PPSMZT-doped piezoelectric ceramic, preparation method thereof and use thereof

A technology of piezoelectric ceramics and ceramics, which is applied in the field of doped PSMZT piezoelectric ceramics and its preparation, can solve the problems of increasing output cost, deterioration of device performance, and difficult control of ceramic microstructure and performance, so as to improve piezoelectric performance and reduce The effect of sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

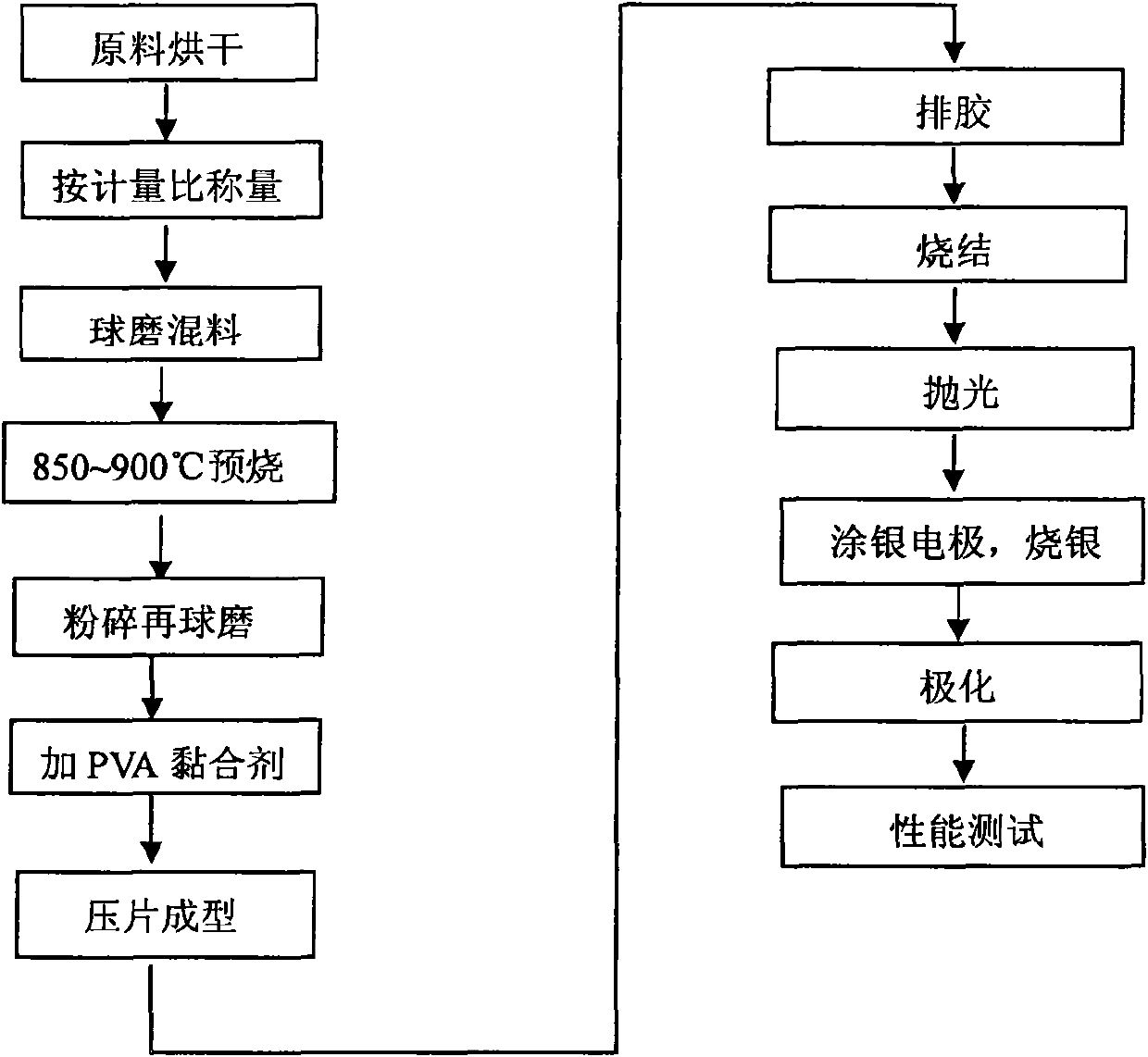

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: (no doping piezoelectric ceramics)

[0031] (1) Weigh Nb according to the molar percentage as Nb:Co=2:1 2 o 5 and Co 2 o 3 Raw materials were dried at 120°C for 5 hours, mixed and ball milled, and CoNb was synthesized at 1100°C 2 o 6 ;

[0032] (2) According to the general formula Pb 0.98 Sr 0.02 (Mn 1 / 3 Sb 2 / 3 ) x (Zr 0.5 Ti 0.5 ) 1-x o 3 , 0 ≤ x ≤ 0.1 mole percent weighing Pb 3 o 4 , SrCO 3 , MnO 2 , Sb 2 o 3 , ZrO 2 and TiO 2 Raw materials, mixed, ball milled for 10 hours, dried at 120°C for 5 hours, passed through an 80-mesh sieve, pre-fired at 850°C and kept for 3 hours to synthesize PSMZT pre-calcined product;

[0033] (3) After pulverizing the PSMZT calcined product, 0.15wt.% CuO+0.2wt.% Bi 2 o 3 +0.2wt.%Li 2 CO 3 +0.15wt.%CoNb 2 o 6 Weigh CuO, Bi 2 o 3 , Li 2 CO 3 、CoNb 2 o 3 Add NiO raw material into PSMZT calcined powder and mix, ball mill again for 19h, dry at 120°C for 5h, pass through 60 mesh sieve, add 7% pol...

Embodiment 2

[0037] Embodiment 2: (doping concentration 0.05%)

[0038] (1) Weigh Nb according to the molar percentage as Nb:Co=2:1 2 o 5 and Co 2 o 3 Raw materials were dried at 120°C for 5 hours, mixed and ball milled, and CoNb was synthesized at 1100°C 2 o 6 ;

[0039] (2) According to the general formula Pb 0.98 Sr 0.02 (Mn 1 / 3 Sb 2 / 3 ) x (Zr 0.5 Ti 0.5 ) 1-x o 3 , 0 ≤ x ≤ 0.1 mole percent weighing Pb 3 o 4 , SrCO 3 , MnO 2 , Sb 2 o 3 , ZrO 2 and TiO 2 Raw materials, mixed, ball milled for 10 hours, dried at 120°C for 5 hours, passed through an 80-mesh sieve, pre-fired at 850°C and kept for 3 hours to synthesize PSMZT pre-calcined product;

[0040] (3) After pulverizing the PSMZT calcined product, 0.15wt.% CuO+0.2wt.% Bi 2 o 3 +0.2wt.%Li 2 CO 3 +0.15wt.%CoNb 2 o 6 +0.05wt.%NiO weighs CuO, Bi 2 o 3 , Li 2 CO 3 、CoNb 2 o 3 Add NiO raw material into PSMZT calcined powder and mix, ball mill again for 19h, dry at 120°C for 5h, pass through 60 mesh sieve, ad...

Embodiment 3

[0045] Embodiment 3: (doping concentration 0.1%)

[0046] (1) Weigh Nb according to the molar percentage as Nb:Co=2:1 2 o 5 and Co 2 o 3 Raw materials were dried at 120°C for 5 hours, mixed and ball milled, and CoNb was synthesized at 1100°C 2 o 6 ;

[0047] (2) According to the general formula Pb 0.98 Sr 0.02 (Mn 1 / 3 Sb 2 / 3 ) x (Zr 0.5 Ti 0.5 ) 1-x o 3 , 0 ≤ x ≤ 0.1 mole percent weighing Pb 3 o 4 , SrCO 3 , MnO 2 , Sb 2 o 3 , ZrO 2 and TiO 2 Raw materials, mixed, ball milled for 10 hours, dried at 120°C for 5 hours, passed through an 80-mesh sieve, pre-fired at 850°C and kept for 3 hours to synthesize PSMZT pre-calcined product;

[0048] (3) After pulverizing the PSMZT calcined product, 0.15wt.% CuO+0.2wt.% Bi 2 o 3 +0.2wt.%Li 2 CO 3 +0.15wt.% CoNb 2 o 6 +0.1wt.%NiO weighs CuO, Bi 2 o 3 , Li 2 CO 3 、CoNb 2 o 3 Add NiO raw material into PSMZT calcined powder and mix, ball mill again for 19h, dry at 120°C for 5h, pass through a 60 mesh sieve, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com