Rotary magnetic field planar target magnetic-controlled sputtering apparatus

A magnetron sputtering device and rotating magnetic field technology, applied in the field of electromechanical, can solve the problems of low target utilization, slow sputtering speed, and small uniform area of sputtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

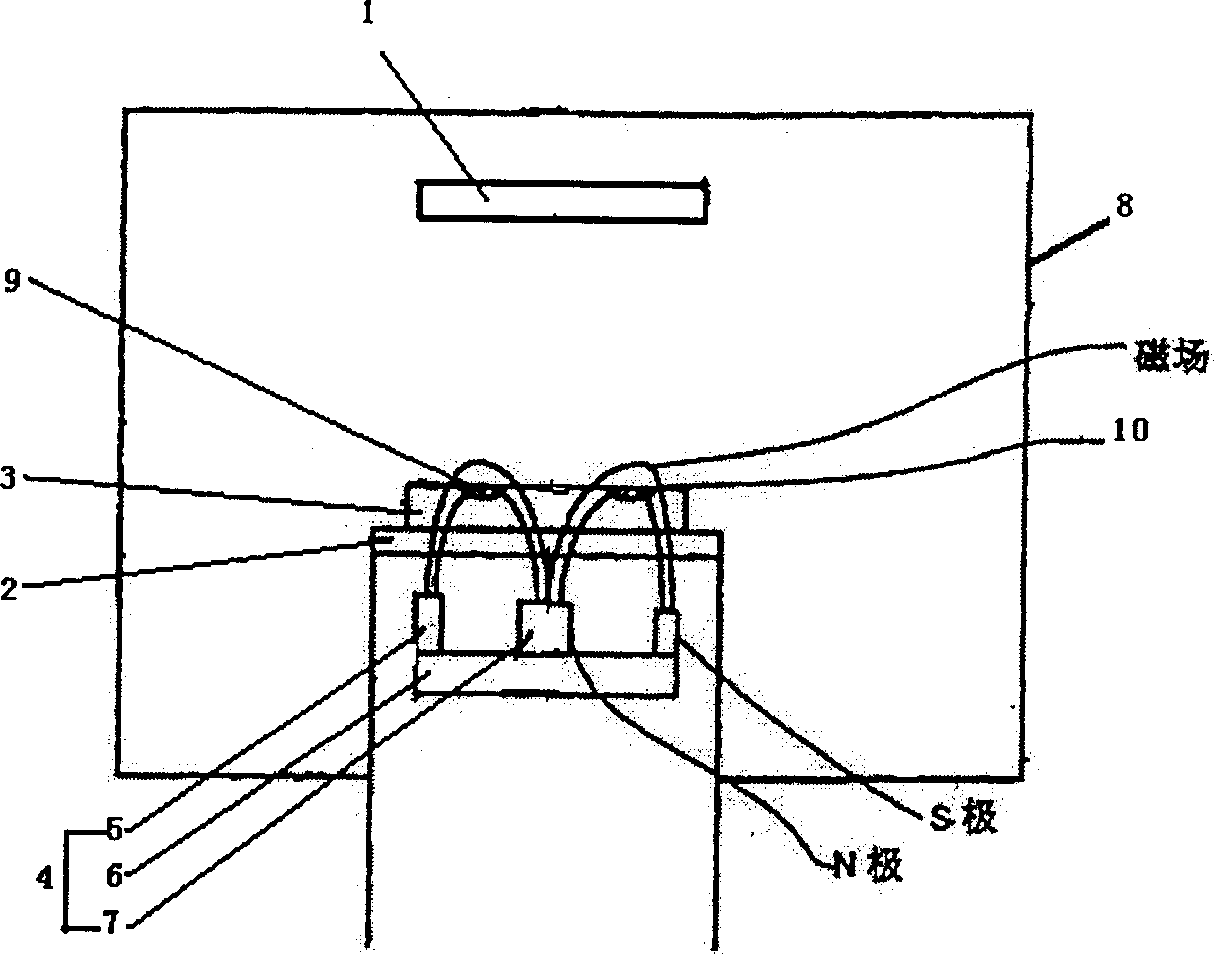

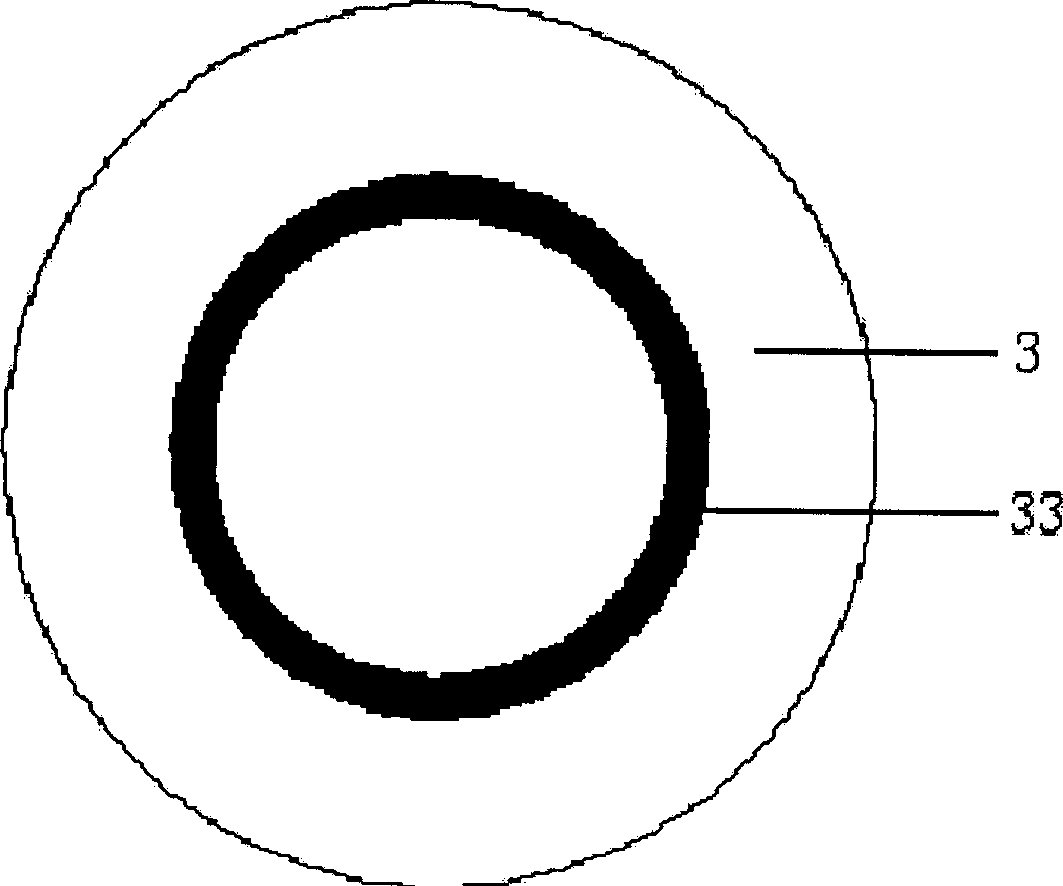

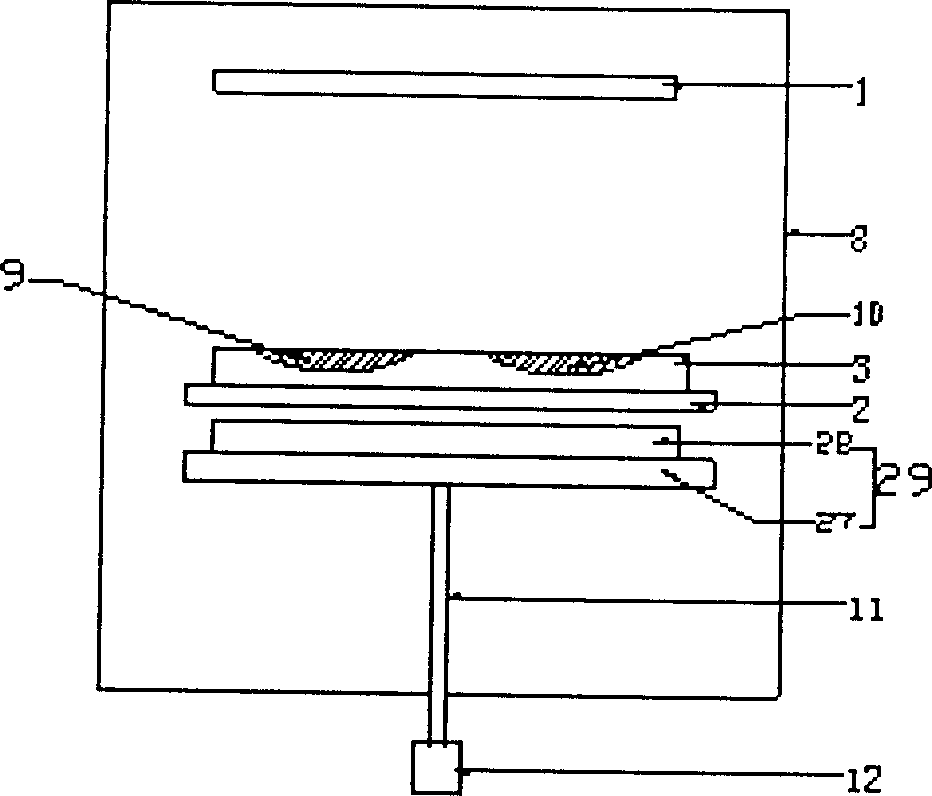

[0033] A rotating magnetic field plane target magnetron sputtering device mainly includes a substrate tray 1, a target holder 2, a target material 3, a vacuum cavity 8, a heater 18, a thermocouple 31 and the like. There is a heater (18) above the substrate tray (1), and the substrate tray (1) and the heater (18) are fixed on the top of the vacuum cavity (8) by connecting rods (21), and can be connected by connecting rods. (17) Properly adjust the distance from the target (3); there is a thermocouple (31) between the substrate tray (1) and the heater (18). The target base (2) and the magnetic steel group (29) are located in the target inner base (23), and the target (3) is installed on the target base (2) and passed through the target pressing frame (22) and bolts (21) Fixed on the target inner seat (23); the rotating motor (12) passes through the vacuum chamber bottom plate (25) and the target inner seat (23) through the transmission shaft (11) and connects with the center of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com