Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

430 results about "Liquid suspension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

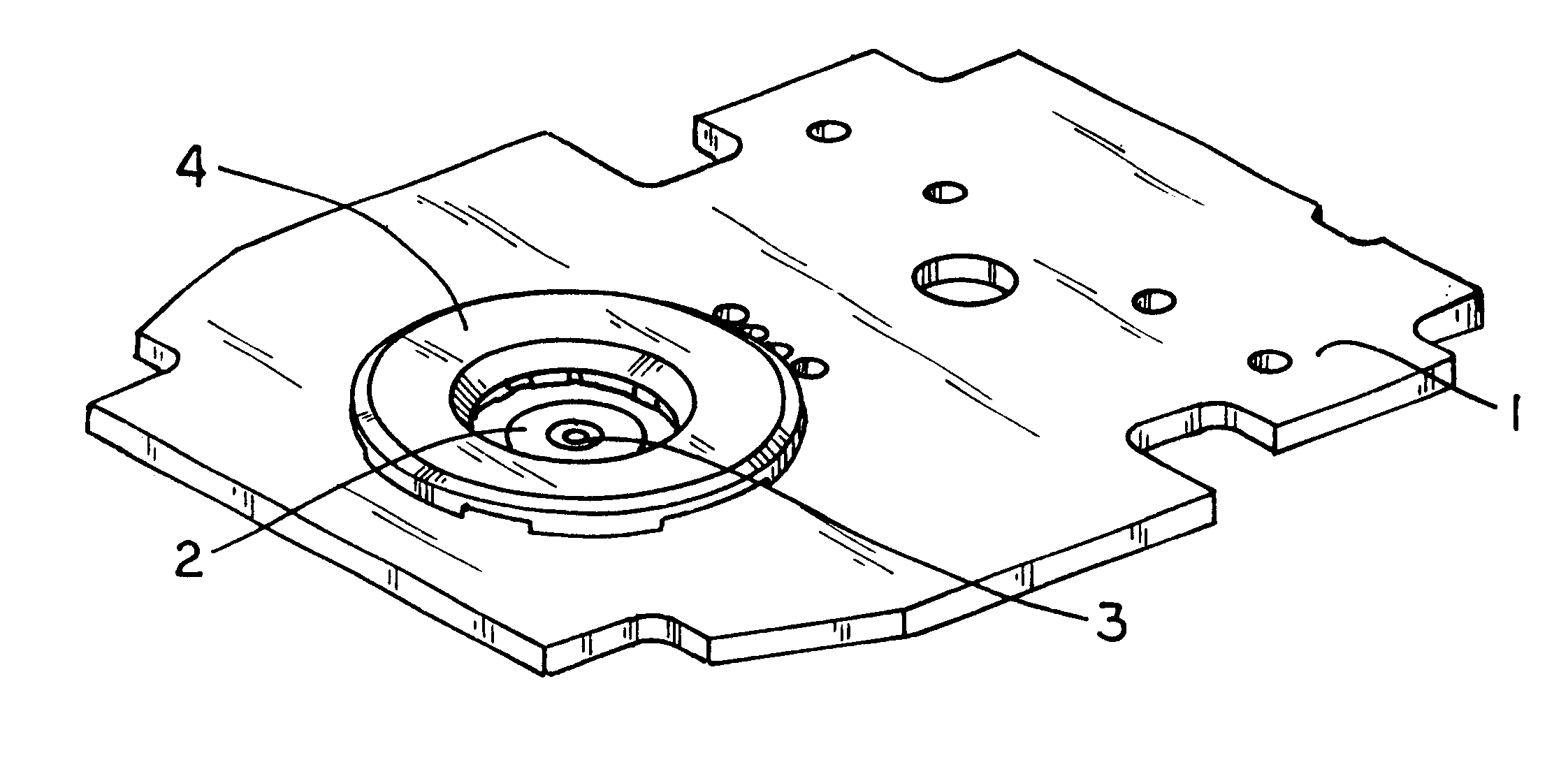

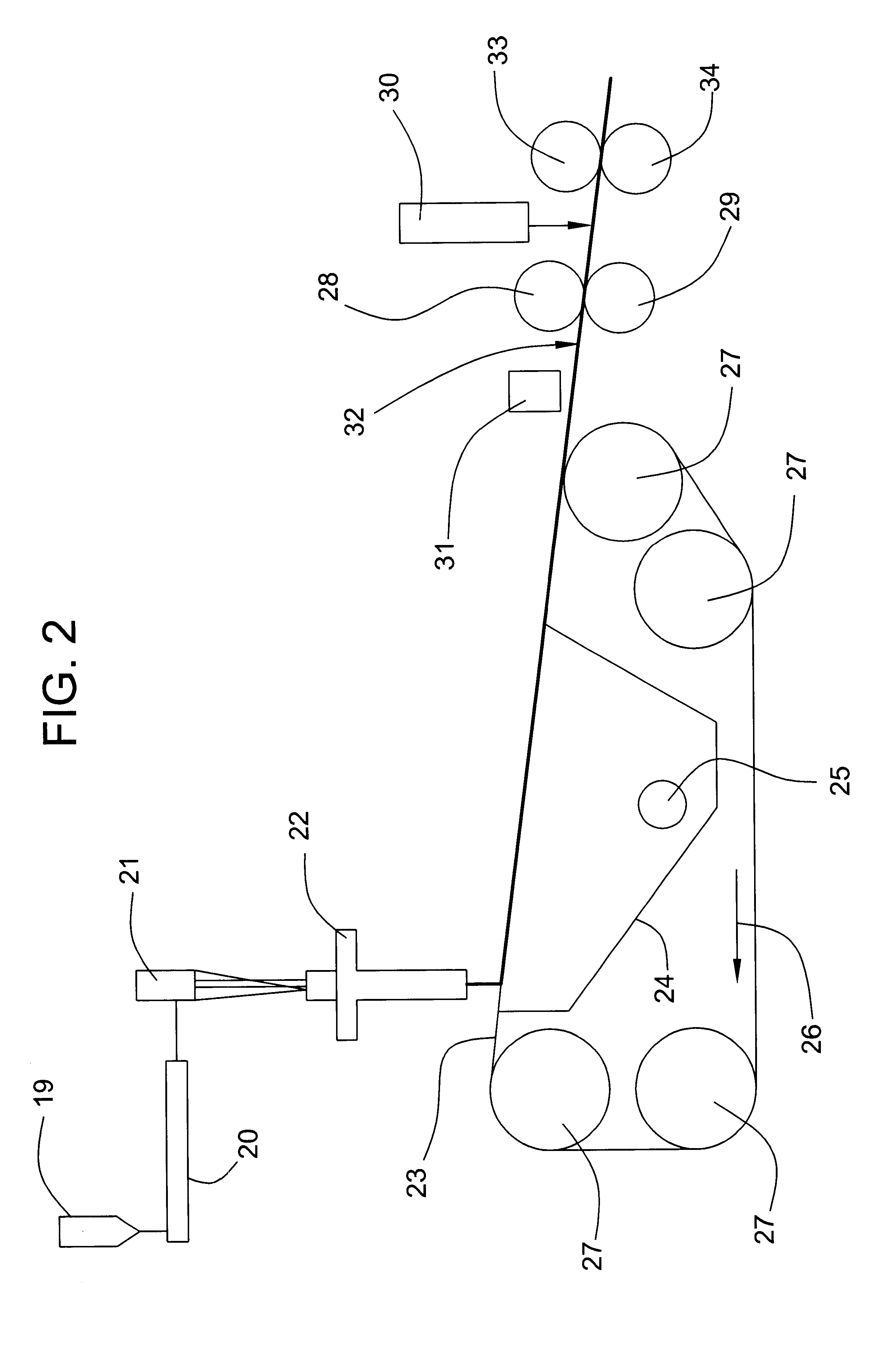

Method and apparatus for the manipulation of particles by means of dielectrophoresis

InactiveUS6942776B2Increase rangeAvoid the needElectrostatic separatorsSludge treatmentPlanar substrateEngineering

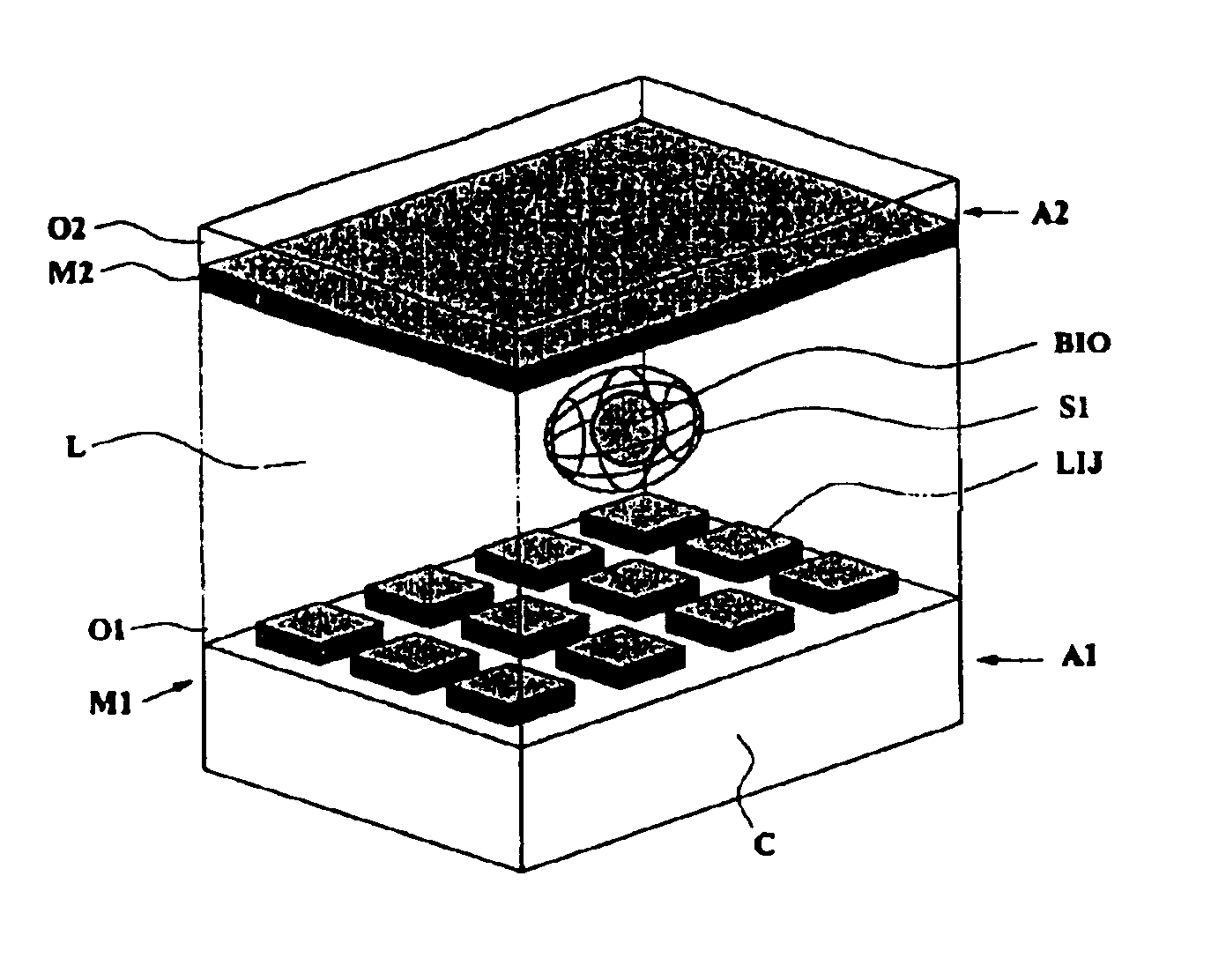

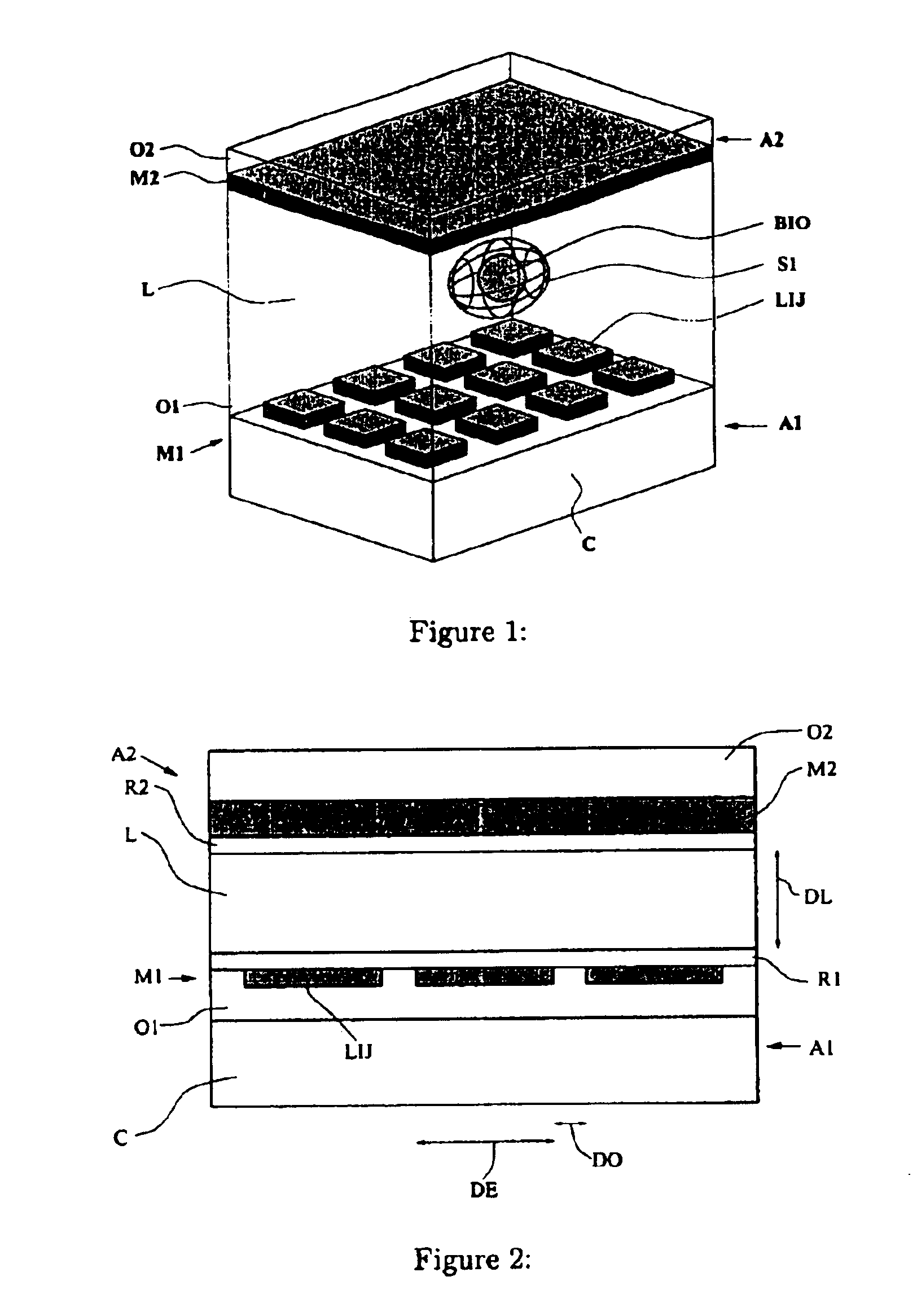

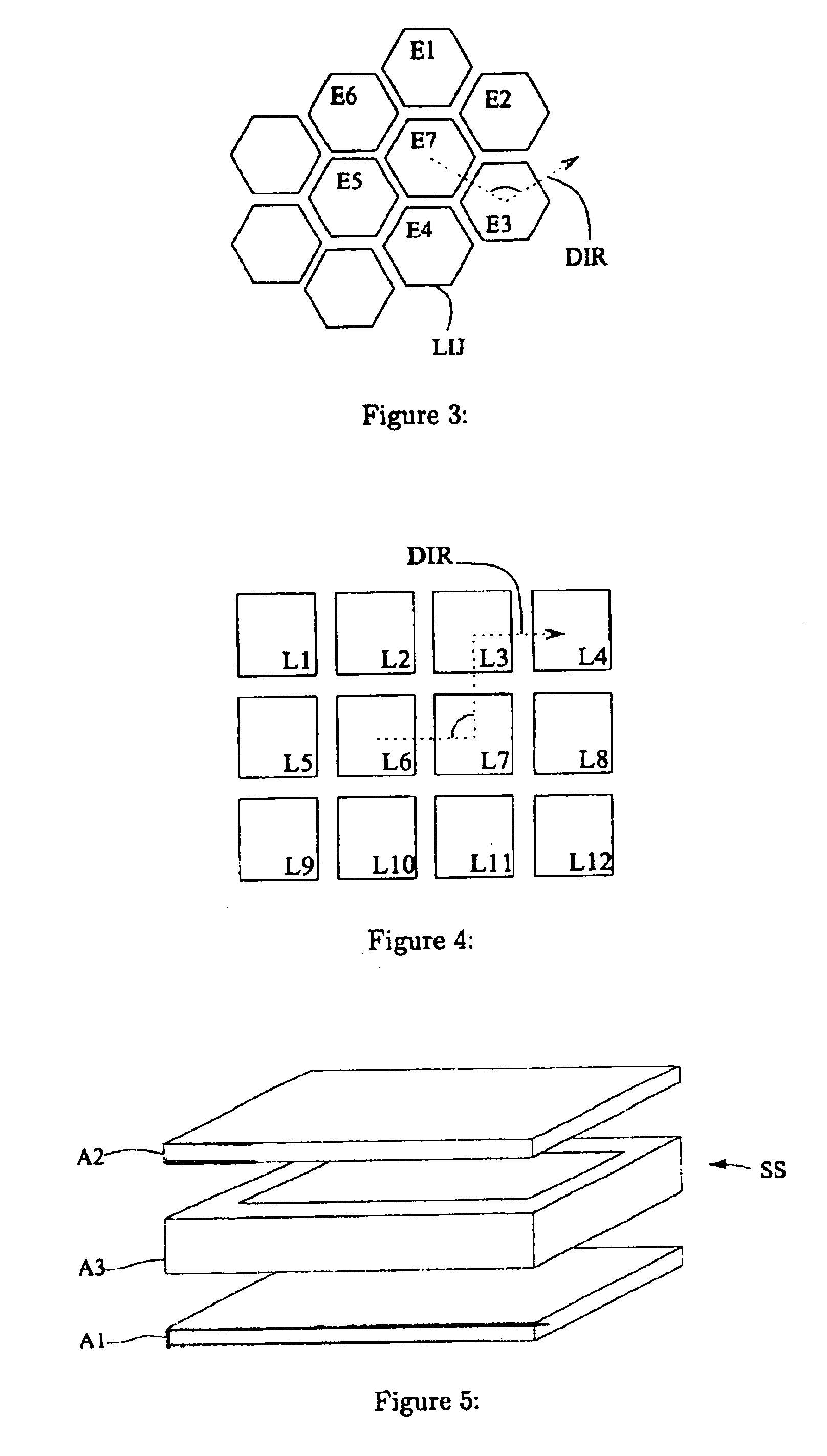

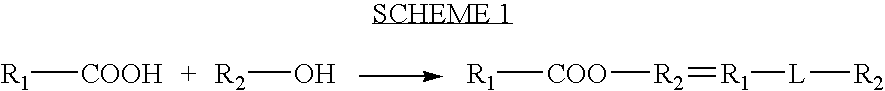

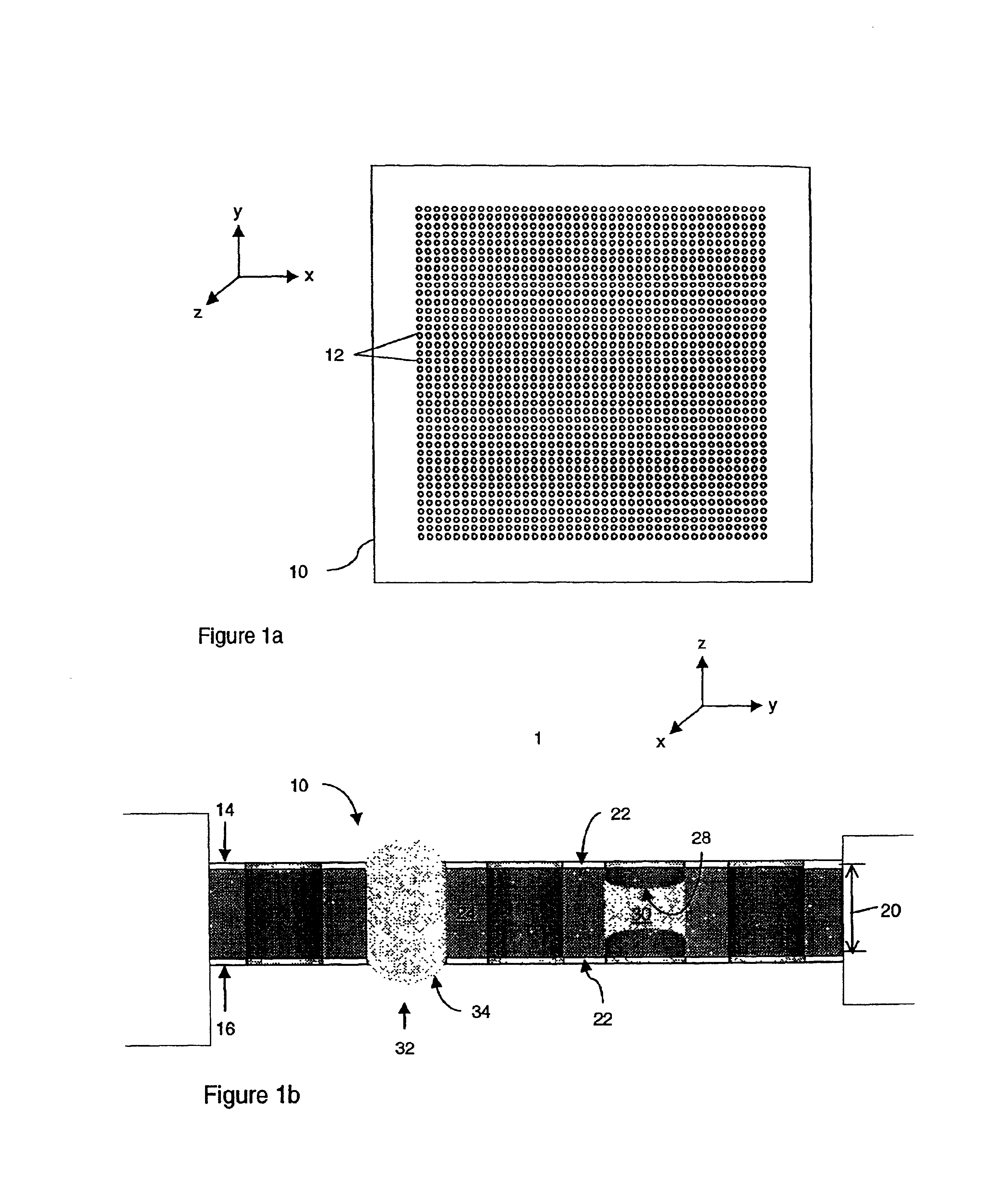

An apparatus and method for establishing closed dielectrophoretic potential cages and precise displacement thereof comprising a first array of selectively addressable electrodes, lying on a substantially planar substrate and facing toward a second array comprising one electrode. The arrays define the upper and lower bounds of a micro-chamber where particles are placed in liquid suspension. By applying in-phase and counter-phase periodic signals to electrodes, one or more independent potential cages are established which cause particles to be attracted to or repelled from cages according to signal frequency and the dielectric characteristics of the particles and suspending medium. By properly applying voltage signal patterns into arrays, cages may trap one or more particles, thus permitting them to levitate steadily and / or move. In the preferred embodiment, where one array is integrated on a semiconductor substrate, displacement of particles can be monitored by embedded sensors.

Owner:SILICON BIOSYSTEMS SPA +1

Dosage forms using drug-loaded ion exchange resins

InactiveUS20050181050A1Avoid breakingPharmaceutical non-active ingredientsPill deliveryOral medicationImmediate release

A multiparticulate, modified release composition for oral administration has been developed. The formulation is made by complexing a drug with an ion-exchange resin in the form of small particles, typically less than 150 microns. The present invention provides novel extended release coated ion exchange particles comprising drug-resin complexes, produced by binding the salt form of the drug, that do not require impregnating agents to insure the integrity of the extended release coat. To prepare a modified release formulation, one or more of the following types of particles are formulated into a final dosage form: (a) Immediate release particles, (b) Enteric coated particles, (c) Extended release particles, (d) Enteric coated-extended release particles; and (e) Delayed release particles. The various drug-containing particles described above can be further formulated into a number of different easy-to-swallow final dosage forms including, but not limited to, a liquid suspension, gel, chewable tablet, crushable tablet, rapidly dissolving tablet, or unit of use sachet or capsule for reconstitution

Owner:COLLEGIUM PHARMA INC

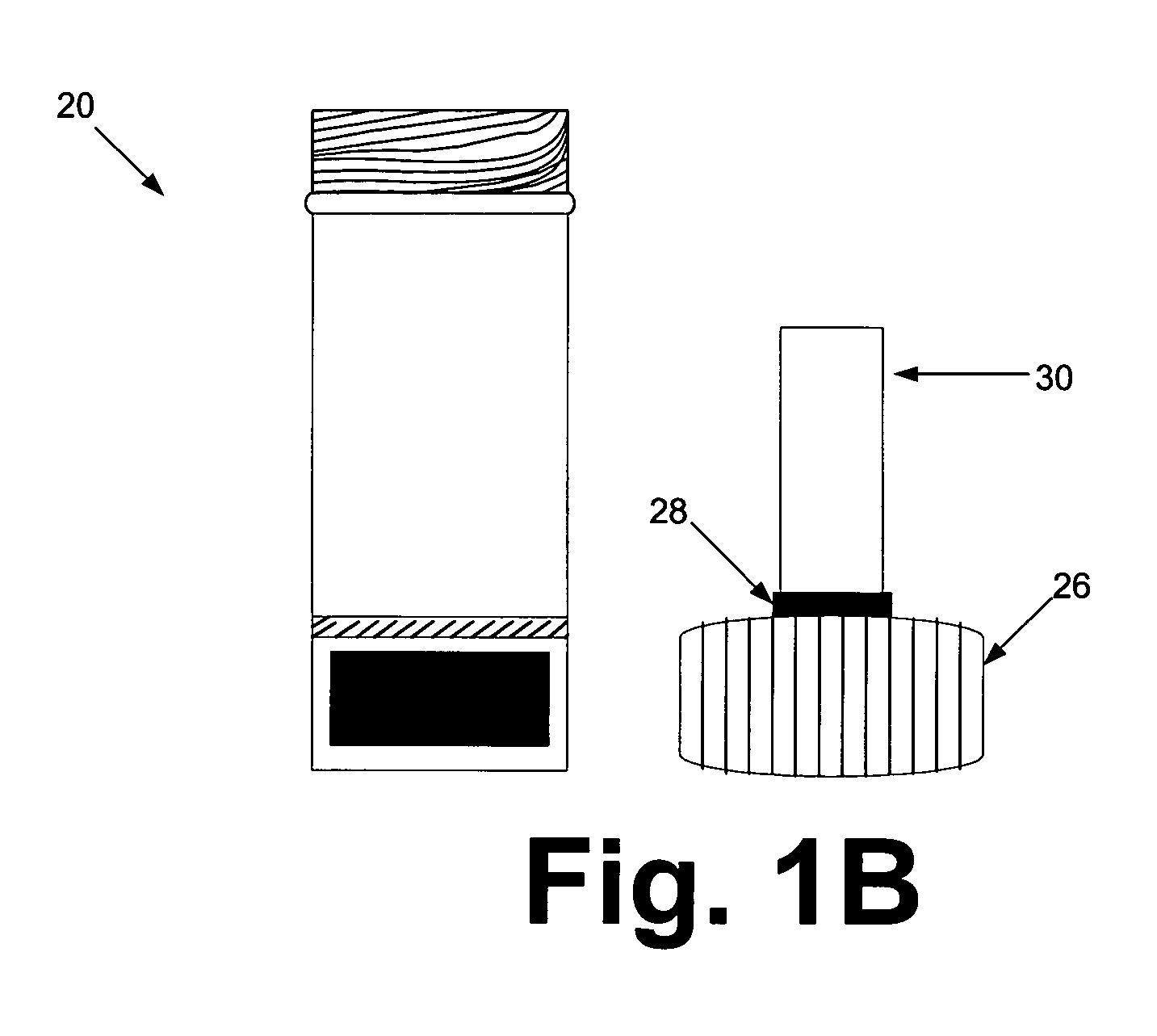

Devices and methods for collection, storage and transportation of biological specimens

InactiveUS20050227269A1Safe and convenient and simple deviceLow costBioreactor/fermenter combinationsBiological substance pretreatmentsTarget analysisAnalyte

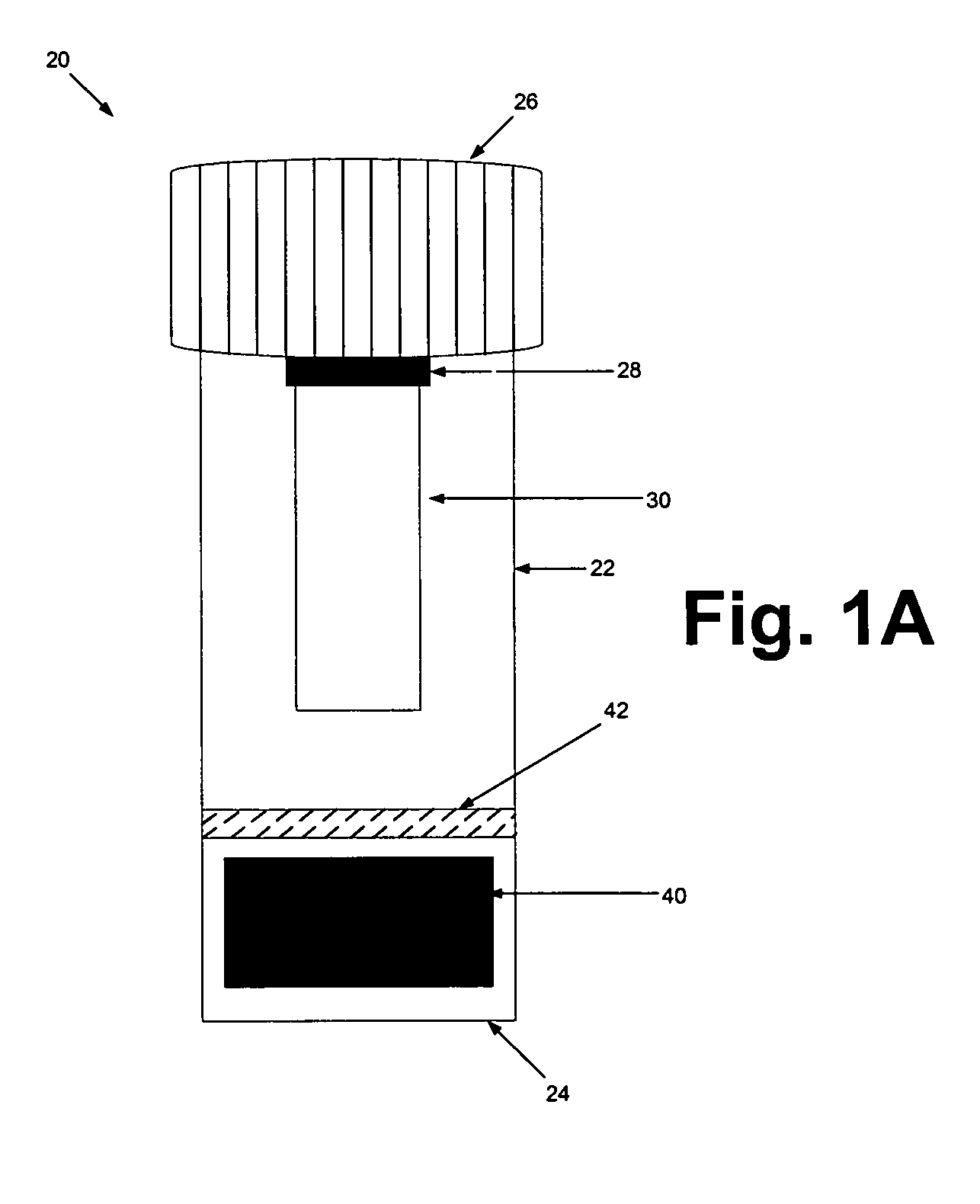

The present invention provides devices and methods for collecting, storing or transporting liquid suspension of biological specimens containing analytes of interest in a dry state. The dried biological specimens containing analytes of interest are reconstituted and released for subsequent analysis by compressing the matrix in the device. Also provided are kits for collecting, storing, transporting and recovering biological specimens containing analytes of interest.

Owner:VIVEBIO

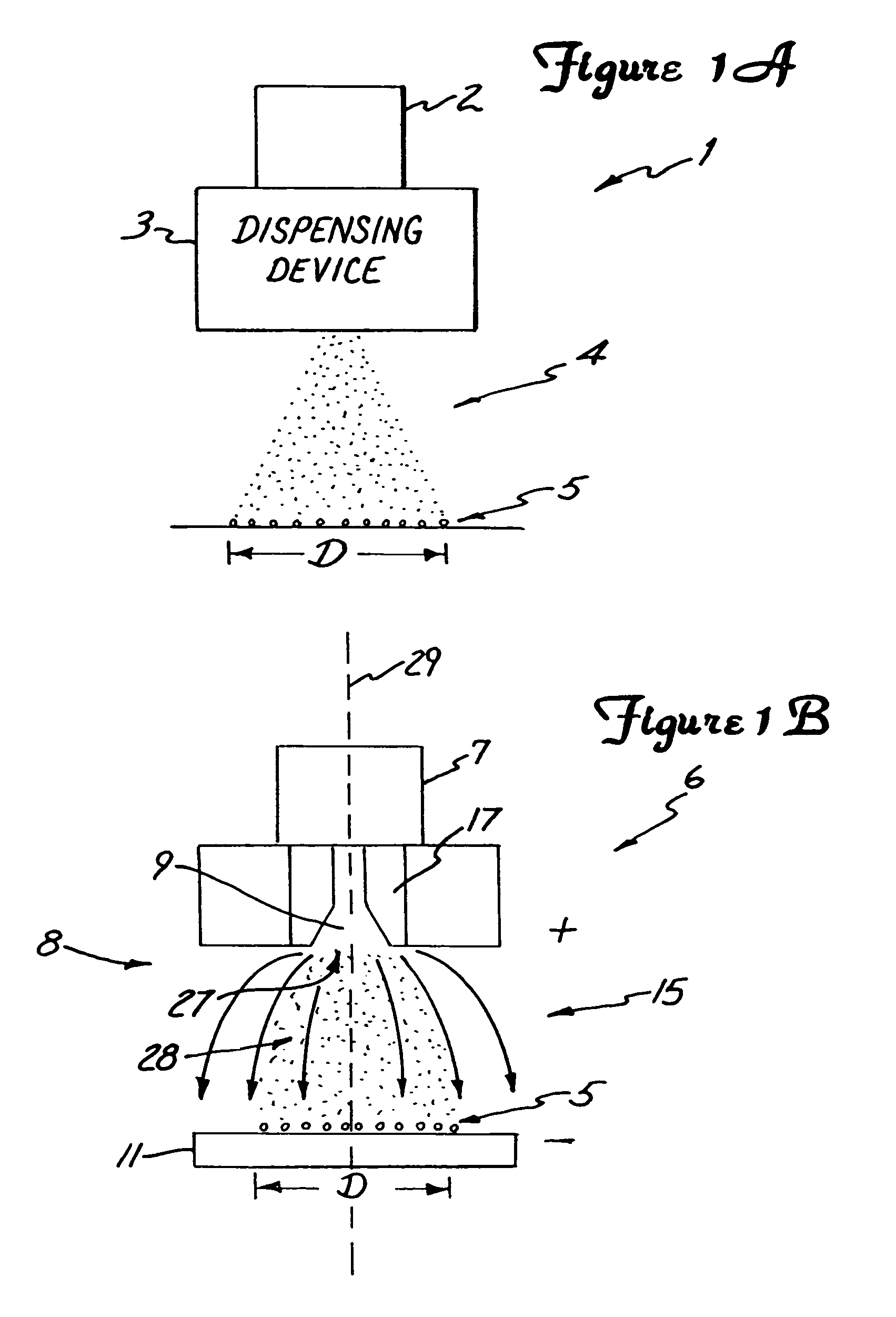

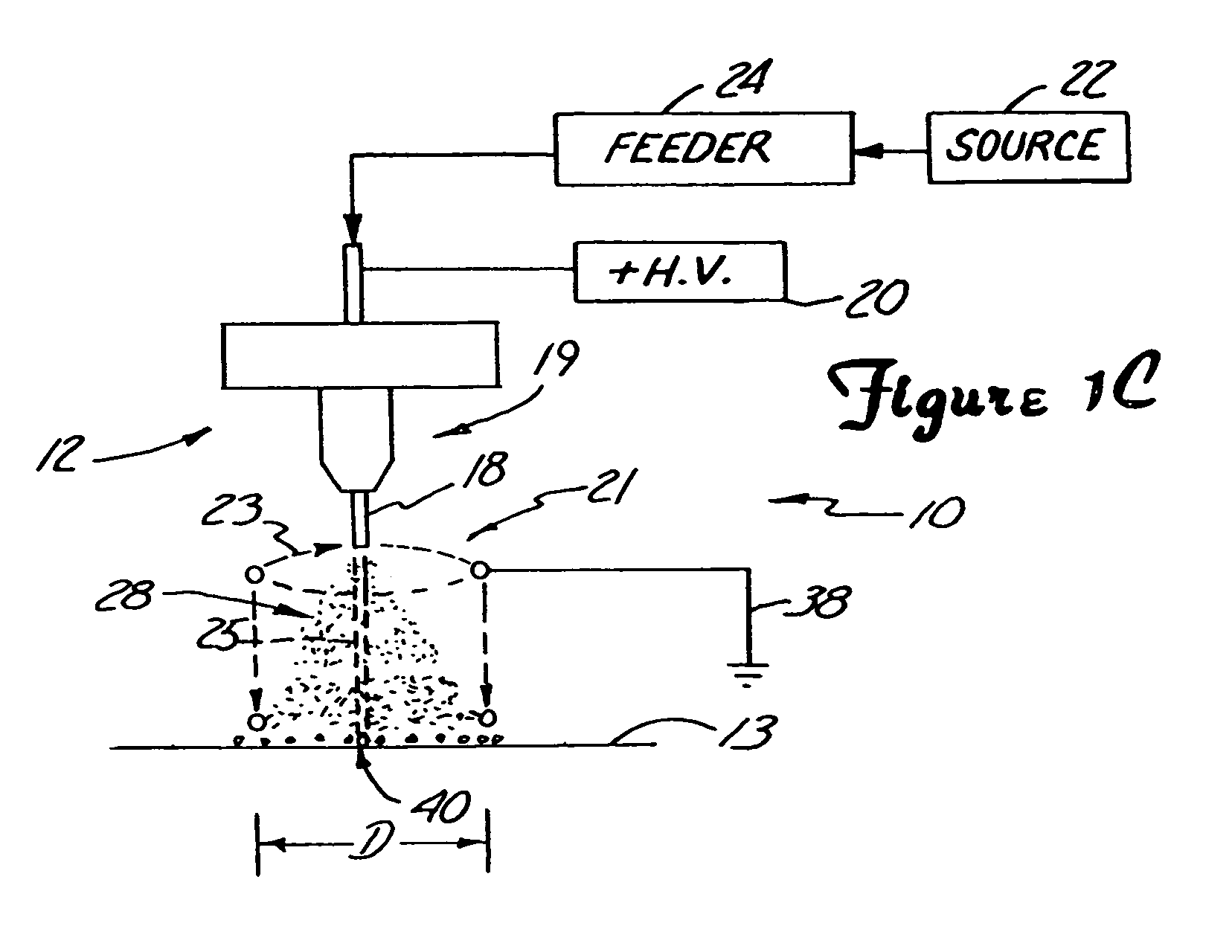

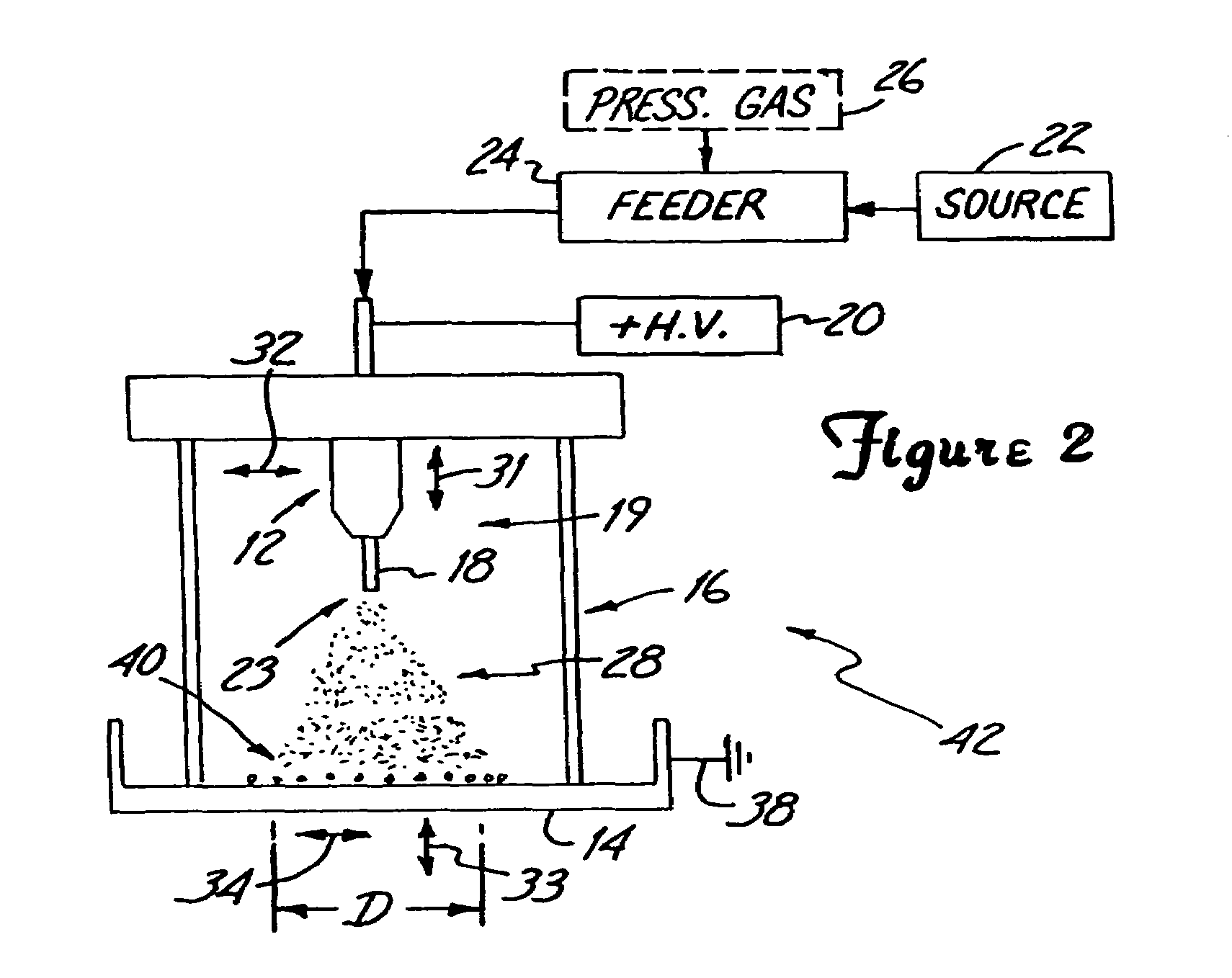

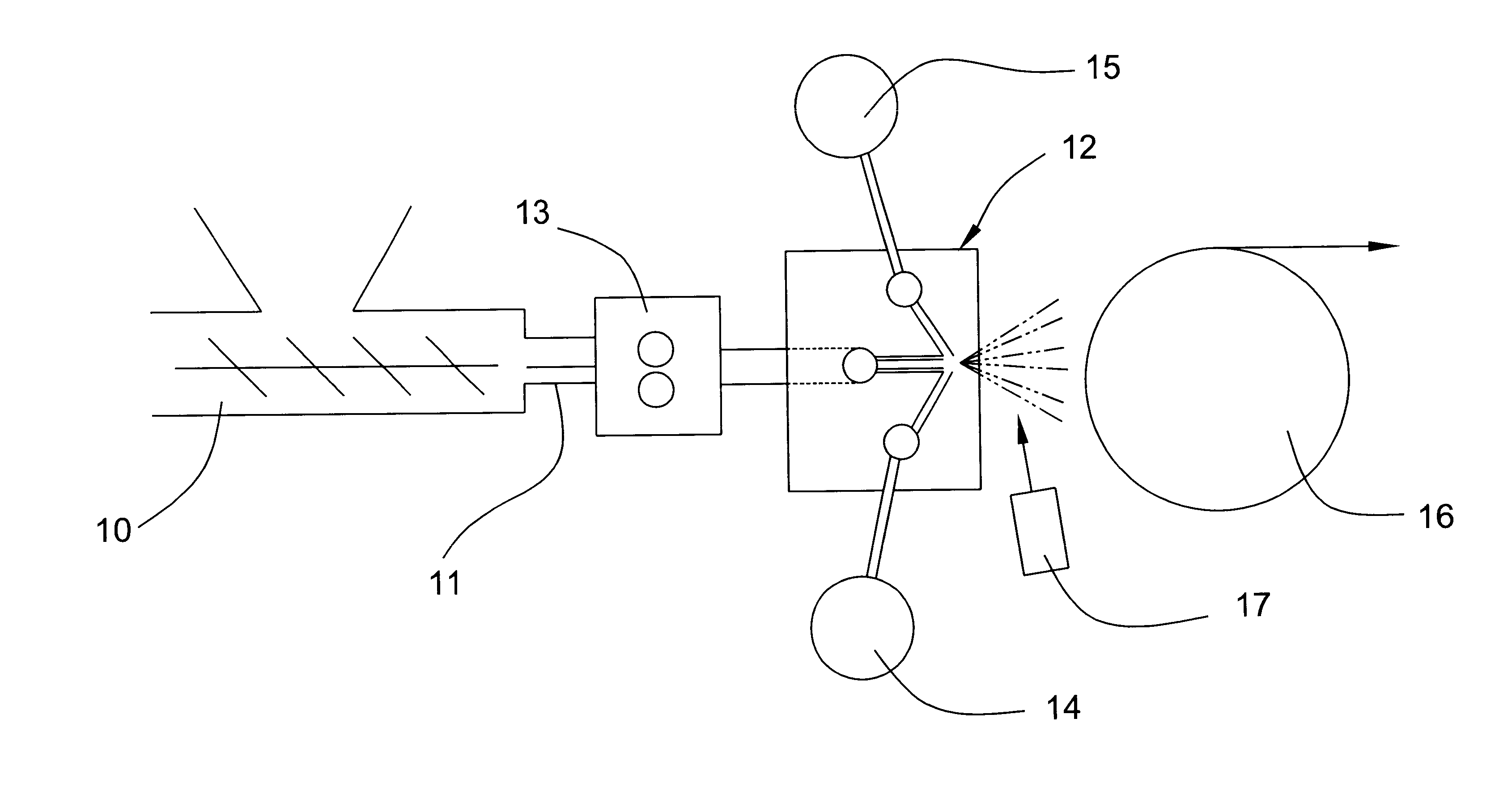

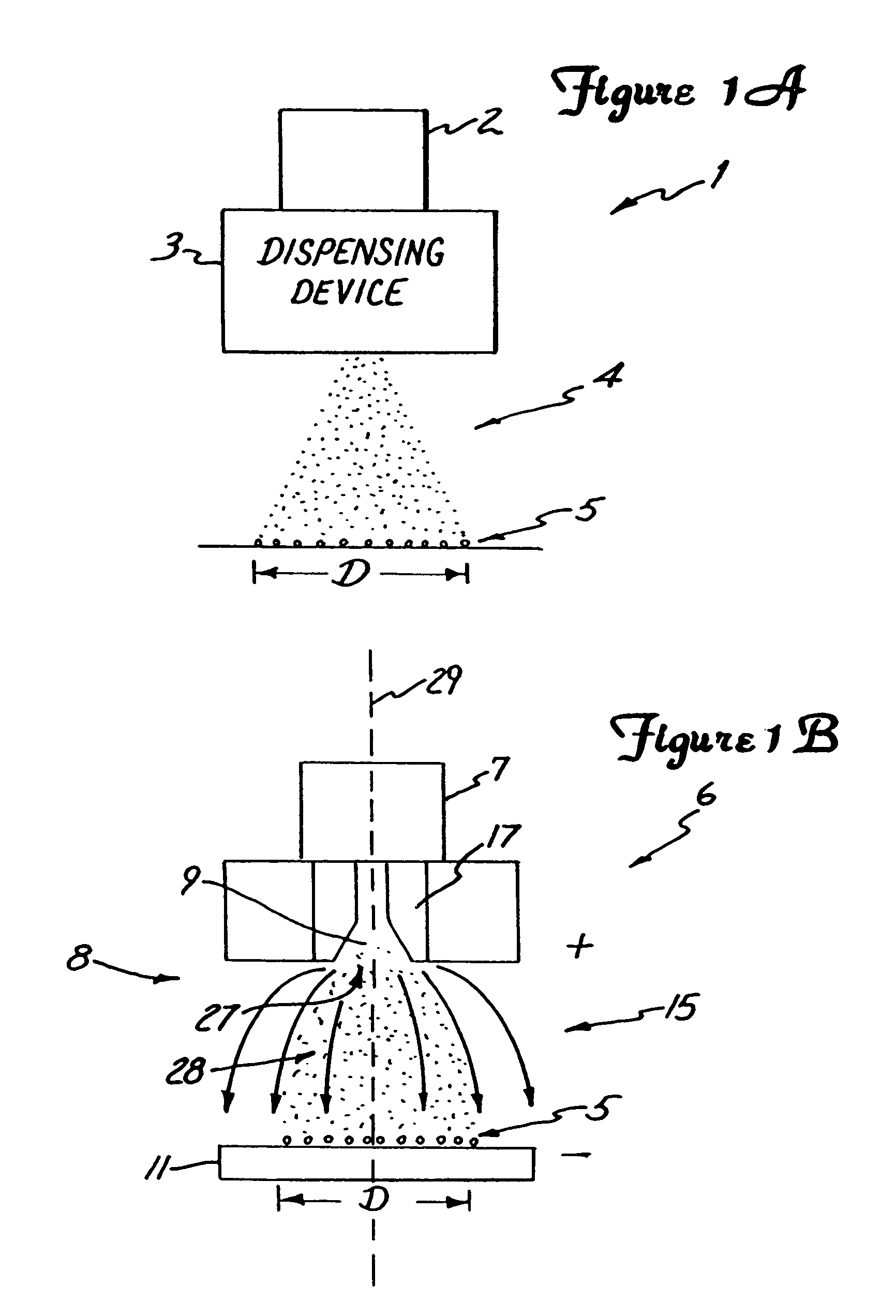

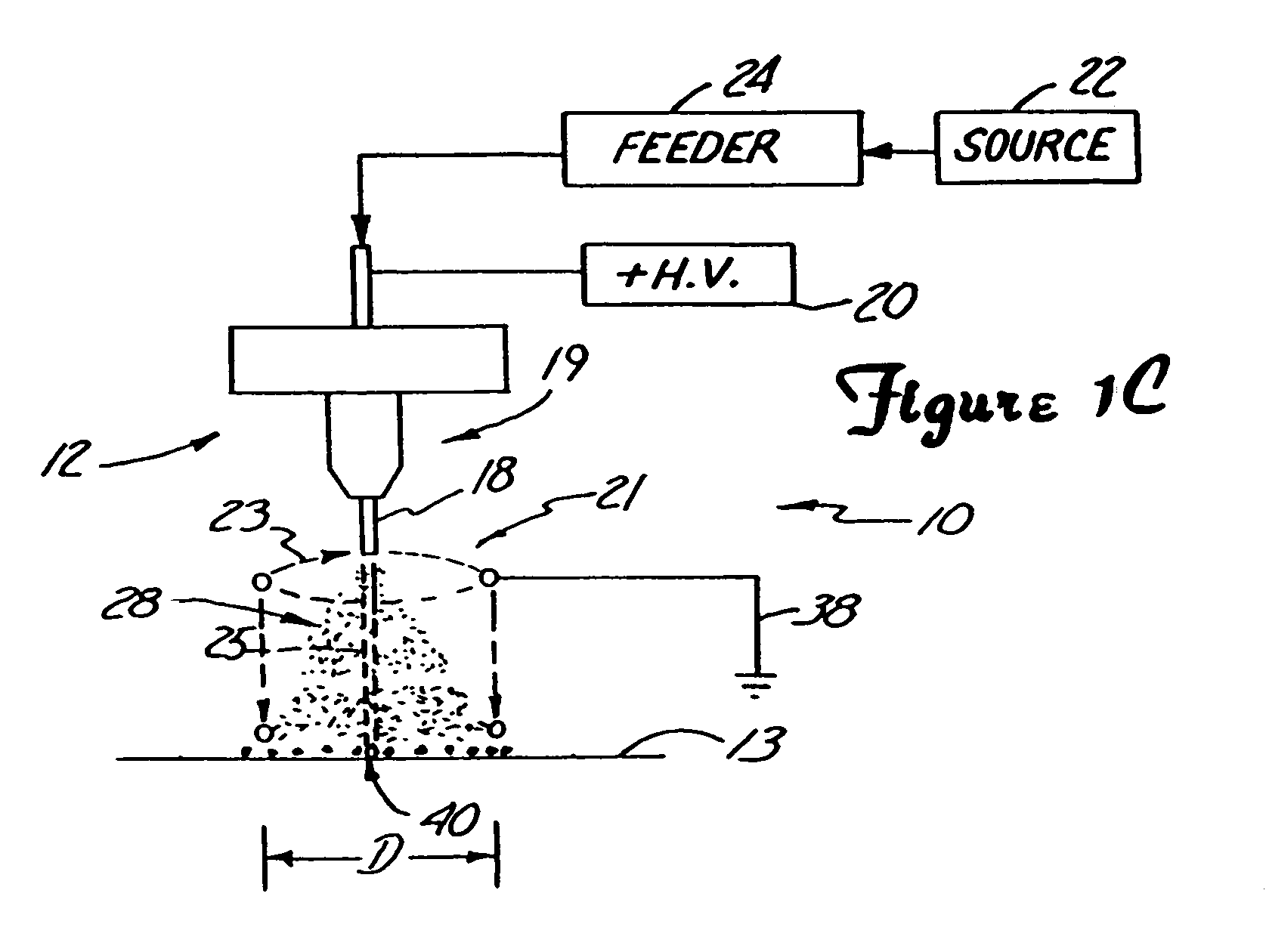

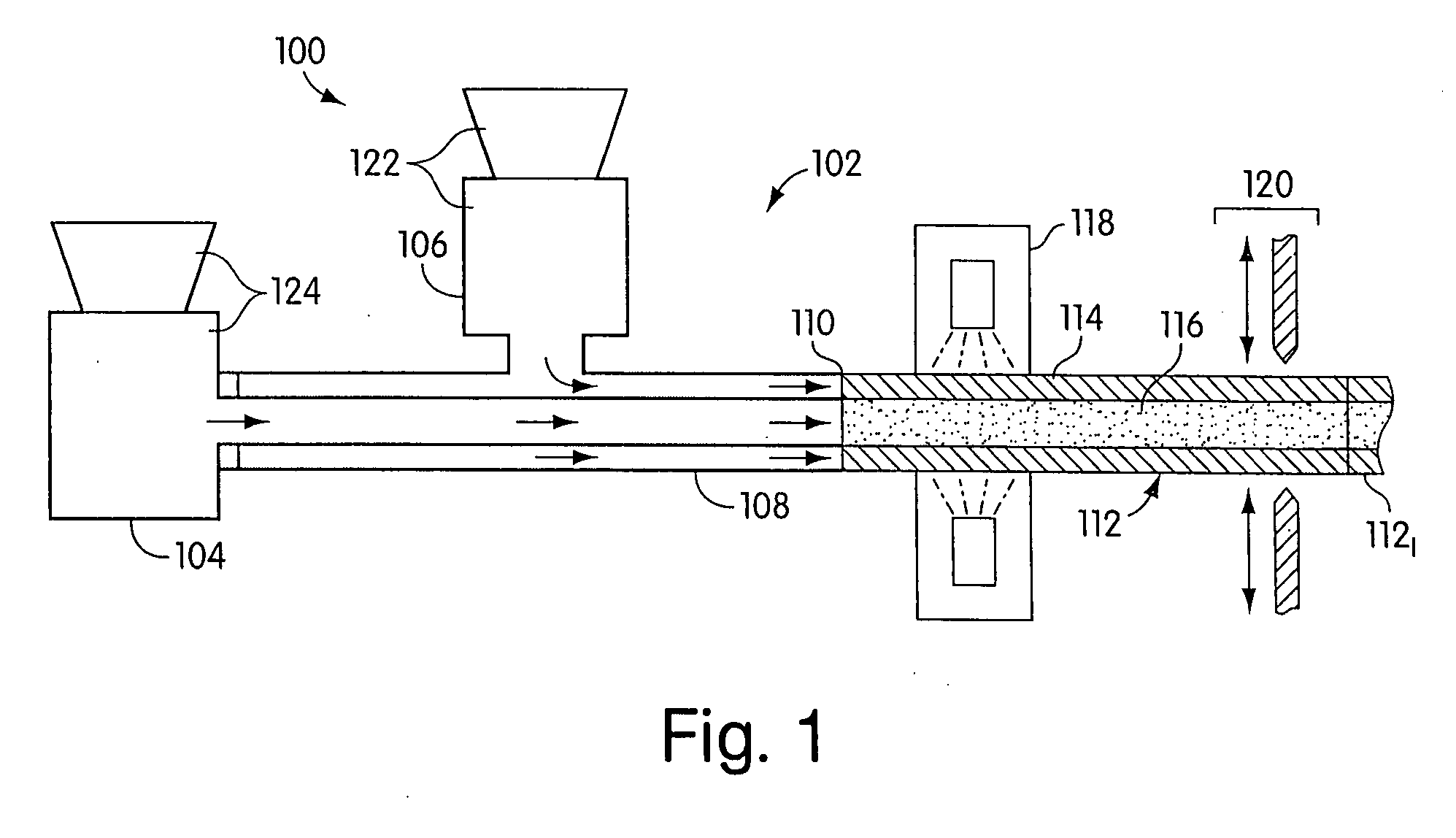

Electrospraying apparatus and method for coating particles

An electrospraying apparatus and / or method is used to coat particles. For example, a flow including at least one liquid suspension may be provided through at least one opening at a spray dispenser end. The flow includes at least particles and a coating material. A spray of microdroplets suspending at least the particles is established forward of the spray dispenser end by creating a nonuniform electrical field between the spray dispenser end and an electrode electrically isolated therefrom. The particles are coated with at least a portion of the coating material as the microdroplet evaporates. For example, the suspension may include biological material particles.

Owner:RGT UNIV OF MINNESOTA

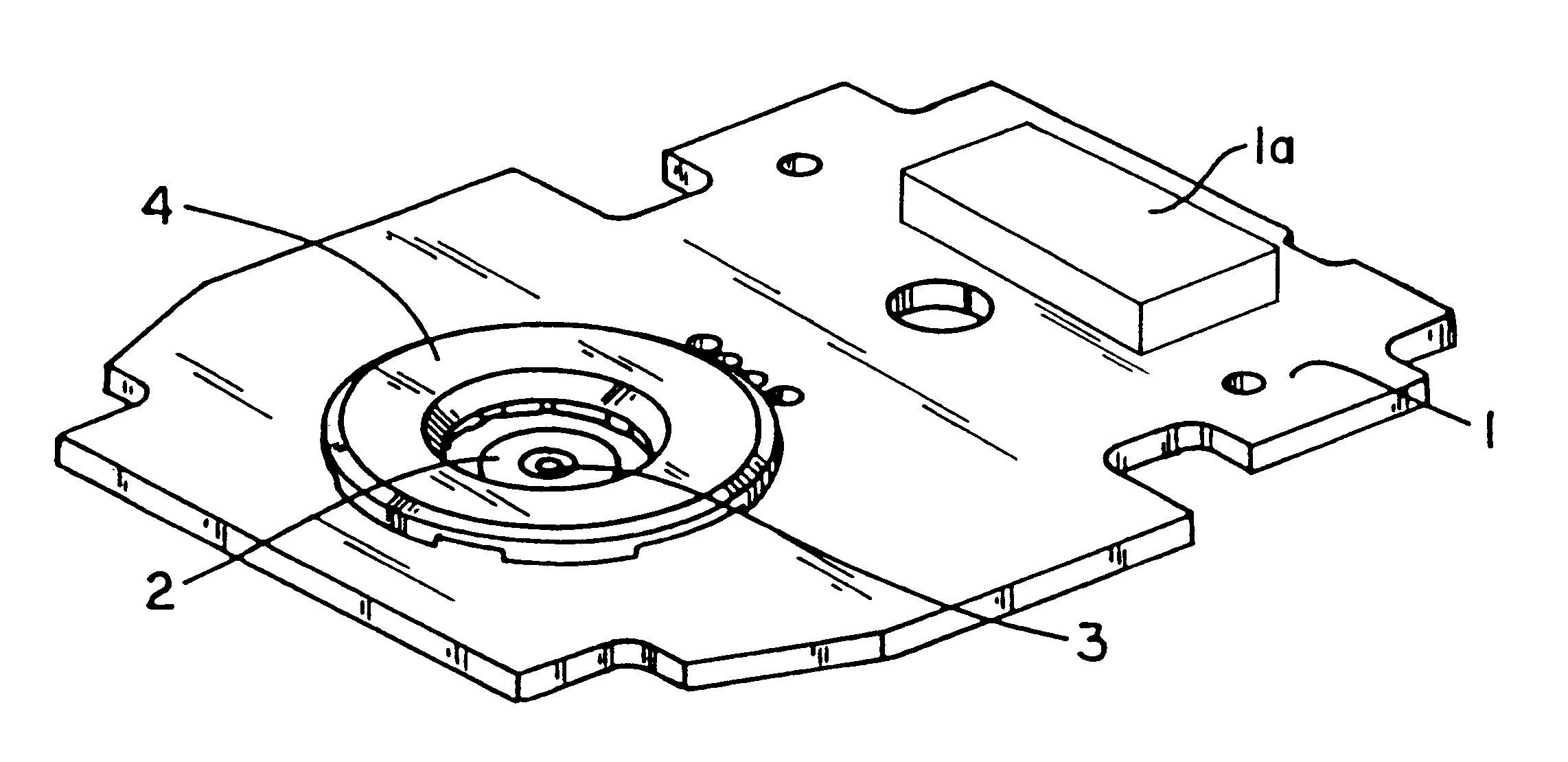

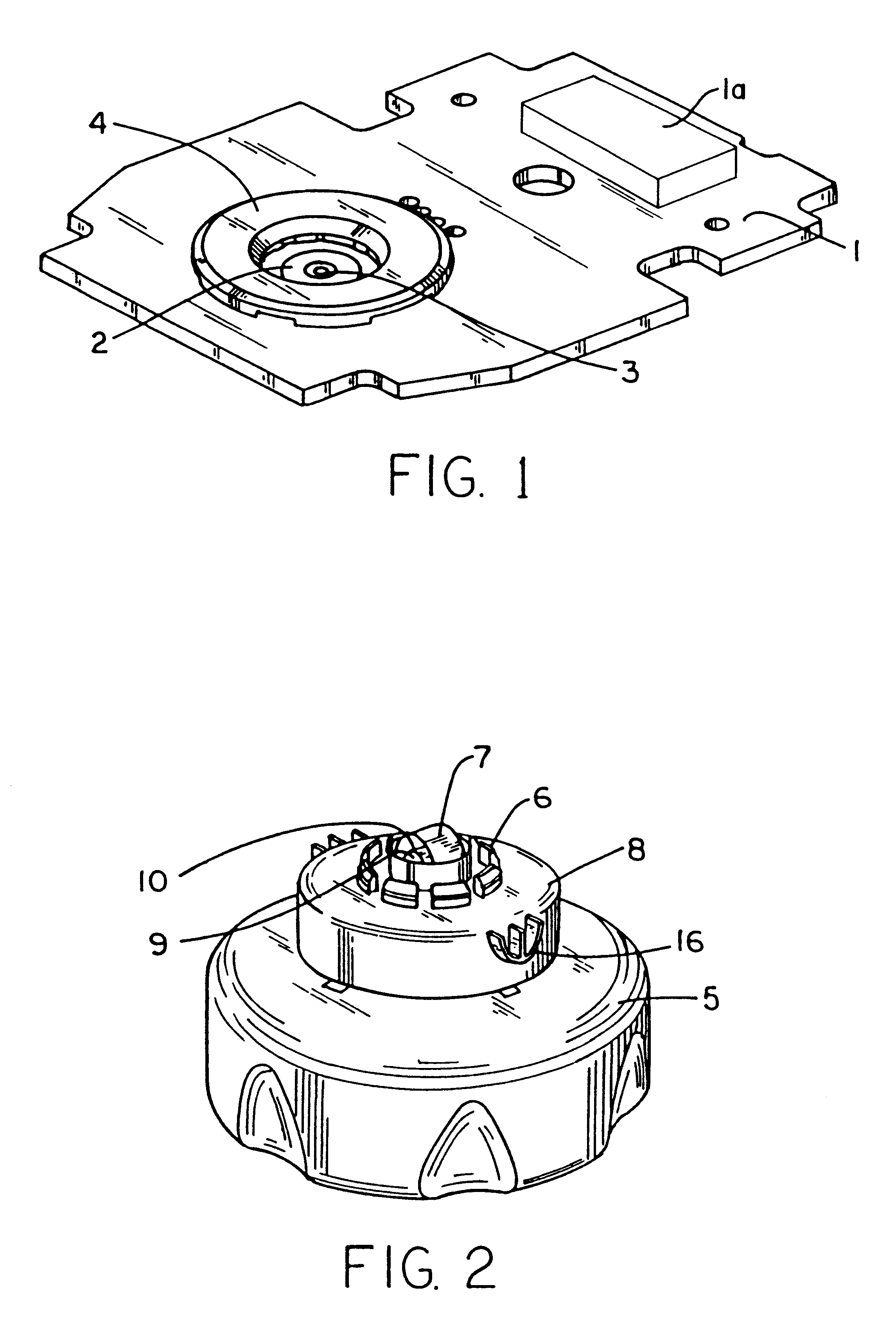

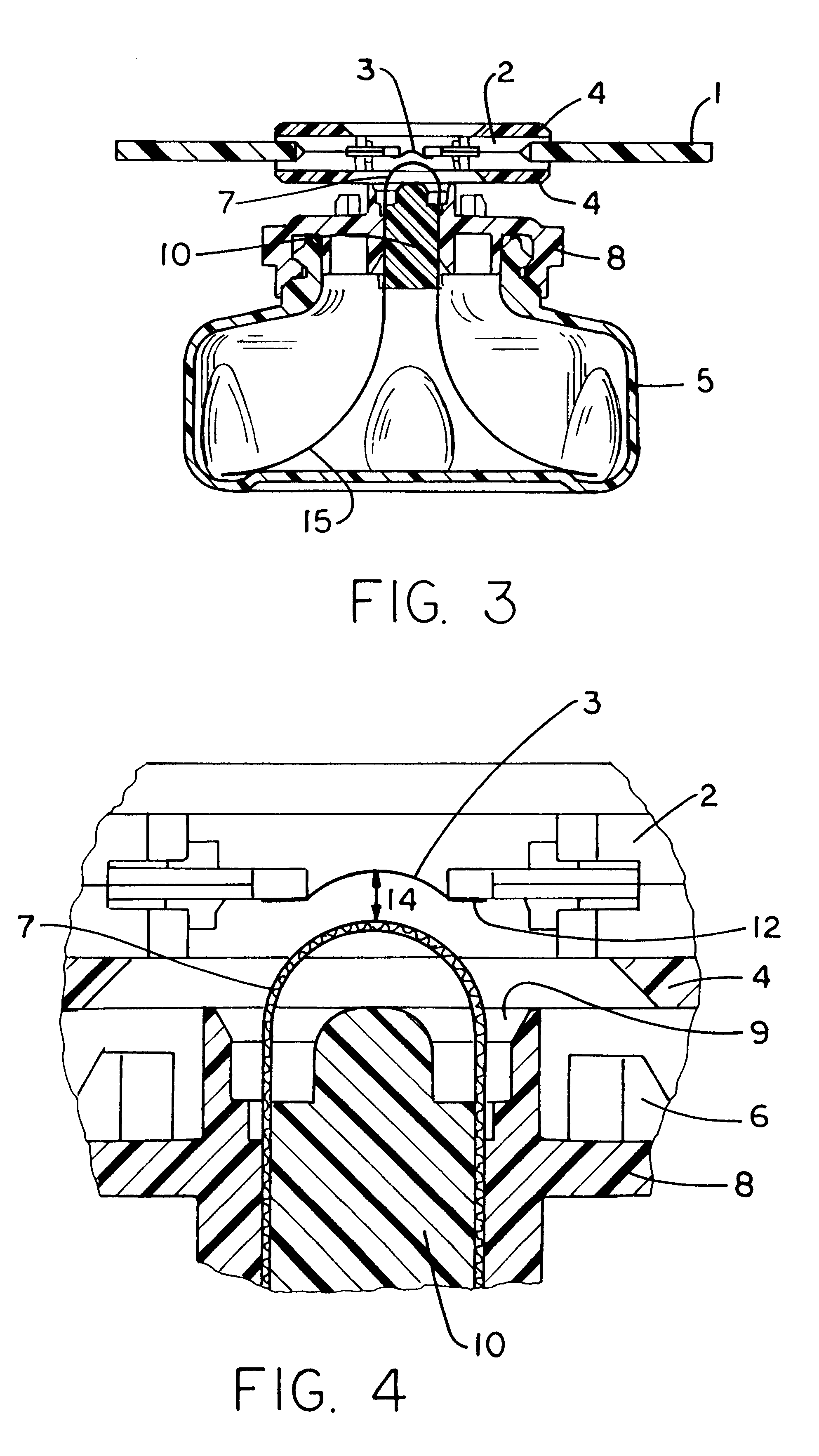

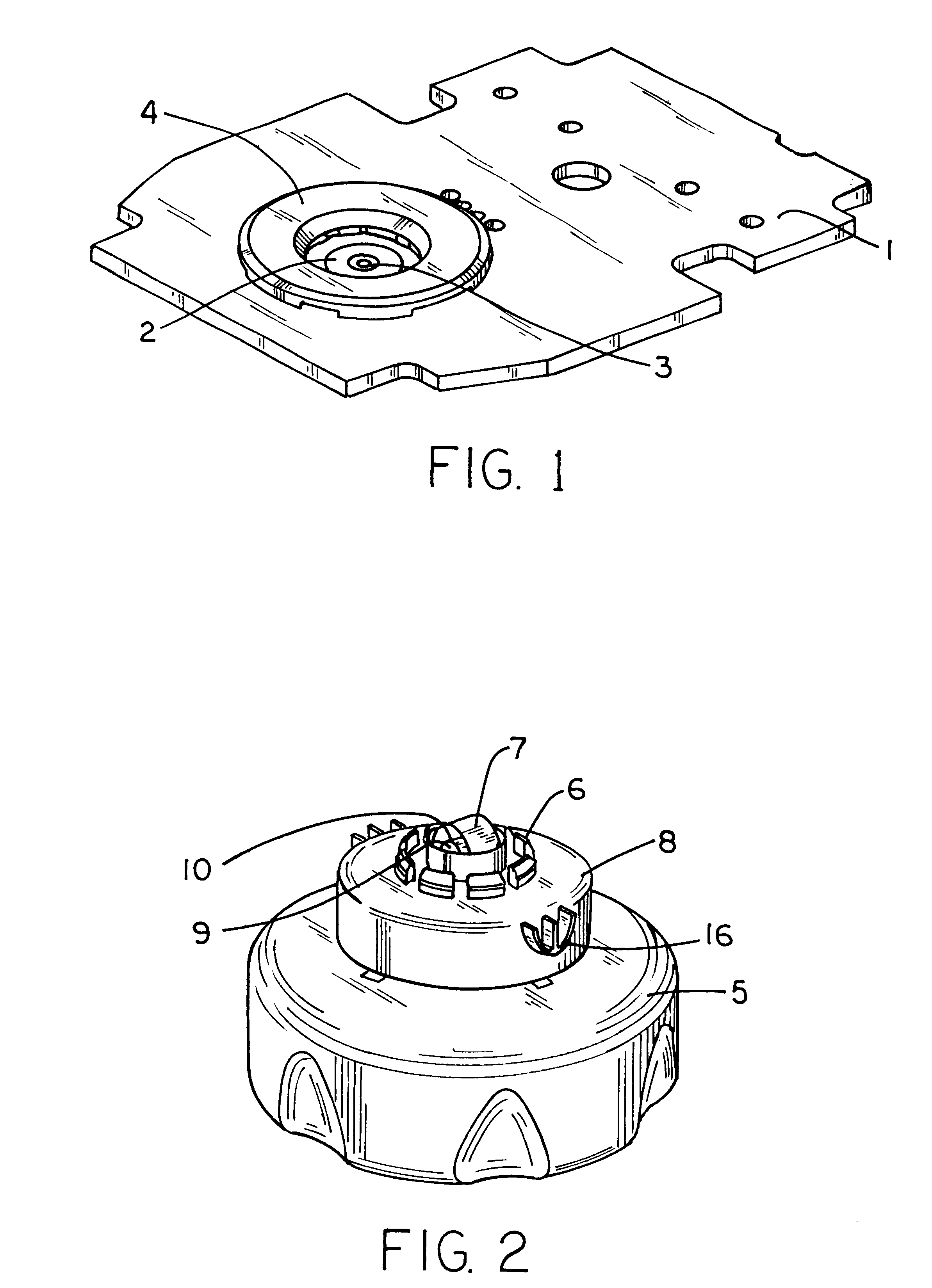

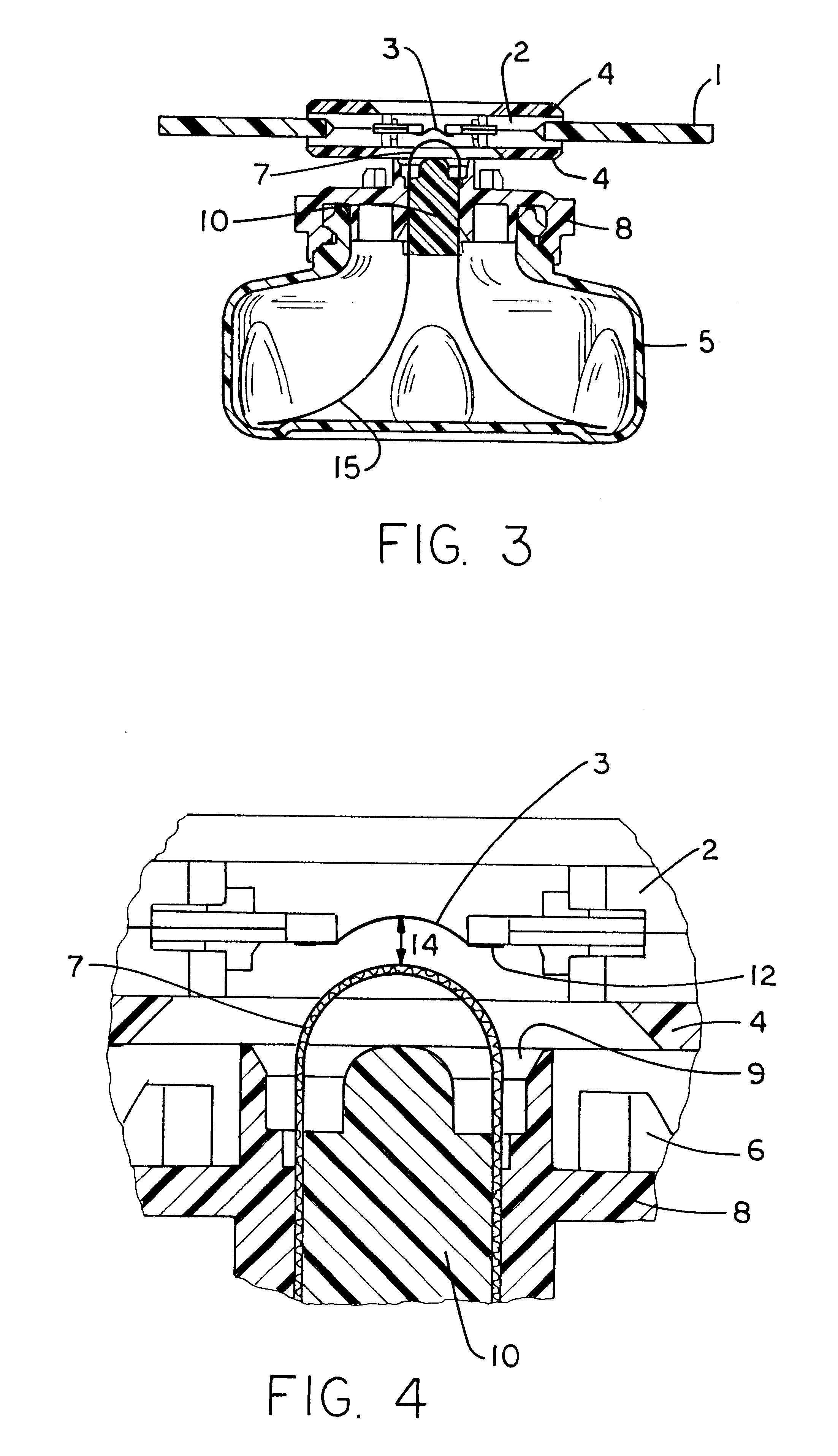

Delivery system for dispensing volatiles

InactiveUS6378780B1Easy to carryMaintain consistencyMovable spraying apparatusSpray nozzlesVena contracta diameterVolatiles

Disclosed herein is a piezoelectric liquid delivery system or atomizer for production of droplets of liquid or liquid suspensions by a battery operated dispenser utilizing an orifice plate in communication with a piezoelectric element. By control of the viscosity and surface tension of the liquid to be dispersed, an improved method of dispensing such liquid is achieved.

Owner:SC JOHNSON & SON INC

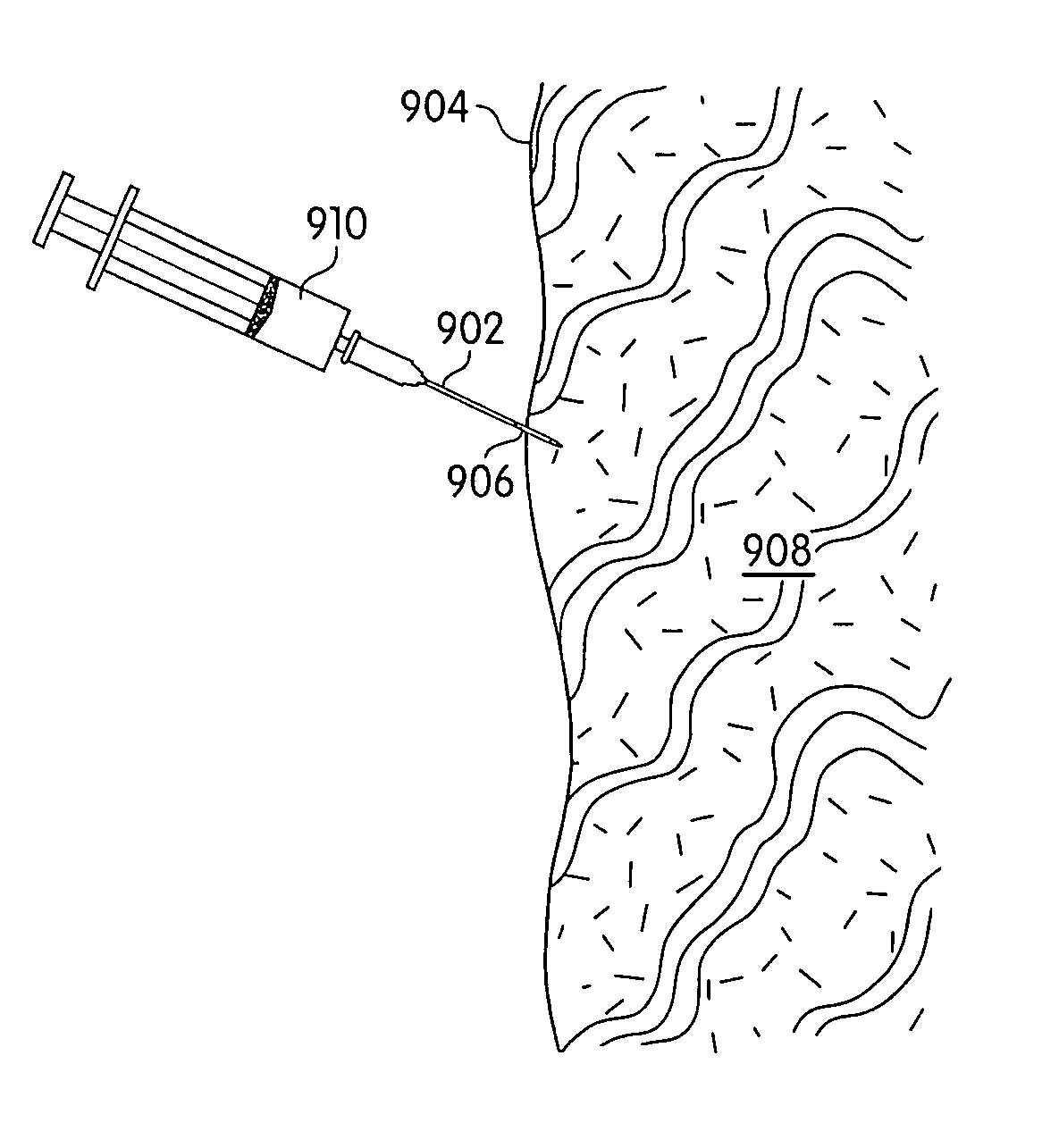

Injectable sustained release delivery devices

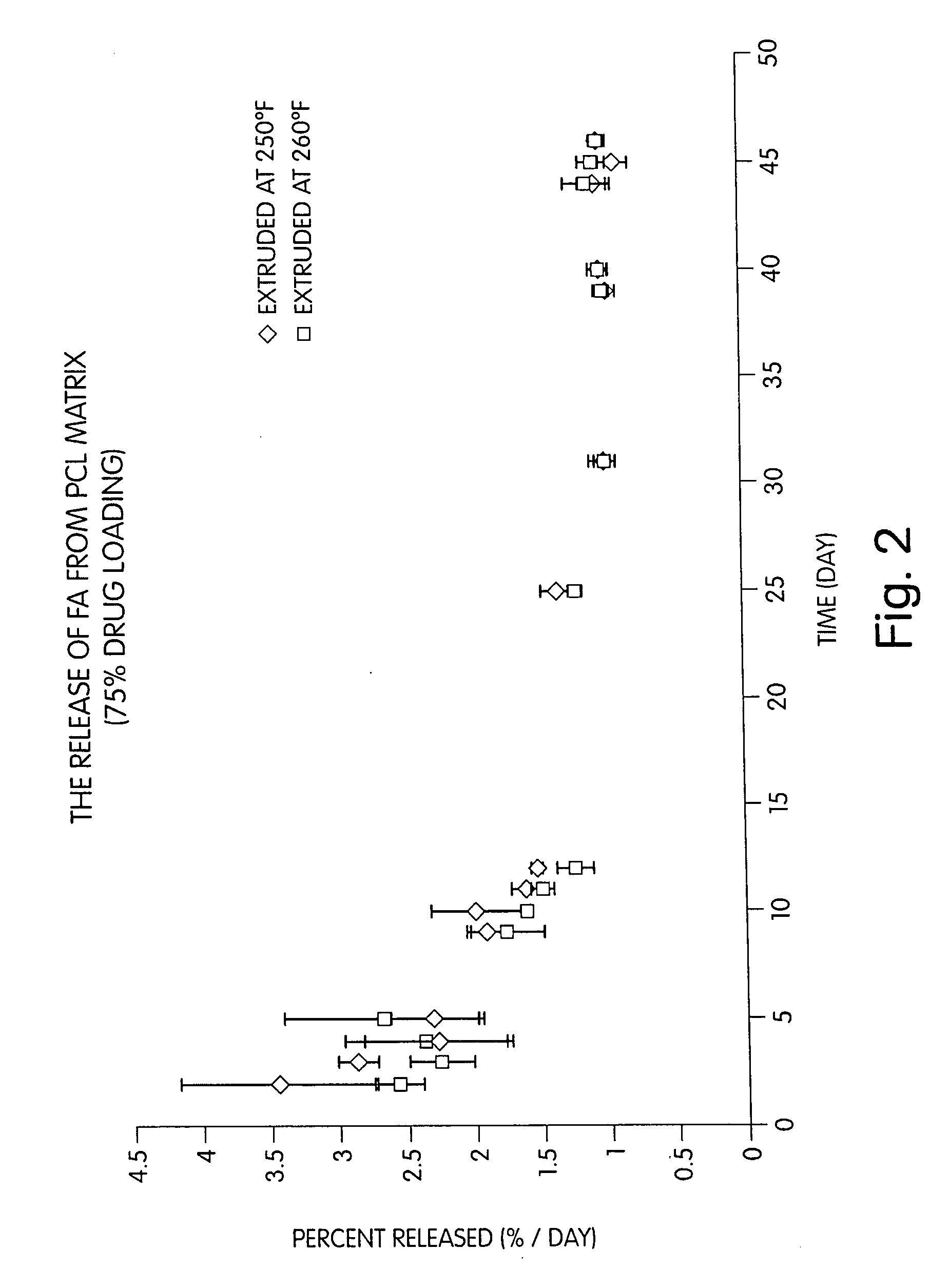

ActiveUS20040176341A1Organic active ingredientsCosmetic preparationsControlled releasePolymer coatings

An injectable drug delivery device includes a core containing one or more drugs and one or more polymers. The core may be surrounded by one or more polymer outer layers (referred to herein as "coatings," "skins," or "outer layers"). In certain embodiments, the device is formed by extruding or otherwise preforming a polymeric skin for a drug core. The drug core may be co-extruded with the skin, or inserted into the skin after the skin has been extruded, and possibly cured. In other embodiments, the drug core may be coated with one or more polymer coatings. These techniques may be usefully applied to fabricate devices having a wide array of drug formulations and skins that can be selected to control the release rate profile and various other properties of the drugs in the drug core in a form suitable for injection using standard or non-standard gauge needles. The device may be formed by combining at least one polymer, at least one drug, and at least one liquid solvent to form a liquid suspension or solution wherein, upon injection, such suspension or solution under goes a phase change and forms a gel. The configuration may provide for controlled release of the drug(s) for an extended period.

Owner:EYEPOINT PHARMA INC

Methods for screening substances in a microwell array

InactiveUS6893877B2Sequential/parallel process reactionsVolume/mass flow measurementEngineeringLiquid suspension

Methods for manufacturing and using an apparatus for manipulating and analyzing a large number of microscopic samples of a liquid or materials, including cells, in liquid suspension. Parallel through-holes are formed in a platen and loaded with a liquid. Loading may be performed in such a way as to create a gradient, with respect to the position of the through-holes, of the concentration of a particular substance or of another quantity. Mixing of the contents of through-holes may be obtained by bringing filled microwell arrays into contact with each other with registration of individual through-holes.

Owner:MASSACHUSETTS INST OF TECH

Attachment method for piezoelectric elements

InactiveUS6382522B2Easy to carryConveniently refillableMovable spraying apparatusSpray nozzlesElectricityVena contracta diameter

Disclosed herein is a piezoelectric liquid delivery system or atomizer for production of droplets of liquid or liquid suspensions by means of a battery operated atomizer utilizing an orifice plate in communication with a ceramic piezoelectric element. By use of solder joining to bond the orifice plate to the piezoelectric element, and subsequent repolarization of the piezoelectric element if necessary, superior results are achieved.

Owner:SC JOHNSON & SON INC

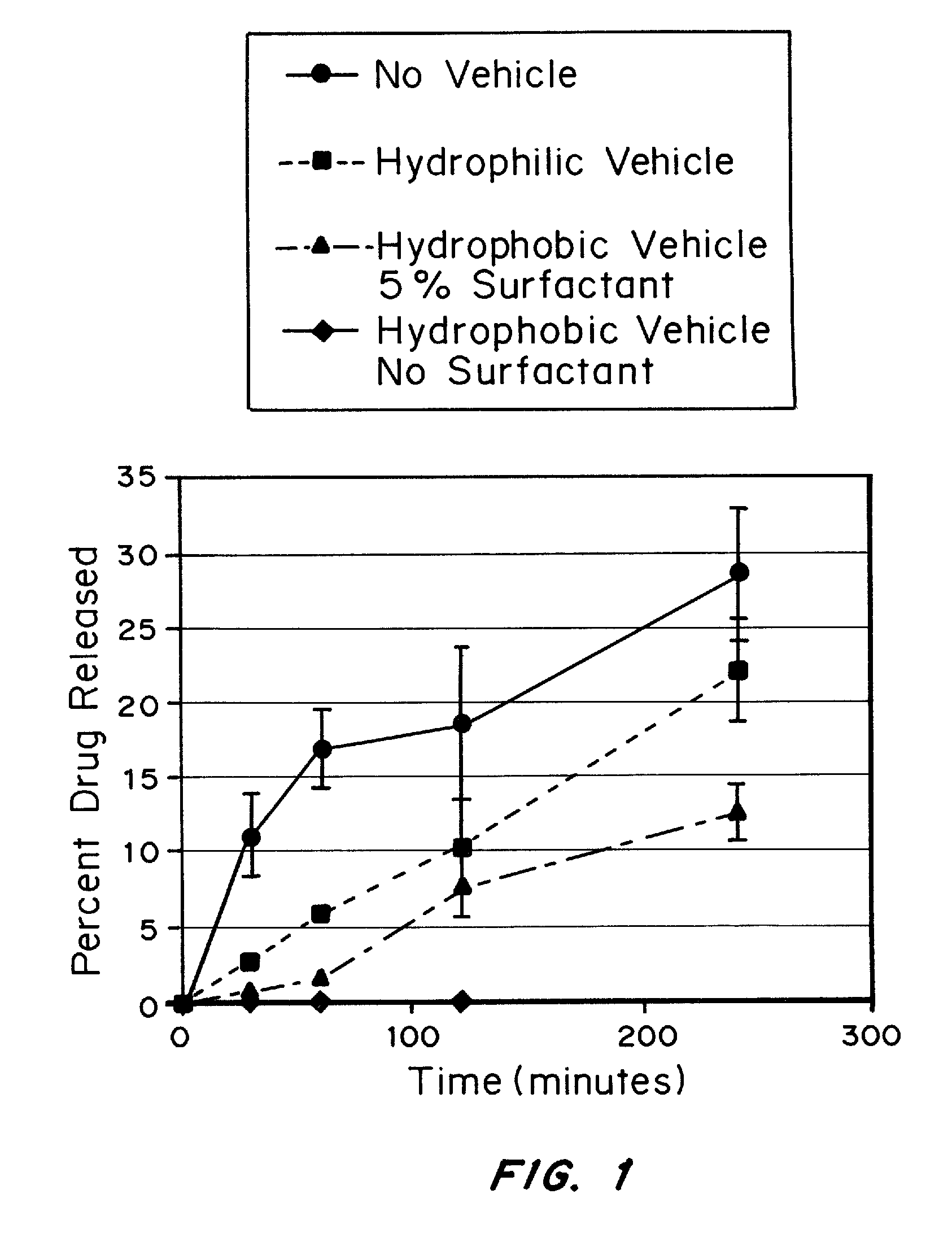

Non-ionic non-aqueous vehicles for topical and oral administration of carrier-complexed active agents

InactiveUS20070036843A1Control releaseLow costOrganic active ingredientsPharmaceutical non-active ingredientsActive agentNon ionic

An improved controlled release composition for non-parenteral administration of active agents and other therapeutics, particularly for oral or topical administration, has been developed. The composition is made by dispersing a complex formed of an active agent bound to an ion-exchange resin or to another form of resin or carrier, in a non-ionic non-aqueous (“NINA”) vehicle. The complexes are optionally coated with one or more layers of coating material to provide a controlled pattern of release of active agent from the carrier. Replacing the usual aqueous vehicle with a NINA vehicle, such as an oil or an ointment, allows the active agent-carrier complexes, with or without coatings, to be both orally and topically administered. The compositions can be formulated as powders, liquids, liquid suspensions, gels, capsules, soft gelatin capsules, tablets, chewable tablets, topical ointments, lotions, pourable or pumpable fluids, semisolid, crushable tablets, and unit-of-use sachets or capsules for reconstitution or direct application. The combination of multiple active agents is possible with this system, in which one or more active agents are bound to particles and one or more active agents are dissolved or dispersed in the NINA vehicle. This allows the combination of two or more active agents, which are otherwise incompatible, into a single dosage form.

Owner:COLLEGIUM PHARMA INC

Process for preparing a non-woven fibrous web

Disclosed is a process for preparing a fibrous web. The fibrous web includes a microencapsulated material, such as a microencapsulated phase change material, adhered to the web. Preferably, the web is prepared in a melt-blowing or spun-bonding process. In the melt-blowing process, cooling water containing the microcapsules is used to cool melt blown fibers prior to collection on a collector. In the spun-bonding process, microcapsules are applied in liquid suspension or in dry form to a heated web, for instance, after the web has been calendared. The fibrous webs thus prepared have numerous uses, and are particularly suited to the manufacture of clothing.

Owner:ENCAPSYS LLC

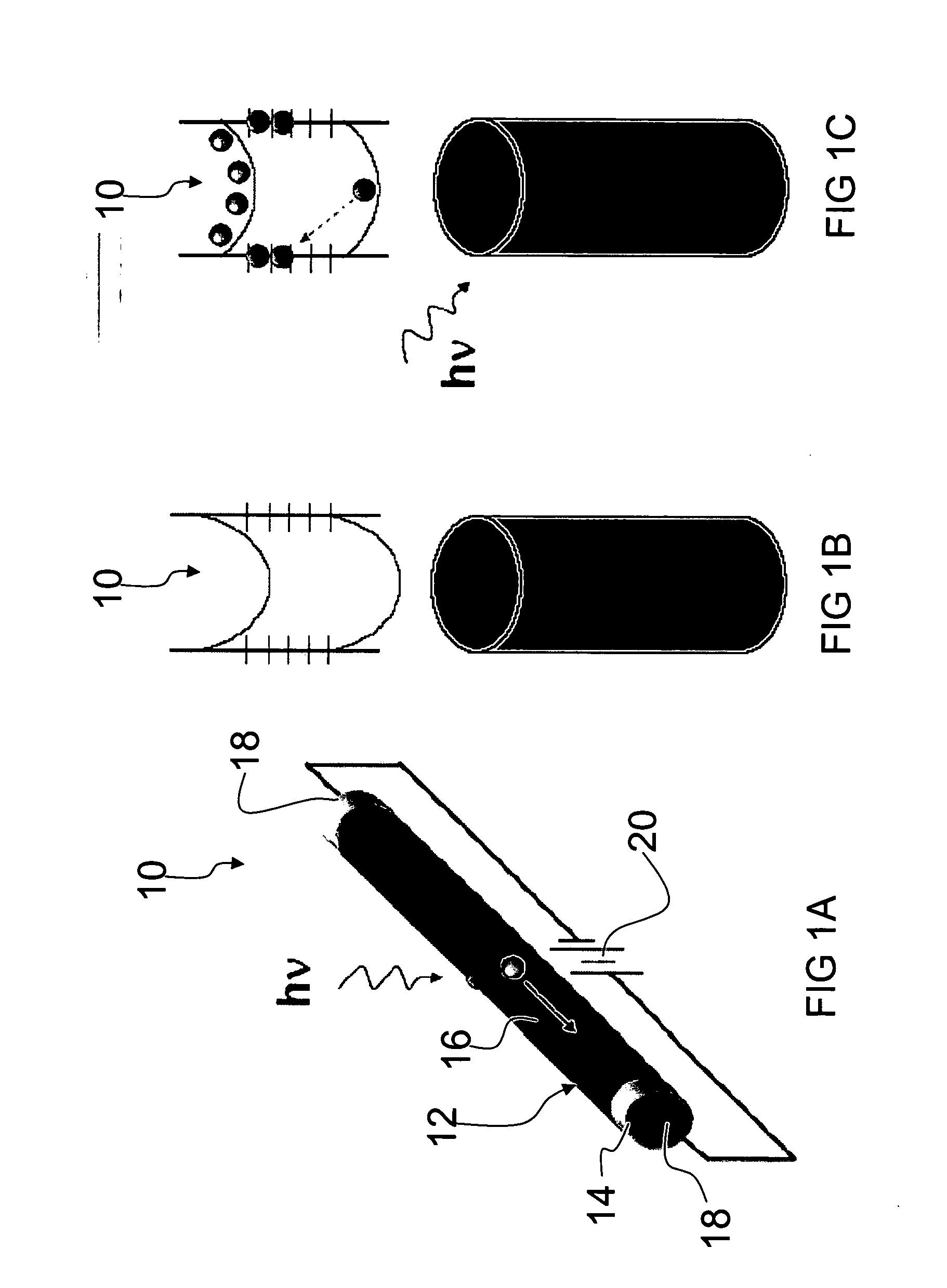

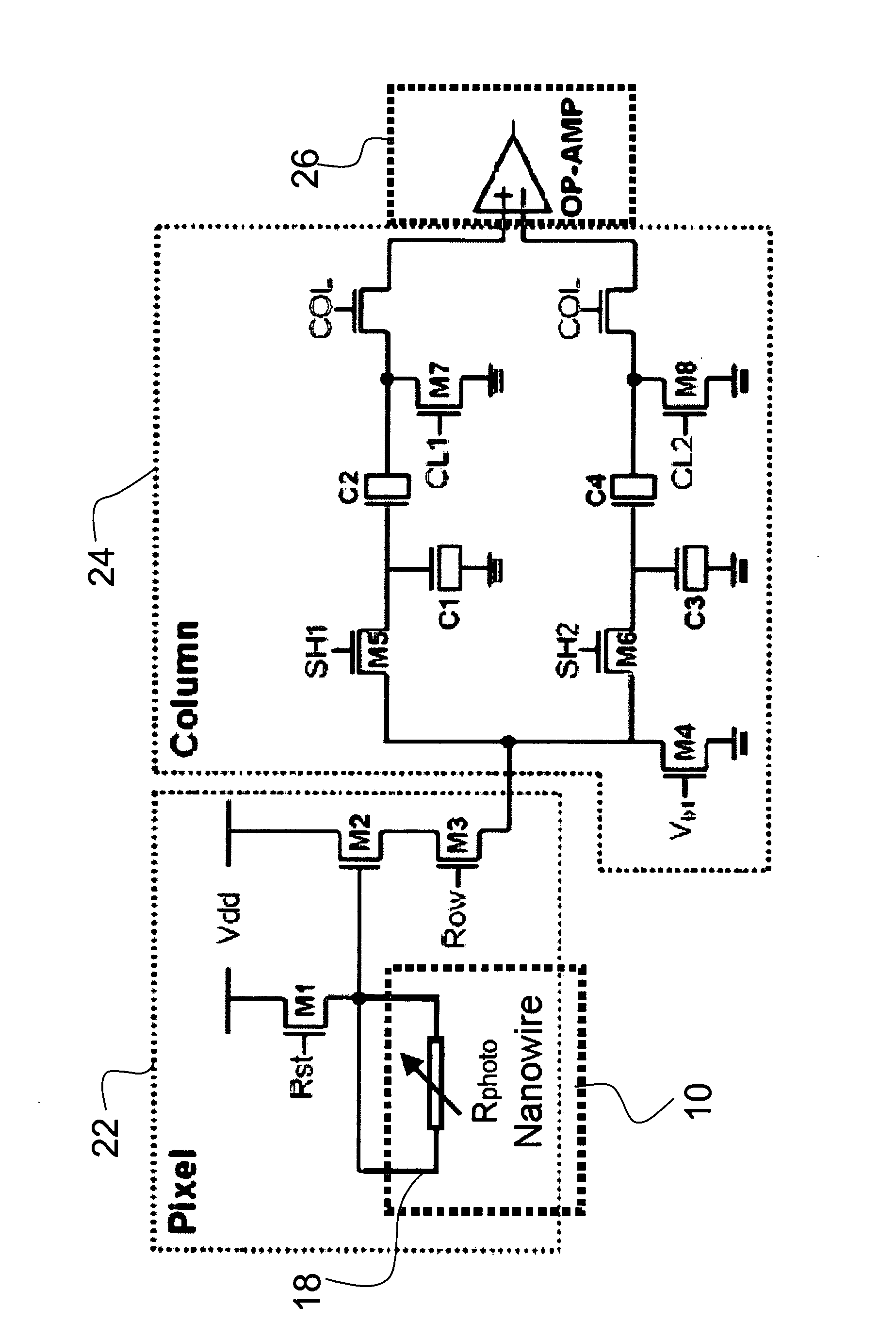

Nanowire photodetector and image sensor with internal gain

InactiveUS20100295019A1High gainHigh photocurrent responseSemiconductor/solid-state device manufacturingNanoopticsResistNanowire

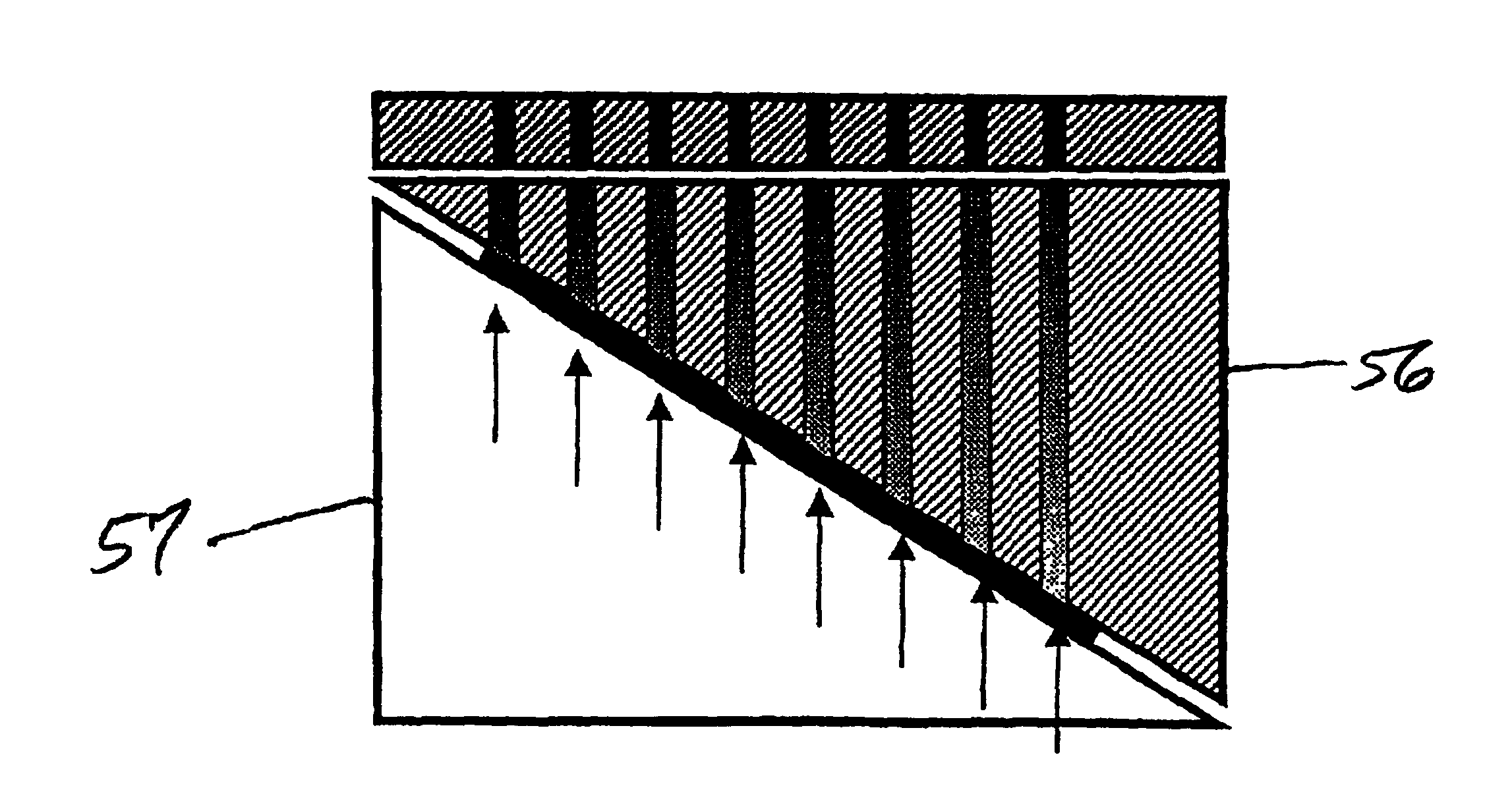

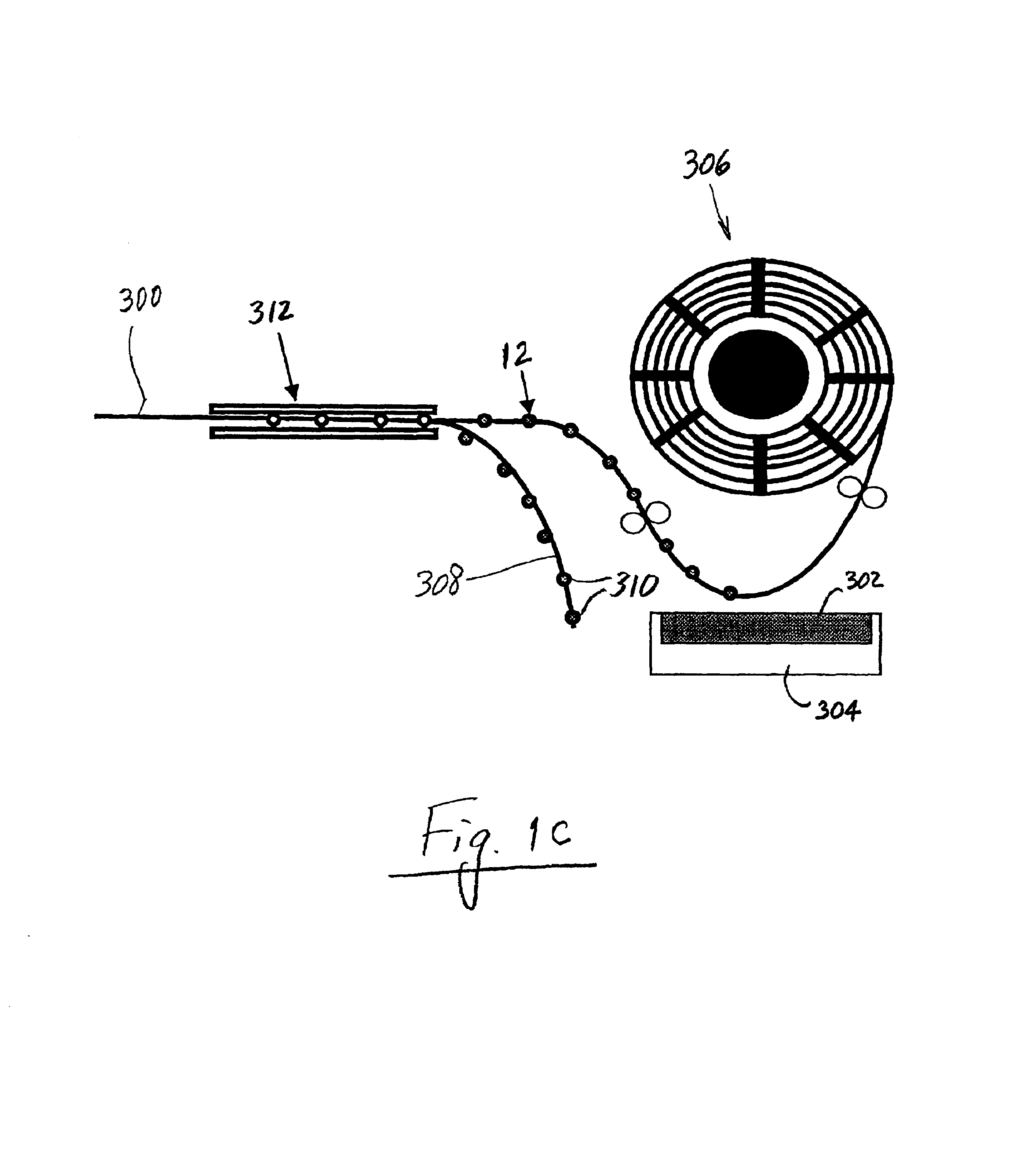

A practical ID nanowire photodetector with high gain that can be controlled by a radial electric field established in the ID nanowire. A ID nanowire photodetector device of the invention includes a nanowire that is individually contacted by electrodes for applying a longitudinal electric field which drives the photocurrent. An intrinsic radial electric field to the nanowire inhibits photo-carrier recombination, thus enhancing the photocurrent response. The invention further provides circuits of ID nanowire photodetectors, with groups of photodetectors addressed by their individual ID nanowires electrode contacts. The invention also provides a method for placement of ID nanostructures, including nanowires, with registration onto a substrate. A substrate is patterned with a material, e.g., photoresist, and trenches are formed in the patterning material at predetermined locations for the placement of ID nanostructures. The ID nanostructures are aligned in a liquid suspension, and then transferred into the trenches from the liquid suspension. Removal of the patterning material places the ID nanostructures in predetermined, registered positions on the substrate.

Owner:RGT UNIV OF CALIFORNIA

Electrospraying method with conductivity control

An electrospraying apparatus and / or method is used to coat particles. For example, a flow including at least one liquid suspension may be provided through at least one opening at a spray dispenser end. The flow includes at least particles and a coating material. A spray of microdroplets suspending at least the particles is established forward of the spray dispenser end by creating a nonuniform electrical field between the spray dispenser end and an electrode electrically isolated therefrom. The particles are coated with at least a portion of the coating material as the microdroplet evaporates. For example, the suspension may include biological material particles.

Owner:RGT UNIV OF MINNESOTA

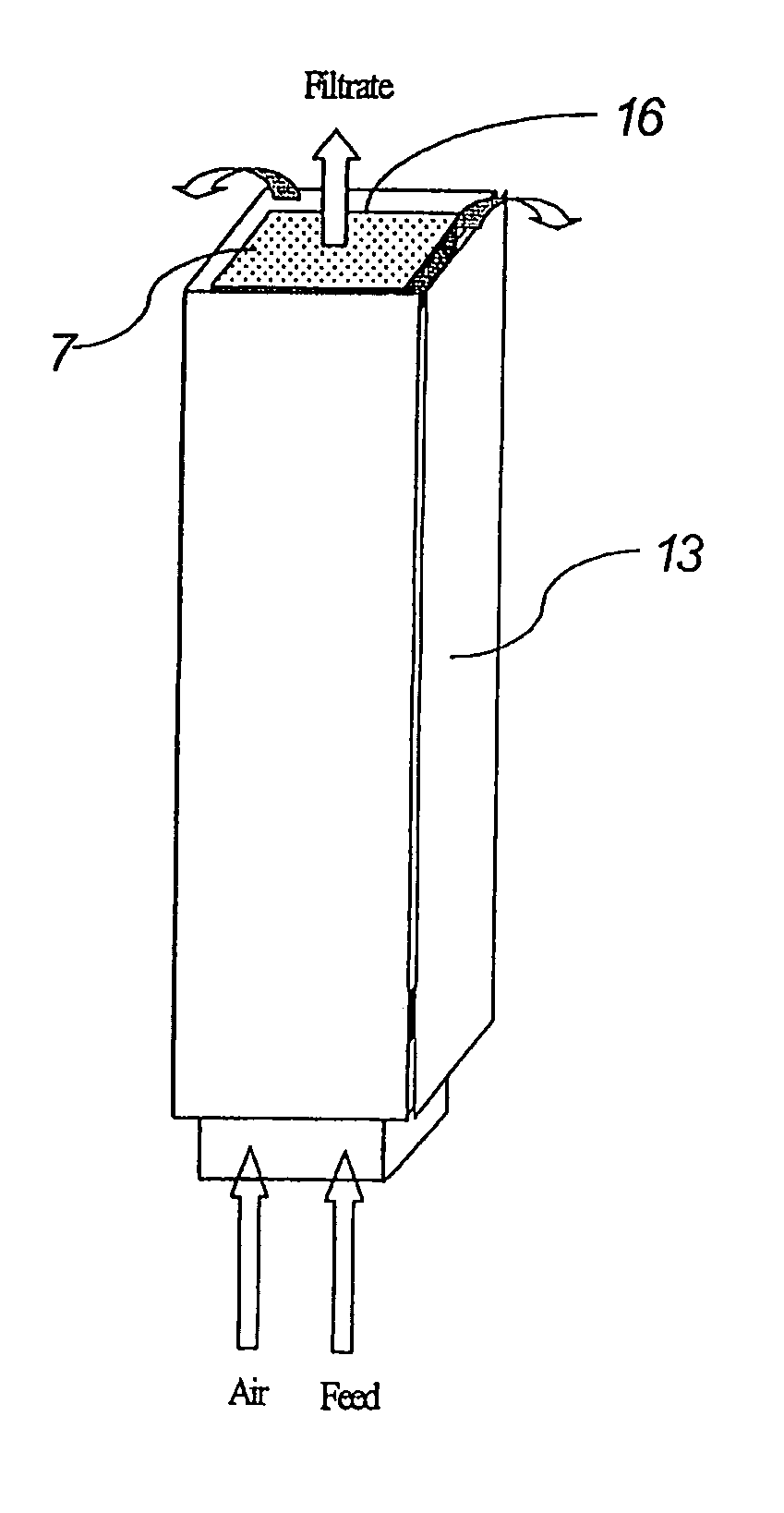

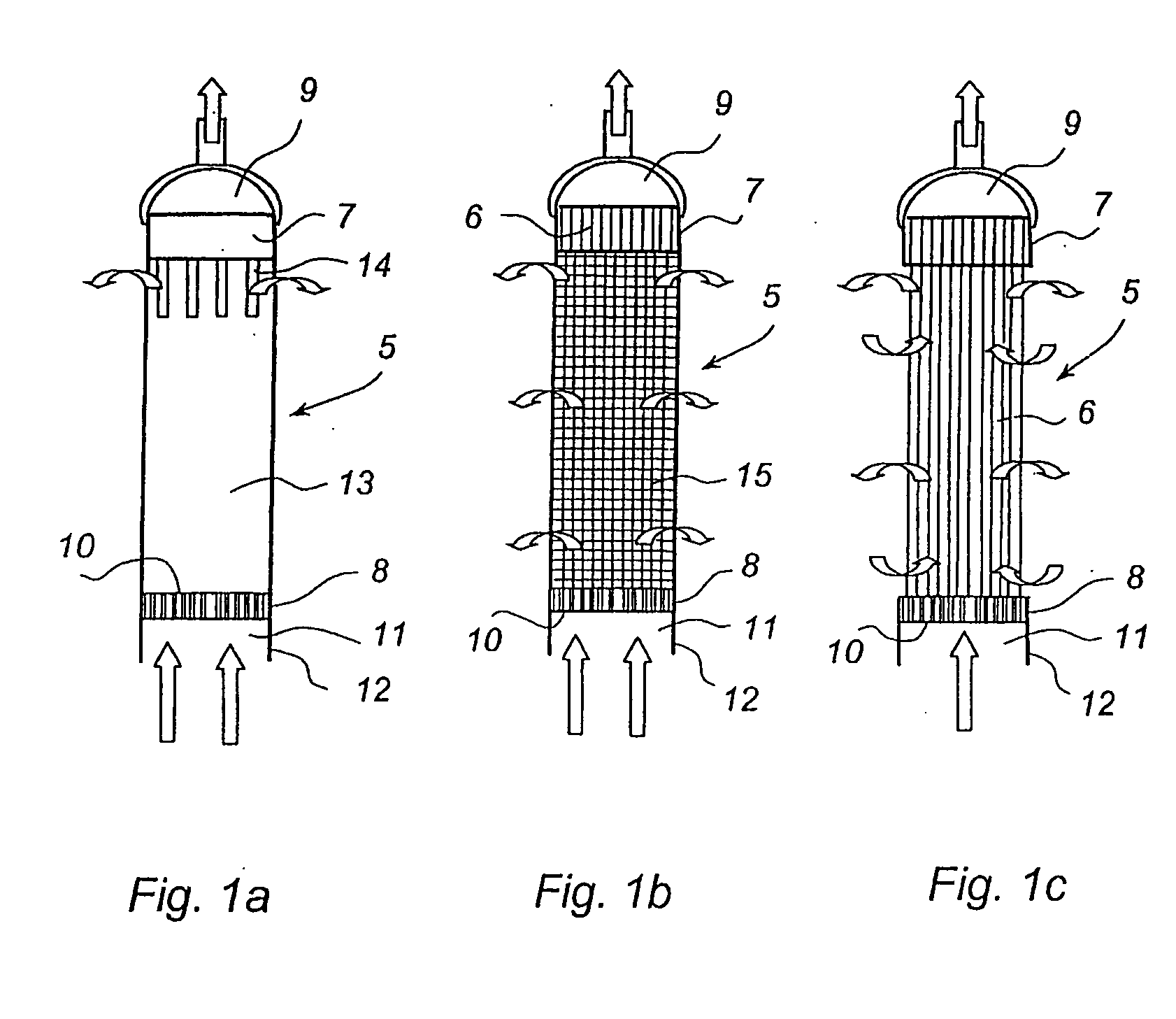

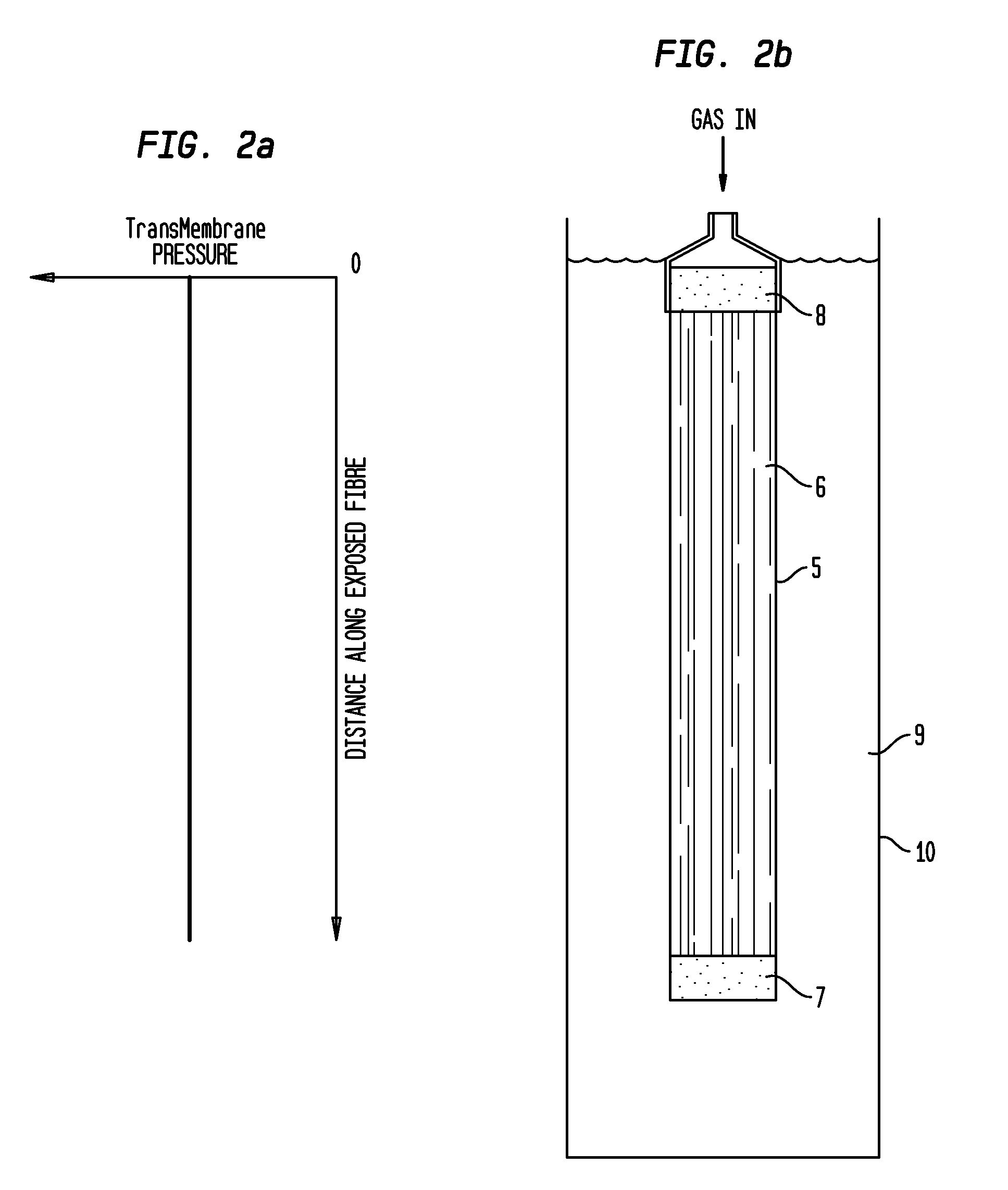

Submerged cross-flow filtration

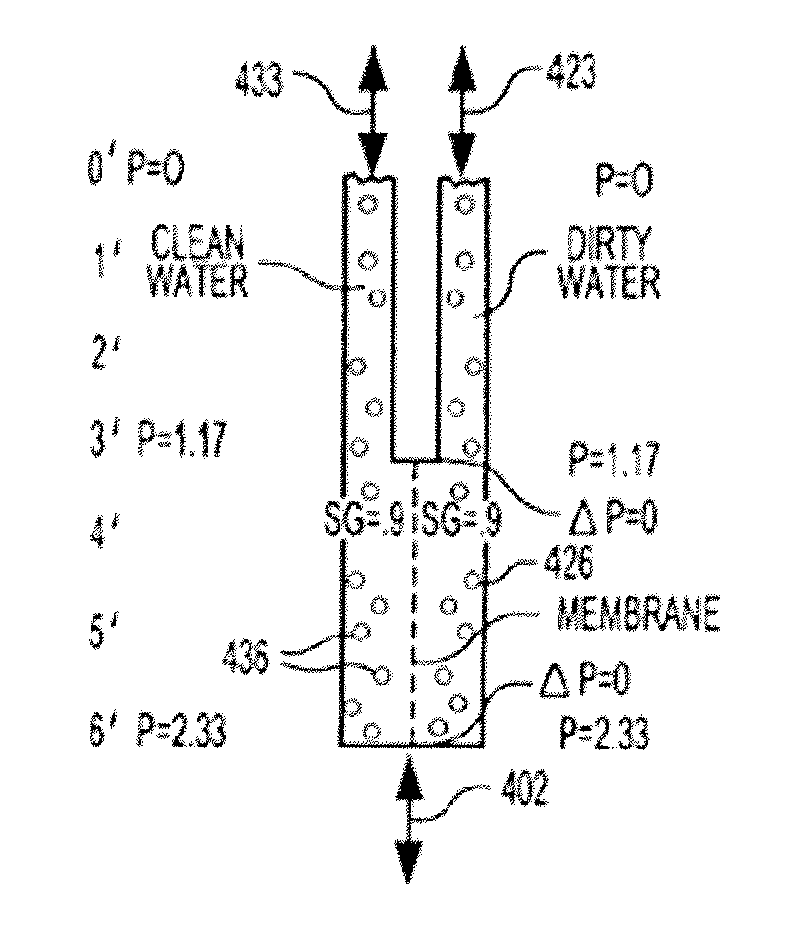

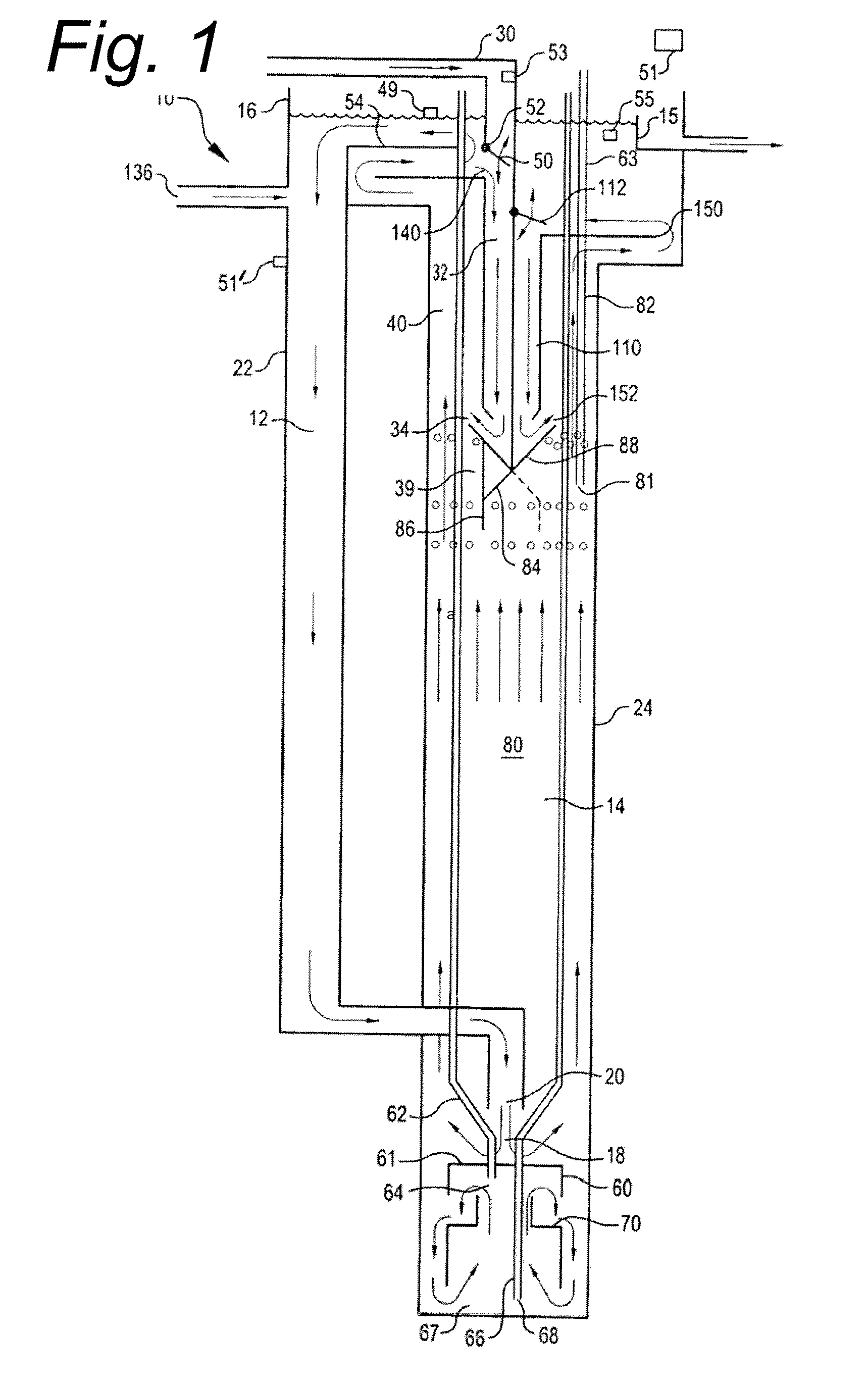

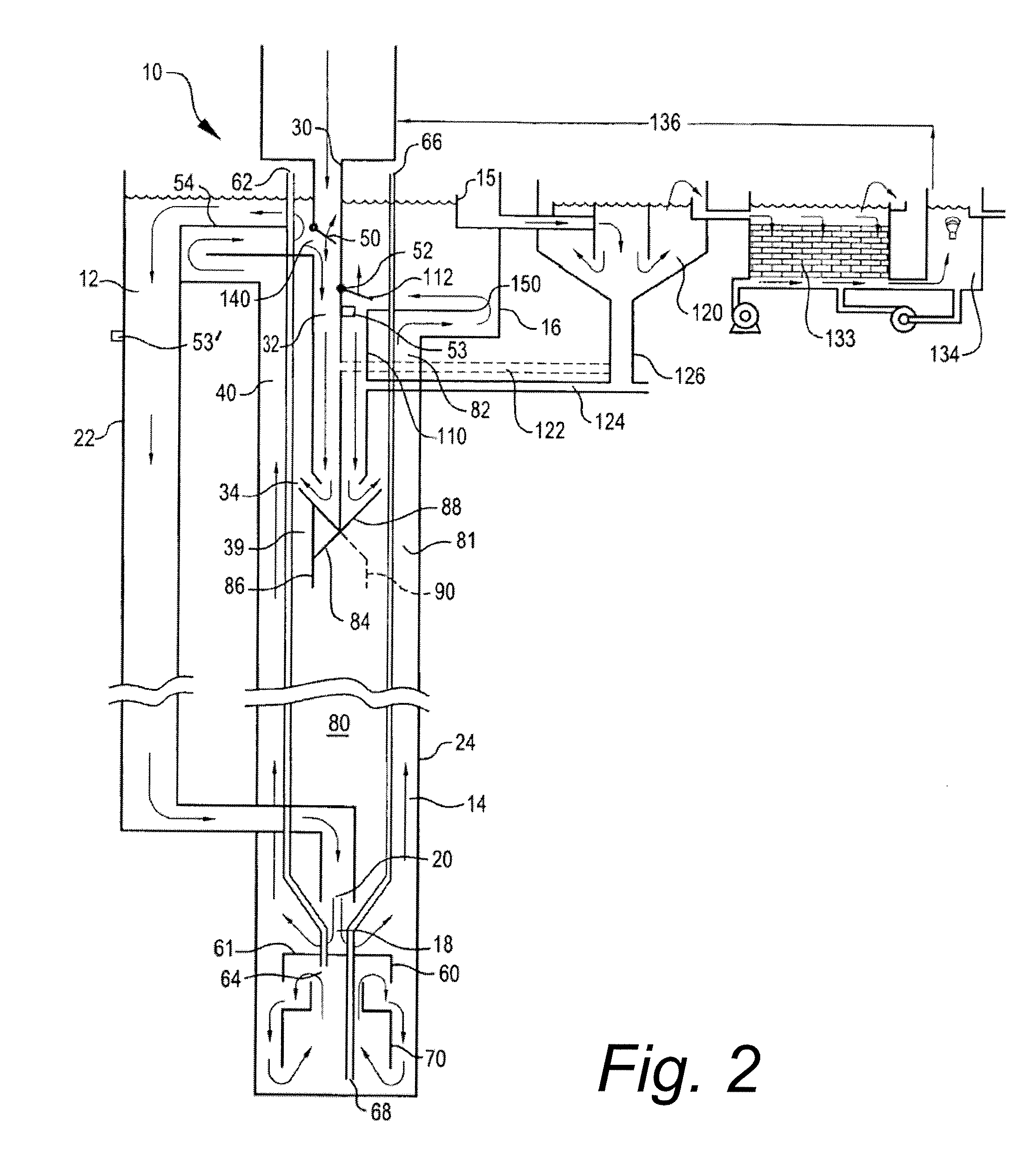

A membrane filtration module having a plurality of permeable, hollow membranes is disclosed. In use, a pressure differential is applied across the walls of the permeable, hollow membranes when immersed in a liquid suspension containing suspended solids. Some of the liquid suspension passes through the walls of the membranes to be drawn off as clarified liquid or permeate, and at least some of the solids are retained on or in the permeable, hollow membranes or otherwise as suspended solids within the liquid suspension. The module has a shell or similar structure that at least partially surrounds the membrane module and substantially effects retaining at least portion of fluid flowed into the membrane module.

Owner:EVOQUA WATER TECH LLC

Carbonising and/or Activating Carbonaceous Material

A method is provided for carbonizing and activating carbonaceous material, which comprises supplying the material to an externally fired rotary kiln maintained at carbonizing and activating temperatures, the kiln having a downward slope to progress the material as it rotates, the kiln having an atmosphere substantially free of oxygen provided by a counter-current of steam or carbon dioxide, and annular weirs being provided at intervals along the kiln to control progress of the material. There may further be provided an externally fired rotary kiln for carbonizing and activating carbonaceous material having a hollow rotary body that has a downward slope towards a discharge end thereof, and which is provided at intervals along its length with annular weirs for controlling progress of the carbonaceous material. In embodiments, there is also provided a process is for producing discrete solid beads of polymeric material e.g. phenolic resin beads having a mesoporous structure, which may be useful as feedstock for the above mentioned carbonization / activation process or which may have other utility e.g. as ion exchange resins. The process may produce resin beads on an industrial scale without aggregates of resin building up speedily and interrupting production. The process comprises the steps of: (a) combining a stream of a polymerizable liquid precursor e.g. a novolac and hexamine as cross-linking agent dissolved in a first polar organic liquid e.g. ethylene glycol with a stream of a liquid suspension medium which is a second non-polar organic liquid with which the liquid precursor is substantially or completely immiscible e.g. transformer oil containing a drying oil; (b) mixing the combined stream to disperse the polymerizable liquid precursor as droplets in the suspension medium e.g. using an in-line static mixer; (c) allowing the droplets to polymerise in a laminar flow of the suspension medium so as to form discrete solid beads that cannot agglomerate; and (d) recovering the beads from the suspension medium. There is also provided apparatus for forming discrete solid beads of polymeric material, said apparatus comprising: a first line for conveying s stream of a polymerizable liquid precursor; a second line for conveying a stream of a dispersion medium with which the polymerizable liquid precursor is substantially or completely immiscible; an in-line mixer configured to receive a combined flow from the first and second lines and to disperse the polymerizable liquid precursor as droplets in the dispersion medium; a vertical polymerization column configured to receive the dispersion medium with the droplets dispersed therein and to permit the polymerizable liquid precursor polymerize while descending the column in a descending flow of polymerization medium; and a vessel at the base of the column for receiving the descending flow of dispersion medium and collecting polymerized solid beads.

Owner:BRITISH AMERICAN TOBACCO (INVESTMENTS) LTD

Submerged cross-flow filtration

A membrane filtration module having a plurality of permeable, hollow membranes is disclosed. In use, a pressure differential is applied across the walls of the permeable, hollow membranes when immersed in a liquid suspension containing suspended solids. Some of the liquid suspension passes through the walls of the membranes to be drawn off as clarified liquid or permeate, and at least some of the solids are retained on or in the permeable, hollow membranes or otherwise as suspended solids within the liquid suspension. The module has a shell or similar structure that at least partially surrounds the membrane module and substantially effects retaining at least portion of fluid flowed into the membrane module.

Owner:EVOQUA WATER TECH LLC

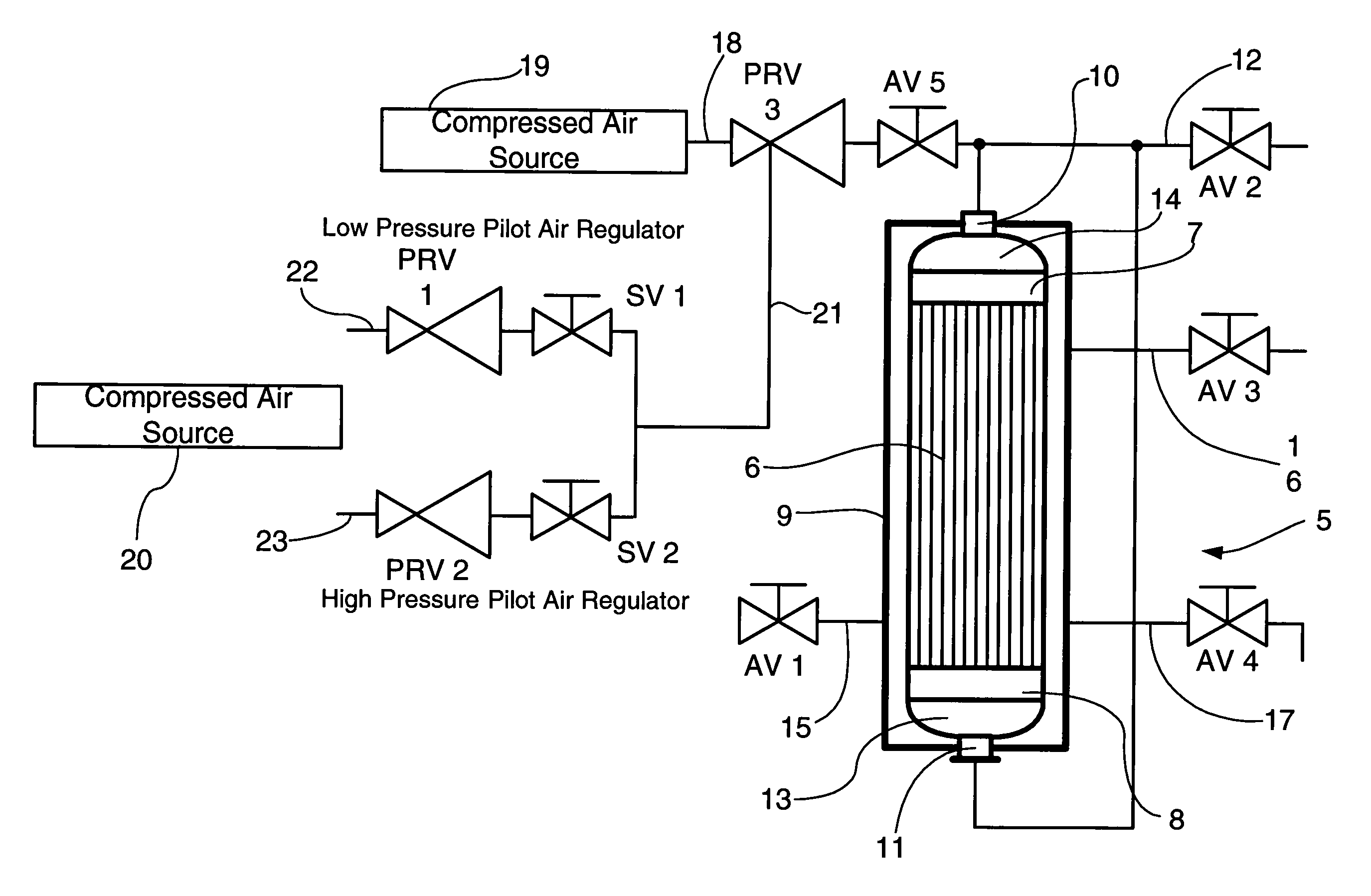

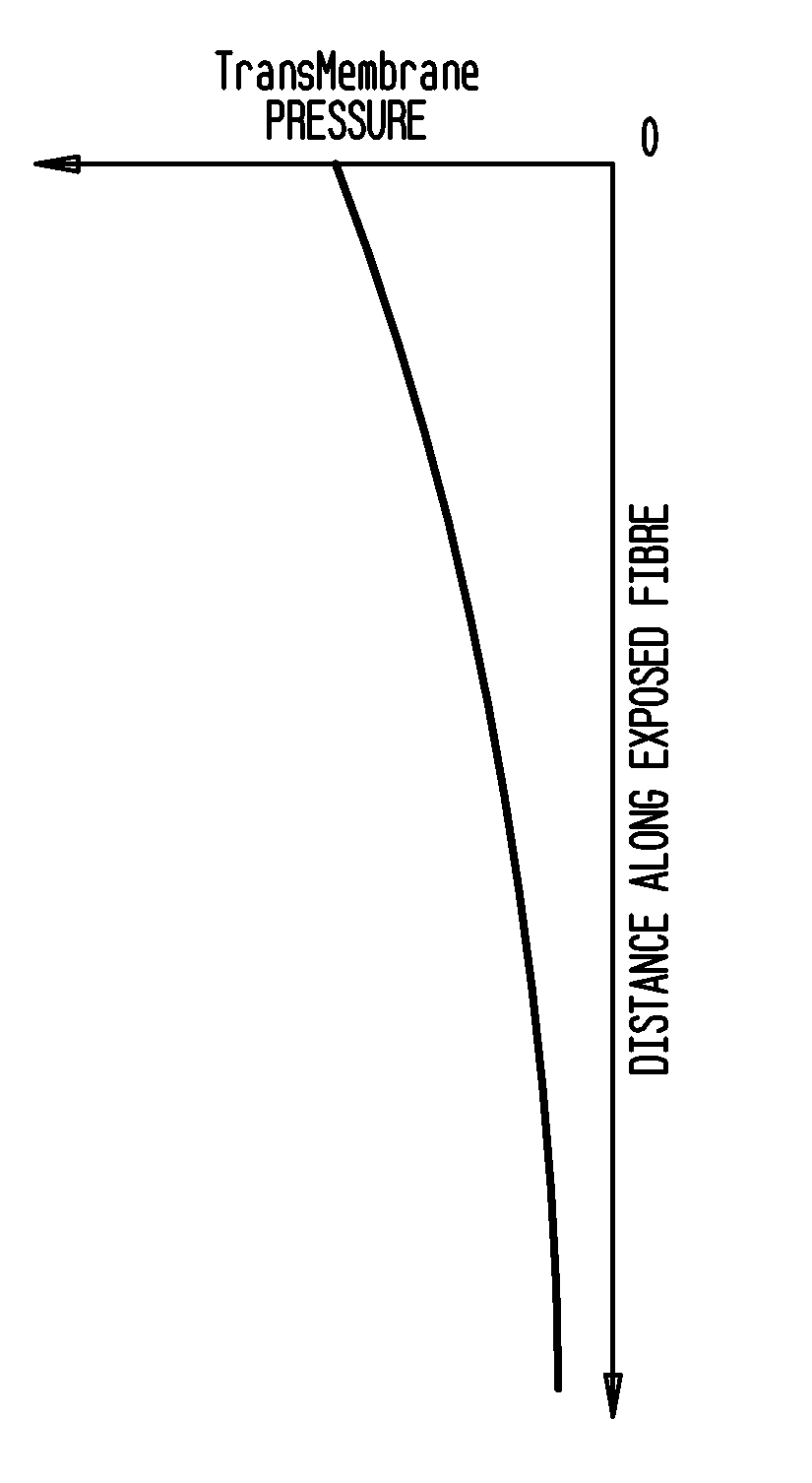

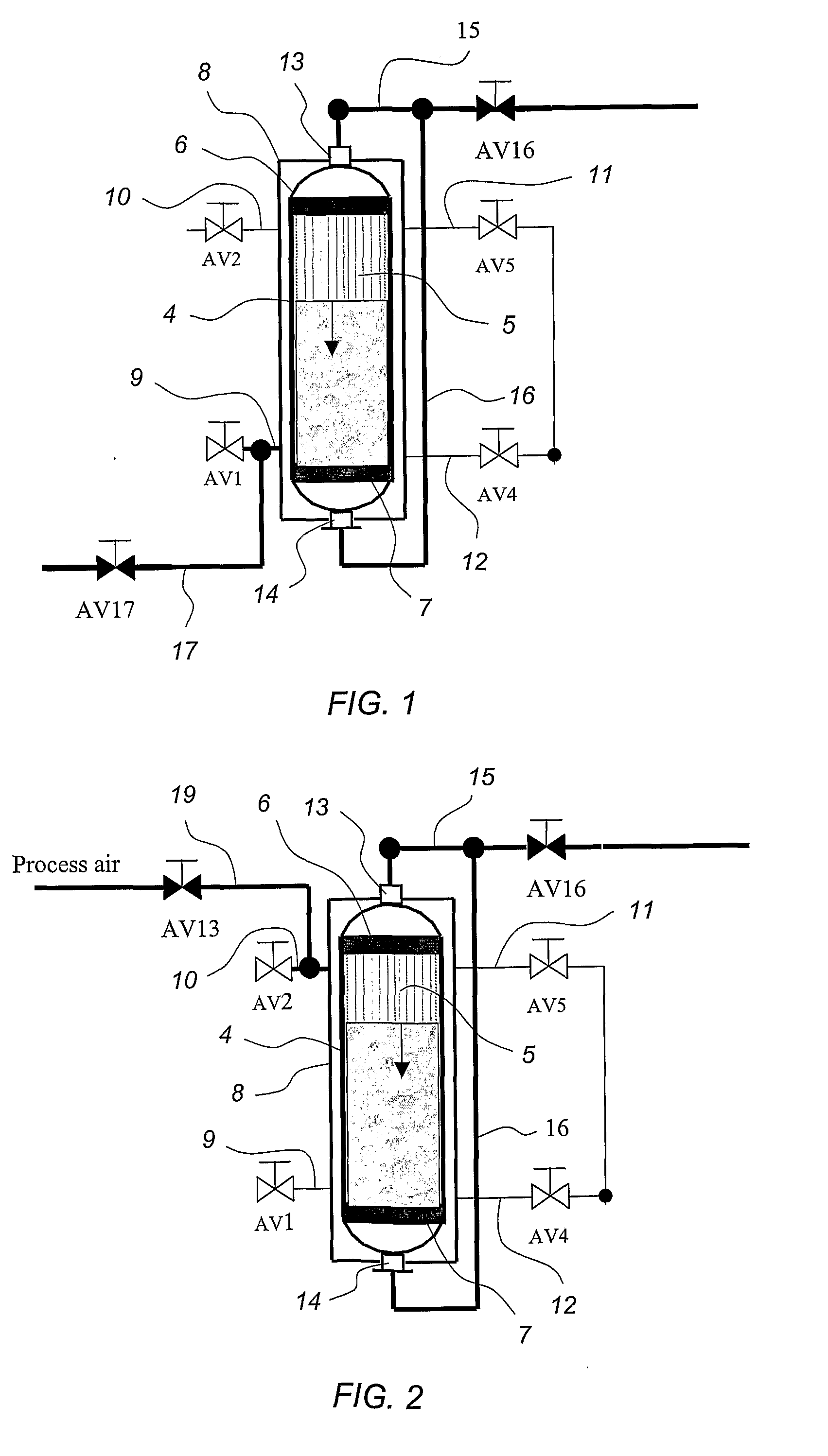

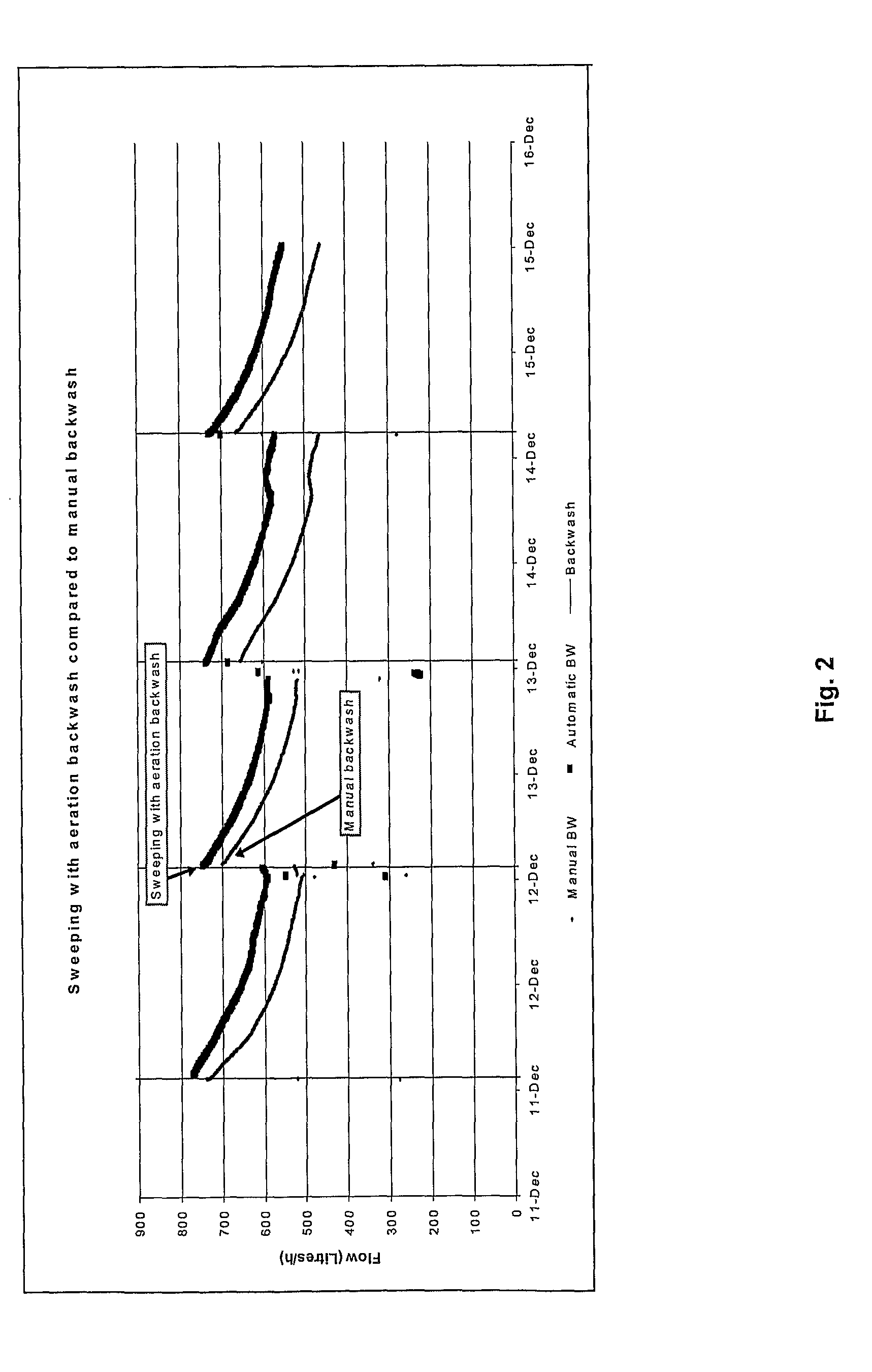

Membrane System Backwash Energy Efficiency

ActiveUS20110139715A1Improve efficiencyLow costMembranesSpecific water treatment objectivesFiberHollow fibre membrane

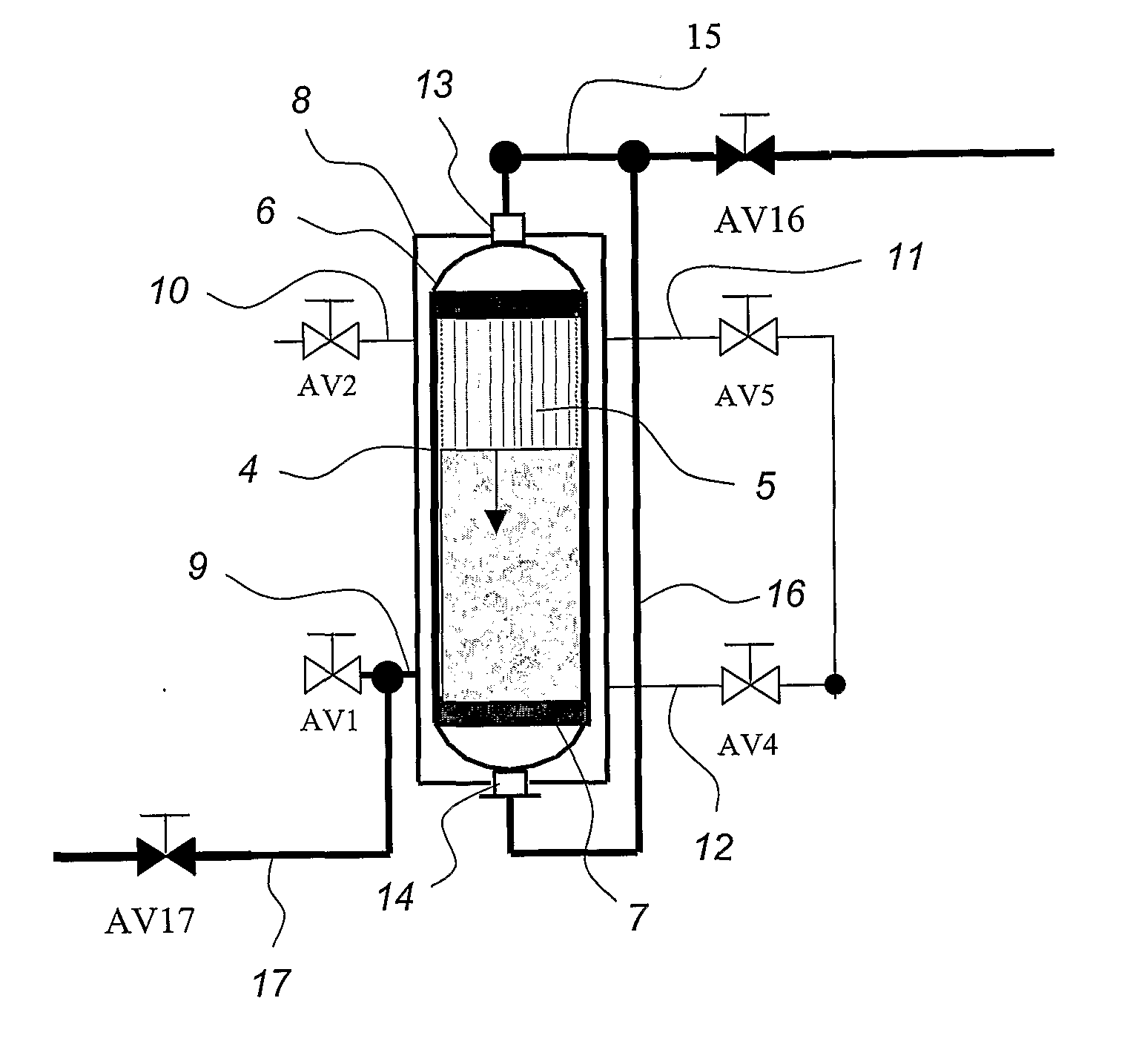

A method of backwashing a membrane filtration system comprising at least one permeable membrane, preferably a hollow fibre membrane, the method comprising the step of applying a pressurised gas at a variable pressure to permeate remaining present in the system when filtration process is stopped or suspended to provide liquid for backwashing pores of the permeable membrane during a backwashing process. Also provided are methods of filtering solids from a liquid suspension using alternating liquid backwash pressures.

Owner:EVOQUA WATER TECH LLC

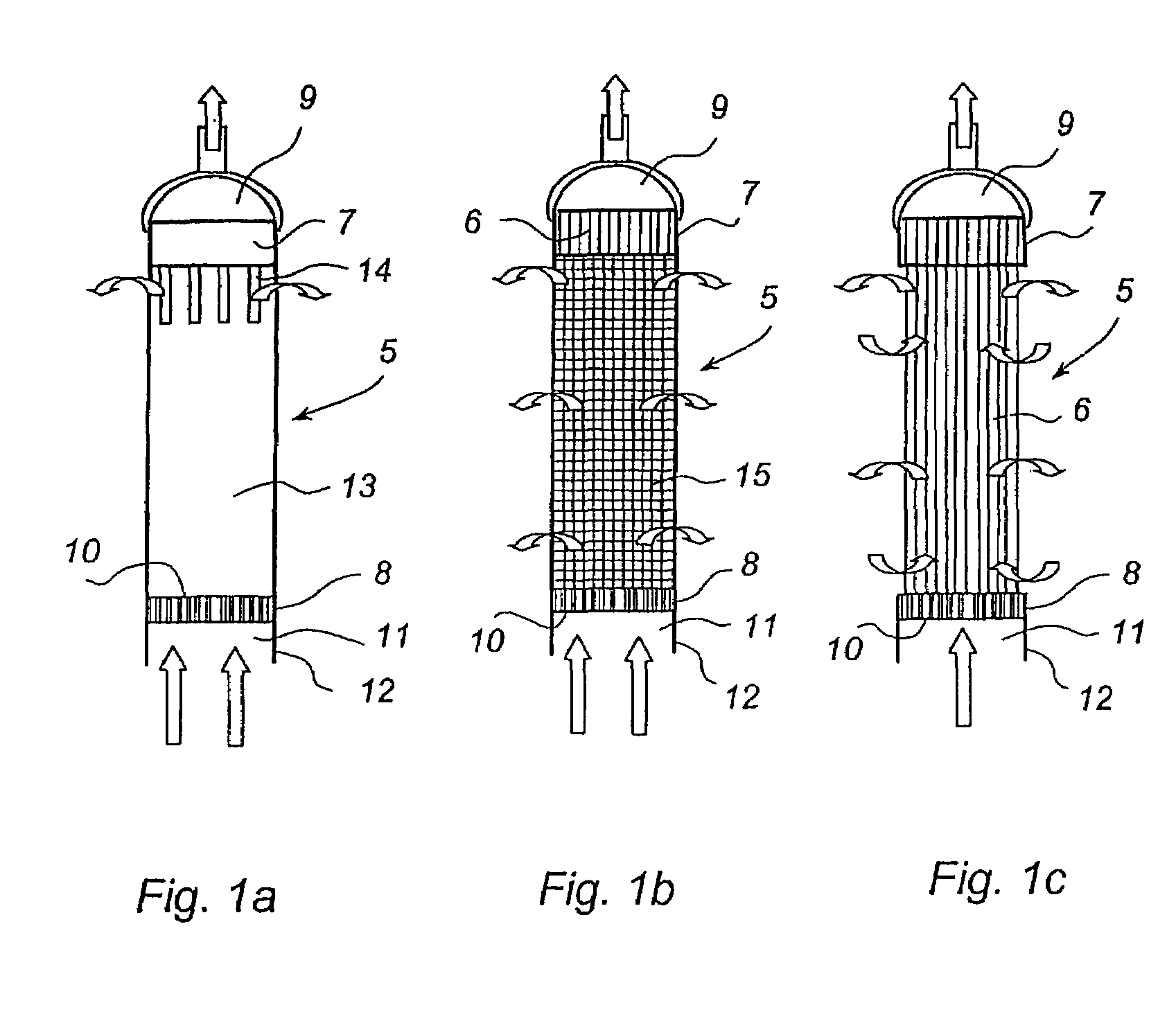

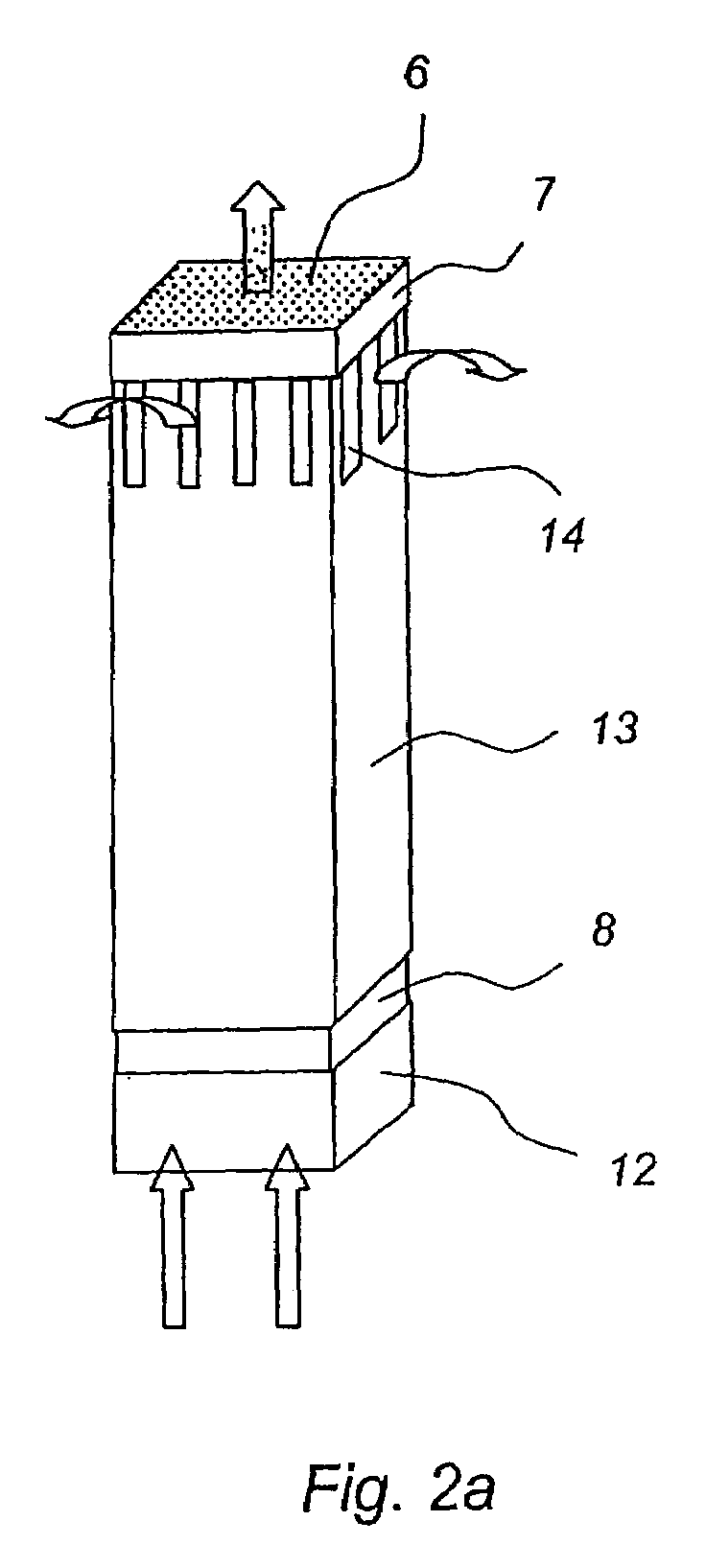

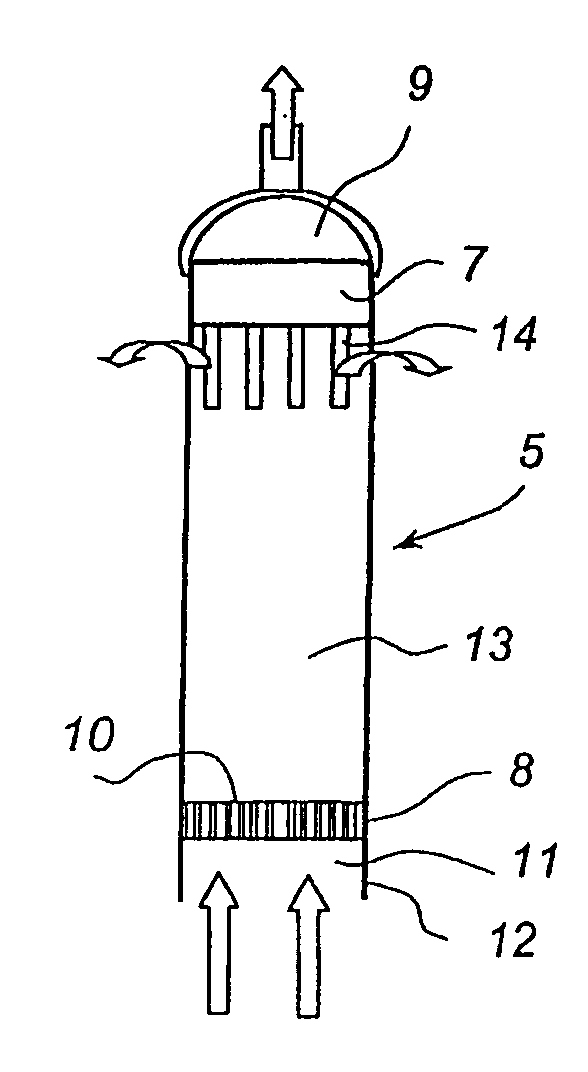

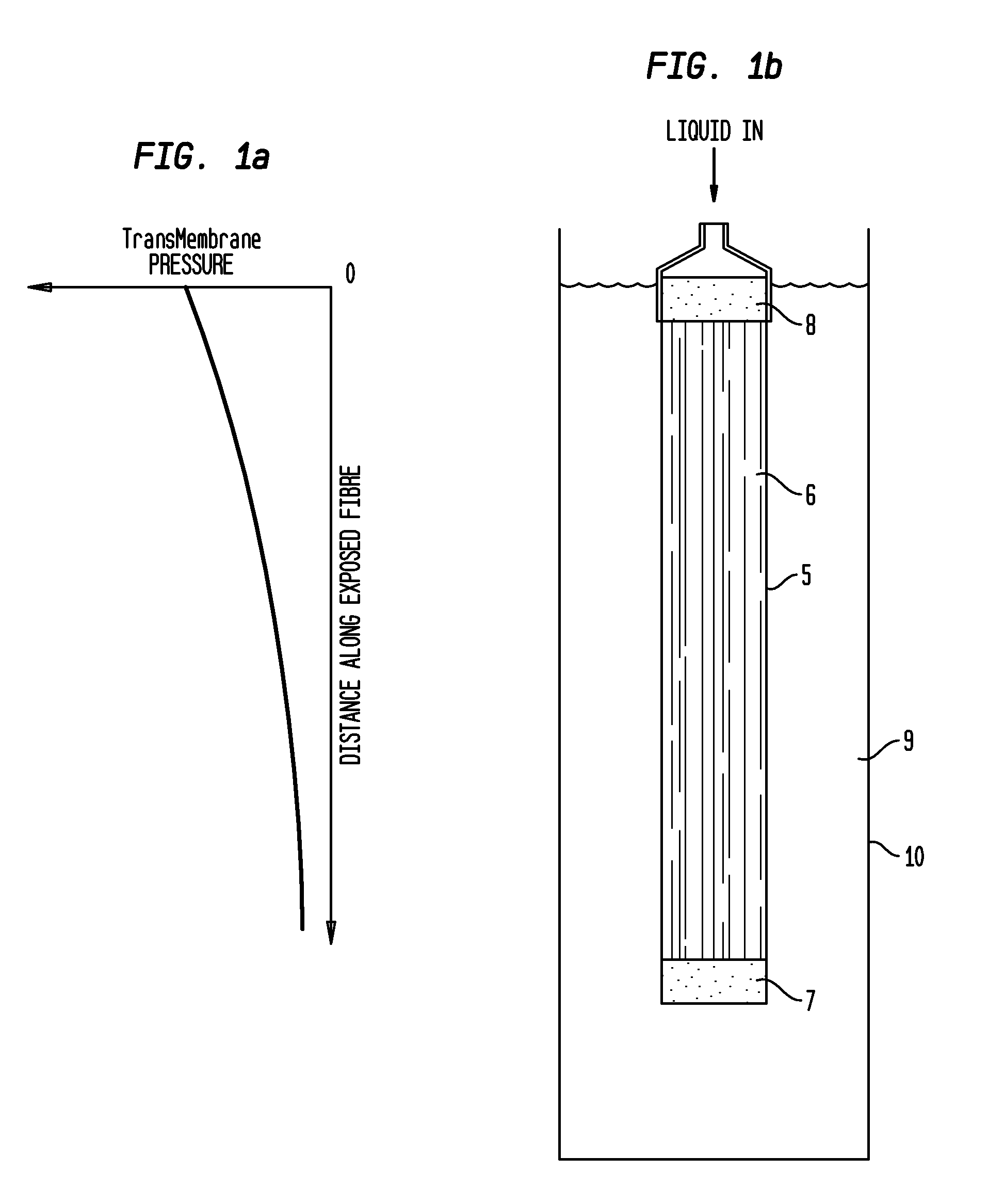

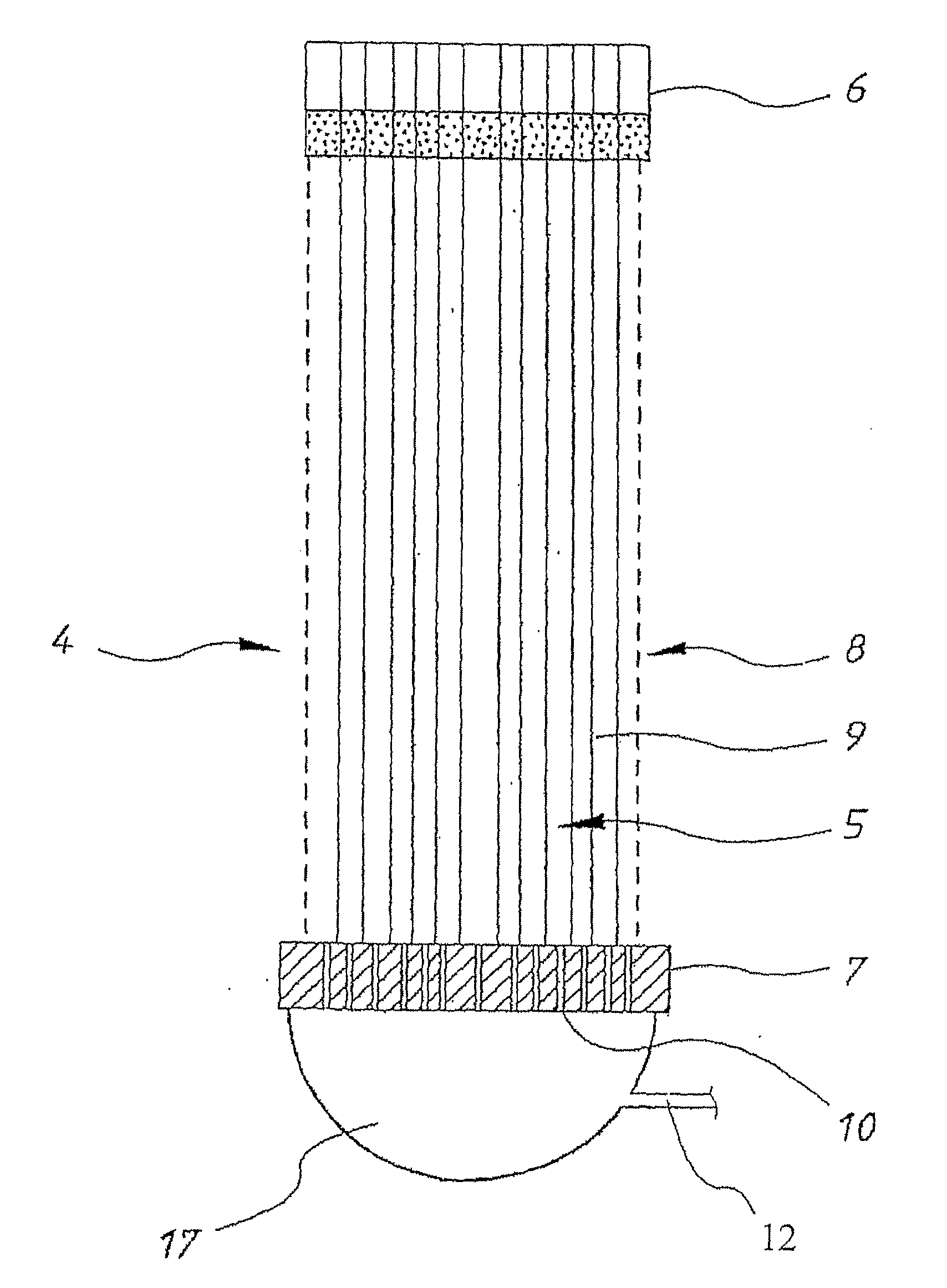

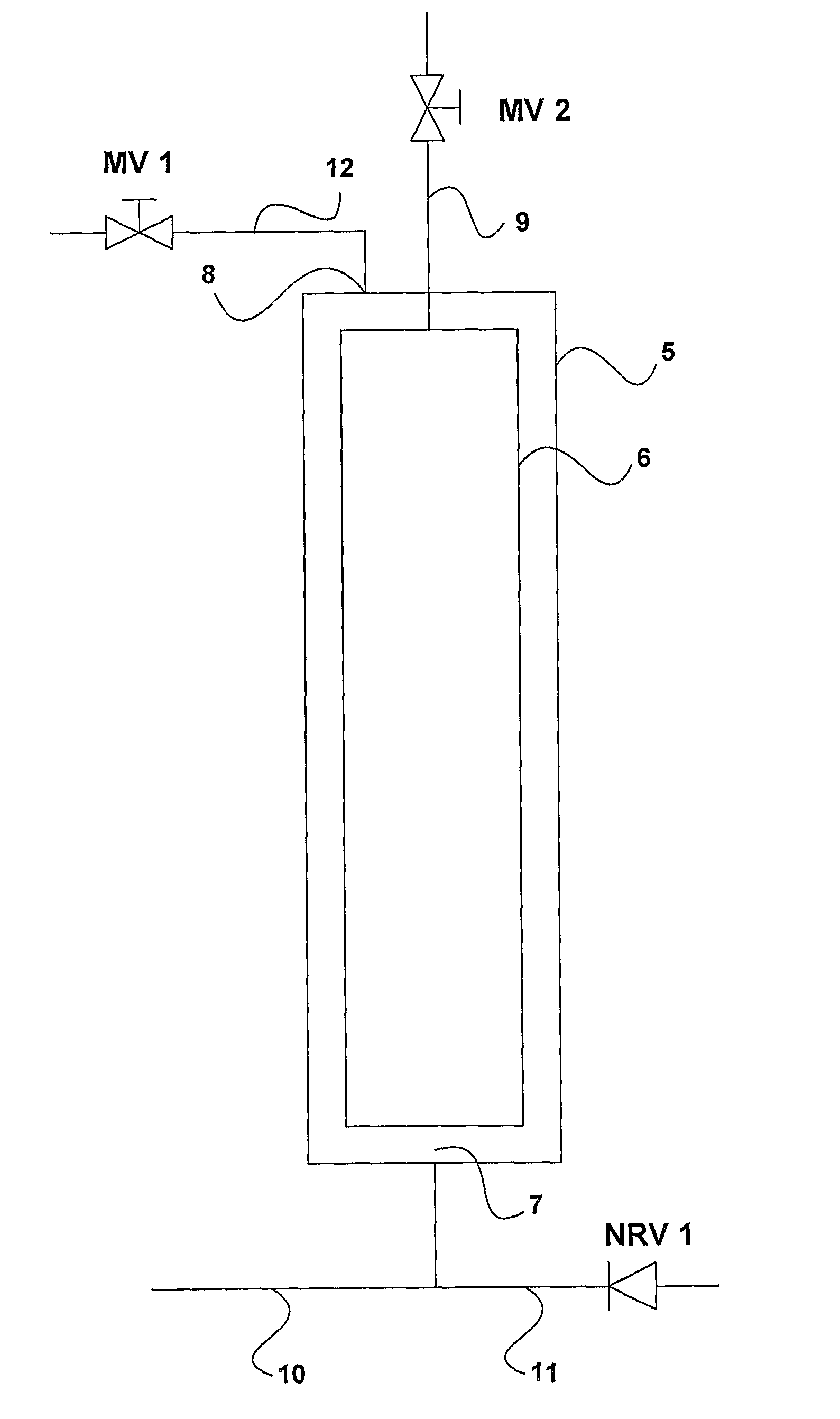

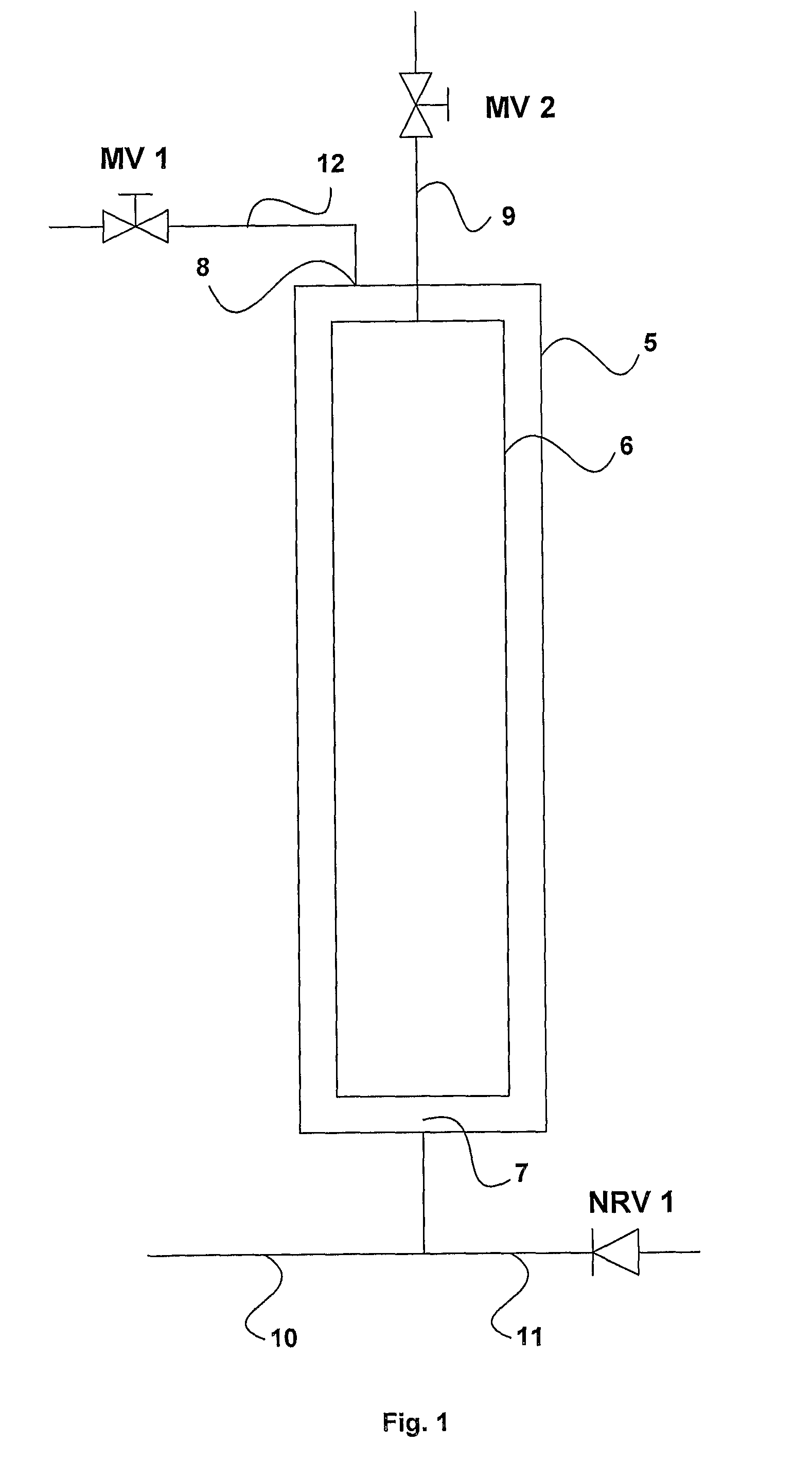

Backwash and cleaning method

InactiveUS20100025320A1Efficient chemical backwashMinimal useMembranesSemi-permeable membranesFiltrationCleaning methods

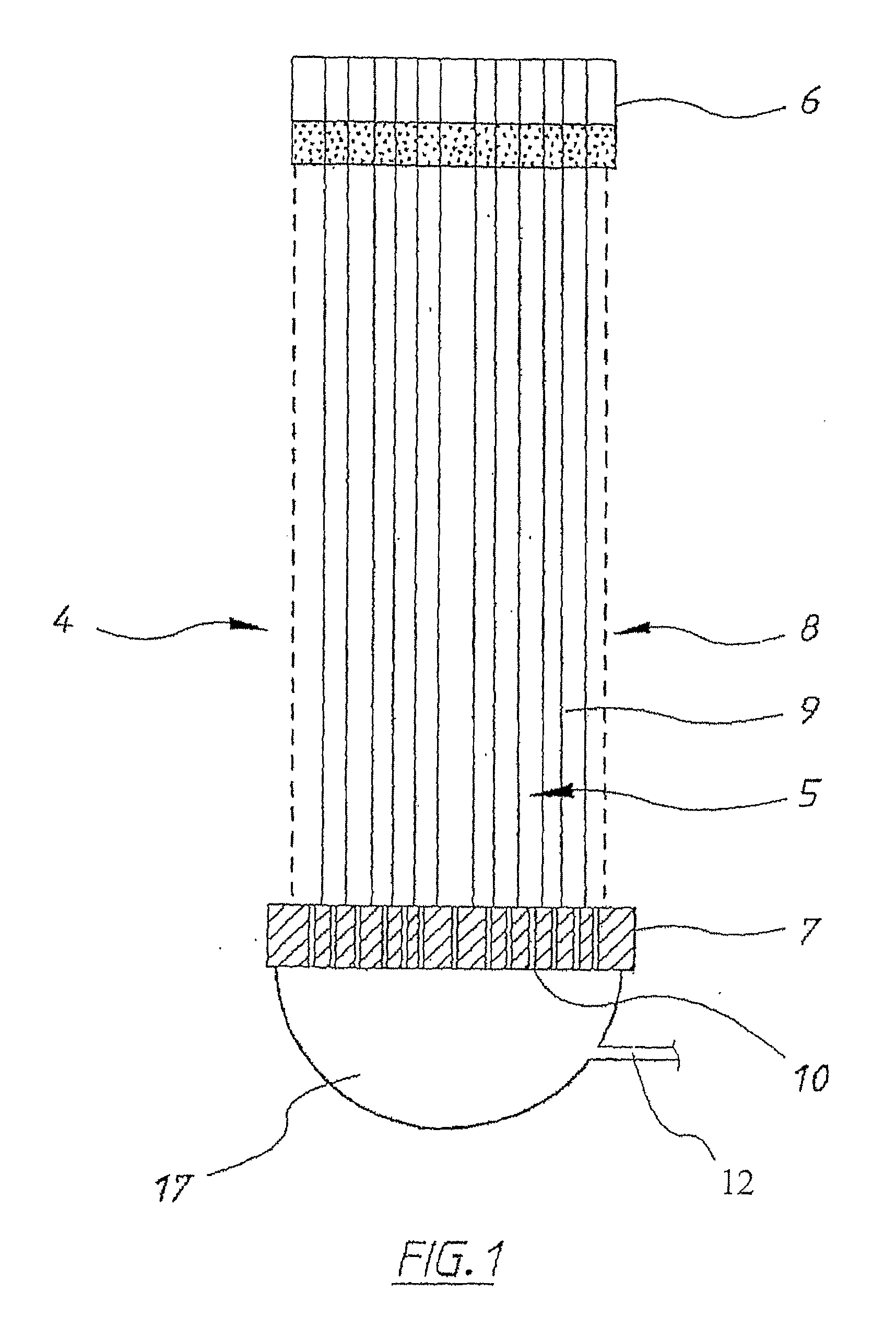

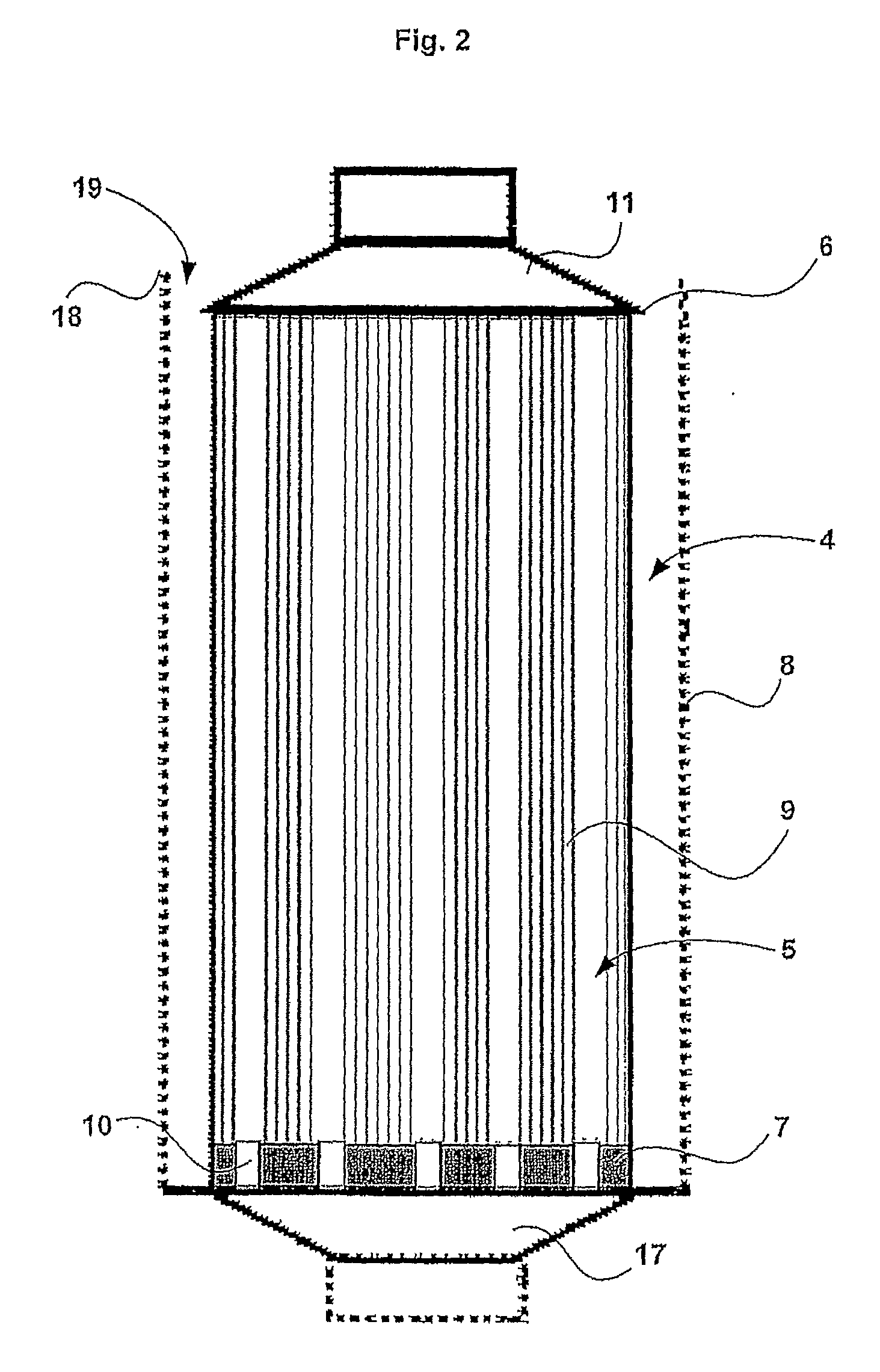

A method of concentrating the solids of a liquid suspension by providing pressure differential across the walls of permable hollow membranes (6) immersed in the liquid suspension (9). The liquid suspension (9) is applied to the outer surface of the porous hollow membranes (6) to induce and sustain filtration through the membrane walls (12) wherein some of the liquid suspension passes through the walls (12) of the membranes (6) to be drawn off as clarified liquid or permeate from the hollow membranes lumens (11), and at least some of the solids are retained on or in the hollow membranes (6) or otherwise as suspended solids within the liquid (9) surrounding the membranes (6). The method includes periodically backwashing the membrane pores using the permeate by applying a gas pressure below the bubble point to the membrane lumens (11) to progressively displace at least some of the liquid permeate within the lumens (11) through the membrane pores resulting in removal the solids retained on or in the hollow membranes into the bulk liquid (9) surrounding the membranes (6).

Owner:JOHNSON WARREN THOMAS

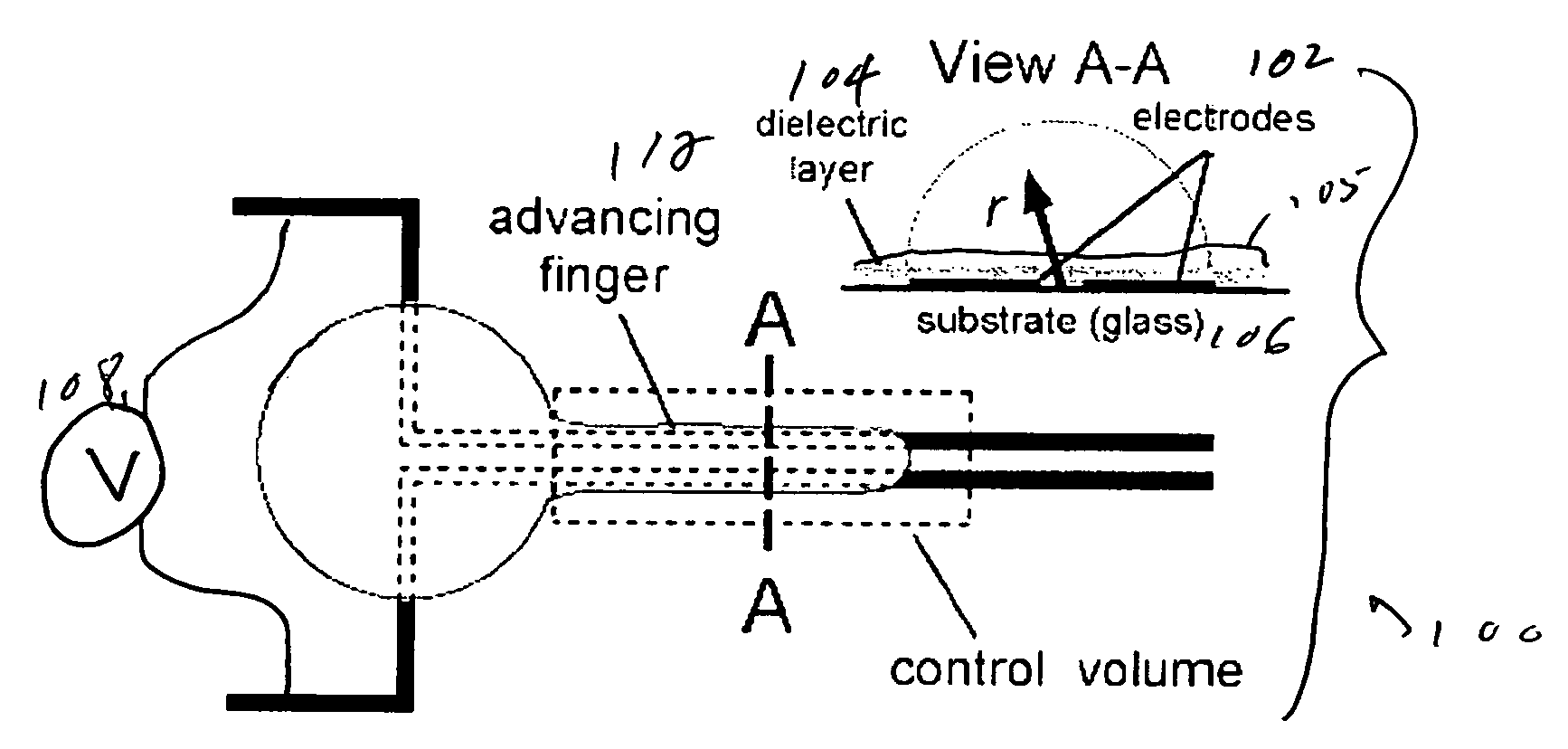

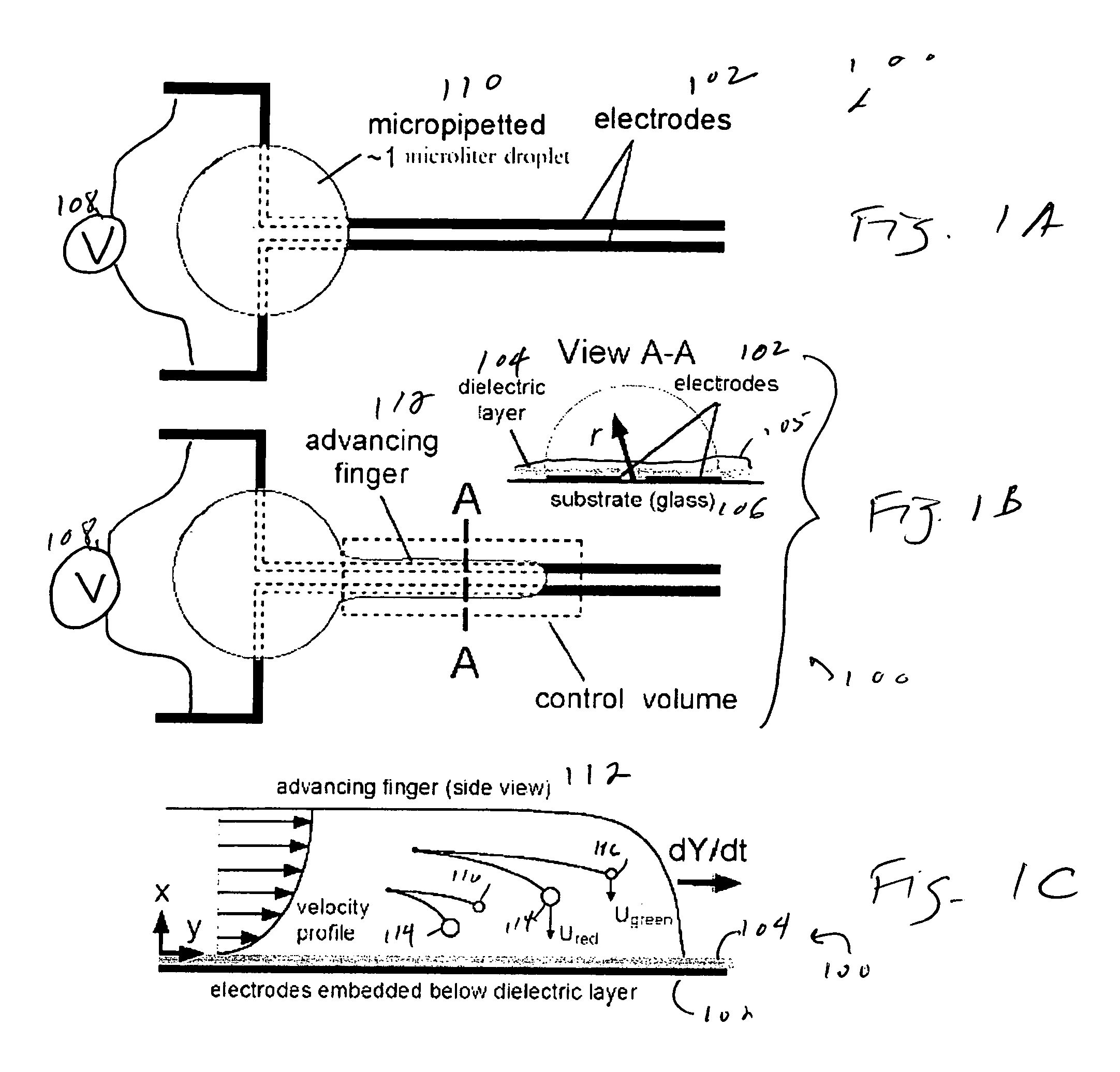

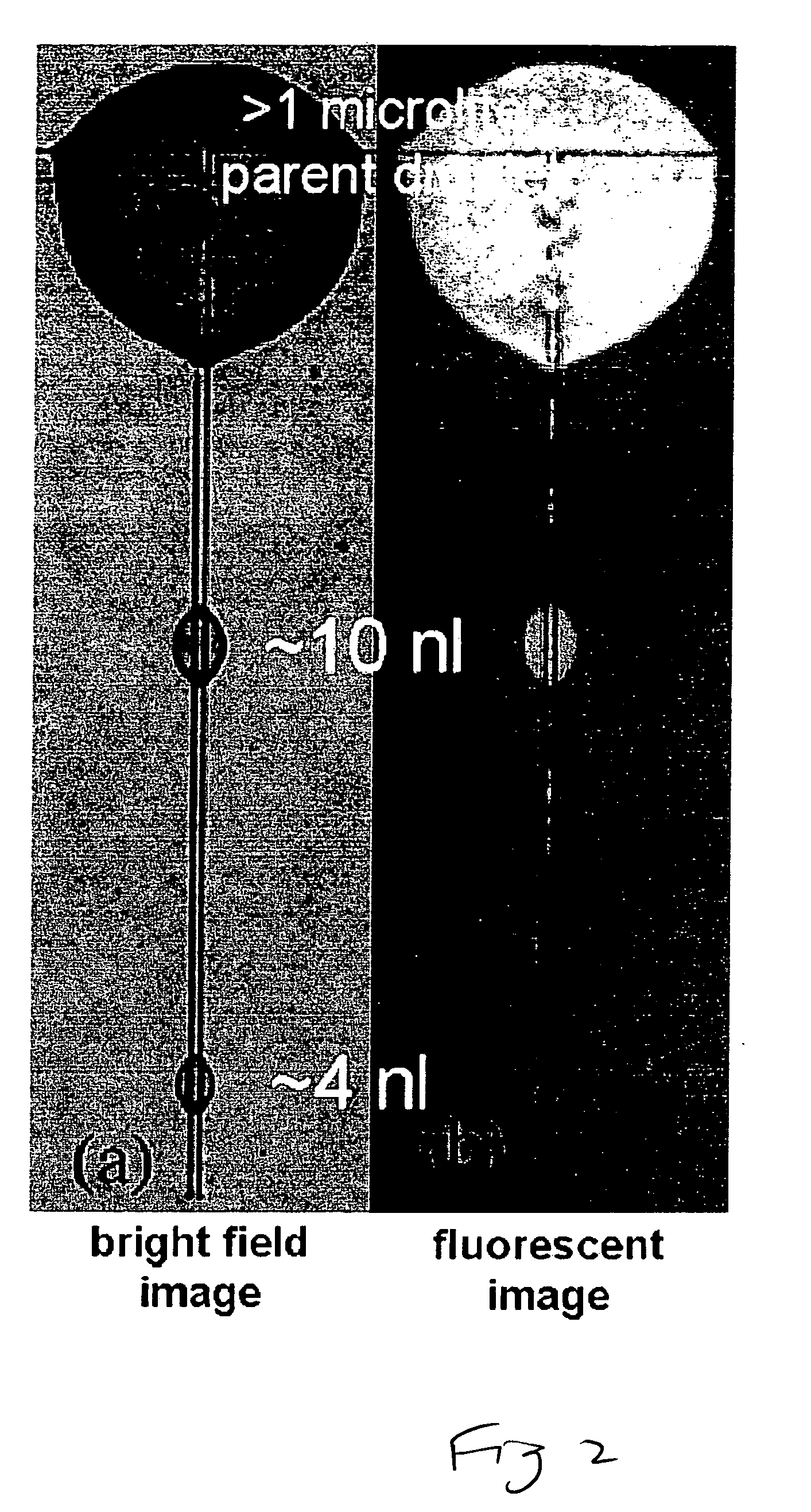

Rapid flow fractionation of particles combining liquid and particulate dielectrophoresis

Rapid, size-based, deposition of particles from liquid suspension is accomplished using a nonuniform electric field created by coplanar microelectrode strips patterned on an insulating substrate. The scheme uses the dielectrophoretic force both to distribute aqueous liquid containing particles and, simultaneously, to separate the particles. Size-based separation is found within nanoliter droplets formed along the structure after voltage removal. Bioparticles or macromolecules of similar size can also be separated based on subtle differences in dielectric property, by controlling the frequency of the AC current supplied to the electrodes.

Owner:UNIVERSITY OF ROCHESTER

Cervical exfoliated cell preservative fluid

InactiveCN101363011AReduce aggregationEfficient killingDead animal preservationTissue cultureRed blood cellCervical cancer screening

The invention relates to a cervical exfoliated cell preservative liquid, the preservative liquid comprises the following components with the contents (by weight): 20 percent to 50 percent of alcohols; 15 percent to 50 percent of anti-aggregation reagent; 5 percent to 10 percent of buffer solution; 1 percent to 20 percent of ion strength maintaining reagent; 0.01 percent to 0.5 percent of anti-microbial reagent; 0.1 to 5 percent of mucus dissolving reagent; and 0 to 0.5 percent of cleaning agent. Compared with the prior art, the preservative liquid can not only lead cells to maintain the shape in an in vitro liquid suspension environment, minimize the protein precipitation, dissolve larger protein substances, such as blood and mucus, and reduce the cell aggregation, but can also selectively eliminate or reduce red cells, effectively kill microbes, prevent the activity of reverse transcriptase and retain the integrity of nucleic acids and proteins for facilitating the later analysis; in addition, the preservative liquid can greatly reduce the costs of consumptive materials for the TCT detection, improve the sensitivity and the specificity of the cervical cancer screening and accelerate the promotion and the popularization of the TCT technology in a medical system.

Owner:SHANGHAI ADICON CLINICAL LAB LNC

Membrane module protection

InactiveUS20100051545A1Big screenAvoid excessive movementSemi-permeable membranesMembranesFiltrationEngineering

A filtration system for removing fine solids from a liquid suspension comprising a vessel for containing the liquid suspension, one or more permeable, membranes (9) within the vessel, means for providing a pressure differential across walls of the membranes (9) such that some of the liquid suspension passes through the walls of the membranes (9) to be drawn off as permeate and means for withdrawing the permeate from the membranes. A screen (8) is positioned in a flow path of the liquid suspension through to the membrane walls.

Owner:SIEMENS IND INC

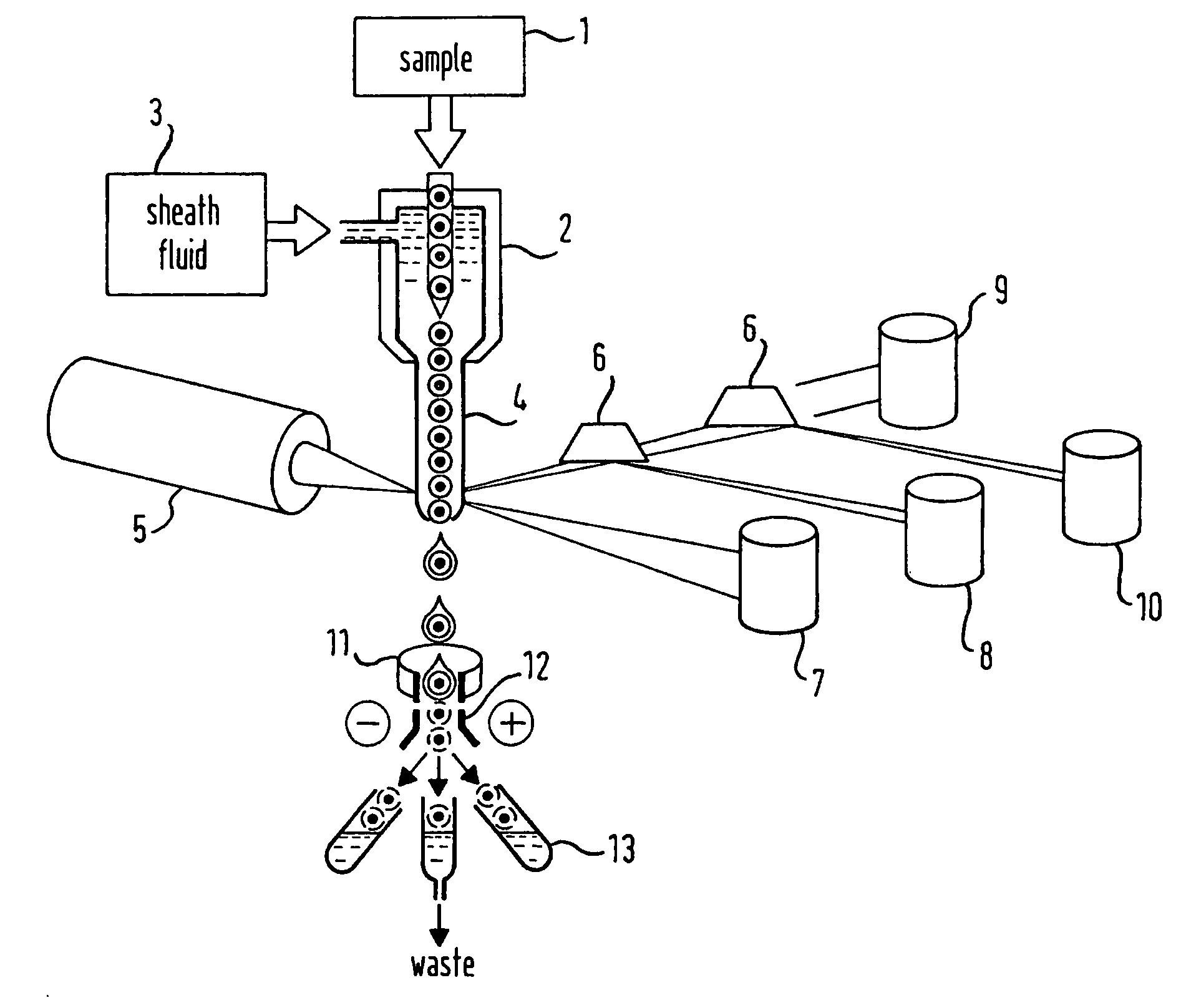

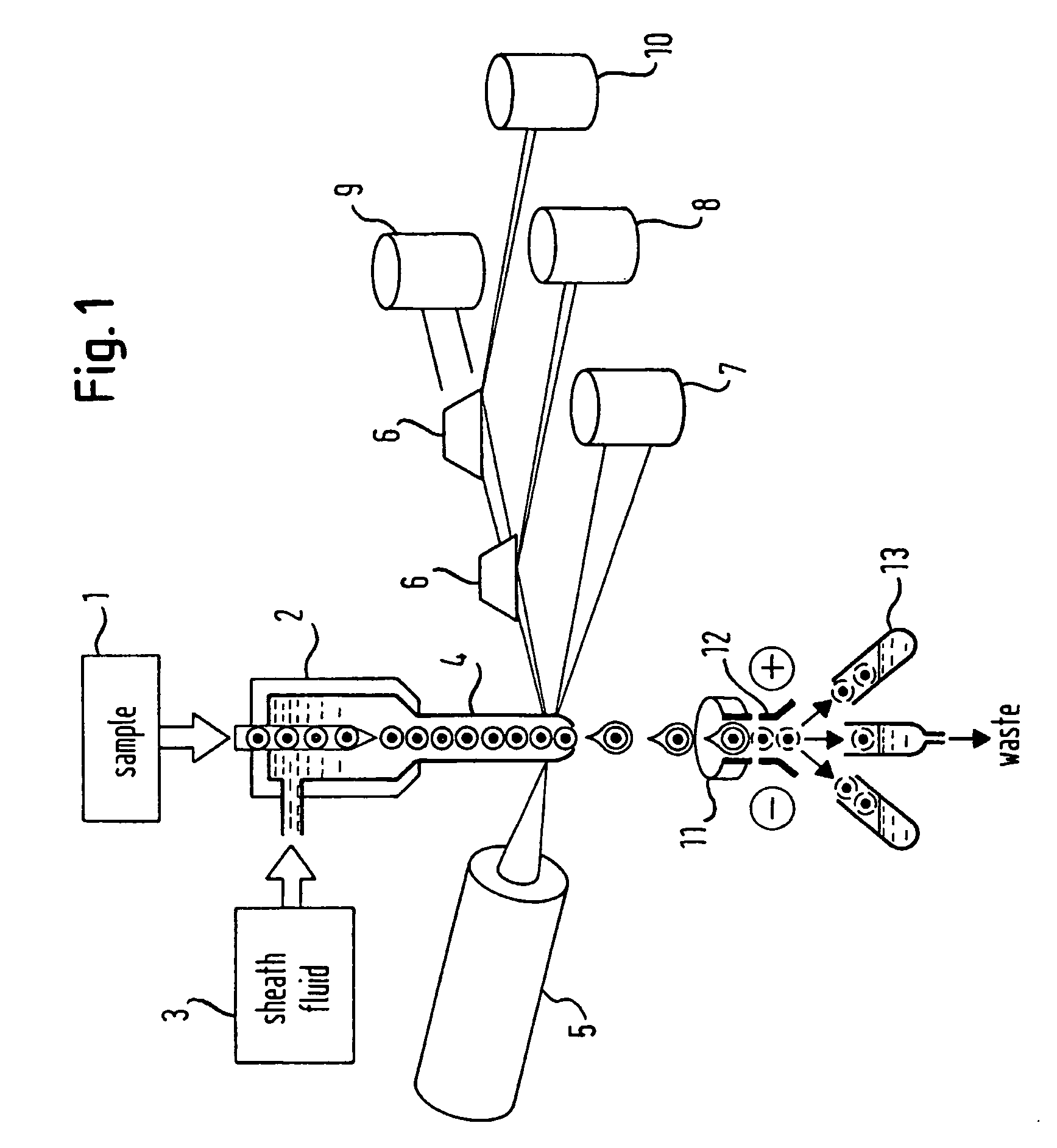

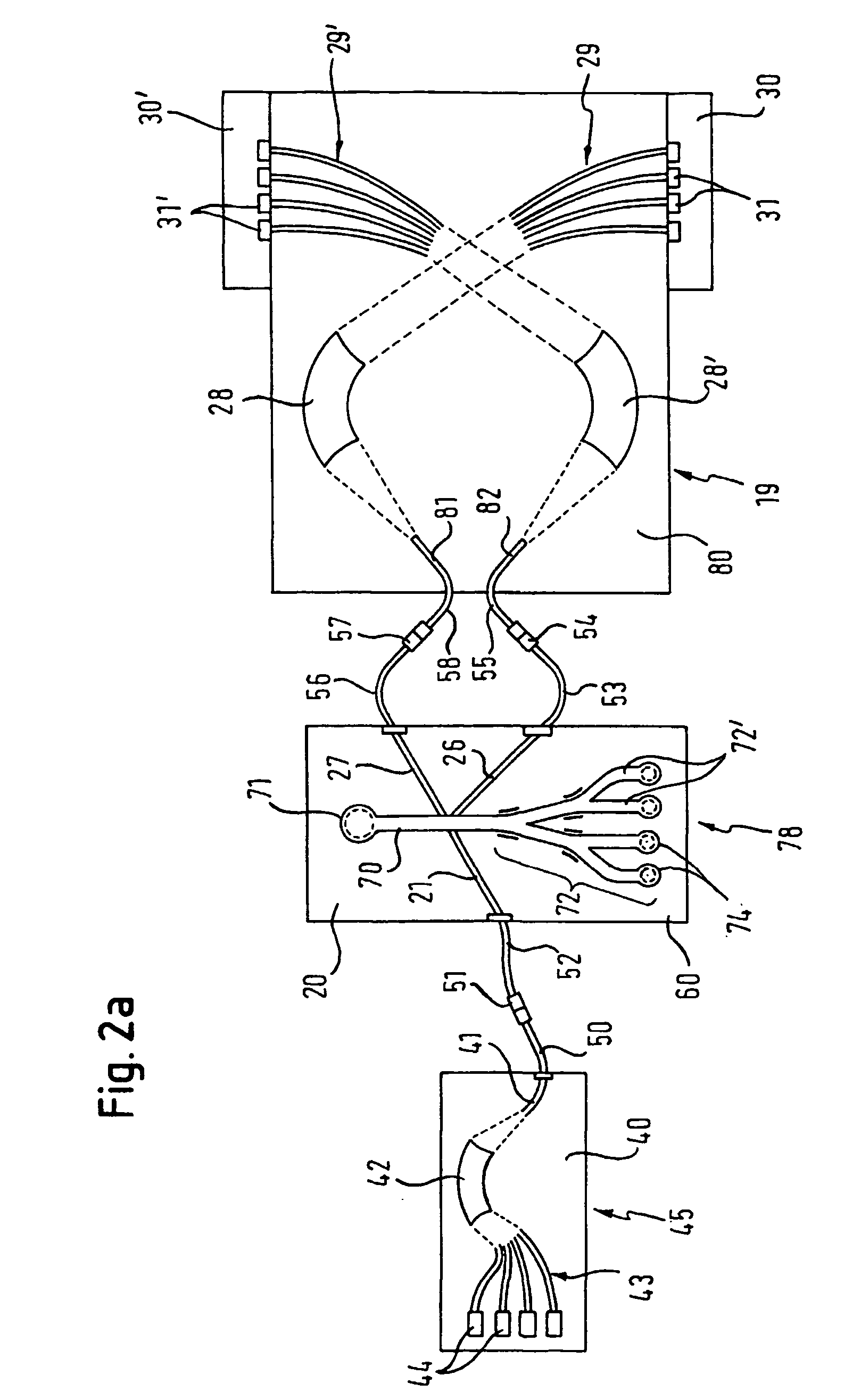

Device and method for investigating analytes in liquid suspension or solution

InactiveUS20050068536A1Small sizeEasy to adaptBioreactor/fermenter combinationsBiological substance pretreatmentsAnalytePlanar substrate

An optical detection device is provided for analysing analytes in a liquid suspension or solution that can detect and process a large number of wavelengths of incident and fluorescent light simultaneously, which is small in size and can be easily adapted to different investigation requirements. In one embodiment an optical detection device comprises a light supplying means (45), an analyte handling means (78), a light directing means (19), and detection means, integrated on planar substrate devices (40), (20), and (30), (30′), respectively. A plurality of optical waveguides are integrated in the substrate devices to direct light emitted by the light supplying means (45) through the different sections of the optical detection device to the detection means. The analyte handling means (78) comprises an analyte channel (70) for the liquid flow of the analyte suspension or solution and an analyte sorting means (72) comprising several sorting channels (72′).

Owner:PROIMMUNE

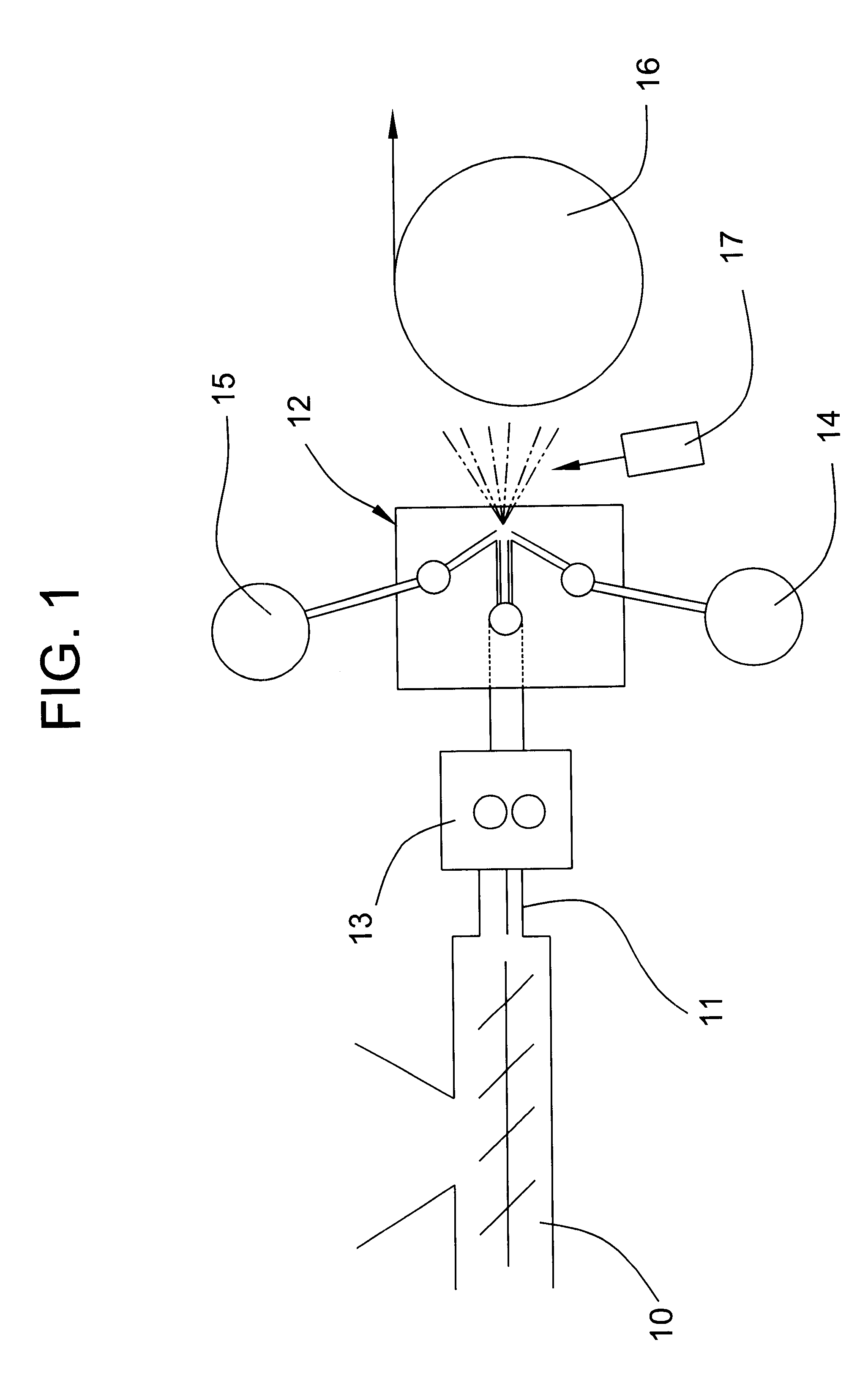

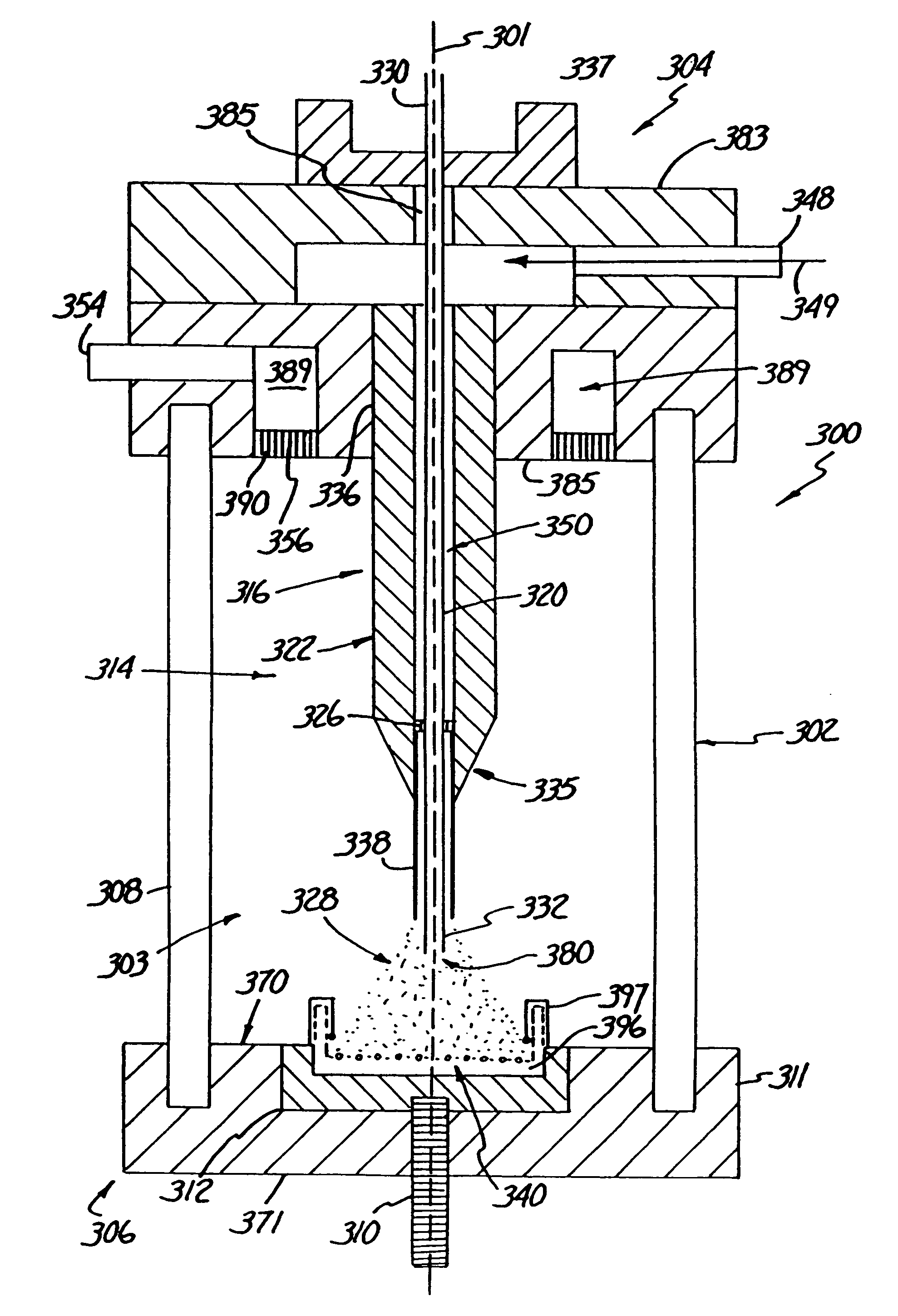

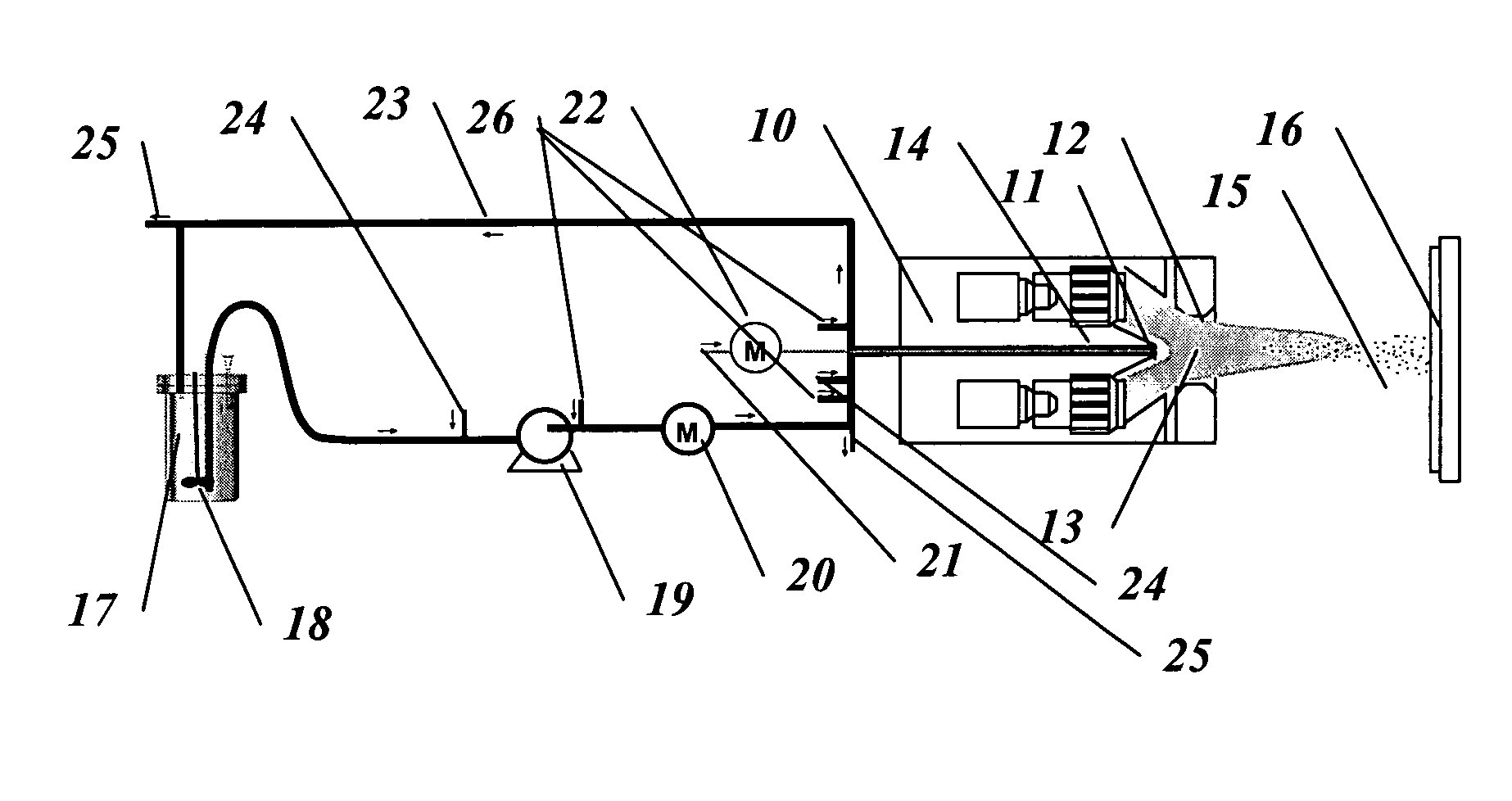

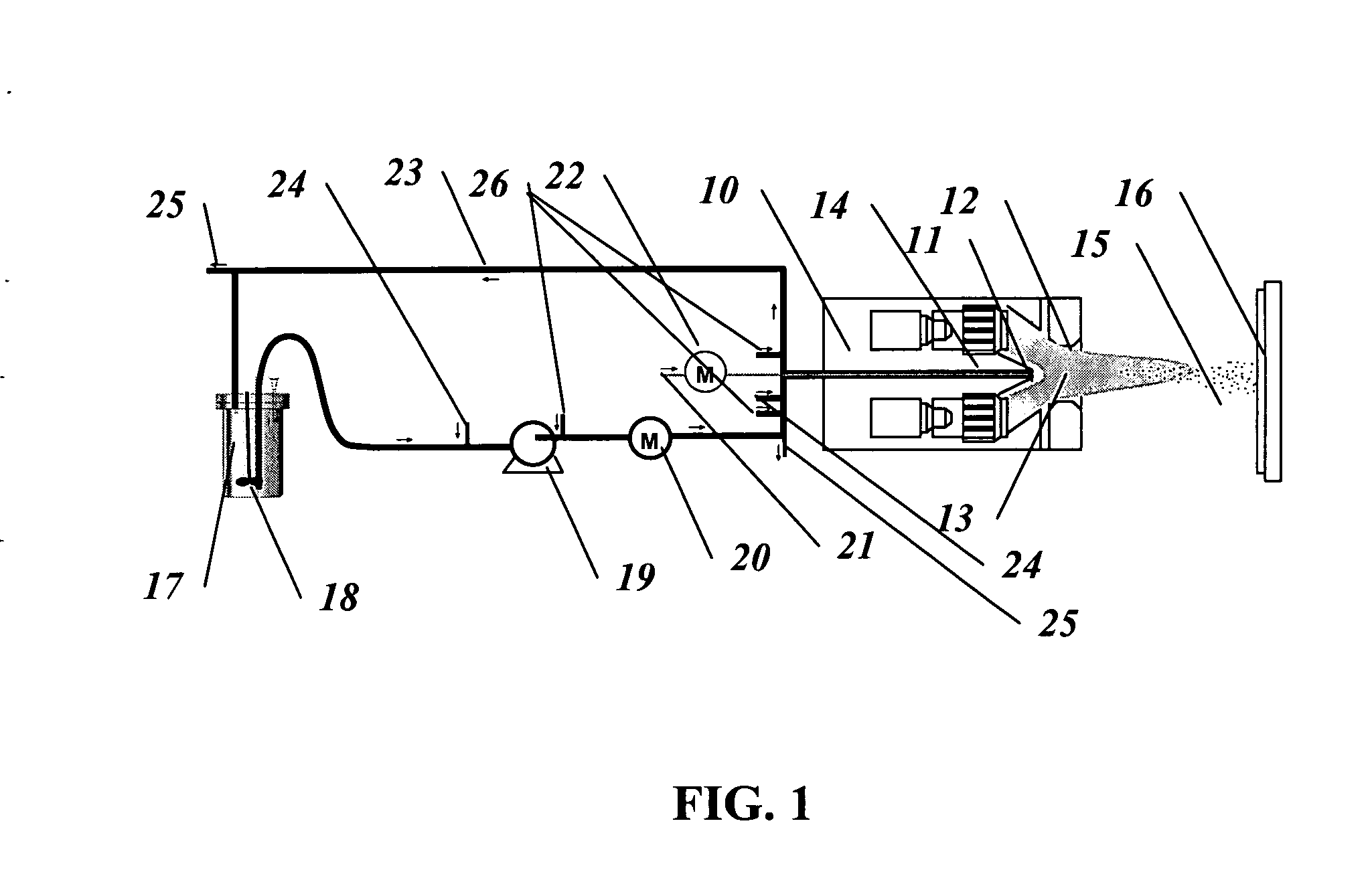

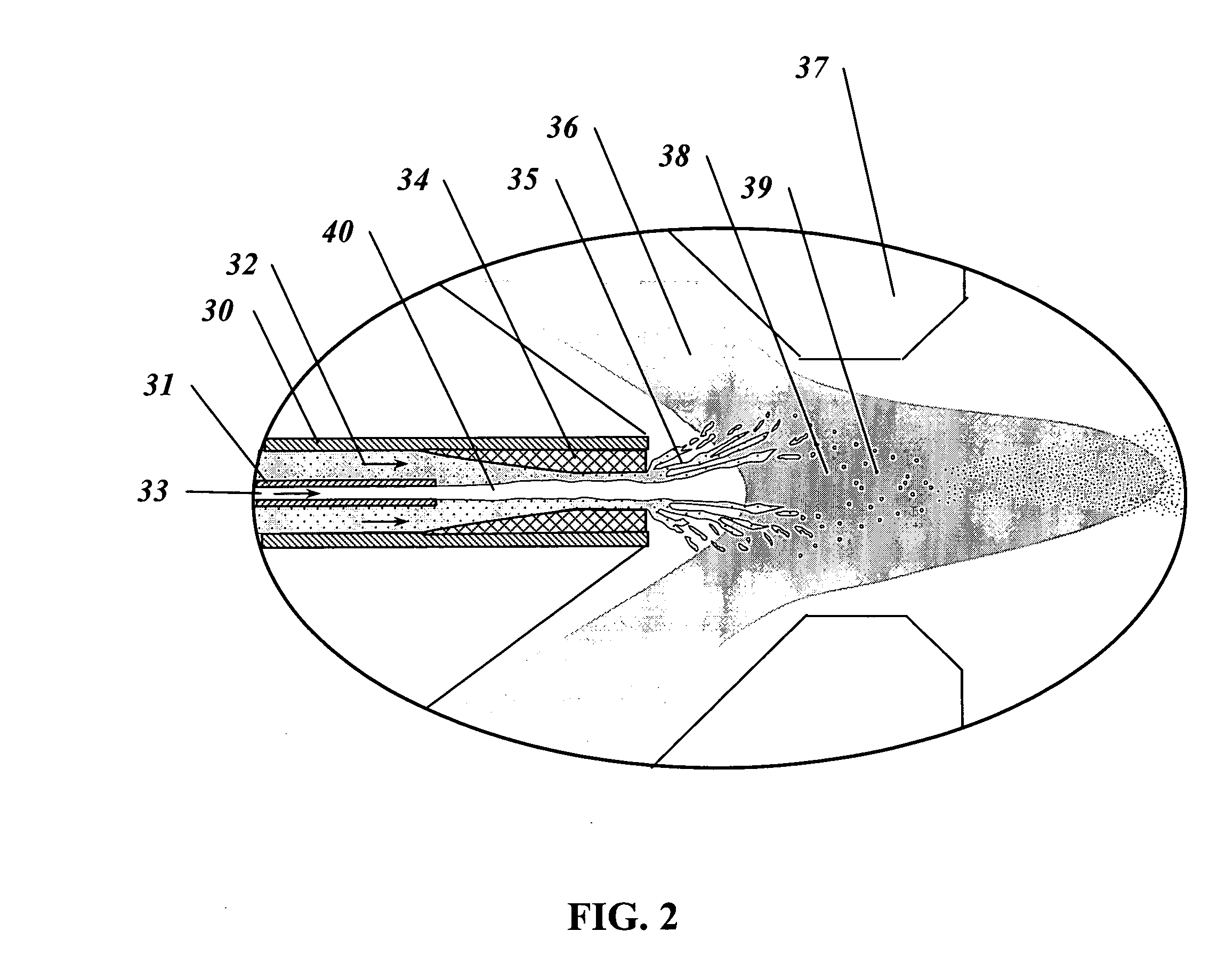

Method and apparatus for fine particle liquid suspension feed for thermal spray system and coatings formed therefrom

ActiveUS20060289405A1Efficient use ofImprove protectionMolten spray coatingCell electrodesThermal sprayingEngineering

This invention relates to a method by which liquid feedstock suspensions containing fine particles, micron- and nano-sized, are injected, with sufficient droplet velocity, preferably axially, into a thermal spray apparatus for the production of high-quality nanostructured coatings. The method allows complete entrainment of the droplets in a high temperature gas stream, while the injection orifice remains potentially blockage-free for long periods of operation.

Owner:NAT RES COUNCIL OF CANADA

Methods and Devices for Improved Aeration From Vertically-Orientated Submerged Membranes

InactiveUS20080017558A1Increase aerationImprove clippingSludge treatmentUltrafiltrationAeration rateMembrane fouling

Submerged gas diffuser assemblies configured to aerate liquid suspensions in reservoirs or deep shafts with enhanced aeration contact patterns and adjustable aeration rates. Aeration contact patterns and rates are varied by the adjusting the spatial configuration of gas permeable membranes, altering the fluid flow patterns around the membranes, manipulating trans-membrane pressures across membranes, varying the sequence of aeration of liquid within the fluid flow patterns, expanding the membrane surface area, and / or by selectively occluding certain portions of membrane surface area of the membrane assemblies. The membrane assemblies are designed to prevent, control, or mitigate membrane fouling and hydro lockup.

Owner:VOST ENVIRONMENTAL TECH

Method of detecting lung disease

A method of facilitating the obtaining of a mucus sample from at least one lung of a subject comprises administering to at least one lung of the subject, in an amount effective to hydrate lung mucous secretions and / or stimulate cilia beat frequency therein, uridine 5'-triphosphate, an active analog thereof, or a pharmaceutically acceptable salt of either thereof, and, optionally, concurrently administering to said at least one lung a physiologically acceptable salt in an amount effective to hydrate lung mucus secretions therein. A sputum or mucus sample is then collected from said at least one lung, which sample can then be analyzed for lung disease. Pharmaceutical compositions useful for carrying out the method comprise UTP or a salt thereof, alone or in combination with a physiologically acceptable salt, or a pharmaceutically acceptable salt of either thereof. The composition may be a liquid / liquid suspension composition or a dry powder composition.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

Reduction of Backwash liquid Waste

A method of filtering solids from a liquid suspension comprising providing a pressure differential across the walls of permeable, hollow membranes (5) immersed in the liquid suspension contained in a vessel (8), the liquid suspension being applied to the outer surface of the porous hollow membrane (5) to induce and sustain filtration through the membrane walls. Some of the liquid suspension passes through the walls of the membranes (5) to be drawn off as permeate from the hollow membrane lumens, and at least some of the solids are retained on or in the hollow membranes or otherwise as suspended solids within the liquid surrounding the membranes (5). The method includes the steps of suspending the flow of the liquid suspension to the vessel (8); reducing the volume of liquid suspension within the vessel (8); suspending the filtration process; cleaning the membranes (5) by dislodging at least some of the solids retained on or in the membranes (5); and removing the liquid containing dislodged solids from the vessel (8).

Owner:EVOQUA WATER TECH LLC

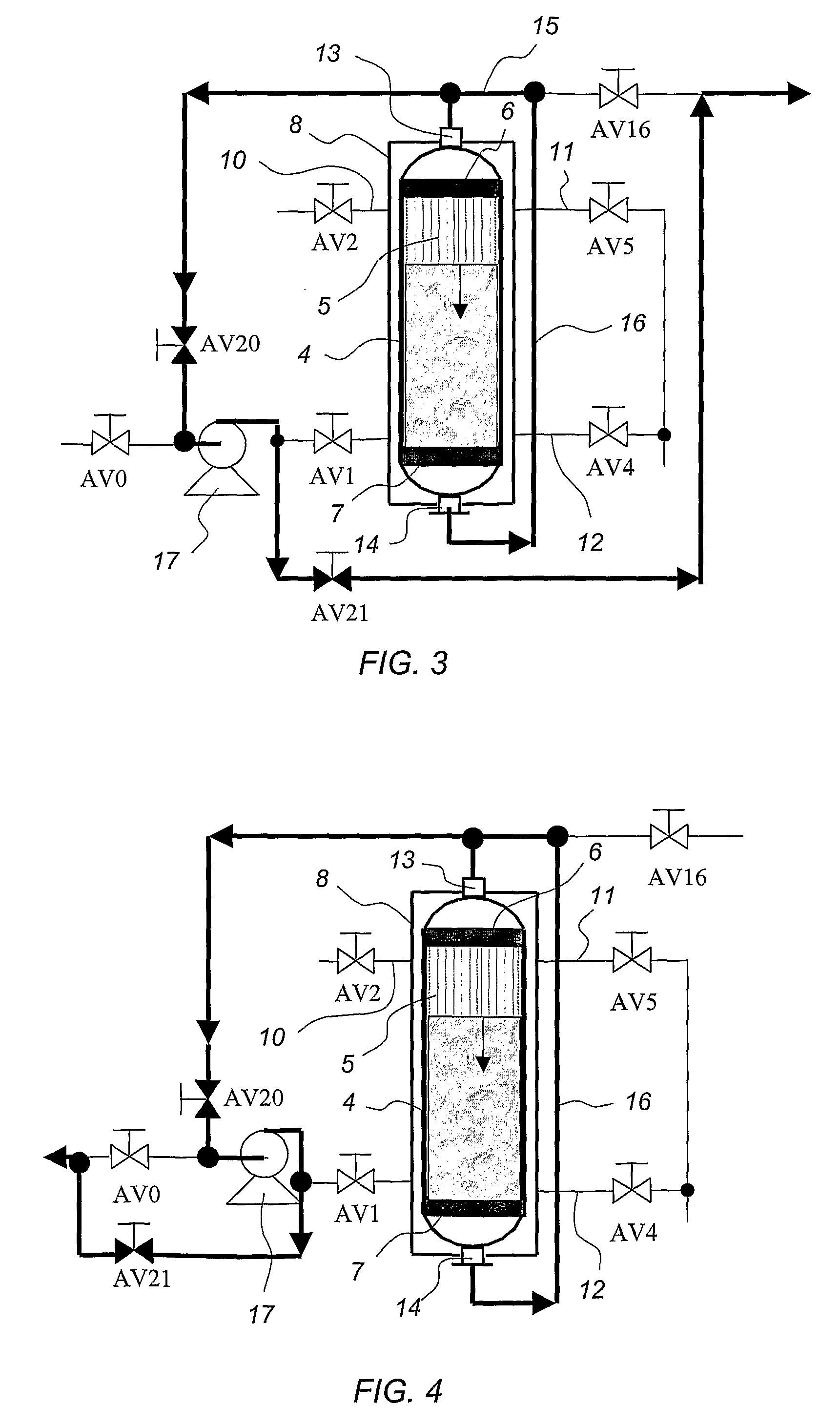

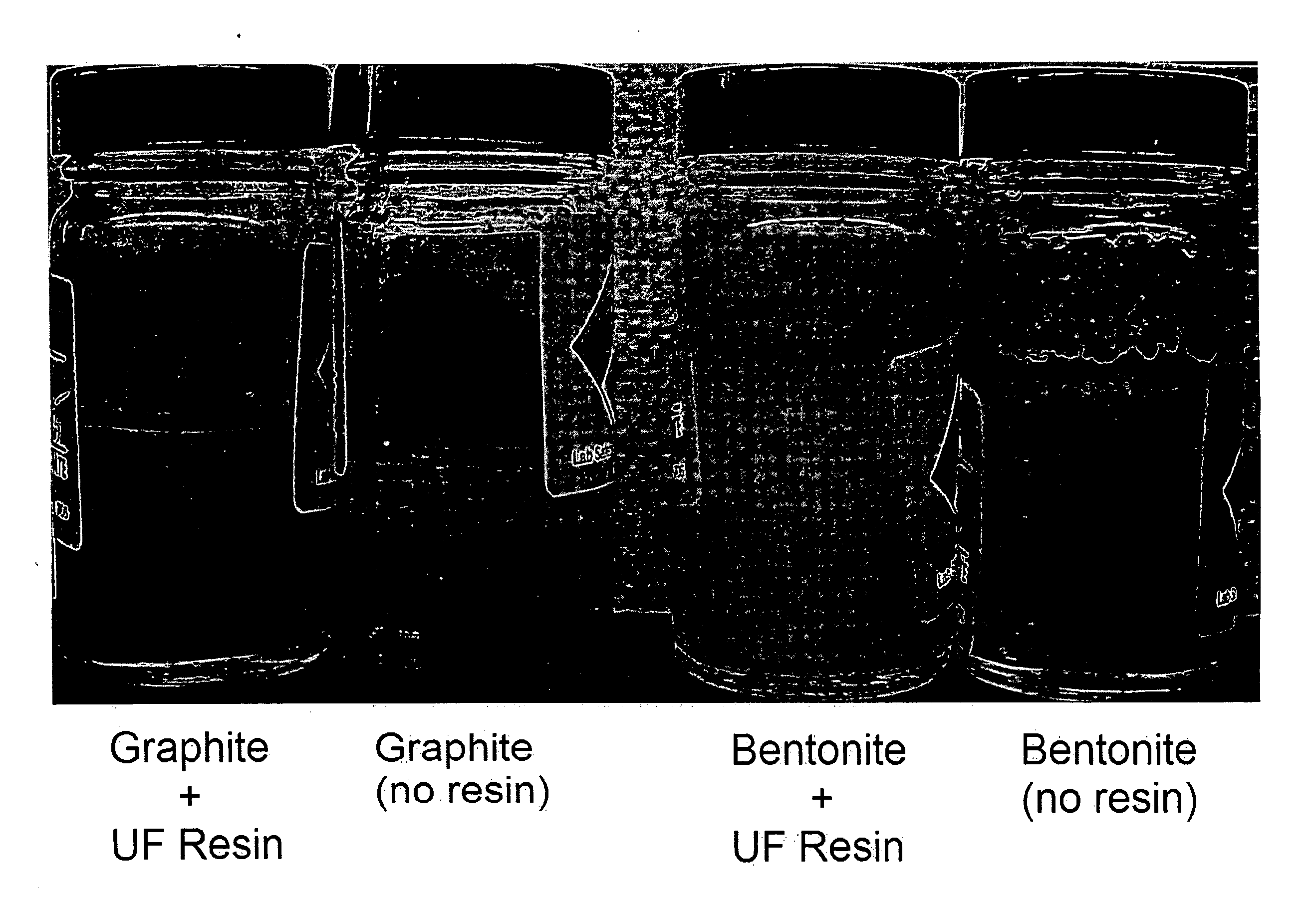

Modified amine-aldehyde resins and uses thereof in separation processes

InactiveUS20070000839A1Easy to disassembleHighly selective bindingTransportation and packagingSolid sorbent liquid separationParticulatesSolid particle

Modified resins are disclosed for removing a wide variety of solids and / or ionic species from the liquids in which they are suspended and / or dissolved. These modified resins are especially useful as froth flotation depressants in the beneficiation of many types of materials (e.g., mineral and metal ores), including the beneficiation of impure coal comprising clay impurities, as well as in the separation of valuable bitumen from solid contaminants such as sand. The modified resins are also useful for treating aqueous liquid suspensions to facilitate the removal of solid particulates, as well as the removal of metallic ions in the purification of water. The modified resins comprise a base resin that is modified with a coupling agent, which is highly selective for binding to solid contaminants and especially siliceous materials such as sand or clay.

Owner:INGEVITY SOUTH CAROLINA

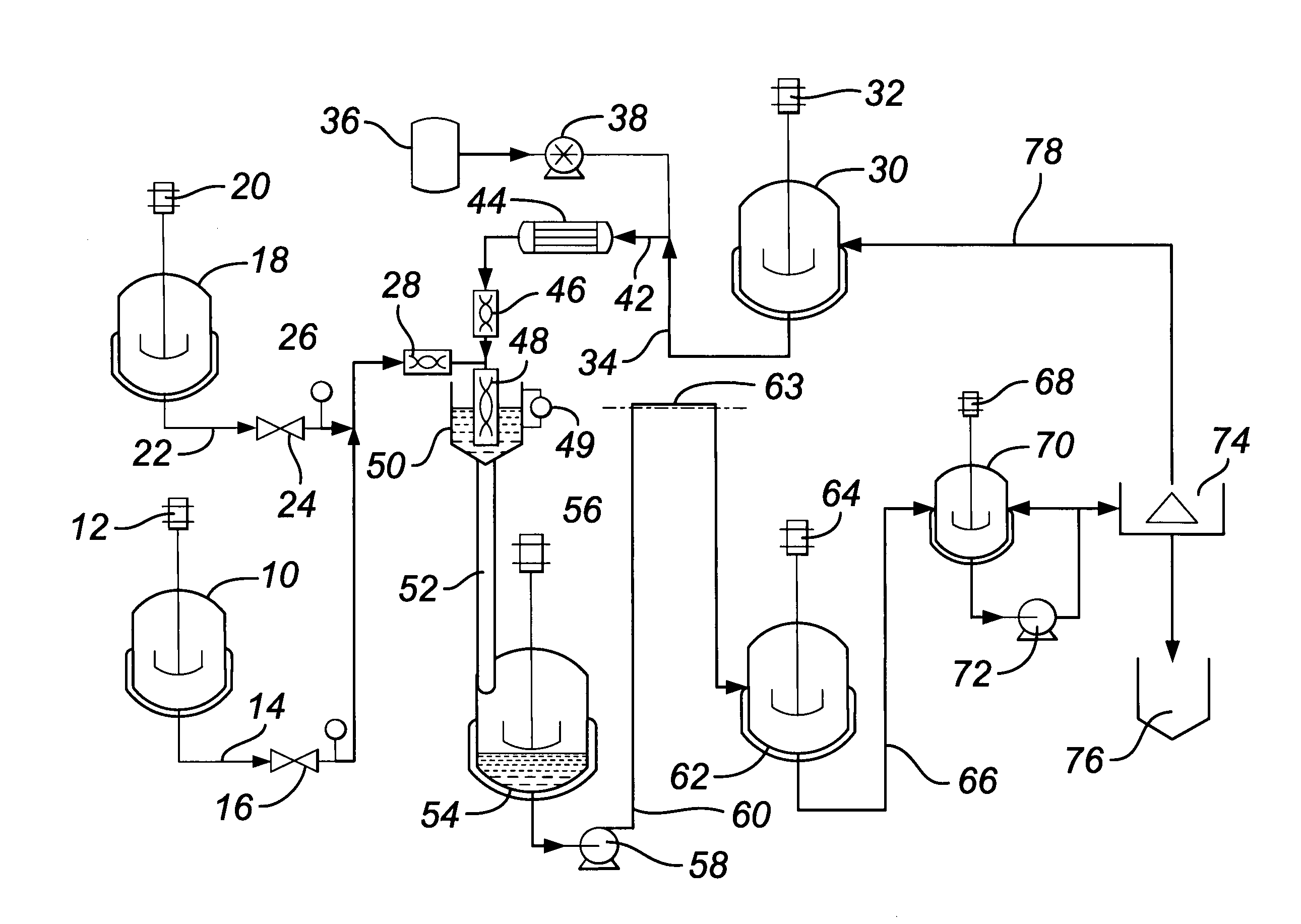

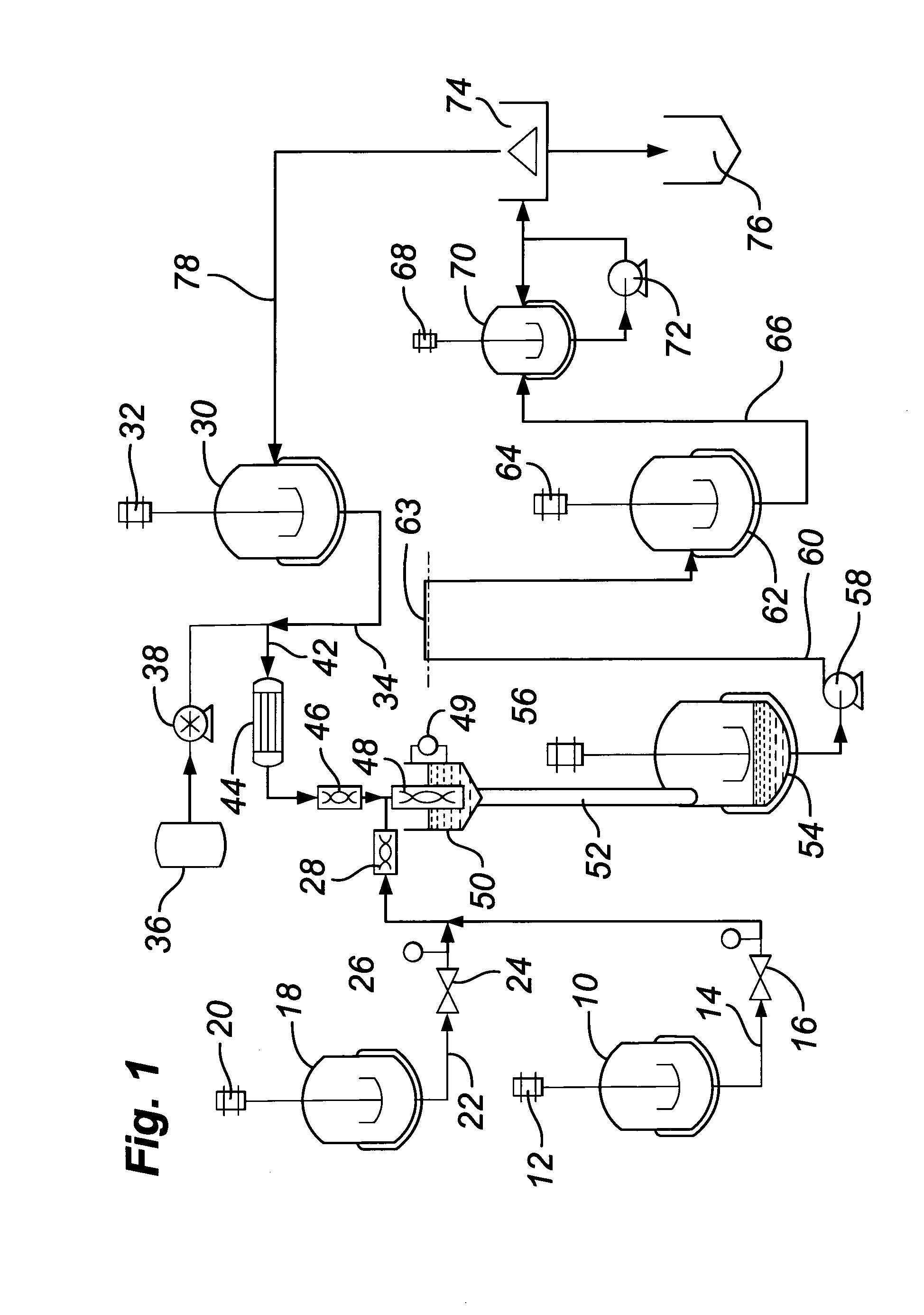

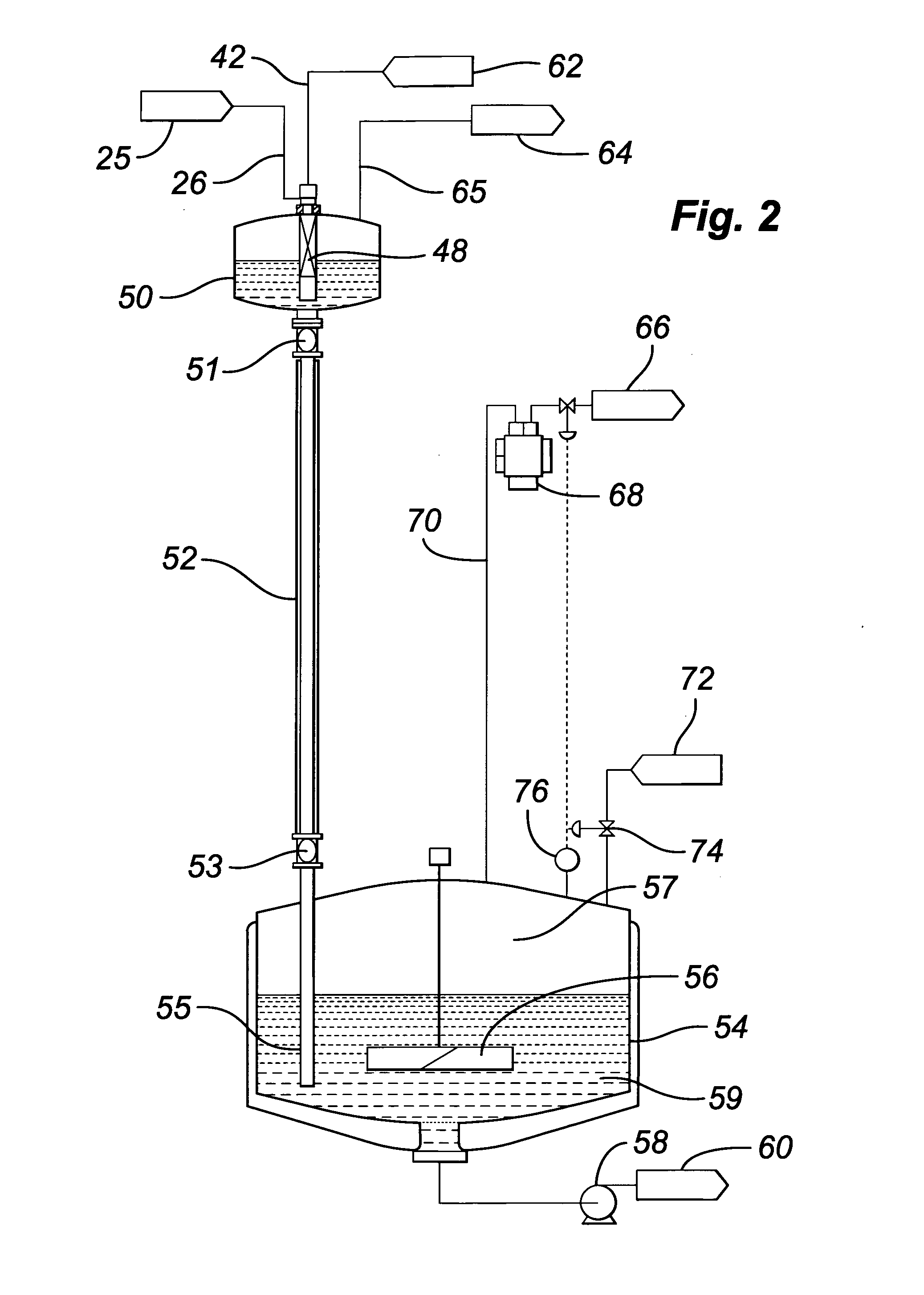

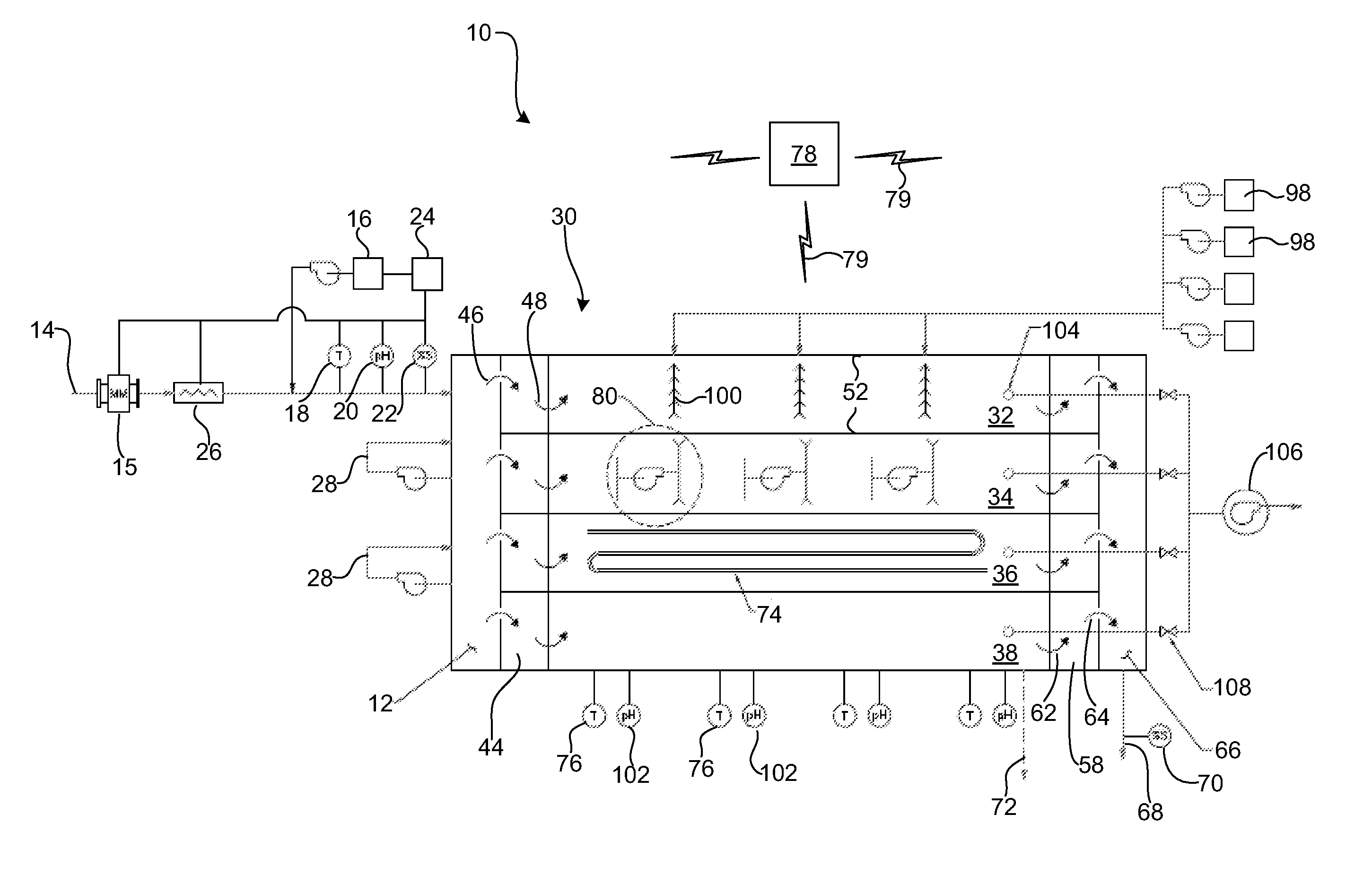

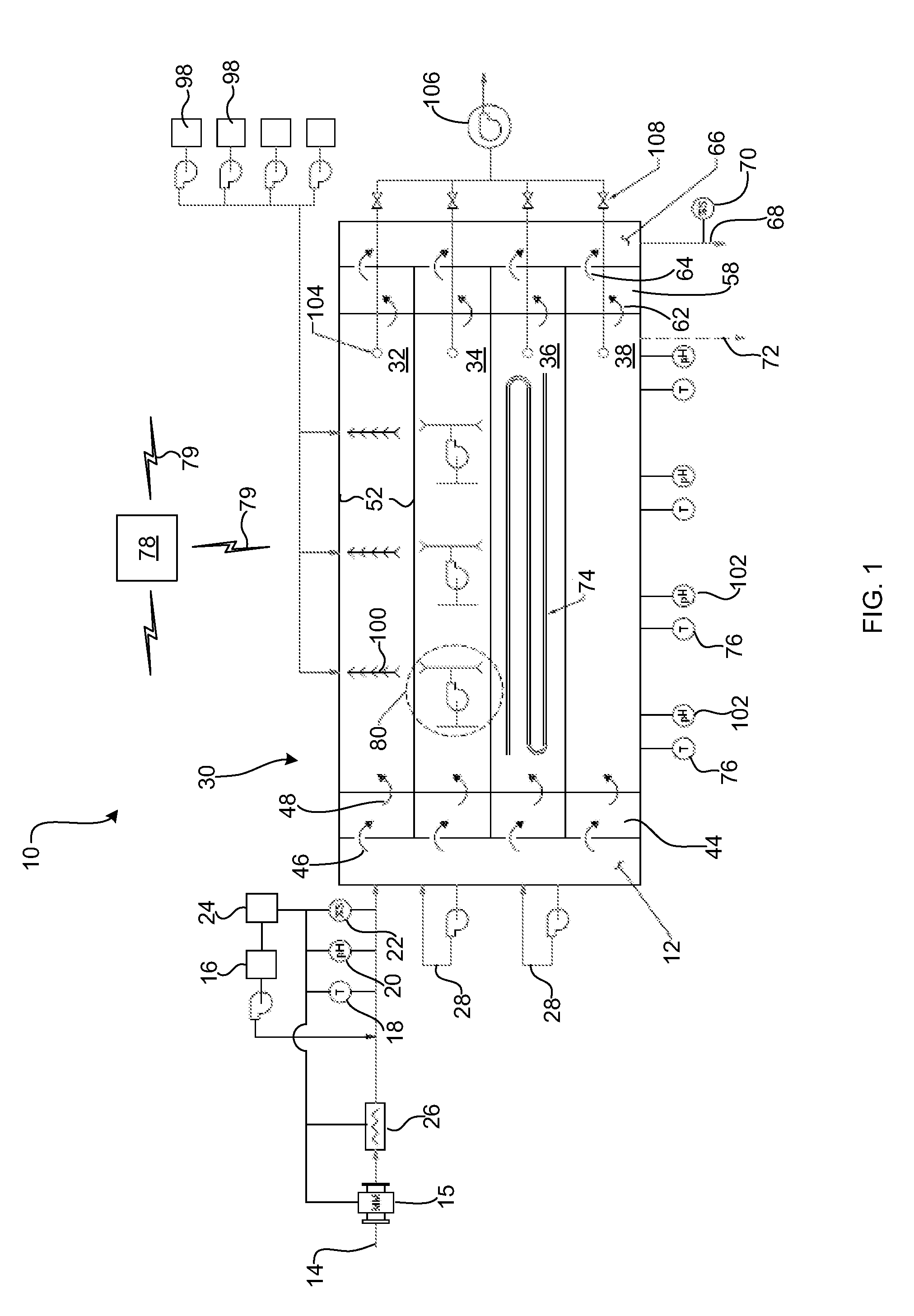

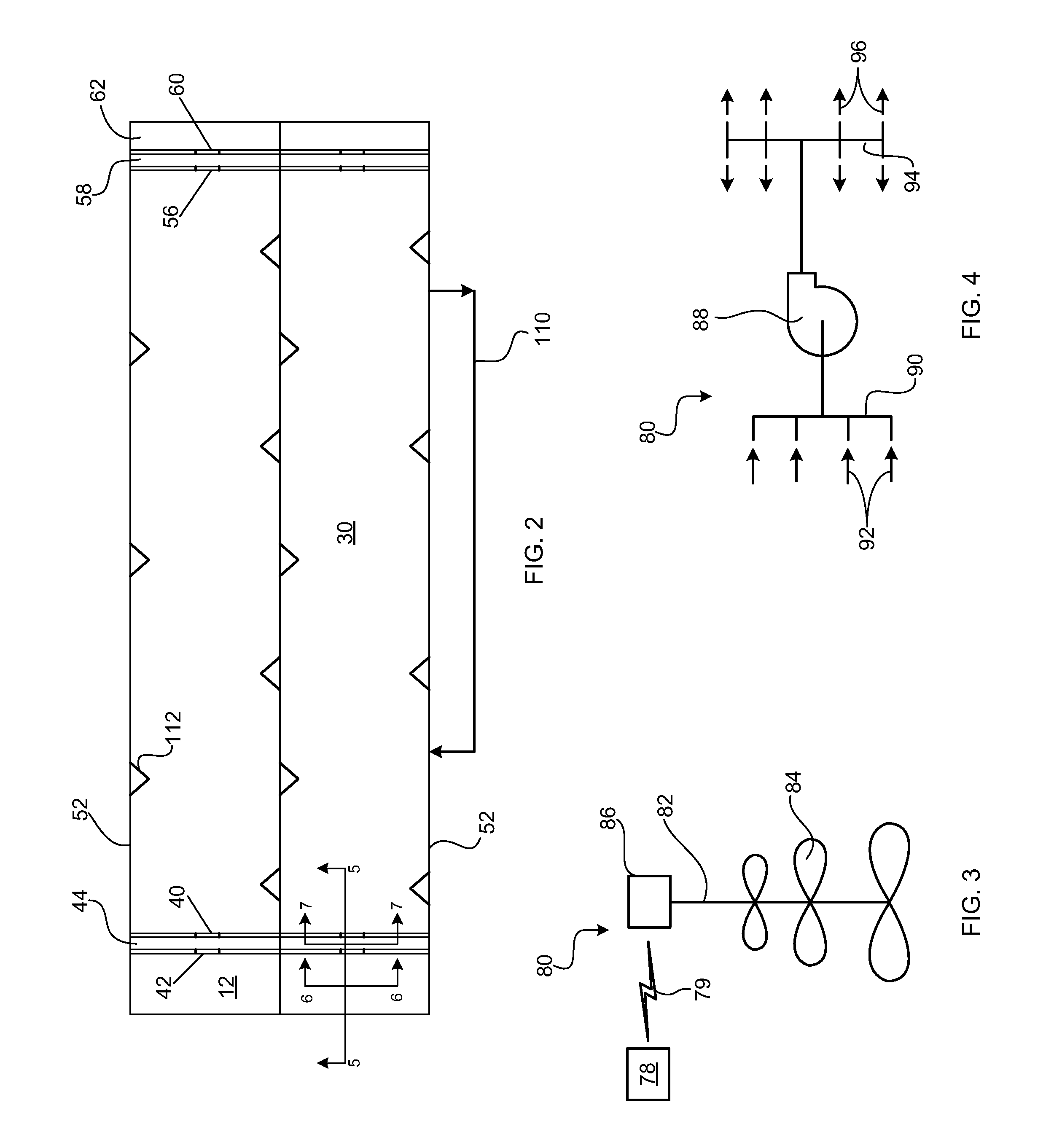

Anaerobic digester design and operation

ActiveUS20100032370A1High carbon contentHigh nitrogen contentBiological substance pretreatmentsIon-exchanger regenerationControl systemDigestion Treatment

An apparatus for the anaerobic digestion of solid waste is disclosed. The apparatus includes a pre-digestion treatment chamber and an anaerobic digester chamber coupled to the pre-digestion treatment chamber. A liquid suspension of solid waste is pretreated under aerobic conditions by heating to a desired pre-digestion temperature. One or more chemical or biological additives are added to the suspension of solid waste to improve the anaerobic digestibility of the solid waste. This may include enzymes to destruct poorly digestible solids and / or materials to provide a desired C:N ratio in the solid waste. The apparatus may include mixers, heaters, chemical or biological additives as needed, various sensors and probes, and a control system to monitor and control the anaerobic digestion process and maintain microbial health of the digester.

Owner:WATER SOLUTIONS TECH LLC

Amine-aldehyde resins and uses thereof in separation processes

InactiveUS20060151397A1Highly versatileEffective isolationWaste water treatment from quariesWaste water treatment from ceramic industriesParticulatesKaolin clay

Amine-aldehyde resins are disclosed for removing a wide variety of solids and / or ionic species from the liquids in which they are suspended and / or dissolved. These resins are especially useful as froth flotation depressants in the separation of bitumen from sand and / or clay or in the beneficiation of clay (e.g., kaolin clay) from an impure clay-containing ore. The resins are also useful for treating aqueous liquid suspensions to remove solid particulates, as well as for removing metallic ions in the purification of water.

Owner:INGEVITY SOUTH CAROLINA

Injectable sustained release delivery devices

InactiveUS20080063687A1Control releaseOrganic active ingredientsCoatingsControlled releasePolymer coatings

Owner:PSIVIDA US INC

Cleaning method for simple filtration systems

InactiveUS20100200503A1Provide usageSemi-permeable membranesSpecific water treatment objectivesFiltrationMembrane surface

A method of cleaning a permeable, hollow membrane (6) in an arrangement of the type wherein a pressure differential is applied across the wall of the permeable, hollow membrane (6) immersed in a liquid suspension provided in a vessel (5), said liquid suspension being applied to the outer surface of the permeable hollow membrane (6) to induce and sustain filtration through the membrane wall. The method of cleaning comprising the steps of: suspending the filtration process; while continuing to supply the liquid suspension to the vessel (5); aerating the membrane (6) by flowing gas into the vessel (5) to produce a flow of gas bubbles around the membrane (6) to dislodge at least some of the retained particulate material from the membrane surface; removing liquid containing dislodged particulate material from the vessel (5) during the aerating step and recommencing the filtration process.

Owner:SIEMENS IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com