Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2340results about "Aluminium silicates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nitride semiconductor wafer

ActiveUS7390359B2Maintain good propertiesQuality improvementPolycrystalline material growthAluminium silicatesPlane orientationSingle crystal

A nitride semiconductor substrate having properties preferable for the manufacture of various nitride semiconductor devices is made available, by specifying or controlling the local variation in the off-axis angle of the principal surface of the nitride semiconductor substrate. In a nitride semiconductor single-crystal wafer having a flat principal surface, the crystallographic plane orientation of the principal surface of the nitride semiconductor single-crystal wafer varies locally within a predetermined angular range.

Owner:SUMITOMO ELECTRIC IND LTD

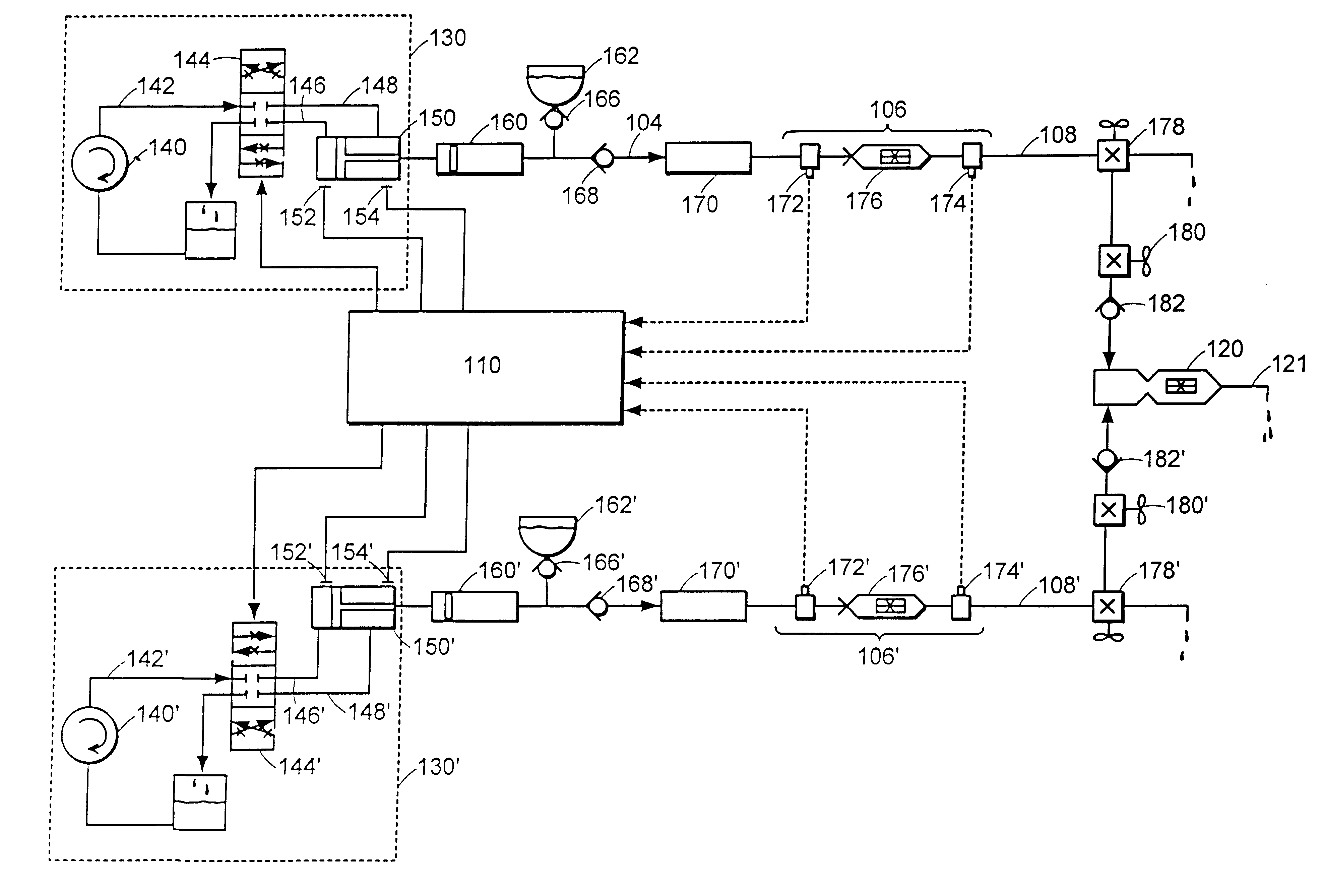

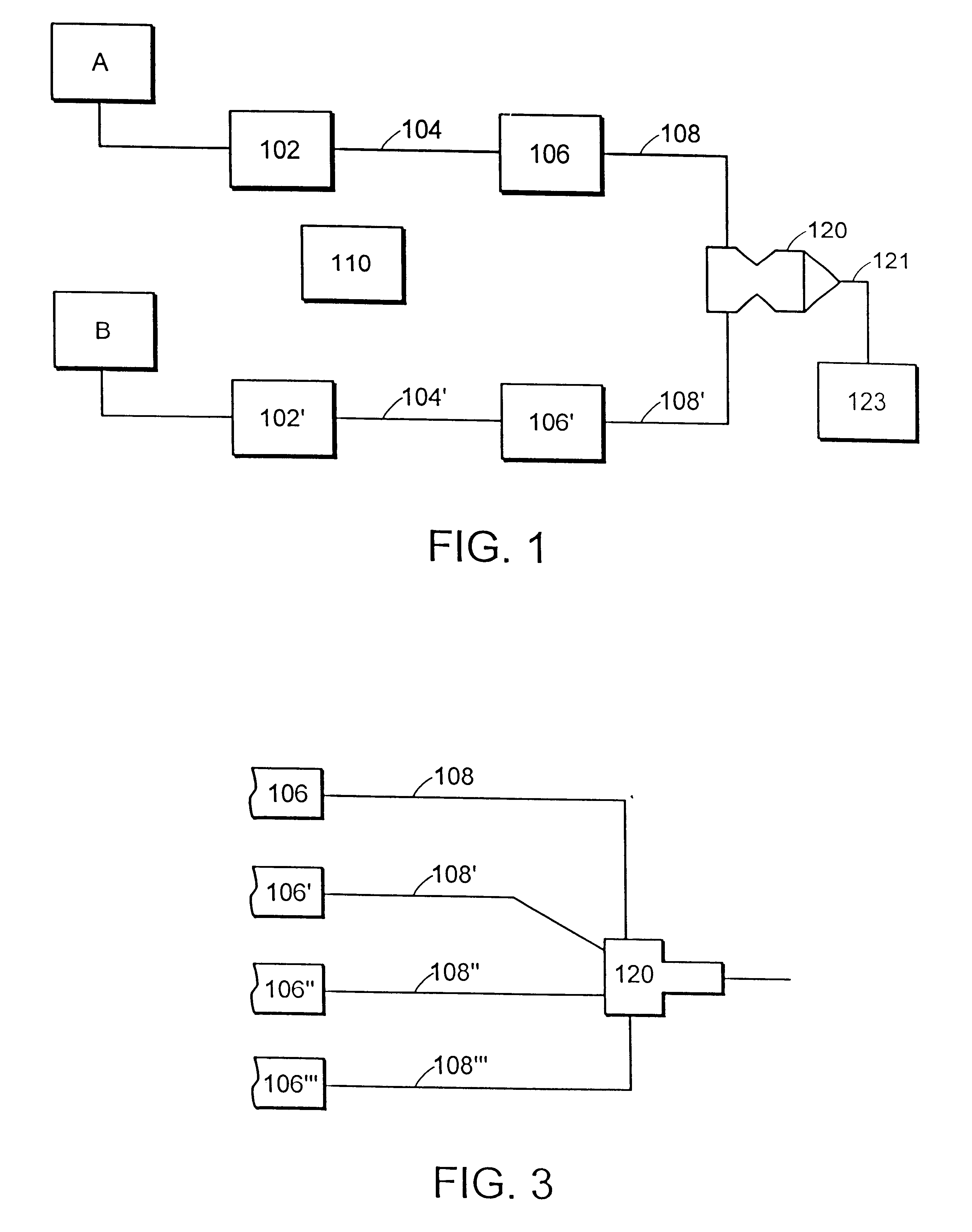

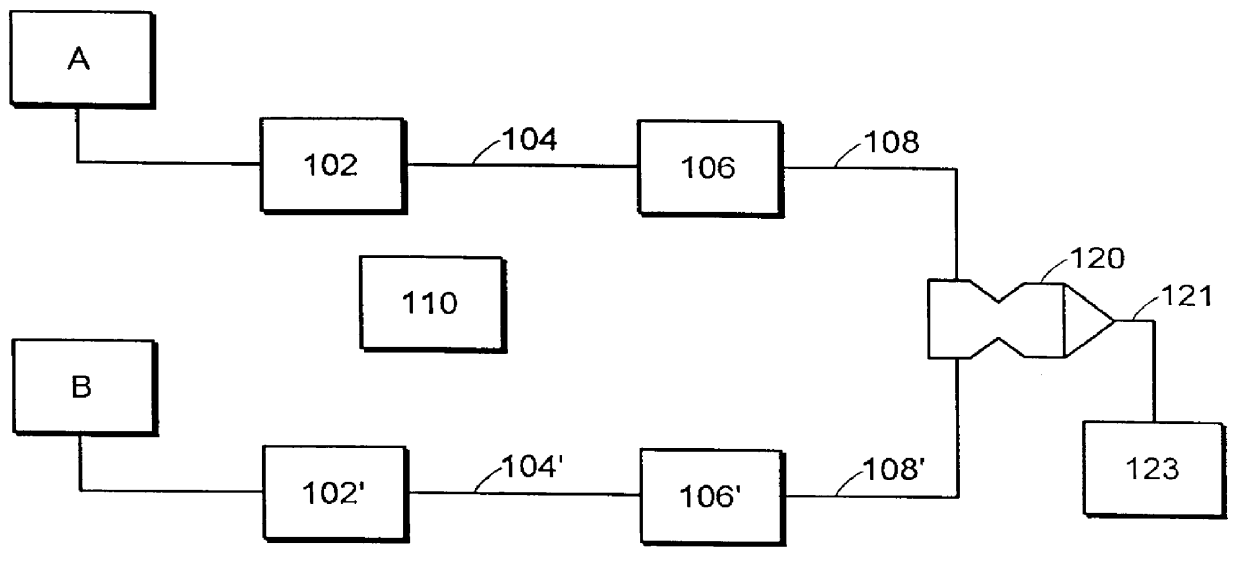

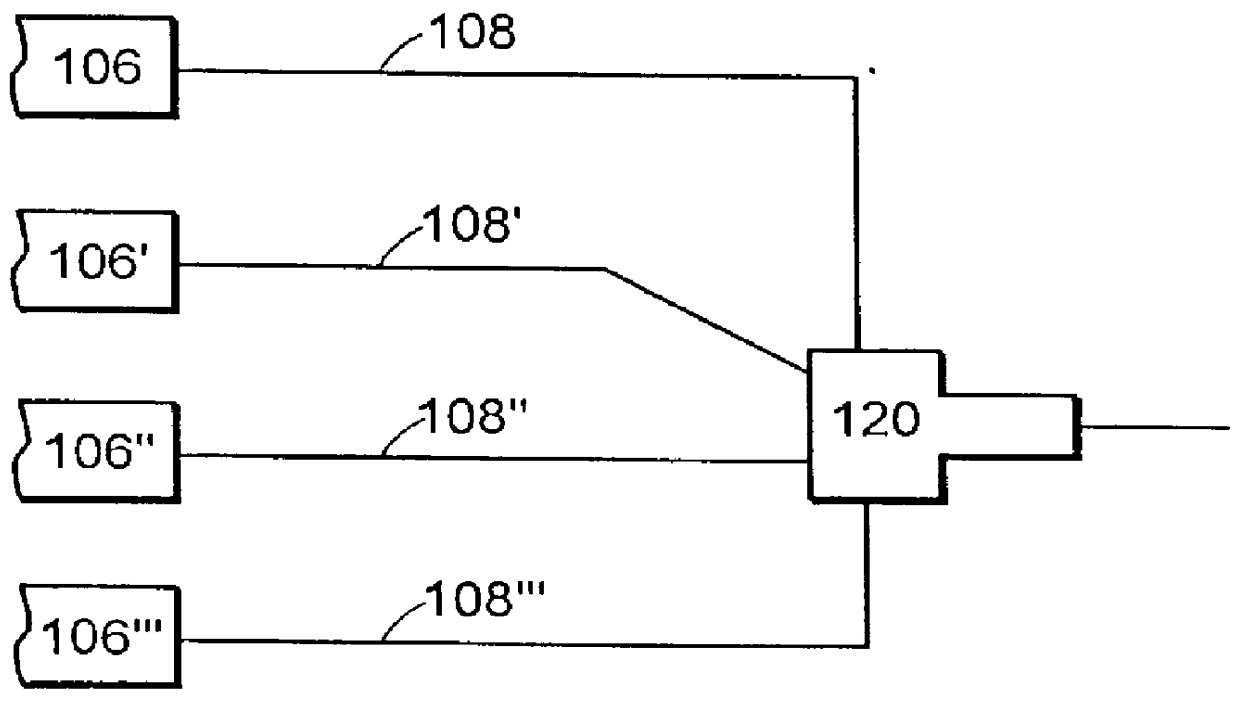

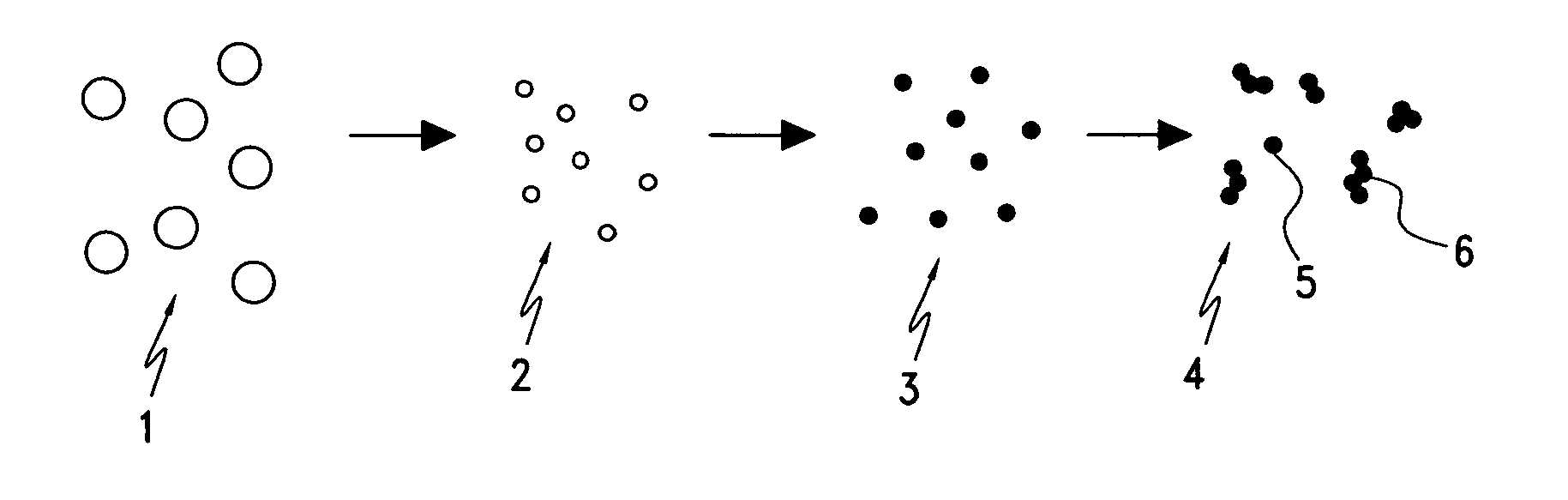

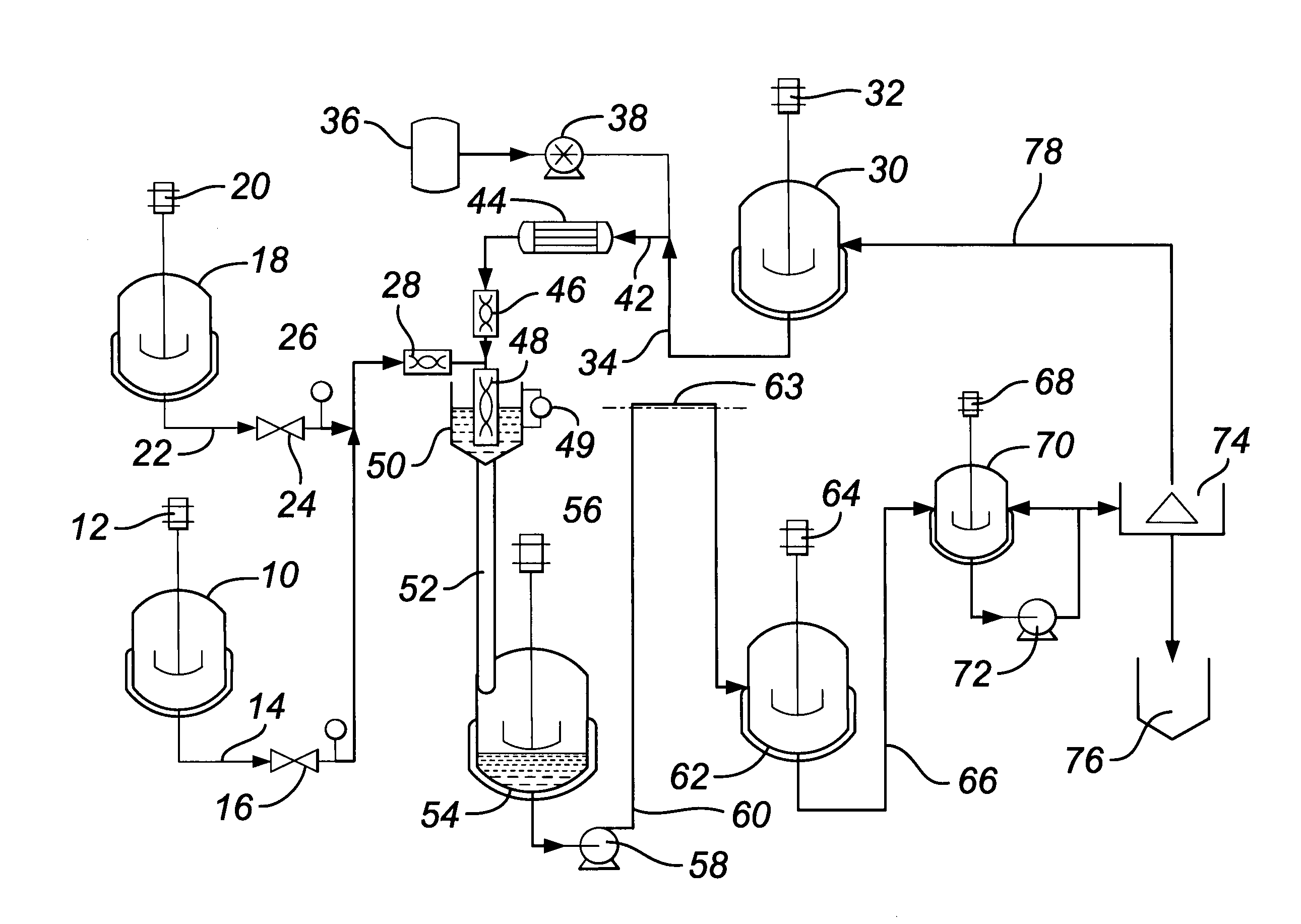

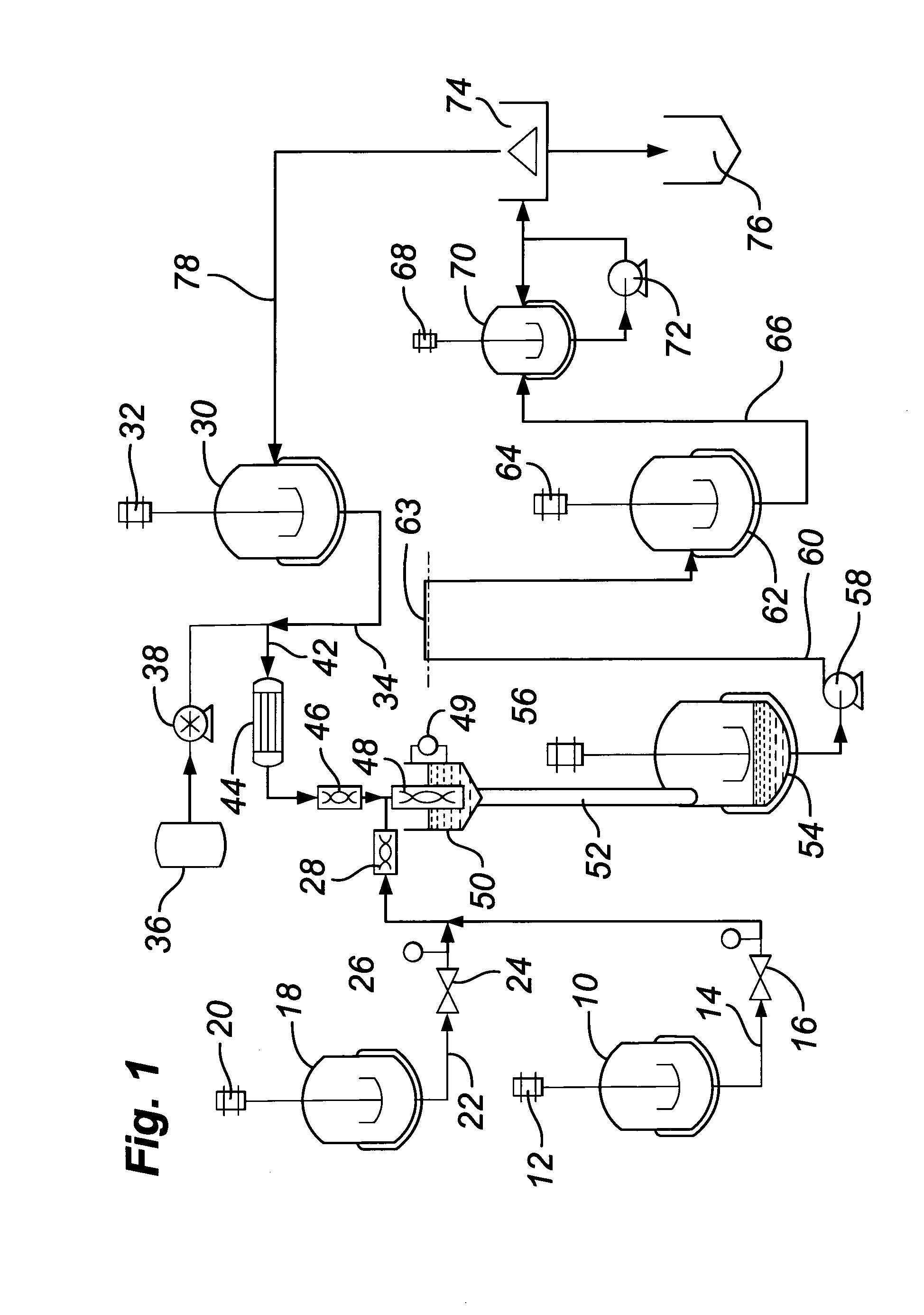

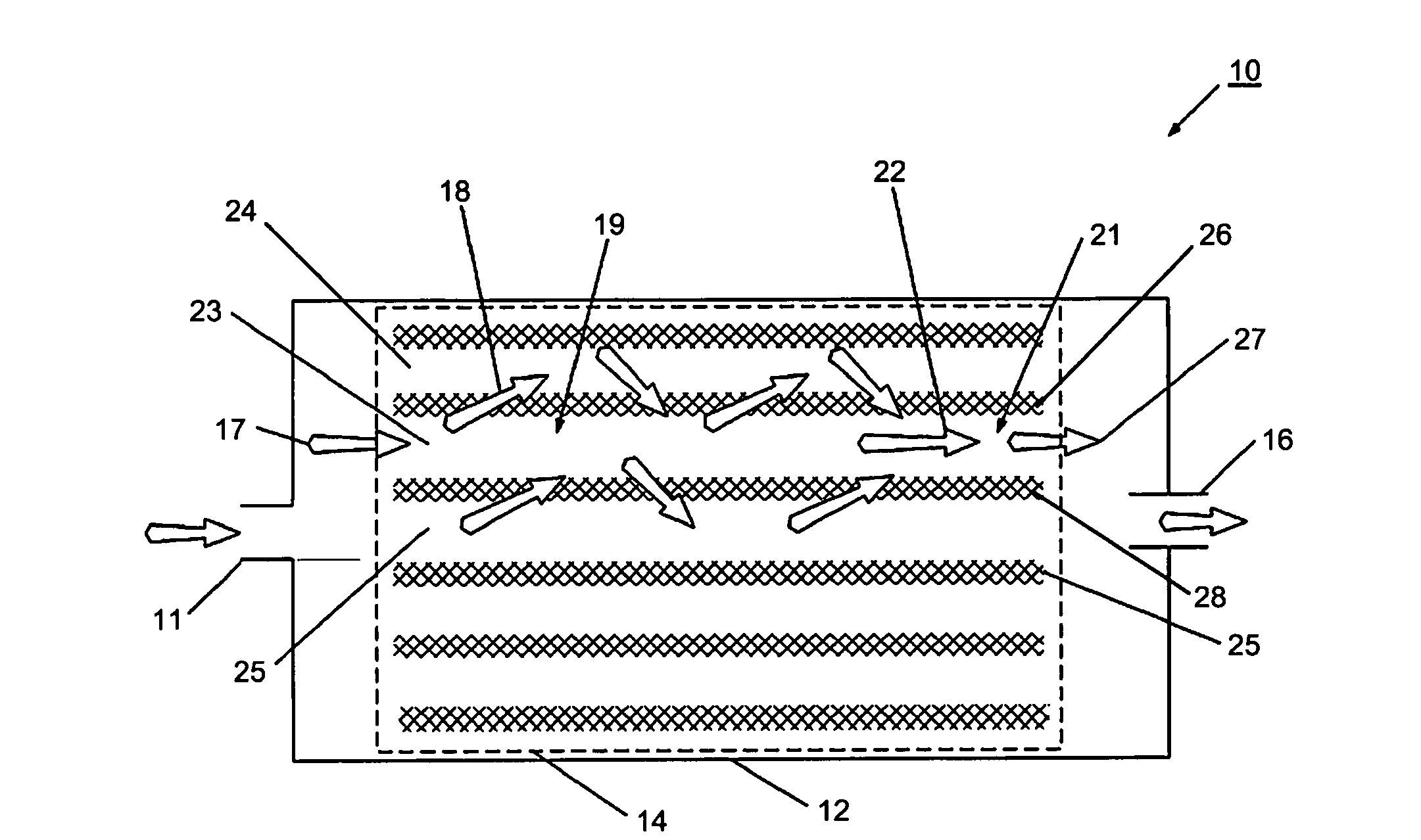

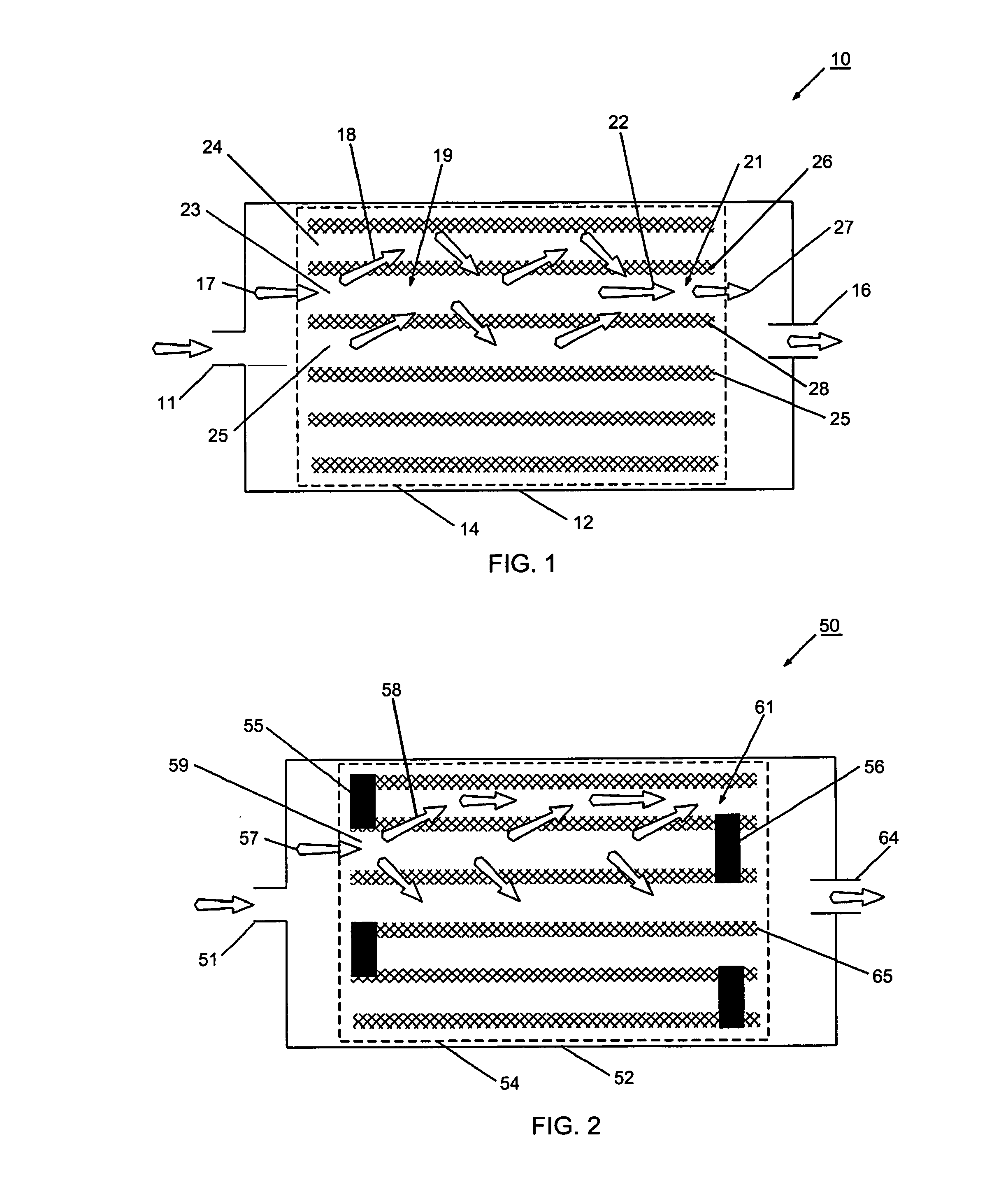

Multiple stream high pressure mixer/reactor

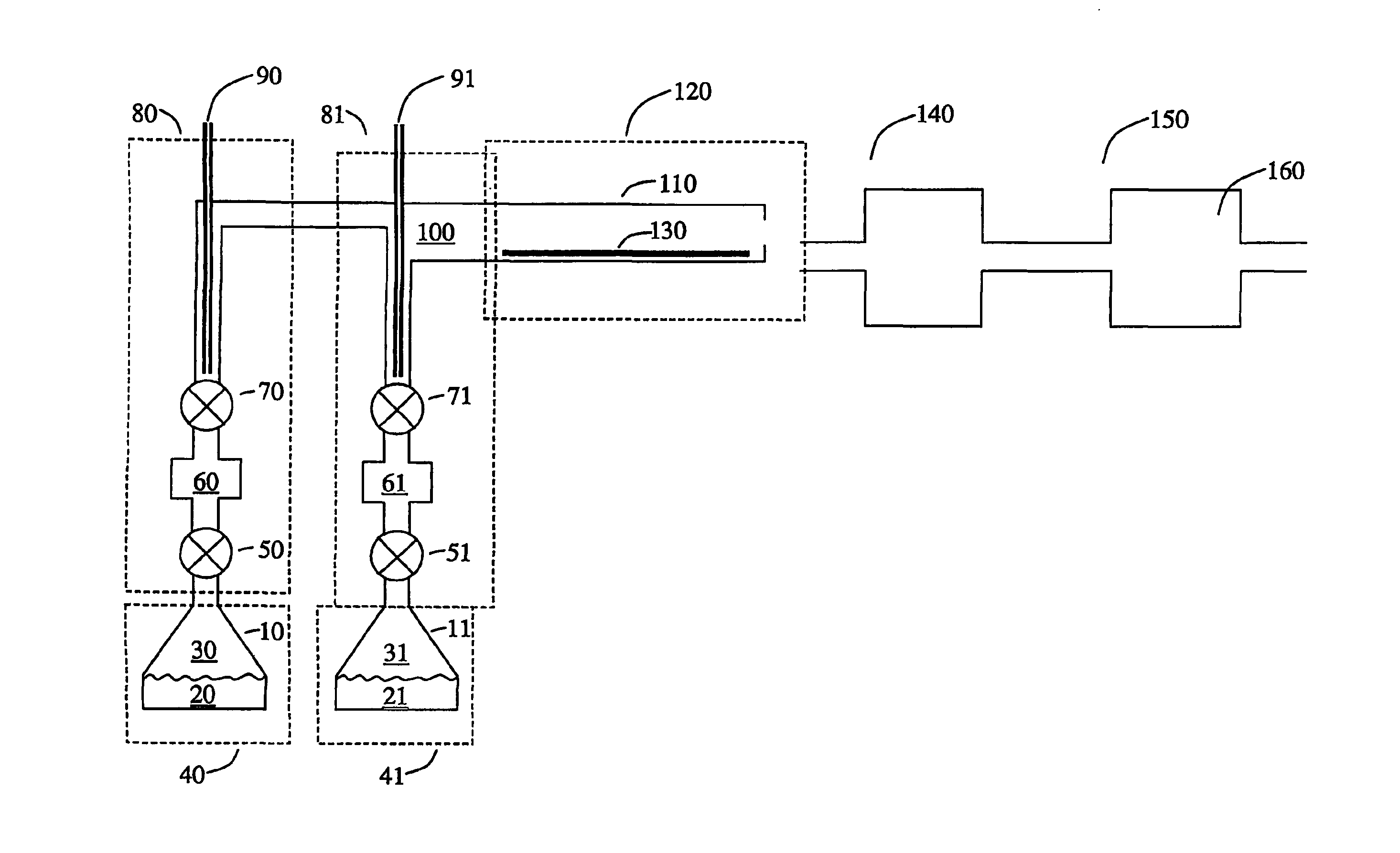

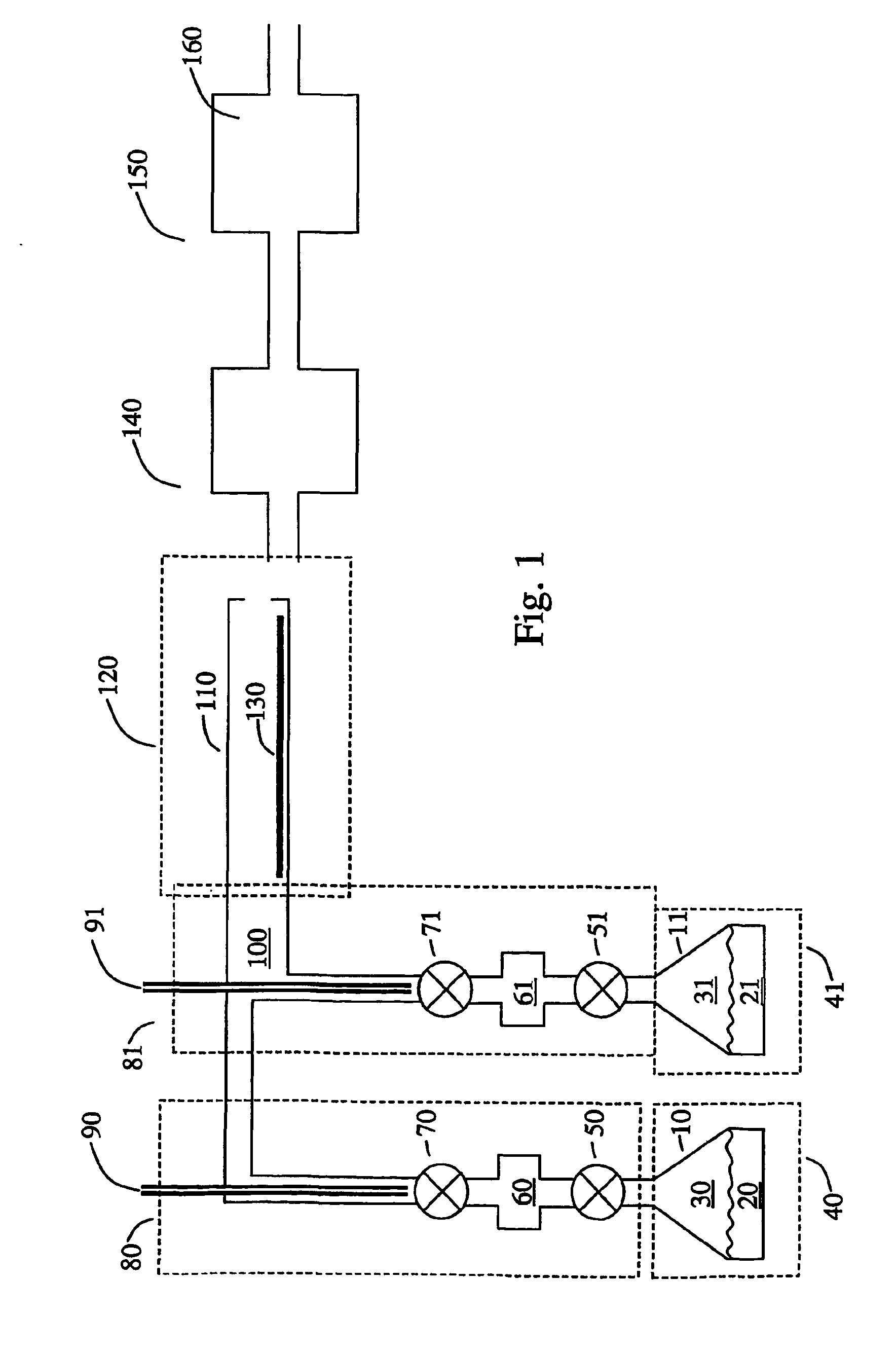

InactiveUS6221332B1Improve reliabilityFew and less partCalcium/strontium/barium carbonatesPressurized chemical processStream flowLow density

Enhanced macromixing, mesomixing, and micromixing of multiple discrete reactant streams, particularly for precipitation reactions of low density pumpable fluids, are obtained by controlled continuous high pressure multiple reactant streams flowing into a chemical mixer / reactor. Individual reactant streams are pressurized to about 8,000 to 50,000 psi and achieve velocities up to about 250 meters / second in the final stage of the chemical mixer / reactor. Reactant flows are controlled by a combination of a fixed restriction and a variable driving pump.

Owner:MICROFLUIDICS INT

Vapor deposition of metal oxides, silicates and phosphates, and silicon dioxide

InactiveUS6969539B2Good step coverageNarrow structureOxygen/ozone/oxide/hydroxideAluminium silicatesAlkylphosphatePhosphate

Metal silicates or phosphates are deposited on a heated substrate by the reaction of vapors of alkoxysilanols or alkylphosphates along with reactive metal amides, alkyls or alkoxides. For example, vapors of tris-(ter-butoxy)silanol react with vapors of tetrakis(ethylmethylamido)hafnium to deposit hafnium silicate on surfaces heated to 300° C. The product film has a very uniform stoichiometry throughout the reactor. Similarly, vapors of diisopropylphosphate react with vapors of lithium bis(ethyldimethylsilyl)amide to deposit lithium phosphate films on substrates heated to 250° C. supplying the vapors in alternating pulse produces these same compositions with a very uniform distribution of thickness and excellent step coverage.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

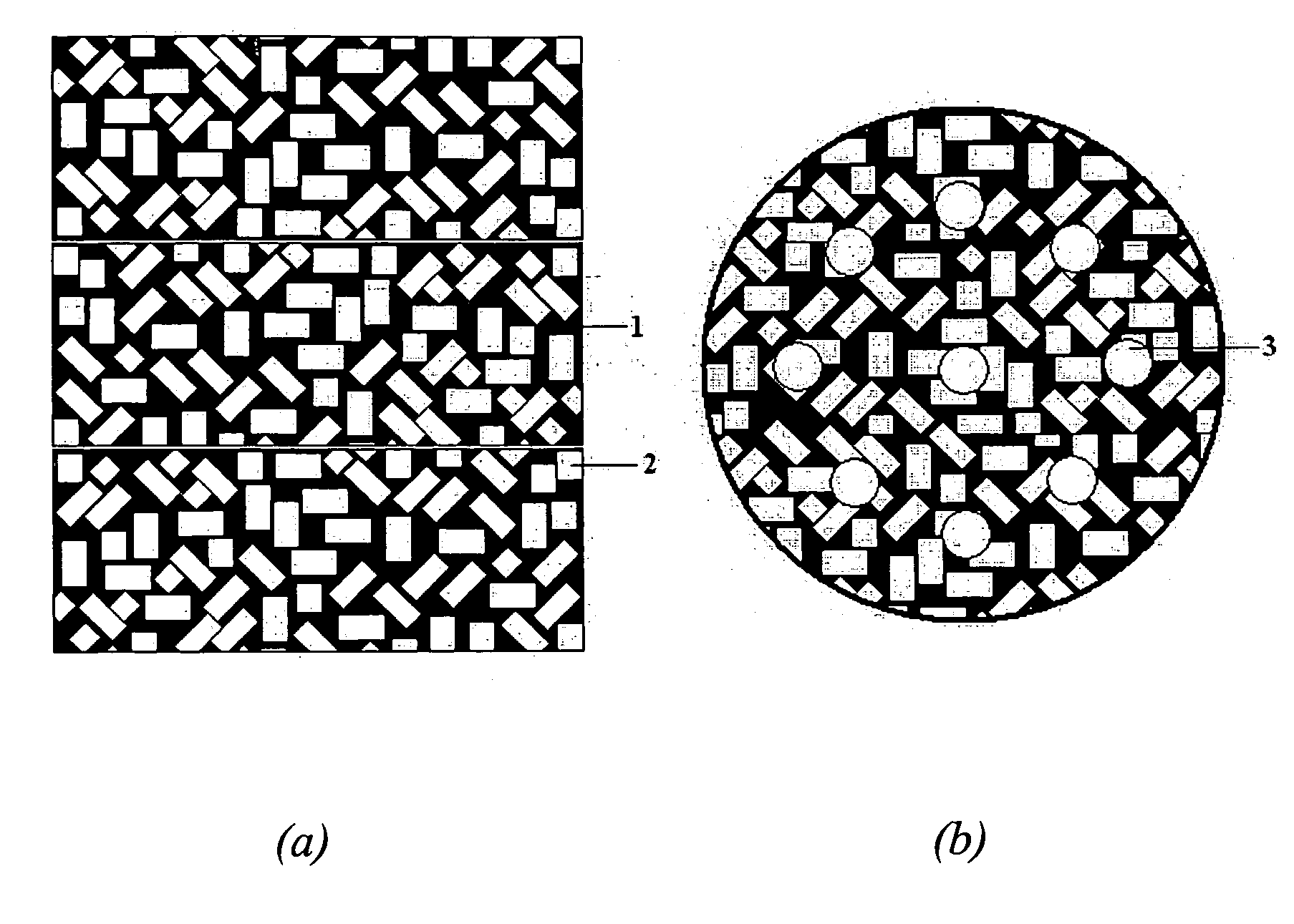

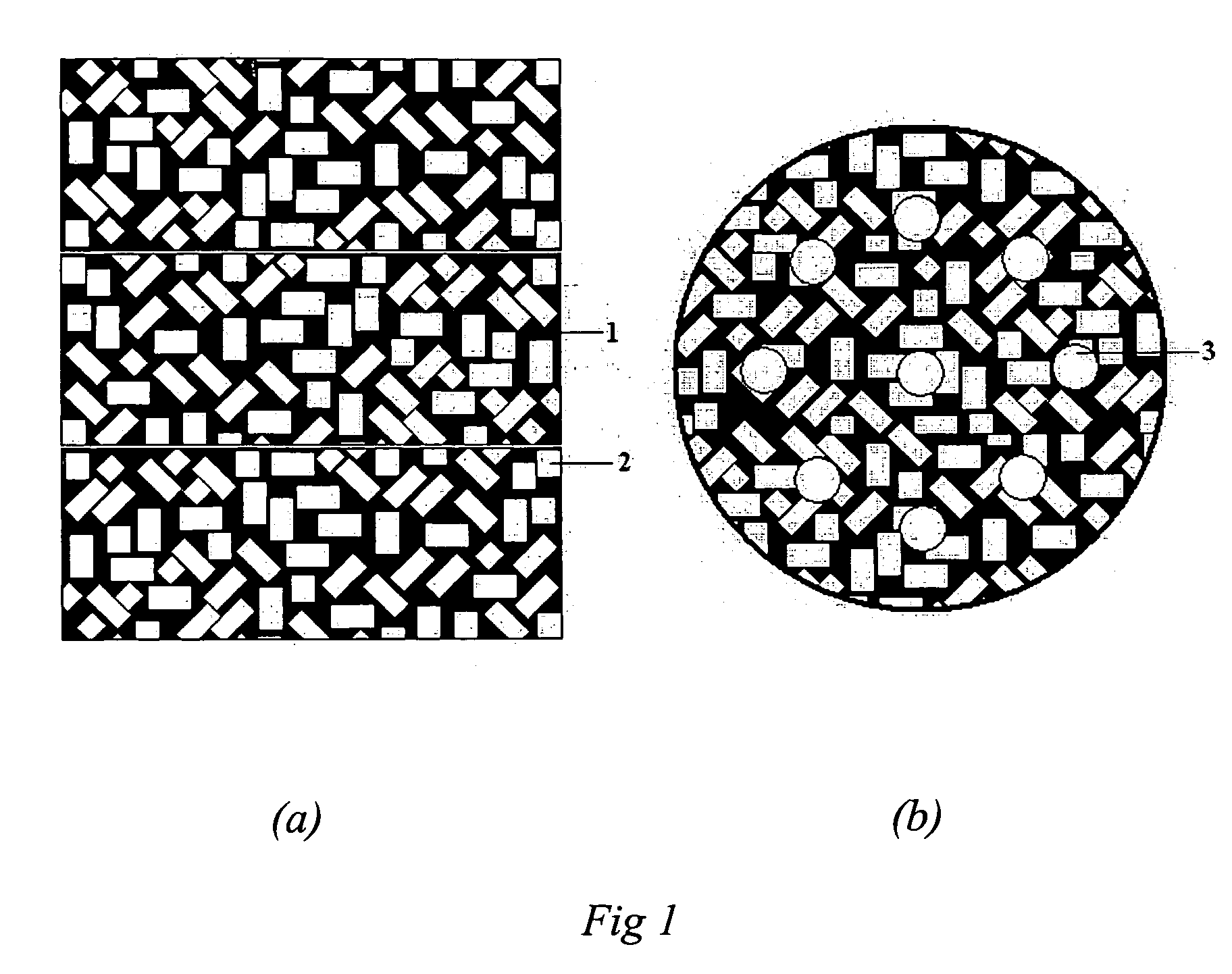

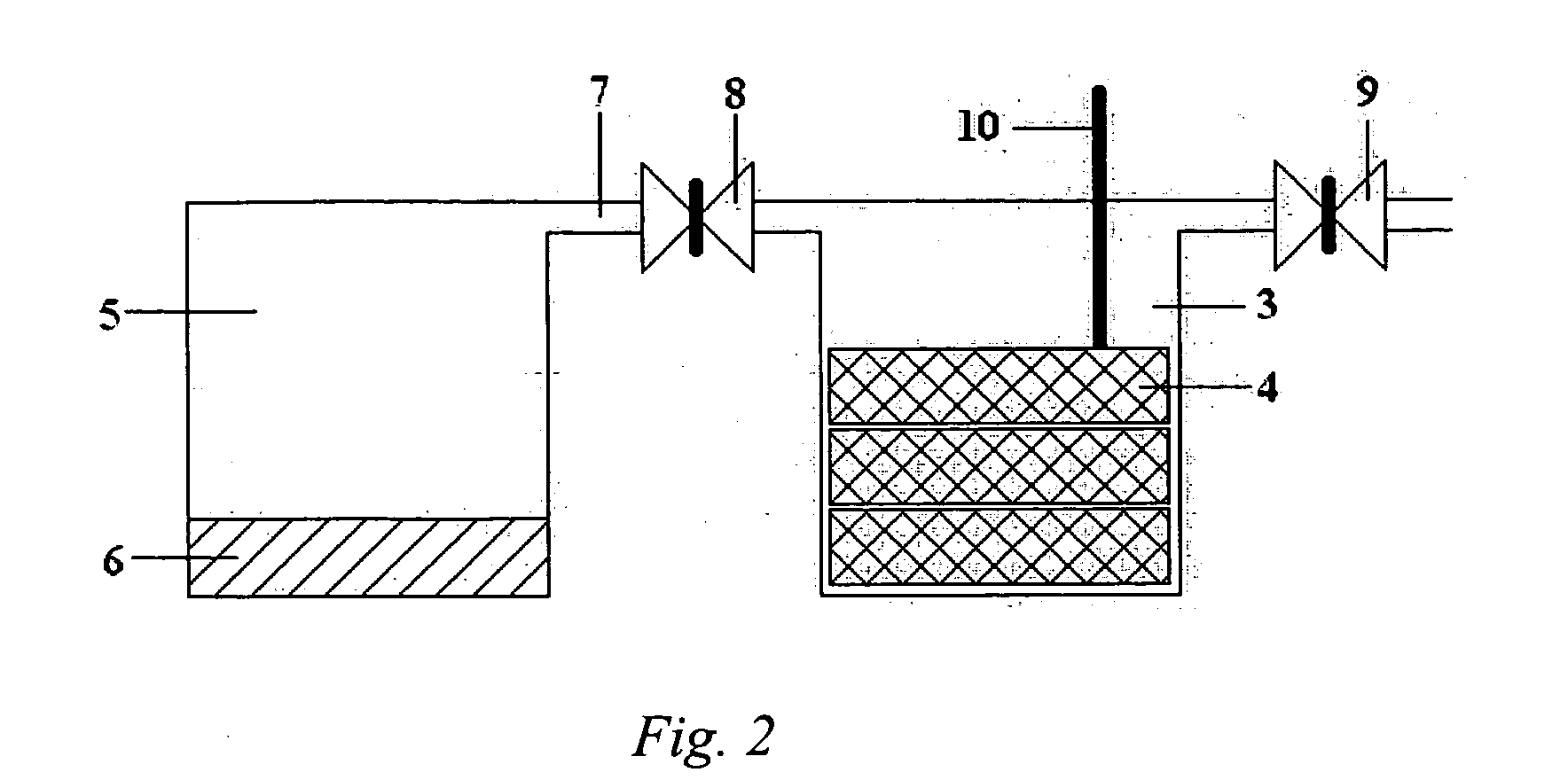

Increased thermal conductivity monolithic zeolite structures

A monolith comprises a zeolite, a thermally conductive carbon, and a binder. The zeolite is included in the form of beads, pellets, powders and mixtures thereof. The thermally conductive carbon can be carbon nano-fibers, diamond or graphite which provide thermal conductivities in excess of about 100 W / m·K to more than 1,000 W / m·K. A method of preparing a zeolite monolith includes the steps of mixing a zeolite dispersion in an aqueous colloidal silica binder with a dispersion of carbon nano-fibers in water followed by dehydration and curing of the binder is given.

Owner:UT BATTELLE LLC

Acidified attapulgite clay

Owner:XUYI BOTU ATTAPULGITE CLAY HIGH TECH DEV

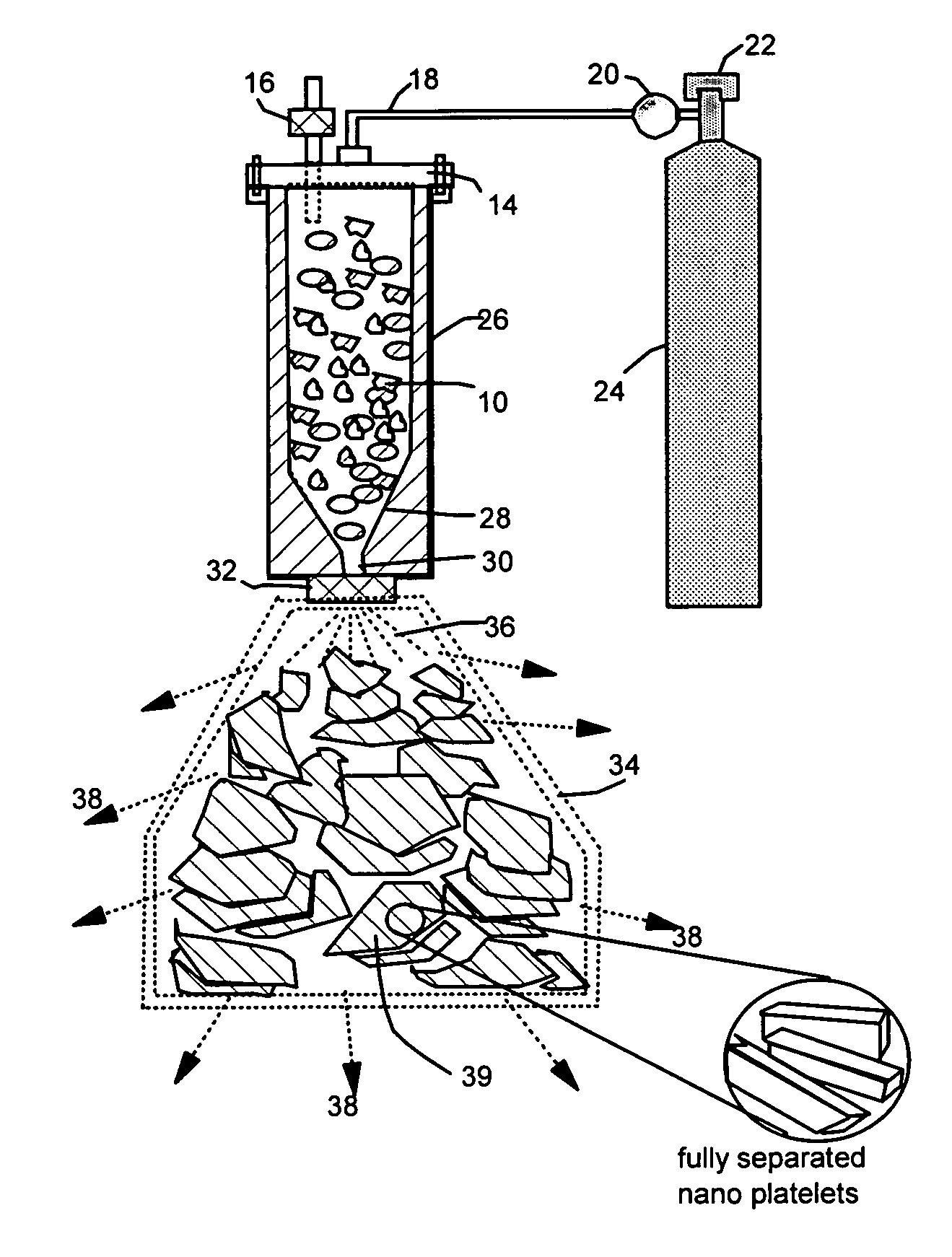

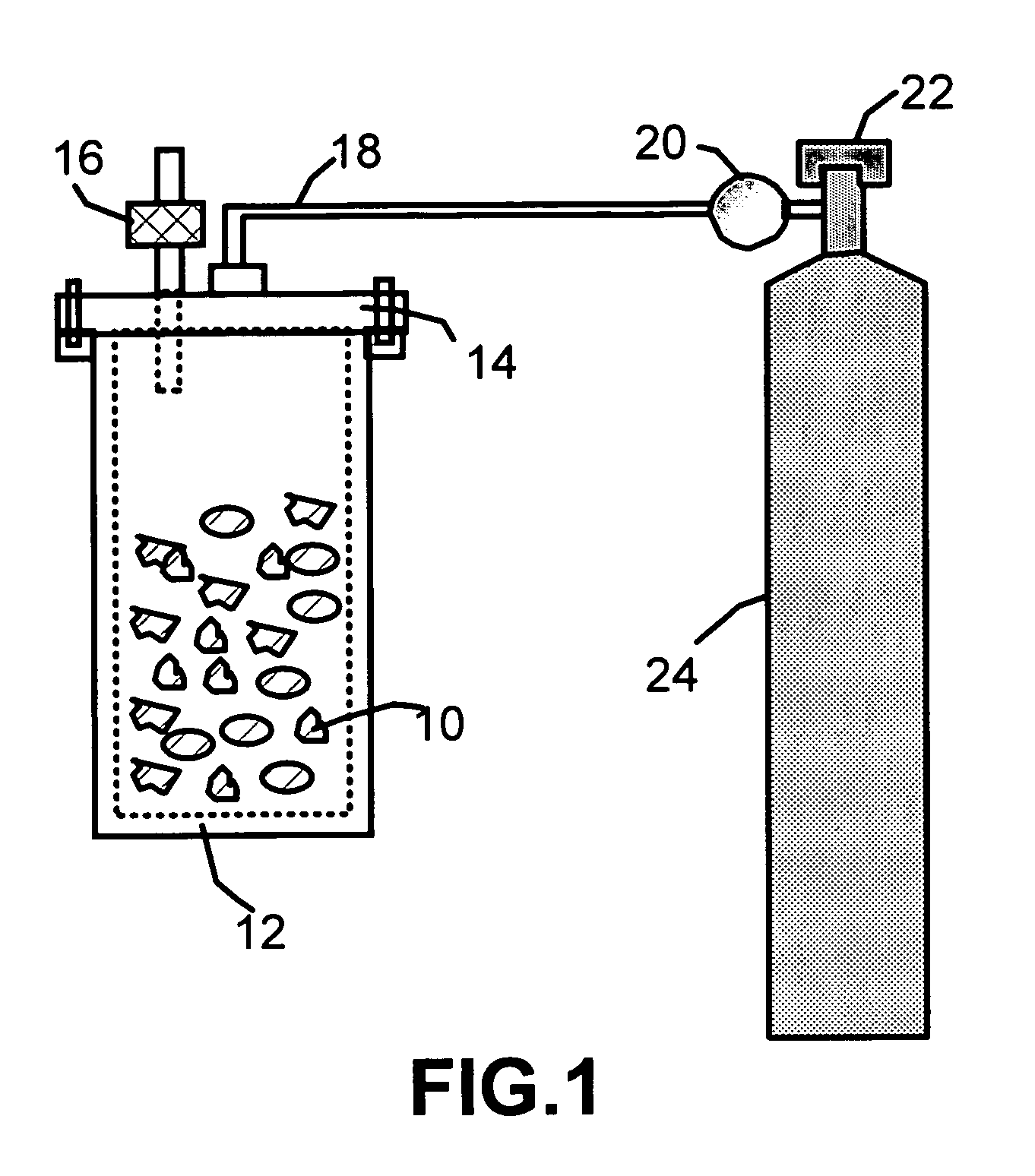

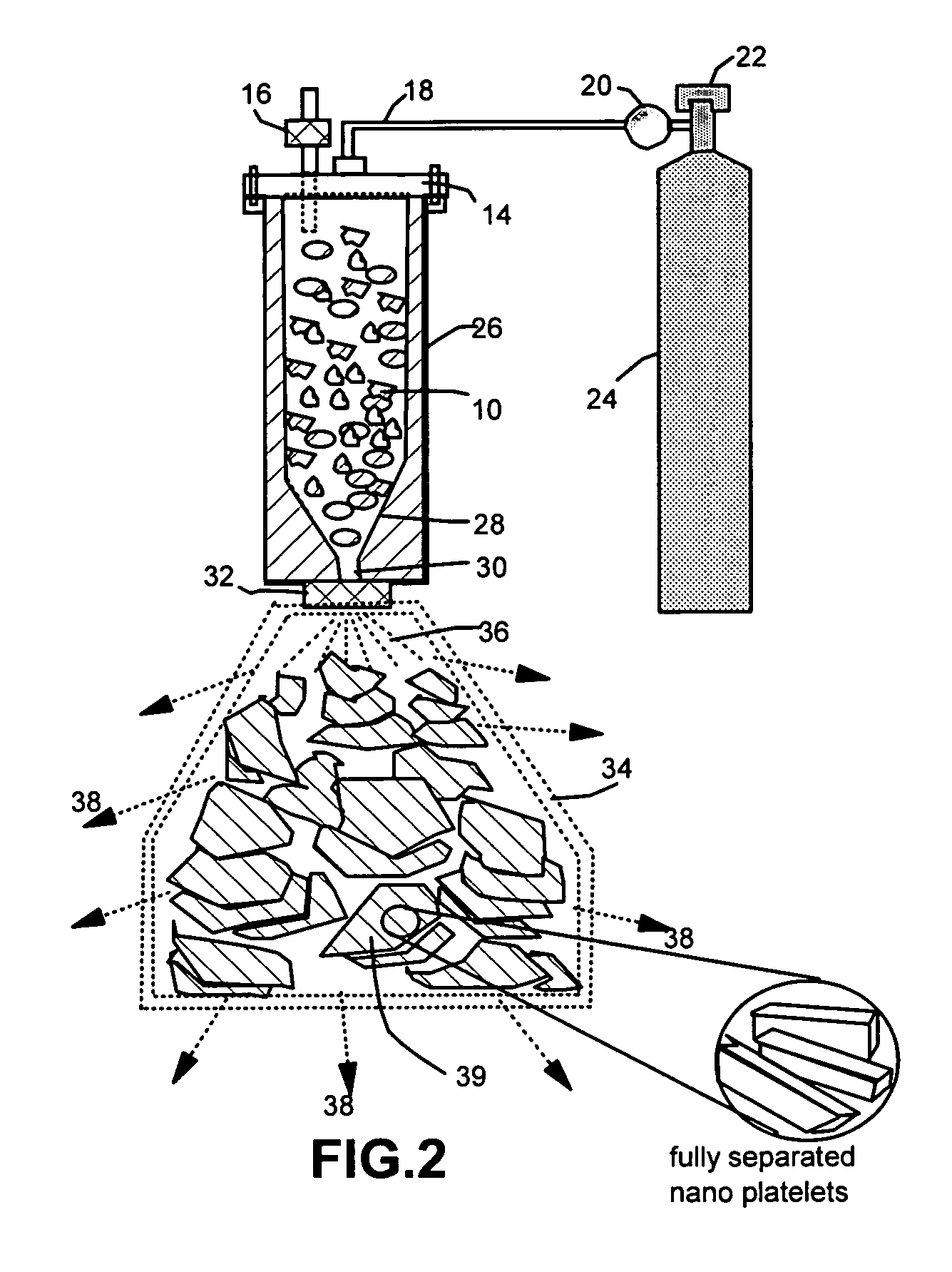

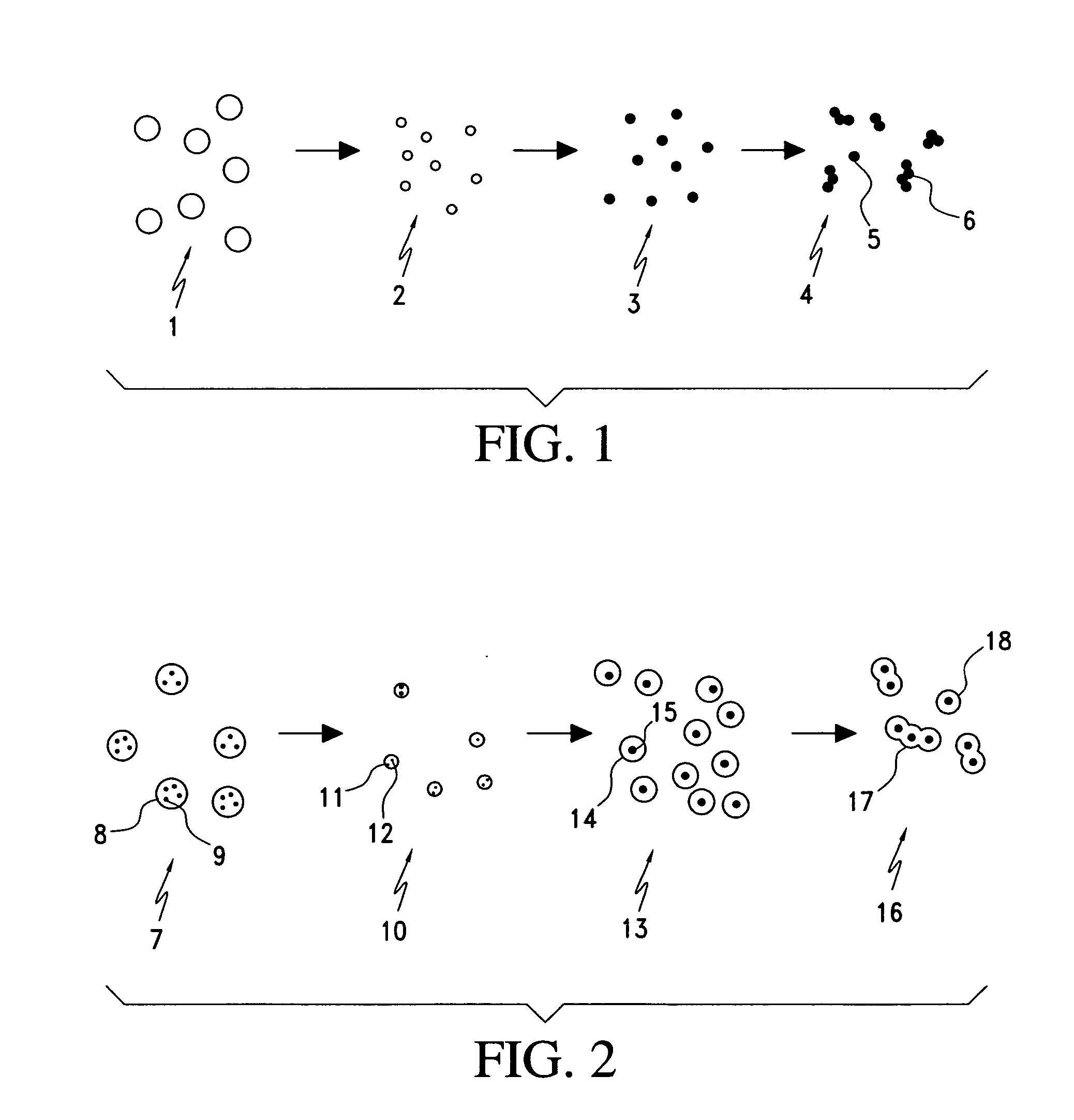

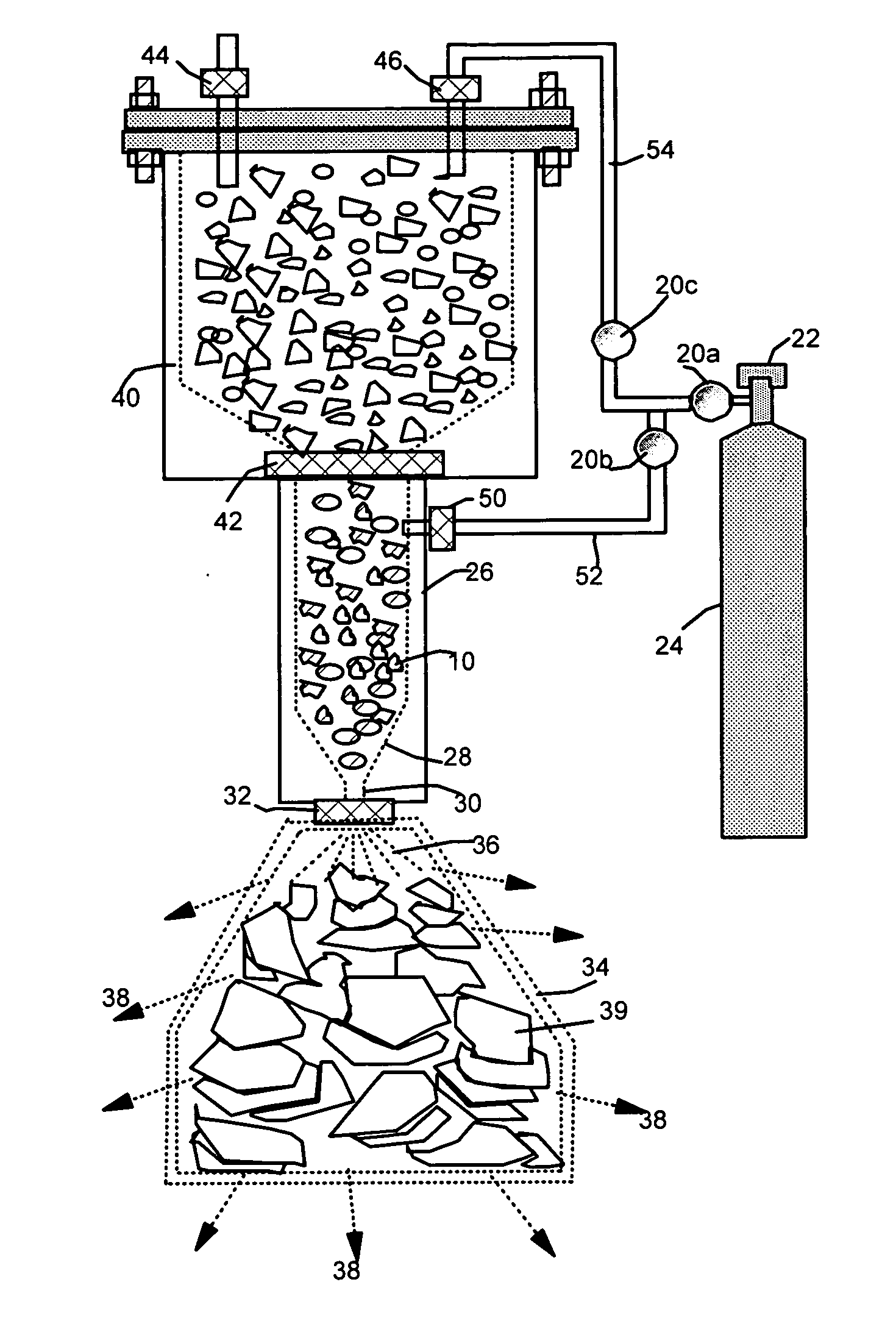

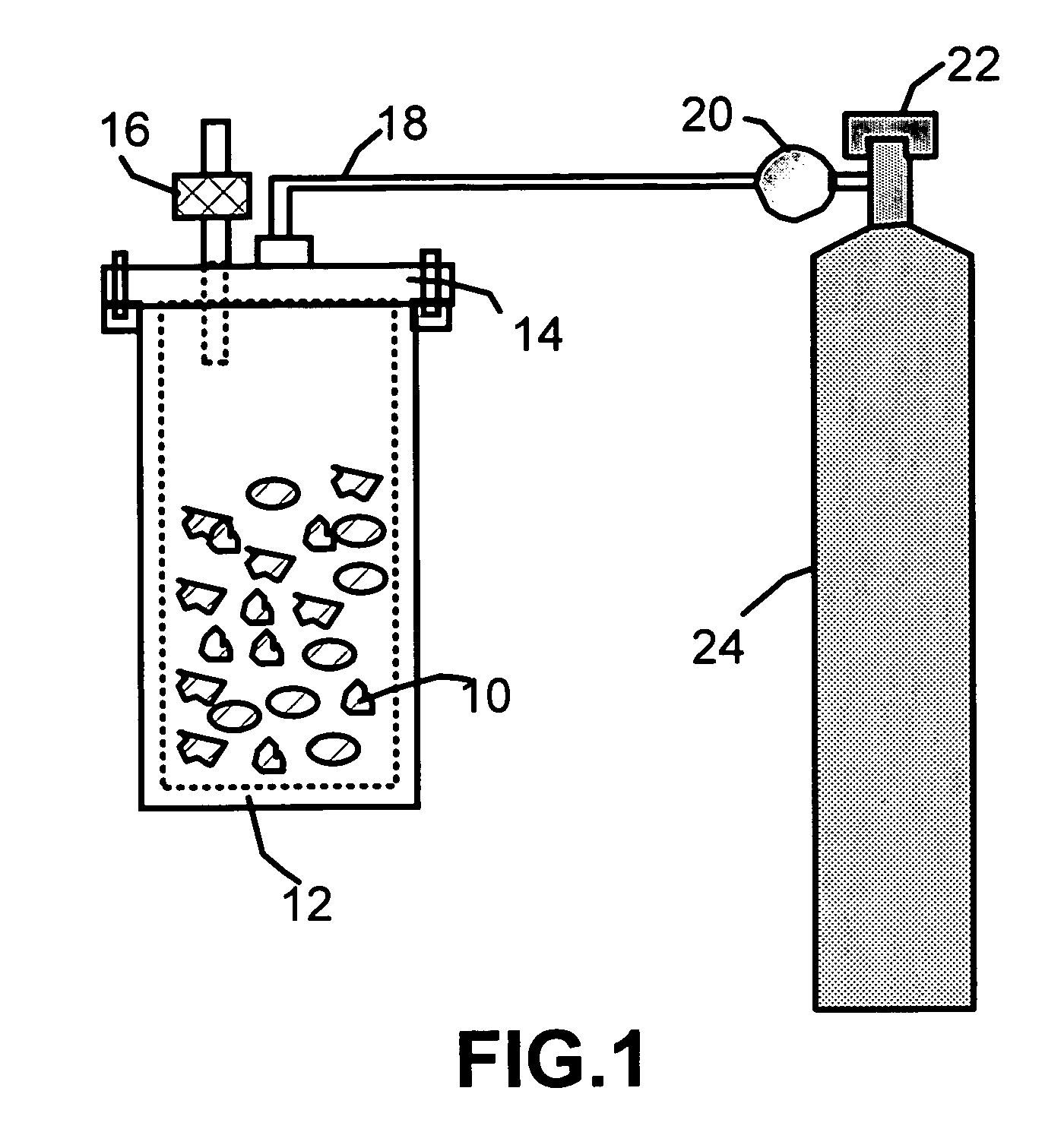

Mass production of nano-scaled platelets and products

ActiveUS7785492B1Reduce necessary intercalation timeSmall thicknessMaterial nanotechnologyGraphiteNoble gasGraphite

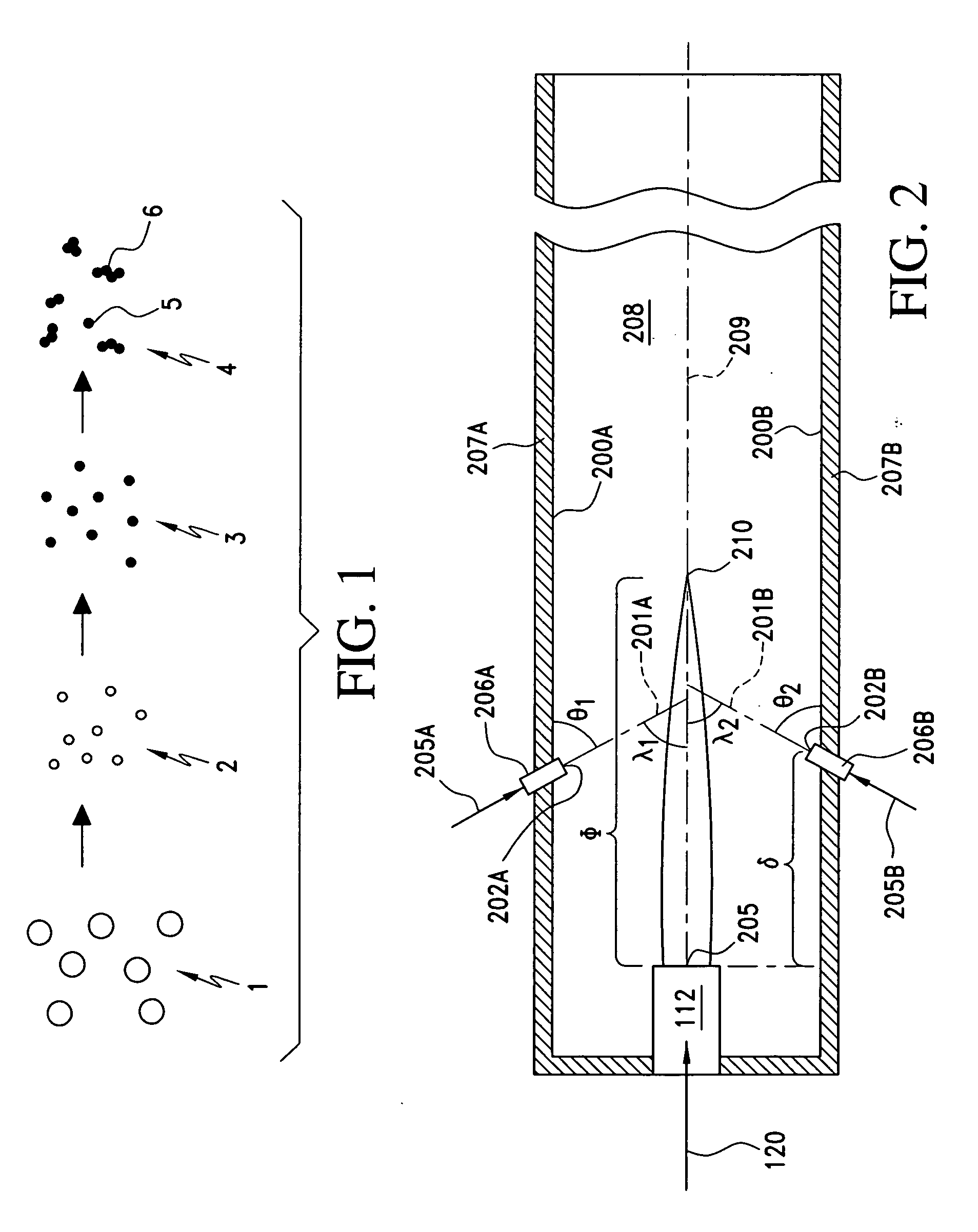

Disclosed is a process for exfoliating a layered material to produce nano-scaled platelets having a thickness smaller than 100 nm, typically smaller than 10 nm, and often between 0.34 nm and 1.02 nm. The process comprises: (a) charging a layered material to an intercalation chamber comprising a gaseous environment at a first temperature and a first pressure sufficient to cause gas species to penetrate into the interstitial space between layers of the layered material, forming a gas-intercalated layered material; and (b) operating a discharge valve to rapidly eject the gas-intercalated layered material through a nozzle into an exfoliation zone at a second pressure and a second temperature, allowing gas species residing in the interstitial space to exfoliate the layered material to produce the platelets. The gaseous environment preferably contains only environmentally benign gases that are reactive (e.g., oxygen) or non-reactive (e.g., noble gases) with the layered material. The process can additionally include dispersing the platelets in a matrix material to form a nanocomposite. The process also can include an additional process of re-compressing the nana-scaled platelets into a product such as a flexible graphite sheet.

Owner:GLOBAL GRAPHENE GRP INC

Use of multiple stream high pressure mixer/reactor

InactiveUS6159442AHigh strengthMaintain good propertiesCalcium/strontium/barium carbonatesPressurized chemical processStream flowHigh pressure

Owner:MICROFLUIDICS INT

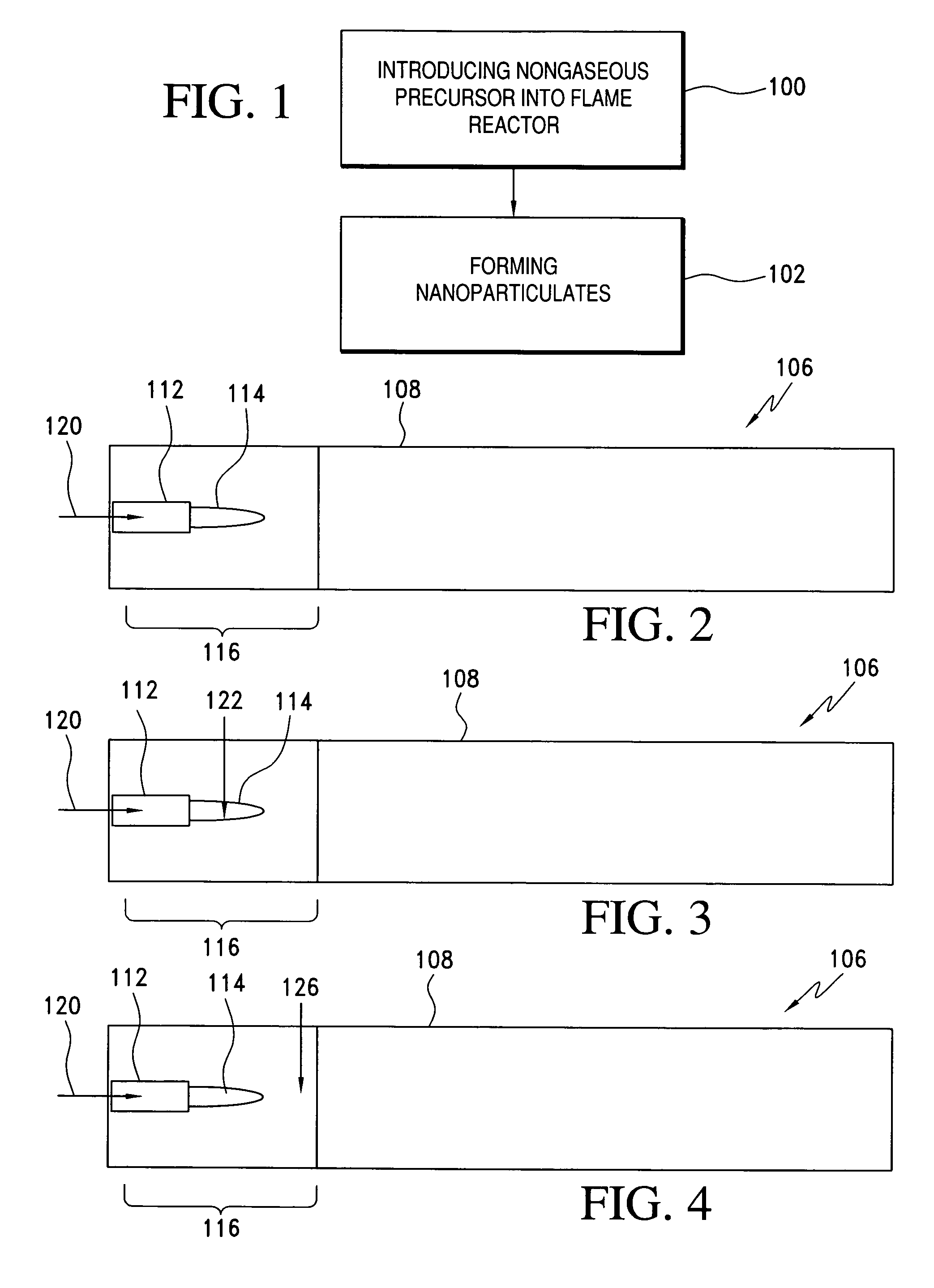

Method of making nanoparticulates and use of the nanoparticulates to make products using a flame reactor

InactiveUS20060166057A1Easy to joinLower melting temperatureMaterial nanotechnologyBurnersMulti materialNanoparticle

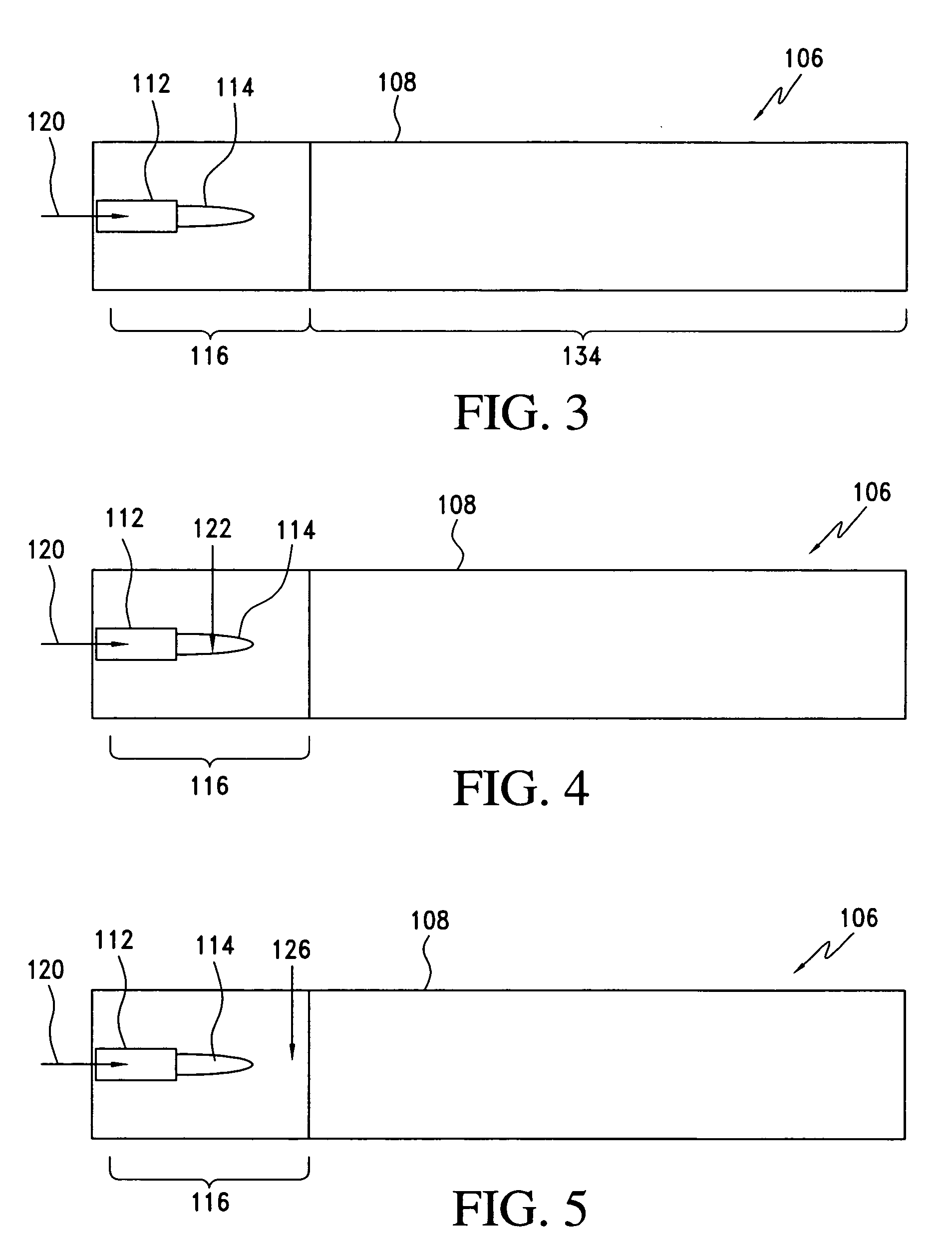

The present invention relates to a method of making nanoparticulates in a flame reactor, the nanoparticulates having controlled properties such as weight average particle size, composition and morphology. The nanoparticulates made with the method of present invention may be tailored to a specific weight average particle size range, such as from about 1 nm to about 500 nm. In addition to weight average particle size, the nanoparticulates made with the method of the present invention may include a variety of materials including metals, ceramics, organic materials, and combinations thereof. Moreover, the method of the present invention allows control over the morphology of the nanoparticulates, which allows the production of nanoparticulates with any desired morphology including spheroidal and unagglomerated; and agglomerated (aggregated) into larger units of hard aggregates.

Owner:CABOT CORP

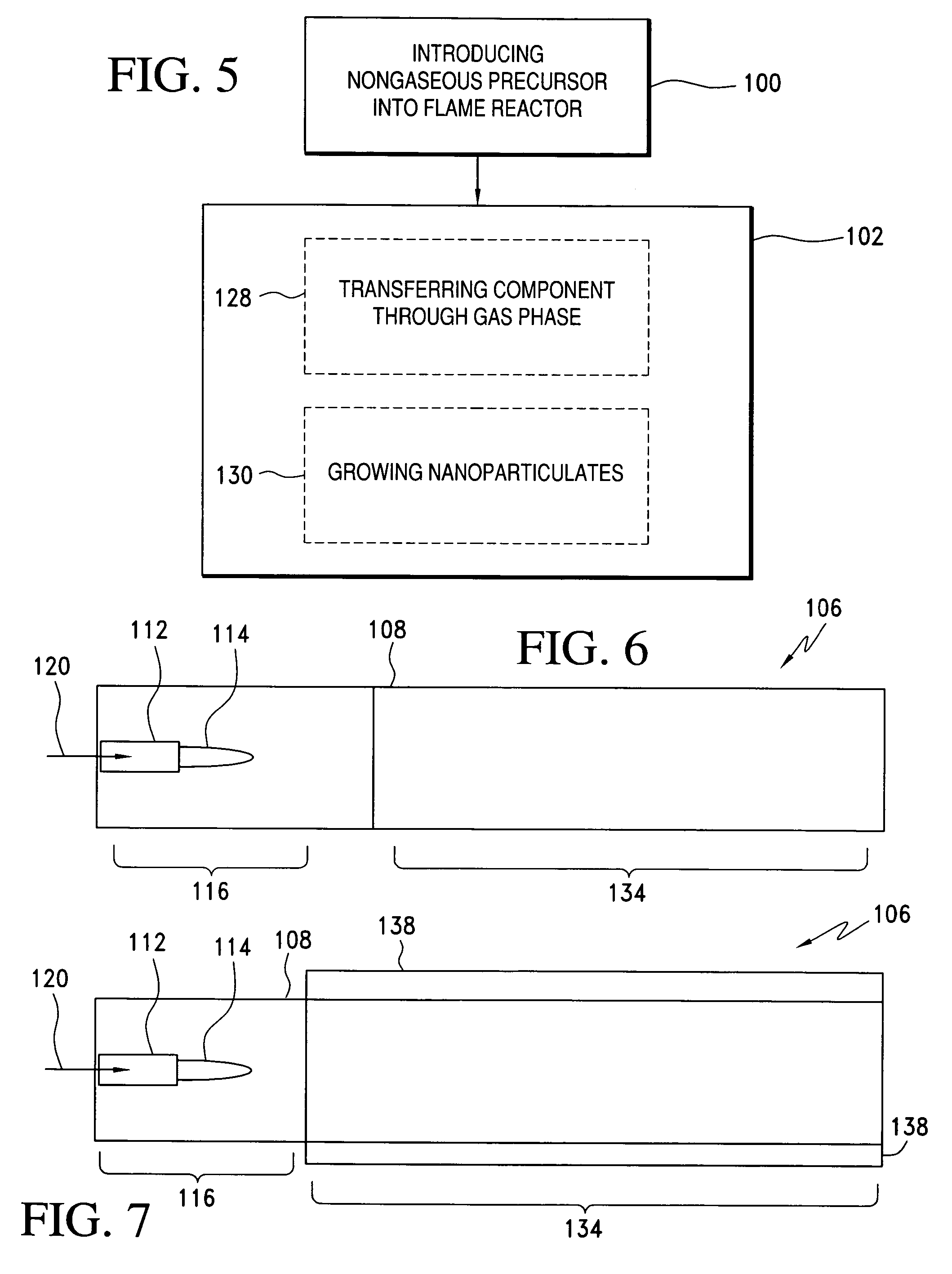

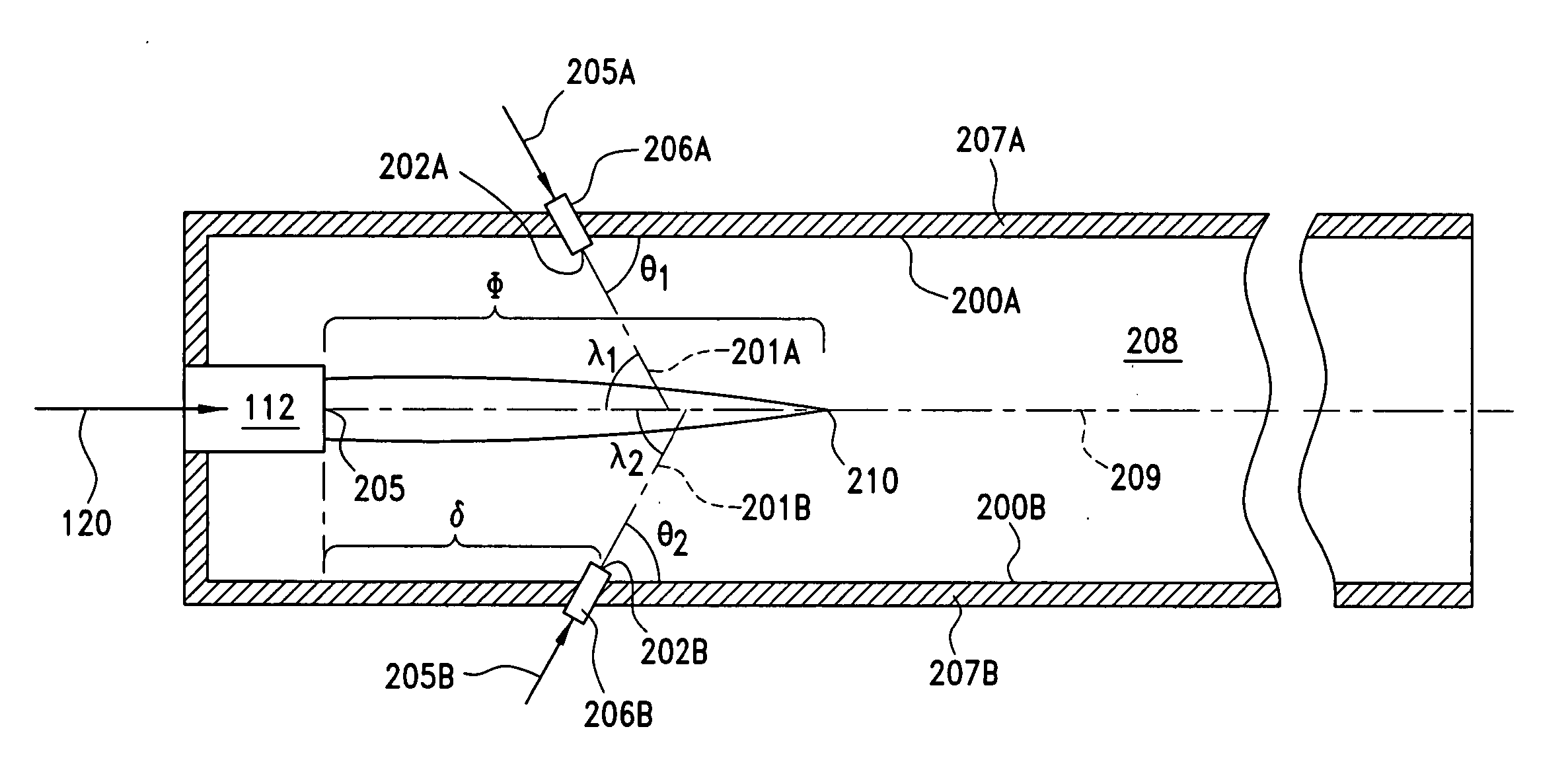

Processes for forming nanoparticles in a flame spray system

In one aspect, the process includes providing a precursor medium comprising a liquid vehicle and a precursor to a component, and flame spraying the precursor medium under conditions effective to form a population of nanoparticles, wherein the nanoparticles include the component. The population of nanoparticles, as formed, comprises less than about 5 percent by volume particles having a particle size greater than 1.0 μm. A size distribution of the population of nanoparticles may have a d50 value less than about 500 nm, and it may be unimodal. The size distribution may have a geometric standard deviation of less than about 2. The process may occur continuously for at least four hours or more. Greater than about 90 percent by weight of the precursor to the component in the precursor medium may be converted to the component in the nanoparticles. The process typically occurs in an enclosed flame spray reactor.

Owner:CABOT CORP

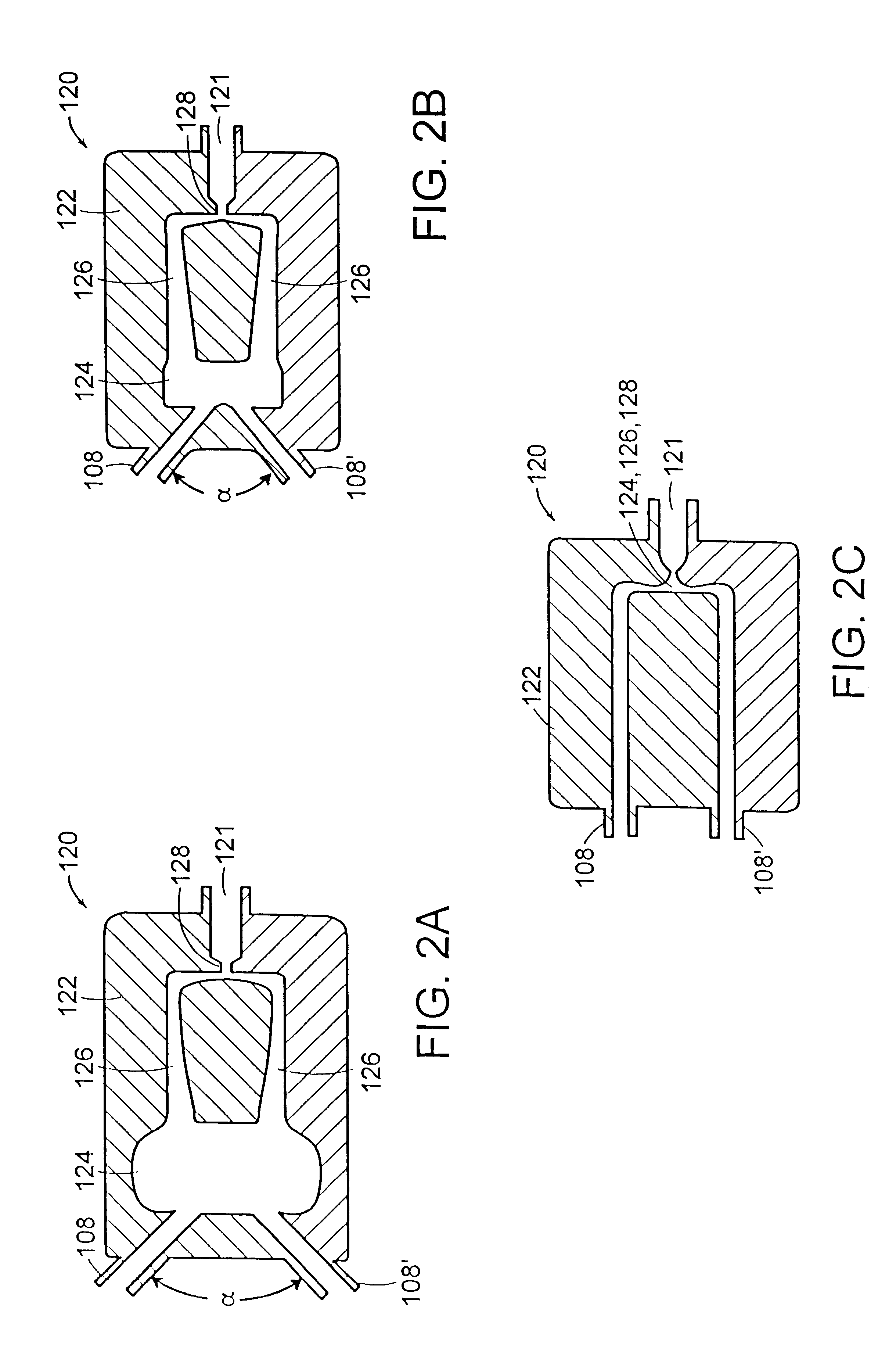

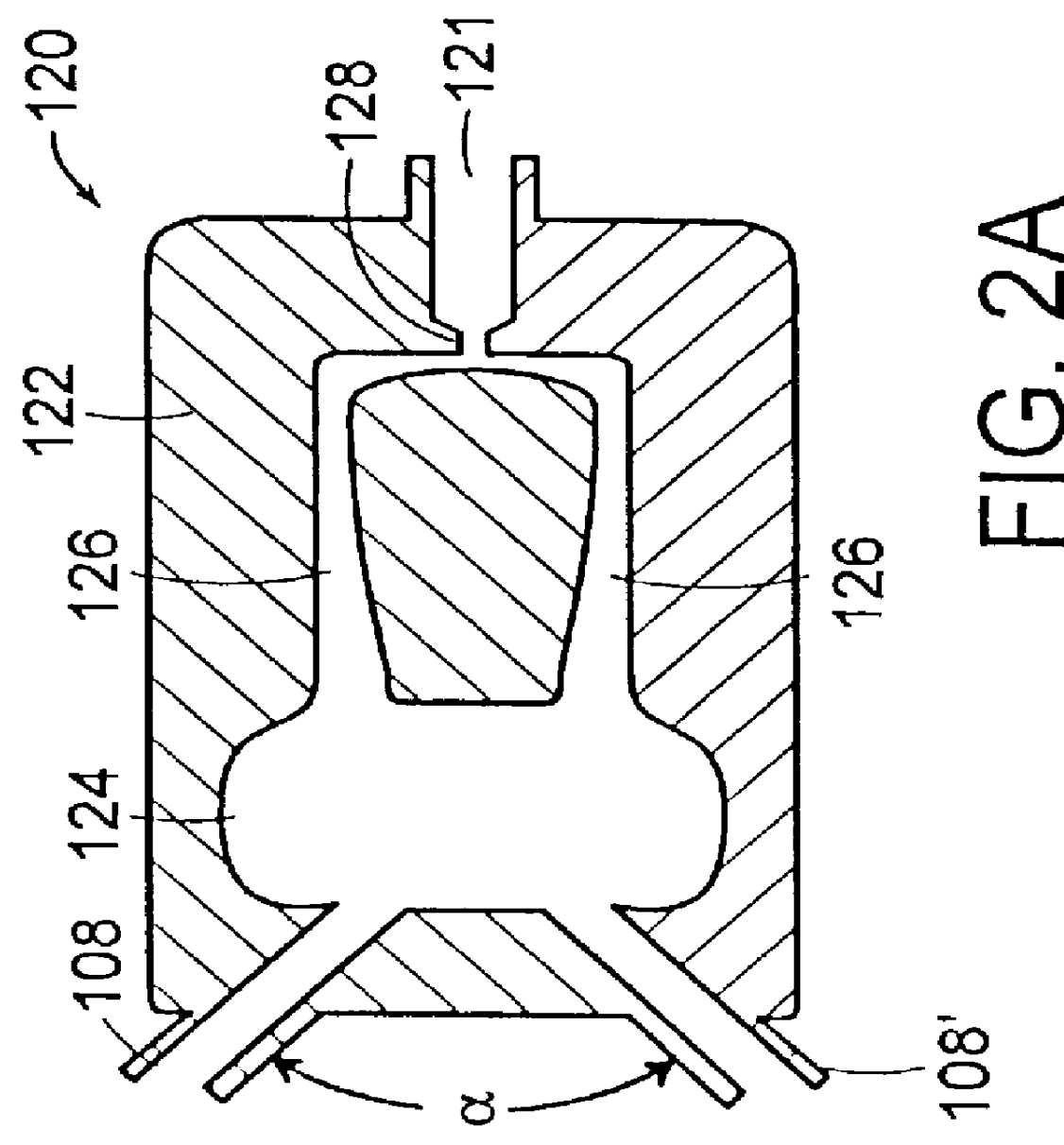

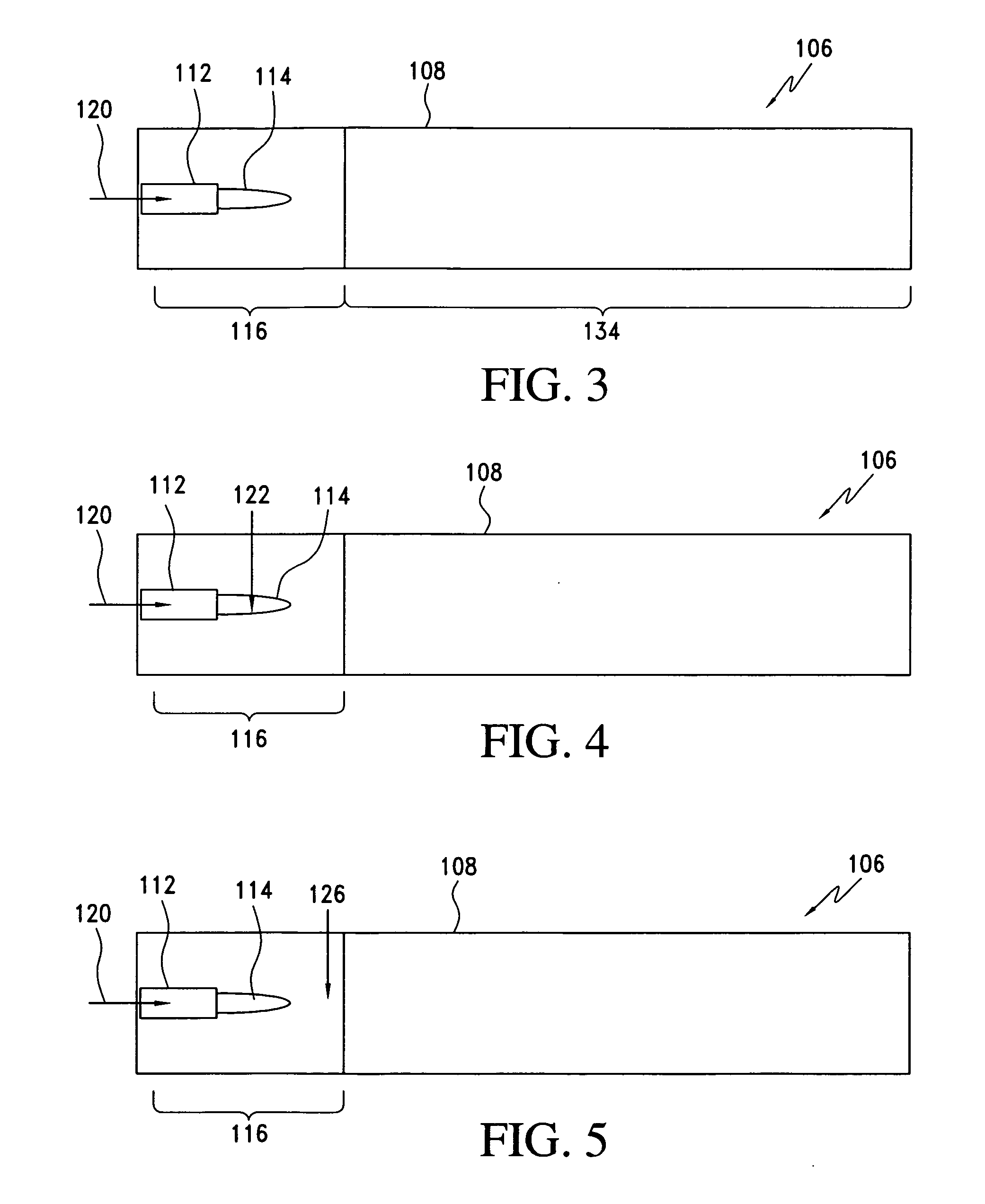

Controlling flame temperature in a flame spray reaction process

The invention relates to a process for decreasing flame temperature in a flame spray reaction system, the process comprising the steps of providing a precursor medium comprising a precursor to a component; flame spraying the precursor medium under conditions effective to form a population of product particles; and decreasing the flame temperature by contacting the flame with a cooling medium. The process of the present invention allows for the control of the size, composition and morphology of the nanoparticles made using the process. The invention also relates to a nozzle assembly that comprises a substantially longitudinally extending atomizing feed nozzle that comprises an atomizing medium conduit and one or more substantially longitudinally extending precursor medium feed conduits. The nozzle assembly of the present invention is used in a flame spray system to produce nanoparticles using the processes described herein.

Owner:CABOT CORP

Silicoaluminophosphate molecular sieve

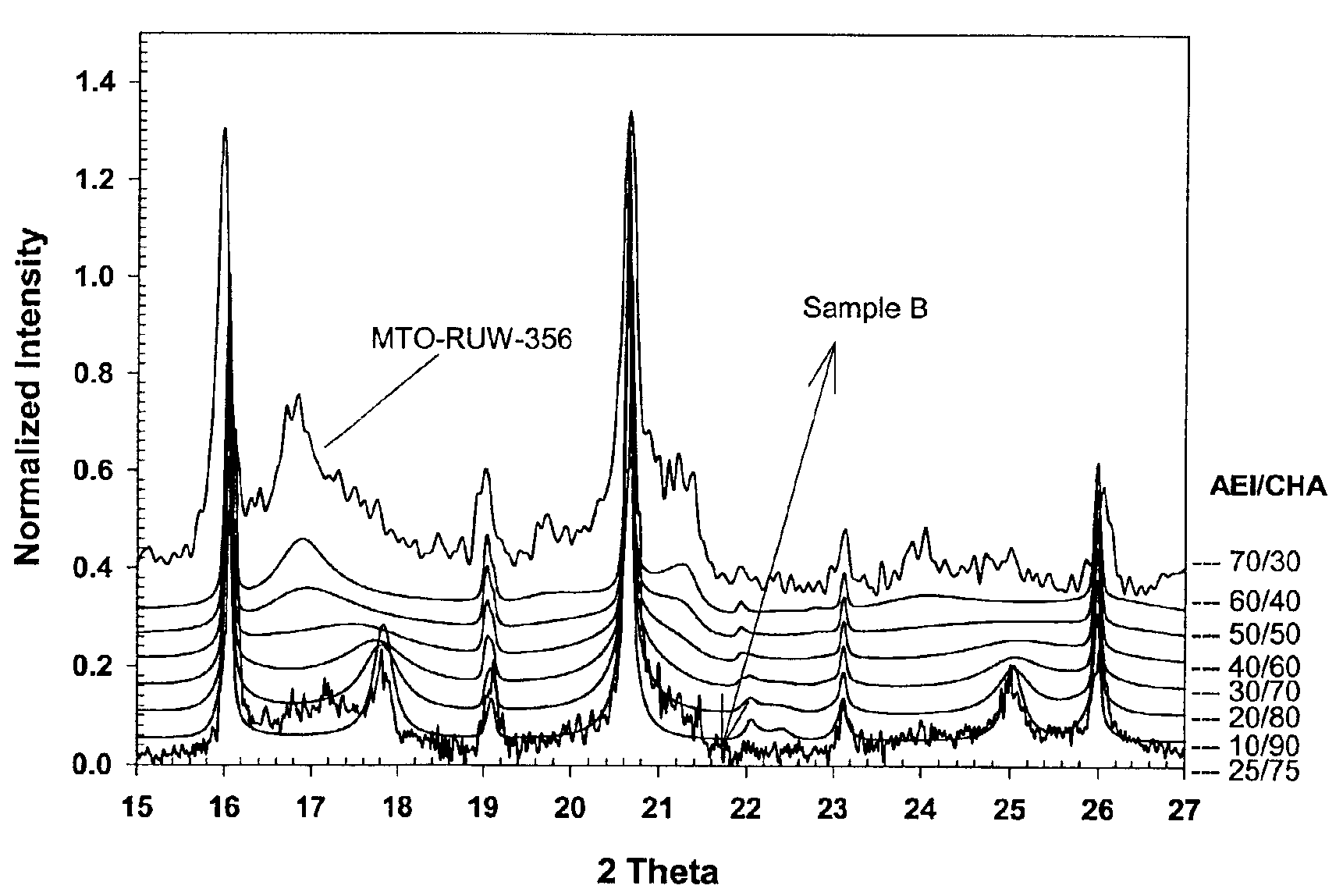

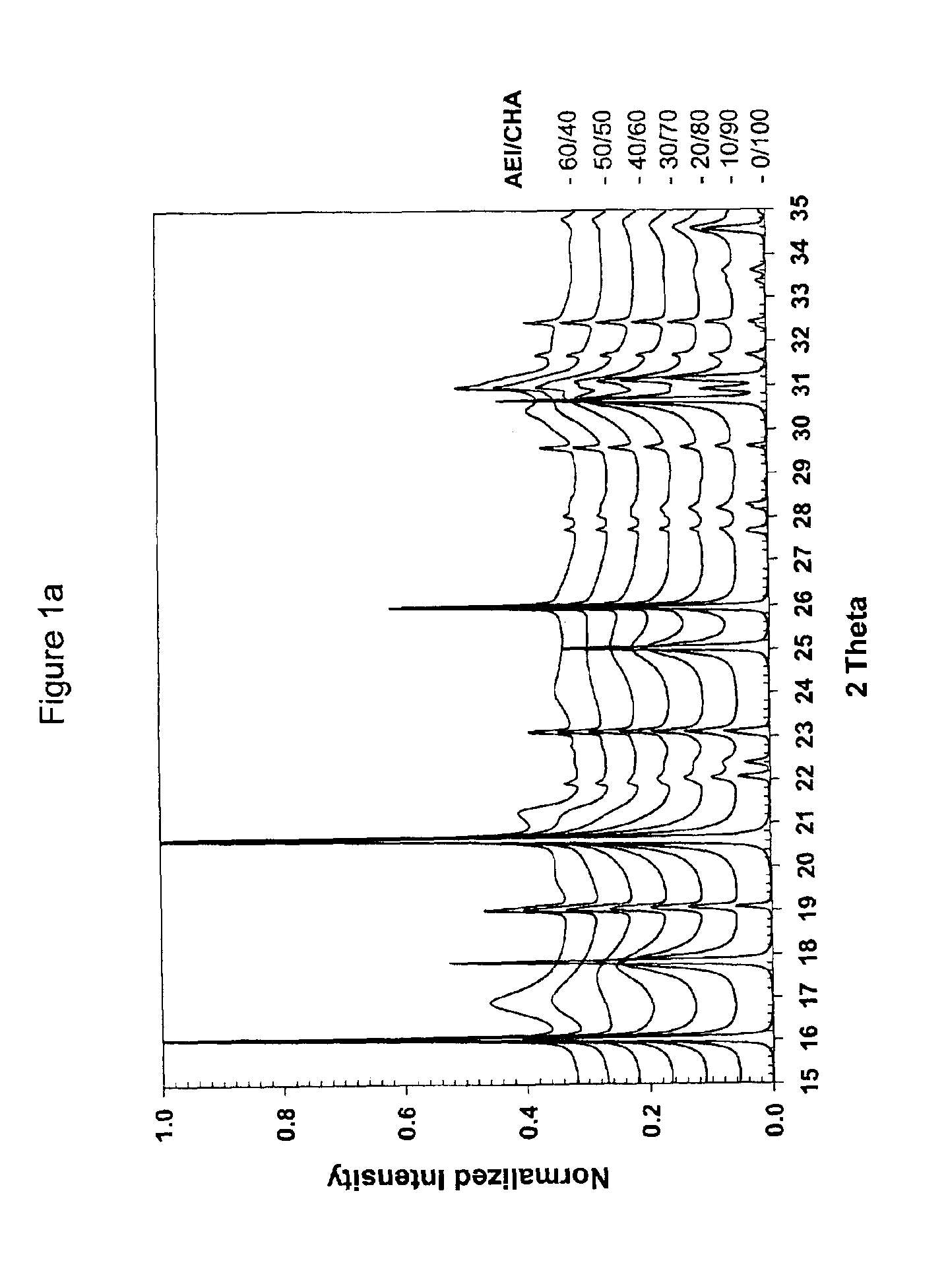

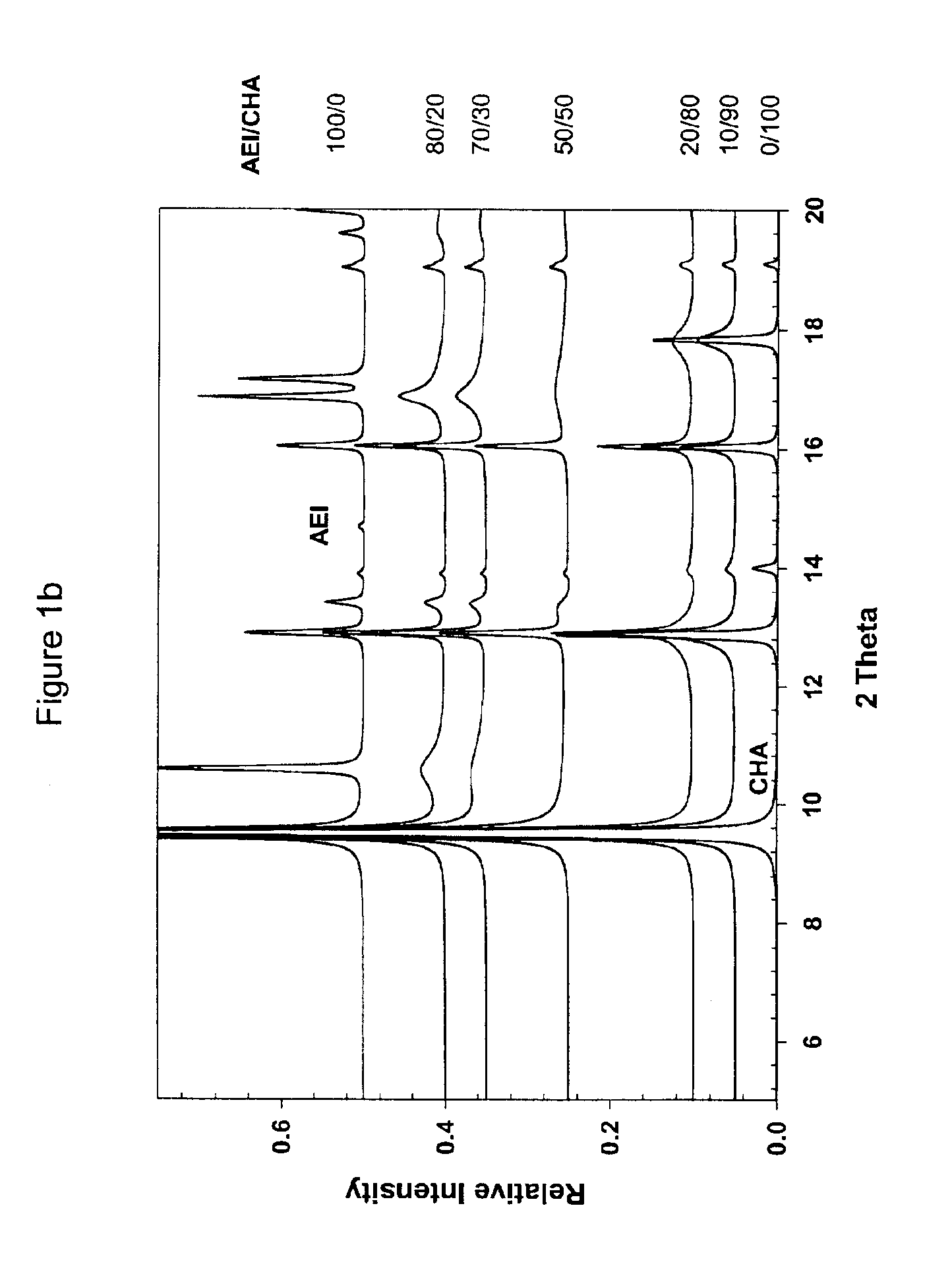

InactiveUS6953767B2Improve catalytic performanceMolecular sieve catalystsAluminium silicatesMolecular sieveX-ray

The present invention relates to a silicoaluminophosphate molecular sieve comprising at least one intergrown phase of molecular sieves having AEI and CHA framework types, wherein said intergrown phase has an AEI / CHA ratio of from about 5 / 95 to 40 / 60 as determined by DIFFaX analysis, using the powder X-ray diffraction pattern of a calcined sample of said silicoaluminophosphate molecular sieve. It also relates to methods for its preparation and to its use in the catalytic conversion of methanol to olefins.

Owner:EXXONMOBIL CHEM PAT INC

Fluorescent substance and process for producing the same, and luminescent element using the same

ActiveUS20090021141A1Improve luminous performanceLarge intensityMaterial nanotechnologyAluminium silicatesFluorescencePhosphor

Provided is a phosphor material for a white LED with a blue LED or ultraviolet LED as a light source.A phosphor comprises an α-sialon represented by the formula: (M1)X(M2)Y(Si)12−(m+n)(Al)m+n(O)n(N)16−n where M1 is at least one element selected from the group consisting of Li, Mg, Ca, Y and lanthanide metals (except for La and Ce), M2 is at least one element selected from Ce, Pr, Eu, Tb, Yb and Er, 0.3≦X+Y≦1.5, 0<Y≦0.7, 0.6≦m≦3.0, 0≦n≦1.5 and X+Y=m / 2; and the oxygen content in a powder of the α-sialon is at most 0.4 mass % larger than a value calculated based on the formula.

Owner:DENKA CO LTD

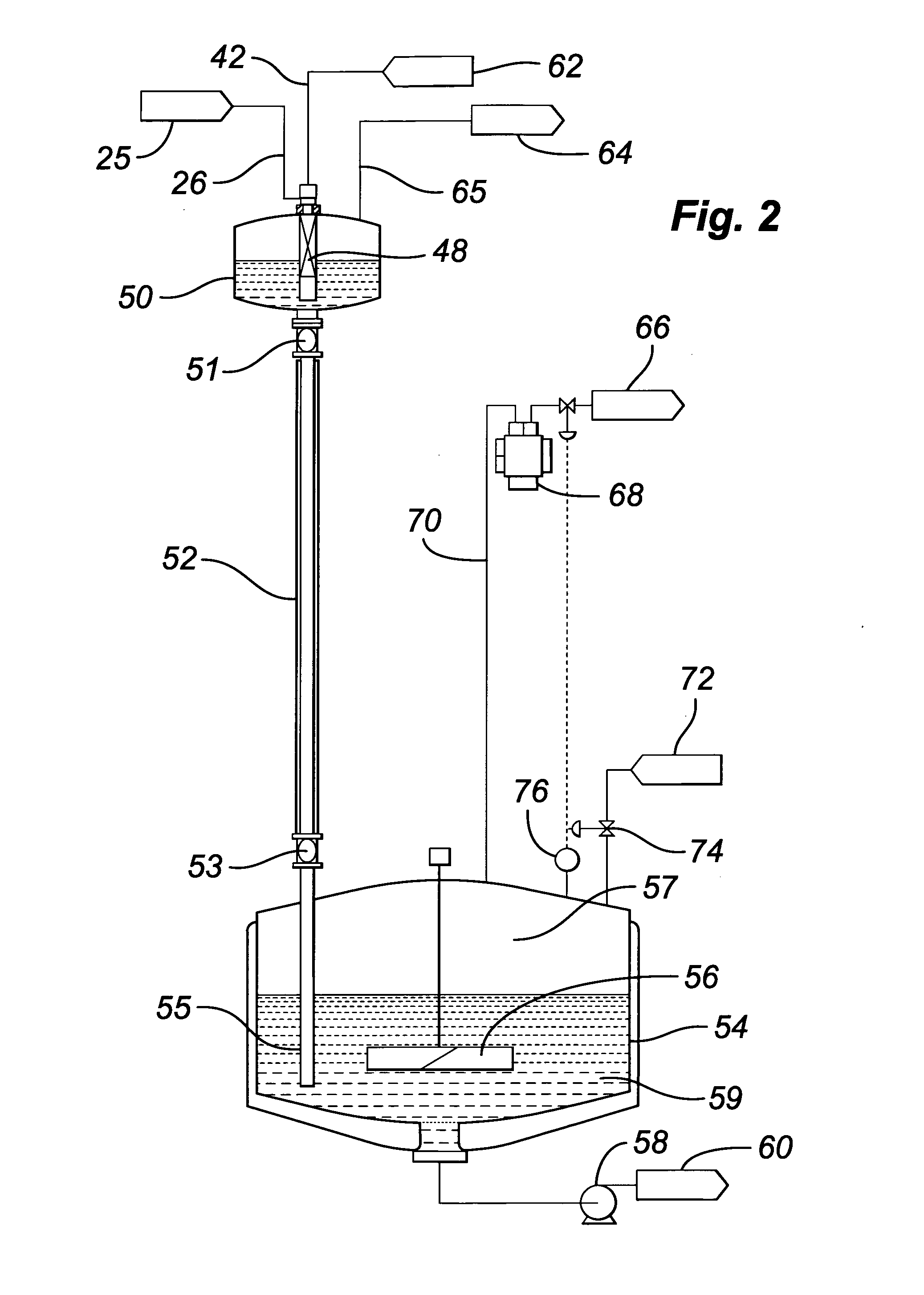

Carbonising and/or Activating Carbonaceous Material

A method is provided for carbonizing and activating carbonaceous material, which comprises supplying the material to an externally fired rotary kiln maintained at carbonizing and activating temperatures, the kiln having a downward slope to progress the material as it rotates, the kiln having an atmosphere substantially free of oxygen provided by a counter-current of steam or carbon dioxide, and annular weirs being provided at intervals along the kiln to control progress of the material. There may further be provided an externally fired rotary kiln for carbonizing and activating carbonaceous material having a hollow rotary body that has a downward slope towards a discharge end thereof, and which is provided at intervals along its length with annular weirs for controlling progress of the carbonaceous material. In embodiments, there is also provided a process is for producing discrete solid beads of polymeric material e.g. phenolic resin beads having a mesoporous structure, which may be useful as feedstock for the above mentioned carbonization / activation process or which may have other utility e.g. as ion exchange resins. The process may produce resin beads on an industrial scale without aggregates of resin building up speedily and interrupting production. The process comprises the steps of: (a) combining a stream of a polymerizable liquid precursor e.g. a novolac and hexamine as cross-linking agent dissolved in a first polar organic liquid e.g. ethylene glycol with a stream of a liquid suspension medium which is a second non-polar organic liquid with which the liquid precursor is substantially or completely immiscible e.g. transformer oil containing a drying oil; (b) mixing the combined stream to disperse the polymerizable liquid precursor as droplets in the suspension medium e.g. using an in-line static mixer; (c) allowing the droplets to polymerise in a laminar flow of the suspension medium so as to form discrete solid beads that cannot agglomerate; and (d) recovering the beads from the suspension medium. There is also provided apparatus for forming discrete solid beads of polymeric material, said apparatus comprising: a first line for conveying s stream of a polymerizable liquid precursor; a second line for conveying a stream of a dispersion medium with which the polymerizable liquid precursor is substantially or completely immiscible; an in-line mixer configured to receive a combined flow from the first and second lines and to disperse the polymerizable liquid precursor as droplets in the dispersion medium; a vertical polymerization column configured to receive the dispersion medium with the droplets dispersed therein and to permit the polymerizable liquid precursor polymerize while descending the column in a descending flow of polymerization medium; and a vessel at the base of the column for receiving the descending flow of dispersion medium and collecting polymerized solid beads.

Owner:BRITISH AMERICAN TOBACCO (INVESTMENTS) LTD

Mesostructured material incorporating particles of nanometric dimensions

InactiveUS6866925B1High crystallinityNanostructure manufactureSilicaMesoporous materialCrystallinity

The invention concerns a heat-stable ordered mesoporous or mesostructured material comprising a mineral phase wherein are dispersed particles of nanometric dimension at least partly crystaline, the global crystallinity index of said mesostructured or ordered mesoporous material being less than 10% in volume. The invention also concern a method for obtaining such a material.

Owner:RHODIA CHEM SA

Precipitated silicic acid

InactiveUS6268424B1Easily dispersible in tire carcassExtended service lifePigmenting treatmentSilicaSilicic acidPhysical chemistry

Precipitated silica having the following parameters:is prepared by reacting alkali silicate with mineral acids and aluminum sulfate solution at temperatures of 60-95° C. at a pH of 7.0-10.0 while stirring constantly, wherein the reaction is continued to a solids concentration of 40-110 g / l, the pH is adjusted to a value between 3 and 5, and the precipitated silica is filtered off, washed and then dried, and optionally ground or granulated.

Owner:EVONIK DEGUSSA GMBH

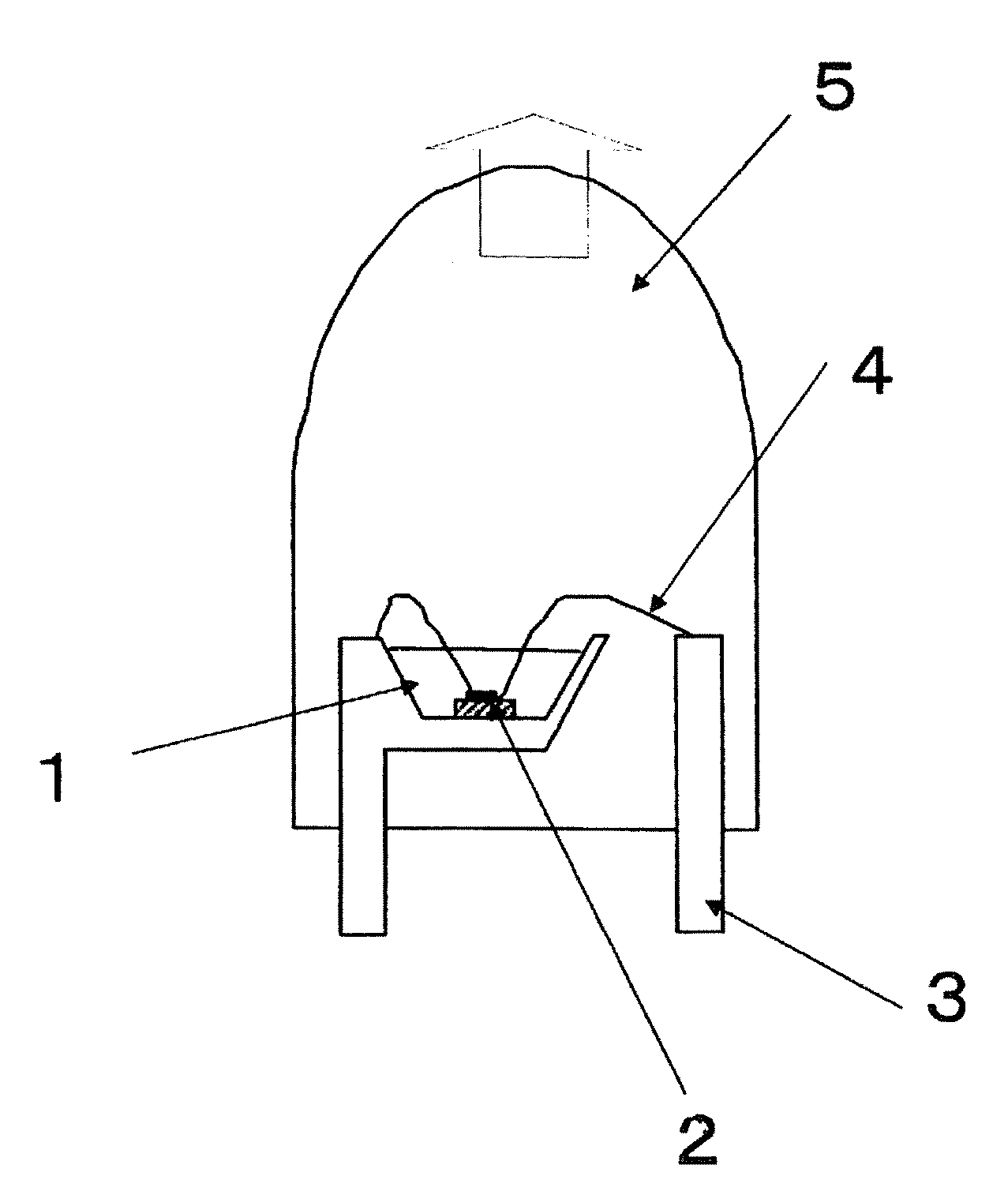

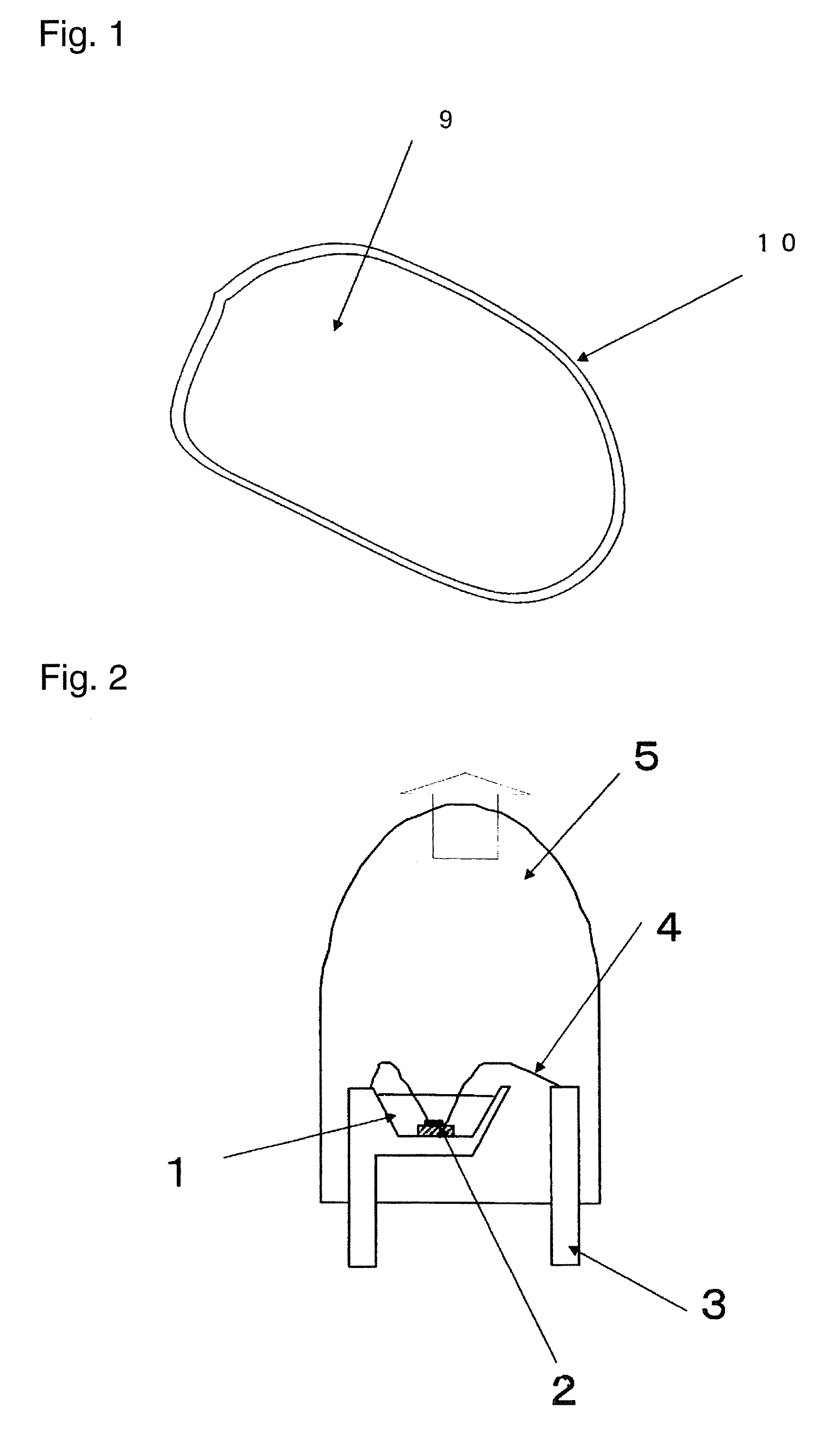

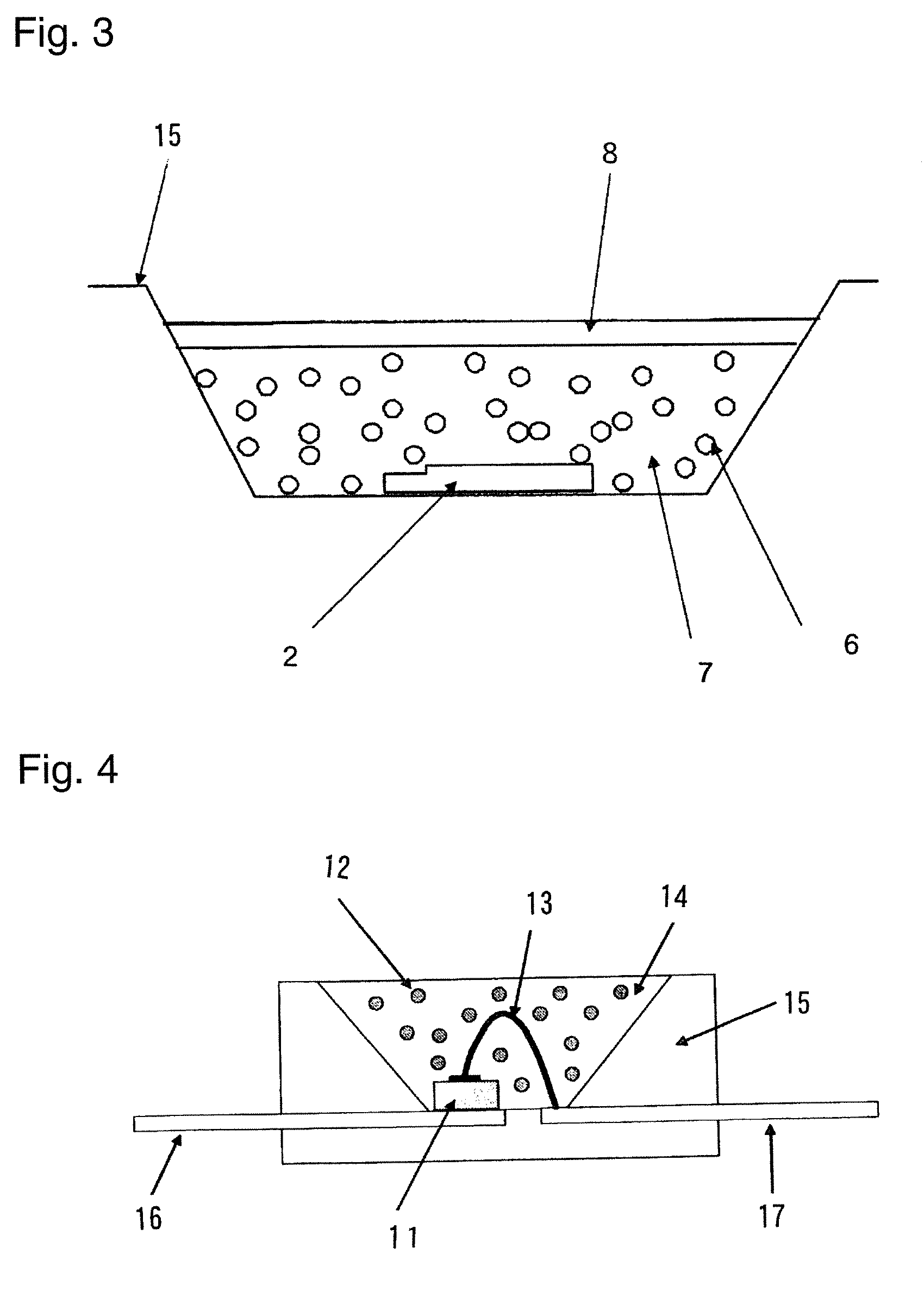

Oxynitride Phosphor and Light-Emitting Device

An oxynitride phosphor containing a luminescent center ion in a crystal lattice of an oxynitride is used, in which the oxynitride is a compound represented by a chemical formula: M2Si5-pAlpOpN8-p, where M is at least one element selected from the group consisting of Mg, Ca, Sr, Ba, and Zn, and p is a numerical value satisfying an expression: 0<p<1. Furthermore, a light-emitting device is formed using a phosphor (2) containing the oxynitride phosphor and a light-emitting element (1) exciting the phosphor (2). Owing to this, there are provided a novel oxynitride phosphor having satisfactory emission characteristics and high emission performance, in particular, an oxynitride phosphor satisfying both high emission efficiency and satisfactory temperature characteristics and emitting red light suitable for industrial production, and a light emitting device using the phosphor.

Owner:PANASONIC CORP

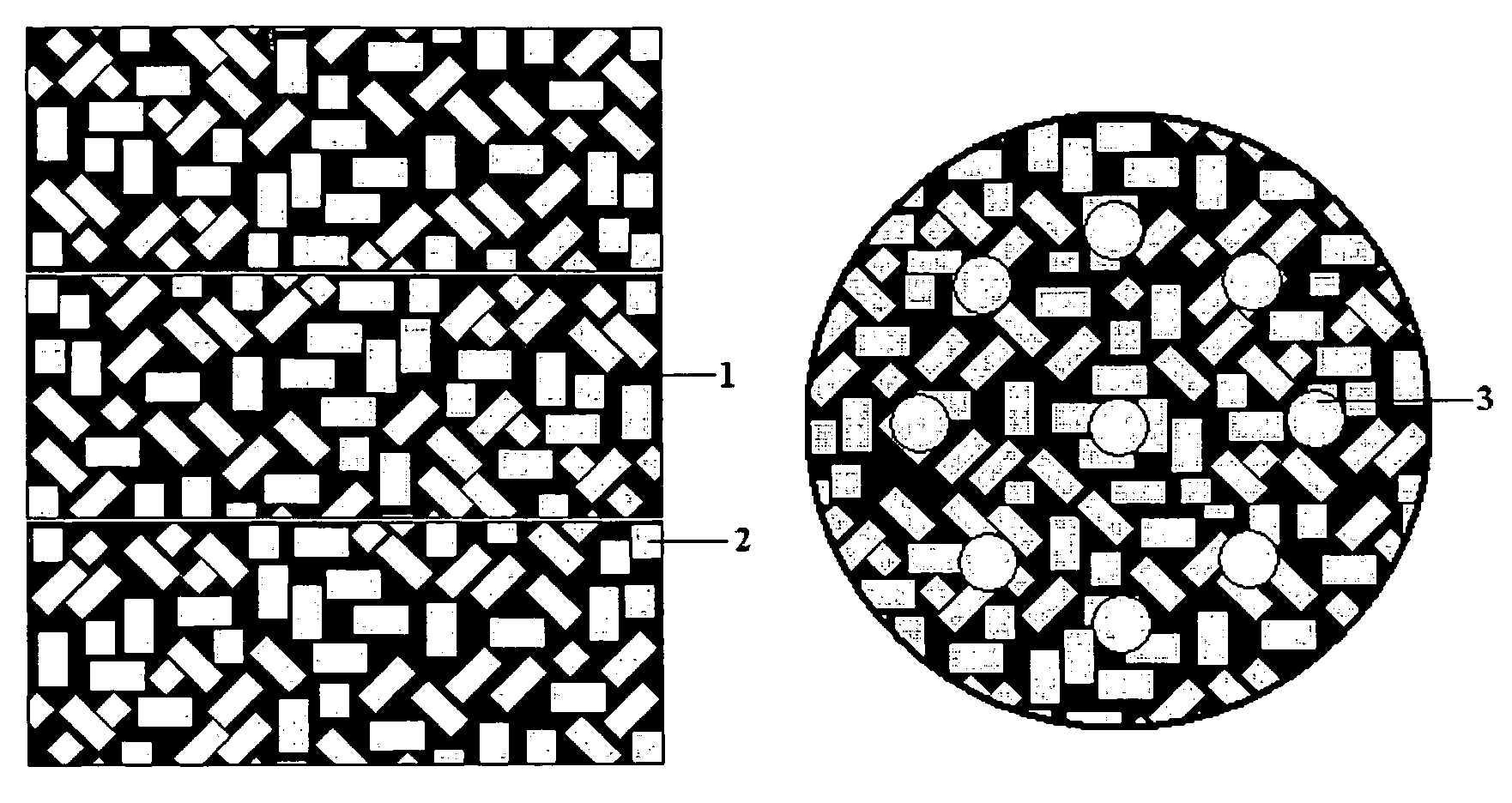

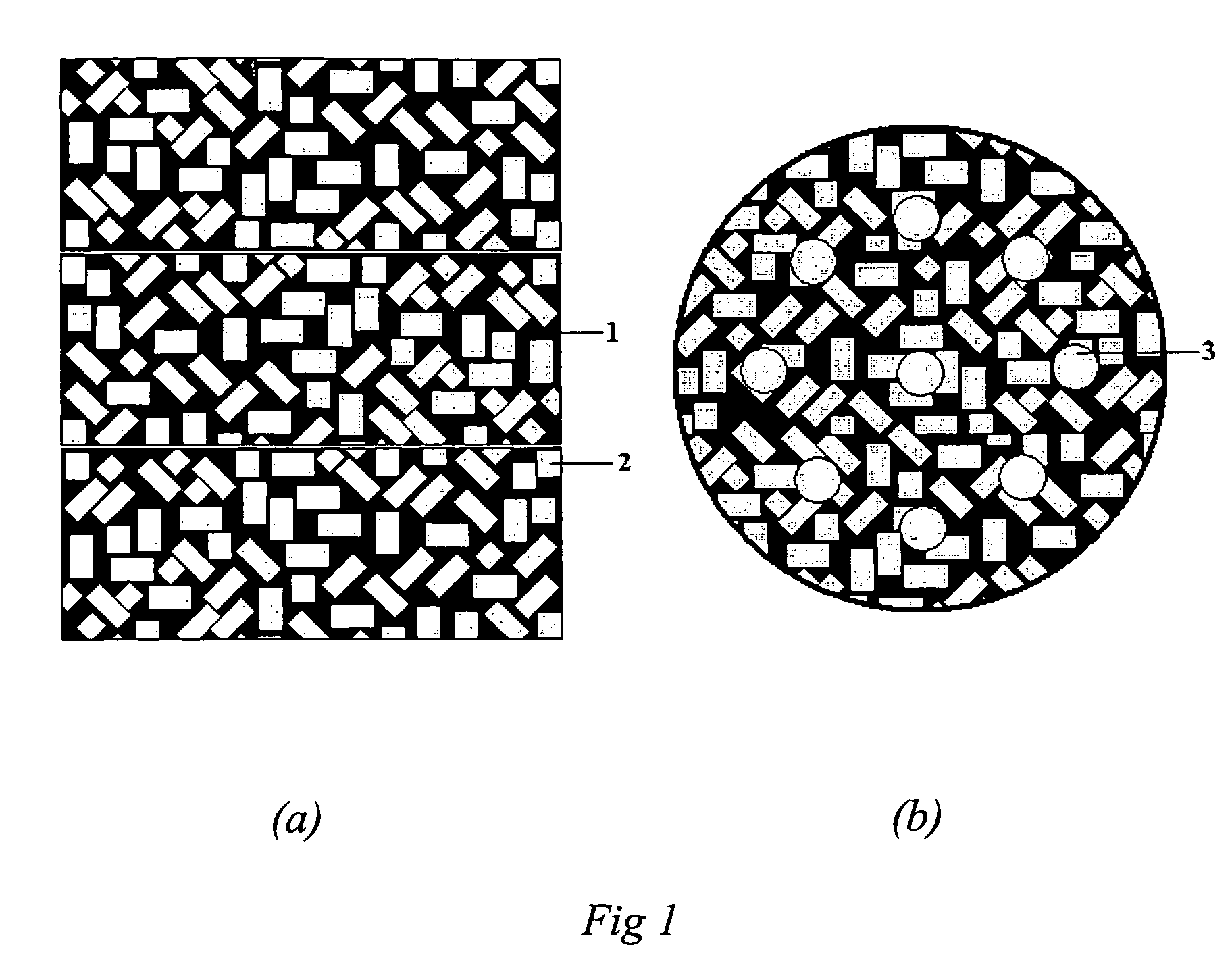

Highly porous mullite particulate filter substrate

A typically monolithic particulate filter including a highly porous block made primarily of intertangled polycrystalline mullite fibers, a set of channels formed through the block, and a set of porous walls separating adjacent channels. Exhaust gas is flowed through the channels and interacts with the walls such that particulate matter carried in the exhaust gas, such as soot particles, is screened out by porous fibrous mullite walls.

Owner:GE02 TECH INC

Increased thermal conductivity monolithic zeolite structures

A monolith comprises a zeolite, a thermally conductive carbon, and a binder. The zeolite is included in the form of beads, pellets, powders and mixtures thereof. The thermally conductive carbon can be carbon nano-fibers, diamond or graphite which provide thermal conductivities in excess of about 100 W / m·K to more than 1,000 W / m·K. A method of preparing a zeolite monolith includes the steps of mixing a zeolite dispersion in an aqueous colloidal silica binder with a dispersion of carbon nano-fibers in water followed by dehydration and curing of the binder is given.

Owner:UT BATTELLE LLC

Preparation method of attapulgite-loaded nanometre iron material

InactiveCN102755883ANot easy to form agglomerationLess prone to autoxidationOther chemical processesAluminium silicatesAqueous solutionNanometre

The invention provides a preparation method of an attapulgite-loaded nanometre iron material. Acidized and modified attapulgite is taken as a load material, and KBH4, NaBH4, N2H4 and the like are taken as reducing agent under the protection of inert gases, so that ferric salt or ferrite can be reduced to be zero-valent iron; and the multi-duct characteristic of the attapulgite is utilized, so that nanometre iron particles are sufficiently dispersed and fixedly loaded on the attapulgite material. Compared with un-loaded nanometre iron, the attapulgite-loaded nanometre iron material prepared by the preparation method has better dispersibility and stability, is more uniform in particle size distribution, not easy to cause particle agglomeration and self-oxidization; and moreover, the attapulgite-loaded nanometre iron material has better suspension property and stability in aqueous solution, a stronger oxidative degradation ability to environmental pollutants, longer effective reaction time, and a better adsorption capacity. The material is expected to be extensively applied to environment pollution abatement and repair engineering, and fills a blank in the filed at home and abroad.

Owner:NANJING UNIV

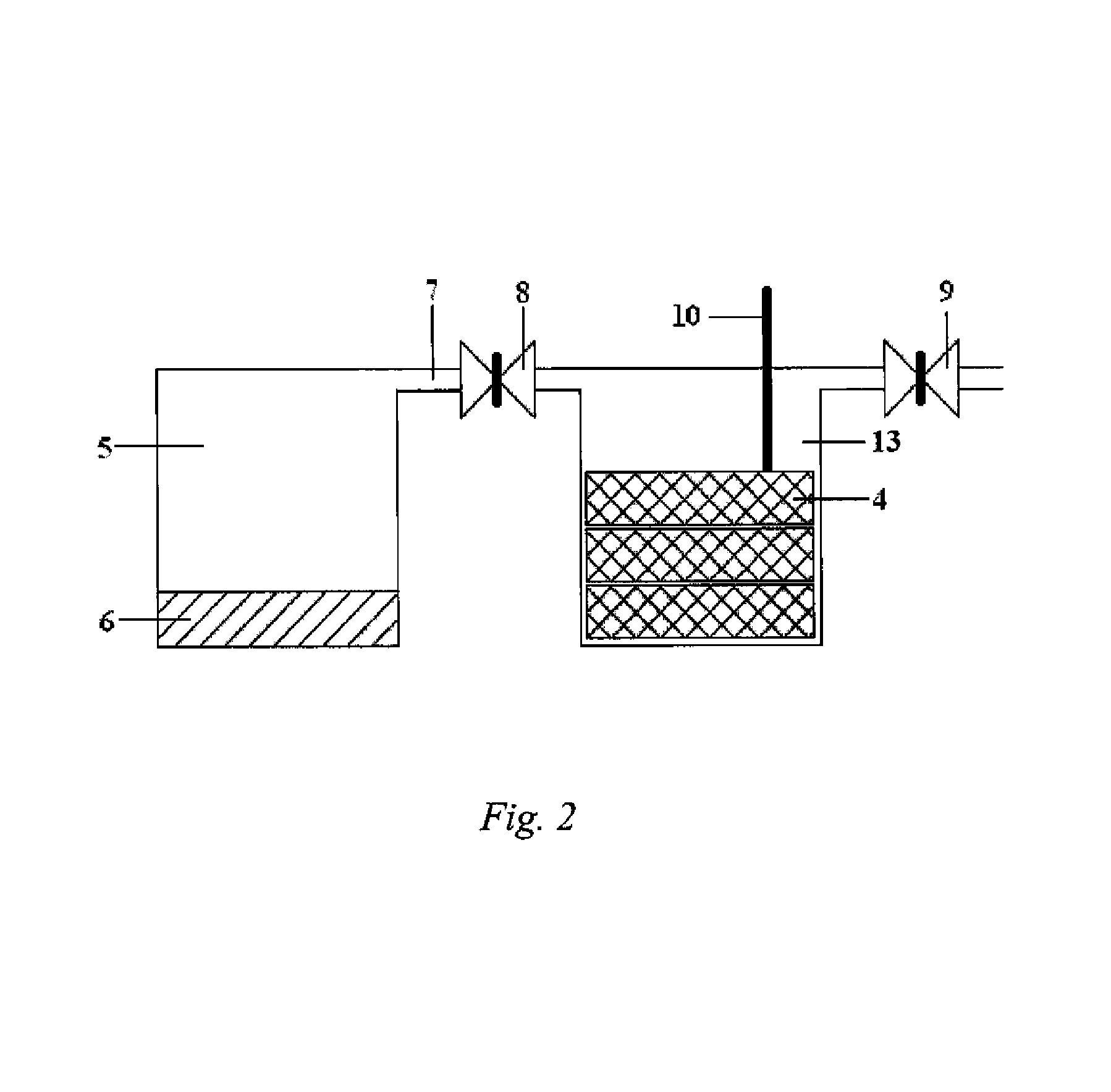

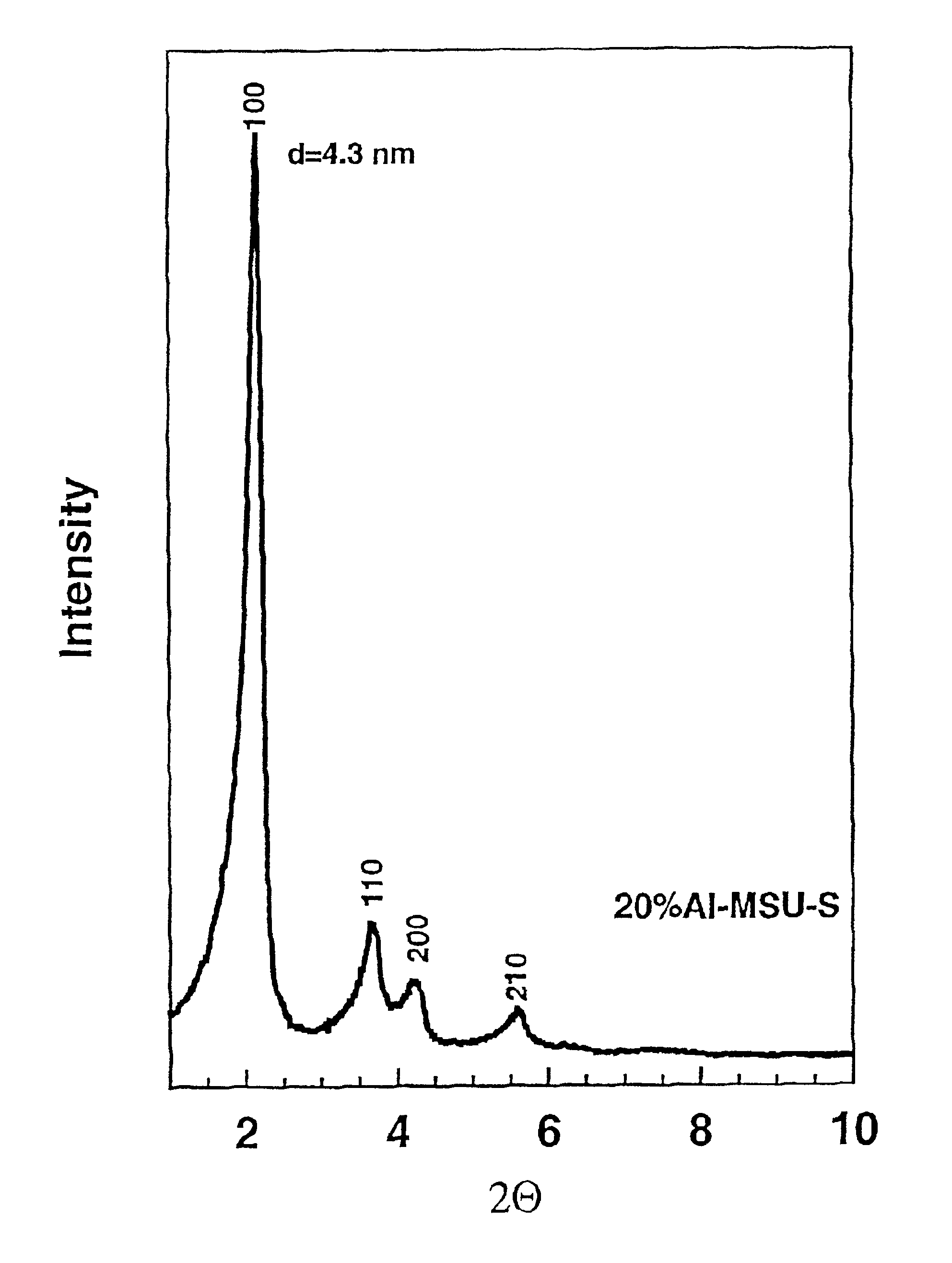

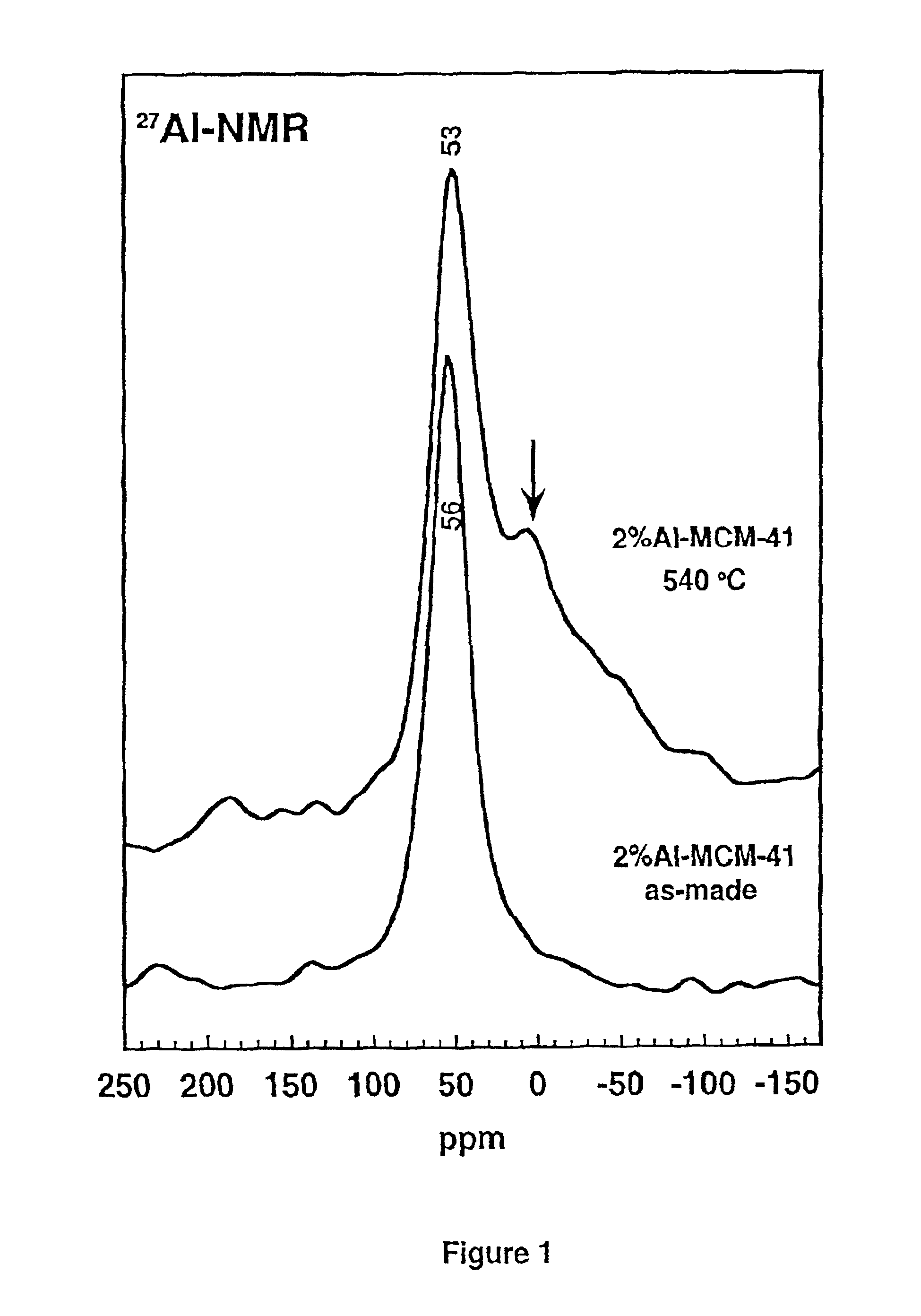

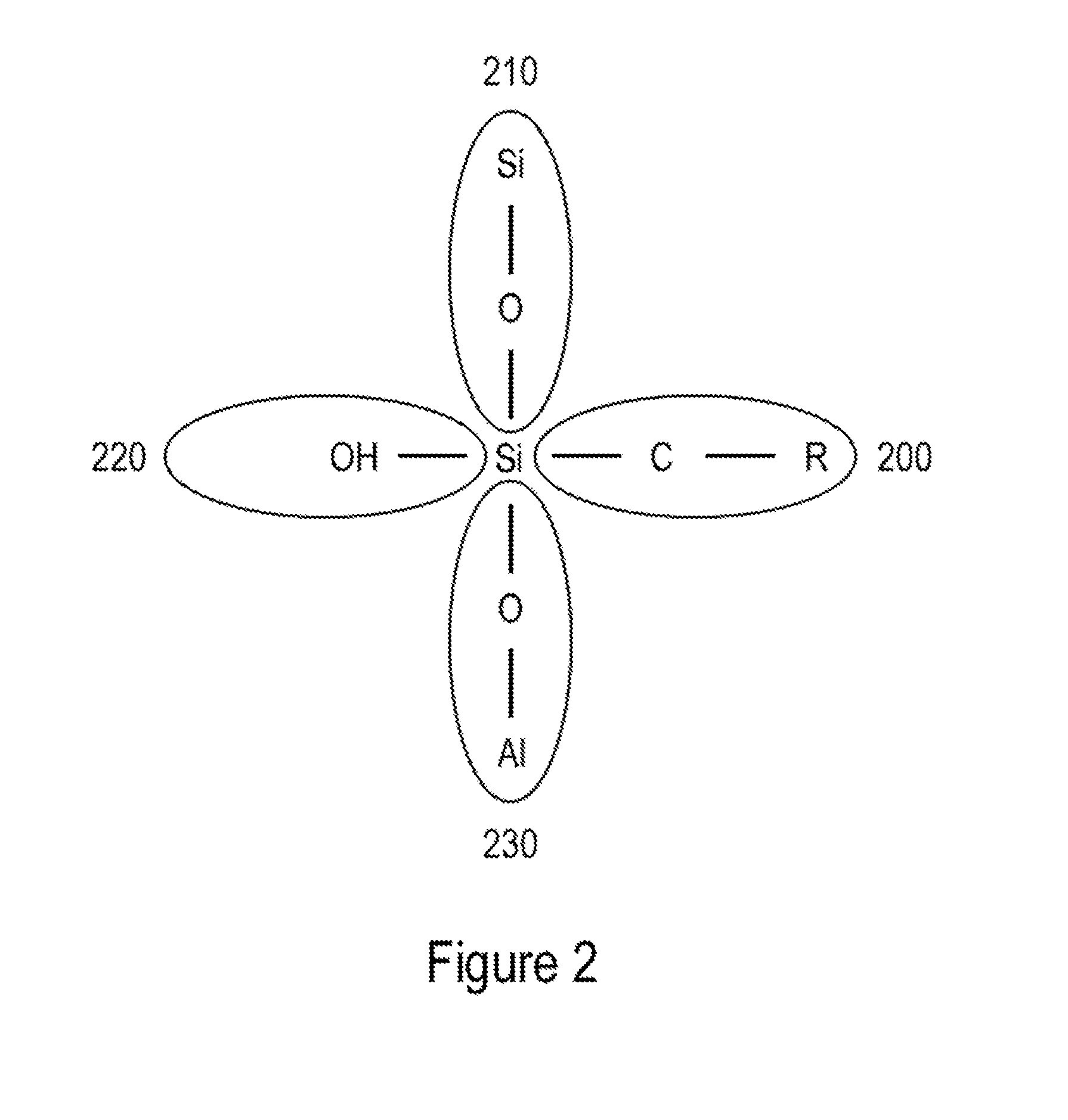

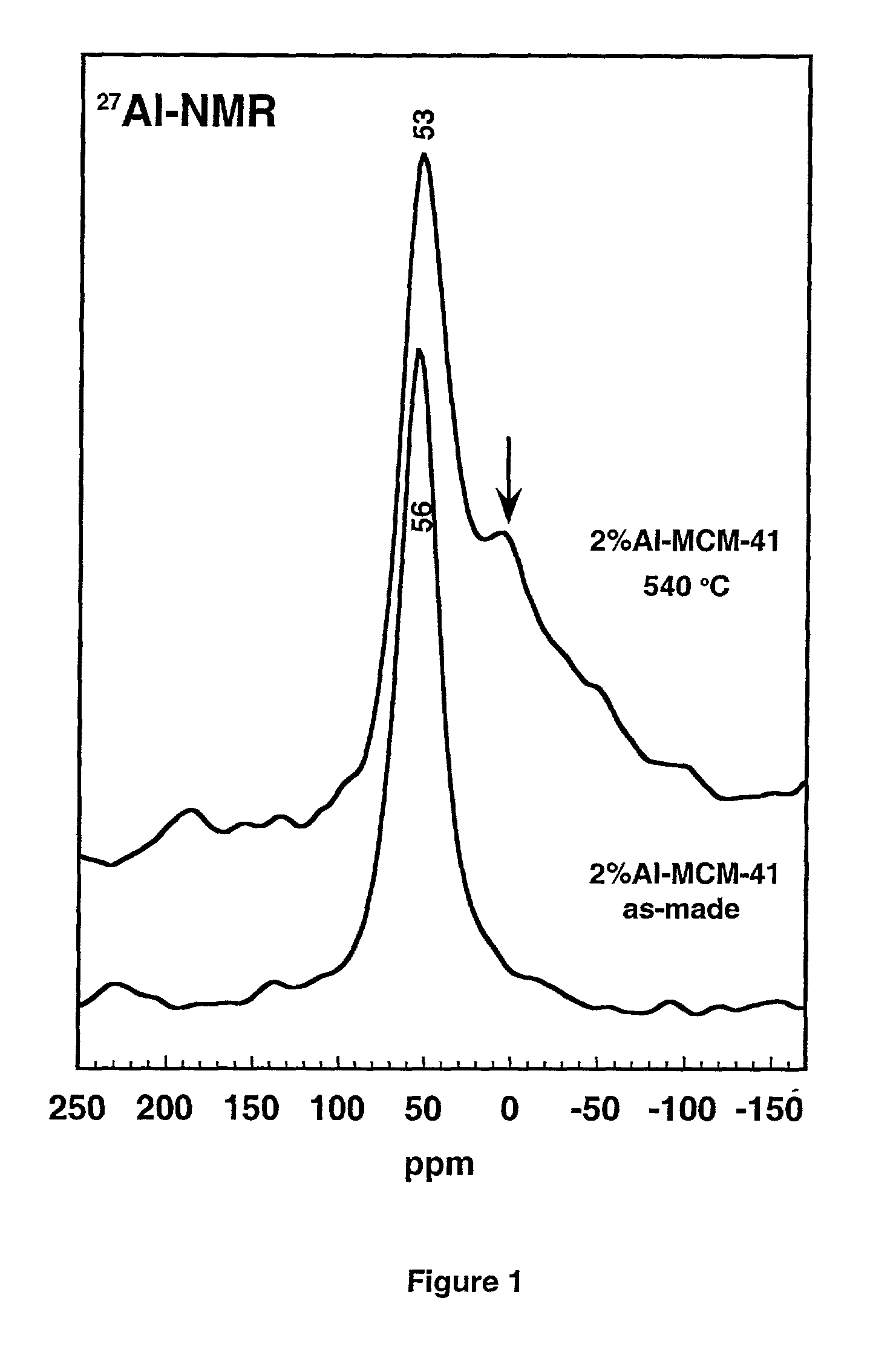

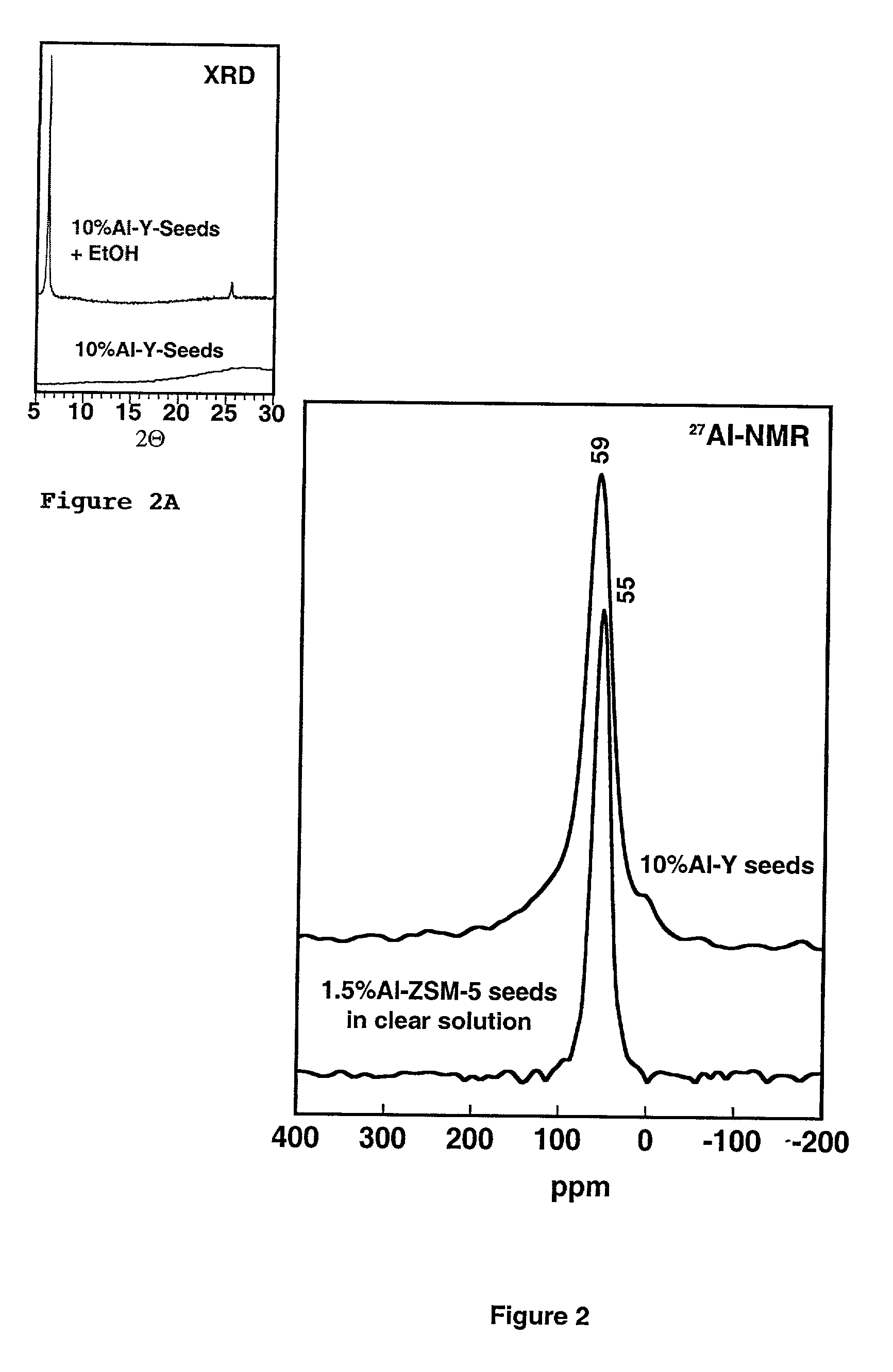

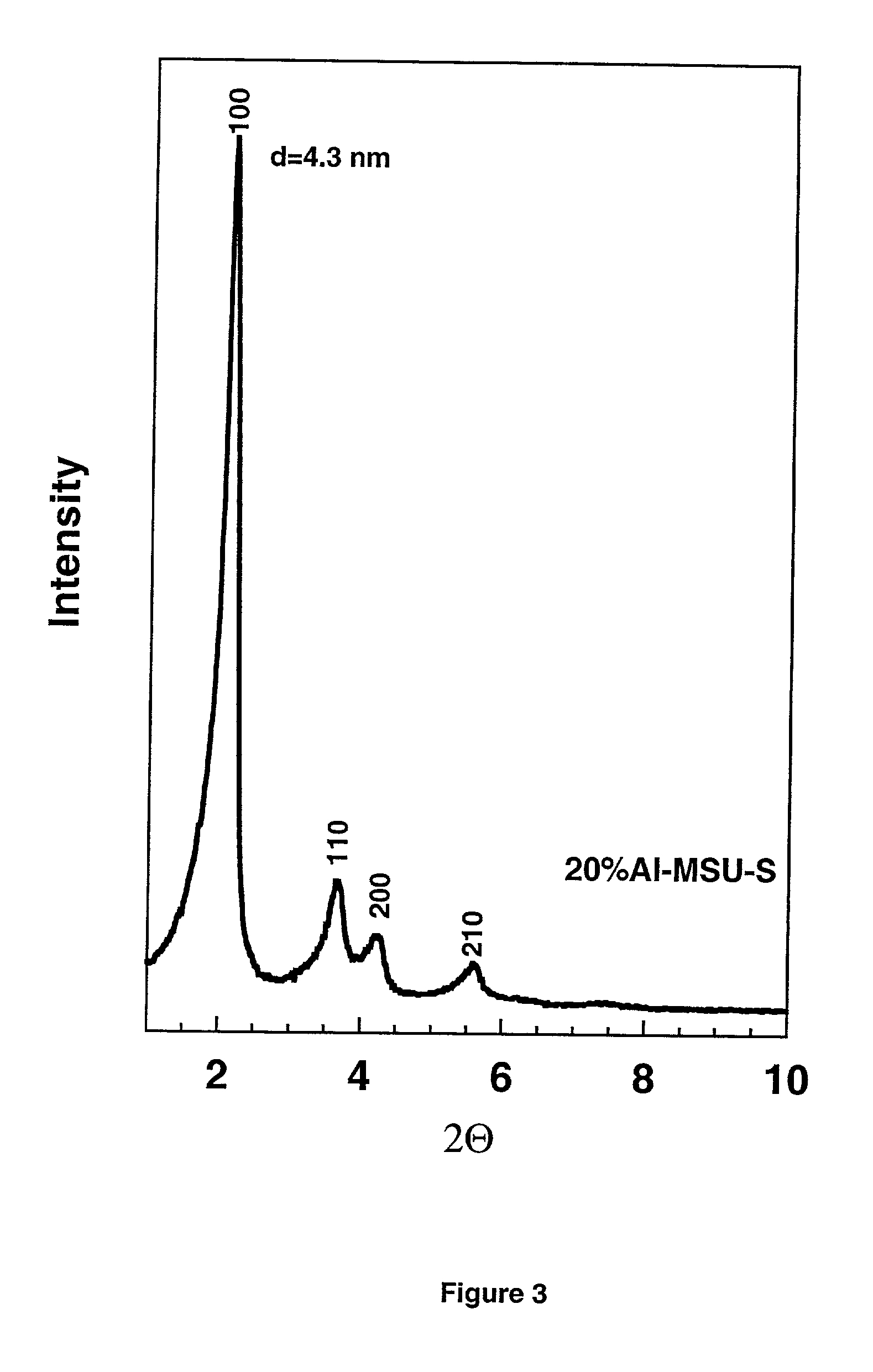

Ultrastable porous aluminosilicate structures and compositions derived therefrom

Porous hexagonal, cubic, lamellar, wormhole, or cellular foam aluminosilicates, gallosilicates and titanosilicates derived from protozeolitic seeds or zeolite fragments using an organic porogen directing agent are described. The porous aluminosilicates optionally also can contain zeolite crystals depending upon the aging of the protozeolitic seeds. The silicon and aluminum, gallium or titanium centers in the structures are stable so that the framework of the structure does not collapse when heated in the presence of water or water vapor (steam). The steam stable compositions can be used as catalysts for hydrocarbon conversions, including the fluidized bed catalytic cracking and the hydrocracking of petroleum oils, and other reactions of organic compounds.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Mass production of nano-scaled platelets and products

ActiveUS20100222482A1Time necessarySmall thicknessMaterial nanotechnologyGraphiteNoble gasProduct gas

Owner:GLOBAL GRAPHENE GRP INC

Production and use of polysilicate particulate materials

ActiveUS20070231249A1Surface acidity of the alumino-silicate product can be modifiedMaterial nanotechnologyPigmenting treatmentParticulatesPorosity

A method of preparing a particulate material comprising the steps of adding silicic acid solution, optionally doped with aluminum, optionally added to a slurry of pre-existing nanoparticles at a neutral to slightly acidic pH of no more than seven, and at a temperature of about 20° to 30° C. This yields a polysilicate particulate dispersion. Then, the pH of the dispersion is raised to greater than seven, to stabilize / reinforce particles of the particulate dispersion. Optionally, the particles may be dried, and have increased porosity and surface area.

Owner:ECOLAB USA INC

Dry delivery hypochlorite

This invention relates to dry powder forms of hypohalite, especially a dry powdered form of dilute or concentrated hypochlorite and hypochlorous acid compositions. The invention also relates to uses for these dry powders, such as for treating hard and soft inanimate surfaces, animate surfaces, air, and for deactivating allergens.

Owner:THE CLOROX CO

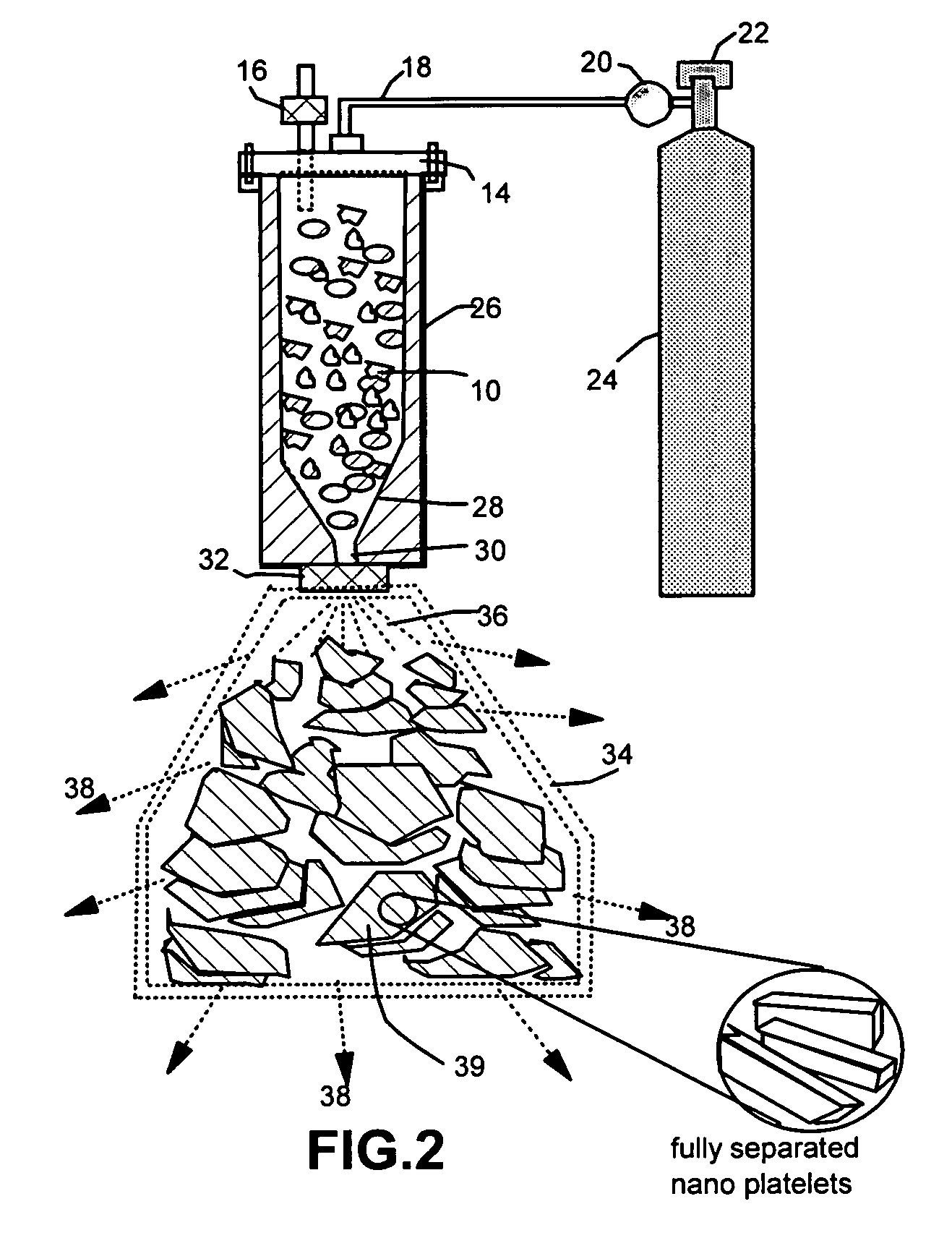

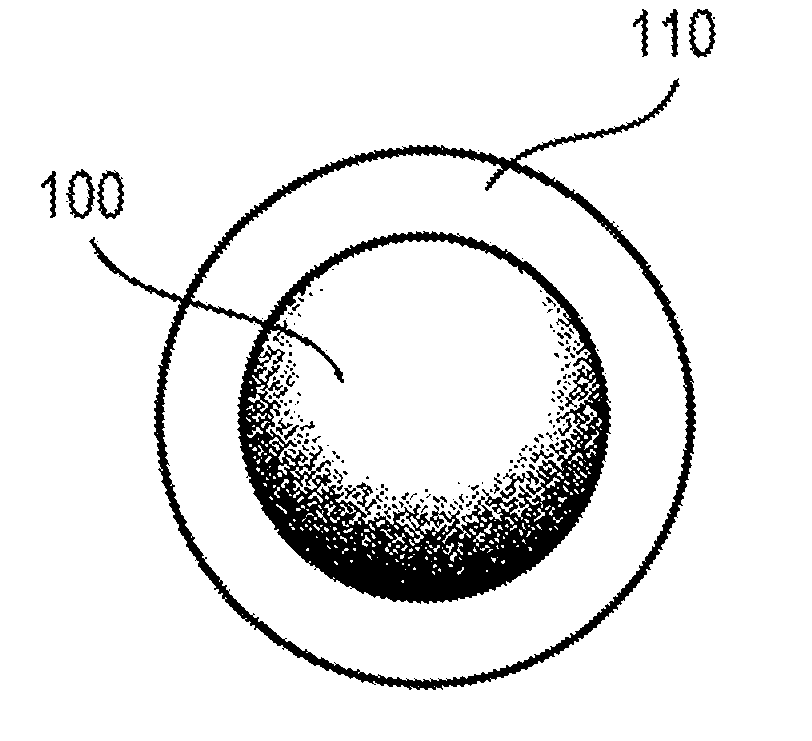

Encapsulated particles

The disclosed technology relates generally to material systems which include a plurality of particles and methods of making the same. The particles have a core and a shell which encapsulates the core and has at least one atomic element not included in the core. The cores of the particles have a median maximum dimension that is less than 10 microns and a median of at least one axial dimension that is between 10 nm and 500 nm. The shells of the particles have a median thickness that is less than 100 nm, a silicon concentration that is between 10% and 50% on the basis of the weight of the shells, and an aluminum concentration that is between 0.01% and 5% on the basis of the weight of the shells.

Owner:NANOCOMPOSIX LLC

Nitrogen oxide adsorbent prepared through ion exchange modification of natural zeolite

InactiveCN102049239AReduce manufacturing costLarge adsorption capacityOther chemical processesAluminium silicatesMetal ions in aqueous solutionSorbent

The invention relates to the modification technology of natural zeolite material and aims to provide a nitrogen oxide adsorbent prepared through ion exchange modification of the natural zeolite. The adsorbent is prepared through the following step: adding the natural zeolite after dealumnization processing and ammonium exchange processing into metal salt aqueous solution to be subjected to metal ion exchange; and washing, drying and then roasting at the high temperature of 300-600 DEG C for 1-5 hours to obtain the nitrogen oxide adsorbent of modified natural zeolite containing corresponding metal elements, wherein the metal salt is any one of hydrochloride, nitrate, sulfate or oxalate of Na, Ca, K, Ba, Ti, Mn, Ni or Cu. The nitrogen oxide adsorbent prepared through modification of the natural zeolite can be used as an environment function material for adsorbing and purifying the industrial tail gas, flue gas and automobile exhaust containing nitrogen oxide. The nitrogen oxide adsorbent is low in production cost and large in adsorption quantity, and has a broad market prospect as the environment function material.

Owner:ZHEJIANG UNIV

Ultrastable porous aluminosilicate structures

Mesoporous hexagonal, cubic, lamellar, wormhole, or cellular foam aluminosilicates, gallosilicates and titanosilicates derived from protozeolitic seeds using an ionic structure directing agent are described. The silicon and aluminum, gallium or titanium centers in the structures are stable so that the framework of the structure does not collapse when heated in the presence of water or water vapor (steam). The steam stable compositions can be used as catalysts for hydrocarbon conversions, including the fluidized bed catalytic cracking and the hydrocracking of petroleum oils, and other reactions of organic compounds.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Manufacturing method of granulated complex molecular sieve composition having multi-functions

InactiveUS6074974AImprove powerMaintain good propertiesMolecular sieve catalystsOther chemical processesMolecular sieveActivated carbon

PCT No. PCT / KR95 / 00188 Sec. 371 Date Aug. 14, 1998 Sec. 102(e) Date Aug. 14, 1998 PCT Filed Dec. 30, 1995 PCT Pub. No. WO97 / 04865 PCT Pub. Date Feb. 13, 1997The present invention relates to a manufacturing method of granulated complex molecular sieve composition having multifunction and useful for removal agent of harmful gas of cigarette or treatment agent of water purification etc. as having multifunctioned adsorption capacity and excellent anti-abrasion property, and convenient process, in particular, to a manufacturing method which is comprised of granulating by mixing alkali metal silicate aqueous solution to mixture of zeolites of various types and active carbon and treating it with water solution of alkali earth metal salt without calcination, and drying.

Owner:KOREA RES INST OF CHEM TECH

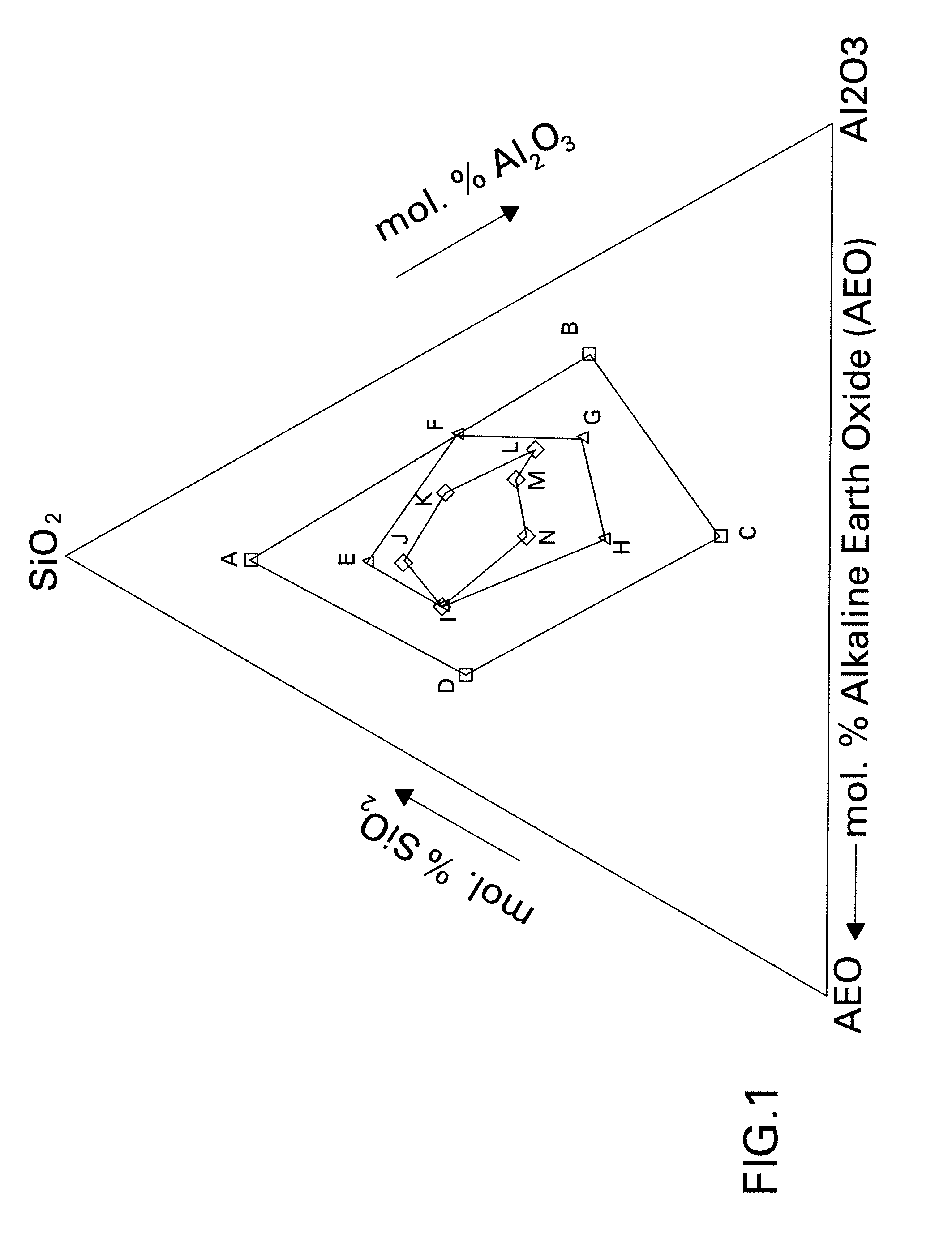

Glasses for flat panel displays

Glasses are disclosed which are used to produce substrates in flat panel display devices. The glasses exhibit a density less than about 2.45 gm / cm3 and a liquidus viscosity greater than about 200,000 poises, the glass consisting essentially of the following composition, expressed in terms of mol percent on an oxide basis: 65-75 SiO2, 7-13 Al2O3, 5-15 B2O3, 0-3 MgO, 5-15 CaO, 0-5 SrO, and essentially free of BaO. The glasses also exhibit a strain point exceeding 650° C.

Owner:CORNING INC

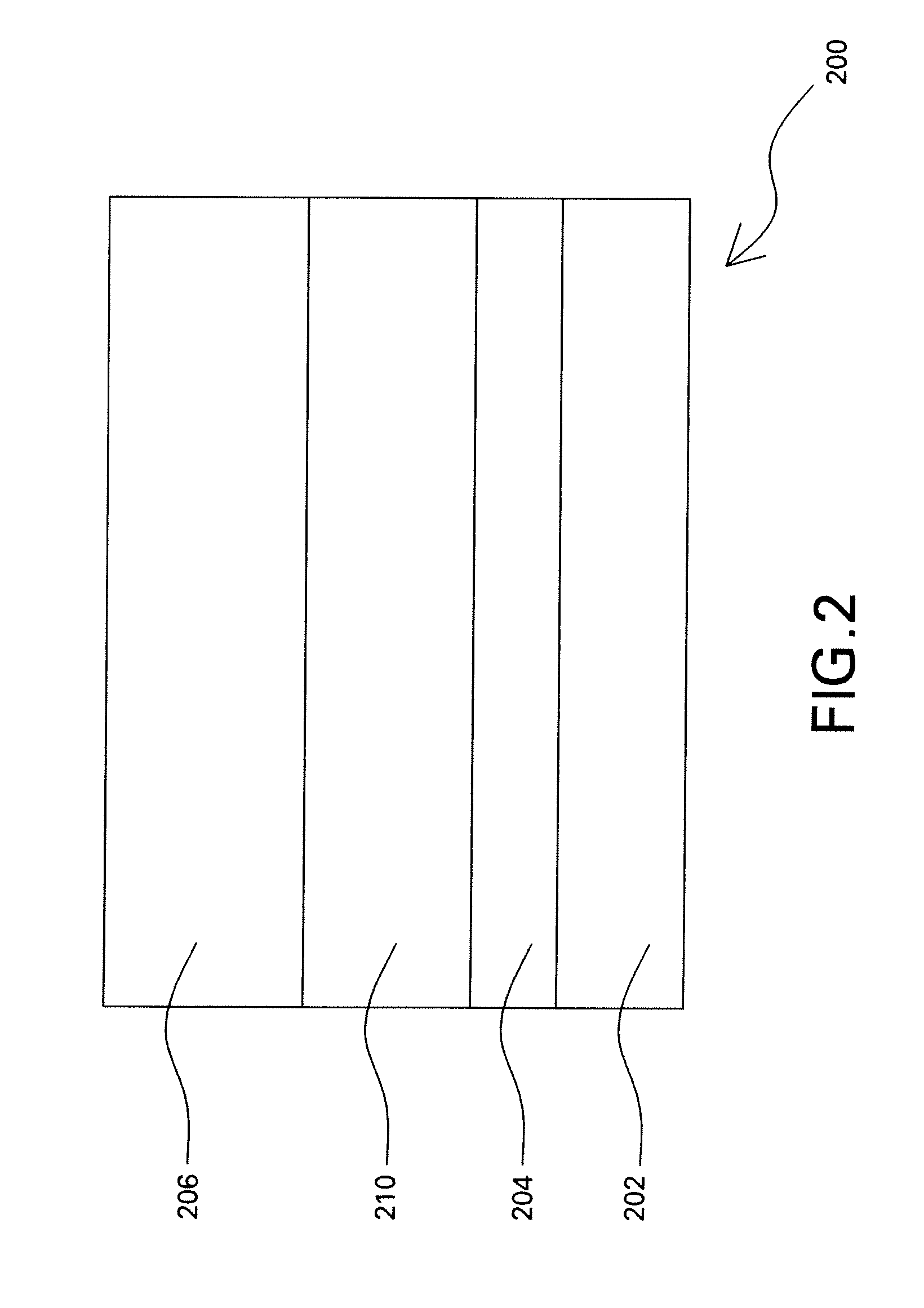

Articles for high temperature service and methods for their manufacture

An article for use in aggressive environments is presented. In one embodiment, the article comprises a substrate and a self-sealing and substantially hermetic sealing layer comprising an alkaline-earth aluminosilicate disposed over the bondcoat. The substrate may be any high-temperature material, including, for instance, silicon-bearing ceramics and ceramic matrix composites. A method for making such articles is also presented. The method comprises providing a substrate; disposing a self-sealing alkaline-earth aluminosilicate layer over the substrate; and heating the sealing layer to a sealing temperature at which at least a portion of the sealing layer will flow.

Owner:GENERAL ELECTRIC CO

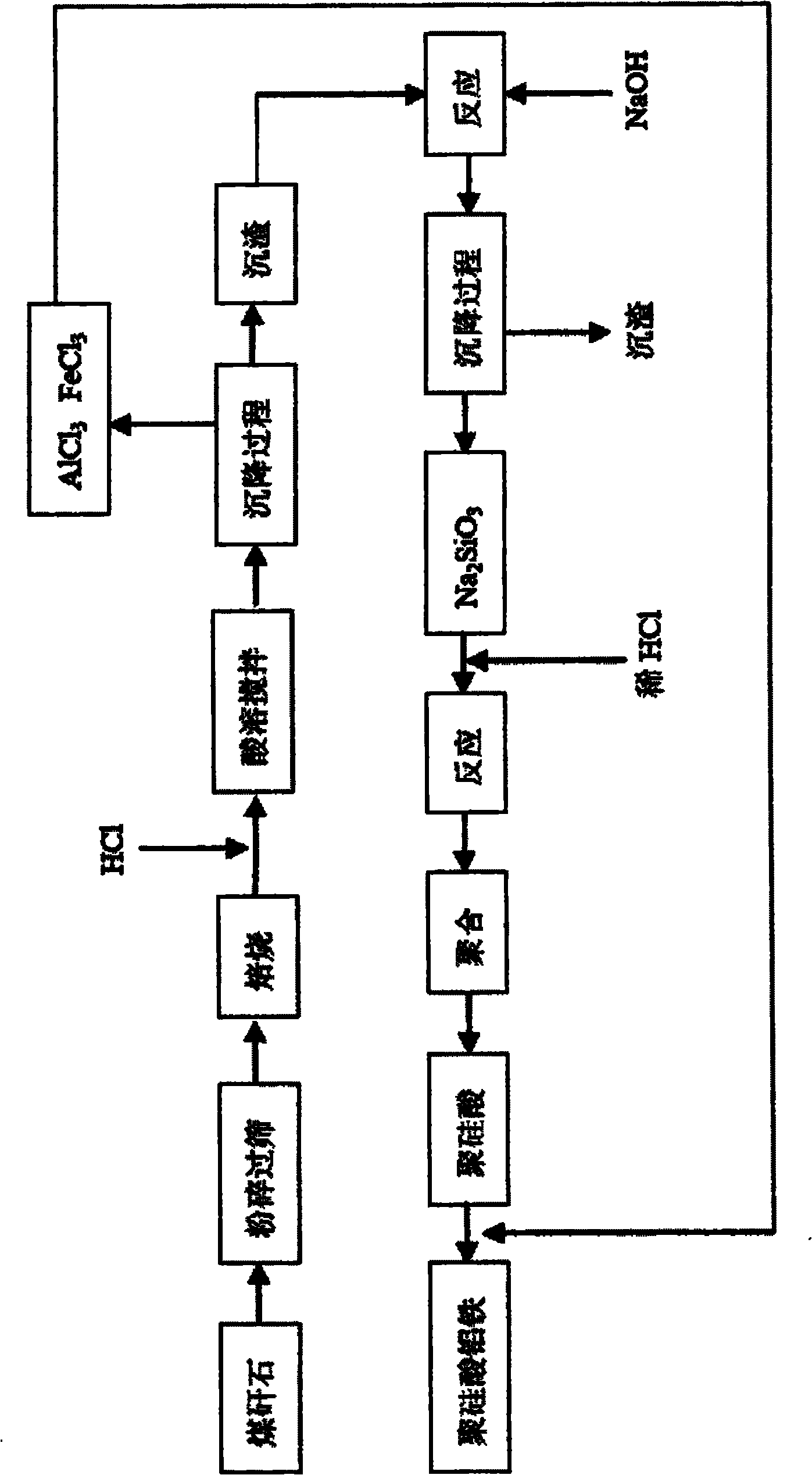

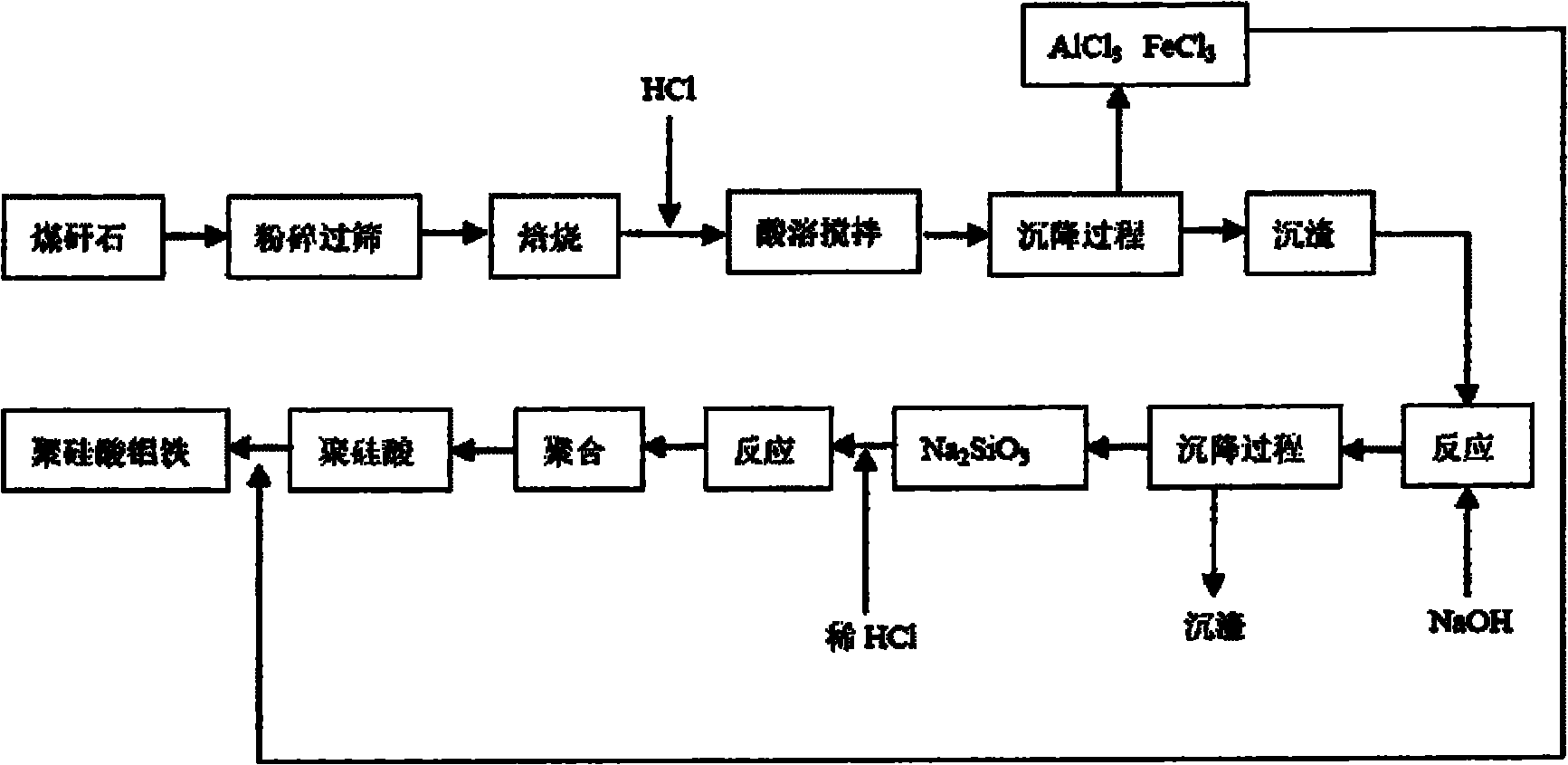

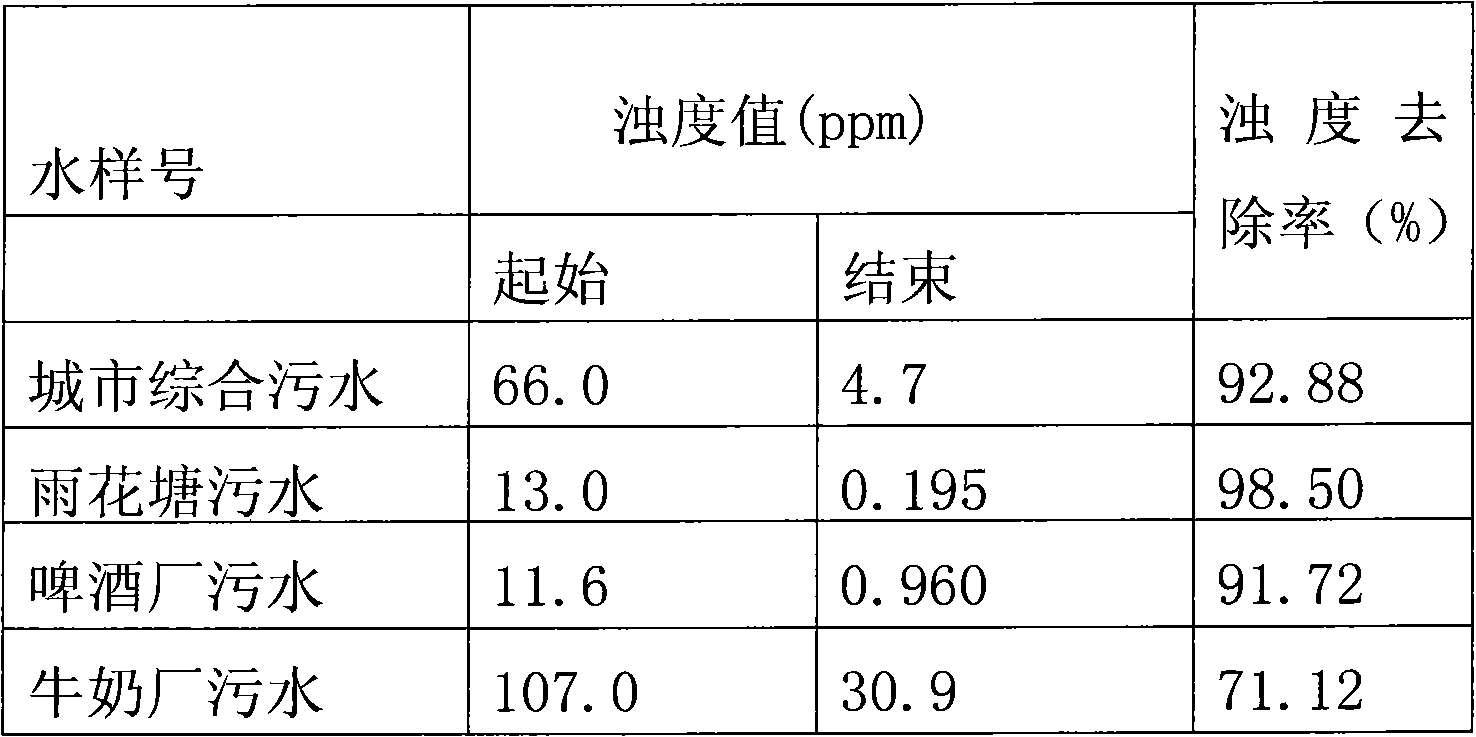

Method for producing poly silicate aluminium ferric flocculating agent by utilizing coal gangue

InactiveCN101823721ASolve the problem of stockpiling and polluting the environmentScientific and streamlined processAluminium silicatesSolid waste disposalSilicic acidMass ratio

The invention relates to the inorganic macromolecule flocculating agent technical field, in particular to a method for producing poly silicate aluminium ferric flocculating agent by utilizing coal gangue. The method includes the following steps: firstly coal gangue is smashed, roasted and mixed with hydrochloric acid by solid-liquid volume ratio of 1:4-6, reaction is carried out, then the obtained reaction liquid is filtered, the obtained residue is for spare use, and the pH value of the obtained filtrate is regulated to be 3-3.5, thus obtaining the poly aluminium ferric solution; then the obtained residue and sodium hydroxide are mixed for reaction by mass ratio of 2-4:1, and the filtrate obtained by filtration of reaction liquid is sodium silicate solution namely; the prepared sodium silicate solution is added with acid for carrying out activation treatment; then the prepared poly aluminium ferric solution and the activated sodium silicate solution are mixed for reaction by mass ratio of 1:1, thus obtaining the poly silicate aluminium ferric flocculating agent. The invention adopts coal gangue as raw material, cost is low, and meanwhile the poly silicate aluminium ferric flocculating agent prepared by the invention has better stability and flocculation effect.

Owner:HEFEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com