Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1470 results about "Solid-state battery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A solid-state battery is a battery technology that uses solid electrodes and a solid electrolyte, instead of the liquid or polymer gel electrolytes found in lithium-ion or lithium polymer batteries. Materials proposed for use as solid electrolytes in solid-state batteries include ceramics (e.g. oxides, sulfides, phosphates), and solid polymers. Solid-state batteries have found use in pacemakers, RFID and wearable devices. They are potentially safer, with higher energy densities, but at a much higher cost.

Ion conducting batteries with solid state electrolyte materials

ActiveUS20140287305A1Final product manufactureActive material electrodesSolid state electrolytePorous layer

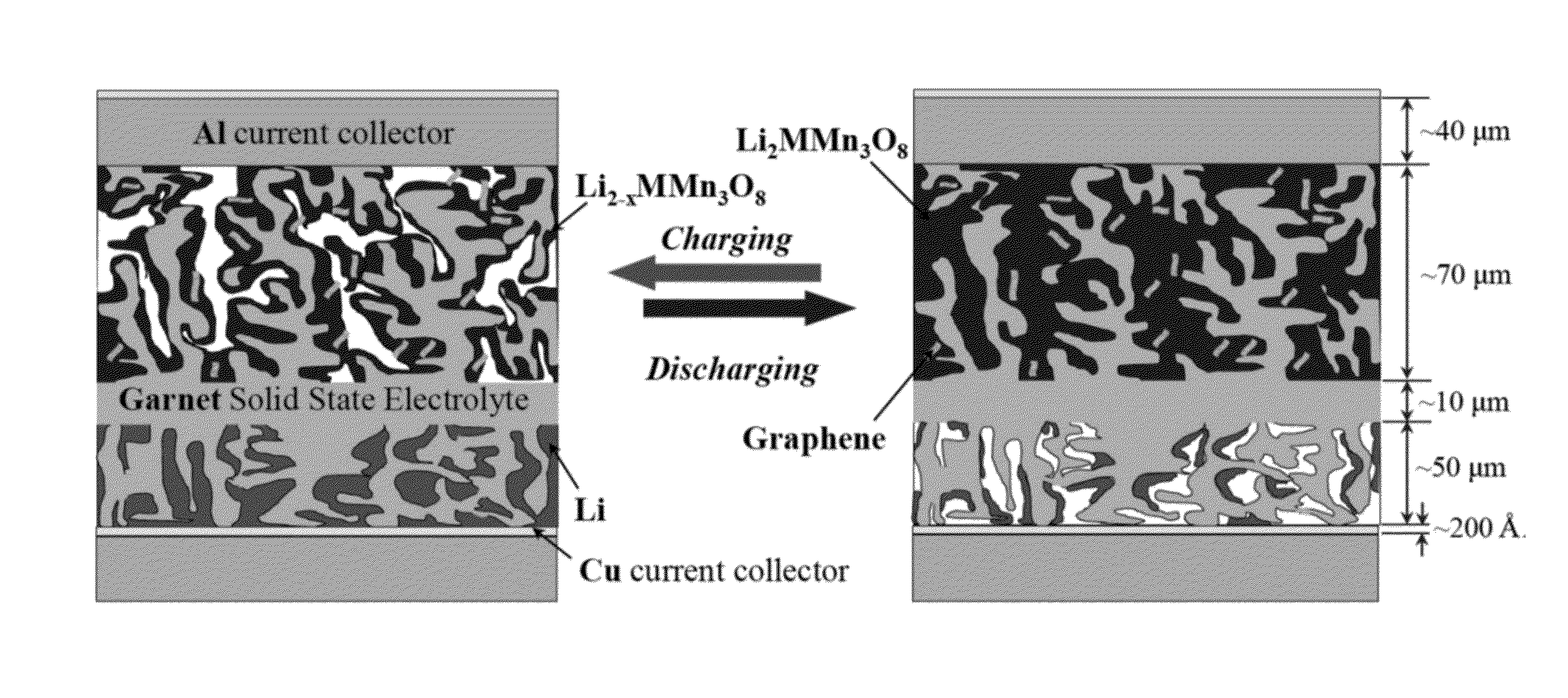

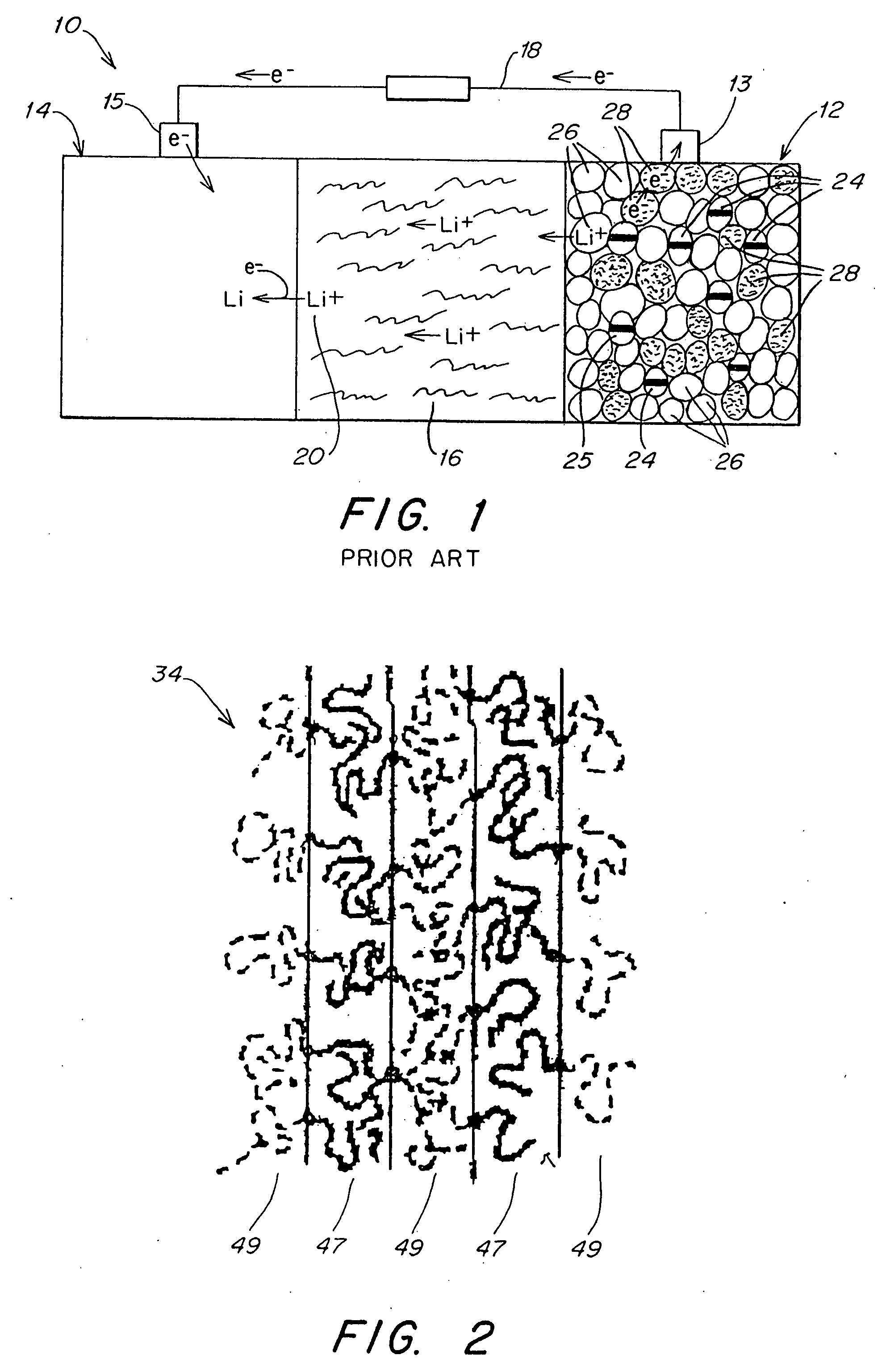

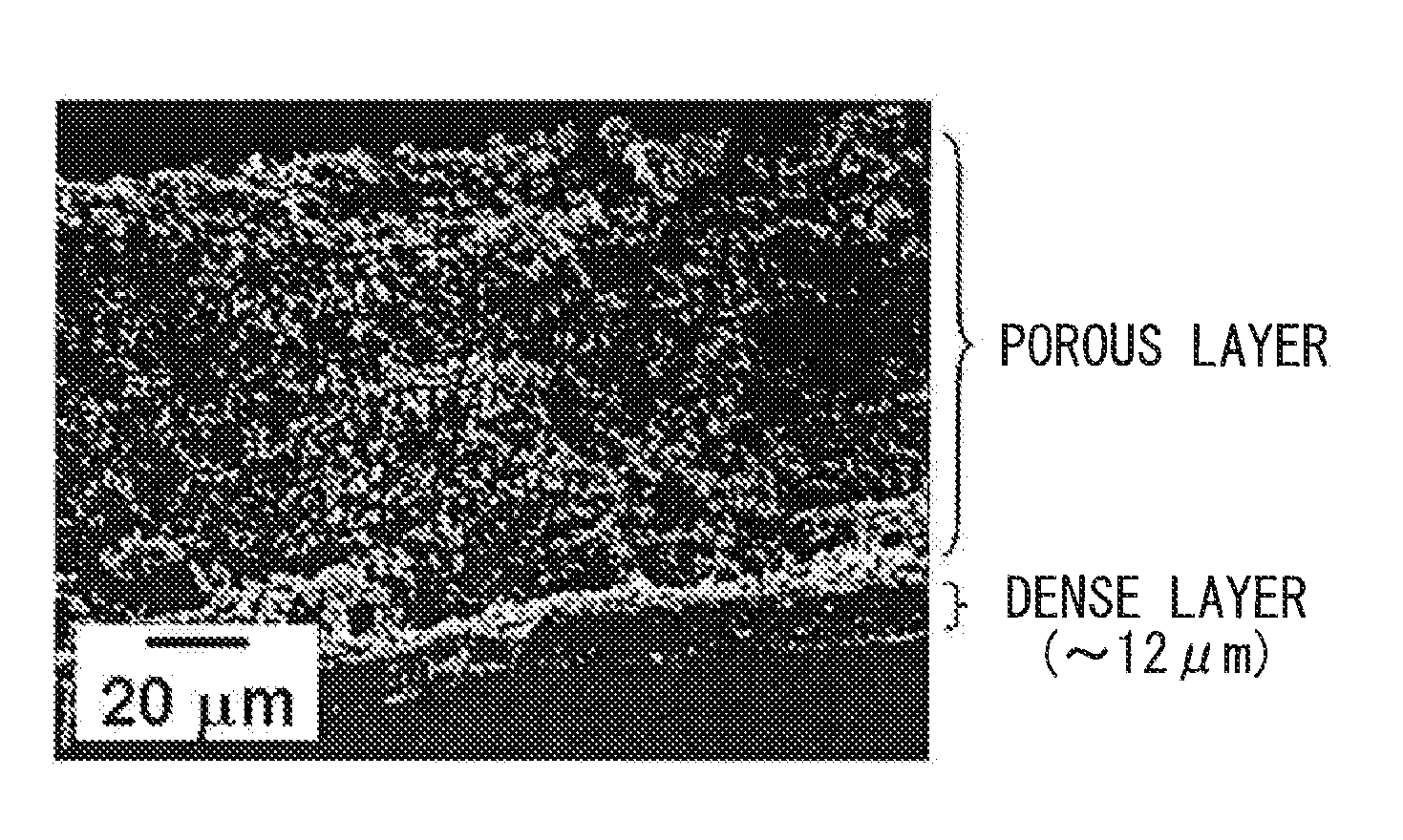

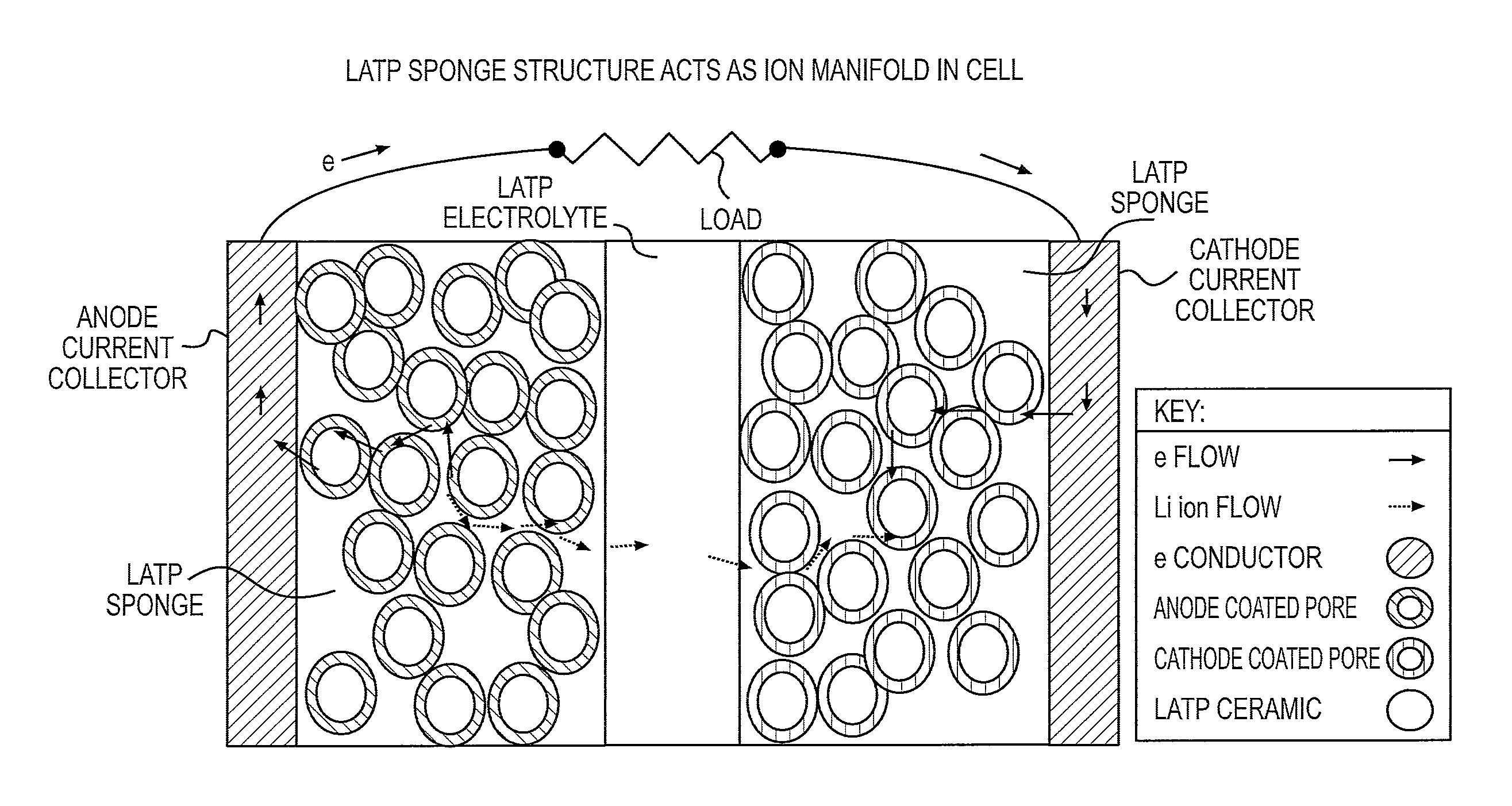

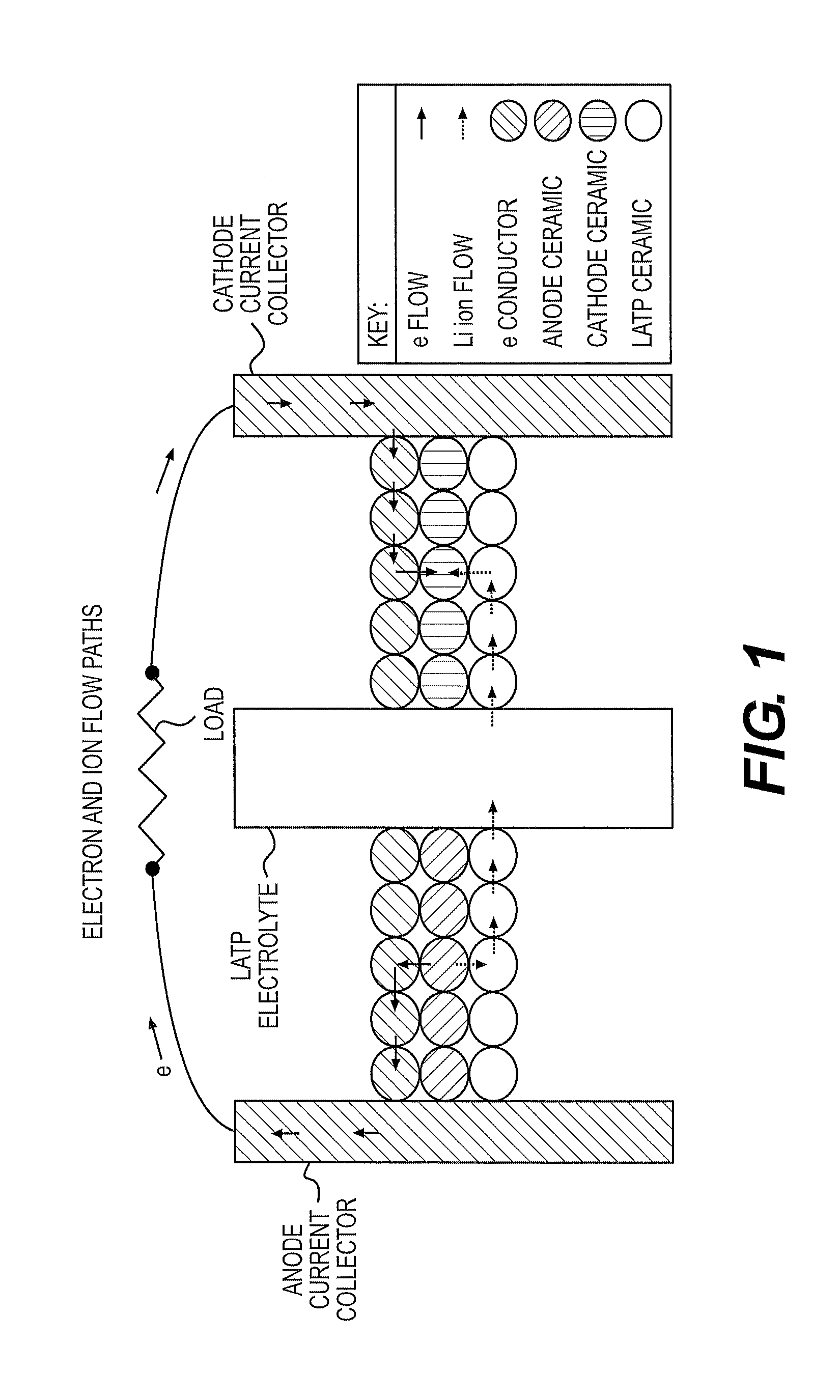

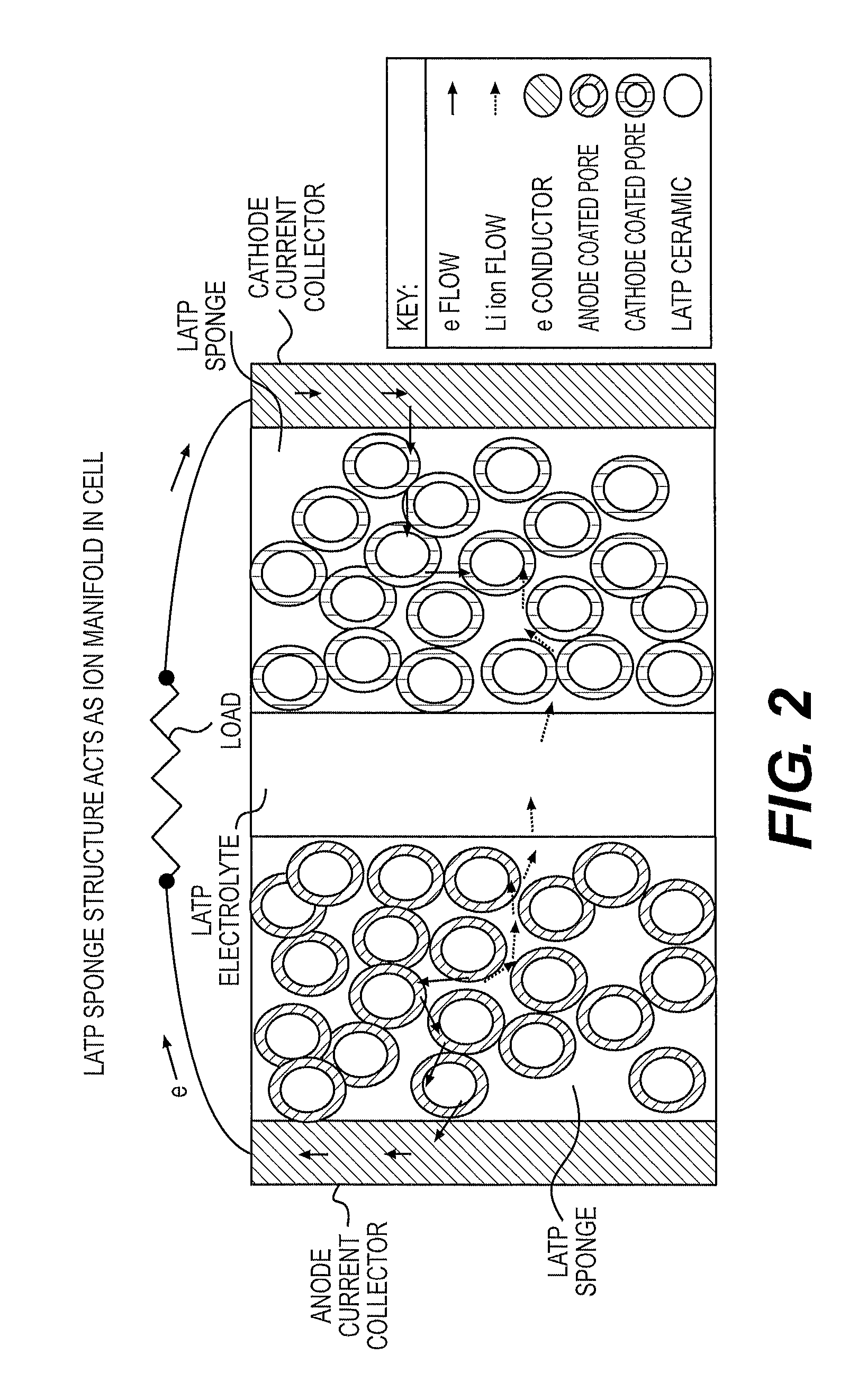

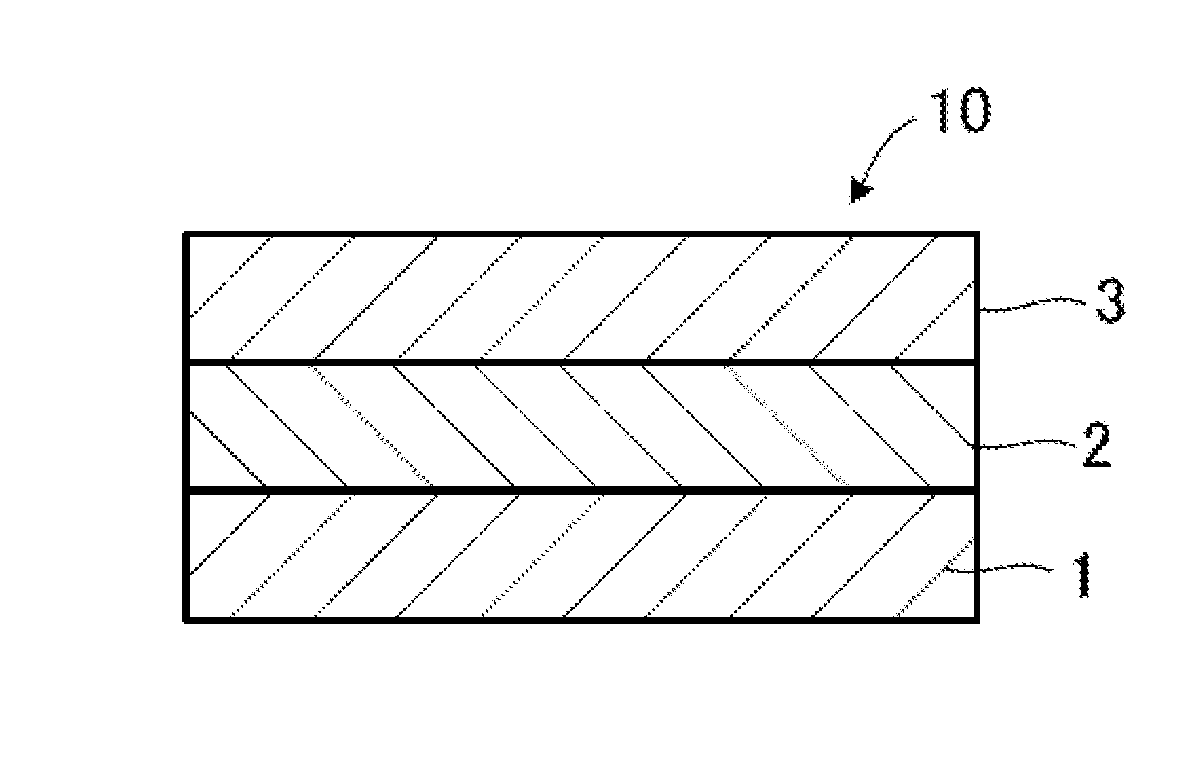

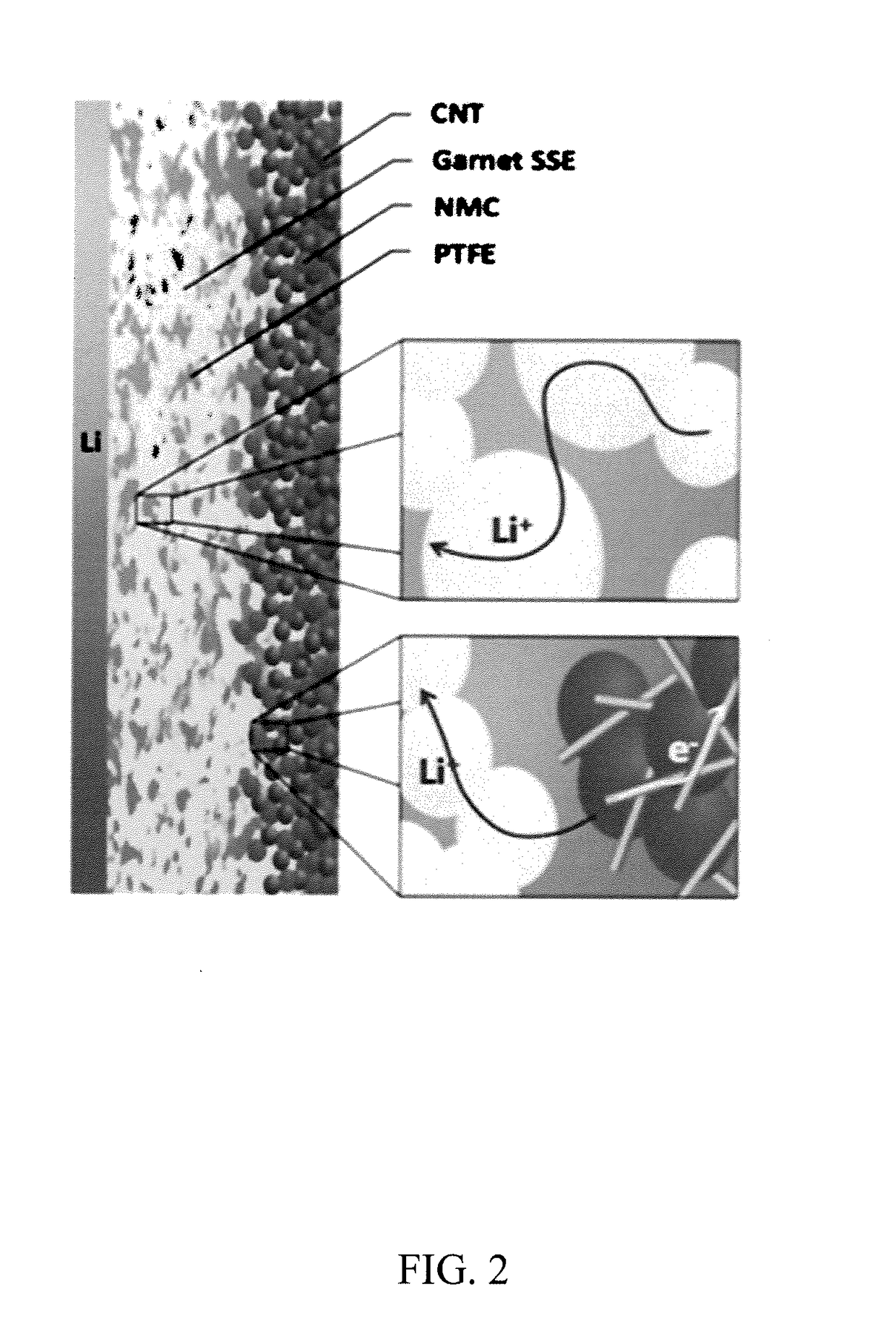

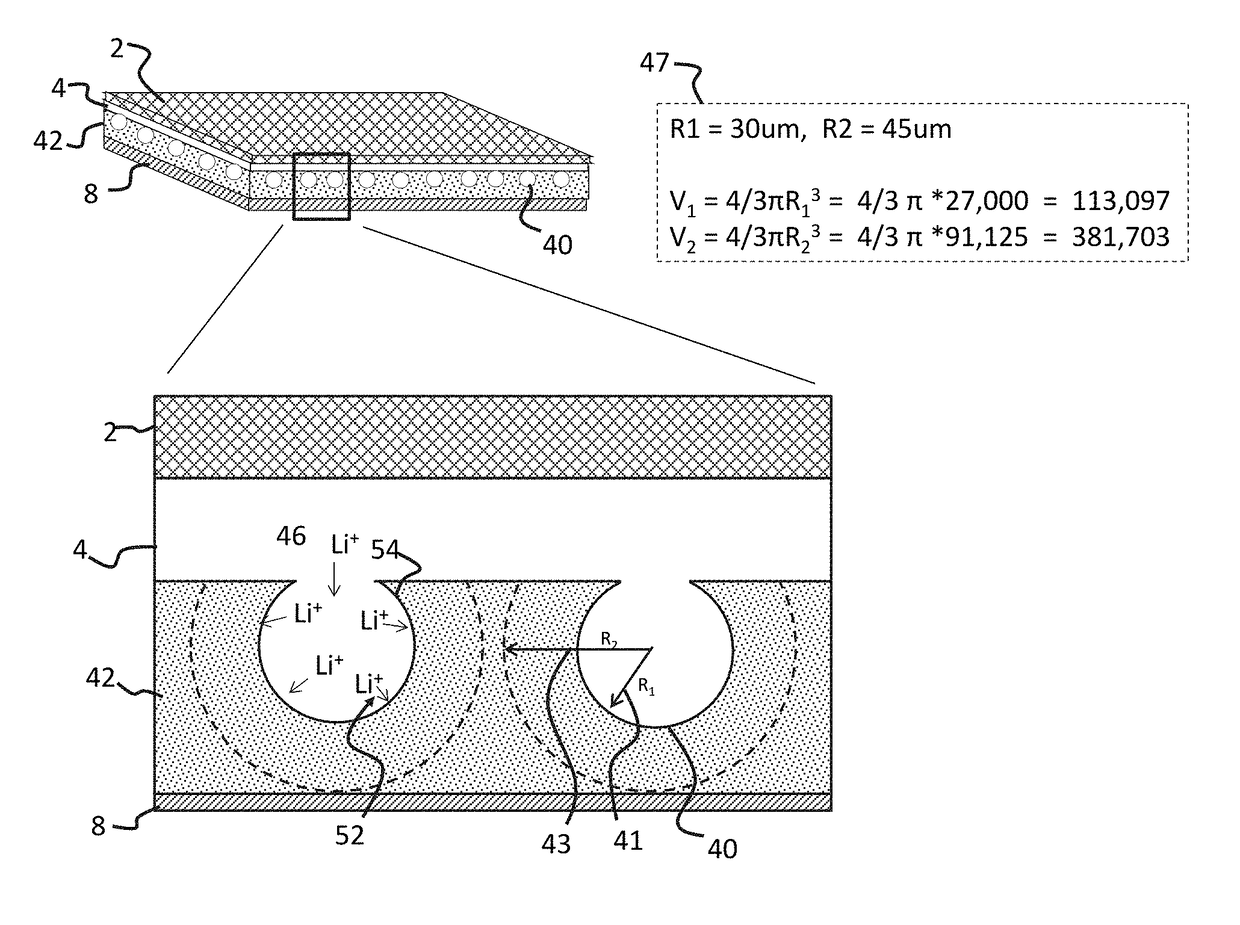

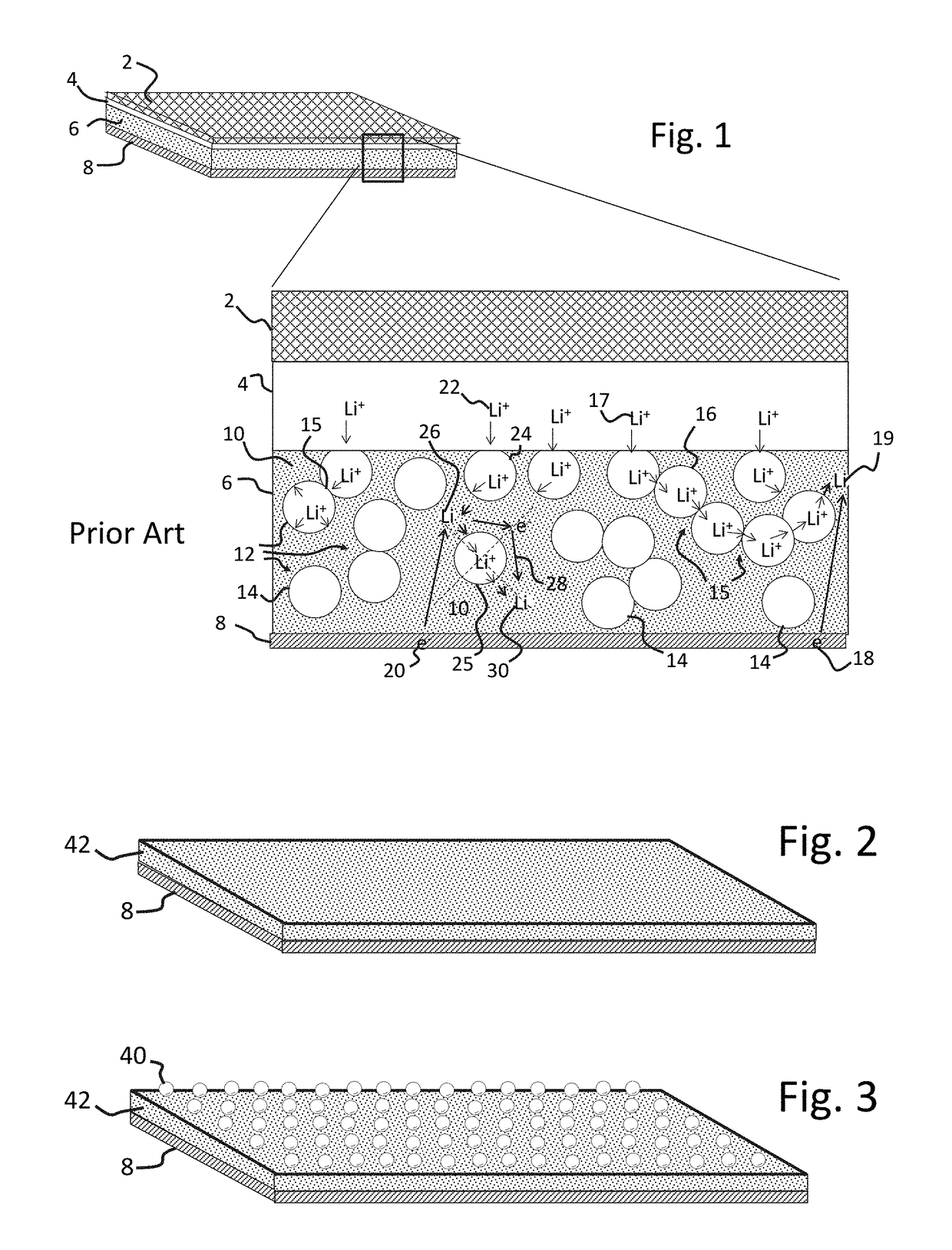

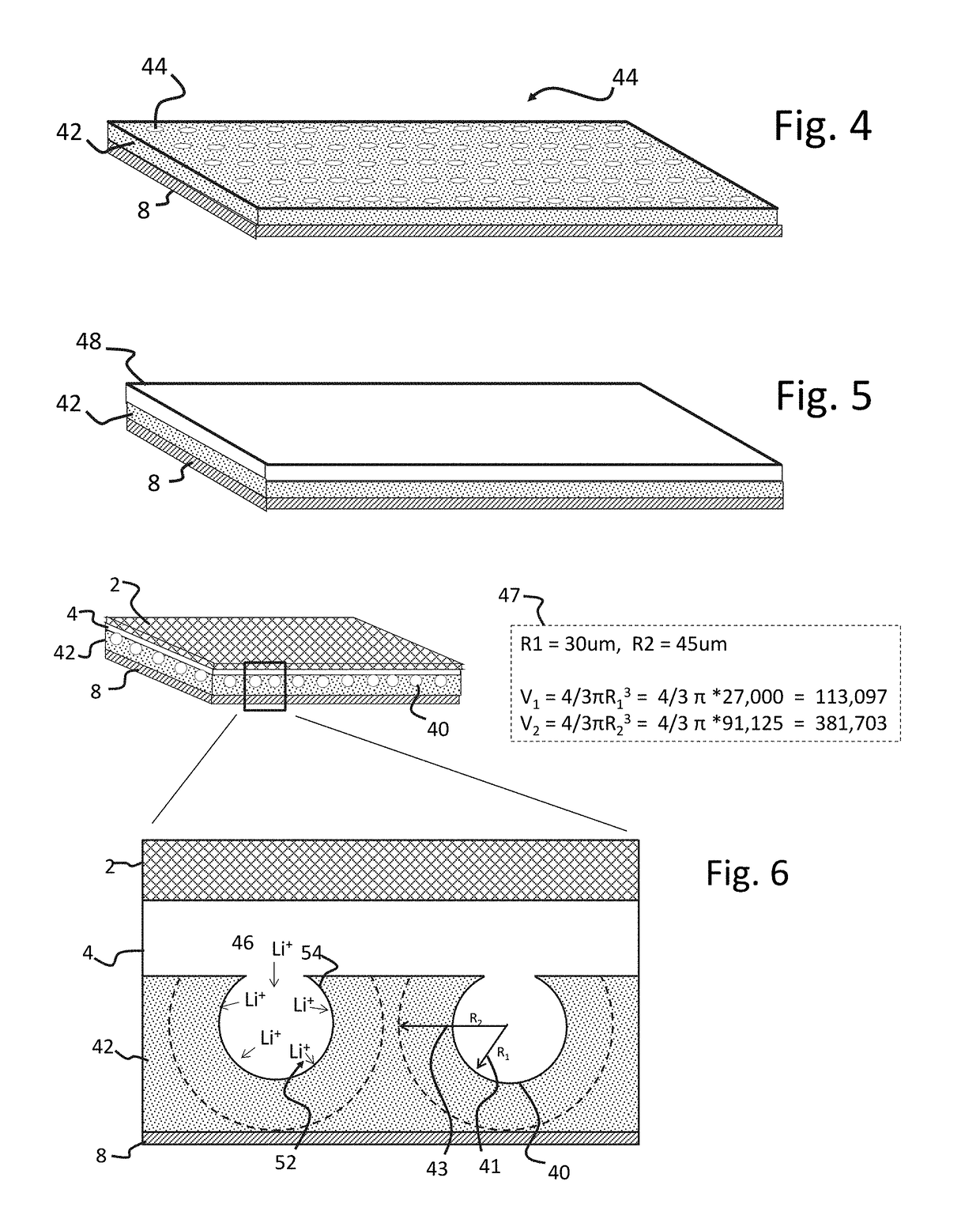

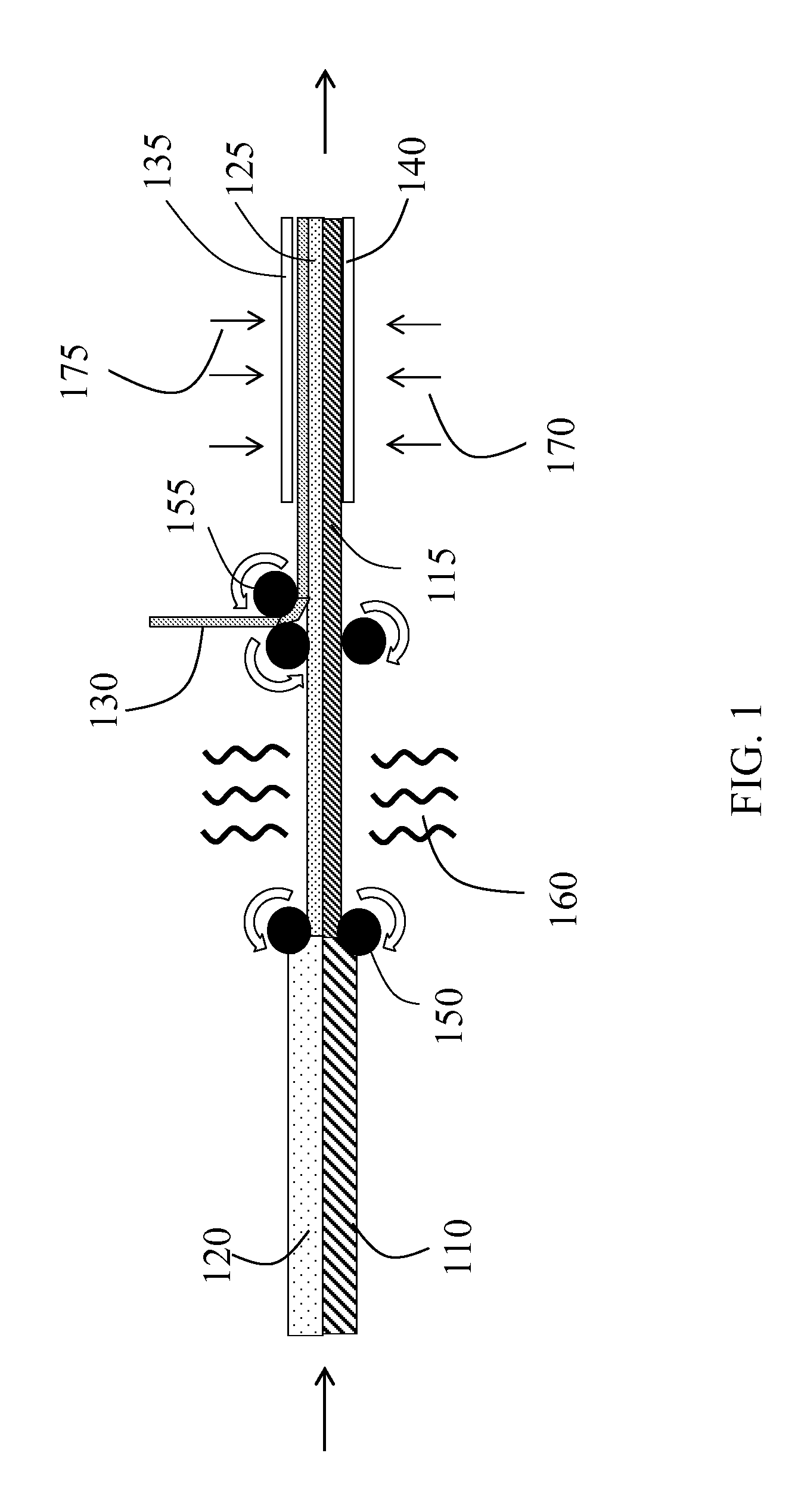

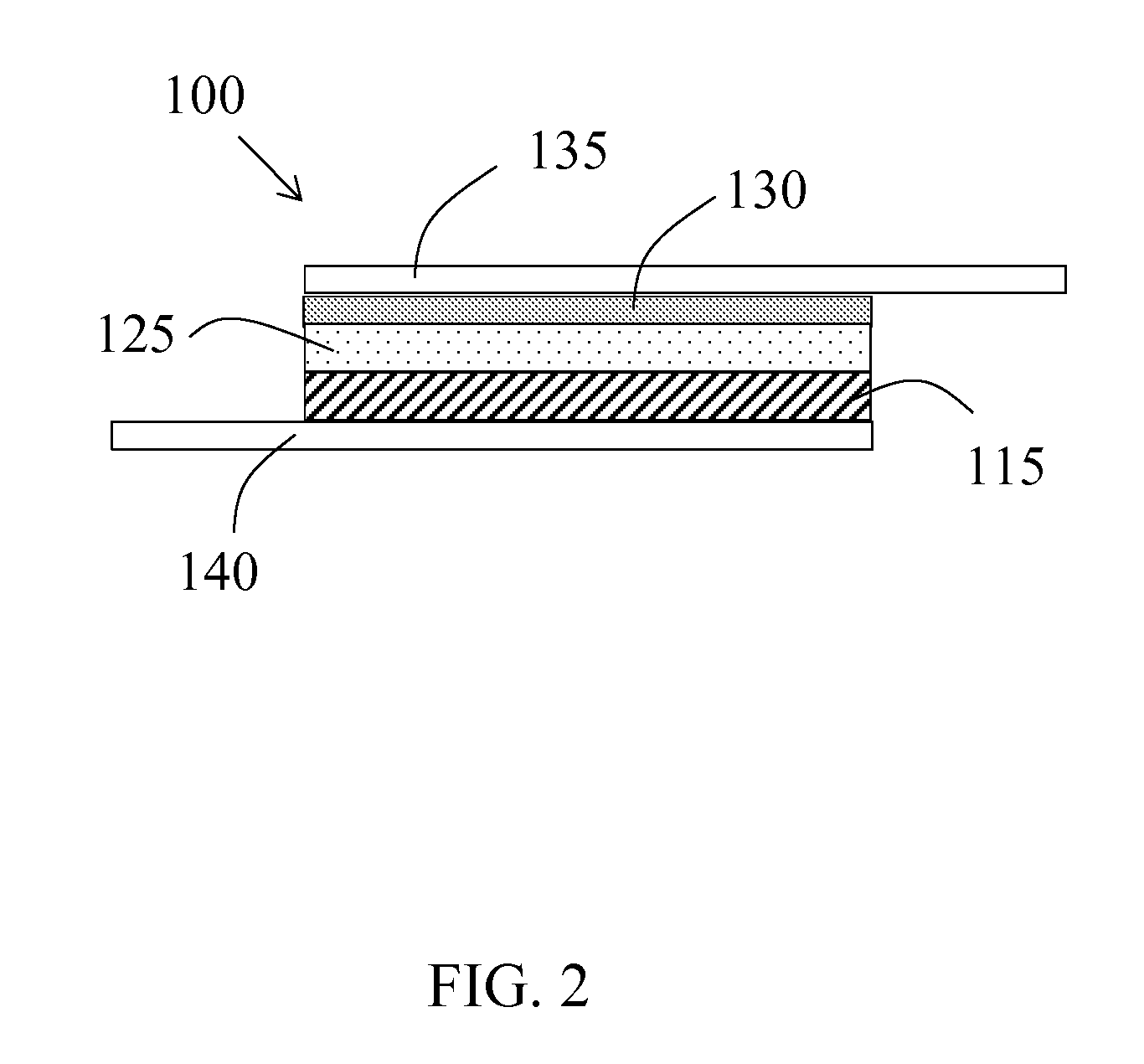

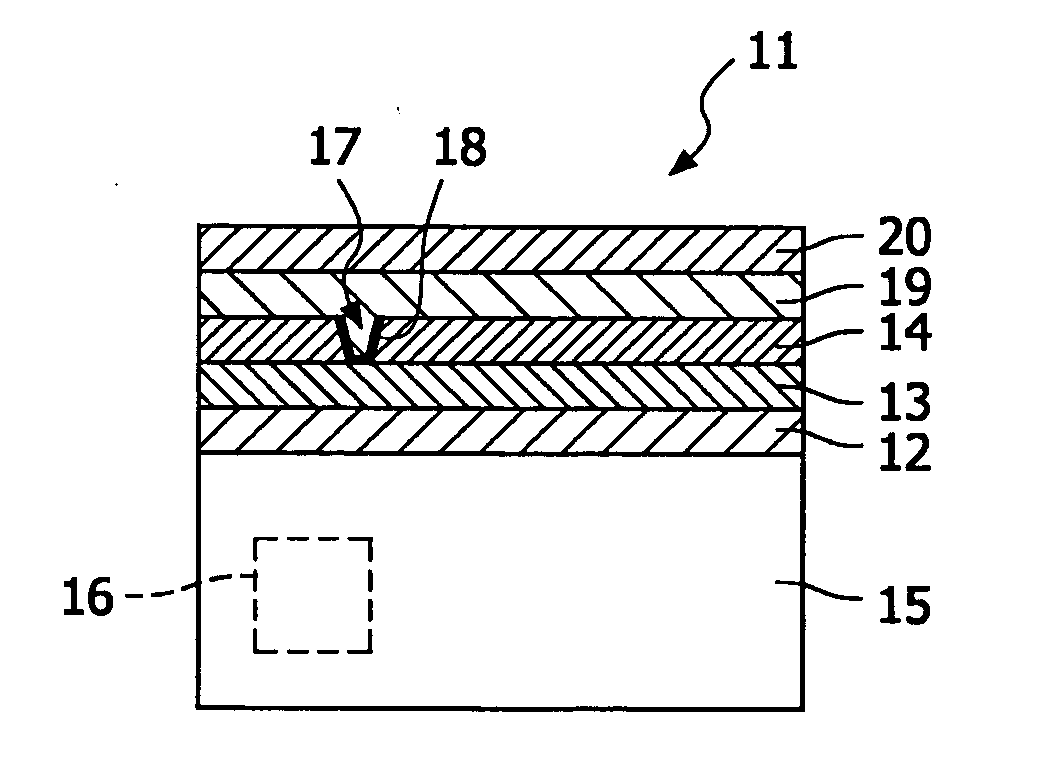

Solid-state, ion-conducting batteries with an ion-conducting, solid-state electrolyte. The solid-state electrolyte has at least one porous region (e.g., porous layer) and a dense region (e.g., dense layer). The batteries are, for example, lithium-ion, sodium-ion, or magnesium-ion conducting solid-state batteries. The ion-conducting, solid-state electrolyte is, for example, a lithium-garnet material.

Owner:UNIV OF MARYLAND

Low Cost Solid State Rechargeable Battery and Method of Manufacturing Same

InactiveUS20090092903A1Solid electrolytesElectrode thermal treatmentOptoelectronicsConductive materials

A solid state Li battery and an all ceramic Li-ion battery are disclosed. The all ceramic battery has a solid state battery cathode comprised of a mixture of an active cathode material, an electronically conductive material, and a solid ionically conductive material. The cathode mixture is sintered. The battery also has a solid state battery anode comprised of a mixture of an active anode material, an electronically conductive material, and a solid ionically conductive material. The anode mixture is sintered. The battery also has a solid state separator positioned between said solid state battery cathode and said solid state battery anode. In the solid state Li battery the all ceramic anode is replaced with an evaporated thin film Li metal anode.

Owner:JOHNSON IP HLDG LLC

Garnet materials for li secondary batteries and methods of making and using garnet materials

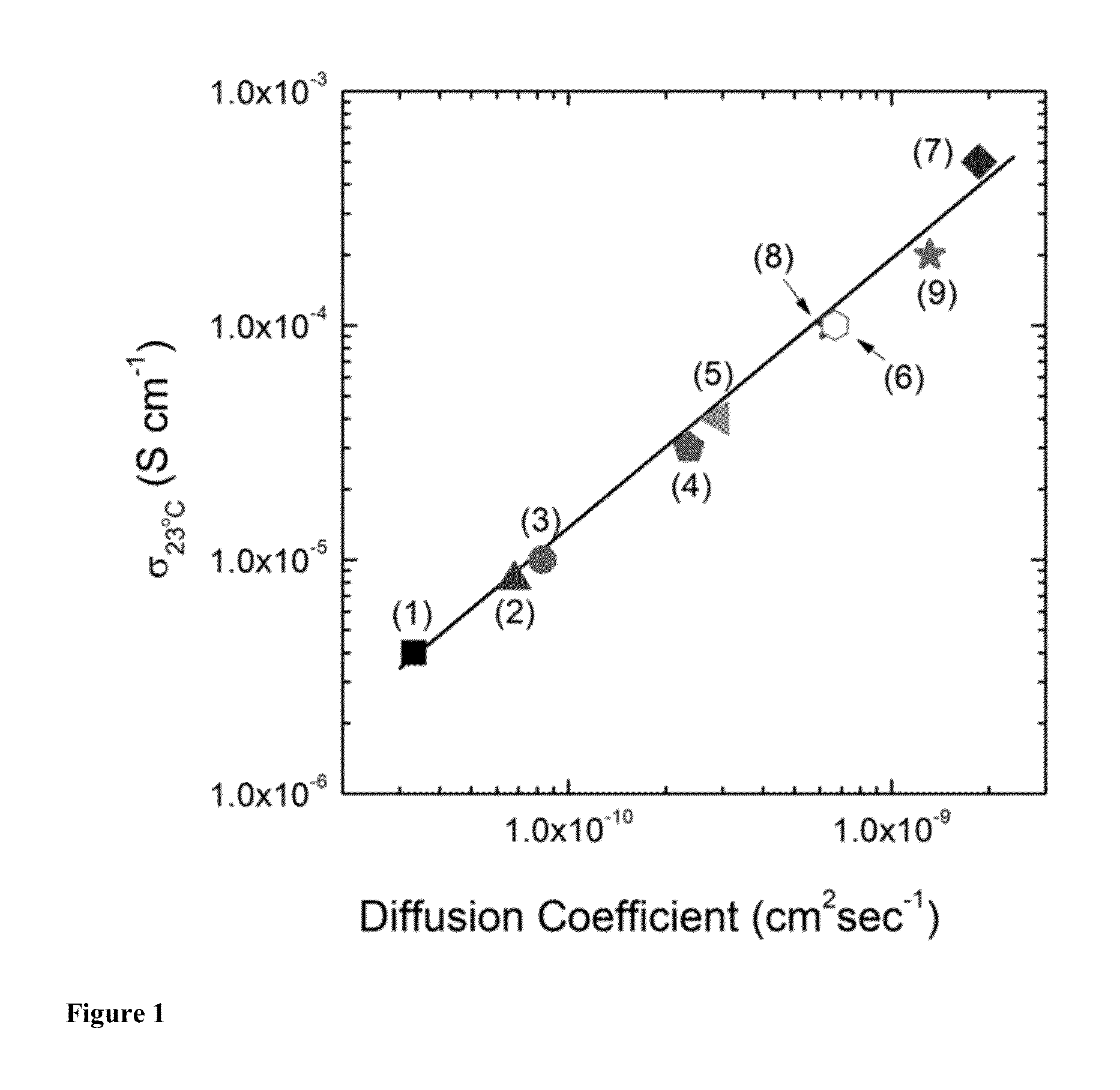

Set forth herein are garnet material compositions, e.g., lithium-stuffed garnets and lithium-stuffed garnets doped with alumina, which are suitable for use as electrolytes and catholytes in solid state battery applications. Also set forth herein are lithium-stuffed garnet thin films having fine grains therein. Disclosed herein are novel and inventive methods of making and using lithium-stuffed garnets as catholytes, electrolytes and / or anolytes for all solid state lithium rechargeable batteries. Also disclosed herein are novel electrochemical devices which incorporate these garnet catholytes, electrolytes and / or anolytes. Also set forth herein are methods for preparing novel structures, including dense thin (<50 um) free standing membranes of an ionically conducting material for use as a catholyte, electrolyte, and, or, anolyte, in an electrochemical device, a battery component (positive or negative electrode materials), or a complete solid state electrochemical energy storage device. Also, the methods set forth herein disclose novel sintering techniques, e.g., for heating and / or field assisted (FAST) sintering, for solid state energy storage devices and the components thereof.

Owner:QUANTUMSCAPE BATTERY INC

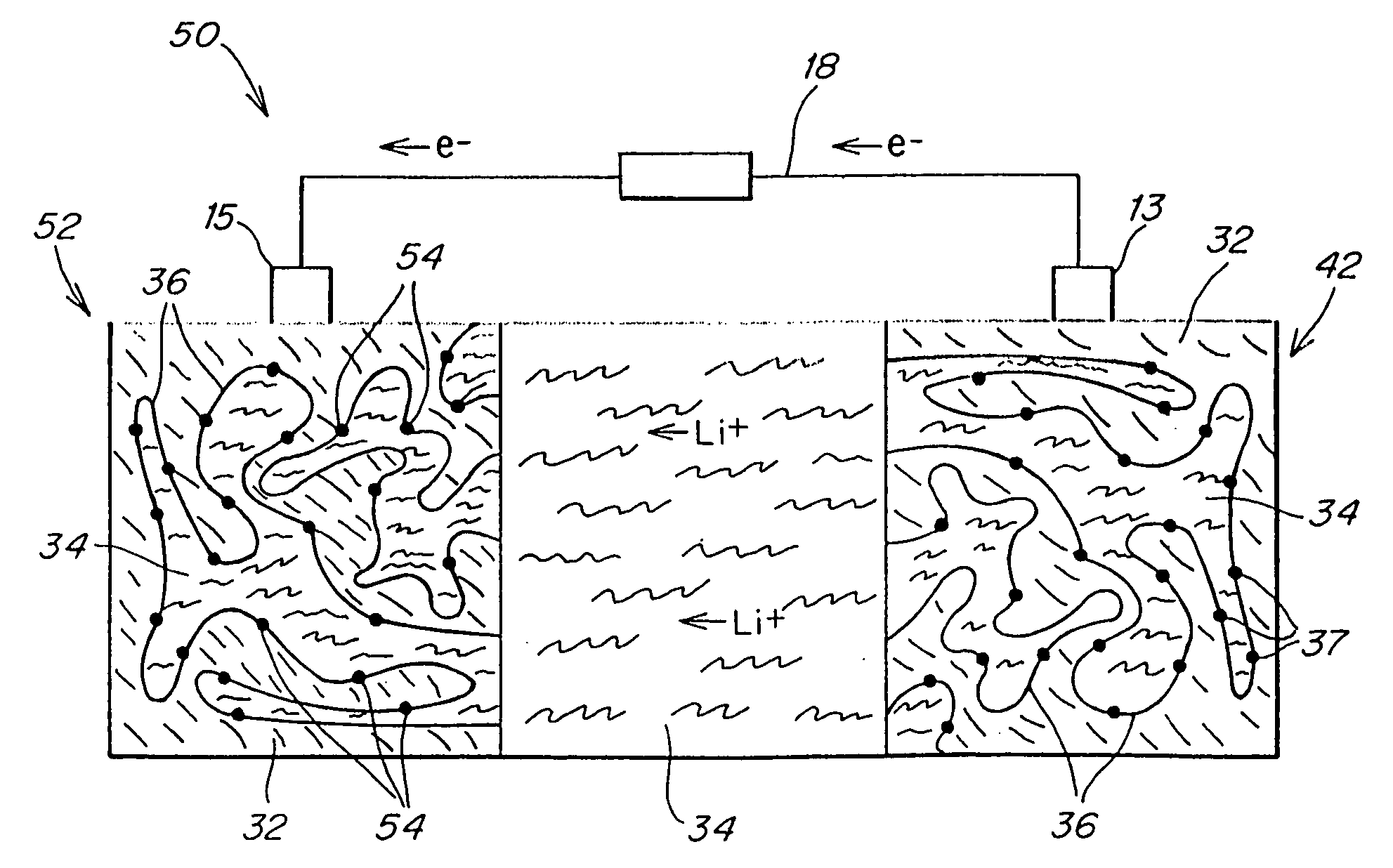

Polymer electrolyte, intercalation compounds and electrodes for batteries

Solid battery components are provided. A block copolymeric electrolyte is non-crosslinked and non-glassy through the entire range of typical battery service temperatures, that is, through the entire range of at least from about 0° C. to about 70° C. The chains of which the copolymer is made each include at least one ionically-conductive block and at least one second block immiscible with the ionically-conductive block. The chains form an amorphous association and are arranged in an ordered nanostructure including a continuous matrix of amorphous ionically-conductive domains and amorphous second domains that are immiscible with the ionically-conductive domains. A compound is provided that has a formula of LixMyNzO2. M and N are each metal atoms or a main group elements, and x, y and z are each numbers from about 0 to about 1. y and z are chosen such that a formal charge on the MyNz portion of the compound is (4-x). In certain embodiments, these compounds are used in the cathodes of rechargeable batteries. The present invention also includes methods of predicting the potential utility of metal dichalgogenide compounds for use in lithium intercalation compounds. It also provides methods for processing lithium intercalation oxides with the structure and compositional homogeneity necessary to realize the increased formation energies of said compounds. An article is made of a dimensionally-stable, interpenetrating microstructure of a first phase including a first component and a second phase, immiscible with the first phase, including a second component. The first and second phases define interphase boundaries between them, and at least one particle is positioned between a first phase and a second phase at an interphase boundary. When the first and second phases are electronically-conductive and ionically-conductive polymers, respectively, and the particles are ion host particles, the arrangement is an electrode of a battery.

Owner:MASSACHUSETTS INST OF TECH

Garnet materials for li secondary batteries and methods of making and using garnet materials

Set forth herein are garnet material compositions, e.g., lithium-stuffed garnets and lithium-stuffed garnets doped with alumina, which are suitable for use as electrolytes and catholytes in solid state battery applications. Also set forth herein are lithium-stuffed garnet thin films having fine grains therein. Disclosed herein are novel and inventive methods of making and using lithium-stuffed garnets as catholytes, electrolytes and / or anolytes for all solid state lithium rechargeable batteries. Also disclosed herein are novel electrochemical devices which incorporate these garnet catholytes, electrolytes and / or anolytes. Also set forth herein are methods for preparing novel structures, including dense thin (<50 um) free standing membranes of an ionically conducting material for use as a catholyte, electrolyte, and, or, anolyte, in an electrochemical device, a battery component (positive or negative electrode materials), or a complete solid state electrochemical energy storage device. Also, the methods set forth herein disclose novel sintering techniques, e.g., for heating and / or field assisted (FAST) sintering, for solid state energy storage devices and the components thereof.

Owner:QUANTUMSCAPE BATTERY INC

Garnet materials for li secondary batteries and methods of making and using garnet materials

Disclosed herein are garnet material compositions, e.g., lithium-stuffed garnets and lithium-stuffed garnets doped with alumina, which are suitable for use as electrolytes and catholytes in solid state battery applications. Also disclosed herein are lithium-stuffed garnet thin films having fine grains therein. Also disclosed herein are methods of making and using lithium-stuffed garnets as catholytes, electrolytes and / or anolytes for all solid state lithium rechargeable batteries. Also disclosed herein are electrochemical devices which incorporate these garnet catholytes, electrolytes and / or anolytes. Also disclosed herein are methods for preparing dense thin (<50 um) free standing membranes of an ionically conducting material for use as a catholyte, electrolyte, and, or, anolyte, in an electrochemical device, a battery component (positive or negative electrode materials), or a complete solid state electrochemical energy storage device. Also disclosed herein are sintering techniques, e.g., for heating and / or field assisted (FAST) sintering, for solid state energy storage devices and the components thereof.

Owner:QUANTUMSCAPE CORP

Impregnated sintered solid state composite electrode, solid state battery, and methods of preparation

InactiveUS20150056520A1Electrode thermal treatmentSolid electrolyte cellsComposite cathodeComposite electrode

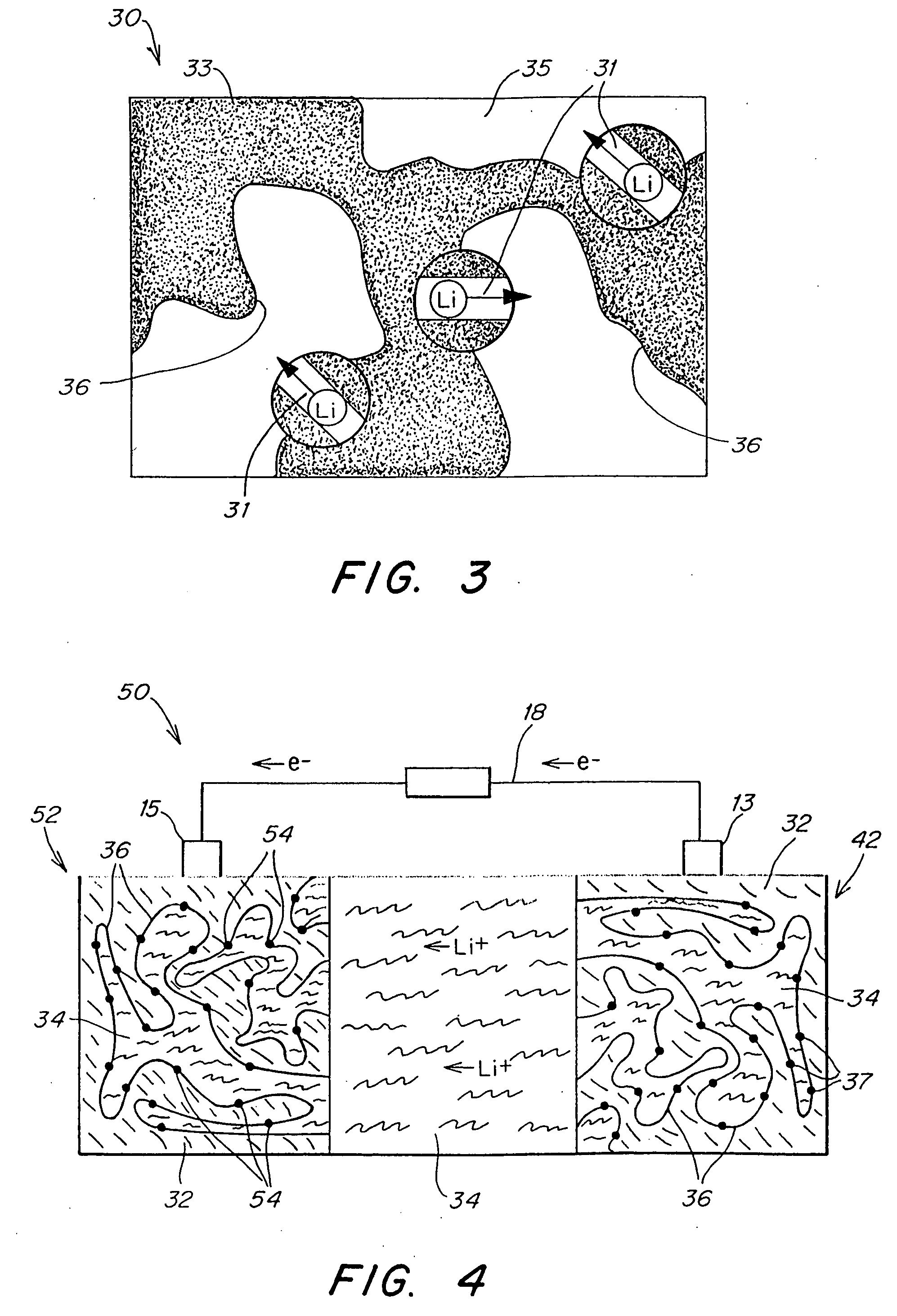

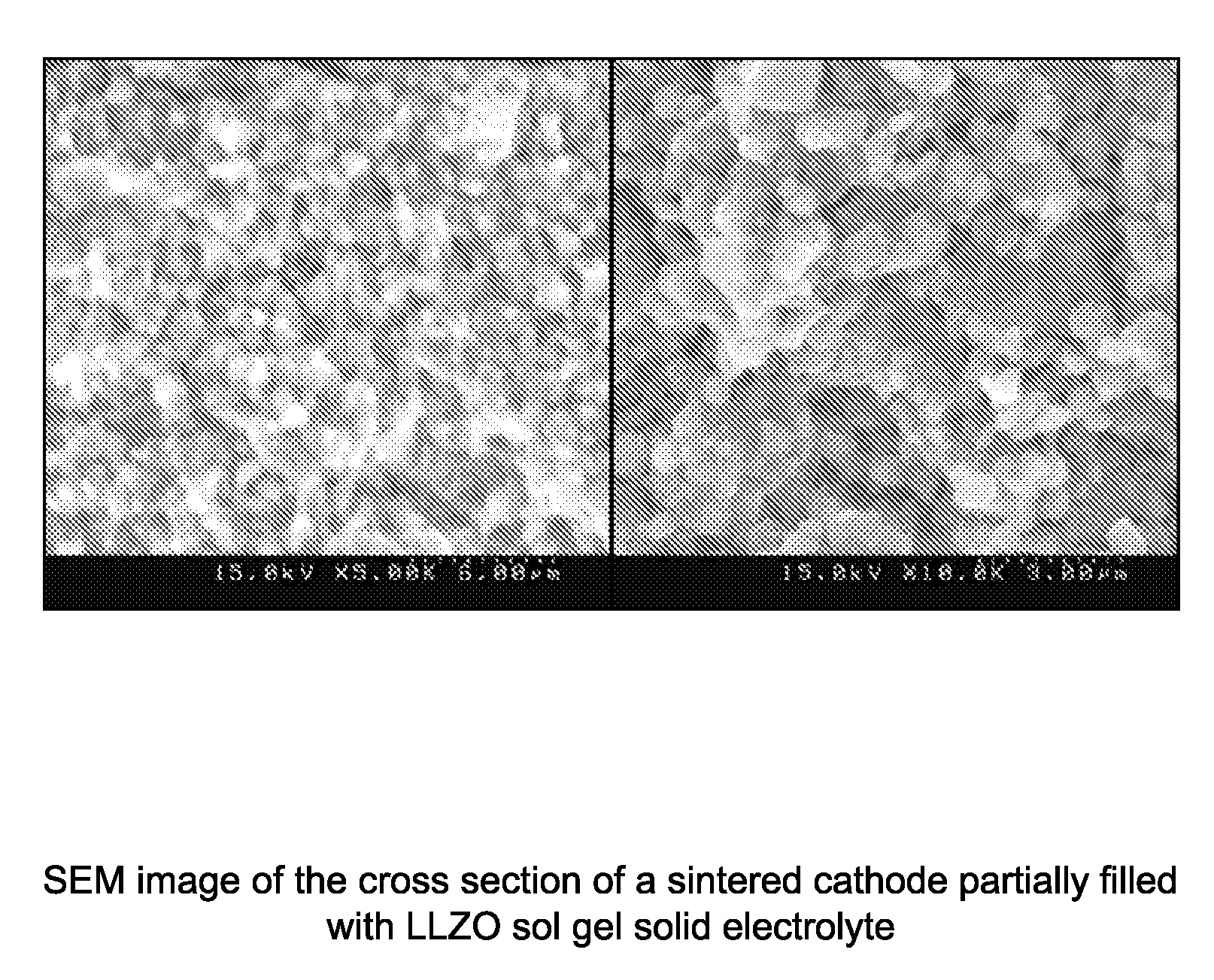

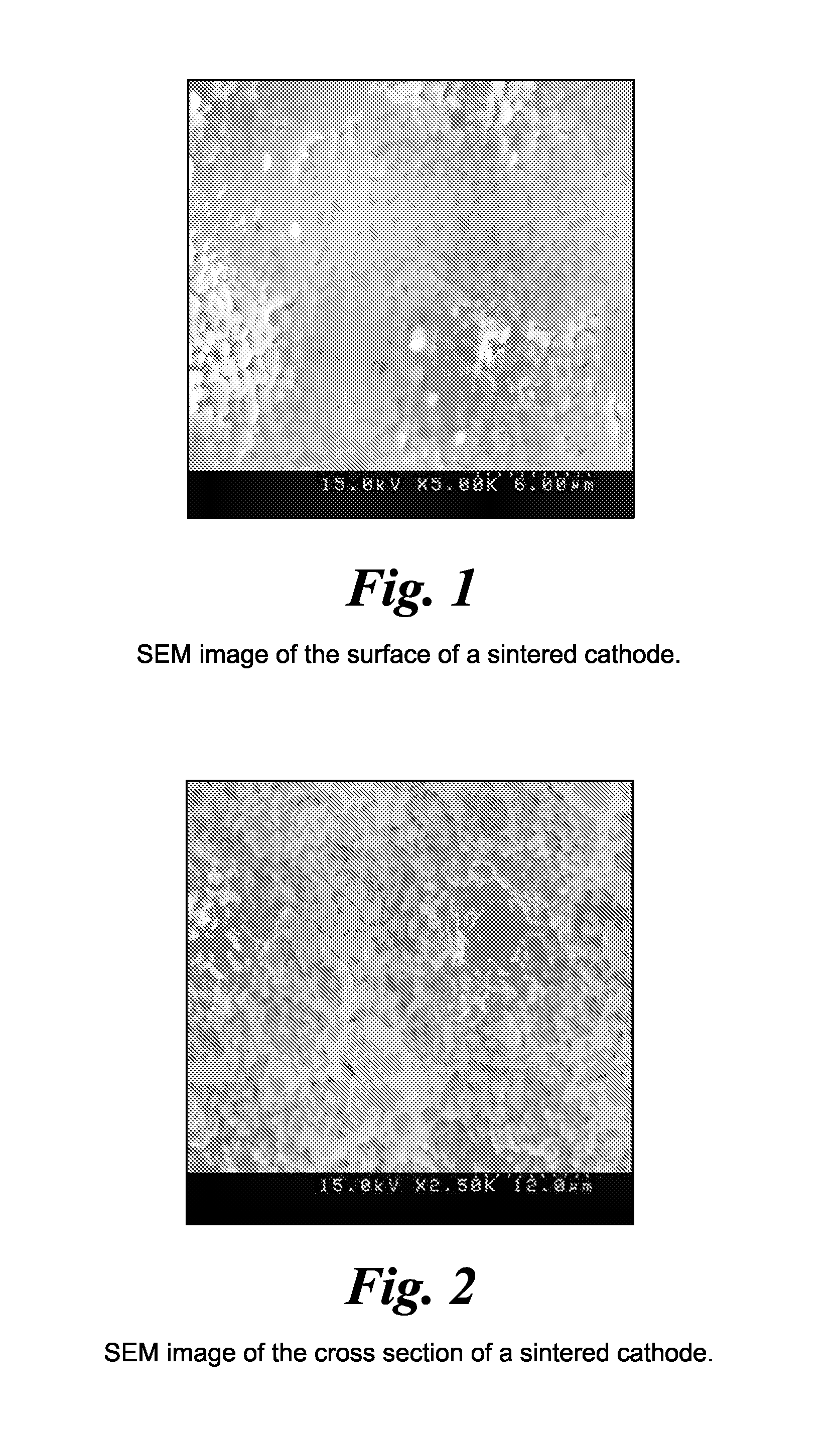

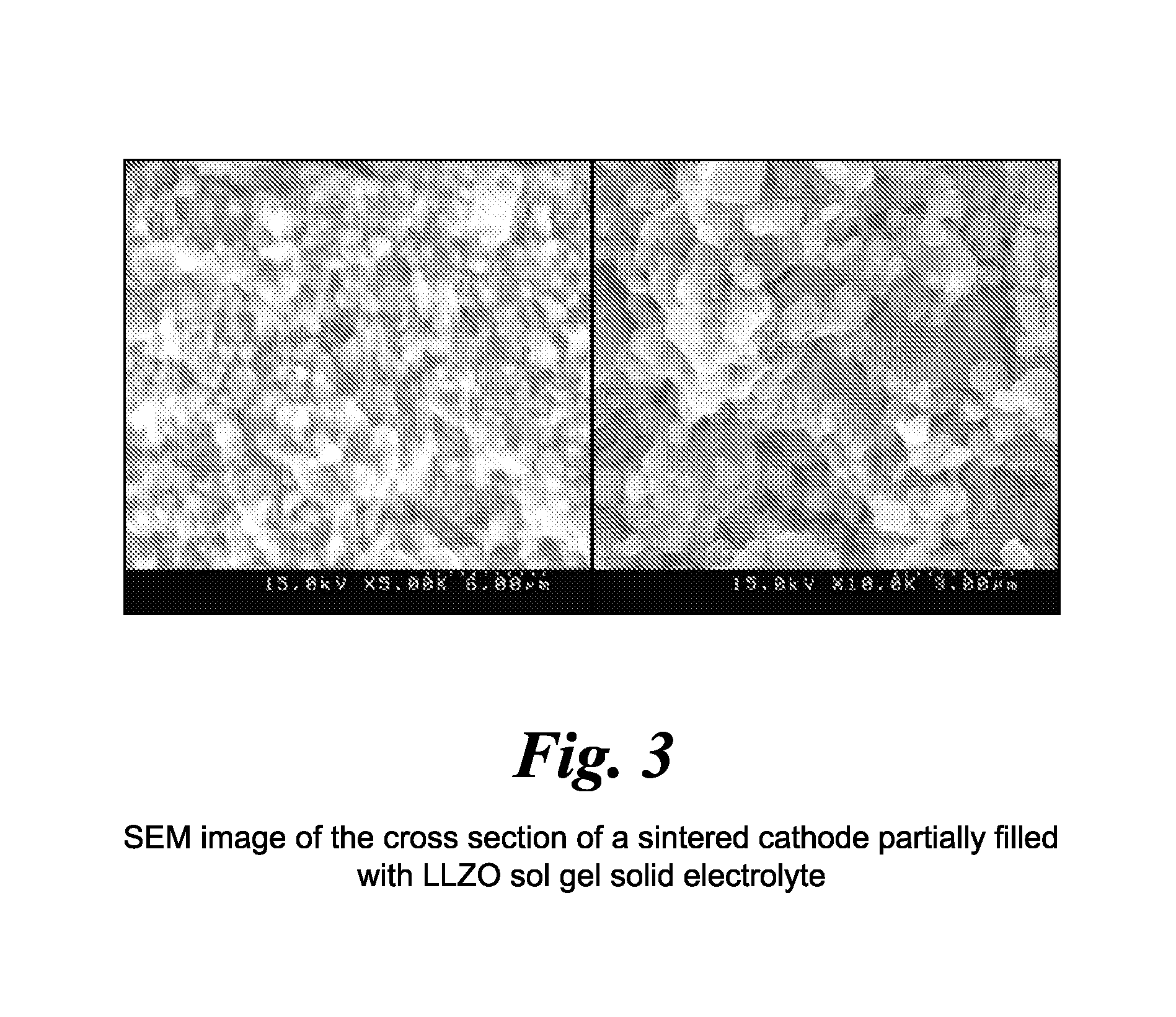

An impregnated solid state composite cathode is provided. The cathode contains a sintered porous active material, in which pores of the porous material are impregnated with an inorganic ionically conductive amorphous solid electrolyte. A method for producing the impregnated solid state composite cathode involves forming a pellet containing an active intercalation cathode material; sintering the pellet to form a sintered porous cathode pellet; impregnating pores of the sintered porous cathode pellet with a liquid precursor of an inorganic amorphous ionically conductive solid electrolyte; and curing the impregnated pellet to yield the composite cathode.

Owner:JOHNSON IP HLDG LLC

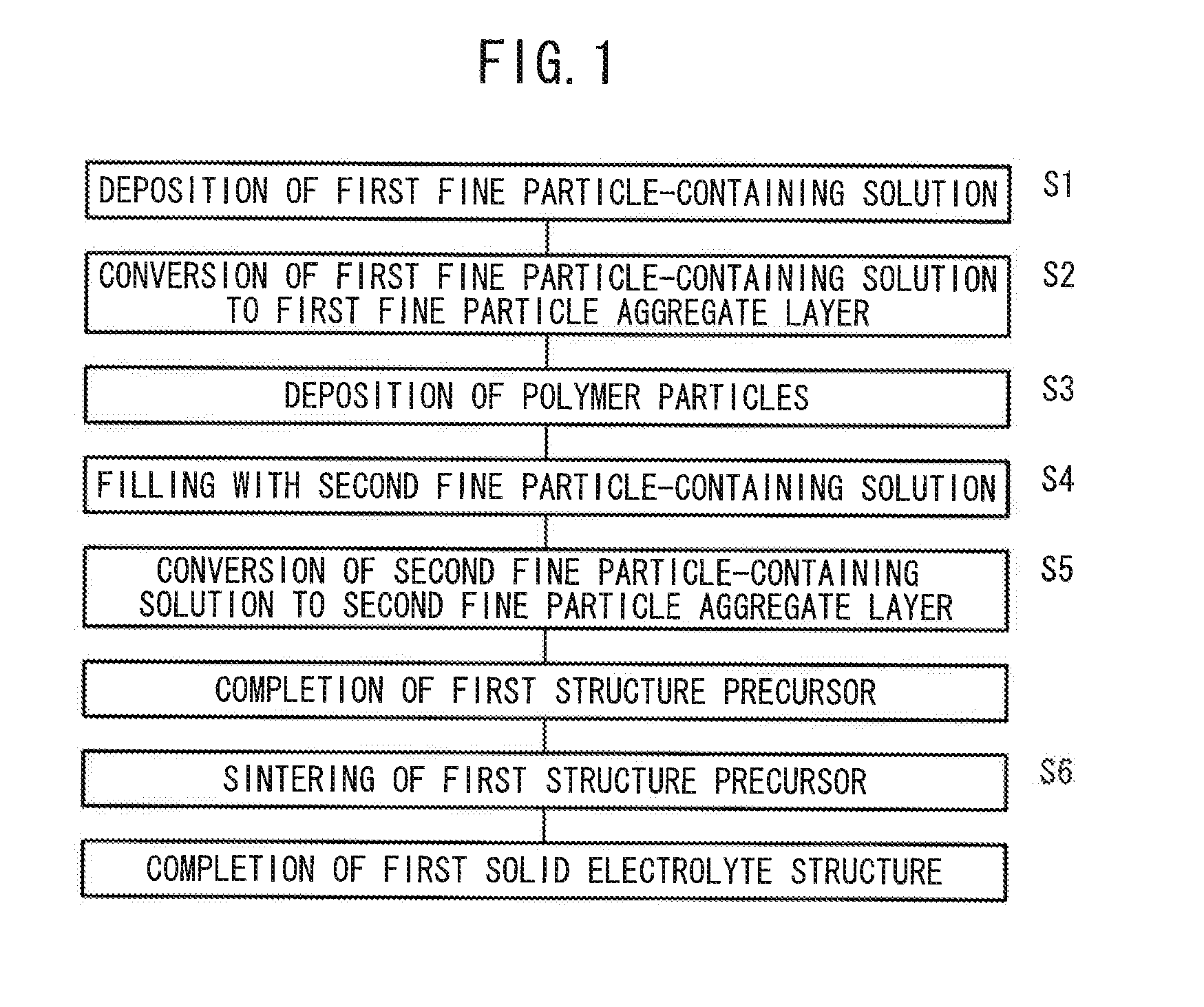

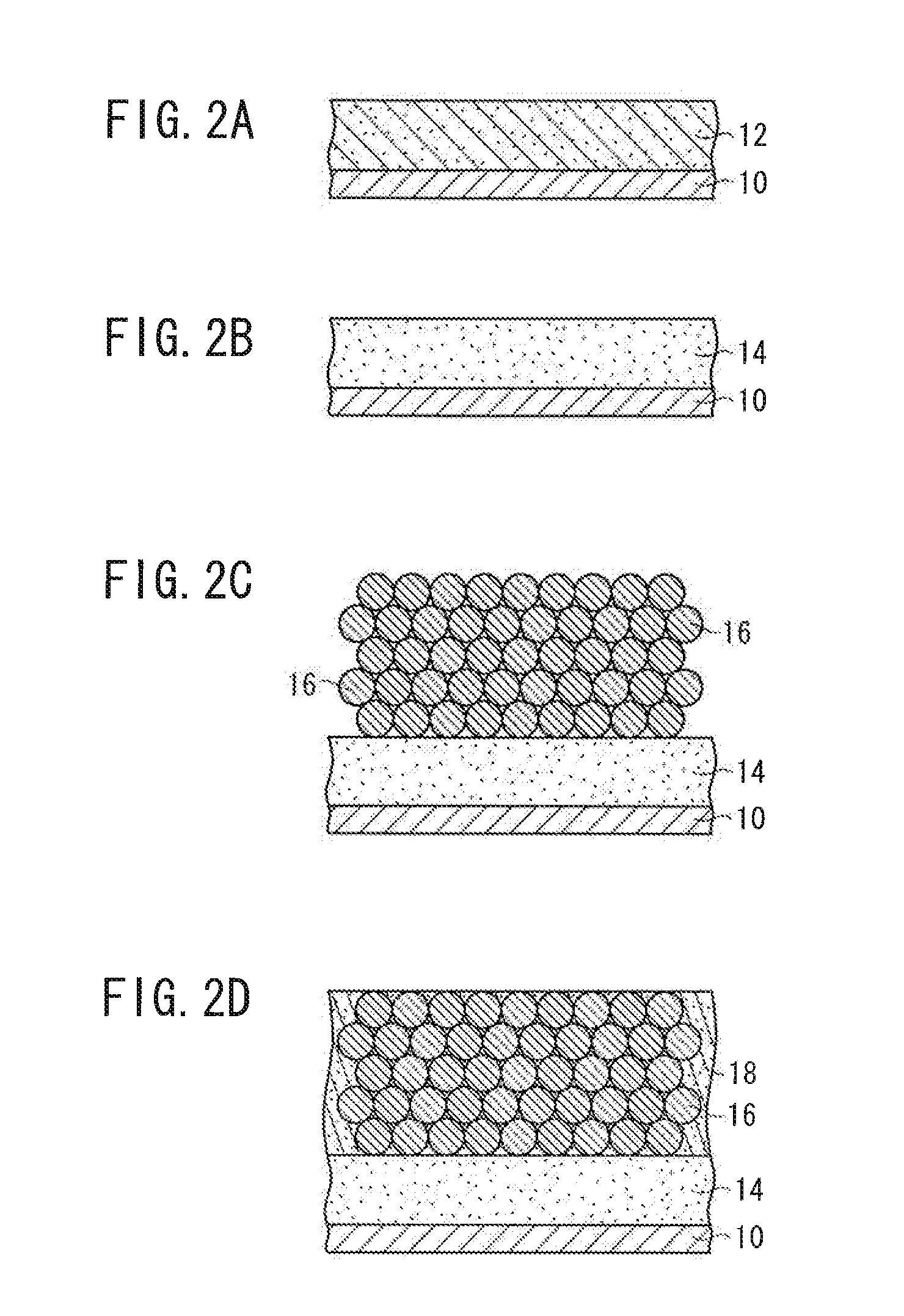

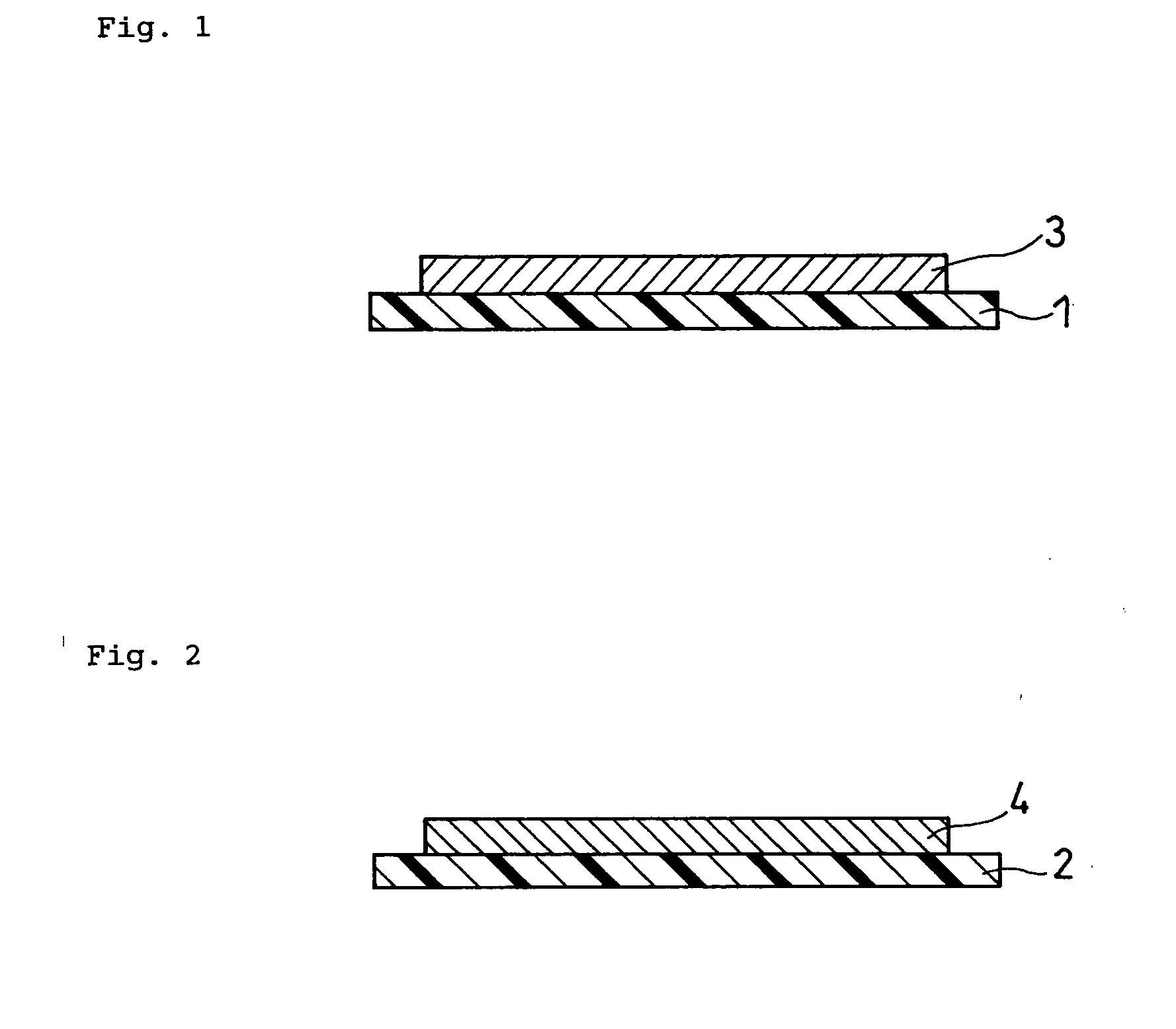

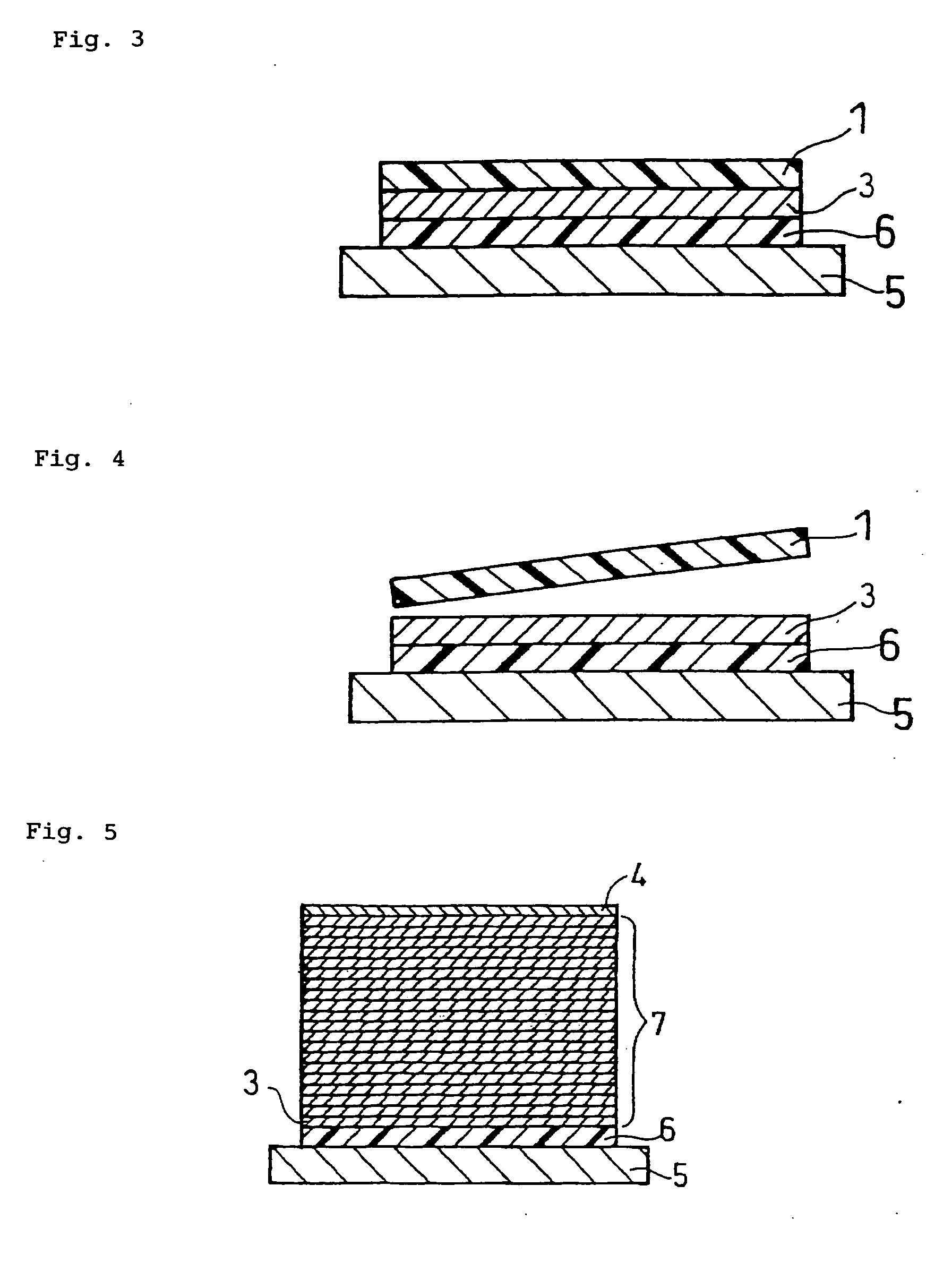

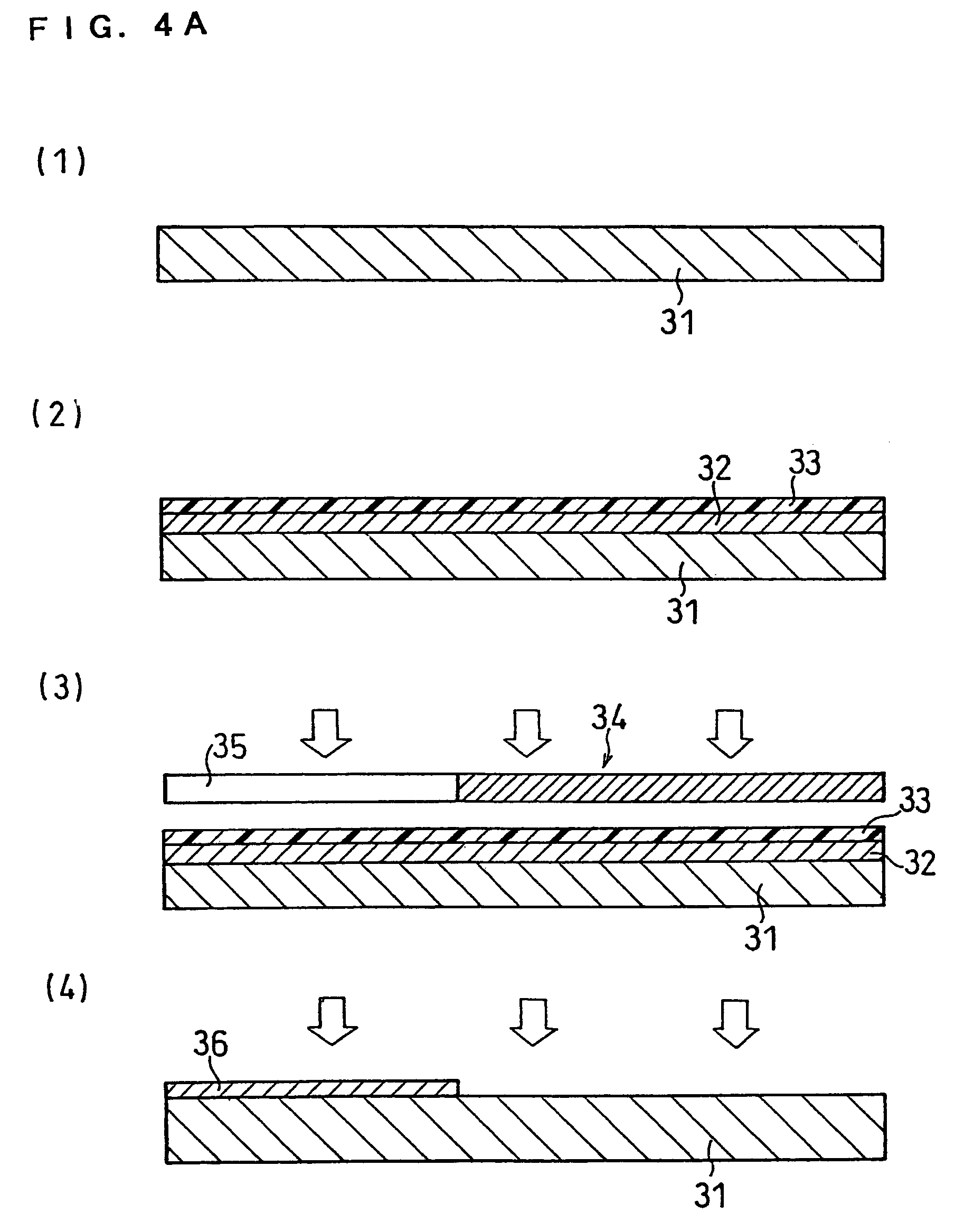

Method for producing solid electrolyte structure, method for producing all-solid-state cell, solid electrolyte structure, and all-solid-state cell

InactiveUS20090226790A1Excellent connection interfaceSimple interfaceElectrode thermal treatmentFinal product manufactureAll solid stateHeat treated

A first fine particle-containing solution is deposited on an appropriate substrate, and dried to form a first fine particle aggregate layer. Polymer particles are deposited on the first fine particle aggregate layer, and are supplied with a second fine particle-containing solution such that the polymer particles are immersed in the second fine particle-containing solution. The second fine particle-containing solution is dried to form a second fine particle aggregate layer containing a large number of the polymer particles embedded. A first structure precursor is completed at this stage. Then, the first structure precursor is separated from the substrate, and thermally treated. Thus, the production of a first solid electrolyte structure, which has a porous solid electrolyte portion and a dense solid electrolyte portion integrated, is completed.

Owner:TOKYO METROPOLITAN UNIVERSITY +1

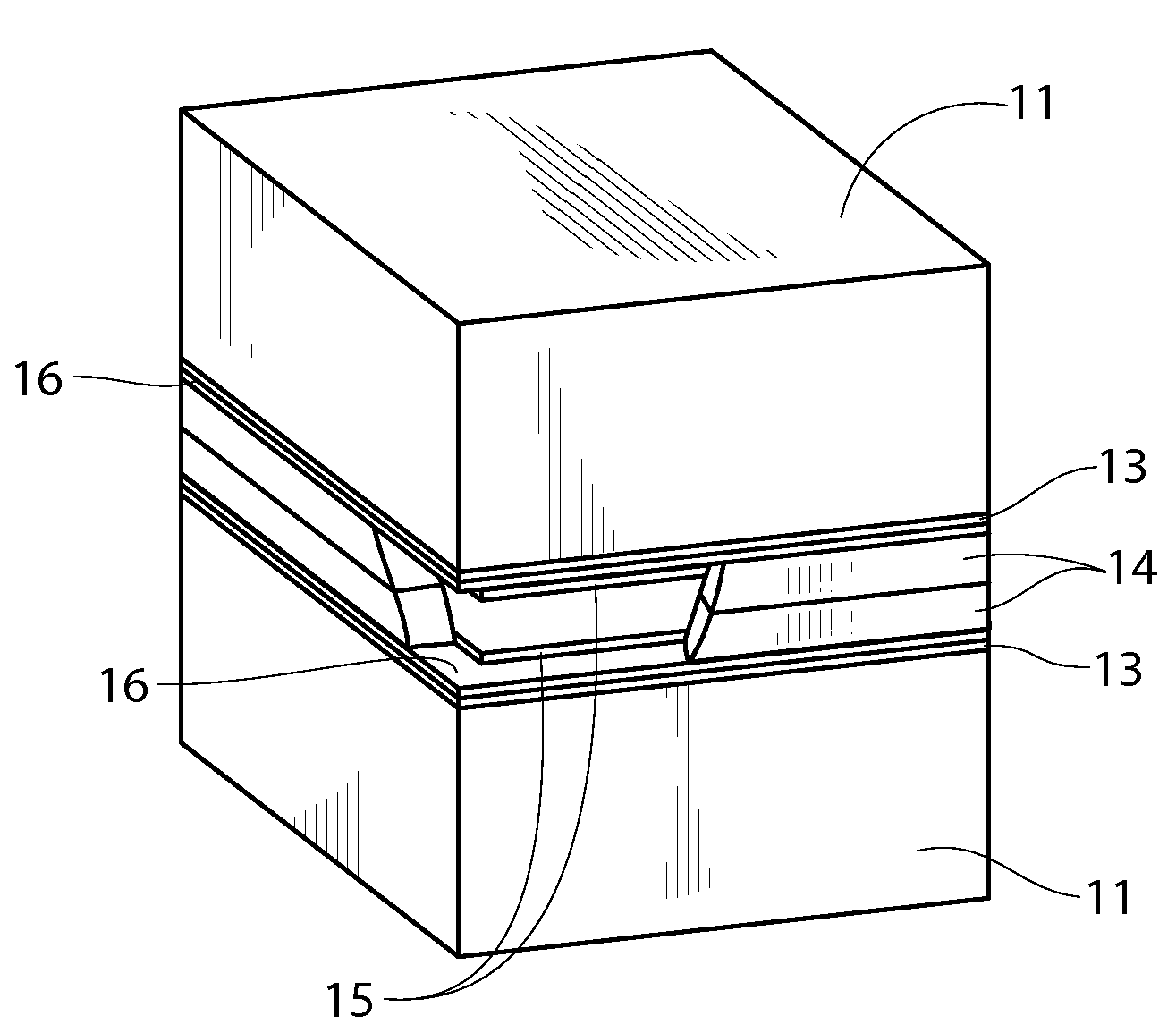

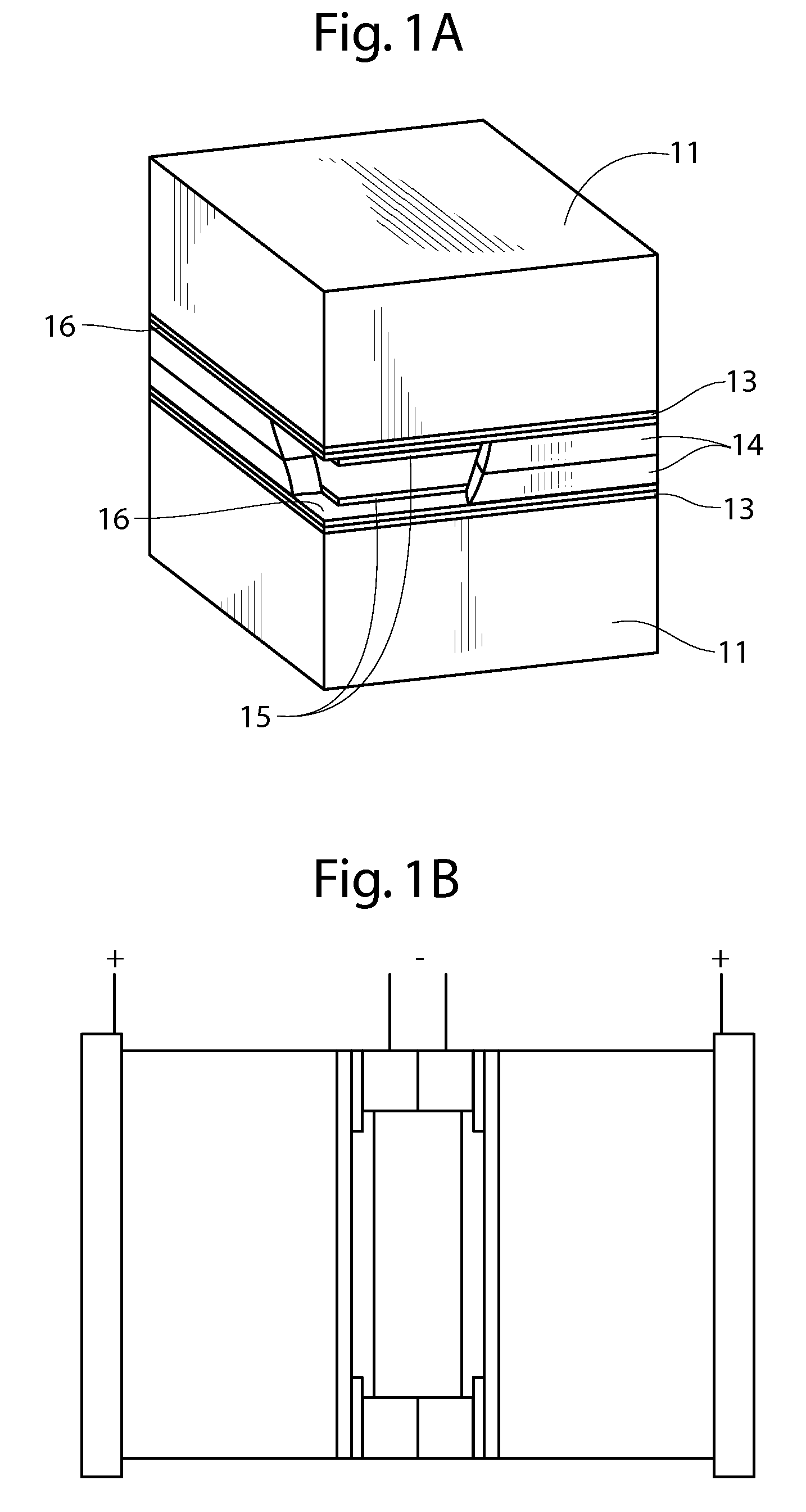

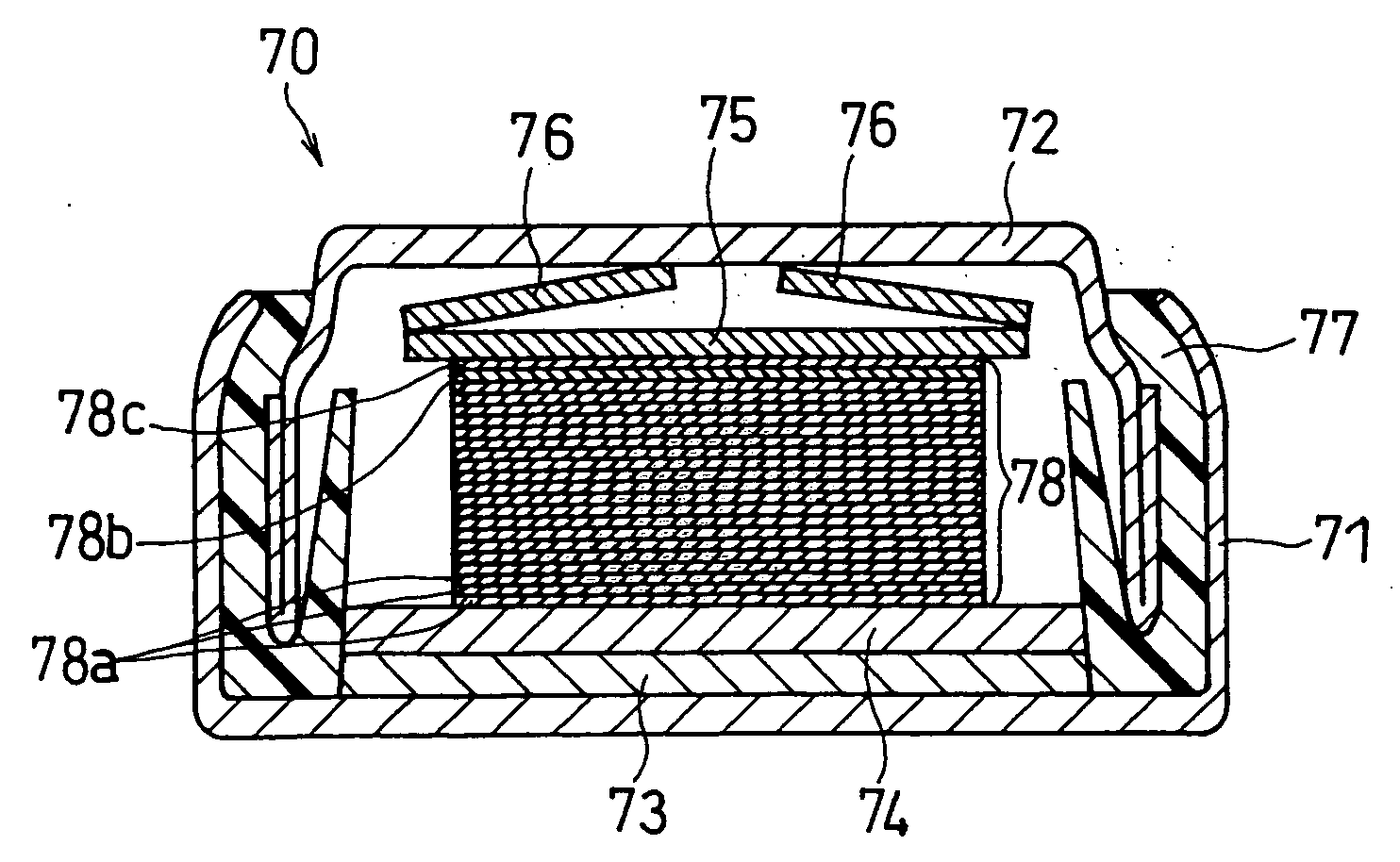

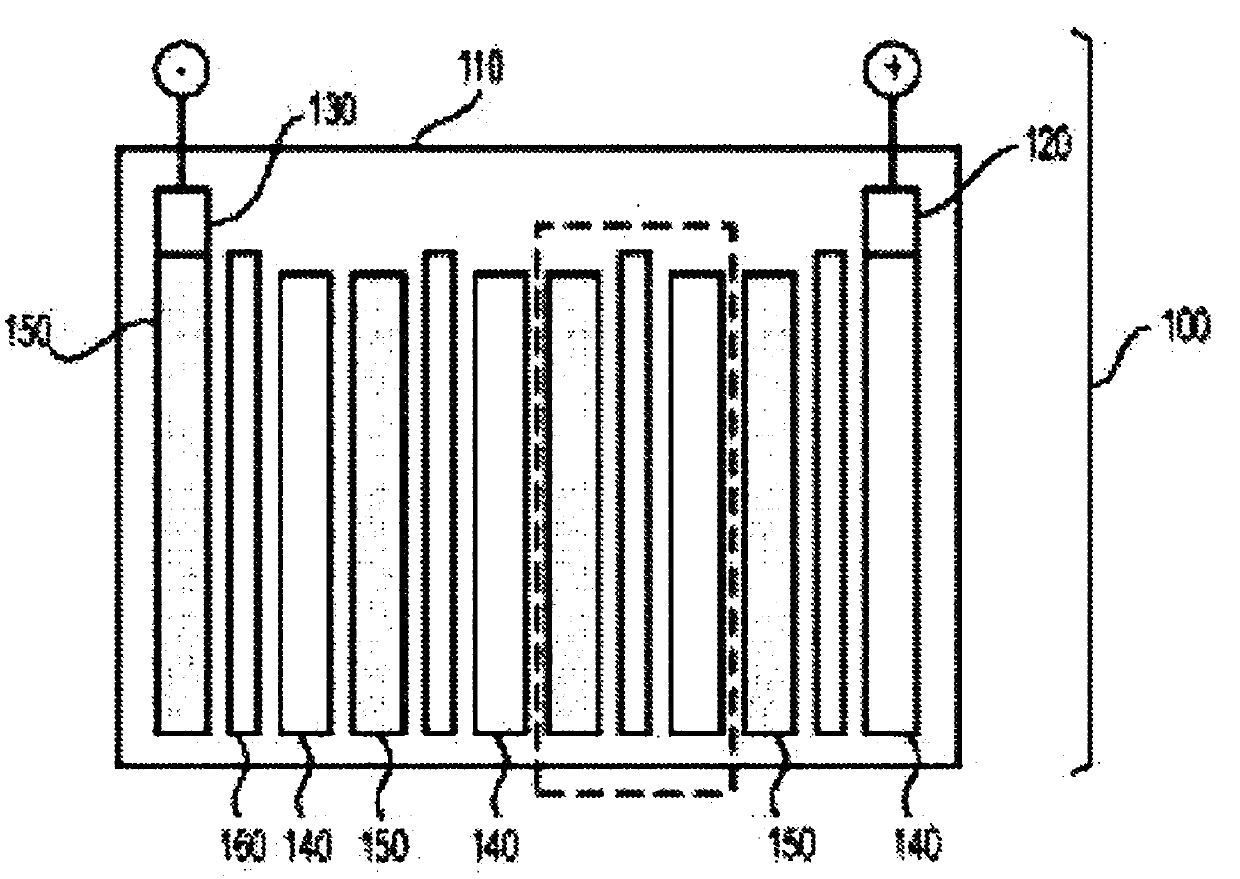

Multi layer ceramic battery

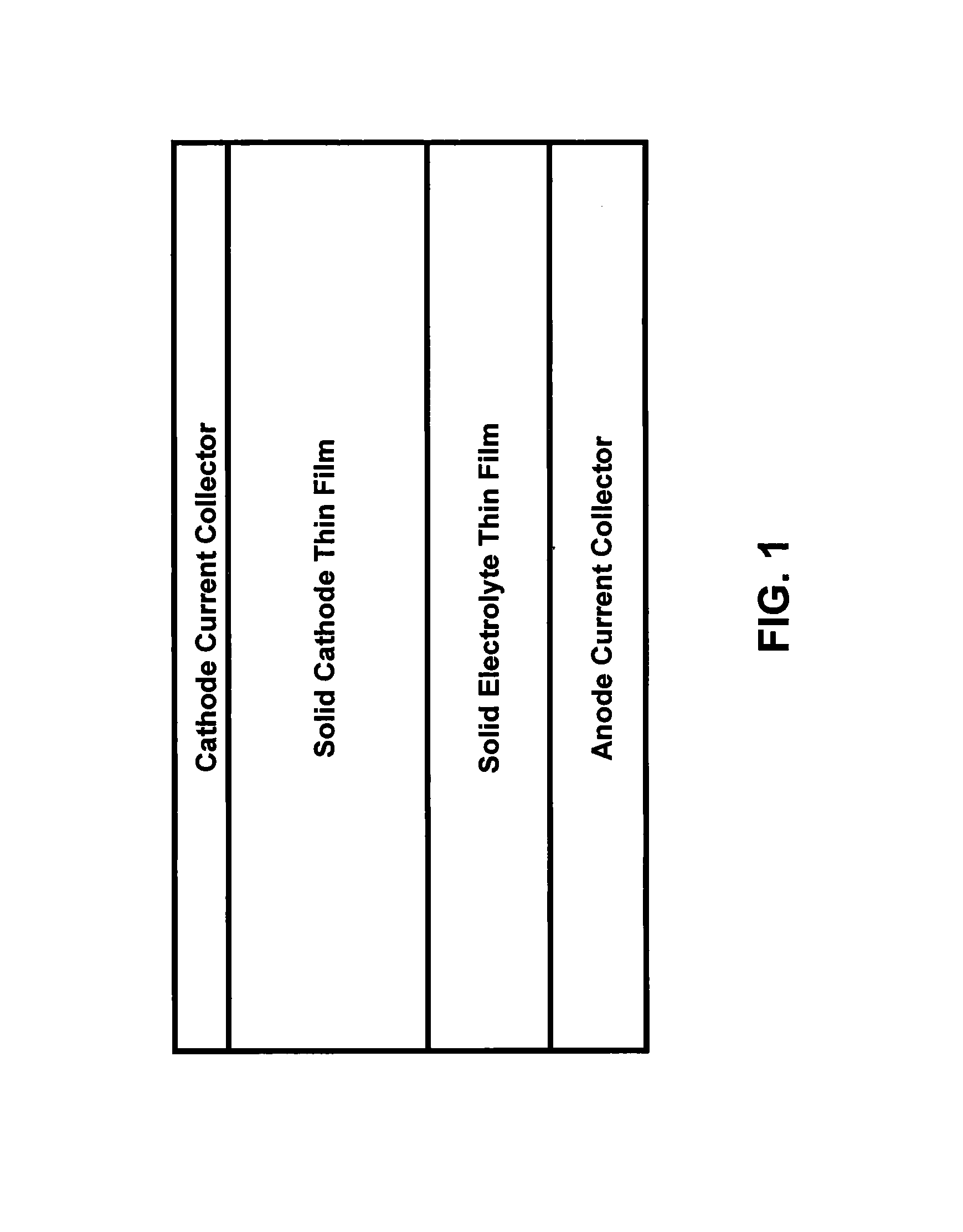

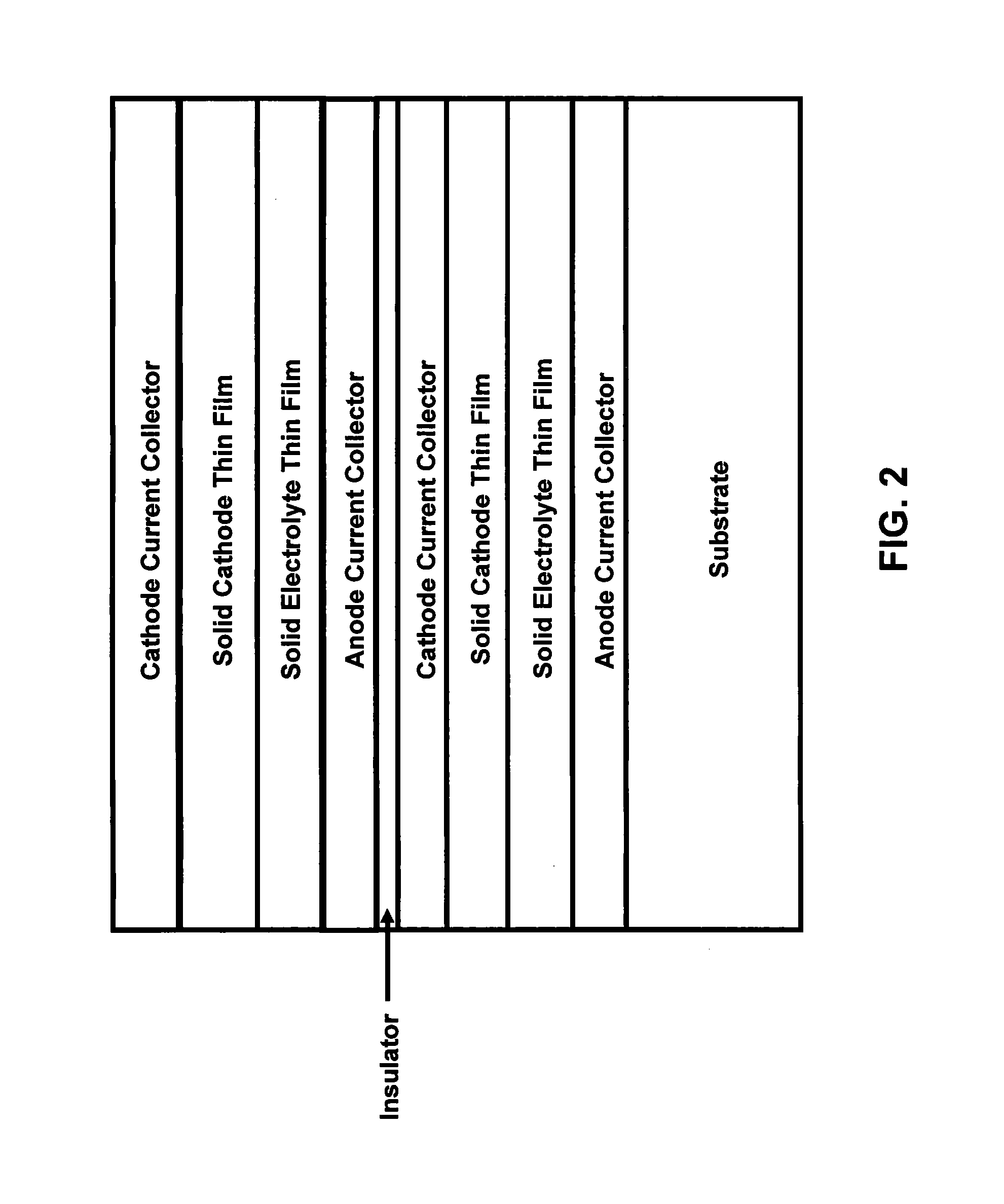

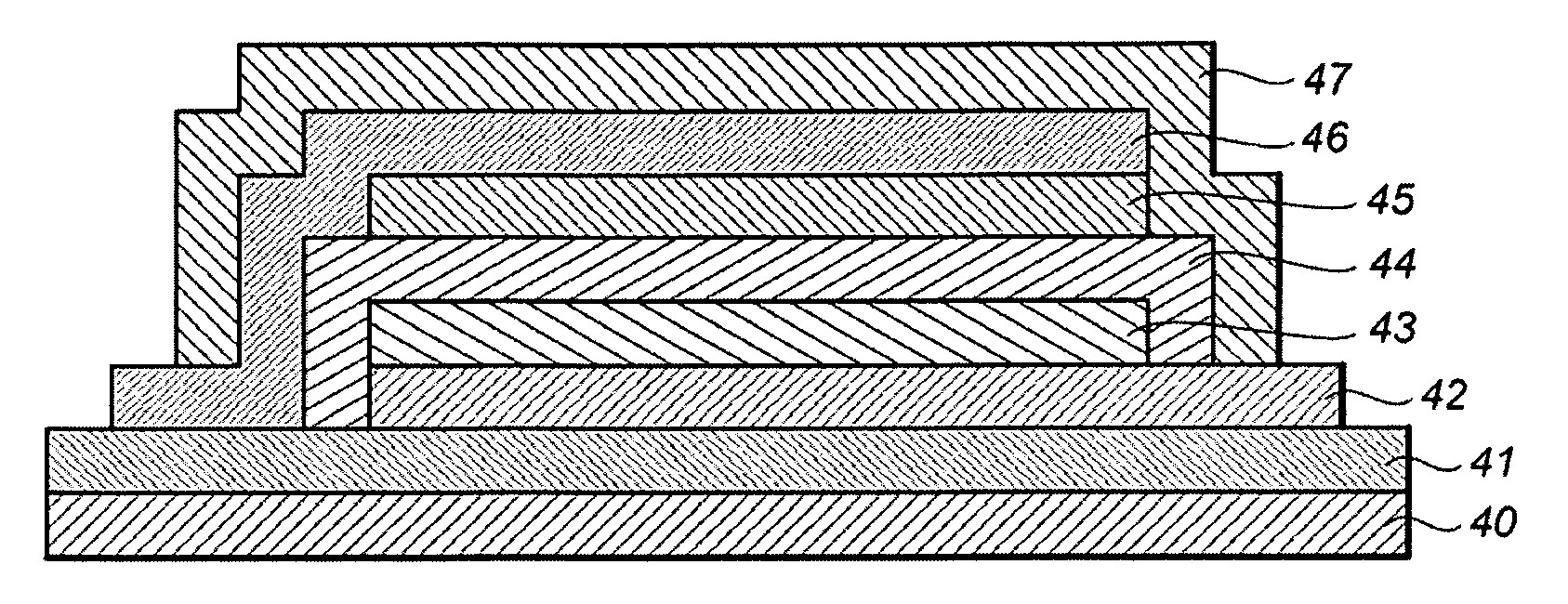

ActiveUS8304115B1High energyIncrease powerNon-aqueous electrolyte accumulatorsCell electrodesSolid state electrolyteMetallurgy

A practical solid-state battery composed primarily of ceramic or glass materials and containing no liquid, gel or polymeric electrolytes. The invention utilizes solid-state electrolyte materials with solid-state anode and cathode materials along with construction concepts utilized in the multi layered ceramic capacitor (MLCC) industry to result in a compact primary or secondary battery.

Owner:POLYMER INNOVATIONS

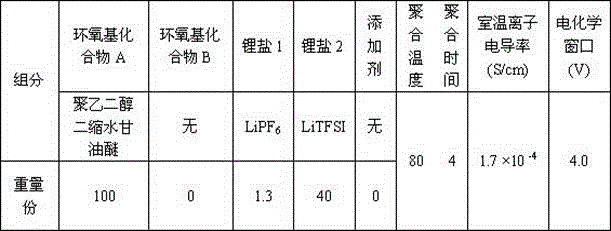

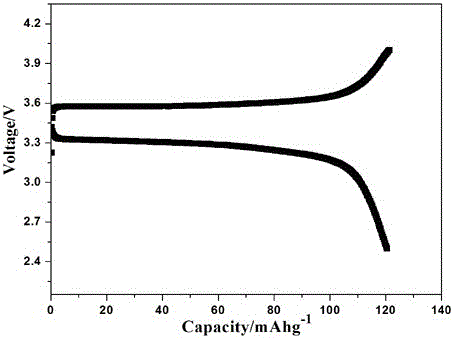

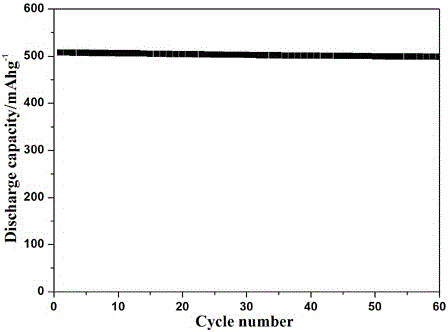

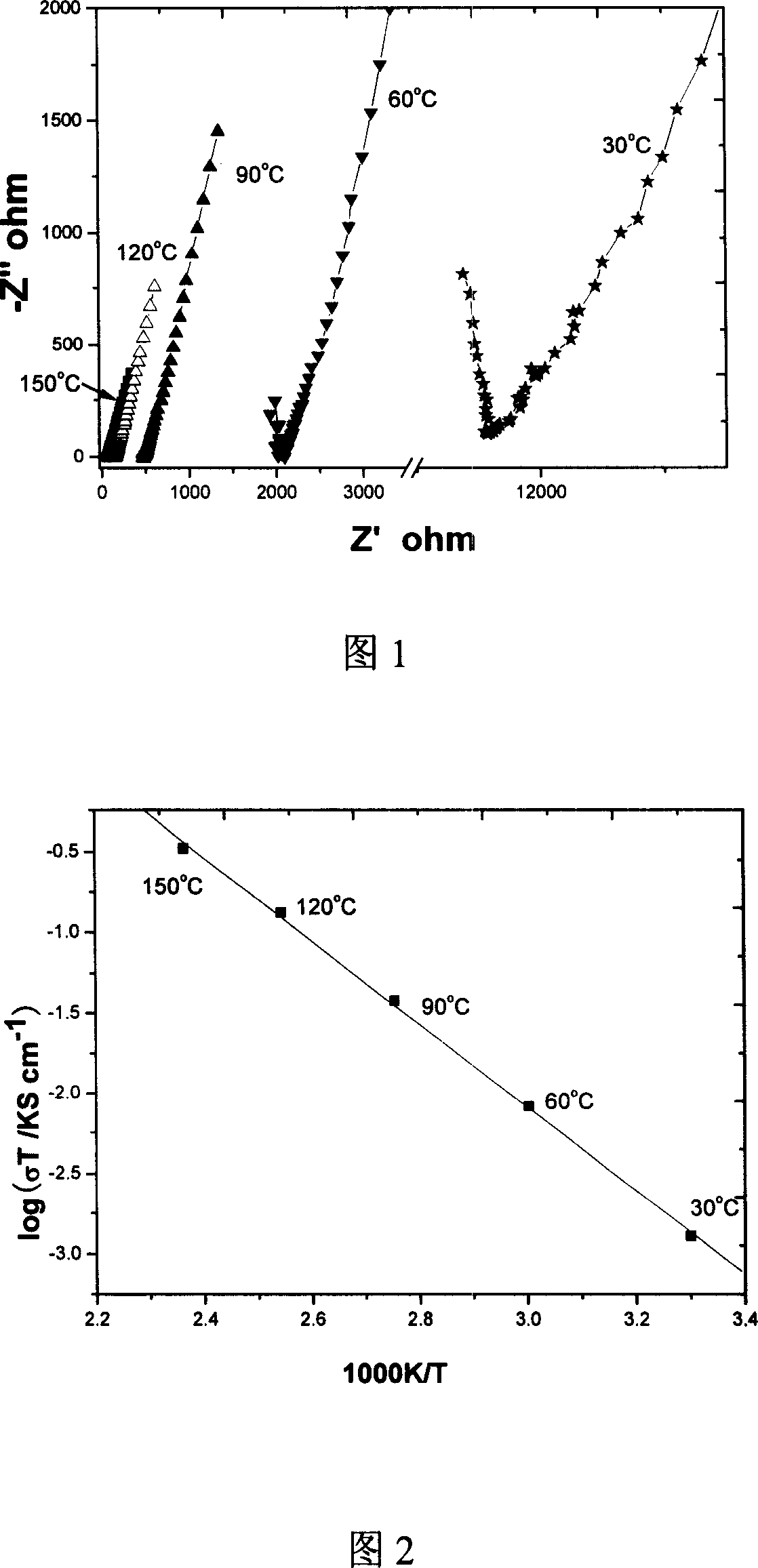

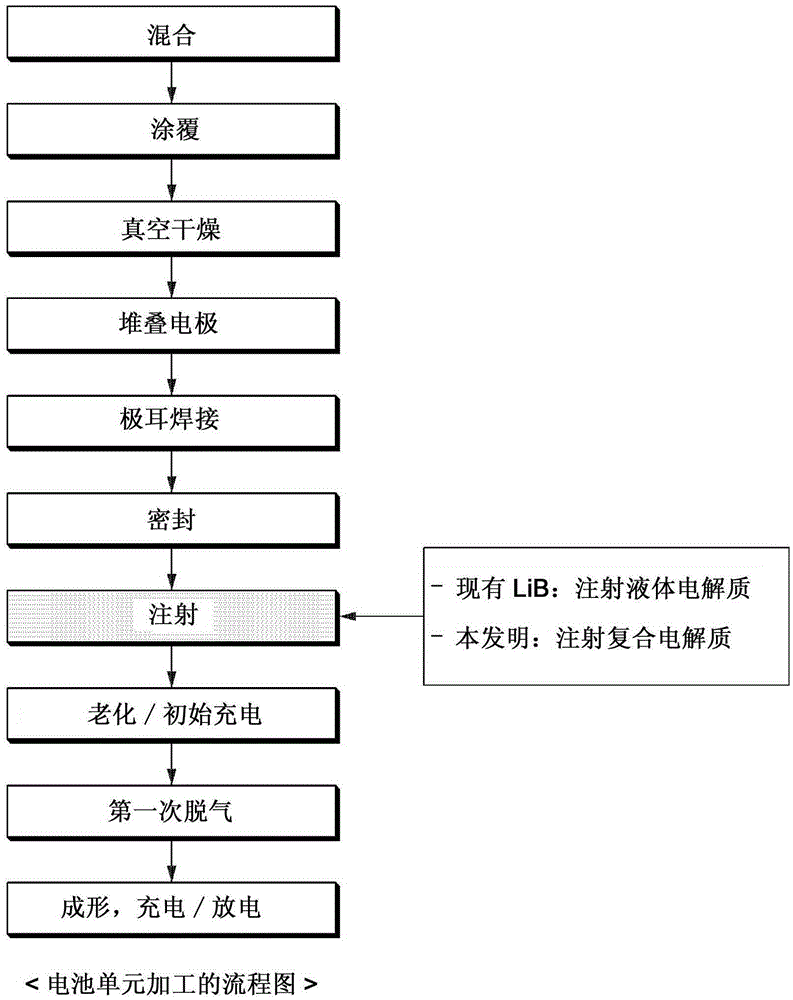

Preparation method of all-solid polymer electrolyte through in-situ ring opening polymerization of epoxy compound, and application of the all-solid polymer electrolyte in all-solid lithium battery

ActiveCN105914405AIncrease contactImprove interface compatibilityFinal product manufactureLi-accumulatorsEpoxySolid state electrolyte

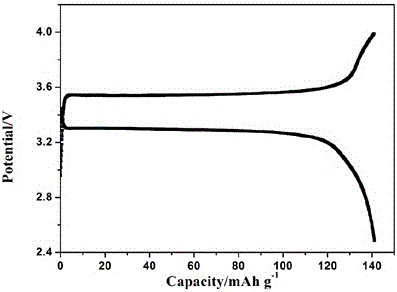

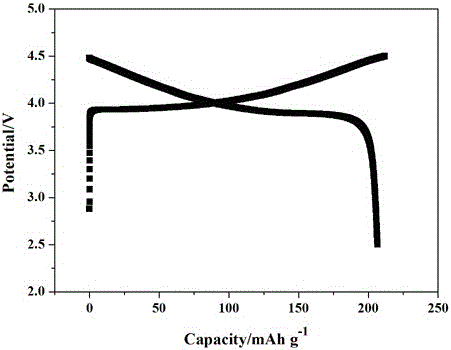

The invention discloses a preparation method of an all-solid polymer electrolyte through in-situ ring opening polymerization of an epoxy compound, and an application of the all-solid polymer electrolyte in an all-solid battery. The preparation method is characterized in that a liquid-state epoxy compound, a lithium salt, a battery additive and the like are employed as precursors and are injected into between a positive pole sheet and a negative pole sheet of the battery, and under a heating condition, in-situ polymerization solidification is carried out to form the all-solid polymer electrolyte, and furthermore, the all-solid battery is produced. The ionic conductivity at room temperature of the all-solid polymer electrolyte can reach from 1*10<-5> S / cm to 9*10<-3> S / cm and electric potential window is 3.5-5 V. The all-solid polymer electrolyte is prepared through the in-situ copolymerization method, so that the all-solid polymer electrolyte has excellent contact with electrodes, thereby greatly improving interface compatibility of the solid-state battery, reducing interface wetting and modification steps of the solid-state battery, reducing production cost of the solid-state battery and improving performances of the solid-state battery. The invention also discloses an all-solid polymer lithium battery assembled from the all-solid polymer electrolyte.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

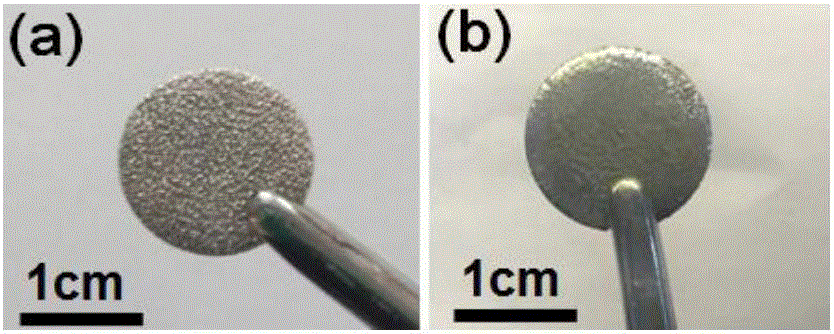

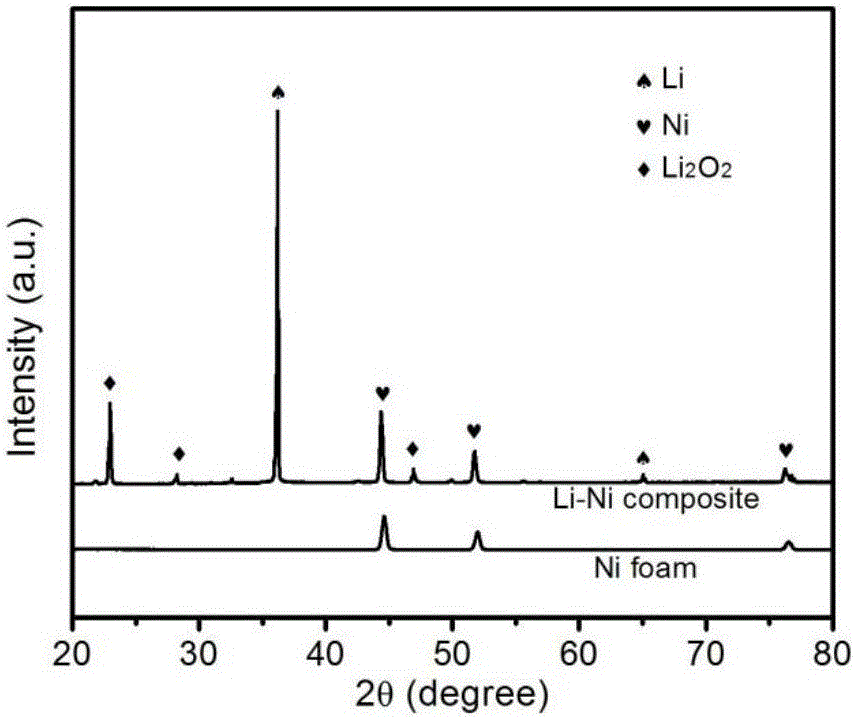

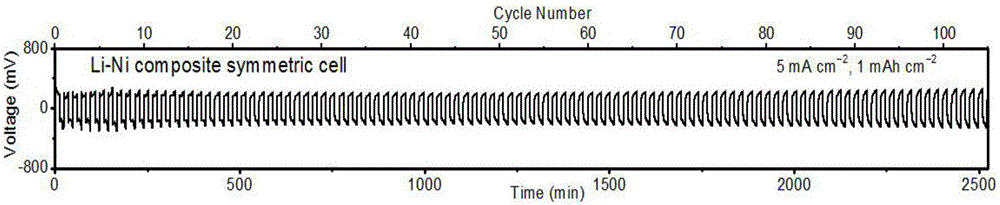

Preparation method of complex lithium negative pole of solid state battery

The present invention discloses a preparation method of a complex lithium negative pole of a solid state battery, and belongs to the technical field of electrochemistry and new energy resources. The preparation method mainly comprises the steps: depositing lithium metal on three-dimensional carbon material or foam porous material gaps by using a heat infusing melting method or an electrodeposition method to obtain the complex lithium negative pole, wherein the application of a three-dimensional framework plays two roles, namely, providing adequate space for pre-storing lithium in the preparation process; providing a carrier for receiving metal lithium in a battery circulation process. The complex lithium negative pole can be widely applied in lithium metal batteries such as lithium ion batteries, lithium-air batteries, lithium-sulfur batteries, and solid state batteries. In the assembled symmetric solid state battery, under large electric current density of 5mA cm-2, a stable voltage decay (200mV) can still be kept after circulation for 100 times, in the battery circulation, the growth of lithium dendrites can be inhibited and the pole volume change can be stabilized, and the advantages of being good in circulation stability, and long service life can be realized; in the present invention, a carrier material is rich, and low in price; the process is controlled, the cost is low, and the batch production can be realized.

Owner:UNIV OF SCI & TECH BEIJING

Solid-state lithium battery

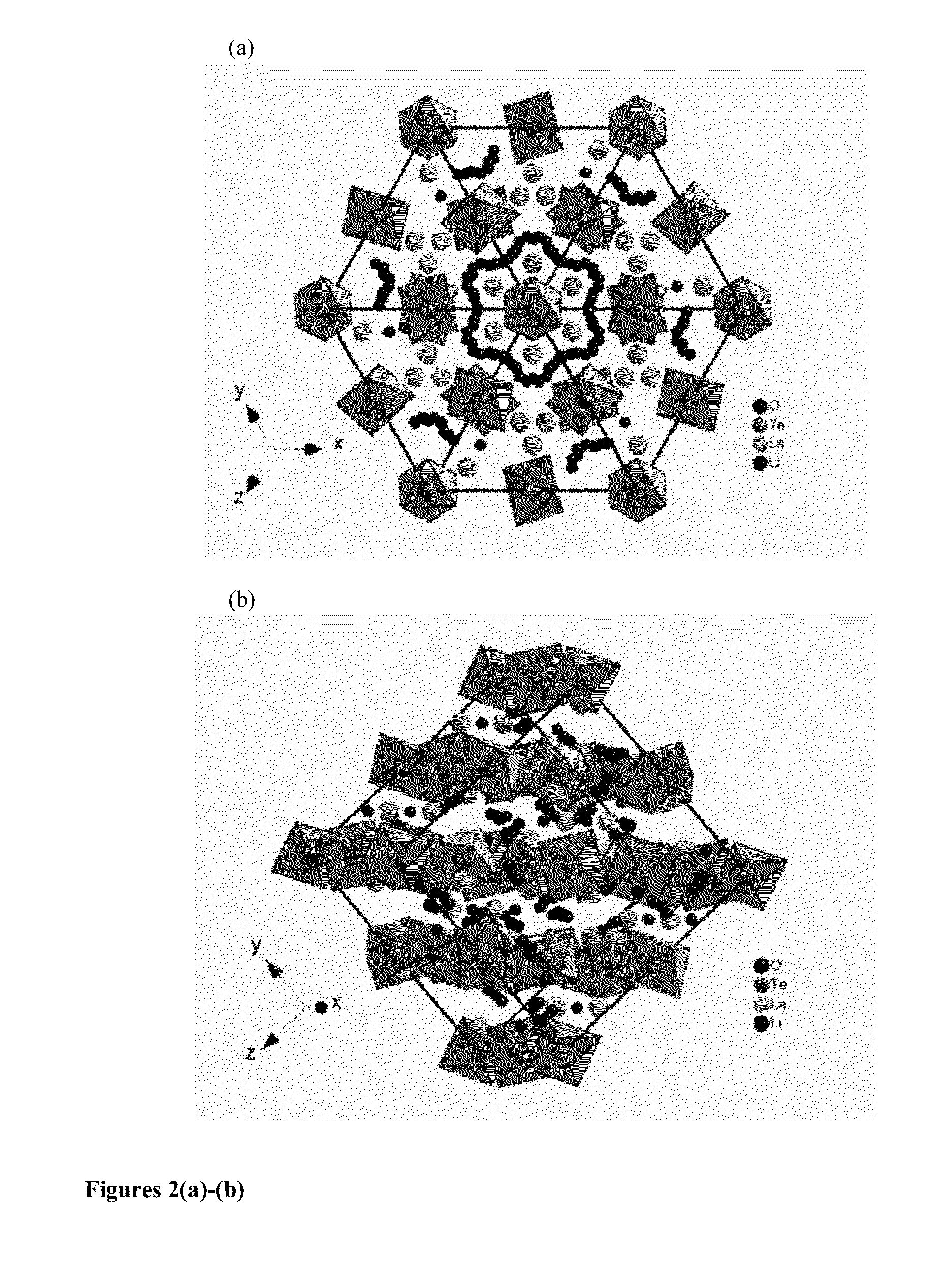

ActiveUS8877388B1Low form factor requirementsIncrease powerTantalum compoundsPrinted batteriesLanthanumLithium.free

The present invention is directed to a higher power, thin film lithium-ion electrolyte on a metallic substrate, enabling mass-produced solid-state lithium batteries. High-temperature thermodynamic equilibrium processing enables co-firing of oxides and base metals, providing a means to integrate the crystalline, lithium-stable, fast lithium-ion conductor lanthanum lithium tantalate (La1 / 3-xLi3xTaO3) directly with a thin metal foil current collector appropriate for a lithium-free solid-state battery.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Solid state lithium-air based battery cell

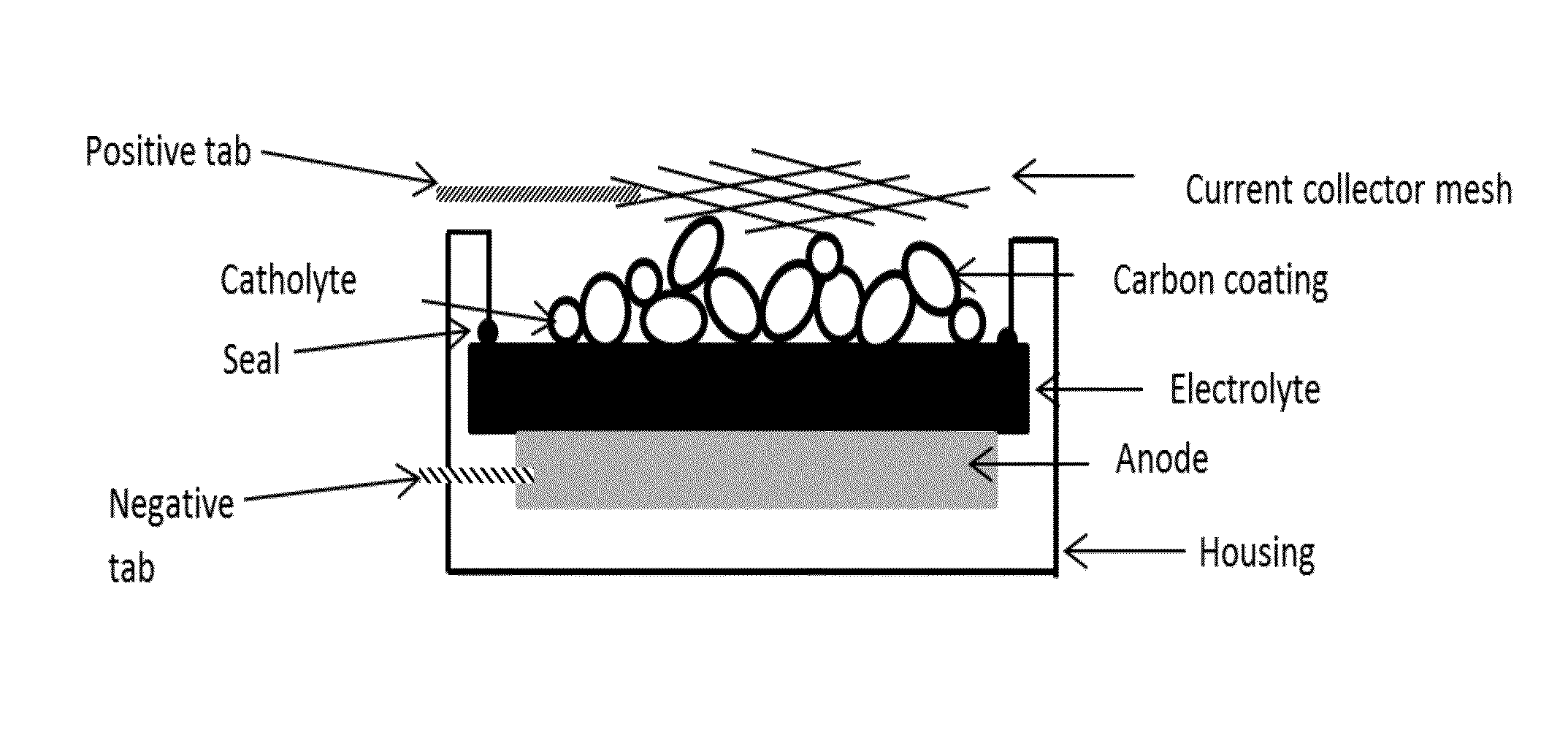

ActiveUS8940446B1High theoretical energy densityIncrease energy densityFuel and secondary cellsHybrid cell detailsPorositySolid-state battery

In an example, the present invention provides a solid state battery device, e.g., battery cell or device. The device has a current collector region and a lithium containing anode member overlying the current collector region. The device has a thickness of electrolyte material comprising a first garnet material overlying the lithium containing anode member. The thickness of electrolyte material has a density ranging from about 80 percent to 100 percent and a porous cathode material comprising a second garnet material overlying the thickness of electrolyte material. The porous cathode material has a porosity of greater than about 30 percent and less than about 95 percent and a carbon bearing material overlying a surface region of the porous cathode material. In an example, the carbon bearing material comprises substantially carbon material, although there can be variations.

Owner:QUANTUMSCAPE BATTERY INC

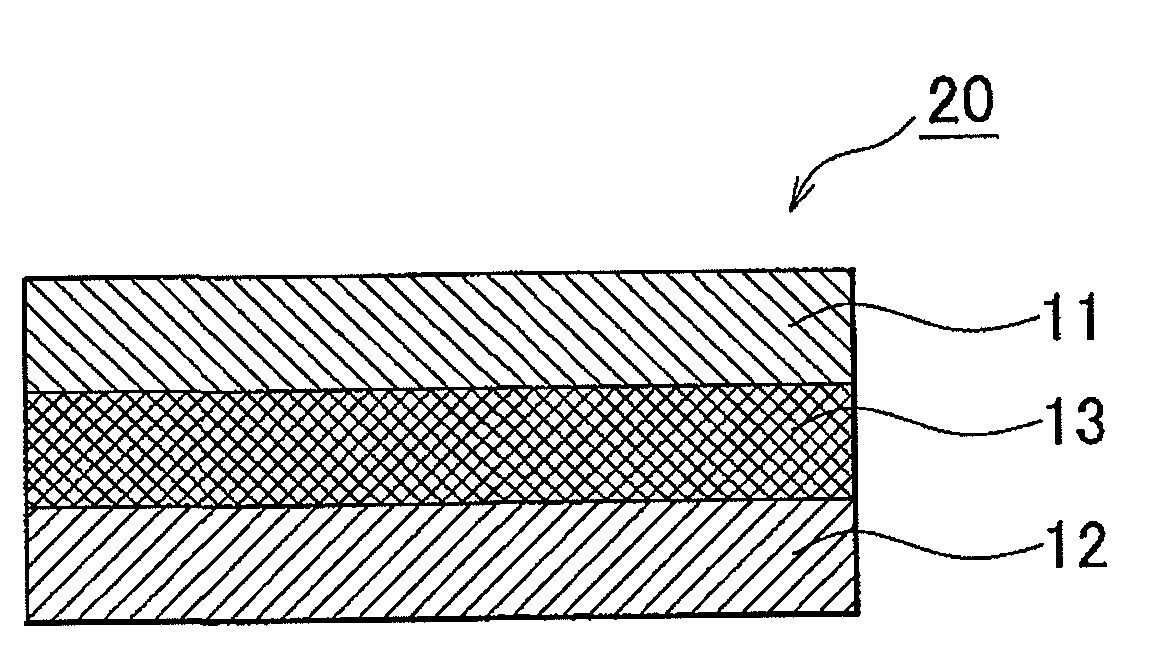

Solid-state battery and method for manufacturing electrode active material

ActiveUS20160204466A1Improve ionic conductivityImprove stabilitySolid electrolytesElectrode thermal treatmentSulfurSolid-state battery

One embodiment provides a solid-state battery that has a positive-electrode layer; a negative-electrode layer; and a lithium-ion-conducting solid electrolyte layer disposed between the positive-electrode layer and the negative-electrode layer. The positive-electrode layer contains a positive-electrode active material and a solid electrolyte comprising a hydride of a complex. Said positive-electrode active material is sulfur-based, and the solid electrolyte layer contains a solid electrolyte comprising a hydride of a complex.

Owner:MITSUBISHI GAS CHEM CO INC +1

Method for producing solid state battery

A method for producing a solid state battery including the steps of: (a) obtaining an active material slurry; (b) obtaining a solid electrolyte slurry; (c) obtaining a current collector slurry; (d) forming an active material green sheet and a solid electrolyte green sheet; (e) laminating the solid electrolyte green sheet on one surface of the active material green sheet to form a first green sheet group, and forming a current collector green sheet layer on the other surface of the active material green sheet to form a second green sheet group; (f) heating the second green sheet group at not less than 200° C. and not greater than 400° C. in an oxidizing atmosphere; and (g) baking the second green sheet group having heated in the step (f) in a low oxygen atmosphere at a baking temperature higher than the heating temperature in the step (f) to obtain a laminate.

Owner:PANASONIC CORP

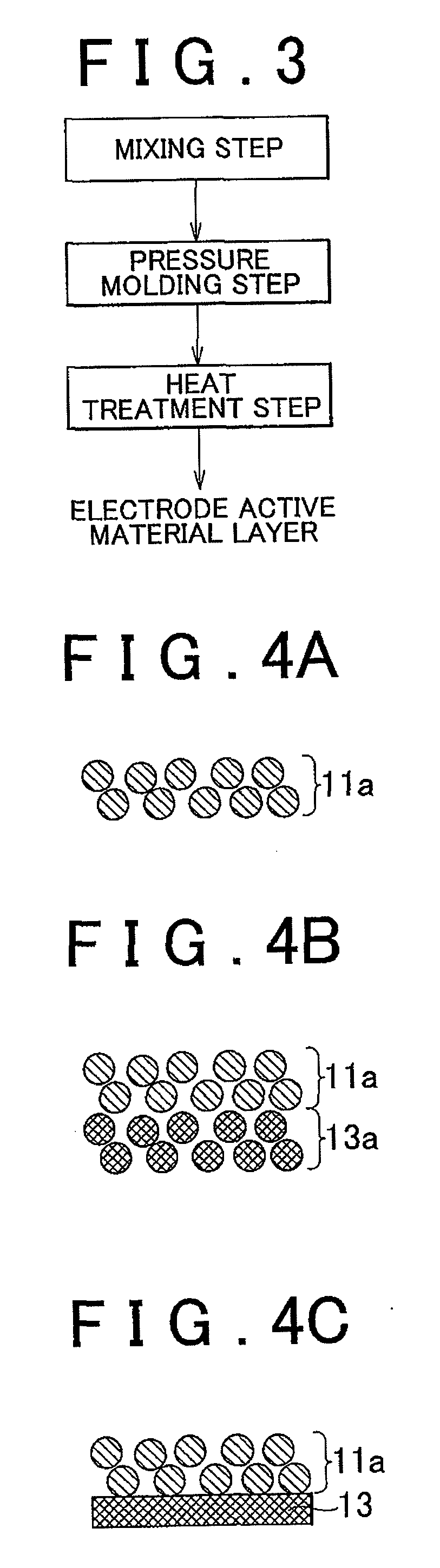

Electrode active material layer, all solid state battery, manufacturing method for electrode active material layer, and manufacturing method for all solid state battery

InactiveUS20110065007A1Reduce interface resistanceSuppress generationSolid electrolytesSolid electrolyte cellsAll solid stateSolid state electrolyte

Owner:TOYOTA JIDOSHA KK

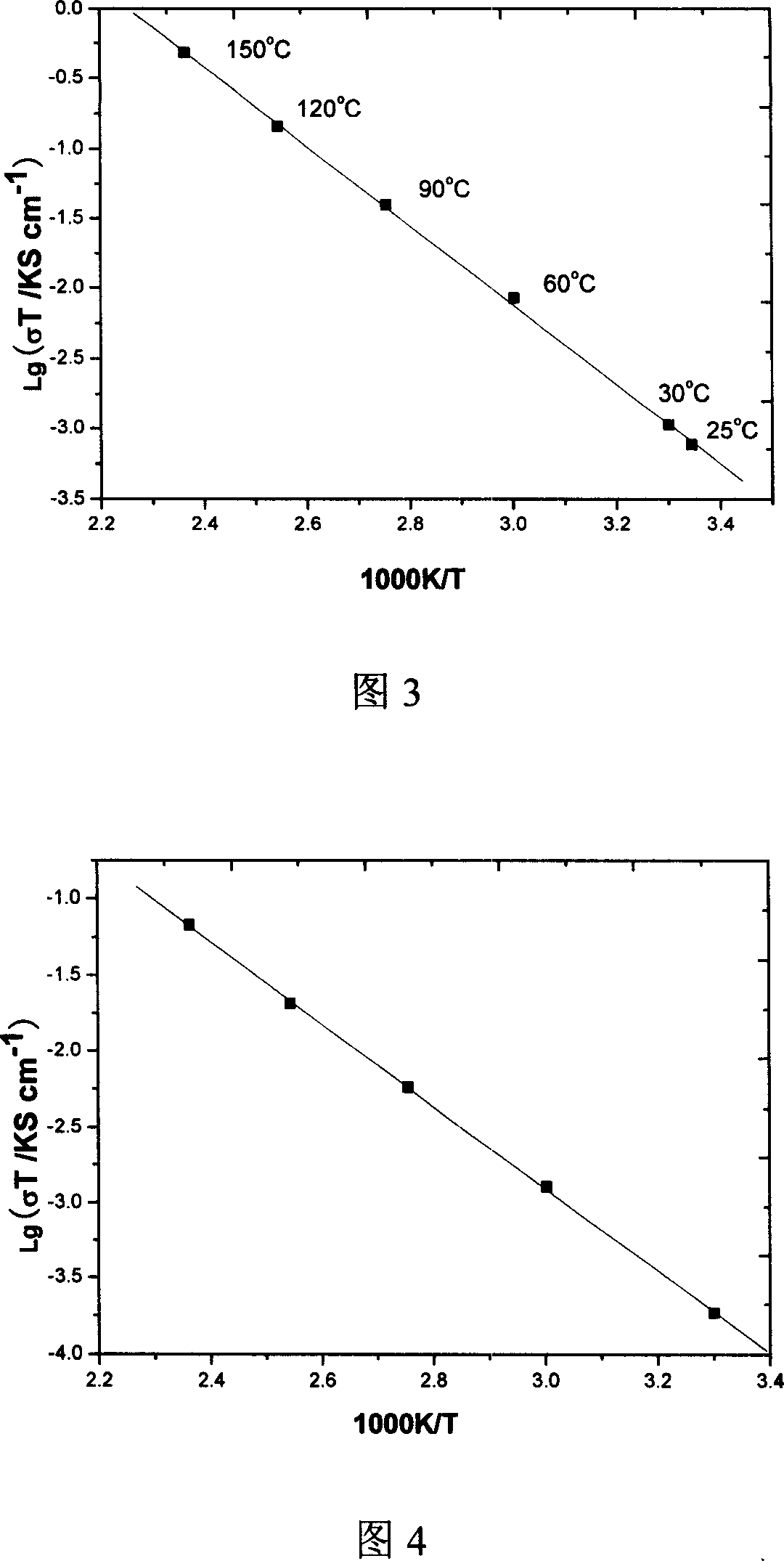

Organic and inorganic composite all-solid-state electrolyte and all-solid-state battery formed from same

InactiveCN105811002AGood flexibilityGood chemical stabilitySolid electrolytesFinal product manufactureElectrical conductorInorganic compound

The invention relates to an organic and inorganic composite all-solid-state electrolyte, in particular to an organic polycarbonate macromolecule and inorganic fast-ion conductor composite all-solid-state electrode and preparation and application of an all-solid-state battery formed from the same. The organic and inorganic composite all-solid-state electrolyte comprises polycarbonate macromolecule, an inorganic fast-ion conductor, a lithium salt and a porous rigid support material, the thickness of the organic and inorganic composite all-solid-state electrolyte is 5-2,000 micrometers, the mechanical strength is 2-150MPa, the room-temperature ionic conductivity is 1*10<-4>-6*10<-3> S / cm, and an electrochemical window is greater than 4V. The organic and inorganic composite all-solid-state electrolyte provided by the invention is easy to prepare and simple to form, has favorable mechanical property, and is relatively high in room-temperature ionic conductivity and relatively wide in electrochemical window; and meanwhile, by the organic and inorganic composite all-solid-state electrolyte, the growth of lithium dendrites of a negative electrode can be effectively prevented, the interface stability is improved, and the long-circulation and safe application performance of the battery are further improved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

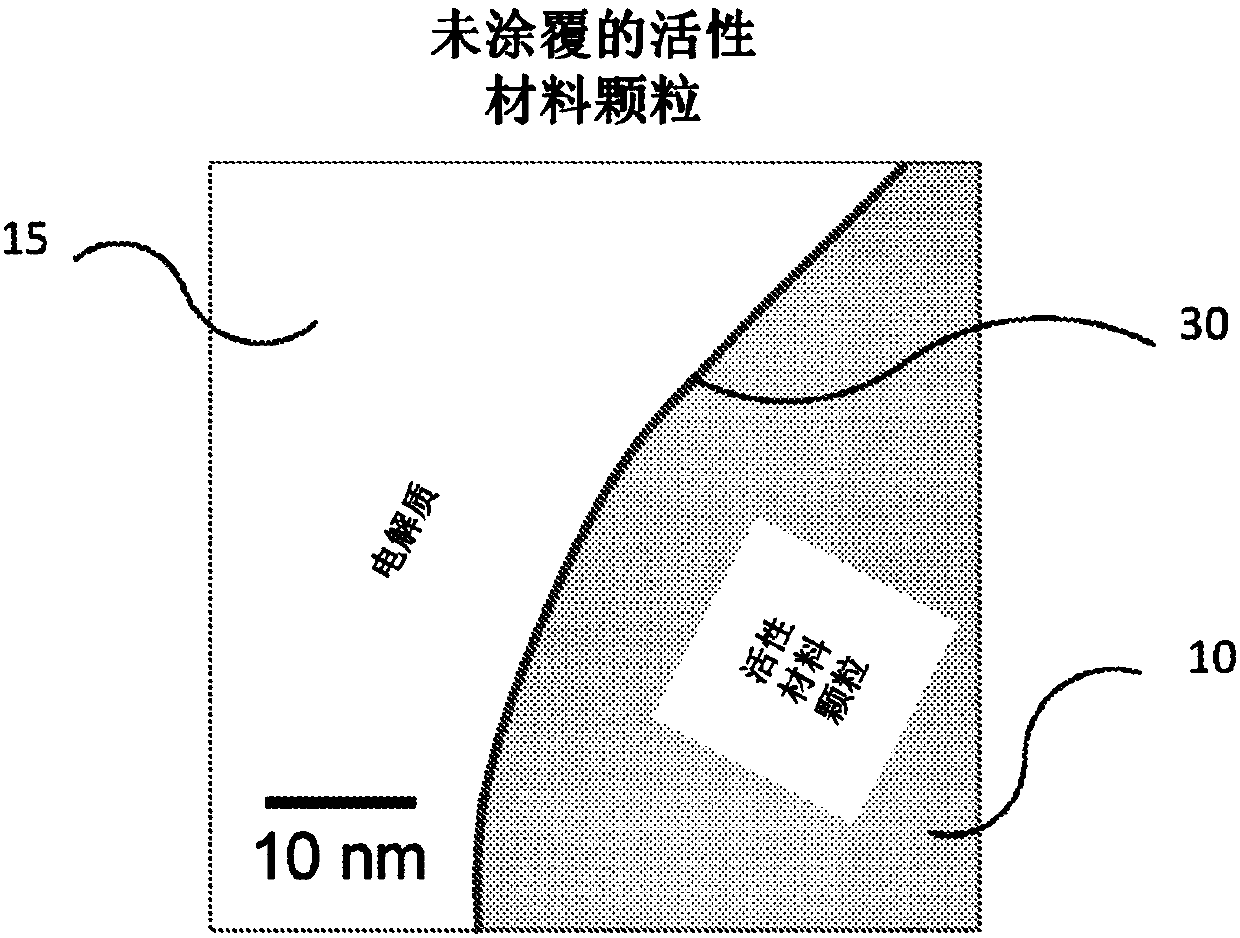

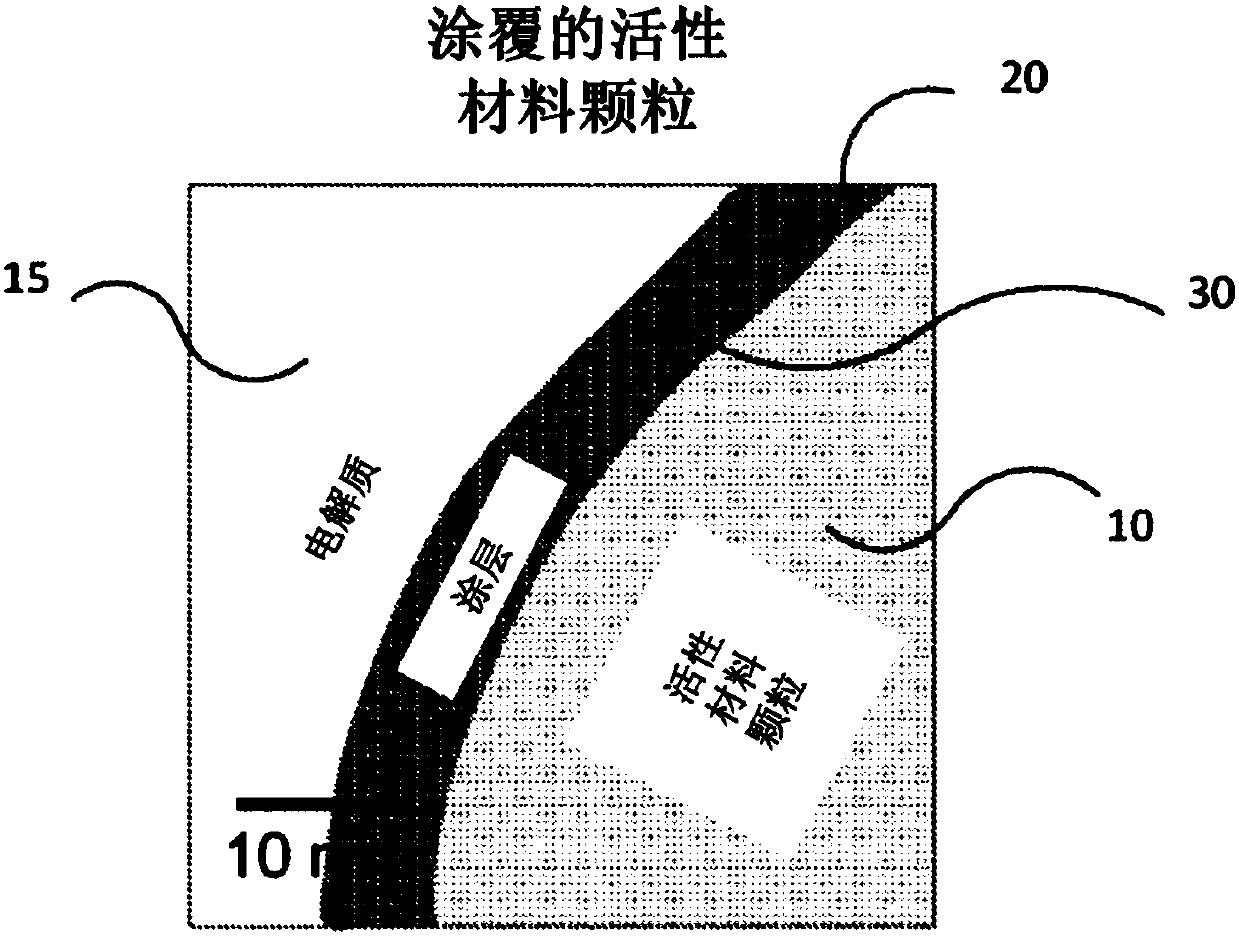

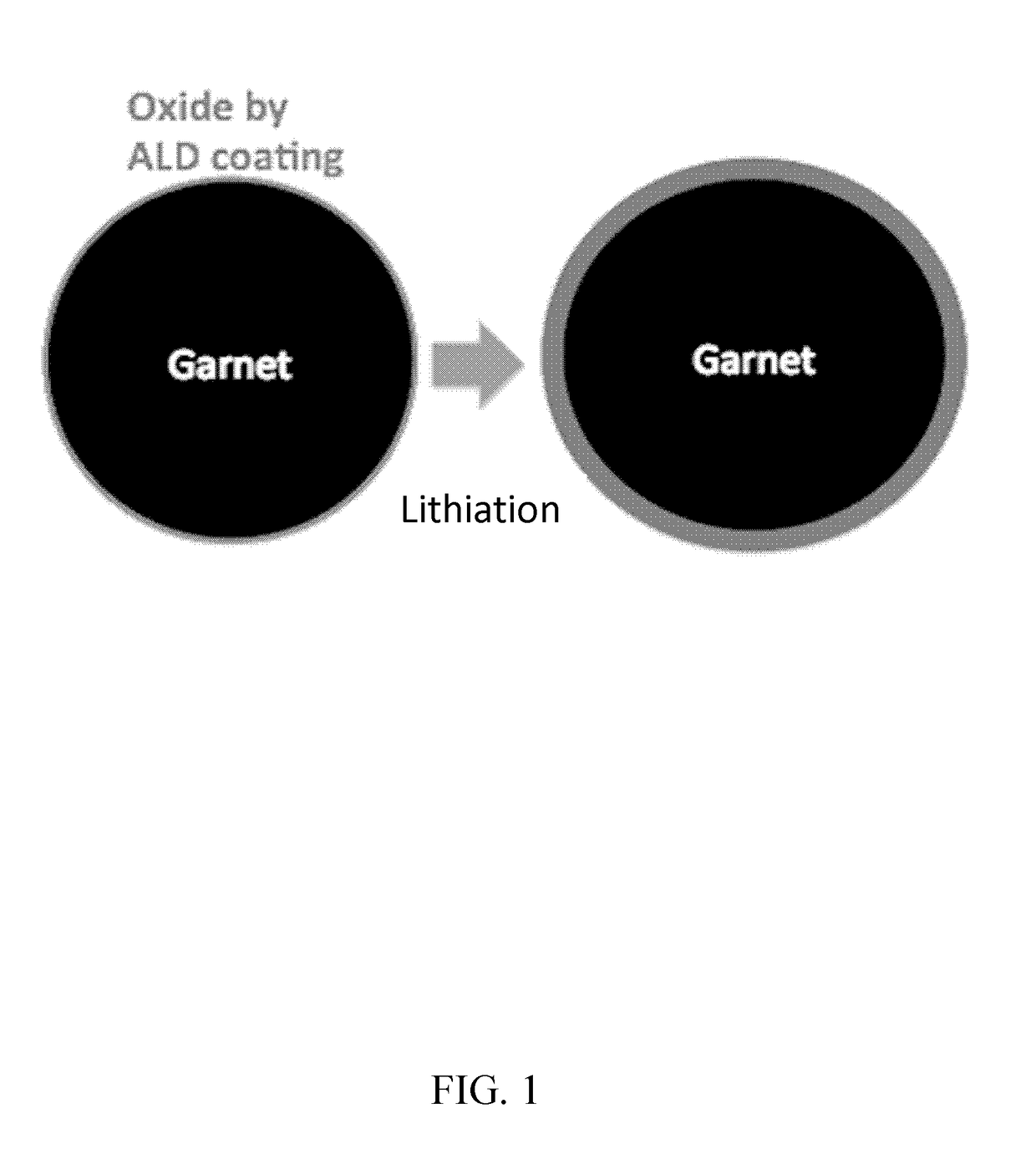

Nano-engineered coatings for anode active materials, cathode active materials, and solid-state electrolytes and methods of making batteries containing nano-engineered coatings

ActiveCN107851840ALower resistanceIncrease choice flexibilitySolid electrolytesCell electrodesSolid state electrolyteSolid-state battery

The present disclosure relates to a nano-engineered coating for cathode active materials, anode active materials, and solid state electrolyte materials for reducing corrosion and enhancing cycle lifeof a battery, and processes for applying the disclosed coating. Also disclosed is a solid state battery including a solid electrolyte layer having a solid electrolyte particle coated by a protective coating with a thickness of 100 nm or less. The protective coating is obtained by atomic layer deposition (ALD) or molecular layer deposition (MLD). Further disclosed is a solid electrolyte layer for asolid state battery, including a porous scaffold coated by a first, solid electrolyte coating. The solid electrolyte coating has a thickness of 60 mu m or less and a weight loading of at least 20 wt.% (or preferable at least 40 wt.% or at least 50 wt.%). Further disclosed is a cathode composite layer for a solid state battery.

Owner:PNEUMATICOAT TECH LLC

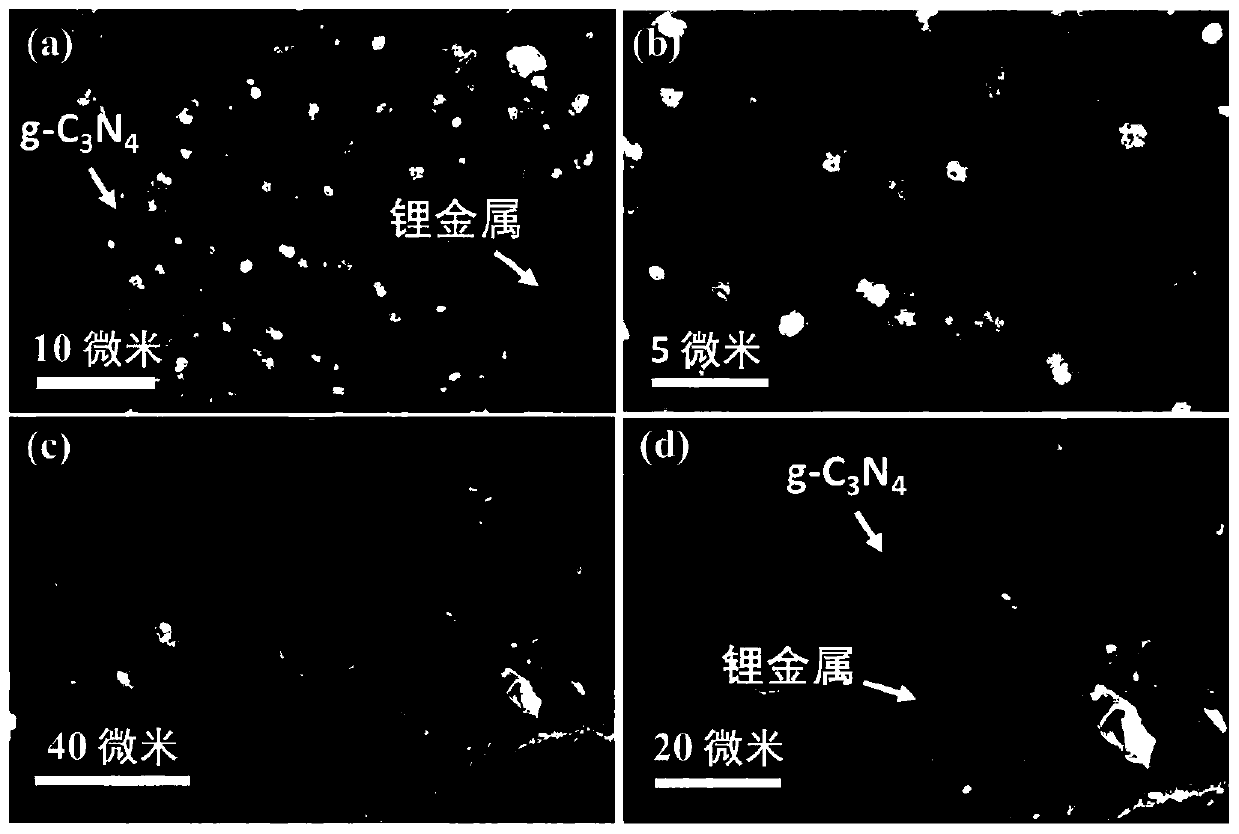

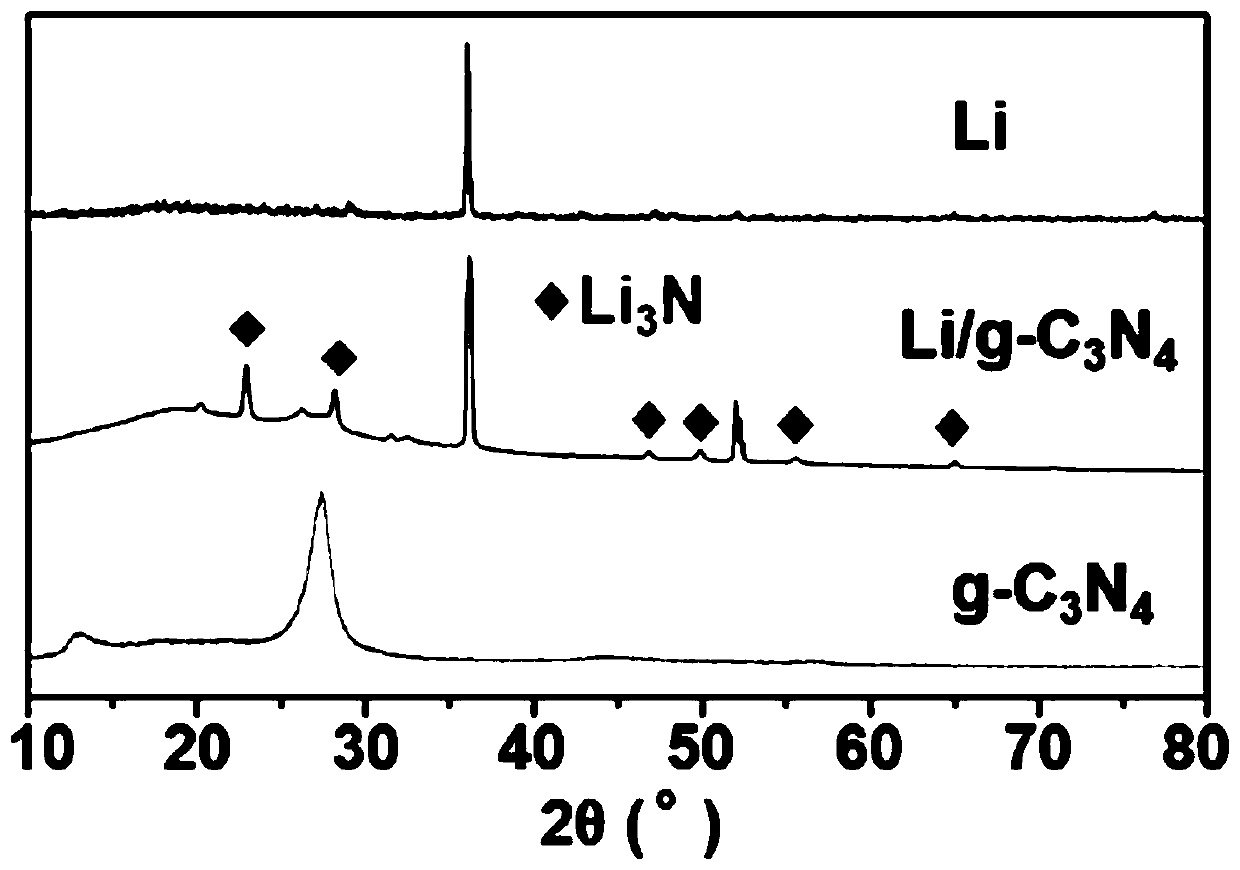

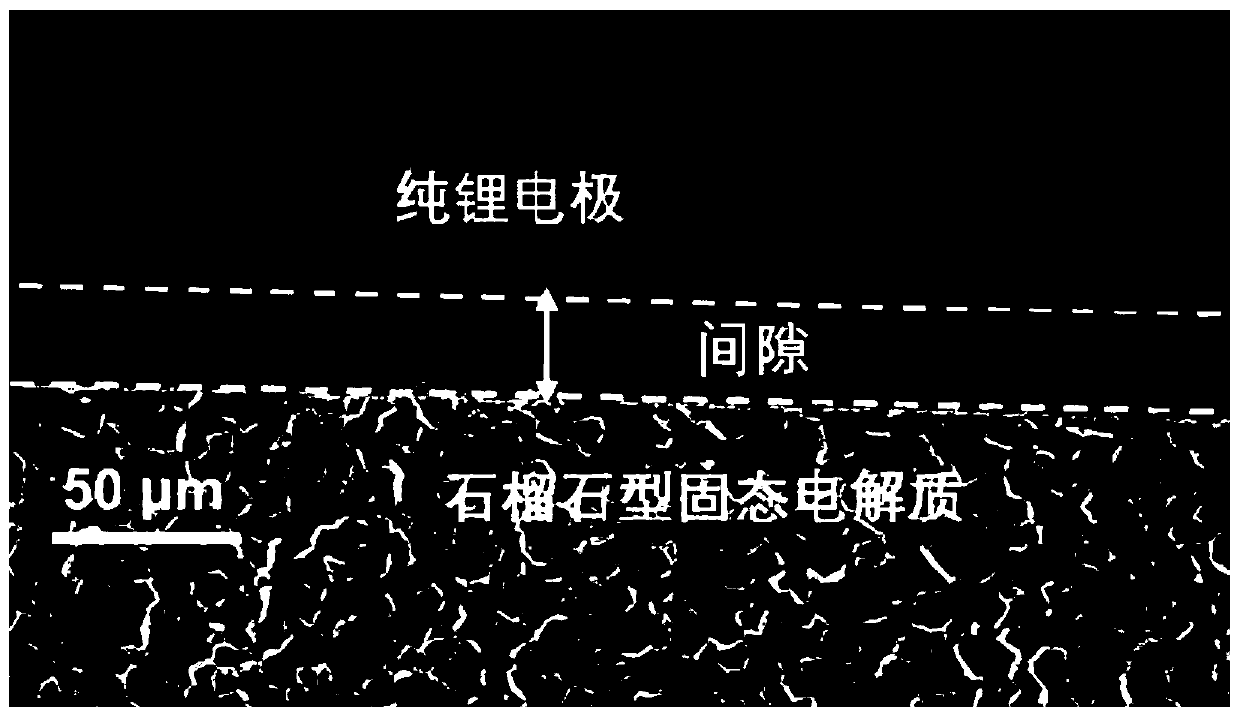

Modified lithium-based composite negative material for solid state battery and preparation and application of material

InactiveCN109841817AOptimize interface compositionImprove cyclic charge and discharge capacityElectrode manufacturing processesSecondary cellsSolid state electrolyteInterfacial resistance

The invention relates to a modified lithium-based composite negative material for a solid state battery and preparation and application of the material. The modified lithium-based composite negative material comprises 50-95 parts of lithium and 5-50 parts of a modified additive by weight; and the modified additive comprises one or multiple nitride or fluoride. The preparation method comprises thatthe lithium and modified additive are mixed, heated to 180-400 DEG C, stirred uniformly, and cooled to the room temperature; and the modified composite negative material is used to the solid state battery, and combined with a solid electrolyte. Compared with the prior art, the lithium metal is mixed with the modified additive by mixing in a heating fusing way, the surface energy of the lithium metal can be reduced effectively, elements including nitrogen and fluorine are introduced in a controllable way, the interfacial resistance between the solid electrolyte and lithium cathode is reduced effectively, the limit current that can be born by the solid electrolyte is increased, the recyclable charge and discharge capacity is improved, and the solid electrolyte and cathode interface is stable for a longer time in the long circulation process.

Owner:TONGJI UNIV

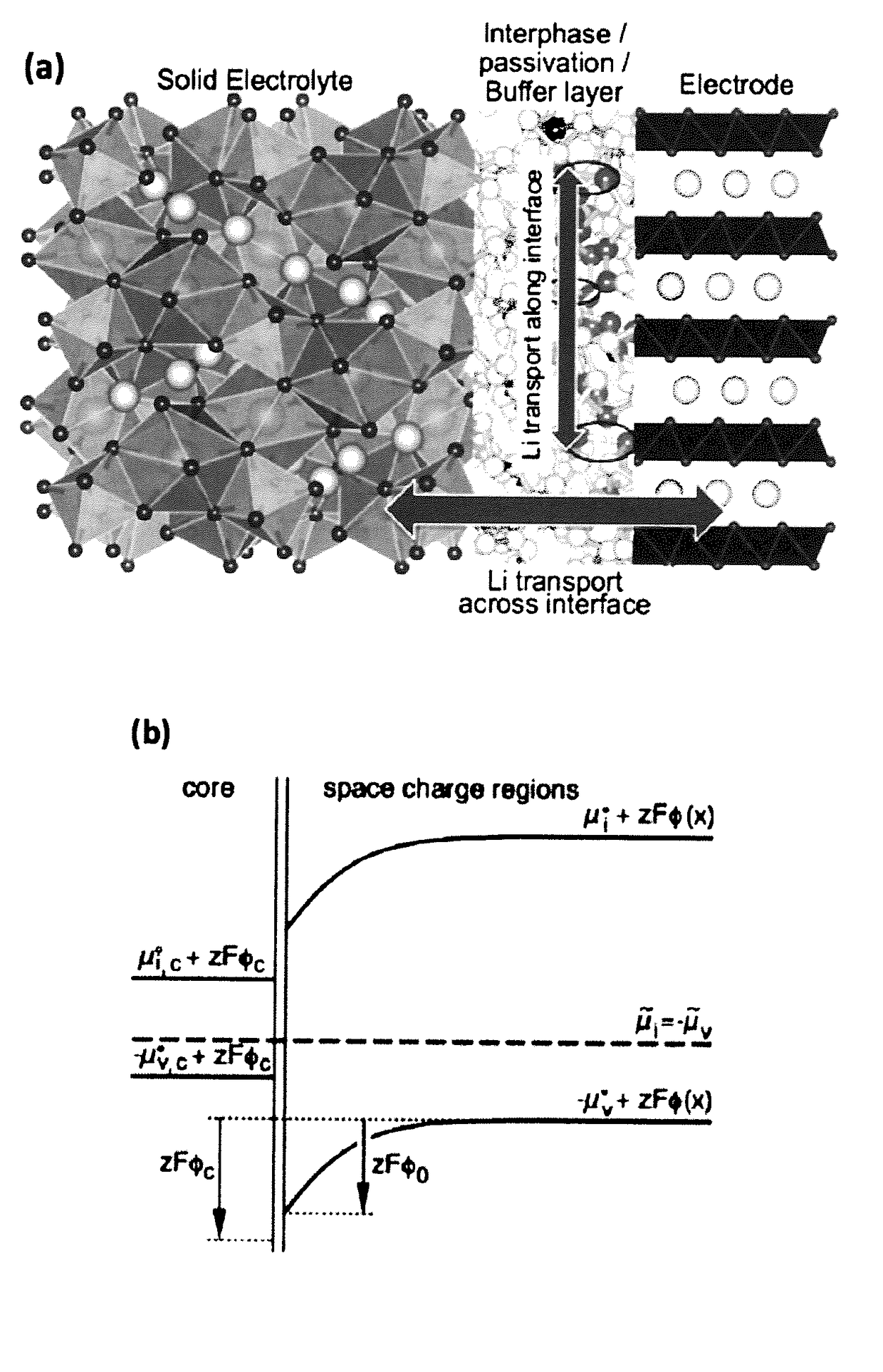

Interfacial layers for solid-state batteries and methods of making same

ActiveUS20170338522A1Fuel and primary cellsSolid electrolytesSolid state electrolyteInorganic materials

One or more interfacial layers in contact with a solid-state electrolyte and hybrid electrolyte materials. Interfacial layers comprise inorganic (e.g., metal oxides and soft inorganic materials) or organic materials (e.g., polymer materials, gel materials and ion-conducting liquids). The interfacial layers can improve the electrical properties (e.g., reduce the impedance) of an interface between an a cathode and / or anode and a solid-state electrolyte. The interfacial layers can be used in, for example, solid-state batteries (e.g., solid-state, ion-conducting batteries).

Owner:UNIV OF MARYLAND

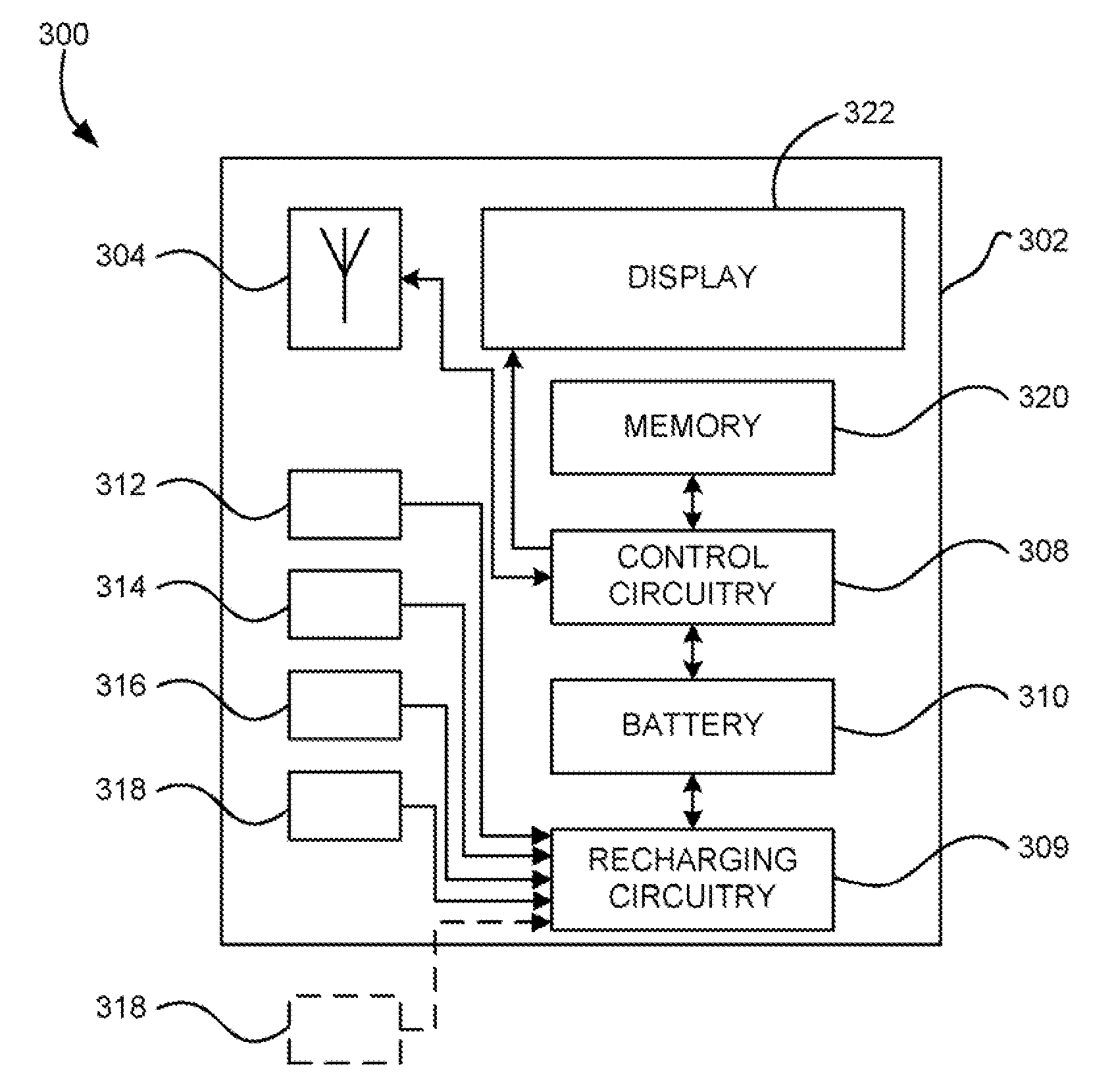

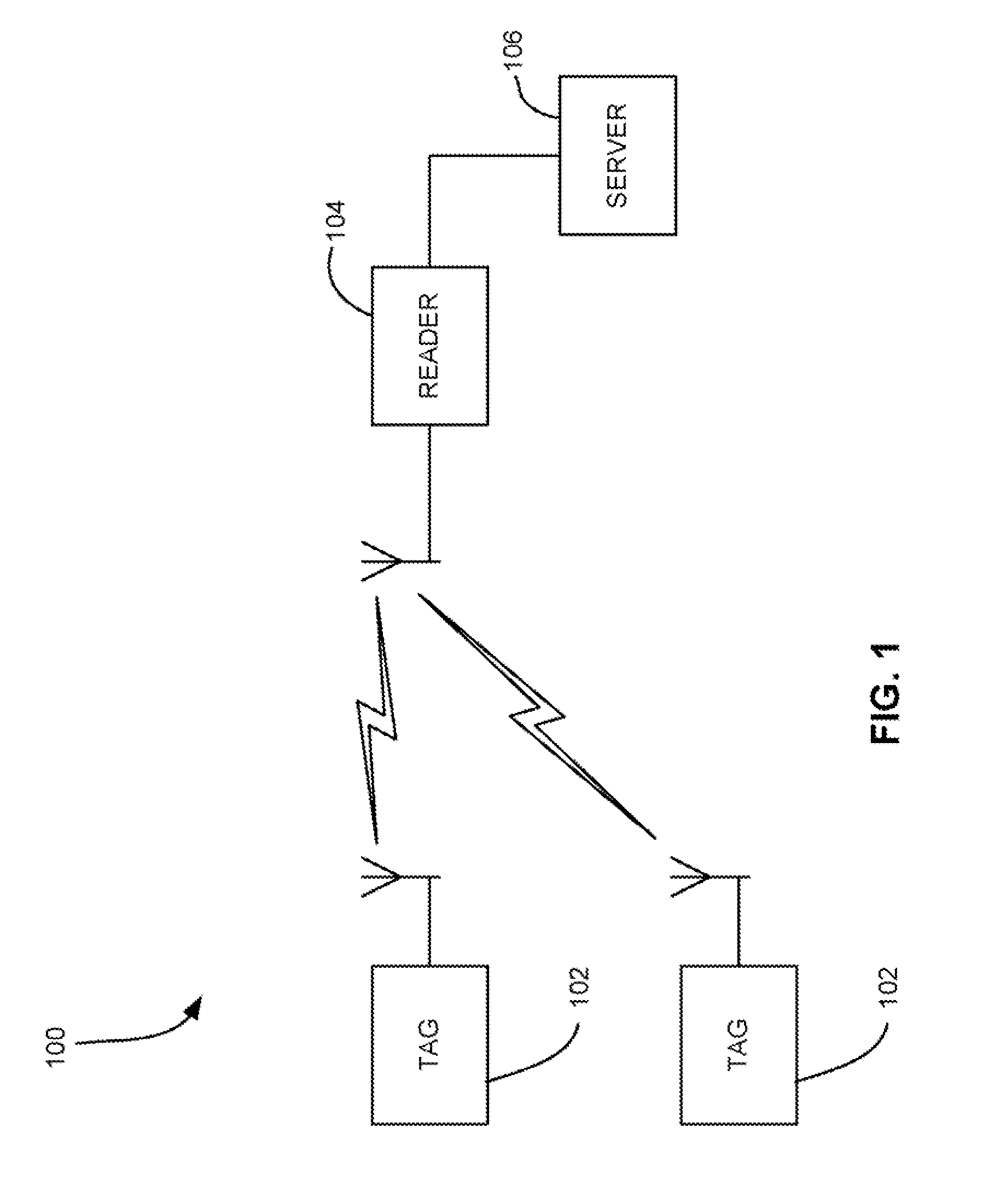

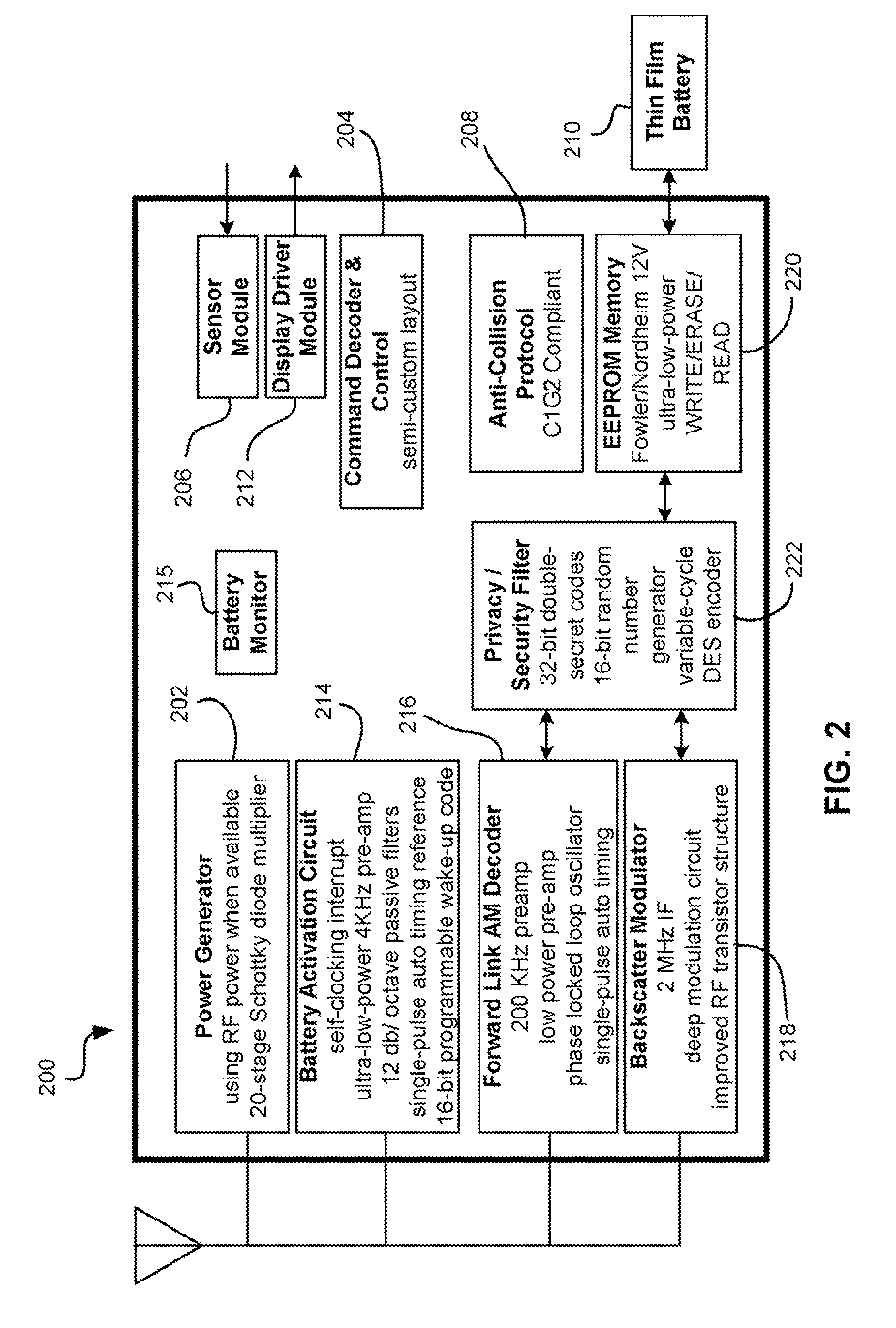

Self-charging RFID tag with long life

ActiveUS20080018466A1Extends active (self-powered) lifeSave battery powerRecord carriers used with machinesBurglar alarm by hand-portable articles removalElectrical batteryEngineering

A Radio Frequency Identification (RFID) device according to one embodiment of the present invention includes a rechargeable solid state battery, control circuitry coupled to the rechargeable solid state battery, and a power source for recharging the rechargeable solid state battery.

Owner:ZEST LABS INC

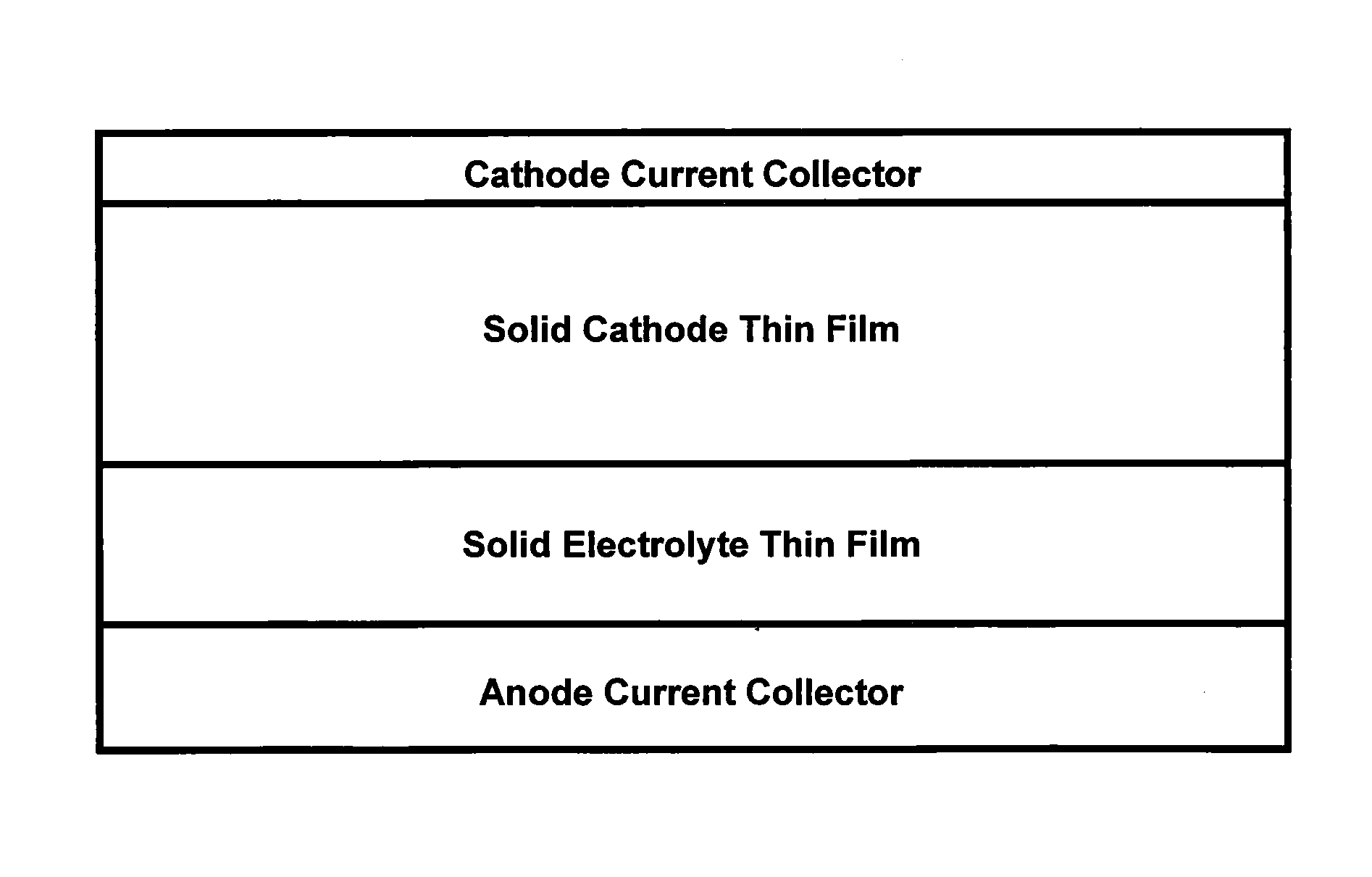

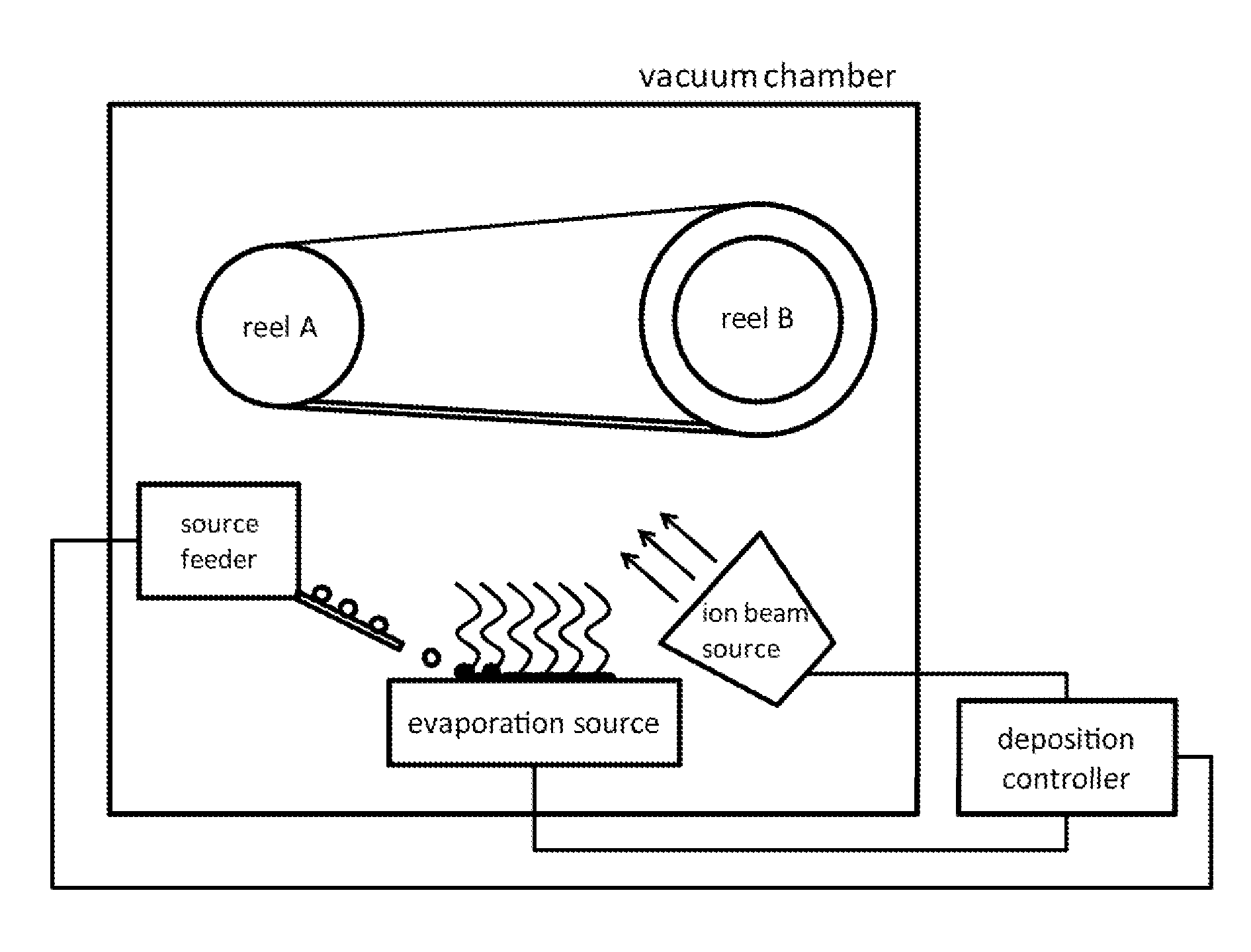

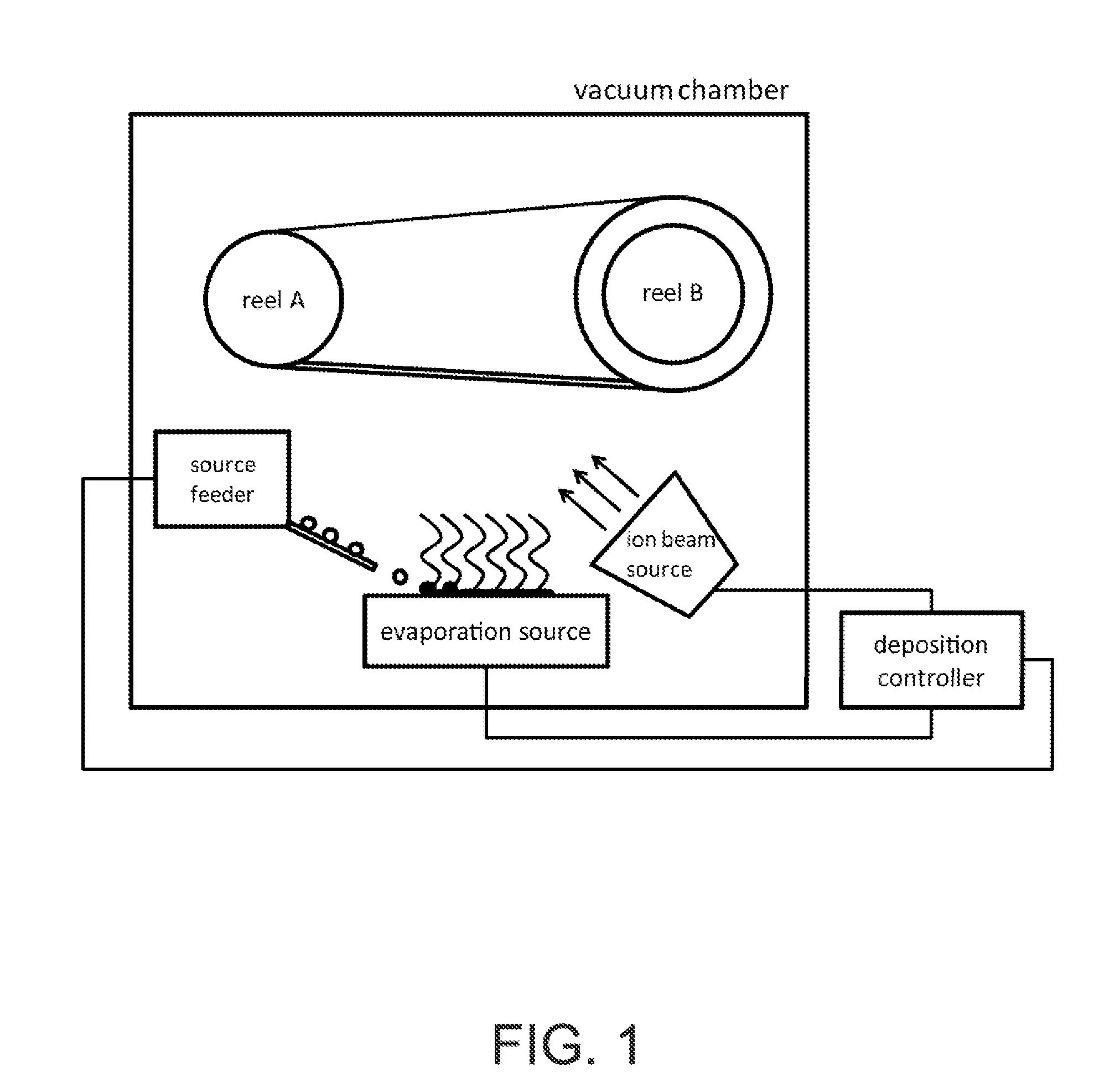

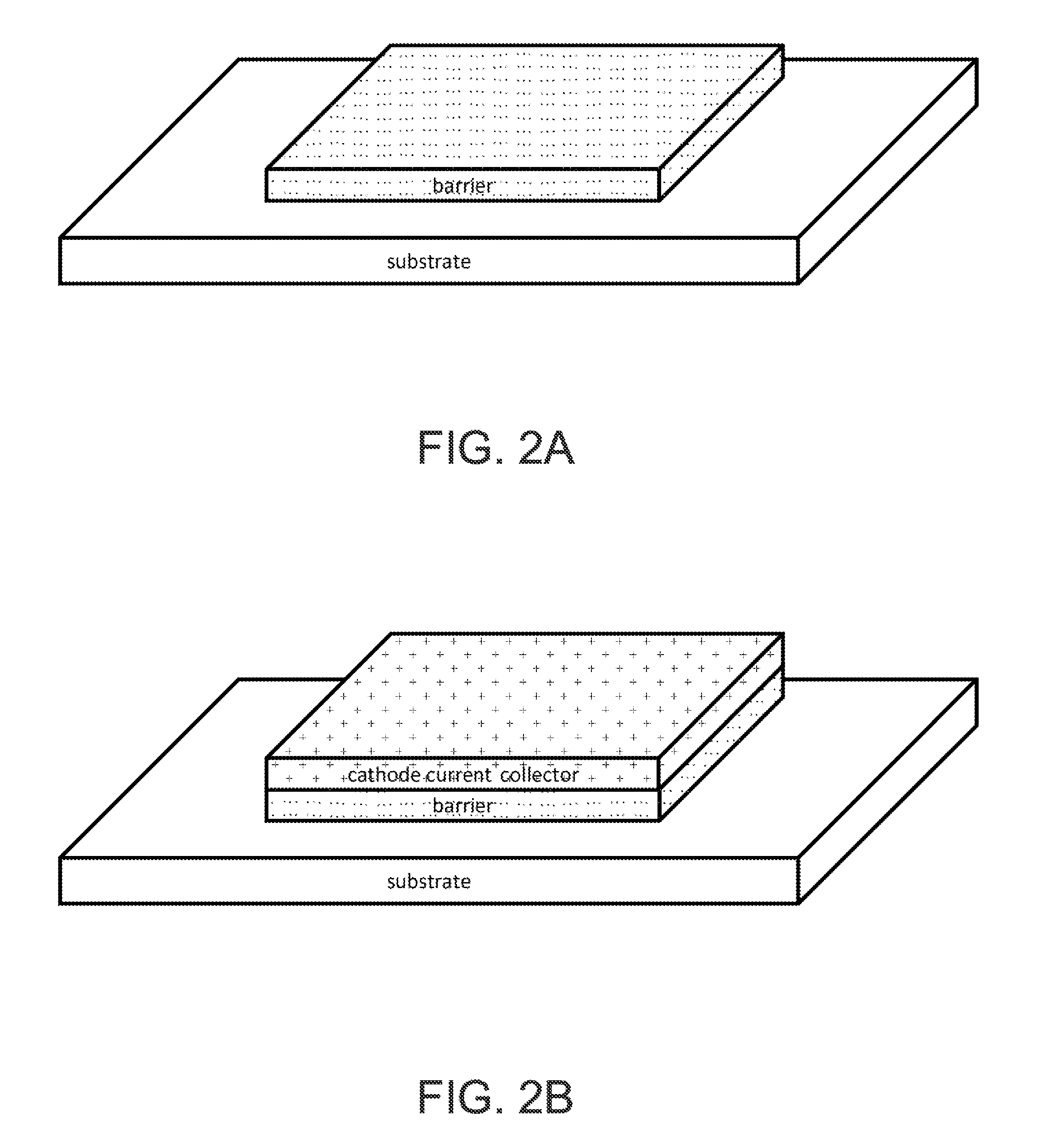

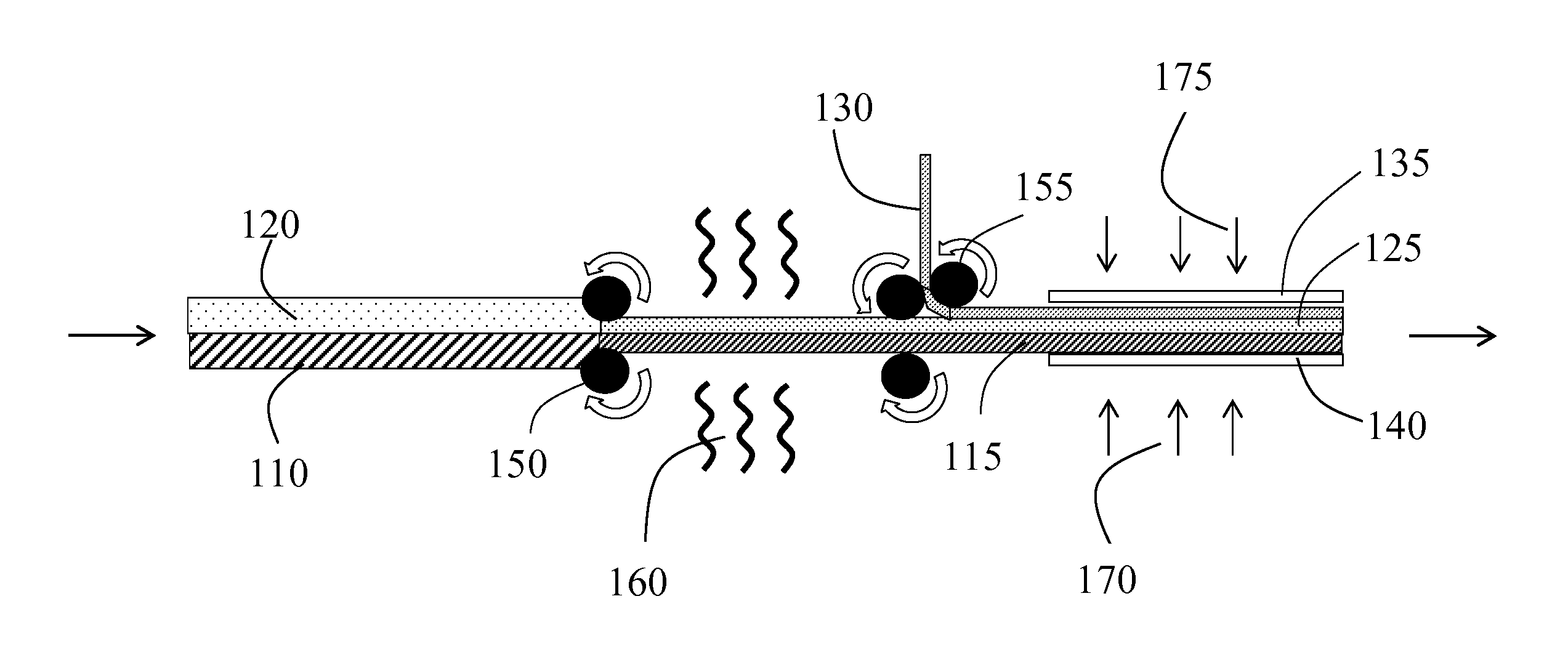

Thermal evaporation process for manufacture of solid state battery devices

ActiveUS20120058280A1Easy to implementEfficient and cost-effectiveFinal product manufactureVacuum evaporation coatingThermal energySource material

A method for manufacturing a solid-state battery device. The method can include providing a substrate within a process region of an apparatus. A cathode source and an anode source can be subjected to one or more energy sources to transfer thermal energy into a portion of the source materials to evaporate into a vapor phase. An ionic species from an ion source can be introduced and a thickness of solid-state battery materials can be formed overlying the surface region by interacting the gaseous species derived from the plurality of electrons and the ionic species. During formation of the thickness of the solid-state battery materials, the surface region can be maintained in a vacuum environment from about 10-6 to 10-4 Torr. Active materials comprising cathode, electrolyte, and anode with non-reactive species can be deposited for the formation of modified modulus layers, such a void or voided porous like materials.

Owner:SAKTI3

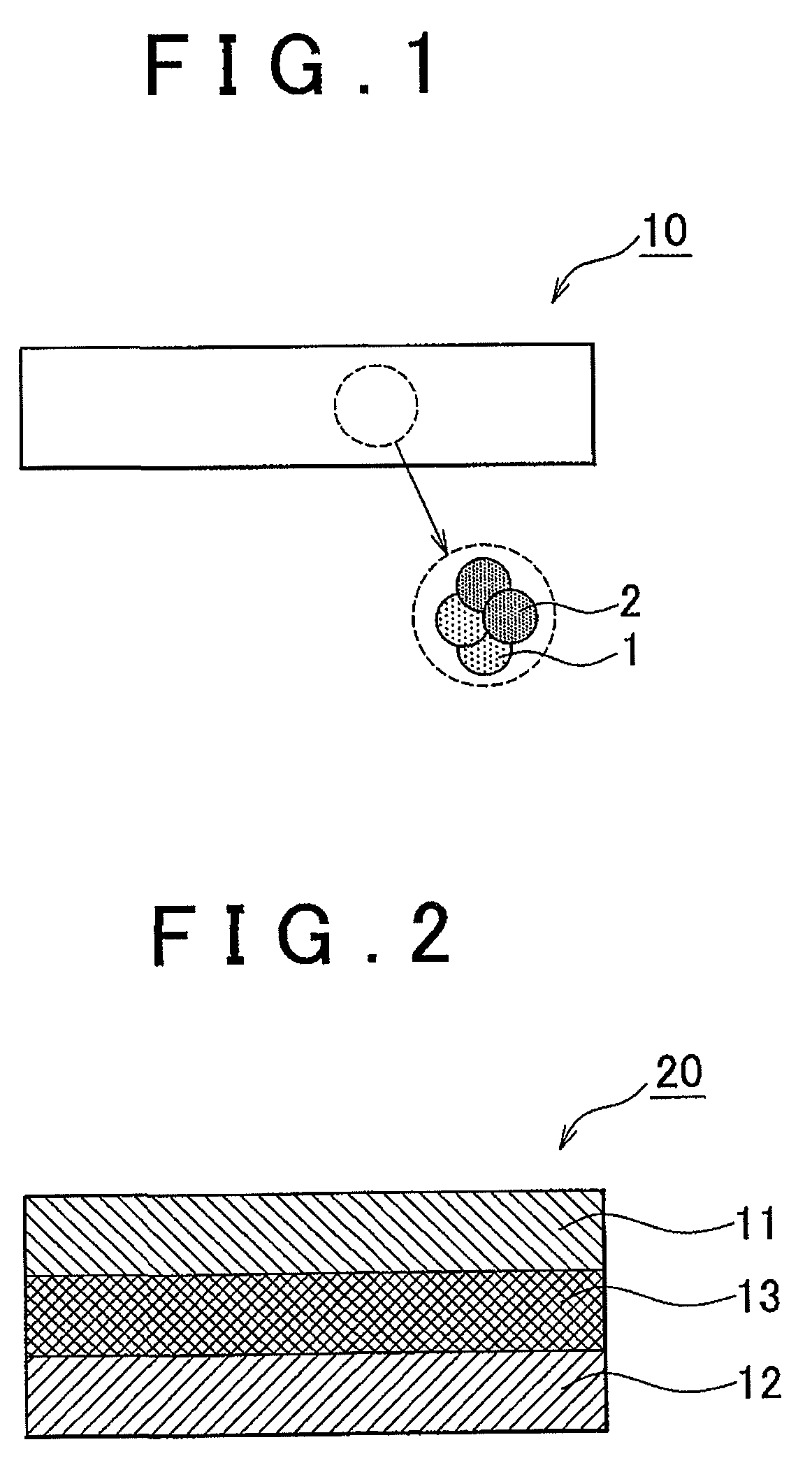

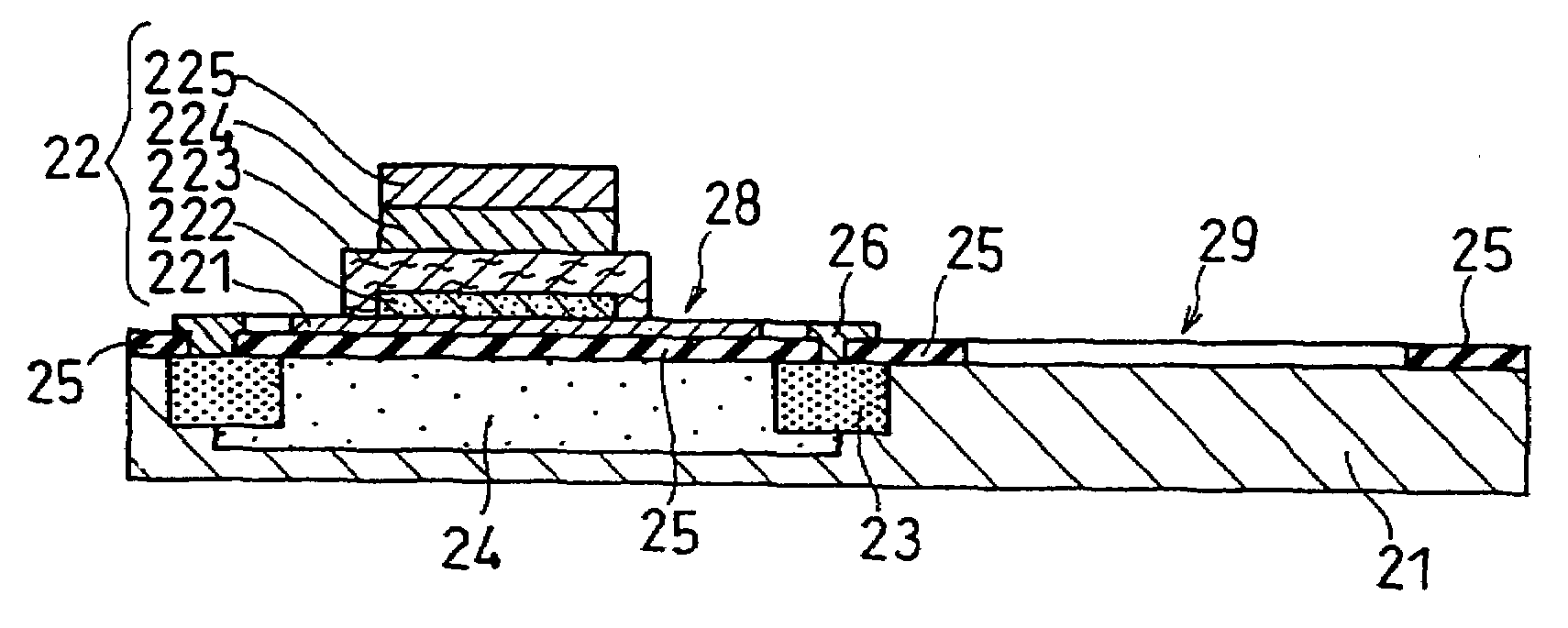

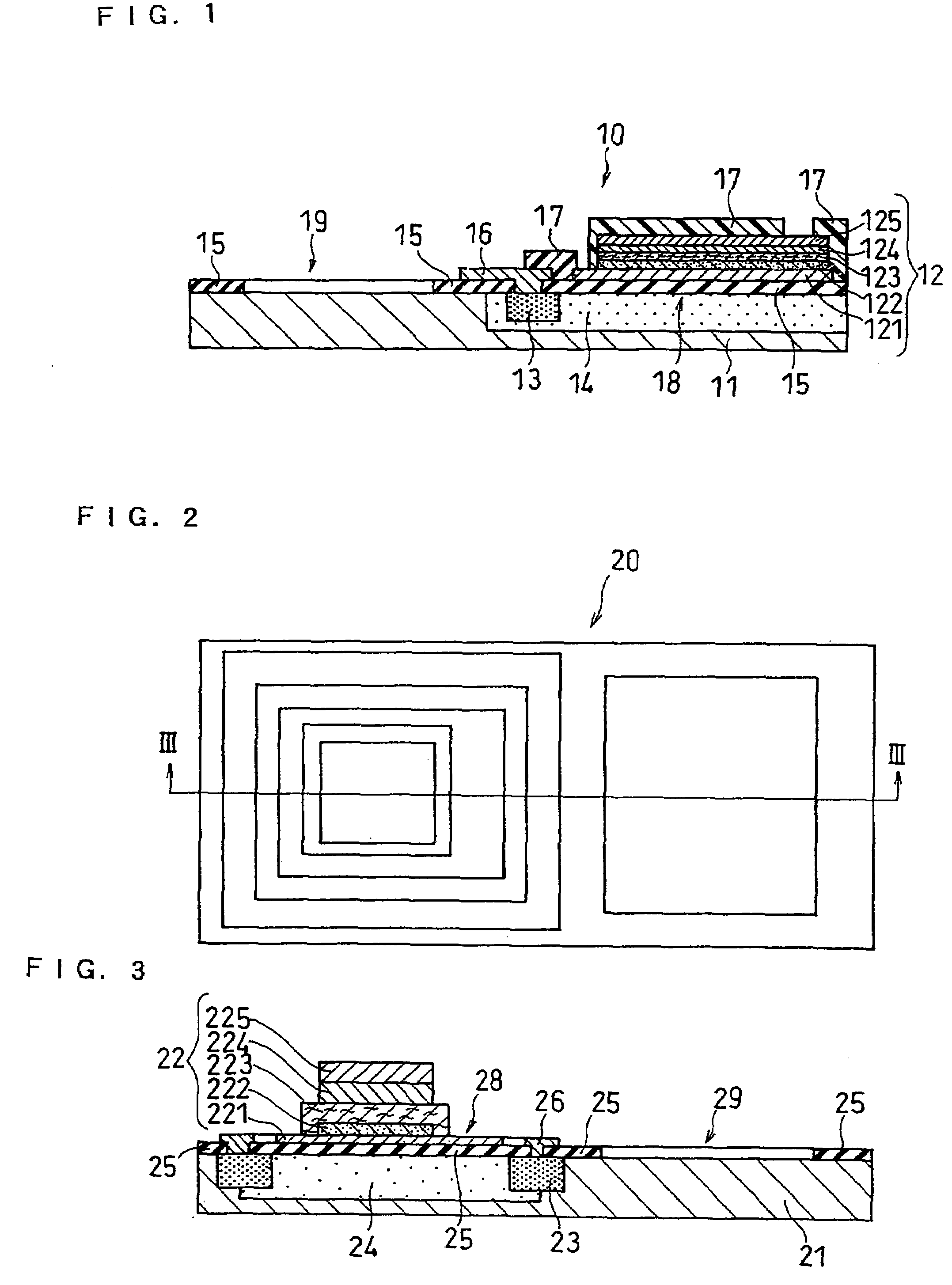

Battery mounted integrated circuit device having diffusion layers that prevent cations serving to charge and discharge battery from diffusing into the integrated circuit region

ActiveUS7253494B2Batteries circuit arrangementsSemiconductor/solid-state device detailsEngineeringSolid-state battery

The present invention relates to a battery mounted integrated circuit device where an integrated circuit and a solid state battery are formed on the same substrate. In this battery mounted integrated circuit device, a first diffusion layer containing an N-type impurity is formed between a region of a semiconductor substrate where the solid state battery is mounted and a region of the semiconductor substrate where the integrated circuit is mounted, and a second diffusion layer containing an N-type impurity is formed below the region of the semiconductor substrate where the solid state battery is mounted, and overlaps with the first diffusion layer.

Owner:PANASONIC CORP

Solid electrolyte material system for all solid state lithium battery and preparation method

ActiveCN101013761AImprove conductivityImprove ionic conductivitySolid electrolyte cellsChemical/physical/physico-chemical processesCrystal systemAll solid state

The invention relates to one solid electrolyte materials and its process method for fix lithium battery, which is characterized by the following: Li2S and other sulfur compound B / S and A / I according to certain mole proportion for compounds to form non-crystal system to provide space for lithium ion transmission to get higher ion conductive rate, wherein, the materials have wider heat stable range to provide one ideal electrolyte prepare materials for solid lithium ion battery.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

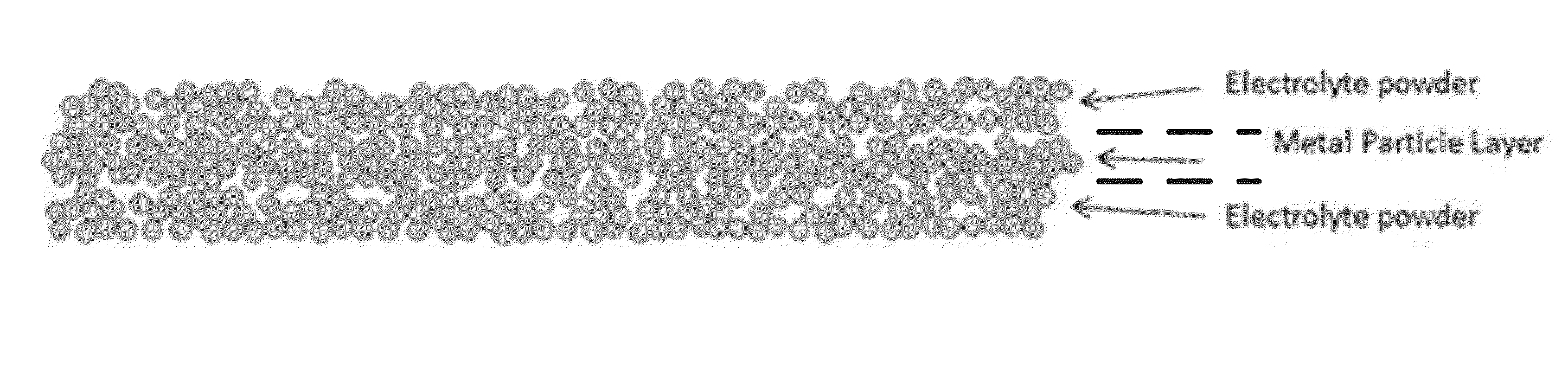

Solid-state batteries, separators, electrodes, and methods of fabrication

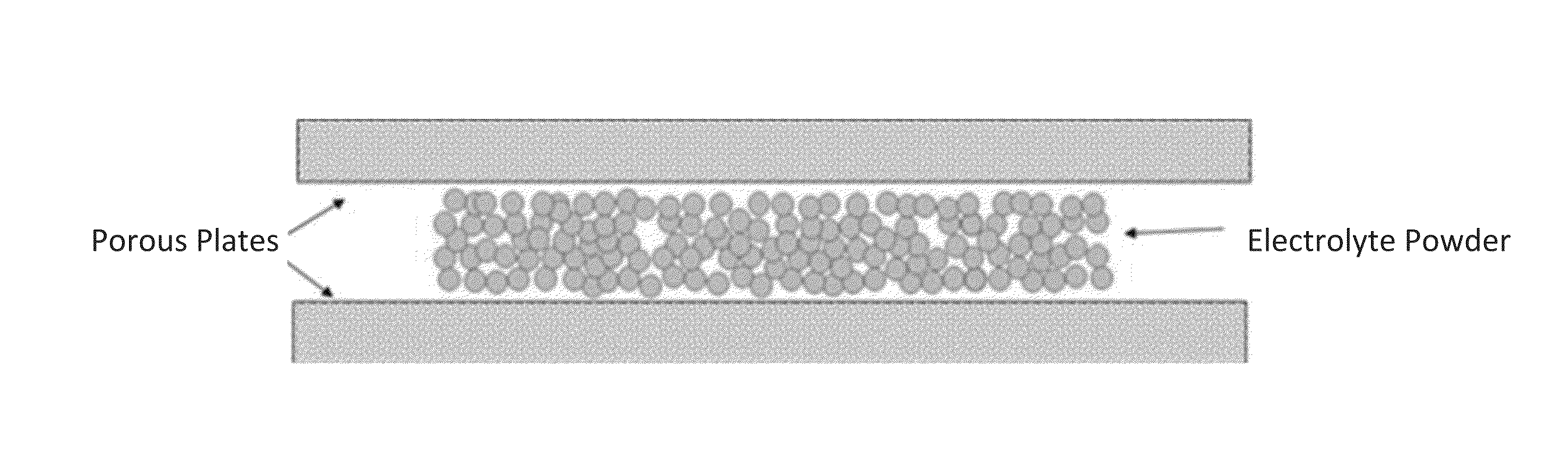

ActiveUS20170179472A1Improve conductivityLow melting pointSolid electrolytesElectrode thermal treatmentParticulatesSolid particle

Solid-state batteries, battery components, and related processes for their production are provided. The battery electrodes or separators contain sintered electrochemically active material, inorganic solid particulate electrolyte having large particle size, and low melting point solid inorganic electrolyte which acts as a binder and / or a sintering aid in the electrode.

Owner:JOHNSON IP HLDG LLC

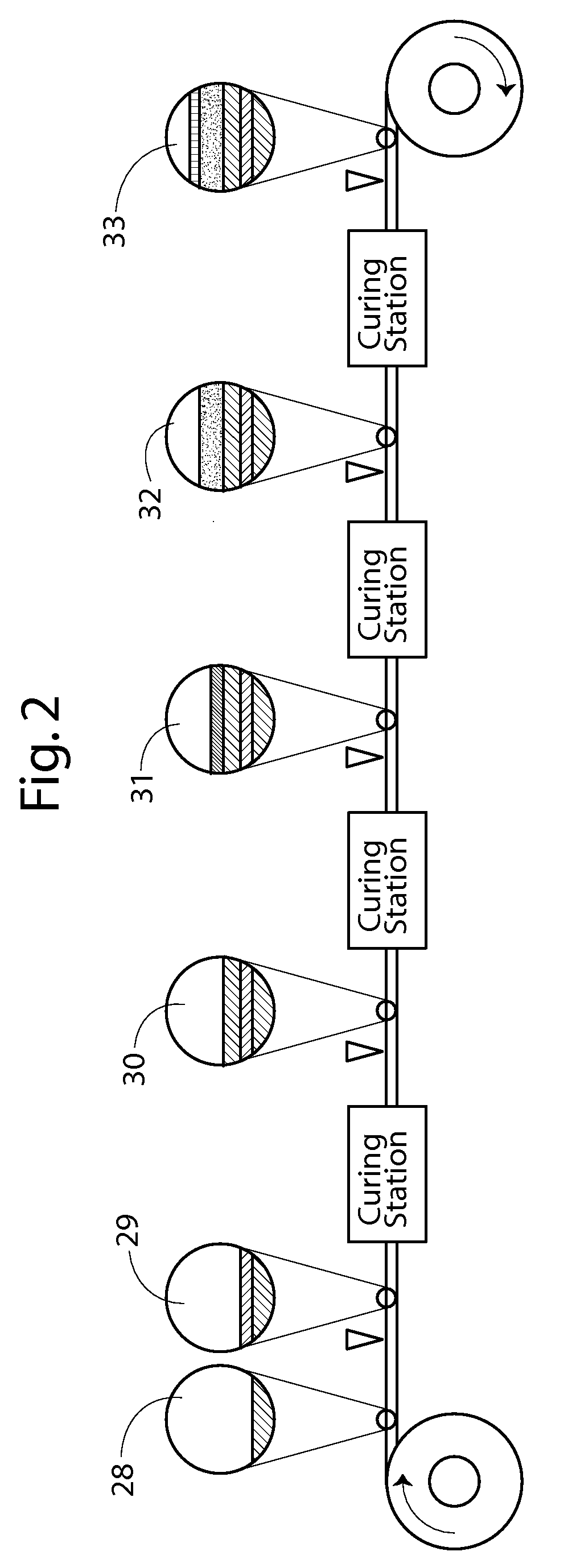

Solid state battery fabrication

ActiveUS20140060723A1Mass productionElectrode thermal treatmentLarge-sized flat cells/batteriesGreen tapePolymer science

Embodiments of the invention generally relate to solid state battery structures, such as Li-ion batteries, methods of fabrication and tools for fabricating the batteries. One or more electrodes and the separator may each be cast using a green tape approach wherein a mixture of active material, conductive additive, polymer binder and / or solid electrolyte are molded or extruded in a roll to roll or segmented sheet / disk process to make green tape, green disks or green sheets. A method of fabricating a solid state battery may include: preparing and / or providing a green sheet of positive electrode material; preparing and / or providing a green sheet of separator material; laminating together the green sheet of positive electrode material and the green sheet of separator material to form a laminated green stack; and sintering the laminated green stack to form a sintered stack comprising a positive electrode and a separator.

Owner:APPLIED MATERIALS INC

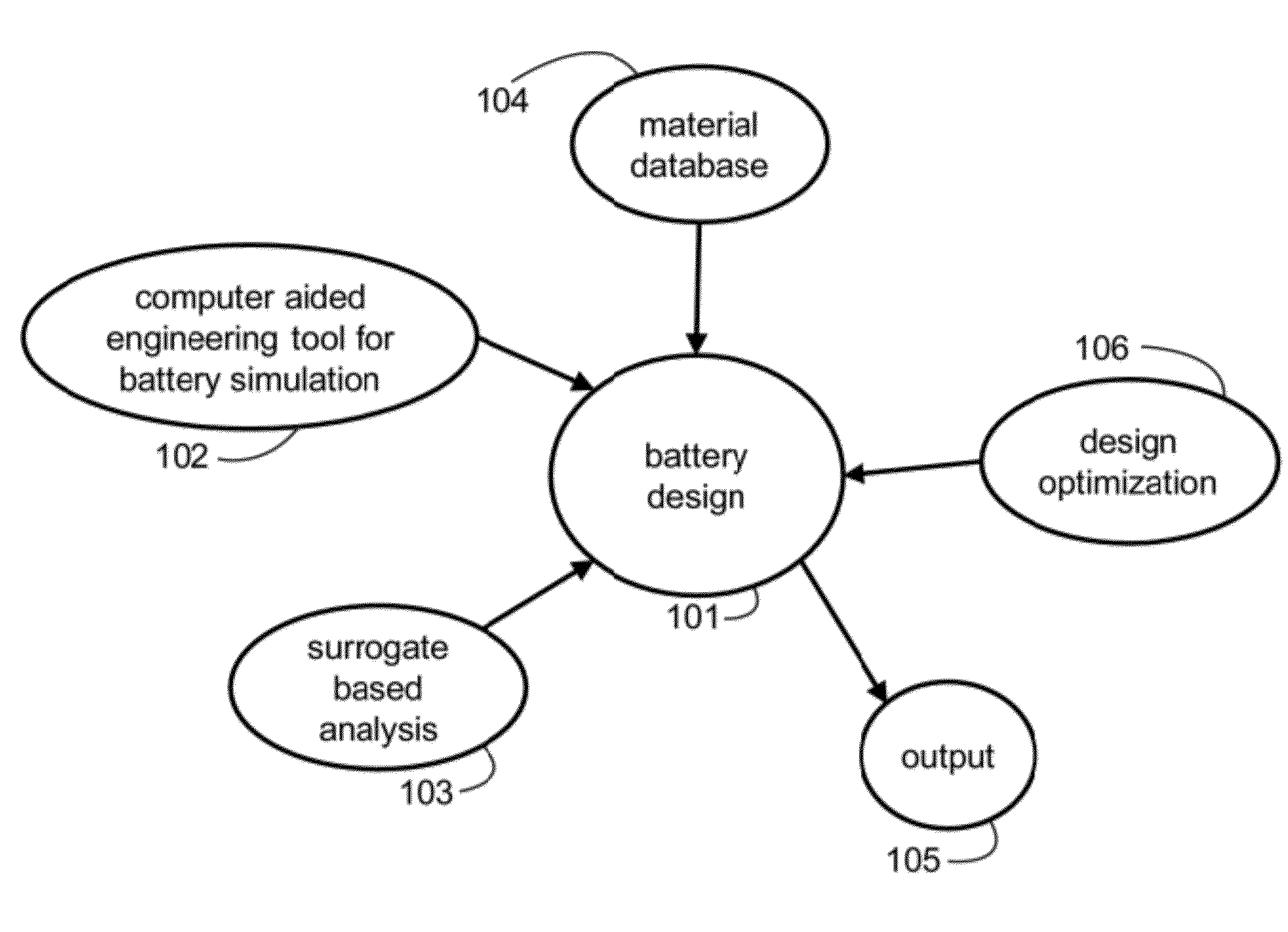

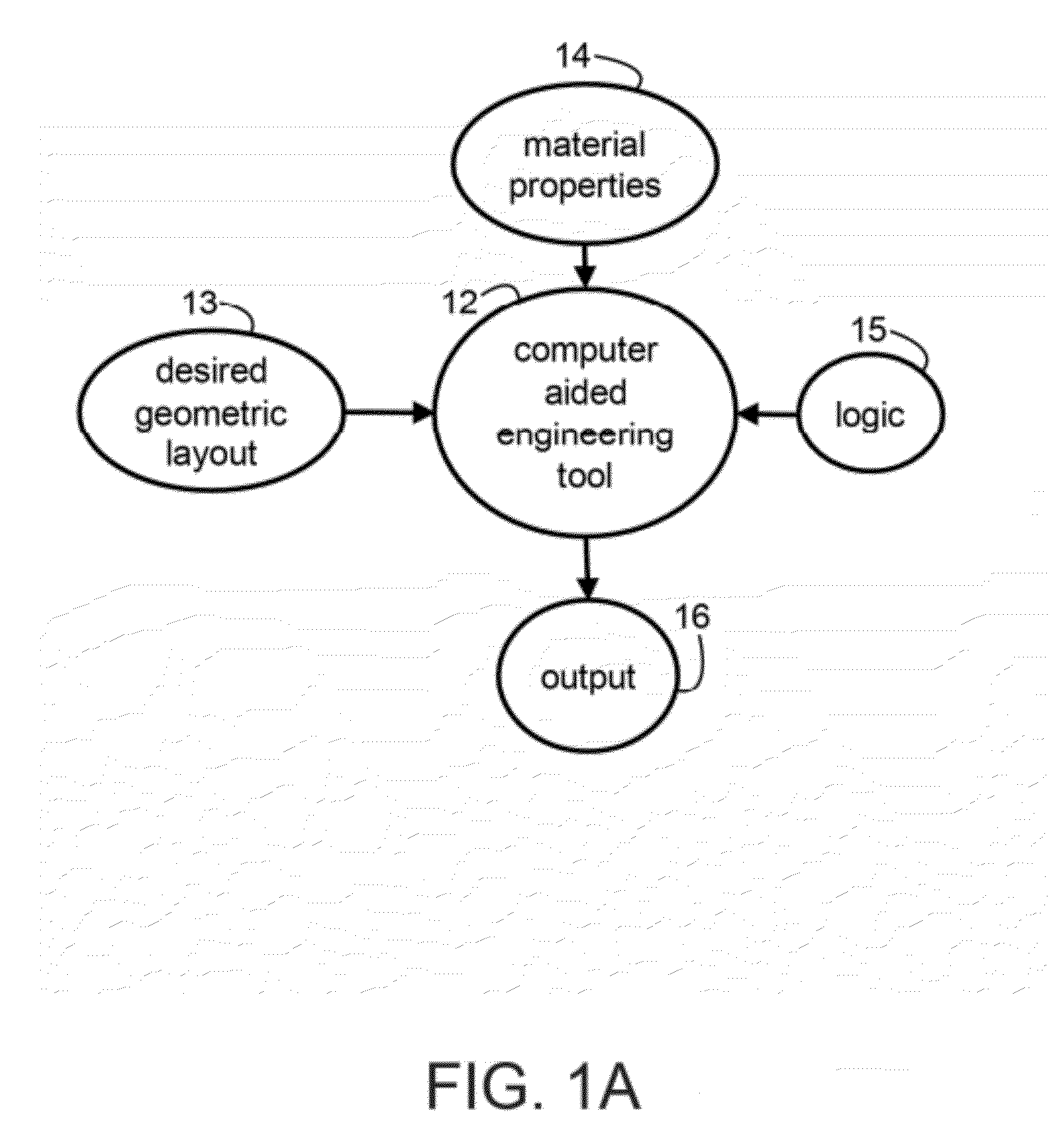

Computer aided solid state battery design method and manufacture of same using selected combinations of characteristics

ActiveUS20120046776A1Eliminates trialEliminate errorsCell electrodesSecondary cells manufactureElectrical batteryProcess engineering

A method of designing and manufacturing a solid-state electrochemical battery cell for a battery device. The method includes building a database of a plurality of first characteristics of a solid-state cells for a battery device and determining at least a third characteristic of the solid-state cell for a given application. The method also includes selecting at least one material of the solid-state electrochemical battery cell, the selected material being from the plurality of first characteristics and forming a plurality of factorial combinations of each component using the selected plurality of first characteristics to derive a respective plurality of solid-state electrochemical battery cells. The method performs a design optimization process for the third characteristic. A step of identifying an optimal design of the second characteristics with the selected first characteristics for each solid-state electrochemical battery cell from the plurality of solid-state cells is included.

Owner:SAKTI3

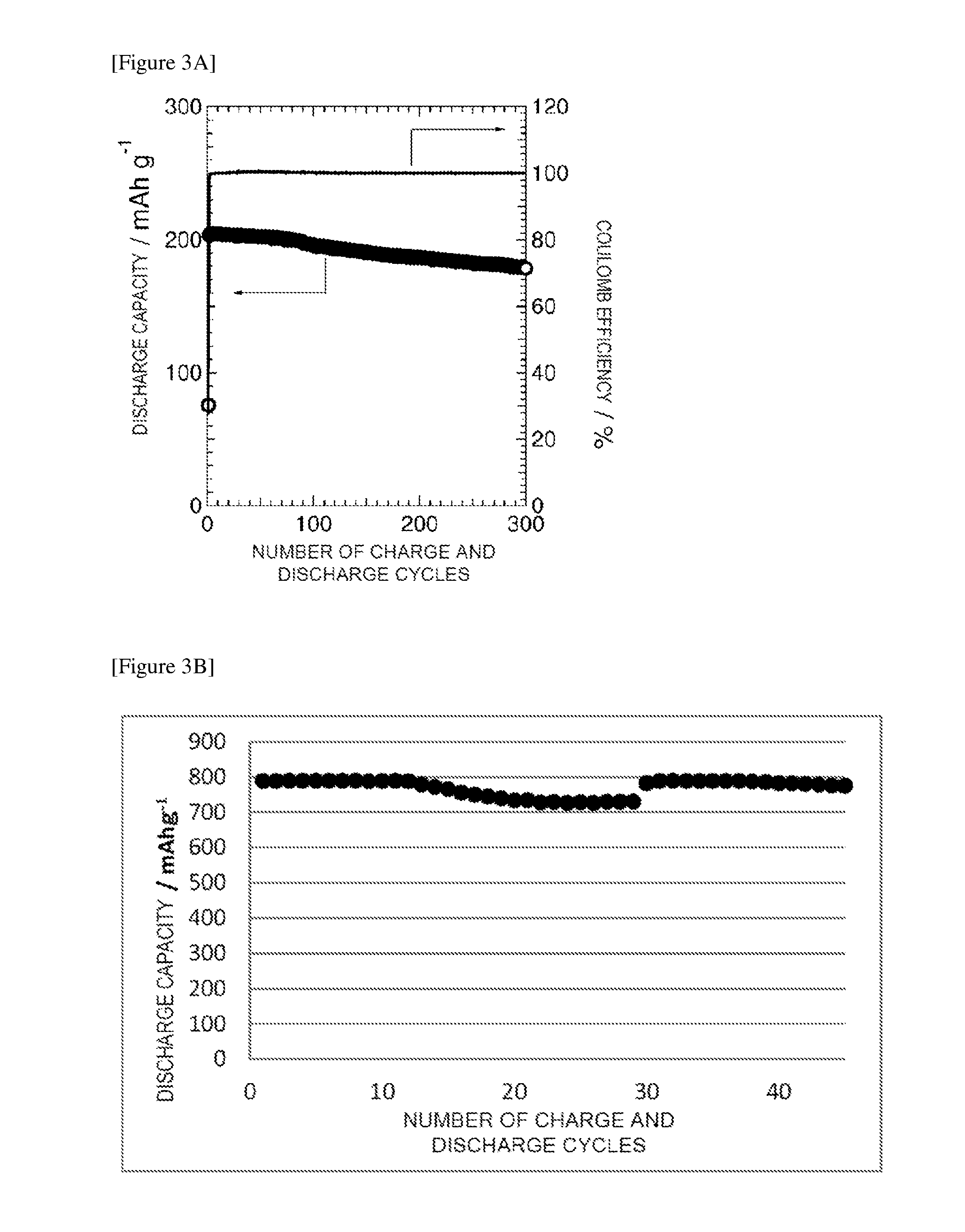

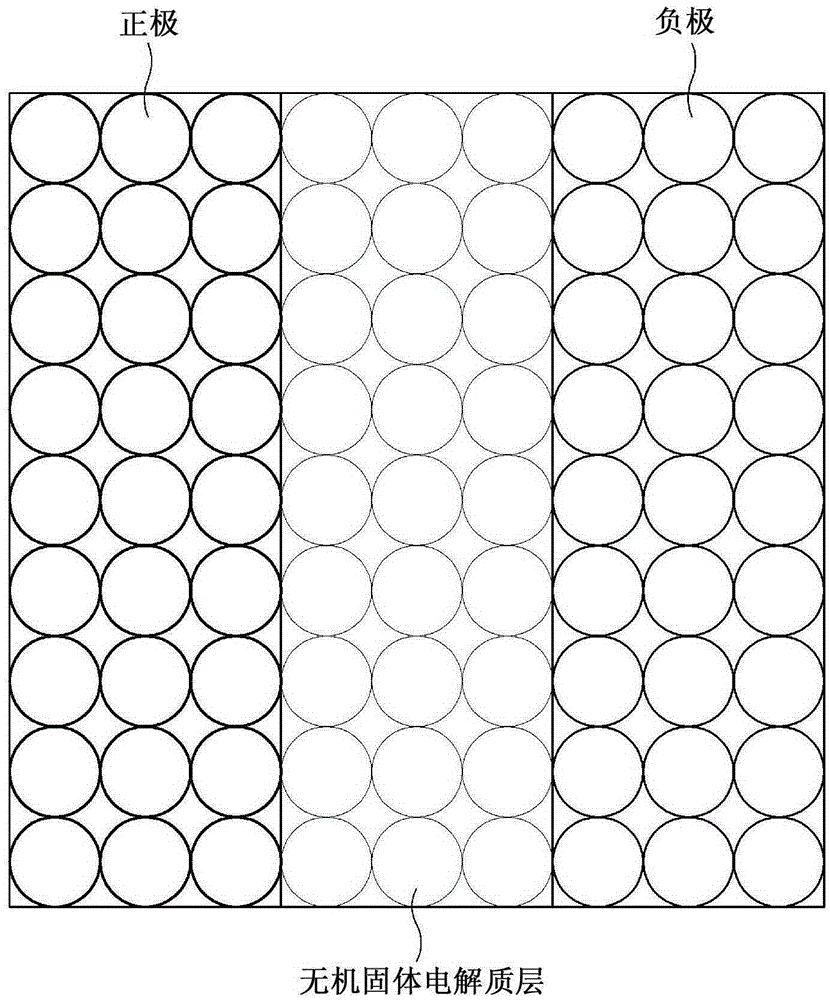

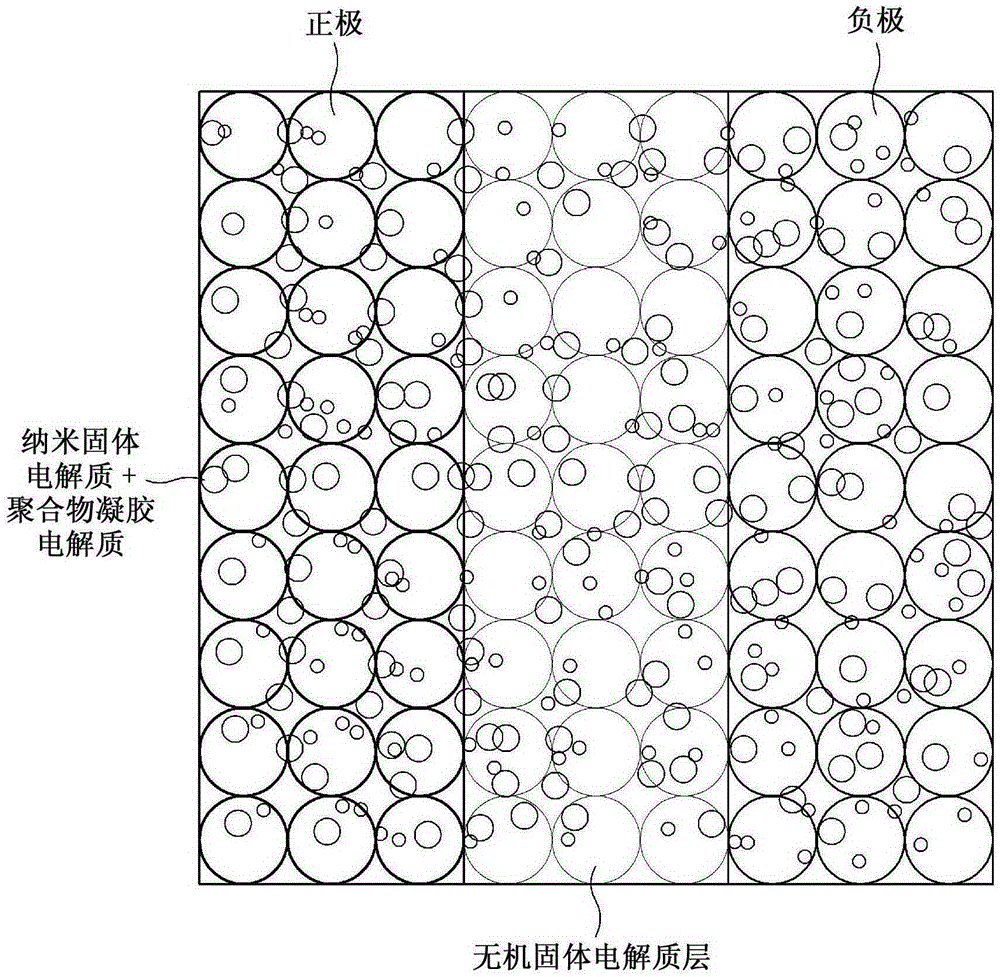

All-solid-state battery containing nano-solid electrolyte and method of manufacturing the same

Provided is an all-solid-state battery containing a nano-solid electrolyte which has excellent stability and enhanced battery performance and can be manufactured without changing an existing process, and a method of manufacturing the same. Due to substantially improved battery performance, as well as having excellent safety, the all-solid-state battery containing a nano-solid electrolyte may be widely used and further contribute to industrial development such as electric vehicles in which medium and large lithium ion rechargeable batteries are used.

Owner:HYUNDAI MOTOR CO LTD

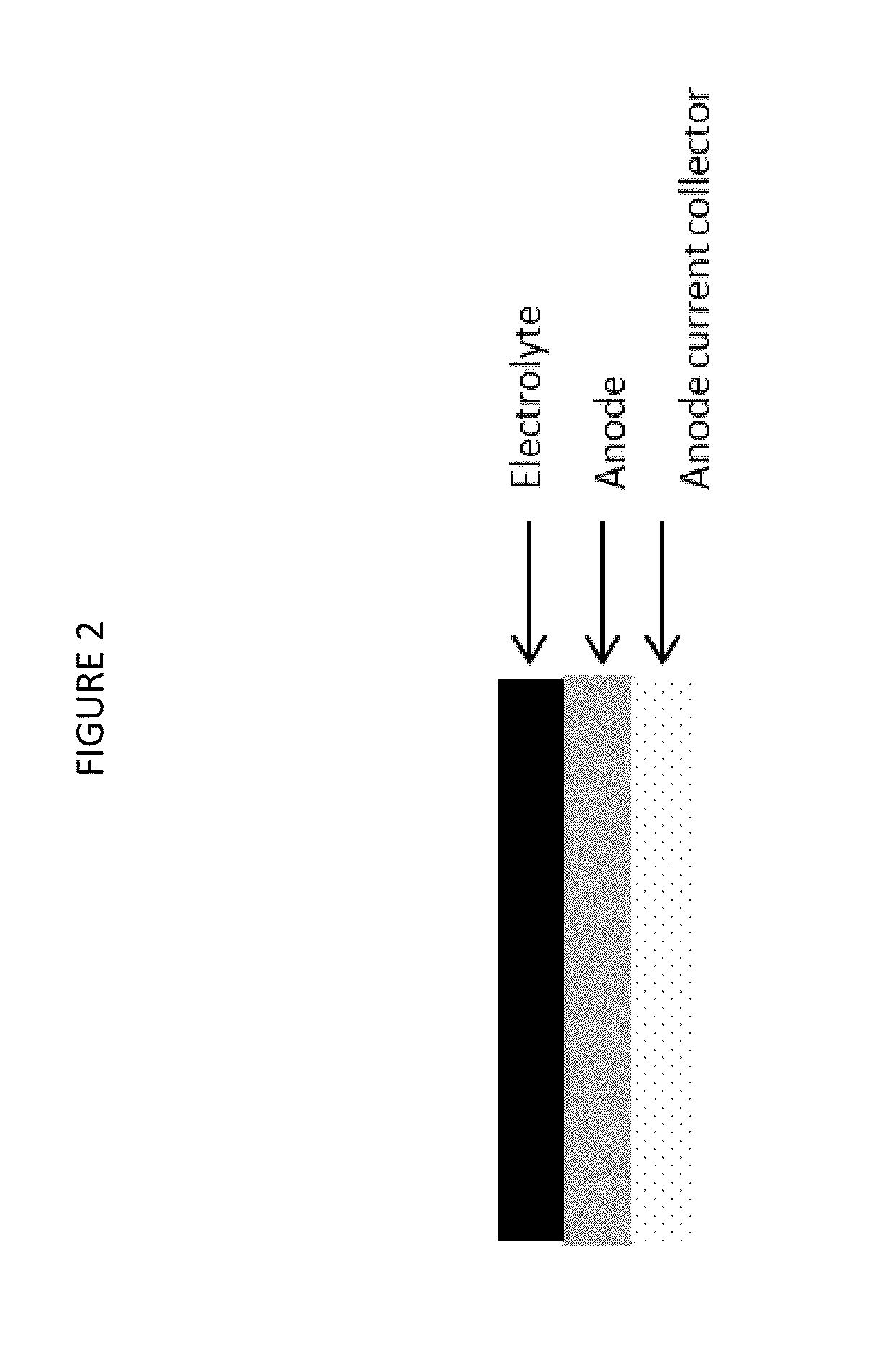

Solid-state battery and method for manufacturing of such a solid-state battery

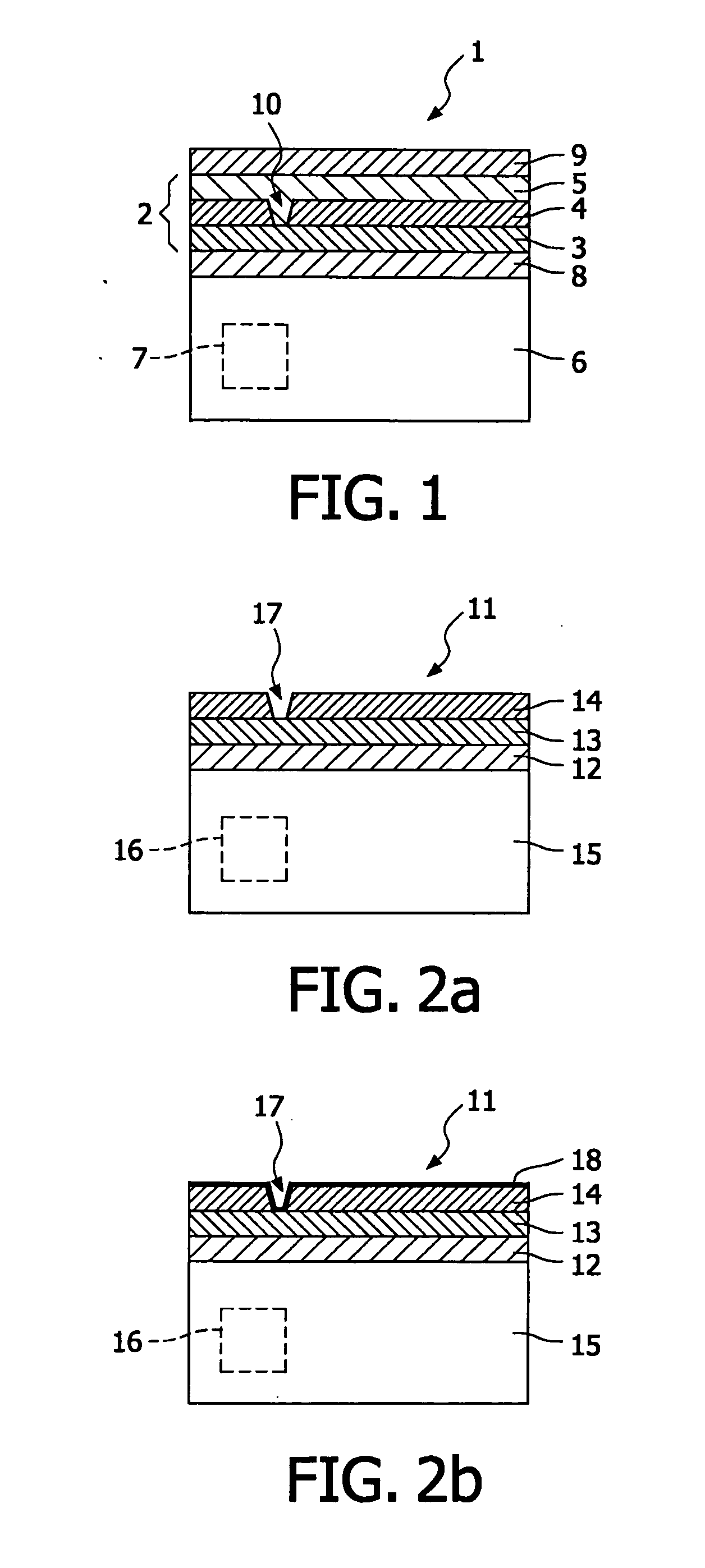

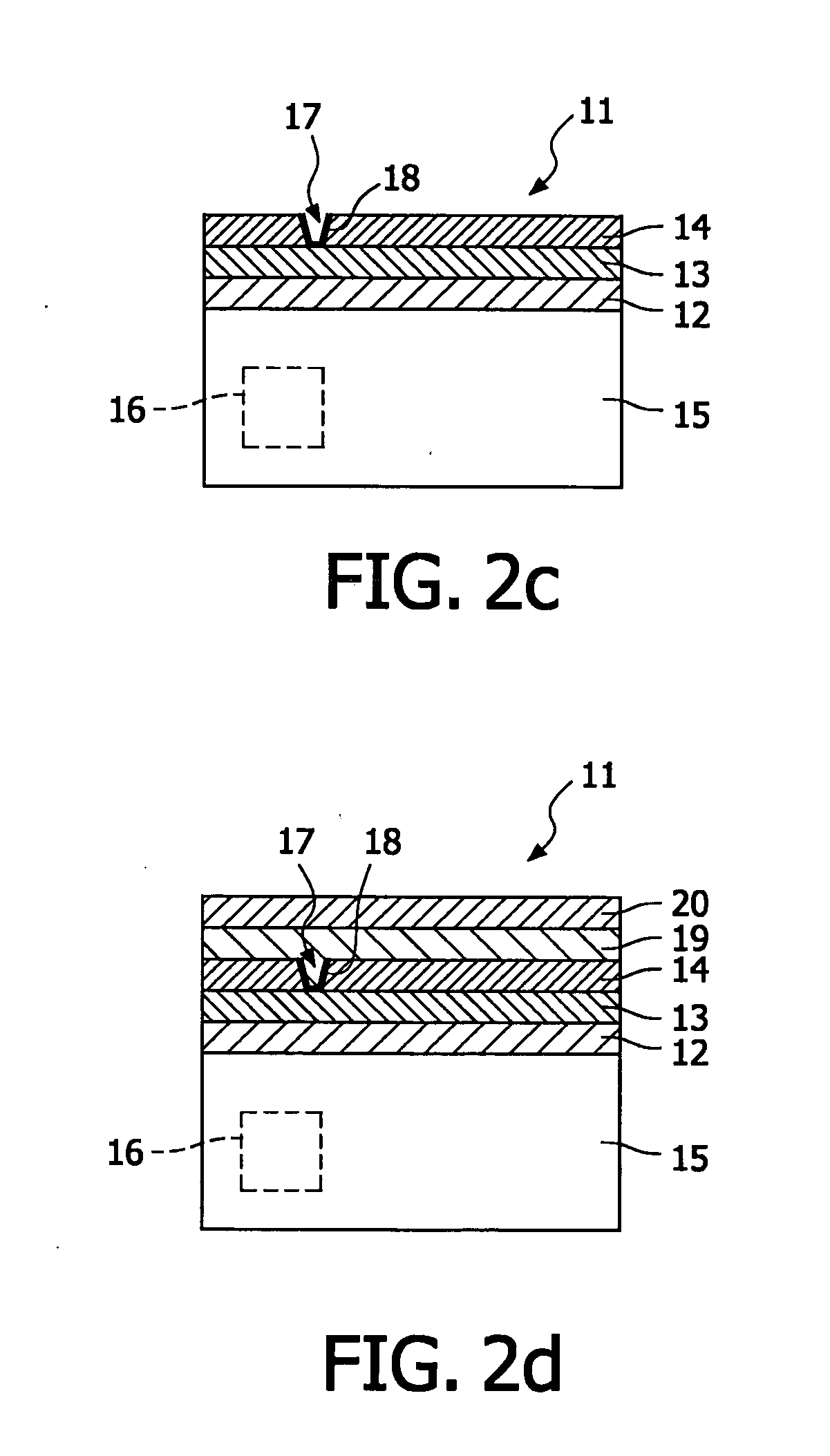

InactiveUS20100233548A1Lower impedanceImprove battery performanceFinal product manufactureElectrode carriers/collectorsSolid state electrolyteElectricity

Batteries based on solid-state electrolytes are known in the art. These (planar) energy sources, or solid-state batteries, efficiently convert chemical energy into electrical energy and can be used as the power sources for portable electronics. The invention relates to a method for manufacturing of a solid-state battery in which the pinholes in a solid electrolyte are at least partially filled by the deposition of an electrically insulating layers. The invention also relates to a battery obtained by performing such a method. The invention further relates to an electronic device provided with such a battery.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

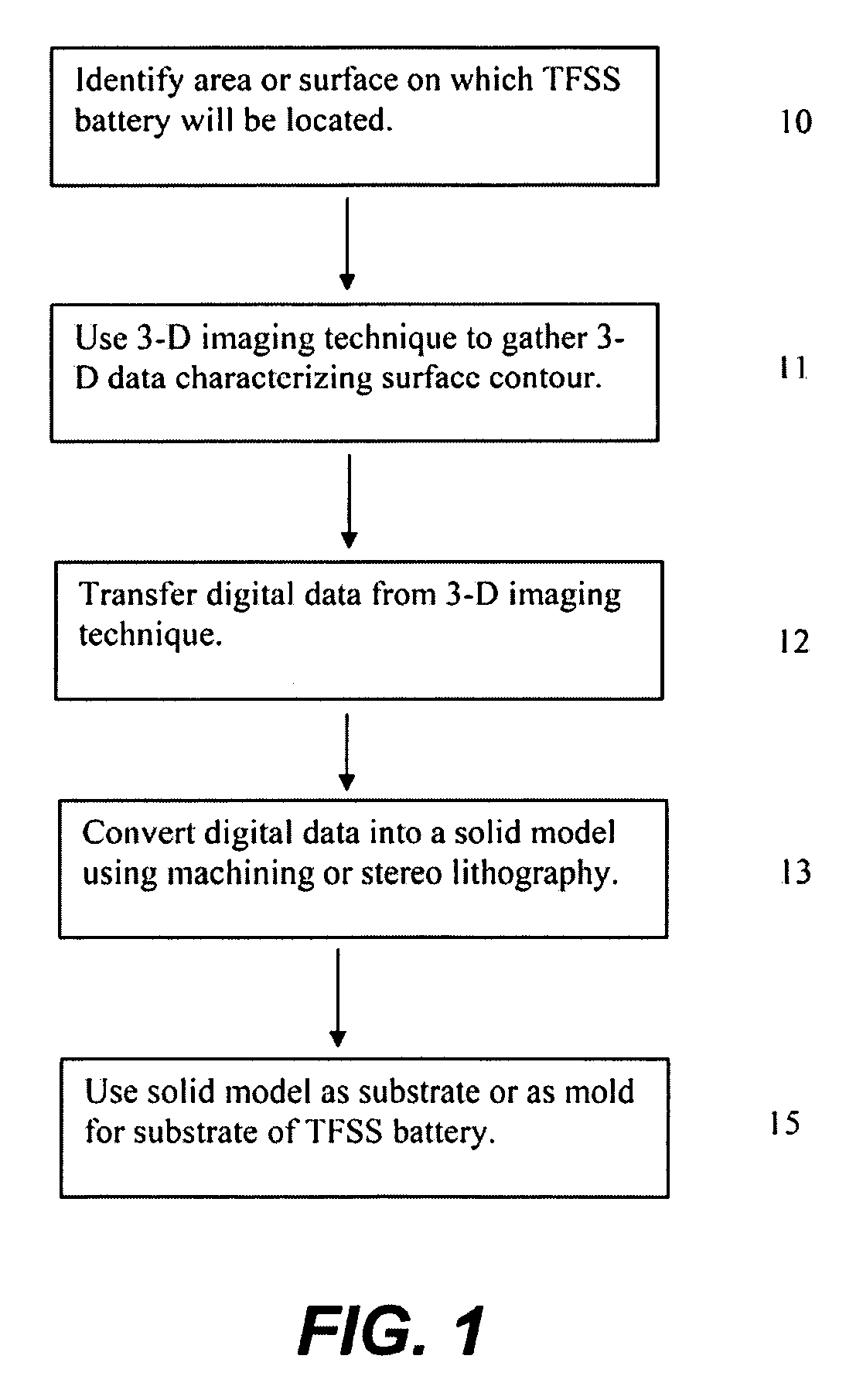

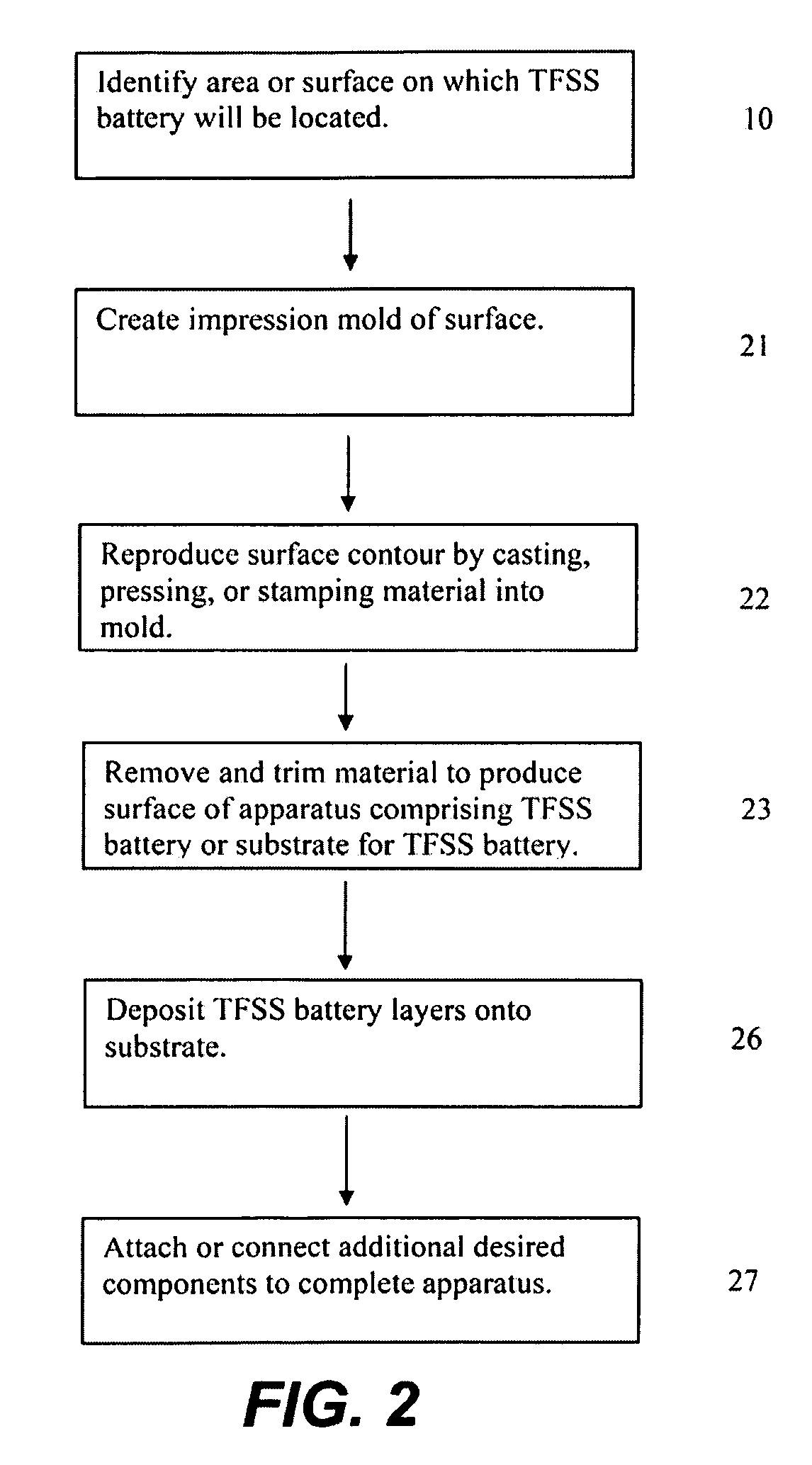

Electrical apparatus with integral thin film solid state battery and methods of manufacture

InactiveUS20090202899A1ElectrotherapyFinal product manufactureElectrical devicesThree dimensional shape

The invention provides a thin film solid state (TFSS) battery that can conform to the surface of an apparatus having a complex, three-dimensional surface. The invention also provides methods for constructing the thin film solid state battery by forming components directly onto a substrate of a complex three-dimensional shape. The resulting thin film solid state battery can be used to power electronics associated with a variety of devices such as medical devices.

Owner:GENESEE NORTHERN RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com