Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

178results about How to "Avoid contact corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for downhole fluid characterization using flexural mechanical resonators

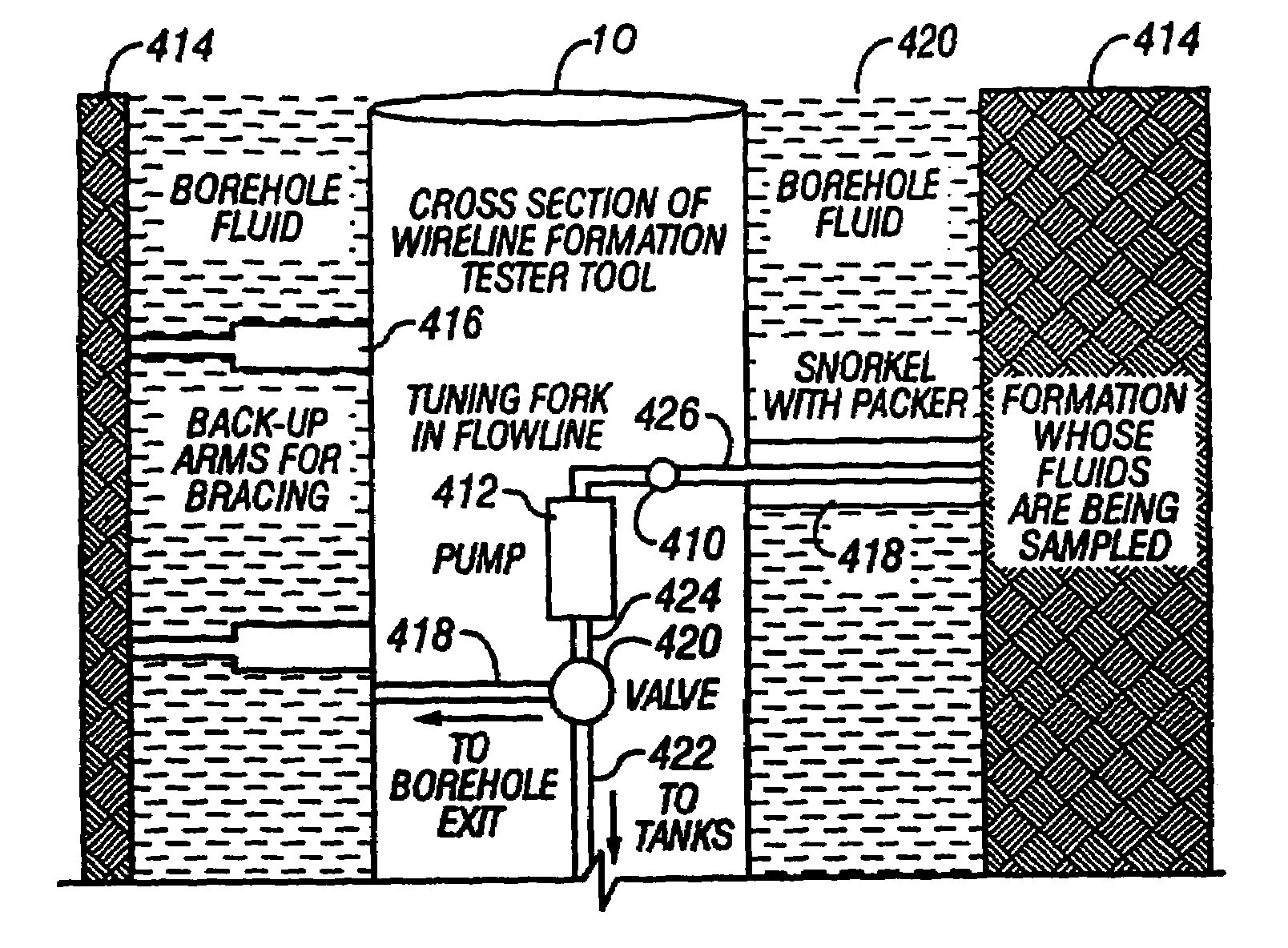

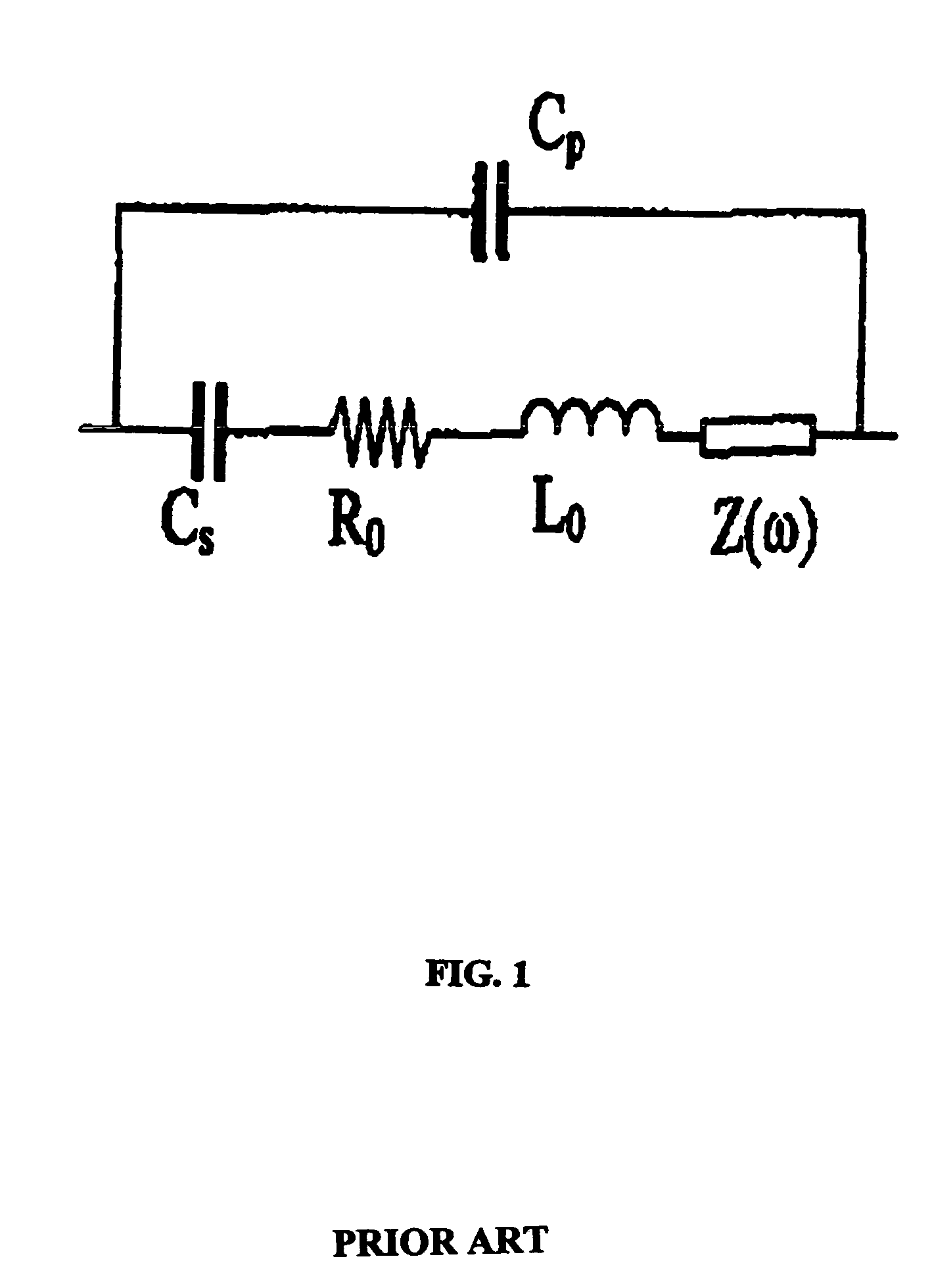

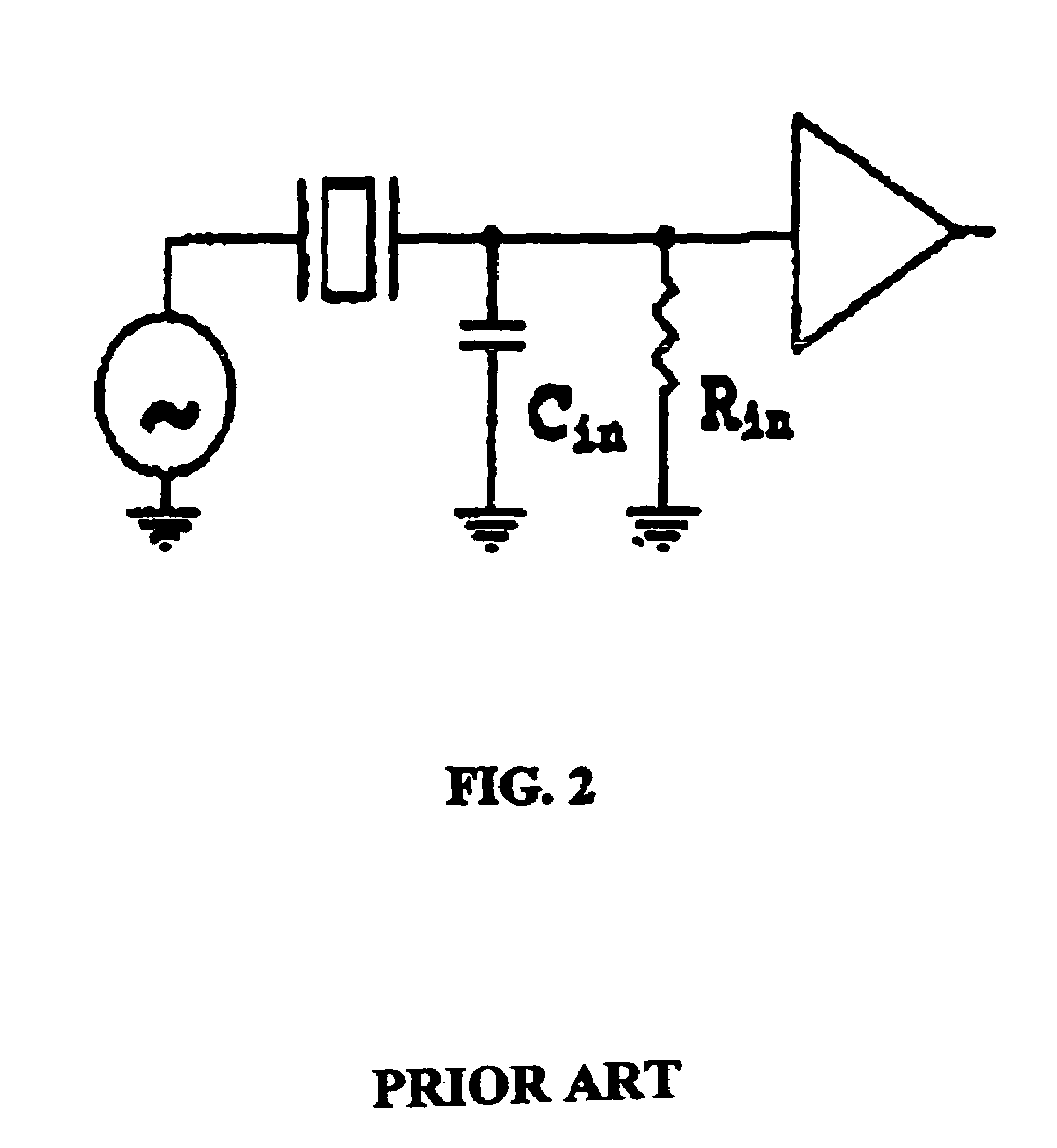

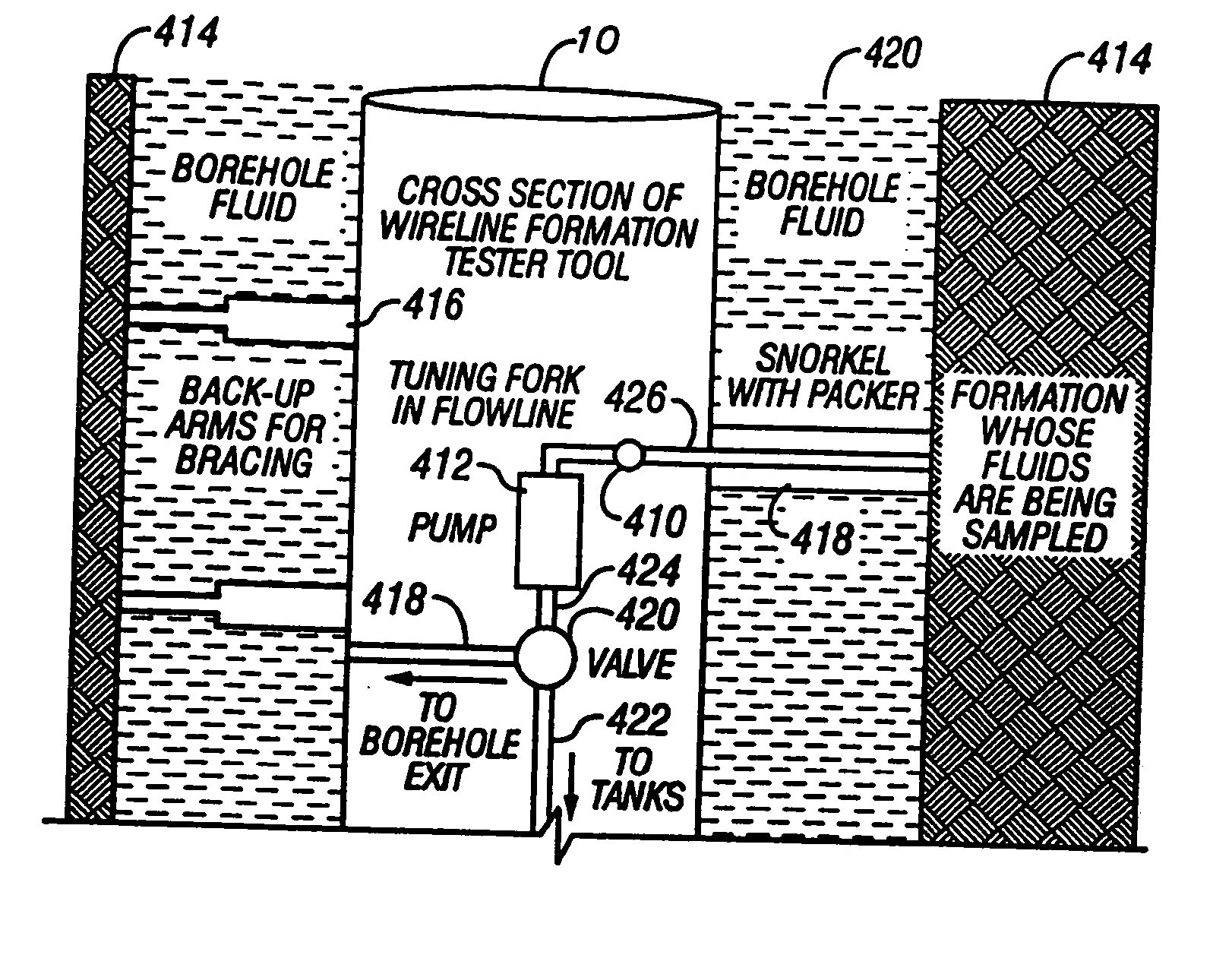

InactiveUS20020178805A1Avoid contact corrosionProtection from damageElectric/magnetic detection for well-loggingAnalysing fluids using sonic/ultrasonic/infrasonic wavesTuning forkFormation fluid

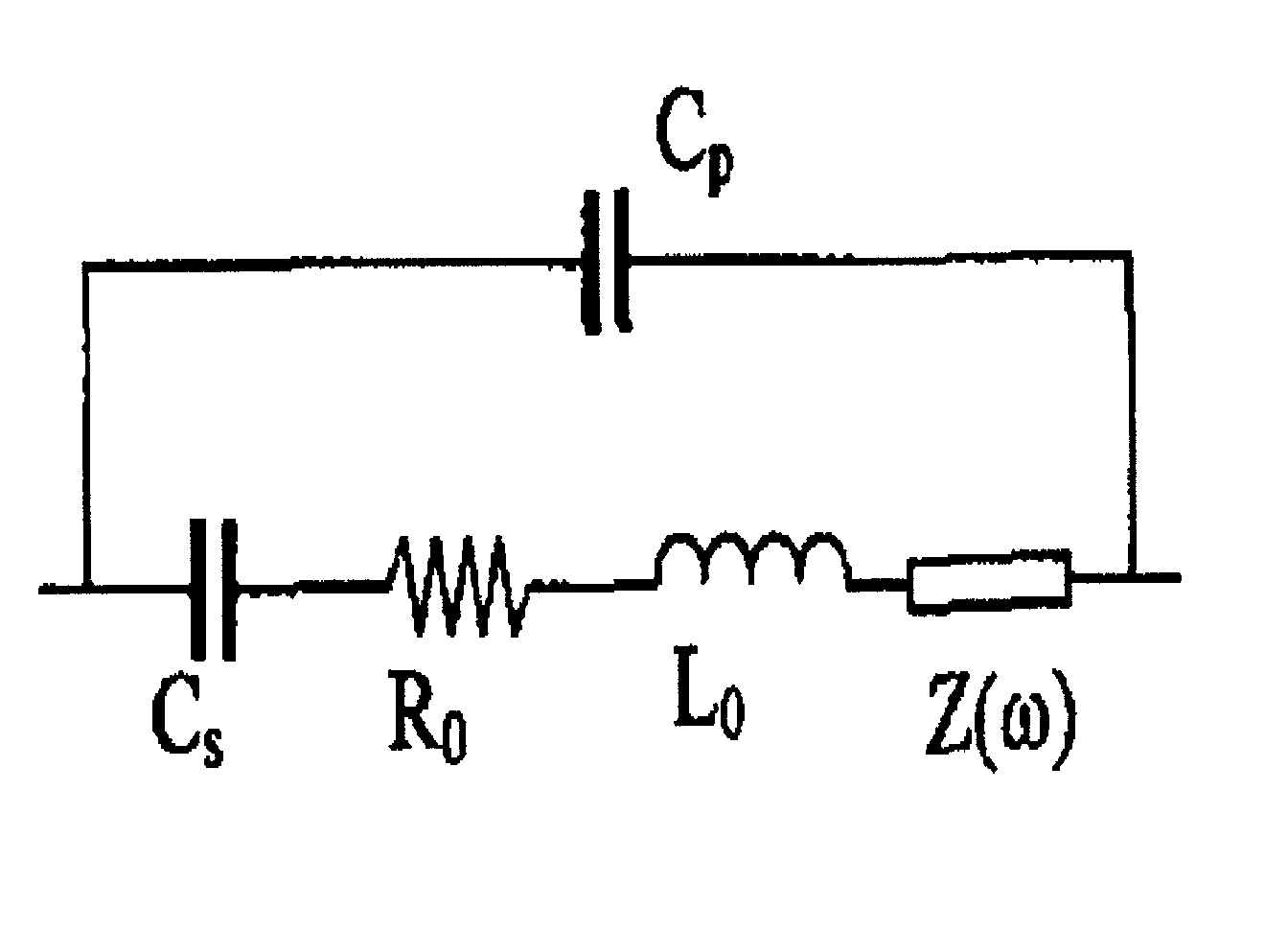

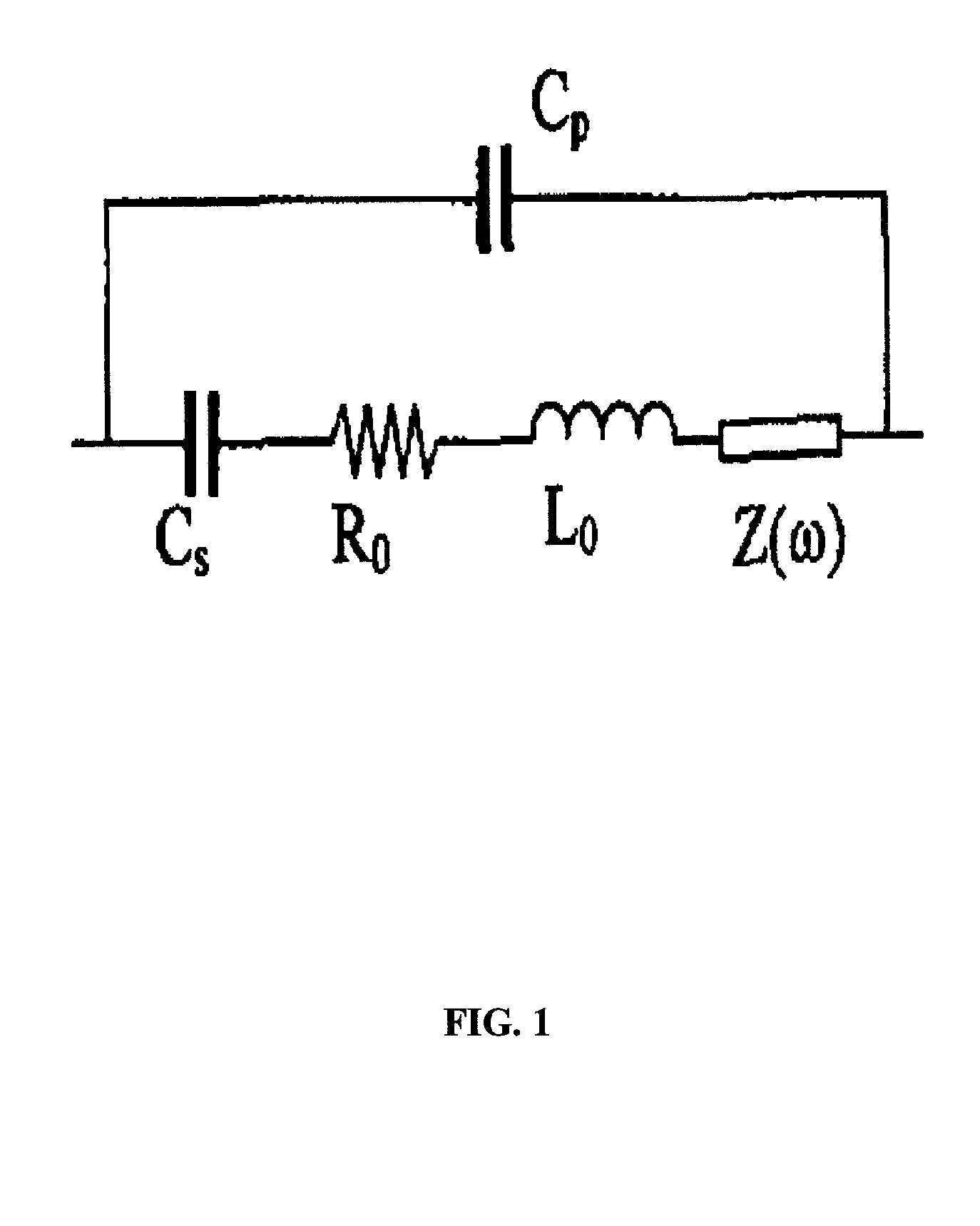

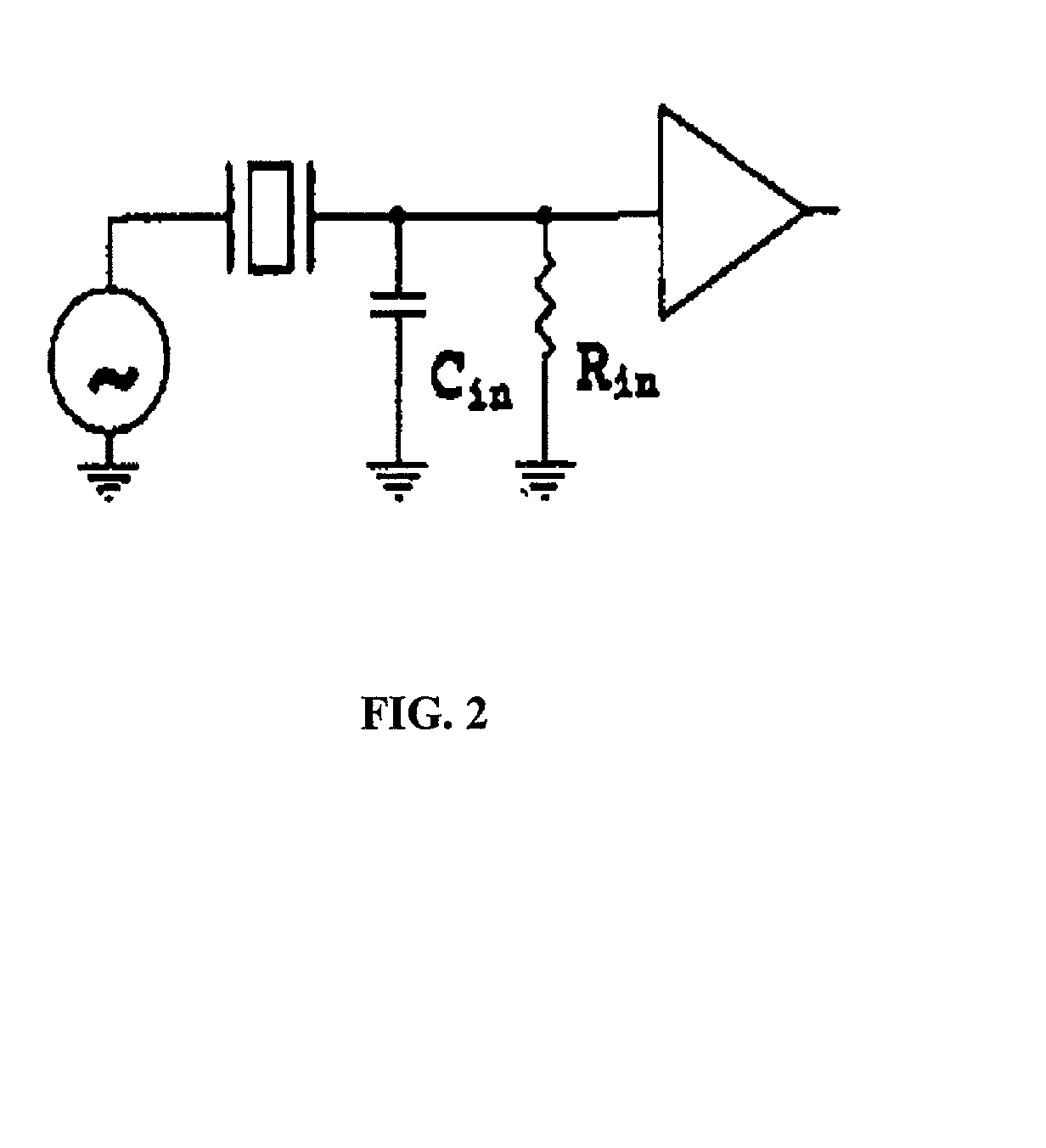

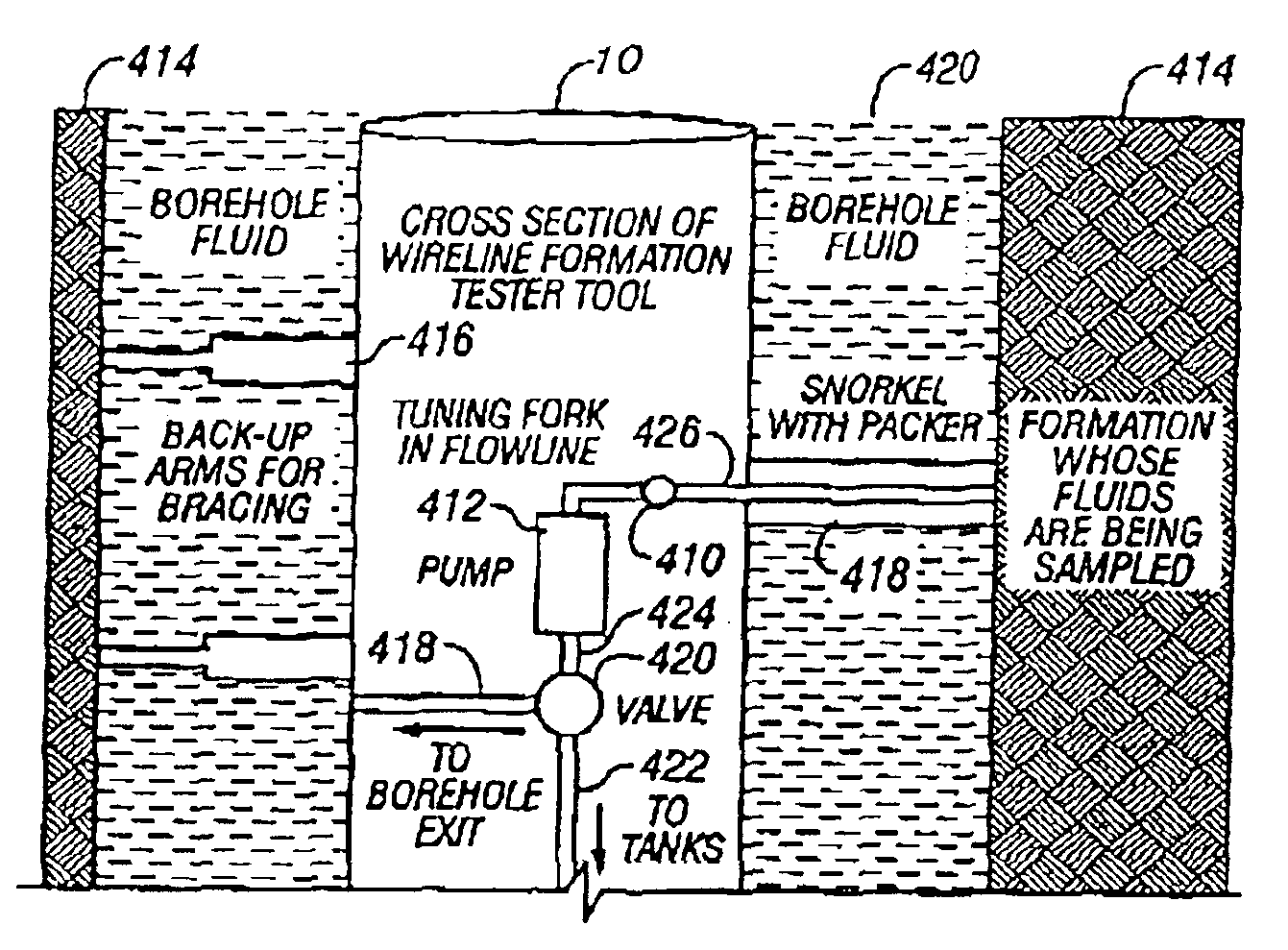

The present invention provides a downhole method and apparatus using a flexural mechanical resonator, for example, a tuning fork to provide real-time direct measurements and estimates of the viscosity, density and dielectric constant of formation fluid or filtrate in a hydrocarbon producing well. The present invention additionally provides a method and apparatus for monitoring cleanup from a leveling off of viscosity or density over time, measuring or estimating bubble point for formation fluid, measuring or estimating dew point for formation fluid, and determining the onset of asphaltene precipitation. The present invention also provides for intercalibration of plural pressure gauges used to determine a pressure differential downhole.

Owner:BAKER HUGHES INC

Method and apparatus for downhole fluid characterization using flexural mechanical resonators

InactiveUS6938470B2Avoid contact corrosionInversely to viscosityElectric/magnetic detection for well-loggingAnalysing fluids using sonic/ultrasonic/infrasonic wavesTuning forkFormation fluid

Owner:BAKER HUGHES INC

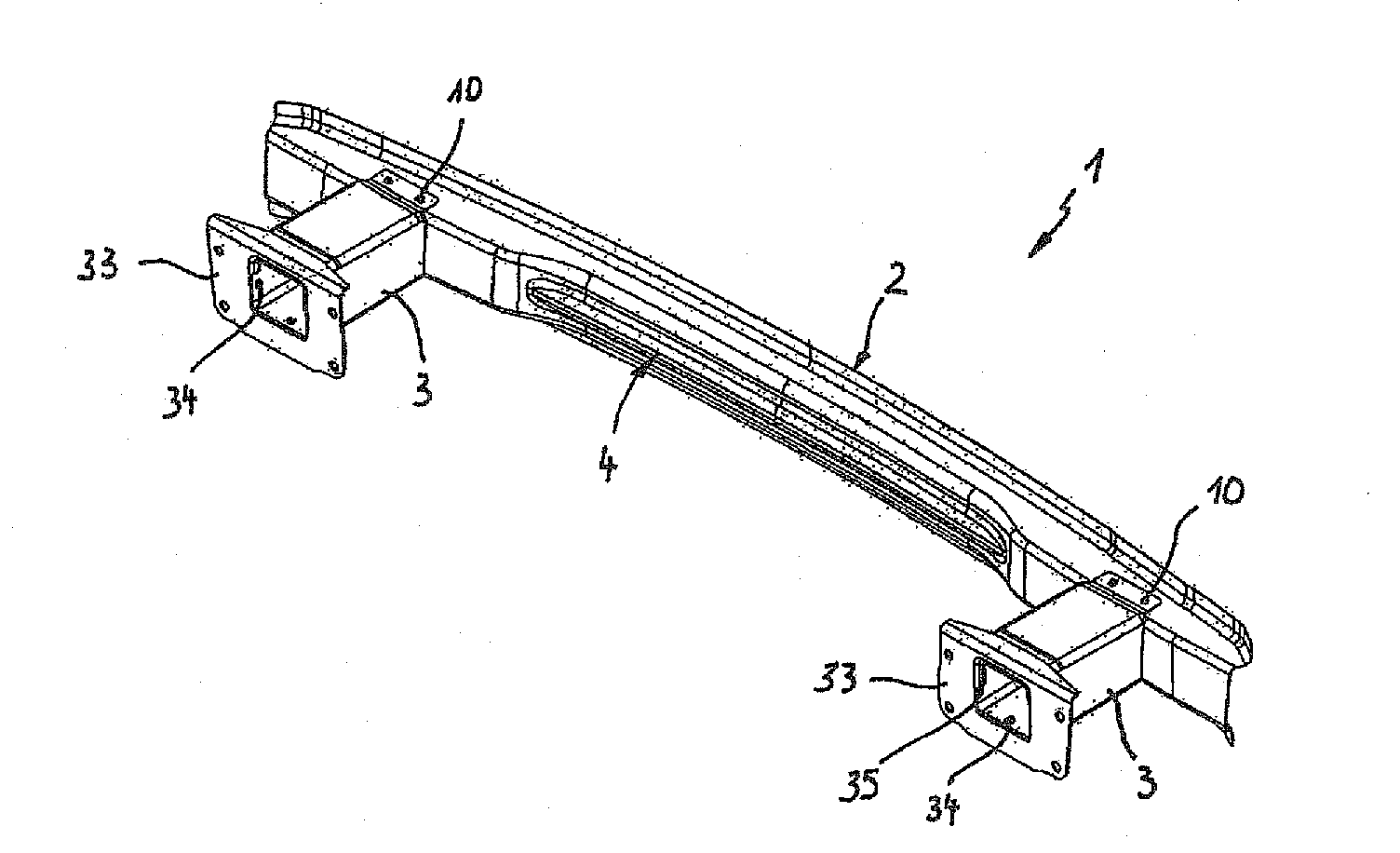

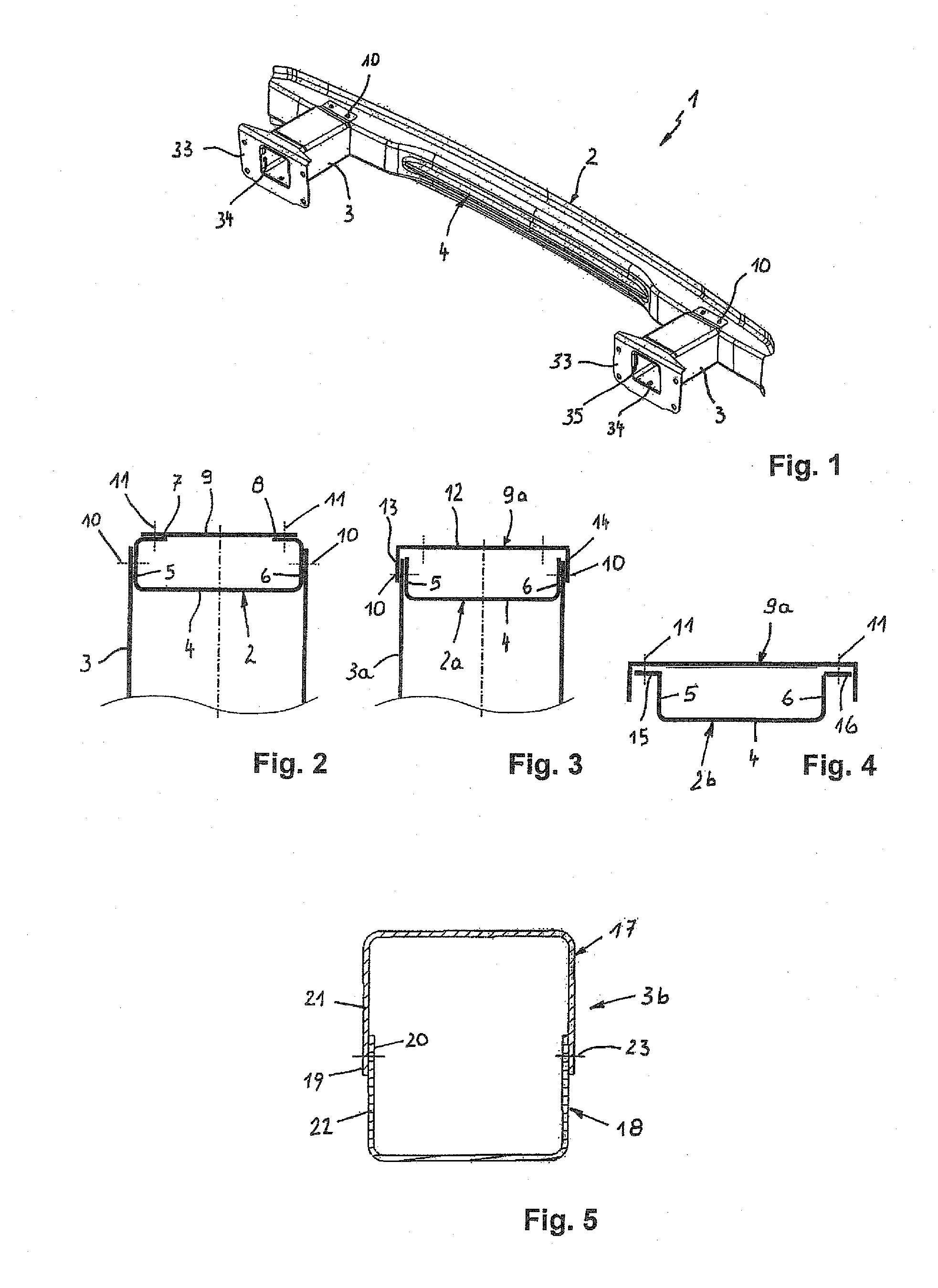

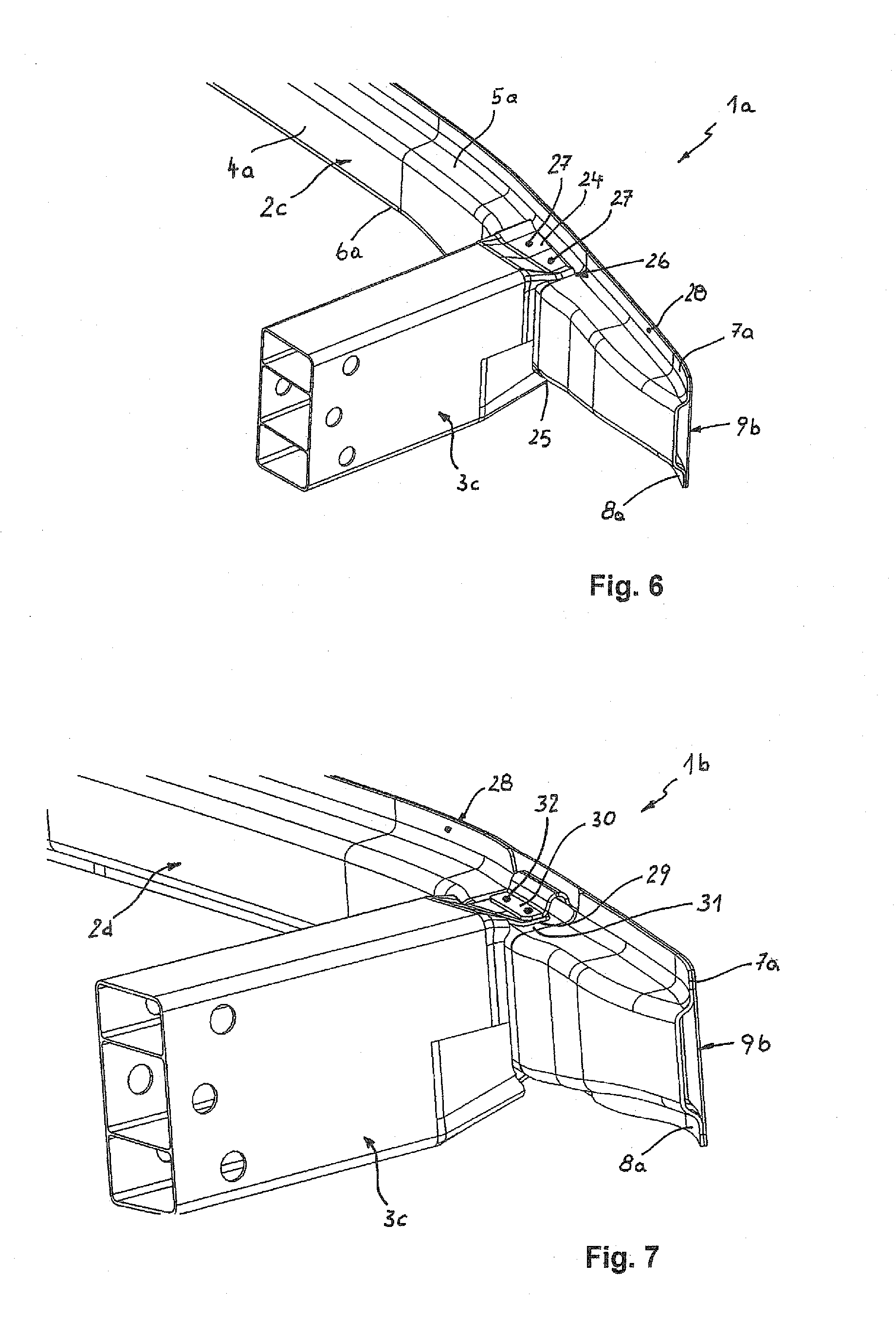

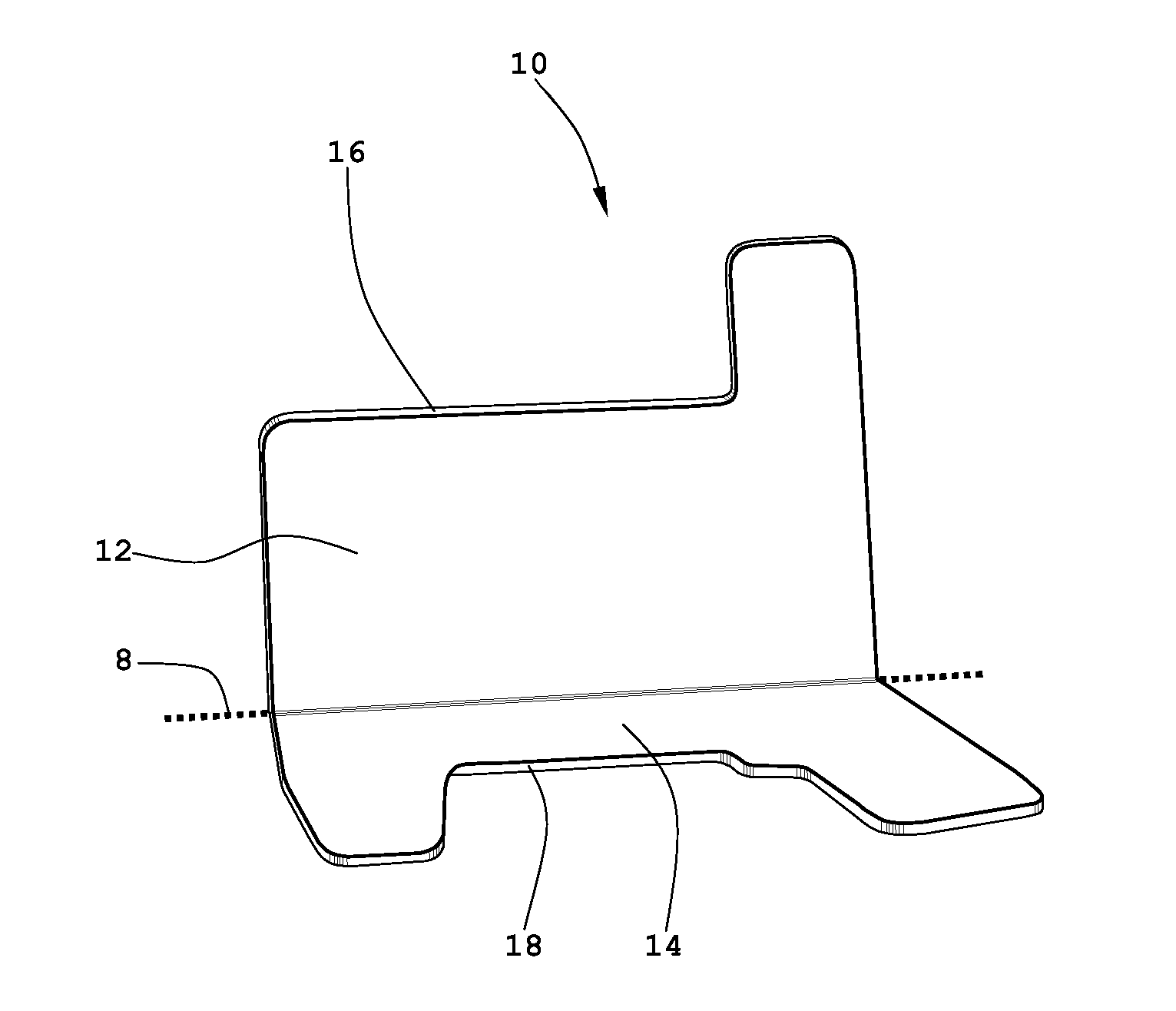

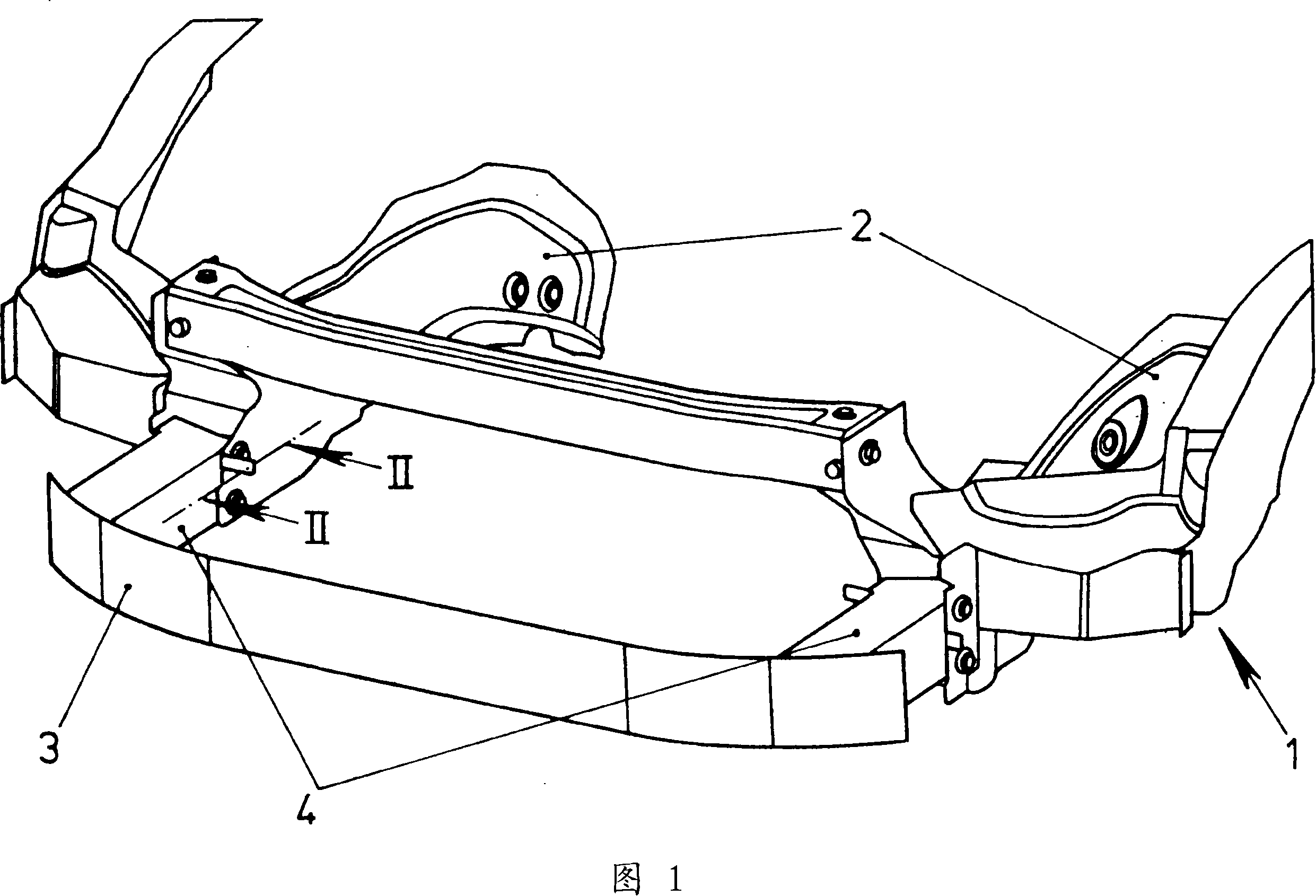

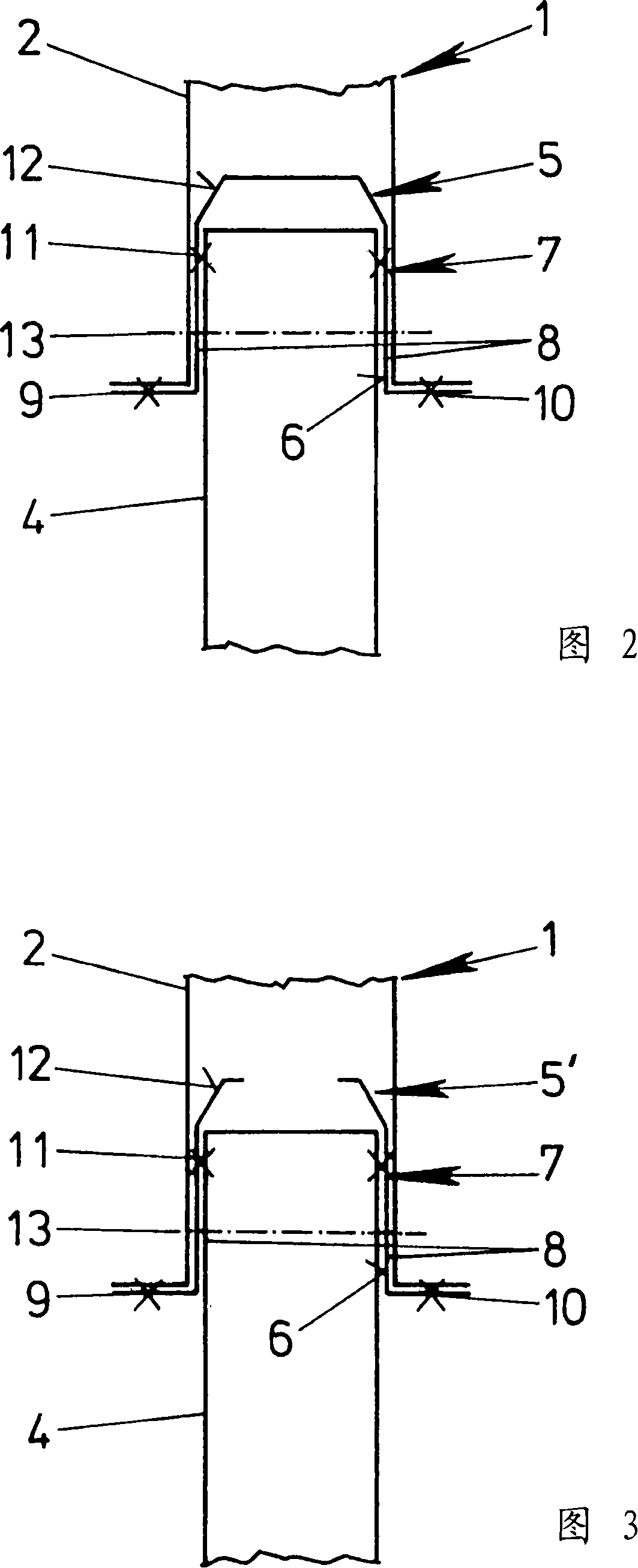

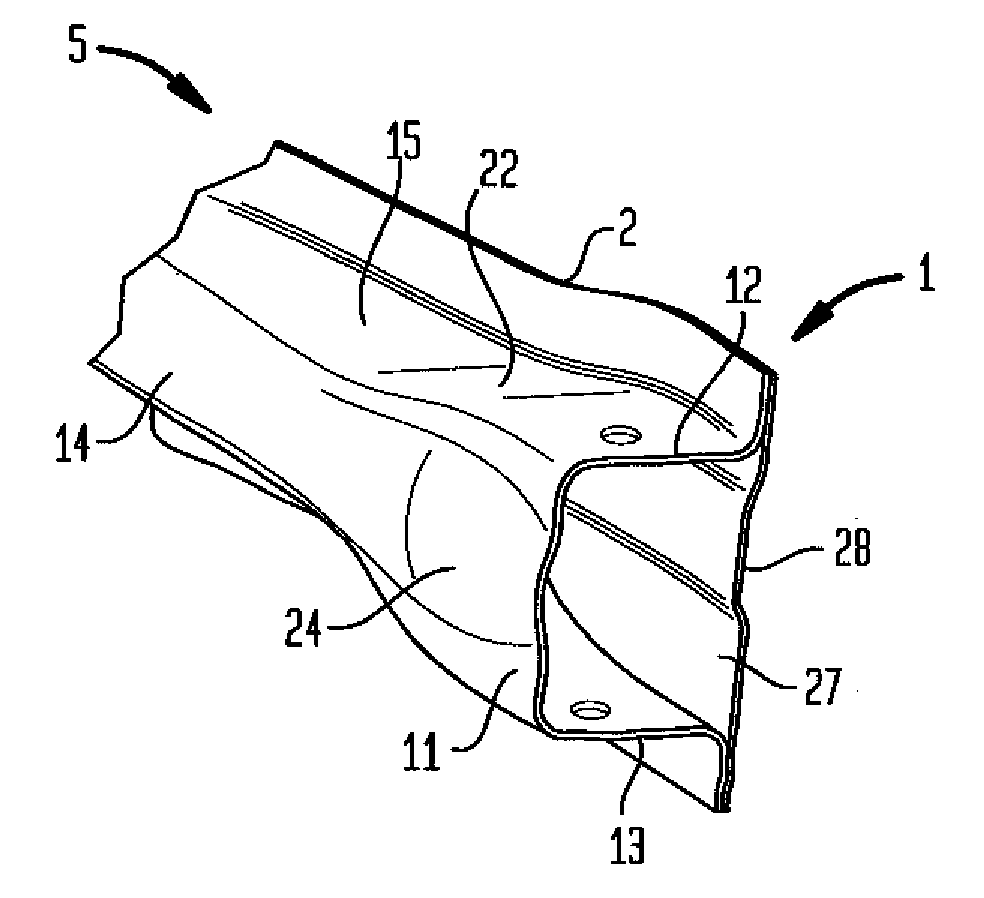

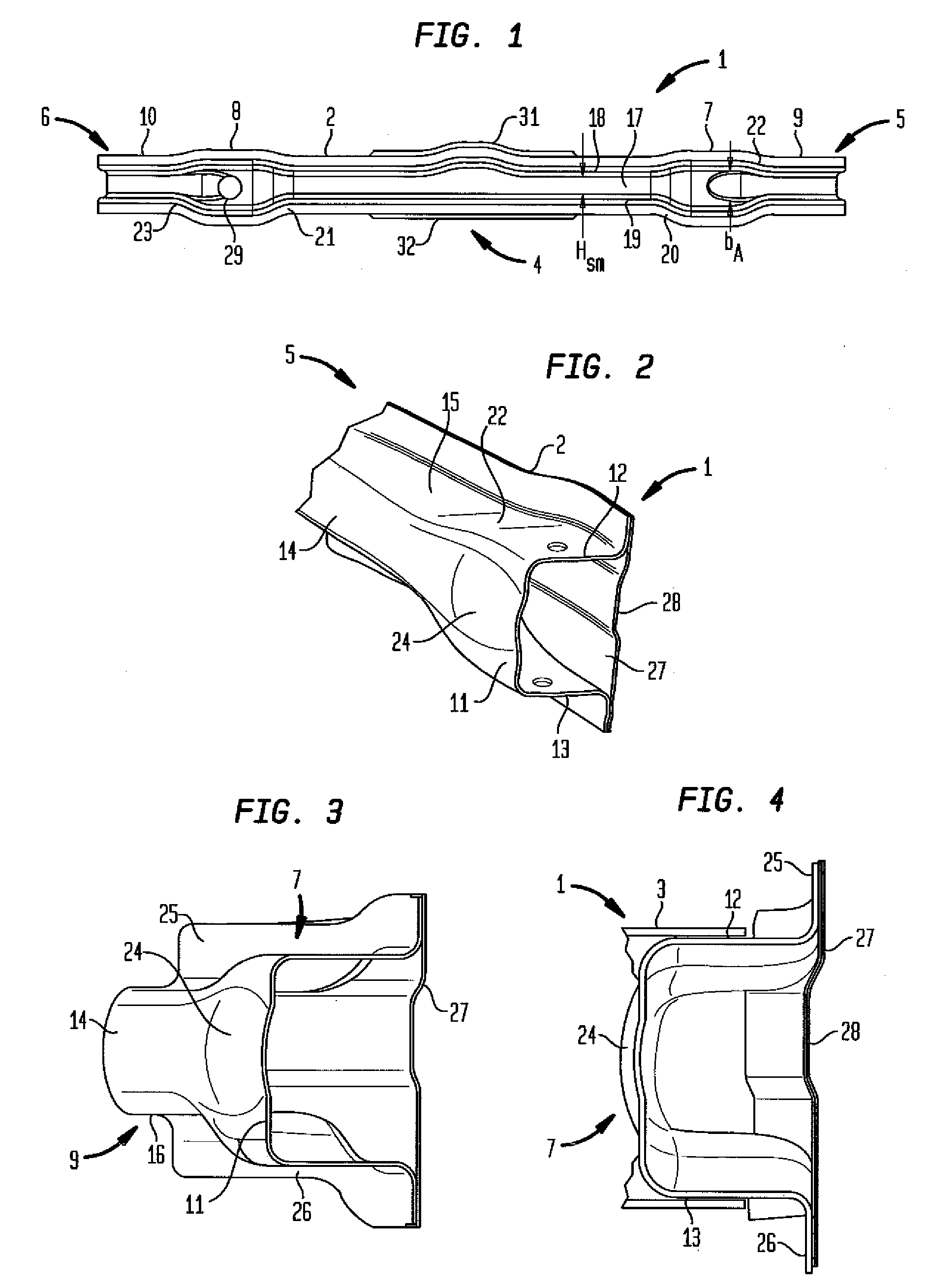

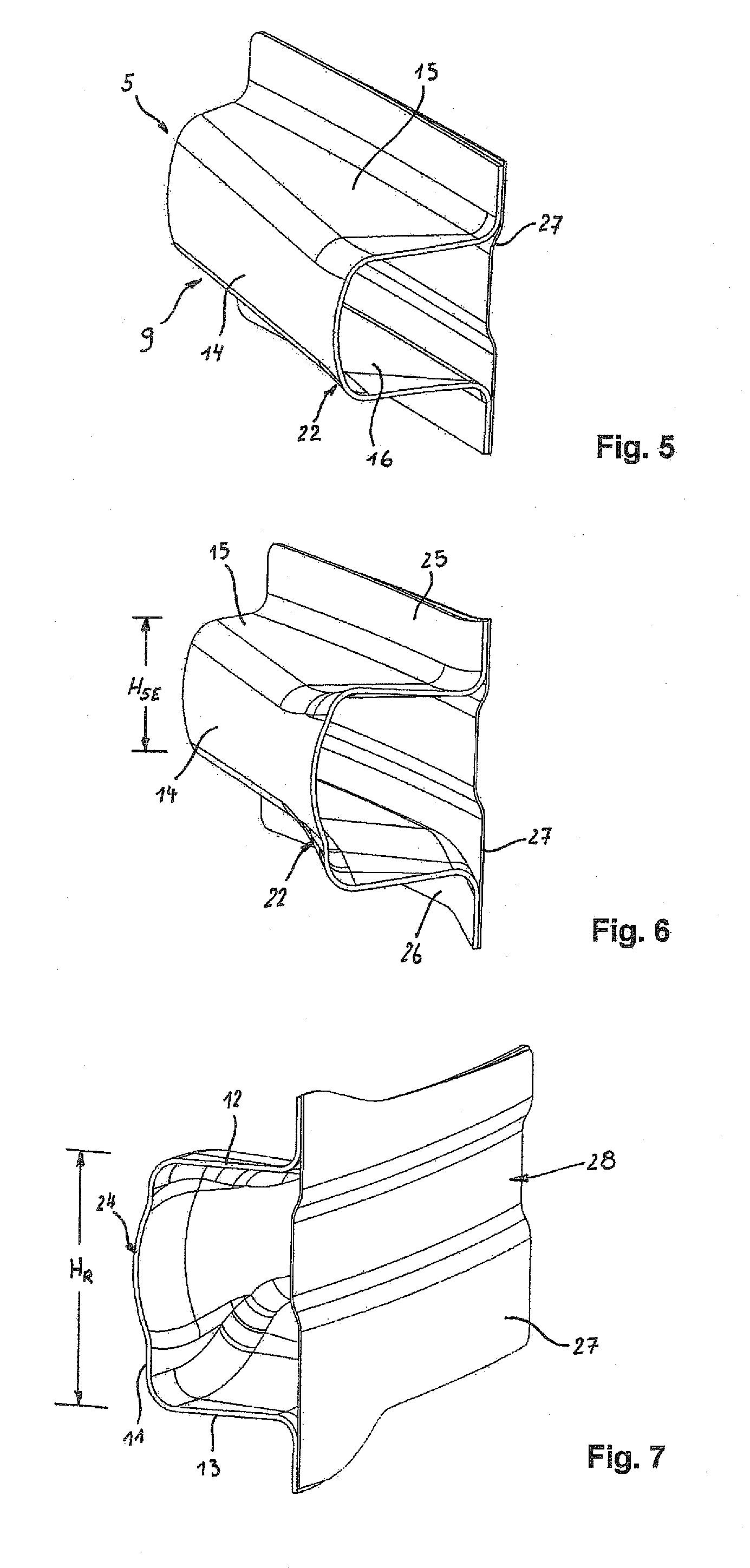

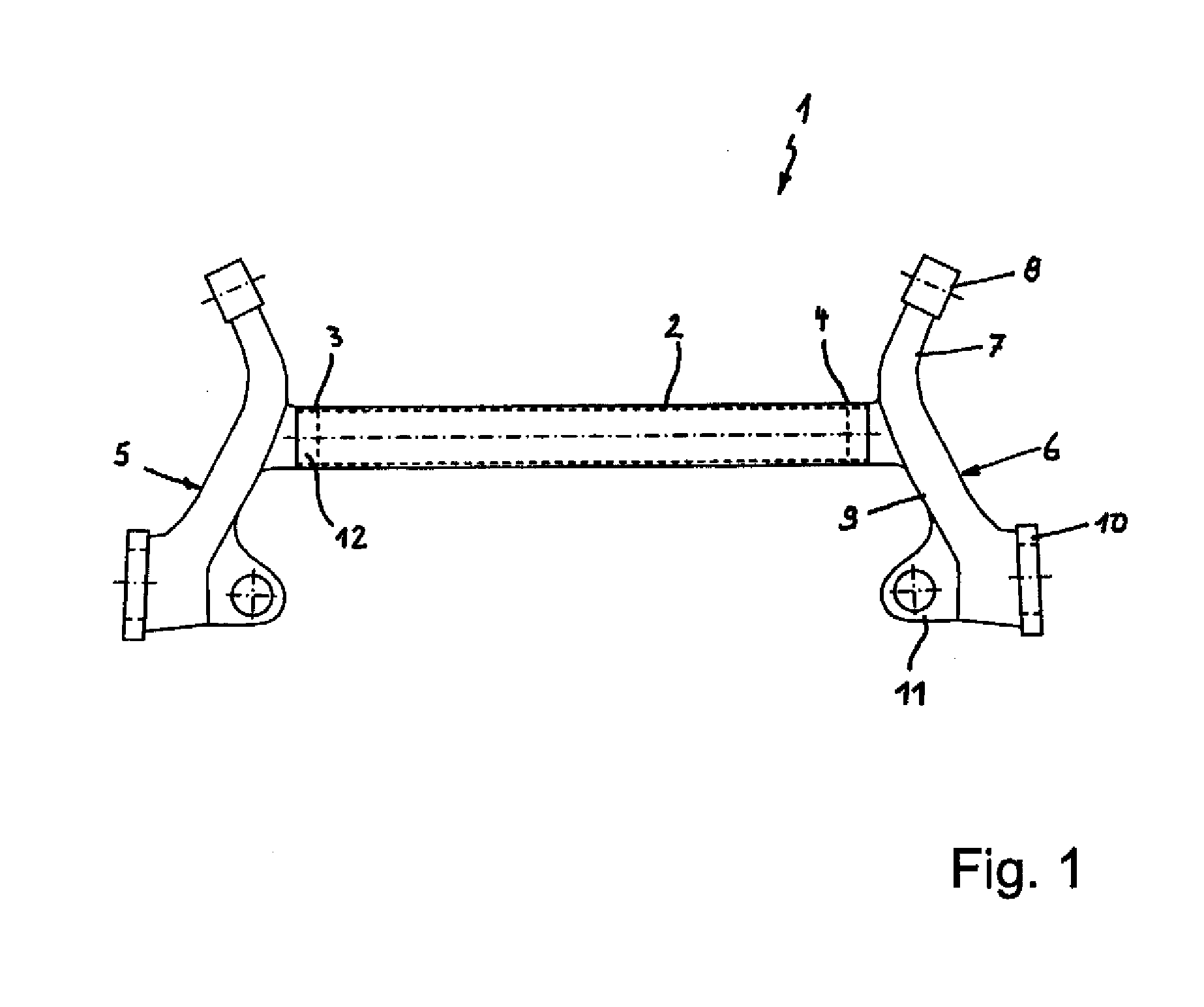

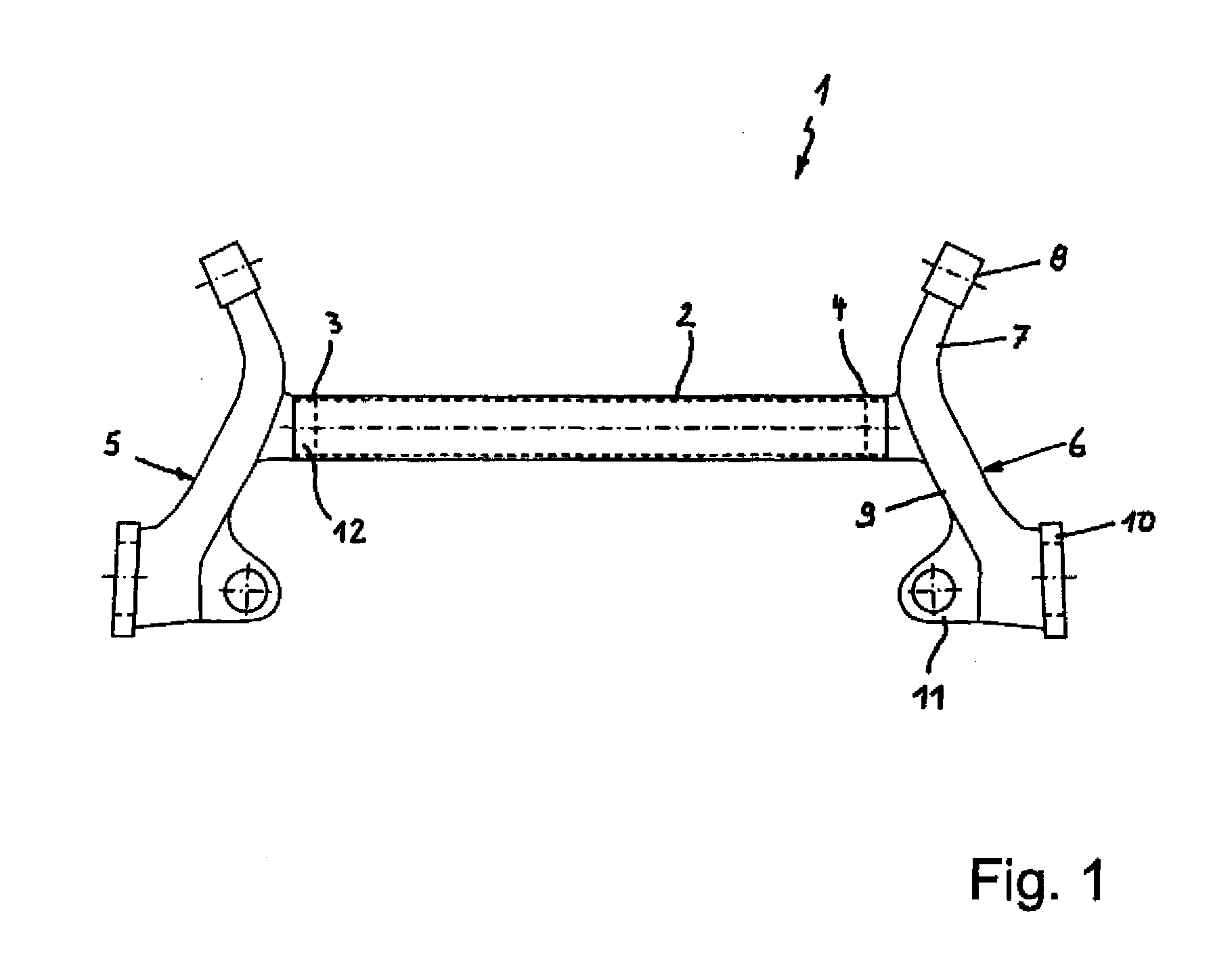

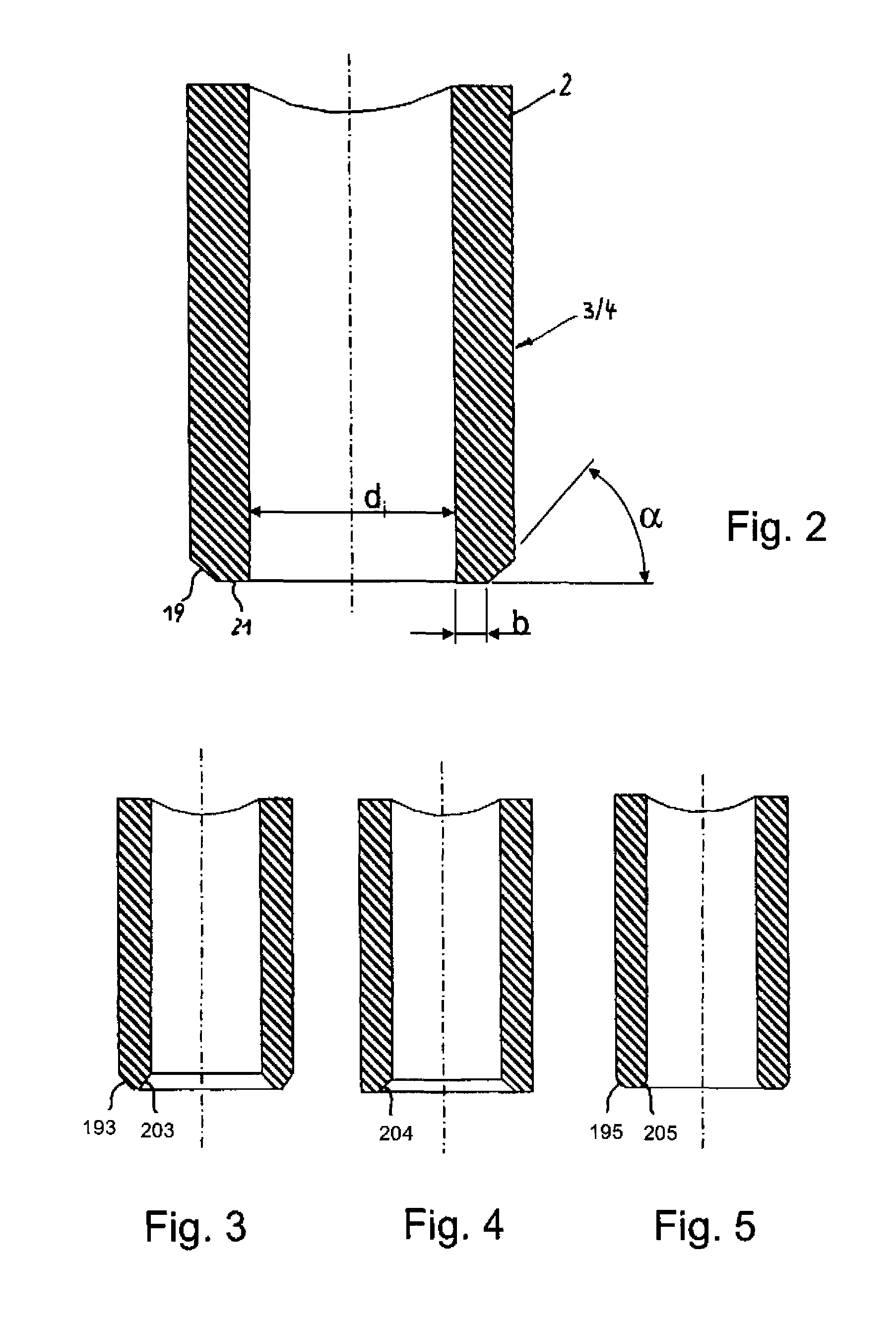

Bumper for a motor vehicle

InactiveUS20100194125A1High corrosion potentialReduce manufacturing costBumpersVehicle frameEngineering

A bumper for a motor vehicle includes a cross member which is disposed transversely to a side rail of a motor vehicle frame. A crash box is incorporated between the cross member and the side rail, with set bolts being provided to join the crash box to the cross member in the absence of prepunching.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Method and apparatus for downhole fluid characterization using flexural mechanical resonators

InactiveUS7162918B2Avoid contact corrosionInversely to viscosityElectric/magnetic detection for well-loggingSurveyTuning forkFormation fluid

The present invention provides a downhole method and apparatus using a flexural mechanical resonator, for example, a tuning fork to provide real-time direct measurements and estimates of the viscosity, density and dielectric constant of formation fluid or filtrate in a hydrocarbon producing well. The present invention additionally provides a method and apparatus for monitoring cleanup from a leveling off of viscosity or density over time, measuring or estimating bubble point for formation fluid, measuring or estimating dew point for formation fluid, and determining the onset of asphaltene precipitation. The present invention also provides for intercalibration of plural pressure gauges used to determine a pressure differential downhole. A hard or inorganic coating is placed on the flexural mechanical resonator (such as a tuning fork) to reduce the effects of abrasion from sand particles suspended in the flowing fluid in which the flexural mechanical resonator is immersed.

Owner:BAKER HUGHES INC

Method and apparatus for downhole fluid characterization using flexural mechanical resonators

InactiveUS20050247119A1Avoid contact corrosionProtection from damageElectric/magnetic detection for well-loggingSurveyTuning forkFormation fluid

The present invention provides a downhole method and apparatus using a flexural mechanical resonator, for example, a tuning fork to provide real-time direct measurements and estimates of the viscosity, density and dielectric constant of formation fluid or filtrate in a hydrocarbon producing well. The present invention additionally provides a method and apparatus for monitoring cleanup from a leveling off of viscosity or density over time, measuring or estimating bubble point for formation fluid, measuring or estimating dew point for formation fluid, and determining the onset of asphaltene precipitation. The present invention also provides for intercalibration of plural pressure gauges used to determine a pressure differential downhole. A hard or inorganic coating is placed on the flexural mechanical resonator (such as a tuning fork) to reduce the effects of abrasion from sand particles suspended in the flowing fluid in which the flexural mechanical resonator is immersed.

Owner:BAKER HUGHES INC

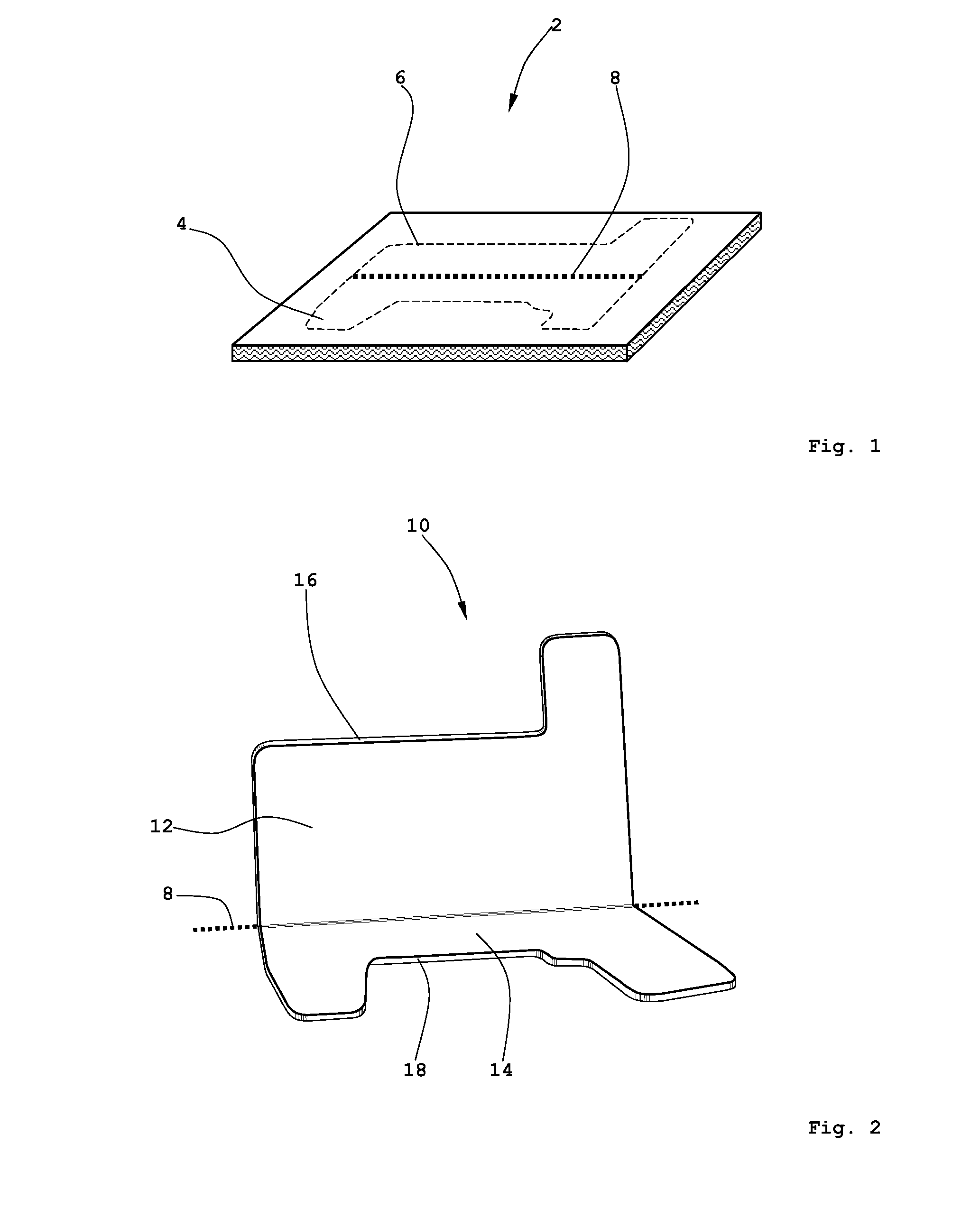

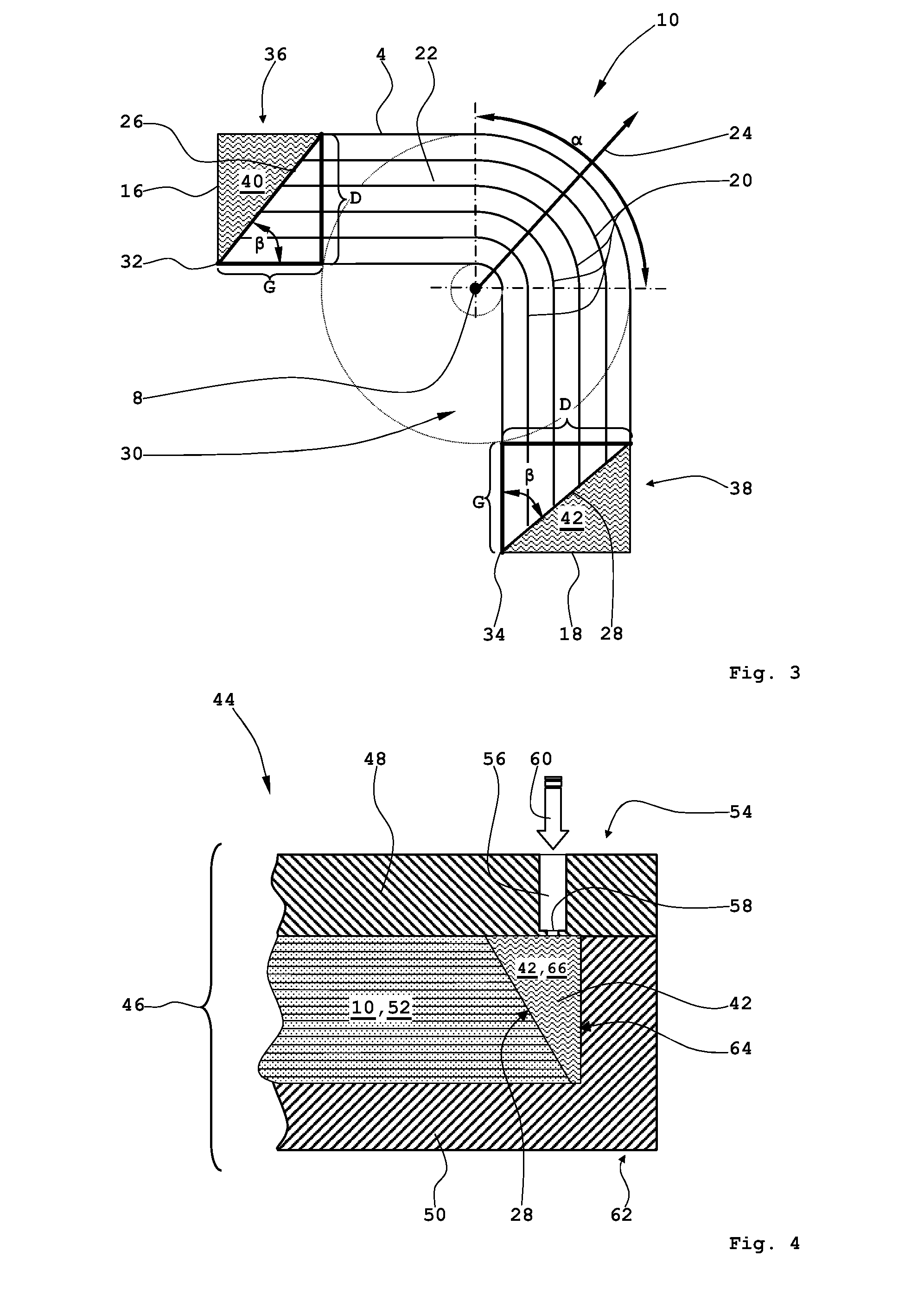

Method for the manufacture of a fiber-reinforced component, device for implementing the method, and fiber-reinforced component

ActiveUS20110155854A1Simplified and easily automatableSmall sizeConfectioneryFuselage bulkheadsCarbon fibersPlastic materials

A method for the manufacture of a fiber-reinforced component includes heating a blank of a carbon-fiber-reinforced thermoplastic plastic material to at least a melting temperature of the thermoplastic plastic material; introducing the blank into an at least two-part moulding tool; forming the fiber-reinforced component by applying pressure on the blank using the moulding tool; and injecting a further thermoplastic plastic material into at least one edge region of the moulding tool so as to form an edge seal.

Owner:AIRBUS OPERATIONS GMBH

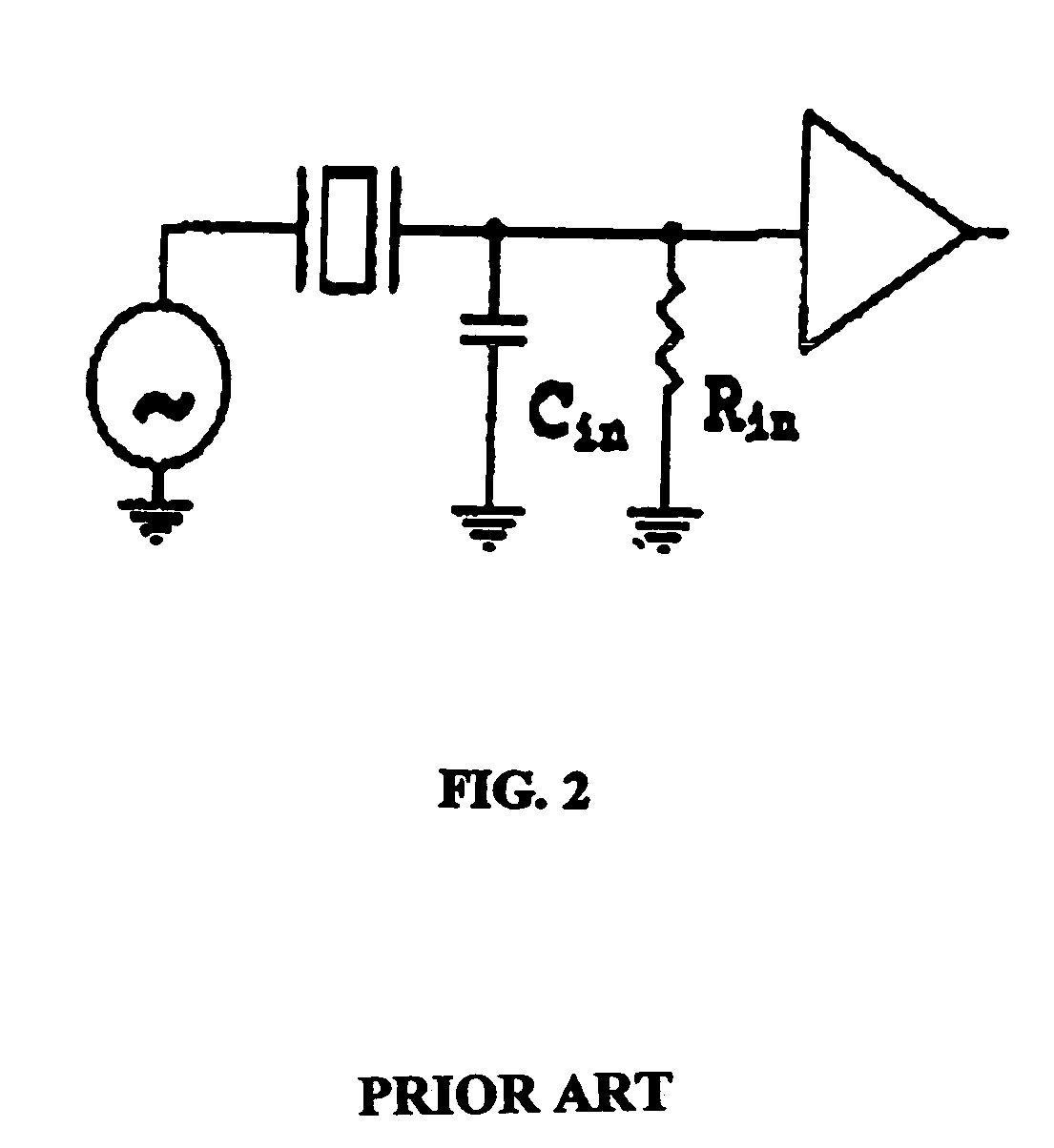

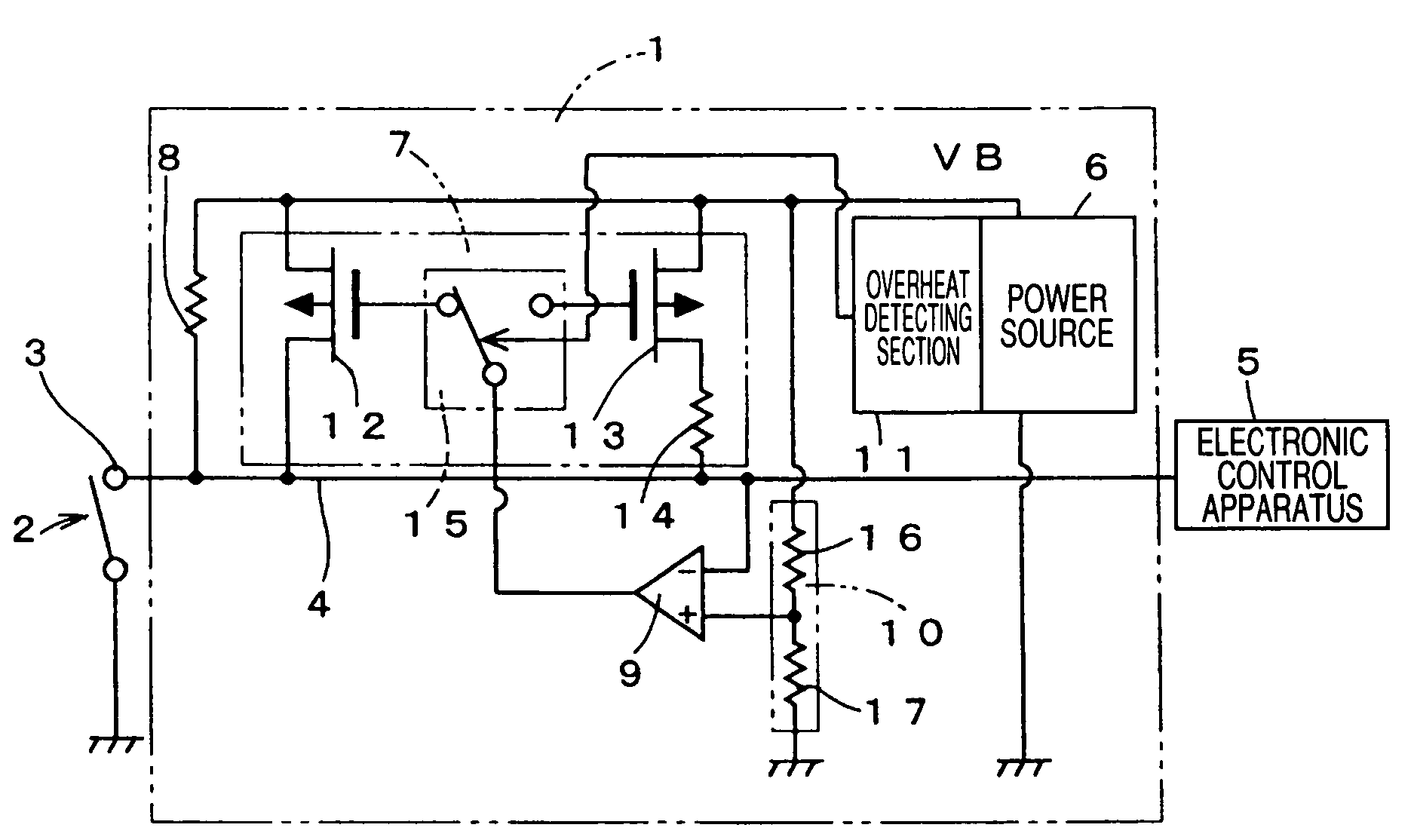

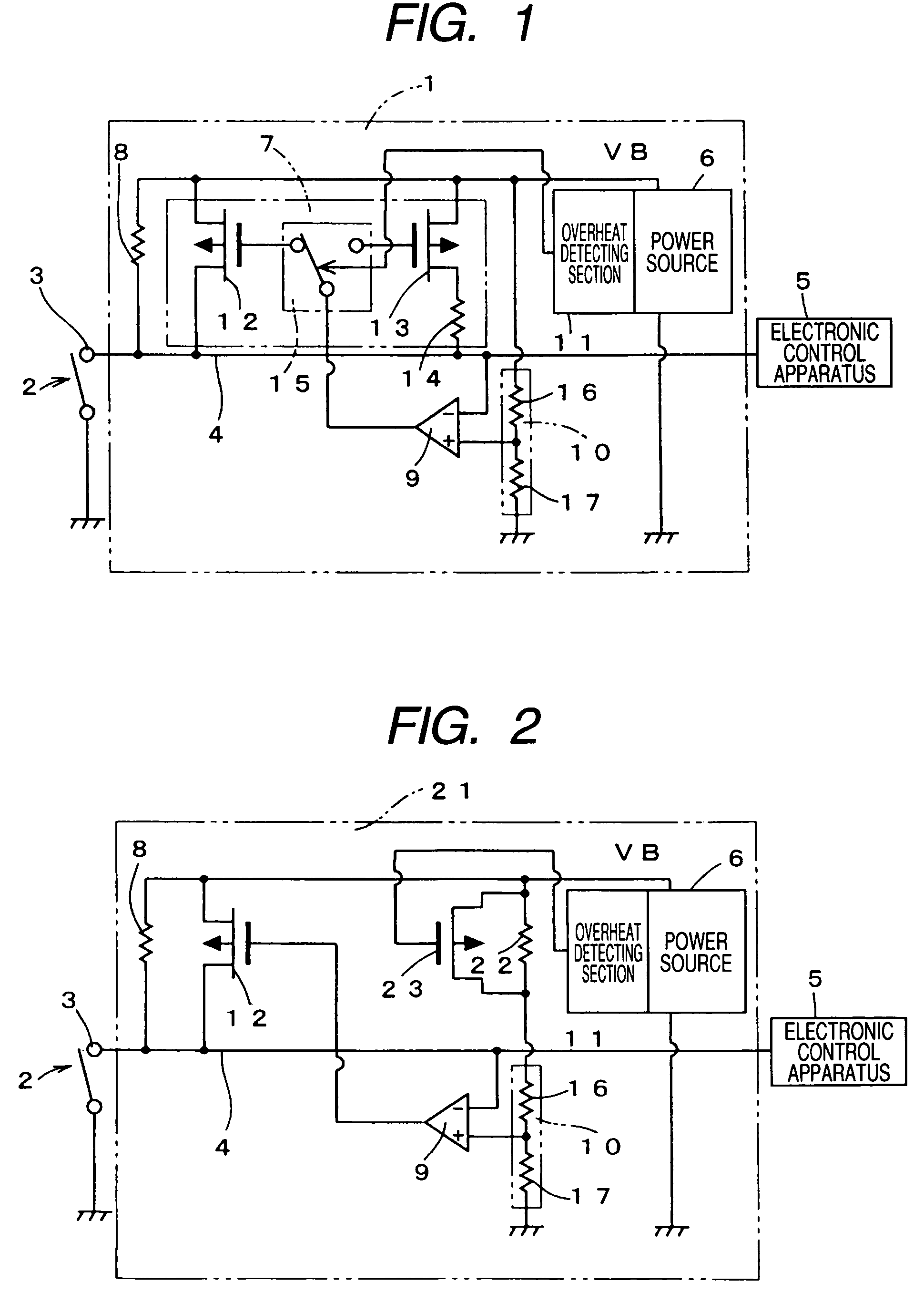

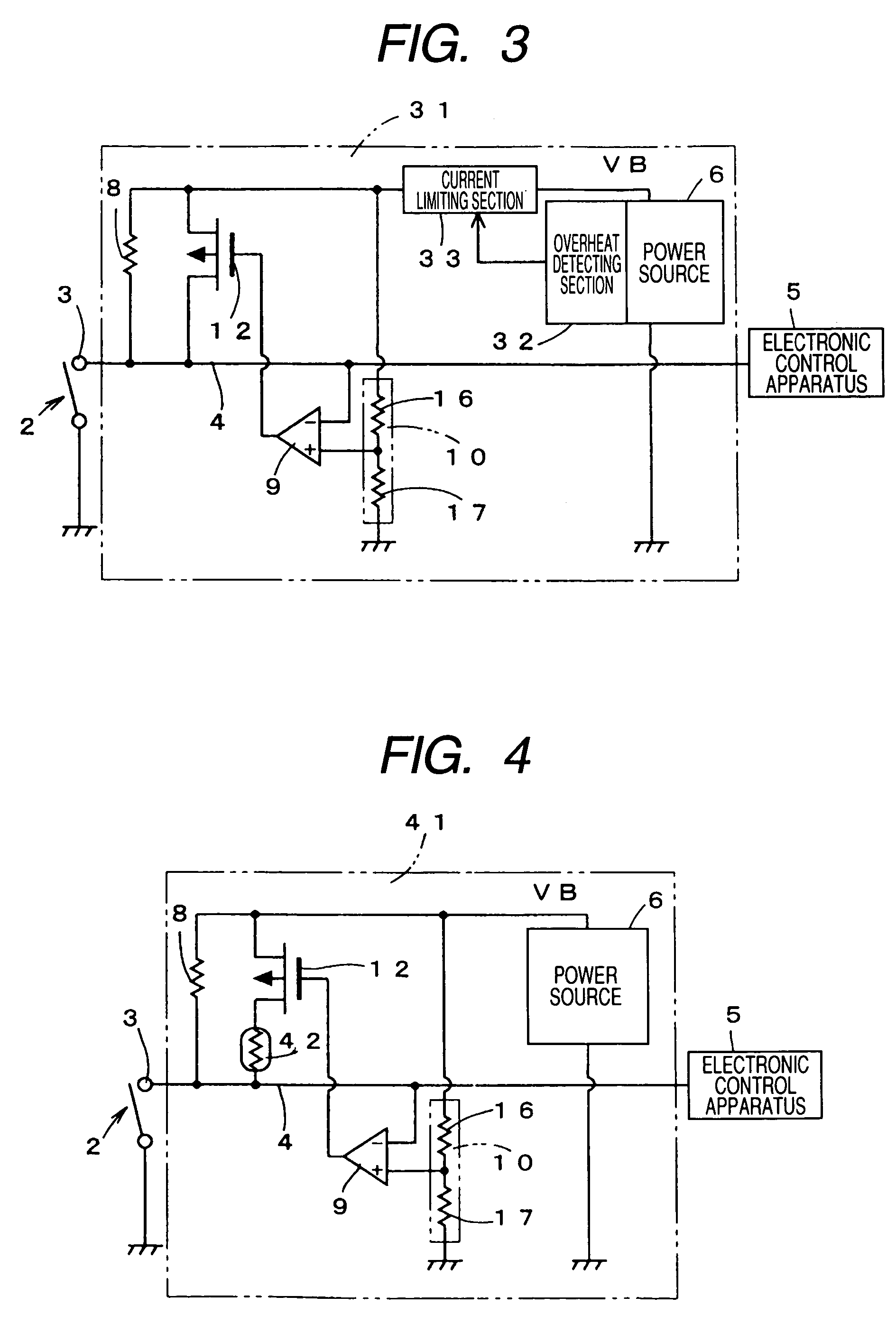

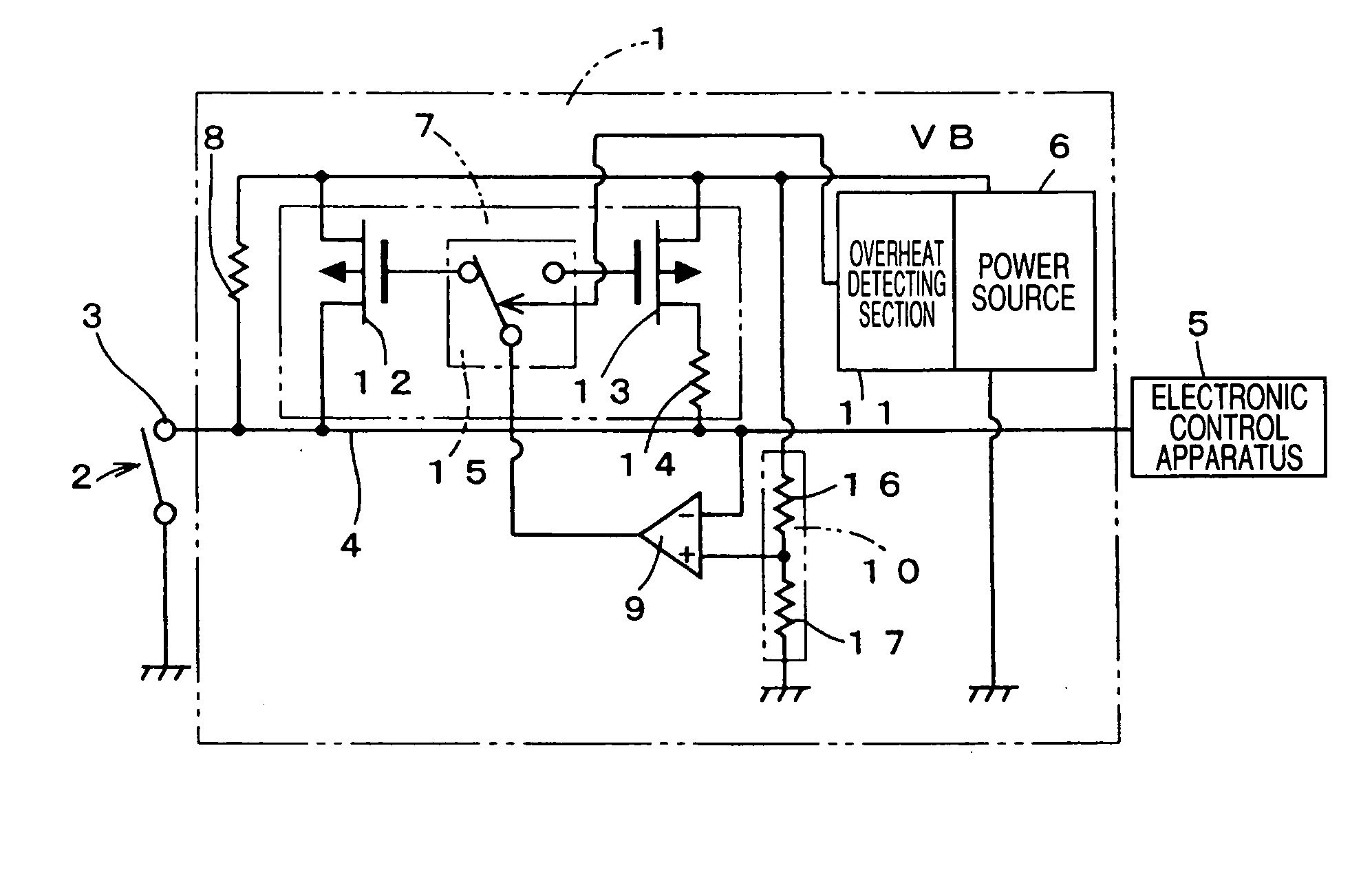

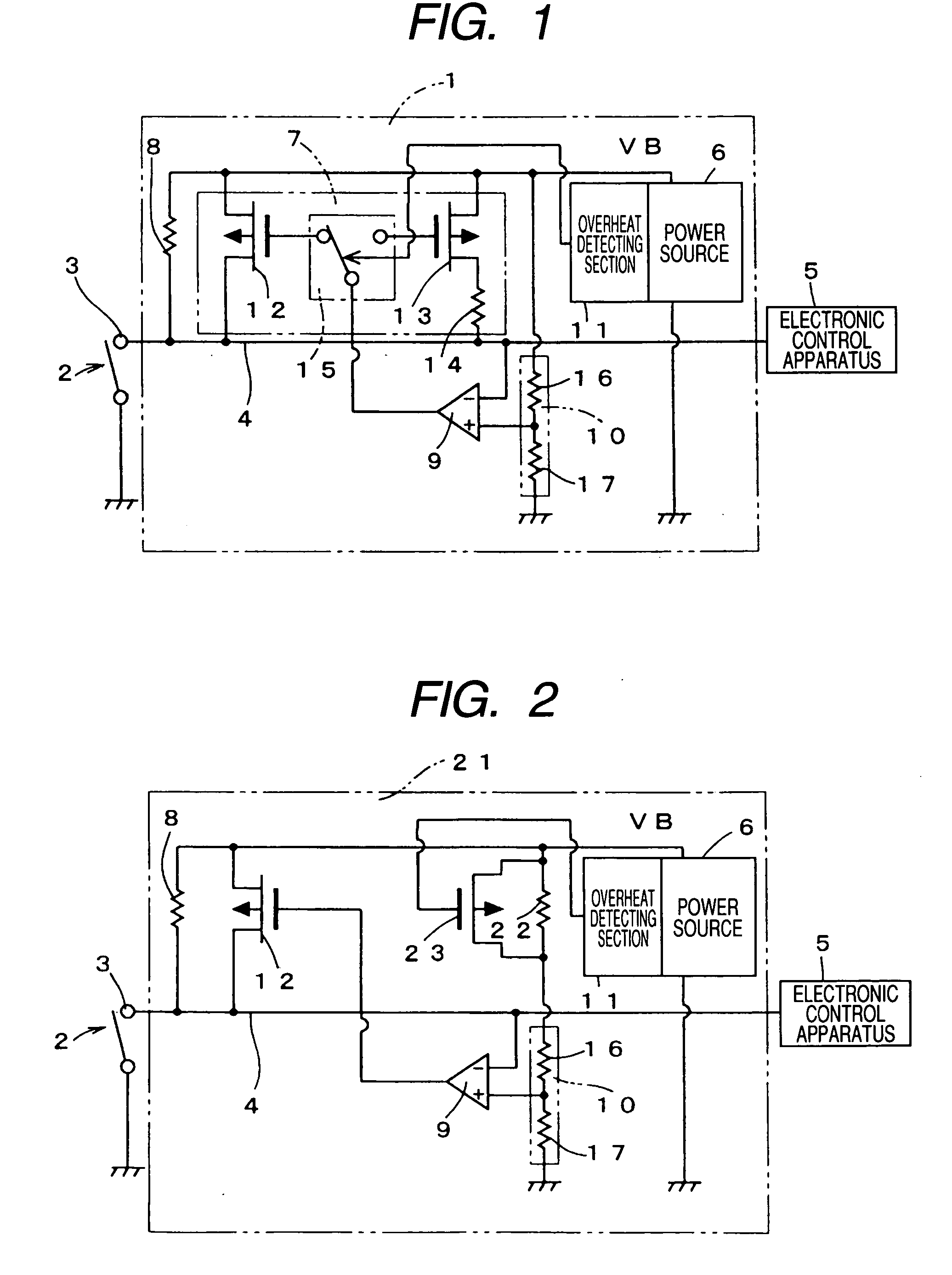

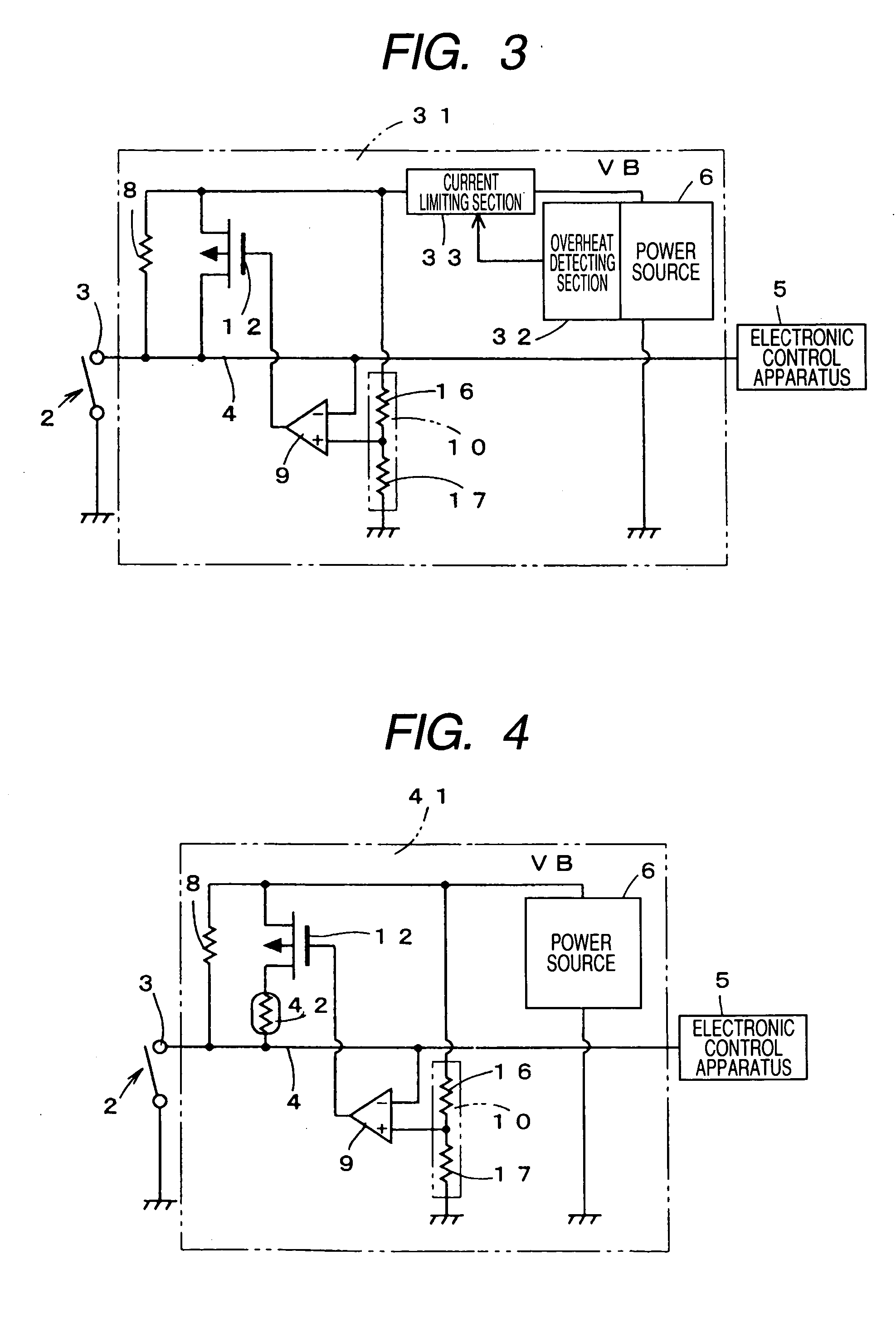

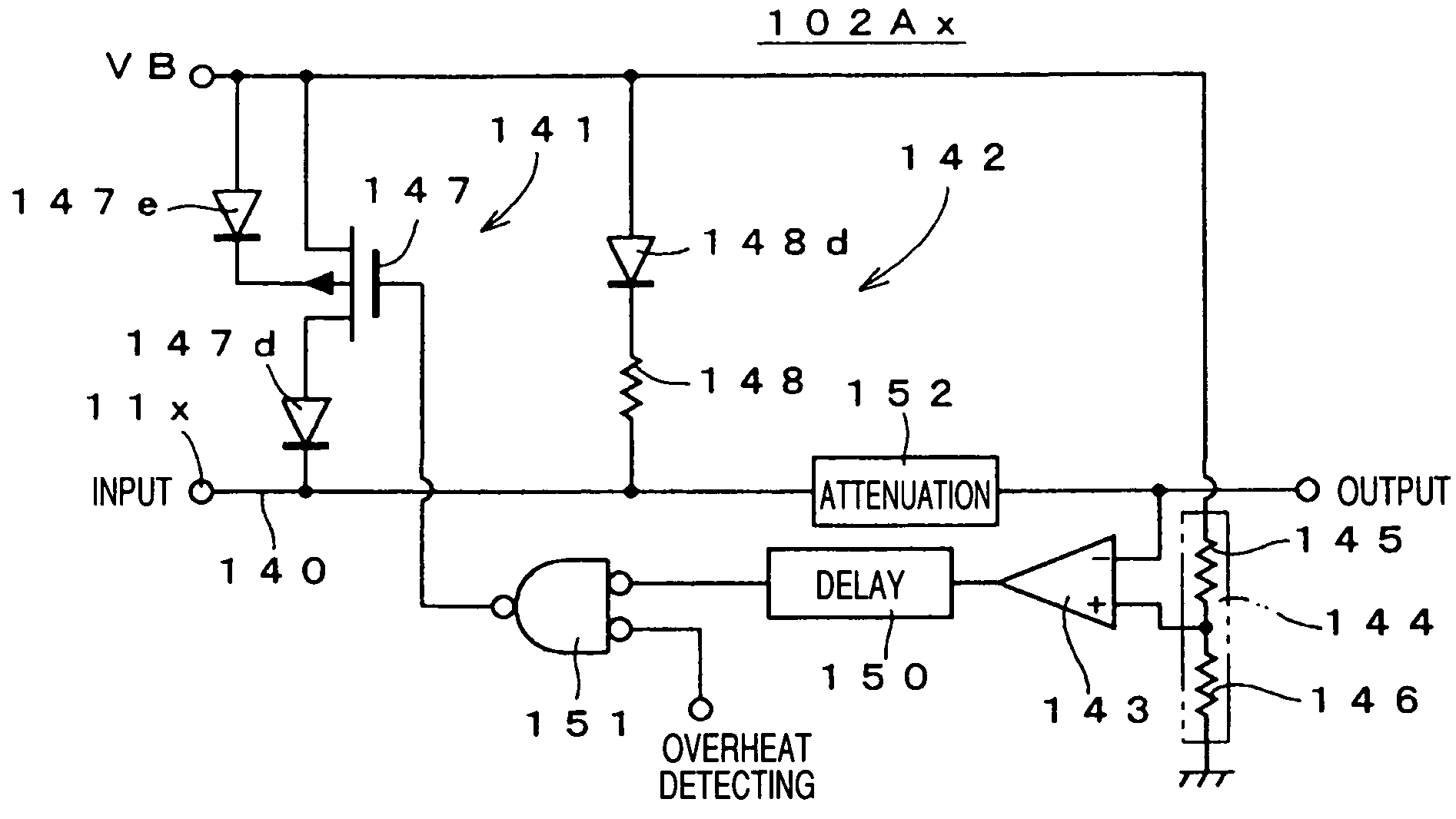

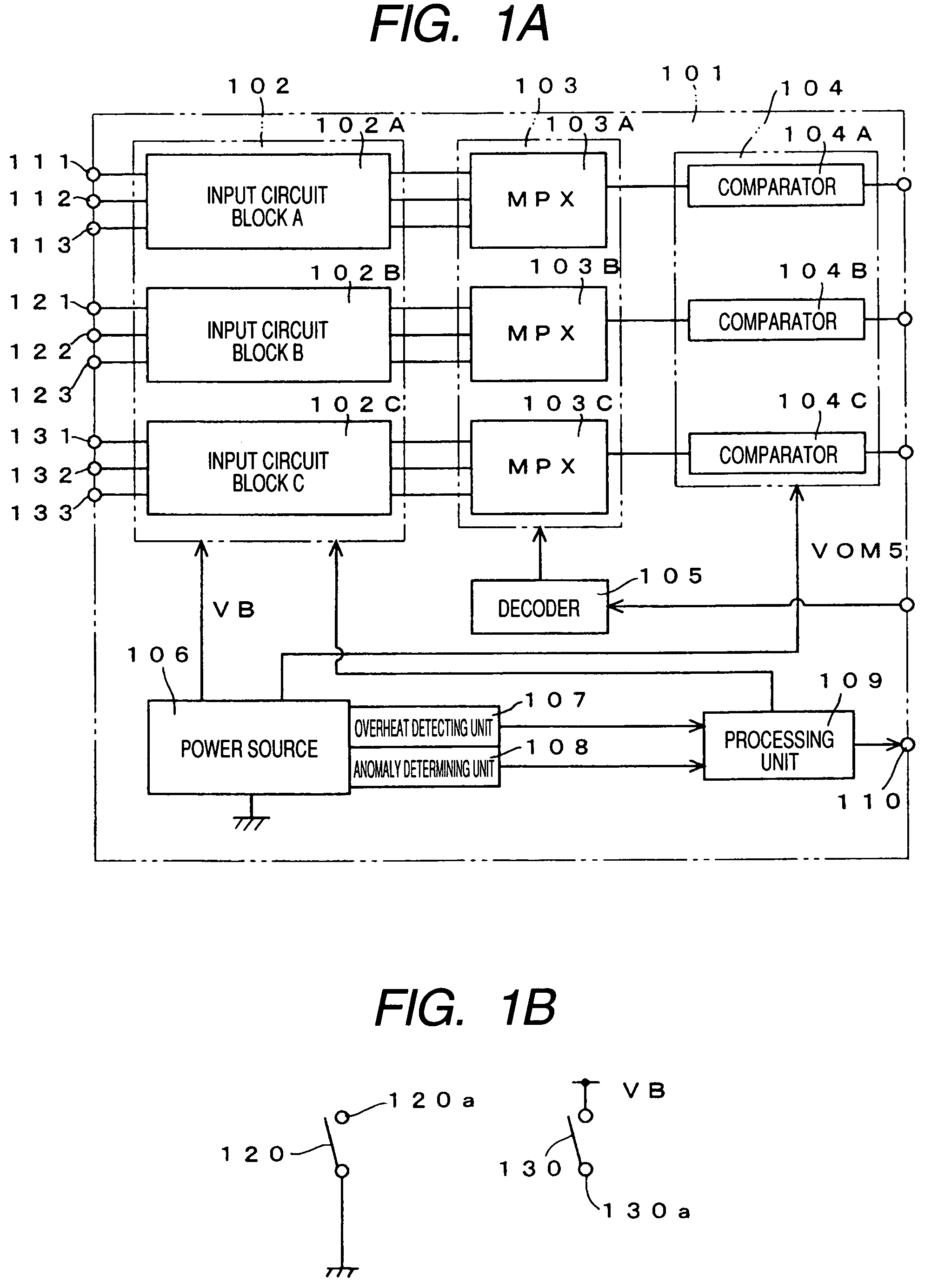

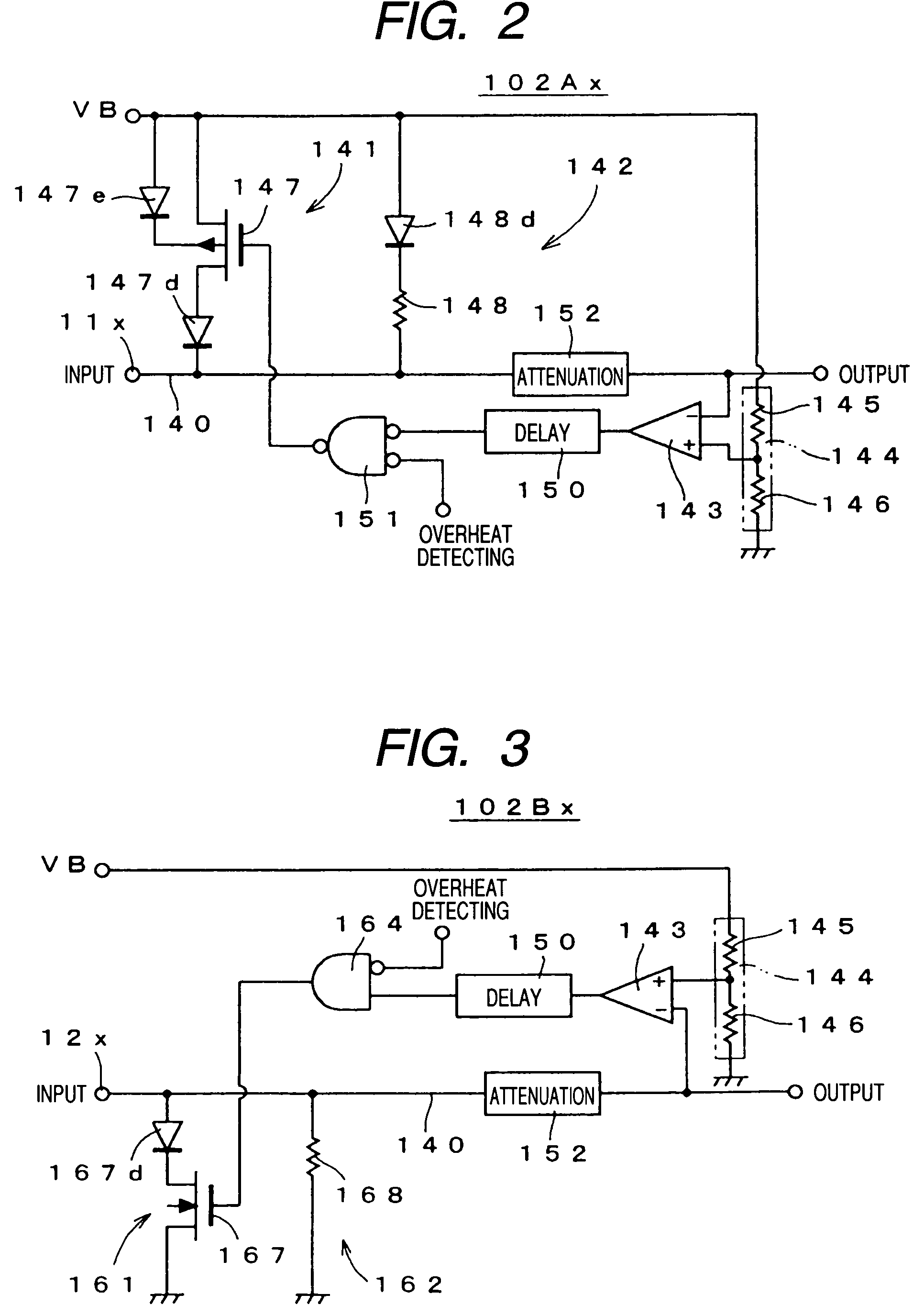

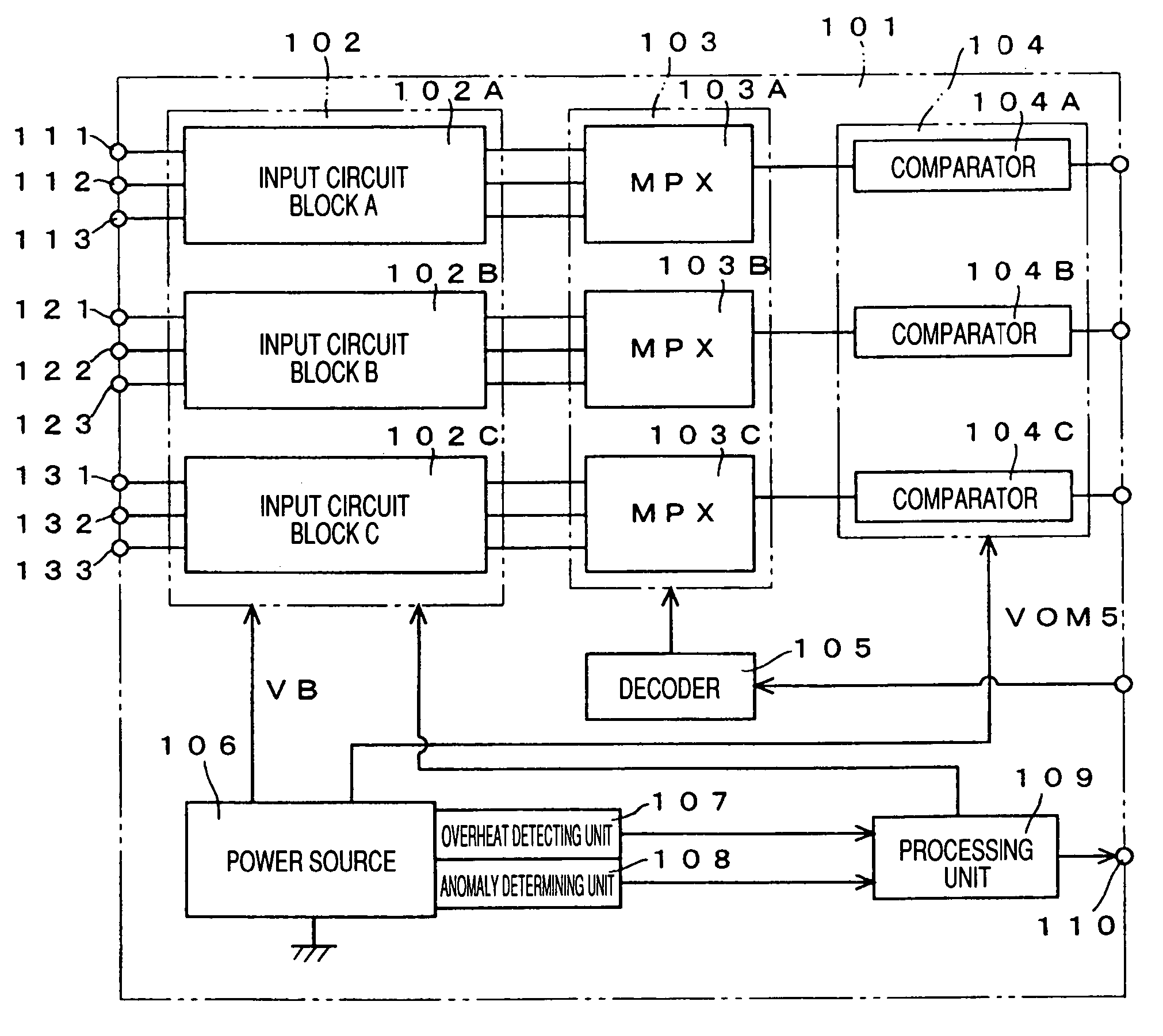

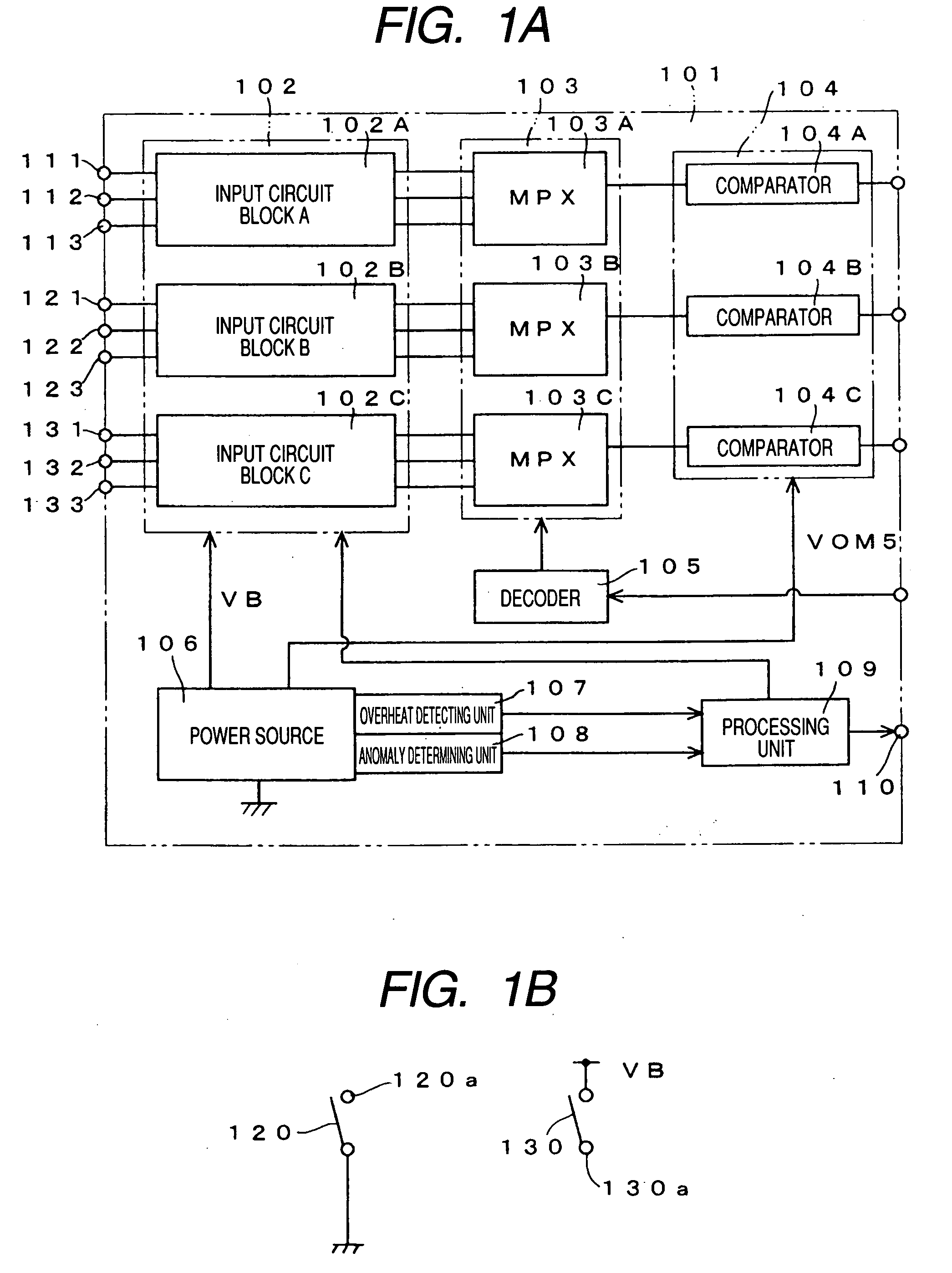

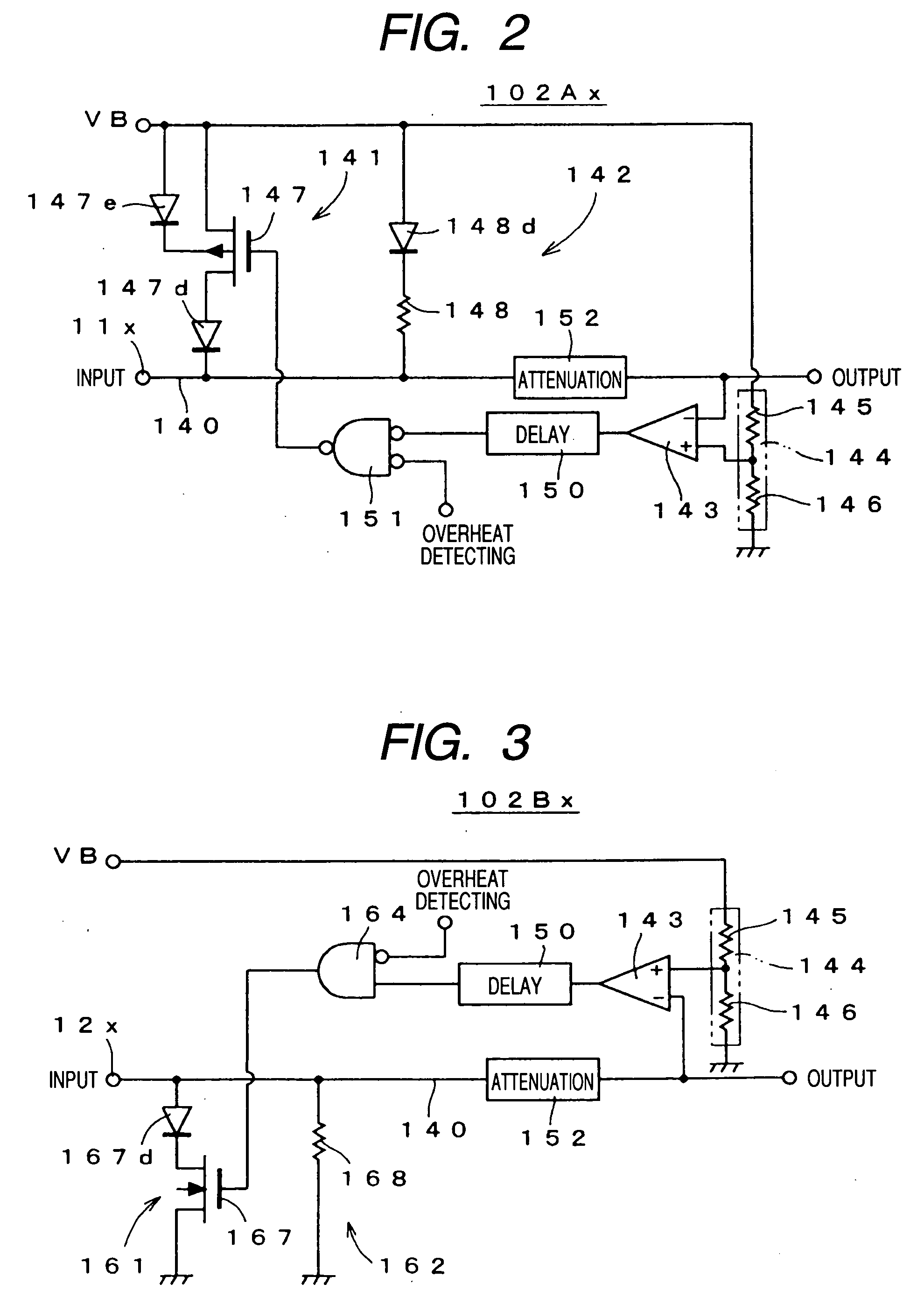

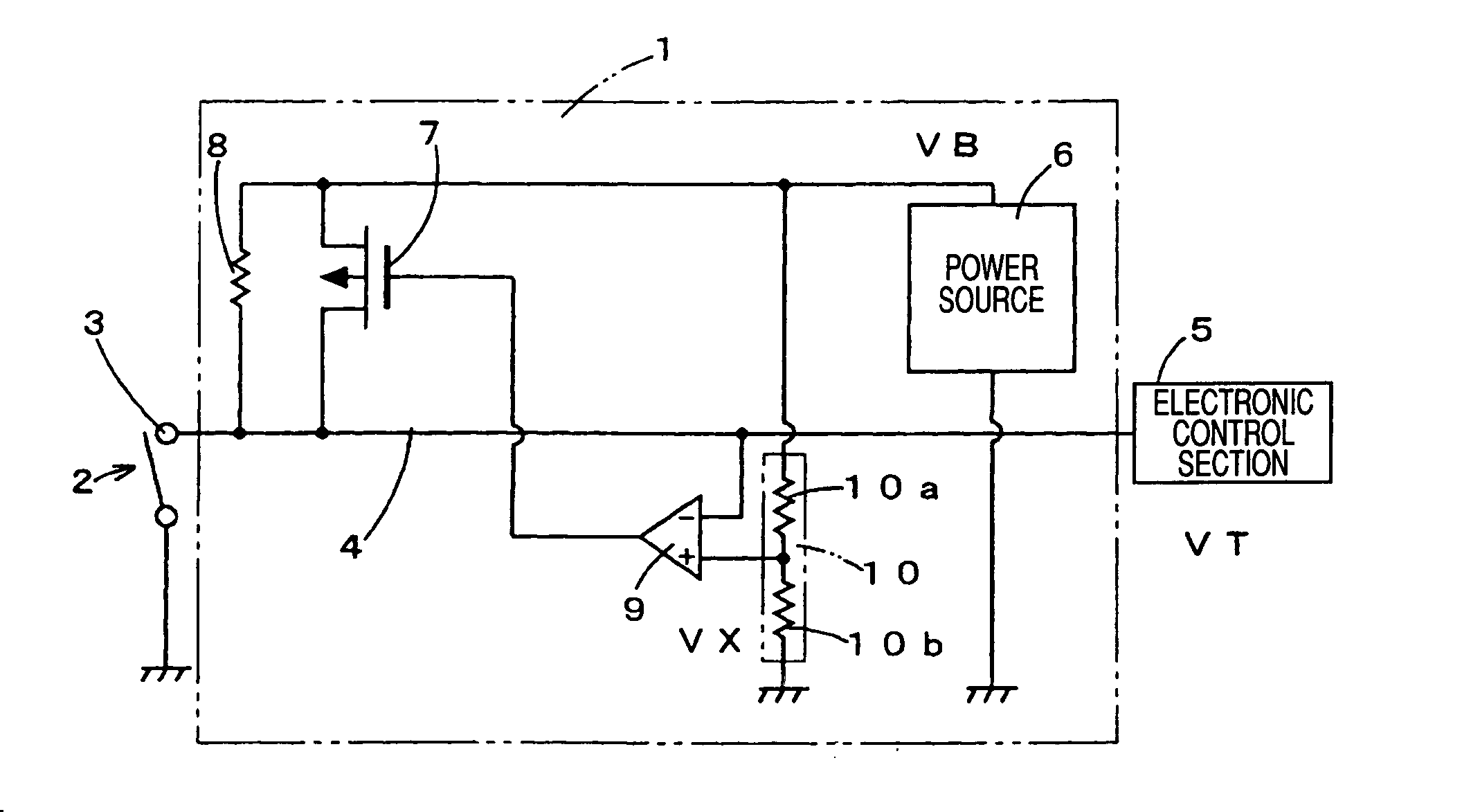

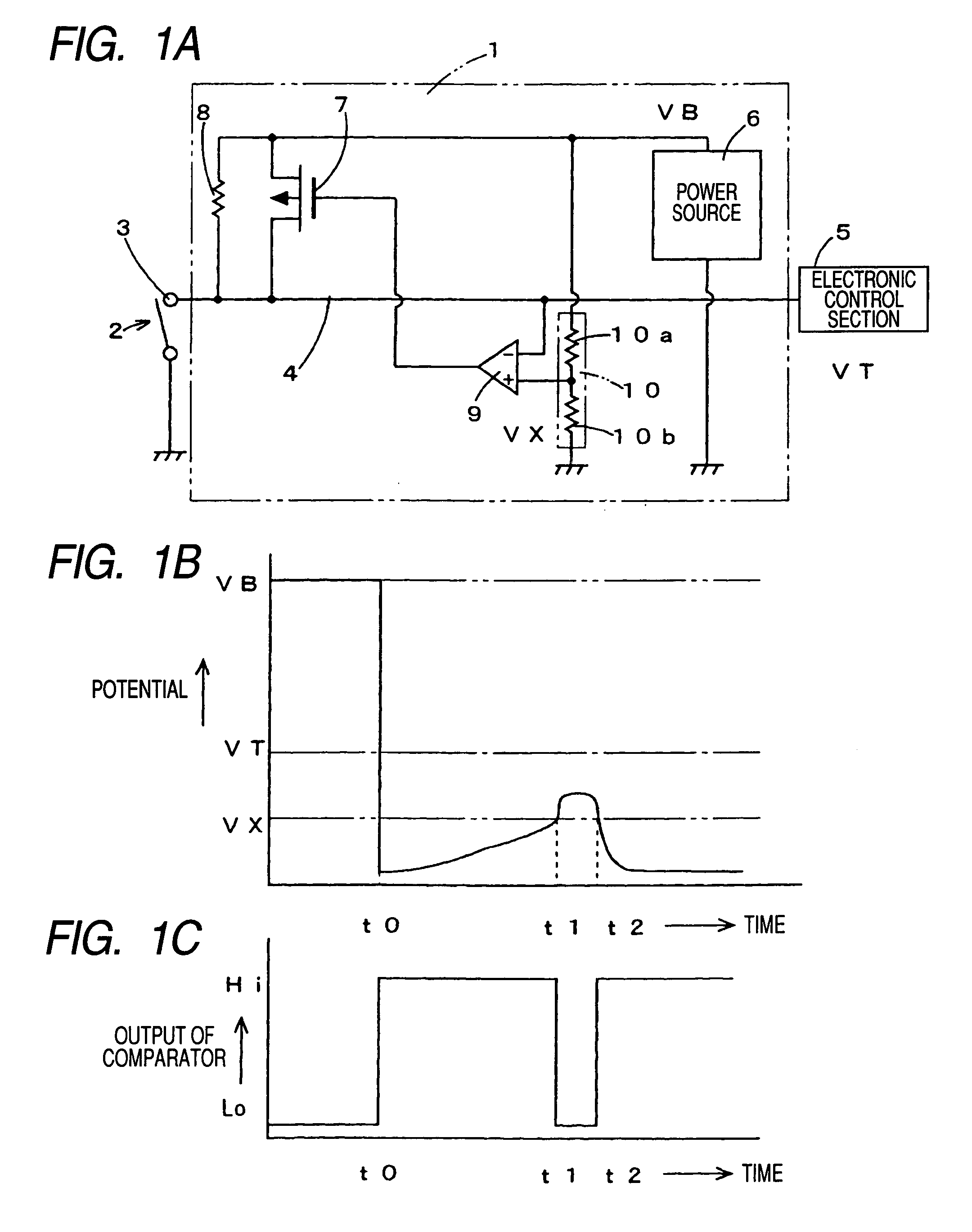

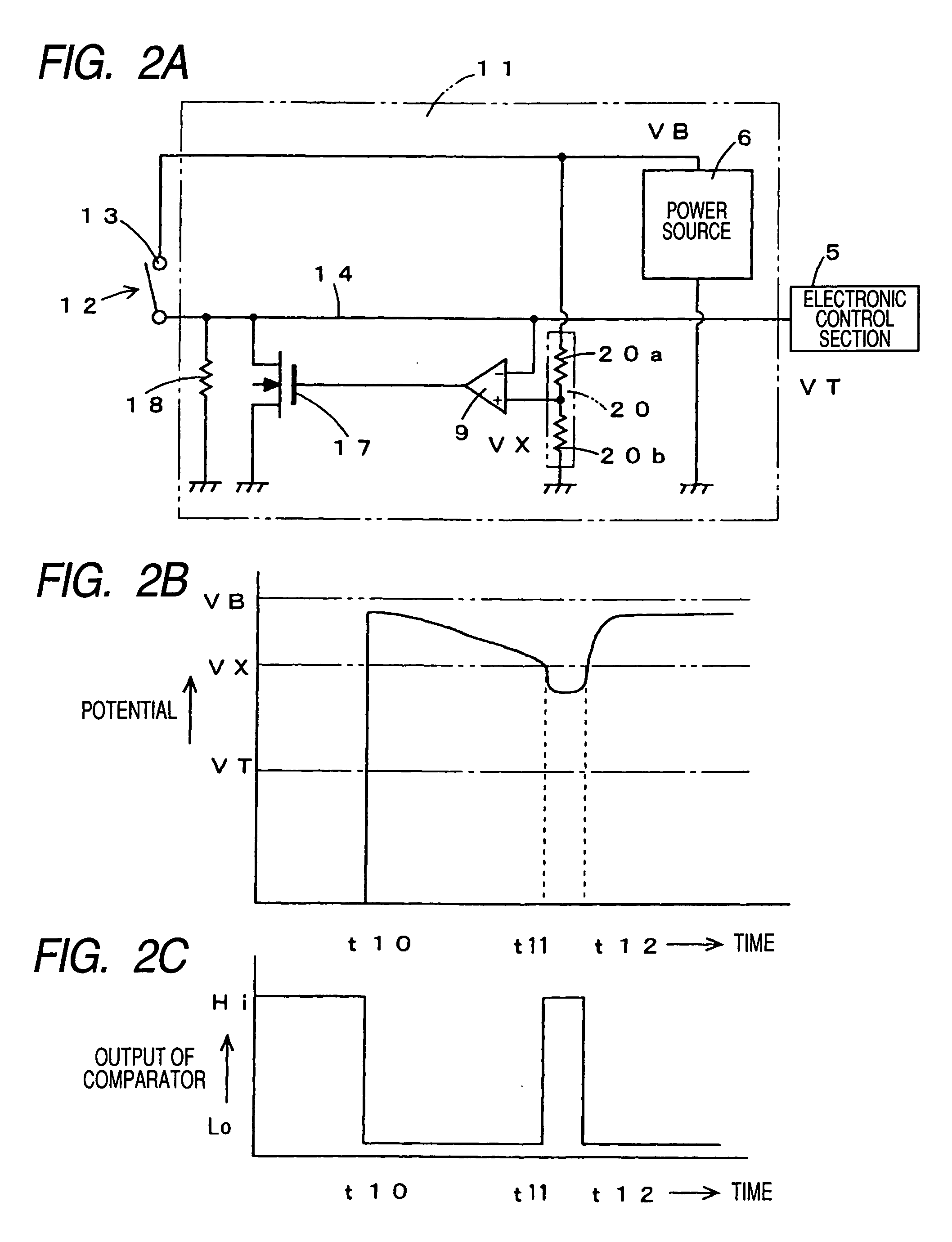

Apparatus for preventing corrosion of contact

InactiveUS7362011B2Avoid contact corrosionEasy to judgeEmergency protective arrangements for automatic disconnectionCapacitorsEngineeringElectrical impedance

Owner:FUJITSU GENERAL LTD

Aluminum-silicon-zinc-rare earth-magnesium-ferrum-containing hot dip coating alloy and method for preparing same

ActiveCN101736217AUniform compositionImprove toughnessHot-dipping/immersion processesRare-earth elementDip-coating

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, magnesium, ferrum and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc, 0.02 to 0.5 percent of rare earth elements, 0.5 to 3.2 percent of magnesium, 0.05 to 1 percent of ferrum, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitable impurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. The hot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titanium alloy.

Owner:JIANGSU LINLONG NEW MATERIALS

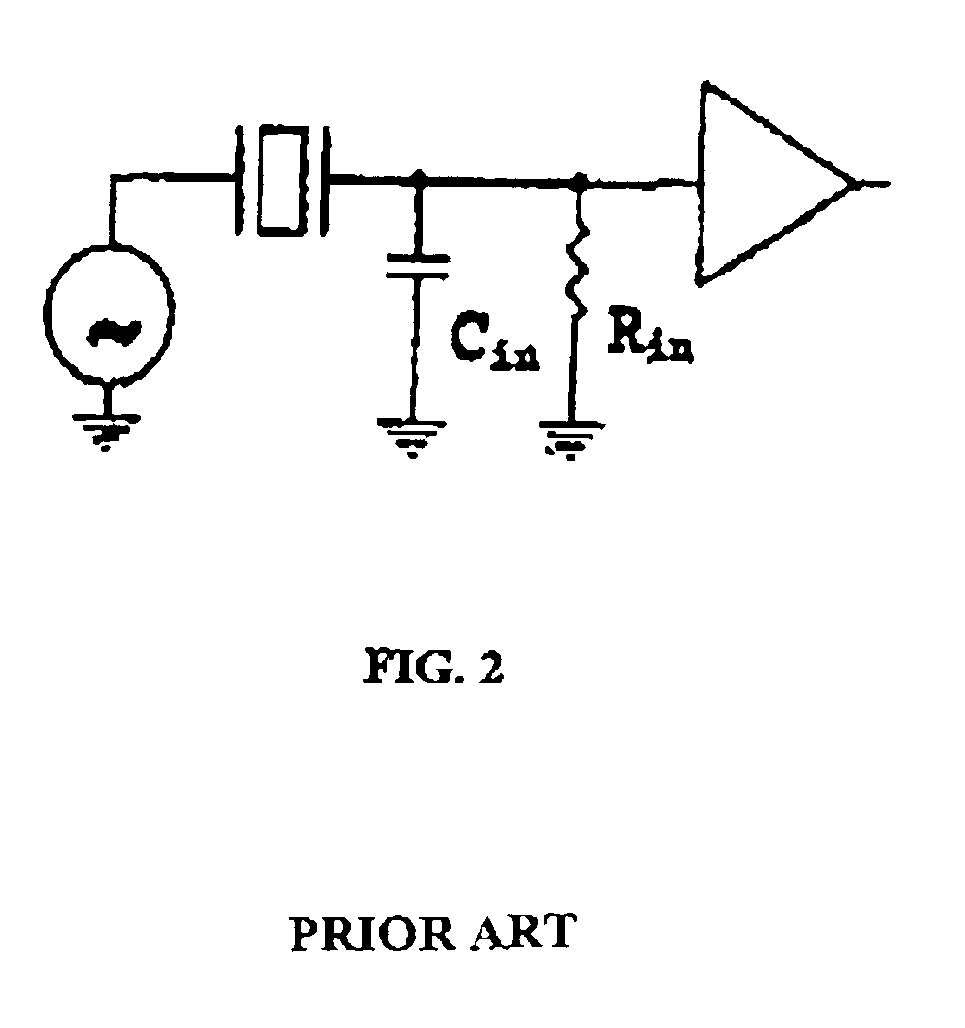

Apparatus for preventing corrosion of contact

InactiveUS20050231876A1Avoid contact corrosionEasy to judgeEmergency protective arrangements for automatic disconnectionHigh-tension/heavy-dress switchesElectrical impedanceComparator

An apparatus for preventing a contact from being corroded includes a power source, a signal line connected to the contact, a resistance connected to the signal line, a switching section, a comparator, and an overheat detecting section. The switching section has a switch between the power source and the signal line. An impedance of the switch is smaller than that of the resistance when the switch is turned on. The comparator compares a potential of the signal line with a predetermined potential to determine as to whether or not the contact is corroded. The comparator outputs a driving signal when the comparator concludes that the contact is corroded. The overheat detecting section detects whether or not temperature of the apparatus exceeds a predetermined temperature. The overheat detecting section decreases current flowing through the switching section when the temperature of the apparatus exceeds the predetermined temperature.

Owner:FUJITSU GENERAL LTD

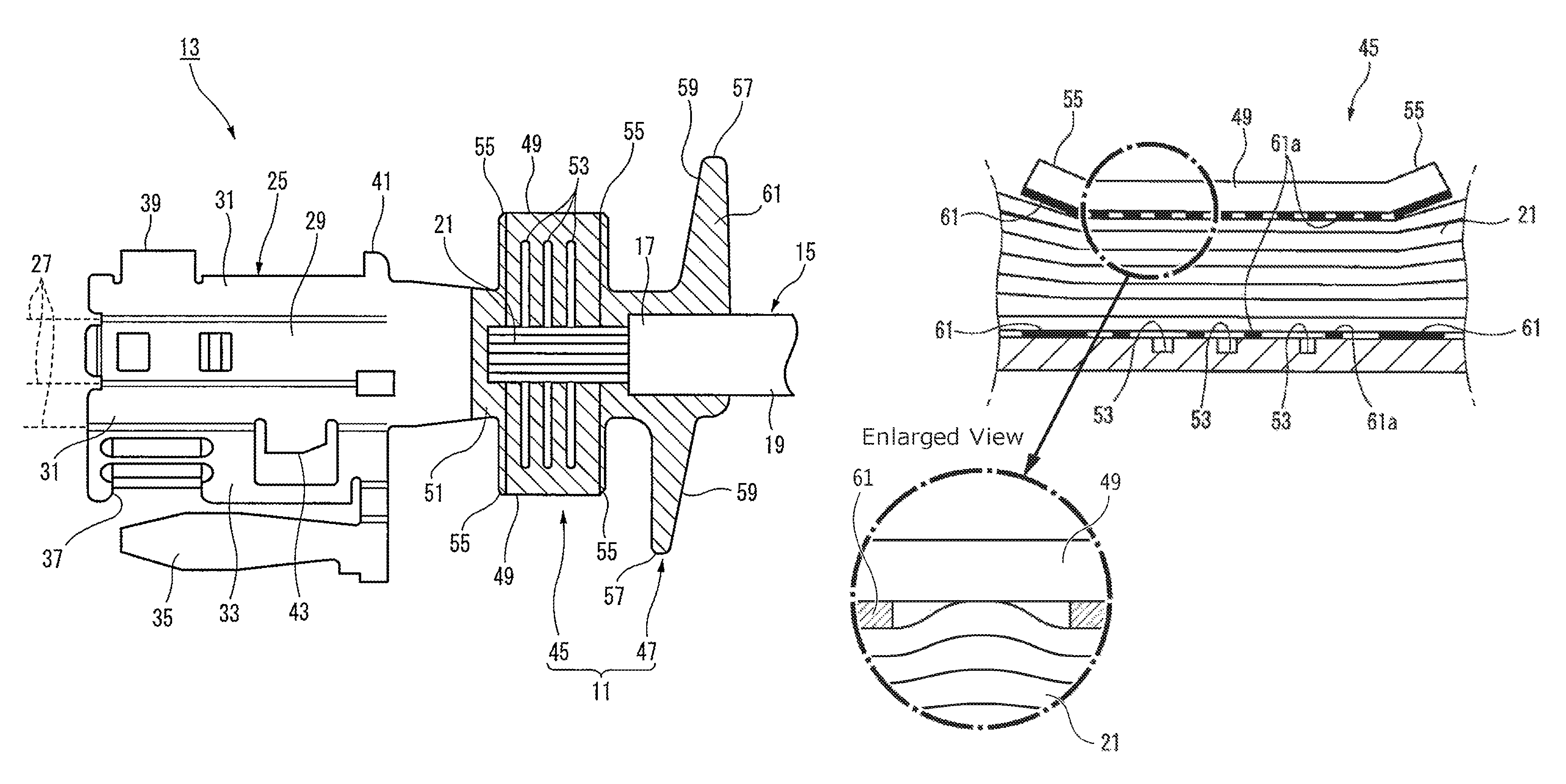

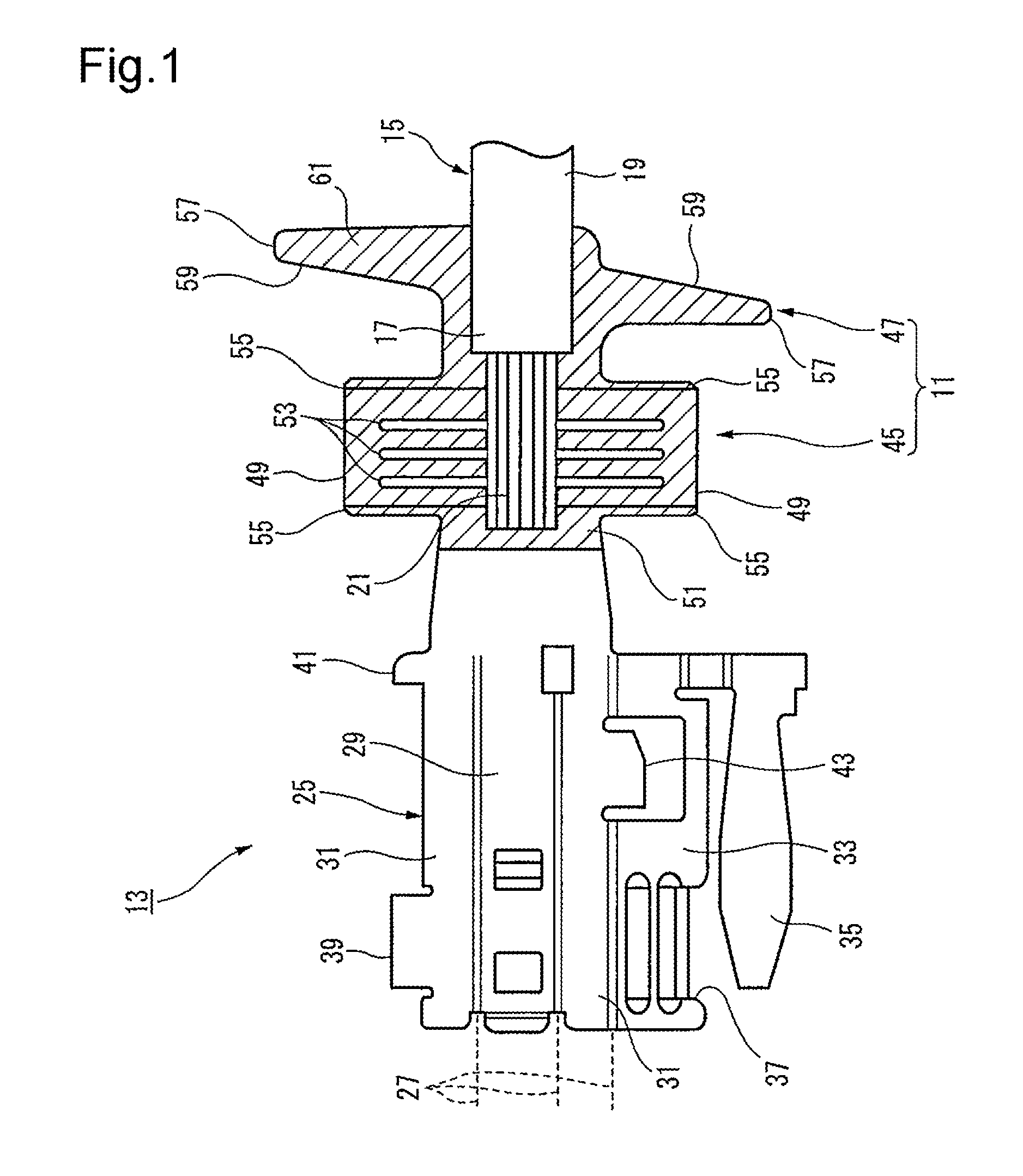

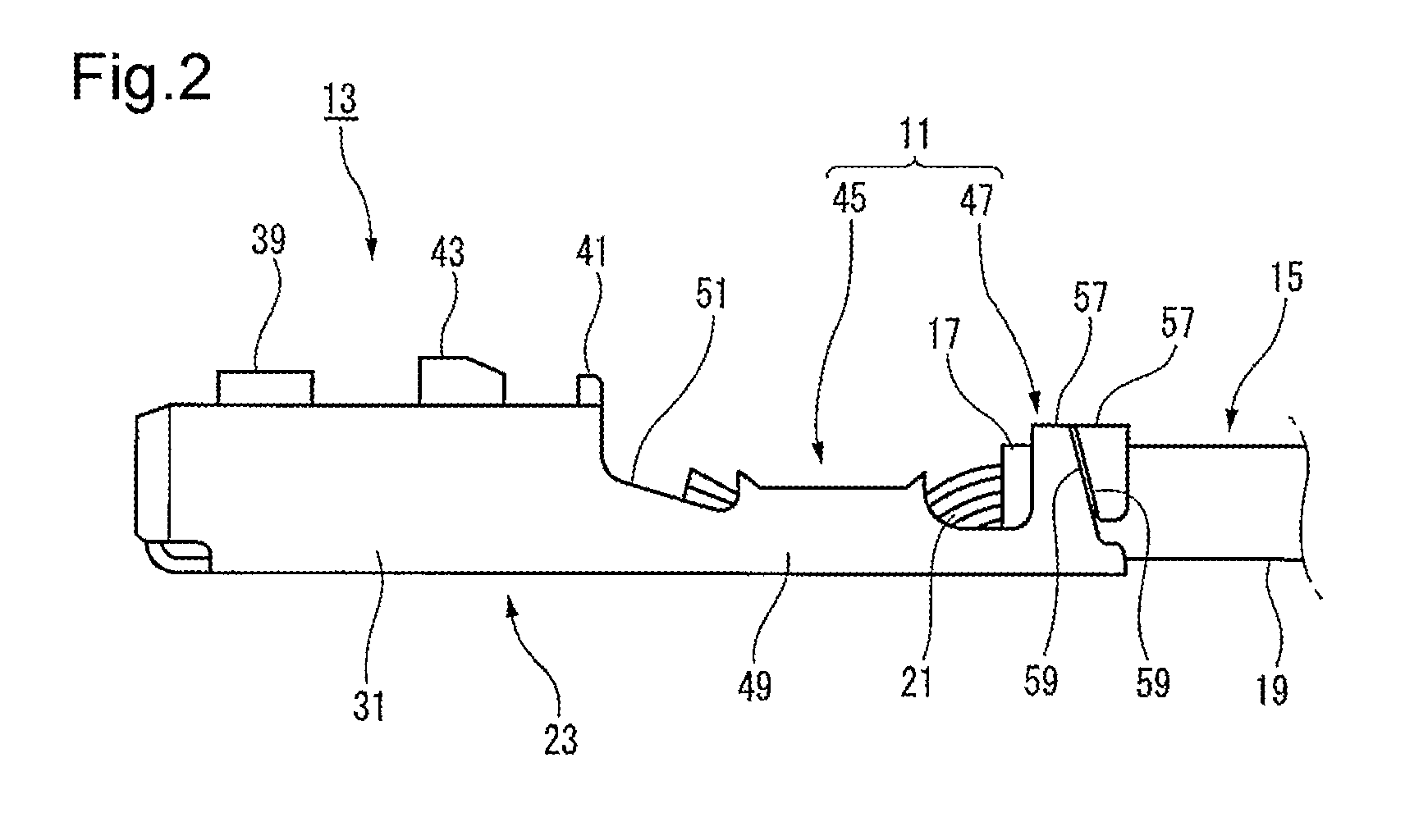

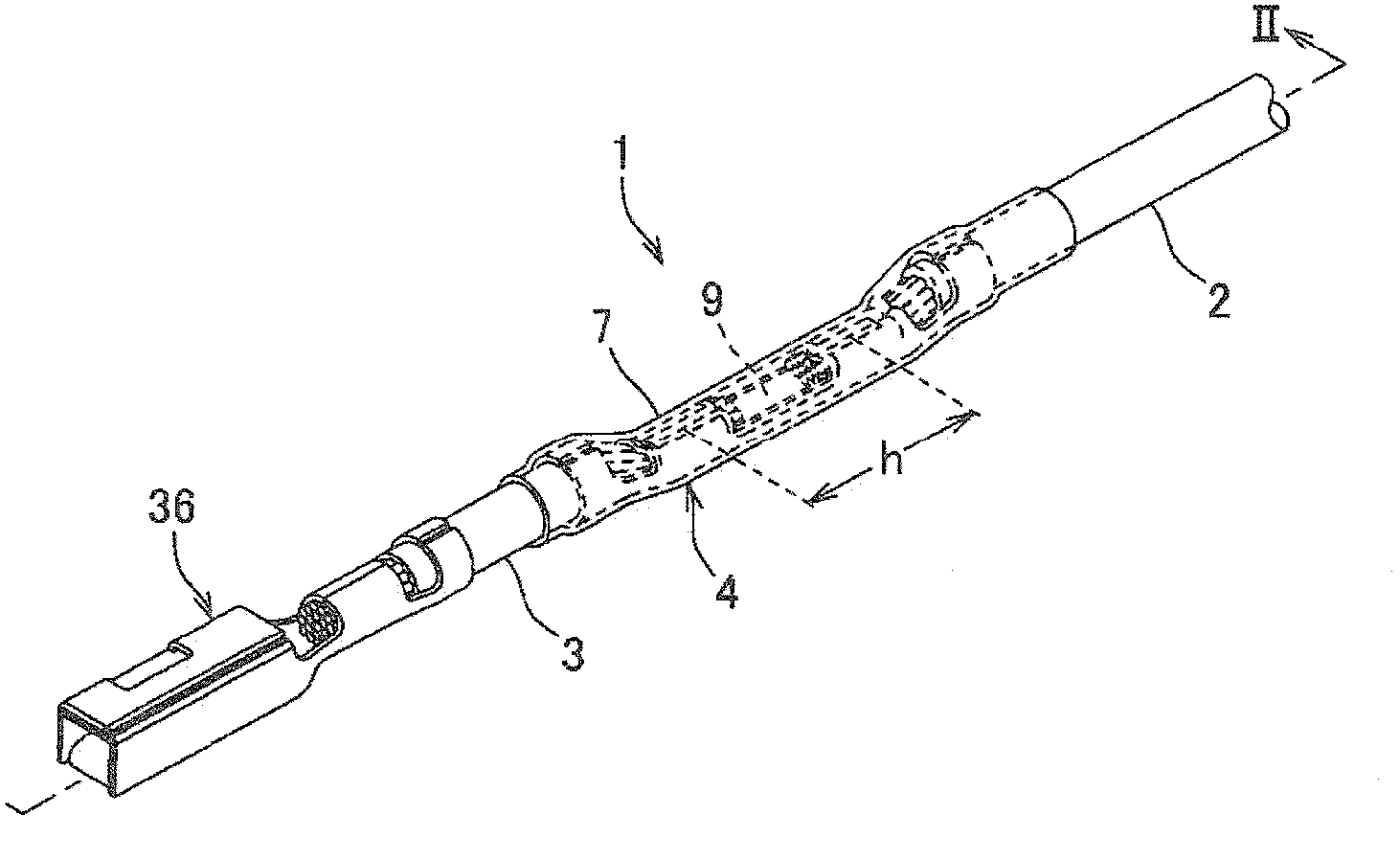

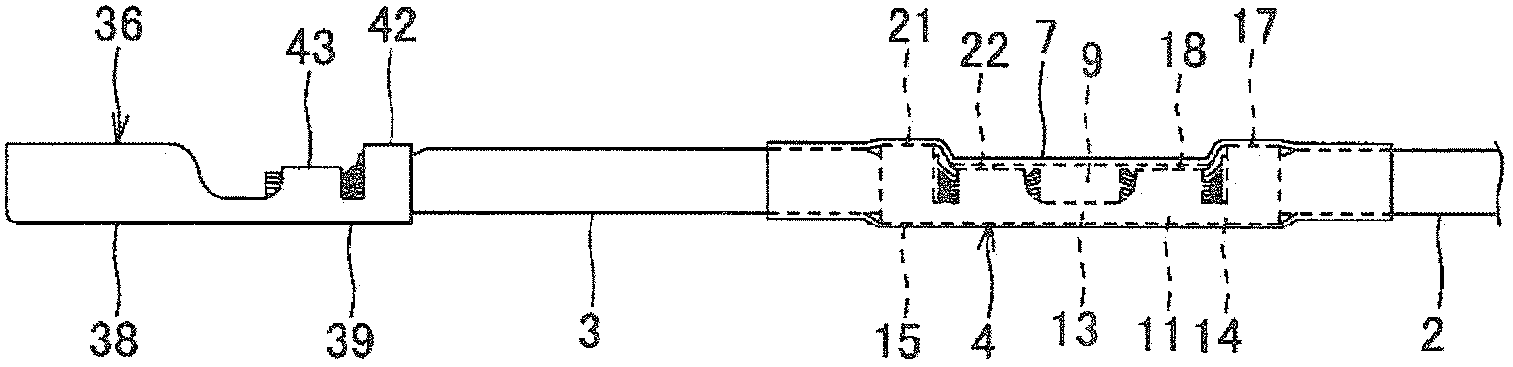

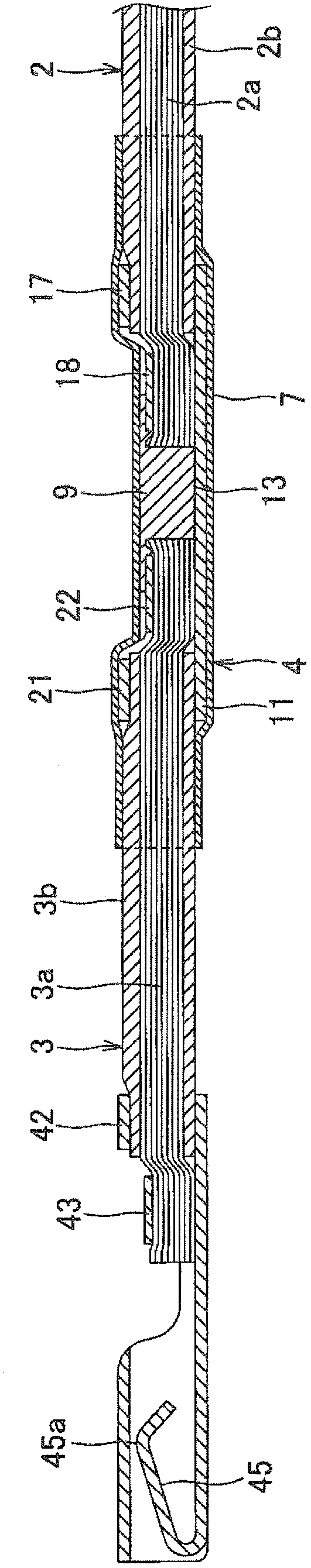

Connector crimping terminal

ActiveUS9391384B2Easy to operateAvoid contact corrosionContact member manufacturingCoupling contact membersElectric wireMetal

A terminal, comprises an electric wire connecting part having a core wire barrel part that crimps a core wire exposed in one end of an electric wire, the core wire being made of a first metal; wherein the electric wire connecting part is made of a second metal whose ionization tendency is lower than that of the first metal, wherein the electric wire connecting part is plated with a third metal whose ionization tendency is between the first metal and the second metal so that a plating layer made of the third metal is formed on the electric wire connecting part, and wherein the core wire barrel part is crimped so as to break down the plating layer formed on a connecting surface of the core wire barrel part on which the core wire is mounted.

Owner:YAZAKI CORP

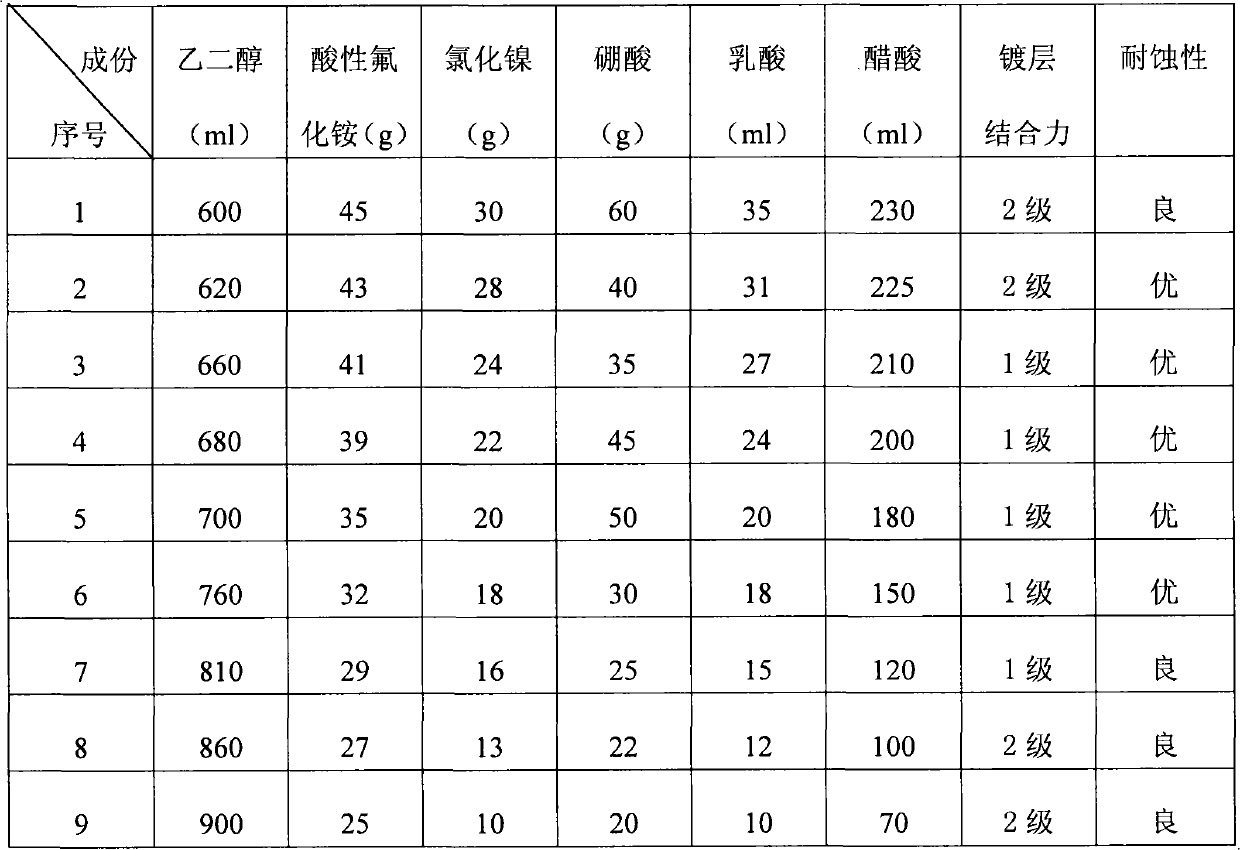

Method for carrying out surface activating treatment on surface of titanium alloy

ActiveCN101768747AShort activation timeNo corrosionHot-dipping/immersion processesVacuum evaporation coatingAcetic acidAfter treatment

The invention relates to a method for carrying out surface activating treatment on the surface of titanium alloy. The method includes the following steps: 1. oil and rust removing is first carried out on a titanium alloy base material part; 2. etching treatment is carried out on the part; 3. surface activating treatment is carried out on the part, wherein activating solution of the surface activating treatment is a mixture of glycol, acidic ammonium fluoride, nickel chloride, boric acid, lactic acid and acetic acid, the temperature of the surface activating treatment is within 40 to 60 DEG C, and the time of the surface activating treatment is within 30 to 40min; 4. drying and after-treatment procedures are carried out. Compared with the prior art, the method has the following characteristics: the activating time is short, the activating effect is good, no corrosion is incurred on the part, the risk of corrosion on the part is basically eliminated, and the environmental pollution is mild; with high stability and quick deposition, the activating solution that the method adopts can form a coating with good corrosion / wear resisting properties and good metallurgical combination with a matrix on the surface of the titanium alloy, thereby preventing contact corrosion between the titanium alloy part and aeronautical materials such as aluminum alloy, high-temperature alloy and the like.

Owner:JIANGSU LINLONG NEW MATERIALS

Vehicle body for a motor vehicle

InactiveCN101081627AImprove stabilityReduce manufacturing costUnderstructuresBumpersMotor vehicle partShape design

A motor vehicle chassis(1) for a motor vehicle(1) has an adapter element(5) to join an aluminum crashbox (4)to a longitudinal supporting beam(2). To accommodate one end of the crashbox(4) the adapter element (5)has a pot-shaped design and introduced into the longitudinal supporting beam(2). Due to this the motor vehicle chassis(1) is particularly simple to construct.

Owner:GM GLOBAL TECH OPERATIONS LLC

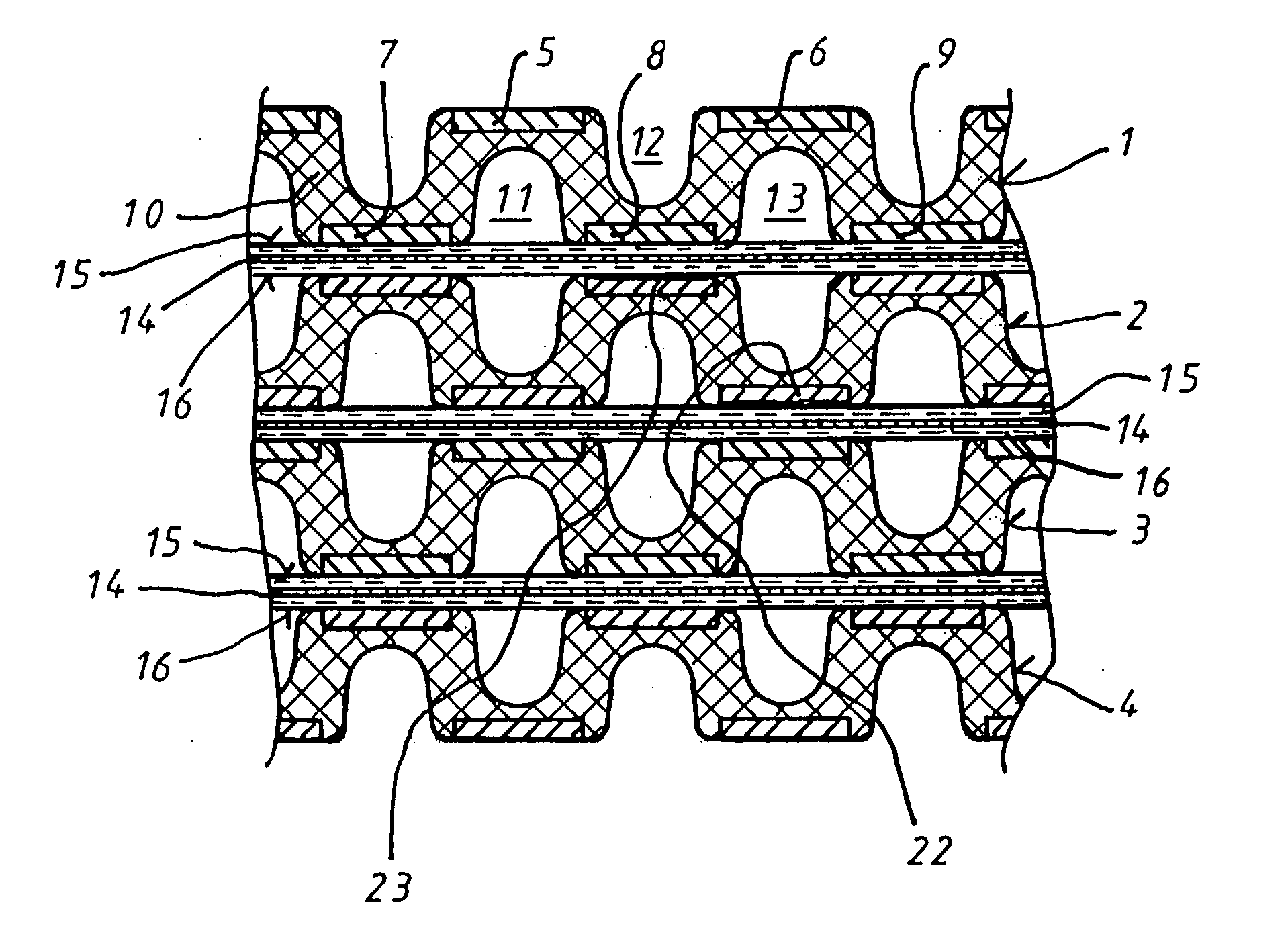

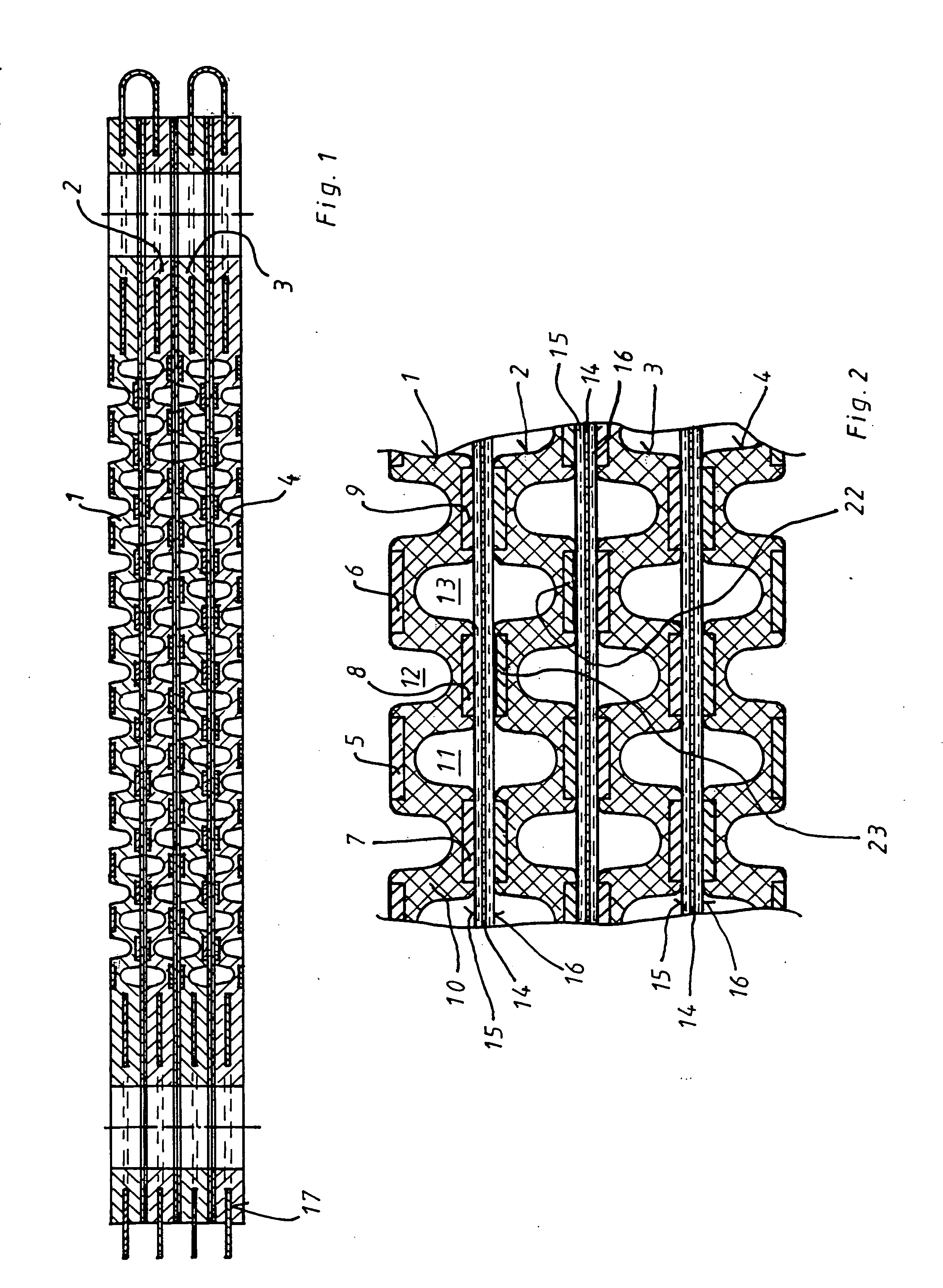

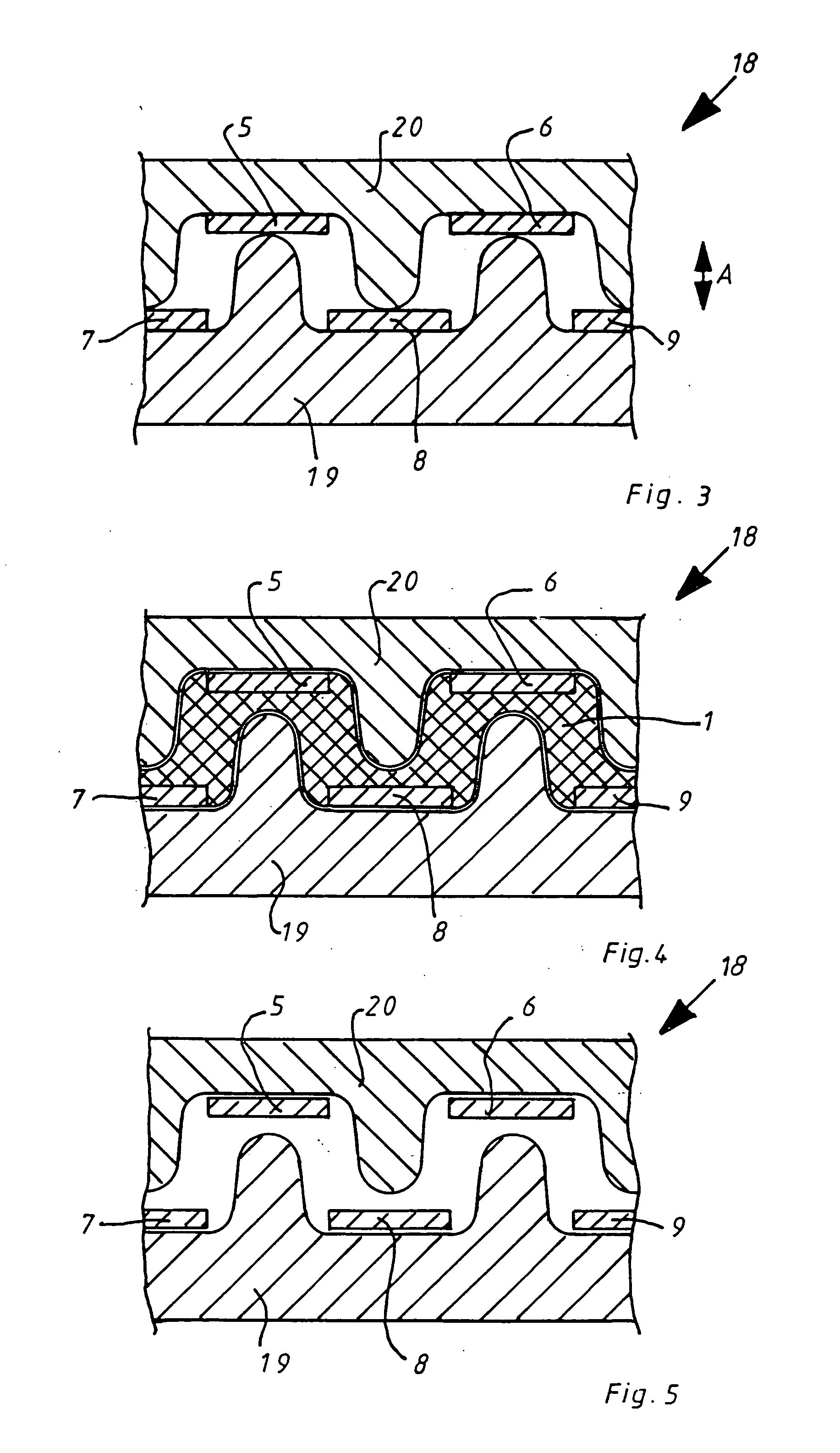

Method for the production of bipolar plates or electrode plates for fuel cells or electrolyzer stacks, method for the production of a stack of bipolar plates or electrode plates, as well as a bipolar plate or electrode plate

InactiveUS20050058878A1Avoid contact corrosionSealing the spaces for the reaction substances (CellsFuel cells groupingFuel cellsEngineering

A method for the production of bipolar plates or electrode plates for fuel cells or electrolyzer stacks is provided, whereby the bipolar plates or electrode plates have at least one punched band and / or at least one punched blank that are punched from a flat material made of a conductive and corrosion-resistant metal and surrounded with plastic, by means of injection molding. A method for the production of a stack of bipolar plates or electrode plates is also provided. The bipolar plate or electrode plate has strips of a punched band material made of a conductive and corrosion-resistant metal.

Owner:HUTTENBERGER PRODNTECHN MARTIN

Aluminum-silicon-zinc-rare earth-copper-containing hot dip coating alloy and method for preparing same

ActiveCN101736222AUniform compositionImprove toughnessHot-dipping/immersion processesRare-earth elementDip-coating

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, copper and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc, 0.02 to 0.5 percent of rare earth elements, 0.05 to 0.5 percent of copper, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitable impurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. The hot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titanium alloy.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Circuit for preventing corrosion of contact

InactiveUS7550878B2Avoid contact corrosionEffective preventionResistance/reactance/impedenceContact testing/inspectionElectrical impedanceComparator

A circuit for preventing corrosion of a contact, includes an input terminal, a signal line, a switch, an impedance element, and a comparator. The input terminal is to be connected to the contact, which is outside the circuit. The signal line is connected to the input terminal. The switch is connected to the signal line. The impedance element is connected to the signal line in parallel to the switch. An impedance of the switching section is smaller than that of the impedance element. The comparator compares a potential of the signal line with a predetermined potential. The switch is turned on based on a comparison result output from the comparator.

Owner:FUJITSU GENERAL LTD

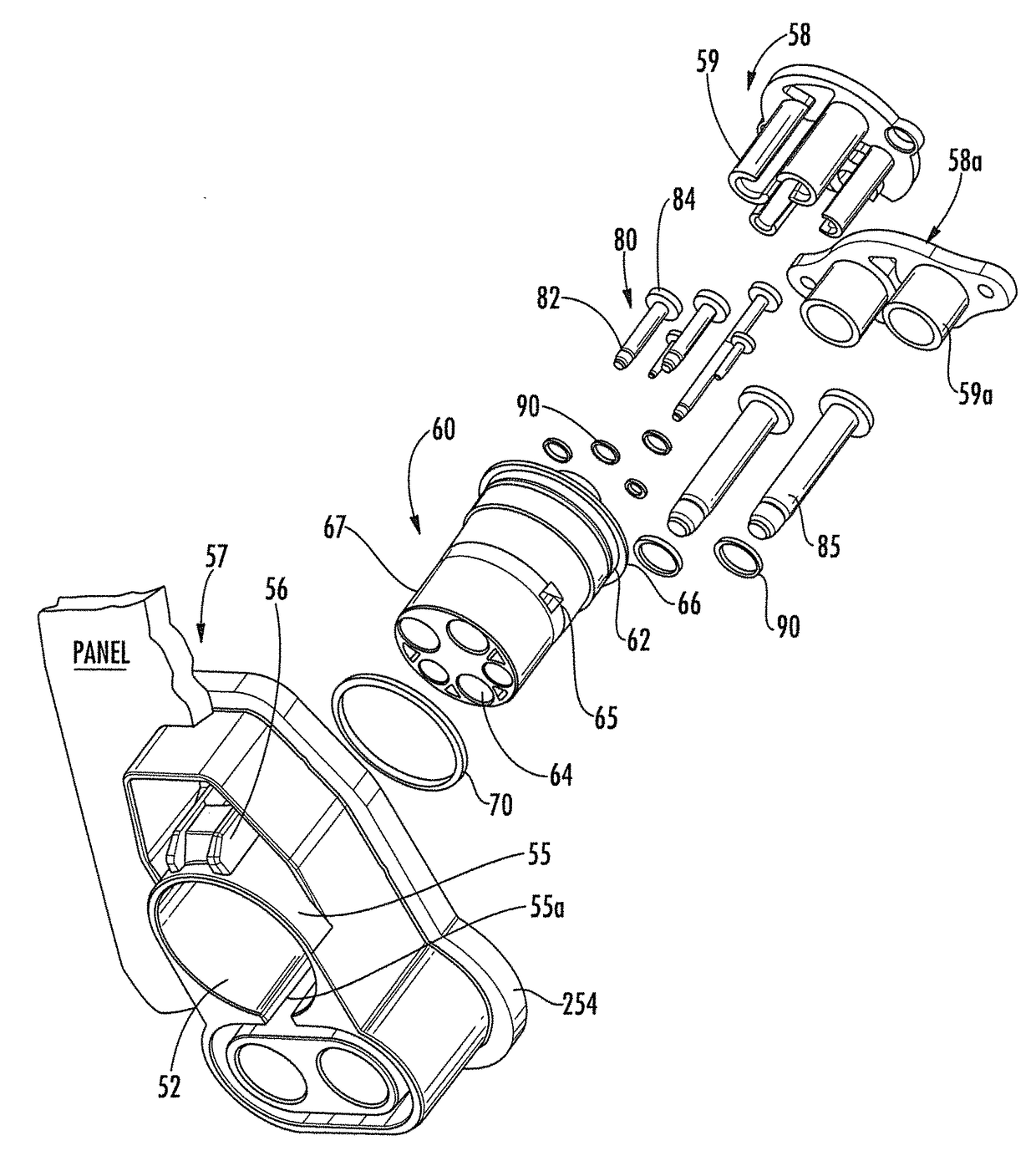

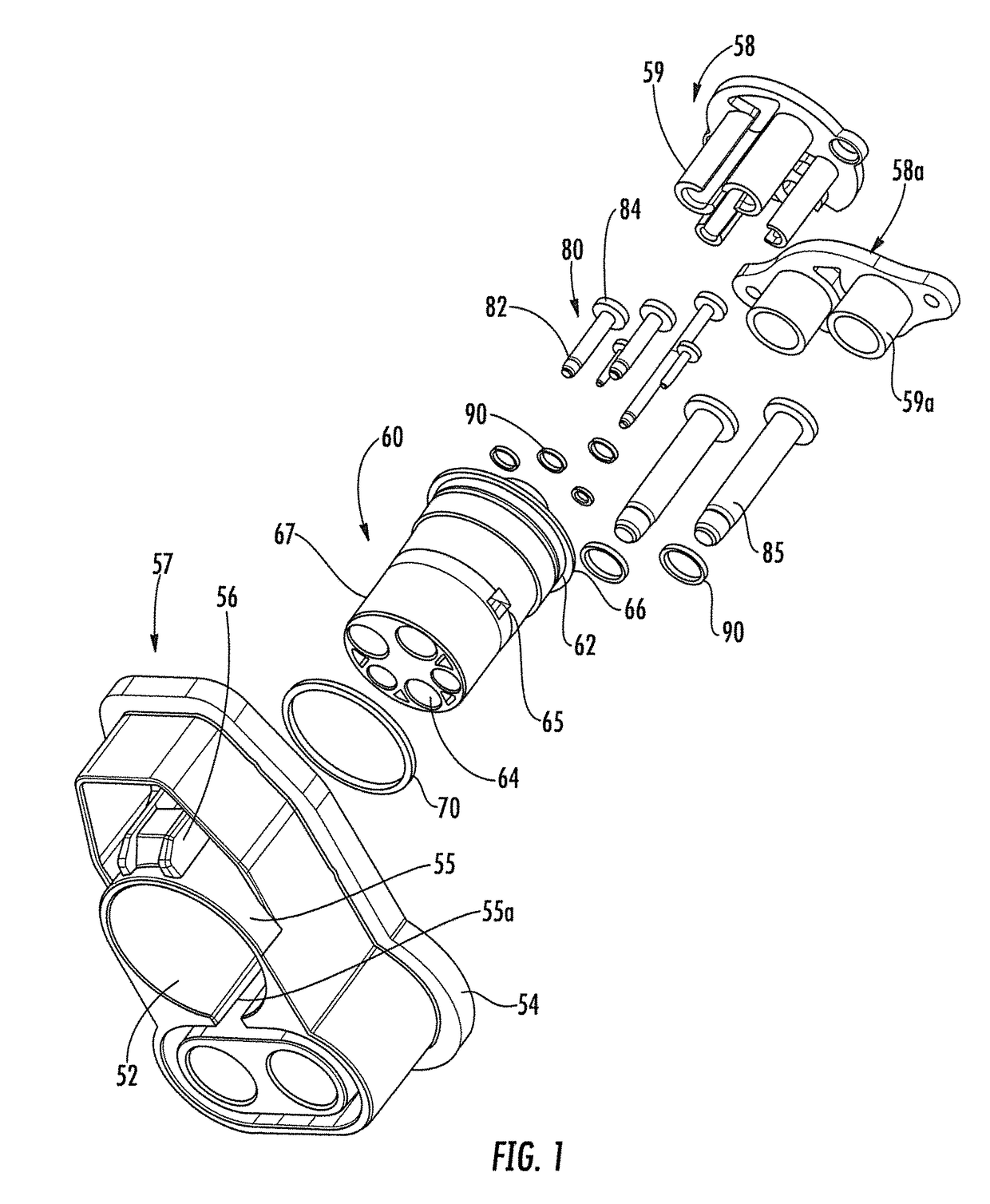

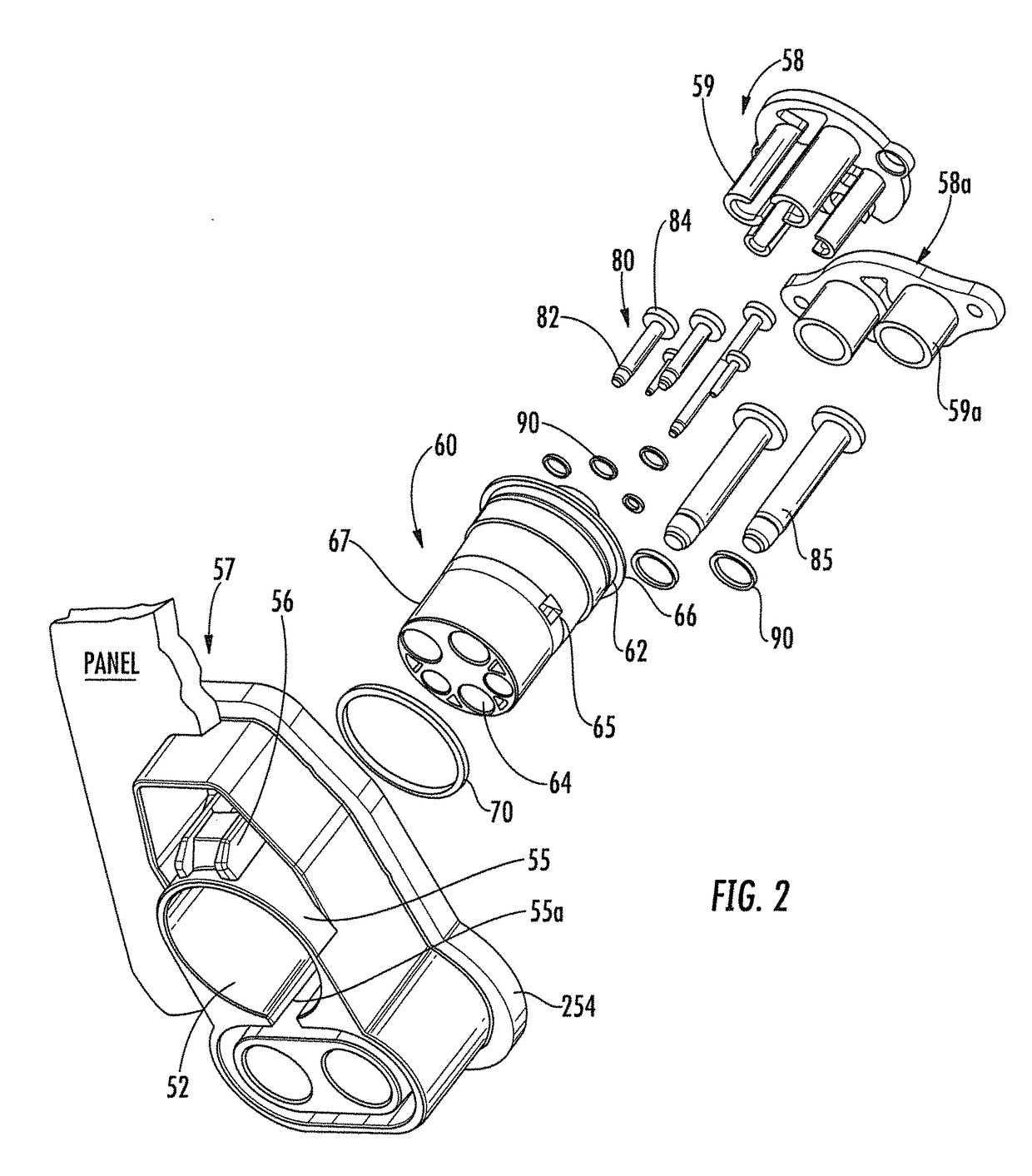

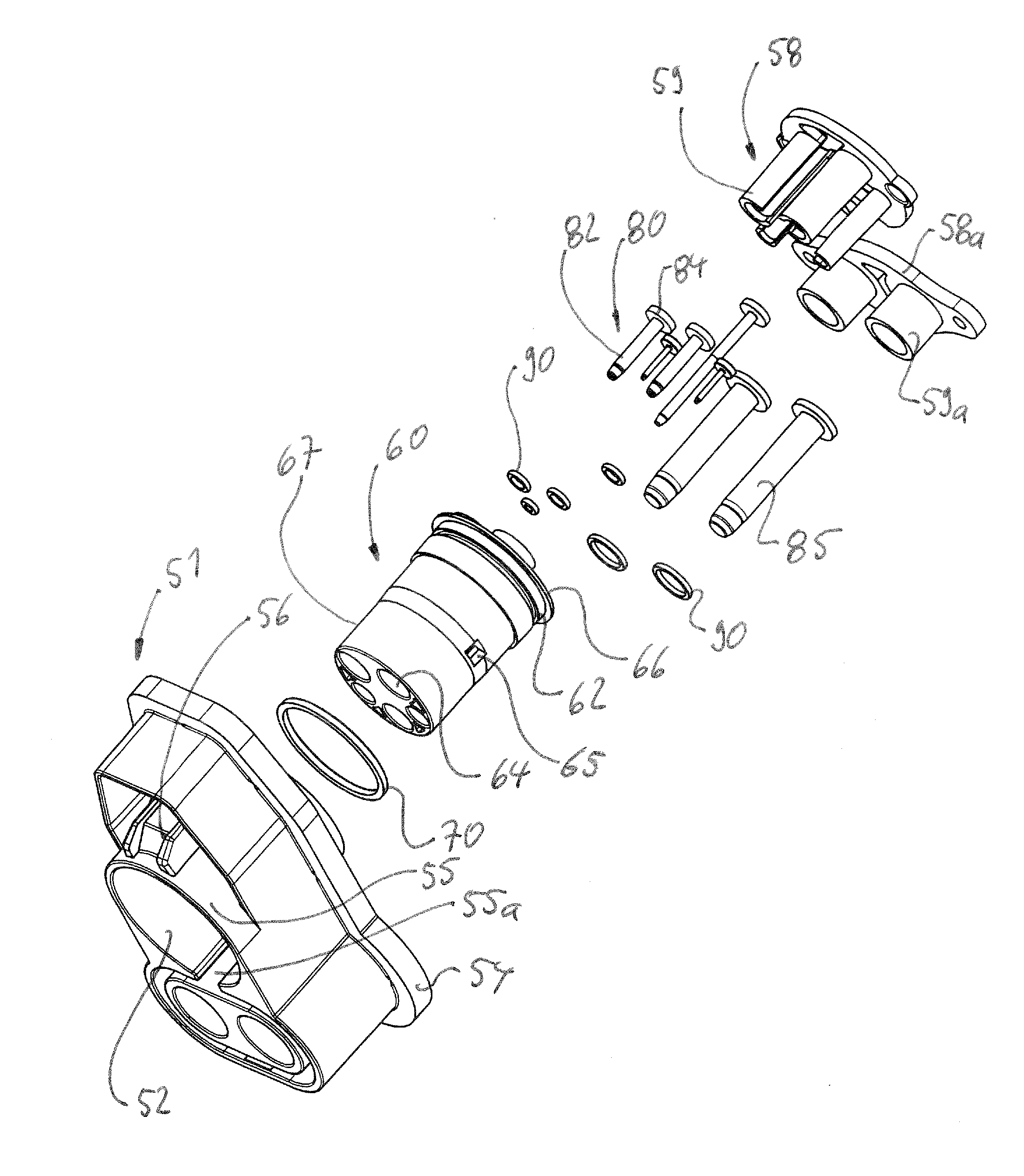

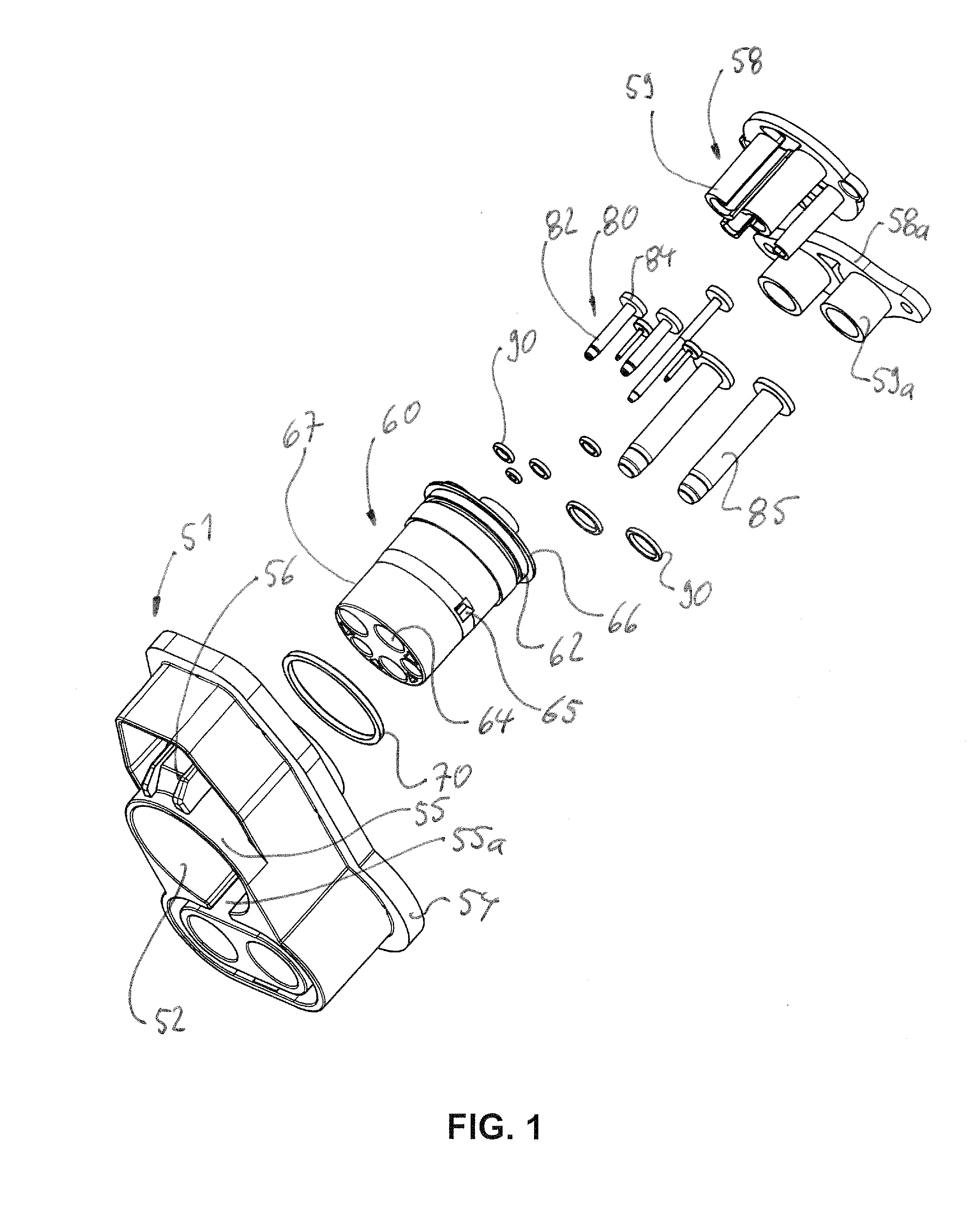

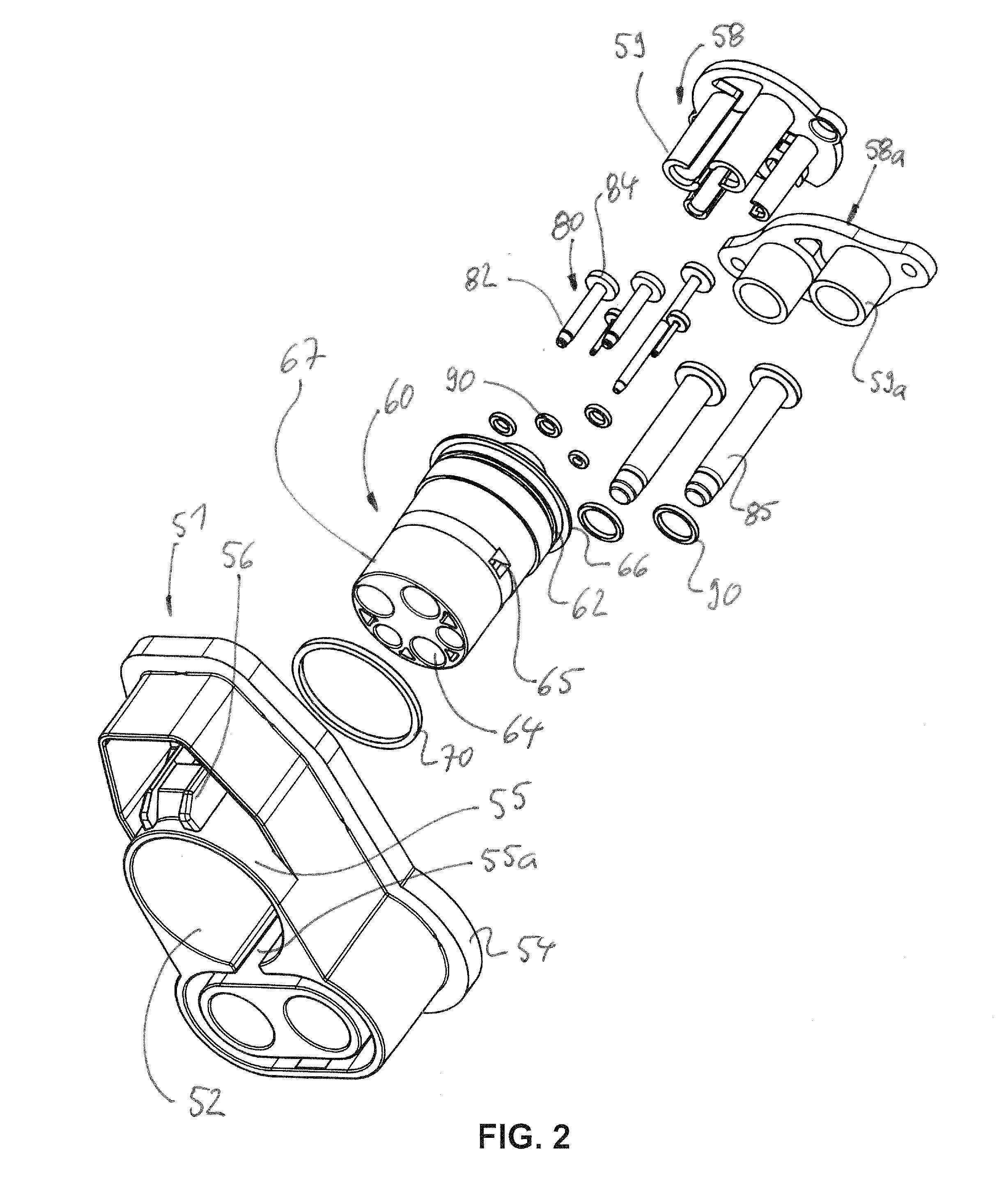

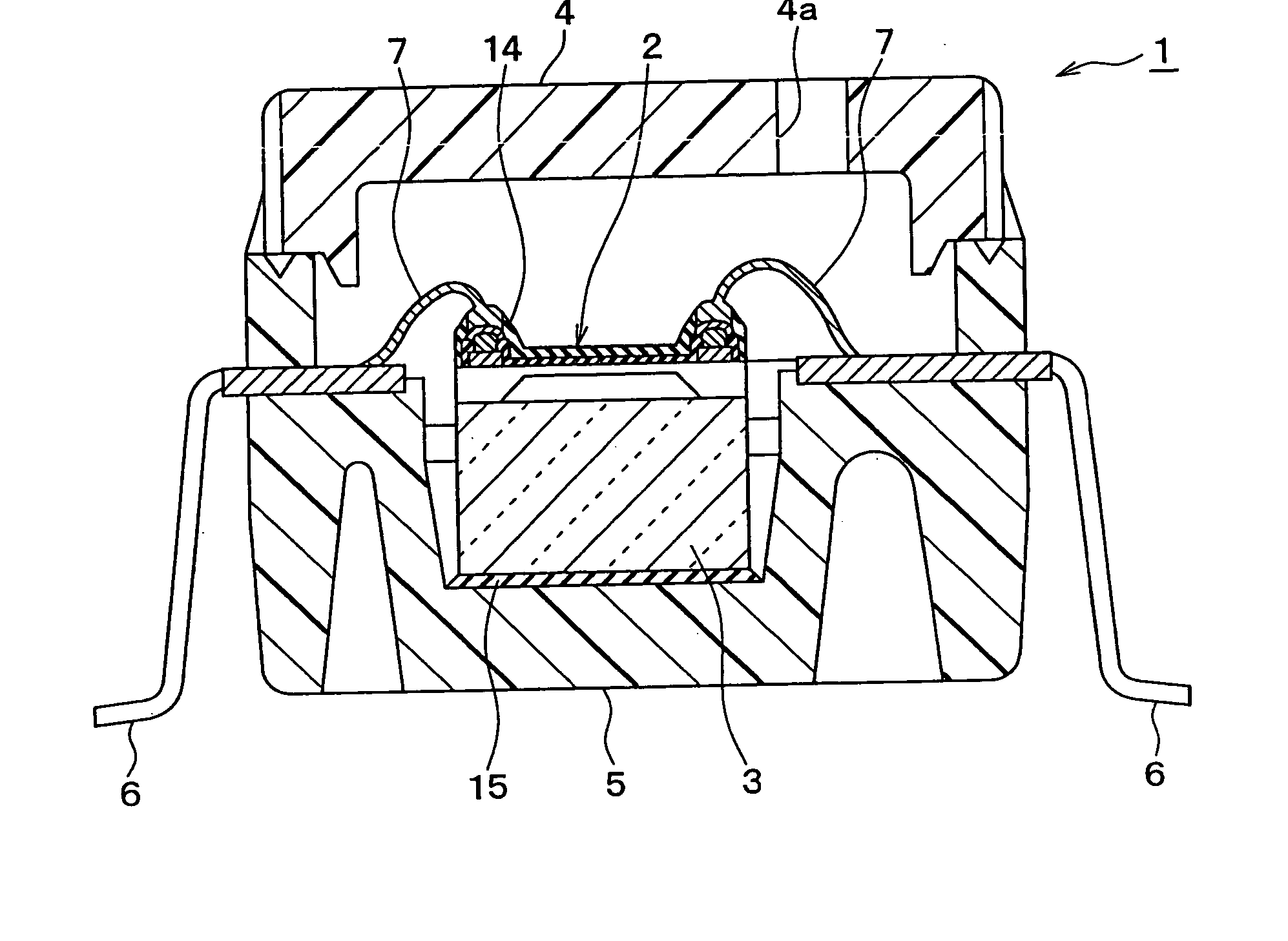

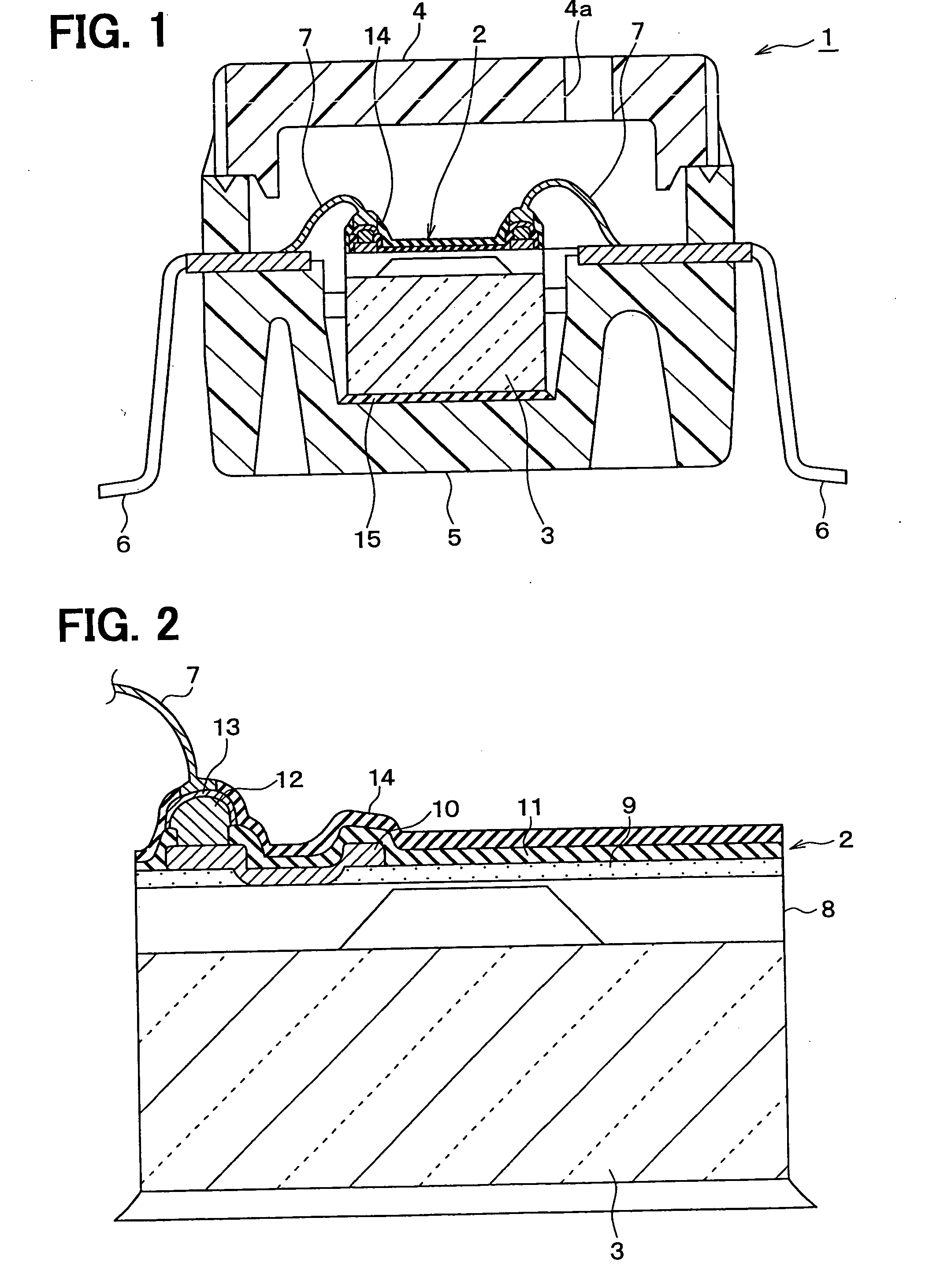

Charging connector and method of mounting the same

ActiveUS9601864B2Easy to disassembleFast and easy to performCouplings bases/casesTowerElectrical and Electronics engineering

Owner:SUMITOMO WIRING SYST LTD

Bumper for a motor vehicle

A bumper for a motor vehicle has a cross member disposed transversely in relation to side rails of a vehicle frame and is supported on the side rails by crash boxes. The cross member includes a central longitudinal section having opposite ends, a crash box attachment section with a substantially vertical rear wall and two legs, and an end section having in cross-section a U-shaped configuration defined by two legs and a web which interconnects the legs and forms an outward-projecting bulge. The bulge is joined with the substantially vertical rear wall of the attachment section.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Circuit for preventing corrosion of contact

InactiveUS20050231877A1Simple configurationConfiguration is complicatedResistance/reactance/impedenceContact testing/inspectionElectrical impedanceComparator

A circuit for preventing corrosion of a contact, includes an input terminal, a signal line, a switch, an impedance element, and a comparator. The input terminal is to be connected to the contact, which is outside the circuit. The signal line is connected to the input terminal. The switch is connected to the signal line. The impedance element is connected to the signal line in parallel to the switch. An impedance of the switching section is smaller than that of the impedance element. The comparator compares a potential of the signal line with a predetermined potential. The switch is turned on based on a comparison result output from the comparator.

Owner:FUJITSU GENERAL LTD

Charging connector and method of mounting the same

ActiveUS20160104967A1Increase freedomWell formedContact member assembly/disassemblySecuring/insulating coupling contact membersElectrical and Electronics engineeringTower

A charging connector for charging a battery in a vehicle has a housing (51) mounted to a vehicle. A tower (60) is in the housing (51) and has at least one accommodating chamber (64) for accommodating at least one terminal fitting (80). The tower (60) is inserted into a mating hole (52) of the housing (51). A seal (70) is between the tower (60) and the housing (51). The accommodating chamber (64) has a fitting (64a) at a rear end for fitting the terminal fitting (80) and an exposed portion (64b) at a front end for exposing a leading contact (82) of the terminal fitting (80) to be contacted with a mating terminal fitting of a mating charging connector on a charging cable. The tower (60) can be assembled and disassembled from the housing (51) with the terminal fitting(s) (80) mounted within the accommodating chamber(s) (64) of the tower (60).

Owner:SUMITOMO WIRING SYST LTD

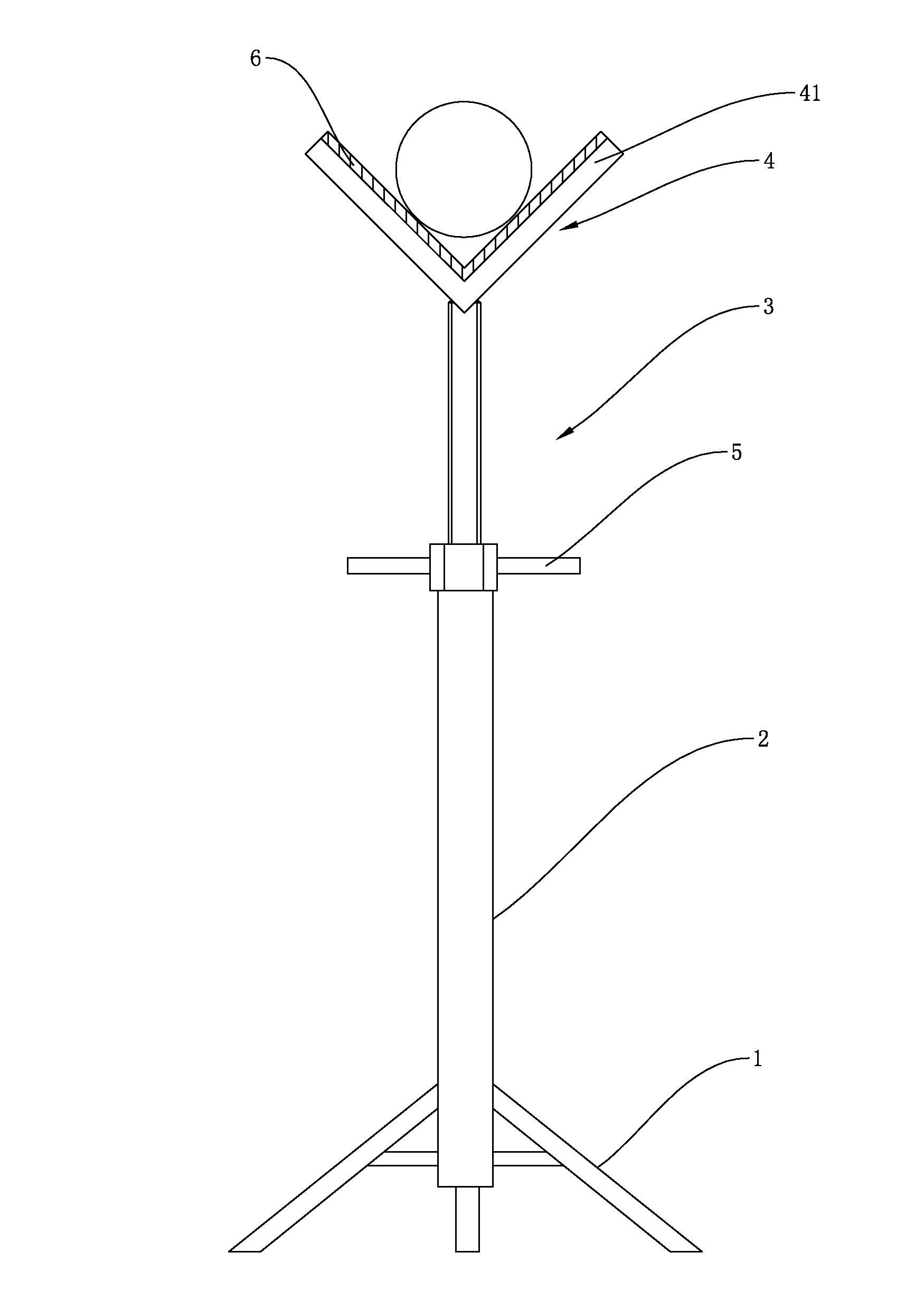

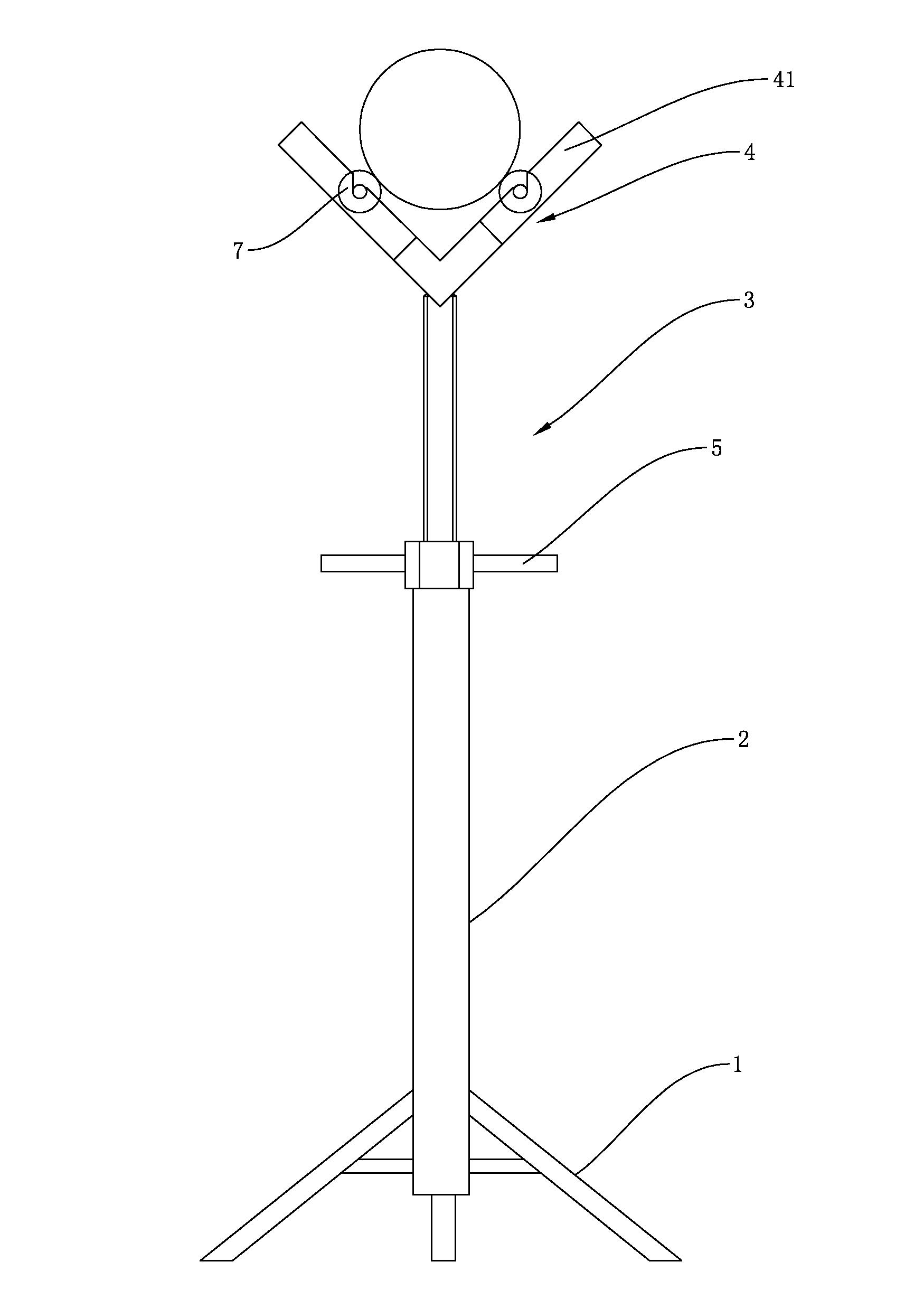

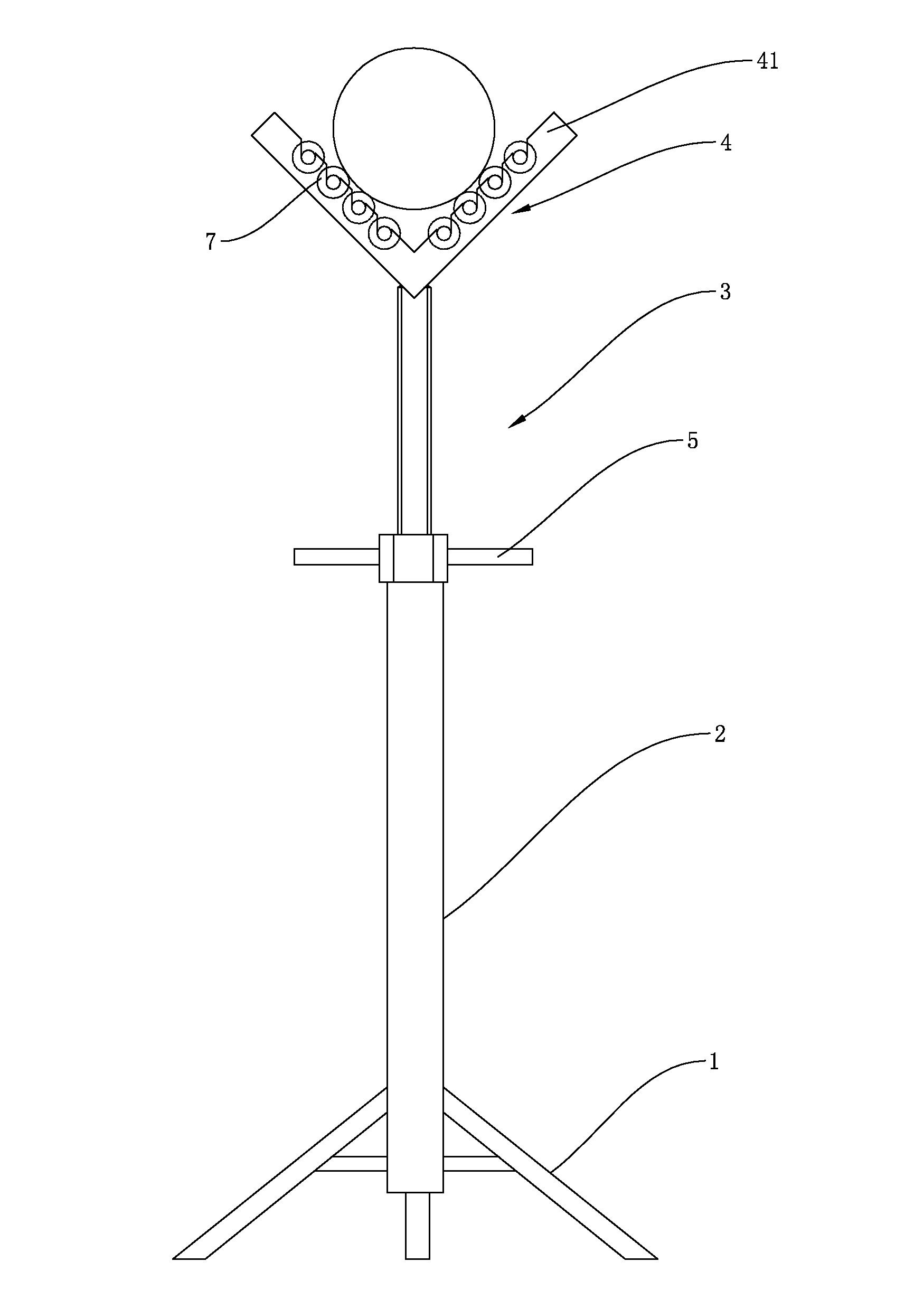

Welding lift frame

InactiveCN102500984AConvenient welding workExtended service lifeWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWelding

The invention discloses a welding lift frame, which comprises a bracket, wherein the upper end of the bracket is provided with a sleeve; a lead screw of a lead screw and nut mechanism is sleeved in the sleeve; the upper end of a lead screw of the lead screw and nut mechanism is provided with a supporting member; a nut of the lead screw and nut mechanism is arranged on the sleeve; and the lead screw and nut mechanism can be used for adjusting the height of the supporting member, so that the height of a workpiece can be adjusted at any time to facilitate the welding of the workpiece.

Owner:江苏利柏特股份有限公司

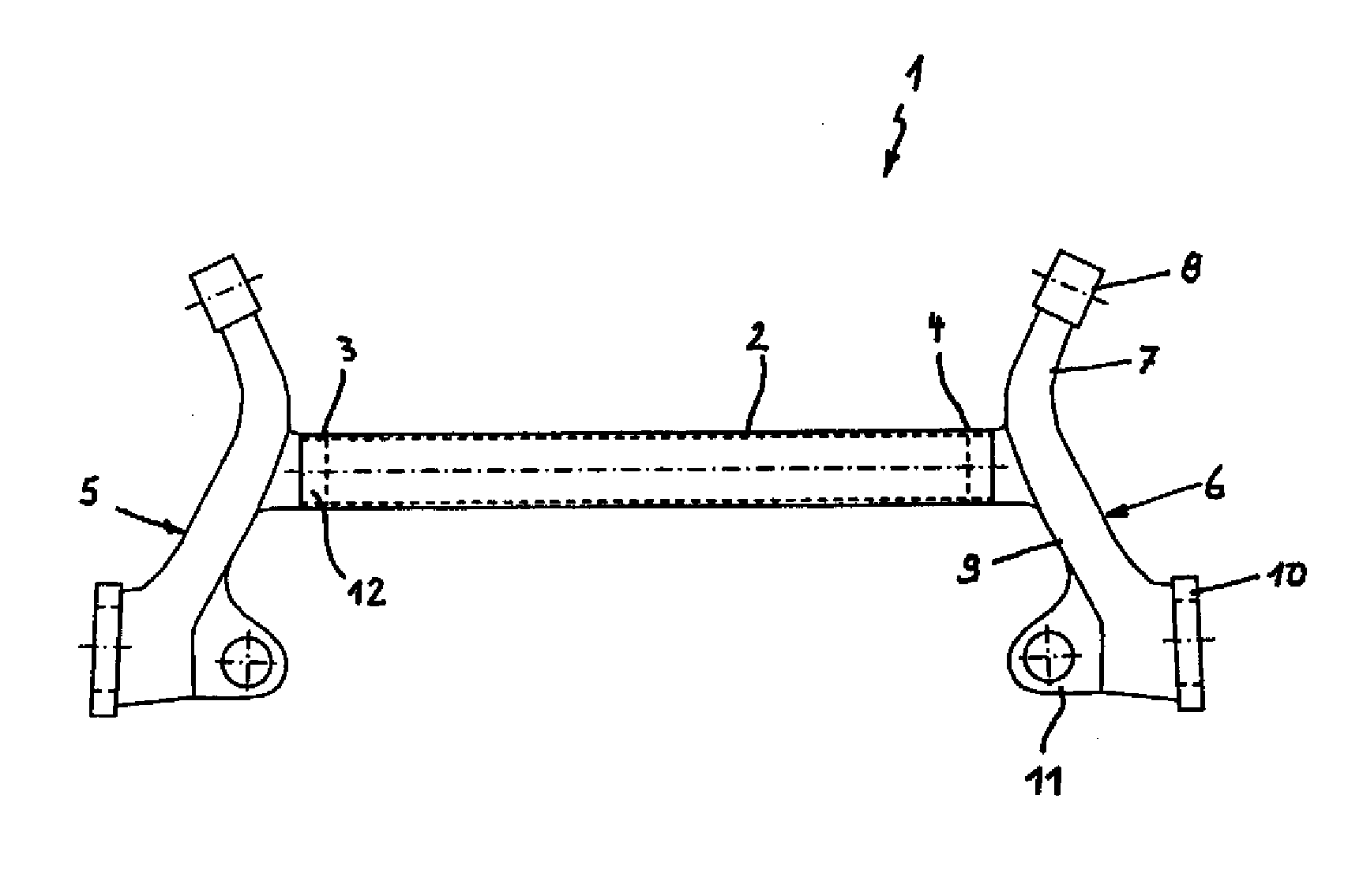

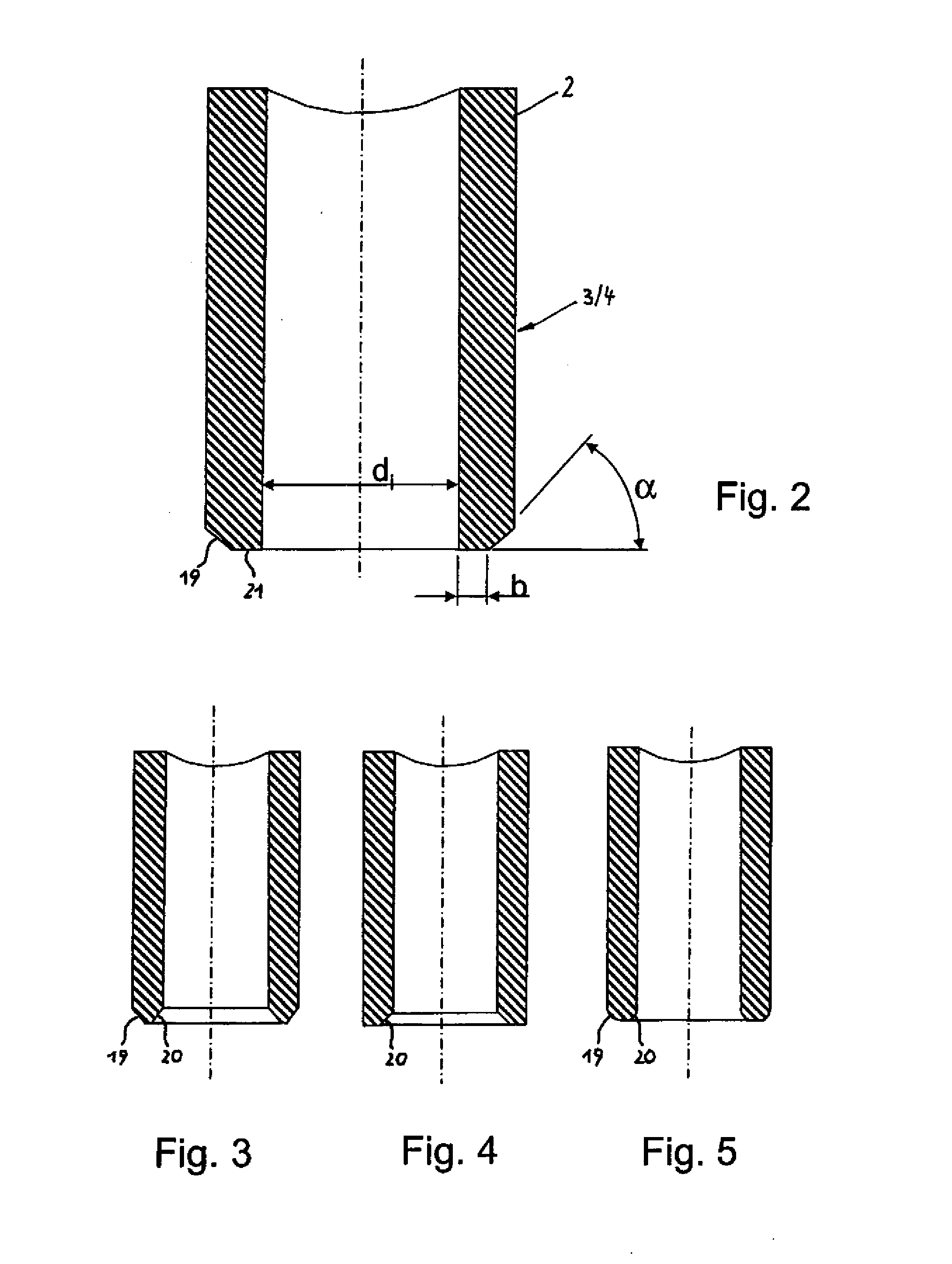

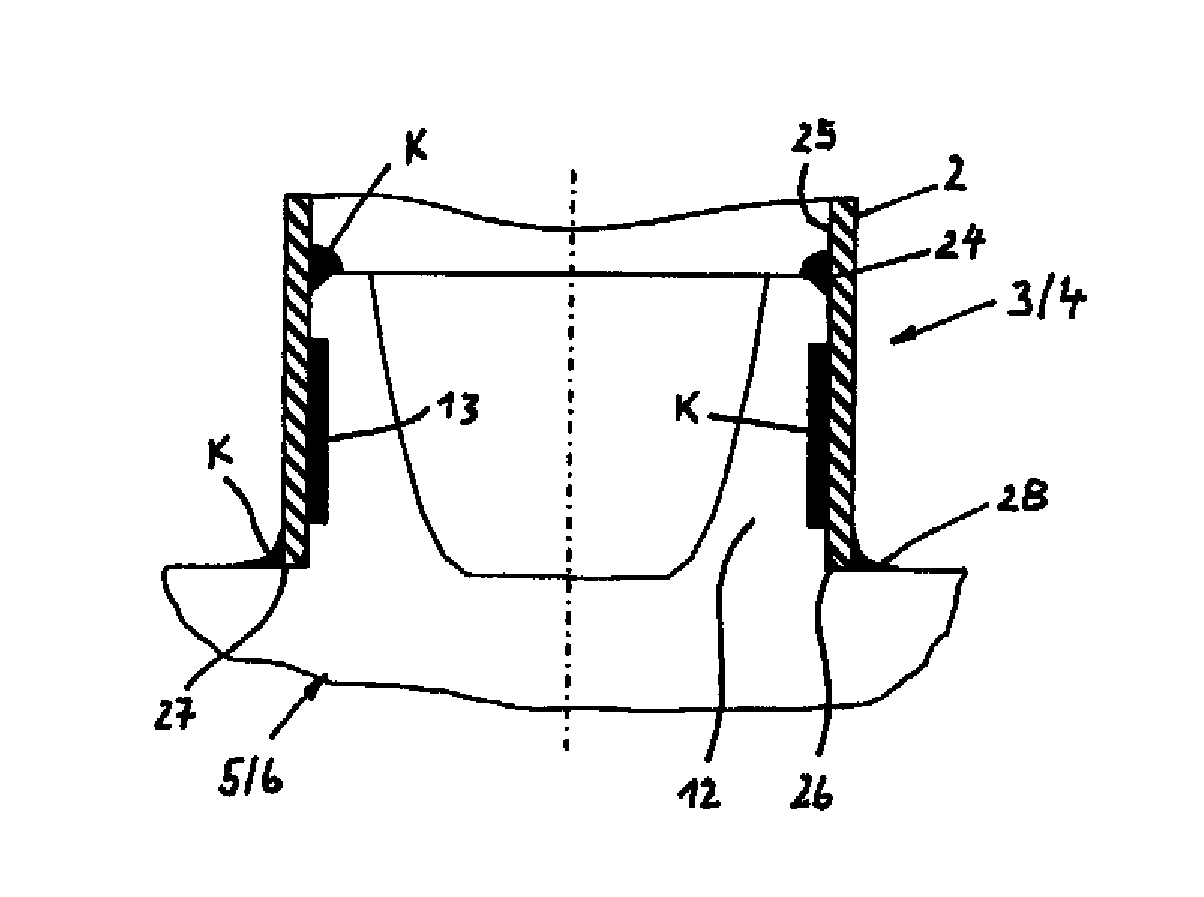

Motor vehicle axle component and method for producing a motor vehicle axle component

InactiveUS20110227402A1Cheap productionImprove adhesionLamination ancillary operationsLaminationAdhesiveSteel tube

The invention relates to a motor vehicle axle component and a method for producing a motor vehicle axle component. The axle component, for example a dead beam axle, includes a light metal body, such as aluminum or magnesium or corresponding alloys, and a tubular body in form of a steel tube, which are adhesively connected with each other. An adhesive pocket filled with an adhesive is formed between an end of the tubular body and a cylindrical receptacle of the light metal body. Respective bezels are arranged on a free end of the receptacle and on a free end of the tubular body. The spaces between the respective bezels and adjacent walls are filled with adhesive, which seals the interior and exterior transition regions of the joint zone, thus protecting the joint zone against corrosion, improving the load characteristic of the axle component and increasing its service life.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

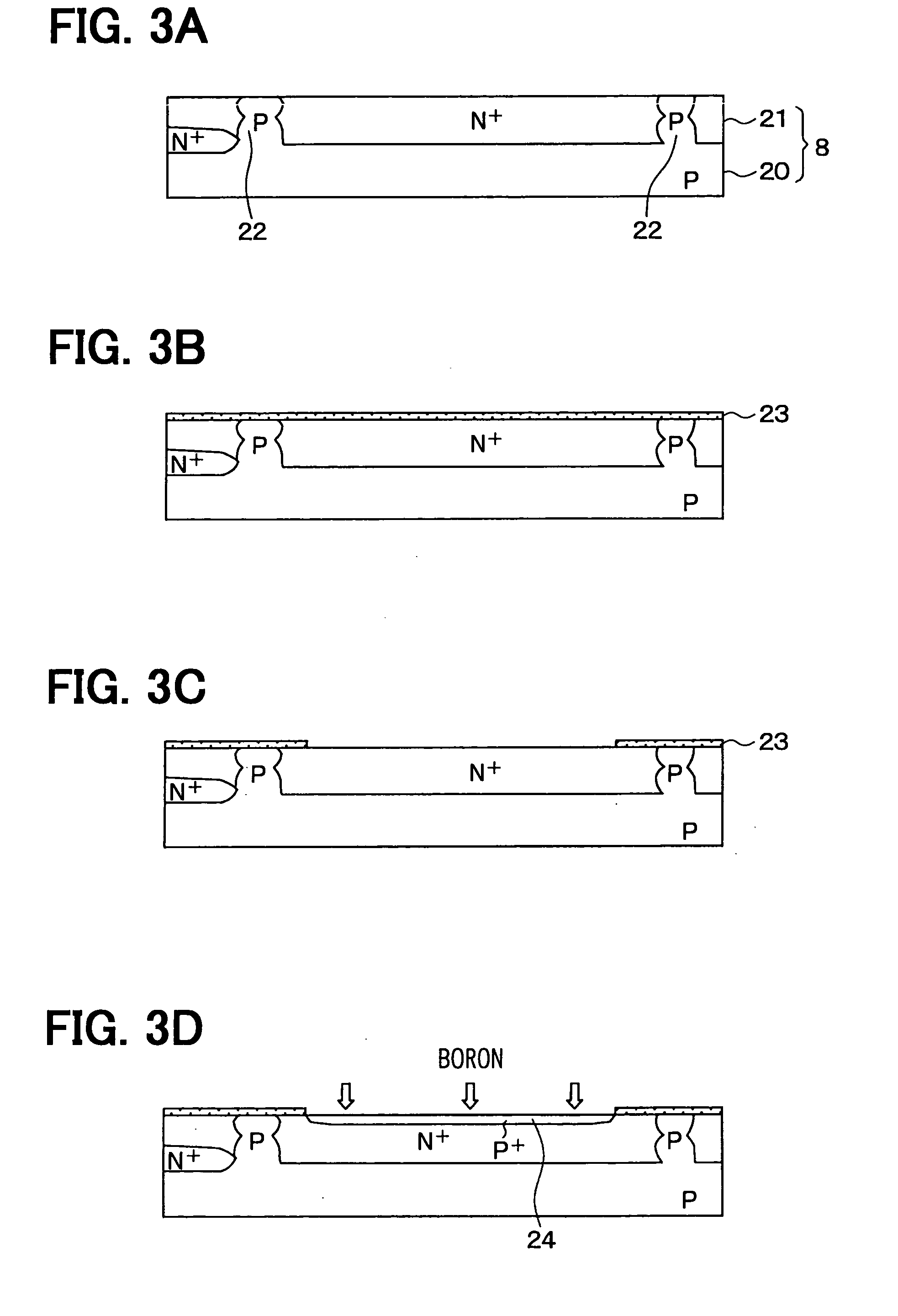

Pressure sensor

ActiveUS20060016267A1Prevents a corrosion of a sensor chipSimple structureFluid pressure measurement by electric/magnetic elementsSolid-state devicesTectorial membraneElectrical conductor

A pressure sensor includes a semiconductor substrate having a diaphragm in which an electrical circuit including a gauge resistance is formed, an insulation film provided on a surface of the semiconductor substrate, an Al film provided on the insulation film and electrically connected to the electrical circuit through a conductor hole of the insulation film, an Au film provided on the Al film through a Ti film, a first protective film which covers the Al film and has an opening portion from which a portion of the Au film is exposed. In the pressure sensor, a second protective film made of polyimideamide or polyimide covers at least the surface of the Au film exposed from the first protective film, and a vicinity of the opening portion of the first protective film. Therefore, corrosion resistance of the Al film can be prevented while the pressure sensor has a reduced component number.

Owner:DENSO CORP

Electrocoppering method for TC2 titanium alloy

The invention discloses an electrocoppering method for TC2 titanium alloy. The method comprises the following steps of (1), selecting Emery with the particle size not larger than 60 meshes for performing abrasive blasting on the TC2 titanium alloy, wherein the abrasive blasting pressure ranges from 0.3 MPa to 0.5 MPa; (2), performing activating treatment on the TC2 titanium alloy in acid solutions after abrasive blasting, and reducing the thickness of the surface of the TC2 titanium alloy by two micrometers to seven micrometers; (3), placing the activated TC2 titanium alloy in the sulfuric acid and hydrochloric acid mixed solutions with the temperature of 18 DEG C to 25 DEG C for 30 min to 60 min for hydrotreating; (4), performing copper plating on the hydrogenated TC2 titanium alloy. According to the method, the binding force of the surface of the TC2 titanium alloy and a plating layer of the TC2 titanium alloy is ensured and improved, the electrical conductivity of the TC2 titanium alloy materials is improved, contact corrosion is prevented from happening to the TC2 titanium alloy materials and cadmium metal, and then the comprehensive performance of the TC2 titanium alloy materials is improved.

Owner:SHENYANG AIRCRAFT CORP

Method for Preparing a Coating Resistant to Contact Corrosion on the Surface of Titanium Alloy

ActiveUS20110300374A1High strengthReduce mechanical property mismatchHot-dipping/immersion processesPretreated surfacesBiological activationTitanium alloy

The invention relates to a method for preparing a coating resistant to contact corrosion on the surface of titanium alloy, which comprises the following steps: 1. carrying out degreasing and derusting to a titanium alloy part; 2. carrying out etching treatment on the titanium alloy part; 3. carrying out surface activation treatment on the titanium alloy part; 4. preheating the titanium alloy part in an atmosphere protection furnace; 5. immersing the preheated titanium alloy part in plating solution; and 6. carrying out diffusion treatment on the immersion-plated titanium alloy part in a vacuum furnace whereby atoms at the interface diffuse to form a diffusion layer on a substrate and thus form a plating diffusion composite layer on the surface of the titanium alloy part. The part treated by the method completely solves the problem of contact corrosion of titanium alloy contacting with aluminum alloy and steel material.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Motor vehicle axle component and method for producing a motor vehicle axle component

InactiveUS8414087B2Improve load characteristicsProtected against corrosionLamination ancillary operationsLaminationAdhesiveSteel tube

The invention relates to a motor vehicle axle component and a method for producing a motor vehicle axle component. The axle component, for example a dead beam axle, includes a light metal body, such as aluminum or magnesium or corresponding alloys, and a tubular body in form of a steel tube, which are adhesively connected with each other. An adhesive pocket filled with an adhesive is formed between an end of the tubular body and a cylindrical receptacle of the light metal body. Respective bezels are arranged on a free end of the receptacle and on a free end of the tubular body. The spaces between the respective bezels and adjacent walls are filled with adhesive, which seals the interior and exterior transition regions of the joint zone, thus protecting the joint zone against corrosion, improving the load characteristic of the axle component and increasing its service life.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Method and apparatus for preventing corrosion of contact

InactiveUS20050231858A1Avoid contact corrosionInhibition effectEmergency protective arrangements for automatic disconnectionExcavationsEngineeringCorrosion prevention

A method for preventing corrosion of a contact, includes comparing a potential of a signal line connected to the contact with a predetermined potential corresponding to the corrosion of the contact; flowing a corrosion-prevention current into the contact when a result of the comparing shows that the contact is corroded; inputting into the signal line a signal used for judging a logical value of a connection state of the contact; and in the magnitude relation, setting the predetermined potential on another side of a threshold level used in the judging of the logical value of the connection state of the contact.

Owner:FUJITSU GENERAL LTD

Hot-dip coating alloy containing aluminum, silicon, zinc, rare earth and magnesium and preparation method thereof

ActiveCN101928901AUniform compositionImprove toughnessHot-dipping/immersion processesRare-earth elementDip-coating

The invention relates to a hot-dip coating alloy which is especially used for surface coatings of titanium alloy parts. The hot-dip coating alloy comprises the following components in weight percentage: 8-24% of silicon, 1.2-3.1% of zinc, 0.02-0.5% of a rare-earth element, 0.5-3.2% of magnesium, 1-2% of a nano-oxide particle reinforcing agent, and the balance of aluminum and unavoidable impurities, wherein the nano-oxide particle reinforcing agent is chosen from one or two of TiO2 and CeO2. The hot-dip coating alloy obtained in the invention can form the coating with good corrosion resistance and good wear resistance on the surface of a titanium alloy, wherein the coating is in good metallurgical bond with a matrix.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

High-strength aluminum alloy rivet line and manufacturing method thereof

The invention discloses a high-strength aluminum alloy rivet line and a manufacturing method thereof. Compared with the prior art, the high-strength aluminum alloy rivet line according to the embodiment of the invention has the advantages that a plurality of elements are alloyed, an intermediate alloy is granulated and added as particles, the technologies of high-temperature rapid aluminum smelting, electromagnetic stirring and the like are utilized comprehensively, and sectional temperature control, directional freezing, continuously casting, cold rolling, repeated thermal treatment and drawing processes are adopted, so that a rivet line with high strength, high shearing strength, excellent plasticity and toughness and superior corrosion resistance can be manufactured, the riveting weight and cost can be lowered, and the safety performance of riveting is enhanced.

Owner:SHANDONG TAIYI METAL SCI & TECH

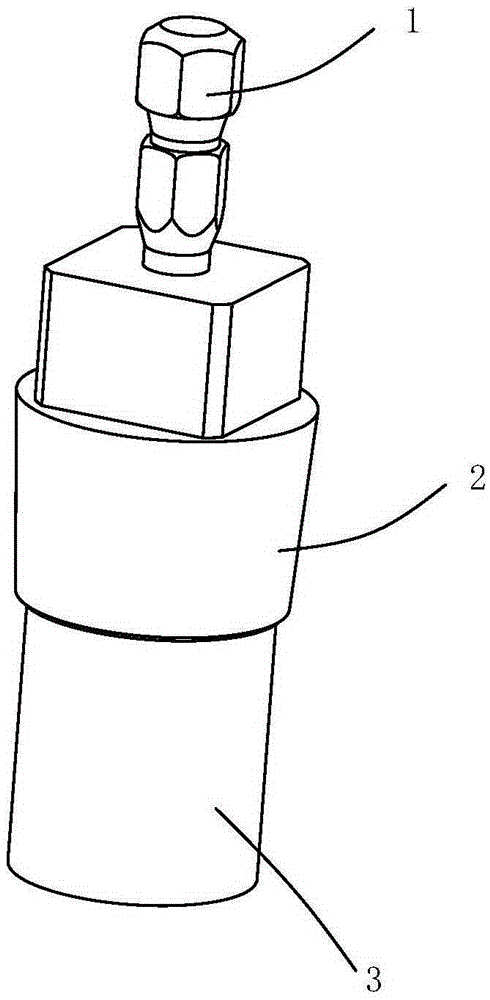

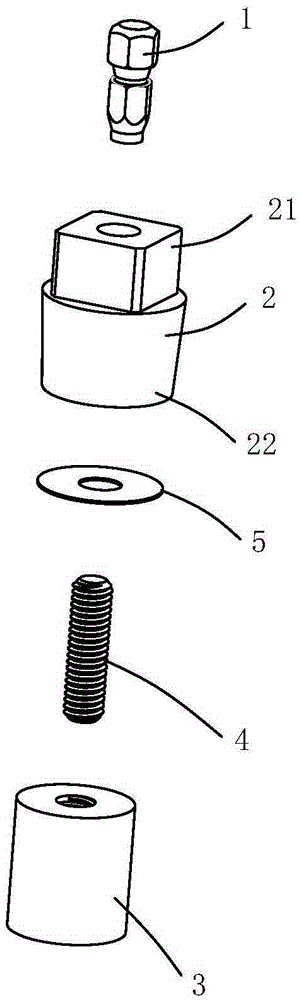

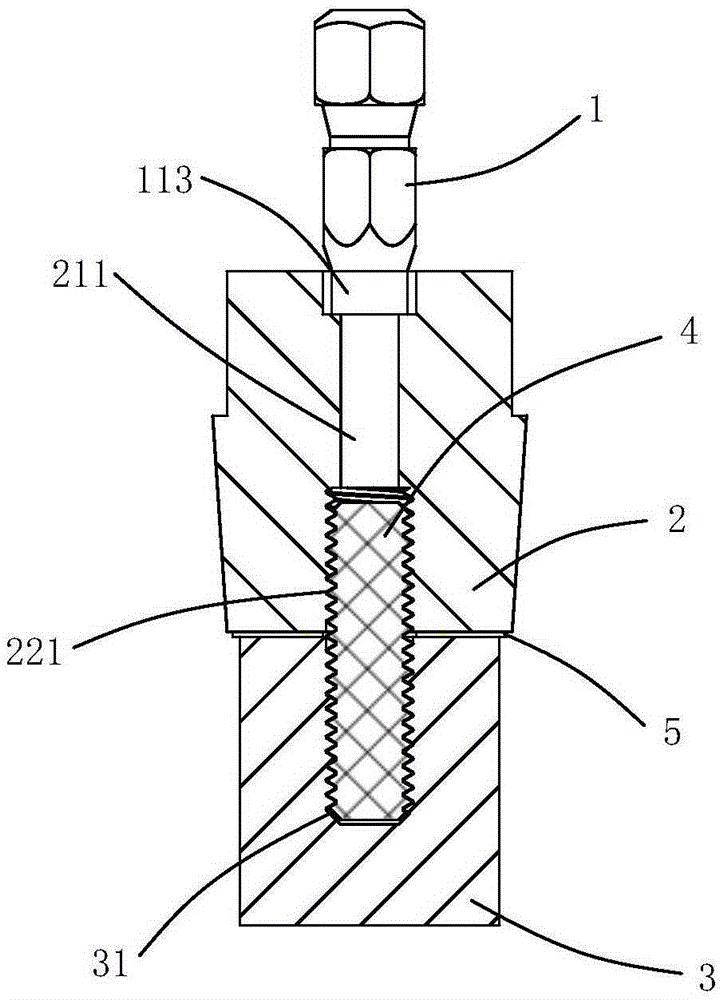

Sacrificial anode structure and method for checking corrosion state of sacrificial anode structure

The invention relates to a sacrificial anode structure. The sacrificial anode structure comprises a checking head, a plug screw and a corrosion block. Both the plug screw and the corrosion block are made of metal. The activity of the corrosion block is higher than that of the plug screw. A first hole and an indication channel are formed in the plug screw. A second hole is formed in the corrosion block. The plug screw and the corrosion block are fixedly connected. The first hole, the second hole and the indication channel are mutually communicated. The checking head is fixedly connected to the end of the plug screw. The sacrificial anode structure is simple, and the requirement for the manufacturing level is quite low; the corrosion state of a sacrificial anode can be known at regular times conveniently and rapidly, and timely monitoring and replacing are conducted; meanwhile, an insulation material is used between the plug screw and the corrosion block so that dissimilar metal contact corrosion between the plug screw and the corrosion block can be avoided, and the service life of the sacrificial anode is prolonged.

Owner:GREE ELECTRIC APPLIANCES INC

Electric cable connection terminal and wire harness having the electric cable connection terminal

ActiveCN102832469AAvoid corrosionAvoid contact corrosionCouplings bases/casesMulticonductor cable end piecesThermal shrinkageEngineering

Provided is an electric cable connection terminal. A first connection part is configured to connect the one electric cable thereto. A second connection part is configured to connect the other electric cable thereto. A waterproof member is configured to be melted to seal leading end portions of core wires of the electrics cable when being heated and configured to be solidified to waterproof the leading end portions when being cooled. An accommodation part accommodating the waterproof member therein is provided between the first and second connection parts. A thermal shrinkage member is provided to cover the first and second connection parts and the accommodation part and configured to be shrunken when being heated to closely contact the first and second connection parts and the accommodation part. When the cables are connected to the first and second connection part, respectively, the core wires are arranged at an interval.

Owner:YAZAKI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com