Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1030 results about "Visual observation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Visual observation in English. observation made by the naked eye, observation done without visual aids or other equipment. Inspection activities to be implemented within the cascade area include visual observation, radiation monitoring and non-destructive assay measurements, environmental sampling, and application and verification of seals.

Sliver type autonomous biosensors

InactiveUS20040180391A1Bioreactor/fermenter combinationsBiological substance pretreatmentsIn vivoElectrochemistry

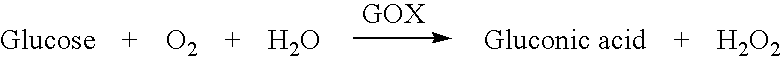

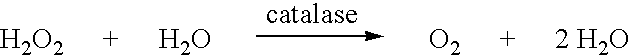

In vivo or in vitro monitoring of chemical and biochemical species (e.g., pH, or glucose levels) in the interstitial fluid of patients or in a sample of a fluid to be analyzed is provided by a probe (10, 70, 210, 270). For in vivo monitoring, the probe is readily inserted by a minimally invasive method. Optical or electrochemical sensing methods are employed to detect a physical or chemical change, such as pH, color, electrical potential, electric current, or the like, which is indicative of the concentration of the species or chemical property to be detected. Visual observation by the patient may be sufficient to monitor certain biochemicals (e.g., glucose) with this approach. A CAP membrane allows high enzyme loadings, and thus enables use of microminiature probes, and / or diagnosis of low levels of the analyte(s), with sufficient signal-to-noise ratio and low background current.

Owner:CASE WESTERN RESERVE UNIV

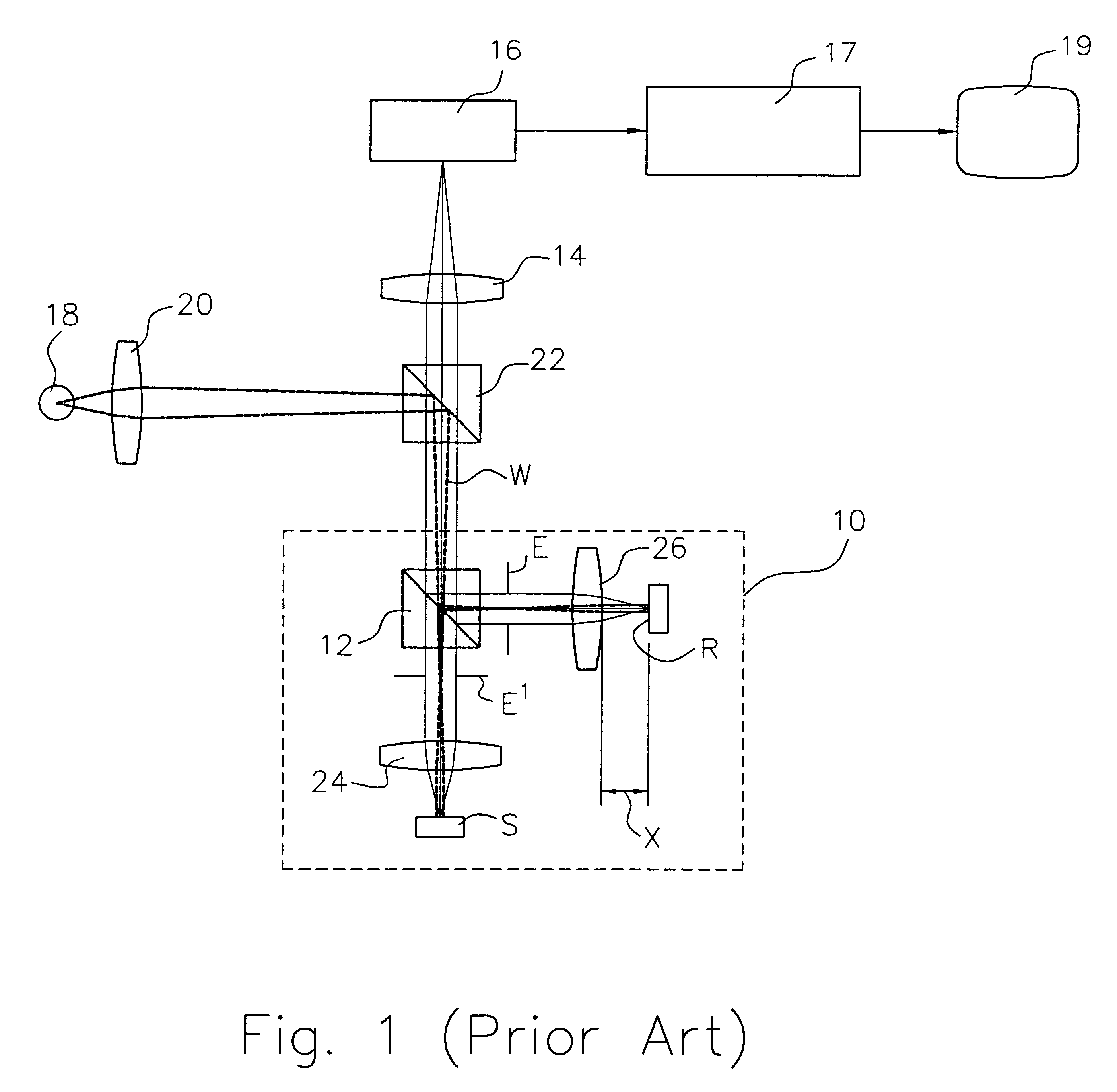

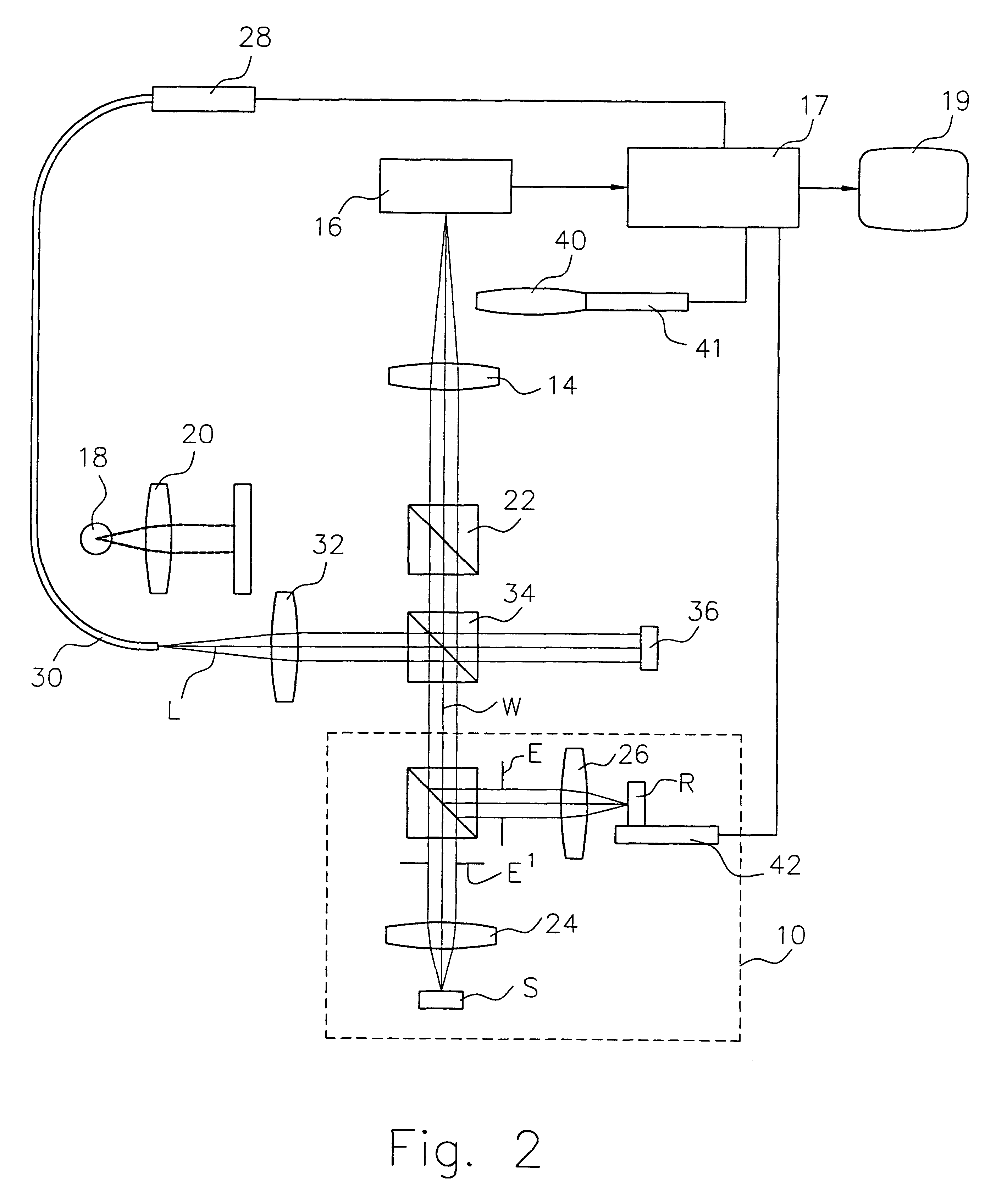

Embedded interferometer for reference-mirror calibration of interferometric microscope

InactiveUS6545761B1Implemented easily and economicallyAccurately determineInterferometersUsing optical meansClosed loopOptoelectronics

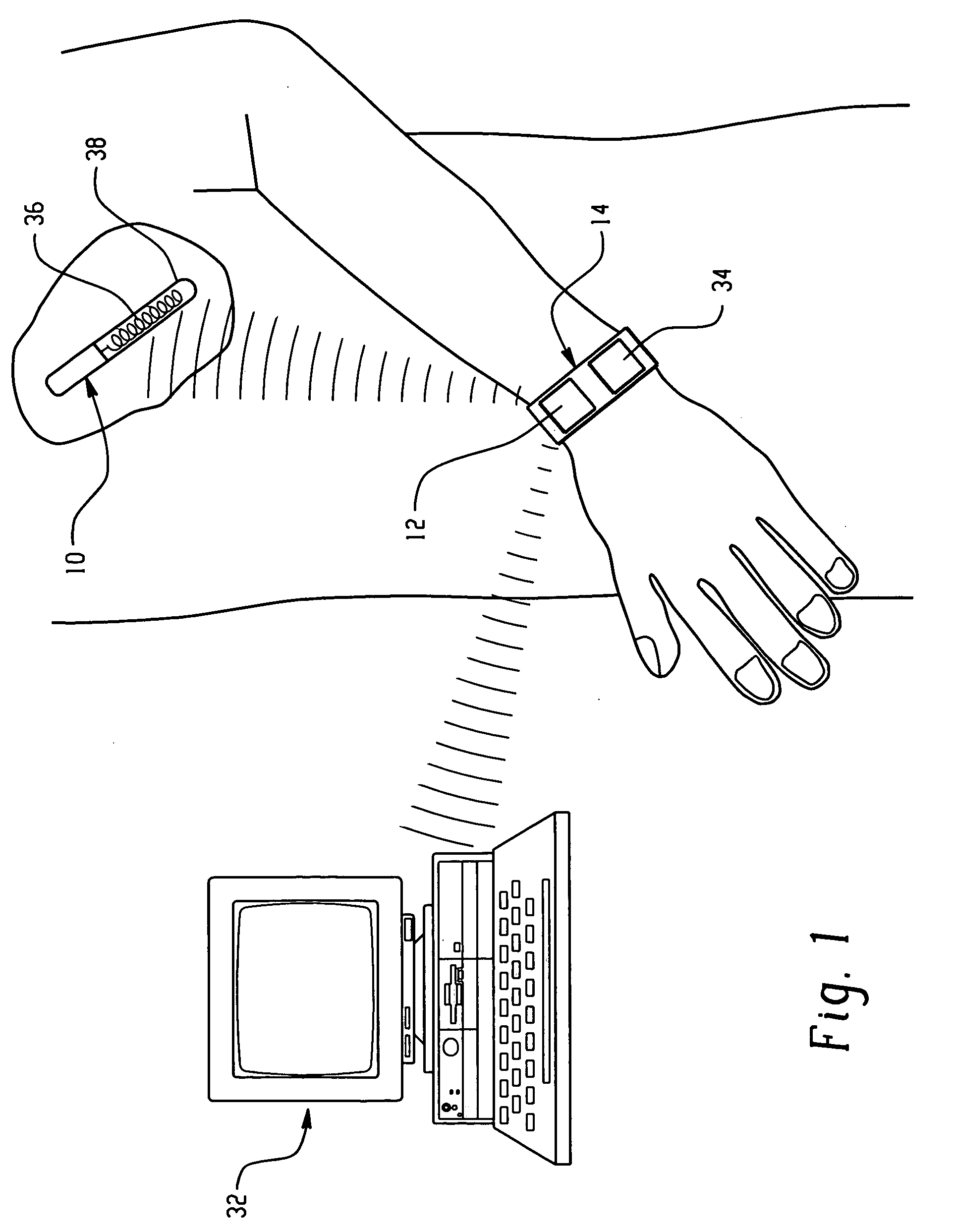

A laser interferometer is embedded into an interference microscope to precisely determine the in-focus position of the microscope objective's reference mirror. A collimated laser beam is introduced into the microscope system and split into two beams directed toward a calibration reference surface and the interference objective. The light reflected from the calibration reference surface is returned to the camera. The light into the interference objective is focused onto the reference mirror and returned to the camera. For the purpose of calibration, the two beams are combined at the camera to produce interference fringes. When the reference mirror is in focus, the returned beam is collimated; if the mirror is on either side of focus, the beam is either converging or diverging. Accordingly, the interferogram produced at the camera reflects the in-focus or out-of-focus condition of the reference mirror. The curvature of the wavefront returned from the reference mirror is determined electronically by analyzing the interference fringes produced with the beam returned from the calibration reference surface. By minimizing the curvature of the reference-mirror wavefront as the mirror is translated along the optical path, the reference mirror can be focused with an accuracy greater than possible by visual observation. Furthermore, by automating the focusing system with a precise translation mechanism driven by closed-loop control, operator-to-operator variations are completely eliminated.

Owner:BRUKER NANO INC

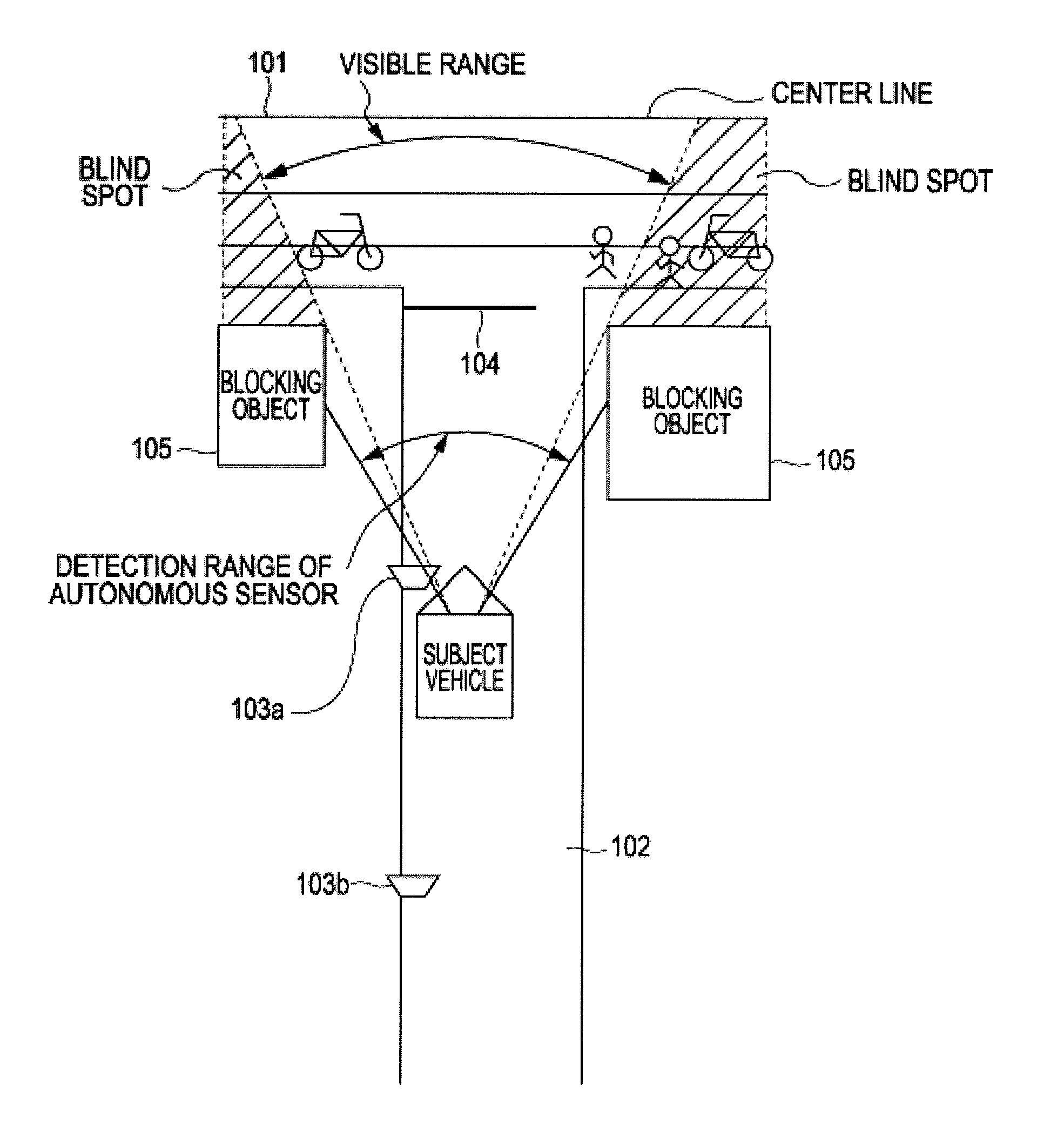

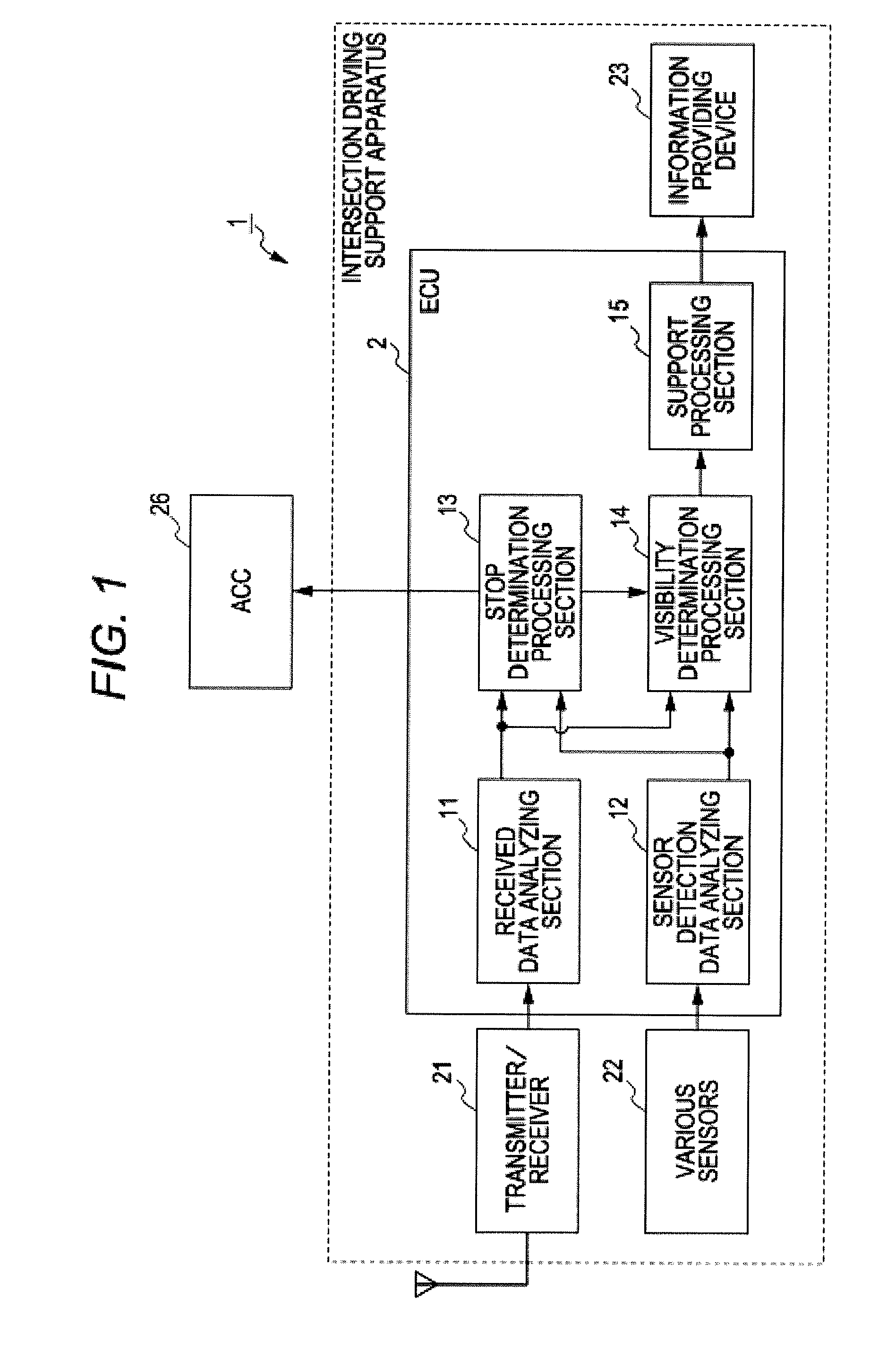

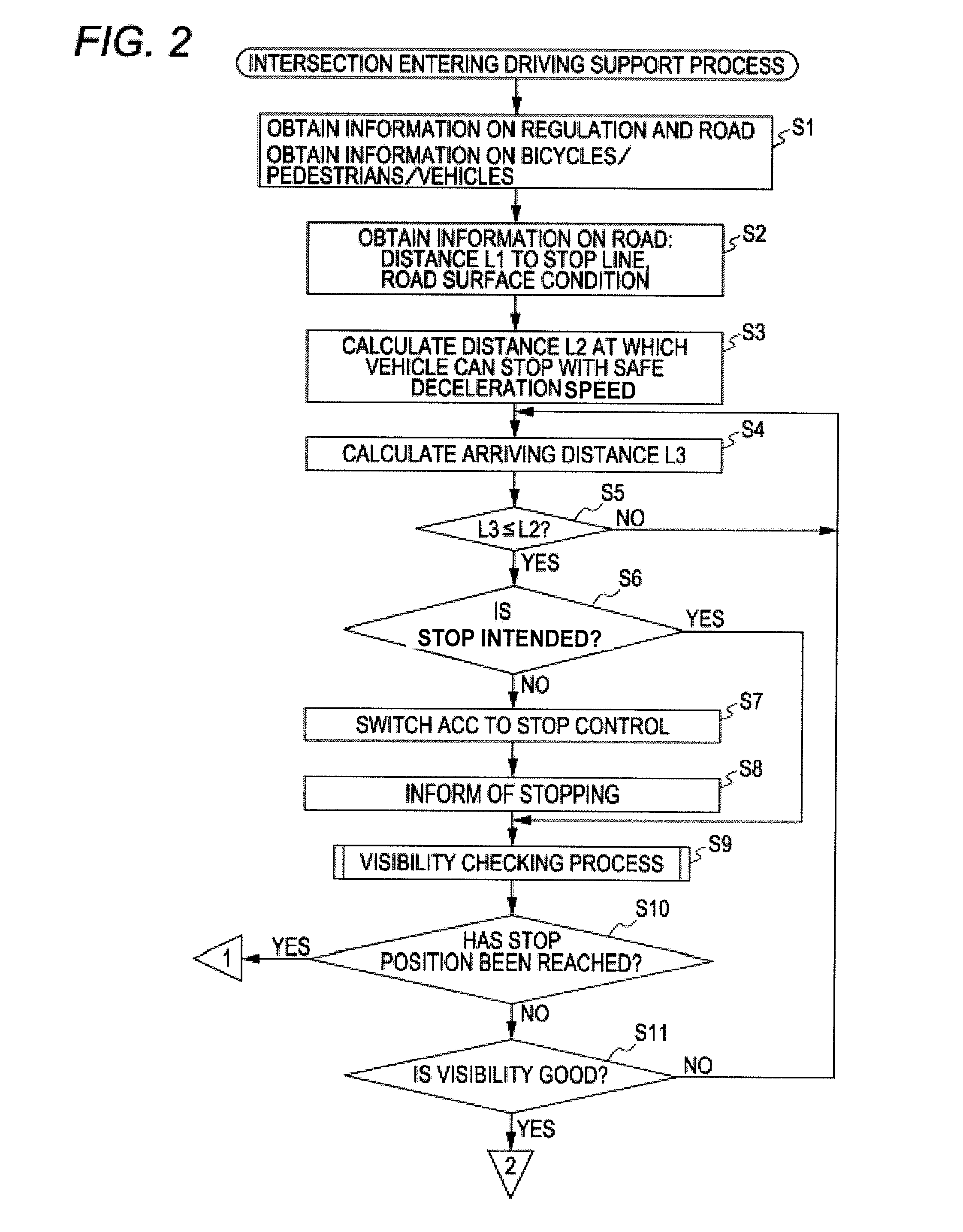

Intersection driving support apparatus

ActiveUS20110102195A1Easy to identifyProvide securityArrangements for variable traffic instructionsPedestrian/occupant safety arrangementVisual observationDriver/operator

When a vehicle attempts to enter a priority road from a non-priority road, a visibility determination processing section compares moving object information on the priority road obtained from a first infrastructure facility installed near a stop position with moving object information on the priority road detected by an autonomous sensor mounted on the vehicle, and determines that the visibility is poor if the former does not match the latter or determines that the visibility is good if the former matches the latter. Then, when the former does not match the latter, the driver is informed of intersection support information. When the former matches the latter, the driver is not informed since it is determined that the driver has already recognized the information by visual observation.

Owner:SUBARU CORP

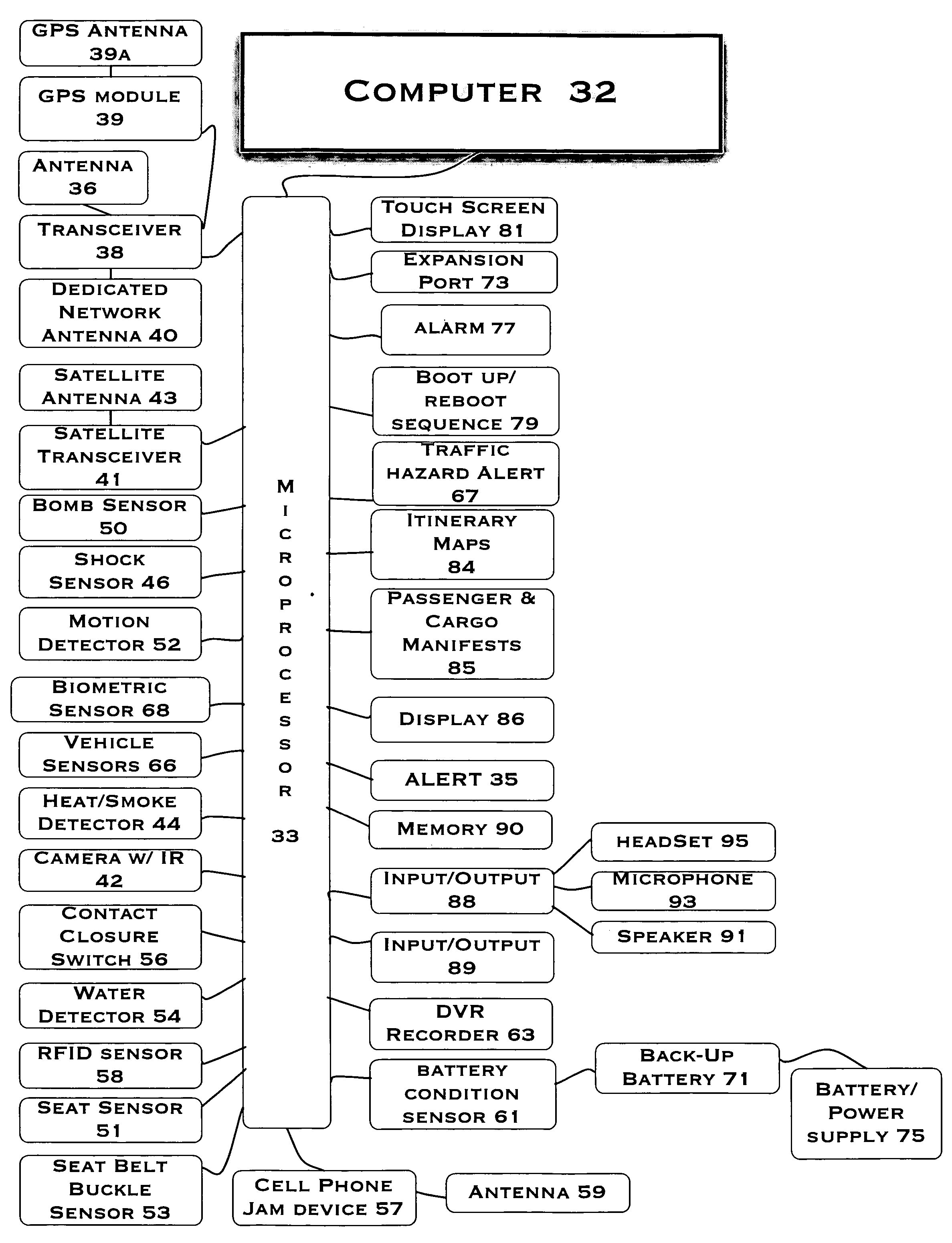

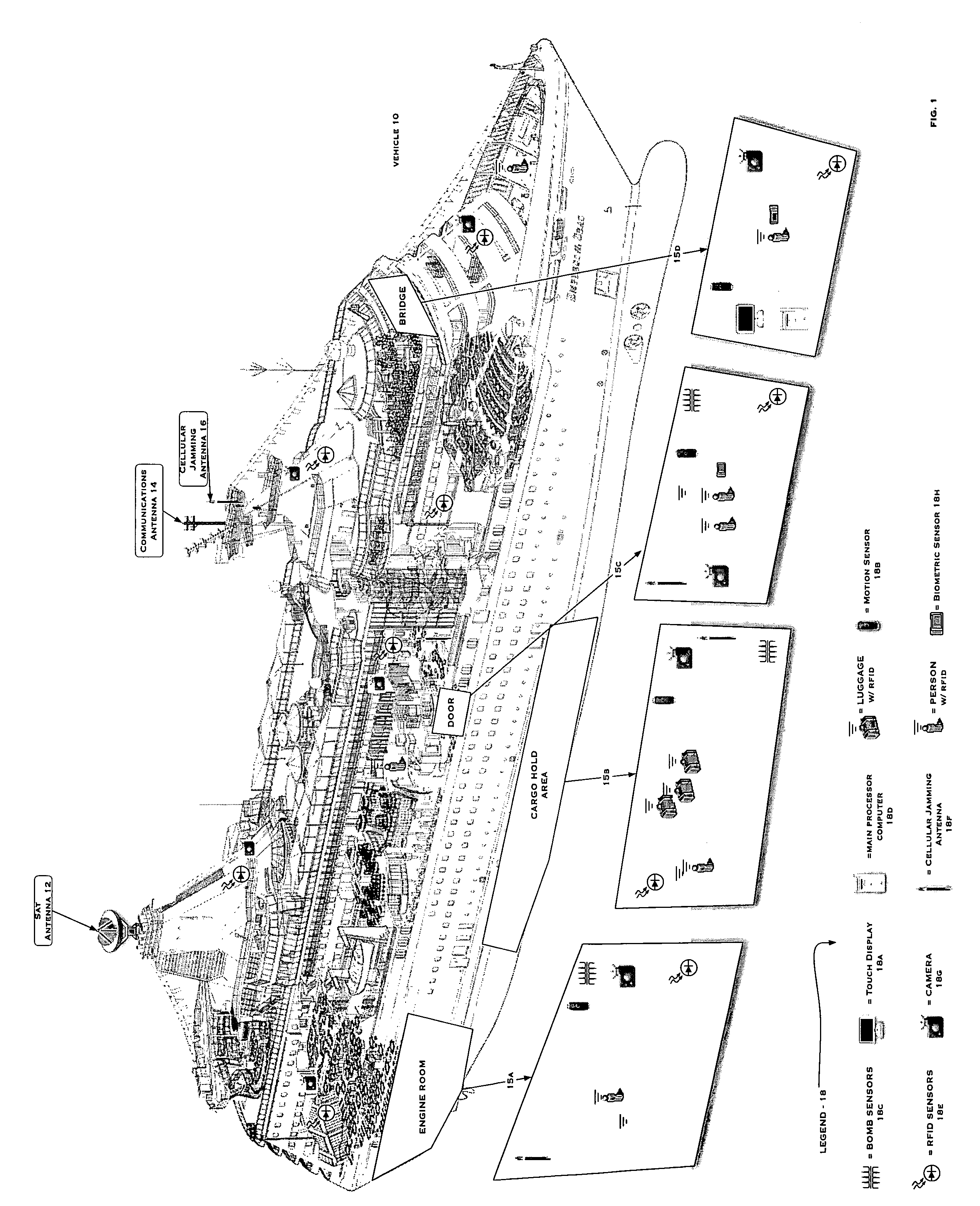

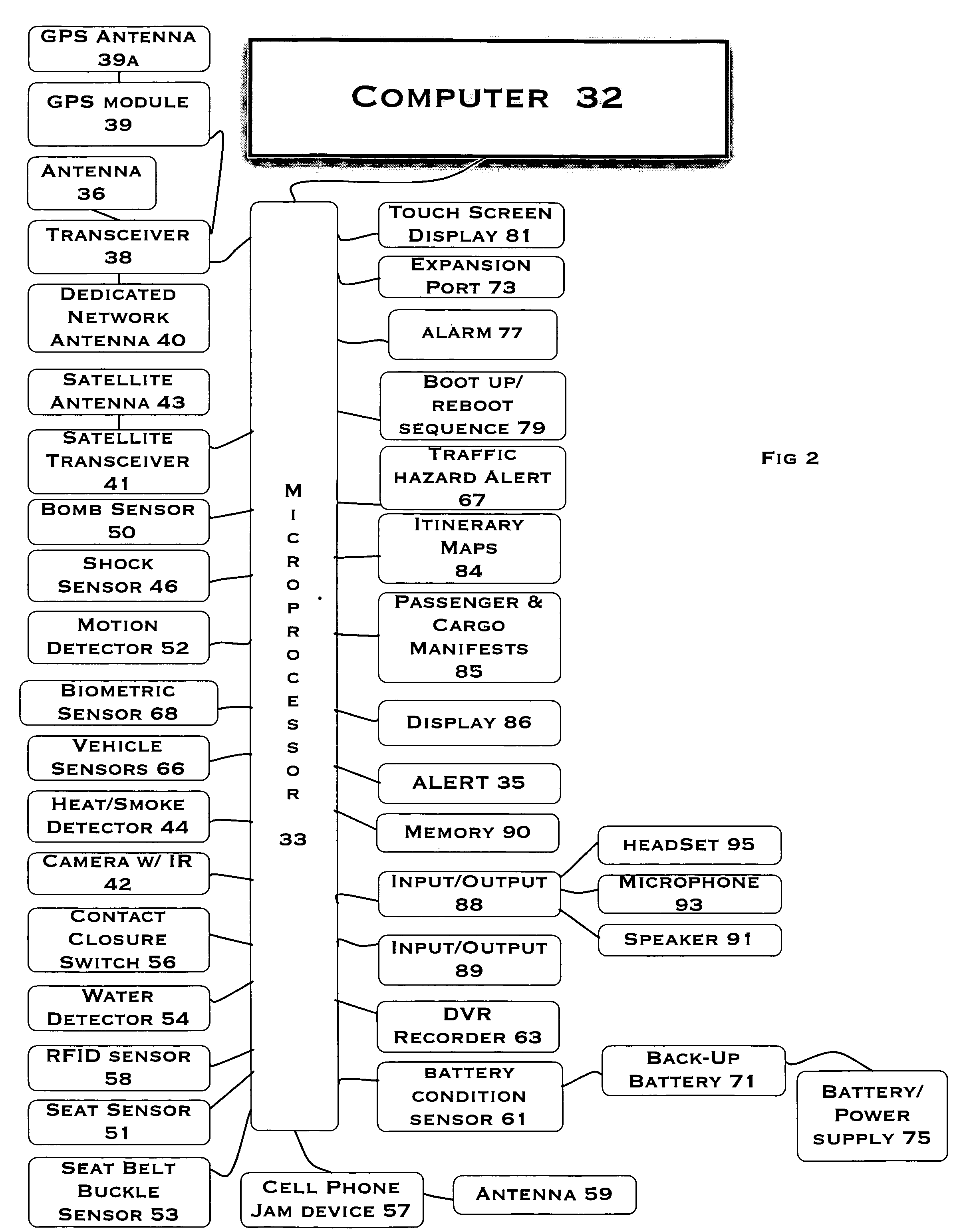

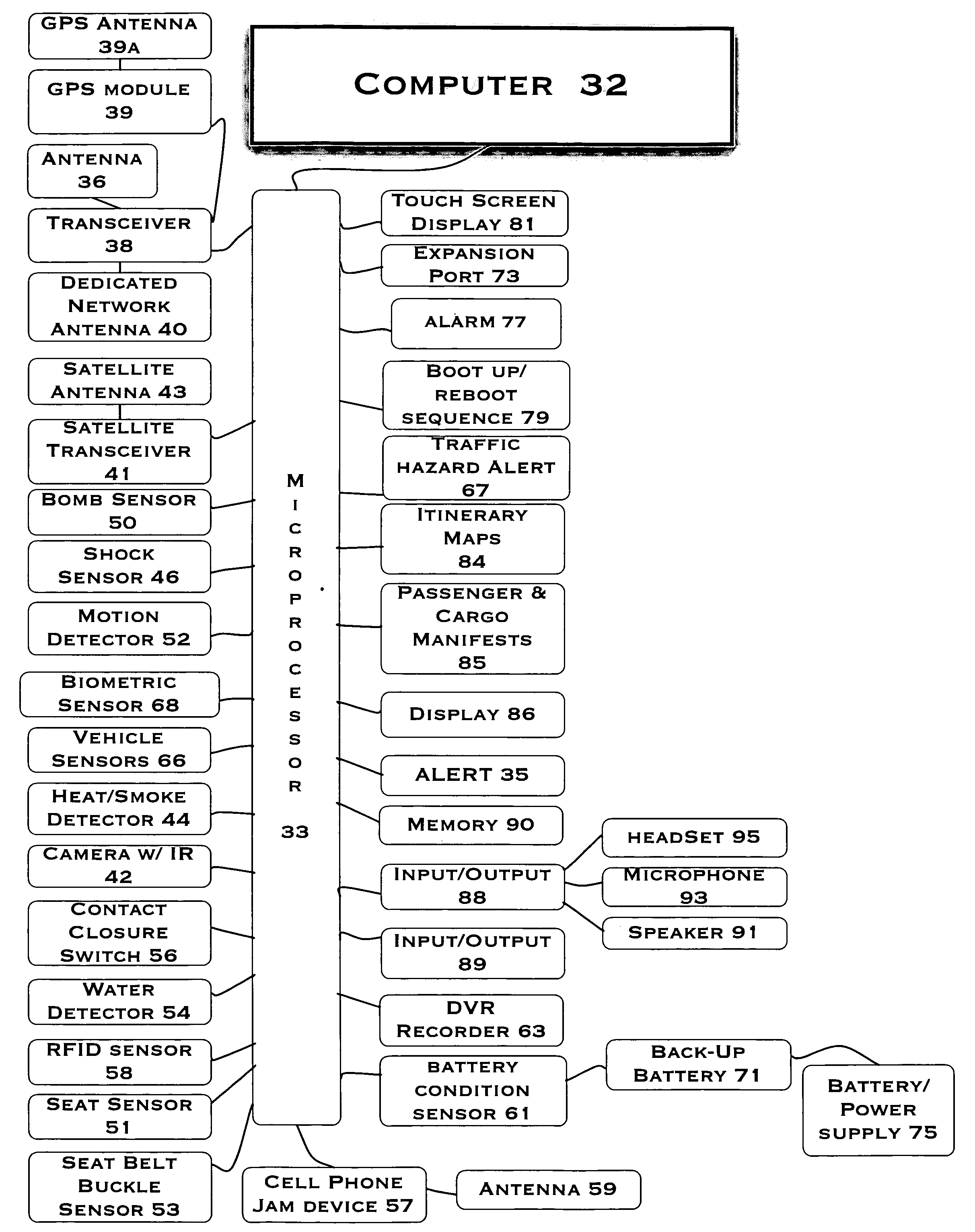

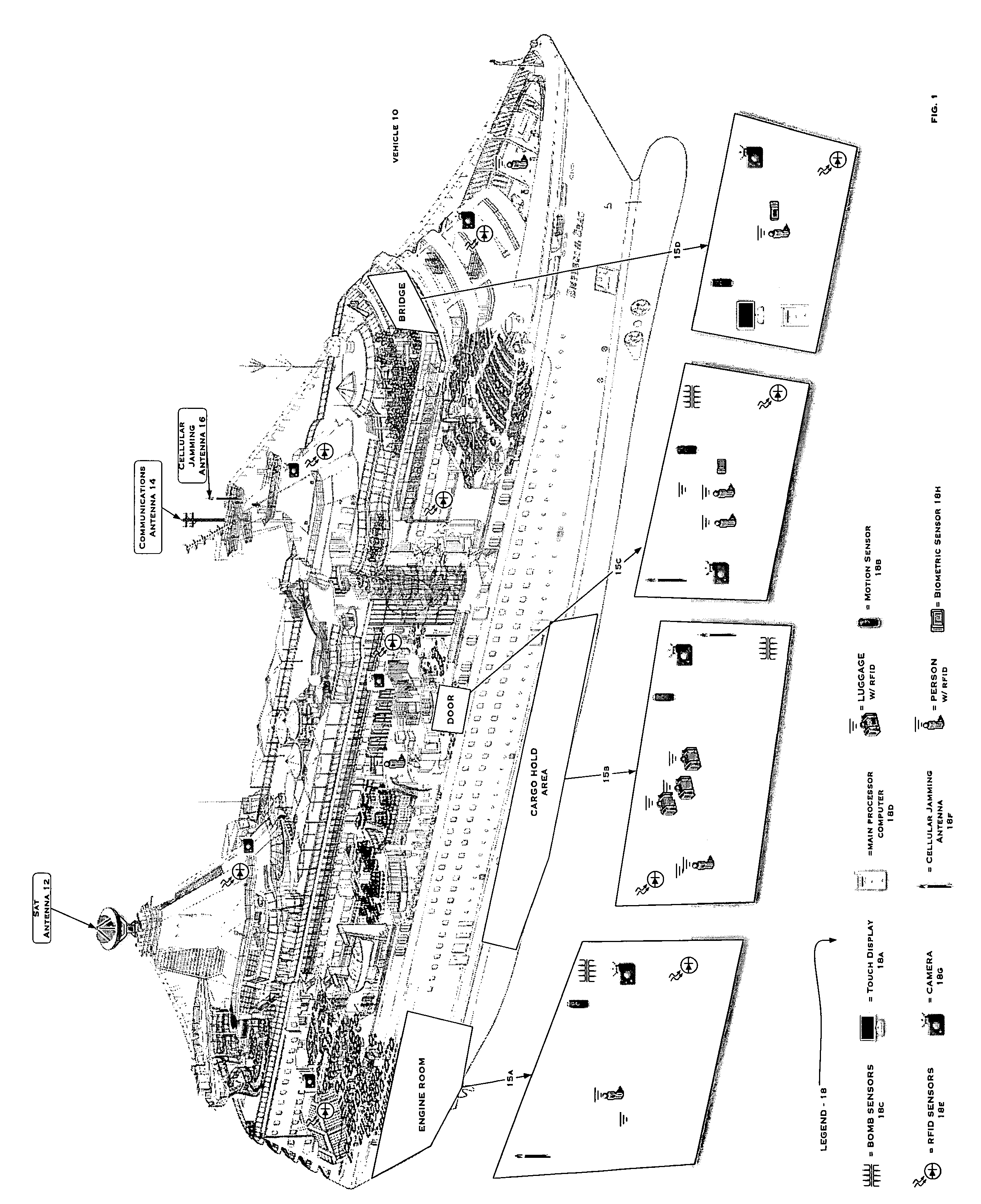

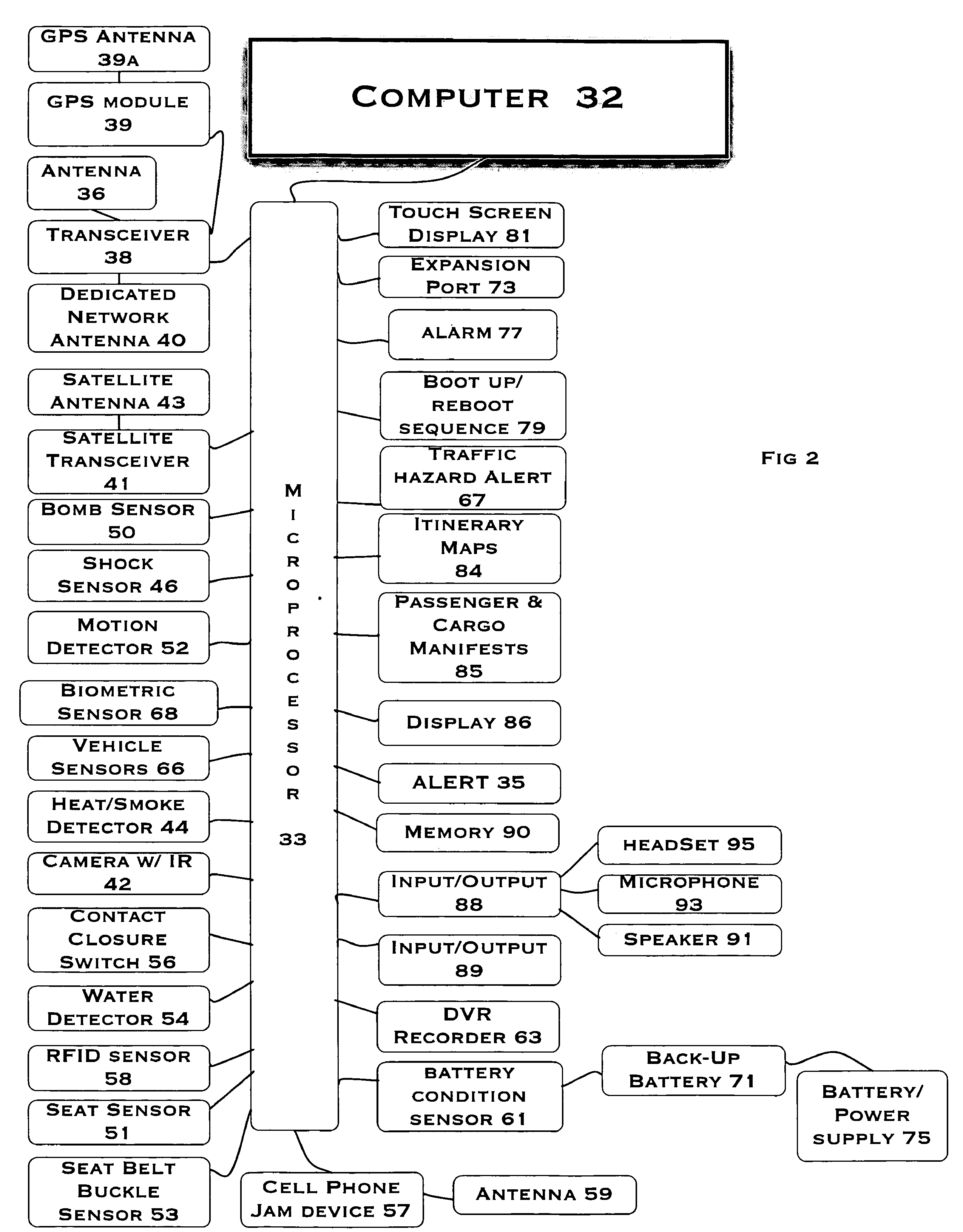

Security system for mass transit and mass transportation

InactiveUS20070040672A1Avoid disasterEasy to implementAnalogue computers for vehiclesAnalogue computers for trafficTelecommunications linkVoice communication

A security system and method for mass transit and mass transportation whereby high capacity mobile vehicles such as ships, buses, planes, trains and subways transporting large numbers of passengers or cargo, are continuously monitored and secured. Sensors are utilized to detect and alert the presence of radioactive or explosive materials on board as well as within close proximity of the vehicle. Sensors are also used to identify and track cargo and people, such as drivers, operators, employees, crew, and passengers, and provide continuous location and tracking thereof from the point of initial entry to the final point of exit. Additionally, a global positioning system (GPS) provides location data, and wireless data and telecommunications link provides two-way data and voice communication with any designated remote location by using one of several modes of wireless telecommunication. Cameras provide visual observation within designated viewable areas, and may be activated by any detection of motion, and are infrared or night vision capable allowing viewing even in extremely poor light conditions. DVR recording allow a huge amount of video content from the cameras to be digitally recorded, then played back later for further analysis. Finally, the Security System may optionally have an Internet Protocol (IP) address thereby allowing authorized persons to access the system from secured Internet connection.

Owner:CHINIGO ANDREW

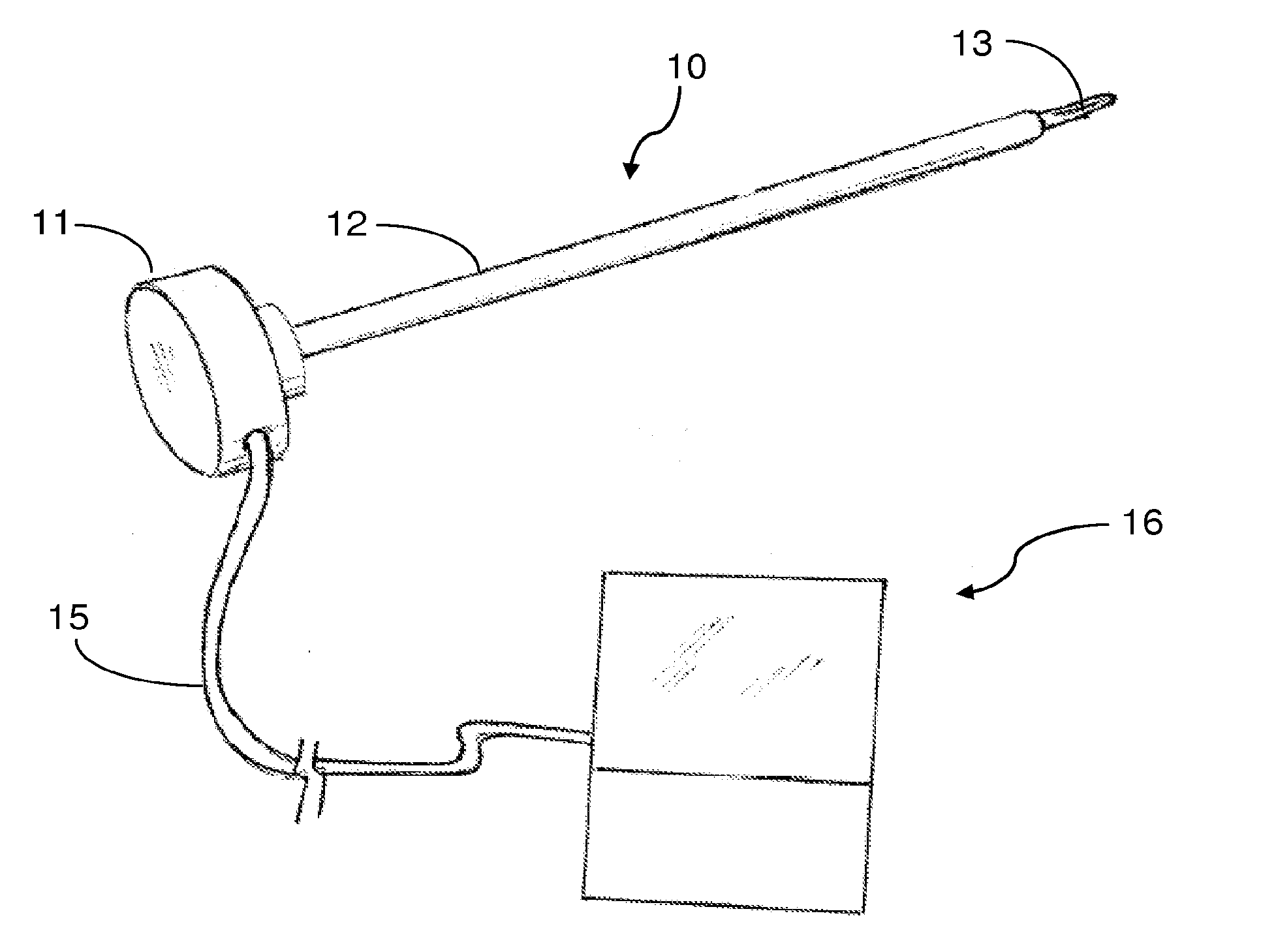

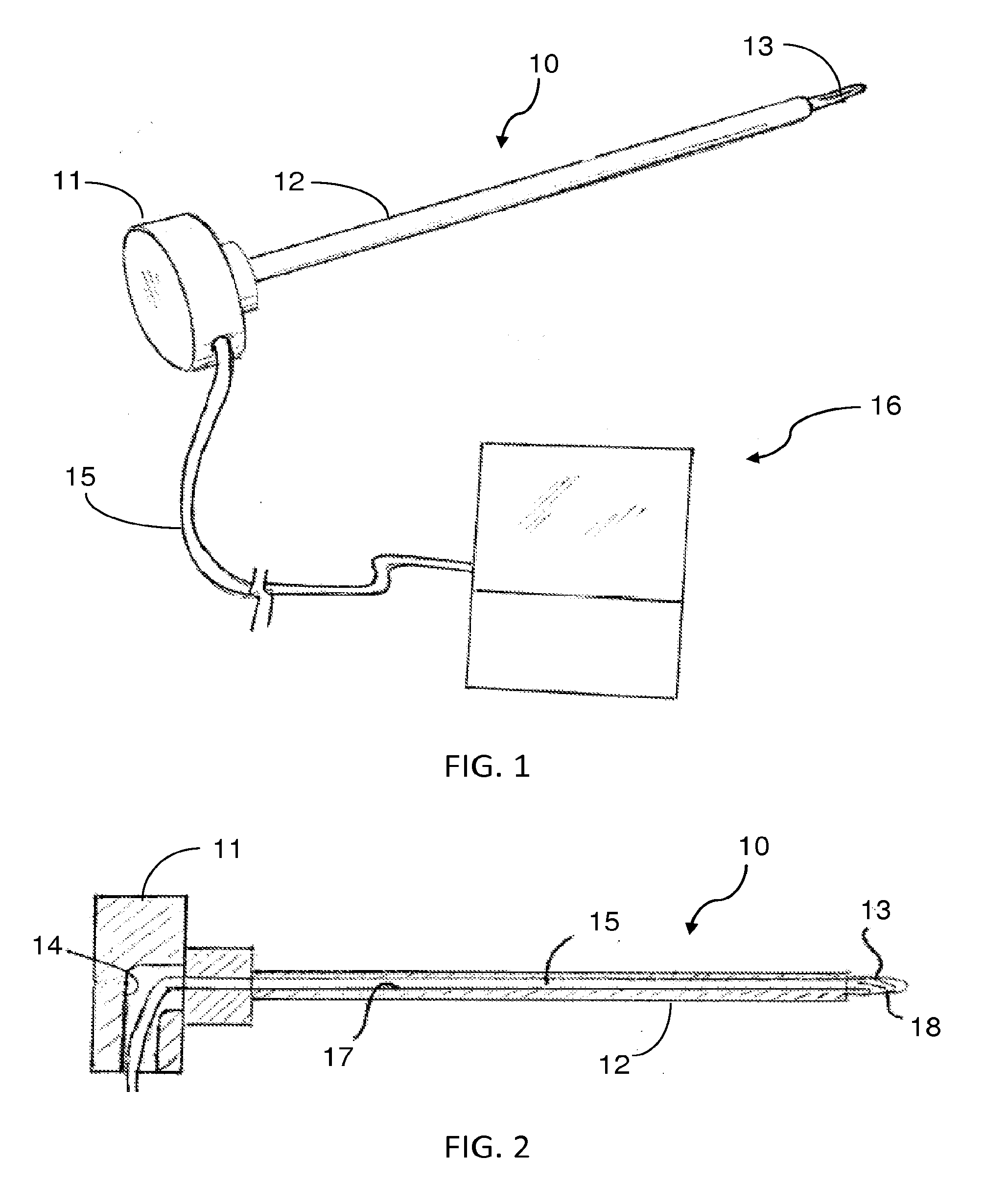

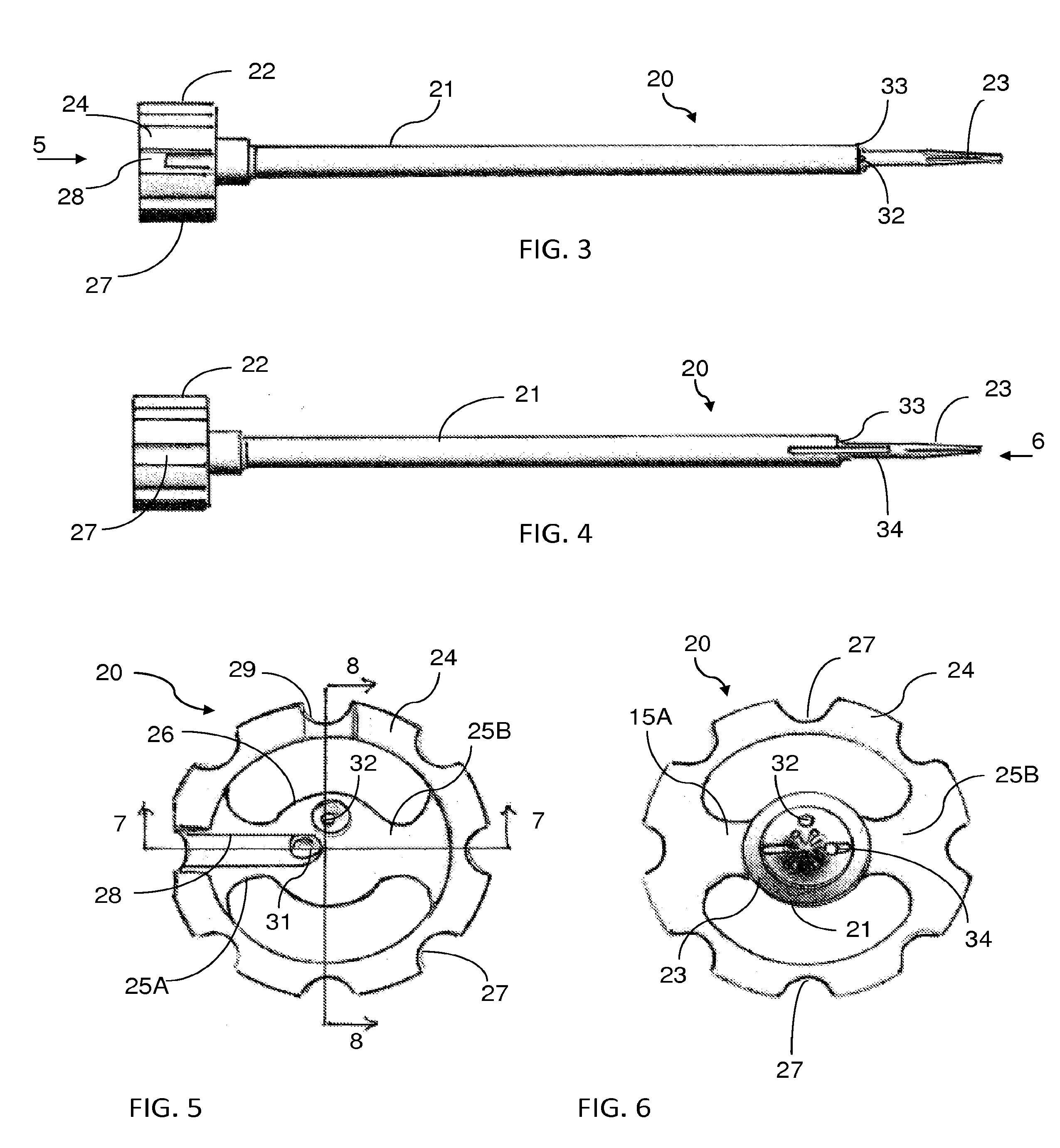

Illuminated endoscopic pedicle probe with dynamic real time monitoring for proximity to nerves

InactiveUS20150342621A1Prevent breachDirectly and accurately determinedSpinal electrodesElectromyographyVisual observationMonitoring system

An endoscopic pedicle probe for use during spinal surgery to form a hole in a pedicle for reception of a pedicle screw has an enlarged proximal end for cooperation with the hand of the surgeon and an elongate shaft terminating in a distal tip that may be pushed through the pedicle to form the hole. An integrated endoscope and light extend through the shaft to enable the surgeon to visually observe the target area, and a conduit extends through the shaft to convey a fluid to irrigate the target area. In a preferred form the probe is connected with an electromyographic or mechanomyographic monitoring system to alert the surgeon when a breach is about to occur. In a further embodiment, two endoscopes are associated with the probe. The complete probe may be disposable, or just the tip may be detachable for disposal or replacement.

Owner:OPTICAL SPINE LLC

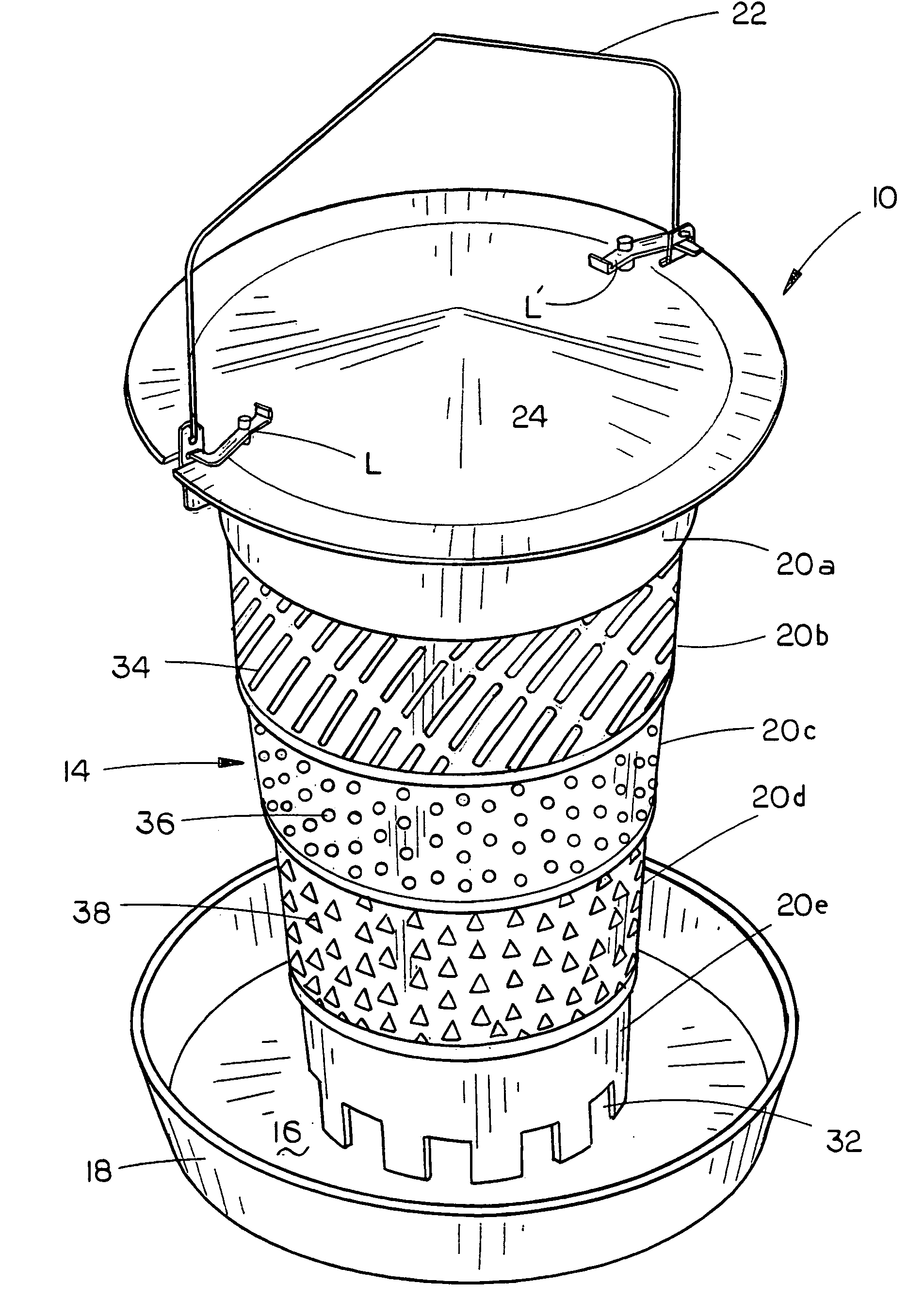

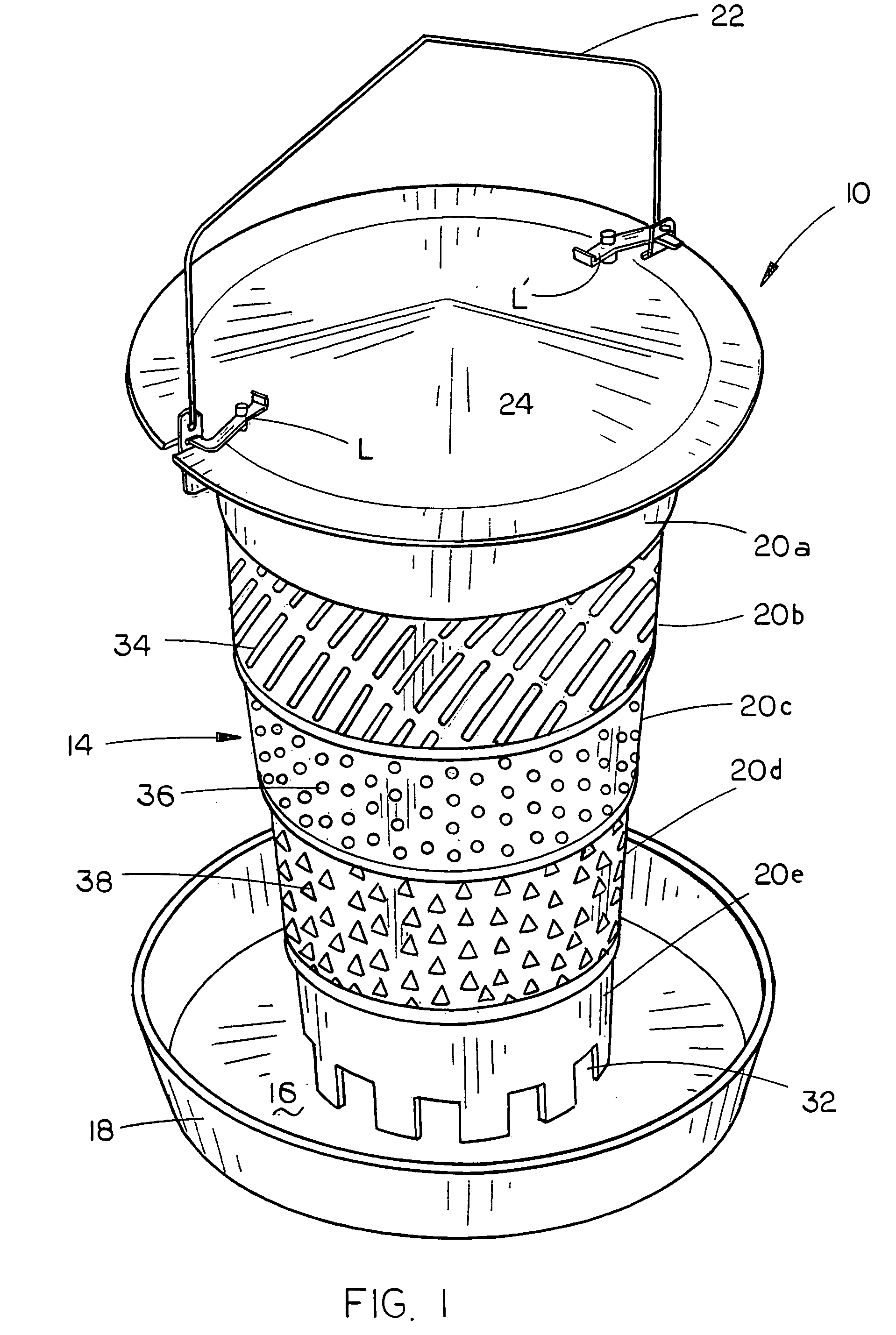

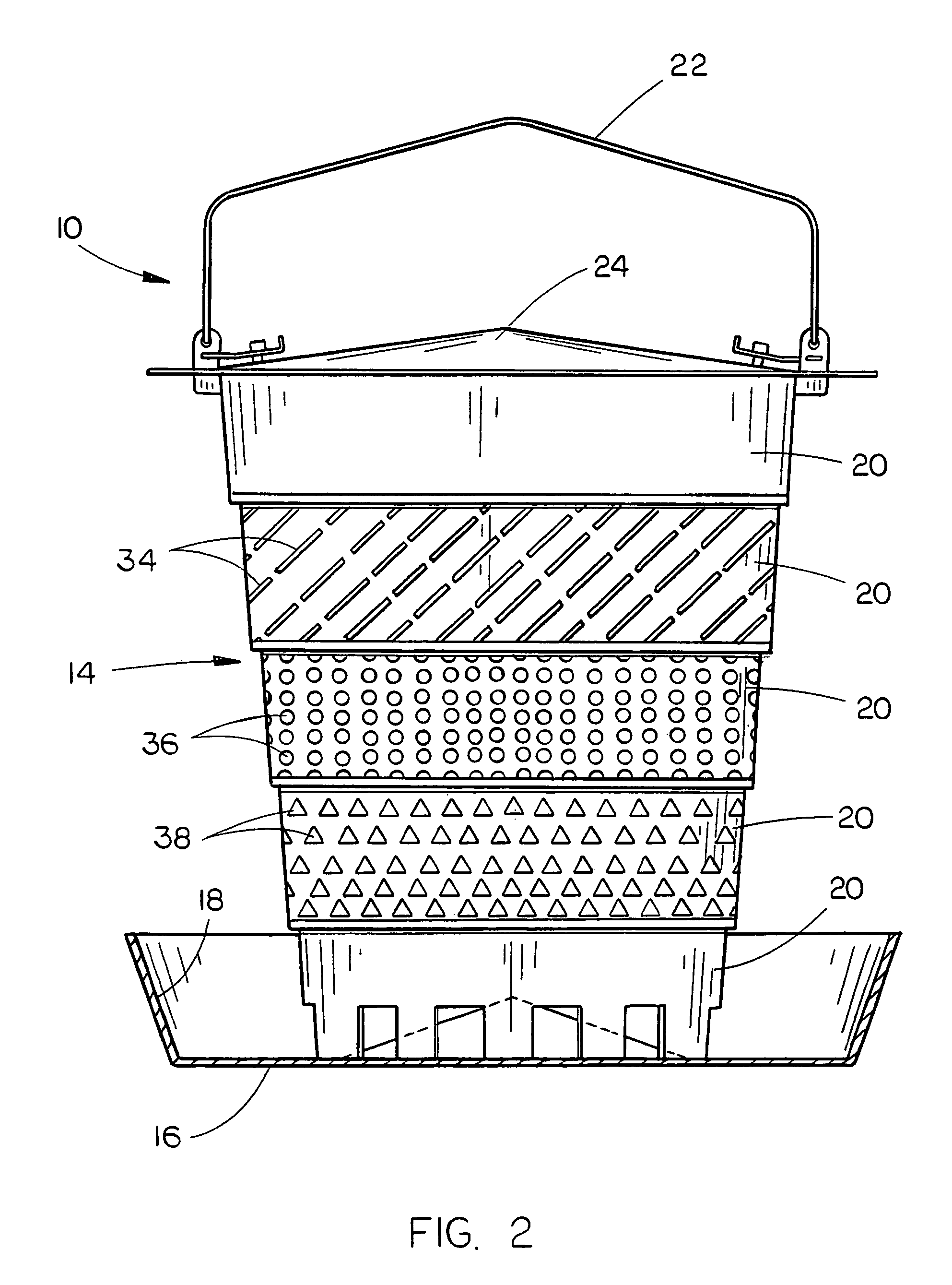

Collapsible feeder

ActiveUS7506611B1Easy to fillEasy to hangAnimal feeding devicesPisciculture and aquariaVisual observationEngineering

A collapsible feeder for birds, squirrels and the like and comprises a feeder body including a base and a rim. A series of hollow body segments of graduated diameters extend upwardly from the base within the rim to form a feeder body. The segment of smallest diameter is joined to the base and has a plurality of feed outlet openings formed therein to enable feed from within the feeder body to pass outwardly therefrom onto the base inwardly of the rim. A feeder lid is provided at the upper end of the segment of greatest diameter when the feeder body is in the extended position. The body segments include structure for yieldably maintaining the feeder in its straight extended position for filling and hanging. At least some of the body segments are comprised of a perforated metal material to enable the visual observation of the feed level within the feeder.

Owner:WOODSTREAM CORP

Security system for mass transit and mass transportation

InactiveUS7880767B2Avoid obsolescenceAnalogue computers for vehiclesAnalogue computers for trafficTelecommunications linkOn board

Owner:CHINIGO ANDREW

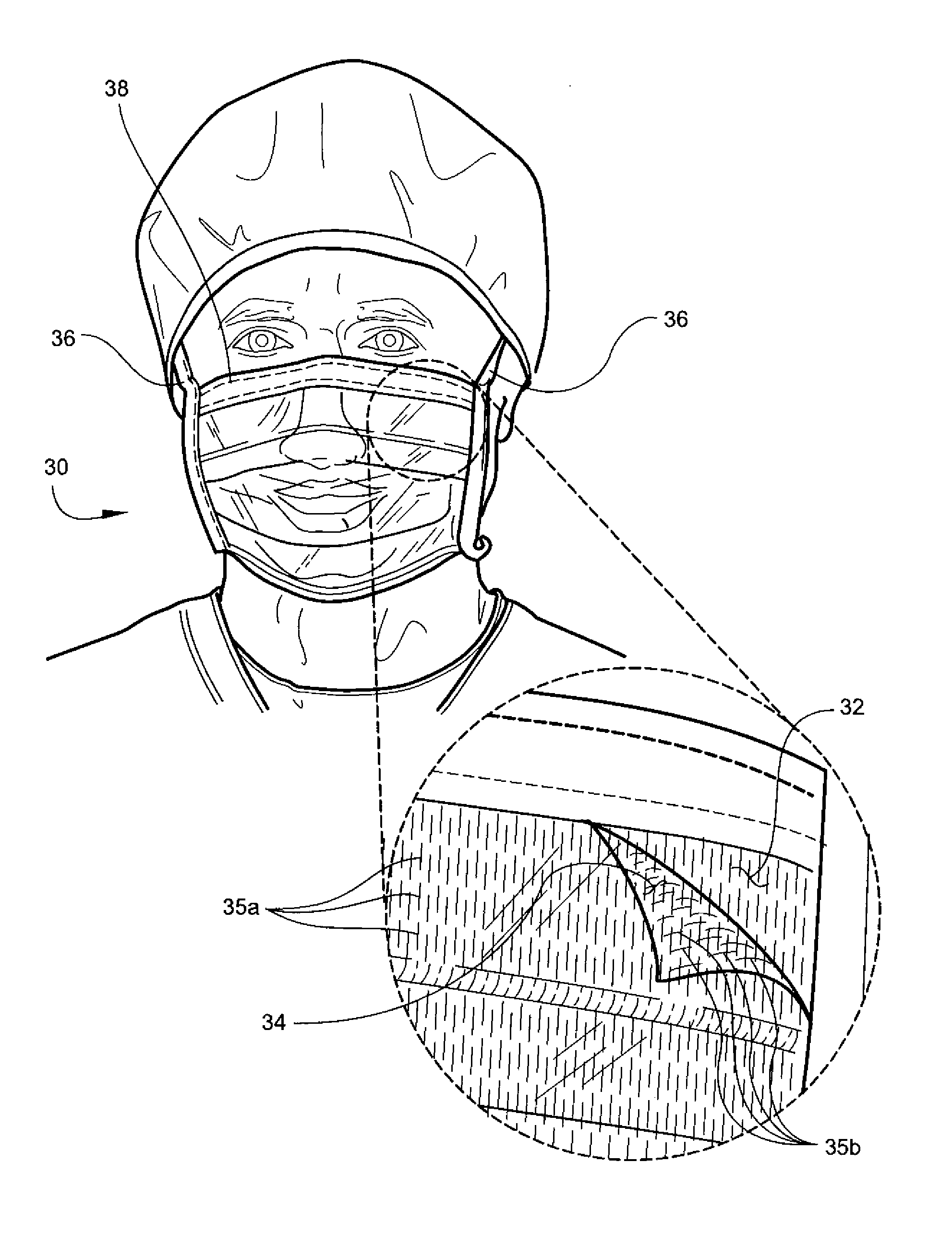

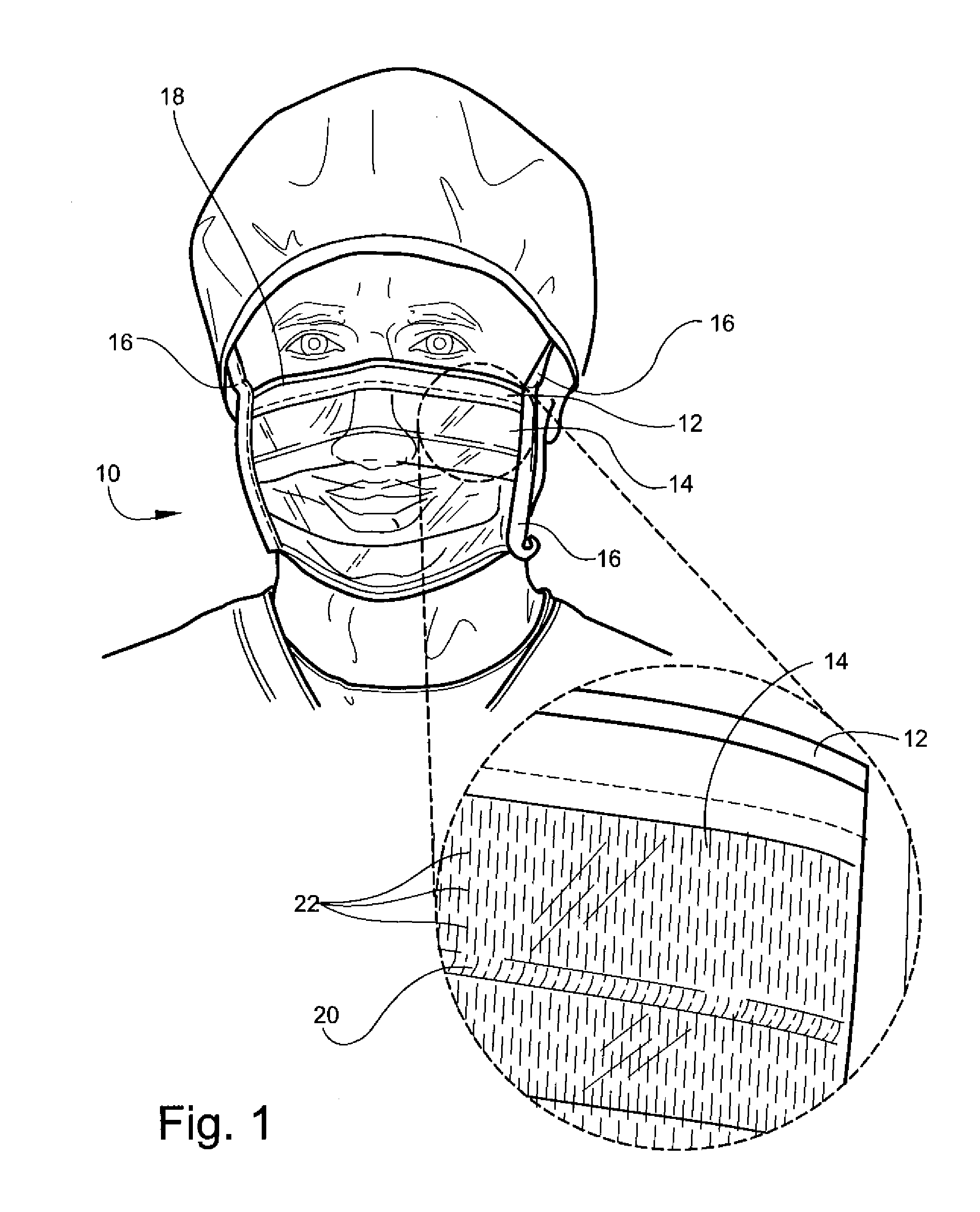

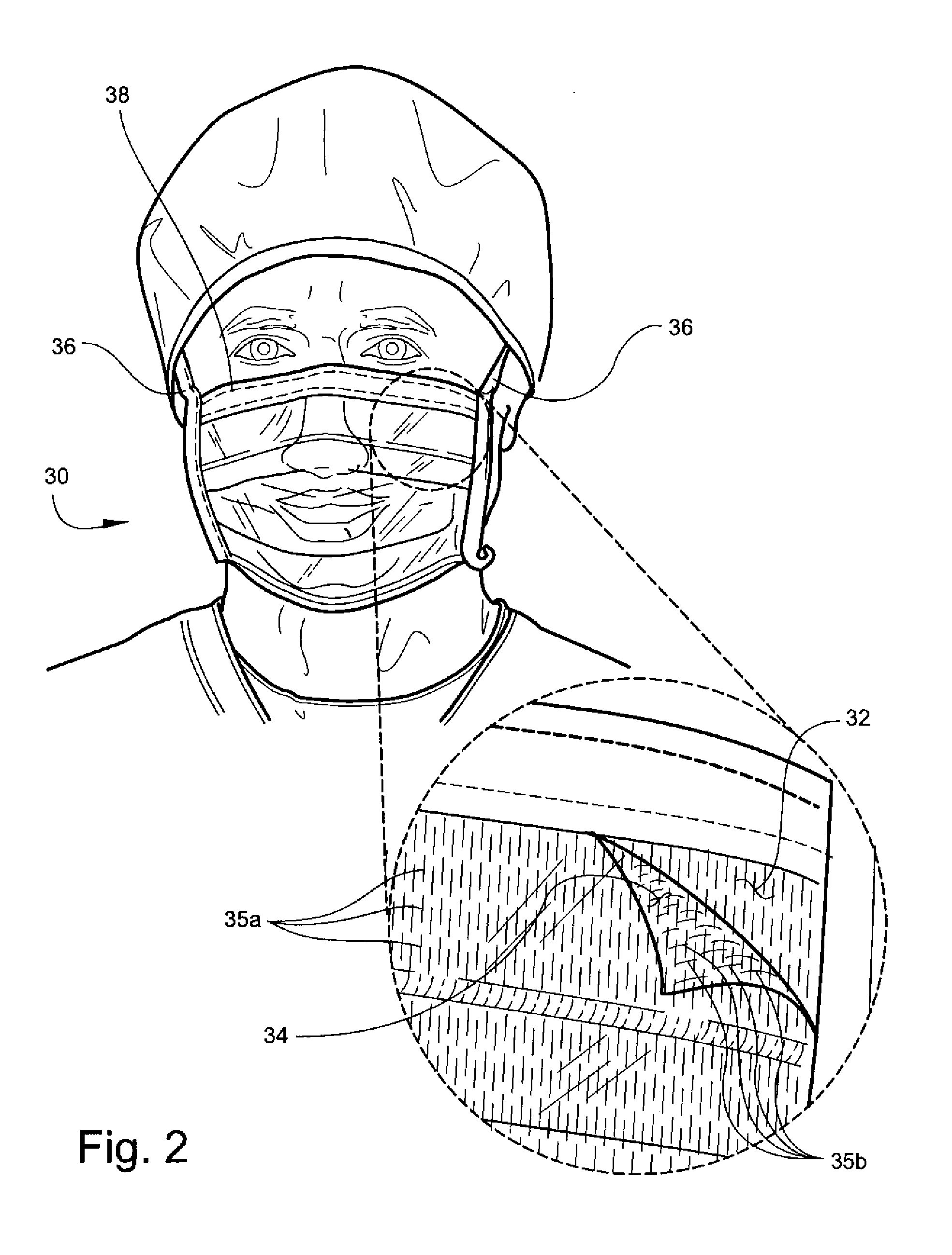

Transparent antimicrobial face mask

InactiveUS20100239625A1Reduce wind resistanceImprove breathabilityHead bandagesBiocideVisual observationNose

A mask for being worn over the nose and mouth of a wearer, and a panel having sufficient transparency to permit visual observation of the mouth of the wearer. The panel is formed from first and second overlying transparent, pleated films perforated with elongate slits sized to permit two-way transit of gases, but not liquids, under atmospheric pressure. The first and second films each include a multitude of projections for maintaining between the first and second films a multitude of tortuous flow paths for permitting respiratory gas flow through the panel.

Owner:PUCKETT ANNE MCINTOSH

Gelation-delayed in-situ polymerized water shutoff gel for high-temperature reservoirs

InactiveCN102382244AGood instant solubilityConvenient dispensing operationDrilling compositionSynaeresisVisual observation

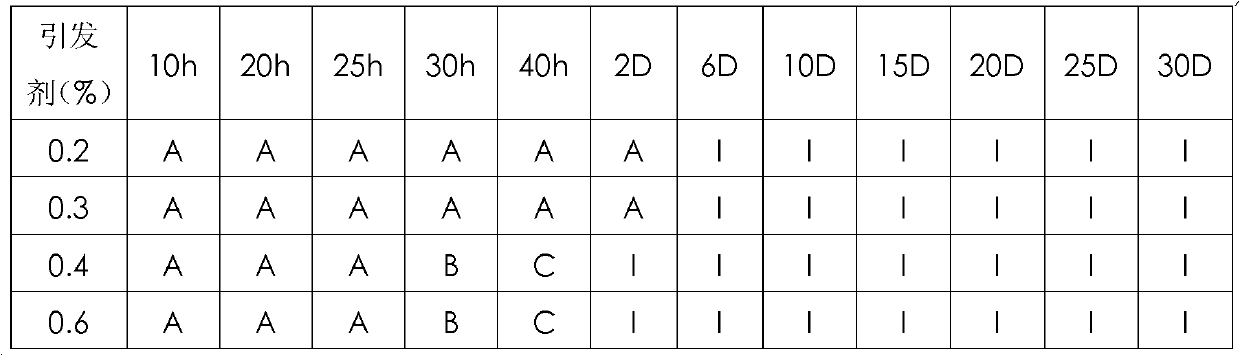

The invention relates to a gelation-delayed in-situ polymerized water shutoff gel for high-temperature reservoirs, which consists of 5 to 7 percent by weight of main agent, 1 to 2 percent by weight of solubilizer, 1 to 2 percent by weight of cross-linking agent, 0.1 to 0.8 percent by weight of initiator and the balance of water, the main agent consists of monomer A and monomer B, the mass ratio of the monomer A to the monomer B is 3:1 to 5:1, the monomer A is acrylamide, and the monomer B is ester. Under high temperature, the pumping time of the gel is relatively longer, the gelation time canbe controlled at 20 to 72 hours under 120 DEG C, the final set strength can reach visual observation code level I, the synaeresis of the gel does not take place in 90 days, and the gel can be used inwater shutoff operation for high-temperature reservoirs under 90 DEG C to 140 DEG C. Because the gel has the advantages of good pumping property, high plugging strength, long service life, simple construction process and the like, the gel has a broad application prospect in chemical profile modification and water shutoff for oil fields.

Owner:SOUTHWEST PETROLEUM UNIV

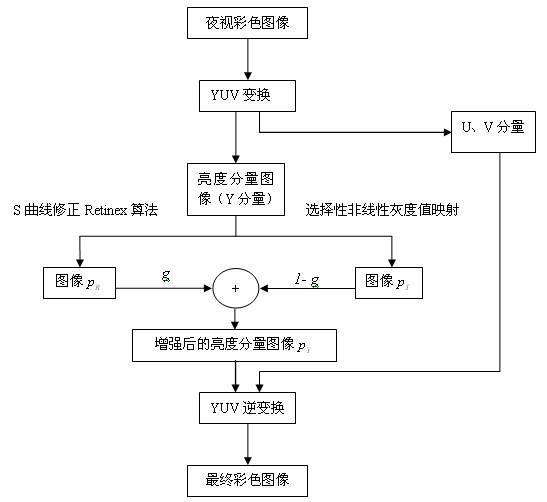

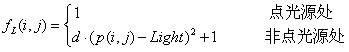

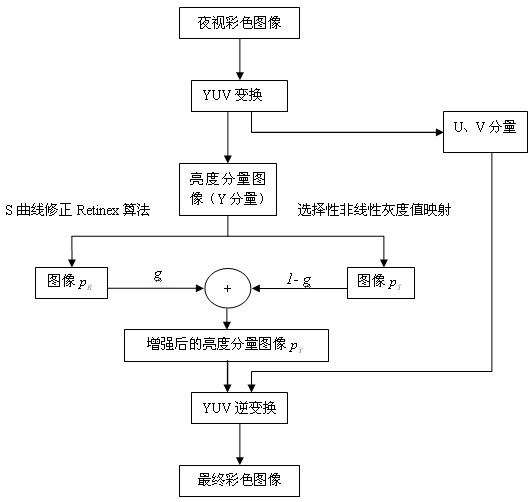

Colorized night vision image brightness enhancement method applicable to automotive assisted driving system

InactiveCN102231206AEfficient removalRecovery details displayImage enhancementNight visionVisual observation

The invention provides a colorized night vision image brightness enhancement method applicable to an automotive assisted driving system. The method comprises the following steps of: firstly, transforming a night vision colorized image from a red, green and blue (RGB) space to a luma and chroma (YUV) space to overcome the shortcoming of color distortion caused by direct processing of the night vision colorized image in the RGB space; then processing a brightness component image by using an S-curve correction Retinex algorithm so as to enhance the detail and the brightness of the image; enhancing the brightness component image by a selective nonlinear grey level mapping method and keeping good shadow information; and finally, performing weighed fusion on the two enhanced images by a weighed fusion method and inversely transforming the weighed fusion brightness component image and a UV component image to the RGB space for displaying. The enhanced image acquired by the method keeps the necessary shadow information and has the detail and the brightness applicable to vision observation; and the night vision colorized image has a good enhancement effect.

Owner:ZHEJIANG SCI-TECH UNIV

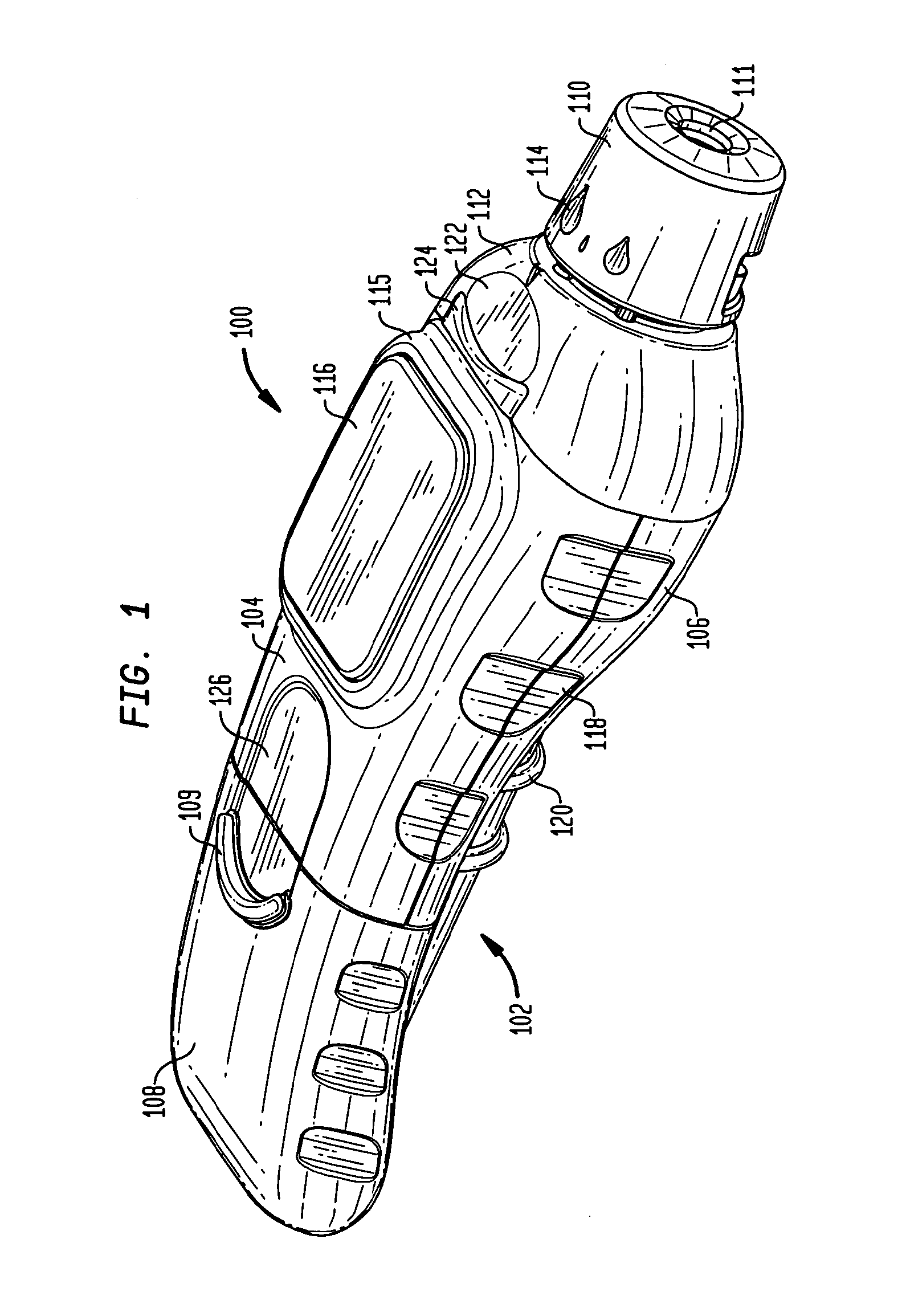

Lancing device

ActiveUS20110184448A1Assisted movementSurgical needlesDiagnostic recording/measuringVisual observationEngineering

A lancing device formed from a main body and a cap. The main body is configured from a lower housing, an upper housing extending over a portion of the lower housing, and an actuator operatively engaged to the upper and lower housings with the actuator extending along the portion of the lower housing not covered by the upper housing. The upper housing further includes an actuator button, wherein a lancet may be placed within the body such that movement of the actuator from a first position to a second position away from said endcap cocks the lancet for firing, which is achieved by depressing the actuator button. Conveniently, the lancing device is configured for tactile recognition in the palm of a human hand and may preferably be operated one handed and without visual observation.

Owner:ASCENSIA DIABETES CARE HLDG AG

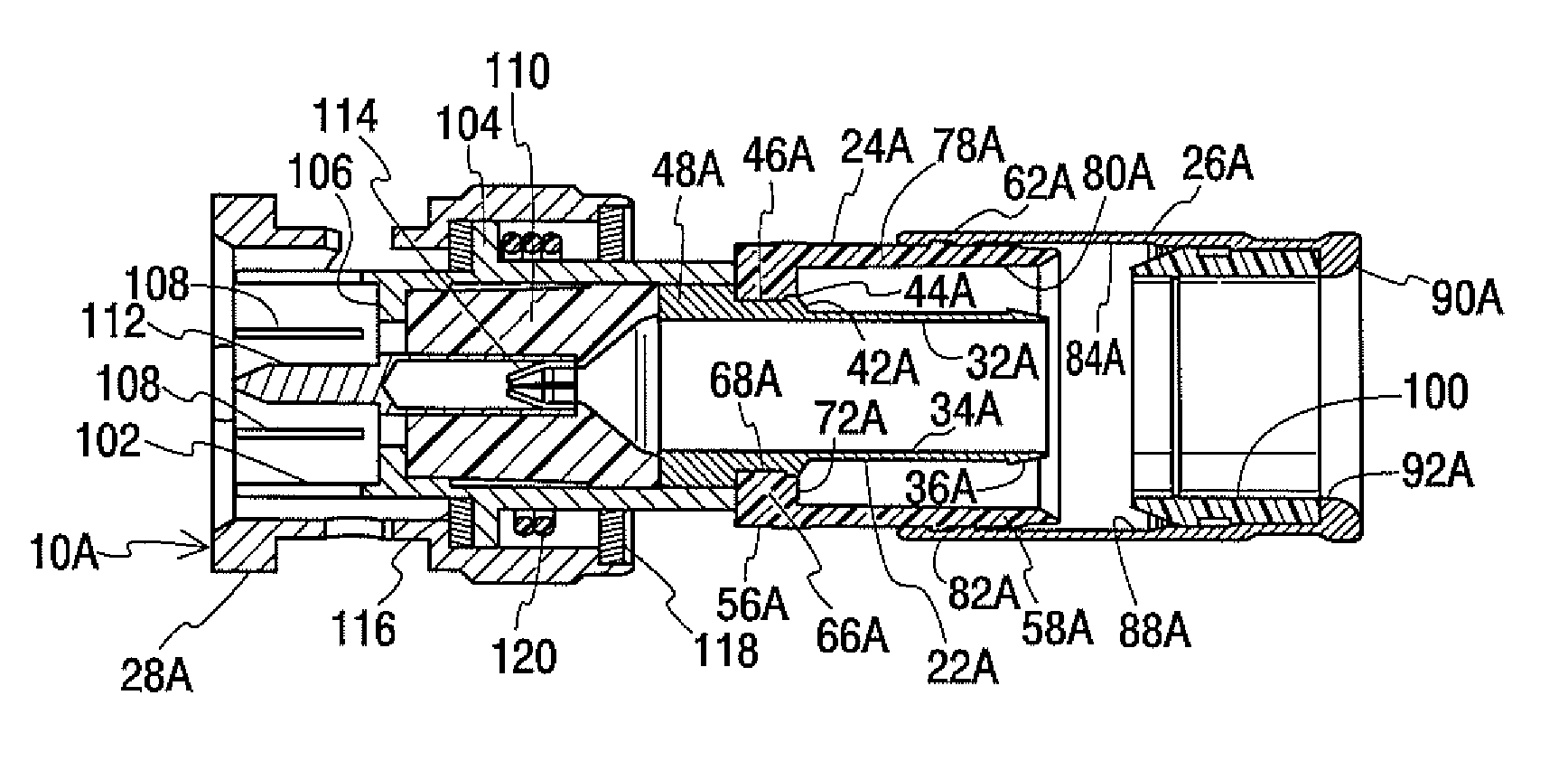

Coaxial cable connector

ActiveUS7914326B2Lower insertion forceSimple processElectrically conductive connectionsVisual observationCoaxial cable

Owner:IDEAL IND INC +1

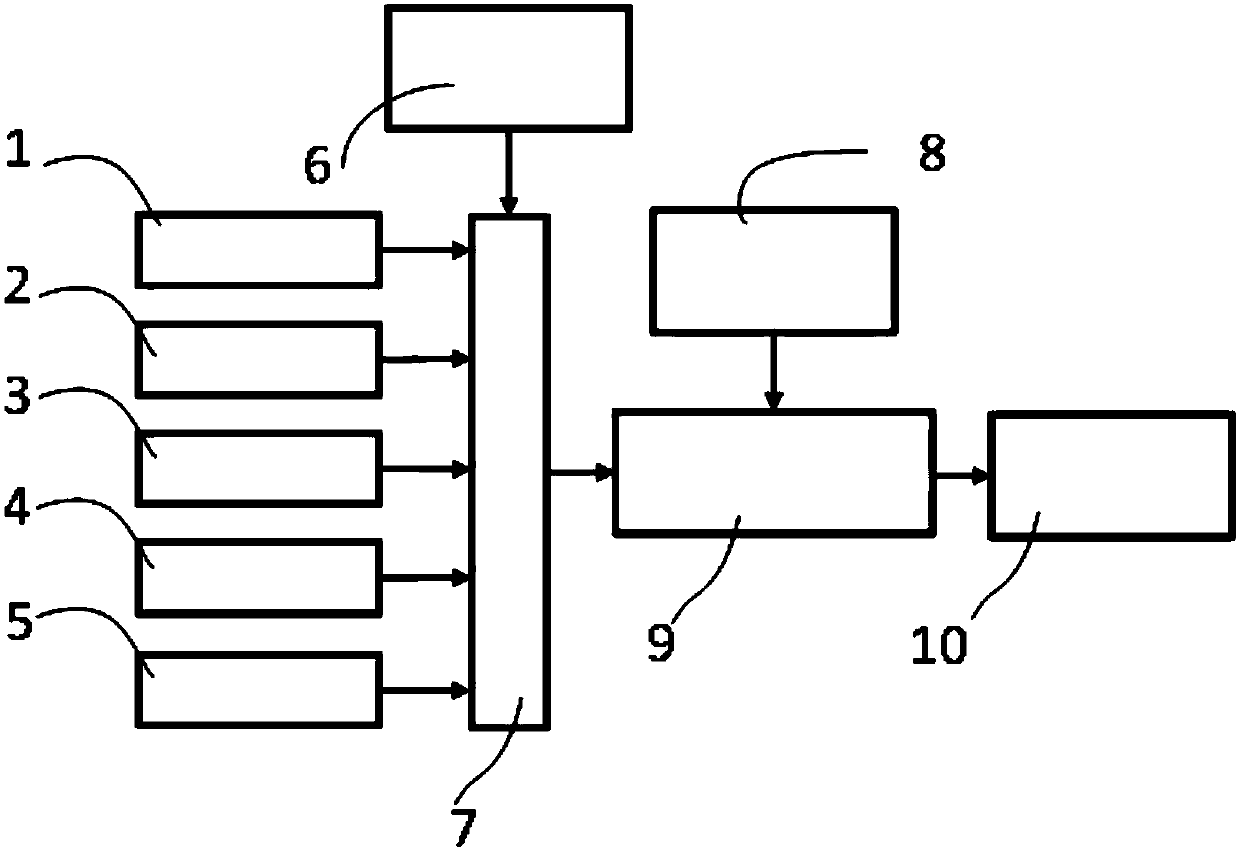

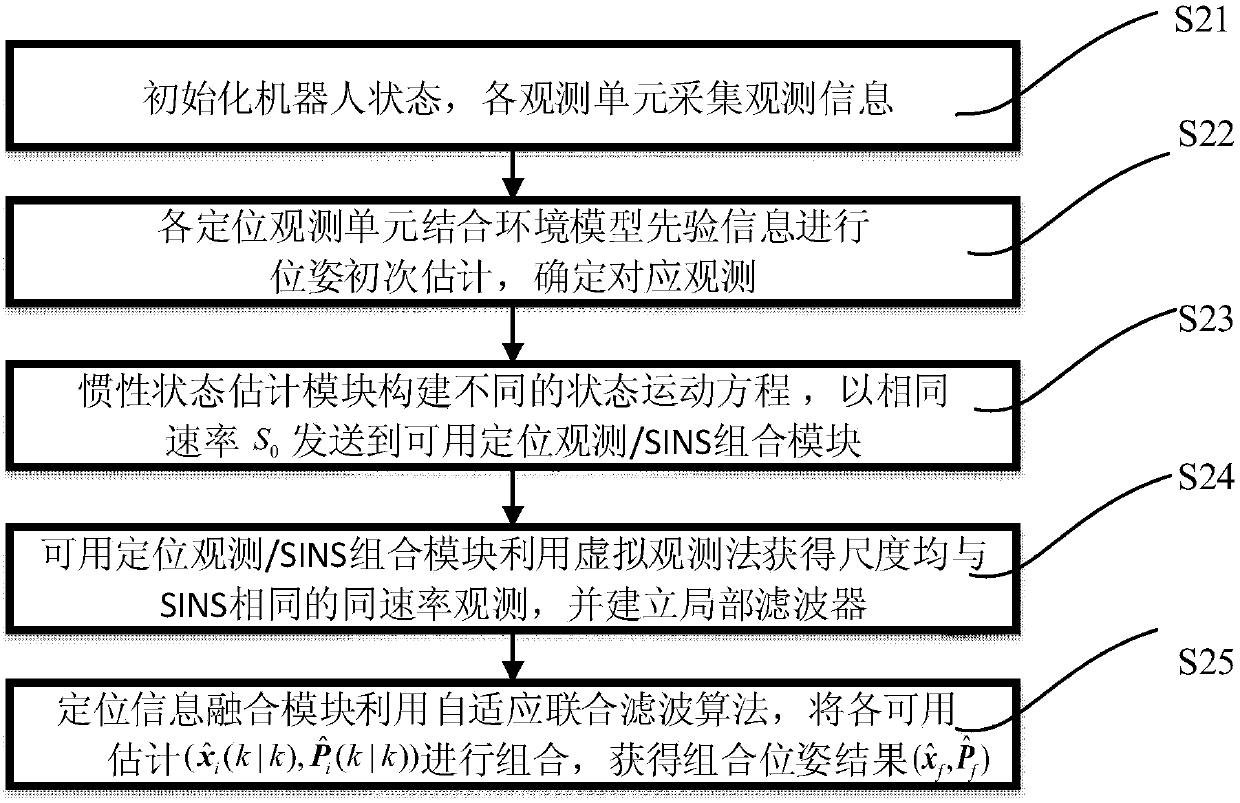

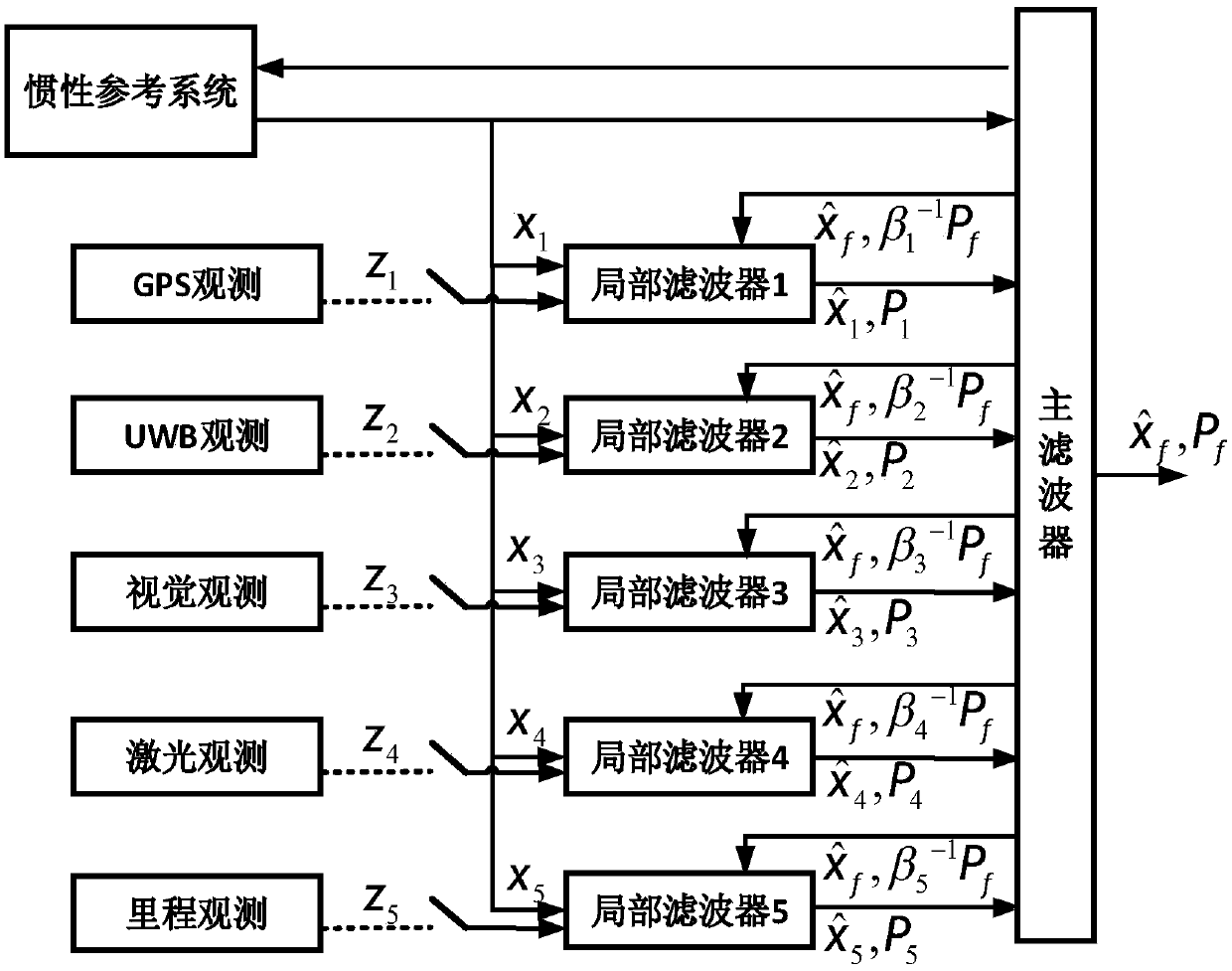

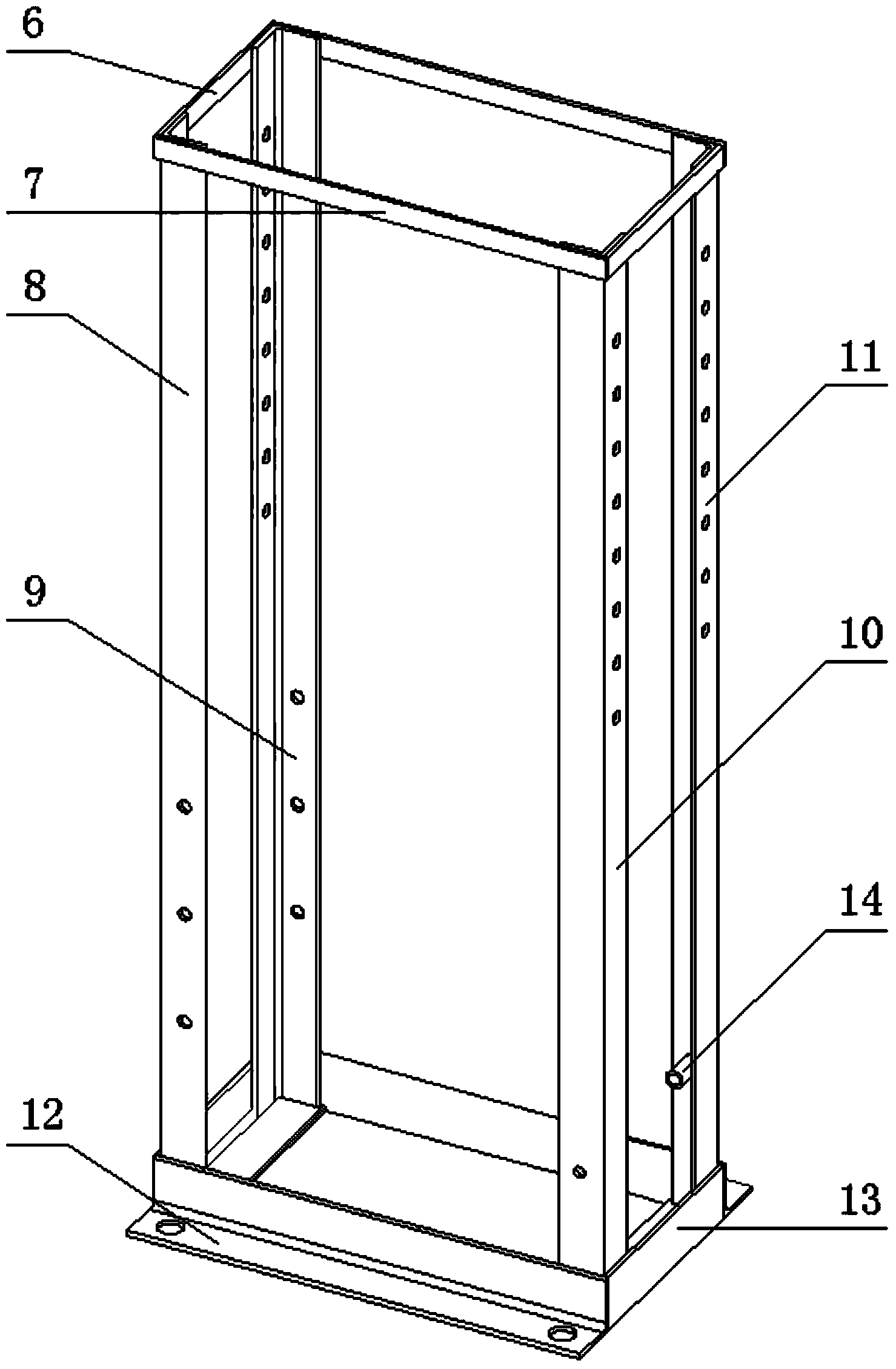

System and method for locating inspection robot in petrochemical plant

ActiveCN108225302AGuaranteed seamless positioningObservation synchronizationNavigation by speed/acceleration measurementsSatellite radio beaconingPetrochemicalGlobal Positioning System

The invention discloses a system and a method for locating an inspection robot in a petrochemical plant. The system comprises a global positioning system (GPS) observation unit, an ultra-wide bandwidth (UWB) observation unit, a visual observation unit, a laser observation unit, a mileage observation unit, a combination decision module, an inertial state estimation module, an available positioningobservation / strapdown inertial navigation system (SINS) combination module, and a positioning information fusion module. The GPS observation unit, the UWB observation unit, the visual observation unit, the laser observation unit and the mileage observation unit acquire the respective observation data and send same to the combination decision module; the combination decision module performs multi-layer map-based positioning by combining an environmental map model stored in an environmental model prior information module so as to determine available observation types; the available positioning observation / SINS combination module combines available observation data with a corresponding motion equation established by an inertial state estimation module, and the combined result is sent to the positioning information fusion module for carrying out final integrated pose estimation. The system and the method solve the problem of seamless positioning of the inspection robot which runs in various complicated regions of the petrochemical plant, and guarantee the continuity of a positioning process and the stability of the positioning result.

Owner:CHINA UNIV OF MINING & TECH +1

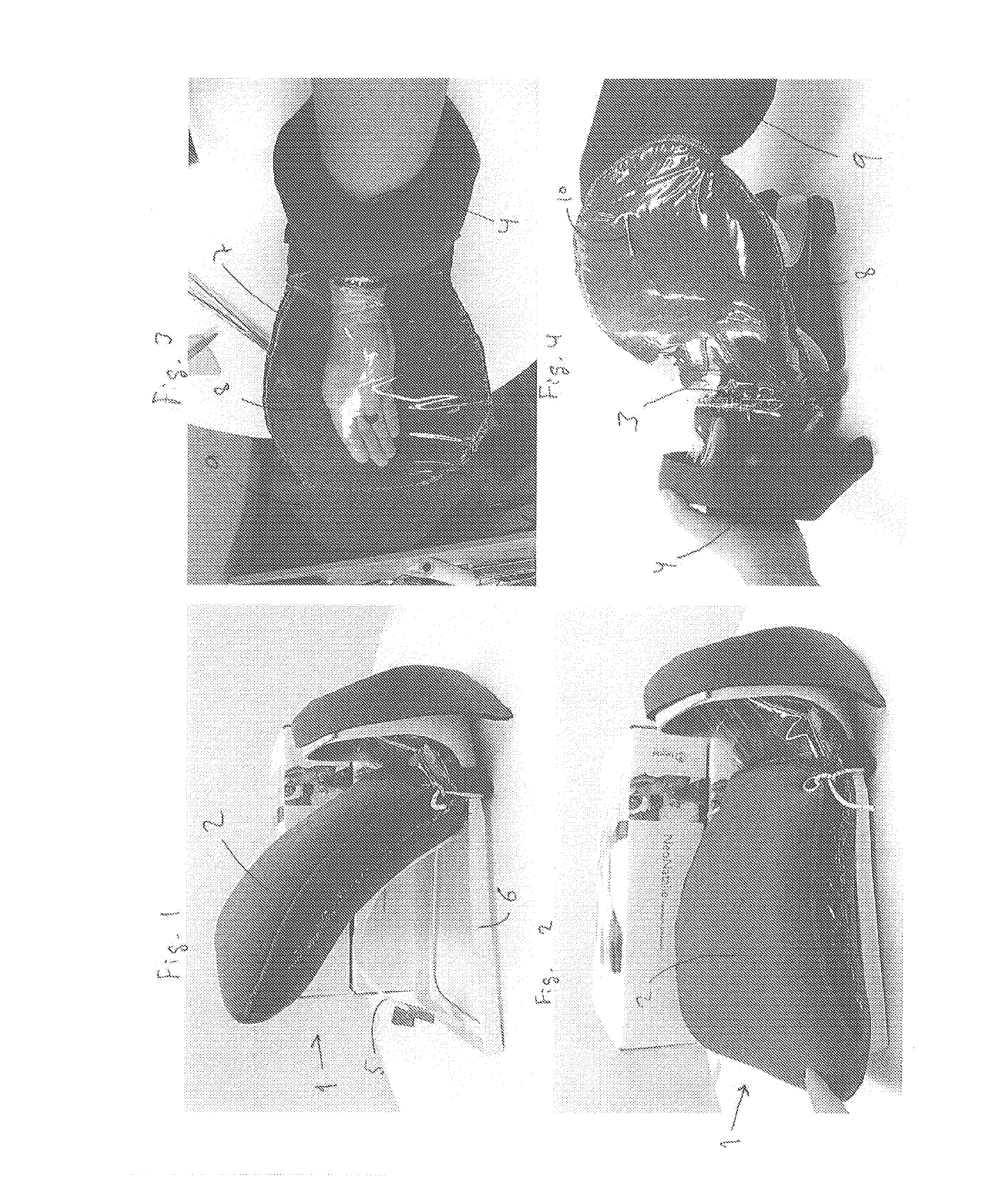

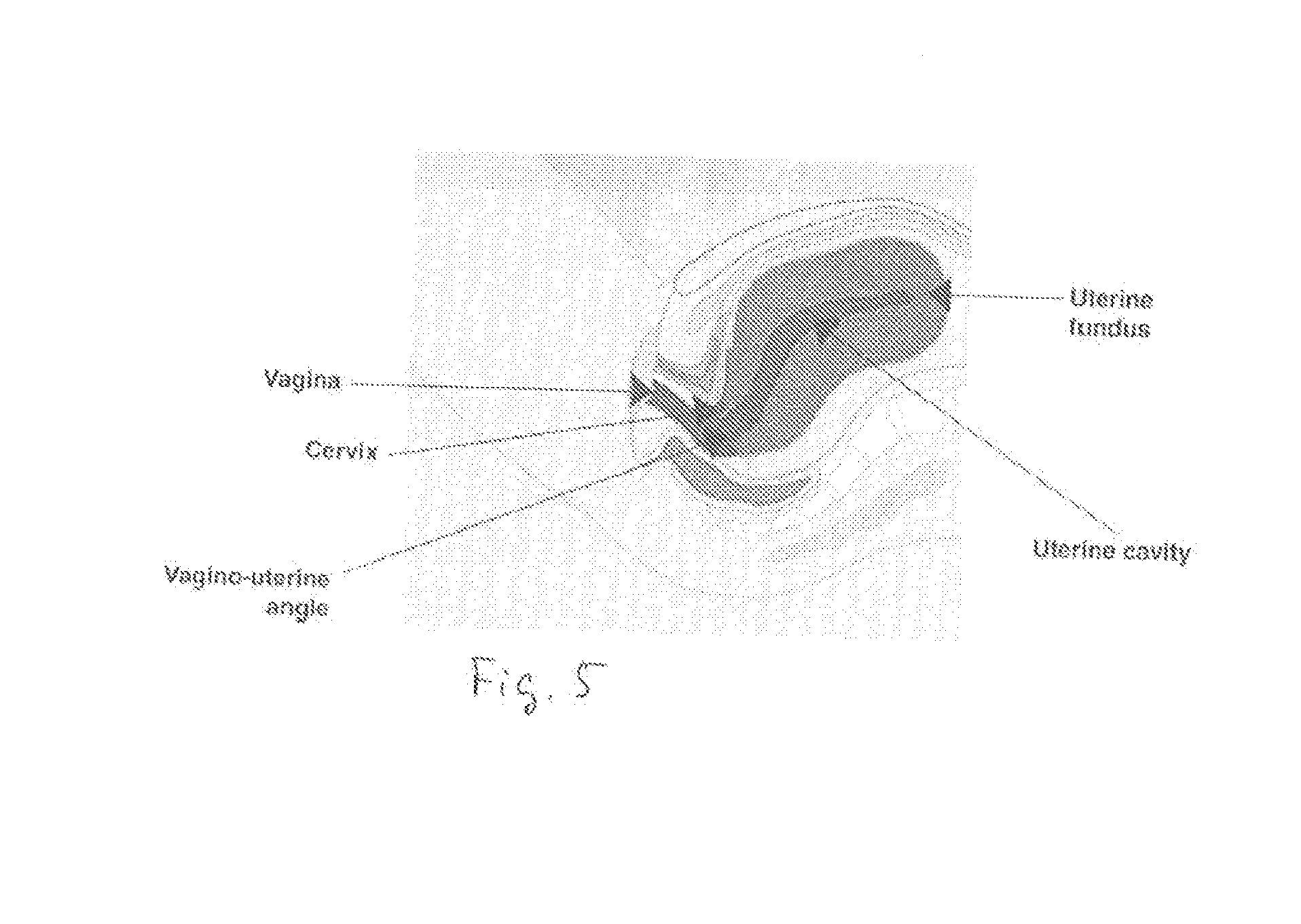

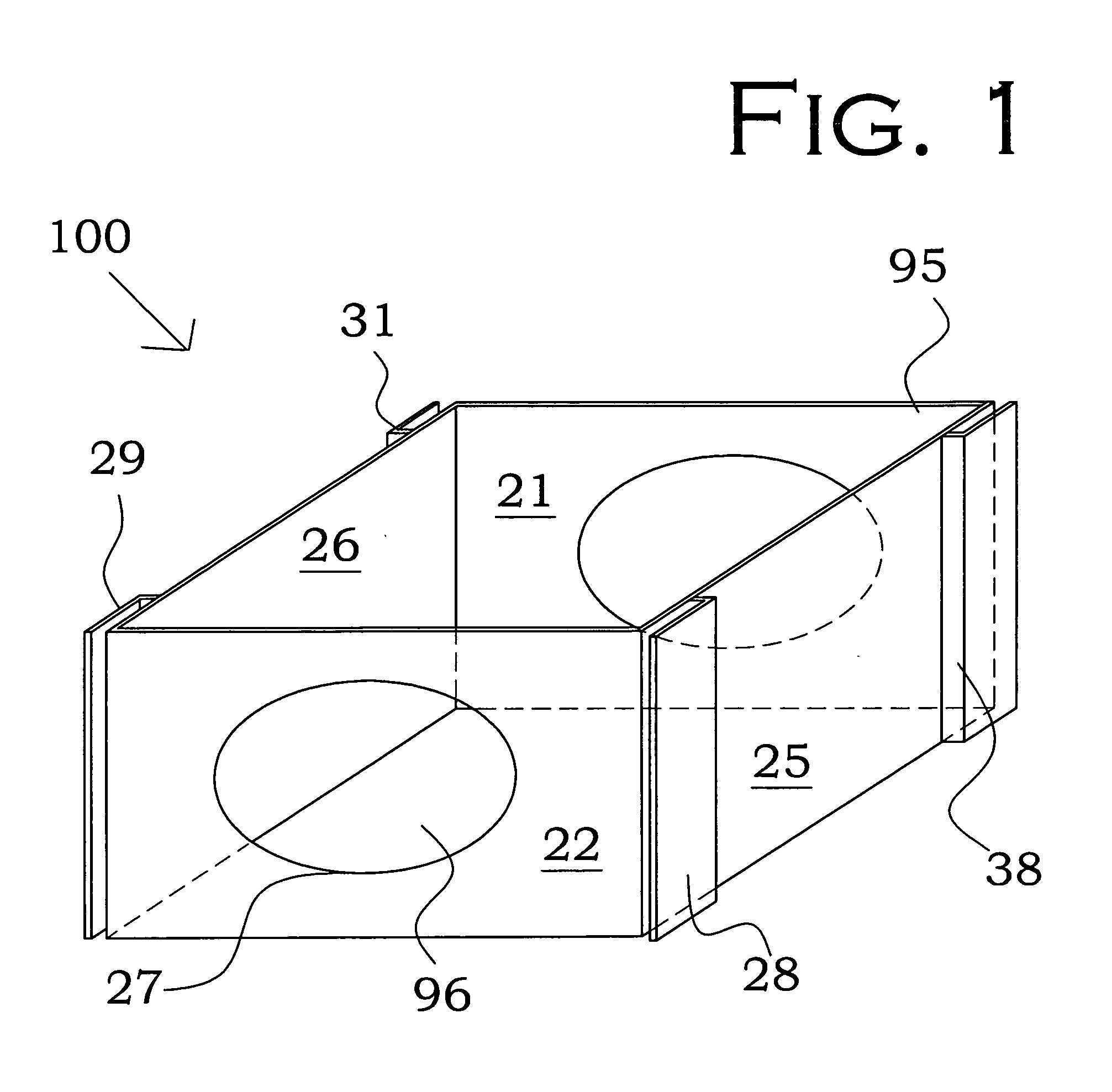

Postpartum uterus model

InactiveUS20150132733A1Realistic trainingEasy to insertEducational modelsVisual observationEngineering

The invention provides a simulator for training of personnel for immediate postpartum medical treatment, distinctive in that the simulator comprises a representation of an immediate postpartum stage uterus, a cervix, a vagina and a resilience member, the uterus is arranged at an angle to the vagina and the resilience member is arranged for allowing said angle to be straightened out by pressing horizontally forward on the uterus. The invention also provides a simulator for training of personnel for immediate postpartum medical treatment, distinctive in that the simulator comprises a representation of an immediate postpartum stage uterus, a cervix and a vagina, the uterus comprises a transparent top or intermediate layer allowing visual observation, and preferably a removable or foldable non-transparent top layer over the transparent layer.

Owner:LAERDAL GLOBAL HEALTH

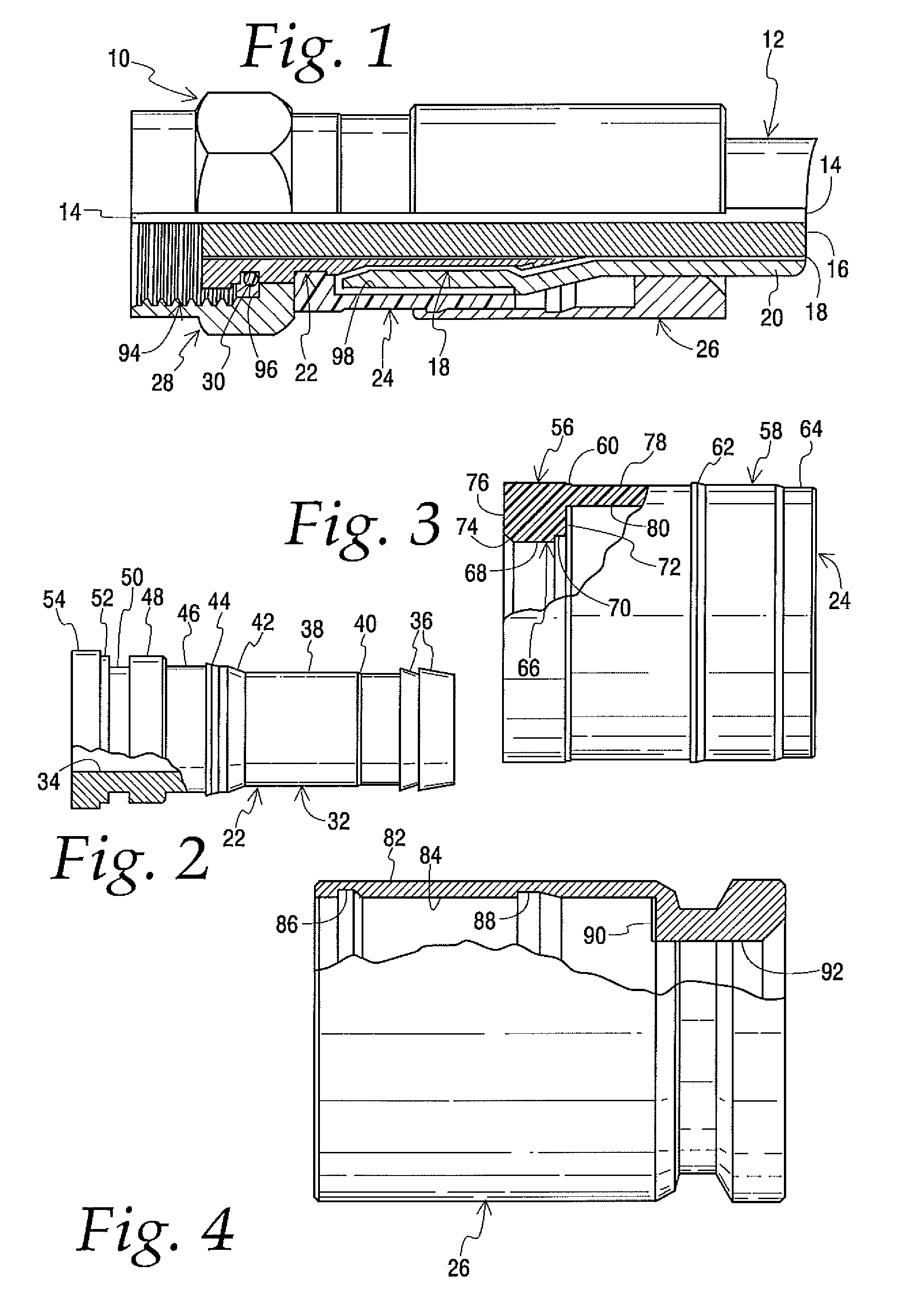

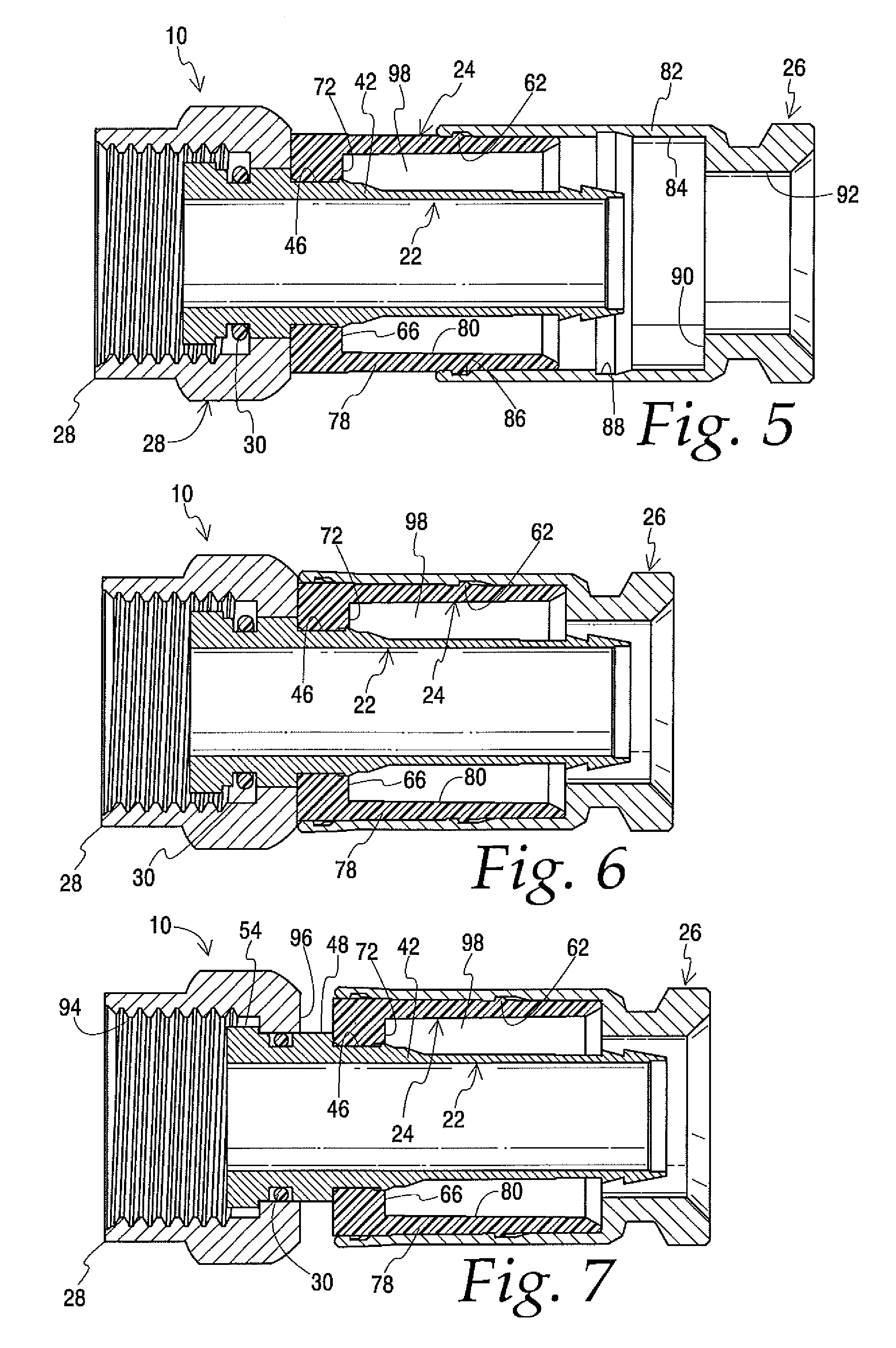

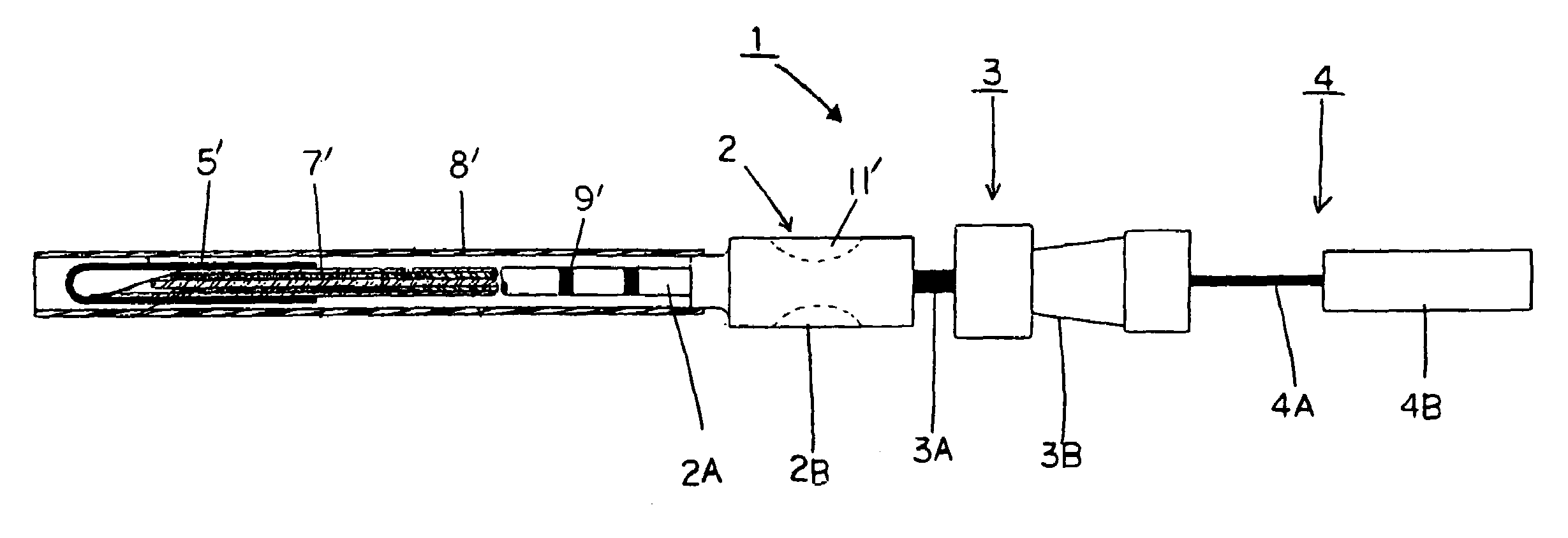

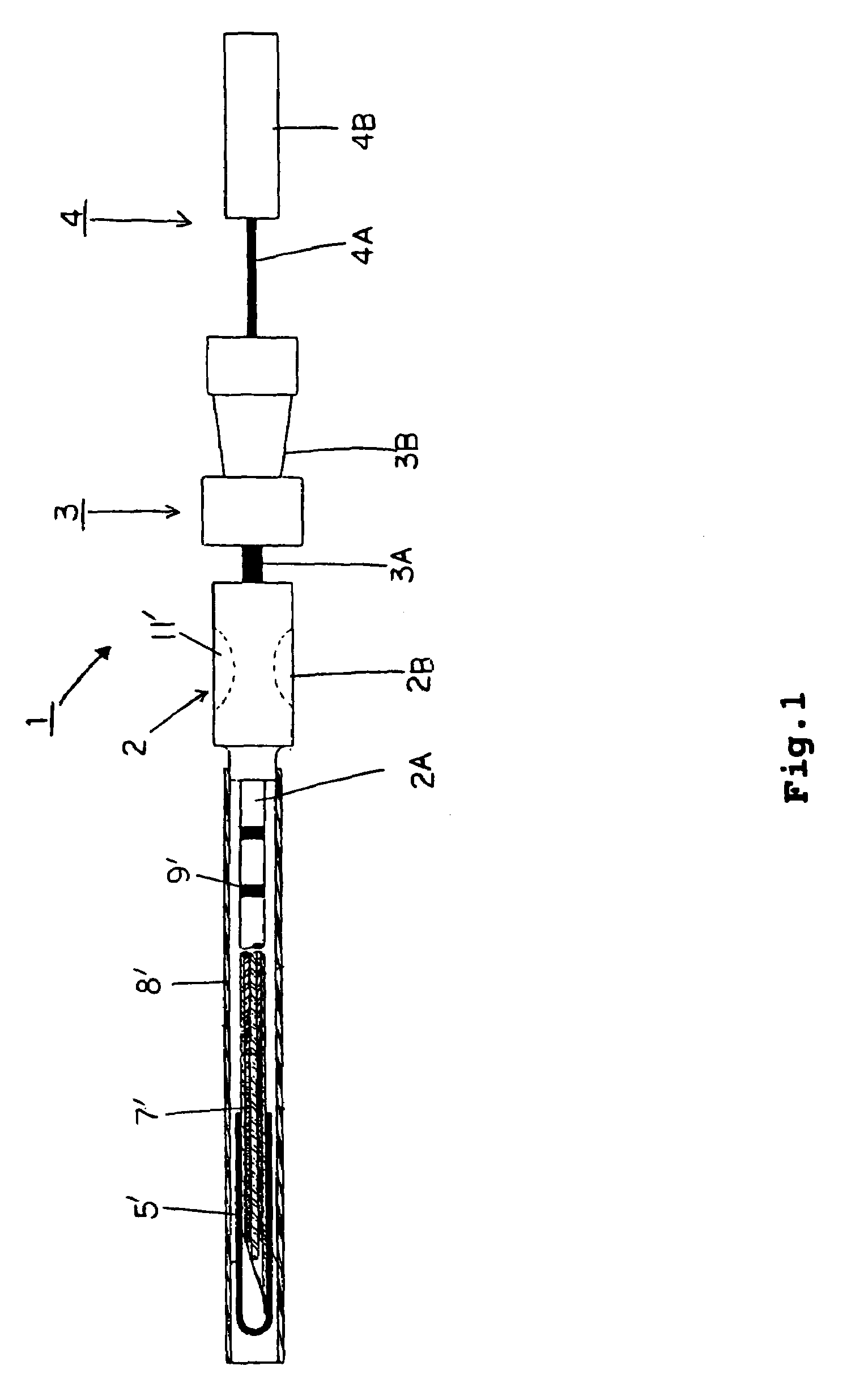

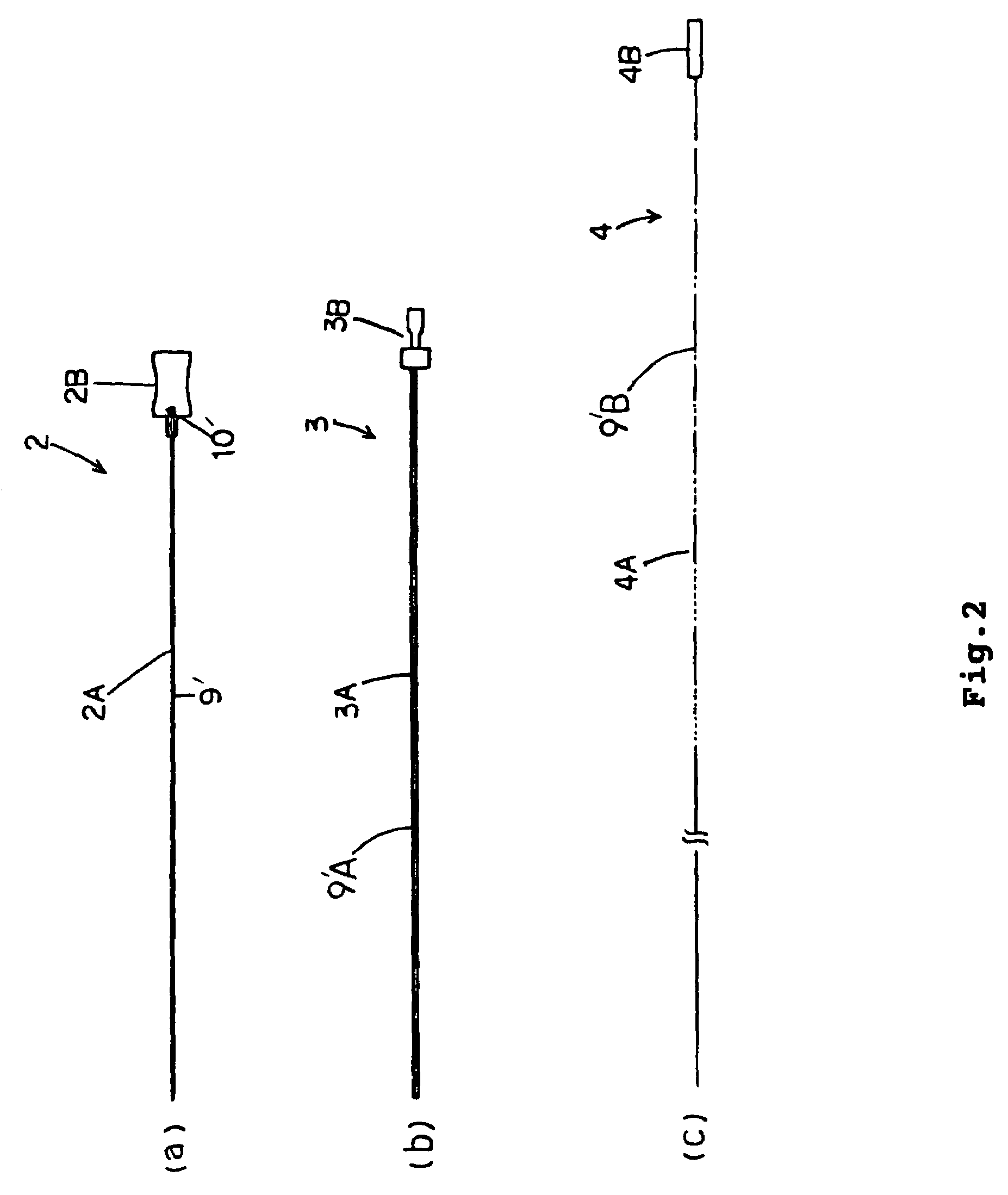

Protective tool for therapeutic material delivery device, cartridge for therapeutic material delivery device, and a therapeutic material delivery device

InactiveUS6988981B2Preventing wrong and accidental stickingPreventing dissipation of blood adheringInfusion needlesSuction devicesVisual observationRadioactive source

A protective tool for a therapeutic material delivery device prevents wrong sticking of the outer needle of the device after use and prevents dissipation of blood adhering to the outer needle and comprises a cover (8′A) and a cap (61) or stopper (65) attached to a forward end of said cover for protecting the forward end of the outer tubular needle (2A), wherein said cover (8′A) is formed of a plurality of tubes (8′A1, 8′A2, 8′A3, . . . ) having different diameters that are formed so as to consecutively decrease from a forward place to the outer needle hub (2B) in a backward place, and said tubes are thereby connected such that the cover (8′A) is extendable in the longitudinal direction, and a cartridge for use with the therapeutic material delivery device permits direct calibration of a radioactive source charged therein and comprises a transparent cartridge body (8, 18, 38) that holds said therapeutic material (10) inside and permits external visual observation of the therapeutic material (10) and a shielding outer tube (9, 19, 39) that is fitted on an outer circumference of the cartridge body, is slidable in the longitudinal direction of said cartridge body and is made of a radioactive ray shielding material, said cartridge body (8, 18, 38) being exposable with said sliding of said shielding outer tube.

Owner:KAWASUMI LABORITORIES INC

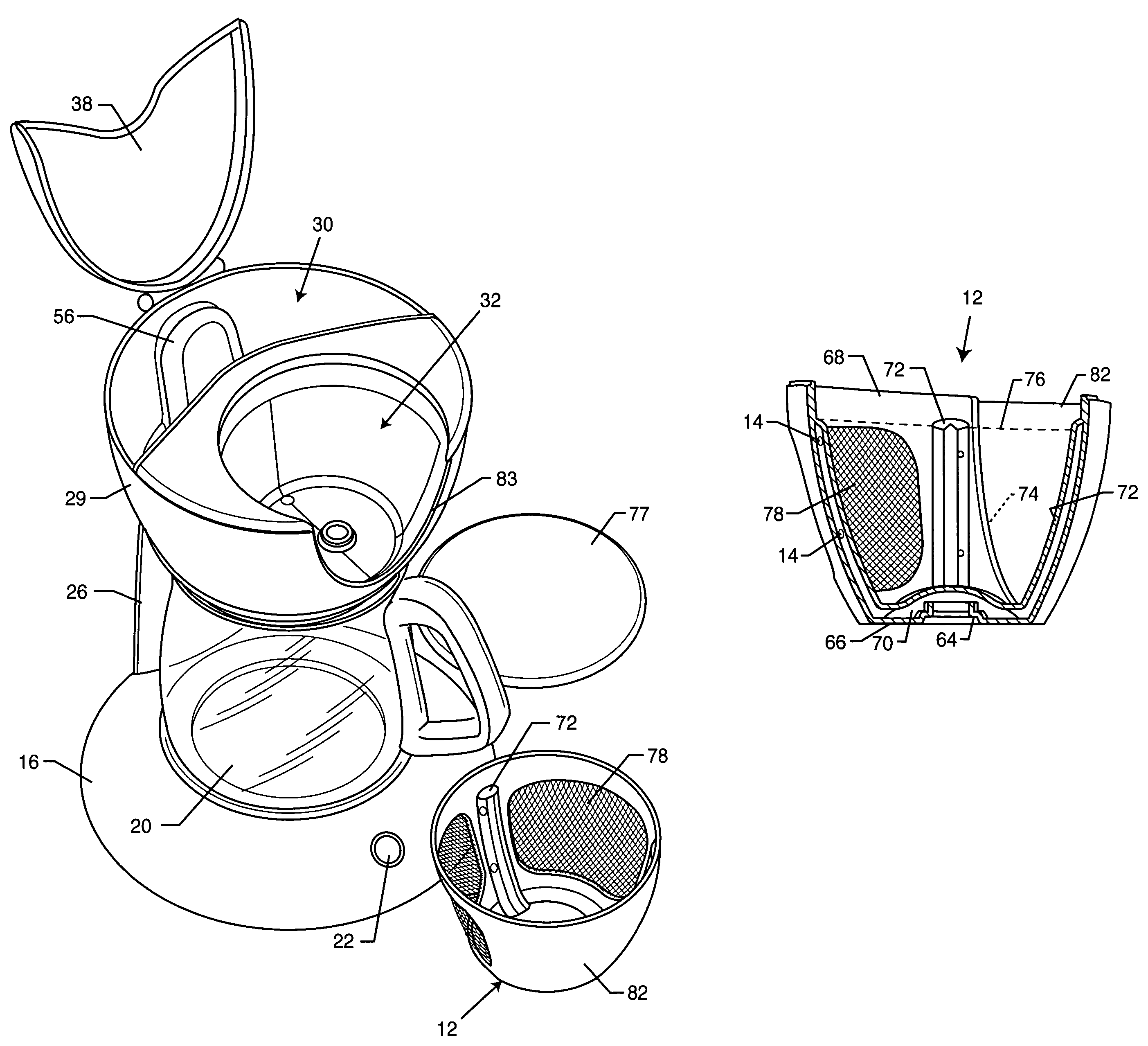

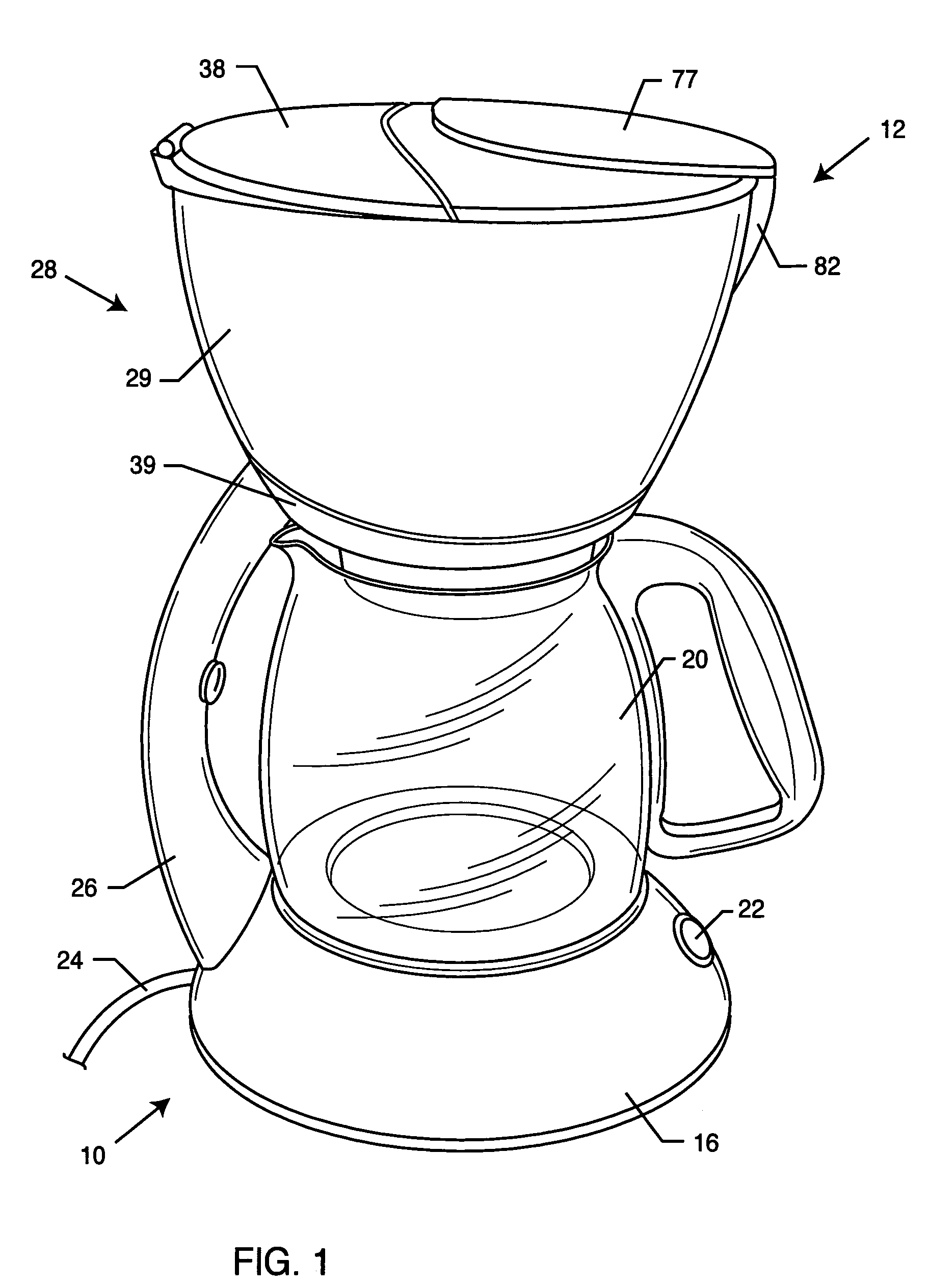

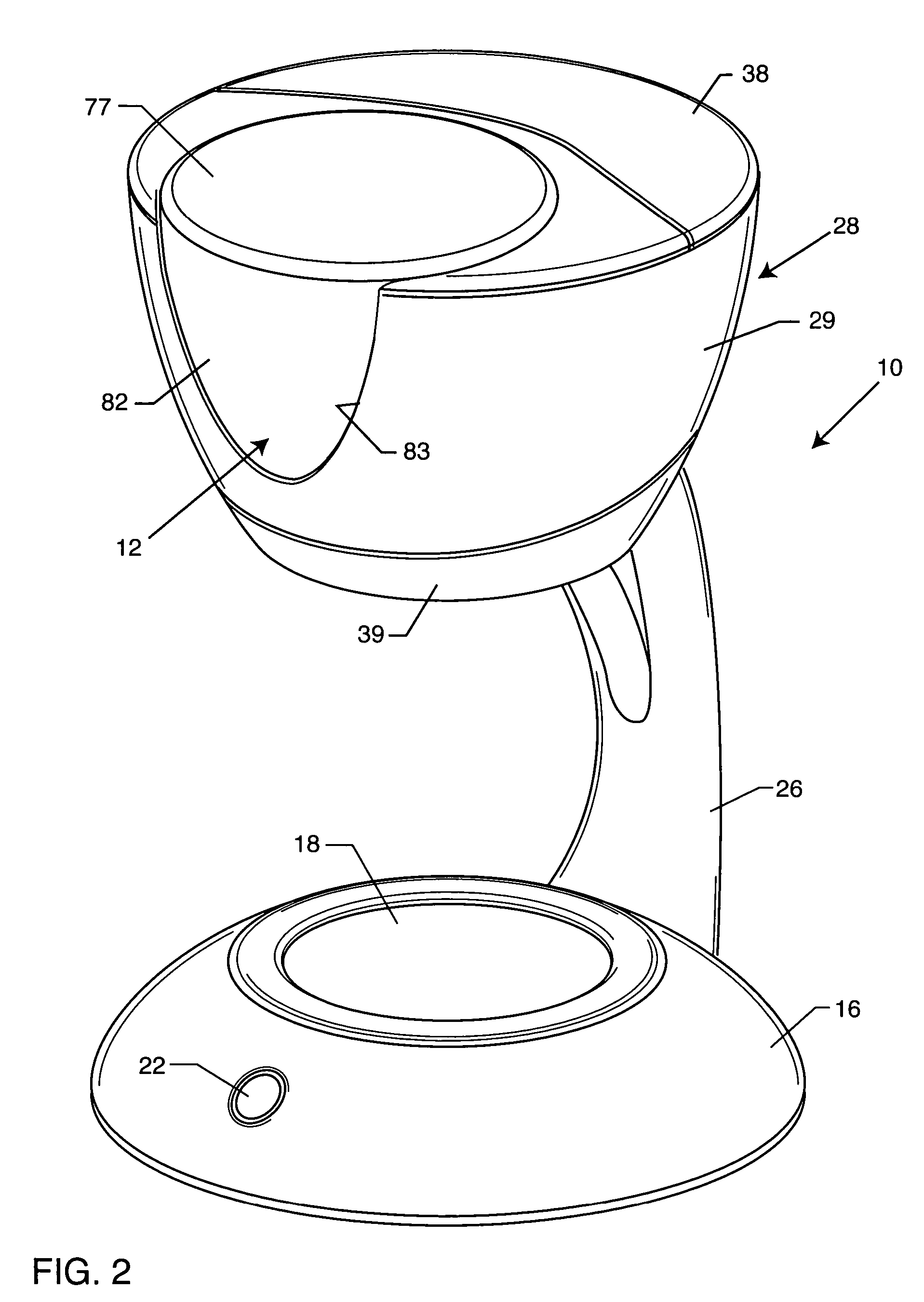

Coffee brewer

An improved coffee brewer and brewing method are provided for producing brewed coffee with improved flavor. The coffee brewer includes a brew basket having jet ports connected to a source of heated water and positioned to deliver hot water streams into the brew basket at a location beneath the level of coffee grounds contained therein. These hot water streams turbulently agitate and stir the coffee grounds to produce a substantially fluidized bed of water-borne coffee grounds for improved flavor extraction and enhanced aroma. This fluidized bed is directed against one or more mesh filter elements forming a wall portion of the brew basket for outward passage of the thus-brewed coffee which is then directed into an underlying carafe or the like. In one preferred form, a portion of the brew basket may incorporate a window to permit visual observation of the fluidized bed therein.

Owner:LVD ACQUISITION +2

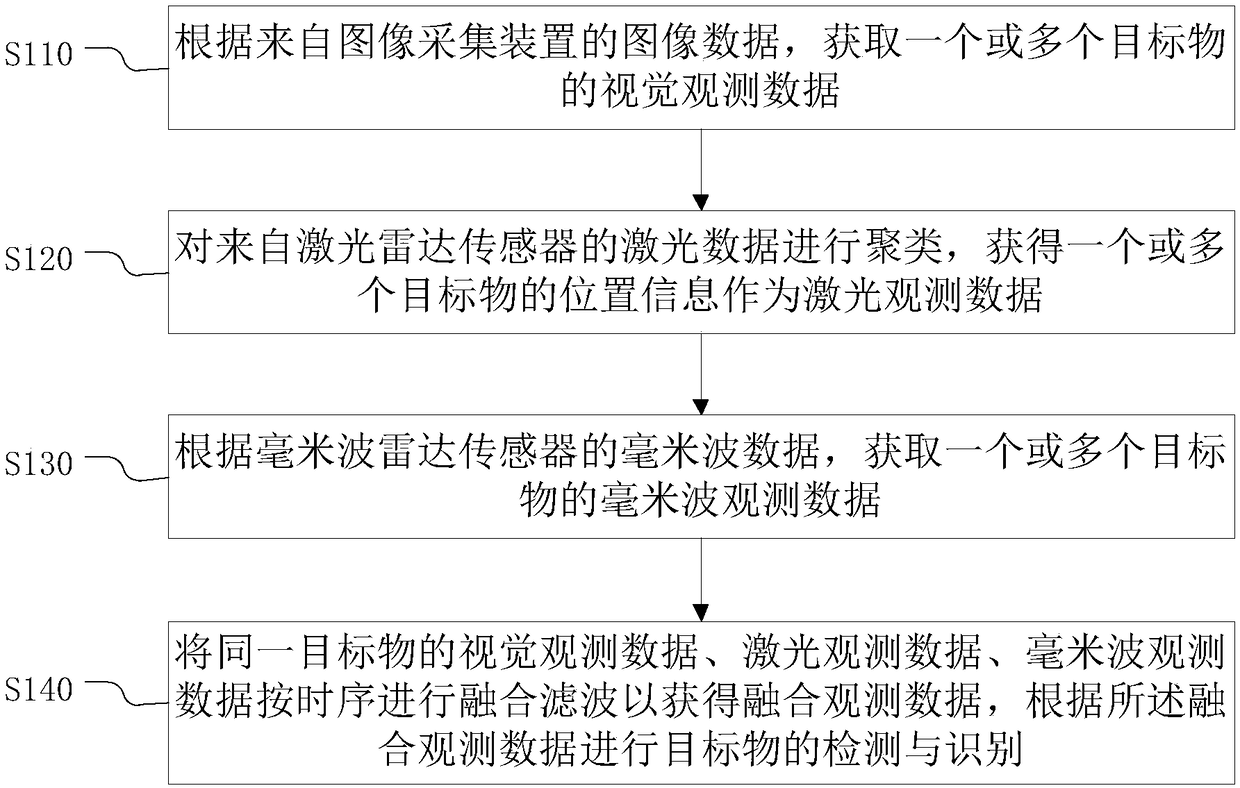

Object detection and identification method, device, electronic equipment and storage medium

InactiveCN108872991AImprove reliabilityImprove stabilityElectromagnetic wave reradiationRadio wave reradiation/reflectionLaser dataObject-class detection

The invention provides an object detection and identification method, device, electronic equipment and a storage medium; the object detection and identification method based on multi-sensor fusion comprises the following steps: obtaining visual observation data of one or more objects according to image data of an image acquisition device; clustering laser data of a laser radar sensor, and obtaining position information of one or more objects to serve as the laser observation data; obtaining millimeter wave observation data of one or more objects according to millimeter wave data of a millimeter wave radar sensor; fusing and filtering the visual observation data, the laser observation data and the millimeter wave observation data of the same object according to time sequence so as to obtainthe fused observation data, and detecting and identifying the object according to the fusion data. The method and device can improve the object detection and identification reliability, stability andrecognition rate.

Owner:SHANGHAI WESTWELL INFORMATION & TECH CO LTD

Flood levee and barrier module and system

A levee and barrier module for fluid control and containment is provided including an outer module shell and a module-to-module connection system to attach adjacent outer shells. The outer module shell, being in the general shape of a prism or prism with curvilinear section, is formed by opposing side walls and two opposing end walls, and is configured to enclose or support filler material. The two opposing end walls are configured with end apertures. The outer module shell defines a top aperture and a bottom aperture. When modules are placed end to end in a levee structure the end apertures allow filler material communication horizontally between adjacent modules. The bottom aperture allows filler material communication with the earth below the module. The top aperture allows filler material to be added to the module, as well as visual observation of, and maintenance of, the amount of contained filler material.

Owner:BOUDREAUX JR JAMES C

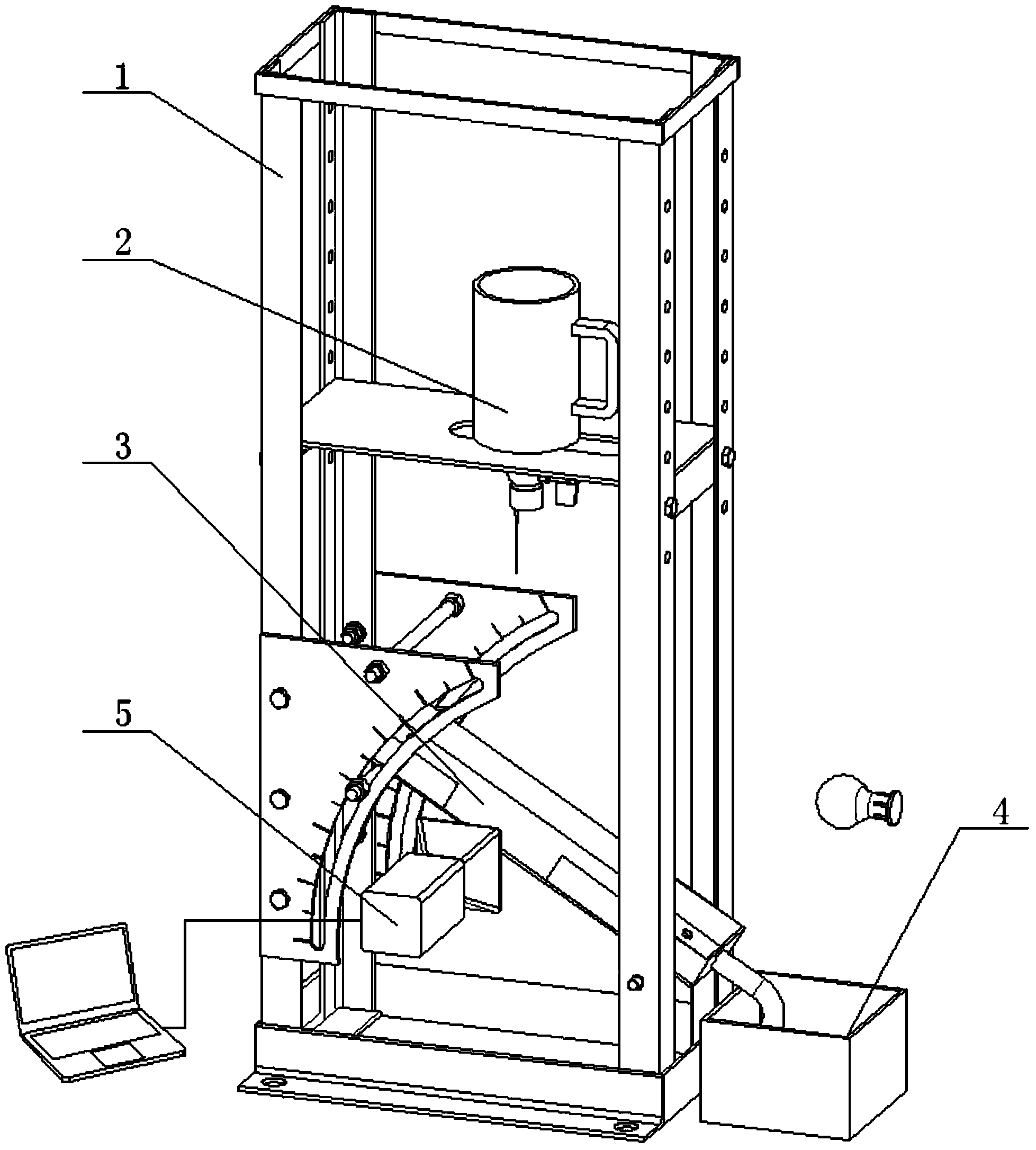

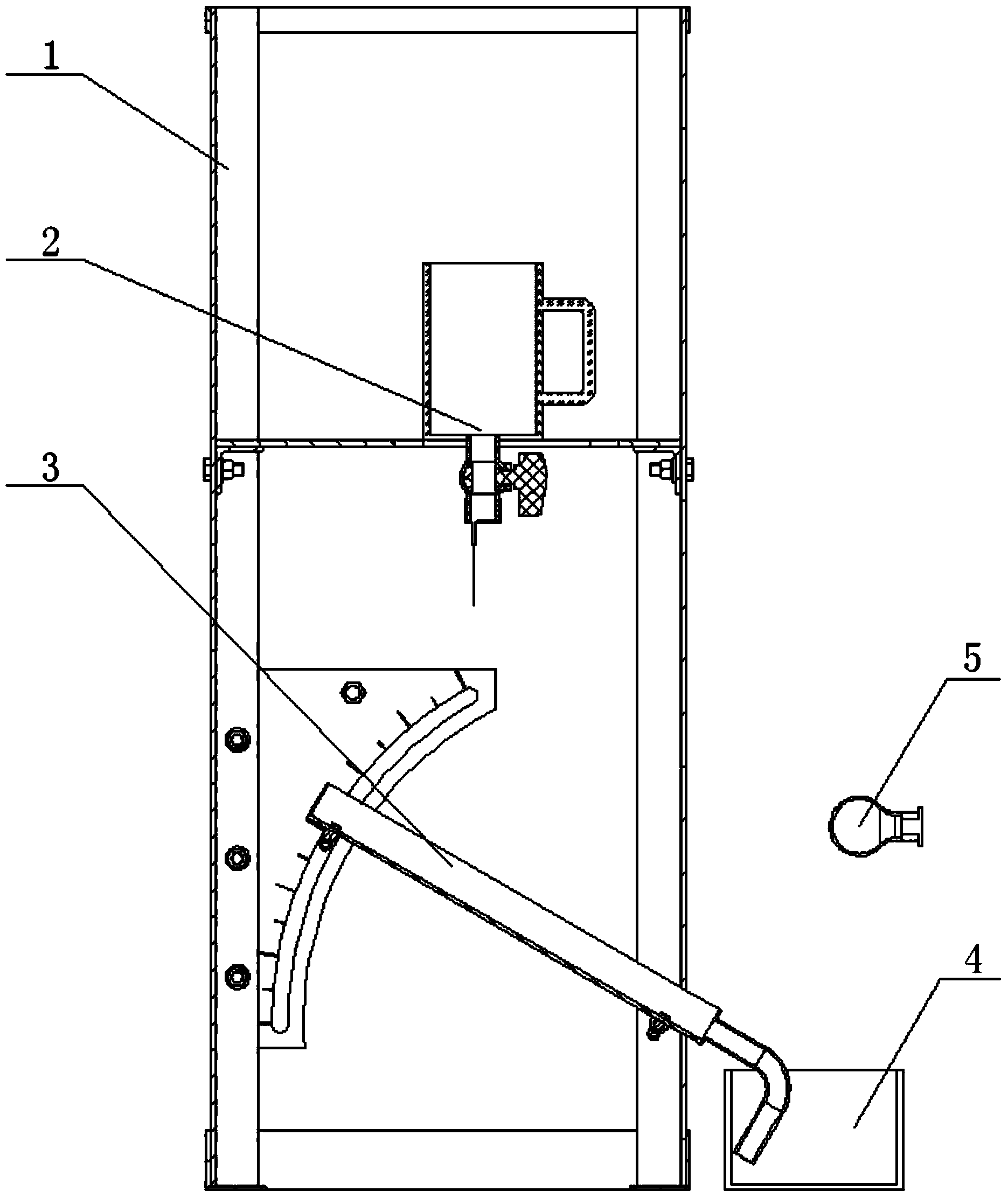

Liquid drop and solid plate oblique collision testing device

InactiveCN104019991ACompact structureLow costMachine bearings testingMaterial analysis by optical meansAviationVisual test

The invention relates to a testing device in the aviation field, in particular to a liquid drop and solid plate oblique collision testing device. The problems that an oil drop and cavity wall collision visual test cannot be carried out in an existing aircraft engine bearing cavity test platform, the physical variance of the adjustment scopes of parameters such as liquid drop sizes of other liquid drop and solid wall face collision testing devices and a bearing cavity project is large, the device is complex in structure and high in cost are solved. According to the technical scheme, the liquid drop and solid plate oblique collision testing device is built and comprises a supporting frame, a liquid drop generation component, an angle-adjustable solid plate component, an oil return component and a lighting pick-up system, the dropping diameters of liquid drops are changed by changing syringe needles of the liquid drop generation component, and the dropping speed of the liquid drops is changed by changing the distance between the liquid drop generation component and a collision plate in a sliding mode; oblique angles of the collision plate can be continuously changed. By means of the liquid drop and solid plate oblique collision testing device, the splashing critical working condition caused after the liquid drop and solid plate oblique collision happens is conveniently determined, visual observation on the oil drop and cavity wall collision can be achieved, and cost is reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

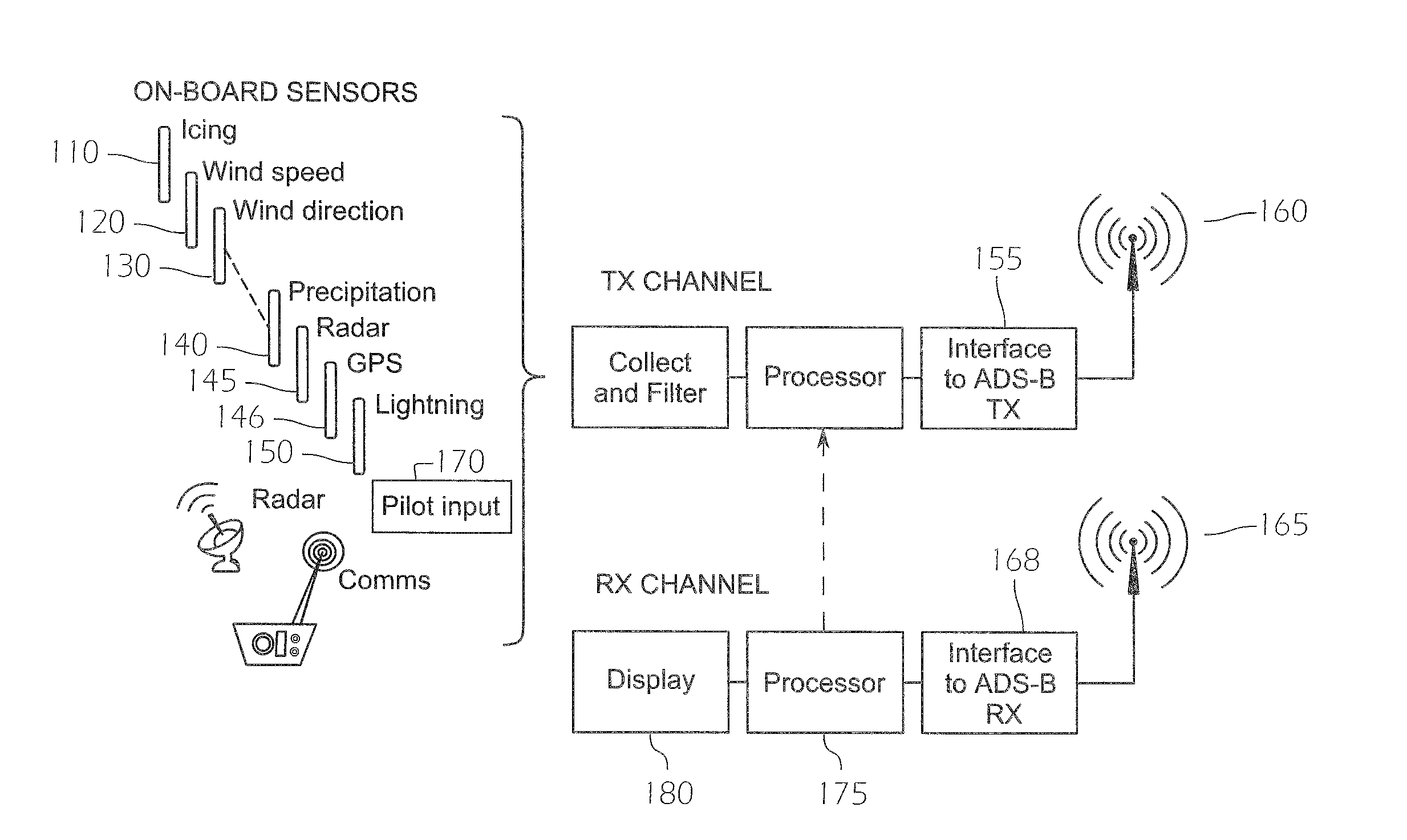

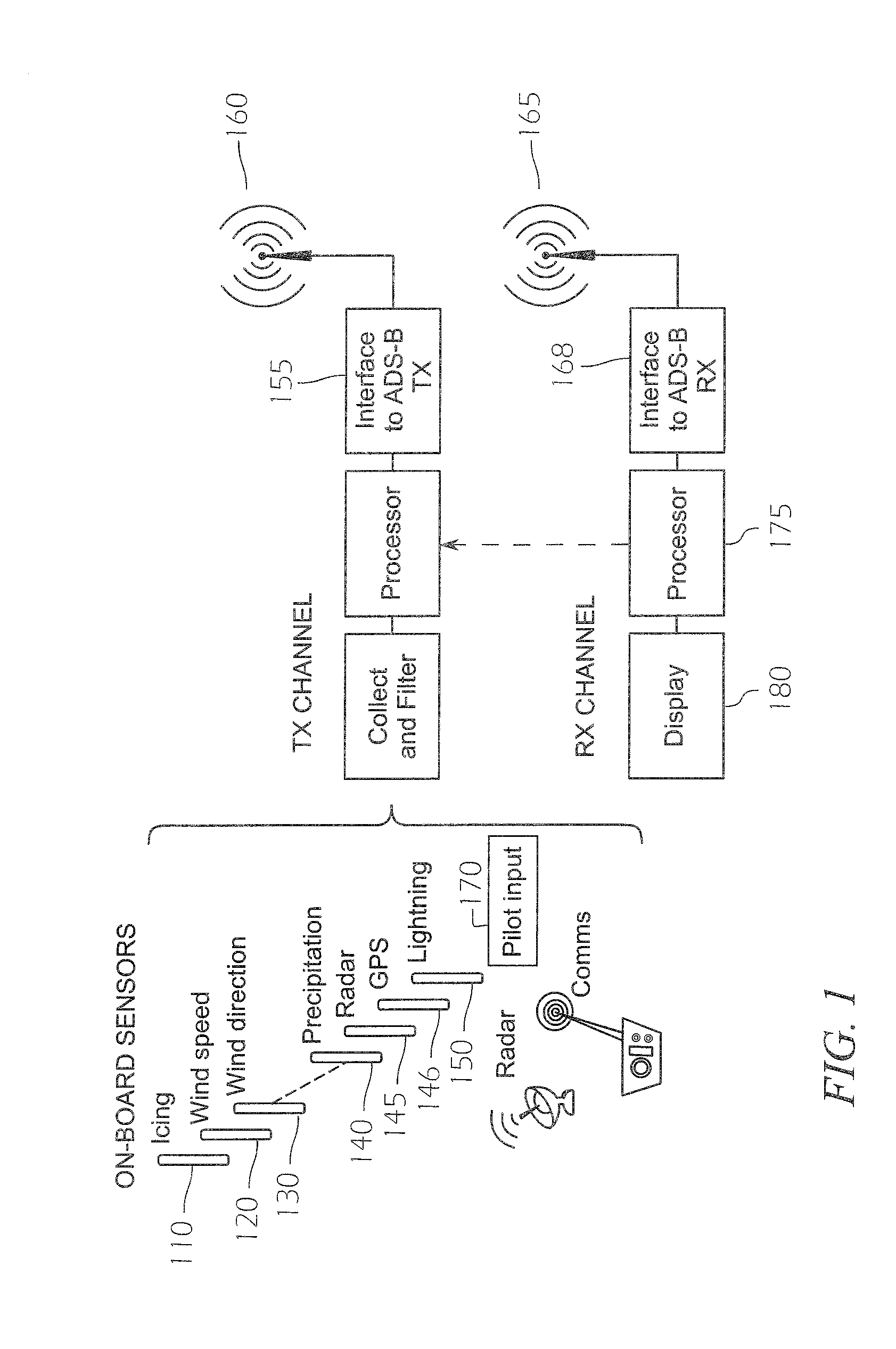

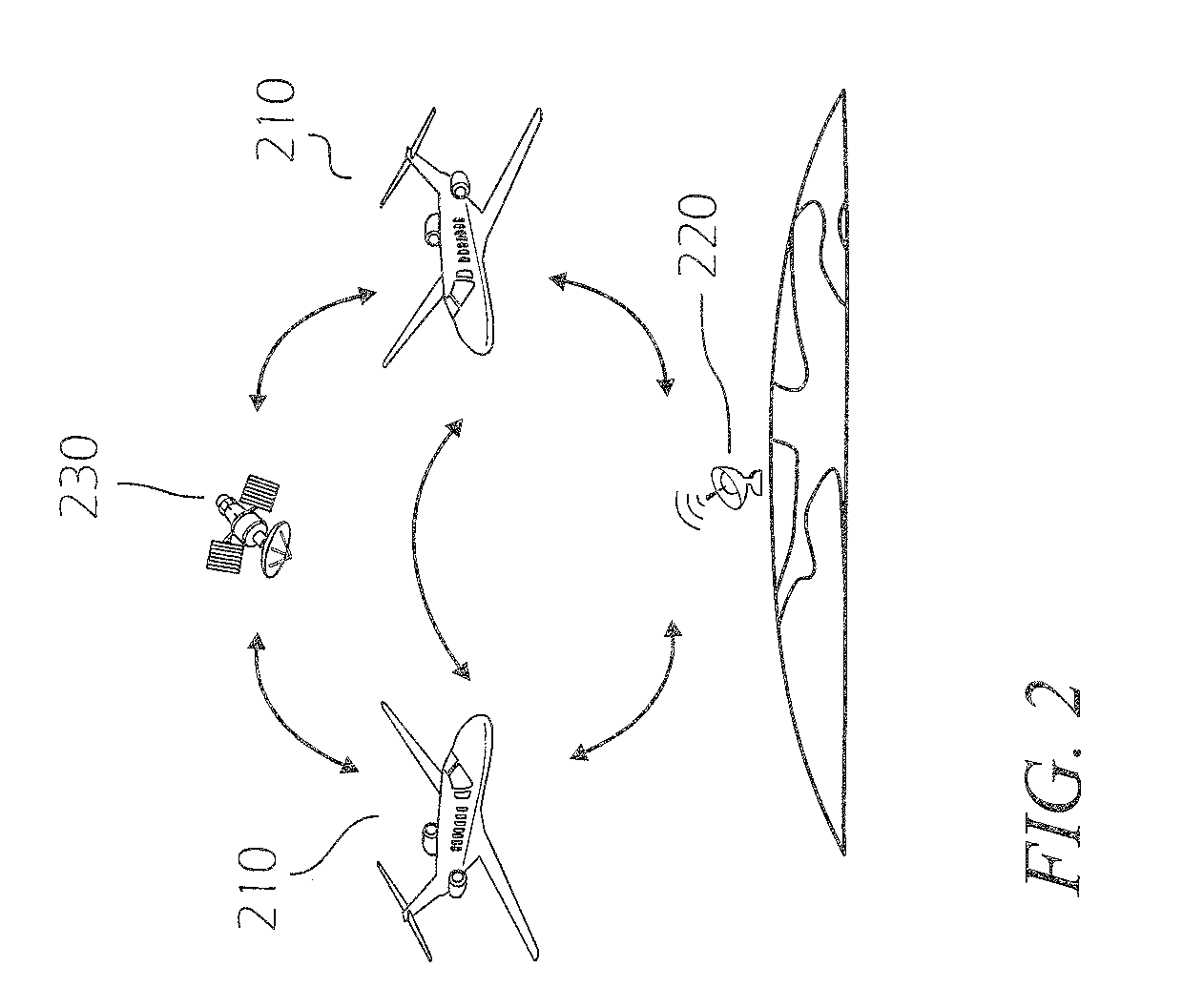

System and method for social networking of aircraft for information exchange

A system and method for exchanging information between aircraft (210). Sensors on a first aircraft (210) provide data about the first aircraft's environment, including hazards such as turbulence, icing, lightning, or birds. The system transmits the data to receiving systems in other aircraft (210), which display the data, to warn the pilots flying the other aircraft of potential hazards. The pilot of the first aircraft may supplement the information with visual observations, about birds or unmanned aerial vehicles, for example. In one embodiment, the information is transmitted from aircraft to aircraft over a data link using ADS-B. In another embodiment, a first aircraft may transmit data to a second aircraft, which may relay, or re-transmit, the data to a third aircraft.

Owner:RAYTHEON CANADA LTD

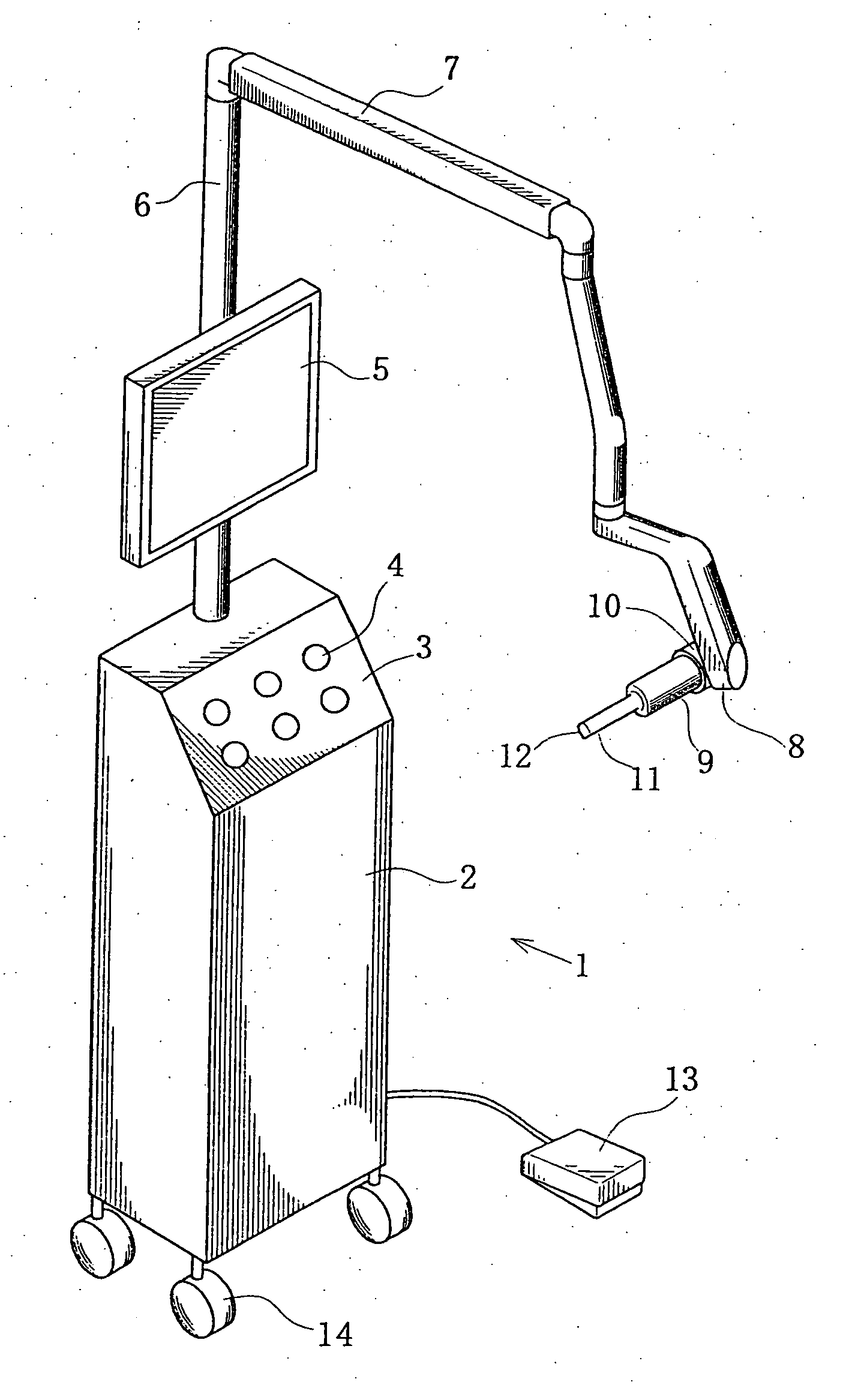

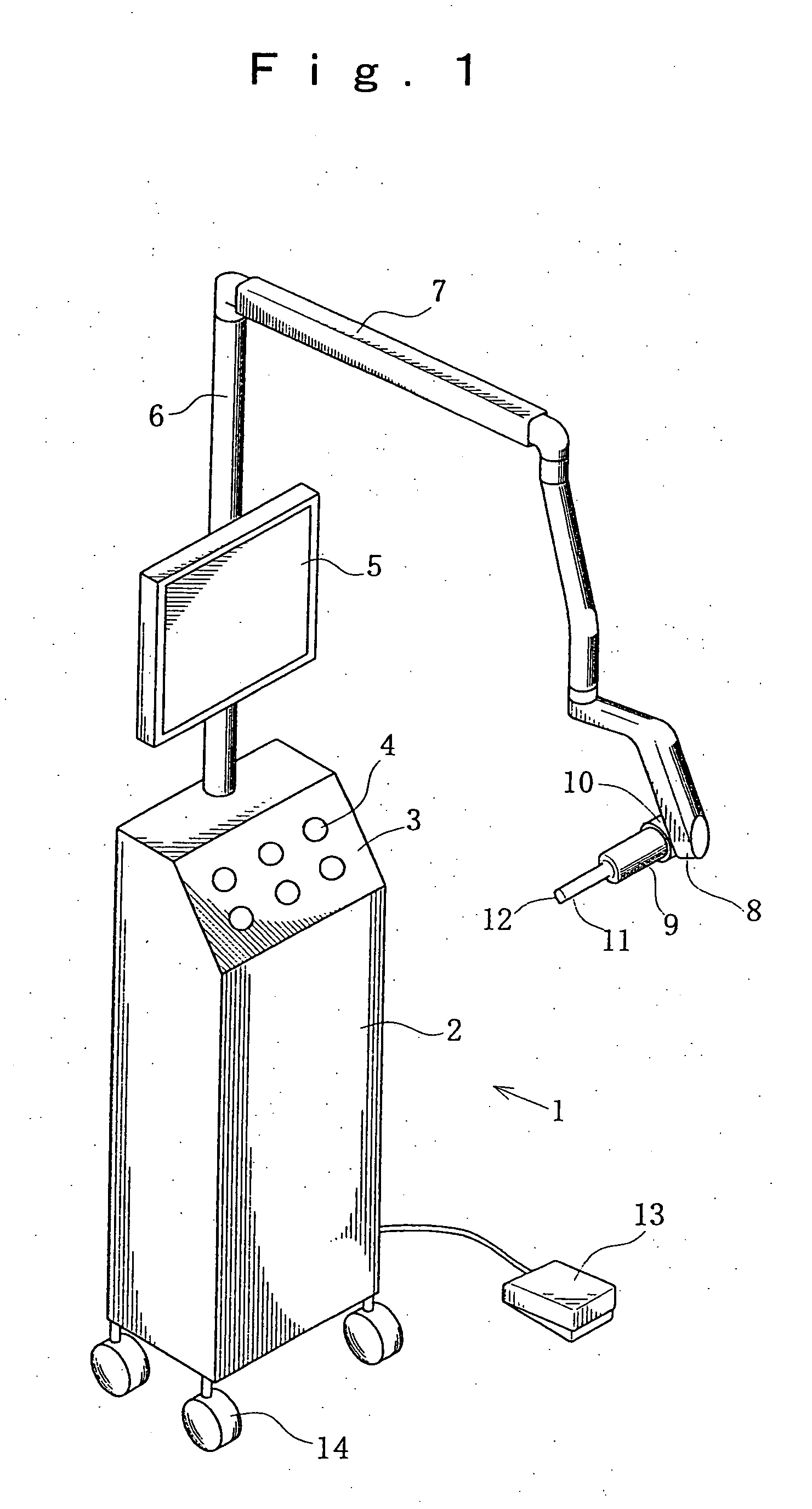

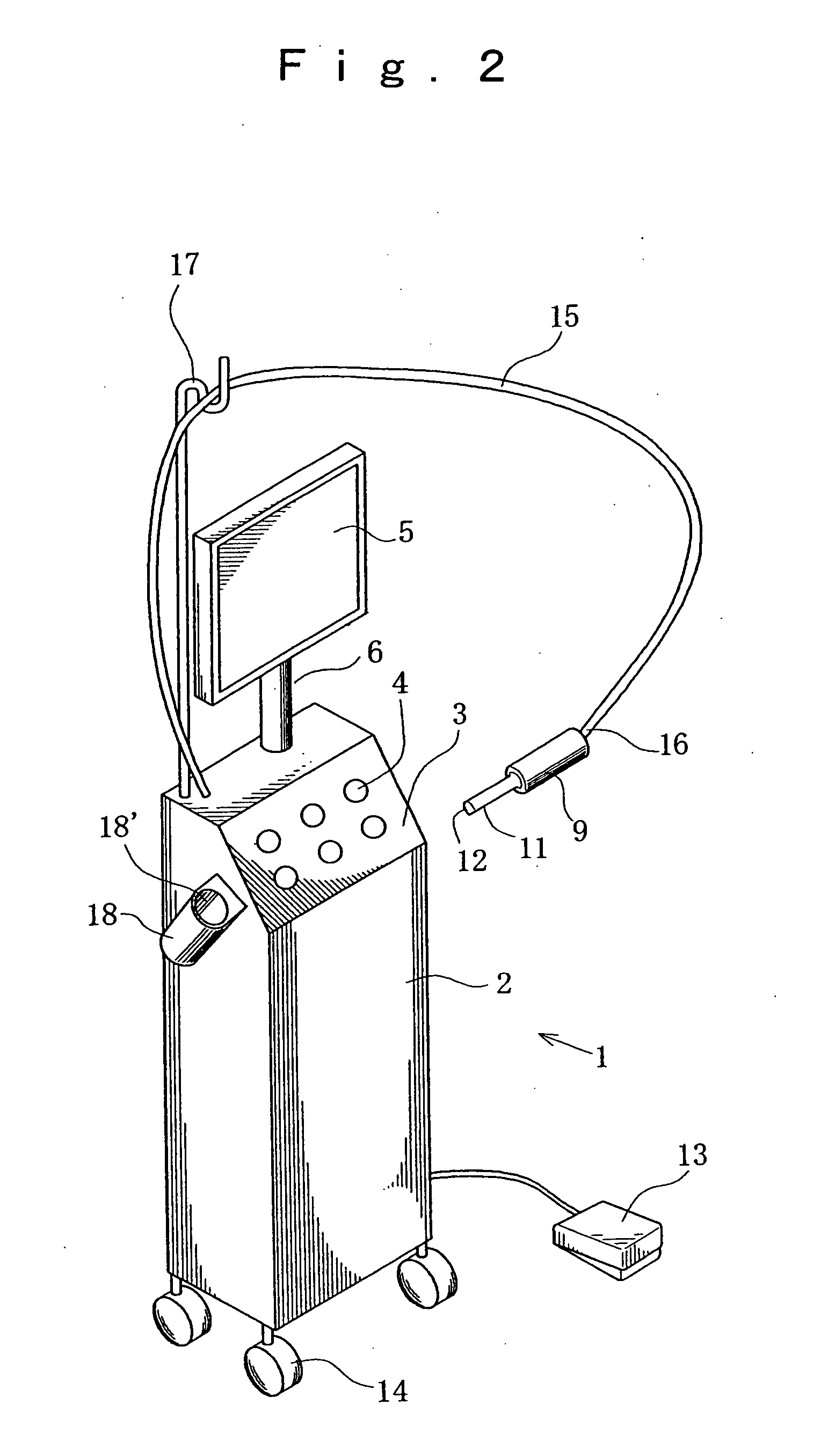

Dental Optical Diagnostic Apparatus

Owner:J MORITA TOKYO MFG CORP

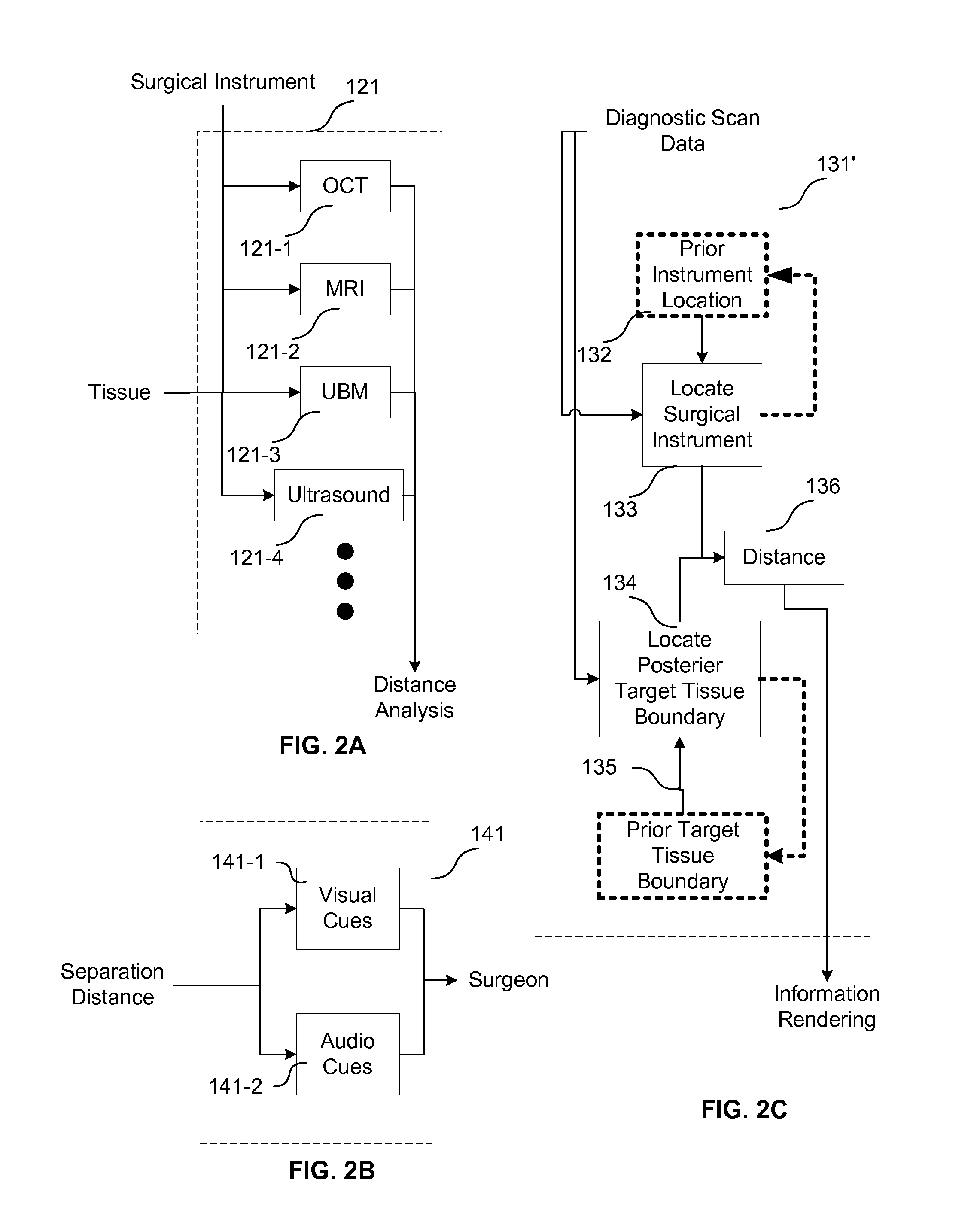

Surgical Procedures Using Instrument to Boundary Spacing Information Extracted from Real-Time Diagnostic Scan Data

InactiveUS20120022546A1Less riskAddressing slow performanceIncision instrumentsEye surgeryImage ViewSurgical department

Specific embodiments of the invention are directed to improved phacoemulsification procedures involving the use of processed non-visual three-dimensional data (i.e. diagnostic scan data) to provide a surgeon with additional guidance (i.e. more than that generally obtained from visual observation of the working area) concerning the distance separating a working end of a phacoemulsification instrument and the posterior portion of the capsule of the eye during surgical procedures involving the removal of the crystalline lens of an eye (e.g. a cataract removal procedure). Such separation (i.e. distance or gap) information may be used to aid the surgeon in cutting or scoring the lens to a desired depth while minimizing the risk of penetrating the posterior portion of the capsule with the working end of the instrument. Some embodiments provide for the visual and / or auditory conveyance of distance information to the surgeon wherein visual information may be conveyed by overlaying it with real visual images of actual surface features viewed by the surgeon. Additional embodiments provide for overlaying visual representations of selected three-dimensional structure information (e.g. depths of troughs cut into the lens) with the real surface feature images viewed by the surgeon.

Owner:VANTAGE SURGICAL SYST

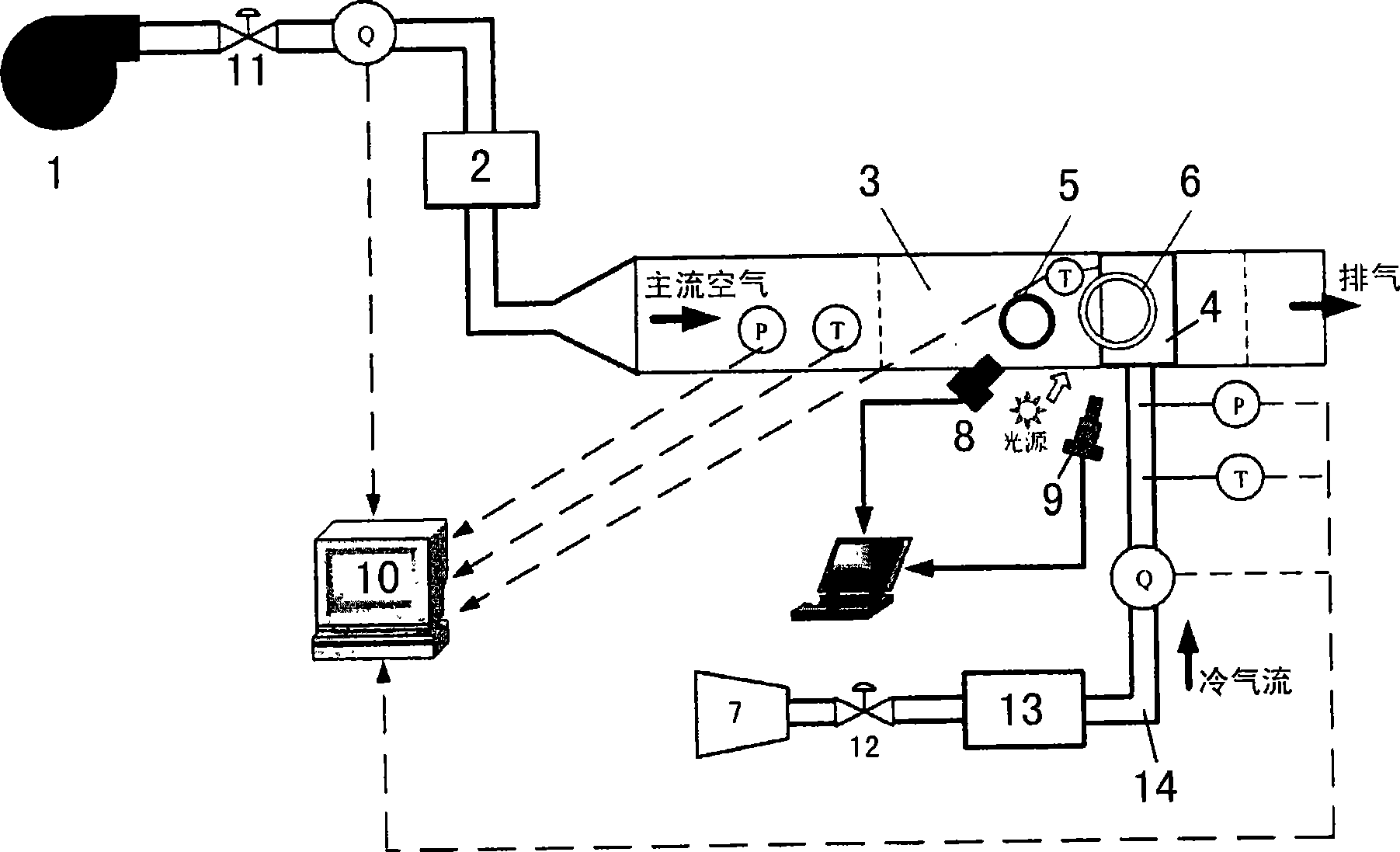

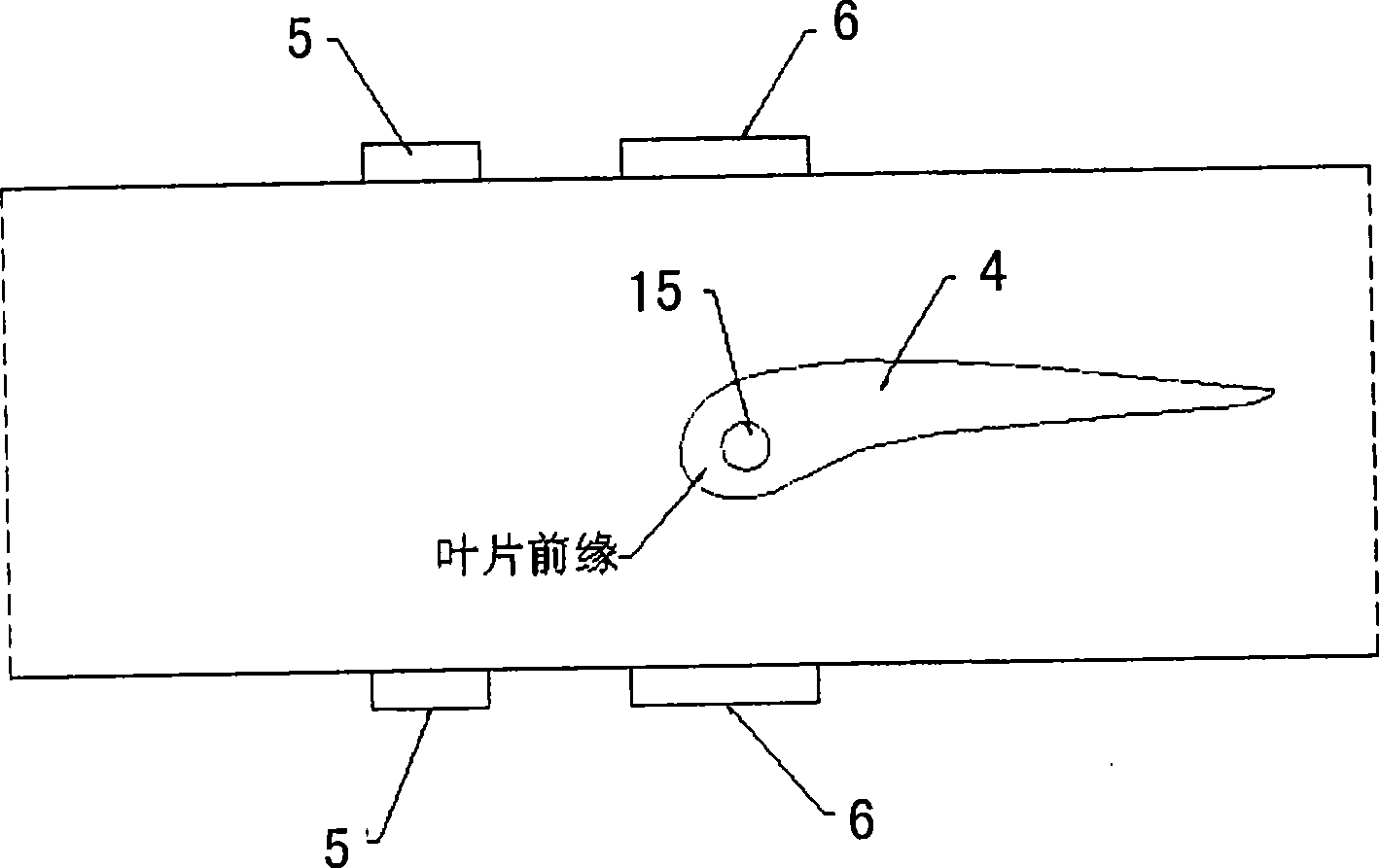

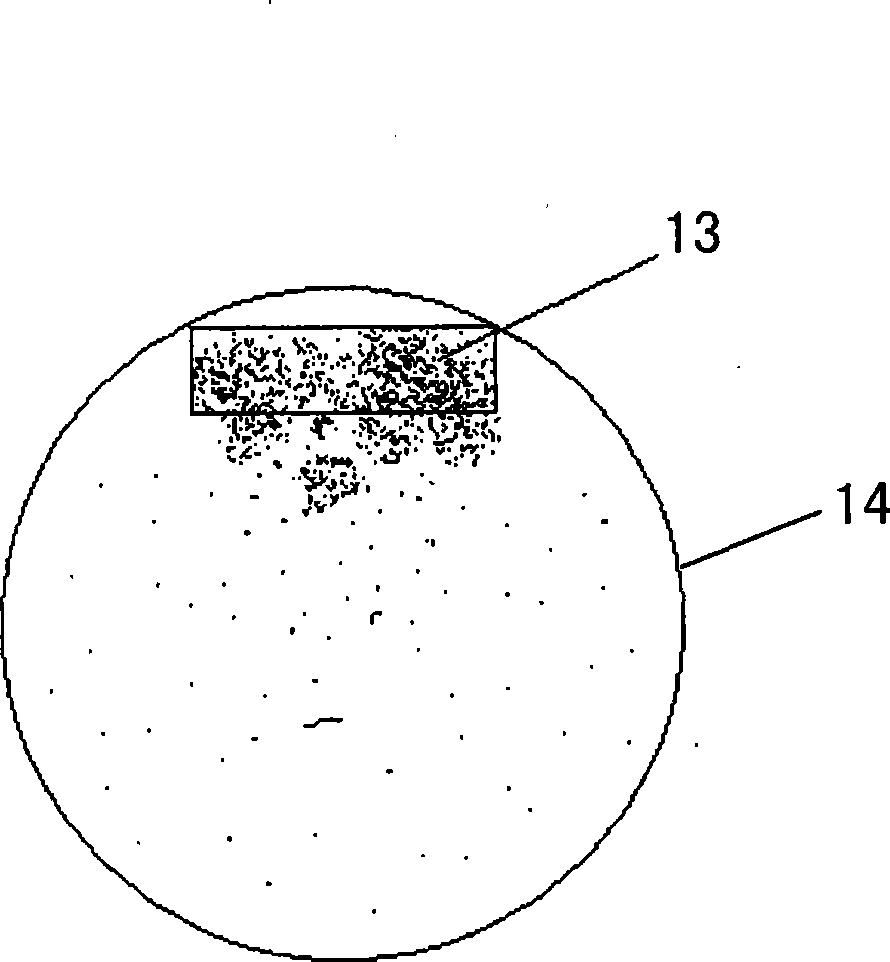

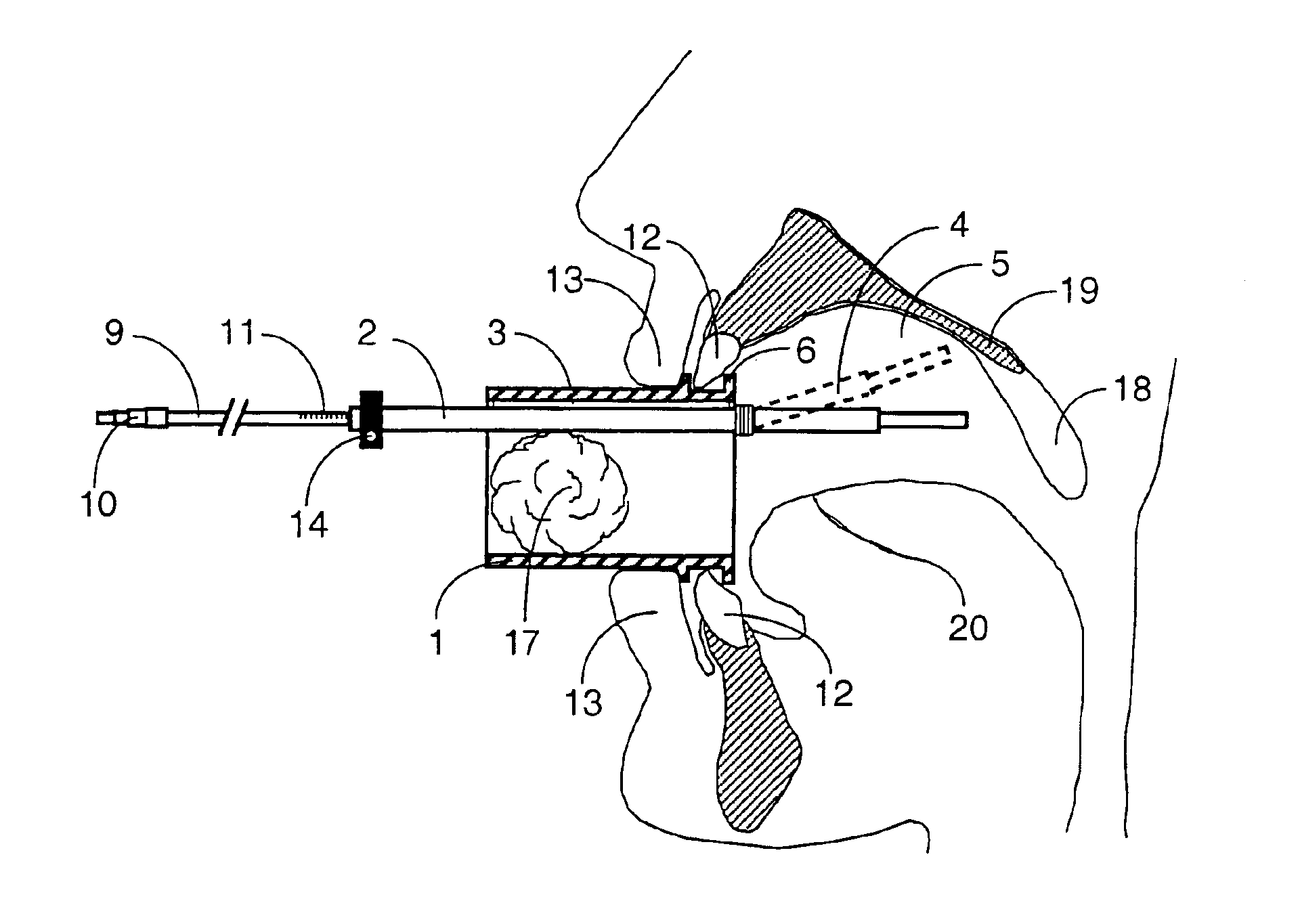

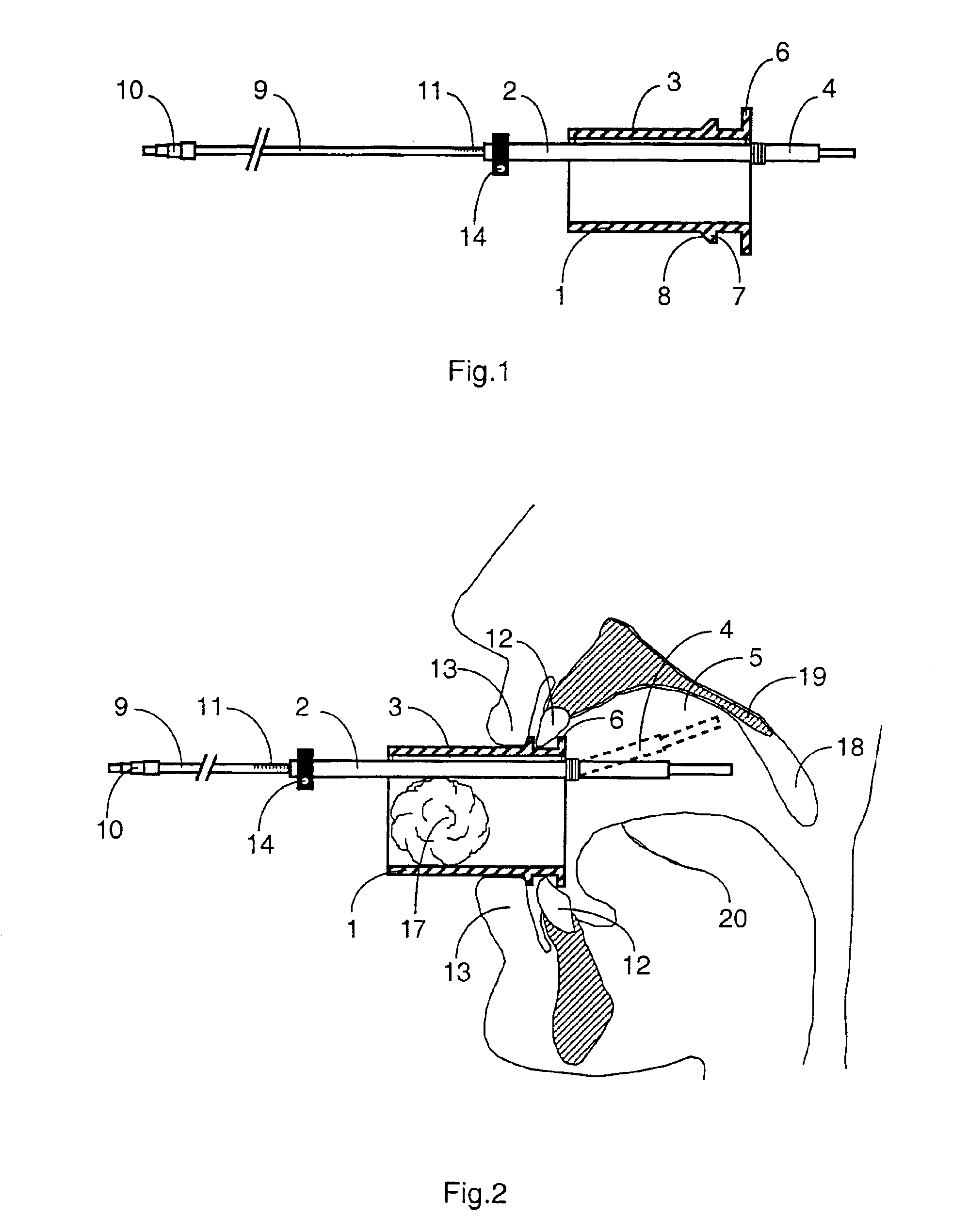

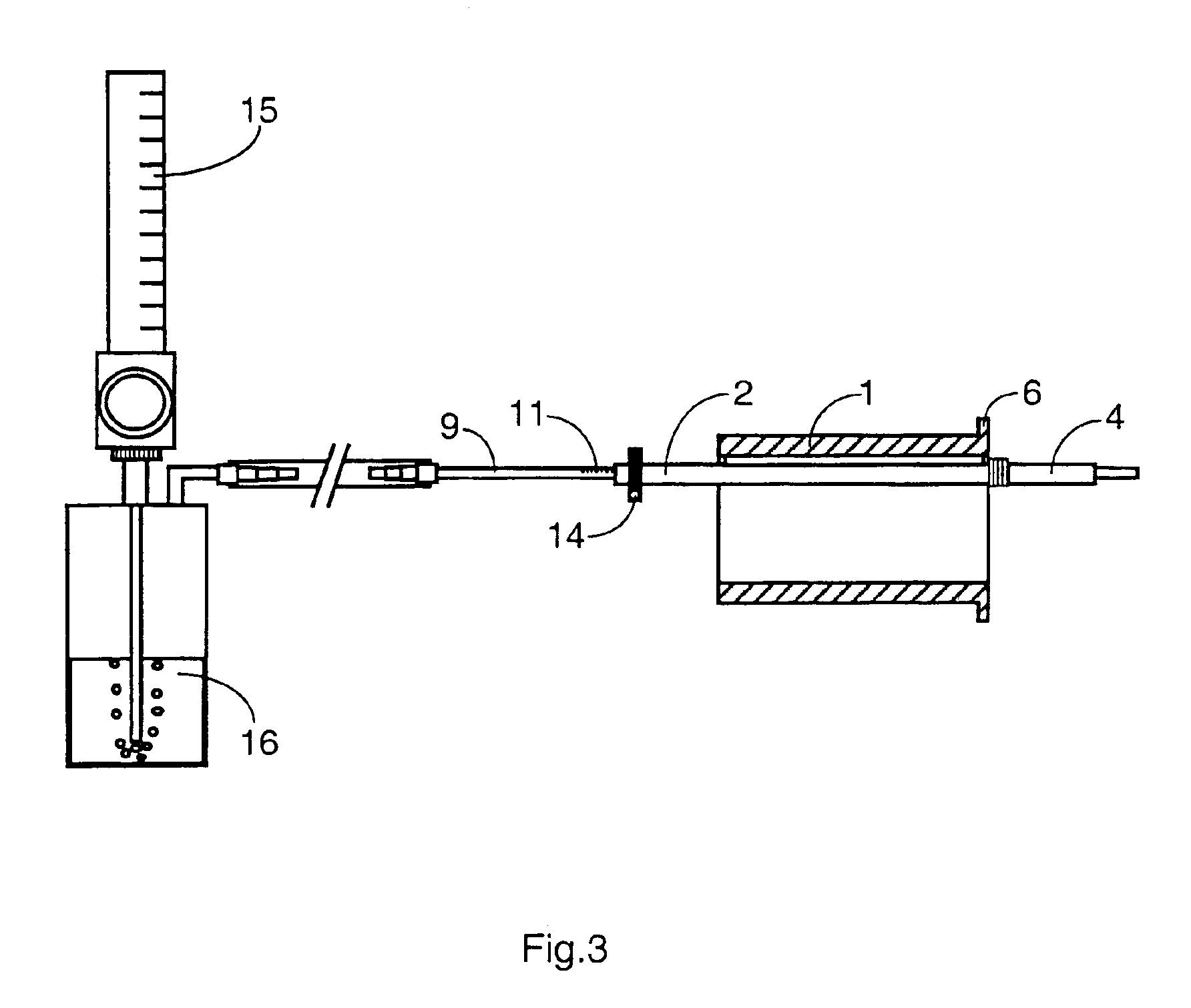

Visual observation and transient measurement method and apparatus for cooling process of turbine blade

The invention relates to a method for carrying out visual observation and transient measurement on a cooling process of a turbine blade, which comprises the following steps: heating main flow air to a pre-determined temperature; introducing cold air flow; allowing the cold air flow to enter to a cooling passage inside the turbine blade first to cool the blade; and allowing the cold air flow to flow to the surface of the turbine blade to form a layer of a cold air film; and recording the temperature and the pressure of each measuring point and observing the conditions of mixing and flowing of the main flow and the cold air flow near the turbine blade. A device for realizing the method comprises an air tunnel, one end of the air tunnel is connected with a hot air source, while the other end is an exhaust port; the turbine blade is placed inside the air tunnel according to an operating state of the blade; a cold air source connected with a jet pipe of the turbine blade in the air tunnel through an air pipe; a pigment feeding device is arranged on the air pipe; infrared probing windows are respectively arranged on two sides of the air tunnel which is positioned in the turbine blade; the infrared probing windows are respectively provided with infrared thermal imagers; visual observing windows are respectively arranged on the two sides of the air tunnel which is positioned in the turbine blade; and the visual observing windows are respectively provided with micro-amplifying photographic devices.

Owner:中科思道(南京)储能技术有限公司

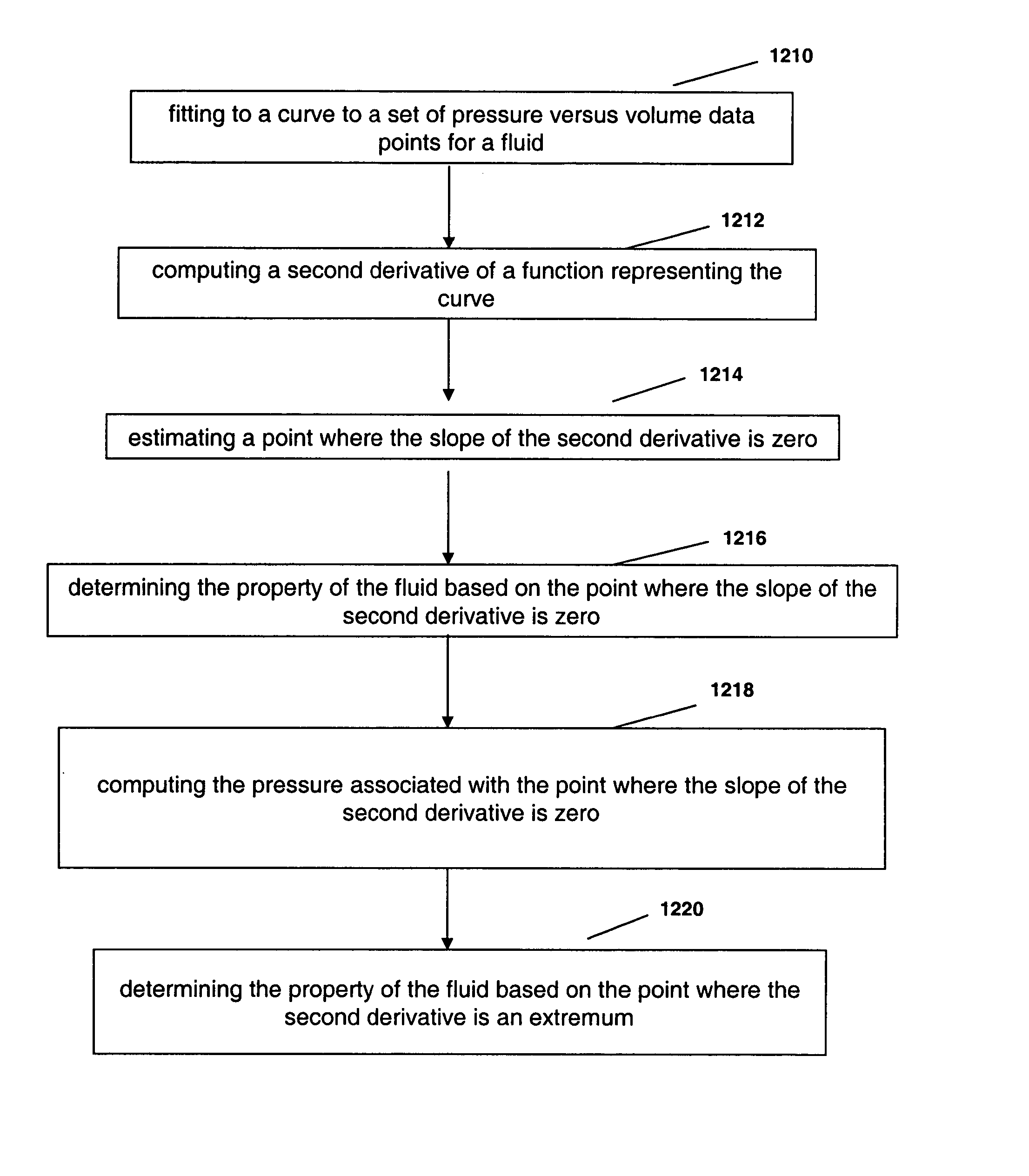

Downhole PV tests for bubble point pressure

InactiveUS20040260497A1Reduction of filtrateSpecific gravity by measuring pressure differencesFlow propertiesVisual observationQuality control

The present invention provides an objective bubble point pressure determination method enables new applications of downhole PV (Pressure Volume) test results such as in situ measurement of the bubble point pressure for use as a quality control parameter for sampling. The present invention provides a method and apparatus to fit data points to a curve and to smooth these points over an interval of N points. The derivative of the curve is determined to obtain peak acceleration. The peak acceleration represents the bubble point pressure. This bubble point pressure is verified by comparison to changes in fluid compressibility and visual observation of a pressure volume plot history.

Owner:BAKER HUGHES INC

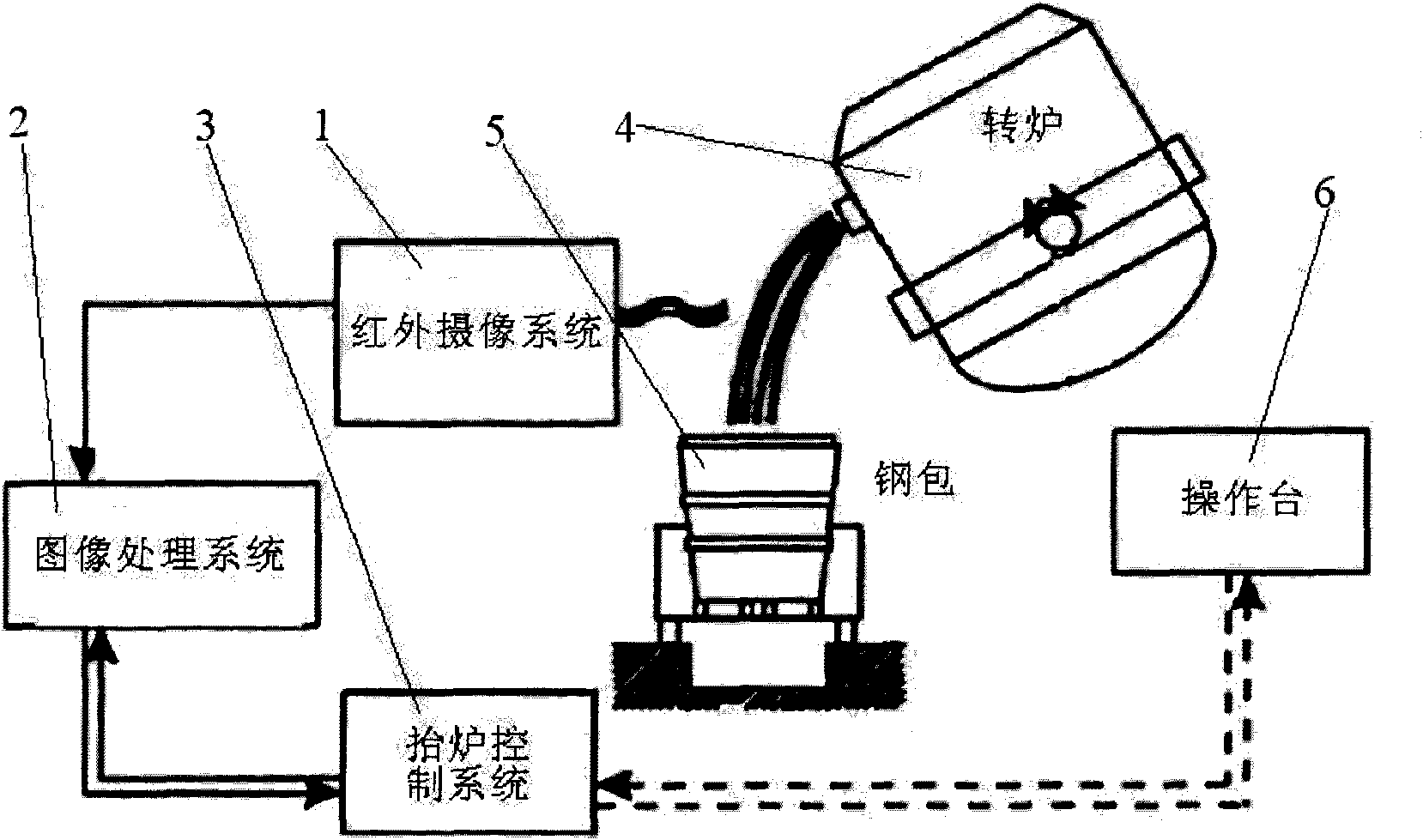

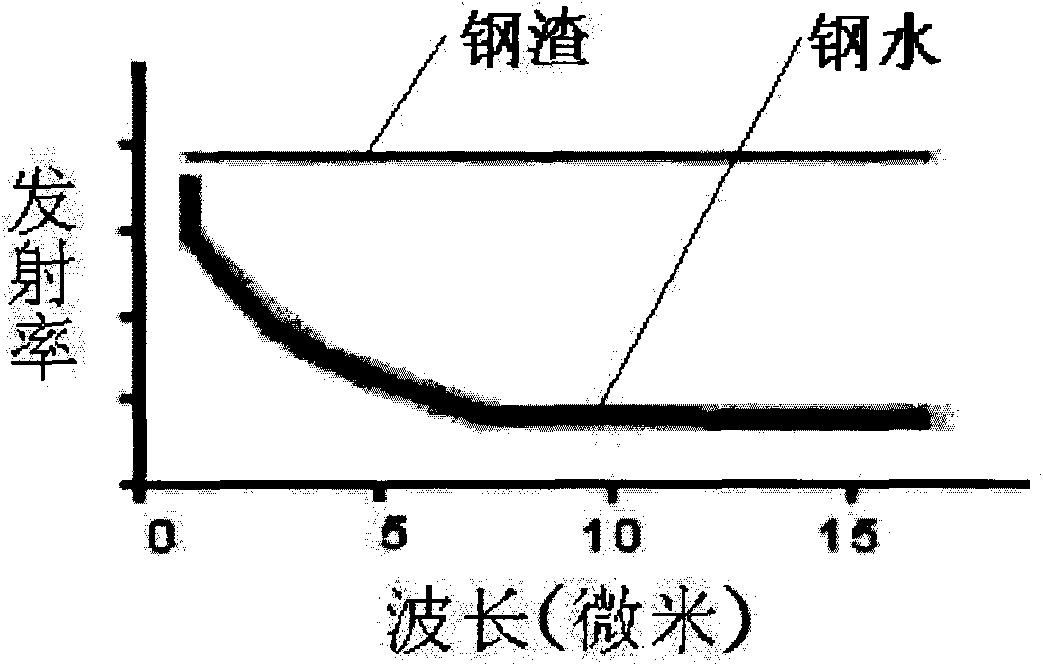

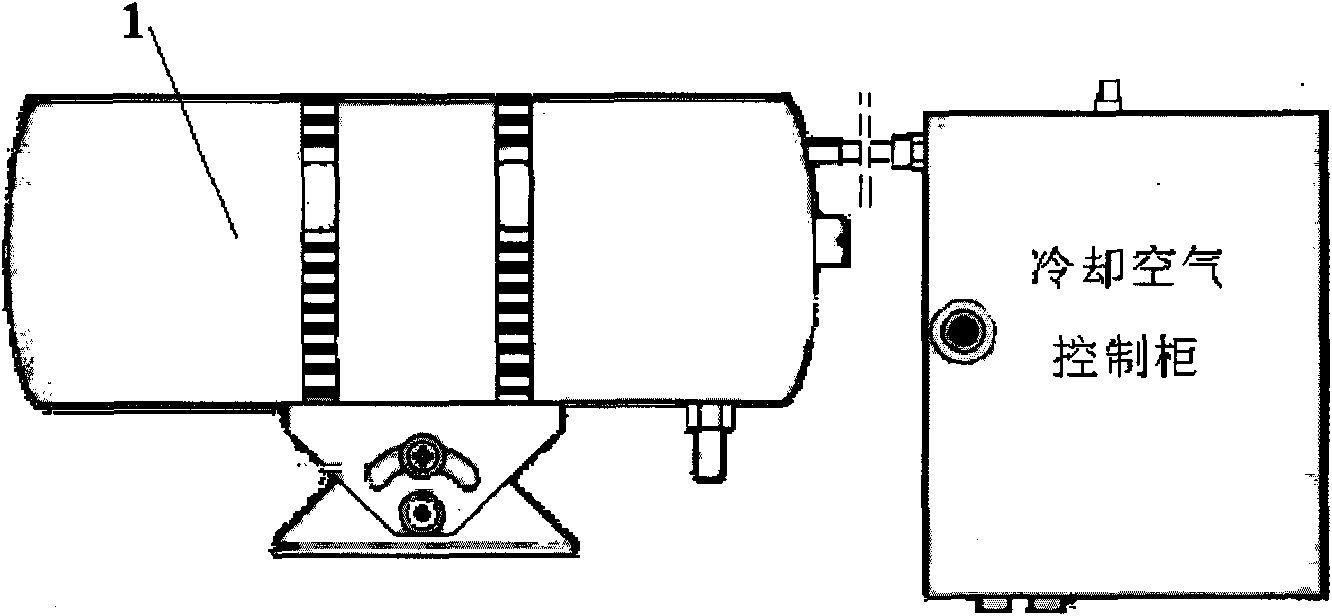

Control system and control method for tapping and slagging of converter

ActiveCN101818228AMonitor the steel statusShake Oven in TimeIncreasing energy efficiencyManufacturing convertersVisual observationSlag

The invention discloses a control system for tapping and slagging of a converter, which comprises the converter (4), a ladle (5), and a console (6). A slagging detection system and an automatic converter-lifting control system (3) are arranged in the control system; and the slagging detection system comprises a thermal infrared imaging detection system (1) and an image analyzing and processing system (2). By adopting the technical scheme of a thermal infrared imaging method, converter slagging conditions can be detected in time; slag can be stopped in combination with a slag-stopping ball at the same time; converter tapping conditions can be continuously monitored in real time; the slag and molten steel can be distinguished accurately; the response speed is high; and the timely judgment, timely converter-shaking and timely addition of the slag-stopping ball can be realized so as to reduce the tapping and slagging amount of the converter. The control system has the advantage of long service life because equipment is far away from a converter body, reliable operation, no need of visual observation of workers, convenient maintenance and few space requirements.

Owner:MAANSHAN IRON & STEEL CO LTD

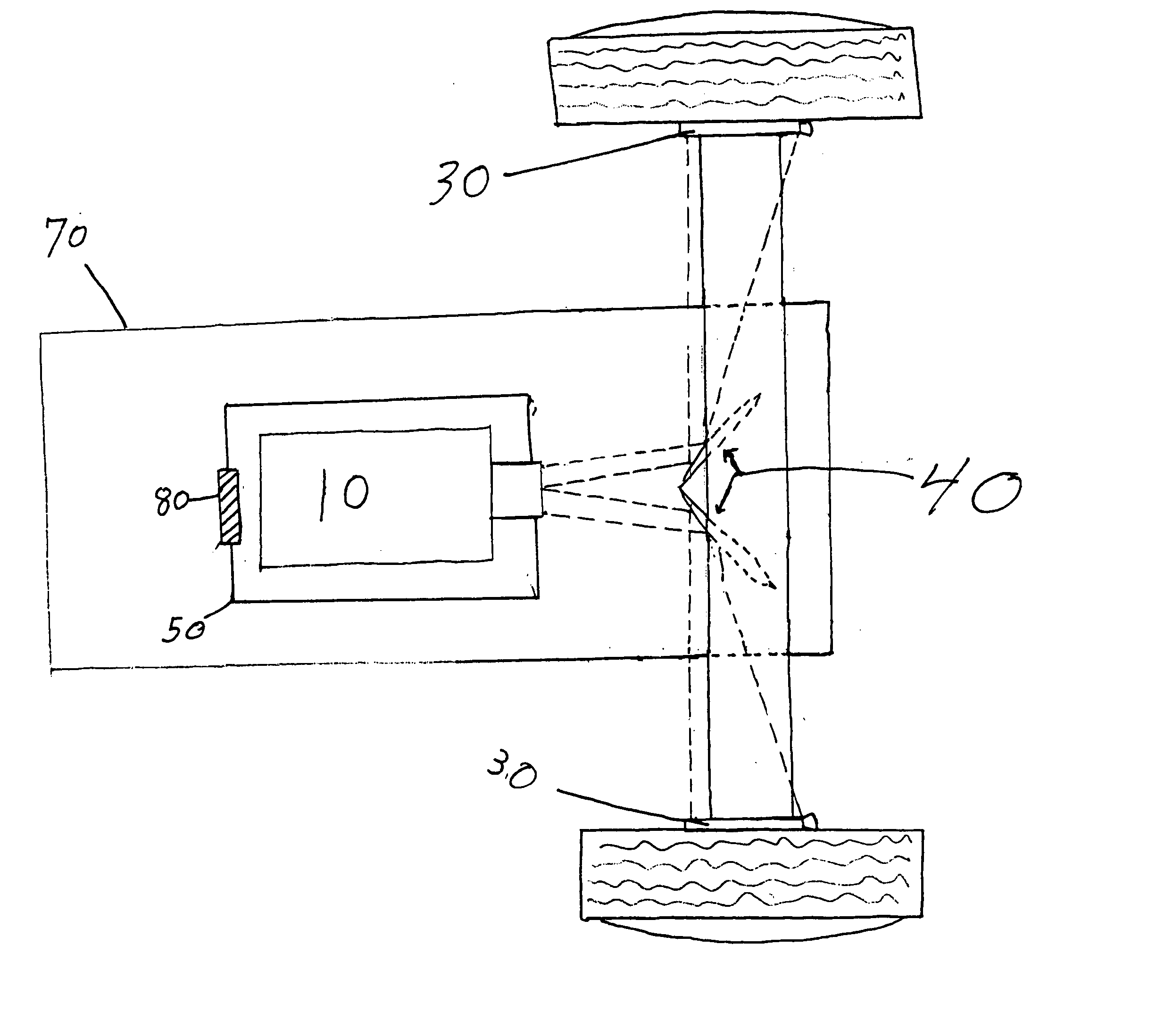

Apparatus for visual comparison of infrared images

InactiveUS20050145794A1Television system detailsMaterial analysis by optical meansVisual comparisonVideo processing

A method and apparatus for visually observing thermal disparities between like vehicular components that are spatially separated. The invention uses only one infrared camera and one or more surfaces to reflect the thermal image of spatially separated components into the camera. The image generated by the infrared camera can be sent directly to a viewing apparatus or to a computer capable of controlling internal camera functions as well and providing video processing and analysis capabilities.

Owner:FAUBION ROBERT CARL

Preparation method for artificially synthesized transparent soil material

InactiveCN103969099AHigh purityWide range of gradingPreparing sample for investigationAlkaneVisual observation

The invention discloses a preparation method for an artificially synthesized transparent soil material. The transparent soil material comprises baked silica sand particles and colorless pore fluids which have the same refractive index, wherein the pore fluids are mixed fluids of 12, alkane and 15# white oil; during preparation, a glass bar is used to stir constantly so as to ensure intensive mixing; a vacuum chamber is adopted for vacuumizing so as to remove residual air in a mixture until the mixture is transparent; finally, a consolidometer is adopted for consolidation. According to the invention, the preparation method is simple and convenient to operate and easy to implement; compared with other preparation methods, the preparation method is wide in material sources, low in cost, pollution-free and non-hazardous and can achieve a better transparent effect; the prepared transparent soil can be effectively used for model tests, and metabolic un-embedding visual observation in soil bodies can be realized.

Owner:HOHAI UNIV

Mouthpiece intended for a device used to assess the sensitivity of the pharynx and a device comprising same

InactiveUS6916287B2Limiting undesirable effectSimple, inexpensive means of evaluating the sensitivityBronchoscopesLaryngoscopesVisual observationPharynx

To assess the sensitivity of a subject's pharynx, an open mouthpiece (1) fitted with a thin guide tube (2), having an articulated end (4), is inserted into the subject's mouth. A pipe (9) is inserted into the guide tube, under visual observation through the mouthpiece, until it touches the subject's palate. The position on a measurement scale (11) provided on the pipe facing a second end of the guide tube is noted, and the pipe is withdrawn over a preset distance, for example 1 cm, and fixed in this position onto the guide tube. A variable gas flow is injected into the pipe and reaches the pharyngeal mucous situated facing the pipe. The sensitivity of the subject's pharynx, measured by the threshold of sense perception, is determined by the lowest flow value perceived by the subject.

Owner:UNIV JOSEPH FOURIER

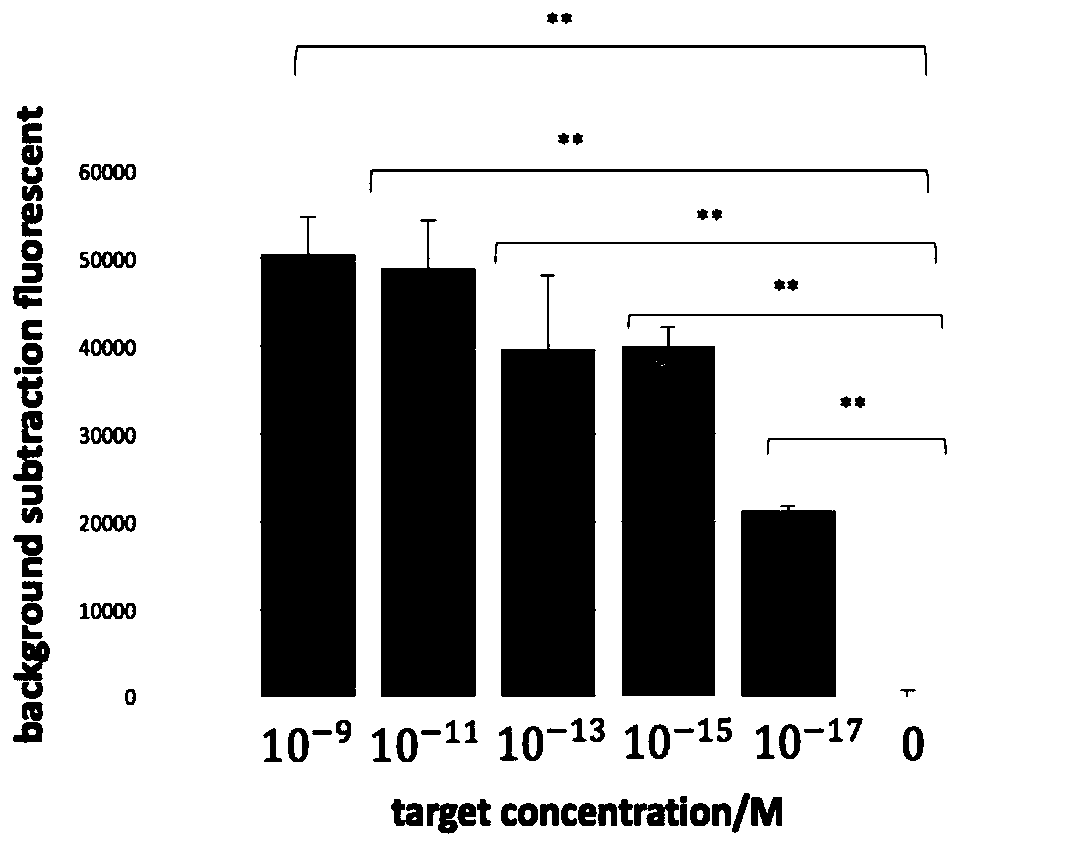

One-step nucleic acid test method based on CRISPR/Cas and isothermal amplification and kit

InactiveCN110184329AQuick checkEasy to detectMicrobiological testing/measurementVisual testFreeze-drying

The invention discloses a one-step nucleic acid test method based on CRISPR / Cas (clustered regularly interspaced short palindromicrepeats / CRISPR-associated protein) and isothermal amplification and akit. The method is a quick field test method used for testing nucleic acid and displaying visual test results through fluorescent light or lateral side immunochromatographic test paper. The test accuracy is effectively ensured through specificity of crRNA (RISPR-derived ribonucleic acid); at a room temperature, whether a test sample contains test nucleic acid can be determined through the test paper or the fluorescent light within 1-2h; and compared with the traditional test method, the precision, simplicity and convenience in operation of the test method are improved to some extent. The kit with purified freeze-drying LbaCas12a, crRNA and RPA (recombinase polymerase amplification) can be formed; a nucleic acid segment of a specific sequence can be conveniently and quickly tested on site;a complicated temperature control instrument such as a PCR (polymerase chain reaction) instrument and other electrophoresis and centrifugation equipment are not required; and nucleic acid of the specific sequence can be tested quickly and sensitively only by a thermostatic device and fluorescence detection equipment and even visual observation.

Owner:SOUTH CHINA UNIV OF TECH

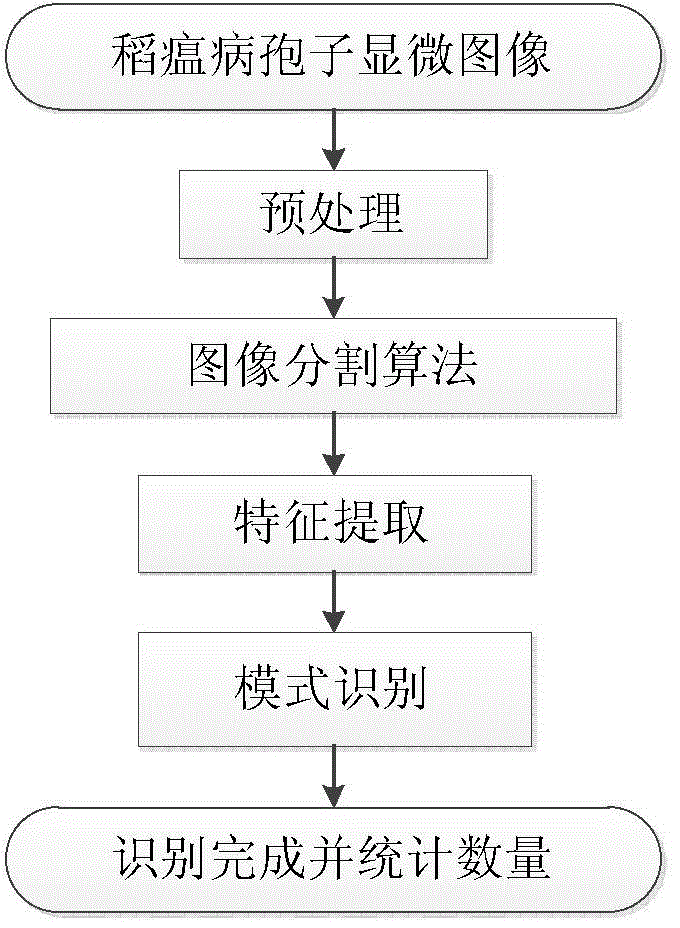

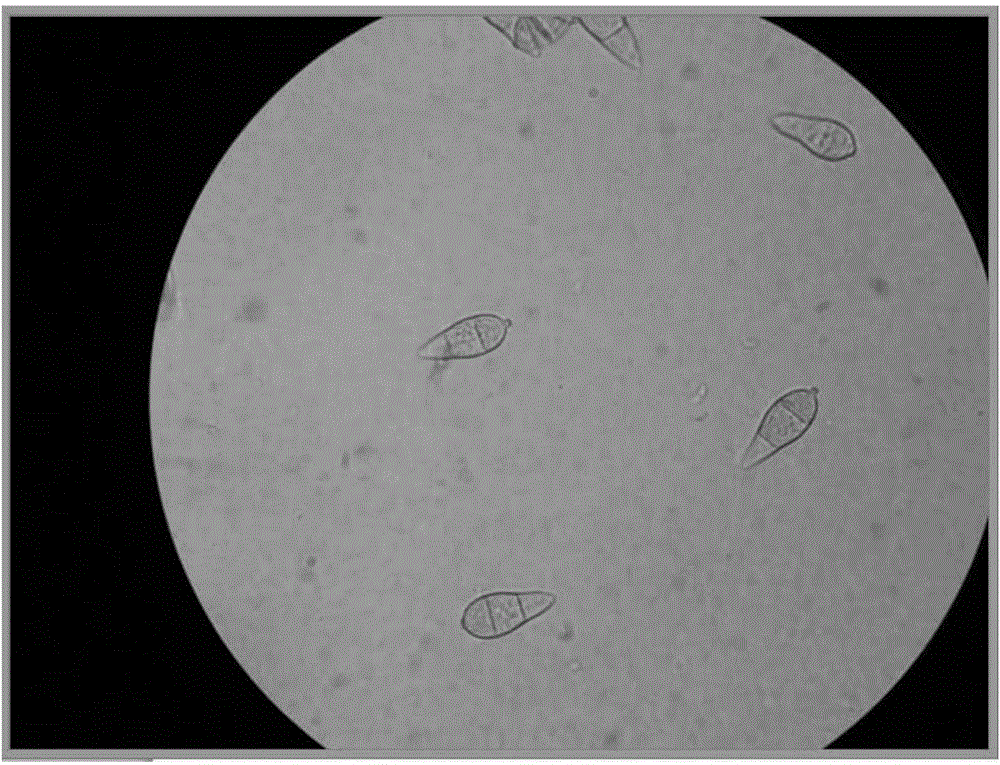

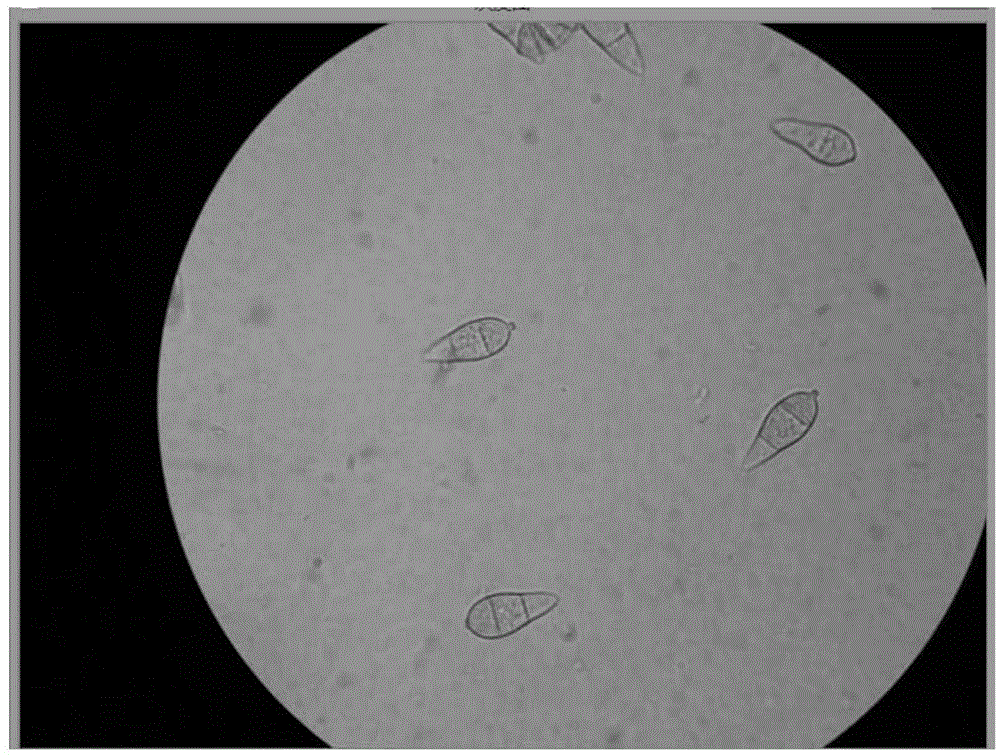

Image processing and mode recognition technology-based rice blast spore microscopic image recognition method

InactiveCN104794502AReduce lossesAvoid situations with low classification accuracyCharacter and pattern recognitionMicroscopic imagePattern recognition

The invention discloses an image processing and mode recognition technology-based rice blast spore microscopic image recognition method, relates to the field of rice blast spore microscopic image recognition, and aims at solving the problems that the field detection is incorrect due to visual observation and judgment, a current experiment is huge in demand for samples and the traditional microscope spore counting needs plenty of time and is high in initial disaster situation finding difficulty. The method comprises the following steps: I, converting an original image into a grey-scale map; II, carrying out image enhancement processing on the grey-scale map; III, obtaining a binarization effect picture; IV, obtaining a denoising effect picture; I, obtaining a graph outline suspected to be rice blast spores; VI, recognizing a rice blast spore microscopic image, finally completing the recognition of the rice blast spores and counting the quantity of the rice blast spores. The image processing and mode recognition technology-based rice blast spore microscopic image recognition method is applied to the field of rice blast spore microscopic images.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com