Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

283 results about "Plane orientation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

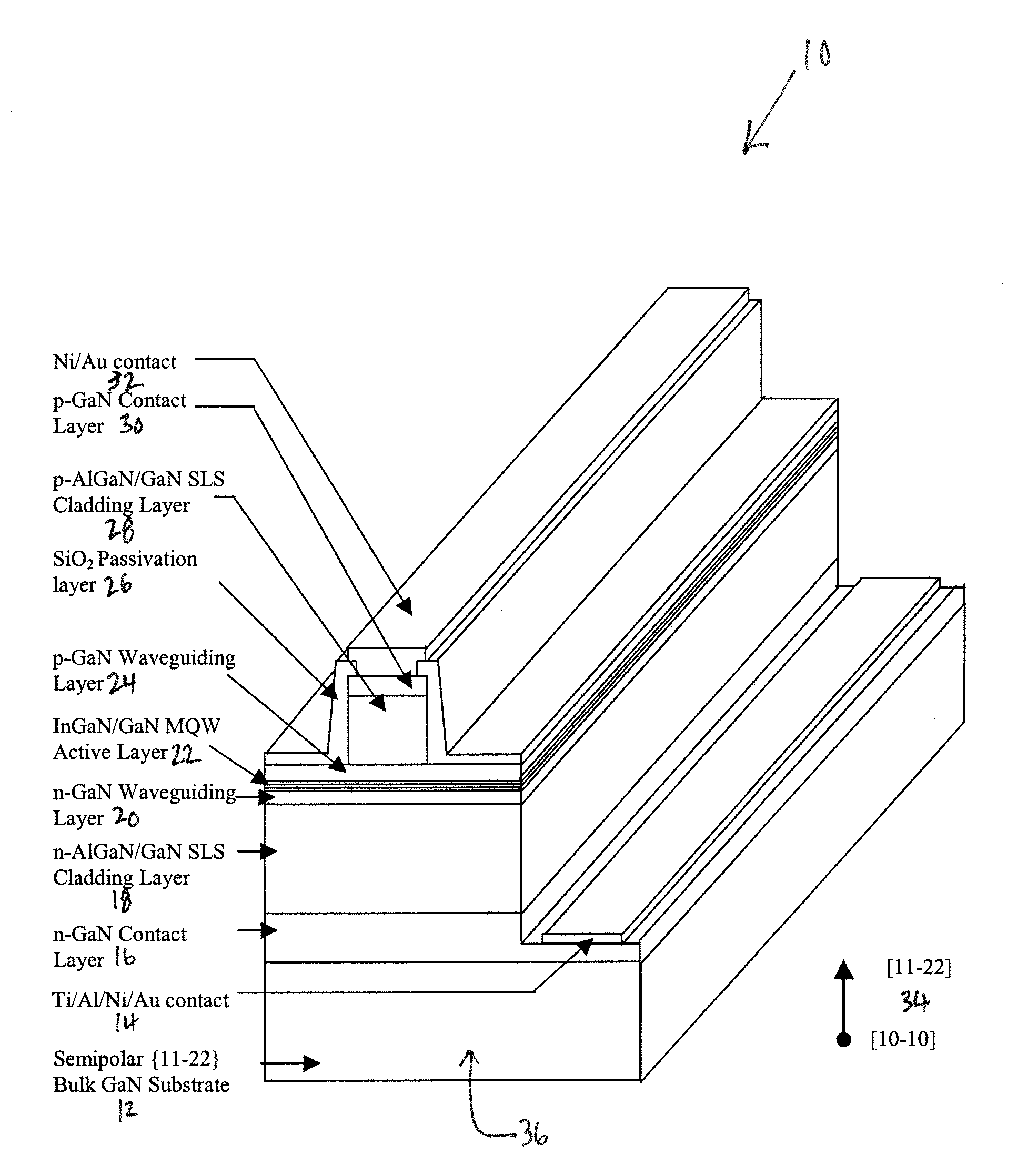

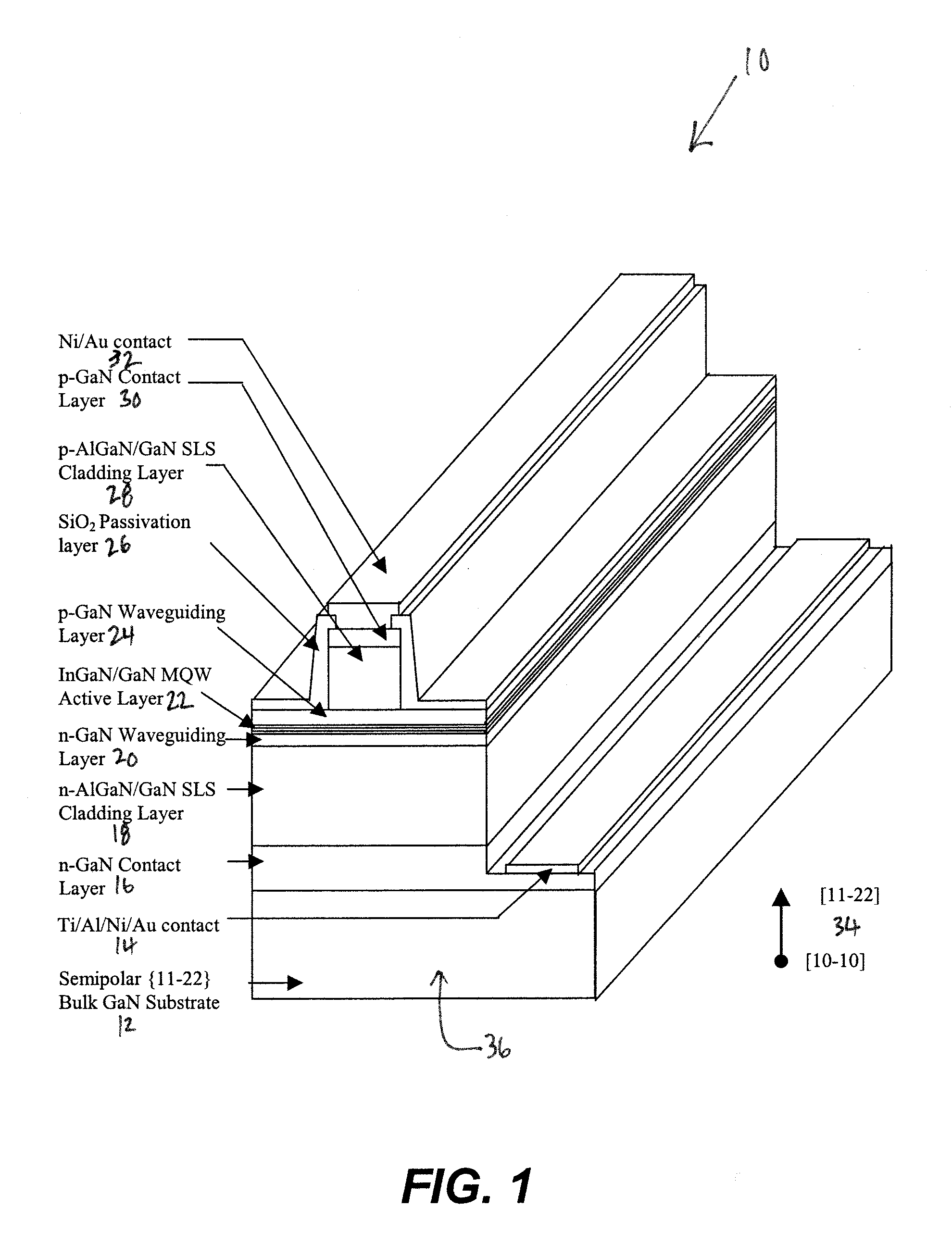

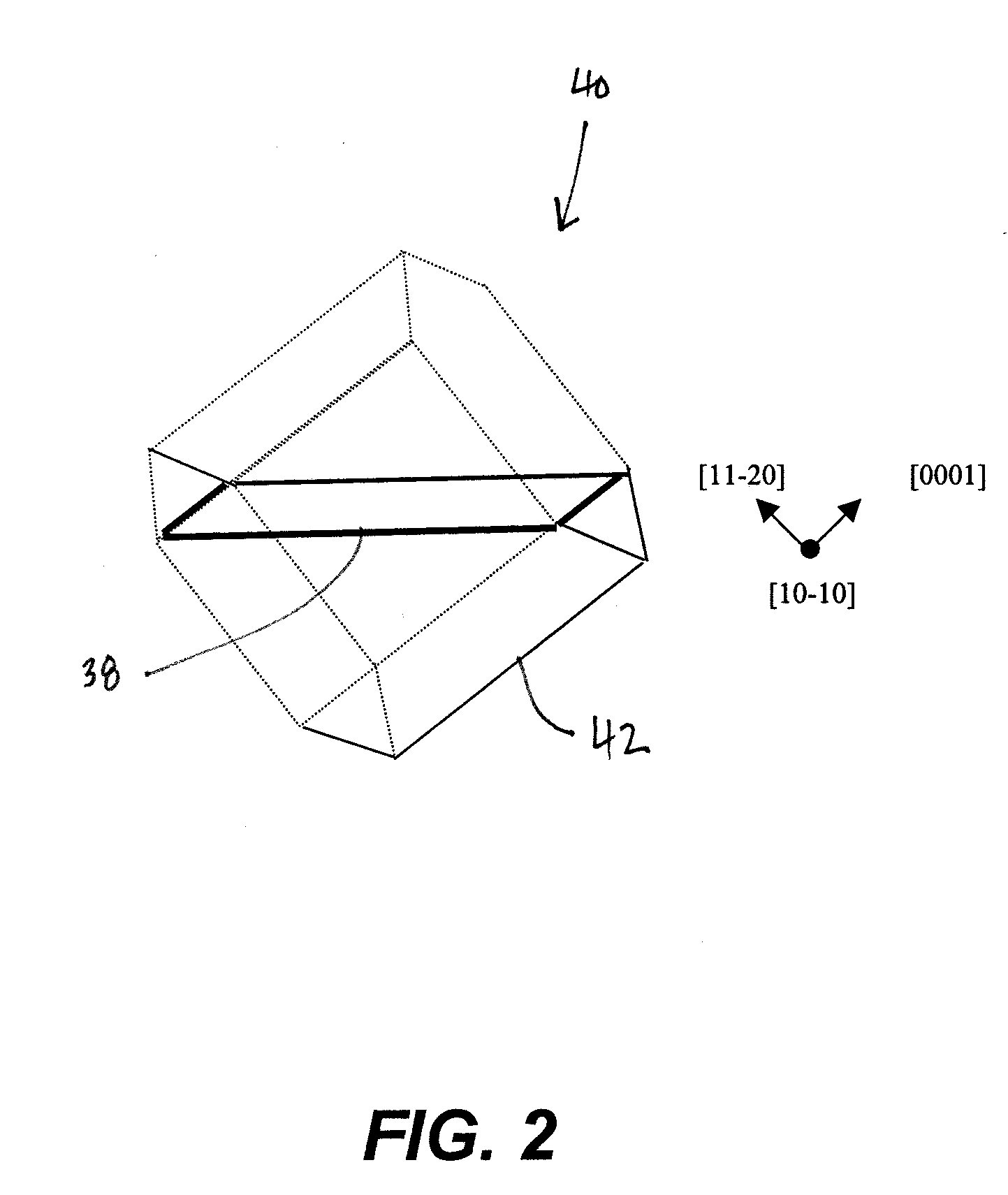

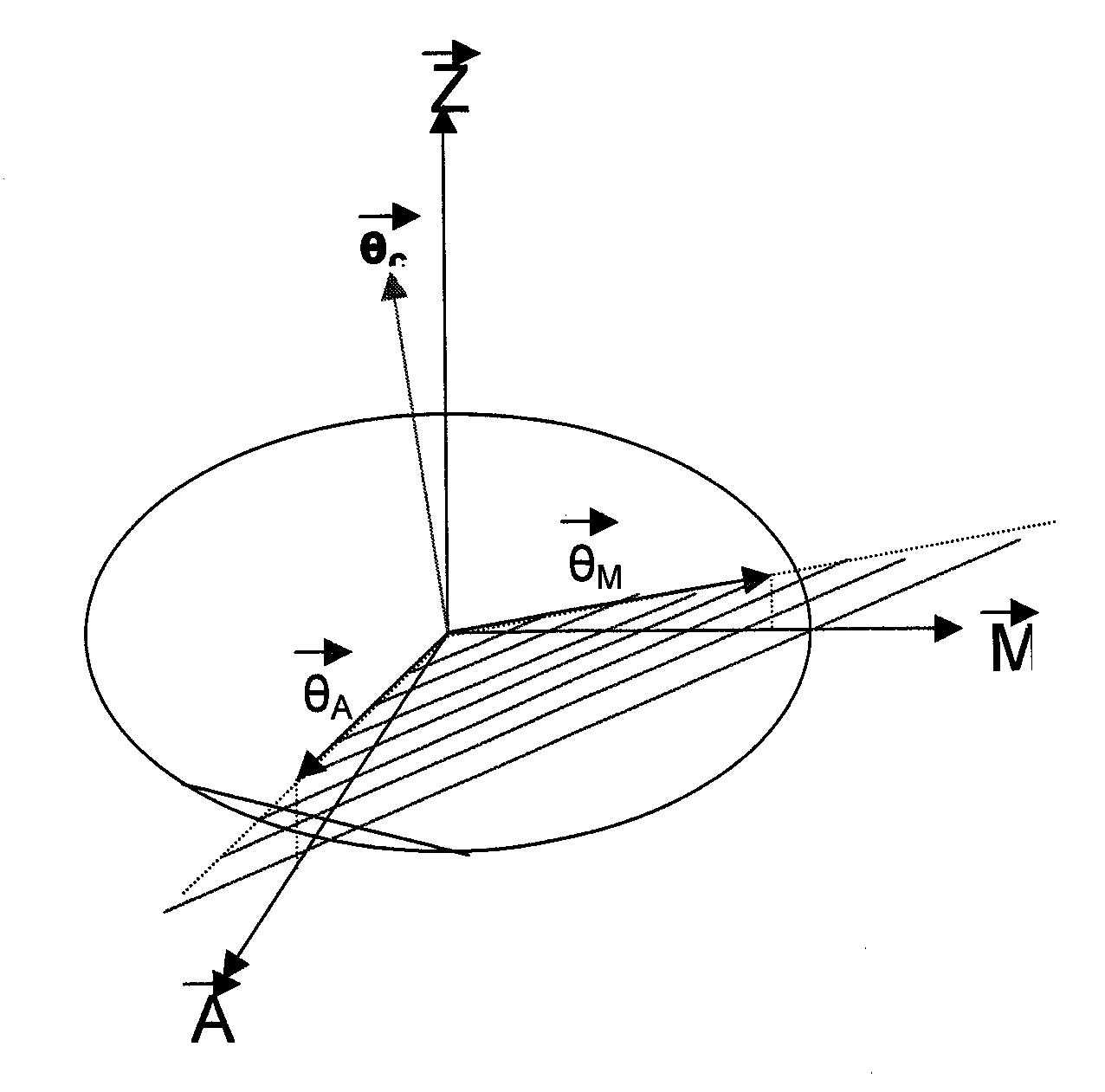

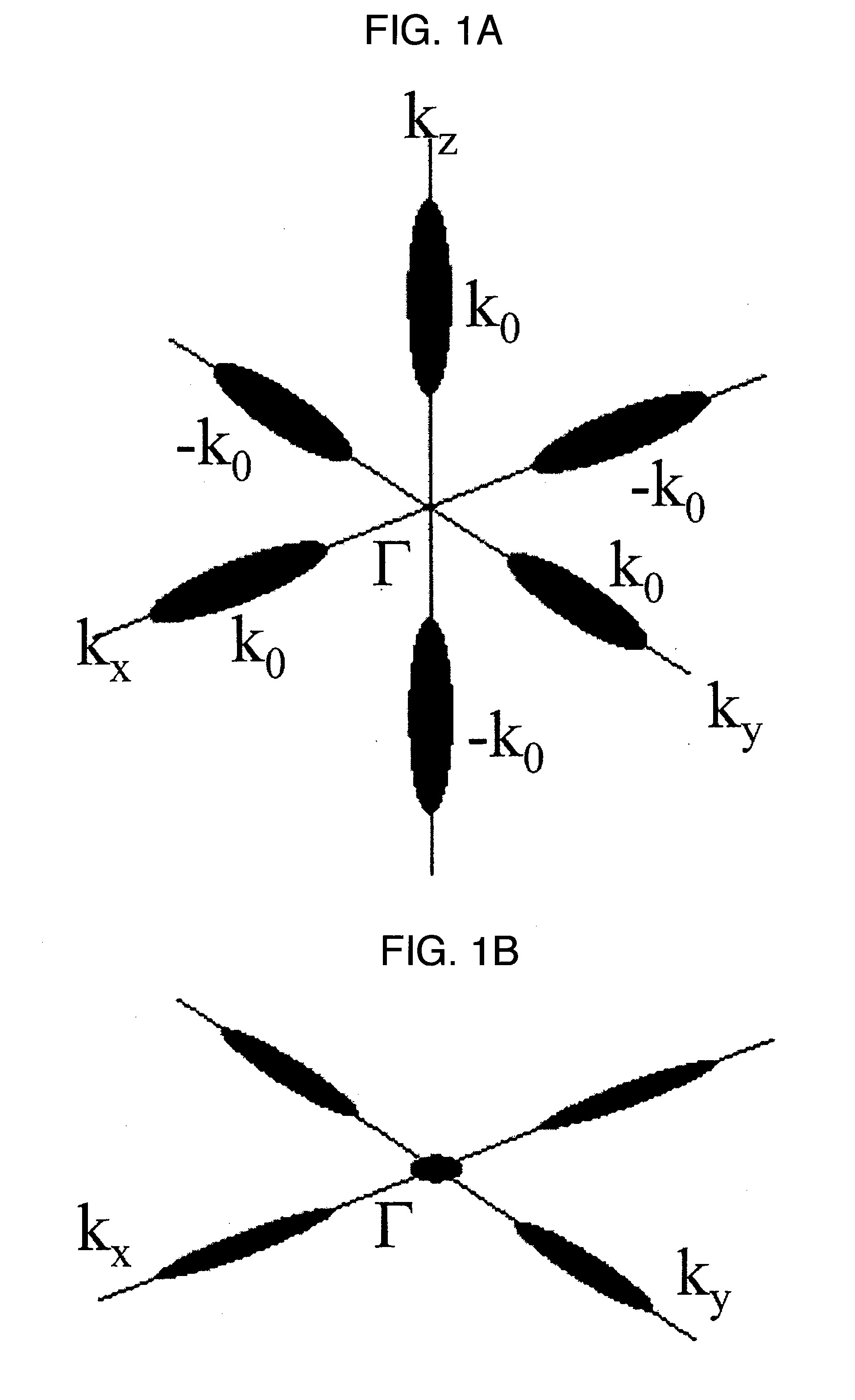

CLEAVED FACET (Ga,Al,In)N EDGE-EMITTING LASER DIODES GROWN ON SEMIPOLAR BULK GALLIUM NITRIDE SUBSTRATES

ActiveUS20080191223A1Optical wave guidanceSemiconductor/solid-state device manufacturingPlane orientationGallium nitride

A III-nitride edge-emitting laser diode is formed on a surface of a III-nitride substrate having a semipolar orientation, wherein the III-nitride substrate is cleaved by creating a cleavage line along a direction substantially perpendicular to a nonpolar orientation of the III-nitride substrate, and then applying force along the cleavage line to create one or more cleaved facets of the III-nitride substrate, wherein the cleaved facets have an m-plane or a-plane orientation.

Owner:RGT UNIV OF CALIFORNIA

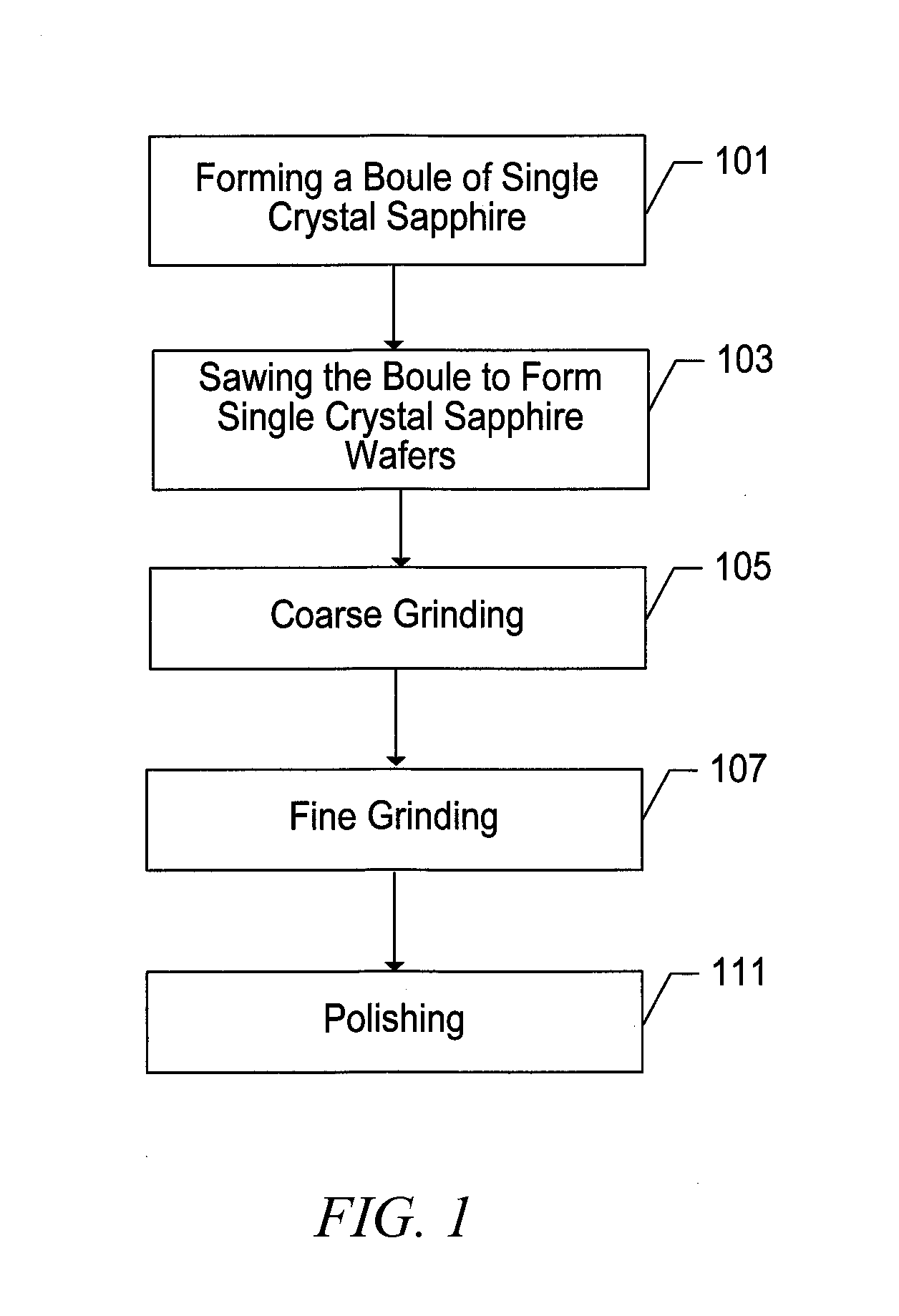

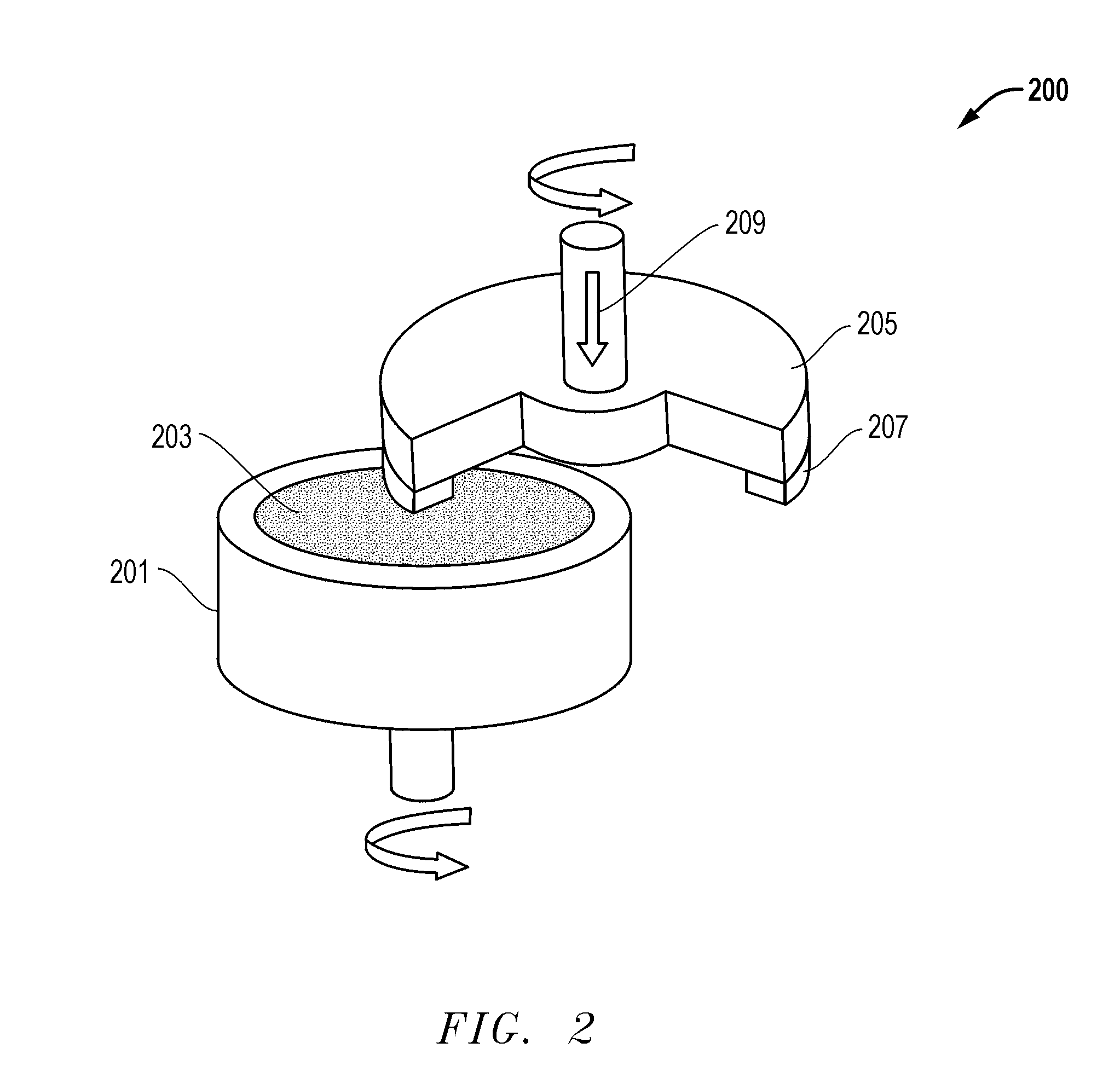

Sapphire substrates and methods of making same

InactiveUS20080164578A1Polycrystalline material growthFine working devicesPlane orientationTotal thickness

A sapphire substrate includes a generally planar surface having a crystallographic orientation selected from the group consisting of a-plane, r-plane, m-plane, and c-plane orientations, and having a nTTV of not greater than about 0.037 μm / cm2, wherein nTTV is total thickness variation normalized for surface area of the generally planar surface, the substrate having a diameter not less than about 9.0 cm.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

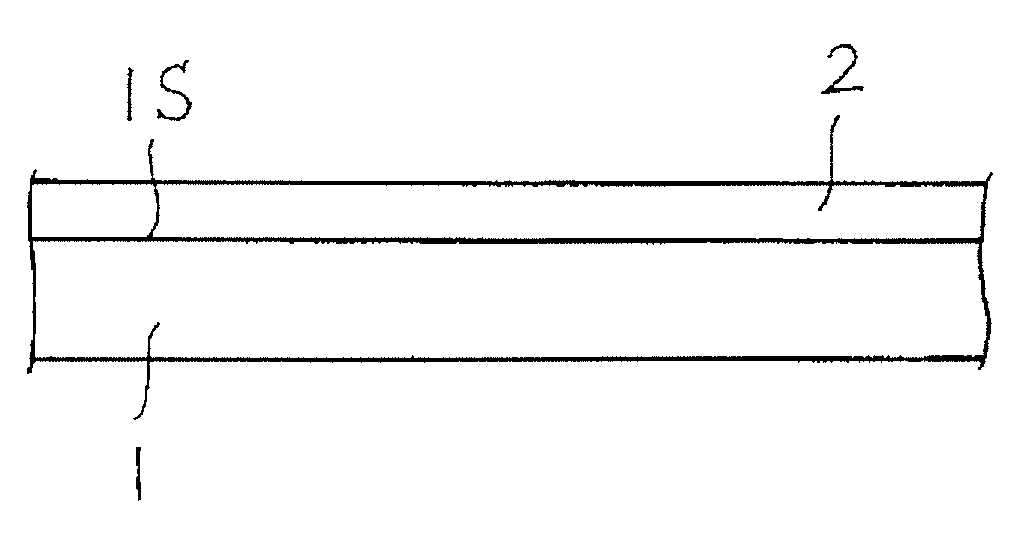

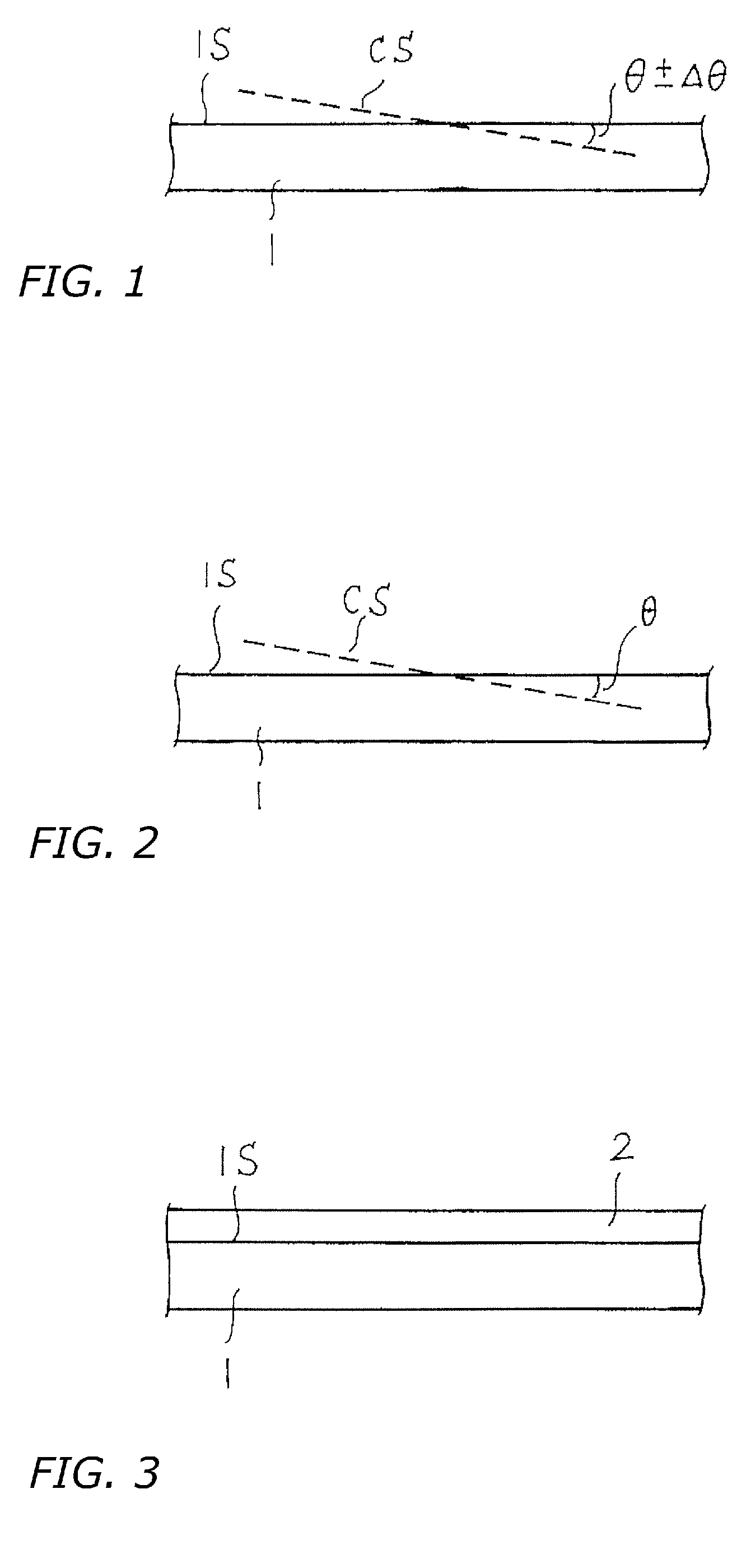

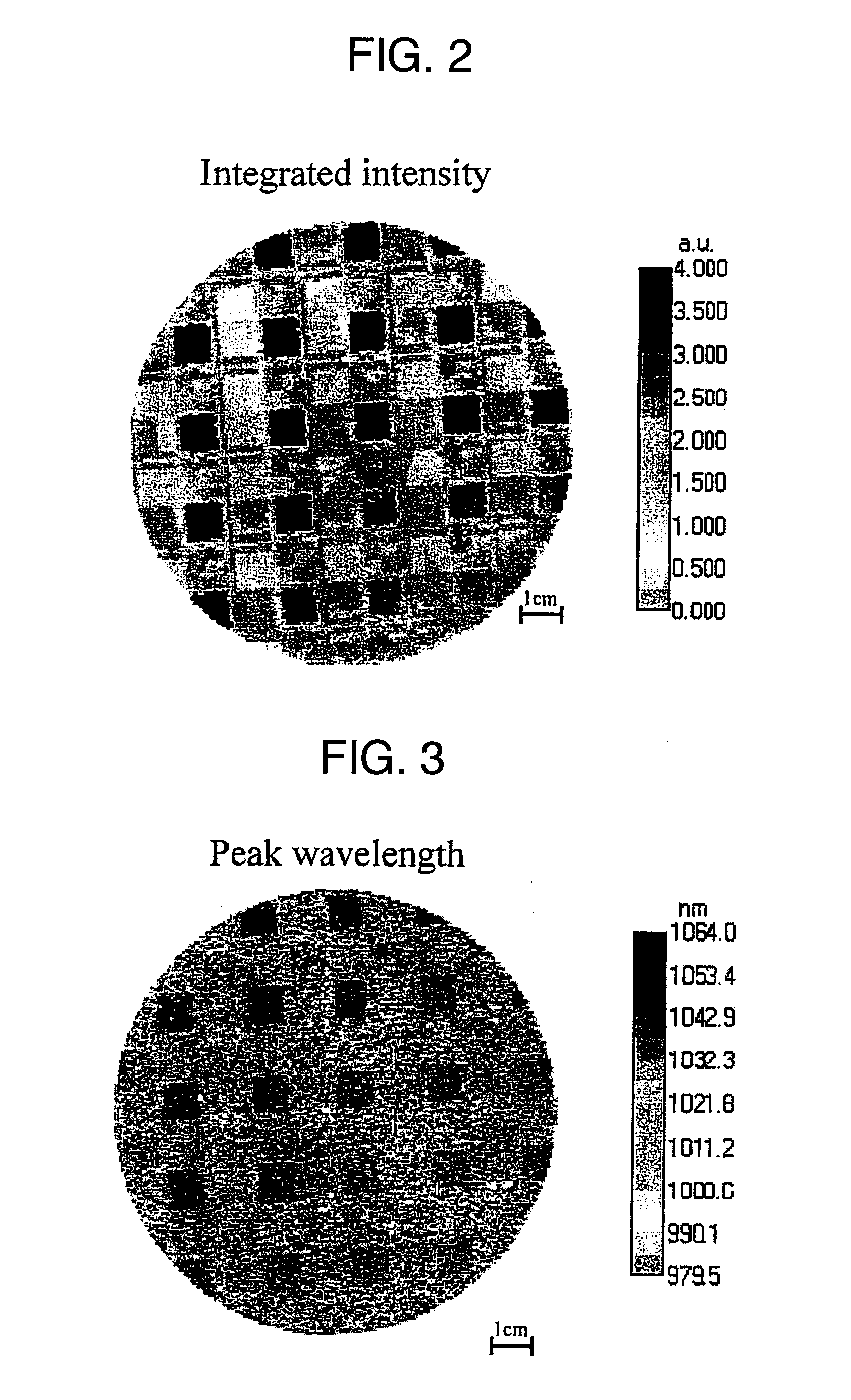

Nitride semiconductor wafer

ActiveUS7390359B2Maintain good propertiesQuality improvementPolycrystalline material growthAluminium silicatesPlane orientationSingle crystal

A nitride semiconductor substrate having properties preferable for the manufacture of various nitride semiconductor devices is made available, by specifying or controlling the local variation in the off-axis angle of the principal surface of the nitride semiconductor substrate. In a nitride semiconductor single-crystal wafer having a flat principal surface, the crystallographic plane orientation of the principal surface of the nitride semiconductor single-crystal wafer varies locally within a predetermined angular range.

Owner:SUMITOMO ELECTRIC IND LTD

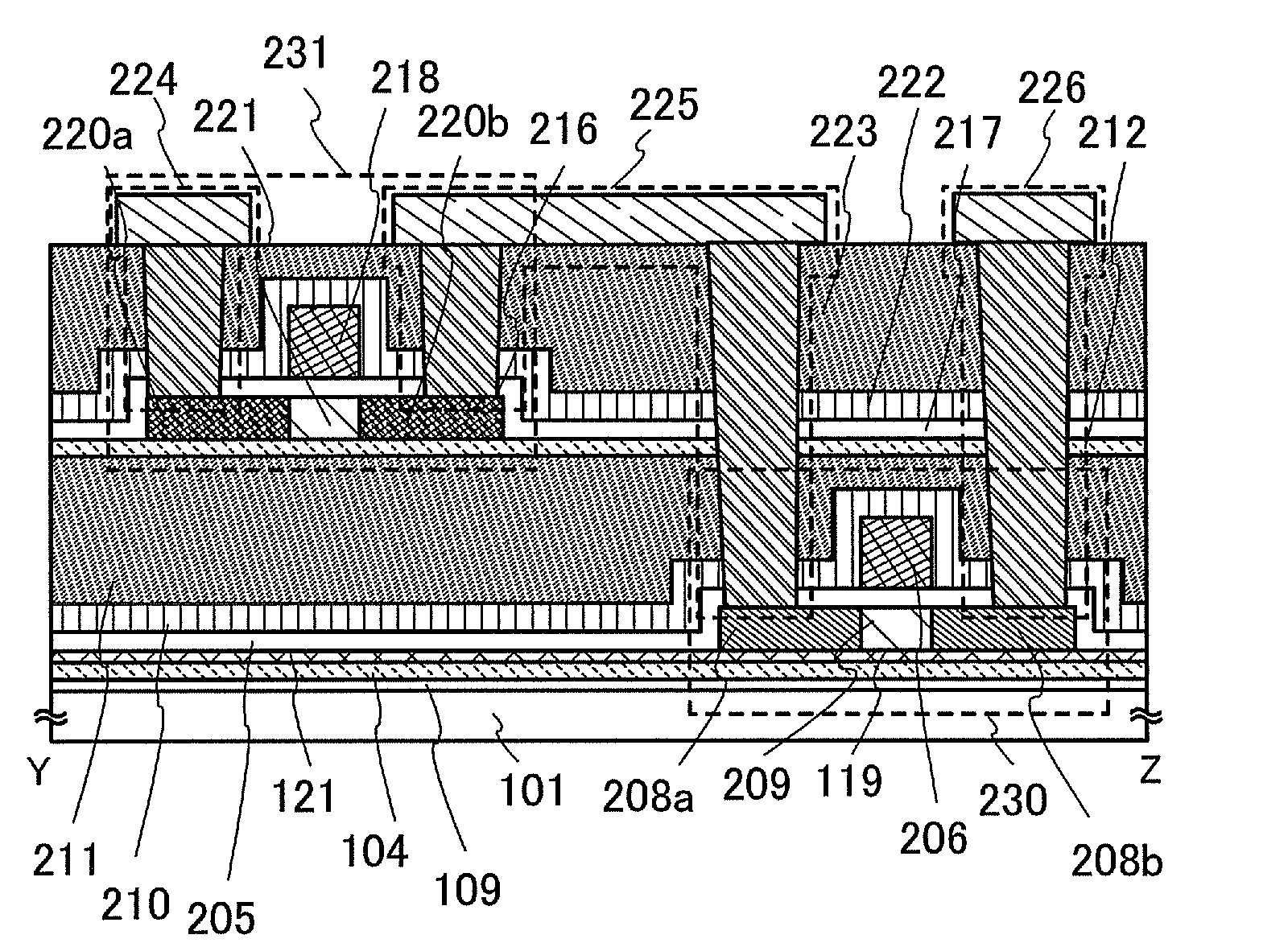

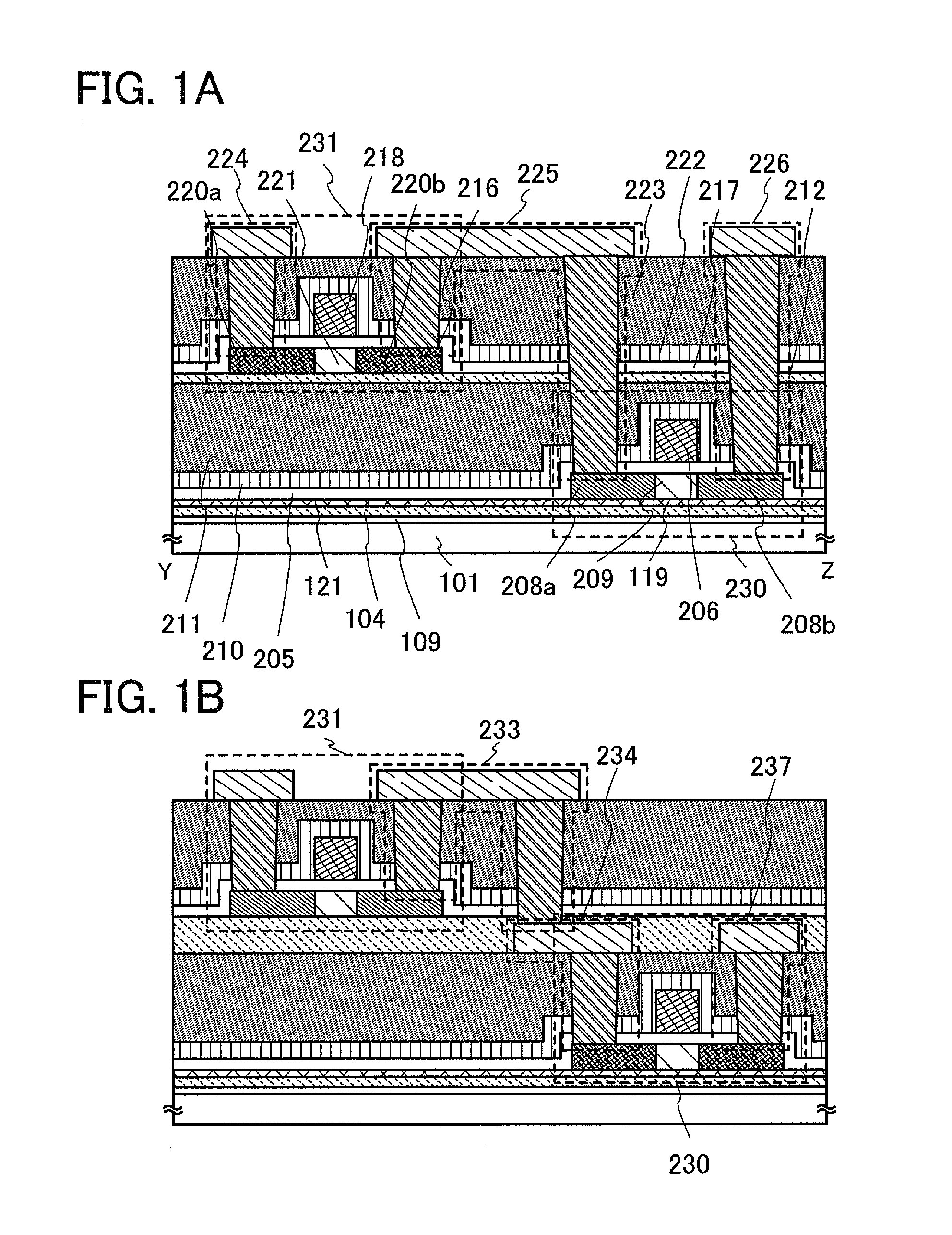

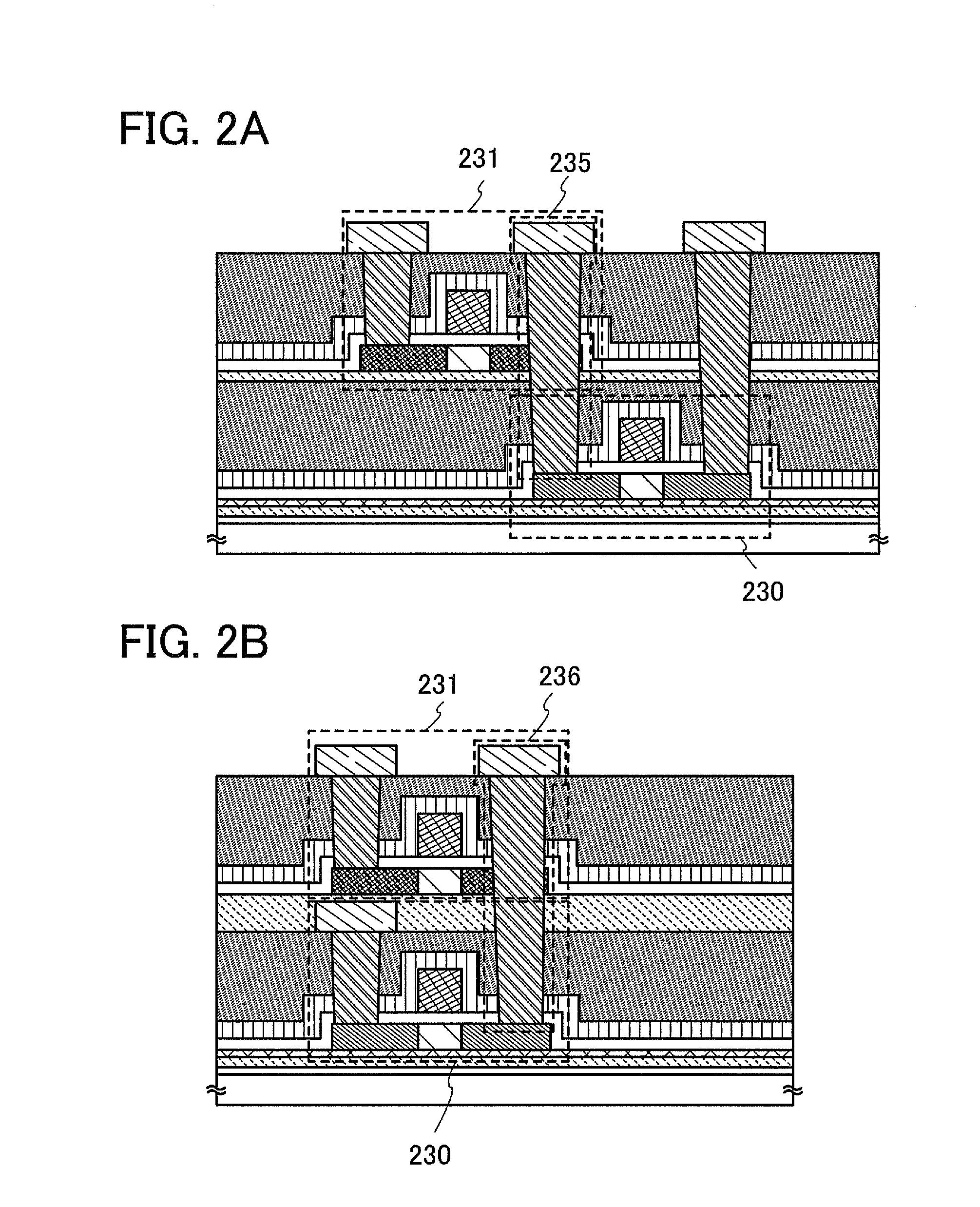

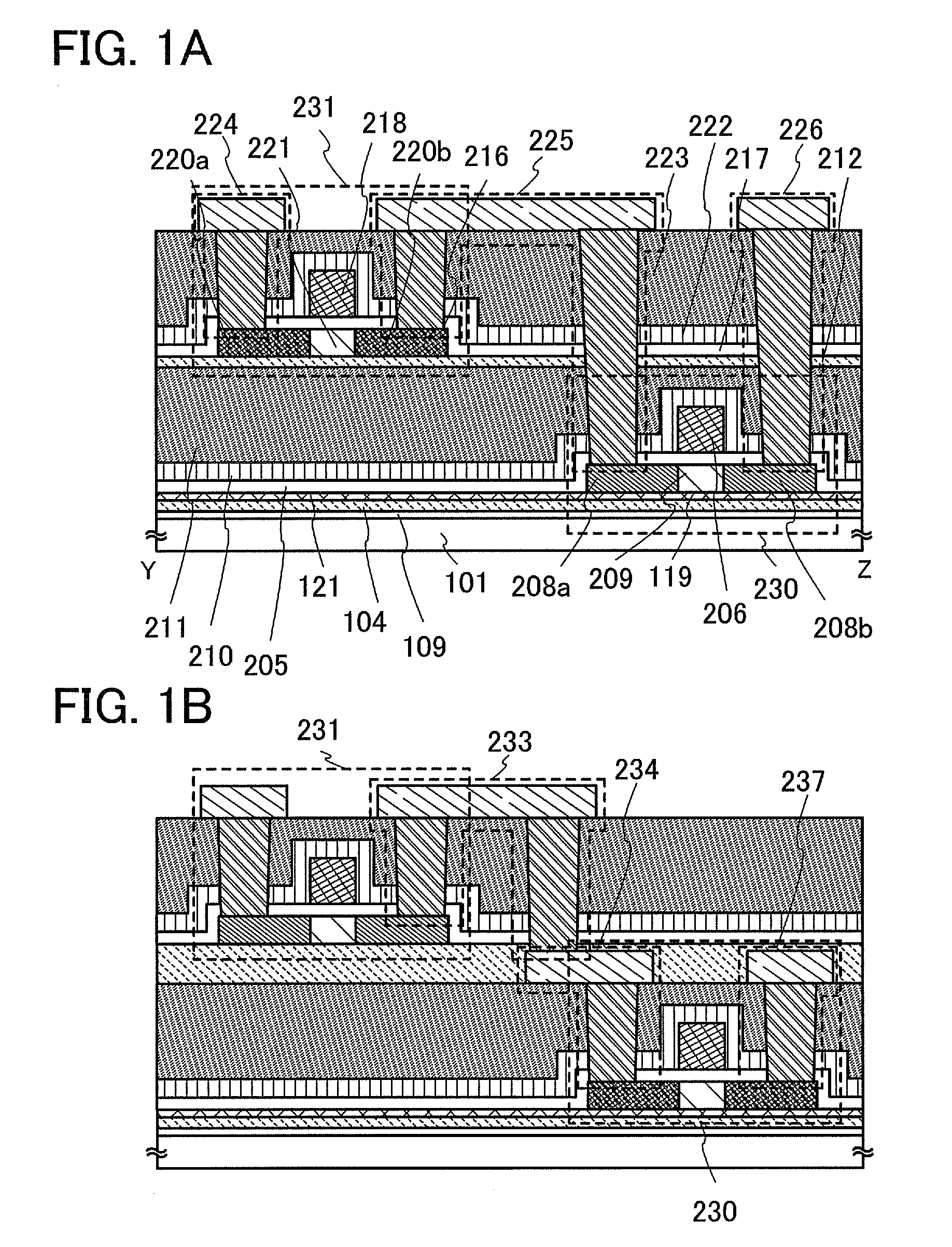

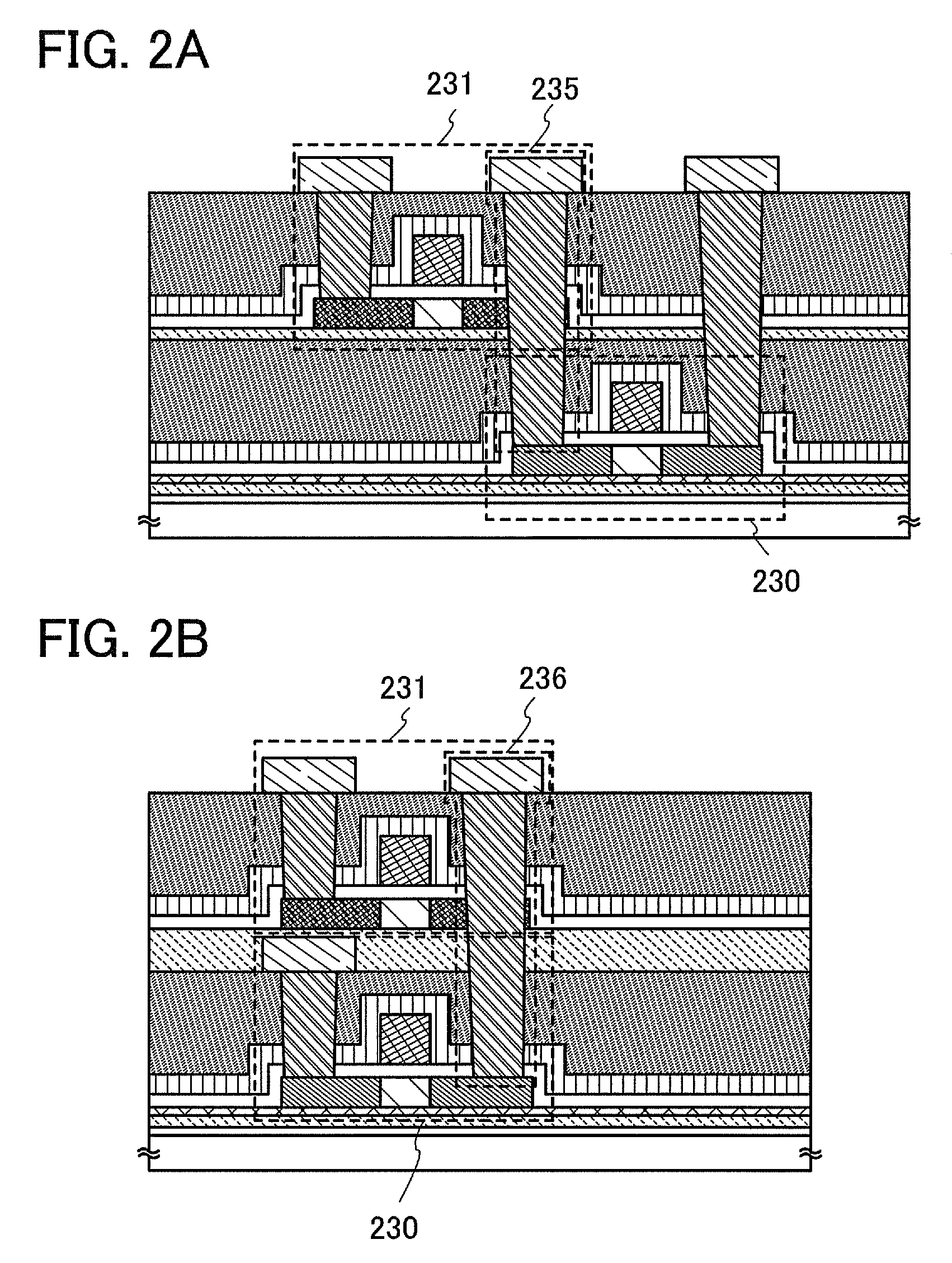

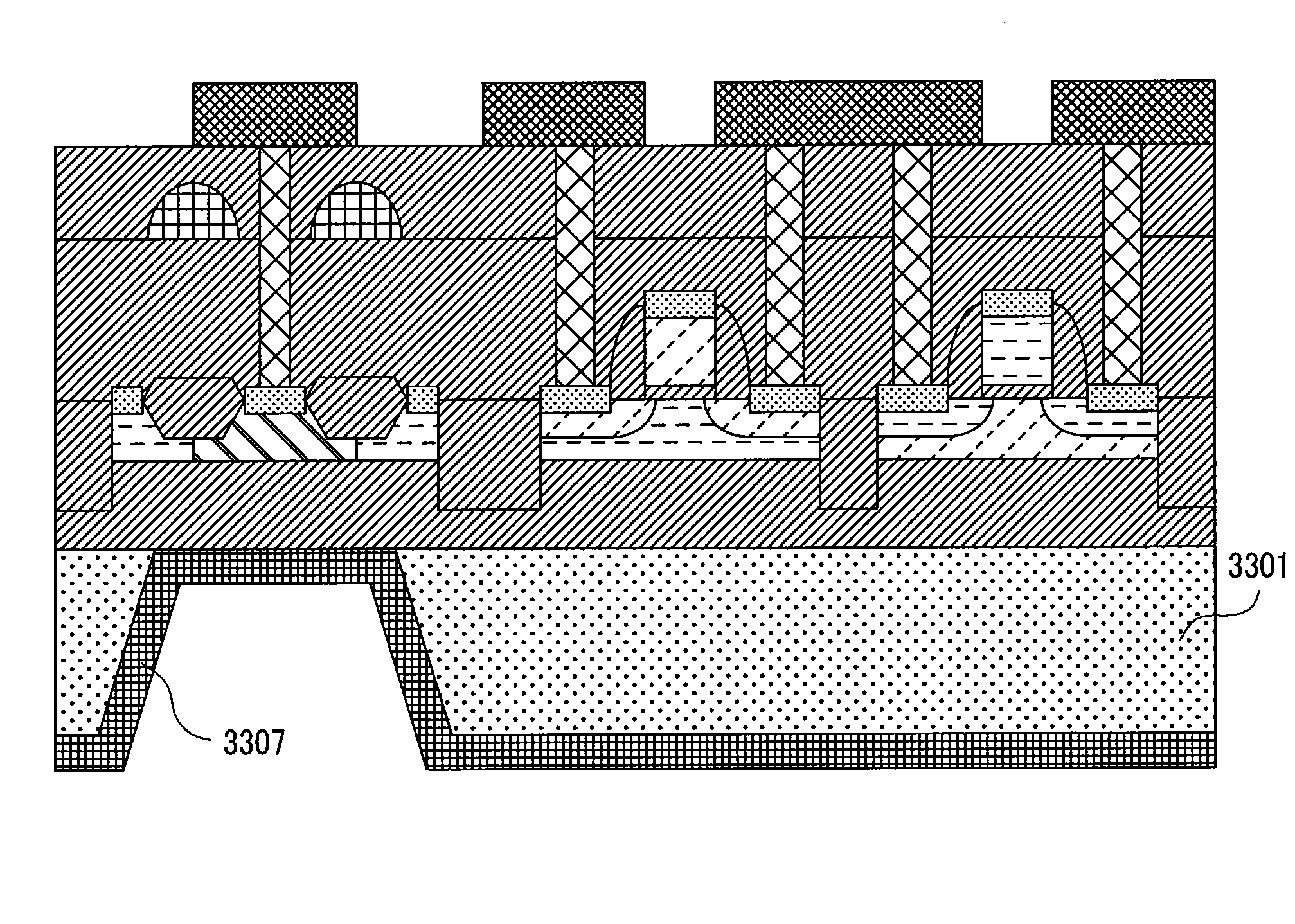

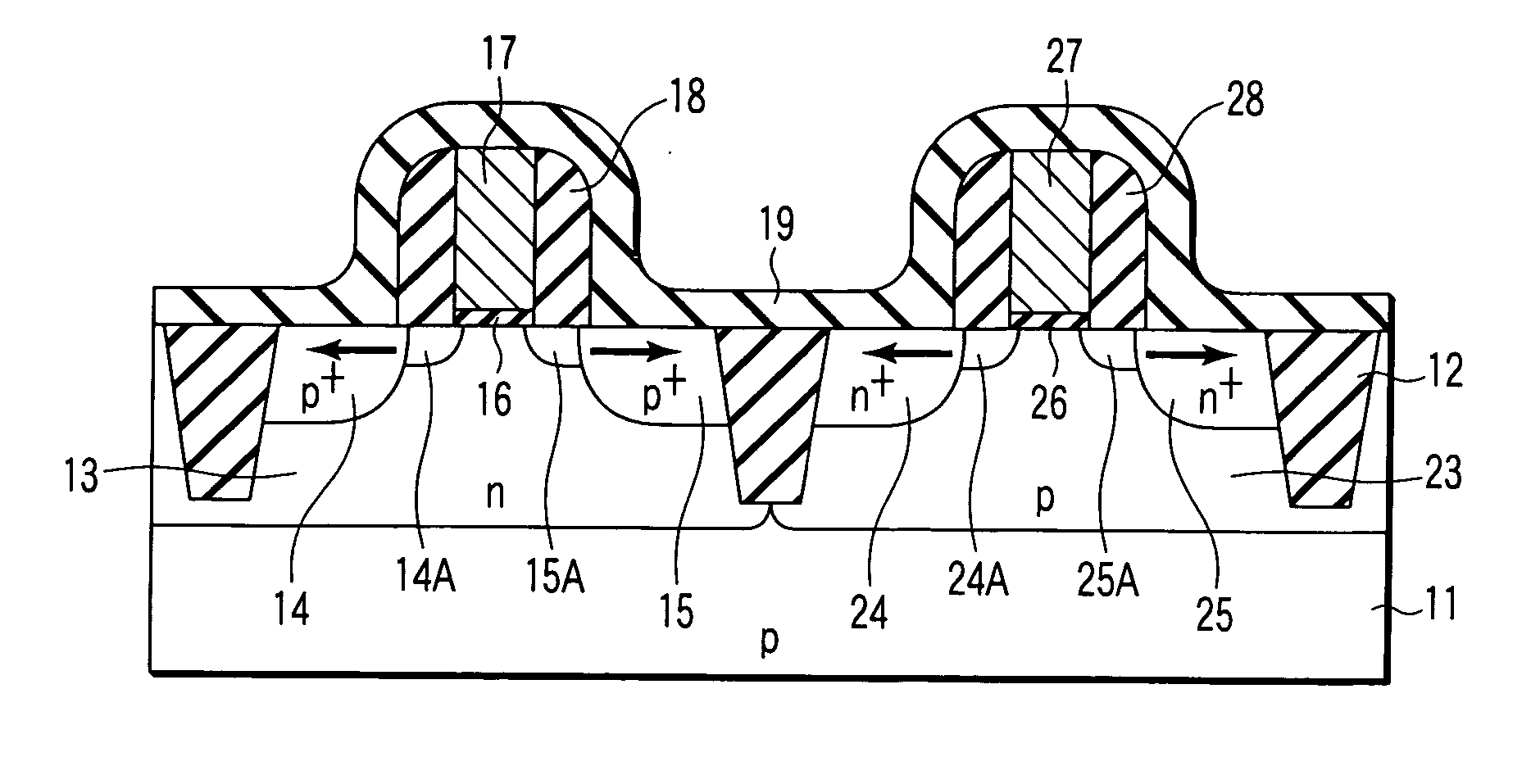

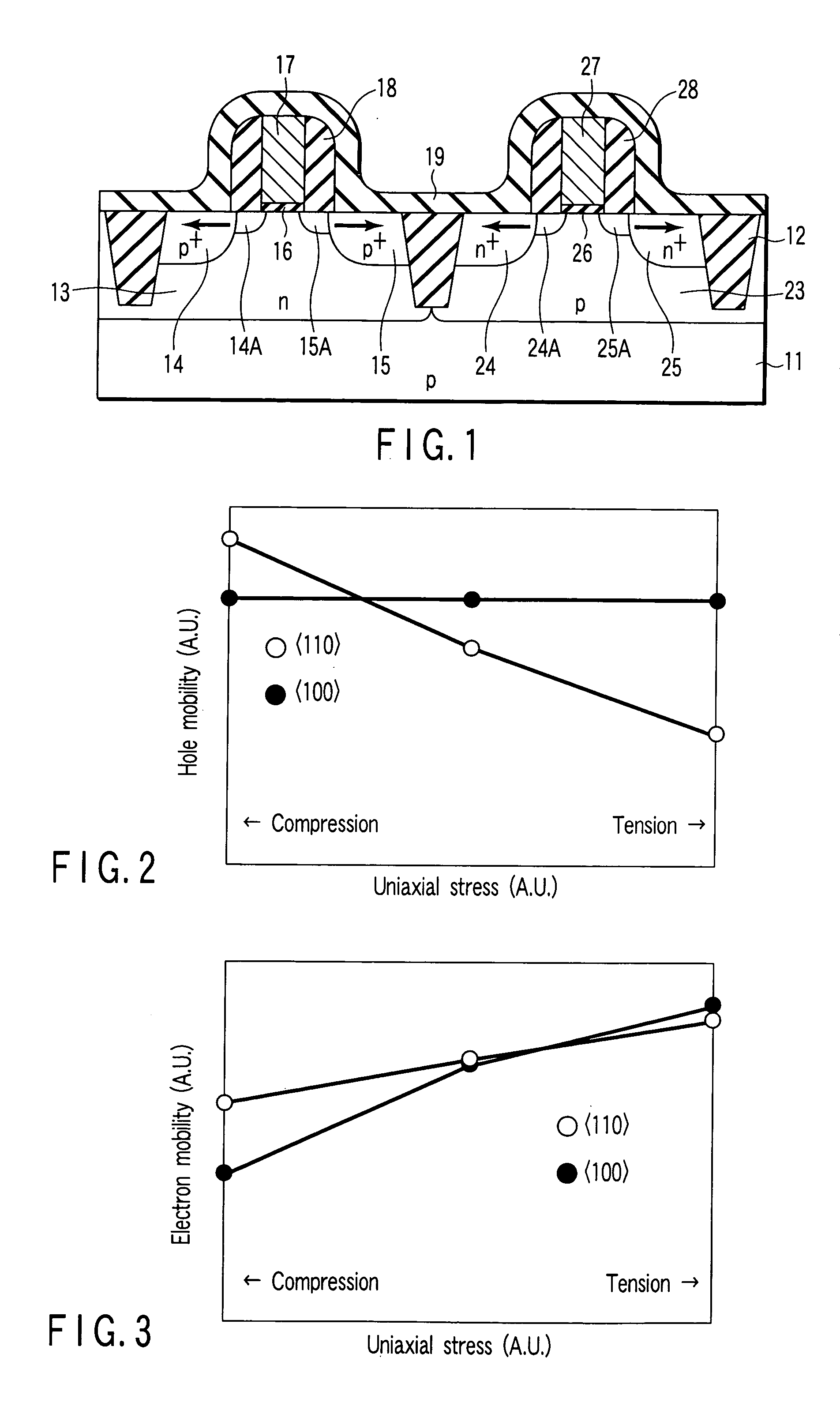

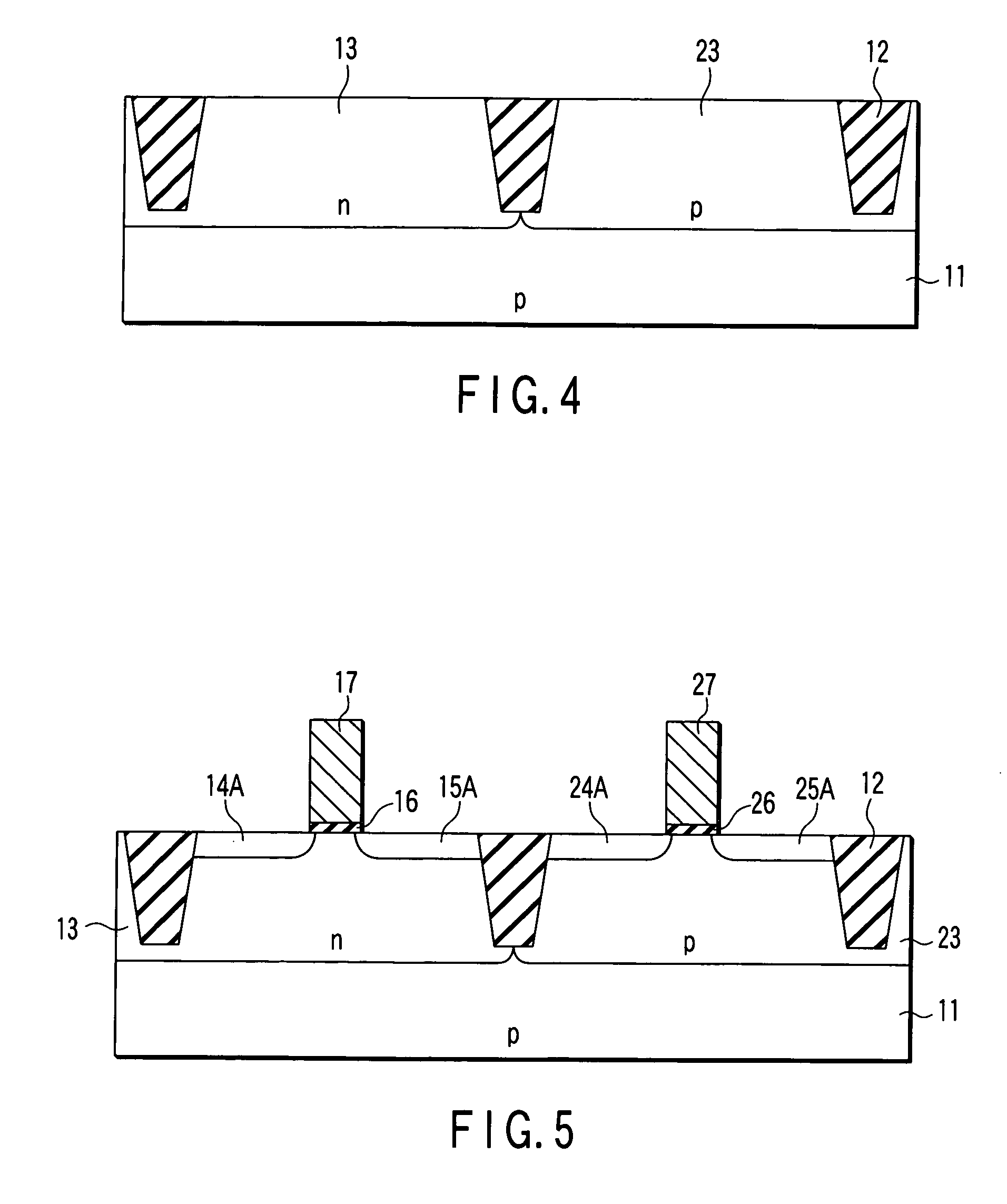

Semiconductor device

ActiveUS20090079000A1Difference in mobilityReduce power consumptionSemiconductor/solid-state device detailsSolid-state devicesDevice materialPlane orientation

An object is to realize high performance and low power consumption in a semiconductor device having an SOI structure. In addition, another object is to provide a semiconductor device having a high performance semiconductor element which is more highly integrated. A semiconductor device is such that a plurality of n-channel field-effect transistors and p-channel field-effect transistors are stacked with an interlayer insulating layer interposed therebetween over a substrate having an insulating surface. By controlling a distortion caused to a semiconductor layer due to an insulating film having a stress, a plane orientation of the semiconductor layer, and a crystal axis in a channel length direction, difference in mobility between the n-channel field-effect transistor and the p-channel field-effect transistor can be reduced, whereby current driving capabilities and response speeds of the n-channel field-effect transistor and the p-channel field-effect can be comparable.

Owner:SEMICON ENERGY LAB CO LTD

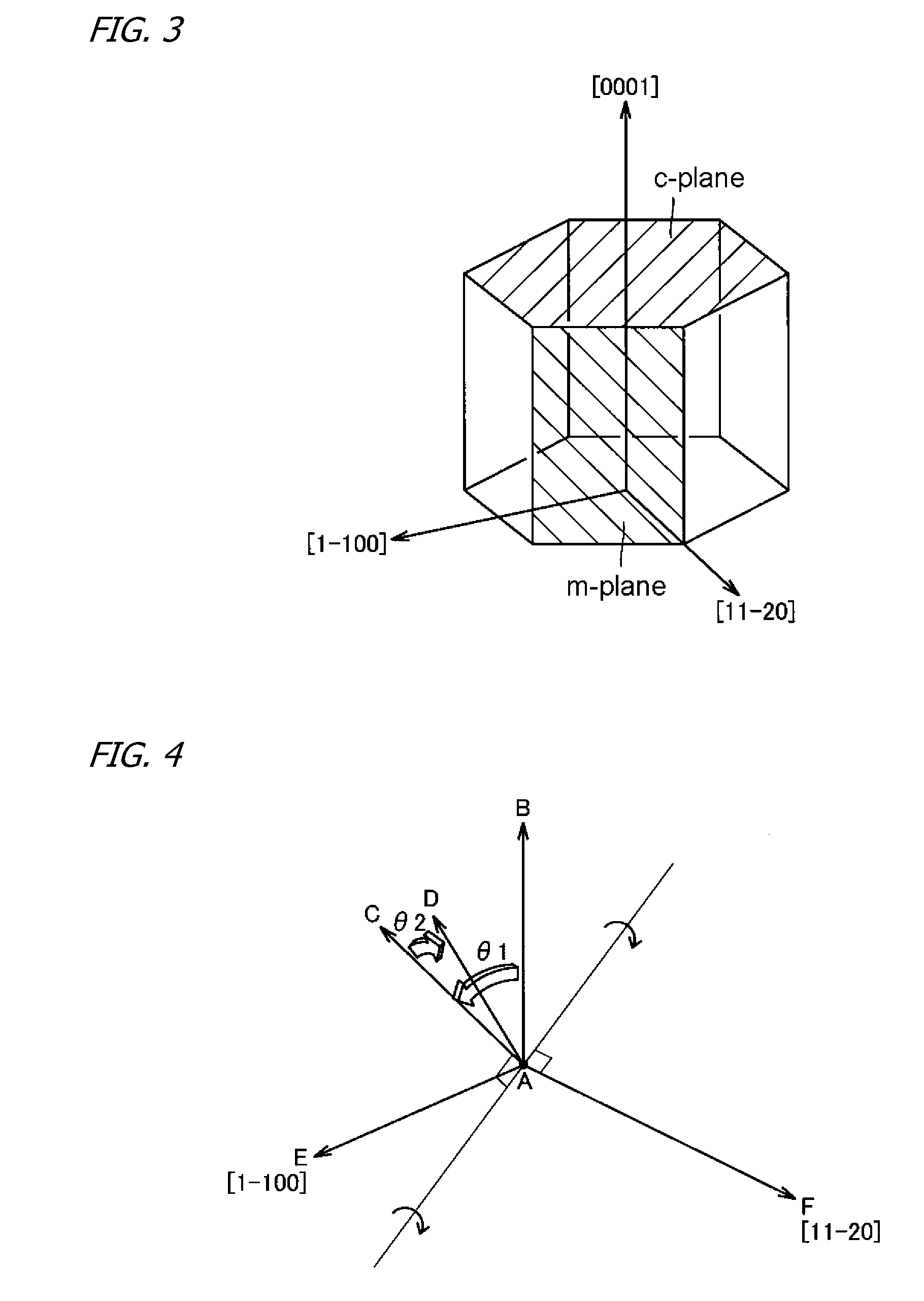

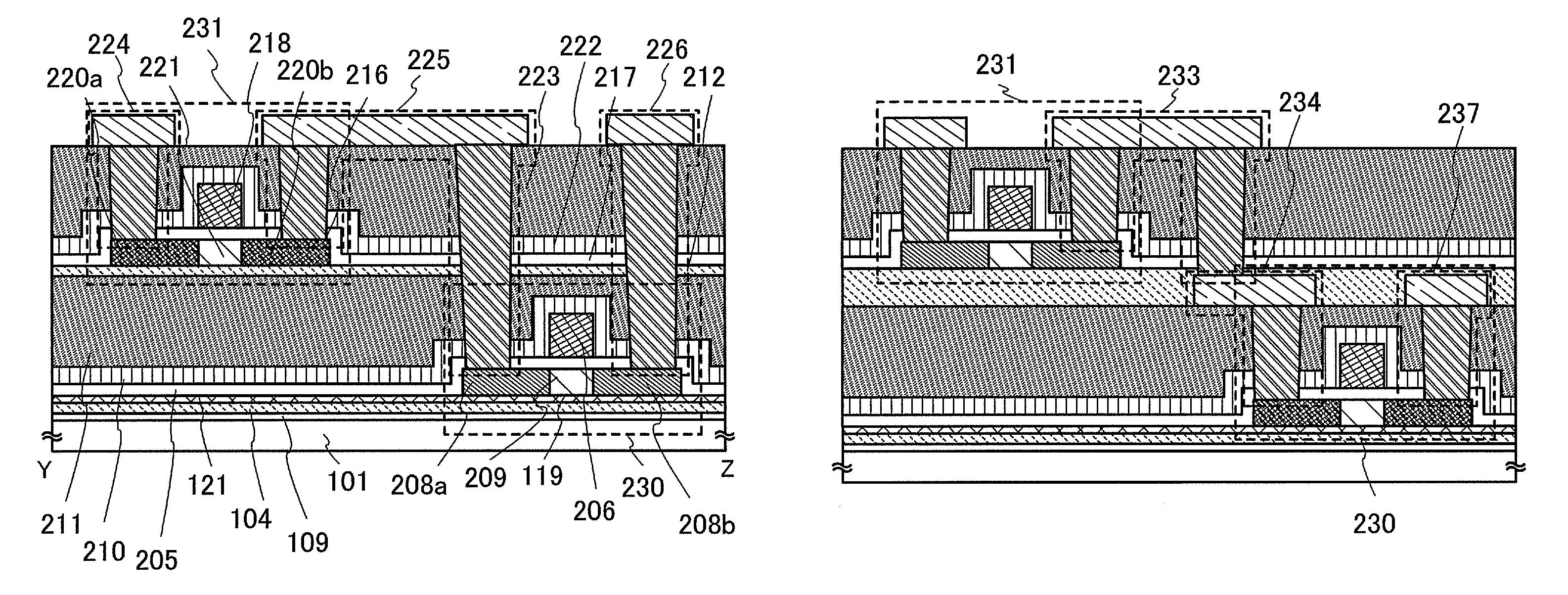

GaN Substrate, Substrate with an Epitaxial Layer, Semiconductor Device, and GaN Substrate Manufacturing Method

InactiveUS20080308815A1Control fluctuationsImprove emission efficiencyAutomatic/semiautomatic turning machinesPolycrystalline material growthDevice materialPlane orientation

Affords a GaN substrate from which enhanced-emission-efficiency light-emitting and like semiconductor devices can be produced, an epi-substrate in which an epitaxial layer has been formed on the GaN substrate principal surface, a semiconductor device, and a method of manufacturing the GaN substrate. The GaN substrate is a substrate having a principal surface with respect to whose normal vector the [0001] plane orientation is inclined in two different off-axis directions.

Owner:SUMITOMO ELECTRIC IND LTD

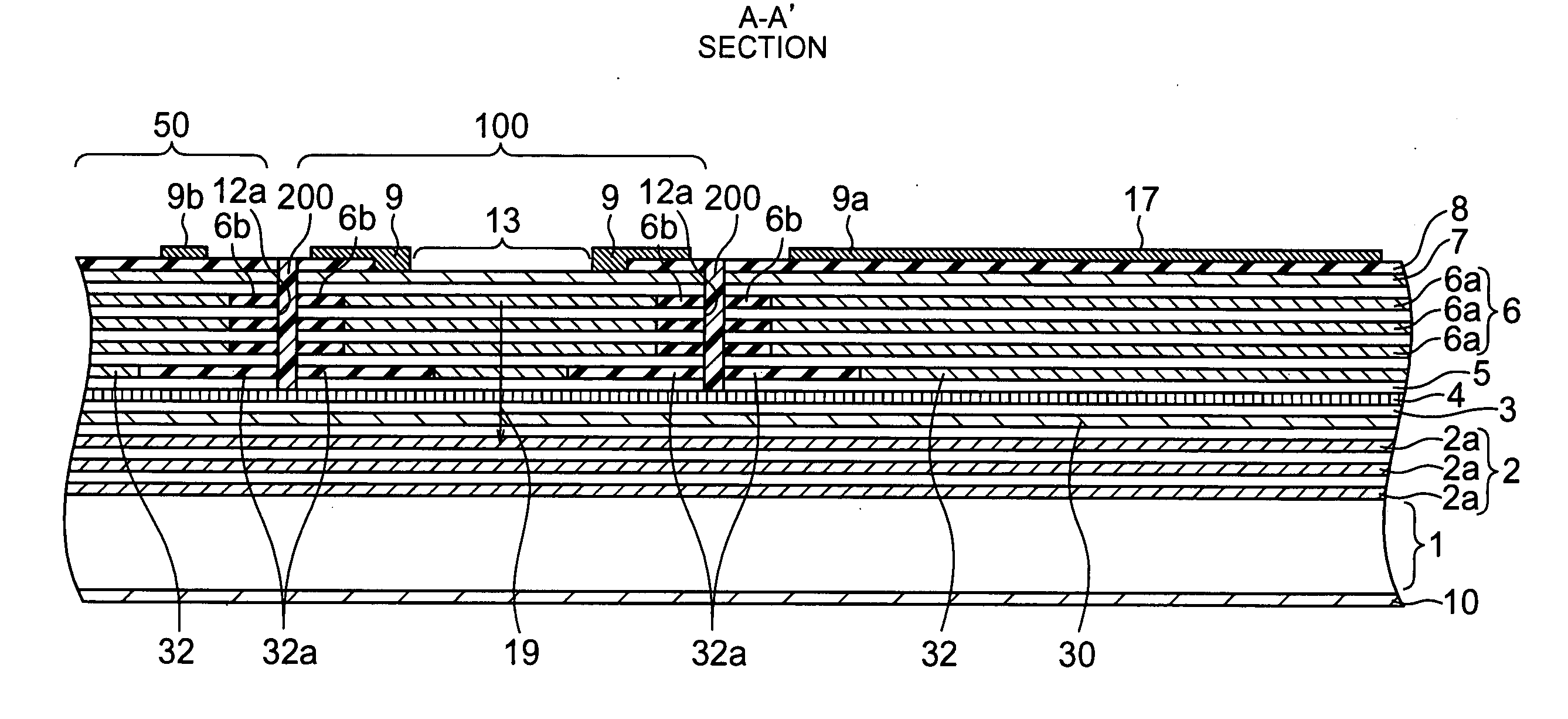

Semiconductor device

InactiveUS8044464B2Guaranteed high speed operationReduce power consumptionSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packagePlane orientation

Owner:SEMICON ENERGY LAB CO LTD

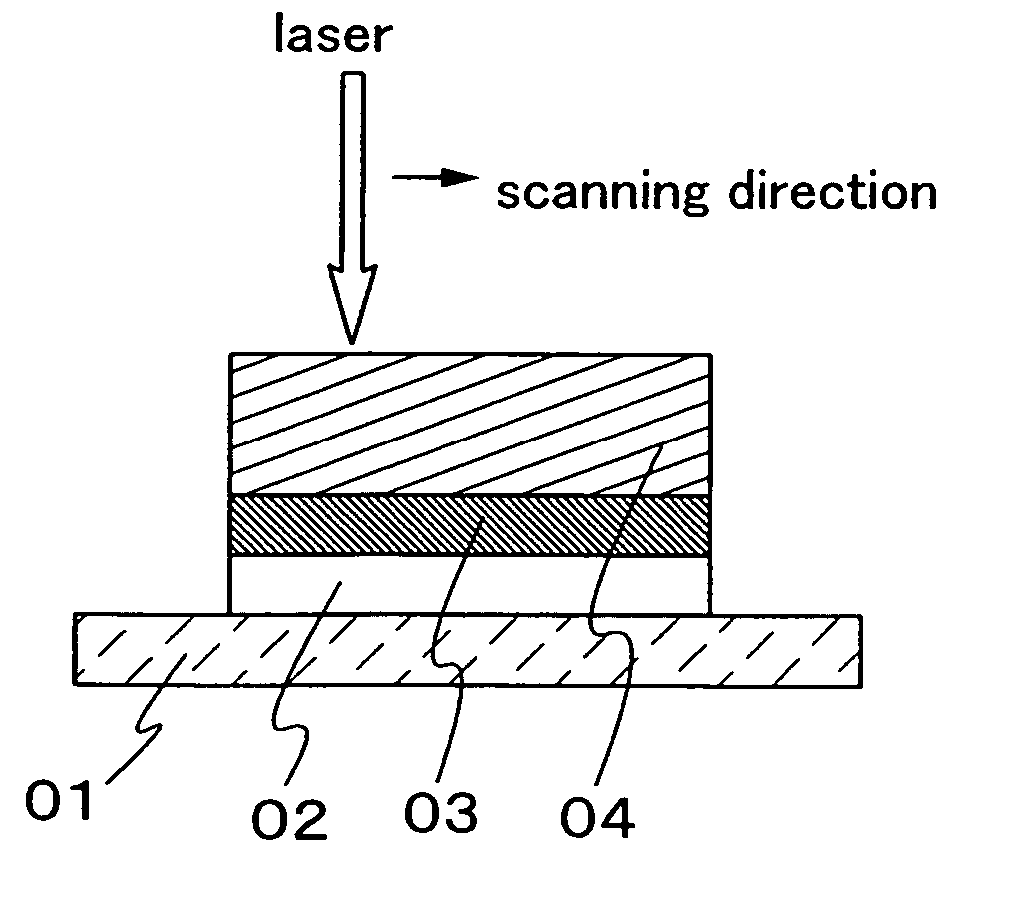

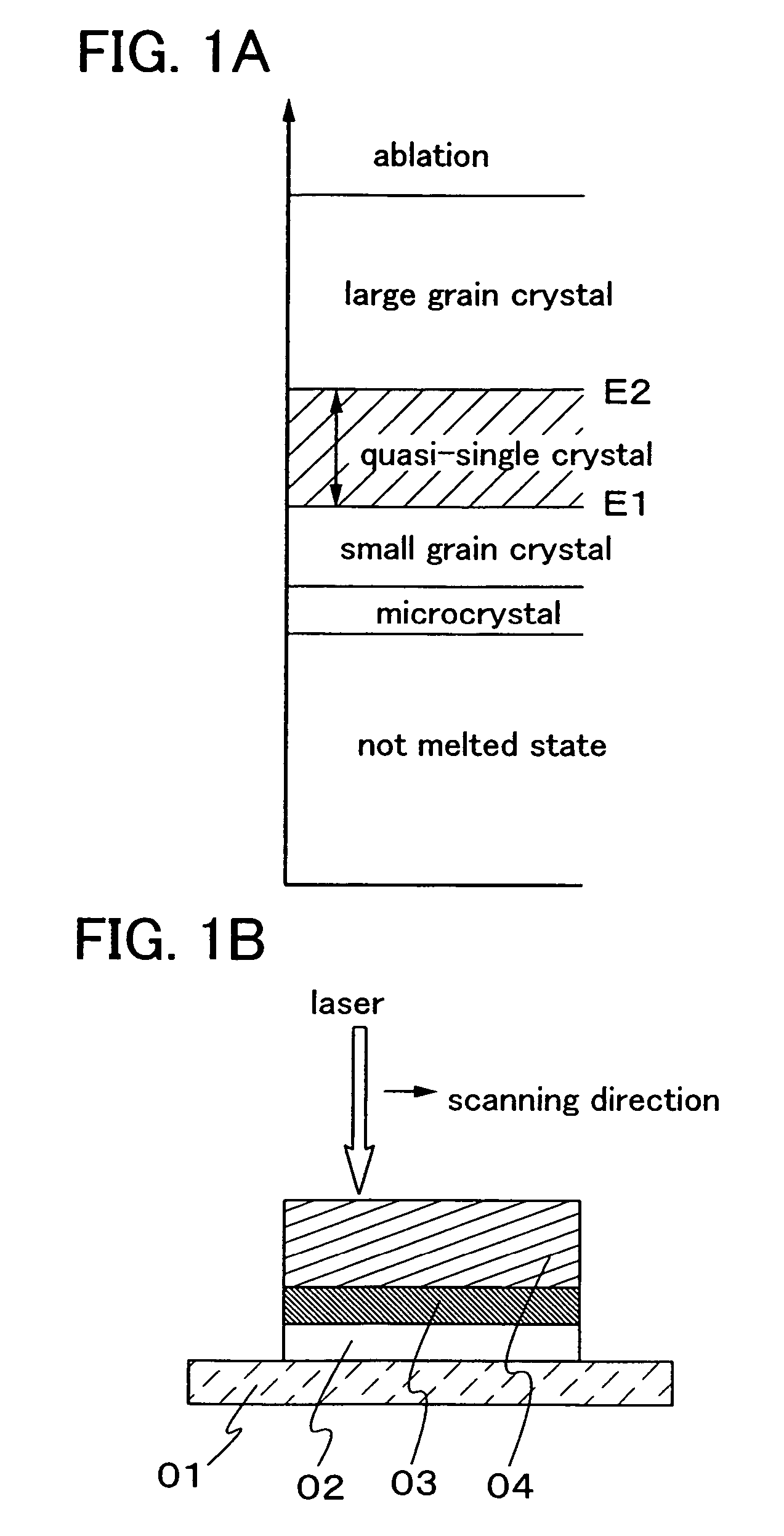

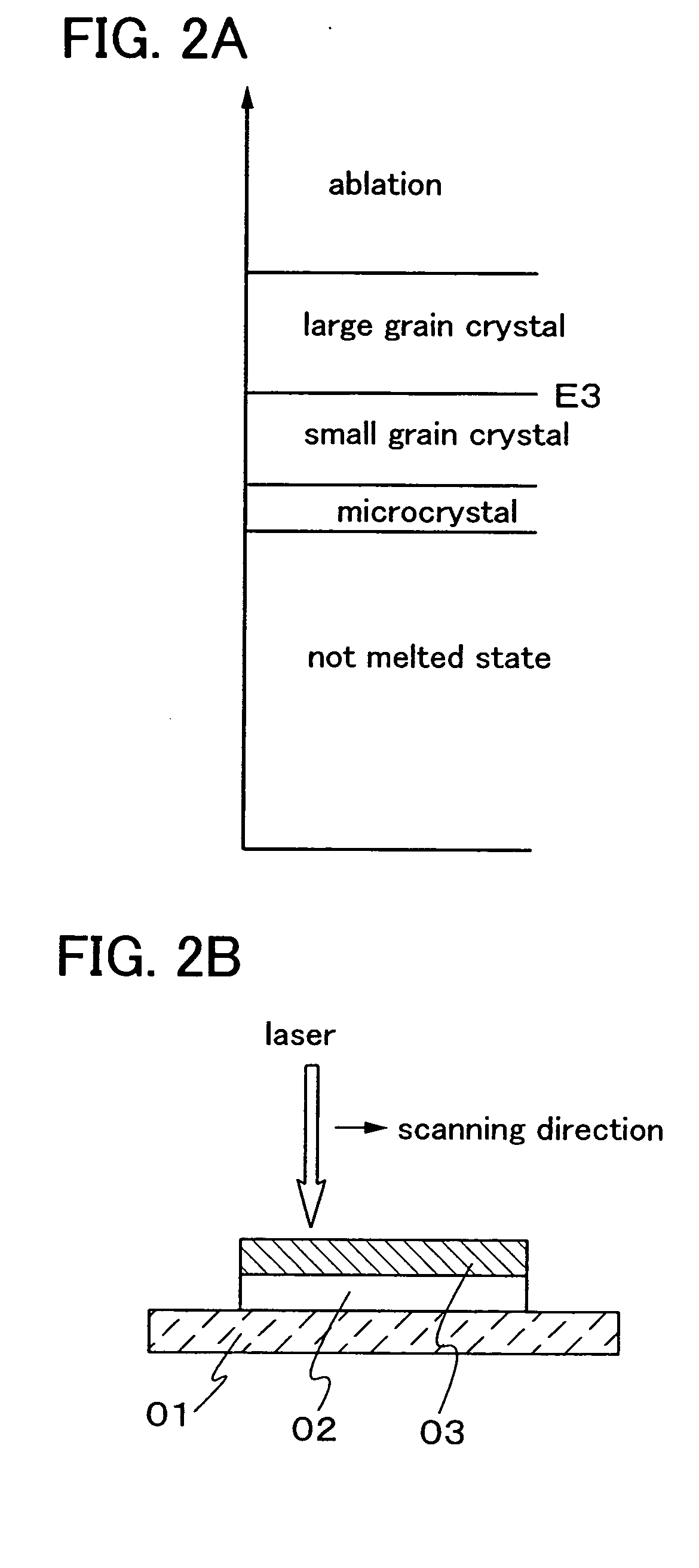

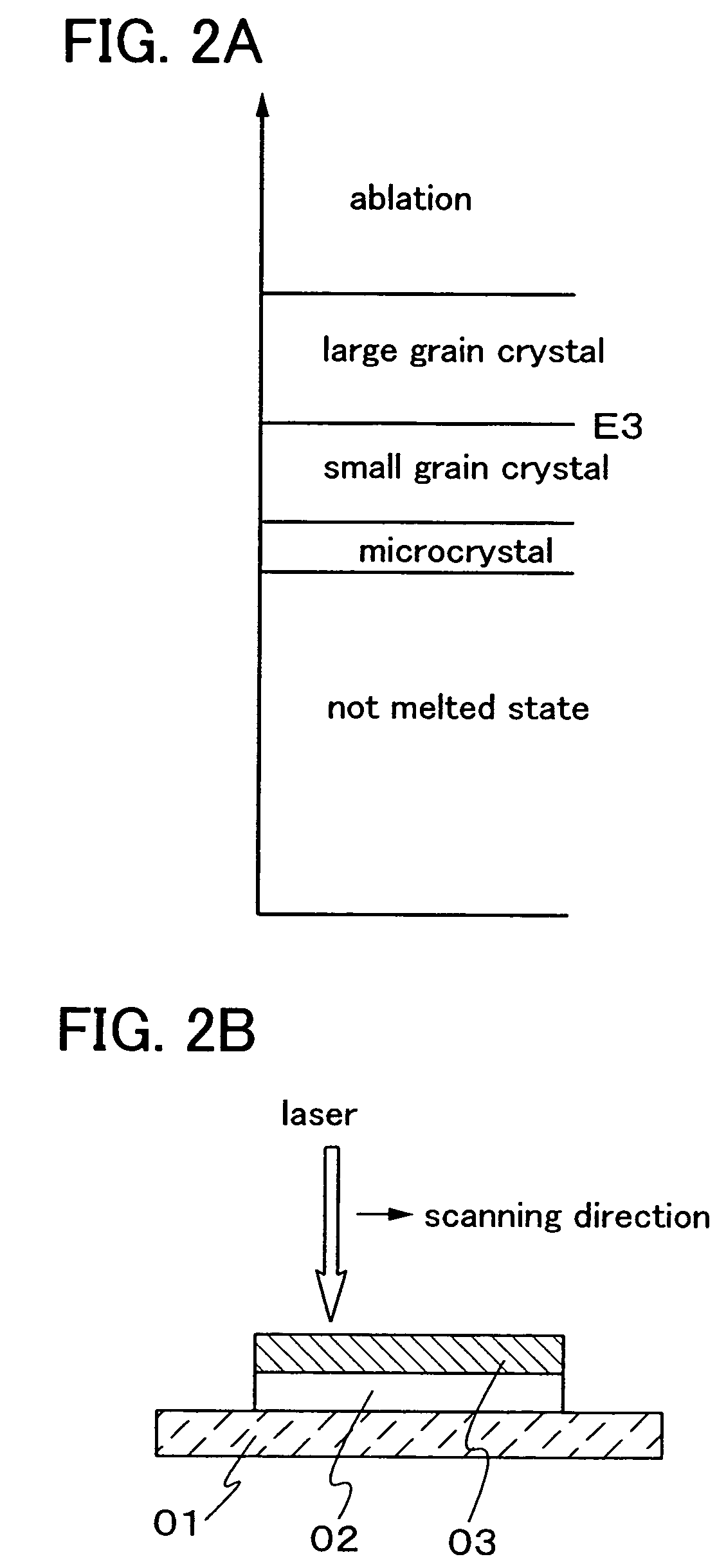

Semiconductor device and manufacturing method thereof

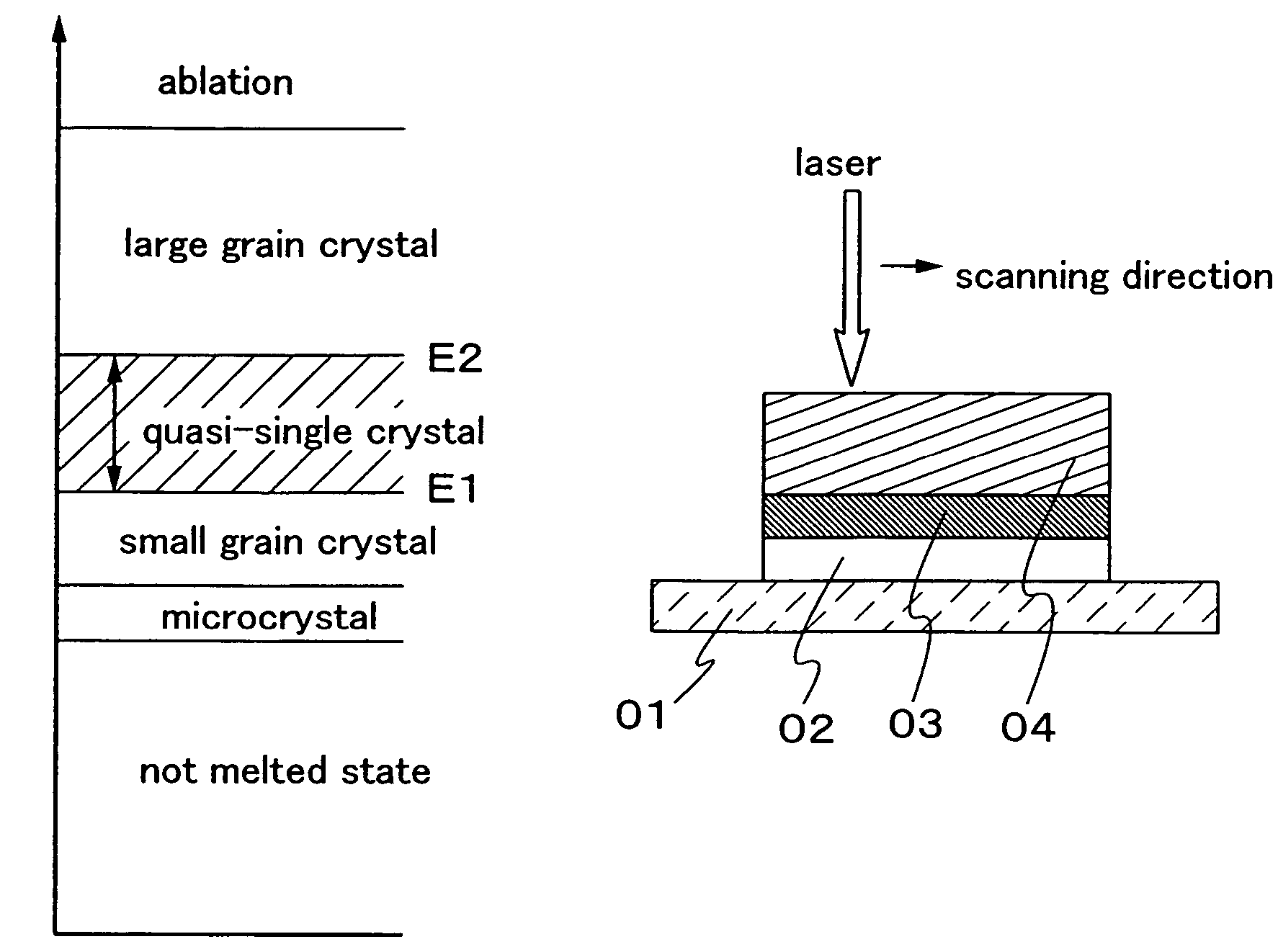

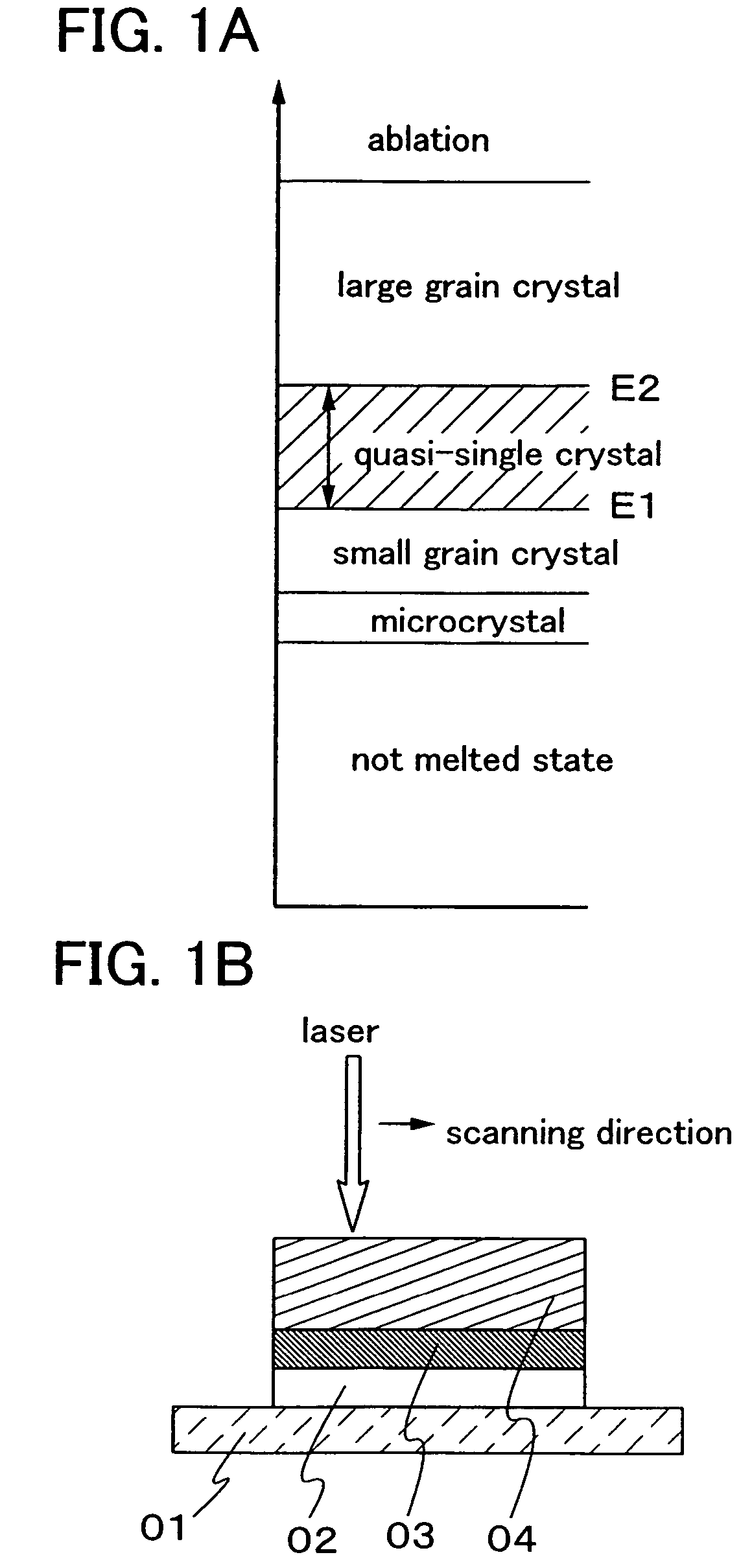

InactiveUS20070087488A1Improve driving abilitySmall characteristic variationSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialPlane orientation

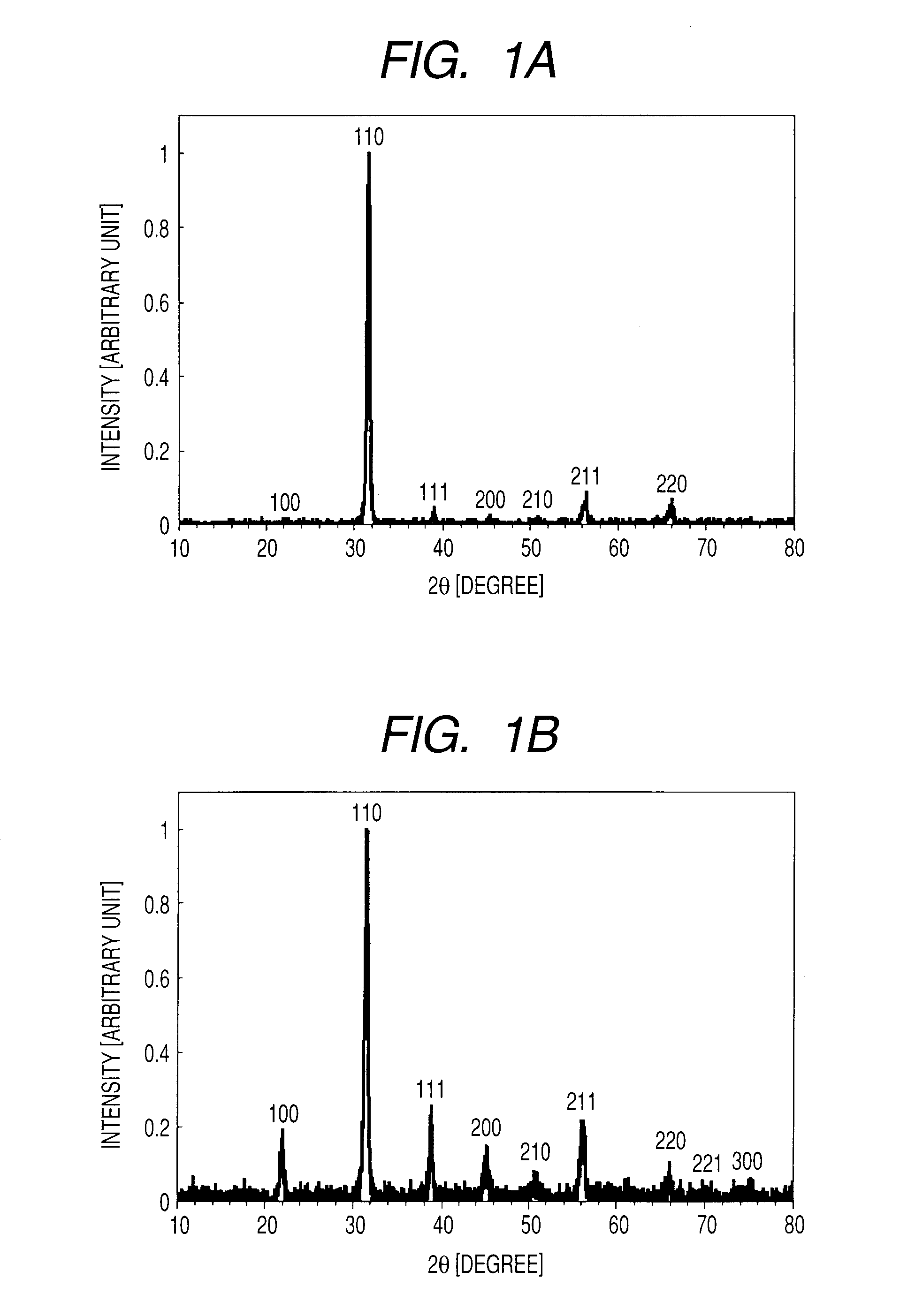

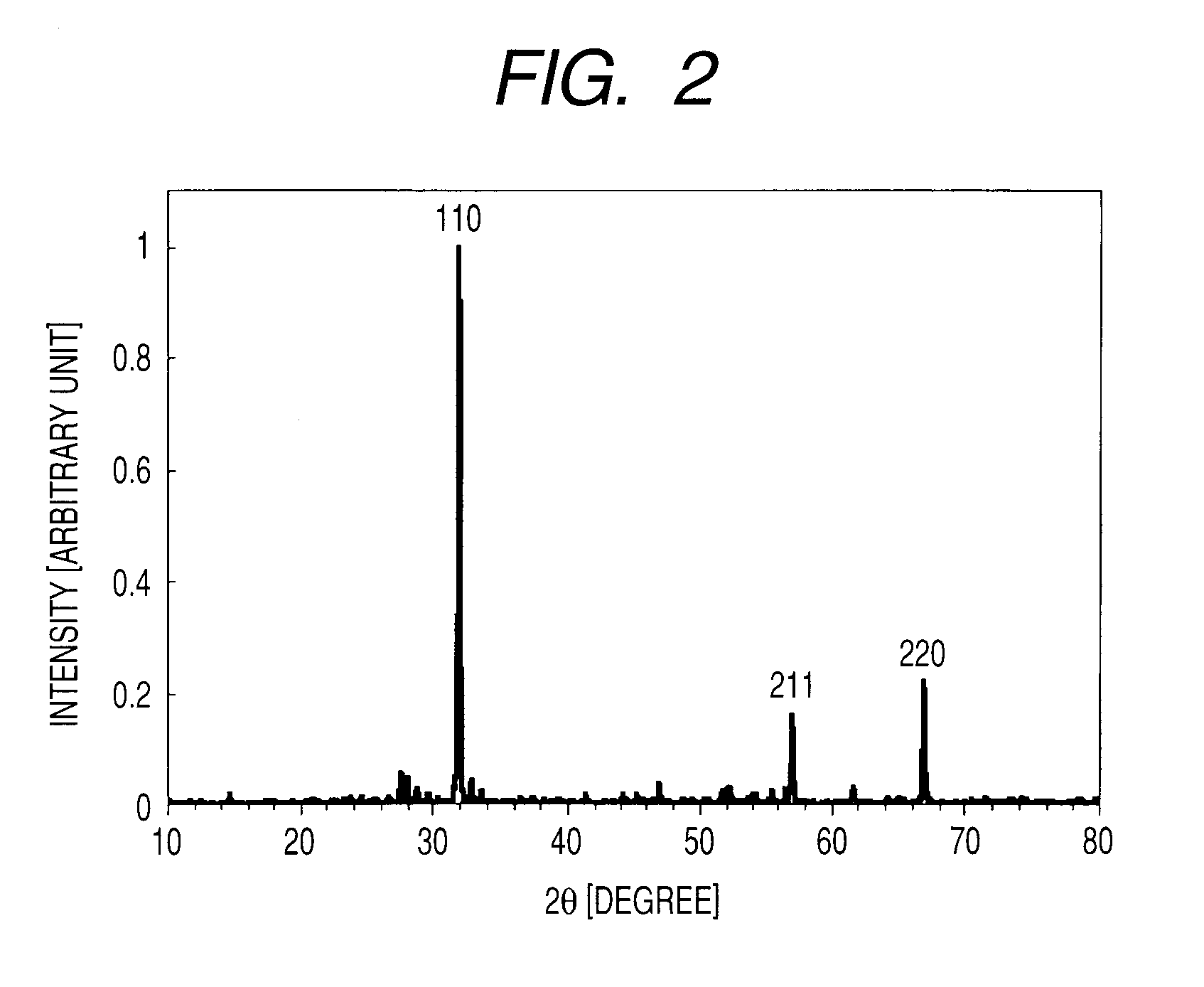

It is an object of the present invention to control the plane orientation of crystal grains obtained by using a laser beam, into a direction that can be substantially regarded as one direction in an irradiation region of the laser beam. After forming a cap film over a semiconductor film, the semiconductor film is crystallized by using a CW laser or a pulse laser having a repetition rate of greater than or equal to 10 MHz. The obtained semiconductor film has a plurality of crystal grains having a width of greater than or equal to 0.01 μm and a length of greater than or equal to 1 μm. In a surface of the obtained semiconductor film, a ratio of an orientation {211} is greater than or equal to 0.4 within the range of an angle fluctuation of ±10°.

Owner:SEMICON ENERGY LAB CO LTD

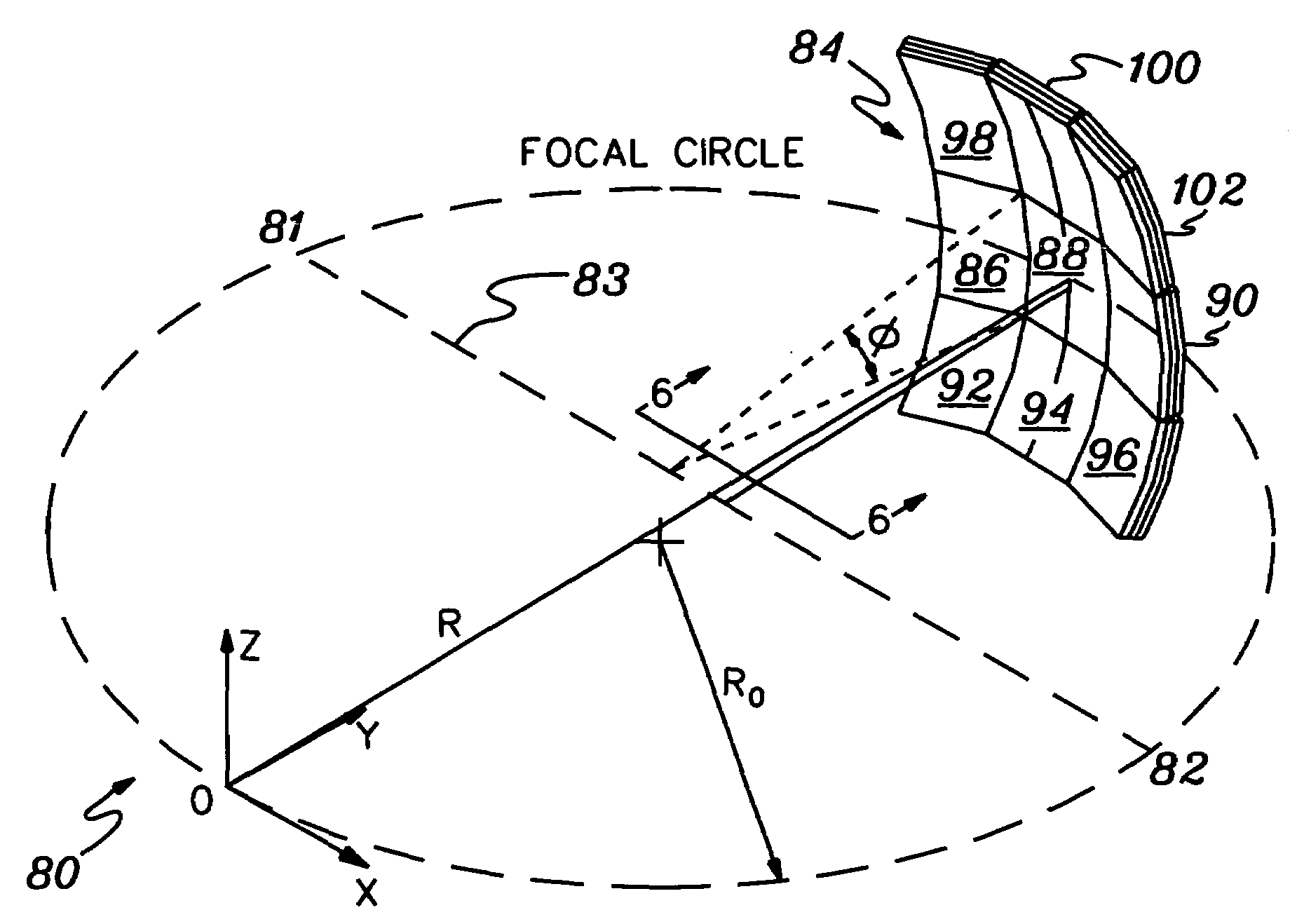

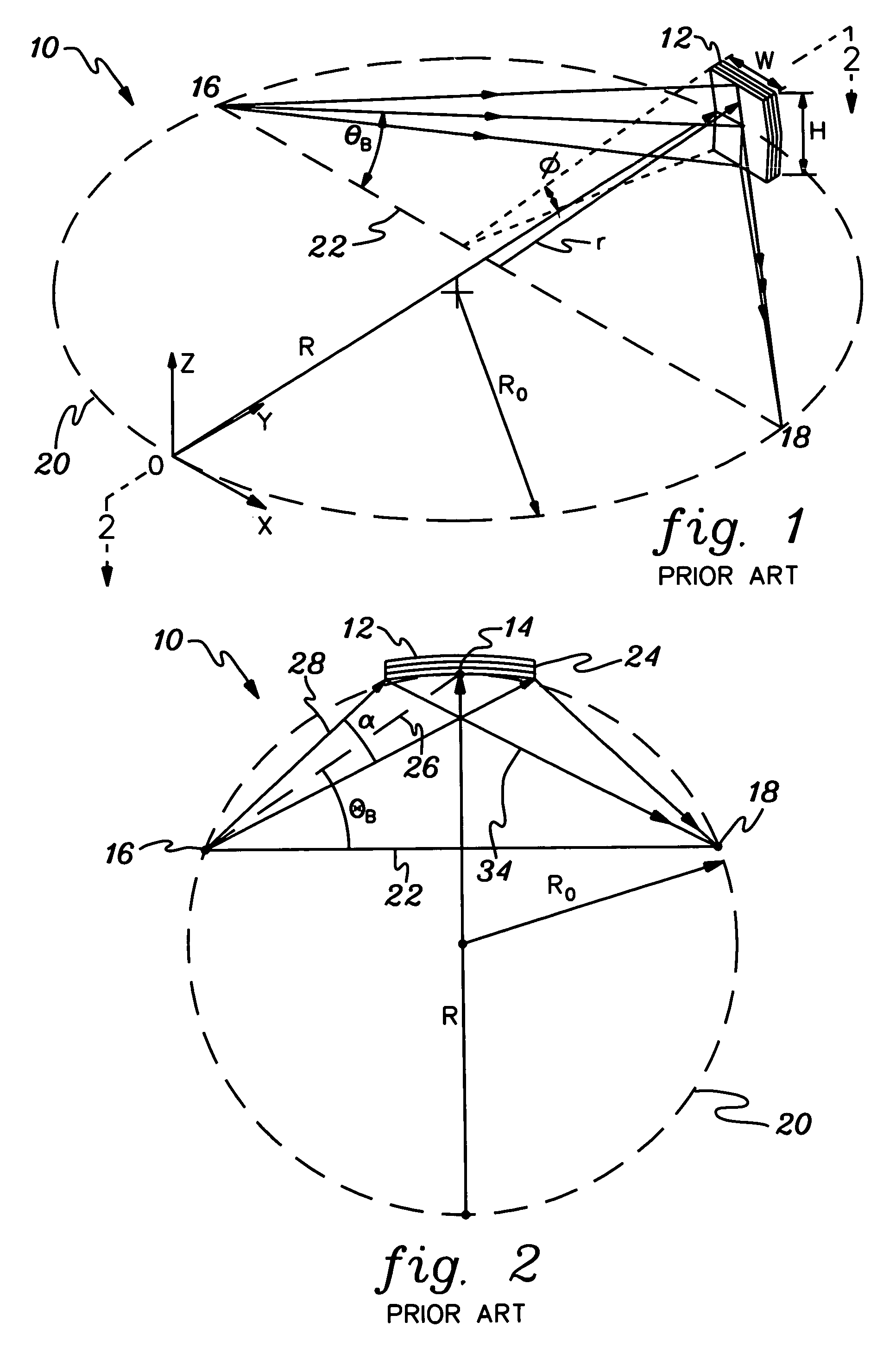

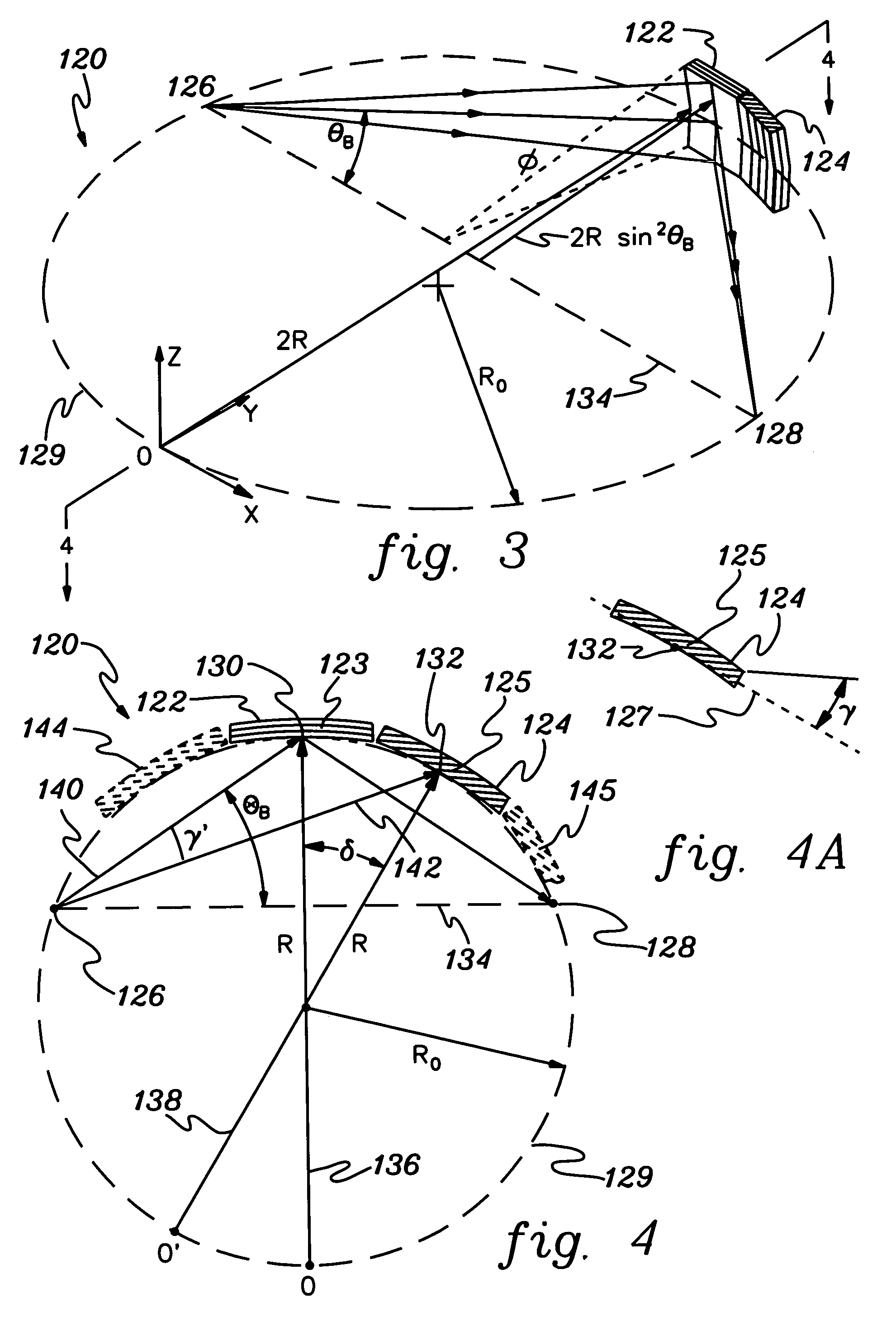

Optical device for directing x-rays having a plurality of optical crystals

InactiveUS7035374B2Material analysis using wave/particle radiationHandling using diffraction/refraction/reflectionSoft x rayHigh energy

Devices for improving the capturing and utilization of high-energy electromagnetic radiation, for example, x-rays, gamma rays, and neutrons, for use in physical, medical, and industrial analysis and control applications are disclosed. The devices include optics having a plurality of optical crystals, for example, doubly-curved silicon or germanium crystals, arranged to optimize the capture and redirection of divergent radiation via Bragg diffraction. In one aspect, a plurality of optic crystals having varying atomic diffraction plane orientations are used to capture and focus divergent x-rays upon a target. In another aspect, a two- or three-dimensional matrix of crystals is positioned relative to an x-ray source to capture and focus divergent x-rays in three dimensions.

Owner:X-RAY OPTICAL SYSTEM INC

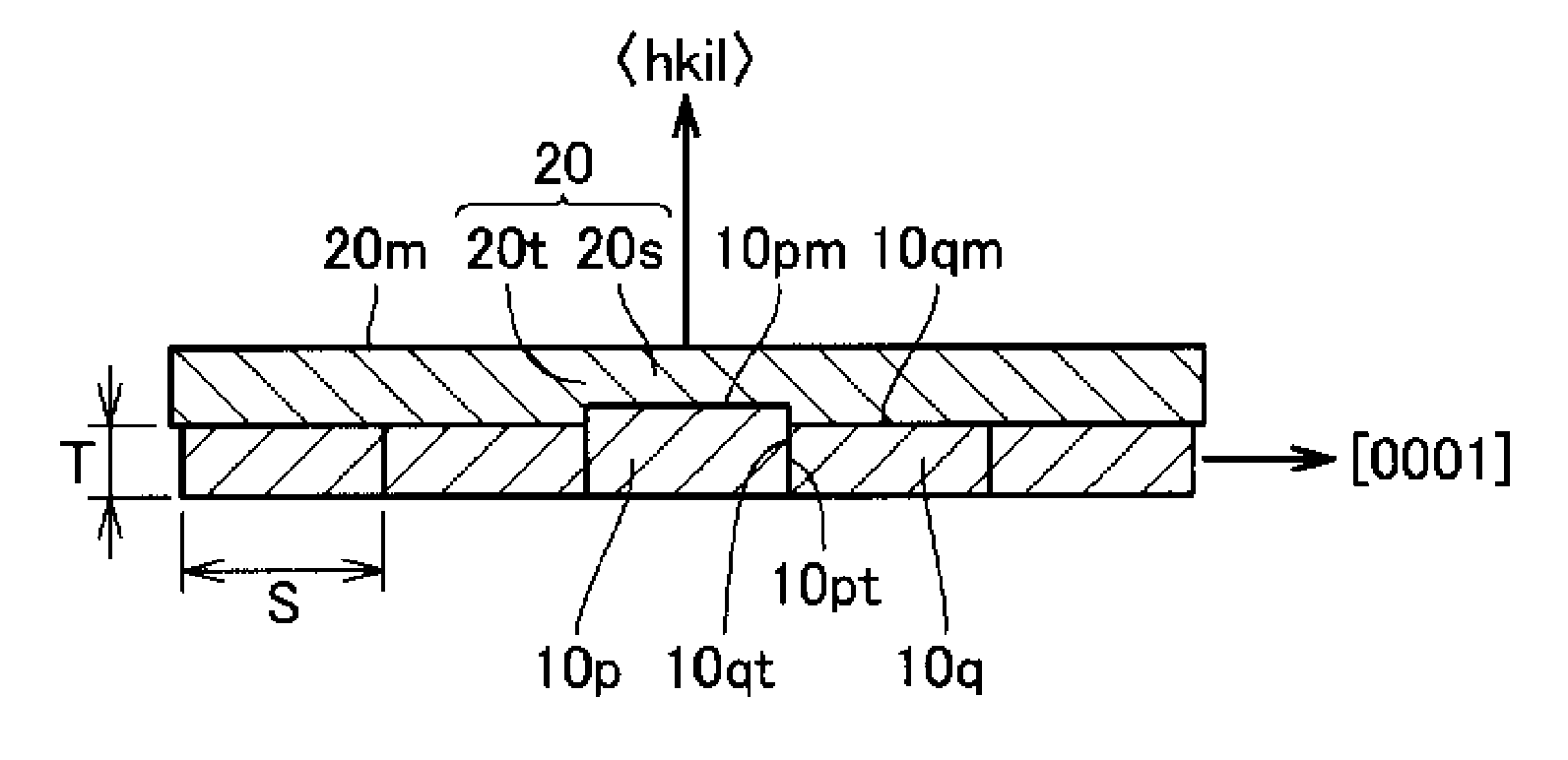

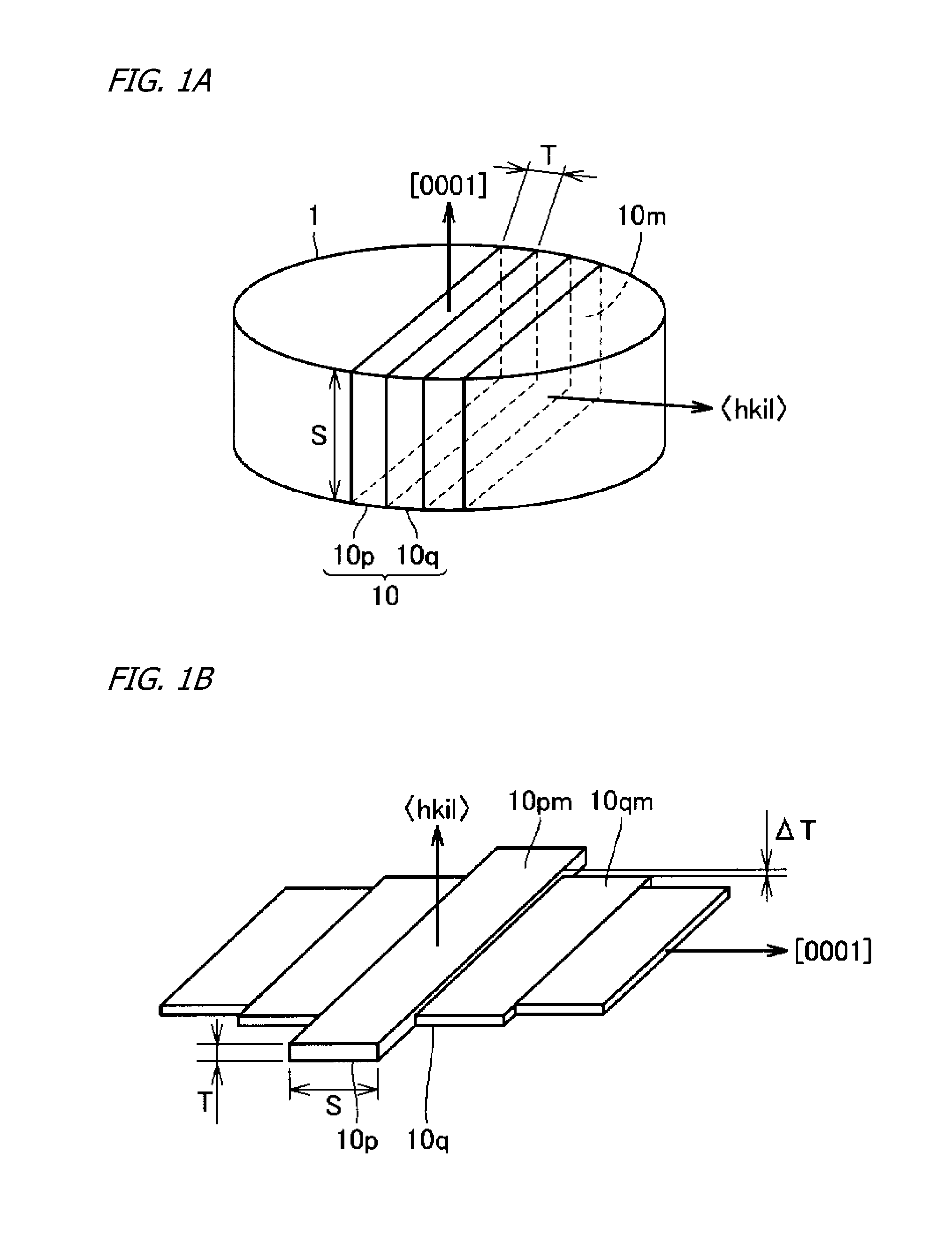

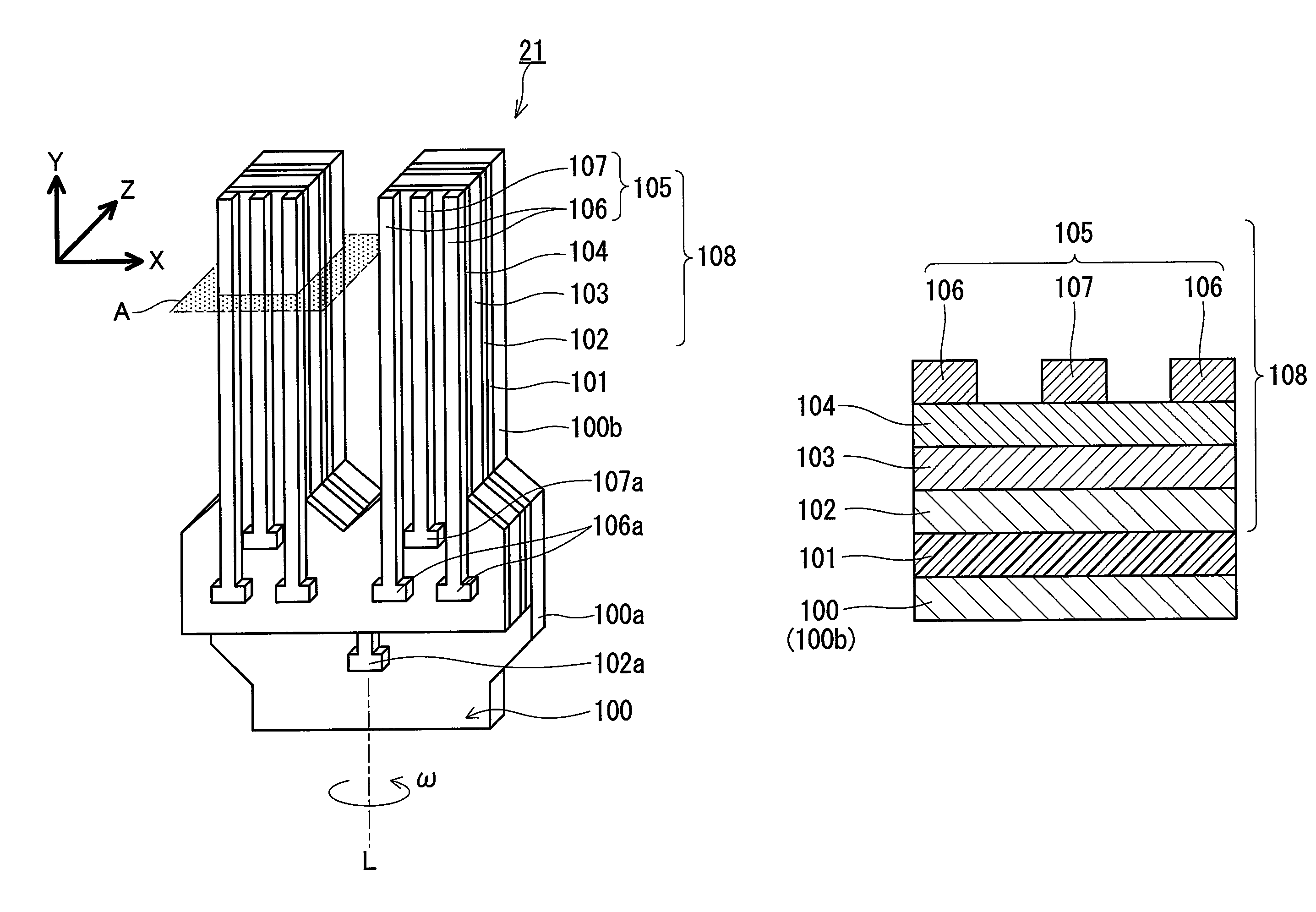

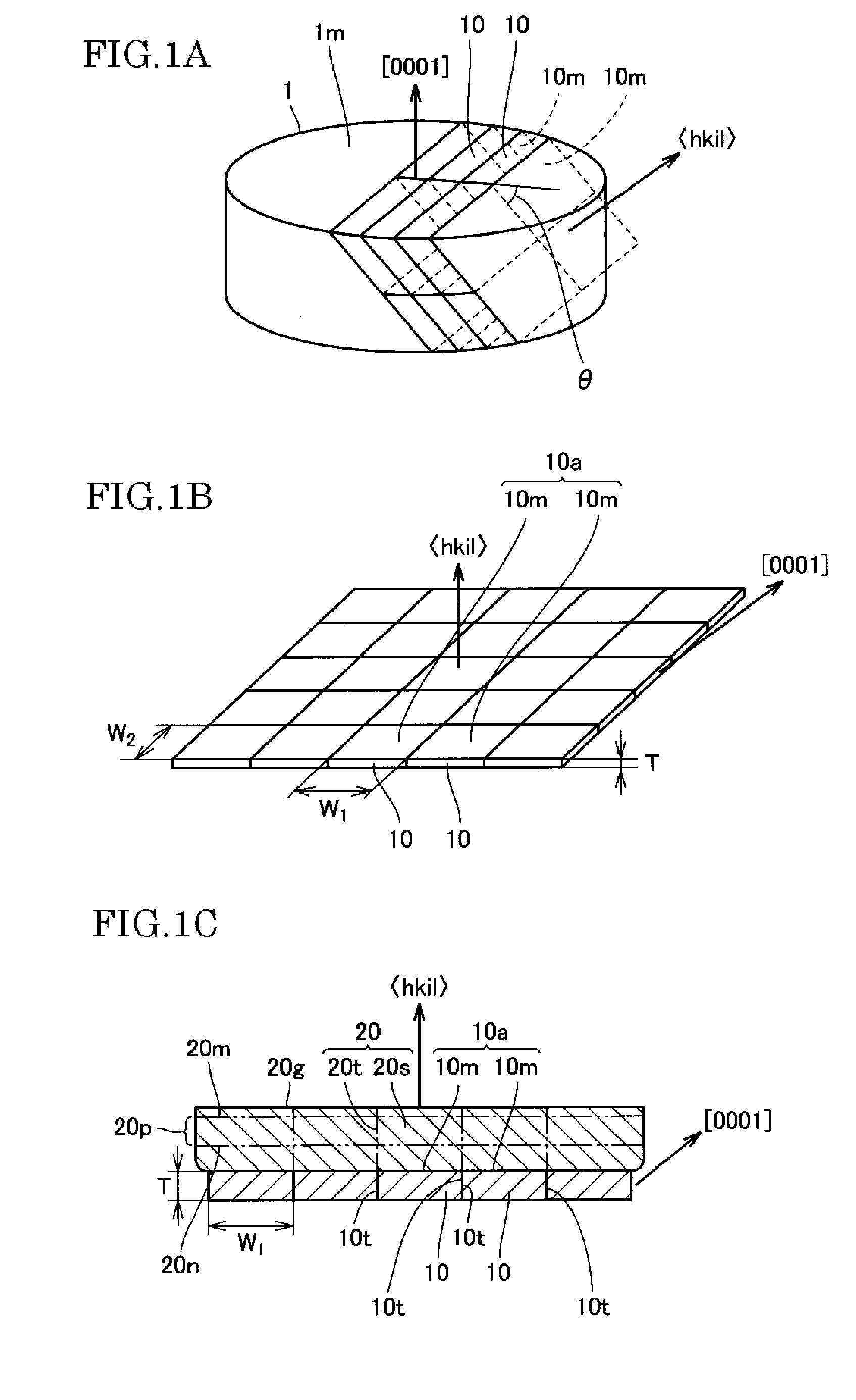

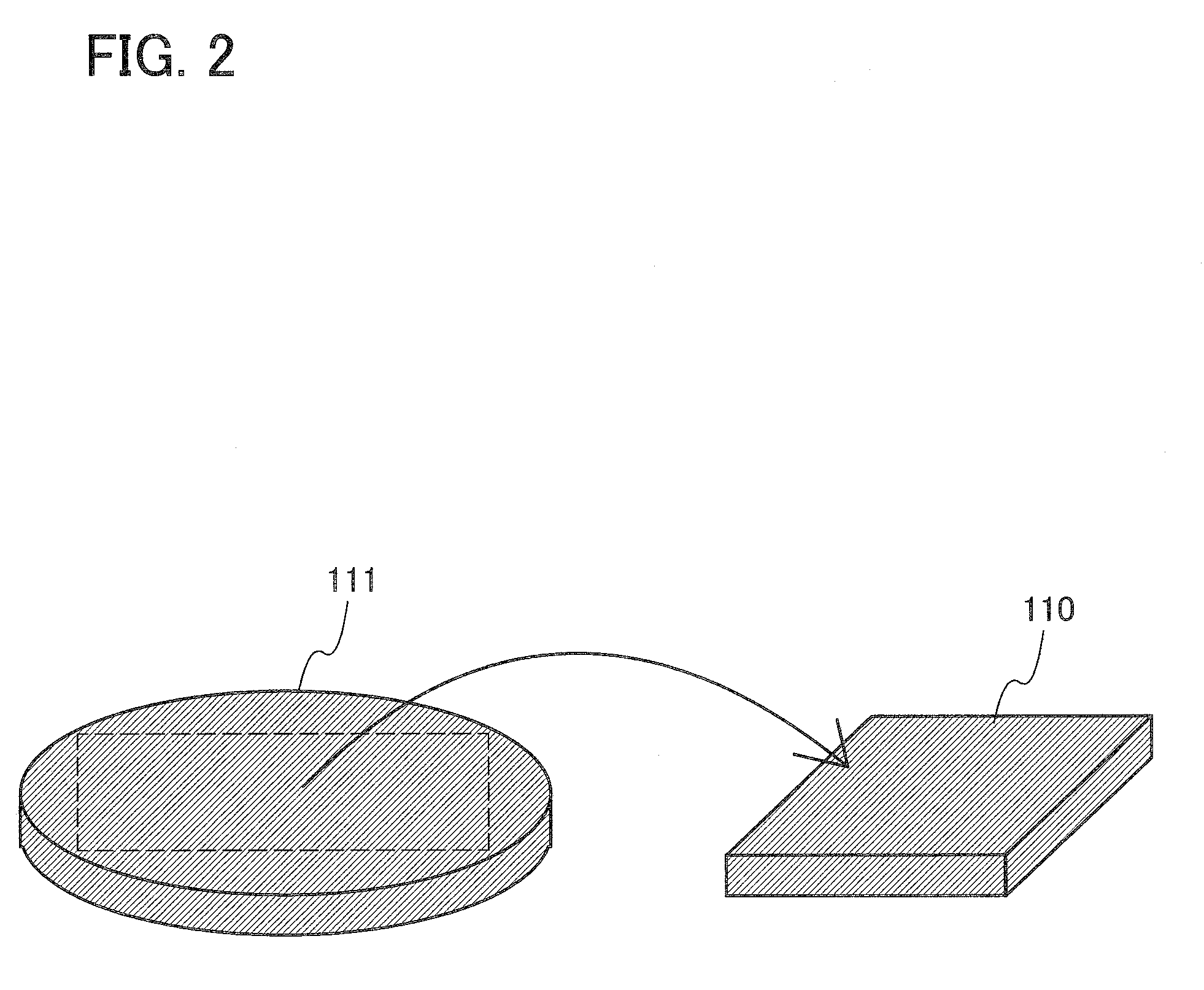

Method of Manufacturing III-Nitride Crystal, and Semiconductor Device Utilizing the Crystal

ActiveUS20090236694A1High crystallinityImprove efficiencyPolycrystalline material growthLiquid-phase epitaxial-layer growthBulk crystalPlane orientation

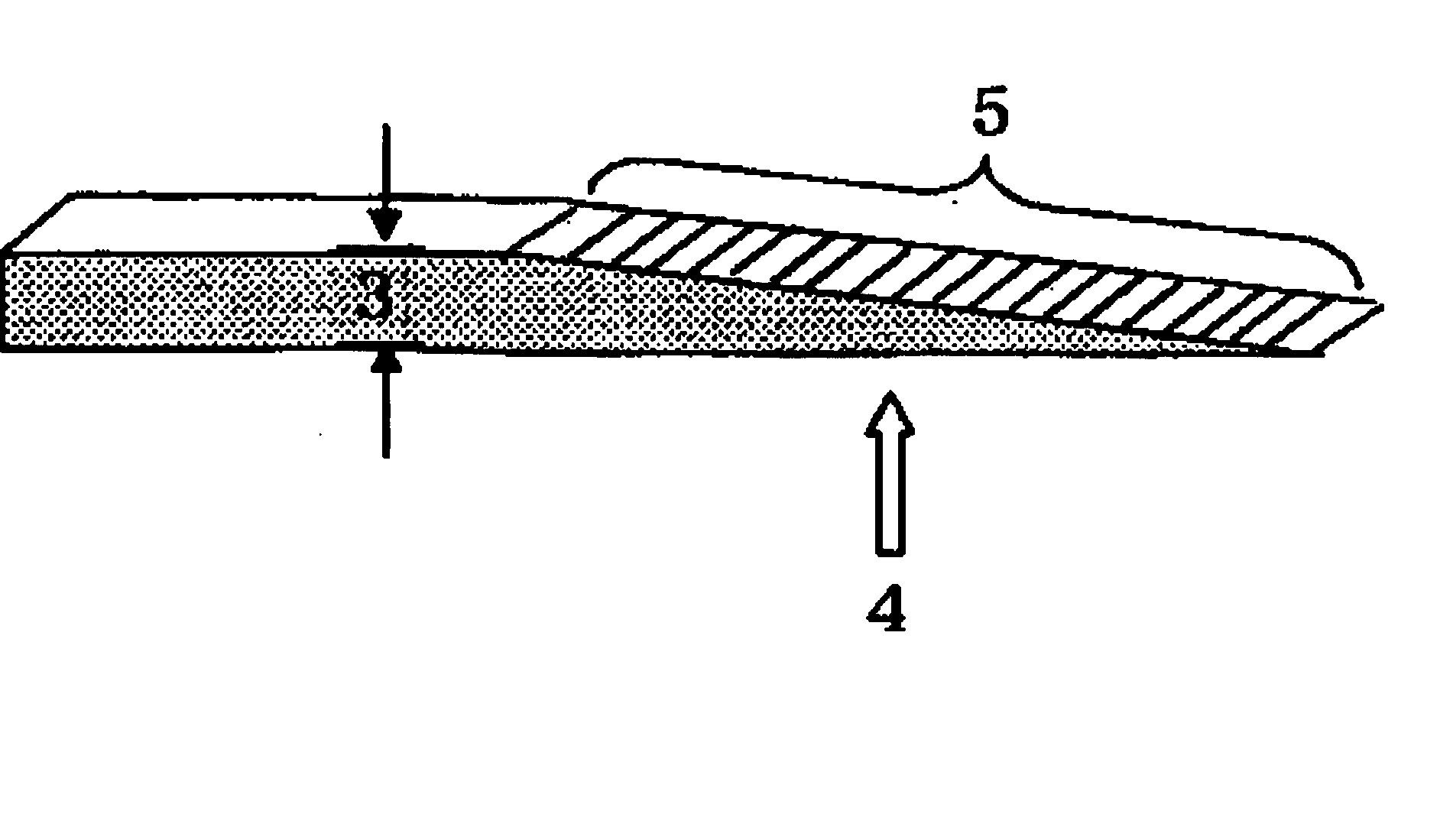

The present III-nitride crystal manufacturing method, a method of manufacturing a III-nitride crystal (20) having a major surface (20m) of plane orientation other than {0001}, designated by choice, includes: a step of slicing III-nitride bulk crystal (1) into a plurality of III-nitride crystal substrates (10p), (10q) having major surfaces (10pm), (10qm) of the designated plane orientation; a step of disposing the substrates (10p), (10q) adjoining each other sideways in such a way that the major surfaces (10pm), (10qm) of the substrates (10p), (10q) parallel each other and so that the [0001] directions in the substrates (10p), (10q) are oriented in the same way; and a step of growing III-nitride crystal (20) onto the major surfaces (10pm), (10qm) of the substrates (10p), (10q).

Owner:SUMITOMO ELECTRIC IND LTD

Biaxially oriented thermoplastic resin film

InactiveUS20050020803A1High modulusHigh melting pointFixed capacitor dielectricSynthetic resin layered productsPlane orientationPeak value

In order to provide a film having excellent heat resistance, thermal dimensional stability, and mechanical properties, in particular, a film capable of satisfying required properties, e.g., higher strength in accordance with the reduction in thickness of a base film, improved thermal dimensional stability and mechanical properties in a use environment, and higher heat resistance and improved thermal dimensional stability in accordance with the needs for miniaturization and more functionality in electrical and electronic areas, a thermoplastic resin is allowed to contain transition metal oxide particles, and is formed into a biaxially oriented thermoplastic resin film, wherein the melting point of the film is allowed to become higher than the melting point of the thermoplastic resin to be used. Preferably, the difference between a peak temperature (melting point T1) of the heat of fusion in the first run of the measurement of the biaxially oriented thermoplastic resin film with a differential scanning calorimeter (DSC) and a peak temperature (melting point T2) of the heat of fusion in the second run is allowed to satisfy the following Formula. 2° C.≦T1−T2≦30°C. Alternatively, the plane orientation factor of the biaxially oriented thermoplastic resin film containing the transition metal oxide particles is controlled at 0.120 or more and less than 0.280.

Owner:TORAY IND INC

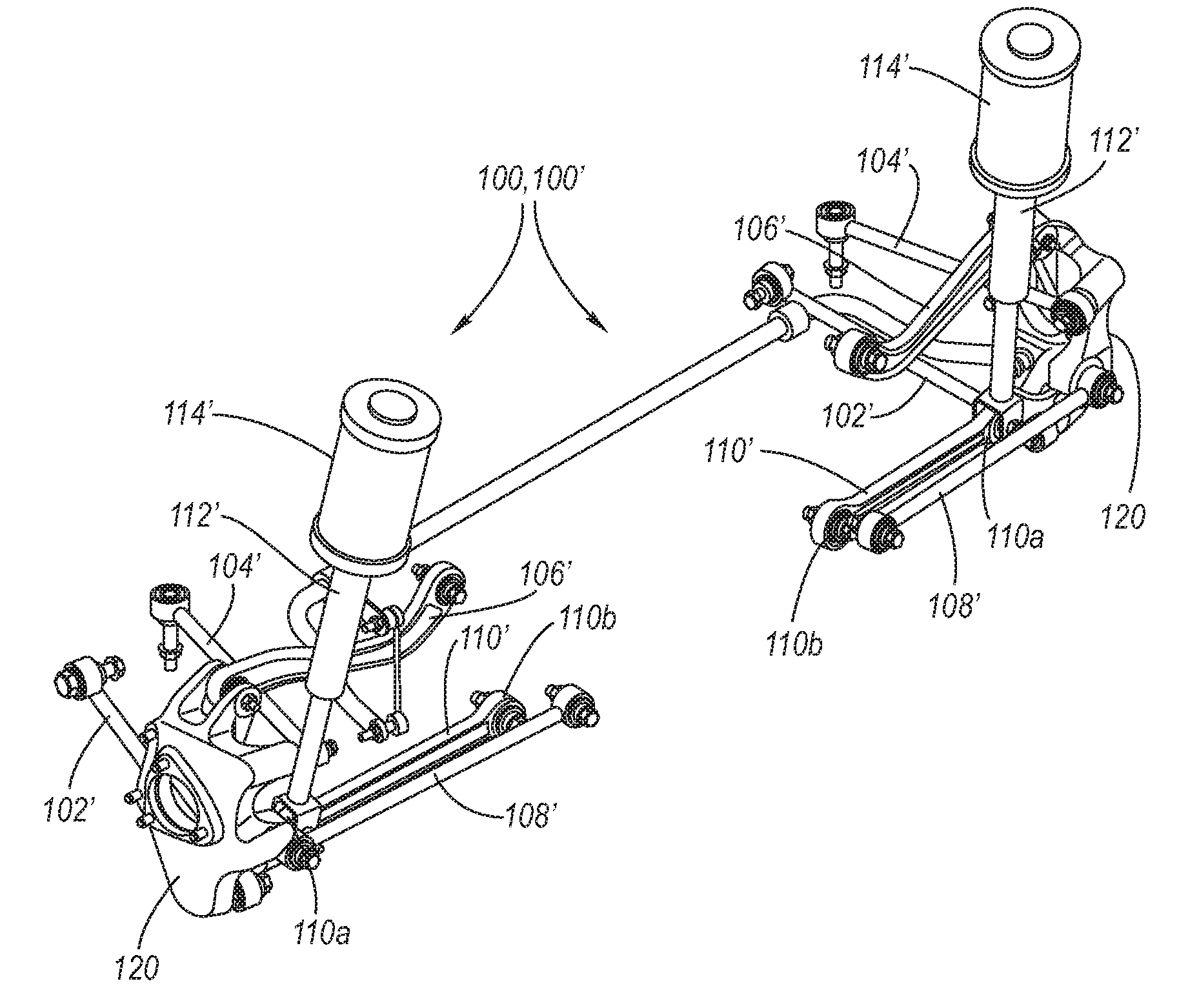

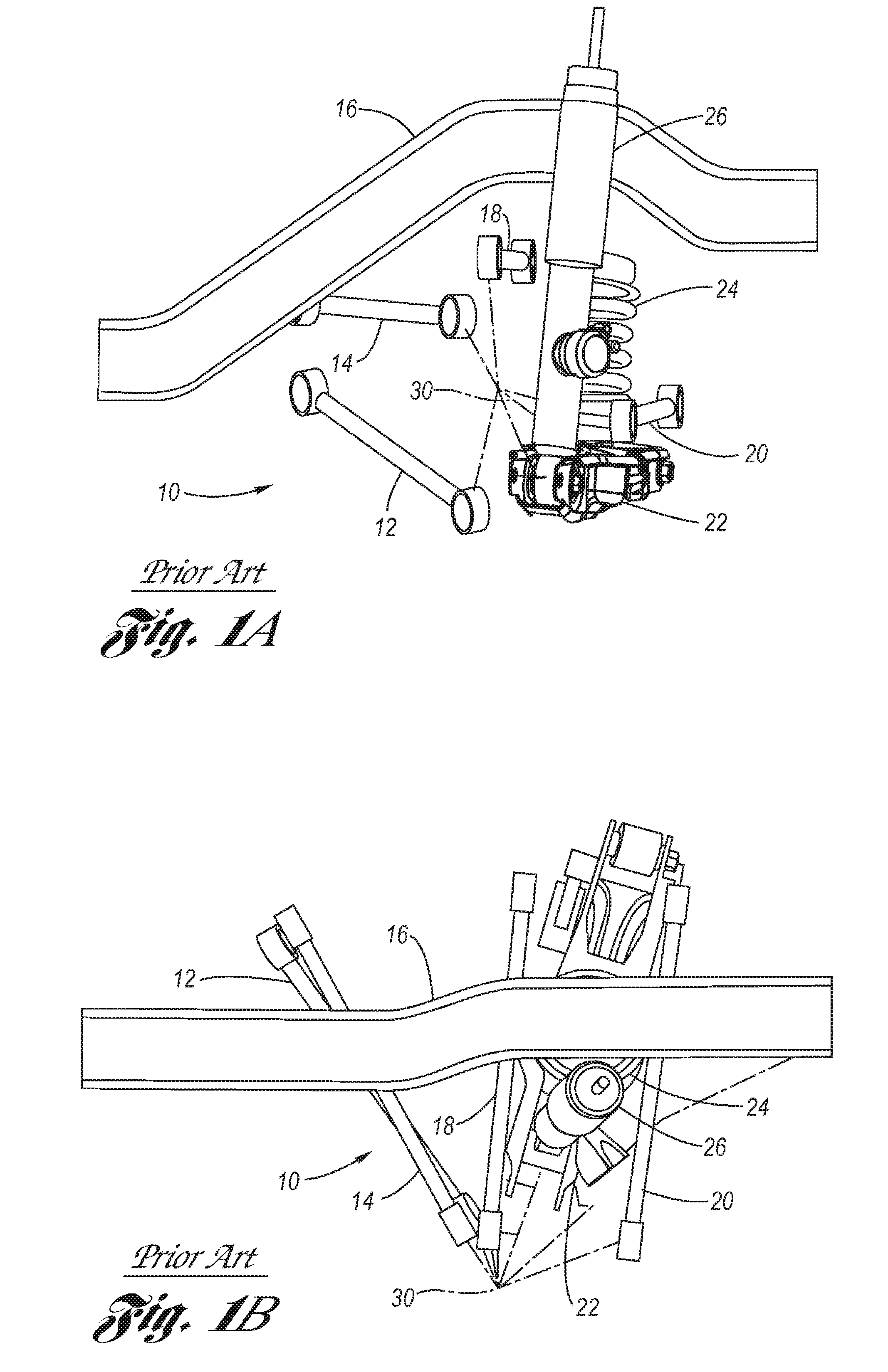

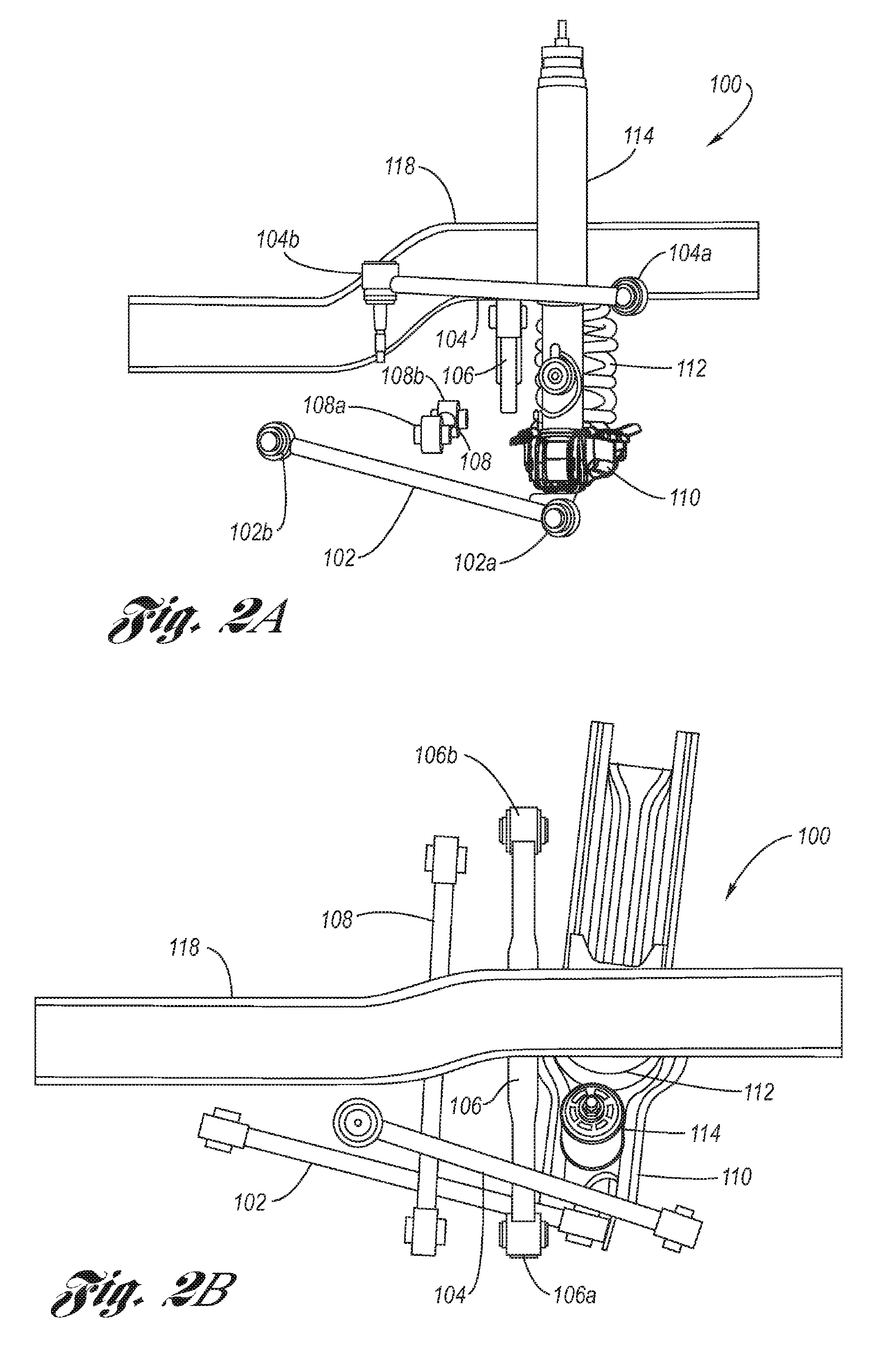

Decoupled 5-link independent rear suspension

InactiveUS7891684B1Easy to manageIncrease spacingInterconnection systemsResilient suspensionsBrake torqueMobile vehicle

A decoupled 5-link independent rear suspension system (IRS) for motor vehicles. Three lateral linkages, the toe, camber and spring links, establish the wheel plane orientation and react to vertical and lateral loads, and two longitudinal links, the upper and lower trailing links, react to tractive loads and brake torques. The upper and lower trailing links are longitudinally orientated and disposed outboard of the body rail, thus allowing for improved load reactions of the suspension system, as well as optimization of the body rail configuration and space accommodation for other vehicle components, such as for example fuel, batteries and exhaust.

Owner:GM GLOBAL TECH OPERATIONS LLC

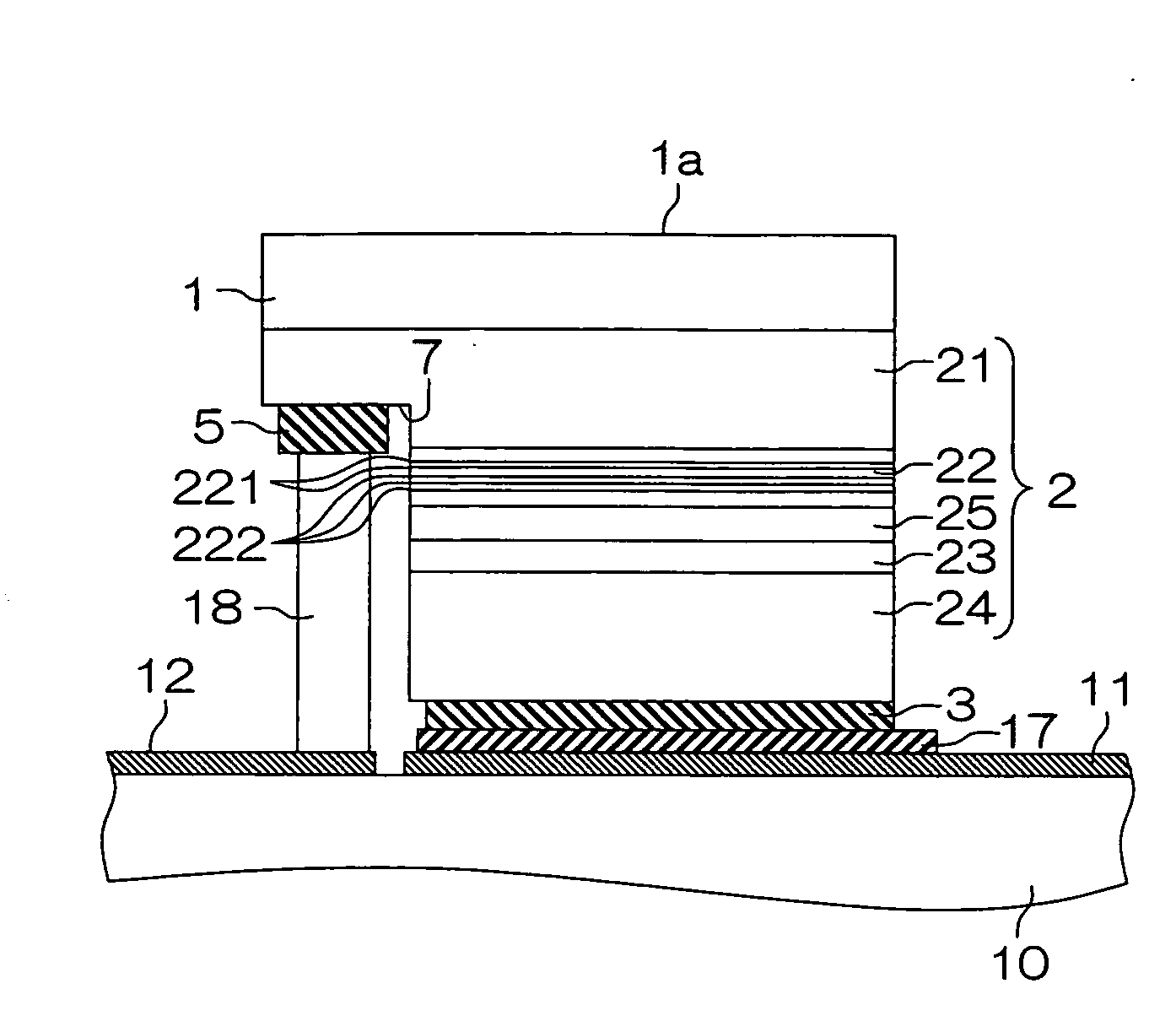

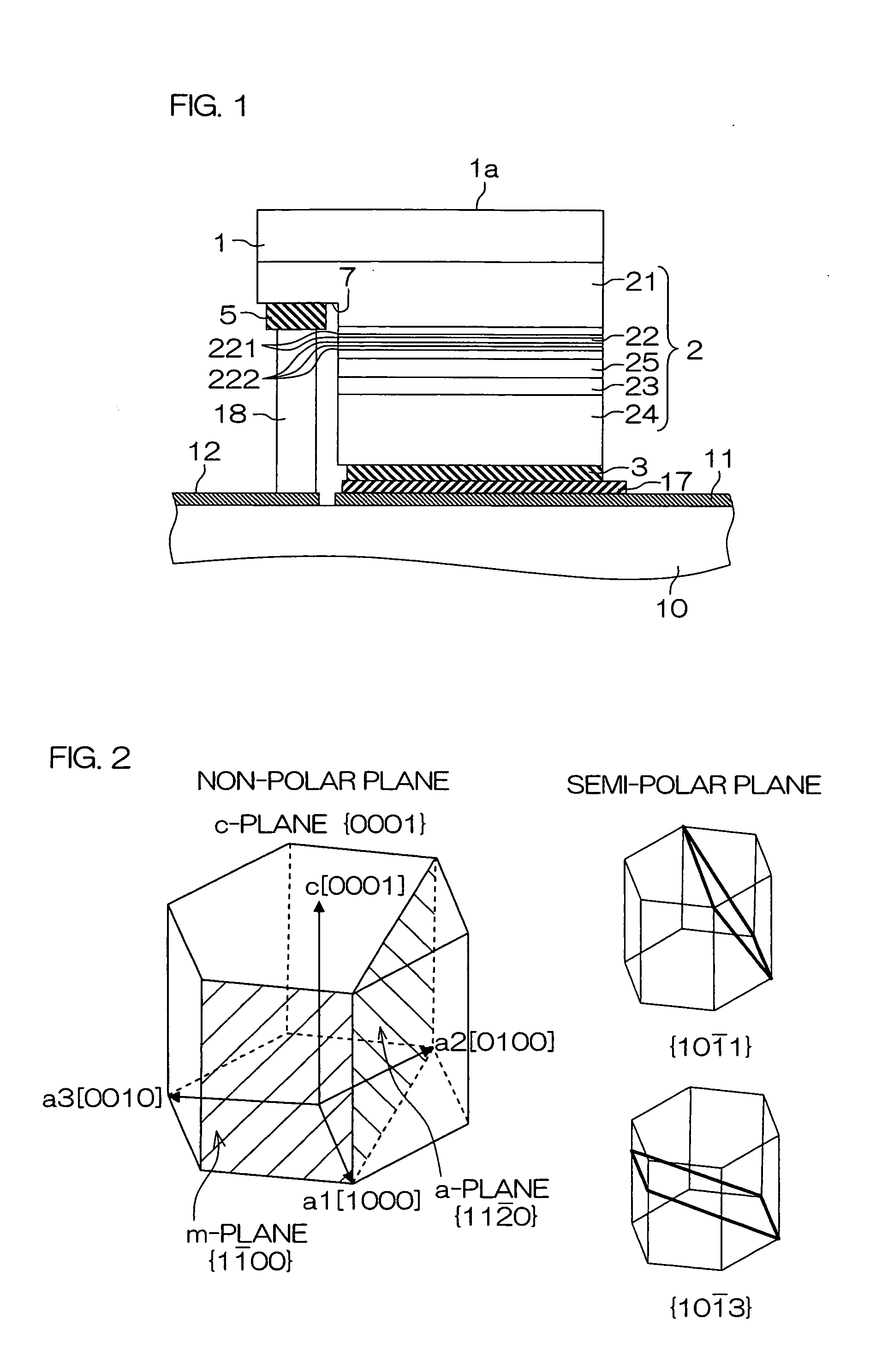

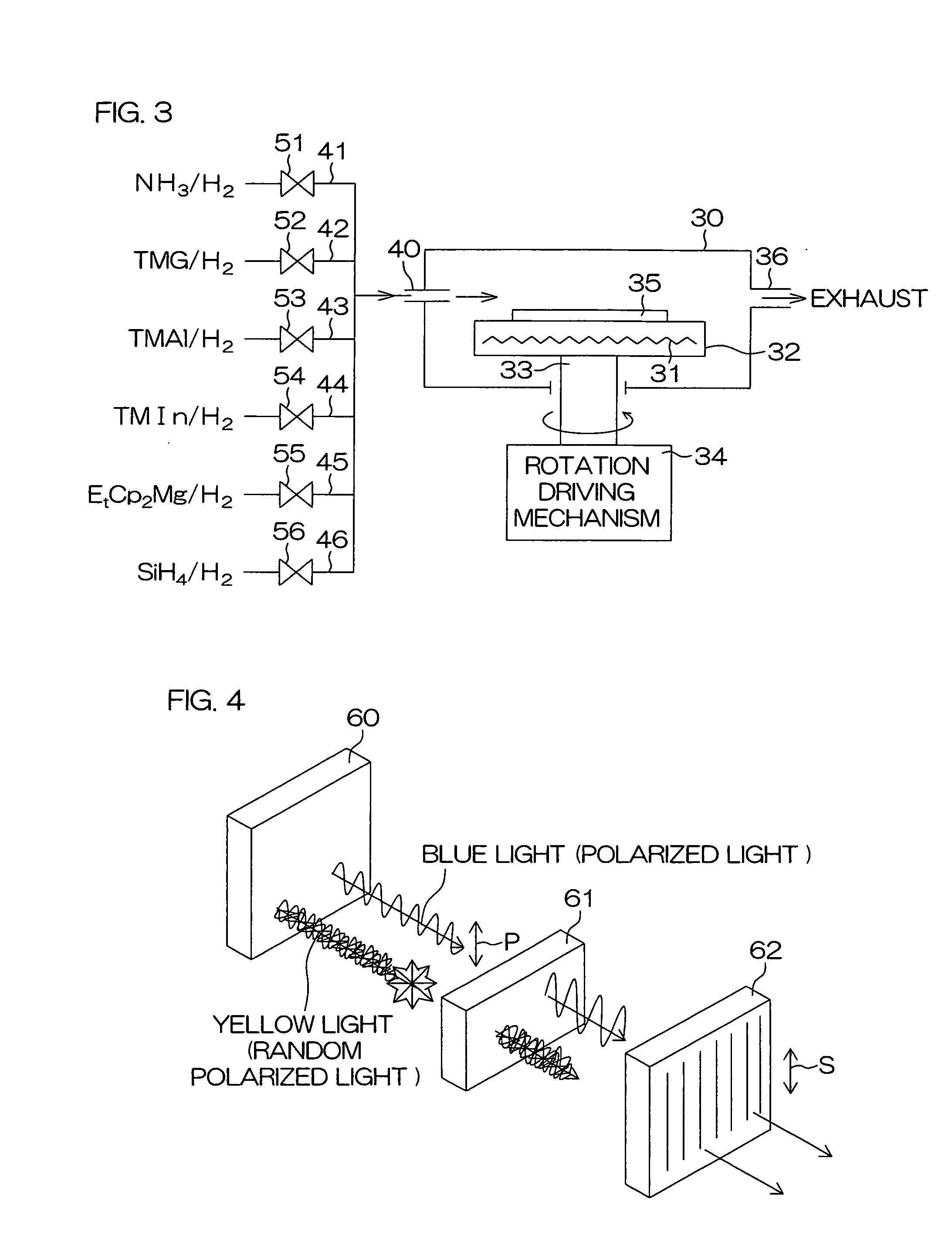

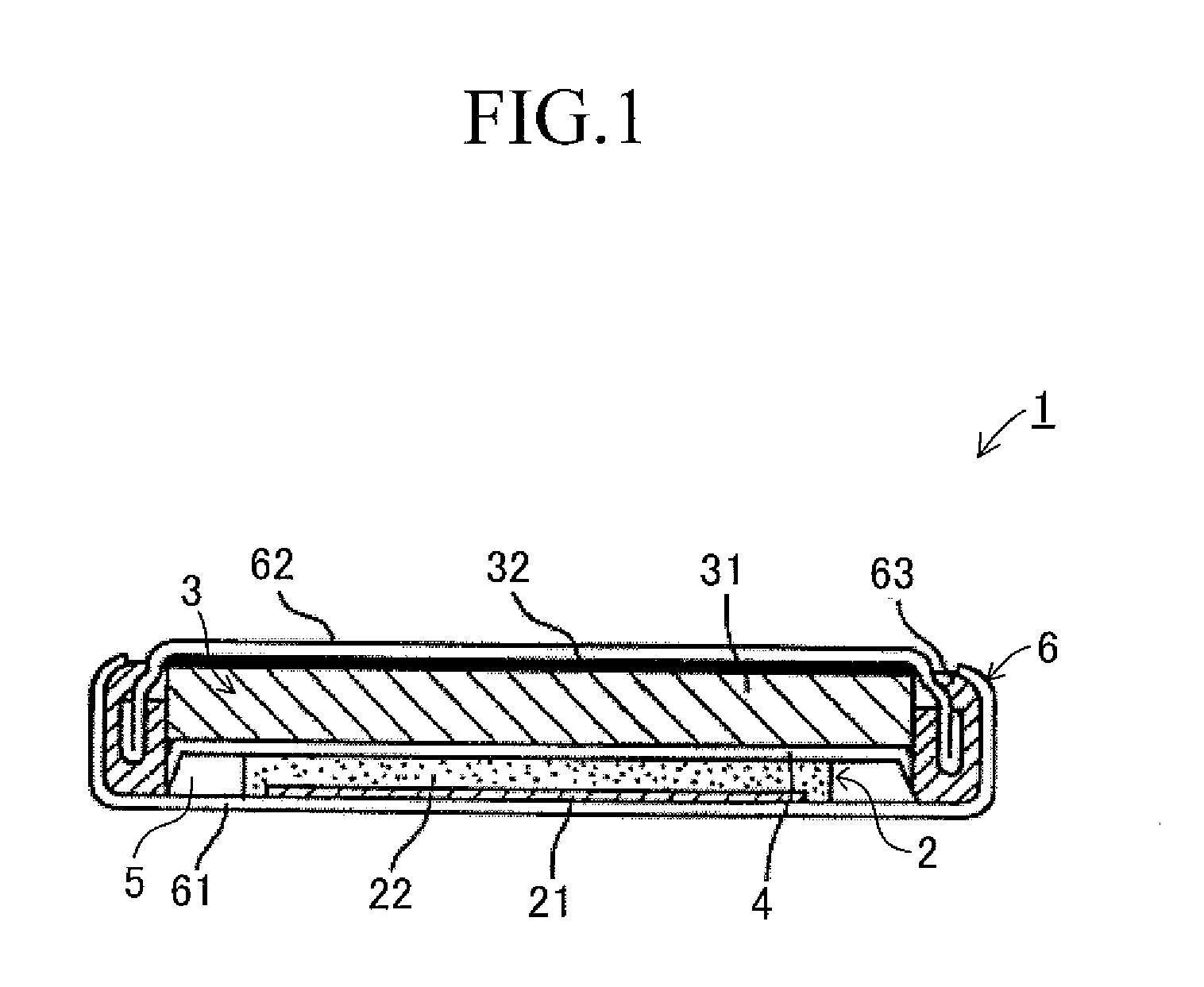

Light emitting device

InactiveUS20080230766A1Efficient extractionLittle unevennessSolid-state devicesSemiconductor devicesPlane orientationLength wave

A light emitting element includes a group III nitride semiconductor substrate that emits a light by absorbing a UV ray and a light emitting diode structure. The light emitting diode structure is formed of a group III nitride semiconductor grown on the group III nitride semiconductor substrate, and has a p-type layer, an active layer that emits a light having a wavelength in the UV region, and an n-type layer. It is preferable that the group III nitride semiconductor substrate has a principal plane of a non-polar plane or a semi-polar plane and the group III nitride semiconductor having a same plane orientation as that of the principal plane is grown on the principal plane.

Owner:ROHM CO LTD

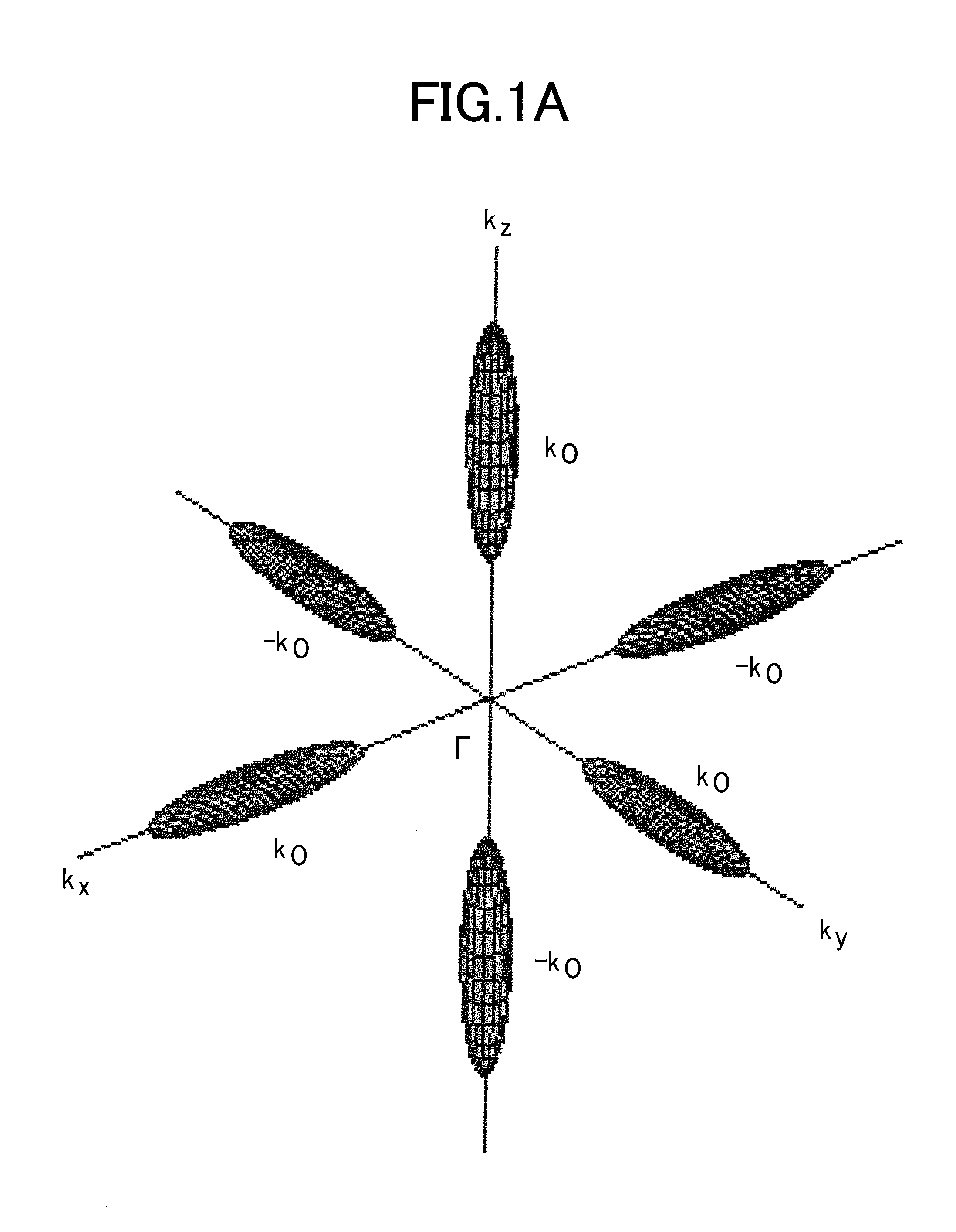

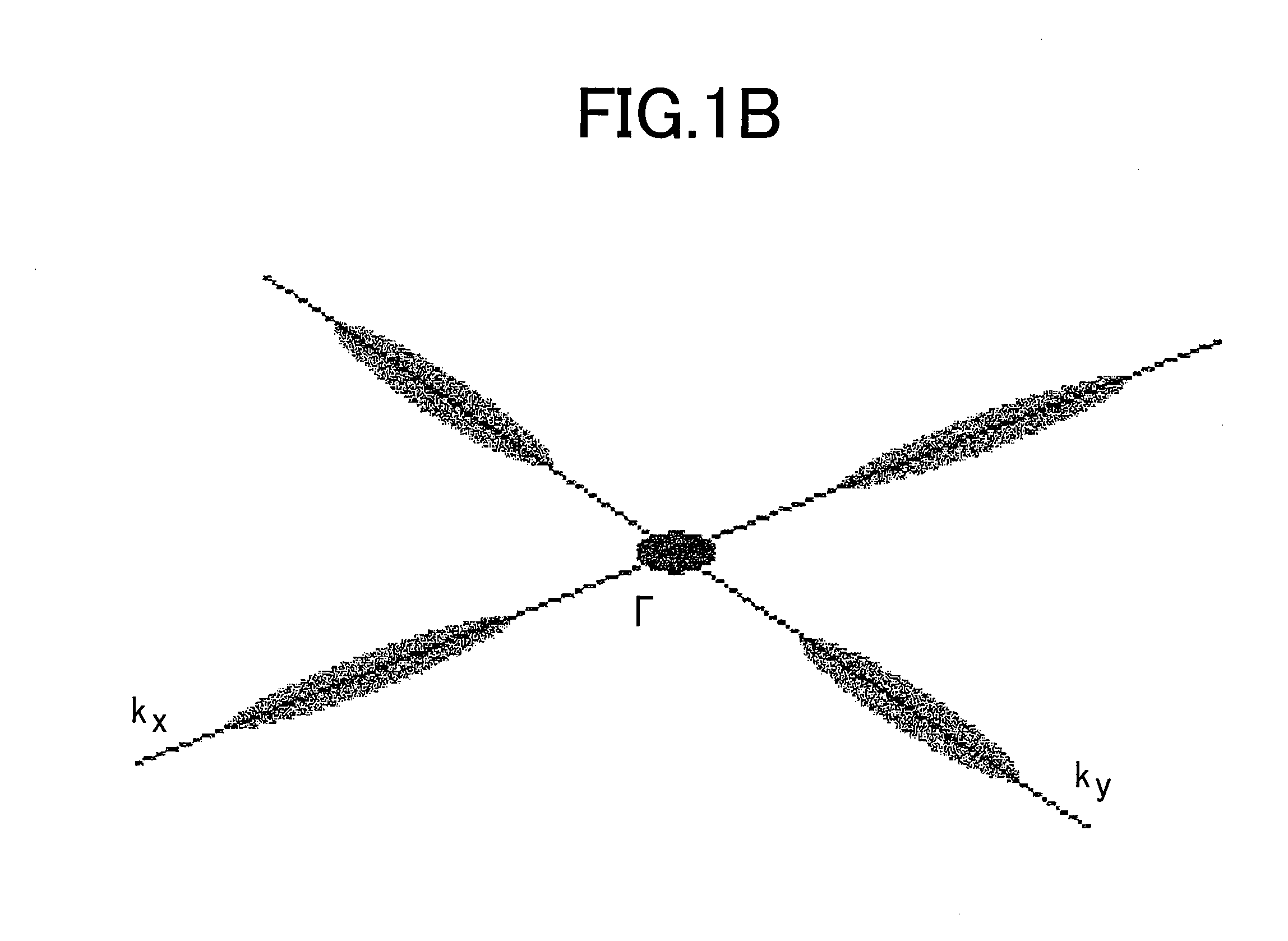

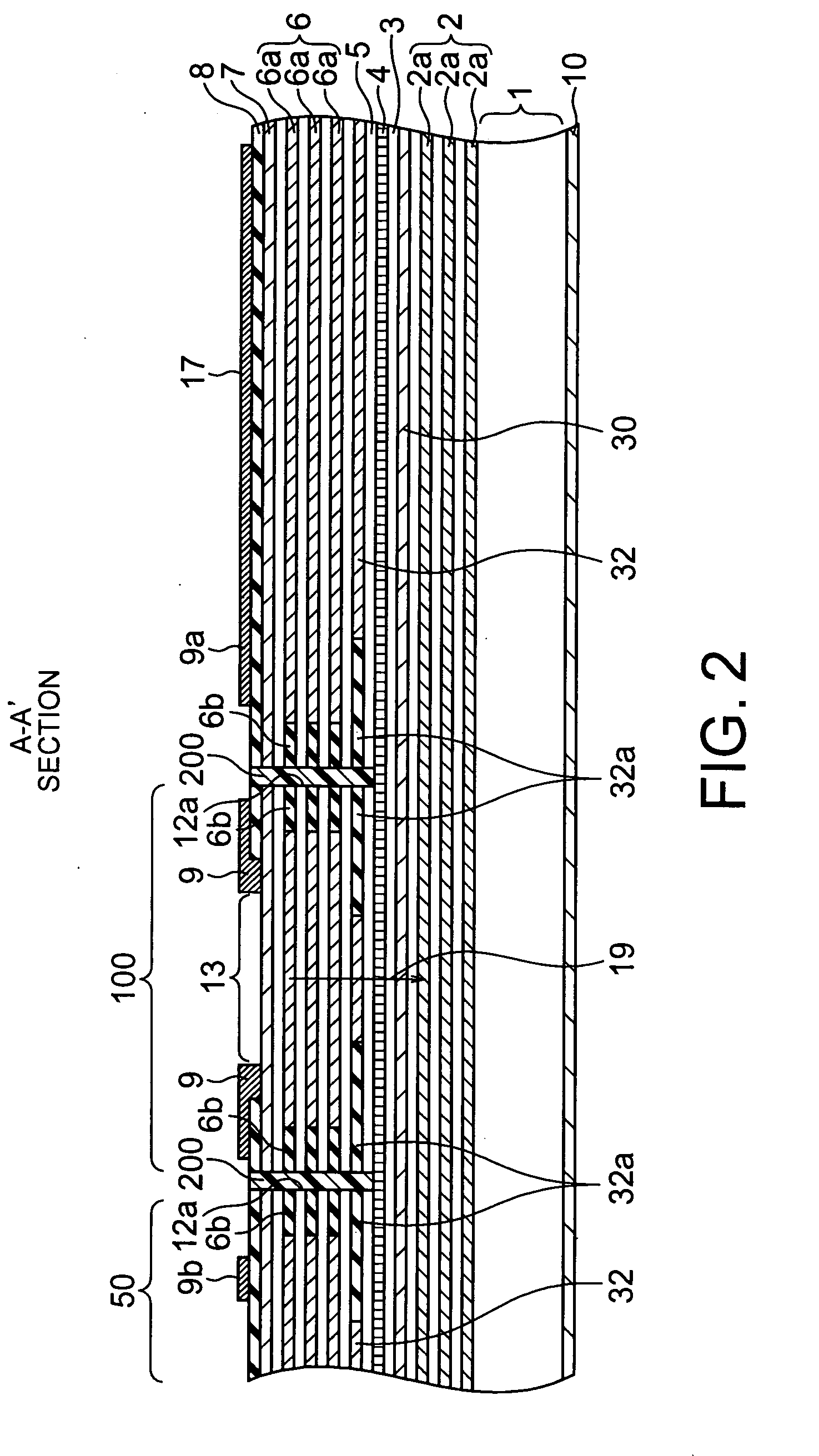

Semiconductor led, opto-electronic integrated circuits (OEIC), and method of fabricating oeic

ActiveUS20080197362A1Solve low luminous efficiencyImprove efficiencyLaser active region structureSolid-state devicesRefractive indexPlane orientation

A light emitting diode demonstrating high luminescence efficiency and comprising a Group IV semiconductor such as silicon or germanium equivalent thereto as a basic component formed on a silicon substrate by a prior art silicon process, and a fabricating method of waveguide thereof are provided. The light emitting diode of the invention comprises a first electrode for implanting electrons, a second electrode for implanting holes, and a light emitting section electrically connected to the first and the second electrode, wherein the light emitting section is made out of single crystalline silicon and has a first surface and a second surface facing the first surface, wherein with respect to plane orientation (100) of the first and second surfaces, the light emitting section crossing at right angles to the first and second surfaces is made thinner, and wherein a material having a high refractive index is arranged around the thin film section.

Owner:HITACHI LTD

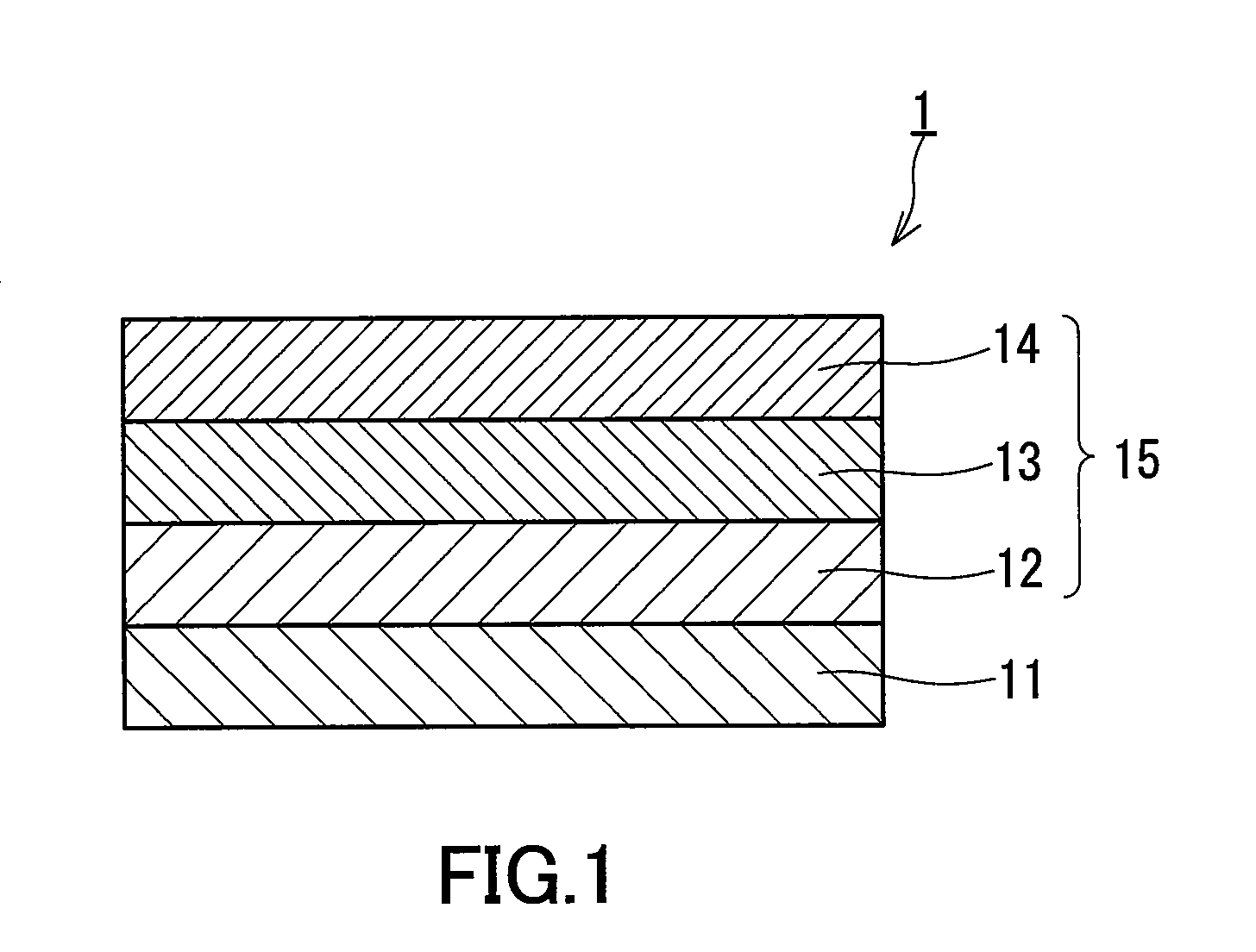

Piezoelectric thin film and method of manufacturing the same, angular velocity sensor, method of measuring angular velocity by the angular velocity sensor, piezoelectric generating element, and method of generating electric power using the piezoelectric generating element

InactiveUS7870787B2Improve piezoelectric performanceHigh sensitivityPiezoelectric/electrostrictive device manufacture/assemblyAcceleration measurement using interia forcesElectricityWide area

Provided are a piezoelectric thin film including a lead-free ferroelectric material and exhibiting high piezoelectric performance comparable to that of PZT, and a method of manufacturing the piezoelectric thin film. The piezoelectric thin film of the present invention has a multilayer structure in which a metal electrode film having a plane orientation of (100), a (Bi,Na)TiO3 film, and a (Bi,Na,Ba)TiO3 film having a plane orientation of (001) are laminated in this order. The piezoelectric thin film of the present invention can be applied to a wide range of fields and uses. For example, with the piezoelectric thin film of the present invention, an angular velocity sensor of the present invention having high sensitivity and a piezoelectric generating element of the present invention having excellent power generation characteristics can be constructed.

Owner:PANASONIC CORP

Semiconductor device and manufacturing method thereof

InactiveUS7709309B2Efficient use ofReduce energy densitySolid-state devicesSemiconductor/solid-state device manufacturingPlane orientationCw laser

It is an object of the present invention to control the plane orientation of crystal grains obtained by using a laser beam, into a direction that can be substantially regarded as one direction in an irradiation region of the laser beam. After forming a cap film over a semiconductor film, the semiconductor film is crystallized by using a CW laser or a pulse laser having a repetition rate of greater than or equal to 10 MHz. The obtained semiconductor film has a plurality of crystal grains having a width of greater than or equal to 0.01 μm and a length of greater than or equal to 1 μm. In a surface of the obtained semiconductor film, a ratio of an orientation {211} is greater than or equal to 0.4 within the range of an angle fluctuation of ±10°.

Owner:SEMICON ENERGY LAB CO LTD

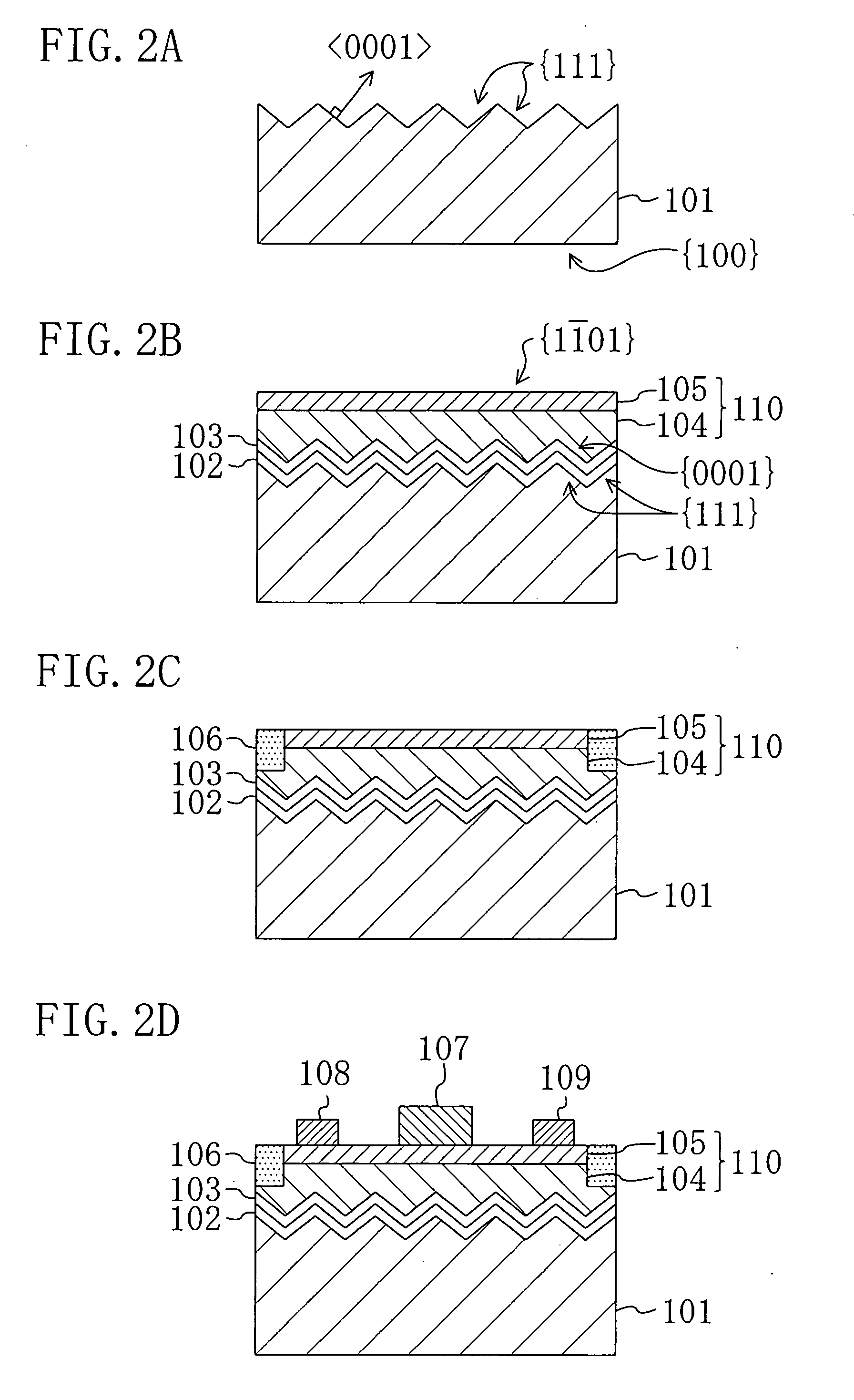

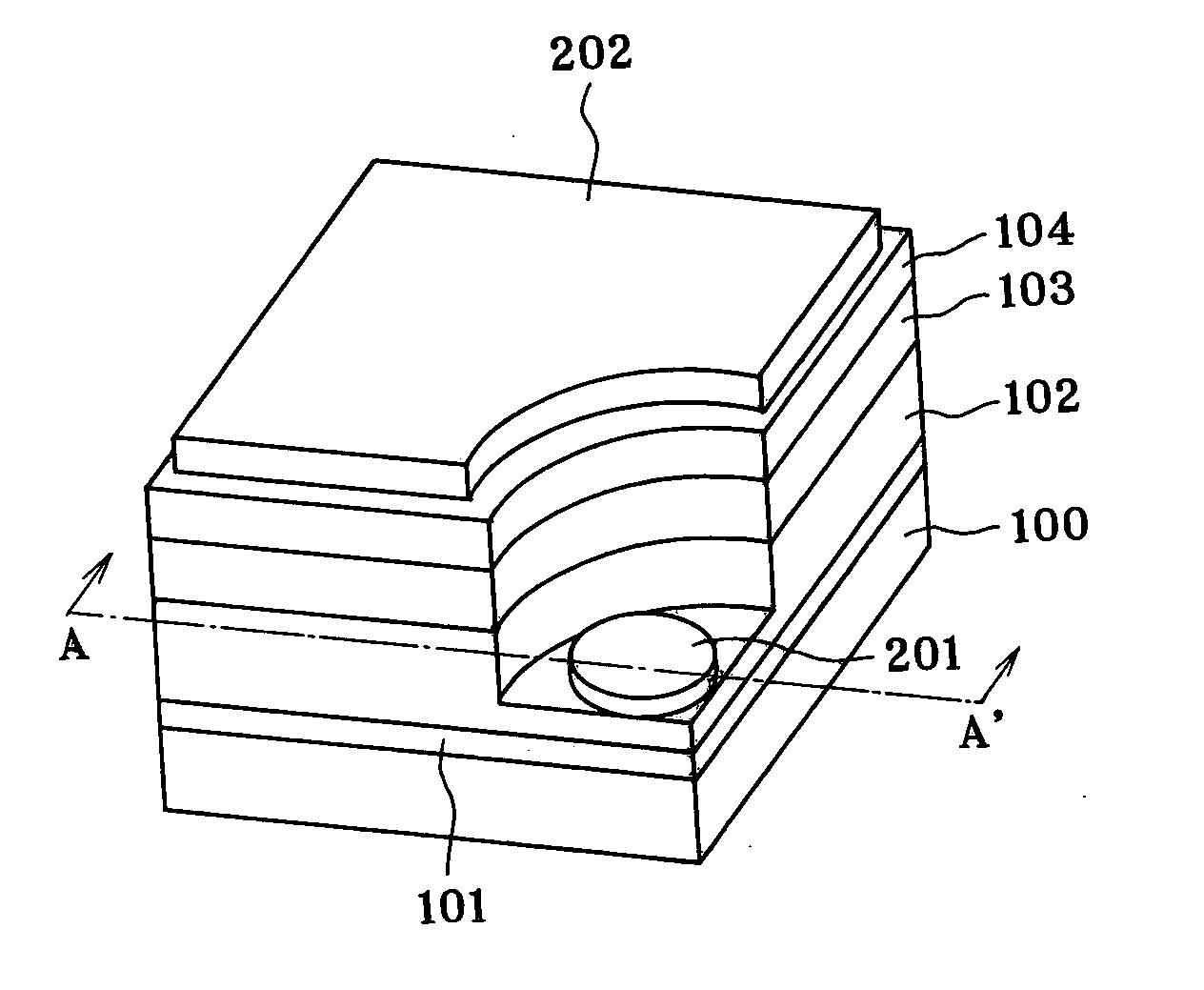

Nitride semiconductor device and method for fabricating the same

ActiveUS20070205407A1Reduce spontaneous polarizationImprove efficiencyTransistorSolid-state devicesPlane orientationActive layer

A nitride semiconductor device includes a semiconductor stacked structure which is formed of a nitride semiconductor having a first principal surface and a second principal surface opposed to the first principal surface and which includes an active layer. The first principal surface of the semiconductor stacked structure is formed with a plurality of indentations whose plane orientations are the {0001} plane, and the plane orientation of the second principal surface is the {1-101} plane. The active layer is formed along the {1-101} plane.

Owner:PANASONIC CORP

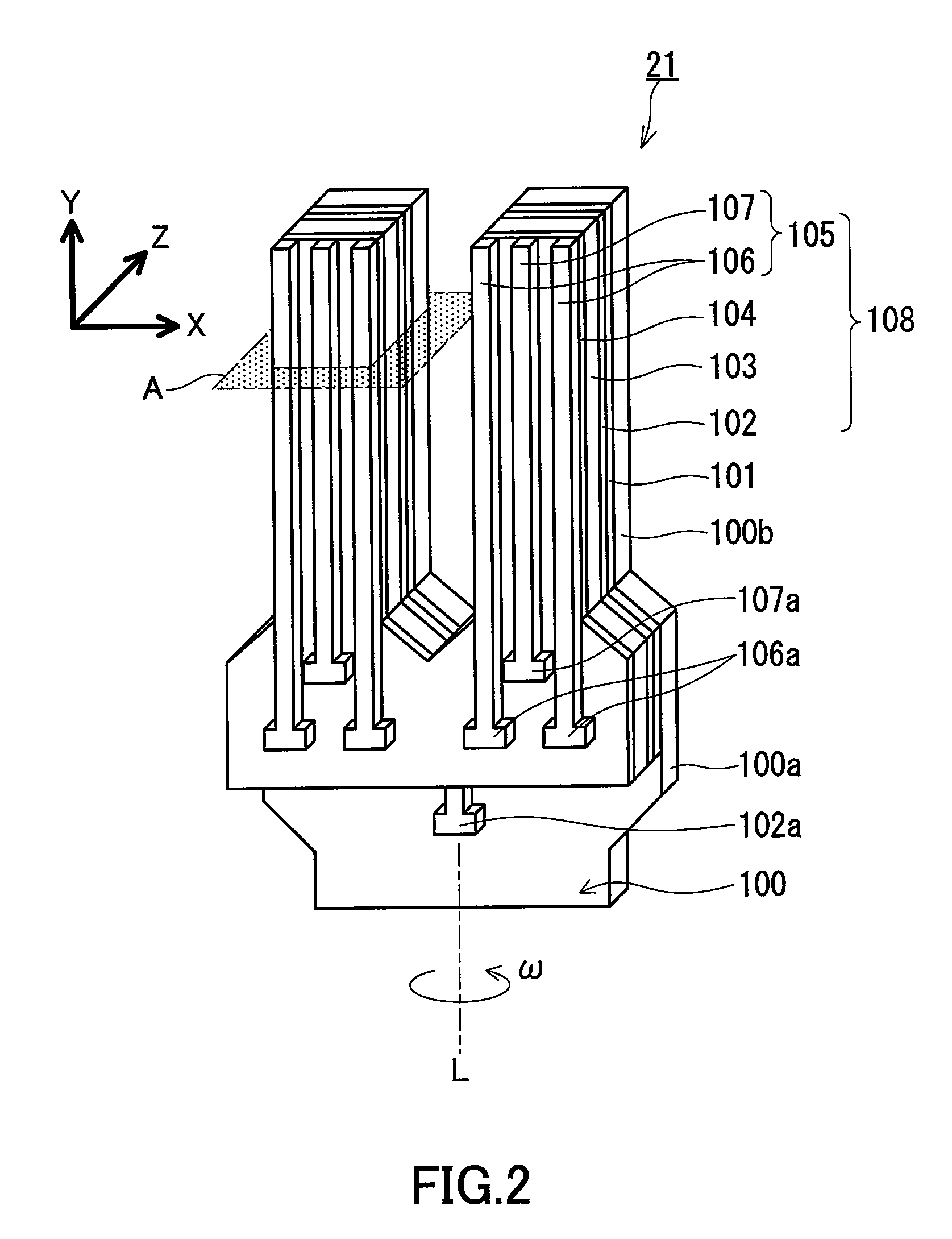

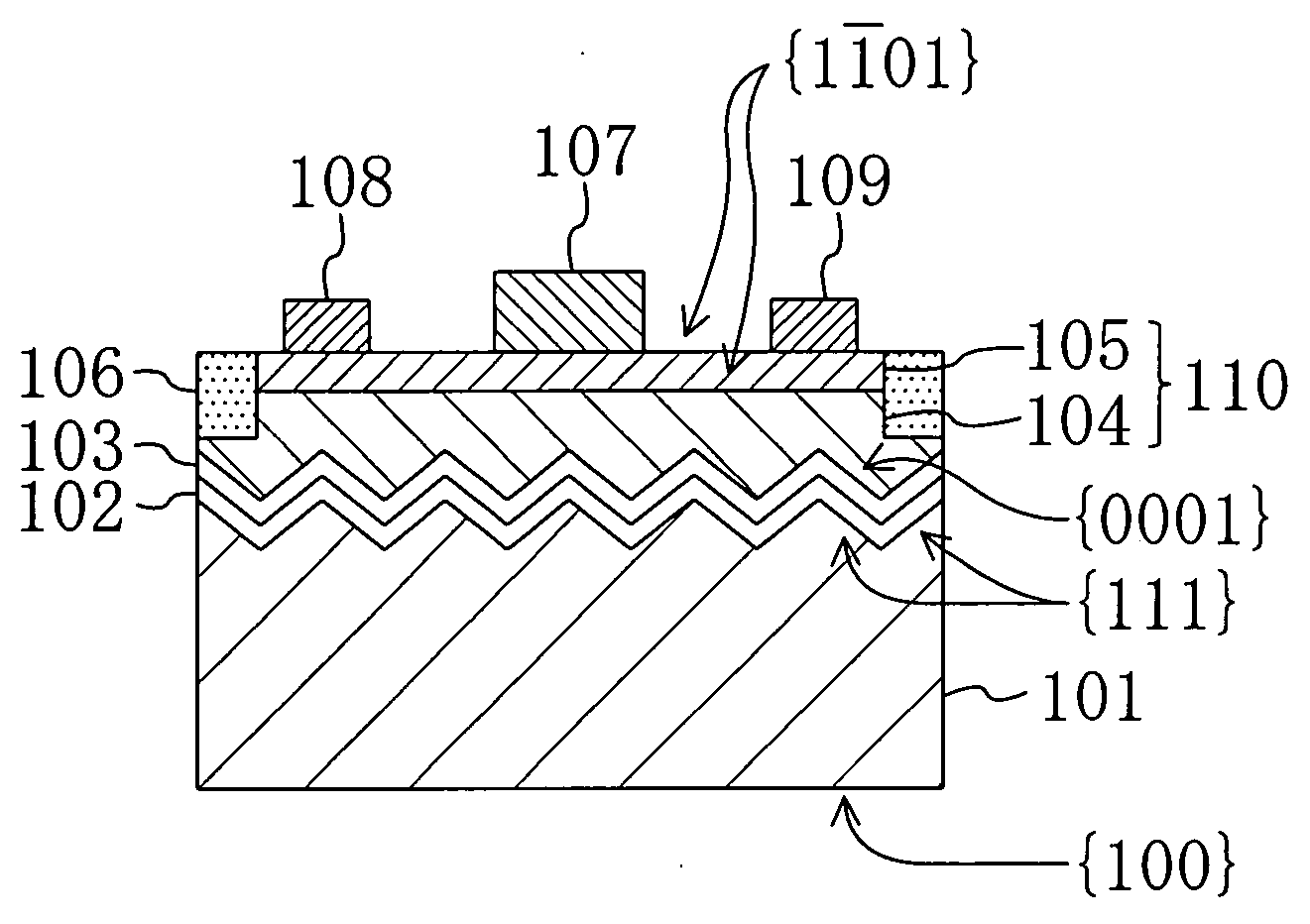

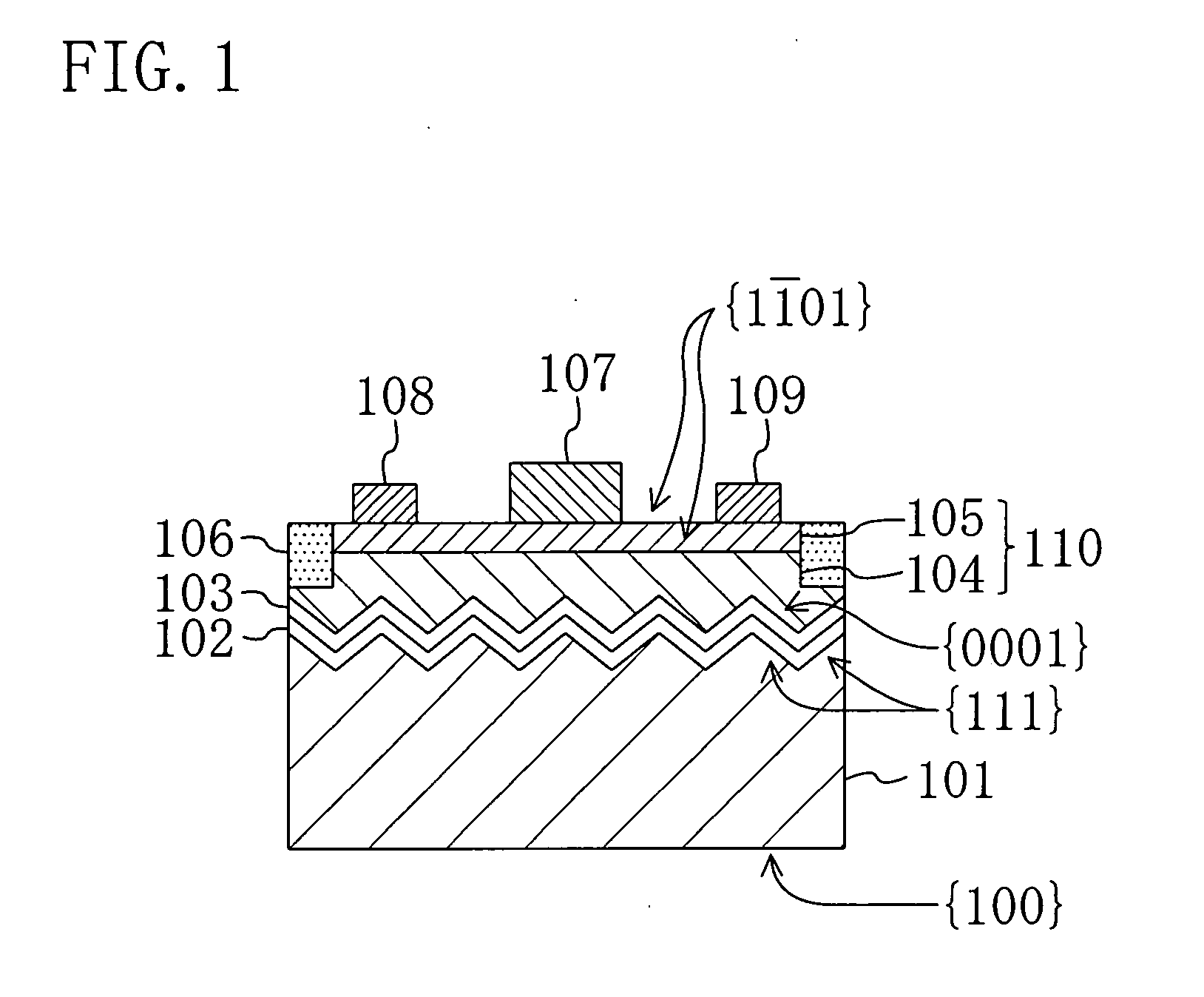

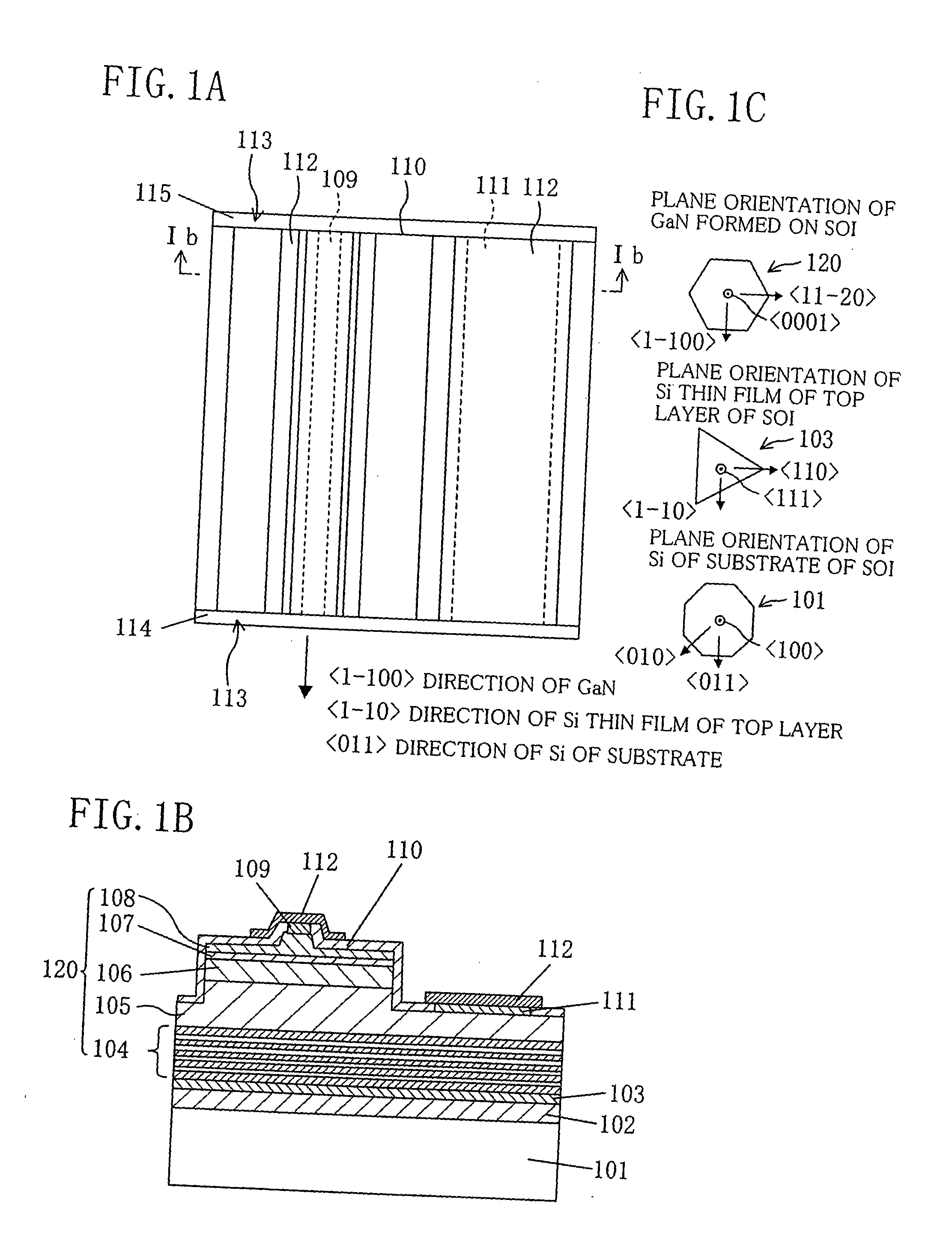

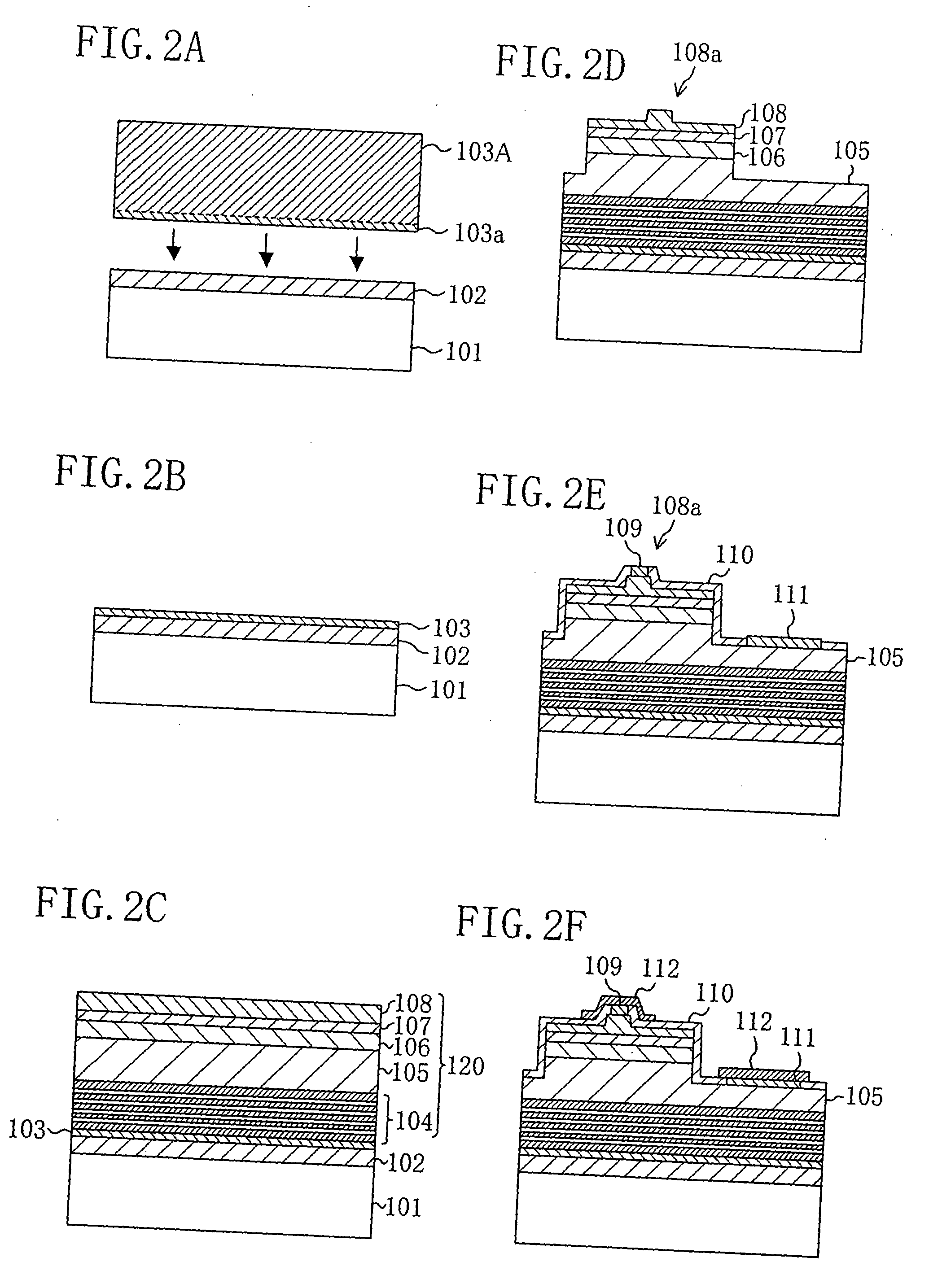

Nitride semiconductor device, and its fabrication process

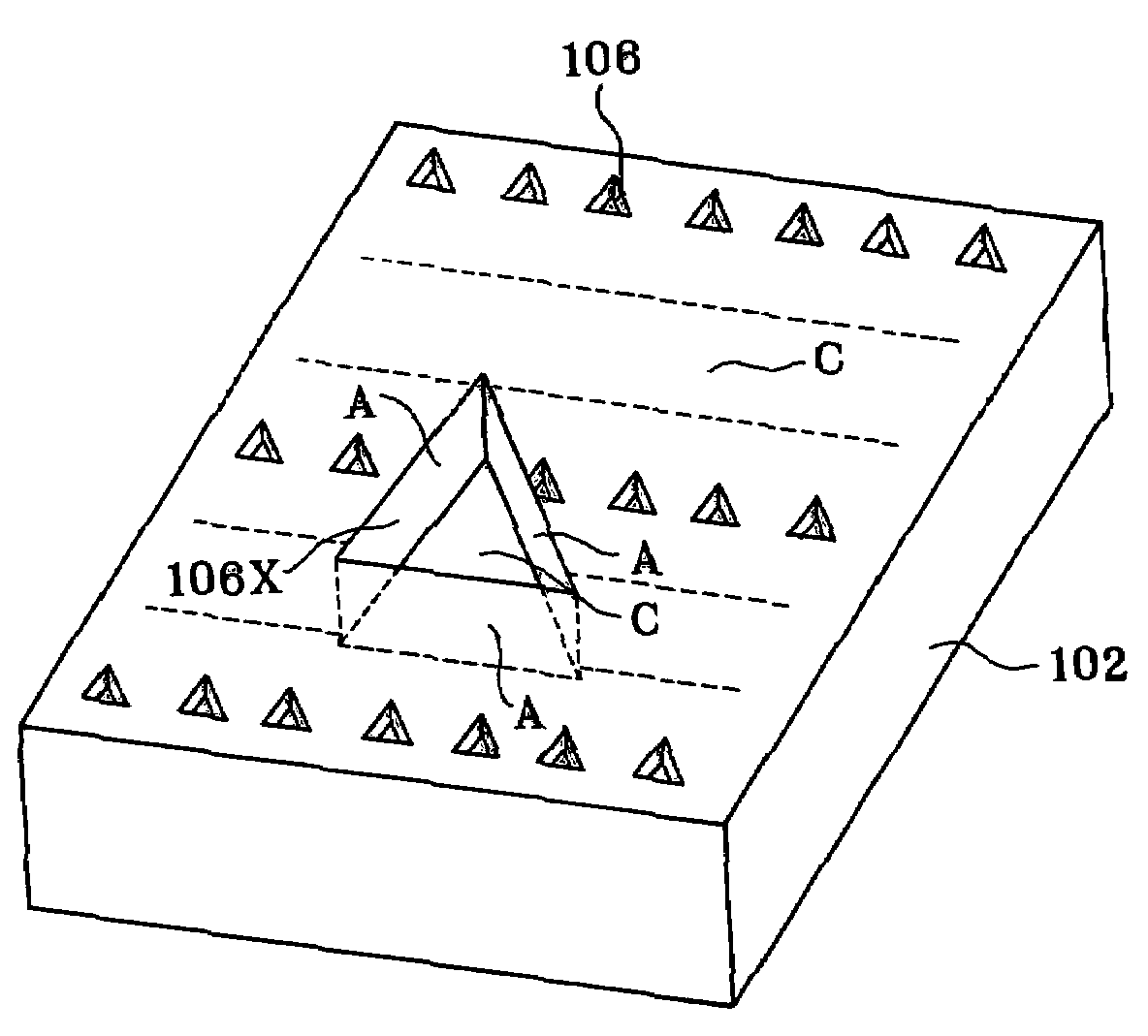

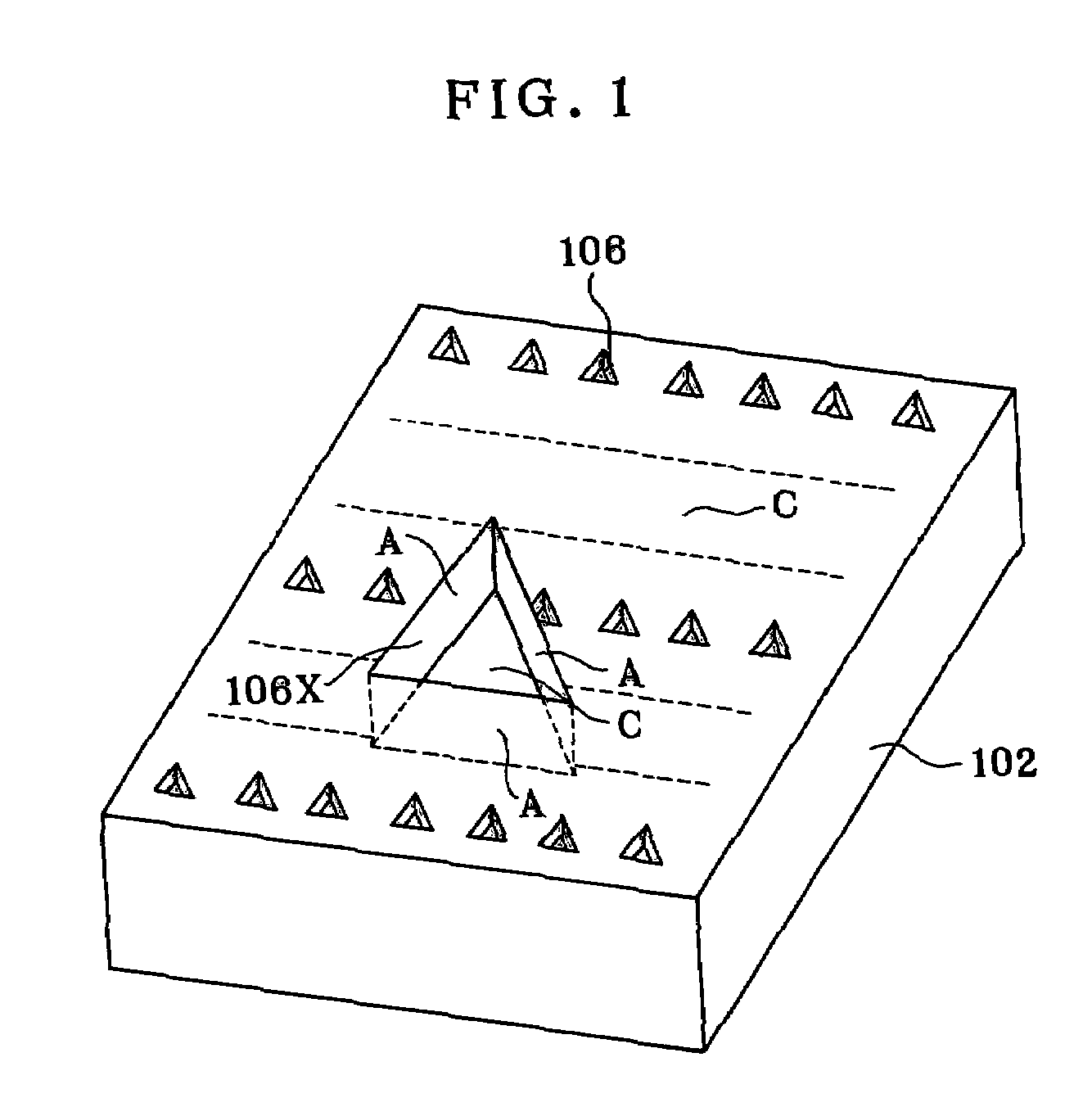

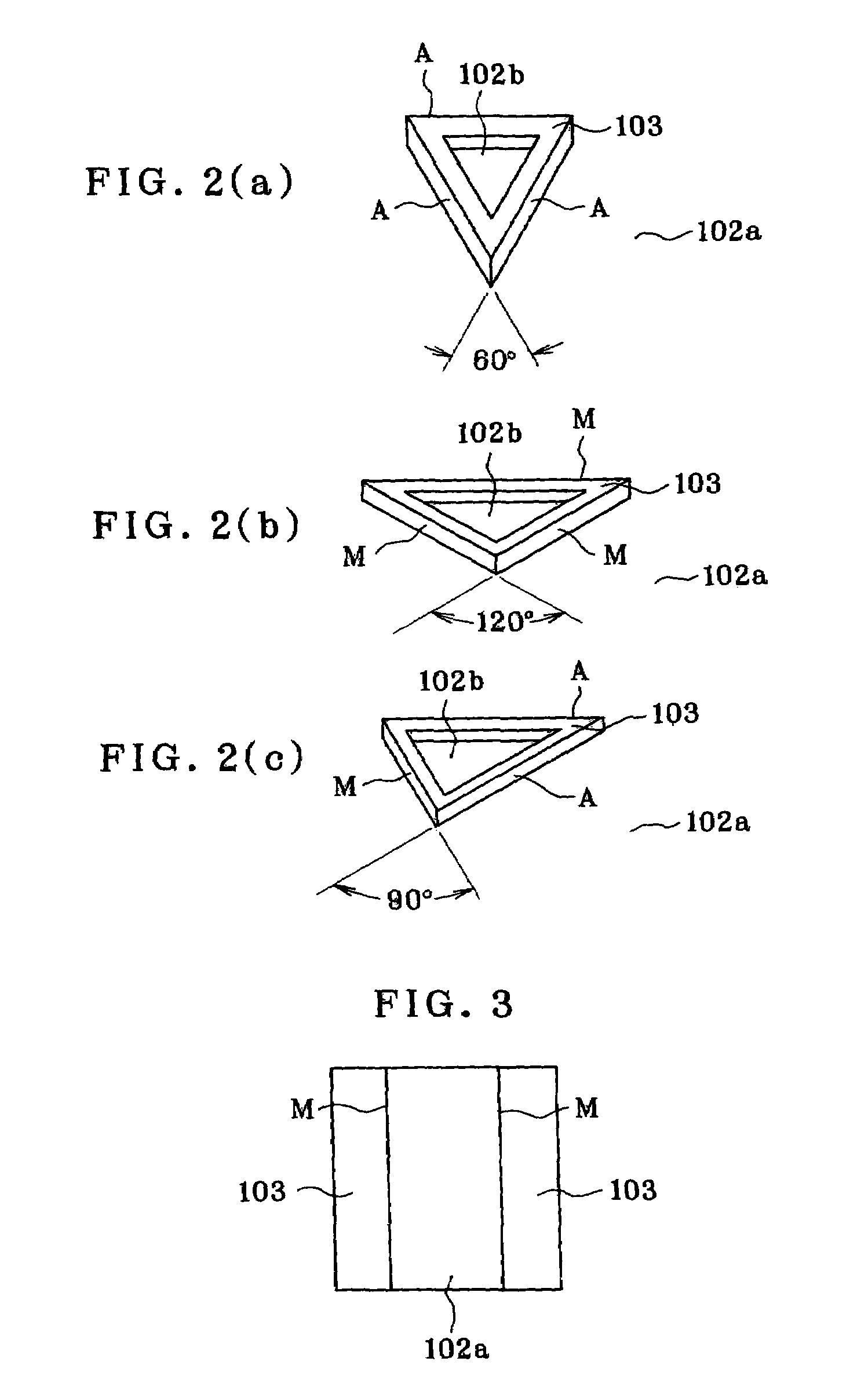

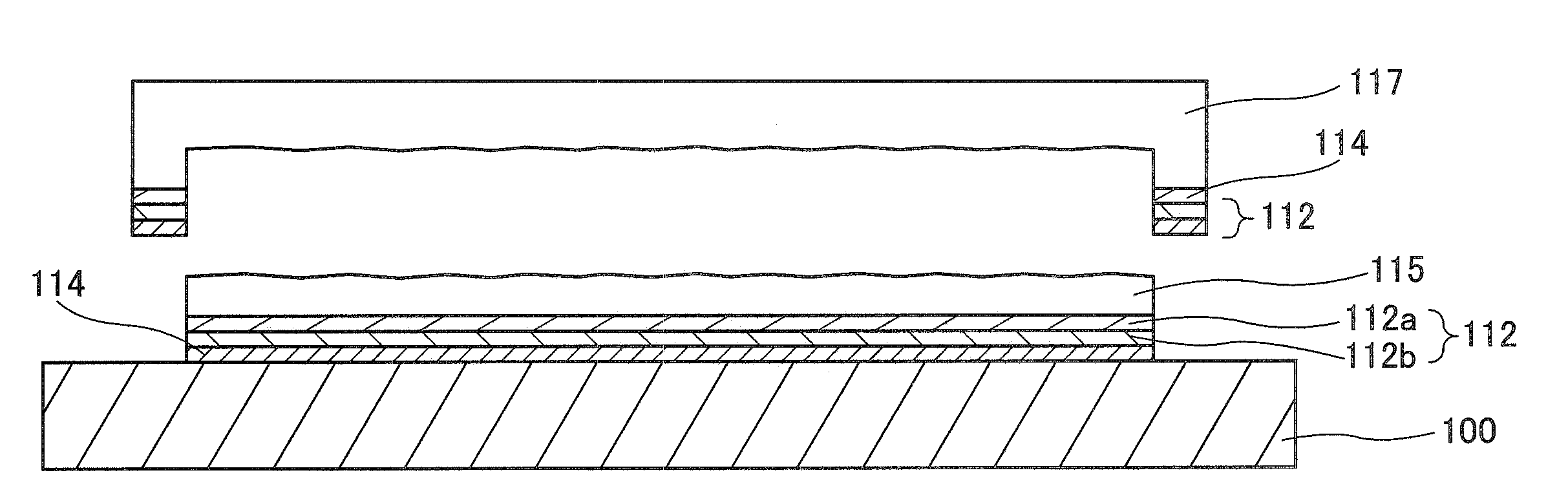

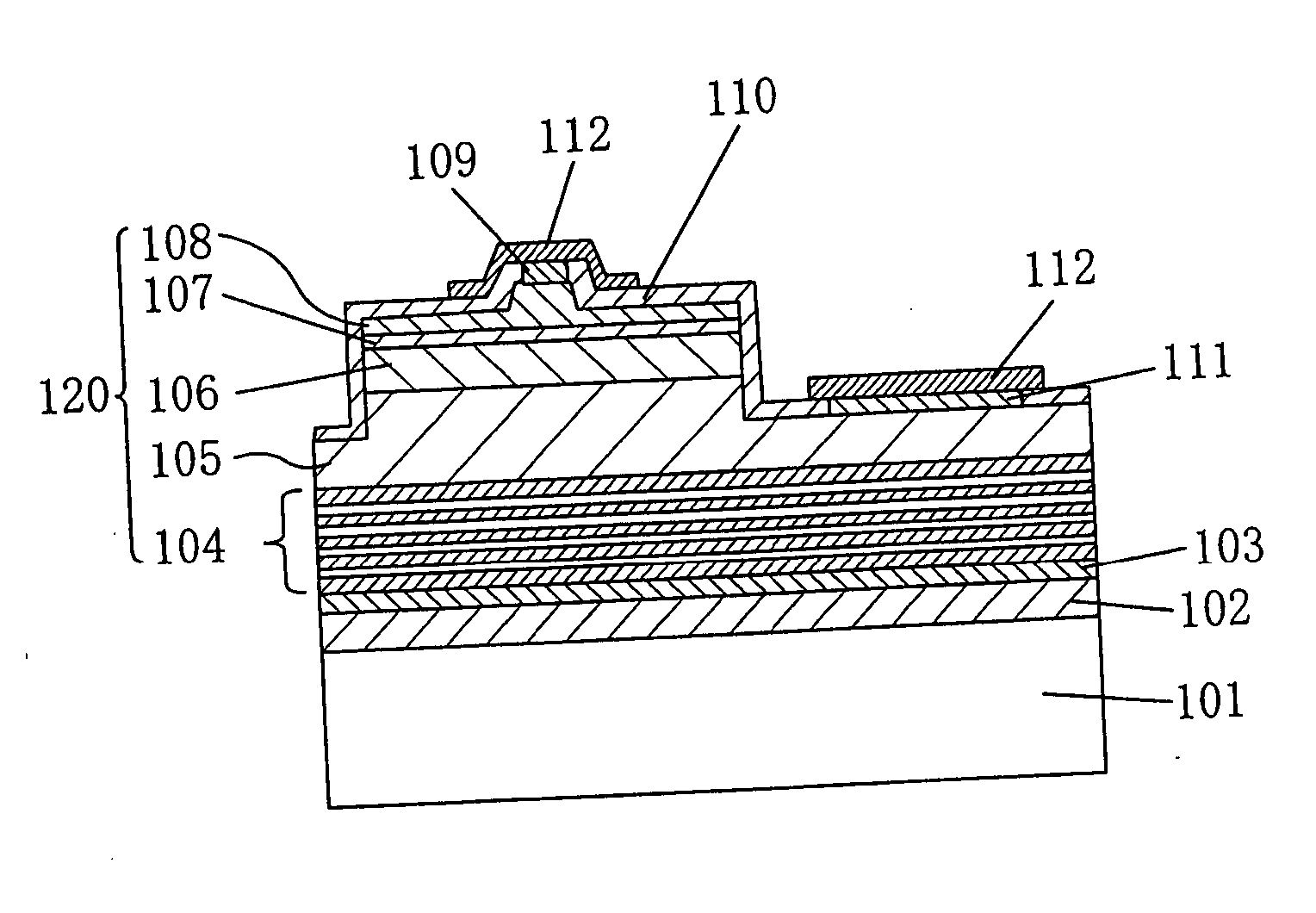

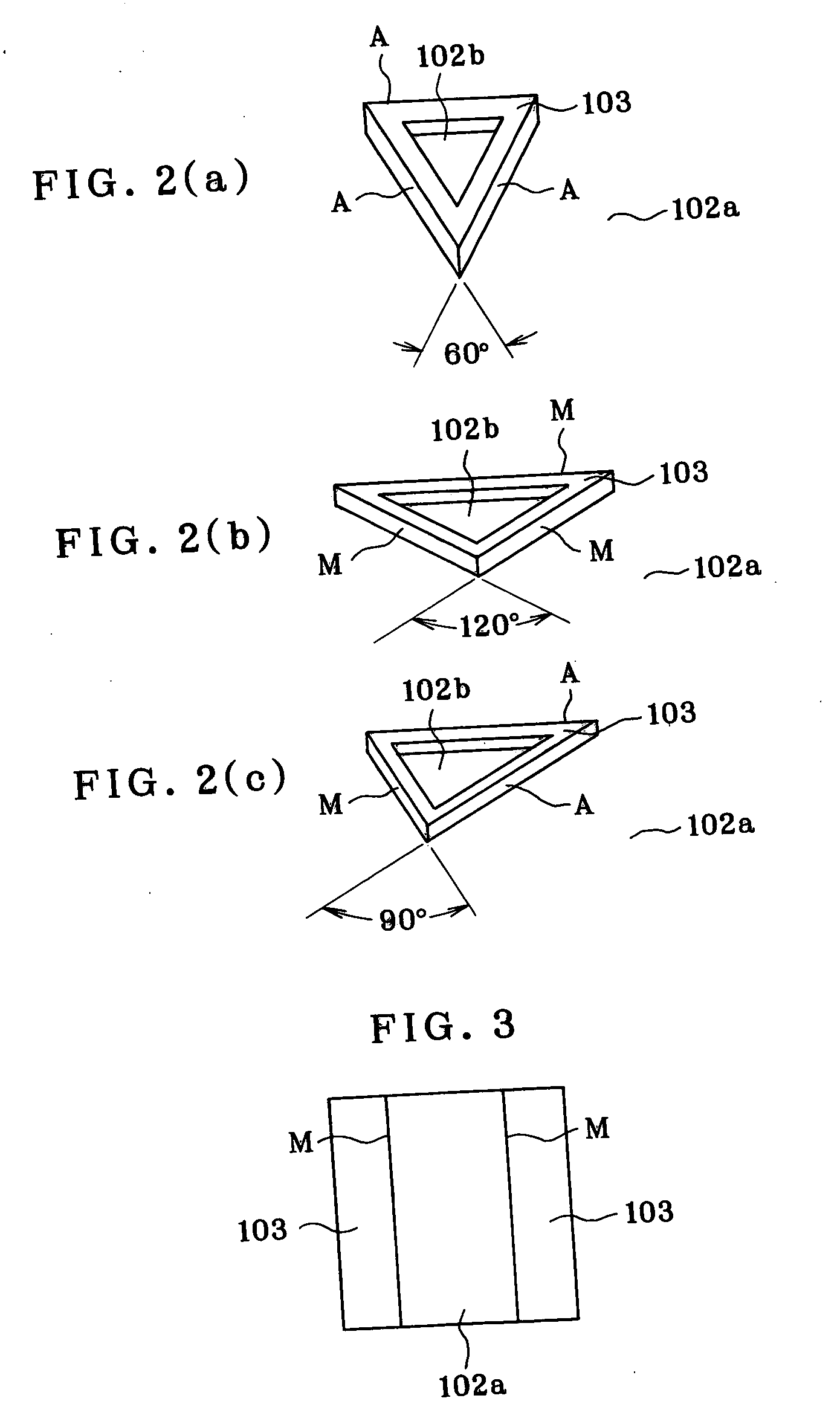

The invention provides a nitride semiconductor light-emitting device comprising gallium nitride semiconductor layers formed on a heterogeneous substrate, wherein light emissions having different light emission wavelengths or different colors are given out of the same active layer. Recesses 106 are formed by etching in the first electrically conductive (n) type semiconductor layer 102 formed on a substrate with a buffer layer interposed between them. Each recess is exposed in plane orientations different from that of the major C plane. For instance, the plane orientation of the A plane is exposed. An active layer is grown and joined on the plane of this plane orientation, on the bottom of the recess and the C-plane upper surface of a non-recess portion. The second electrically conductive (p) type semiconductor layer is formed on the inner surface of the recess. With the active layer formed contiguously to the semiconductor layer in two or more plane orientations, a growth rate difference gives rise to a difference in the thickness across the quantum well (active layer), giving out light emissions having different light emission wavelength peaks or different colors.

Owner:NICHIA CORP +4

Ceramic, piezoelectric device, and production method thereof

ActiveUS20110298336A1Material nanotechnologyPiezoelectric/electrostrictive device manufacture/assemblyPlane orientationCeramic

To provide a piezoelectric ceramic containing BiFeO3 having a {110} plane orientation in a pseudo-cubic form, which is suited for the domain engineering, the piezoelectric ceramic includes a perovskite-type metal oxide represented by the following general formula (1), and has a {110} plane orientation in a pseudo-cubic form:xBiFeO3-(1-x)ABO3 General Formula (1)where A and B each represent one kind or more of metal ions; A represents a metal ion having a valence of 1, 2 or 3; and B represents a metal ion having a valence of 3, 4, or 5, provided that x is within a range of 0.3≦x≦1.

Owner:CANON KK +1

Process for Producing Graphite Film

A graphite film having excellent thermal conductivity, surface hardness, surface adhesion and appearance can be obtained. Further, a thick graphite film in which each of such properties is excellent can be obtained. There is provided a process for producing a graphite film in which a polymer film is thermally treated at a temperature of 2,000° C. or more, the process comprising the step of bringing a polymer film into contact with a substance containing a metal during graphitization treatment. When a polymer film having a high plane orientation is used as a raw material and the raw material is brought into contact with a metal to thermally treat the material, a problem of separation of graphite from the surface can be solved which has not been solved by the prior art, and furthermore a graphite can be obtained having excellent thermal conductivity, surface hardness, density and surface adhesion. An effect that cannot be expected in the prior art can be achieved by bringing a polymer film having a high plane orientation into contact with a metal to thermally treat the film.

Owner:KANEKA CORP

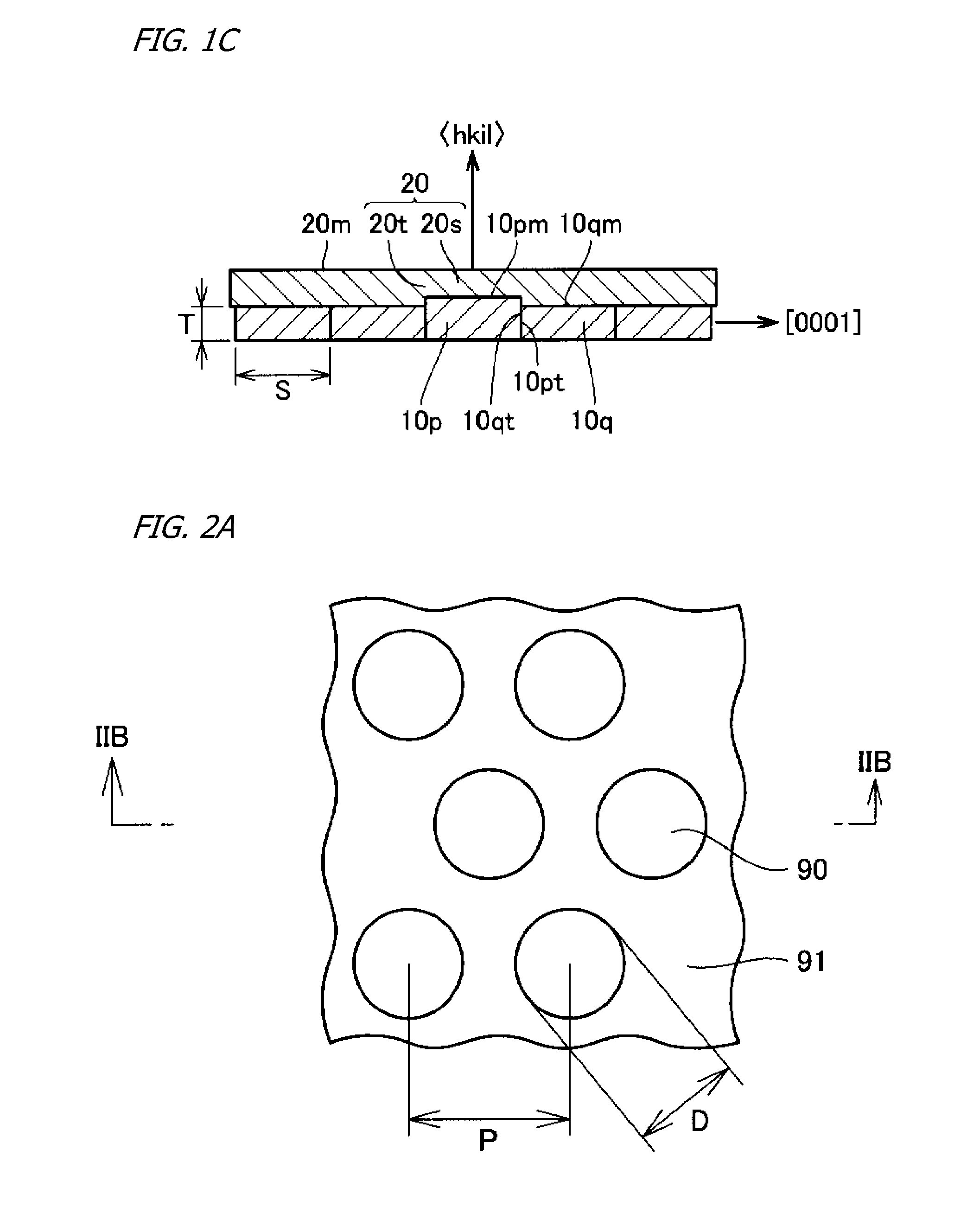

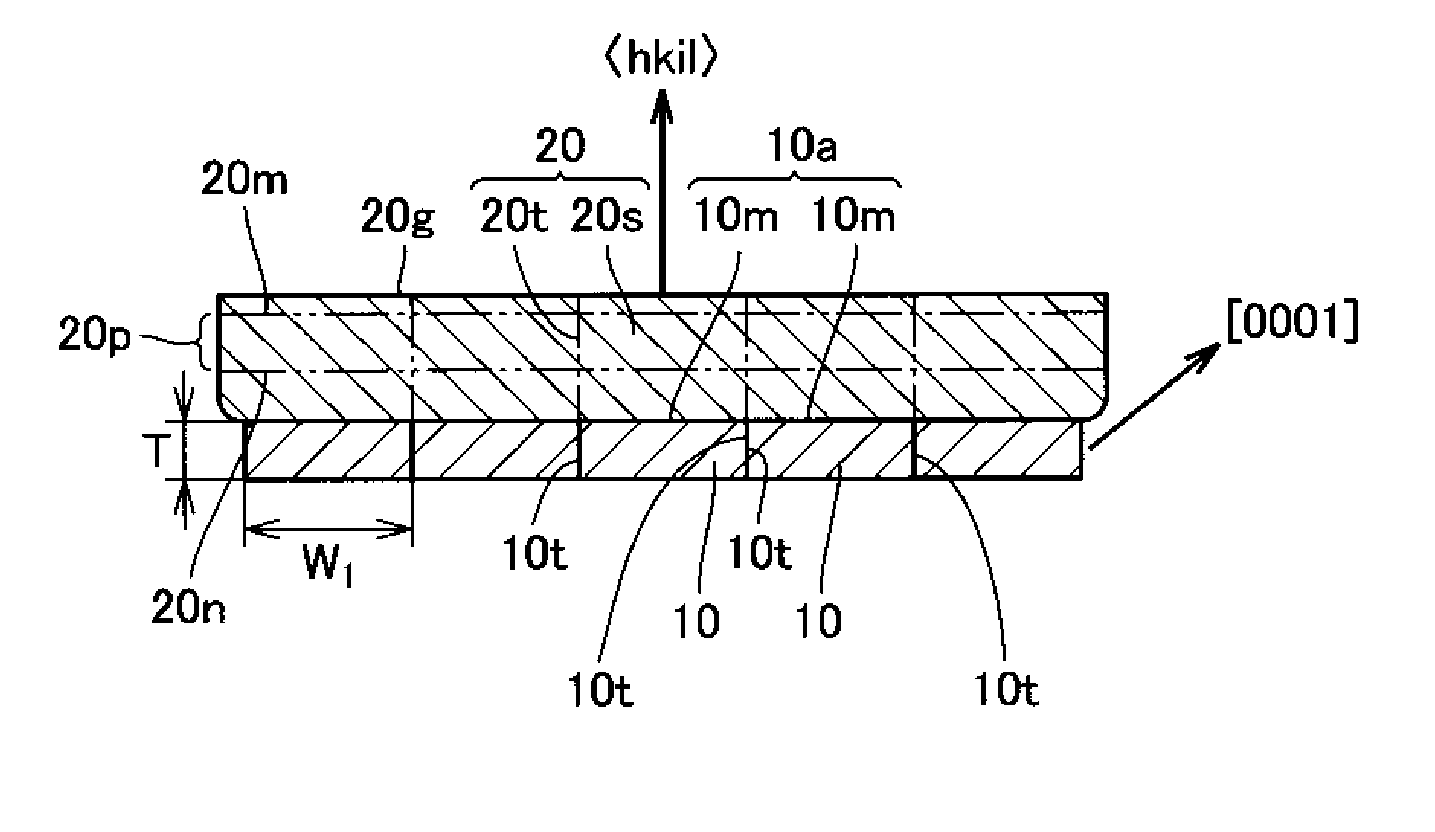

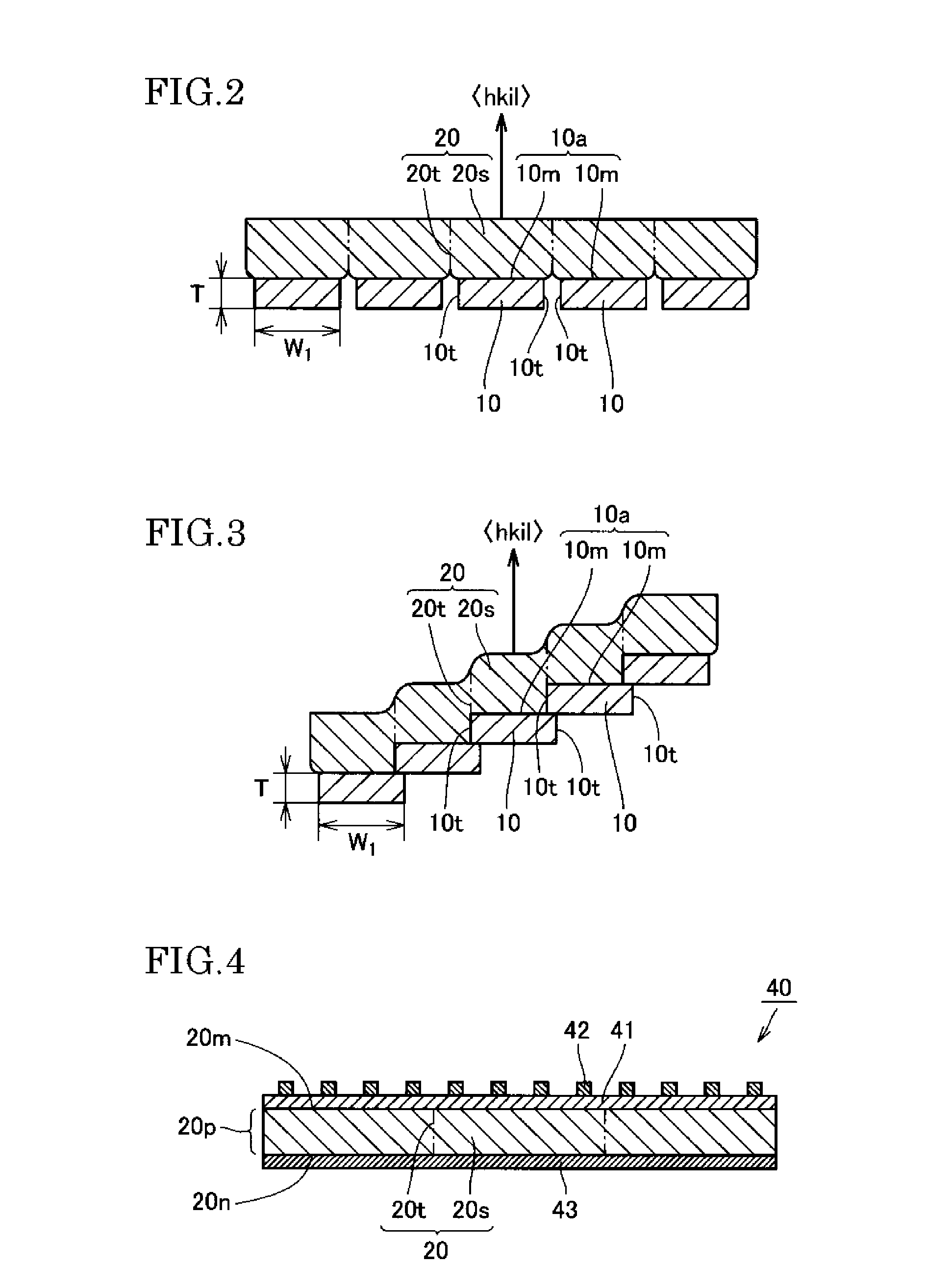

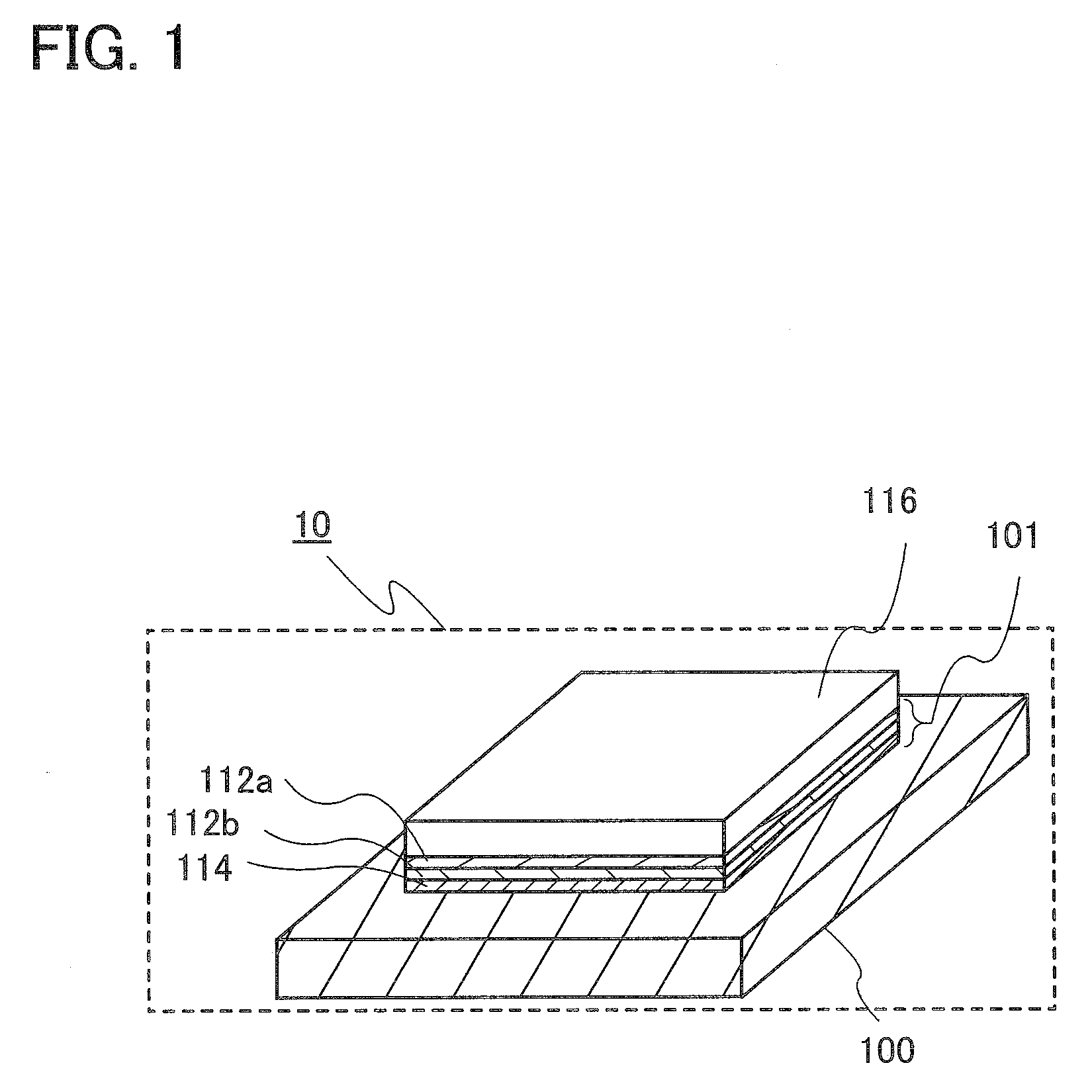

Method of Manufacturing III Nitride Crystal, III Nitride Crystal Substrate, and Semiconductor Device

ActiveUS20090298265A1Little variancePolycrystalline material growthLiquid-phase epitaxial-layer growthPhysicsPlane orientation

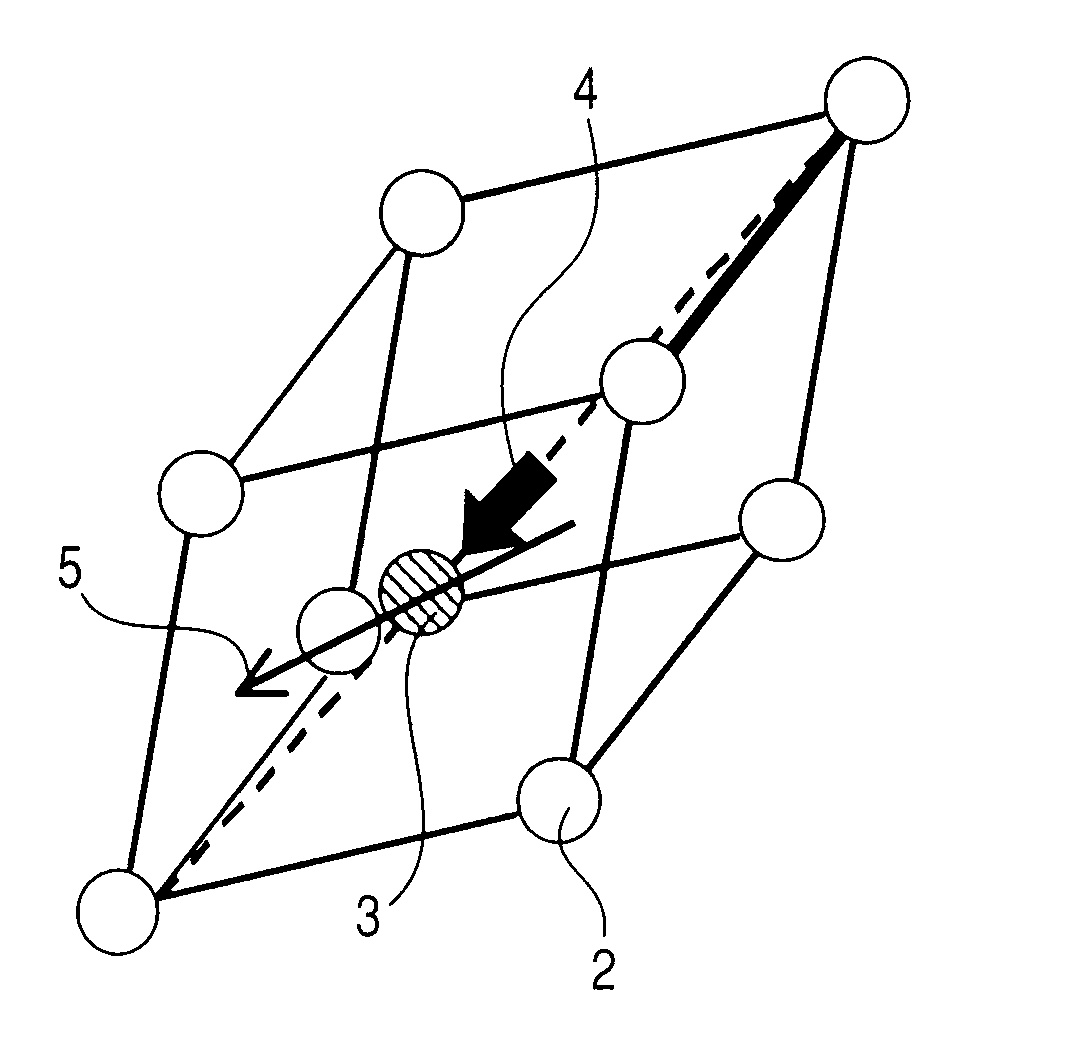

Affords III-nitride crystals having a major surface whose variance in crystallographic plane orientation with respect to an {hkil} plane chosen exclusive of the {0001} form is minimal. A method of manufacturing the III-nitride crystal is one of: conditioning a plurality of crystal plates (10) in which the deviation in crystallographic plane orientation in any given point on the major face (10m) of the crystal plates (10), with respect to an {hkil} plane chosen exclusive of the {0001} form, is not greater than 0.5°; arranging the plurality of crystal plates (10) in a manner such that the plane-orientation deviation, with respect to the {hkil} plane, in any given point on the major-face (10m) collective surface (10a) of the plurality of crystal plates (10) will be not greater than 0.5°, and such that at least a portion of the major face (10m) of the crystal plates (10) is exposed; and growing second III-nitride crystal (20) onto the exposed areas of the major faces (10m) of the plurality of crystal plates (10).

Owner:SUMITOMO ELECTRIC IND LTD

Method for manufacturing semiconductor substrate, semiconductor device and electronic device

InactiveUS20090115028A1Improve flatnessEasy to optimizeTransistorSolid-state devicesHydrogenSingle crystal

A semiconductor substrate including a single crystal semiconductor layer with a buffer layer interposed therebetween is manufactured. A semiconductor substrate is doped with hydrogen to form a damaged layer containing a large amount of hydrogen. After the single crystal semiconductor substrate and a supporting substrate are bonded, the semiconductor substrate is heated so that the single crystal semiconductor substrate is separated along a separation plane. The single crystal semiconductor layer is irradiated with a laser beam from the single crystal semiconductor layer side to melt a region in the depth direction from the surface of the laser-irradiated region of the single crystal semiconductor layer. Recrystallization progresses based on the plane orientation of the single crystal semiconductor layer which is solid without being melted; therefore, crystallinity of the single crystal semiconductor layer is recovered and the surface of the single crystal semiconductor layer is planarized.

Owner:SEMICON ENERGY LAB CO LTD

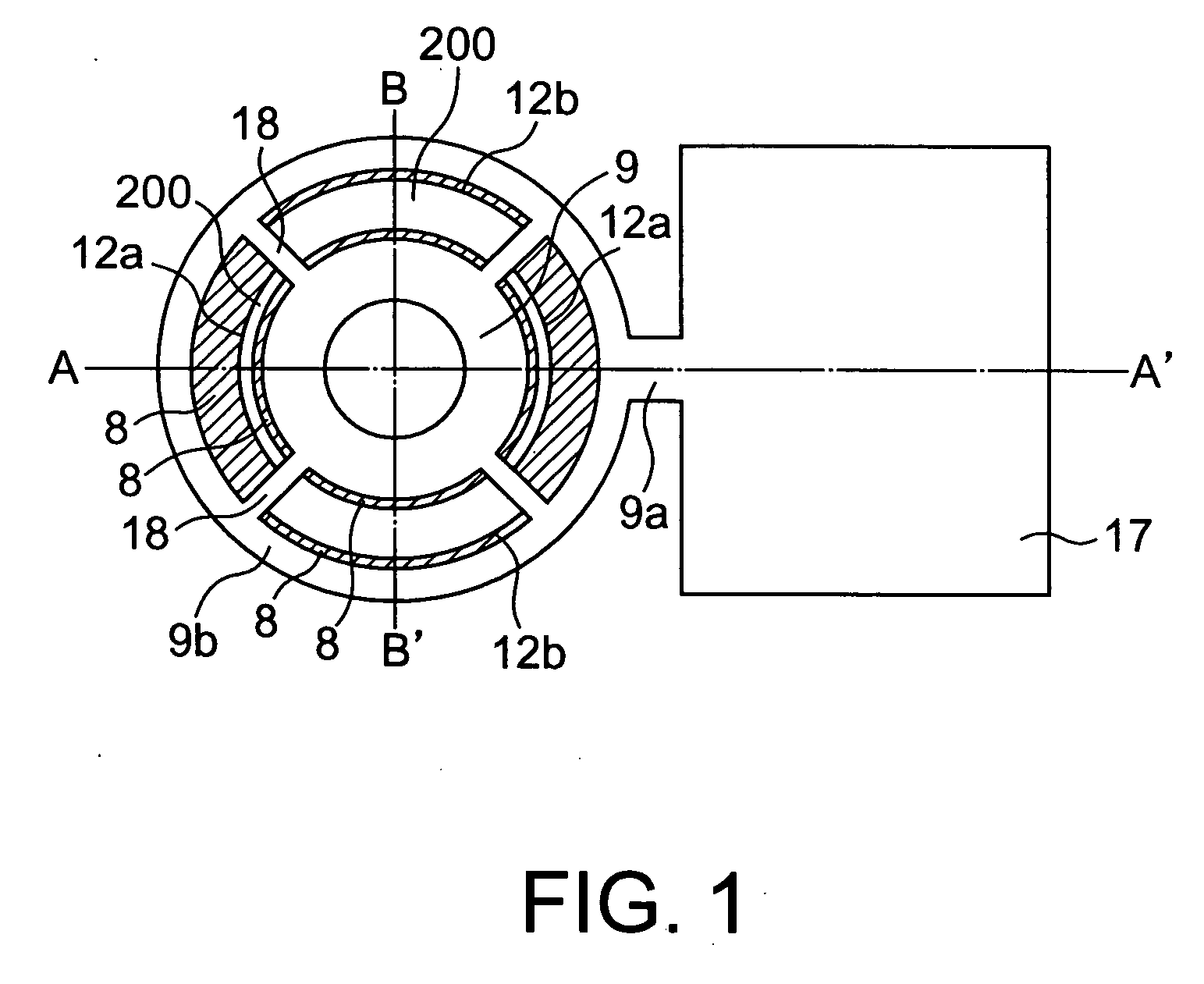

Nitride semiconductor laser diode

InactiveUS20080112448A1Reduce the numberImprove performanceLaser detailsSemiconductor lasersPlane orientationActive layer

A nitride semiconductor laser diode includes: a substrate made of silicon in which a plane orientation of a principal surface is a {100} plane; and a semiconductor that includes a plurality of semiconductor layers formed on the substrate and including an active layer, each of the plurality of semiconductor layers being made of group III nitride. The semiconductor has a plane parallel to a {011} plane which is a plane orientation of silicon as a cleaved facet, the cleaved facet forming a facet mirror.

Owner:PANASONIC CORP

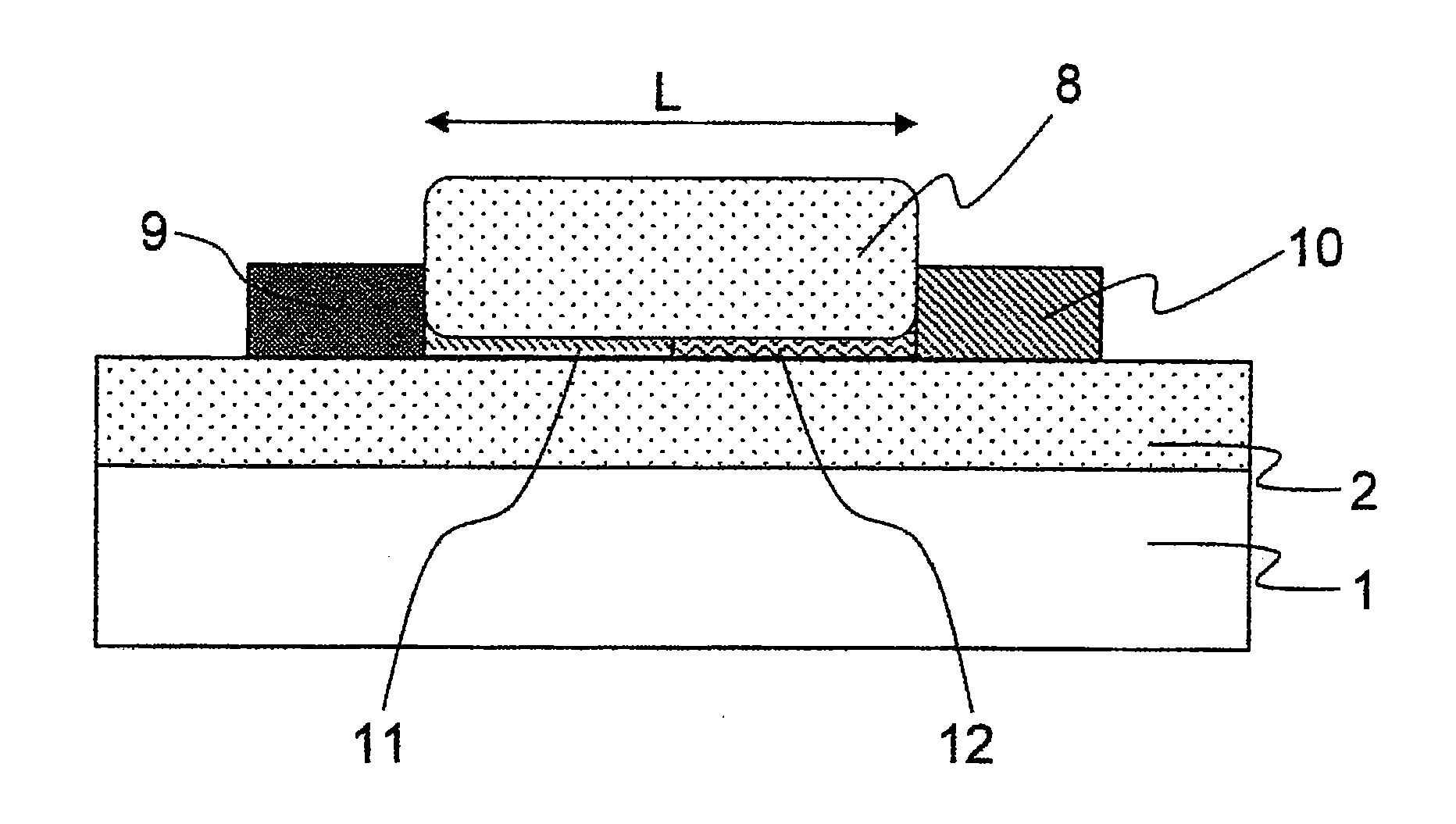

Silicon light emitting diode, silicon optical transistor, silicon laser and its manufacturing method

InactiveUS20080128713A1Easy to makeImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingPlane orientationLight emitting device

A light-emitting device according to the present invention includes a first electrode unit 9 for injecting an electron, a second electrode unit 10 for injecting a hole, and light-emitting units 11 and 12 electrically connected to the first electrode unit 9 and the second electrode unit 10 respectively, wherein the light-emitting units 11 and 12 are formed of single-crystal silicon, the light-emitting units 11 and 12 having a first surface (topside surface) and a second surface (underside surface) opposed to the first surface, plane orientation of the first and second surfaces being set to a (100) plane, thicknesses of the light-emitting units 11 and 12 in a direction orthogonal to the first and second surfaces being made extremely thin.

Owner:HITACHI LTD

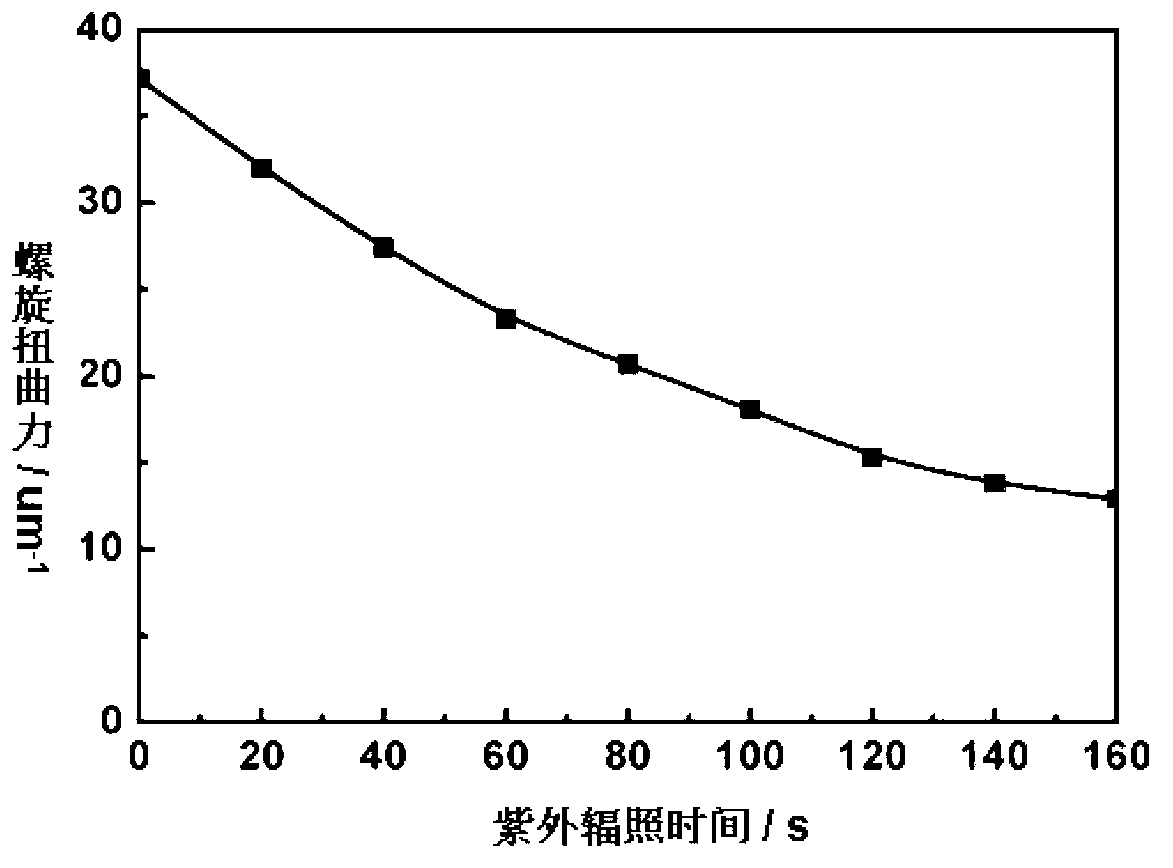

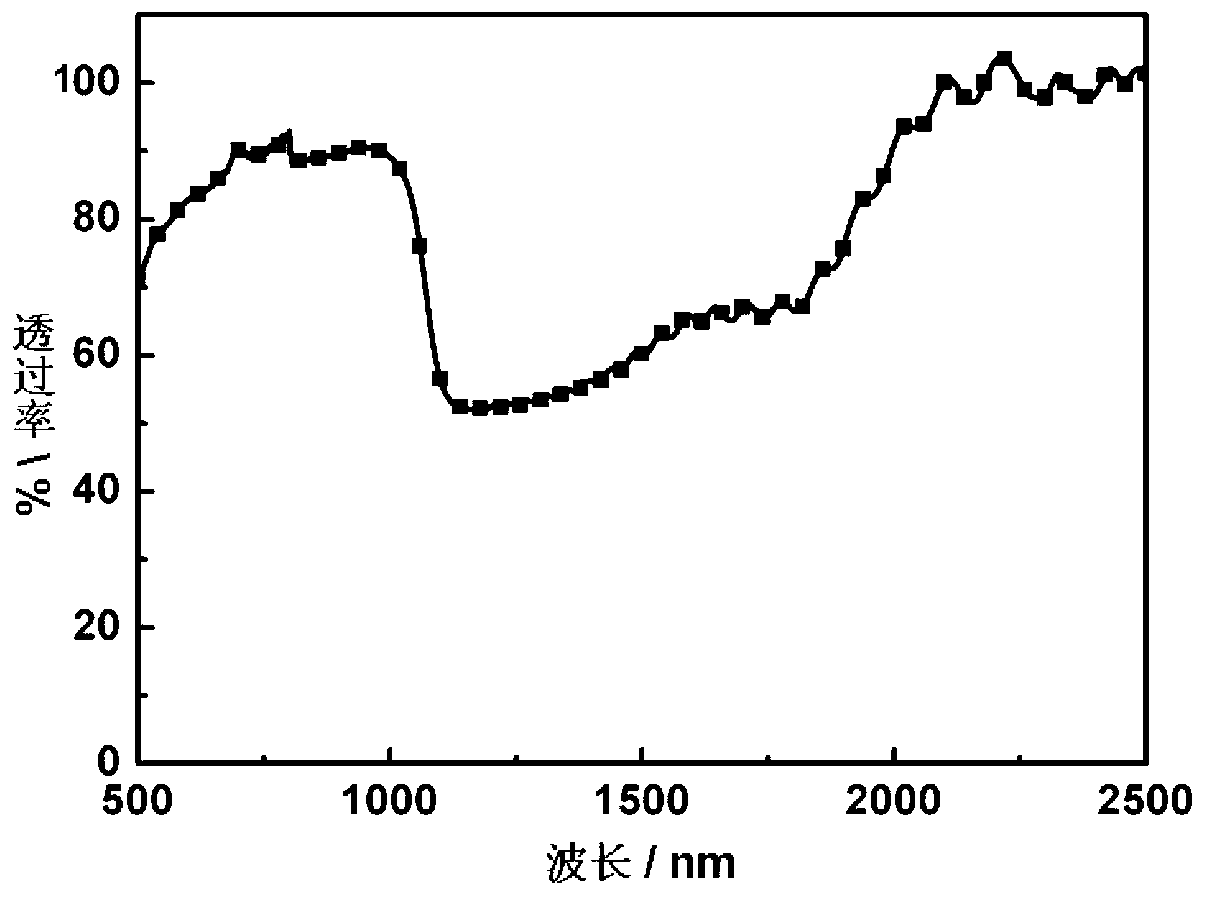

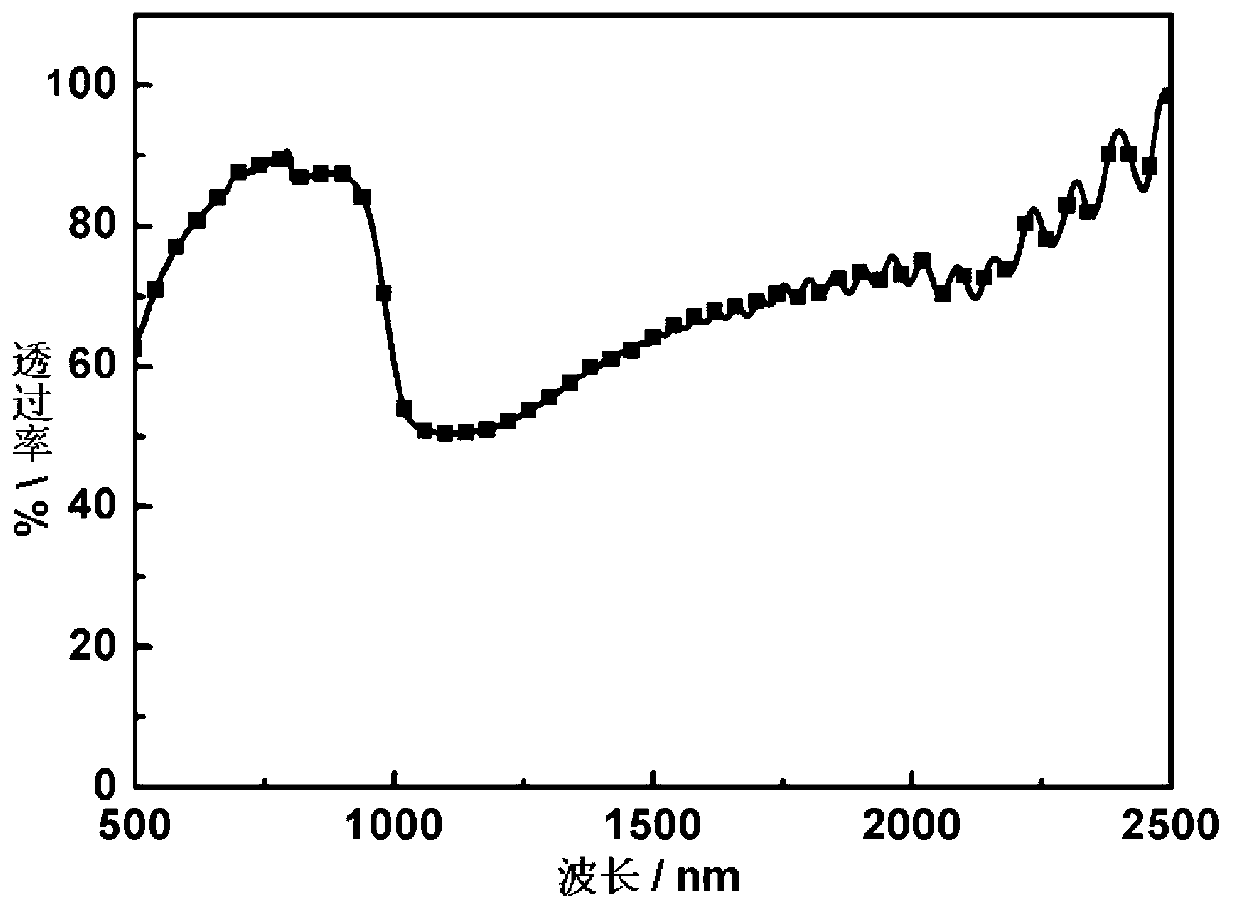

Preparation method of polymer-stabilized liquid crystal thin film material with wide wave reflection

InactiveCN103275736AReflected wave width and broadeningWith broadband reflectionLiquid crystal compositionsNon-linear opticsLight irradiationPlane orientation

The invention relates to a preparation method of a polymer-stabilized liquid crystal thin film material with wide wave reflection. The preparation method belongs to the technical field of optical thin film materials. In order to solve the problem that a present technological process is complex, is not easy to control and has a disadvantage of narrow reflected wave, the invention provides the preparation method of the polymer-stabilized liquid crystal thin film material with wide wave reflection. The preparation method comprises the following steps: mixing 5wt%-85wt% of a nematic phase liquid crystal, 5.0wt%-15wt% of a chiral compound and 8.0wt%-20wt% of a liquid crystal polymerizable monomer, adding 0.2wt%-1.5wt% of an azo chiral compound and 0.01wt%-10wt% of a photoinitiator so as to obtain a mixed liquid crystal system; injecting into a liquid crystal cell which has undergone plane orientation in advance so as to obtain a thin film sample; and carrying out UV-light irradiation within the cholesteric phase temperature so as to obtain the liquid crystal thin film material. The preparation method provided by the invention has advantages of simple process, wide temperature range of the cholesteric phase and wide wave reflection, and is easy to operate.

Owner:ZHEJIANG XINGXING OPTICS MATERIAL

Semiconductor device including field-effect transistor

InactiveUS20060118880A1Semiconductor/solid-state device manufacturingSemiconductor devicesDevice materialPlane orientation

A semiconductor device includes a semiconductor region, source and drain regions, gate insulating film, and gate electrode. The semiconductor region has a plane orientation of (001). The source and drain regions are formed away from each other in the semiconductor region, and a channel region is formed in the semiconductor region between the source and drain regions. The channel length direction of the channel region is set along the direction of <100> of the semiconductor region. Tensile stress is produced in the channel length direction. The gate insulating film is formed on the semiconductor region between the source and drain regions. The gate electrode is formed on the gate insulating film.

Owner:KK TOSHIBA

Vertical cavity surface emitting laser diode

InactiveUS20060187997A1Improve performanceHigh polarizationOptical resonator shape and constructionSemiconductor lasersVertical-cavity surface-emitting laserPlane orientation

It is made possible to obtain high performance having high controllability in polarization mode even when a vertical cavity surface emitting laser diode is fabricated on an ordinary substrate with a plane orientation (100) plane or the like. A vertical cavity surface emitting laser diode includes: a substrate; a semiconductor active layer which is formed on the substrate and has a light emitting region; a first reflecting mirror and a second reflecting mirror sandwiching the semiconductor active layer; a first recess which has a first groove depth penetrating at least the semiconductor active layer from the outermost layer of the first reflecting mirror; a second recess having a second groove depth shallower than the first groove depth; a mesa portion which is surrounded by the first and second recesses; and an insulating film which is buried in the first recess.

Owner:KK TOSHIBA

Nitride semiconductor device, and its fabrication process

The invention provides a nitride semiconductor light-emitting device comprising gallium nitride semiconductor layers formed on a heterogeneous substrate, wherein light emissions having different light emission wavelengths or different colors are given out of the same active layer. Recesses 106 are formed by etching in the first electrically conductive (n) type semiconductor layer 102 formed on a substrate with a buffer layer interposed between them. Each recess is exposed in plane orientations different from that of the major C plane. For instance, the plane orientation of the A plane is exposed. An active layer is grown and joined on the plane of this plane orientation, on the bottom of the recess and the C-plane upper surface of a non-recess portion. The second electrically conductive (p) type semiconductor layer is formed on the inner surface of the recess. With the active layer formed contiguously to the semiconductor layer in two or more plane orientations, a growth rate difference gives rise to a difference in the thickness across the quantum well (active layer), giving out light emissions having different light emission wavelength peaks or different colors.

Owner:NICHIA CORP +4

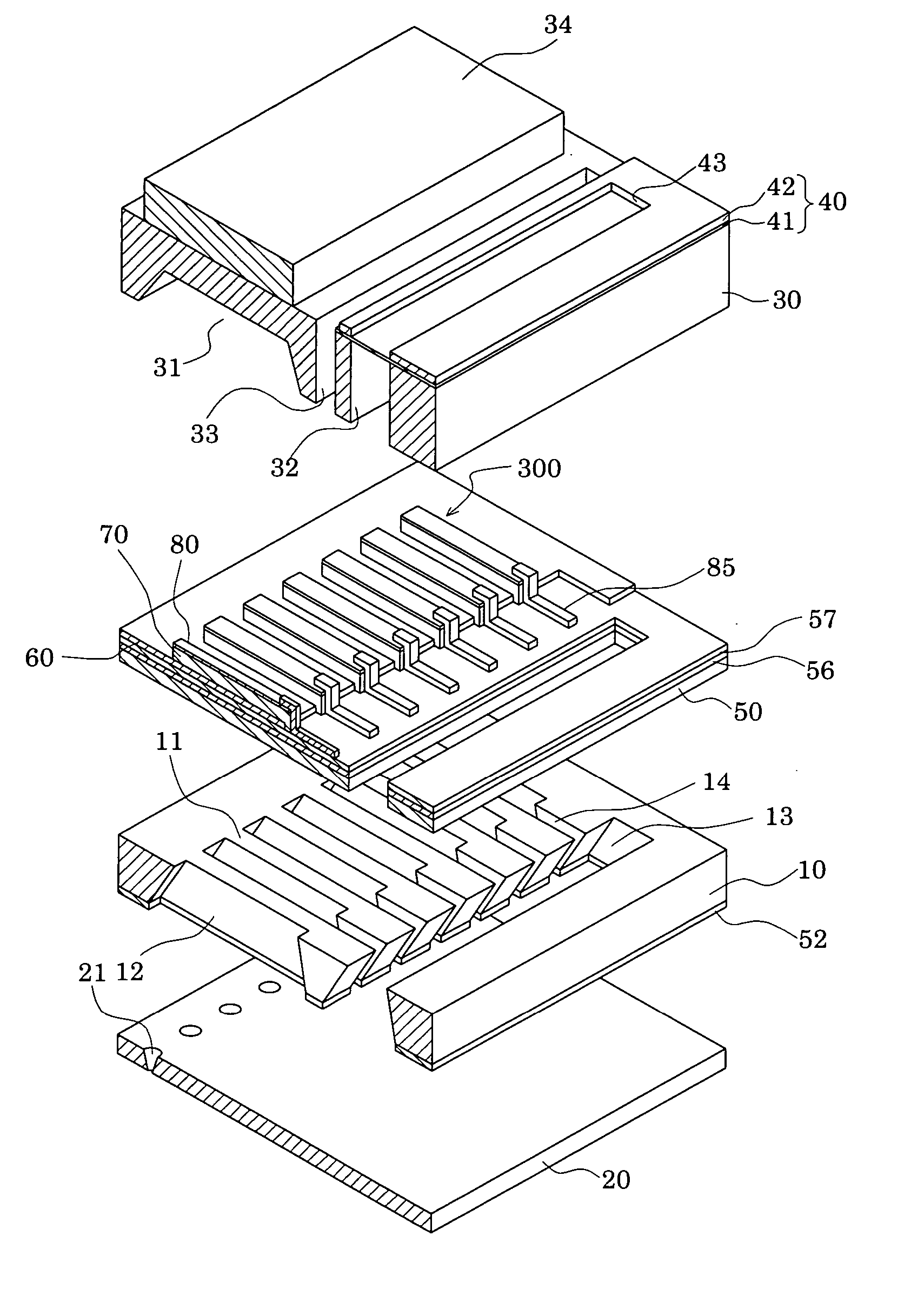

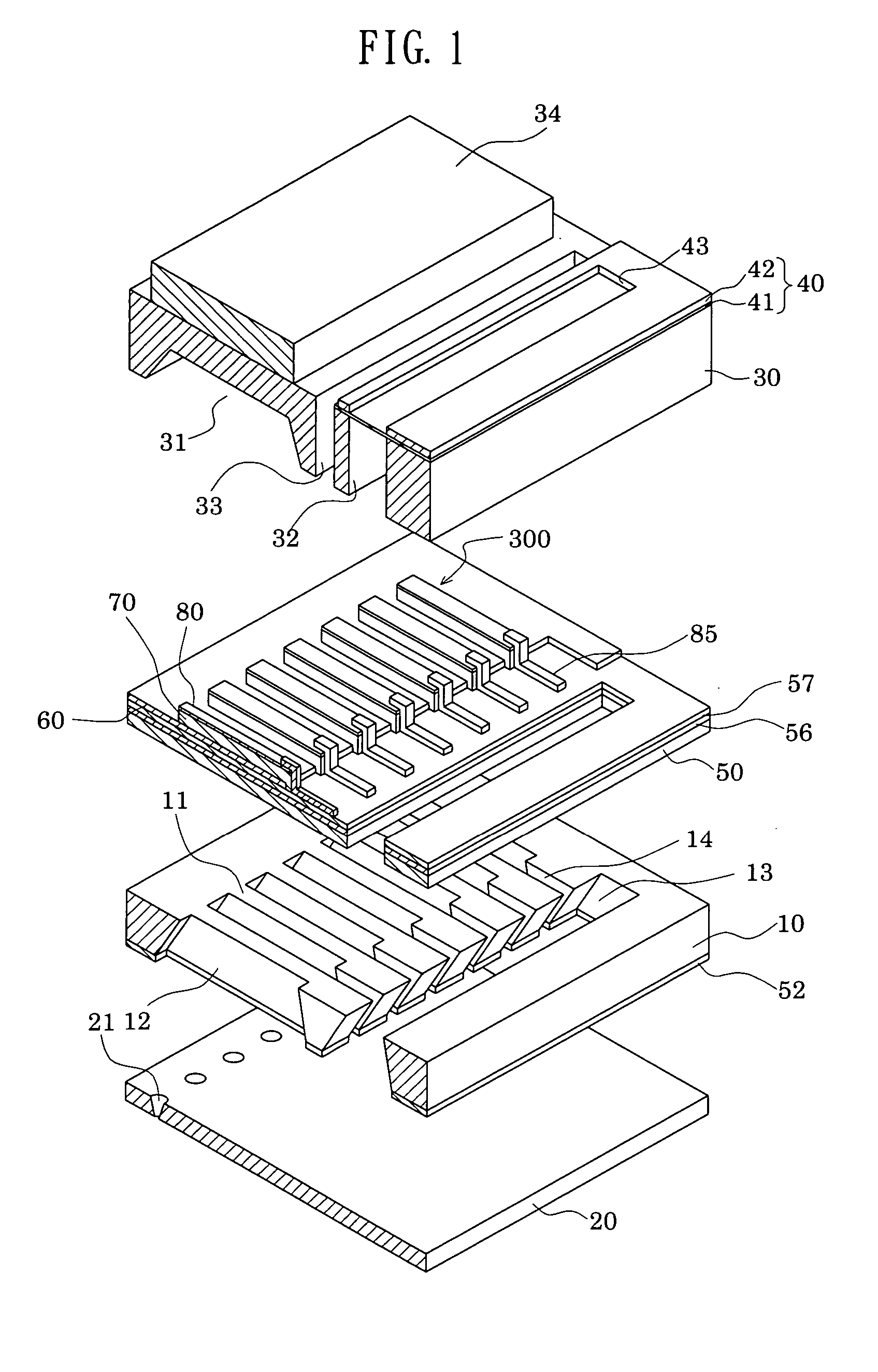

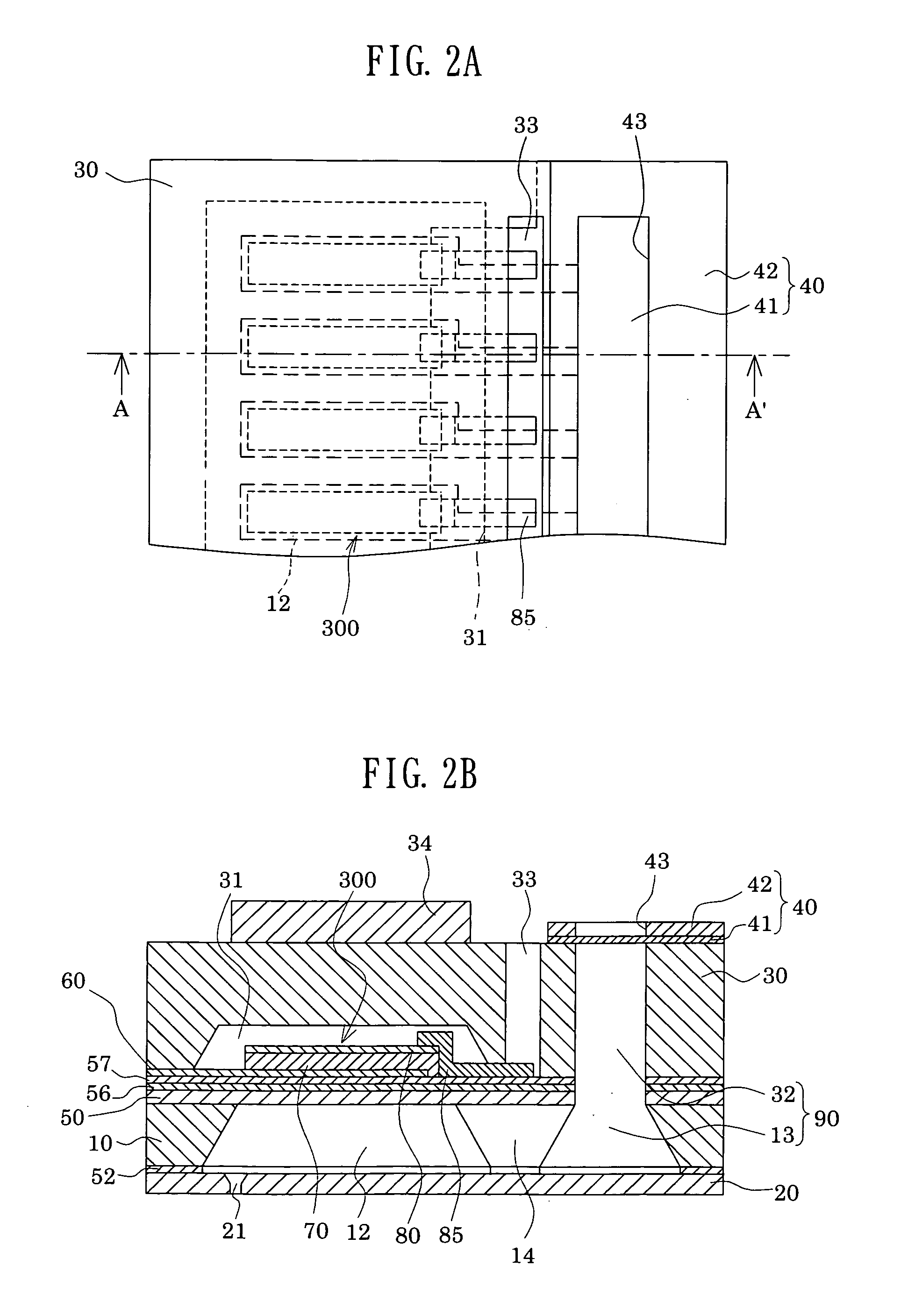

Actuator device, liquid-jet head and liquid-jet apparatus

InactiveUS20070007860A1Suppress fluctuationsIncreased durabilityInking apparatusPiezoelectric/electrostriction/magnetostriction machinesLiquid jetCrystal system

An actuator device includes: a layer provided on a single crystal silicon (Si) substrate, and made of silicon dioxide (SiO2); at least one buffer layer provided on the layer made of silicon dioxide (SiO2); a base layer provided on the buffer layer, and made of lanthanum nickel oxide (LNO) having the (100) plane orientation; and a piezoelectric element. The piezoelectric element includes: a lower electrode provided on the base layer, and made of platinum (Pt) having the (100) plane orientation; a piezoelectric layer made of a ferroelectric layer whose plane orientation is the (100) orientation, the piezoelectric layer formed on the lower electrode by epitaxial growth where a crystal system of at least one kind selected from a group consisting of a tetragonal system, a monoclinic system and a rhombohedral system dominates the other crystal systems; and an upper electrode provided on the piezoelectric layer.

Owner:SEIKO EPSON CORP

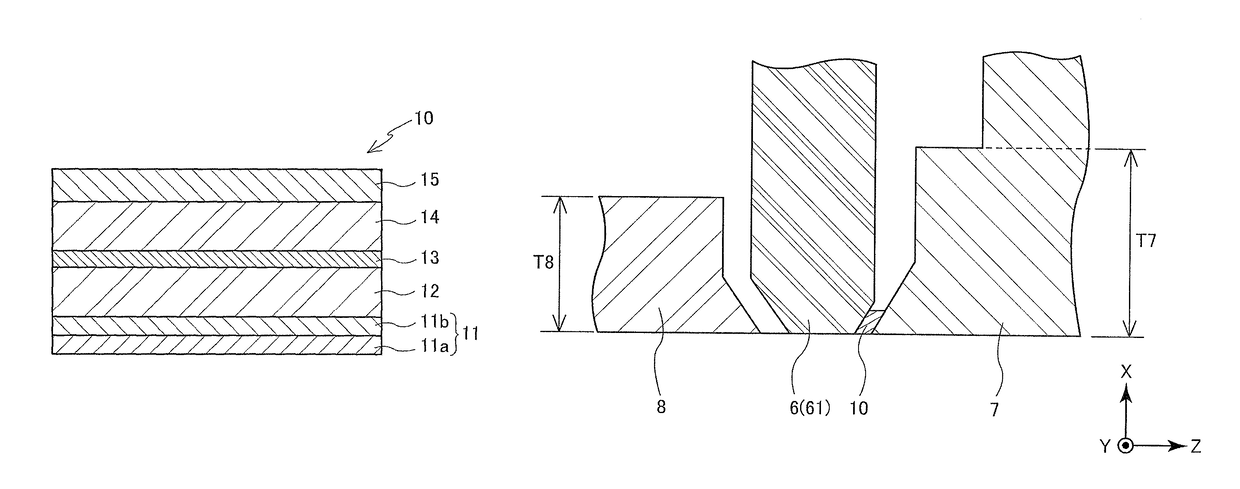

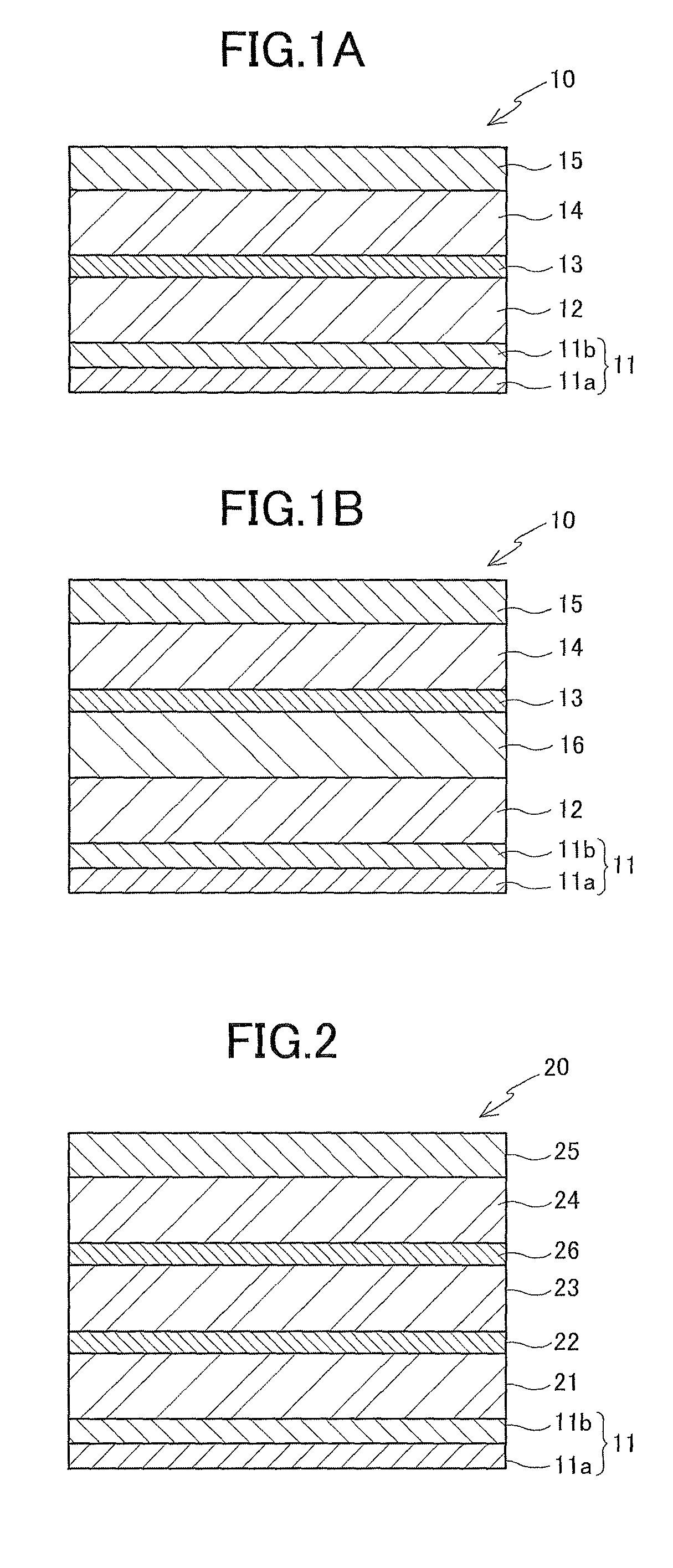

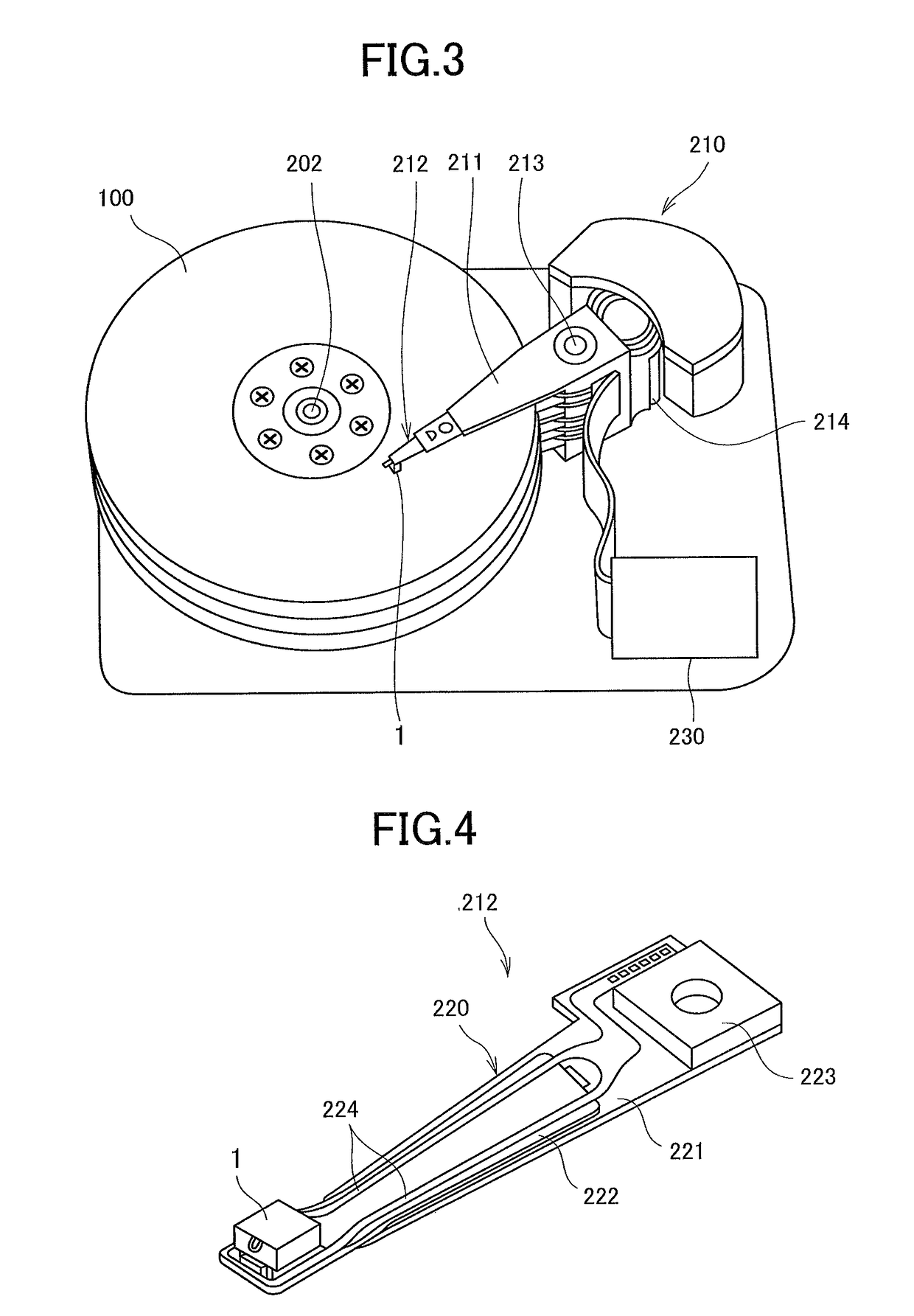

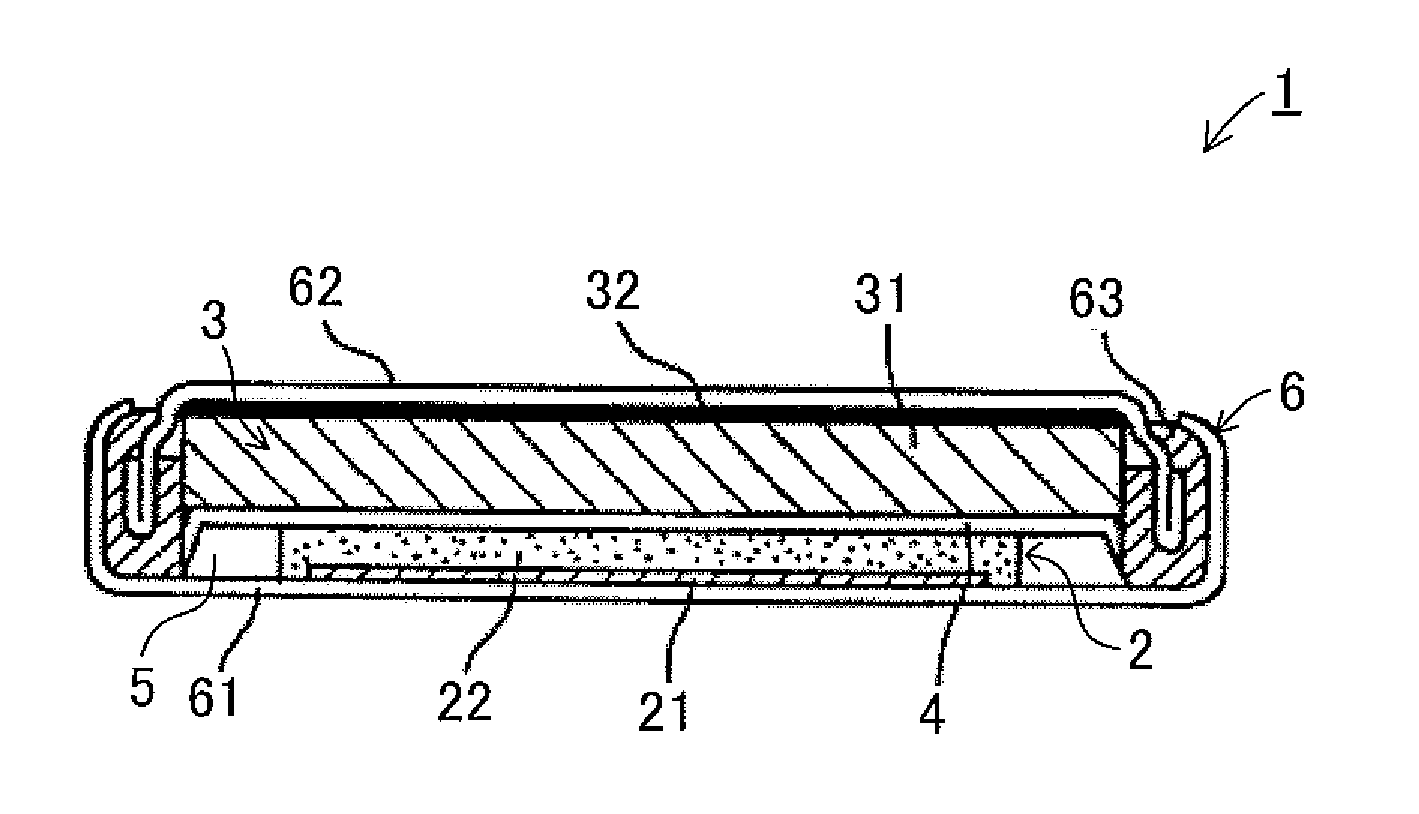

Multilayer element including base multilayer body, magnetic sensor and microwave assisted magnetic head

A base multilayer body is made by laminating a seed layer and a buffer layer in respective order. The seed layer is an alloy layer containing tantalum (Ta) and at least one type of other metal, and having an amorphous structure or a microcrystal structure. The buffer layer is an alloy layer having a [001] plane orientation hexagonal close-packed structure and containing at least one type of a group VI metal and at least one type of a group IX metal in the periodic table. With this configuration, a magnetic layer providing a desired magnetic characteristic(s) can be laminated on the thinned base multilayer body.

Owner:TDK CORPARATION

Lithium secondary battery and cathode active material therefor

InactiveUS20120258369A1Enhanced electron-conductivityEnhanced lithium-ion-conductivityConductive materialActive material electrodesLithiumPlane orientation

The lithium secondary battery cathode active material having a layered rock salt structure is characterized in that the material is formed of a plurality of primary particles having a mean particle size of 0.01 to 5 μm, and contains secondary particles having a mean particle size of 1 to 100 μm and an aspect ratio, which is a ratio of long axis diameter to short axis diameter, of 1.0 or more and less than 2; and that the primary particles forming the secondary particles have a (003) plane orientation degree of 50% or higher.

Owner:NGK INSULATORS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com