Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48 results about "Planar magnetron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

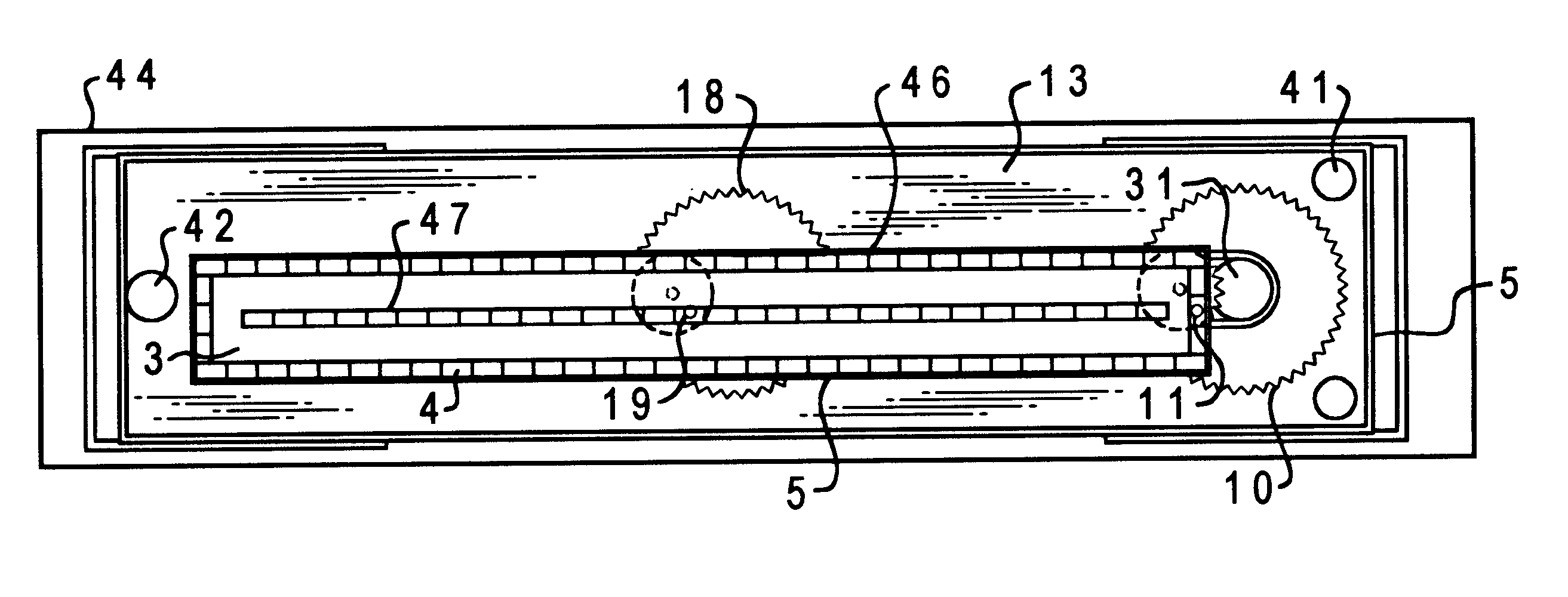

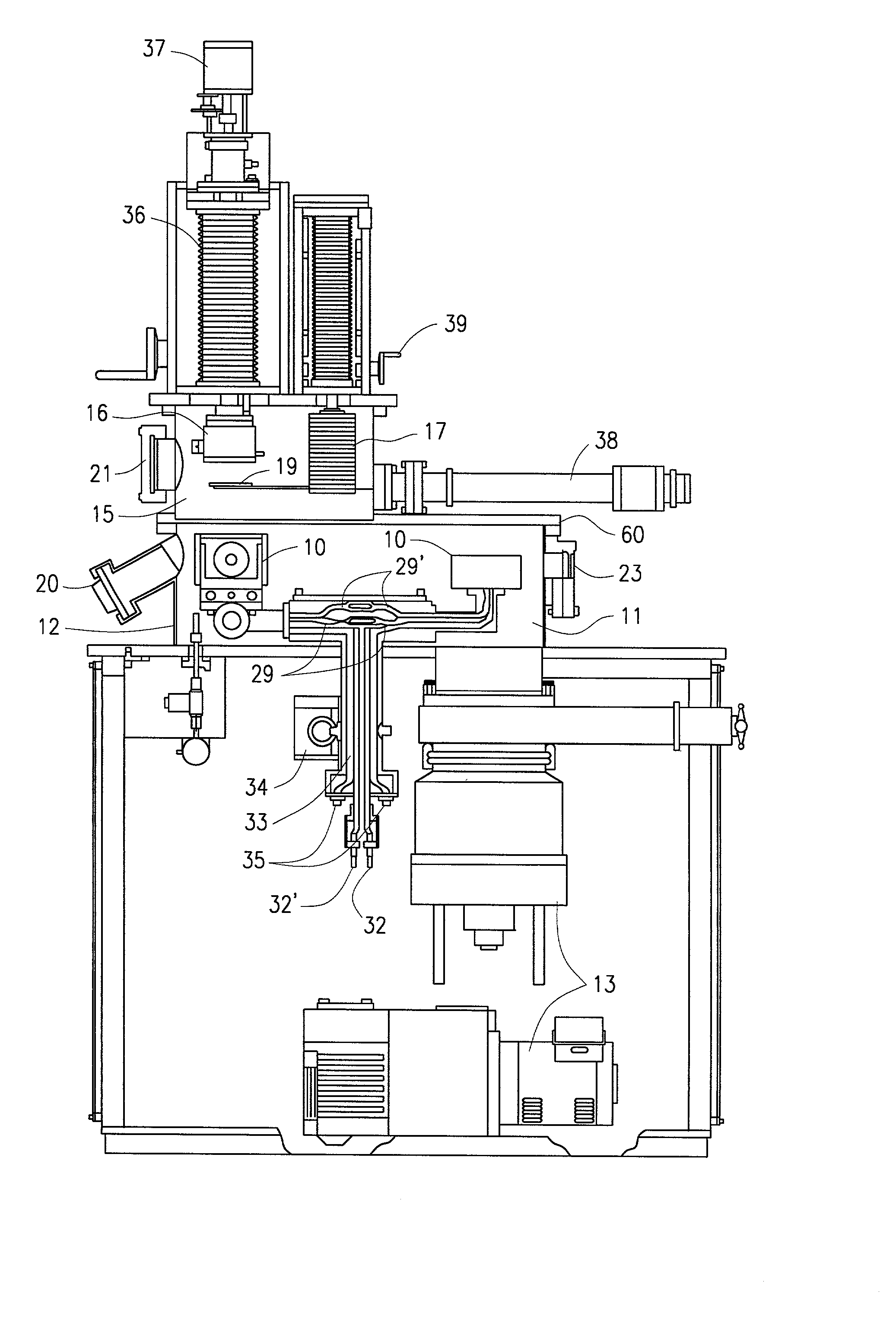

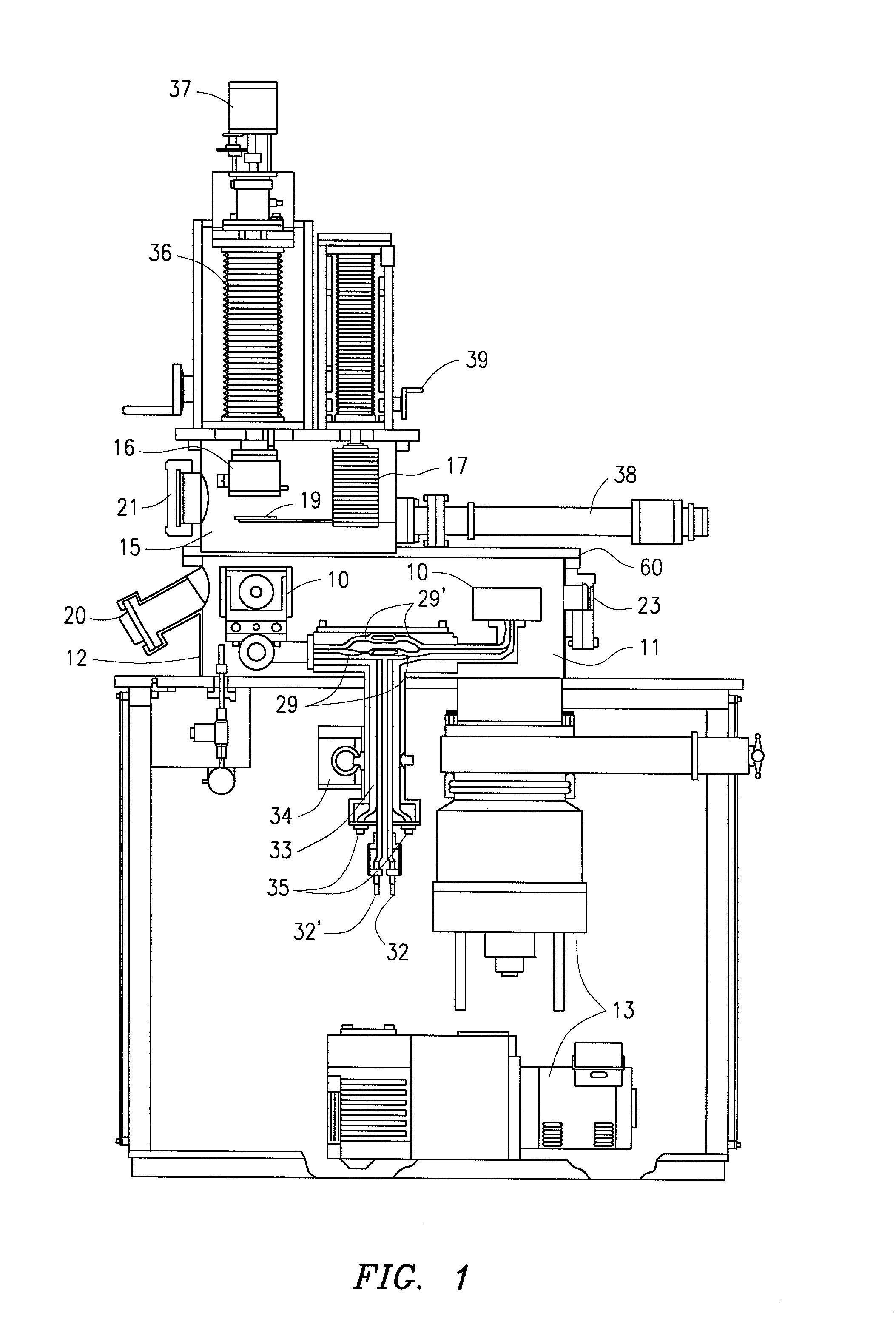

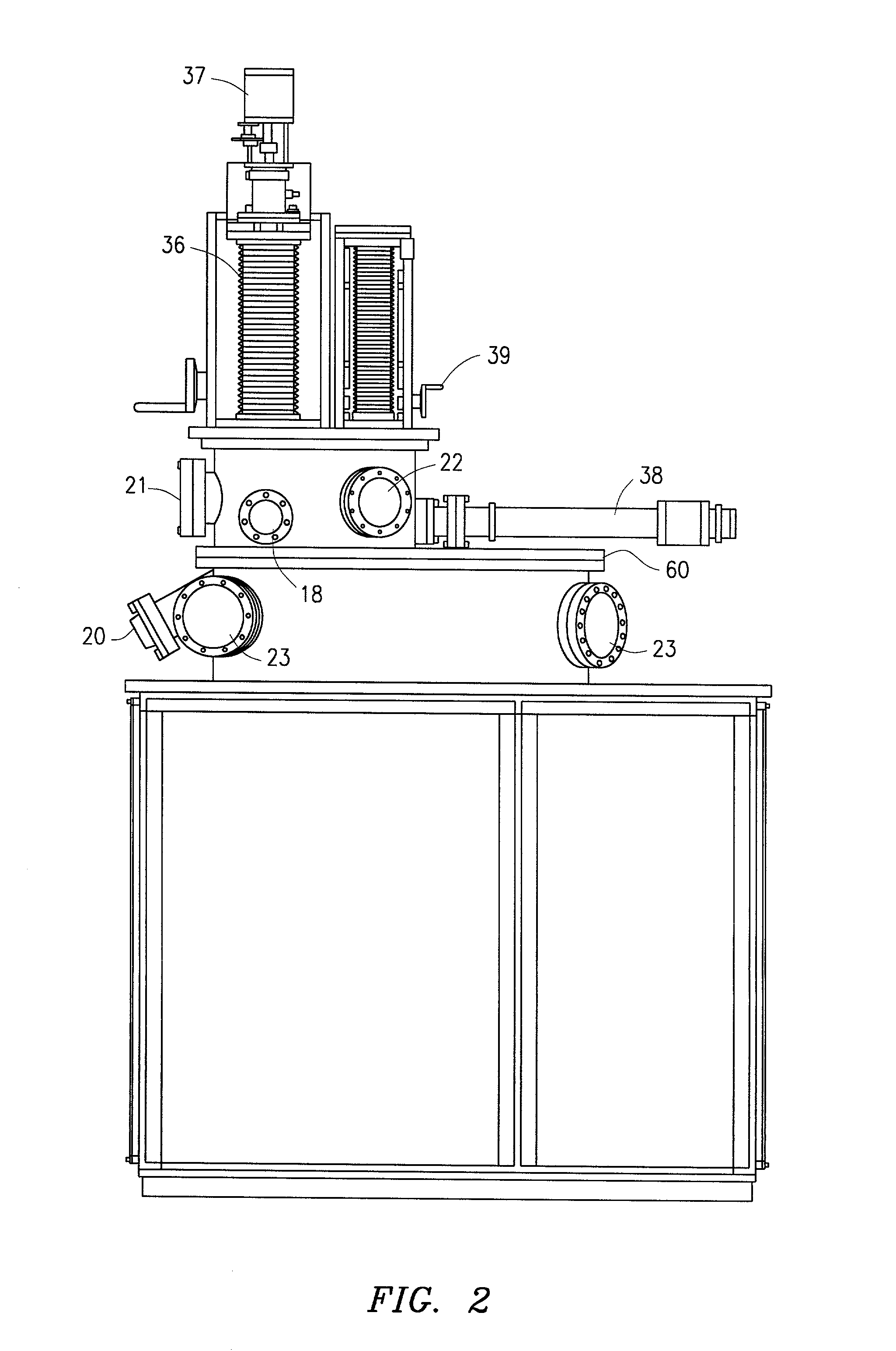

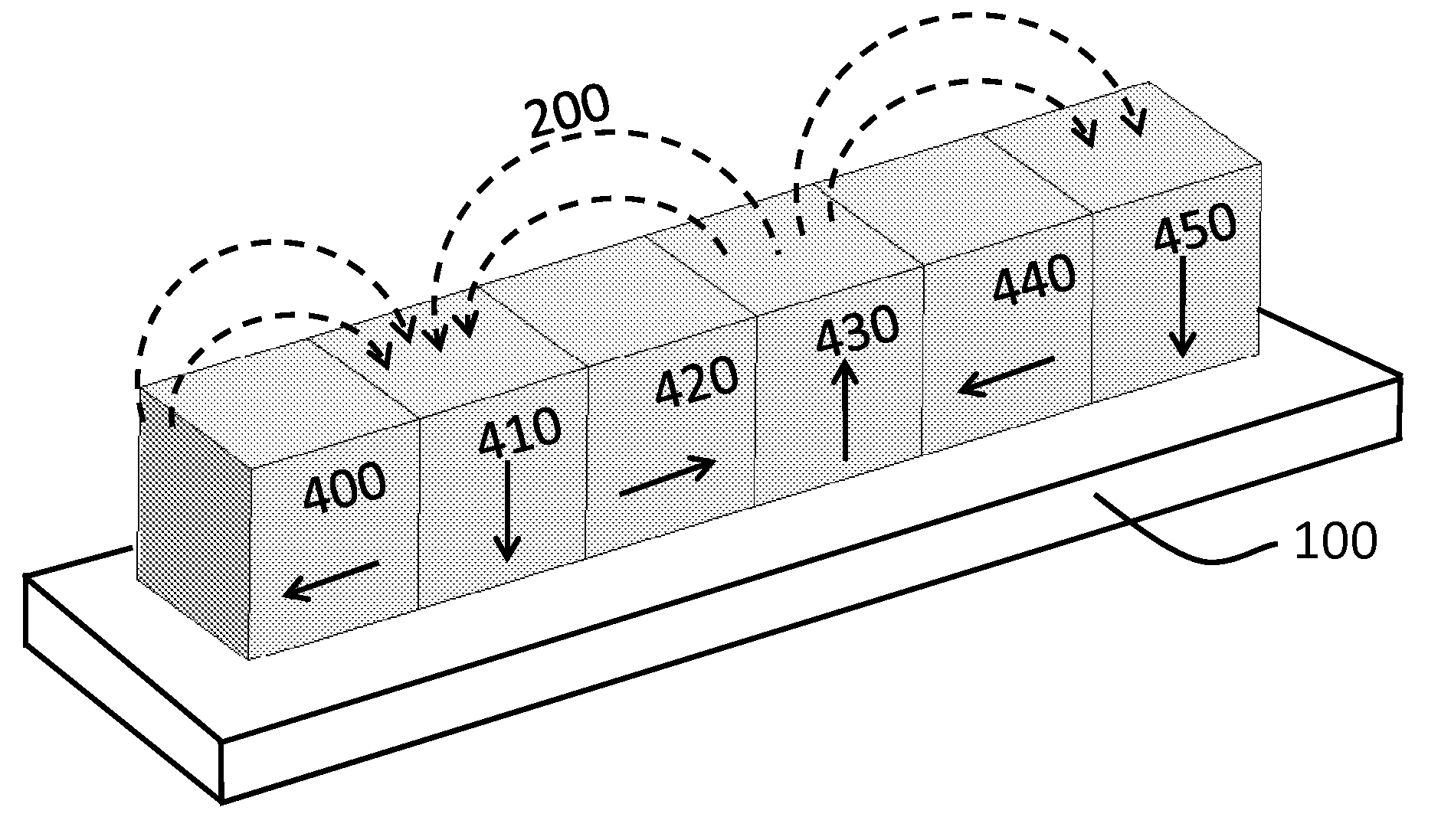

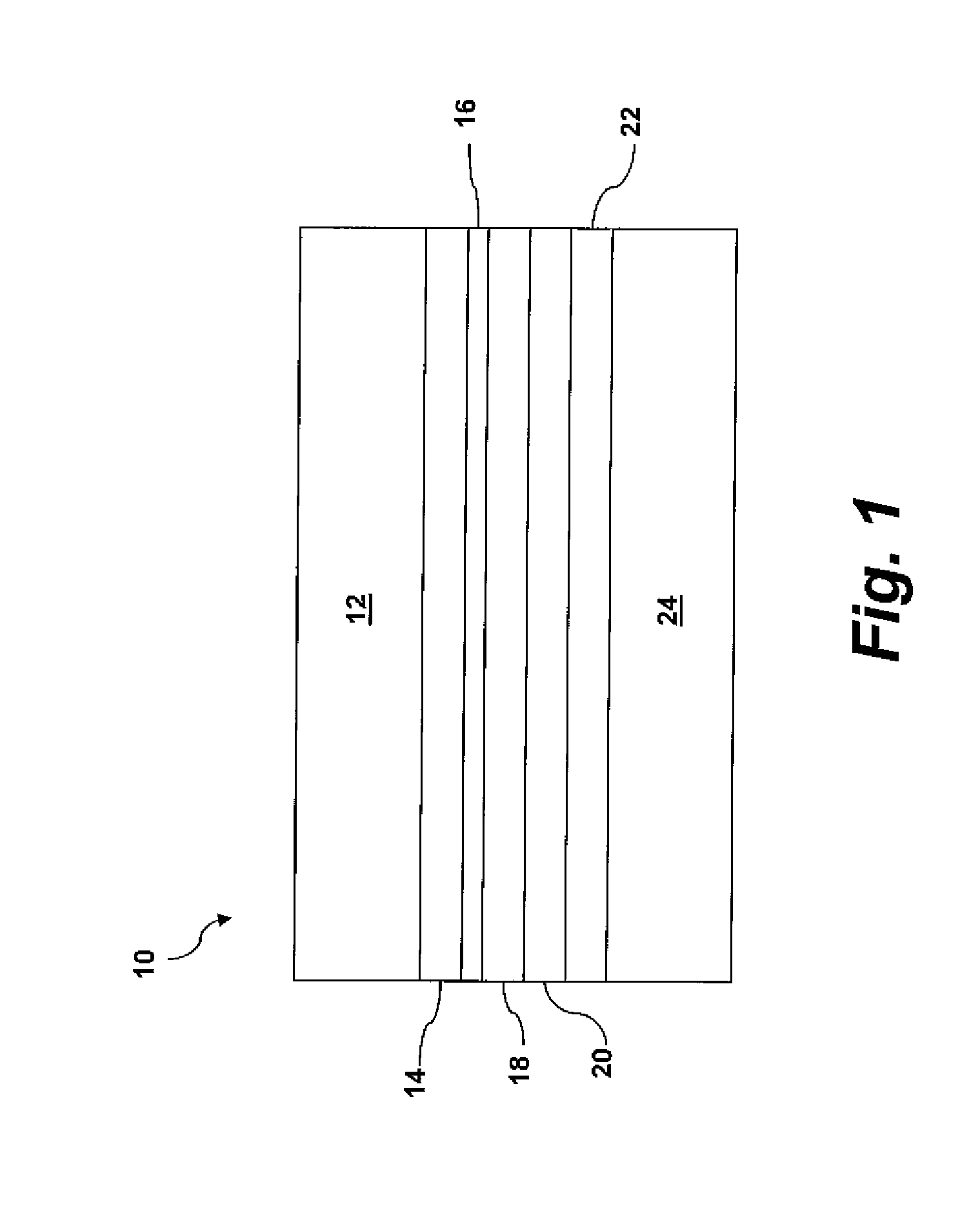

Planar magnetron with moving magnet assembly

InactiveUS6322679B1Simple driving mechanismSimple and efficientCellsElectric discharge tubesClosed loopEngineering

The present invention provides a planar magnetron including a surface for mounting a planar substantially polygonal target (2) having a substantially central target area for sputtering onto a substrate. The magnetron comprises an array of magnets (4) defining a closed loop magnetic field for generating an elongated plasma race-track above the target (2). Means for establishing cyclical, relative, substantially translational movement between the race-track and the target support surface are provided, the substantially translational movement being substantially parallel to this surface and the trace of the substantially translational movement being a two-dimensional figure. The periphery of the race-track lies substantially within said substantially central target area throughout each cycle, the establishing means being adapted to provide a substantially uniform erosion of the target (2) at least within said substantially central target area.

Owner:BEKAERT ADVANCED COATINGS

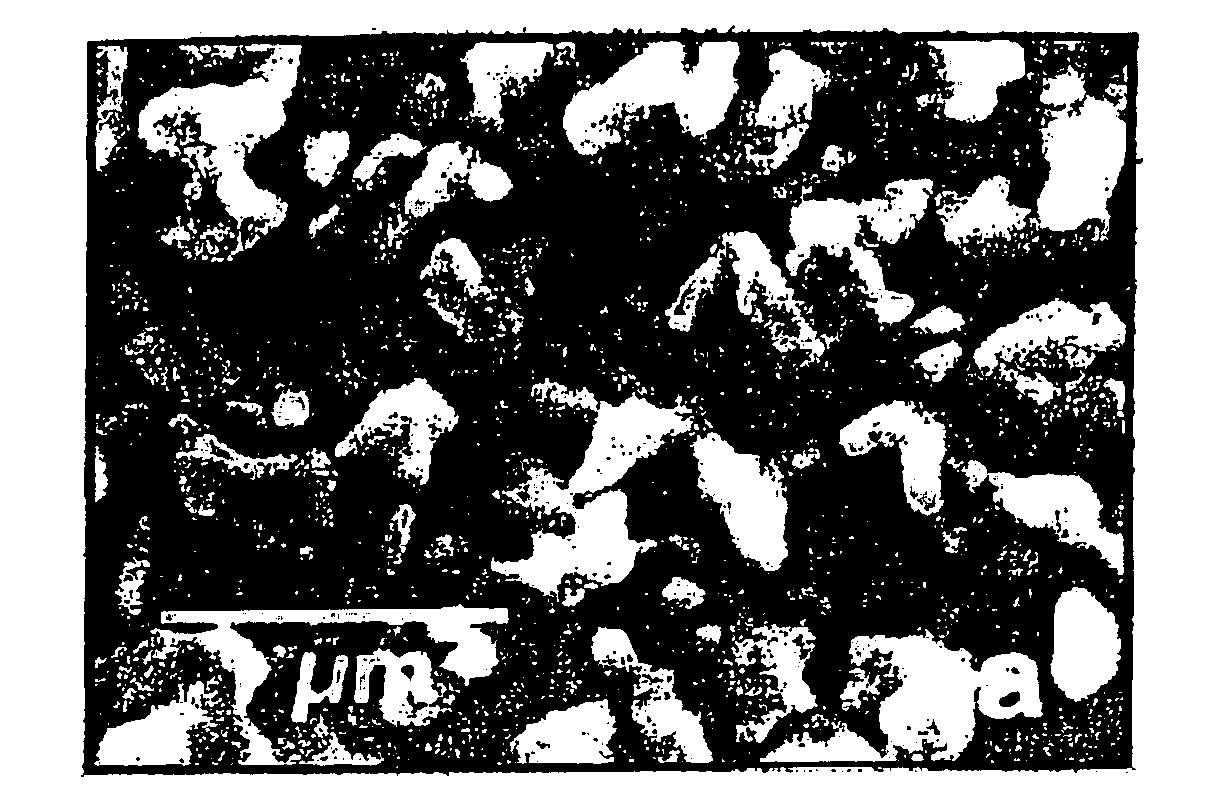

Vapor-deposited porous films for energy conversion

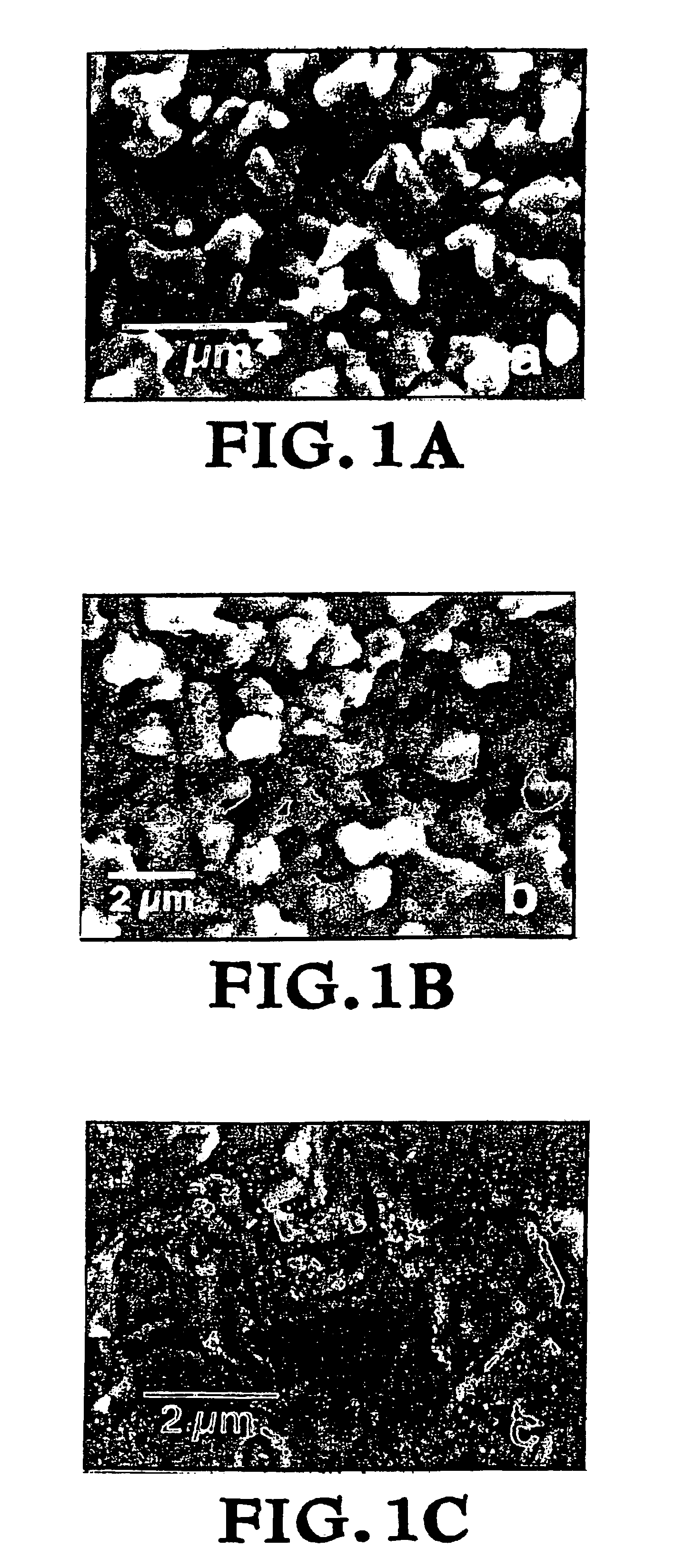

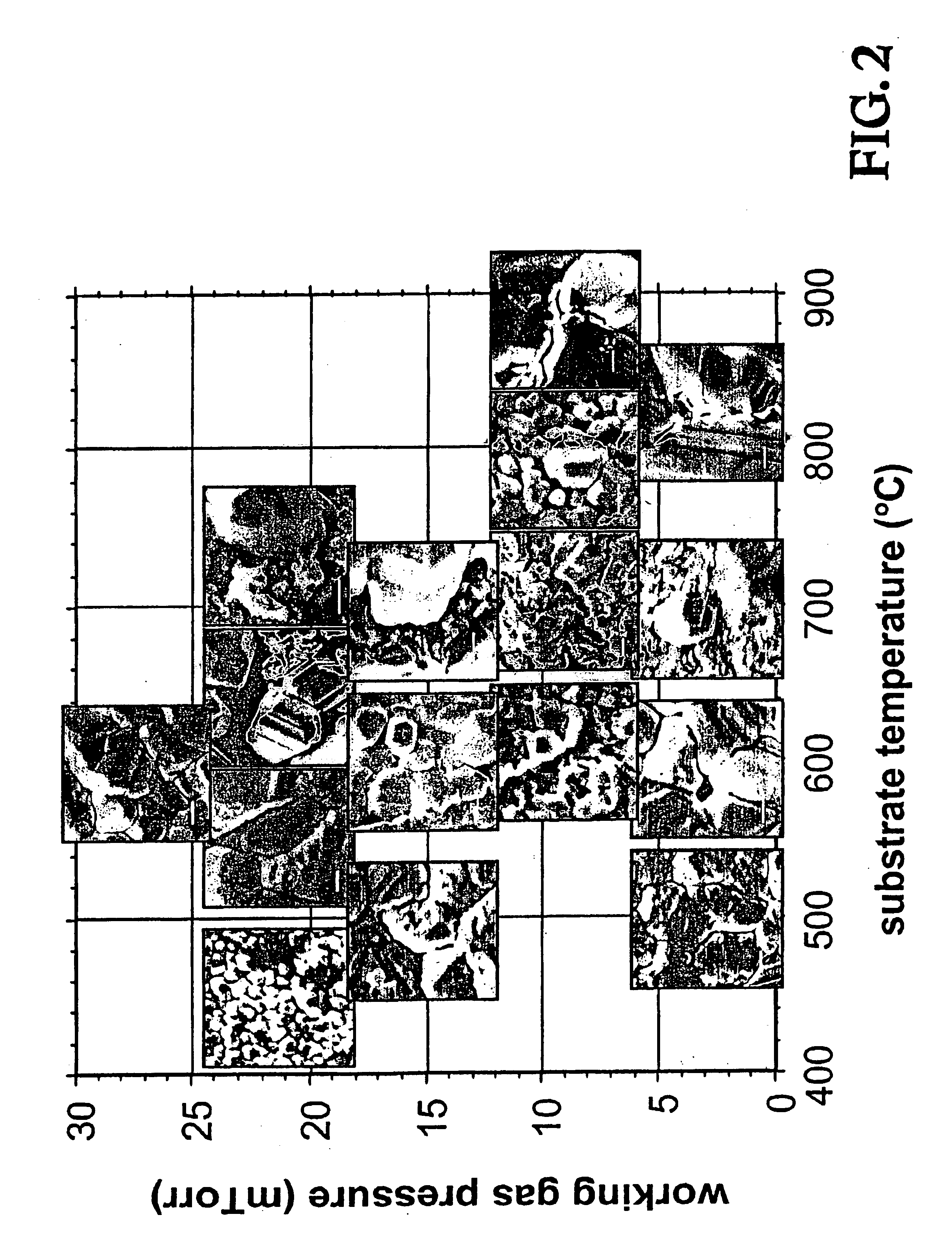

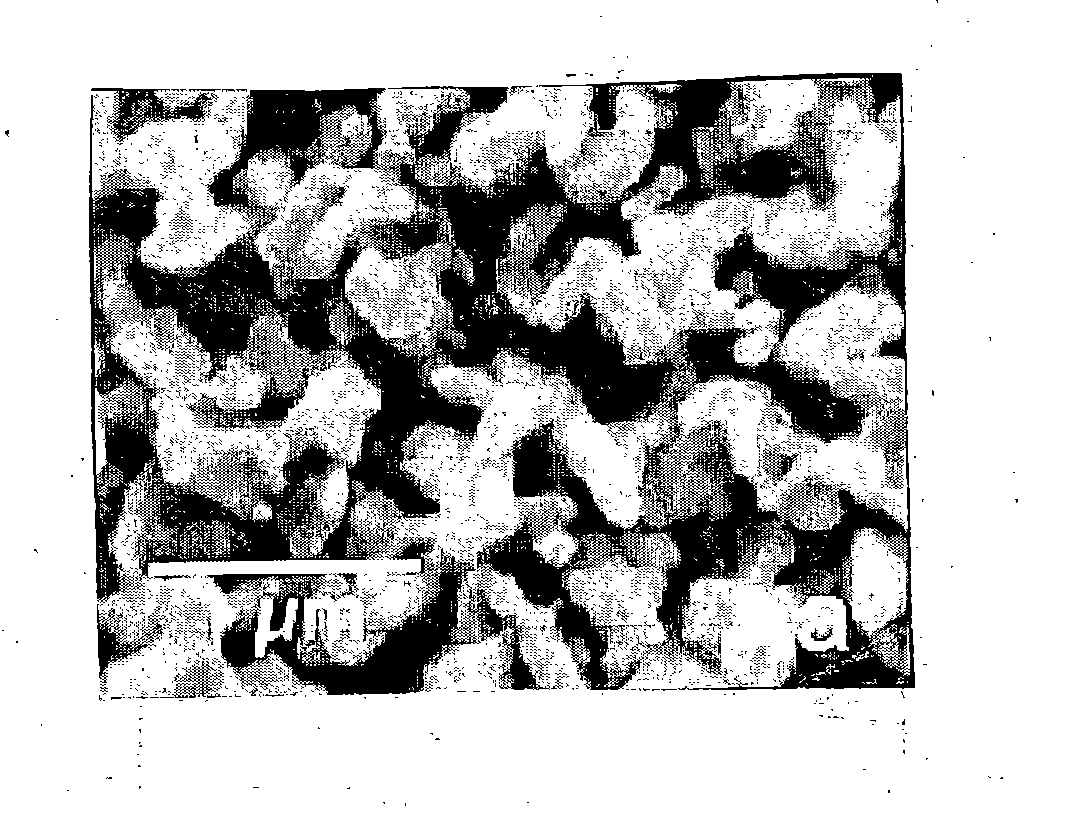

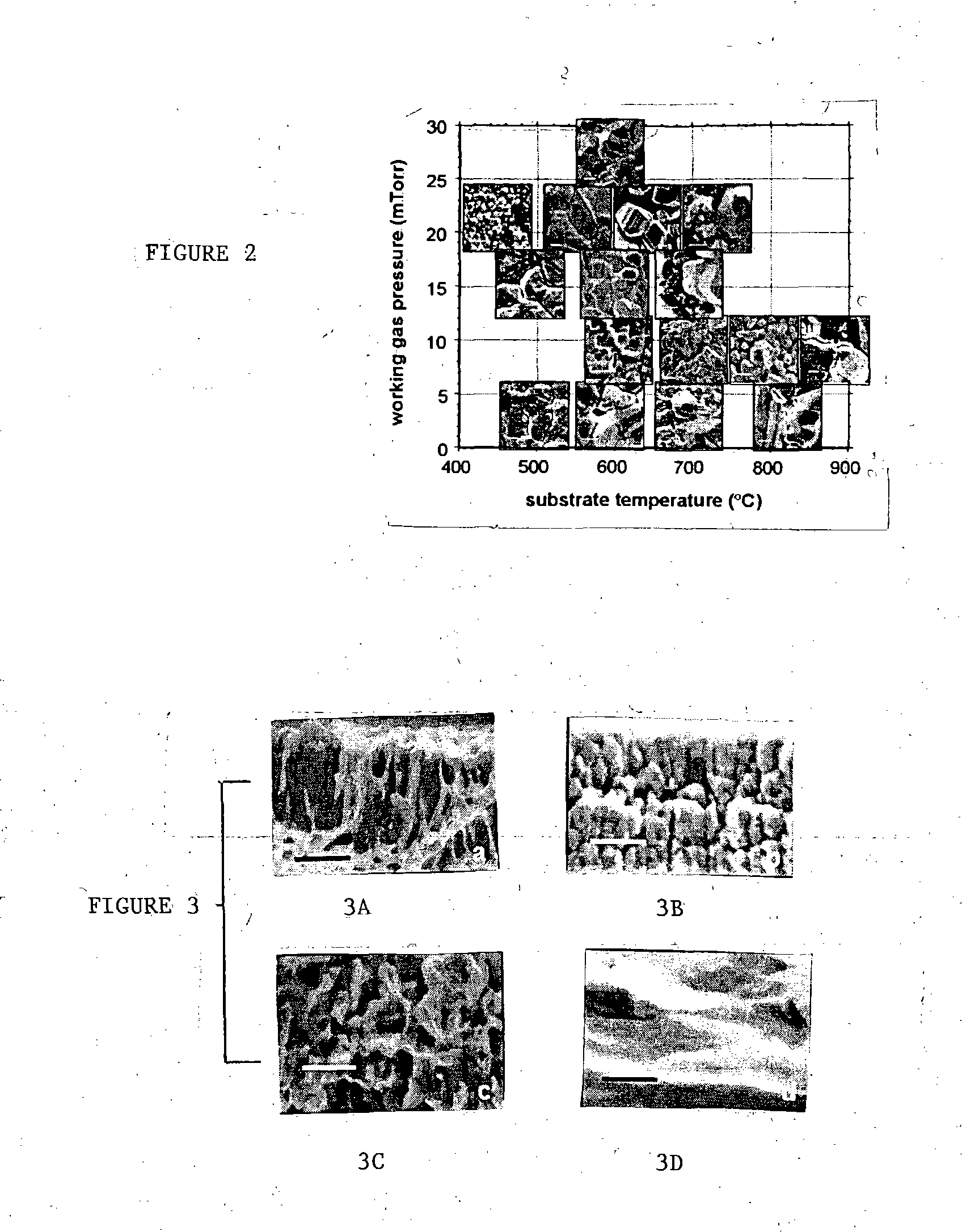

Metallic films are grown with a “spongelike” morphology in the as-deposited condition using planar magnetron sputtering. The morphology of the deposit is characterized by metallic continuity in three dimensions with continuous and open porosity on the submicron scale. The stabilization of the spongelike morphology is found over a limited range of the sputter deposition parameters, that is, of working gas pressure and substrate temperature. This spongelike morphology is an extension of the features as generally represented in the classic zone models of growth for physical vapor deposits. Nickel coatings were deposited with working gas pressures up 4 Pa and for substrate temperatures up to 1000 K. The morphology of the deposits is examined in plan and in cross section views with scanning electron microscopy (SEM). The parametric range of gas pressure and substrate temperature (relative to absolute melt point) under which the spongelike metal deposits are produced appear universal for other metals including gold, silver, and aluminum.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

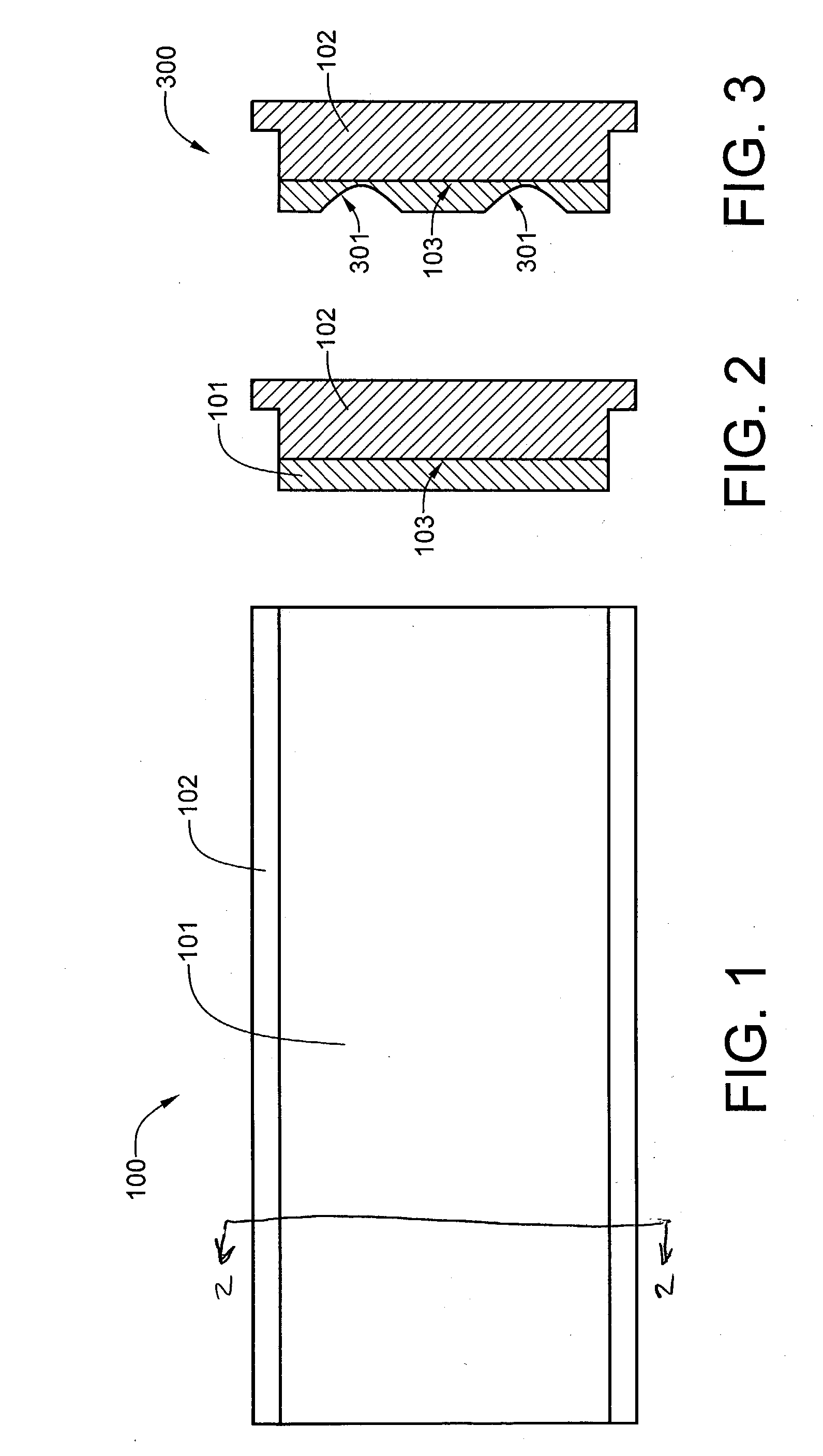

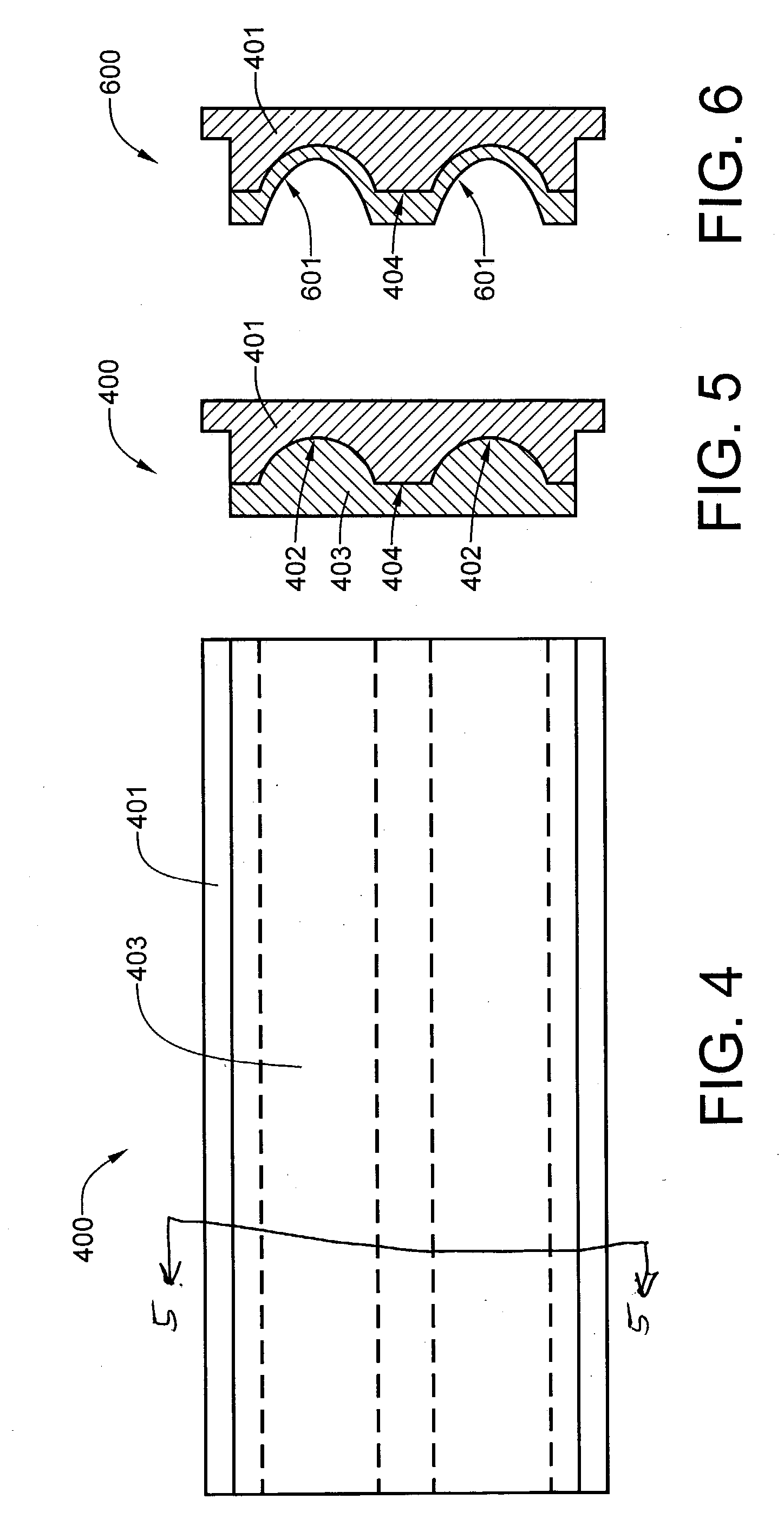

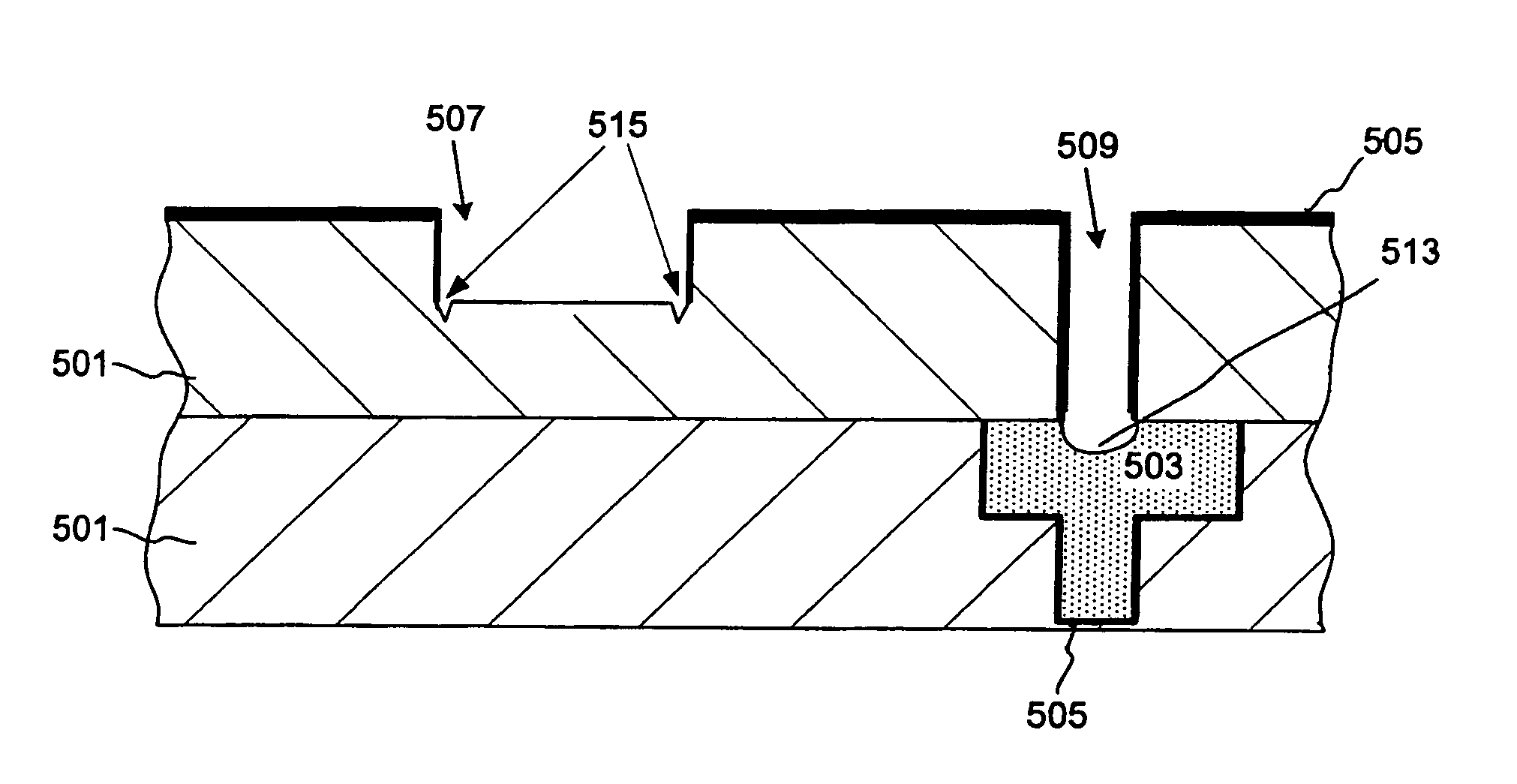

Planar magnetron targets having target material affixed to non-planar backing plates

Planar magnetron targets are disclosed which include a backing plate which is grooved in the regions where erosion of the target material mainly occurs, thereby permitting greater erosion depth of the target material. The life of the target material may be further extended by employing an in-relief upper surface for the target material. The in-relief surface may be prepared by a number of well-known techniques, which include casting and computer-controlled plasma spray. The target material may be either sprayed on or bonded to the backing plate. For a preferred embodiment of the invention, the backing plate is grooved to create undercut ledges which retain the target material on the backing plate, even if adhesion between the surfaces of the target material and the backing plate material fails as the result of thermal cycling.

Owner:LYNN DAVID MARK +1

Sputtering device

The present invention is directed to a sputtering device for depositing multi-layer films on a substrate, the sputtering device comprising at least one planar-magnetron-sputtering-cathode and at least one facing-targets-sputtering-cathode housed in a single vacuum chamber, and adapted such that each planar-magnetron-sputtering-cathode and facing-targets-sputtering-cathode can be selectively positioned for sputtering deposition onto a substrate

Owner:DATA STORAGE INST

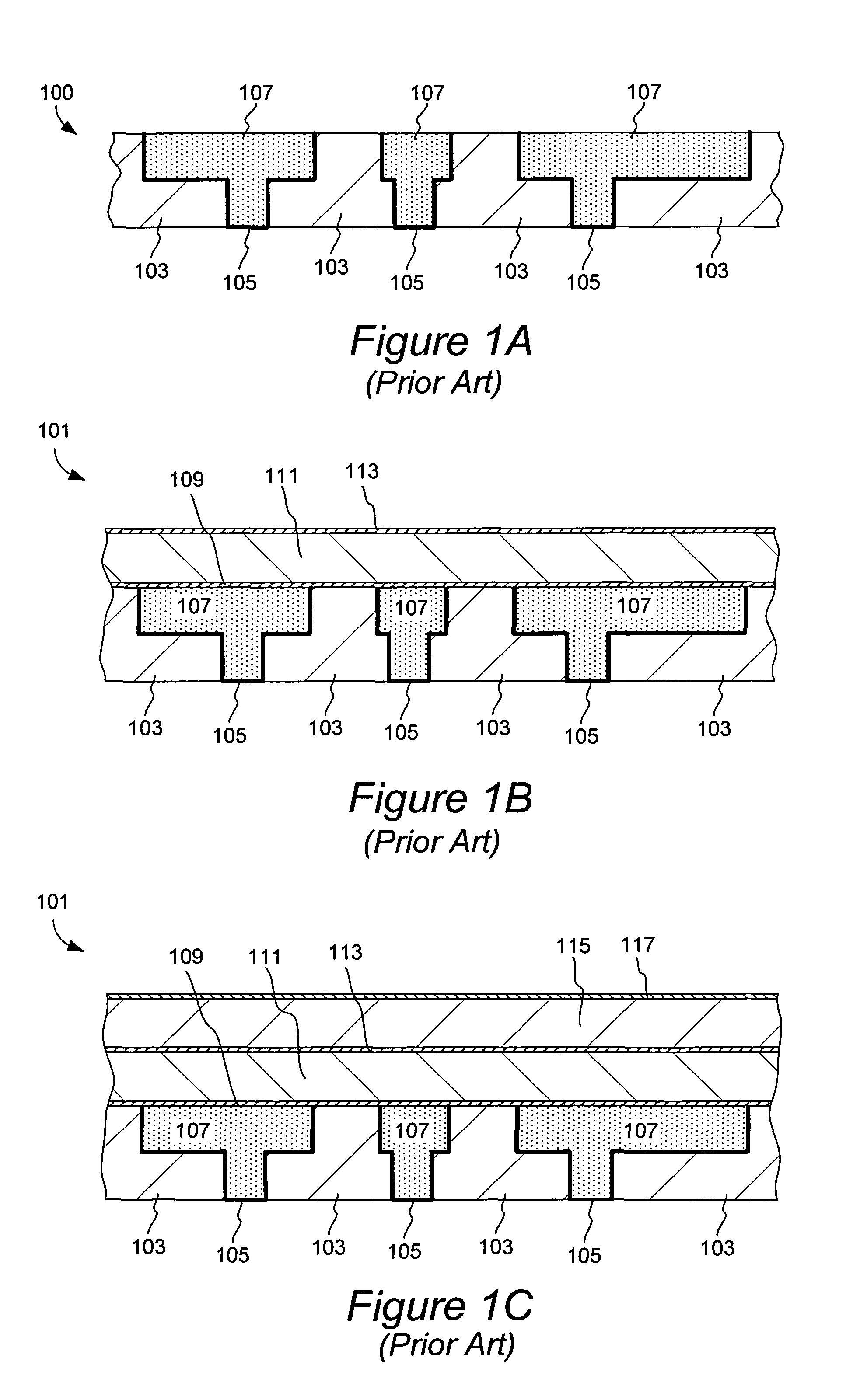

Resputtering process for eliminating dielectric damage

InactiveUS7781327B1Improves several characteristicMinimize damageVacuum evaporation coatingSputtering coatingWaferingEngineering

Methods of resputtering material from the wafer surface include at least one operation of resputtering material under a pressure of at least 10 mTorr. The methods can be used in conjunction with an iPVD apparatus, such as hollow cathode magnetron (HCM) or planar magnetron. The resputtered material may be a diffusion barrier material or a conductive layer material. The methods provide process conditions which minimize the damage to the dielectric layer during resputtering. The methods allow considerable etching of the diffusion barrier material at the via bottom, while not damaging exposed dielectric elsewhere on the wafer. Specifically, they provide a solution for the dielectric microtrenching problem occurring during conventional resputter process. Furthermore, the methods increase the etch rate to deposition rate ratio (E / D) and improve the etch back nonuniformity (EBNU) of resputter process. In general, the methods provide IC devices with higher reliability and decrease wafer manufacturing costs.

Owner:NOVELLUS SYSTEMS

Sputtering device

The present invention is directed to a sputtering device for depositing multi-layer films on a substrate, the sputtering device comprising at least one planar-magnetron-sputtering-cathode and at least one facing-targets-sputtering-cathode housed in a single vacuum chamber, and adapted such that each planar-magnetron-sputtering-cathode and facing-targets-sputtering-cathode can be selectively positioned for sputtering deposition onto a substrate.

Owner:DATA STORAGE INST

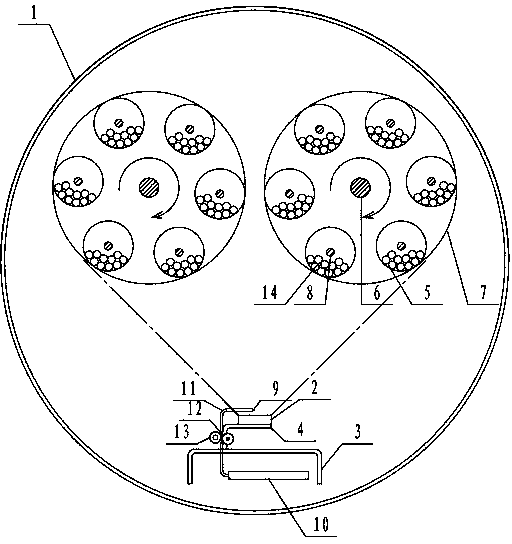

Composite coating equipment and manufacturing method for neodymium iron boron rare-earth permanent magnetic device

InactiveCN103820765AIncrease useImprove corrosion resistanceVacuum evaporation coatingSputtering coatingRare earthPlanar magnetron

The invention discloses composite coating equipment and a manufacturing method for a neodymium iron boron rare-earth permanent magnetic device. The coating equipment comprises a vacuum chamber, a cylindrical rotary cathode magnetron target, a planar cathode magnetron target, a cylindrical or rectangular cathode multi-arc ion target, an anode layer linear ion source, a rotating stand and a charging basket. When the coating equipment works, the rotating stand revolves in the vacuum chamber, and rotating shafts at two ends of the netlike charging basket are arranged on the rotating stand, namely that the rotating stand rotates automatically along with revolution. The cylindrical rotary cathode magnetron target is arranged in the rotating stand in the vacuum chamber; the planar magnetron target, the multi-arc ion target, the anode layer linear ion source and a heating device are arranged around the rotating stand in the vacuum chamber; a composite coating is divided into three layers, wherein the first layer is a magnetron sputtering coating of which the thickness is 0.1-5mu m, the second layer is a magnetron sputtering and multi-arc mixed coating of which the thickness is 1-15mu m, and the third layer is a magnetron sputtering coating of which the thickness is 0.1-5mu m. The composite coating is used for a surface treatment procedure of the rare-earth permanent magnetic device, so that the corrosion resistance of the rare-earth permanent magnetic device is improved, and the magnetic performance of the rare-earth permanent magnetic device is also improved.

Owner:SHENYANG CHINANORTH VACUUM TECH CO LTD

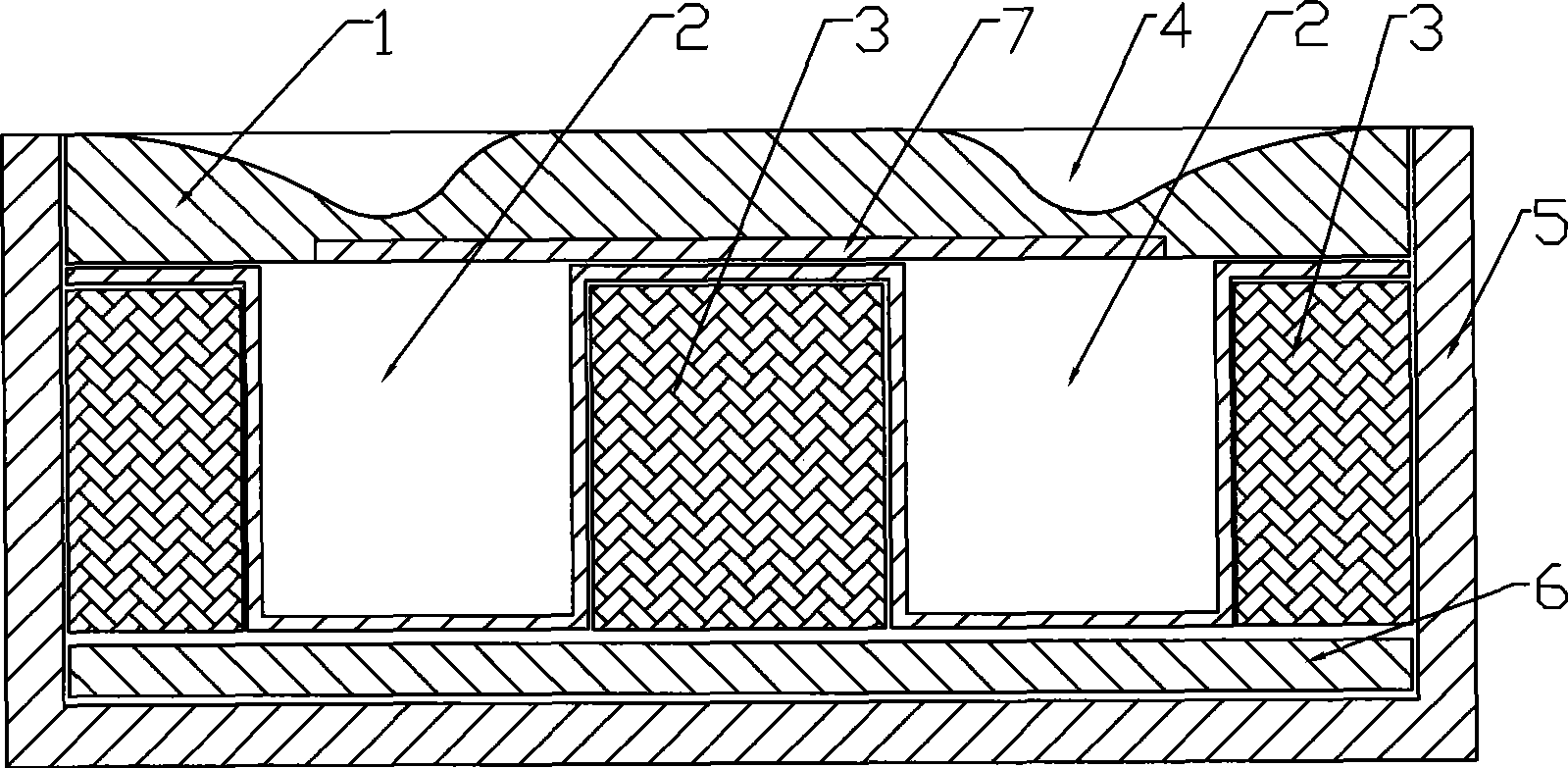

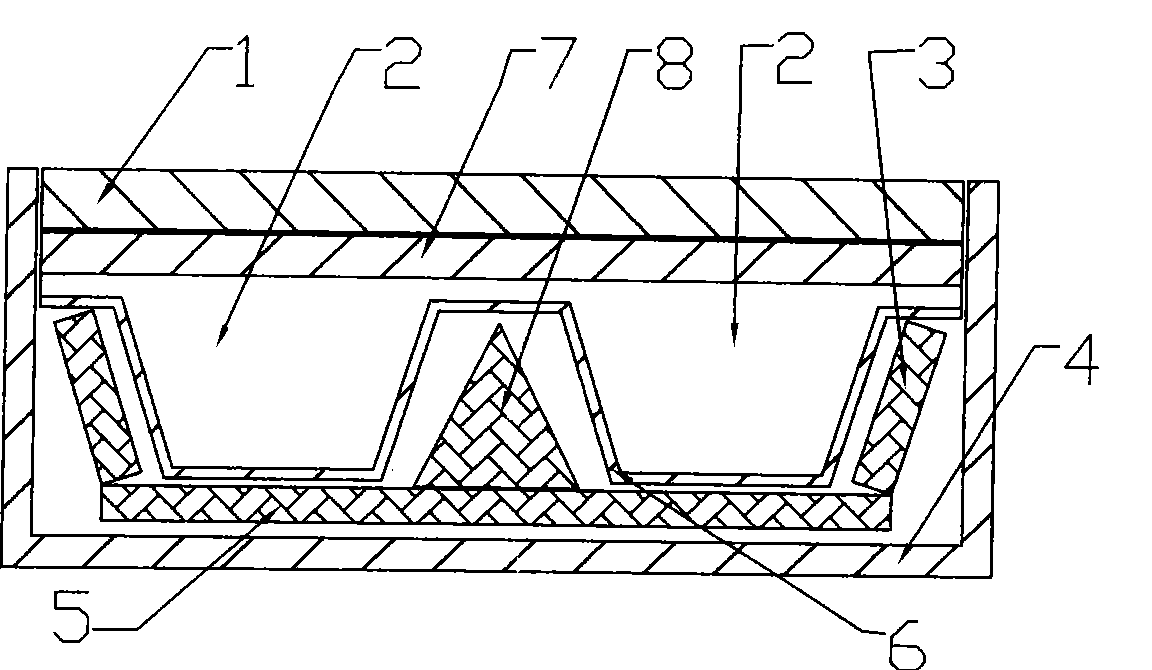

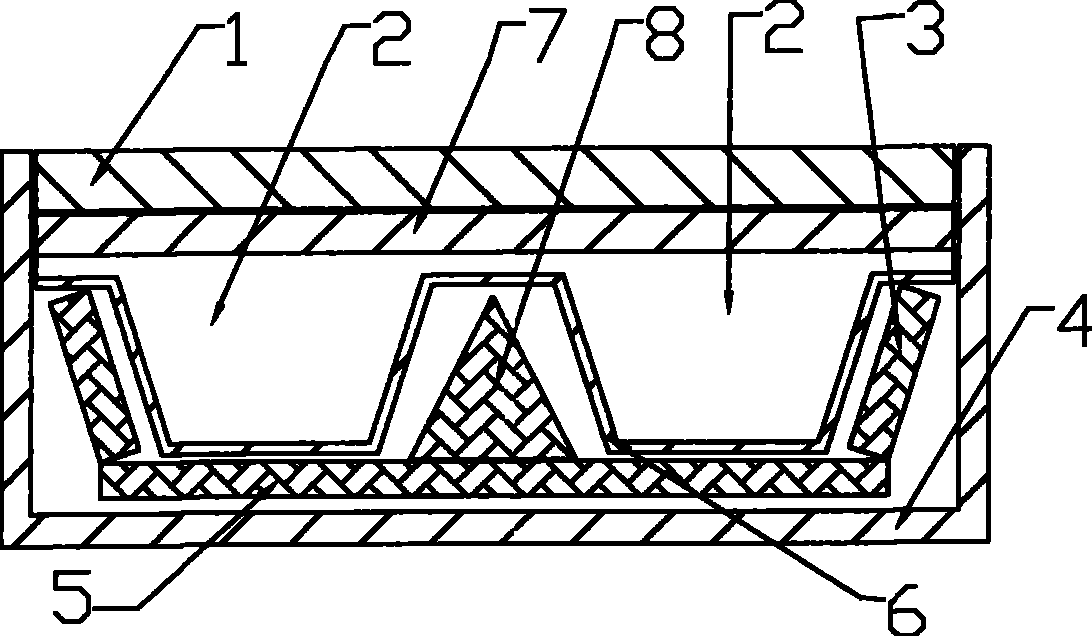

Planar magnetron sputtering cathode capable of improving target material utilization rate

InactiveCN101418433AIncrease profitUniform magnetic fieldVacuum evaporation coatingSputtering coatingSputteringOptoelectronics

The invention relates to a planar magnetron sputtering cathode which can increase the utilization rate of a target and belongs to a planar magnetron sputtering cathode. The planar magnetron sputtering cathode mainly solves the problems that the utilization rate of the target of the prior planar cathode is comparatively low and the like. The key points of the technical proposal are as follows: the planar magnetron sputtering cathode consists of a cathode body shell (5), a magnetic boot (6), a magnet (3), a cooling channel (2) and the target (1), wherein a leaf metal (7) for adjusting a magnetic field is arranged between the target (1) and the cooling channel (2); and the leaf metal (7) is made of magnetic metal material. The leaf metal (7) is fixedly connected with the bottom of the target (1). The bottom part of the target (1) is provided with a groove, and the leaf metal (7) is embedded in the groove arranged on the bottom part of the target (1). The planar magnetron sputtering cathode can enable the horizontal magnetic field on the surface of the target to achieve uniformity in a wider range, thereby improving the utilization rate of the target to 35 to 38 percent from normally 20 to 28 percent. The planar magnetron sputtering cathode can be widely applied to the technical field of magnetron sputtering coating.

Owner:湖南玉丰真空科学技术有限公司

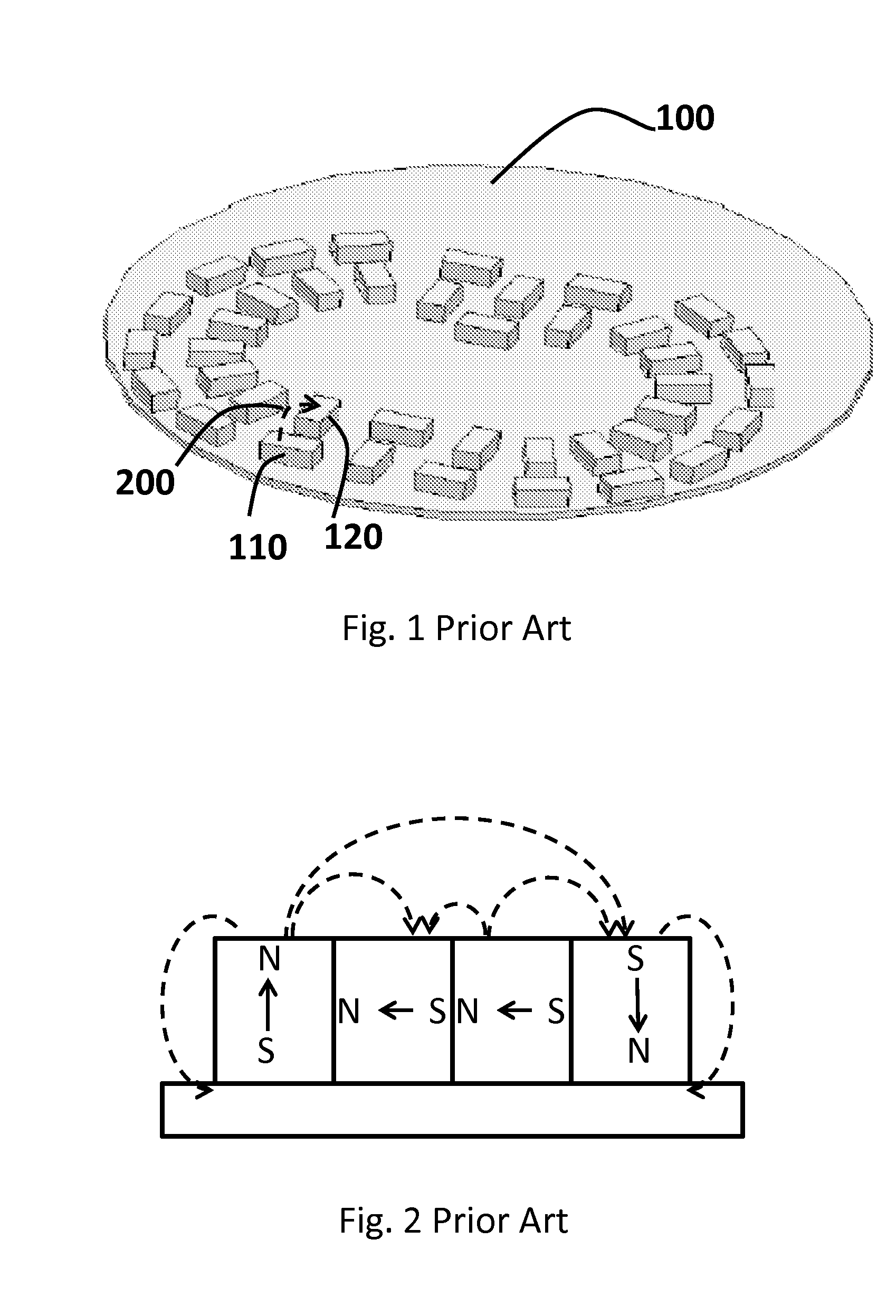

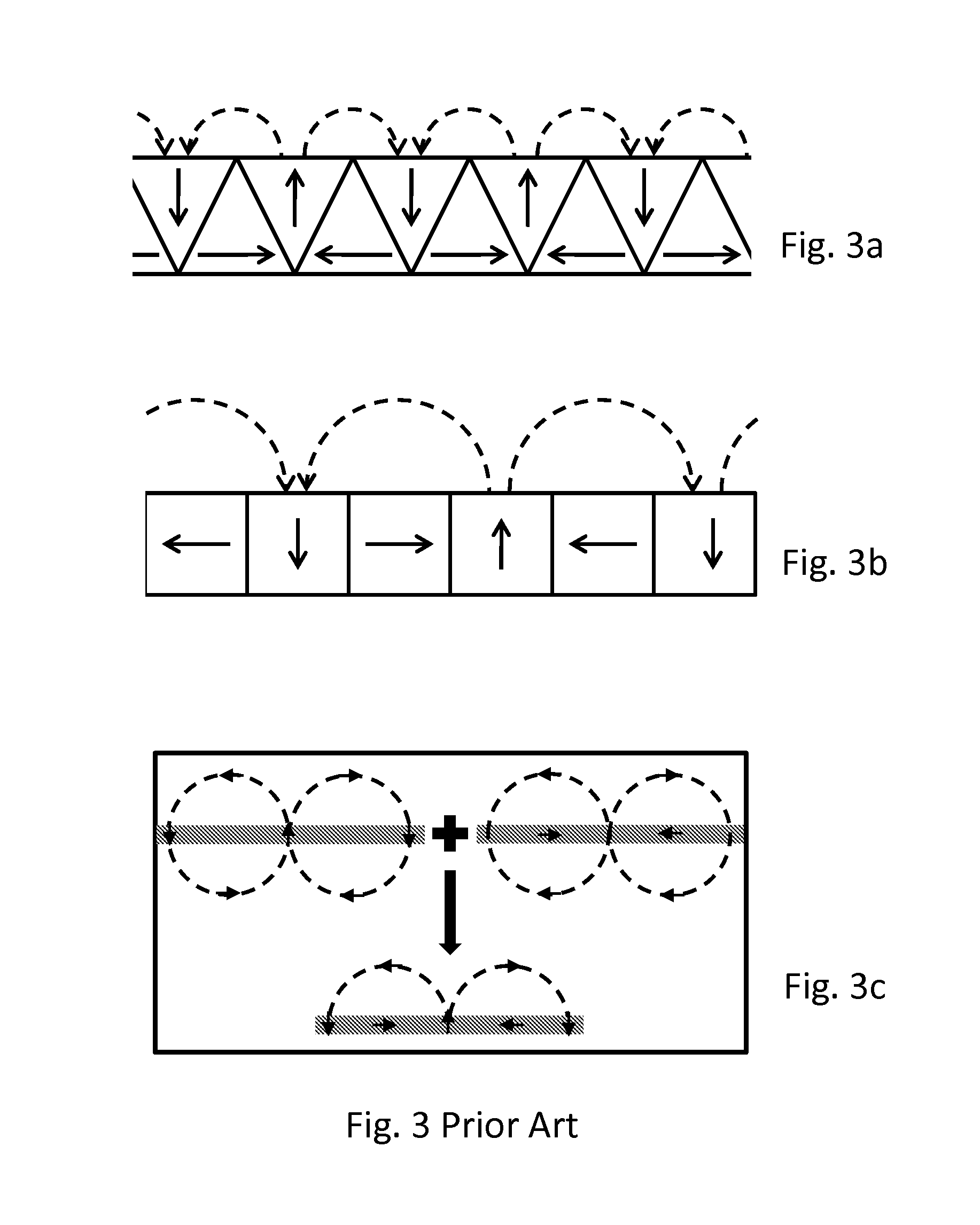

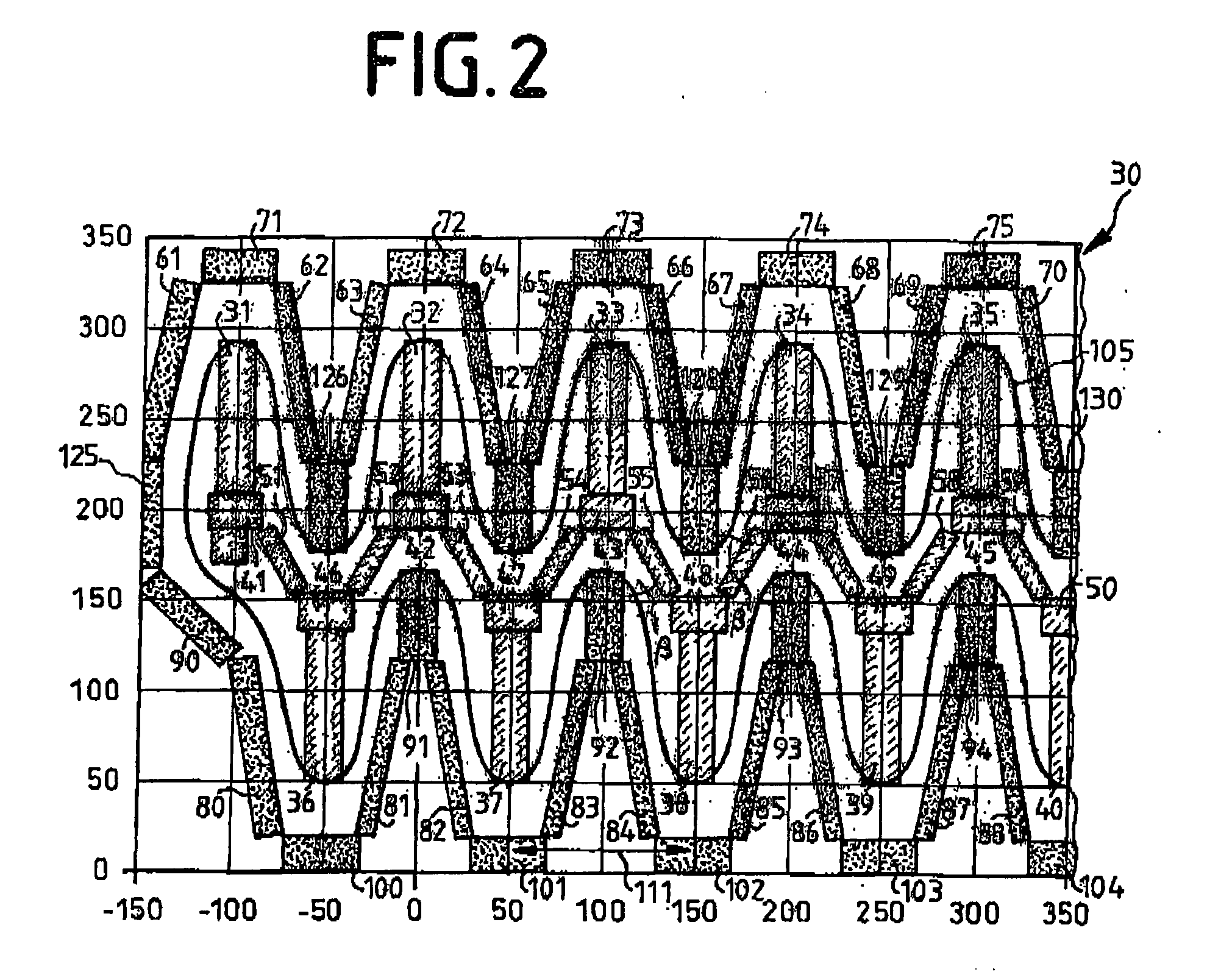

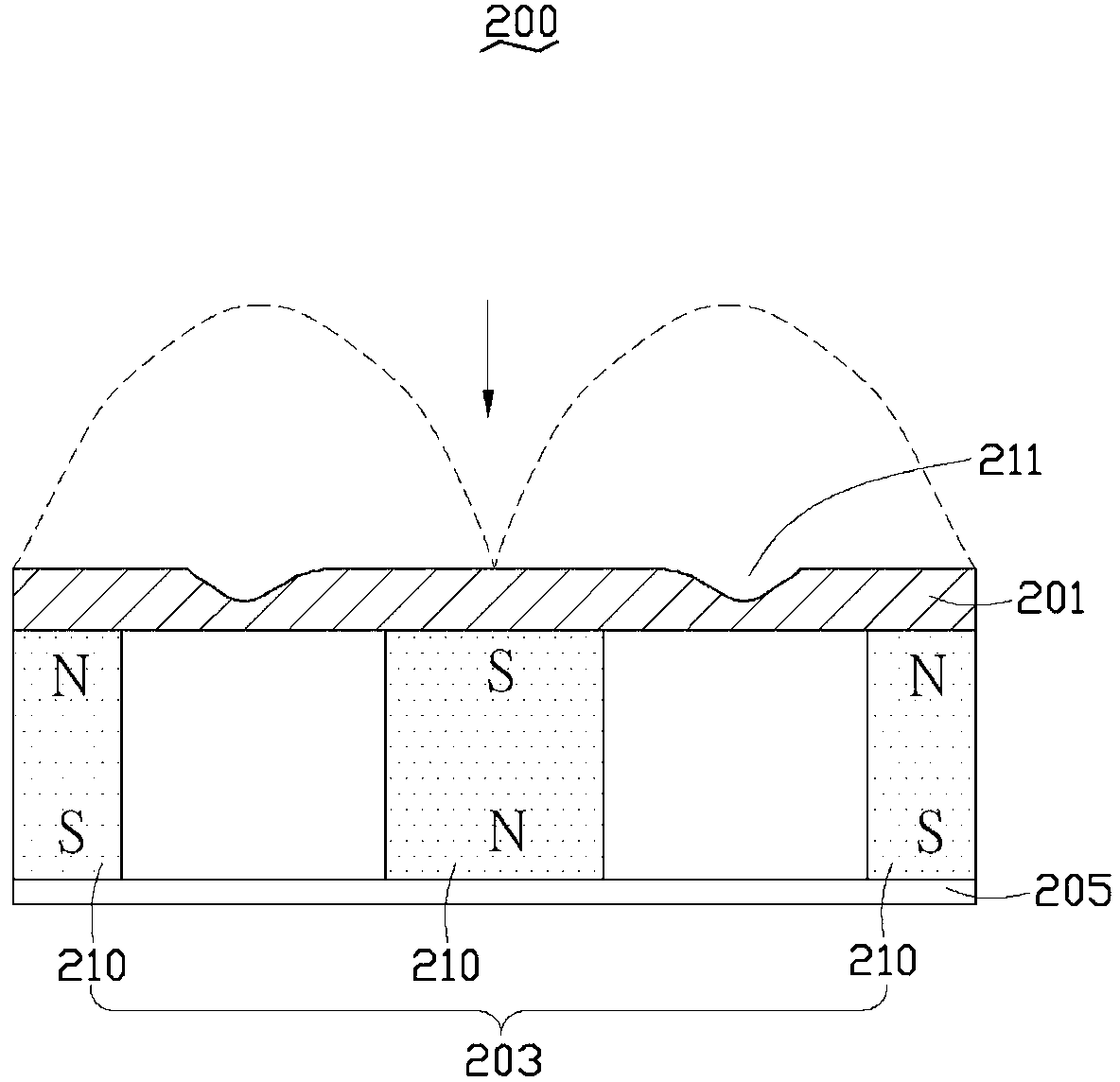

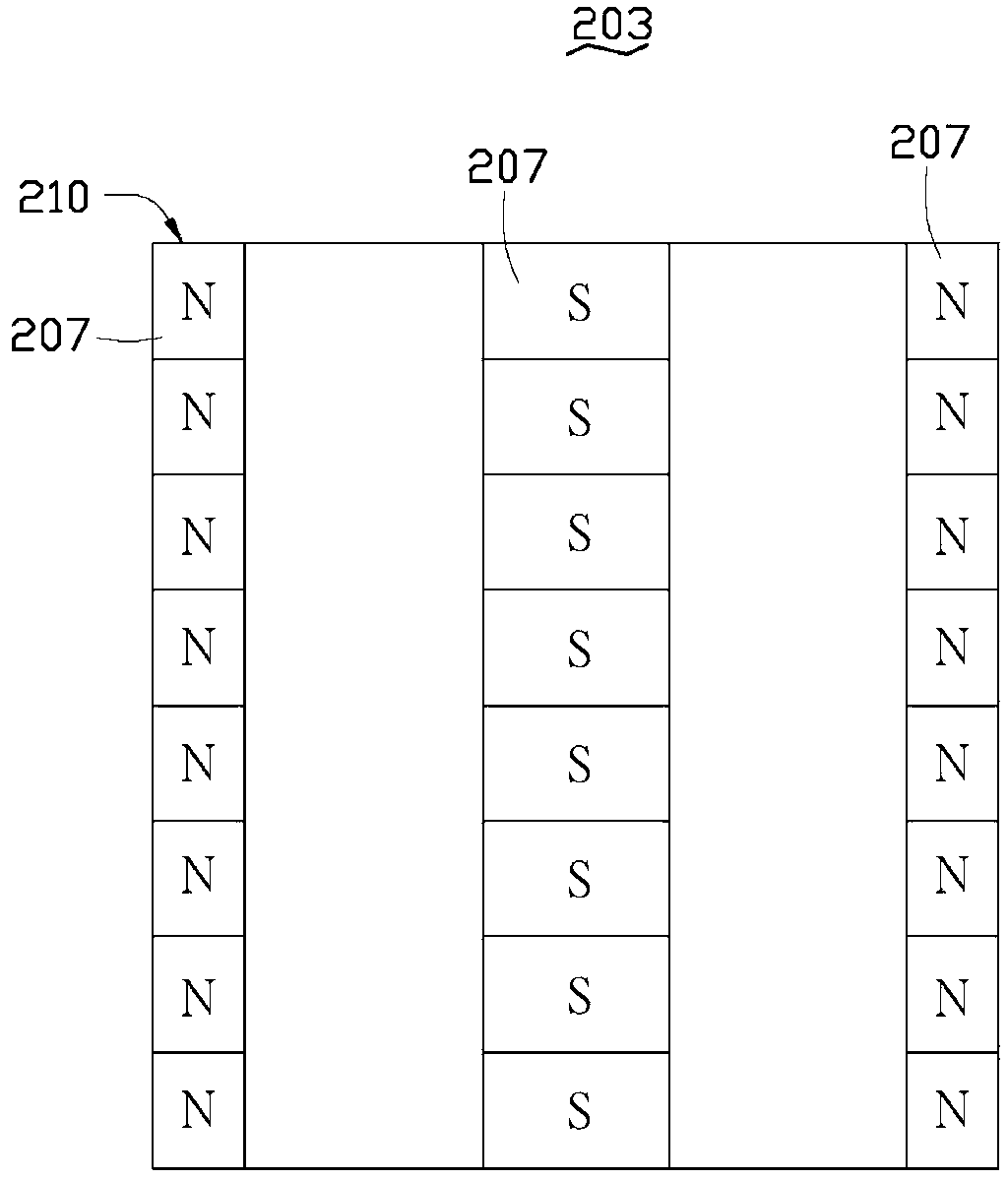

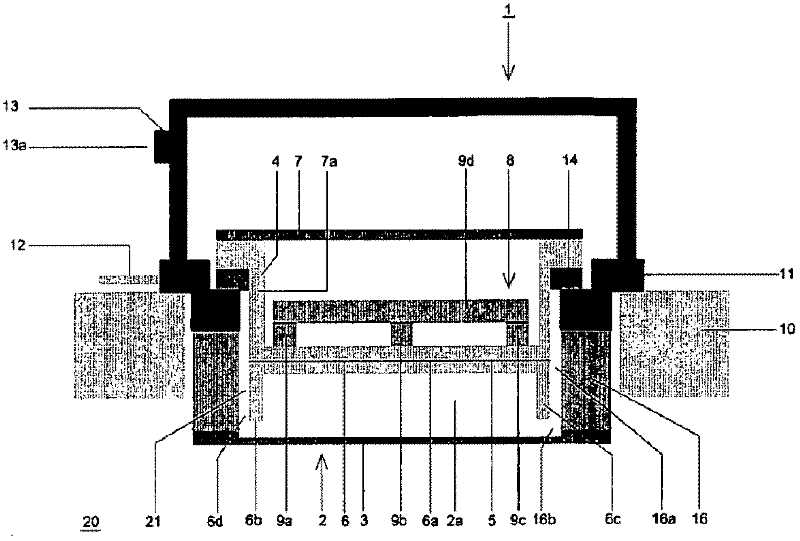

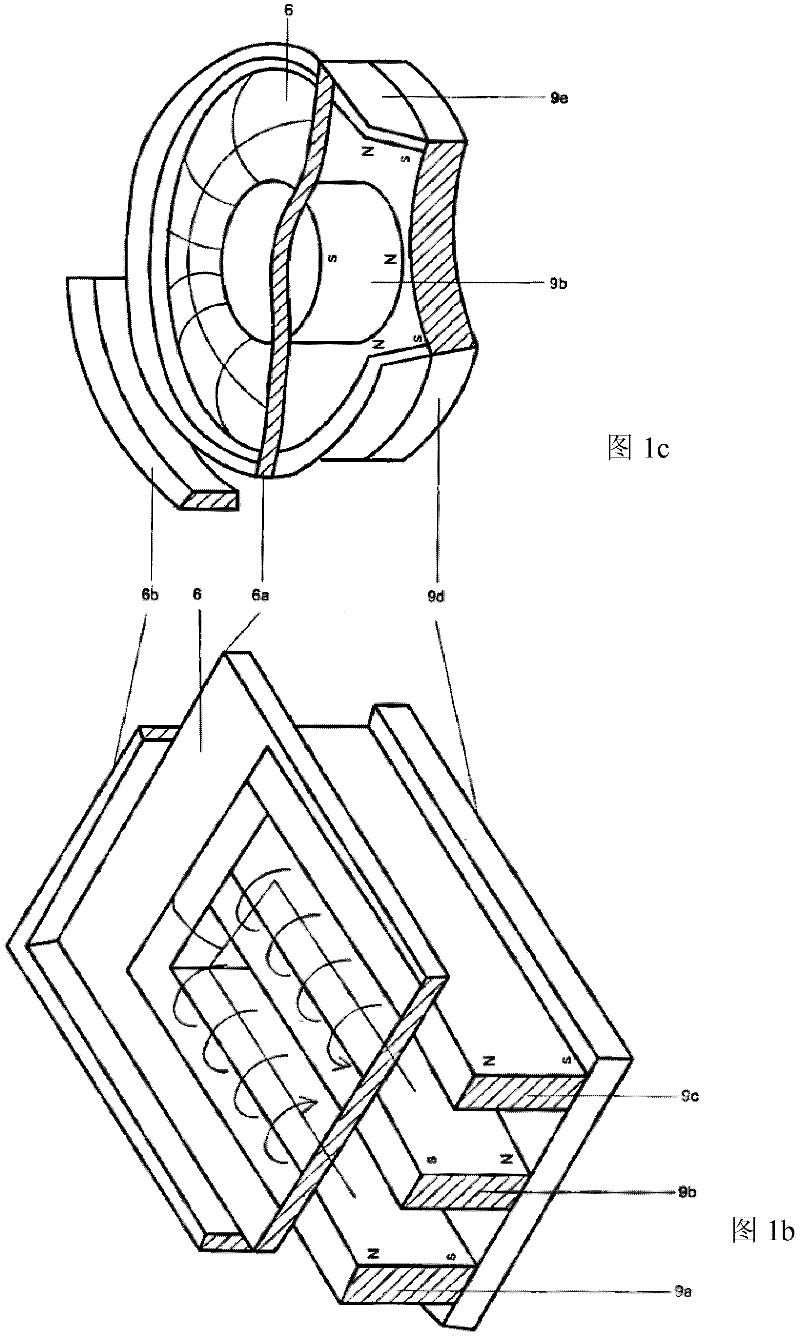

Permanent Magnets Array for Planar Magnetron

InactiveUS20120119861A1Minimum magnetic flux lossReinforce magnetic fieldElectric discharge tubesPermanent magnetsMagnetizationLife time

Permanent magnets array for use in a planar magnetron in which magnets in a magnet-segment is arranged in a Halbach array with their magnetization directions alternating in directions perpendicular with each other. The magnet-segments are closely packed to form different shapes, such as heart, square, circular . . . , in a Halbach Array style, which leads to minimum magnetic flux loss. Such arrangement of permanent magnets will also reinforce the magnetic field on one side of the array while cancel the field to near zero on the other side. The reinforced field strength is twice as large on the side on which the flux is confined. The permanent magnets arrangement and the resulting stationary and / or rotating planar magnetron, provides the high magnetic flux density and uniform flux distribution need to penetrate thick sputtering target, and increased not only the target usage, but also the usable the target life time.

Owner:PLASMA INNOVATIONS

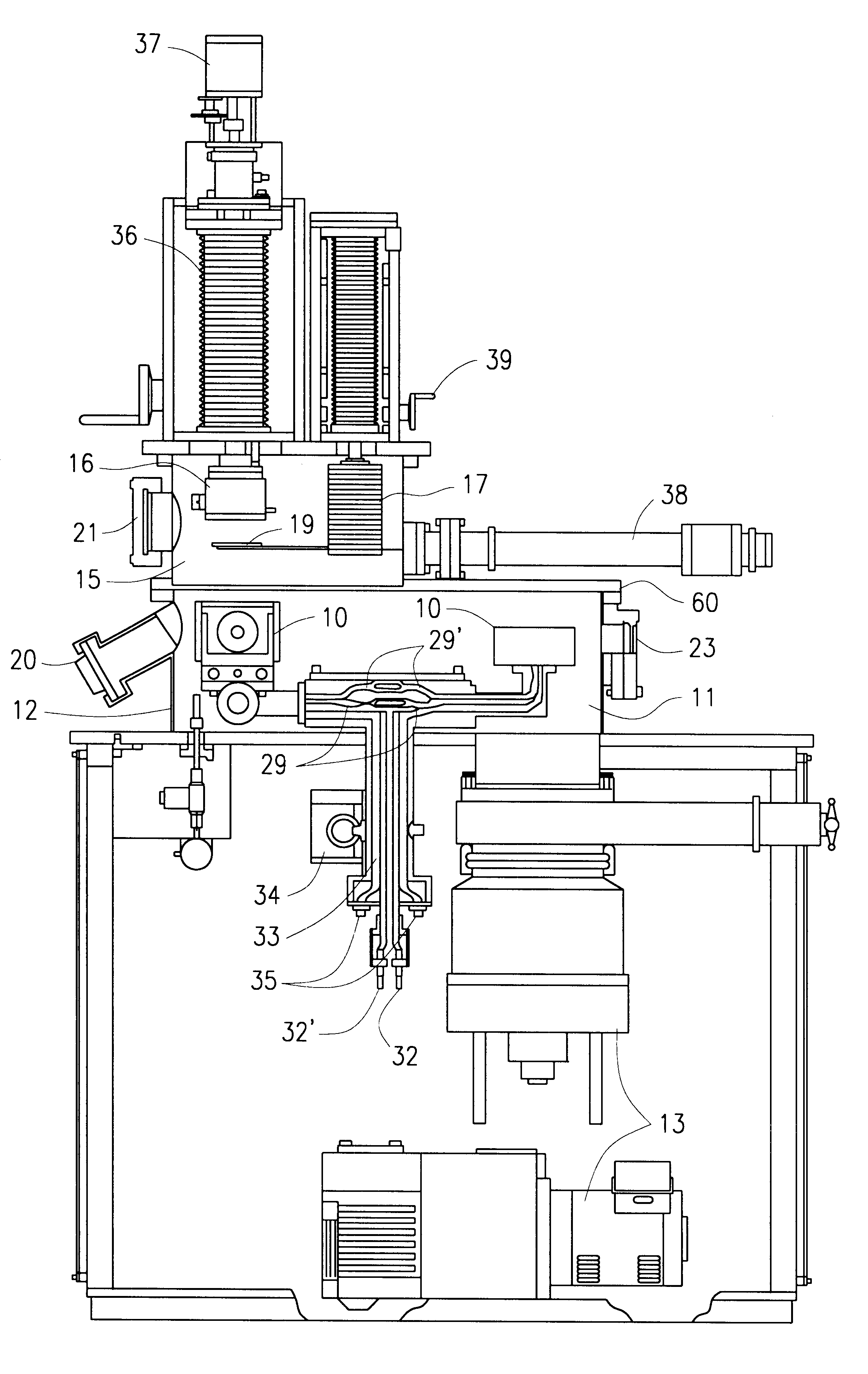

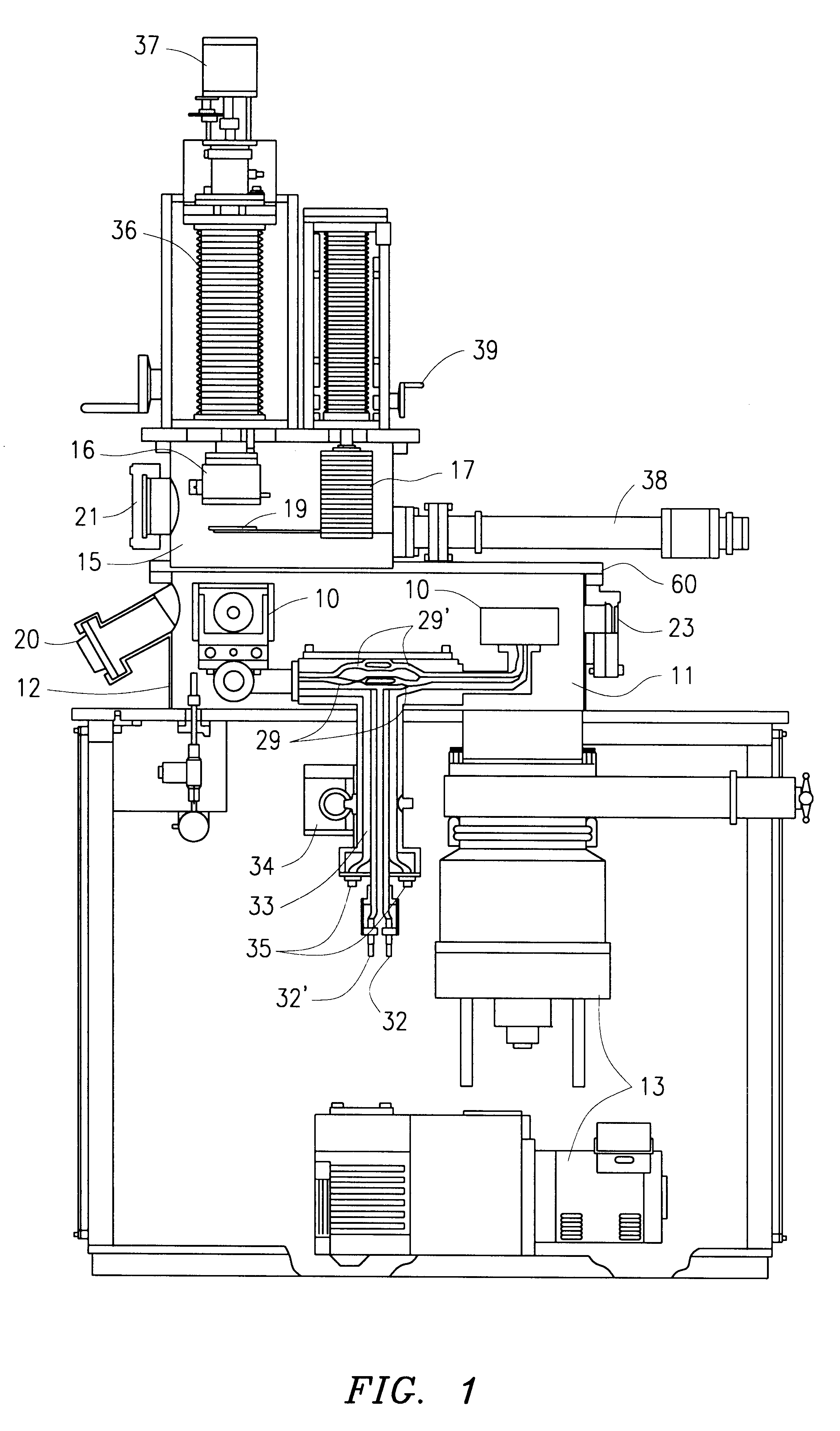

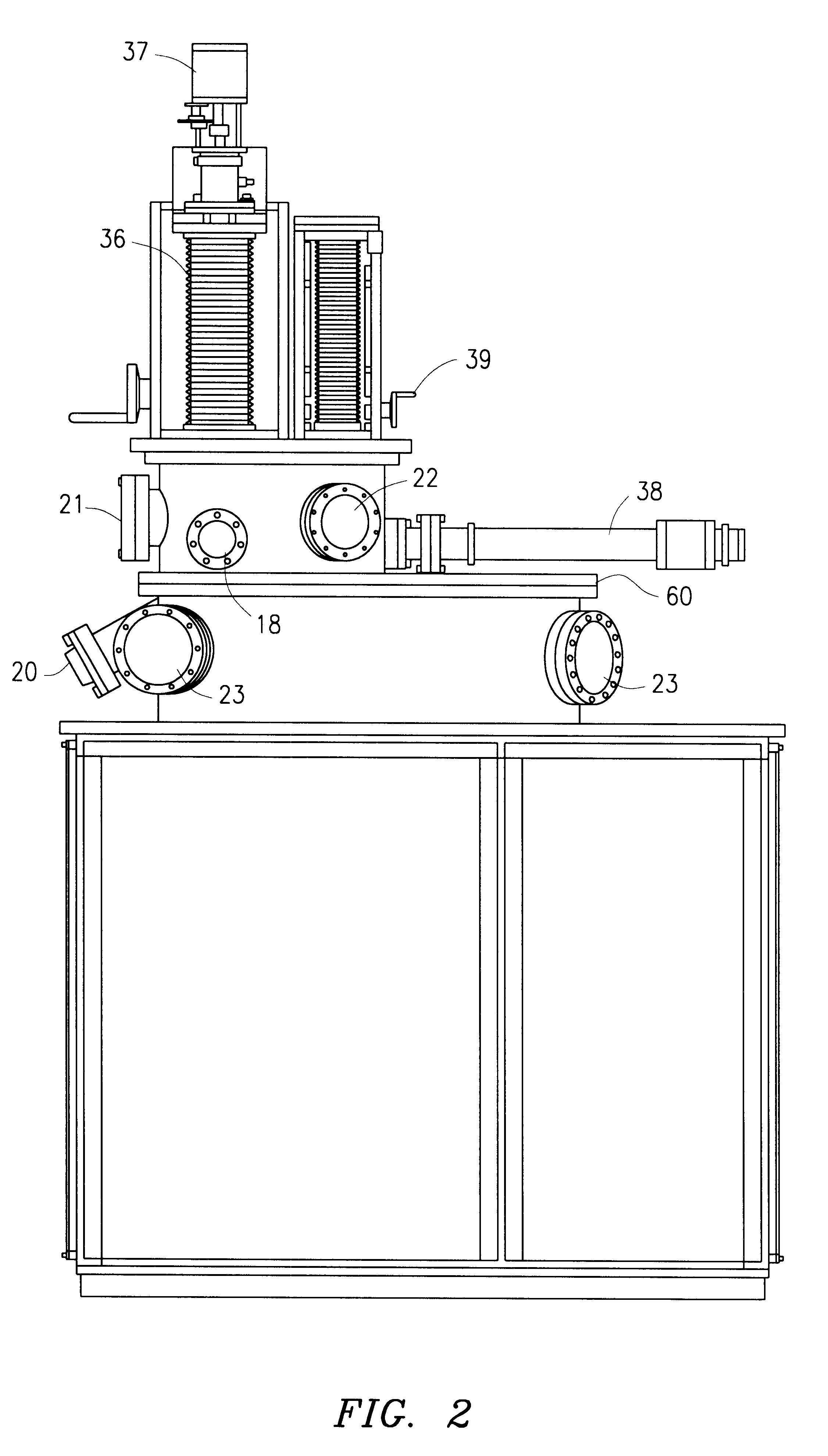

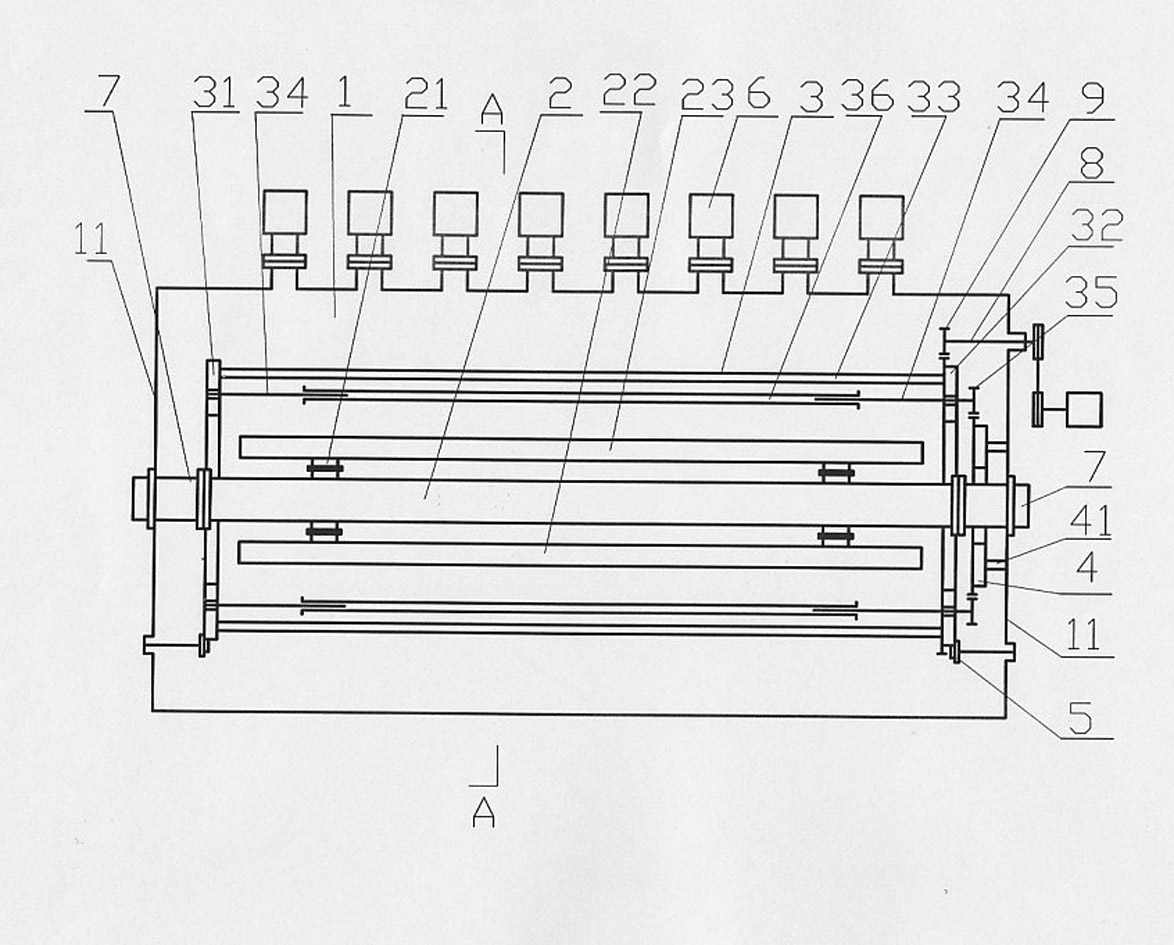

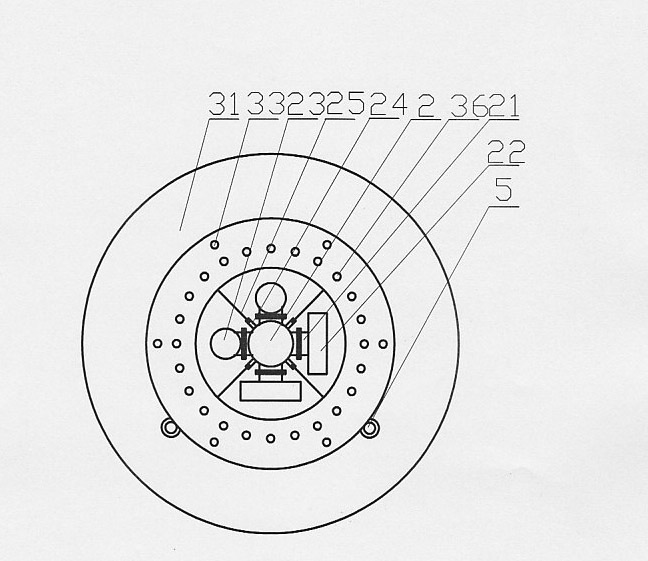

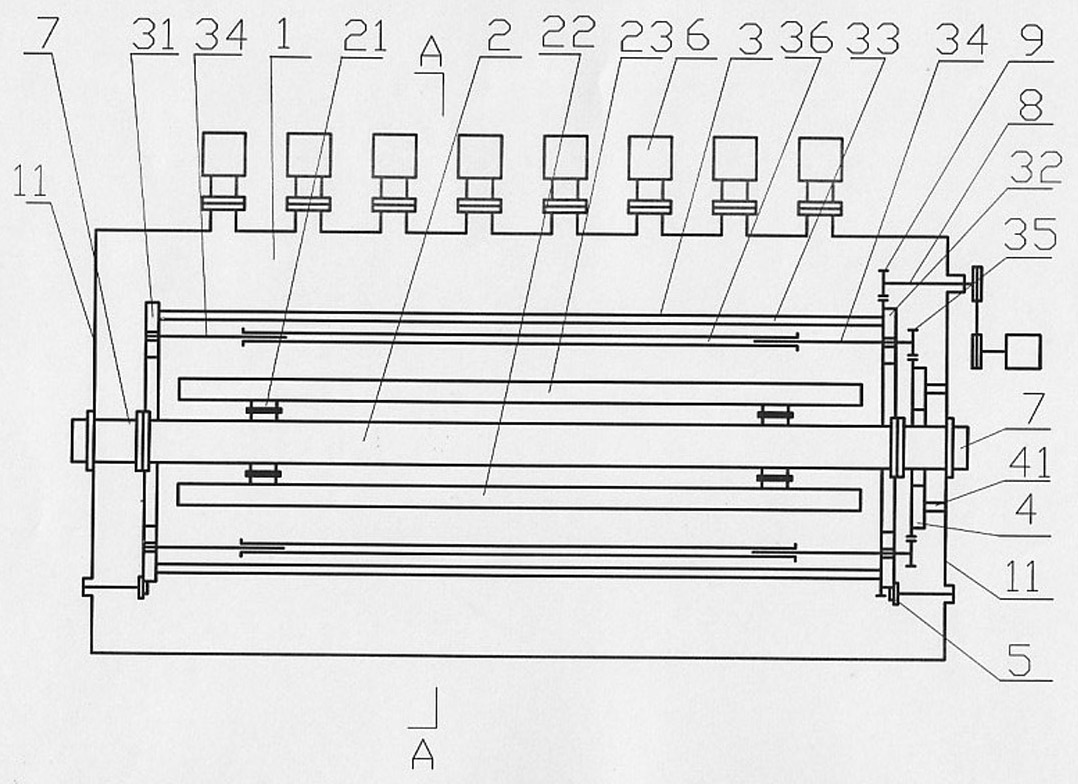

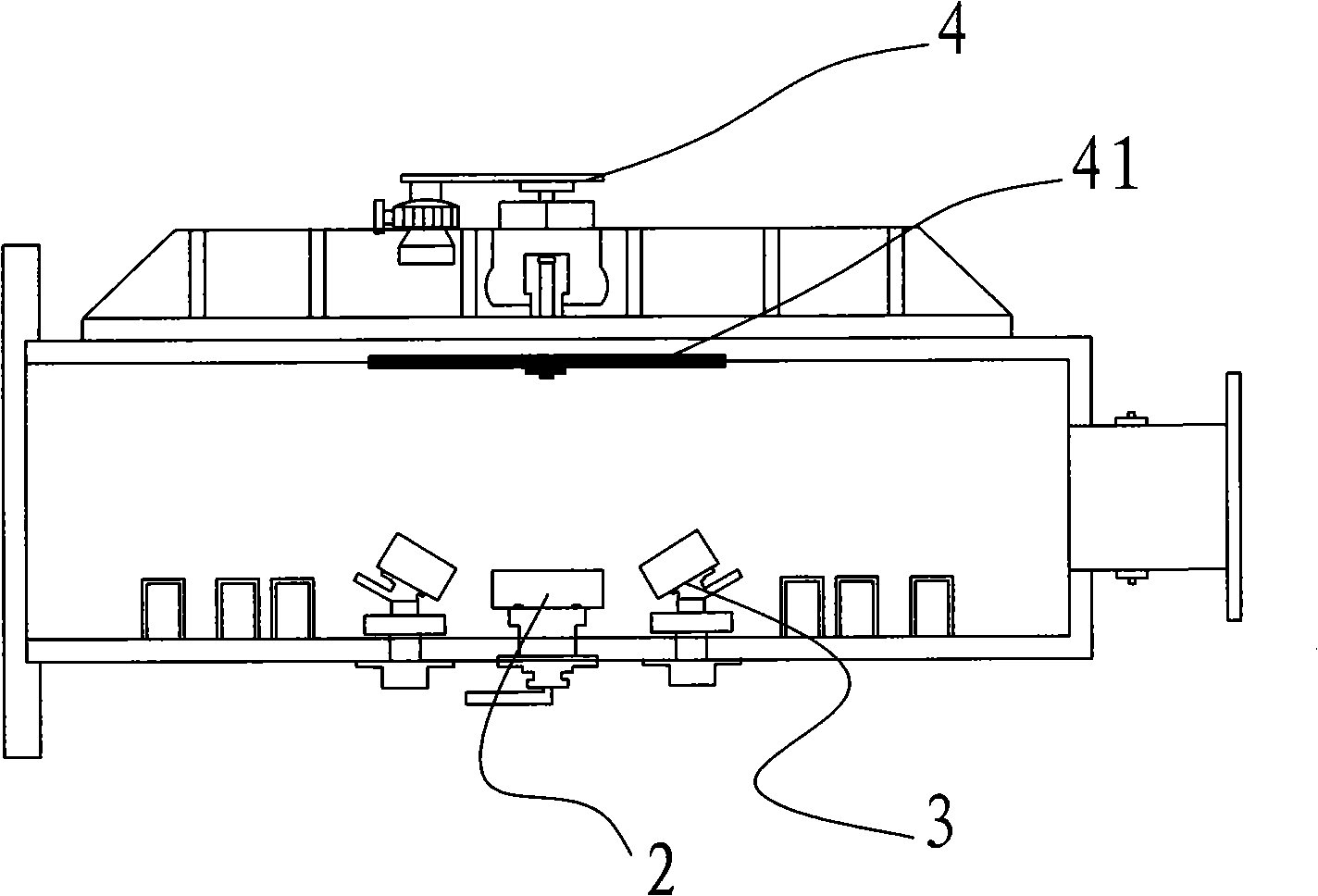

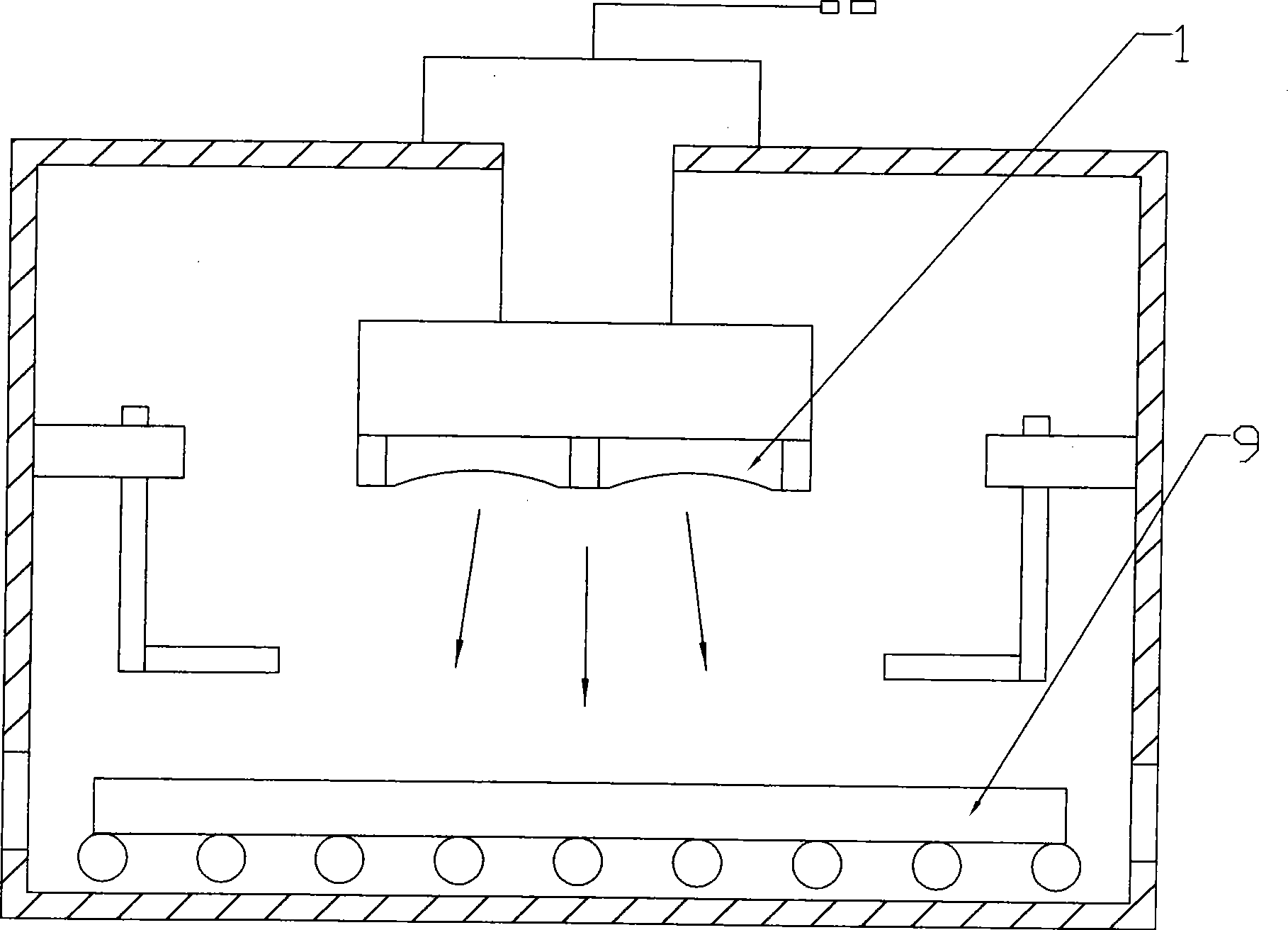

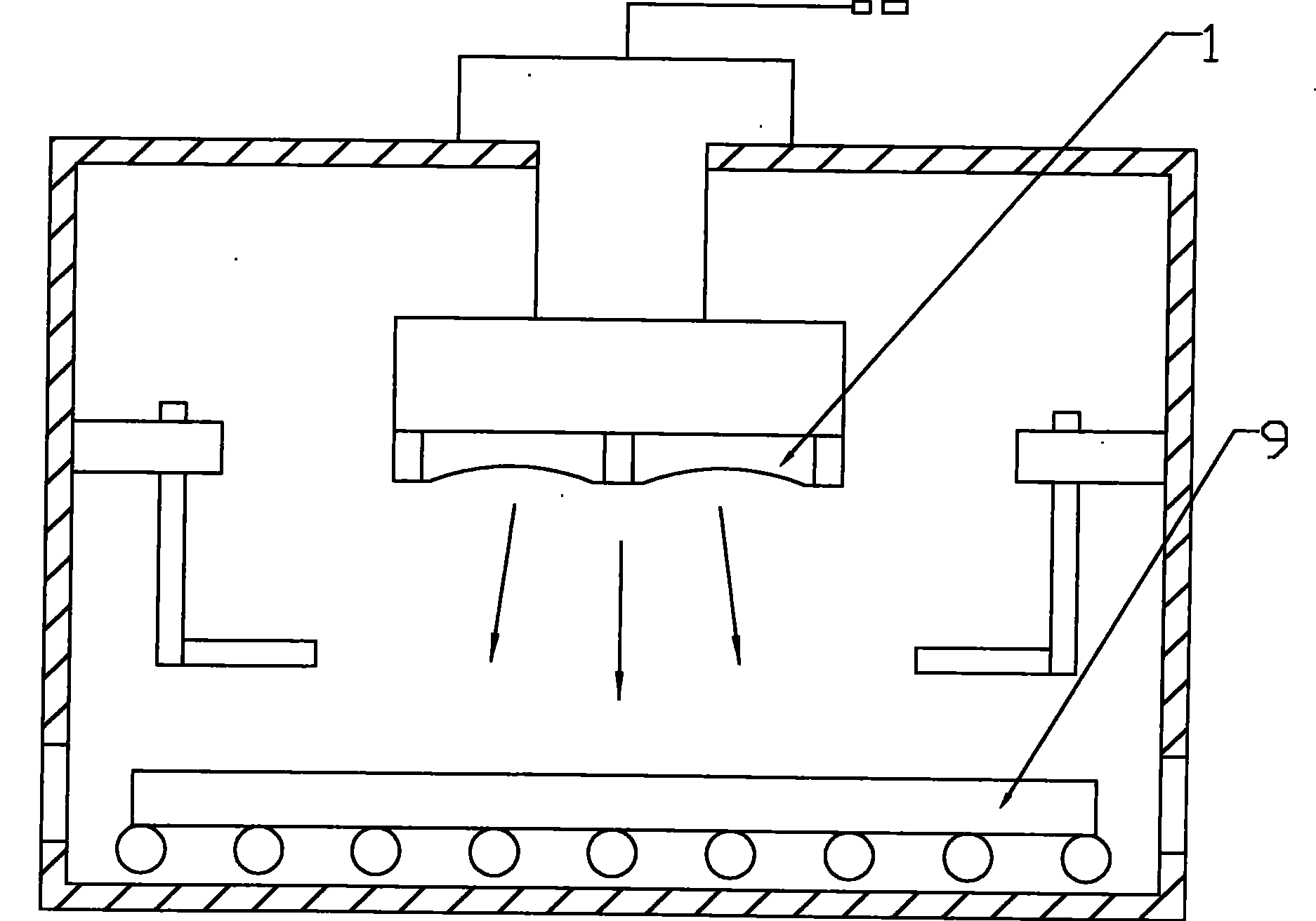

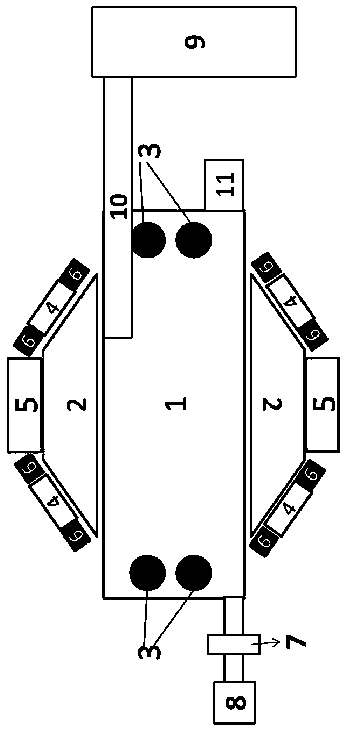

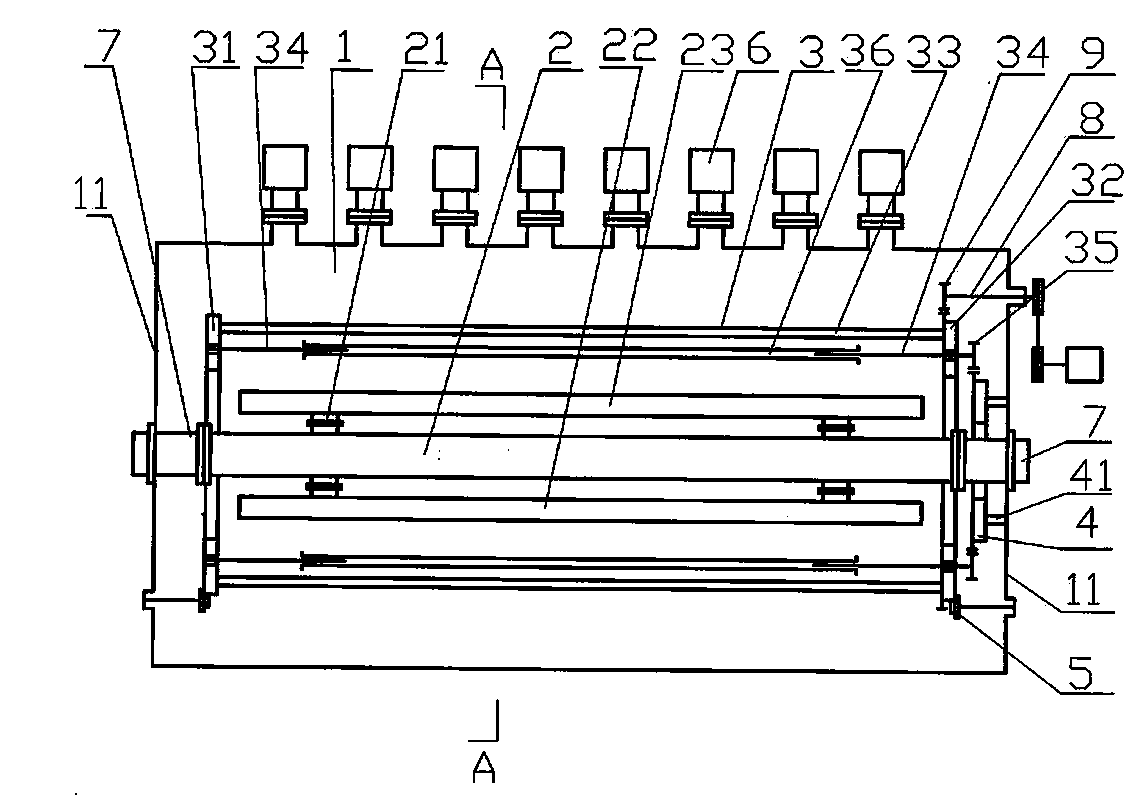

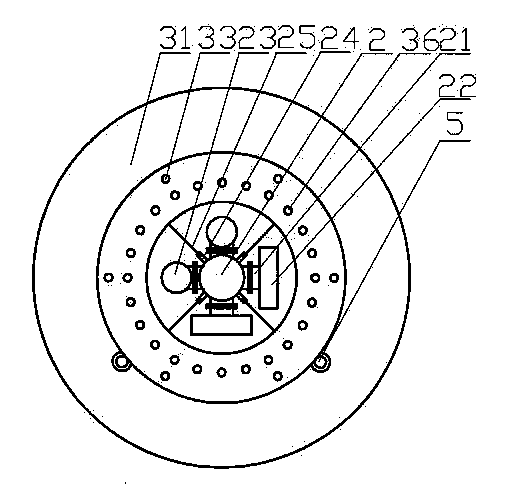

Method for coating film on solar high-temperature heat collection tube used for power generation and horizontal film coating machine

InactiveCN102051590ACracking device super highCrack factory super highVacuum evaporation coatingSputtering coatingPlanar magnetronVacuum chamber

The invention discloses a horizontal film coating machine for a solar high-temperature heat collection tube used for power generation. The horizontal film coating machine comprises a vacuum chamber 1, a target installment tube 2, a workpiece frame 3, a fixed fluted disc 4, a support wheel 5 and a rotary driving mechanism, wherein the vacuum chamber has a cylindrical and horizontal structure with a door at the upper part, the target installment tube 2 is installed on the left and right side plates 11 in the vacuum chamber 1 through left and right flanges 7 and provided with a planar magnetron sputtering target 22 or / and a rotary cylindrical magnetron sputtering target 23; the workpiece frame 3 consists of a turntable 31, a fluted disc 32, a connecting rod 33 and left and right telescopic autorotating shafts 34; a fixed gear 4 is fixed on the right side plate 11 of the vacuum chamber 1 through support columns 41; and the rotary driving mechanism comprises a power input shaft 8 and a driving gear 9 connected with the power input shaft 8, wherein the driving gear 9 is engaged with the turntable 31. By changing a vertical structure into a horizontal structure, the invention solves the problems on ultrahigh equipment, ultrahigh workshops, use and maintenance and the like caused by the film coating of an overlength tube. The horizontal film coating machine is convenient and reliable to operate, has no oil or gas pollution, and better ensures the quantity of a coated film.

Owner:湖南菲尔姆真空设备有限公司

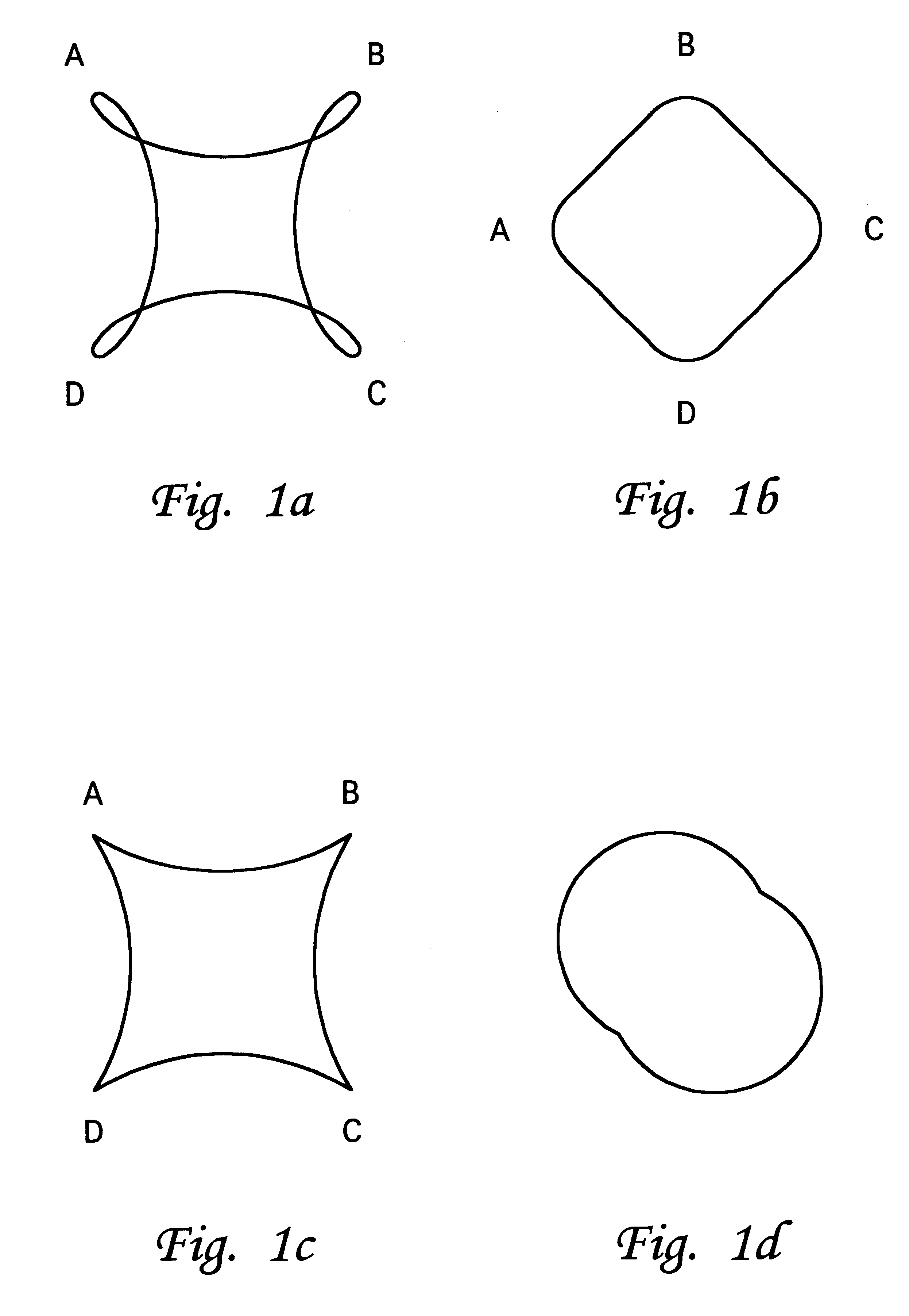

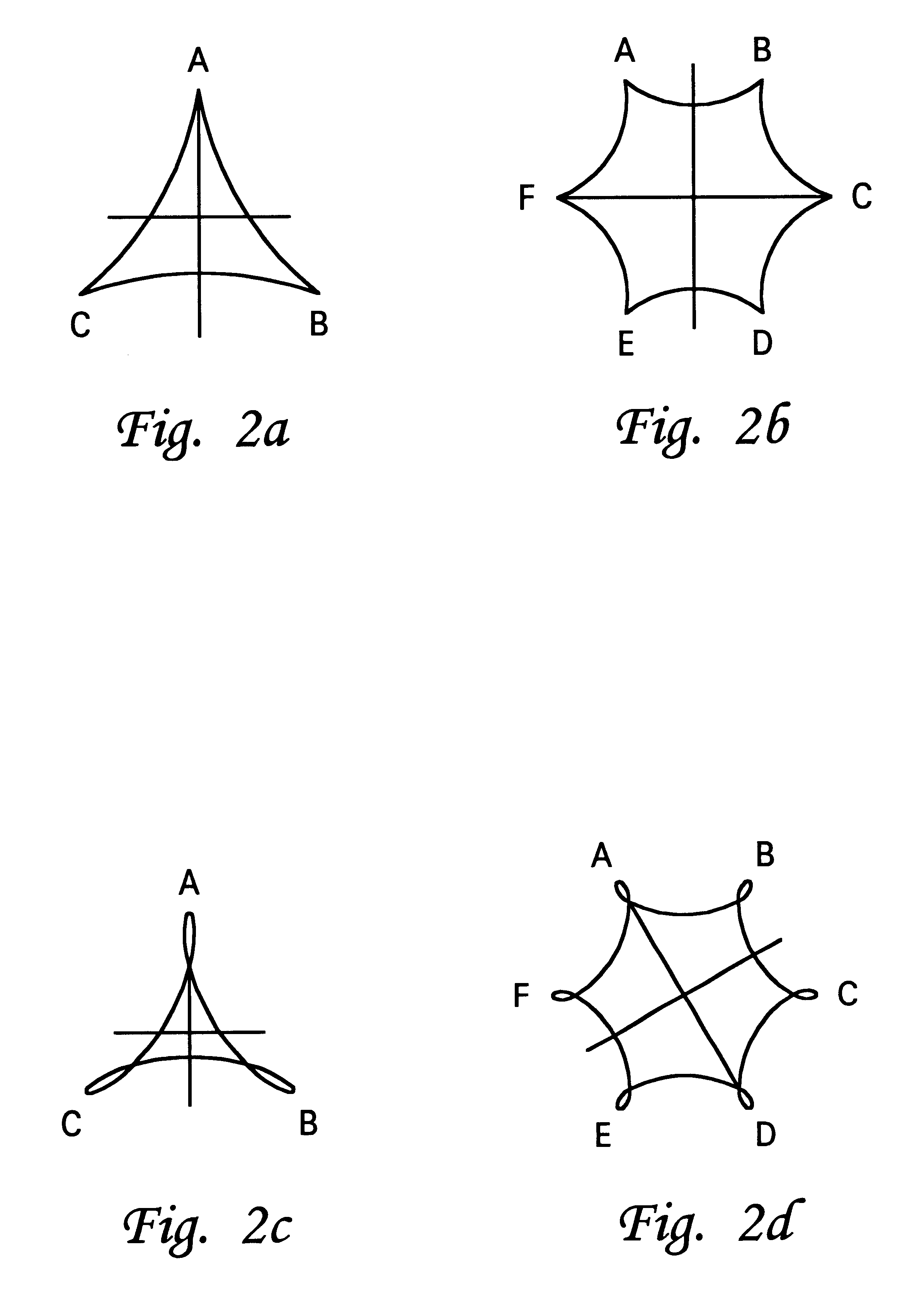

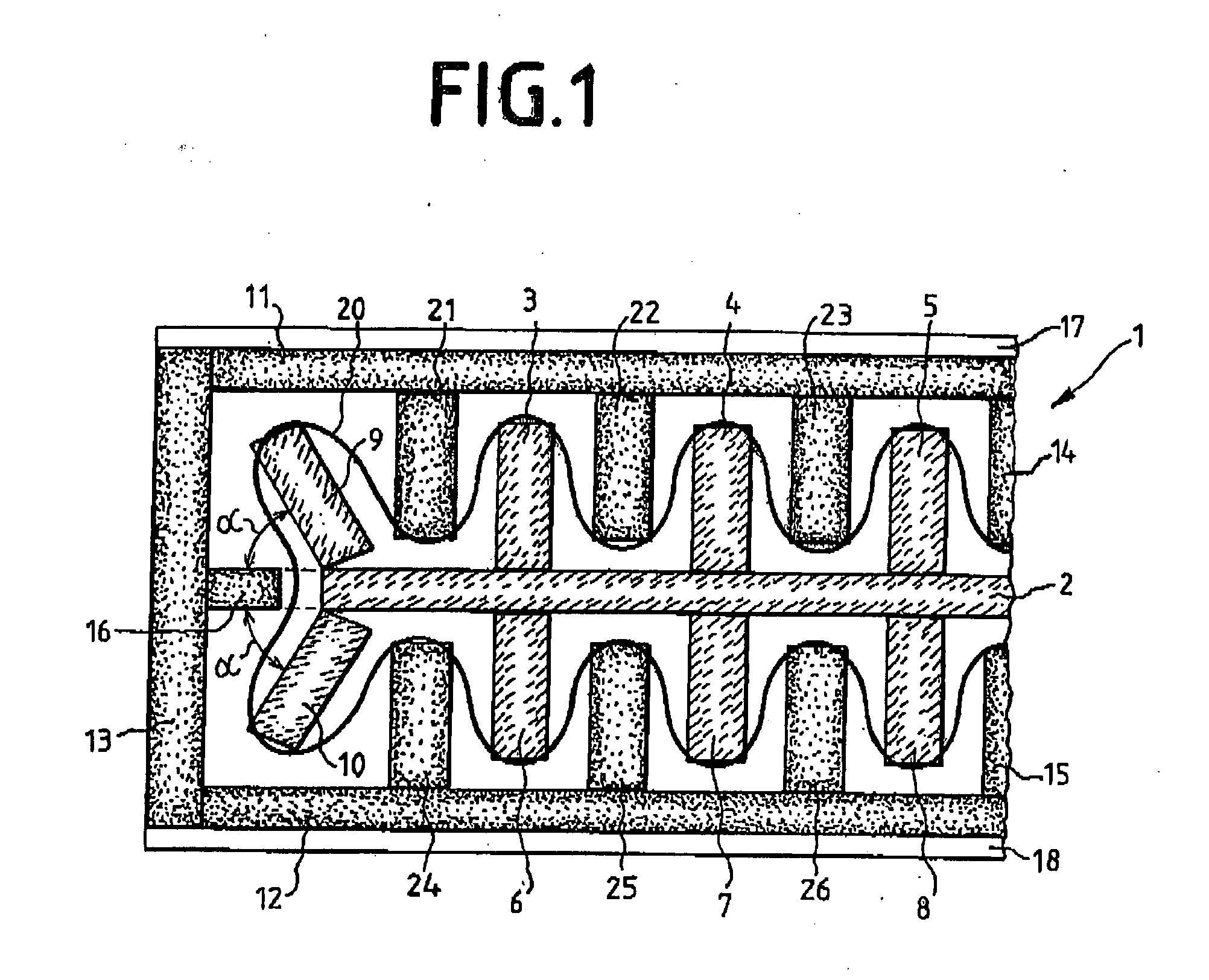

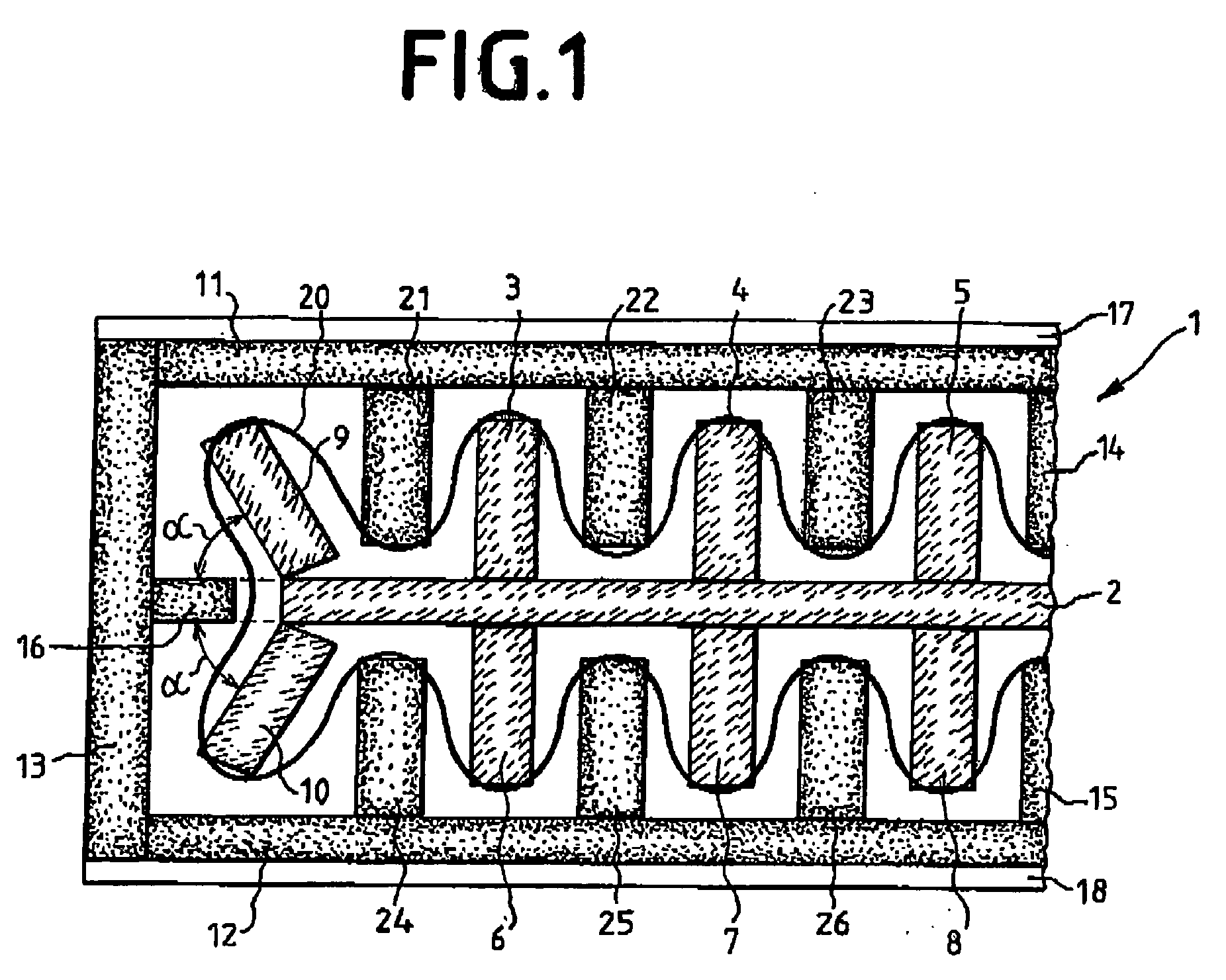

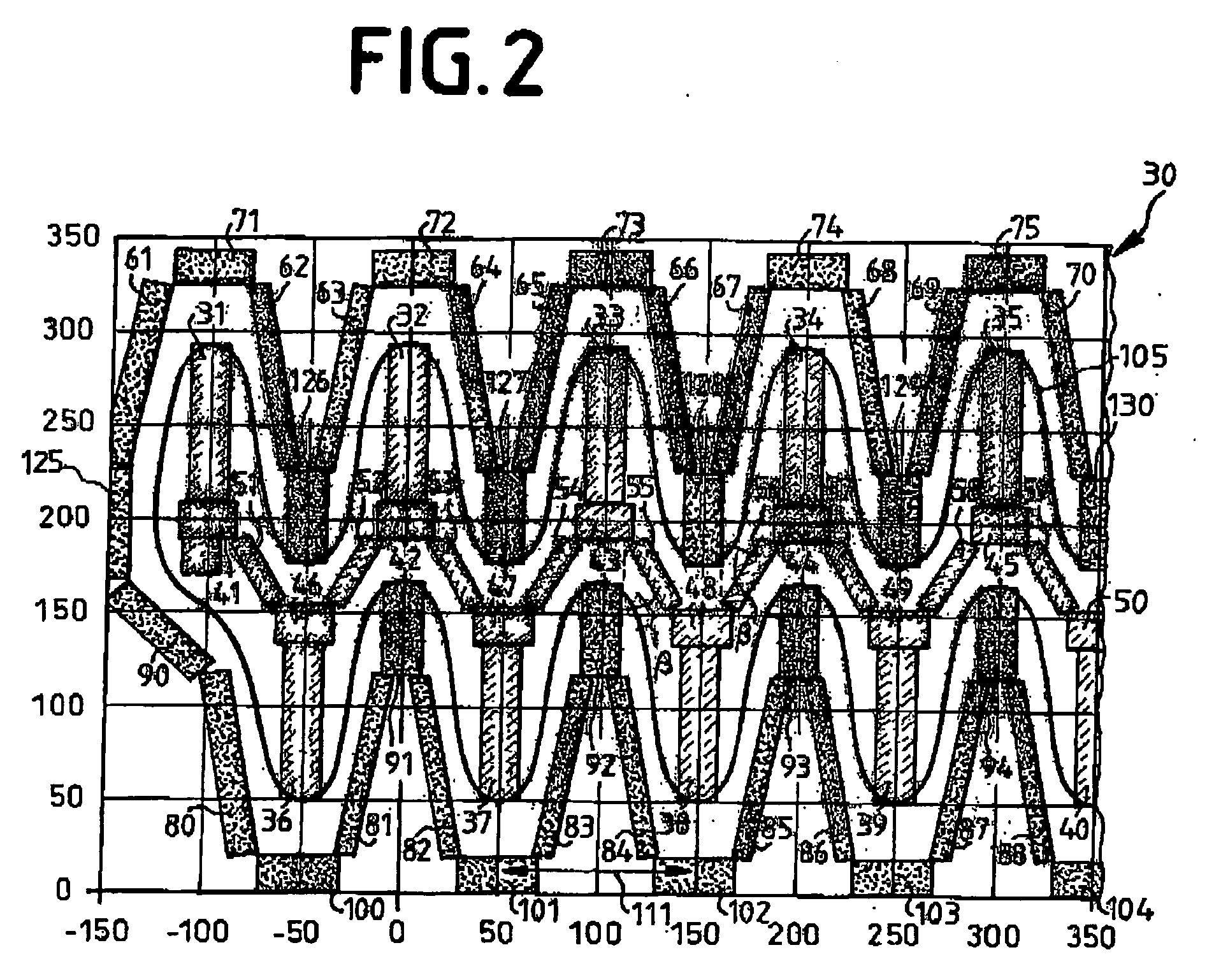

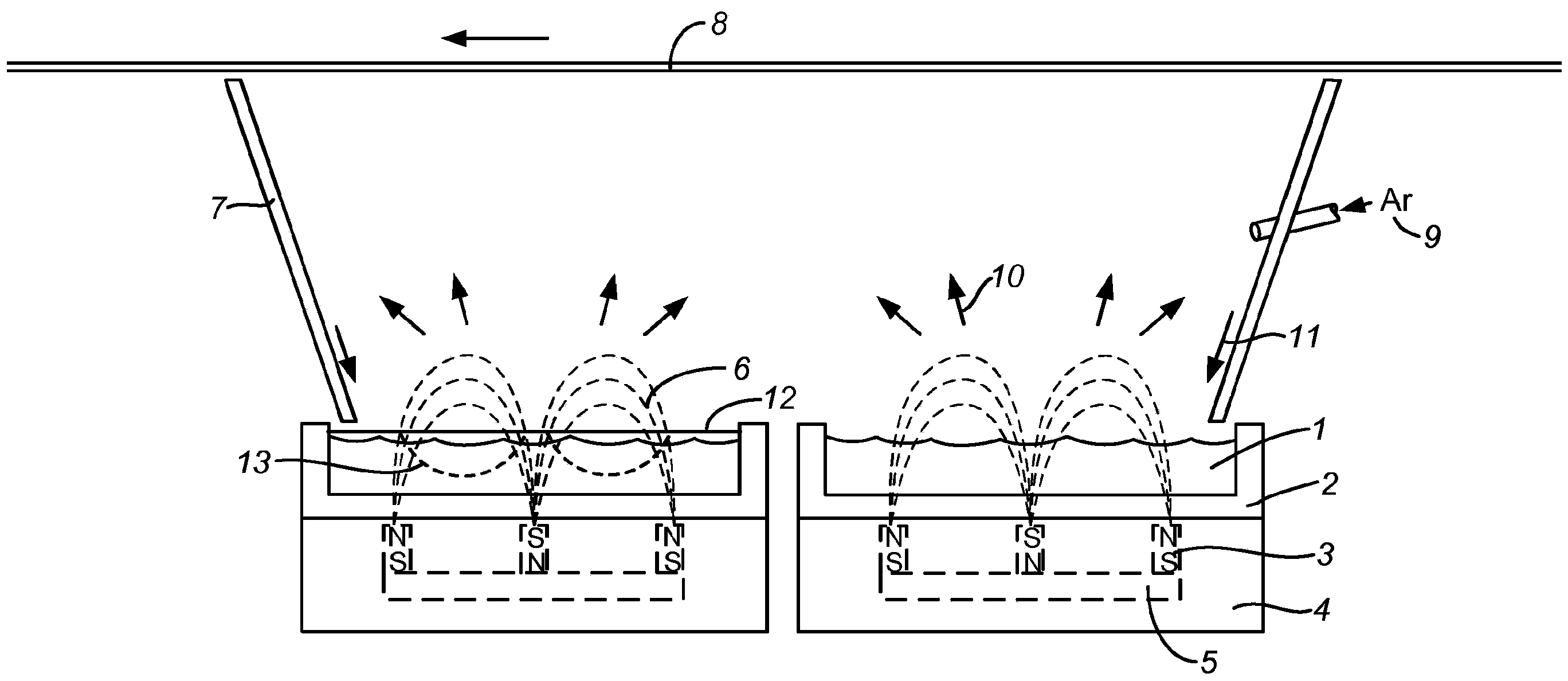

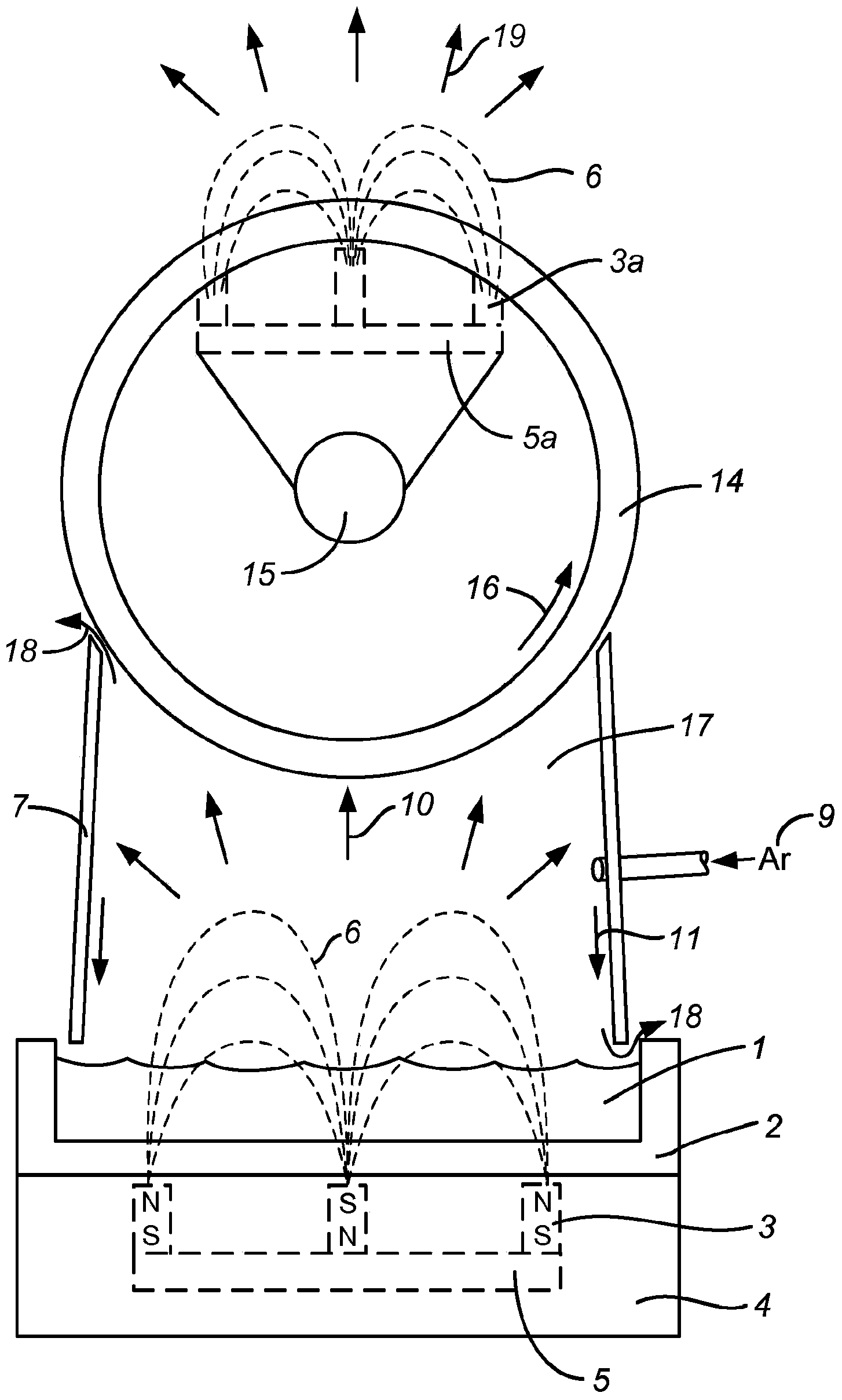

Magnet arrangement for a planar magnetron background and summary of the invention

InactiveUS20080067062A1Good effectIncrease probabilityCellsElectric discharge tubesTarget surfaceMagnetic poles

A magnetic arrangement for a planar magnetron, in which an initial magnetic pole encompasses a second magnetic pole. This magnetic arrangement is moved linear in longitudinal direction to a target by a specific value and then moved back in opposite direction by the same value. In one version, an additional perpendicular motion is effected. The magnet arrangement is designed so that north and south pole interlock and waviform racetracks are generated. This enables constant sputtering from the entire target surface.

Owner:DEPPISCH THOMAS +1

Method for improving utilization rate of rectangular planar magnetron sputtering cathode target material

InactiveCN103820759AIncrease profitLow costVacuum evaporation coatingSputtering coatingSputteringPlanar magnetron

The invention relates to the technical field of magnetron sputter coating production equipment, in particular to a method for improving the utilization rate of a rectangular planar magnetron sputtering cathode target material. The target material is characterized by being mounted twice and sputtered twice. The method comprises the following specific steps: during mounting of the target material for the first time, sputtering the target material, wherein an etching area is positioned on one side of the target material; then horizontally rotating the target material for 180 degrees, re-mounting the target material on a cathode, and sputtering the target material for the second time, wherein the etching areas for two-time sputtering are exactly connected to form a larger etching area. Compared with the prior art, the method has the advantages that after being mounted for the first time, the target material is sputtered, and the etching area is positioned on one side of the target material; then the target material is horizontally rotated for 180 degrees, is re-mounted on the cathode, and is sputtered for the second time, so that the etching areas for the two-time sputtering are exactly connected to form the larger etching area; in addition, shielding covers of which the section is L-shaped are arranged on two sides of the outer part of a cathode seat to shield more than 50 percent of the area on the target material, so that the utilization rate of the target material is improved, and the cost is reduced.

Owner:CHINA TRIUMPH INT ENG

Vapor-deposited porous films for energy conversion

InactiveUS20050016832A1Electrode carriers/collectorsVacuum evaporation coatingGas phasePlanar magnetron

Metallic films are grown with a “spongelike” morphology in the as-deposited condition using planar magnetron sputtering. The morphology of the deposit is characterized by metallic continuity in three dimensions with continuous and open porosity on the submicron scale. The stabilization of the spongelike morphology is found over a limited range of the sputter deposition parameters, that is, of working gas pressure and substrate temperature. This spongelike morphology is an extension of the features as generally represented in the classic zone models of growth for physical vapor deposits. Nickel coatings were deposited with working gas pressures up 4 Pa and for substrate temperatures up to 1000 K. The morphology of the deposits is examined in plan and in cross section views with scanning electron microscopy (SEM). The parametric range of gas pressure and substrate temperature (relative to absolute melt point) under which the spongelike metal deposits are produced appear universal for other metals including gold, silver, and aluminum.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Mid-frequency direct current compound magnetron sputtering device

InactiveCN101538701AApplicable needsVacuum evaporation coatingSputtering coatingControl systemEngineering

The invention relates to a mid-frequency direct current compound magnetron sputtering device comprising a vacuum chamber, an air extraction system, an air supply system, a film thickness measuring and controlling system and an electric control cabinet, a direct current planar magnetron sputtering target is arranged in the vacuum chamber, and a pair of mid-frequency twin magnetron sputtering targets are arranged on two sides of the direct current planar magnetron sputtering target. The device comprises the direct current planar magnetron sputtering target, and a pair of the mid-frequency twin magnetron sputtering targets are arranged on the two sides of the direct current planar magnetron sputtering target, thereby being very applicable to plating a plurality of layers of compound films and simple substance films on a substrate. The device has low manufacturing cost, convenience and flexibility.

Owner:HUZHOU JINTAI PLATING IND

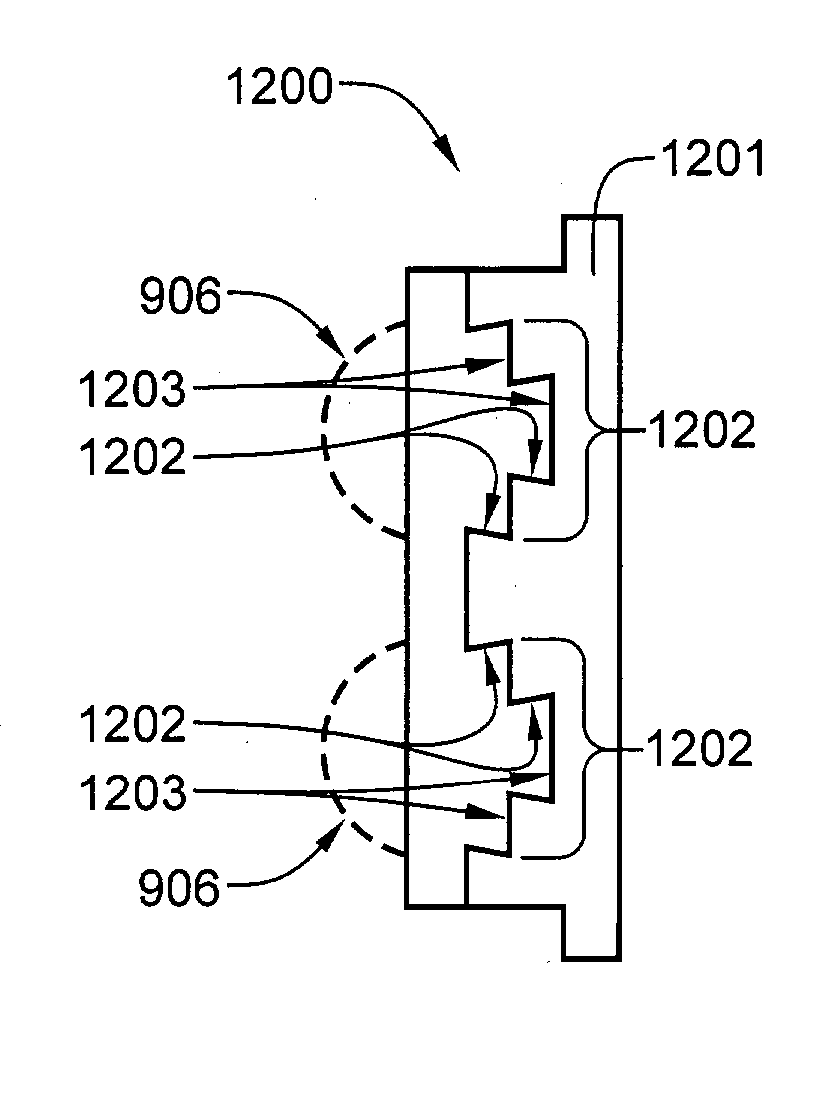

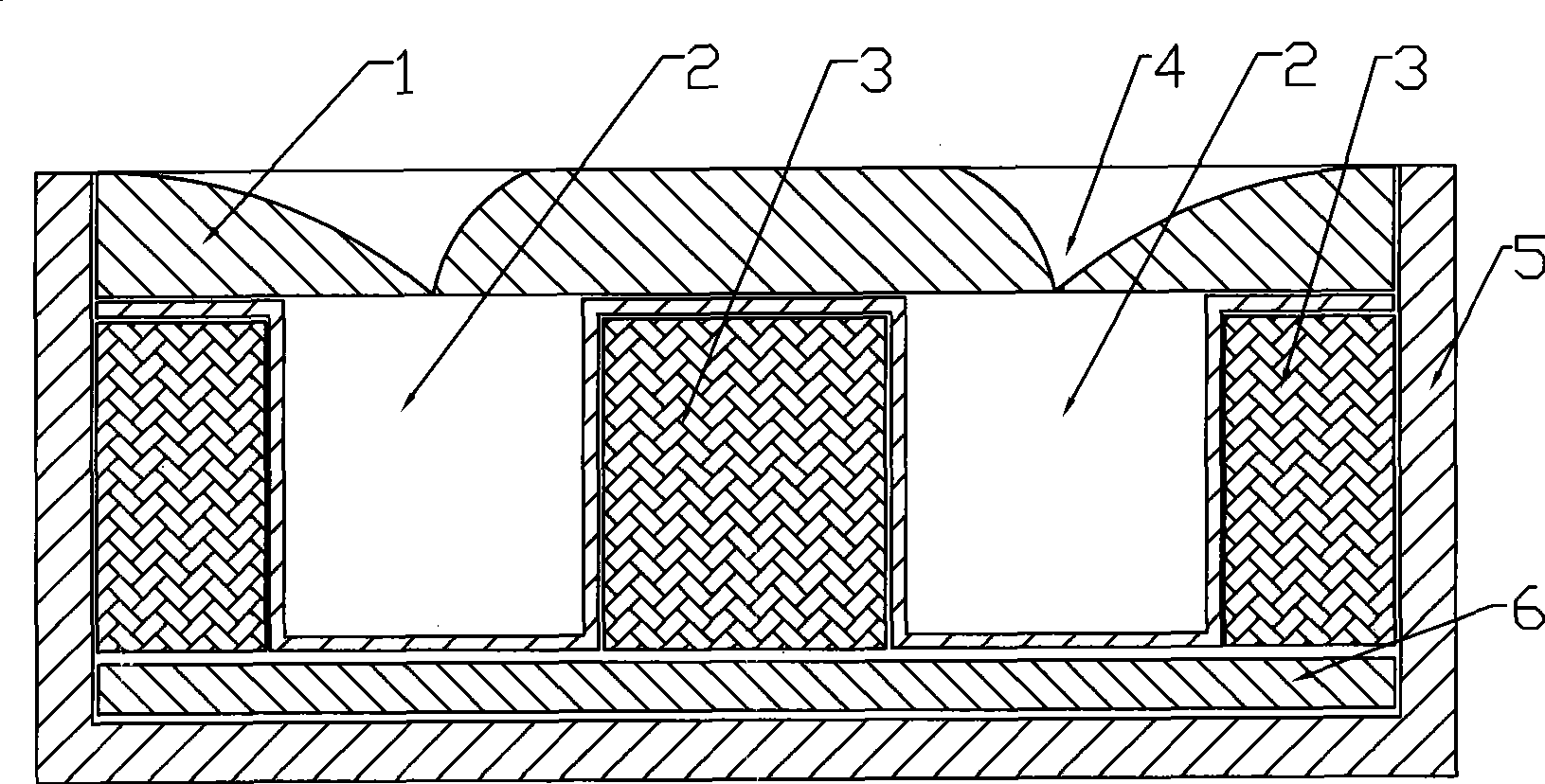

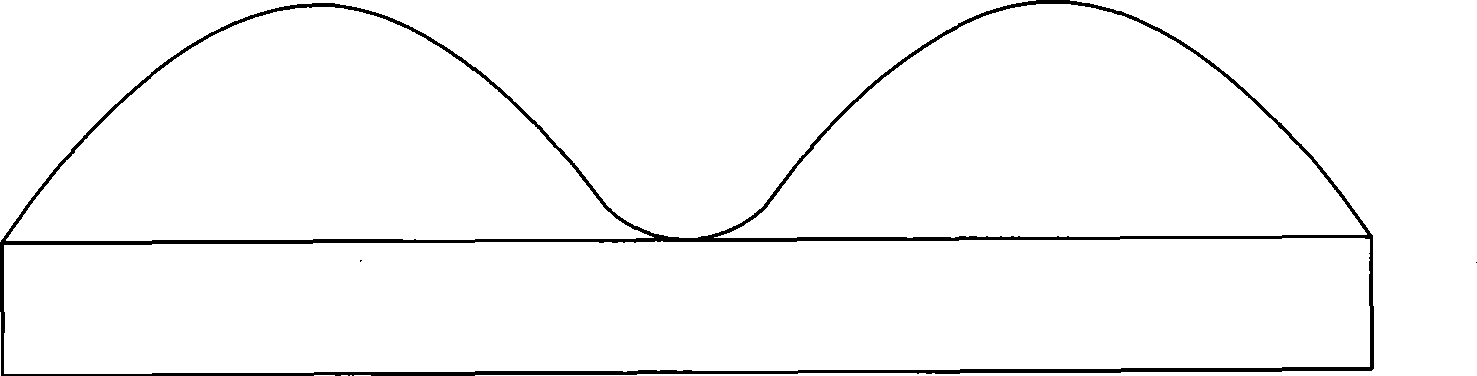

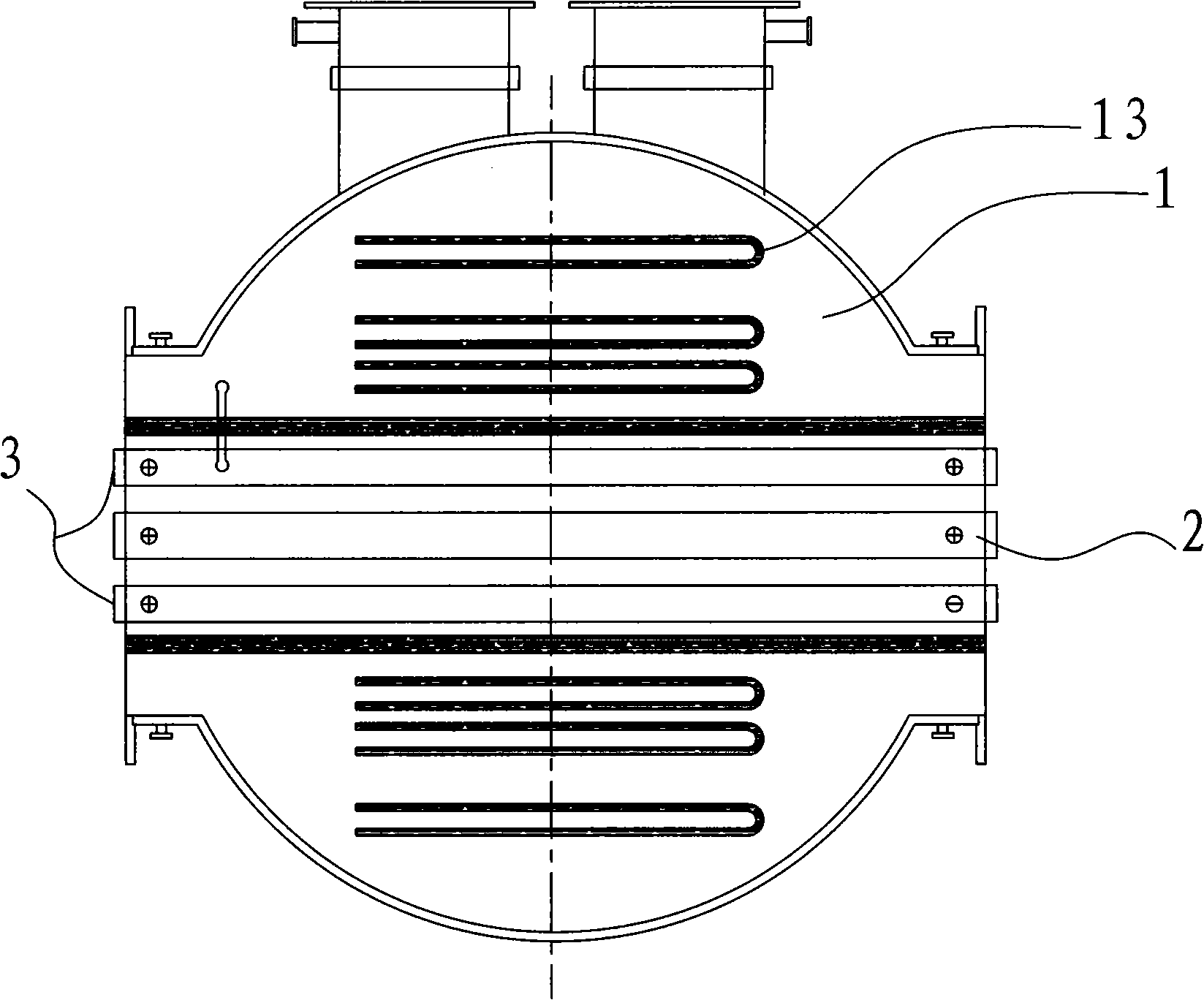

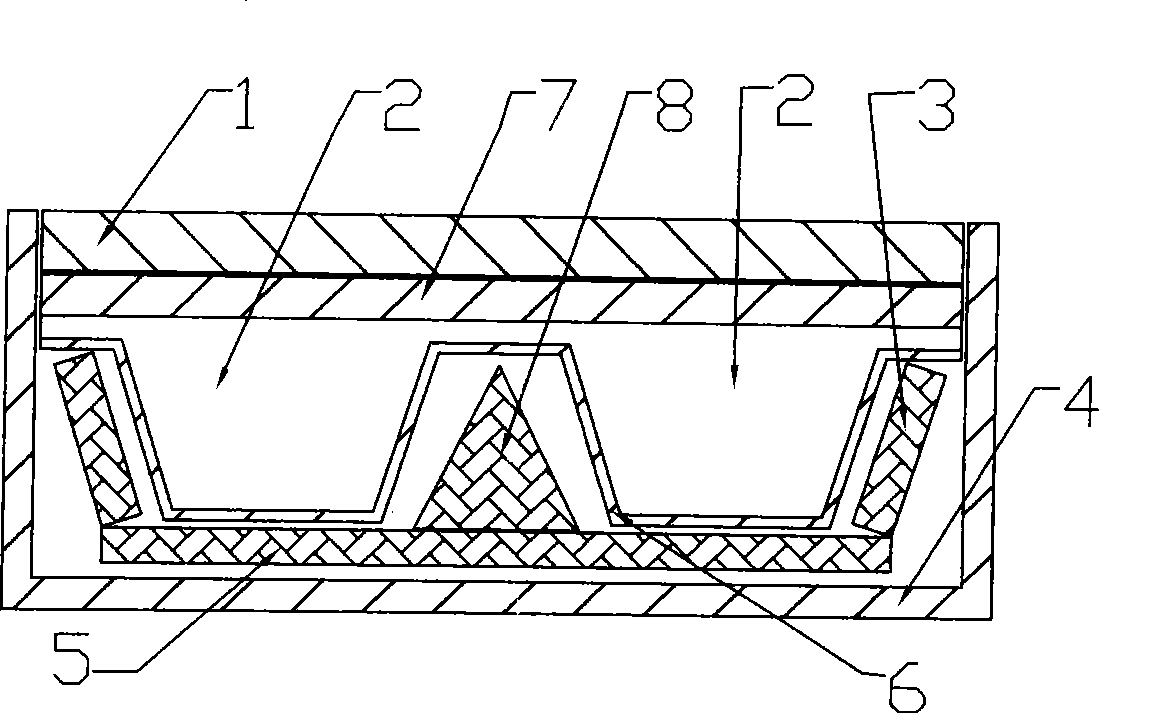

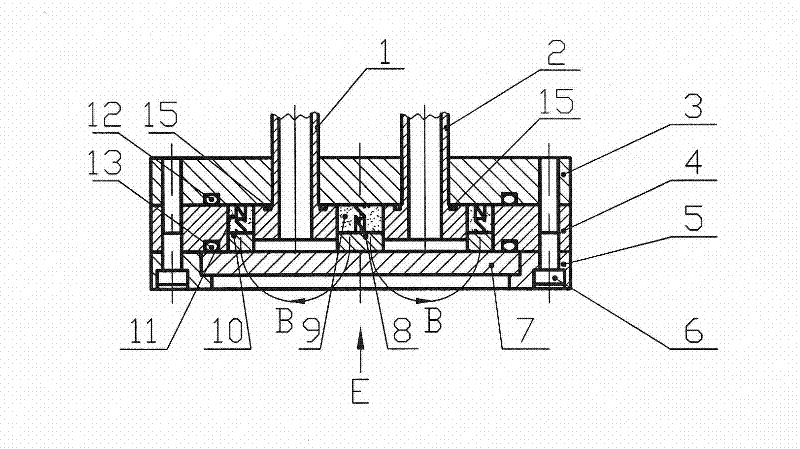

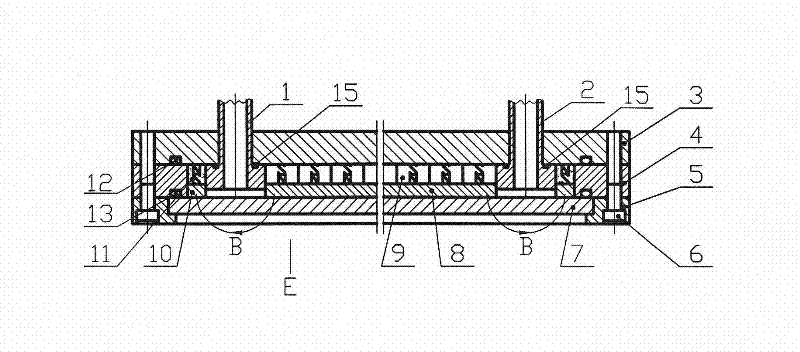

High-capacity planar magnetron sputtering cathode

ActiveCN101418432AAvoid corrosionImprove cooling effectVacuum evaporation coatingSputtering coatingSputteringLow emissivity

The invention relates to a high-power planar magnetron sputtering cathode, which belongs to a double silver-layer low emissivity film and mainly solves the technical problems that the magnet of the prior planar magnetron sputtering cathode is steeped in water and will be degaussed after being used for a long time and the like. The key points of the technical proposal are as follows: the high-power planar magnetron sputtering cathode consists of a cathode body (4), a target (1) and a magnet, wherein the target (1) is arranged on the upper part of the cathode body (4); an airtight cooling channel (2) is arranged in the inner cavity of the cathode (4); a magnetic boot (5) is arranged between the bottom and the cooling channel (2) in the inner cavity of the cathode body (4); and the magnet (3) is arranged between the cooling channel (2) and the magnetic boot (5). Because an independent cooling channel is arranged in the cathode body, the magnet does not contact with cooling media to avoid the permanent magnet from being eroded by the cooling media; besides, high-power planar magnetron sputtering cathode is designed with a heat conduction plate made of materials with high thermal conductivity to contact with the target in a large area, so that the target can be cooled sufficiently and the cathode can bear higher power. The high-power planar magnetron sputtering cathode can be widely applied to a vacuum magnetron sputtering coating device.

Owner:湖南玉丰真空科学技术有限公司

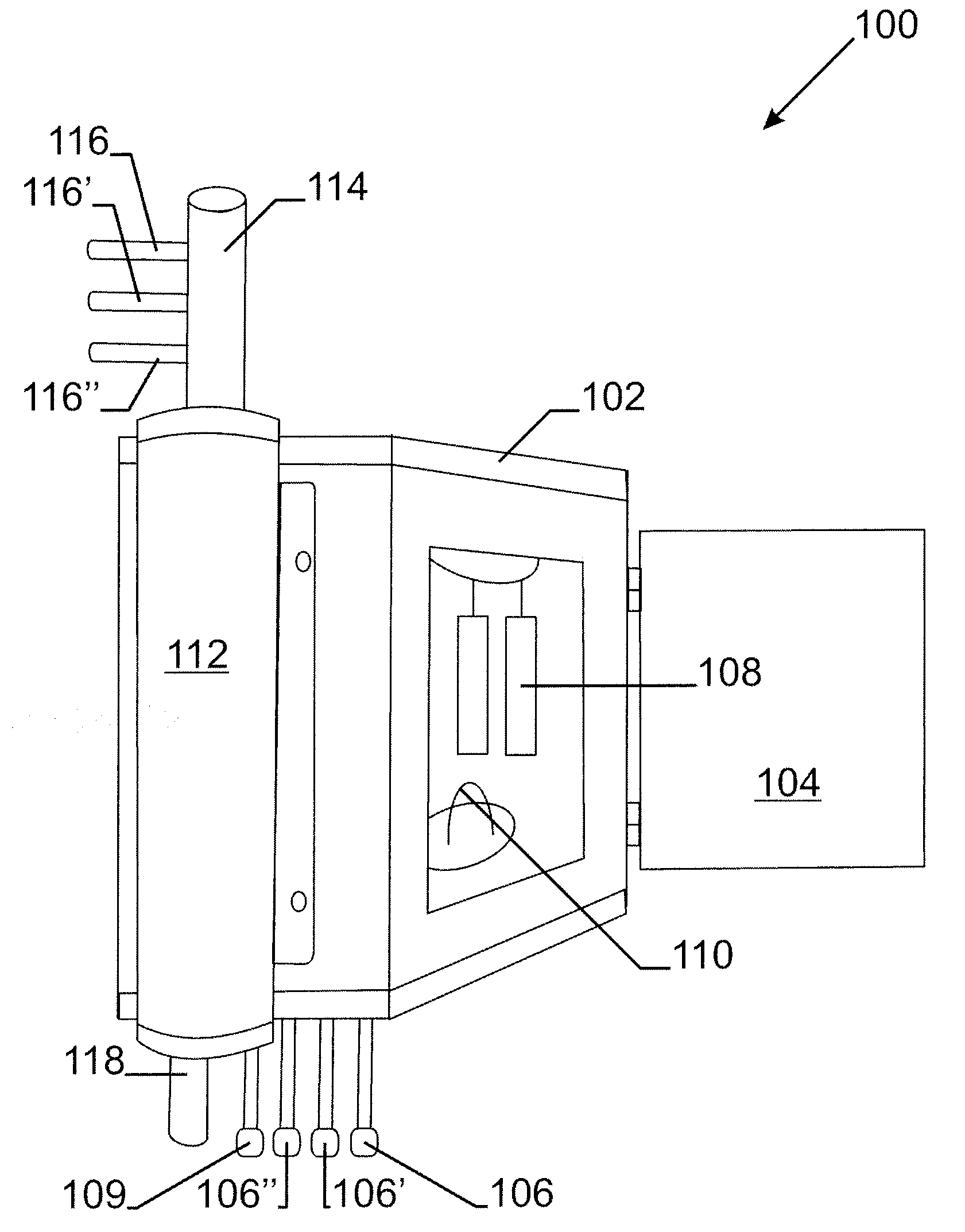

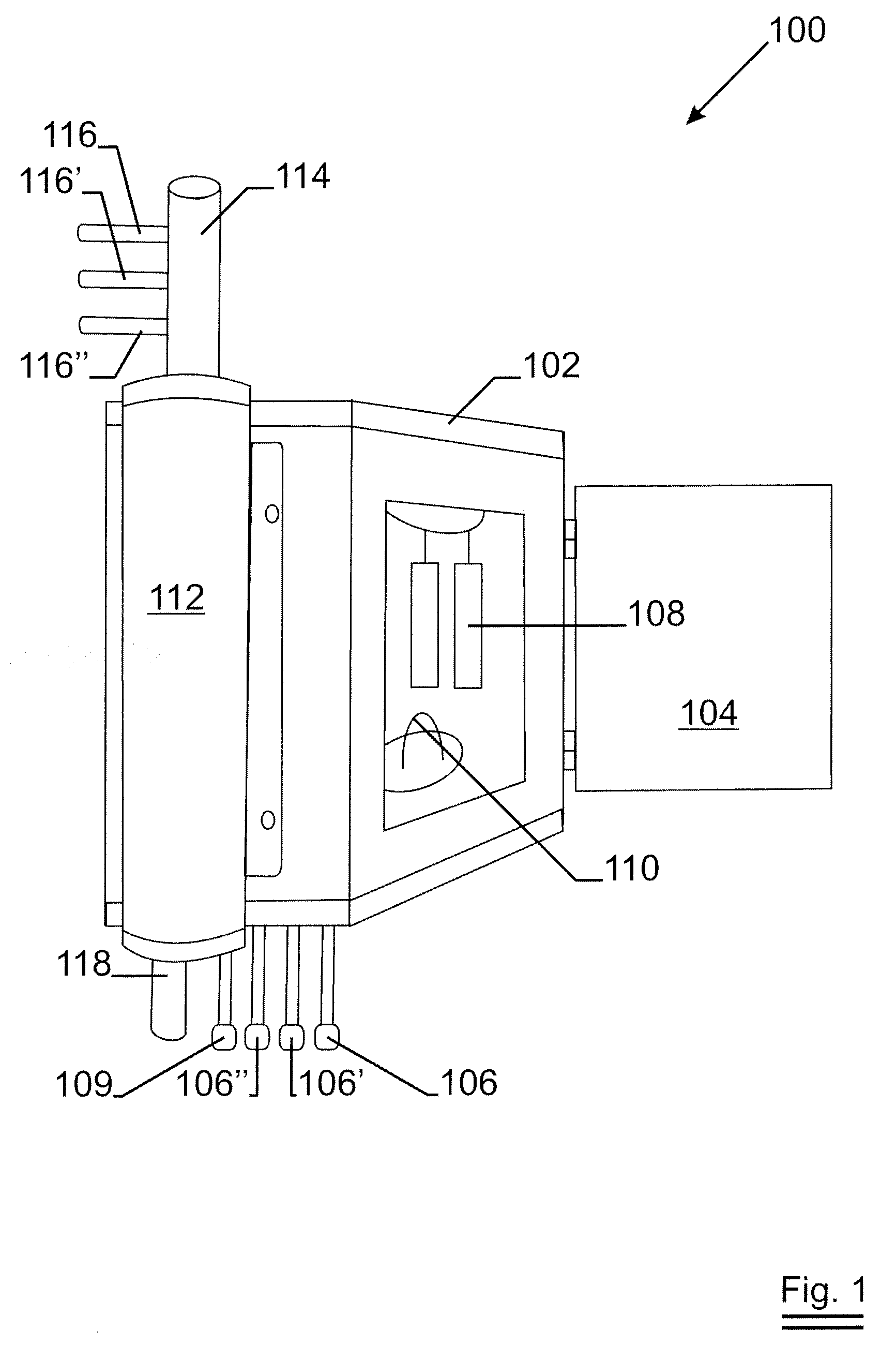

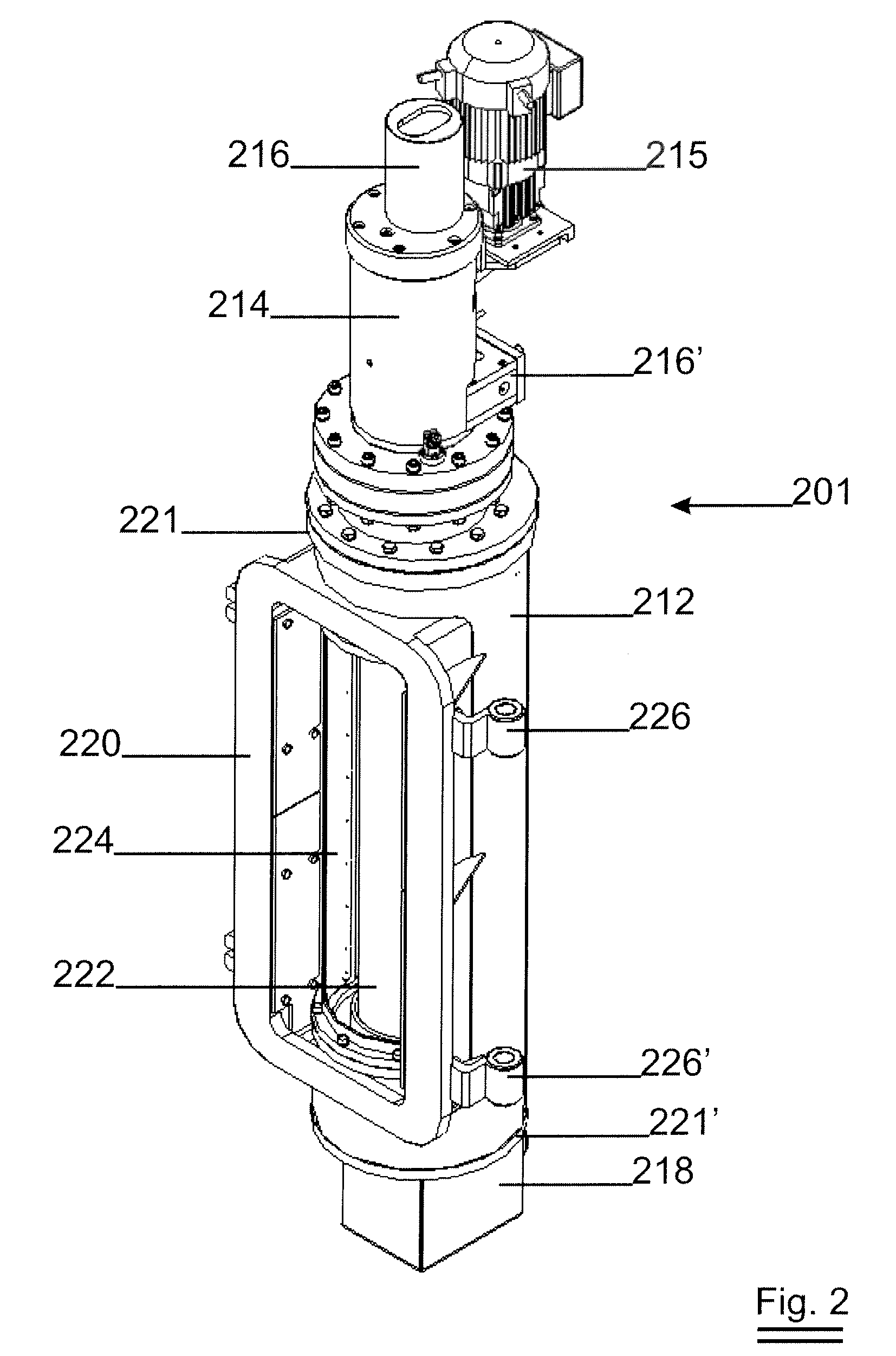

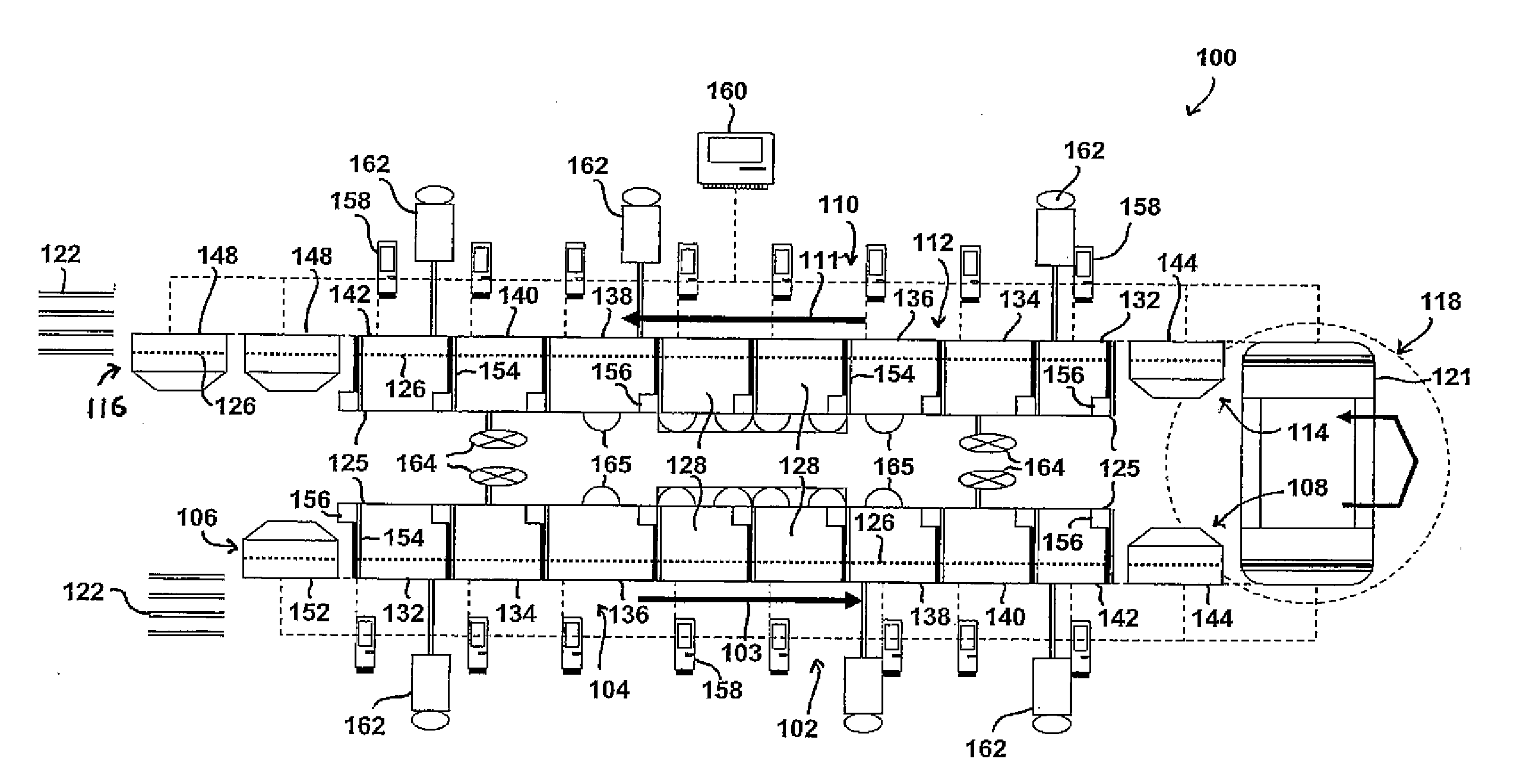

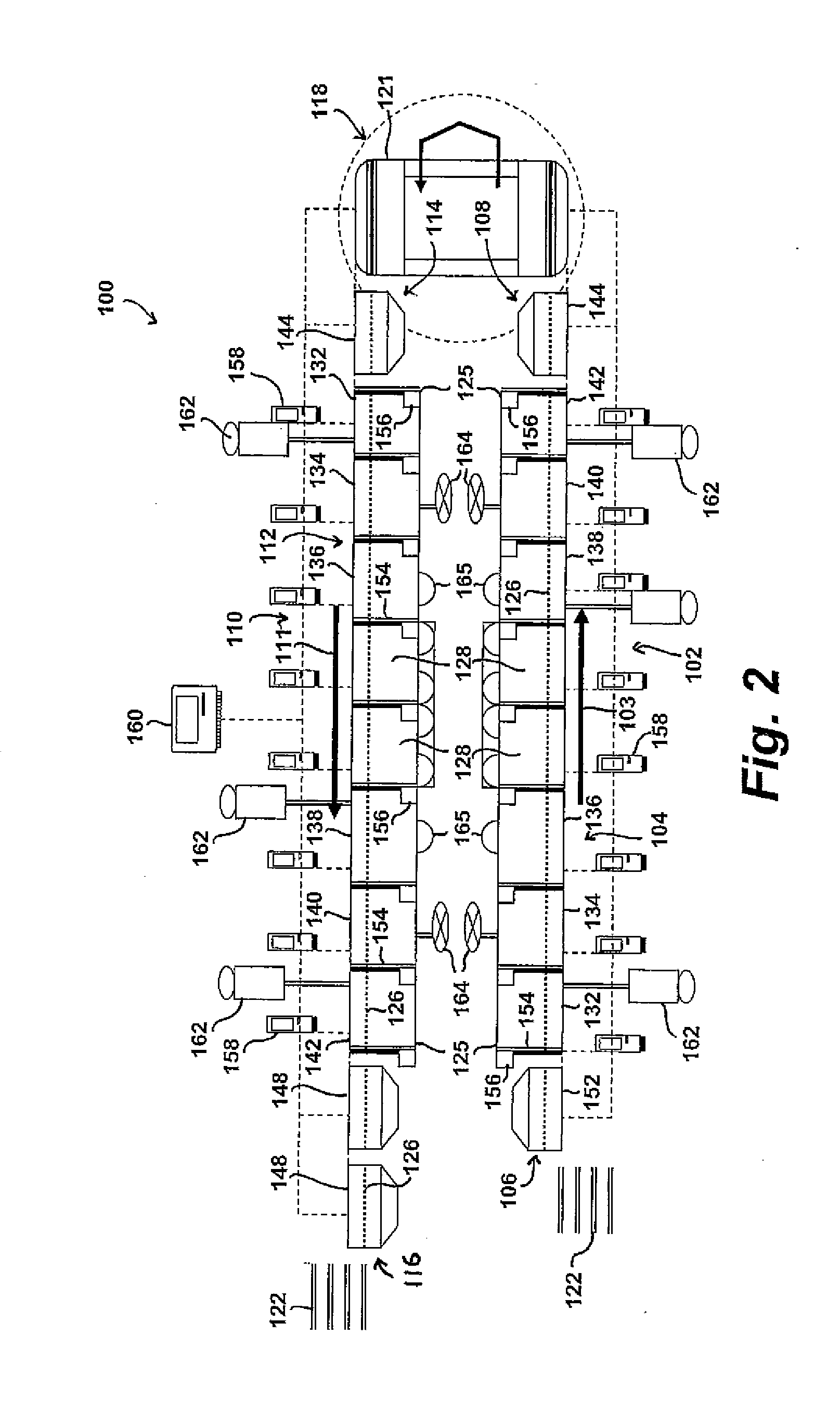

Coating apparatus

InactiveUS20090130336A1Time-efficient process scheduleCellsElectric discharge tubesEngineeringChemical vapor deposition

A coating apparatus (100) for batch coating of substrates is presented. In the batch coater layers of a stack can be deposited by means of physical vapour deposition, by means of chemical vapour deposition or by a mixture of both processes. When compared to previous apparatus, the mixed mode process is particularly stable. This is achieved by using a rotatable magnetron (112) rather than the prior-art planar magnetrons. The apparatus is further equipped with a rotatable shutter that allows for concurrent or alternating process steps.

Owner:SOLERAS ADVANCED COATINGS NV

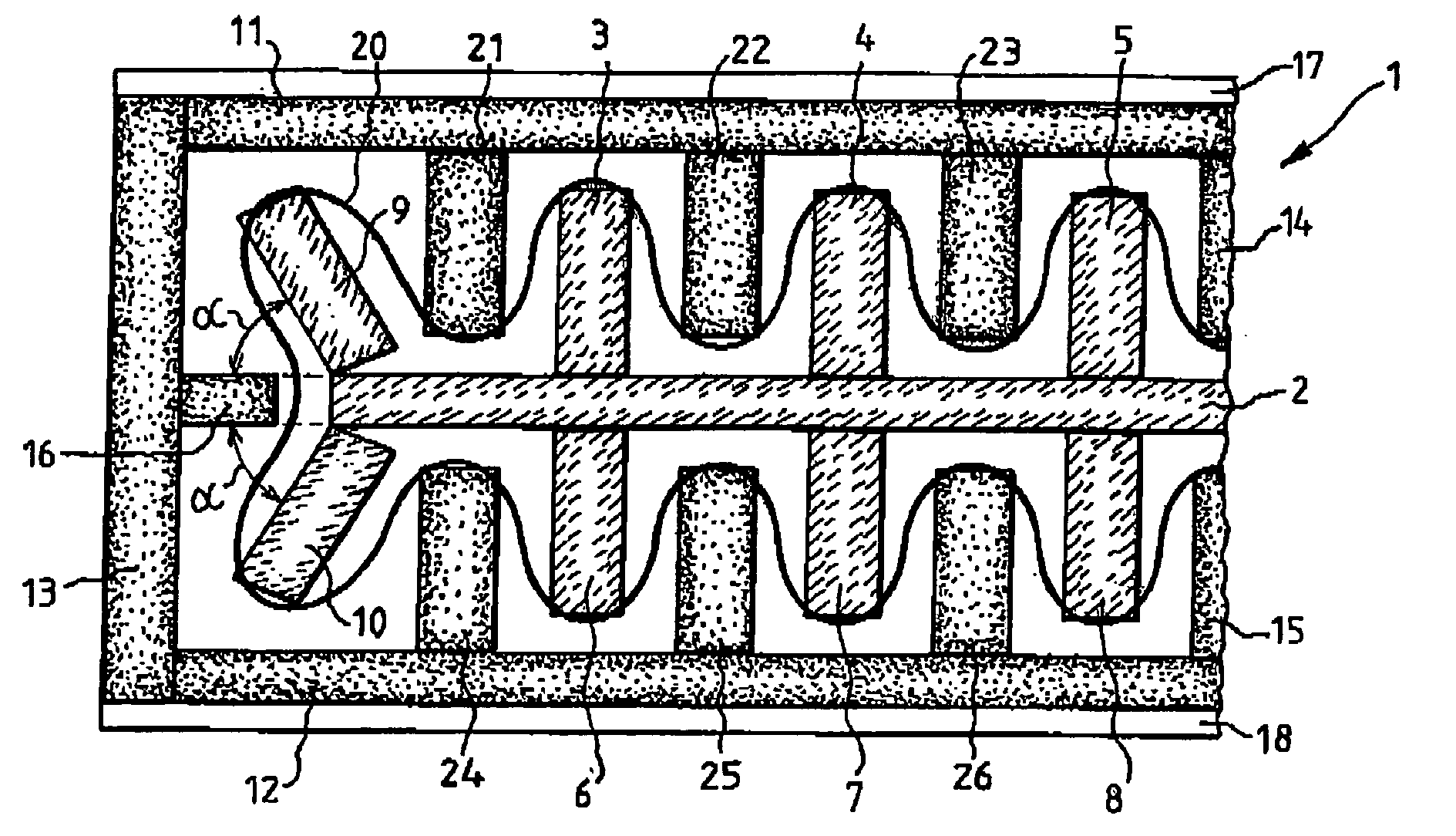

Magnet arrangement for a planar magnetron

InactiveUS20060219550A1Improve sputtering effectIncrease probabilityCellsElectric discharge tubesTarget surfaceWave shape

A magnetic arrangement for a planar magnetron, in which an initial magnetic pole encompasses a second magnetic pole. This magnetic arrangement is moved linear in longitudinal direction to a target by a specific value and then moved back in opposite direction by the same value. In one version, an additional perpendicular motion is effected. The magnet arrangement is designed so that north and south pole interlock and waviform racetracks are generated. This enables constant sputtering from the entire target surface.

Owner:APPLIED MATERIALS GMBH & CO KG

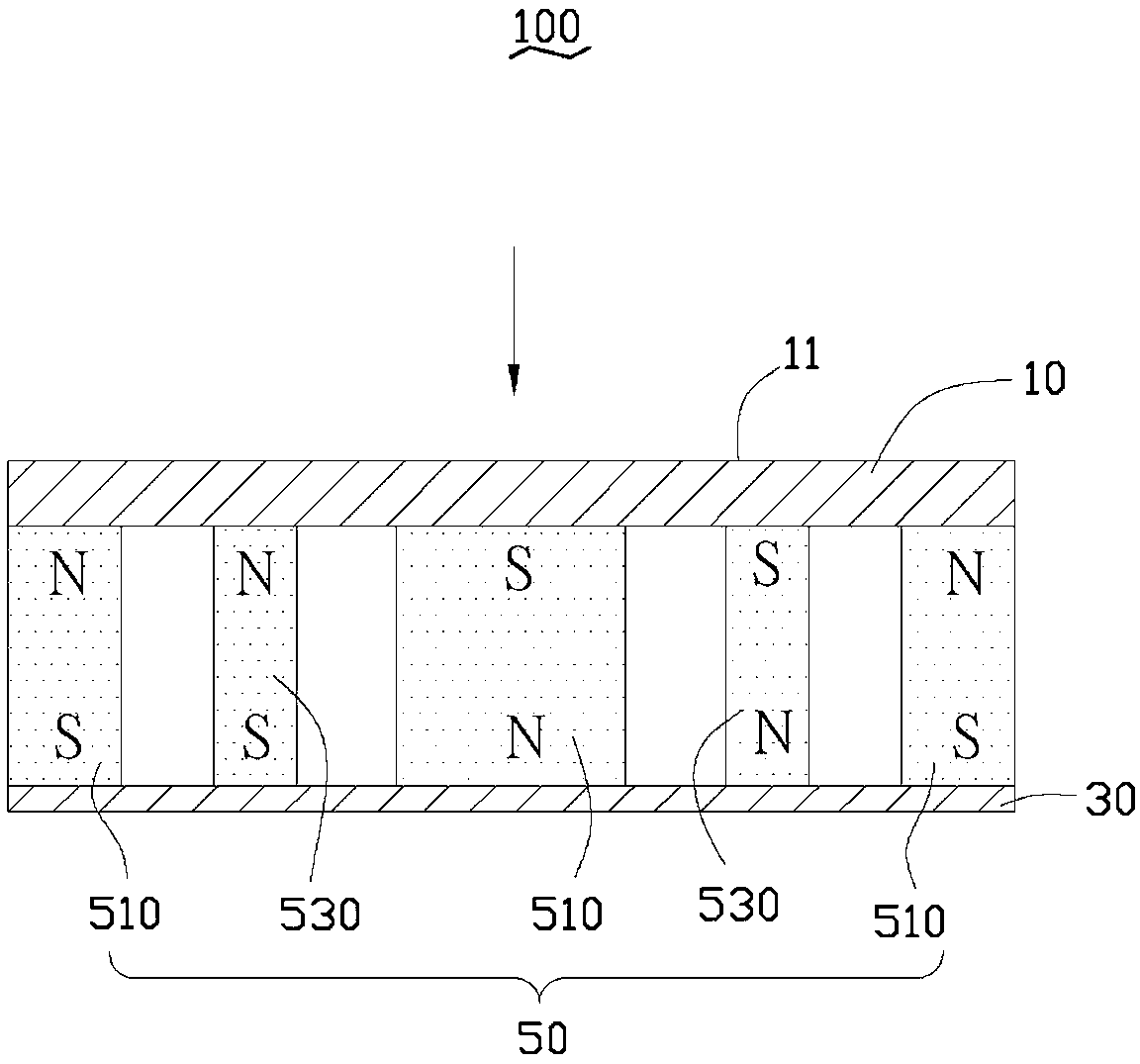

Planar magnetron sputtering cathode

InactiveCN103050358AIncrease profitUniform distribution of magnetic field strengthElectric discharge tubesSputteringElectrical polarity

The invention discloses a planar magnetron sputtering cathode which comprises a target material, a magnet device and a magnet shoe, wherein the magnetic device is arranged on one surface, which is opposite to a sputtering surface, of the target material, the magnet shoe is arranged on one surface, which is far away from the target material, of the magnet device, the magnet device comprises three first magnets which are arranged in parallel at uniform intervals and are respectively positioned on two sides and the middle of the target material, polarities of the two adjacent first magnets are opposite, the magnet device also comprises two second magnet groups, each second magnet group is arranged between two adjacent first magnets, each second magnet group comprises a plurality of second magnets arranged longitudinally at uniform intervals, and polarities of two adjacent second magnets in each second magnet group are opposite. According to the planar magnetron sputtering cathode, the magnetic field strength on the surface of the target material is more uniformly distributed to ensure that the etching region on the surface of the target material is greatly widened, and thus the utilization rate of the target material is effectively utilized.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

High-capacity planar magnetron sputtering cathode

ActiveCN101418432BAvoid corrosionImprove cooling effectVacuum evaporation coatingSputtering coatingSputteringLow emissivity

The invention relates to a high-power planar magnetron sputtering cathode, which belongs to a double silver-layer low emissivity film and mainly solves the technical problems that the magnet of the prior planar magnetron sputtering cathode is steeped in water and will be degaussed after being used for a long time and the like. The key points of the technical proposal are as follows: the high-power planar magnetron sputtering cathode consists of a cathode body (4), a target (1) and a magnet, wherein the target (1) is arranged on the upper part of the cathode body (4); an airtight cooling channel (2) is arranged in the inner cavity of the cathode (4); a magnetic boot (5) is arranged between the bottom and the cooling channel (2) in the inner cavity of the cathode body (4); and the magnet (3) is arranged between the cooling channel (2) and the magnetic boot (5). Because an independent cooling channel is arranged in the cathode body, the magnet does not contact with cooling media to avoidthe permanent magnet from being eroded by the cooling media; besides, high-power planar magnetron sputtering cathode is designed with a heat conduction plate made of materials with high thermal conductivity to contact with the target in a large area, so that the target can be cooled sufficiently and the cathode can bear higher power. The high-power planar magnetron sputtering cathode can be widely applied to a vacuum magnetron sputtering coating device.

Owner:HUNAN YUFENG VACUUM SCI & TECH CO LTD

Sputtering systems for liquid target materials

A sputtering system comprises a magnetron assembly for depositing liquid metal films on a substrate. The magnetron assembly comprises a horizontal planar magnetron with a liquid metal target, a cylindrical rotatable magnetron with a metal target and a set of one or more shields forming a chamber between the planar and the rotatable magnetron.

Owner:NUVOSUN

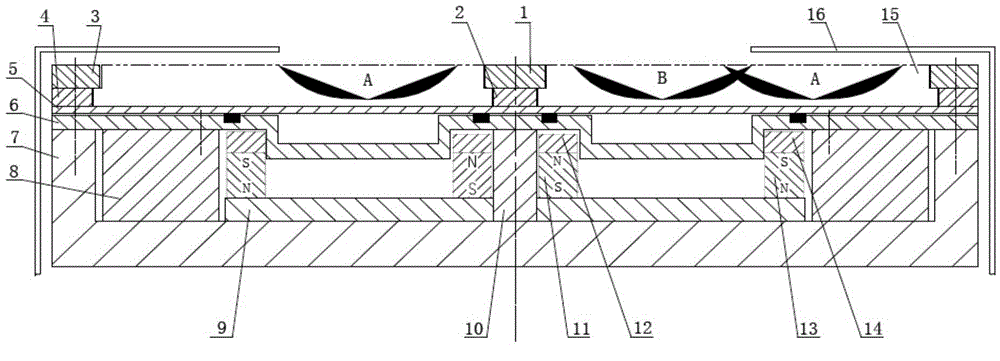

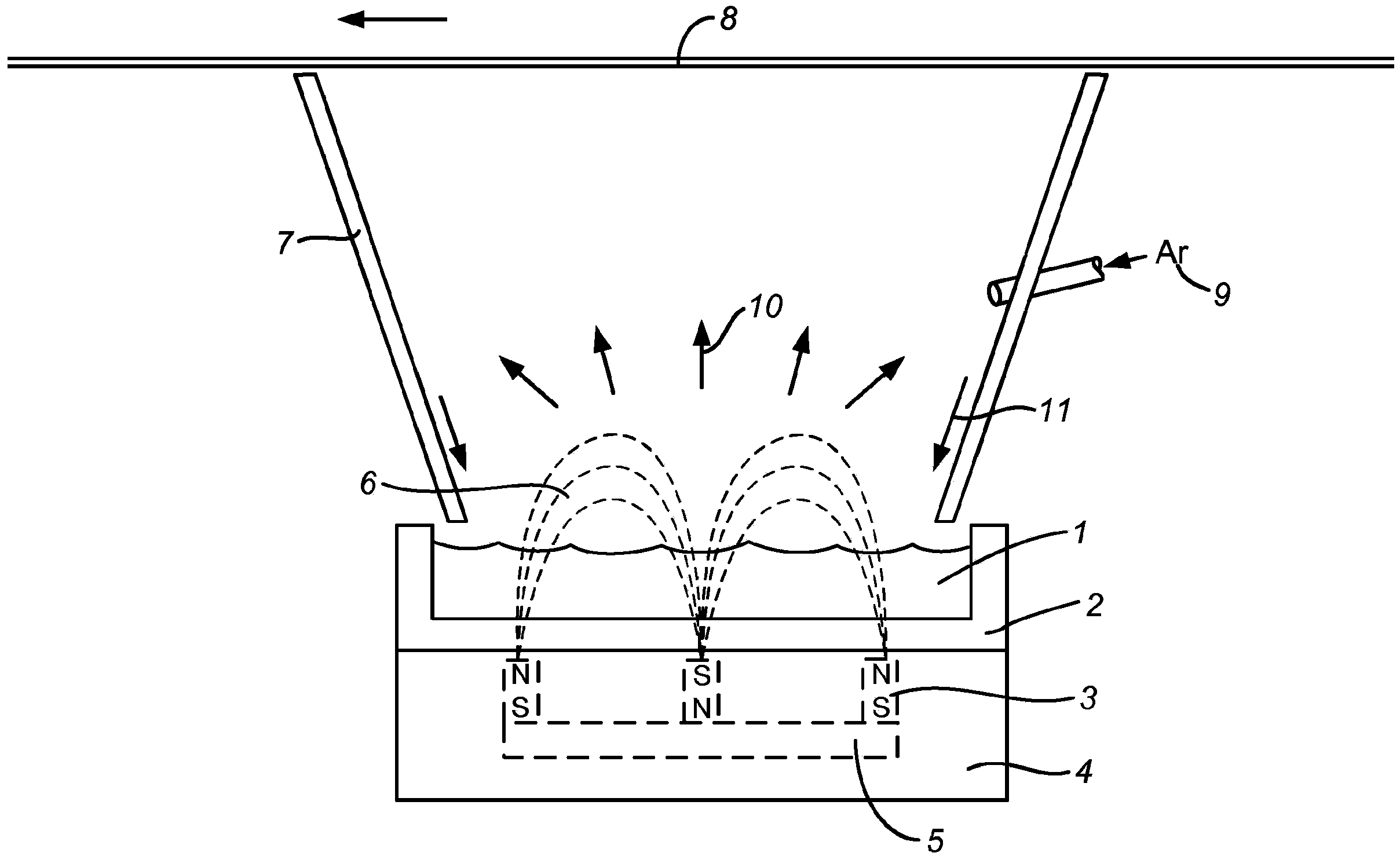

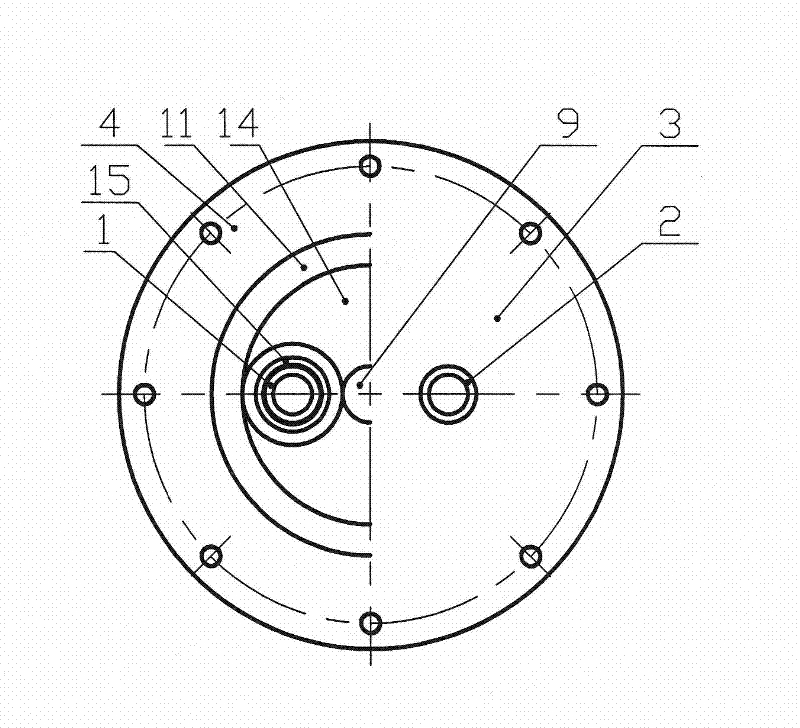

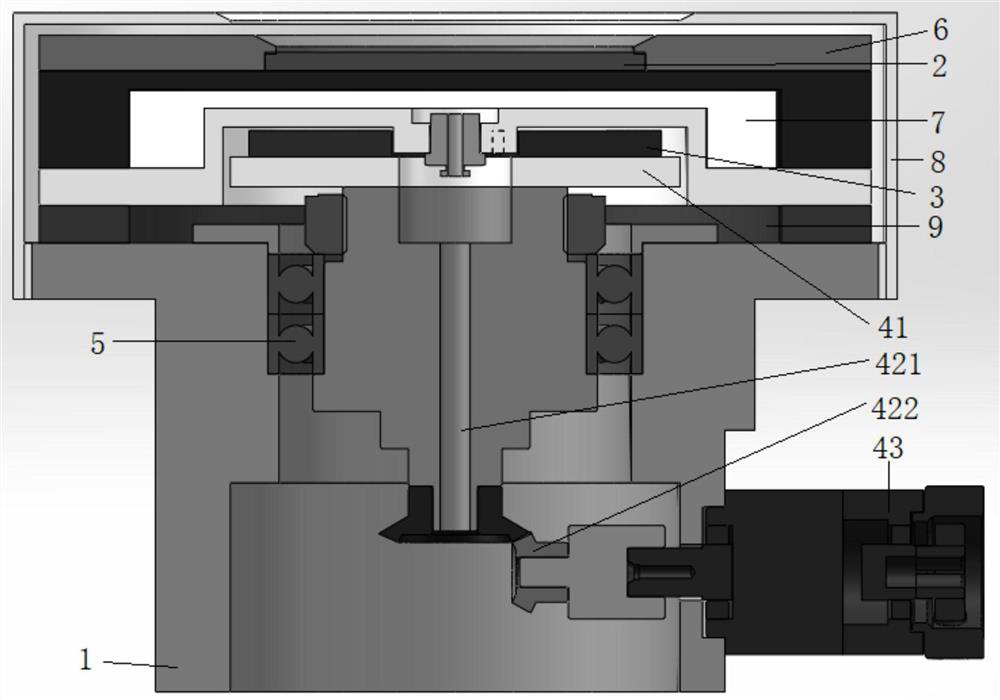

Magnetic water separation type planar magnetron sputtering target

InactiveCN102330061AExtended service lifeWill not polluteVacuum evaporation coatingSputtering coatingPlanar magnetronWater pipe

The invention discloses a magnetic water separation type planar magnetron sputtering target, which comprises a cooling water feeding pipe 1, a cooling water draining pipe 2, a concentrating flux plate 3, a cathode body 4, a target pressure ring 5, a boult 6, a target 7, a central pole shoe 8, a central permanent magnet block 9, a tip pole shoe 10, a tip permanent magnet block 11 and a lower sealing ring 13, wherein the cathode body 4 is provided with an annular rectangular groove 41; a circular blind hole 42 is formed in the center of the cathode body 4; the circle center of the annular rectangular groove 41 is superposed with that of the circular blind hole 42; the cooling water feeding pipe 1 and the cooling water draining pipe 2 upwards penetrate through the through holes on the concentrating flux plate 3 and the cathode body 4 and are sealed with the cathode body 4 by using a water pipe sealing ring 43; the central pole shoe 8 and the central permanent magnet block 9 are positioned in the circular blind hole 42; and the tip pole shoe 10 and the tip permanent magnet block 11 are positioned in the annular rectangular groove 41. A novel structure of separating a cathode magnetic path from a cooling water path is adopted in the magnetic water separation type planar magnetron sputtering target, so that the service life of a magnet is greatly prolonged; and meanwhile, cooling water cannot be polluted or blocked, and the quality of a plated film is stably improved.

Owner:衡阳市真空机电设备有限公司

Method for producing a plasma jet and plasma source

In the method for producing a plasma jet, which is extracted from a plasma produced by electric and magnetic fields by a high frequency voltage being applied to an extraction electrode and an HF electrode apparatus having an excitation electrode with an excitation surface, a plasma chamber being arranged between an extraction electrode and an excitation surface and, as compared with the extraction electrode, the time average of the plasma lying at a higher potential accelerating positive plasma ions, and the plasma and extracted plasma jet being influenced by a magnetic field, the invention provides that, in order to produce a magnetic field, use is made of a planar magnetron which is arranged after the excitation electrode on the side facing away from the plasma, and the magnetic north poles and magnetic south poles of which are directed into the interior of the plasma chamber, so that a curved magnetic field projecting into the interior of the plasma chamber is formed. In the plasma source for carrying out the method, having a plasma vessel with an extraction electrode and having an HF electrode apparatus, having an excitation electrode with an excitation surface, which is or can be connected via a matching network to an HF generator, a plasma chamber, in which a plasma can be excited, being located between excitation surface and extraction electrode, and the size of the area of the extraction electrode and of the excitation surface being chosen such that virtually all of the high frequency voltage is dropped across the extraction electrode; having a magnetic device for reducing the magnetic field, provision is made for the magnetic device to have at least one magnetic north pole and one magnetic south pole, which are in each case arranged after the excitation electrode on the side facing away from the plasma chamber and are directed into the interior of the plasma chamber, so that a curved magnetic field projecting into the interior of the plasma chamber can be formed, wherein at least one of the north or south poles is designed to be elongated, so that a tunnel-like region can be formed in which charged particles can be retained and along which they are able to propagate.

Owner:LEYBOLD OPTICS

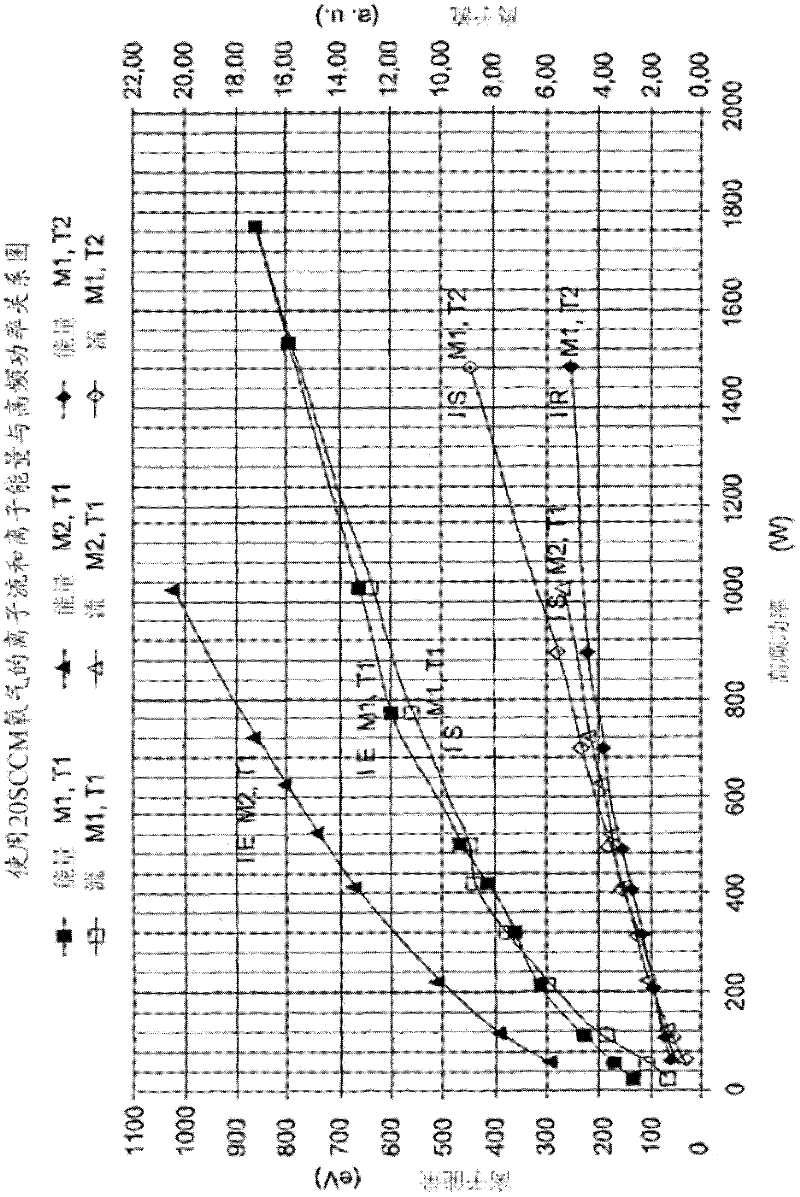

Methods for high-rate sputtering of a compound semiconductor on large area substrates

Methods are generally provided for sputtering thin films on individual substrates. Individual substrates can be conveyed into a vacuum chamber to draw a sputtering pressure that is less than about 50 mTorr. Then, the individual substrates can be conveyed into a sputtering chamber and past a planar magnetron continuously sputtering a target by an ionized gas at the sputtering pressure such that a thin film is formed on a surface of the individual substrate. The target is subjected to a high frequency power having a frequency from about 400 kHz to about 4 MHz at power levels of greater than about 1 kW. In one particular embodiment, the method can be generally directed to sputtering thin films on individual substrates defining a surface having a surface area of about 1000 cm2 to about 2500 cm2.

Owner:FIRST SOLAR INC (US)

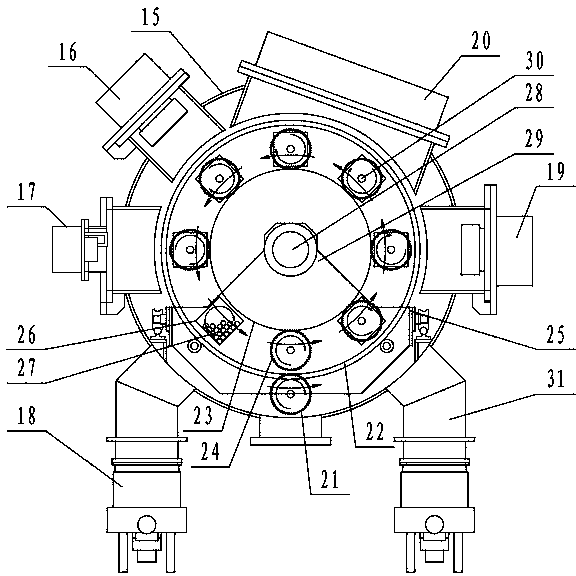

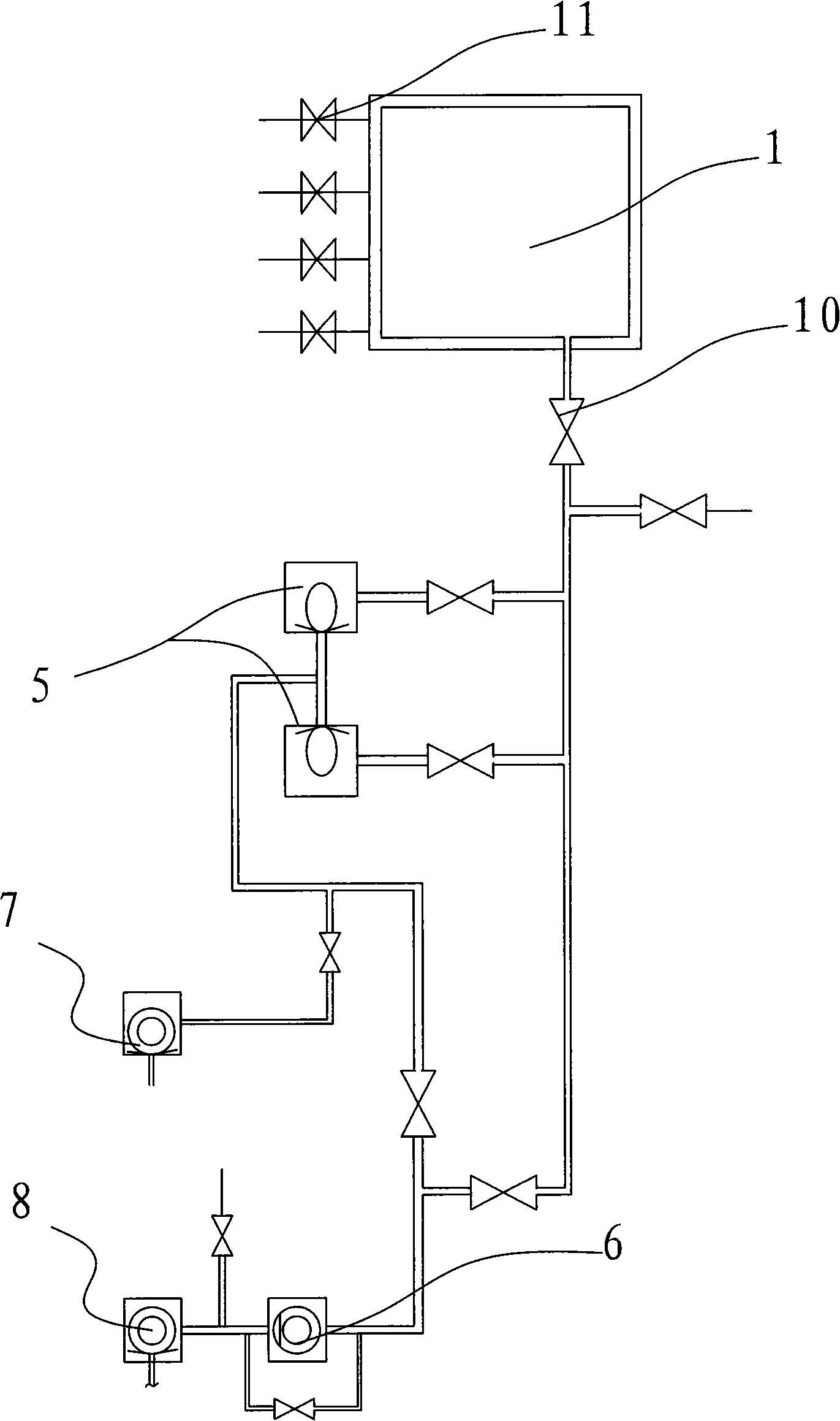

Excitation modulation anode auxiliary magnetron sputtering ion plating system

ActiveCN111411337AIncreased chance of collisionIncrease ionization rateVacuum evaporation coatingSputtering coatingSputteringControl system

The invention relates to an excitation modulation anode auxiliary magnetron sputtering ion plating system. The system comprises a vacuum cavity, a vacuum pump set, a vacuum measuring device, a power supply control cabinet and a PLC+ICP+closed loop control system which are connected together. One side of the vacuum cavity is connected with the vacuum pump set through a pipeline valve body via an air exhaust hole, and the other side is connected with the vacuum measuring device; the vacuum cavity is provided with a vacuum cavity door body with a clam type hinged door; a pair of planar magnetroltargets are symmetrically arranged on the front surface of the vacuum cavity door body, and two pairs of auxiliary water-cooling anodes with gas distribution systems are symmetrically arranged on theside surfaces; an excitation field modulation coil is arranged on the periphery of each auxiliary water-cooled anode; two pairs of twin columnar magnetron sputtering cathodes are symmetrically inserted into the vacuum cavity; and the columnar magnetron sputtering cathodes, the auxiliary water-cooled anodes, the planar magnetron targets, the excitation field modulation coil, the pipeline valve body, the vacuum pump set and the vacuum measuring device are connected with the PLC+ICP+closed loop control system and the power supply control cabinet through line bridges correspondingly. According tothe system, target poisoning can be effectively prevented, and the coating quality is improved.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Anti-static ceramic and preparation method thereof

InactiveCN106810199AIntegrity guaranteedGuaranteed anti-static effectClaywaresPlanar magnetronFeldspar

The invention discloses anti-static ceramic and a preparation method thereof. The preparation method involves a ceramic preparation process including preform body preparation, molding, forming, drying, glazing and firing. The ceramic preparation process specifically includes the steps of (1), preform body preparation, namely mixing, by weight, 60-90 parts of quartz, 100-150 parts of feldspar and 300-500 parts of kaolin with a specific amount of clear water. The anti-static ceramic comprises an anti-static layer. The anti-static ceramic and the preparation method thereof have the advantages that through adoption of all ceramic preparation processes, ceramic integrity is guaranteed; the anti-static layer is sprayed on the outer surface of the produced ceramic by means of planar magnetron sputtering, so that anti-static effects of anti-static substances are ensured sufficiently, and the possibility that the anti-static substances are damaged during firing in a traditional process is decreased; the anti-static layer cannot be destroyed through multilayer spraying.

Owner:FENGYANG JIAHE AGRI TECH

Method for coating film on solar high-temperature heat collection tube used for power generation and horizontal film coating machine

InactiveCN102051590BSolve loading and unloading difficultiesQuality improvementVacuum evaporation coatingSputtering coatingEngineeringPlanar magnetron

Owner:湖南菲尔姆真空设备有限公司

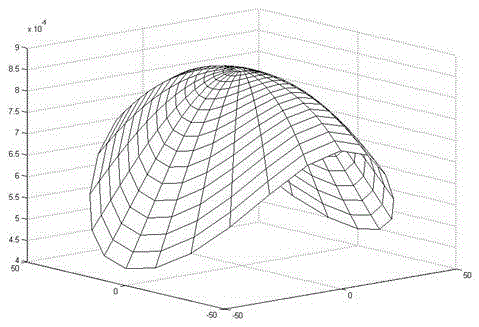

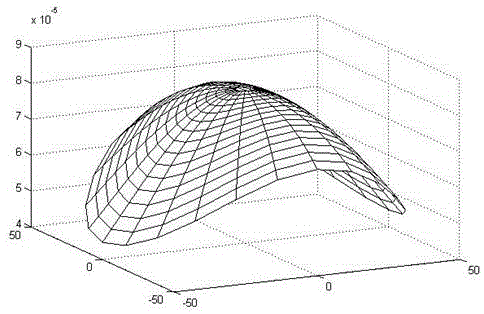

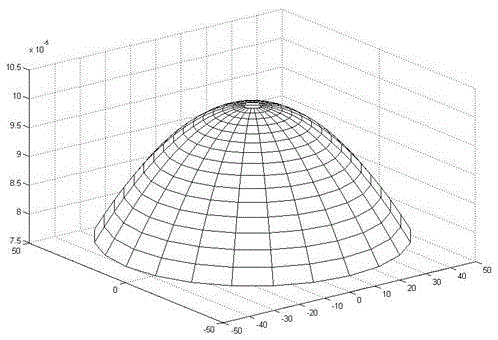

A Substrate Eccentric Rotation Method for Improving Thickness Uniformity of Magnetron Sputtering Rectangular Target

ActiveCN104233209BControl UniformitySolve the technical problem of uneven thicknessVacuum evaporation coatingSputtering coatingRotation methodOptoelectronics

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Planar magnetron cathode

InactiveCN104611674AOvercome the problem of thermal expansionAvoid thermal expansionVacuum evaporation coatingSputtering coatingThermal expansionCopper

The invention discloses a planar magnetron cathode. The planar magnetron cathode includes: a nuclear body, which is embedded with a magnet equipped with a channel; a copper plate, which seals the channel; and a target material, which is formed by splicing multiple target blocks and is fixedly connected to the copper plate. The planar magnetron cathode provided by the invention can prevent thermal expansion.

Owner:WUHU VACUUM TECH

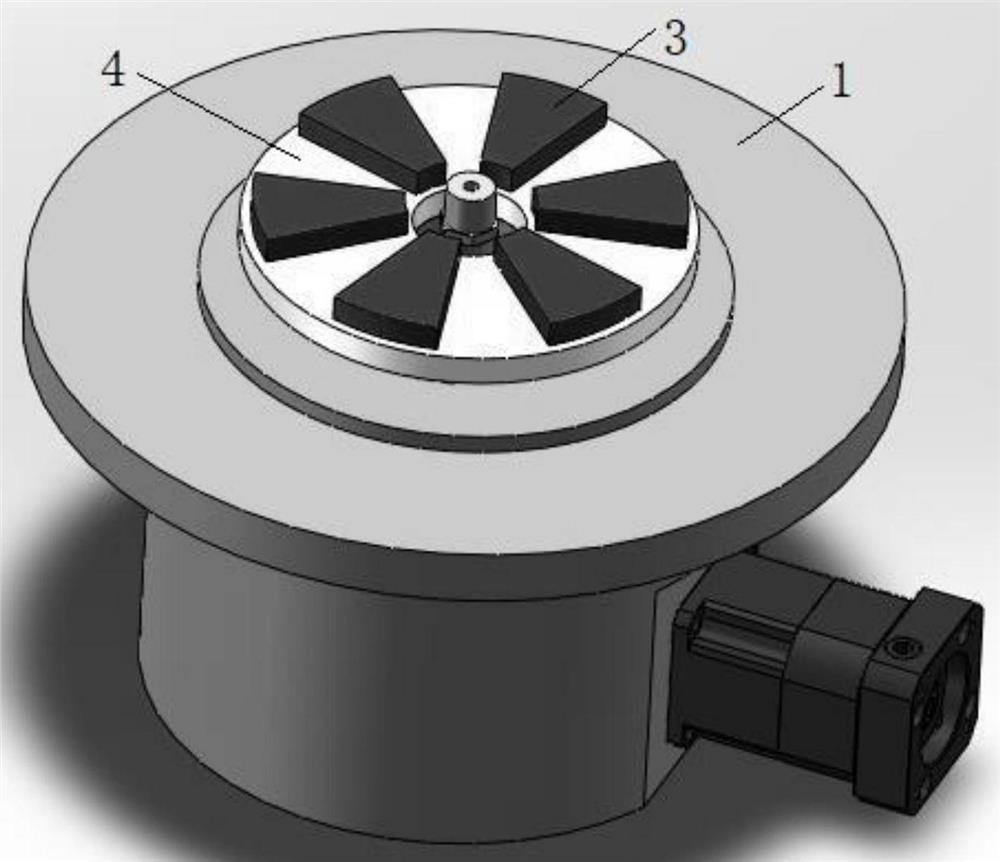

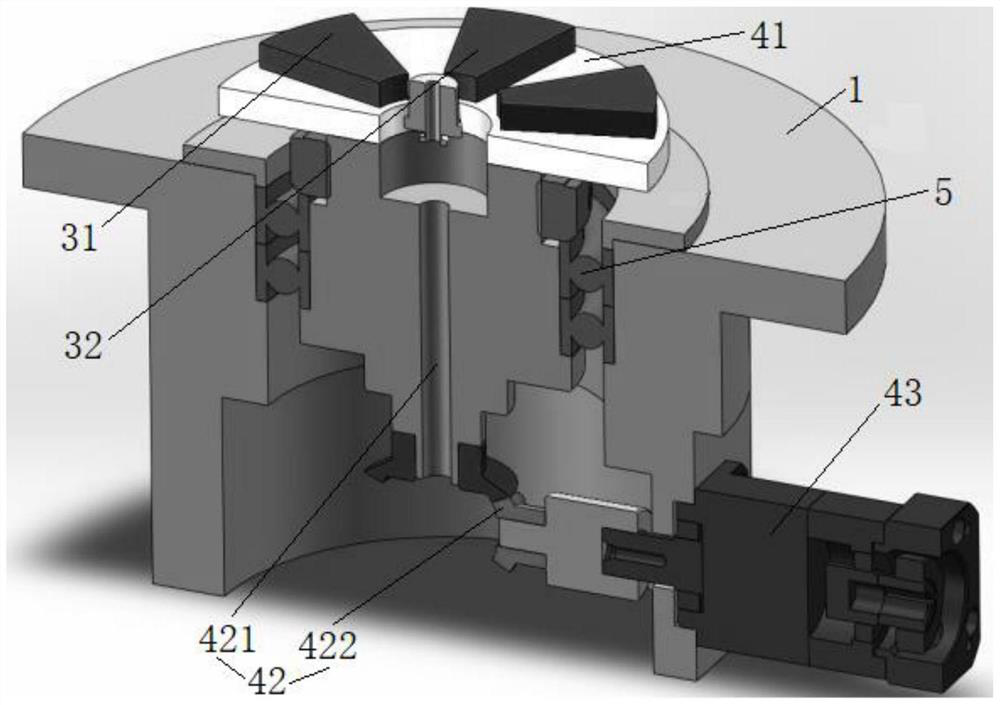

A circular planar magnetron sputtering target with rotating magnetic poles

ActiveCN113174576BIncrease sputtering areaIncrease deposition rateVacuum evaporation coatingSputtering coatingMagnetic polesParticle physics

The invention provides a circular planar magnetron sputtering target with magnetic pole rotation, comprising: a target base, which is a hollow cylindrical structure; a magnetic pole rotation system, which is arranged on the target base and is movable with the target base. connection; the magnetic pole rotation system is a rotatable structure; the magnetic pole is set on the magnetic pole rotation system and driven to rotate by the magnetic pole rotation system. In the present invention, a plurality of magnetic poles are evenly distributed along the radial direction of the magnetic pole rotation system, so that the magnetic induction lines are arranged along the circumferential direction of the target, and the magnetic poles in the present invention can be rotated, thereby preventing the formation of obvious etching grooves on the surface of the target and improving the The utilization rate of the target and the sputtering rate are improved, thereby solving the deficiencies in the prior art.

Owner:HUNAN CITY UNIV

Method for preparing single-sided hot-melt adhesive-coated aluminum-plated shielding fabric

ActiveCN106758174AImprove consistencyIncrease productivityFilm/foil adhesivesFibre treatmentSputteringMetal coating

The invention discloses a method for preparing a single-sided hot-melt-adhesive coated aluminum-plated shielding fabric. The method comprises the following steps: unreeling a substrate on a coating line and passing through a non-scratch hot-melt adhesive coating head, and coating a hot-melt adhesive layer on a single side; and putting the hot-melt adhesive-coated substrate in a vacuum chamber, removing air from the vacuum chamber to the negative pressure, then introducing argon into the vacuum chamber, and sputtering an aluminum target by using magnetron sputtering coating equipment, wherein a target source of the magnetron sputtering coating equipment adopts a rectangular planar magnetron target and a coaxial cylindrical magnetron target to form a cylindrical planar magnetron sputtering target. According to the method provided by the invention, the material is coated with the hot-melt adhesive layer on the surface before being not coated with a metal coating layer, and then the surface metal layer is processed so that the hardness of the fabric is improved after the fabric is coated, the probability of wrinkling of the deposited metal layer working procedure is reduced, and the yield of the product is improved.

Owner:菏泽天源电子科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com