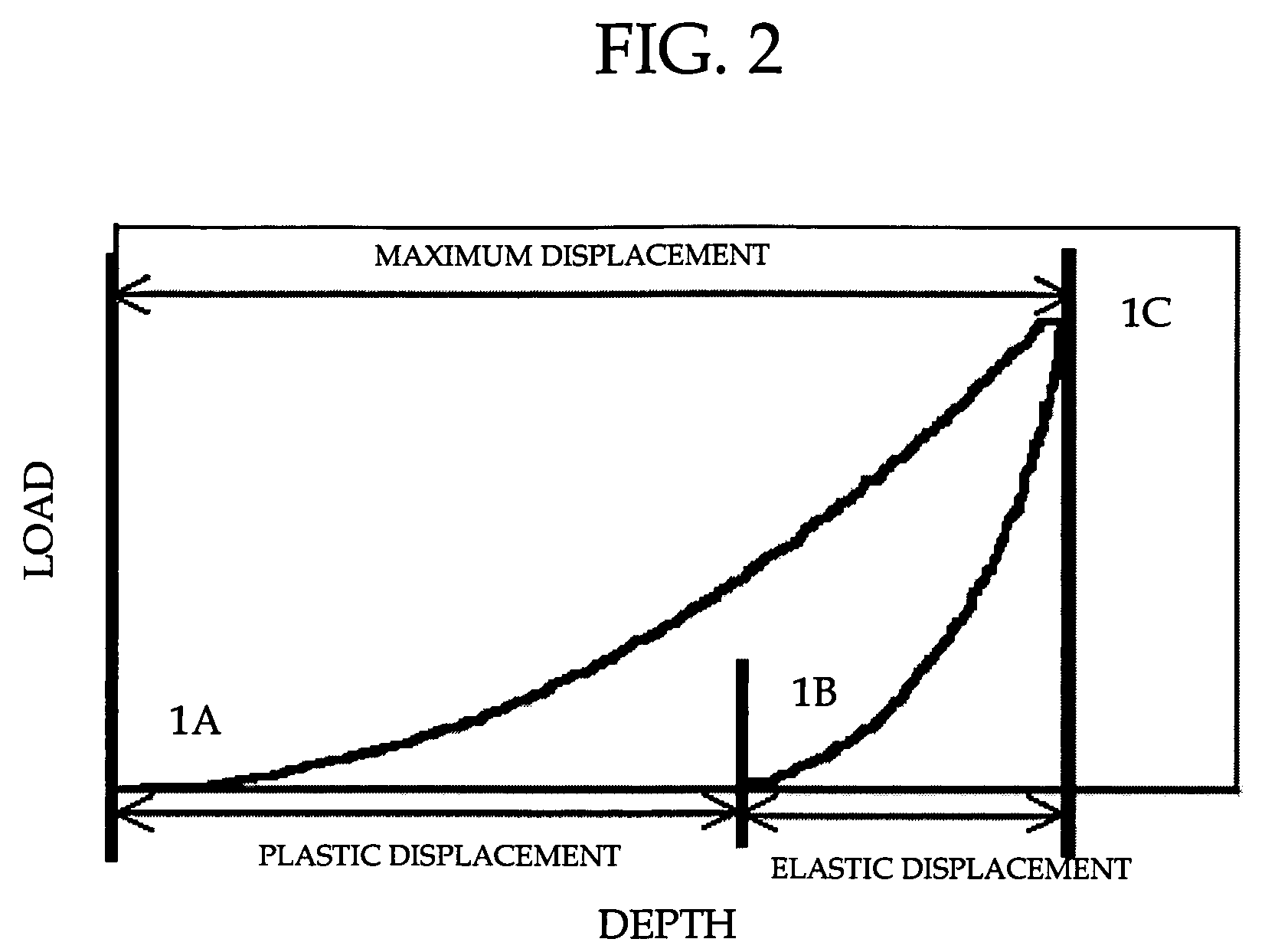

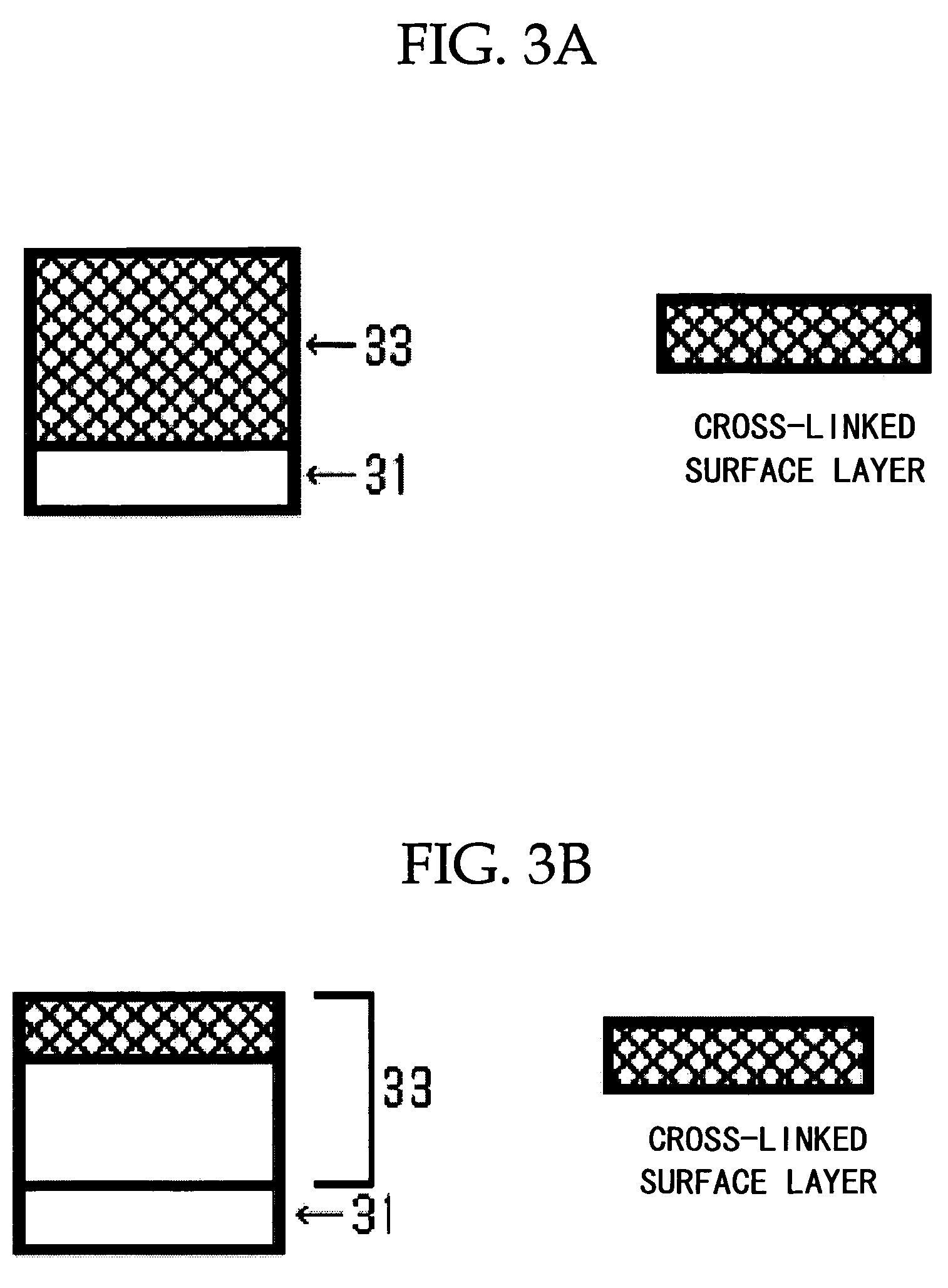

ActiveUS20040253527A1Electrographic process apparatusElectrographic processes using charge patternSurface layerElectrical conductor

Disclosed is an electrophotographic photoconductor including at least a photoconductive layer on a conductive substrate, wherein the surface layer of the photoconductive layer contains at least a surface crosslinked layer formed by curing a tri- or more-functional radical polymerizable monomer without having a charge transporting structure and a mono-functional radical polymerizable compound having a charge transporting structure and the surface crosslinked layer has a surface roughness Rz of 1.3 mum or less.

Owner:RICOH KK

Method of preventing surface roughening during hydrogen prebake of SiGe substrates

InactiveUS20050148161A1Avoid creatingAvoid roughnessPolycrystalline material growthSemiconductor/solid-state device manufacturingHydrofluoric acidRough surface

The invention forms an epitaxial silicon-containing layer on a silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface and avoids creating a rough surface upon which the epitaxial silicon-containing layer is grown. In order to avoid creating the rough surface, the invention first performs a hydrofluoric acid etching process on the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. This etching process removes most of oxide from the surface, and leaves a first amount of oxygen (typically 1×1013-1×1015 / cm2 of oxygen) on the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. The invention then performs a hydrogen pre-bake process which heats the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface sufficiently to remove additional oxygen from the surface and leave a second amount of oxygen, less than the first amount, on the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. The heating process leaves an amount of at least 5×1012 / cm2 of oxygen (typically, between approximately 1×1013 / cm2 and approximately 5×1013 / cm2 of oxygen) on the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. By leaving a small amount of oxygen on the silicon germanium, patterned strained silicon, or patterned silicon-on-insulator surface, the heating processes avoid changing the roughness of the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. Then the process of epitaxially growing the epitaxial silicon-containing layer on the silicon germanium, patterned strained silicon, or patterned silicon-on-insulator surface is performed.

Owner:IBM CORP

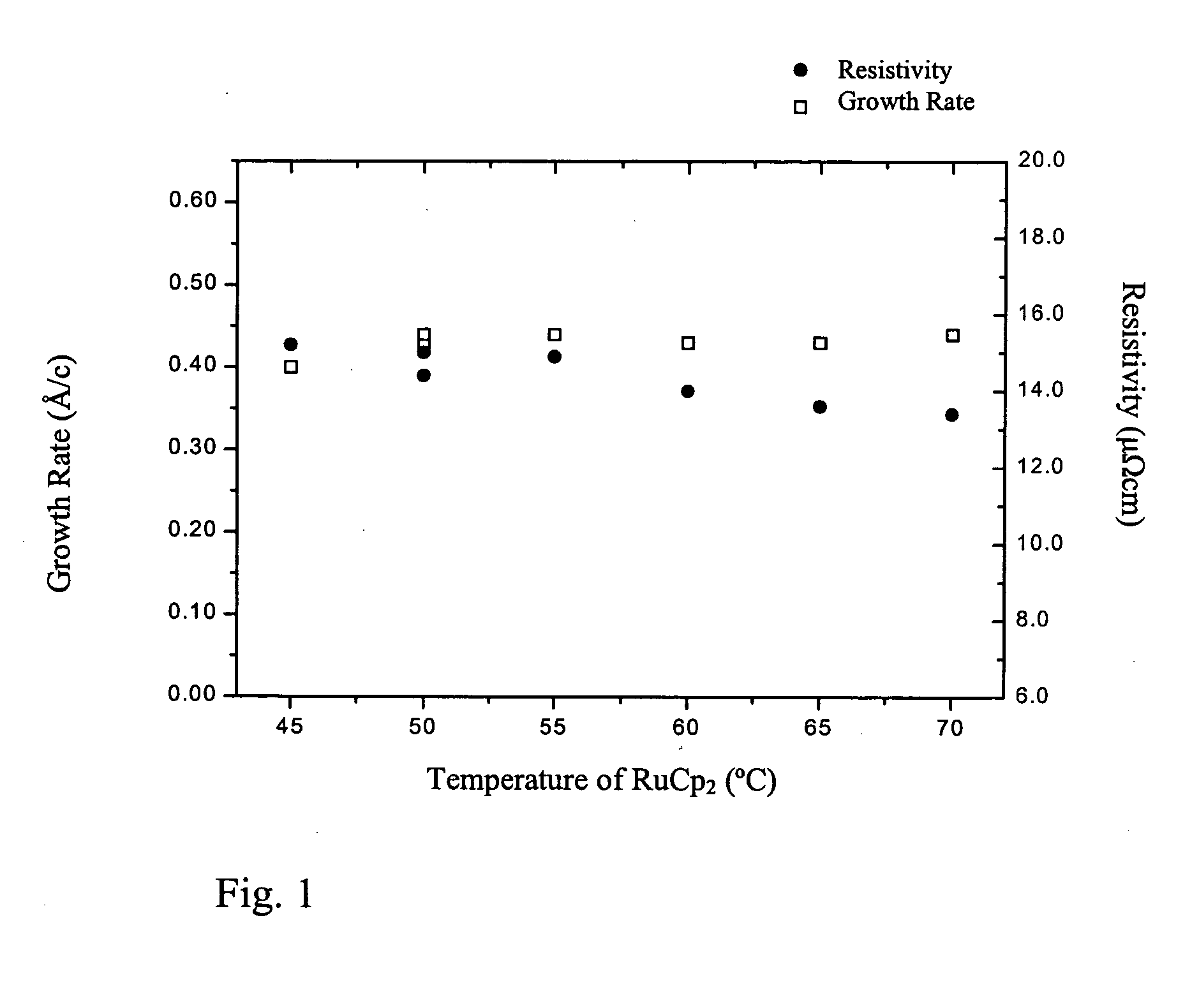

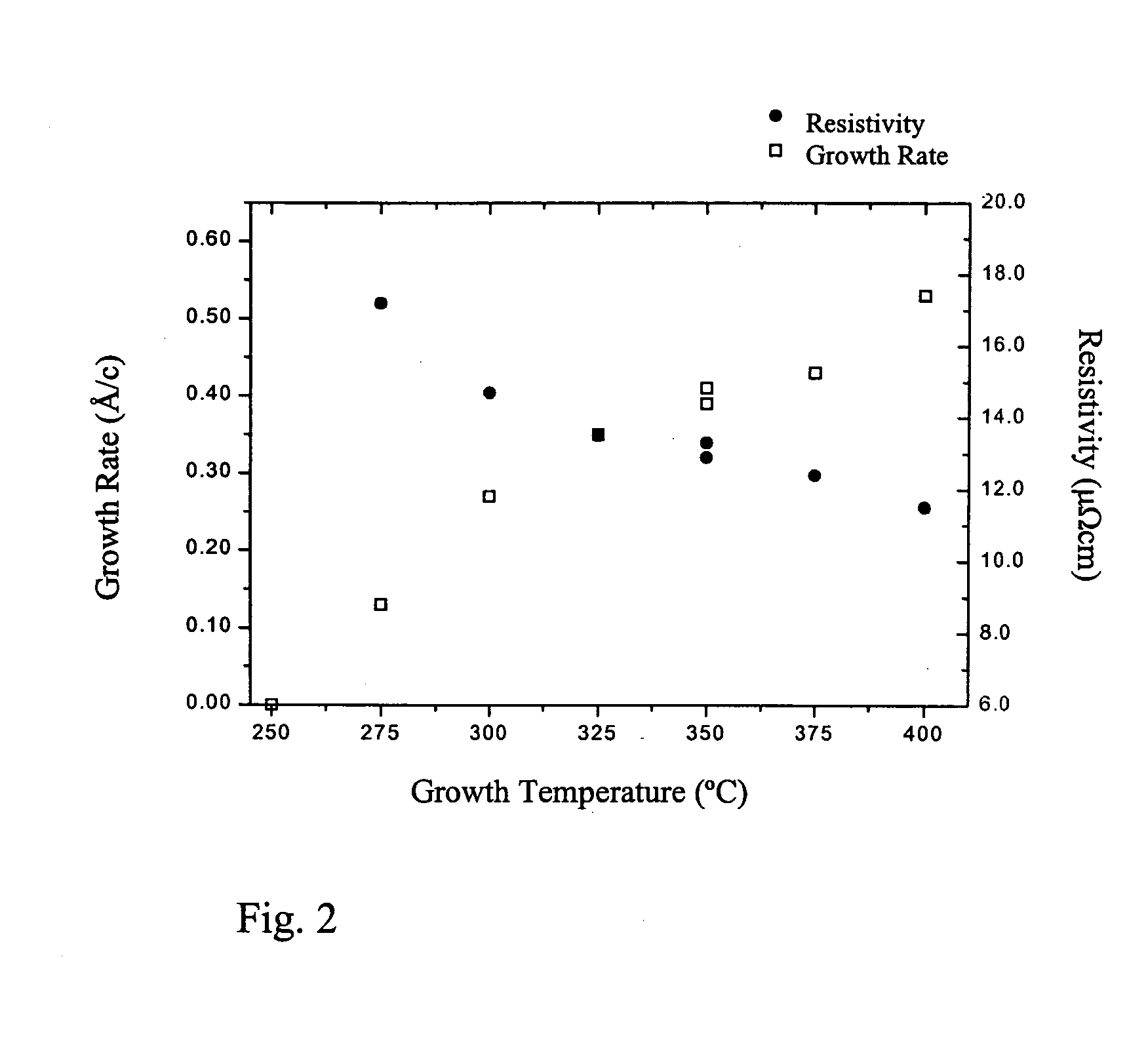

Process for producing metal thin films by ALD

InactiveUS20050020060A1Promote nucleationGood film uniformityNanomagnetismSolid-state devicesHigh elevationSurface structure

The invention relates generally to processes for producing electrically conductive noble metal thin films on a substrate by atomic layer deposition. According to one embodiment of the invention a substrate with a surface is provided in a reaction chamber and a vaporised precursor of a noble metal is pulsed into the reaction chamber. By contacting the vaporised precursor with the surface of the substrate, no more than about a molecular layer of the metal precursor is formed on the substrate. In a next step, a pulse of molecular oxygen-containing gas is provided in the reaction chamber, where the oxygen reacts with the precursor on the substrate. Thus, high-quality metal thin films can be deposited by utilising reactions between the metal precursor and oxygen. In one embodiment, electrically conductive layers are deposited in structures that have high aspect ratio vias and trenches, local high elevation areas or other similar surface structures that make the surface rough.

Owner:ASM INTERNATIONAL

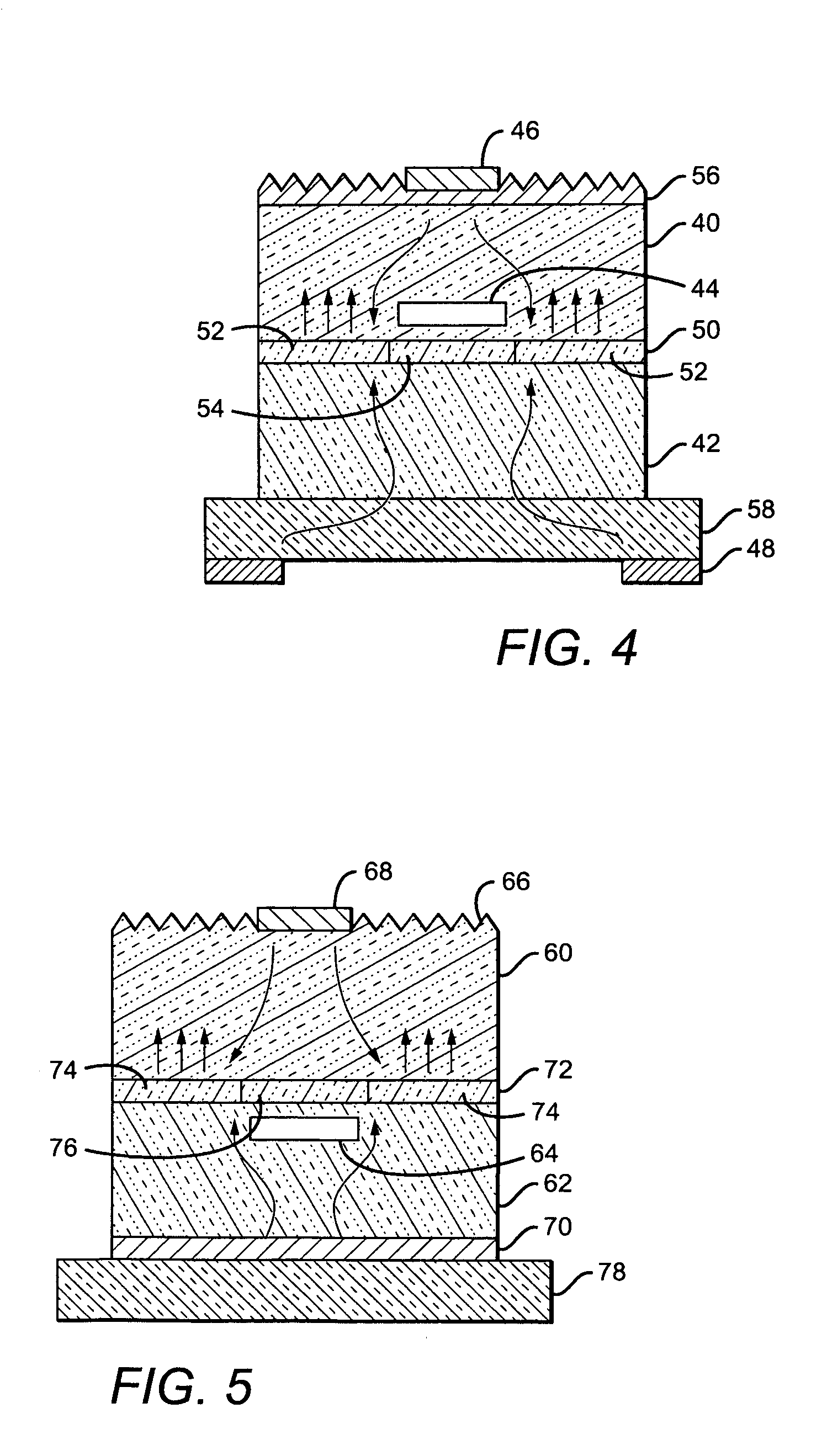

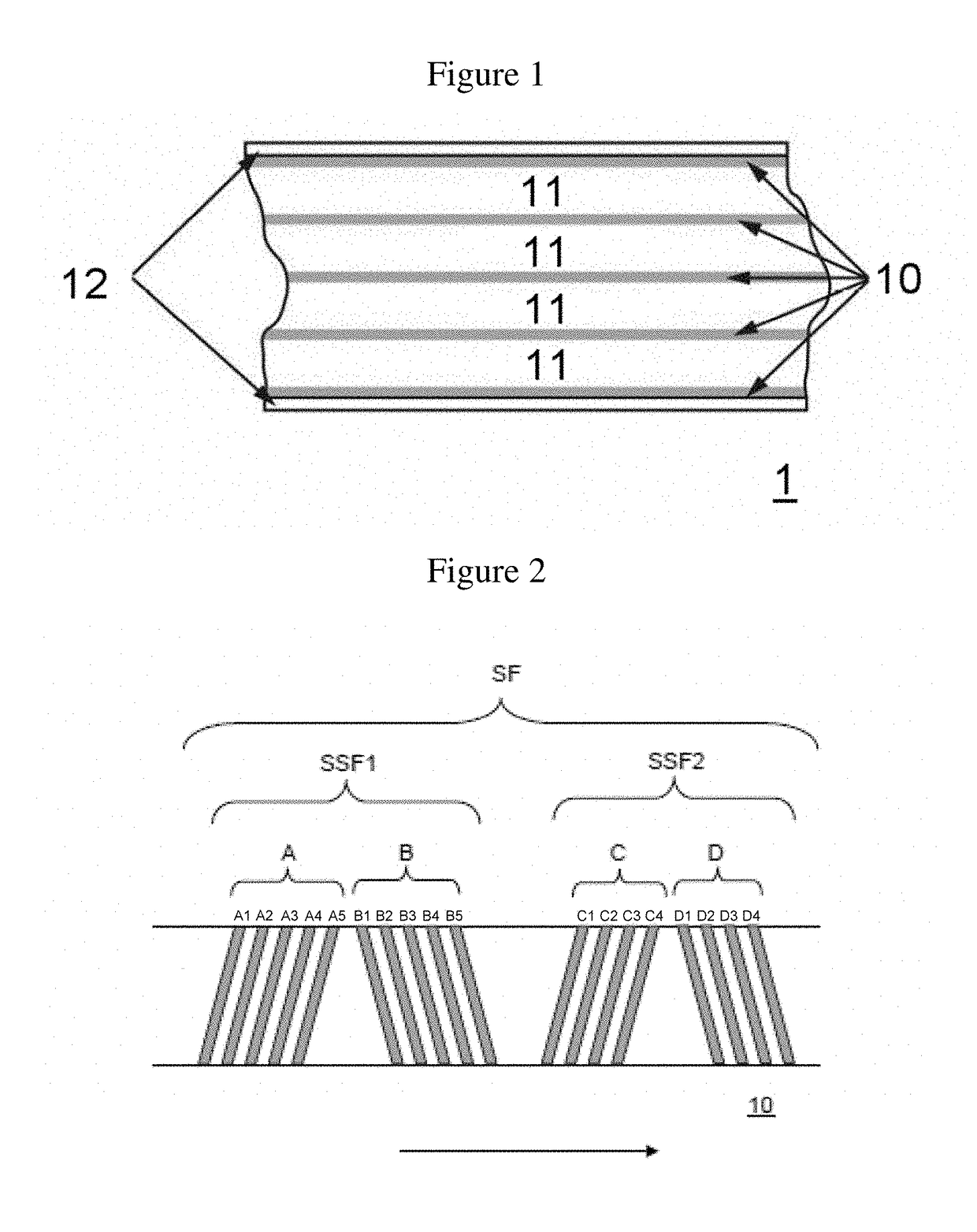

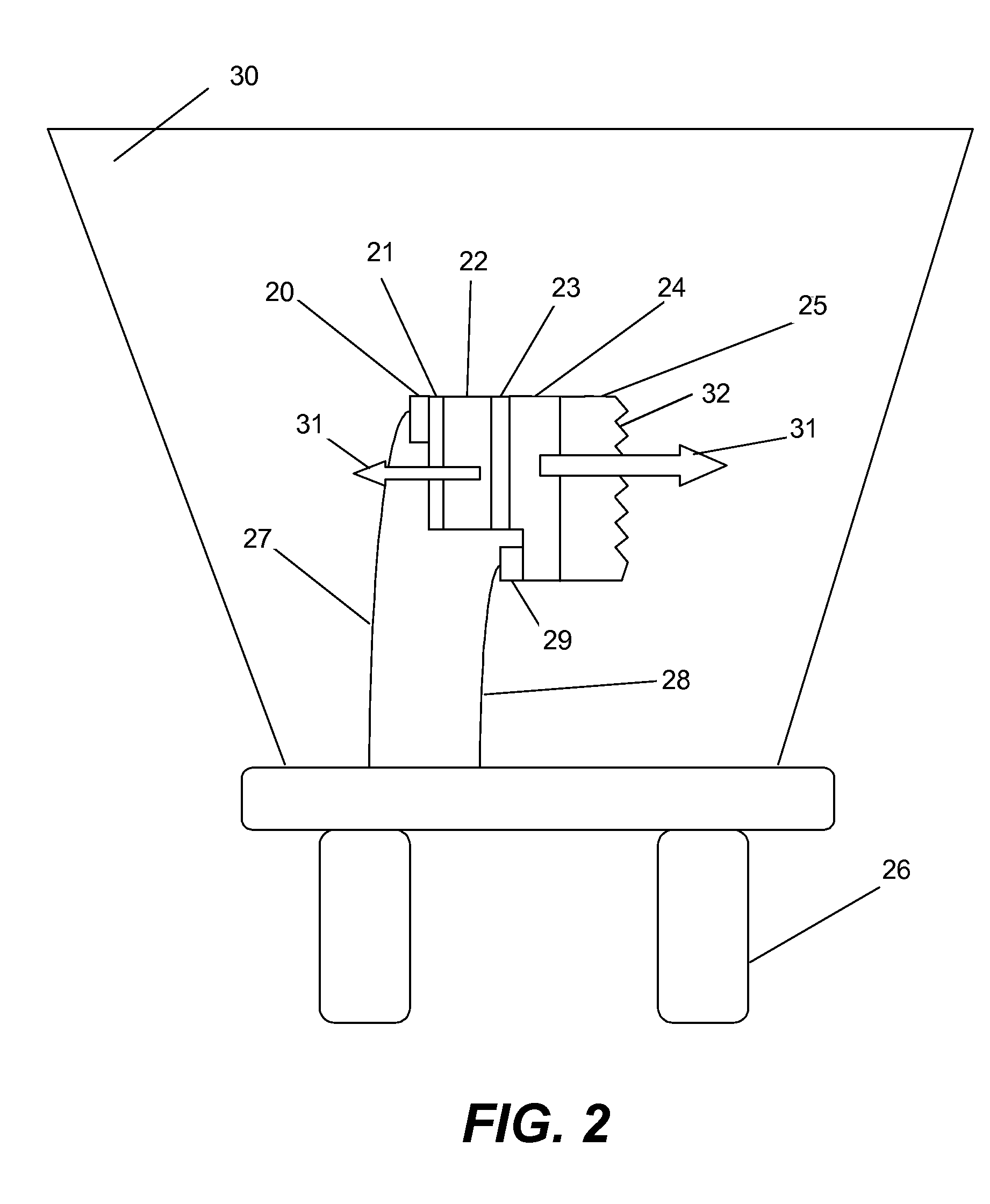

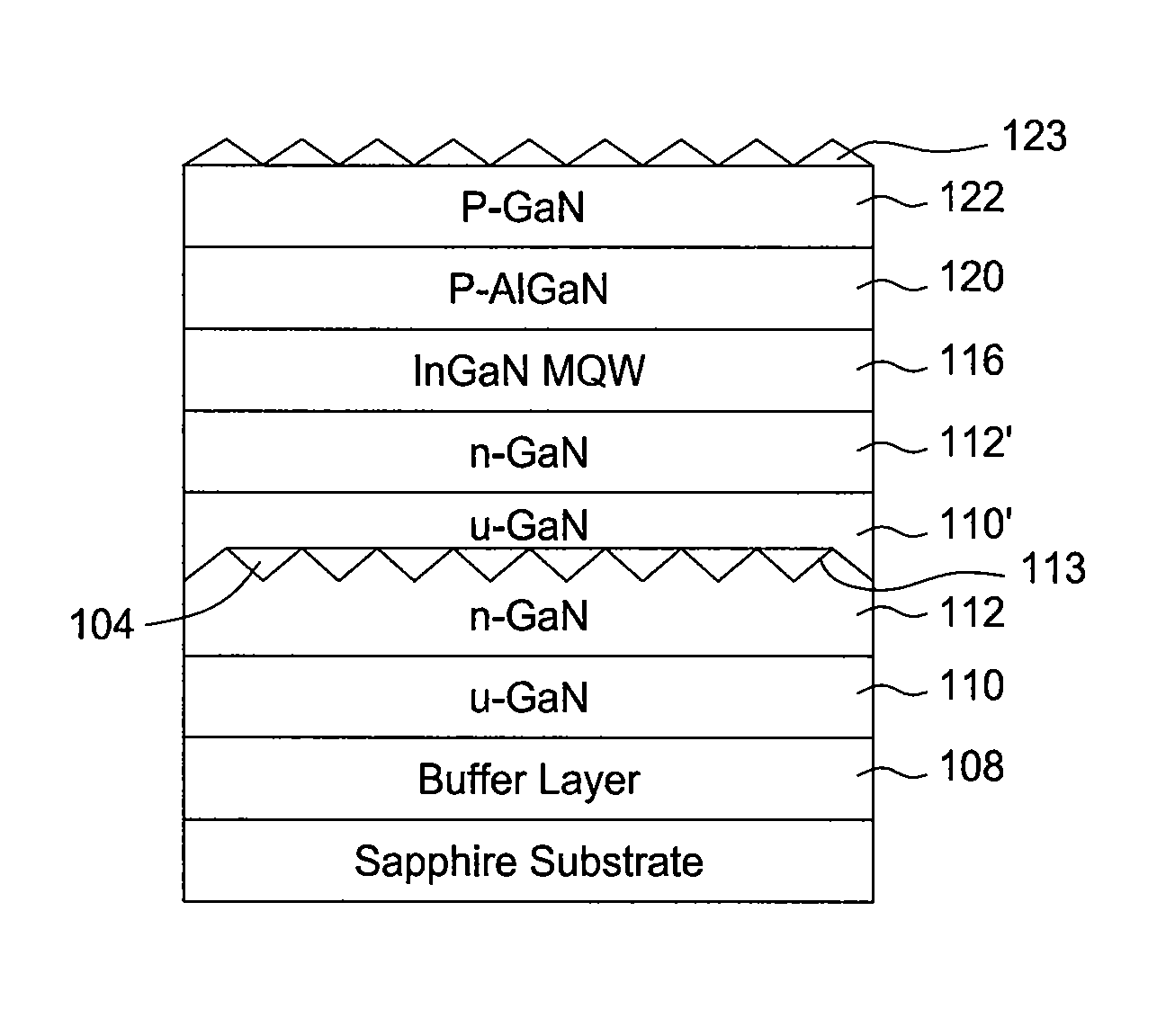

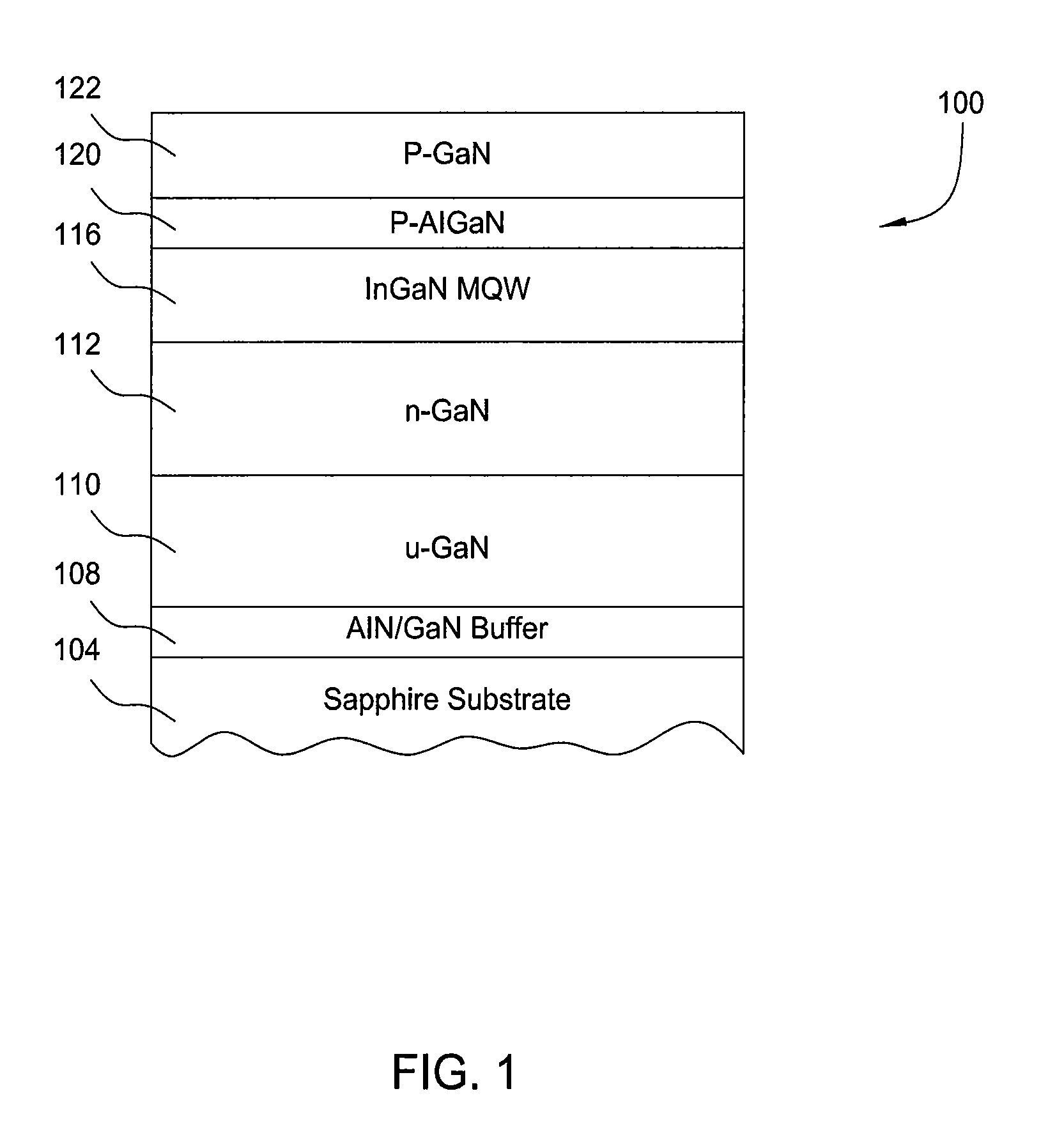

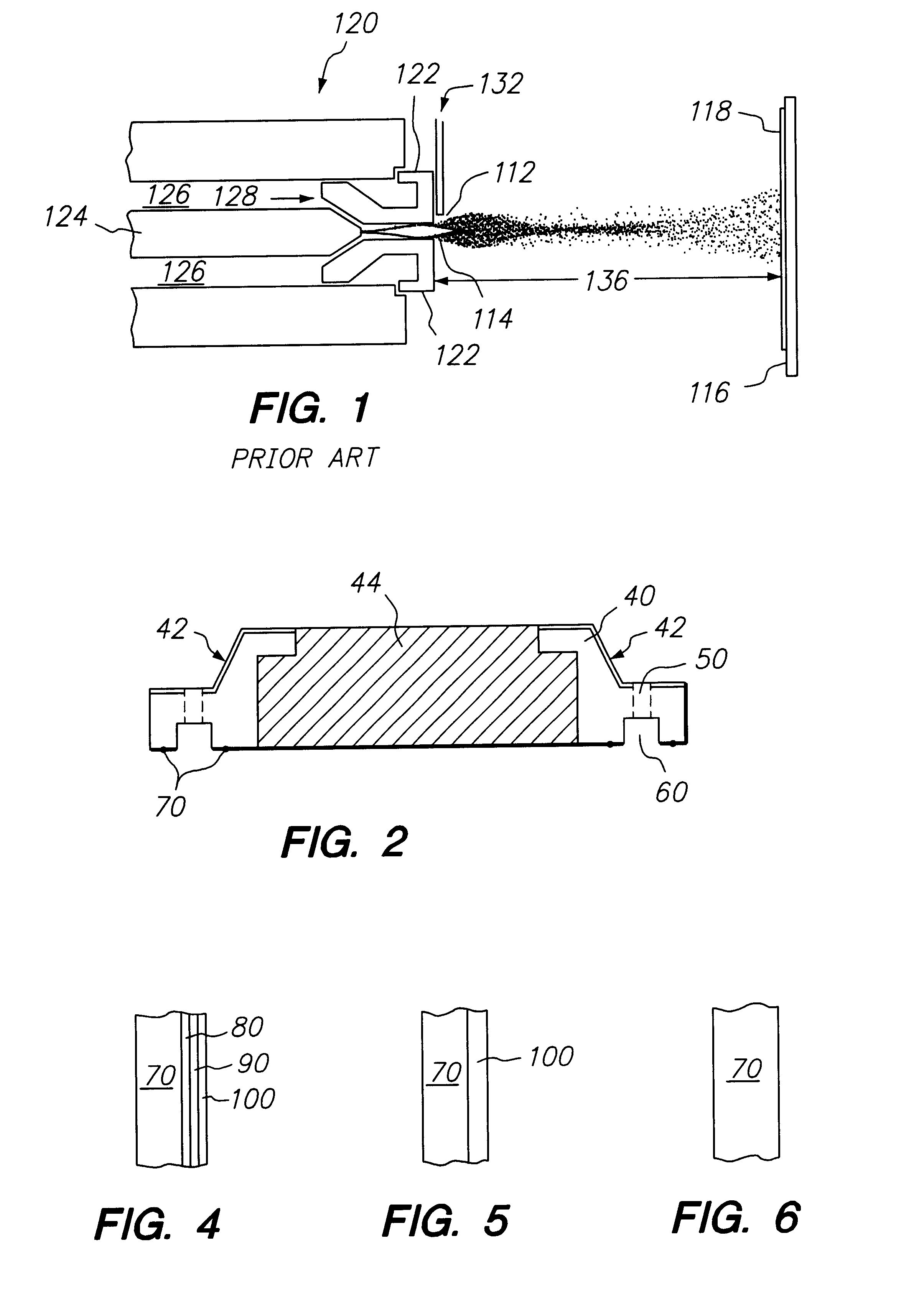

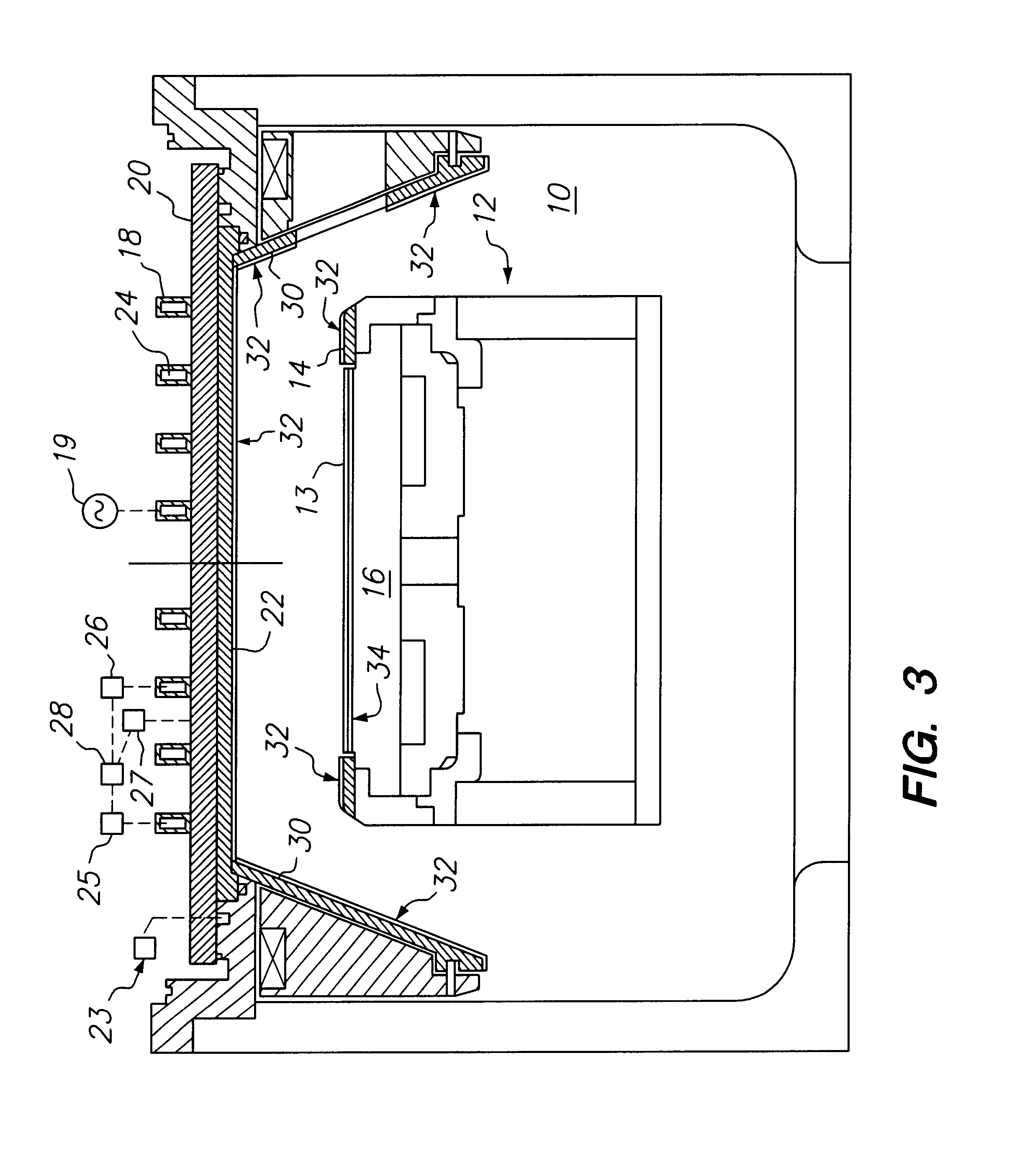

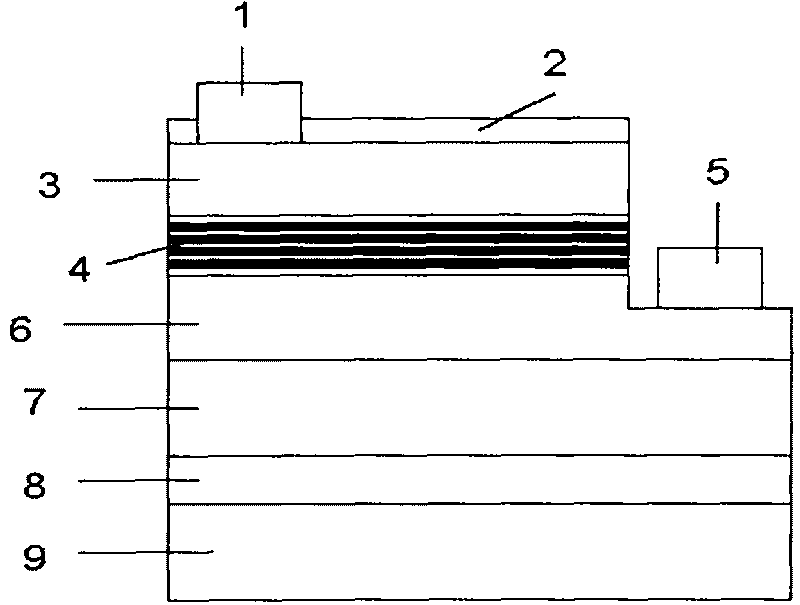

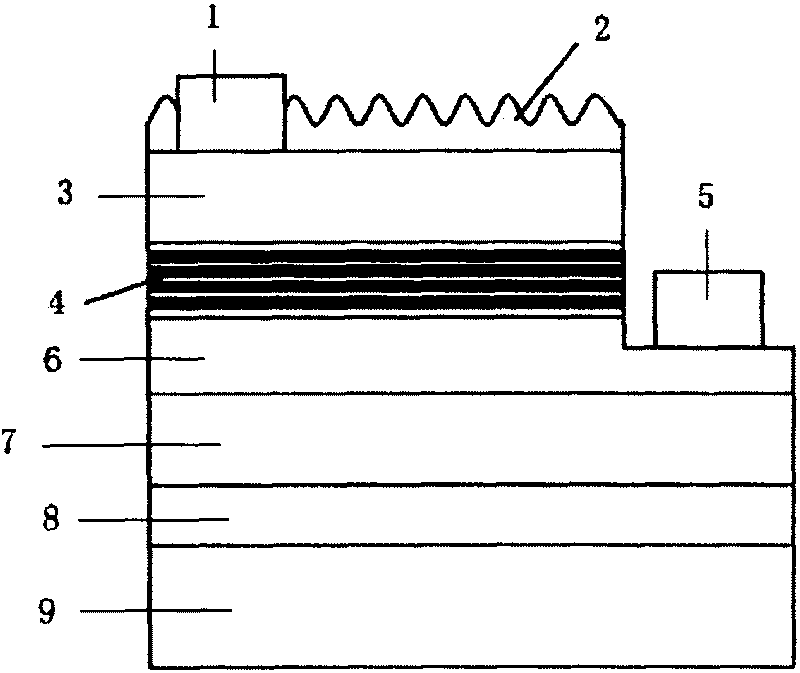

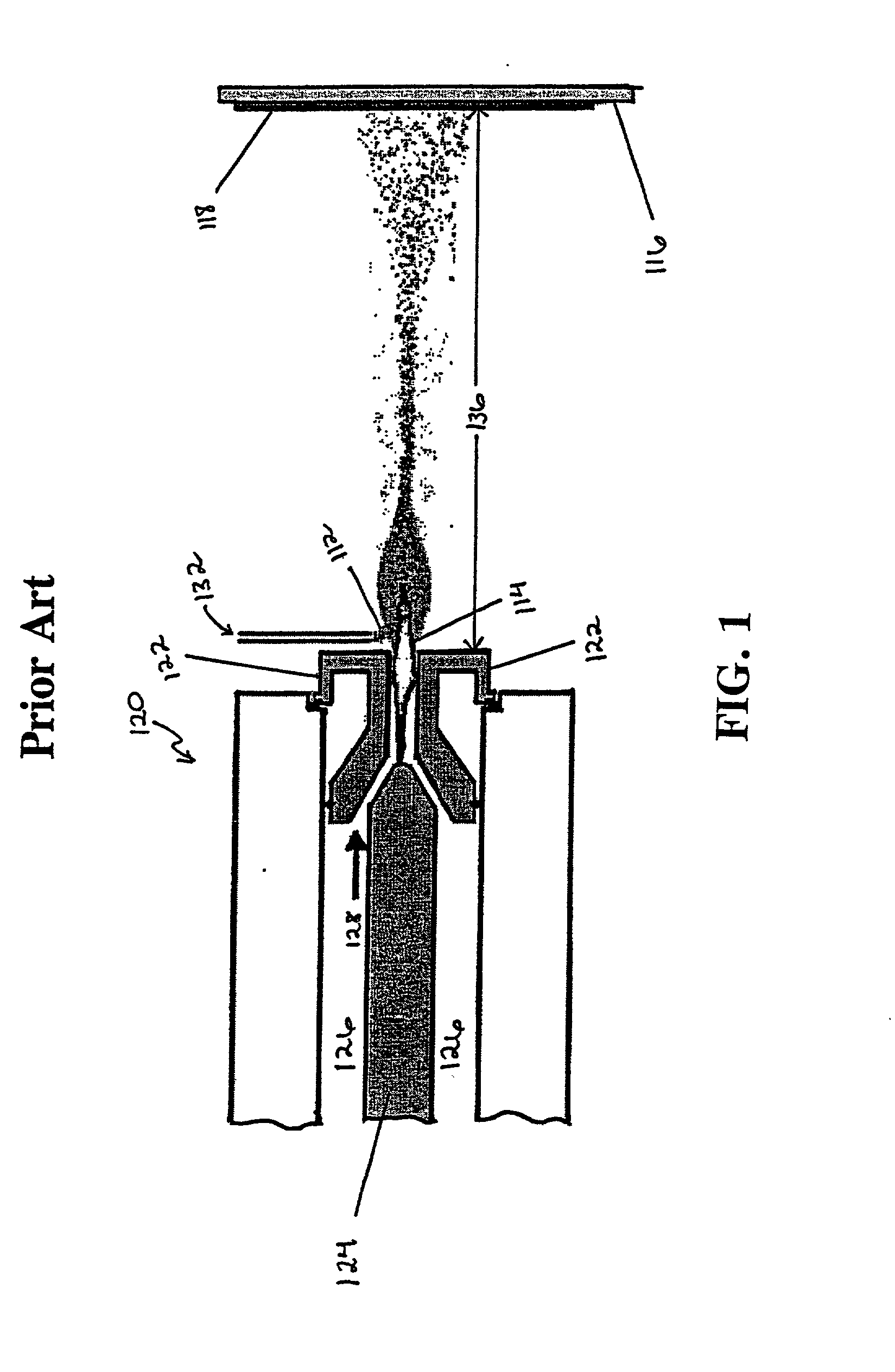

Enhancement of LED light extraction with in-situ surface roughening

ActiveUS20110227037A1Improve external quantum efficiencyImprove light extractionCellsPolycrystalline material growthQuantum efficiencyActive layer

The embodiments of the present invention generally relates to methods for enhancing the light extraction by surface roughening of the bottom n-GaN layer and / or top p-GaN layer so that the internal light from the active region is scattered outwardly to result in a higher external quantum efficiency. In one embodiment, a surface roughening process is performed on the n-GaN layer to form etching pits in a top surface of the n-GaN layer. Once the etching pits are formed, growth of the n-GaN material may be resumed on the roughened n-GaN layer to partially fill the etching pits, thereby forming air voids at the interface of the n-GaN layer and the subsequent, re-growth n-GaN layer. These air voids provide one or more localized regions with indices of reflection different from that of the n-GaN layer, such that the internal light generated by the active layers (e.g., the InGaN MQW layer), when passing through the n-GaN layer, is scattered by voids or bubbles. The surface roughening process may be further performed on a top surface of a p-GaN layer to scatter the light emitted from the active layers outwardly rather than being reflected back to the active layers.

Owner:APPLIED MATERIALS INC

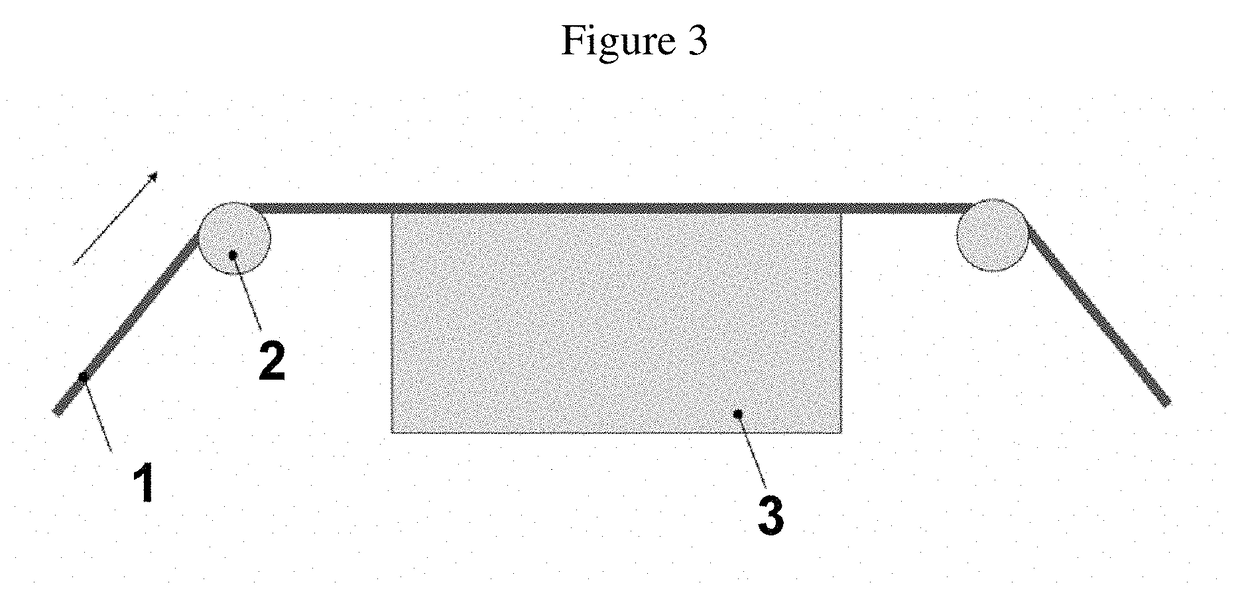

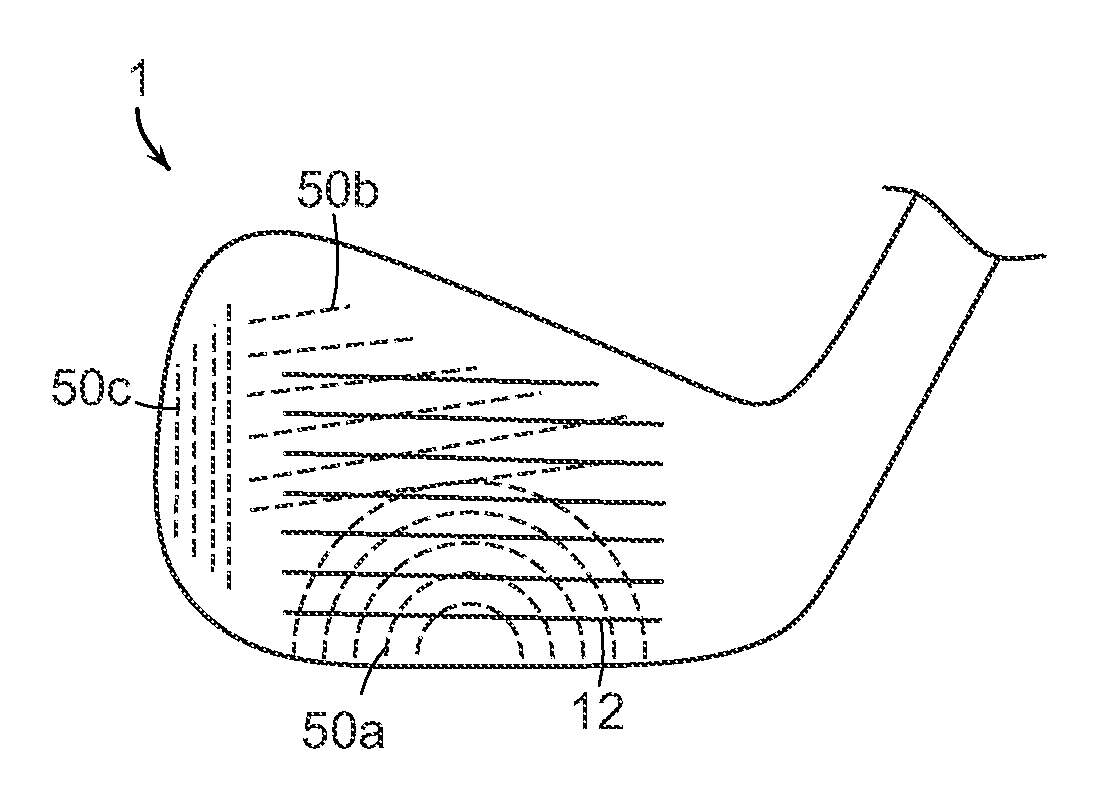

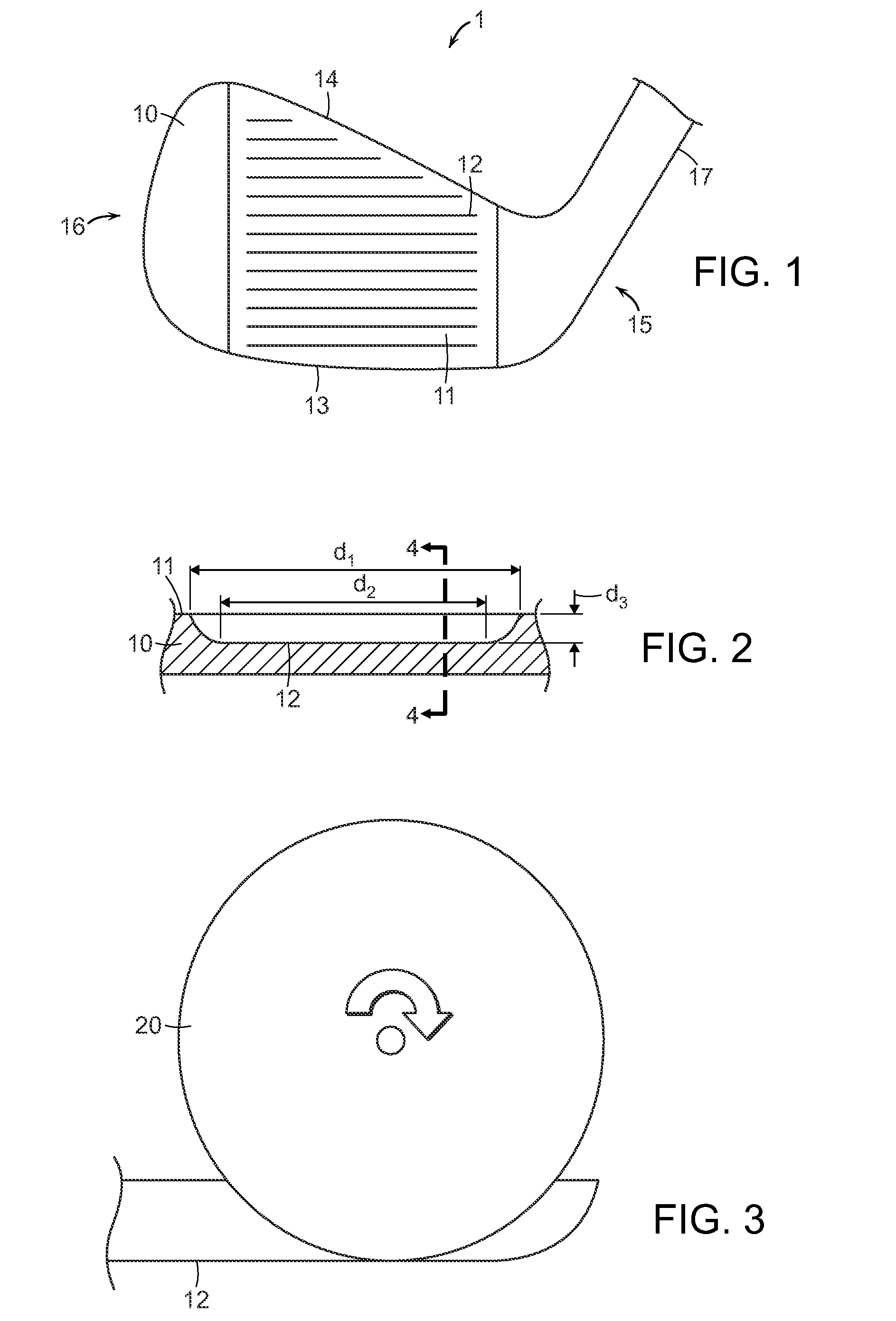

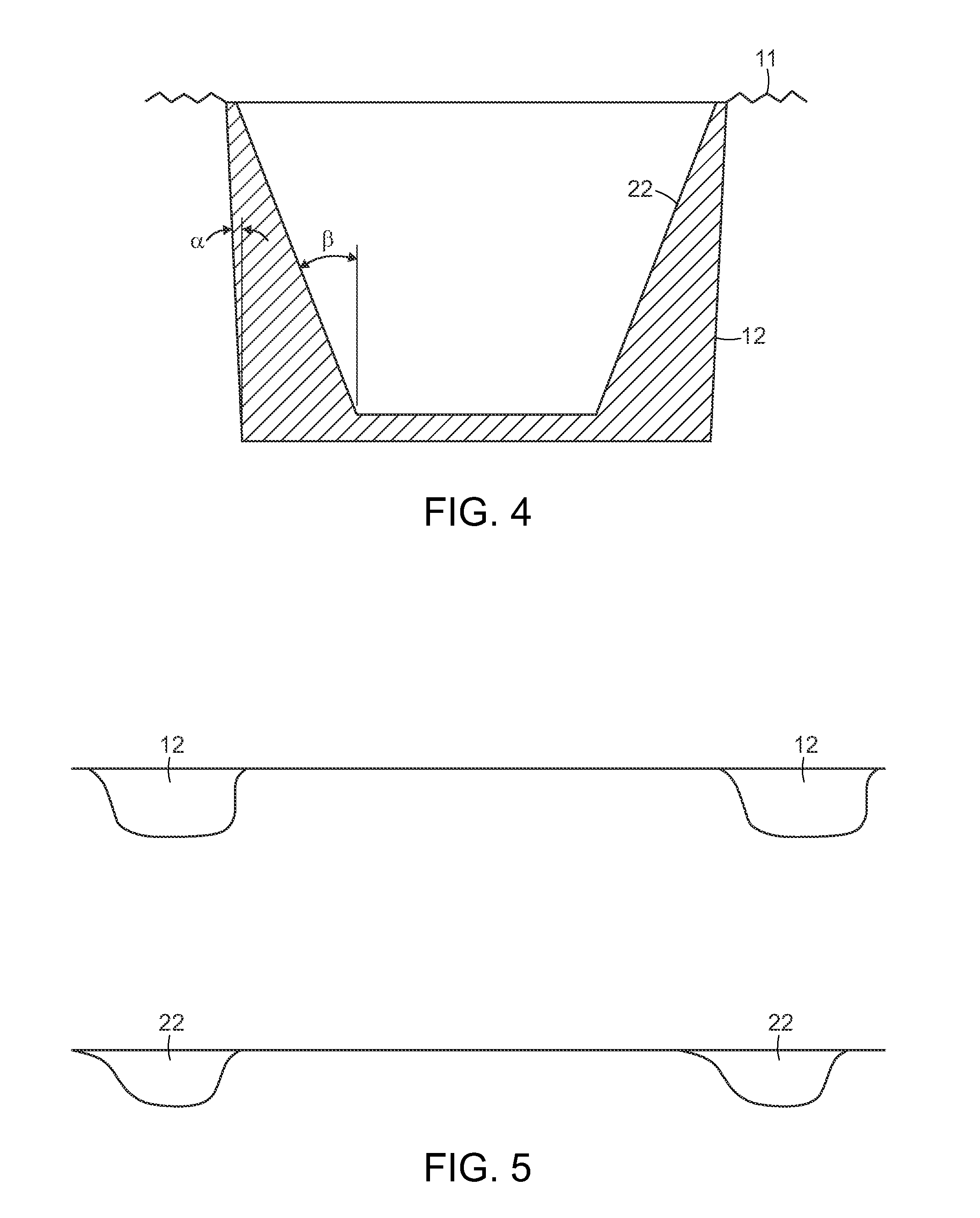

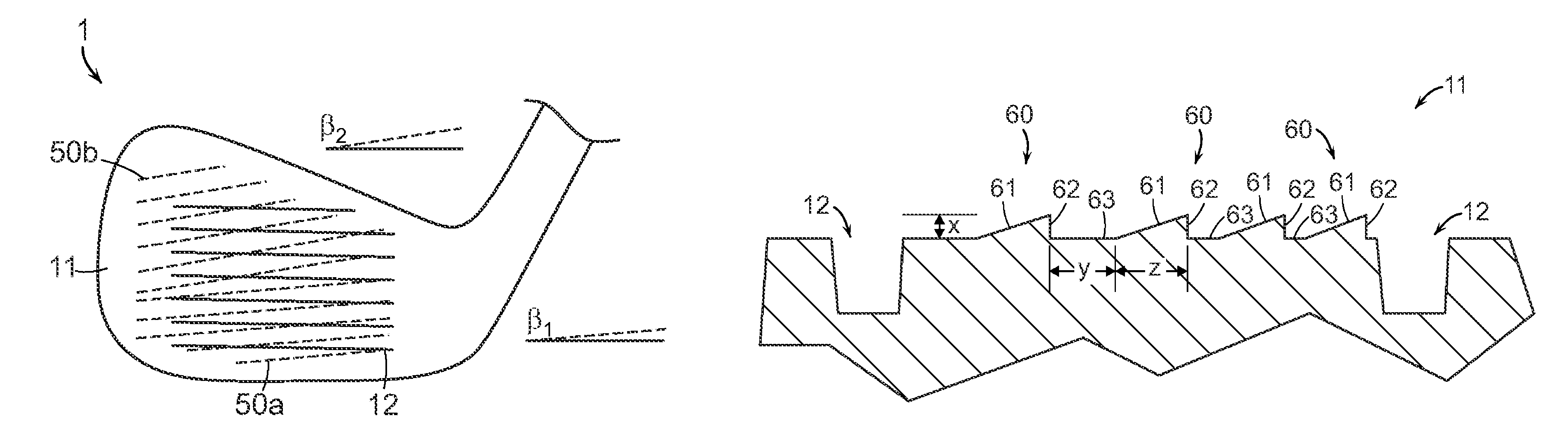

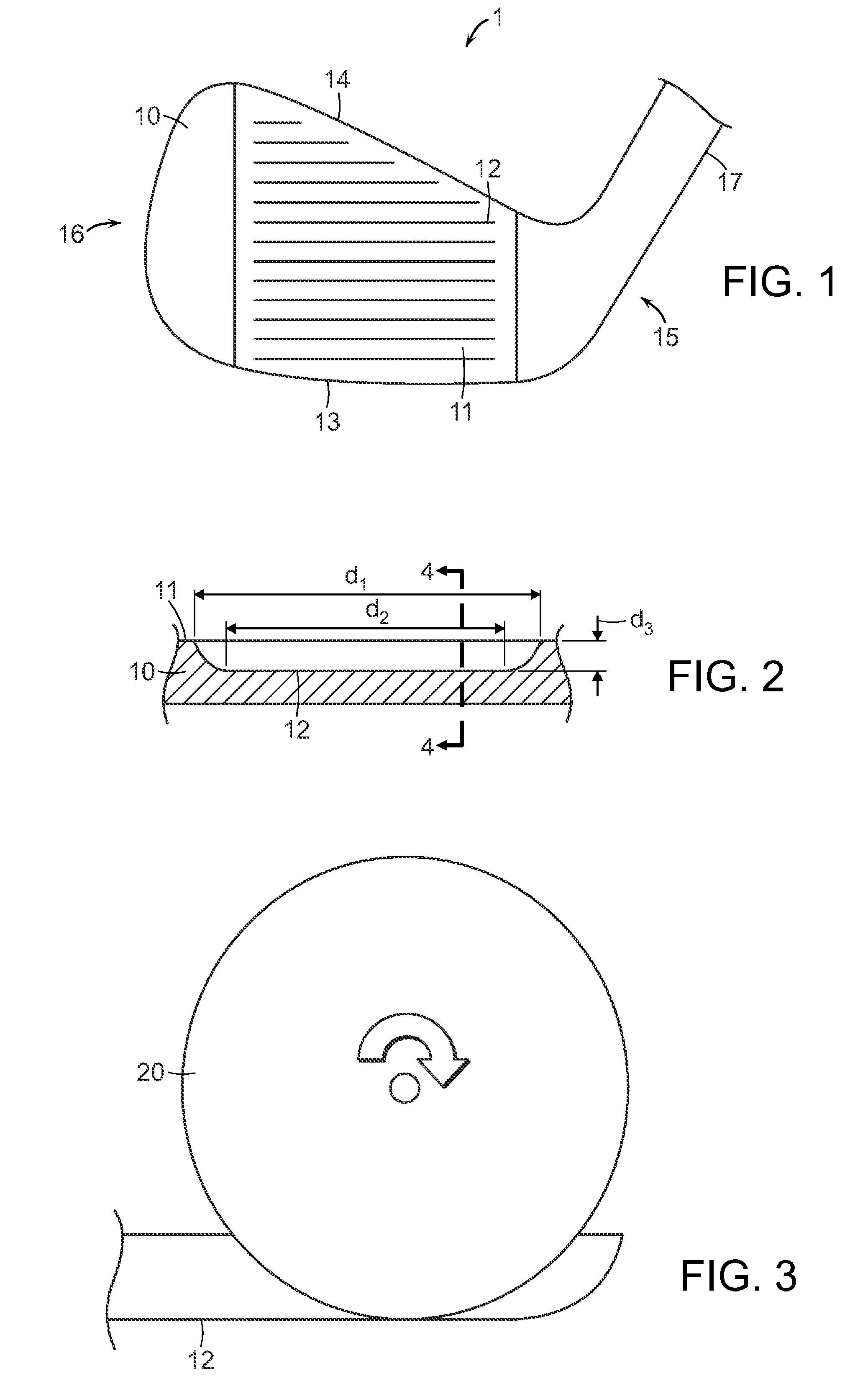

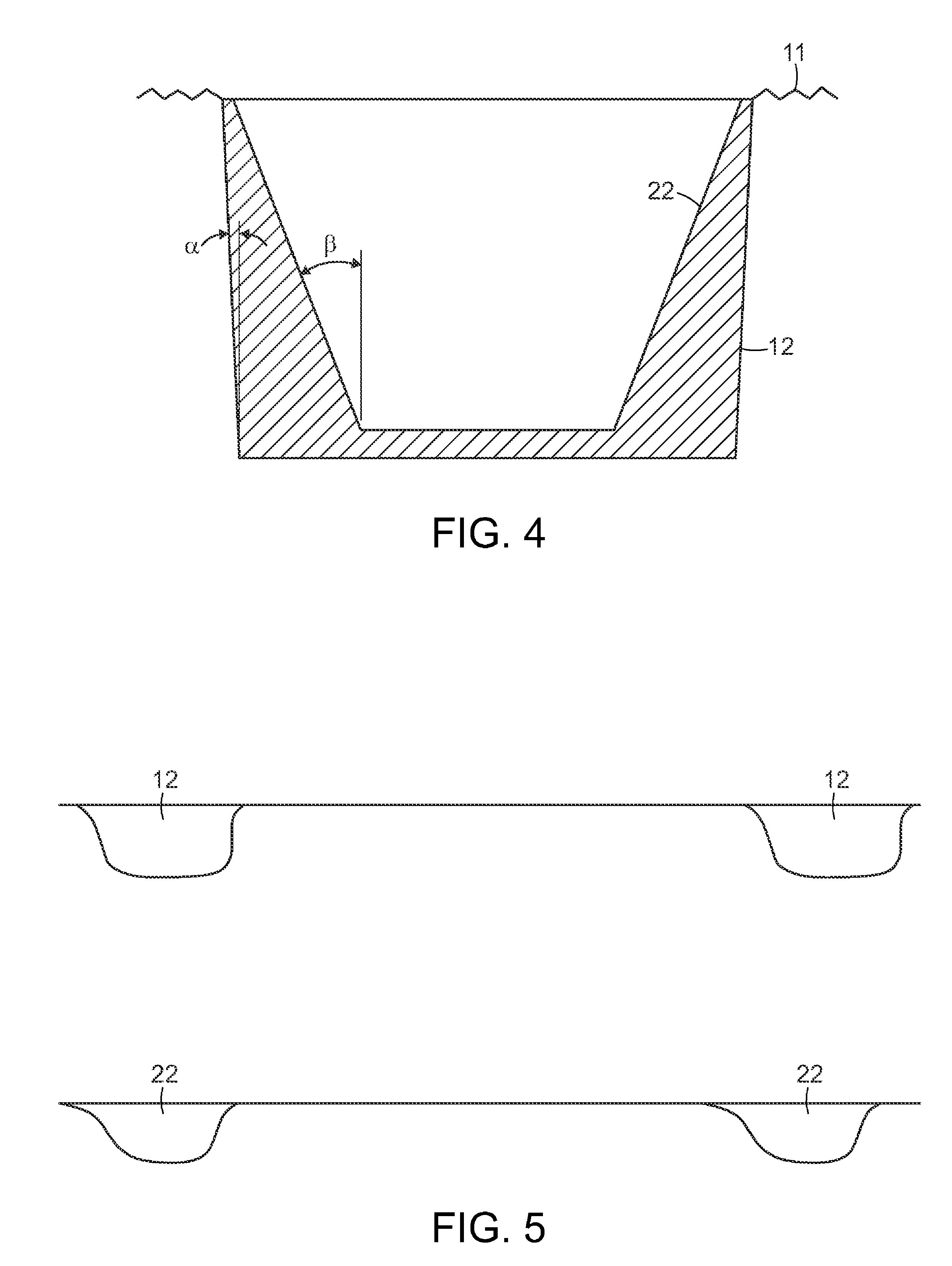

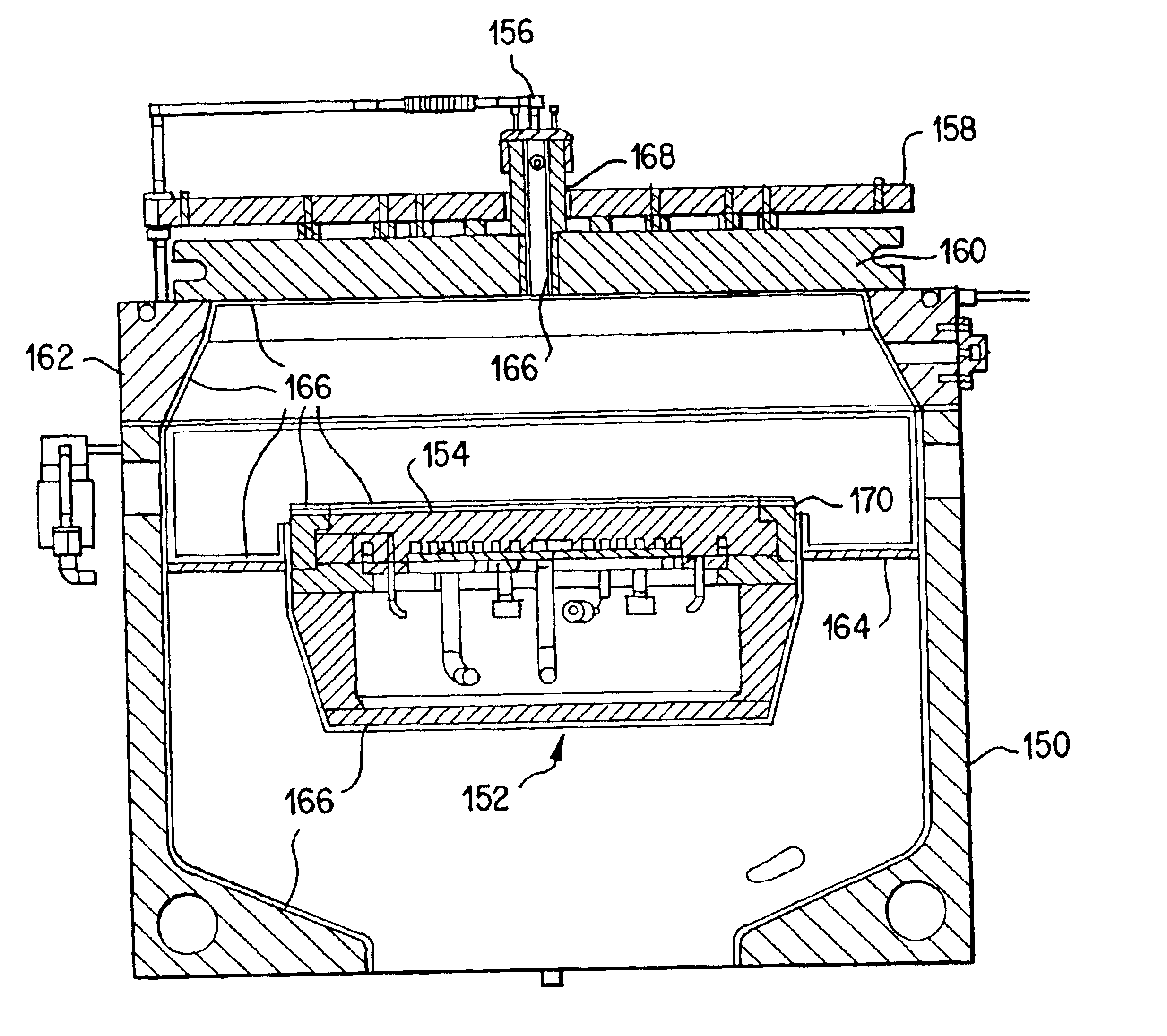

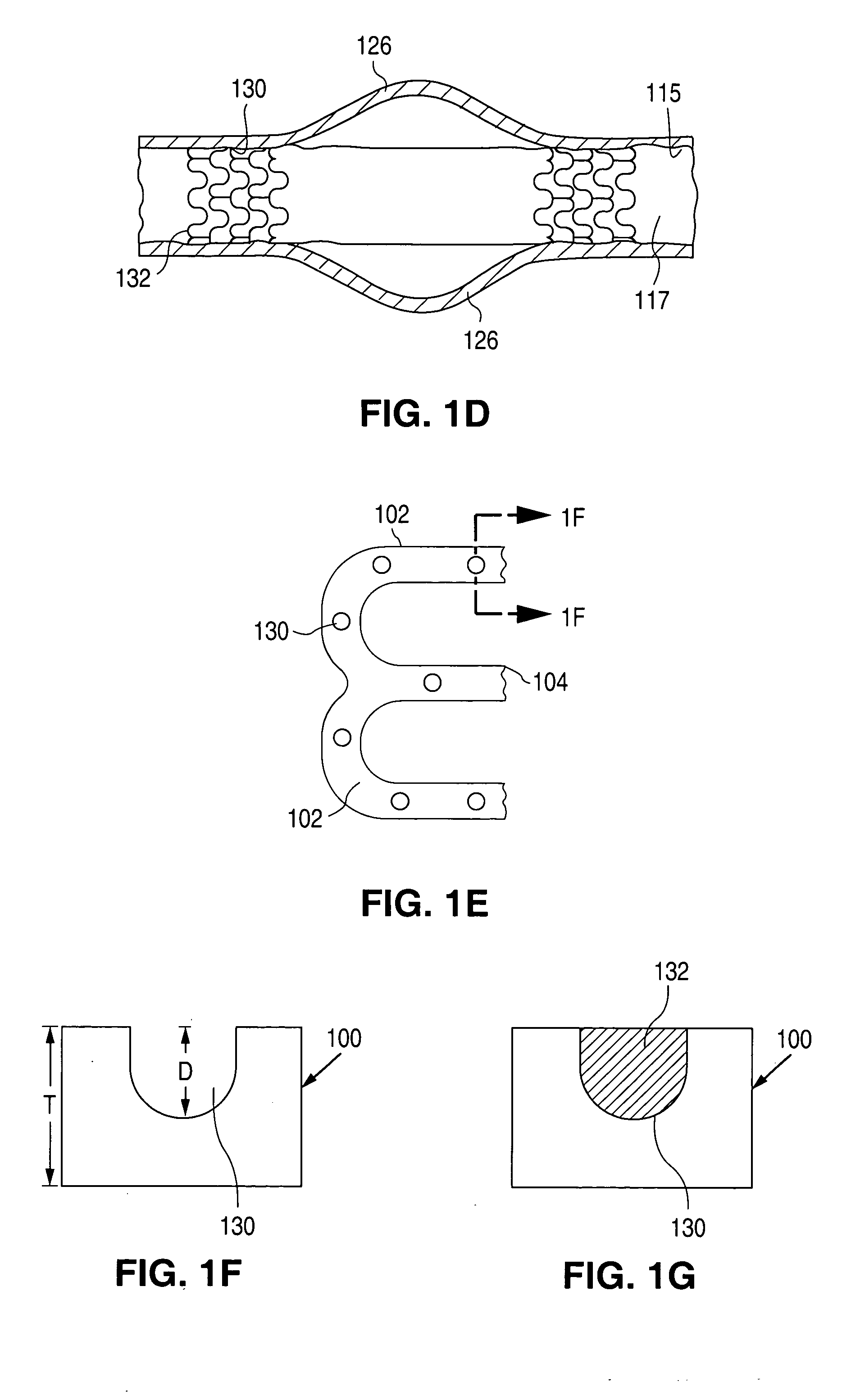

Golf club head having a grooved and textured face

The present invention is directed to a golf club head with an improved striking surface. The grooves are machined into the strike surface with tight tolerances. The face may be selectively textured to enhance certain shots that the golfer may perform. This may include providing a plurality of distinct sets of texturing and surface roughening to accommodate a plurality of different shots. The grooves may contain a plurality of portions, including a radiused or angled portion, a portion having substantially parallel walls, a portion having a v-shape, and a curved portion. The grooves may also be characterized by various dimensions, including draft angle, inclusive side wall angle, width, depth, cross-sectional area, spacing, and pitch ratio.

Owner:ACUSHNET CO

Golf club head having a grooved and textured face

The present invention is directed to a golf club head with an improved striking surface. The grooves are machined into the strike surface with tight tolerances. The face may be selectively textured to enhance certain shots that the golfer may perform. This may include providing a plurality of distinct sets of texturing and surface roughening to accommodate a plurality of different shots. The grooves may contain a plurality of portions, including a radiused or angled portion, a portion having substantially parallel walls, a portion having a v-shape, and a curved portion. The grooves may also be characterized by various dimensions, including draft angle, inclusive side wall angle, width, depth, cross-sectional area, spacing, and pitch ratio.

Owner:ACUSHNET CO

Cerium oxide containing ceramic components and coatings in semiconductor processing equipment and methods of manufacture thereof

InactiveUS6830622B2Reduce corrosionReduce erosion rateLiquid surface applicatorsMolten spray coatingCeramic coatingCerium

Owner:LAM RES CORP

Hydrolysis-resistant double-component polyurethane adhesive for structure adhesion

ActiveCN102559126AImprove hydrolysis resistanceHigh bonding strengthPolyureas/polyurethane adhesivesPolyesterAdhesion force

The invention relates to a hydrolysis-resistant double-component polyurethane adhesive for structure adhesion. The hydrolysis-resistant double-component polyurethane adhesive for structure adhesion consists of a component A and a component B, wherein the component A comprises the following components in part by weight: 30 to 70 parts of polyisocyanate resin, 5 to 20 parts of plasticizing agent, 0.25 to 5 parts of thixotropic agent, 10 to 50 parts of incremental filler and 0.25 to 1 part of water-removing agent; and the component B comprises the following components in part by weight: 5 to 30 parts of polyester polyol, 5 to 30 parts of vegetable oil polyol, 5 to 30 parts of polyether polyol, 3 to 15 parts of water-absorbing filler, 1 to 10 parts of thixotropic agent, 3 to 15 parts of incremental filler, 0.1 to 10 parts of pigment, 0.1 to 5 parts of adhesion force accelerator, 0.1 to 2 parts of chain extender and 0.01 to 0.2 part of catalyst. An adhesion system improves adhesion property, solves the problem that a thermosetting composite material is subjected to surface roughening treatment before adhesion and improves the using efficiency. Aiming at the problem of poor hydrolysis resistance of a polyester type polyurethane adhesive system, the hydrolysis resistance is improved through molecule design of polyurethane soft and hard sections.

Owner:TONSAN ADHESIVES INC

Magnetic tape device employing TMR head and magnetic tape with characterized magnetic layer, and head tracking servo method

ActiveUS10403314B2Improve accuracyAccurate informationMagnetic materials for record carriersAlignment for track following on tapesIn planeX-ray

Owner:FUJIFILM CORP

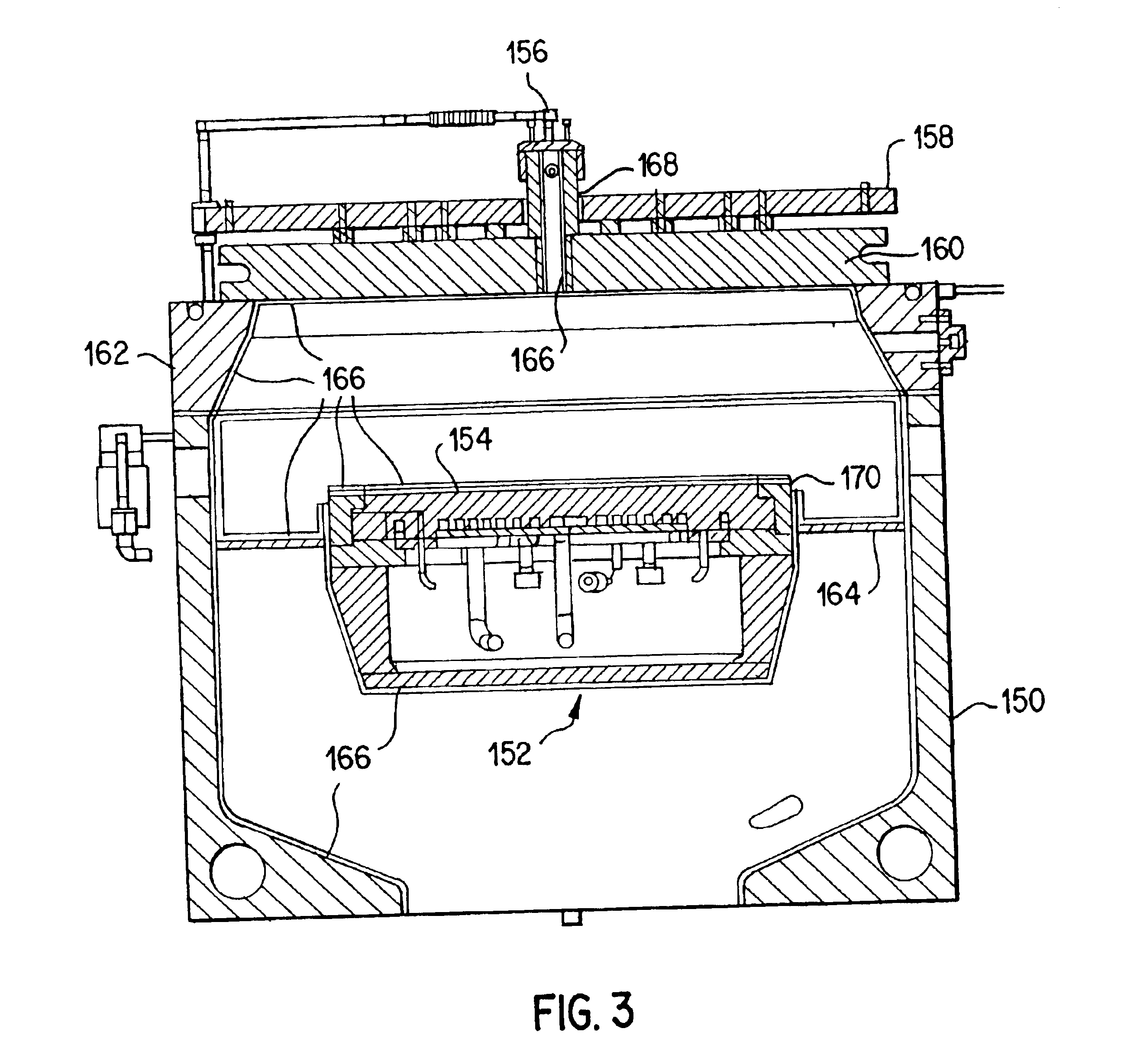

Zirconia toughened ceramic components and coatings in semiconductor processing equipment and method of manufacture thereof

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber comprises zirconia toughened ceramic material as an outermost surface of the component. The component can be made entirely of the ceramic material or the ceramic material can be provided as a coating on a substrate such as aluminum or aluminum alloy, stainless steel, or refractory metal. The zirconia toughened ceramic can be tetragonal zirconia polycrystalline (TZP) material, partially-stabilized zirconia (PSZ), or a zirconia dispersion toughened ceramic (ZTC) such as zirconia-toughened alumina (tetragonal zirconia particles dispersed in Al2O3). In the case of a ceramic zirconia toughened coating, one or more intermediate layers may be provided between the component and the ceramic coating. To promote adhesion of the ceramic coating, the component surface or the intermediate layer surface may be subjected to a surface roughening treatment prior to depositing the ceramic coating.

Owner:LAM RES CORP

Highly efficient gallium nitride based light emitting diodes via surface roughening

ActiveUS20100025717A1Solid-state devicesSemiconductor/solid-state device manufacturingLight reflectionNitrogen

A gallium nitride (GaN) based light emitting diode (LED), wherein light is extracted through a nitrogen face (N-face) of the LED and a surface of the N-face is roughened into one or more hexagonal shaped cones. The roughened surface reduces light reflections occurring repeatedly inside the LED, and thus extracts more light out of the LED. The surface of the N-face is roughened by an anisotropic etching, which may comprise a dry etching or a photo-enhanced chemical (PEC) etching.

Owner:RGT UNIV OF CALIFORNIA

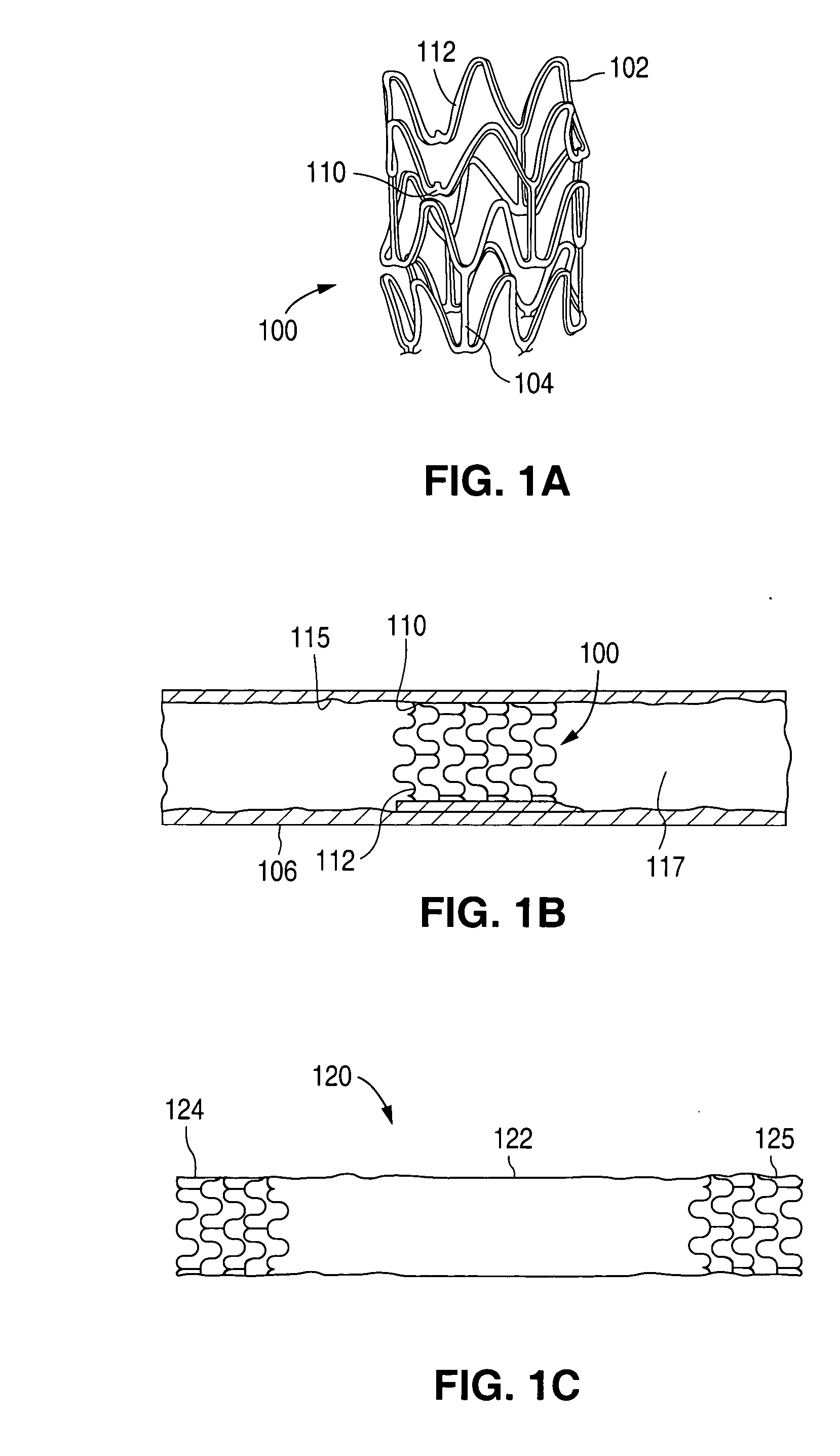

Surface features of an implantable medical device

Owner:WU STEVEN Z +6

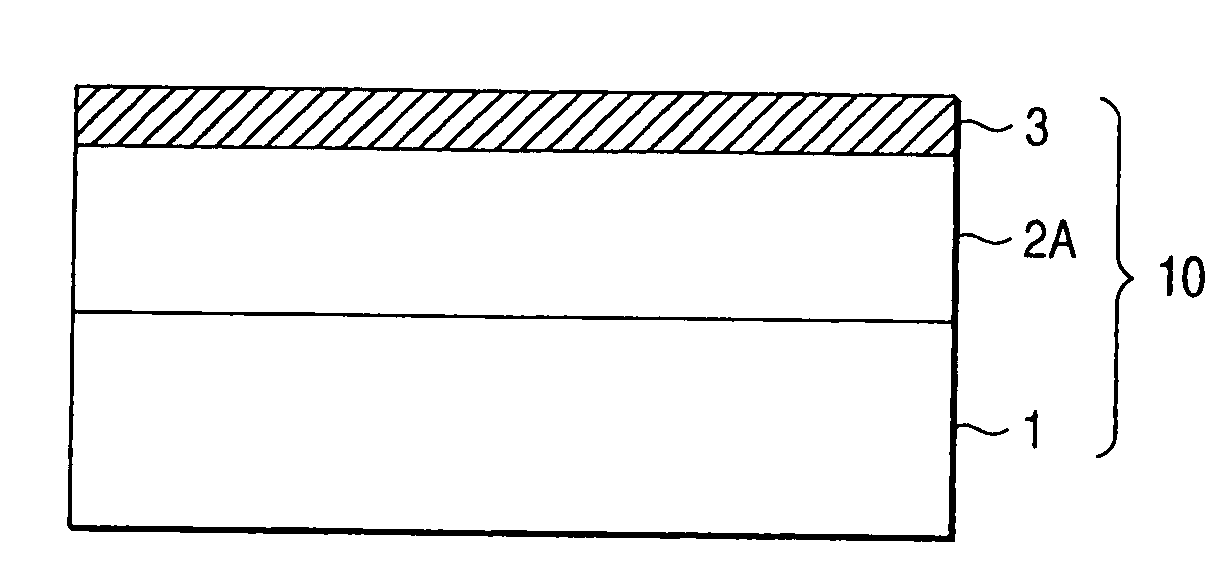

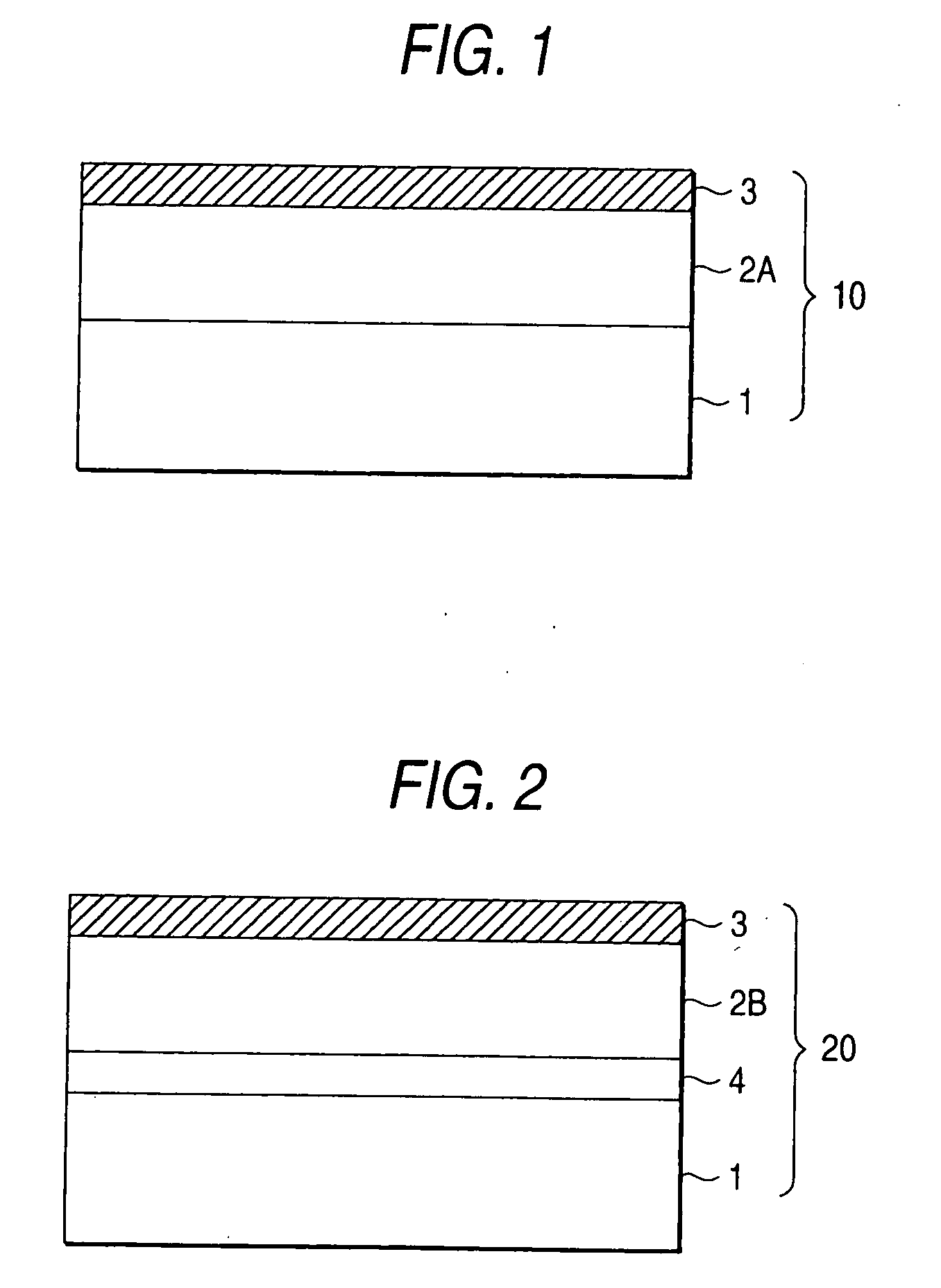

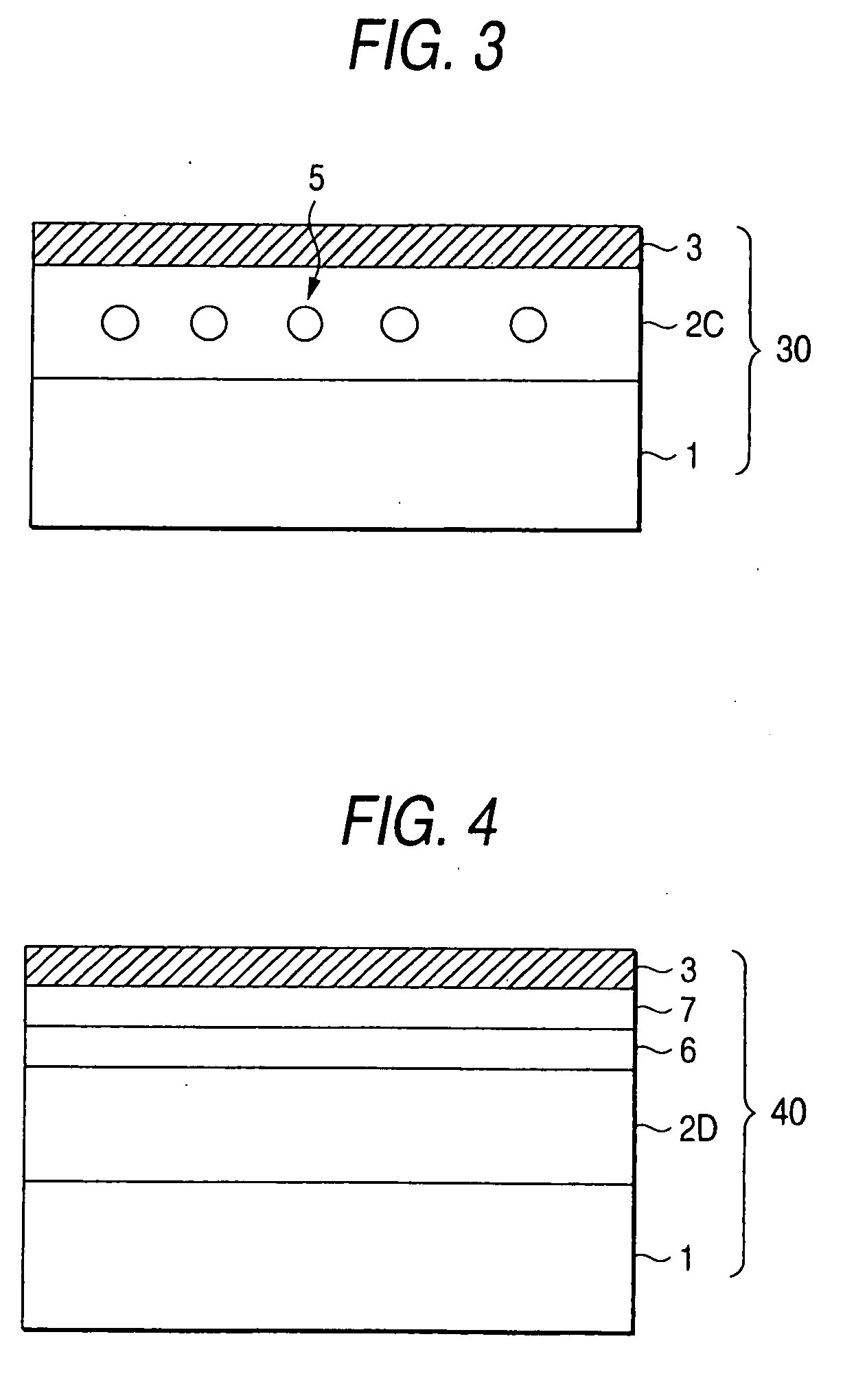

Anti-reflection film, polarizing plate, and liquid crystal display device

InactiveUS20090135356A1Eliminates white blurringRemove image blurProjectorsPolarising elementsLiquid-crystal displayRefractive index

An anti-reflection film comprising: a transparent support; at least one high refractive index hard coat layer; and a low refractive index layer disposed as an outermost layer, in this order, wherein (i) the high refractive index hard coat layer has a refractive index of 1.55 or more and a thickness of 4 to 15 μm; (ii) the anti-reflection film has a surface roughness Ra (center line average roughness) of 0.10 μm or less; and (iii) the low refractive index layer comprises a hollow silica microparticle having an average particle diameter of 5 to 200 nm and a refractive index of 1.17 to 1.40.

Owner:FUJIFILM CORP

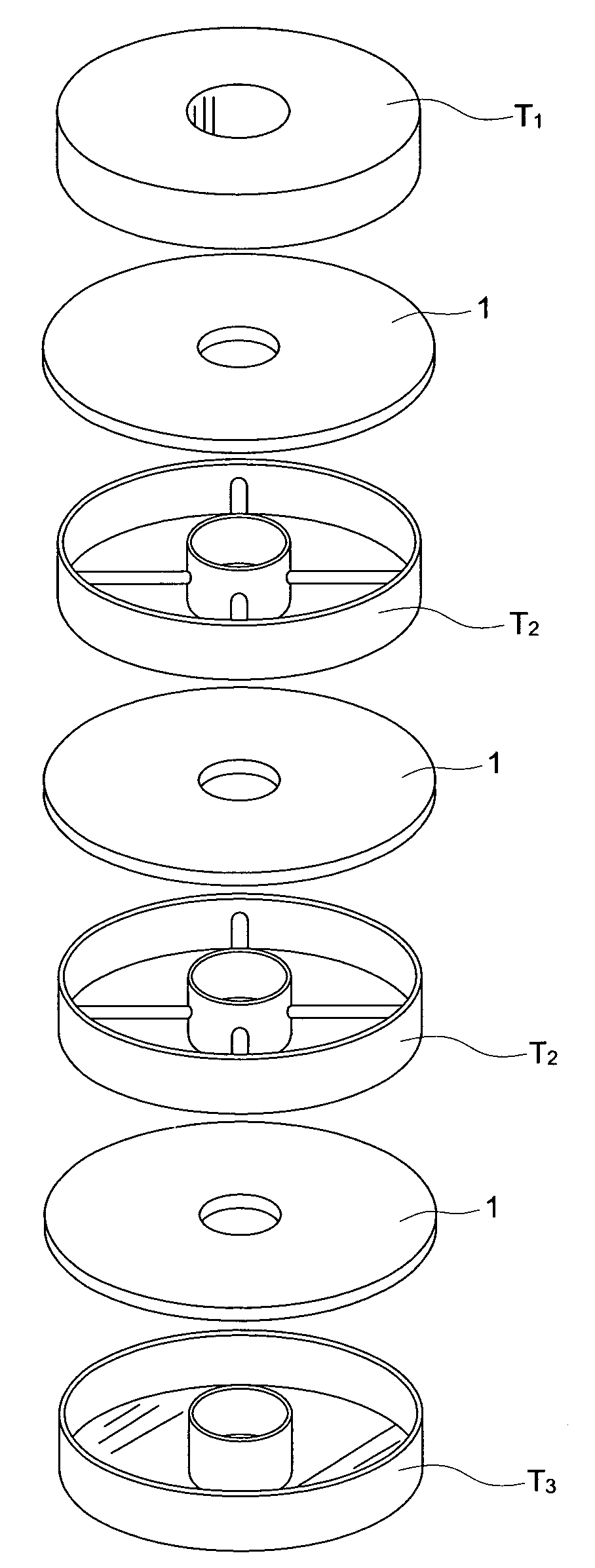

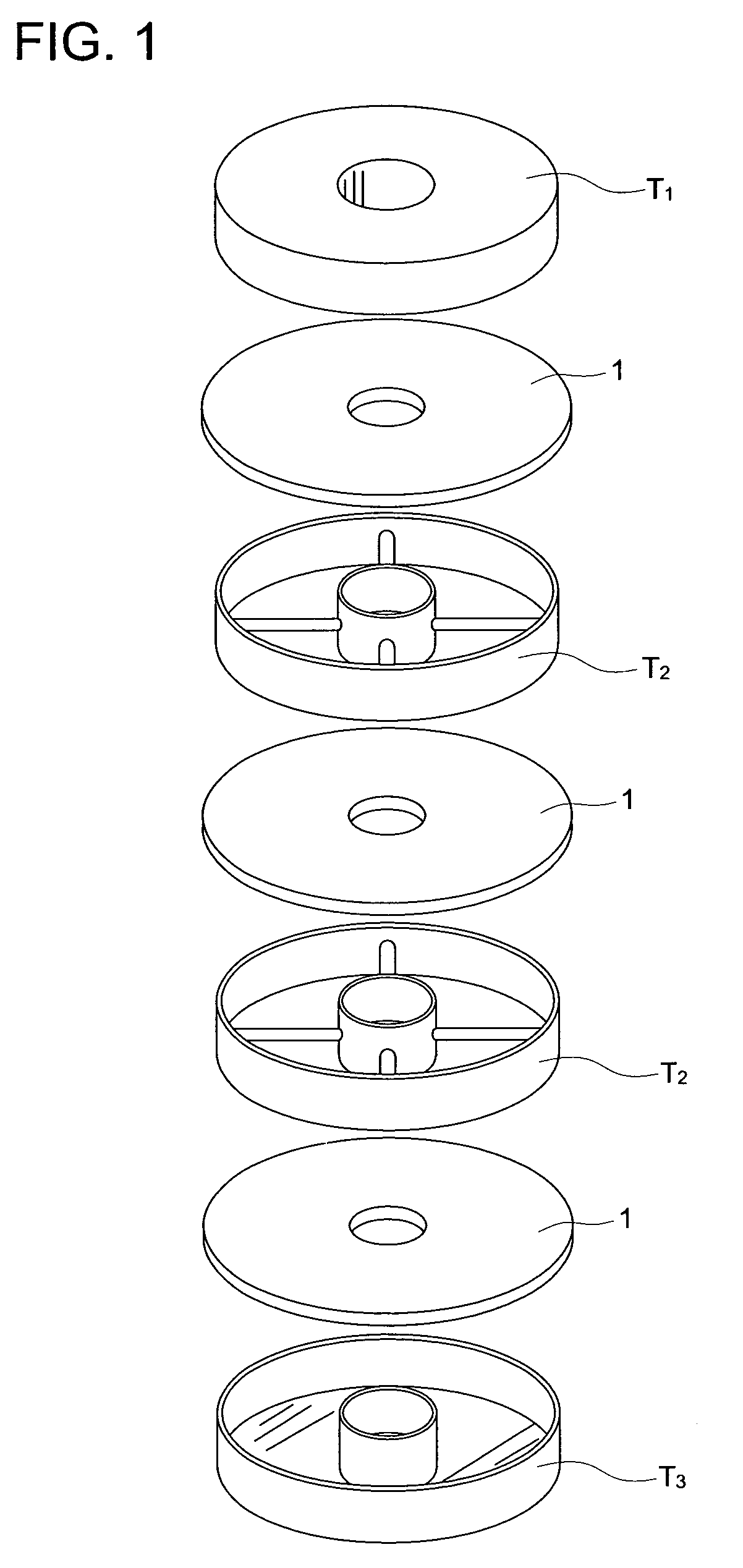

Glass Substrate for Information Recording Medium, and Method of Manufacturing Glass Substrate for Magnetic Recording Medium and Information Recording Medium

InactiveUS20090162703A1Prevent elutionExcellent chemical durabilityMagnetic materials for record carriersBase layers for recording layersCrystallographyChemical treatment

Not only chemical durability of a glass substrate for an information recording medium is improved, but also no deformation of the substrate and no alteration of substrate characteristics are to be made. A chemical treatment layer formed on the glass substrate surface is made thicker toward a large surface roughness portion of the glass substrate, prior to being subjected to a chemical treatment, from a small surface roughness portion of the glass substrate. Layer thickness D of the resulting chemical treatment layer preferably satisfies the following inequality (1) in view of acquisition of chemical durability.100 Ra≦D≦3000 Ra (1)wherein Ra is surface roughness of the glass substrate prior to being subjected to the chemical treatment.

Owner:KONICA MINOLTA OPTO

Zirconia toughened ceramic components and coatings in semiconductor processing equipment and method of manufacture thereof

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber comprises zirconia toughened ceramic material as an outermost surface of the component. The component can be made entirely of the ceramic material or the ceramic material can be provided as a coating on a substrate such as aluminum or aluminum alloy, stainless steel, or refractory metal. The zirconia toughened ceramic can be tetragonal zirconia polycrystalline (TZP) material, partially-stabilized zirconia (PSZ), or a zirconia dispersion toughened ceramic (ZTC) such as zirconia-toughened alumina (tetragonal zirconia particles dispersed in Al2O3). In the case of a ceramic zirconia toughened coating, one or more intermediate layers may be provided between the component and the ceramic coating. To promote adhesion of the ceramic coating, the component surface or the intermediate layer surface may be subjected to a surface roughening treatment prior to depositing the ceramic coating.

Owner:LAM RES CORP

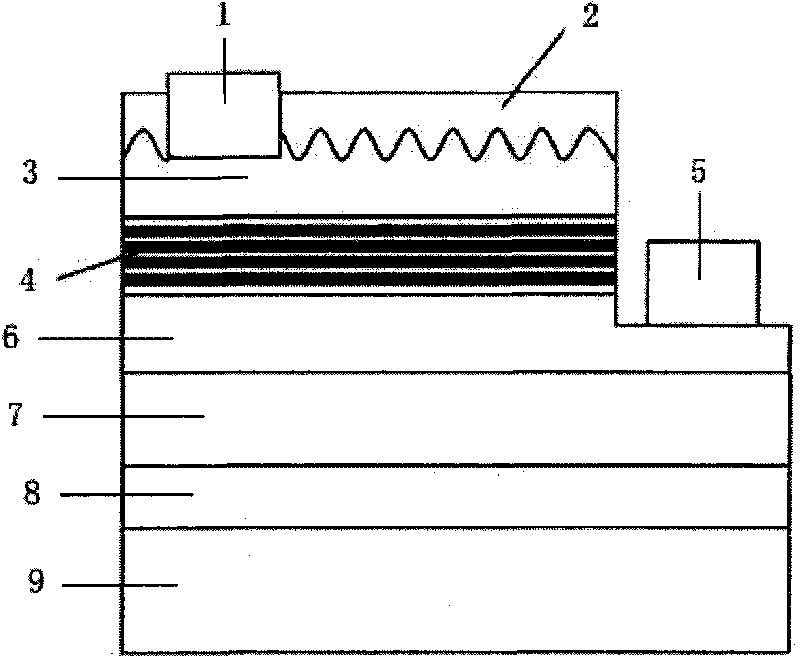

Surface roughening method of p-GaN layer or ITO layer in GaN-based LED chip structure

InactiveCN101702419ADamage reflectionIncreased chance of escaping from the device surfaceSemiconductor devicesOptoelectronicsNanometre

The invention discloses a surface roughening method of a p-GaN layer or an ITO layer in a GaN-based LED chip structure. The method comprises the following steps: (1) growing a low-temperature GaN buffer layer, an undoped GaN layer, an n-GaN layer, a multiple quantum well layer, a stack-up structure of the p-GaN layer and an extended layer evaporating ITO current on a semiconductor substrate in sequence; and (2) preparing monolayer nickel nano particles as a mask, and preparing a roughening structure on the p-GaN layer or the ITO layer. The method of the invention has simple steps, low cost, good roughening effect; by carrying out surface roughening on the p-GaN layer or the ITO layer of the GaN-based LED by the method of the invention, the total reflection of the photon in the chip can be inhibited and the light outgoing efficiency of the devices can be improved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Cerium oxide containing ceramic components and coatings in semiconductor processing equipment and methods of manufacture thereof

InactiveUS20020142611A1Reduce corrosionReduce erosion rateLiquid surface applicatorsMolten spray coatingCeramic coatingCerium

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber comprises a cerium oxide containing ceramic material as an outermost surface of the component. The cerium oxide containing ceramic material comprises one or more cerium oxides as the single largest constituent thereof. The component can be made entirely of the cerium oxide containing ceramic material or, alternatively, the cerium oxide containing ceramic can be provided as a layer on a substrate such as aluminum or an aluminum alloy, a ceramic material, stainless steel, or a refractory metal. The cerium oxide containing ceramic layer can be provided as a coating by a technique such as plasma spraying. One or more intermediate layers may be provided between the component and the cerium oxide containing ceramic coating. To promote adhesion of the cerium oxide containing ceramic coating, the component surface or the intermediate layer surface may be subjected to a surface roughening treatment prior to depositing the cerium oxide containing ceramic coating.

Owner:LAM RES CORP

Processes for texturing a surface prior to electroless plating

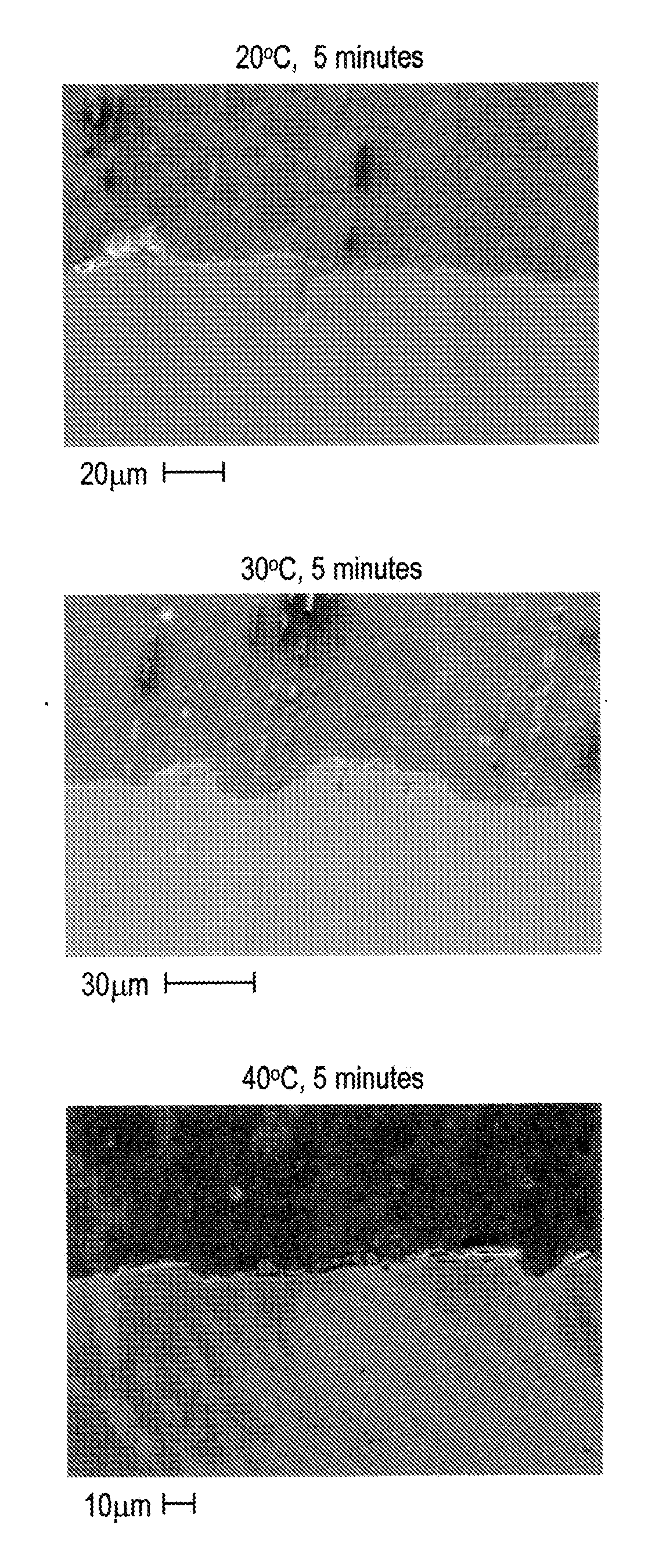

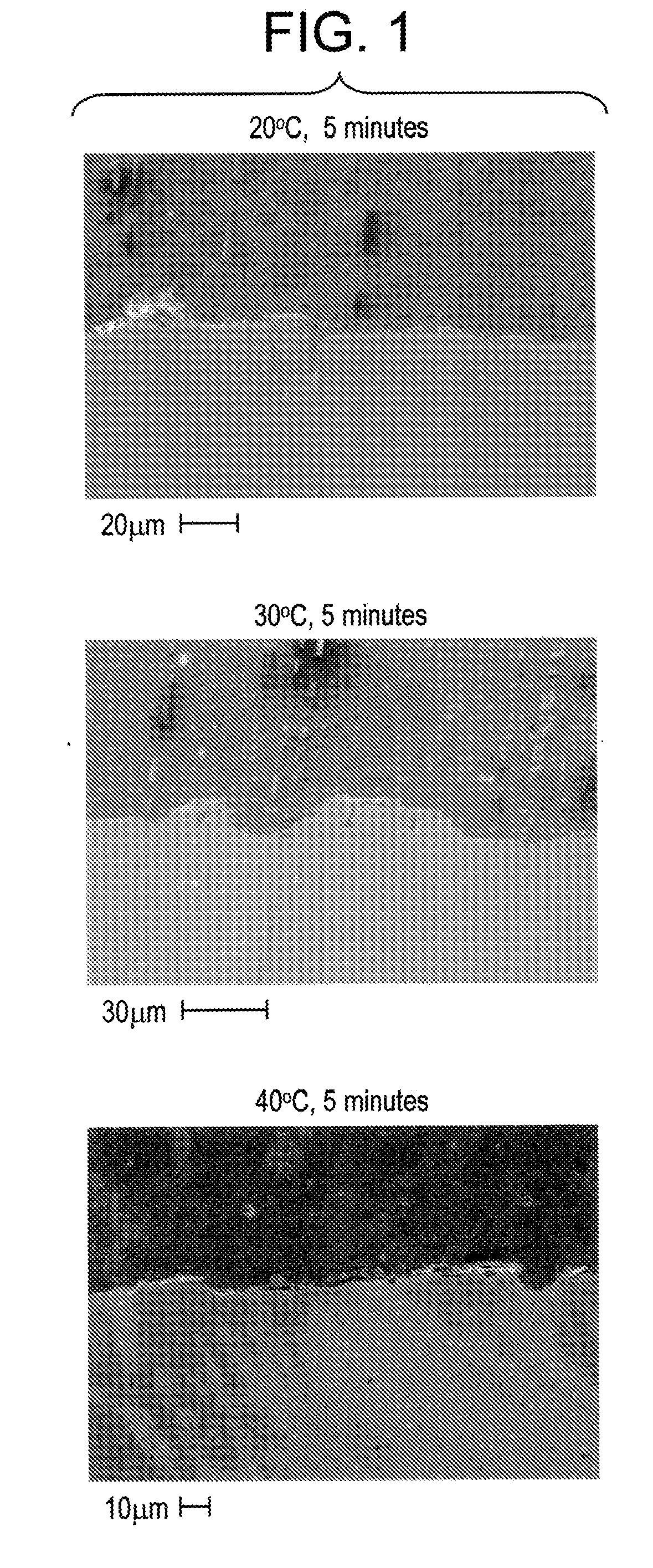

InactiveUS20090302005A1Improve surface roughnessEasy to understandDecorative surface effectsBlade accessoriesOXALIC ACID DIHYDRATEAqueous solution

Process for roughening a surface of a base metal substrate includes contacting the surface with an aqueous solution comprising oxalic acid, sulfuric acid, and hydrogen peroxide at a temperature and for a period of time effective to roughen the surface to an average roughness greater than 60 Ra, removing a modest amount of base material, and generating no narrow and deep crevices at all. The surface is roughened prior to application of an electroless coating onto the substrate.

Owner:GENERAL ELECTRIC CO

Electrophotographic photoconductor, and image forming process, image forming apparatus and process cartridge for an image forming apparatus using the same

ActiveUS7175957B2Increase resistanceMaintain good propertiesElectrographic process apparatusElectrographic processes using charge patternElectrical conductorSurface layer

Disclosed is an electrophotographic photoconductor including at least a photoconductive layer on a conductive substrate, wherein the surface layer of the photoconductive layer contains at least a surface crosslinked layer formed by curing a tri- or more-functional radical polymerizable monomer without having a charge transporting structure and a mono-functional radical polymerizable compound having a charge transporting structure and the surface crosslinked layer has a surface roughness Rz of 1.3 μm or less.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com