Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

191results about How to "Good film uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

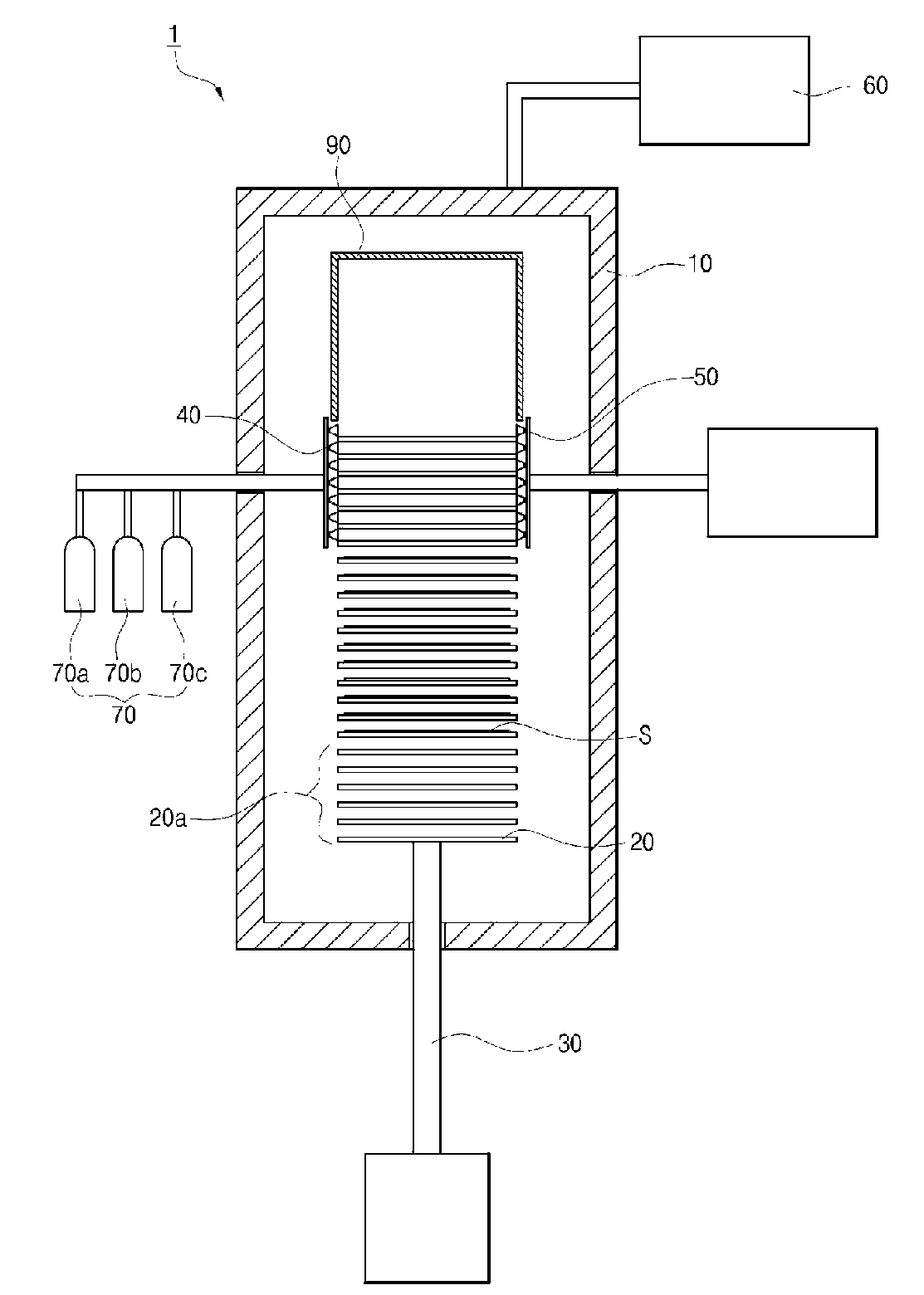

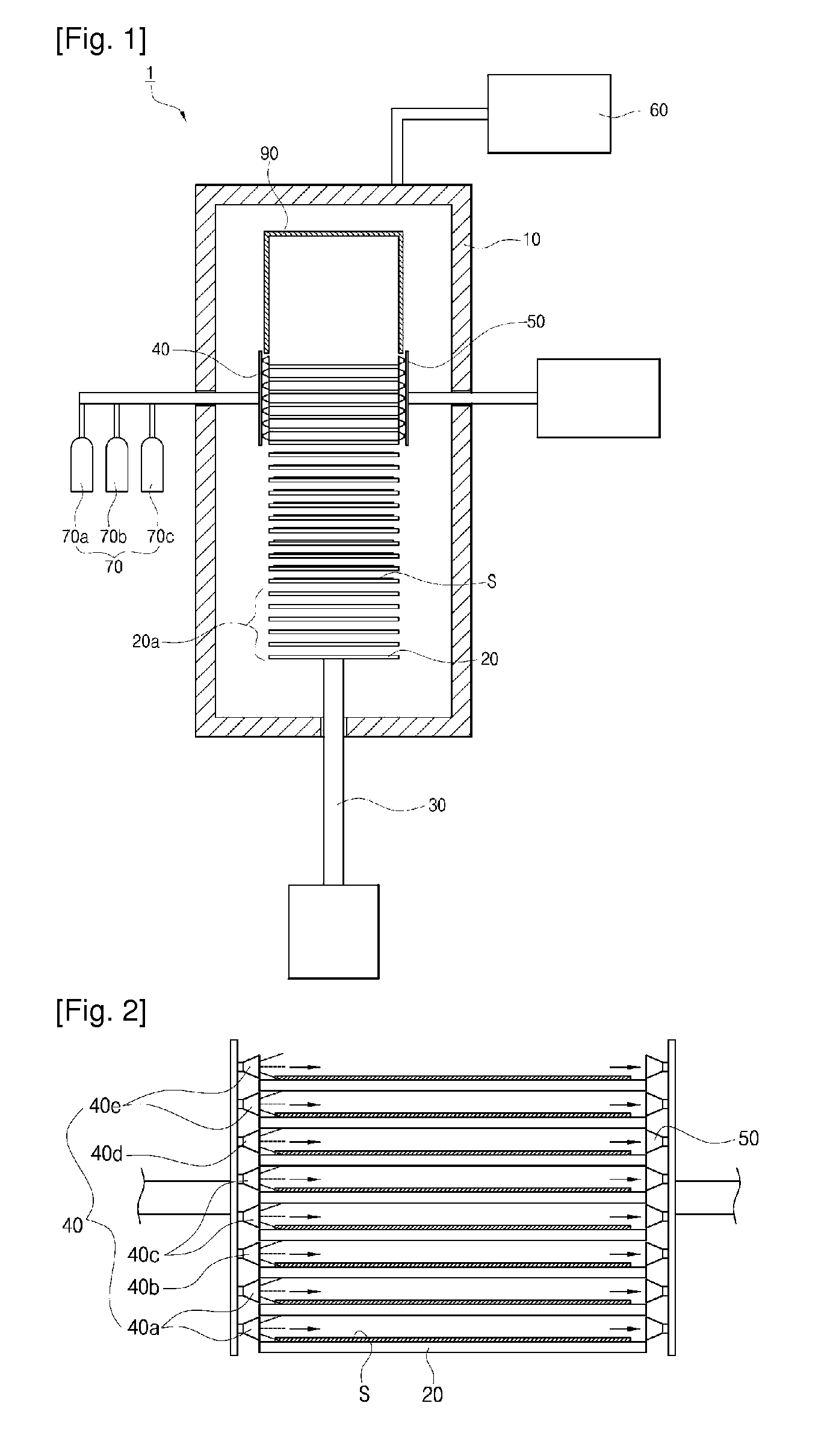

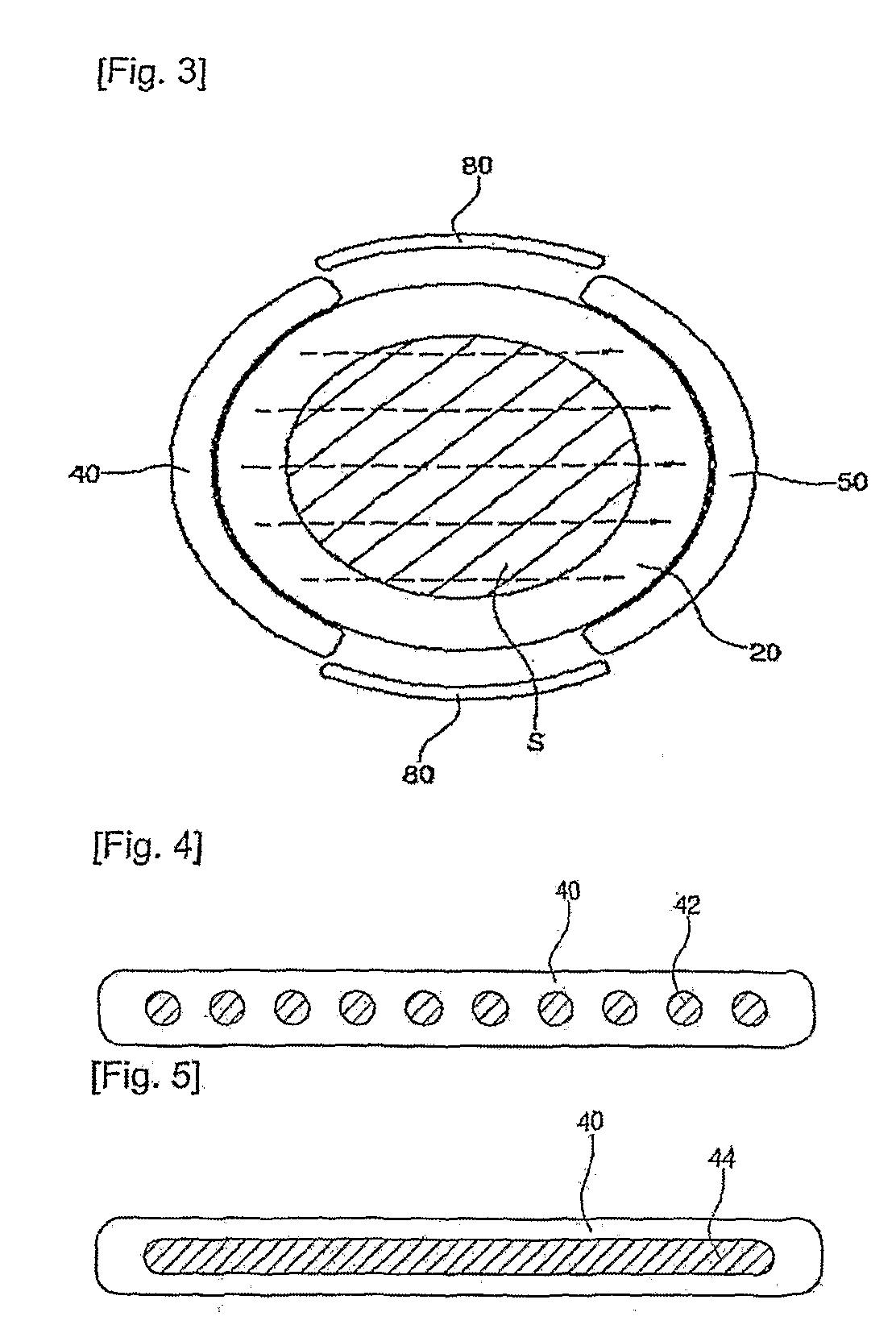

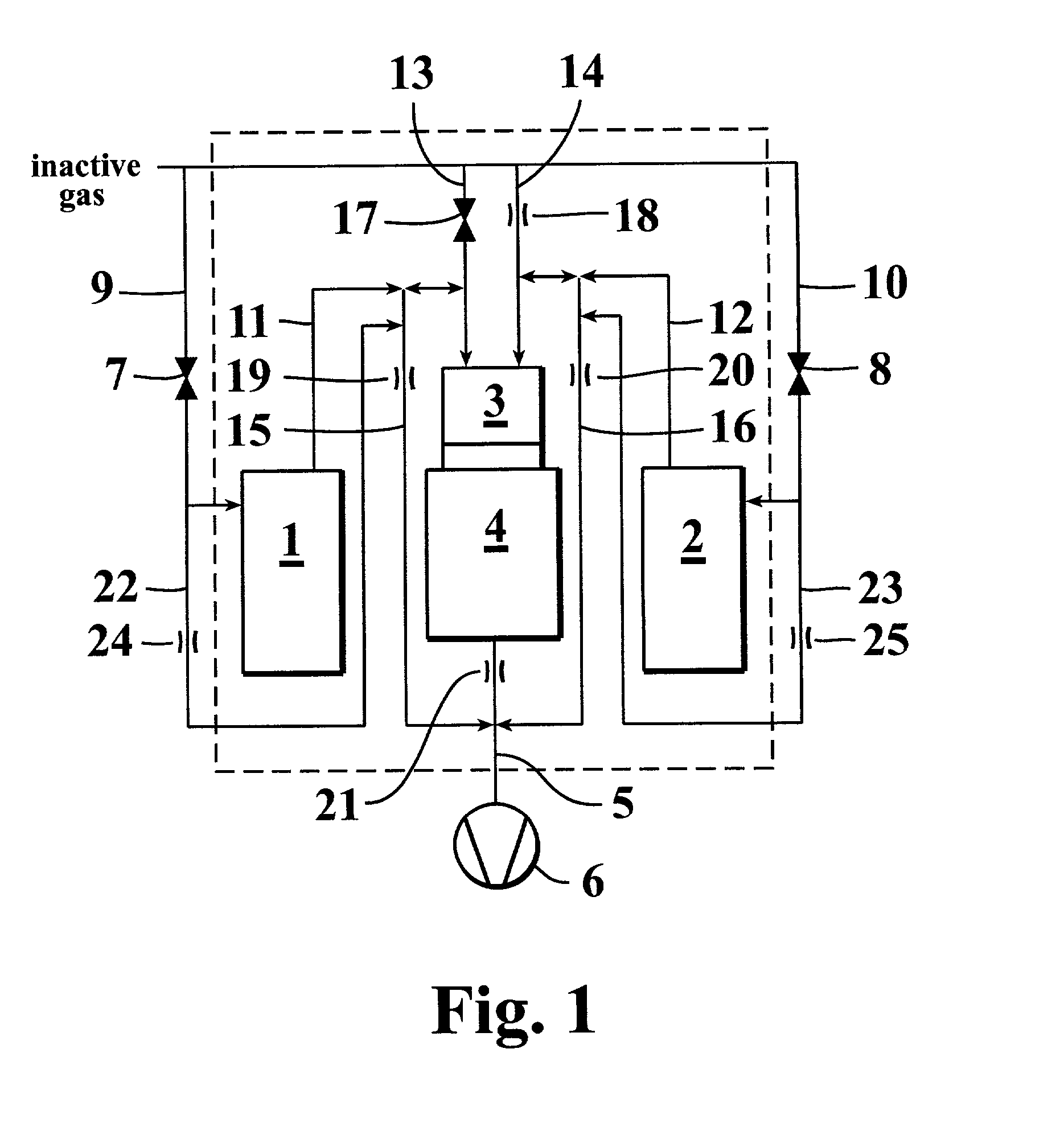

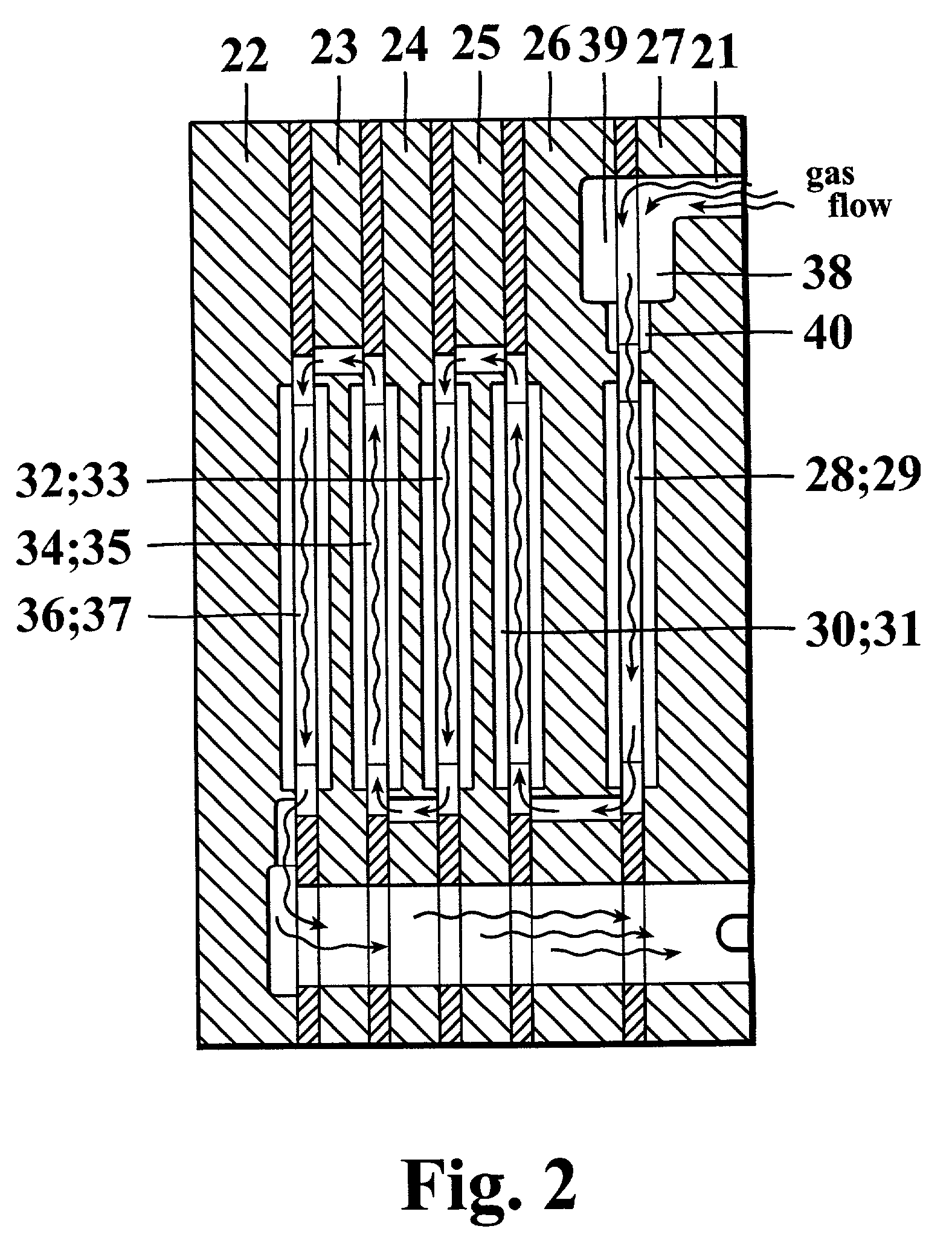

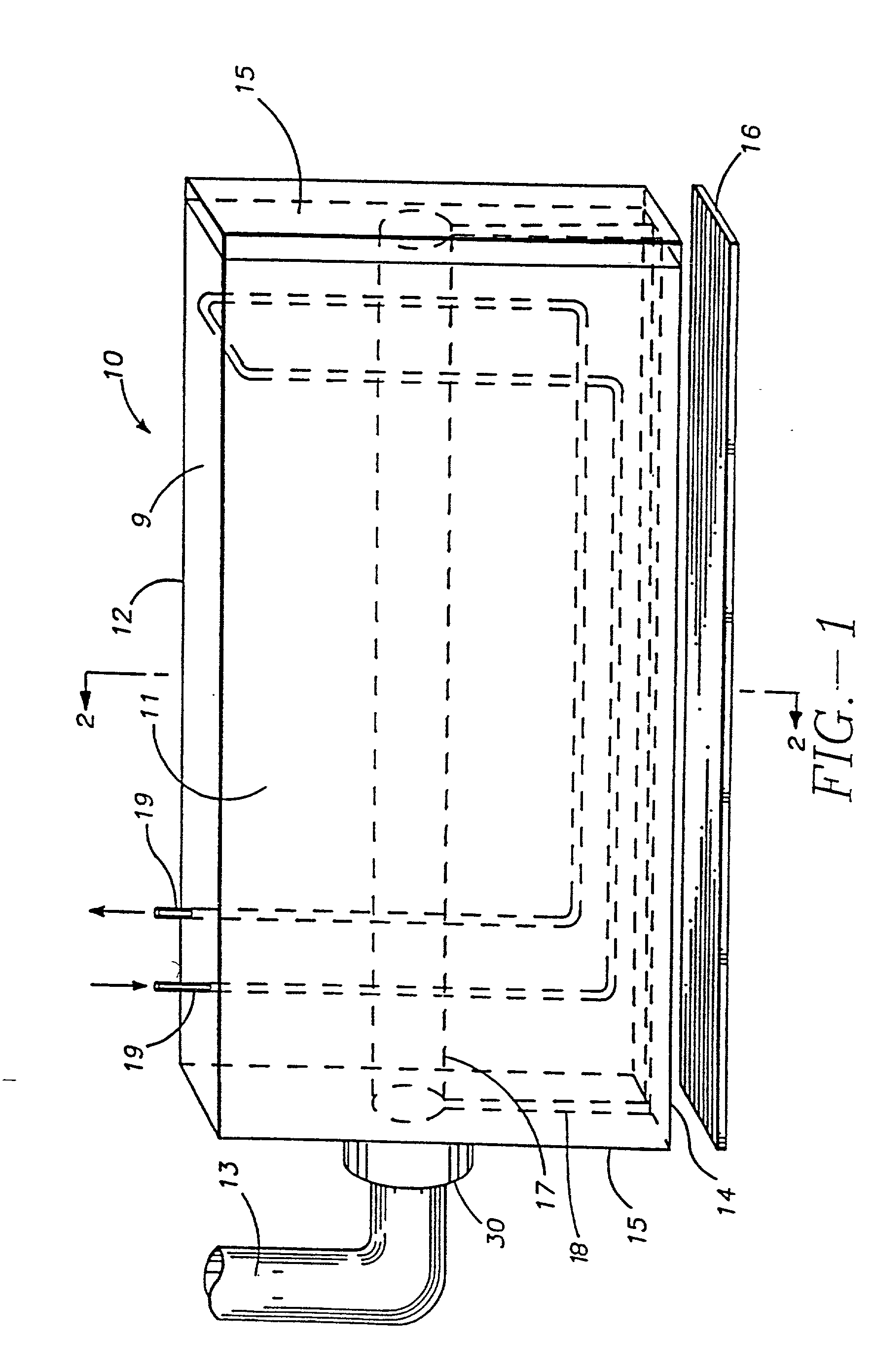

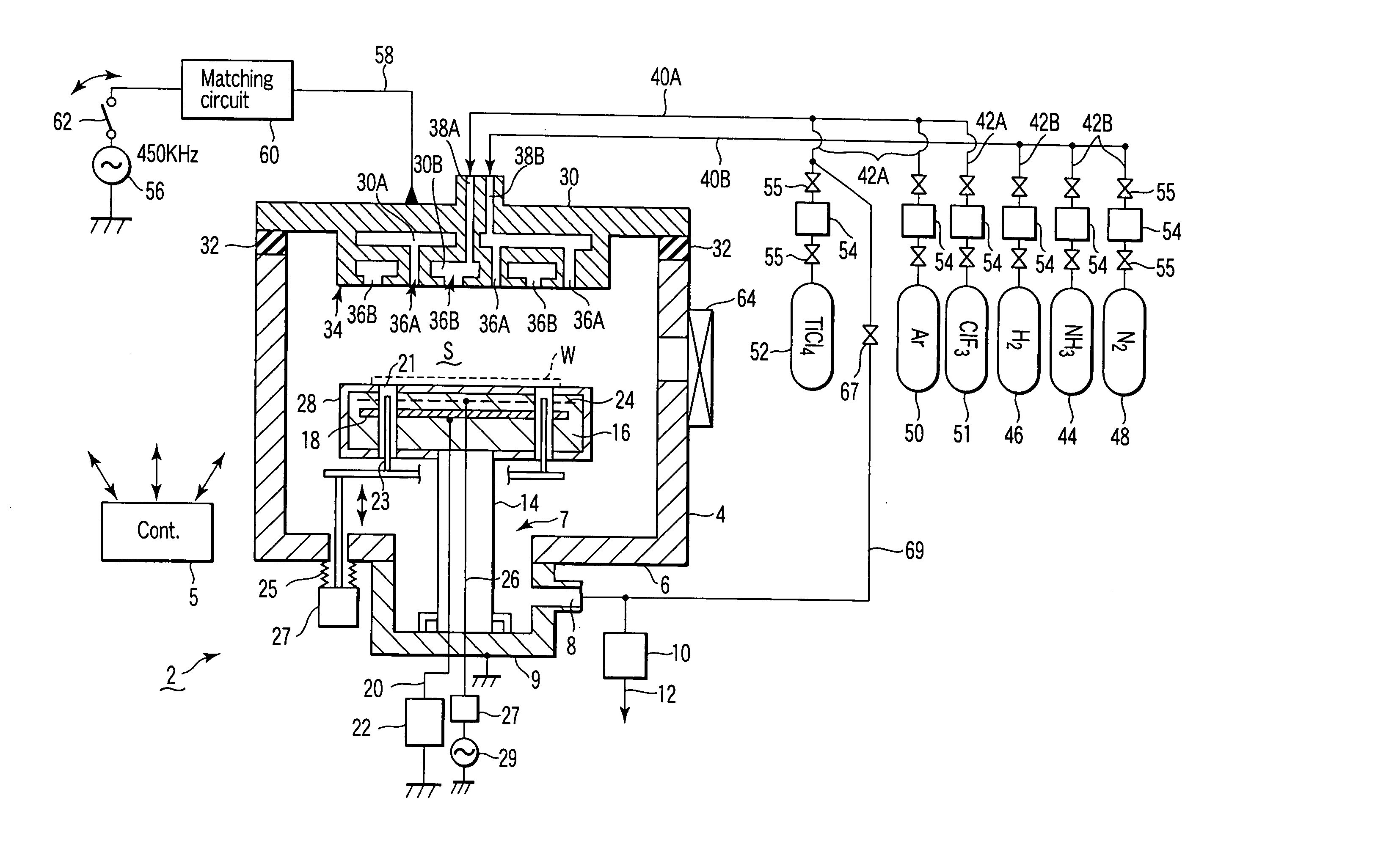

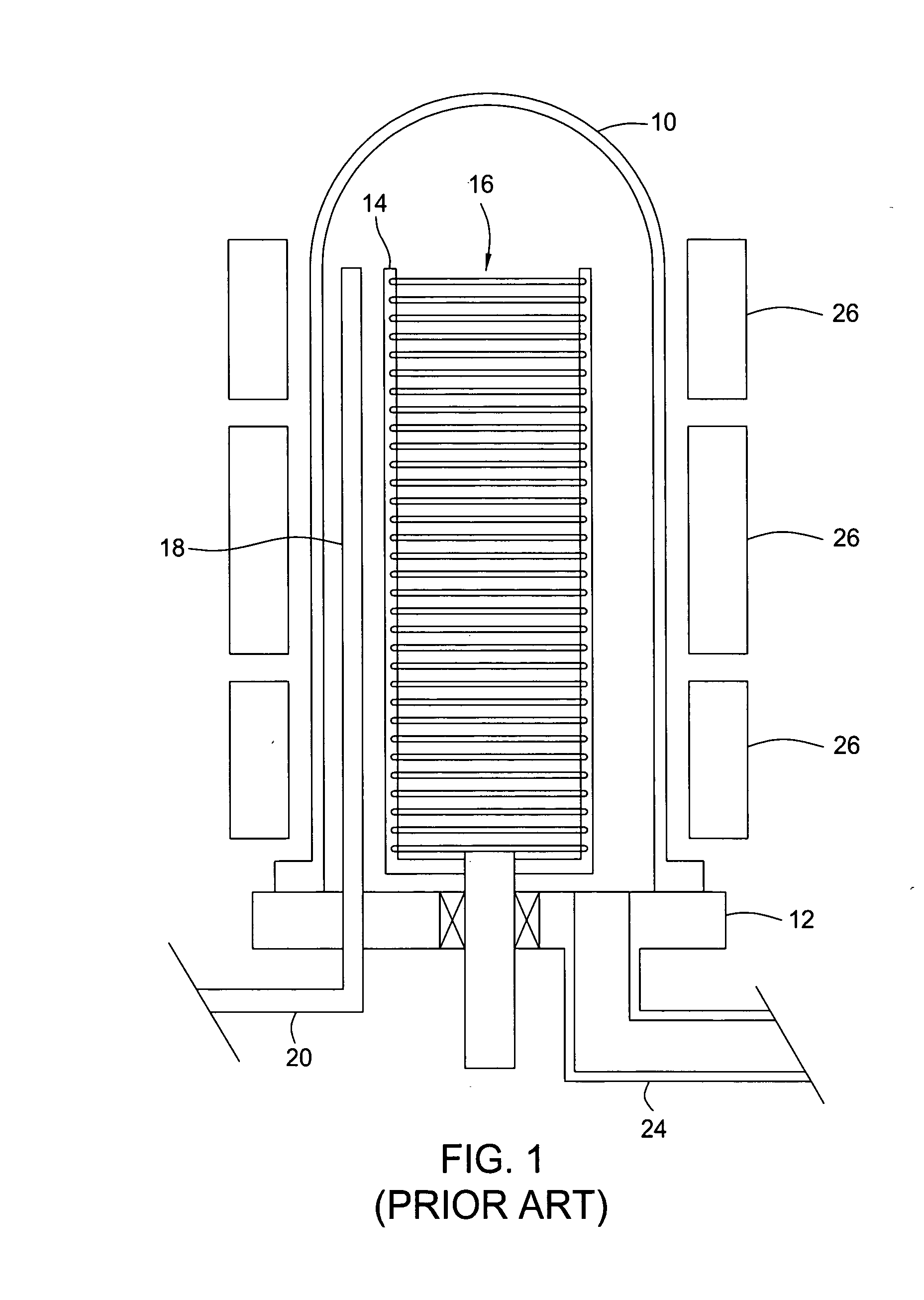

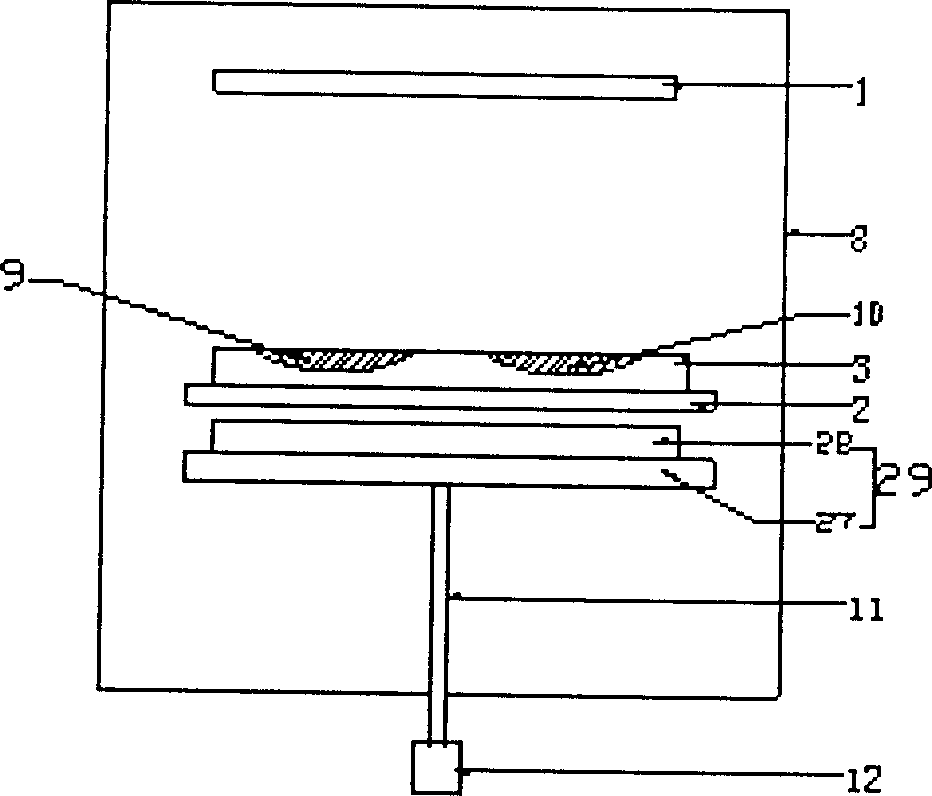

Batch type atomic layer deposition apparatus

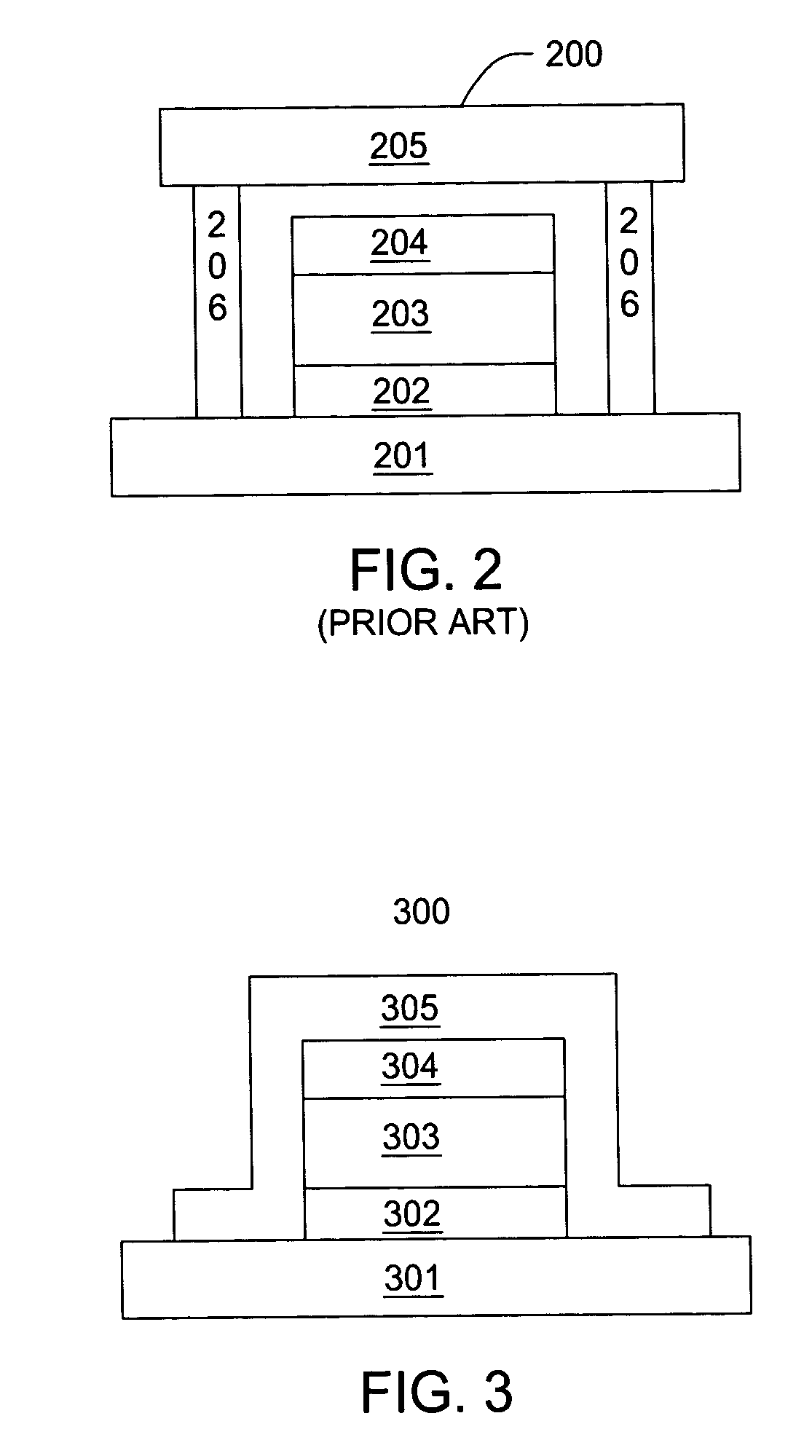

InactiveUS20100326358A1Improve throughputImprove deposition efficiencyChemical vapor deposition coatingEngineeringAtomic layer deposition

Provided is a batch-type Atomic Layer Deposition (ALD) apparatus for performing ALD processing collectively for a plurality of substrates, leading to an improved throughput, and achieving perfect uniformity of ALD on the substrates. The batch-type ALD apparatus includes: a chamber that can be kept in a vacuum state; a substrate support member, disposed in the chamber, supporting a plurality of substrates to be stacked one onto another with a predetermined pitch; a substrate movement device moving the substrate support member upward or downward; a gas spray device continuously spraying a gas in a direction parallel to the extending direction of each of the substrates stacked in the substrate support member; and a gas discharge device, disposed in an opposite side of the chamber to the gas spray device, sucking and evacuating the gas sprayed from the gas spray device.

Owner:CHOI KYU JEONG

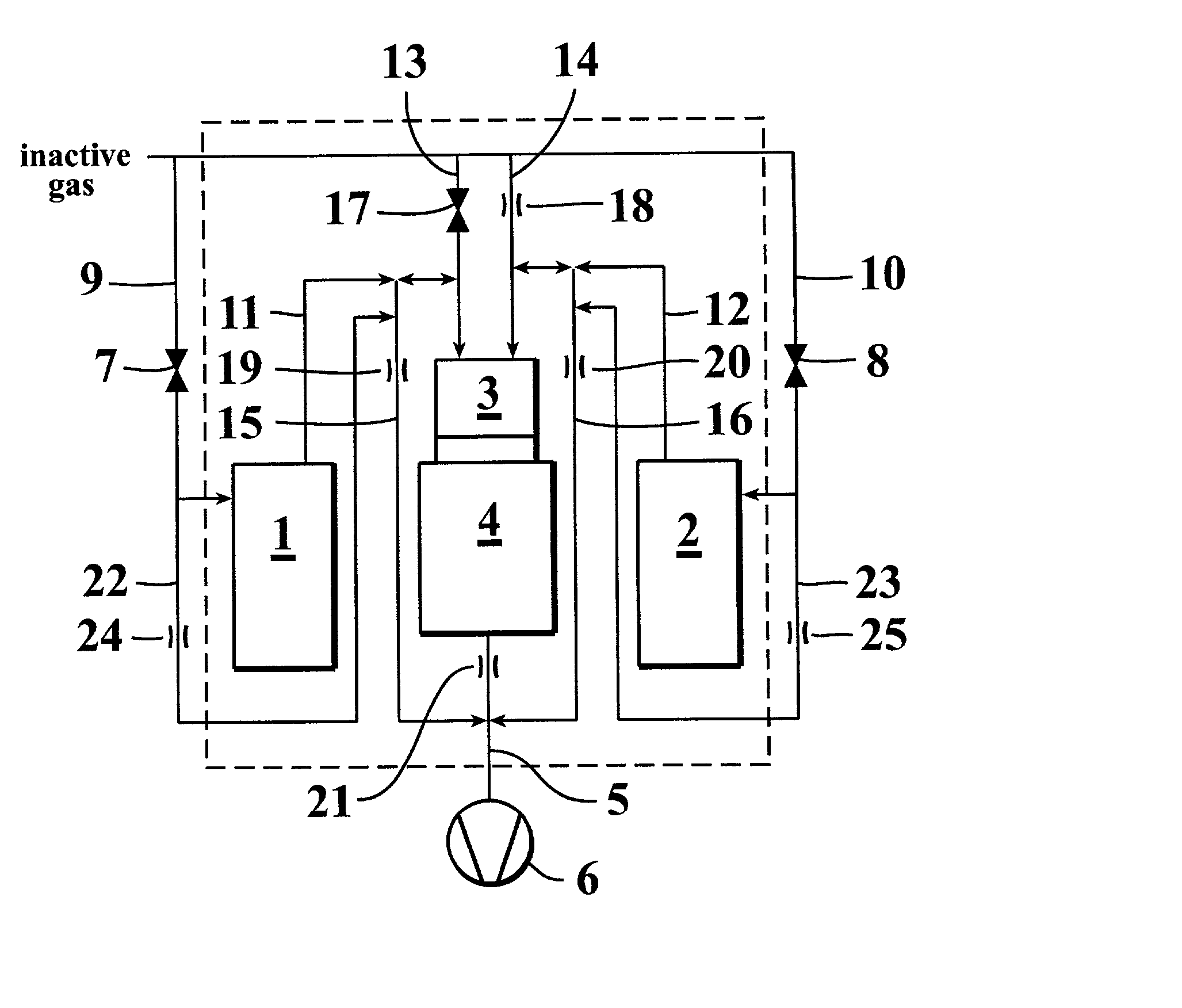

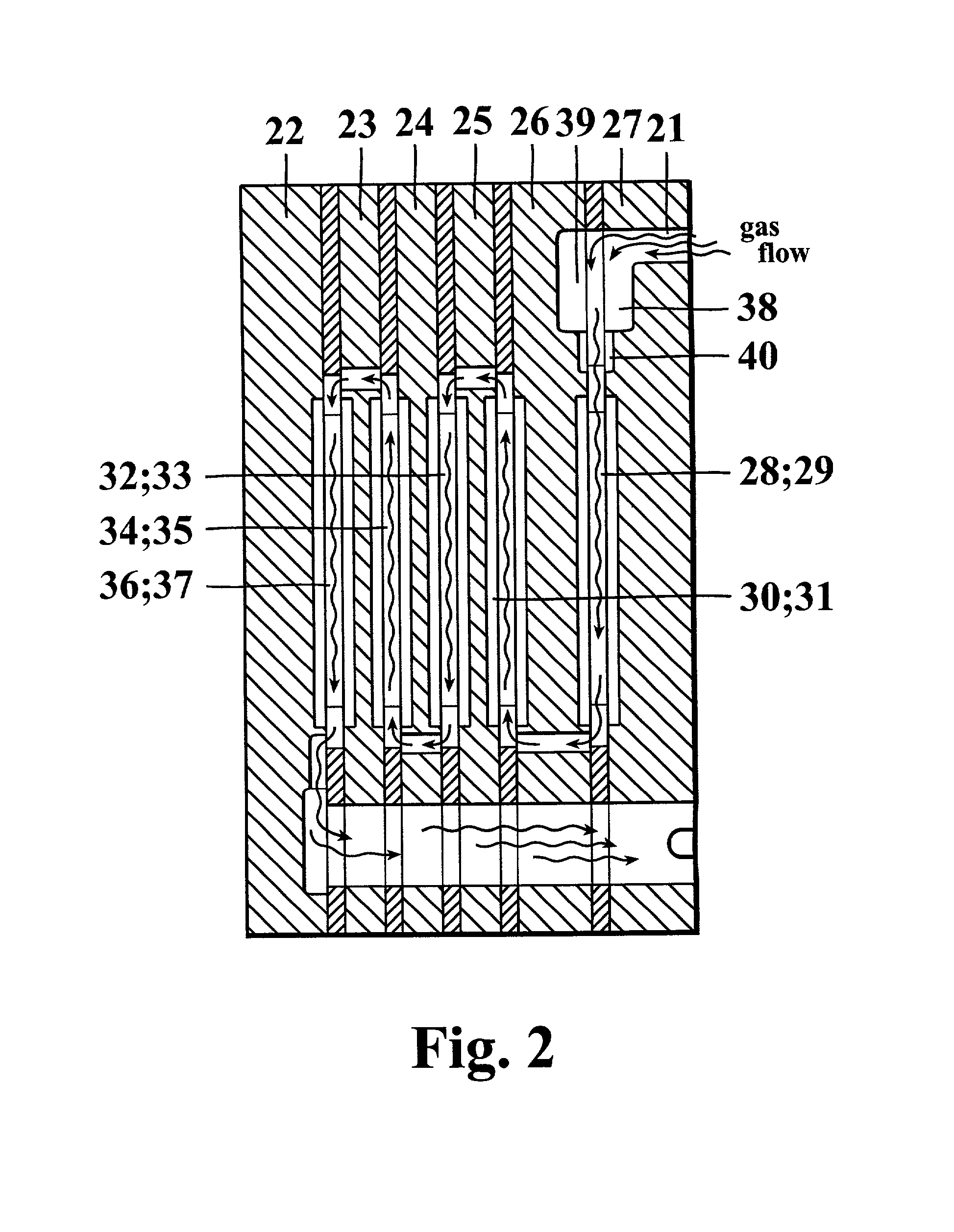

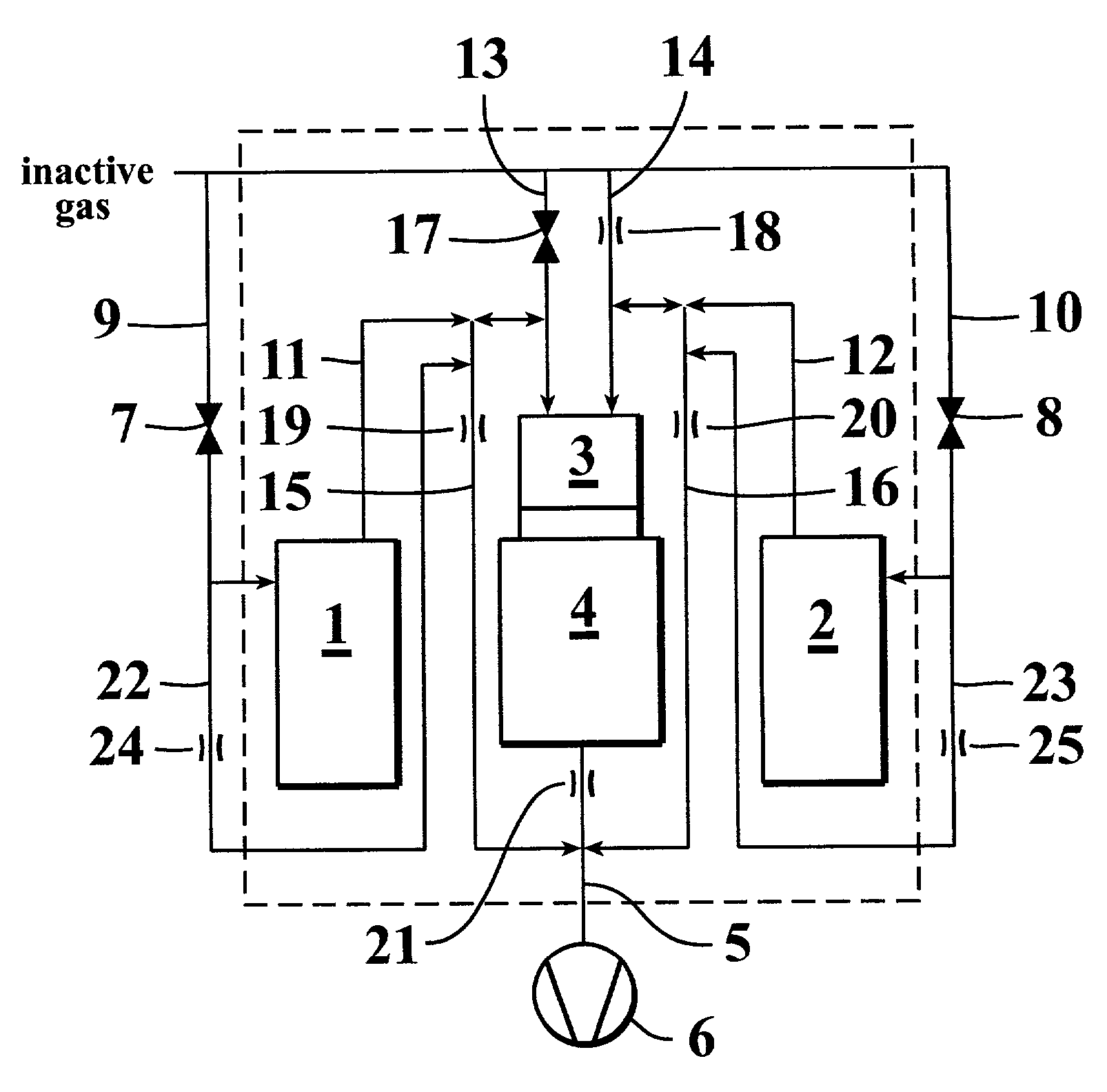

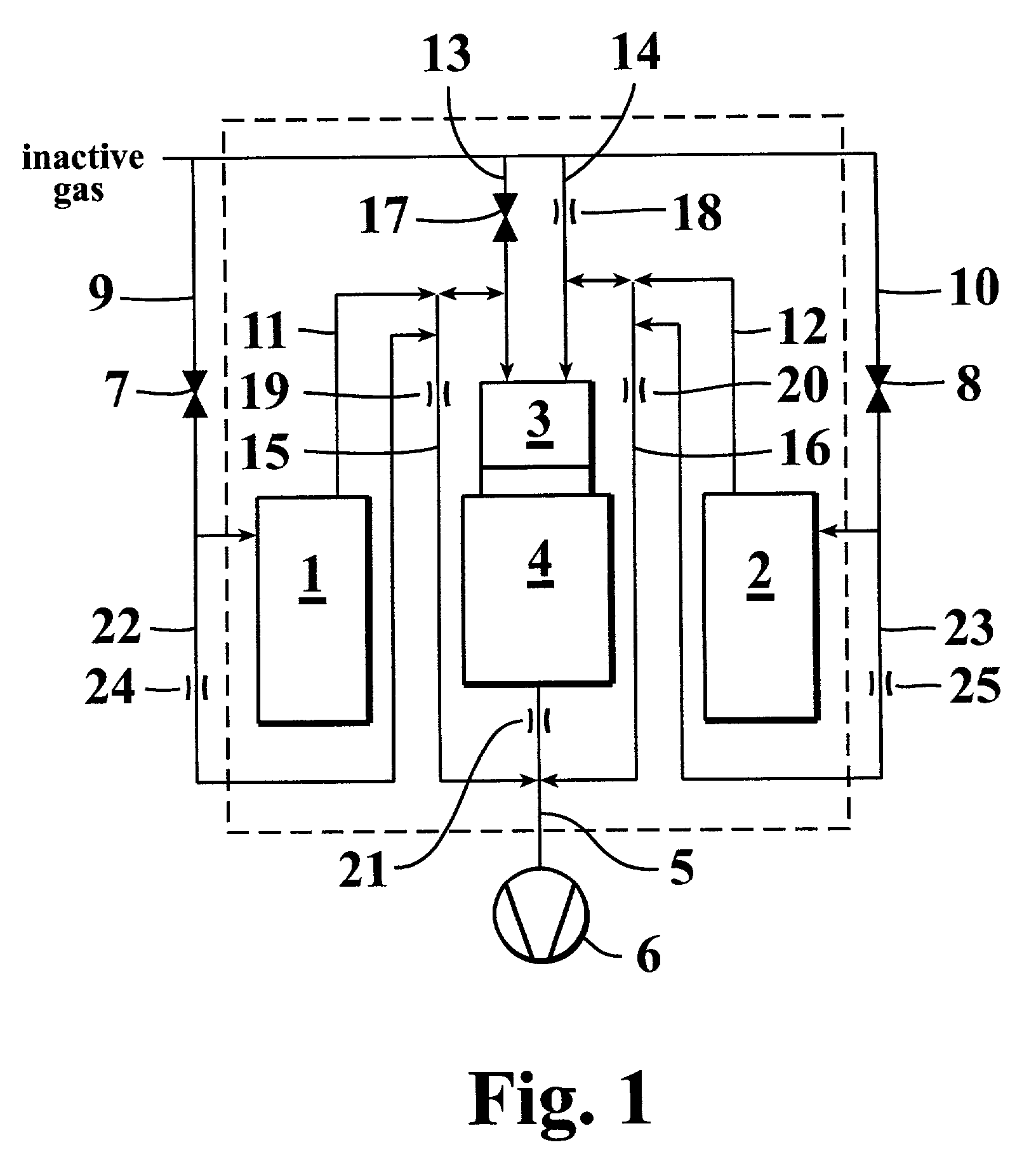

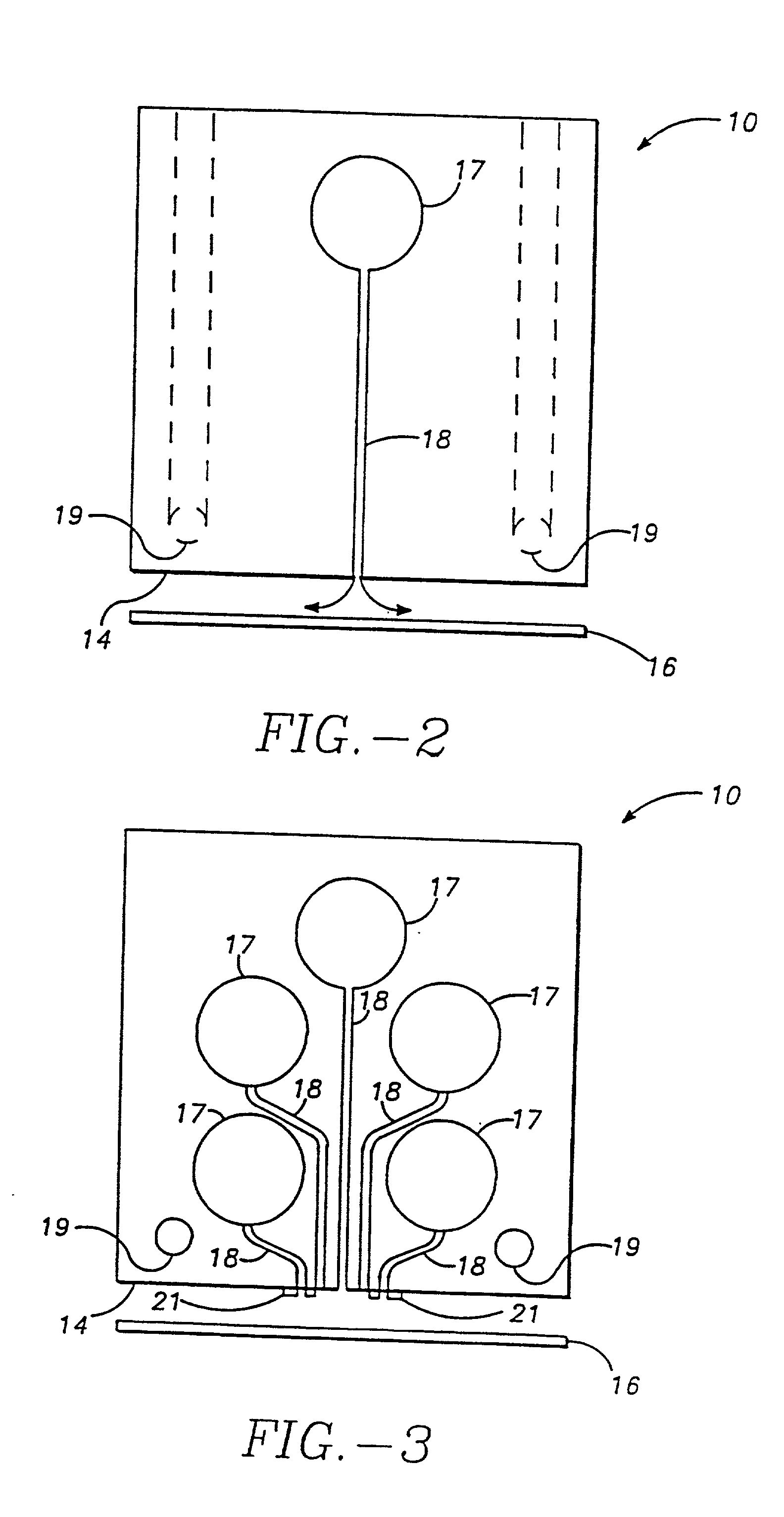

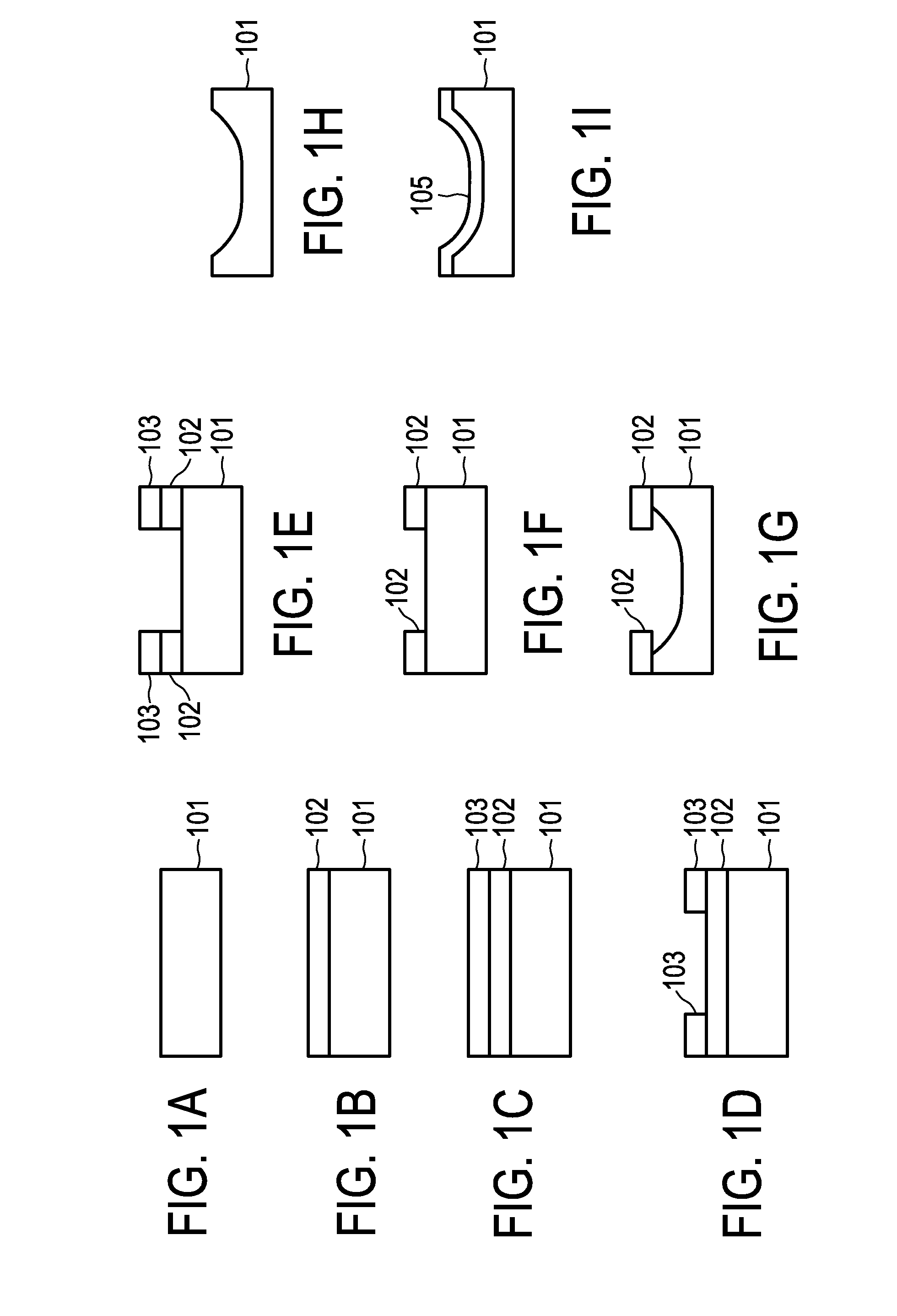

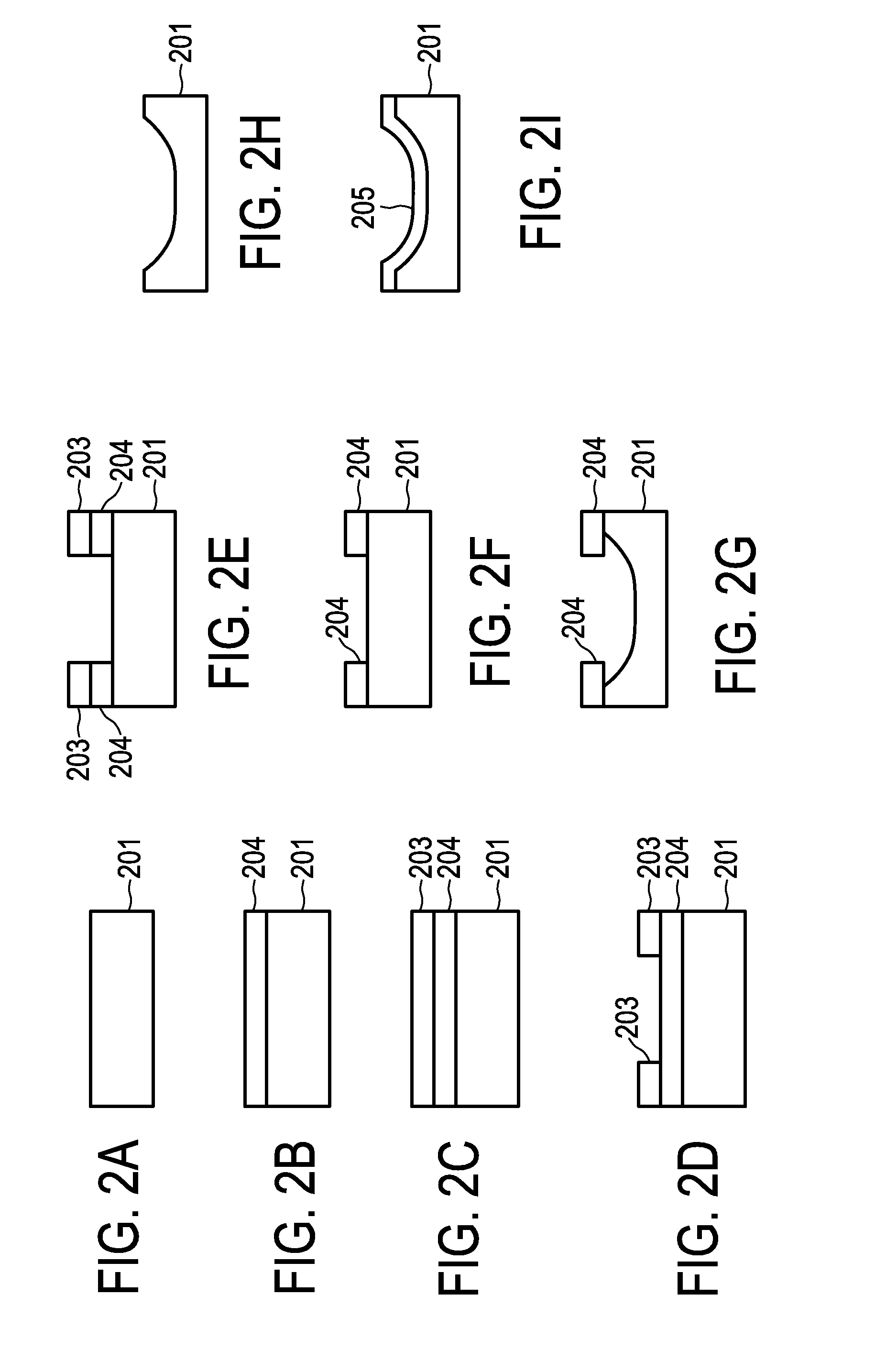

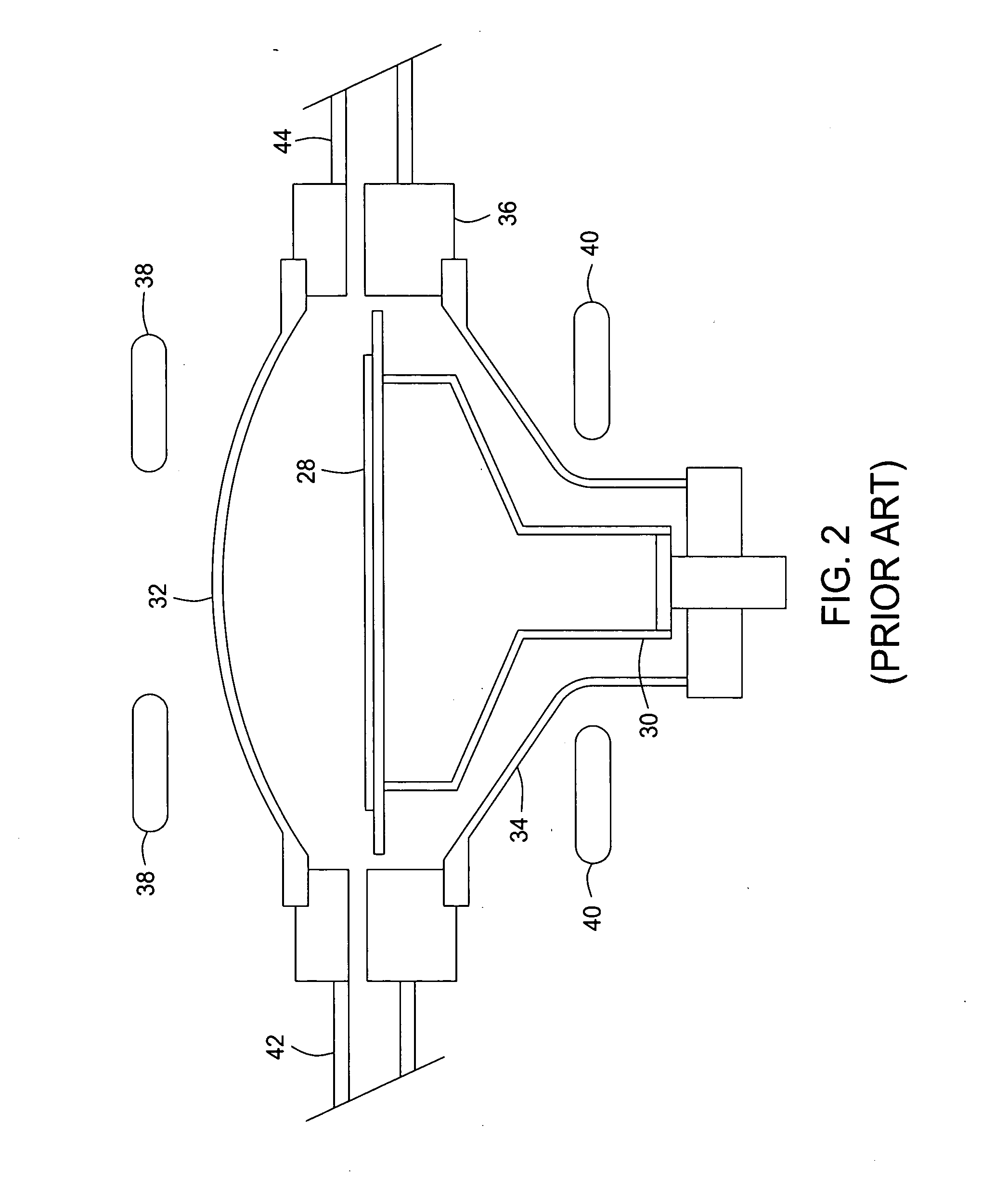

Method and apparatus of growing a thin film onto a substrate

InactiveUS20020108570A1Good film uniformitySimple and efficientPolycrystalline material growthSemiconductor/solid-state device manufacturingInlet channelGas phase

A method and an apparatus for growing a thin film onto a substrate by the ALD process. The apparatus comprises a reaction chamber into which the substrate can be disposed; a plurality of inlet channels communicating with said reaction chamber, said inlet channels being suited for feeding the reactants employed in a thin-film growth process in the form of vapor-phase pulses into said reaction chamber; at least one outlet channel communicating with said reaction chamber, said outlet channel being suited for the outflow of reaction products and excess amounts of reactants from said reaction space; and a pre-reaction chamber arranged immediately upstream of the reaction chamber, said pre-reaction chamber forming a first reaction zone, in which the reactants of successive vapor-phase pulses can be reacted with each other in the vapor phase to form a solid product, whereas said reaction chamber forming a second reaction zone can be operated under conditions conducive to ALD growth of a thin film.

Owner:ASM INTERNATIONAL

Deposition sub-chamber with variable flow

ActiveUS7993457B1Enhanced chamber performanceImprove performanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringMechanical engineering

Owner:NOVELLUS SYSTEMS

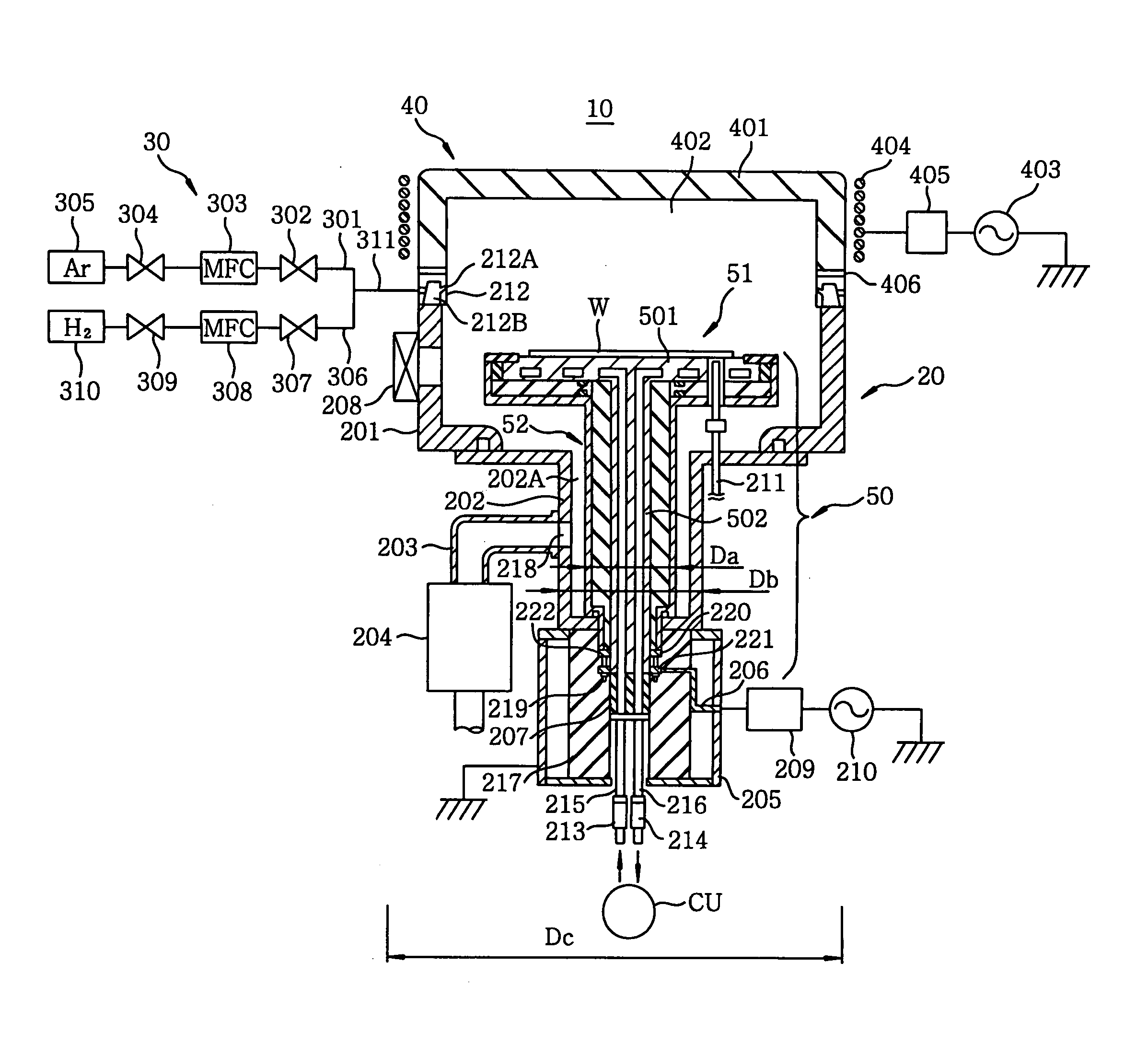

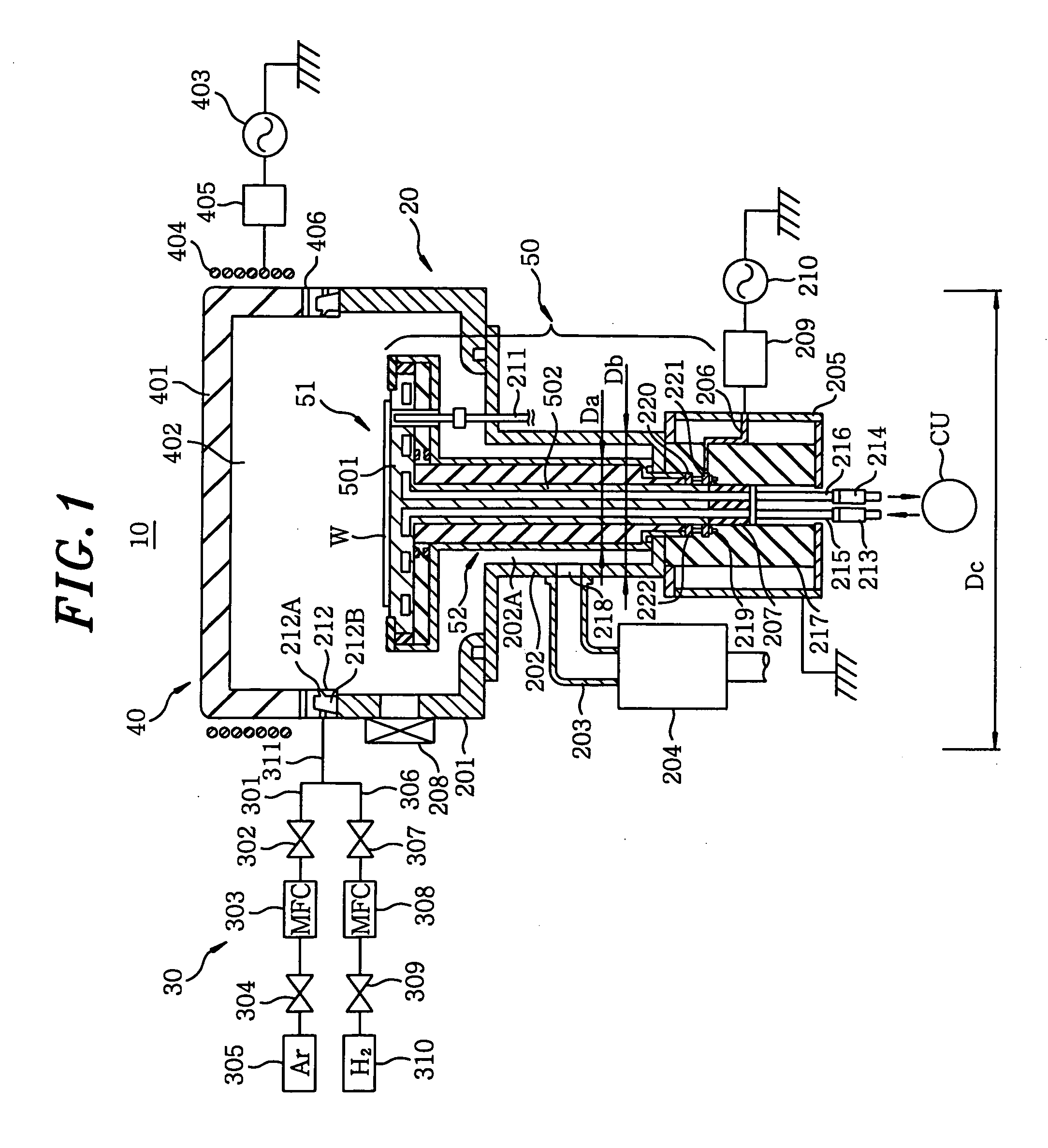

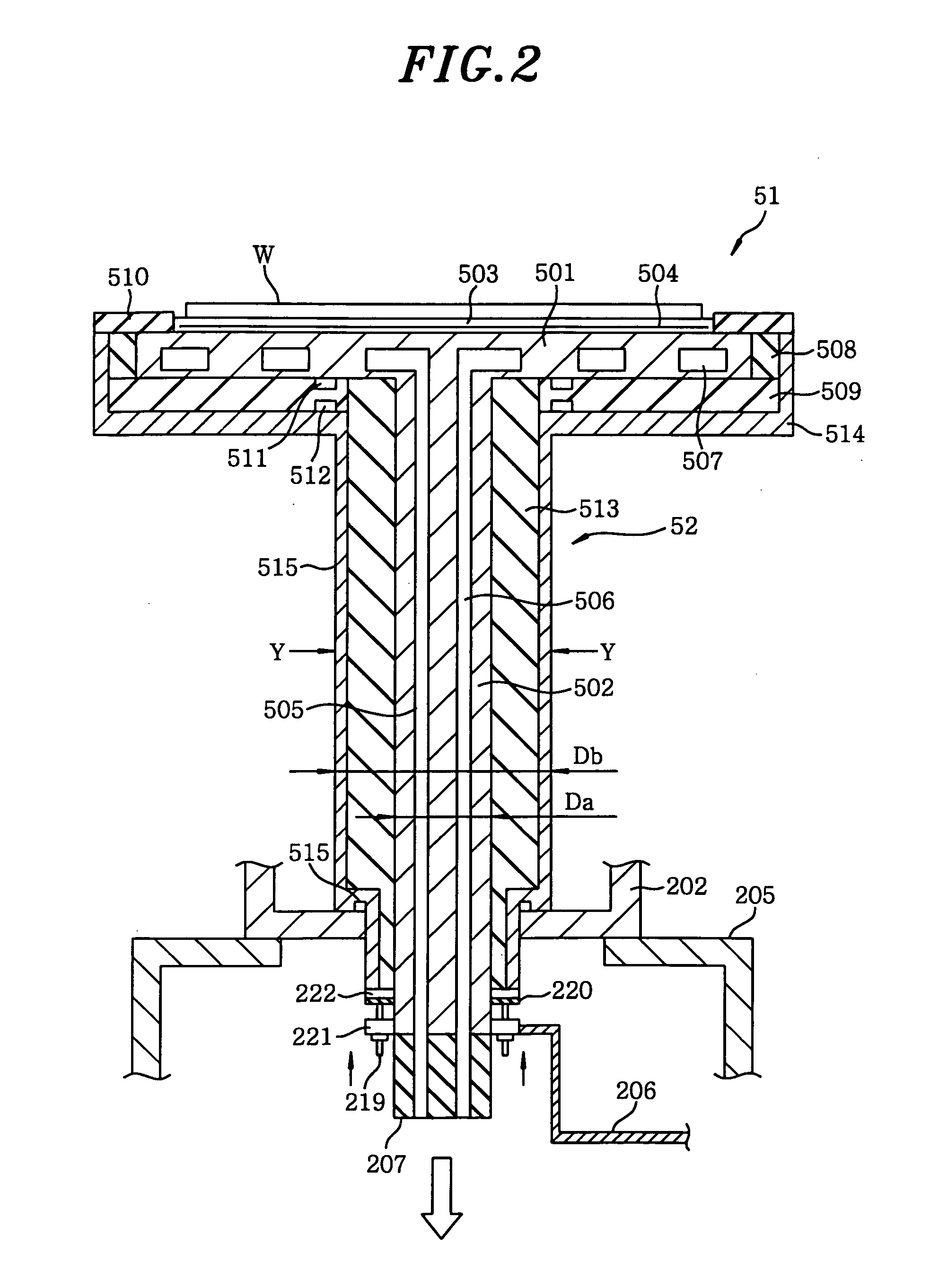

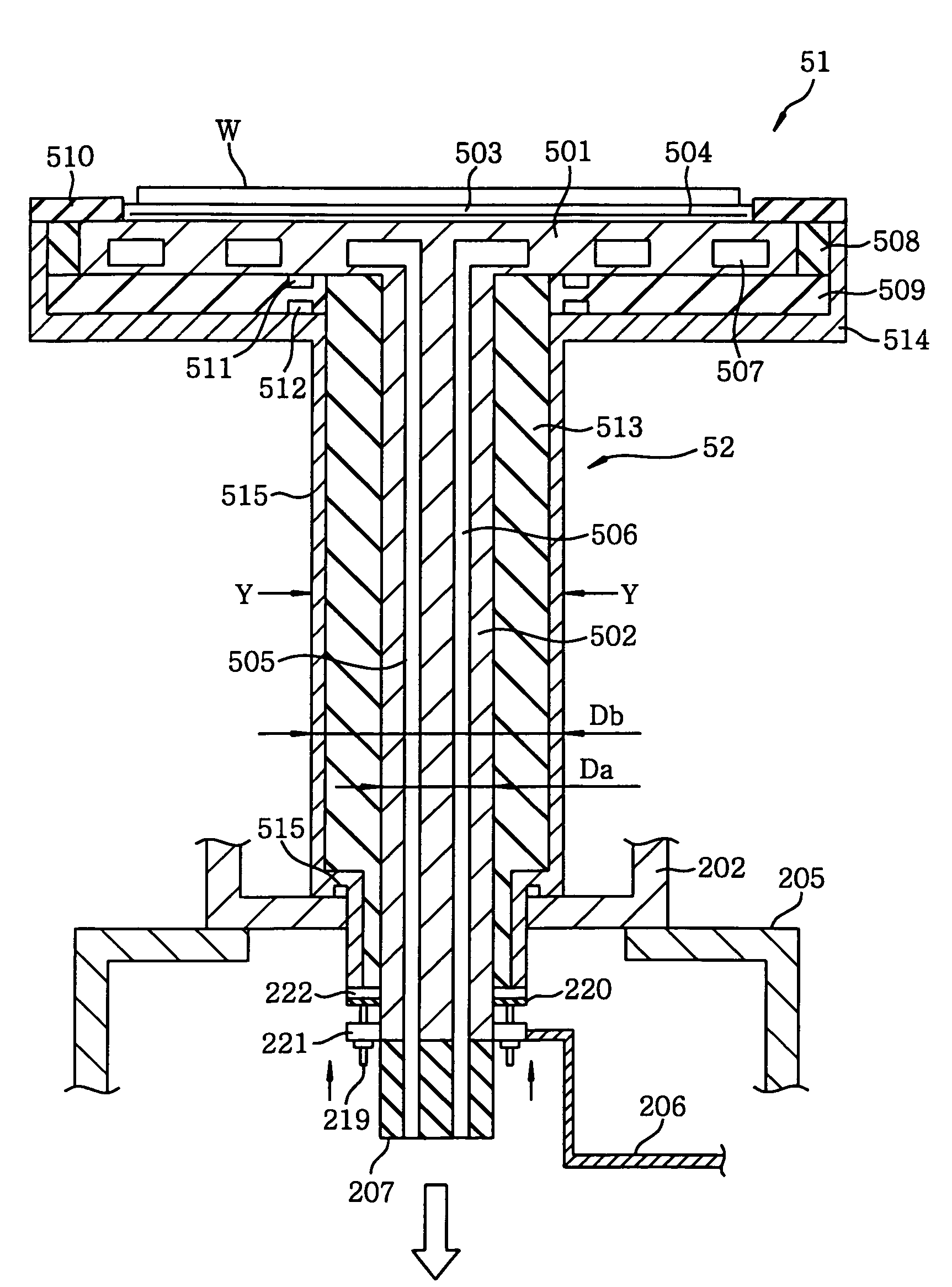

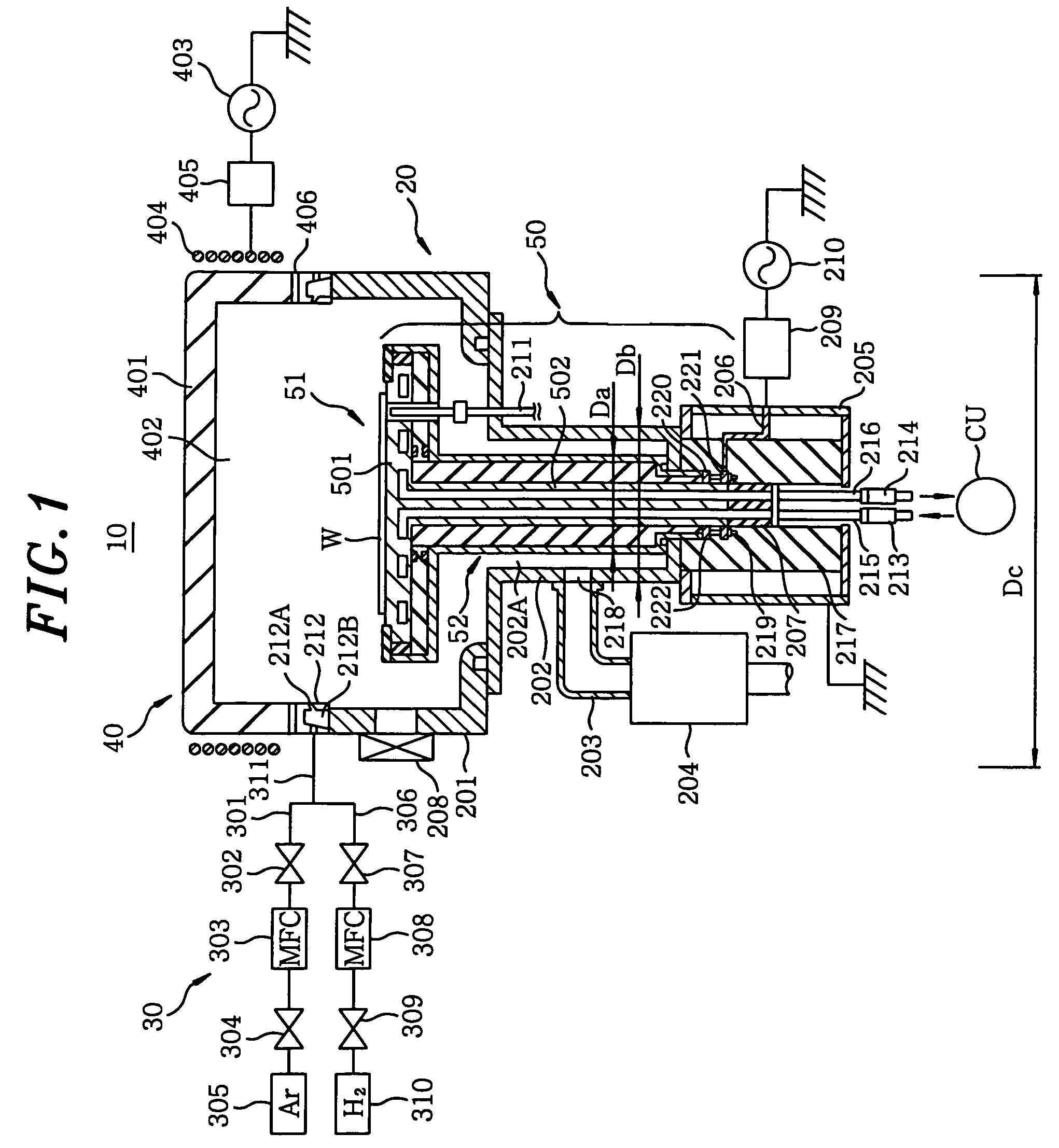

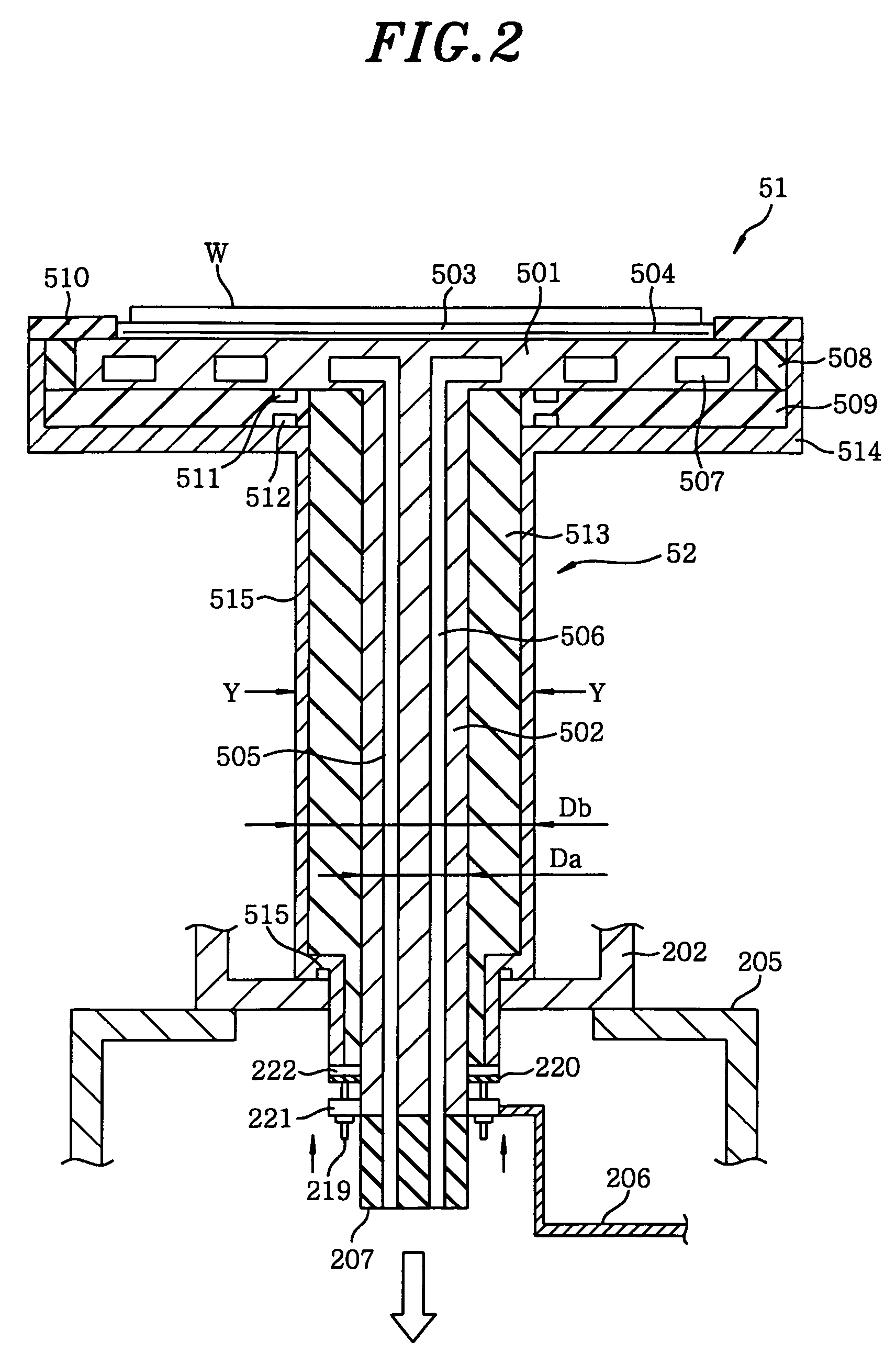

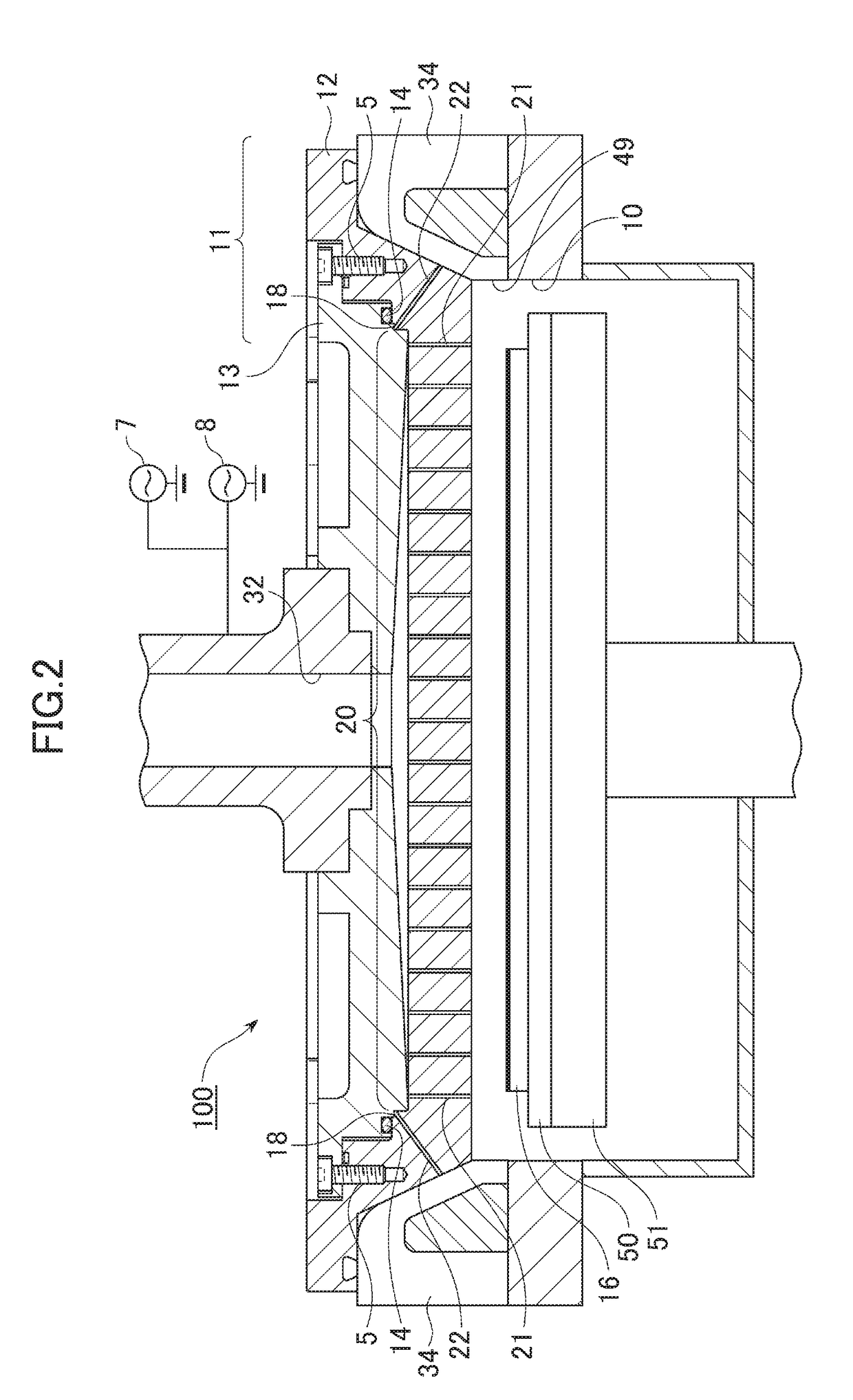

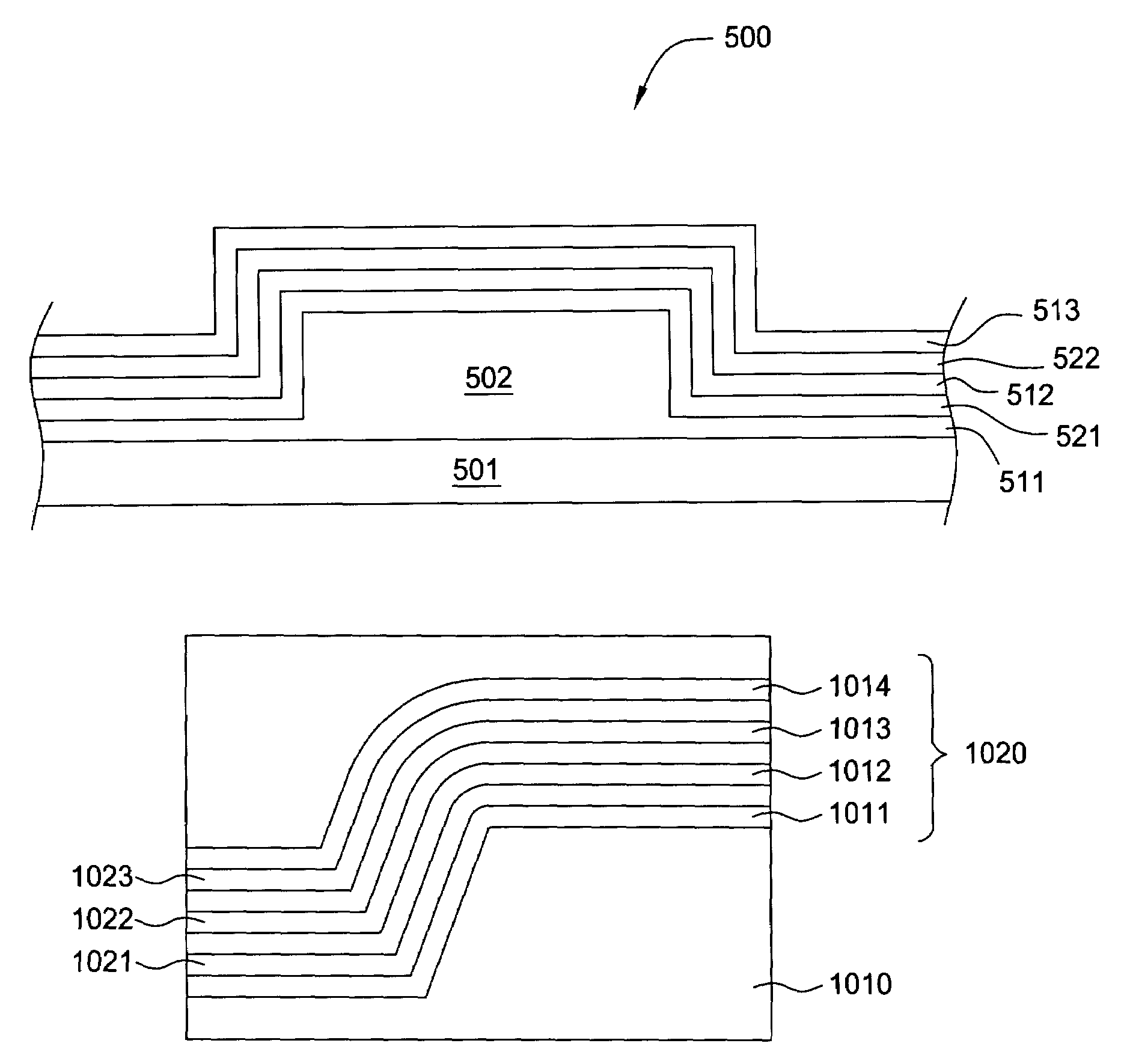

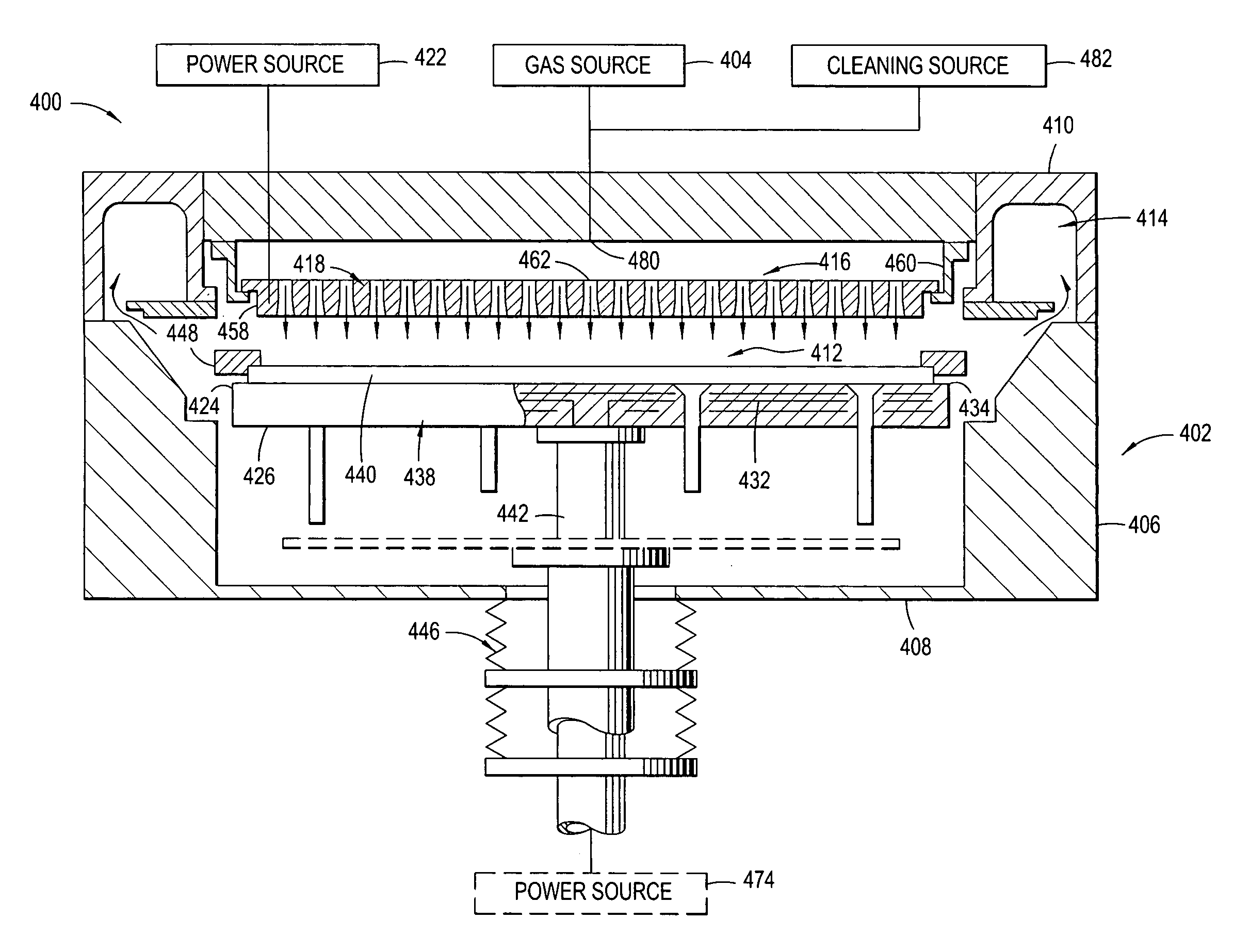

Substrate supporting structure for semiconductor processing, and plasma processing device

InactiveUS20060005930A1Low costGood film uniformitySleeve/socket jointsElectric discharge tubesTemperature controlHigh frequency power

A substrate supporting structure (50) for semiconductor processing, comprising a mounting table (51) for placing a processed substrate (W) disposed in a processing chamber (20), wherein temperature control spaces (507) for storing the fluid used as a heat exchange medium are formed in the mounting table (51), a conductive transmission path (502) is disposed to lead a high frequency power to the mounting table (51), and flow channels (505, 506) feeding or discharging the heat exchange medium fluid to or from the temperature control spaces (507) are formed in the transmission path (502).

Owner:TOKYO ELECTRON LTD

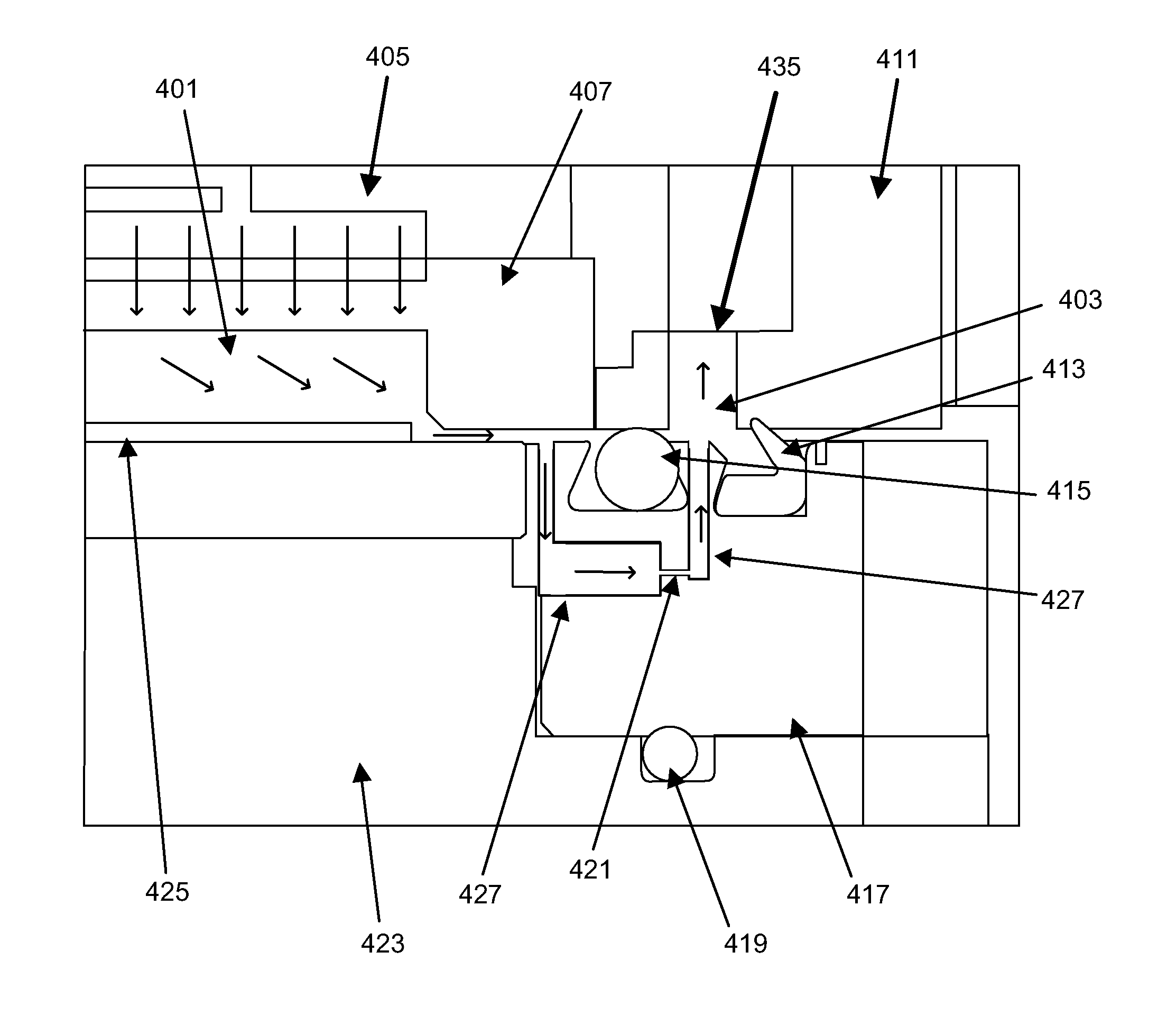

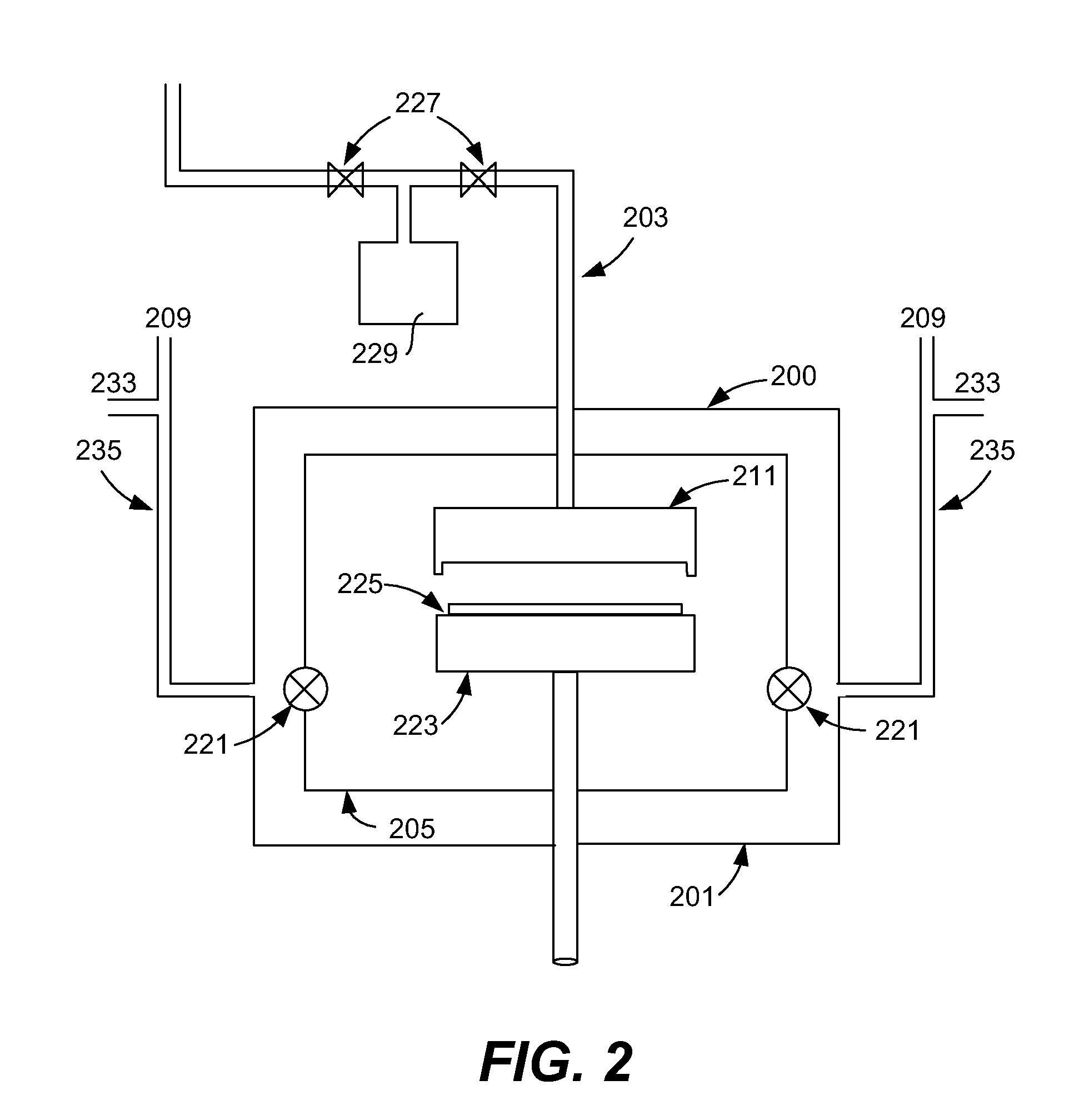

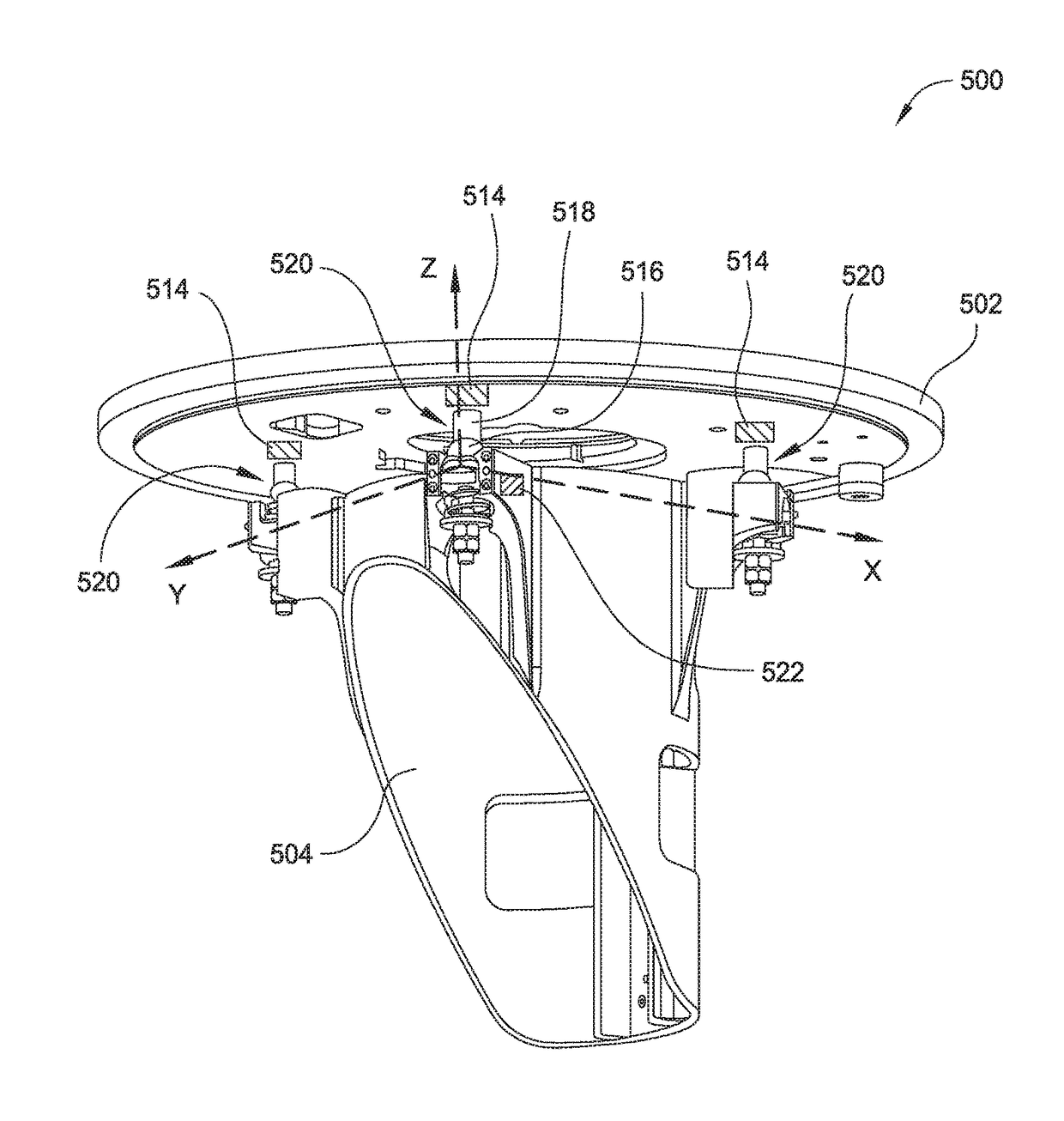

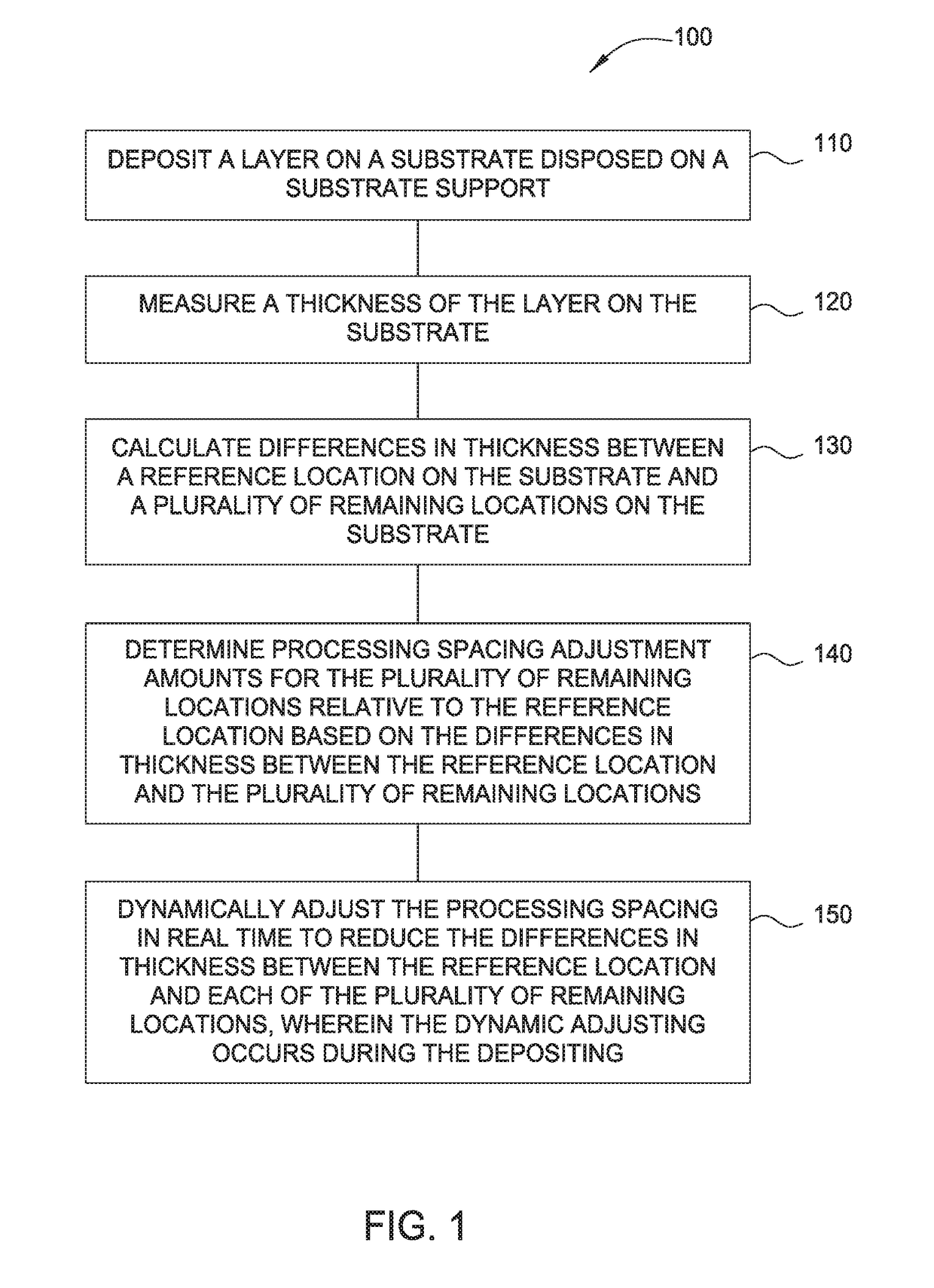

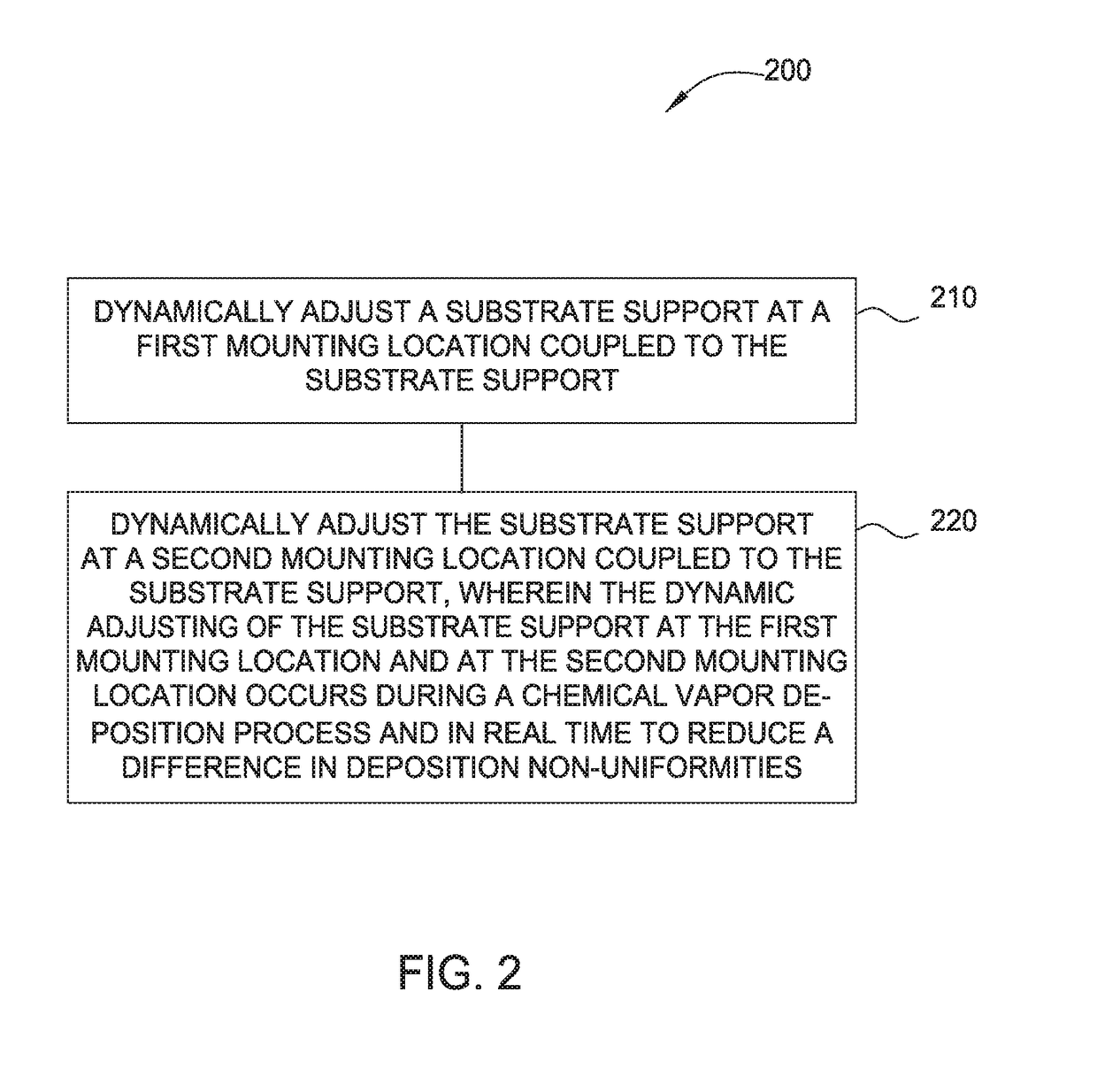

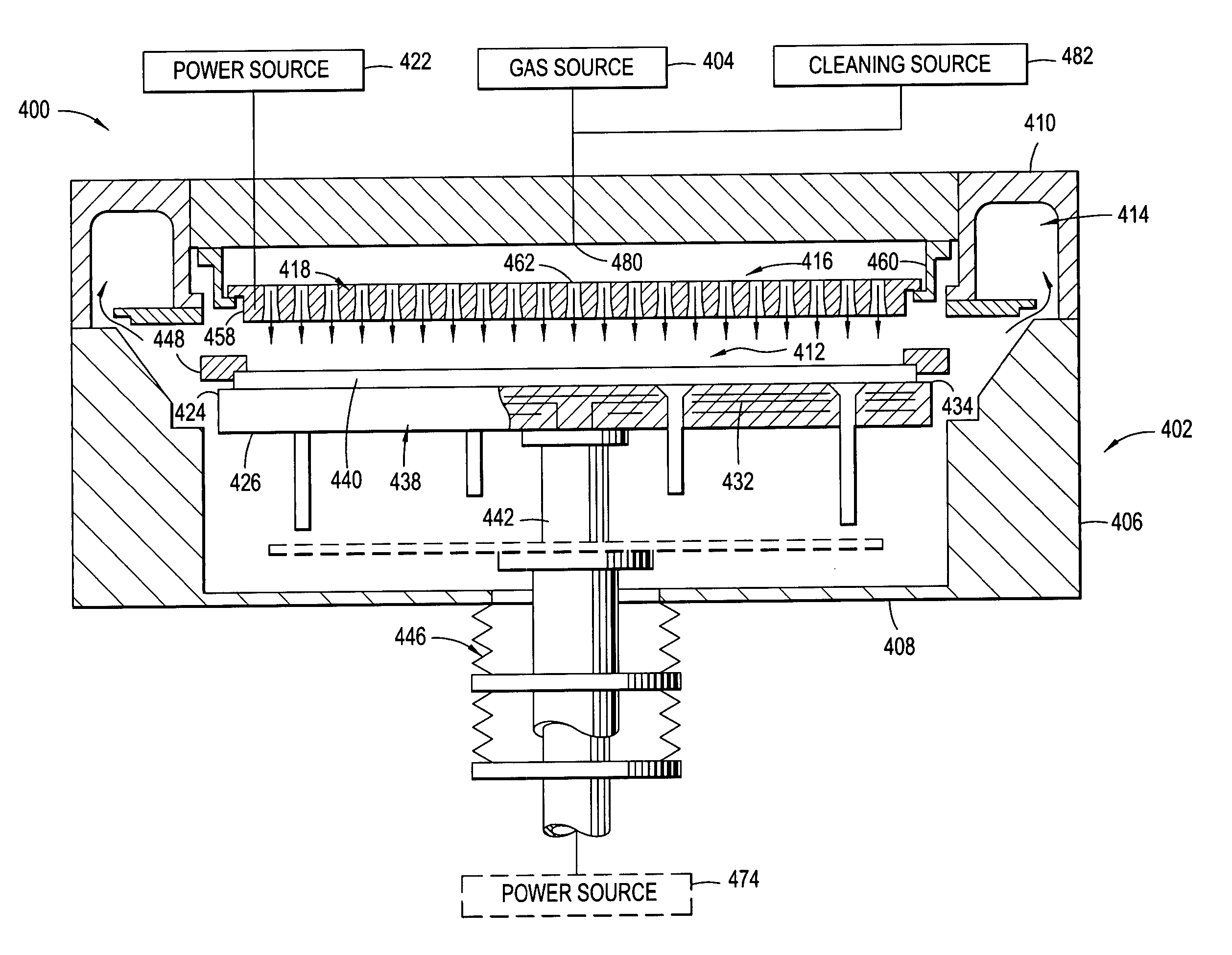

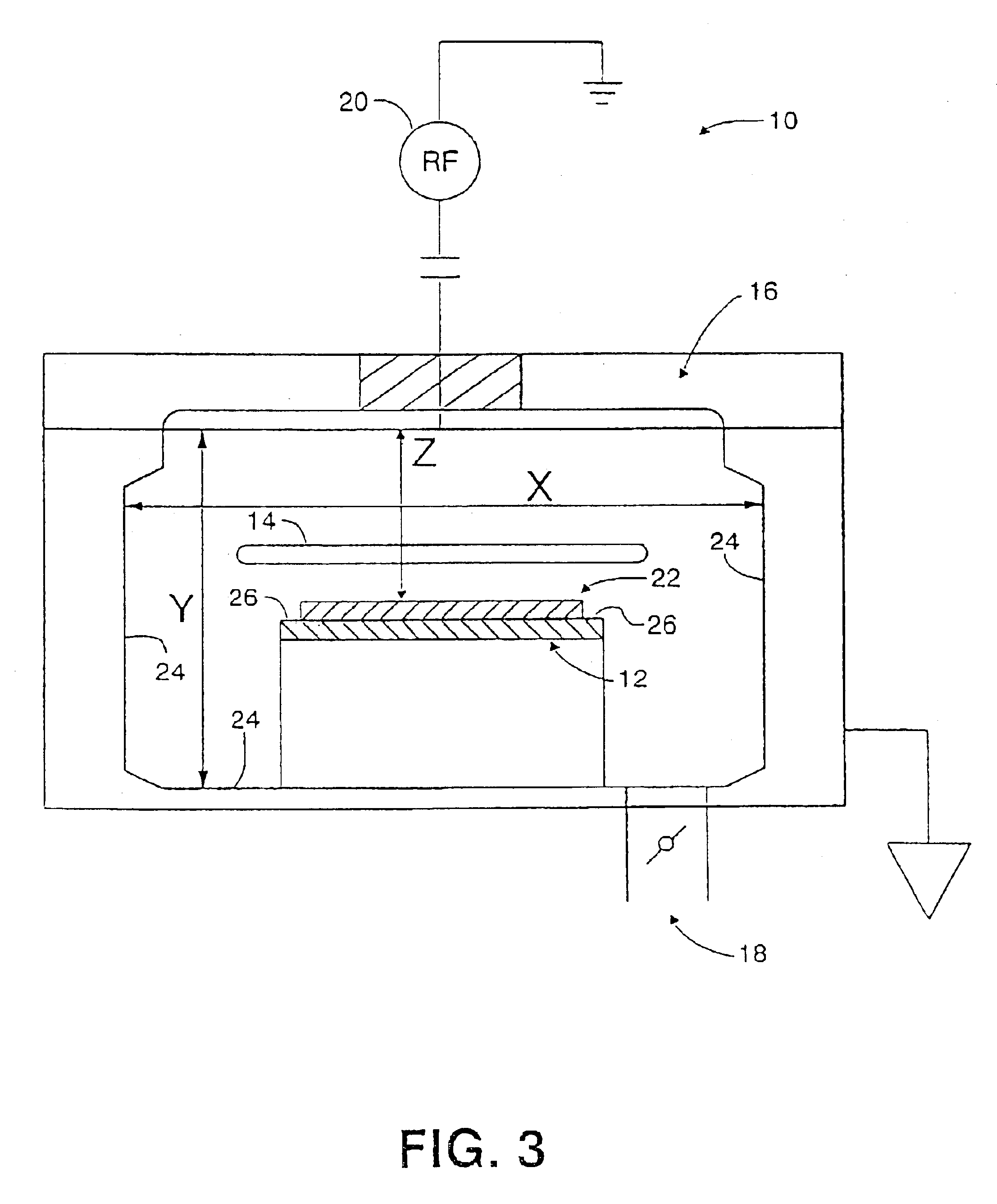

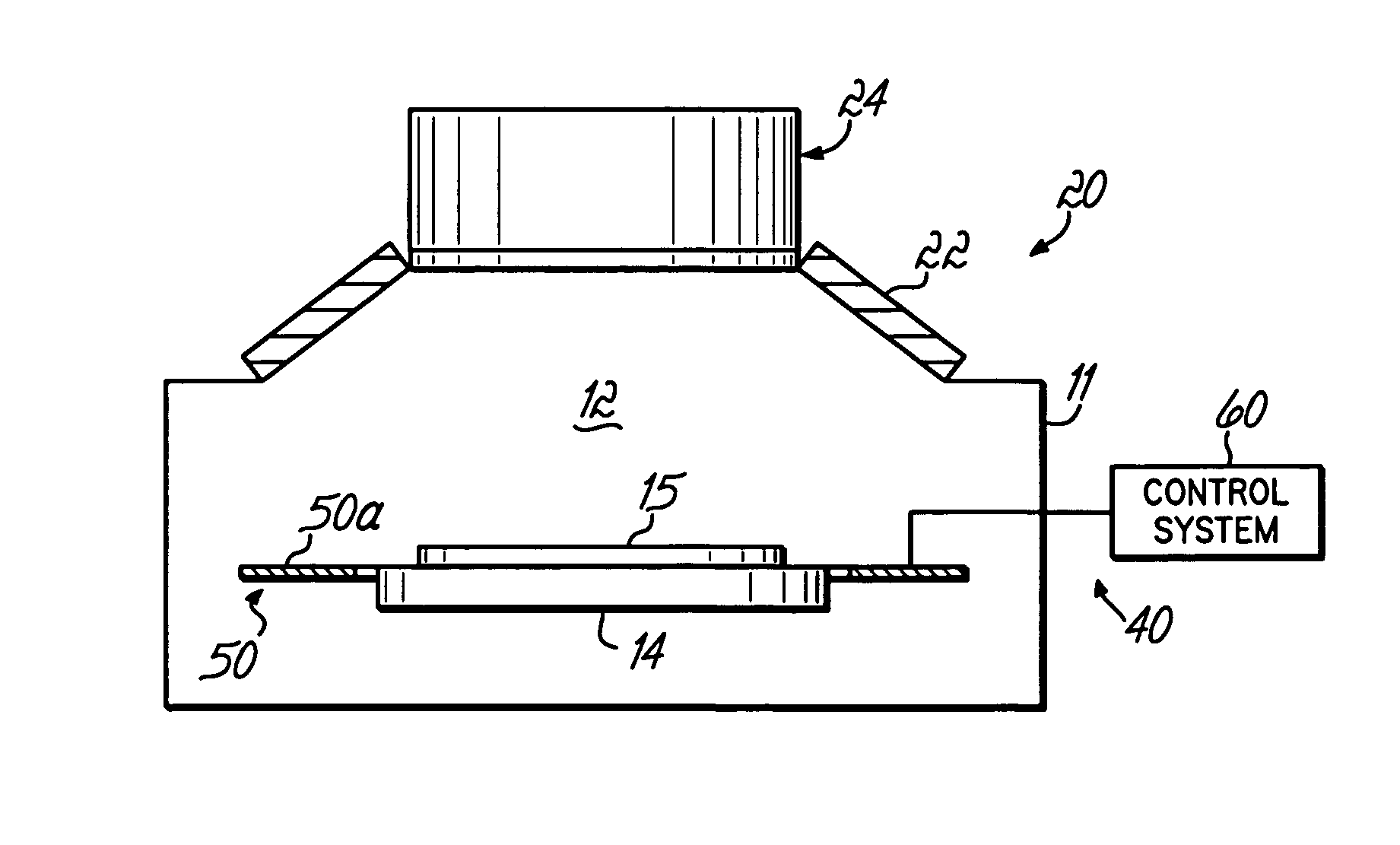

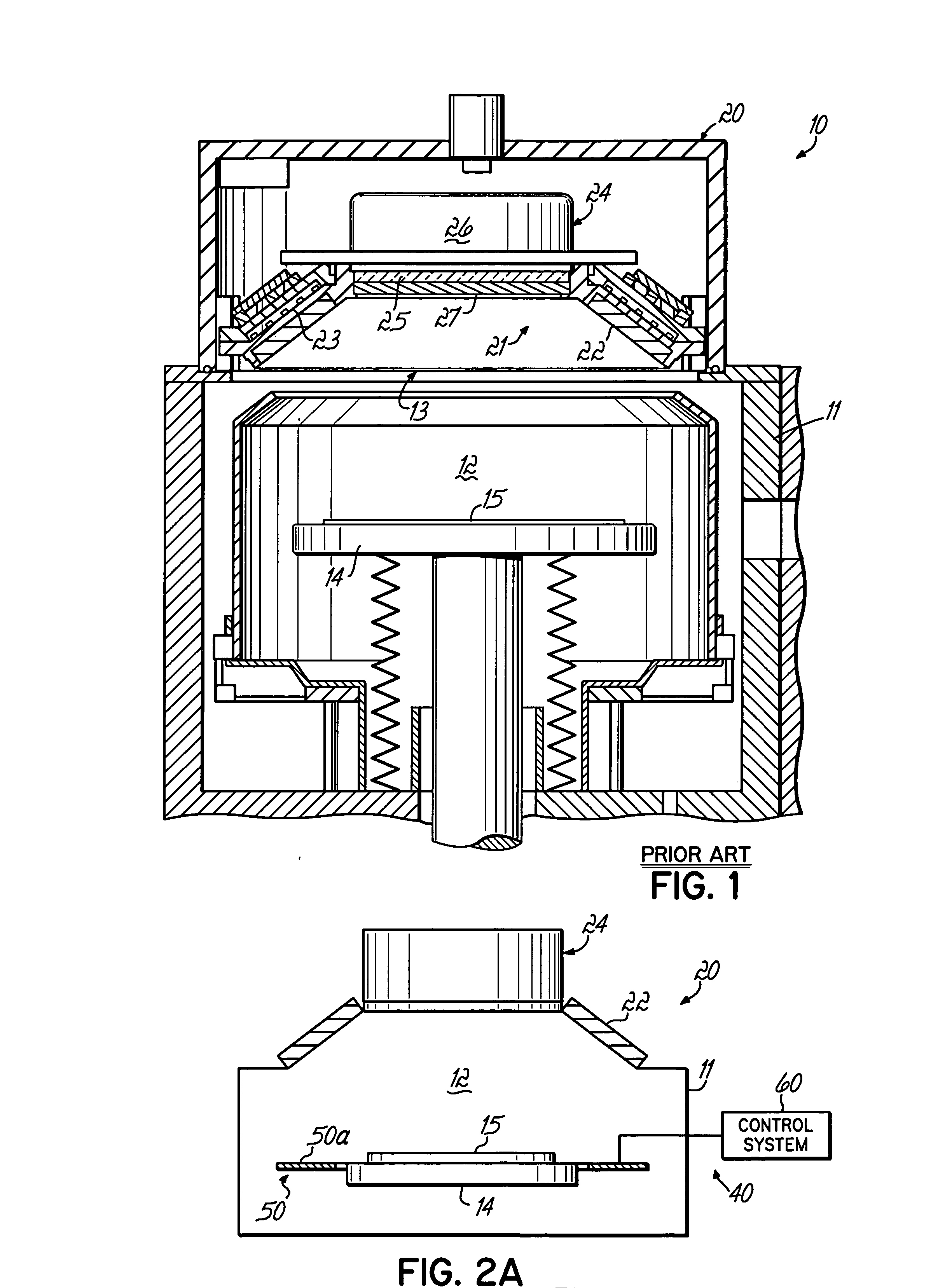

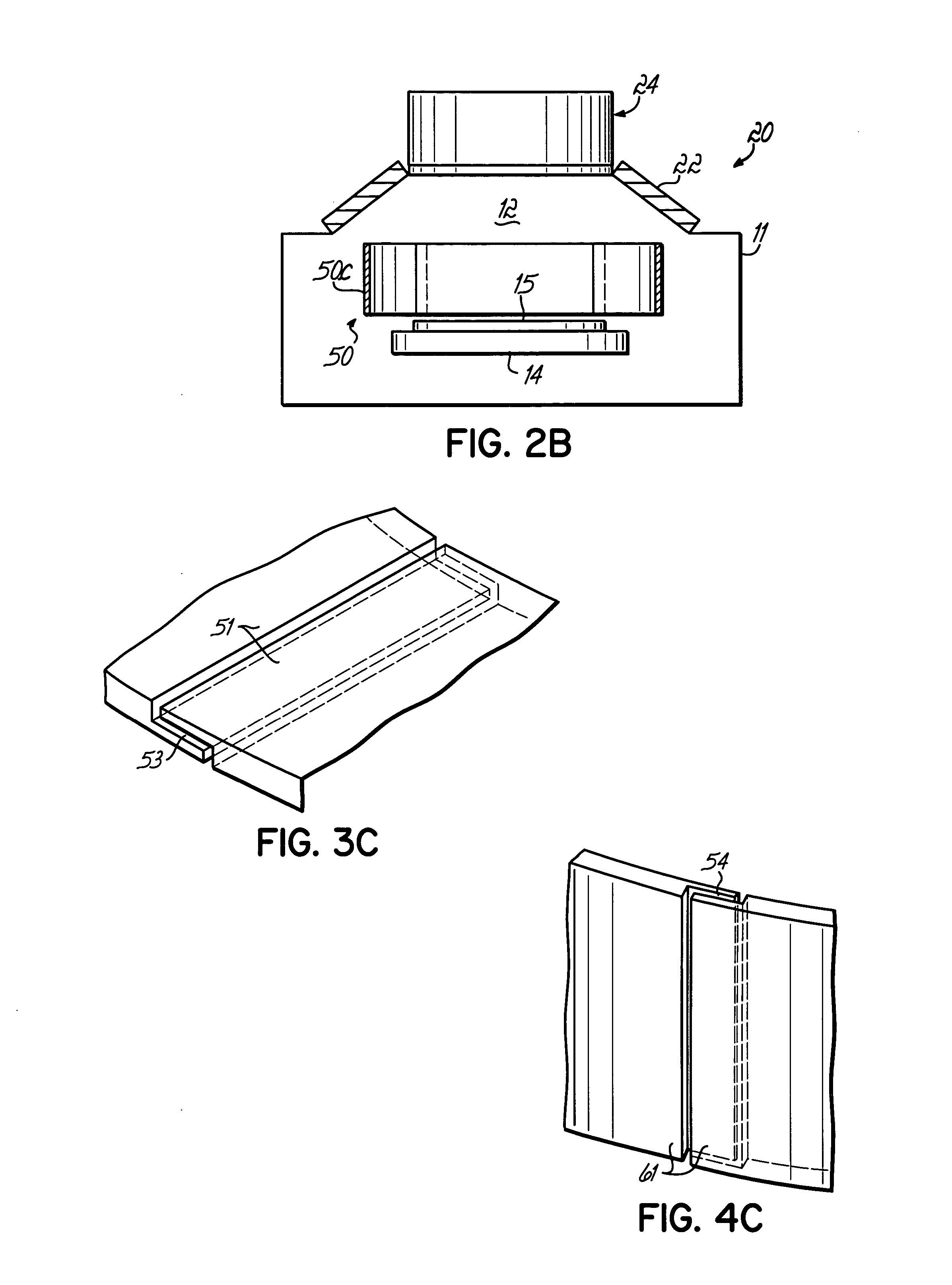

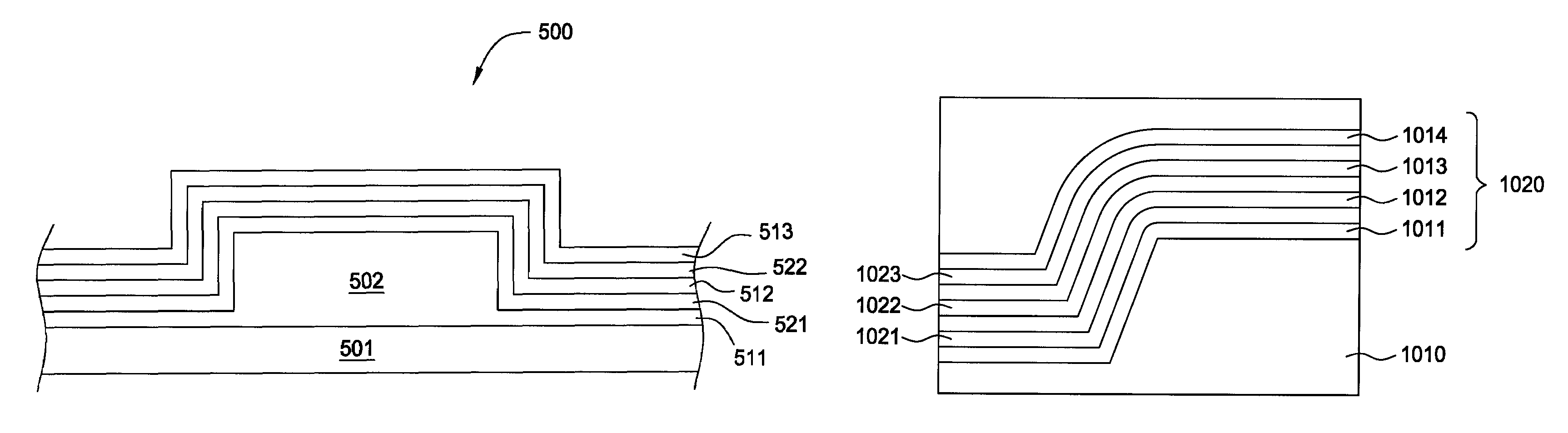

Dynamic wafer leveling/tilting/swiveling during a chemical vapor deposition process

ActiveUS20170309528A1Good film uniformityImprove the deposition effectSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingGas phaseDegrees of freedom

The implementations described herein generally relate to the dynamic, real-time control of the process spacing between a substrate support and a gas distribution medium during a deposition process. Multiple dimensional degrees of freedom are utilized to change the angle and spacing of the substrate plane with respect to the gas distributing medium at any time during the deposition process. As such, the substrate and / or substrate support may be leveled, tilted, swiveled, wobbled, and / or moved during the deposition process to achieve improved film uniformity. Furthermore, the independent tuning of each layer may be had due to continuous variations in the leveling of the substrate plane with respect to the showerhead to average effective deposition on the substrate, thus improving overall stack deposition performance.

Owner:APPLIED MATERIALS INC

Substrate supporting structure for semiconductor processing, and plasma processing device

InactiveUS7837828B2Low costGood film uniformitySleeve/socket jointsElectric discharge tubesTemperature controlHigh frequency power

A substrate supportingstructure (50) for semiconductor processing, comprising a mounting table (51) for placing a processed substrate (W) disposed in a processing chamber (20), wherein temperature control spaces (507) for storing the fluid used as a heat exchange medium are formed in the mounting table (51), a conductive transmission path (502) is disposed to lead a high frequency power to the mounting table (51), and flow channels (505, 506) feeding or discharging the heat exchange medium fluid to or from the temperature control spaces (507) are formed in the transmission path (502).

Owner:TOKYO ELECTRON LTD

Shower plate structure for exhausting deposition inhibiting gas

ActiveUS20180171472A1Simple structureGood film uniformityLiquid surface applicatorsElectric discharge tubesPlasma depositionEngineering

A shower plate adapted to be installed in a plasma deposition apparatus including a gas inlet port, a shower head, a reaction chamber and an exhaust duct, the shower plate being adapted to be attached to the showerhead and having: a front surface adapted to face the gas inlet port; and a rear surface opposite to the front surface, wherein the shower plate has multiple apertures each extending from the front surface to the rear surface, and wherein the shower plate further has at least one aperture extending from the front surface side of the shower plate to the exhaust duct.

Owner:ASM IP HLDG BV

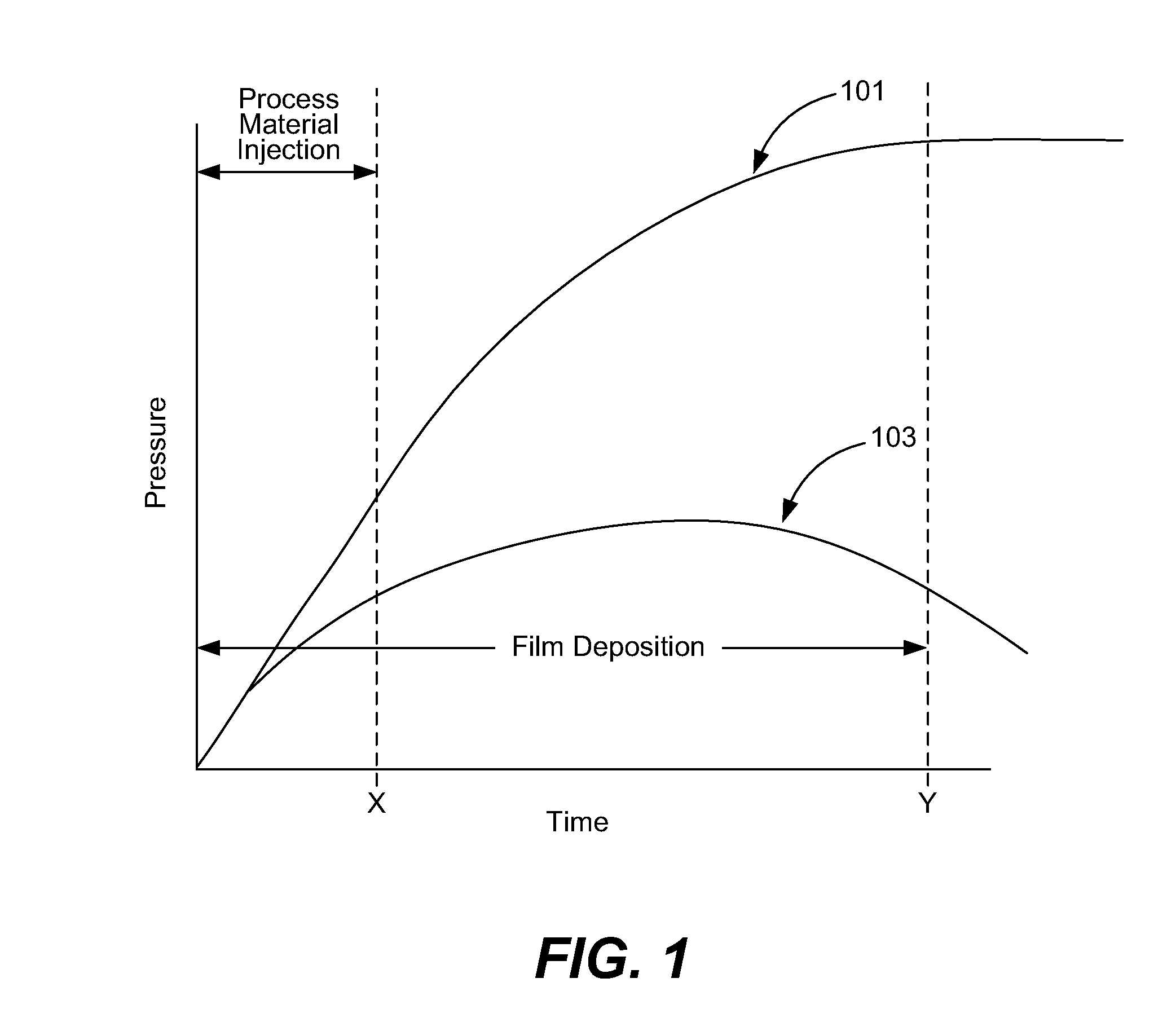

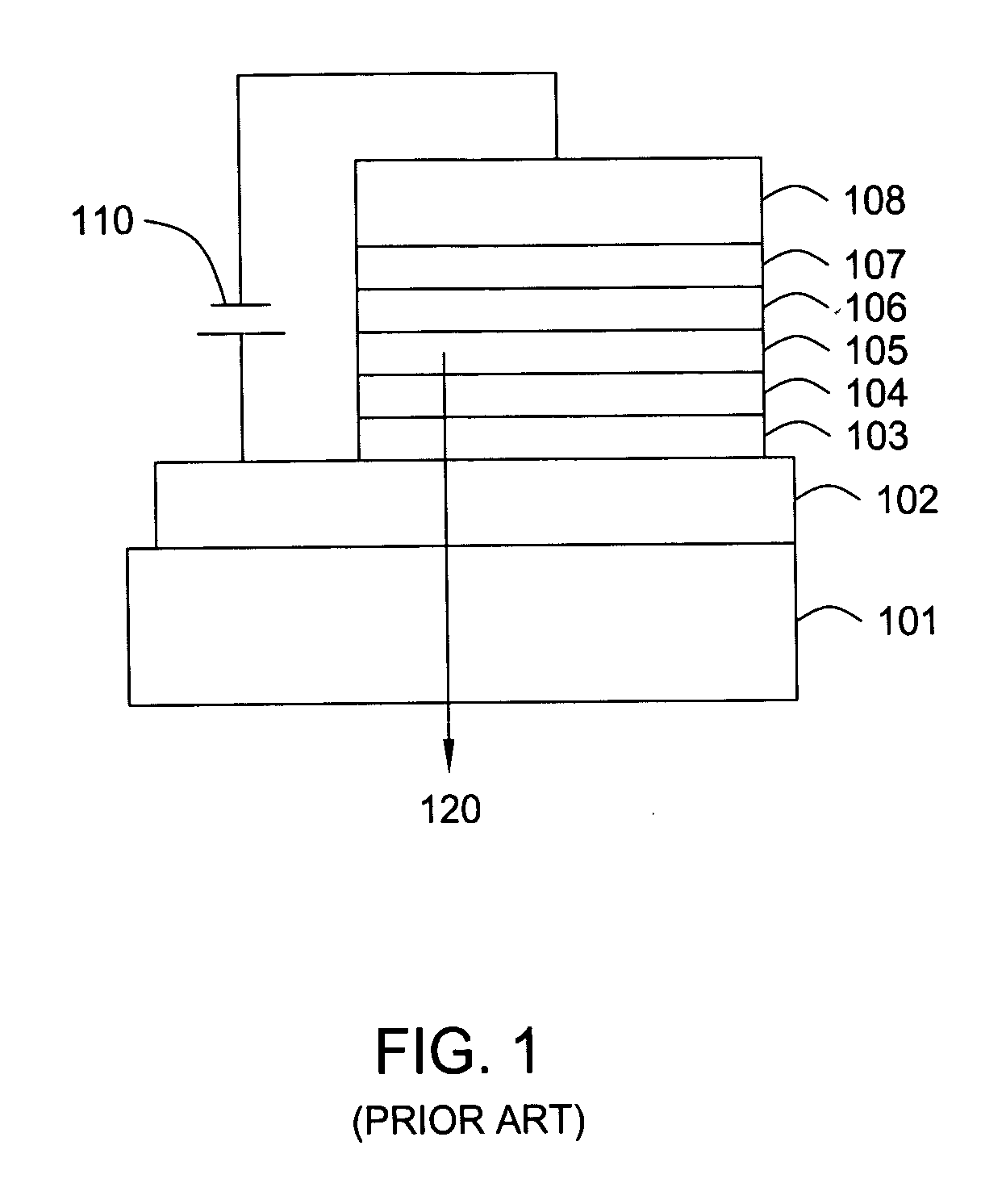

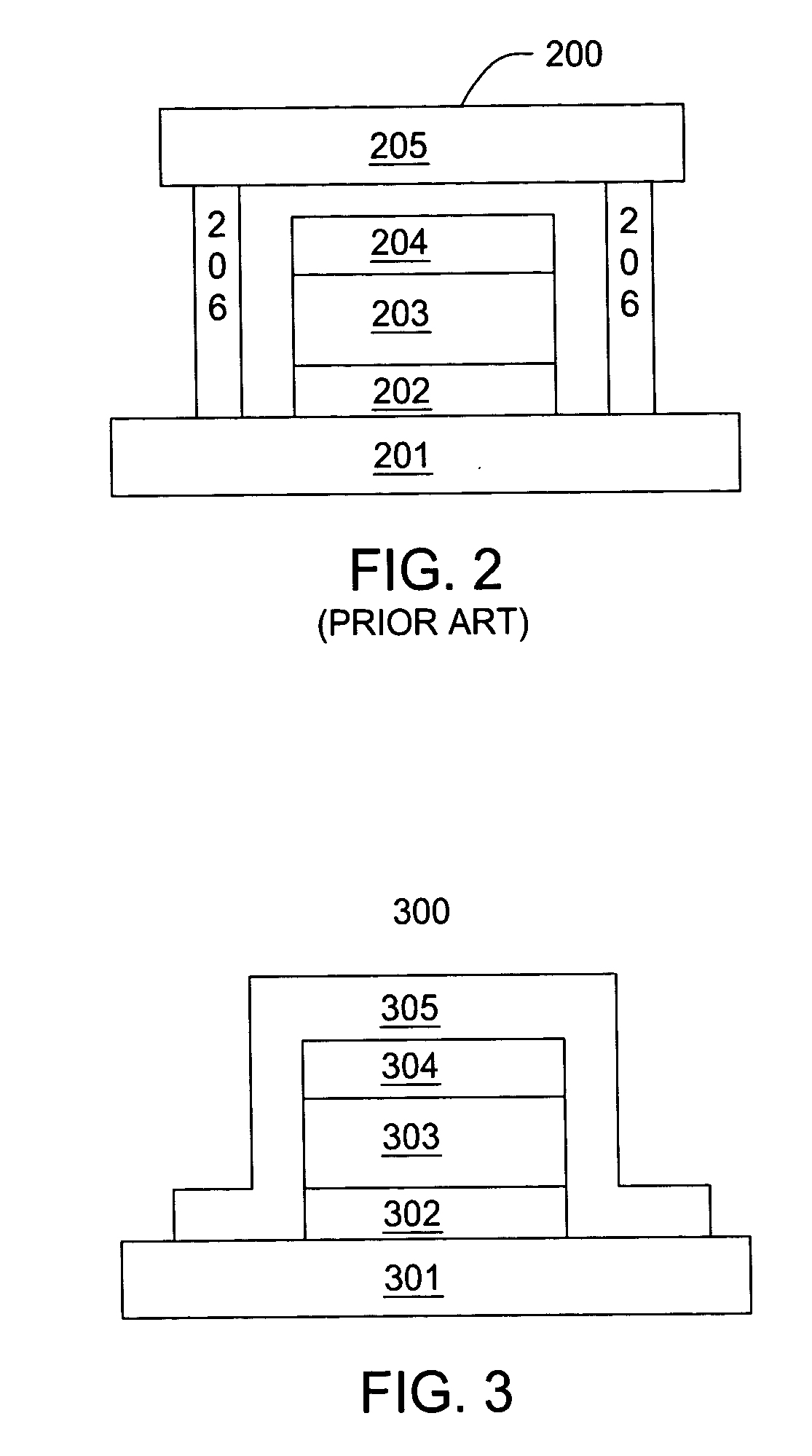

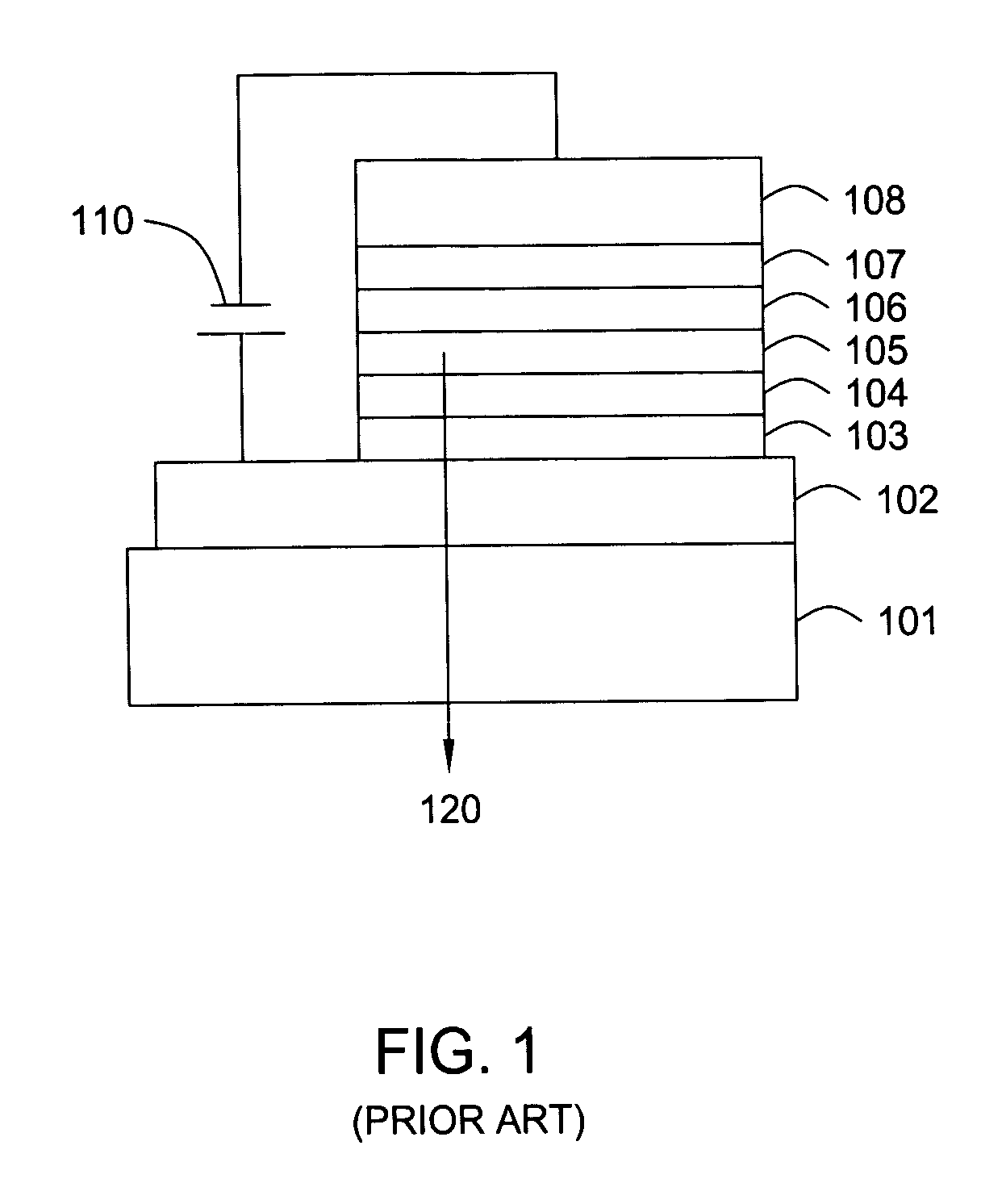

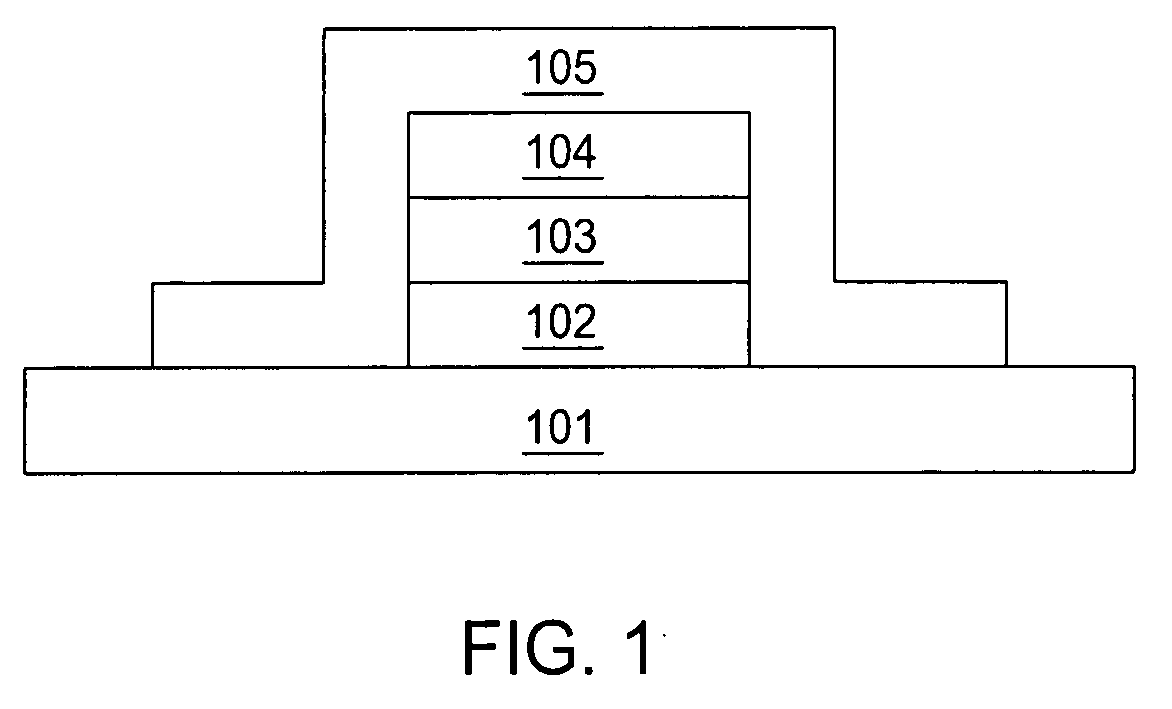

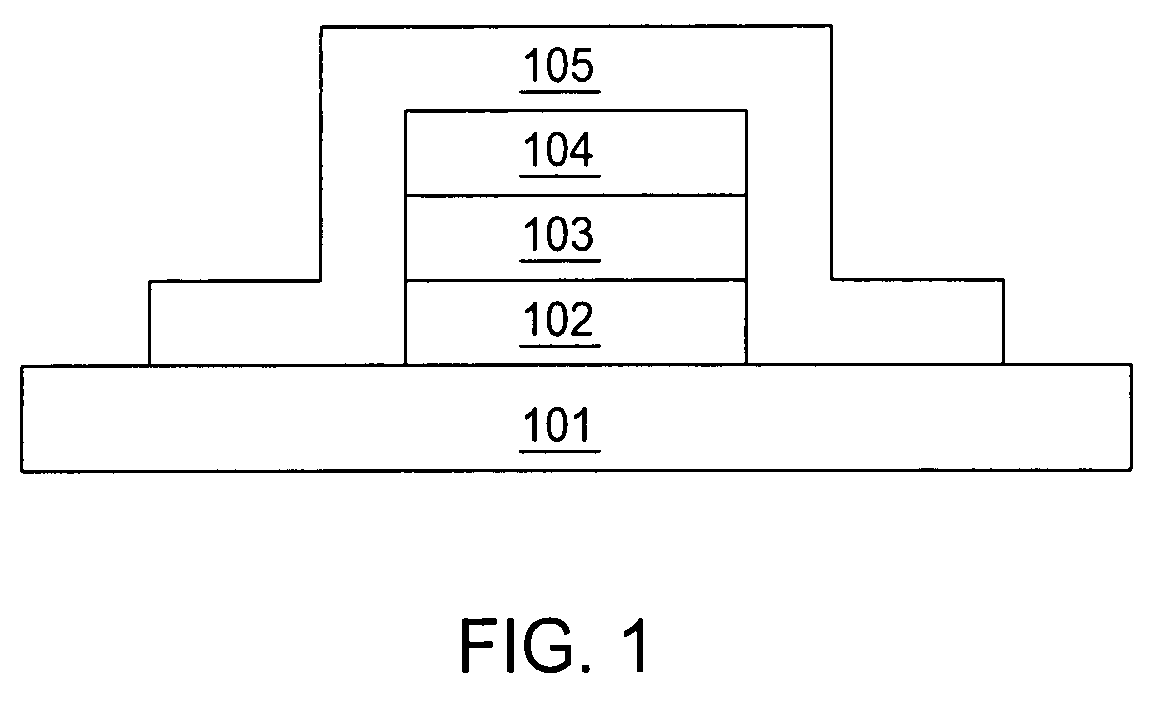

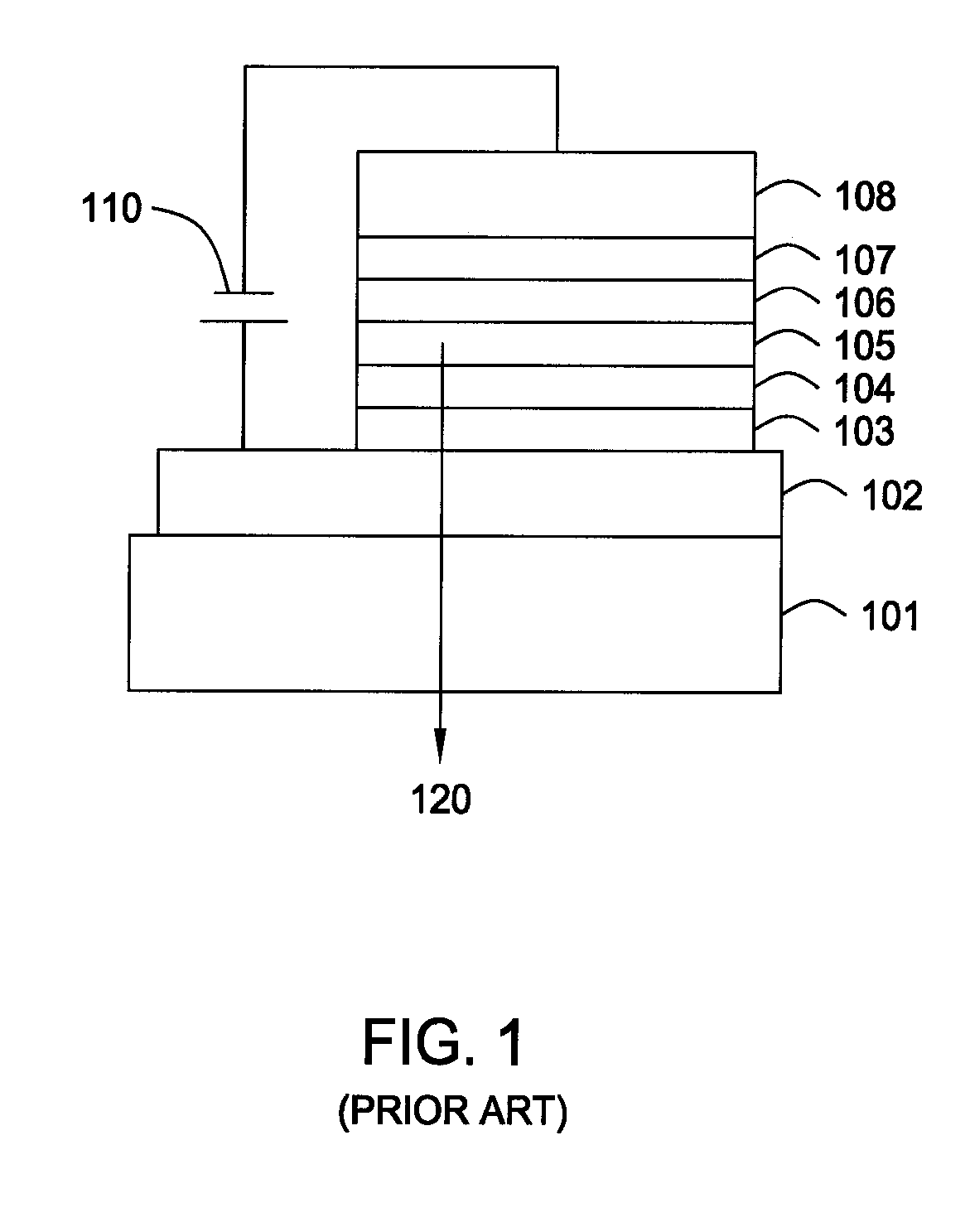

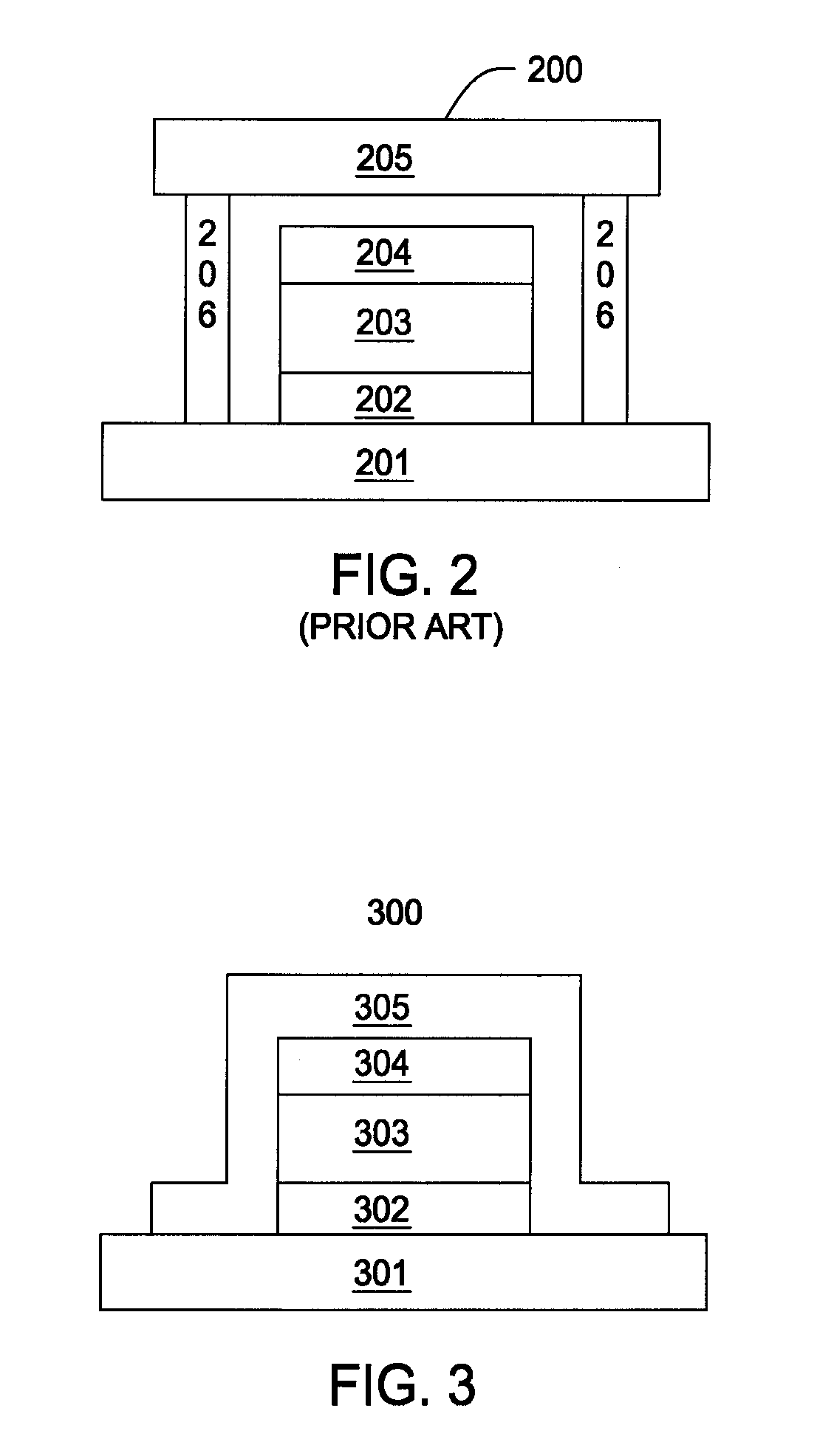

Water-barrier performance of an encapsulating film

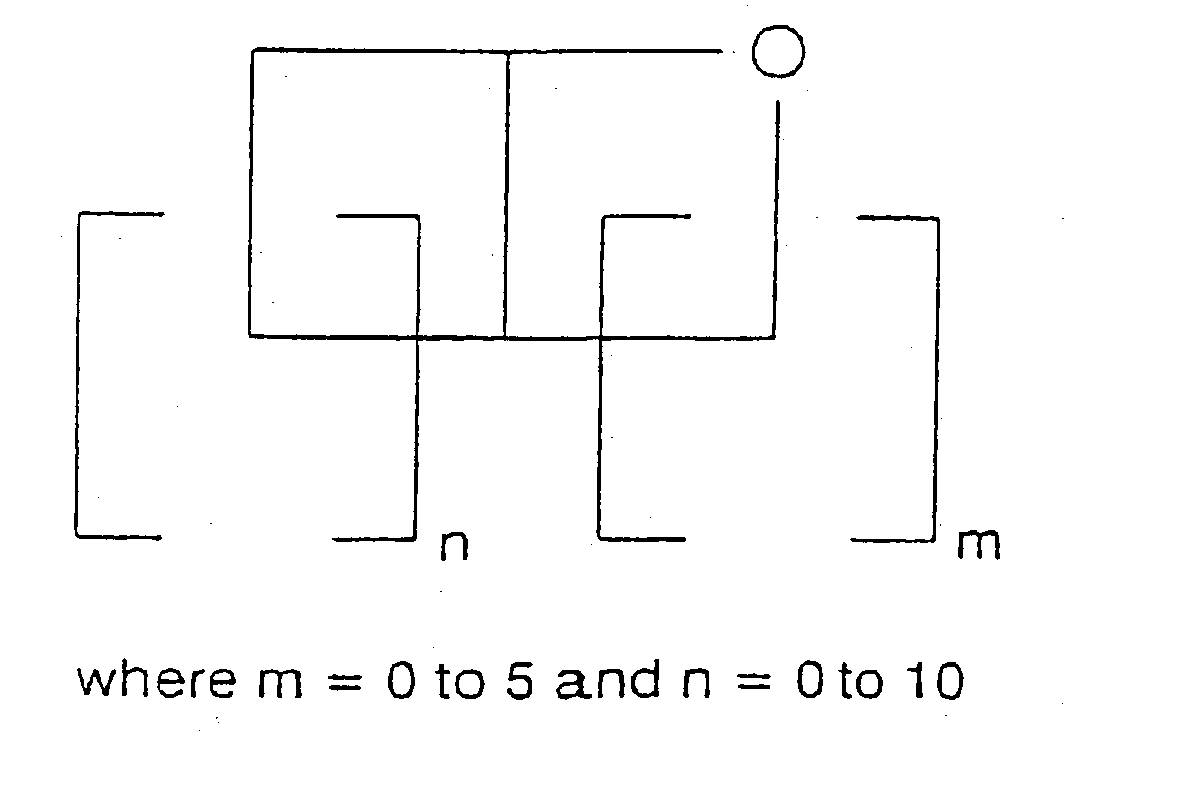

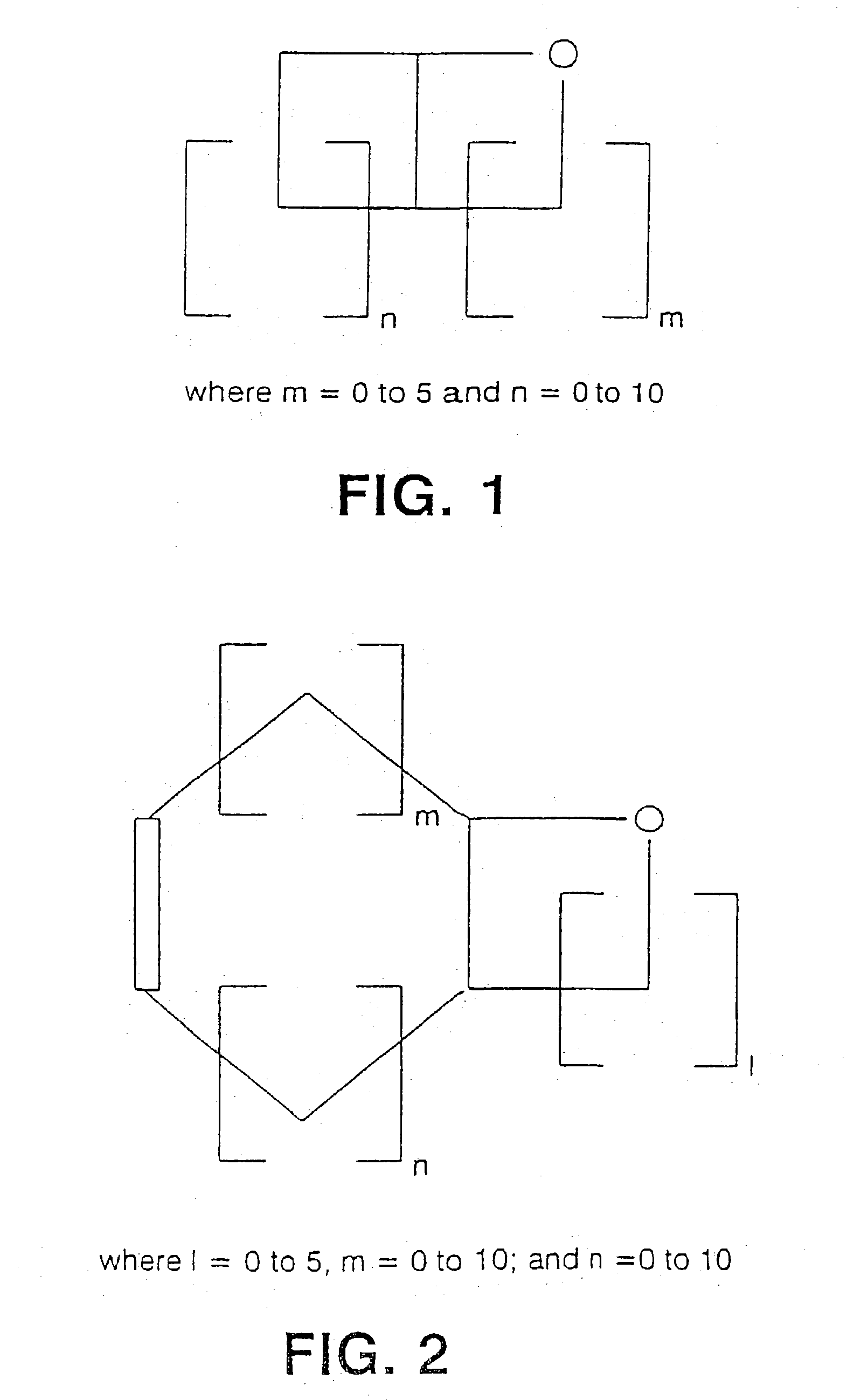

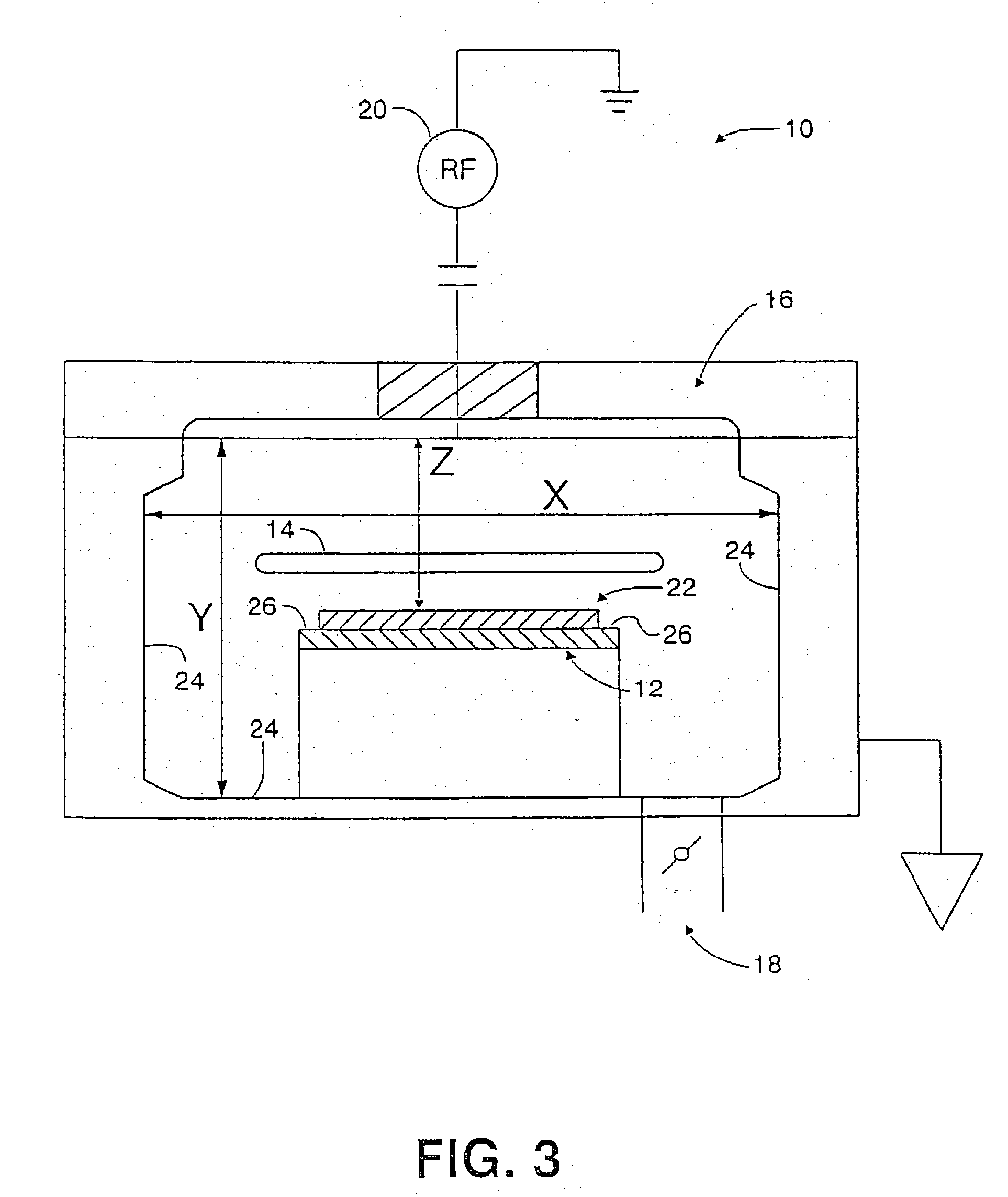

ActiveUS20050287688A1Improve waterproof performanceGood film uniformitySemiconductor/solid-state device manufacturingSolid state diffusion coatingLow temperature depositionSubstrate type

A method and apparatus for depositing a material layer onto a substrate is described. The method includes delivering a mixture of precursors for the material layer into a process chamber and depositing the material layer on the substrate at low temperature. The material layer can be used as an encapsulating layer for various display applications which require low temperature deposition process due to thermal instability of underlying materials used. In one aspect, the encapsulating layer includes one or more material layers (multilayer) having one or more barrier layer materials and one or more low-dielectric constant materials. The encapsulating layer thus deposited provides reduced surface roughness, improved water-barrier performance, reduce thermal stress, good step coverage, and can be applied to many substrate types and many substrate sizes. Accordingly, the encapsulating layer thus deposited provides good device lifetime for various display devices, such as OLED devices. In another aspect, a method of depositing an amorphous carbon material on a substrate at low temperature is provided. The amorphous carbon material can be used to reduce thermal stress and prevent the deposited thin film from peeling off the substrate.

Owner:APPLIED MATERIALS INC

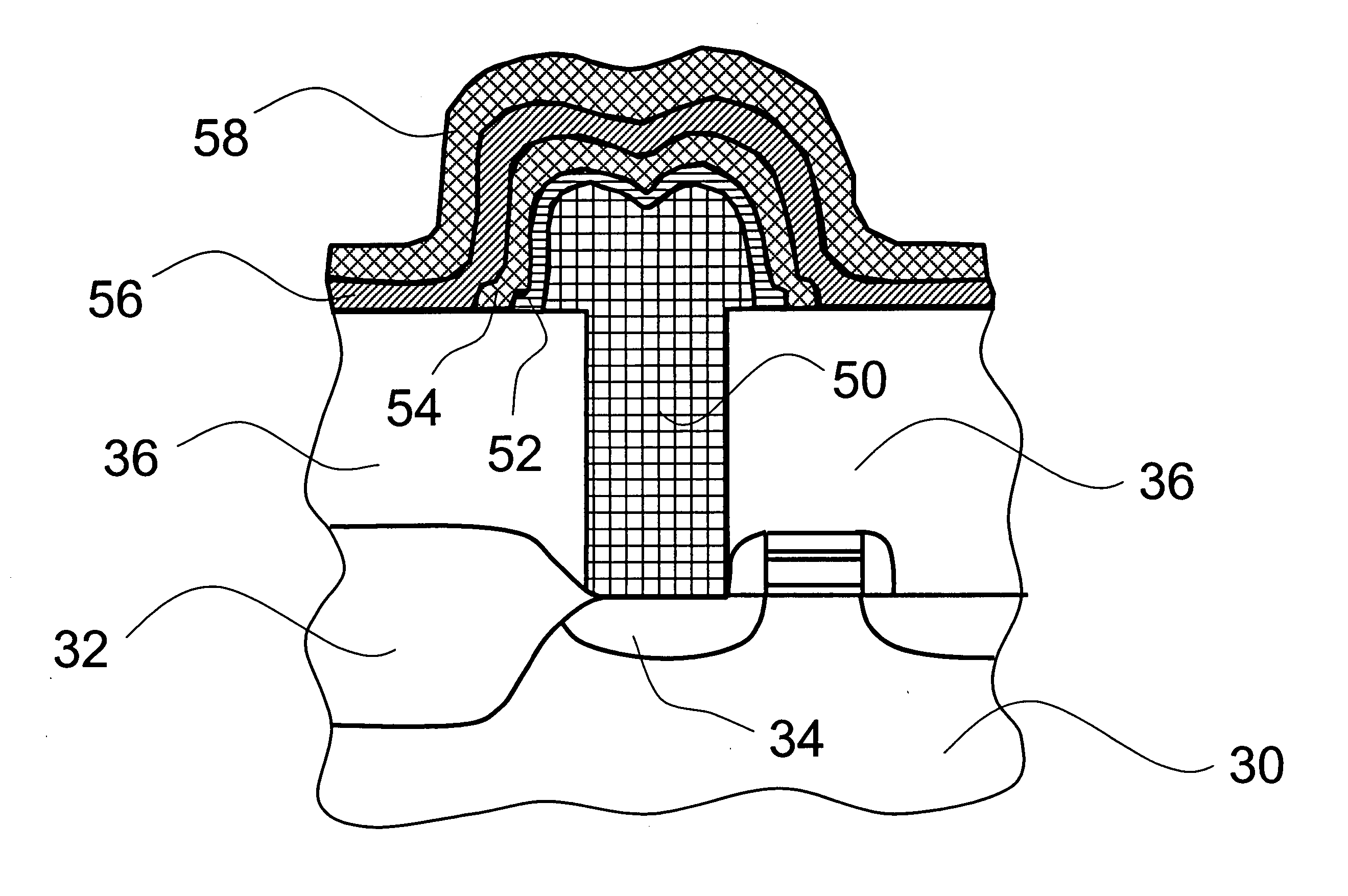

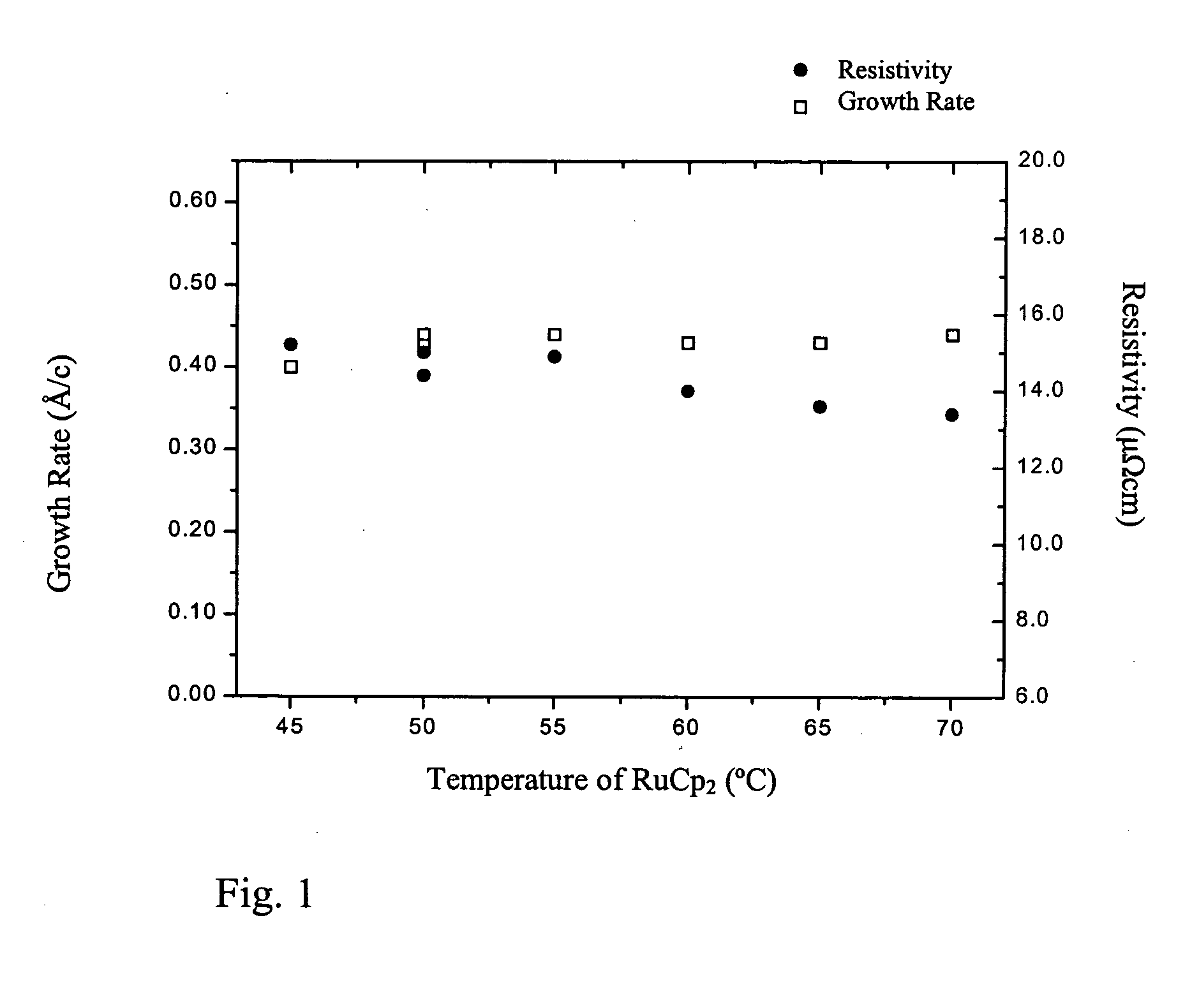

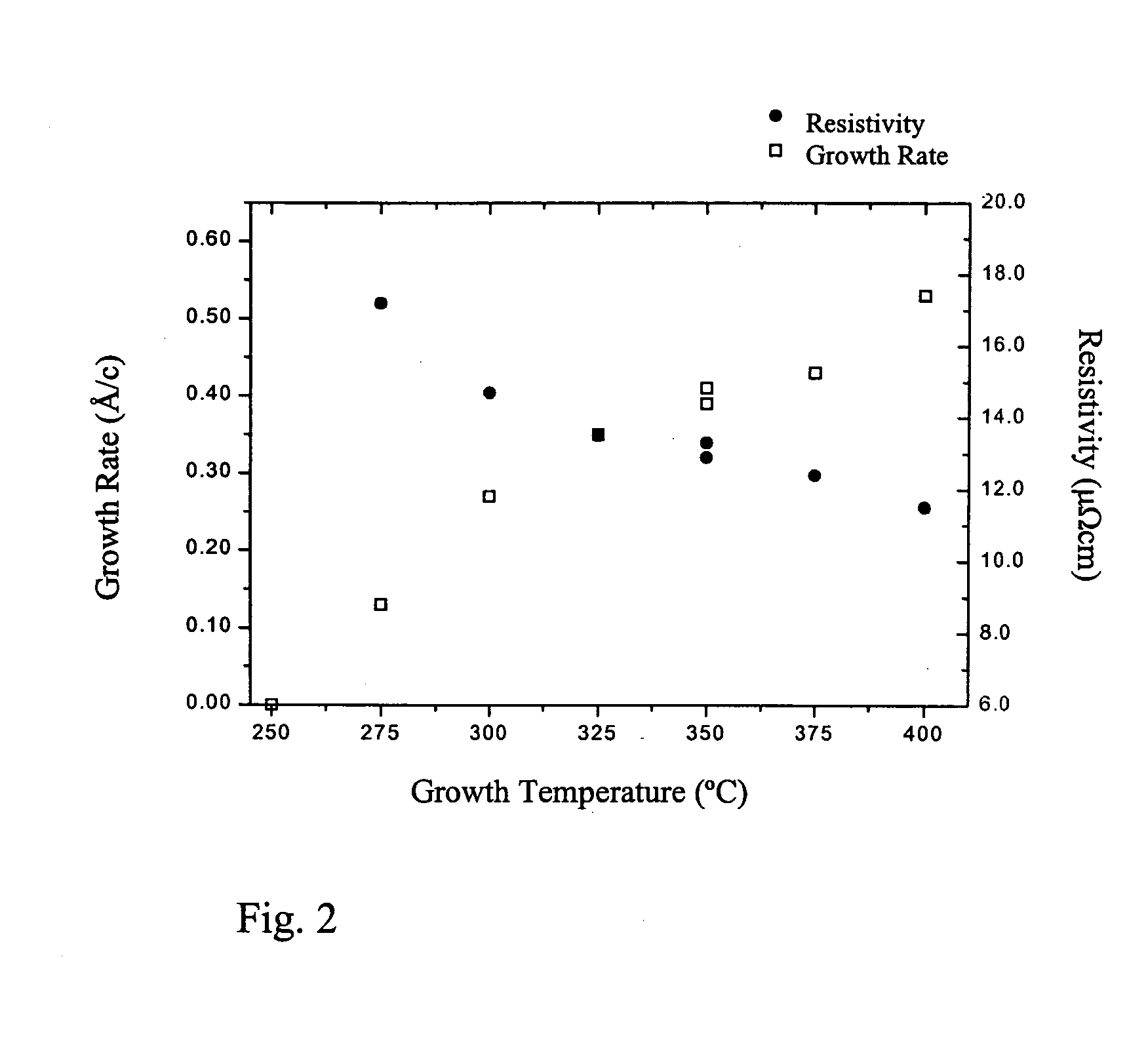

Process for producing metal thin films by ALD

InactiveUS20050020060A1Promote nucleationGood film uniformityNanomagnetismSolid-state devicesHigh elevationSurface structure

The invention relates generally to processes for producing electrically conductive noble metal thin films on a substrate by atomic layer deposition. According to one embodiment of the invention a substrate with a surface is provided in a reaction chamber and a vaporised precursor of a noble metal is pulsed into the reaction chamber. By contacting the vaporised precursor with the surface of the substrate, no more than about a molecular layer of the metal precursor is formed on the substrate. In a next step, a pulse of molecular oxygen-containing gas is provided in the reaction chamber, where the oxygen reacts with the precursor on the substrate. Thus, high-quality metal thin films can be deposited by utilising reactions between the metal precursor and oxygen. In one embodiment, electrically conductive layers are deposited in structures that have high aspect ratio vias and trenches, local high elevation areas or other similar surface structures that make the surface rough.

Owner:ASM INTERNATIONAL

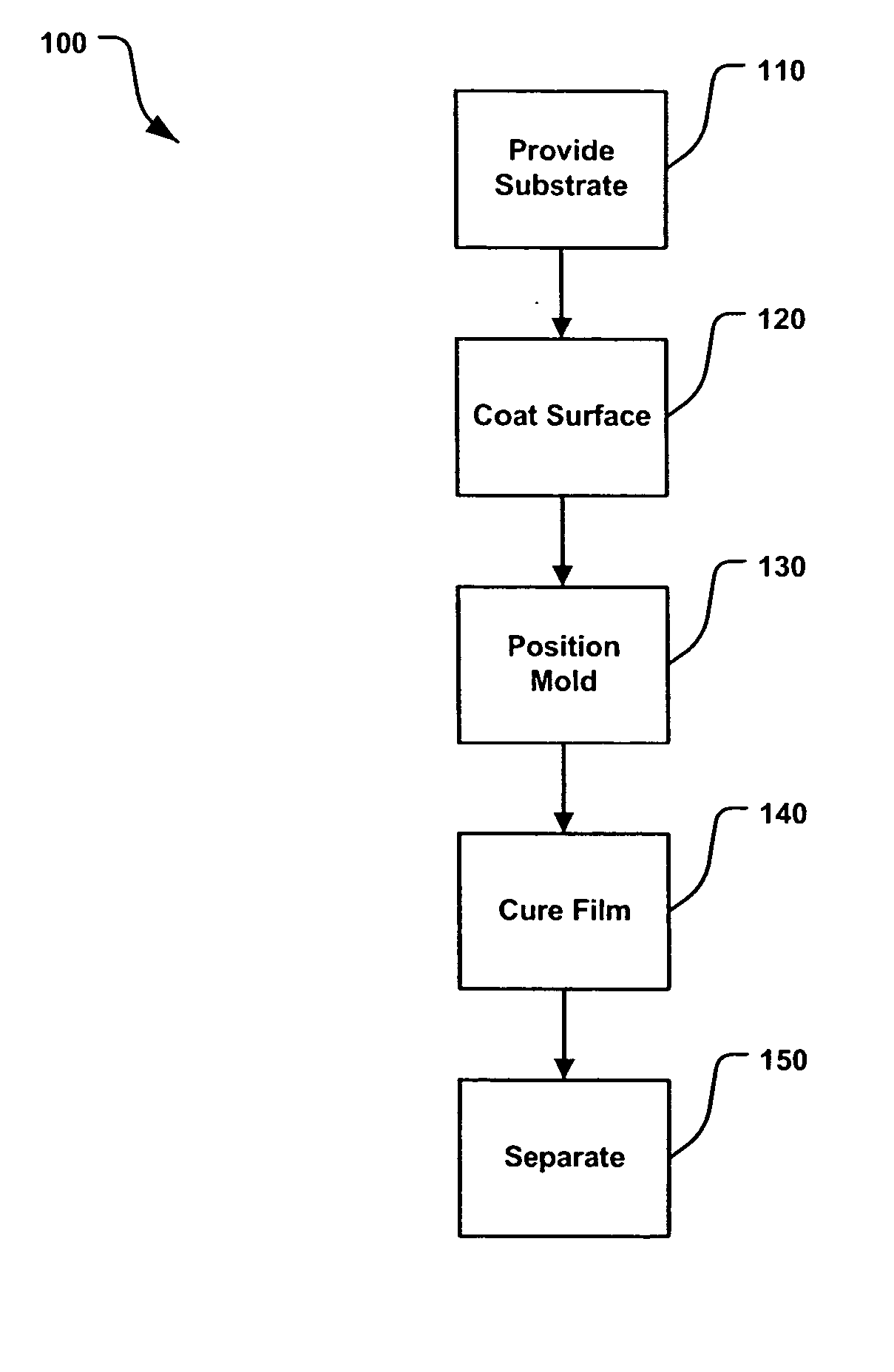

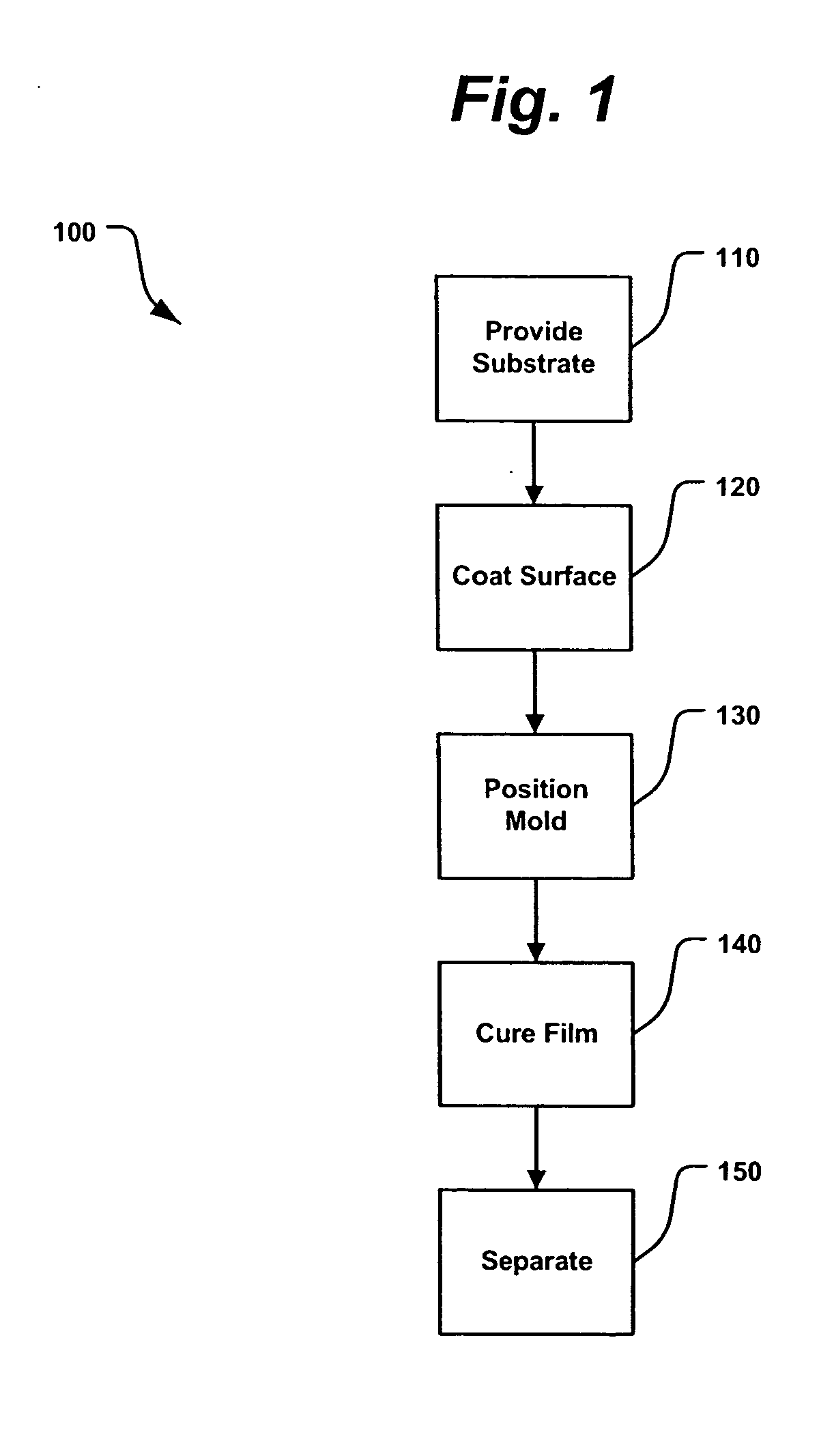

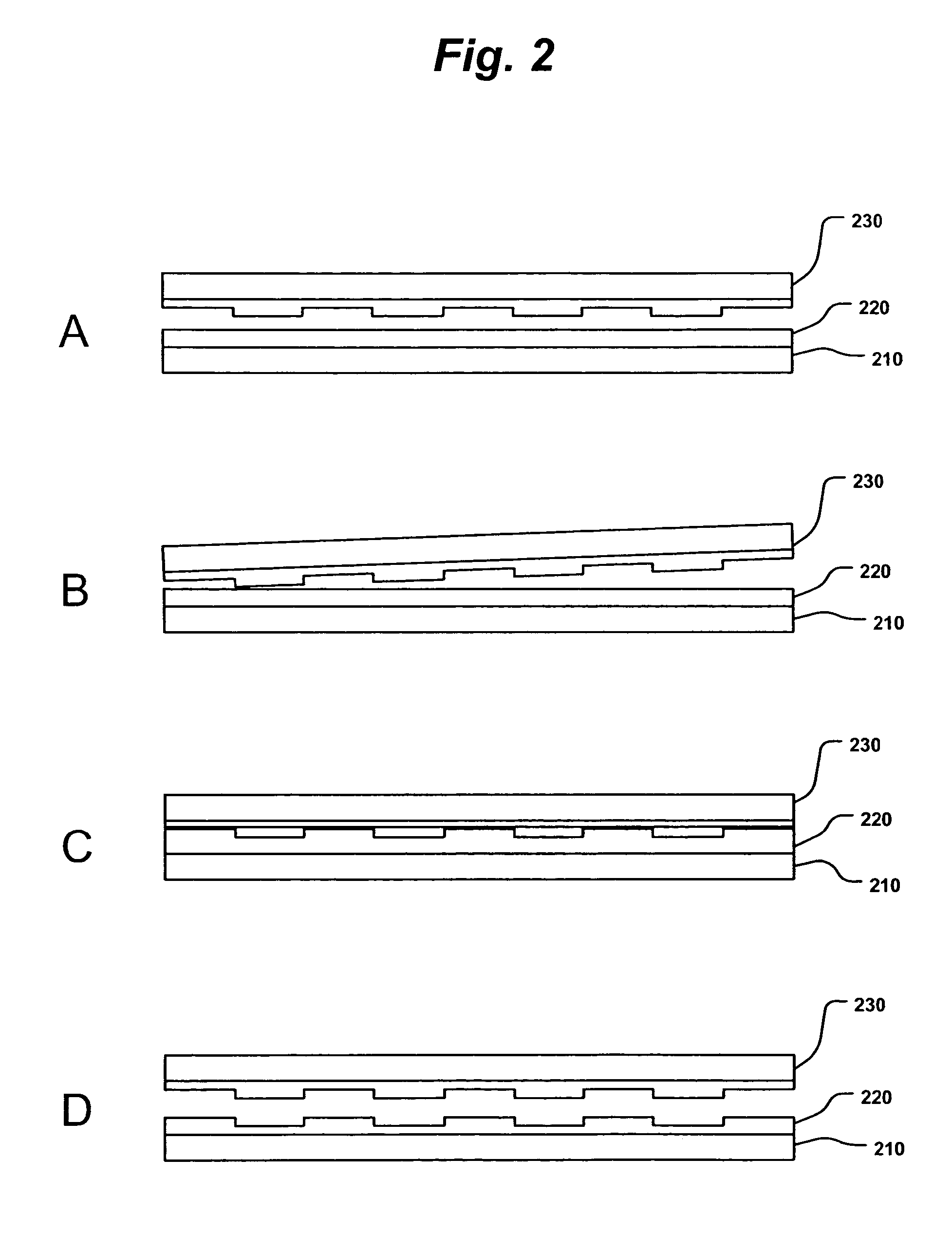

Sub-micron-scale patterning method and system

InactiveUS20050084613A1Control thicknessGood film uniformityNanoinformaticsSolid-state devicesLiquid layerMicron scale

A method for replicating a nanopattern is disclosed. This method includes identifying a substrate; coating a surface of the substrate with a liquid layer; positioning a mold having a plurality of recesses defining a negative of the nanopattern in sufficient proximity with the coated liquid layer to cause the liquid layer to self-fill at least a portion of the plurality of recesses of the mold; and, chemically transforming the liquid layer to enable the transformed film to substantially retain the nanopattern.

Owner:WANG JIAN +2

Water-barrier performance of an encapsulating film

ActiveUS7183197B2Improve waterproof performanceGood film uniformityTransistorSemiconductor/solid-state device manufacturingLow temperature depositionSubstrate type

A method and apparatus for depositing a material layer onto a substrate is described. The method includes delivering a mixture of precursors for the material layer into a process chamber and depositing the material layer on the substrate at low temperature. The material layer can be used as an encapsulating layer for various display applications which require low temperature deposition process due to thermal instability of underlying materials used. In one aspect, the encapsulating layer includes one or more material layers (multilayer) having one or more barrier layer materials and one or more low-dielectric constant materials. The encapsulating layer thus deposited provides reduced surface roughness, improved water-barrier performance, reduce thermal stress, good step coverage, and can be applied to many substrate types and many substrate sizes. Accordingly, the encapsulating layer thus deposited provides good device lifetime for various display devices, such as OLED devices. In another aspect, a method of depositing an amorphous carbon material on a substrate at low temperature is provided. The amorphous carbon material can be used to reduce thermal stress and prevent the deposited thin film from peeling off the substrate.

Owner:APPLIED MATERIALS INC

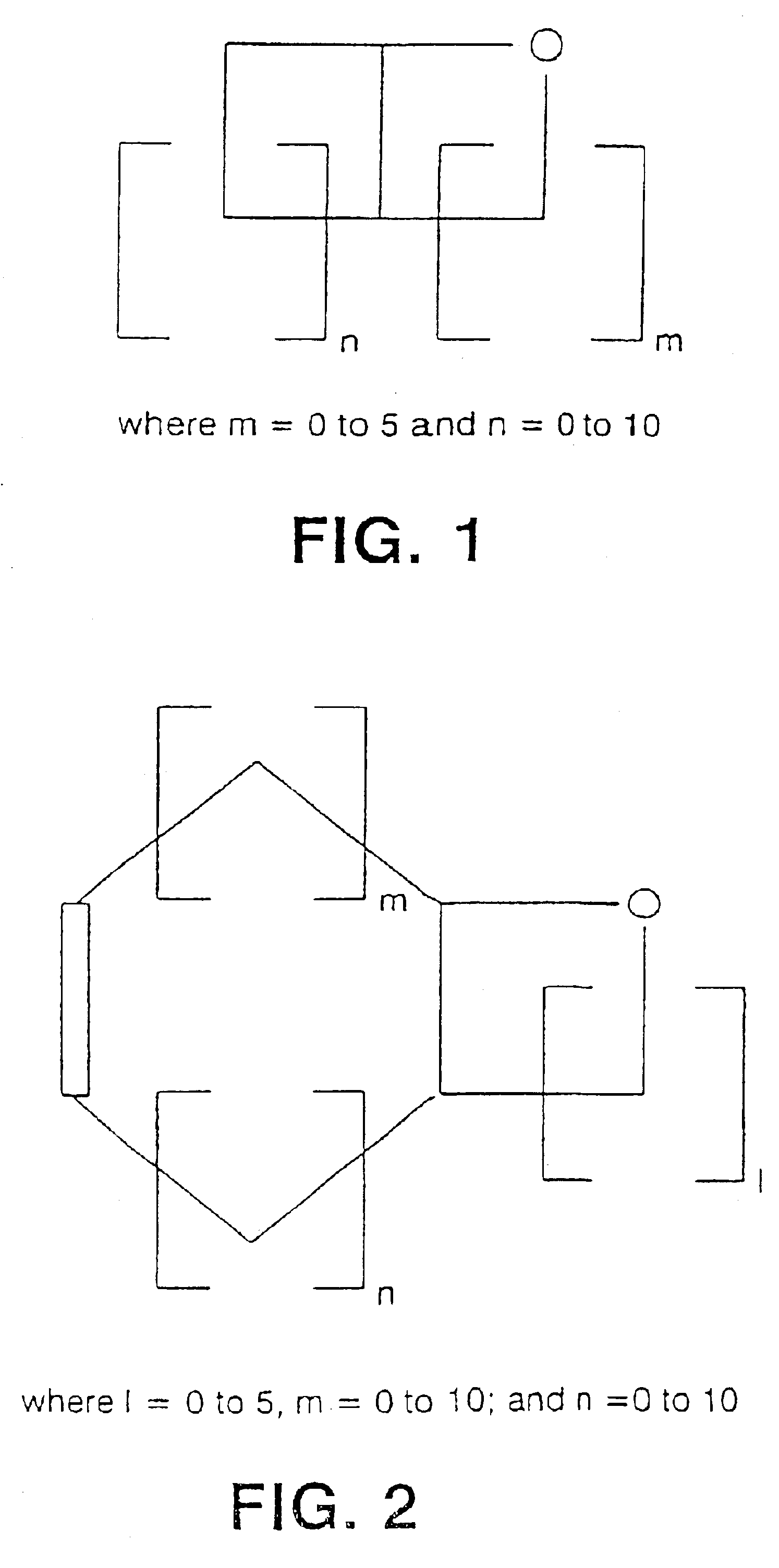

Method for fabricating an ultralow dielectric constant material

InactiveUS6770573B2Increase depositionSimple methodSemiconductor/solid-state device detailsSolid-state devicesParallel plateGas phase

A method for fabricating a thermally stable ultralow dielectric constant film comprising Si, C, O and H atoms in a parallel plate chemical vapor deposition process utilizing plasma enhanced chemical vapor deposition ("PECVD") process is disclosed. To enable the fabrication of thermally stable ultralow dielectric constant film, specific precursor materials are used, such as, cyclic siloxanes and organic molecules containing ring structures, for instance, tetramethylcycloterasiloxane and cyclopentene oxide. To stabilize plasma in the PECVD reactor and thereby improve uniformity of the deposited film, CO2 is added to TMCTS as a carrier gas, or CO2 or a mixture of CO2 and O2 are added to the PECVD reactor.

Owner:INTEL CORP

Segmented biased peripheral electrode in plasma processing method and apparatus

InactiveUS20070029193A1Reduce unevennessGood film uniformityCellsElectric discharge tubesPlasma treatmentPeripheral

A system and method for enhancing the plasma etch process uniformity in an ionized PVD semiconductor wafer processing system is provided. The system and method controls chamber conditions so as to produce highly uniform processing for a deposition-etch process sequence and yielding improved coverage capabilities of high aspect ratio (HAR) features when the deposition and etch steps are performed within same processing chamber. Plasma is generated and maintained by an inductively coupled plasma (ICP) source. In the deposition portions of the process, metal or other coating material is produced from a target of a PVD source. A segmented peripheral electrode surrounds the wafer at a distance from its outer edge. RF induced bias is applied to the electrode, cycling around the segment so as to subject each to a duty cycle controlled by a processor. The tendency of the etching or sputtering of the wafer surface that occurs with deposition to produce a radially selective coverage of the wafer, particularly of inside features and the flat field of the wafer, are offset by the bias electrode. A segmented biased-ring electrode is controlled to provide conditions for azimuthal improvement of etch rate and overall etch rate uniformity across the wafer.

Owner:TOKYO ELECTRON LTD

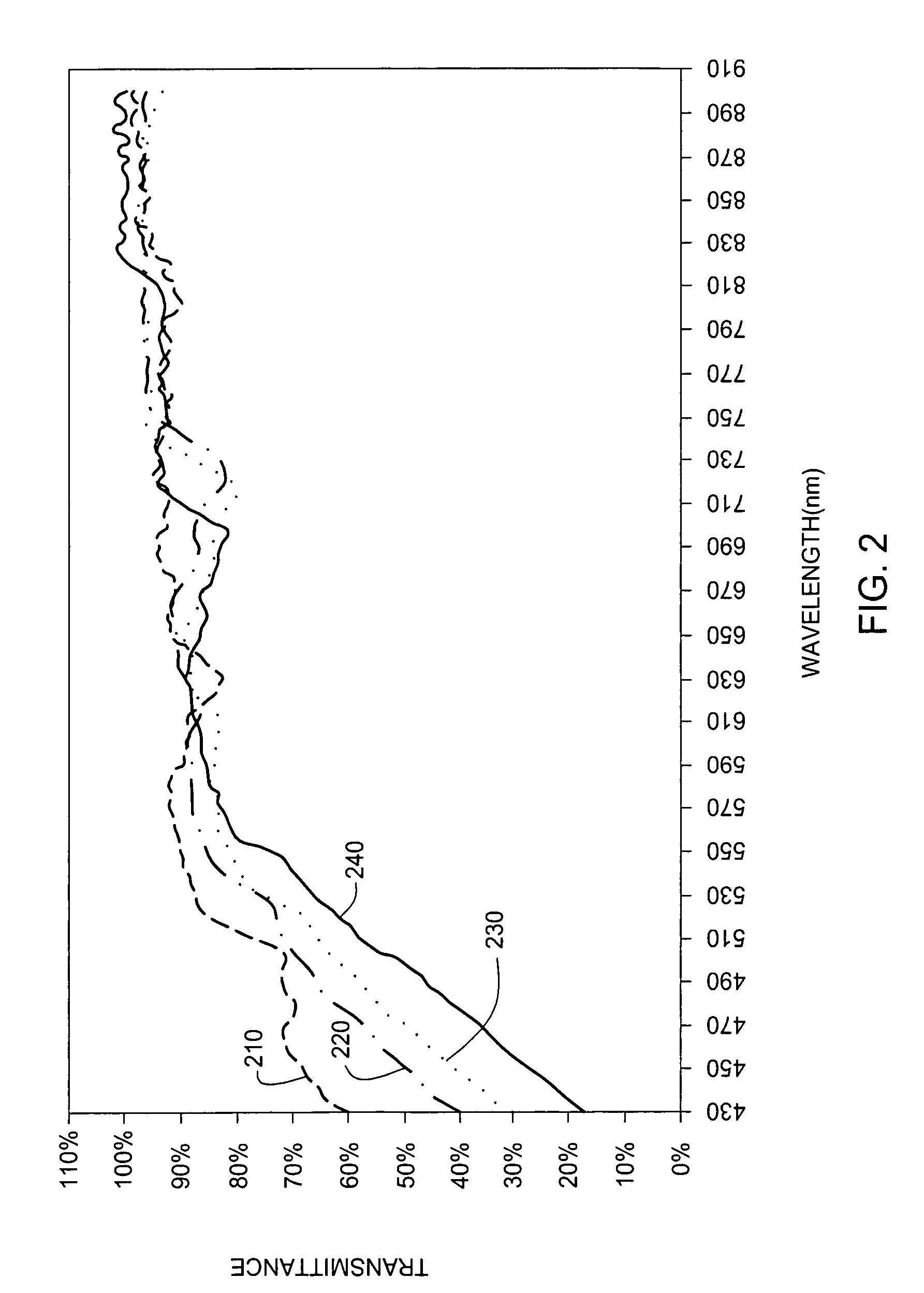

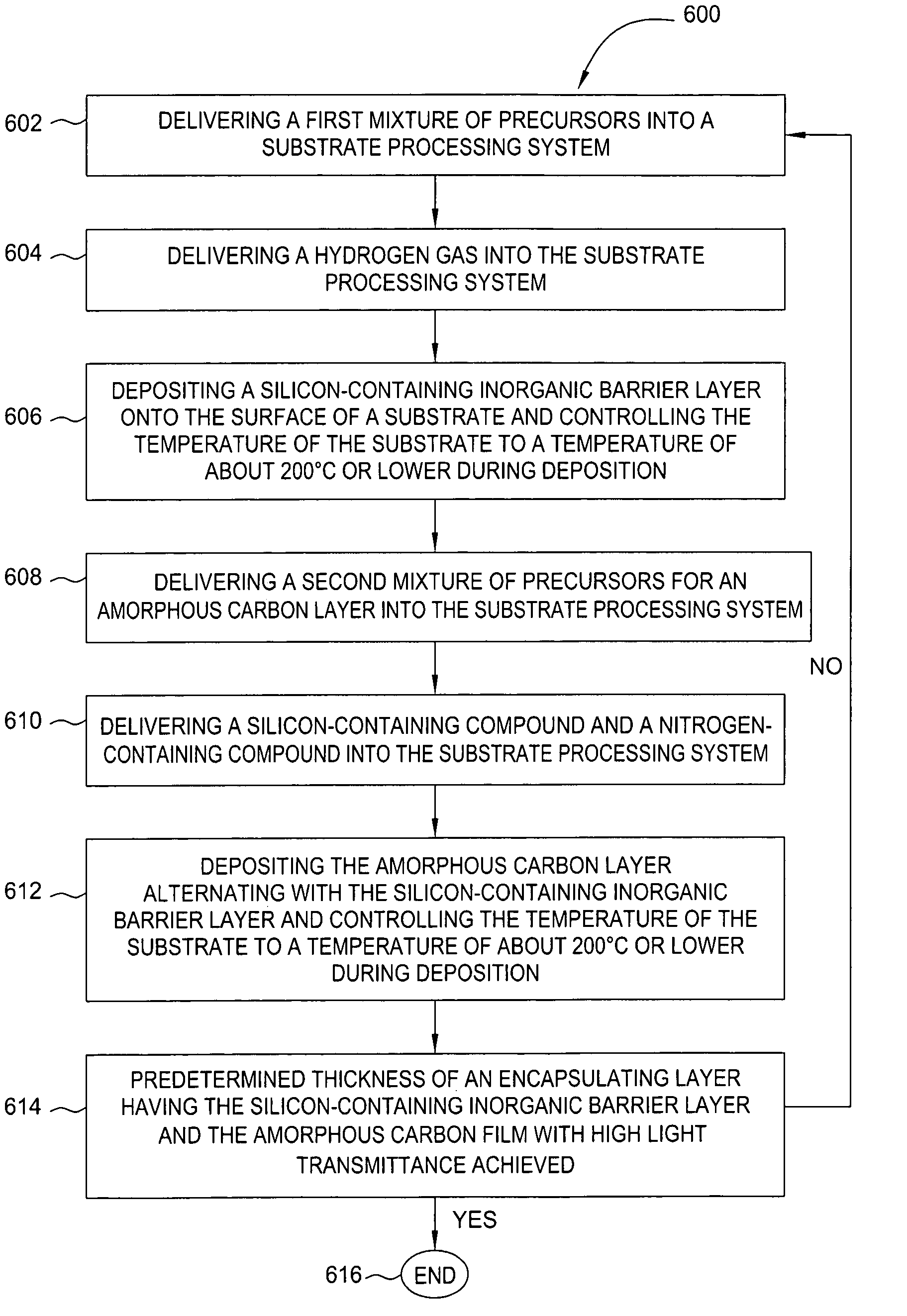

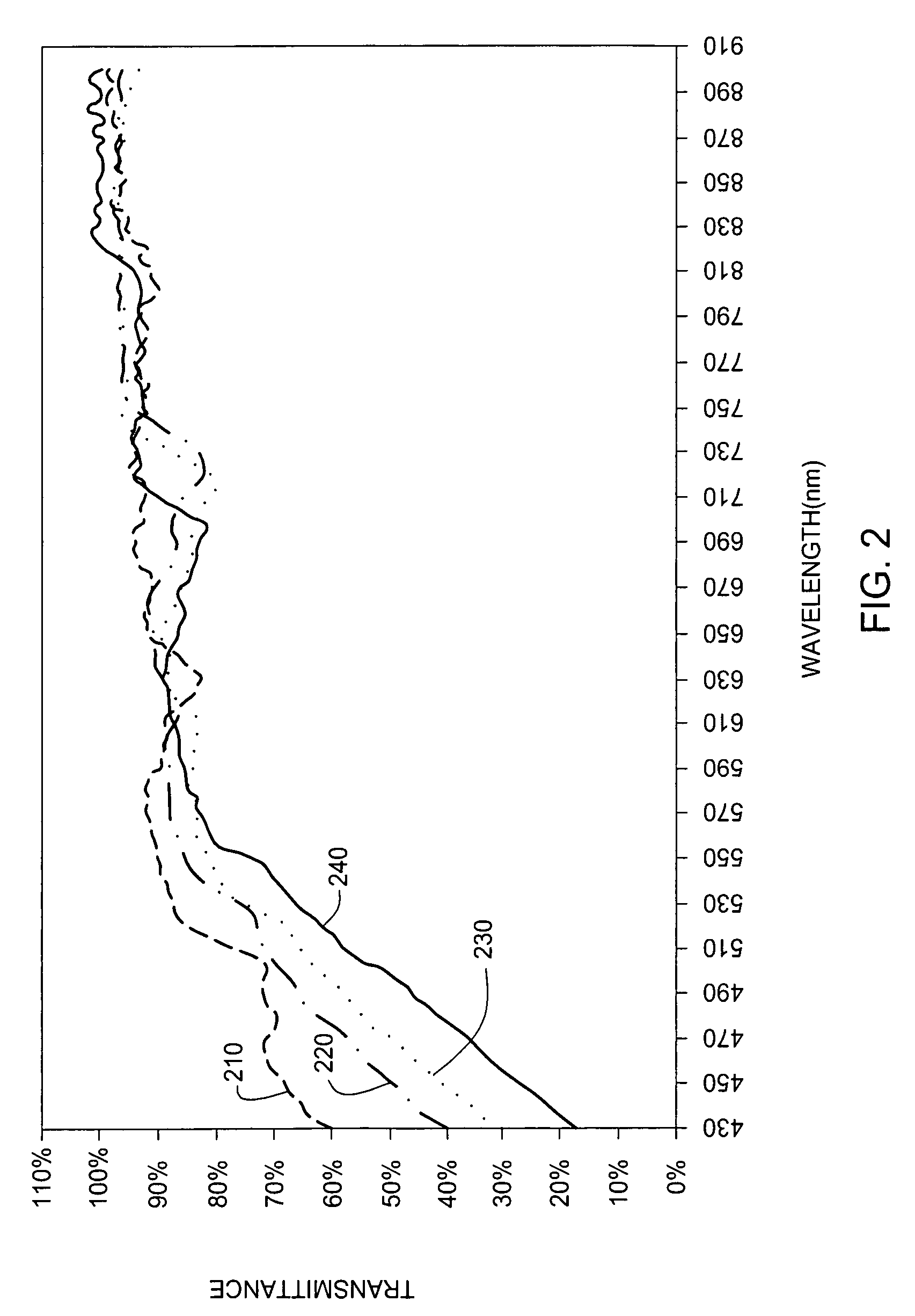

Method to improve transmittance of an encapsulating film

ActiveUS20060078677A1Good film uniformityHigh light transmittanceSolid-state devicesSemiconductor/solid-state device manufacturingLow temperature depositionThermal instability

A method for depositing a carbon-containing material layer onto a substrate includes delivering a mixture of precursors for the carbon-containing material layer into a process chamber, doping the carbon-containing material layer with silicon, and depositing the carbon-containing material layer at low temperature. In one aspect, improved light transmittance of the carbon-containing material layer at all wavelengths of a visible light spectrum is obtained. In addition, a method for depositing an encapsulating layer is provided for various display applications which require low temperature deposition process due to thermal instability of underlying materials used. The encapsulating layer may include one or more barrier layer material layers and one or more amorphous carbon material layers. The amorphous carbon material can be used to reduce thermal stress and prevent the deposited thin film from peeling off the substrate.

Owner:APPLIED MATERIALS INC

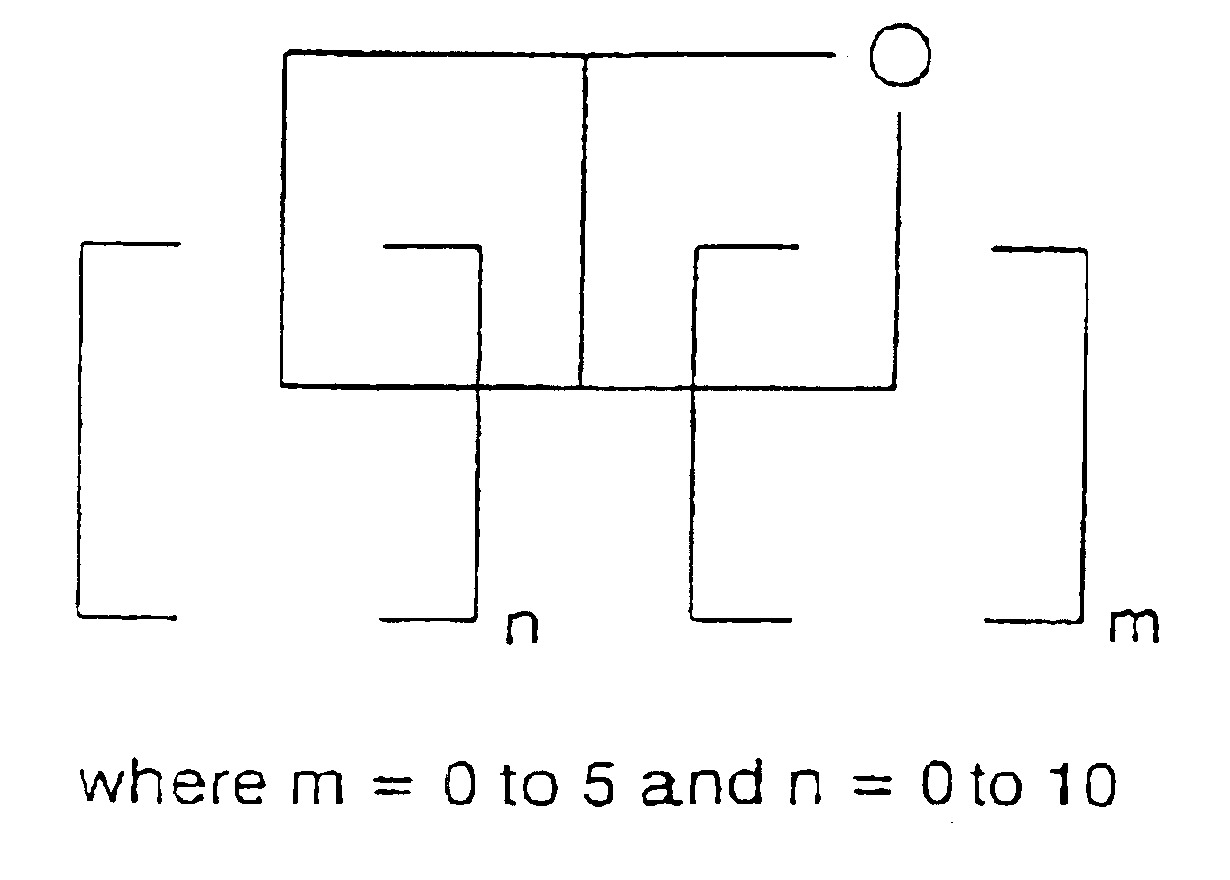

Method and apparatus of growing a thin film onto a substrate

InactiveUS7105054B2Reduce concentrationGood film uniformityPolycrystalline material growthSemiconductor/solid-state device manufacturingInlet channelGas phase

A method and an apparatus for growing a thin film onto a substrate by the ALD process. The apparatus comprises a reaction chamber into which the substrate can be disposed; a plurality of inlet channels communicating with said reaction chamber, said inlet channels being suited for feeding the reactants employed in a thin-film growth process in the form of vapor-phase pulses into said reaction chamber; at least one outlet channel communicating with said reaction chamber, said outlet channel being suited for the outflow of reaction products and excess amounts of reactants from said reaction space; and a pre-reaction chamber arranged immediately upstream of the reaction chamber, said pre-reaction chamber forming a first reaction zone, in which the reactants of successive vapor-phase pulses can be reacted with each other in the vapor phase to form a solid product, whereas said reaction chamber forming a second reaction zone can be operated under conditions conducive to ALD growth of a thin film.

Owner:ASM INTERNATIONAL

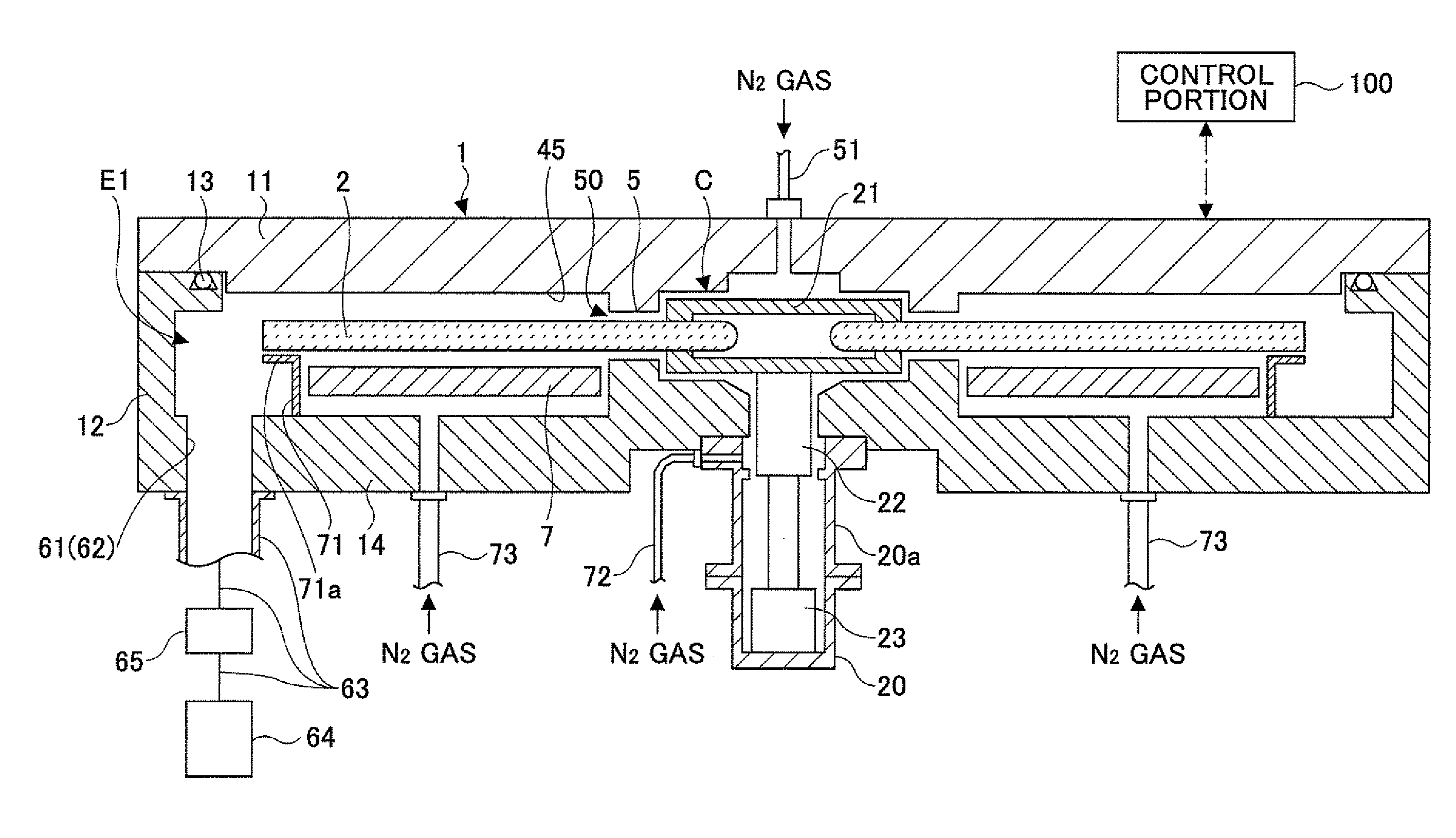

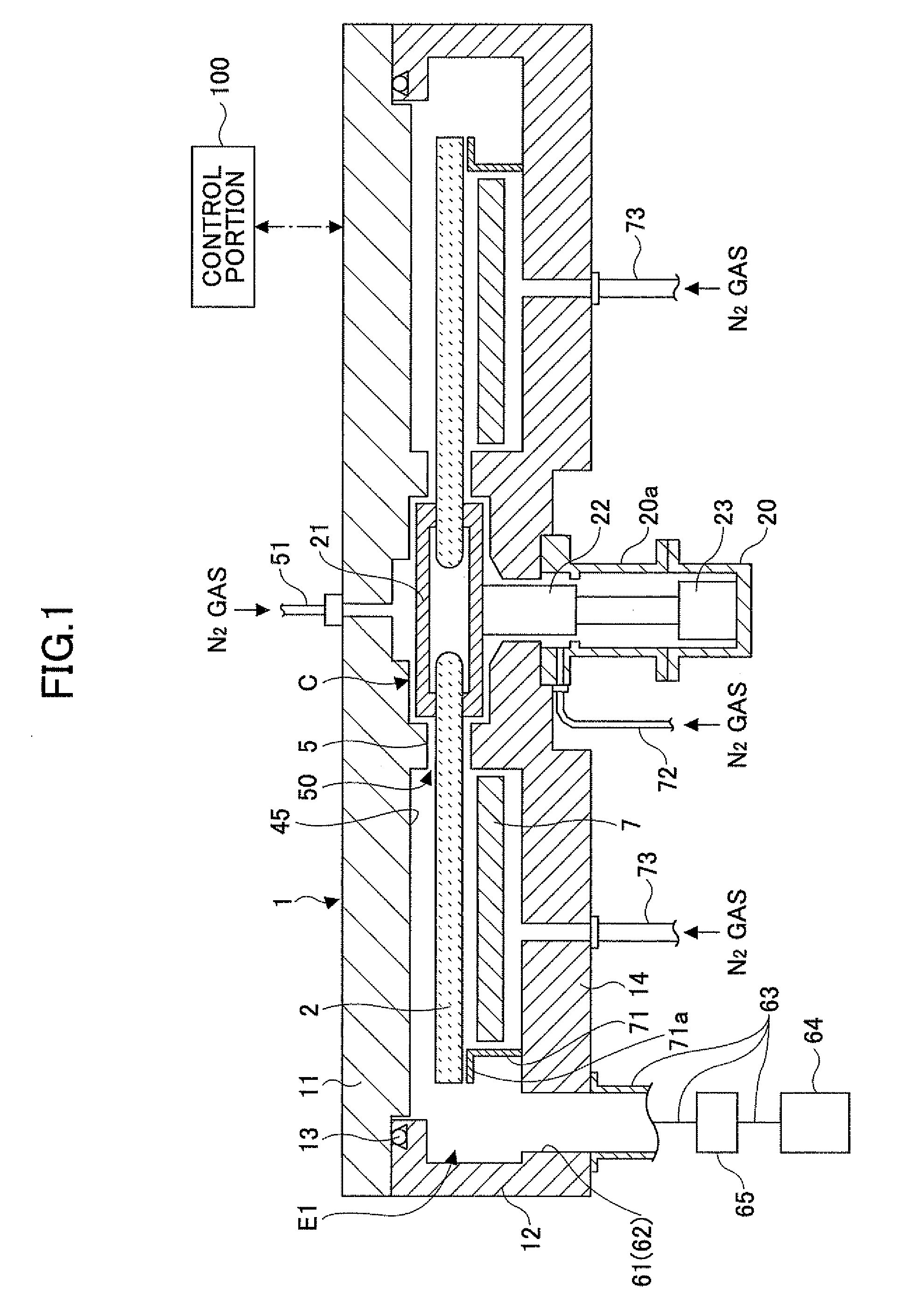

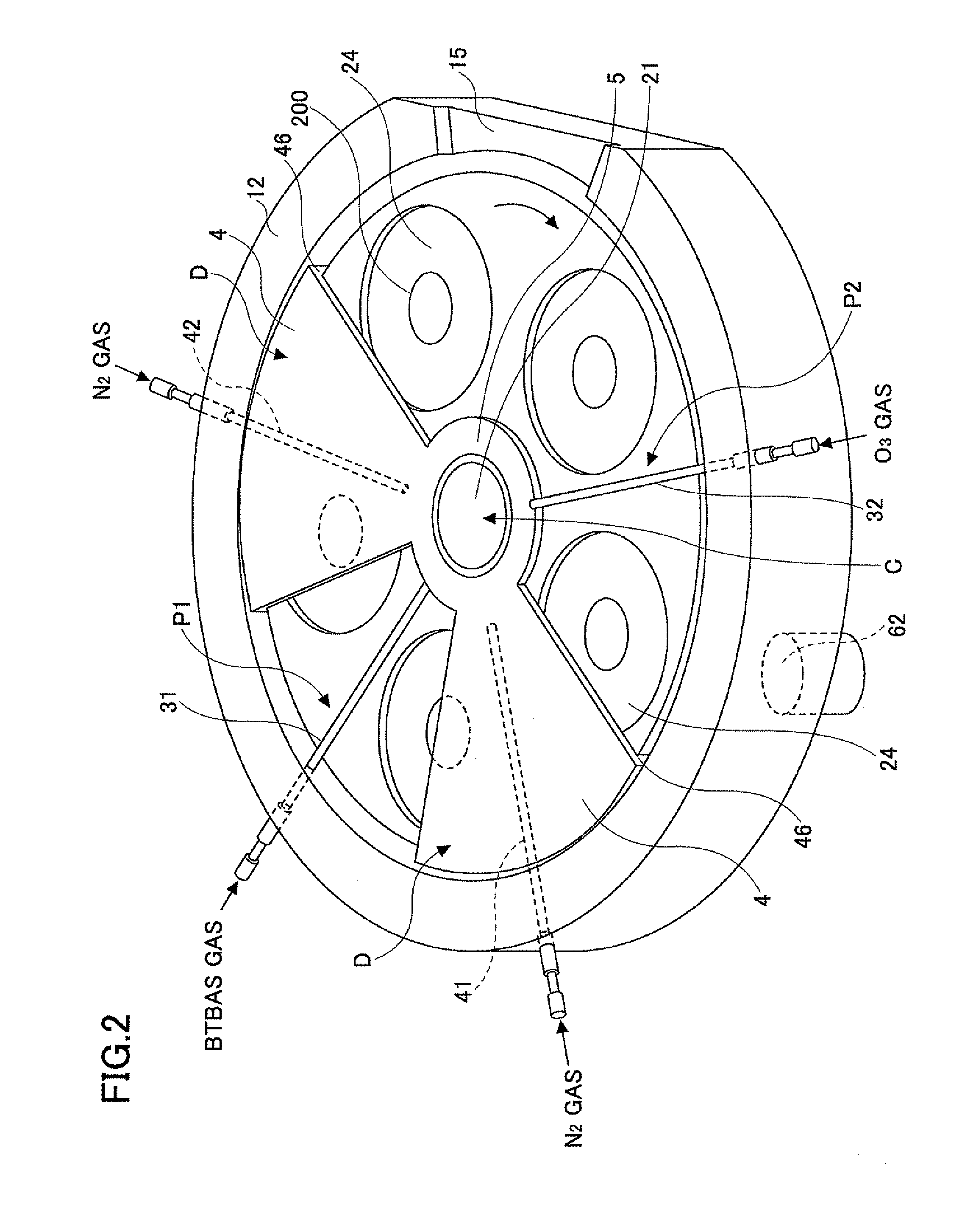

Film deposition apparatus, film deposition method, and computer readable storage medium

InactiveUS20100227059A1Good film uniformityLiquid surface applicatorsChemical vapor deposition coatingSusceptorGas supply

A film is deposited to a predetermined thickness on a wafer by allowing the wafer placed on a susceptor to alternately move through plural process areas where corresponding plural reaction gases are supplied from corresponding plural reaction gas supplying portions and a separation area where a separation gas is supplied from a separation gas supplying portion in order to separate the plural reaction gases. Such movement is achieved by rotating the susceptor relative to the plural reaction gas supplying portions and the separation gas supplying portion, or rotating the plural reaction gas supplying portions and the separation gas supplying portion relative to the susceptor. Then, when the film is deposited in the above manner to a predetermined thickness, the film deposition is temporarily stopped; the wafer is rotated around its center; and the film is deposited to another predetermined thickness in the same manner.

Owner:TOKYO ELECTRON LTD

Method for fabricating an ultralow dielectric constant material

InactiveUS20030139062A1Increase depositionSimple methodSemiconductor/solid-state device detailsSolid-state devicesGas phaseMaterials science

A method for fabricating a thermally stable ultralow dielectric constant film comprising Si, C, O and H atoms in a parallel plate chemical vapor deposition process utilizing plasma enhanced chemical vapor deposition ("PECVD") process is disclosed. To enable the fabrication of thermally stable ultralow dielectric constant film, specific precursor materials are used, such as, cyclic siloxanes and organic molecules containing ring structures, for instance, tetramethylcycloterasiloxane and cyclopentene oxide. To stabilize plasma in the PECVD reactor and thereby improve uniformity of the deposited film, CO2 is added to TMCTS as a carrier gas, or CO2 or a mixture of CO2 and O2 are added to the PECVD reactor.

Owner:INTEL CORP

Method to improve transmittance of an encapsulating film

ActiveUS7214600B2Good film uniformityHigh light transmittanceSolid-state devicesSemiconductor/solid-state device manufacturingLow temperature depositionThermal instability

A method for depositing a carbon-containing material layer onto a substrate includes delivering a mixture of precursors for the carbon-containing material layer into a process chamber, doping the carbon-containing material layer with silicon, and depositing the carbon-containing material layer at low temperature. In one aspect, improved light transmittance of the carbon-containing material layer at all wavelengths of a visible light spectrum is obtained. In addition, a method for depositing an encapsulating layer is provided for various display applications which require low temperature deposition process due to thermal instability of underlying materials used. The encapsulating layer may include one or more barrier layer material layers and one or more amorphous carbon material layers. The amorphous carbon material can be used to reduce thermal stress and prevent the deposited thin film from peeling off the substrate.

Owner:APPLIED MATERIALS INC

Single body injector and deposition chamber

InactiveUS20010004881A1Complicated machined partLow costSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringInjector

An injector and deposition chamber for delivering gases to a substrate or wafer for processing of said substrate or wafer is provided. The injector is provided comprising an elongated member with end surfaces and at least one gas delivery surface extending along the length of the member and which includes a number of first elongated passages formed therein for received a gas. The gas delivery surface contains rounded side regions and a center recessed region. Also formed within the member are a number of thin distribution channels which extend between the first elongated passages and the center recessed region of the gas delivery surface. In another embodiment, the injector further includes at least one second elongated passage formed therein for receiving an etchant species. The etchant species is conveyed via at least one thin distribution channel which extends between the second elongated passage and one of the rounded side regions of the gas delivery surface. Metering tubes may be inserted into each elongated passage and are spaced from the walls of said passages and extend between the ends. The deposition chamber includes at least one injector as described above; a plurality of vent blocks having end surfaces and at least one elongated external surface extending along the length of each of the vent blocks; and a support positioned beneath the injector and vent blocks, creating a deposition region therebetween. The vent blocks are positioned adjacent one on each side of the injector, and spaced from the injector to define exhaust channels therebetween for removing the gas.

Owner:ASML US LLC

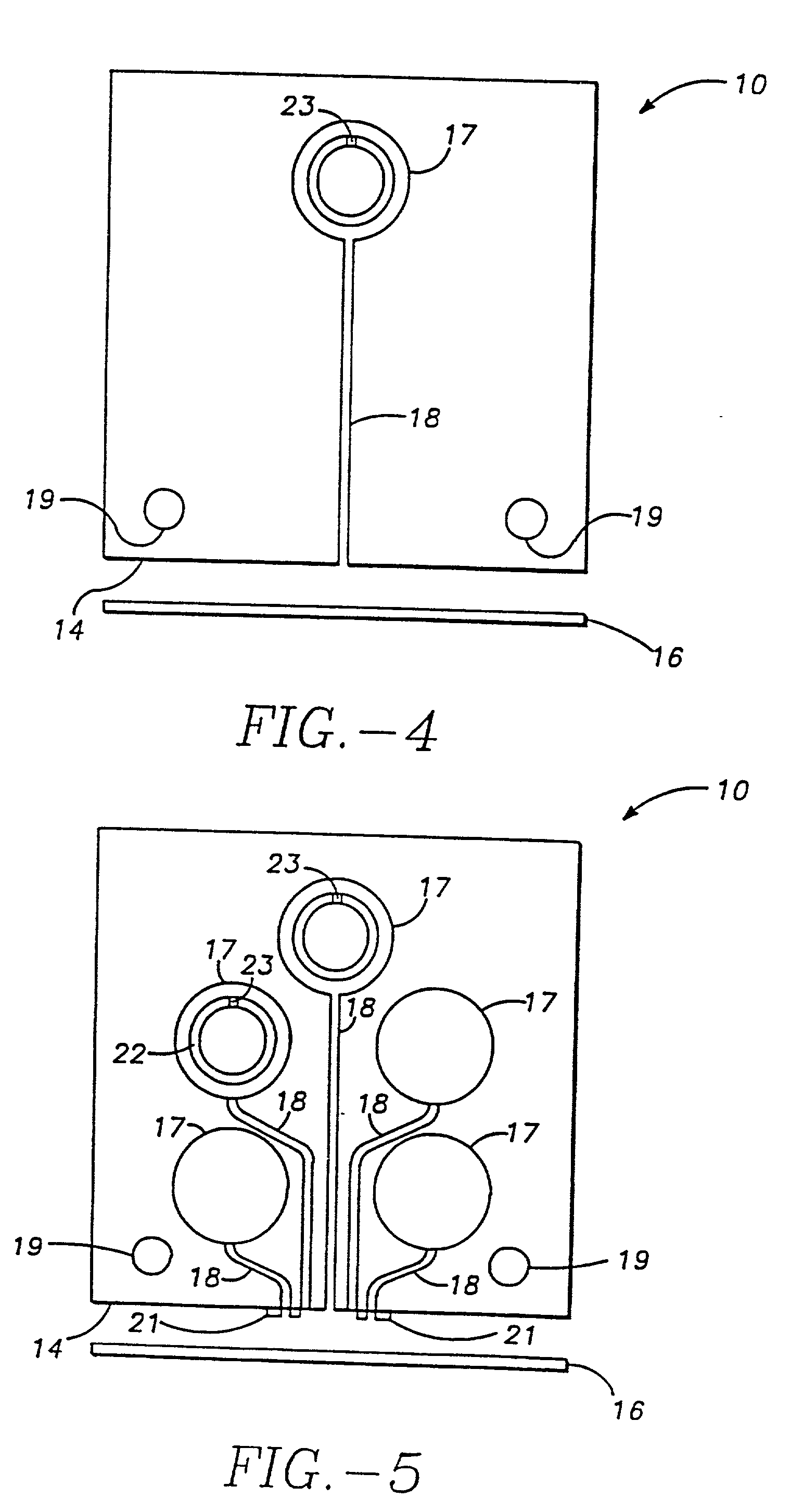

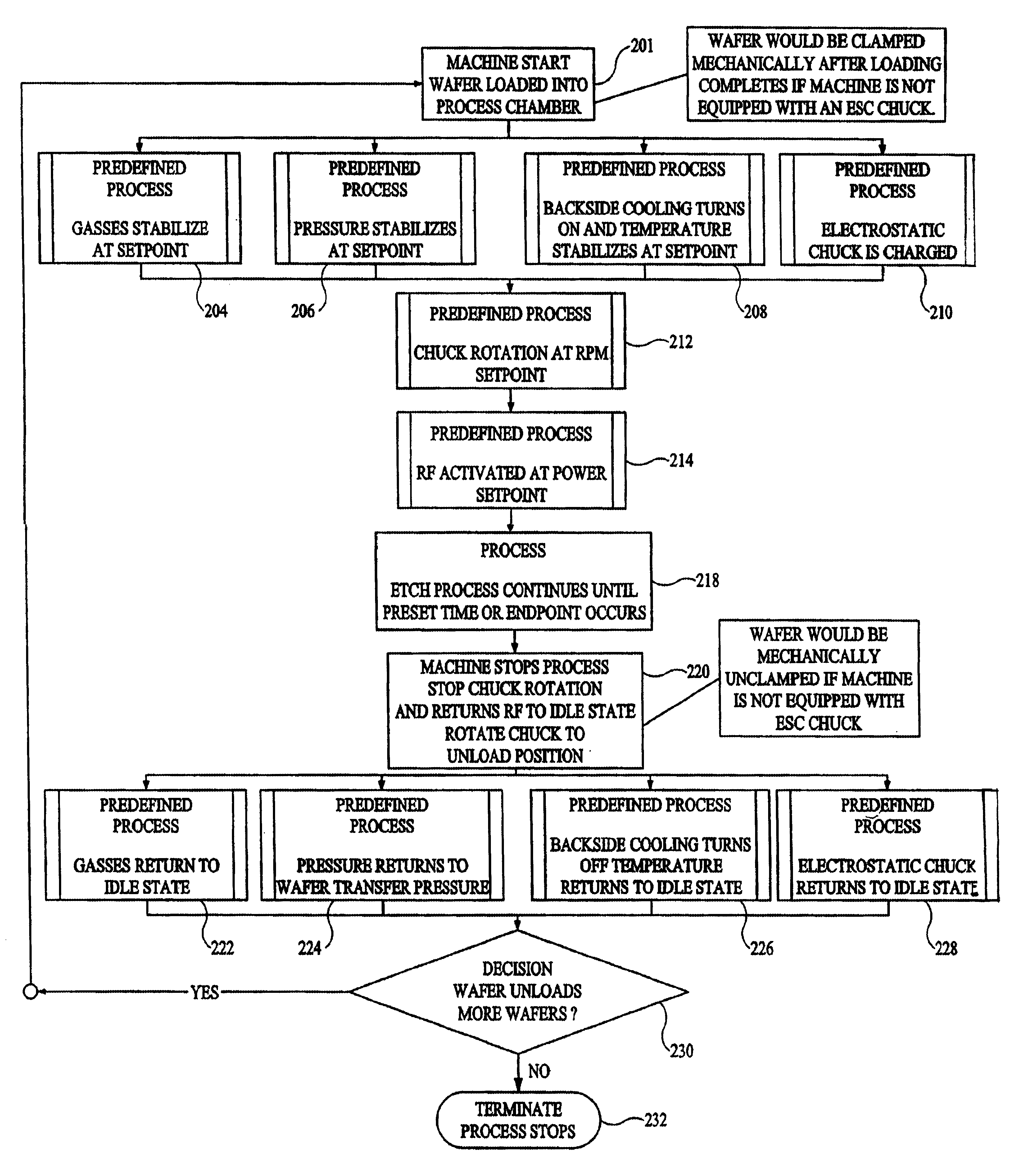

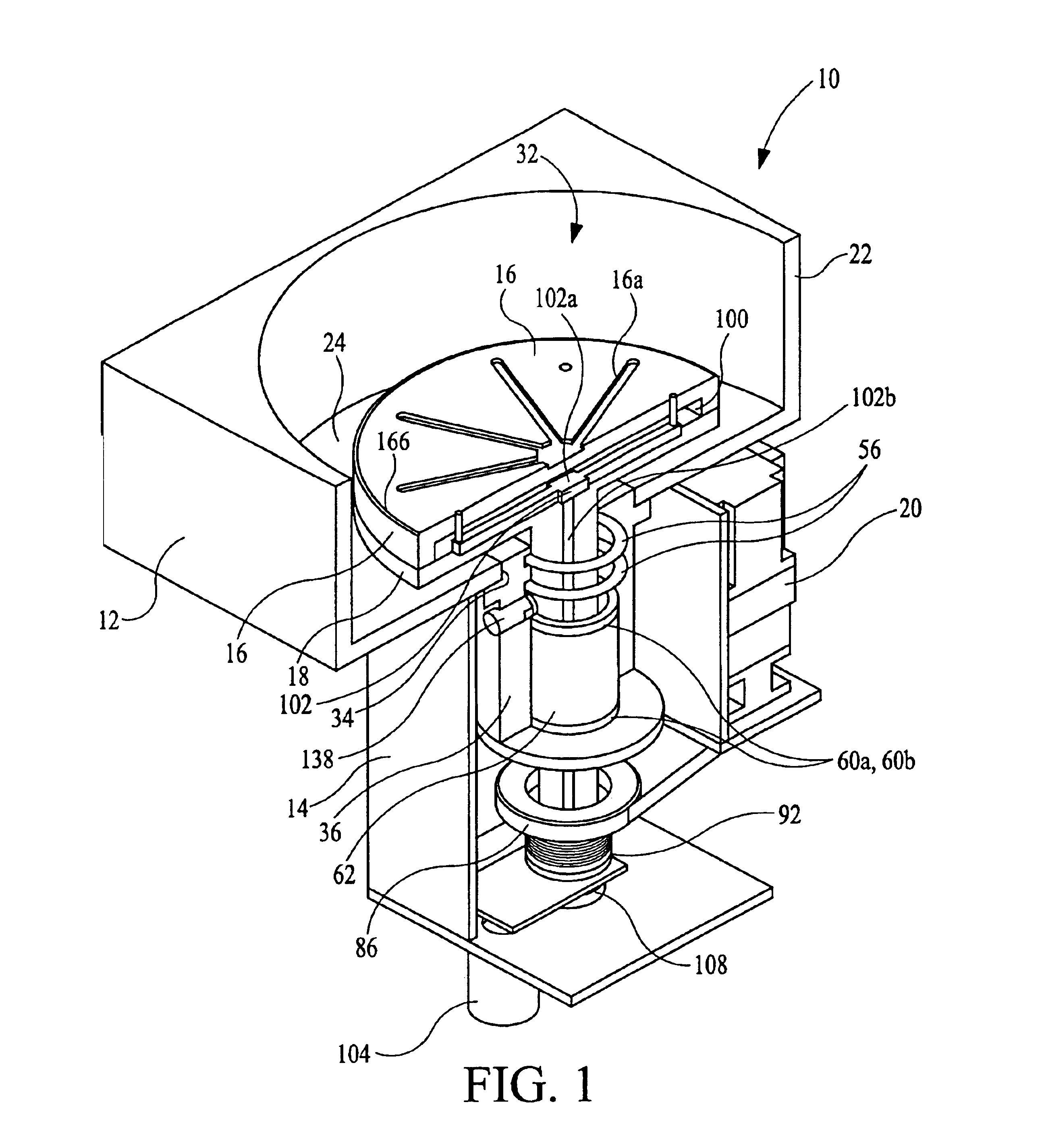

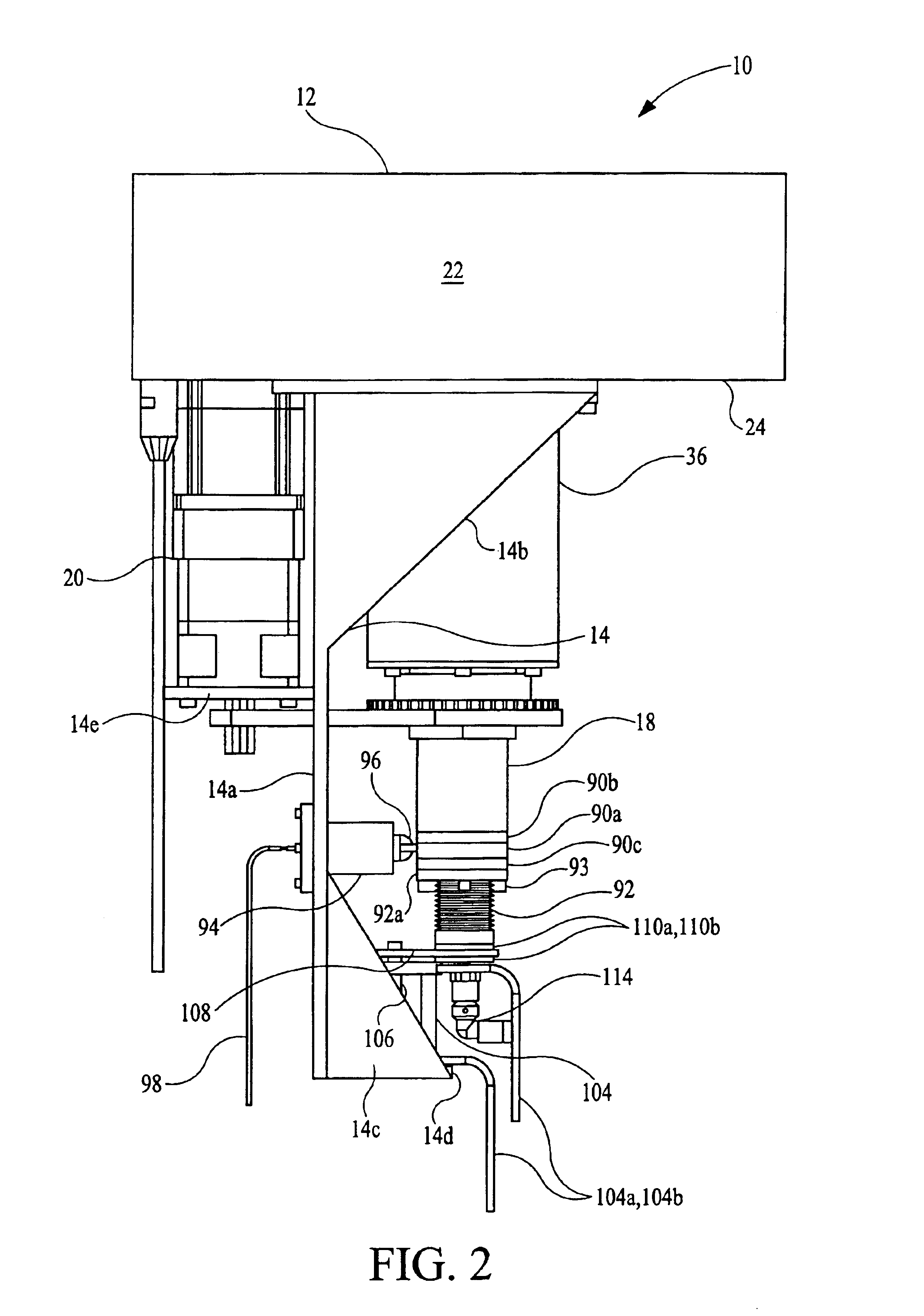

Method and apparatus for plasma etching a wafer

InactiveUS6838390B2Good film uniformityOvercomes shortcomingSleeve/socket jointsElectric discharge tubesEngineeringIonization

A method utilizing a plasma etching machine which comprises a process chamber defining an interior region and including a bottom wall having an aperture and a block disposed in the aperture and including a longitudinally extending bore. A shaft extends through the bore and includes a spider push rod extending longitudinally therethrough. An internally cooled chuck is coupled to the shaft and disposed in the interior region and cooperates with the shaft to define a chamber. A spider is disposed in the chamber and is coupled to the push rod. A lift mechanism is coupled to the shaft and the push rod so that the spider pushes up on a wafer in response to actuation of the lift mechanism. A wafer clamping mechanism is coupled to the push rod if a mechanical clamp is used. In the case of electrostatic clamp the bias applied to the chuck is coupled with the use of a rotational roller to allow the bias to be applied to the chuck for the duration of the etch process. A RF source is needed for ionization of the gas. If the plasma etching machine has RF power applied through the bottom, then a rotational roller is used for this as well and must be isolated from the electrostatic voltage used to clamp the wafer.

Owner:MICRON TECH INC

Target of high-purity nickel or nickel alloy and its producing method

ActiveUS20040256035A1Improve permeabilityFlux changeVacuum evaporation coatingSputtering coatingSputteringNickel alloy

Provided is high purity nickel or nickel alloy target for magnetron sputtering having superior sputtering film uniformity and in which the magnetic permeability of the target is 100 or more, and this high purity nickel or a nickel alloy target for magnetron sputtering capable of achieving a favorable film uniformity (evenness of film thickness) and superior in plasma ignition (firing) even during the manufacturing process employing a 300 mm wafer. The present invention also provides the manufacturing method of such high purity nickel or nickel alloy target.

Owner:NIKKO MATERIAL

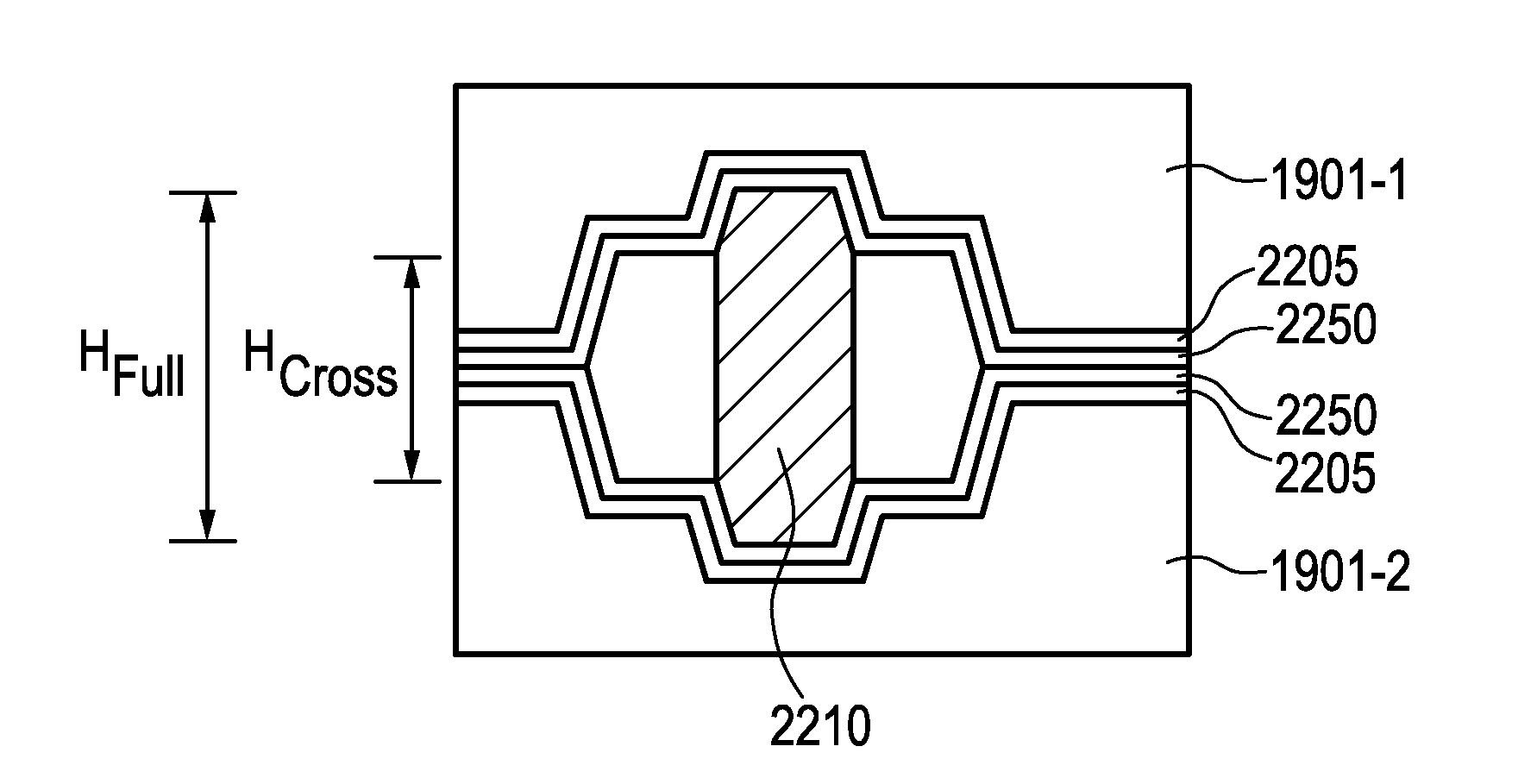

Precision batch production method for manufacturing ferrite rods

InactiveUS20160254579A1Optimize layoutReduce decreaseSemiconductor/solid-state device manufacturingConductive/insulating/magnetic material on magnetic film applicationCrystallographyFerrite layer

The present invention relates to a method of manufacturing a ferrite rod. The method comprises etching cavities into two semiconductor substrates and depositing ferrite layers into the cavities. The semiconductor substrates are attached to each other such that the ferriote layers form a ferrite rod. The present invention employs conventional photolithography and bulk isotropic micromachining of semiconductor wafers to precisely and repeatably form a template or mould, into which magnetic material can be deposited to form a Faraday rotation or phase-shifting element.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

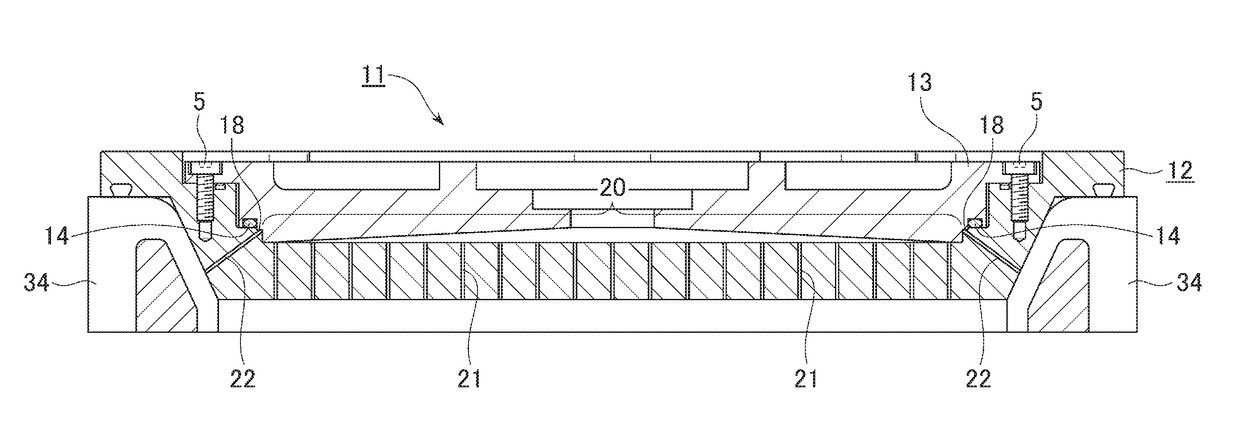

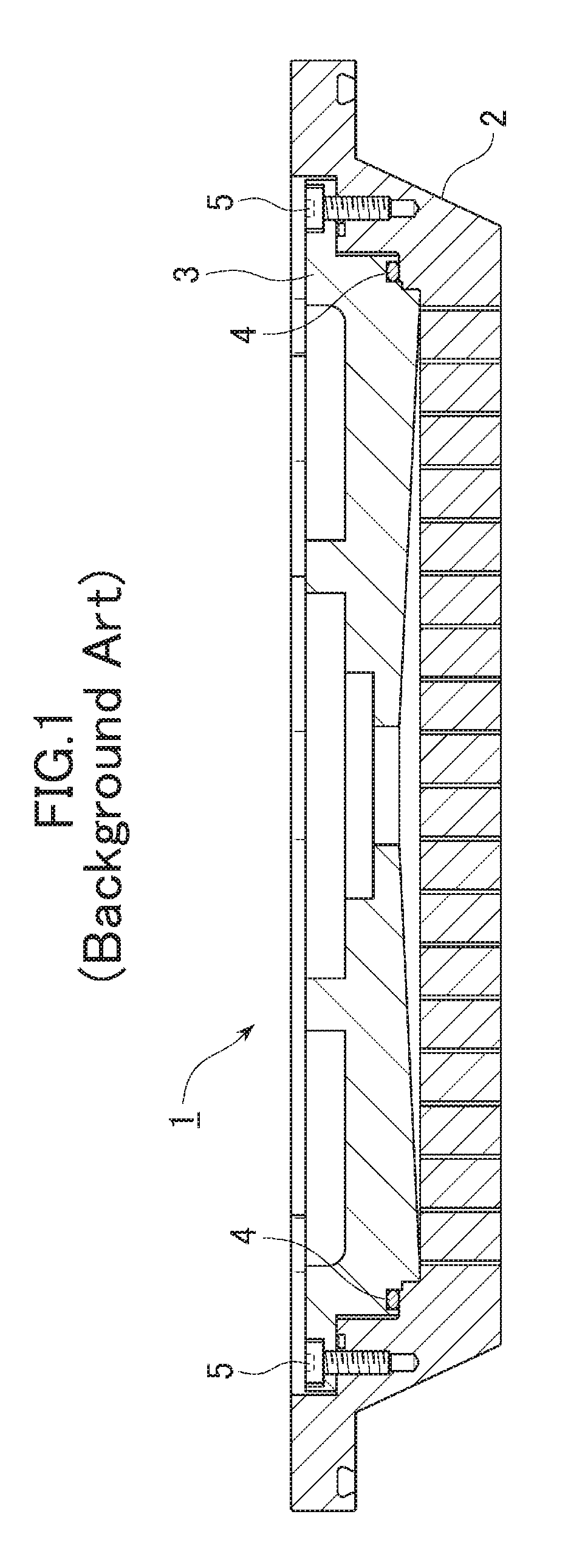

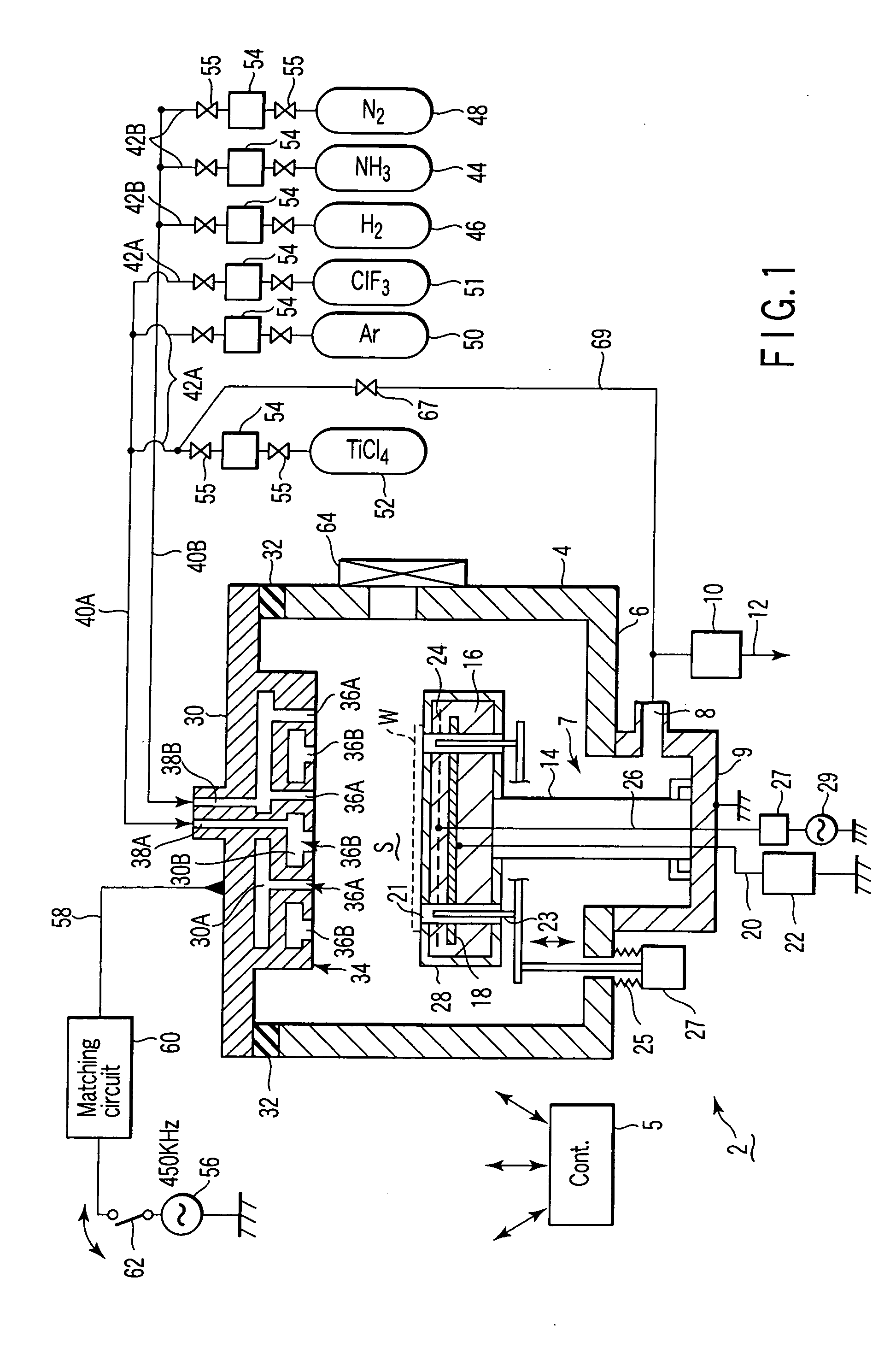

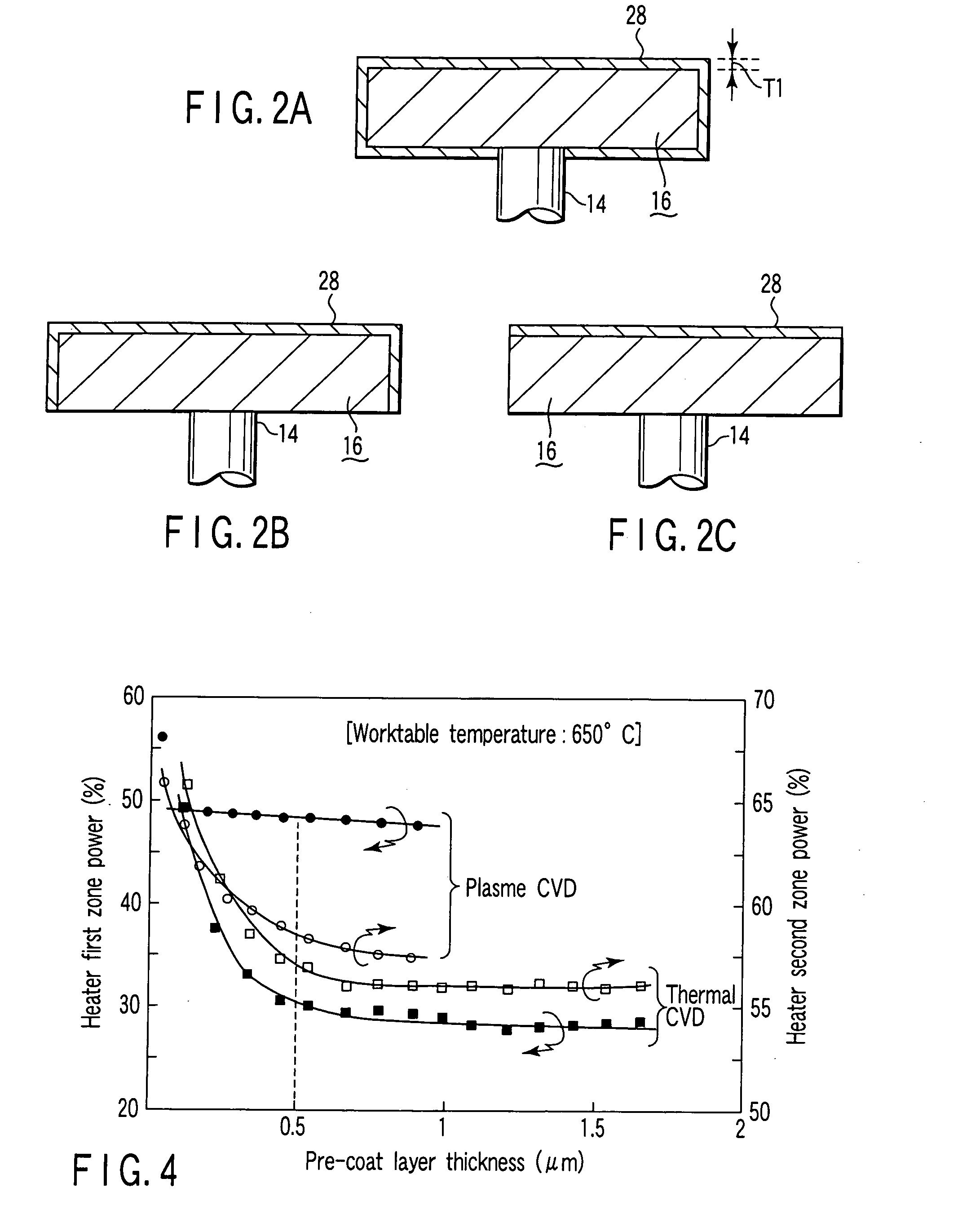

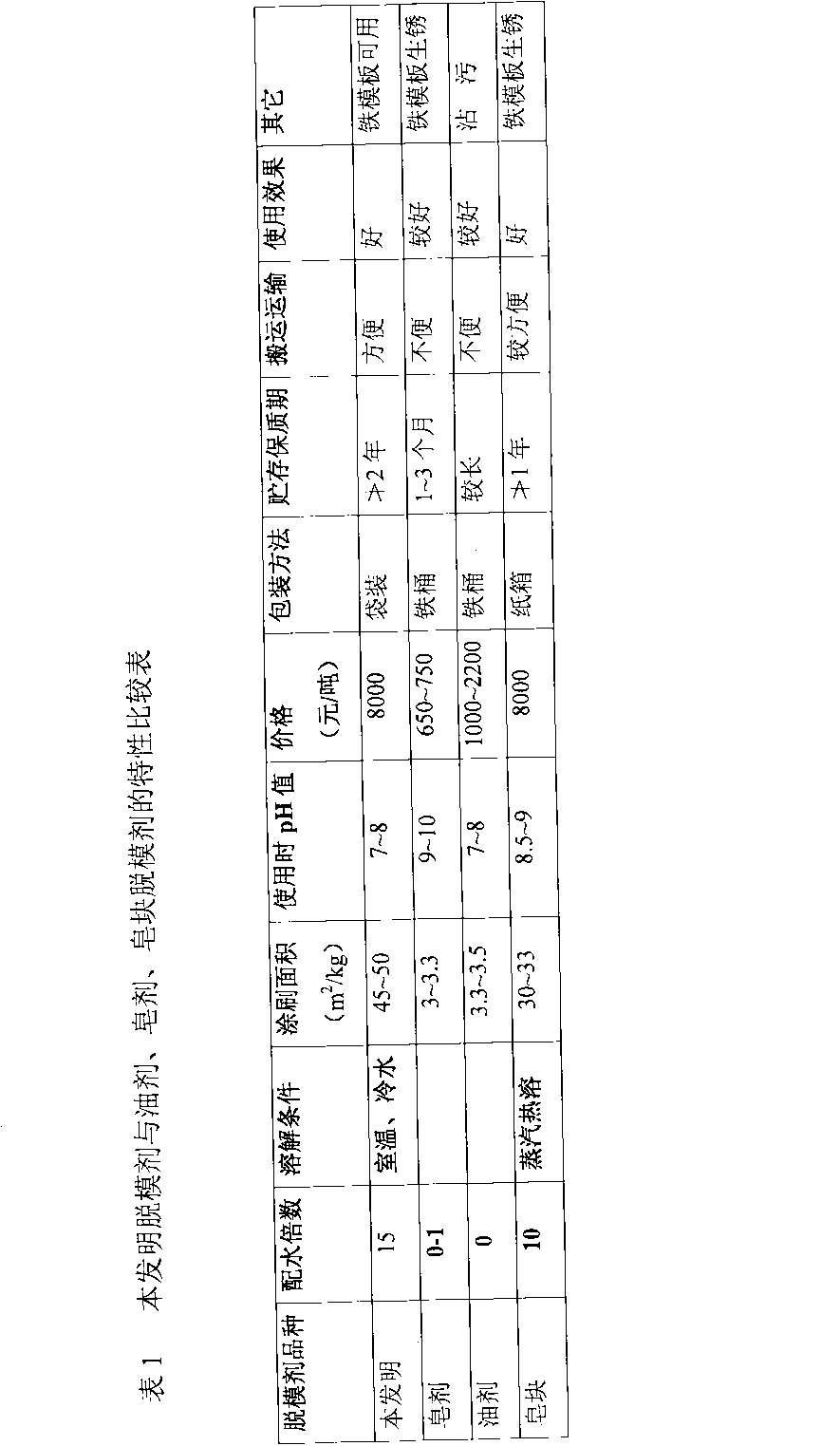

Worktable device, film formation apparatus, and film formation method for semiconductor process

InactiveUS20050257747A1Good film uniformityGood reproducibilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringRadiant heat

A worktable device is disposed inside a film formation process container for a semiconductor process. The worktable device includes a worktable including a top surface to place a target substrate thereon, and a side surface extending downward from the top surface, and a heater disposed in the worktable and configured to heat the substrate through the top surface. A CVD pre-coat layer covers the top surface and the side surface of the worktable. The pre-coat layer has a thickness not less than a thickness which substantially saturates the amount of radiant heat originating from heating of the heater and radiated from the top surface and the side surface of the worktable.

Owner:TOKYO ELECTRON LTD

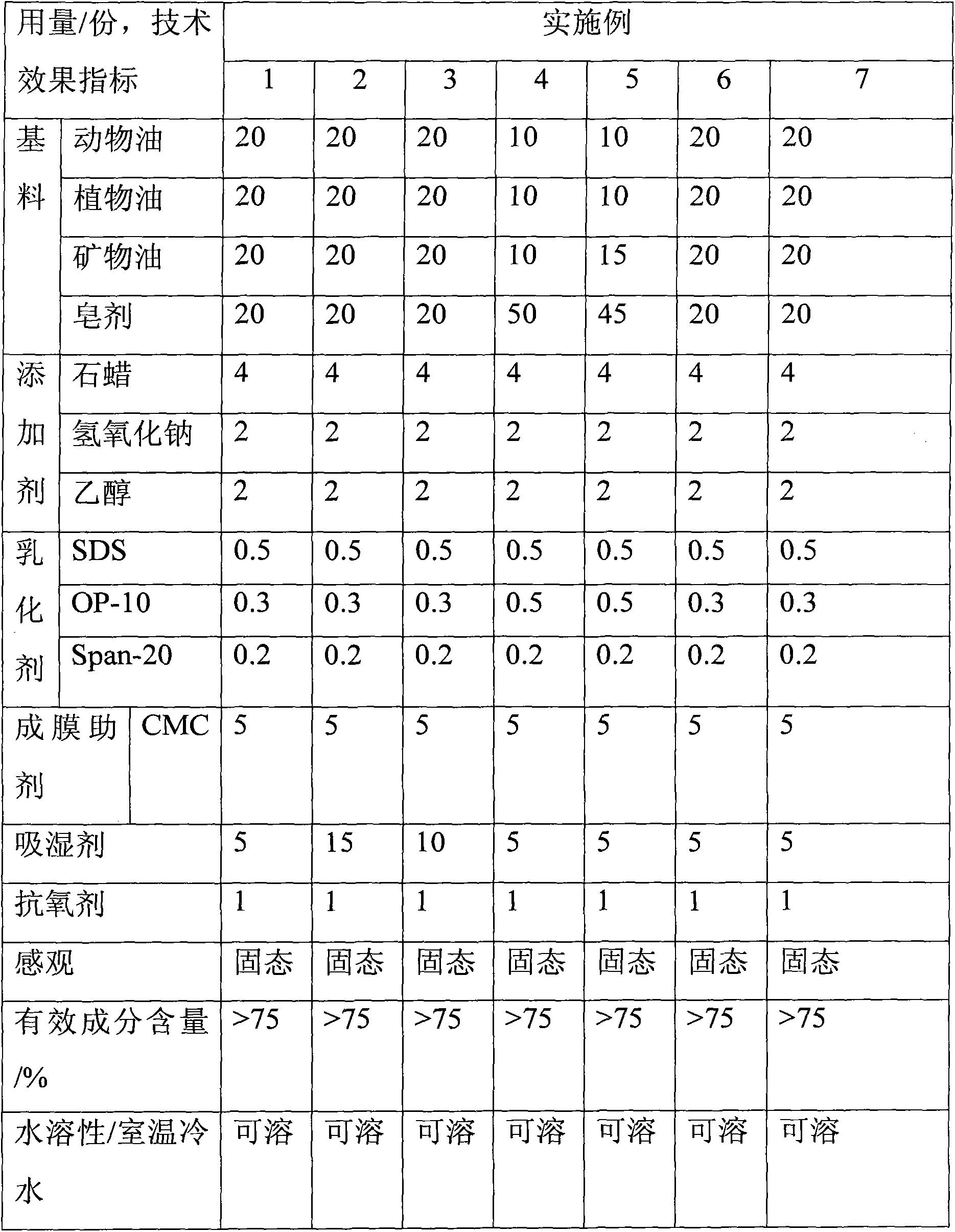

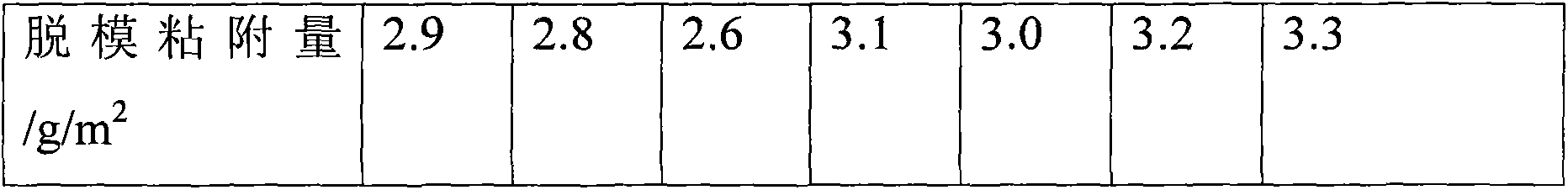

Oily solid releasing agent and preparation method thereof

ActiveCN103450995AChange physical propertiesIncrease distanceLubricant compositionParaffin waxAlcohol

The invention provides an oily solid releasing agent which is prepared from the following components in parts by weight: 80-85 parts of base material, 0.8-1.2 parts of emulsifier, 5-10 parts of film-forming assistant, 5-15 parts of additive, 5-15 parts of moisture absorber and 1-5 parts of antioxidant. The base material contains animal oil, vegetable oil, mineral oil and a soaping agent. The additive is a compounded additive containing high-carbon hydrocarbon, alcohol and alkali, wherein the high-carbon hydrocarbon is paraffin; the additive accounts for 5% of the base material. The invention also relates to a preparation method of the releasing agent.

Owner:北京慕湖外加剂有限公司

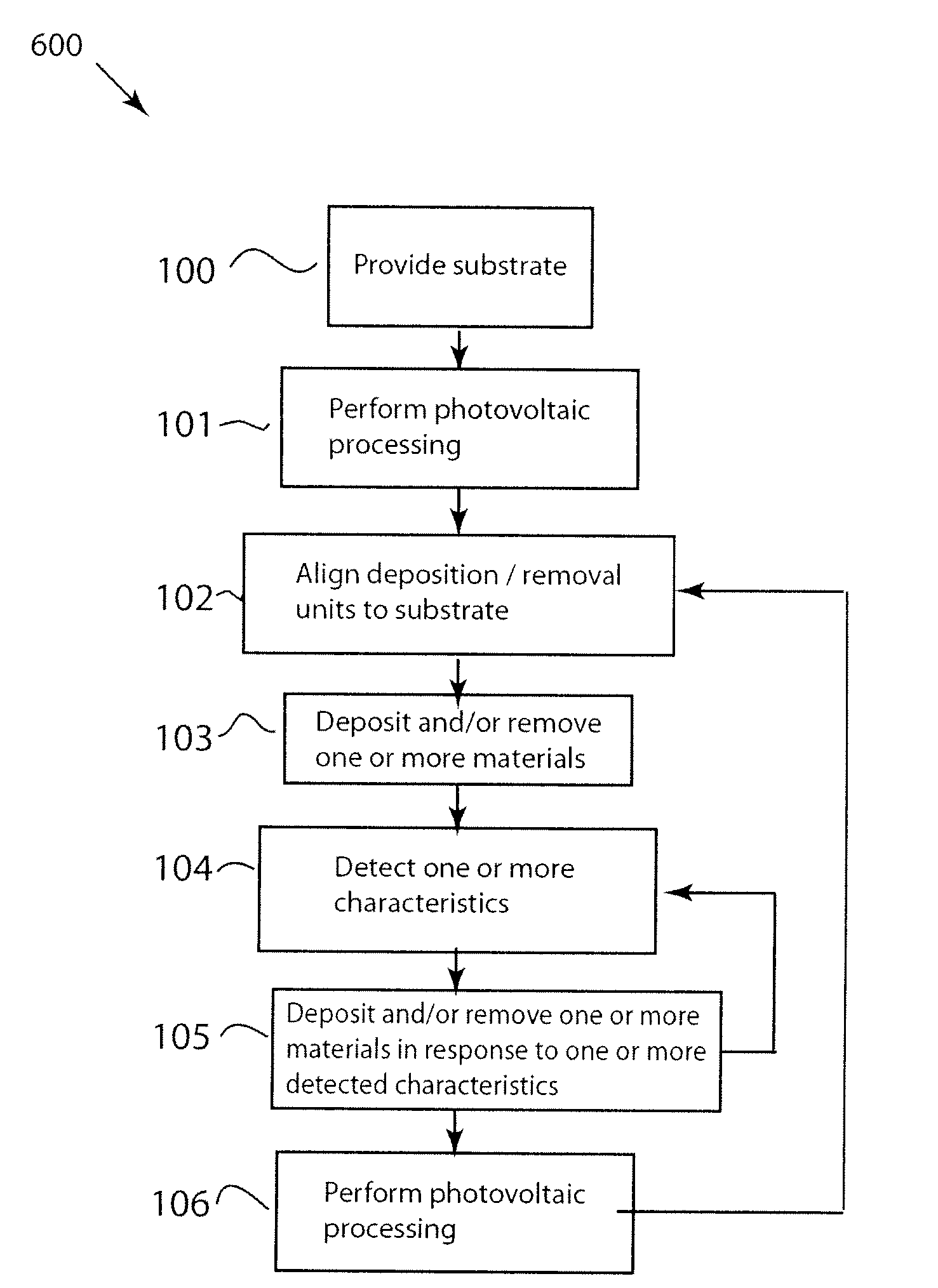

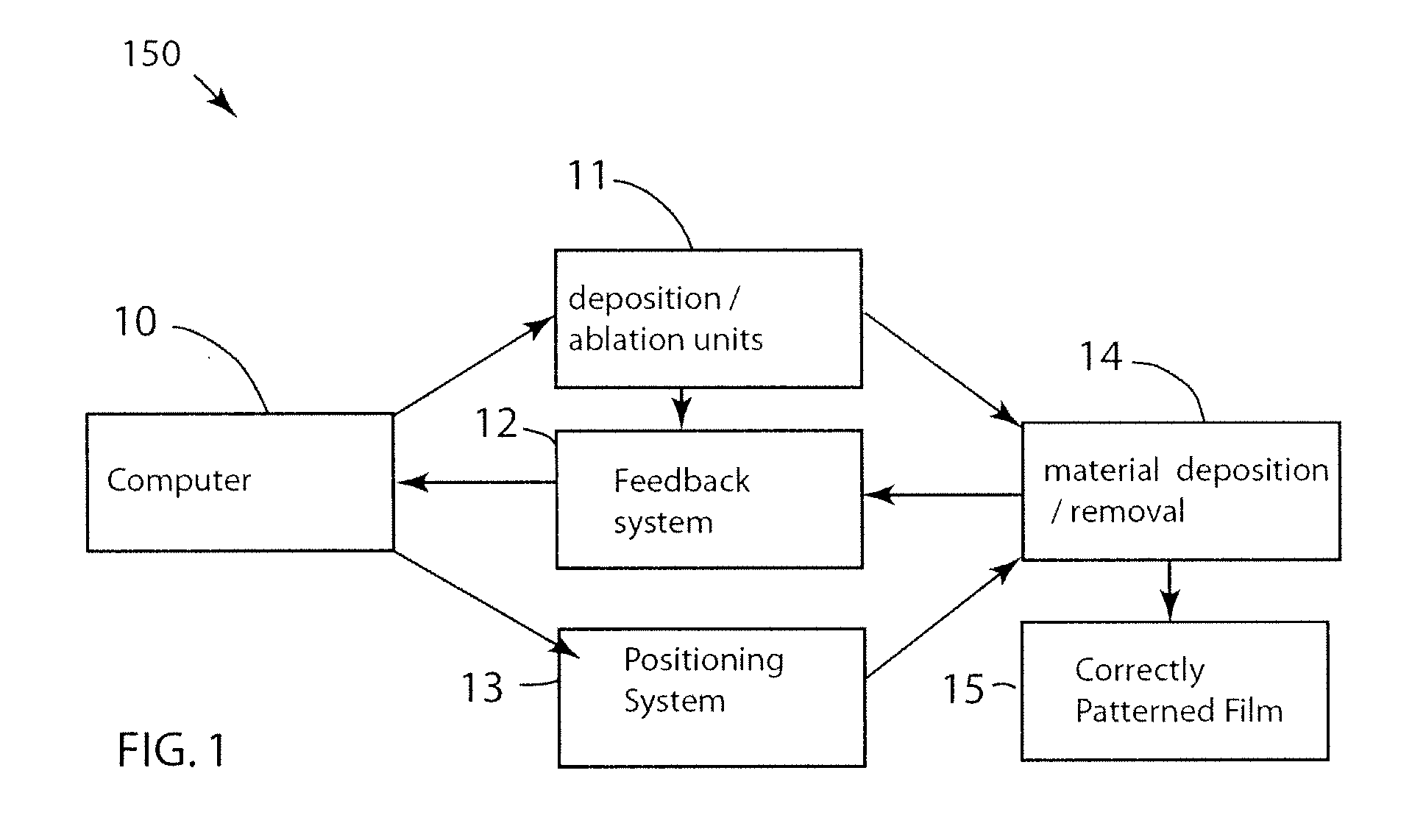

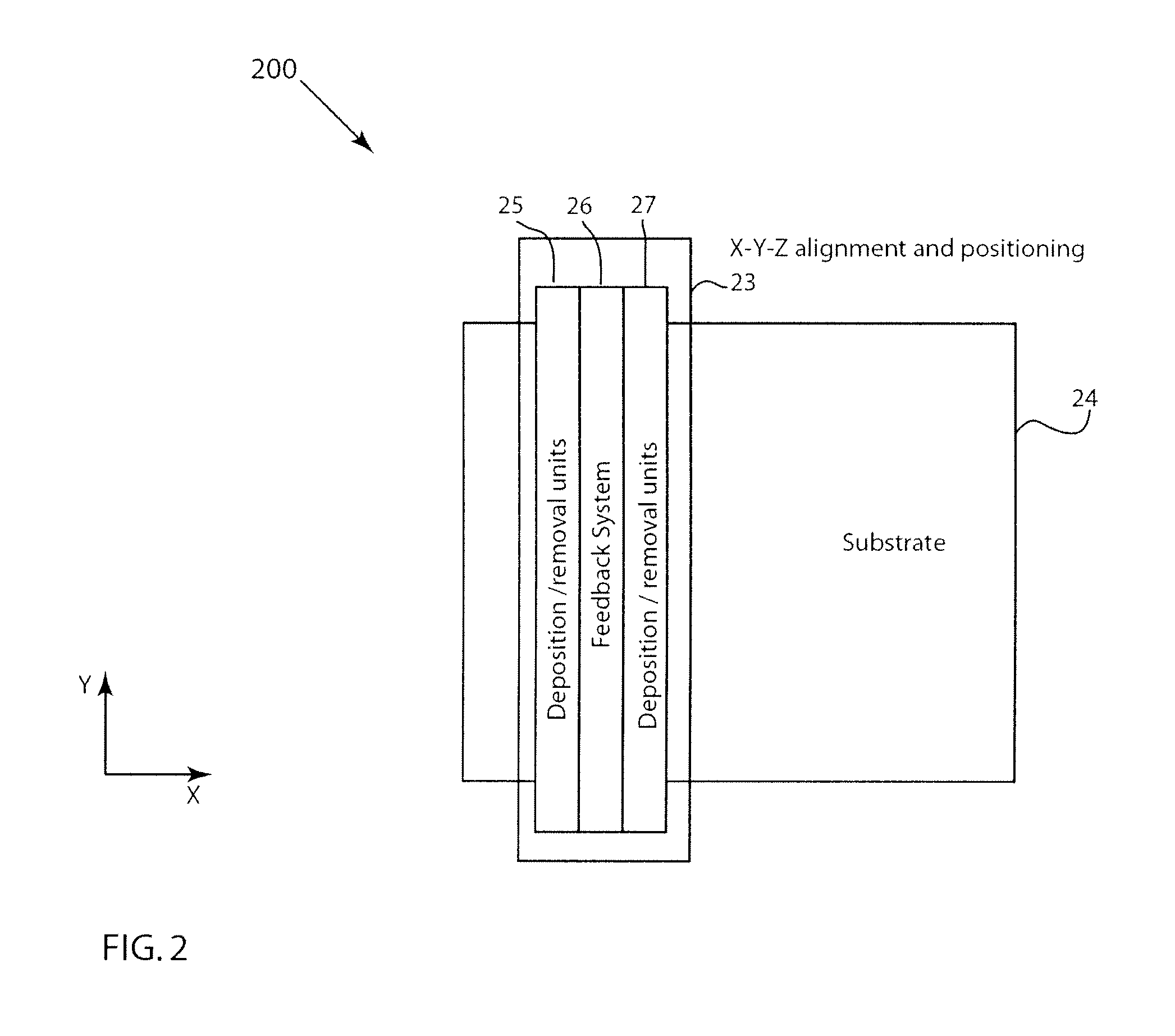

Systems and methods for depositing patterned materials for solar panel production

InactiveUS20100184244A1Improve edge definitionGood film uniformityLiquid surface applicatorsSolid-state devicesElectrical and Electronics engineering

Method and system for forming one or more predetermined patterns on a substrate for making a photovoltaic device. The method includes aligning at least a first droplet source with a substrate, dispensing one or more first droplets associated with one or more first materials from the first droplet source, and forming at least a first pattern of one or more second materials on the substrate by at least the first droplet source. Additionally, the method includes providing a first light beam incident on at least the first pattern, obtaining a first signal associated with the first pattern in response to the first light beam, processing information associated with the first signal, and determining one or more first characteristics of the first pattern based on at least information associated with the first signal.

Owner:ALION

Preparing method for transparent conductive oxide film

ActiveCN102646759ASimple process equipmentGood film uniformitySemiconductor devicesElectrically conductiveChemistry

The invention relates to the semiconductor photoelectric material field, and provides a preparing method for transparent conductive oxide film. The method includes the following steps: step one, obtaining a sol solution of zinc salt or indium salt and doped metal salt, wherein, viscosity of the sol ranges from 15m Pa.s to 20 m Pa.s, concentration of zinc or indium in the zinc salt or the indium salt ranges from 0.1 mol / L to 1 mol / L, the mole ratio of zinc and the doped metal salt is between 0.001 and 0.03, and the mole ratio of indium and the doped metal salt is between 0.05 and 0.15; step two, immersing media into the sol solution and allowing the mixture to stand for 1s to 30s, pulling the media out of the sol solution at a speed of 1 cm / min to 300 cm / min, maintaining the media for 0.5 min to 30 min at a temperature in a range of 80 DEG C to 300 DEG C, and cooling the media; step three, repeating step two till the thickness of the film on the media achieves the required thickness, and obtaining the transparent conductive oxide film. The transparent conductive oxide film prepared through the method has the advantages of being high in rate of finished products, capable of preparing film with large areas, high in material using ratio, and suitable for mass production.

Owner:徐东

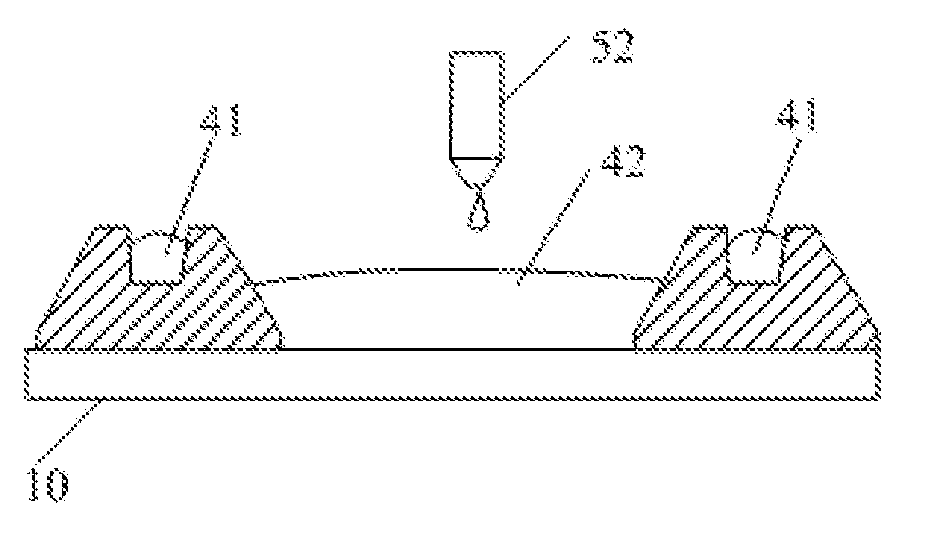

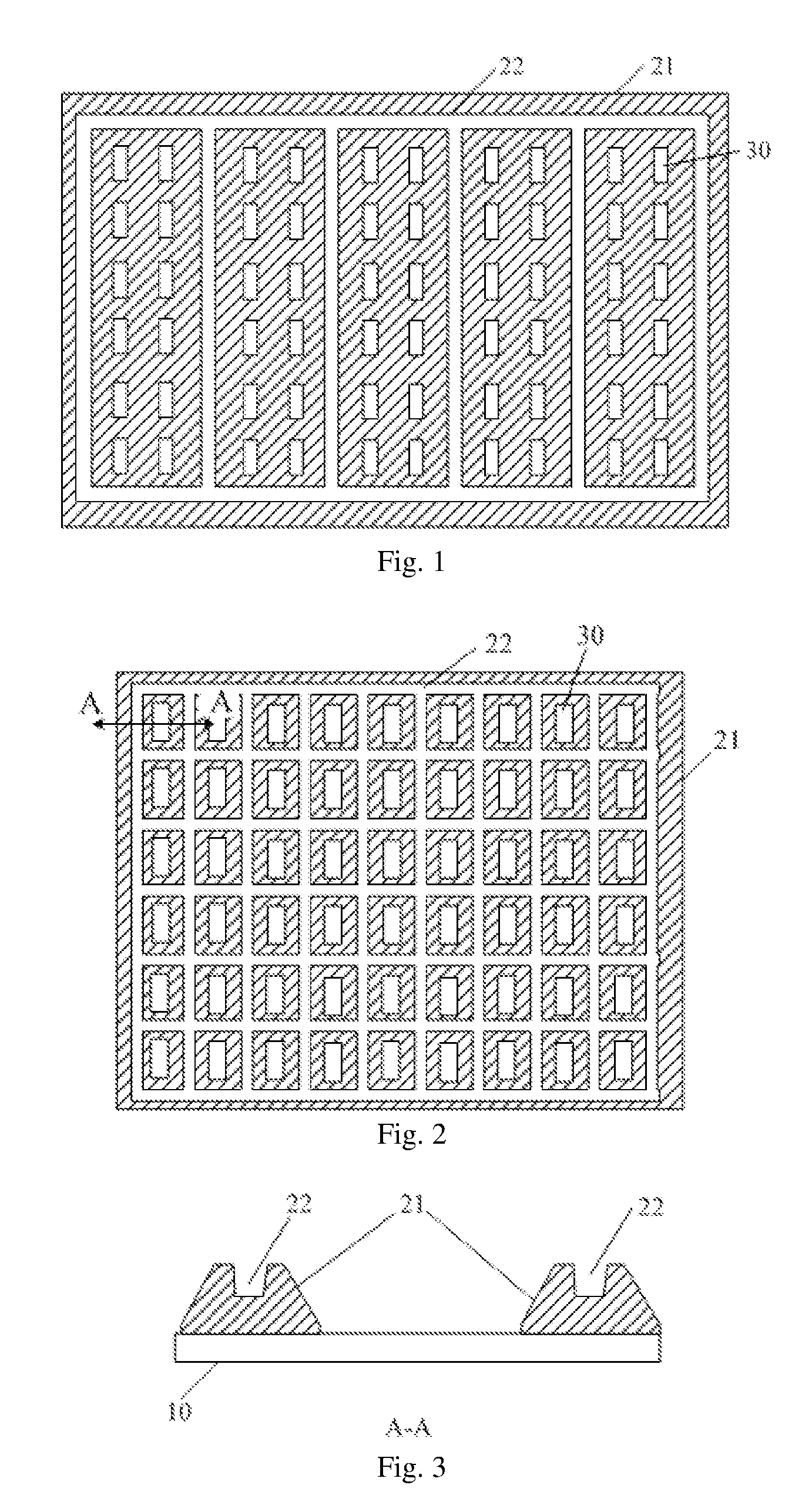

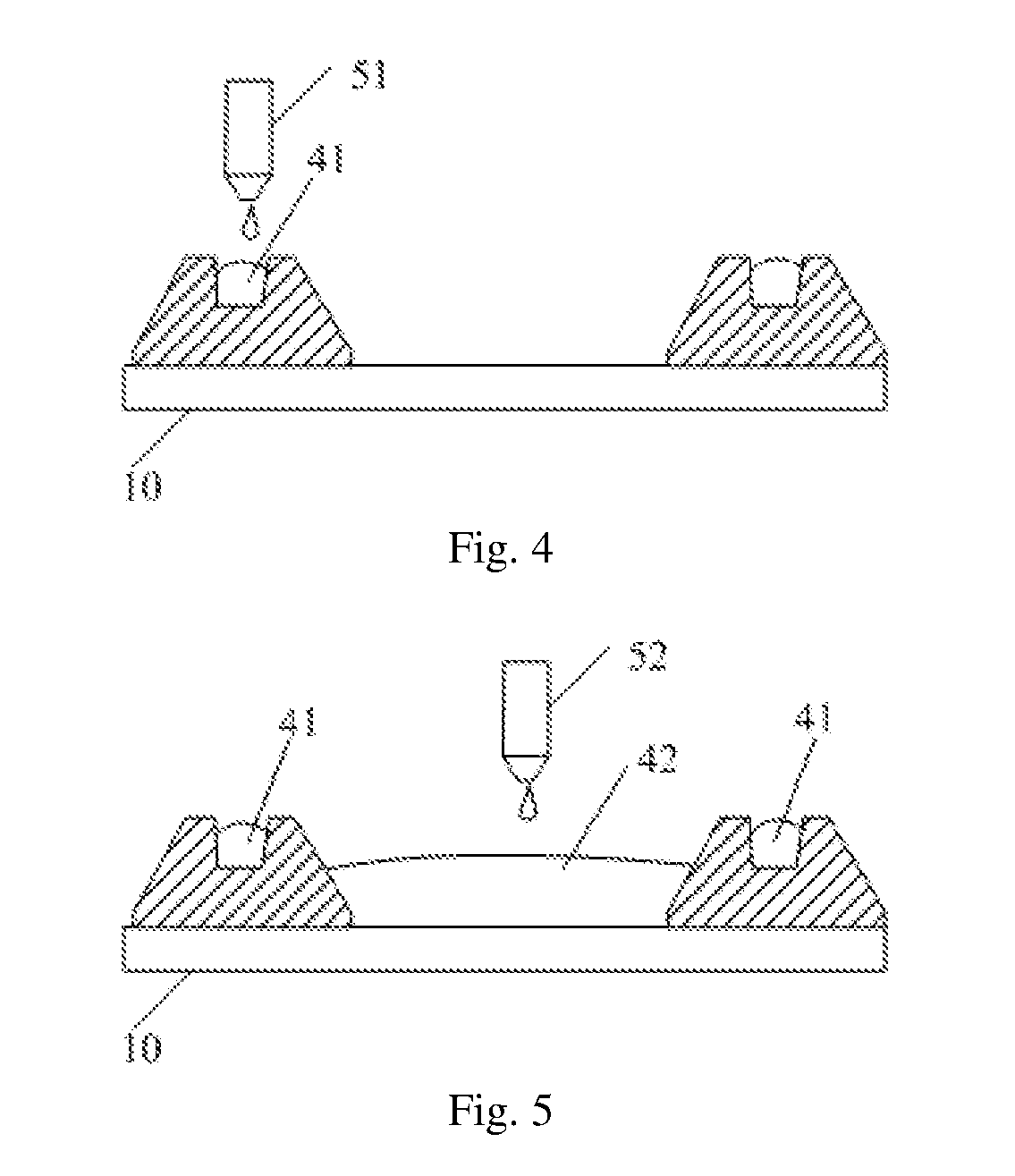

Organic light-emitting display substrate, manufacturing method thereof and display device

ActiveUS20160365396A1Good film uniformityImprove brightness uniformitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceMaterials science

Disclosed is an organic light-emitting display substrate, including a substrate and a pixel defining layer on the substrate which includes a plurality of dams crisscrossing in a display area of the substrate to define a plurality of pixel units and define the boundary of the display area, wherein the pixel defining layer further includes a groove arranged on a top surface of each dam, the grooves at least define one frame-shaped area, at least one pixel unit is arranged in each frame-shaped area, and the grooves are used for accommodating a solvent when forming an organic light-emitting element by inkjet printing. Also disclosed is a manufacturing method of an organic light-emitting display substrate and a display device. The present invention can improve the film forming effect of a film layer formed on the substrate, so that the brightness of a display image of the display device is more uniform.

Owner:BOE TECH GRP CO LTD

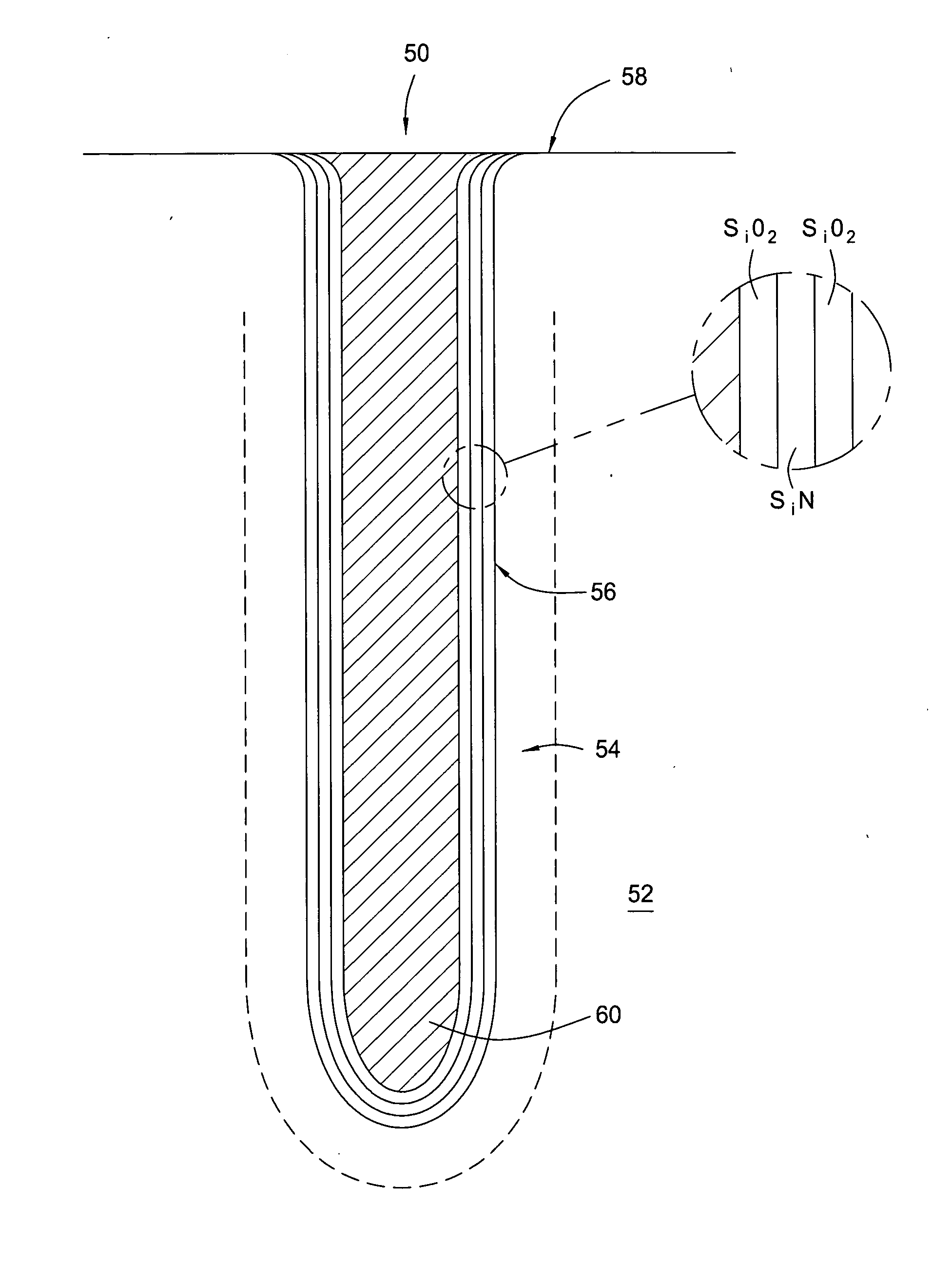

Process sequence for doped silicon fill of deep trenches

InactiveUS20060128139A1Increase deposition rateShort staySolid-state devicesSemiconductor/solid-state device manufacturingDopantFirst Fill

A method for void free filling with in-situ doped amorphous silicon of a deep trench structure is provided in which a first fill is carried out in at a temperature, pressure and dopant to silane ratio such that film deposition occurs from the bottom of the trench upwards. By way of this first fill, step coverages well in excess 100% are achieved. In the second fill step, deposition is carried out under changed conditions so as to reduce the impact of dopant on deposition rate, whereby trench fill is completed at a deposition rate which exceeds the deposition rate of the first fill. In an application of this method to the formation of deep trench capacitor structures, the intermediate steps further including the capping of the void free filled trench with a thick layer of amorphous silicon, planarization of the wafer thereafter, followed by a thermal anneal to re-distribute the dopant within the filled trench. Thereafter, additional steps can be performed to complete the formation of the capacitor structure.

Owner:APPLIED MATERIALS INC

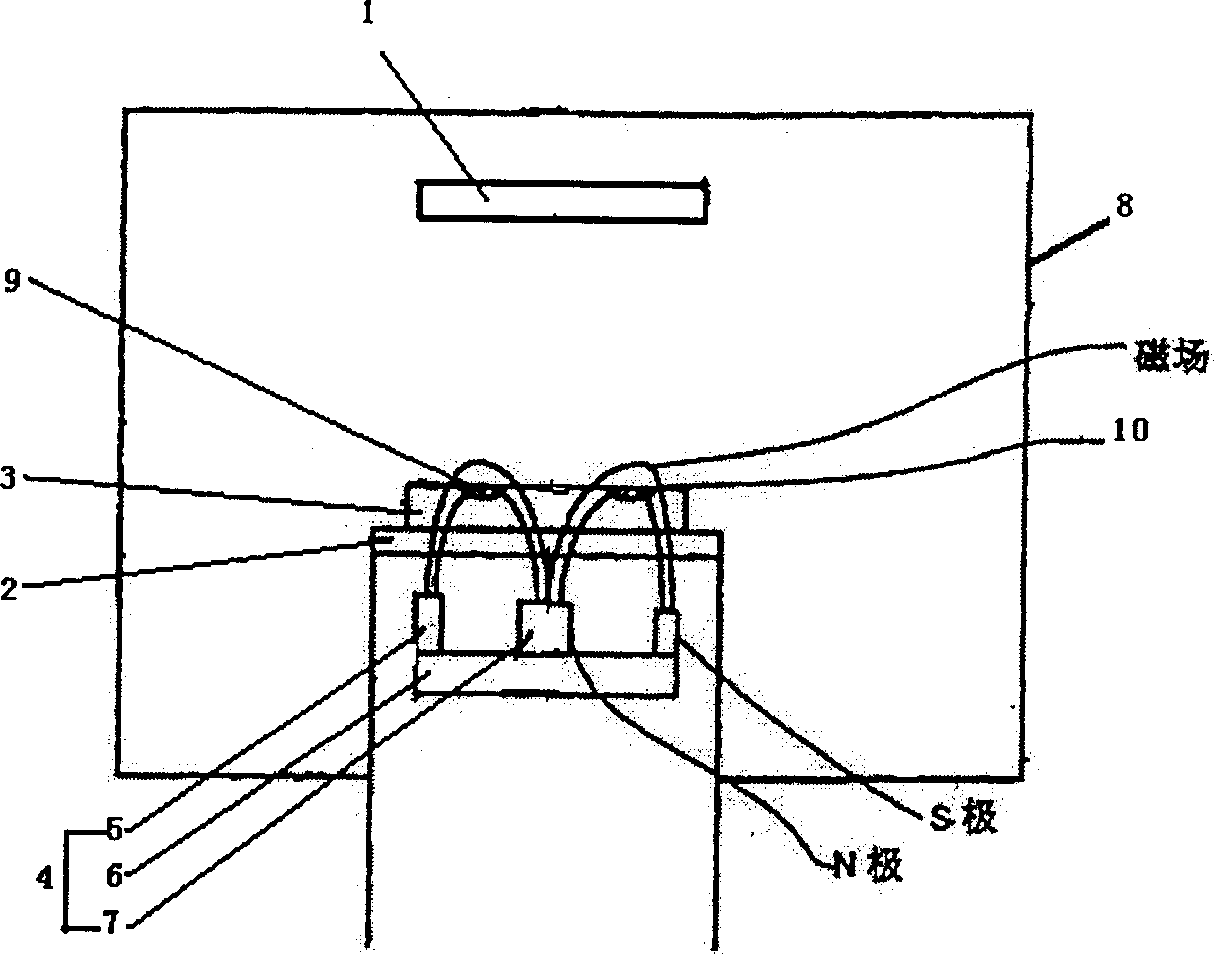

Rotary magnetic field planar target magnetic-controlled sputtering apparatus

InactiveCN1743498AIncrease profitMany particlesVacuum evaporation coatingSputtering coatingSputteringDrive shaft

This invention relates to a magnet control sputtering coating device of a rotary magnetic field plane target including a chip tray, a target base, a target material and a vacuum cavity, among which, the tray, the target base and the material are in the vacuum cavity, the tray is above the base and the material, the material is installed on the base characterizing in also including a magnetic steel group and a rotation motor, among which, the group is composed of a base plate and magnetic steels, more than one magnetic steels are set on the base eccentrically, the entire group is under the place close to the base, the rotation motor is connected with the center of the base via a driving shaft to drive rotation of the group.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Water-barrier performance of an encapsulating film

ActiveUS7504332B2Improve waterproof performanceGood film uniformitySolid-state devicesSemiconductor/solid-state device manufacturingSubstrate typeLow temperature deposition

A method and apparatus for depositing a material layer onto a substrate is described. The method includes delivering a mixture of precursors for the material layer into a process chamber and depositing the material layer on the substrate at low temperature. The material layer can be used as an encapsulating layer for various display applications which require low temperature deposition process due to thermal instability of underlying materials used. In one aspect, the encapsulating layer includes one or more material layers (multilayer) having one or more barrier layer materials and one or more low-dielectric constant materials. The encapsulating layer thus deposited provides reduced surface roughness, improved water-barrier performance, reduce thermal stress, good step coverage, and can be applied to many substrate types and many substrate sizes. Accordingly, the encapsulating layer thus deposited provides good device lifetime for various display devices, such as OLED devices. In another aspect, a method of depositing an amorphous carbon material on a substrate at low temperature is provided. The amorphous carbon material can be used to reduce thermal stress and prevent the deposited thin film from peeling off the substrate.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com