Piezoelectric active bone repair composite material and preparation method thereof

A composite material and bone repair technology, applied in medical science, prosthesis, etc., can solve problems such as poor piezoelectric properties and lack of biocompatibility, and achieve improved interface, simple preparation and processing methods, and good tissue compatibility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

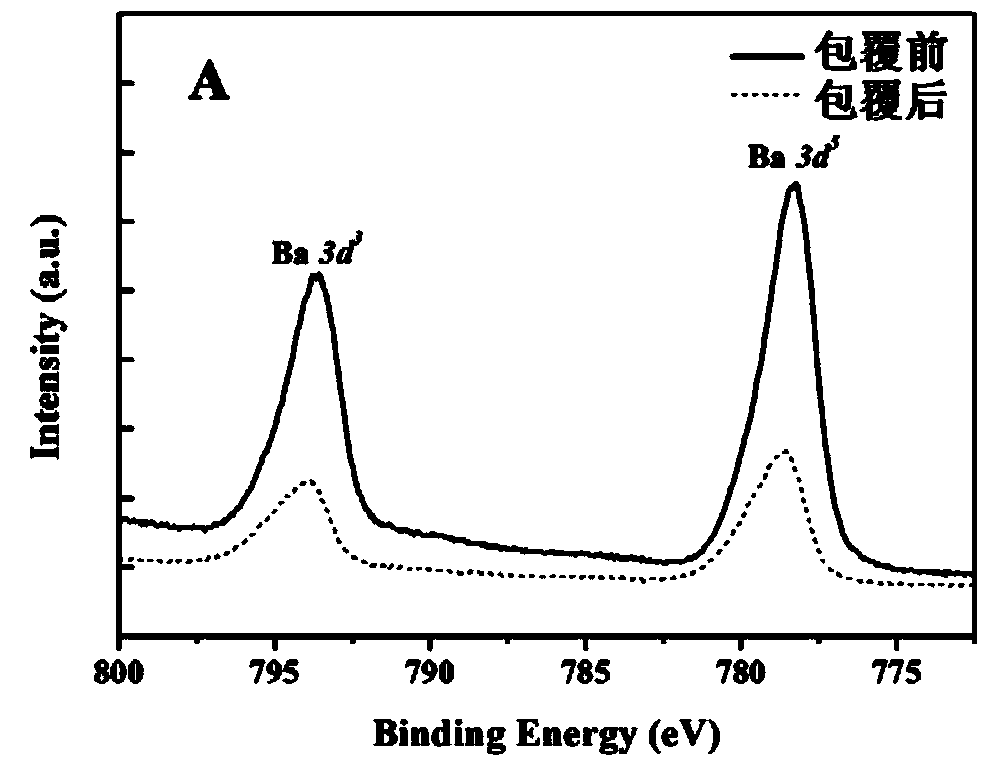

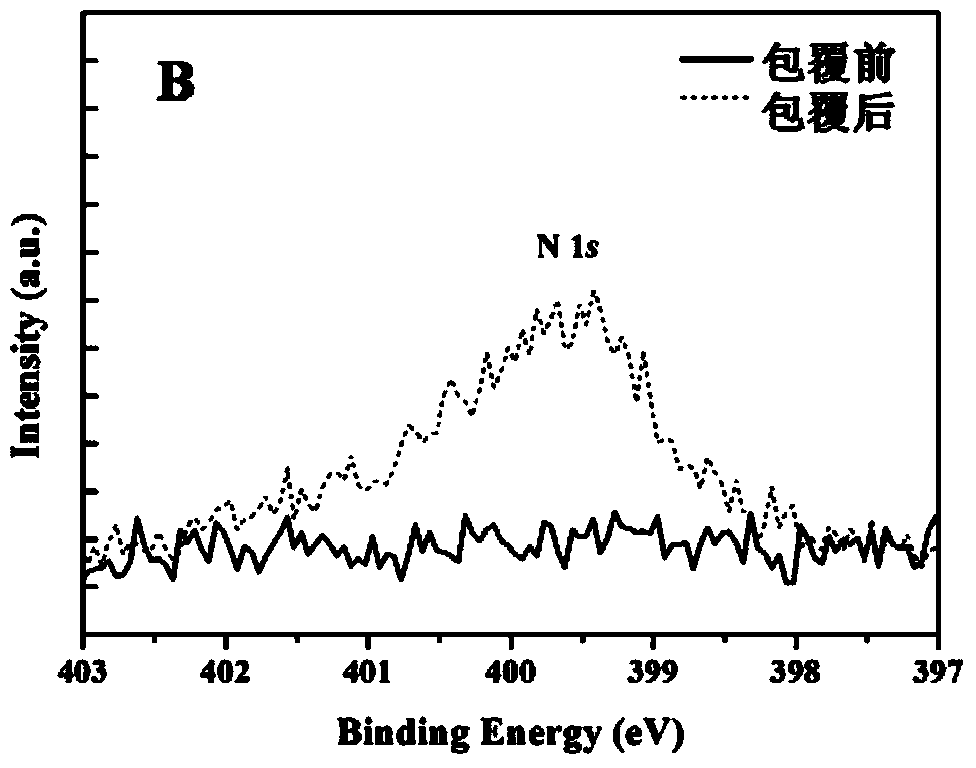

[0033] (1) Prepare a dopamine aqueous solution with a concentration of 0.01mol / L, and weigh 0.2g of BaTiO with a diameter of 30nm 3 Nano-ceramic particles were ultrasonically dispersed in 20 mL of dopamine aqueous solution, stirred in a water bath at 40°C for 12 h, centrifuged and washed 5 times to obtain barium titanate nano-ceramic particle fillers with a core-shell structure with a dopamine coating thickness of 1 nm (record for BNPDopa);

[0034] (2) Weigh 0.45g BNPDopa and place it in 5mL organic solvent DMF, and use ultrasonic vibration combined with stirring for 2h to make BNPDopa form a stable suspension in the solvent;

[0035] (3) Weigh 2g of polymer P(VDF-TrFE), add 15mL of organic solvent DMF, stir for 4h to completely dissolve;

[0036] (4) adding the suspension obtained in step (2) to the polymer solution in step (3), stirring for 10 h so that BNPDopa is evenly dispersed in the polymer matrix to obtain a mixed solution;

[0037] (5) Take the mixed liquid obtaine...

Embodiment 2

[0040] (1) Prepare a dopamine aqueous solution with a concentration of 0.05mol / L, and weigh 0.6g of BaTiO with a diameter of 100nm 3Nano-ceramic particles were ultrasonically dispersed in 20 mL of dopamine aqueous solution, stirred in a water bath at 60°C for 10 h, centrifuged, and washed three times to obtain barium titanate nano-ceramic particle fillers with a core-shell structure and a dopamine coating thickness of 4 nm (record for BNPDopa);

[0041] (2) Weigh 0.075g BNPDopa and place it in 5mL organic solvent DMF, and use ultrasonic vibration combined with stirring for 1h to make BNPDopa form a stable suspension in the solvent;

[0042] (3) Weigh 2g polymer PVDF, add 15mL organic solvent DMF, stir for 3h to make it completely dissolved;

[0043] (4) Add the suspension obtained in step (2) to the polymer solution in step (3), and stir for 6 hours so that BNPDopa is evenly dispersed in the polymer matrix to obtain a mixed solution;

[0044] (5) Take the mixed liquid obtain...

Embodiment 3

[0047] (1) Prepare a dopamine aqueous solution with a concentration of 0.08mol / L, and weigh 1.2g of BaTiO with a diameter of 200nm 3 Nano-ceramic particles were ultrasonically dispersed in 20 mL of dopamine aqueous solution, stirred in a water bath at 80°C for 6 h, centrifuged and washed 4 times to obtain a barium titanate nano-ceramic particle filler with a core-shell structure with a dopamine coating thickness of 6 nm (record for BNPDopa);

[0048] (2) Weigh 0.9g BNPDopa and place it in 5mL organic solvent DMF, and use ultrasonic oscillation combined with stirring for 2h to make BNPDopa form a stable suspension in the solvent;

[0049] (3) Weigh 2g of polymer P(VDF-TrFE), add 15mL of organic solvent DMF, stir for 6h to completely dissolve;

[0050] (4) adding the suspension obtained in step (2) to the polymer solution in step (3), stirring for 10 h so that BNPDopa is evenly dispersed in the polymer matrix to obtain a mixed solution;

[0051] (5) Take the mixed solution obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com