Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2199 results about "Polymer substrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymers and plastics known as polymer substrates are used for banknotes and other everyday products. The banknote is more durable than paper, won't become soaked in liquids and is harder to counterfeit, though not impossible. Countries whose whole banknote production is in polymer are: Australia, Romania, Vietnam and New Zealand. Other countries that have partial polymer and paper issue include Papua New Guinea, Samoa, Solomon Islands, Mexico, Zambia, Brunei, Malaysia, Singapore, Nigeria, Chile, England and Nepal. The material is also used in commemorative notes in some other countries. The process of polymer substrate creation was developed by the Australia CSIRO. Countries like Bulgaria have issued a combination of paper and polymer as the 200 Lev banknote.

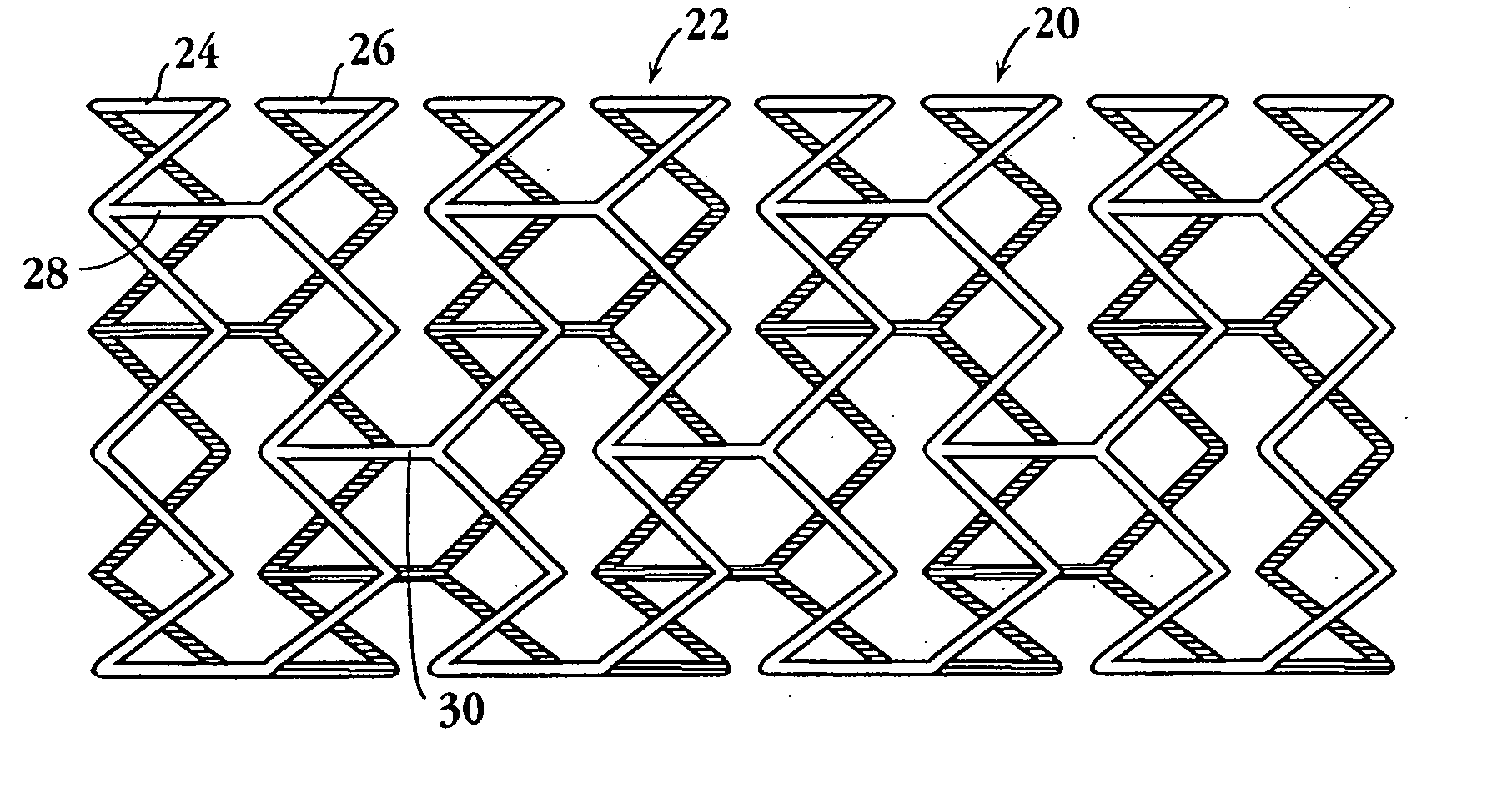

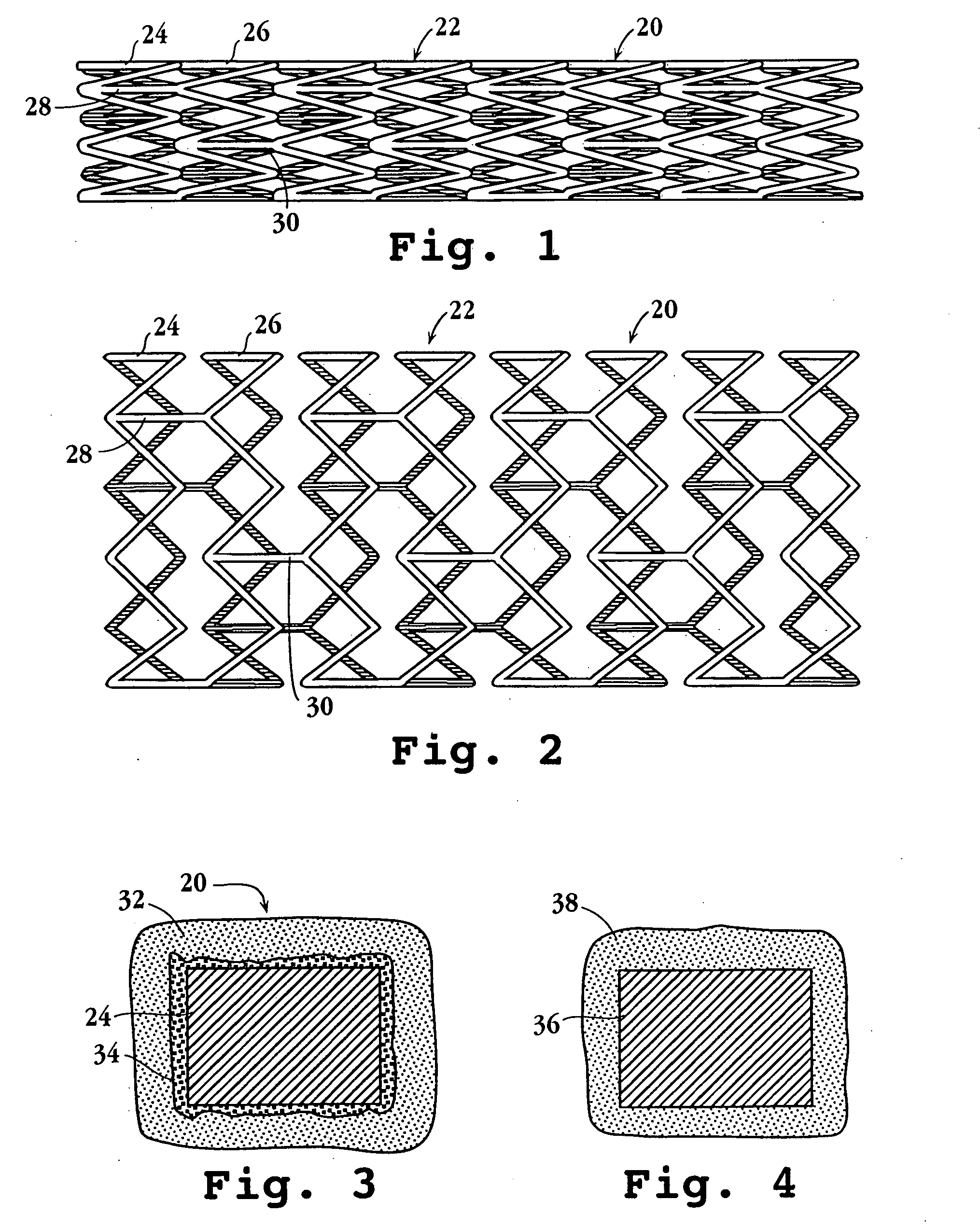

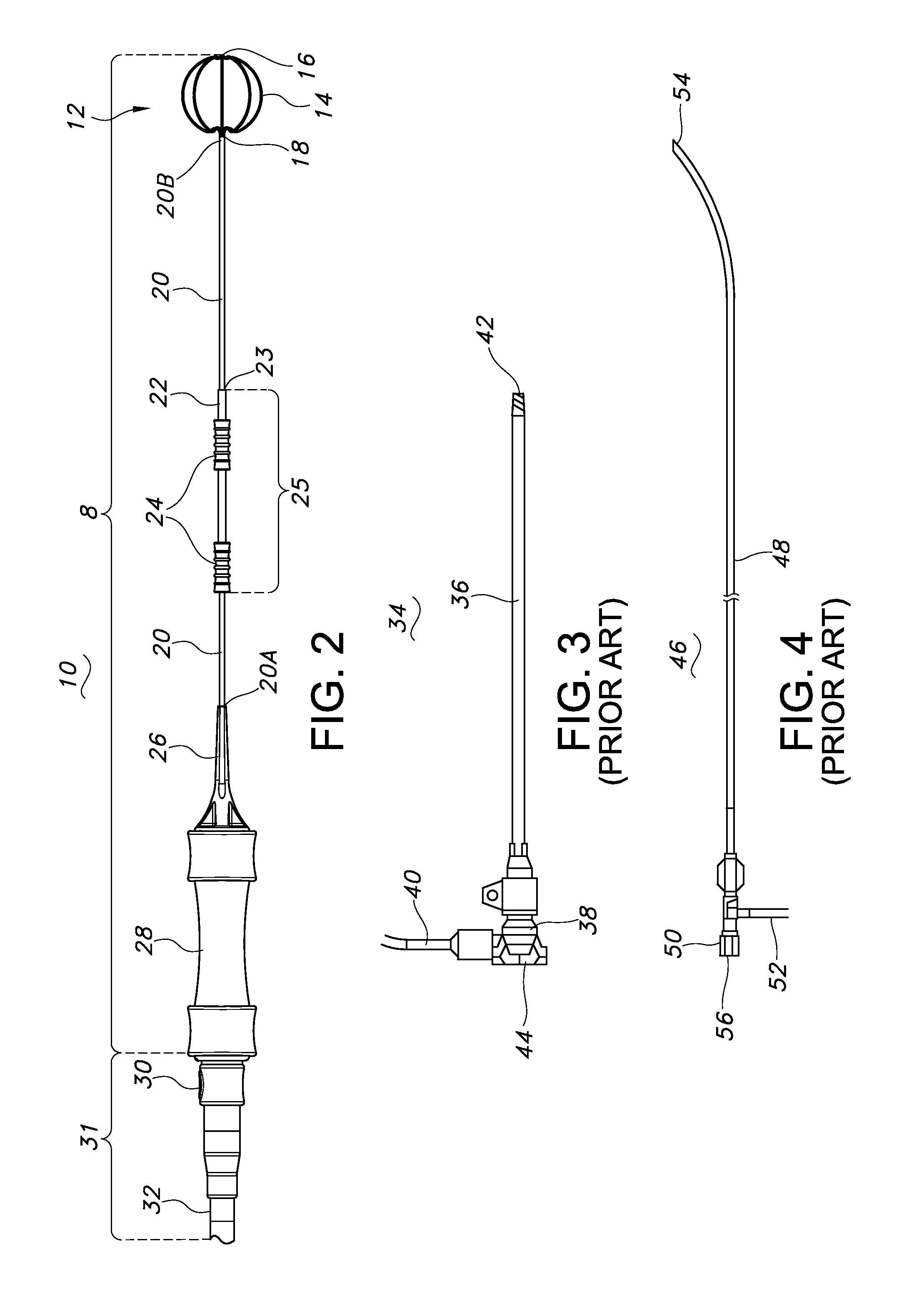

Drug-delivery endovascular stent and method for treating restenosis

InactiveUS6939376B2Efficient releaseOrganic active ingredientsOrganic chemistryRestenosisPoly dl lactide

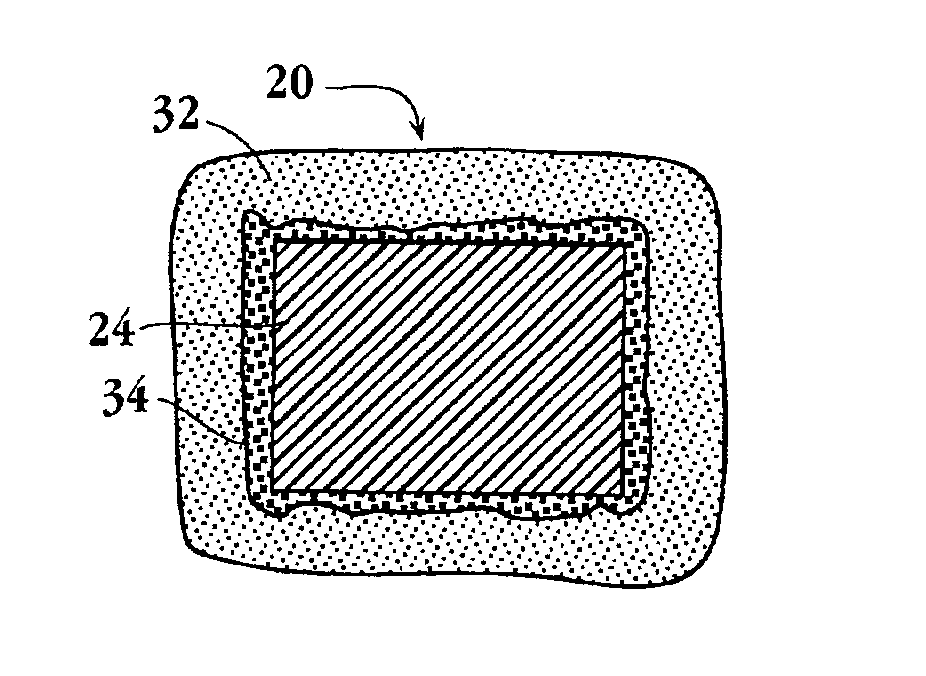

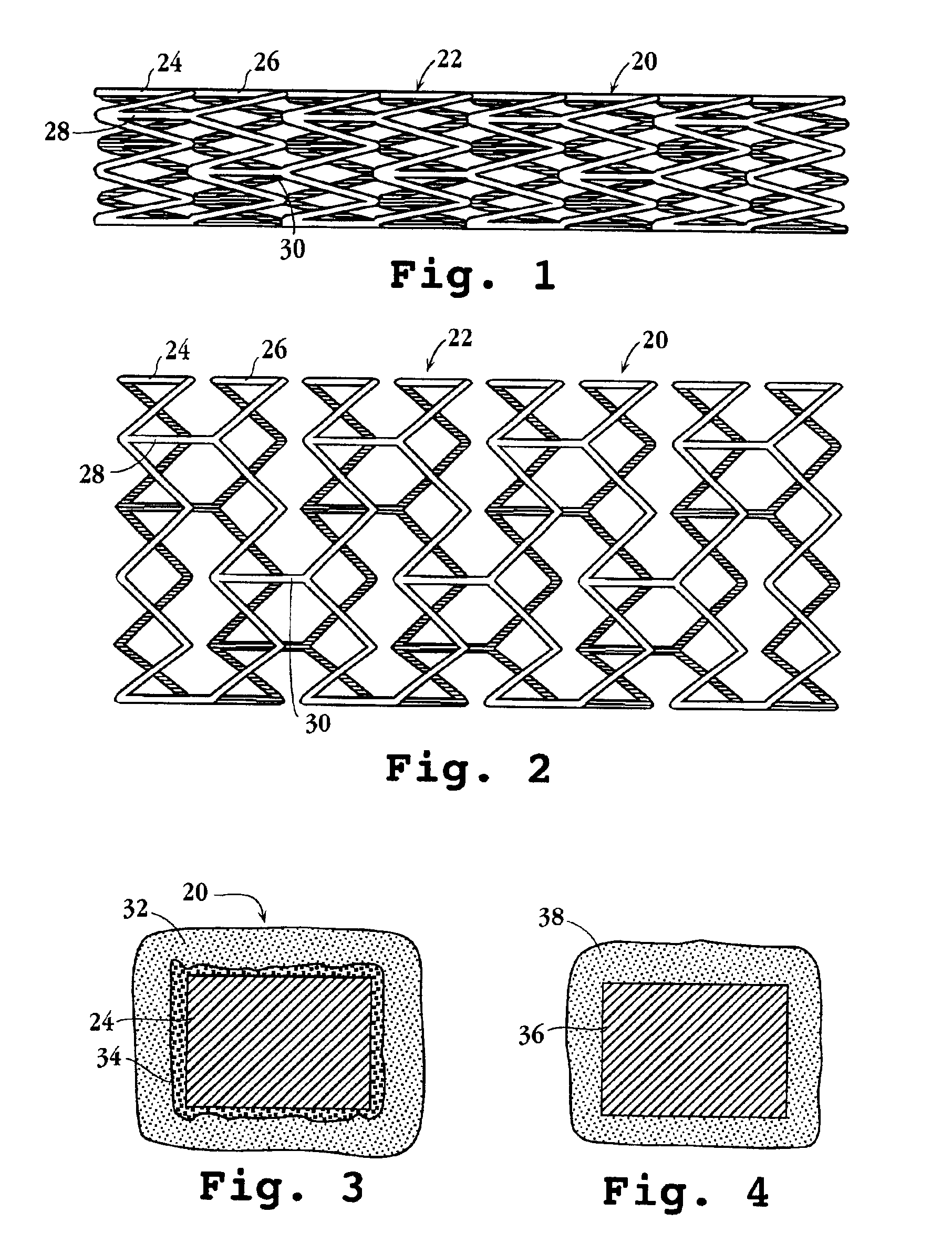

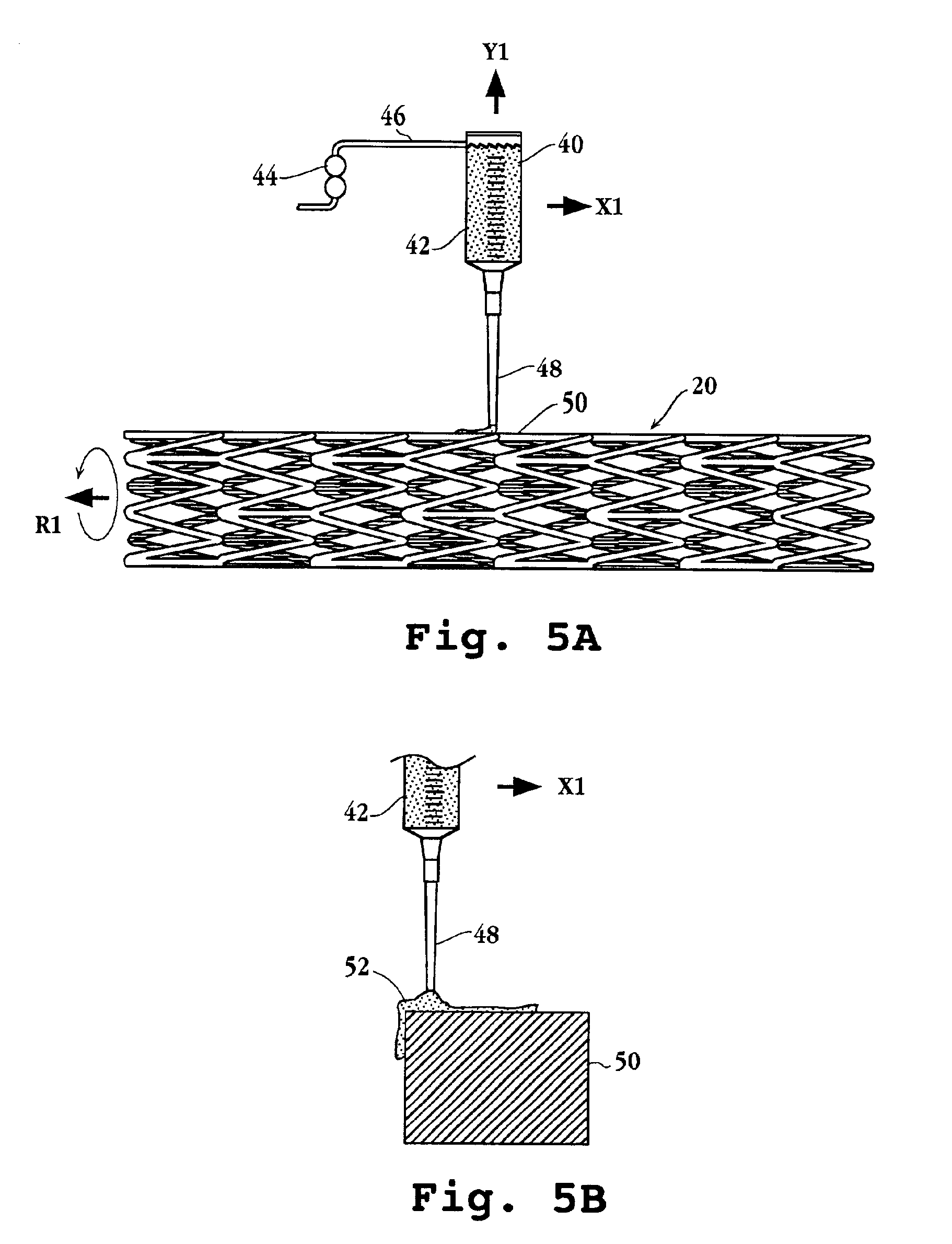

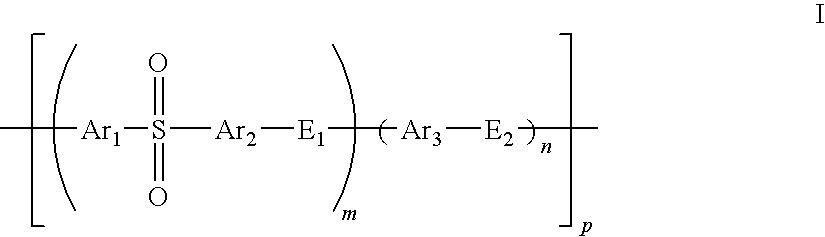

An intravascular stent and method for inhibiting restenosis, following vascular injury, is disclosed. The stent has an expandable, linked-filament body and a drug-release coating formed on the stent-body filaments, for contacting the vessel injury site when the stent is placed in-situ in an expanded condition. The coating releases, for a period of at least 4 weeks, a restenosis-inhibiting amount of a monocyclic triene immunosuppressive compound having an alkyl group substituent at carbon position 40 in the compound. The stent, when used to treat a vascular injury, gives good protection against clinical restenosis, even when the extent of vascular injury involves vessel overstretching by more than 30% diameter. Also disclosed is a stent having a drug-release coating composed of (i) 10 and 60 weight percent poly-dl-lactide polymer substrate and (ii) 40-90 weight percent of an anti-restenosis compound, and a polymer undercoat having a thickness of between 1-5 microns.

Owner:BIOSENSORS INT GROUP

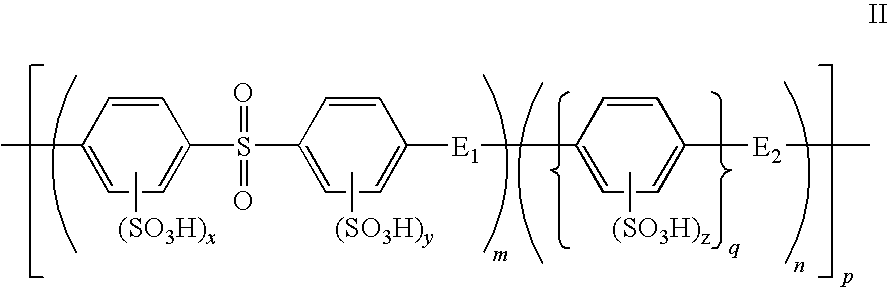

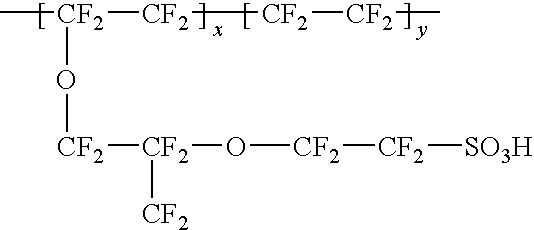

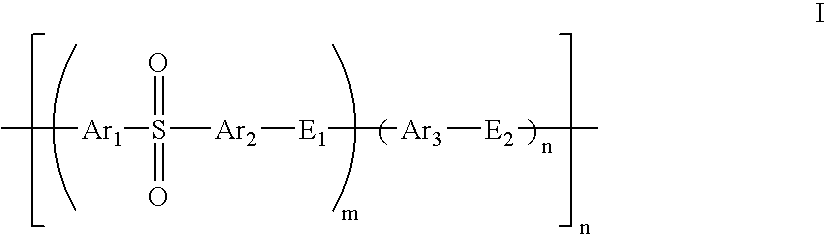

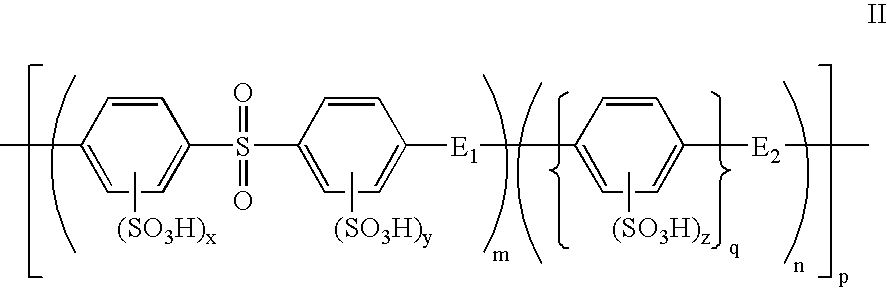

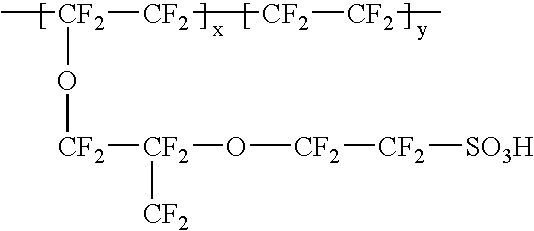

Composite solid polymer electrolyte membranes

InactiveUS7550216B2Improve performanceLow costElectrolyte holding meansMembranesPolymer electrolytesFuel cells

Owner:FOSTER-MILLER

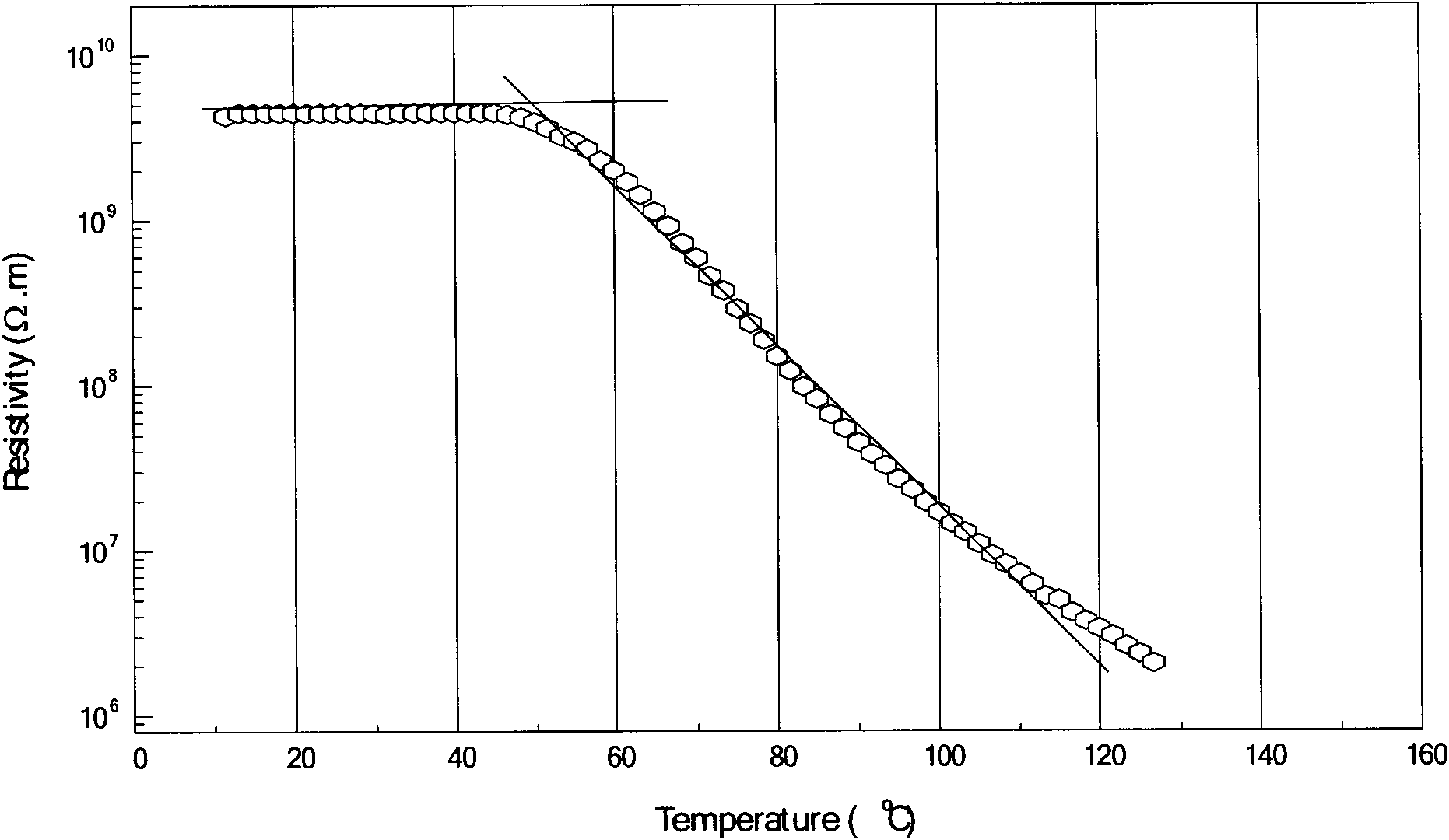

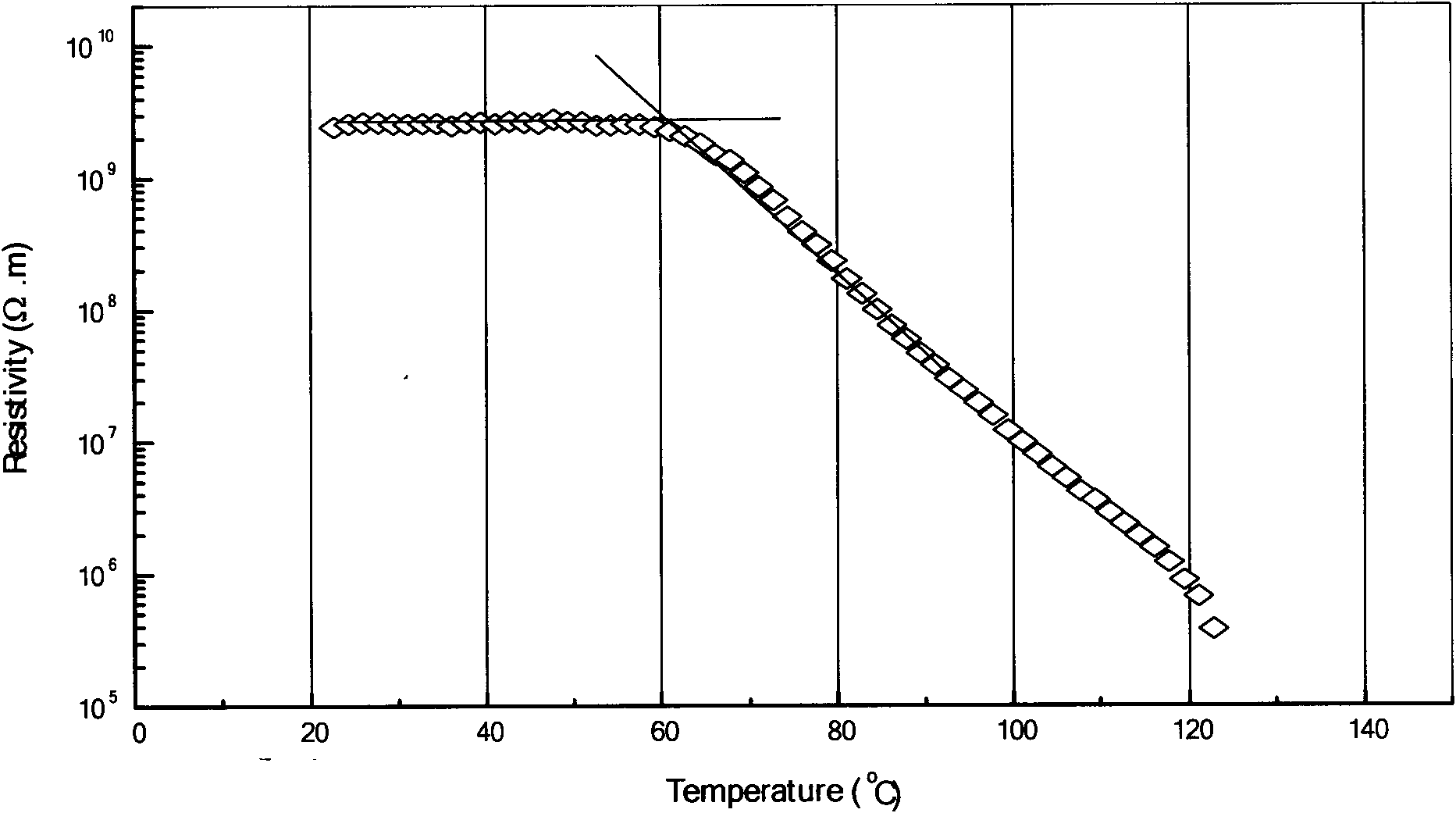

Temperature sensing cable material with CRT characteristics and preparation method thereof

ActiveCN101613504AWith CTR featureFlexibleRubber insulatorsPlastic/resin/waxes insulatorsProcedure AgentsAntioxidant

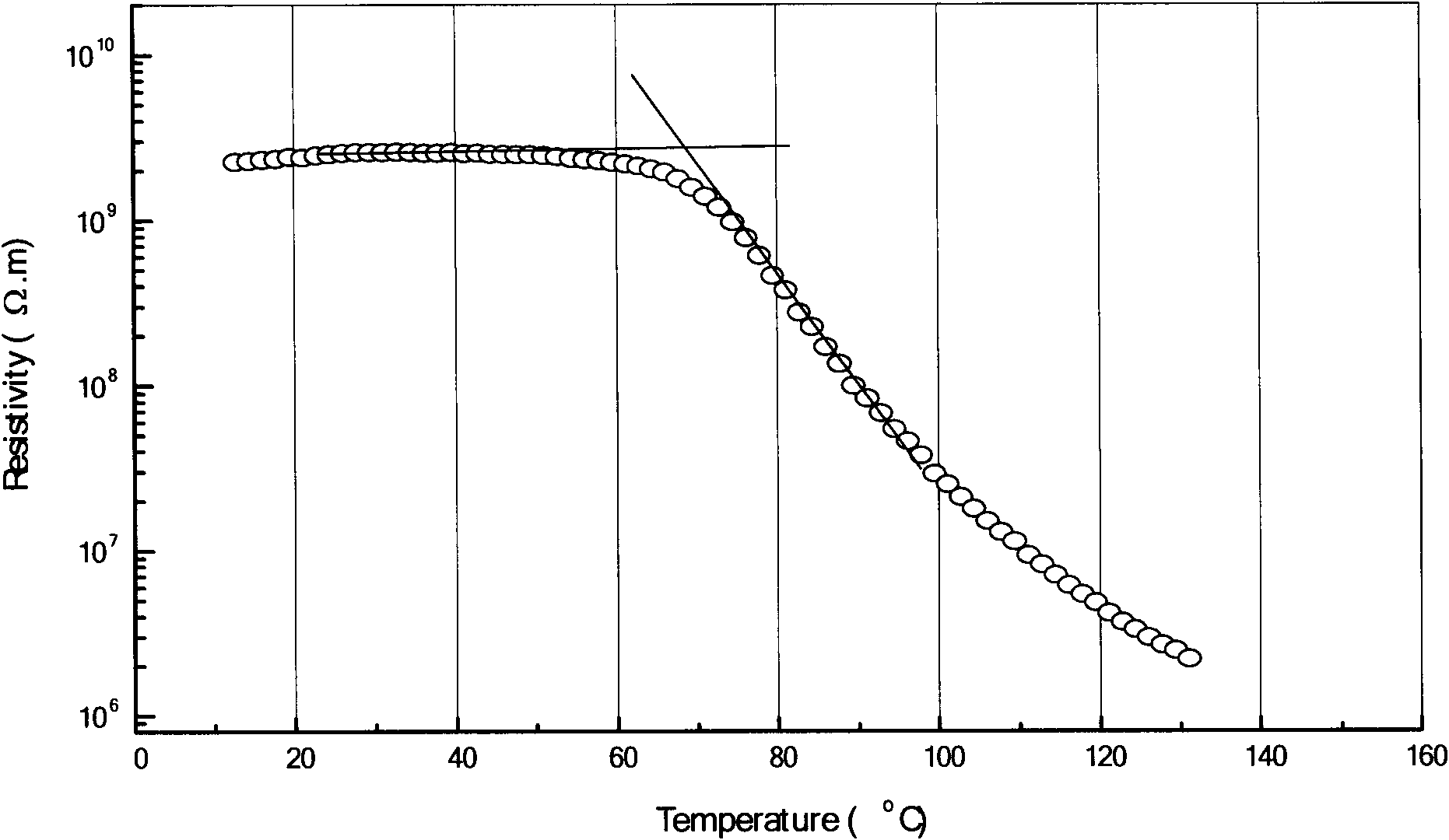

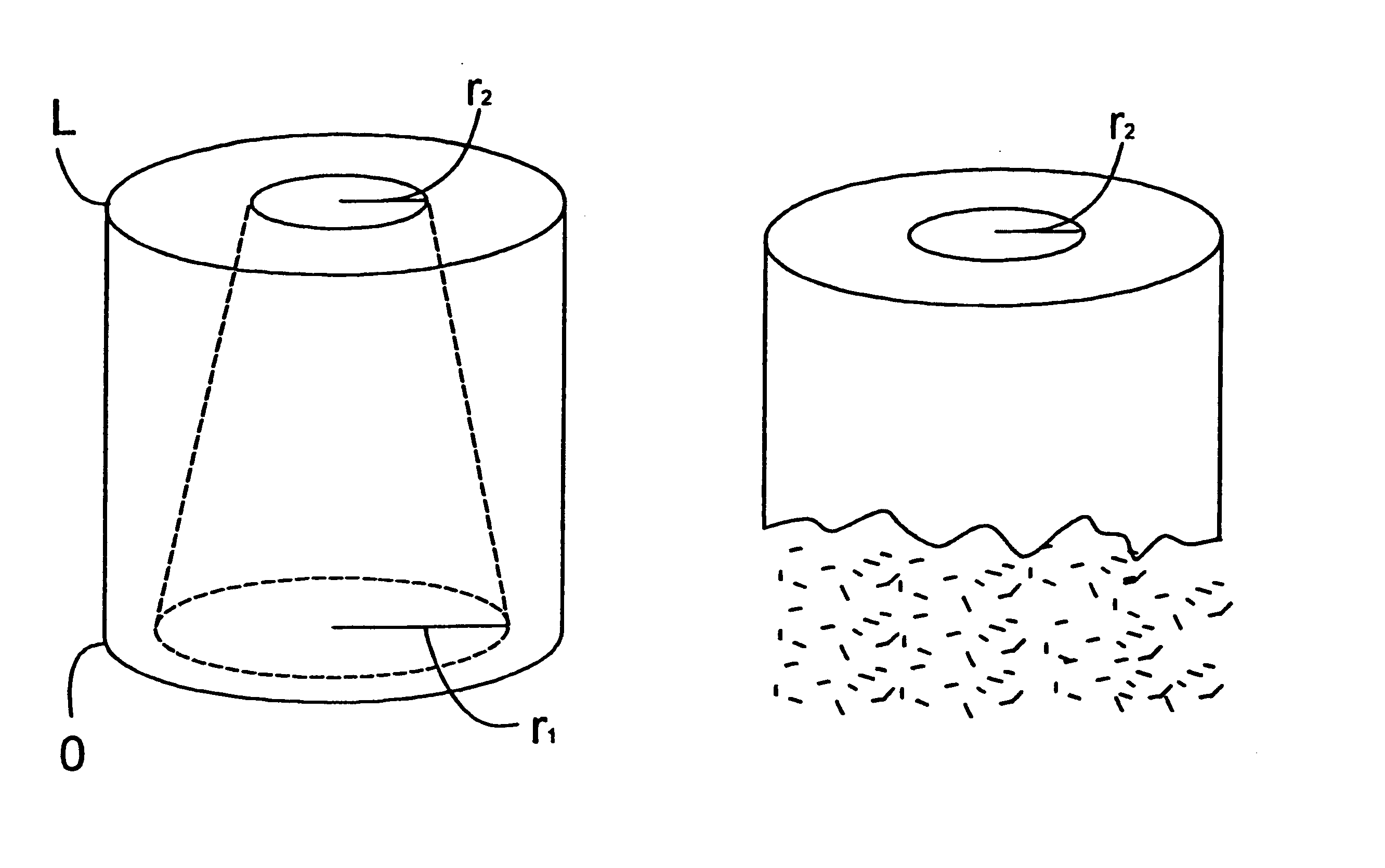

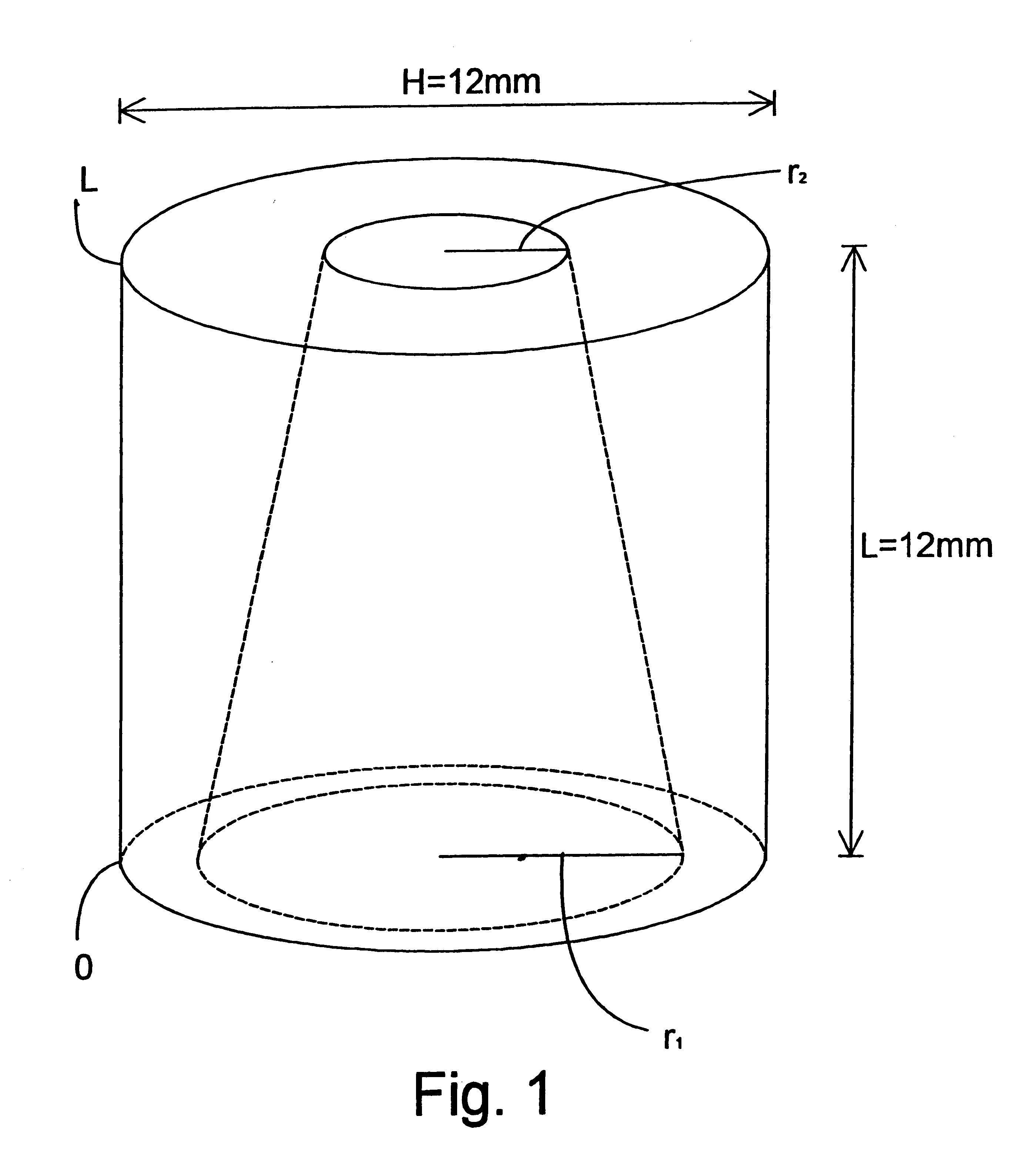

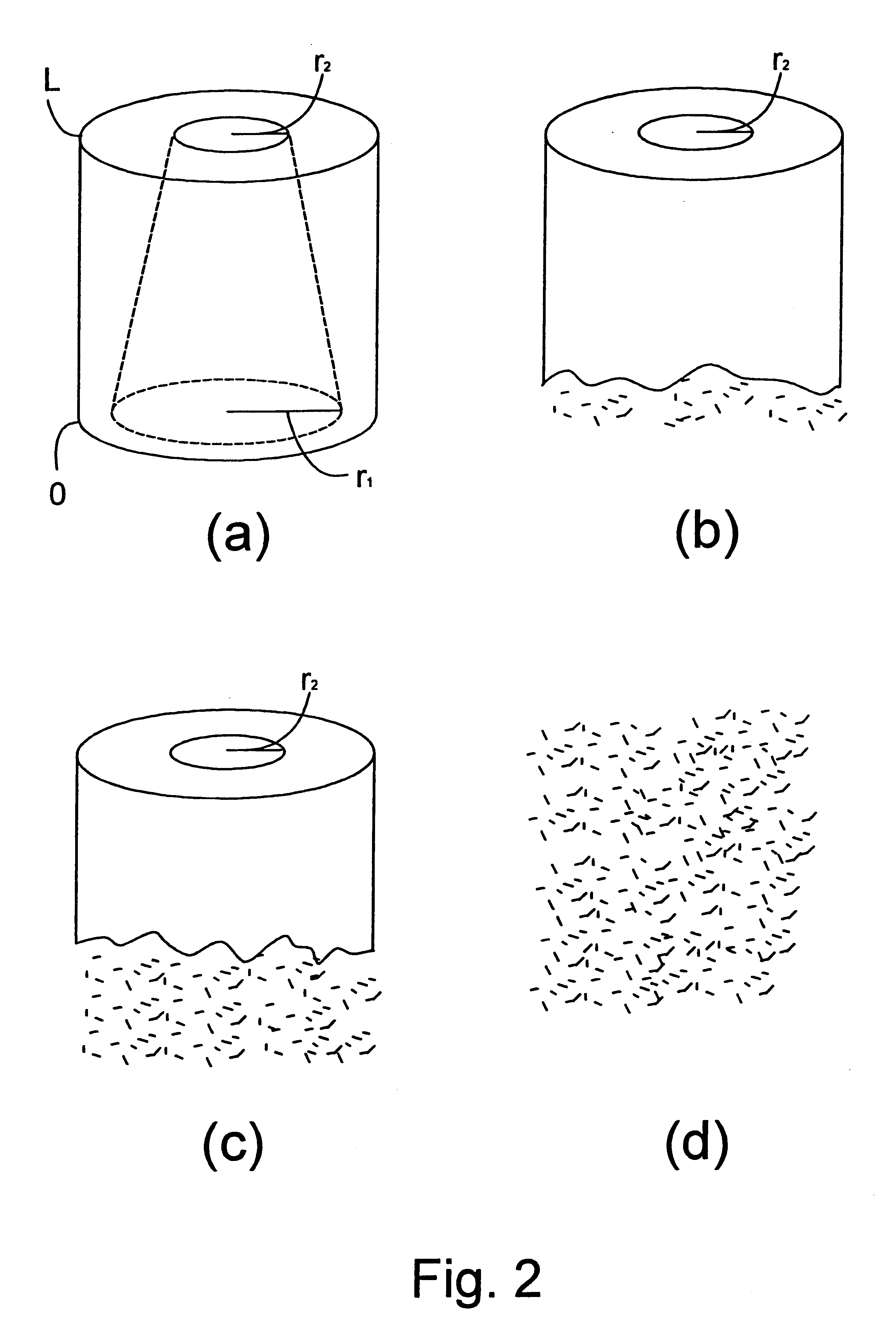

The invention relates to technical fields of materials, chemical engineering and electronics, in particular to a cable material with a polymer substrate and CTR effect and a preparation method thereof. The temperature sensing cable material with CRT characteristics consists of thermoplastic polymer, a filling agent, a plasticizer, functional additives, a stabilizing agent, a flame retardant, a lubricant, an antioxidant and a processing agent, has the use temperature range between -30 and 150 DEG C, and can be applied on occasions such as recoverable line-type temperature sensing cables, fire prewarning and alarm devices, temperature measurement, overheating alarm and protection and the like. The temperature sensing cable material with the CRT characteristics takes a polymer material as a substrate, and is added with multiple organic and inorganic compounds with special CTR characteristics taken as the functional additives, and has the characteristics of flexibility, and capacities of being continuously processed and being used like a common cable material.

Owner:QINGDAO SUNYFIRE TECHNOLOGE

Biodegradable implant manufactured of polymer-based material and a method for manufacturing the same

The invention relates to a biodegradable implant or the like manufactured of polymer-based material and intended to be installed in tissue conditions. In the macroscopic structure of the implant two or several zones are created in a manner that the biodegradable polymer-based material has in different zones a different detaching time from the macroscopic structure under tissue conditions.

Owner:BIONX IMPLANTS

Drug-delivery endovascular stent and method of forming the same

ActiveUS20050038505A1Prevent restenosisEfficient releaseOrganic active ingredientsOrganic chemistryPolymer substrateInsertion stent

An intravascular stent and method for inhibiting restenosis, following vascular injury, is disclosed. The stent has an expandable, linked-filament body and a drug-release coating formed on the stent-body filaments, for contacting the vessel injury site when the stent is placed in-situ in an expanded condition. The coating releases, for a period of at least 4 weeks, a restenosis-inhibiting amount of a monocyclic triene immunosuppressive compound having an alkyl group substituent at carbon position 40 in the compound. The stent, when used to treat a vascular injury, gives good protection against clinical restenosis, even when the extent of vascular injury involves vessel overstretching by more than 30% diameter. Also disclosed is a stent having a drug-release coating composed of (i) 10 and 60 weight percent poly-d / -lactide polymer substrate and (ii) 40-90 weight percent of an anti-restenosis compound, and a polymer undercoat having a thickness of between 1-5 microns.

Owner:BIOSENSORS INT GROUP

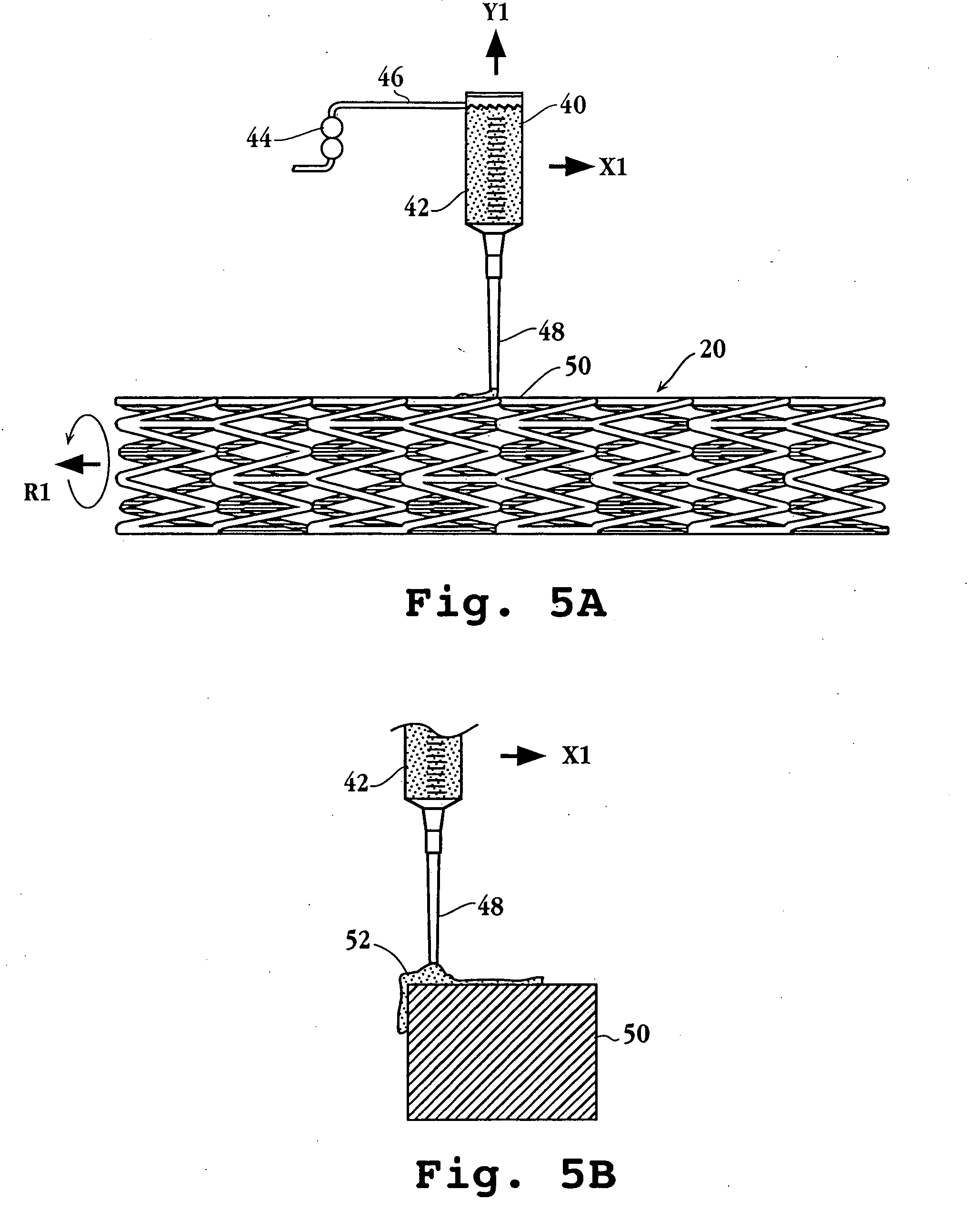

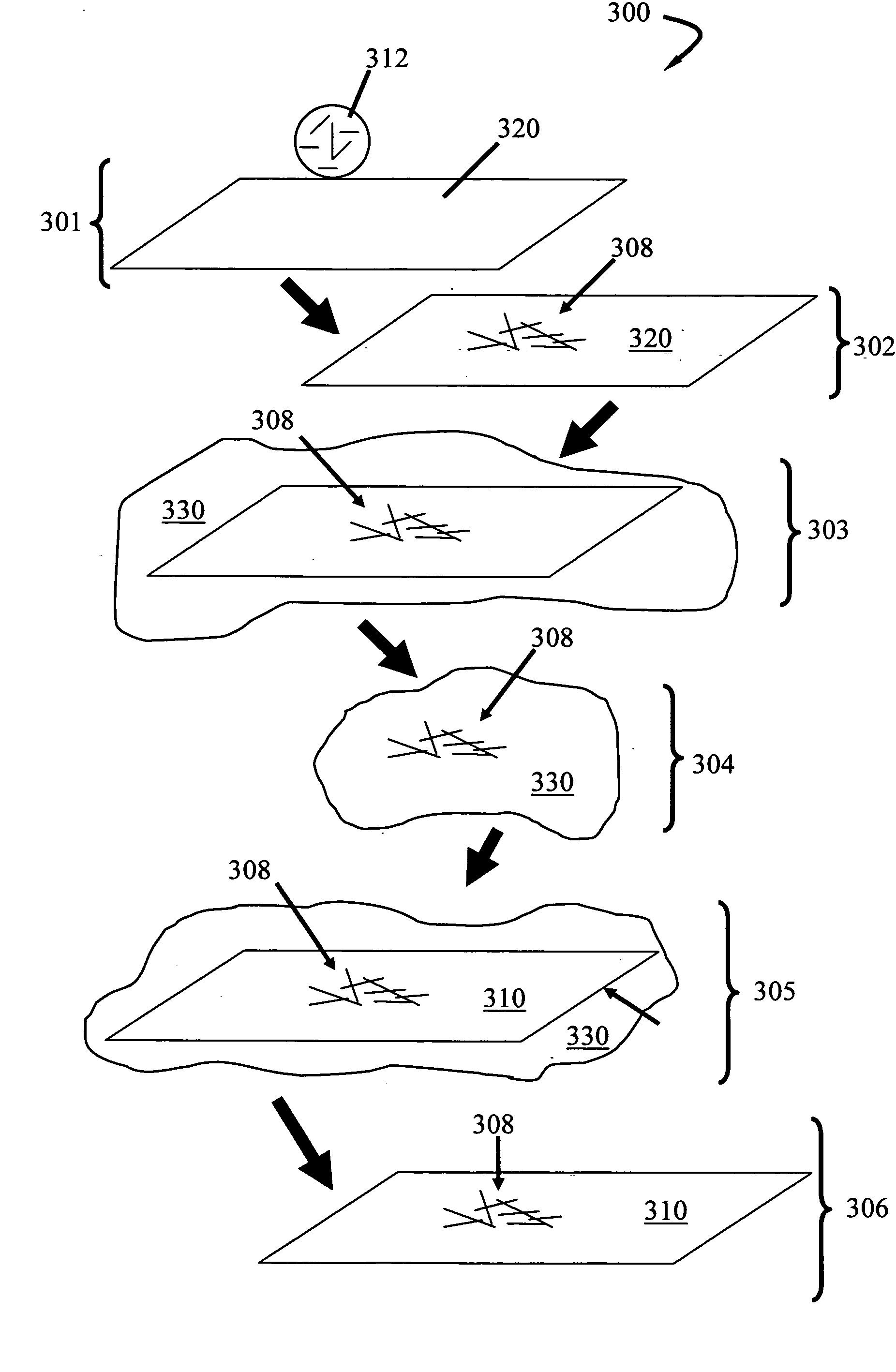

Imaged article on polymeric substrate

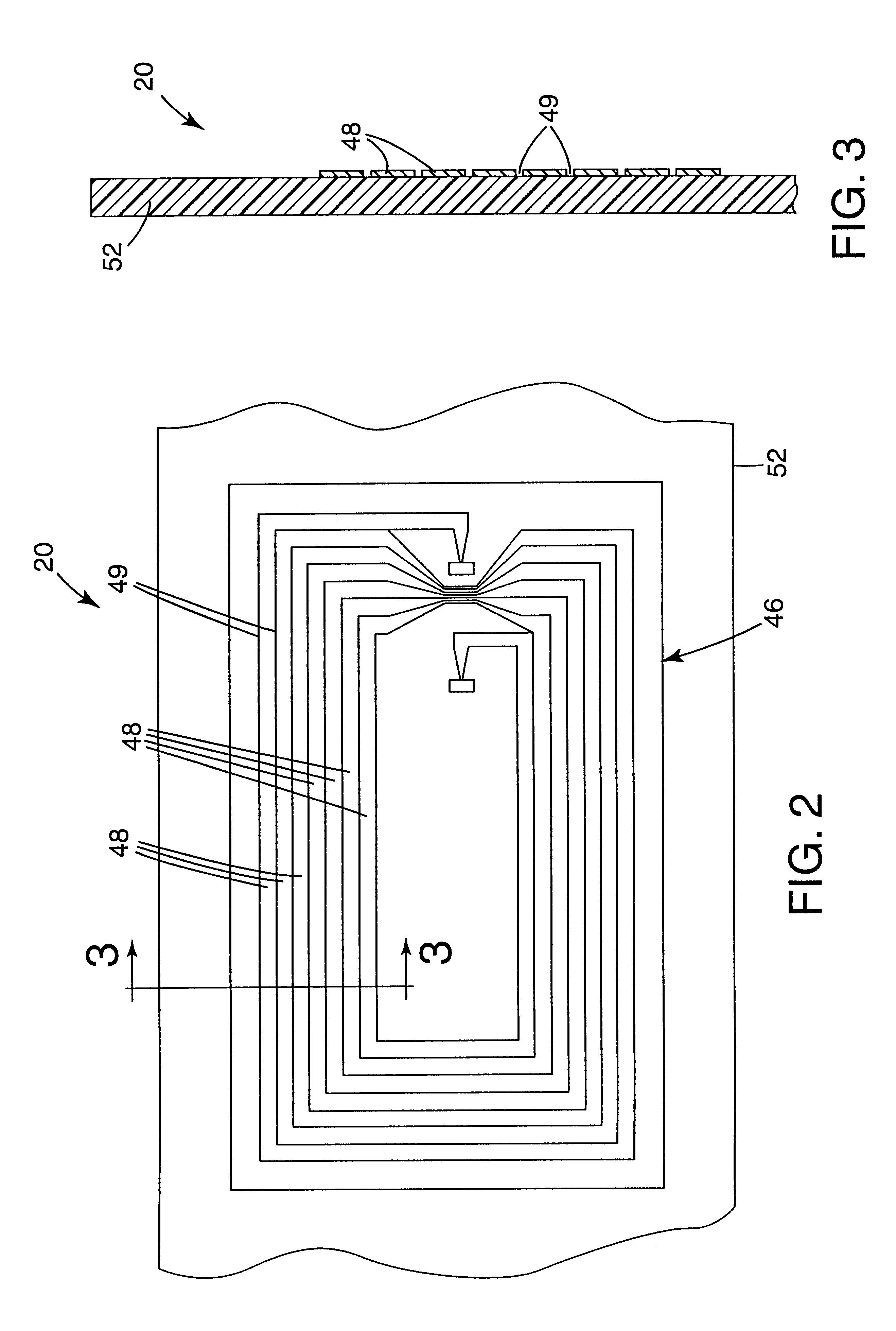

InactiveUS6203952B1Increasing the thicknessSmooth peelingAntenna supports/mountingsLoop antennasResistPolymer substrate

Patterned articles, such as RFID antenna, are made by subablation, a process comprising the steps of:A. providing a substrate having a coating, such as a metal or metal oxide, and an interface comprising the thin region where the coating and the substrate are closest to each other;B. exposing at least one part of the total area of the coating to a flux of electromagnetic energy, such as a focused excimer laser beam, sufficient to disrupt the interface but insufficient to ablate the coating; andC. removing the parts of the coating in registry with the portion of the interface area that was disrupted, by means such as ultrasonic agitation.The process has advantages over photo-resist processes in that there is no residual chemical resist left on the product and no undercutting of the pattern or image. It has advantages over laser ablation processes in that higher throughput is possible at the same energy level and there is no microscopic debris left on the product surface.

Owner:3M INNOVATIVE PROPERTIES CO

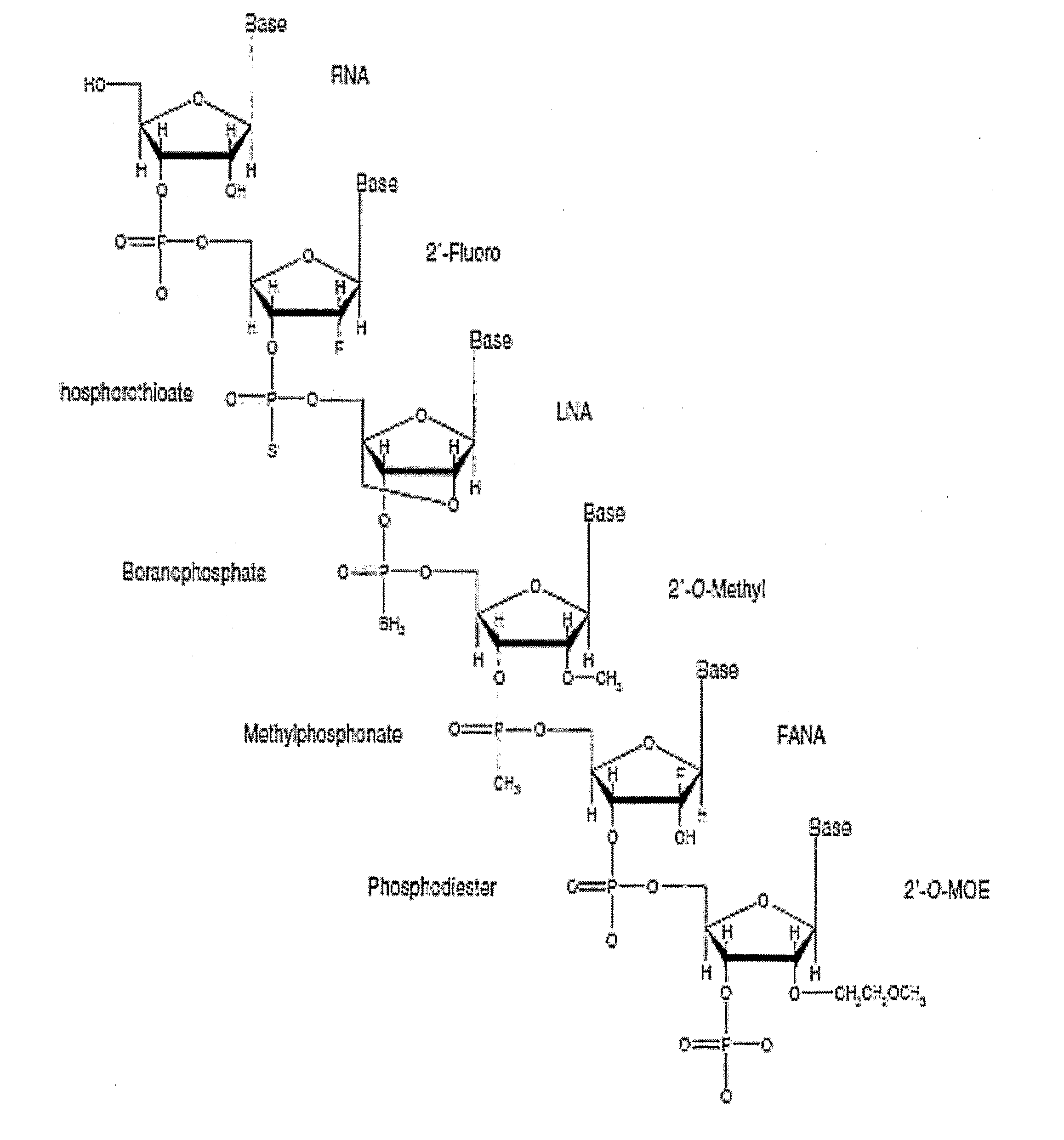

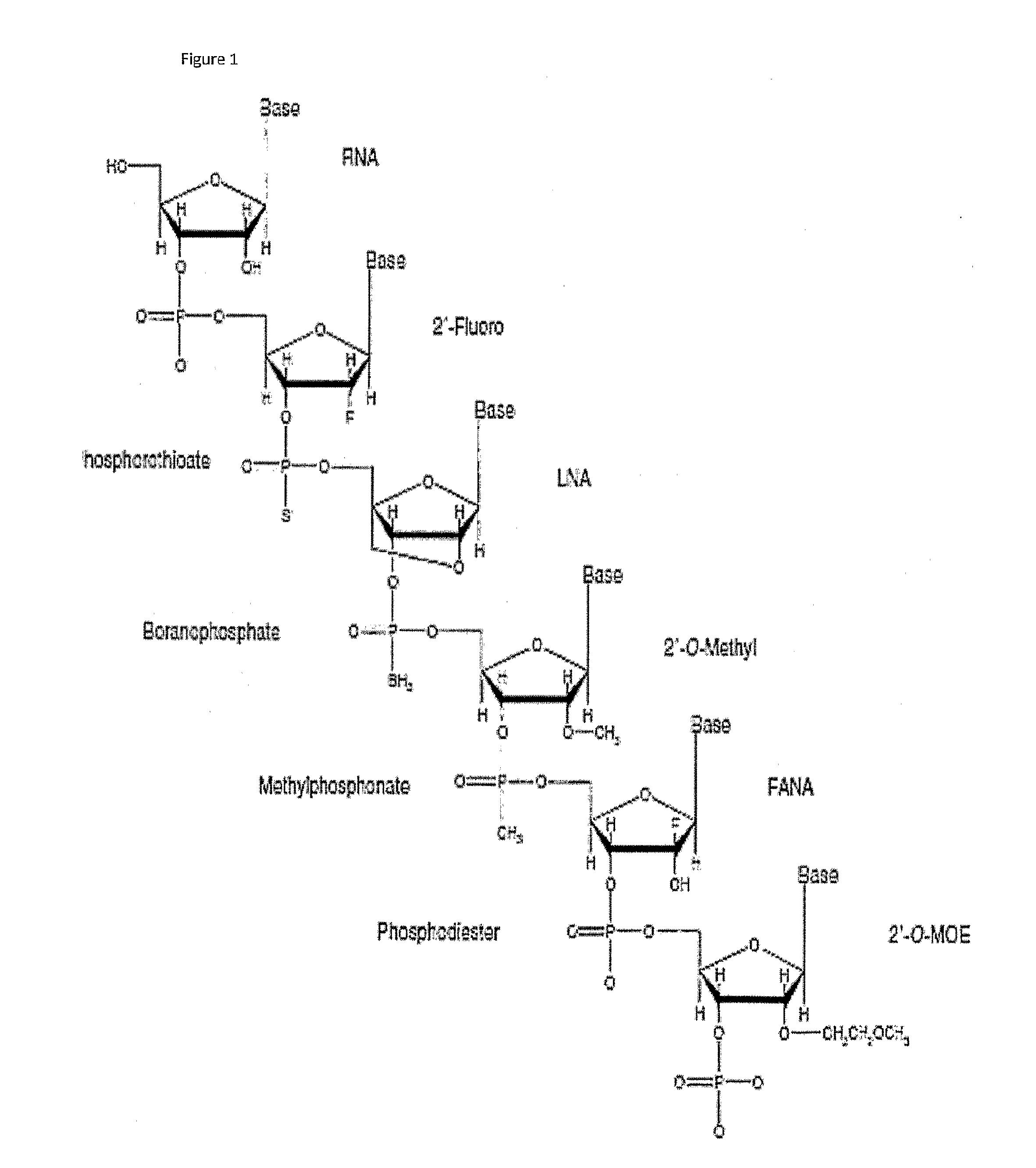

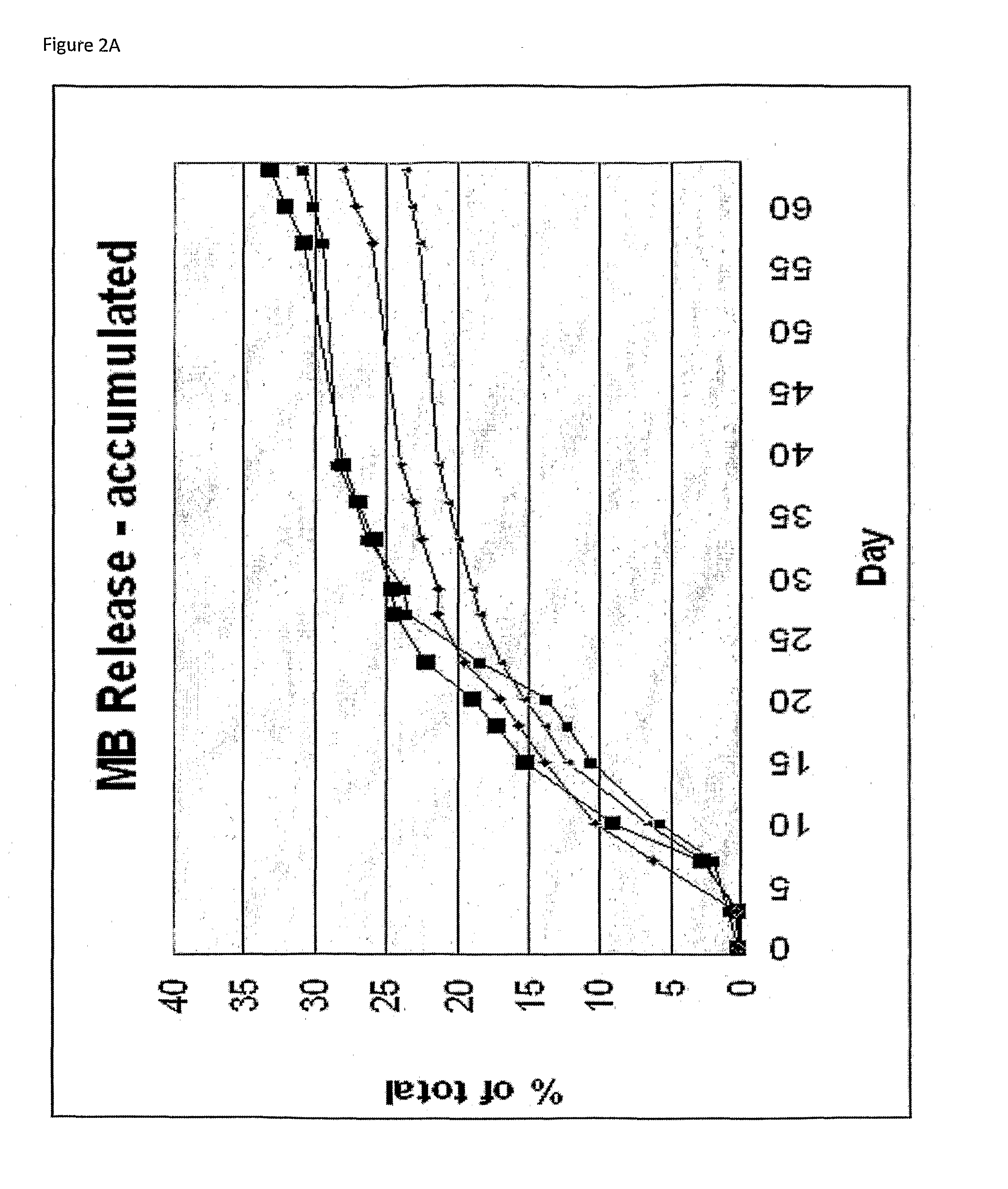

Methods, compositions and systems for local delivery of drugs

ActiveUS20110195123A1Reduce degradationImprove permeabilityBiocidePowder deliveryCell-Extracellular MatrixBrachytherapy

Implantable medical device eluting drug locally and in prolonged period is provided, including several types of such a device, the treatment modes of implementation and methods of implantation. The device comprising of polymeric substrate, such as a matrix for example, that is used as the device body, and drugs, and in some cases additional scaffolding materials, such as metals or additional polymers, and materials to enhance visibility and imaging. The selection of drug is based on the advantageous of releasing drug locally and in prolonged period, where drug is released directly to the extracellular matrix (ECM) of the diseased area such as tumor, inflammation, degeneration or for symptomatic objectives, or to injured smooth muscle cells, or for prevention. One kind of drug is the gene silencing drugs based on RNA interference (RNAi), including but not limited to si RNA, sh RNA, or antisense RNA / DNA, ribozyme and nucleoside analogs. The modes of implantation in some embodiments are existing implantation procedures that are developed and used today for other treatments, including brachytherapy and needle biopsy. In such cases the dimensions of the new implant described in this invention are similar to the original implant. Typically a few devices are implanted during the same treatment procedure.

Owner:SILENSEED LTD

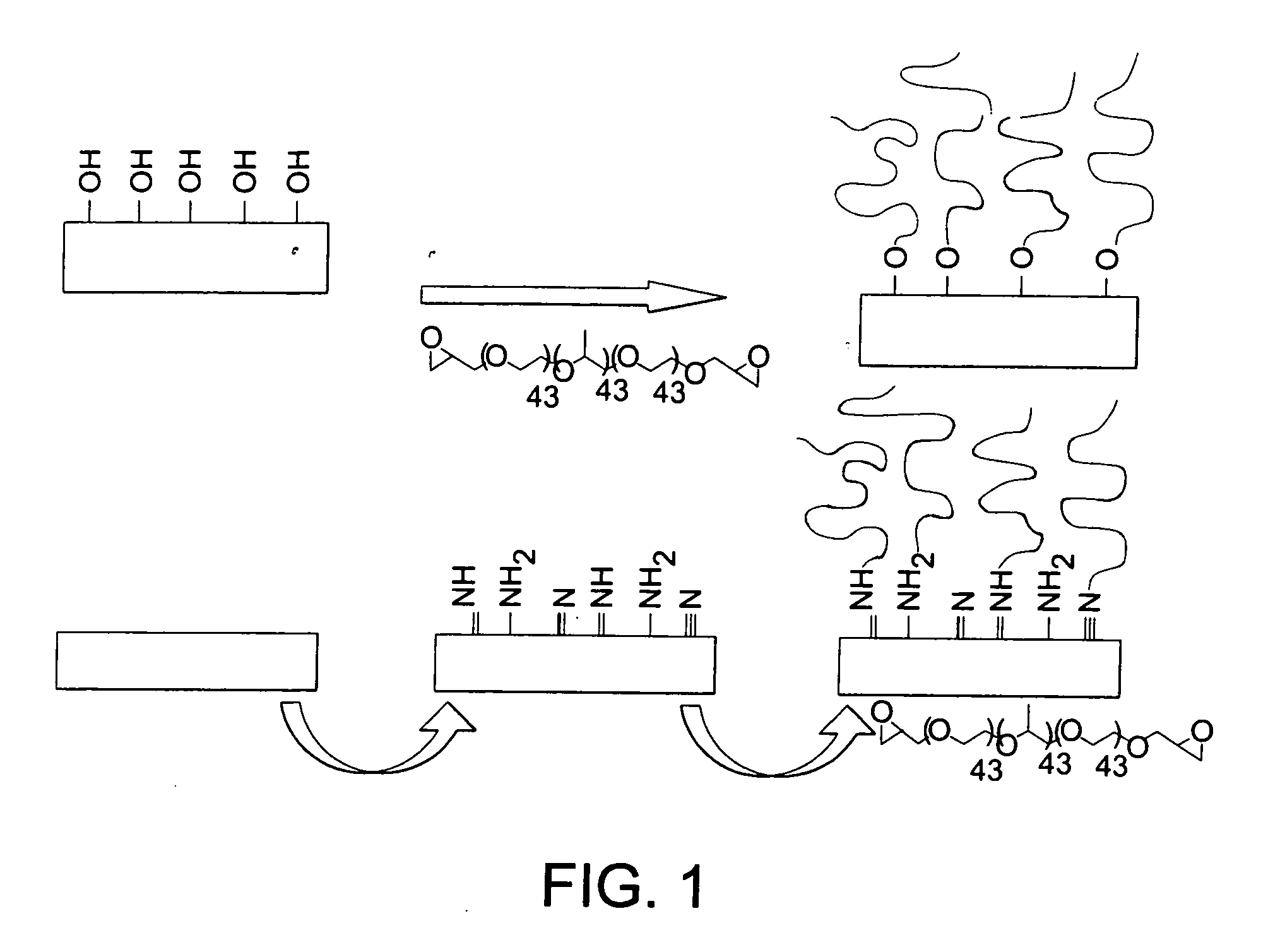

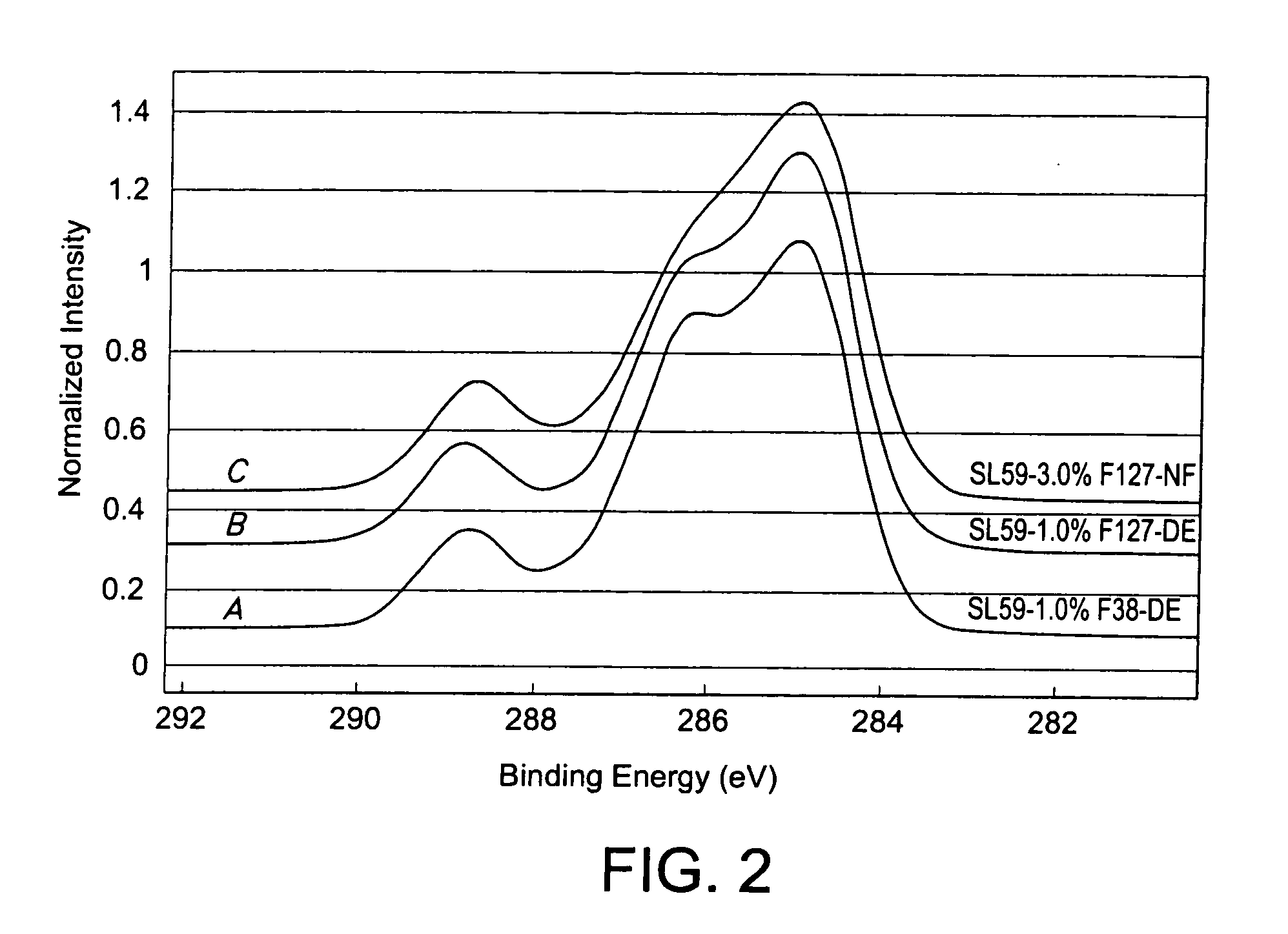

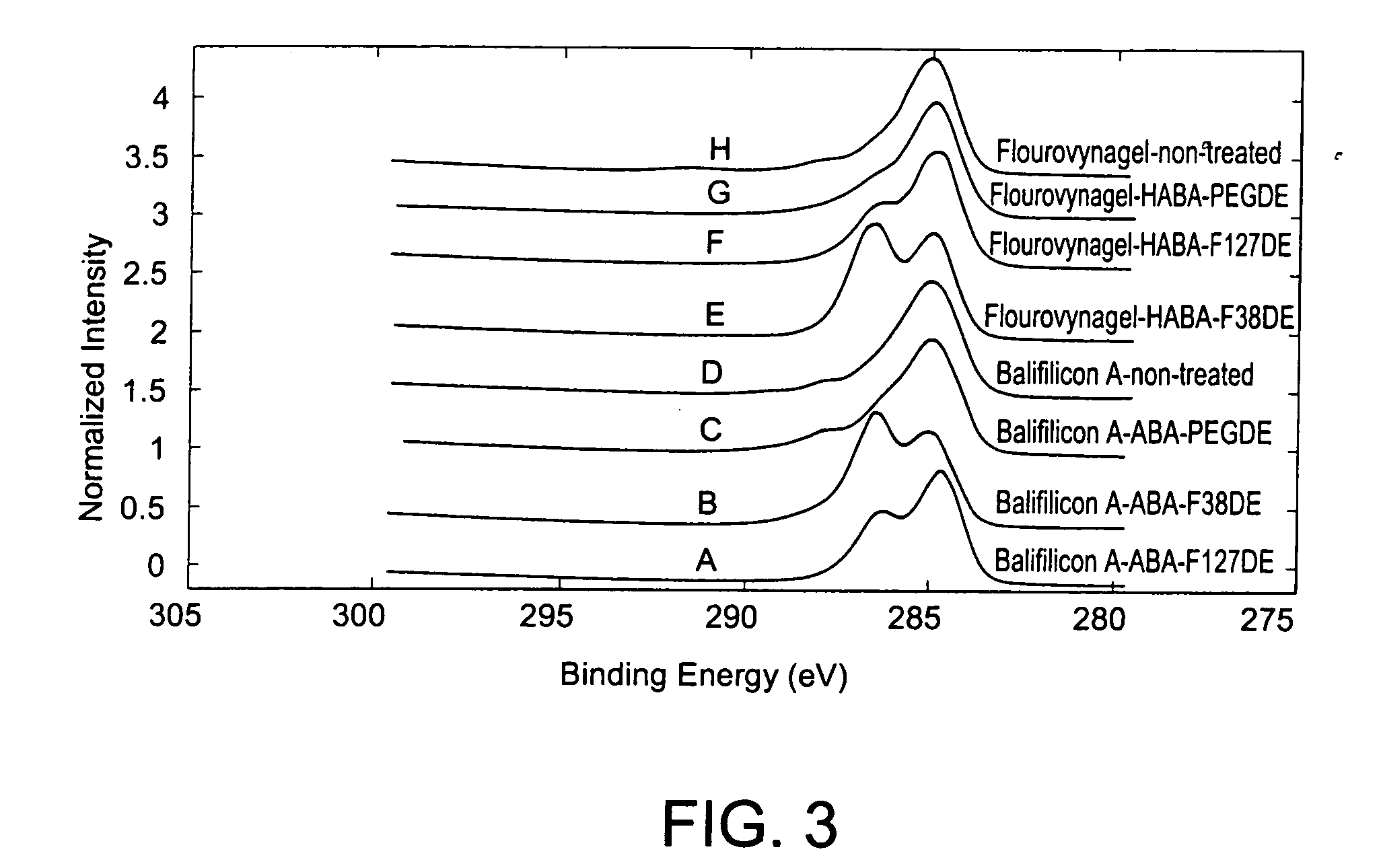

Coatings on ophthalmic lenses

This invention is directed toward surface treatment of a device. The surface treatment comprises the attachment of terminal functionalized surfactants to the surface of the substrate by means of reactive functionalities of the terminal functionalized surfactant material reacting with complementary surface reactive functionalities in monomeric units along the polymer substrate. The present invention is also directed to a surface modified medical device, examples of which include contact lenses, intraocular lenses, vascular stents, phakic intraocular lenses, aphakic intraocular lenses, corneal implants, catheters, implants, and the like, comprising a surface made by such a method.

Owner:BAUSCH & LOMB INC

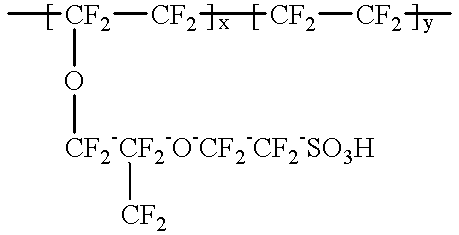

Composite solid polymer elecrolyte membranes

InactiveUS20020045085A1Optimize swellingOptimize fuel crossover resistanceElectrolyte holding meansFinal product manufacturePolymer electrolytesPolymer science

The present invention relates to composite solid polymer electrolyte membranes (SPEMs) which include a porous polymer substrate interpenetrated with an ion-conducting material. SPEMs of the present invention are useful in electrochemical applications, including fuel cells and electrodialysis.

Owner:FOSTER-MILLER

Method for creating a cell growth surface on a polymeric substrate

InactiveUS6617152B2Extraordinary levels of cell attachmentPromote cell adhesionBioreactor/fermenter combinationsBiological substance pretreatmentsCell adhesionAdhesion process

A method, apparatus and product for producing an advantaged cell growth surface. According to the present invention, a stream of plasma is comprised of activated gaseous species generated by a microwave source. This stream is directed at the surface of a polymer substrate in a controlled fashion such that the surface is imparted with attributes for cell adhesion far superior to that of untreated polymer or polymer treated by other known methods.

Owner:CORNING INC

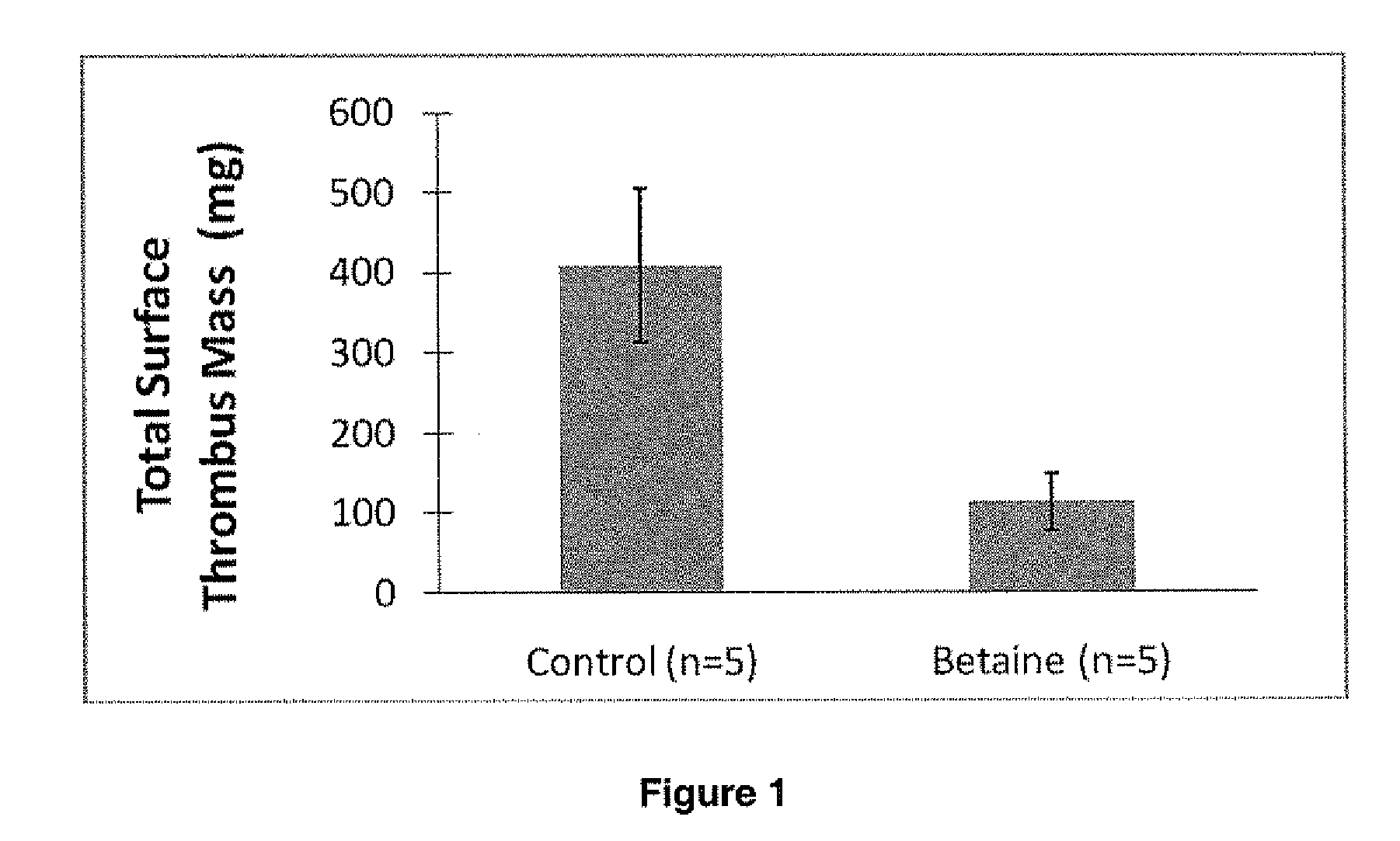

Non-fouling, Anti-microbial, Anti-thrombogenic graft-from compositions

InactiveUS20100152708A1Reduce penetrationRadiation applicationsSurgeryMicroorganismPolymer substrate

Substrates, optionally coated with an undercoating layer, having grafted there from one or more non-fouling materials are described herein. The non-fouling, polymeric material can be grafted from a variety of substrate materials, particularly polymeric substrates and / or polymeric undercoating layers. The graft-from techniques described herein can result in higher surface densities of the non-fouling material relative to graft-to formulations. Graft-from methods can be used to produce covalently tethered polymers. The compositions described herein are highly resistant protein absorption, particularly in complex media and retain a high degree of non-fouling activity over long periods of time. The compositions described herein may also demonstrate antimicrobial and / or anti-thrombogenic activity. The non-fouling material can be grafted from the substrate, or optionally from an undercoating layer on the substrate, preferably without significantly affecting the mechanical and / or physical properties of the substrate material.

Owner:ARROW INT INC

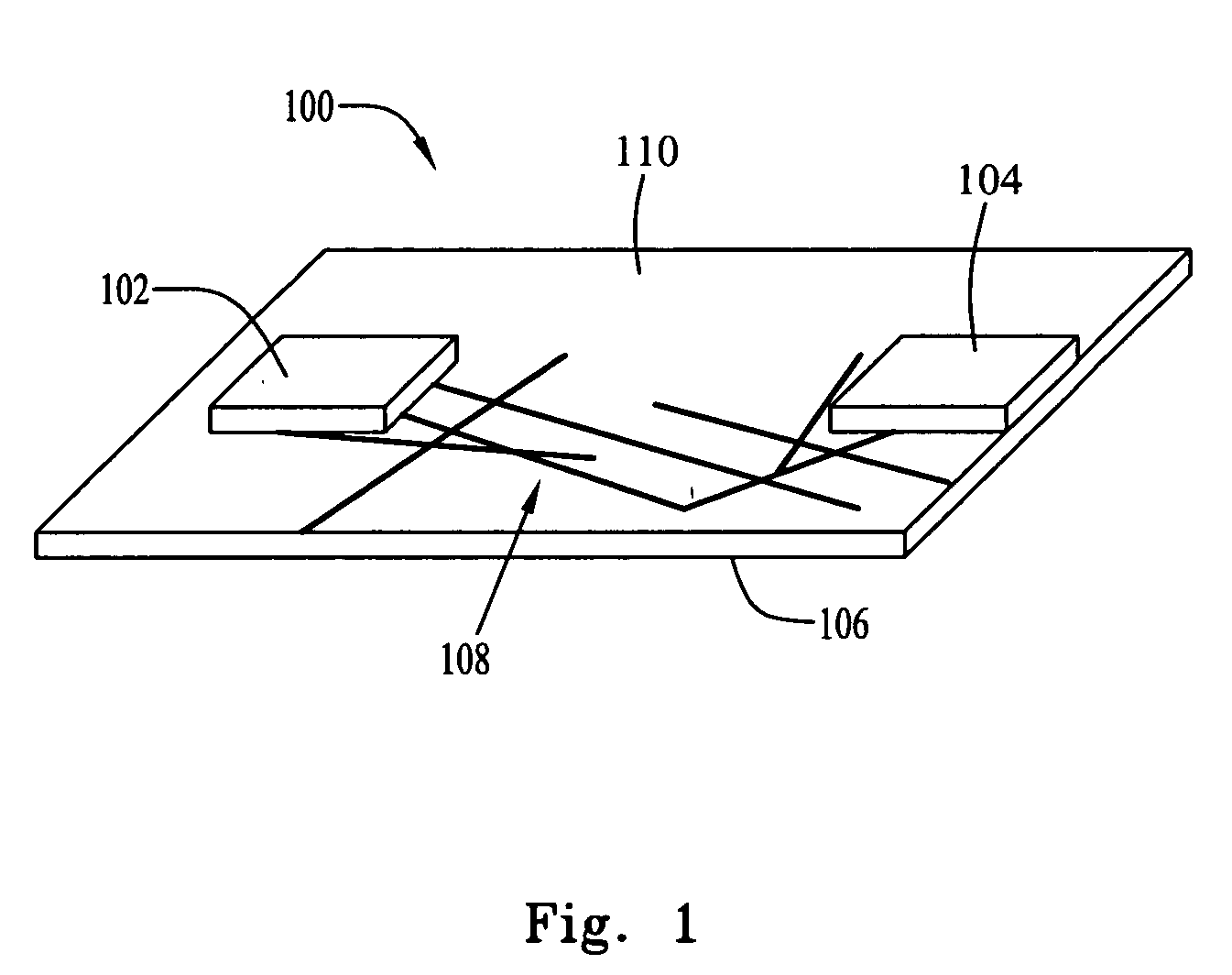

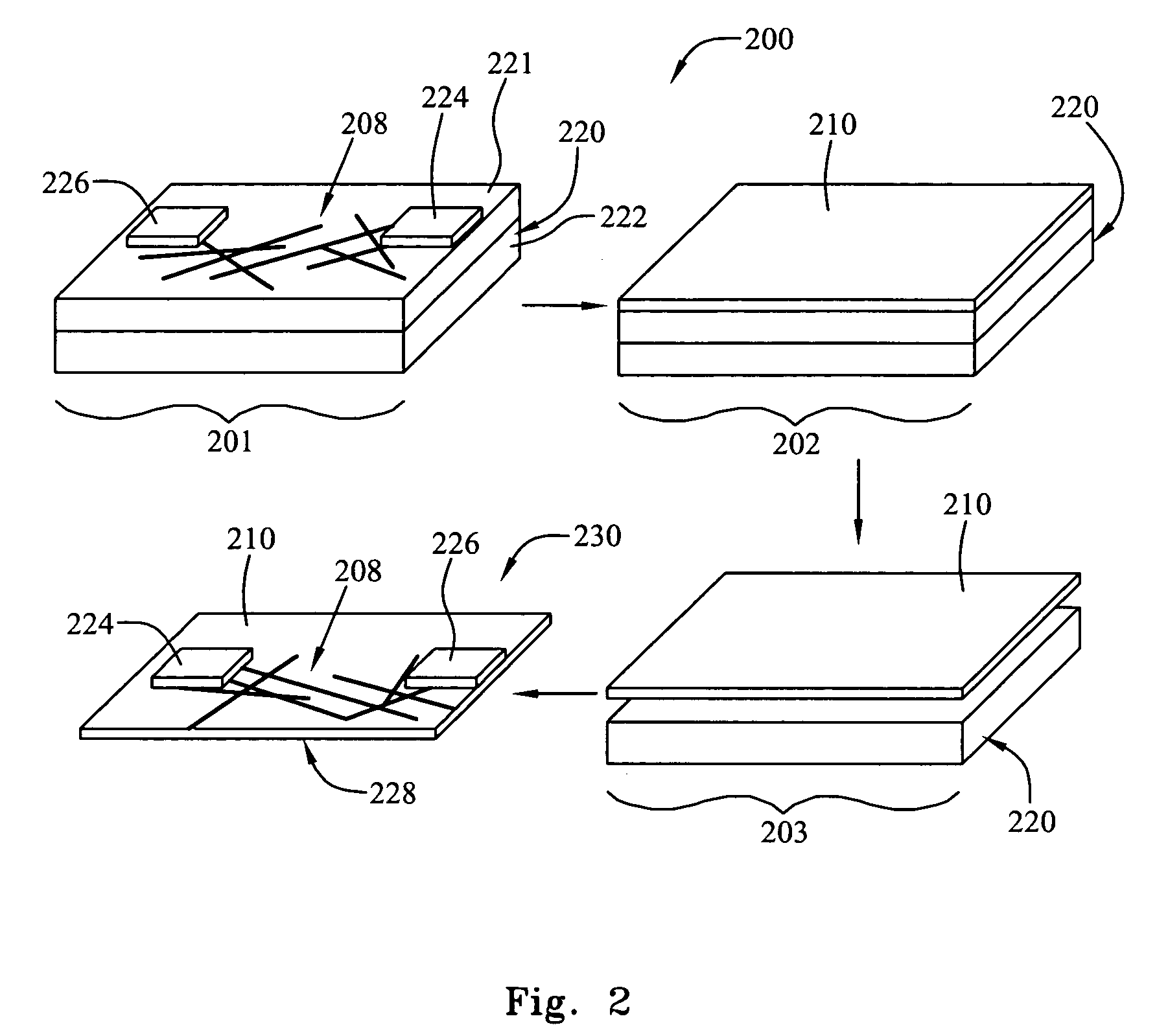

Flexible nanostructure electronic devices

A flexible electronic device is made up of nanostructures. Specifically, the device includes a flexible substrate, a film of nanostructures in contact with the flexible substrate, a first conducting element in contact with the film of nanostructures, and a second conducting element in contact with the film of nanostructures. The nanostructures may comprise nanotubes, such as carbon nanotubes disposed along the flexible substrate, such as an organic or polymer substrate. The first and second conductive elements may serve as electrical terminals, or as a source and drain. In addition, the electronic device may include a gate electrode that is in proximity to the nanotubes and not in electrical contact with the nanotubes. In this configuration, the device can operate as a transistor or a FET. The device may also be operated in a resistive mode as a chemical sensor (e.g., for sensing NH3).

Owner:NANOMIX +1

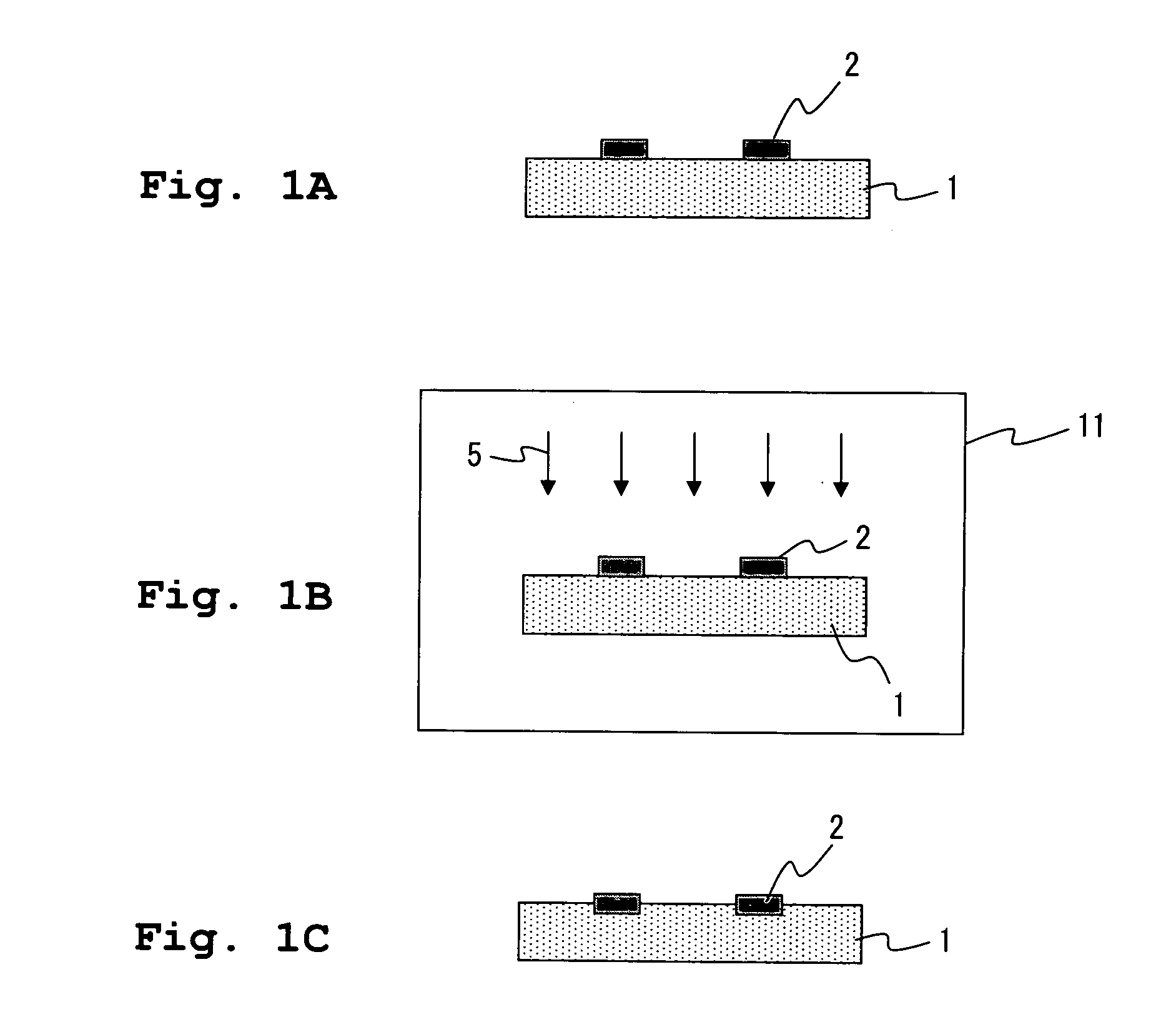

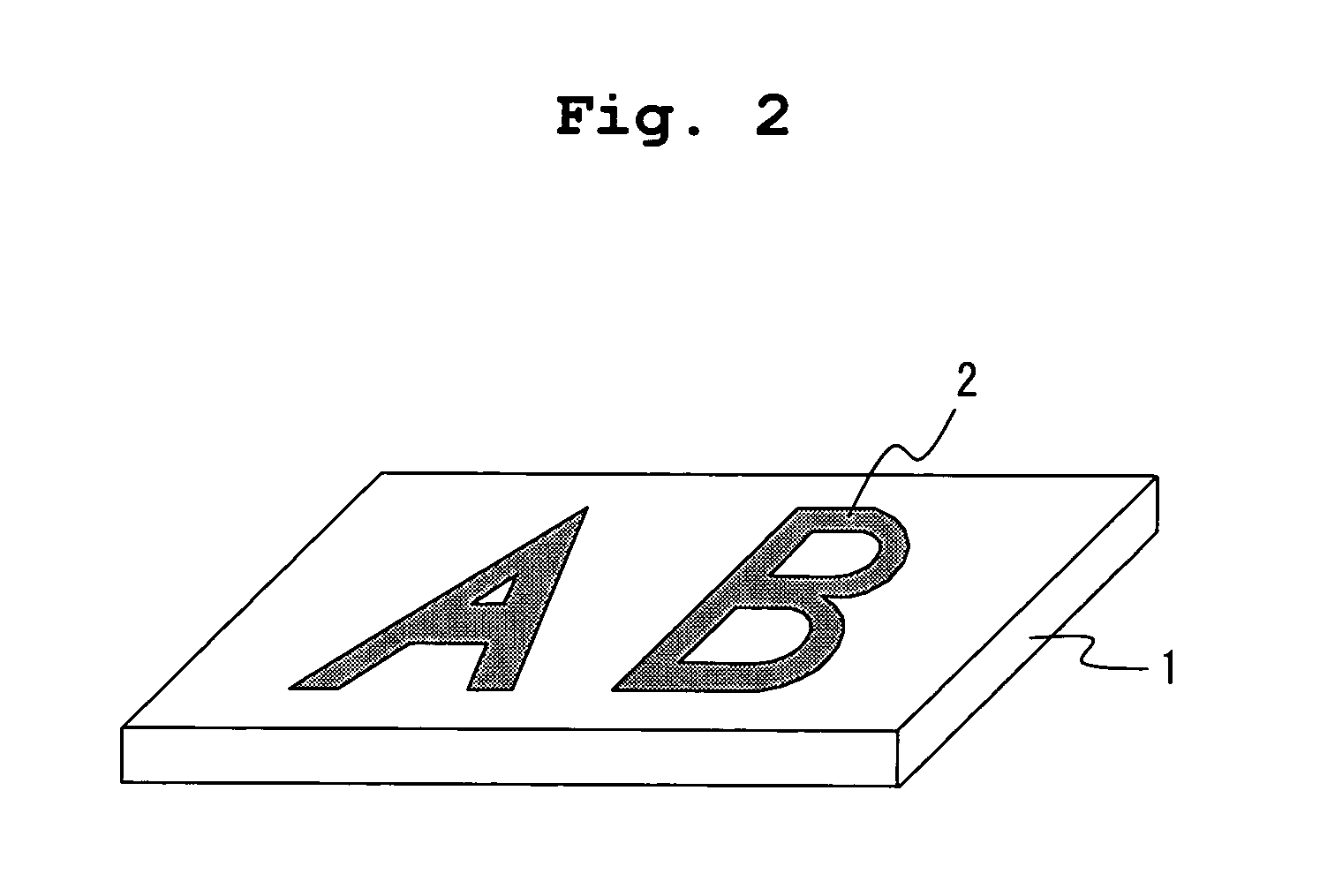

Method for modifying surface of polymer substrate, method for forming plated film on polymer substrate, method for producing polymer member, and coating member

InactiveUS20060257633A1Decorative surface effectsDuplicating/marking methodsPolymer sciencePolymer substrate

A method for modifying the surface of a polymer substrate is provided, which includes applying a permeating substance to predetermined region on the surface of the polymer substrate, and bringing a supercritical fluid into contact with the surface of the polymer substrate to which the permeating substance has been applied to cause the permeating substance to permeate into the polymer substrate. This method makes it possible to selectively (partially) modify a portion of the surface of the polymer substrate by an easier method.

Owner:HITACHT MAXELL LTD

Lithium ion polymer electrolytes

InactiveUS6413676B1Prevent kinkingAvoid deformationElectrode manufacturing processesFinal product manufacturePorosityCross-link

A dimensionally stable, highly resilient, hybrid copolymer solid-solution electrolyte-retention film for use in a lithium ion battery in one preferred embodiment has a predominantly amorphous structure and mechanical strength despite contact with liquid solvent electrolyte. The film is a thinned (stretched), cast film of a homogeneous blend of two or more polymers, one of which is selected for its pronounced solvent retention properties. A very high surface area inorganic filler dispersed in the blend during formation thereof serves to increase the porosity of the film and thereby enhance electrolyte retention. The film is soaked in a solution of liquid polymer with liquid organic solvent electrolyte and lithium salt, for absorption thereof. Use of a cross-linked liquid polymer enhances trapping of molecules of the electrolyte into pores of the film. The electrolyte film is sandwiched between flexible active anode and cathode layers to form the lithium ion battery. Novel methods are provided for forming the electrodes, the polymer substrate, and other elements of the battery.

Owner:LITHIUM POWER TECH

Papermaking belts and industrial textiles with enhanced surface properties

InactiveUS7105465B2Improve adhesionFibre treatmentSynthetic resin layered productsThermoplasticPolymer substrate

An industrial textile including a polymeric substrate and a resin system grafted onto the polymeric substrate by way of a primer. The resin system includes a water-borne thermoplastic, a polyhydroxyether resin and / or an analogue of a polyhydroxyether resin, and at least one co-resin.

Owner:VOITH FABRICS HEIDENHEIM GMBH & CO KG

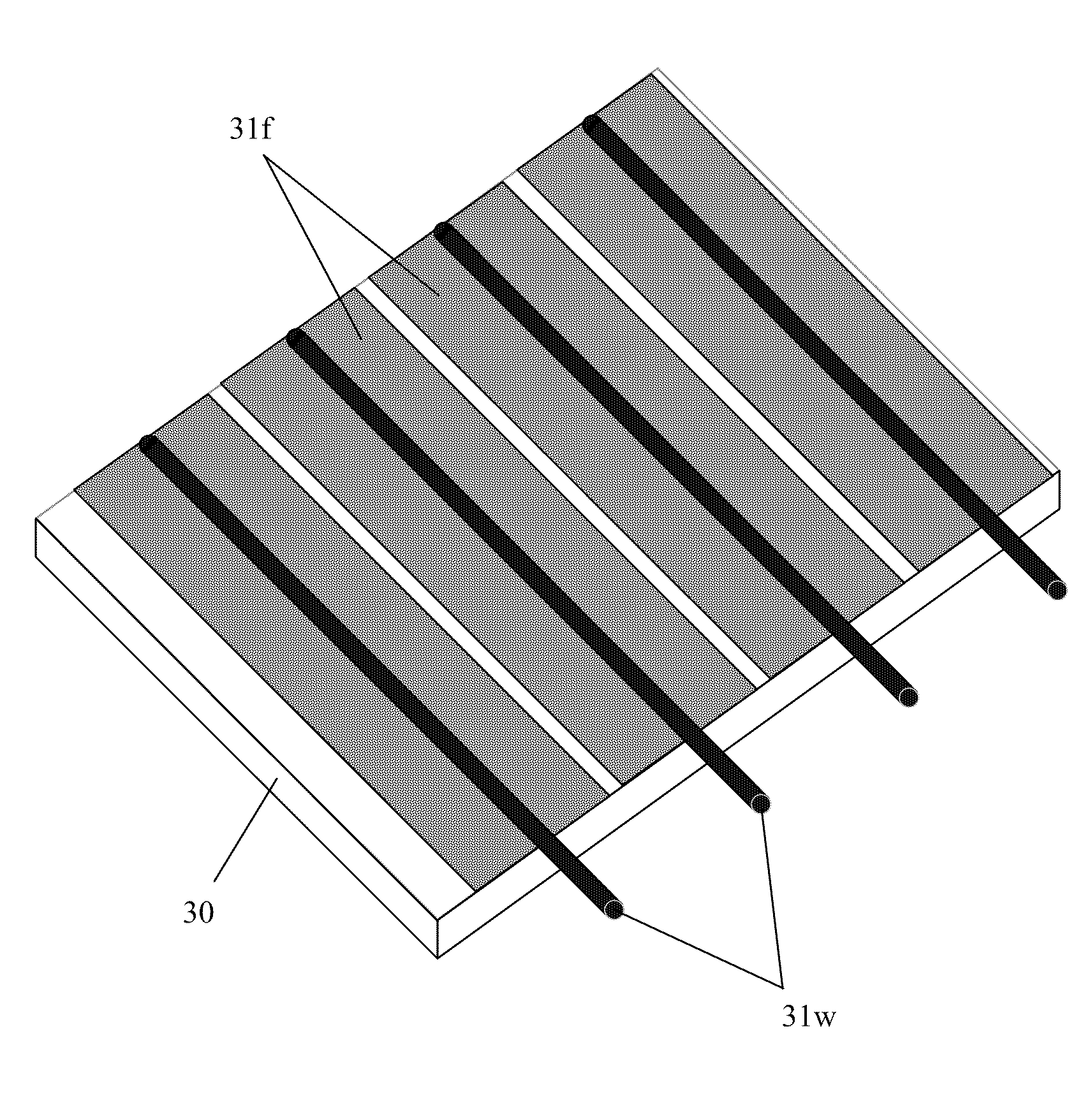

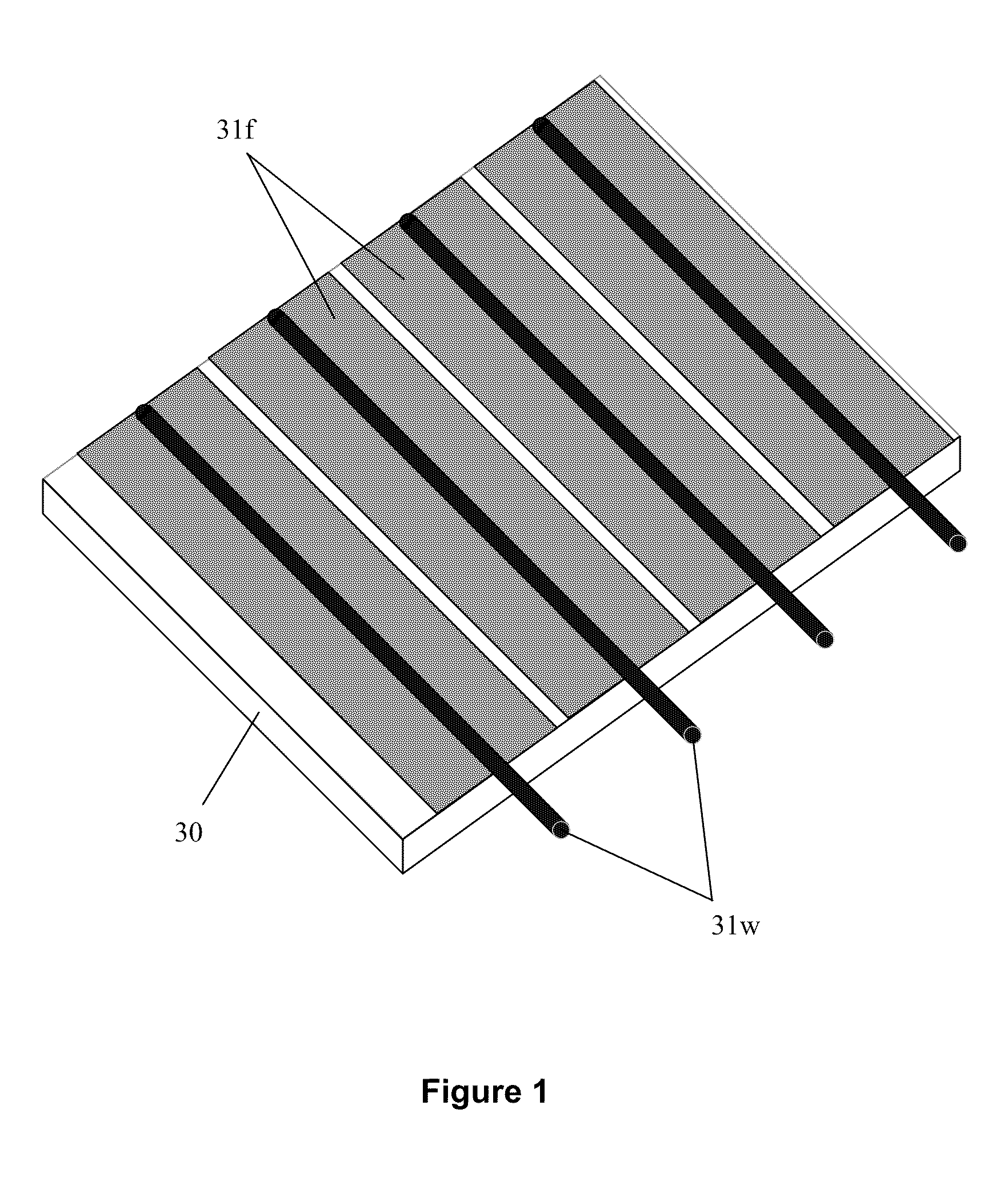

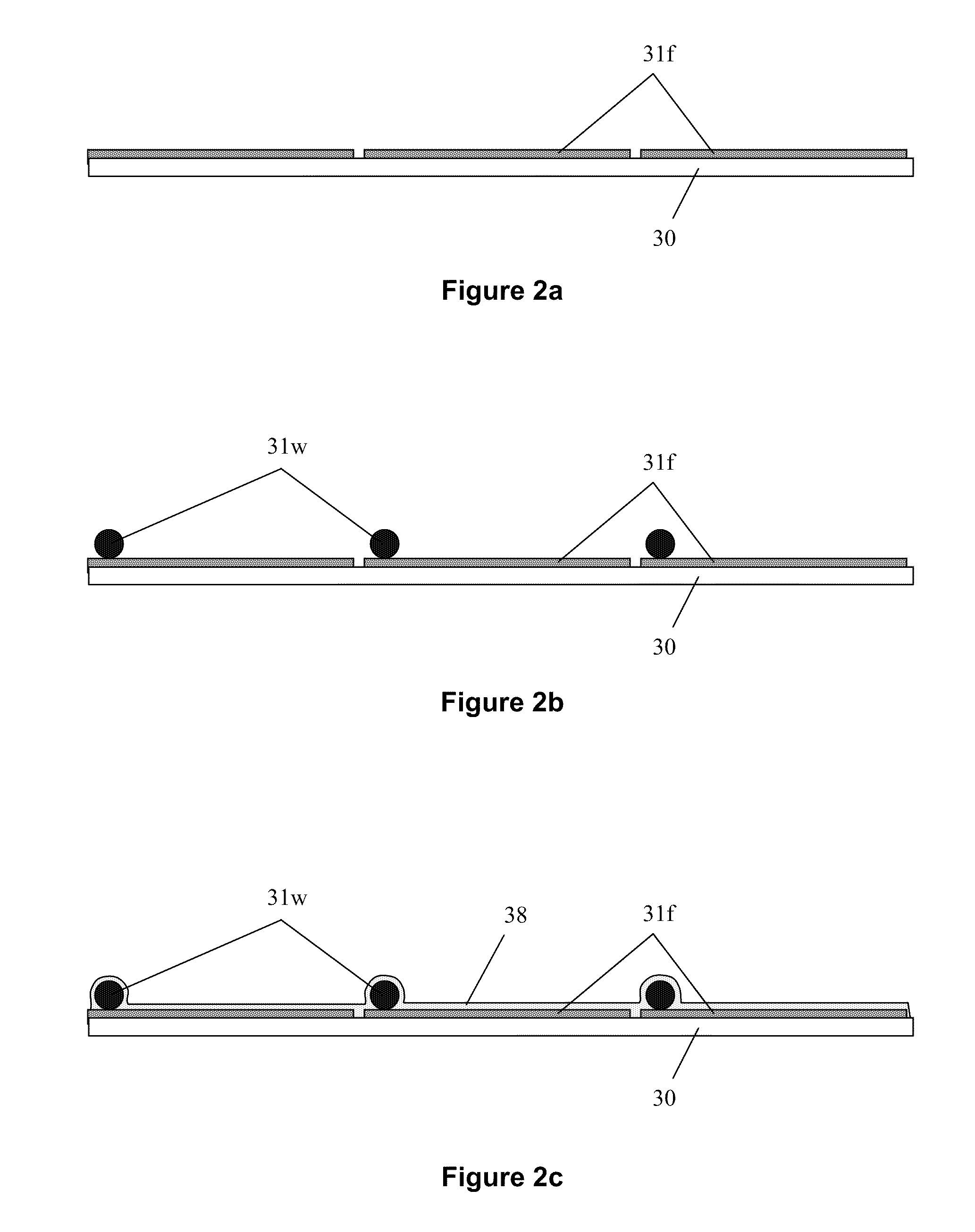

ELECTRODED SHEET (eSheet) PRODUCTS

InactiveUS20080314626A1Reliable electrical connectionImprove conductivitySolid-state devicesActive material electrodesPolymer substrateElectronic form

A sheet in an electronic display is composed of a substrate containing an array of wire electrodes. The wire electrodes are preferably electrically connected to patterned transparent conductive electrode lines. The wire electrodes are used to carry the bulk of the current. The wire electrodes are capable of being extended away from the substrate and connected directly to the printed circuit board. The transparent conductive electrode (TCE) is used to spread the charge or voltage from the wire electrode across the pixel. The TCE is a patterned film and must be at least 50% transparent, and, for most applications, is preferably over 90% transparent. In most applications, the electroded surface of the electroded sheet has to be flattened. Use of a thin polymer substrate yields a light, flexible, rugged sheet that may be curved, bent or rolled.

Owner:MOORE CHAD B

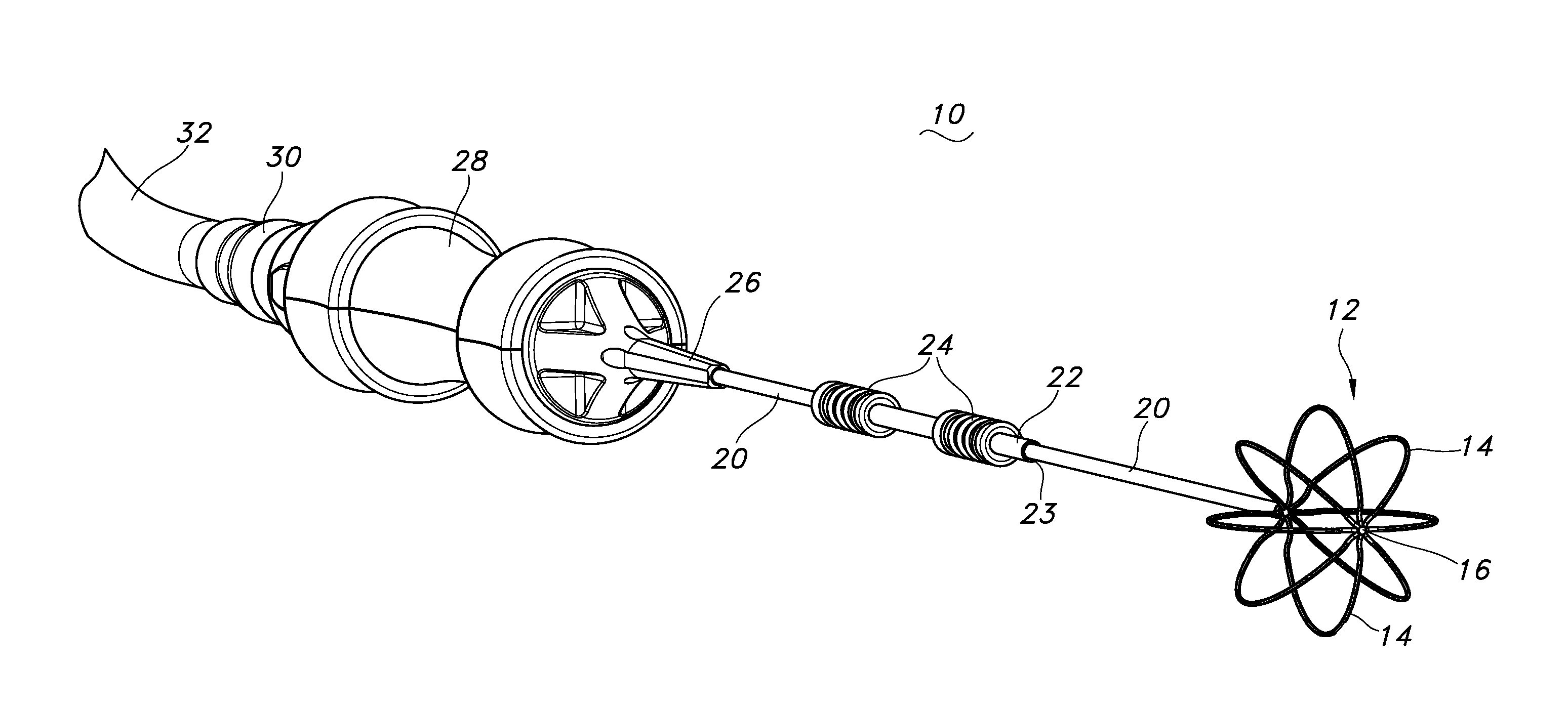

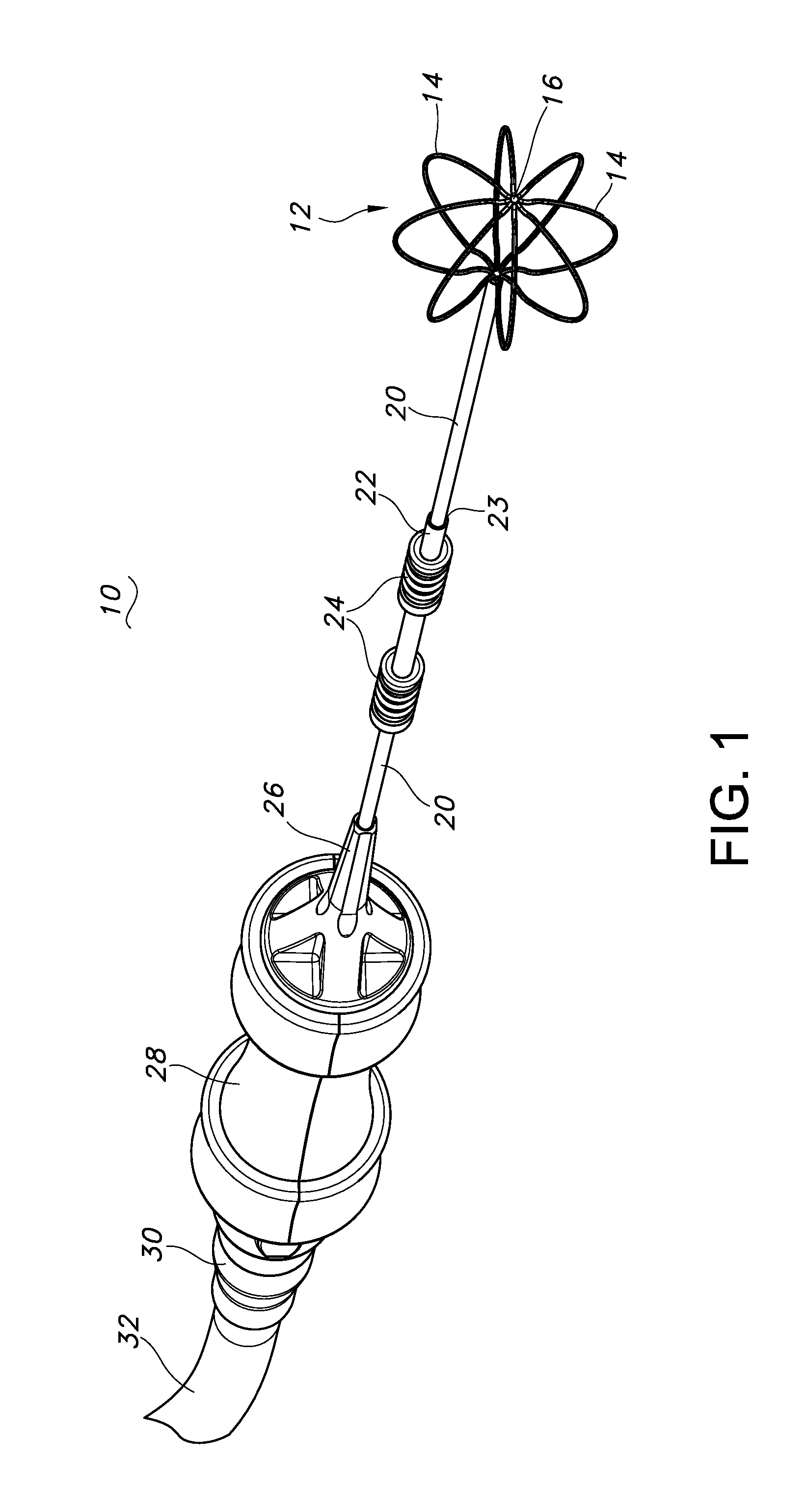

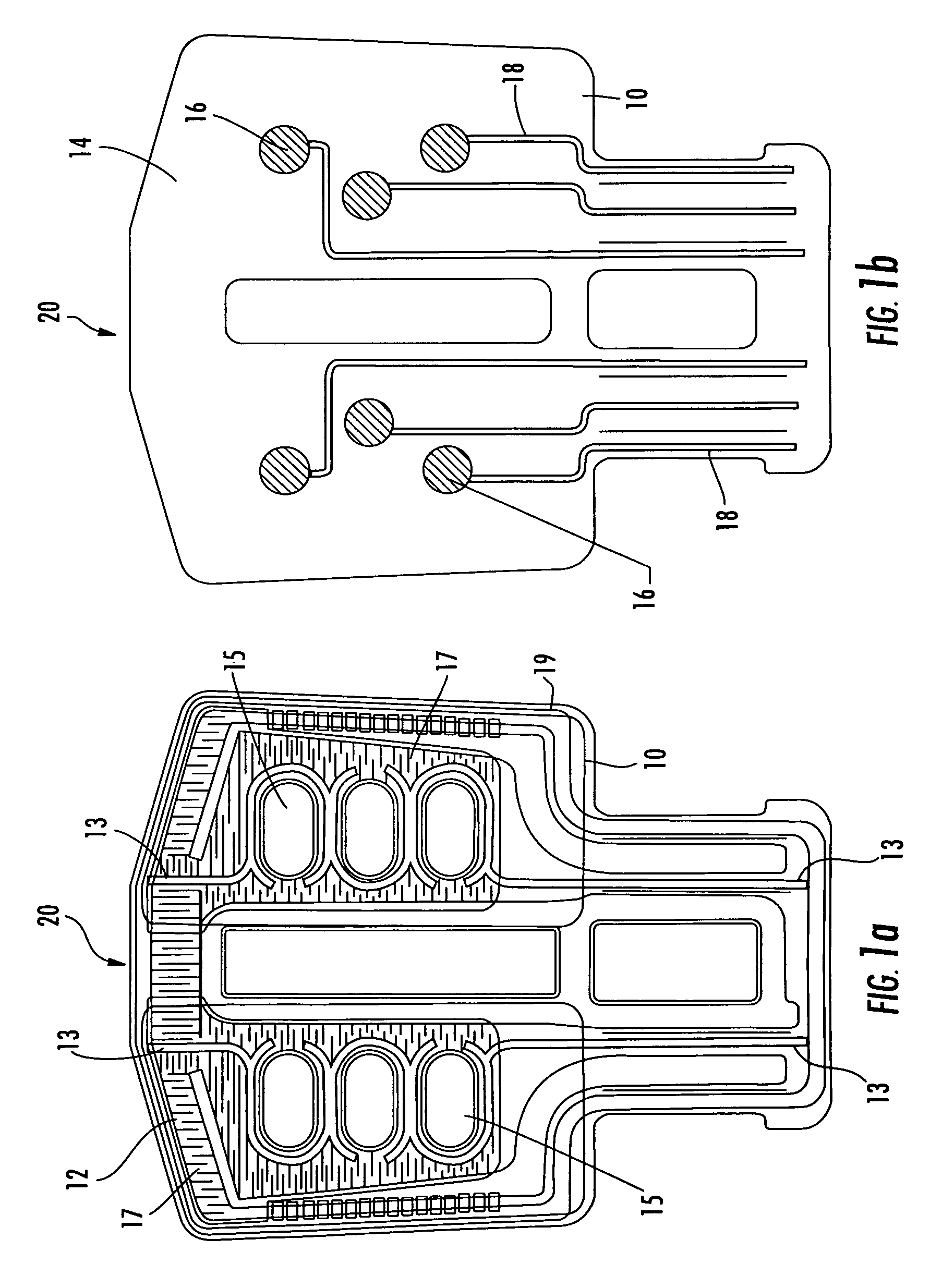

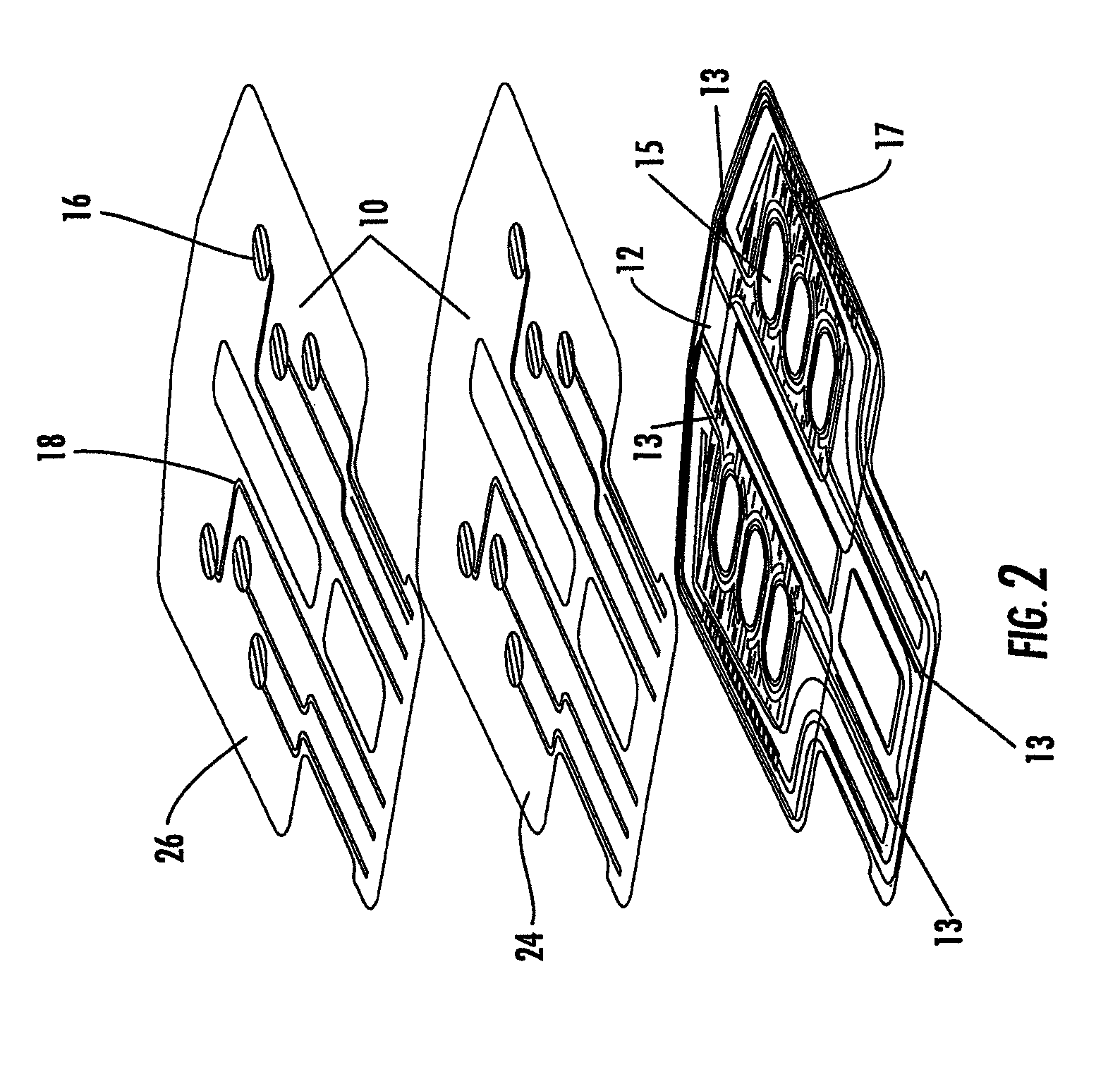

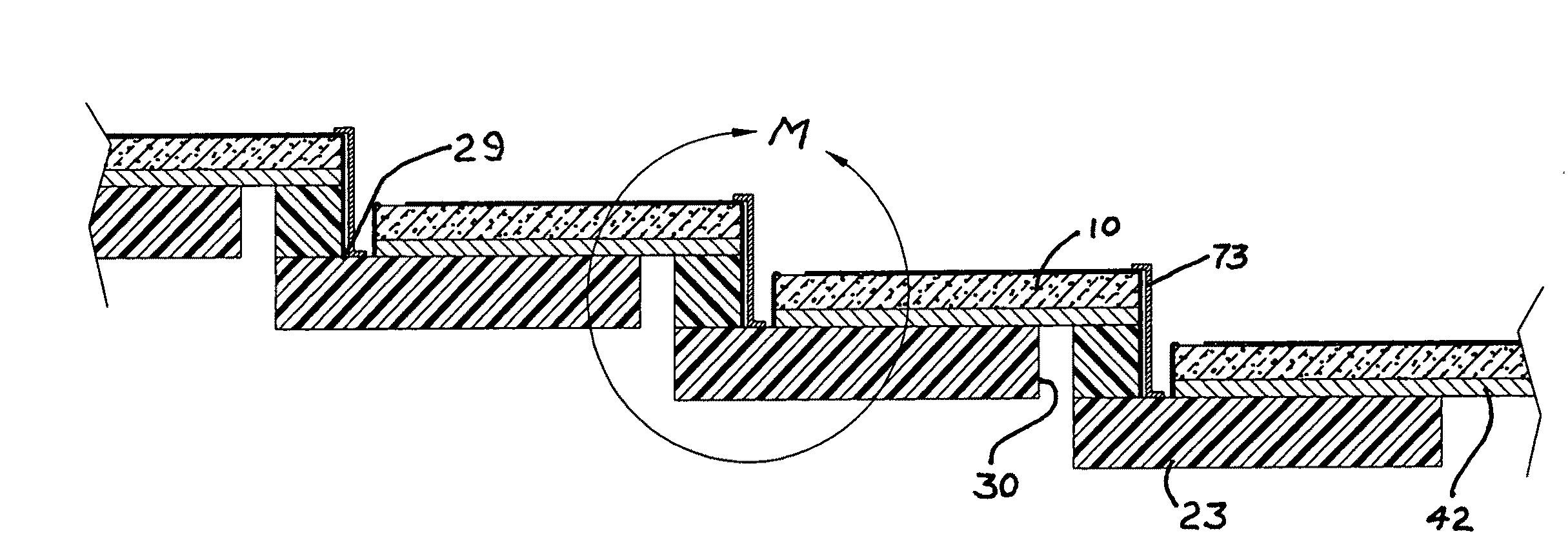

Flexible electrode assembly for insertion into body lumen or organ

A device for insertion into a body lumen, includes: an electrode assembly strip with exposed electrodes including: a polymeric substrate having an upper surface and an opposed lower surface; one or more electrodes disposed over a portion of the upper surface of the polymeric substrate; one or more electrical traces disposed over a portion of the lower surface of the polymeric substrate in electrical communication with the one or more electrodes by way of metal plated holes through the substrate; and a flexible polymeric substrate having a substrate surface and a substrate wall; wherein the electrode assembly strip is compressingly and thermally bonded to the substrate surface of the flexible polymeric substrate to define a flexible electrode assembly strip; and wherein the electrode assembly strip has a thickness from about 0.0005 inches to about 0.008 inches.

Owner:TOPERA

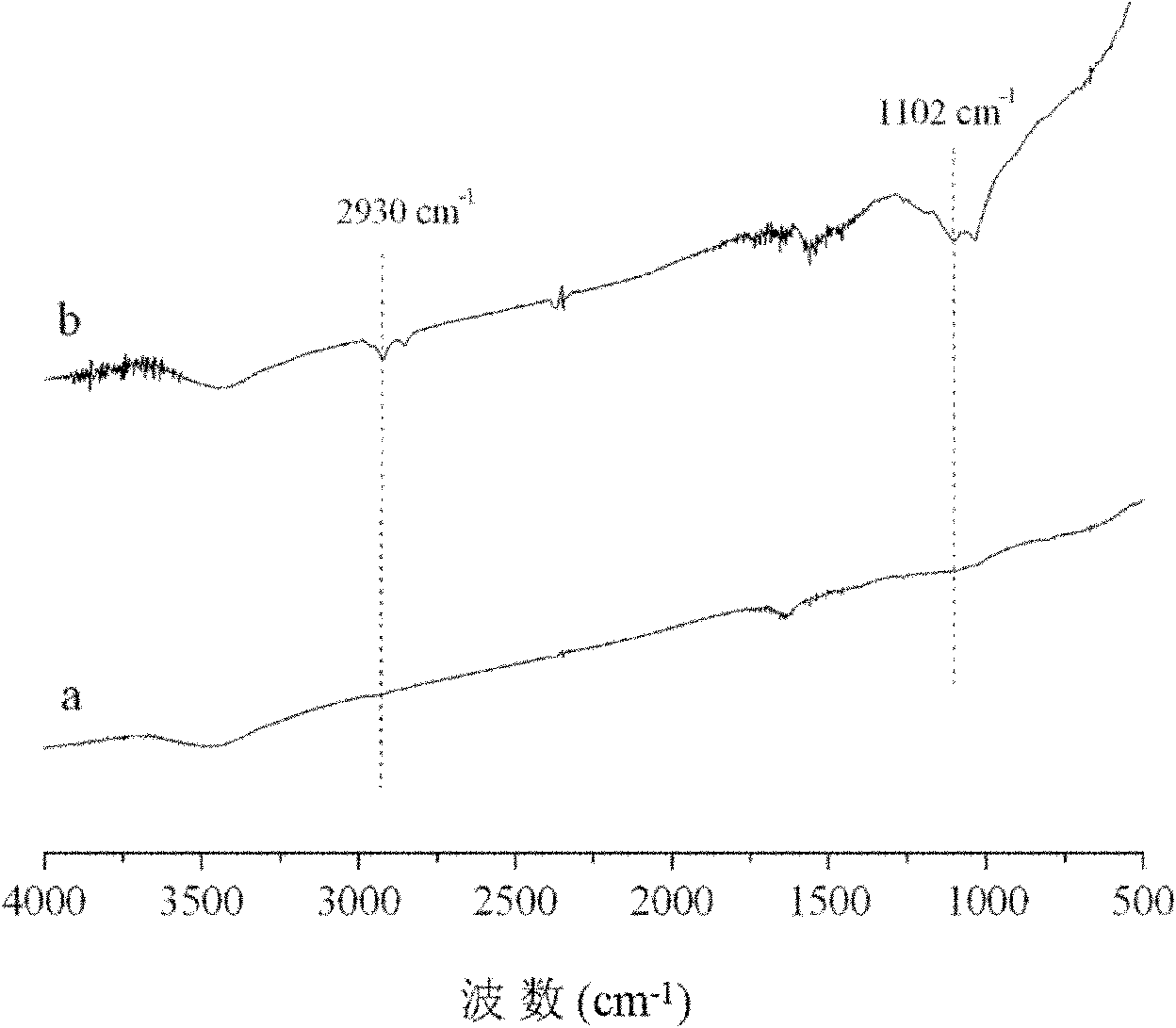

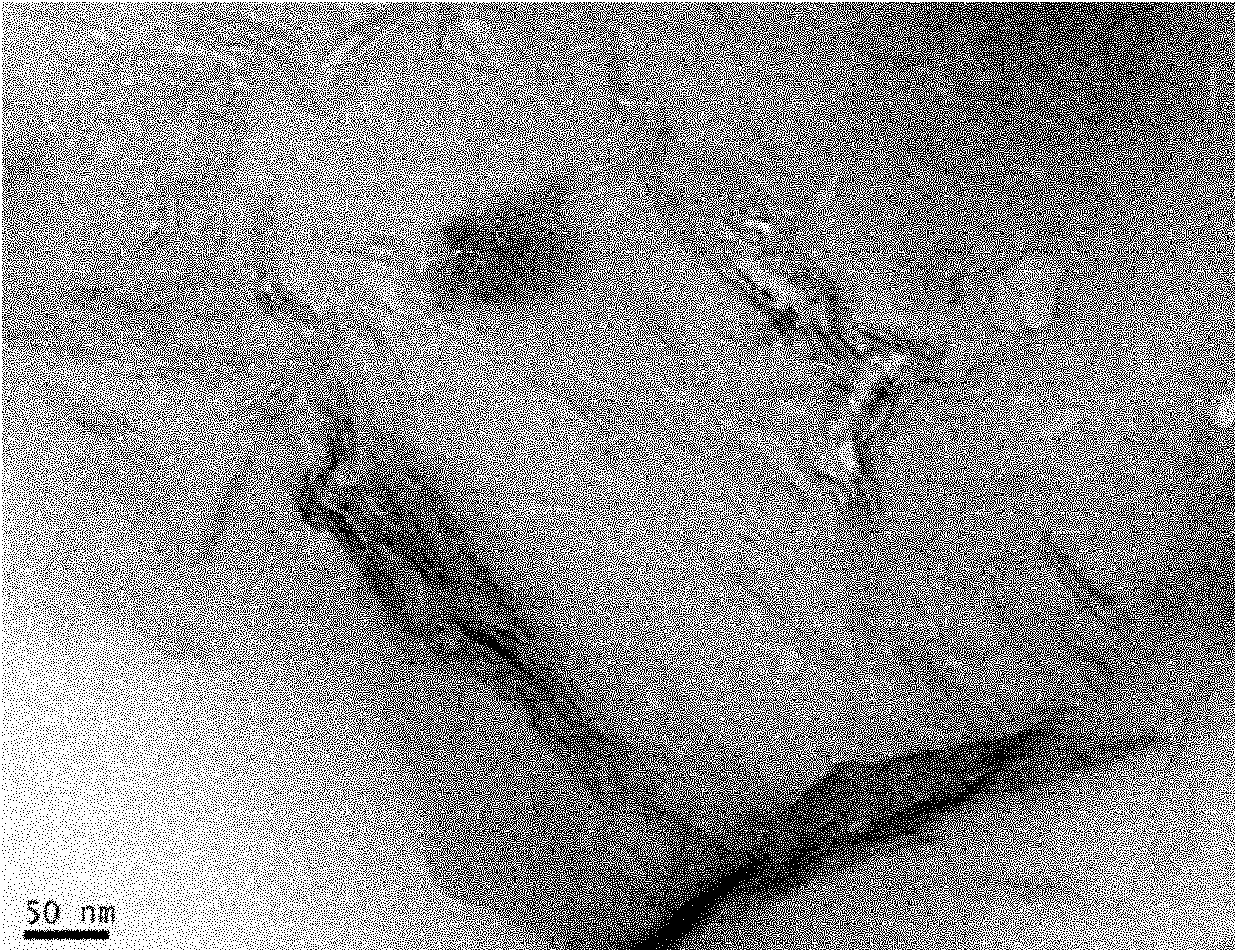

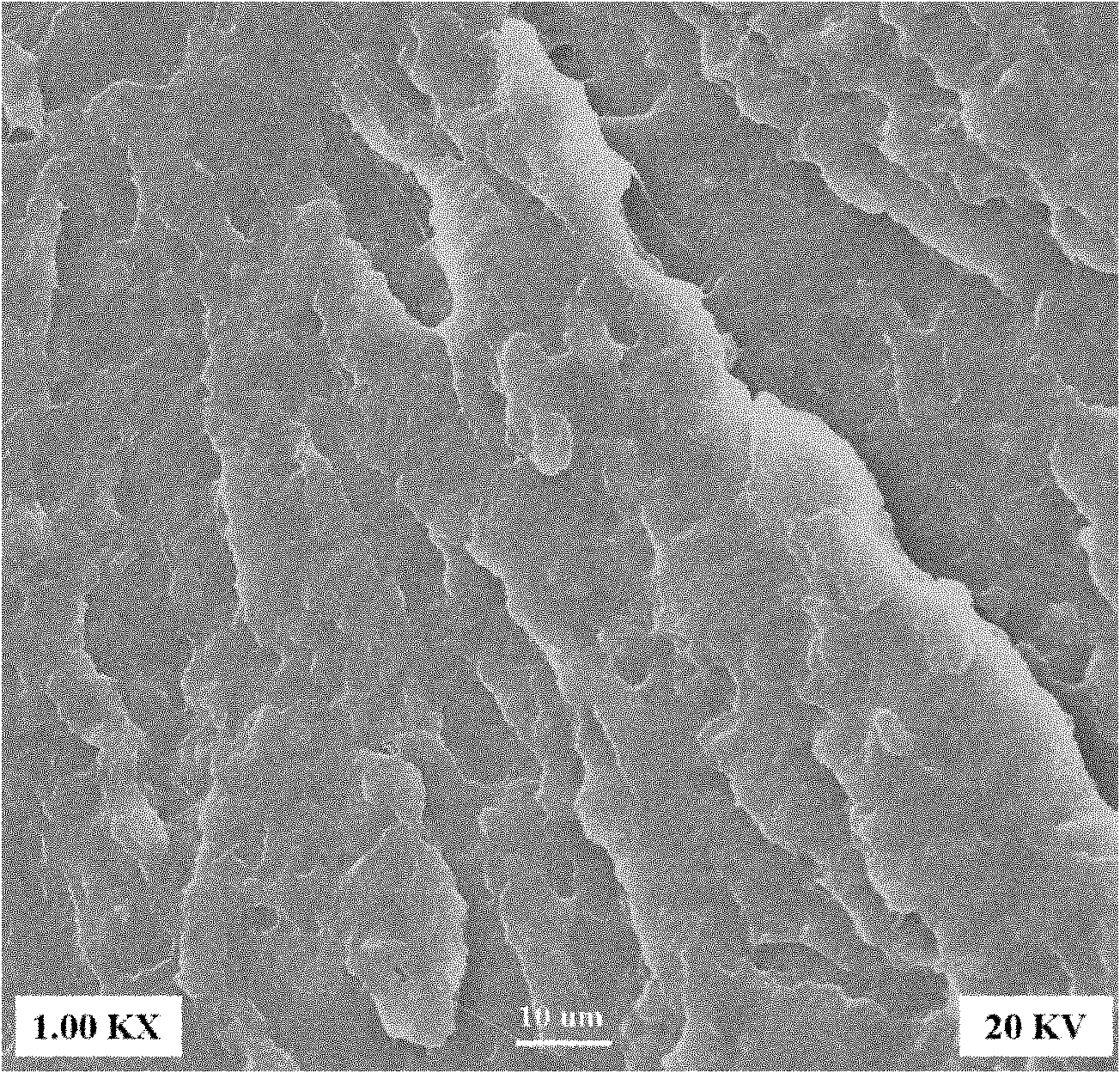

Graphene composite material and preparation method thereof

The embodiment of the invention discloses a graphene composite material and a preparation method thereof. In the method, graphene and organosilane are taken as reactants; the organosilane undergoes a hydrolysis reaction, and then undergoes a dehydration condensation reaction with hydroxyl on the graphene so as to obtain organosilane-modified graphene. Compared with the prior art, the organosilane-modified graphene expands the interlayer spacing of graphene, so that the organosilane-modified graphene is difficultly agglomerated when the organosilane-modified graphene is mixed with a polymer, the organosilane-modified graphene is uniformly dispersed in a polymer substrate, and a prepared graphene composite material has an enhanced effect. Moreover, the organosilane-modified graphene undergoes chemical bonding or intermolecular force with the polymer, so that the prepared graphene composite material has excellent interface compatibility. Proved by experiment results, the graphene composite material prepared in the invention has high mechanical property.

Owner:UNIV OF SCI & TECH OF CHINA

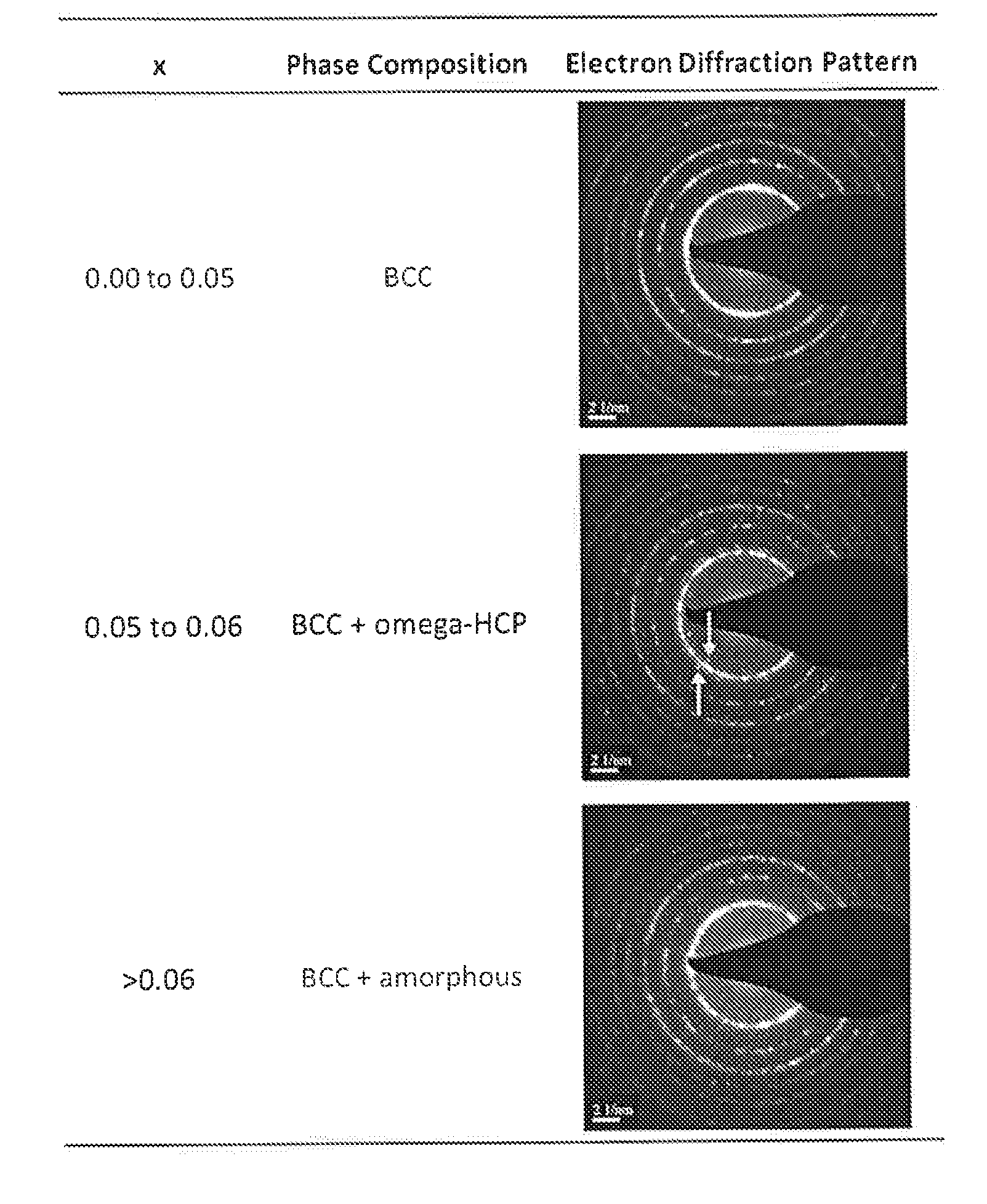

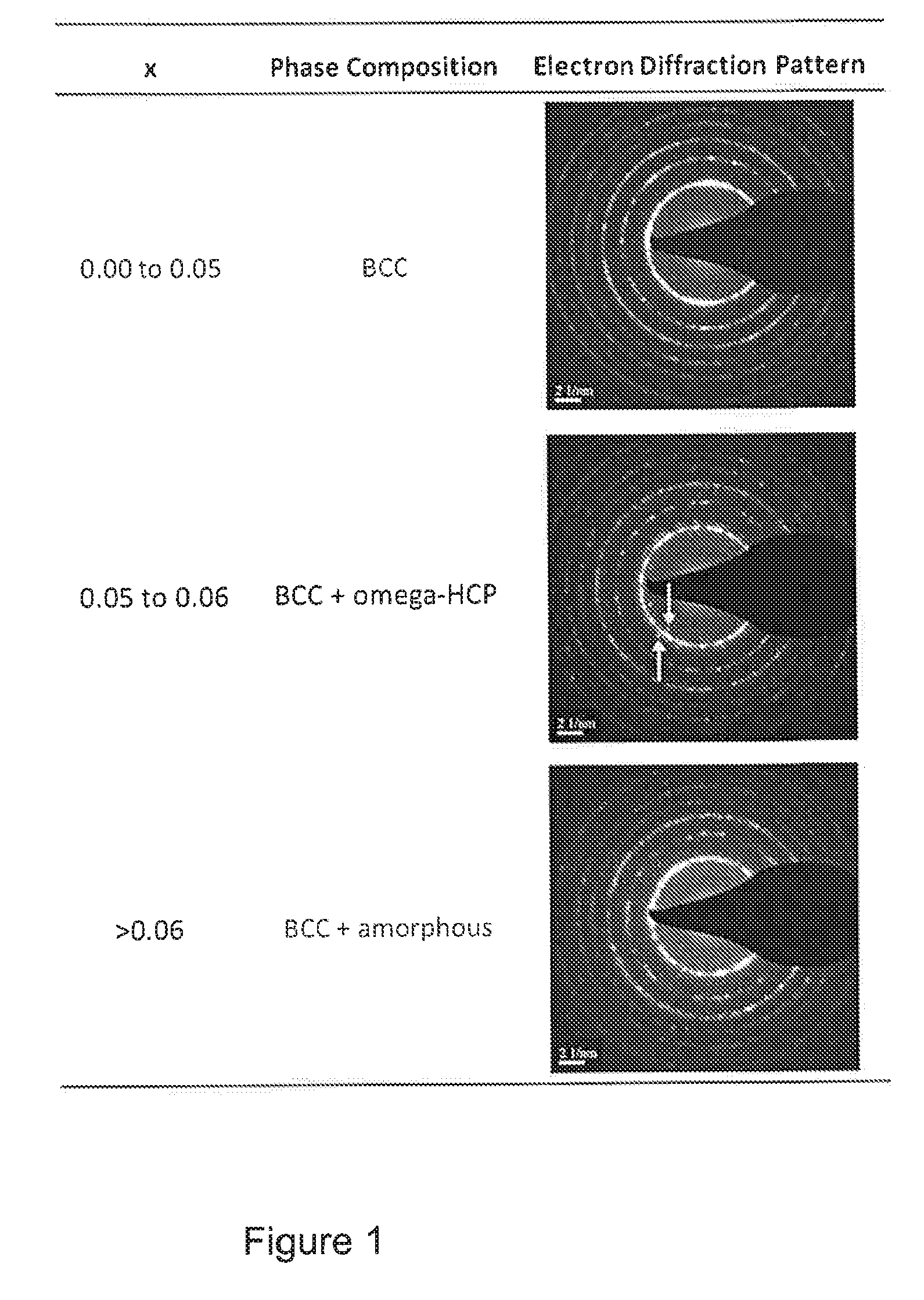

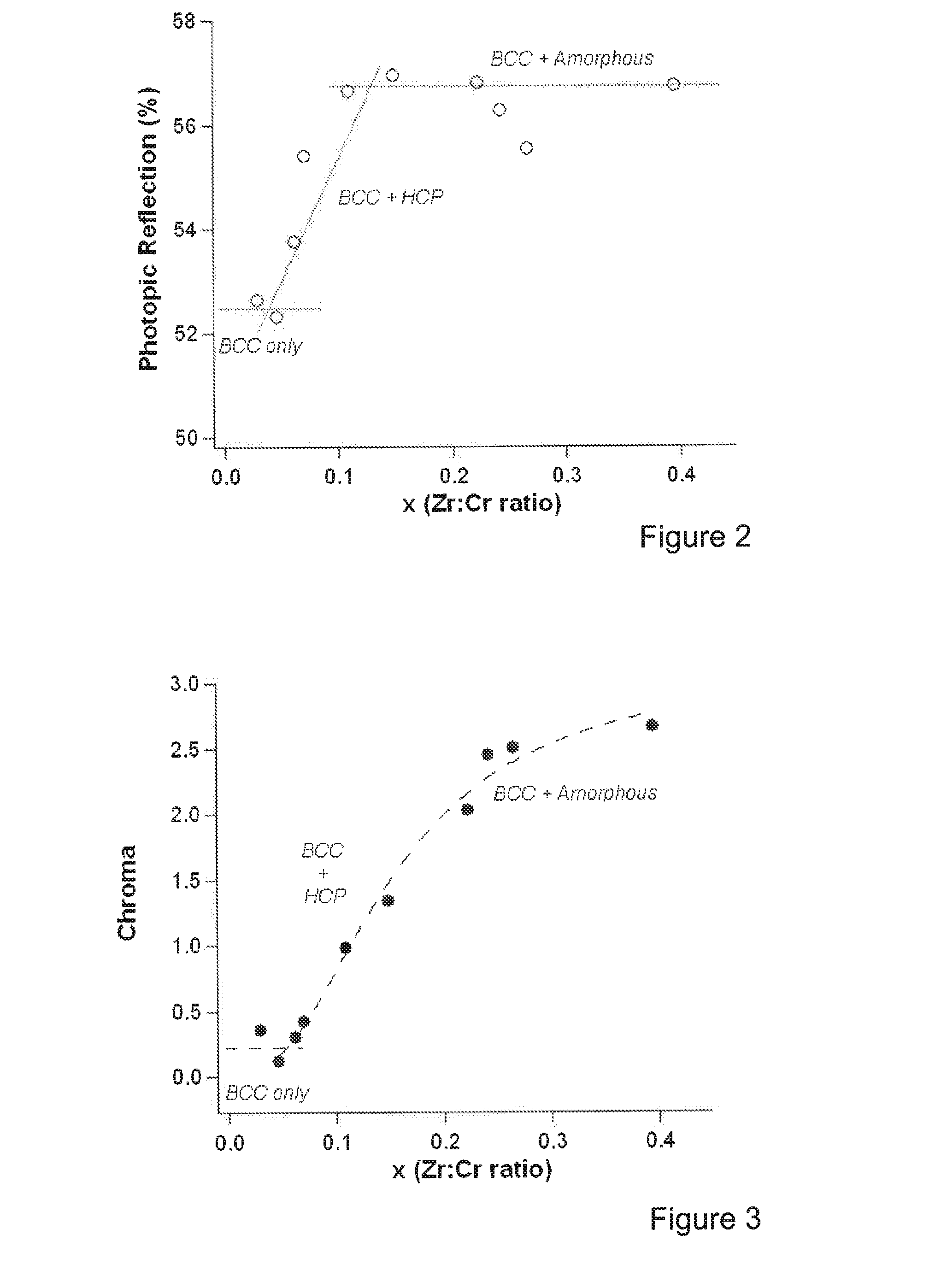

Chromium-based reflective coating

ActiveUS9181616B2High melting pointStable crystal structureMirrorsLighting and heating apparatusDopantPolymer substrate

A chromium-based reflective coating for a polymeric substrate, wherein the coating has a thickness of 200 nm or less and is an alloy of chromium and a dopant material, the dopant material being selected from the hexagonally close-packed transition metals, the alloy having a crystal structure of a primary body-centered cubic phase in coexistence with a secondary omega hexagonally close-packed phase.

Owner:SMR PATENTS S A R L +1

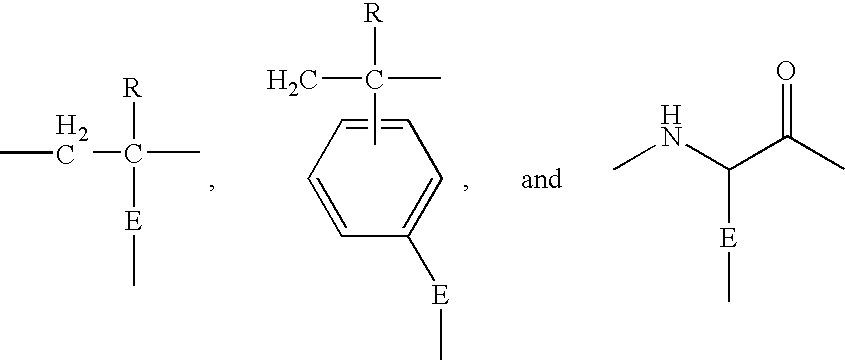

Thermochromic responsive elastic polymer substrate

InactiveUS20090143516A1Male contraceptivesTemperature measurement in household appliancesBetaineThermochromism

A material composition including a flexible, polymeric matrix and a reverse-thermochromic colorant is described. When subjected to a heat source, the polymeric material can change color from a pale or neutral color to a darker or more vibrant color of a Delta E (ΔE) change of >3. The reverse-thermochromic colorant exhibits a color change when exposed to a heat source within a period of about 30 seconds, and is observable by an unaided human eye under either natural daylight or ambient artificial normal lighting conditions. One or more different reverse-thermochromic colorants in combination may be incorporated. The polymeric matrix surrounds or encapsulates a solvatochromic dye molecule with a phenolate betaine structure. The polymeric matrix includes a dipole orientating agent that induces said solvatochromic dye to express locally when subjected to a temperature change. Various uses for the composition and articles that incorporate the composition are also described, in addition to a method of indicating the temperature of an object or environmental condition.

Owner:KIMBERLY-CLARK WORLDWIDE INC

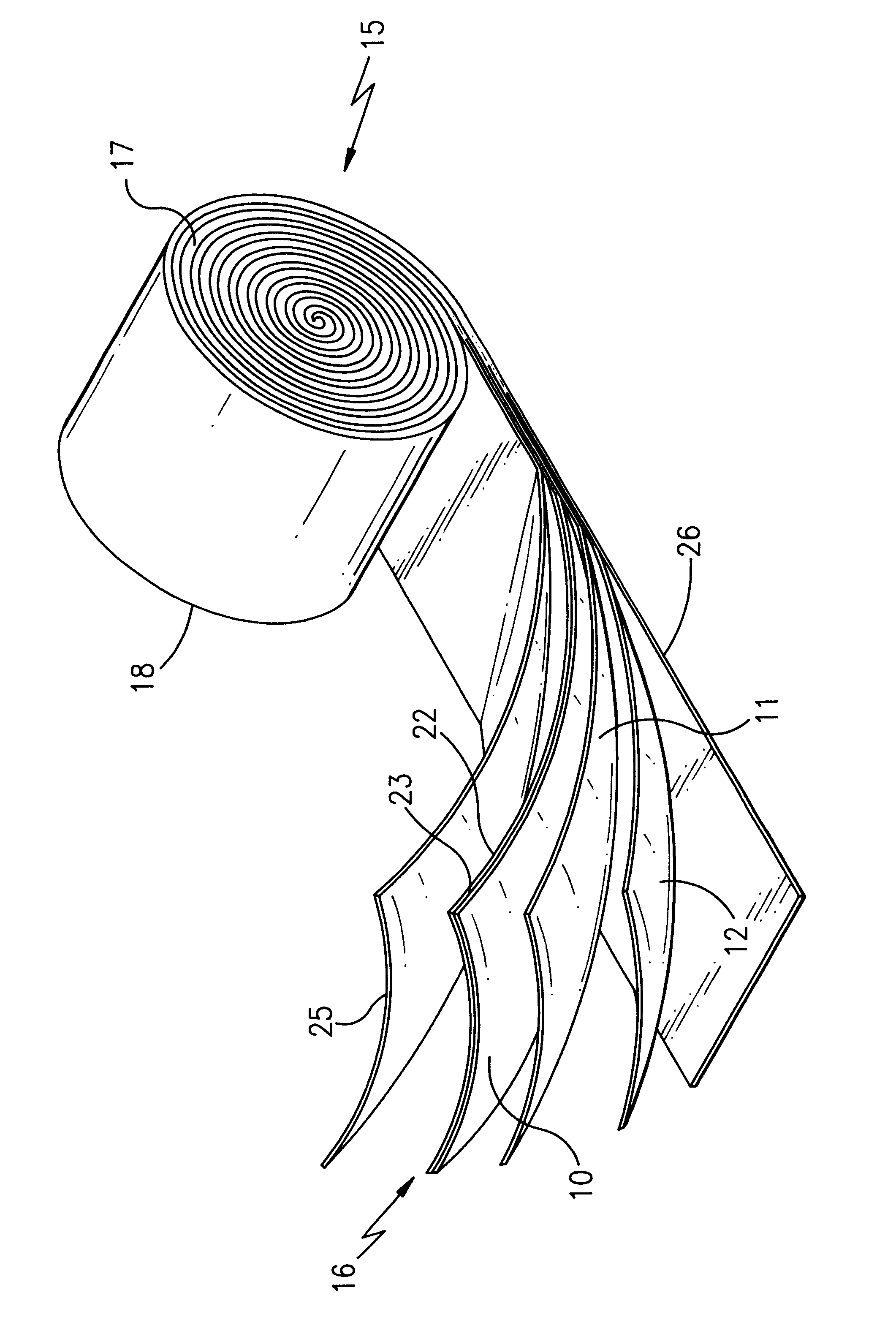

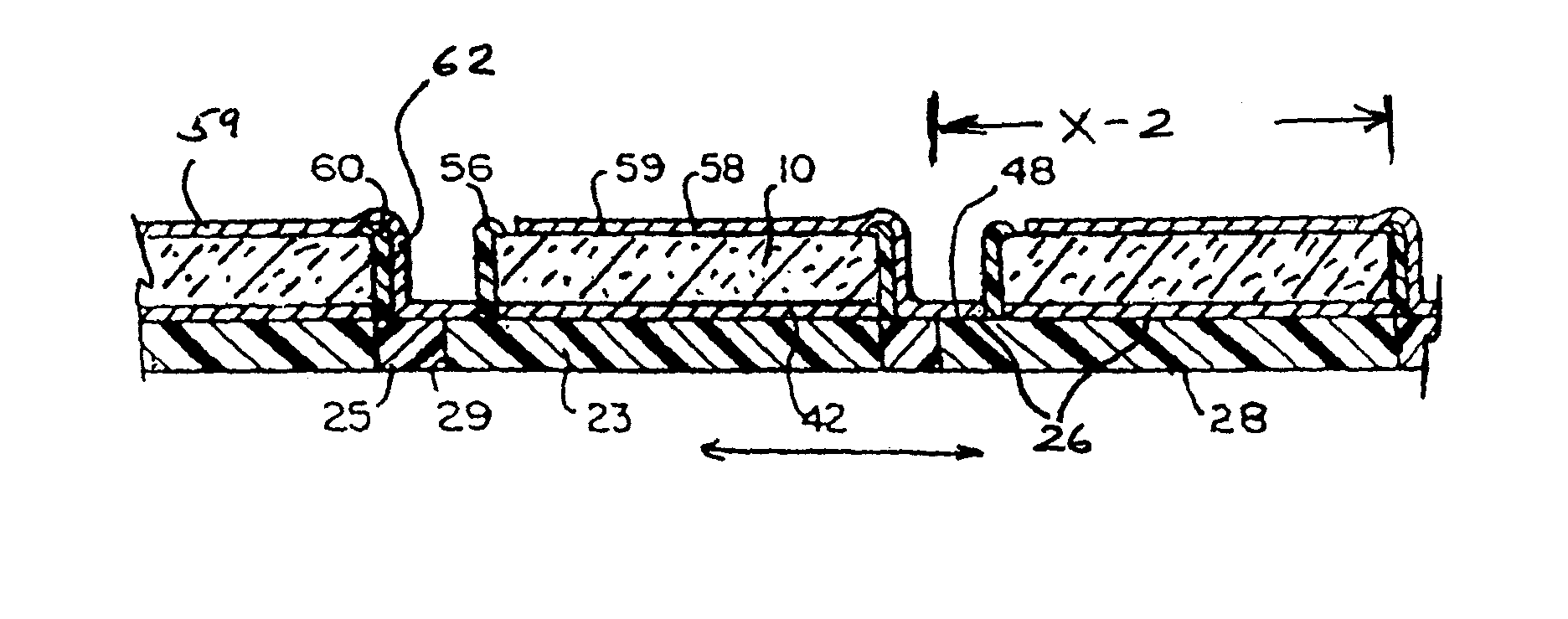

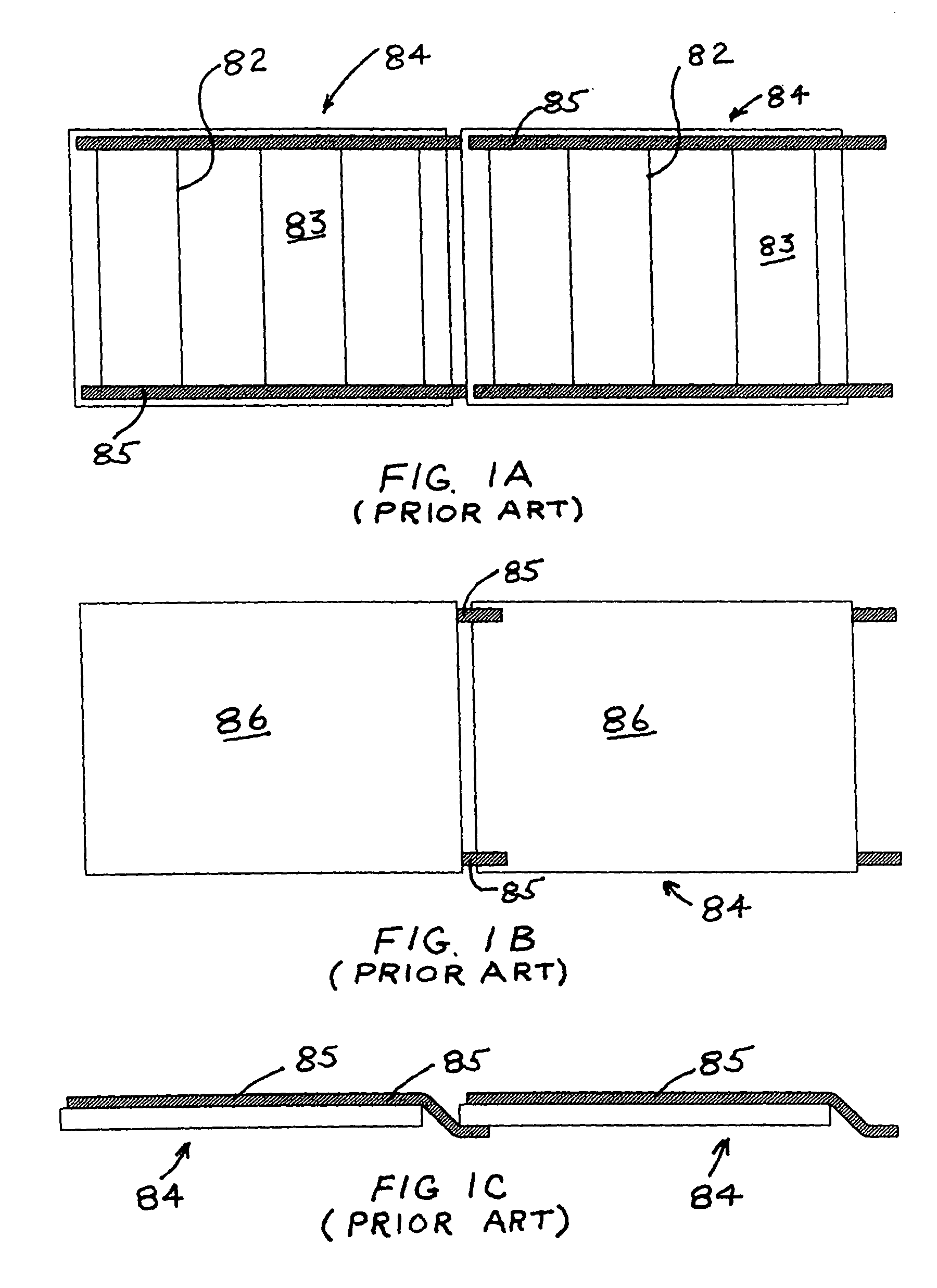

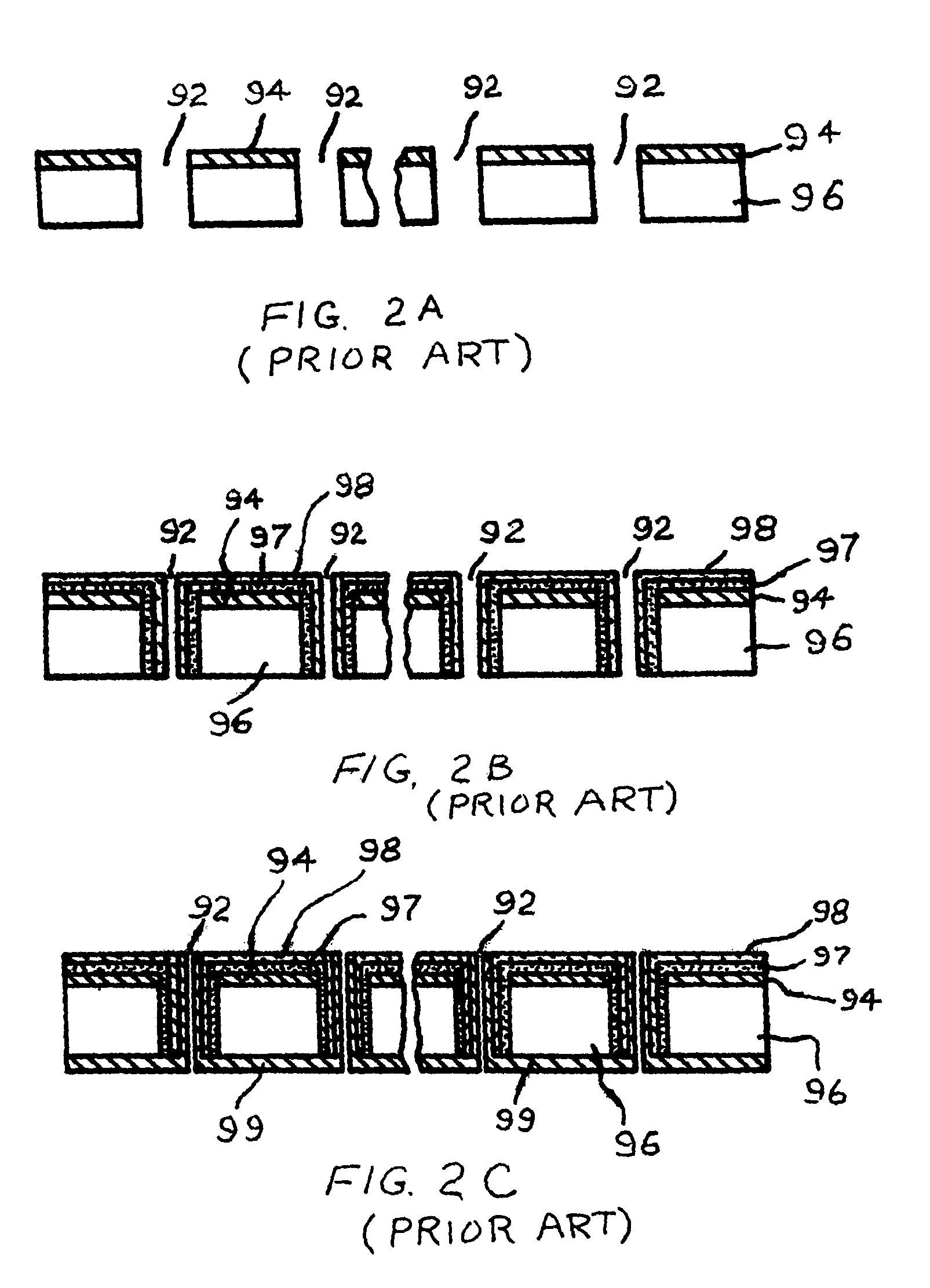

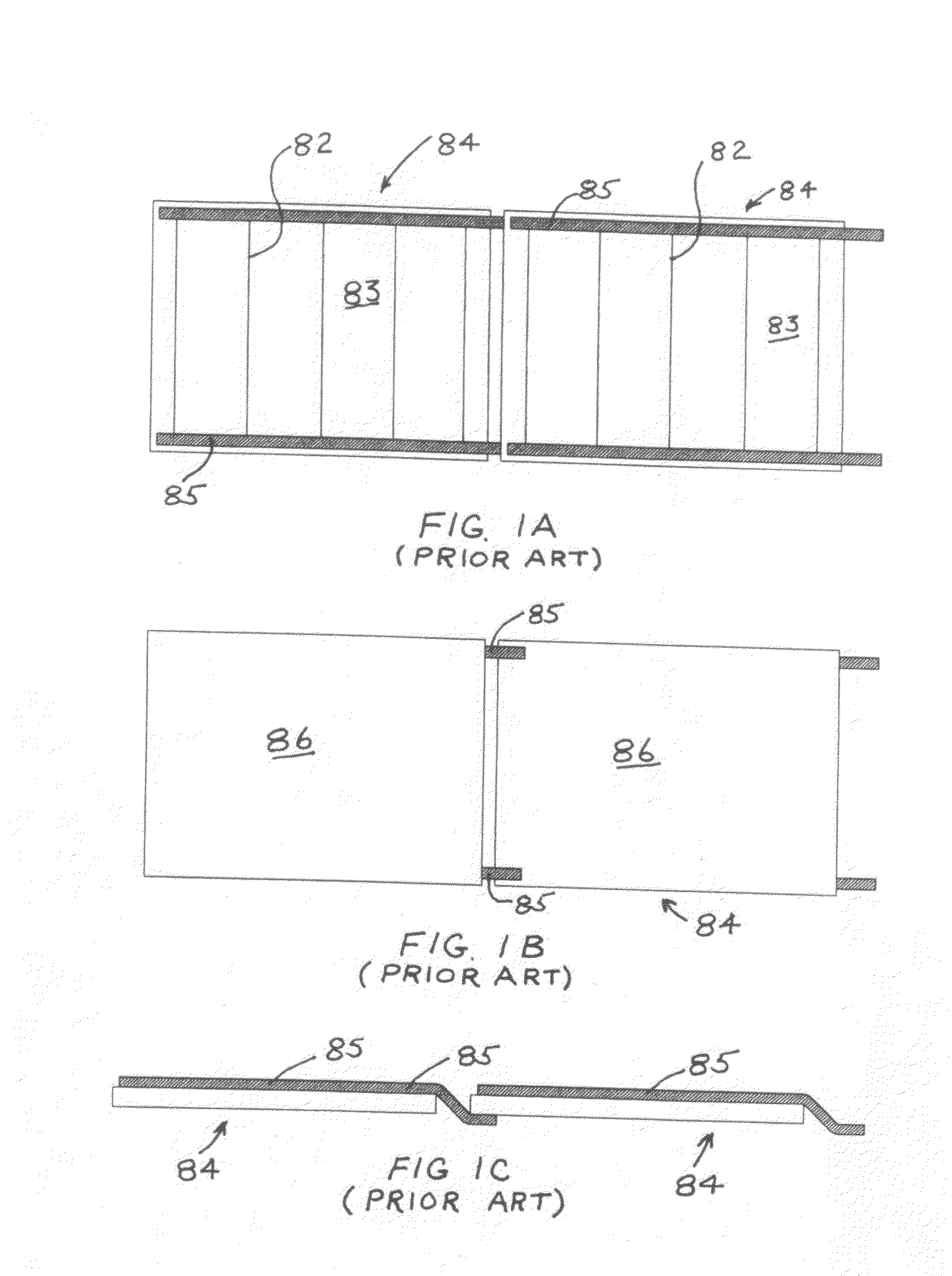

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS7732243B2Eliminate deficienciesFacilitate electrical interconnectionPV power plantsSolid-state devicesPolymer substrateMaterial removal

Owner:SOLANNEX

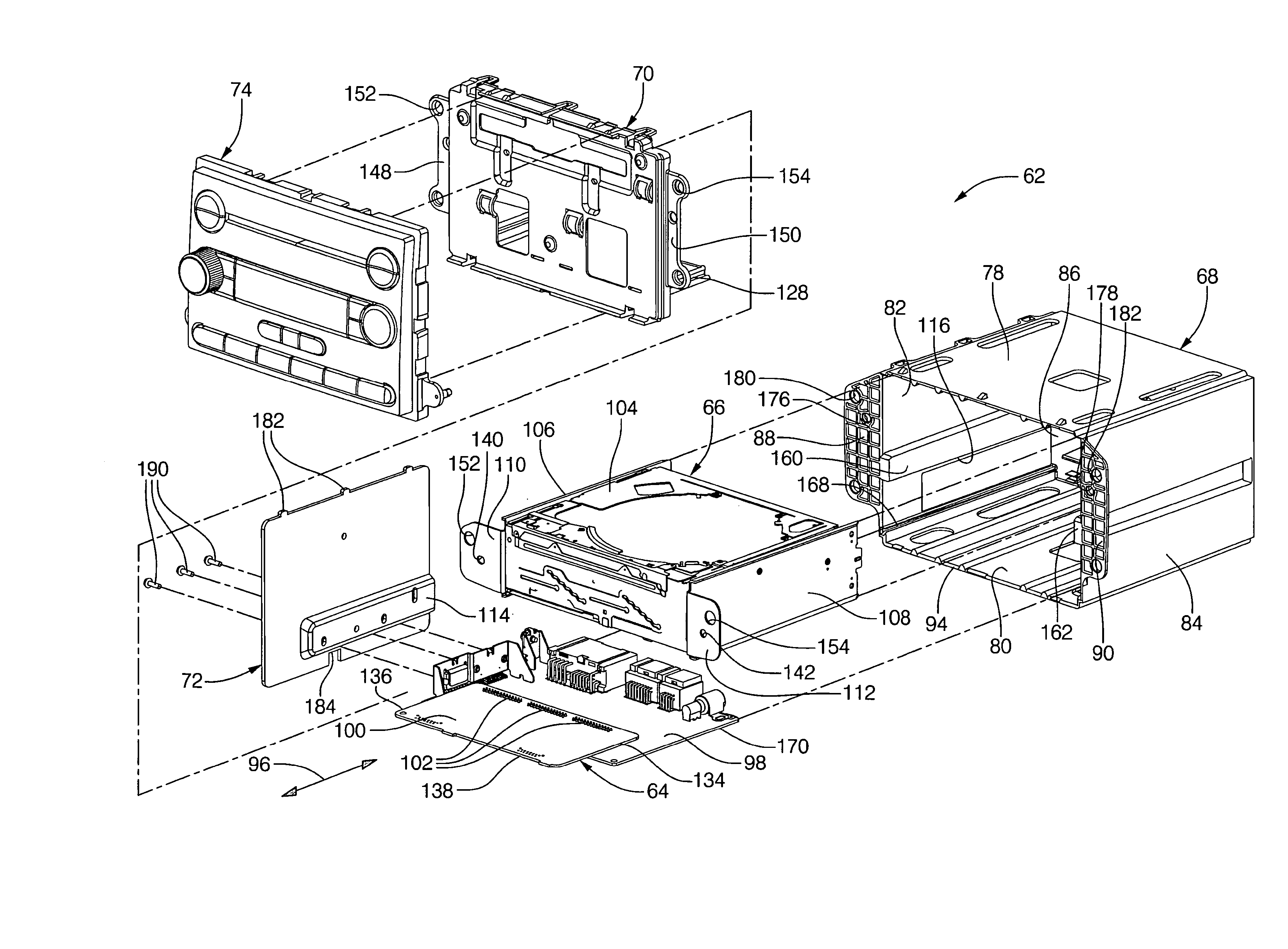

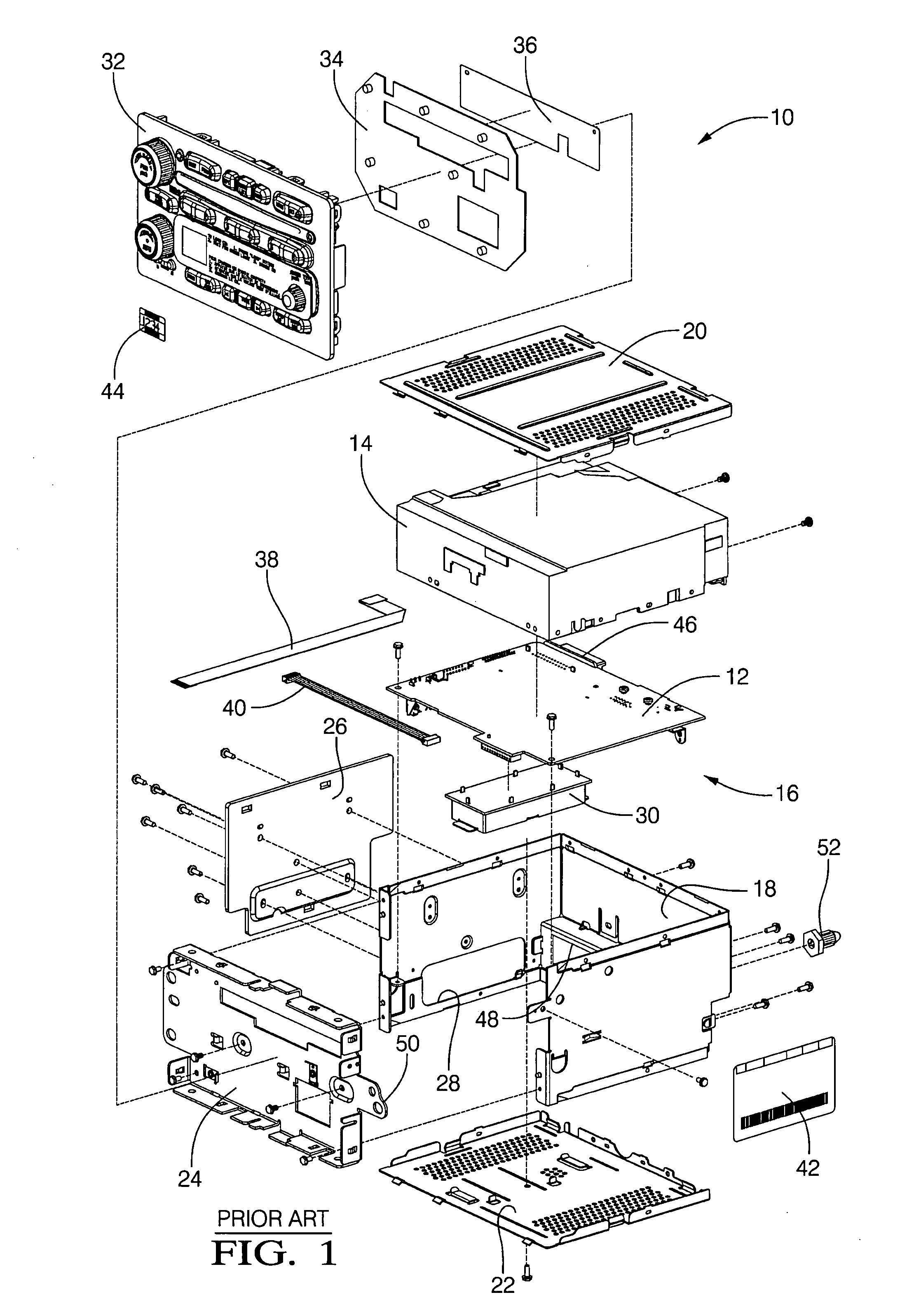

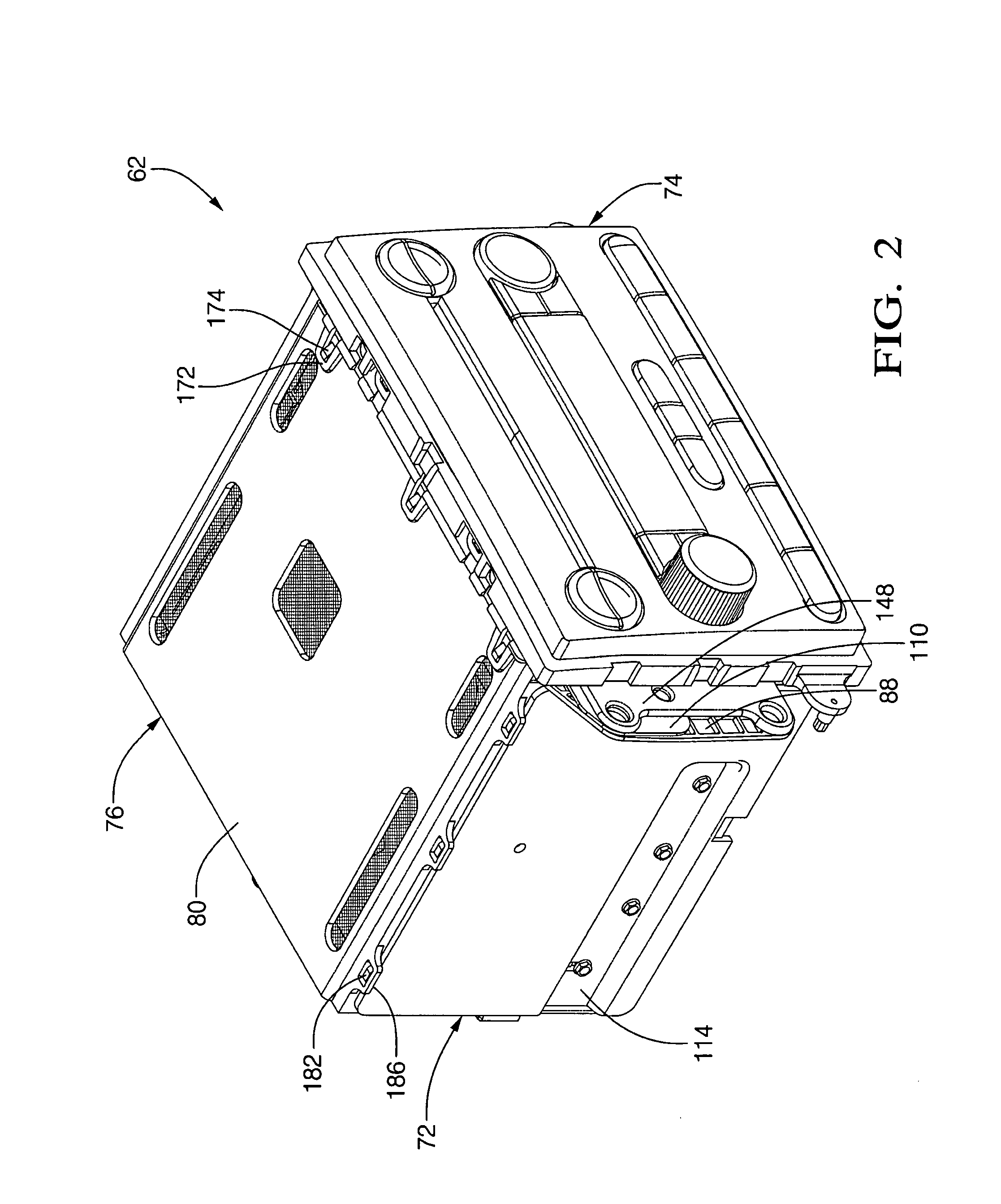

Lightweight audio system for automotive applications and method

InactiveUS20080049949A1Substantial costSubstantial labor savingVehicle testingShielding materialsRadio receiverPolymer substrate

A lightweight radio / CD player for vehicular application is virtually “fastenerless” and includes a case and frontal interface formed of polymer based material that is molded to provide details to accept audio devices such as playback mechanisms (if desired) and radio receivers, as well as the circuit boards required for electrical control and display. The case and frontal interface are of composite structure, including an insert molded electrically conductive wire mesh screen that has been pre-formed to contour with the molding operation. The wire mesh provides EMC, RFI, BCI and ESD shielding and grounding of the circuit boards via exposed wire mesh pads and adjacent ground clips. The PCB architecture is bifurcated into a first board carrying common circuit components in a surface mount configuration suitable for high volume production, and a second board carrying application specific circuit components in a wave soldered stick mount configuration. The major components and subassemblies are self-fixturing during the final assembly process, eliminating the need for dedicated tools, fixtures and assembly equipment. The major components and subassemblies self-interconnect by integral guide and connection features effecting “slide lock” and “snap lock” self-interconnection. The radio architecture includes improved push buttons employing 4-bar living hinge linkage and front loaded decorative trim buttons.

Owner:APTIV TECH LTD

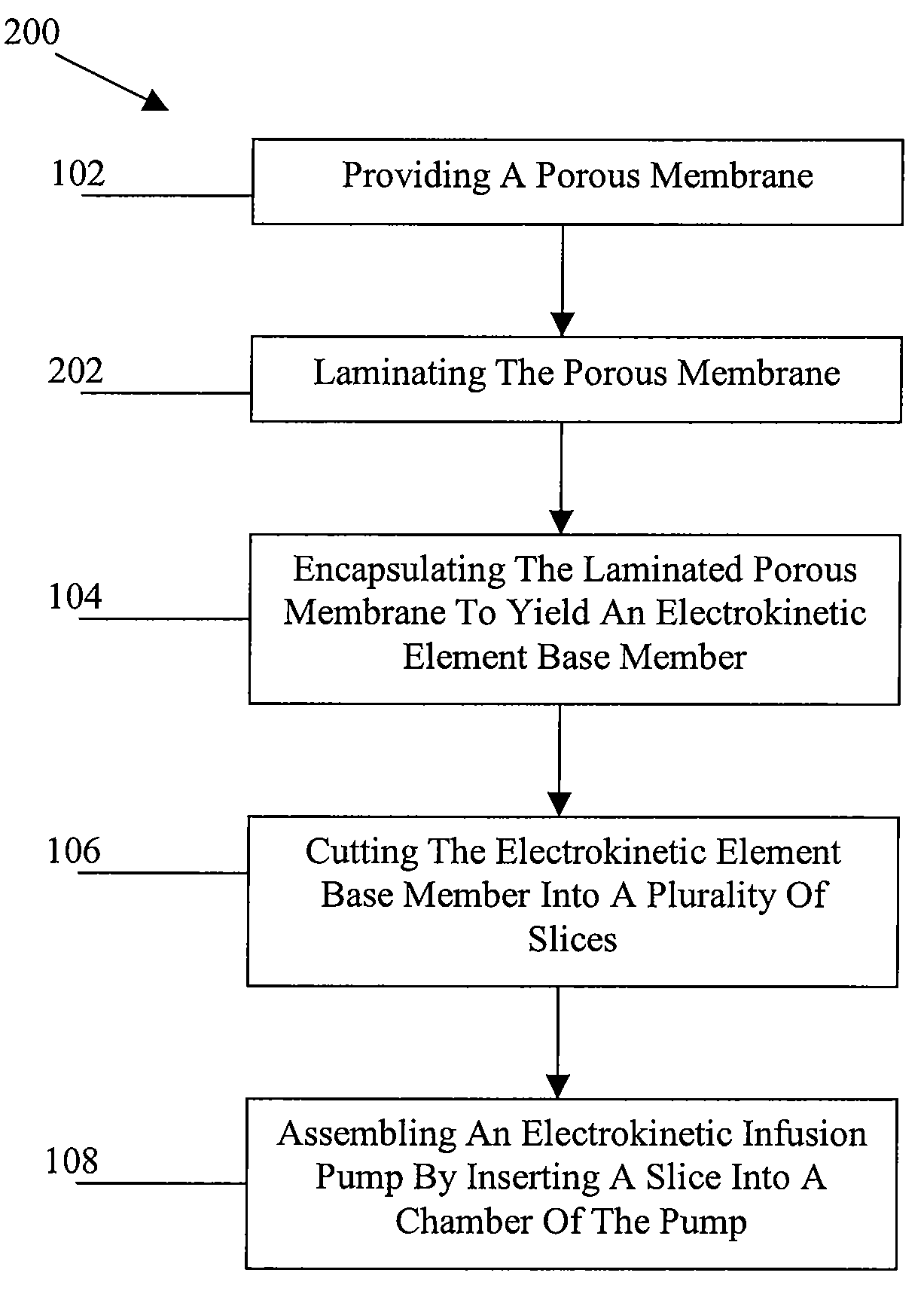

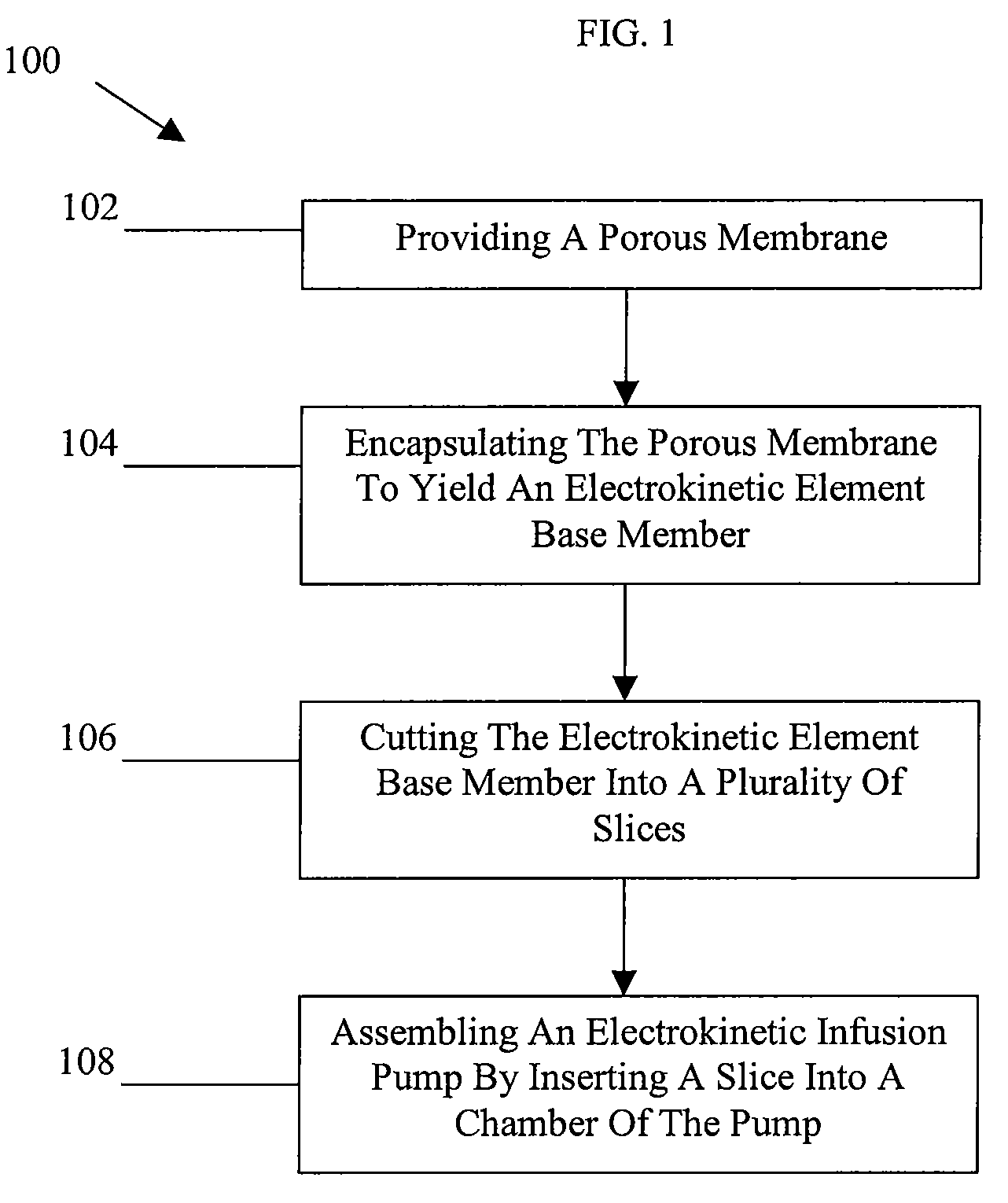

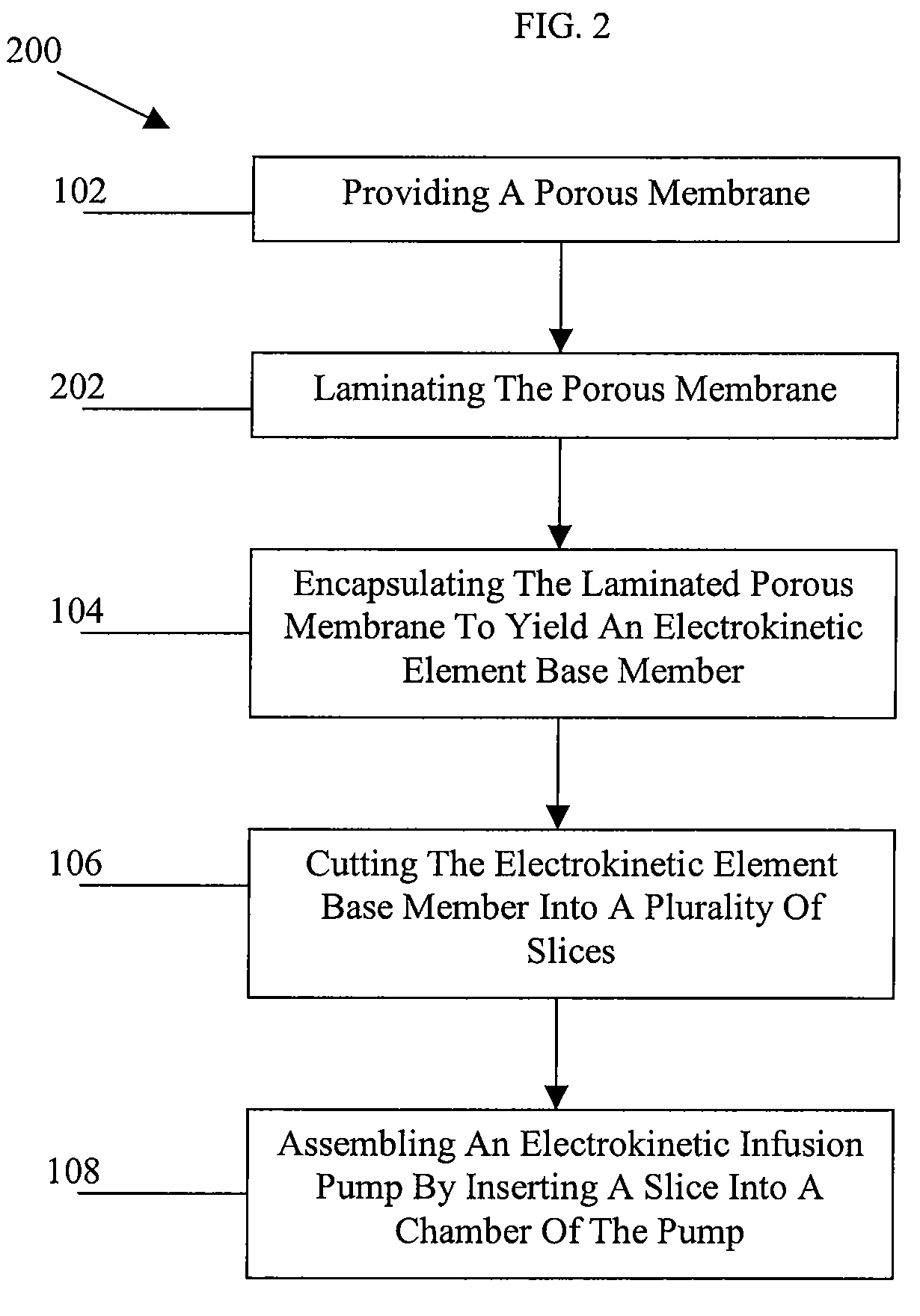

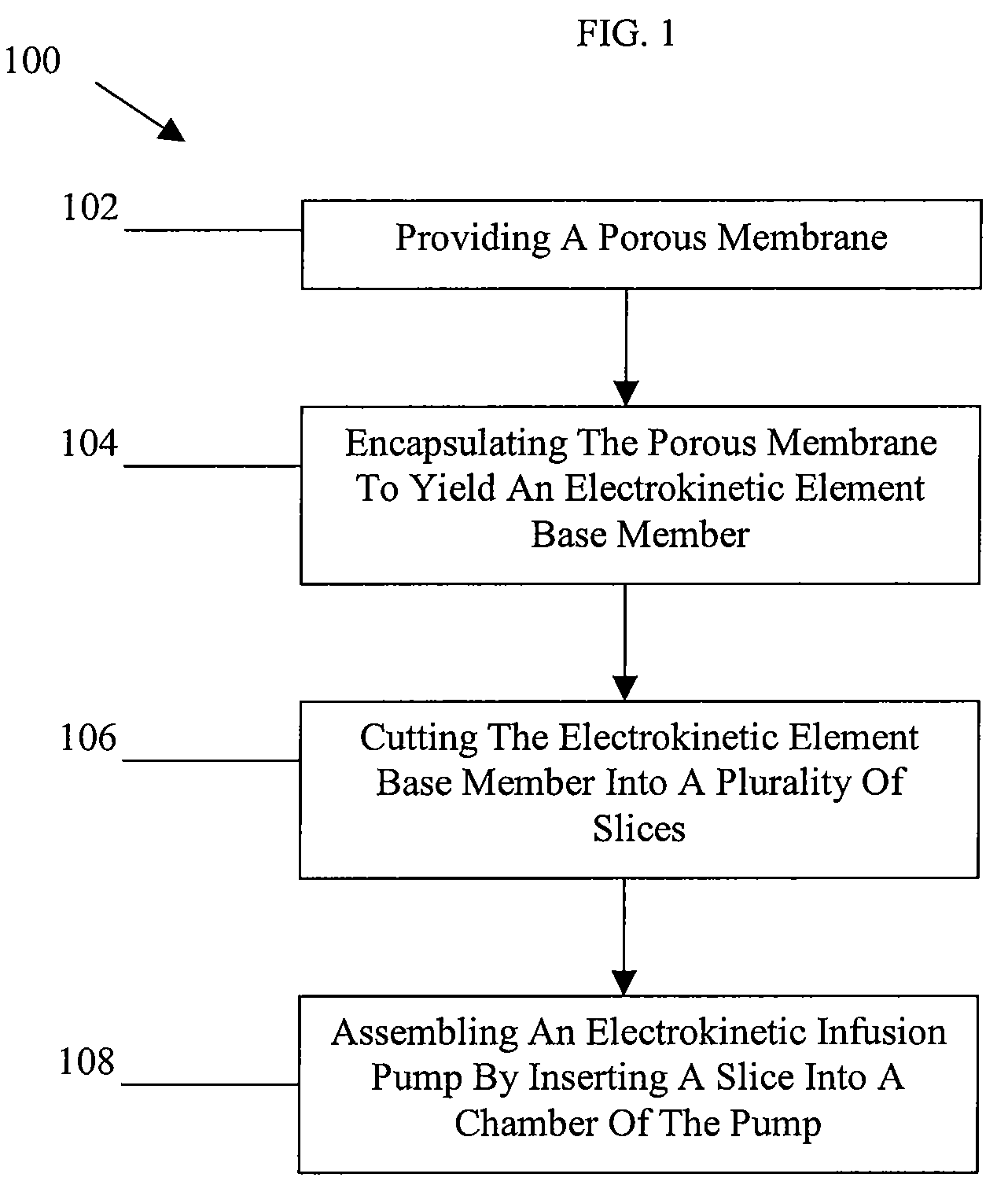

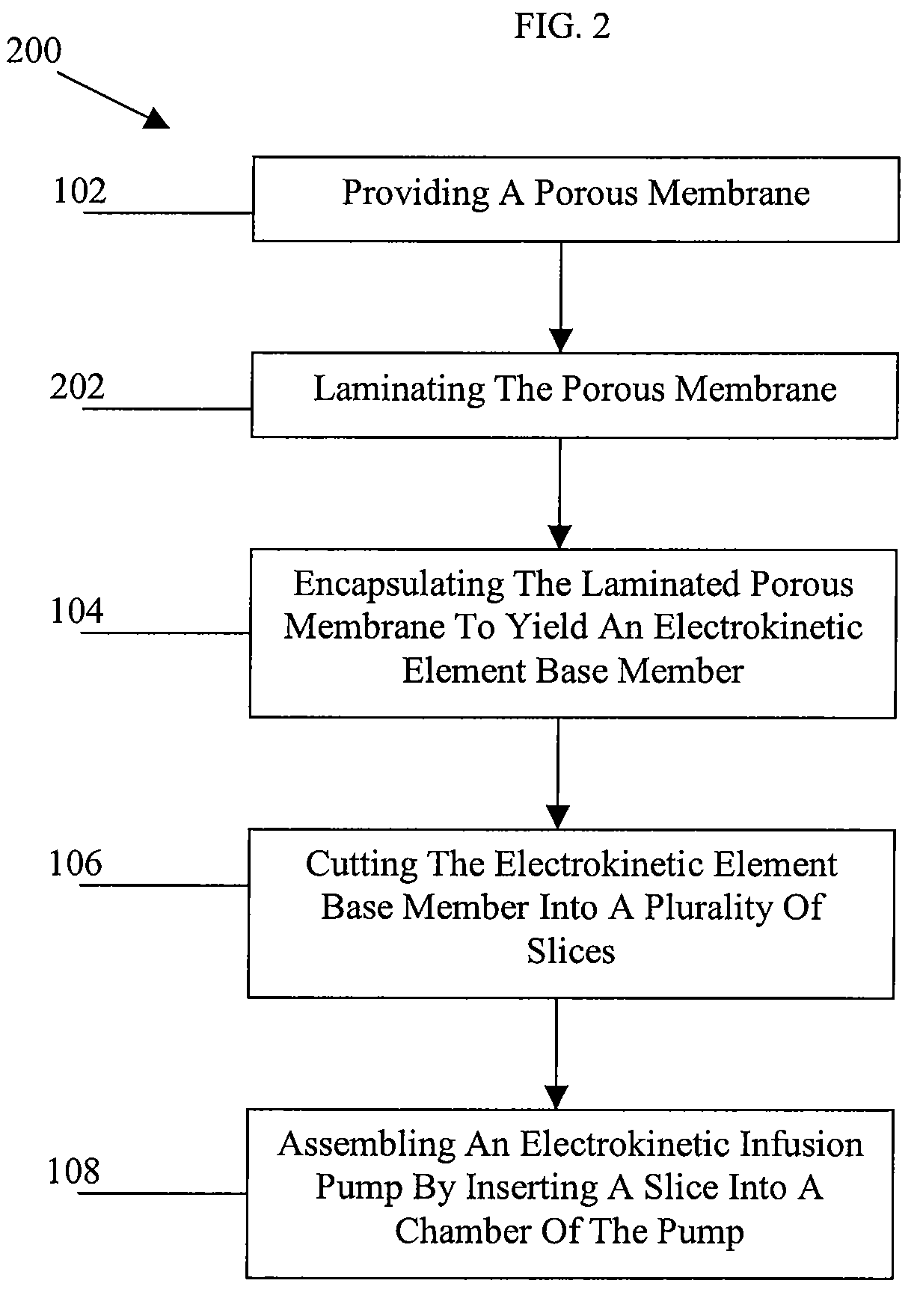

Method for preparing an electrokinetic element

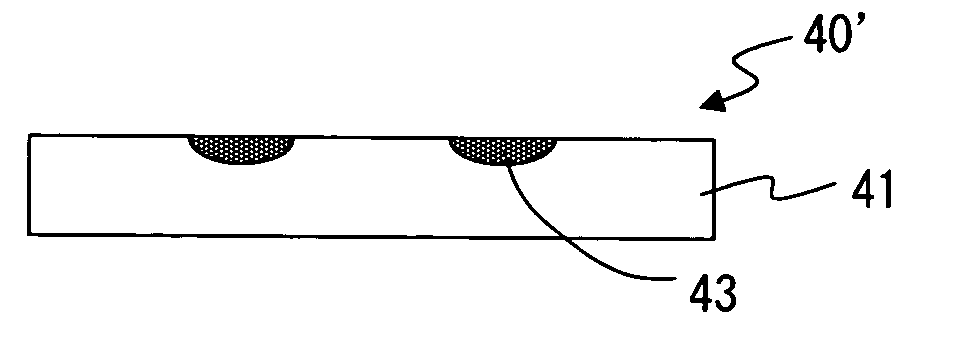

A method for preparing an electrokinetic element is provided and generally includes providing a porous membrane adapted for use in an electrokinetic pump and encapsulating the porous membrane within a polymer substrate to yield an electrokinetic element base member having the porous membrane encapsulated by the polymer. In one embodiment, the method can include laminating the porous membrane between opposed sheets of a polymer before the step of encapsulating. The method can also include cutting the electrokinetic element base member into a plurality of slices and assembling an electrokinetic infusion pump by inserting a slice into a chamber of the pump.

Owner:LIFESCAN IP HLDG LLC

Method for preparing an electrokinetic element

A method for preparing an electrokinetic element is provided and generally includes providing a porous membrane adapted for use in an electrokinetic pump and encapsulating the porous membrane within a polymer substrate to yield an electrokinetic element base member having the porous membrane encapsulated by the polymer. In one embodiment, the method can include laminating the porous membrane between opposed sheets of a polymer before the step of encapsulating. The method can also include cutting the electrokinetic element base member into a plurality of slices and assembling an electrokinetic infusion pump by inserting a slice into a chamber of the pump.

Owner:LIFESCAN IP HLDG LLC

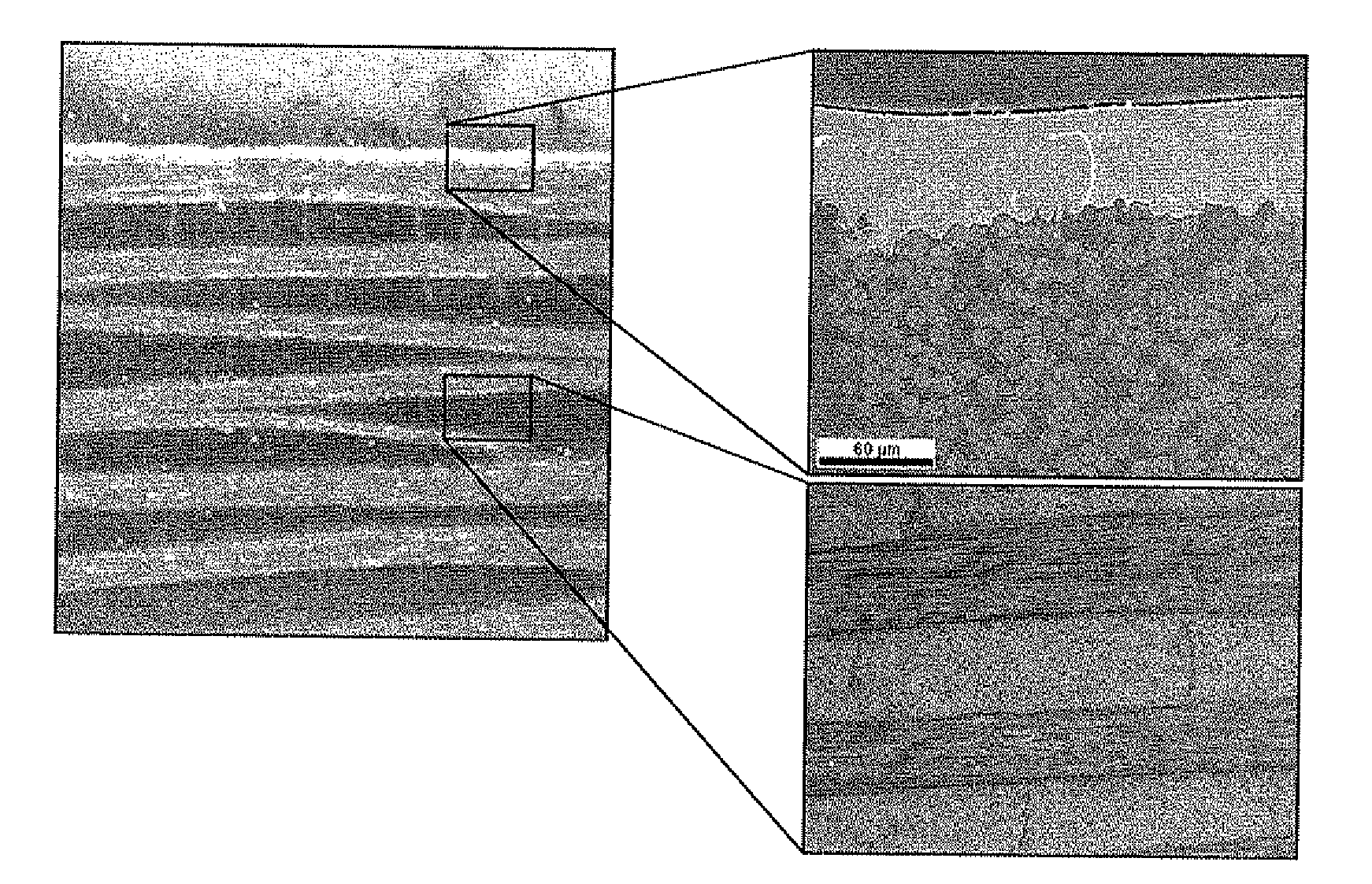

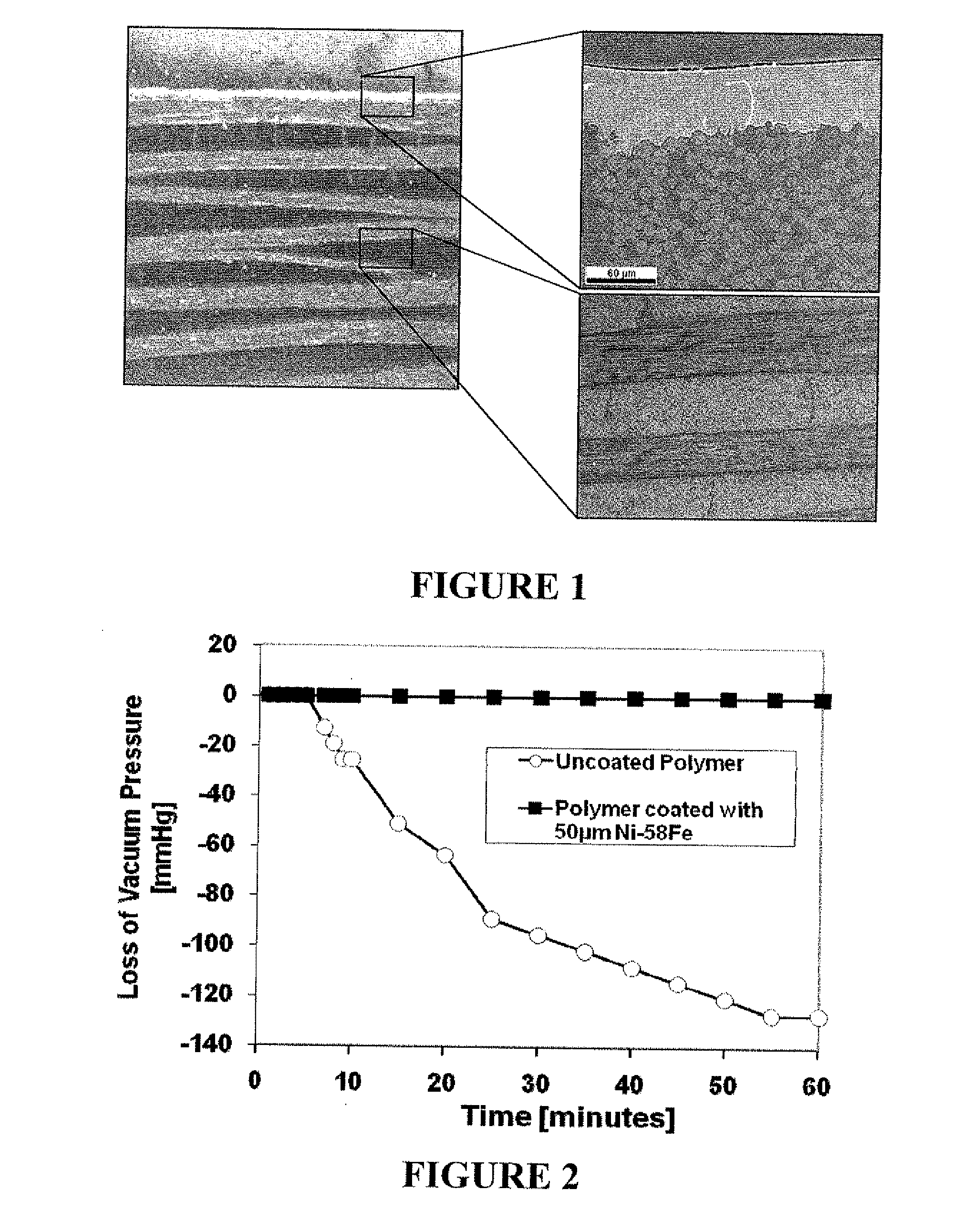

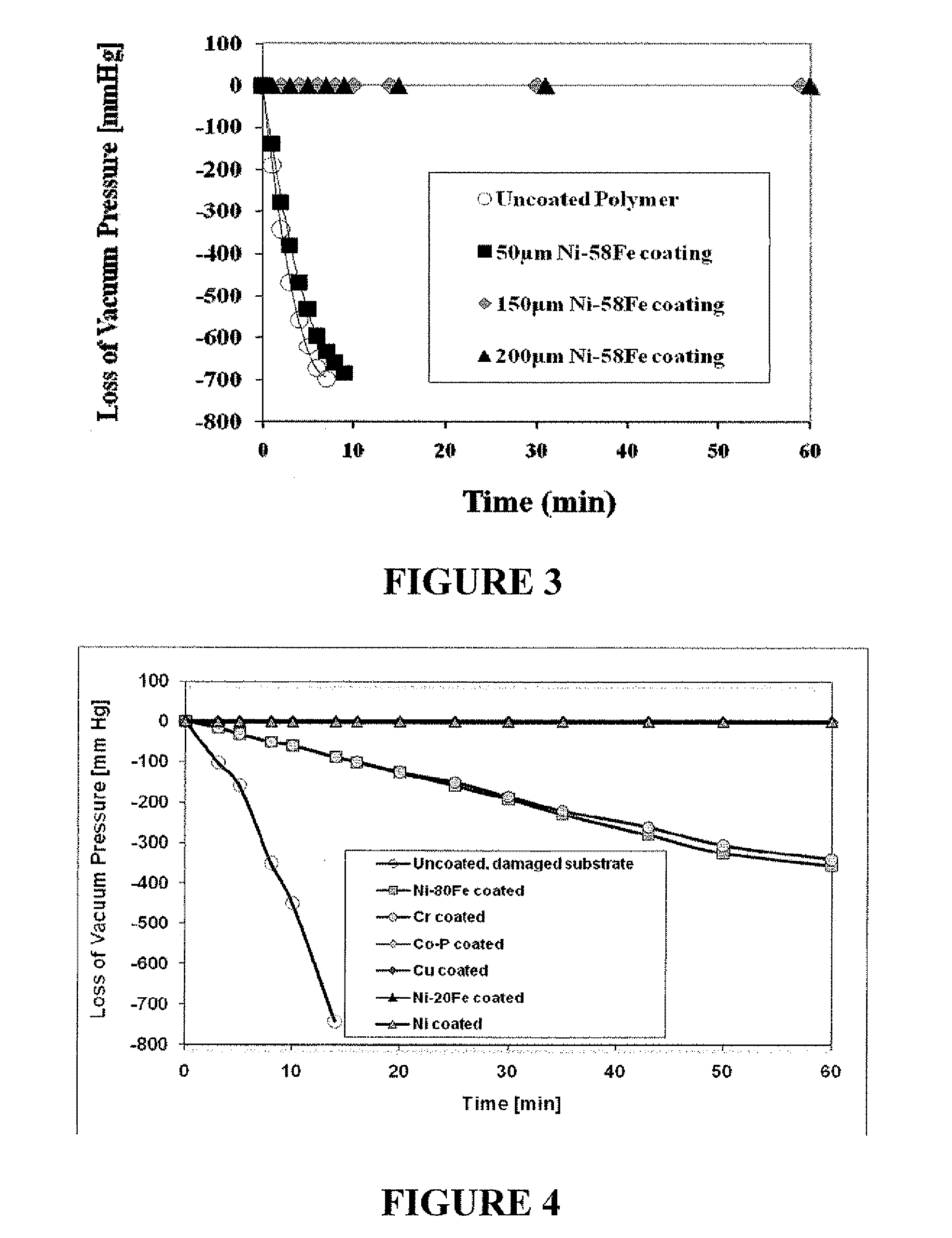

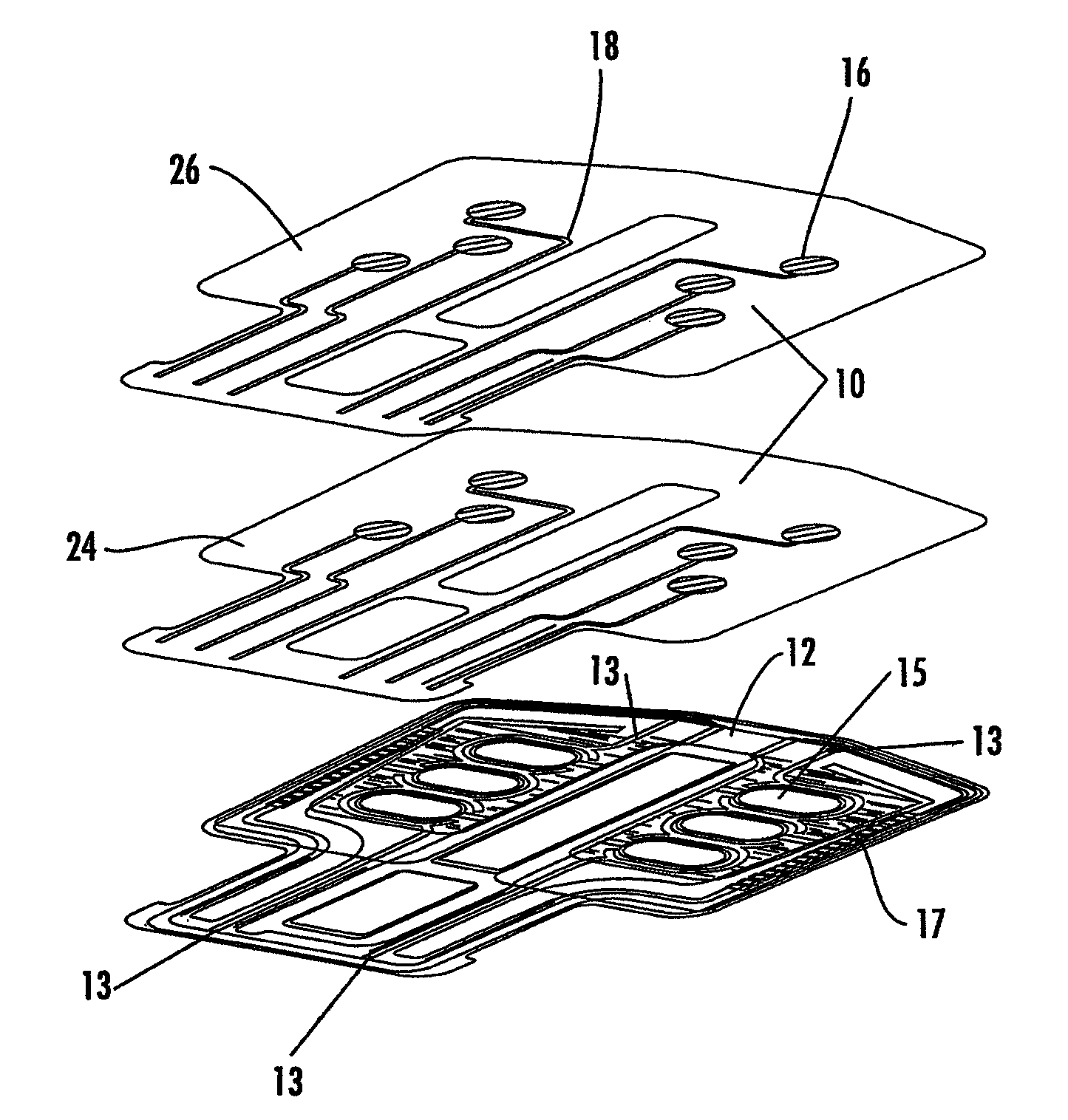

Metal-coated polymer article of high durability and vacuum and/or pressure integrity

InactiveUS20100304063A1Increased durabilityEnhance pressure integrityPretreated surfacesSolid state diffusion coatingPolymer compositesPolymer substrate

Metal-coated polymer articles containing structural substantially porosity-free, fine-grained and / or amorphous metallic coatings / layers optionally containing solid particulates dispersed therein on polymer substrates, are disclosed. The substantially porosity-free metallic coatings / layers / patches are applied to polymer or polymer composite substrates to provide, enhance or restore vacuum / pressure integrity and fluid sealing functions. Due to the excellent adhesion between the metallic coating and the polymer article satisfactory thermal cycling performance is achieved. The invention can also be employed as a repair / refurbishment technique. The fine-grained and / or amorphous metallic coatings are particularly suited for strong and lightweight articles, precision molds, sporting goods, aerospace and automotive parts and other components exposed to thermal cycling and stress created by erosion and impact damage.

Owner:INTEGRAN TECH

Seat heater with occupant sensor

ActiveUS7500536B2Reduce misreadingLow costSeat heating/ventillating devicesElectric devicesPolymer substrateSeat belt

The present invention relates to a combination heater and occupant sensor device that may be used in an automobile seat. The device will heat a seat and sense the mass of an occupant in the seat. The device provides the ability to combine occupant sensors with a seat heater without damaging the sensors or obtaining incorrect sensor readings. The sensor results may be processed and used to control air bag deployment, for example, or to indicate if the seat belt of an occupied seat is not being employed. To provide flexibility of the device during use, the device may be formed on a polymer substrate and configured to include apertures throughout. In addition, in the heating portion of the device, conductive material may be blended in a polymer and the device may be configured to limit conductor cracking after repeated flexing of the device thus extending the life of the device.

Owner:ILLINOIS TOOL WORKS INC

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS20080314433A1Minimization requirementsIncrease volumePV power plantsPhotovoltaic energy generationPolymer substrateMaterial removal

This invention comprises manufacture of photovoltaic cells by deposition of thin film photovoltaic junctions on metal foil substrates. The photovoltaic junctions may be heat treated if appropriate following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation, an interconnection substrate structure is provided, optionally in a continuous fashion. Multiple photovoltaic cells are then laminated to the interconnection substrate structure and conductive joining methods are employed to complete the array. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials employing optimal processing unique to polymeric materials. Furthermore, the photovoltaic junction and its metal foil support can be produced in bulk without the need to use the expensive and intricate material removal operations currently taught in the art to achieve series interconnections.

Owner:SOLANNEX

Flexible electrode array for artifical vision

An image is captured or otherwise converted into a signal in an artificial vision system. The signal is transmitted to the retina utilizing an implant. The implant consists of a polymer substrate made of a compliant material such as poly(dimethylsiloxane) or PDMS. The polymer substrate is conformable to the shape of the retina. Electrodes and conductive leads are embedded in the polymer substrate. The conductive leads and the electrodes transmit the signal representing the image to the cells in the retina. The signal representing the image stimulates cells in the retina.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC +1

Hydrophobic self-cleaning coating composition

InactiveUS20080250978A1Efficient use ofSolve the lack of resistanceSemiconductor/solid-state device manufacturingMixingWater basedMineral spirit

The present invention provides a water based, low VOC super hydrophobic coating composition that can be used to make wet and dry dirt repellent surfaces to keep the surfaces clean for a reasonable period of time. The coating utilizes hydrophobic nanoparticles dispersed in water. This treatment produces a virtually transparent coating releasing very little or no VOC compounds whereas previous coatings of comparable hydrophobicity release up to 99 percent VOC compounds. The coating can be applied by a simple, single application method and the super hydrophobic property can be achieved by drying at room temperature for 5 to 10 minutes. A preferred coating can be easily removed and renewed when desired. The aqueous hydrophobic self cleaning coating composition that can be applied by conventional methods such as by spraying the composition onto a surface creating a wet and dry dirt repellent coating on the surface. The hydrophobic self cleaning coatings are used on exterior automotive and boat surfaces, and in many other applications, to produce a self cleaning surface, reduce adherence of dirt and contaminants to a treated surface, and reduce drag in some applications providing an energy savings. The coating solves the problem of poor resistance to UV light, opaque appearance, and / or abrasion found in previous coatings of similar nature. A preferred coating has good resistance to UV light and some resistance to abrasion. Clear, nearly transparent and translucent coatings are produced as compared to conventional coatings of comparable hydrophobicity which are typically white or opaque. The coating can be applied by a single and easy spraying method and the super hydrophobic property can be achieved by drying the film by evaporation of the solvent wetting solution and water based carrier at ambient temperature for 5 to 10 minutes. Embodiments of the hydrophobic self-cleaning coating composition can be produced resulting in a clear coating or in some cases a translucent dirt repellant film or coating on painted material, plastic, metal, glass, ceramic, fiberglass or a polymer substrate. The coating typically utilizes hydrophobic nanoparticles of fumed silica and / or titania wetted by a hydrophilic solvent such as acetone for no VOC applications, or with mineral spirits, alcohol or a light distillate if VOC are not a consideration, together with a selected surfactant typically having an HLB value in a range of from 9 to 13.At least one preferred coating composition comprising an effective amount of a treated fumed silica wetted with a solvent and dispersed in water, upon drying, resulted in a coated surface providing a contact angle of at least 165 degrees and a surface energy below 12 dynes / centimeter as compared to water having a contact angle of from 65 to 80 degrees on a noncoated surface. The composition imparts a degree of hydrophobicity to a surface so that the surface will have a tilt angle of sliding of less than 2 degrees as compared to water on a noncoated surface having a tilt angle of sliding of 90 degrees or higher. The coating composition is removed by washing with a detergent or applying pressure to the coating wiping same from the treated surface. Exposure to water in the form of rain or snow does not remove the coating composition.

Owner:ASHLAND LICENSING & INTPROP LLC

Composite solid polymer electrolyte membranes

InactiveUS20050031925A1Improve performanceLow costElectrolyte holding meansSemi-permeable membranesPolymer electrolytesPolymer science

The present invention relates to composite solid polymer electrolyte membranes (SPEMs) which include a porous polymer substrate interpenetrated with a water soluble ion-conducting material. SPEMs of the present invention are useful in electrochemical applications, including fuel cells and electrodialysis.

Owner:FOSTER-MILLER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com