Piezoelectric element, manufacturing method thereof and liquid discharge apparatus

A piezoelectric element and a manufacturing method technology, which are applied in the manufacture/assembly of piezoelectric/electrostrictive devices, electrical components, piezoelectric devices/electrostrictive devices, etc., and can solve problems such as low usefulness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

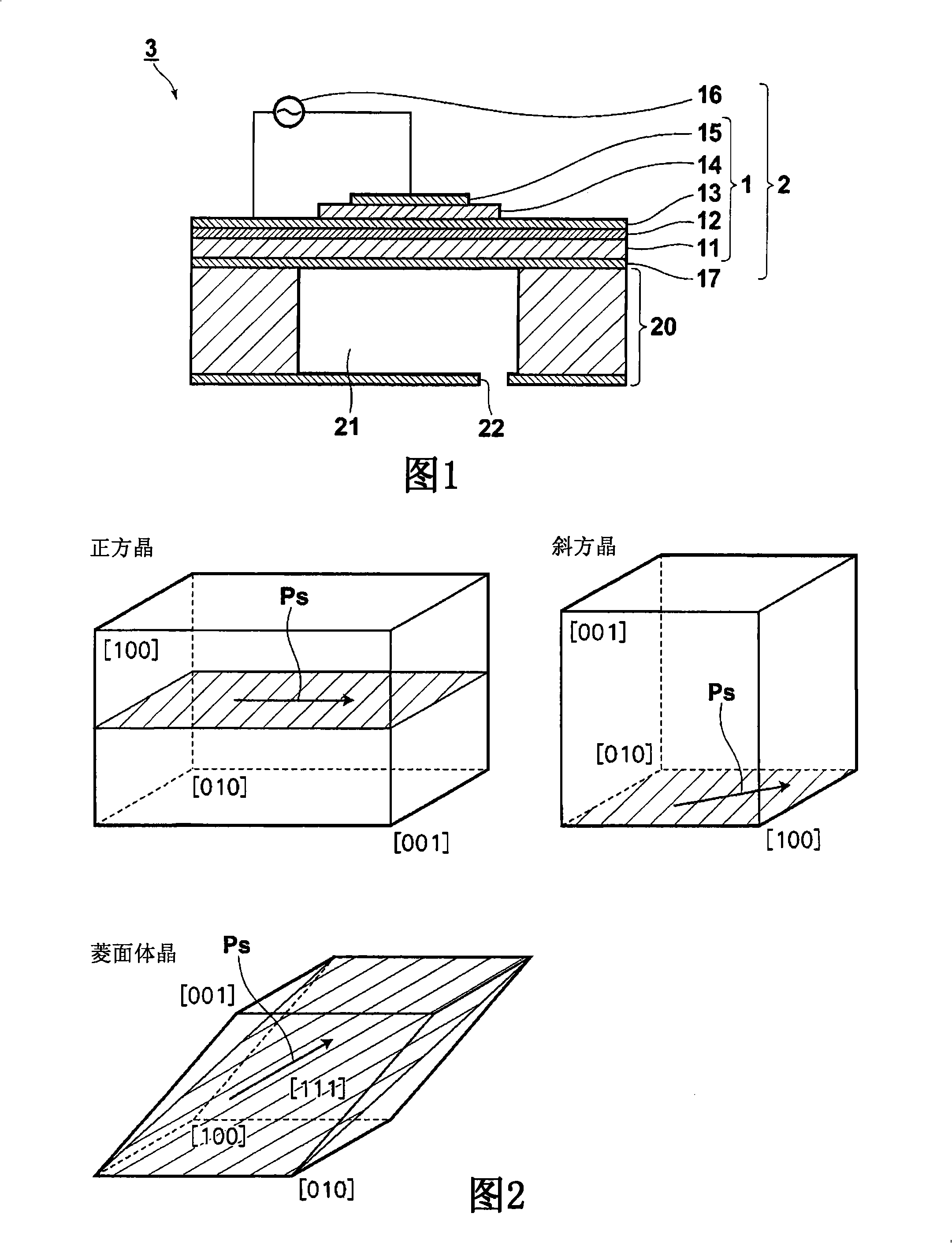

[0171] As a substrate, a Si single crystal substrate having a 300 nm-thick thermal oxide film formed on the surface was prepared. On the surface of the substrate, a 20 nm-thick Ti adhesion layer and a 200 nm-thick Pt lower electrode were sequentially formed by sputtering at a substrate temperature of 300°C.

[0172] Next, a 4 μ thick Nb-doped PZT piezoelectric film was formed on the lower electrode by sputtering at a substrate temperature of 550°C. Next, a Pt upper electrode with a thickness of 200 nm was grown at room temperature by sputtering to obtain the piezoelectric element of the present invention.

[0173] Finally, on the back side of the Si substrate, use Al as a mask to form a pattern using ICP-RIE (inductivelycoupled plasma-reactive ion etching) to form a 300μm×300μm ink chamber, and form a vibration plate and an ink chamber through the processing of the substrate itself. chamber and the ink nozzle of the ink discharge port to obtain the ink jet recording head of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com