Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

280 results about "Bubble point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In thermodynamics, the bubble point is the temperature (at a given pressure) where the first bubble of vapor is formed when heating a liquid consisting of two or more components. Given that vapor will probably have a different composition than the liquid, the bubble point (along with the dew point) at different compositions are useful data when designing distillation systems.

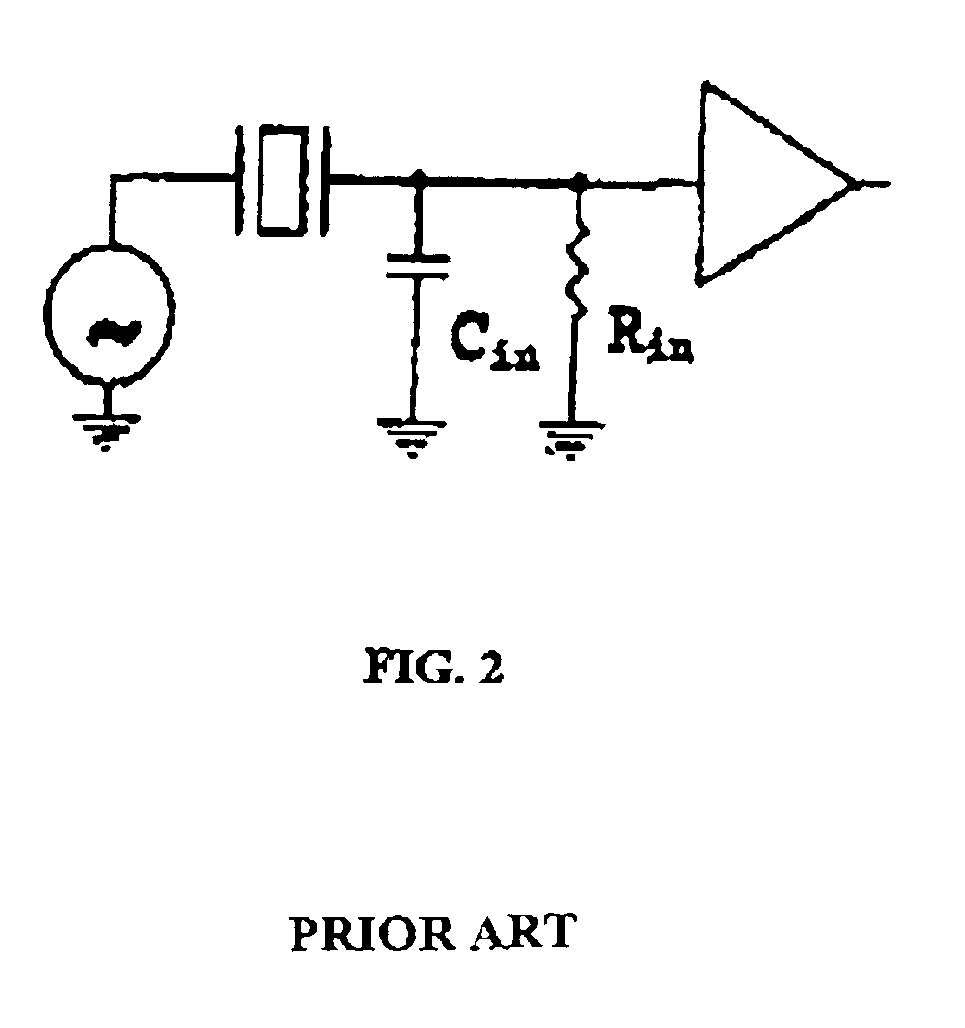

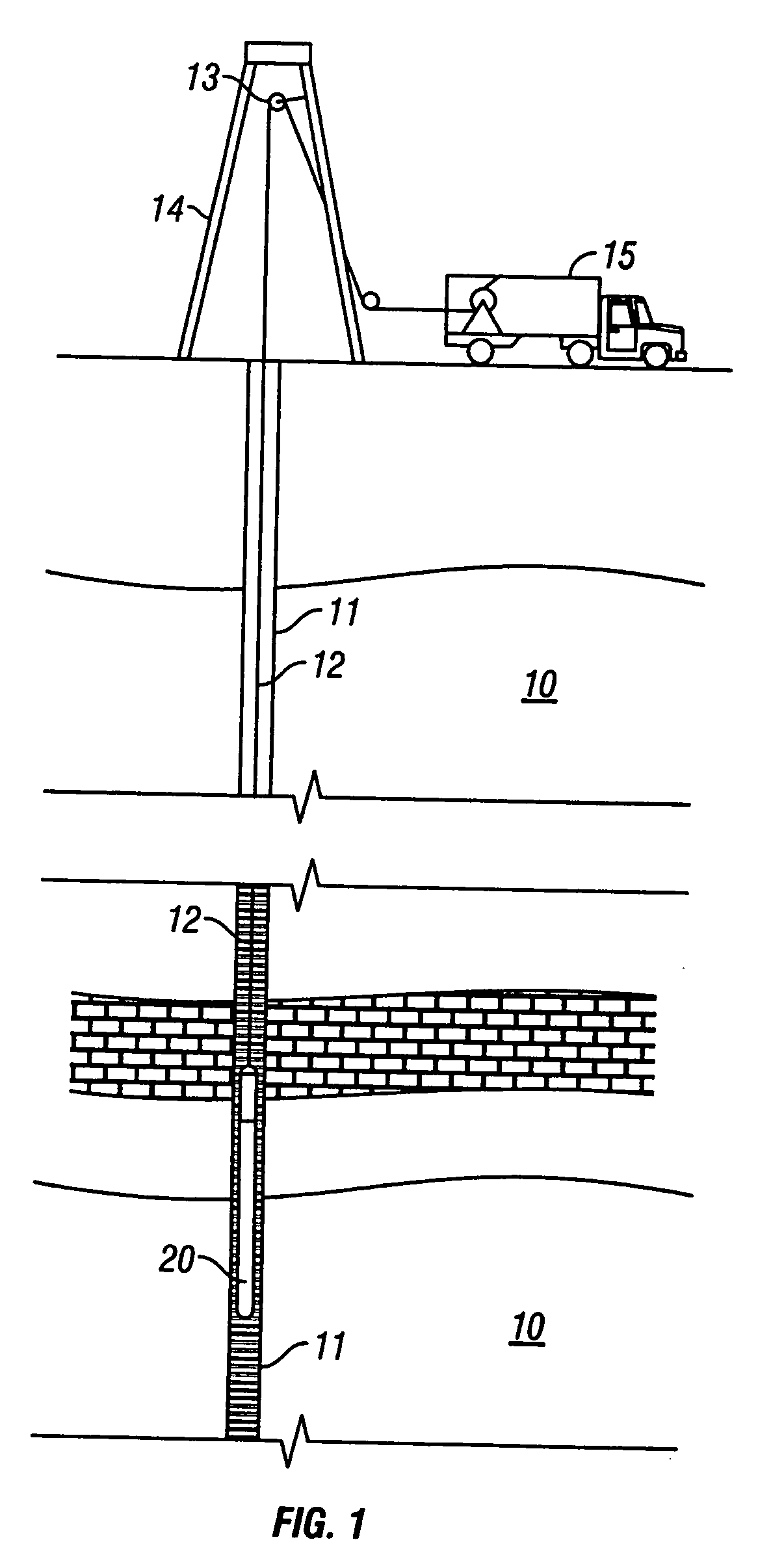

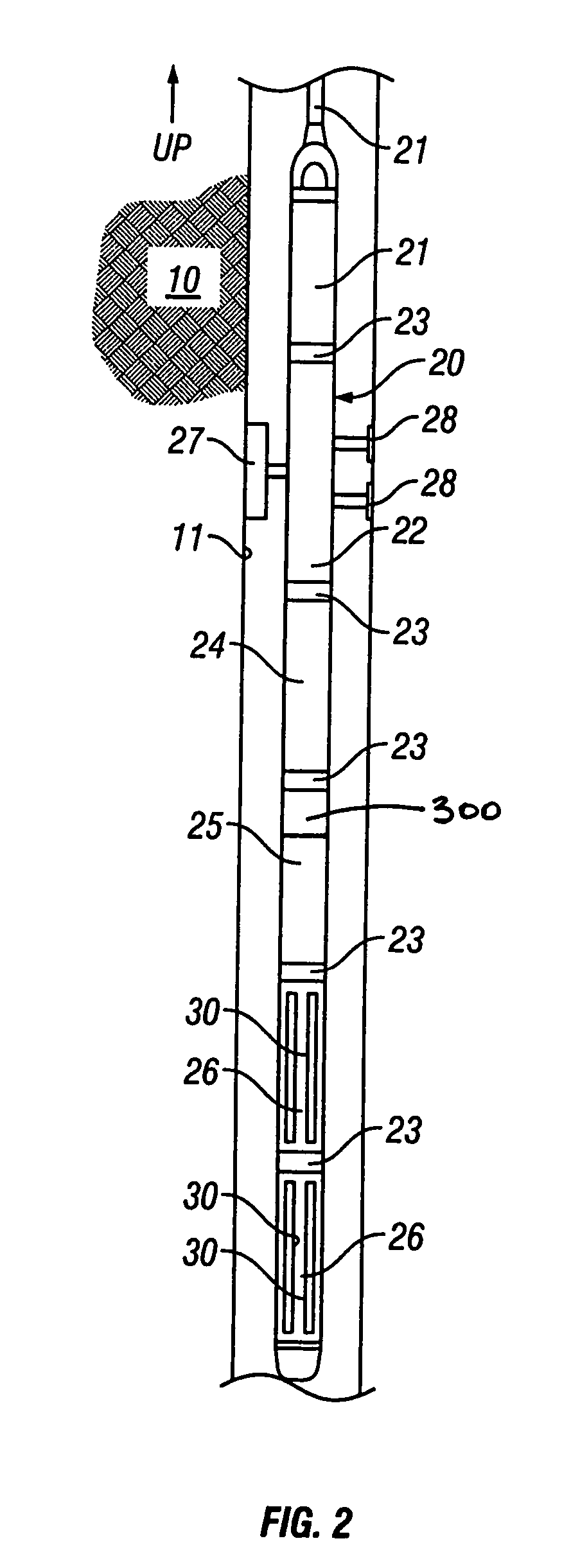

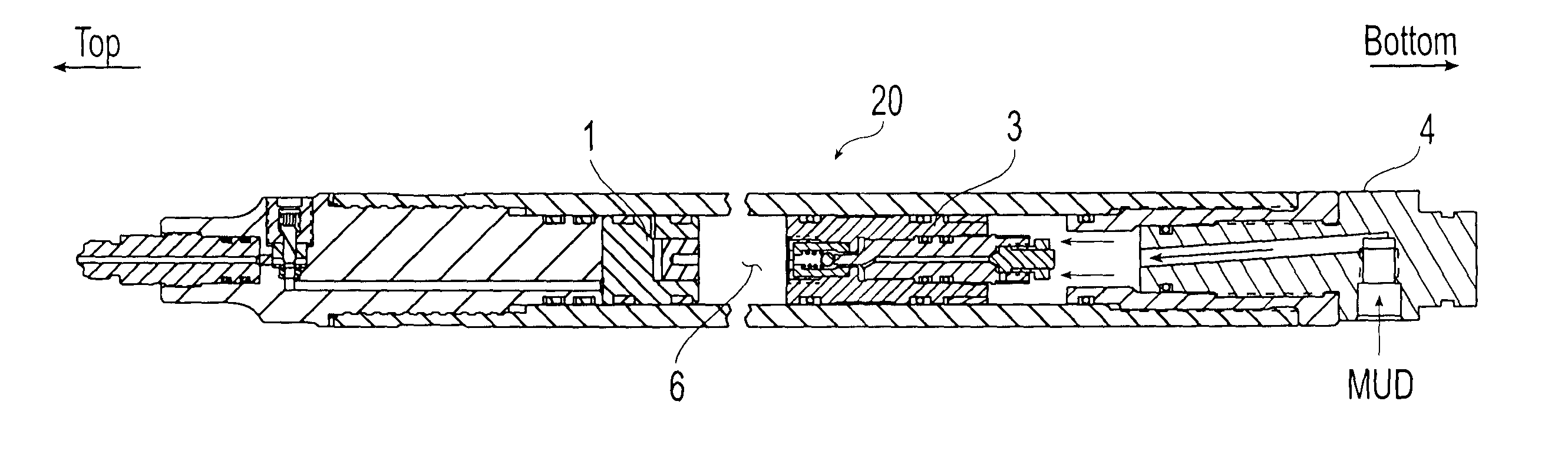

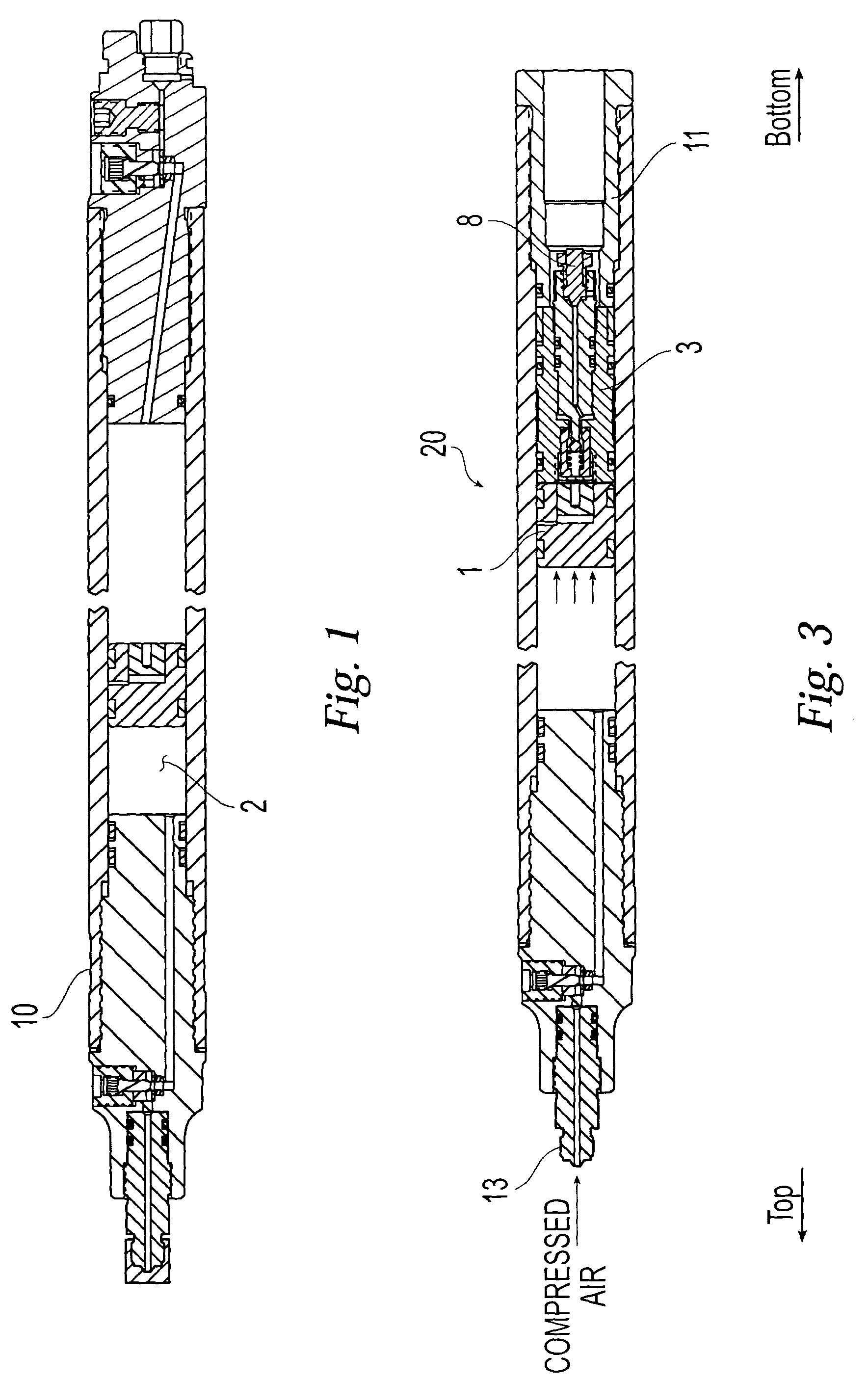

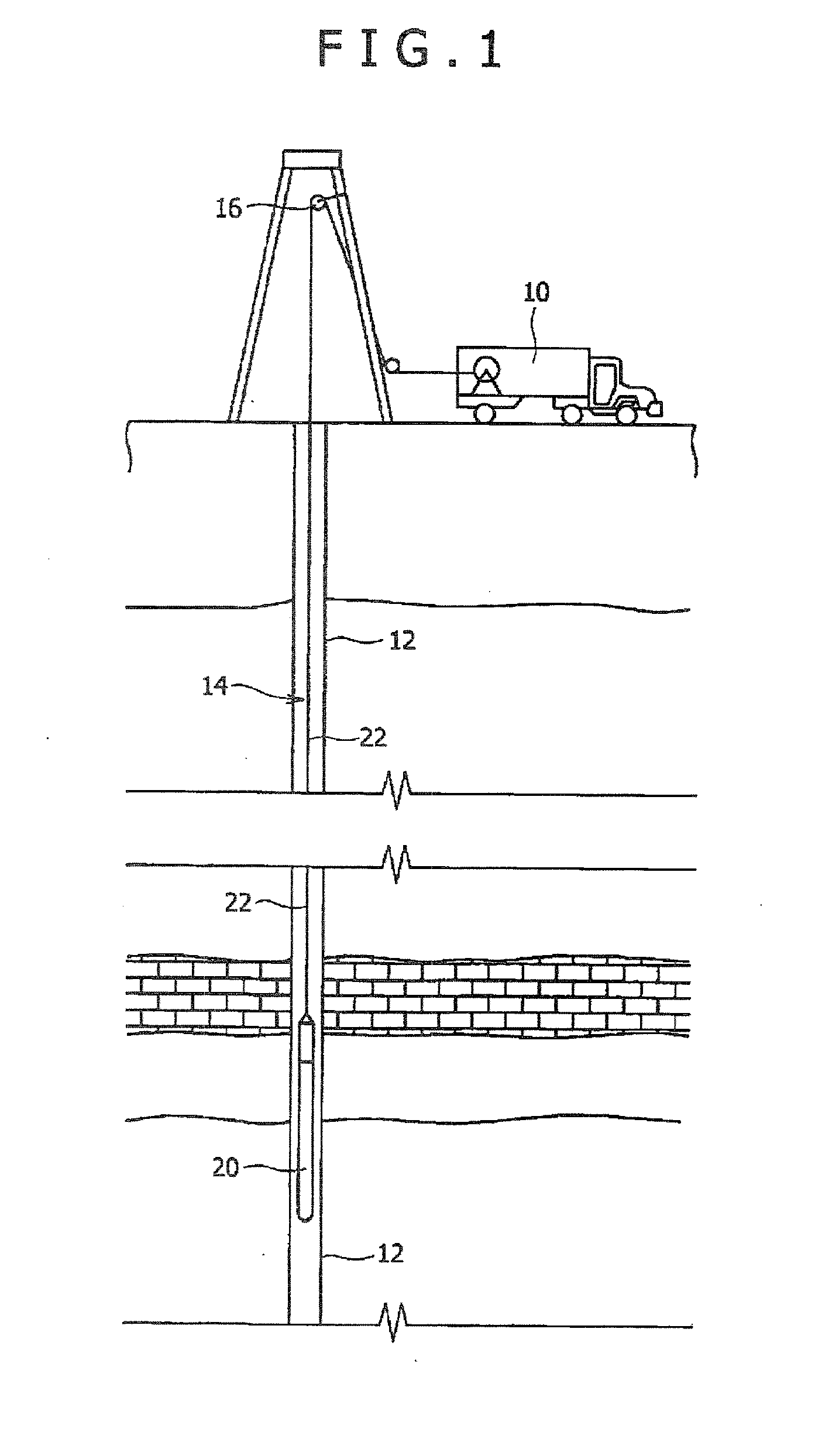

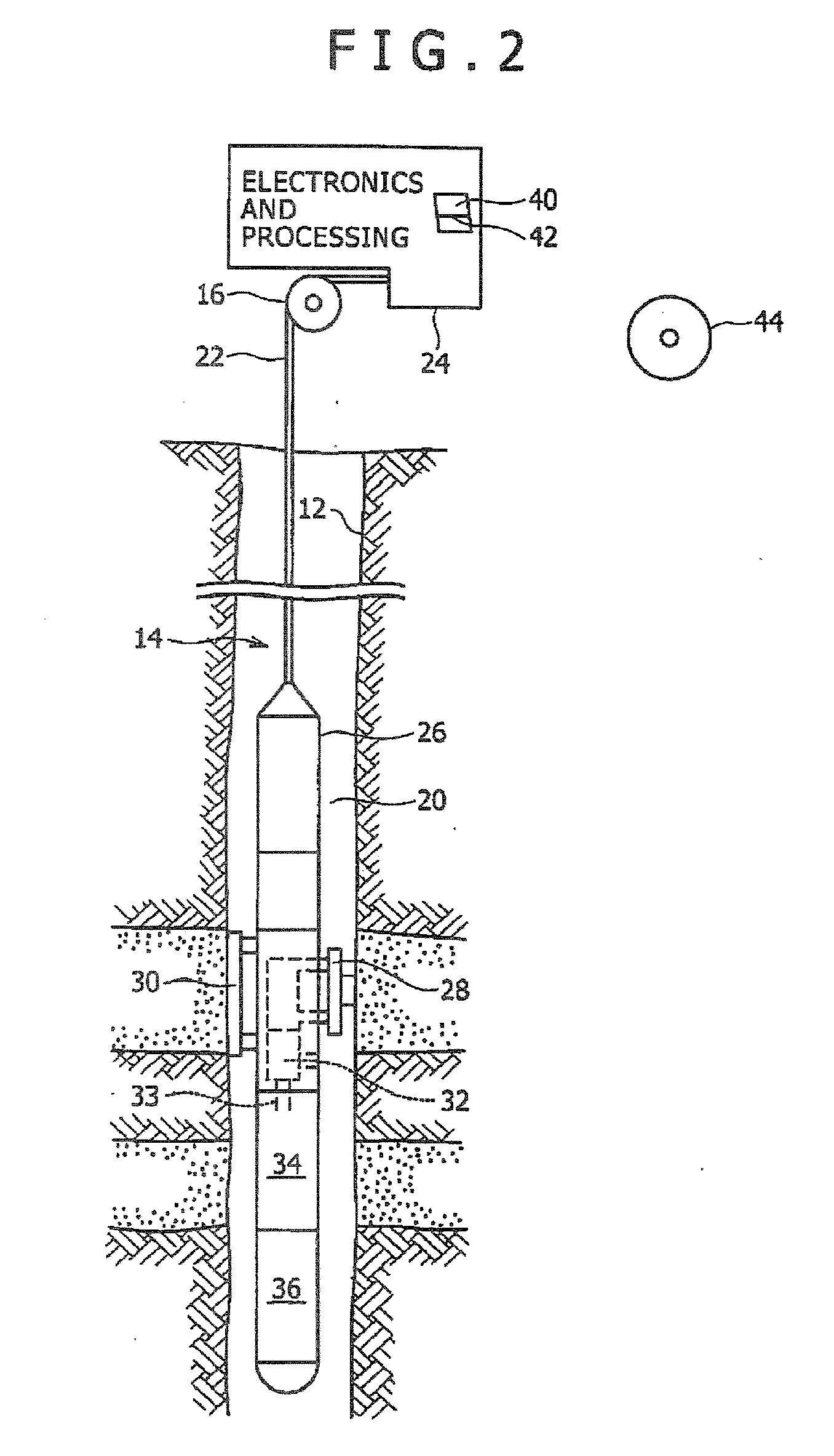

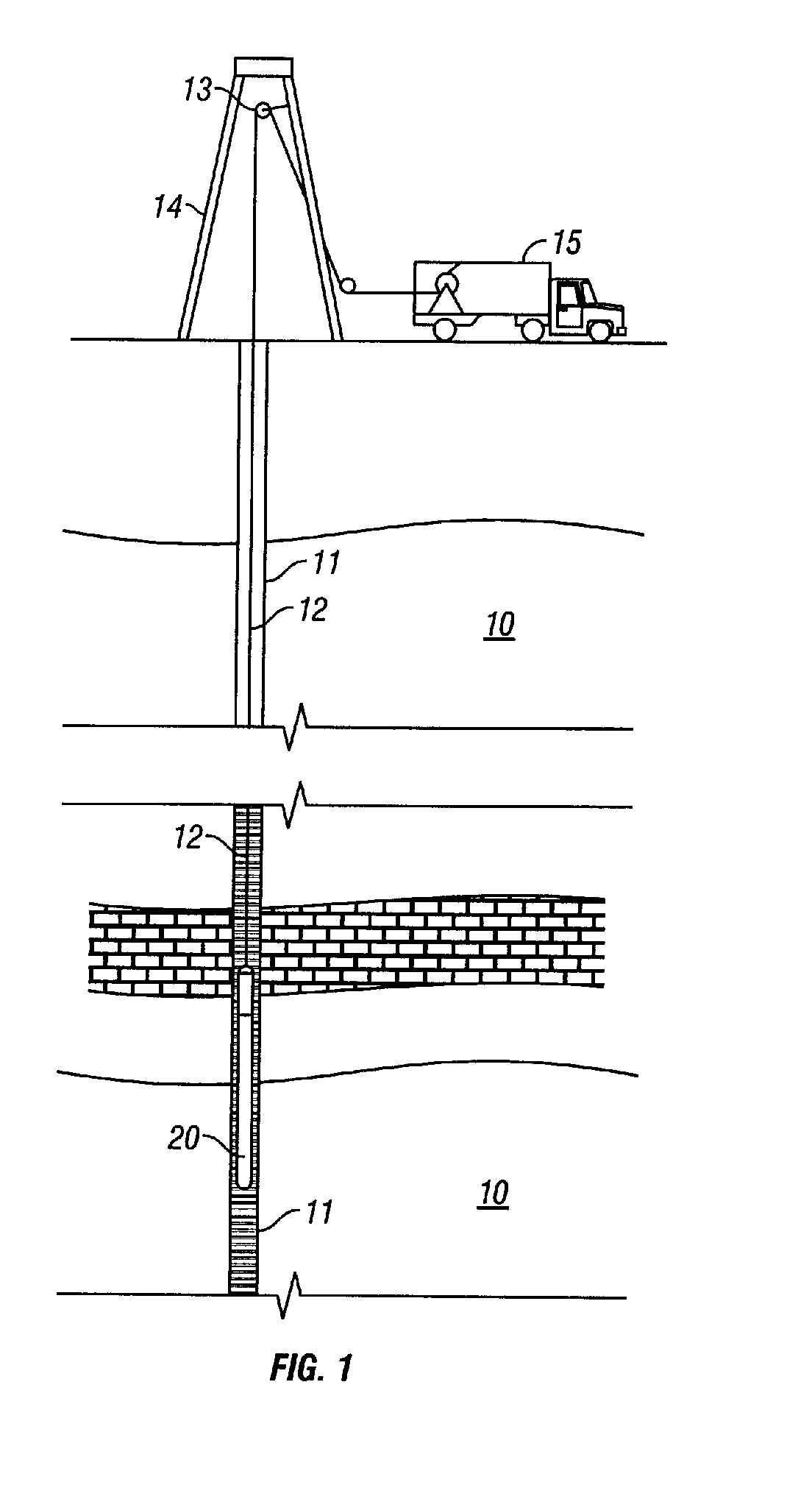

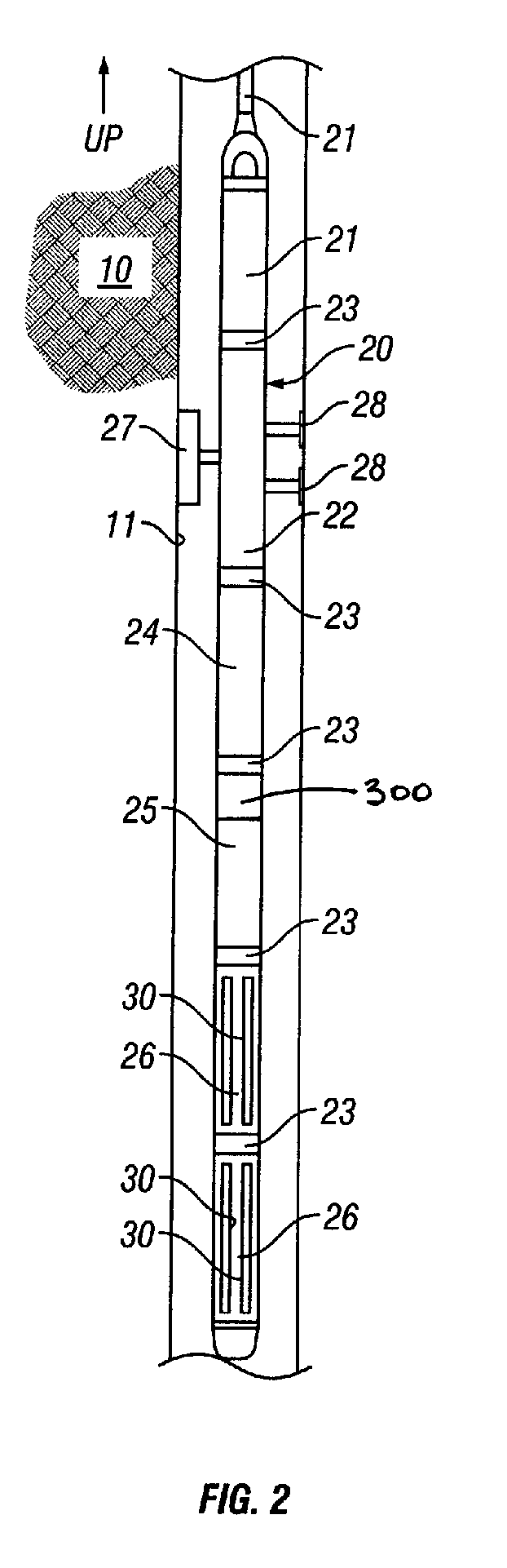

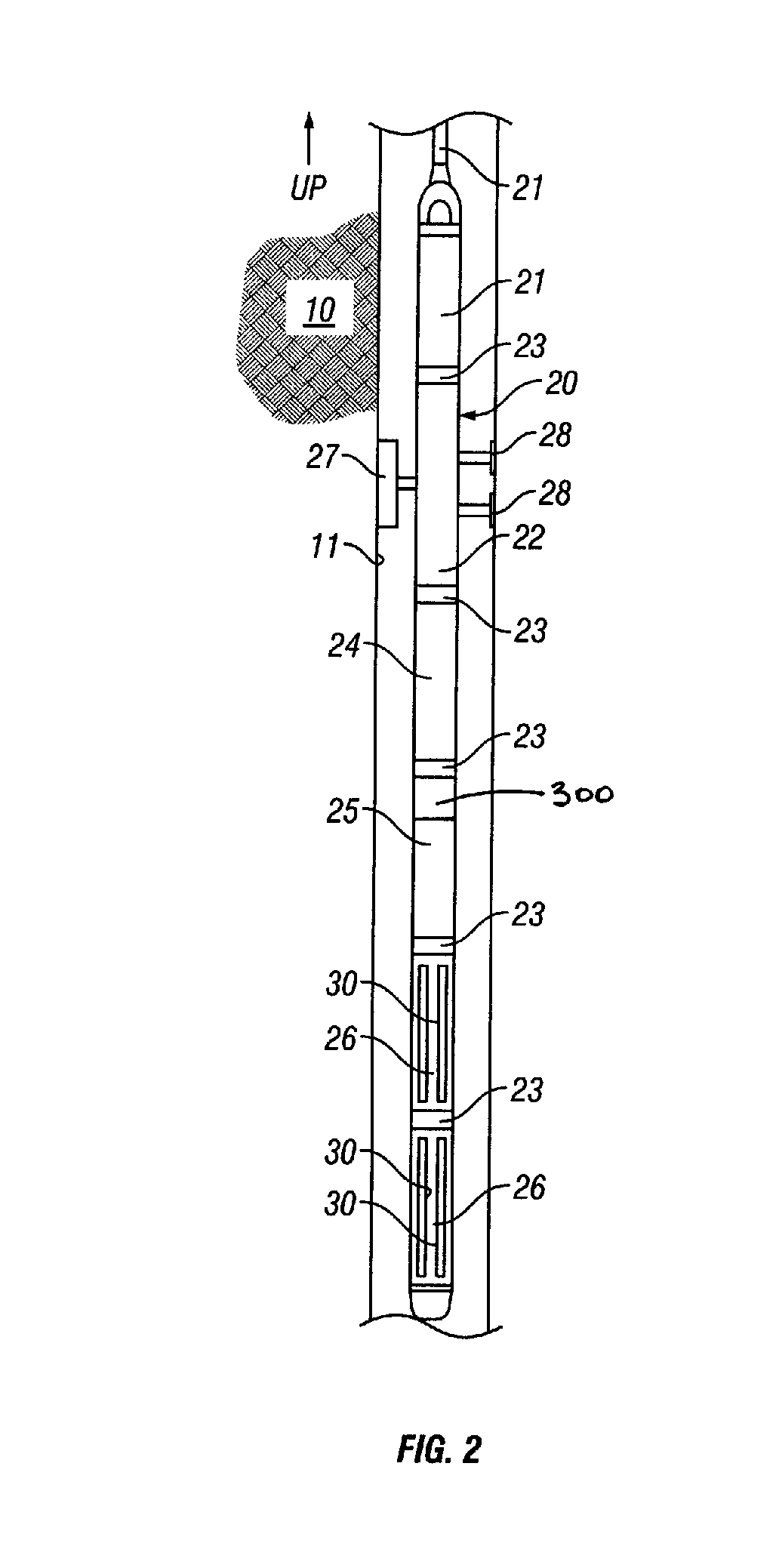

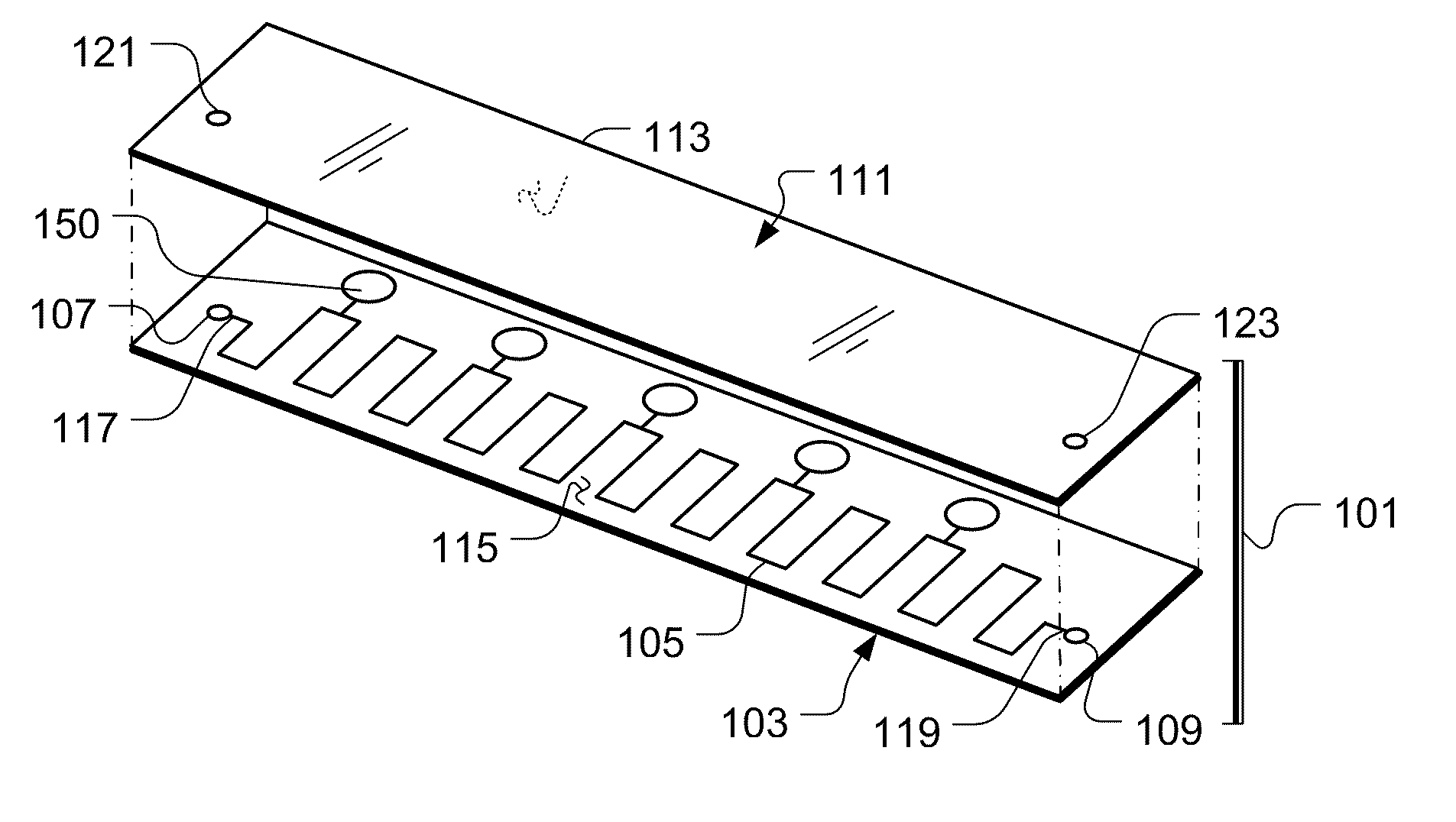

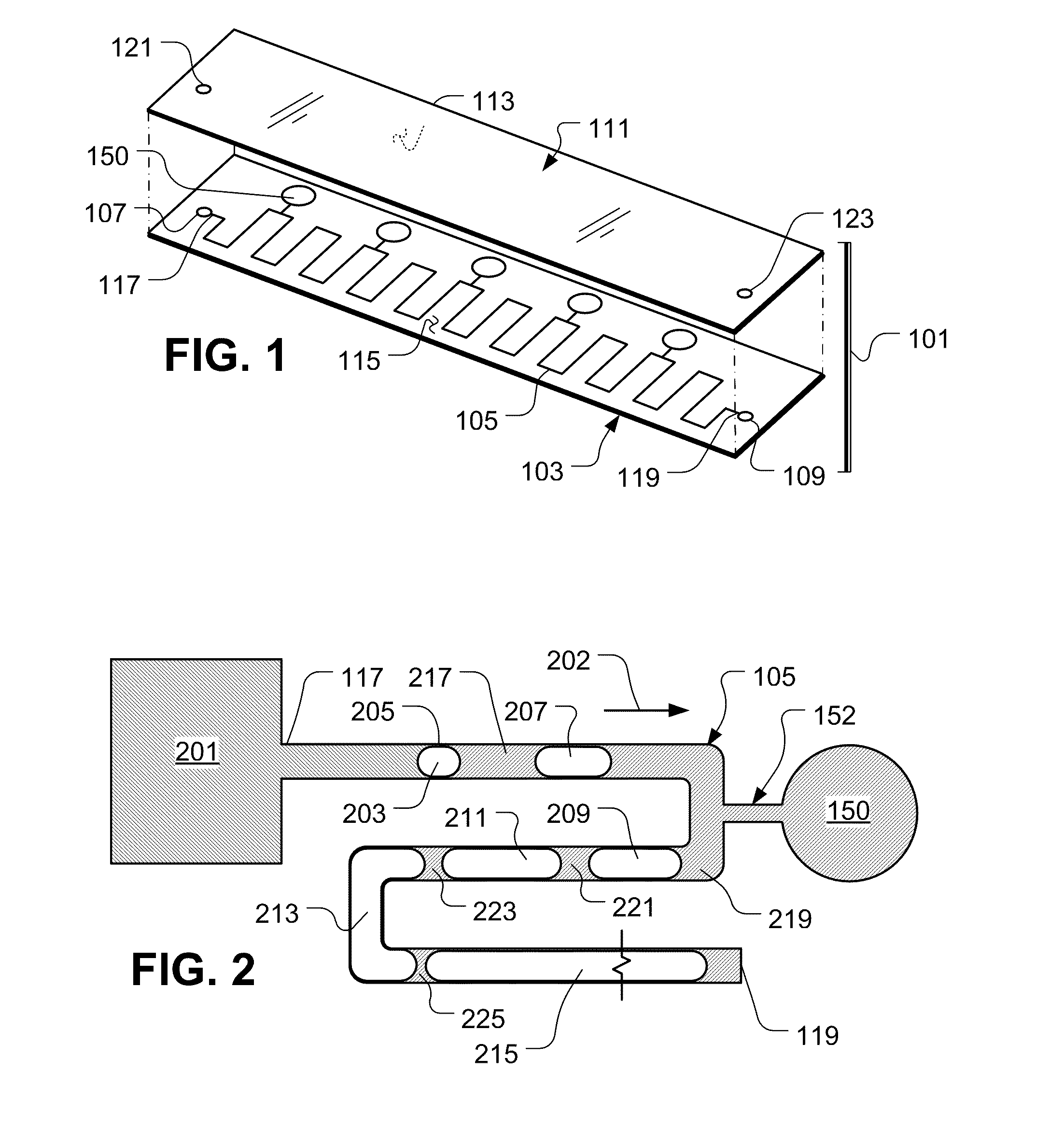

Method and apparatus for downhole fluid characterization using flexural mechanical resonators

InactiveUS20020178805A1Avoid contact corrosionProtection from damageElectric/magnetic detection for well-loggingAnalysing fluids using sonic/ultrasonic/infrasonic wavesTuning forkFormation fluid

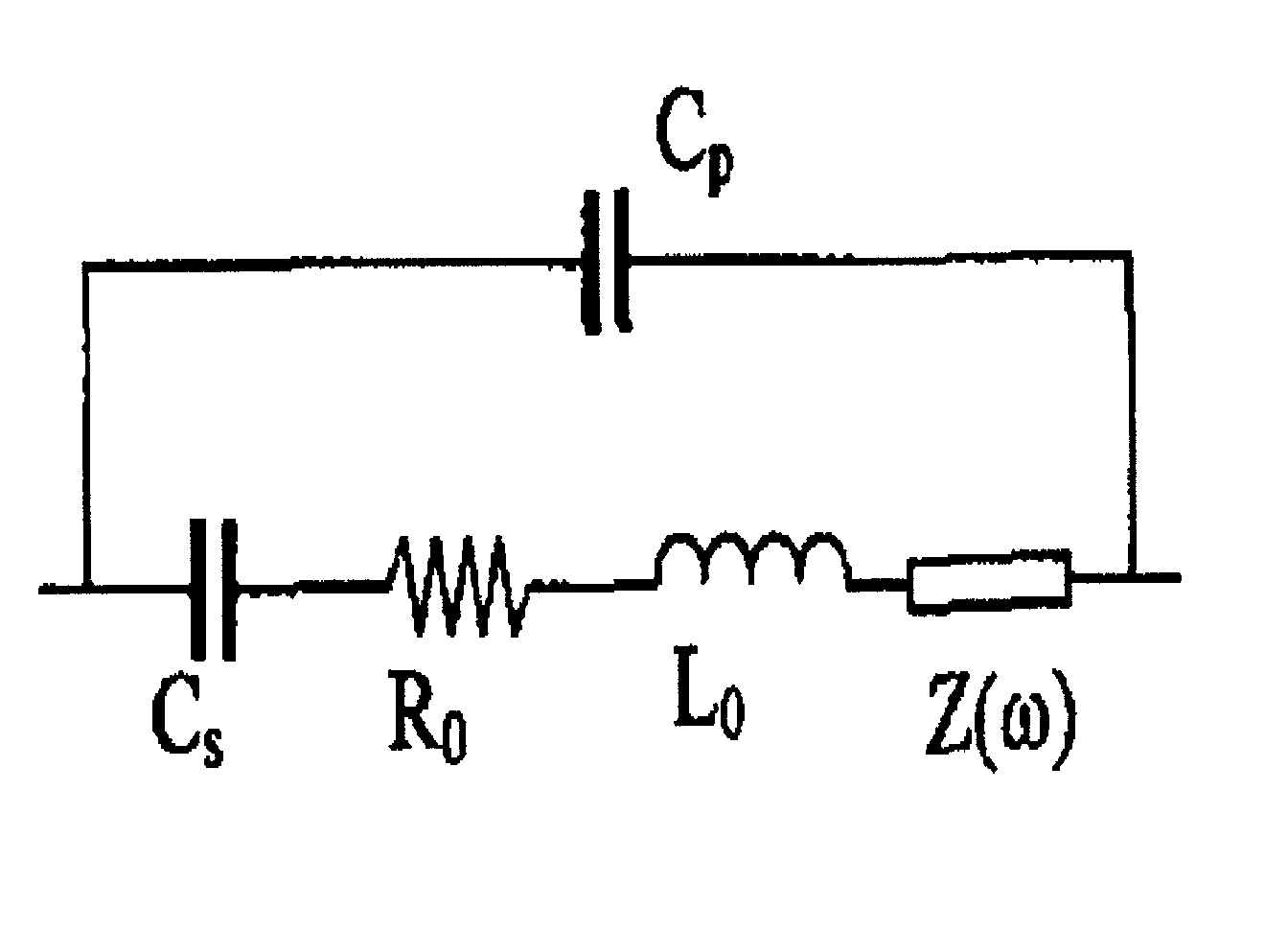

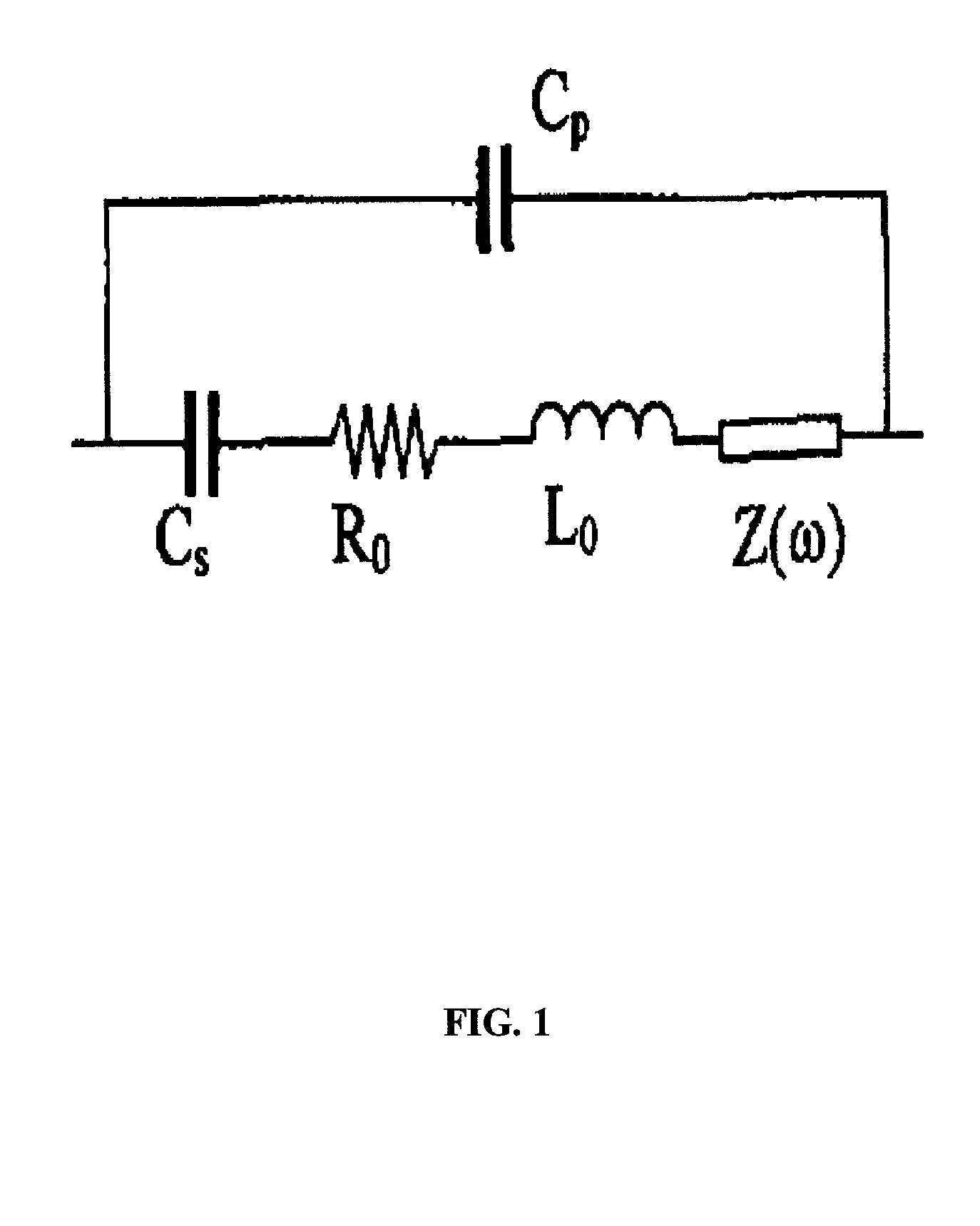

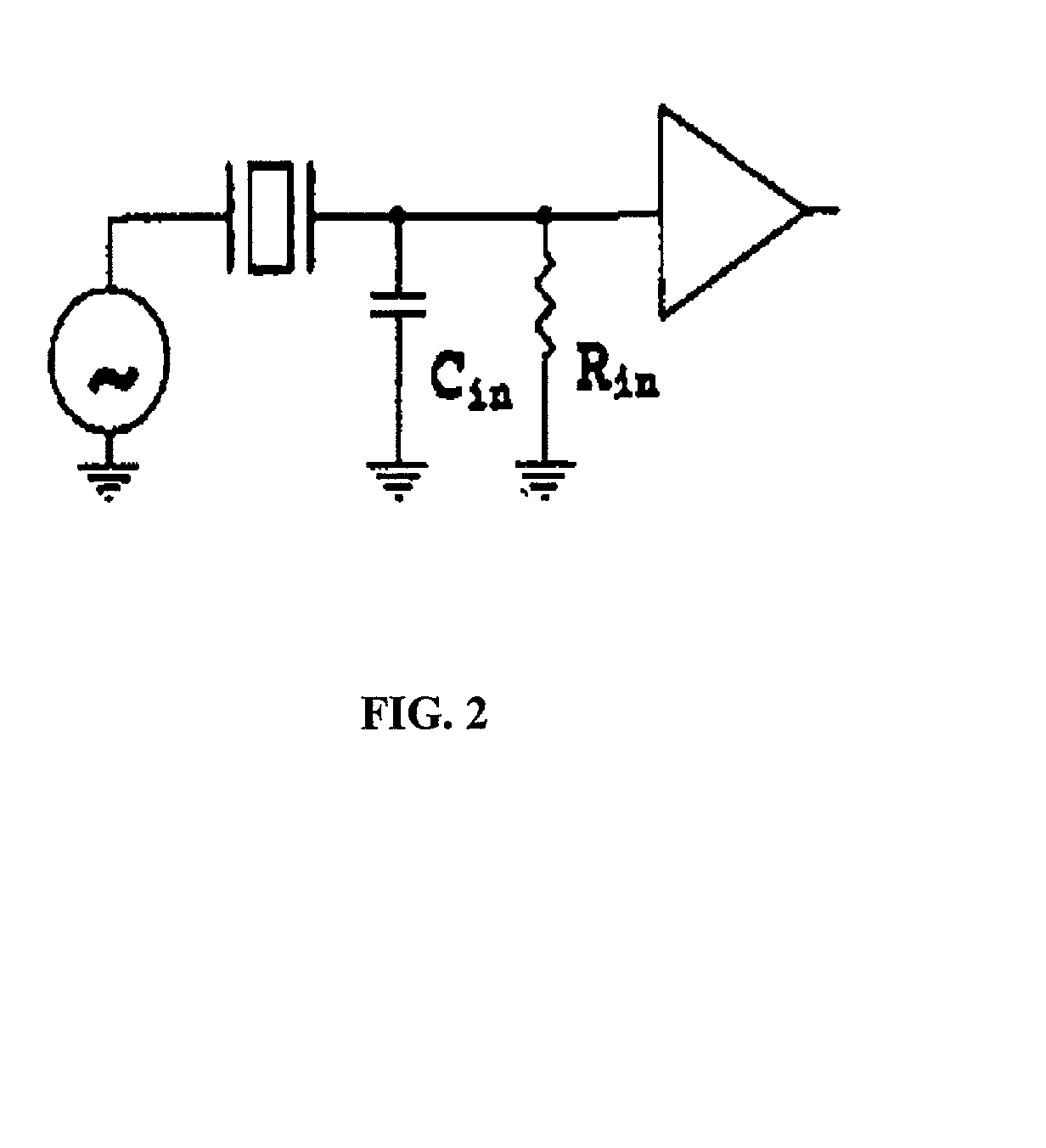

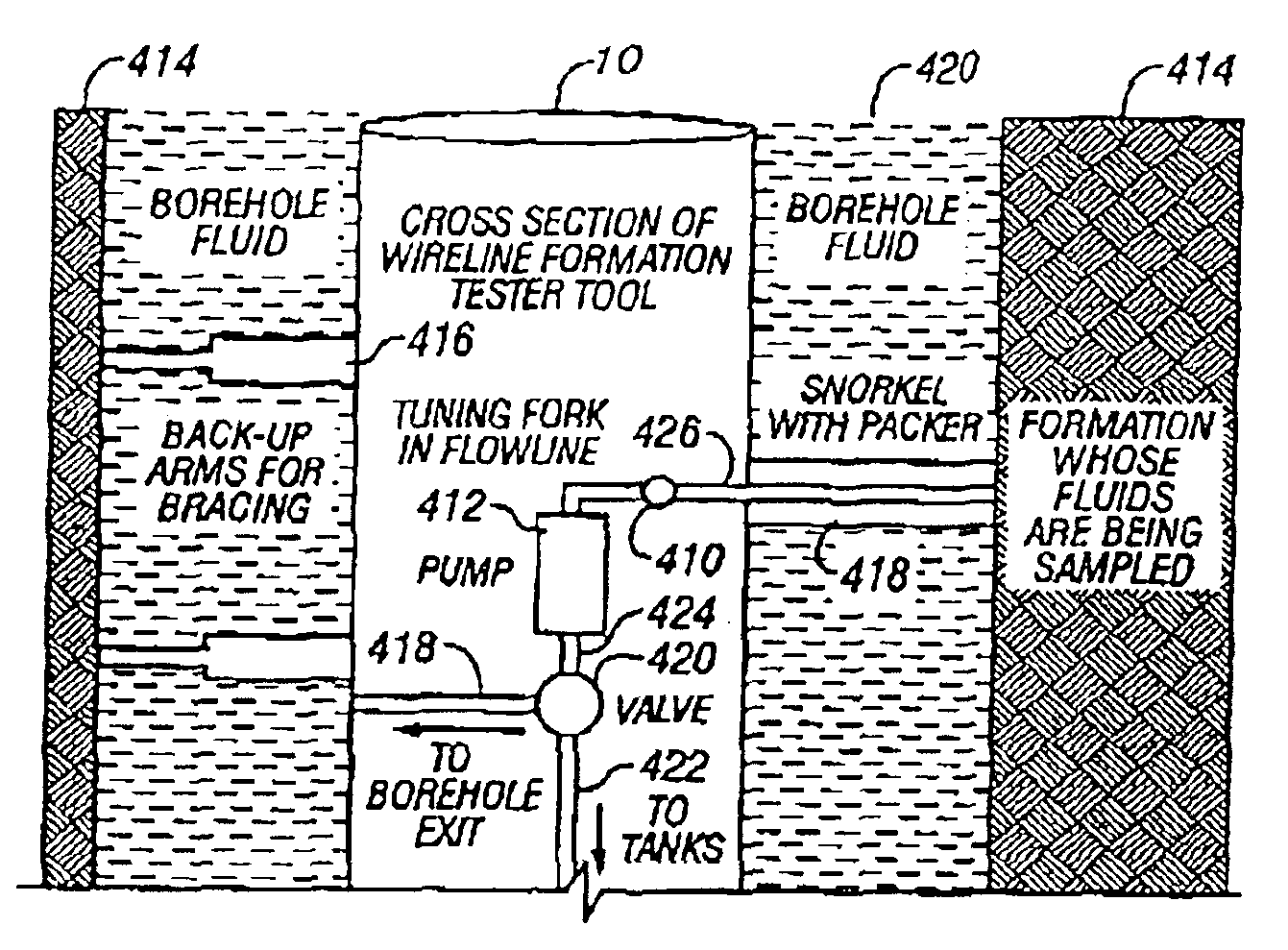

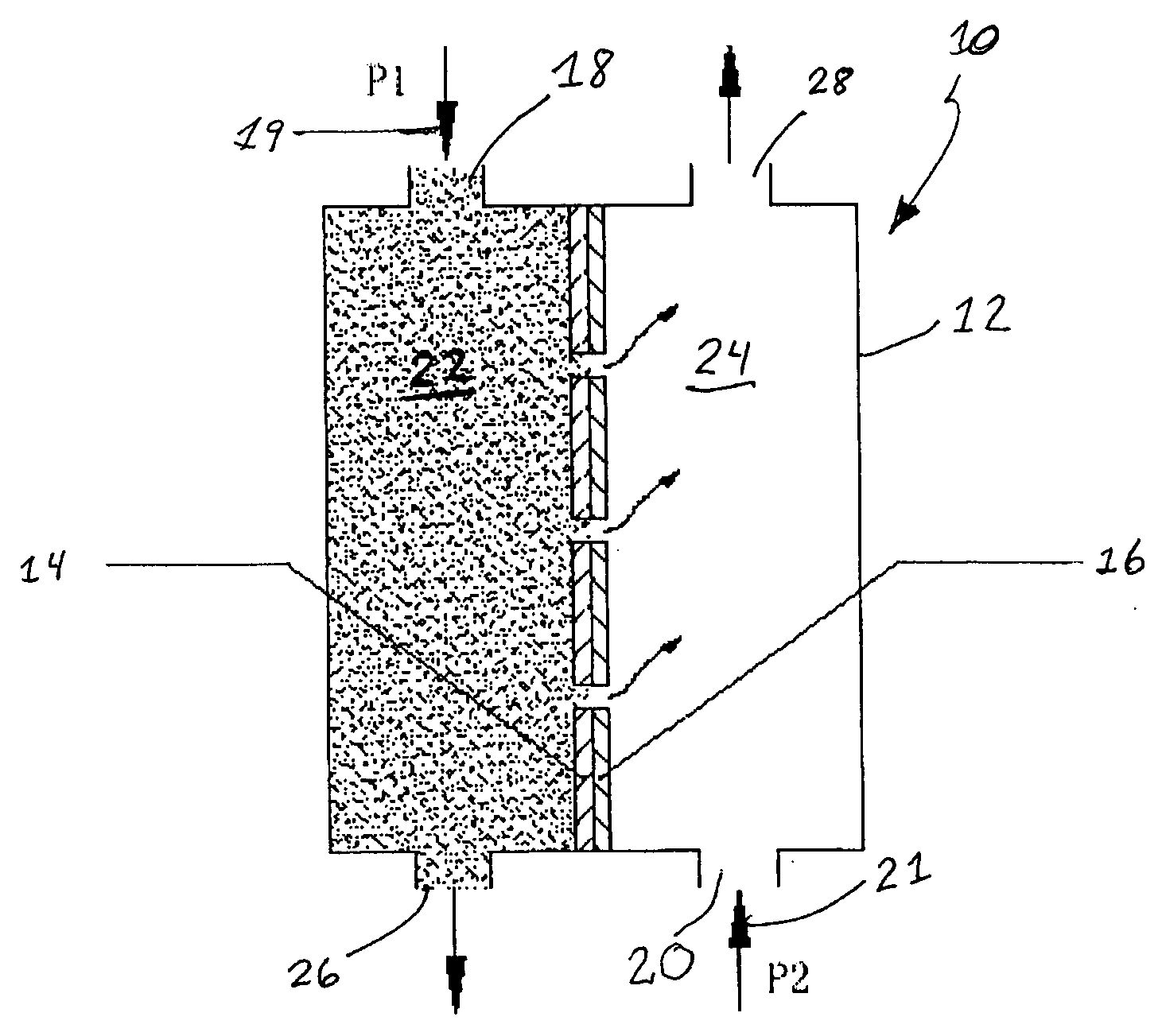

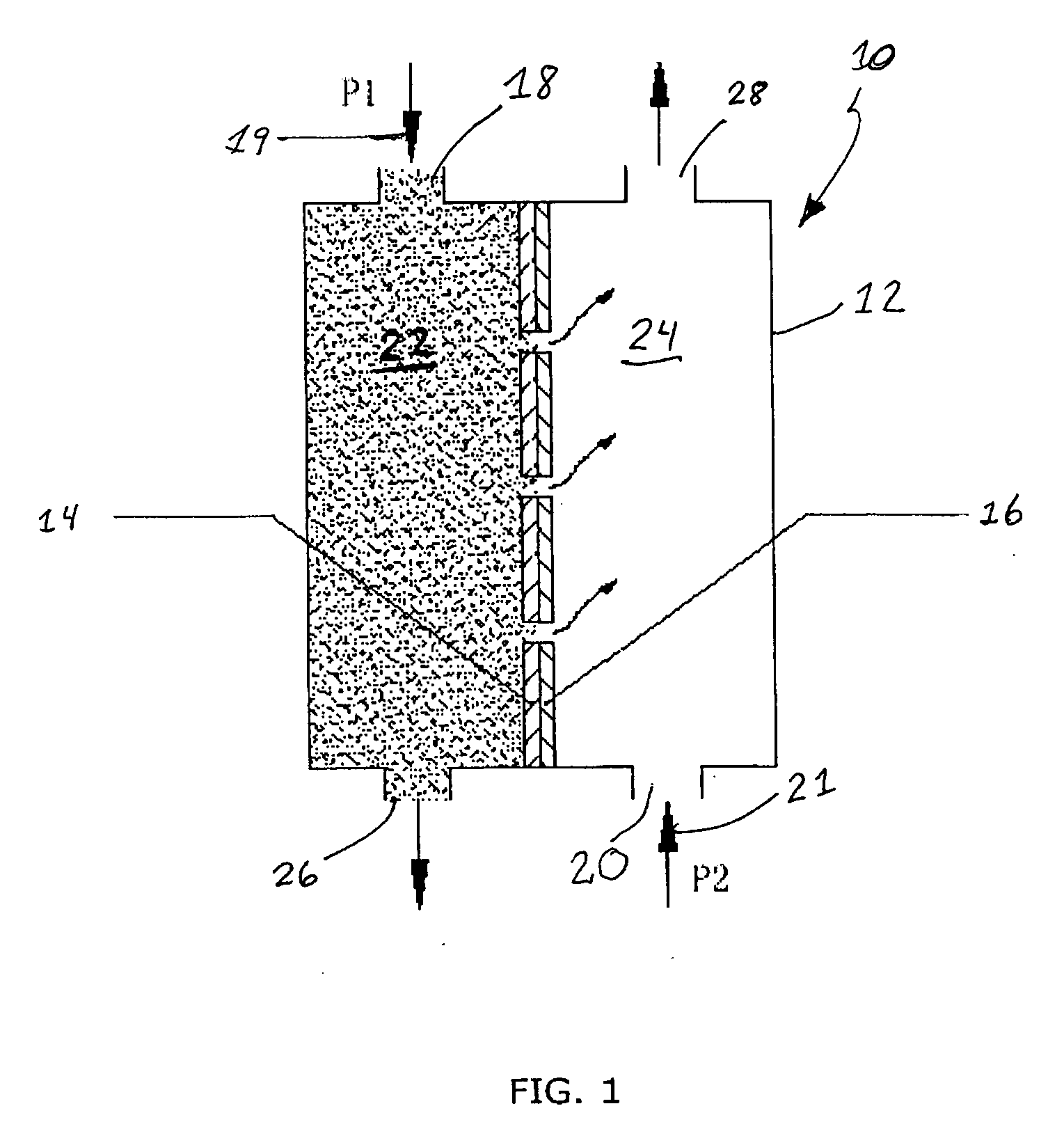

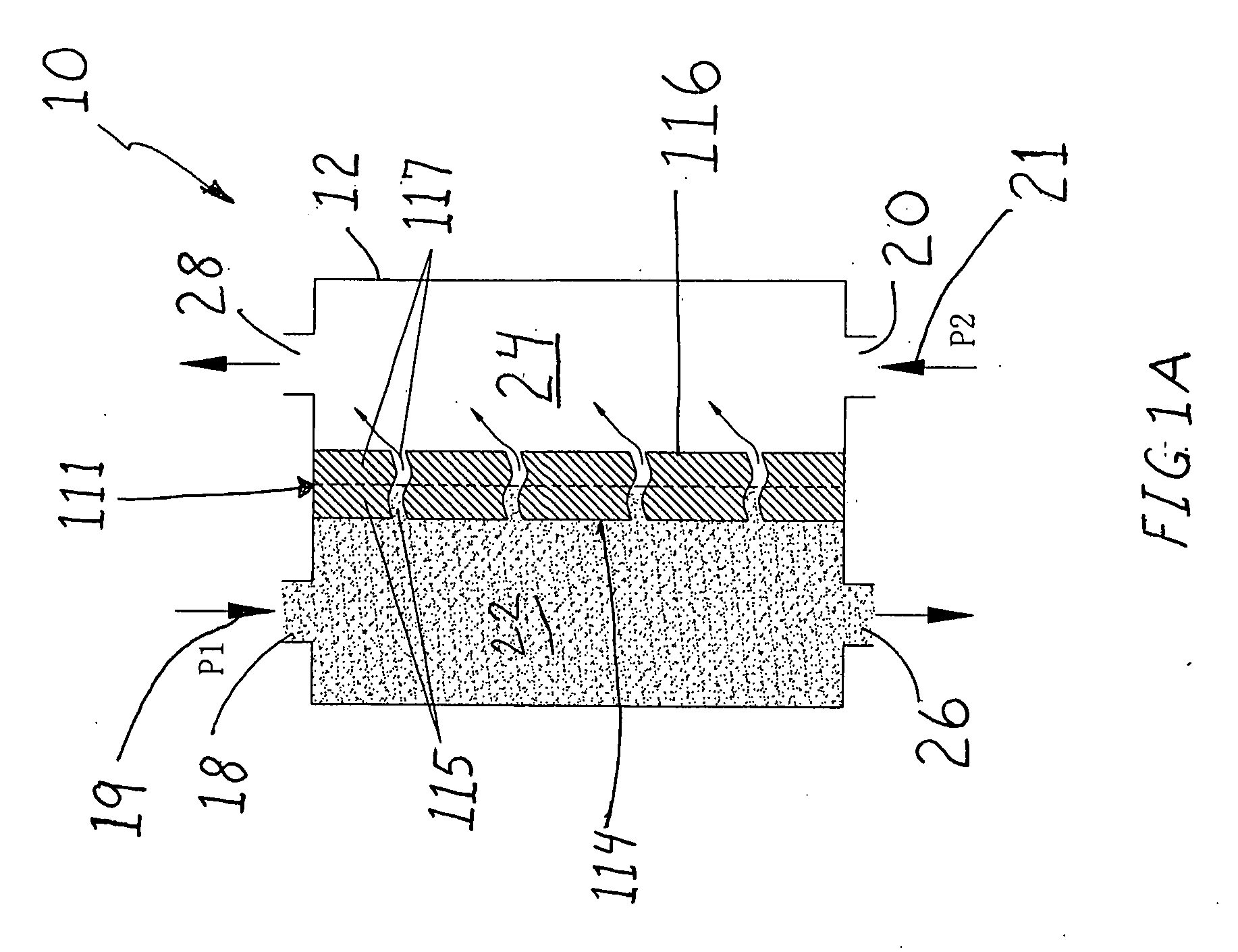

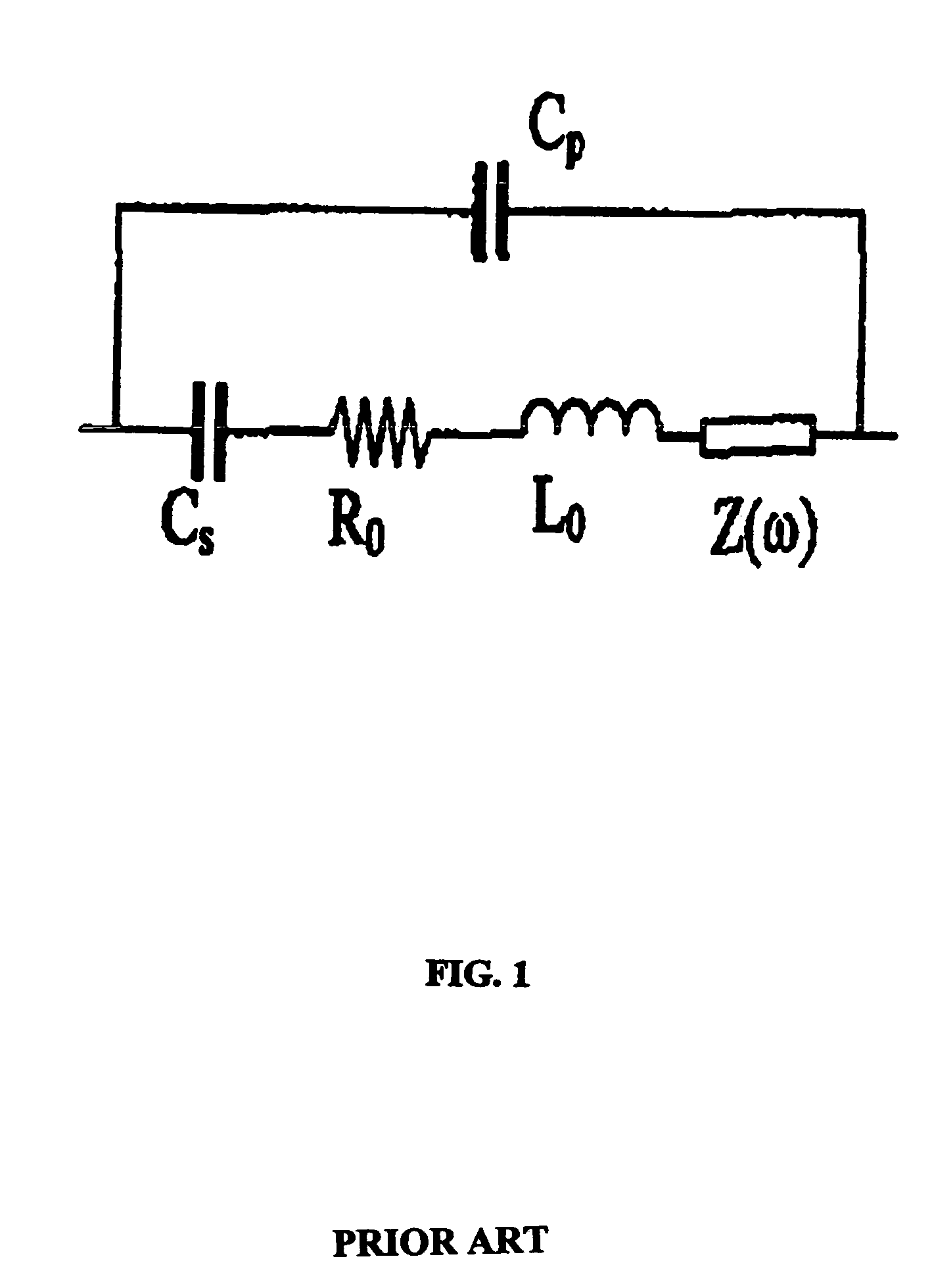

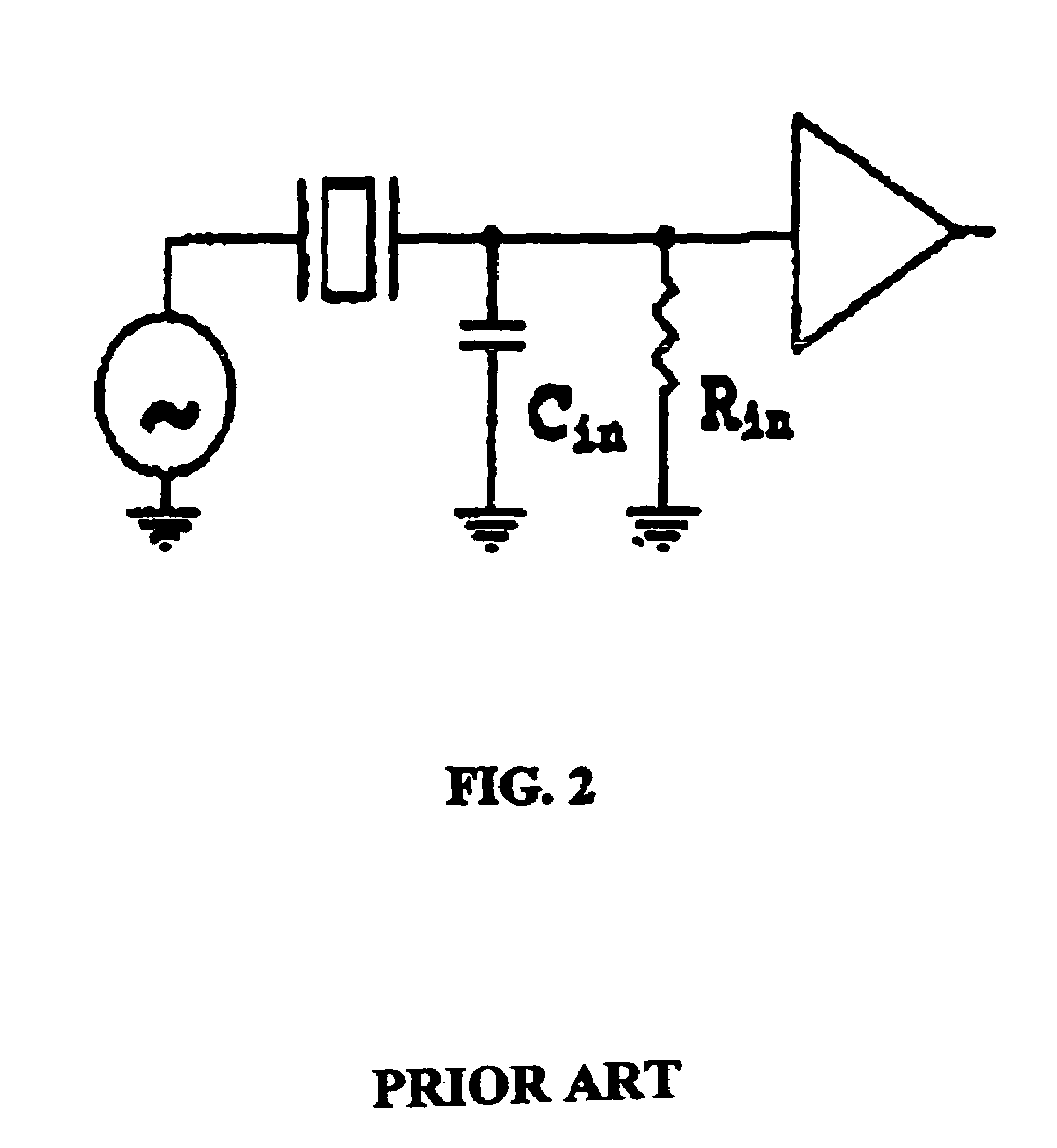

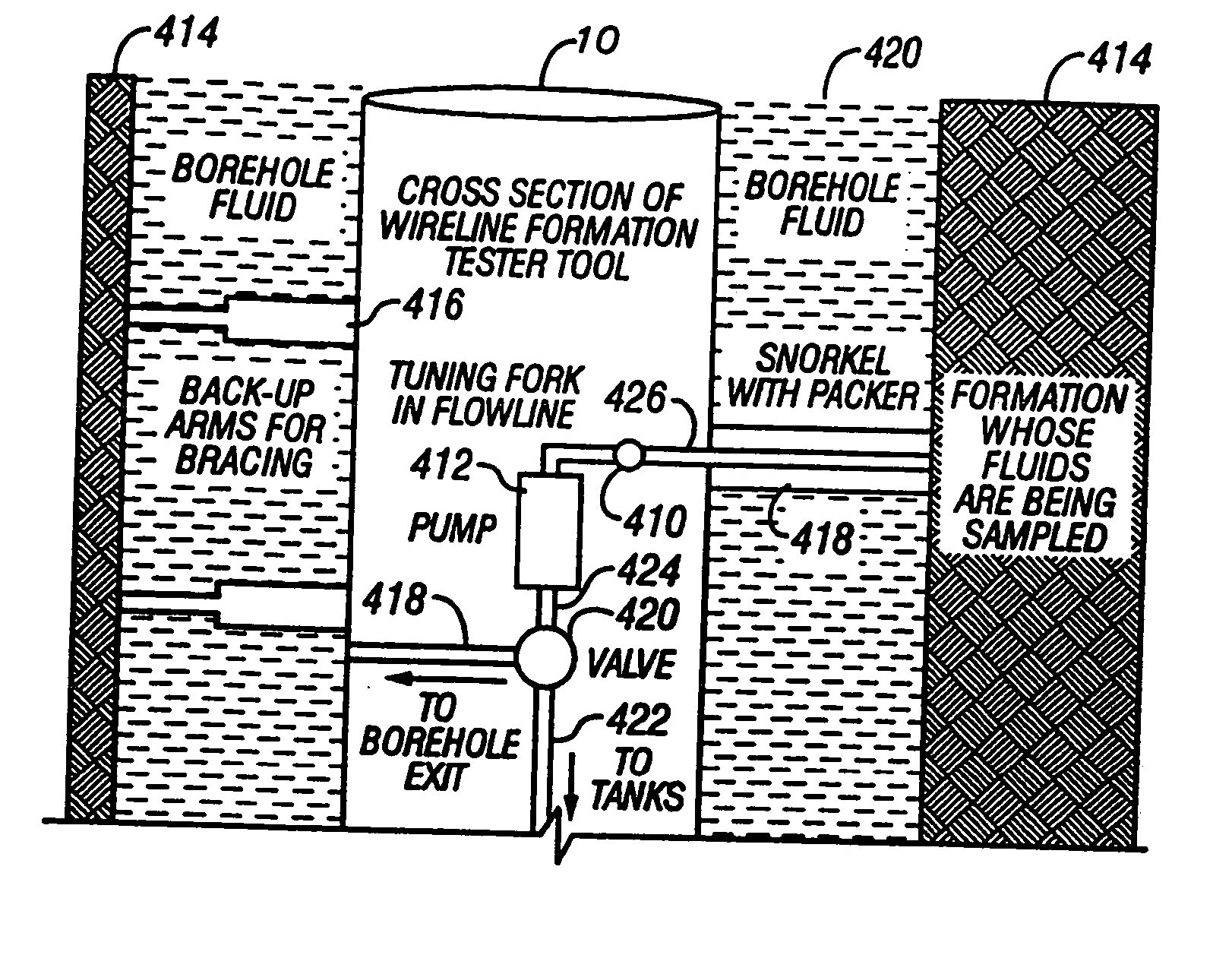

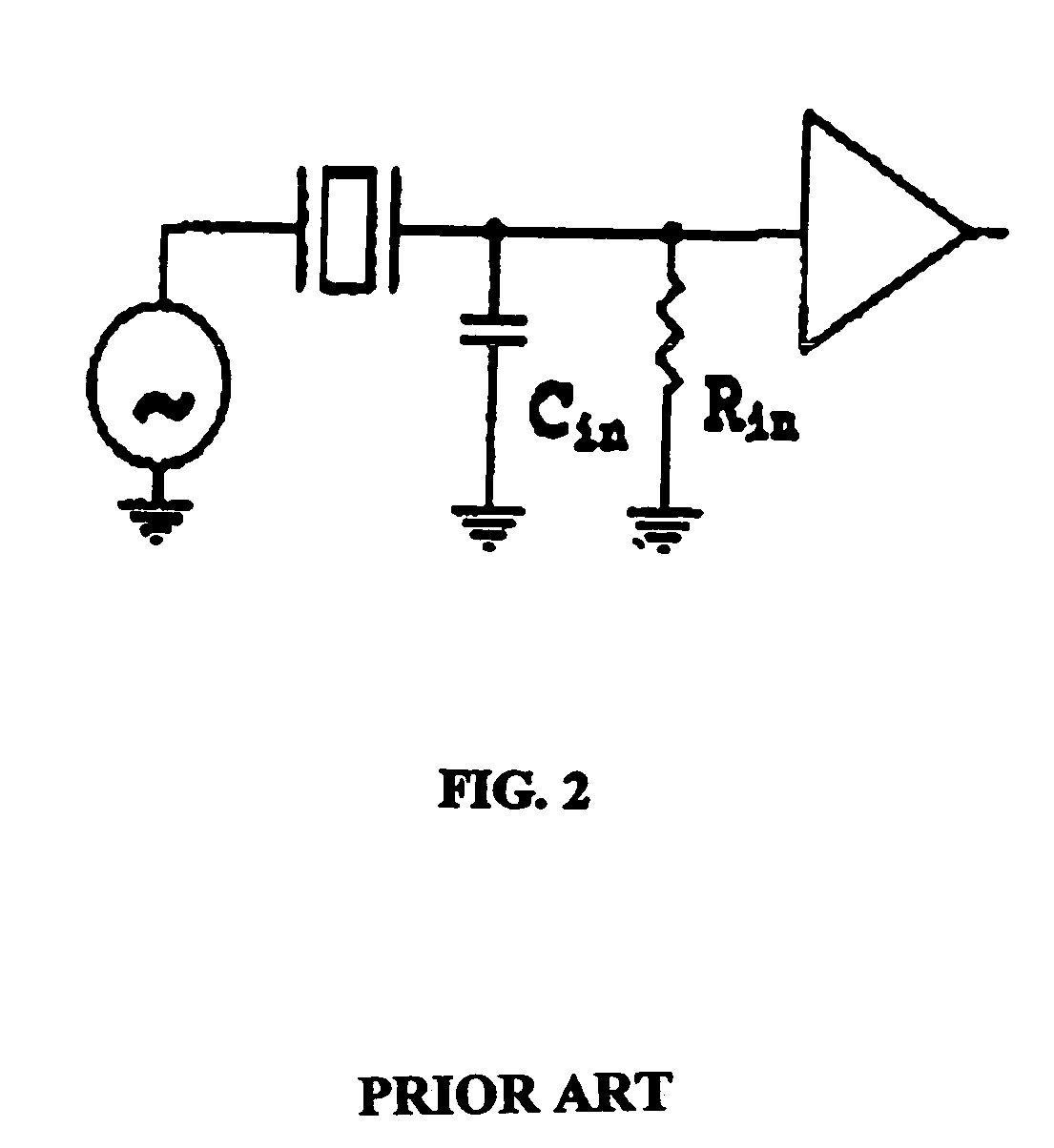

The present invention provides a downhole method and apparatus using a flexural mechanical resonator, for example, a tuning fork to provide real-time direct measurements and estimates of the viscosity, density and dielectric constant of formation fluid or filtrate in a hydrocarbon producing well. The present invention additionally provides a method and apparatus for monitoring cleanup from a leveling off of viscosity or density over time, measuring or estimating bubble point for formation fluid, measuring or estimating dew point for formation fluid, and determining the onset of asphaltene precipitation. The present invention also provides for intercalibration of plural pressure gauges used to determine a pressure differential downhole.

Owner:BAKER HUGHES INC

Method and apparatus for downhole fluid characterization using flexural mechanical resonators

InactiveUS6938470B2Avoid contact corrosionInversely to viscosityElectric/magnetic detection for well-loggingAnalysing fluids using sonic/ultrasonic/infrasonic wavesTuning forkFormation fluid

Owner:BAKER HUGHES INC

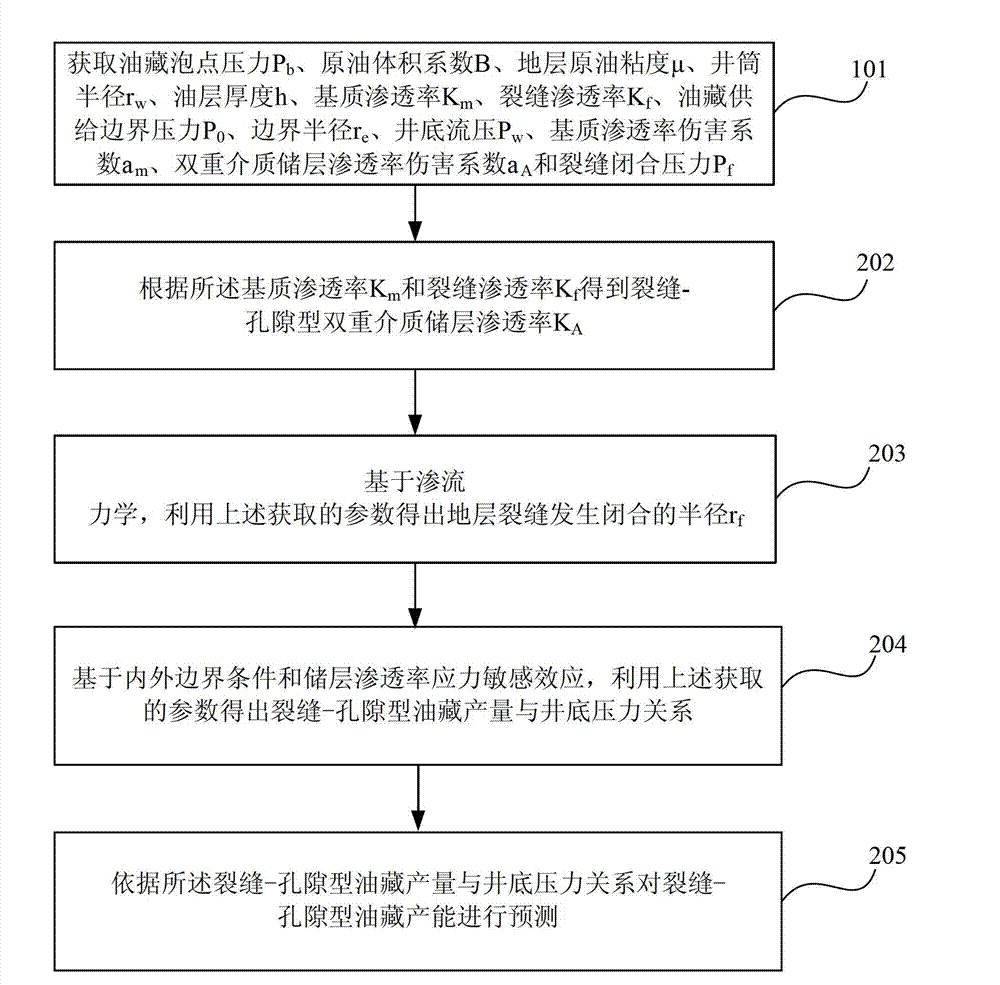

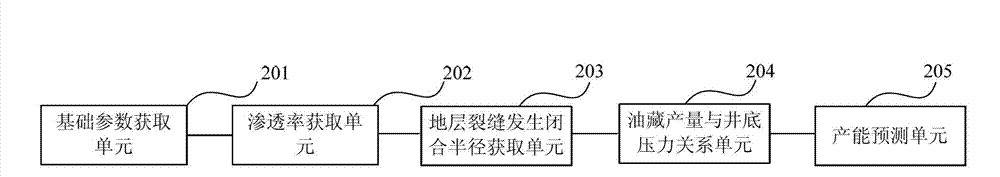

Method and device for predicting capacity of fissure-hole type oil deposit

ActiveCN102865059AForecast outputRich multi-media seepage theoryFluid removalDamage factorBottom pressure

The invention relates to a method and a device for predicting the capacity of a fissure-hole type oil deposit. The method includes the steps of acquiring oil deposit bubble point pressure Pb, a volumetric factor B, in-place oil viscosity mu, the shaft radius rw, the oil reservoir thickness h, matrix permeability Km, fissure permeability Kf, oil deposit supply boundary pressure Pe, the boundary radius re, shaft bottom flow pressure Pw, a matrix permeability damage factor alpha m, a double-medium reservoir permeability damage factor alpha A and fissure closing pressure Pf. Fissure-hole type double-medium reservoir permeability KA is obtained according to the matrix permeability Km and the fissure permeability Kf; on the basis of permeation fluid mechanics, the stratum fissure closed radius rf is obtained by the acquired parameters; on the basis of inner and outer boundary conditions and reservoir permeability stress sensitive effects, the relation between the capacity of the fissure-hole type oil deposit and shaft bottom pressure is obtained by the acquired parameters; and the capacity of the fissure-hole type oil deposit is predicted according to the relation between the capacity of the fissure-hole type oil deposit and the shaft bottom pressure.

Owner:PETROCHINA CO LTD

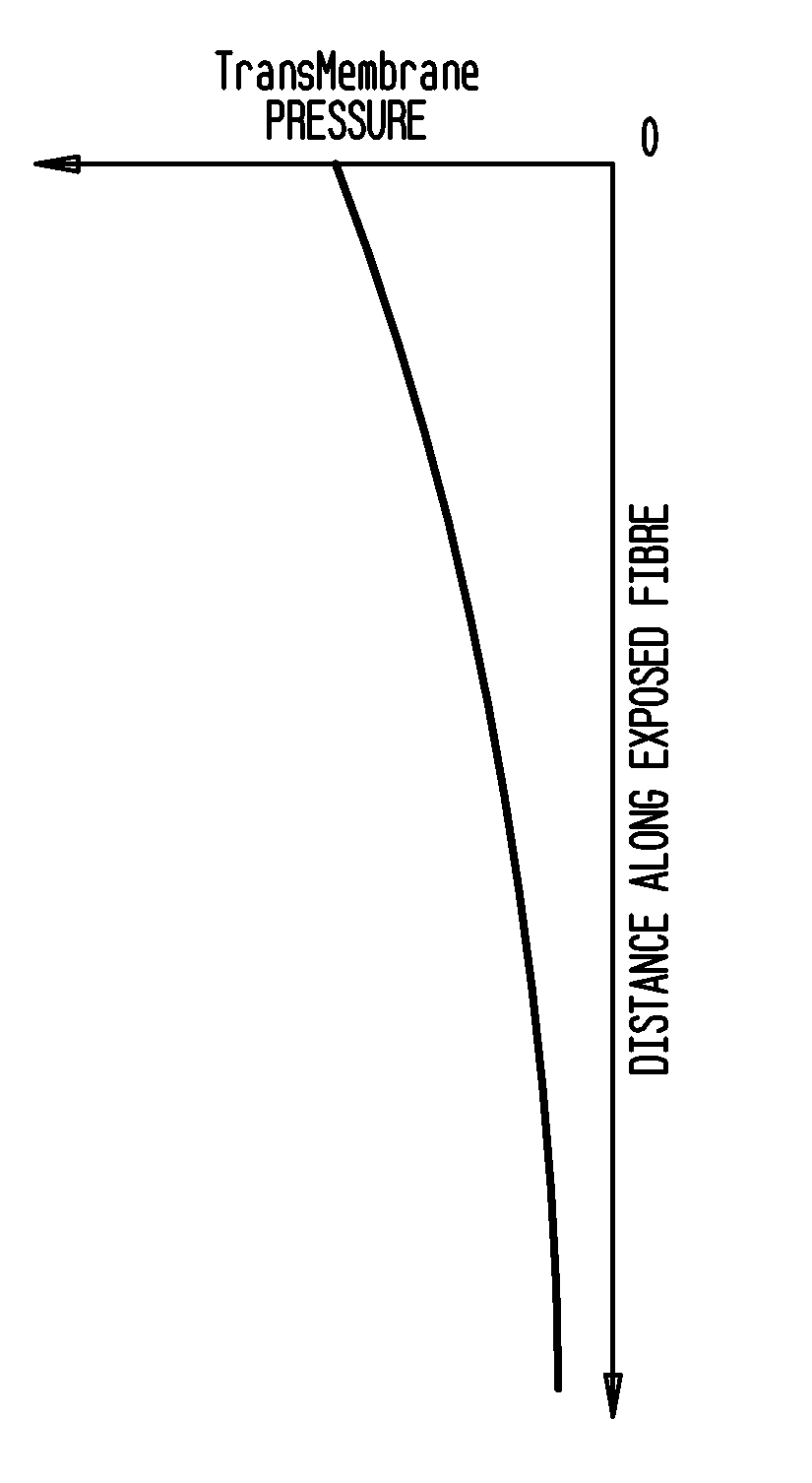

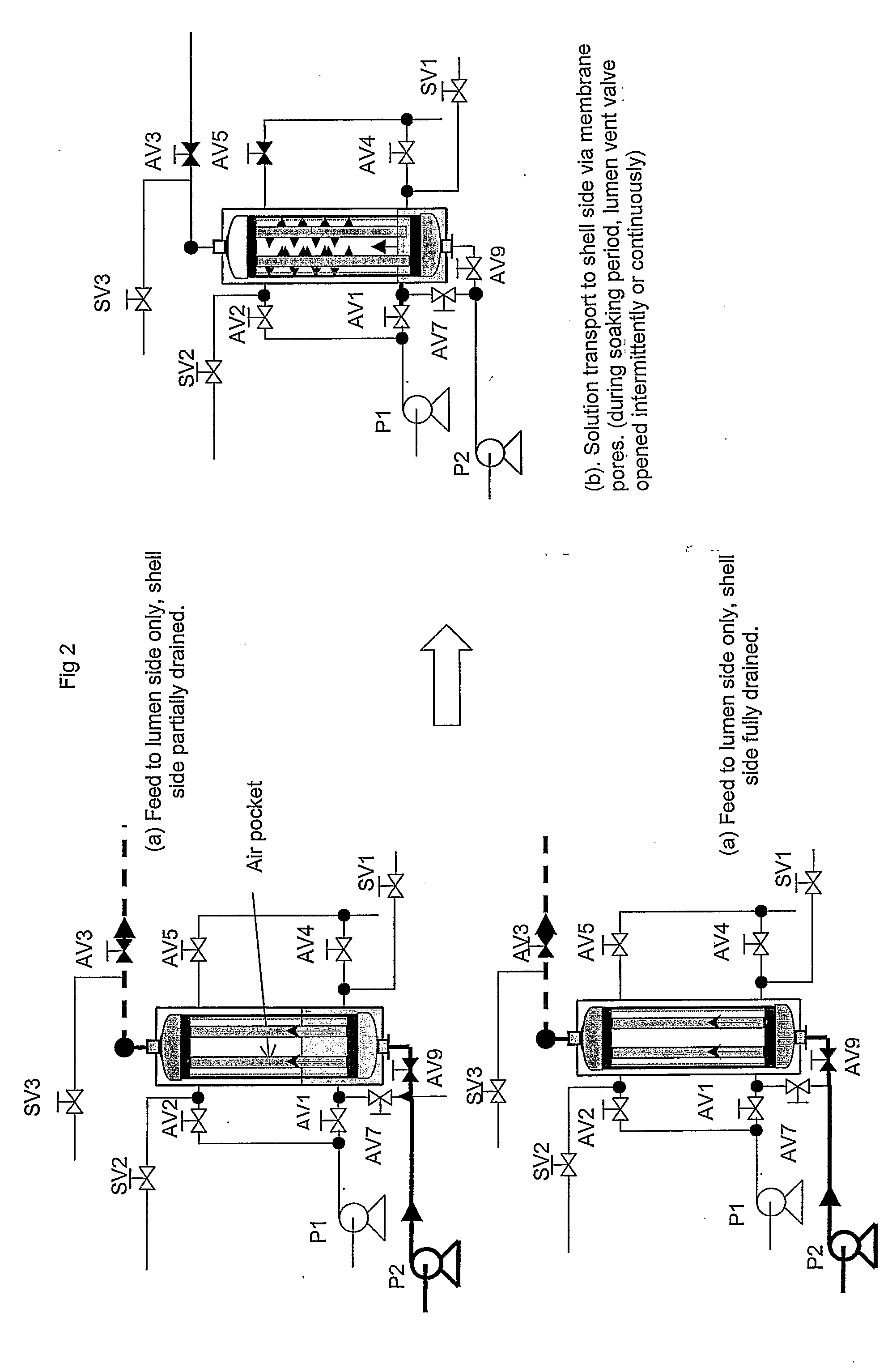

Backwash and cleaning method

InactiveUS20100025320A1Efficient chemical backwashMinimal useMembranesSemi-permeable membranesFiltrationCleaning methods

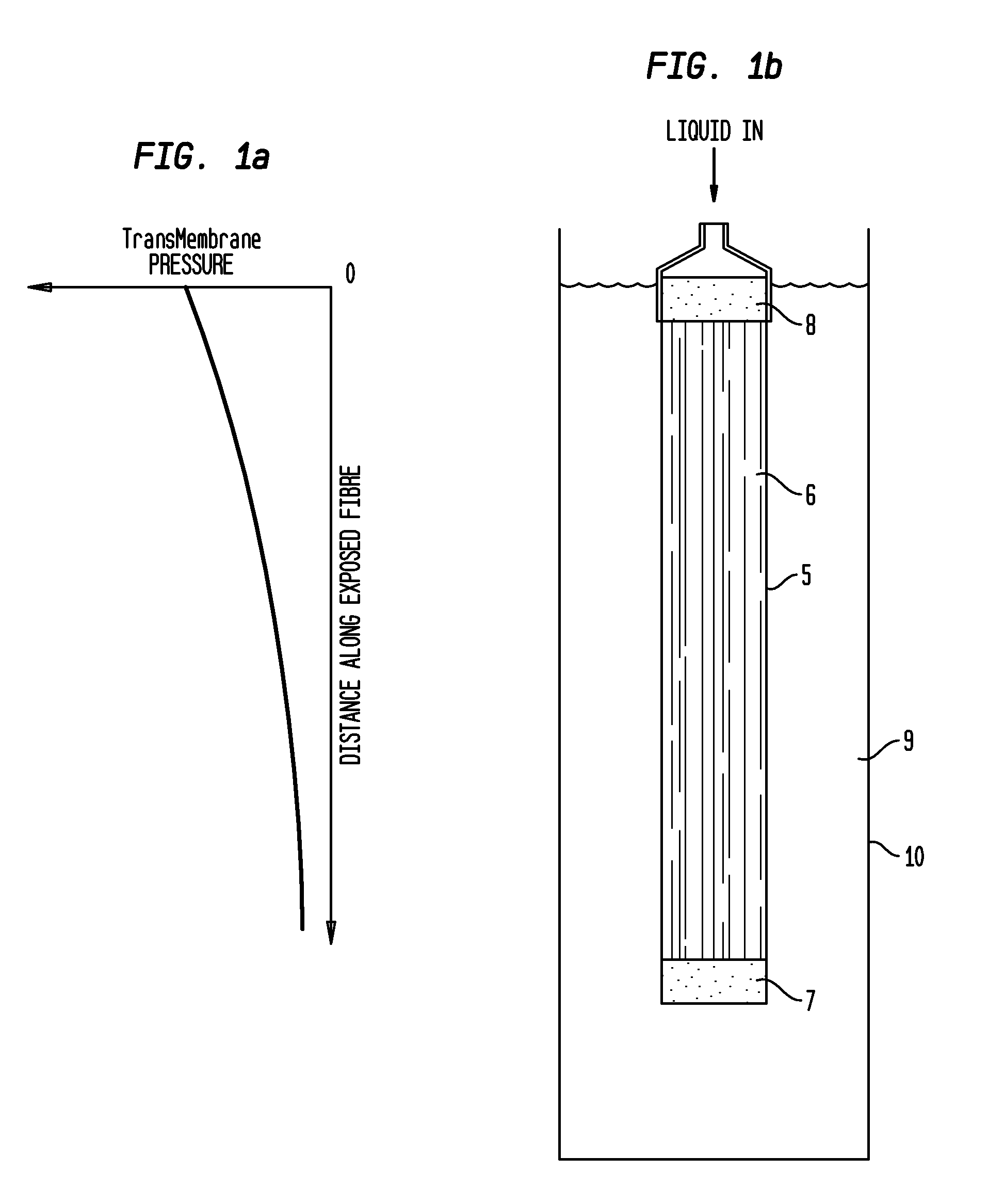

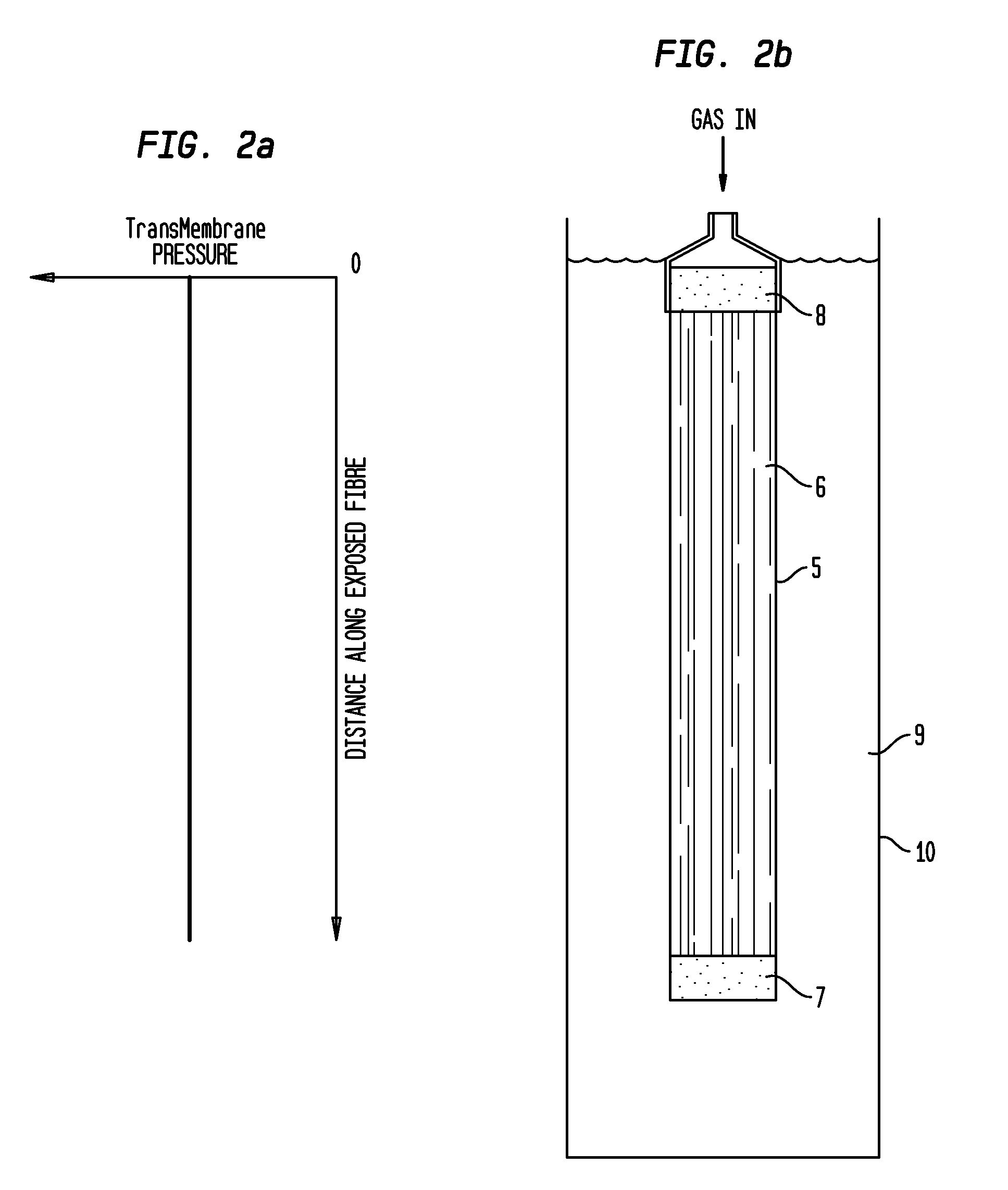

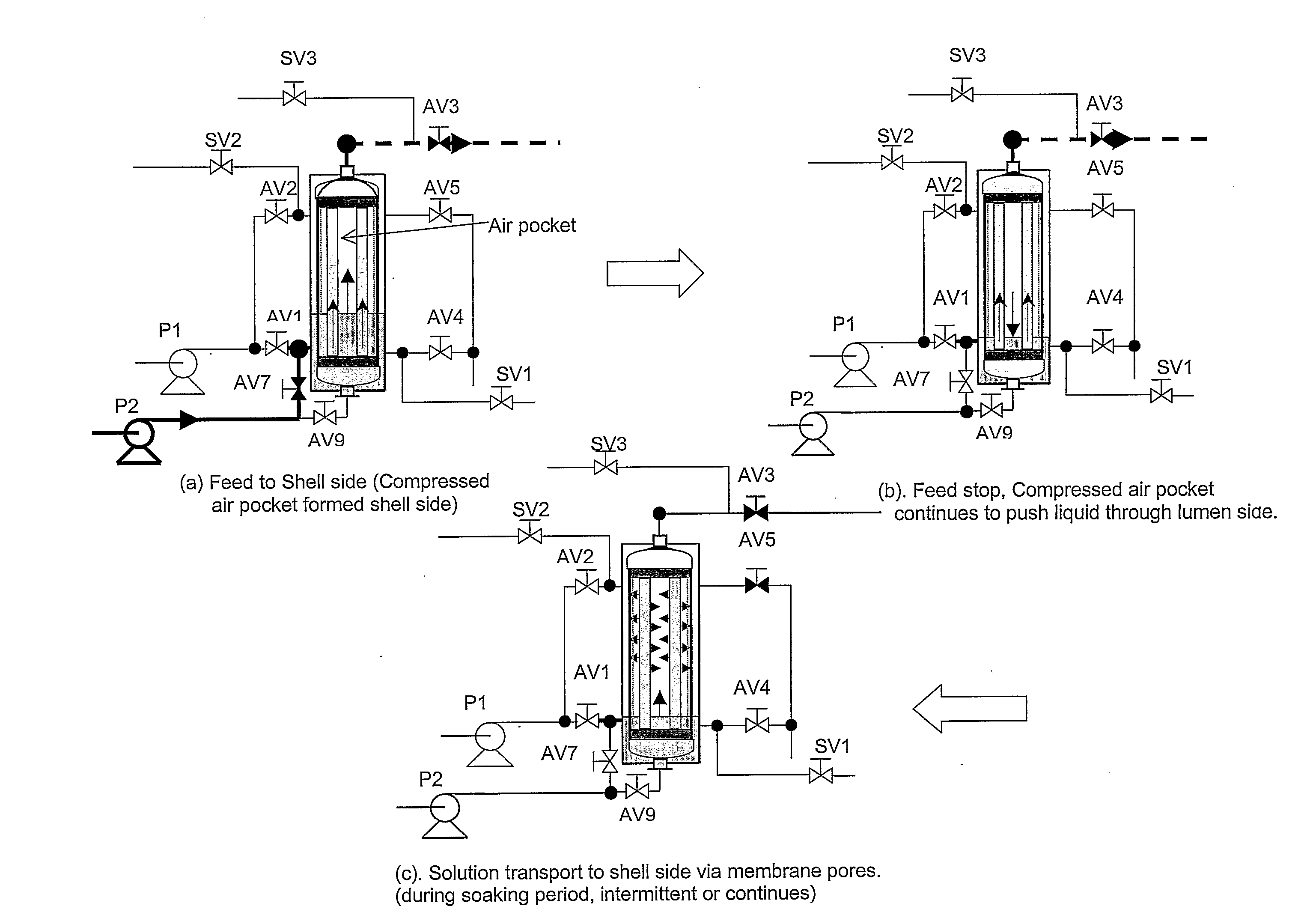

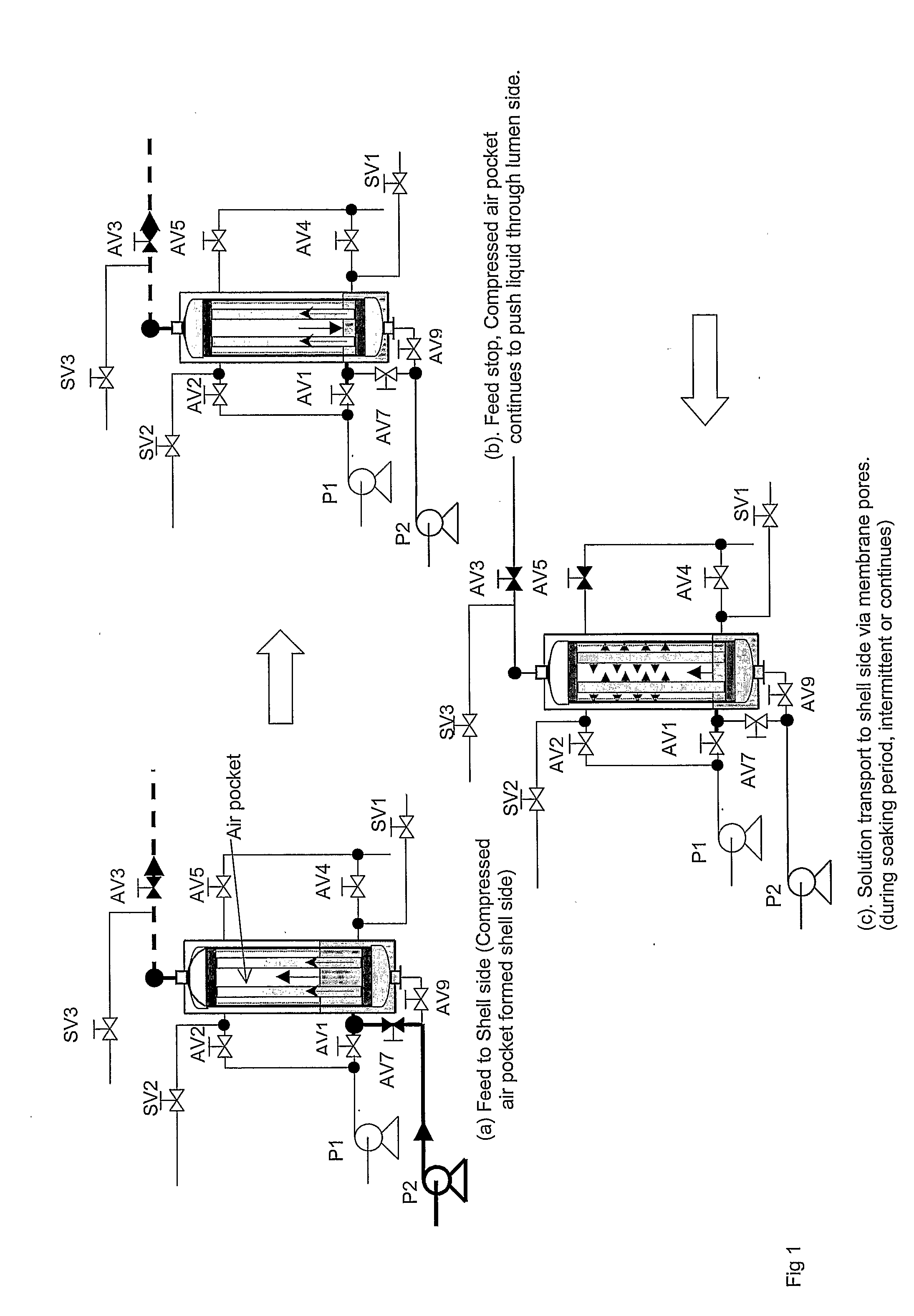

A method of concentrating the solids of a liquid suspension by providing pressure differential across the walls of permable hollow membranes (6) immersed in the liquid suspension (9). The liquid suspension (9) is applied to the outer surface of the porous hollow membranes (6) to induce and sustain filtration through the membrane walls (12) wherein some of the liquid suspension passes through the walls (12) of the membranes (6) to be drawn off as clarified liquid or permeate from the hollow membranes lumens (11), and at least some of the solids are retained on or in the hollow membranes (6) or otherwise as suspended solids within the liquid (9) surrounding the membranes (6). The method includes periodically backwashing the membrane pores using the permeate by applying a gas pressure below the bubble point to the membrane lumens (11) to progressively displace at least some of the liquid permeate within the lumens (11) through the membrane pores resulting in removal the solids retained on or in the hollow membranes into the bulk liquid (9) surrounding the membranes (6).

Owner:JOHNSON WARREN THOMAS

Chemical Clean For Membrane Filter

ActiveUS20080203017A1Facilitate wetting out and dissolvingLower the volumeSpecific water treatment objectivesUltrafiltrationConcentration gradientCleansing Agents

A method of cleaning a porous polymeric membrane having a feed side and a permeate side including the steps of introducing a fluid containing a cleaning agent to the permeate side of a membrane allowing the cleaning agent to contact the permeate side of the membrane for a predetermined time, and contact the pores of the membrane, or introducing a fluid containing a cleaning agent to the feed side of a membrane; applying a transmembrane pressure to force the fluid containing the cleaning agent from the feed side to the permeate side of the membrane; allowing the cleaning agent to contact the permeate side of the membrane for a predetermined time, and contact the pores of the membrane. Preferably a concentration gradient between the feed side fluid and the lumen side fluid containing the cleaning agent causes cleaning agent to diffuse into the feed side fluid. Pressure may be applied to the fluid containing a cleaning agent to dislodge, where present, dissolved and undissolved solid from the membrane pores. The pressure may be applied in a pulsed fashion, and can be by way of compressed air at a pressure not more than the membrane's bubble point. The methods of the present invention may be preceded by, or followed with a backwash.

Owner:EVOQUA WATER TECH LLC

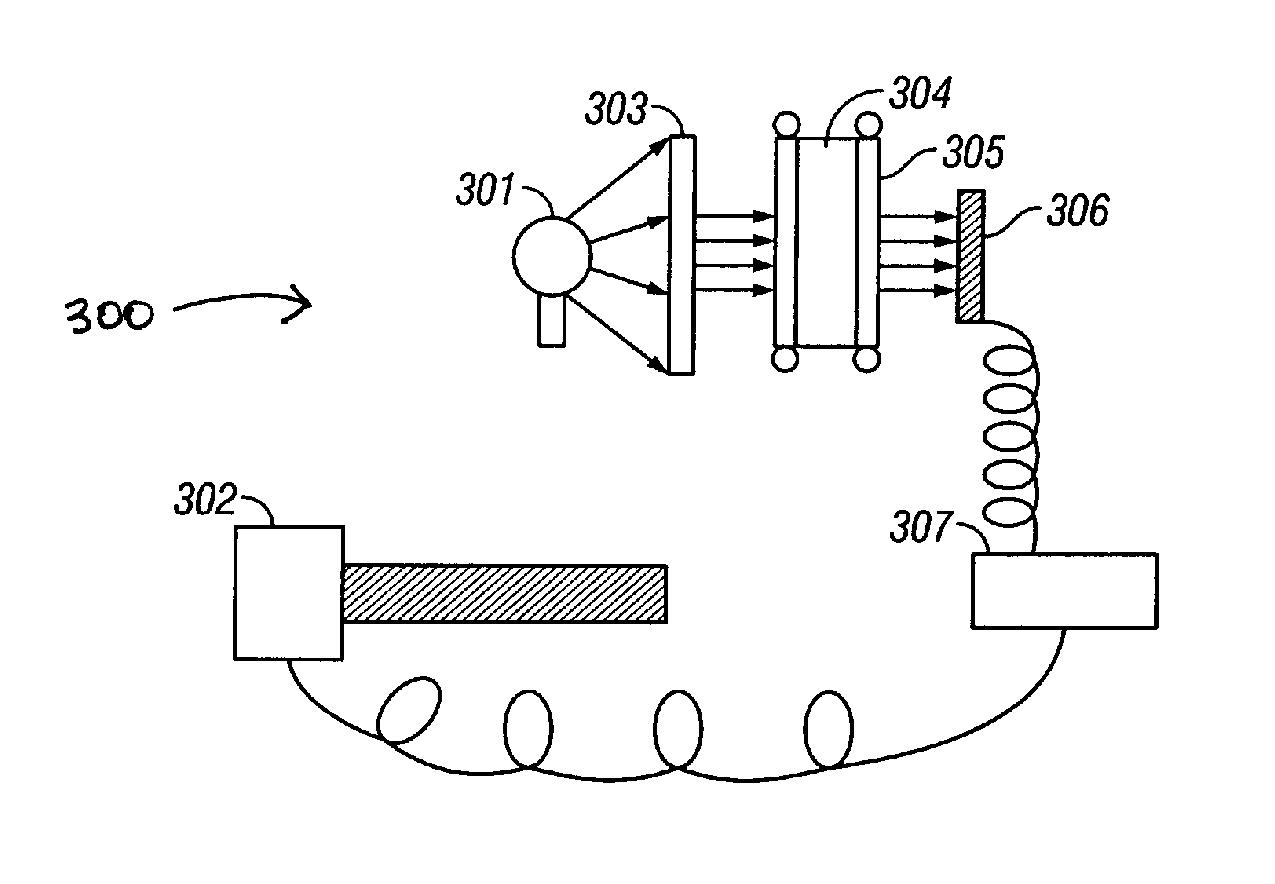

Method and apparatus for determining an optimal pumping rate based on a downhole dew point pressure determination

ActiveUS20040231408A1Reduce capacityReduce pressureElectric/magnetic detection for well-loggingFluid pressure measurement by electric/magnetic elementsLight energyDew

The present invention provides a down hole spectrometer for determination of dew point pressure to determine an associated optimal pumping rate during sampling to avoid precipitation of asphaltenes in a formation sample. A sample is captured at formation pressure in a controlled volume. The pressure in the controlled volume is reduced. Initially the formation fluid sample appears dark and allows less light energy to pass through a sample under test. The sample under test, however, becomes lighter and allows more light energy to pass through the sample as the pressure is reduced and the formation fluid sample becomes thinner or less dense under the reduced pressure. At the dew point pressure, however, the sample begins to darken and allows less light energy to pass through it as apshaltenes begin to precipitate out of the sample. Thus, the dew point is that pressure at which peak light energy passes through the sample. The dew point pressure is plugged into an equation to determine the optimum pumping rate for a known mobility, during sampling to avoid dropping the pressure down to the dew point pressure to avoid asphaltene precipitation or dew forming in the sample. The bubble point can be plugged into an equation to determine the optimum pumping rate for a known mobility, during sampling to avoid dropping the pressure down to the bubble point pressure to avoid bubbles forming in the sample.

Owner:BAKER HUGHES INC

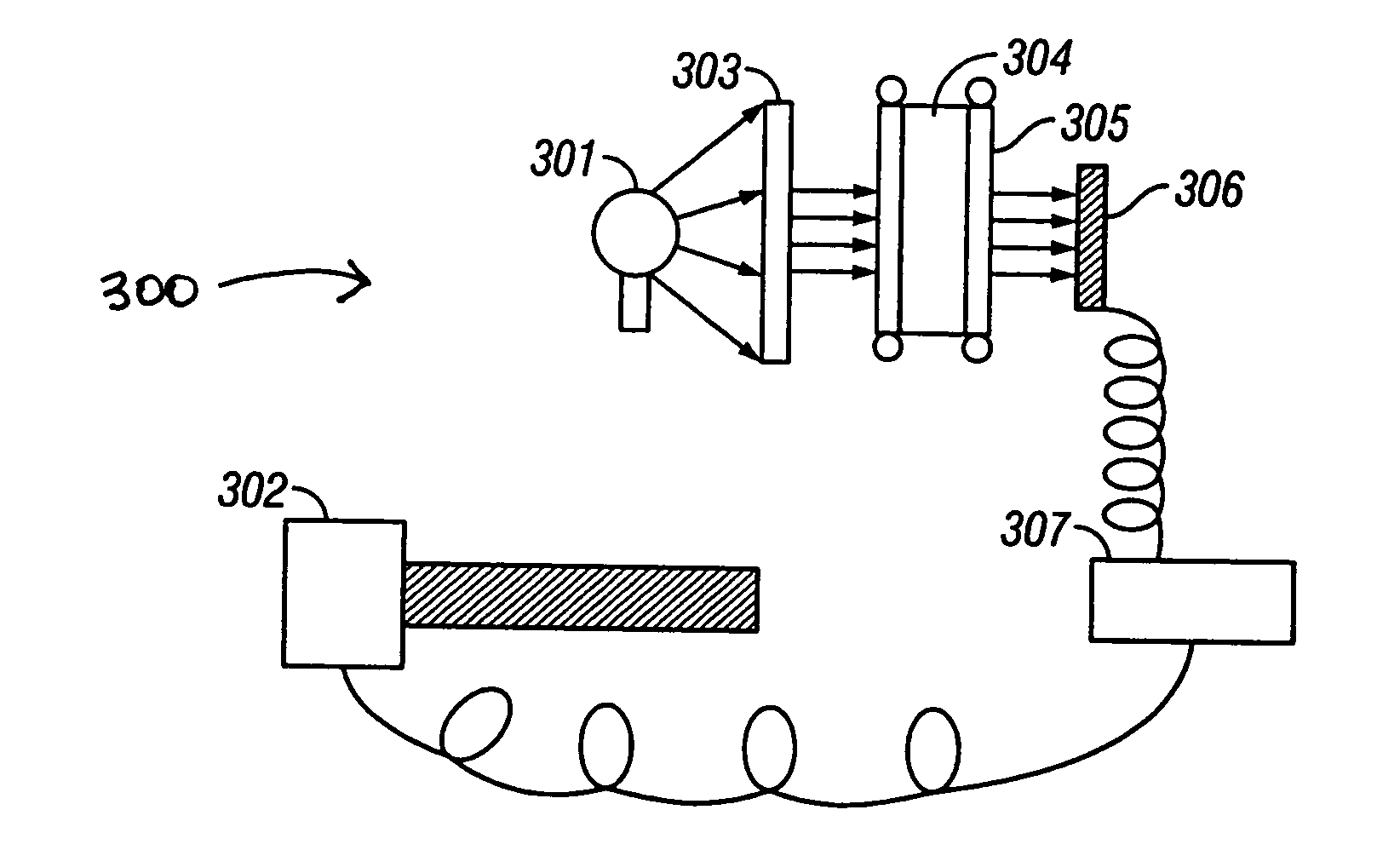

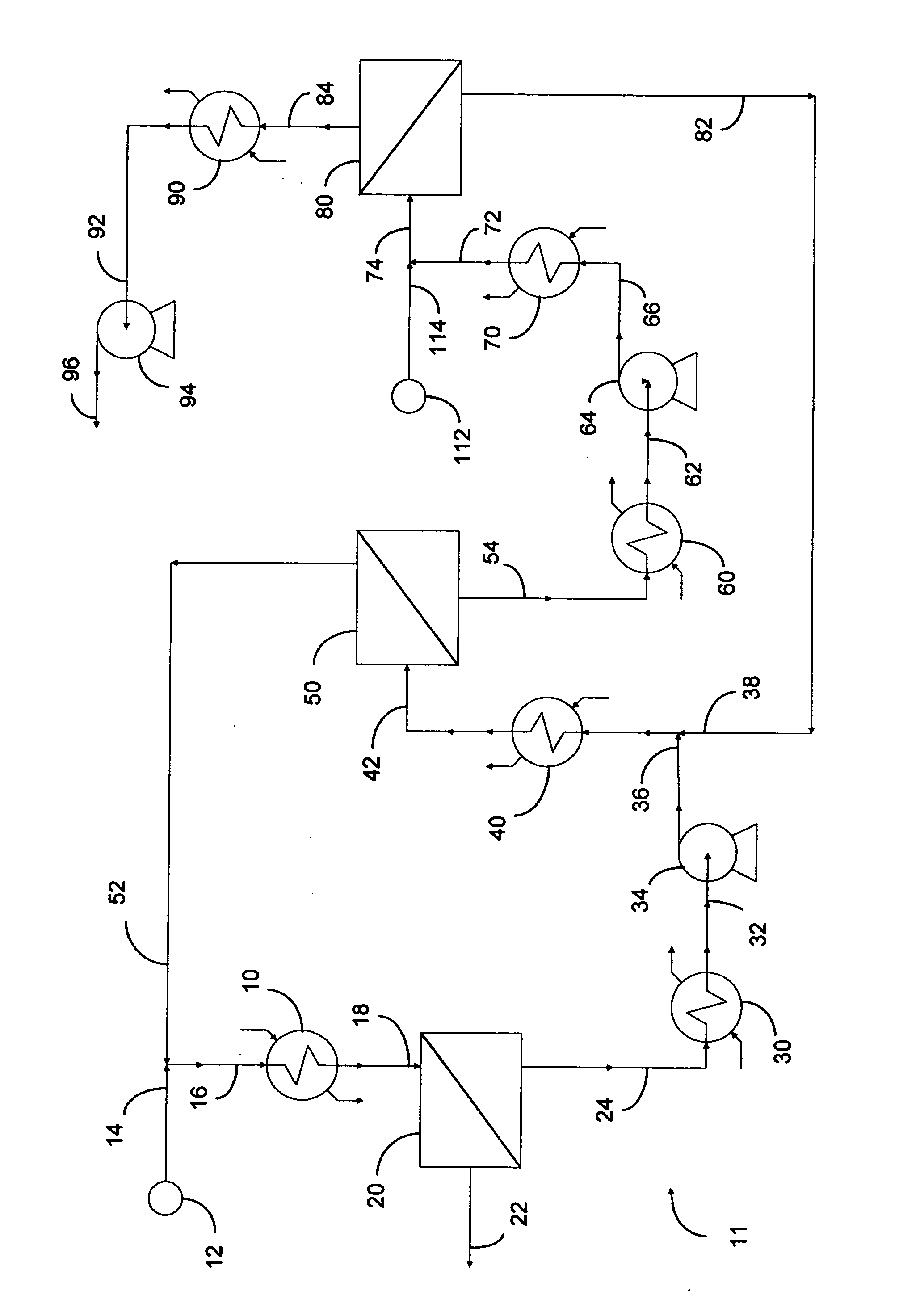

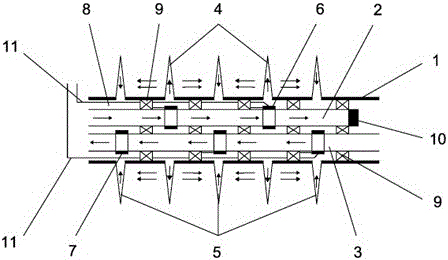

Selective separation of fluid compounds utilizing a membrane separation process

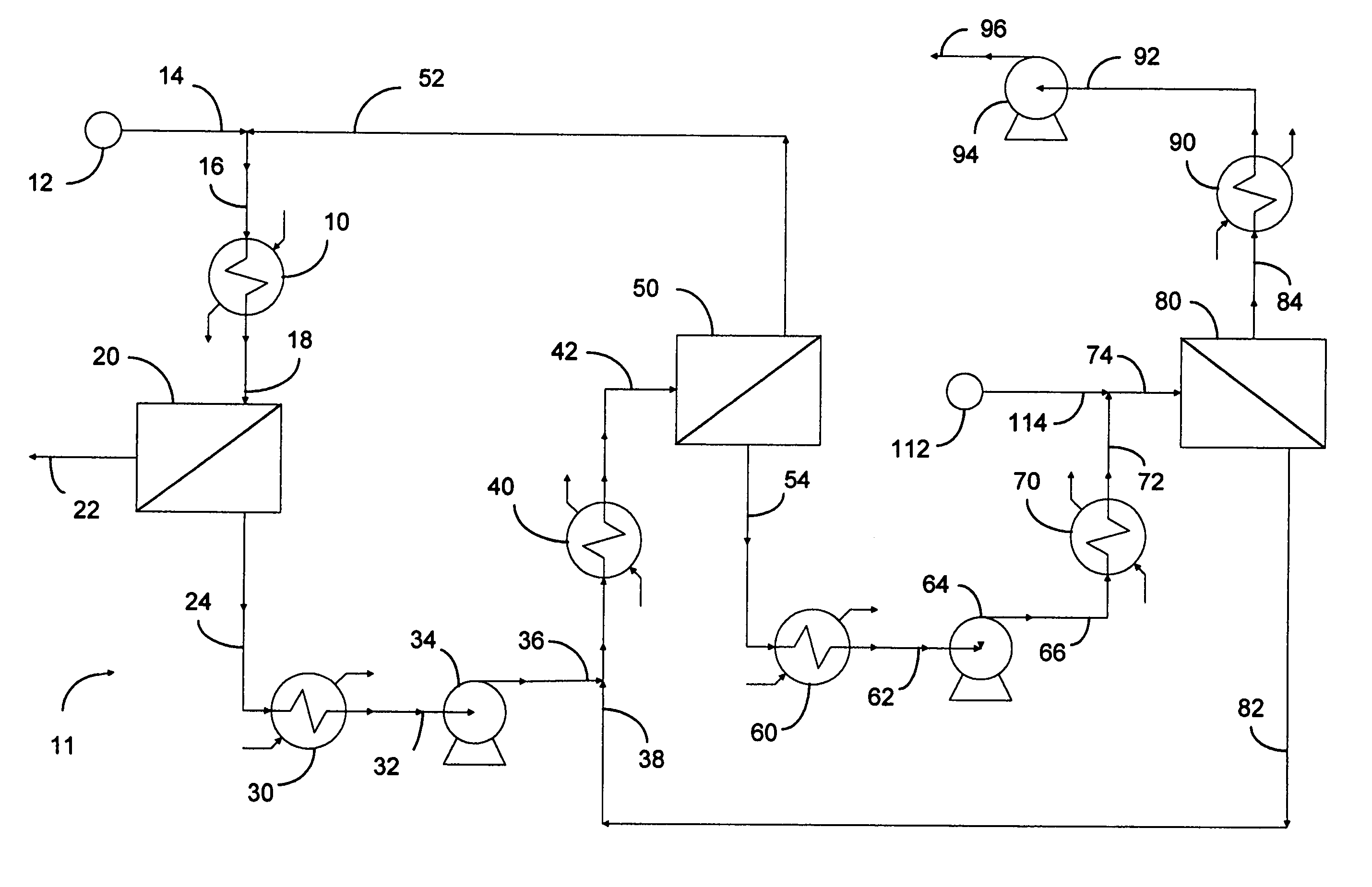

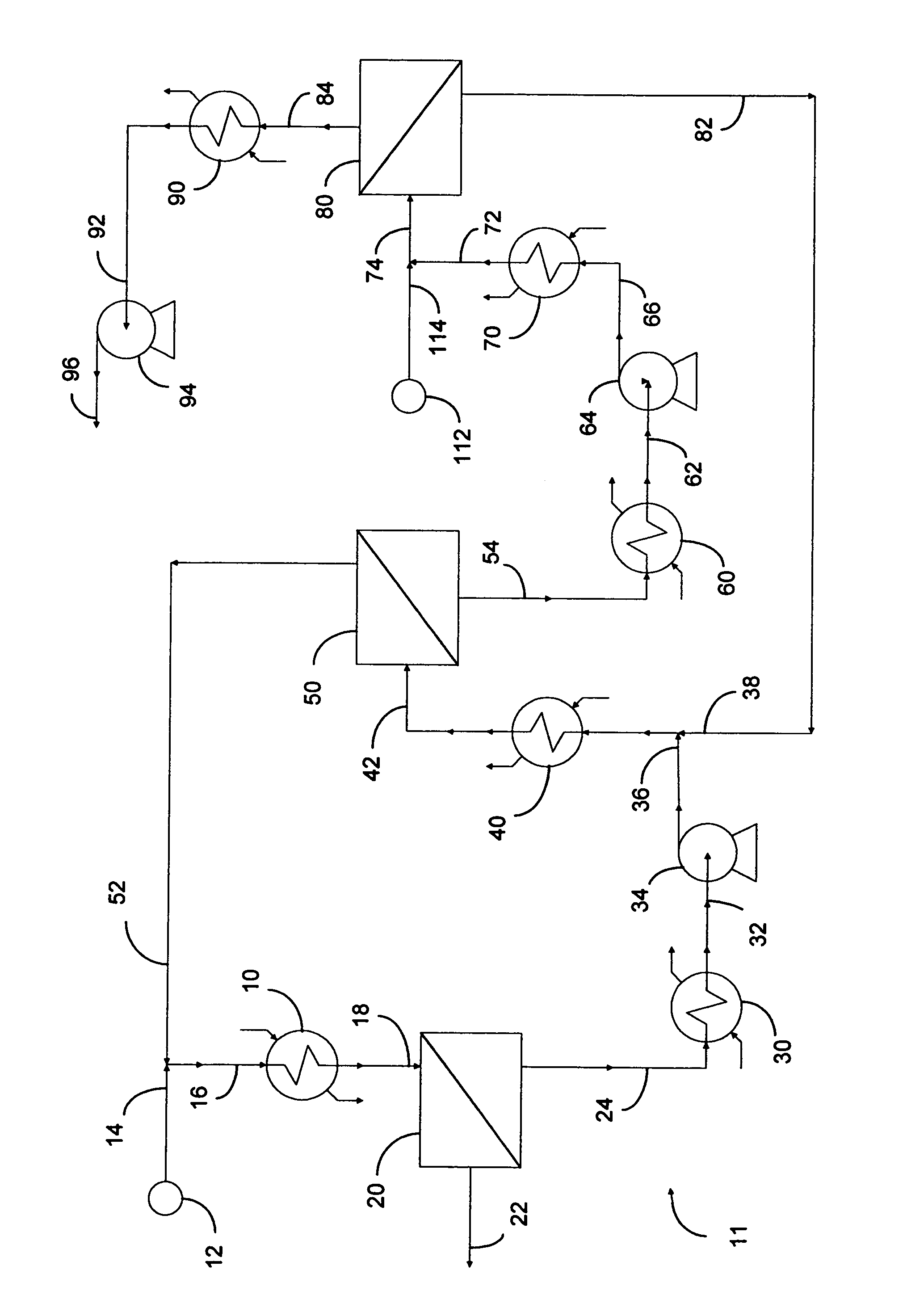

InactiveUS6986802B2Low costCost prohibitiveGas treatmentLiquid degasificationPermselective membraneControl equipment

Apparatus and processes are disclosed for economical separation of fluid mixtures utilizing perm-selective membranes. Broadly, apparatus of the invention comprises a plurality of membrane modules comprising a solid perm-selective membrane and equipment for controlling enthalpy of selected fluids within the apparatus. Advantageously, the membrane modules are disposed in a first product group, a second product group, and at least one intermediate group. Apparatus of the invention is particularly useful for simultaneous recovery of a very pure permeate product, and / or a desired non-permeate stream, from fluid mixtures of two or more compounds which when subjected to appropriately altered conditions of temperature and / or pressure exhibit a bubble point.

Owner:BP CORP NORTH AMERICA INC

Single phase sampling apparatus and method

ActiveUS7191672B2Easy to useAvoid separationAnalysis using chemical indicatorsWithdrawing sample devicesHydrostatic pressureFormation fluid

A single phase sampling apparatus and method for retrieving a formation fluid sample at or above the bubble point of the sample. The apparatus utilizes a gas charge contained between a sample piston and a charging piston to maintain a formation sample at the desired pressure. The charging piston utilizes the hydrostatic pressure present at the depth of the desired formation sample to compress and therefore increase the gas charge to the appropriate pressure necessary to maintain the formation sample at the desired pressure. The utilization of hydrostatic pressure to increase the pressure of the gas charge allows the use of a low pressure gas charging system to prepare the apparatus prior to sampling, thereby increasing the safety and ease of use of the device.

Owner:HALLIBURTON ENERGY SERVICES INC

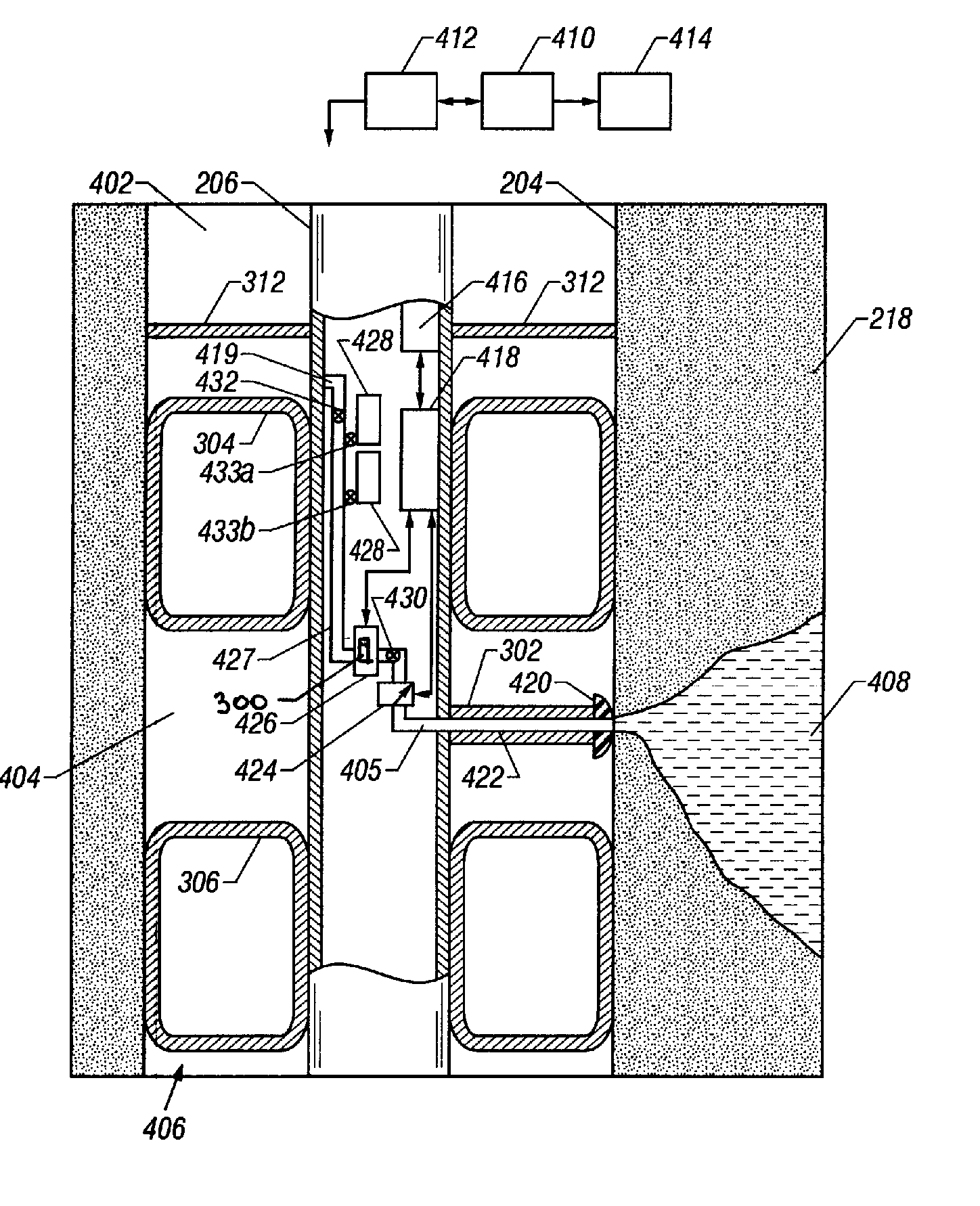

Method of downhole characterization of formation fluids, measurement controller for downhole characterization of formation fluids, and apparatus for downhole characterization of formation fluids

ActiveUS20090078036A1Fast and precise bubble point measurementQuick changeSurveyConstructionsFormation fluidBubble point

A method of downhole characterization of formation fluids is provided. The method includes: estimating a rough value of the bubble point pressure of the formation fluids; depressurizing the formation fluids at a first speed to a certain pressure which is a predetermined value higher than the estimated rough value while the formation fluids are isolated in a portion of the flowline; and depressurizing the isolated fluids at a second speed which is slower than the first speed in order to measure a precise value of the bubble point pressure.

Owner:SCHLUMBERGER TECH CORP

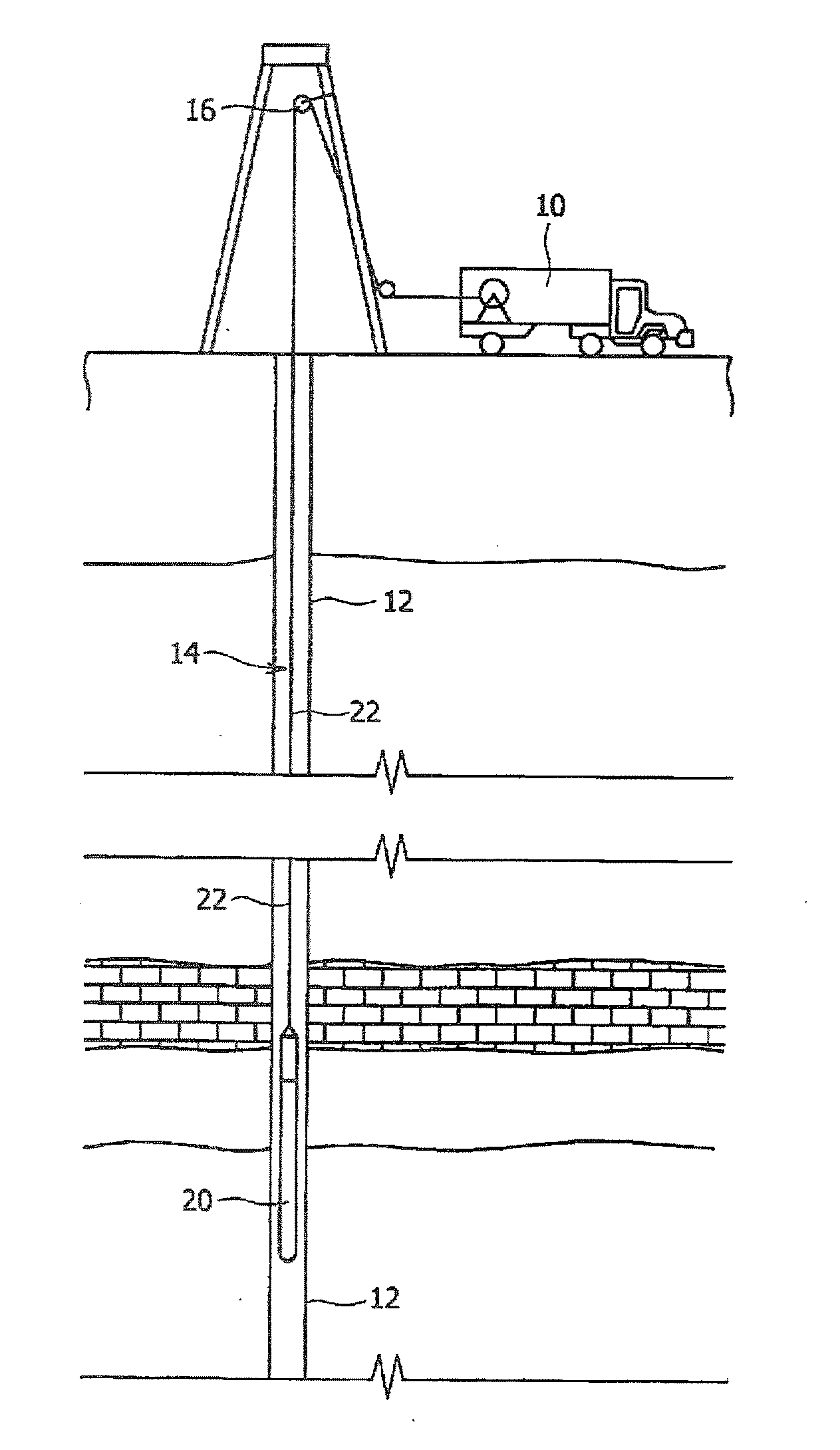

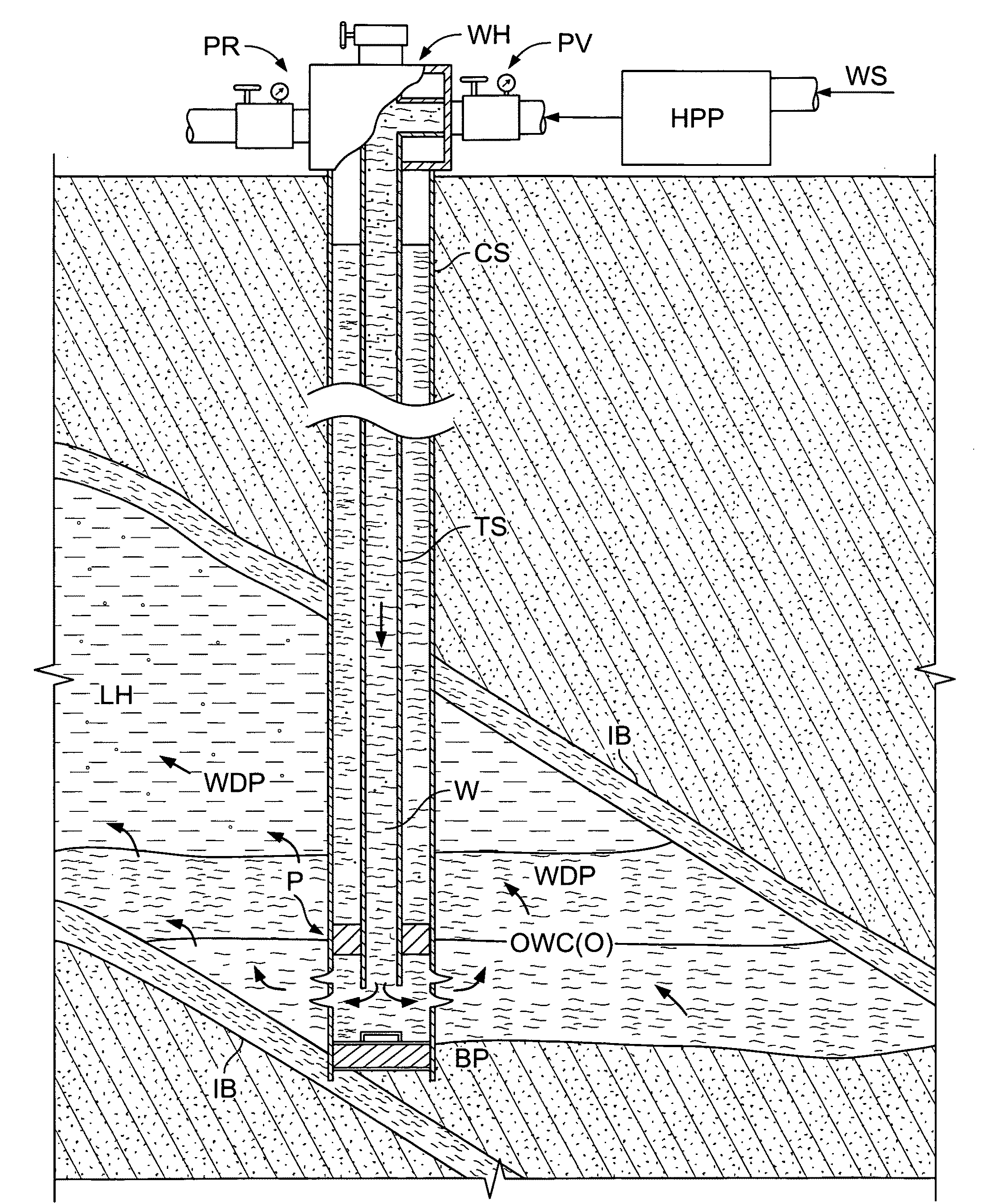

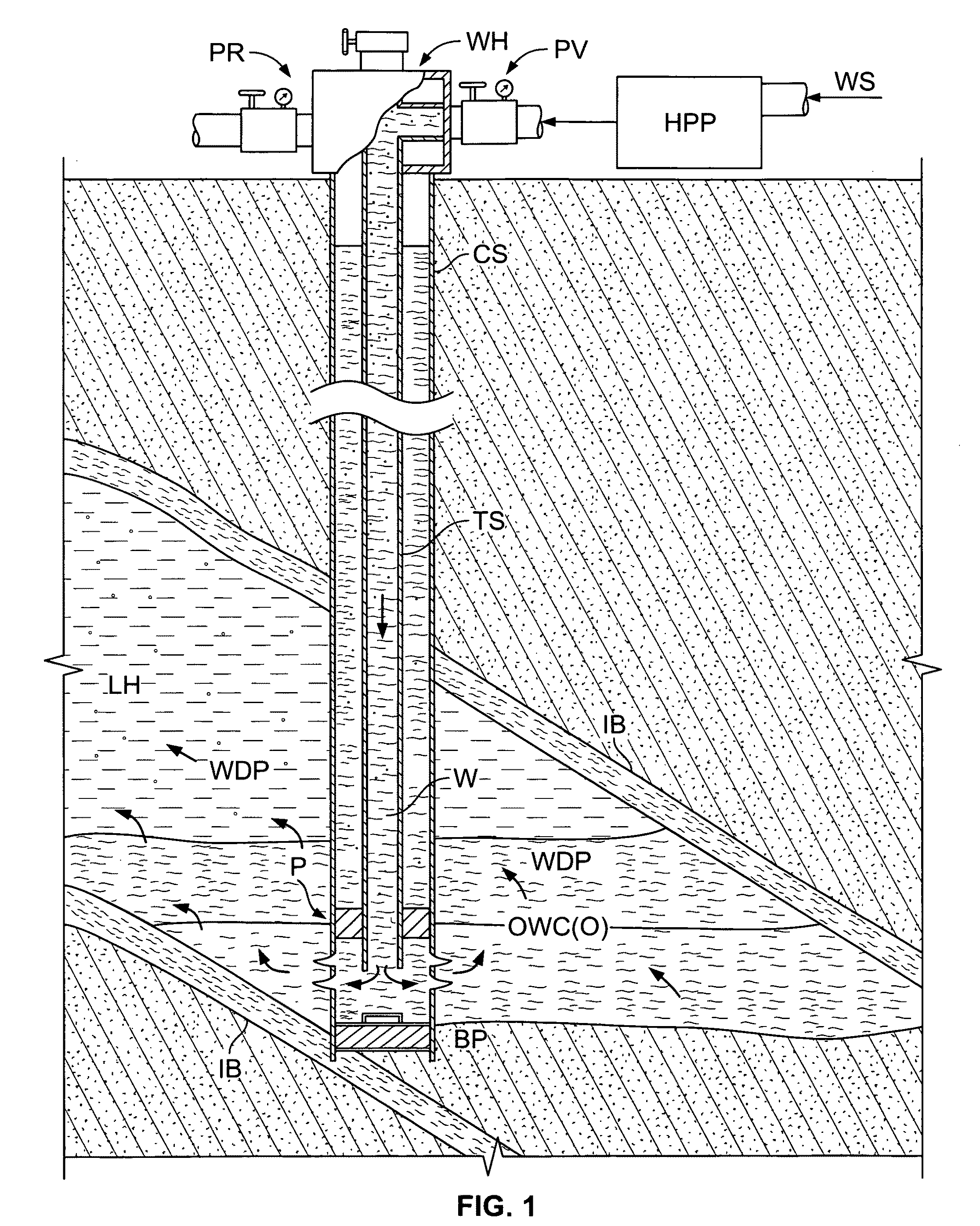

Total in place hydrocarbon recovery by isolated liquid & gas production through expanded volumetric wellbore exposure +

Higher volumetric hydrocarbon exposed original or restored by miscible gas injection, solution gas saturated oil is recovered through enlarged expandable liner, sand screened wellbores by controlled wellbore to formation pressure maintained above recovering oils critical bubble point. Exclusively hydrocarbon formation liquids are differential pressure forced through invention's centralizer held larger O.D. Liquid Displacer into the production tubing, while maintaining gas volume, pressure, and solution gas saturation in the formation, for higher volume flow for total in place oil recovery. Injected downstructure waterdrive pressure WDP into oil or gas formations augments oil and / or gas production and recovery.Complete gas well De-liquefying is attained by flowing gas recovery through enlarged expandable liner and sand screened wellbores and up the wellbore annulus dry, while producing all liquids separately through the centralized larger O.D. Liquid Displacer into the production tubing, to be artificial lifted to surface, while waterdrive pressure WDP augments natural gas recovery.

Owner:KELLEY TERRY EARL

Method of downhole characterization of formation fluids, measurement controller for downhole characterization of formation fluids, and apparatus for downhole characterization of formation fluids

ActiveUS7788972B2Fast and precise bubble point measurementQuick changeSurveyConstructionsFormation fluidBubble point

A method of downhole characterization of formation fluids is provided. The method includes: estimating a rough value of the bubble point pressure of the formation fluids; depressurizing the formation fluids at a first speed to a certain pressure which is a predetermined value higher than the estimated rough value while the formation fluids are isolated in a portion of the flowline; and depressurizing the isolated fluids at a second speed which is slower than the first speed in order to measure a precise value of the bubble point pressure.

Owner:SCHLUMBERGER TECH CORP

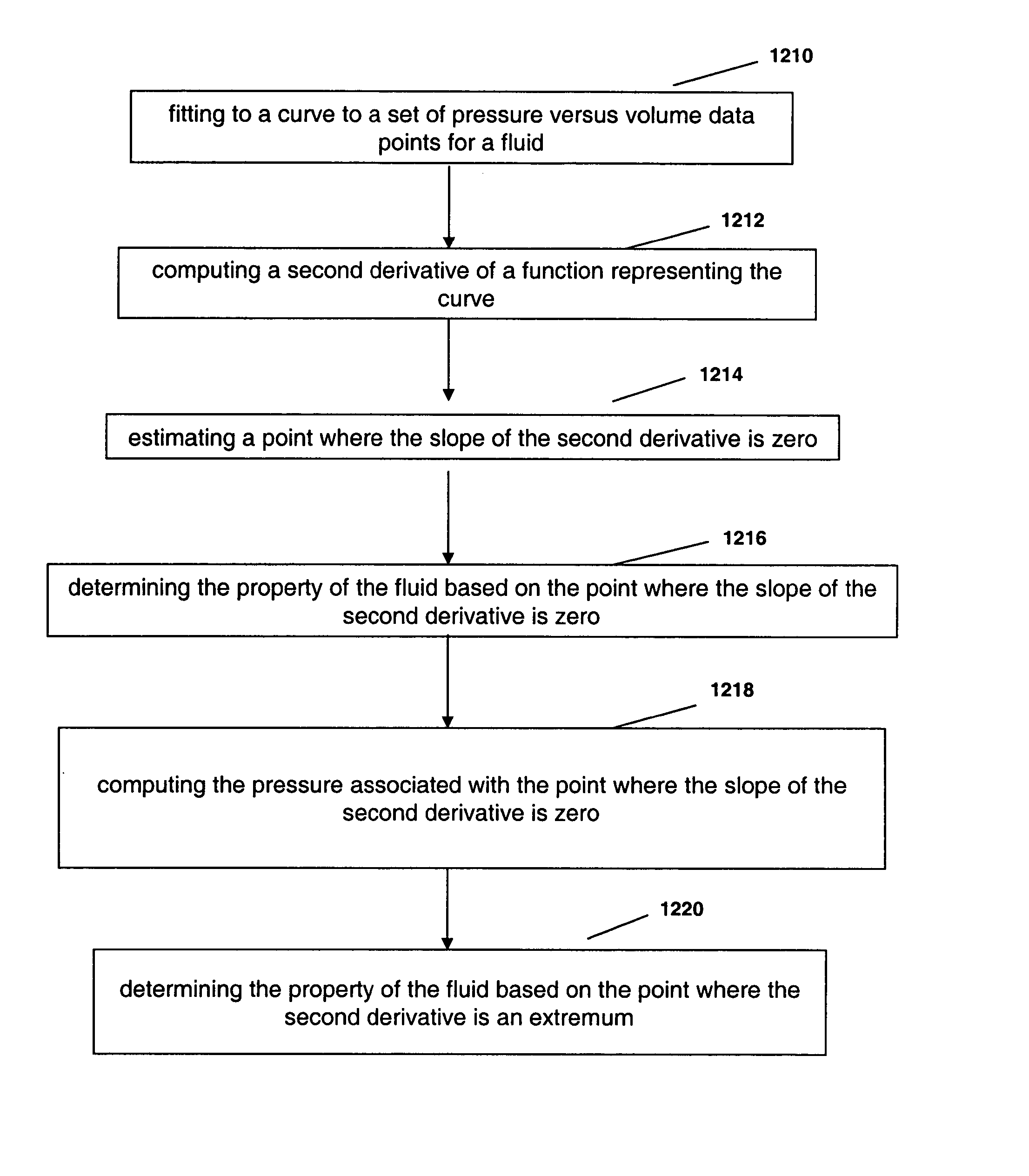

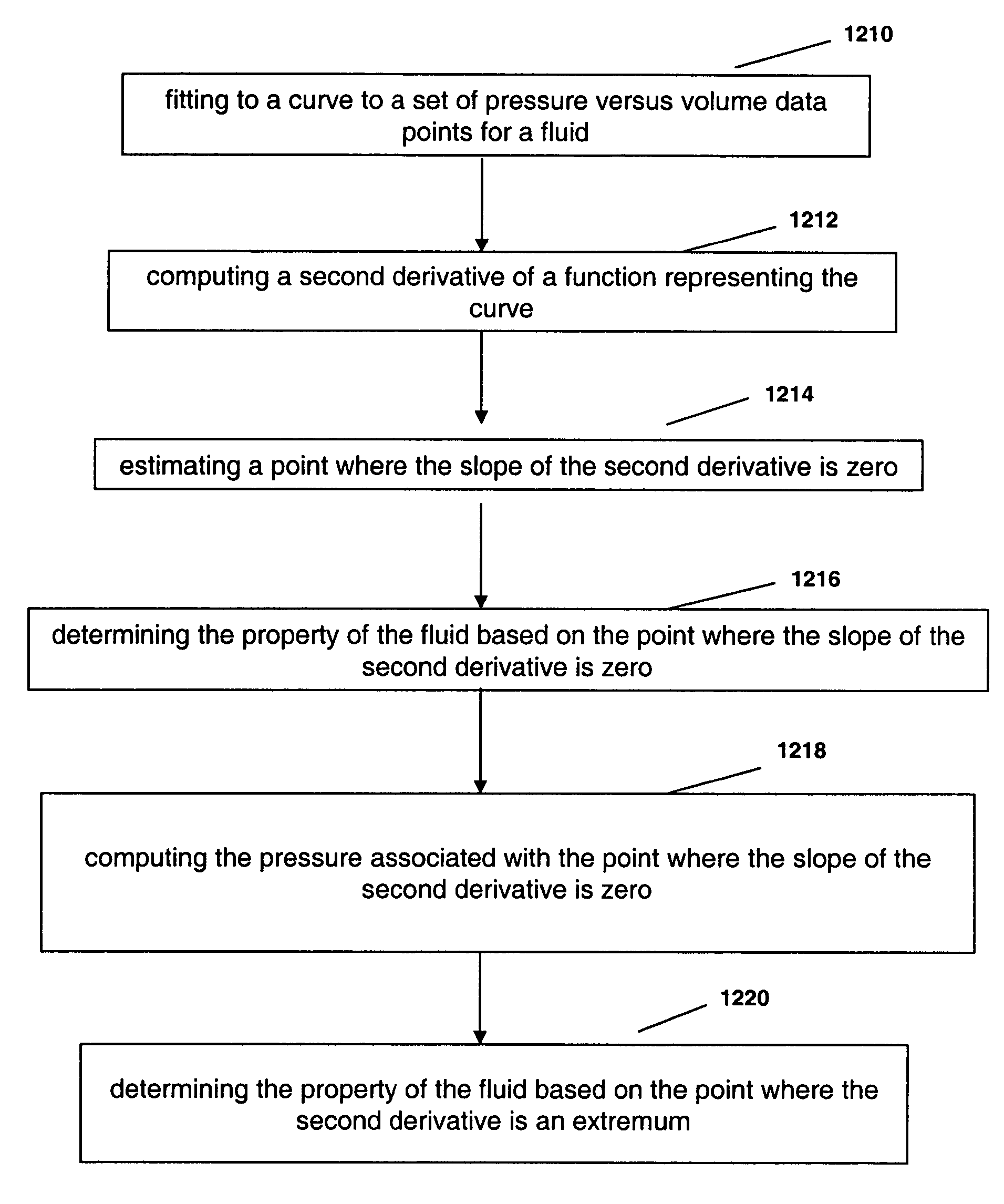

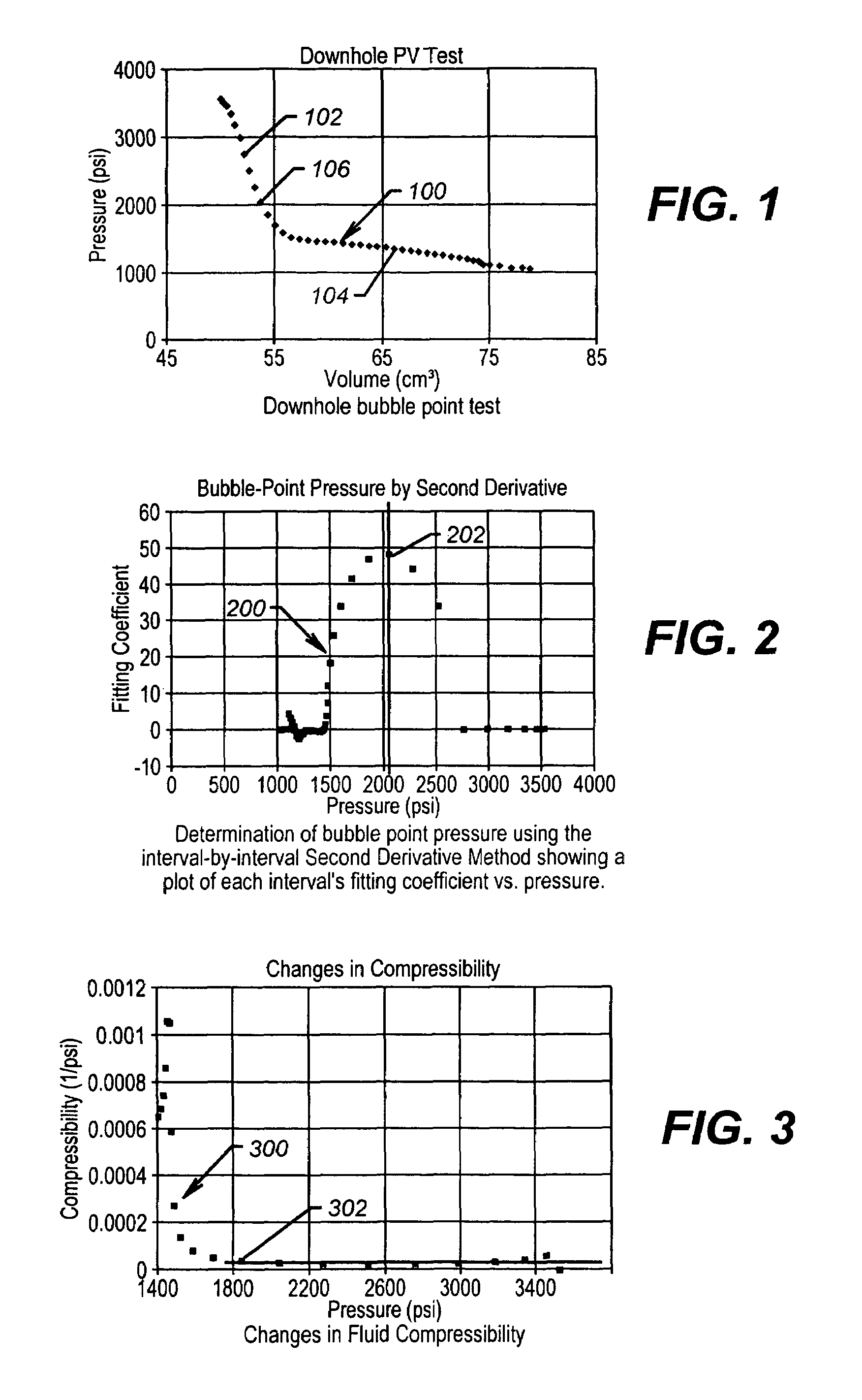

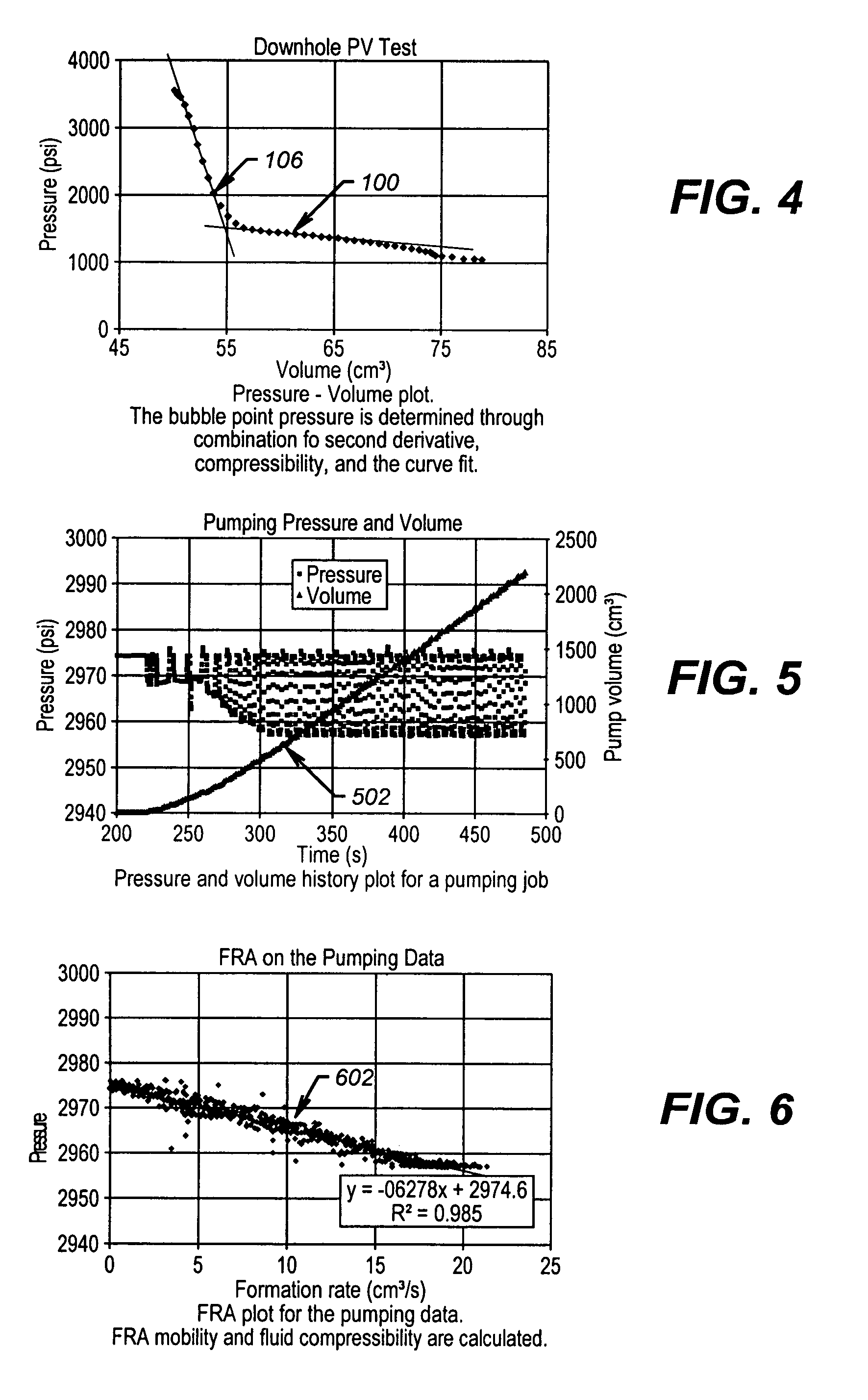

Downhole PV tests for bubble point pressure

InactiveUS20040260497A1Reduction of filtrateSpecific gravity by measuring pressure differencesFlow propertiesVisual observationQuality control

The present invention provides an objective bubble point pressure determination method enables new applications of downhole PV (Pressure Volume) test results such as in situ measurement of the bubble point pressure for use as a quality control parameter for sampling. The present invention provides a method and apparatus to fit data points to a curve and to smooth these points over an interval of N points. The derivative of the curve is determined to obtain peak acceleration. The peak acceleration represents the bubble point pressure. This bubble point pressure is verified by comparison to changes in fluid compressibility and visual observation of a pressure volume plot history.

Owner:BAKER HUGHES INC

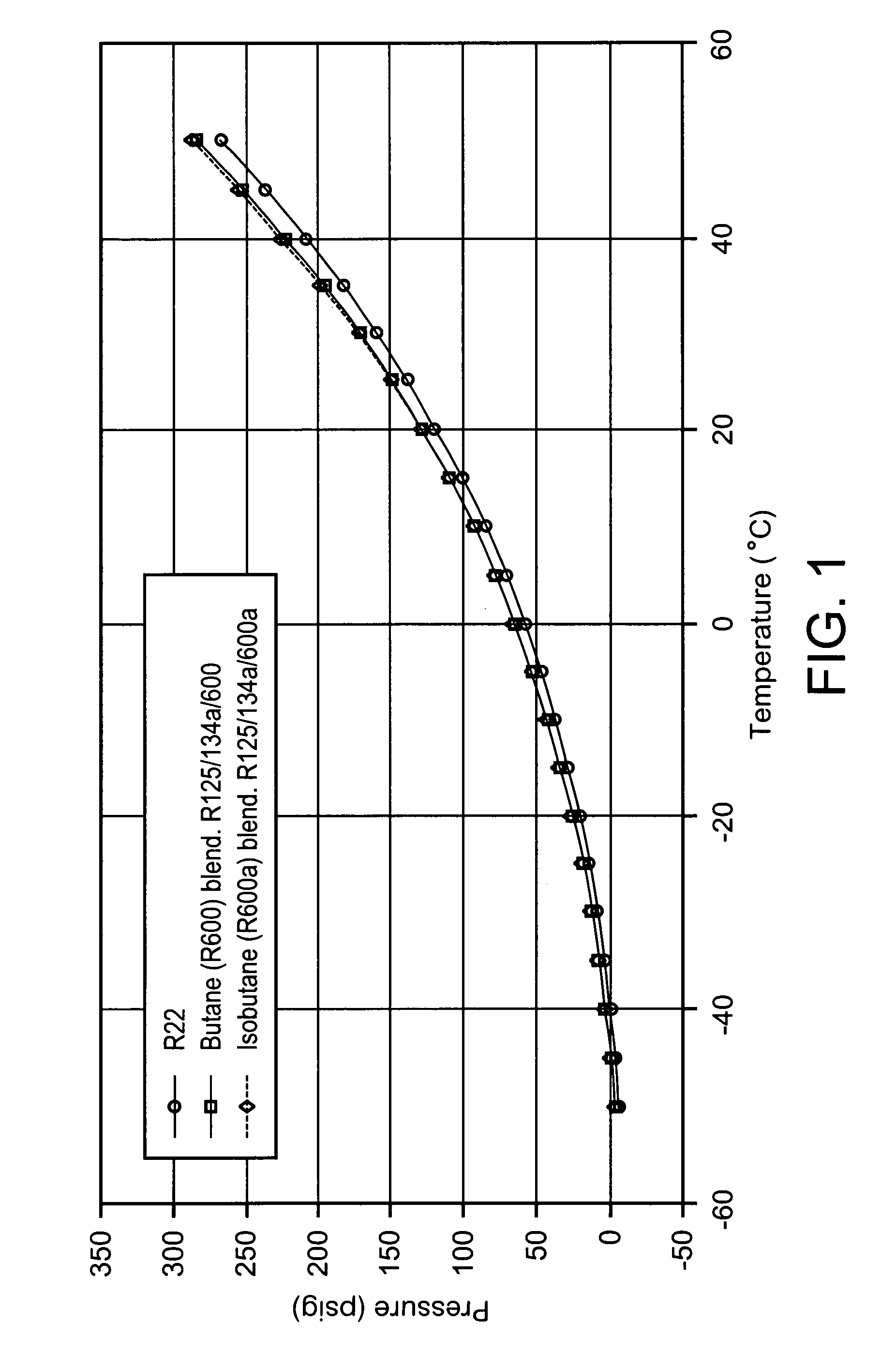

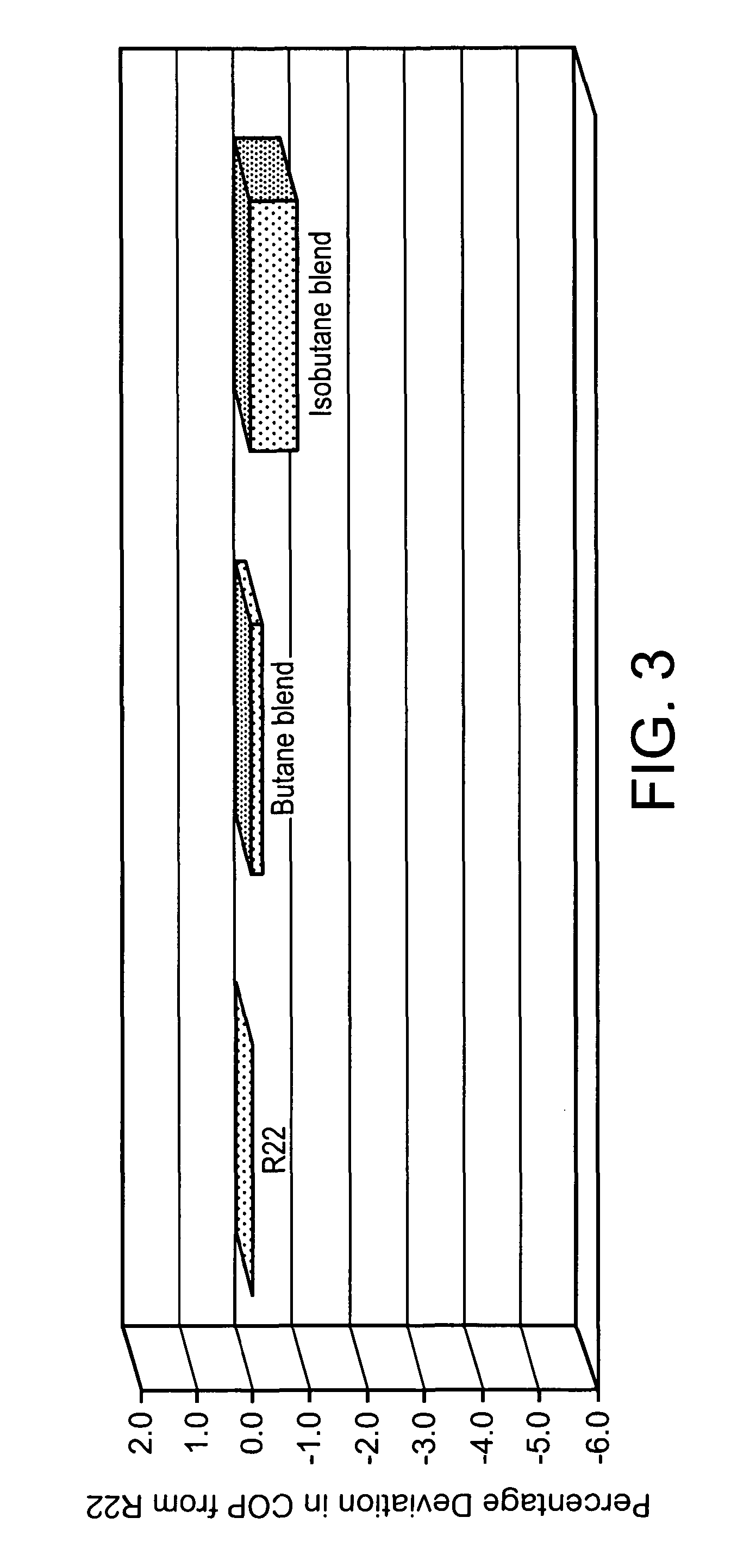

Refrigerant composition

Refrigerant compositions are provided which include:(a) pentafluoroethane or trifluoromethoxydifluoromethane or hexafluorocyclopropane or mixtures thereof, in an amount from about 60 to about 70% by weight based on the weight of the composition;(b) 1,1,1,2- or 1,1,2,2-tetrafluoroethane or trifluoromethoxypentafluoroethane or 1,1,1,2,3,3-heptafluoropropane or mixtures thereof, in an amount from about 26 to 36% by weight based on the weight of the composition; and(c) an ethylenically unsaturated or saturated hydrocarbon, optionally containing one or more oxygen atoms, having a boiling point from −12° C. to +10° C., or a mixture thereof, or a mixture of one or more of the hydrocarbons with one or more other hydrocarbons or ethers, said mixture having a bubble point from −12° C. to +10° C., in an amount from about 1% to 4% by weight based on the weight of the composition. Also provided is a process of refrigeration using the refrigerant compositions and a refrigeration apparatus containing the refrigerant compositions.

Owner:THE CHEMOURS CO FC LLC +1

Method and apparatus for an optimal pumping rate based on a downhole dew point pressure determination

InactiveUS20070214877A1Reduce pressureLess-light energyBorehole/well accessoriesLight energyFormation fluid

Owner:BAKER HUGHES HLDG LLC

Downhole PV tests for bubble point pressure

InactiveUS7346460B2Reduction of filtrateFlow propertiesSpecific gravity by measuring pressure differencesVisual observationEngineering

The present invention provides an objective bubble point pressure determination method enables new applications of downhole PV (Pressure Volume) test results such as in situ measurement of the bubble point pressure for use as a quality control parameter for sampling. The present invention provides a method and apparatus to fit data points to a curve and to smooth these points over an interval of N points. The derivative of the curve is determined to obtain peak acceleration. The peak acceleration represents the bubble point pressure. This bubble point pressure is verified by comparison to changes in fluid compressibility and visual observation of a pressure volume plot history.

Owner:BAKER HUGHES INC

Method and apparatus for determining an optimal pumping rate based on a downhole dew point pressure determination

ActiveUS7222524B2Reduce pressureLess-light energyElectric/magnetic detection for well-loggingFluid pressure measurement by electric/magnetic elementsLight energyDew

Owner:BAKER HUGHES HLDG LLC

Porous membrane

InactiveUS20110268959A1Improve stabilityHigh strengthSemi-permeable membranesMembranesPorous membraneEntry pressure

A membrane including a sheet of expanded polytetrafluoroethylene. The sheet is porous and has a gas permeability of at least 0.2 CFM according to ASTM D737 testing. The gas permeability of the membrane changes by less than 30% when the membrane is exposed to a temperature of 180° C. for a time of one hour. The sheet also has an average Mullen Hydrostatic Entry pressure of at least 135 psi according to ASTM D751 testing. The average Mullen Hydrostatic Entry pressure is substantially unchanged after exposure to a temperature of 180° C. for a time of one hour. The membrane has a bubble point value that changes by less than 20% when the membrane is exposed to a temperature of 180° C. for a time of one hour.

Owner:BHA ALTAIR

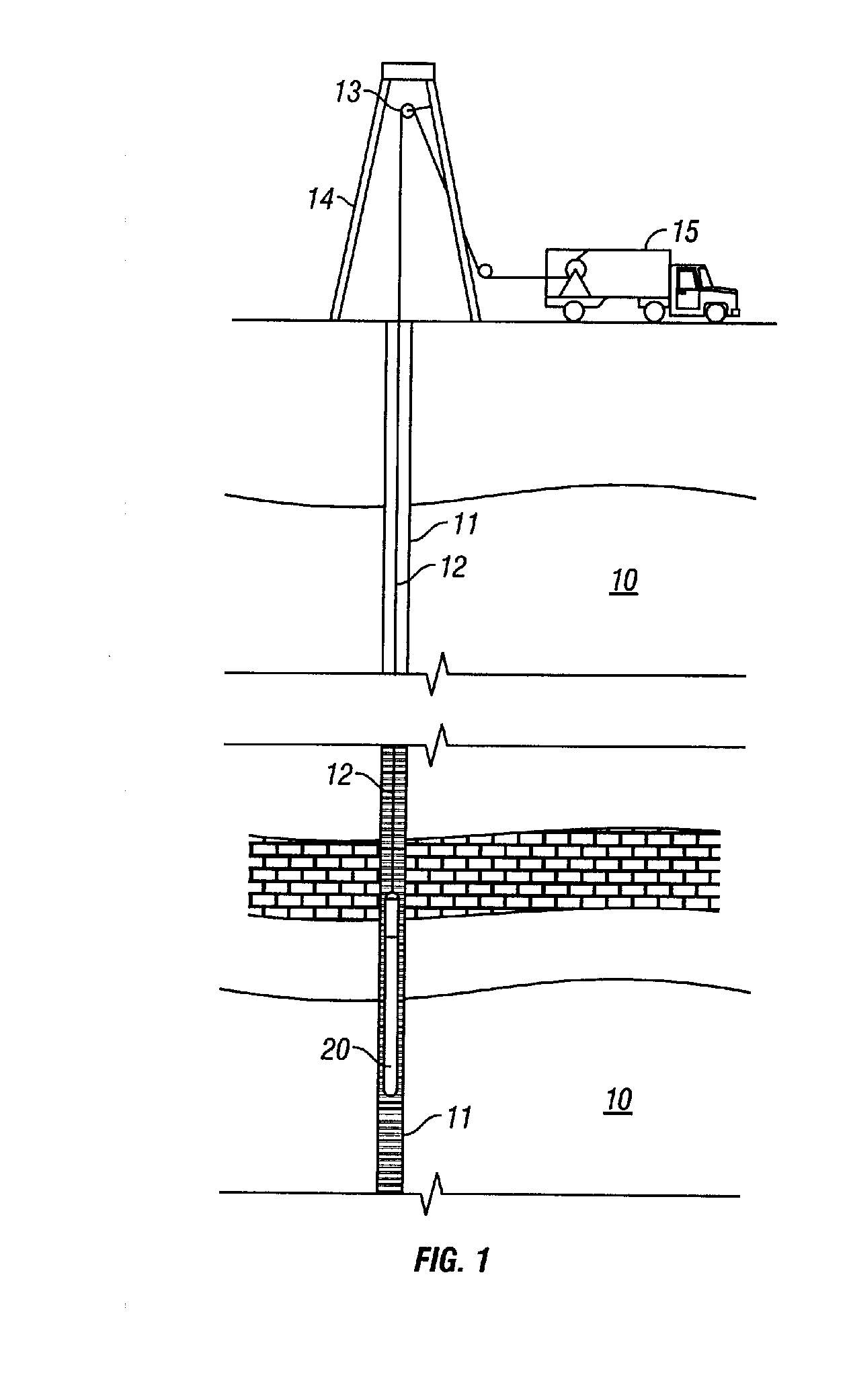

Phase change analysis in logging method

InactiveUSRE38129E1Accurate measurementSimple methodAnalysing fluids using sonic/ultrasonic/infrasonic wavesSurveyChange analysisPhase analysis

An improved method of fluid analysis in the borehole of a well. A fluid sampling tool is fitted with a pumpout module that can be used to draw fluids from the formation, circulate them through the instrument, and then expel this fluid to the borehole. It has been determined that certain measurements would be most valuable to implement down hole, such as the formation fluid bubble point and dew point. Accurate bubble point and dew point measurements are made by forming bubbles or a liquid drop in a measured sample, and detecting same.

Owner:SCHLUMBERGER TECH CORP

Membrane based contactor module for mass and heat transfer

ActiveUS20110285038A1Lighting and heating apparatusUsing liquid separation agentMembrane configurationHydrophobic surfaces

An apparatus for the transfer of mass and heat including a membrane having a hydrophilic surface and an opposing hydrophobic surface. The construction prevents transmission or leakage of fluids from one side of the membrane to the other regardless of pressure gradients within the membrane bubble point or water intrusion pressure range, but allows the transfer of vaporized fluid from one side of the membrane to the other.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS CORP

Method and apparatus for downhole fluid characterization using flexural mechanical resonators

InactiveUS7162918B2Avoid contact corrosionInversely to viscosityElectric/magnetic detection for well-loggingSurveyTuning forkFormation fluid

The present invention provides a downhole method and apparatus using a flexural mechanical resonator, for example, a tuning fork to provide real-time direct measurements and estimates of the viscosity, density and dielectric constant of formation fluid or filtrate in a hydrocarbon producing well. The present invention additionally provides a method and apparatus for monitoring cleanup from a leveling off of viscosity or density over time, measuring or estimating bubble point for formation fluid, measuring or estimating dew point for formation fluid, and determining the onset of asphaltene precipitation. The present invention also provides for intercalibration of plural pressure gauges used to determine a pressure differential downhole. A hard or inorganic coating is placed on the flexural mechanical resonator (such as a tuning fork) to reduce the effects of abrasion from sand particles suspended in the flowing fluid in which the flexural mechanical resonator is immersed.

Owner:BAKER HUGHES INC

Method for preparing tubular ceramic membrane for oil-water separation

ActiveCN103521095AAchieve separationThe effect is positive and obviousSemi-permeable membranesFatty/oily/floating substances removal devicesOil phaseDrying time

A method for preparing a tubular ceramic membrane for oil-water separation includes the steps of selecting an aluminum oxide ceramic membrane tube with the initial bubble point larger than 0.5Mpa as a base body, coating a layer of fluorine-contained or silicone-contained membrane preparing liquid on the base body, and placing the ceramic membrane tube which undergoes the coating procedure into a drying oven to be dried, wherein parameters in the coating procedure include the flow velocity, ranging from 1m / s to 5m / s, of the membrane preparing liquid, the inlet and outlet pressure difference, ranging from 0.1MPa to 0.2MPa , of the membrane tube and the flow coating time ranging from 5 seconds to 60 seconds, the temperature in the drying oven ranges from 50 DEG C to 150 DEG C, and the drying time ranges from 1 hour to 18 hours. The product obtained through the method is suitable for an oil-water separation system with the oil content higher than 70%, and the water content in an oil phase obtained through oil-water separation can reach less than 200ppm.

Owner:上海赛奥分离技术工程有限公司

Separator for organic electrolyte battery, process for producing the same and organic electrolyte battery including the separator

InactiveUS20060154140A1Good yieldPrevent fine powder short circuitCell seperators/membranes/diaphragms/spacersFinal product manufactureFiberPore diameter

An organic electrolyte battery separator is composed of a nonwoven comprising a heat-and-humidity gelling resin capable of gelling by heating in the presence of moisture and another fiber. The other fiber is fixed with a gel material obtained by causing the heat-and-humidity gelling resin to gel under heat and humidity. The nonwoven has a mean flow pore diameter of 0.3 μm to 5 μm and a bubble point pore diameter of 3 μm to 20 μm as measured in accordance with ASTM F 316 86. Thereby, the other fiber constituting the nonwoven can be fixed with the heat-and-humidity gelling resin, thereby making it possible to obtain a desired mean flow pore diameter and bubble point pore diameter. As a result, an organic electrolyte battery having a high level of safety, less occurrence of a short circuit, high battery characteristics is provided.

Owner:DAIWA BOSEKI KK

Method and apparatus for downhole fluid characterization using flexural mechanical resonators

InactiveUS20050247119A1Avoid contact corrosionProtection from damageElectric/magnetic detection for well-loggingSurveyTuning forkFormation fluid

The present invention provides a downhole method and apparatus using a flexural mechanical resonator, for example, a tuning fork to provide real-time direct measurements and estimates of the viscosity, density and dielectric constant of formation fluid or filtrate in a hydrocarbon producing well. The present invention additionally provides a method and apparatus for monitoring cleanup from a leveling off of viscosity or density over time, measuring or estimating bubble point for formation fluid, measuring or estimating dew point for formation fluid, and determining the onset of asphaltene precipitation. The present invention also provides for intercalibration of plural pressure gauges used to determine a pressure differential downhole. A hard or inorganic coating is placed on the flexural mechanical resonator (such as a tuning fork) to reduce the effects of abrasion from sand particles suspended in the flowing fluid in which the flexural mechanical resonator is immersed.

Owner:BAKER HUGHES INC

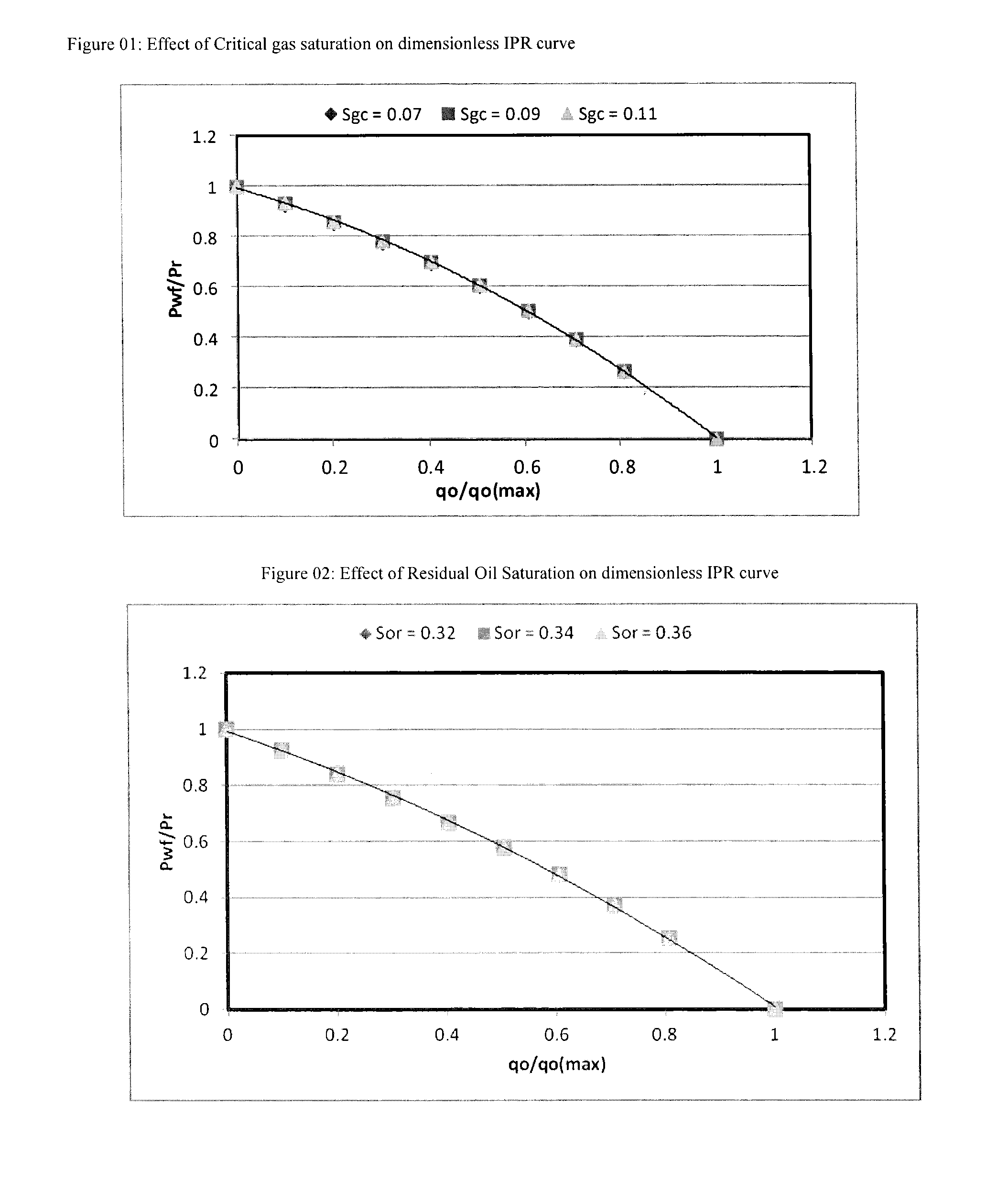

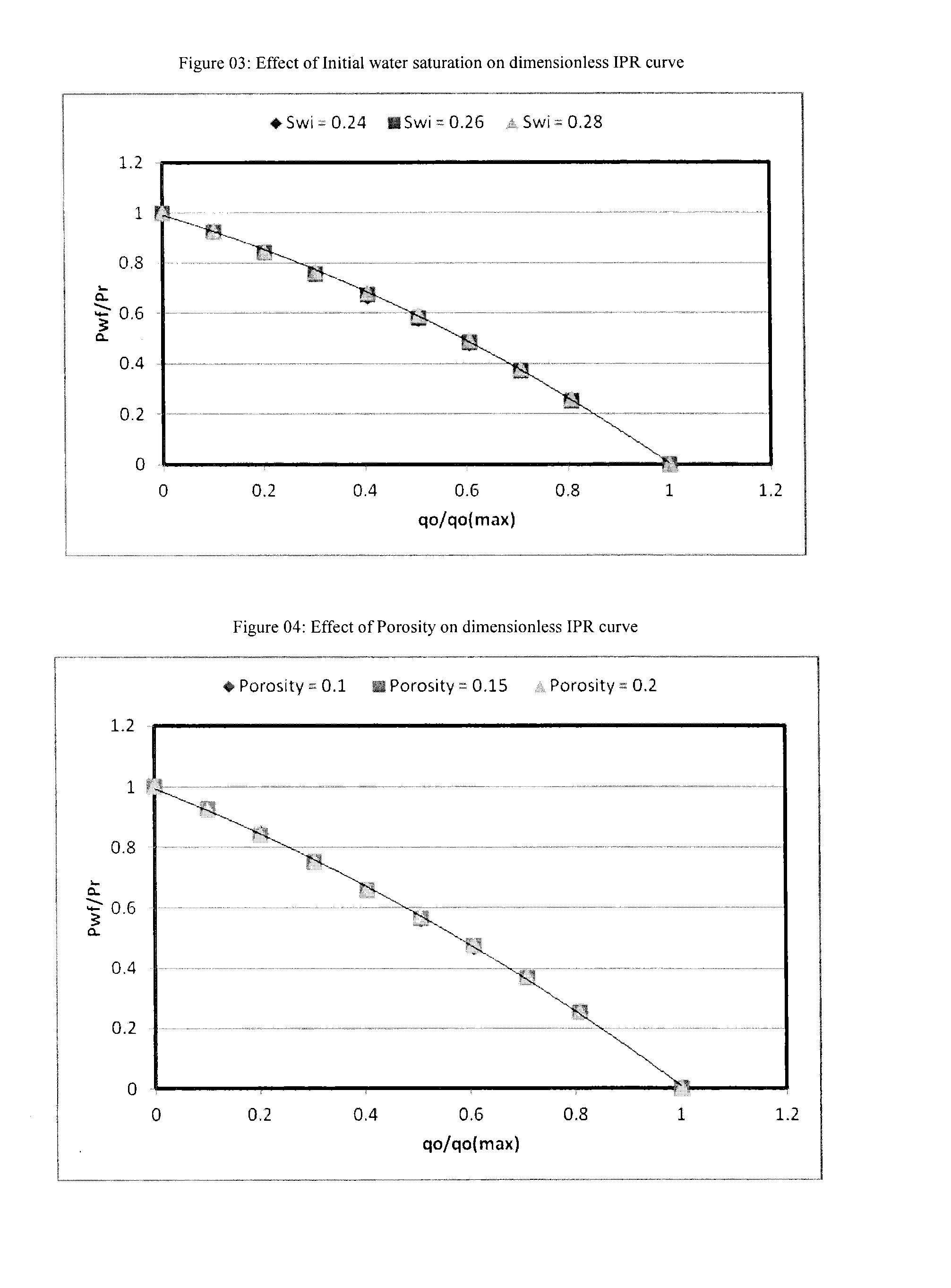

Inflow performance relationship for horizontal wells producing oil from multi-layered heterogeneous solution gas-drive reservoirs

ActiveUS20150168596A1Small and acceptable average absolute errorLess varianceElectric/magnetic detection for well-loggingSurveyHorizontal wellsEclipse

The invention investigates the effects of reservoir heterogeneity on IPR curves for horizontal wells drilled in heterogeneous solution gas drive reservoirs. To achieve the desired objective, a commercial simulator Eclipse is utilized to develop IPRs for horizontal wells producing oil from solution gas drive reservoirs. Firstly, a simulation model is developed where a base case is considered with typical rock, fluid and reservoir properties using a black oil model. Dimensionless IPR curves are generated by obtaining a set of points relating to flowing bottom-hole pressures to oil production rates. The effects of several reservoir and fluid properties such as bubblepoint pressure, oil gravity, residual oil saturation, critical gas saturation, initial water saturation, porosity and absolute permeabilities on the calculated curves are investigated.Reservoir heterogeneity is included in the simulation model by incorporating a semi-variogram function. Finally, a new single empirical IPR model is obtained for horizontal wells producing oil from heterogeneous solution gas drive reservoirs suitable for systems with different reservoir permeability. The new empirical IPR model is then compared to published correlations and is found to have a small and acceptable average absolute error of less than 2%. Furthermore, the invention also shows that bubble point pressure has significant effect on dimensionless IPR curves. However, plots for other properties indicate that although the curves are not identical, they are similar in shape and demonstrate much less variance than the bubble point pressure plot. Therefore, these properties have only a minor effect on calculated, dimensionless IPR curves.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

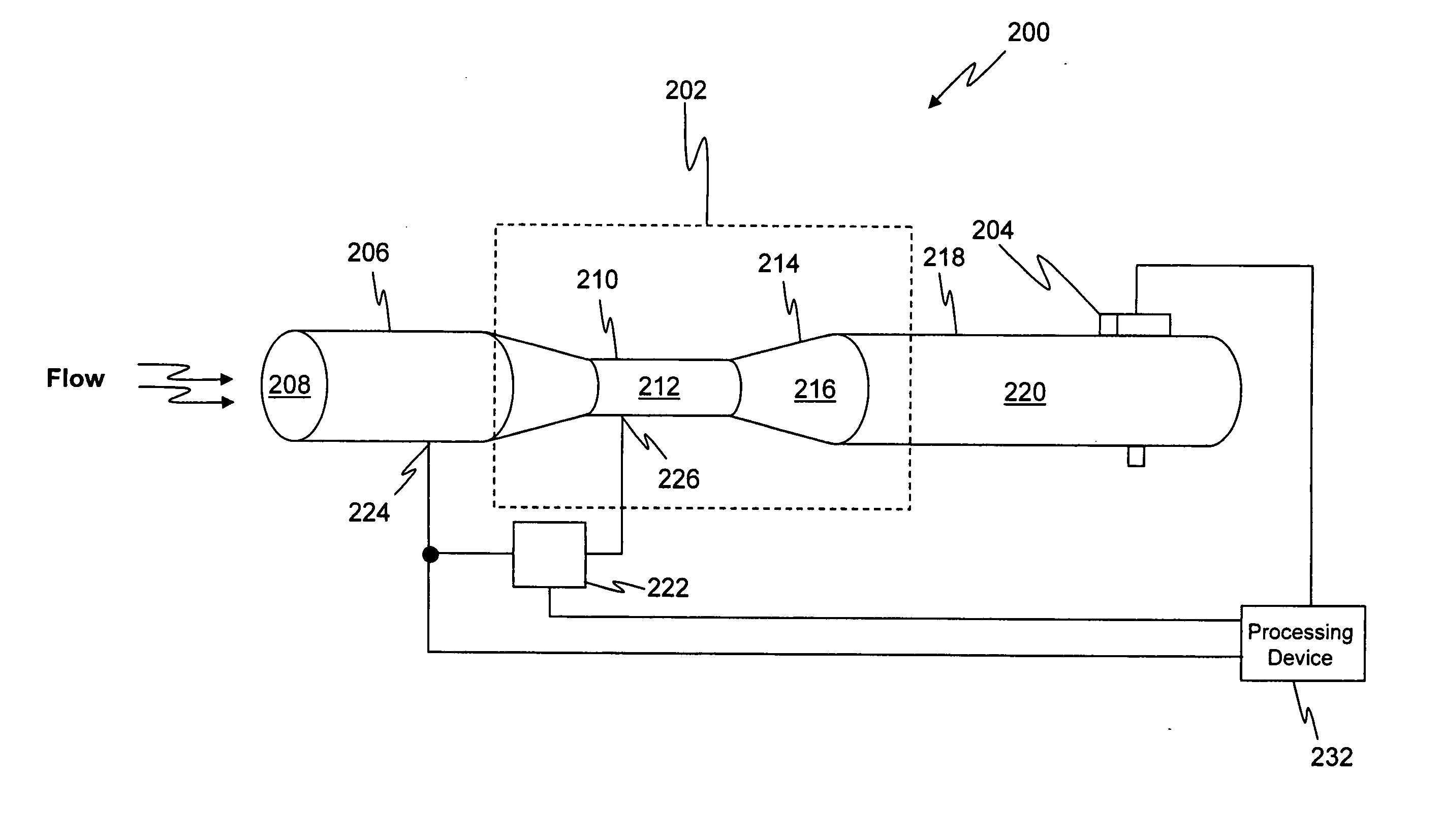

Flow rate determination

ActiveUS20050033530A1Flow propertiesFluid pressure measurement by mechanical elementsLine tubingPressure data

A method for determining the bubble point pressure and the true flow rate of a fluid in a flow line of a flowing well is provided, wherein the method includes modifying fluid pressure in a predetermined region of the flow line, generating pressure data responsive to the flow line, obtaining apparent flow rate data responsive to the pressure data, examining the apparent flow rate data to identify a discontinuity in the apparent flow rate data and generating true flow rate data responsive to the discontinuity.

Owner:SCHLUMBERGER TECH CORP

Novel separator, an electrochemical cell therewith and use thereof therein

ActiveUS20130337368A1Constant maintenanceConstantCellsFinal product manufacturePotassium hydroxideEngineering

An ion-permeable web-reinforced separator, said ion-permeable web-reinforced separator comprising two separator elements separated by an (optionally integrated) substantially hollow by-pass channel, wherein the separator elements each comprise a binder and a metal oxide or hydroxide dispersed therein and the separator elements have a bubble point of at least 1 bar (0.1 MPa) and a back-wash resistance of at least 1 bar (0.1 MPa) and optionally have a specific resistance less than 4 Ω-cm at 30° C. in 6M potassium hydroxide solution; an electrochemical cell involving the production or consumption of at least one gas, said electrochemical cell comprising said ion-permeable web-reinforced separator; and the use thereof in an electrochemical cell involving the production or consumption of at least one gas.

Owner:VLAAMSE INSTELLING VOOR TECHNOLOGISCH ONDERZOEK NV VITO

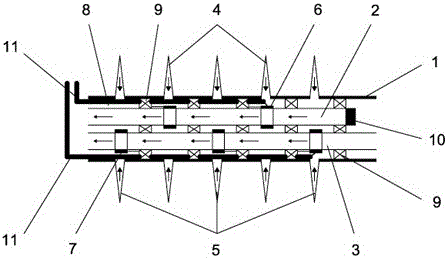

Phase behavoir analysis using a microfluidic platform

ActiveUS20090326827A1Electric/magnetic detection for well-loggingGas dispersion analysisGas phasePhase state

Methods and related systems are described for analyzing phase properties in a microfluidic device. A fluid is introduced under pressure into microchannel, and phase states of the fluid are optically detected at a number of locations along the microchannel. Gas and liquid phases of the fluid are distinguished based on a plurality of digital images of the fluid in the microchannel. Bi-level images can be generated based on the digital images, and the fraction of liquid or gas in the fluid can be estimated versus pressure based on the bi-level images. Properties such as bubble point values and / or a phase volume distribution ratio versus pressure for the fluid are can be estimated based on the detected phase states of the fluid.

Owner:SCHLUMBERGER TECH CORP

Selective separation of fluid compounds utilizing a membrane separation process

InactiveUS20050045029A1Reduced capitalReduce stepsGas treatmentLiquid degasificationMembrane configurationProduct group

Apparatus and processes are disclosed for economical separation of fluid mixtures utilizing perm-selective membranes. Broadly, apparatus of the invention comprises a plurality of membrane modules comprising a solid perm-selective membrane and means for controlling enthalpy of selected fluids within the apparatus. Advantageously, the membrane modules are disposed in a first product group, a second product group, and at least one intermediate group. Apparatus of the invention is particularly useful for simultaneous recovery of a very pure permeate product, and / or a desired non-permeate stream, from fluid mixtures of two or more compounds which when subjected to appropriately altered conditions of temperature and / or pressure exhibit a bubble point.

Owner:BP CORP NORTH AMERICA INC

Multistage fracturing horizontal well inter-crack interval CO2 flooding oil extraction method

ActiveCN106194131AImprove production statusEnhanced overall recoveryFluid removalBottom hole pressureCo2 flooding

The invention relates to a multistage fracturing horizontal well inter-crack interval CO2 flooding oil extraction method. The method includes following steps: performing sectional fracturing on a horizontal well shaft to form multiple fracturing cracks perpendicular to the horizontal well shaft; mounting an oil pipe I and an oil pipe II in a casing in the horizontal well shaft, mounting flow controllers I at positions, corresponding to even-level cracks, of the oil pipe I, mounting flow controllers II at positions, corresponding to odd-level cracks, of the oil pipe II, and arranging a packer at a position, between the odd-level cracks and the even-level cracks, in an annular space of an oil jacket; at an initial production stage, utilizing natural energy for extraction until bottom hole pressure is lowered to bubble point pressure, and utilizing crack intervals for extraction, injecting CO2 into the oil pipe I, wherein CO2 enters the even-level cracks, and crude oil is output from the odd-level cracks and enters the oil pipe II at the same time; when oil yield is lower than economic limit yield, stopping injecting CO2. By the method, crude oil recovery rate can be increased substantially, and gas channeling can be inhibited effectively.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Determining fluid bubble point pressure using an adjustable choke

A method of determining the real time bubble point pressure of a fluid originating from a subsurface earth formation using an adjustable choke positioned downhole adjacent to the formation. The adjustable choke is placed into communication with the wellbore fluid flowing from the formation to the surface. The adjustable choke has a remotely adjustable choke opening for selectively restricting the flowrate of the fluid flowing through the choke. The adjustable choke has a pressure sensor for measuring the fluid pressure downstream of the choke opening. The method includes obtaining downstream fluid pressure data as a function of choke size for generating a plot of downstream pressure versus choke size data which exhibits substantially linear behavior having two different slopes. Extrapolating a best-fit line through the set of data having a first slope so as to intersect an extrapolation of a best-fit line through the set of data having a second slope thereby provides the bubble point pressure of the fluid as the pressure corresponding to the intersection of the two lines.

Owner:WOOD GROUP LOGGING SERVICES HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com