Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

113 results about "Green tape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of manufacturing heat pipe having sintered powder wick

InactiveUS20060197245A1Improve heat transfer performanceImprove the preparation effectLinings repairLaminationGreen tapeMetallurgy

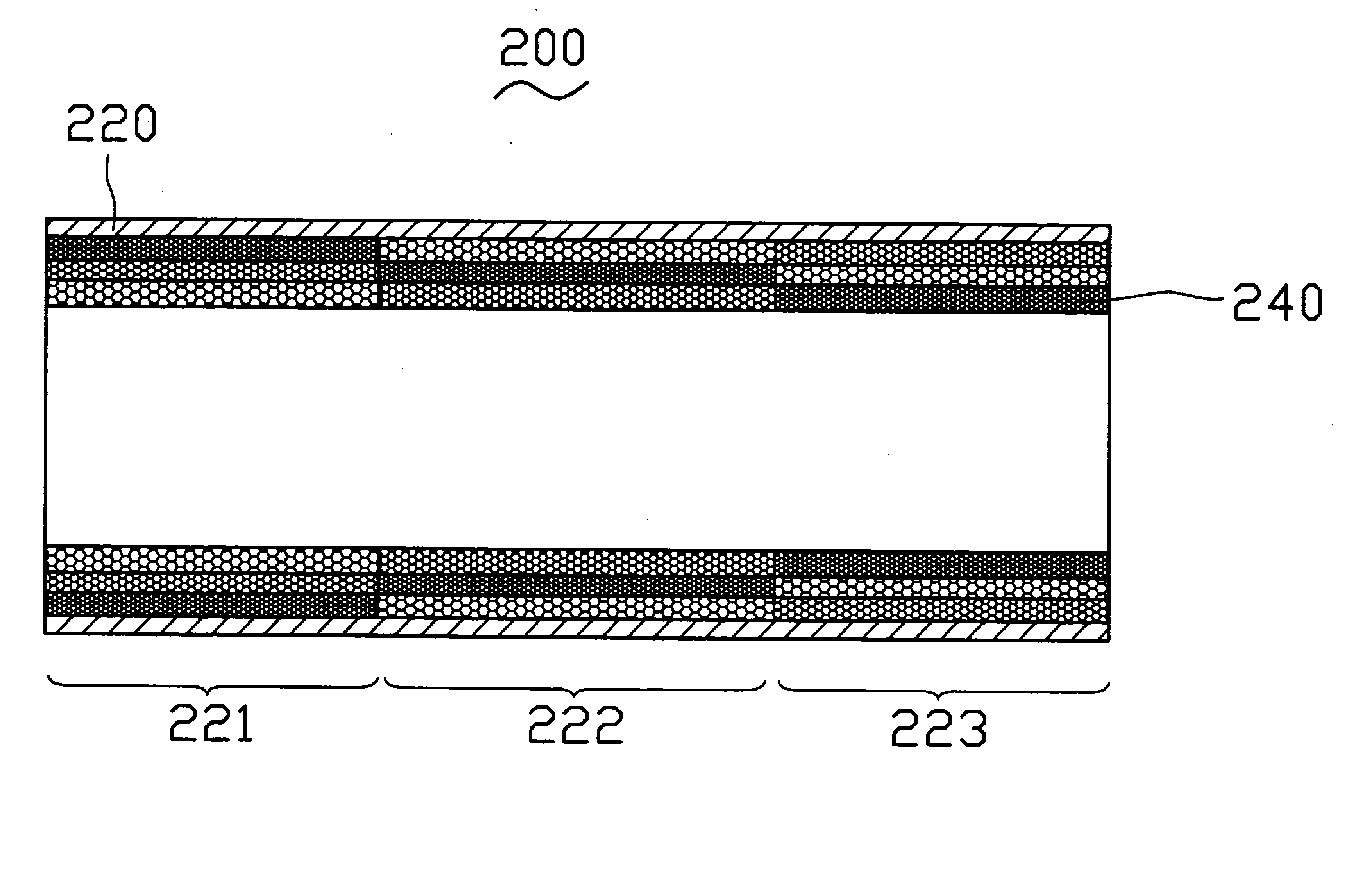

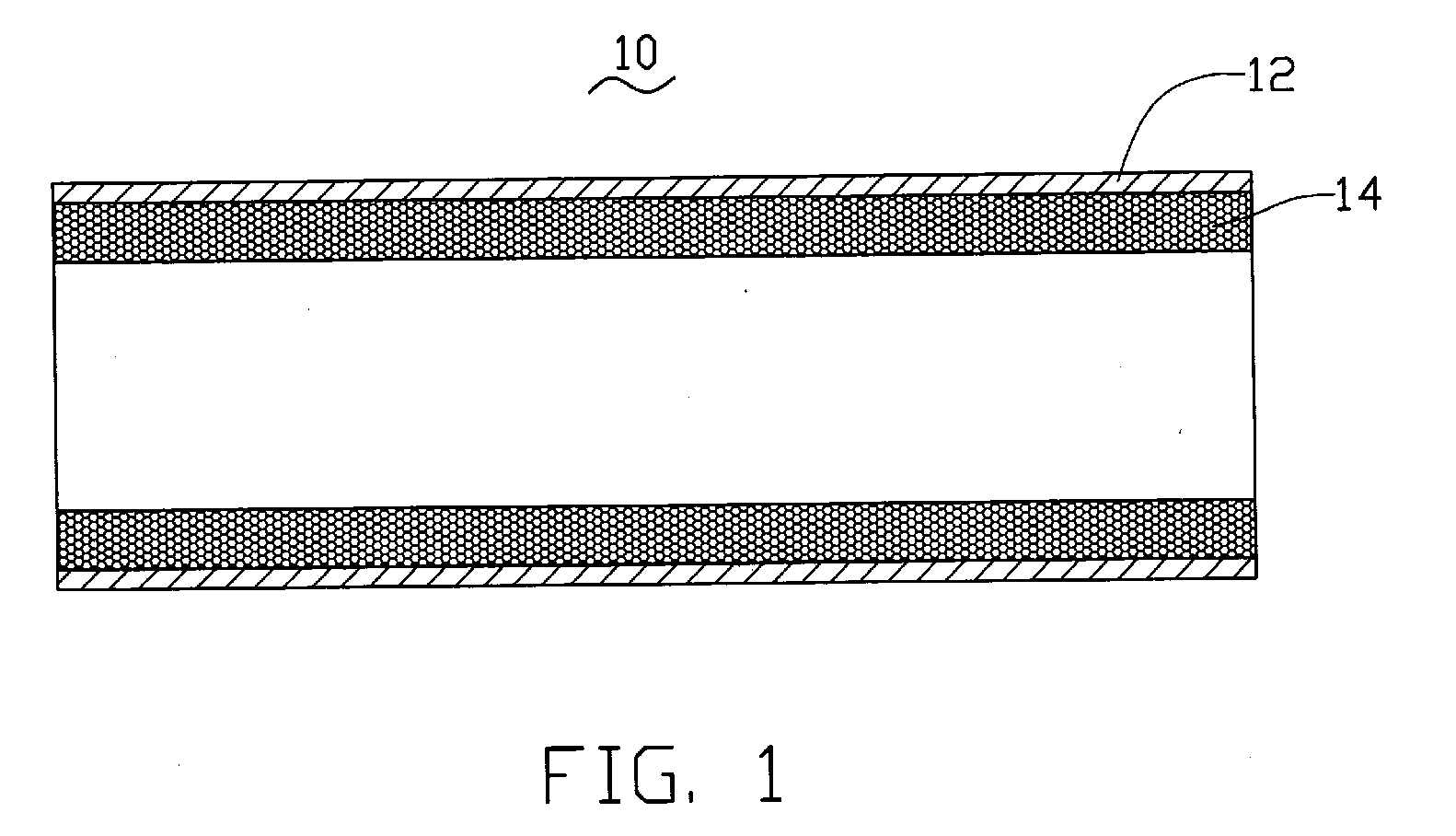

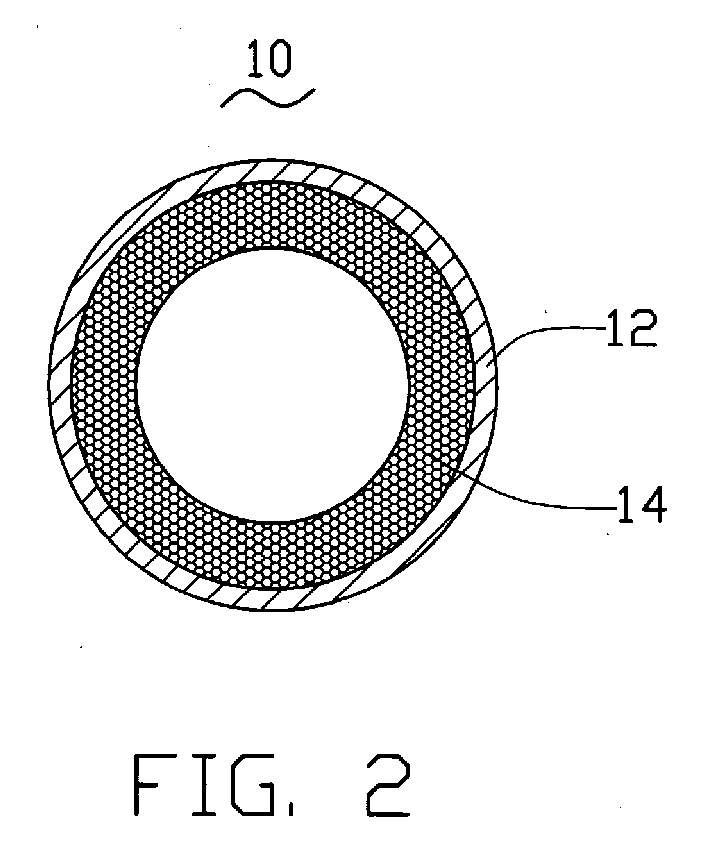

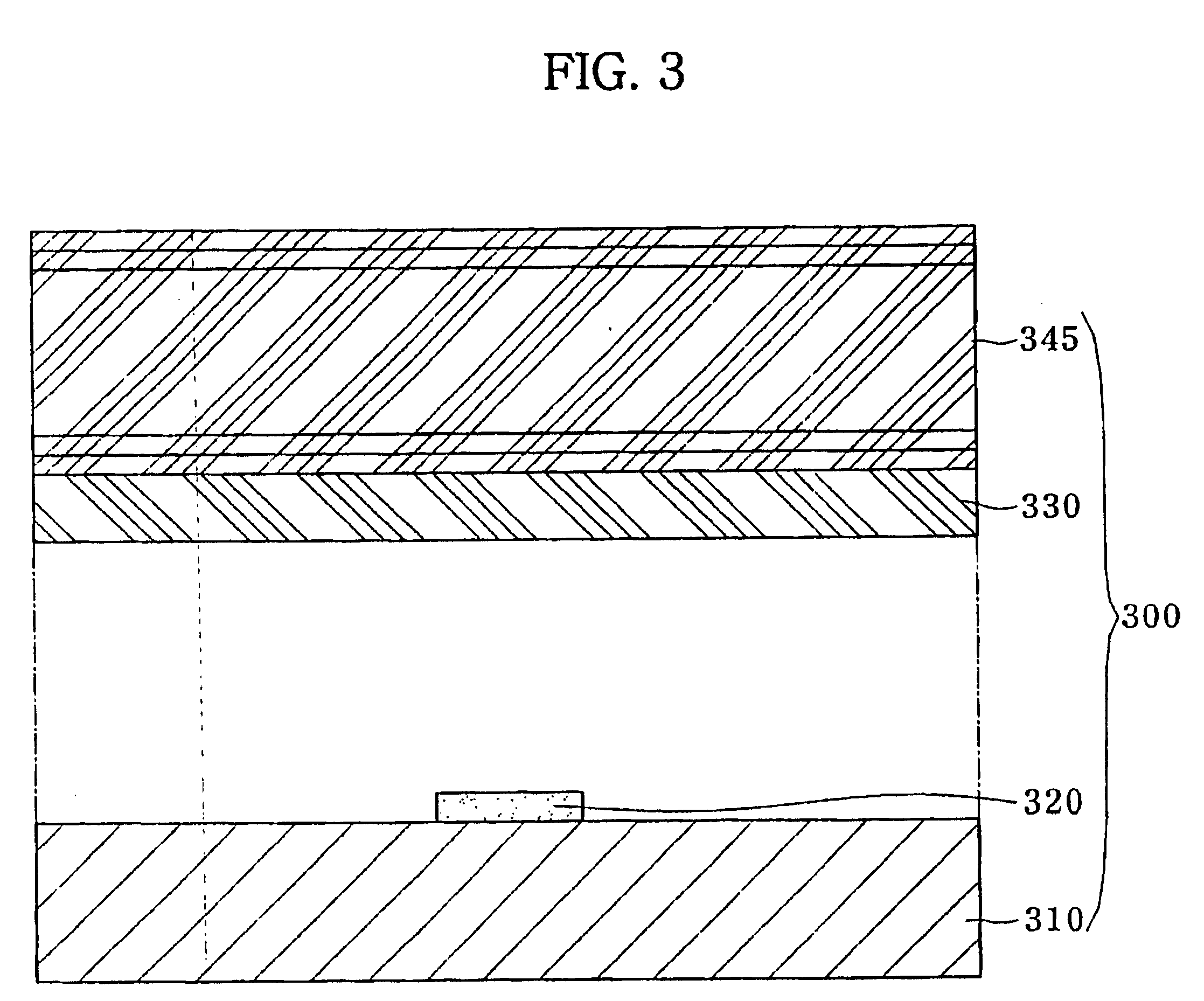

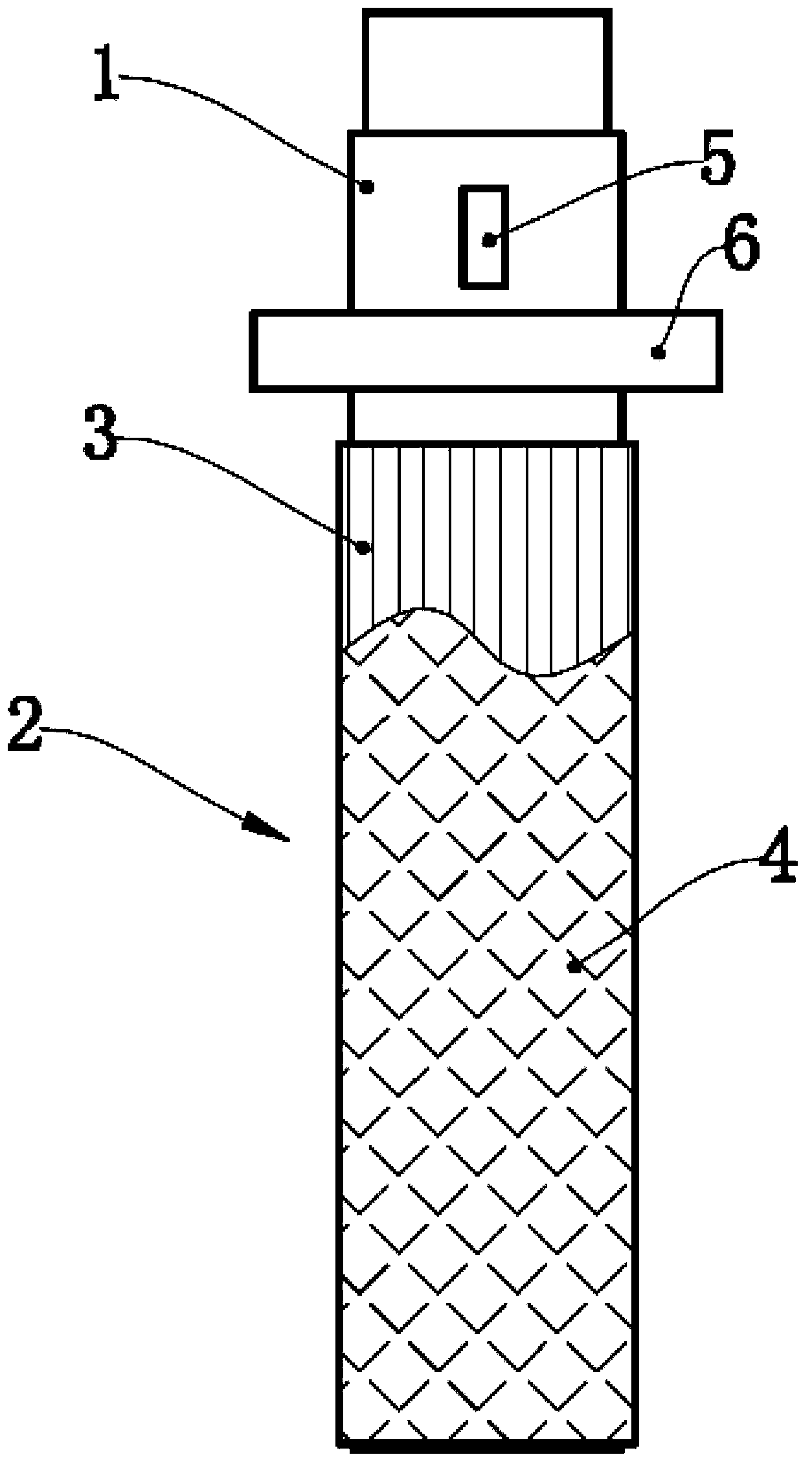

A method is disclosed to produce a heat pipe with a sintered powder wick formed inside the heat pipe. The method employs tape-casting technology to firstly produce thin sheets of powder and then these sheets are sintered to form the wick. In the tape casting procedure, a slurry of the powders necessary to construct said wick is cast onto a moving surface to form a slurry layer and then the slurry layer is dried to form a green tape. The green tape is rolled onto a mandrel and then is inserted into a hollow casing and sintered to cause the powders in the green tape to diffusion-bond together. Thus, the sintered powder wick is constructed.

Owner:HON HAI PRECISION IND CO LTD

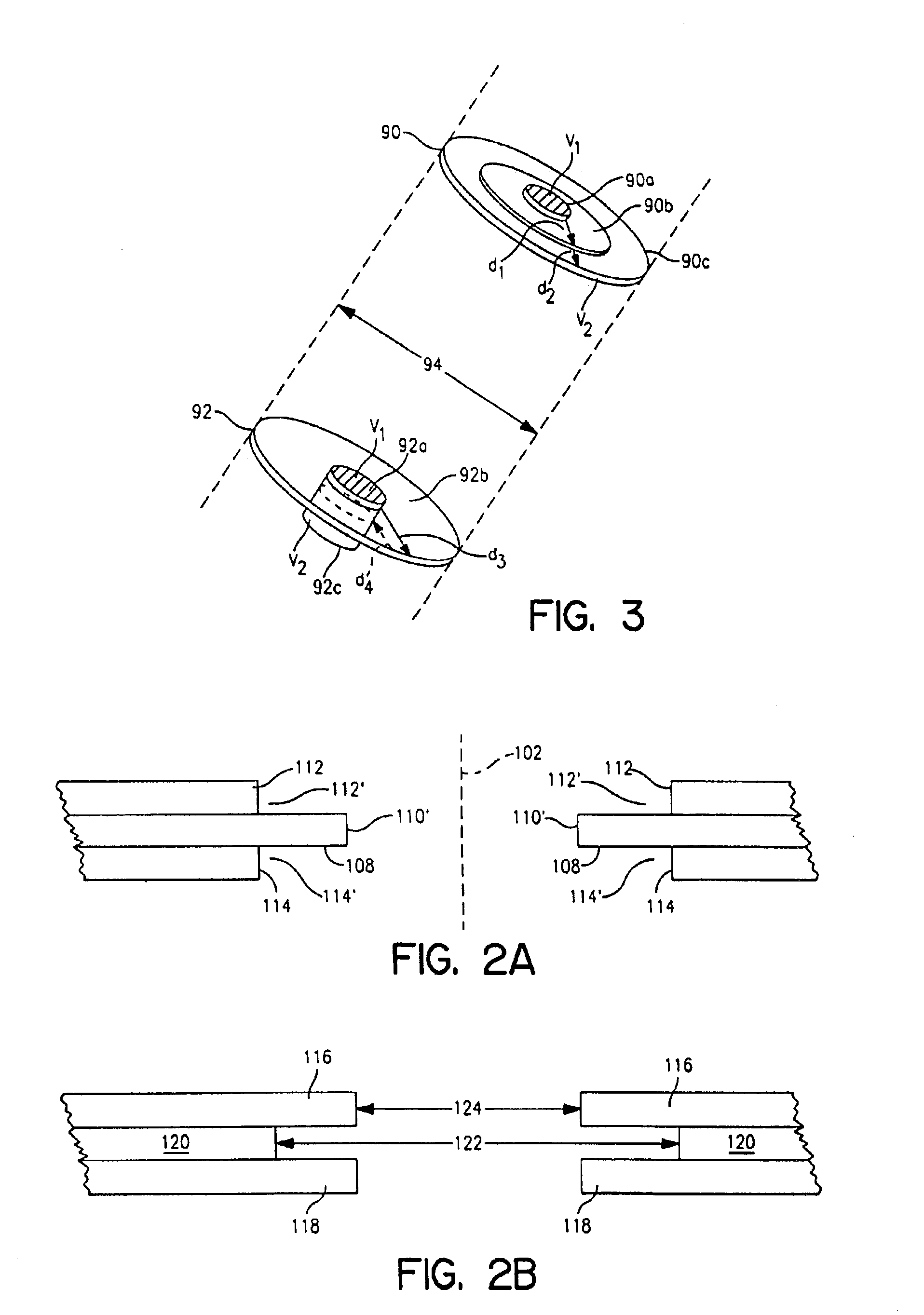

Unitary vacuum tube incorporating high voltage isolation

InactiveUS6837766B2Improve isolationLinear distance increasesGas filling substance selectionCathode-ray/electron-beam tube vessels/containersGreen tapeHigh pressure

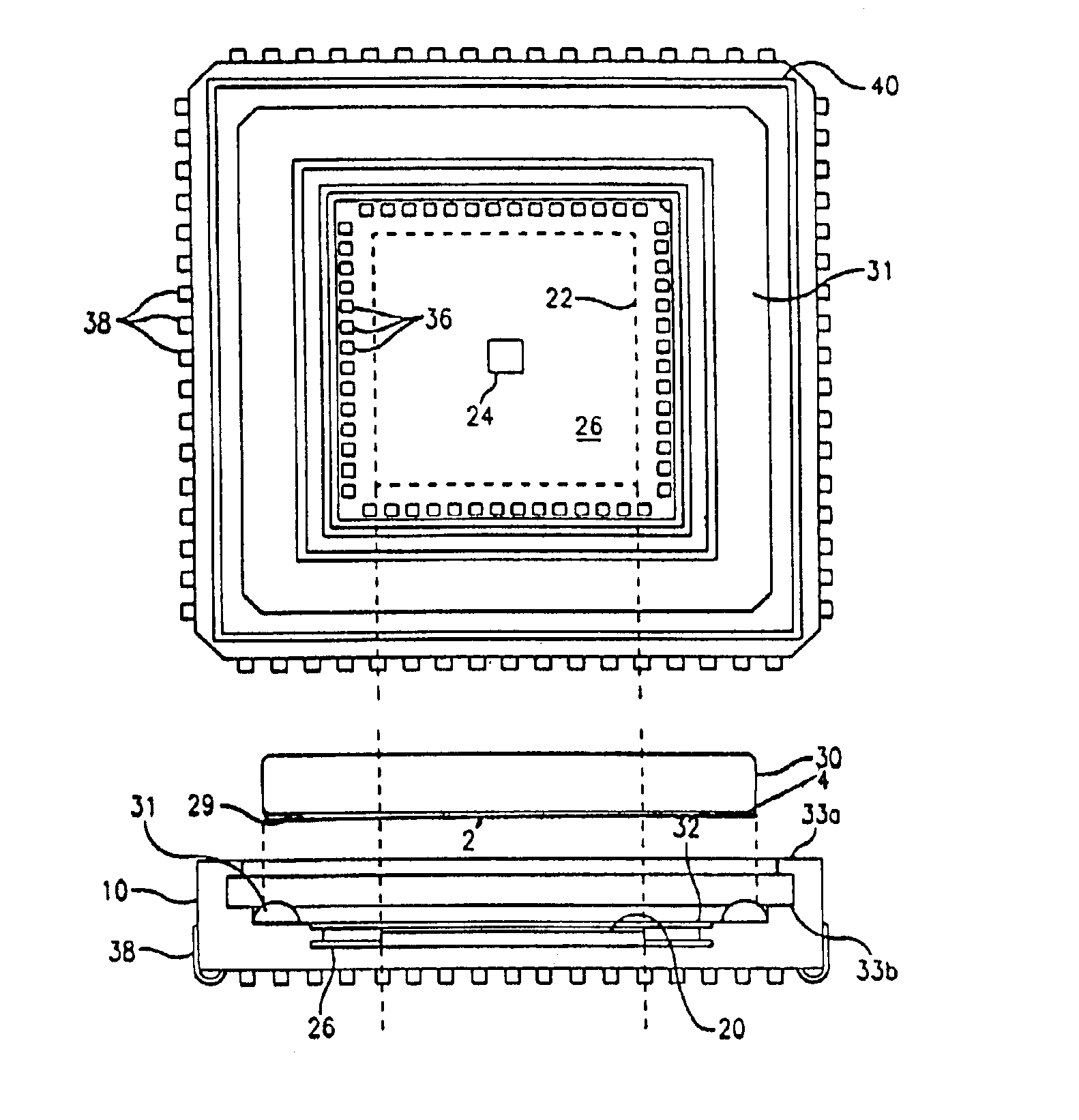

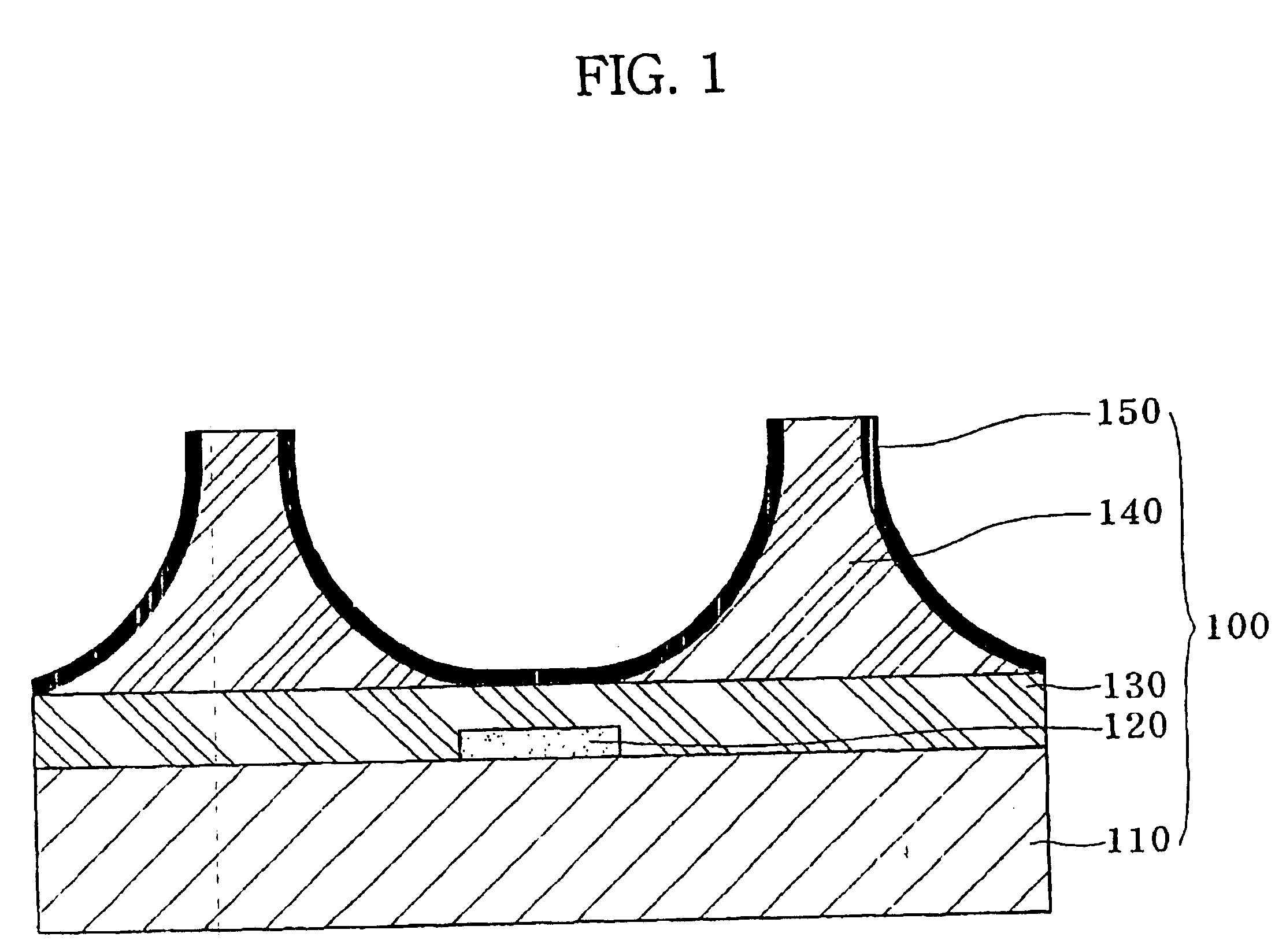

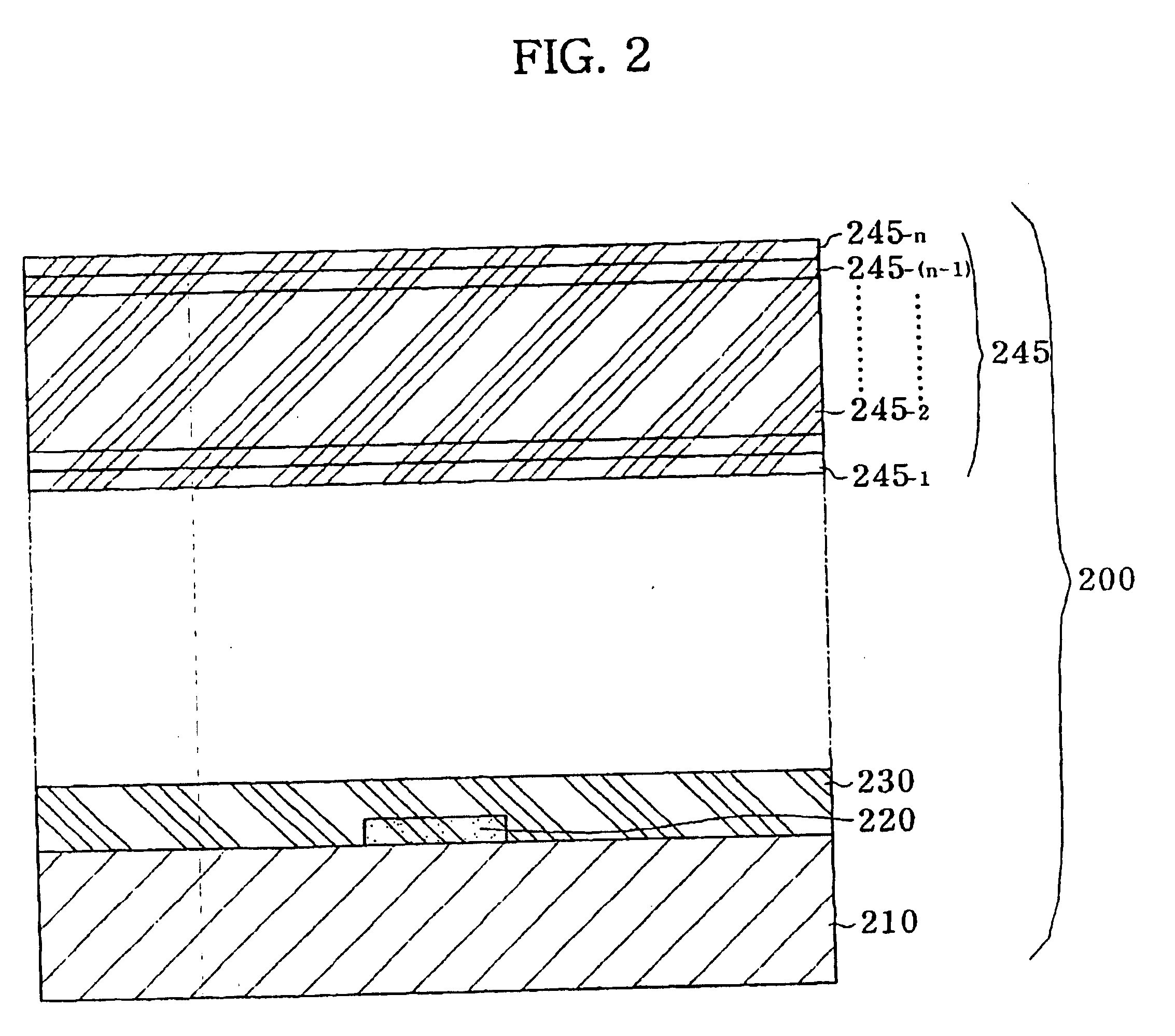

A housing for microelectronic devices requiring an internal vacuum for operation, e.g., an image detector, is formed by tape casting and incorporates leads between interior and exterior of the housing where the leads are disposed on a facing surface of green tape layers. Adjacent green tape layers having corresponding apertures therein are stacked on a first closure member to form a resulting cavity and increased electrical isolation or channel sub-structures are achievable by forming adjacent layers with aperture dimension which vary non-monotonically. After assembly of the device within the cavity, a second closure member is sealed against an open face of the package in a vacuum environment to produce a vacuum sealed device.

Owner:EOTECH LLC

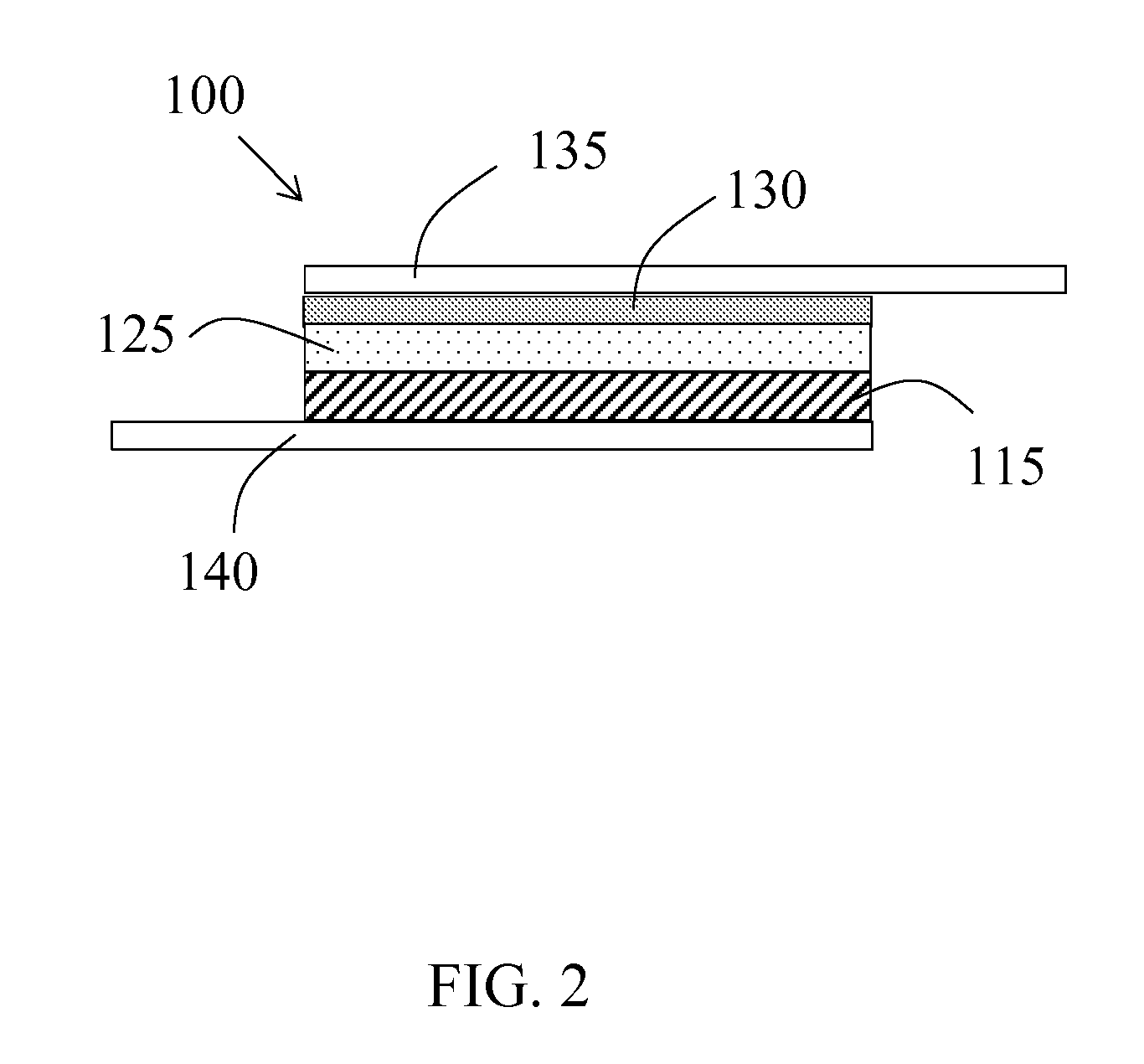

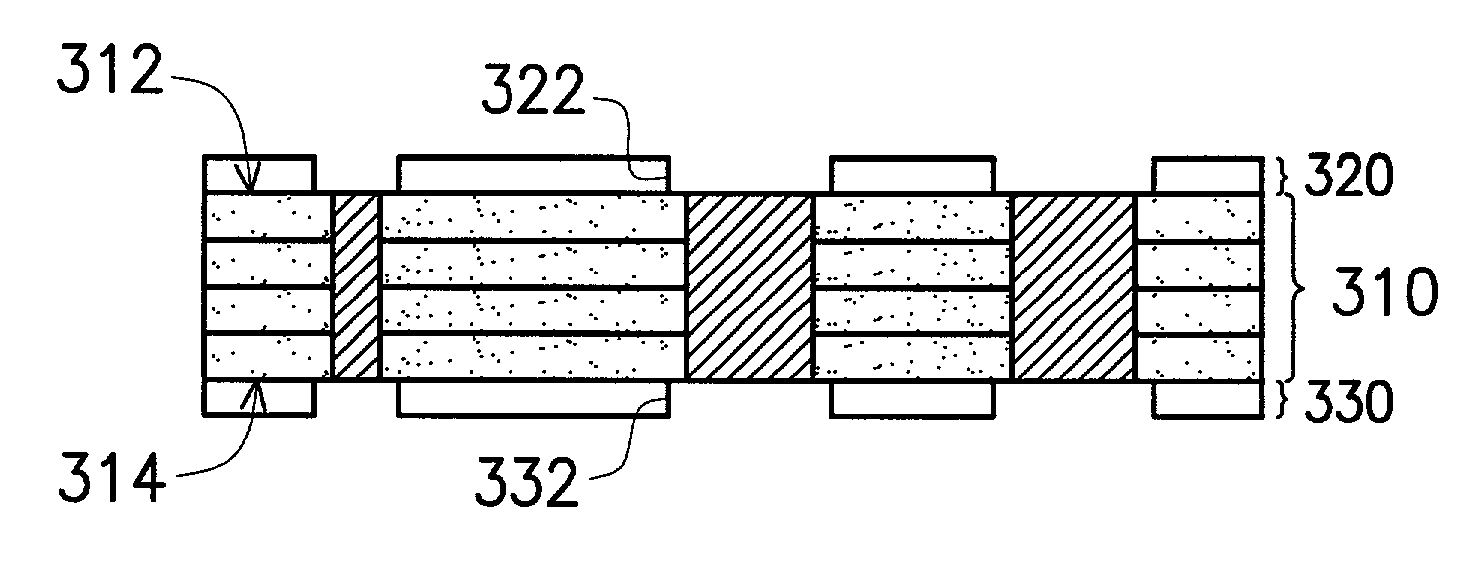

Solid state battery fabrication

ActiveUS20140060723A1Mass productionElectrode thermal treatmentLarge-sized flat cells/batteriesGreen tapePolymer science

Embodiments of the invention generally relate to solid state battery structures, such as Li-ion batteries, methods of fabrication and tools for fabricating the batteries. One or more electrodes and the separator may each be cast using a green tape approach wherein a mixture of active material, conductive additive, polymer binder and / or solid electrolyte are molded or extruded in a roll to roll or segmented sheet / disk process to make green tape, green disks or green sheets. A method of fabricating a solid state battery may include: preparing and / or providing a green sheet of positive electrode material; preparing and / or providing a green sheet of separator material; laminating together the green sheet of positive electrode material and the green sheet of separator material to form a laminated green stack; and sintering the laminated green stack to form a sintered stack comprising a positive electrode and a separator.

Owner:APPLIED MATERIALS INC

Hand-held terminal product appearance ceramic thin type member and production method thereof

A method for making a thin ceramic part involves making a casting slurry including a ceramic powder, a solvent, a binder, a plasticizer, and a dispersant. The casting slurry is tape casted to achieve a single layer green tape. At least two single layer green tapes are laminated to form a green tape lamination. The green tape lamination is dry pressed, dried, shaped, degreased, and fired to achieve the exterior component required.

Owner:TSINGHUA UNIV +1

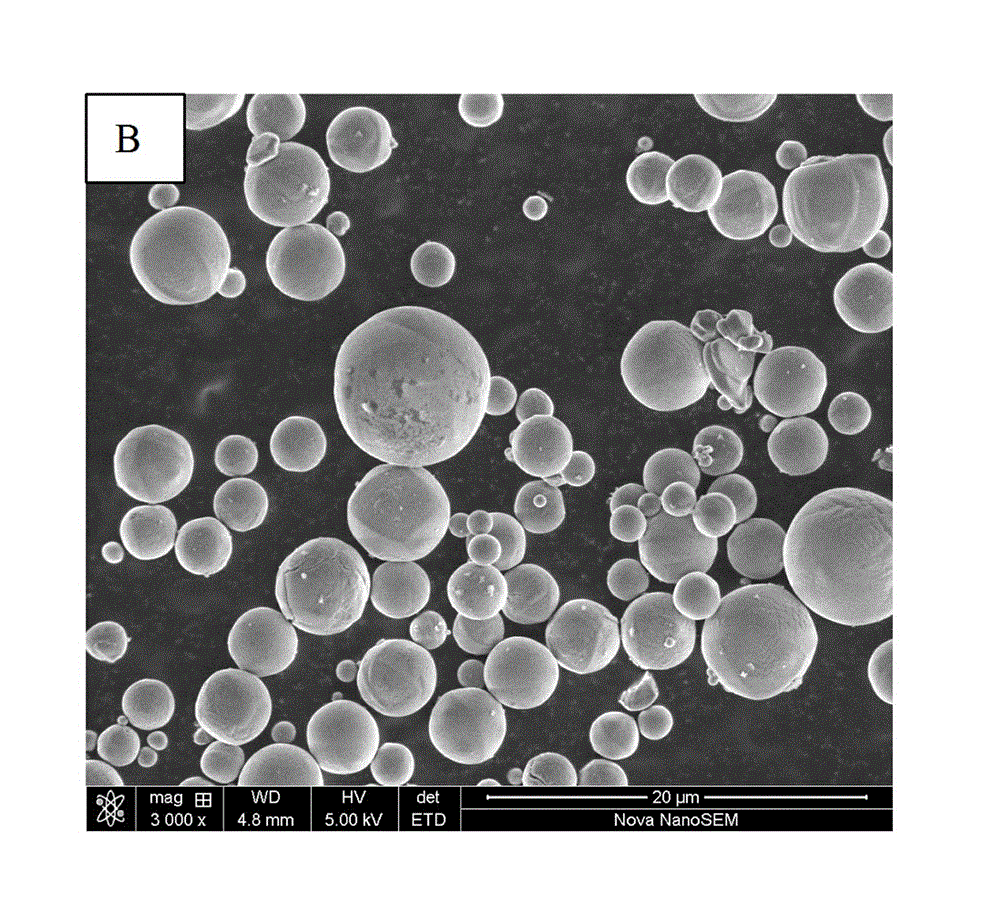

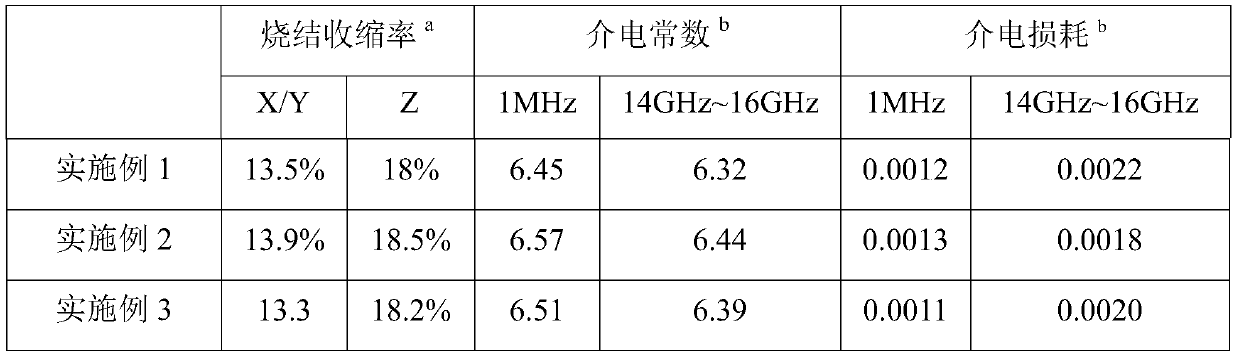

Borosilicate glass-spherical alumina low temperature co-fired ceramic green tape and preparation method thereof

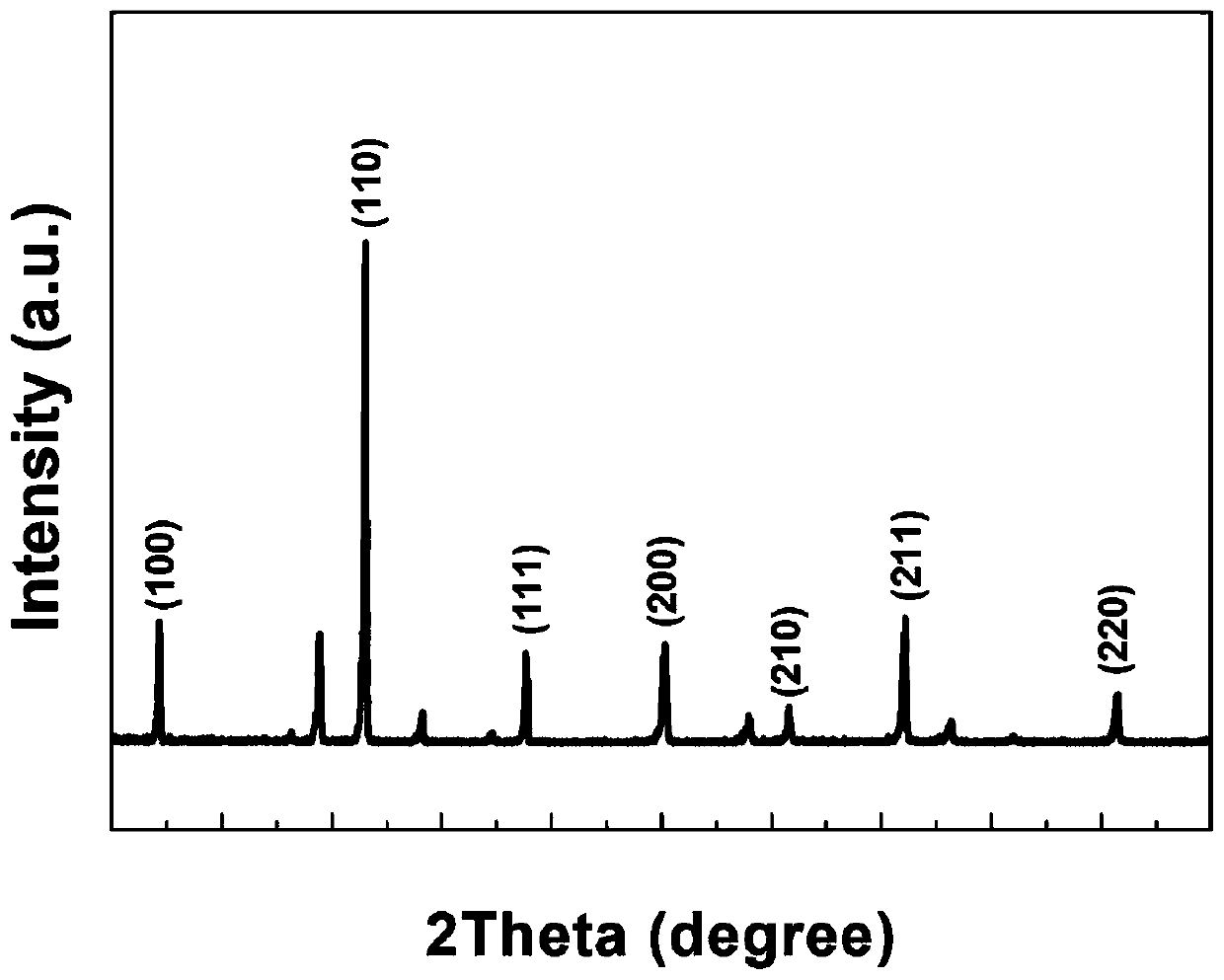

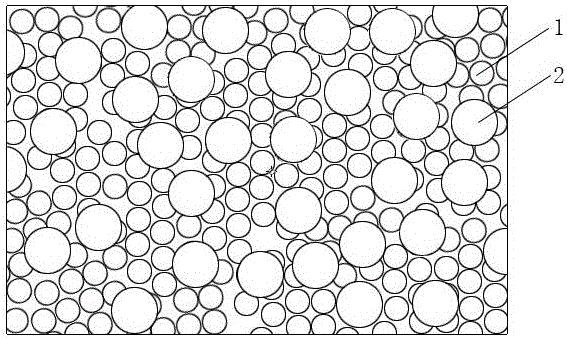

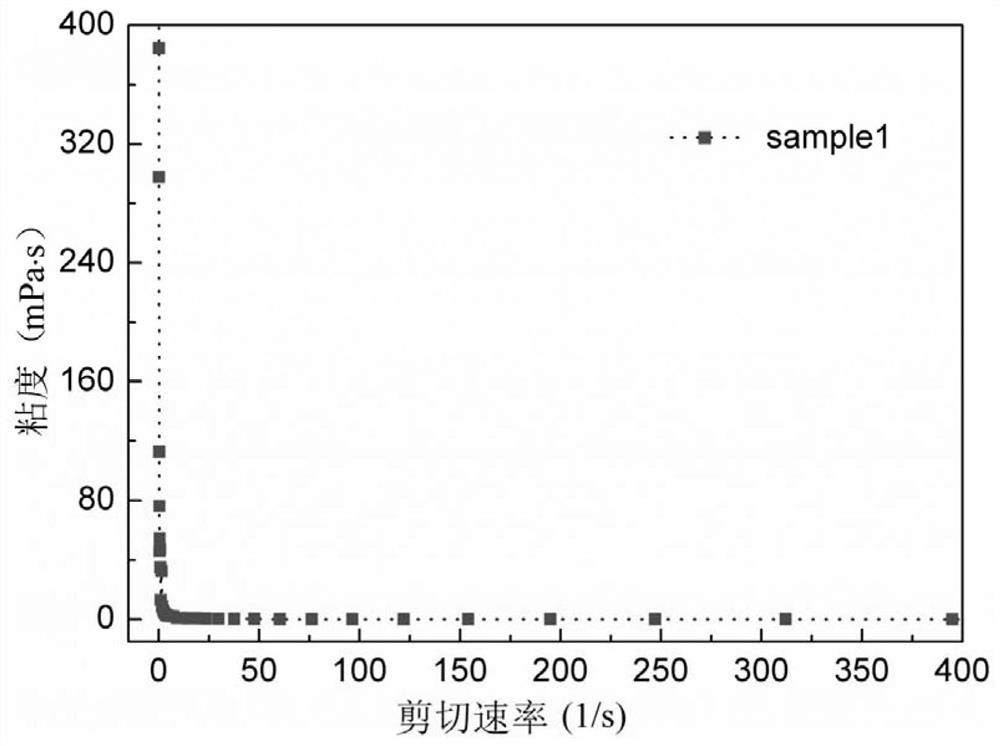

The invention discloses a borosilicate glass-spherical alumina low temperature co-fired ceramic (LTCC) green tape and its preparation method. The green tape is composed of a glass-ceramic composite material and a casting medium. Specifically, the glass-ceramic composite material consists of borosilicate glass and spherical alumina. The casting medium consists of a mixed solvent, a monomer binder, a plasticizer and a dispersing agent. The low temperature co-fired ceramic green tape prepared in the invention has a level and smooth surface, a solid content up to 88-92wt%, and a firing shrinkage rate of 9-11%. The difference between the sintering shrinkage rate of each direction is small. And the green tape can achieve wiring co-firing with Au, Ag and other low melting point metals at 850DEG C. The raw material tape sintered ceramic body provided in the invention has excellent dielectric properties. Under the condition of less than 10GHz, the dielectric constant (epsilon r) of 7-8, the dielectric loss (Tan delta) is less than 2*10<-3>, and effectively solves the anisotropy problem of traditional LTCC green tape sintering shrinkage.

Owner:凤阳凯盛硅材料有限公司

Method to anchor foils for green-tape circuits

Method to anchor foils for green-tape circuits, whereby the foils of alumina in the raw state or of another like or analogous material, which are personalized, printed and dried, are superimposed on each other in a coordinated and organized manner, at least one green-tape foil (10) being bonded to at least one other previously positioned green-tape foil (10) by means of at least one weld (11-12-13-14-15) made by a source of heat (laser, microwaves, ultrasounds, hot point, etc.).

Owner:A & E MFG +1

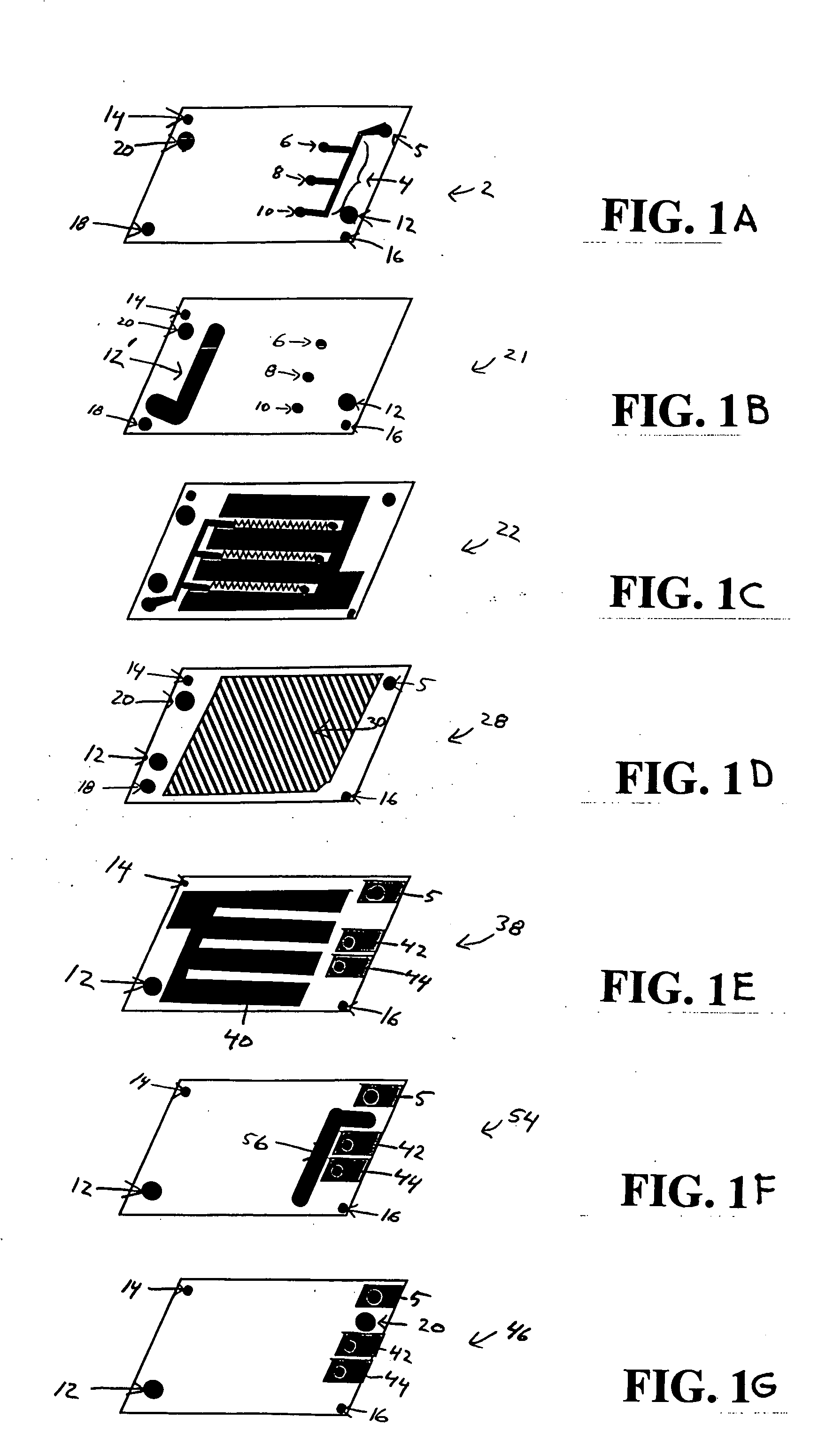

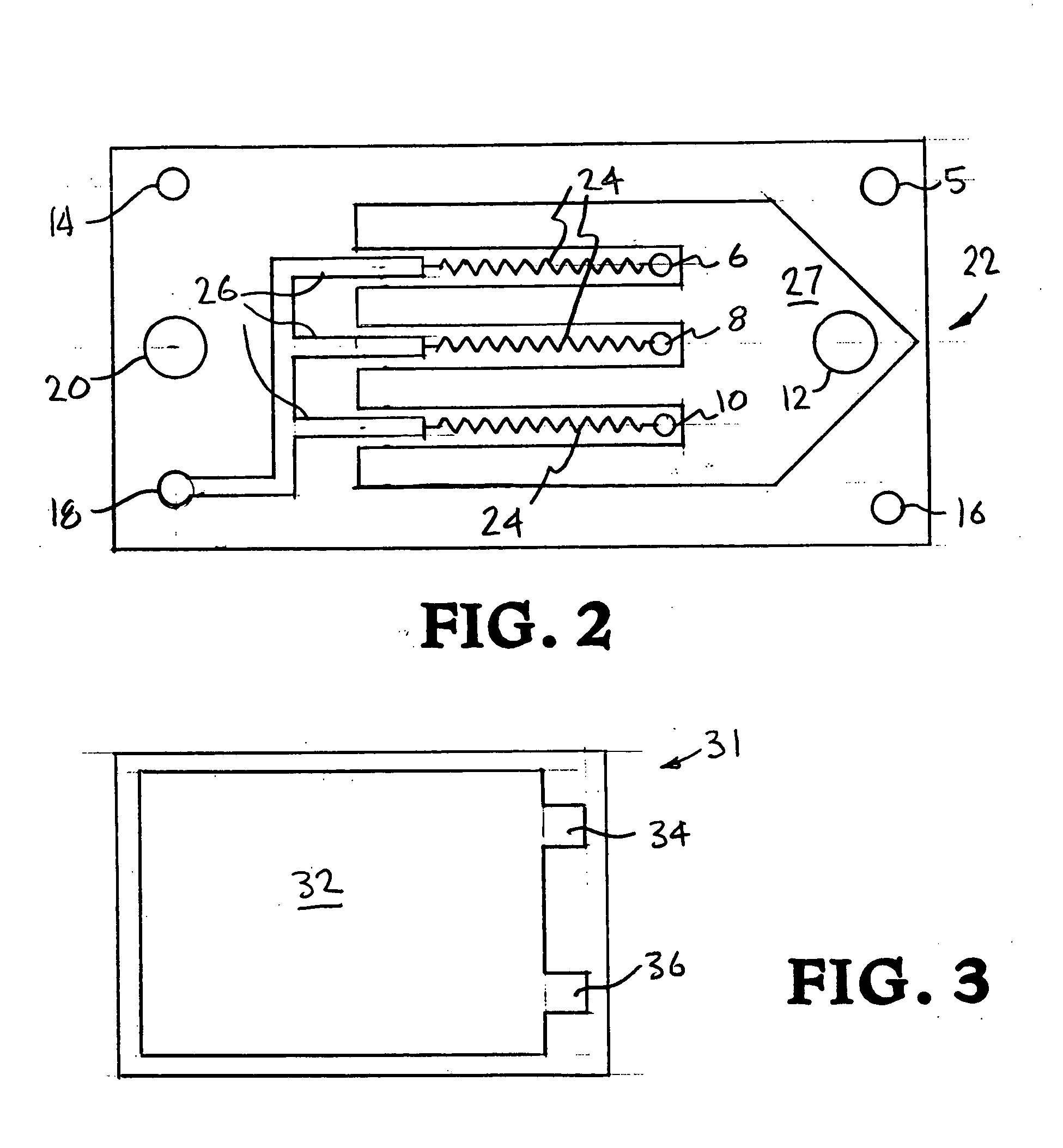

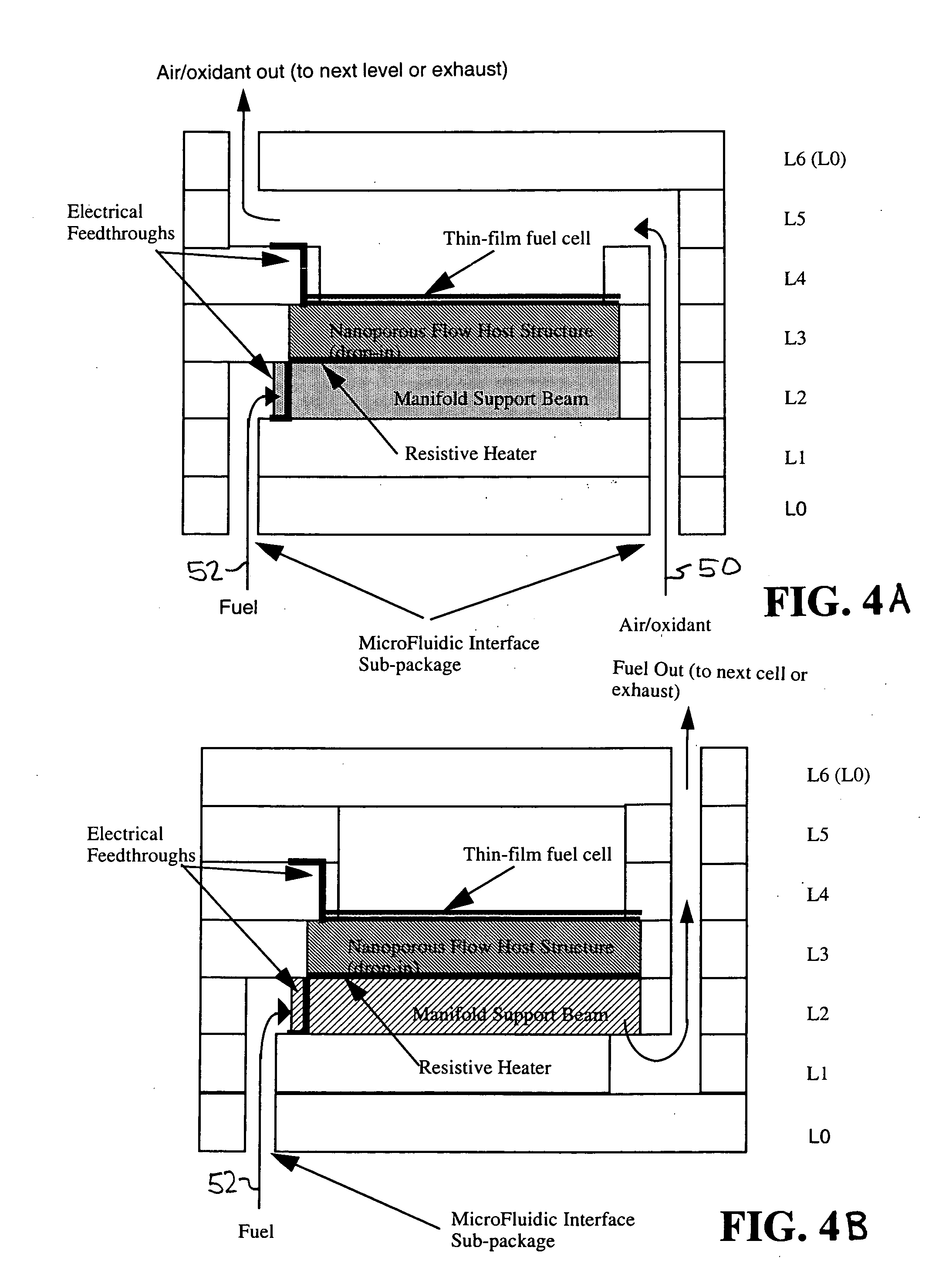

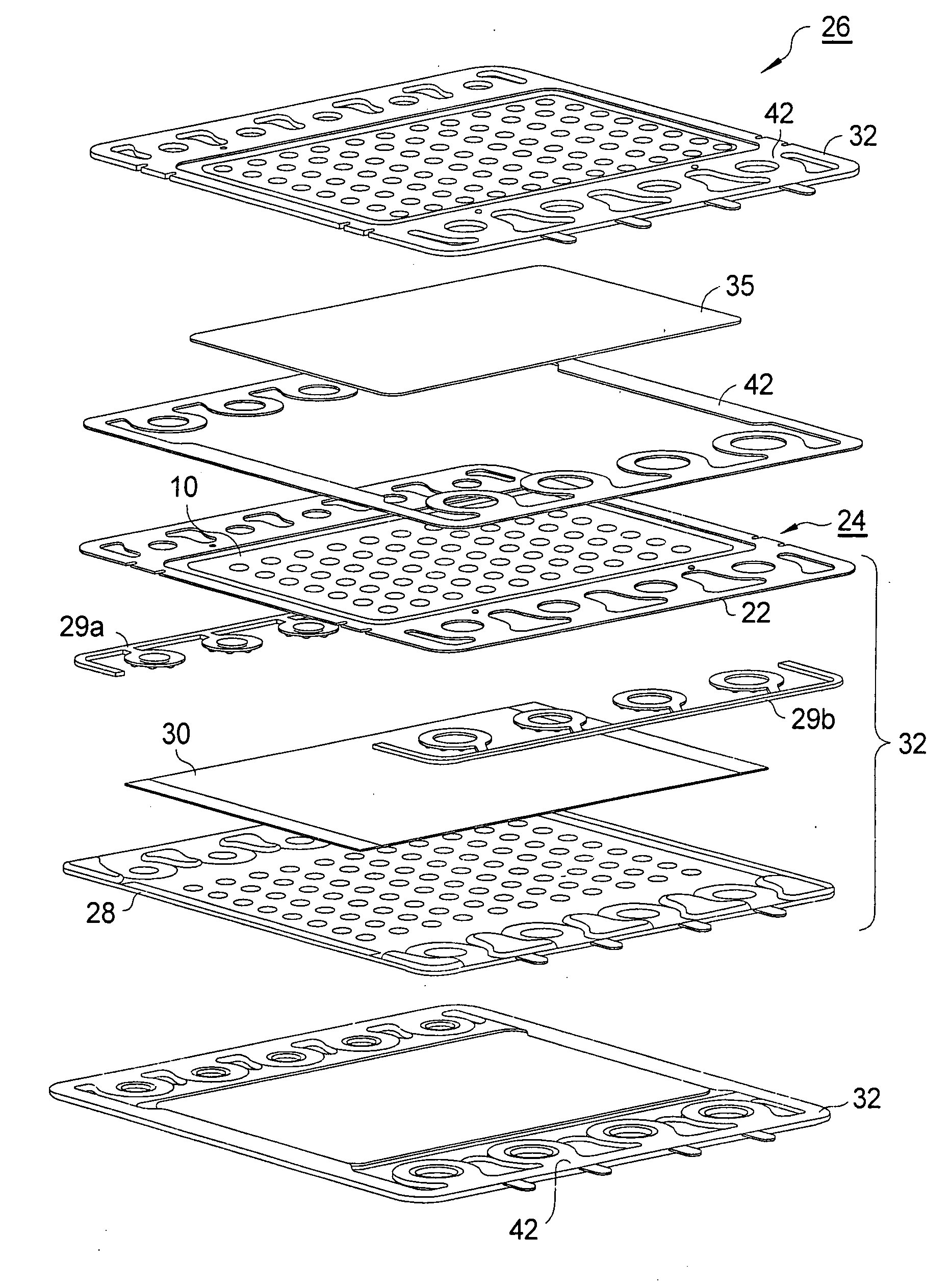

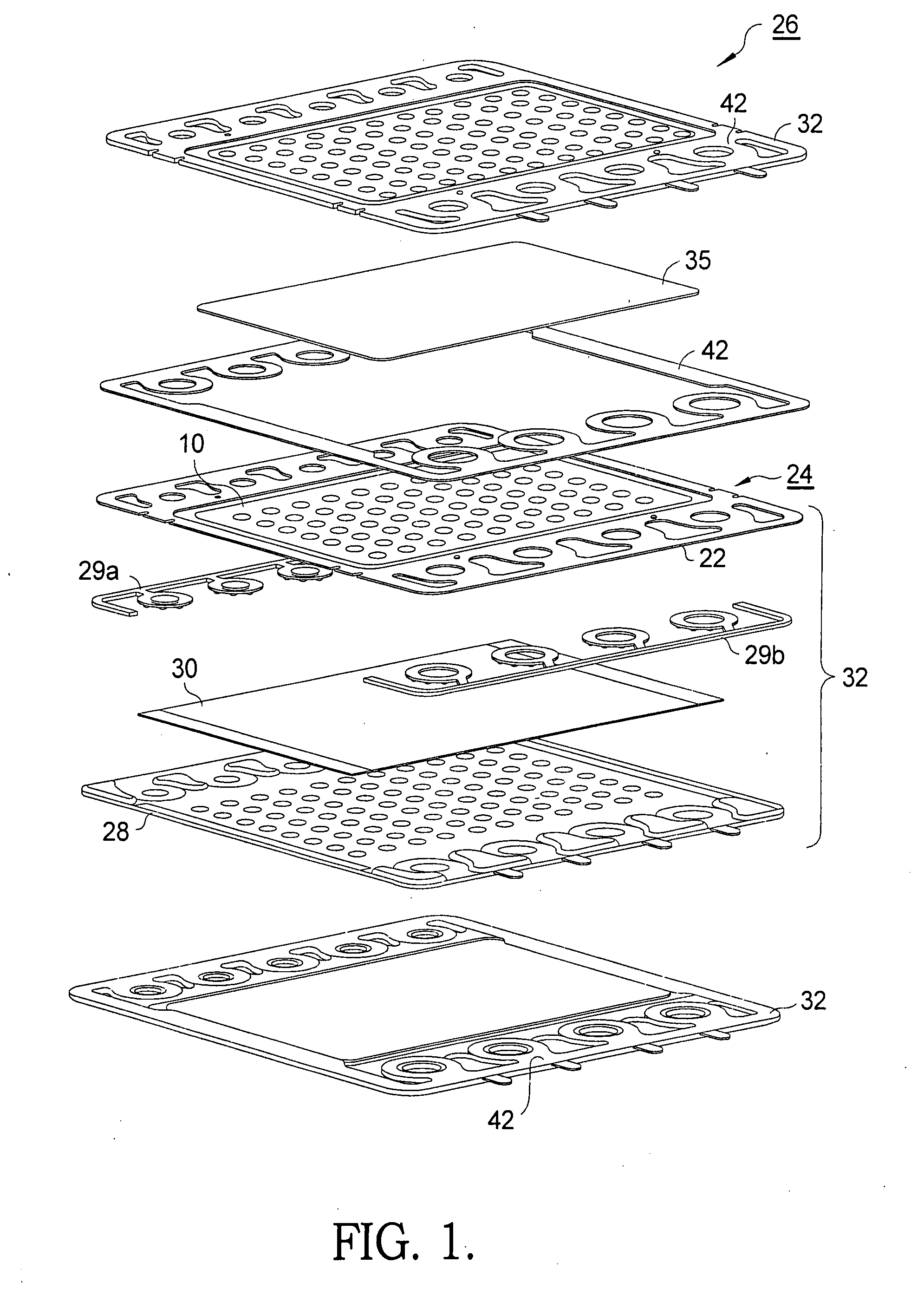

Method of forming a package for MEMS-Based fuel cell

A MEMS-based fuel cell package and method thereof is disclosed. The fuel cell package comprises seven layers: (1) a sub-package fuel reservoir interface layer, (2) an anode manifold support layer, (3) a fuel / anode manifold and resistive heater layer, (4) a Thick Film Microporous Flow Host Structure layer containing a fuel cell, (5) an air manifold layer, (6) a cathode manifold support structure layer, and (7) a cap. Fuel cell packages with more than one fuel cell are formed by positioning stacks of these layers in series and / or parallel. The fuel cell package materials such as a molded plastic or a ceramic green tape material can be patterned, aligned and stacked to form three dimensional microfluidic channels that provide electrical feedthroughs from various layers which are bonded together and mechanically support a MEMS-based miniature fuel cell. The package incorporates resistive heating elements to control the temperature of the fuel cell stack. The package is fired to form a bond between the layers and one or more microporous flow host structures containing fuel cells are inserted within the Thick Film Microporous Flow Host Structure layer of the package.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Method of making multilayer structures using tapes on non-densifying substrates

ActiveUS7547369B2Tight dimensional controlRoof covering using sealantsMetallic material coating processesGreen tapeCeramic coating

A method of applying a ceramic coating to a substrate comprises laminating one or more layers of a green ceramic tape to a rigid substrate using a tackifying resin to adhere the tape to the substrate. Upon firing, the tackifying resin ensures near zero shrinkage of the tape in the XY plane without usage of elevated pressures or temperatures during lamination of green tape to the substrate. The thermal degradation completion temperature of the tackifying resin is lower than that of the resin binder used in the green tape.

Owner:FERRO CORP

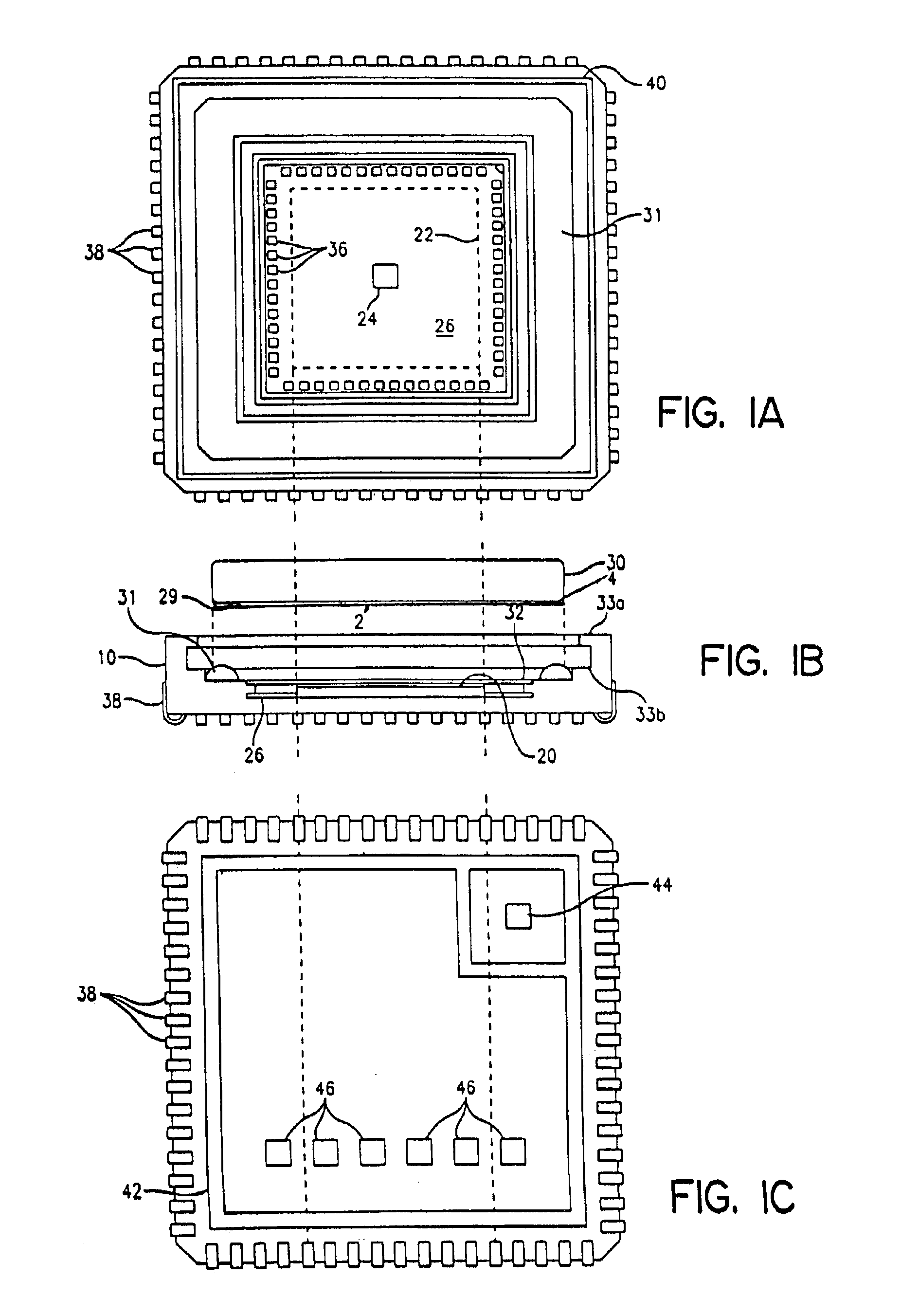

Method of fabricating a ceramic substrate with a thermal conductive plug of a multi-chip package

ActiveUS7222419B2Low production costSimplify the manufacturing processDecorative surface effectsSemiconductor/solid-state device detailsGreen tapeMaterials science

A method of fabricating a thermal conductive plug of a ceramic substrate of a multi-chip package. A plurality of conductive openings and thermal conductive openings are formed on green tapes. A metal paste is filled into the conductive openings and the thermal conductive openings. The green tapes are stacked together so that the metal paste inside the conductive openings and the thermal conductive openings of every green tape is in contact respectively with its neighboring metal paste within the conductive openings and thermal conductive openings of the green tapes. Cofire those green tapes and the metal paste to form a pre-substrate. The pre-substrate comprises an insulating structure, a plurality of thermal conductive plugs and conductive plugs.

Owner:NAT CHUNG SHAN INST SCI & TECH

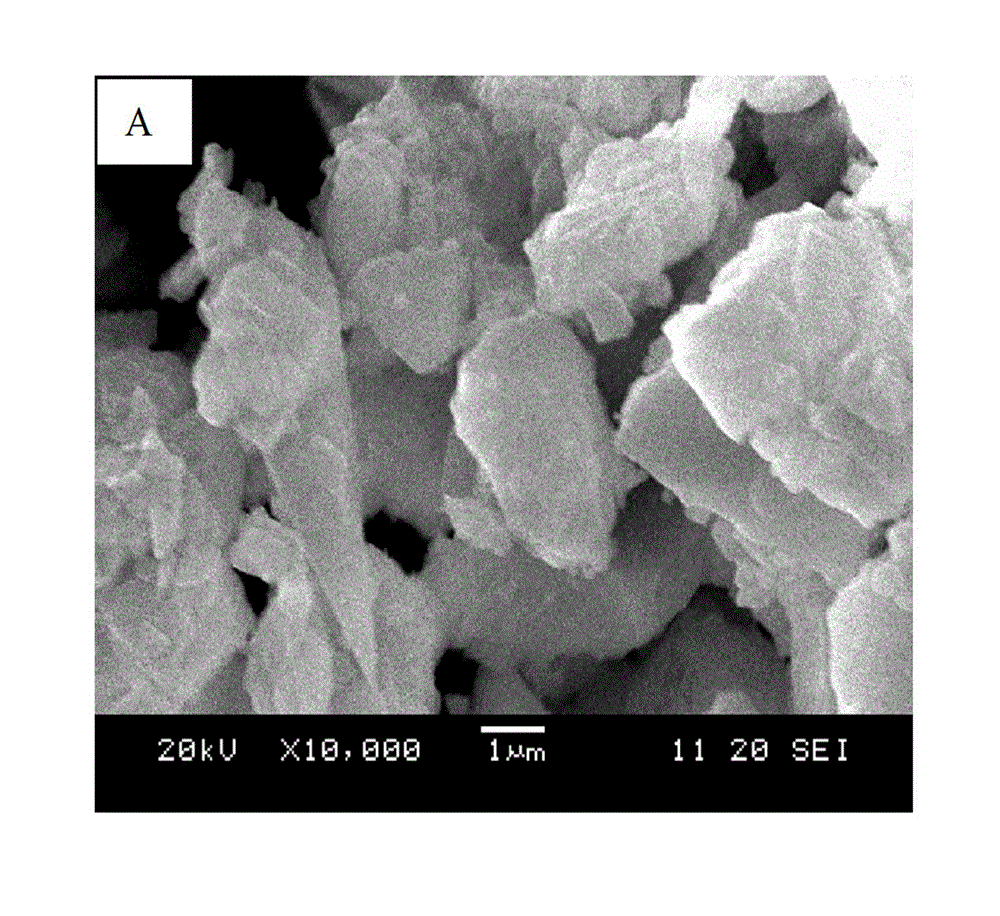

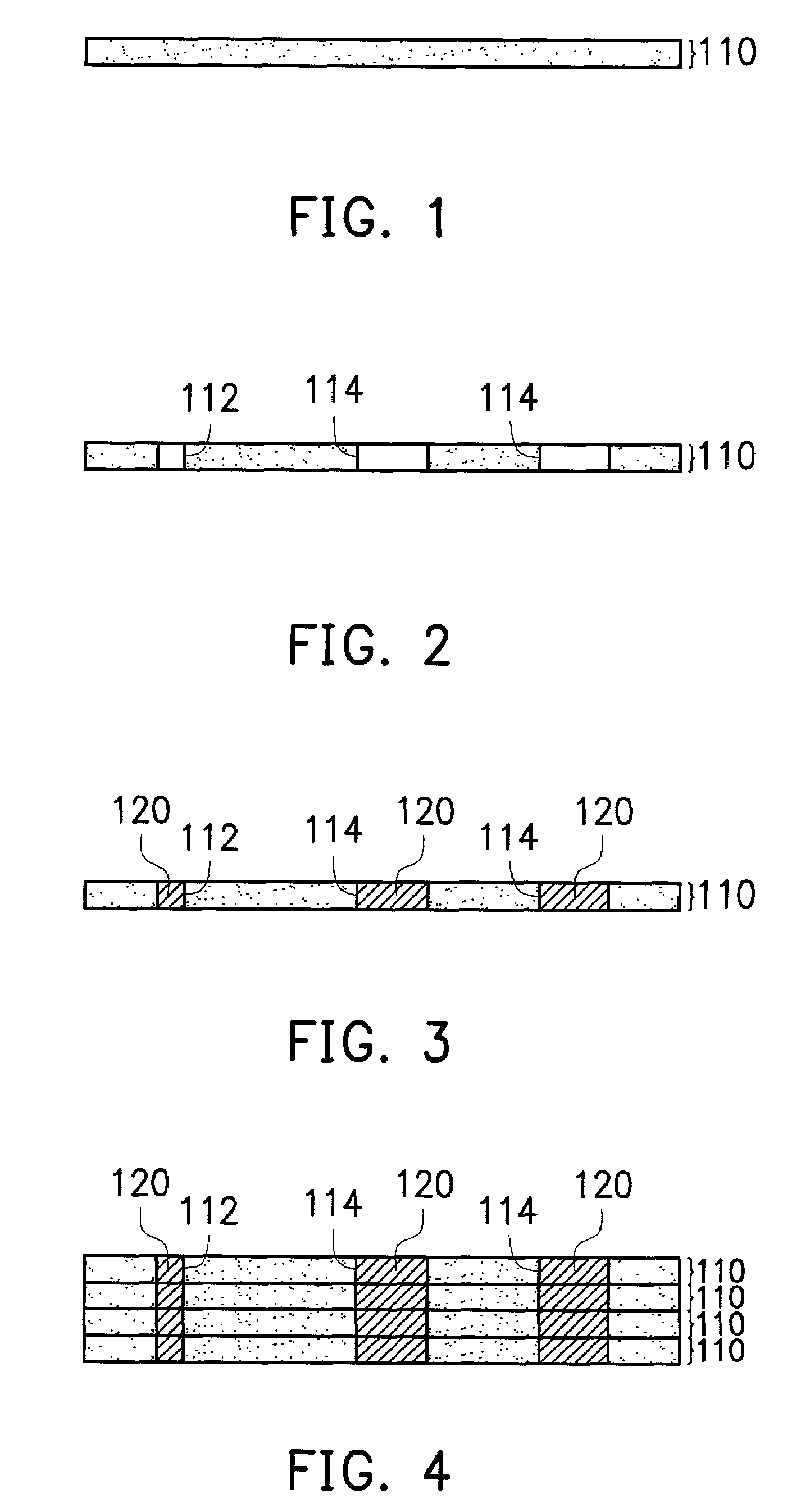

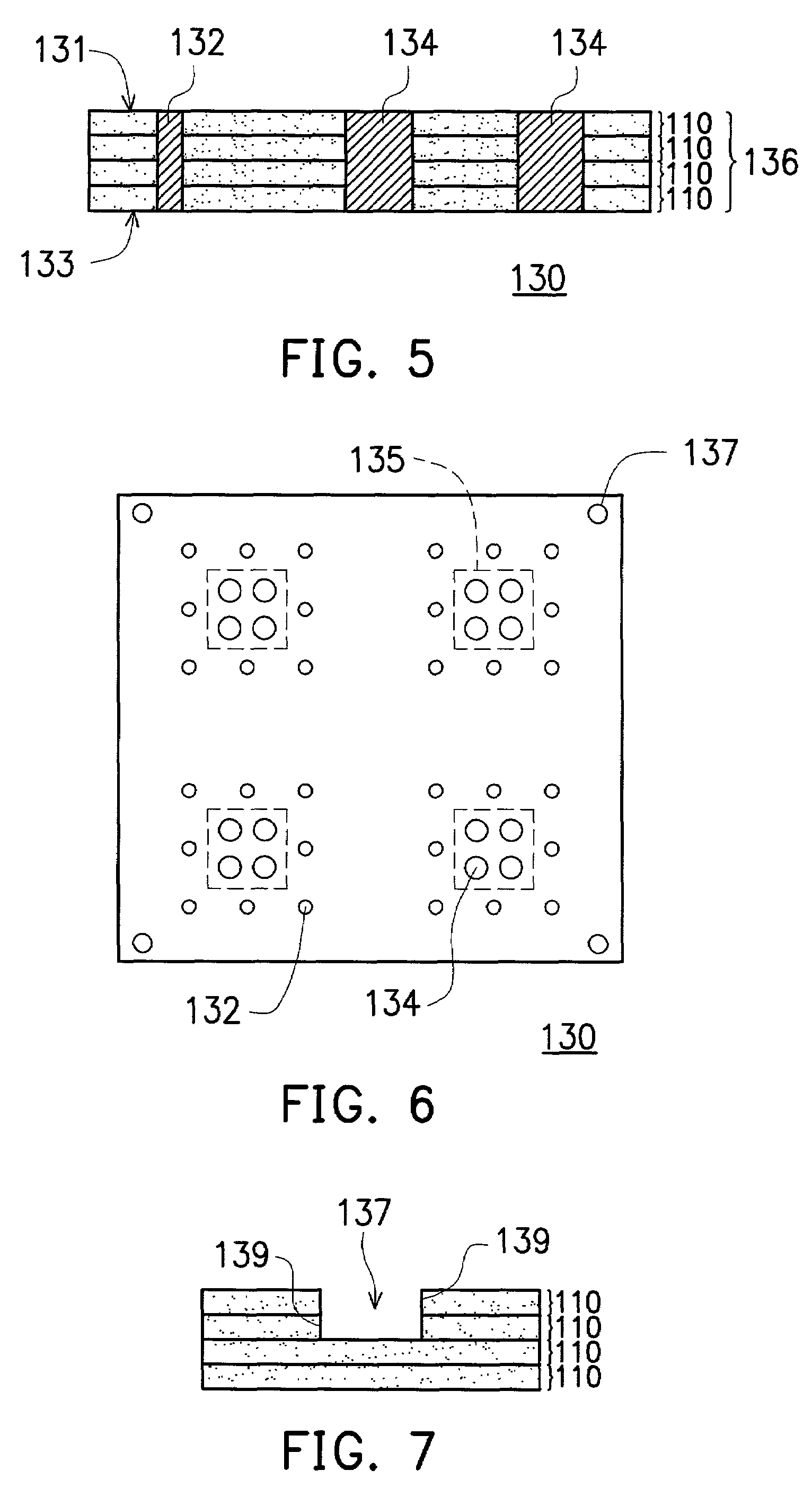

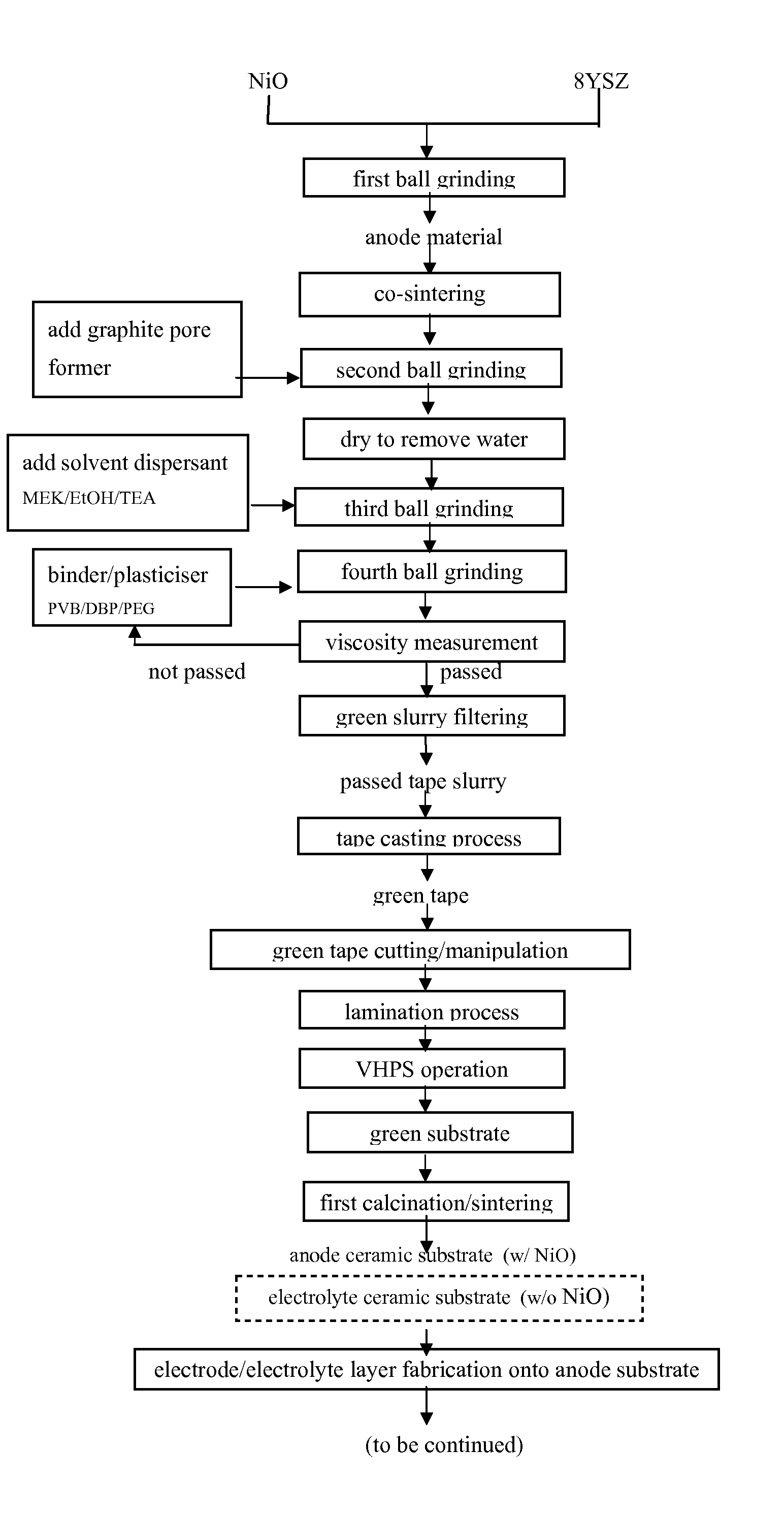

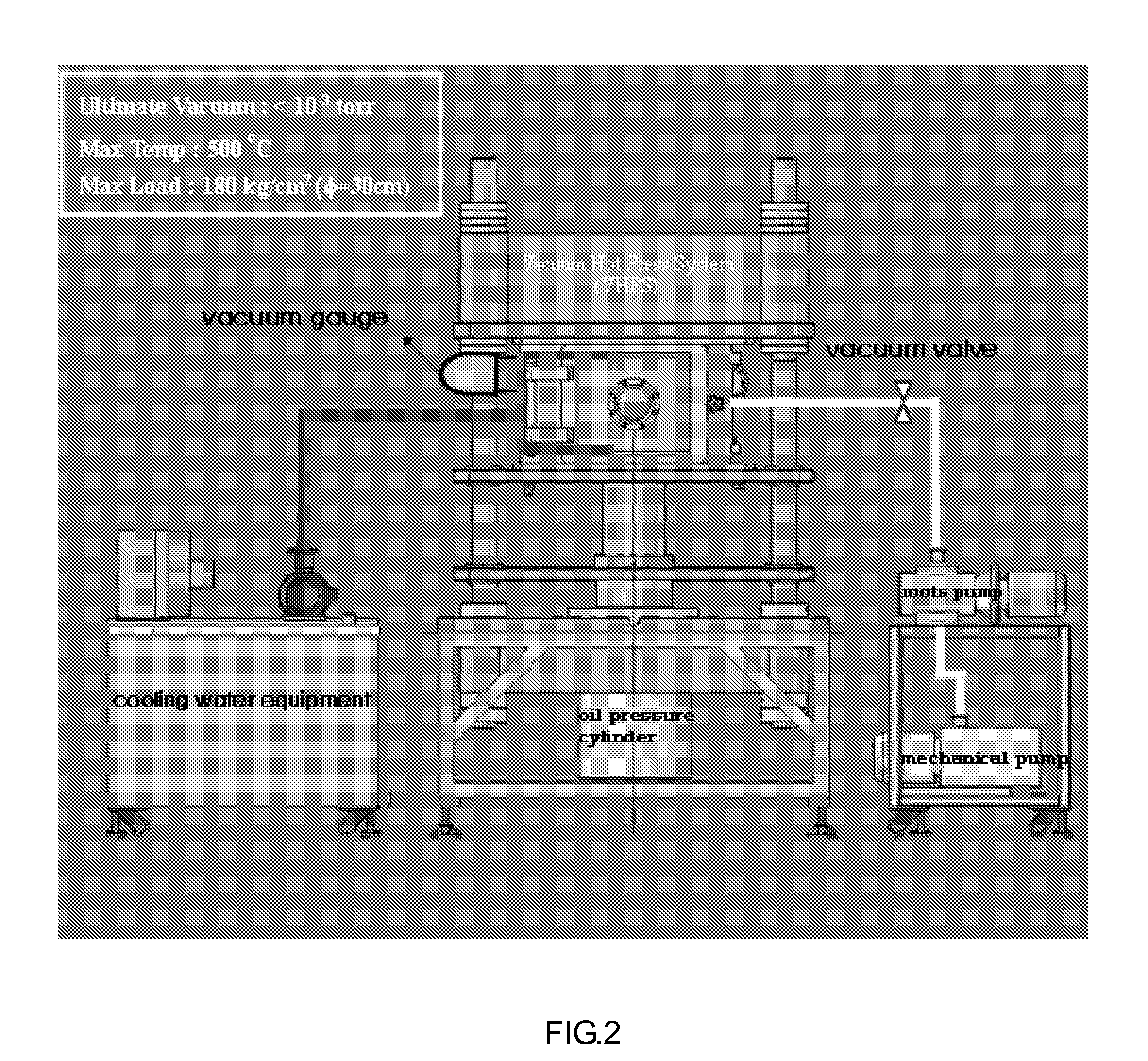

Novel synergistic process and recipe for fabrication of a high integrity membrane electrode assembly of solid oxide fuel cell

ActiveUS20090068373A1Improve integrityIncrease ratingsMolten spray coatingCell electrodesGreen tapeFuel cells

A recipe and two sequential processes for fabrication of electrode substrates of solid oxide fuel cells (SOFCs) are described in this invention. The typical recipe consists of 50˜86 wt % electrolyte (8YSZ) or 50˜80 wt % anode electrode (NiO / 8YSZ), 12˜22 wt % MEK (solvent 1), 5˜9 wt % EtOH (solvent 2), 1˜2 wt % TEA (dispersant), 0.5˜2 wt % DBP (plasticizer 1), 0.5˜2 wt % PEG (plasticizer 2), 3˜6 wt % PVB (binder), and 0.1˜10 wt % graphite (pore former). Two sequential processes include: 1. The process for preparation of the green tape slurry from materials of the recipe, 2. The synergistic process for fabrication of a high integrity membrane electrode assembly (MEA) of SOFC from the prepared electrode substrates.

Owner:INST NUCLEAR ENERGY RES ROCAEC

Glass seal with ceramic fiber for a solid-oxide fuel cell stack

A glass ceramic composition for sealing adjacent metal cassettes in an SOFC stack. The seal composition comprises an alumina-silicate glass ceramic matrix and a ceramic fiber aggregate dispersed in the matrix. Preferably, the fiber is selected from the group consisting of zirconium oxide fiber, alumina fiber, and combinations thereof. Preferably, the fiber is present at 1-60 weight percent with respect to the weight of glass ceramic, preferably about 30 weight percent. Preferably, the zirconia is stabilized by up to about 10% yttria. Alumina fiber may substitute for a portion of the zirconia fiber. Preferably, a green seal is die cut from a green tape sheet formed by extrusion of a slurry comprising water and a latex binder. The green seal is sintered during the final SOFC stack assembly process to form the final stack seal.

Owner:MUKERJEE SUBHASISH +5

Method Of Making Multilayer Structures Using Tapes On Non-Densifying Substrates

ActiveUS20080053592A1Tight dimensional controlExemption stepsRoof covering using sealantsMetallic material coating processesGreen tapeCeramic coating

A method of applying a ceramic coating to a substrate comprises laminating one or more layers of a green ceramic tape to a rigid substrate using a tackifying resin to adhere the tape to the substrate. Upon firing, the tackifying resin ensures near zero shrinkage of the tape in the XY plane without usage of elevated pressures or temperatures during lamination of green tape to the substrate. The thermal degradation completion temperature of the tackifying resin is lower than that of the resin binder used in the green tape.

Owner:FERRO CORP

Low-dielectric LTCC green tape as well as preparation method and use thereof

The invention discloses a low-dielectric LTCC green tape as well as a preparation method and use thereof. The low-dielectric LTCC green tape is composed of a powder, a solvent, a dispersing agent, a binder and a plasticizer, wherein the powder is in a mass fraction of 40-60%, and prepared from 10-40wt% of a glass material, 1-10wt% of a low melting point oxide sintering aid and the balance of a ceramic material; the chemical composition of the ceramic material is Zn2-xSiO4-x, where x=0.05-0.3. In the present invention, the problem of low-temperature sintering ofZn2-xSiO4-x ceramic is solved byadding the crystallizable glass material and the sintering aid together, and the mechanical properties and the high-frequency electrical characteristics of the system can be improved.

Owner:NO 43 INST OF CHINA ELECTRONICS TECH GRP CETC

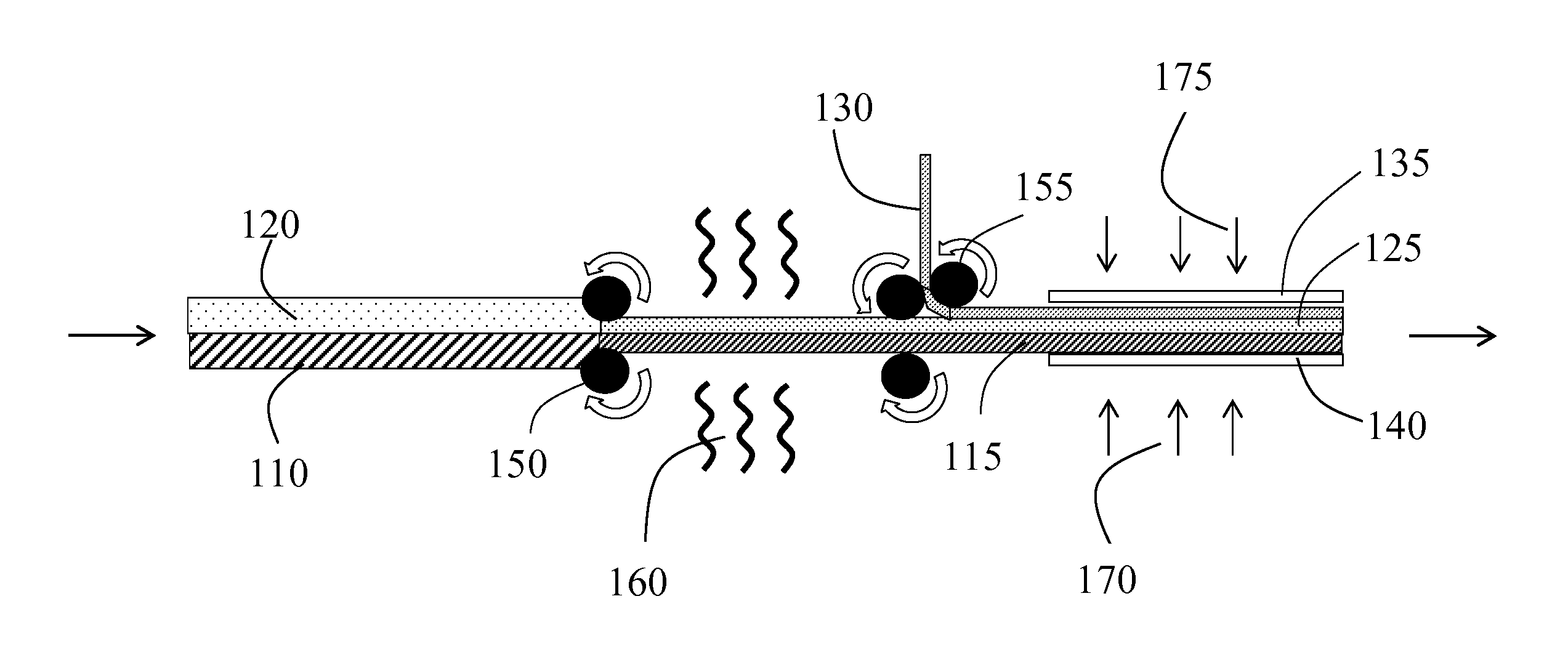

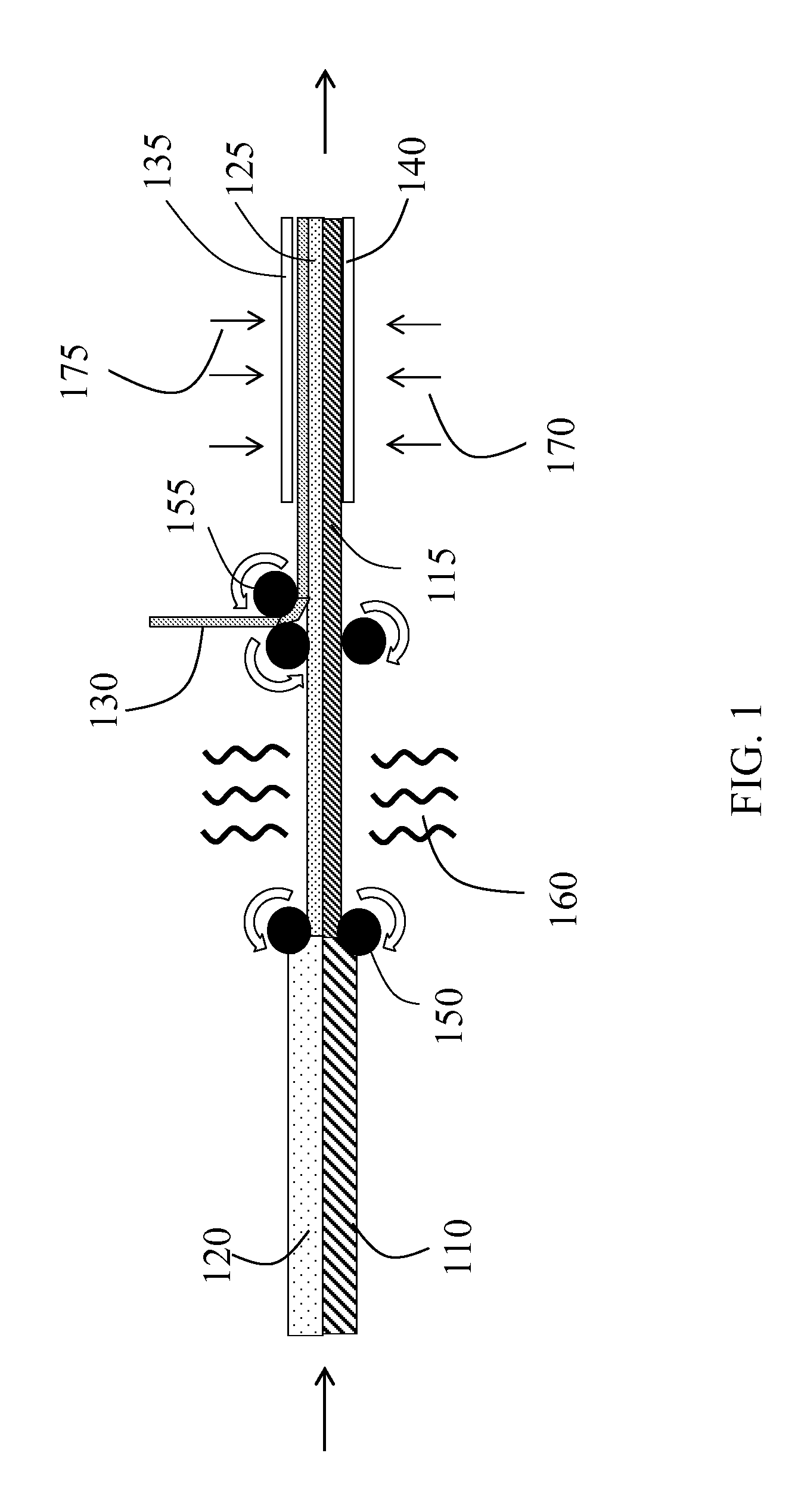

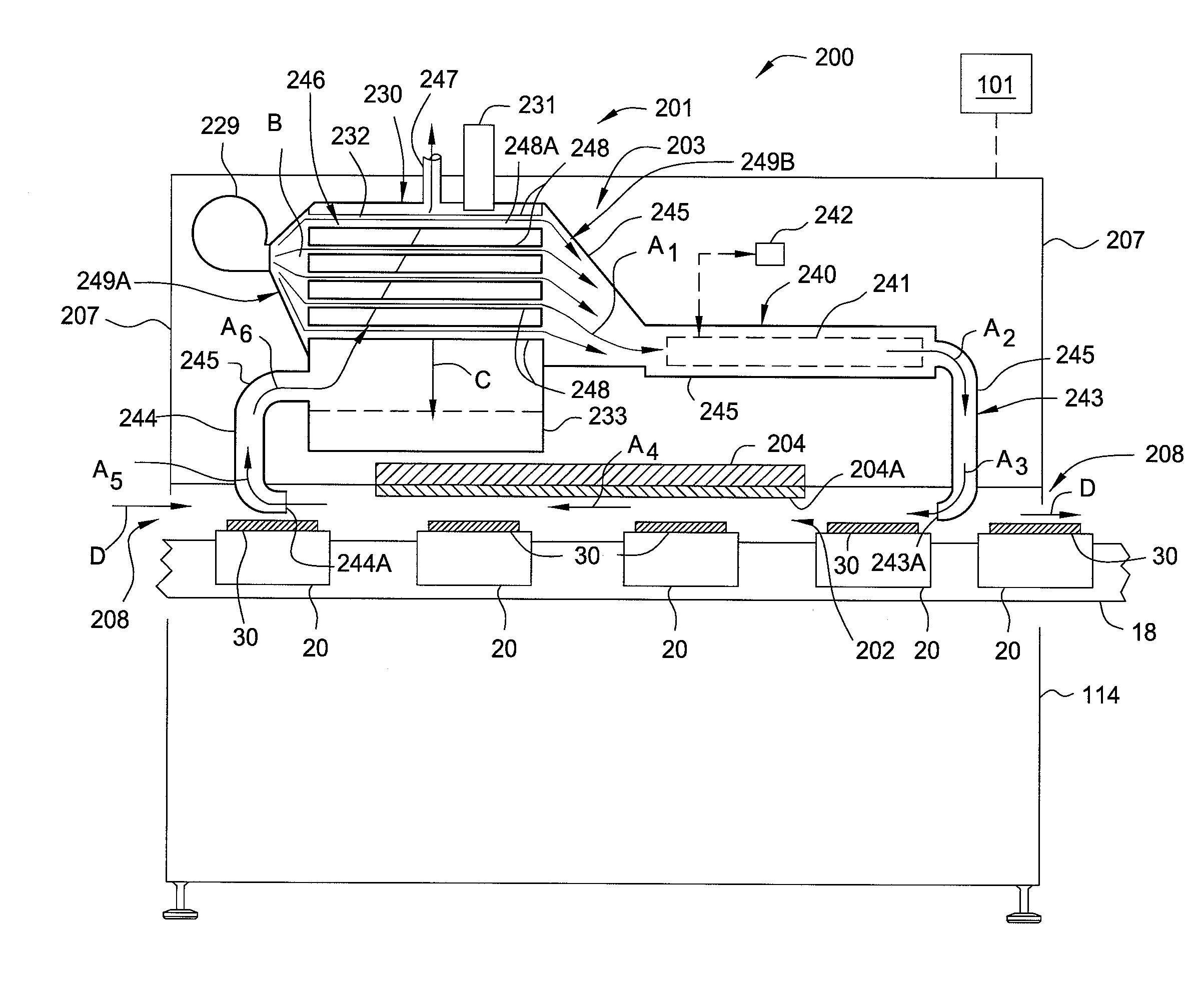

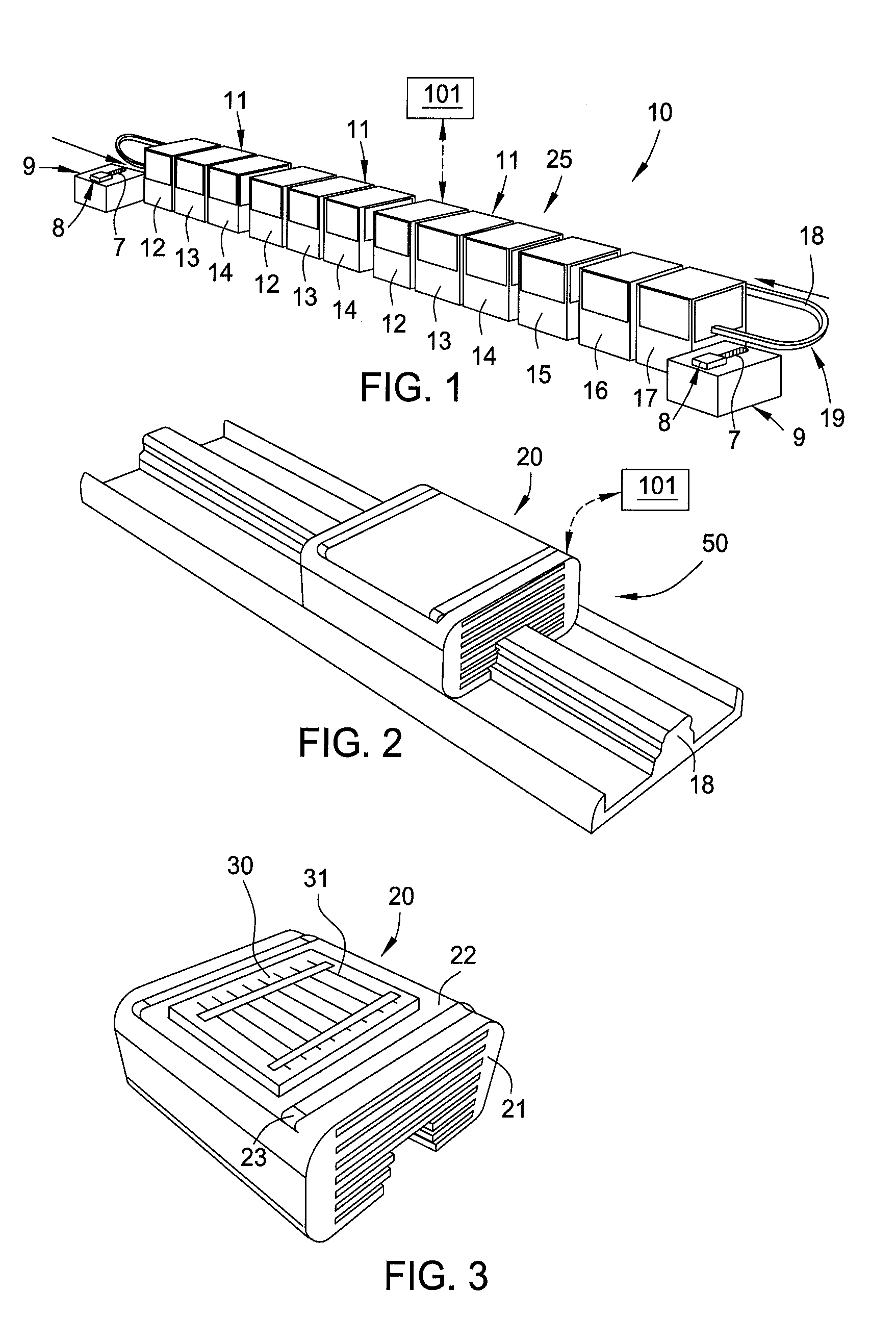

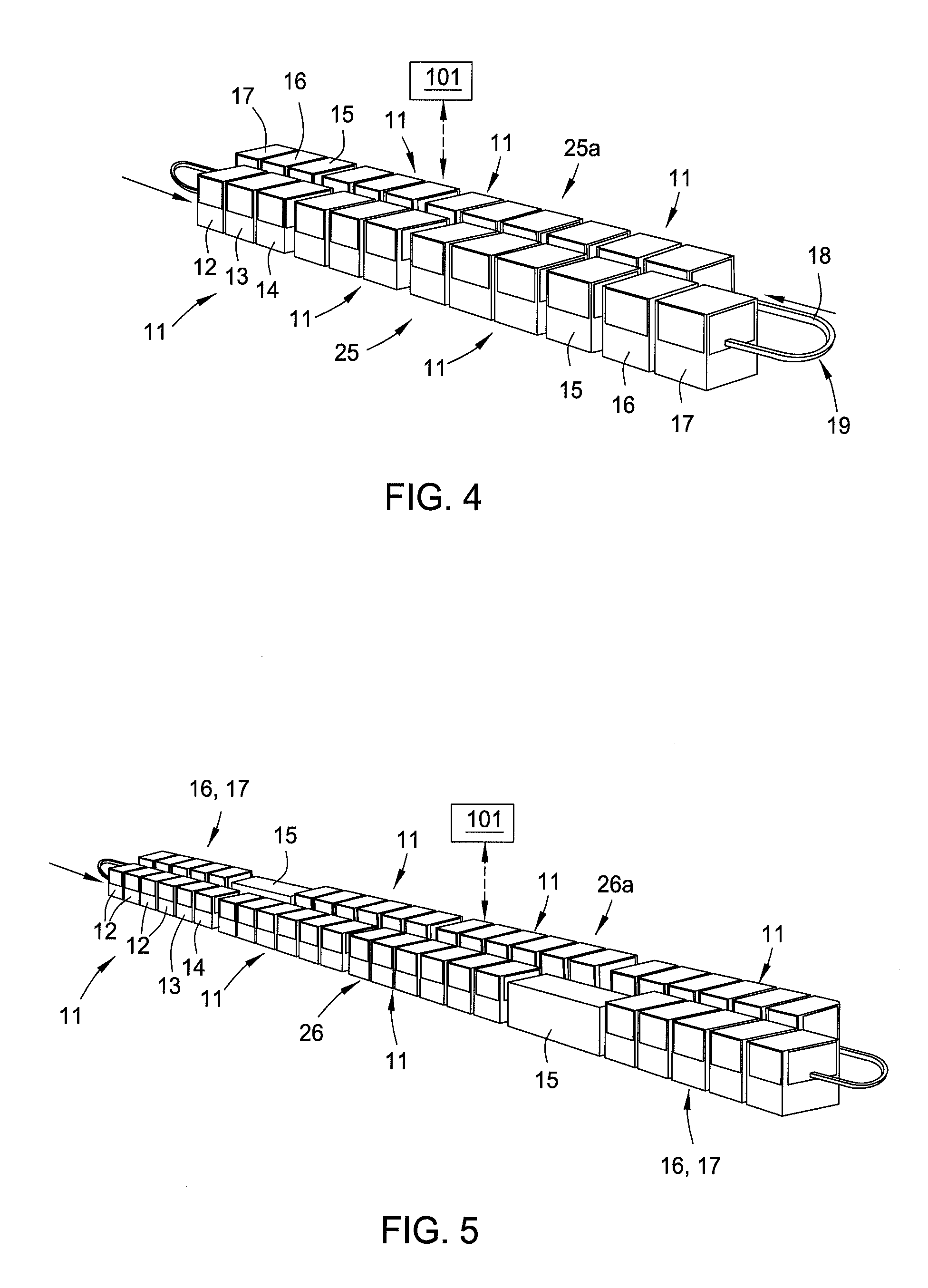

Plant for forming electronic circuits on substrates

InactiveUS20110165316A1Increase production capacityIncrease speedPretreated surfacesSemiconductor/solid-state device manufacturingGreen tapePower station

Embodiments of the present invention generally provide a cluster tool 10 that can be used to form electronic circuits on a substrate in an automated fashion. In one embodiment, the cluster tool 10 is adapted to process portions of a substrate to form part of a photovoltaic cell or a green-tape type circuit device in an automated fashion using a system controller 101. In one embodiment, the cluster tool 10 having plurality of work stations that comprise at least one station to deposit a layer on a substrate, a drying oven to dry the substrates, a testing station to test the substrates, and a storage station to store the substrates, and a transport element that is positionable in each of the work stations. A guide defines a substantially closed circuit along which a plurality of transport elements are able to be moved, on each of which at least one of the substrates is disposed.

Owner:APPLIED MATERIALS ITALIA SRL

Method for manufacturing ceramic part with closed cavity structure for high-frequency high-speed ceramic package shell

ActiveCN105810591AGood lookingImprove applicabilitySemiconductor/solid-state device detailsSolid-state devicesGreen tapeScreen printing

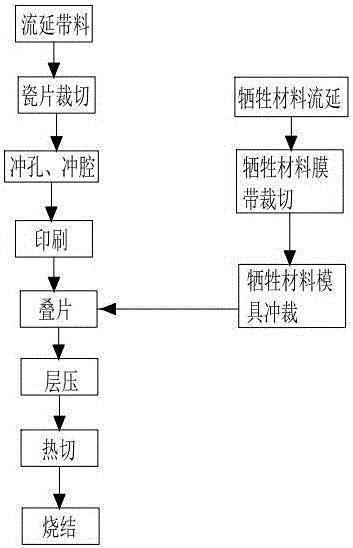

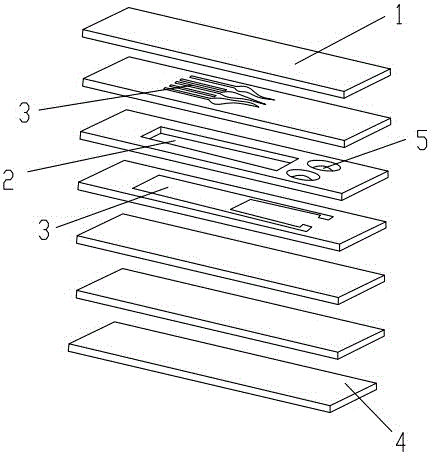

The invention discloses a method for manufacturing a closed-cavity ceramic part for a high-frequency and high-speed ceramic packaging shell, and relates to the technical field of semiconductor microelectronic device preparation. The method comprises the following steps: preparing a green porcelain tape; using a punching device to punch holes and form a cavity on the cut green porcelain tape at a position where holes need to be punched and forming a cavity; The required metallization pattern is printed by screen printing on the corresponding position of the side wall; the sacrificial material is filled inside the formed cavity; the laminated green ceramic sheet is laminated, and the interlayer density is controlled by adjusting the process parameters and the shape of the cavity; sintering the prepared green porcelain piece, during the sintering process of the green porcelain piece, the sacrificial material is burnt out, and a ceramic piece with a closed cavity structure is prepared. The inside of the closed cavity of the ceramic part prepared by the method has a good shape, and the wiring on the bottom side of the closed cavity can meet the higher frequency signal transmission requirements.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

Organic composition added in preparation of tape-casting slurry and application of organic composition

The invention discloses an organic composition added to early and later stages in preparation of tape-casting slurry. The organic composition added at the early stage comprises a solvent and a dispersing agent, wherein the solvent is at least one of reagents such as ethanol; the dispersing agent is at least one of the reagents such as tributyl phosphate; the organic composition added at the later stage comprises a solvent, an organic binder and a plasticizer, wherein the solvent is at least one of the reagents such as the ethanol, the plasticizer is at least one of the reagents such as polyethylene glycol, and the organic binder mainly is polyvinyl butyral. An application of the organic composition in a tape-casting process concretely comprises the following steps: firstly, mixing and ball-milling ceramic powder, an inorganic bonding phase, and the organic composition added at the early stage, and then adding the organic composition added at the later stage to carry out secondary ball-milling; stirring and defoaming to obtain the tape-casting slurry; adjusting a blade gap and the tape-casting speed of a tape-casting machine; preparing into a wet biscuit; and stripping from a carrier band after drying, so as to prepare a green tape. The organic composition is simple in preparation process, and short in preparation period; the prepared biscuit film is stable in quality, and does not easily crack.

Owner:NAT UNIV OF DEFENSE TECH +1

Rear plate for plasma display panel

InactiveUS20060232206A1Improve featuresSuperior electric and optical characteristicGas discharge electrodesAlternating current plasma display panelsGreen tapeSlurry

Disclosed is a rear plate of a plasma display panel. In the rear plate, a dielectric layer or a barrier wall layer is formed by forming slurry in a tape of a green tape and then attaching the green tape to upper surfaces of electrodes and a glass substrate. Therefore, a PDP employing a rear plate according to the present invention has superior electric and optical characteristics.

Owner:LG MICRON

Tape-casting method of aluminum oxide ceramics

A method for tape casting of alumina ceramics, mixing alumina ceramic powder with dispersant, binder and plasticizer in a solvent to form a uniform and stable suspended slurry; then passing the slurry from a hopper through a casting machine The lower part flows to the base belt to form a blank film; then the blank film and the base belt are sent to the drying room for drying, and the solvent is evaporated to form a green sheet with a certain strength and flexibility; then it can be cut and punched according to the required shape sheet or perforated; finally, the finished product is obtained through degreasing and sintering; when the blank film and the base belt are sent to the drying room for drying, a protective atmosphere is introduced into the drying room to reduce the drying speed of the upper surface of the blank film belt; and in alumina ceramics The powder is mixed with the dispersant, binder and plasticizer in the solvent to increase the solid phase content of the alumina powder in the casting slurry, reduce the solvent content, and make the green body easier to dry; at the same time, a slow drying rate is used in the formula And the solvent with low boiling point, fast drying speed and high boiling point makes the green body dry more uniformly.

Owner:HUNAN ZHENGYANG PRECISION CERAMIC

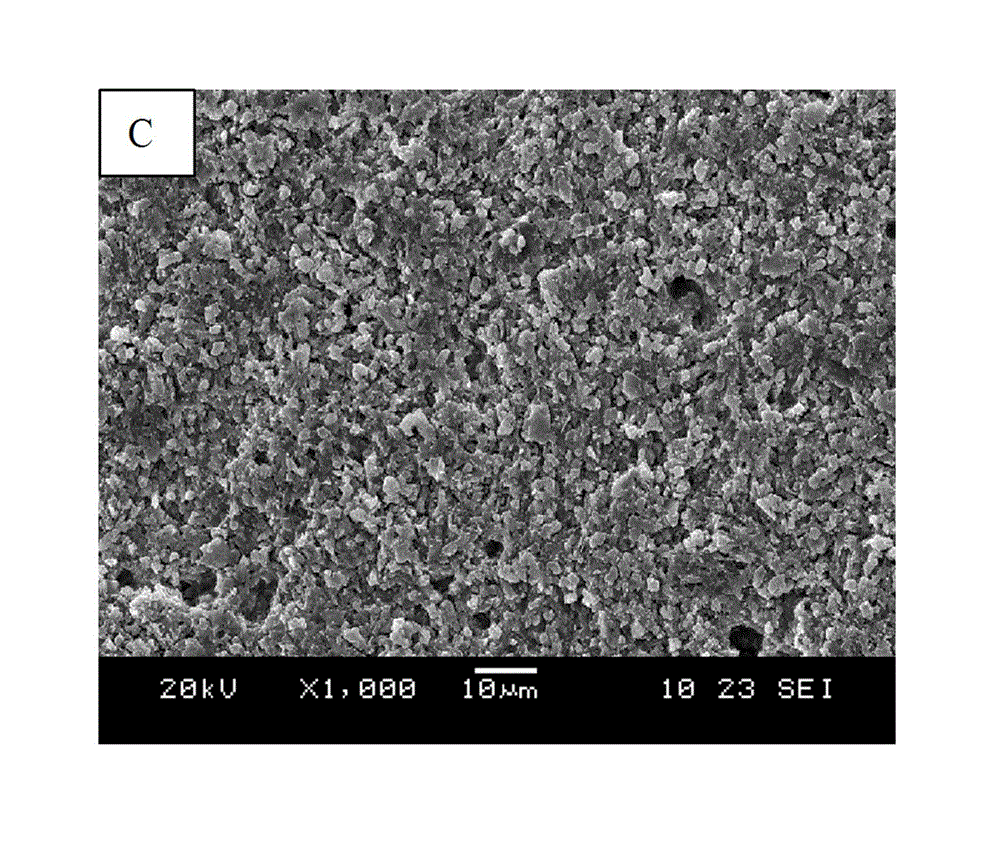

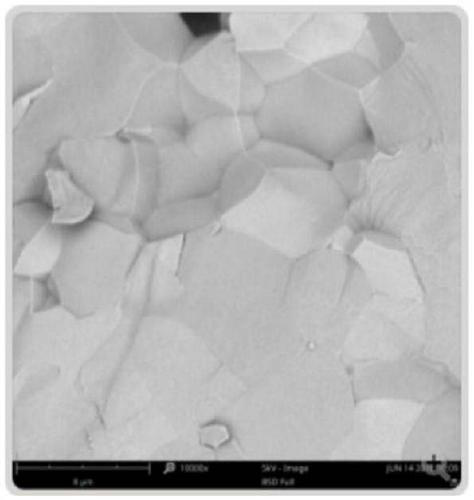

Sm-modified lead magnesium niobate-lead titanate-based piezoelectric and ferroelectric thick film material and preparation method thereof

The invention belongs to the technical field of ferroelectric and piezoelectric functional materials, and discloses a Sm-modified lead magnesium niobate-lead titanate-based piezoelectric and ferroelectric thick film material. The molecular formula of the Sm-modified lead magnesium niobate-lead titanate-based piezoelectric and ferroelectric thick film material is [Sm<x>-Pb<(1-1.5x)>][(Mg<1 / 3>Nb<2 / 3>)<(1-Y)>Ti<y>]O3, wherein 0<X<=0.1,0.25<Y<=0.32, the preparation method comprises the steps that S1, raw materials areweighed according to stoichiometric ratio; S2, a two-step solid-phase reaction method is adopted to prepare and obtain Sm-modified lead magnesium niobite-lead titanate powder body ofperovskite phase; S3, the powder body is mixed with a dispersing agent and a binder to obtain a slurry; S4,the slurry is subjected to tape casting, drying, cutting, and lamination to obtain a green tape in a desired shape; S5, the green tape is adhered and sintered to obtain the piezoelectric and ferroelectric thick film material. Thepiezoelectric and ferroelectric thick film material is of a perovskite phase structure, microstructure is compact, piezoelectric performanceis excellent, sinteringcan be conducted at a low temperature, preparation technology is simple, the cost is low, industrial production is advantageous, and the piezoelectric and ferroelectric thick film material is expected to be used for piezoelectric ultrasonic transducer and high frequency piezoelectric ultrasonic transducer arrays, piezoelectric actuators, and sensors.

Owner:GUANGDONG JC TECHNOLOGICAL INNOVATION ELECTRONICS CO LTD +1

Preparation method of aluminum nitride raw ceramic sheet for high temperature co-fired ceramic

The invention discloses a preparation method of an aluminum nitride raw ceramic sheet for high temperature co-fired ceramic. The preparation method comprises the following steps: 1) loading a grindingball; 2) disposing slurry; 3) performing primary grinding; 4) configuring casting slurry; 5) performing secondary grinding; 6) performing vacuum defoaming; 7) casting, wherein the casting slurry subjected to vacuum defoaming is transferred to a casting machine for casting operation, and the thickness of a green tape is controlled within a range of 0.05 to 1 mm; and 8) cutting. The raw material does not contain toxic components such as benzene, ketone and aldehyde, and organic toxic and harmful substances and waste liquid are not generated in the production process, thereby reducing environmental pollution. The raw ceramic sheet produced by the method has high strength, good thermal conductivity and uniform density, and is less prone to deformation, high in punching printing precision andgood in flatness and has good shrinkage matching with metallized slurry in the production process of high temperature co-fired ceramics. The film coating operation is not needed in the production process, the problems of softness, difficult processing, high probability of offset filling printing and lamination misalignment and the like are solved, and the production efficiency is improved while the production cost is lowered.

Owner:NINGXIA AISENDA NEW MATERIALS TECH

High performance embedded RF filters

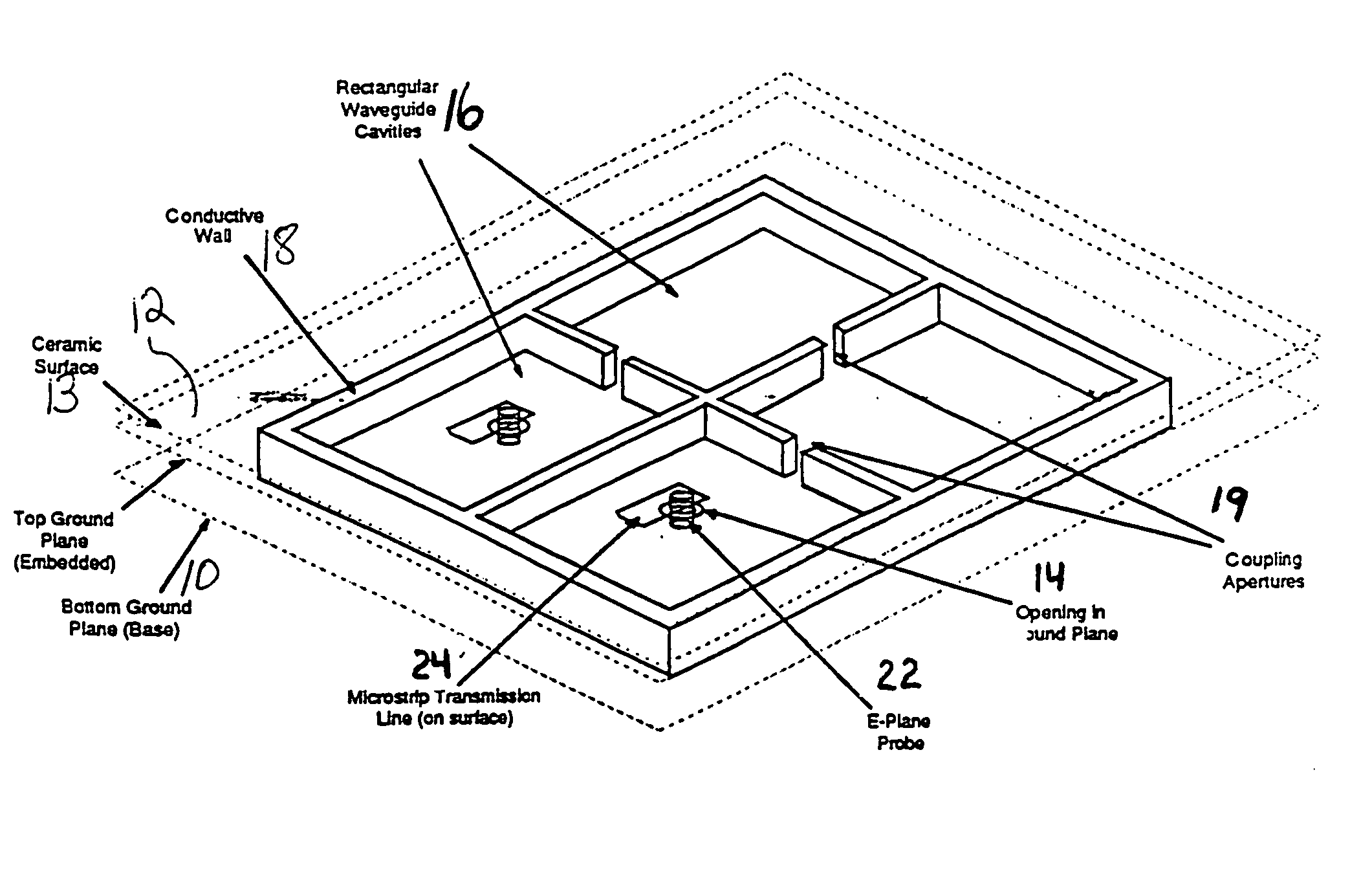

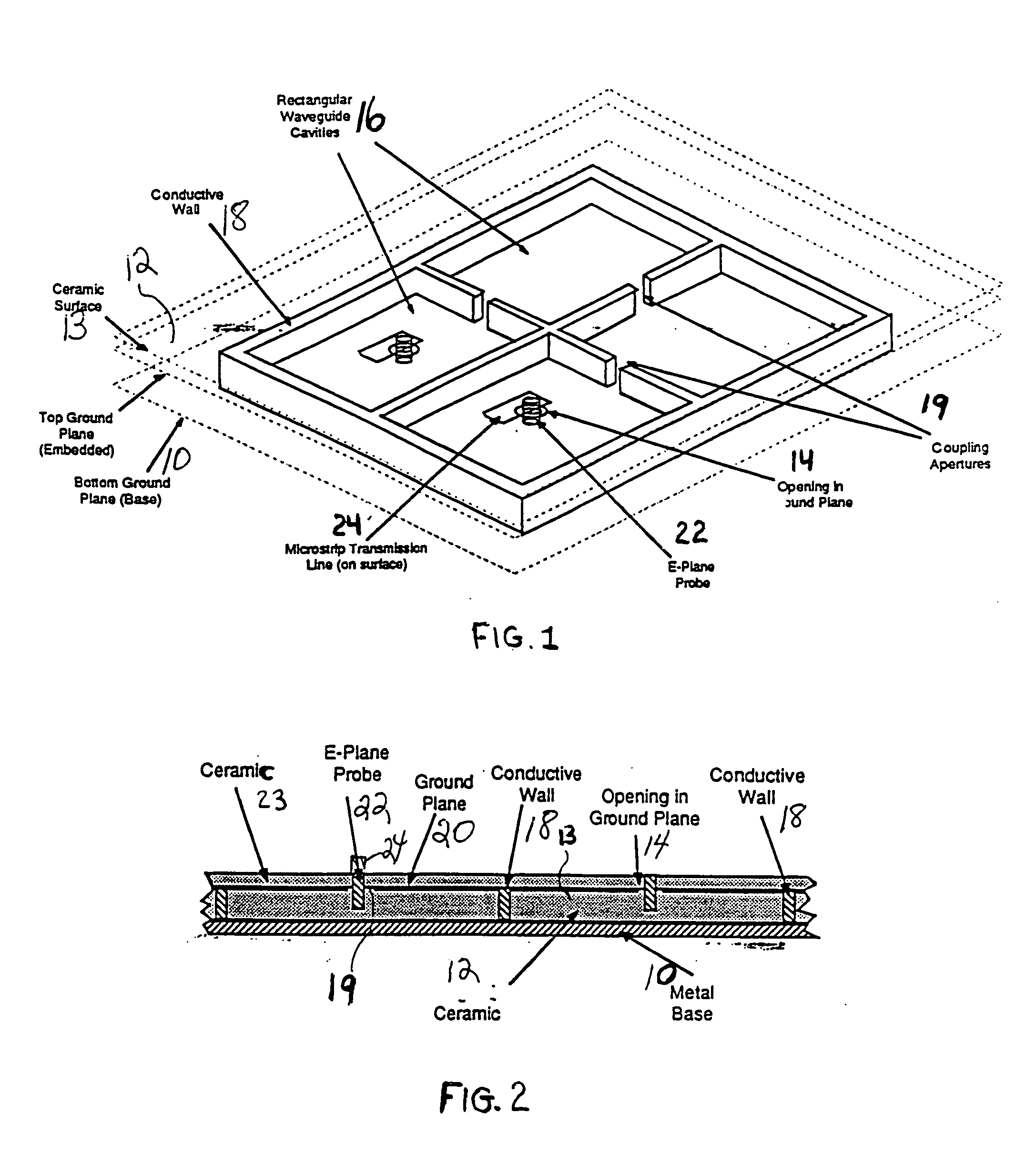

InactiveUS20050217786A1Lamination ancillary operationsSemiconductor/solid-state device detailsGreen tapeCoupling

Embedded, coupled, shaped waveguide resonators having conductive walls sandwiched between two fired green tape stacks, said conductive walls having apertures therein whose size and location determine the degree of coupling. These waveguides are made by forming openings in a first green tape stack, defining walls and apertures therein, mounting a second green tape stack having a conductive layer thereon thereover and firing the assembly. E-plane probes are inserted in openings in the second green tape stack and connected to microstrip transmission lines on an external surface pf this green tape stack.

Owner:LAMINA LIGHTING

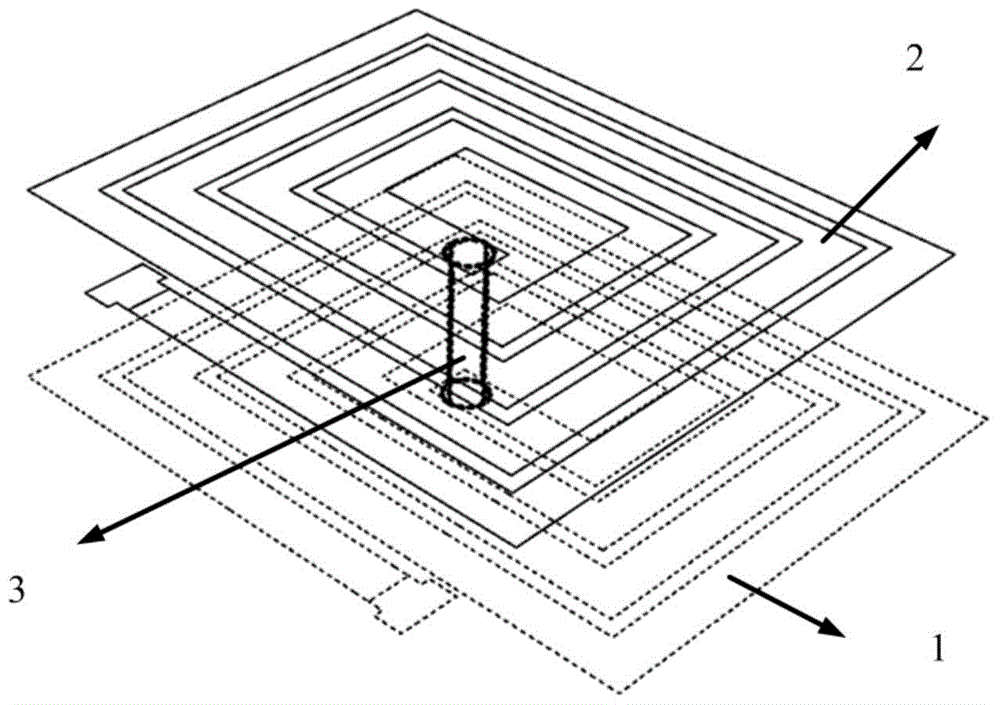

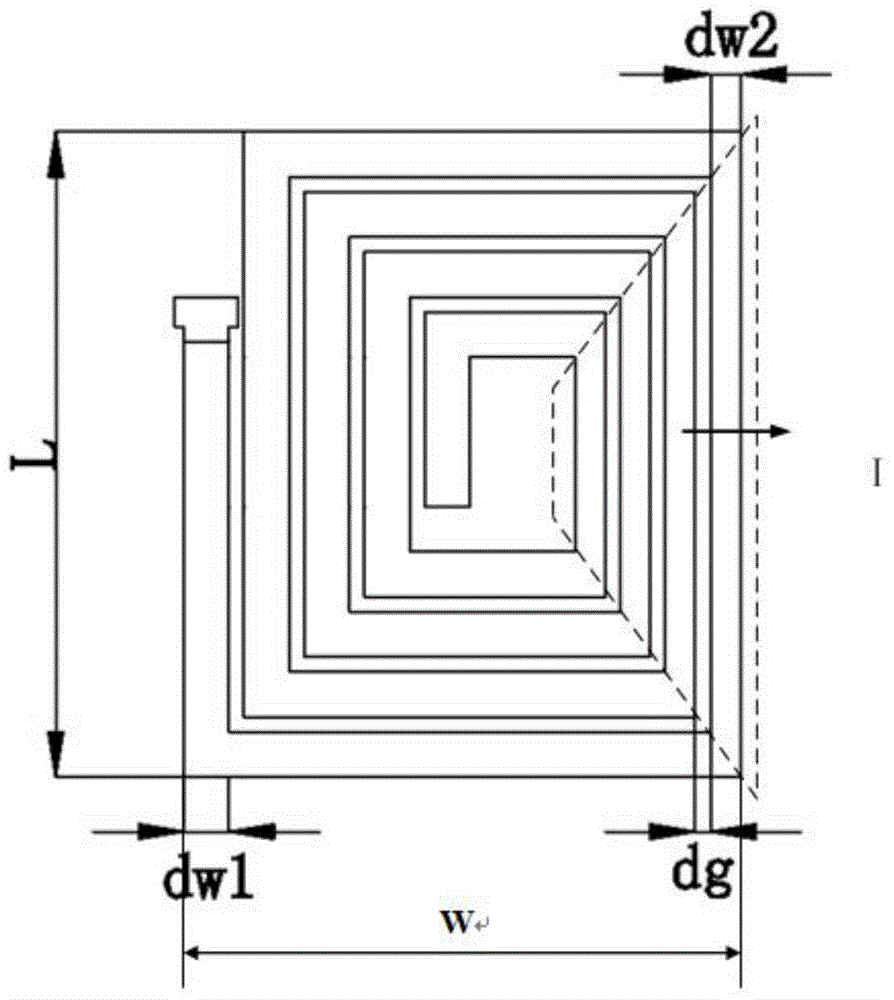

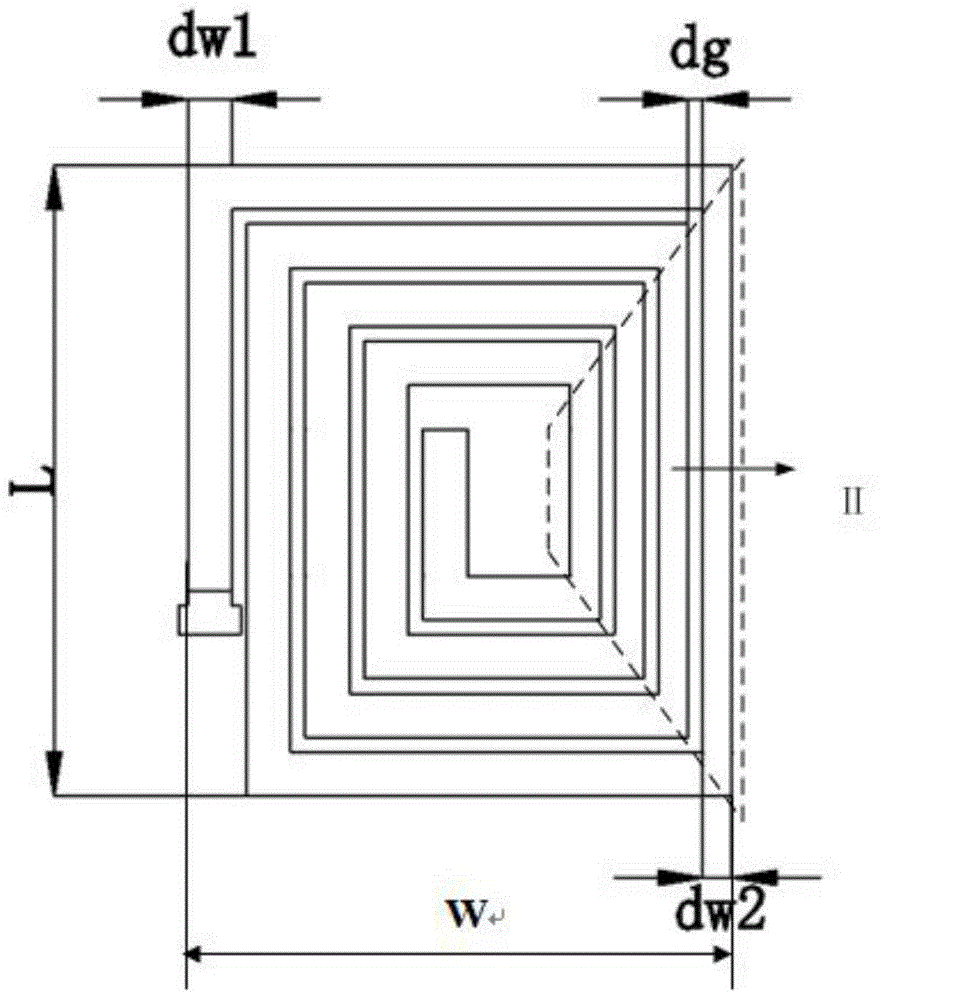

Low-power magnetic resistance sensor based on LTCC technology and preparation method therefor

ActiveCN105005010AEnhanced magnetic fieldThe magnetic field satisfiesMagnetic measurementsManufacture of electrical instrumentsGreen tapeEnergy consumption

The invention provides a low-power magnetic resistance sensor based on the LTCC technology and a preparation method therefor, and belongs to the magnetic material and component technology field. The low-power magnetic resistance sensor comprises a substrate and also comprises a bottom layer coil, a first green tape layer, a top layer coil, a second green tape layer and a four-terminal Wheatstone-bridge-type anisotropic magnetic resistance sensing unit layer which are located on the substrate in order. The bottom layer coil and the top layer coil are connected through a metal through hole, current flowing directions in the bottom layer coil and the top layer coil are consistent, and the magnetic field can be enhanced. The magnetic resistance sensor employs setting / resetting coil layers with optimized structures and employs the LTCC technology for preparation, thus a magnetic field meeting application demands is provided based on no addition of any magnetic auxiliary layer, energy consumption caused by setting / resetting operation is lowered, the technology is simple and implementation is easy.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Low-loss low-temperature co-fired ceramic green tape and preparation method thereof

The invention relates to the technical field of low-temperature co-fired ceramics of electronic ceramic materials, in particular to a low-loss low-temperature co-fired ceramic green tape and a preparation method thereof. The invention provides a low-loss low-temperature co-fired ceramic green tape and a preparation method thereof. The low-loss low-temperature co-fired ceramic green tape is formed by oxidizing and mixing two kinds of borate crystallized glass (glass A and glass B) with different softening temperatures and one or two kinds of subvalent metal, wherein the crystallized glass A is borate crystallized glass with low softening temperature, and the composition of the crystallized glass A is CaO-B2O3-SiO2-M'xOy; M'xOy is one or more metal oxidation mixtures of P, Zr, Zn, Nb, Na and K; the crystallized glass B is borate crystallized glass with high softening temperature, and the composition of the B is CaO-B2O3-SiO2-M''xOy; and M''xOy is one or more metal oxidation mixtures of Al, Mg and Zr. The green tape is composed of 50-70 parts of crystallized glass powder, 0.1-2 parts of subvalent metal oxide and 30-50 parts of an organic adhesive. The dielectric constant of the green tape is 5.5-6.5, and the dielectric loss of the green tape is lower than 0.002 (40GHz).

Owner:安徽华封电子科技有限公司

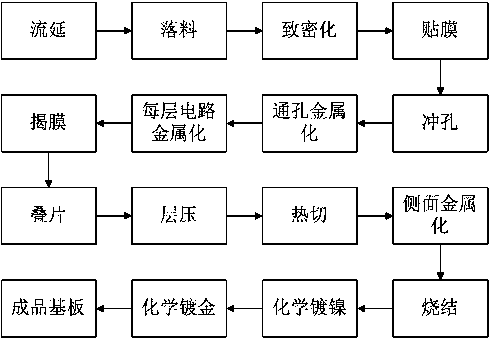

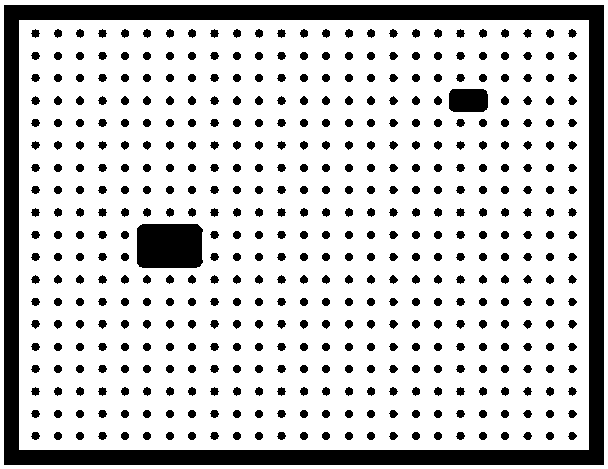

Multi-layer aluminum nitride substrate for highly integrated module level packaging, and manufacturing method thereof

InactiveCN109545771AReduce volumeSolve the heat dissipation problem of miniaturized and highly integrated module-level packagingSemiconductor/solid-state device detailsSolid-state devicesGreen tapeThermal expansion

The invention relates to a multi-layer aluminum nitride substrate for highly integrated module level packaging, and a manufacturing method thereof. The structure of the substrate comprises upper and lower surface layers, wherein the upper and lower surface layers are high-precision and high-density metalized welding pads; the side walls of the substrate are fully metalized; and the substrate is internally provided with multi-layer metalized wiring. The upper and lower surface layer metalized welding pads are welded with ball gates of a silicon-based chip; the side walls are fully metalized torealize signal shielding; the multi-layer metalized wiring inside the substrate satisfies complicated circuit signal transmission and interconnection. By utilizing a multi-layer co-firing process, aluminum nitride ceramic is selected as the ceramic base body material, tungsten is used as the metallization material, a green tape binding micro-deformation process adopted, and a tungsten metal circuit layer on the surface layer is plated by adopting chemical nickel-plating and chemical gilding processes. The multi-layer aluminum nitride substrate and the manufacturing method thereof have the advantages that the aluminium nitride substrate and the silicon-based chip are highly matched in coefficients of thermal expansion, and the reliability of ball gate welding packaging of the silicon-basedchip is realized; and the thermal conductivity of the substrate is increased to 170 W / mK, thereby being capable of meeting the high power density packaging and heat dissipation requirements of the highly integrated module.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

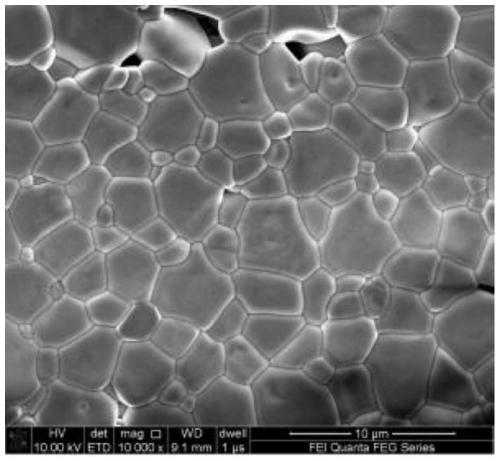

Tetragonal zirconia based composite ceramic ultrathin cover plate and preparation process thereof

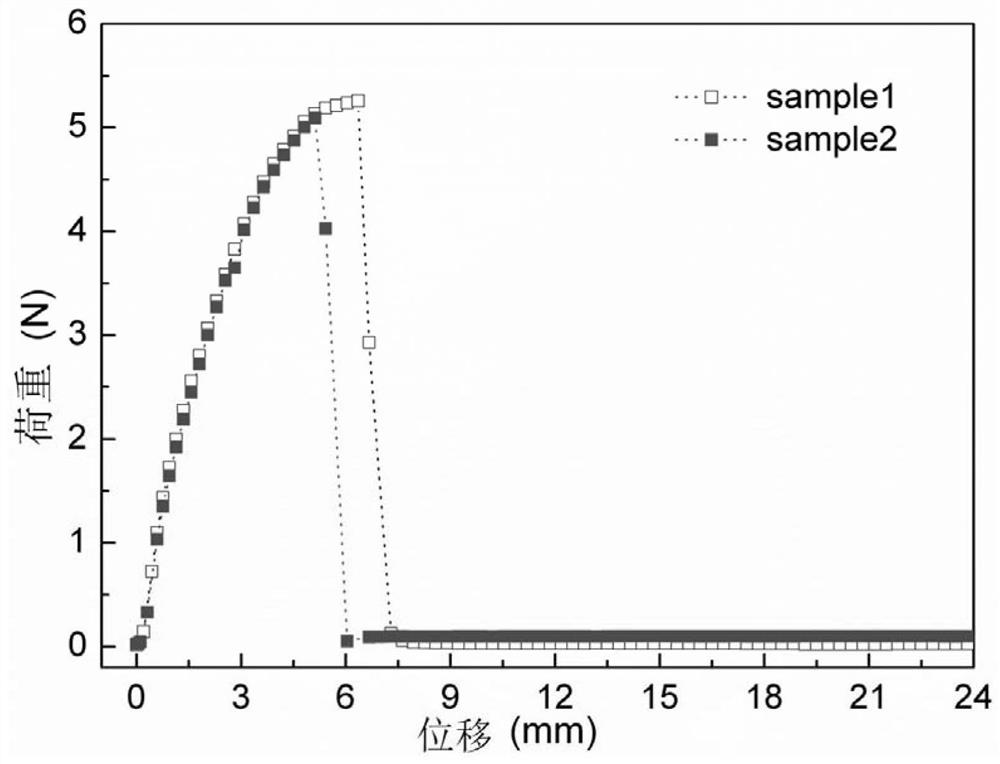

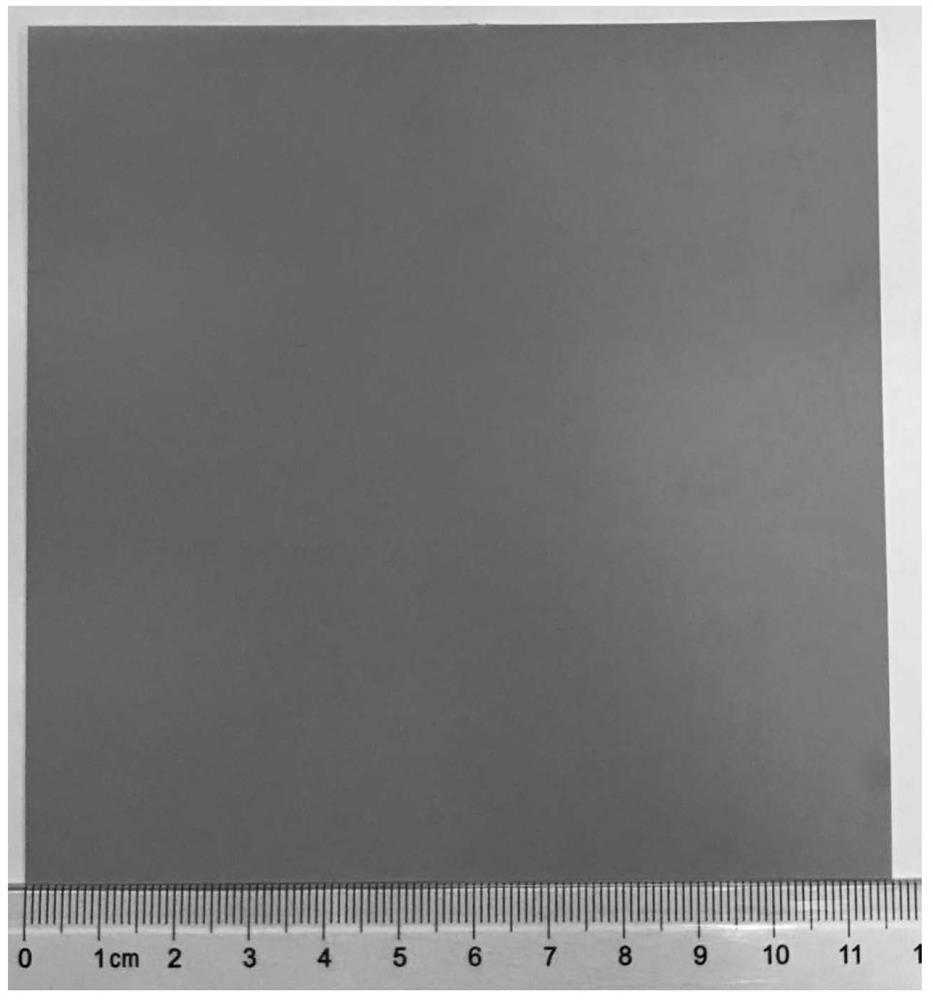

The invention relates to a tetragonal zirconia based composite ceramic ultrathin cover plate and a preparation process thereof, and belongs to the field of preparation of fine ceramics. Ceramic powder of the composite ceramic ultrathin cover plate is a trans-scale mixture formed by nanometer zirconia powder and micrometer powder, wherein the nanometer zirconia powder accounts for 40-70% of the ceramic powder in volume. The preparation process comprises the following steps: adding appropriate dispersing agent, adhesive, plasticizer and defoamer into raw materials to prepare ceramic slurry; preparing an ultrathin ceramic green tape of which the solid content is above 63% through a tape casting process; then cutting and shaping; and preparing the ultrathin composite ceramic cover plate with high flatness and controllable shrinkage ratio for a fingerprint identification function through a special sintering pot. Compared with the existing fingerprint cover plate, the composite ceramic ultrathin cover plate prepared by the invention has low sintering temperature and favorable electrical and mechanical properties, satisfies the performance requirements of fingerprint identification for high sensitivity, drop resistance, wear resistance and ultrathinness, is low in cost, and has an important practical meaning.

Owner:SHANTOU UNIV

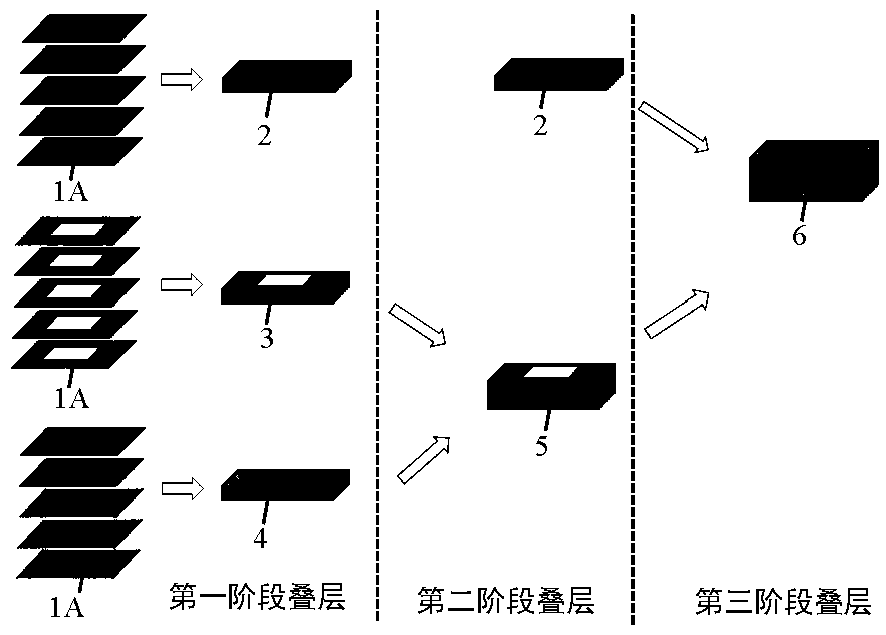

Method for preparing low temperature co-fired ceramic substrate cavity structure

ActiveCN107591336AReduce manufacturing costEase of mass productionSemiconductor/solid-state device manufacturingGreen tapeCo-fired ceramic

The method for preparing a low temperature co-fired ceramic substrate cavity structure comprises the following steps: cutting a LTCC (Low Temperature Co-fired Ceramic) green tape into LTCC green sheets; sequentially performing first-stage lamination of the LTCC green sheets after cutting to form an upper cover plate, a sub-layer plate and a lower plate; performing second-stage lamination of the sub-layer plate and the lower plate to form a laminated plate; and performing lamination of the upper cover plate and the laminated plate to form a LTCC bar block; and performing cutting of the LTCC barblock to form a LTCC substrate biscuit, and performing sintering of a LTCC substrate, wherein the lamination pressure, temperature and time in the technology of the third-stage lamination are all smaller than parameters in the technologies in the first-stage and second-stage laminations. According to the invention, the manufacturing cost of a low-temperature co-fired ceramic substrate with a cavity structure can be greatly reduced so as to facilitate batch production of a low-temperature co-fired ceramic substrate cavity structure.

Owner:ZHEJIANG SIRAMIC TECH CO LTD

Instant ceramic heating tube and processing technology thereof

InactiveCN103582193ASimple processModerate dielectric constantHeating element shapesGreen tapeTungsten

The invention provides an instant ceramic heating tube comprising a ceramic rod and a resistive film. According to the resistive film, an aluminum oxide green tape serves as a substrate, and a tungsten metal heating circuit film is printed on the substrate. An external electrode is lead out through brazing of the tungsten metal heating circuit film. The aluminum oxide green type wraps the ceramic rod. The aluminum oxide green tape and the ceramic rod are fired together and form a whole. A preparation method of the instant ceramic heating tube comprises the steps that firstly, the ceramic rod and the resistive film are prepared, the ceramic rod is coated with the resistive film, hot-pressing and co-firing are conducted, and the instant ceramic heating tube is formed. The instant ceramic heating tube is simple and compact in structure, high in temperature rising speed, even in heating, resistant to corrosion, environmentally friendly, and capable of saving energy.

Owner:HUNAN XINHUA COUNTY QIRUI ELECTRONICS APPLIANCES

Low-temperature co-fired ceramic substrate and preparation method thereof

The invention relates to a low-temperature co-fired ceramic substrate and a preparation method thereof. The preparation method of the low-temperature co-fired ceramic substrate comprises the following steps: (1) mixing 40-60 wt% of ceramic powder, 30-50 wt% of a solvent, 5-15 wt% of a binder and 0.2-2 wt% of a dispersant to obtain ceramic tape casting slurry, the binder being polymethacrylate; (2) carrying out tape casting on the obtained ceramic tape casting slurry to obtain a ceramic casting green tape; and (3) placing the obtained ceramic casting green tape in an air atmosphere or an oxygen-free atmosphere, discharging glue at 380-450 DEG C, and sintering the material to obtain the ceramic substrate, or printing at least one of the Cu electrode and the Ni electrode on the ceramic casting green tape and then placing the green tape in the oxygen-free atmosphere, carrying out glue discharging at the temperature of 380-450 DEG C, and sintering the green tape to form the low-temperature co-fired ceramic substrate.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

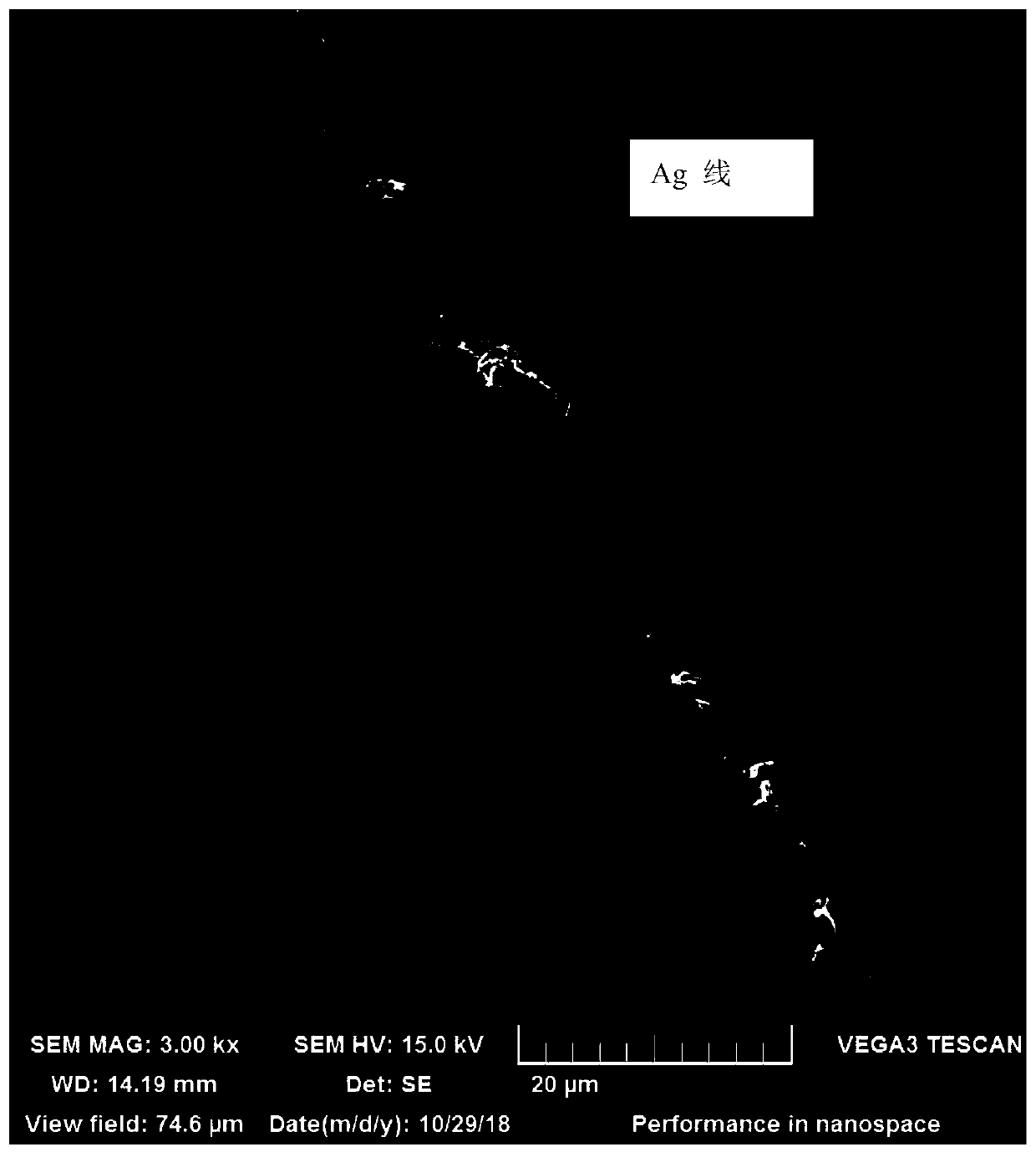

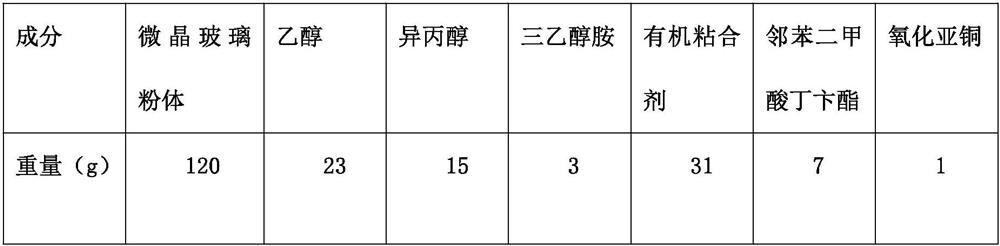

Silver paste for multilayer wiring of low-temperature co-fired low-dielectric-constant dielectric ceramic

ActiveCN111312427AImprove performanceEliminate DiffusionNon-conductive material with dispersed conductive materialGreen tapeSilver paste

The invention relates to silver paste for multilayer wiring of low-temperature co-fired low-dielectric-constant dielectric ceramic, which belongs to the technical field of materials. The silver pastecomprises the components of, by mass, 80 to 90% of silver powder, 0.2 to 5% of an inorganic modifier, 0 to 3% of glass powder and 8 to 19.5% of an organic carrier. The silver paste can be co-fired with a microcrystalline glass and glass ceramic composite system low-temperature co-fired ceramic green tape at 850 DEG C, and has excellent matching performance. According to the multilayer wiring structure made of the silver paste, conductor silver wire patterns are clear, surrounding porcelain bodies do not turn yellow, and the bad silver diffusion phenomenon is eliminated.

Owner:LUOYANG INST OF SCI & TECH

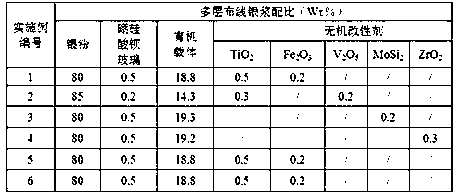

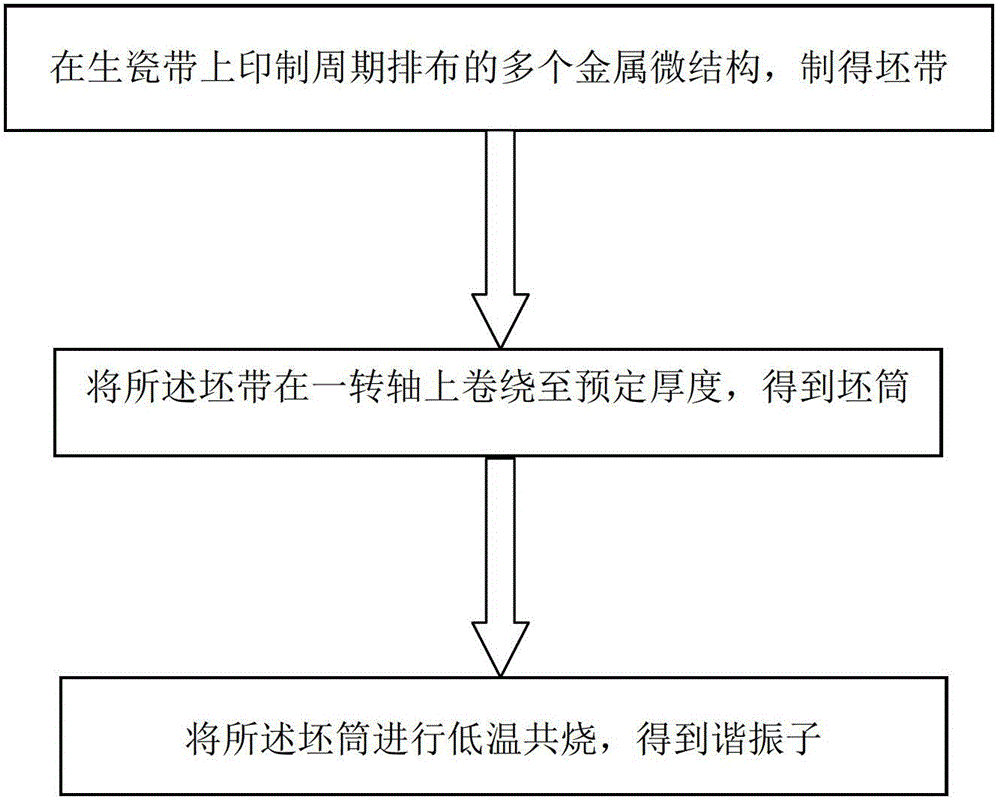

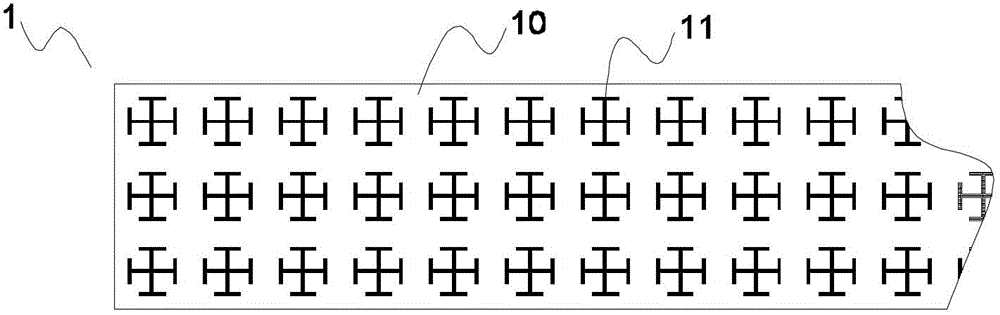

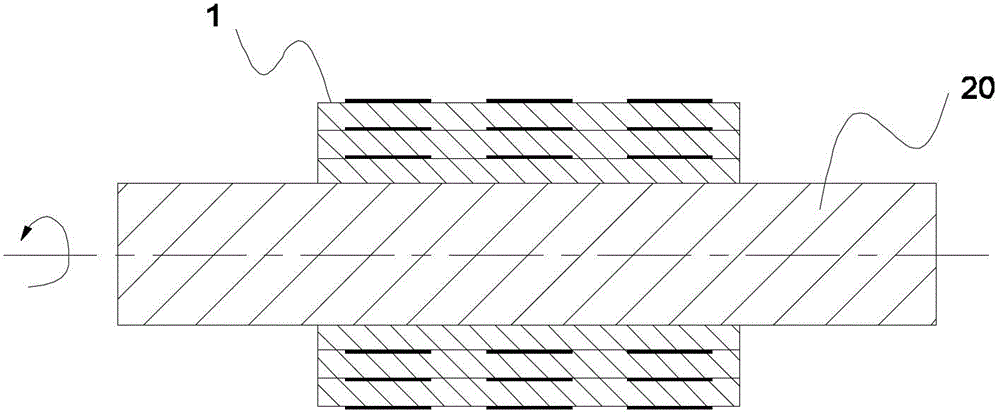

TM mode harmonic oscillator and preparation method thereof

The invention relates to a method for preparing a TM mode harmonic oscillator, and the method comprises the following steps of manufacturing strip billet: printing a plurality of metal micro-structures which are periodically distributed on a green tape to prepare the strip billet; manufacturing barrel billet: coiling the strip billet on a rotating shaft to a preset thickness to obtain the barrel billet; sintering: conducting the low-temperature cofiring for the barrel billet to obtain the TM mode harmonic oscillator. The invention also relates a TM mode harmonic oscillator prepared by the method. Since a magnetic field direction when the TM mode is formed by a curved surface on which the metal micro-structures stay and the TM mode harmonic oscillator in a filter is basically parallel, the magnetic field can pass by the curved surface on which the metal micro structures stay, so that the sensing current produced by an alternative magnetic field is small, and the loss caused by the metal micro structures is small; and meanwhile, the metal micro structures are basically parallel to the direction of an electric field, so that the dielectric constant of the harmonic oscillator is maximally improved, and the sizes of a harmonic oscillation chamber and the filter are reduced.

Owner:KUANG CHI INST OF ADVANCED TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com