Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

269 results about "All ceramic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

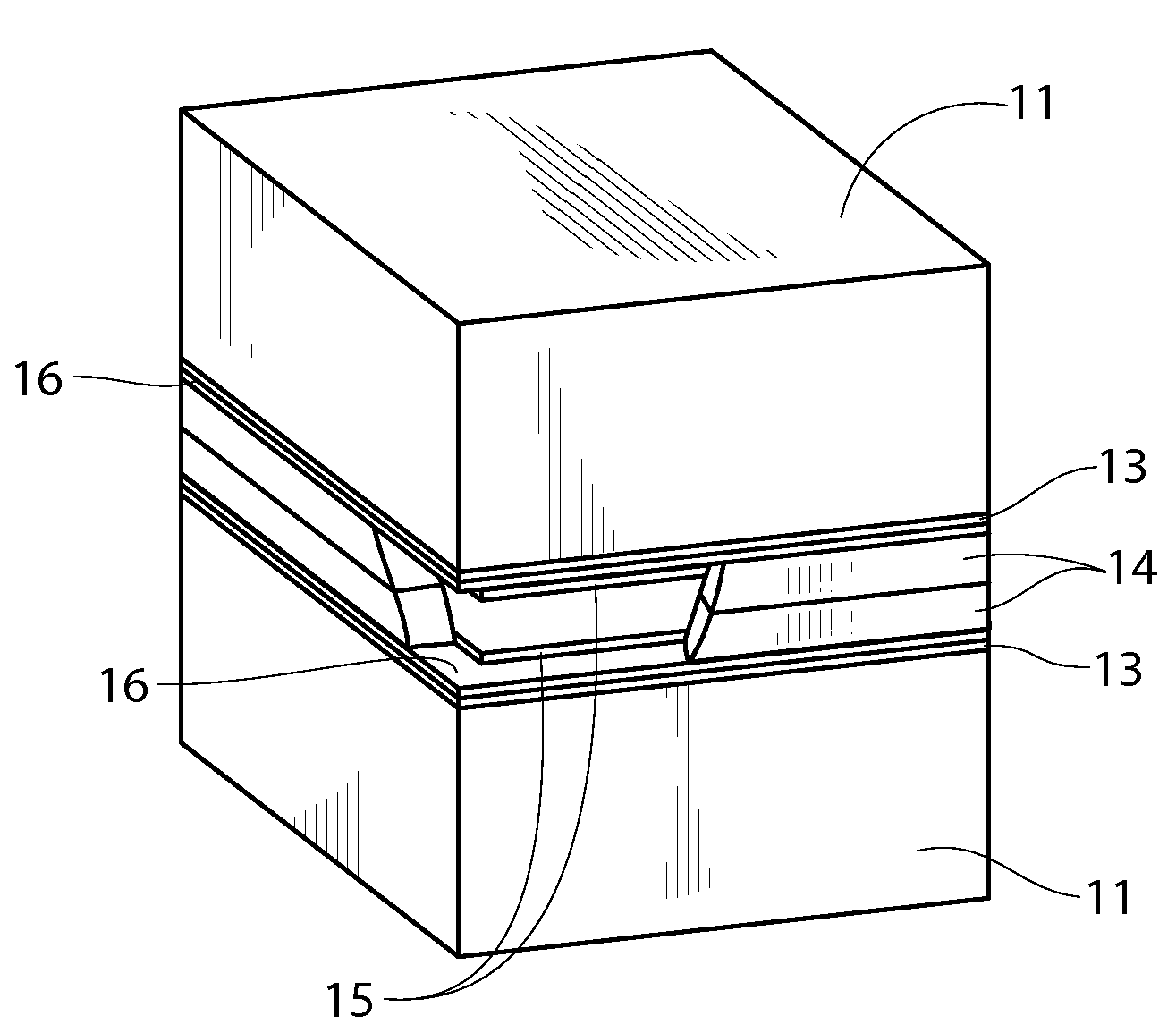

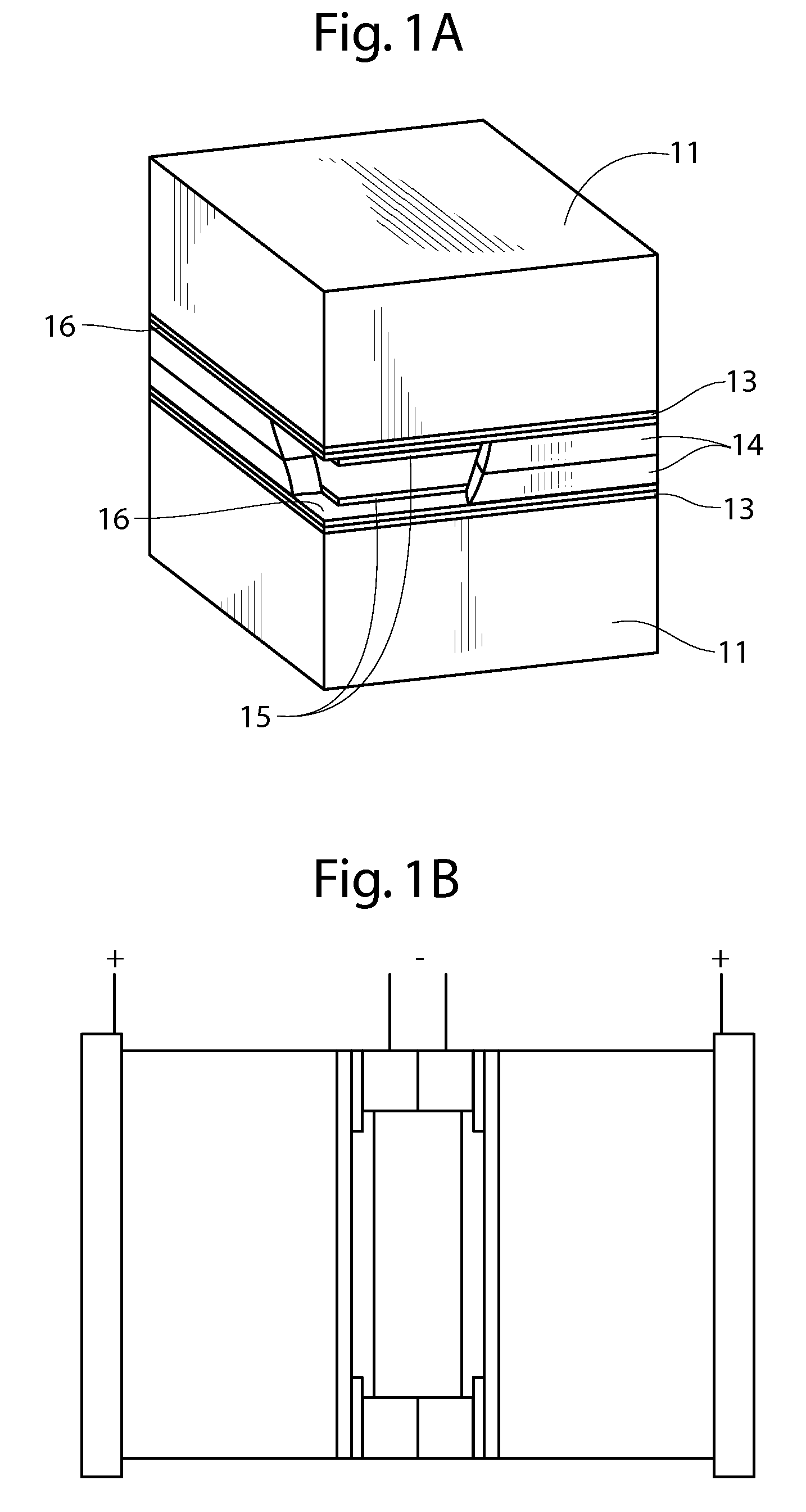

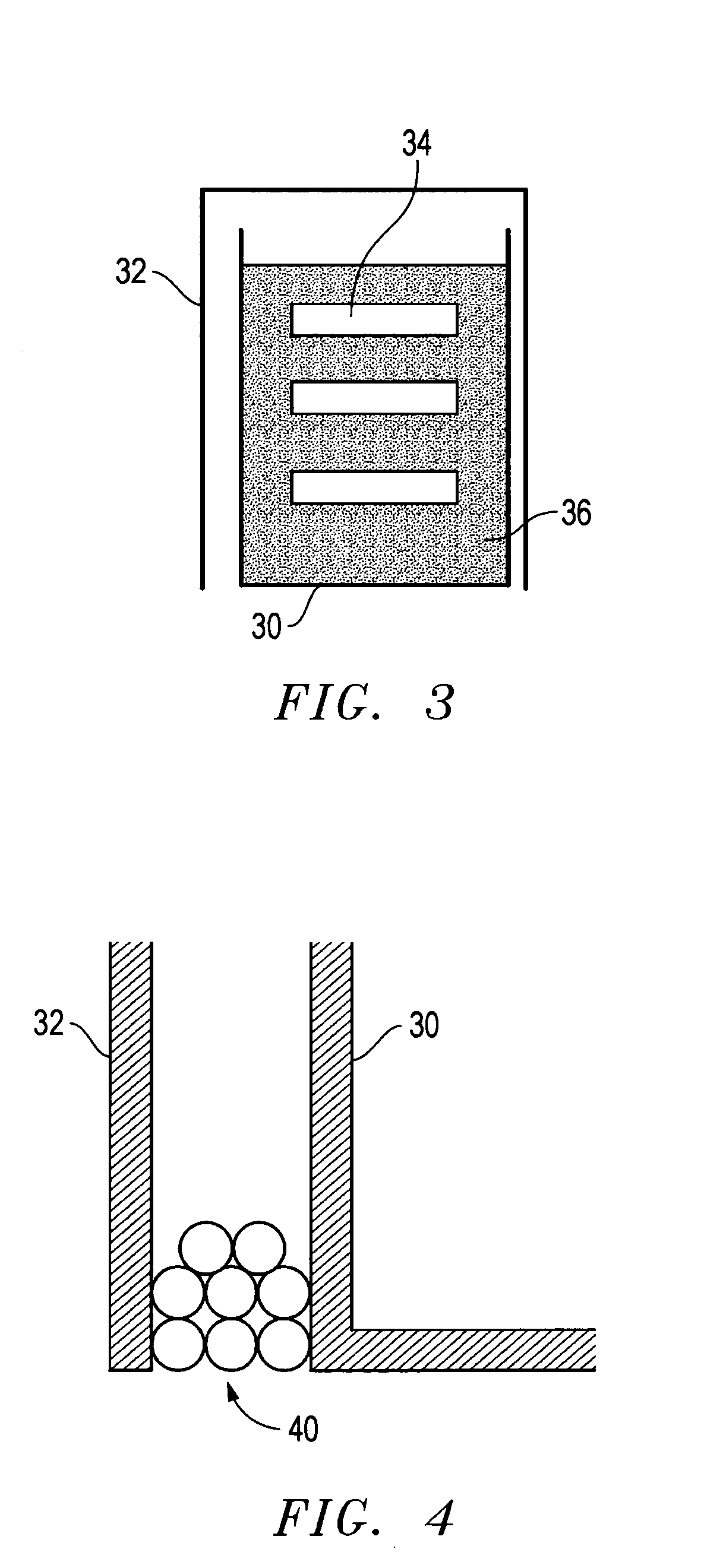

Low Cost Solid State Rechargeable Battery and Method of Manufacturing Same

InactiveUS20090092903A1Solid electrolytesElectrode thermal treatmentOptoelectronicsConductive materials

A solid state Li battery and an all ceramic Li-ion battery are disclosed. The all ceramic battery has a solid state battery cathode comprised of a mixture of an active cathode material, an electronically conductive material, and a solid ionically conductive material. The cathode mixture is sintered. The battery also has a solid state battery anode comprised of a mixture of an active anode material, an electronically conductive material, and a solid ionically conductive material. The anode mixture is sintered. The battery also has a solid state separator positioned between said solid state battery cathode and said solid state battery anode. In the solid state Li battery the all ceramic anode is replaced with an evaporated thin film Li metal anode.

Owner:JOHNSON IP HLDG LLC

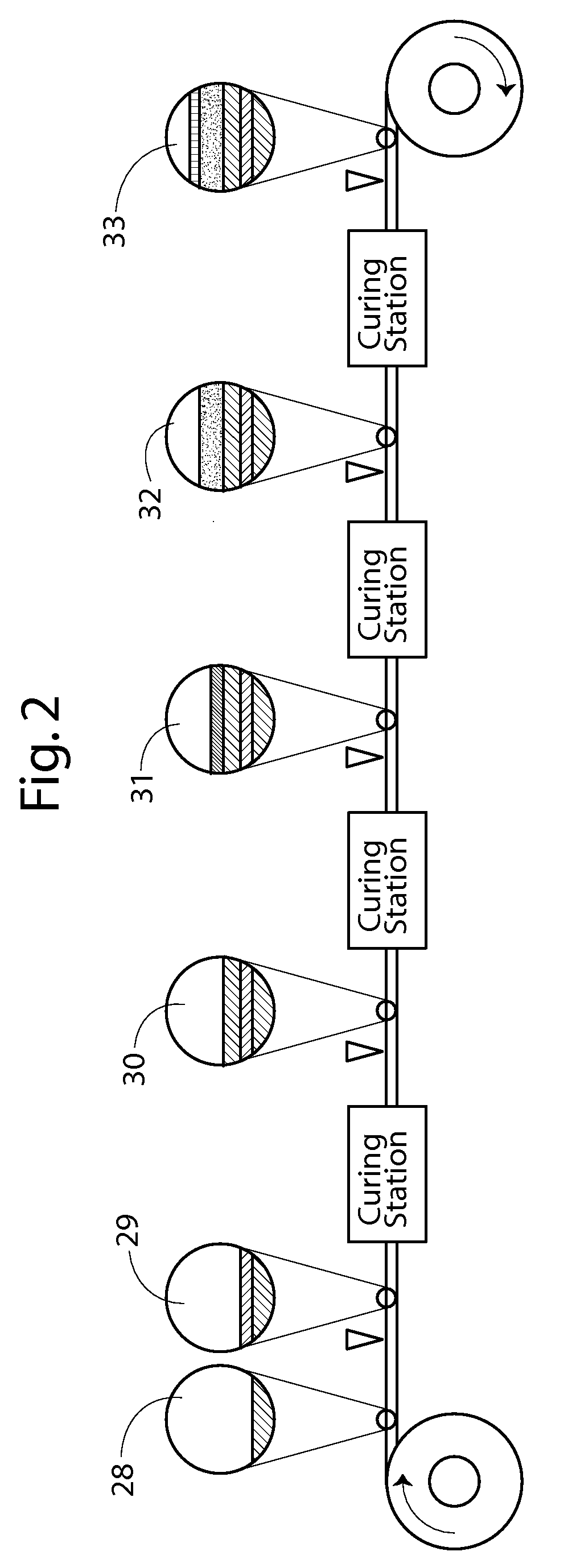

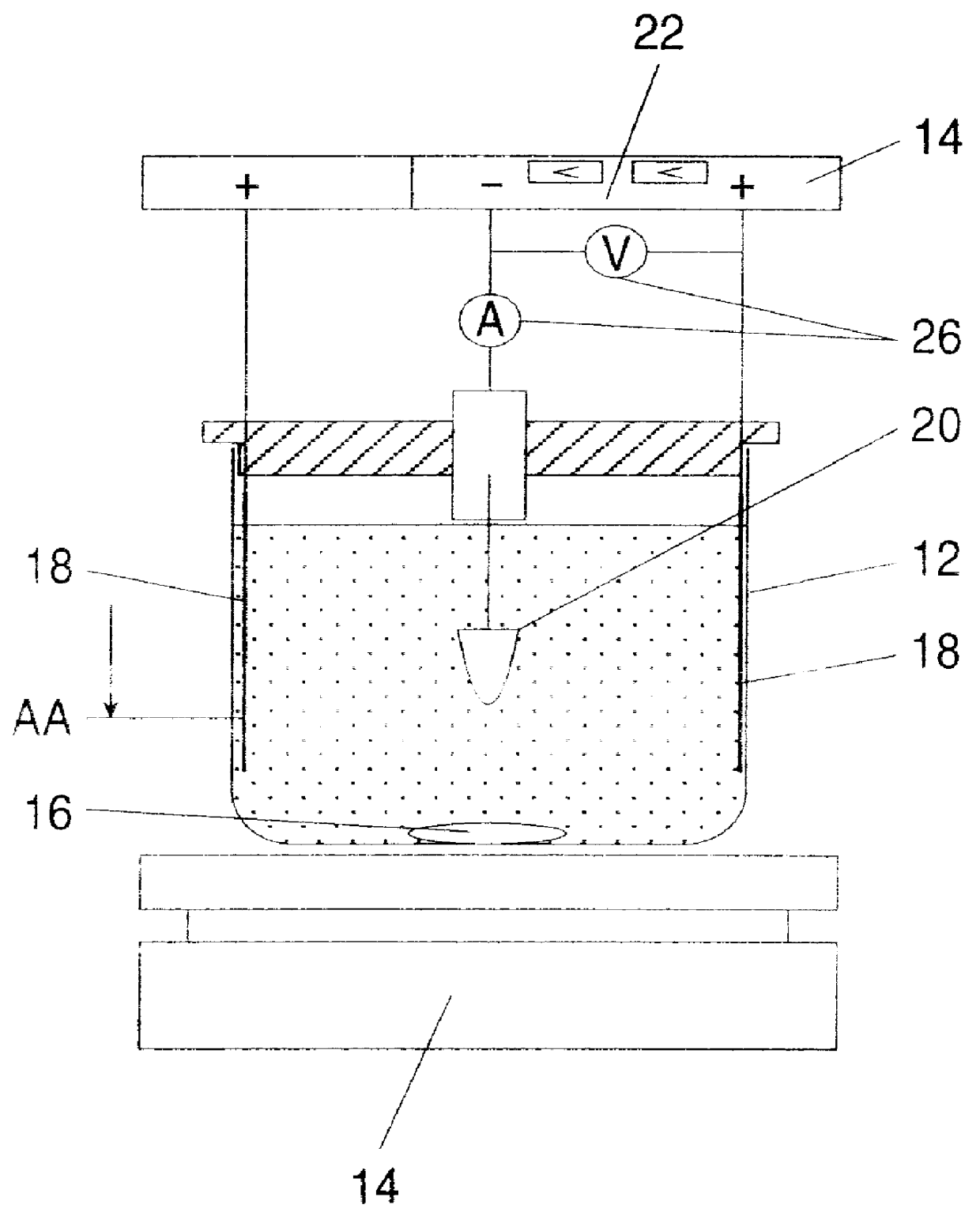

Method of electrophoretic deposition of ceramic bodies for use in manufacturing dental appliances

InactiveUS6059949AHigh strengthImprove toughnessElectrolysis componentsTeeth fillingMetallurgyElectrophoresis

A method for electrophoretic deposition of ceramic particles as a green body shaped as a dental appliance, the method comprising the steps of (a) forming a suspension of the ceramic particles in a first polar solvent, the ceramic particles constituting at least about 5% of the first suspension by weight; (b) passing a direct electrical current through the first suspension, using a deposition electrode shaped as the dental appliance to form a green body; (c) coating the green body with glass particles; and (d) sintering the resultant coated body for obtaining a glass coated all-ceramic dental appliance.

Owner:CEREL CERAMIC TECH

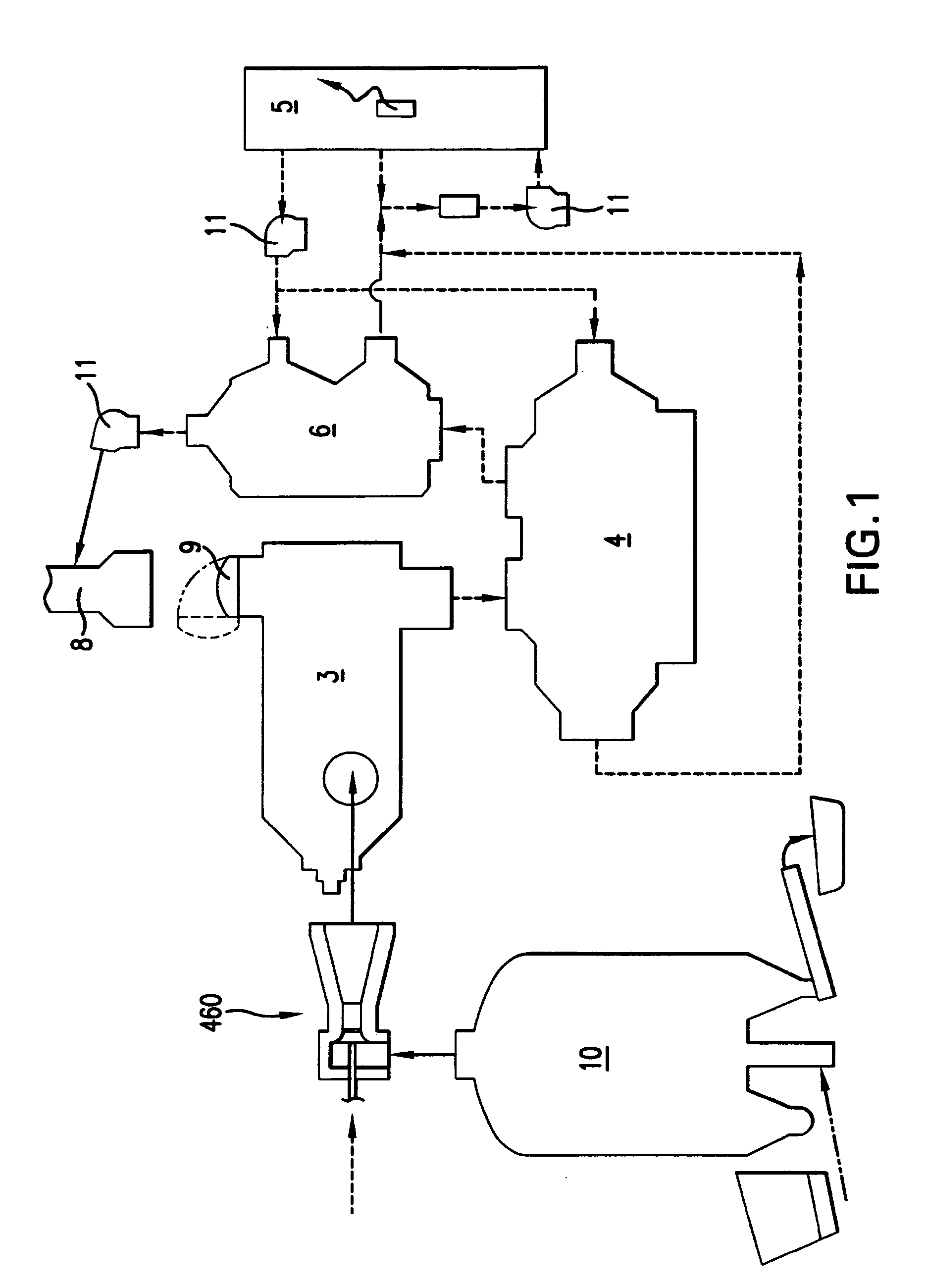

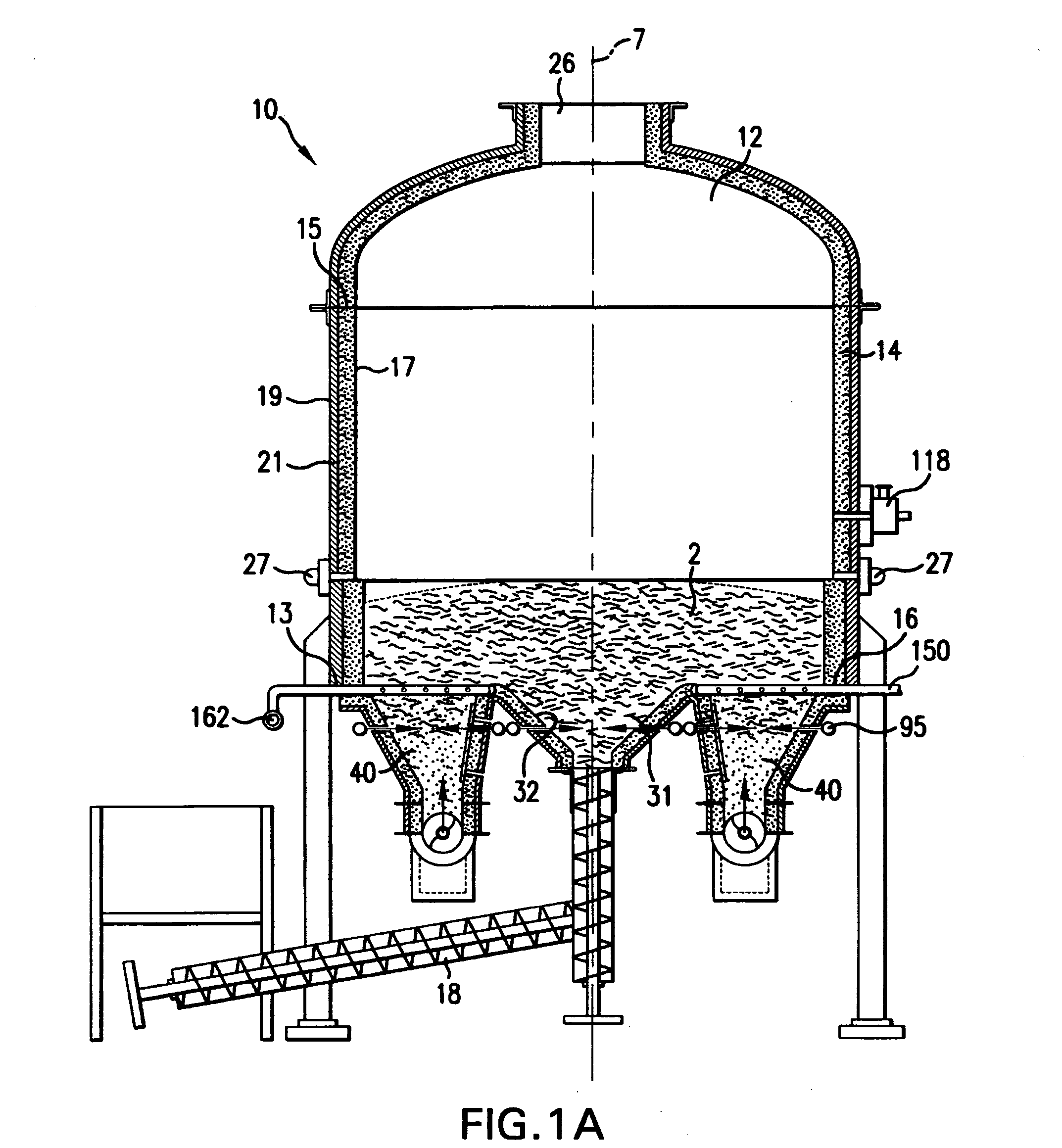

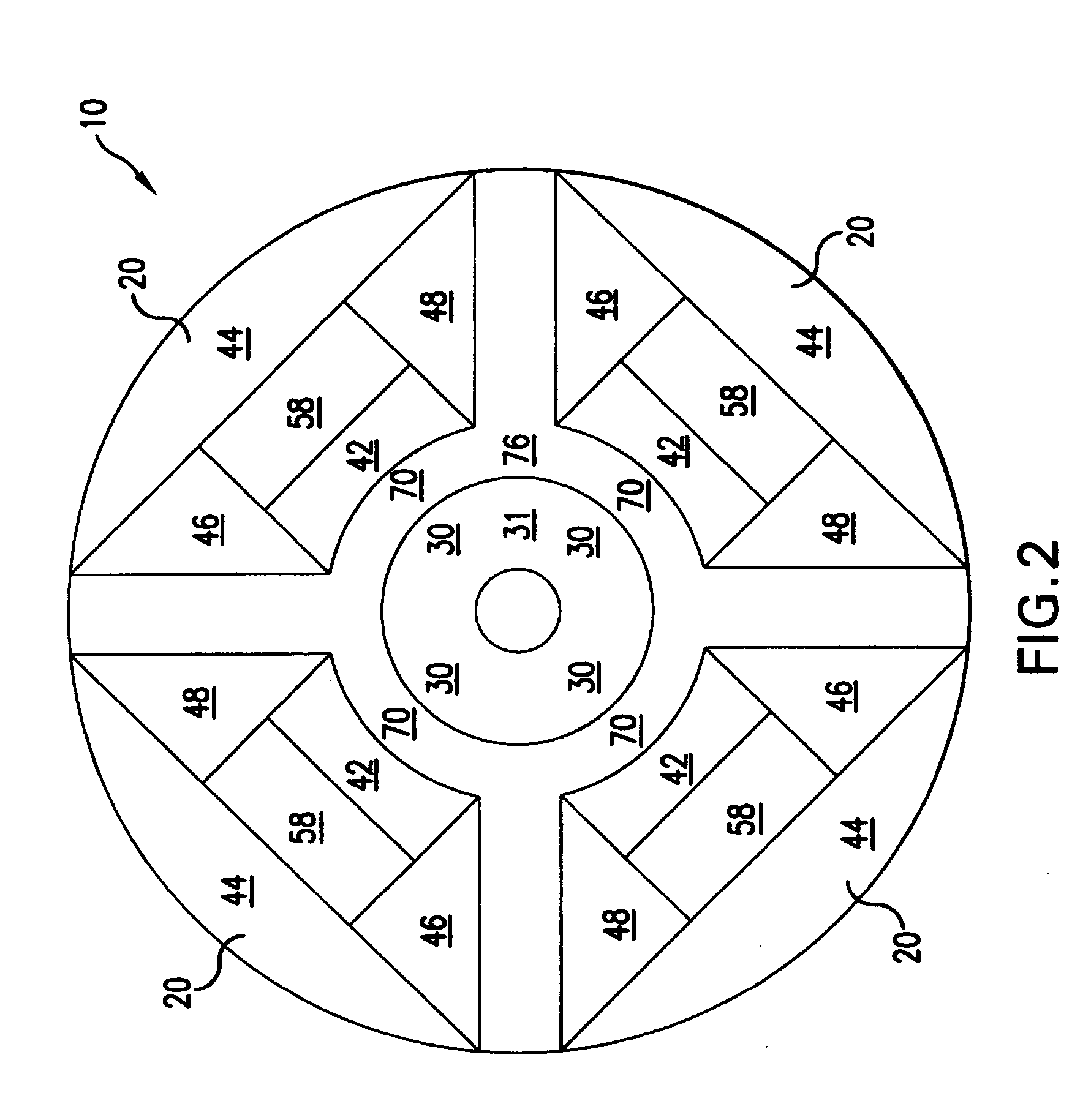

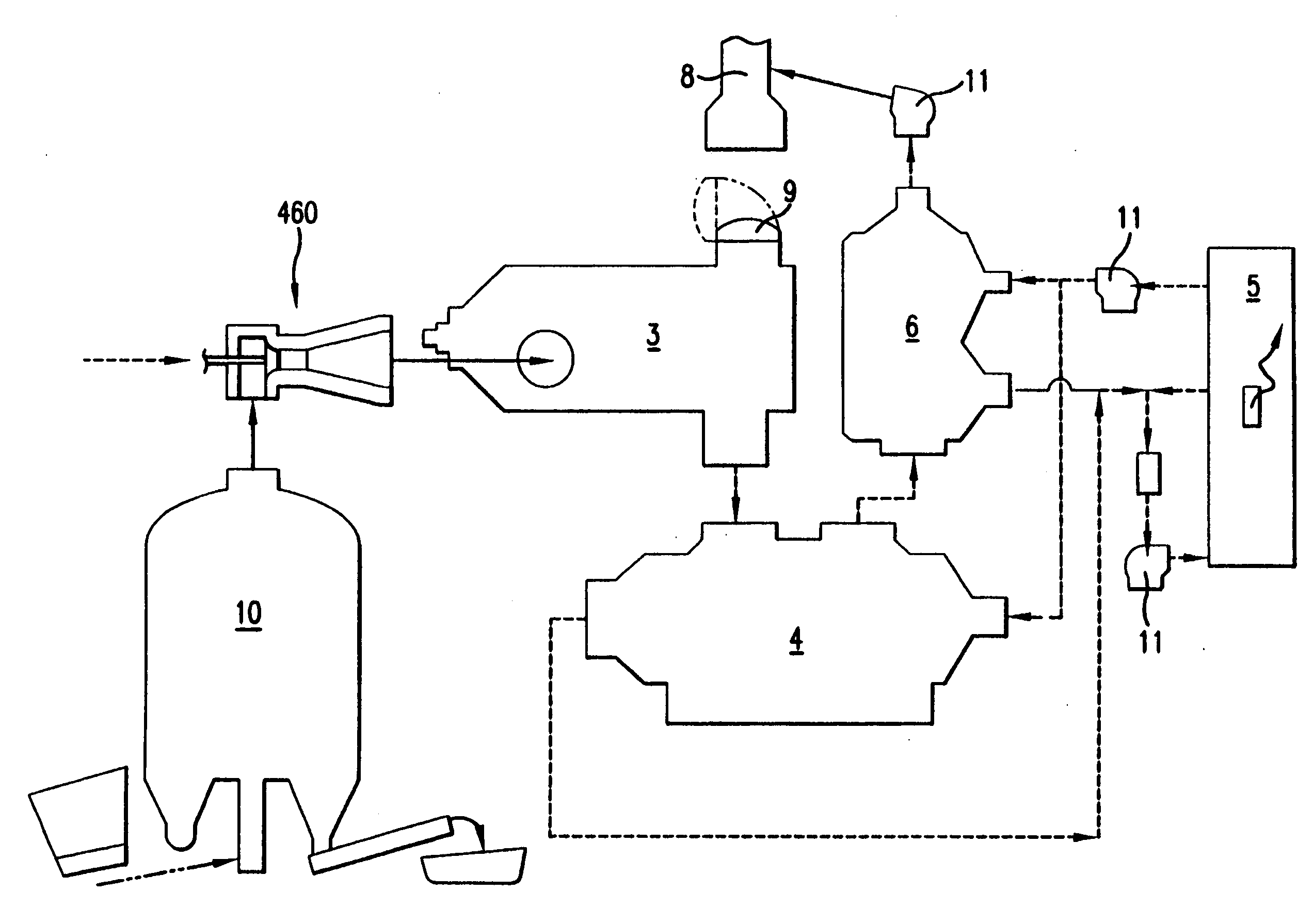

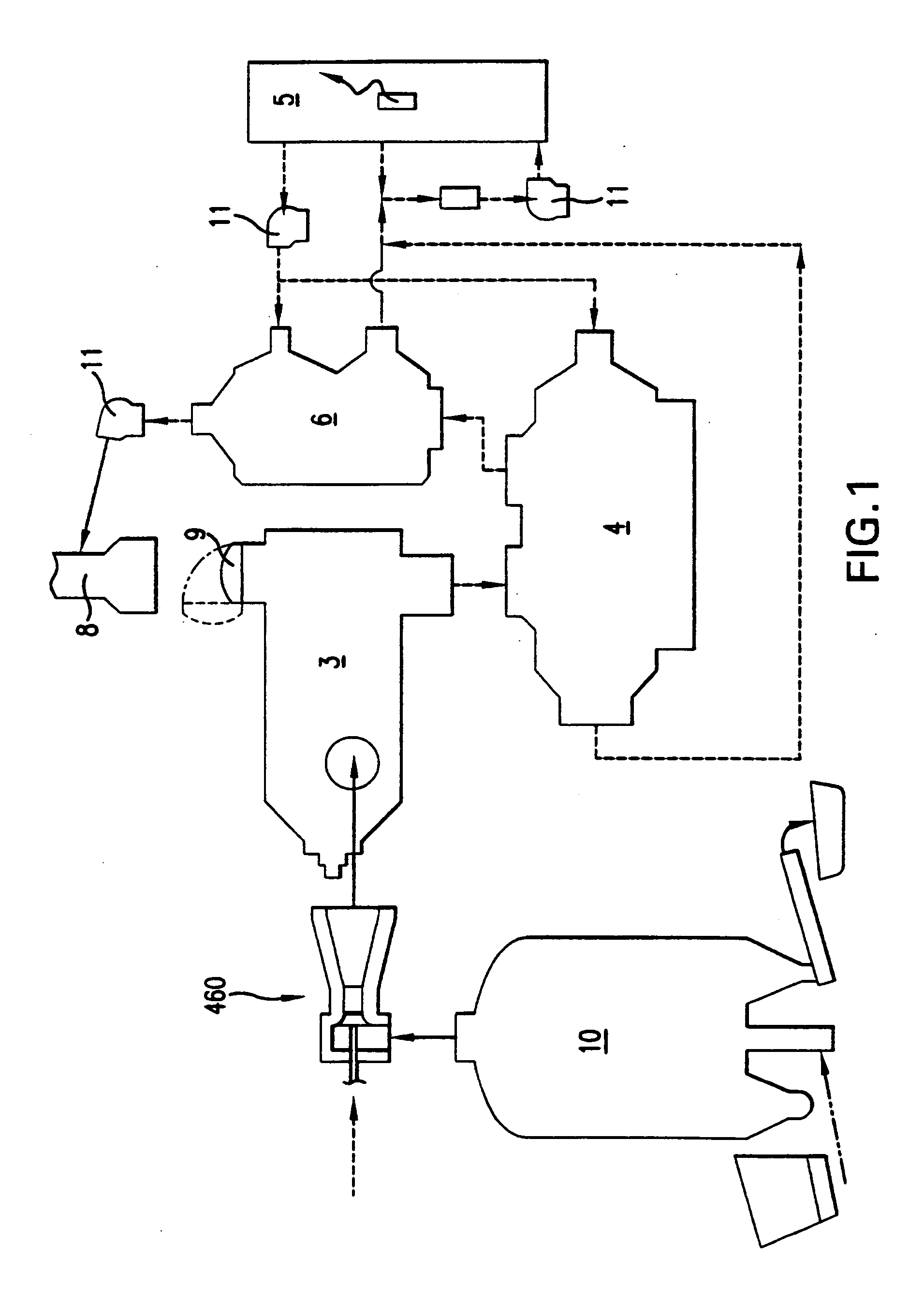

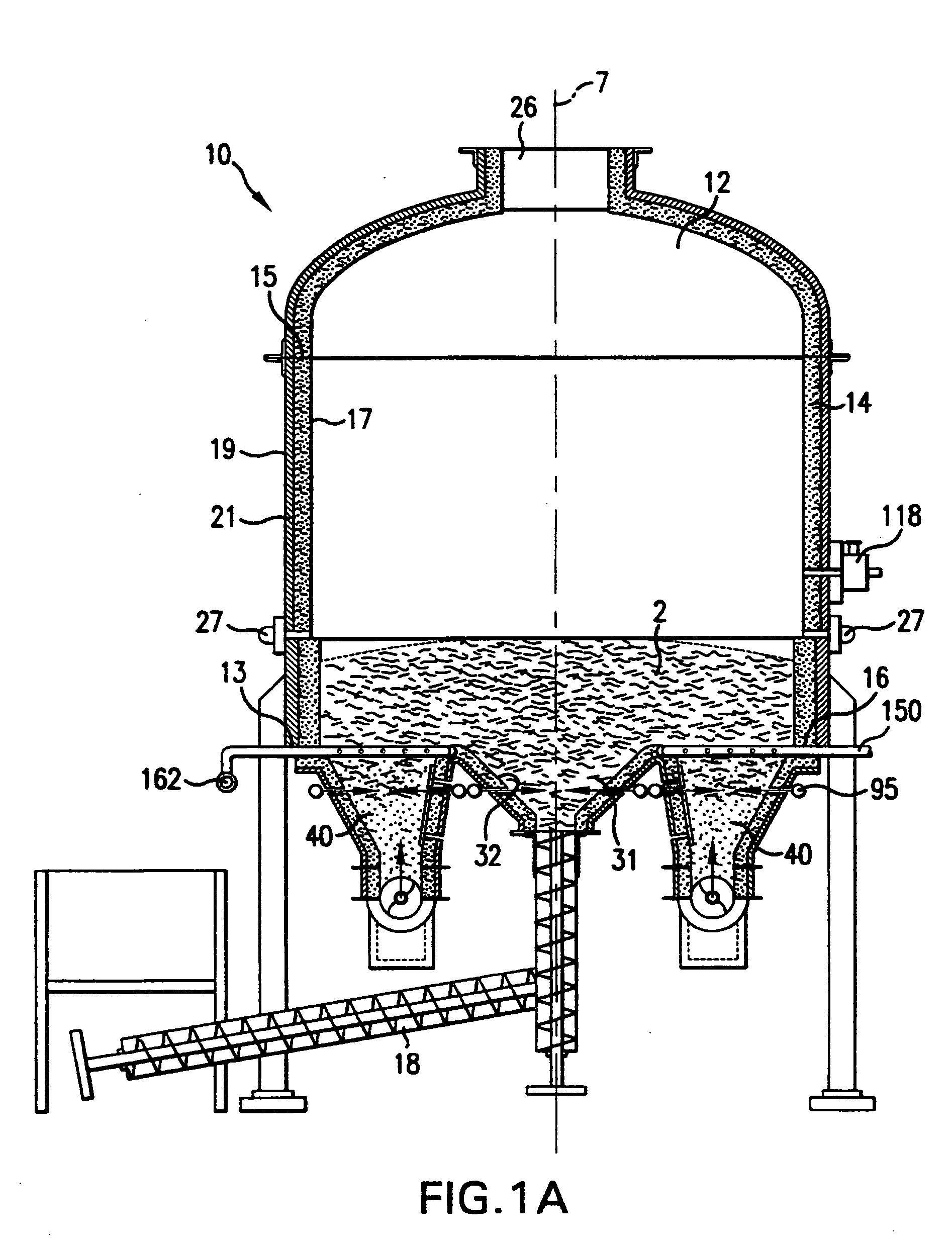

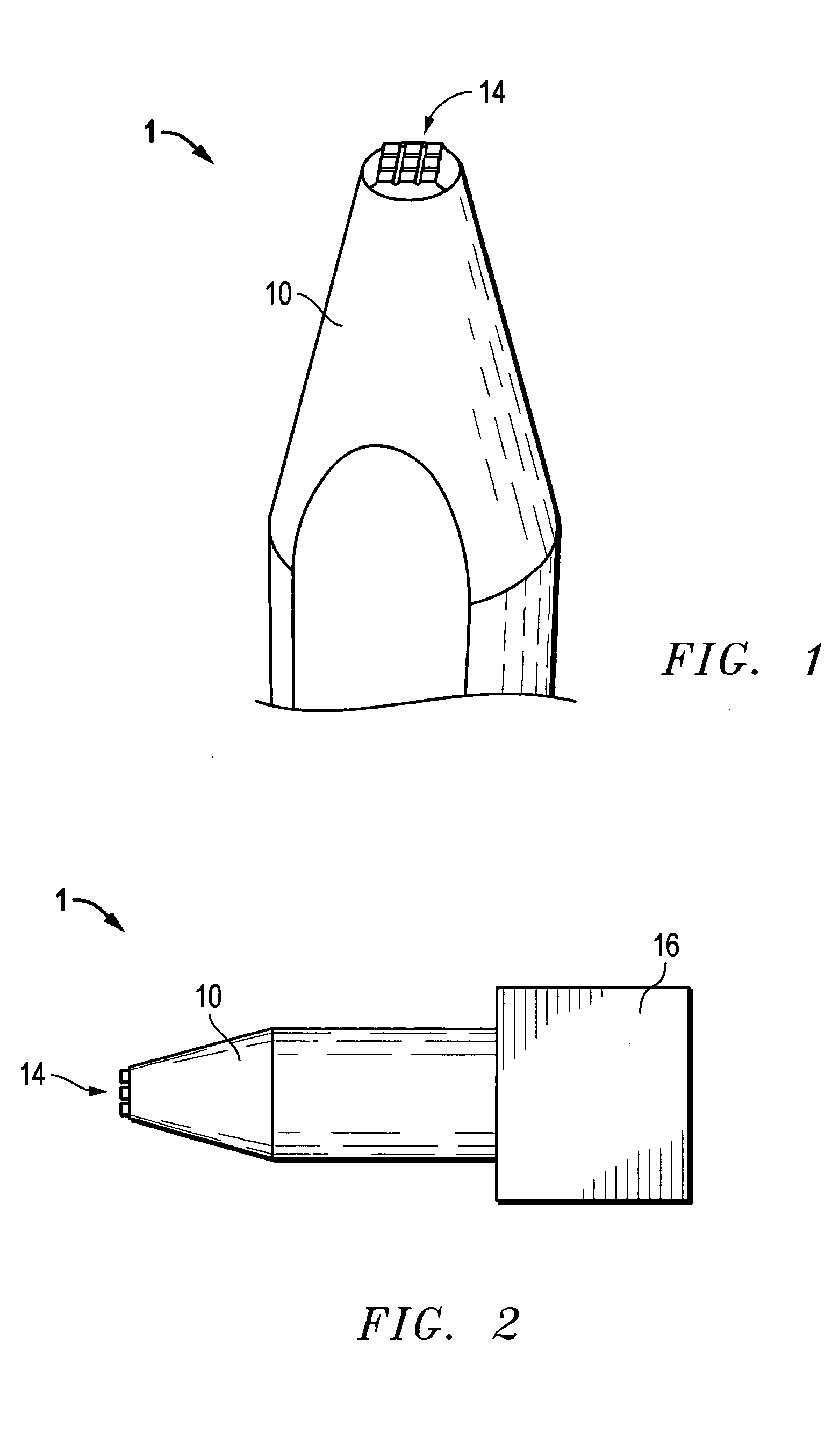

Pyrolyzing gasification system and method of use

InactiveUS20050109603A1High gasifier discharge temperatureEfficient processGasifier mechanical detailsBiofuelsHydrocotyle bowlesioidesExternal combustion engine

Pyrolyzing gasification system and method of use including primary combustion of non-uniform solid fuels such as biomass and solid wastes within a refractory lined gasifier, secondary combustion of primary combustion gas within a staged, cyclonic, refractory lined oxidizer, and heat energy recovery from the oxidized flue gas within an indirect air-to-air all-ceramic heat exchanger or external combustion engine. Primary combustion occurs at low substoichoimetric air percentages of 10-30 percent and at temperatures below 1000 degrees F. Secondary combustion is staged and controlled for low NOx formation and prevention of formation of CO, hydrocarbons, and VOCs. The gasifier includes a furnace bed segmented into individual cells, each cell is independently monitored using a ramp temperature probe, and provided with controlled air injection. Gasifier air injection includes tuyere arrays, lances, or both. The oxidizer includes three serially aligned stages separated by air injecting baffles, and ability to adjust the exit air temperature.

Owner:HEAT TRANSFER INT

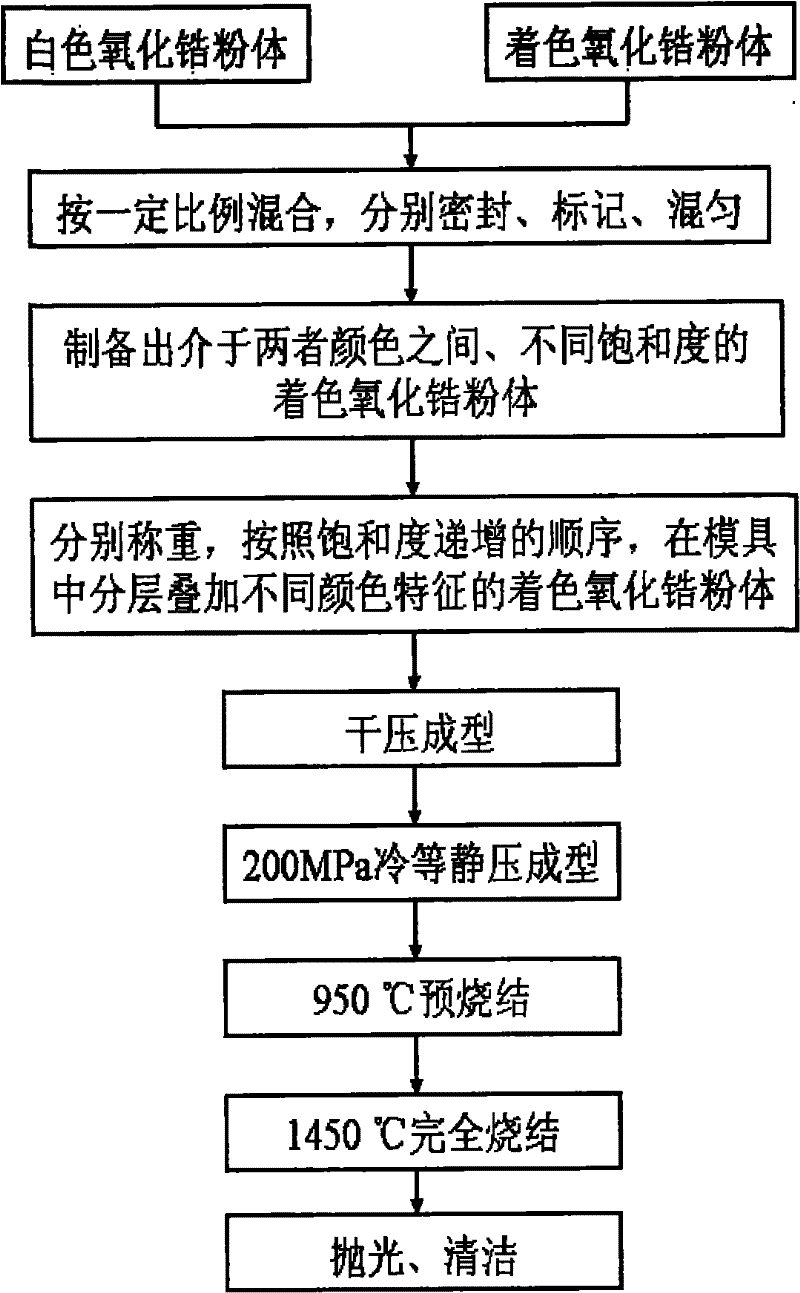

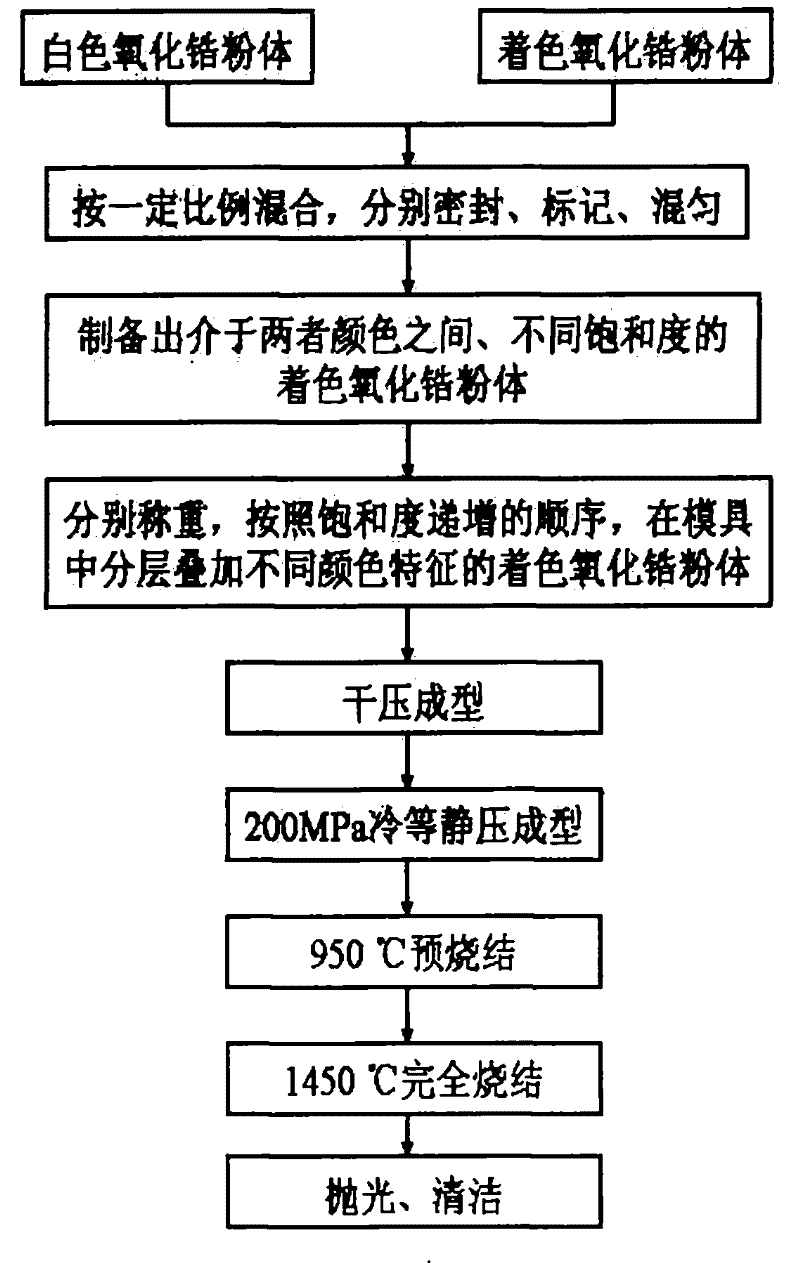

Dental complex color machinable zirconia ceramics and preparation method

InactiveCN102285795AHigh simulationFull aestheticsImpression capsDentistry preparationsAll ceramicAbutment

A dental multi-color machinable zirconia ceramic and its preparation method. The zirconia ceramic has the characteristics of translucence and color gradient, and contains more than five porcelain layers with the same hue and different saturation. The lightness gradually decreases from the top of the ceramic to the bottom layer, and the saturation The density gradually increases, and the color transitions naturally with a sense of hierarchy; the pre-sintered porous ceramic body of the zirconia ceramic is easy to cut and shape, and can be used to make personalized and beautiful dental zirconia all-ceramic restorations through the CAD / CAM system, which is conducive to preserving the abutment teeth. Improve the repair success rate. The preparation method of the dental complex color machinable zirconia ceramic is simple, effective and easy to popularize.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY +1

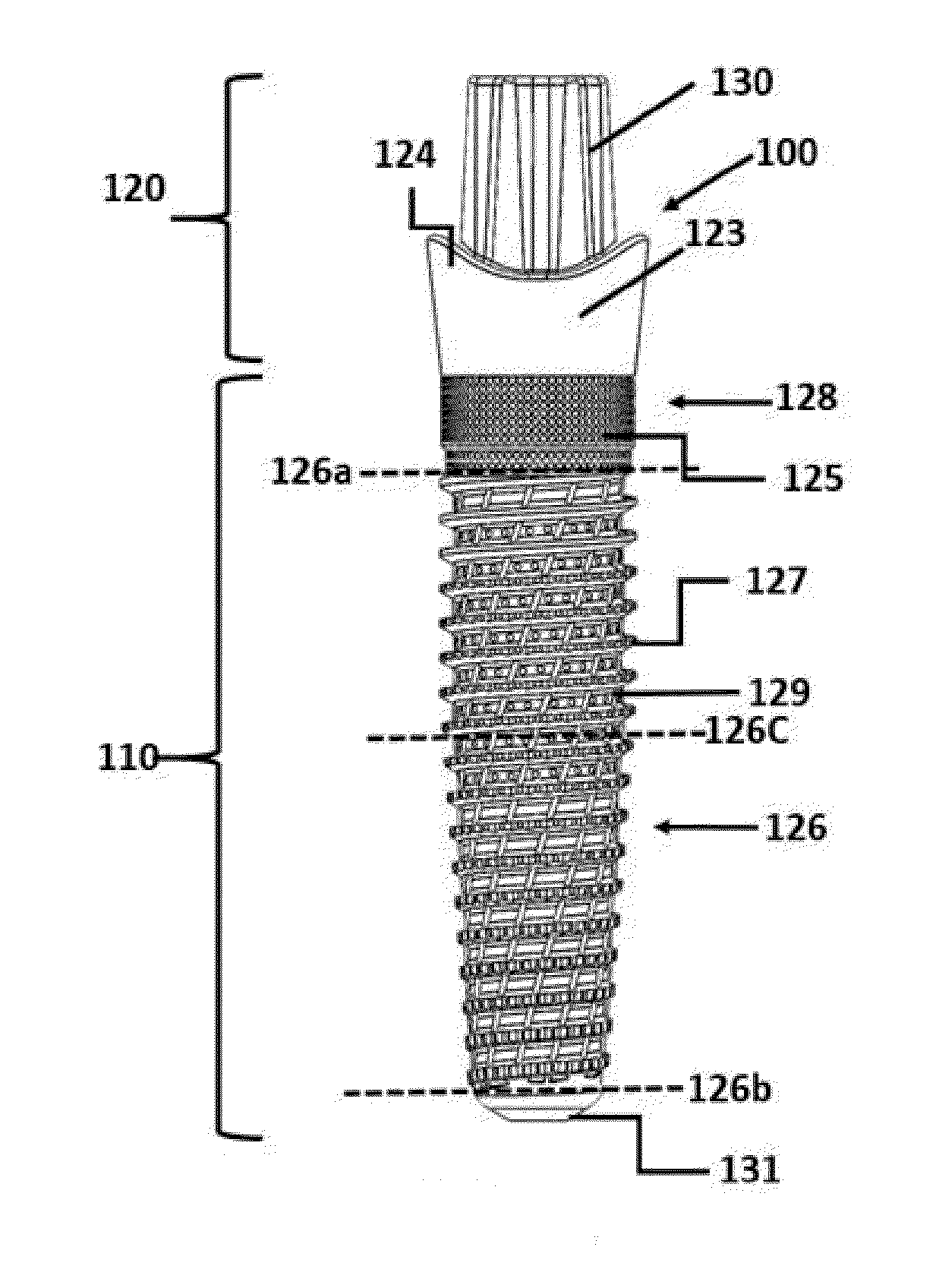

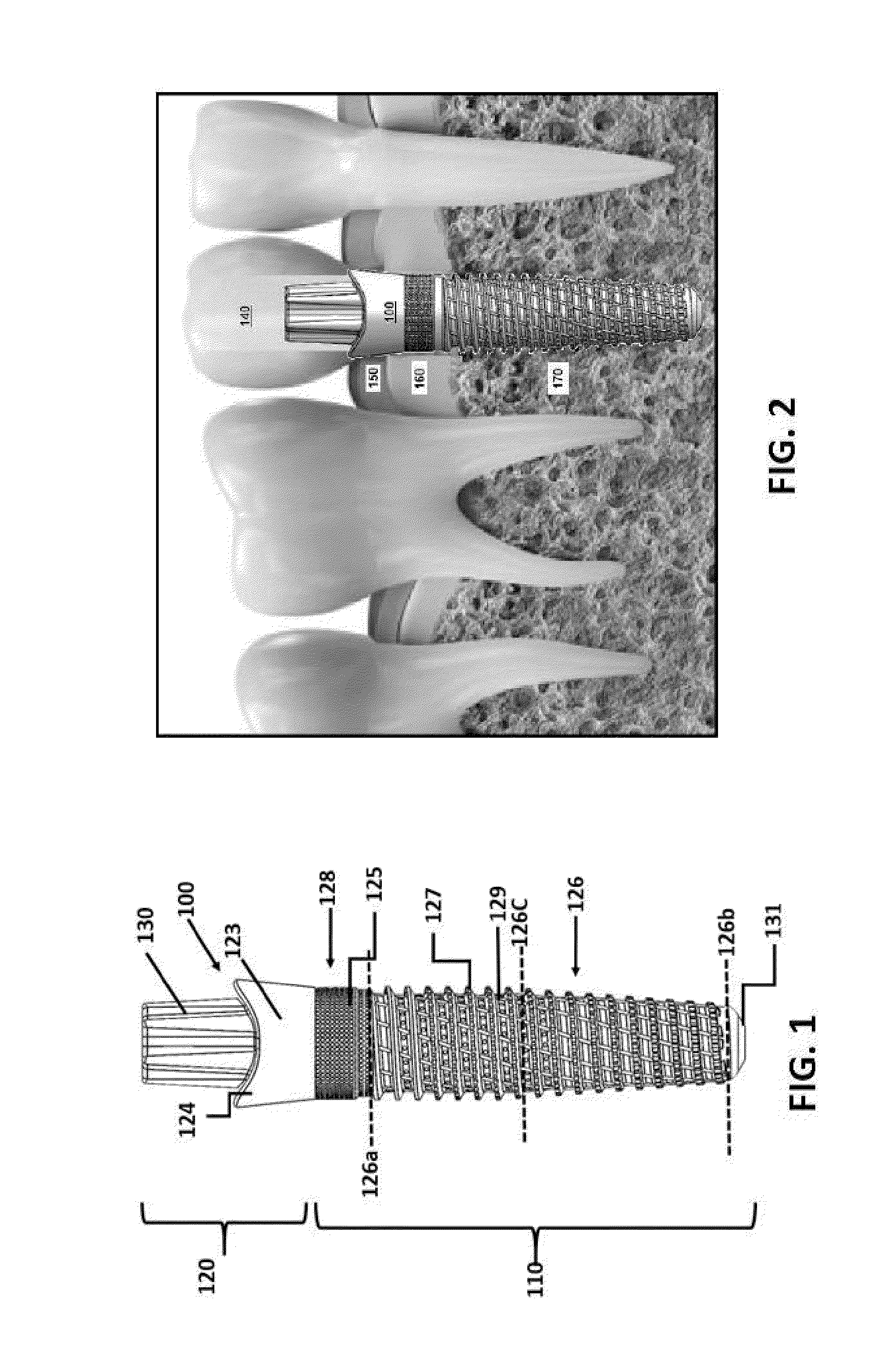

Osseointegrative surgical implant

InactiveUS20160015483A1Improve primary stabilityPromote healingSuture equipmentsDental implantsCeramic compositeSurgical implant

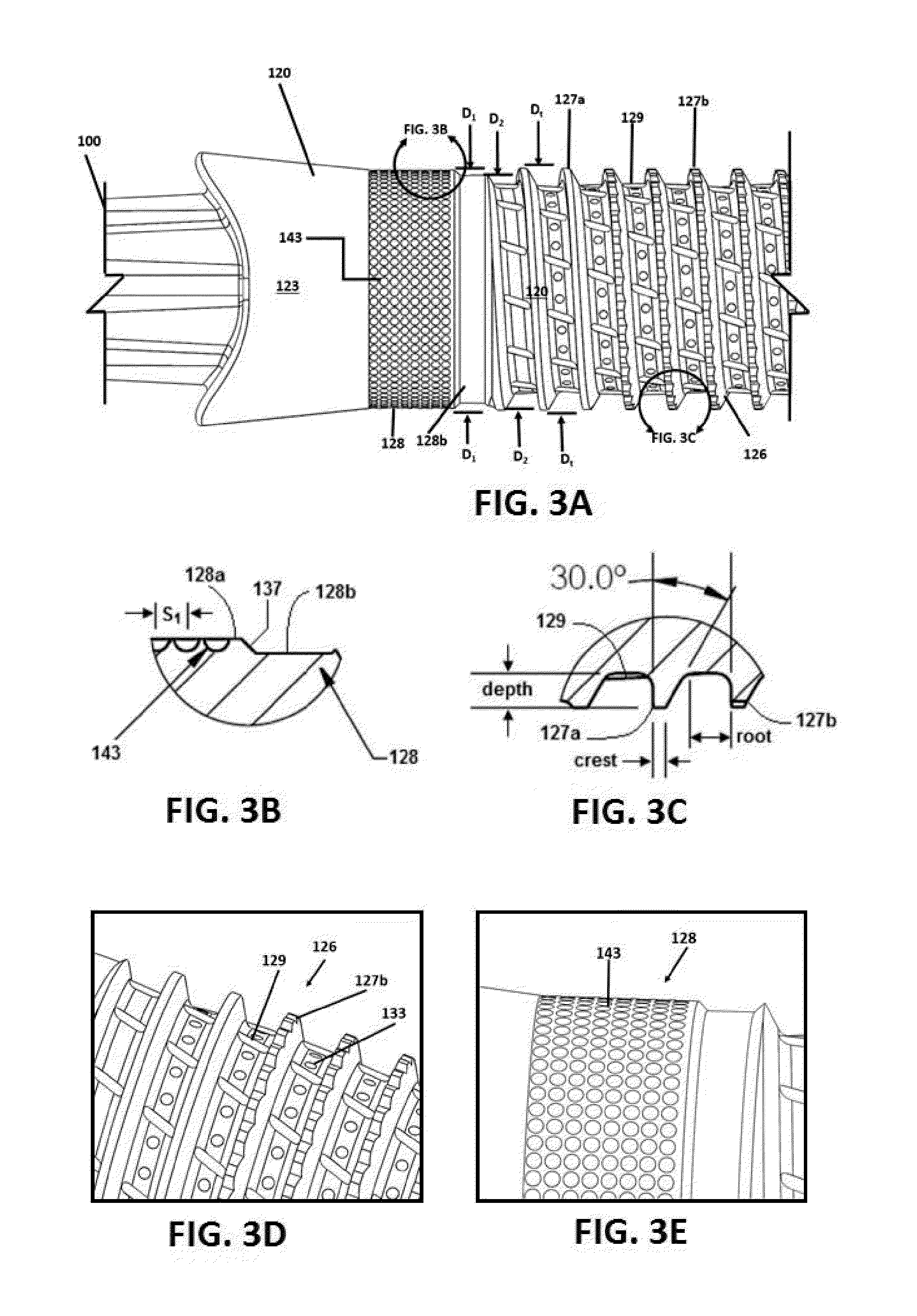

Embodiments of the present invention provide an osseointegrative implant and related tools, components and fabrication techniques for surgical bone fixation and dental restoration purposes. In one embodiment an all-ceramic single-stage threaded or press-fit implant is provided having finely detailed surface features formed by ceramic injection molding and / or spark plasma sintering of a powder compact or green body comprising finely powdered zirconia. In another embodiment a two-stage threaded implant is provided having an exterior shell or body formed substantially entirely of ceramic and / or CNT-reinforced ceramic composite material. The implant may include one or more frictionally anisotropic bone-engaging surfaces. In another embodiment a densely sintered ceramic implant is provided wherein, prior to sintering, the porous debound green body is exposed to ions and / or particles of silver, gold, titanium, zirconia, YSZ, α-tricalcium phosphate, hydroxyapatite, carbon, carbon nanotubes, and / or other particles which remain lodged in the implant surface after sintering. Optionally, at least the supragingival portions of an all-ceramic implant are configured to have high translucence in the visible light range. Optionally, at least the bone-engaging portions of an all-ceramic implant are coated with a fused layer of titanium oxide.

Owner:OSSEODYNE SURGICAL SOLUTIONS LLC

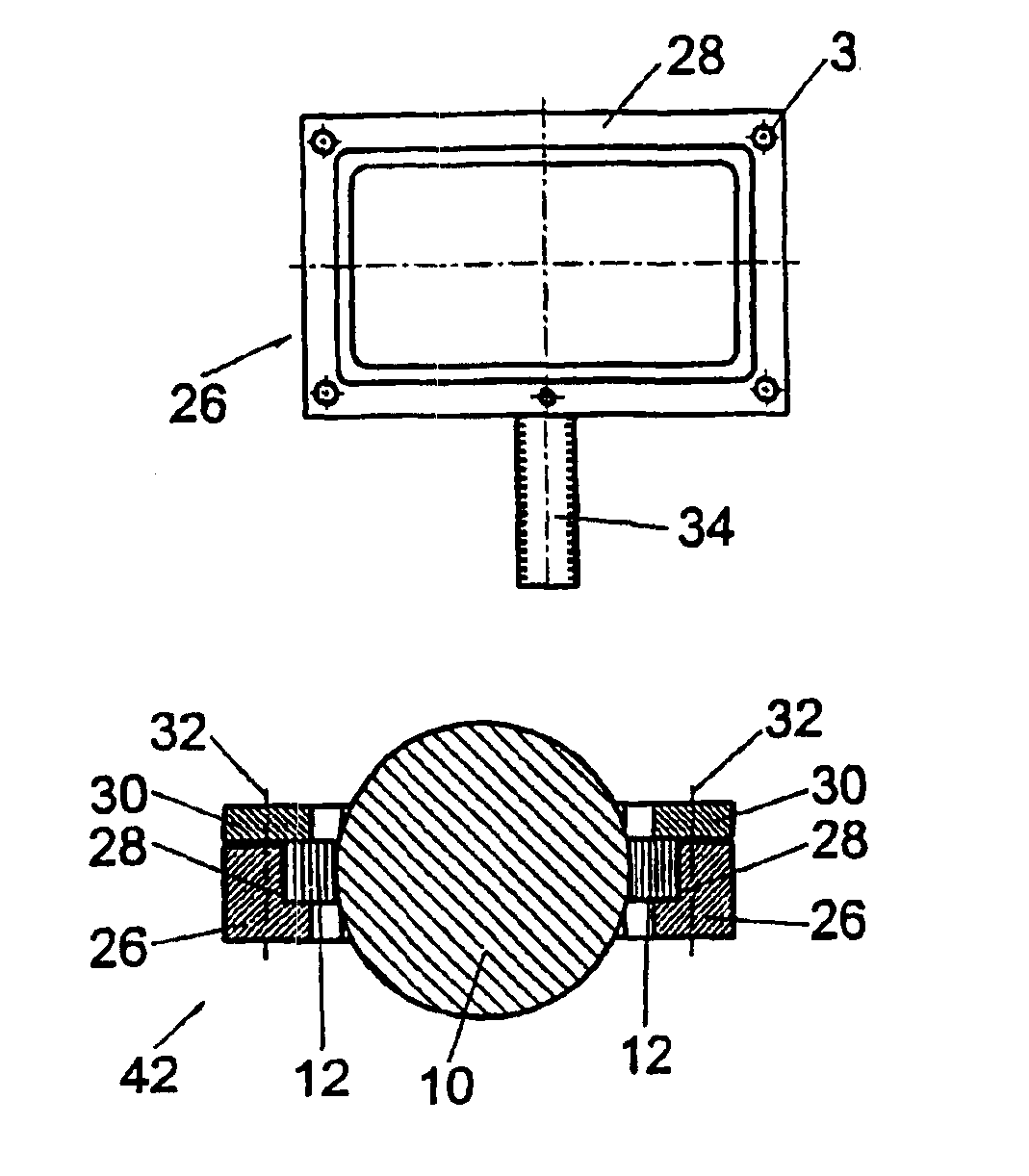

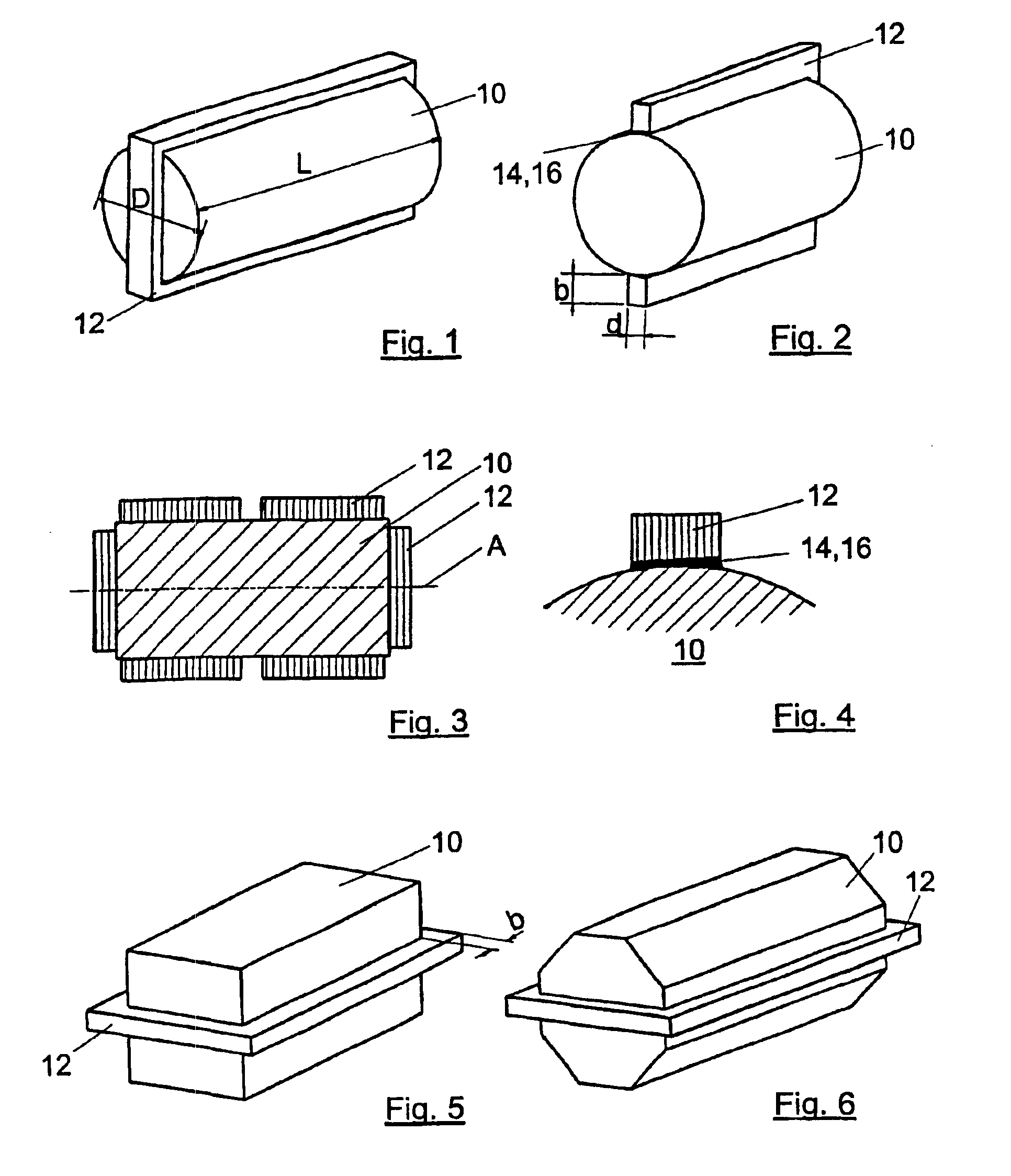

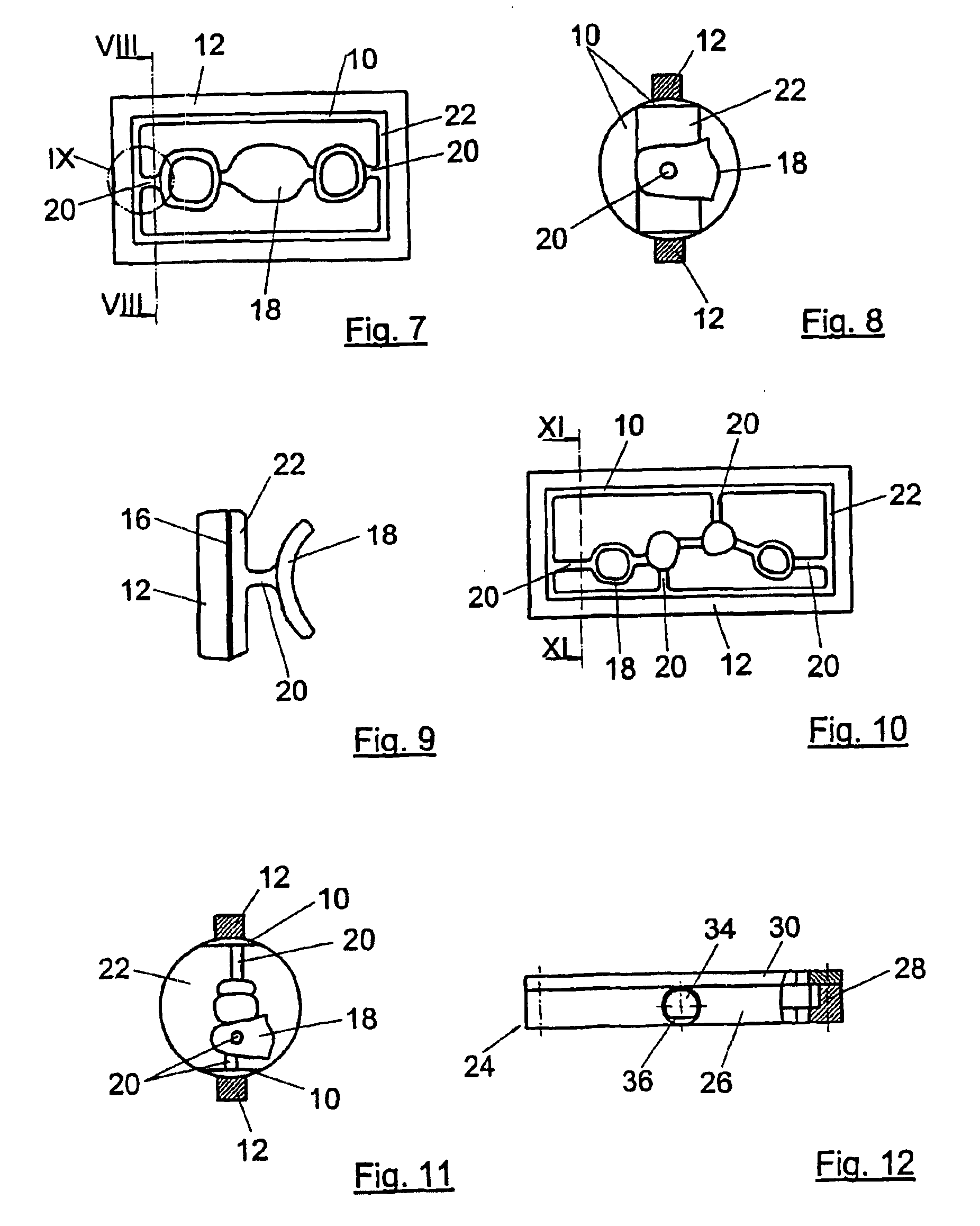

Holding device for a ceramic blank

A holding device comprises a cylindrical or prismatic, porous ceramic blank and elements for clamping in a machine tool for processing the blank by removing material, in order to produce a ceramic workpiece. A narrow frame is fixed by an adhesive connection over at least part of the periphery of the blank, which is held without stresses, in the area of a plane encompassing the longitudinal middle axis (A) of the blank. The frame only covers a small part of the surface of the blank and can be detached and held in a stable holder with a clamping adapter, in such a way that it cannot slide. The entire combination is fixed in the machine tool in such a way as to be resistant to twisting and sliding. The ceramic workpiece emerges continuously form the ceramic blank without predetermination of the advance direction, until holding segments which can then only be freely selected according to number and location have been formed. The holding segments end on the residual material of the blank in the area of the frame or on the frame itself. The holding device is used especially as a workpiece for producing fully ceramic dental prostheses, particularly crowns or bridges.

Owner:EIDGENOSSISCHE TECHN HOCHSCHULE ZURICH NICHTMETALLISCHE WERKSTOFFE

Pyrolyzing gasification system and method of use

InactiveUS20060196398A1Reduce formationLarge volumeGasifier mechanical detailsBiofuelsHydrocotyle bowlesioidesExternal combustion engine

Owner:HEAT TRANSFER INT

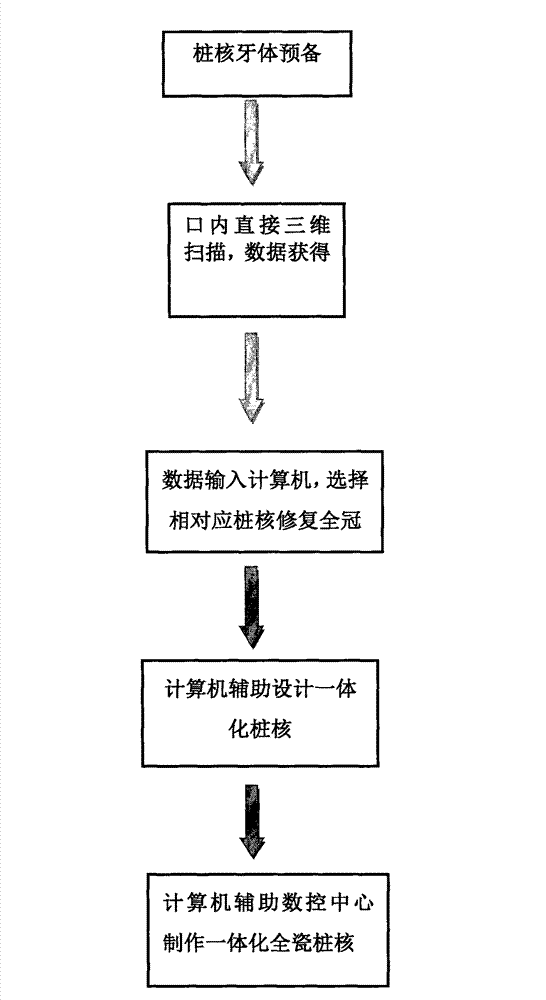

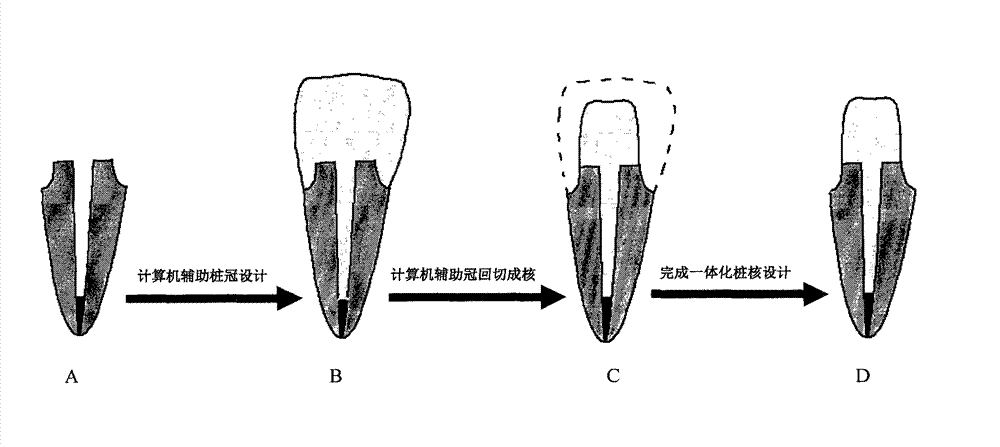

Preparation method of personalized and integrated all-ceramic post-and-core of dentistry

InactiveCN103083094AShorten visit timeShorten the overall cycleMechanical/radiation/invasive therapiesFastening prosthesisPersonalizationNumerical control

The invention provides a manufacture method of a clinical personalized and integrated all-ceramic post-and-core of dentistry. The manufacture method is characterized in that a high-precision and short-wavelength visible scanner is adopted and directly used for scanning intraoral defected teeth subjected to root canal preparation, the CAD / CAM (Computer Aided Design / Computer Aided Manufacturing) central incisor prosthetic design is adopted, the design of integrating the post and the core is accomplished, and then the incisor back-cut method design is carried out to accomplish the design of the integrated all-ceramic post-and-core, and numerical control processing equipment is adopted and used for processing in order to accomplish the manufacture of the all-ceramic post-and-core.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

Zirconia toughened alumina ESD safe ceramic composition, component, and methods for making same

ActiveUS20060175584A1Conductive materialSemiconductor/solid-state device manufacturingAll ceramicZirconia Toughened Alumina

ESD safe ceramic component is provided which includes a sintered composition which is formed of a base material and a resistivity modifier. The base material includes a primary component and a secondary component, the primary component including Al2O3 and the secondary component including tetragonal-ZrO2.

Owner:COORSTEK INC

Annular circular polarization ceramic antenna based on quadrature coupling feed

InactiveCN101752664AAvoid the difficult problem of high impedance matchingIncrease freedomSimultaneous aerial operationsAntenna supports/mountingsAntenna feedBand width

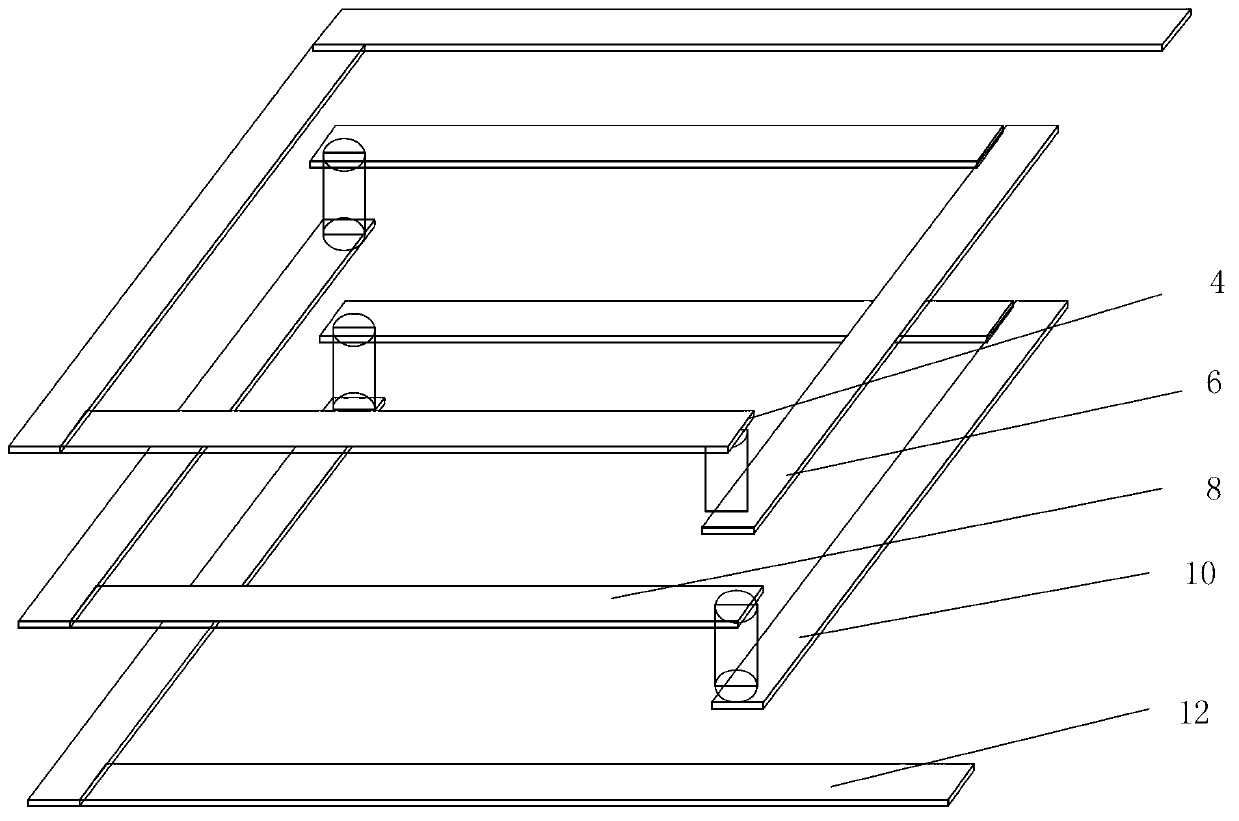

The invention discloses an annular circular polarization ceramic antenna based on quadrature coupling feed, which comprises an upper layer microstrip antenna structure, an upper medium substrate, a middle layer medium substrate, a metal floor layer, a lower layer medium substrate and a bottom layer Wilkinson power divider; the upper layer microstrip antenna structure includes an annular antenna and two metal circular sheets which are small circular sheets respectively taking two points as circle centers, and are respectively positioned at the area of two arcs and inner circle; the bottom layer Wilkinson power divider is composed of a high impedance wire, a first low impedance wire, a second low impedance wire and a SMD resistor; the feature impedance of the high impedance wire is times ofthe feature impedance z0 of the first low impedance wire and the second low impedance wire; the upper layer medium substrate, the middle layer medium substrate and the lower layer medium substrate are all ceramic medium. The antenna feed mechanism adopts two circular metal sheets to generate two quadrature current sources with the same amplitude and also can extend the axial ratio bandwidth of the annular metal antenna to increase the adjusting degree of freedom of the antenna.

Owner:SOUTH CHINA UNIV OF TECH

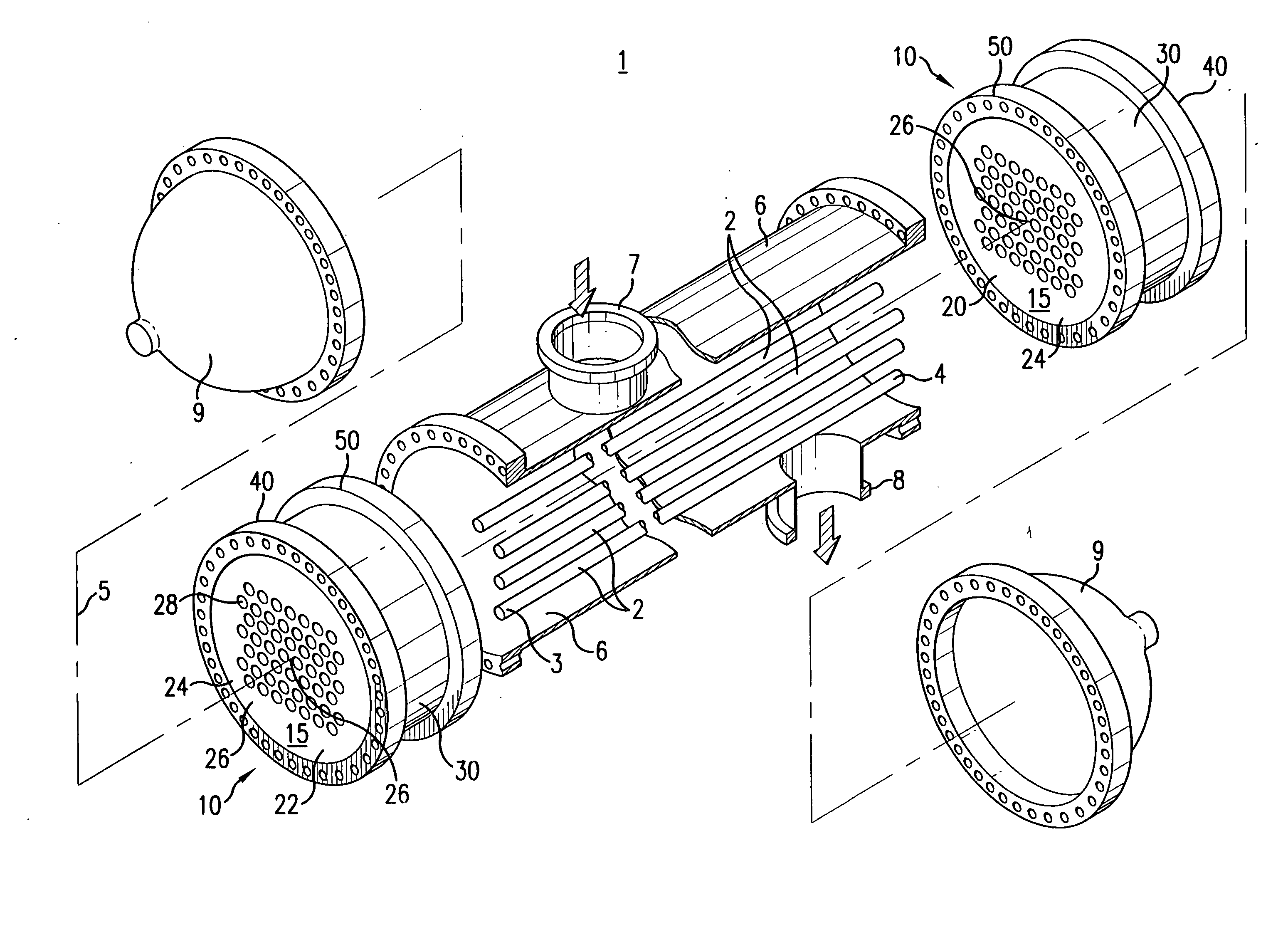

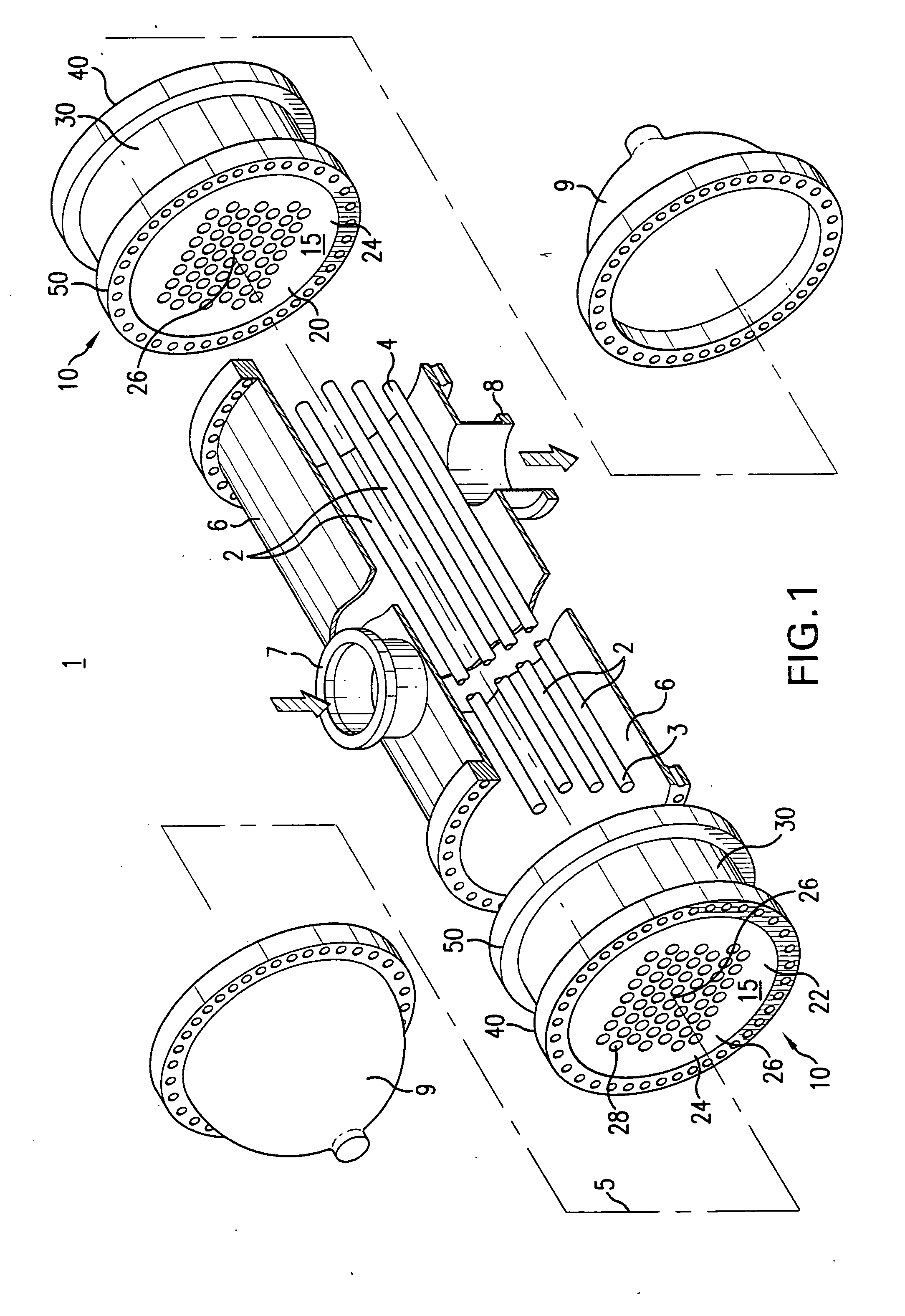

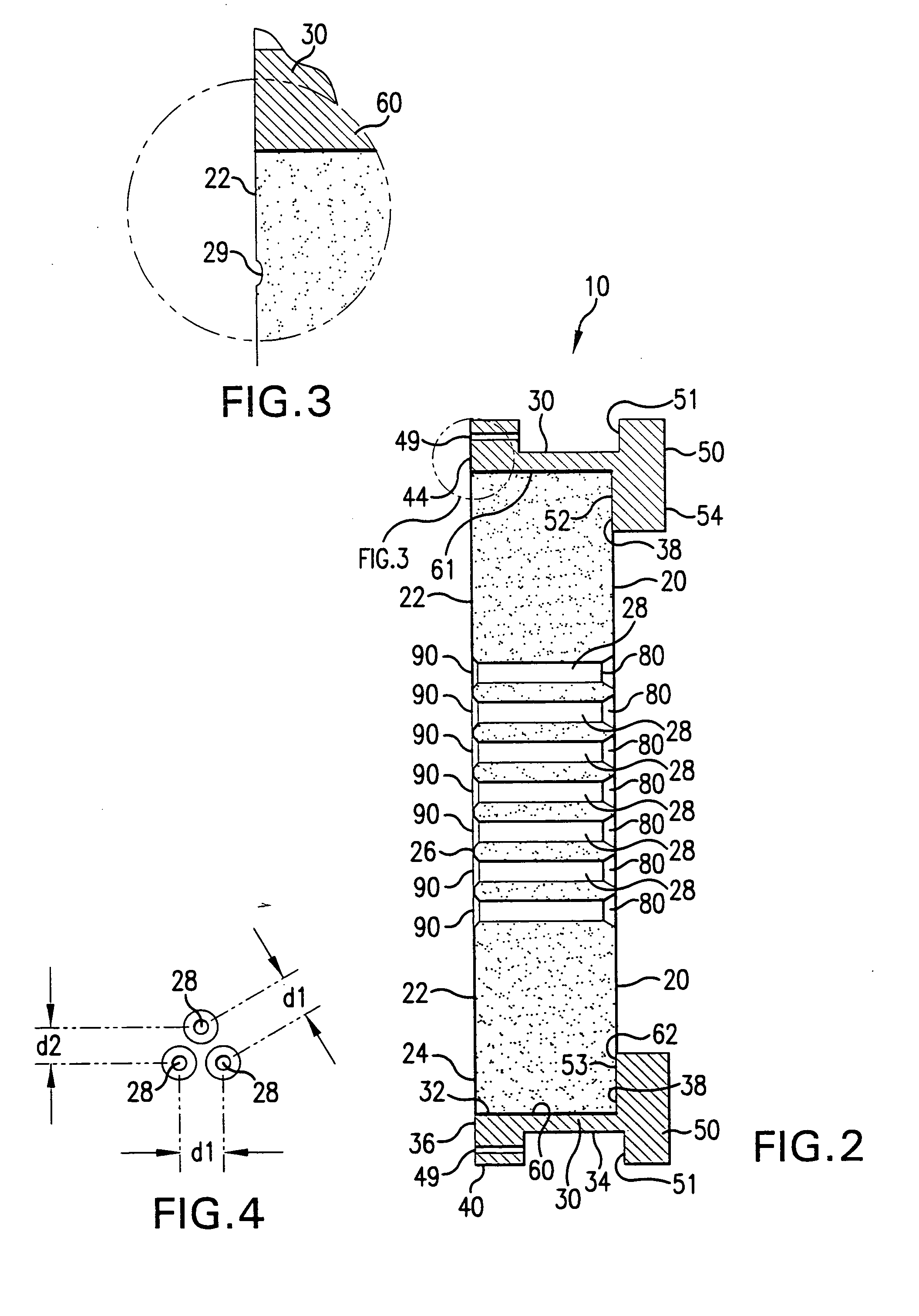

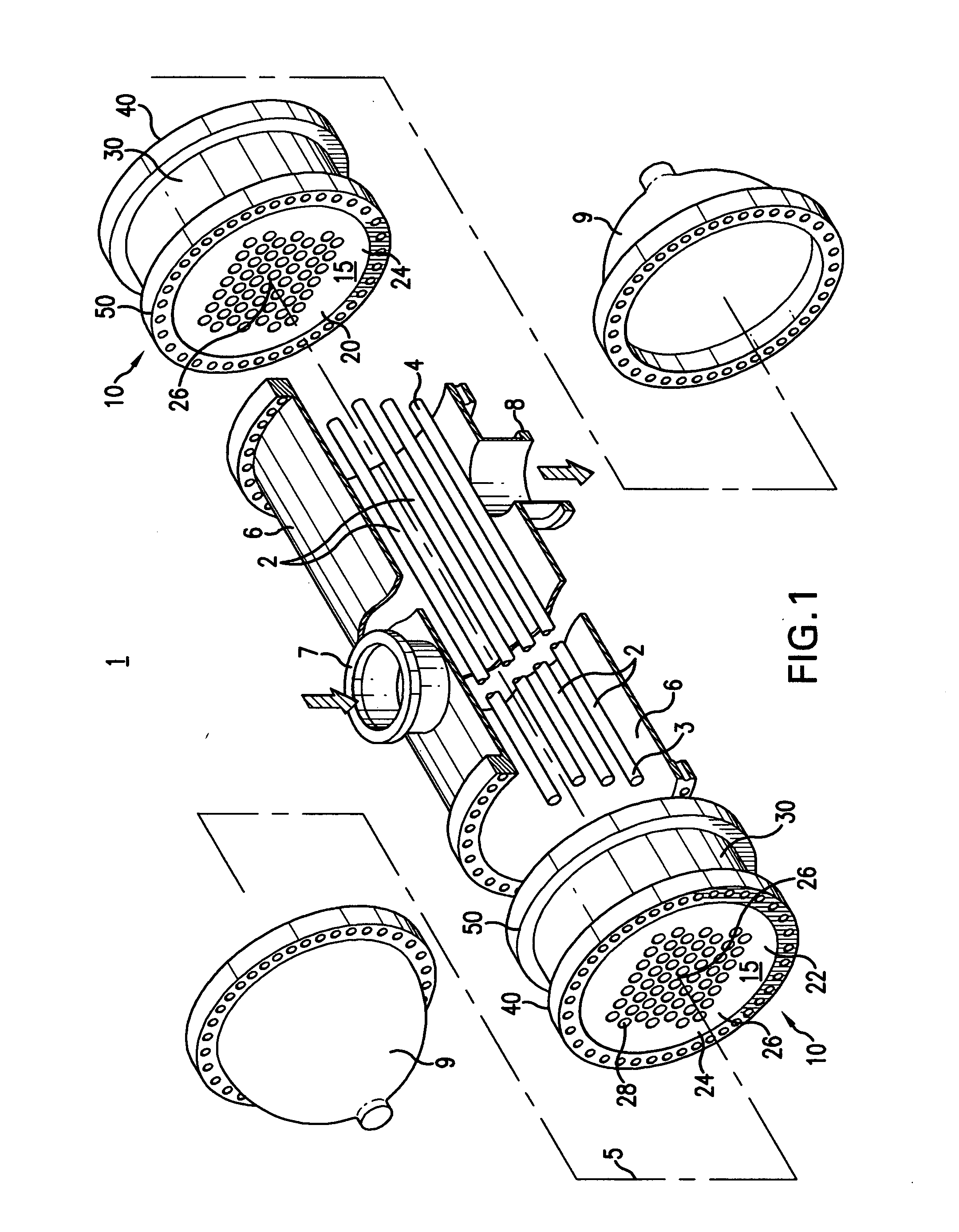

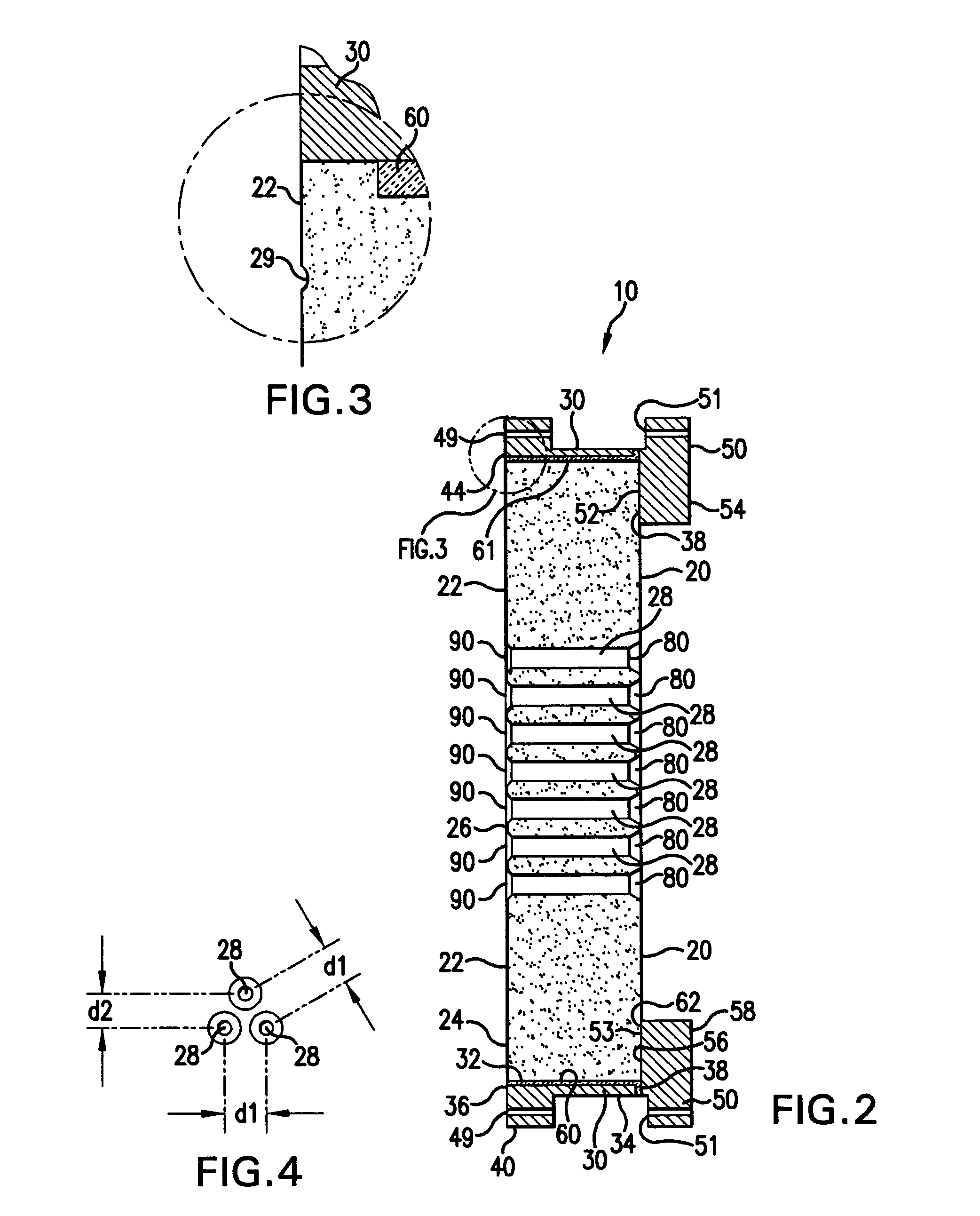

Monolithic tube sheet and method of manufacture

A monolithic refractory ceramic tube sheet for use in all-ceramic air-to-air indirect heat exchangers, the heat exchanger used in medium to high temperature, and high pressure applications. A method for forming the monolithic tube sheet includes-casting a refractory ceramic in a mold, where portions of the mold comprise the housing of the heat exchanger. Precisely formed negatives are used to form through channels and vacancies within the tube sheet, which are precisely positioned within the mold allowing uniform and flush formation of openings that receive the ceramic tubes therein. The same mold is used to provide both tube sheets of a tube sheet pair allowing accurate alignment of tubes within the exchanger vessel resulting in ease of assembly and equal loading of tubes when in use.

Owner:GRAHAM ROBERT G

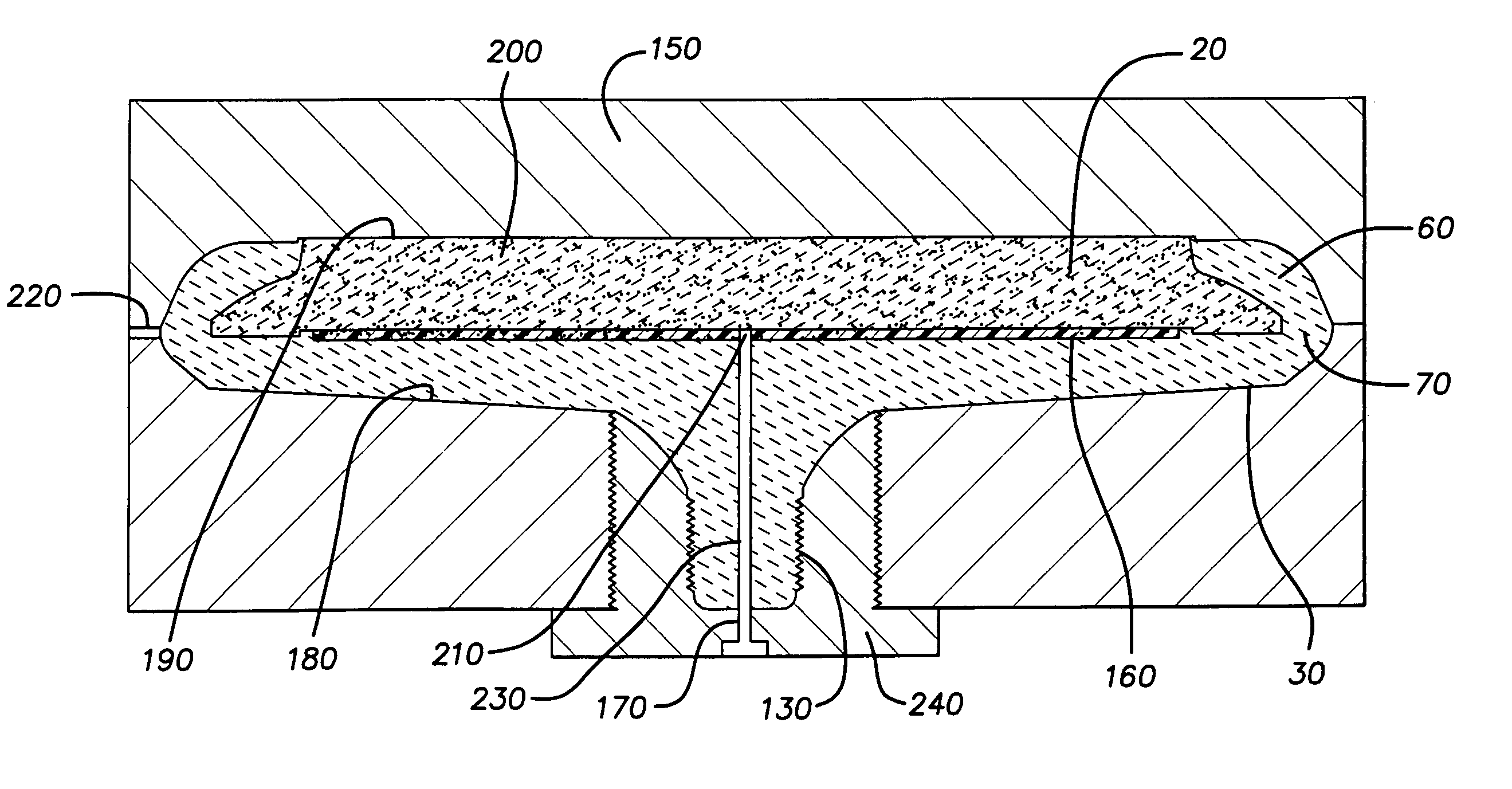

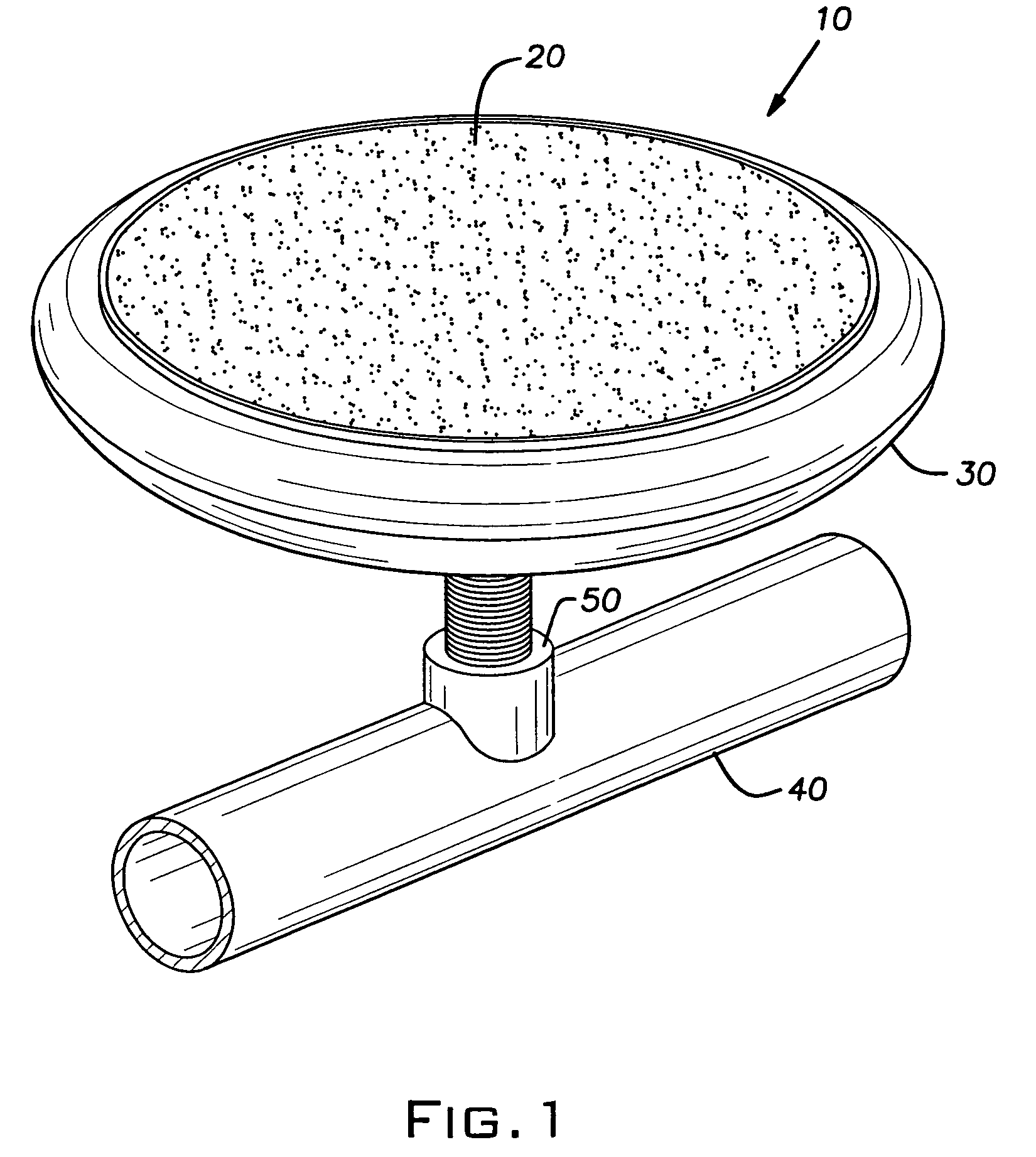

Method of making a diffuser assembly

The present invention provides an all-ceramic diffuser assembly that includes a diffuser element formed of a porous ceramic material and a base formed of a non-porous ceramic material. The base includes a peripheral undercut shoulder portion that overlaps a perimeter edge of the diffuser element to sealingly connect the diffuser element to the base. A conduit is formed in a fitting portion of the base for directing a stream of gas or liquid that is capable of diffusing through the diffuser element into a chamber formed between an inner surface of the diffuser element and a floor portion of the base. The present invention also provides a method of forming the diffuser assembly.

Owner:FILTROS

Synchronous line fixing-moving joint restoration method

ActiveCN106580496AReduce the number of clinic visitsImprove product qualityArtificial teethDental surgeryRestoration methodOral Prosthesis

The invention discloses a synchronous line fixing-moving joint restoration method. The synchronous line fixing-moving joint restoration method has the advantages that a scanning measurer, computer-aided design software of a dental prosthesis, a miniature SLM (synchronous line module)-metal 3D printer and a numerically-controlled milling machine are used for preparing all-ceramic and metal prosthesises, the fixing restoration of removable partial denture butment and the restoration of removable partial denture are synchronously completed, the clinical restoration efficiency of complicated cases is greatly improved, the clinical frequency of a patient is greatly reduced, and the chair-side operation time is shortened; the complicated procedure of traditional dental prosthesis manufacturing method is overcome, the manufacturing quality and stability of the prosthesis are improved, the purpose of quick, accurate and personalized manufacturing is realized, and the urgent demand of patients with tooth lack is well met.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Raw material for all-ceramic dental restoration system and rapid prototyping method of raw material

InactiveCN104997643AFast preparationReduce defectsImpression capsArtificial teethOral ProsthesisAll ceramic

The invention provides a raw material for an all-ceramic dental restoration system and a rapid prototyping method of the raw material, which belongs to the technical field of materials and preparation methods thereof. The raw material comprises the following components in weight part: 20 to 75 parts of ultrafine ceramic powders, 0.1 to 5 parts of coloring agent, 0.1 to 5 parts of fluorescent agent, 0.1 to 5 parts of dispersant, 0 to 20 parts of flocculating agent, 0 to 5 parts of thickening agent, 0 to 5 parts of flow promoting agent and 0 to 10 parts of strengthening auxiliary. According to the technical scheme of the invention, embryo bodies can be directly molded without the need of adding any binder. Therefore, dental restorations are high in strength after the later sintering process.

Owner:谢宝军

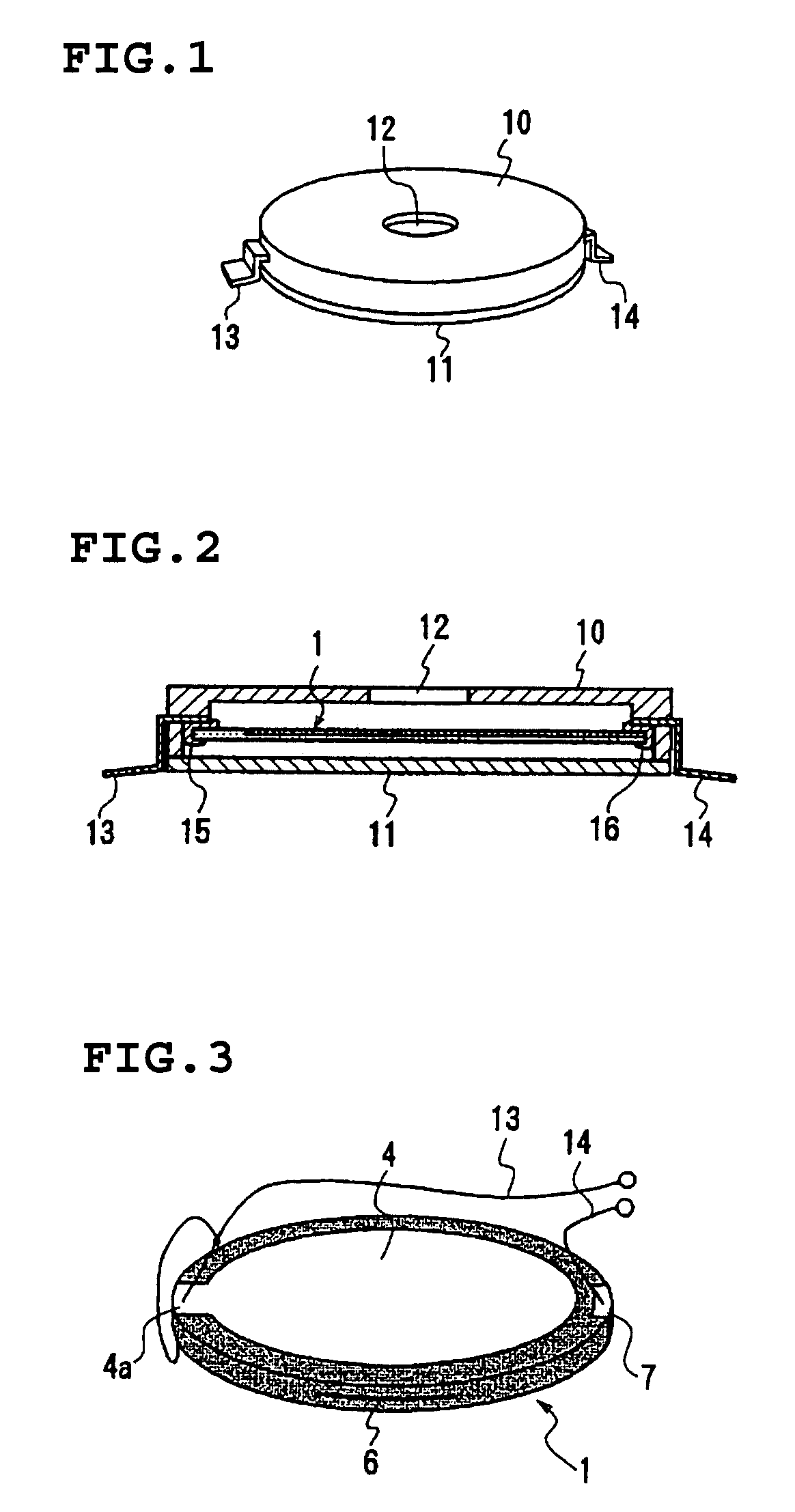

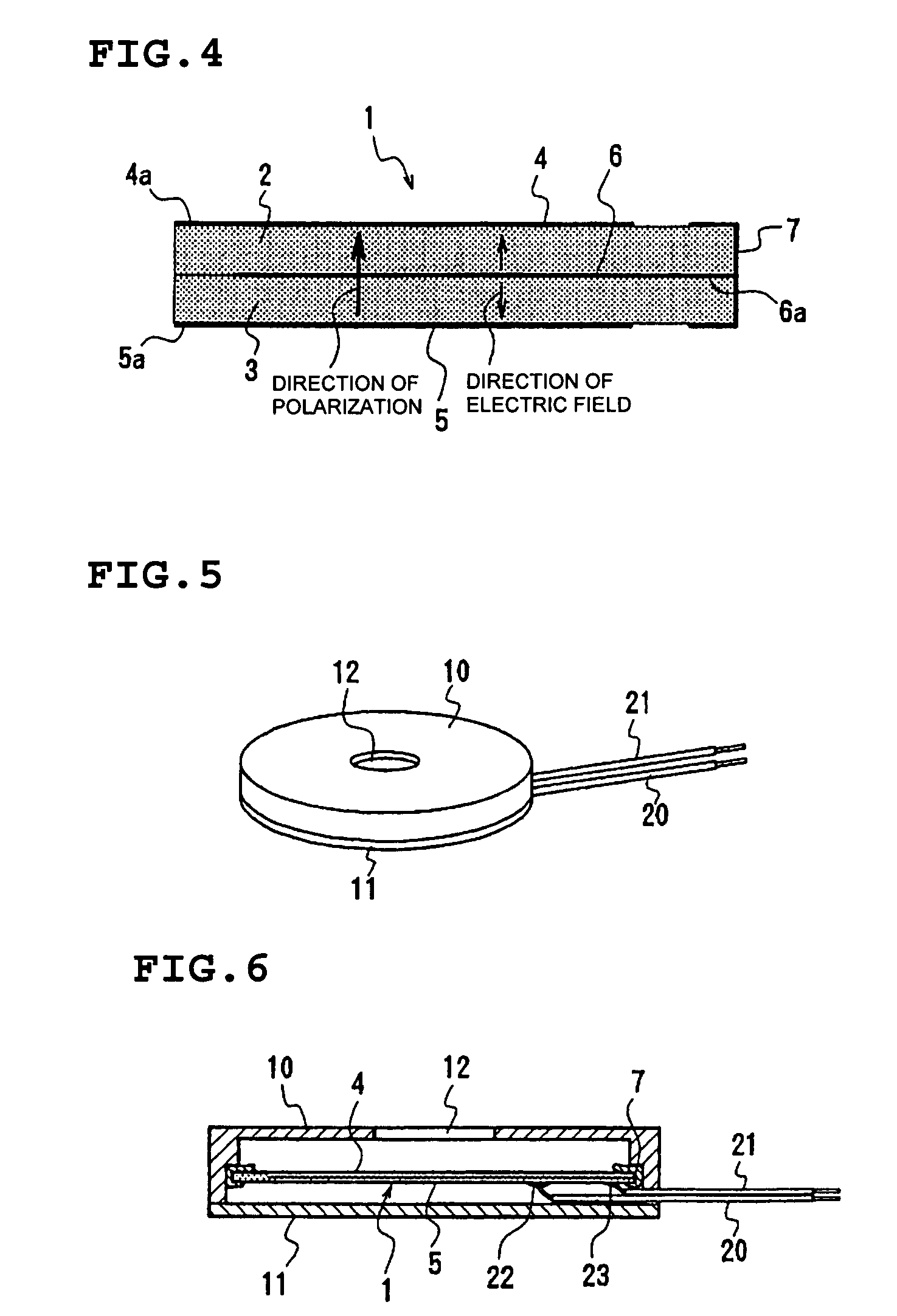

Piezoelectric electroacoustic transducer

InactiveUS6969942B2Simple processEliminate needPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive transducersTransducerAll ceramic

A piezoelectric electroacoustic transducer eliminates the need for the interconnection between main surface electrodes and internal electrodes, and is capable of constructing a bimorph diaphragm using a simple connection structure. The piezoelectric electroacoustic transducer includes a laminated body formed by laminating two or three piezoelectric ceramic layers, main surface electrodes each provided on the top and bottom main surfaces, and an internal electrode provided between any adjacent two piezoelectric ceramic layers. In the piezoelectric electroacoustic transducer, all ceramic layers are polarized in the same direction with respect to the thickness direction, and by applying an alternating voltage across the main surface electrodes and the internal electrode, the laminated body generates a bending vibration in its entirety.

Owner:MURATA MFG CO LTD

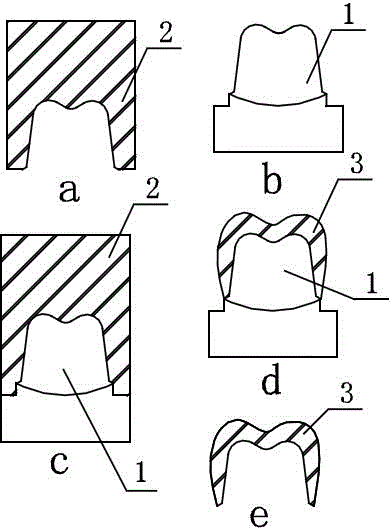

Wet forming production method of dental all-ceramic restoration

The invention discloses a wet forming production method of a dental all-ceramic restoration. According to the method, a prefabricated ceramic block is not used for processing, and in production processes, a support column is not required for fixing the ceramic block and the restoration, so that the process steps of manually removing the support column by milling to separate the formed restoration and the surrounding ceramic block and burnishing and polishing the excessively rough outer surface of the restoration caused by removing the support column by milling are avoided, and the risks of disintegration of the restoration and premature fracture failure are further reduced. A ceramic hard biscuit for milling processing is produced by adopting a wet forming technology, and compared with the ceramic block which is formed by dry pressing and partially sintered, the microscopic structure is more uniform and contains fewer particle packing defects. Through milling processing of the ceramic hard biscuit which is not sintered, the surface finish which is higher than that obtained by processing the ceramic block which is partially sintered can be obtained. The dental all-ceramic restoration produced by adopting the technical scheme of the invention has the advantages of no connection points for the support column on the outer surface, no partial milling marks and ceramic cracks, bright and clean surface, uniform and consistent structure and high reliability.

Owner:HANGZHOU ERRAN TECH

Metal-supported solid oxide fuel cell and preparation method thereof

ActiveCN103872366ALow costAvoid difficultiesFinal product manufactureCell electrodesCeramic moldingElectrical battery

A provided metal-supported solid oxide fuel cell comprises an electrolyte layer and porous electrode precursor layers at two sides of the electrolyte layer, an anode active material is deposed on the hole inner wall of the porous electrode precursor layer at one side for forming the cell anode, a cathode active material is deposed on the hole inner wall of the porous electrode precursor layer at the other side for forming the cell cathode, and the porous electrode precursor layers at two sides both comprise a porous alloy layer. According to the technical scheme, a rare earth ceramic material in a cell support of a total ceramic structural solid oxide fuel cell is replaced by alloy, so that cost is substantially reduced. The cell support is prepared by utilizing conventional ceramic molding technology, so that the technology is simplified, the cost is low, the operability is high, and batch production is facilitated. The anode material and the cathode material are deposed at the hole inner walls of the porous alloy electrode precursor layers at two side of the electrolyte by employing a chemical liquid-phase deposition process, so that the preparation difficulty of the electrodes of the metal-supported solid oxide fuel cell is solved, and the metal-supported solid oxide fuel cell has good electrochemical properties.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Lithium disilicate glass ceramic used for dental zirconia veneering porcelain and preparation method and application thereof

InactiveCN108751721AImprove flexural strengthImprove processing stabilityCrack resistanceFlexural strength

The invention discloses a lithium disilicate glass ceramic used for dental zirconia veneering porcelain and a preparation method and application thereof, the lithium disilicate glass ceramic comprises56%-58% of SiO2, 27%-29% of Li2CO3, 3.7%-3.8% of K2CO3, 2.7%-2.8% of Al2O3, 2.3%-2.4% of ZrO2, 2.5%-2.6% of P2O5, 2.2%-3.8% of B2O3, 0.5% of Ti2O and 0.5% of CeO2. The preparation method comprises the steps that after raw material ball-milling and mixing, melting is performed, a melt is obtained, the melt is poured into a mold, then annealing is performed, and a glass blank is obtained; the glassblank is subjected to crystallization heat treatment, and the lithium disilicate glass ceramic is obtained. The obtained lithium disilicate glass ceramic is high in flexural strength, and the damageprobability of a restoration body due to veneering porcelain cracking can be remarkably reduced. The invention provides a method applying the lithium disilicate glass ceramic as zirconia veneering porcelain, in the restoration body obtained with the method, the bonding strength of the lithium disilicate glass ceramic veneering porcelain with a zirconia substrate is far higher than that of traditional zirconia decoration ceramic porcelain with the zirconia substrate, and the cracking resistance of a zirconia all-ceramic restoration body can be improved remarkably and the service life can be prolonged.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Milling forming production method of dental all-ceramic restoration

The invention discloses a milling forming production method of a dental all-ceramic restoration. In production processes, a support column is not required for fixing a ceramic block and the restoration, so that the process steps of manually removing the support column by milling to separate the formed restoration and the surrounding ceramic block and burnishing and polishing the excessively rough outer surface of the restoration caused by removing the support column by milling are avoided, and the risks of disintegration of the restoration and premature fracture failure are further reduced. Under the condition of being supported by a model material block, the milling of the ceramic block is more conductive to processing a thin-walled neck edge, and particularly, the milling of a ceramic hard biscuit which is not sintered is more conductive to improving the degree of finish of the outer surface of the dental all-ceramic restoration. The dental all-ceramic restoration produced by adopting the technical scheme of the invention has the advantages of no connection points for the support column on the outer surface, no partial milling marks and ceramic cracks, bright and clean surface, uniform and consistent structure and high reliability.

Owner:HANGZHOU ERRAN TECH

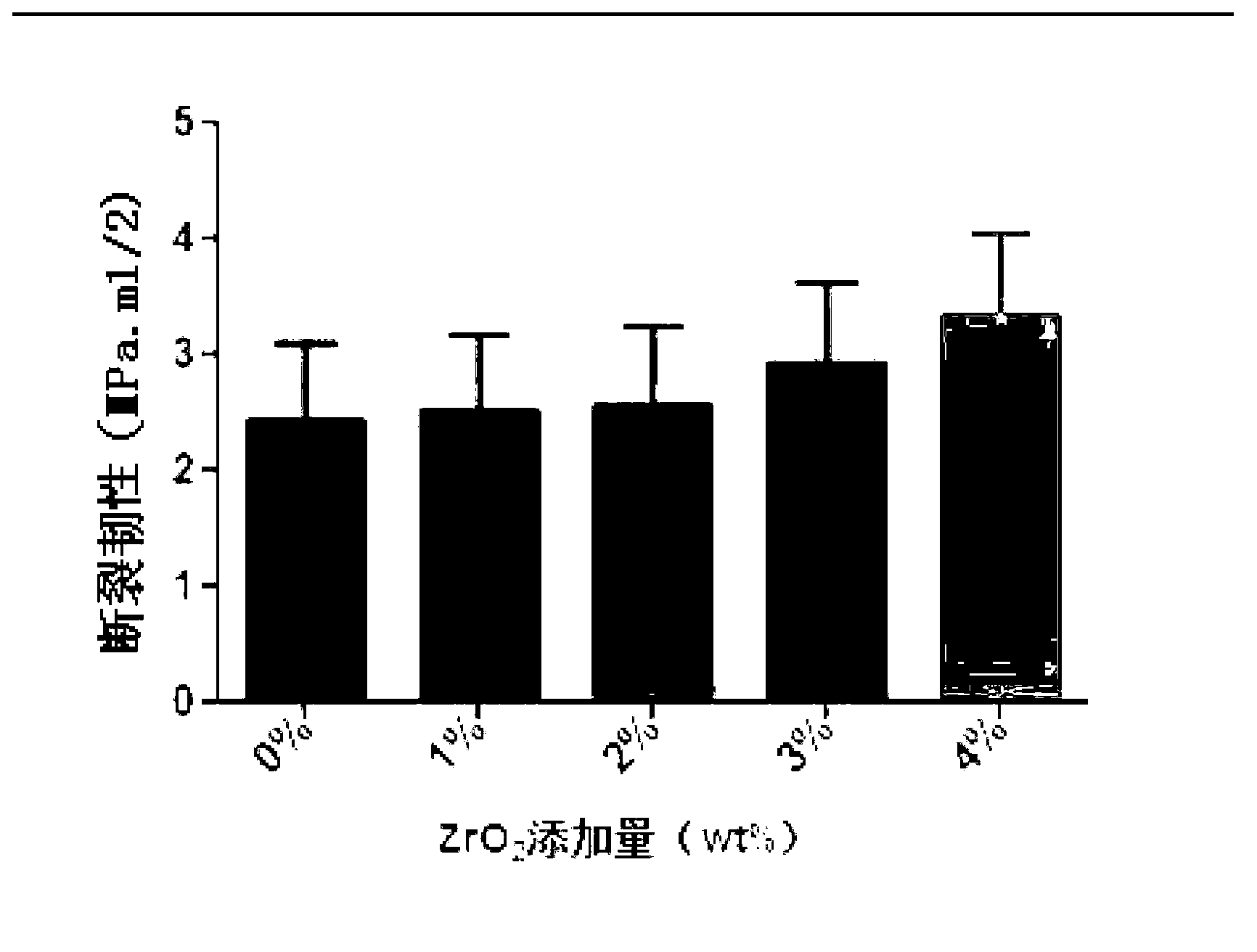

Strengthening-toughening glass ceramic and preparation method thereof

The invention belongs to the field of all-ceramics materials for the dentistry, and discloses a strengthening-toughening glass ceramic and a preparation method thereof. The strengthening-toughening glass ceramic comprises the following components in percentage by mass: 96 to 99% of basic component, and 1.0 to 4.0% of toughening component, wherein the basic component comprises the following components in percentage by mass: 58 to 62% of SiO2, 28 to 30% of Li2CO3, 3.5 to 4.0% of K2CO3, 2.5 to 3.0% of Al2O3, 11.4 to 1.6% of CeO2, and 2.6 to 3.0% of P2O5, and the toughening component is ZrO2.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Manufacturing process for chemically plating NiP-Cu electrode on partial surface of ceramic element

ActiveCN102409322AImprove adhesionImprove performanceLiquid/solution decomposition chemical coatingTopical surfaceChemical plating

The invention relates to a manufacturing process for chemically plating a NiP-Cu electrode on the partial surface of a ceramic element, in particular to a process for manufacturing an electrode by a chemical deposition method for base metal copper or nickel. The process comprises the following steps of: preparing the ceramic element, cleaning, drying, roughening, printing, activating, soaking, preplating, plating copper, dehydrating, drying, performing heat treatment, welding, testing and the like. The invention has the advantages that: a base metal layer on the surface of the ceramic element has high adhesion force and high performance and is easy to weld; the partial surface is chemically plated, so that the process is simple, and adhering, abrading and scattering processes of the conventional full electrode chemical plating process are eliminated; raw materials are saved, and the cost is reduced to one fifth of the original cost; and a plating solution formula is perfected, so that mass production of the electrode which is chemically plated on the partial surface of the ceramic element can be realized. The process is suitable for manufacturing electrodes of all ceramic elements.

Owner:ANSHAN ZHONGPU INSTR ELECTRONICS EQUIP

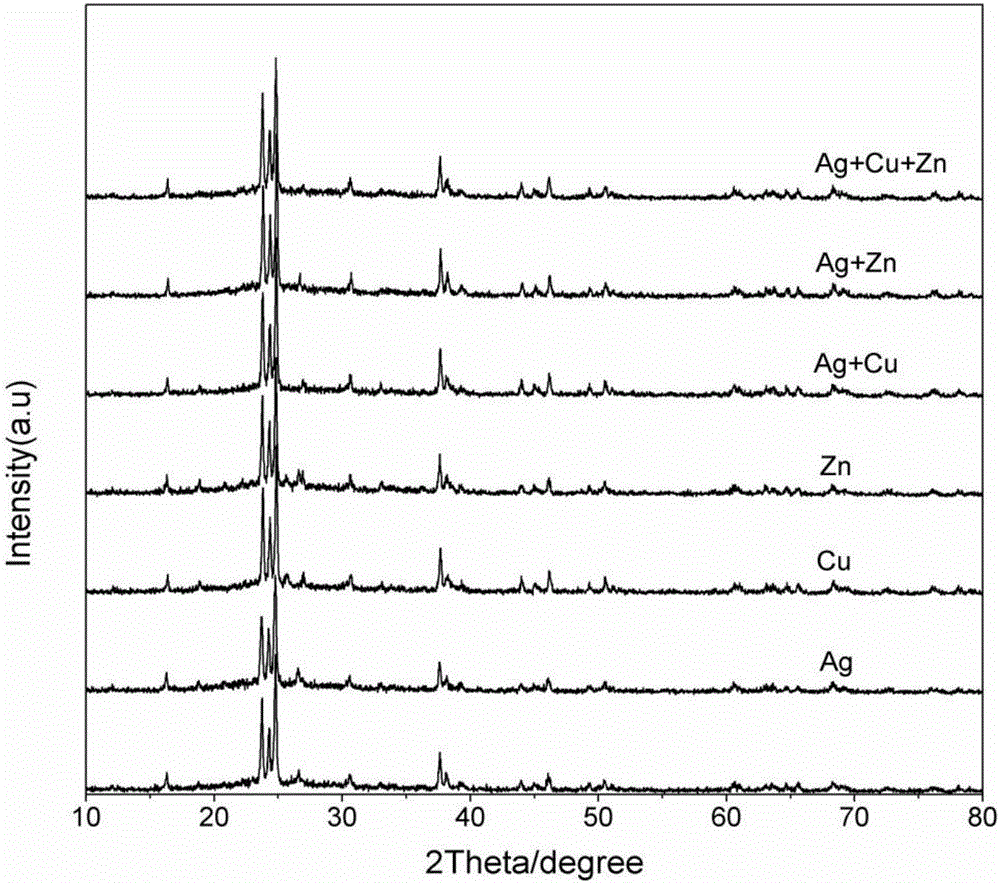

High-strength bacteriostatic antibacterial lithium disilicate glass ceramic and preparation method thereof

ActiveCN106746675AHigh strengthMaintain aestheticsImpression capsDentistry preparationsRestorative materialHigh intensity

High-strength bacteriostatic antibacterial lithium disilicate glass ceramic and a preparation method thereof belong to the technical field of biological materials. In the prior art, a dental department all-ceramic restorative material obtained by doping Ag<+>, Zn<2+> and Cu<2+> in lithium disilicate glass ceramic does not exist. The high-strength bacteriostatic antibacterial lithium disilicate glass ceramic is characterized by preparing materials for matrix glass according to the weight percentage of the matrix glass, additionally determining the total weight of Ag2O, ZnO and CuO in the high-strength bacteriostatic antibacterial lithium disilicate glass ceramic according to the ratio of 0.1 to 8 percent of the weight of the matrix glass, and preparing the matrix glass by adopting a high temperature melting method, wherein the content of the Ag2O is larger than or equal to 0 percent but less than or equal to 2 percent, ZnO is larger than or equal to 0 percent but less than or equal to 5 percent and CuO is larger than or equal to 0 percent but less than or equal to 1 percent, wherein only the content of AgO2, ZnO and CuO is allowed to be equal to 0 at the same time; coring the prepared matrix glass at the temperature of 450 to 550 DEG C for 1.5 to 2.5 hours; performing three-step crystallization: crystallizing at the temperature of 650 to 680 DEG C for 1 to 3 hours, crystallizing at the temperature of 710 to 740 DEG C for 20 to 60 minutes, crystallizing at the temperature of 800 to 830 DEG C for 10 to 20 minutes, so as to obtain the high-strength bacteriostatic antibacterial lithium disilicate glass ceramic.

Owner:CHANGCHUN UNIV OF SCI & TECH

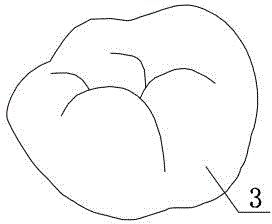

Making method for bionic ceramic dental prosthesis

InactiveCN108618969AImprove wear performanceAchieve bionic color effectsImpression capsDentistry preparationsColor effectWear resistant

The invention relates to a making method for a bionic ceramic dental prosthesis. The method comprises the steps that conventional 3mol% yttrium-stabilized zirconium dioxide ceramic with high strengthand low transparency and ceramic with high transparency are selected as prefabricated powder; a blank block / disc is pressed in a layered mode; in a transition buffer layer from the lower surface of ablank to the upper surface, the proportion of the 3mol% yttrium-stabilized zirconium dioxide ceramic is gradually decreased from 100% to 0, and the proportion of the ceramic with low strength and hightransparency is gradually increased from 0 to 100%; an occlusal surface or an attractive area of a CAD digital model of the dental prosthesis is placed on a bionic performance / color layer, and an axial surface area is placed on a high-strength anti-fracture layer; and making is completed by utilizing dental prosthesis manufacturing equipment. The method has the advantages that the problems that ajaw tooth is excessively worn by a high-strength single-layer full zirconia prosthesis, no stress buffer exists in the all-ceramic prosthesis implanting process, and the prosthesis is prone to beingfractured in the long time when totally adopting a bionic abrasion-resistant ceramic material can be solved, and meanwhile, the bionic color effect of the prosthesis can be achieved.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

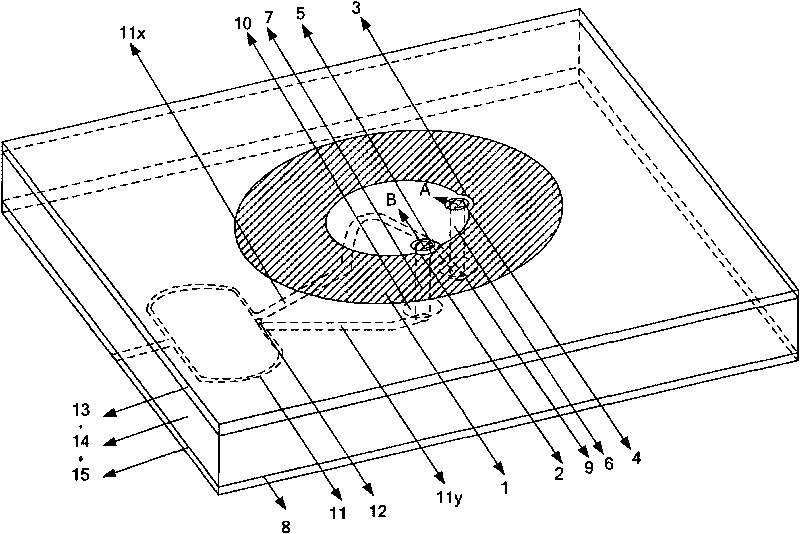

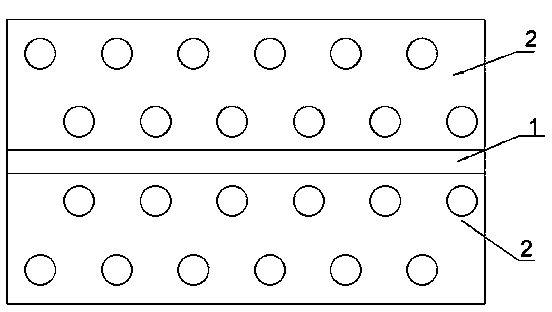

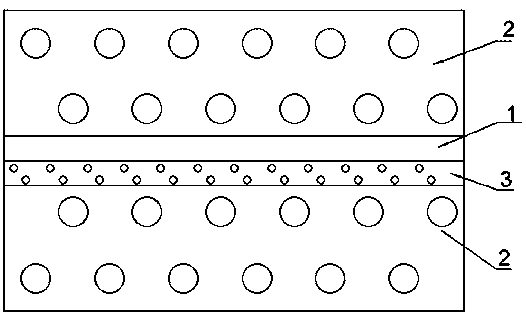

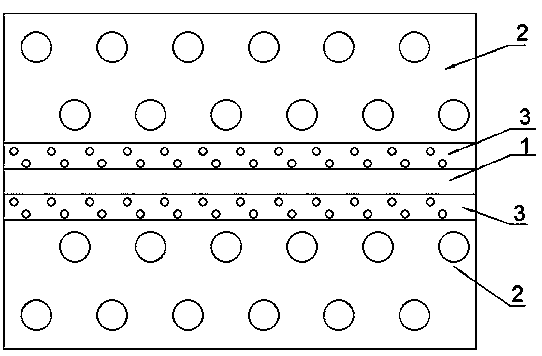

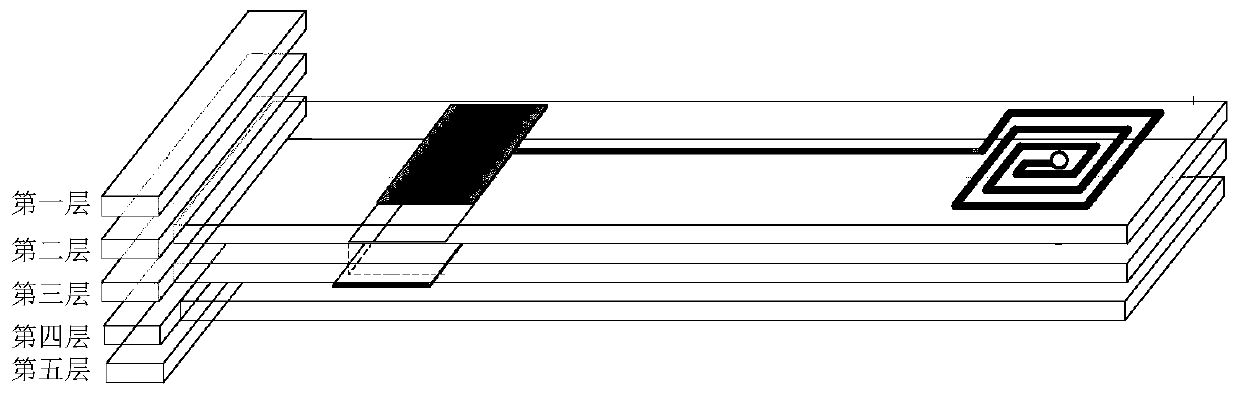

LTCC (Low Temperature Co-Fired Ceramic)-based passive LC (inductive-capacitive) humidity sensor

InactiveCN103344679AReduce manufacturing costSuitable for mass productionMaterial capacitanceCapacitanceCeramic sintering

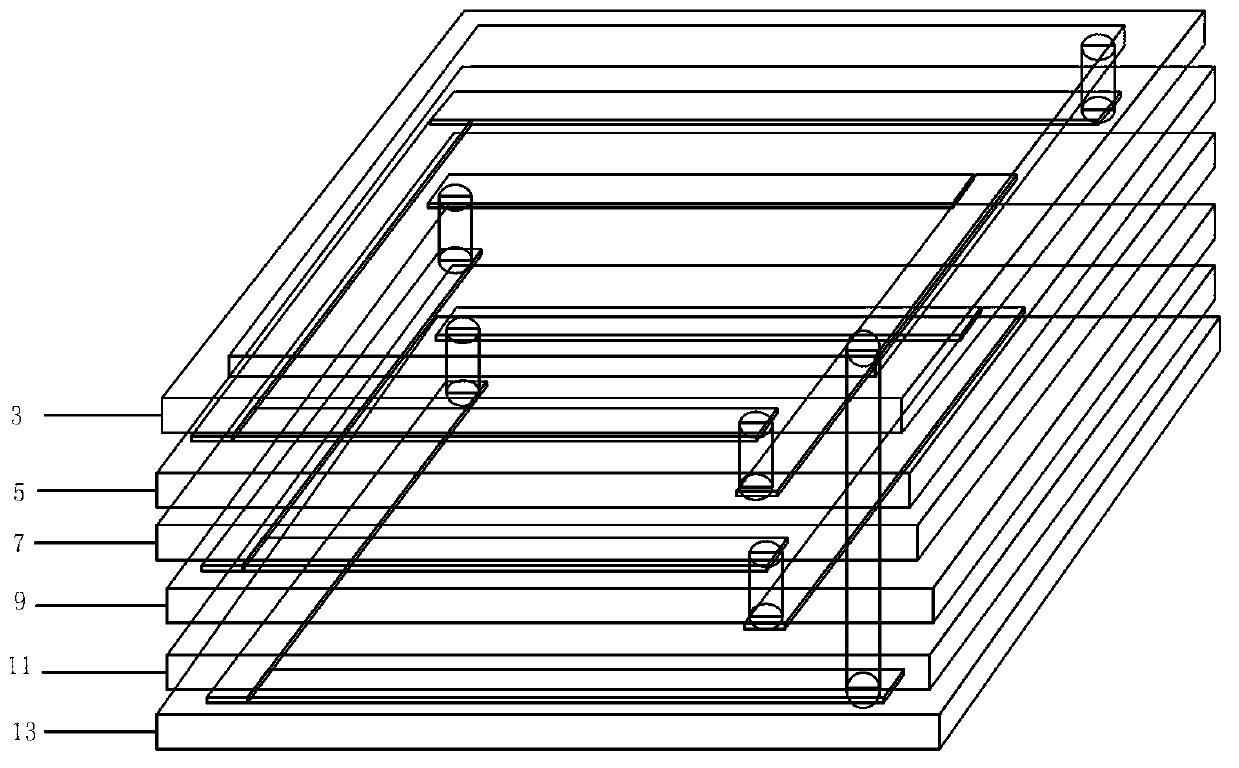

The invention discloses an LTCC (Low Temperature Co-Fired Ceramic)-based passive LC (Inductive-Capacitive) humidity sensor. The LTCC-based passive LC humidity sensor comprises thirteen layers from top to bottom, wherein the layers with odd numbers are all ceramic dielectric layers, the layers with even numbers are all metal layers, the second capacitance metal layer is exposed out of a window of the first dielectric layer, so that the capacitance layer can sense the humidity, the fourth, sixth, eighth, tenth and twelfth metal layers are all inductance metal layers, and two ends of inductors positioned in the fourth and twelfth metal layers are connected with two ends of the second capacitance metal layer by through holes to form a parallel LC circuit. The LTCC-based passive LC humidity sensor is realized by utilizing an LTCC technology, and can be used for effectively reducing the production process and greatly reducing the production cost, and a quality factor of a ceramic material is high, so that the loss of the circuit is low. More importantly, the LTCC ceramic material is good in stability and not sensitive to environmental changes, and a ceramic sintering body is compact in structure and low in moisture permeability, so that the sensor can be applied in a high-humidity environment without encapsulation.

Owner:XIDIAN UNIV

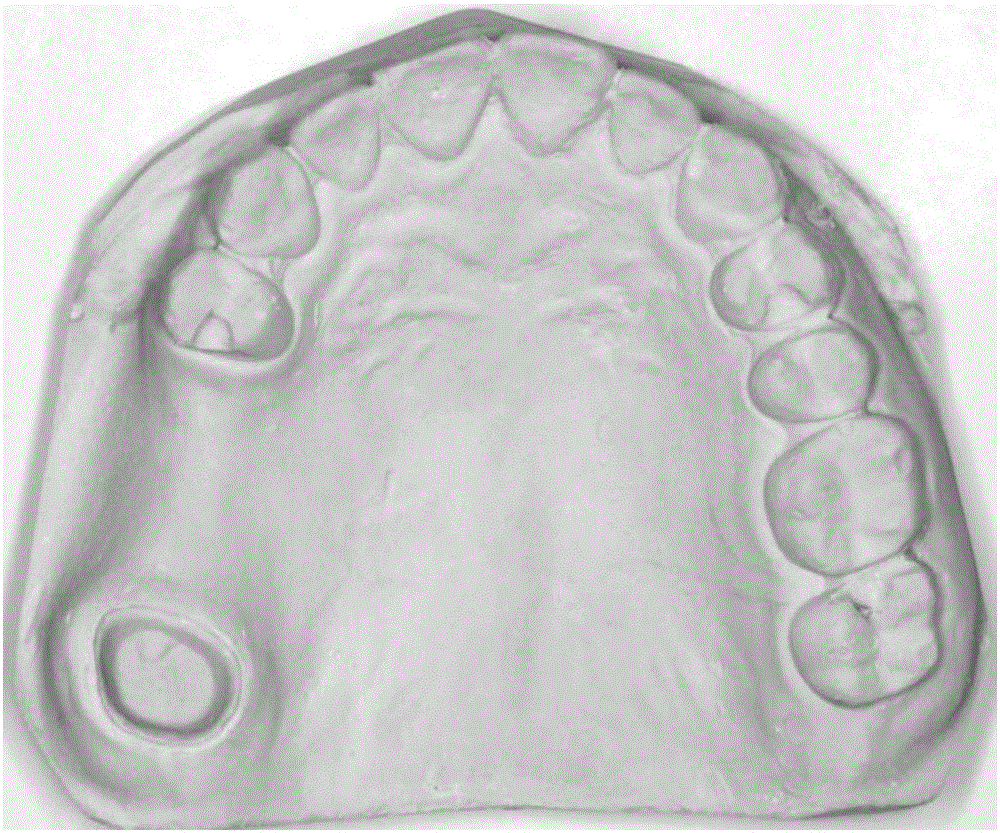

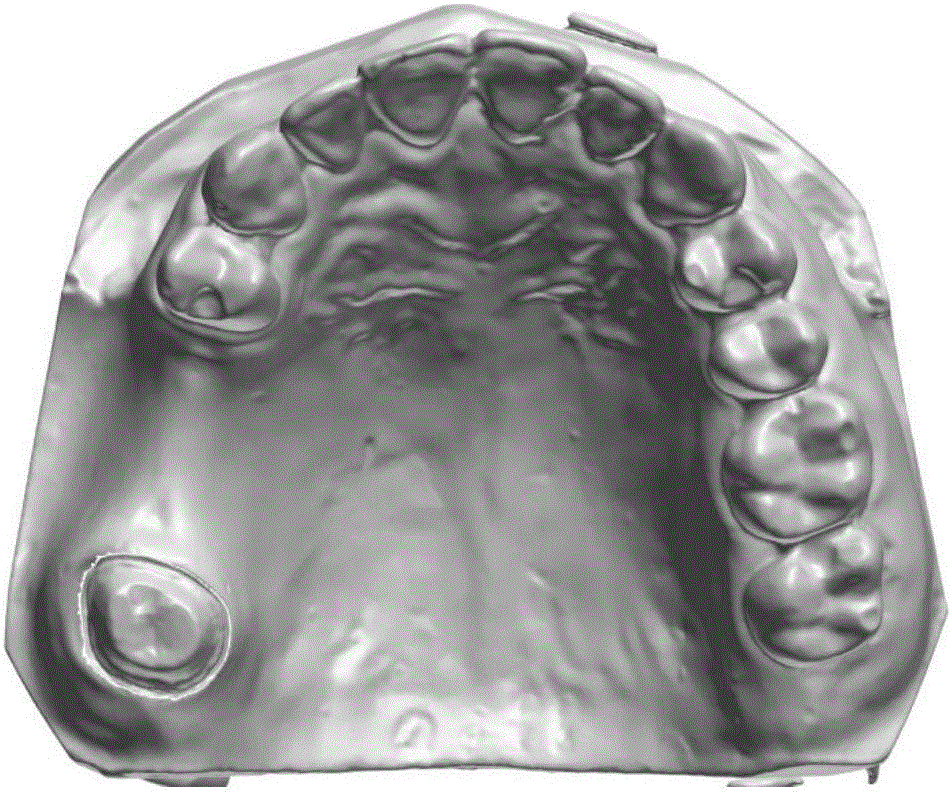

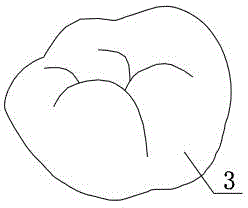

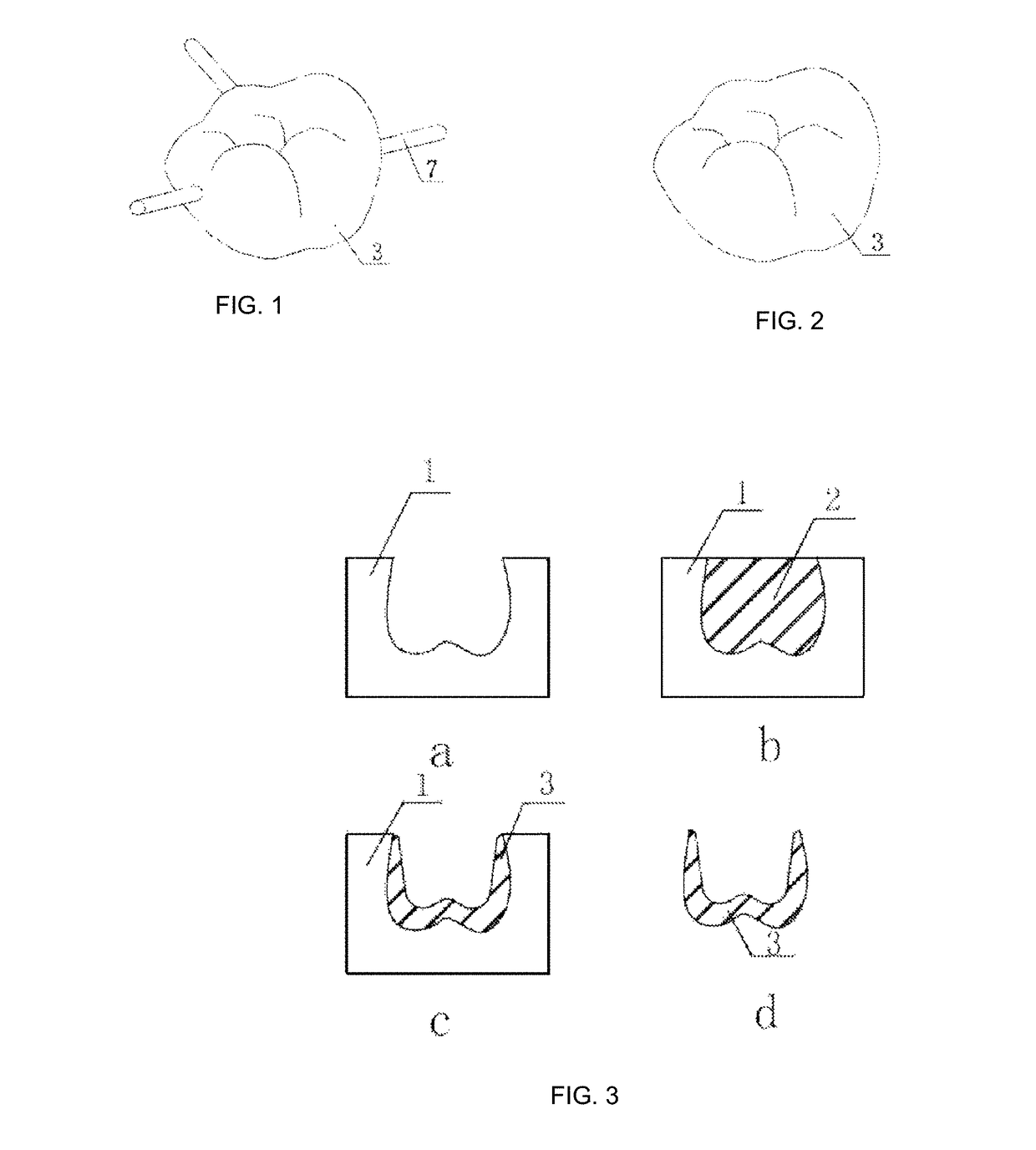

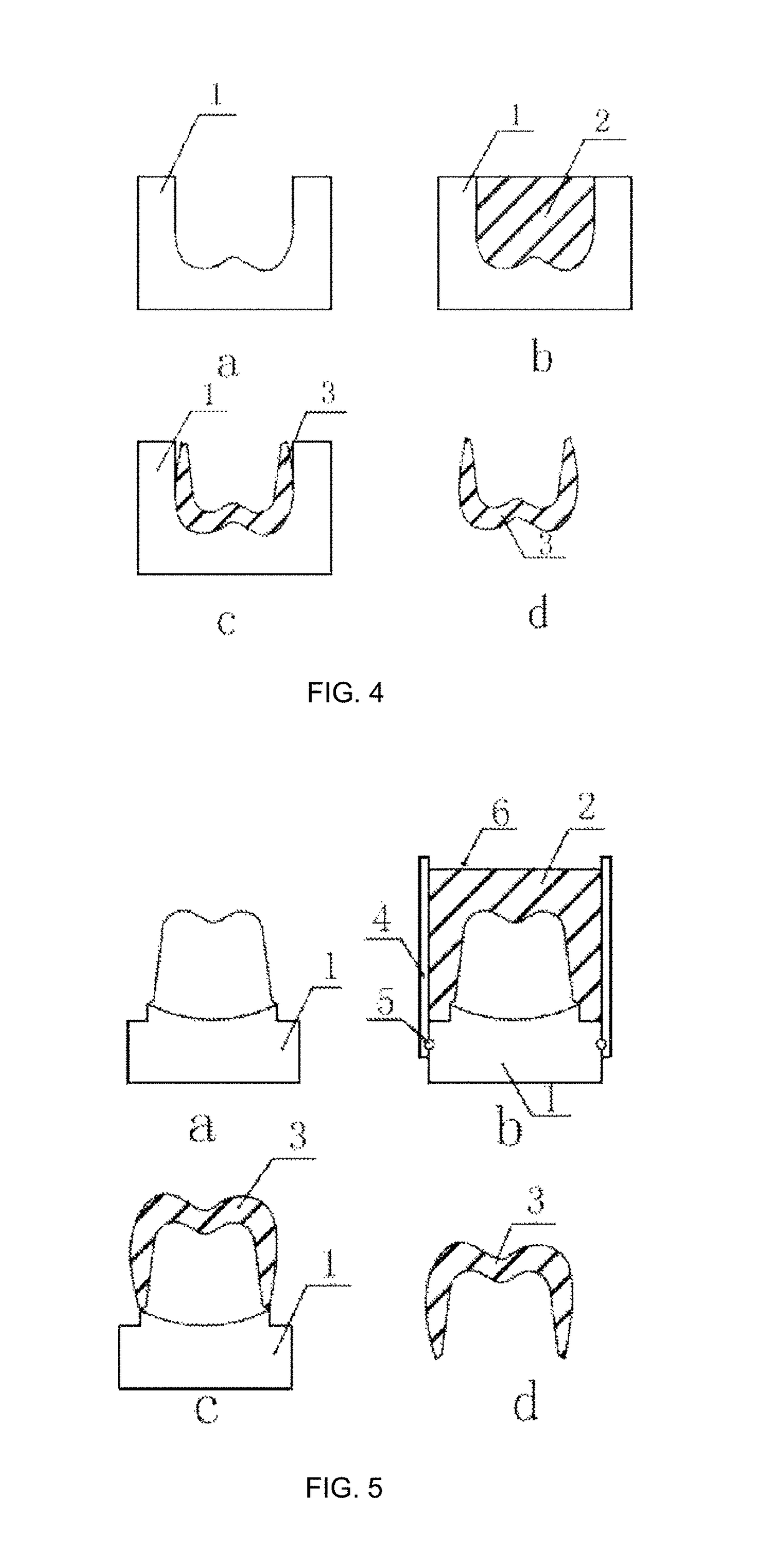

Dental all-ceramic restoration and manufacturing method thereof

ActiveUS20170231730A1Improve surface smoothnessIncrease success rateDental implantsImpression capsSurface finishParticle packing

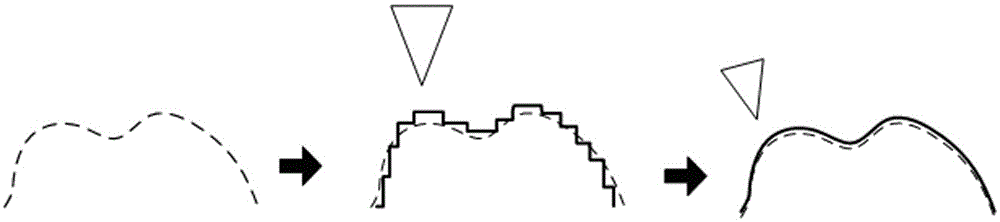

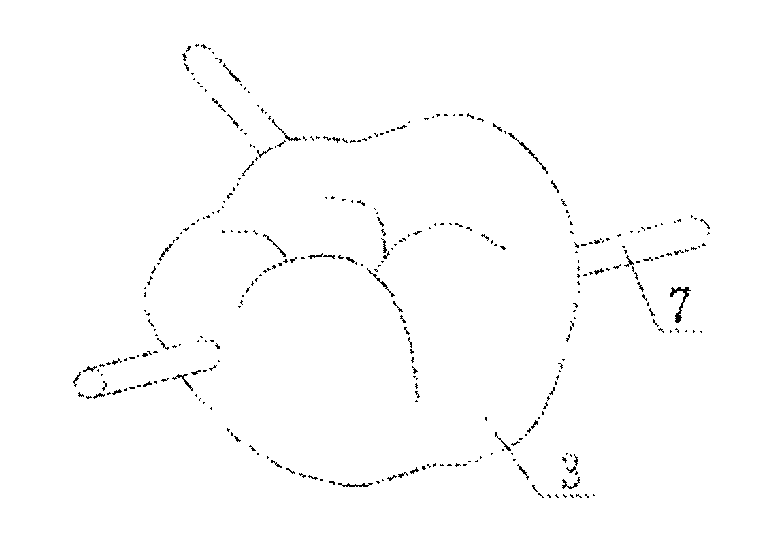

A dental all-ceramic restoration and manufacturing method thereof; the outer surface of the dental all-ceramic restoration has neither visible marks remaining from the removal of the connecting bars (7) nor local grinding traces and chipping, and is smooth with uniform structure. The manufacturing method thereof is wet-forming or milling. No connecting bars are needed to connect the dental restoration bodies (3) with a surrounding mould blank or ceramic blank. This eliminates the need for manually cutting off the connecting bars (7) to separate the forming body from the surrounding ceramic blank, further grinding and polishing process to treat the excessively rough outer surface, and thereby reducing the risk of chipping and premature failure. In the manufacturing processes thereof, the hardened ceramic green body (2) made by wet-forming technique has more homogenous microstructure and less particle packing defects than the dry-pressed blanks and partially sintered blanks. Furthermore, higher surface smoothness can be obtained by milling unsintered hardened ceramic green body than by milling partially sintered blanks. The dental all-ceramic restoration has a high degree of surface finish, and can be directly used without polishing, veneering or glazing.

Owner:HANGZHOU ERRAN TECH

Compact type hydro-hybrid ceramic main shaft device

InactiveCN102133649AIncrease speedIncreased operating lifeMaintainance and safety accessoriesStress concentrationThrust bearing

The invention discloses a compact type hydro-hybrid ceramic main shaft device. On the structural design, the mode of radial middle and thrusting two ends is adopted, simultaneously, the structure that the metal fully includes a ceramic friction pair is adopted, and shape deformation of all ceramic parts can be avoided on design. In the invention, support bearings are taken as ceramic hydro-hybridceramic bearings, and simultaneously have the radial bearing function and axial thrusting function; the ceramic parts are prevented from bearing large tension action, or the condition that the parts are broken due to the overlarge stress of the edges of the parts is prevented, the concentration stress at the inner part of the ceramic parts is reduced, and breakage accidents caused by design flaw of the ceramic parts can be prevented; the lubricating liquid flow is saved as liquid outlet pressure of a radial bearing is taken as the liquid supply pressure of a thrust bearing; the seam of the radial bearing is taken as a choke holder of the thrust bearing, so that the cost of the choke holder is saved; and the radial baring can be tightly combined with the thrust bearing, so that the length is shortened under the condition of unchangeable radial bearing function and axial thrusting function of the main shaft, the structure is more compact and simple and the processing is convenient.

Owner:TIANJIN UNIV

Monolithic tube sheet and method of manufacture

InactiveUS20050035591A1Easy to assembleEasy alignmentPipe supportsFluid pressure sealed jointsMetallurgyAll ceramic

A monolithic refractory ceramic tube sheet for use in all-ceramic air-to-air indirect heat exchangers, the heat exchanger used in all temperature and all pressure applications. A method for forming the monolithic tube sheet includes casting a refractory ceramic in a mold, where portions of the mold comprise the housing of the heat exchanger. Precisely formed negatives are used to form through channels and vacancies within the tube sheet, which are precisely positioned within the mold allowing uniform and flush formation of openings which receive the ceramic tubes therein. The same mold is used to provide both tube sheets of a tube sheet pair allowing accurate alignment of tubes within the exchanger vessel resulting in ease of assembly and equal loading of tubes when in use.

Owner:HEAT TRANSFER INT

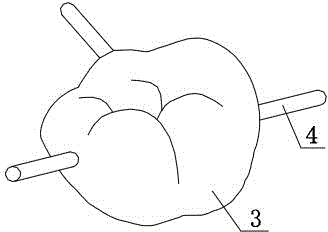

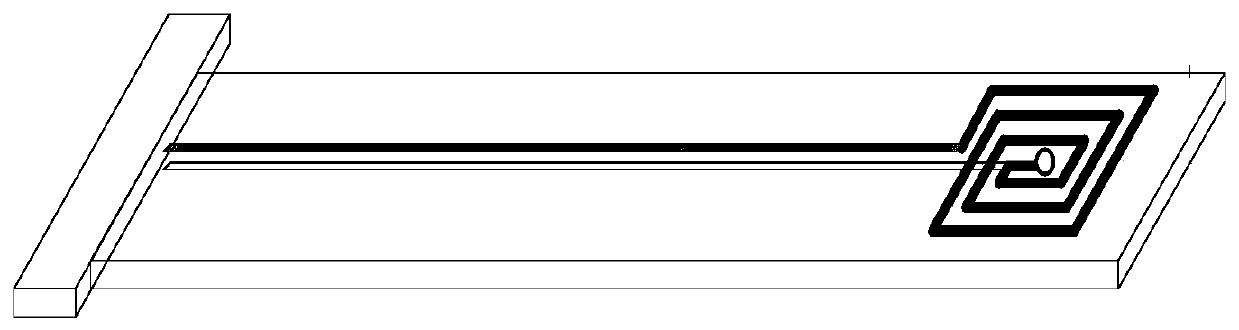

All-ceramic ultrahigh-temperature pressure sensor and packaging method thereof

InactiveCN110057487AAvoid using leadsImprove sealingInternal combustion piston enginesForce measurementCapacitanceWorking temperature

The invention discloses an all-ceramic ultrahigh-temperature pressure sensor. The all-ceramic ultrahigh-temperature pressure sensor comprises a high-temperature-resistant ceramic pressure sensitive element, a high-temperature-resistant ceramic prototype packaging case and a high-temperature-resistant ceramic reading antenna, wherein the high-temperature-resistant ceramic pressure sensitive elementconsists of a high-temperature-resistant voltage dependent capacitor and a rectangular spiral inductance coil; the high-temperature-resistant ceramic pressure sensitive element is arranged on one side in the high-temperature-resistant ceramic prototype packaging case; high-temperature-resistant heat-proof and shock-proof cotton is arranged between the high-temperature-resistant ceramic pressure sensitive element and the high-temperature-resistant ceramic prototype packaging case; the high-temperature-resistant ceramic reading antenna is arranged on the other side in the high-temperature-resistant ceramic prototype packaging case; and the high-temperature-resistant ceramic reading antenna is coupled with an inductor in a pressure-sensitive LC loop to realize the transmission of pressure parameters. Through adoption of the all-ceramic ultrahigh-temperature pressure sensor, the problems of low working temperature and poor air tightness of a sensor prototype in the pressure parameter testing process are solved, and in-situ measurement of the pressure parameters in an ultrahigh-temperature environment of which the temperature is 1000 DEG C or more is realized.

Owner:ZHONGBEI UNIV

Preparation method of full-ceramic microencapsulated fuel core block

ActiveCN108249925AComplete structureEvenly distributedNuclear energy generationReactor fuel susbtancesSilicon carbideHot pressing

The invention belongs to the technical field of fuel core block preparation, and particularly relates to a preparation method of a full-ceramic microencapsulated fuel core block. The method comprisesthe following steps: step 1, adding a silicon carbide powder and a sintering aid; step 2, applying silicon carbide powder on the surface of the TRISO particles; step 3, pre-forming the fuel core block; step 4, performing hot-pressing sintering on the fuel core block. The full-ceramic microencapsulated fuel core block prepared by the method is in a cylindrical shape, and the density of the full-ceramic microencapsulated fuel core block is more than or equal to 3.1g / cm<3>; the inner TRISO particles of the core block are kept complete in structure and are uniformly distributed in the silicon carbide substrate.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

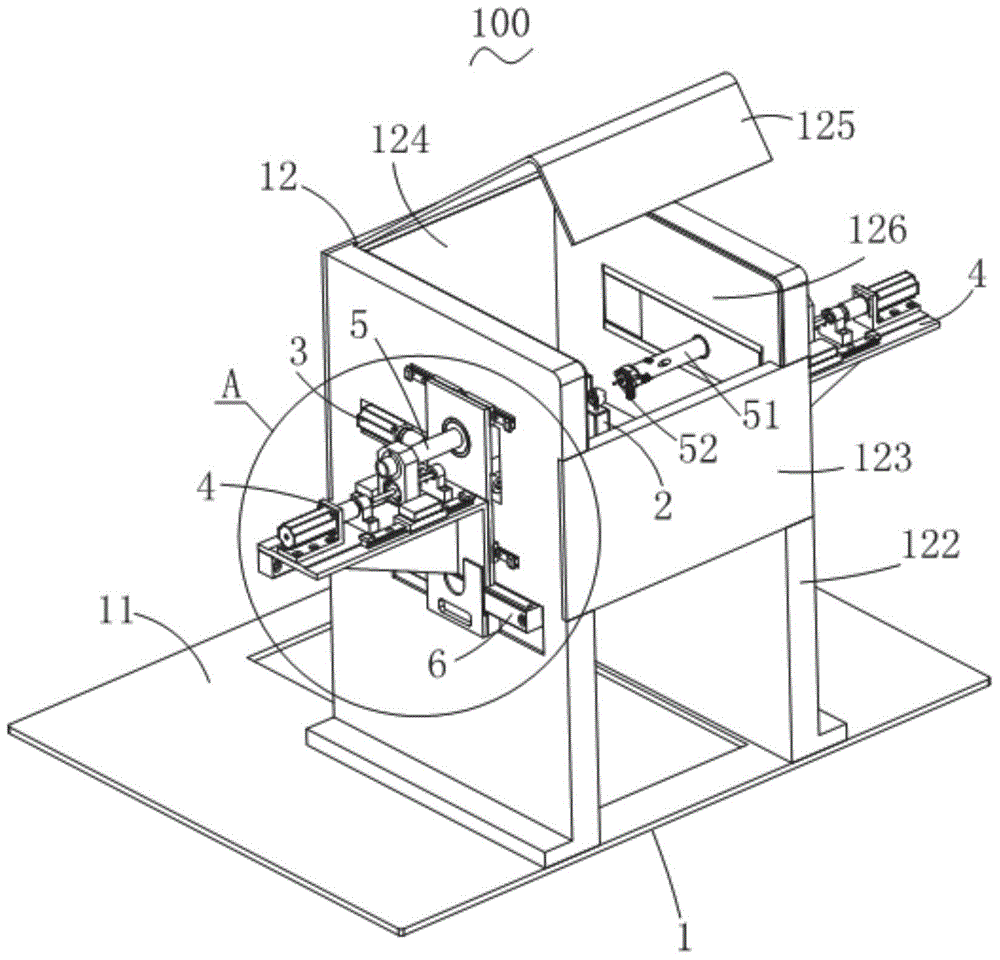

All-ceramic denture grinding system and method for fabricating denture

The invention relates to an all-ceramic denture grinding system and a method for fabricating a denture. By adopting the system, a denture briquette is fabricated into the denture. The system comprises a bracket, and a Z-axis displacement mechanism, X-axis displacement mechanisms, Y-axis displacement mechanisms and a grating ruler which are arranged on the bracket, wherein the Z-axis displacement mechanism comprises a Z-axis movement seat; the Z-axis movement seat is used for fixing the denture briquette and a temporary metal denture; two groups of X-axis displacement mechanisms and two groups of Y-axis displacement mechanisms are oppositely arranged on two sides of the Z-axis displacement mechanism respectively; a tool component for depicting the temporary metal denture and cutting the denture briquette is arranged on each group of Y-axis displacement mechanisms; each group of Y-axis displacement mechanisms pushes the tool component to move along the Y-axis direction; each group of X-axis displacement mechanisms is connected with the corresponding tool component, and pushes the tool component to move along the X-axis direction; and the grating ruler is used for recording displacement data of the tool component moving along the Y-axis direction and the X-axis direction in real time.

Owner:衡水明德全瓷义齿有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com