Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

520results about How to "Improve piezoelectric performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

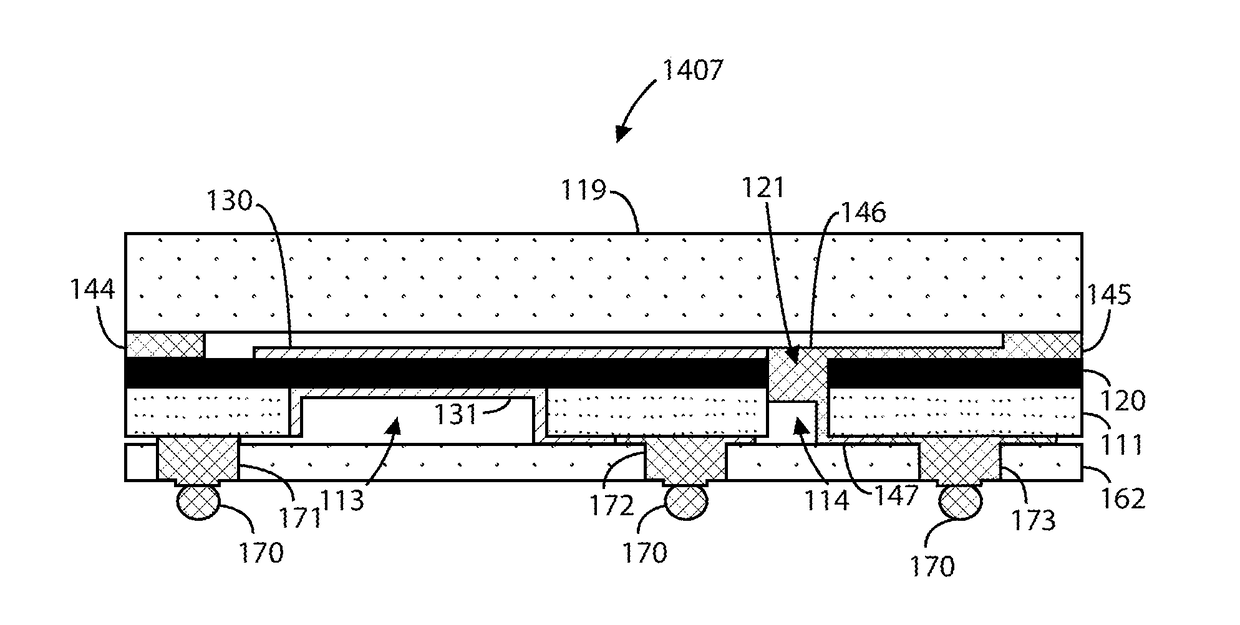

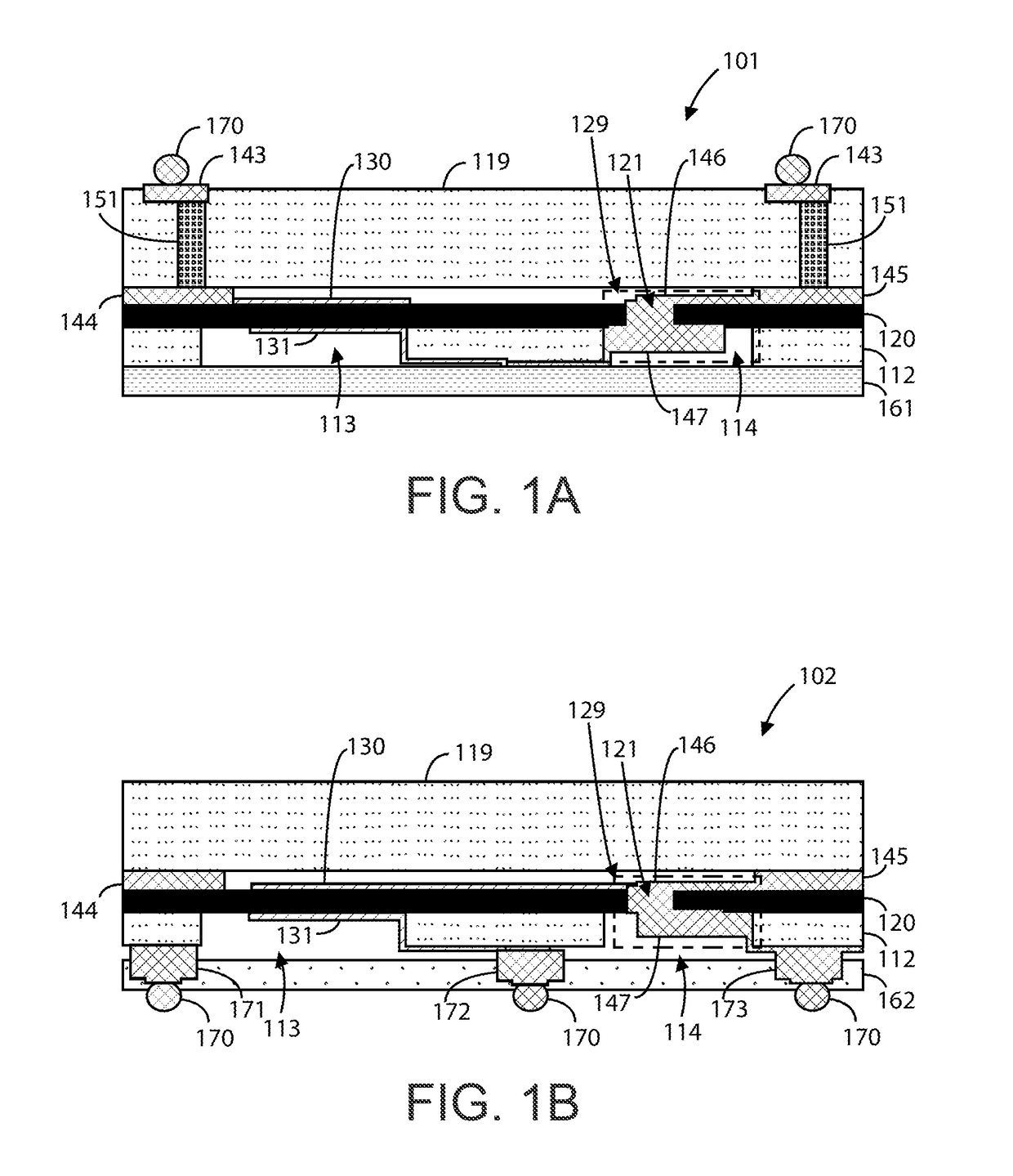

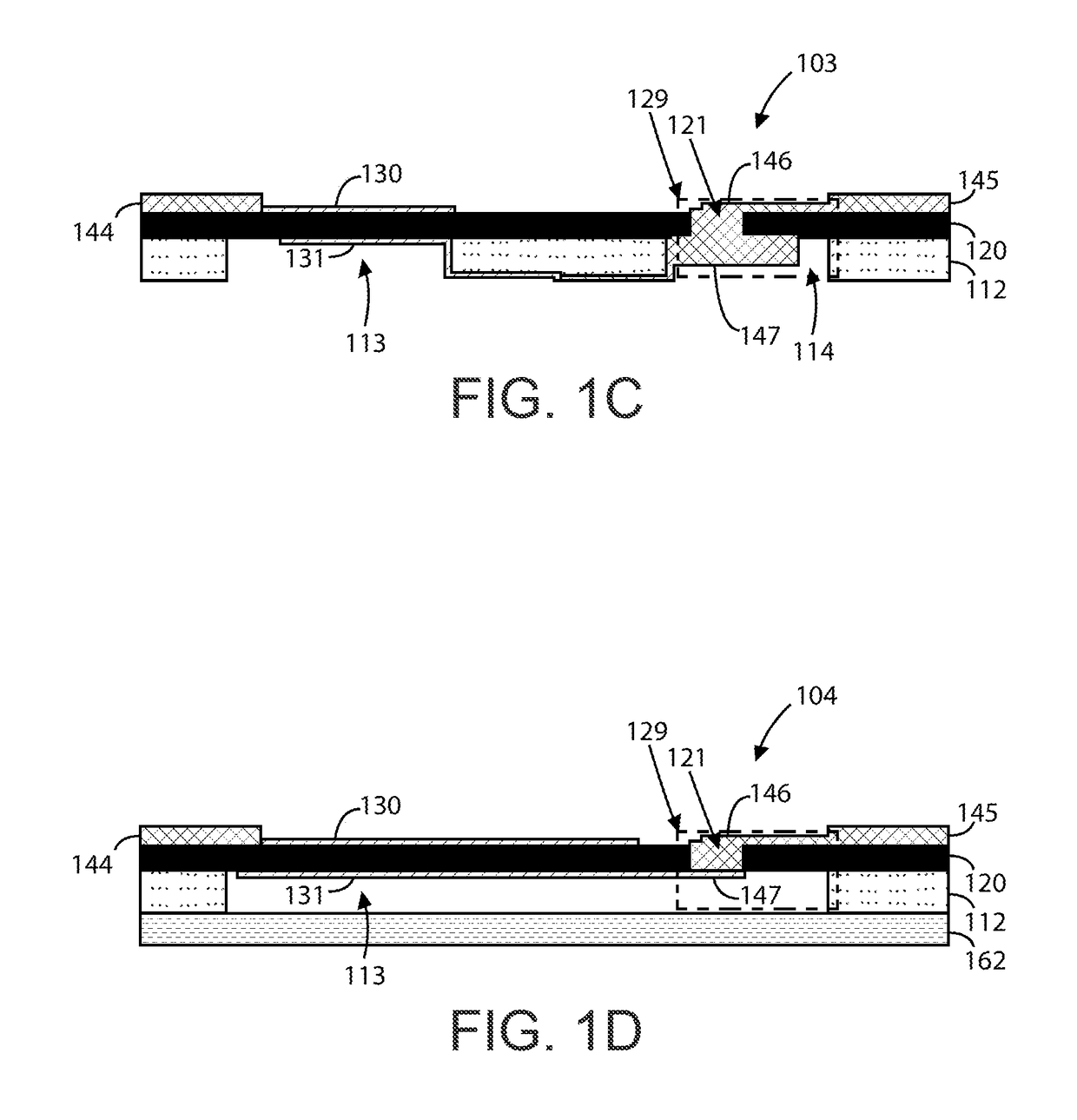

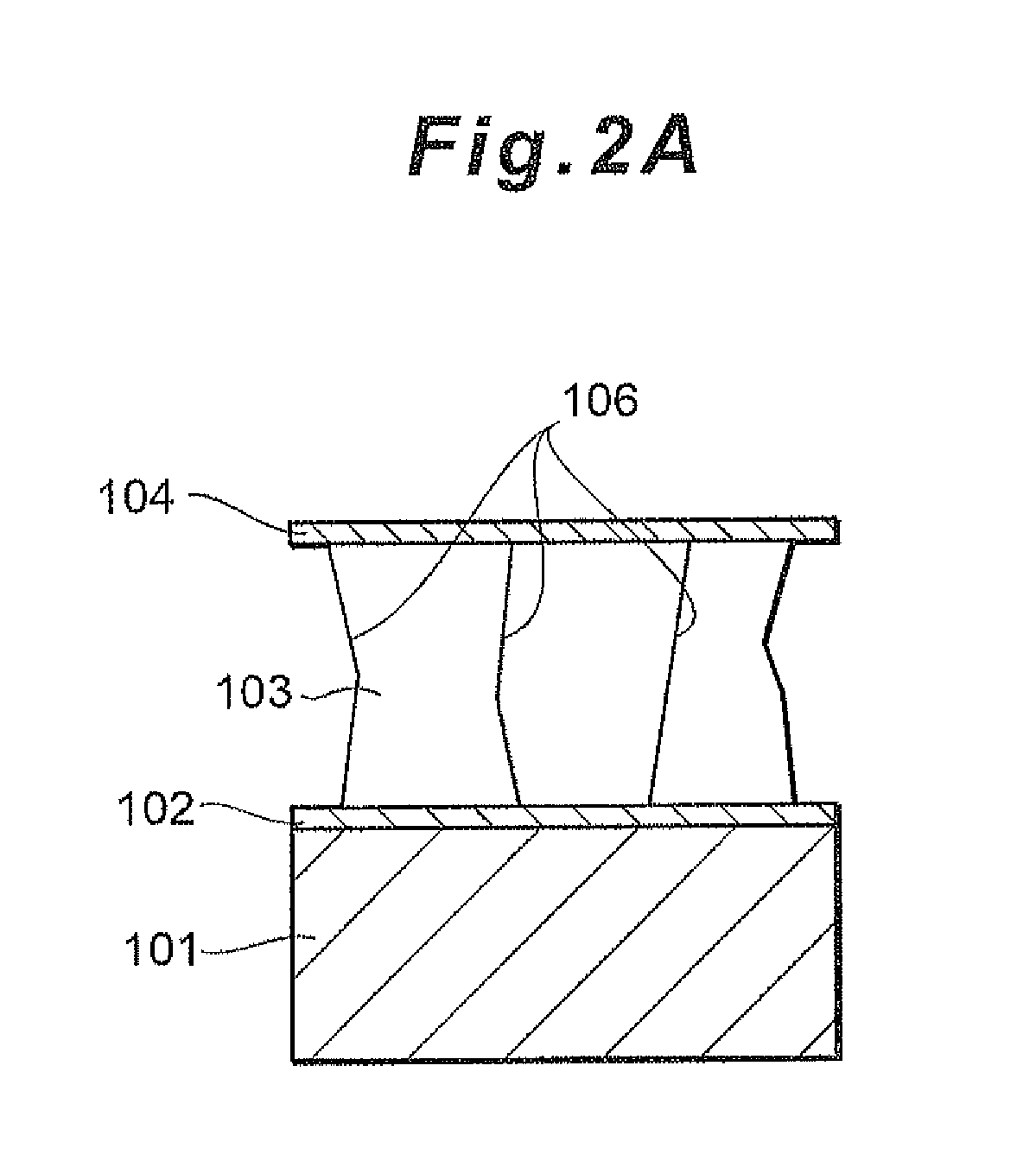

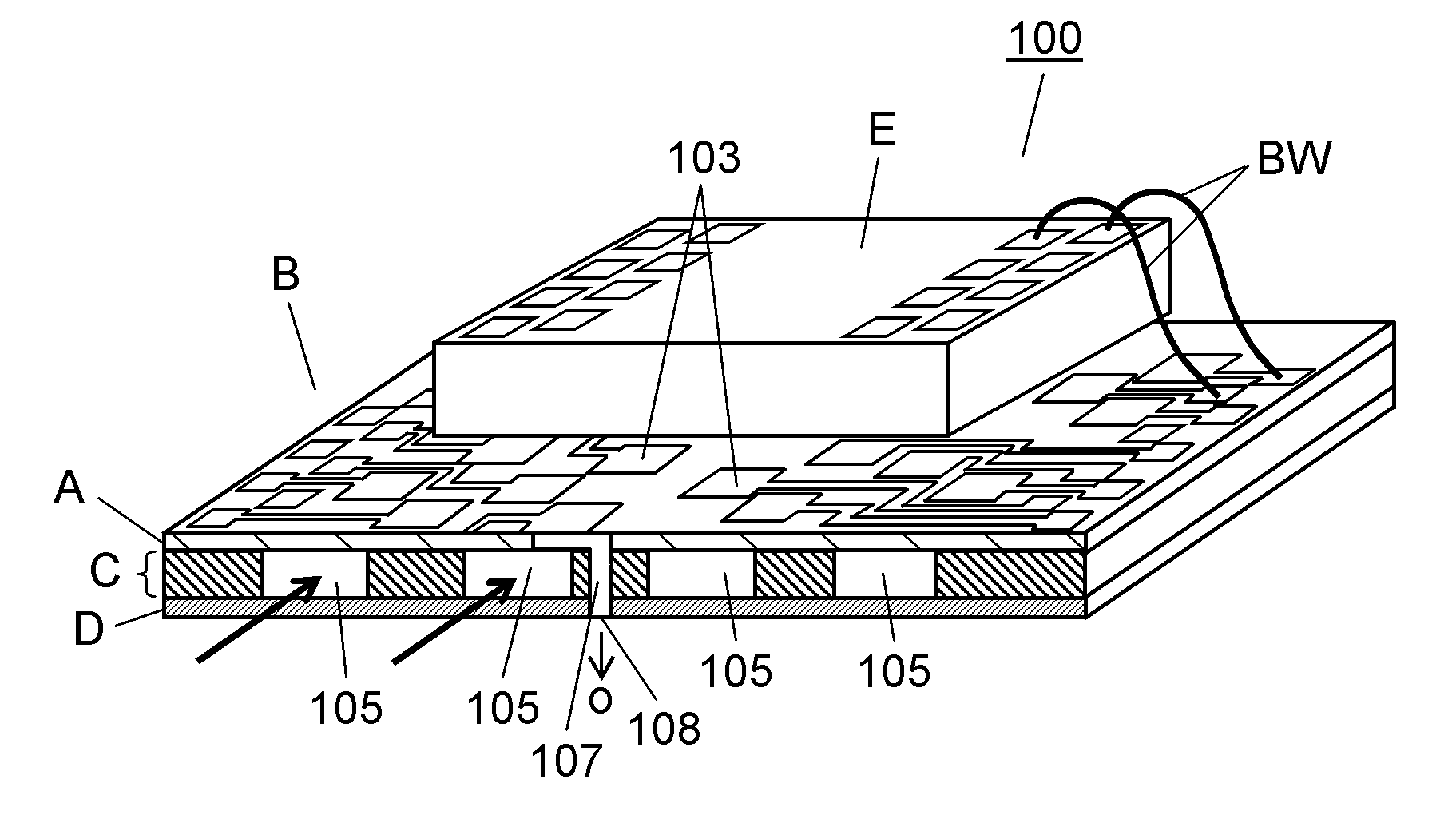

Method of manufacture for single crystal acoustic resonator devices using micro-vias

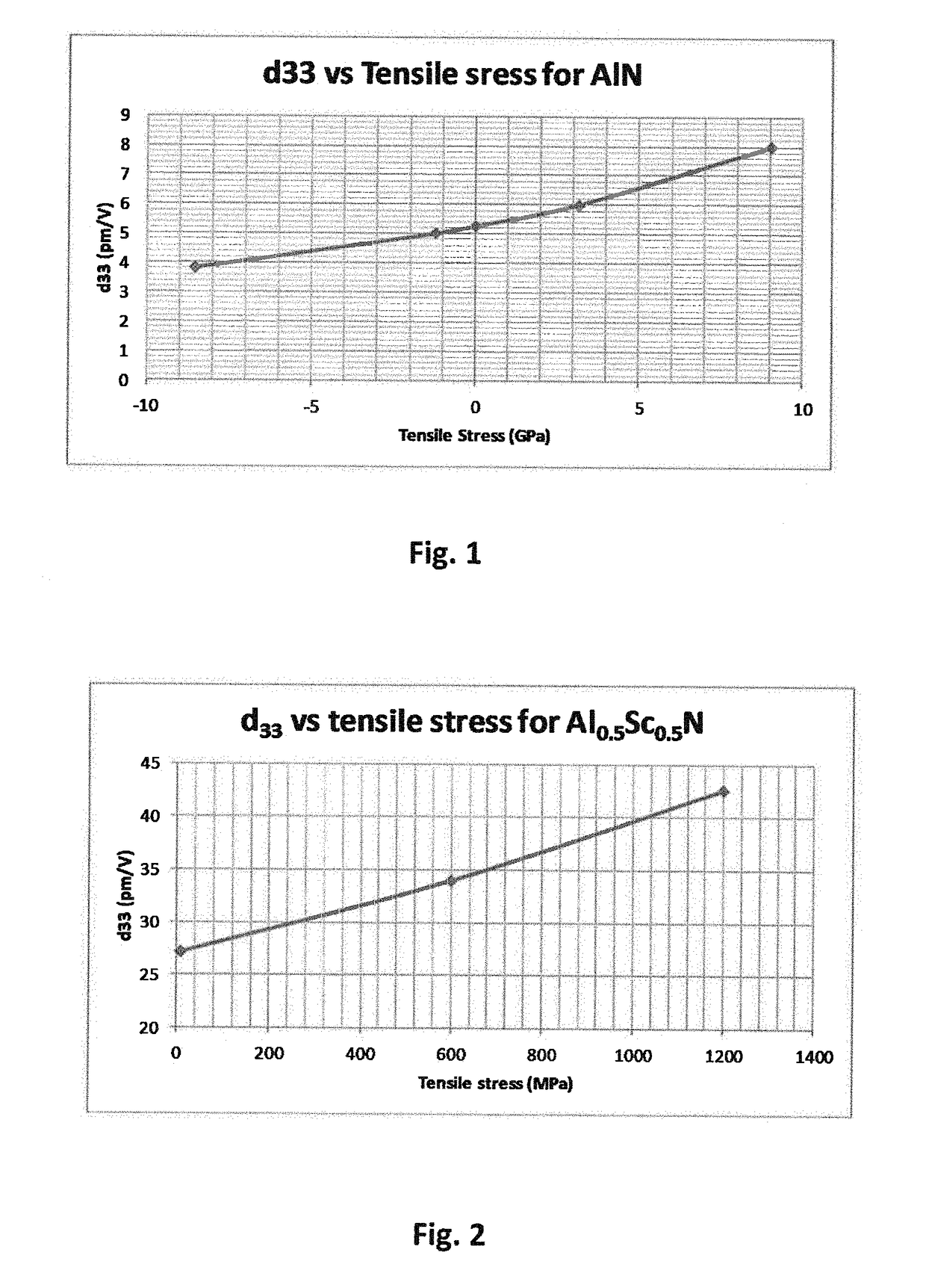

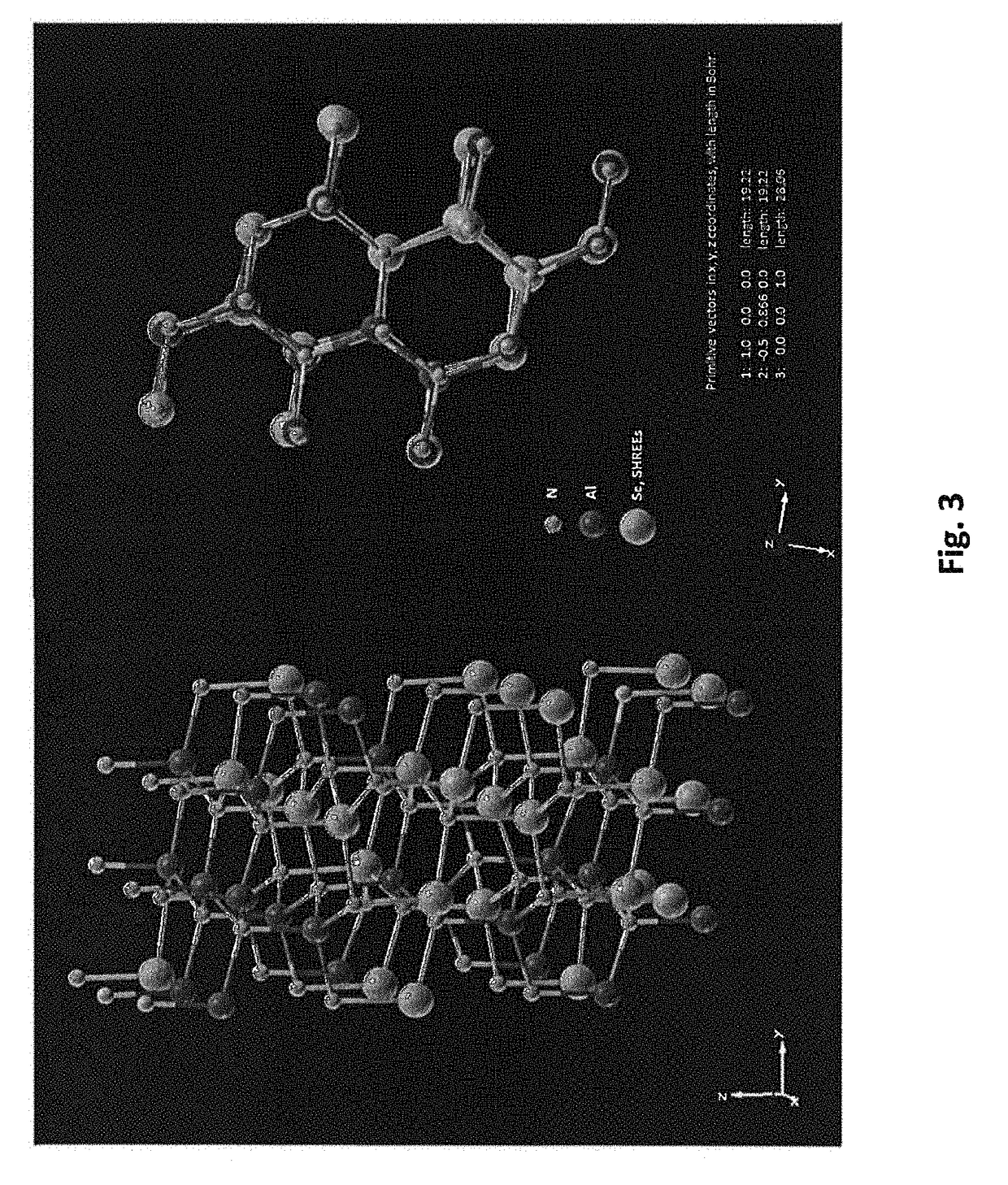

ActiveUS20170264256A1Simple and cost-effectiveImprove piezoelectric performanceImpedence networksSingle crystalNucleation growth

A method of manufacture for an acoustic resonator device. The method includes forming a nucleation layer characterized by nucleation growth parameters overlying a substrate and forming a strained piezoelectric layer overlying the nucleation layer. The strained piezoelectric layer is characterized by a strain condition and piezoelectric layer parameters. The process of forming the strained piezoelectric layer can include an epitaxial growth process configured by nucleation growth parameters and piezoelectric layer parameters to modulate the strain condition in the strained piezoelectric layer. By modulating the strain condition, the piezoelectric properties of the resulting piezoelectric layer can be adjusted and improved for specific applications.

Owner:AKOUSTIS INC

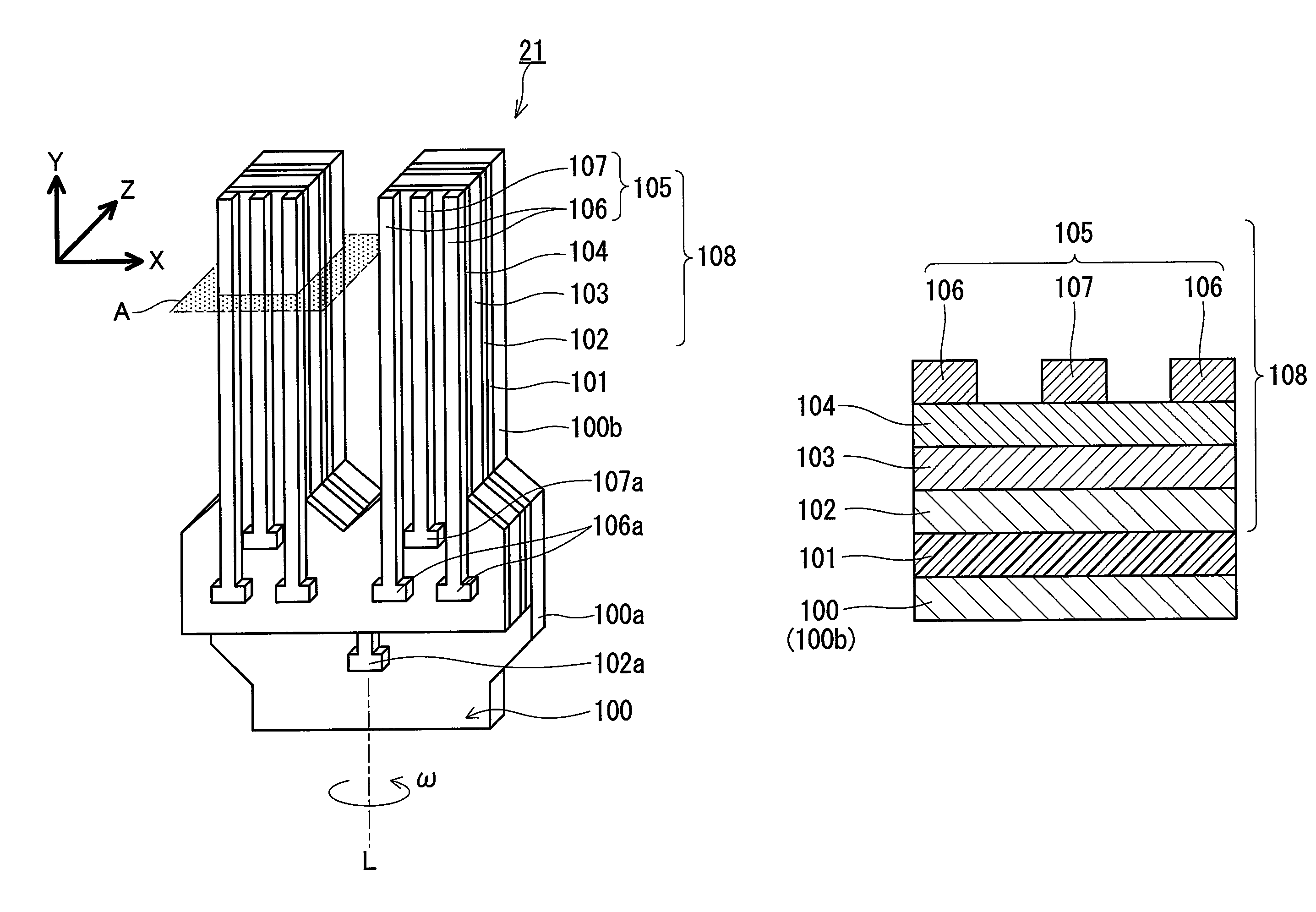

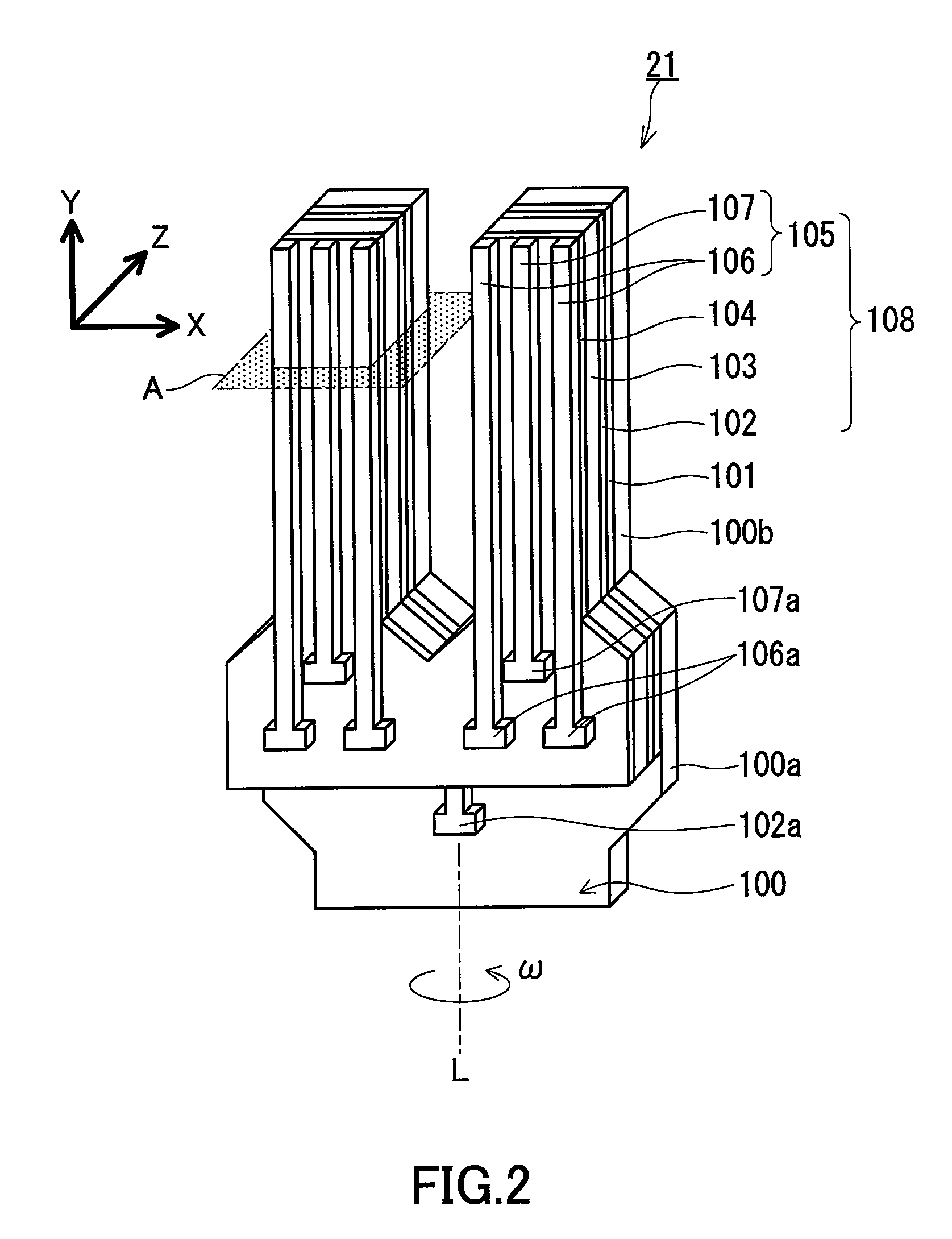

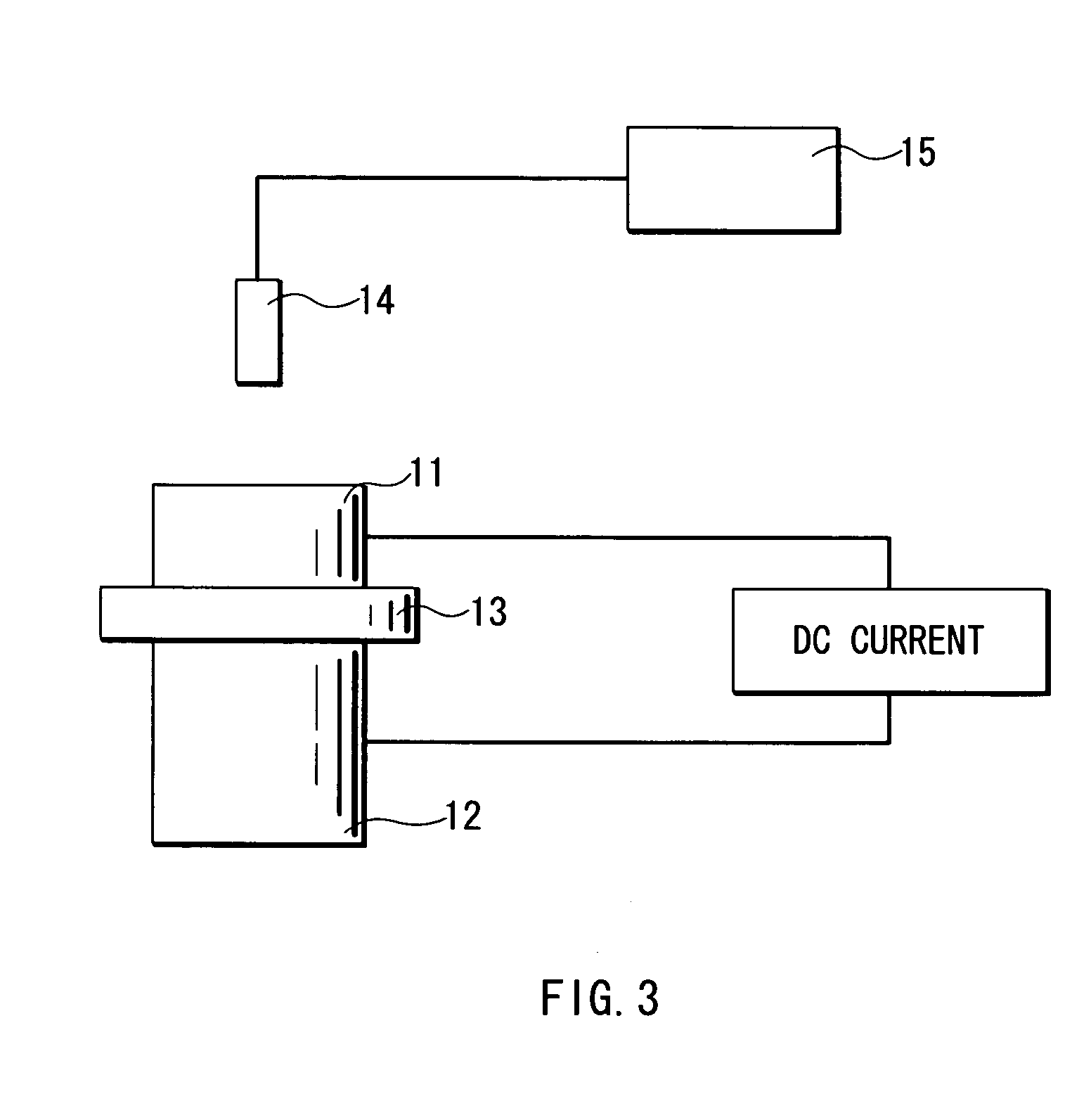

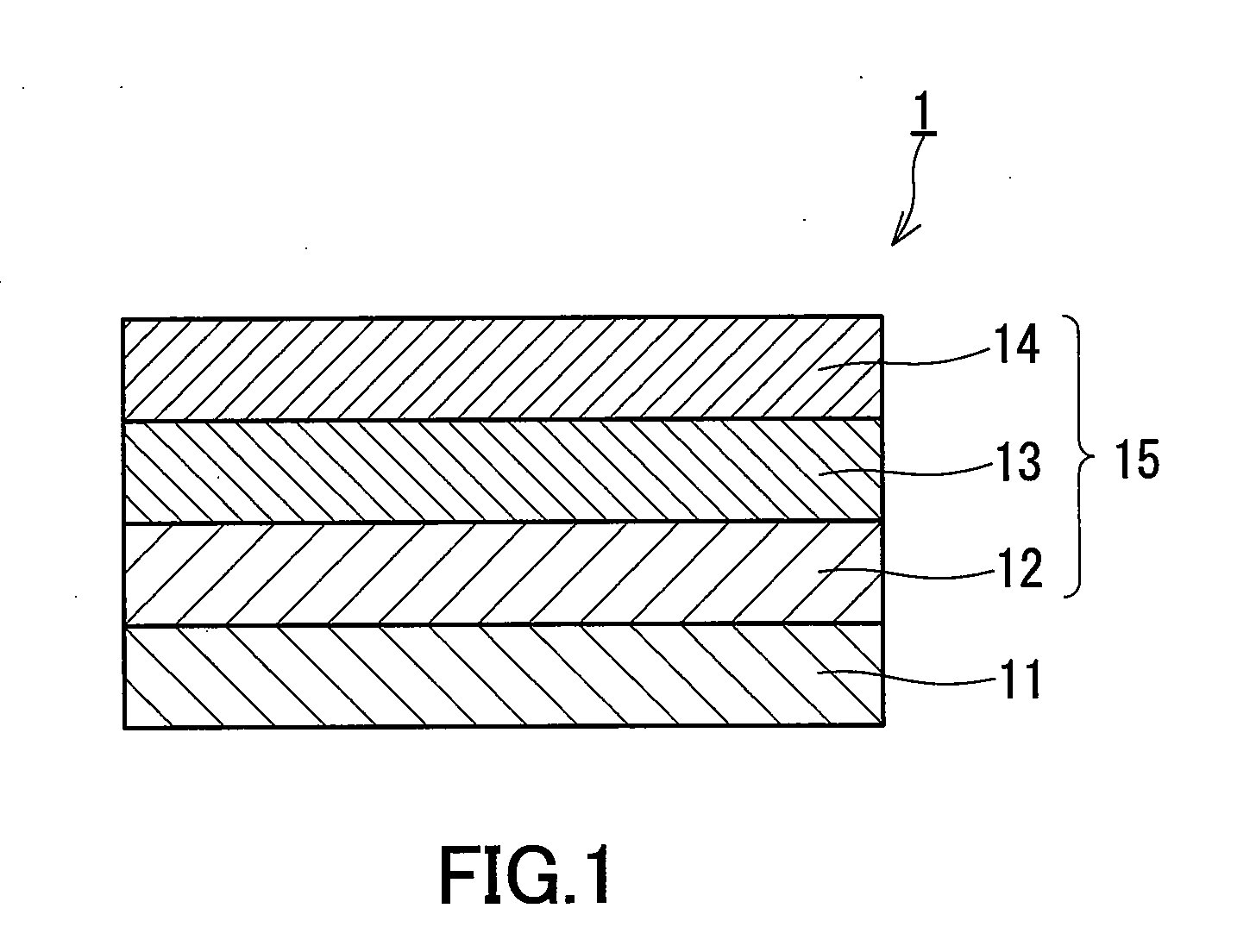

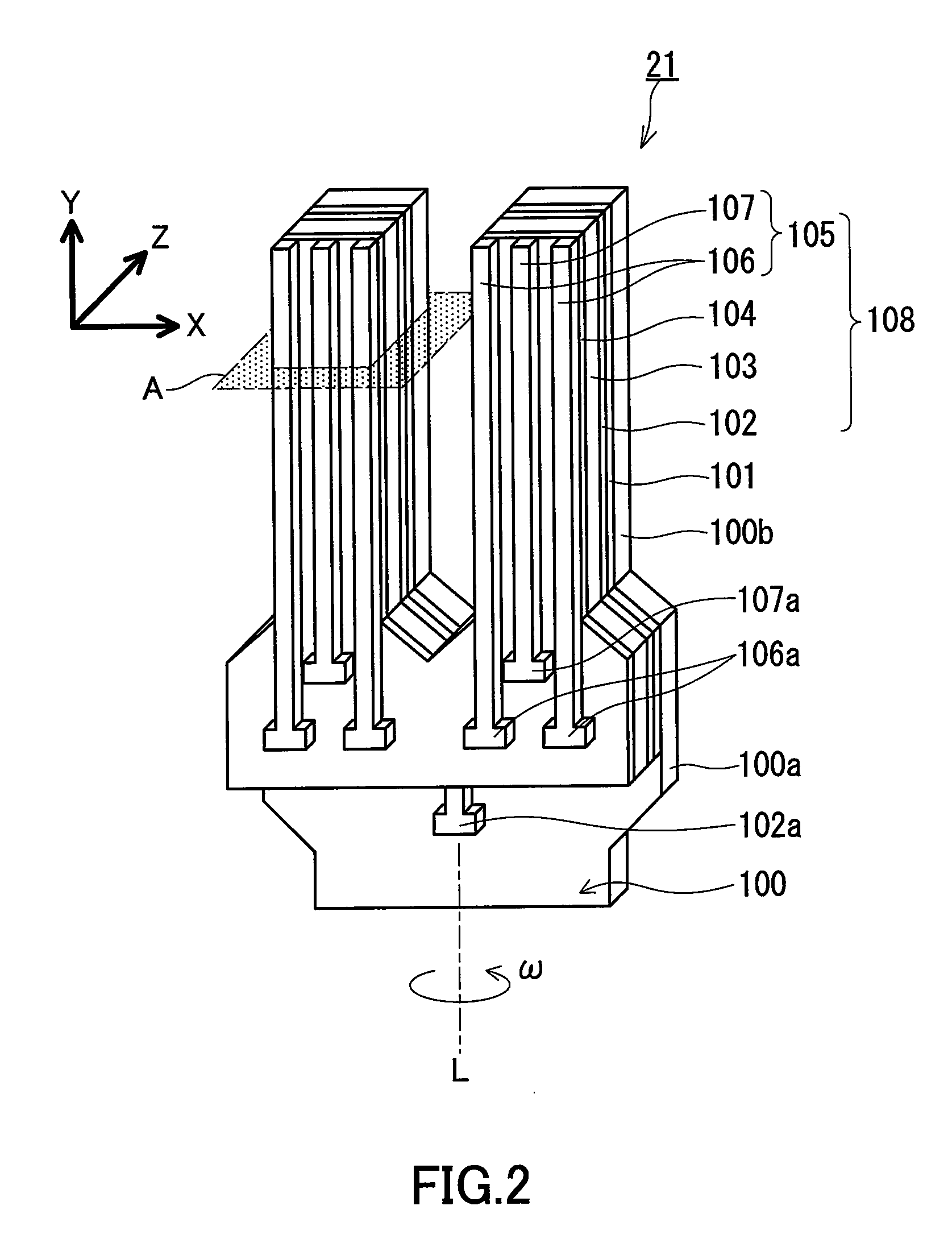

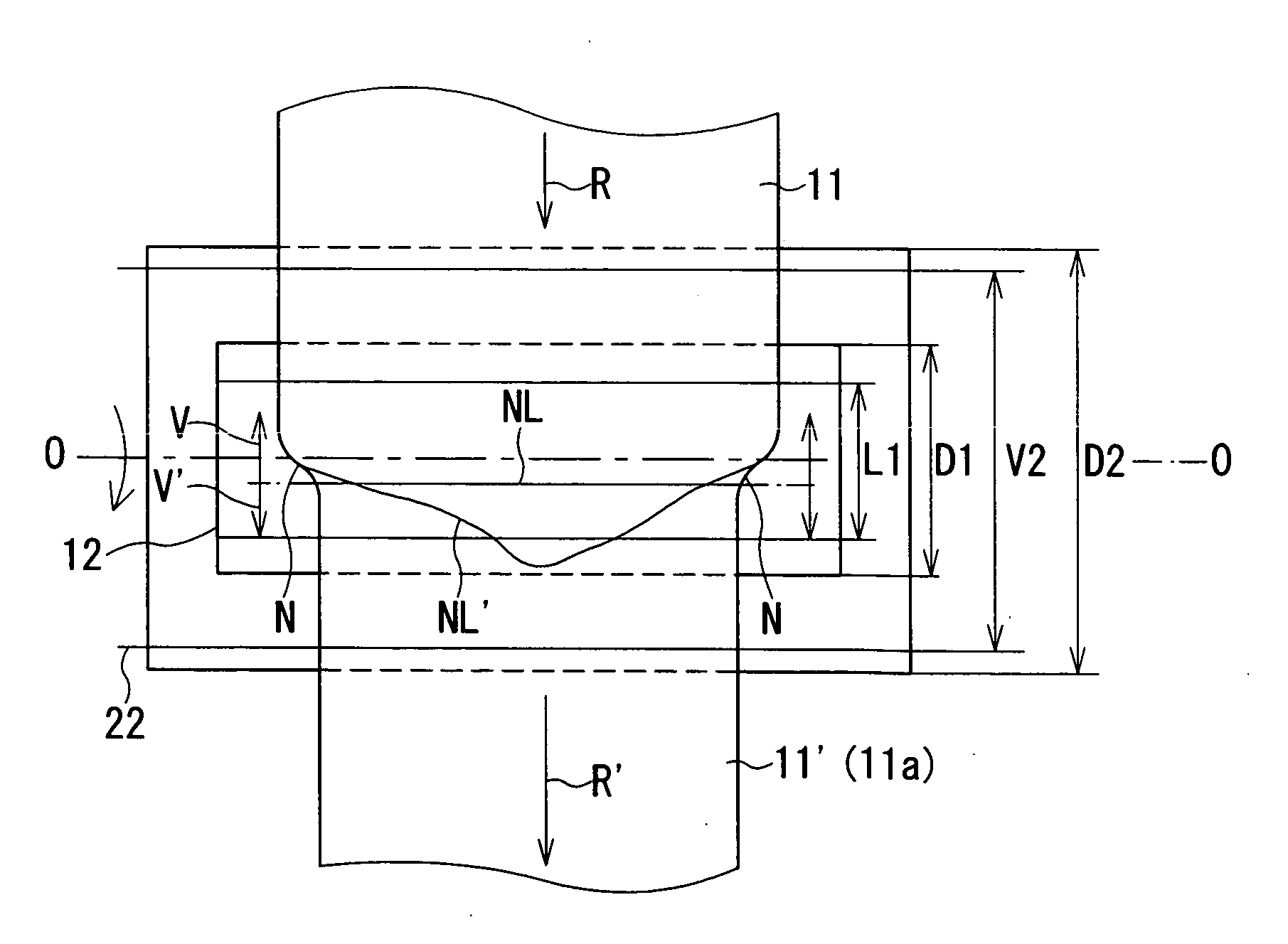

Piezoelectric thin film and method of manufacturing the same, angular velocity sensor, method of measuring angular velocity by the angular velocity sensor, piezoelectric generating element, and method of generating electric power using the piezoelectric generating element

InactiveUS7870787B2Improve piezoelectric performanceHigh sensitivityPiezoelectric/electrostrictive device manufacture/assemblyAcceleration measurement using interia forcesElectricityWide area

Provided are a piezoelectric thin film including a lead-free ferroelectric material and exhibiting high piezoelectric performance comparable to that of PZT, and a method of manufacturing the piezoelectric thin film. The piezoelectric thin film of the present invention has a multilayer structure in which a metal electrode film having a plane orientation of (100), a (Bi,Na)TiO3 film, and a (Bi,Na,Ba)TiO3 film having a plane orientation of (001) are laminated in this order. The piezoelectric thin film of the present invention can be applied to a wide range of fields and uses. For example, with the piezoelectric thin film of the present invention, an angular velocity sensor of the present invention having high sensitivity and a piezoelectric generating element of the present invention having excellent power generation characteristics can be constructed.

Owner:PANASONIC CORP

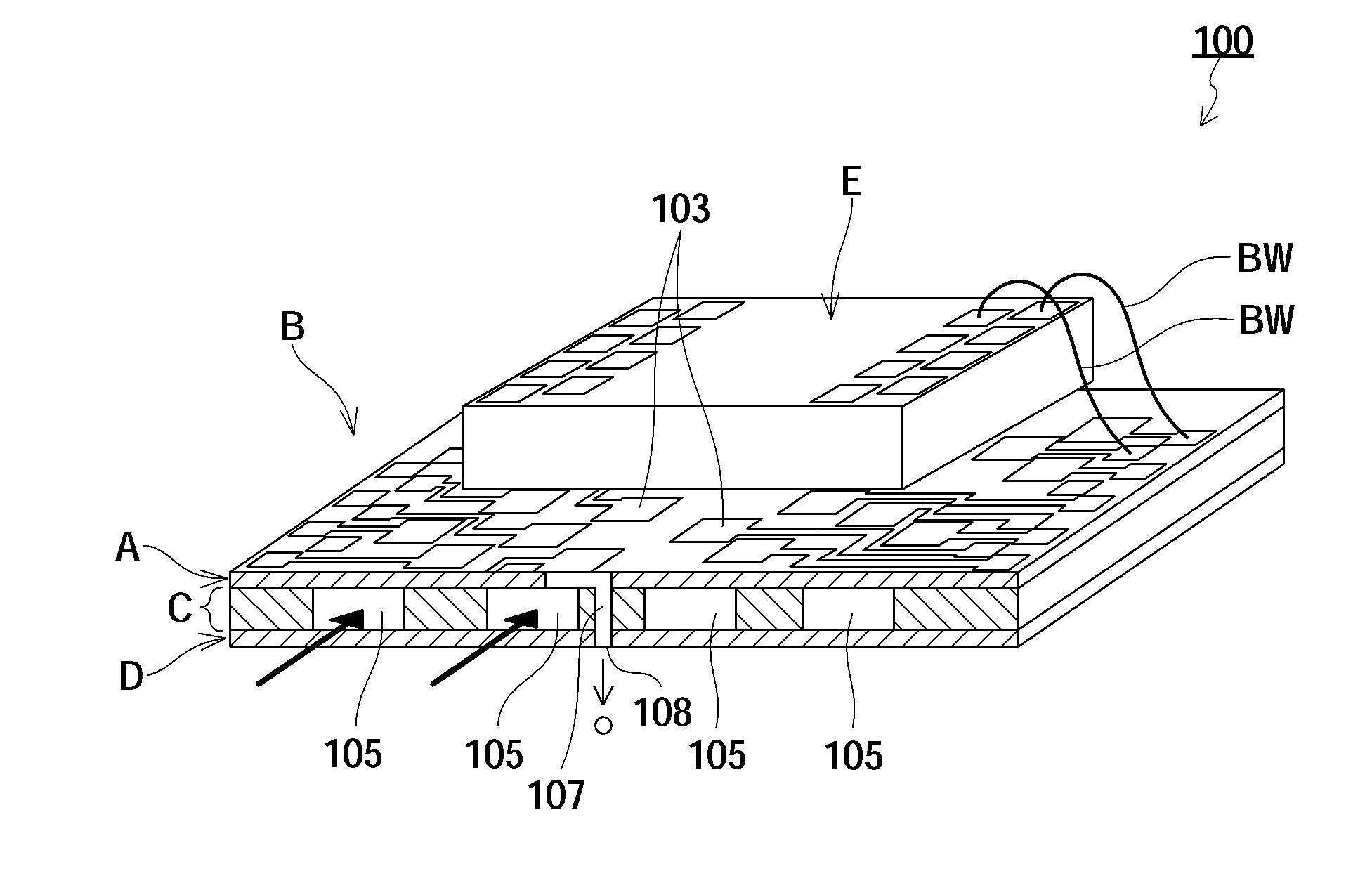

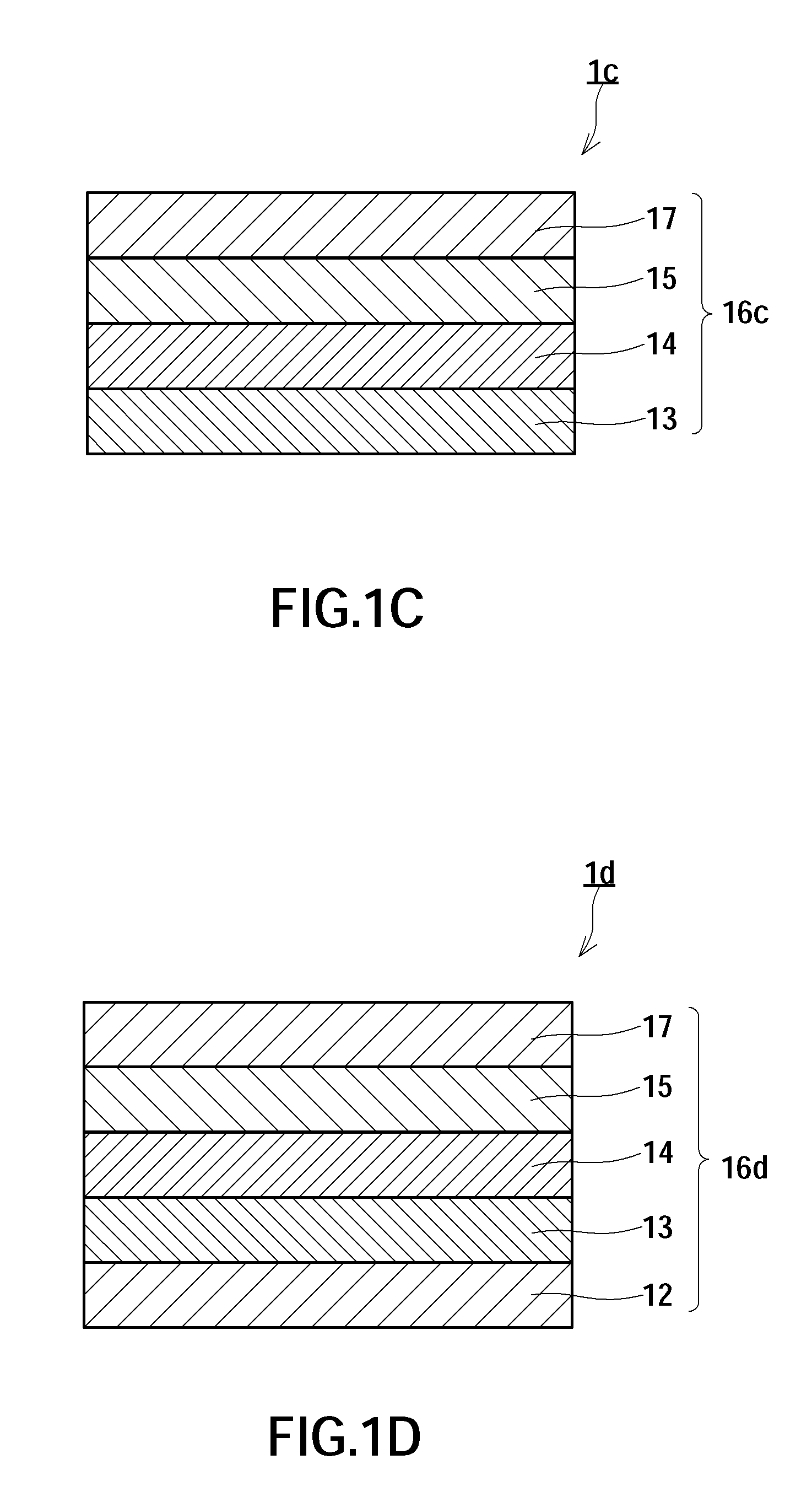

Thin-film piezoelectric element, thin-film piezoelectric actuator, thin-film piezoelectric sensor, hard drive disk, and inkjet printer

ActiveUS20140339961A1Leakage currentReduce leakage currentInking apparatusPiezoelectric/electrostriction/magnetostriction machinesHard disc drivePiezoelectric actuators

A thin film piezoelectric element according to the present invention includes a potassium sodium niobate thin film having a structure in which a plurality of crystal grains are present in a film thickness direction; and a pair of electrode films sandwiching the potassium sodium niobate thin film. When the potassium sodium niobate thin film is divided into three regions of the same thickness in the film thickness direction and average crystal grain sizes A1, A2, and A3 of the respective regions are determined, a ratio m / M of the smallest average crystal grain size m among A1, A2, and A3 to the largest average crystal grain size M among A1, A2, and A3 is 10% to 80%. The region having the smallest average crystal grain size m lies next to one of the pair of electrode films.

Owner:TDK CORPARATION

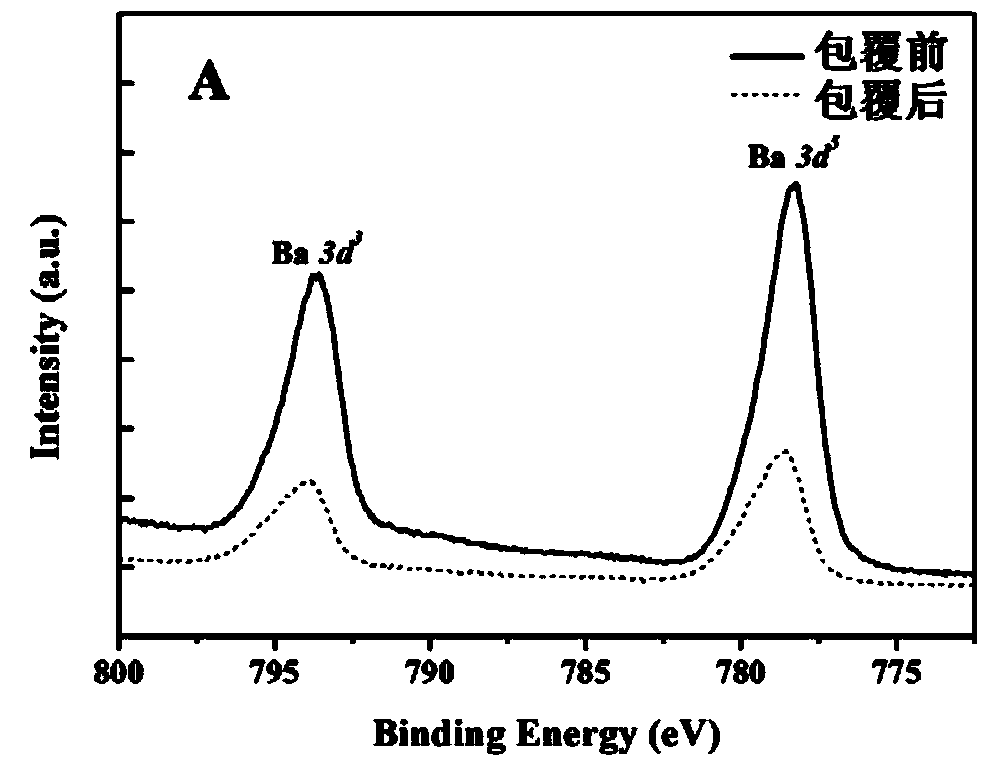

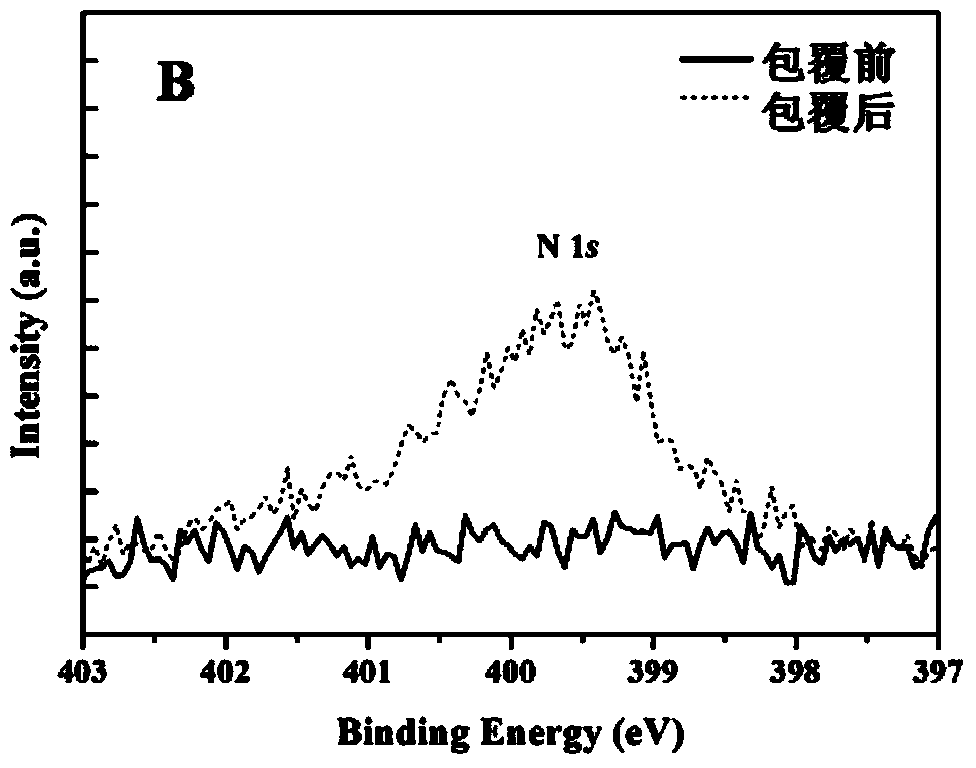

Piezoelectric active bone repair composite material and preparation method thereof

The invention relates to a piezoelectric active bone repair composite material and a preparation method thereof, aiming at solving the problems that the existing material does not have biocompatibility and is poor in piezoelectric property. The piezoelectric active bone repair composite material comprises ceramic particle filler with a core-shell structure, and polymer matrix, wherein the ceramic particle filler with the core-shell structure is evenly dispersed in the polymer matrix; the core body of the ceramic particle filler with the core-shell structure is formed by ceramic particles, and the surfaces of the ceramic particles are covered by organic matter coating layers. The invention also provides the preparation method of the piezoelectric active bone repair composite material. The preparation method can be widely applied to the field of preparation of the bone repair composite material.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

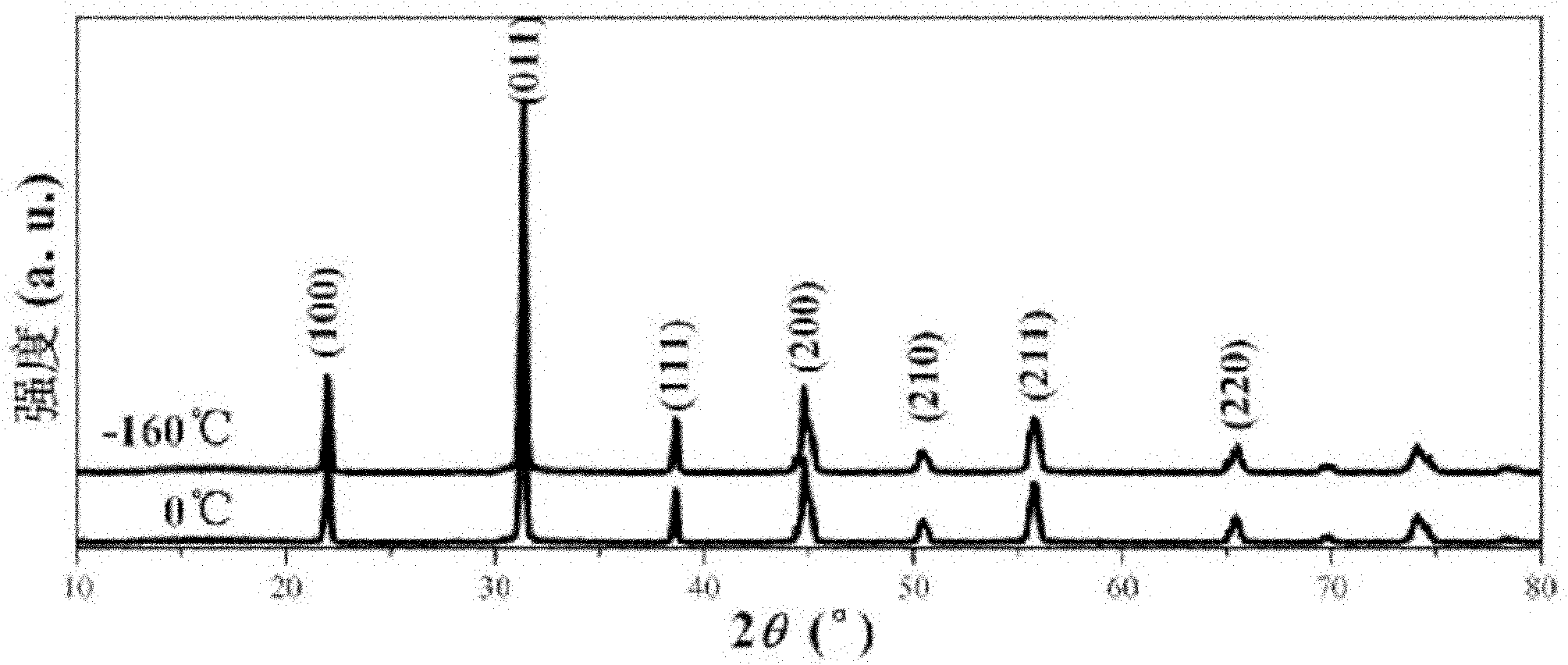

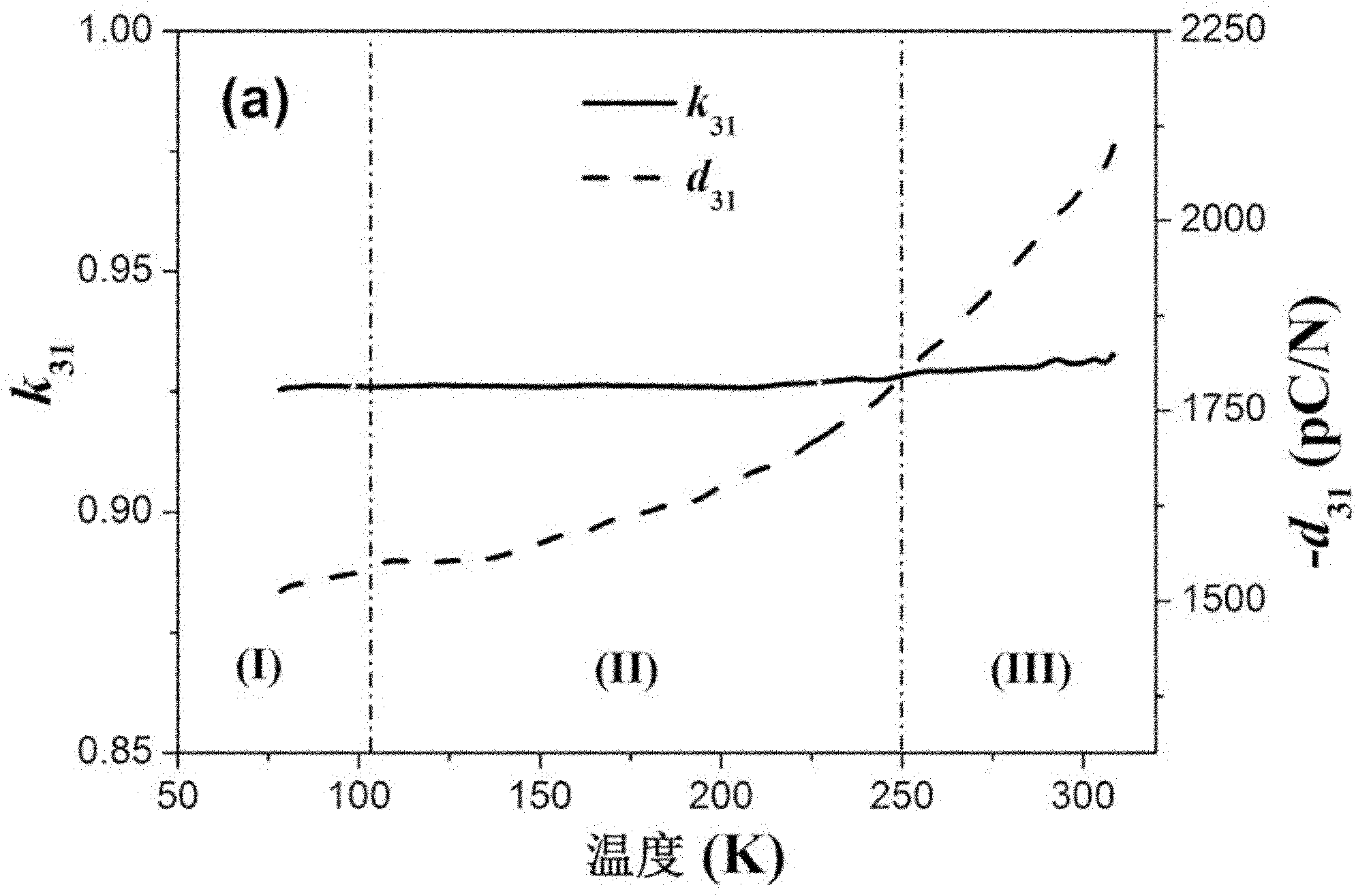

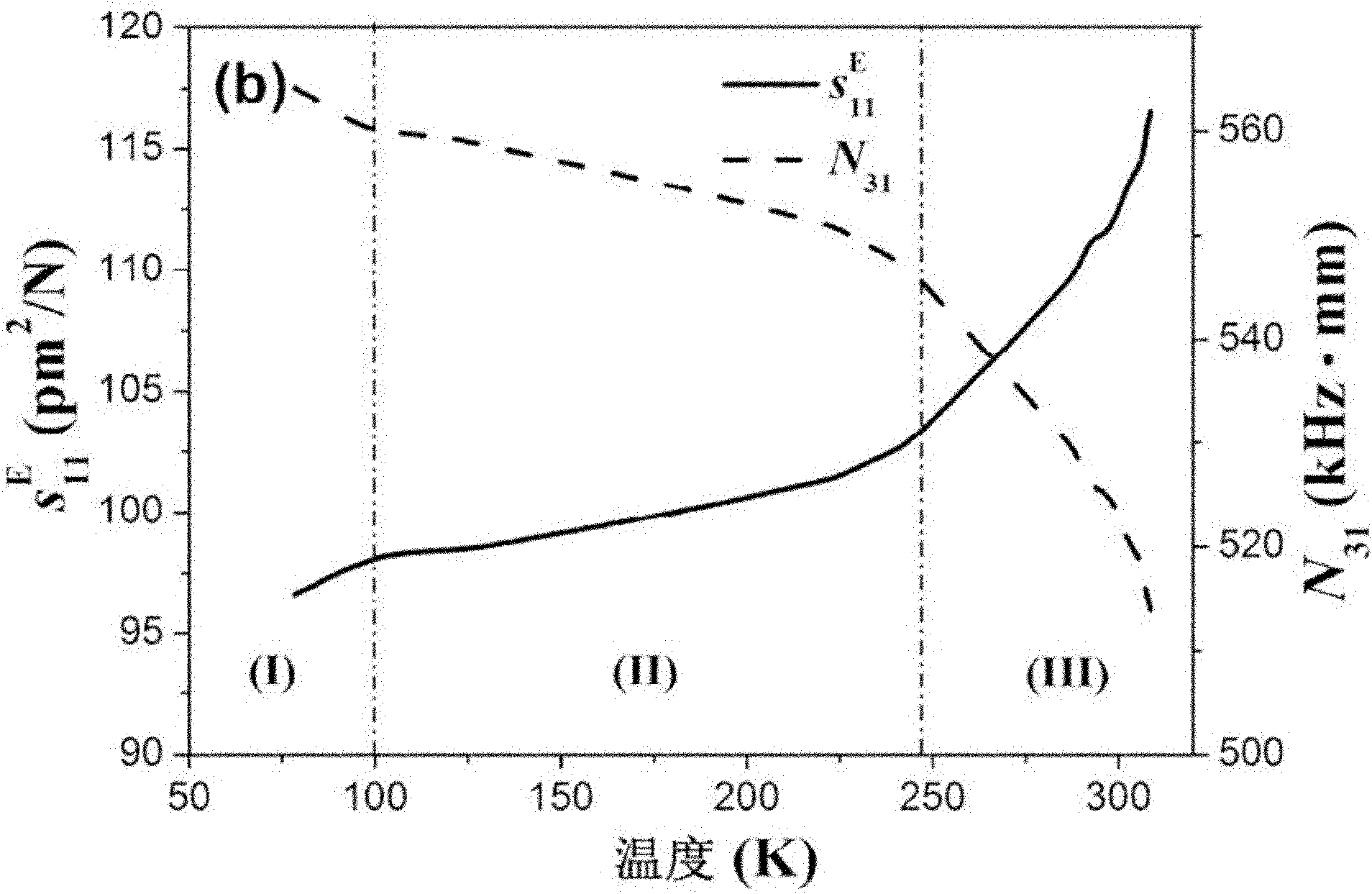

Ternary system relaxation ferroelectric single crystal material and preparation method thereof

InactiveCN101985775ASmall sizeQuality improvementPolycrystalline material growthFrom frozen solutionsBridgman methodSingle crystal

The invention discloses a ternary system relaxation ferroelectric single crystal material. The material comprises the following chemical components: xPb(In1 / 2Nb1 / 2)O3-yPb(Mg1 / 3Nb2 / 3)O3-(1-x-y)PbTiO3, wherein the x is equal to 0.1-0.45, and the y is equal to 0.1-0.5. A preparation method of the single crystal material PIMNT is an improved Bridgman method and comprises the following steps of: processing raw materials, melting by raising the temperature, and performing crucible degrowth and crystal cooling growth. The prepared single crystal material overcomes the defects of over low Curie point of PMNT single crystals, difficult crystallization and difficult batch growth of the PINT single crystals in the prior art, has high piezoelectric performance and pyroelectric performance, higher temperature stability and wide application prospect and adds a new product in the field.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

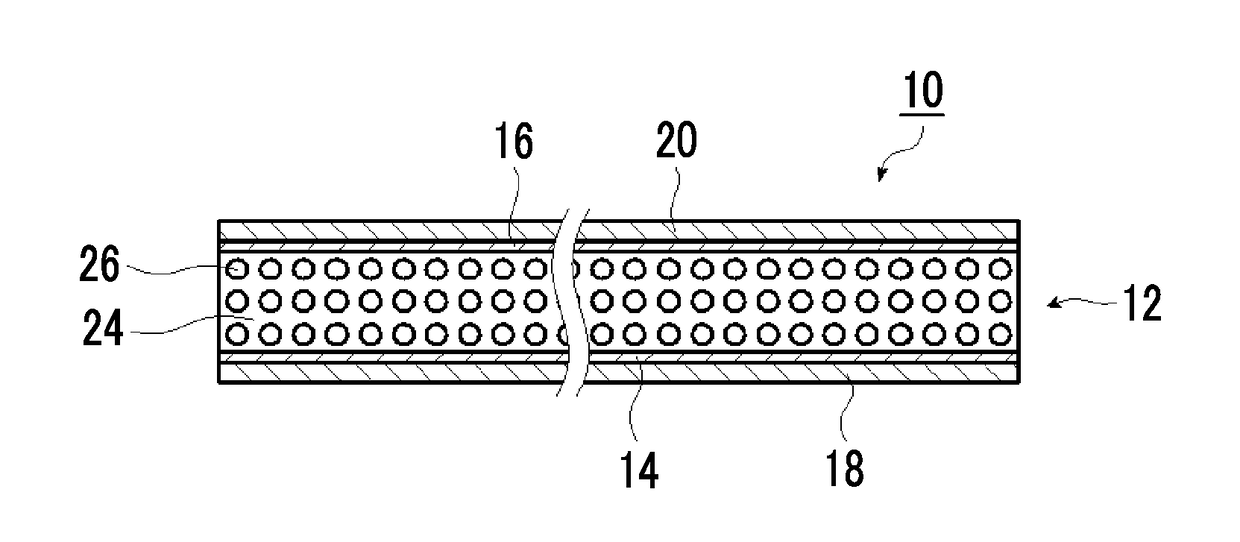

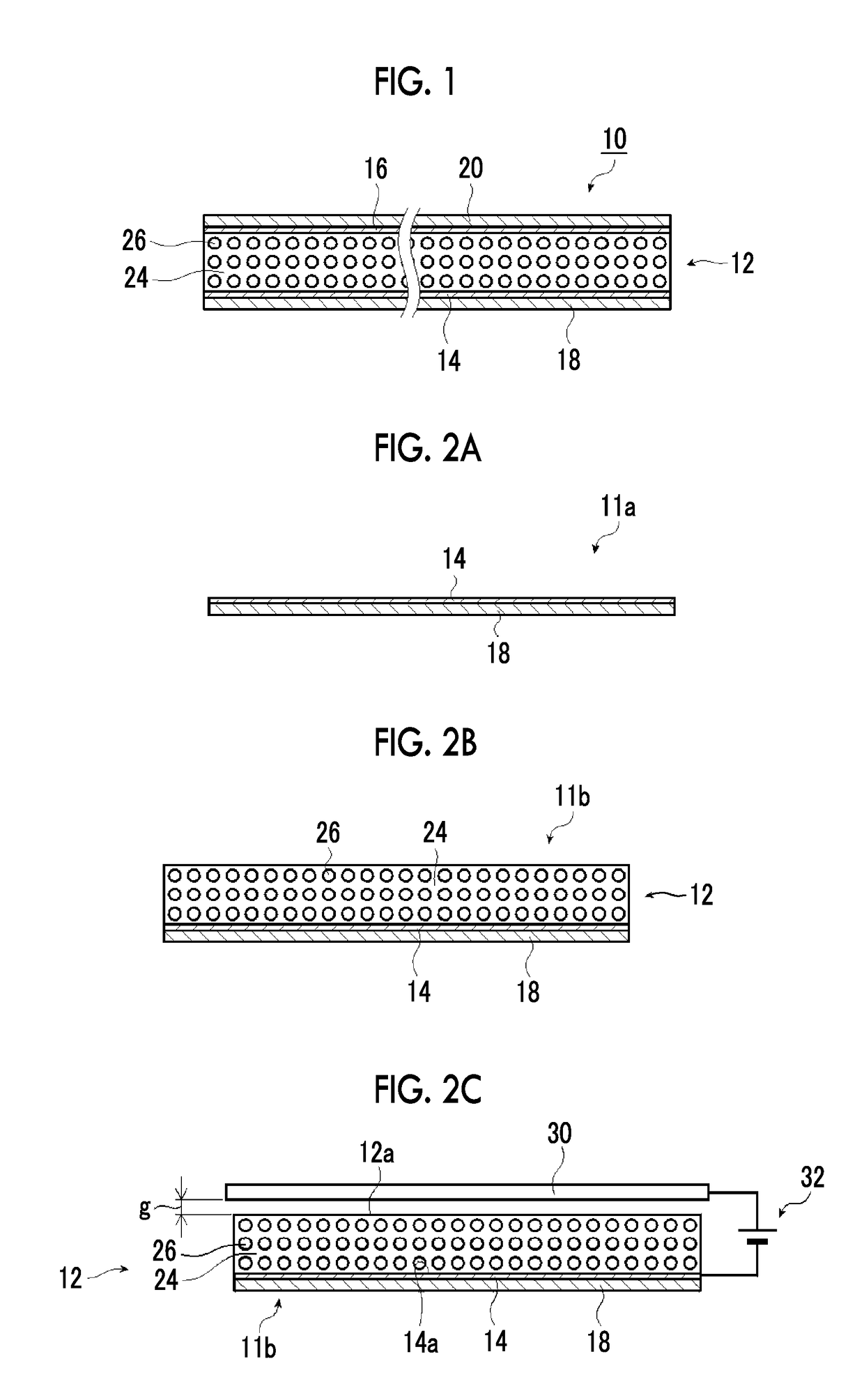

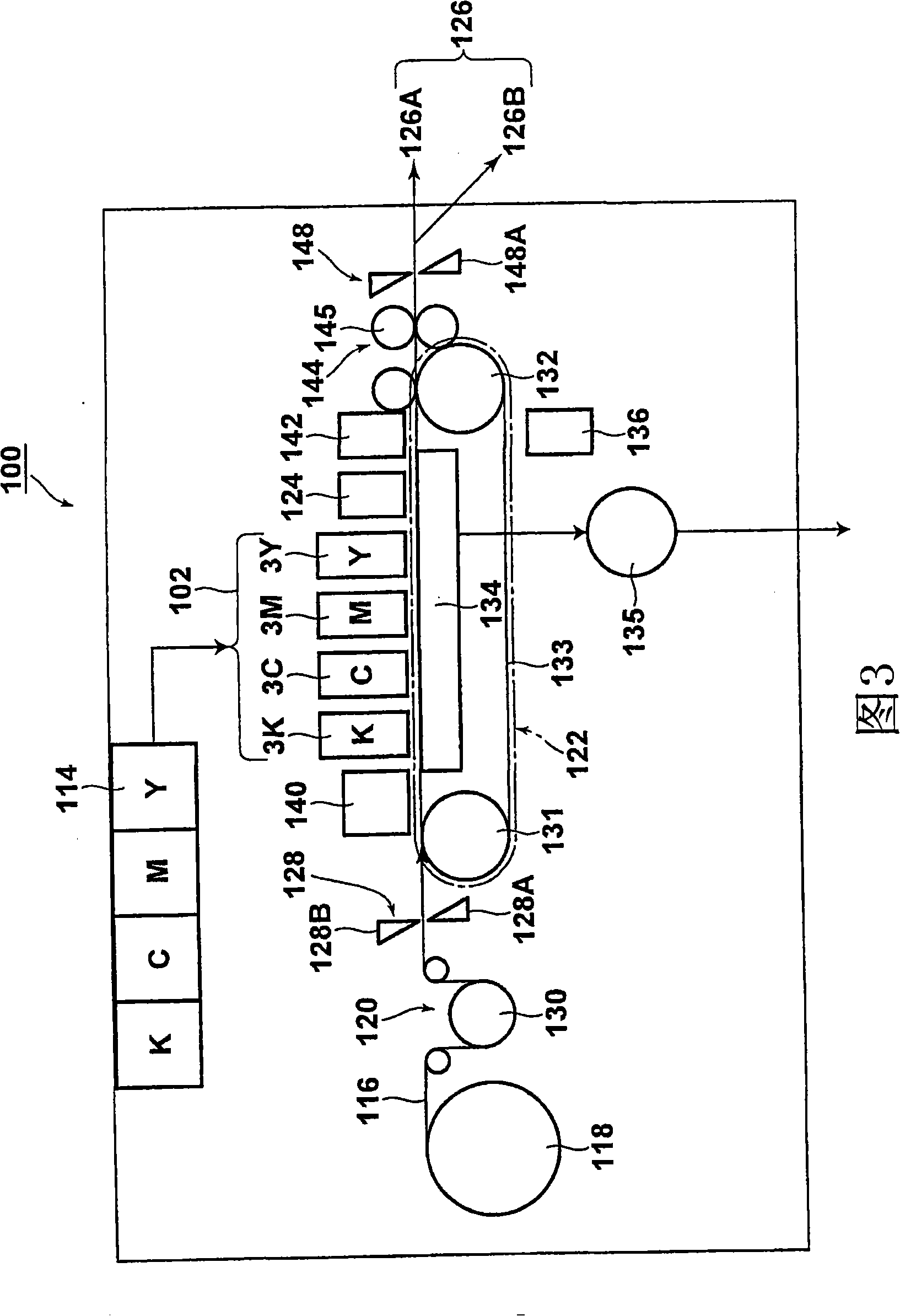

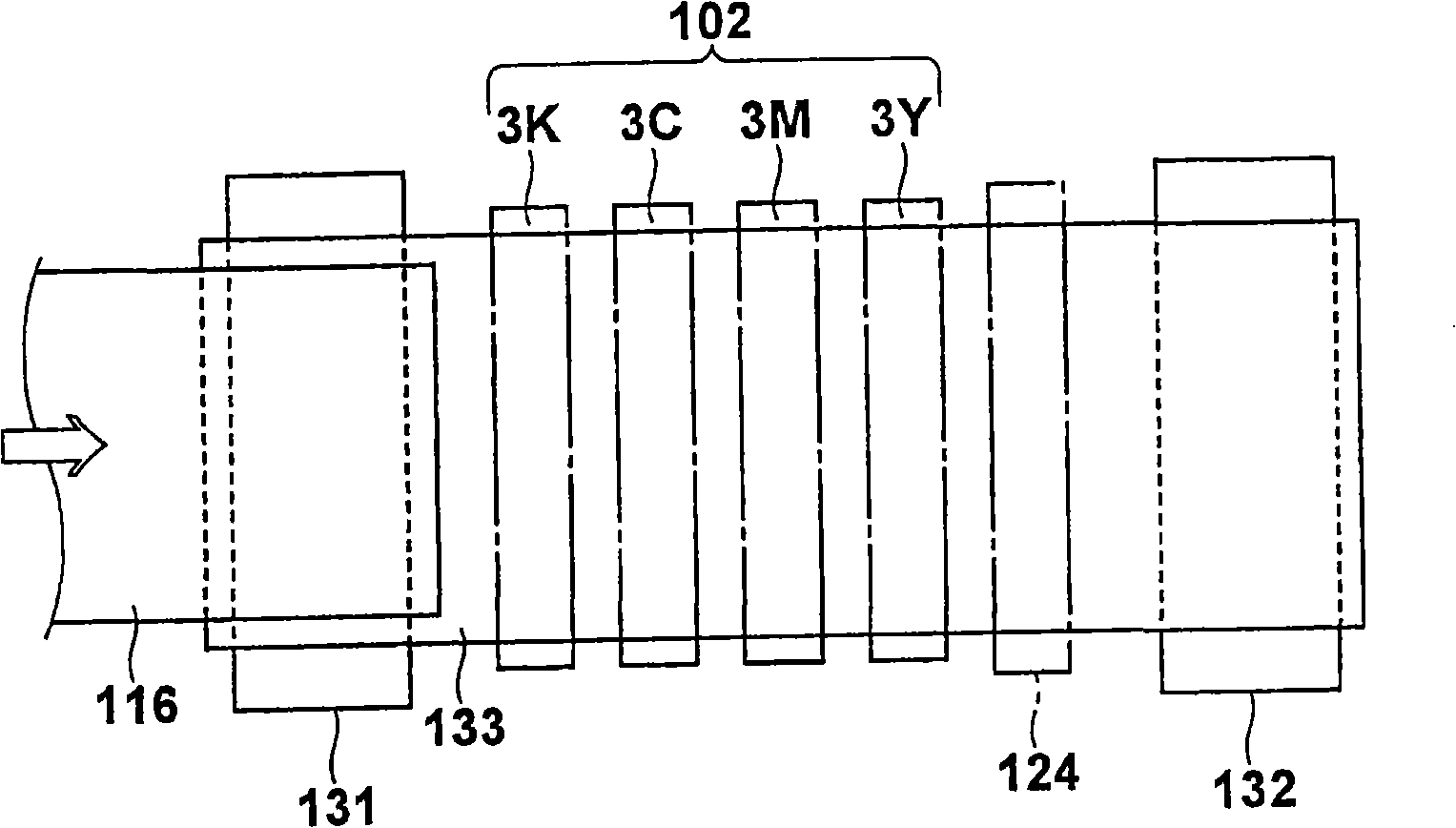

Electroacoustic transduction film and manufacturing method thereof, electroacoustic transducer, flexible display, vocal cord microphone, sensor for musical instrument

ActiveUS20180160248A1Sufficient volumeImprove conversion efficiencyPiezoelectric/electrostrictive microphonesElectrophonic musical instrumentsX-rayEngineering

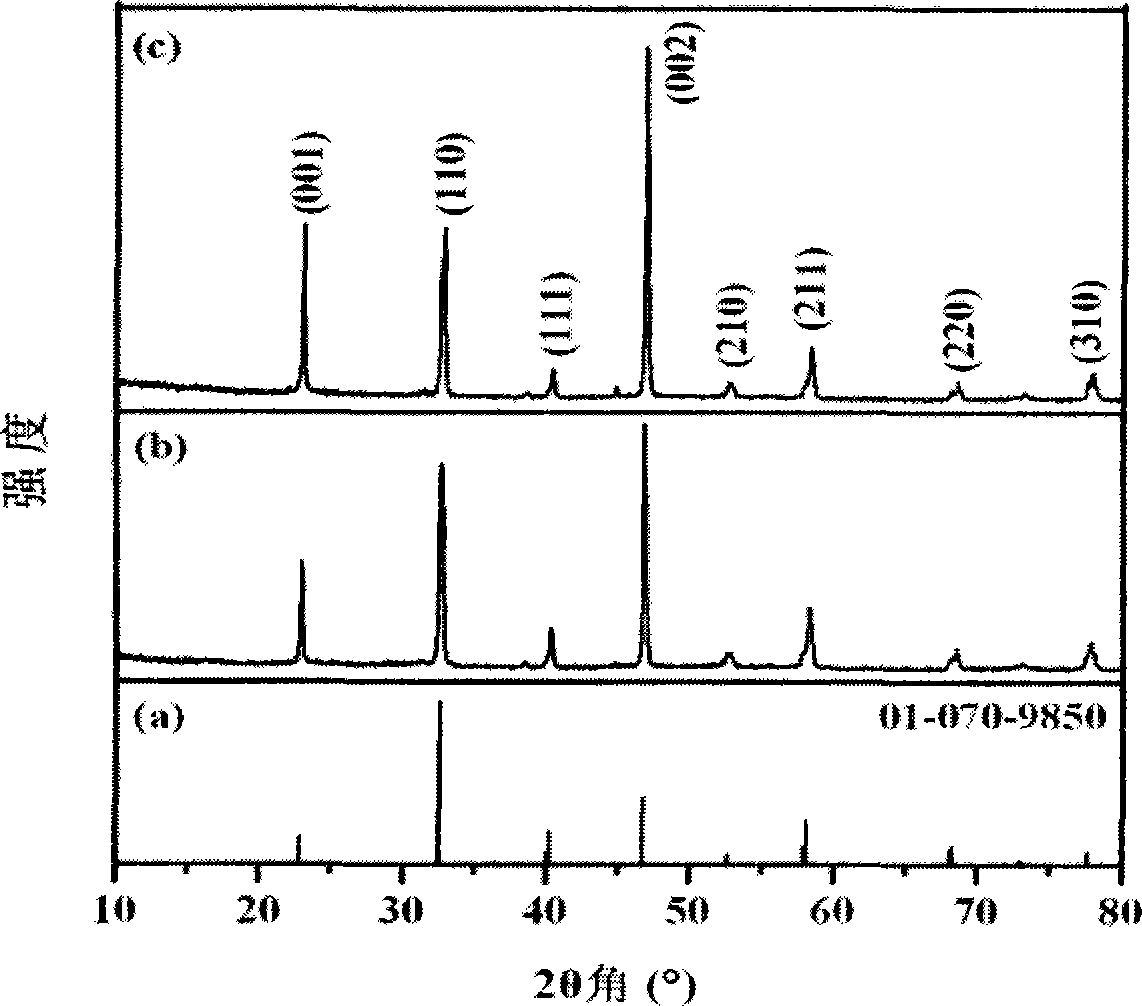

Provided are an electroacoustic transduction film capable of reproducing a sound with a sufficient sound volume at a high conversion efficiency, a manufacturing method thereof, an electroacoustic transducer, a flexible display, a vocal cord microphone, and a sensor for a musical instrument. The electroacoustic transduction film includes: a polymer composite piezoelectric body in which piezoelectric body particles are dispersed in a viscoelastic matrix formed of a polymer material having viscoelasticity at a normal temperature; two thin film electrodes laminated on both surfaces of the polymer composite piezoelectric body; and two protective layers respectively laminated on the two thin film electrodes, in which an intensity ratio α1=(002) plane peak intensity / ((002) plane peak intensity+(200) plane peak intensity) between a (002) plane peak intensity and a (200) plane peak intensity derived from the piezoelectric body particles in a case where the polymer composite piezoelectric body is evaluated by an X-ray diffraction method is more than or equal to 0.6 and less than 1.

Owner:FUJIFILM CORP

Piezoelectric thin film and method of manufacturing the same, ink jet head, method of forming image with the ink jet head, angular velocity sensor, method of measuring angular velocity with the angular velocity sensor, piezoelectric generating element, and method of generating electric power with the piezoelectric generating element

ActiveUS20110143146A1Low dielectric lossImprove piezoelectric performanceAcceleration measurement using interia forcesPiezoelectric/electrostriction/magnetostriction machinesLead zirconate titanateAngular velocity

Provided are a piezoelectric thin film including a lead-free ferroelectric material and exhibiting high piezoelectric performance comparable to that of lead zirconate titanate (PZT), and a method of manufacturing the piezoelectric thin film. The piezoelectric thin film of the present invention comprises: a LaNiO3 film having a (001) orientation; a NaNbO3 film having a (001) orientation; and a (Bi, Na, Ba) TiO3 film having a (001) orientation. The LaNiO3 film, the NaNbO3 film, and the (Bi, Na, Ba)TiO3 film are laminated in this order.

Owner:PANASONIC CORP

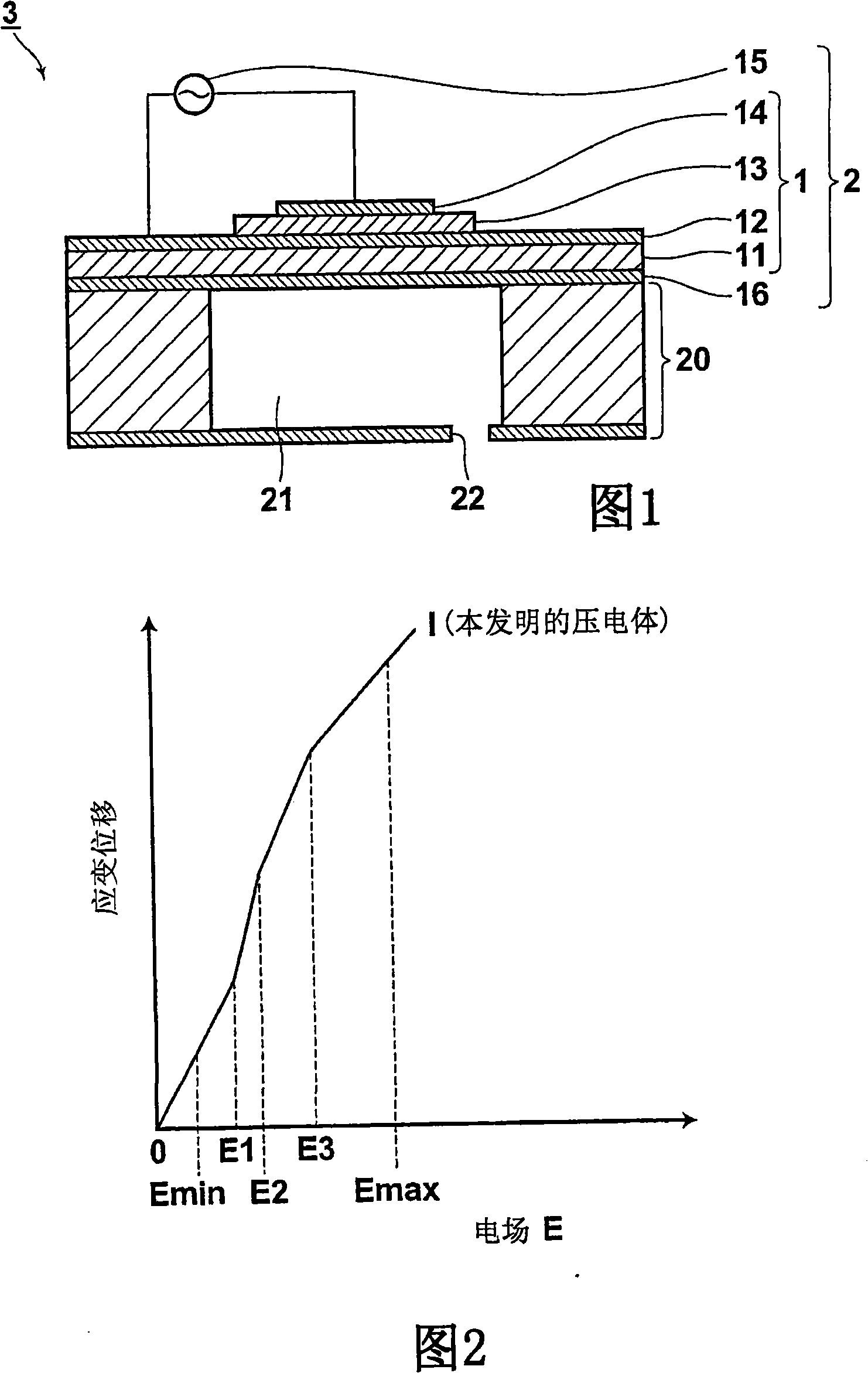

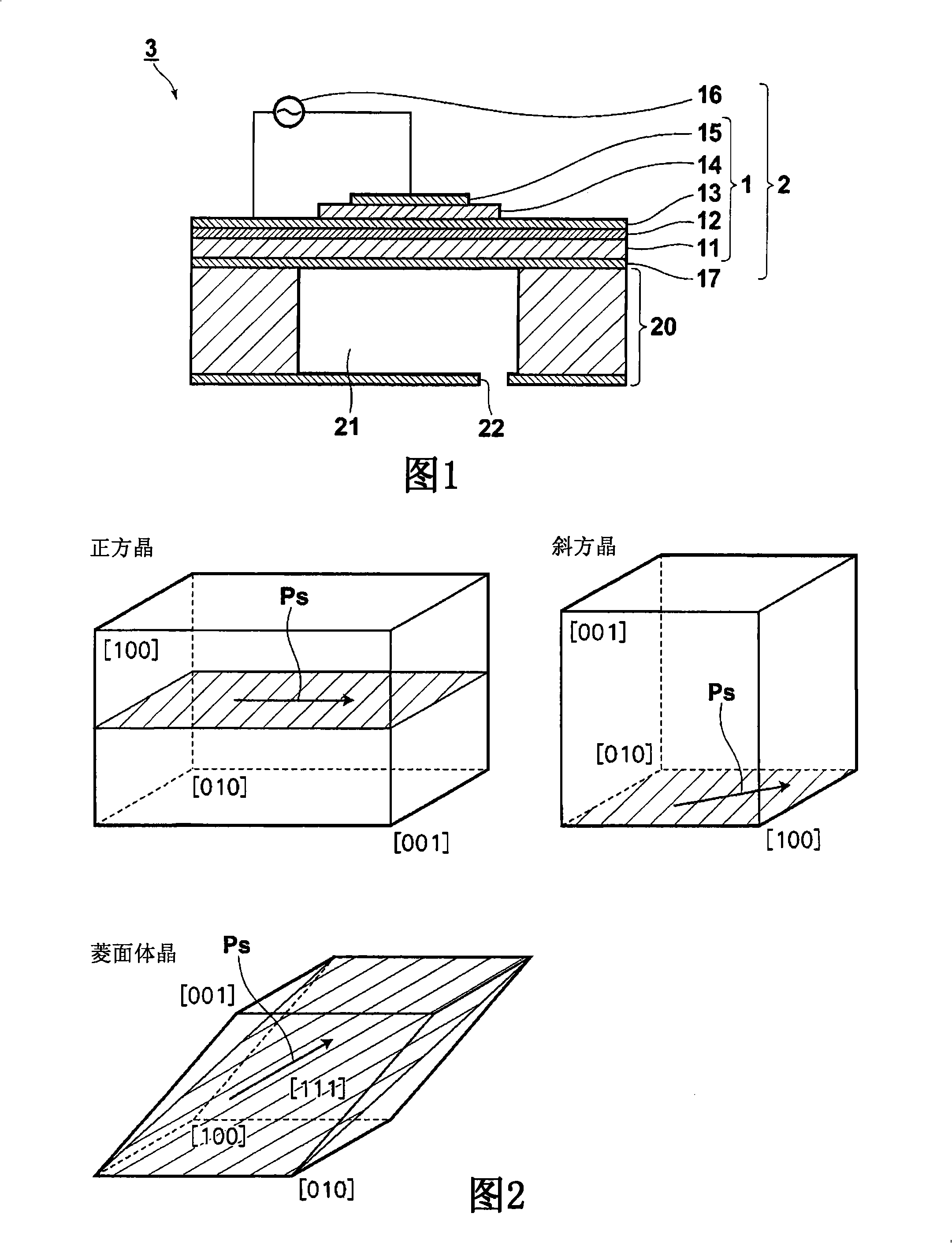

Piezoelectric body, piezoelectric device, and liquid discharge apparatus

ActiveCN101295762AEasy phase changeImprove piezoelectric performancePiezoelectric/electrostrictive device material selectionPrintingElectricityCrystal system

A piezoelectric body contains a ferroelectric substance phase having characteristics such that, in cases where an applied electric field is increased from the time free from electric field application, phase transition of the ferroelectric substance phase to a ferroelectric substance phase of a different crystal system occurs at least two times. The piezoelectric body should preferably be actuated under conditions such that a minimum applied electric field Emin and a maximum applied electric field Emax satisfy Formula (1)wherein the electric field E 1 represents the electric field at which the first phase transition of the ferroelectric substance phase begins.

Owner:FUJIFILM CORP

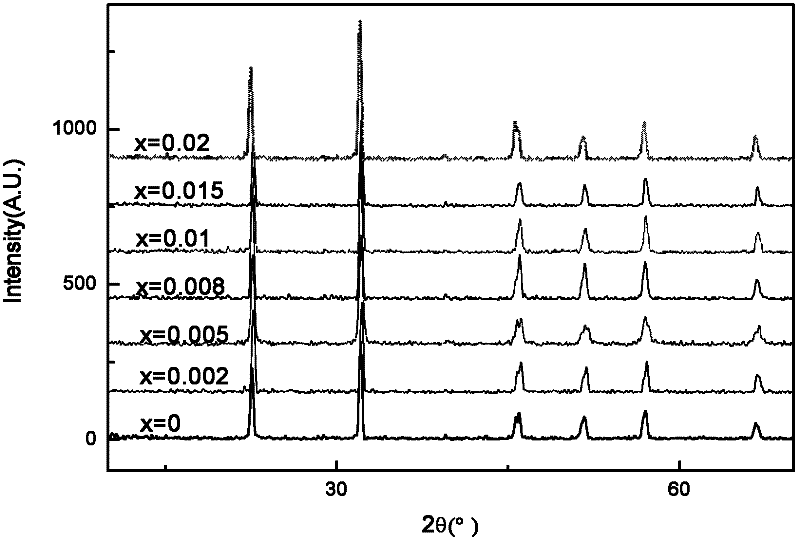

Calcium barium zirconate titanate base piezoceramics and preparation method thereof

InactiveCN101648807ALower coercive fieldLow equipment requirementsPiezoelectric/electrostrictive/magnetostrictive devicesBarium titanateZirconium dioxide

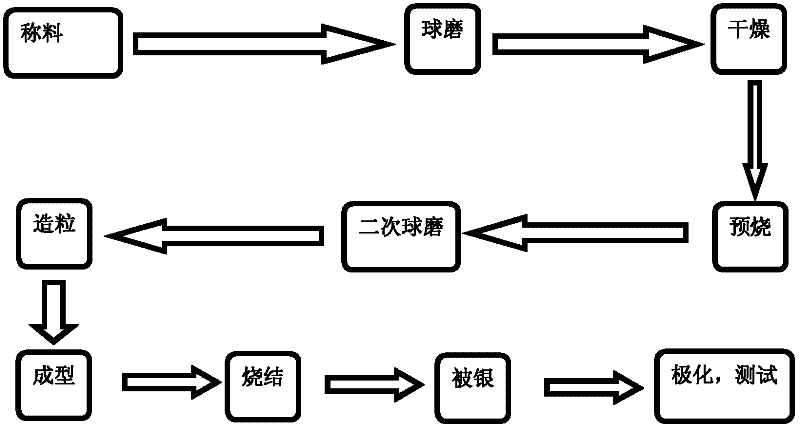

The invention discloses calcium barium zirconate titanate base piezoceramics and a preparation method thereof. The chemical formula of the calcium barium zirconate titanate base piezoceramics is (1-x-y)BaTiO3-xCaTiO3-yBaZrO3, wherein x is greater than 0 and smaller than 0.5, y is greater than 0 and smaller than 0.5, and both x and y are molar fractions. The preparation method comprises the following steps: mixing barium carbonate, calcium carbonate, titanium dioxide and zirconium dioxide according to the stoichiometric proportion (1-x-y)BaTiO3-xCaTiO3-yBaZrO3 (x is greater than 0 and smaller than 0.5, y is greater than 0 and smaller than 0.5, and both x and y are molar fractions), ball-milling, calcining, ball-milling for the second time, granulating, moulding, removing the binder, high-temperature sintering and the like so as to finally prepare the calcium barium zirconate titanate base piezoceramics with high piezoelectric performance. The method greatly enhances the piezoelectric performance of the lead-free piezoceramic system and the technical stability of the material, so that the lead-free piezoceramics in the barium titanate system achieve the practical level in the aspectsof components and technique.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

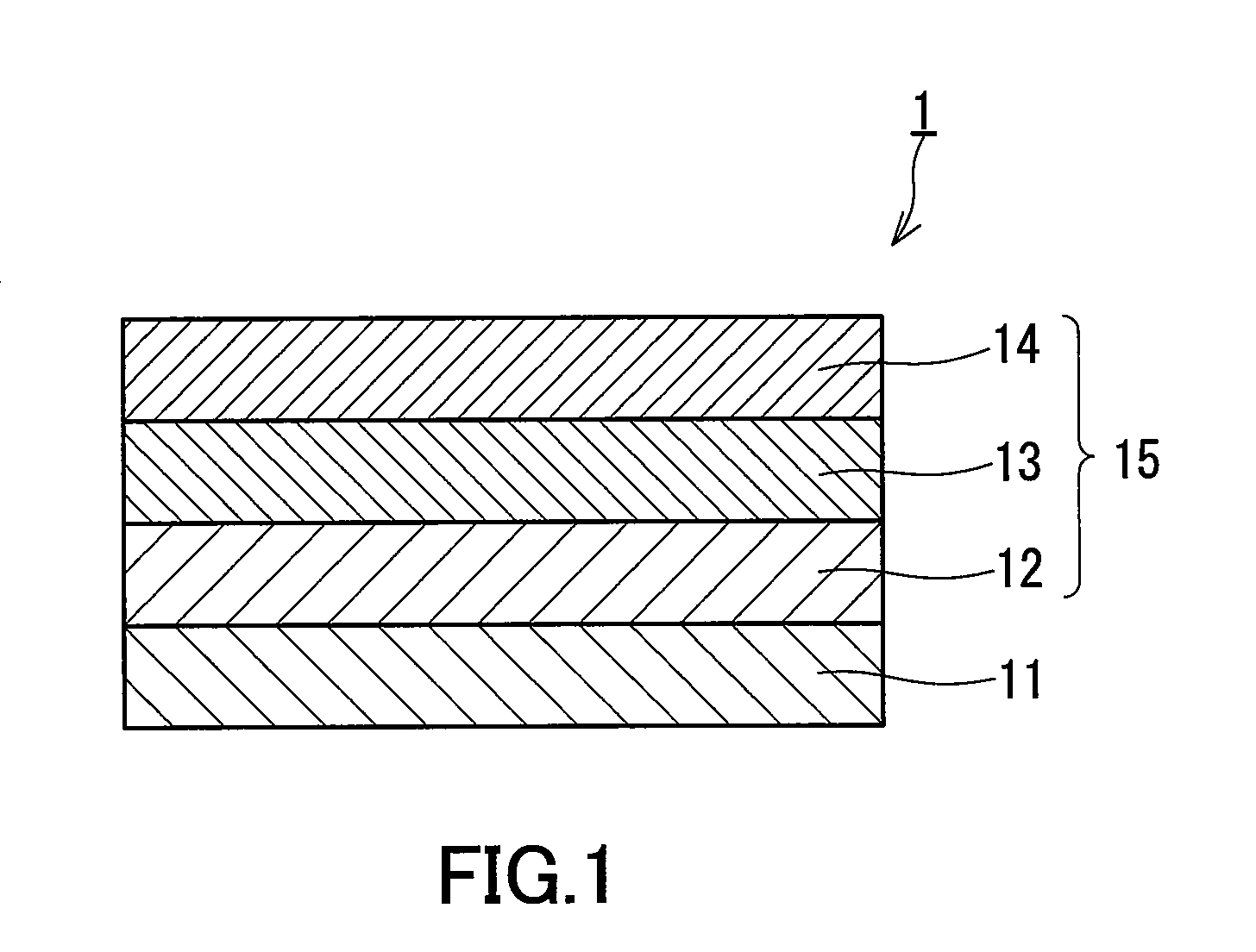

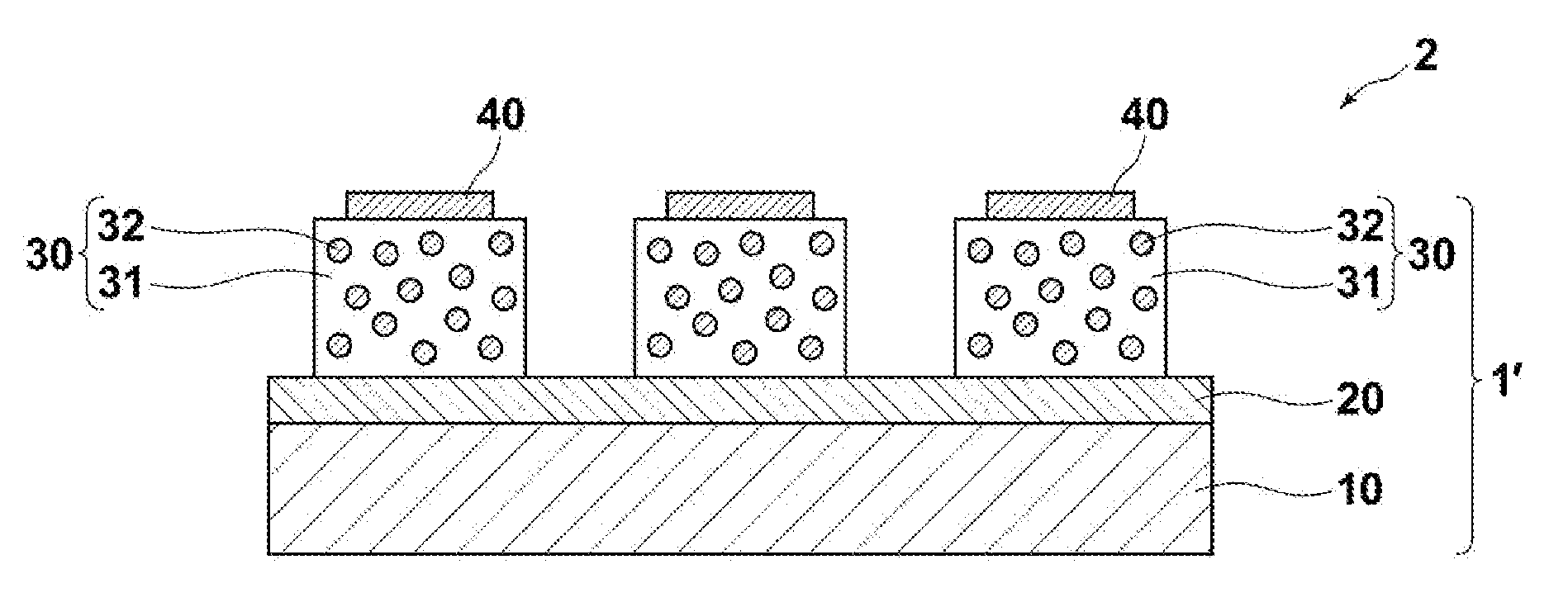

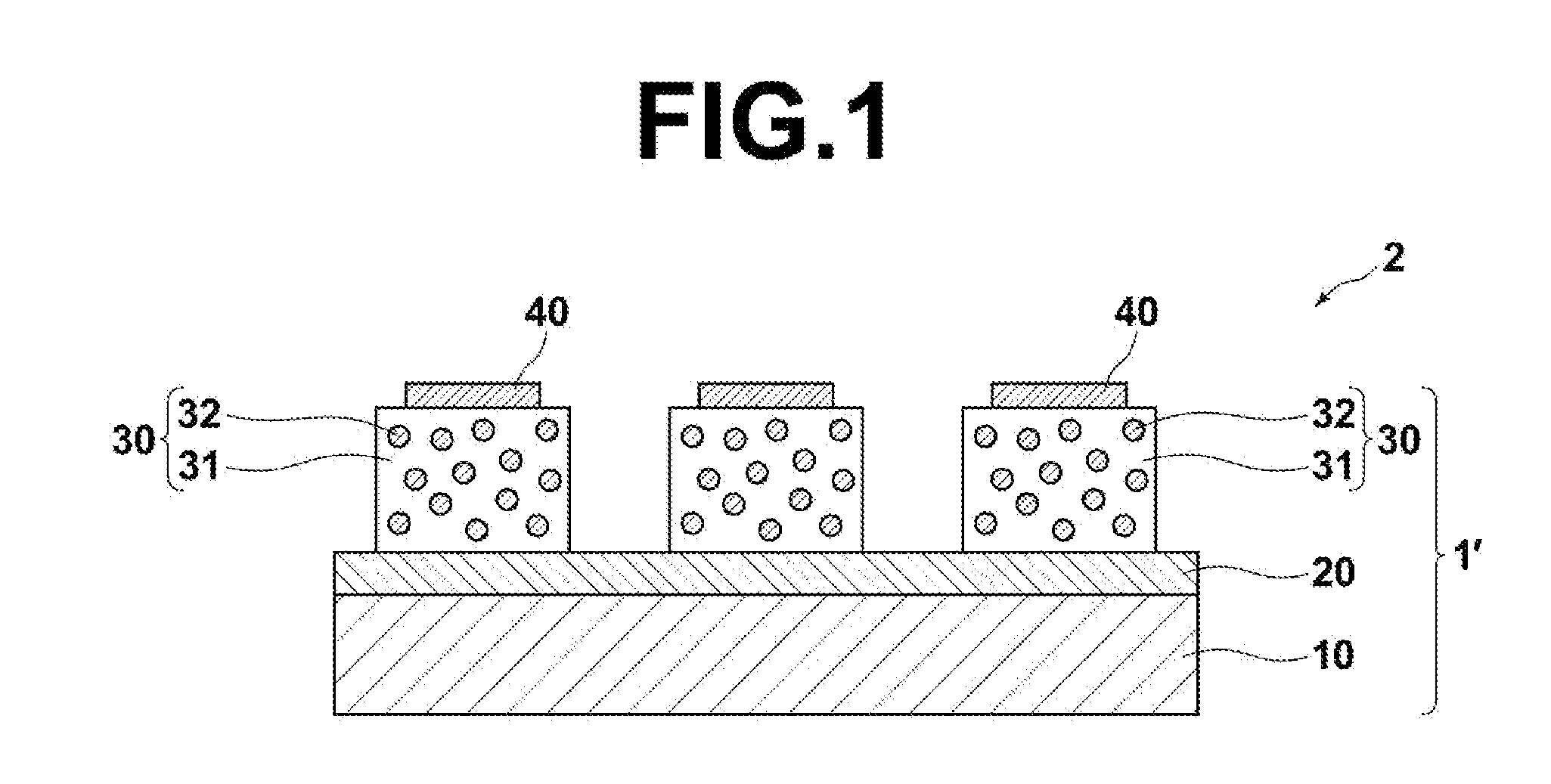

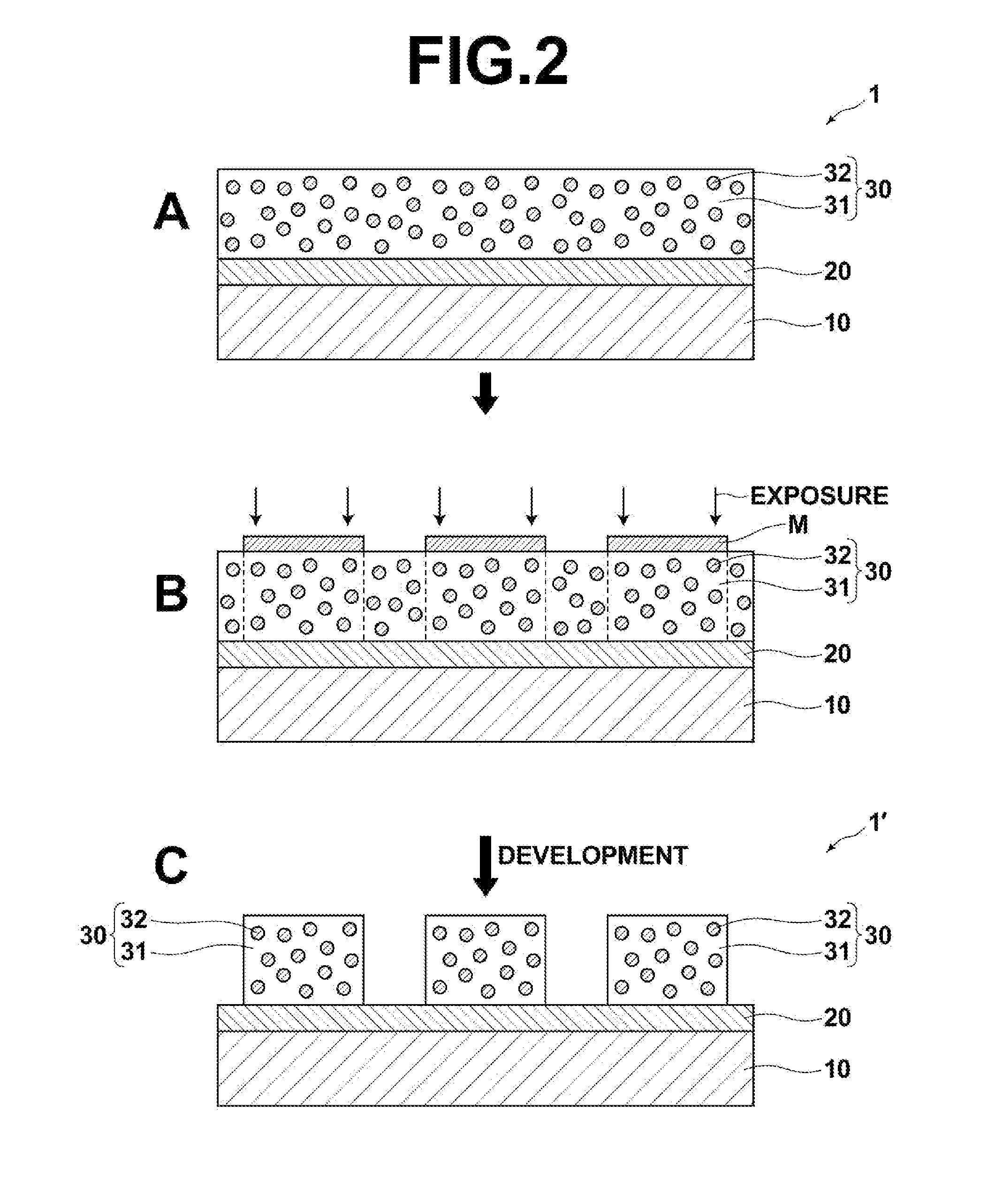

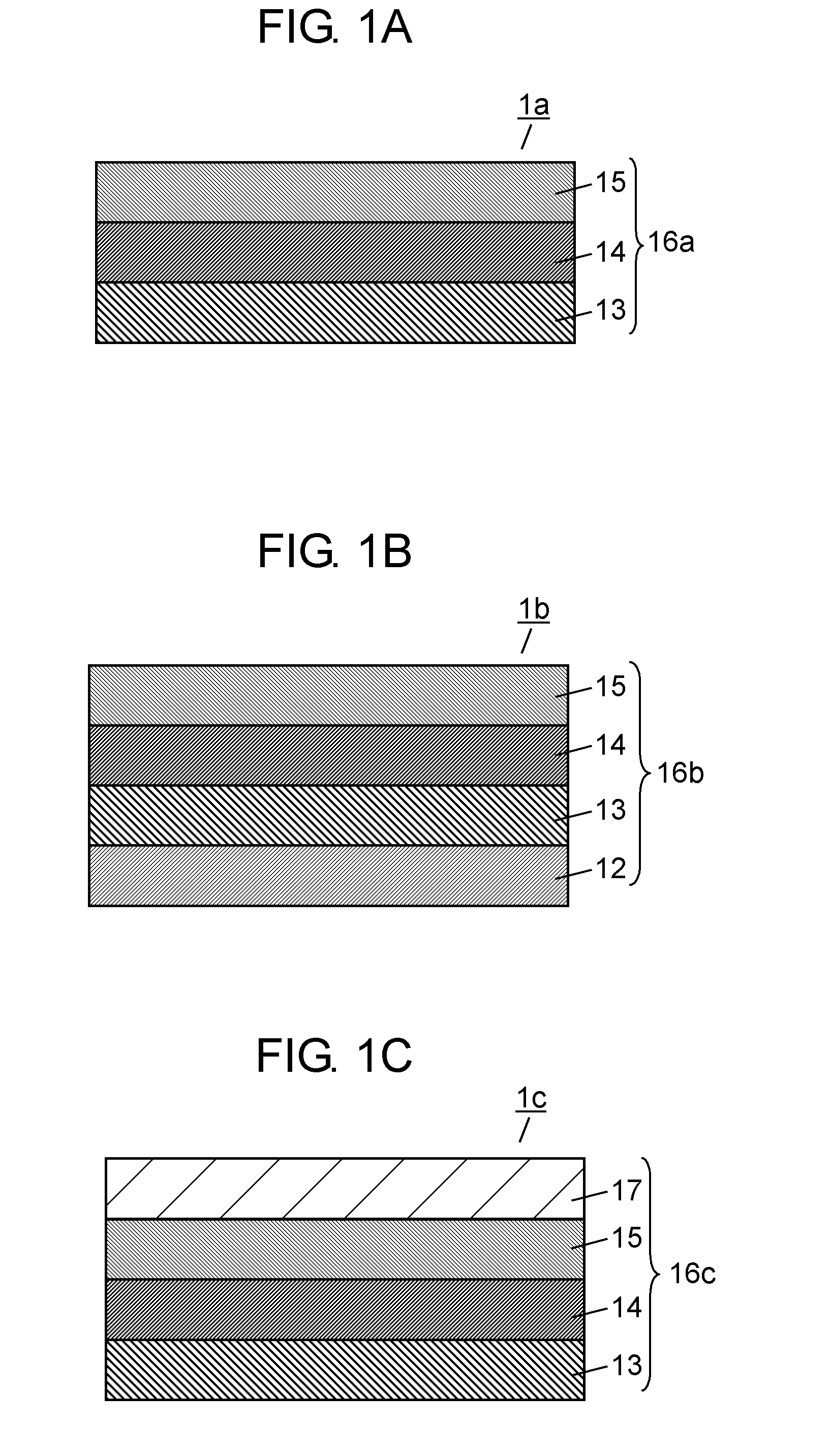

Layered structure and piezoelectric device using the same

ActiveUS20110217519A1Excellent piezoelectric propertiesImprove reliabilityPiezoelectric/electrostrictive device manufacture/assemblyPhotomechanical exposure apparatusResin matrixOrganic polymer

A layered structure, including a flexible resin substrate and a composite piezoelectric film formed on the resin substrate and constituted by an organic polymer resin matrix and a plurality of inorganic piezoelectric bodies dispersed in the matrix.

Owner:FUJIFILM CORP

Piezoelectric compositions

ActiveUS20100230629A1Useful applicationImprove piezoelectric performancePiezoelectric/electrostrictive device material selectionActive polymerManufacturing technology

Piezoelectric compositions are provided wherein mechanical and piezoelectric properties can be separately modulated. Preferred compositions include resin blends that comprise: (a) a piezoelectrically active polymer and (b) a matrix polymer, methods of making, and use of such resin blends. Advantages of preferred resin blends of the invention can include high piezoelectricity, mechanical strength and flexibility, convenient fabrication process, and high sensitivity at high temperatures.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

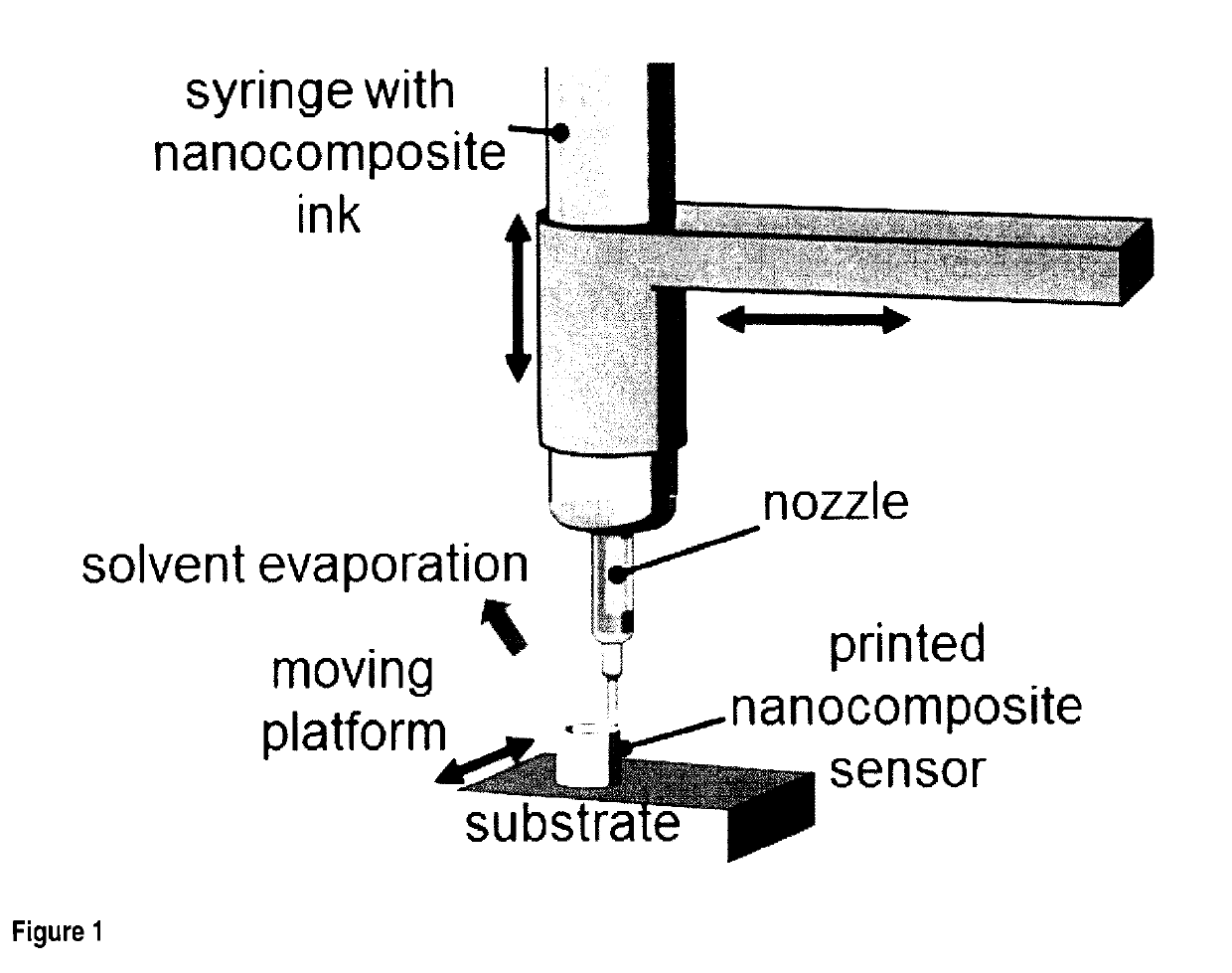

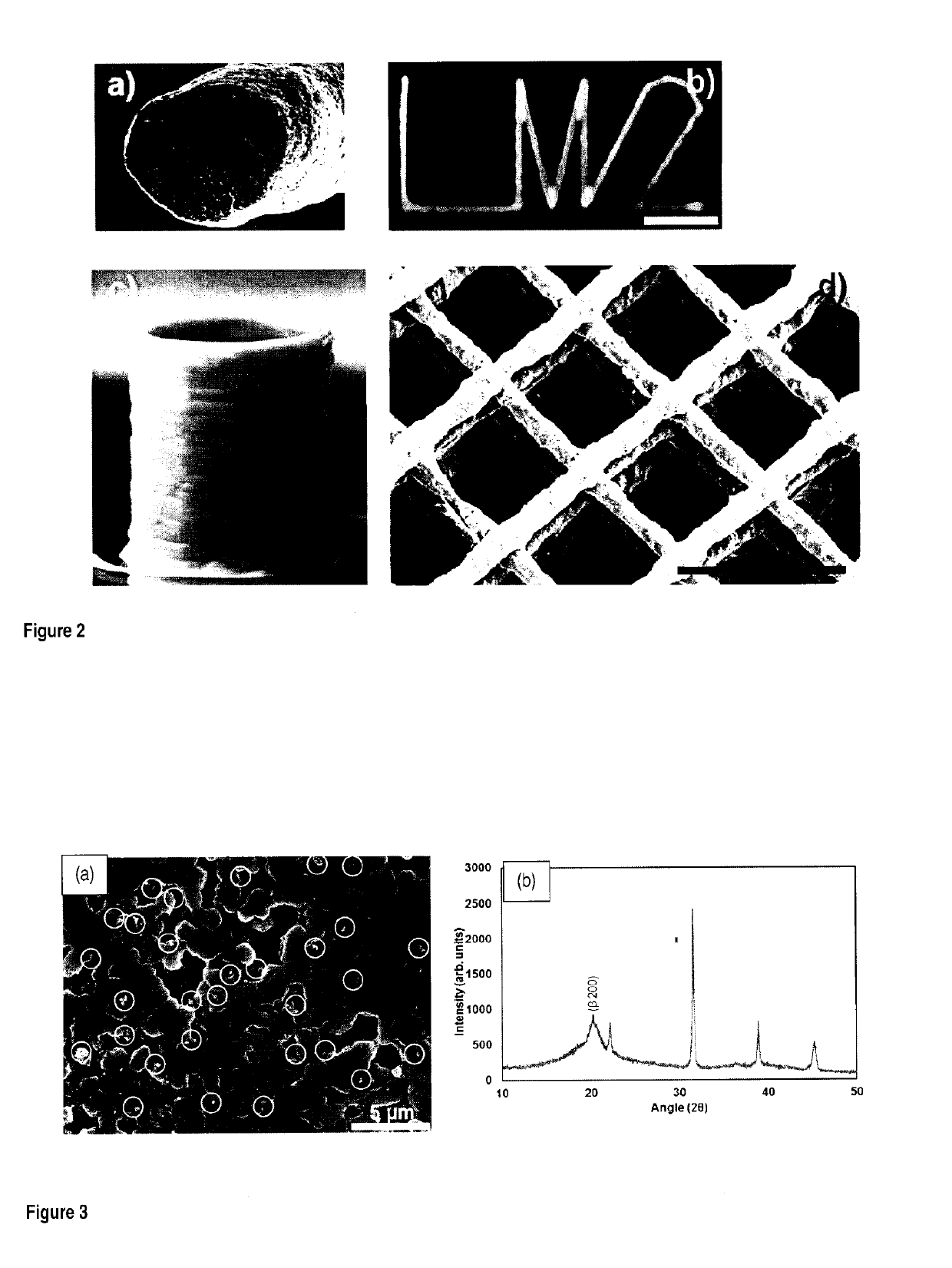

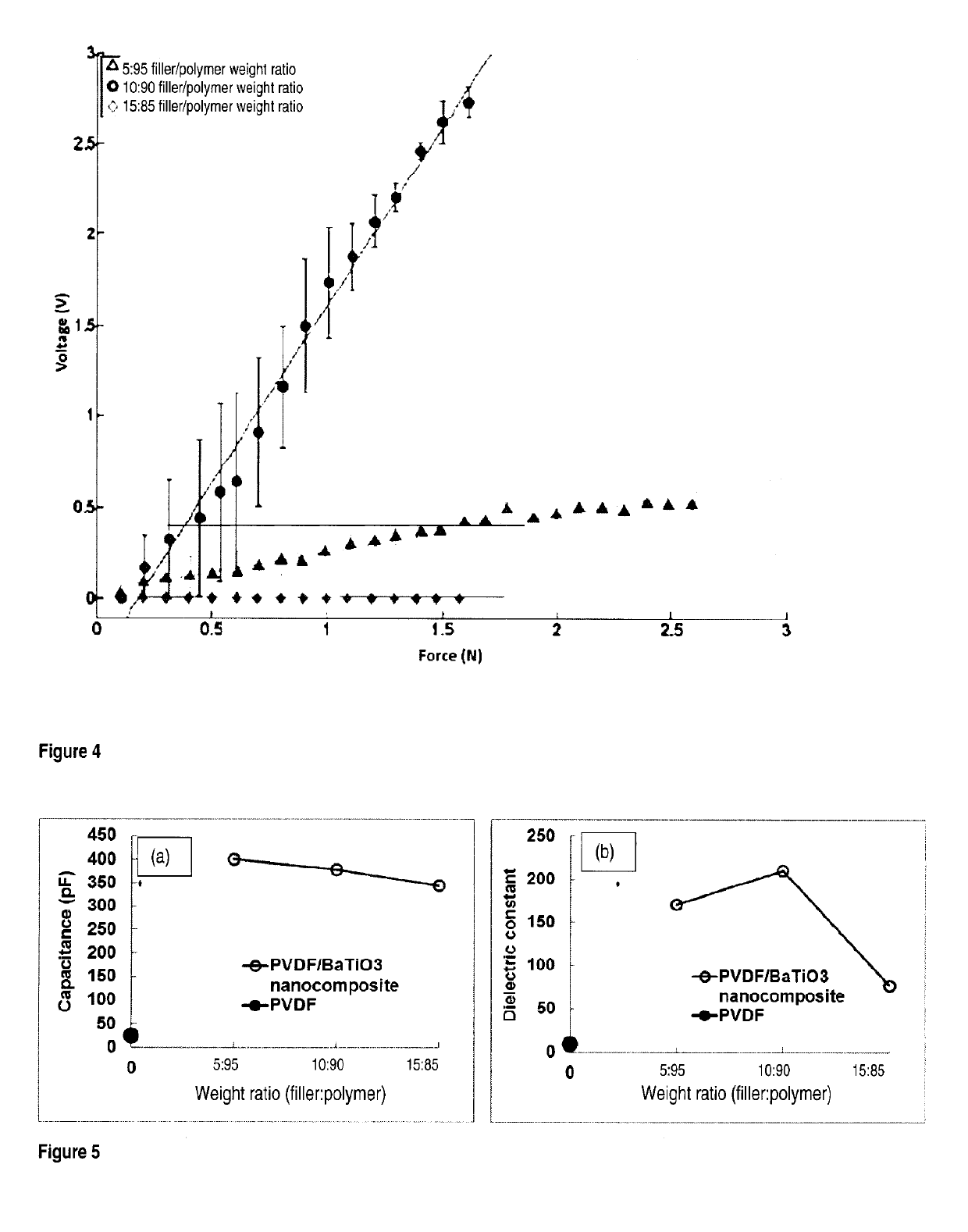

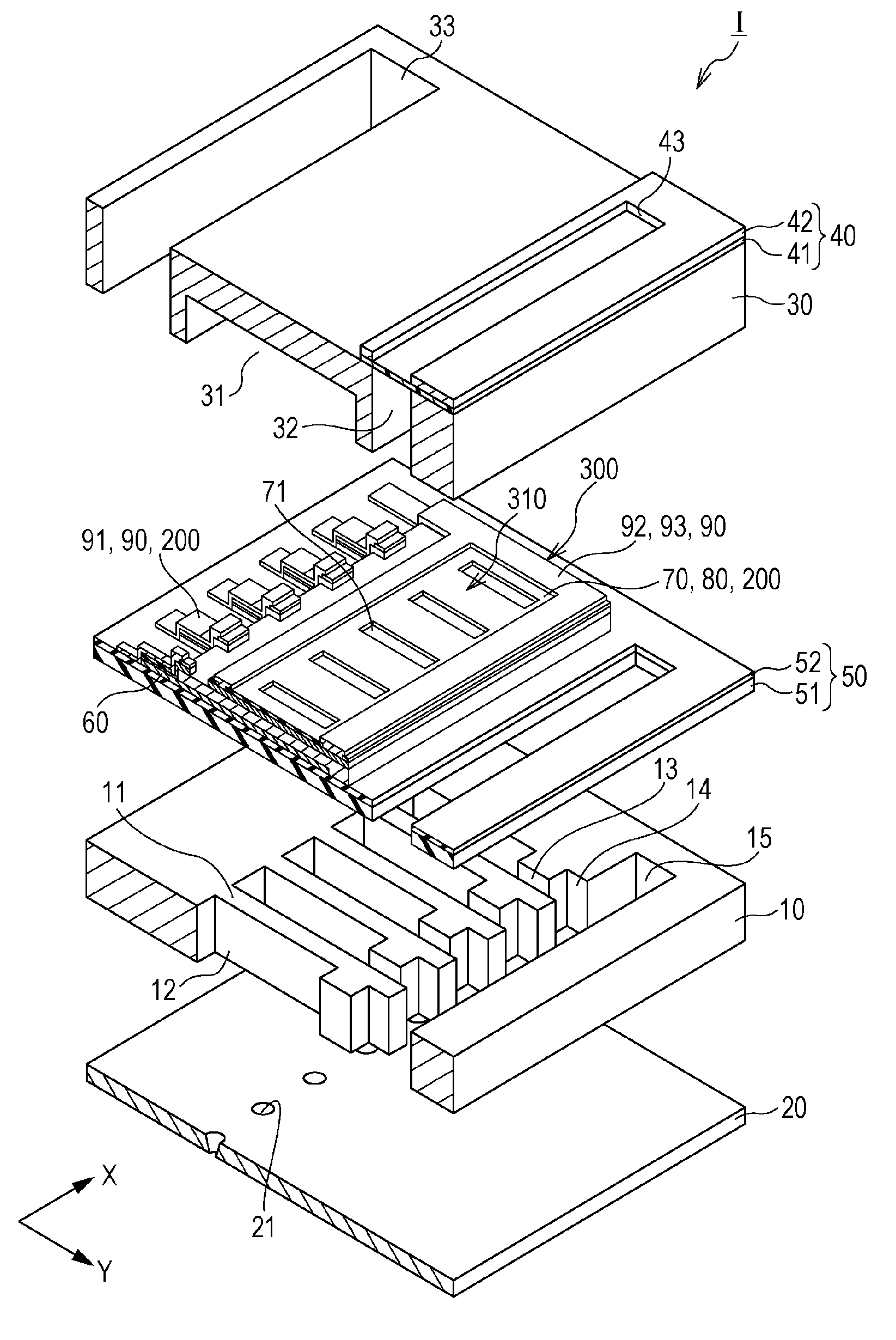

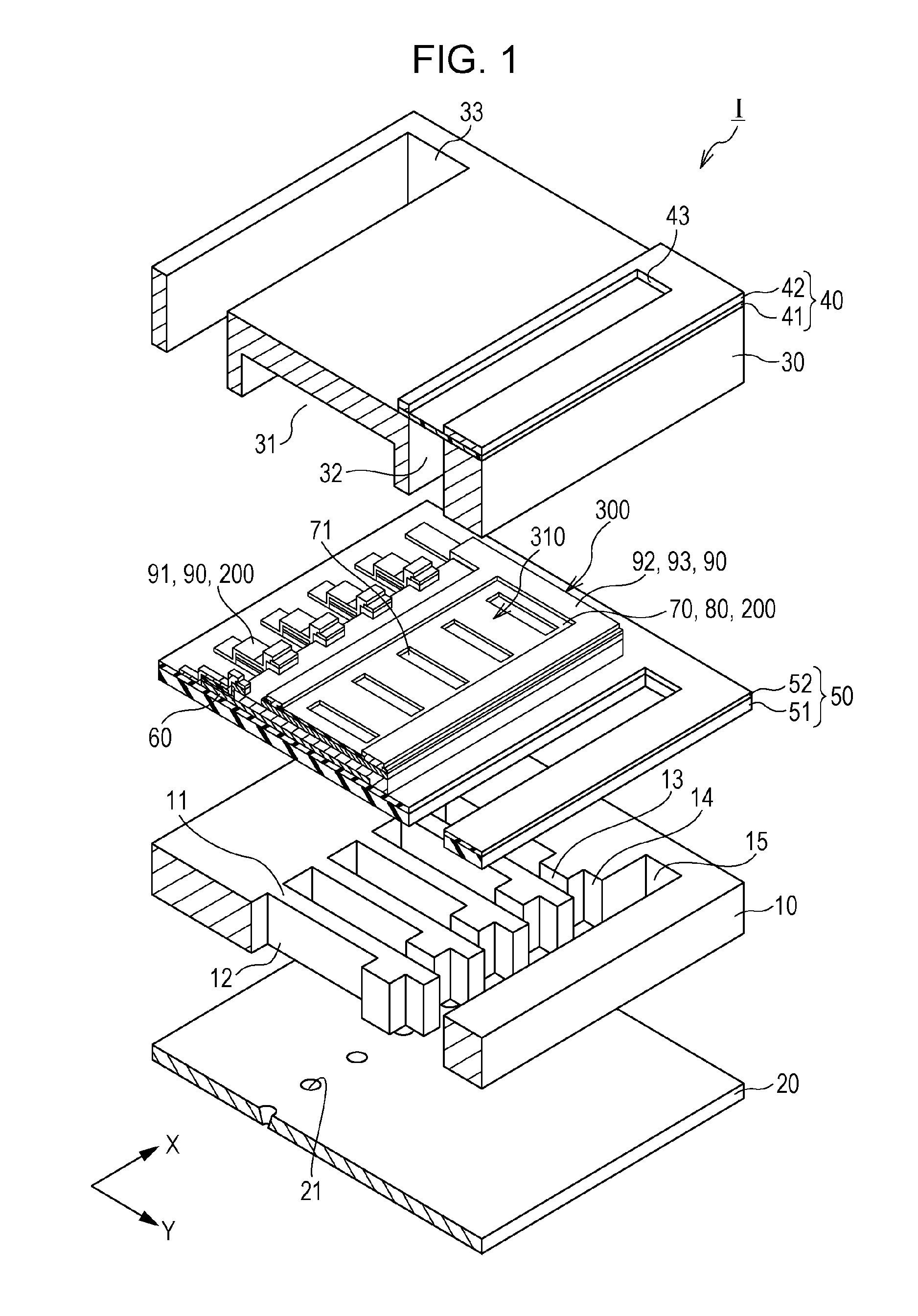

Piezoelectric composite, ink and ink cartridge for 3D printing, bifunctional material comprising the piezoelectric composite, manufacture and uses thereof

ActiveUS20190284423A1Highly flexibleReduce chanceMaterial nanotechnologyAdditive manufacturing apparatusSolventPiezoelectric composite

There is provided a piezoelectric composite comprising a piezoelectric polymer and particles of a filler dispersed in the polymer, wherein the filler is in micro or nanoparticle form and is present in a filler:polymer weight ratio between about 1:99 and about 95:5. There is also provided an ink and ink cartridge for 3D printing of the piezoelectric composite. There is also provided a piezoelectric 3D printed material comprising the piezoelectric composite and a bifunctional material comprising the piezoelectric composite with one or more conductive electrodes adjacent to the piezoelectric composite. Methods of manufacture and uses thereof are also provided, including methods for 3D printing of a piezoelectric 3D printed material via solvent-cast or FDM 3D printing starting from the piezoelectric composite and / or the ink.

Owner:POLYVALOR LP

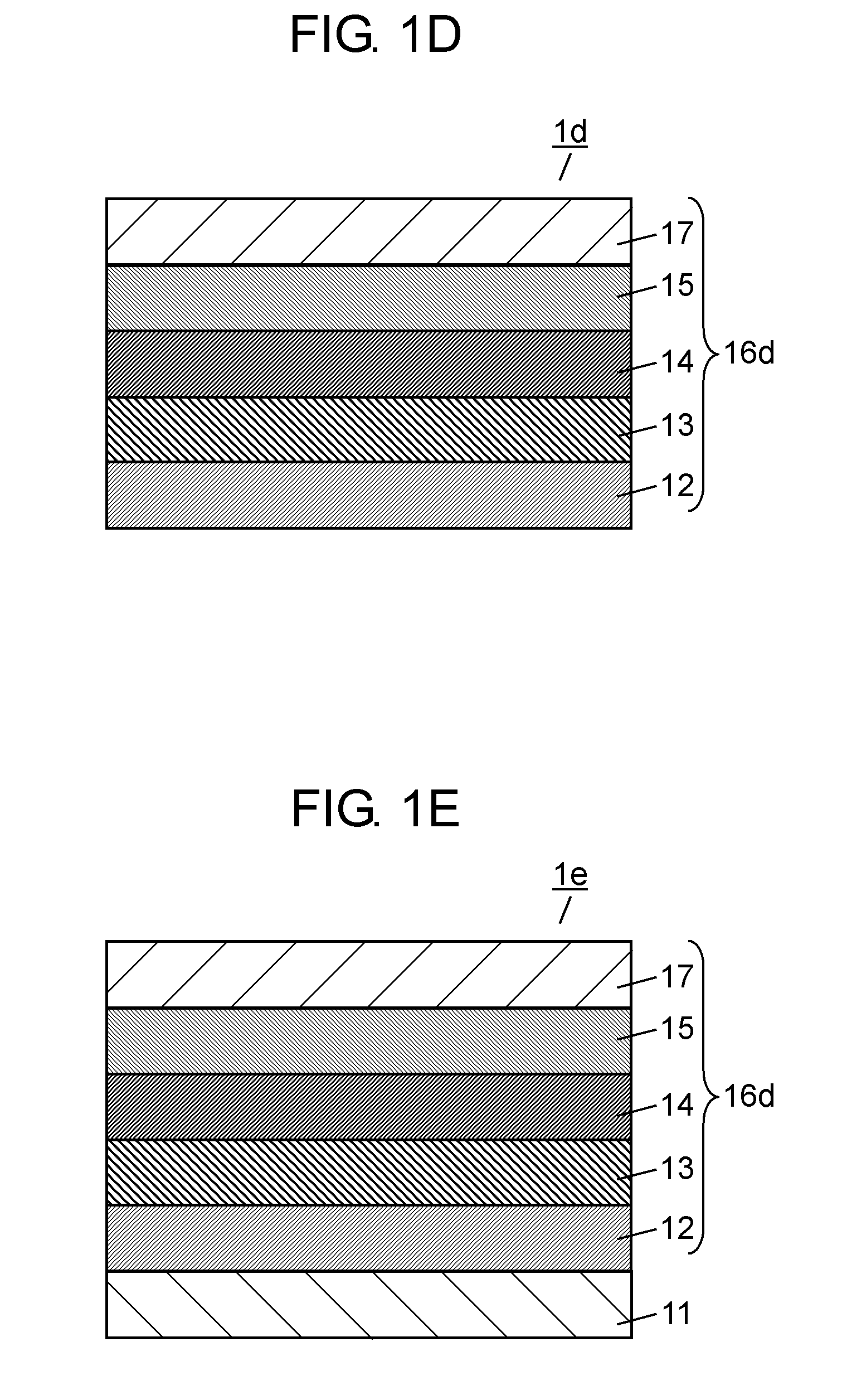

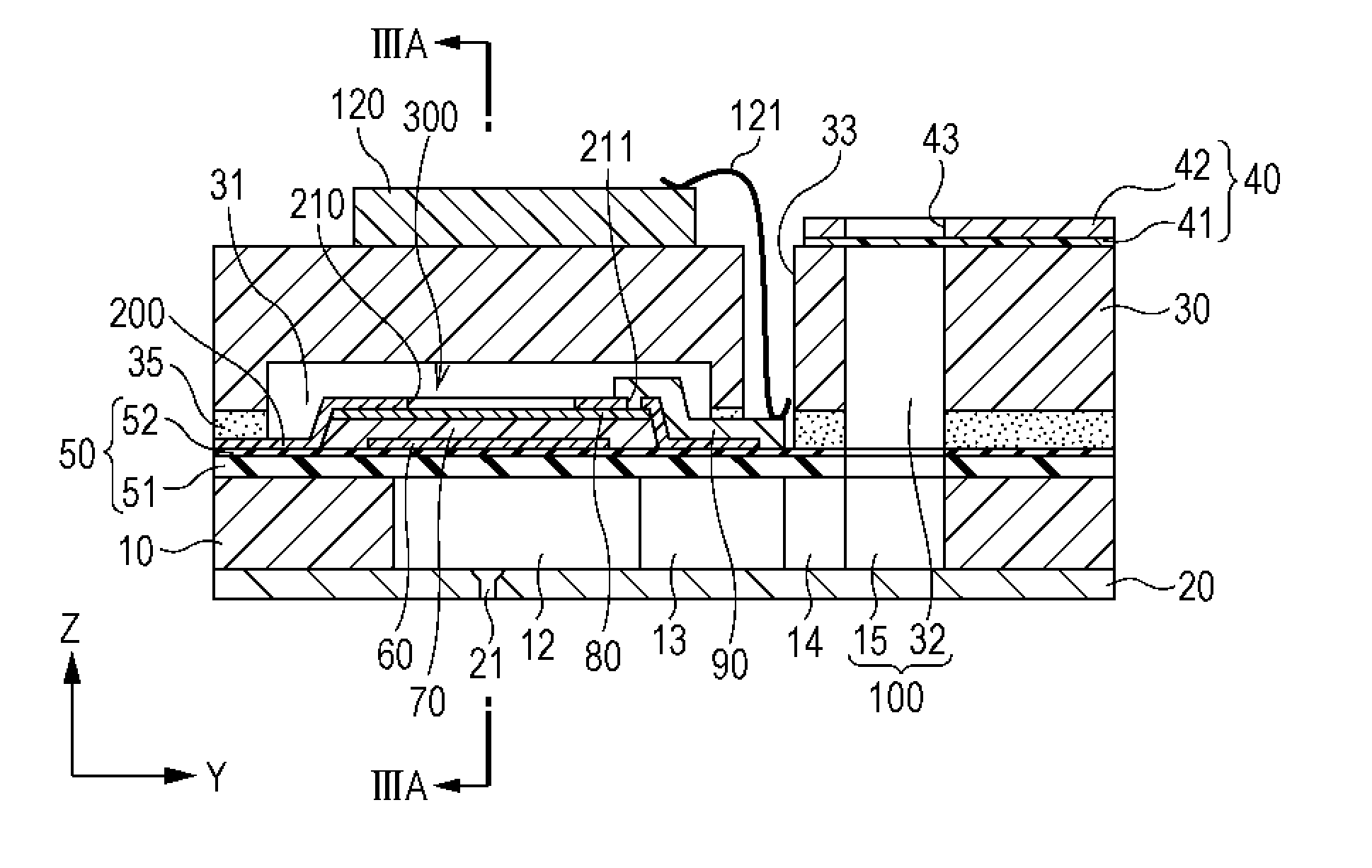

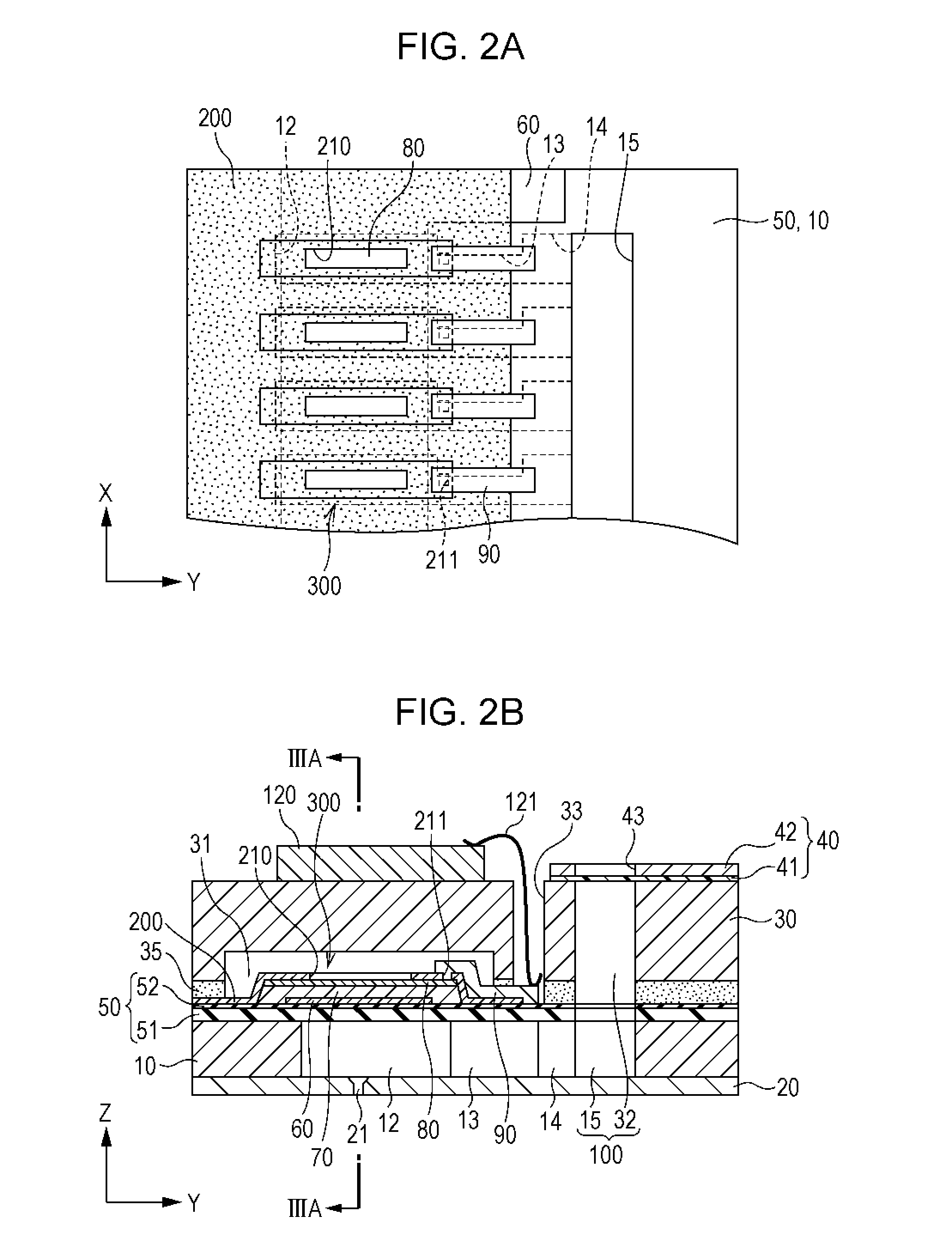

Liquid ejecting head, liquid ejecting apparatus, piezoelectric element, and method for manufacturing piezoelectric element

ActiveUS20140176646A1Improve piezoelectric performanceLow costPiezoelectric/electrostrictive device manufacture/assemblyInking apparatusEngineeringTitanium

A flow channel substrate has pressure chambers, and the pressure chambers communicate with nozzle openings for ejecting liquid. Each of piezoelectric elements on the flow channel substrate has a piezoelectric layer, a pair of electrodes, and a wiring layer coupled to the electrodes. The wiring layer has an adhesion layer and a conductive layer on the adhesion layer. The adhesion layer contains at least one selected from nickel, chromium, titanium, and tungsten. The piezoelectric element has an insulating film at least between the wiring layer and the electrodes. The wiring layer and the electrodes of the piezoelectric element are coupled via contact holes created through the insulating film.

Owner:SEIKO EPSON CORP

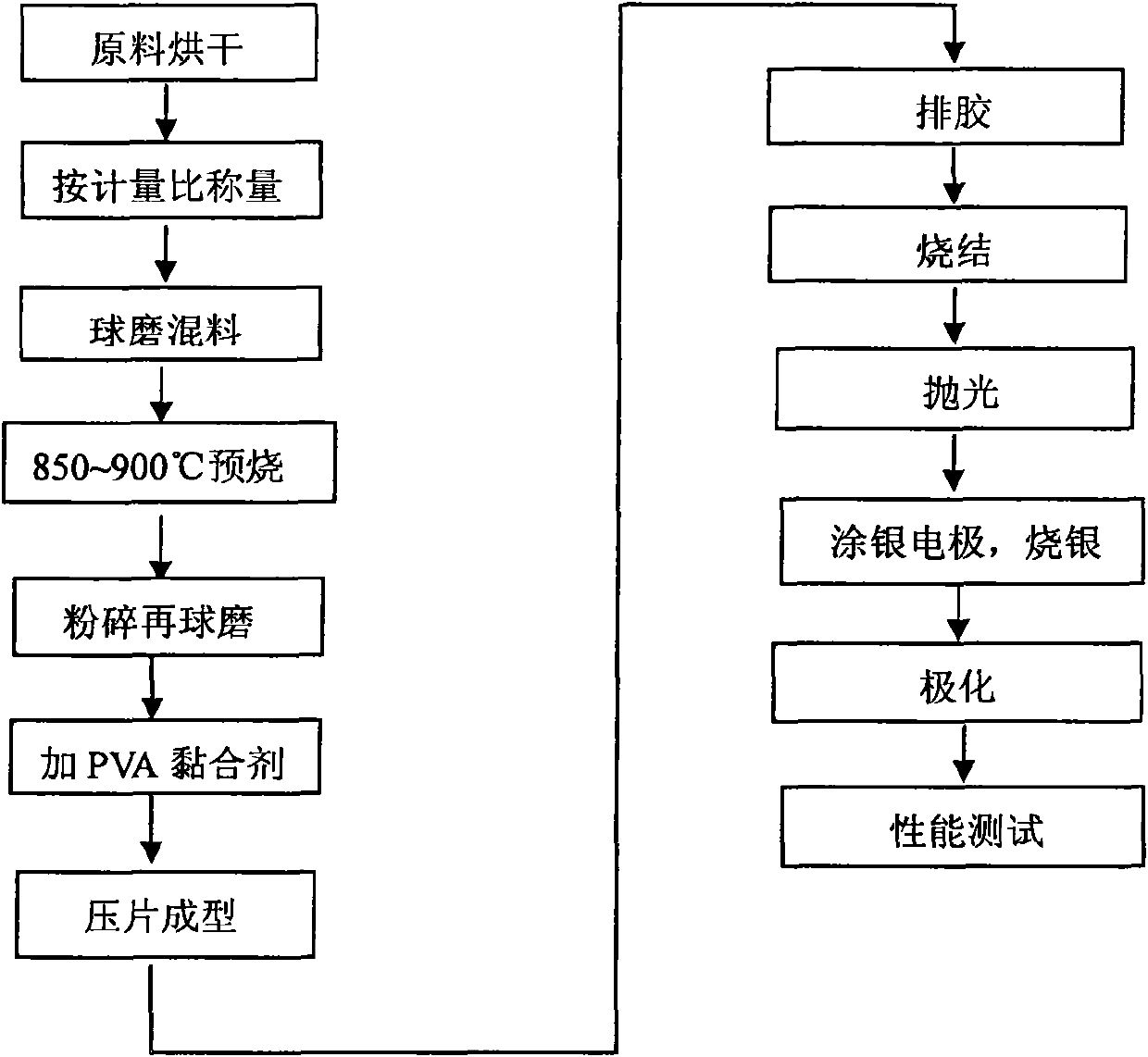

High efficiency piezoelectric ceramic material with low sintering temperature and preparation technology thereof

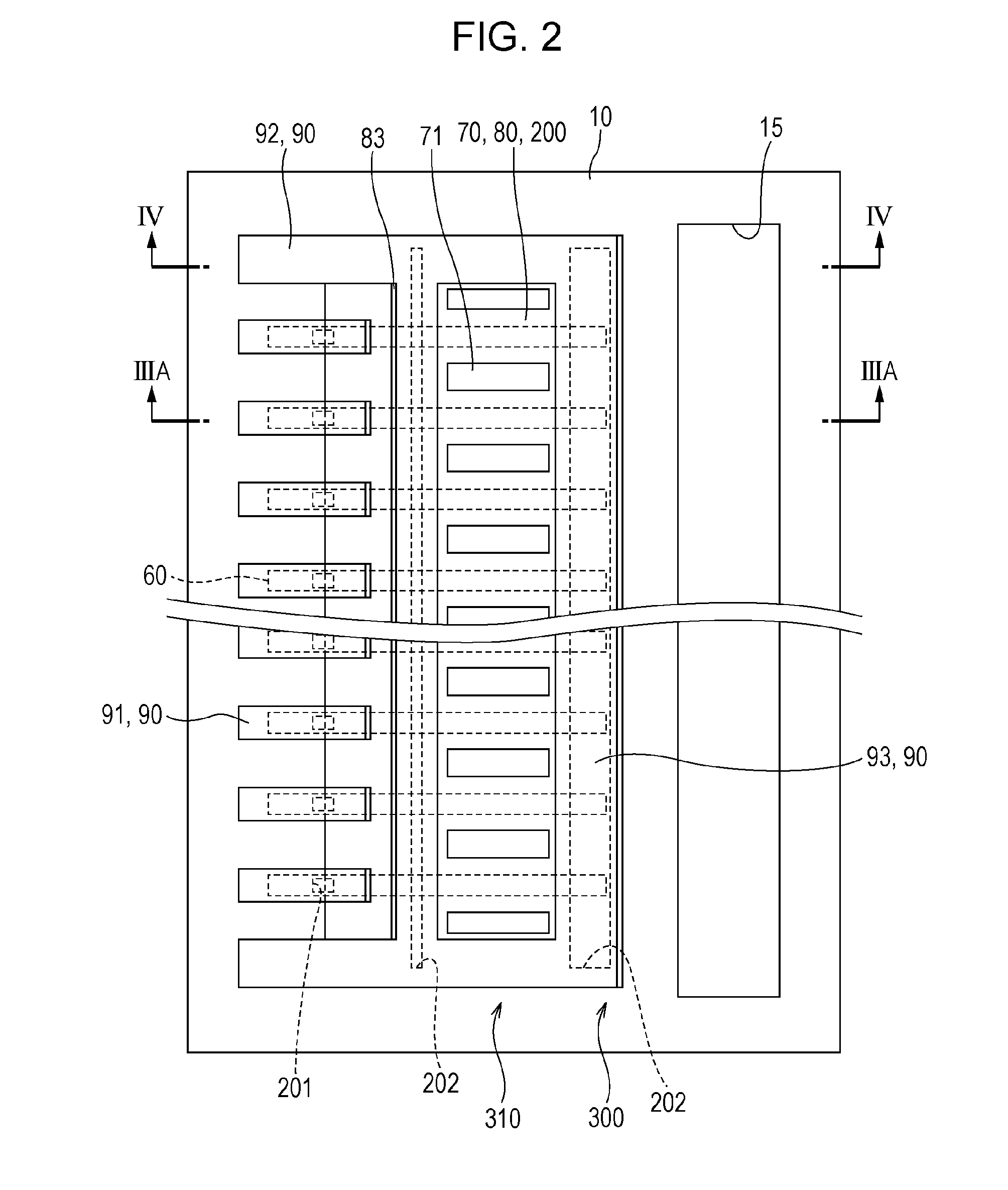

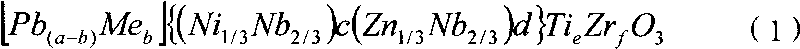

The invention discloses a piezoelectric ceramic with low sintering temperature and high piezoelectric property and preparation technology thereof. The piezoelectric ceramic comprises main ingredients and auxiliary ingredients. The chemical formula of the main ingredients is as below, wherein Me is any one or two of Ba, Ca and Sr, and the auxiliary ingredients are SiO2, H3BO3 or the mixture of the two ingredients, and Sb2O5 or Sb2O3, Bi2O3 or Bi2O5, Li2CO3 or Na2CO3 or the mixture of the two ingredients, and CuO. The preparation technology comprises mixing, ball milling, stoving, presintering, ball milling, pelleting, forming, dumping, sintering, silver brushing, silver sintering and polarizing. The piezoelectric ceramic provided by the invention has the advantages of energy saving, environmental protection, low cost, high property and the like, has wide application prospect and is especially suitable for piezoelectric ceramic loudspeakers and piezoelectric buzz films with large power.

Owner:AUDIOWELL ELECTRONICS GUANGDONG

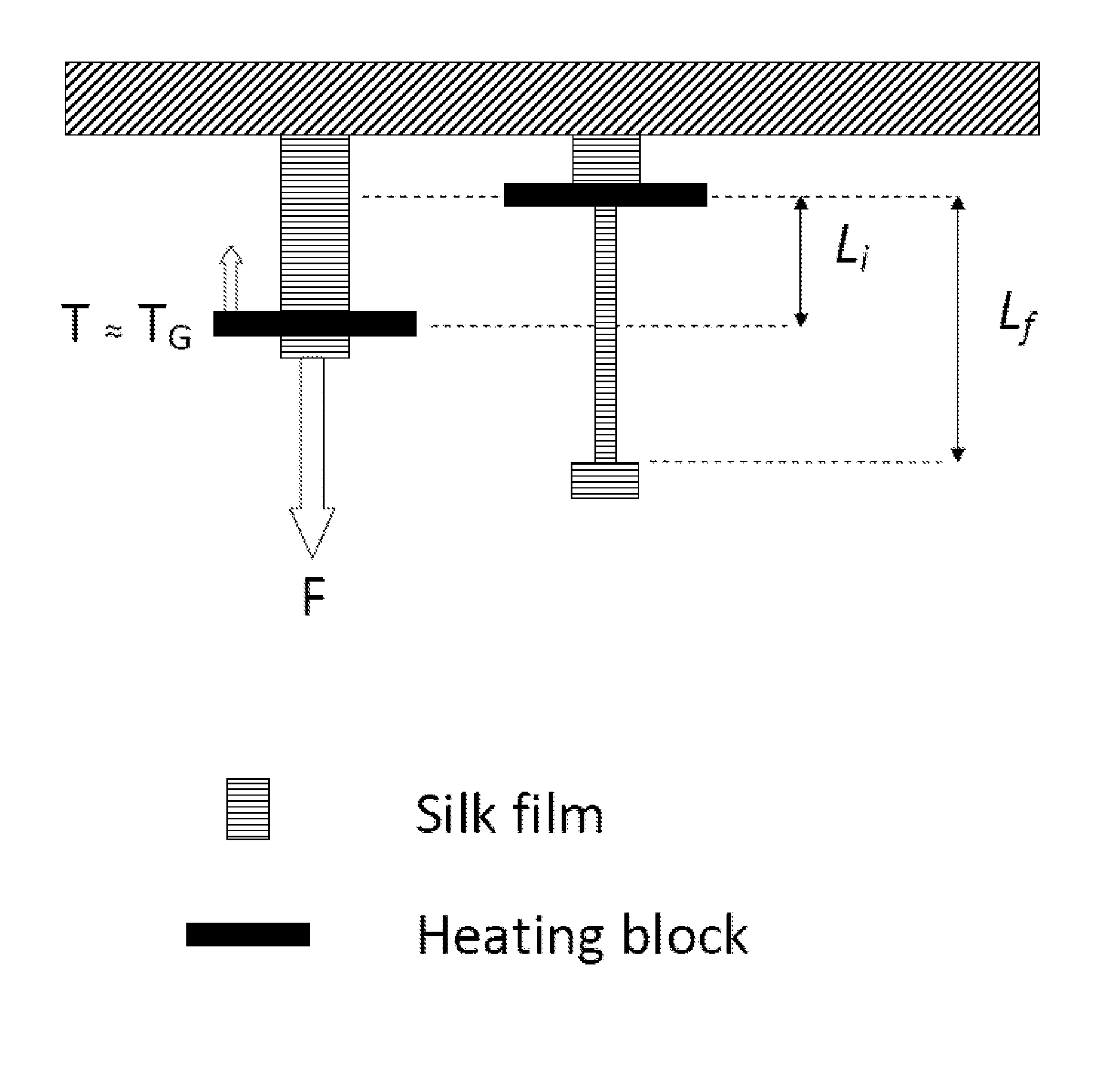

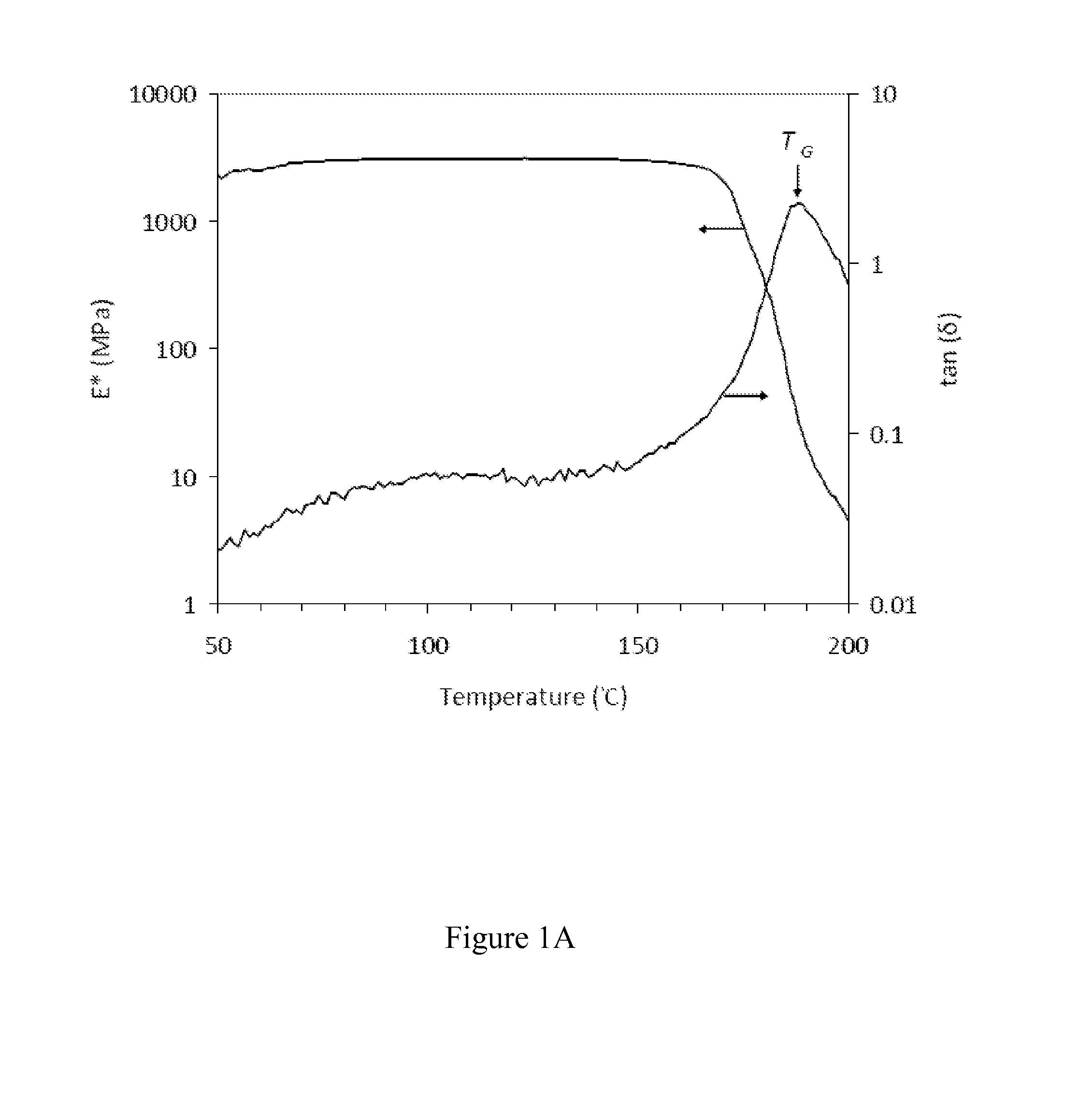

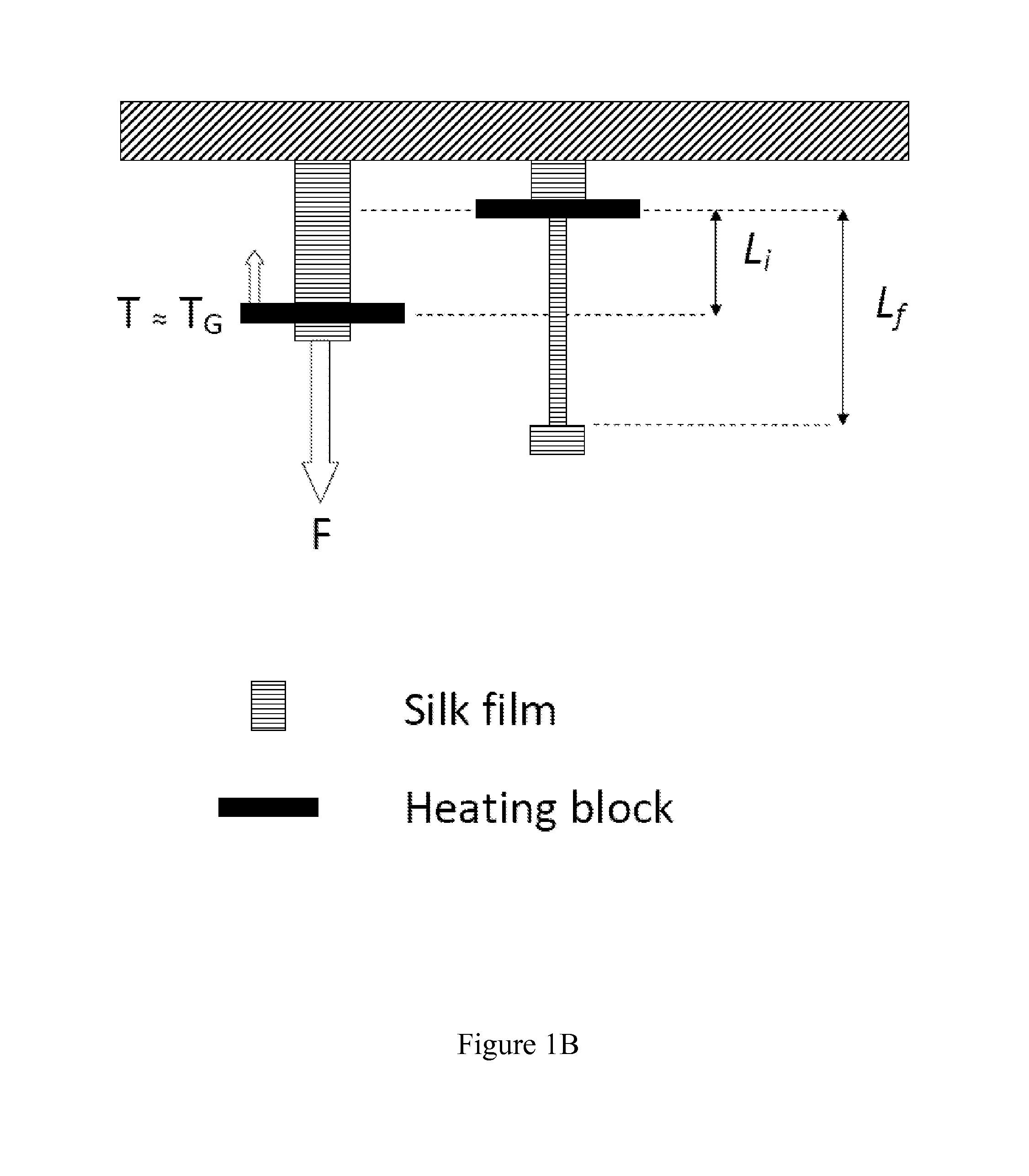

Silk-based piezoelectric materials

ActiveUS20140145365A1Stable and robust oscillationImprove energy conversion efficiencyPiezoelectric/electrostrictive device manufacture/assemblyElectrotherapyPolymer scienceOrganic chemistry

The invention relates to methods and compositions for preparing silk-based piezoelectric materials and methods for increasing piezoelectricity in silk matrices.

Owner:TUFTS UNIV

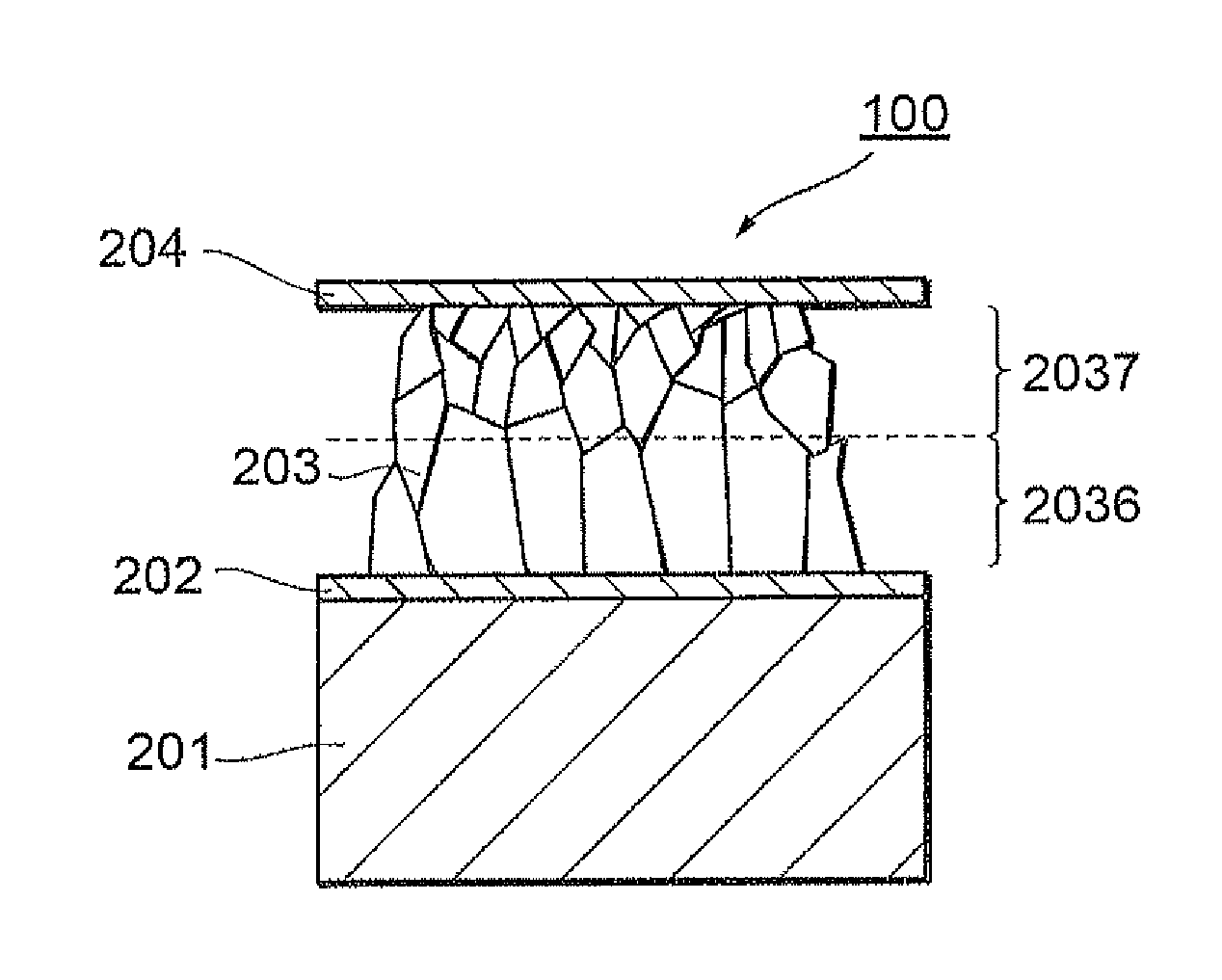

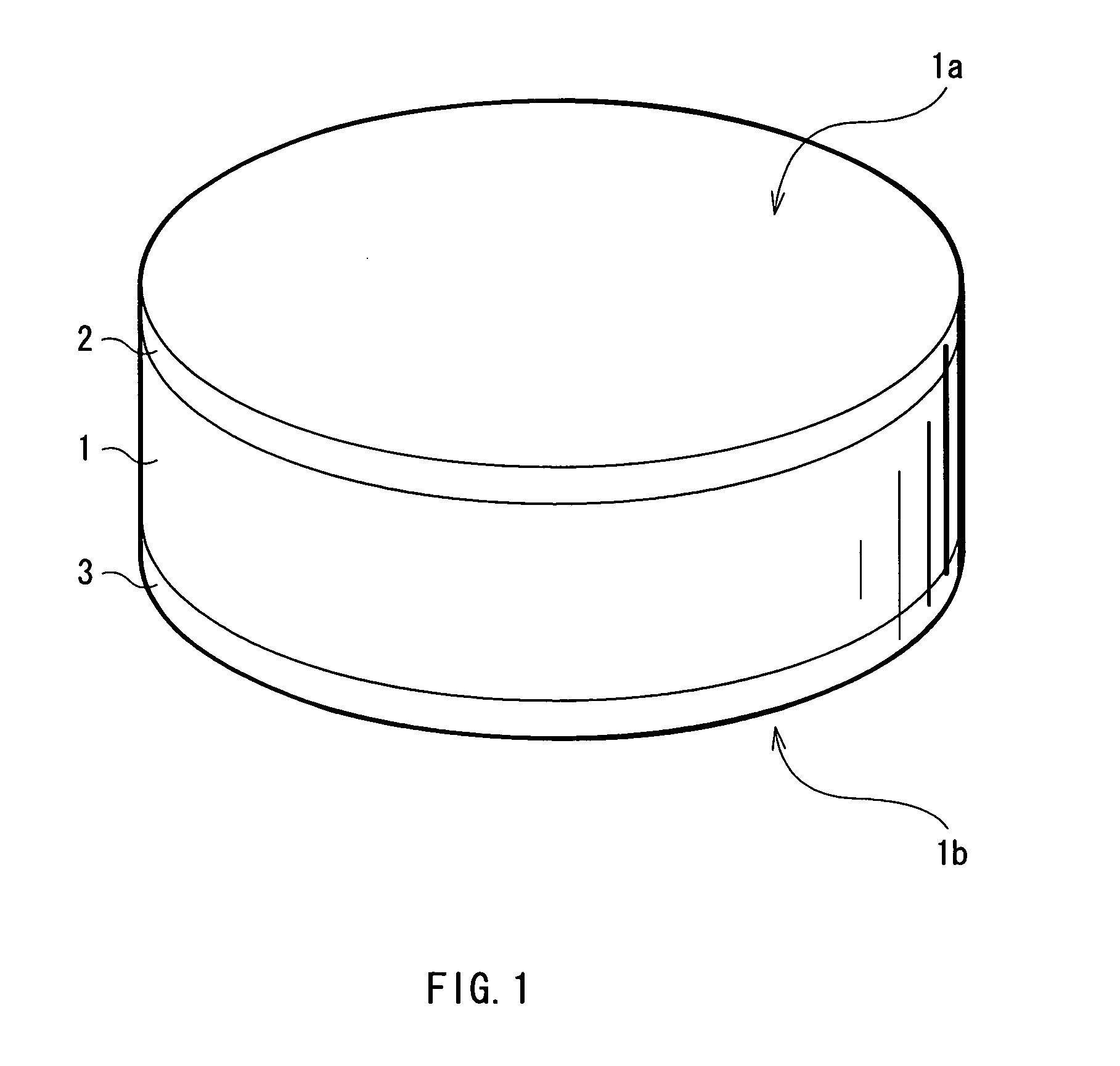

Piezoelectric thin film, ink jet head, method of forming image by the ink jet head, angular velocity sensor, method of measuring angular velocity by the angular velocity sensor, piezoelectric generating element, and method of generating electric power using the piezoelectric generating element

InactiveUS20120038714A1Low dielectric lossImprove piezoelectric performancePiezoelectric/electrostrictive device manufacture/assemblyAcceleration measurement using interia forcesDielectric lossAngular velocity

The present invention provides a piezoelectric thin film comprising an electrode film with a (001) orientation, a (NaxBi0.5)TiO0.5x+2.75—BaTiO3 film with a (001) orientation (x represents not less than 0.29 and not more than 0.4) and a (Na,Bi)TiO3—BaTiO3 piezoelectric layer, the electrode film, the (NaxBi0.5)TiO0.5x+2.75—BaTiO3 film, and the (Na,Bi)TiO3—BaTiO3 piezoelectric layer being laminated in this order.The lead-free piezoelectric thin film of the present invention has low dielectric loss and high piezoelectric performance.

Owner:PANASONIC CORP

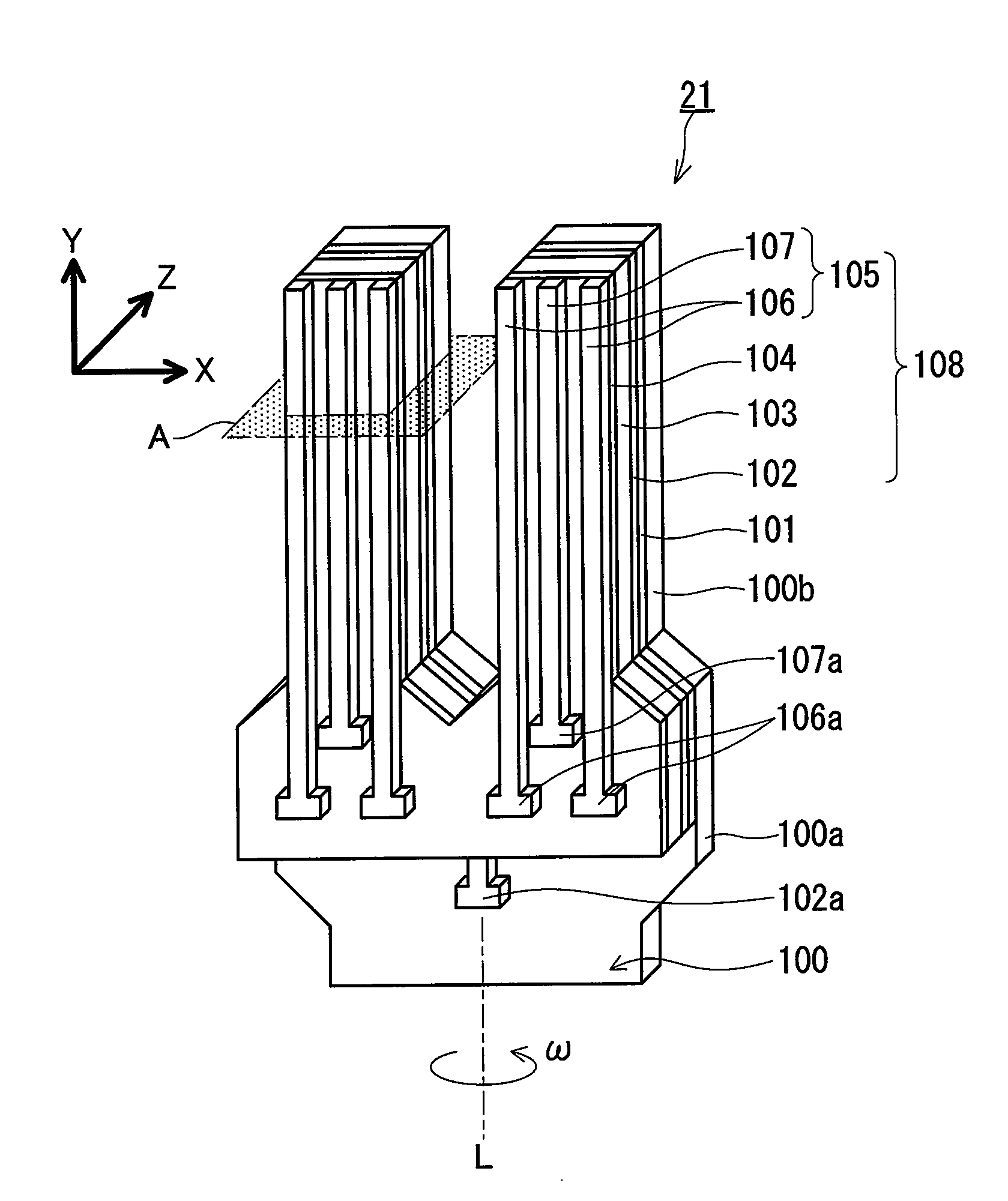

Piezoelectric element, liquid ejecting head, liquid ejecting apparatus, ultrasonic transducer, and ultrasonic device

InactiveUS20140267504A1Improve performanceImprove piezoelectric performanceInking apparatusPiezoelectric/electrostriction/magnetostriction machinesTectorial membraneSilicon oxide

Provided is a piezoelectric element which includes a first electrode, a piezoelectric body layer provided on the first electrode, a second electrode provided on the piezoelectric body layer, and a protection film constituted by a silicon oxide layer that is formed using trimethoxysilane and a liquid-phase zirconia layer, in which the protection film is formed to extend from upper portions of the first electrode and the second electrode to boundary portions between the electrodes and the piezoelectric body layers.

Owner:SEIKO EPSON CORP

Piezoelectric ceramic and method of manufacturing the same

InactiveUS20070152183A1Improve piezoelectric performanceImprove sintering performancePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionAlkaline earth metalCurie temperature

There is provided a piezoelectric ceramic having a wider operating temperature range, being capable of obtaining a larger amount of displacement, being easily sintered, and being superior in terms of low emission, environment and ecology. A piezoelectric substrate (1) includes (1−m−n){(Na1-x-yKxLiy)(Nb1-zTaz)O3}+m{(M1)ZrO3}+n{M2(Nb1-wTaw)2O6} as a main component. M1 and M2 each represent an alkaline-earth metal element, and the values of x, y, m and n are preferably within a range of 0.1≦x≦0.9, 0≦y≦0.1, 0<m<0.1 and 0<n≦0.01, respectively. Thereby, a higher Curie temperature and a larger amount of displacement can be obtained, and sintering can be more easily performed. At the time of sintering, after (M1) ZrO3 is formed, other materials are mixed.

Owner:TDK CORPARATION

Piezoelectric thin film and method of manufacturing the same, angular velocity sensor, method of measuring angular velocity by the angular velocity sensor, piezoelectric generating element, and method of generating electric power using the piezoelectric generating element

InactiveUS20100194245A1Improve piezoelectric performanceExcellent power generation characteristicsPiezoelectric/electrostrictive device manufacture/assemblyAcceleration measurement using interia forcesElectricityWide area

Provided are a piezoelectric thin film including a lead-free ferroelectric material and exhibiting high piezoelectric performance comparable to that of PZT, and a method of manufacturing the piezoelectric thin film. The piezoelectric thin film of the present invention has a multilayer structure in which a metal electrode film having a plane orientation of (100), a (Bi,Na)TiO3 film, and a (Bi,Na,Ba)TiO3 film having a plane orientation of (001) are laminated in this order. The piezoelectric thin film of the present invention can be applied to a wide range of fields and uses. For example, with the piezoelectric thin film of the present invention, an angular velocity sensor of the present invention having high sensitivity and a piezoelectric generating element of the present invention having excellent power generation characteristics can be constructed.

Owner:PANASONIC CORP

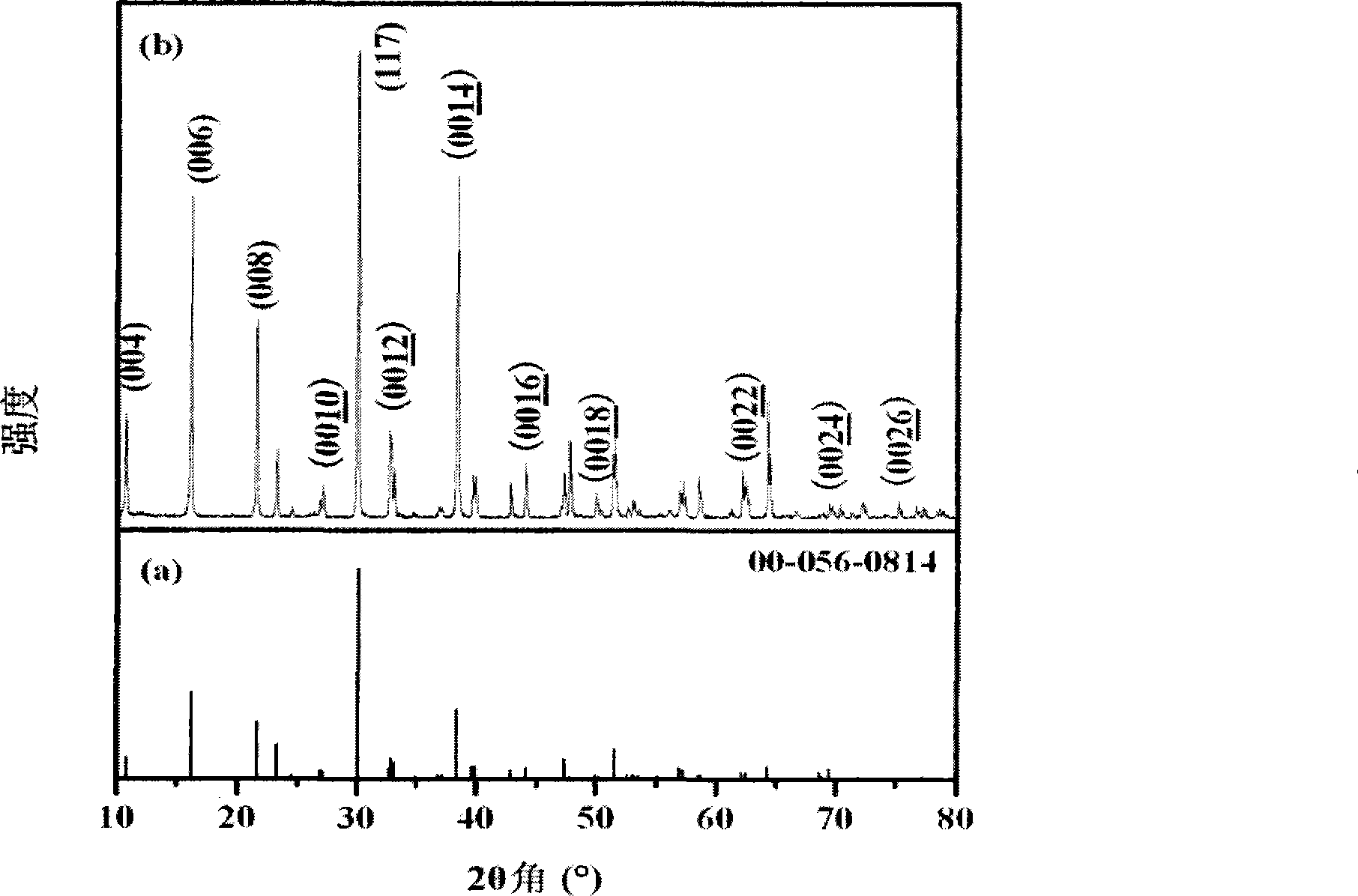

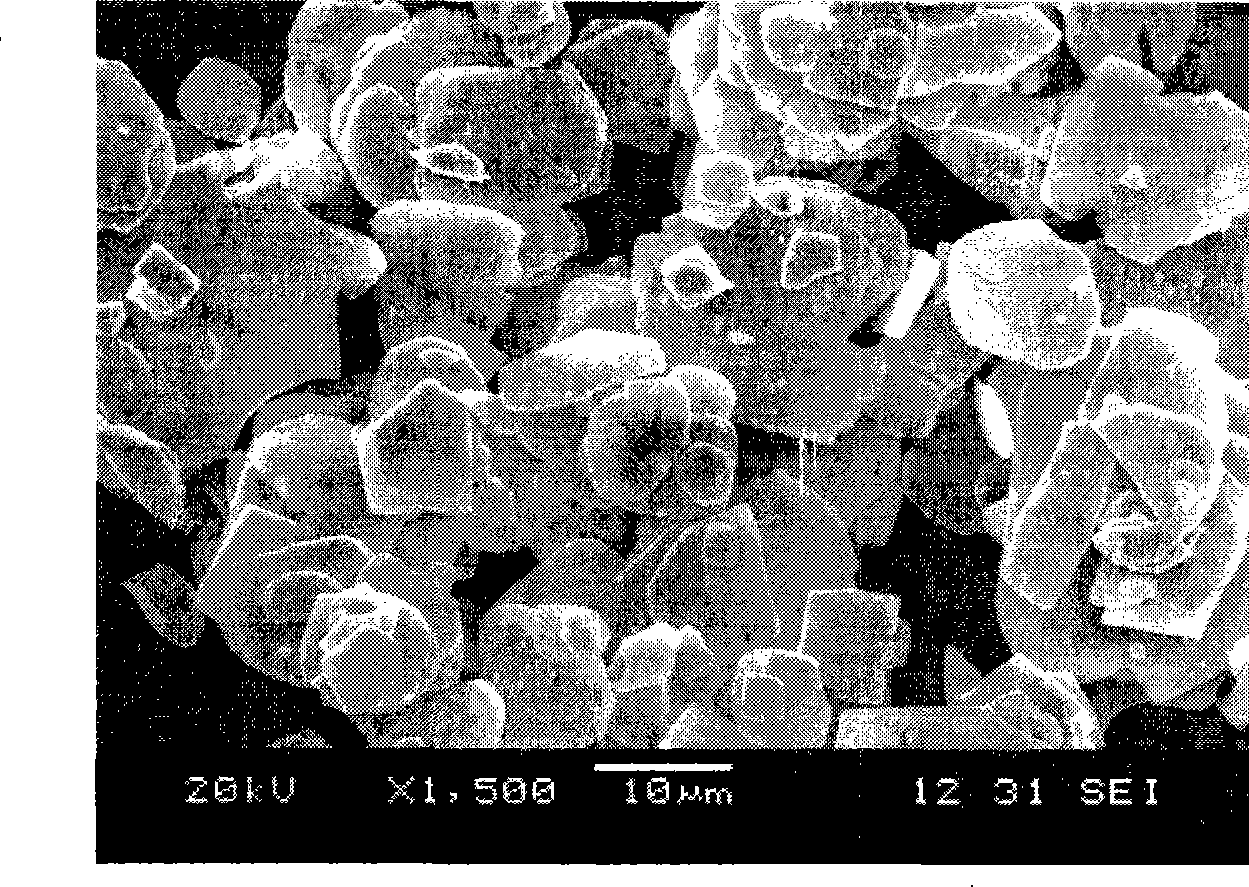

Sheet bismuth sodium titanate mould plate grain and manufacture method thereof

The invention relates to a schistic bismuth sodium titanate template crystal grain and a preparation method thereof, belonging to the preparation field of textured non-lead piezoelectric ceramic template crystal grain, the chemical formula of the template grains is Na0.5Bi0.5TiO3, the appearance of the crystal grain is schistic, the radial length is 5 to 15Mum, the thickness is 0.5 to 1.0Mum, the crystal grain has large aspect ratio and strong orientation, which is an ideal template crystal grain. The crystal grain adopts schistic Bi4Ti3O12 as a precursor which is synthesized by molten salt method, in the molten salt system of NaCl, the crystal grain can have topological chemical reaction with Na2CO3, TiO2 so as to produce schistic polycrystalline Na0.5Bi0.5TiO3 template crystal grain and the crystal grain can be regarded as the template for various textured bismuth sodium tianate non-lead piezoelectric ceramics, which has positive effect for improving the density, the orientation and piezoelectric properties of textured bismuth sodium tianate non-lead piezoelectric ceramics.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

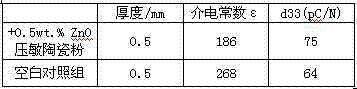

Piezoelectric composite material and preparation method thereof

The invention provides a piezoelectric ceramic, polyvinylidene fluoride (PVDF) and pressure-sensitive material three-phase composite material with high piezoelectric property. The pressure-sensitive material is added to a piezoelectric ceramic / PVDF piezoelectric composite material as an intermediate layer, so as to play a bridging role; the interfacial bonding properties of the piezoelectric ceramic and the PVDF are improved; coupling between the piezoelectric ceramic and the PVDF is increased; electron migration between ceramic particles is promoted; and the polarization voltage of a ceramic phase is improved. In addition, due to the nonlinear current-voltage characteristics of the pressure-sensitive material, when the pressure-sensitive material is added to the piezoelectric ceramic and PVDF composite material, the polarization-resistant voltage of the piezoelectric composite material is improved; and the overall piezoelectric property of the composite material is improved. Therefore, the piezoelectric composite material is simple in process, and low in cost; the piezoelectric composite film with excellent overall performance and large size can be prepared; and the piezoelectric composite material is expected to be applied to a piezoelectric touchpad, thus industrialized production is achieved.

Owner:SUZHOU PANT PIEZOELECTRIC TECH

Piezoelectric Alloy Films

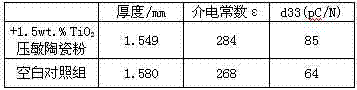

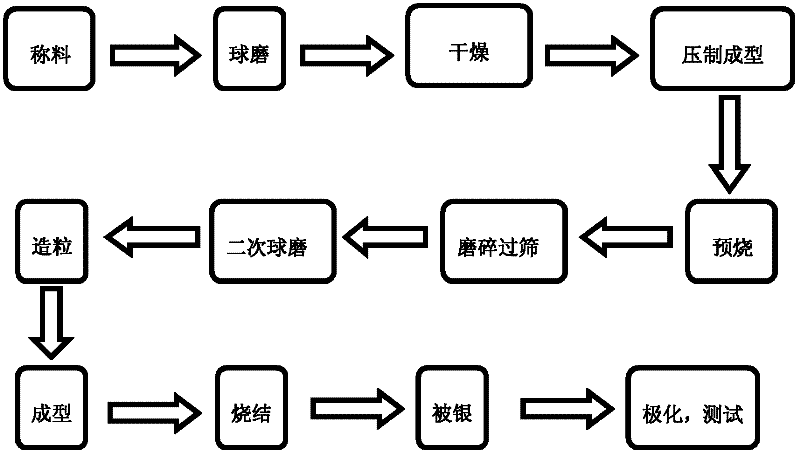

InactiveUS20170263847A1Improve piezoelectric performanceImprove the overall coefficientVacuum evaporation coatingSputtering coatingAlloy

A thin film XyAl(1-y)N alloy preferably deposited with an intrinsic tensile stress significantly enhances the piezoelectric properties of AlN. The alloy contains y percent of the compound XN, where X is selected from the group consisting of Yb, Ho, Dy, Lu, Tm, Tb, and Gd. The percentage of XN preferably lies in the range 10-60%, and the stress is preferably in the range 200 MPa-1.5 GPa. The film is useful in MEMS devices.

Owner:CORP DE LECOLE POLYTECHNIQUE DE MONTREAL +1

Preparation methods of nanometer piezoelectric film and nanometer composite piezoelectric generator

ActiveCN104201280AEvenly distributedEven by forcePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionNetwork structurePiezoelectric generator

The invention discloses preparation methods of a nanometer piezoelectric film and a nanometer composite piezoelectric generator. The methods are characterized in that biocompatible bacterial cellulose is taken as a substrate, and nanometer (or submicron) piezoelectric particles having high piezoelectric coefficients are taken as a filling material, the piezoelectric film is obtained by compounding the bacterial cellulose and the piezoelectric particles, and the piezoelectric film is used for constructing the flexible nanometer composite piezoelectric generator. Through the unique spatial three-dimensional network structure of the bacterial cellulose, the piezoelectric particles are naturally and uniformly distributed in the bacterial cellulose, and the internal stress of the film is uniformly, thereby greatly improving the output performance of the nanometer composite piezoelectric generator. The nanometer composite piezoelectric generator is biocompatible, and can be implanted into a living body to collect energy. Moreover, a preparation process is simple, the cost is low, and the nanometer piezoelectric film and the nanometer composite piezoelectric generator have very good application prospects.

Owner:UNIV OF SCI & TECH BEIJING

Potassium-sodium niobate based leadless piezoelectric ceramic and preparation method thereof

ActiveCN105272244AImprove piezoelectric performanceLower sintering temperatureMaterials sciencePotassium sodium

The invention relates to potassium-sodium niobate based leadless piezoelectric ceramic and a preparation method thereof and belongs to the field of functional ceramic materials. The chemical formula of the ceramic is as follows: (ABO3)1-x(BaZrO3)y(MnO2)y. The preparation method is as follows: K2CO3, Na2CO3, Nb2O5, Bi2O3, Li2CO3, TiO2, BaCO3, ZrO2 and MnO2 are mixed, absolute ethyl alcohol is added, the mixture is subjected to ball milling and dried, then mixed powder is obtained, and the powder is pre-sintered; absolute ethyl alcohol is added to the sintered powder, the mixture is subjected to ball milling again and dried, and mixed powder is obtained; the mixed powder is subjected to cold press molding, rough ceramic blank is obtained and sintered, and a ceramic sample is obtained; the ceramic sample is subjected to polarization treatment, and the potassium-sodium niobate based leadless piezoelectric ceramic is obtained. The prepared potassium-sodium niobate based leadless piezoelectric ceramic has excellent piezoelectric performance and temperature stability.

Owner:TSINGHUA UNIV

High-performance potassium sodium niobate-based leadless piezoelectric ceramic and preparation method for same

InactiveCN102515760AImprove performanceImprove piezoelectric performanceSocial benefitsPotassium sodium

The invention discloses a high-performance potassium sodium niobate-based leadless piezoelectric ceramic, expressed by a general formula of (1-x)(KNa)<c>Li<d>(Nb<e>Ta<f>Sb<g>)O3 - xBaZrO3, wherein a, b, c, d, e, f and g are molar fractions, a is greater than 0.35 and not greater than 0.6, b is greater than 0.35 and not greater than 0.6, c is greater than 0.92 and not greater than 0.99, d is greater than 0 and not greater than 0.25, e is greater than 0.74 and not greater than 0.89, f is greater than 0.1 and not greater than 0.3, and g is not less than 0.01 and less than 0.3; and x represents the molar percentage of BaZrO3 for (KNa)<c>Li<d>(Nb<e>Ta<f>Sb<g>)O3, and x is not less than 0 and not greater than 30%. Additionally, a preparation method for the high-performance potassium sodium niobate-based leadless piezoelectric ceramic is further disclosed. The high-performance potassium sodium niobate-based leadless piezoelectric ceramic and the preparation method for the same disclosed by the invention remarkably improve the piezoelectric properties and dielectric properties of ceramic material, thereby obtaining dielectric material excellent and stable in performances; and the high-performance potassium sodium niobate-based leadless piezoelectric ceramic can completely replace traditional lead-based piezoelectric ceramic in application, as well as has important practical significance and social benefits.

Owner:JINGDEZHEN CERAMIC INSTITUTE

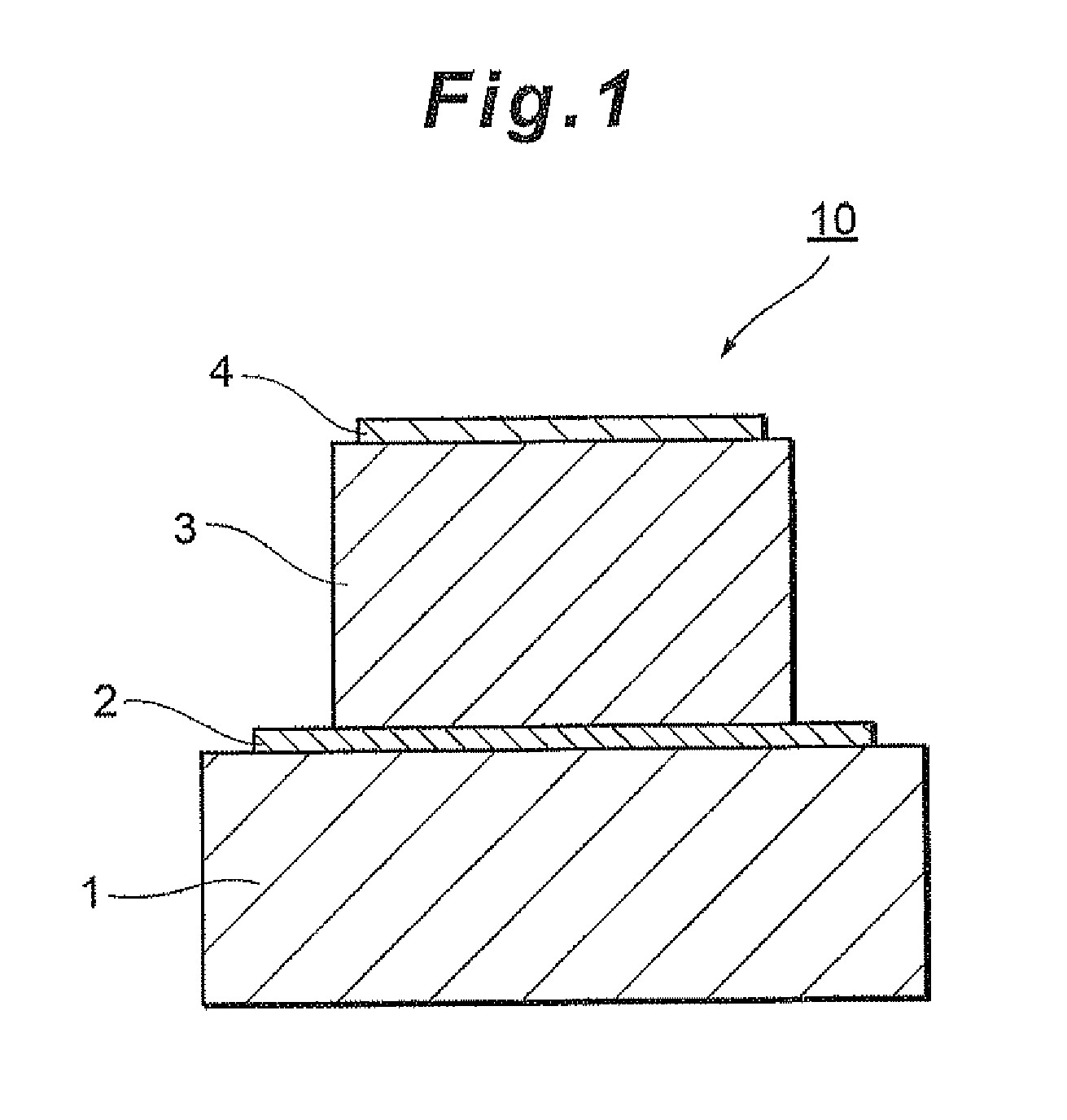

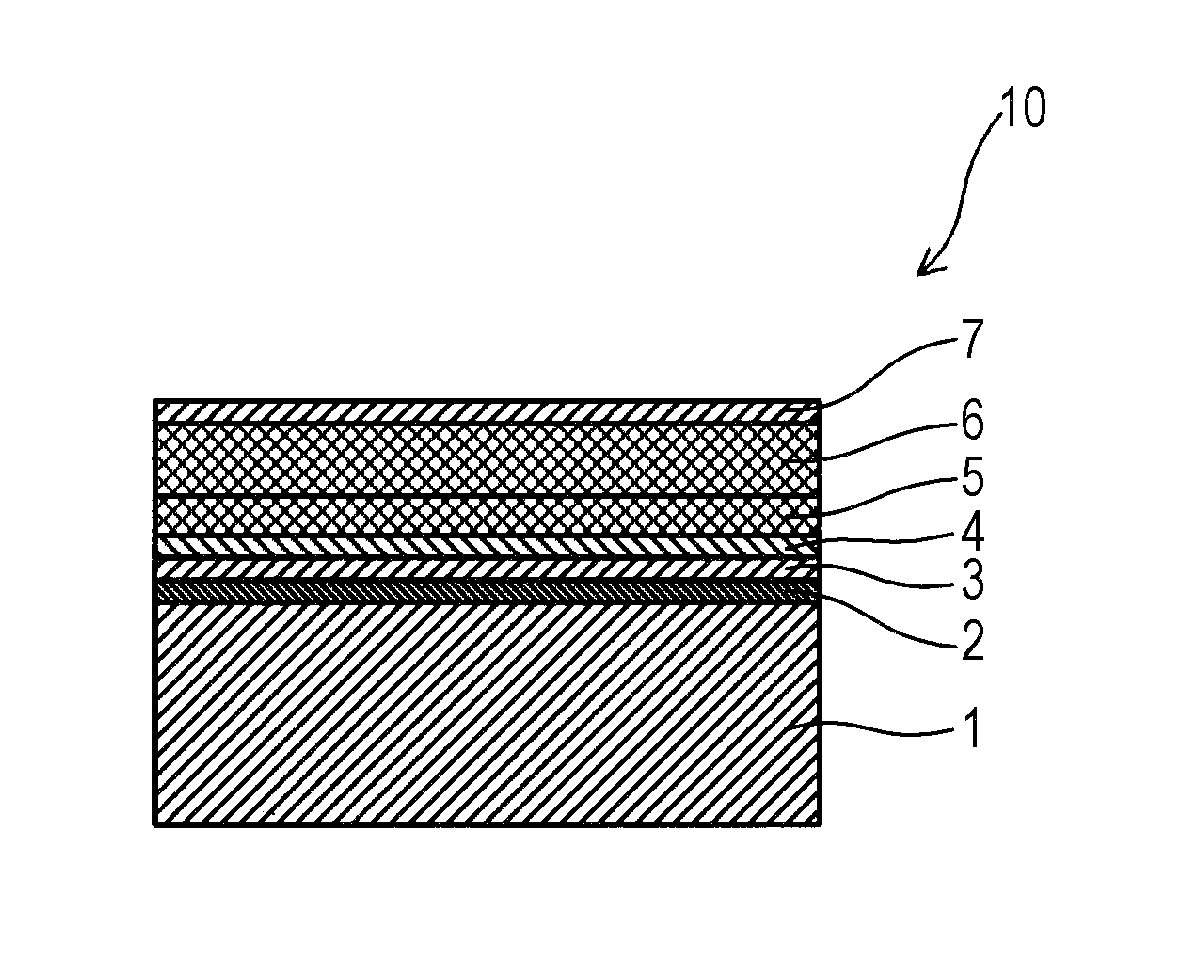

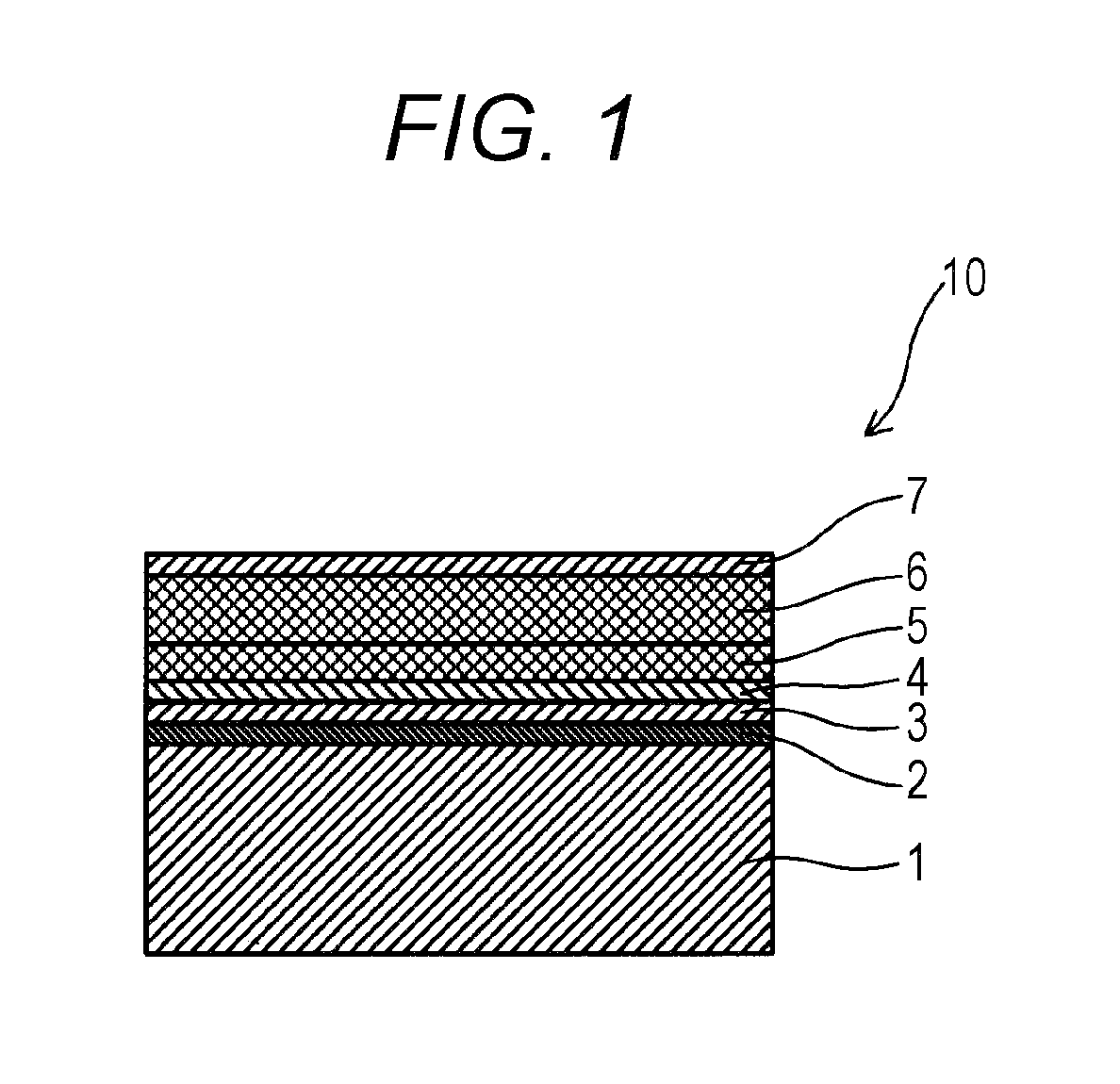

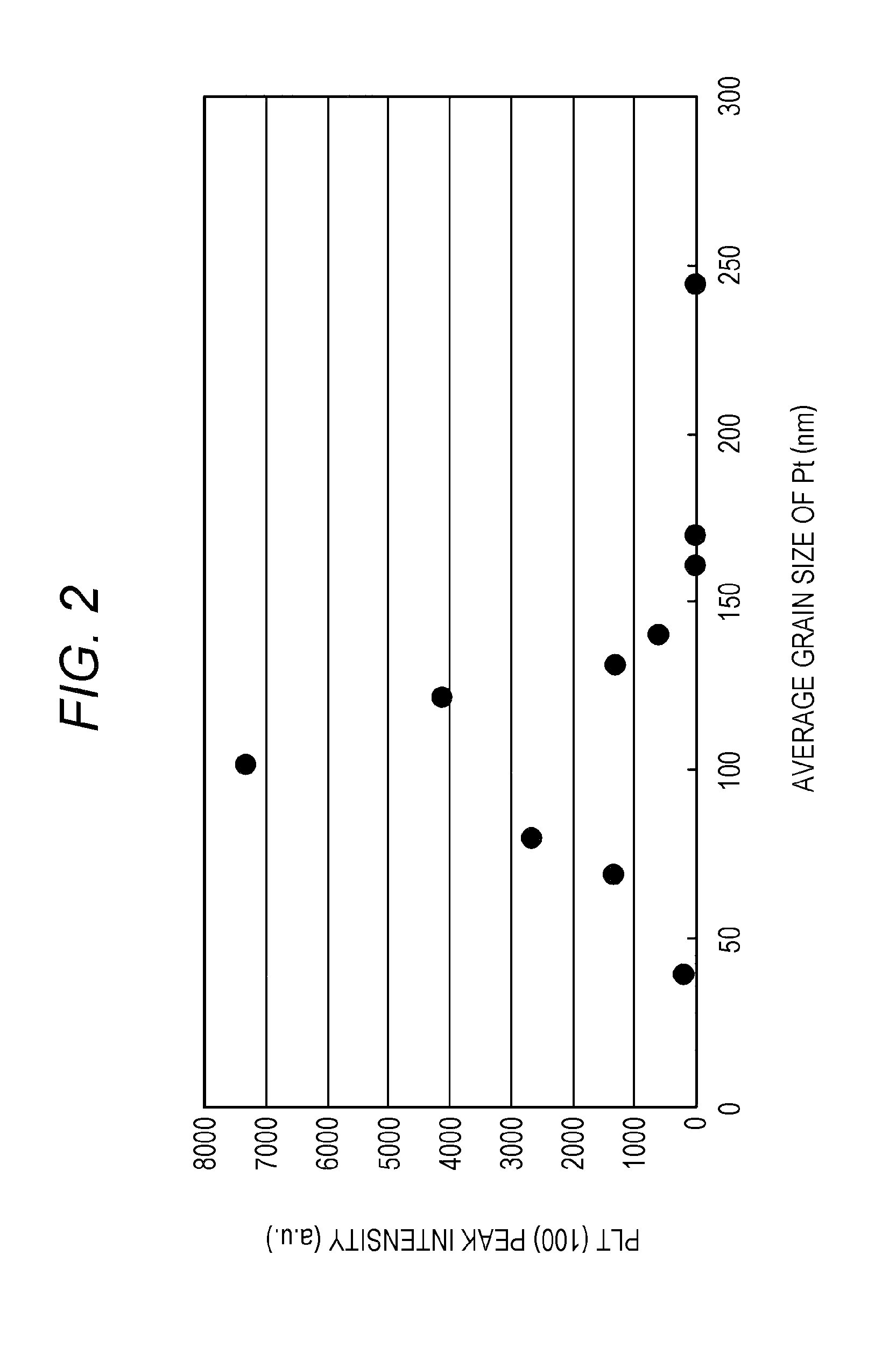

Piezoelectric element

ActiveUS20150084486A1High self-orientationWell formedPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesFerroelectric thin filmsThin membrane

Disclosed is a piezoelectric element wherein a lower electrode made of Pt, a buffer layer made of PLT, and a piezoelectric thin film to be a perovskite ferroelectric thin film are formed in this order on a substrate. The average crystal grain size of Pt forming the lower electrode is not smaller than 50 nm and not larger than 150 nm.

Owner:KONICA MINOLTA INC

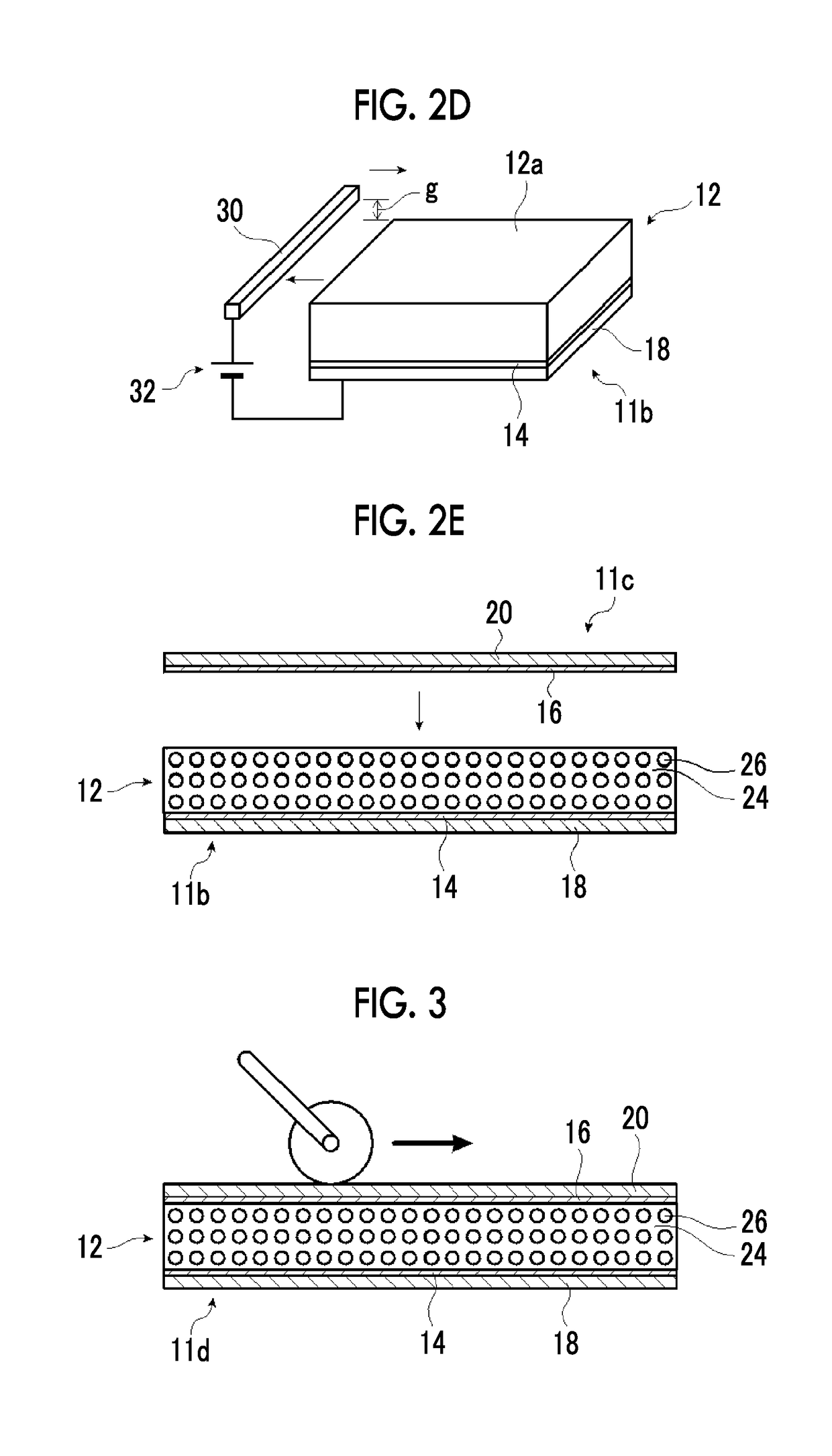

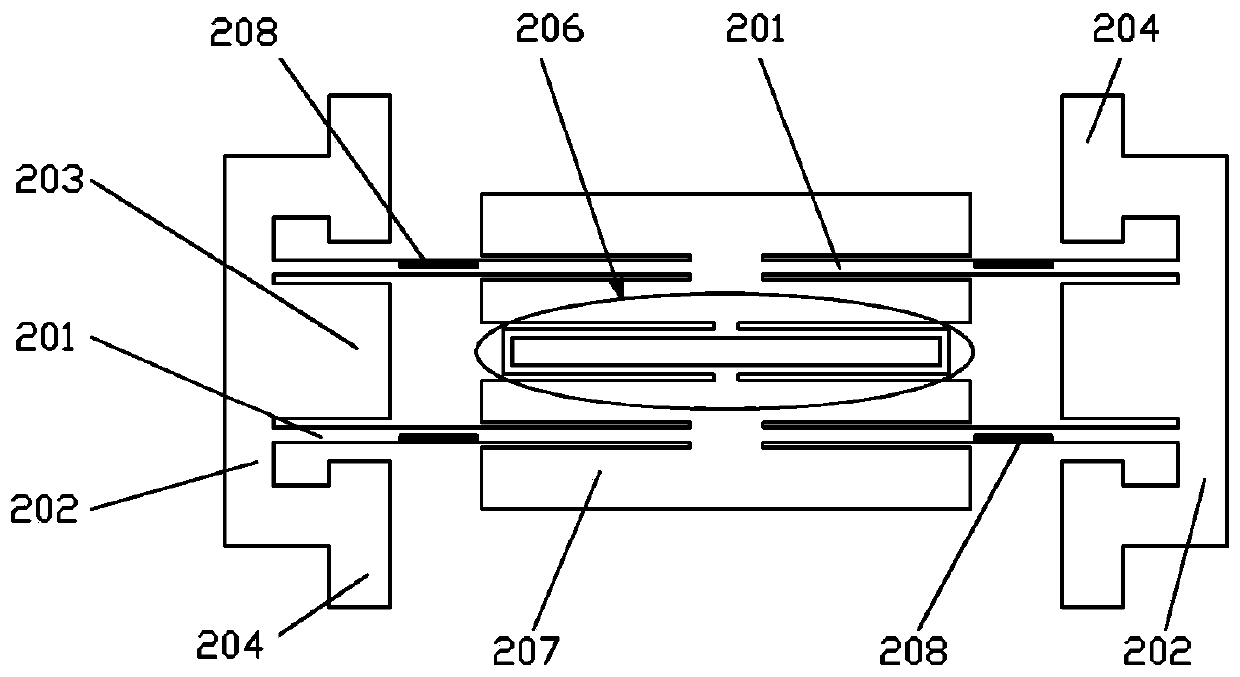

Piezoelectric excitation pulled silicon micro-resonant pressure sensor chip and preparation method thereof

ActiveCN109786422AHigh sensitivityHigh quality factorPiezoelectric/electrostrictive device manufacture/assemblySolid-state devicesGlass coverPiezoelectric actuators

The invention provides a piezoelectric excitation pulled silicon micro-resonant pressure sensor chip and a preparation method thereof. The pressure sensor chip mainly comprises a sealed glass cover, aresonator layer, a pressure sensitive film layer, a stress isolation pad, a piezoelectric excitation element and a resistance vibration pick-up element. A composite structure of a pressure sensitivediaphragm and a resonator is adopted. For a second sensitive mode, the resonator layer comprises a resonant beam and a torsion beam. An extension part at one end of two adjacent resonant beams is connected to the same suspended torsion beam, and the other end is connected to a mass block. A coupling beam is arranged in the middle of the mass block. The resonator is connected to an anchor point through a connection point. A pressure guide hole is formed in the stress isolation pad, and the pressure is delivered to the rectangular pressure sensitive diaphragm under the guidance of the pressure guide hole to cause deformation. The deformation is amplified by the anchor point, and delivered to the resonator layer. Piezoelectric actuators and resistive vibration pick-up elements are respectively arranged on the outer surface of the resonant beam and the coupling beam. The piezoelectric actuators and the resistive vibration pick-up elements are connected with an external circuit through leads respectively.

Owner:XI AN JIAOTONG UNIV

Piezoelectric element, manufacturing method thereof and liquid discharge apparatus

ActiveCN101304068AImprove piezoelectric performancePiezoelectric/electrostrictive device manufacture/assemblyVacuum evaporation coatingPiezoelectric coefficientElectric field

A piezoelectric device includes a piezoelectric film, and electrodes through which an electric field can be applied to the piezoelectric film along the thickness direction of the piezoelectric film. The piezoelectric film contains a ferroelectric phase in which the thickness direction and a normal of a plane determined by the spontaneous-polarization axis and the [010] axis makes an angle thetam satisfying the condition that -45 degrees<thetam<+45 degrees and thetam<>0 degrees. Further, the spontaneous-polarization axis or the [010] axis may be perpendicular to the thickness direction of the piezoelectric film.

Owner:FUJIFILM CORP

PPSMZT-doped piezoelectric ceramic, preparation method thereof and use thereof

InactiveCN101948309AImprove piezoelectric performanceLower sintering temperaturePiezoelectric/electrostrictive/magnetostrictive devicesSilver inkLithium

The invention discloses a PPSMZT-doped piezoelectric ceramic, a preparation method thereof and use thereof. The preparation method comprises the following steps: synthesizing a ternary Pb0.98Sr0.02(Mn1 / 3Sb2 / 3)x(Zr0.5Ti0.5)1-xO3(PSMZT) pre-burnt product; doping cobalt-niobium-bismuth-lithium-copper-nickel low-melting-point glass with the pre-burnt product according a stoichiometric ratio; granulating; tabletting; removing bonder; sintering; polishing; firing silver ink; and polarizing and thus obtaining the PPSMZT-doped piezoelectric ceramic. The method of the invention obviously reduce the sintering temperature of the ceramic and retaining the performance of the ceramic, is applicable to high-power piezoelectric material, and provides a raw material for manufacturing laminated piezoelectric ceramic elements.

Owner:JINAN UNIVERSITY

Method for manufacturing polymeric piezoelectric film and polymeric piezoelectric film

ActiveUS20100068460A1Large piezoelectricityStable piezoelectric performancePiezoelectric/electrostrictive device manufacture/assemblyLayered productsRelative displacementPeak value

A method for producing a polymer piezoelectric film, comprising: a process of moving and stretching a crystalline polar polymer sheet in contact with a conductive stretching roller having a diameter of at least 30 mm and a surface friction coefficient which has been reduced to such a level as to allow a relative displacement of the crystalline polar polymer sheet in contact with the conductive stretching roller: and a step in the process of applying a polarization voltage between an electrode disposed opposite to the crystalline polar polymer sheet and the conductive stretching roller to polarize the crystalline polar polymer sheet. As a result, it is possible to stably produce a polymer piezoelectric film exhibiting stable piezoelectricity over a large area. Especially, it is possible to obtain polymer piezoelectric film exhibiting a temperature-dispersion peak temperature of d31 piezoelectricity coefficient at least 120° C. and surface scratches extending in one direction.

Owner:KUREHA KAGAKU KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com