Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

394results about How to "Convenient welding work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

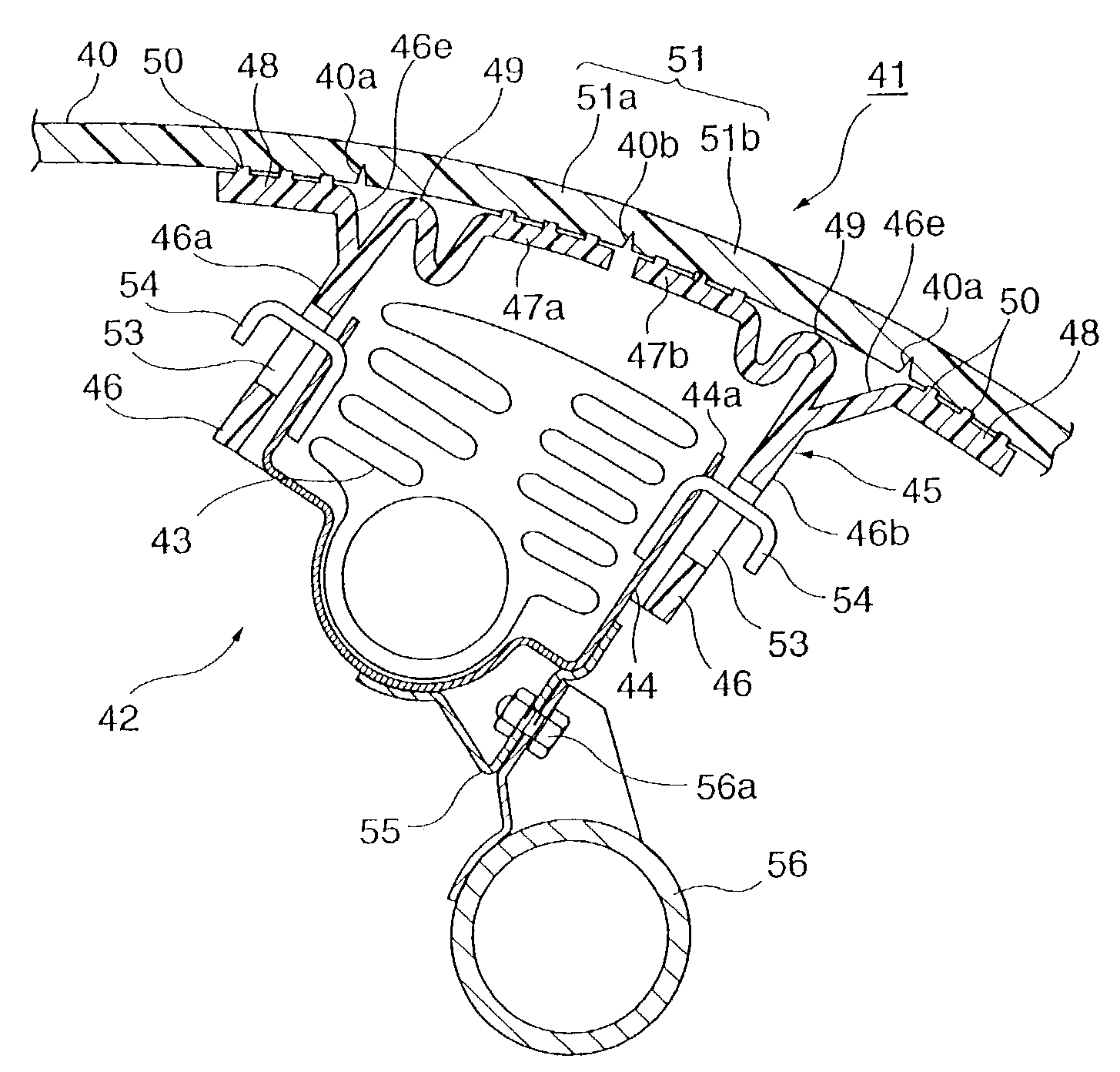

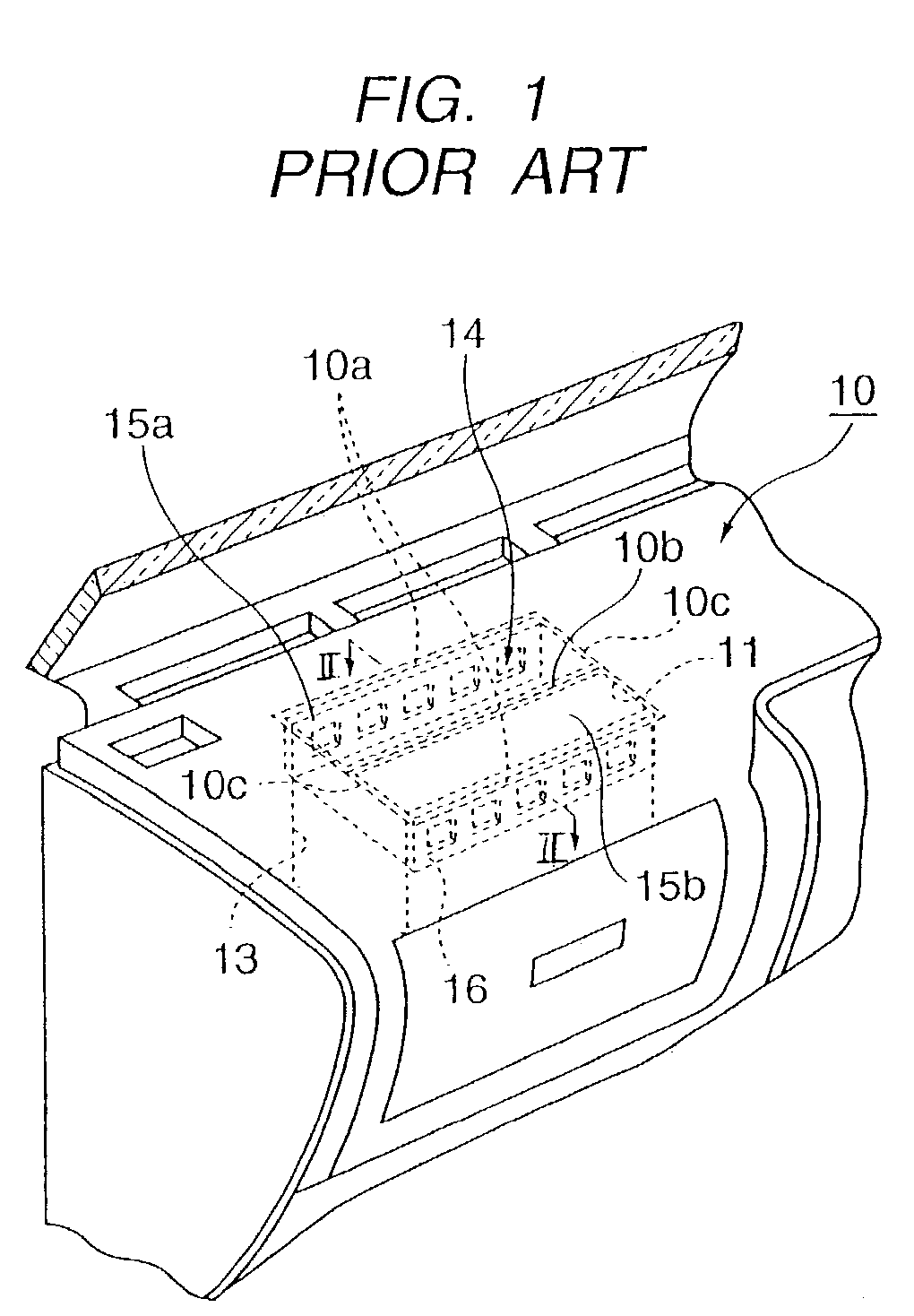

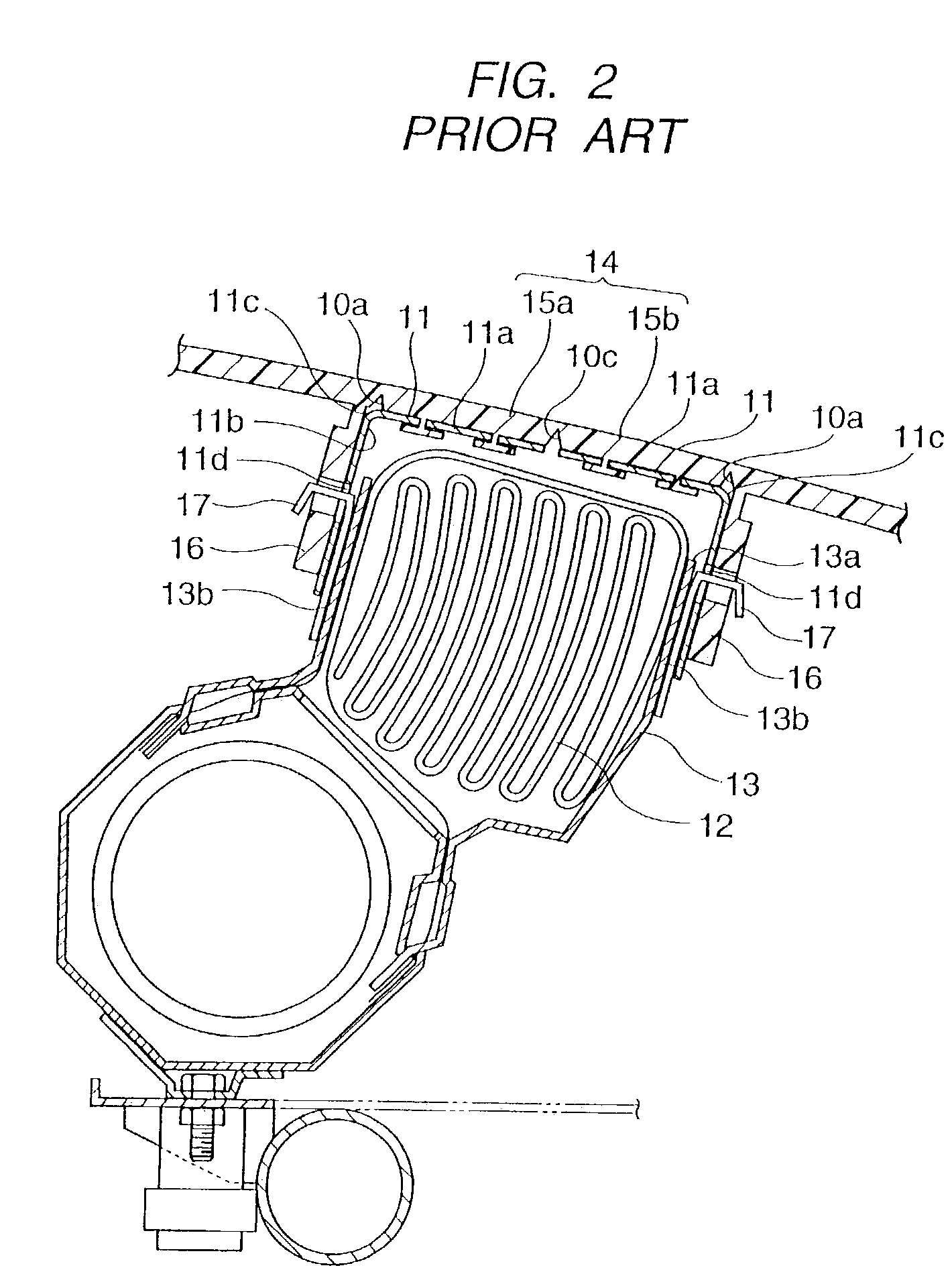

Airbag apparatus for automobile

InactiveUS7007970B2Convenience to workSuppression of impactPedestrian/occupant safety arrangementDomestic articlesAirbagSurface plate

An airbag apparatus for an automobile includes an airbag case for accommodating an airbag, a fracture-opening section of the surface panel, and a reinforcement frame member having a frame portion, at least one fracture-section reinforcement portion, and an edge reinforcement potion. The frame portion has an engagement portion to which the airbag case is connected. The fracture-section reinforcement portion is joined to the inside surface of the surface panel to cover and reinforce the fracture-opening section. The edge reinforcement portion is joined to the inside surface of the surface panel to cover and reinforce a surface panel portion surrounding the fracture-opening section.

Owner:SANGO GOSEI

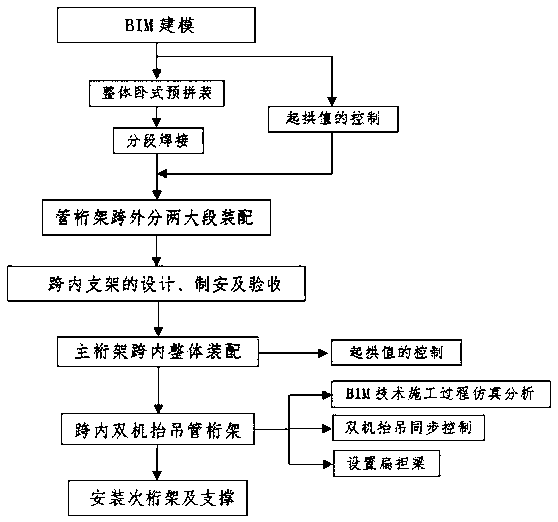

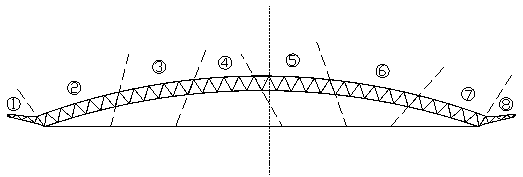

Rapid construction method of arched pipe truss

InactiveCN110259145ASee the connectionAccurately determine the center of gravityGeometric CADBuilding material handlingRisk strokeRapid construction

The invention discloses a rapid construction method of an arched pipe truss. The rapid construction method comprises the following steps that (1) a BIM structural model of the arched pipe truss is established; (2) horizontal integrated pre-assembly and segment welding are performed in a factory for the pipe truss to form truss bodies to be transport to a site; (3) the truss bodies are assembled to form two main trusses; (4) in-span brackets are installed; (5) the two main trusses are lifted and welded to connect the two main trusses into the pipe truss; (6) the assembled pipe truss is lifted in place to complete installation of the pipe truss; (7) the steps 2-6 are repeated to form two pipe trusses, a secondary truss and a roof support are installed, so that the installed part forms a whole force system; and (8) the steps 2-7 are repeated until all pipe trusses are installed. According to the rapid construction method of the arched pipe truss, in-span vertical one-time splicing rapid construction of the arched pipe truss can be completed in the case of poor on-site site conditions, the risks of working at height are reduced, the construction period is ensured, the construction cost is saved, and multiple purposes are achieved at one stroke.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

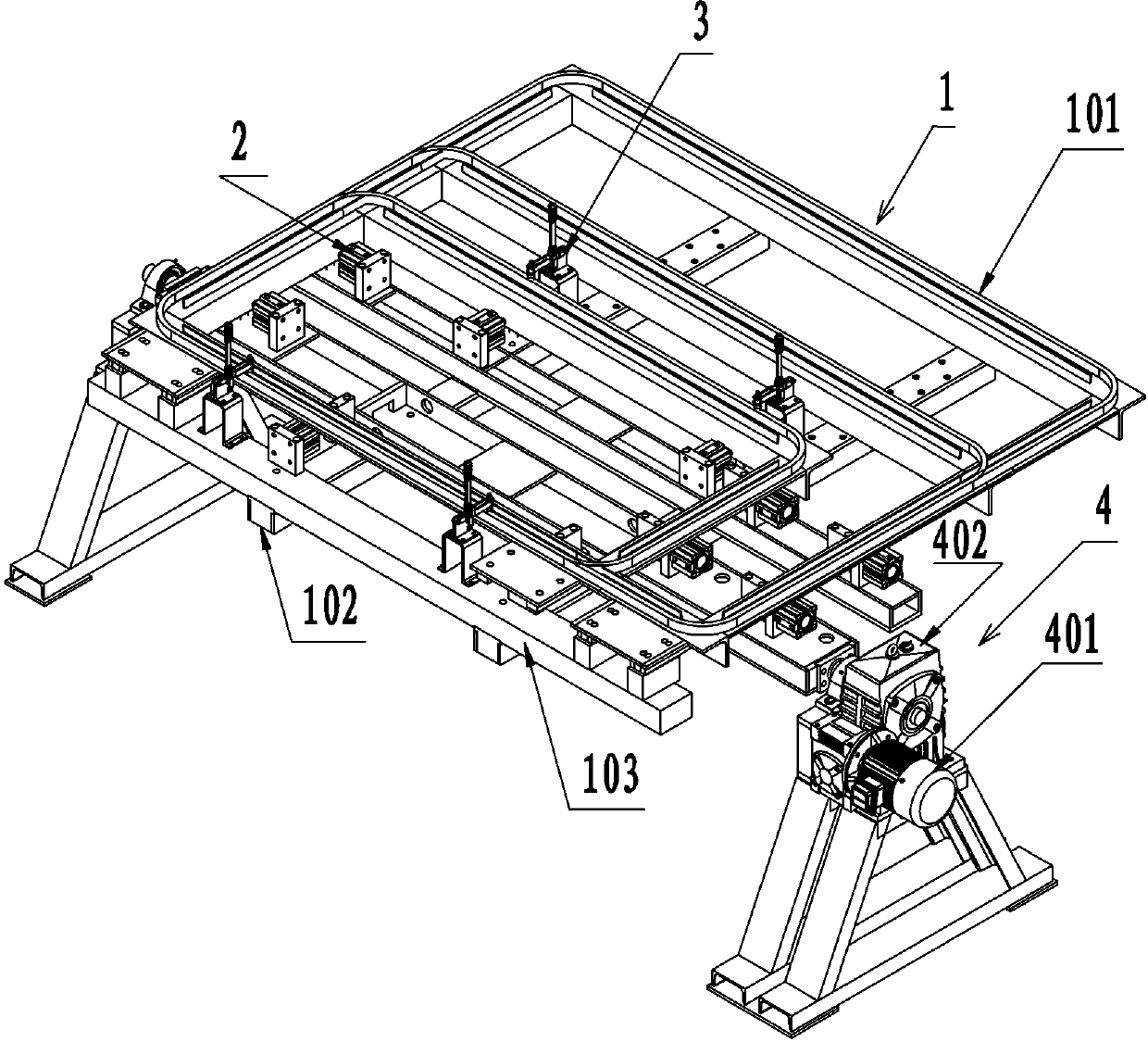

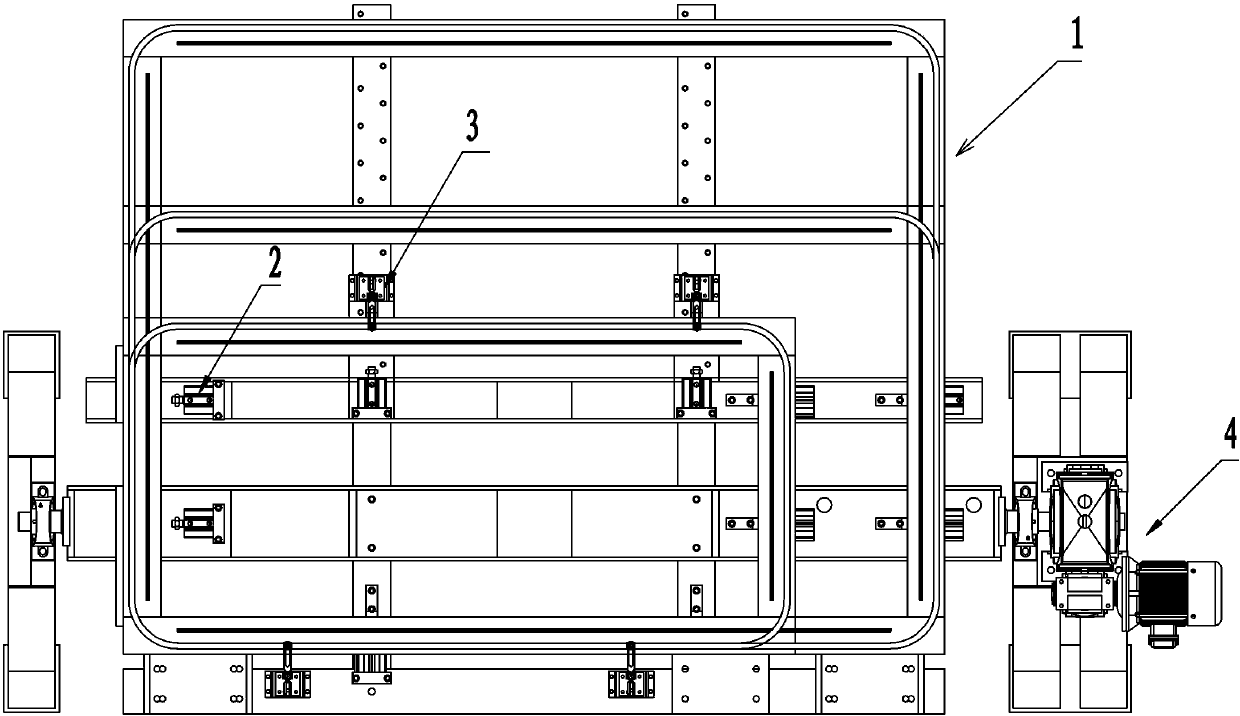

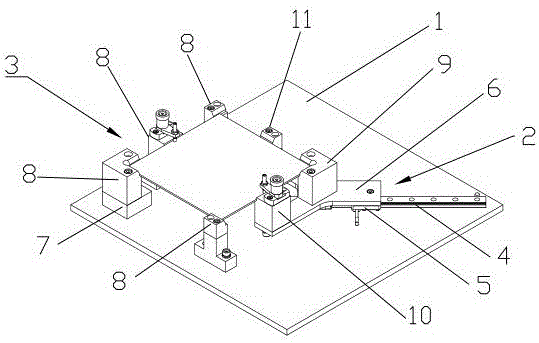

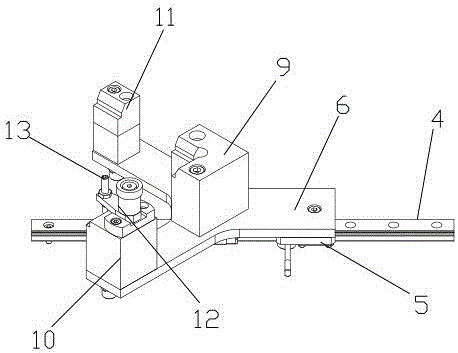

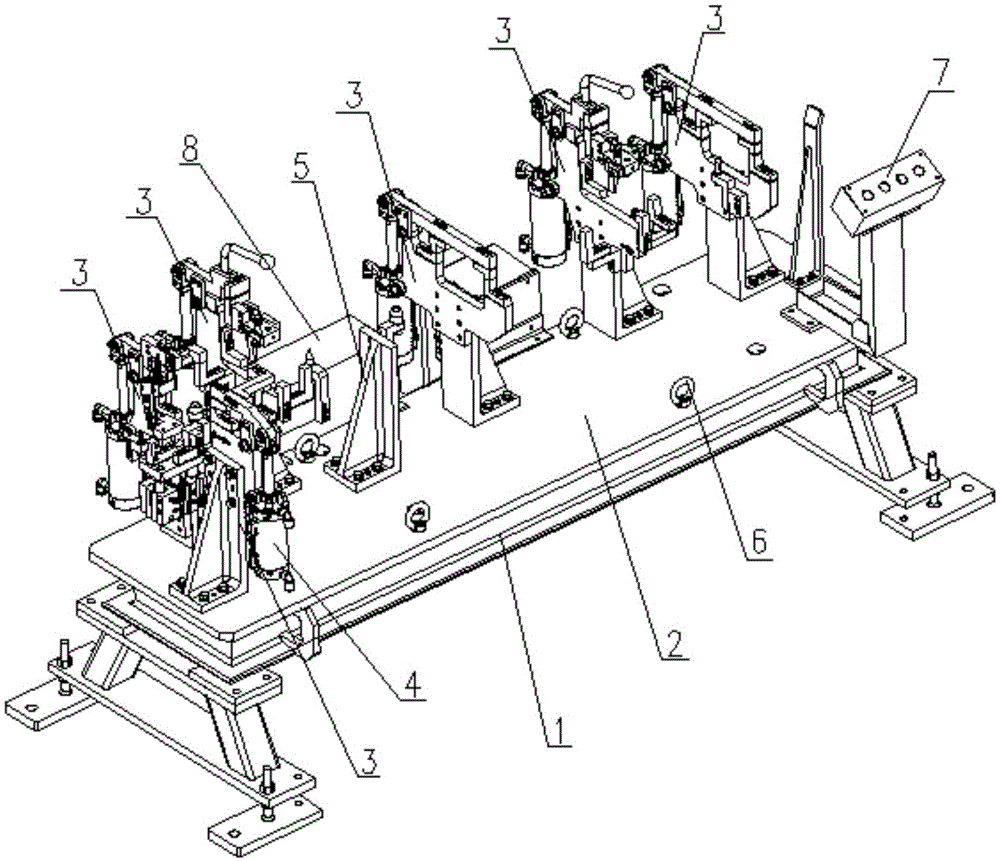

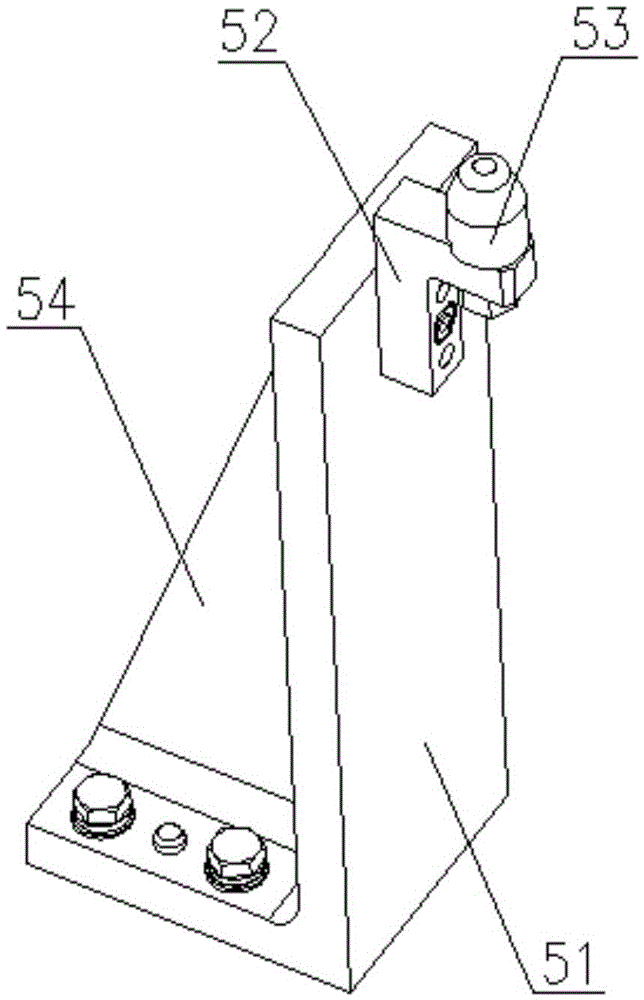

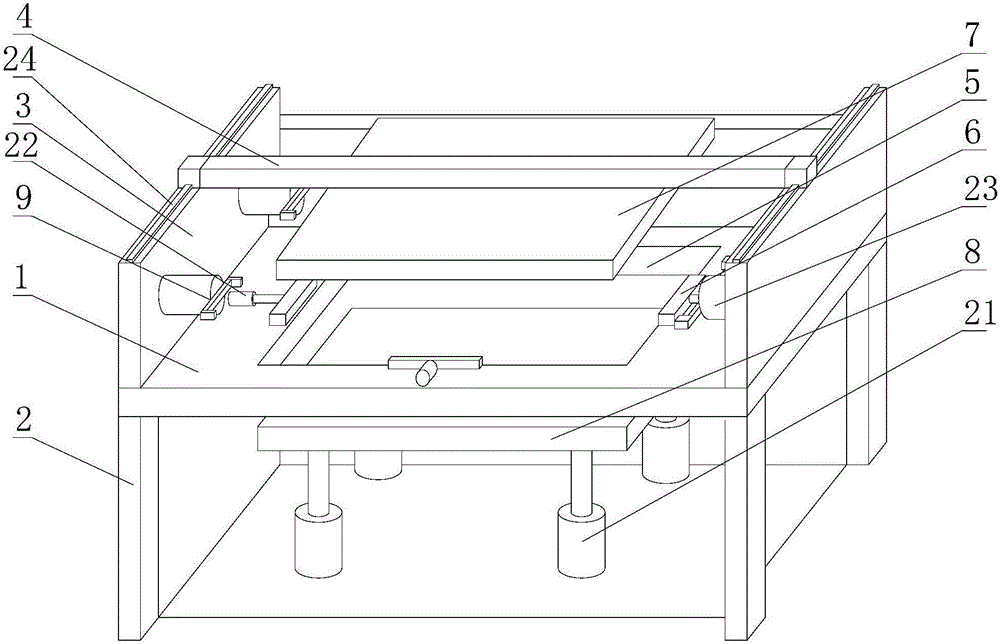

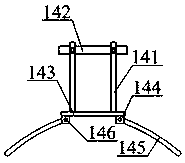

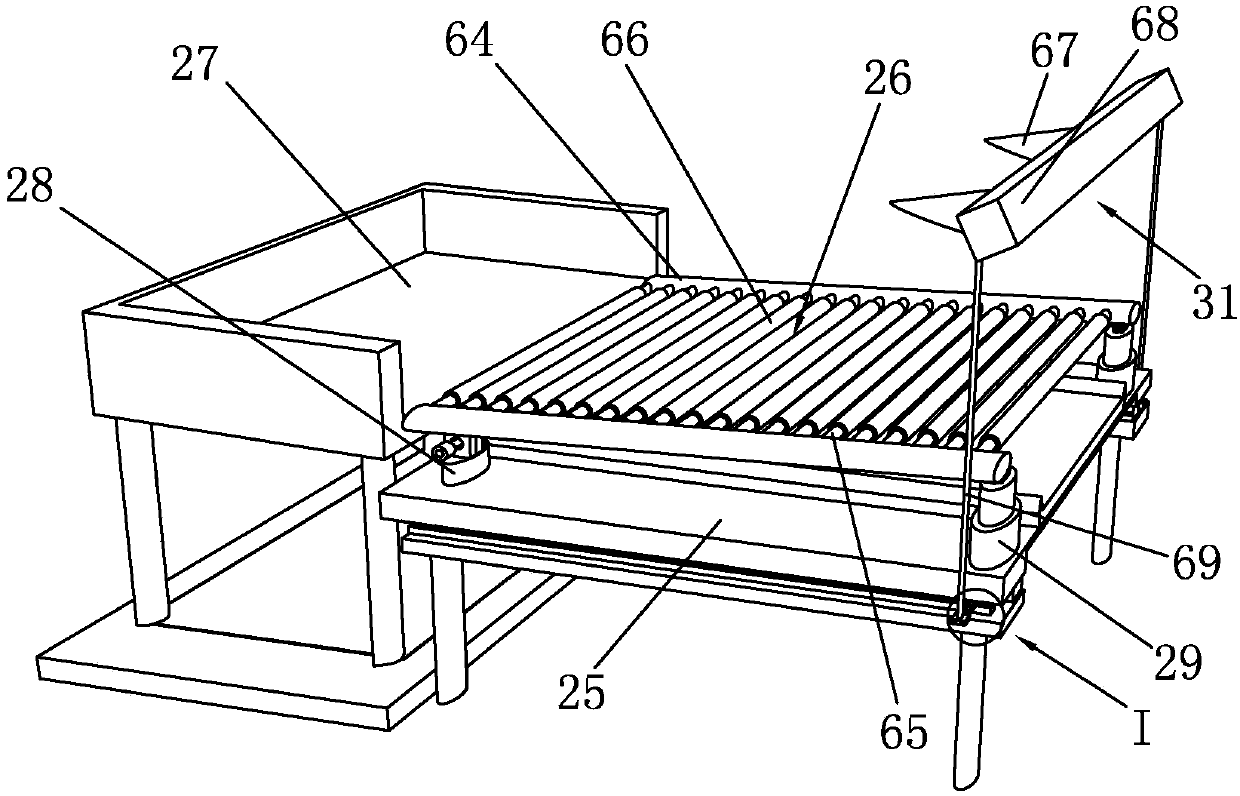

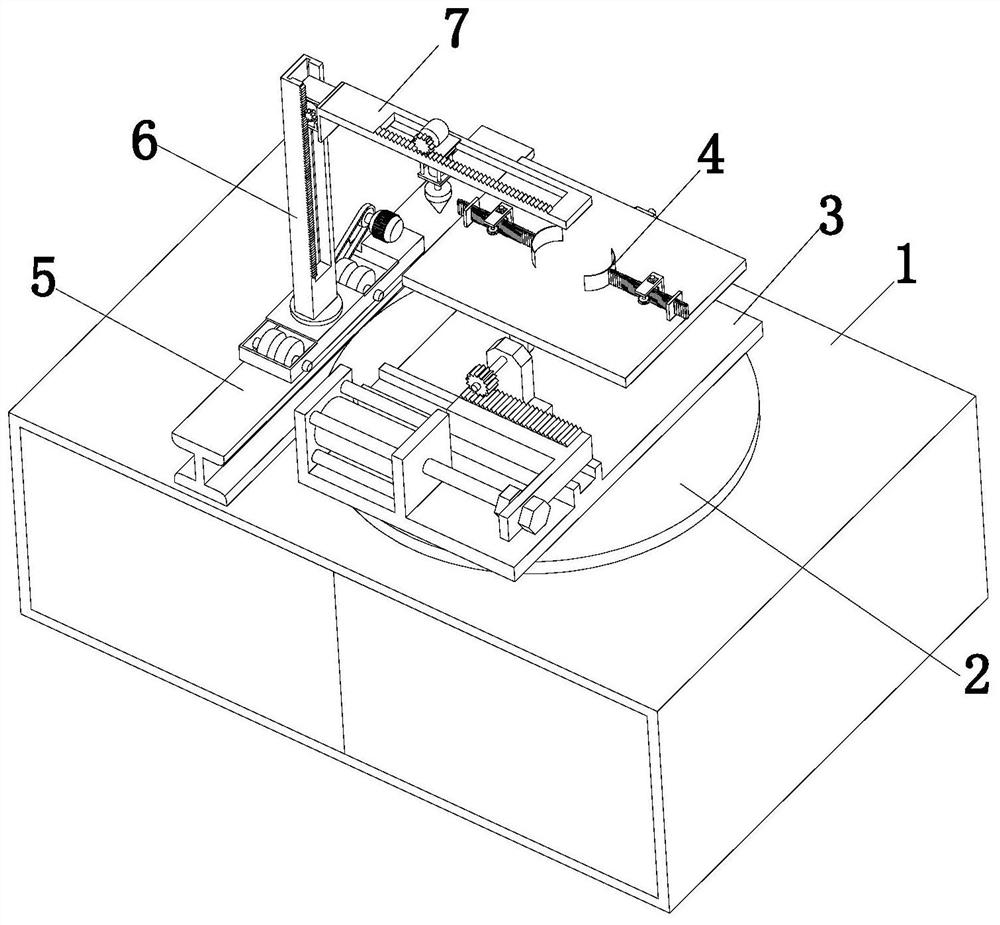

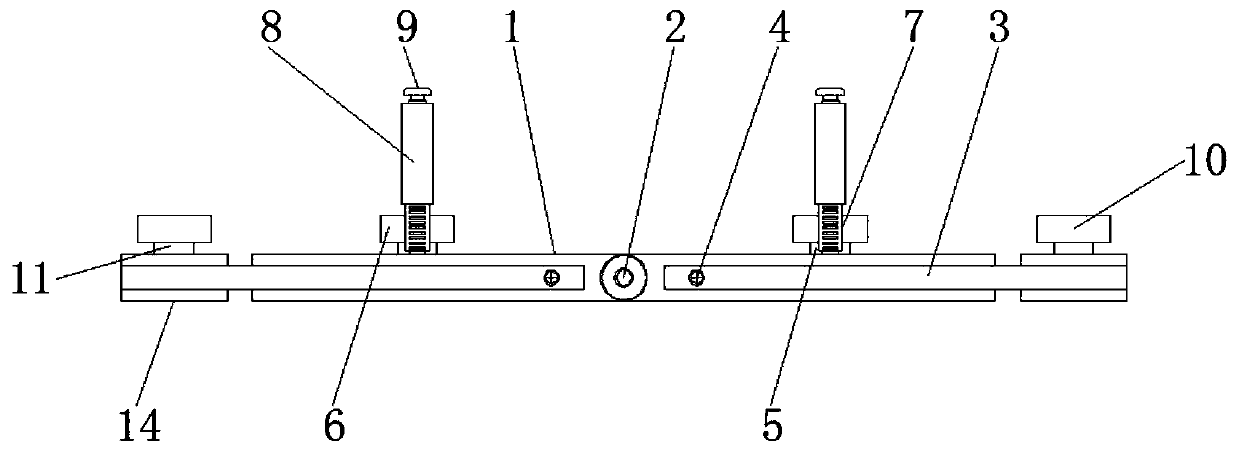

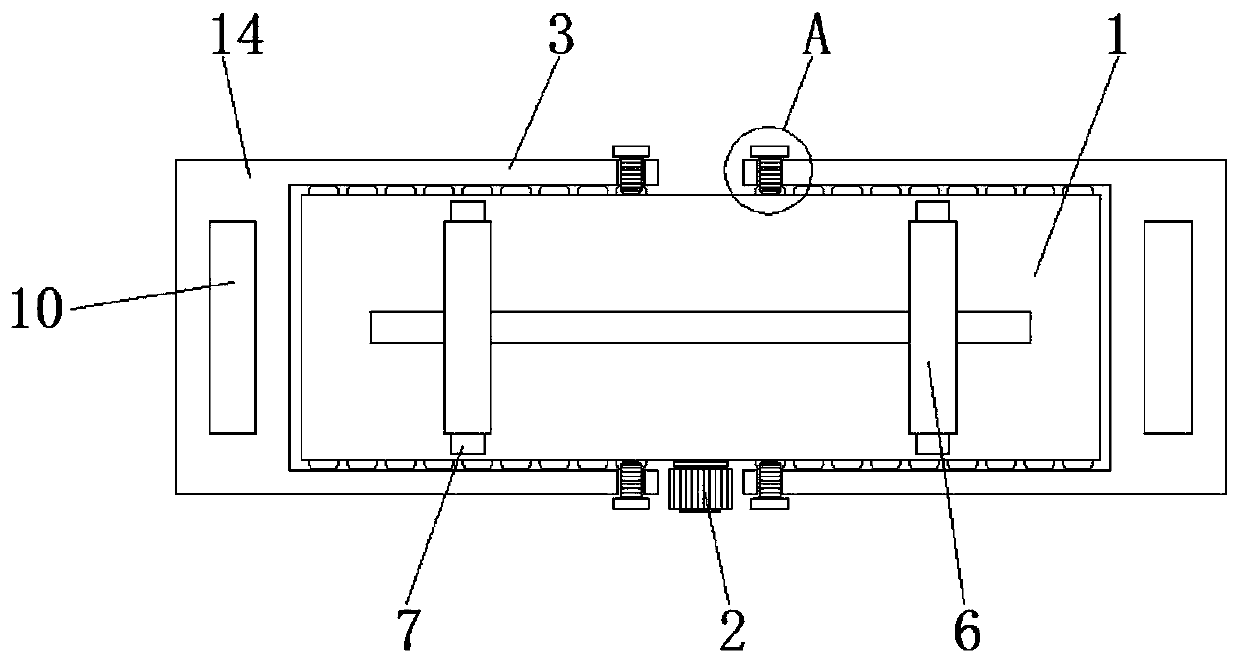

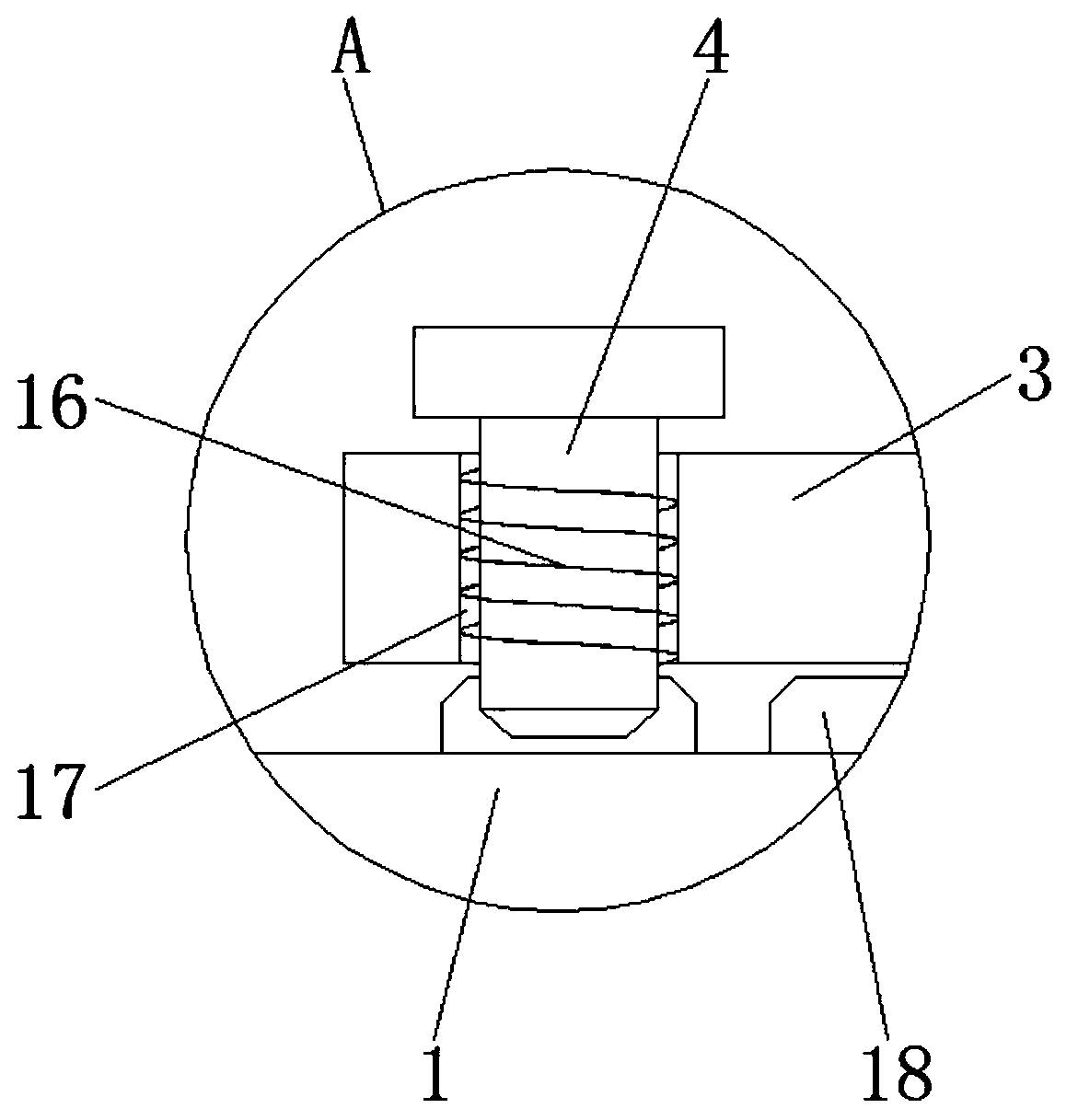

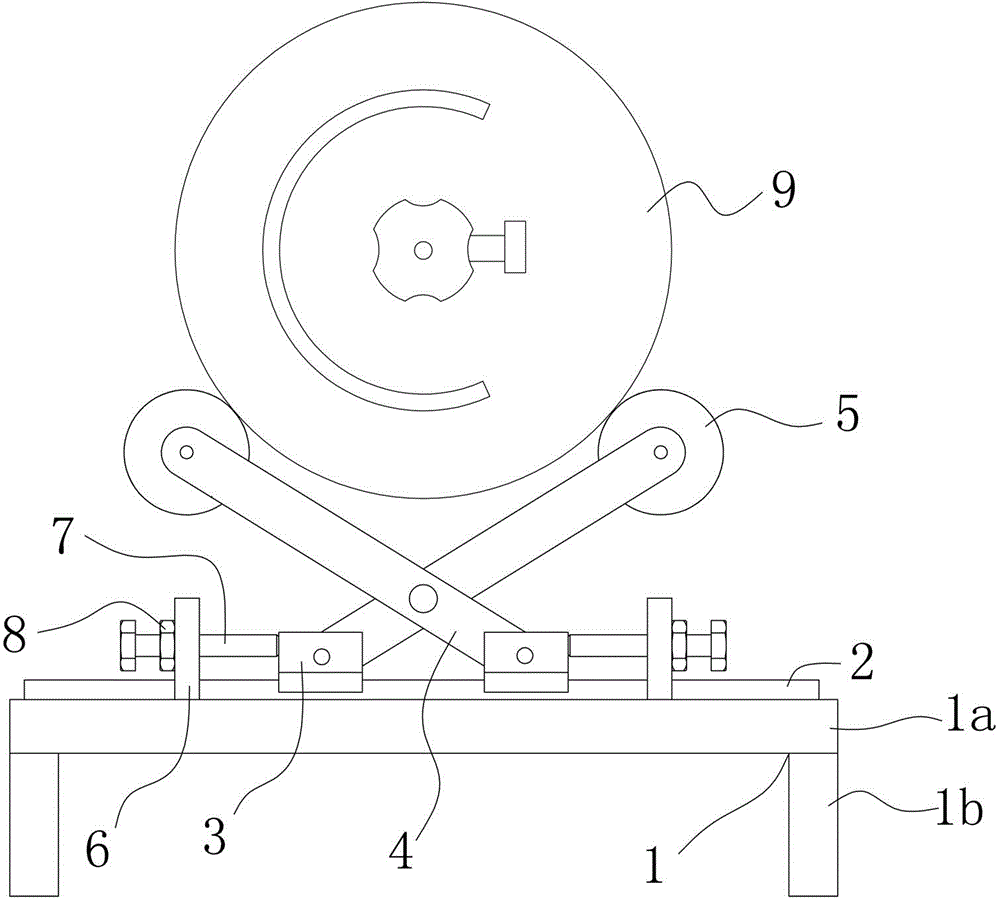

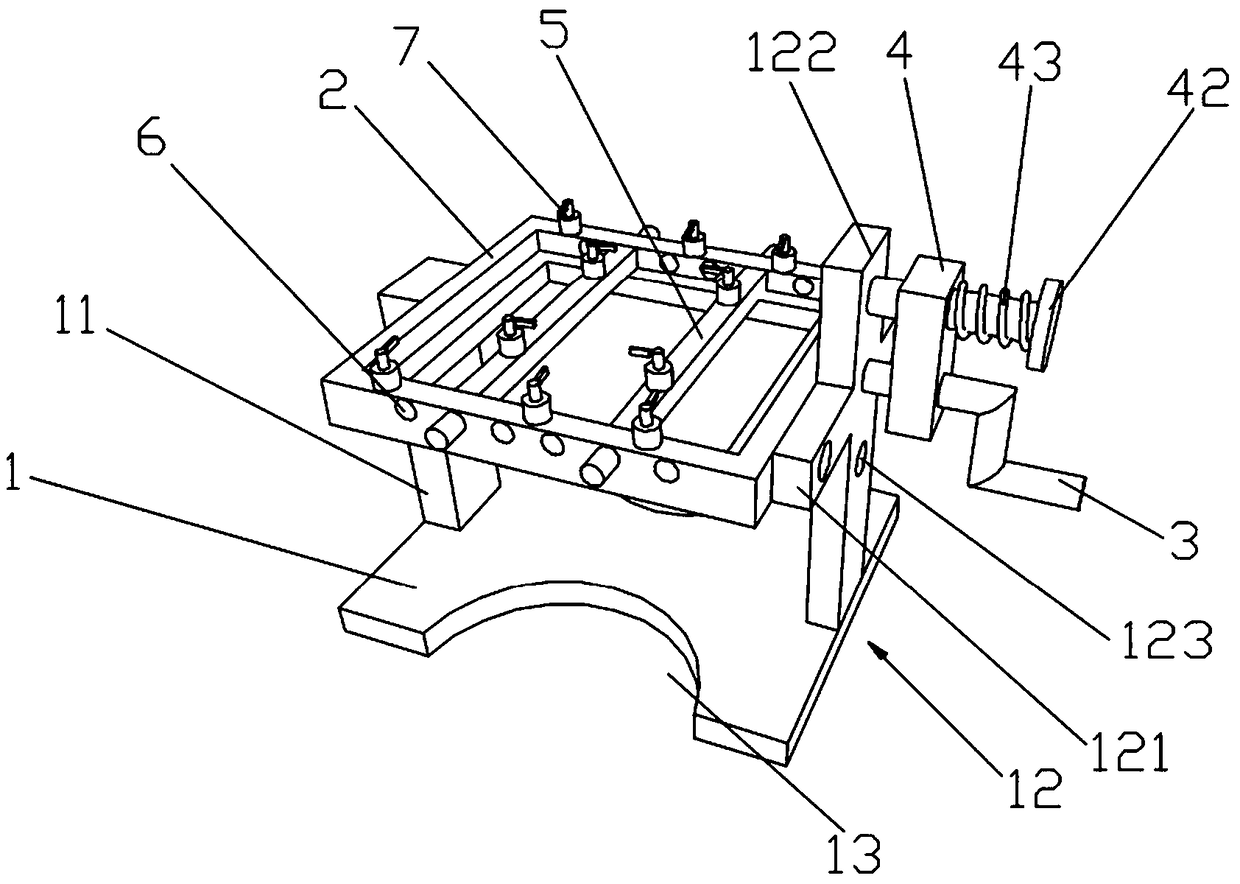

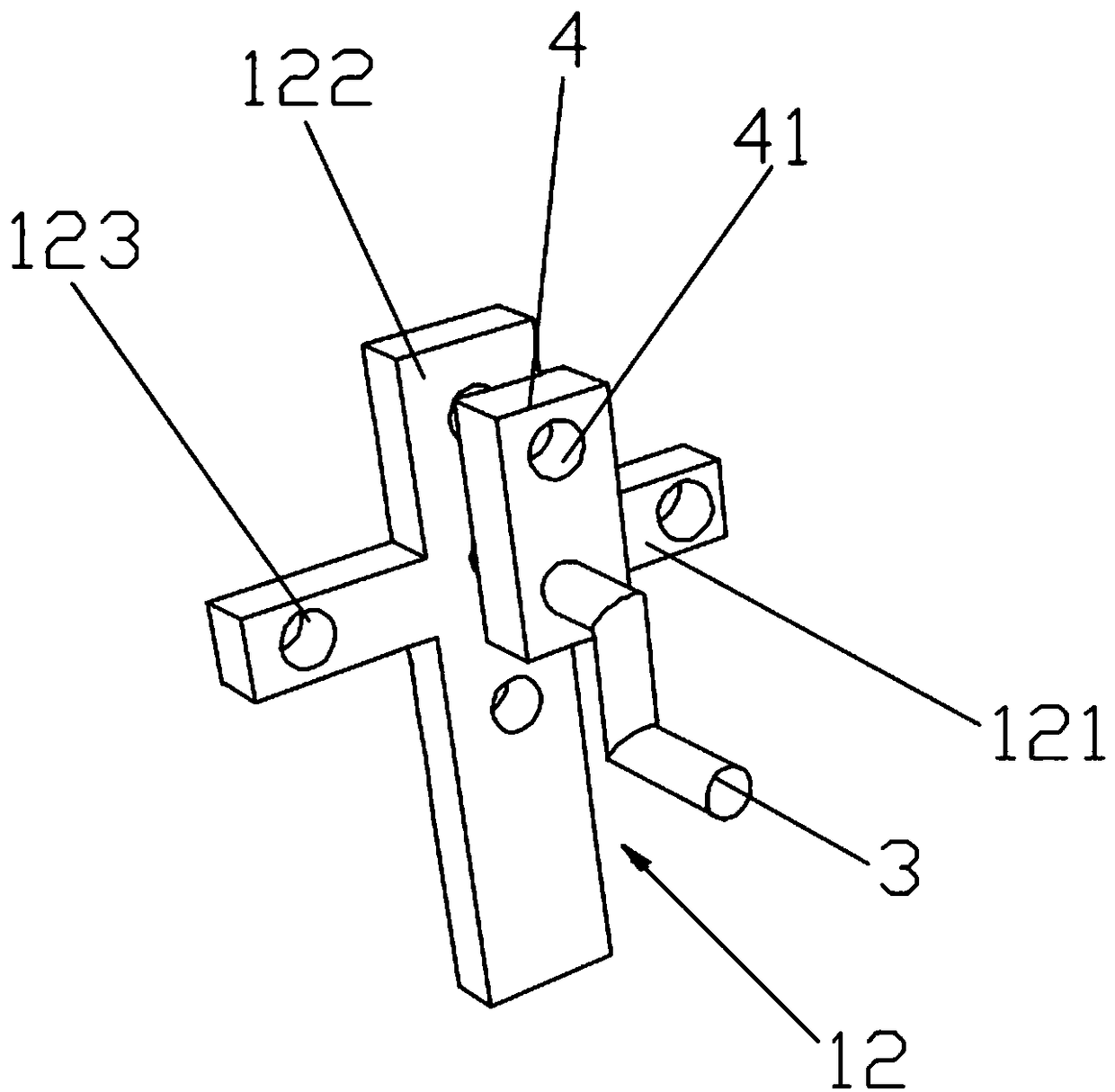

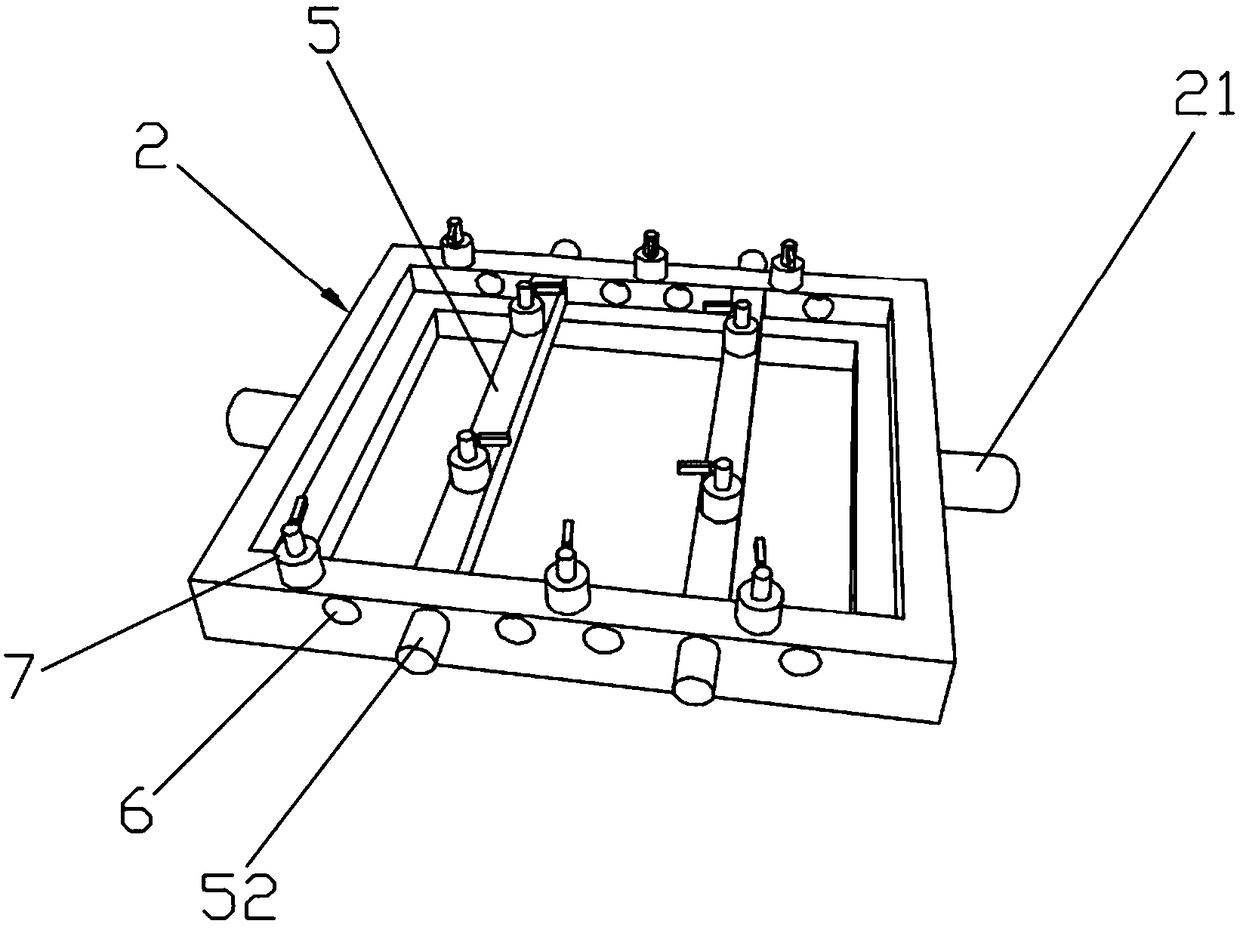

Clamping operation workbench for door frame combination welding and mounting

InactiveCN104191148AConvenient welding workImprove production efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention provides a clamping operation workbench for door frame combination welding and mounting. The clamping operation workbench comprises a workbench body, multiple groups of positioning cylinders and pressing devices and a turning device, the positioning cylinders and the pressing devices respectively used for positioning and clamping door frames are arranged on the workbench body, the turning device capable of driving the workbench body to turn by 180 degrees is arranged on one side of the workbench body, and the pressing devices on one side of the door frame can be adjusted to move along the workbench body and used for pressing of the door frames of different specifications. The positioning cylinders and the pressing devices respectively used for positioning and clamping the door frames are mounted on the workbench body and the pressing devices capable of being adjusted to move along the workbench body and used for pressing the door frames of different specifications are arranged on one side of the workbench body, so that the clamping operation workbench is better in universality.

Owner:广州精准机械有限公司

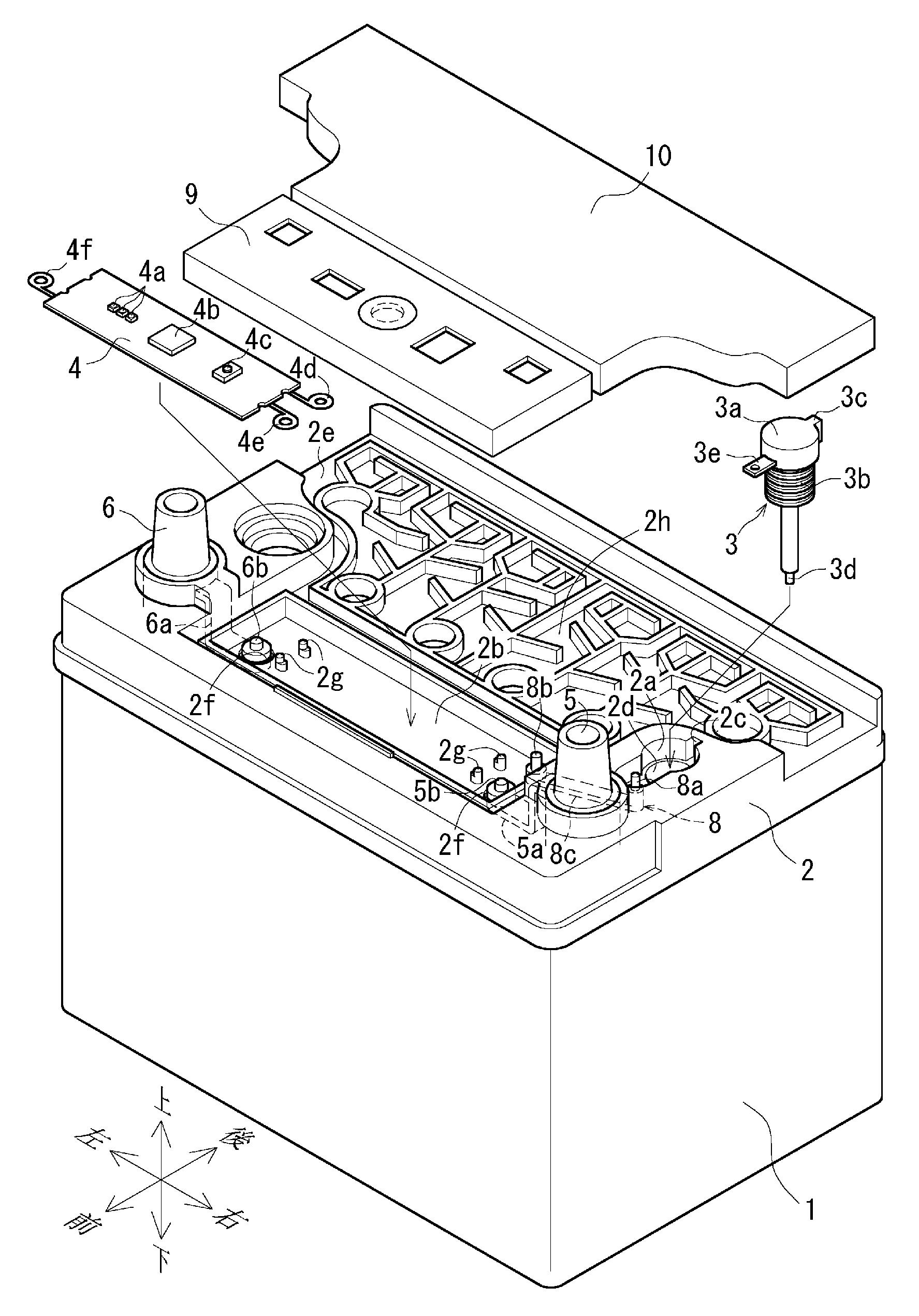

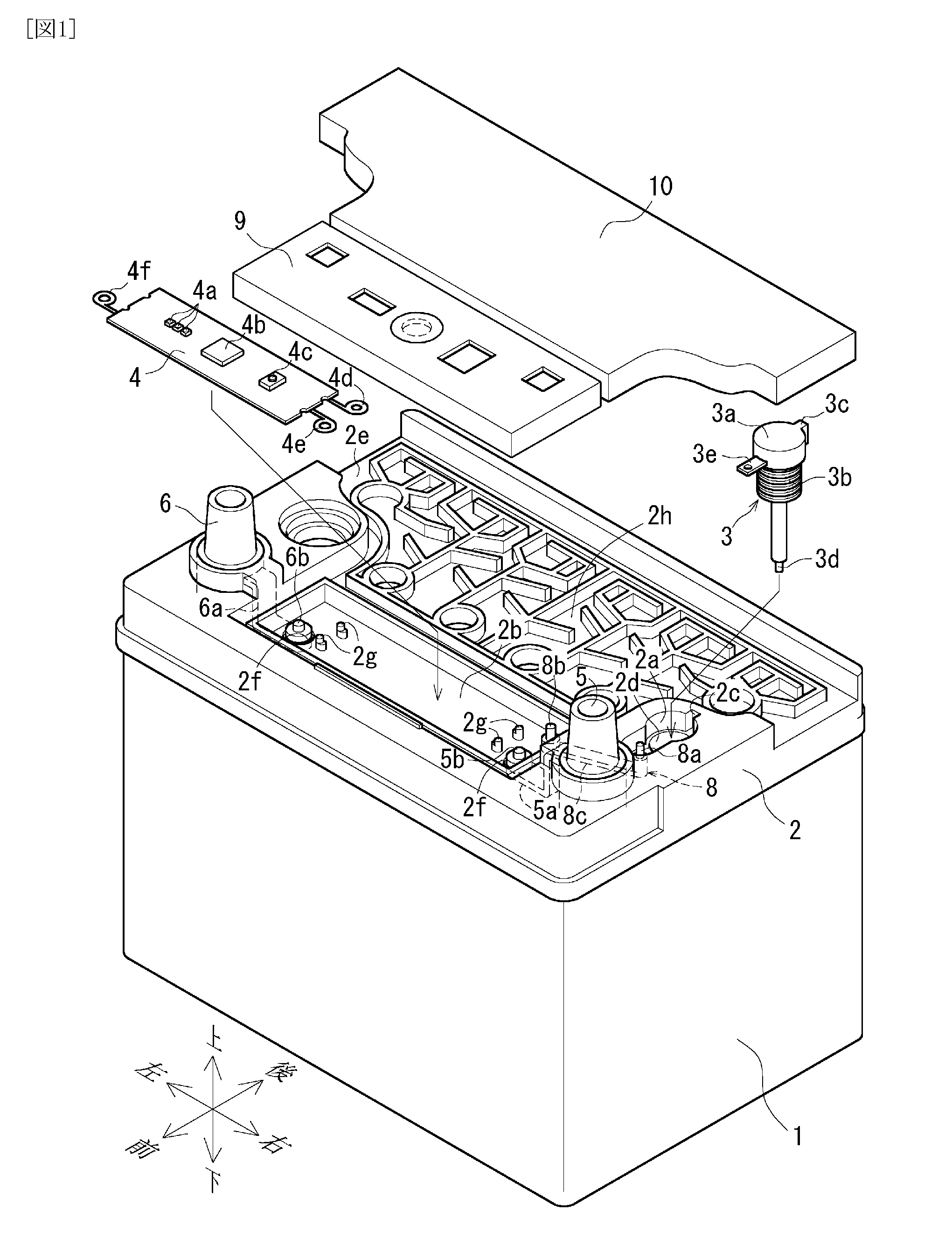

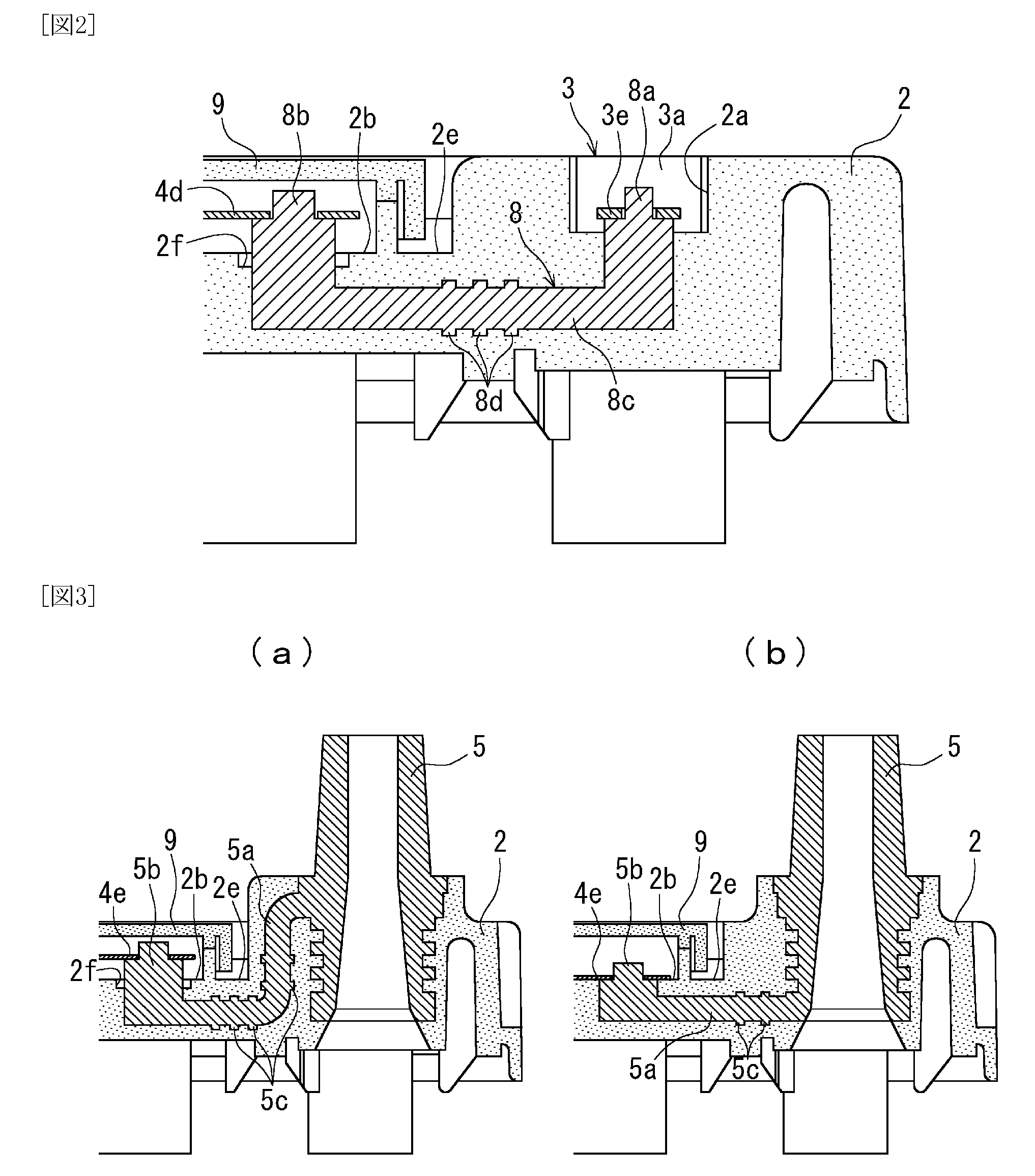

Lead Acid Battery

InactiveUS20100297478A1Good lookingAvoid passingFinal product manufactureCell lids/coversElectrical conductorLiquid surfaces

An object of the invention is to provide a lead acid battery having a liquid surface sensor (3) installed to a liquid surface sensor installation portion (2a) on a top face of a container lid (2), an electronic circuit board (4) contained in a recessed portion (2b) on the top face of the container lid (2), terminal connecting conductors (5a, 6a) connecting the electronic circuit board (4) to terminals (5, 6), and a liquid surface sensor connecting conductor (8) connecting the liquid surface sensor (3) to the electronic circuit board (4), preventing from catching on an object on the top face of the container lid (2) by insert molding the terminal connecting conductors (5a, 6a) and the liquid surface sensor connecting conductor (8) in the container lid (2), preventing the terminal connecting conductors (5a, 6a) and the liquid surface sensor connecting conductor (8) from being corroded by an electrolyte solution even if the electrolyte solution is spotted on the top face, and improving the outer appearance.

Owner:GS YUASA INT LTD

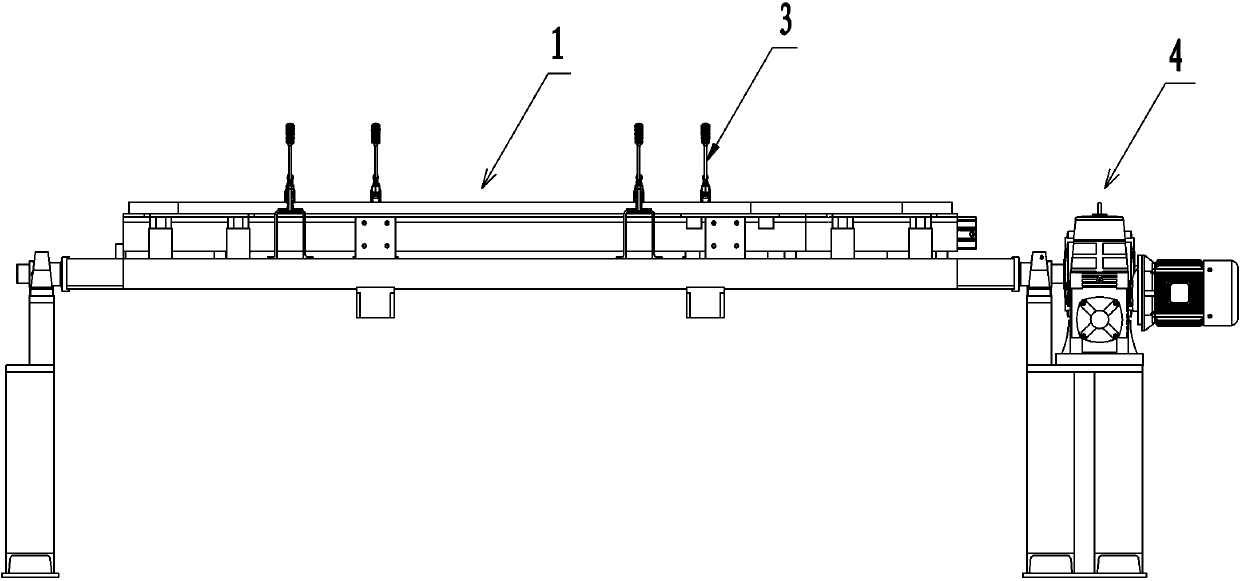

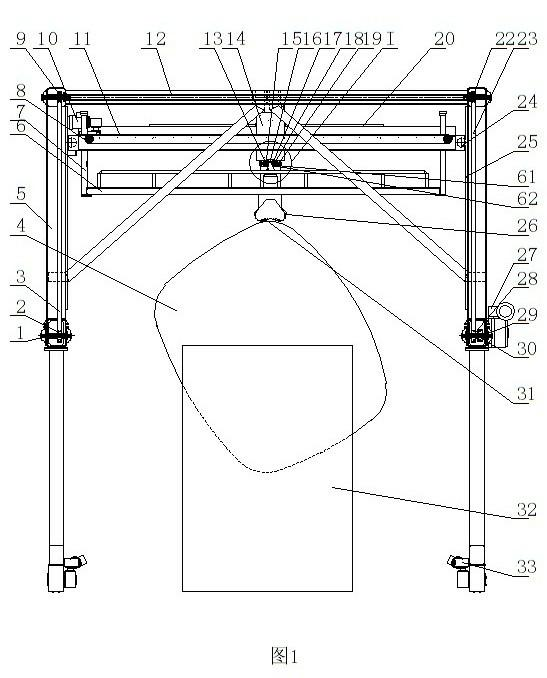

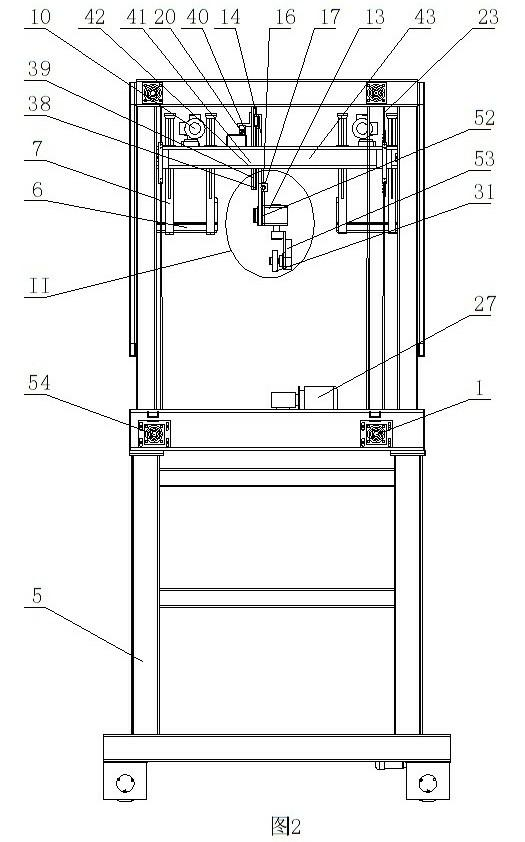

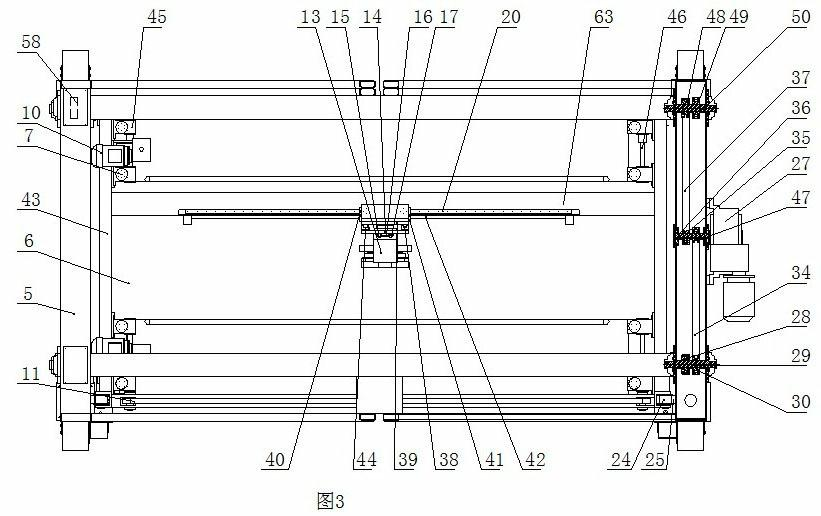

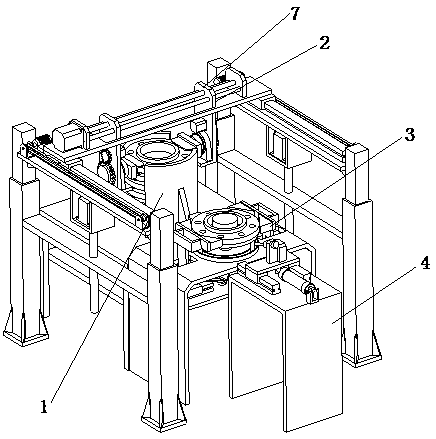

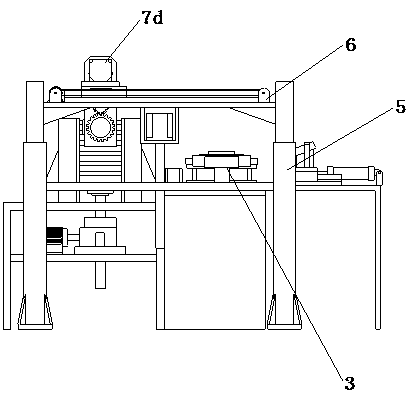

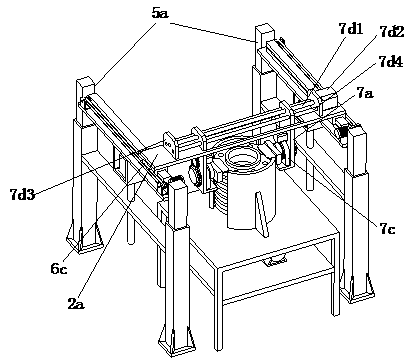

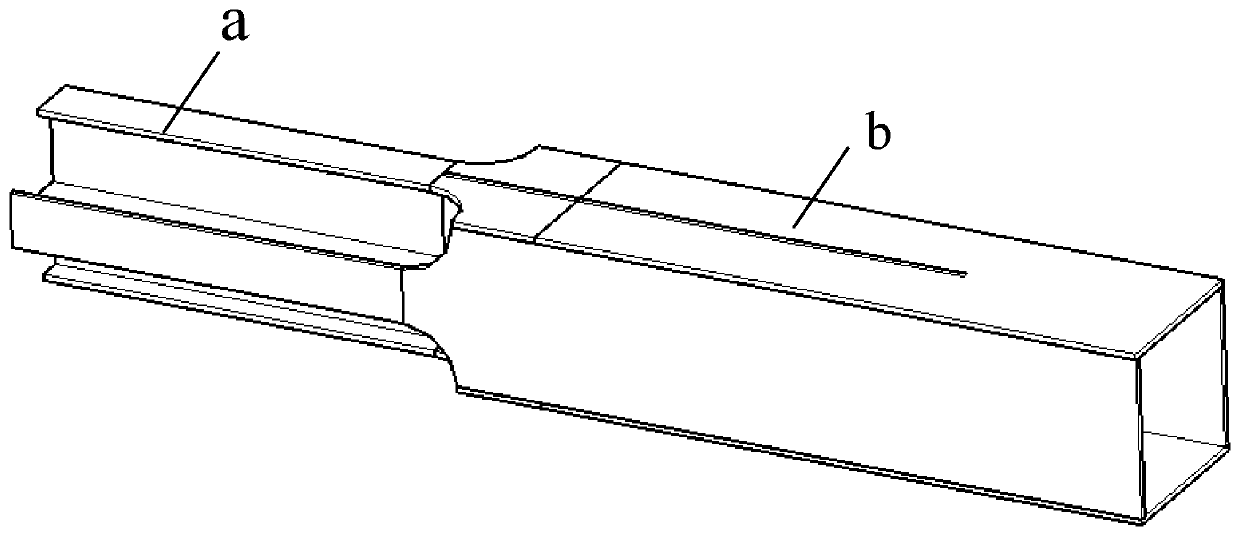

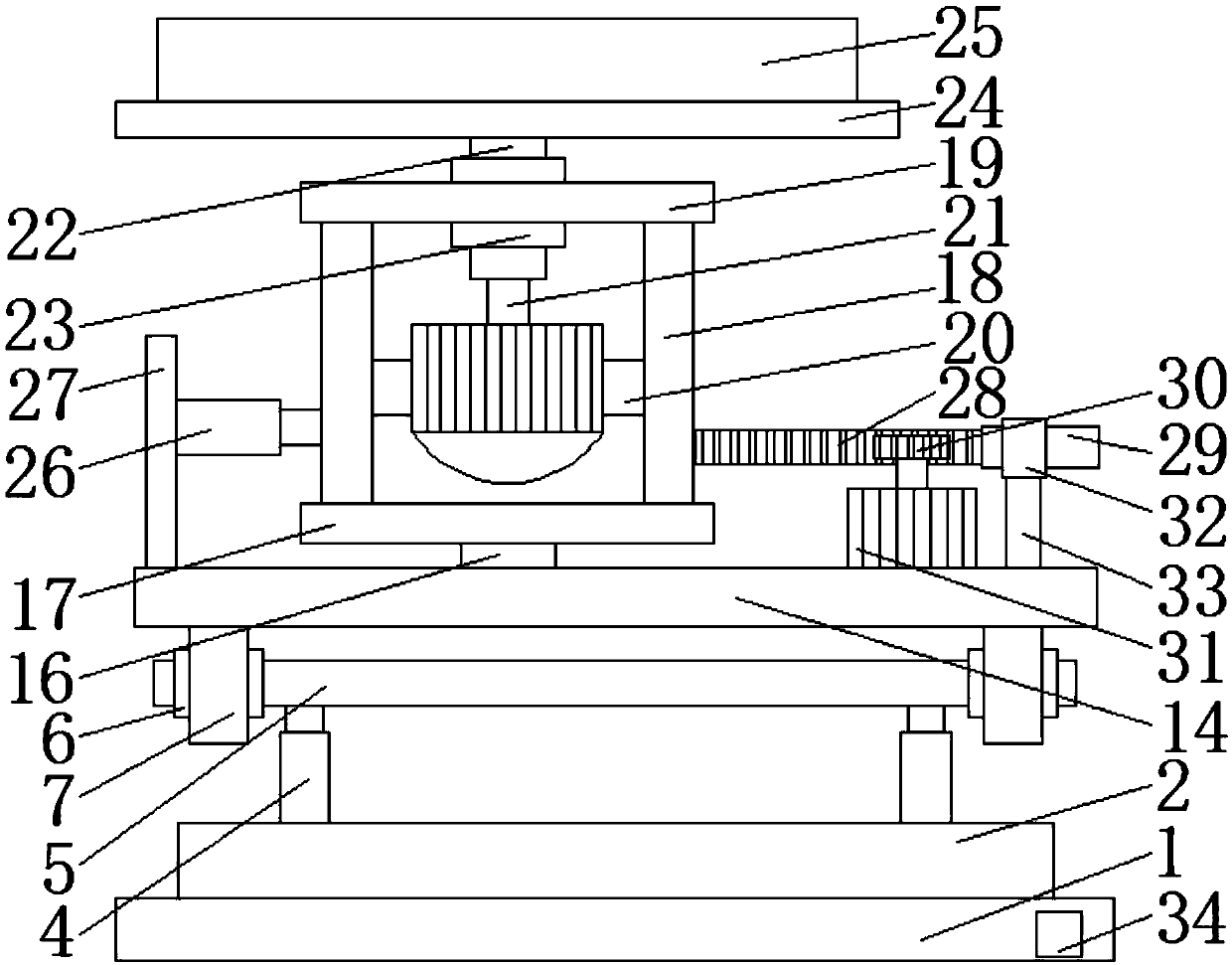

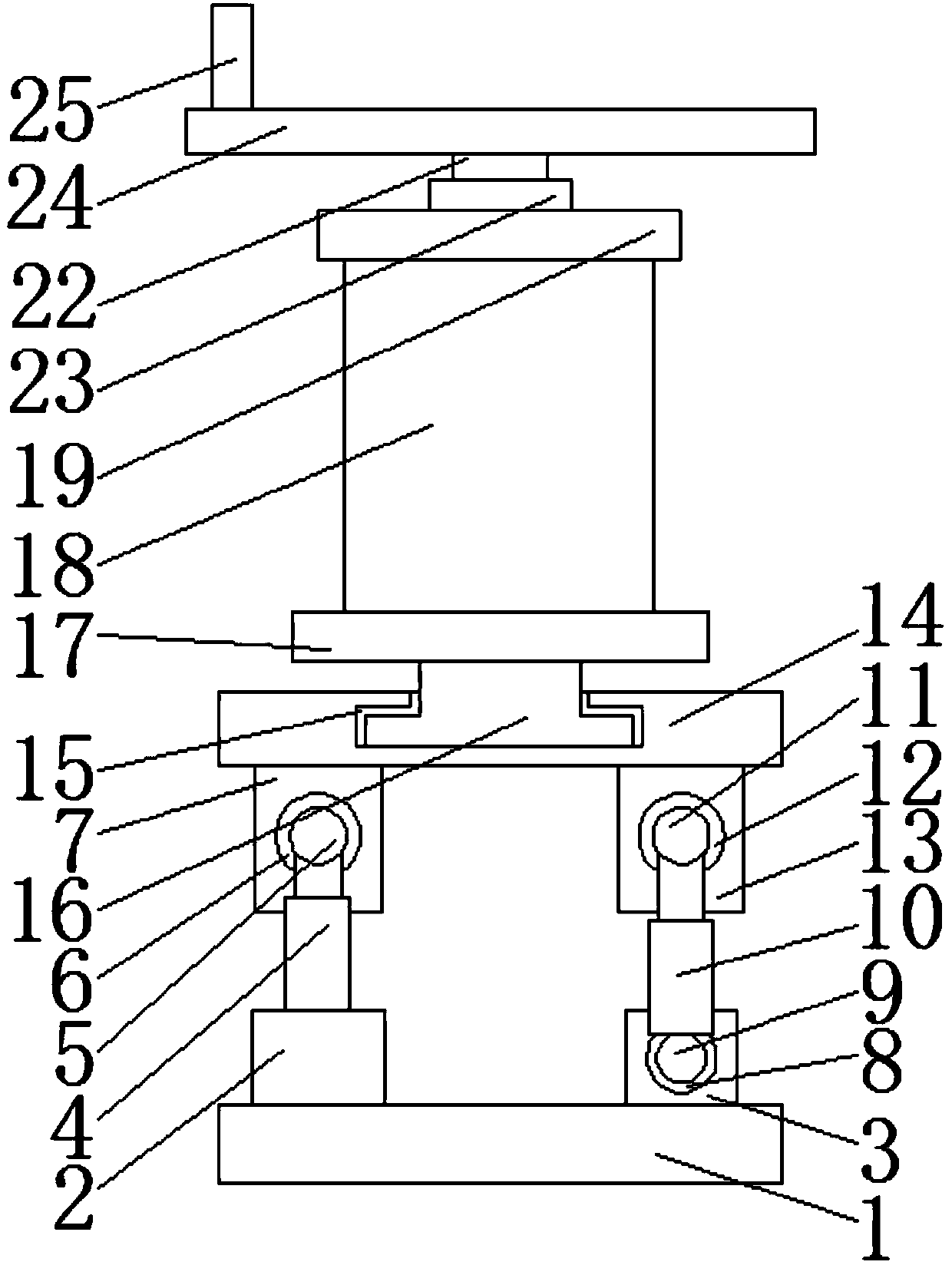

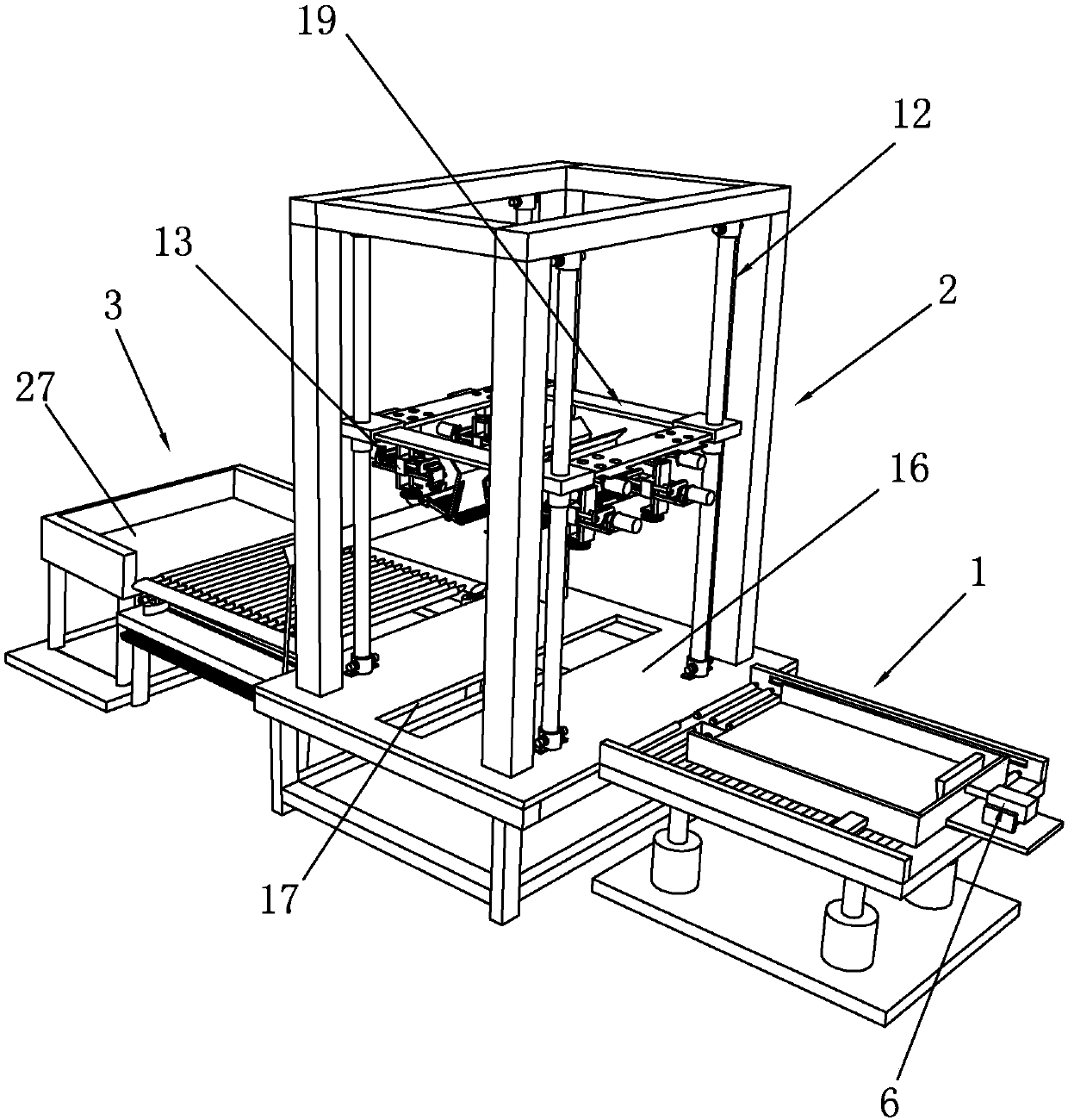

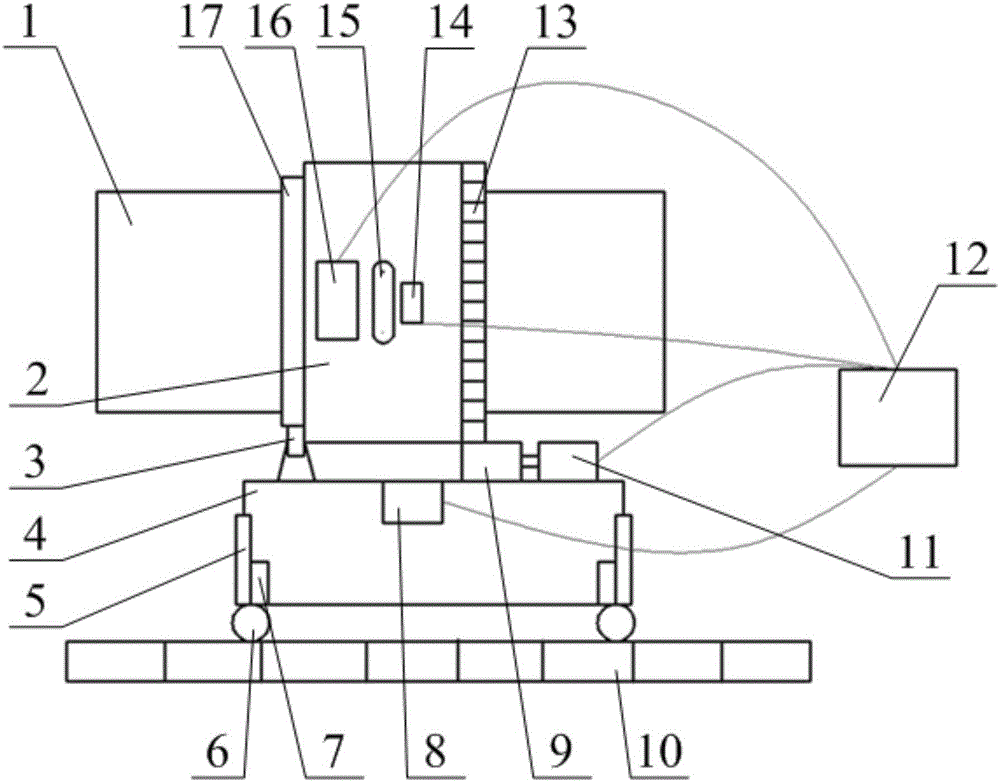

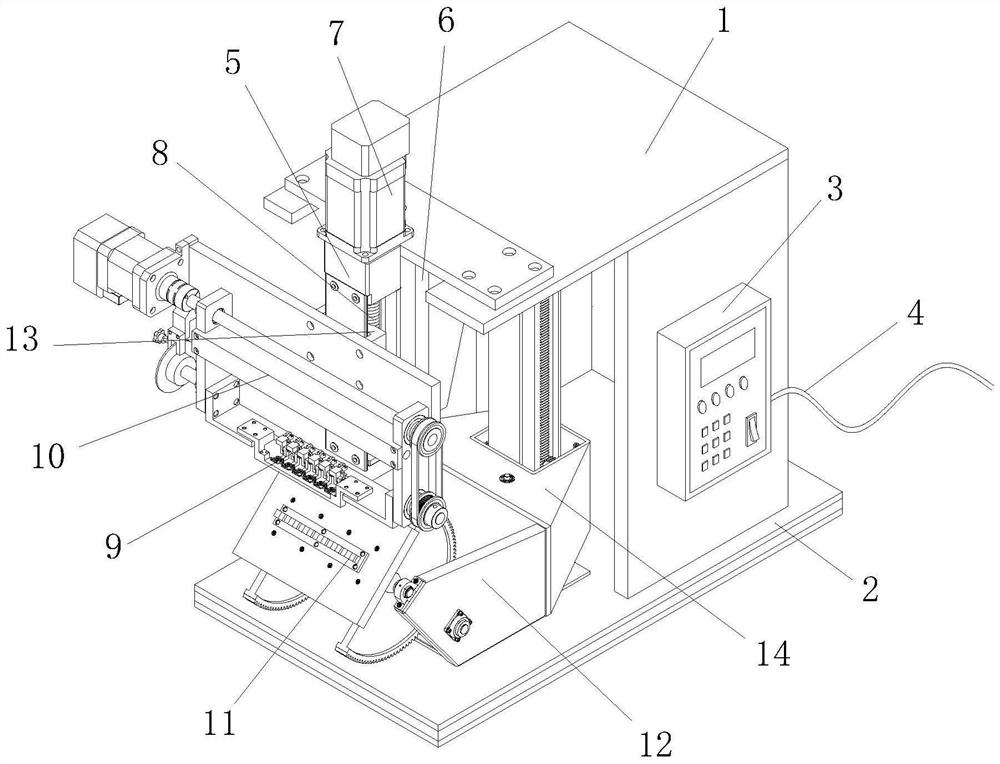

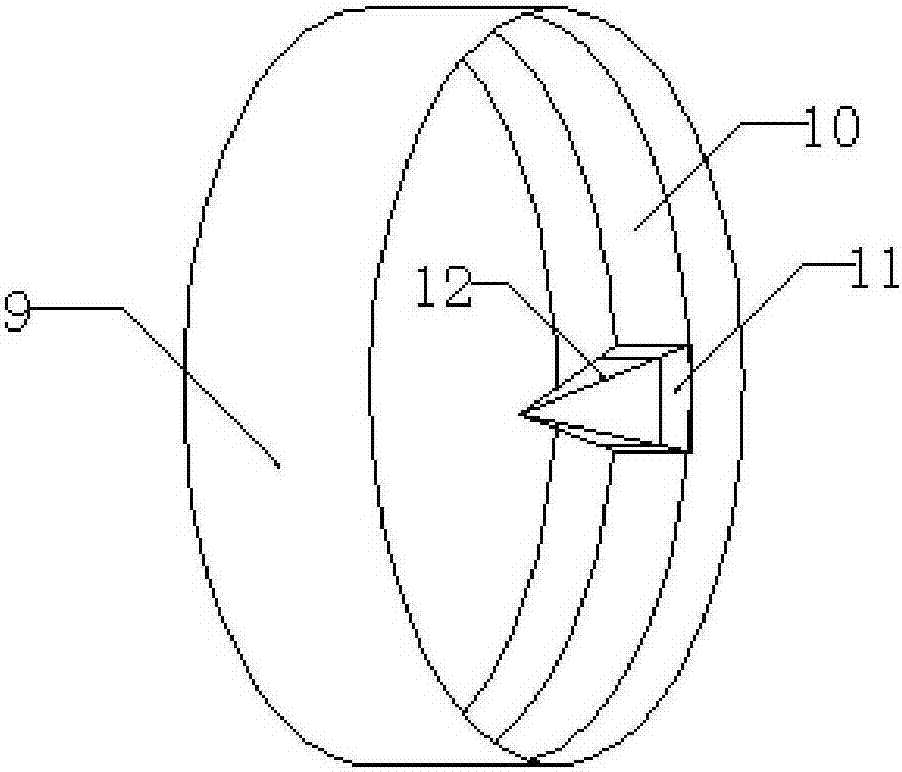

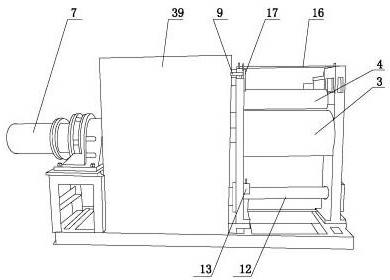

Tank body circular seam welding machine

ActiveCN102133696AConvenient welding workImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesSlide plateSeam welding

The invention discloses a tank body circular seam welding machine comprising a rack. A lifting mechanism is arranged on the rack, and a lifting platform is arranged on the lifting mechanism and is movably matched with the rack; a working platform lifting mechanism is arranged on the lifting platform, and an operating platform is arranged on the working platform lifting mechanism; a first horizontal guide rail is horizontally arranged on the lifting platform, a first sliding block is arranged on the first horizontal guide rail, a fixed sliding plate is arranged on the first sliding block, a vertical guide rail is arranged on the fixed sliding plate, a vertical sliding block is arranged on the vertical guide rail, a vertical sliding plate is arranged on the vertical sliding block, a welding mechanism is arranged on the vertical sliding plate, a shaft is arranged on the vertical sliding plate, a welding trolley is arranged on the shaft, a profiling mechanism is arranged on the welding trolley, two profiling wheels and a profiling wheel driving mechanism are arranged on the welding trolley, and the profiling wheel driving mechanism is connected with the two profiling wheels. In the tank body circular seam welding machine, the liftable operating platform is arranged, so that more convenience is provided for welding operation of operators, the accurate welding control can be realized, and the efficiency and the accuracy of welding are improved.

Owner:SHANDONG SHUIBO WELDING & CUTTING EQUIP MFG CO LTD

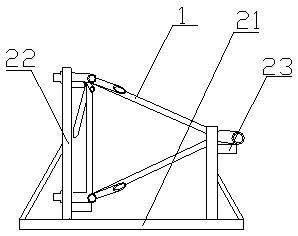

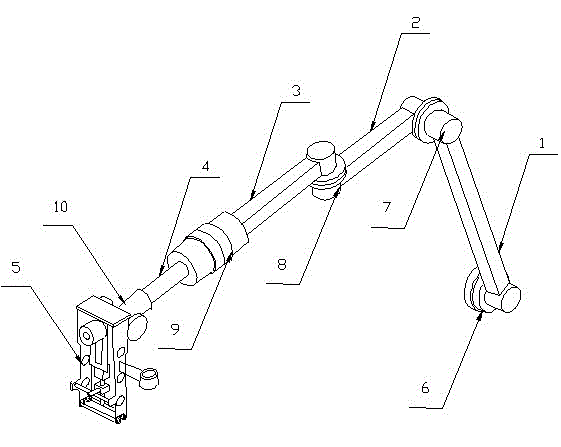

Multifunctional automatic welding manipulator

InactiveCN102717384AIngenious designClear principleProgramme-controlled manipulatorJointsManipulatorEngineering

The invention relates to a multifunctional automatic welding manipulator, which is characterized by comprising a main arm (1), a first assistant arm (2), a second assistant arm (3), a rotating arm (4) and a handpiece (5), wherein one end of the main arm (1) is hinged with a machine body of a welding machine to form a first rotating joint (6); the other end of the main arm (1) is hinged with one end of the first assistant arm (2) to form a second rotating joint (7); the other end of the first assistant arm (2) is hinged with one end of the second assistant arm (3) to form a third rotating joint (8); the other end of the second assistant arm (3) is hinged with one end of the rotating arm (4) to form a fourth rotating joint (9); and the other end of the rotating arm (4) is hinged with the handpiece (5) to form a fifth rotating joint (10). The multifunctional automatic welding manipulator has ingenious design, clear principle, strong maneuverability, outstanding effect, and capability of realizing welding of various component forms.

Owner:CHINA CONSTR STEEL STRUCTURE JIANGSU CO LTD

Automatic flange welding robot

ActiveCN109175824AHigh degree of automationReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringTransfer mechanism

The invention discloses an automatic flange welding robot, and belongs to the technical field of welding equipment. The automatic flange welding robot comprises a storage mechanism, a transferring mechanism, a limiting mechanism and a welding mechanism, wherein the transferring mechanism comprises a mounting plate, a lifting assembly, a feeding component and a clamping assembly; the clamping assembly comprises a driving component and two clamping components, and the two clamping components are identical in structure and each comprise a supporting vertical plate and a rotating piece; and each supporting vertical plate is of an L-shaped structure. According to the robot, a flange can be overturned by 180 degrees through the rotating pieces to complete the turnover operation of the flange, aworker does not need to manually carry out the turnover operation, and the automatic feeding operation of the flange can be achieved through the storage mechanism and the transferring mechanism. Besides, the flange can be automatically rotated through a rotating assembly, a notch in the flange can be aligned to a welding machine, and the welding operation can be carried out conveniently on the notch of the flange through the welding machine.

Owner:山东祥通橡塑科技有限公司

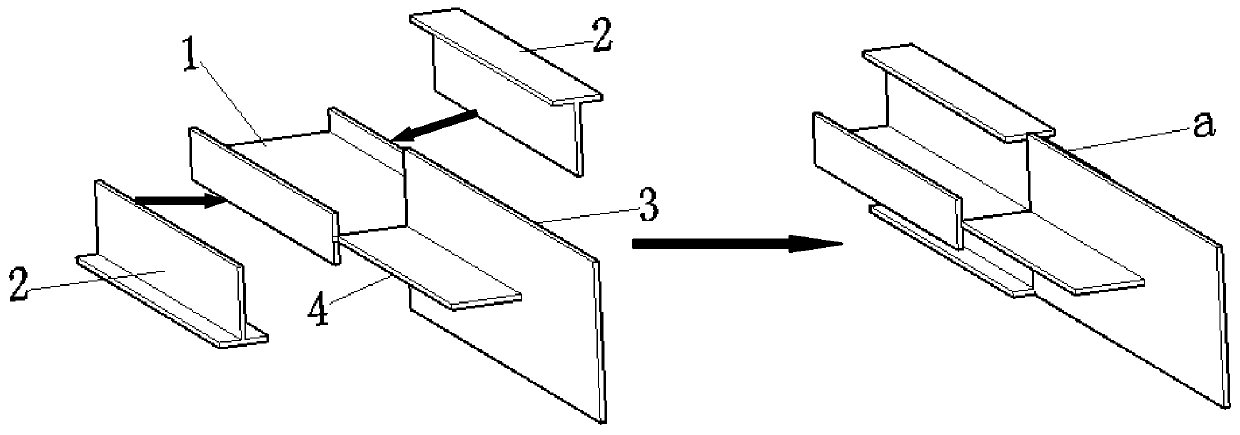

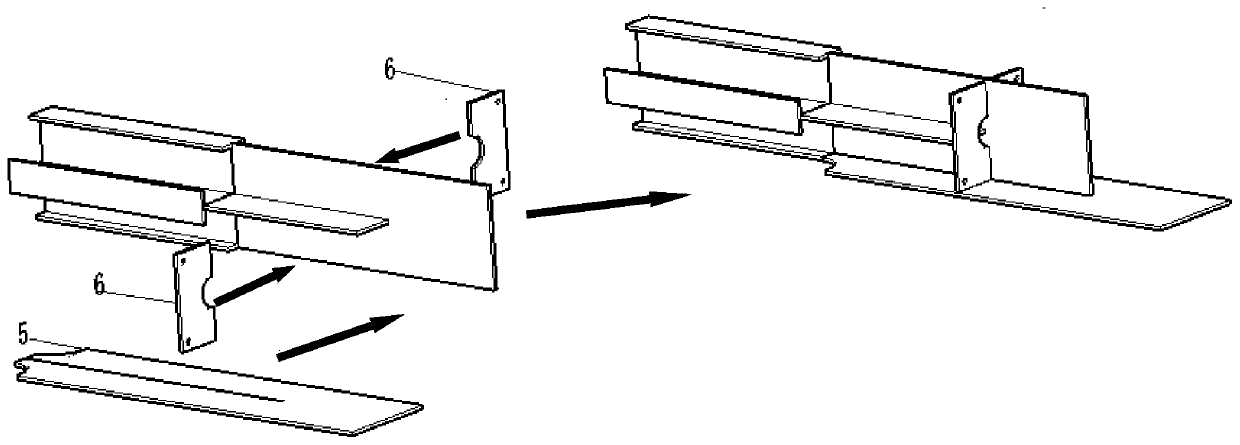

Manufacturing method of cross-shaped box type joint

ActiveCN110711961AOptimize assembly processControl deformationBuilding constructionsWelding apparatusStress concentrationButt welding

The invention discloses a manufacturing method of a cross-shaped box type joint. The method includes assembling and splicing of a cross-shaped column and a box type column. Firstly, the cross-shaped column is assembled and spliced, wherein the cross-shaped column comprises H-shaped steel and two pieces of T-shaped steel; secondly, the box type column is assembled and spliced, wherein a bottom plate and interior of the box type column are assembled, a U-shaped structure of the box type column is assembled, a deformed part is corrected to be qualified according to process manufacturing requirements, and a cover plate of the box type column is assembled; and thirdly, a transition inlaying section is welded. According to the method, a top partition plate welding seam of the box type column iswelded, then the cross-shaped column and the box type column are welded to be connected with the welding seam, and finally, wing plates of the cross-shaped column and the cover plate of the box type column are in butt joint with the welding seam, so that the stress concentration problem is well avoided. The connecting welding seam between the cross-shaped column and the box type column adopts opengroove external plug welding, so that the situation that a welding hole is formed in the end of the cross-shaped column or in the outer side of the box type column and accordingly the appearance of acomponent is affected is avoided, the welding quality of the cross-shaped column and the box type column is controllable, and the cross-shaped box type cross section welding process is optimized.

Owner:YCIH STEEL STRUCTURE CO LTD

Fixing clamp for circuit board welding

InactiveCN106624536AFix fixSimple structureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a fixing clamp for circuit board welding. The fixing clamp for circuit board welding comprises a base and a clamp device; the clamp device is installed on the base; the clamp device comprises a movable assembly and a fixed assembly; the movable assembly comprises a guide rail, a sliding block and a fixed plate, the guide rail is fixedly installed on the base and provided with the sliding block which is connected with the fixed plate, and a movable clamping block is installed on the fixed plate; and the fixed assembly comprises a fixed seat and a fixed clamping block, the fixed seat is fixedly installed on the base and provided with the fixed clamping block. When a circuit board needs to be fixed, firstly the circuit board is placed on the fixed clamping block, then the sliding block is pushed to move on the guide rail, the movable clamping block works on the circuit board, thus the circuit board is fixed, and accordingly welding work of the circuit board by workers is facilitated; the fixing clamp is simple in structure, convenient and practical and can be applied to circuit boards with different sizes; and labor intensity of the workers is effectively reduced, and production efficiency is improved.

Owner:王丽春

Automobile doorsill beam welding clamp

InactiveCN105479076AReduce spacingAvoid shakingWelding/cutting auxillary devicesAuxillary welding devicesWeldingEngineering

The invention discloses an automobile doorsill beam welding clamp which comprises a base, wherein a fixed plate is arranged on the base; six clamping mechanisms are fixedly mounted on the fixed plate; a pressure block used for clamping the doorsill beam, a dowel pin I and a clamping air cylinder used for driving each clamping mechanism pressure arm are arranged on the corresponding clamping mechanism; the fixed plate is provided with an auxiliary positioning device at a position, between the adjacent two clamping mechanisms, close to the middle part; the auxiliary positioning device comprises an L-shaped vertical plate which is fixedly mounted on the fixed plate, wherein the top of one side of the L-shaped vertical plate is fixedly provided with a dowel pin II by virtue of an L-shaped connecting block; the dowel pin II is perpendicular to the horizontal plane; and the dowel pin II and the dowel pins I on the clamping mechanisms positioned at the two sides of the dowel pin are on the same straight line. The automobile doorsill beam welding clamp is high in positioning precision, adopts the clamping air cylinders to drive pressure blocks, and is convenient to operate, so that the working efficiency is improved.

Owner:CHONGQING SHANLIAN SCI & TECH DEV CO LTD

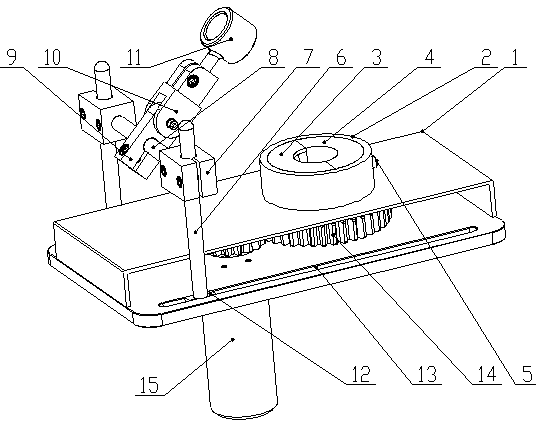

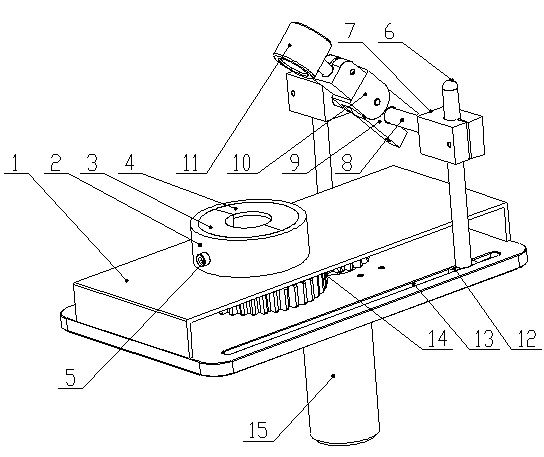

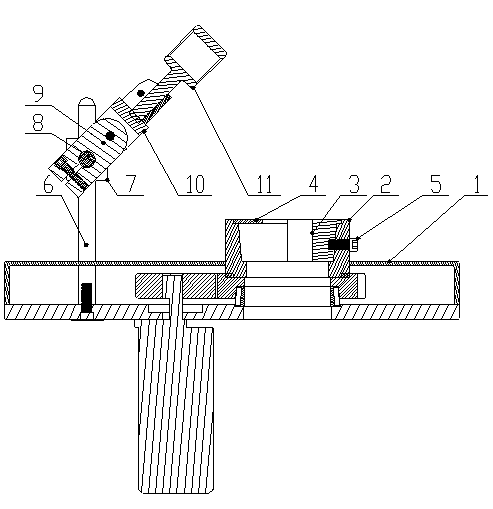

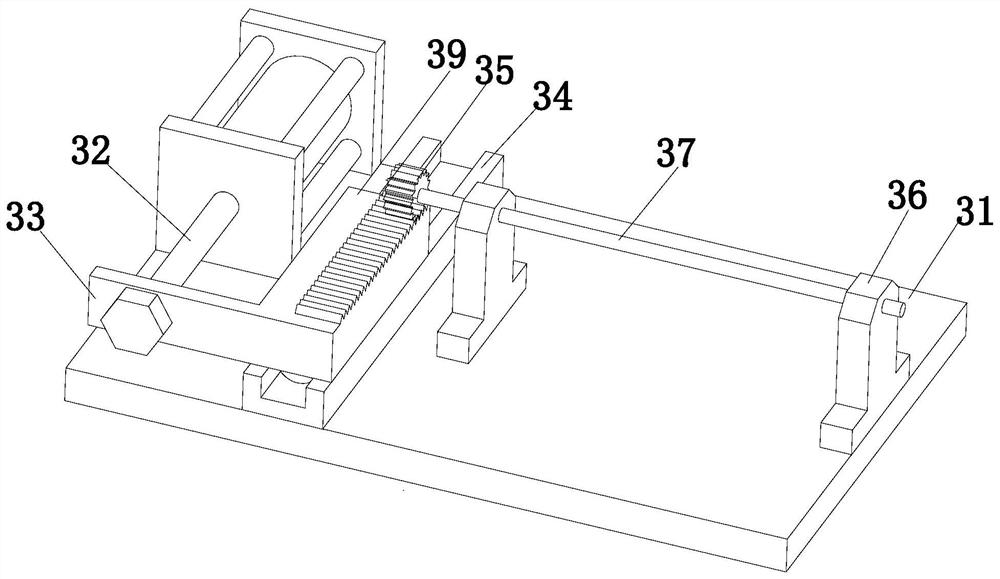

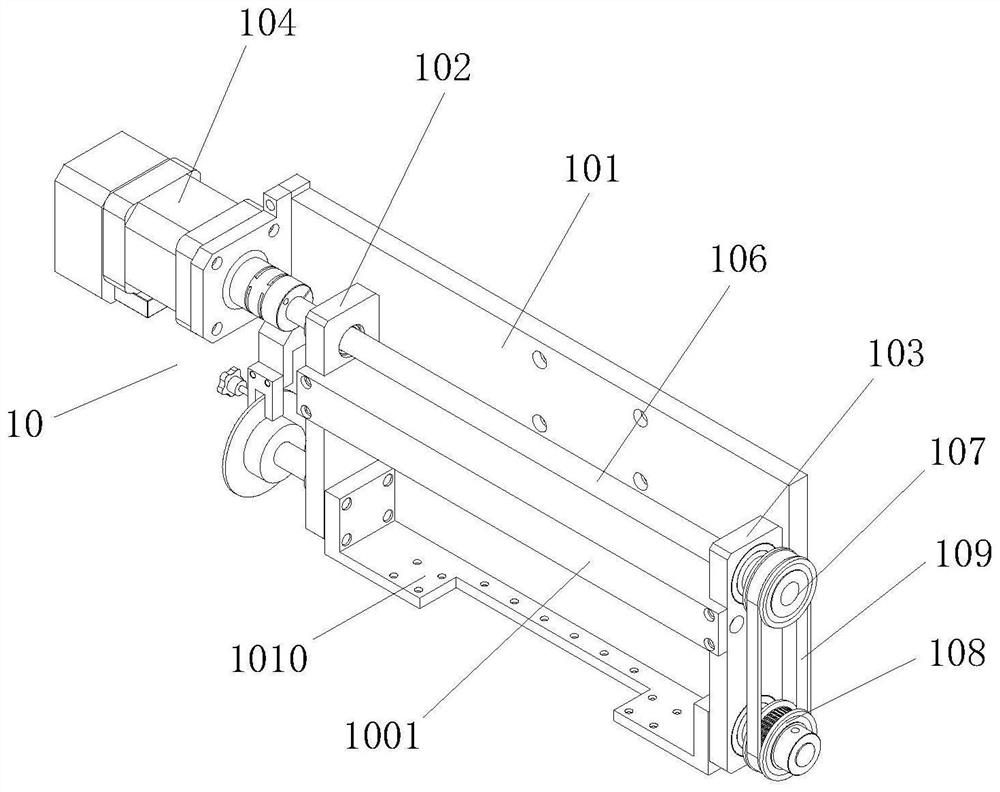

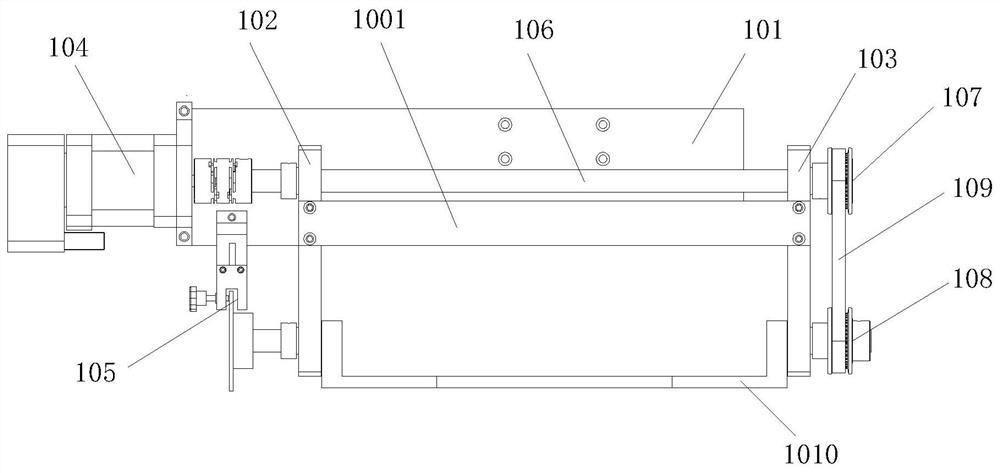

Lifting and rotatable device for circuit board welding

InactiveCN107825036AReduce welding efficiencyConvenient welding workWelding/cutting auxillary devicesAuxillary welding devicesGear wheelEngineering

The invention discloses a lifting and rotating circuit board welding device, comprising a bottom plate, a first fixing block and two second fixing blocks are arranged on the upper surface of the bottom plate, and the two second fixing blocks are both located on the first The rear side of a fixed block, and the upper surface of the first fixed block is fixedly connected with the lower surface of the first rotating shaft through two first electric push rods, and the surface of the first rotating shaft is sleeved with two first bearings. The device for welding circuit boards that can be lifted and rotated can place The height of the board is adjusted, which is convenient for workers to weld the circuit board, so that the position of the circuit board can be adjusted by rotating the board and moving the board left and right, so that workers do not need to hold the board to weld the board. Thereby improving the welding efficiency of workers to the circuit board.

Owner:江苏万通塑业有限公司

Frame welding positioning device

InactiveCN106271348AGuaranteed uptimeWon't cause slidingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a frame welding positioning device. The frame welding positioning device comprises a horizontally-arranged installation table and stand columns connected with the bottom of the installation table to form stand bars; the two side edges and the back edge of the installation table are each vertically provided with a baffle, and a transverse beam is horizontally arranged on the baffles on the two side edges; an installation groove which is vertically through is formed in the middle portion of the installation table, positioning assemblies are arranged on the four edges of the installation groove, a pressure applying assembly installed on the transverse beam is correspondingly installed above the installation groove, and a tray assembly is correspondingly arranged at the lower portion of the installation groove; clamping assemblies are arranged on the inner walls of the baffles on the two side edges in a left-and-right opposite manner; and a control device is further connected to the frame welding positioning device. The frame welding positioning device has the at least two advantages that the frame welding positioning device can be suitable for welding frames in different specifications, operation processes are simple and stable, the automatic degree is high, and the heights of the welding frames relative to the device are adjustable in the welding process.

Owner:TAICANG GOLDENMA METAL STRUCTURE

Efficient shape welding machine and using method thereof

InactiveCN103008942AQuick welding jobConvenient welding workWelding/cutting auxillary devicesAuxillary welding devicesDrive motorEngineering

The invention relates to an efficient shape welding machine and a using method thereof. The efficient shape welding machine comprises a working platform, wherein a rotary barrel is arranged on the working platform; a magnet of which the section is circular-arc-shaped is arranged in the rotary barrel, so that the outer circumferential wall of a welded part is fixed on the inner side arc face of the magnet; and a support frame for fixing a welding gun is arranged beside the rotary barrel. The method comprises the following steps of: I, adsorbing a welded part onto the inner circumferential wall of the magnet to realize fixing of the welded part; II, covering a separation blade for matching the separation blade with the magnet to sleeve the outer circumferential wall of the welded part; III, adjusting relative positions of a vertical rod, a first slide block and a swing stem to make a circular tube reach a corresponding position and position the welding gun erected on the circular tube at a welding position; and IV, starting the welding gun and a driving motor, wherein the driving motor is used for driving the rotary barrel to rotate for driving the welded part to rotate, and the welding gun is used for welding the welded part at the welding position through the driving motor, so that welding work of bent parts can be finished conveniently and rapidly.

Owner:江苏冠赛达工贸有限公司

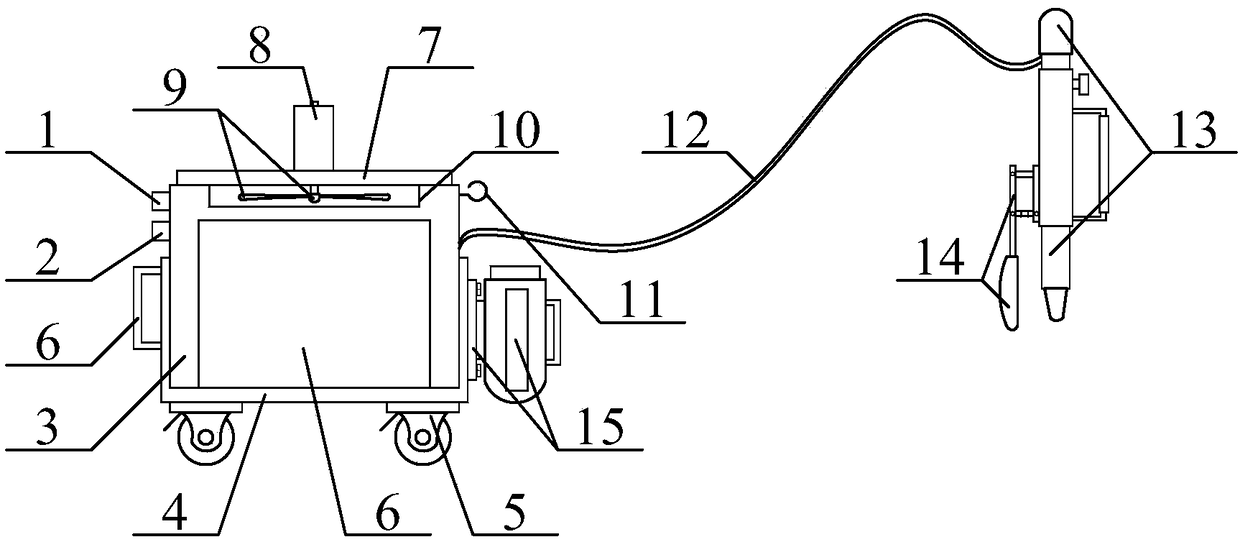

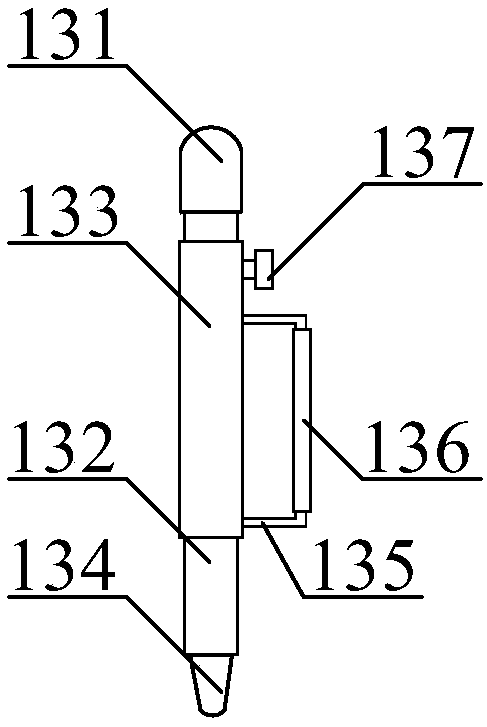

Handheld laser welding device

The invention discloses a handheld laser welding device. The handheld laser welding device comprises a welder switch, a cooling switch, a welding cabinet, a U-shaped moving base, universal wheels provided with brake pads, a welder, a cabinet cover, a cooling motor, blades, a hollowed-out hood, a drag hook, an optical fiber, an adjustable handheld welding gun structure, an adjustable splash-proof protective cover structure and a suction-type scrap temporary collection and storage barrel structure. According to the handheld laser welding device, a gun cap, a welding gun body, a fixing pipe, a gun head, a U-shaped handheld rod, an anti-slip sleeve and an adjustment bolt are arranged, the position of the welding gun body in the fixing pipe can be adjusted easily by loosening the adjustment bolt, and thus, welding can be conducted more easily, and the welding device can be held by hand so as to be used more conveniently; and a supporting base, a connecting base, a rotary rod, a splash-proofcover, a connecting shaft and an adjustable telescopic rod are arranged, and the inclination angle of the splash-proof cover can be adjusted according to welding requirements so as to prevent splashmore conveniently.

Owner:宁波海天增材科技有限公司

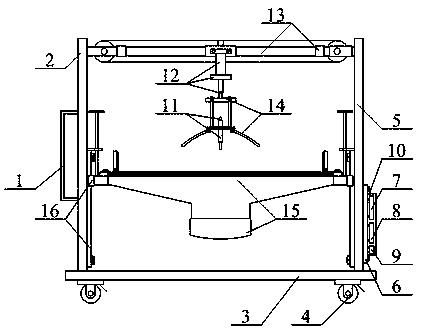

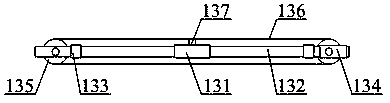

Multifunctional welding robot

InactiveCN109262168ARealize self-moving functionGuaranteed welding requirementsWelding/cutting auxillary devicesAuxillary welding devicesPush and pullEngineering

The invention provides a multifunctional welding robot. The multifunctional welding robot comprises a U-shaped push handle, a main supporting seat, a movable base, universal wheels with brake pads, anauxiliary supporting seat, a circuit board, a host, a control screen, a master control switch, a dustproof shield, a welding gun, a lifting cylinder, a self-movement type robot moving machine, a liftable adjusting light-proof shield structure, a push-and-pull type waste cleaning and collecting hopper structure and a liftable adjusting rod structure, wherein the U-shaped push handle is mounted inthe middle of the left side of the main supporting seat by a bolt; and the longitudinal lower end of the main supporting seat is mounted on the left upper portion of the movable base through a bolt. By arrangement of a self-moving slider, a stainless steel sliding track, a limiting switch, a self-moving type motor, a belt pulley, a synchronous belt and a connecting plate, a self-moving function ofthe robot is fulfilled favorably to meet welding requirements of the robot; and by arrangement of the limiting switch, a good limiting effect is achieved favorably.

Owner:青岛泽丰汽车零部件有限公司

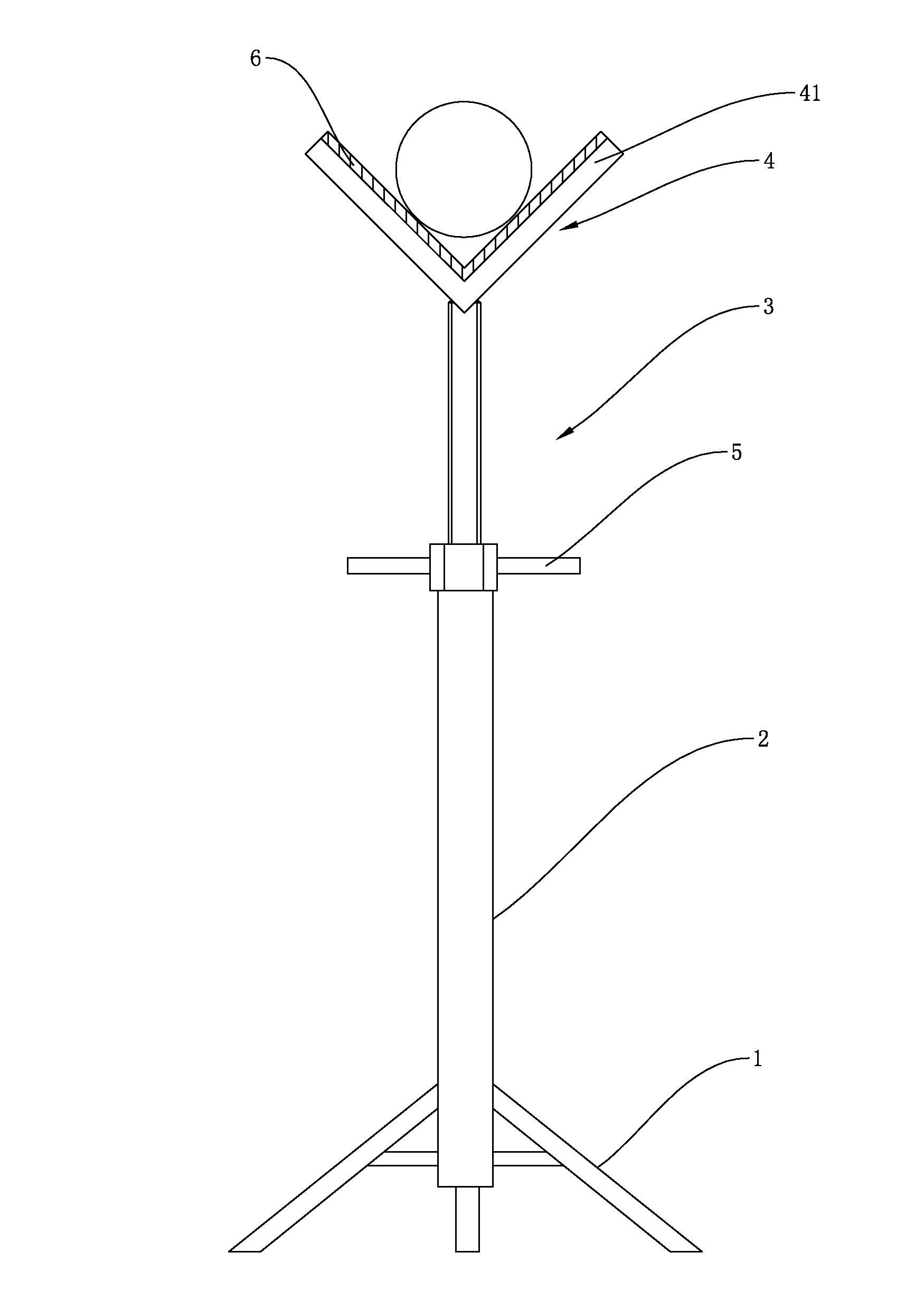

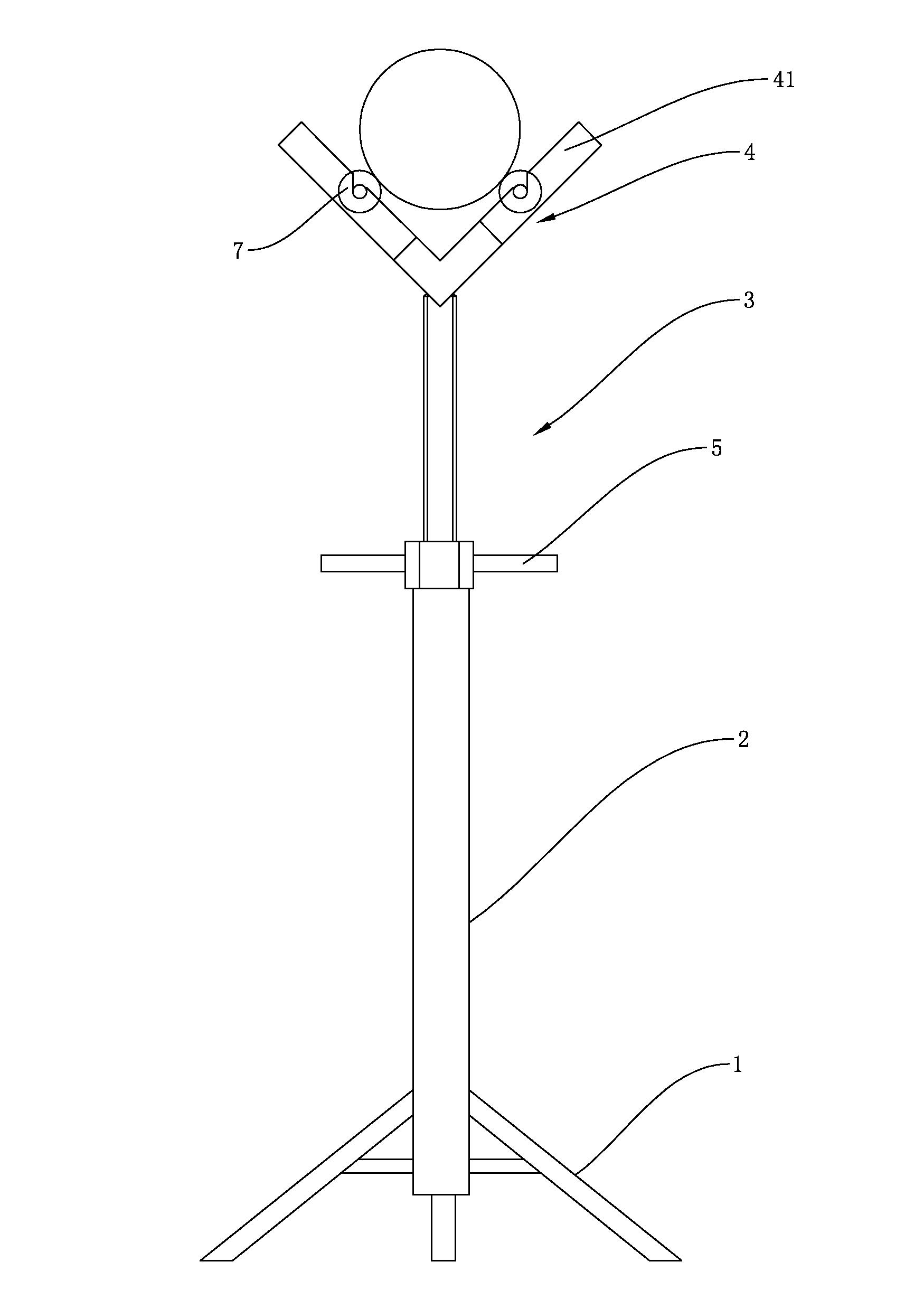

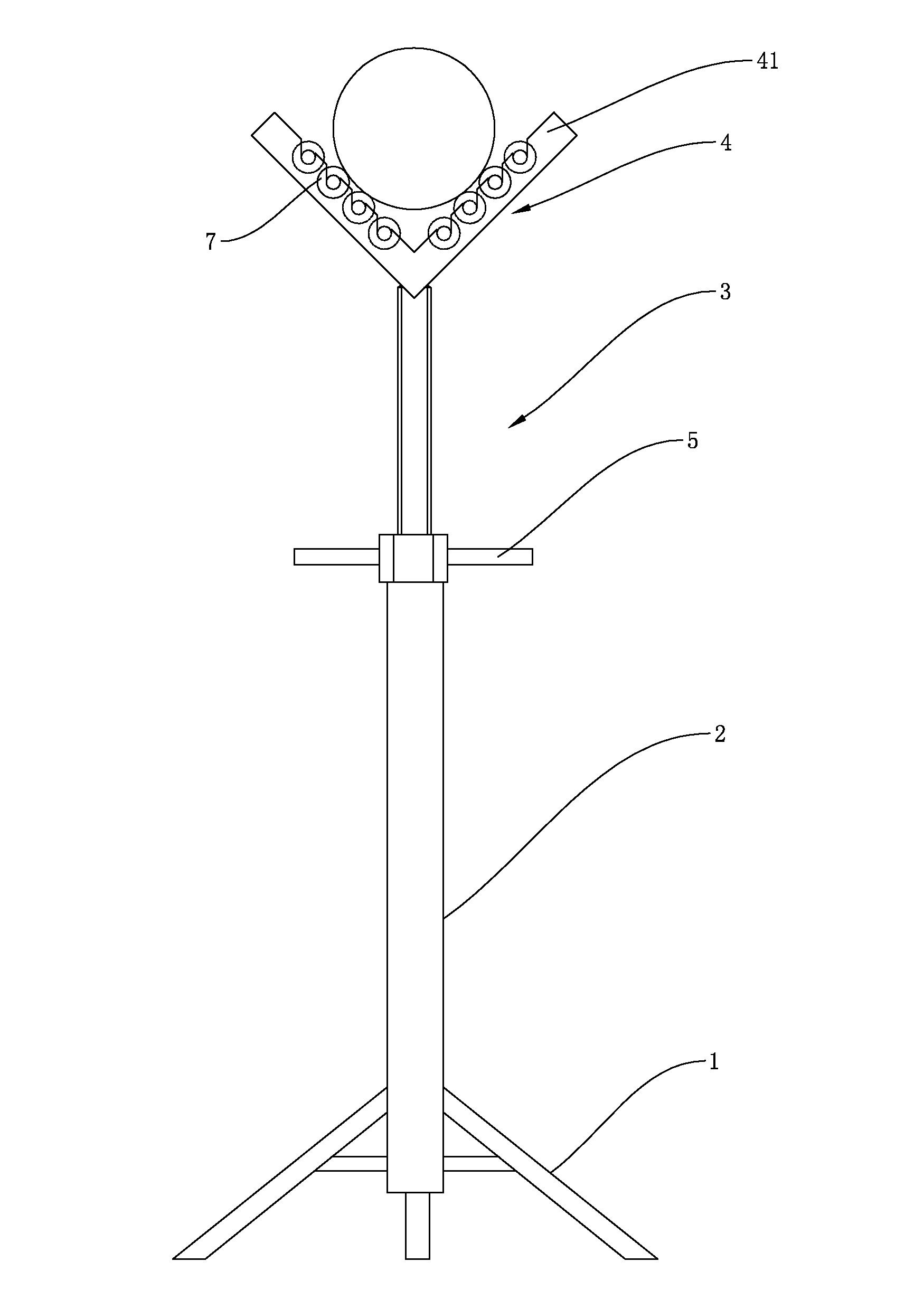

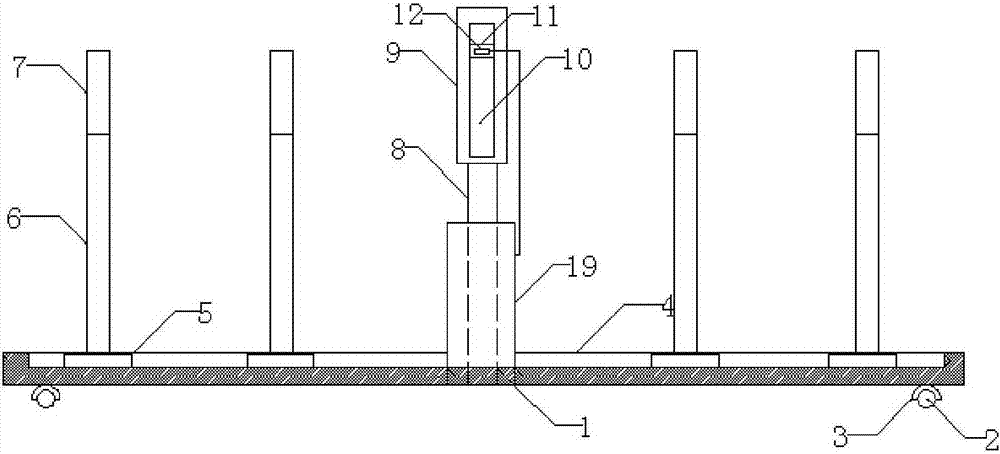

Welding lift frame

InactiveCN102500984AConvenient welding workExtended service lifeWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWelding

The invention discloses a welding lift frame, which comprises a bracket, wherein the upper end of the bracket is provided with a sleeve; a lead screw of a lead screw and nut mechanism is sleeved in the sleeve; the upper end of a lead screw of the lead screw and nut mechanism is provided with a supporting member; a nut of the lead screw and nut mechanism is arranged on the sleeve; and the lead screw and nut mechanism can be used for adjusting the height of the supporting member, so that the height of a workpiece can be adjusted at any time to facilitate the welding of the workpiece.

Owner:江苏利柏特股份有限公司

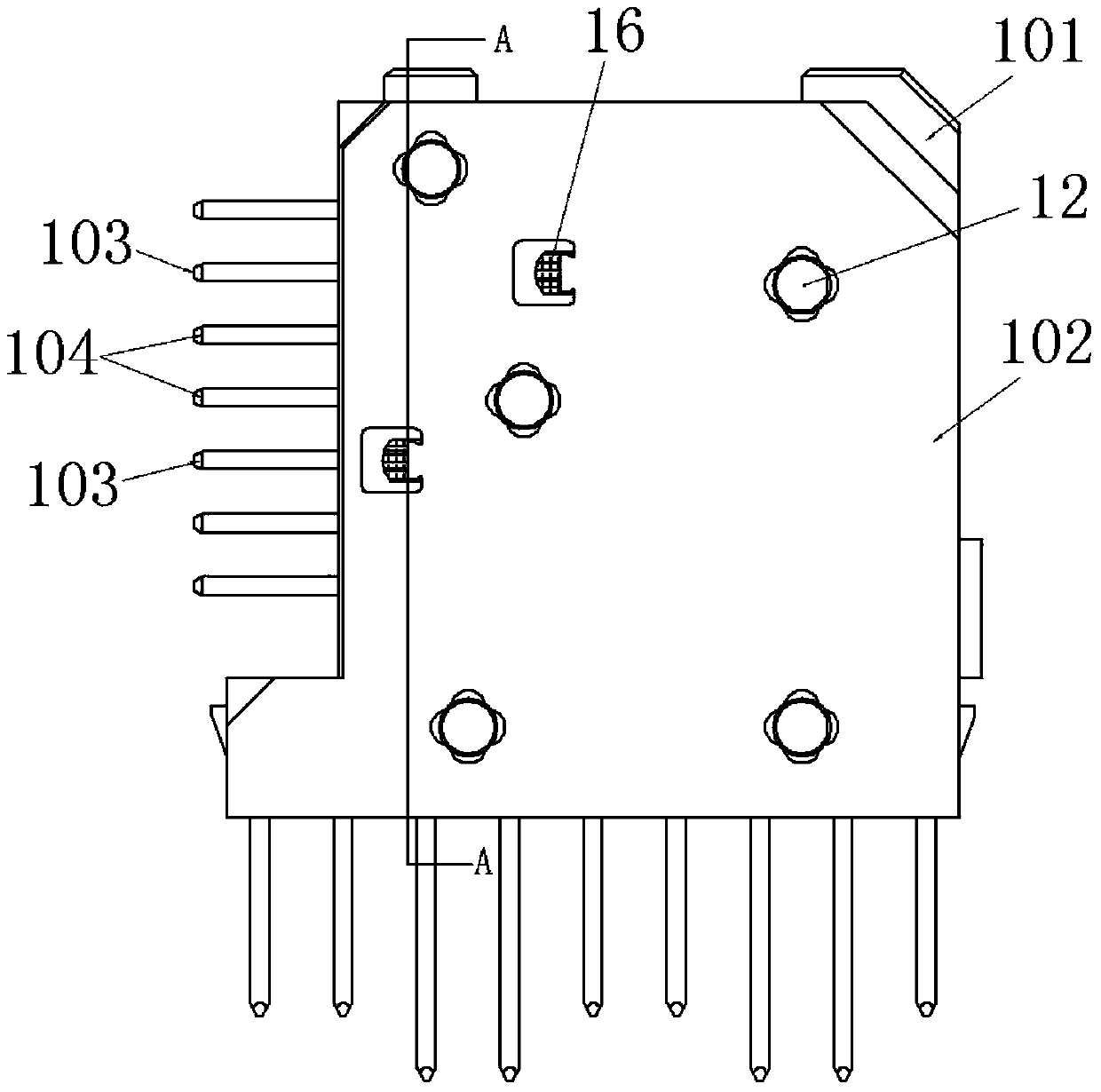

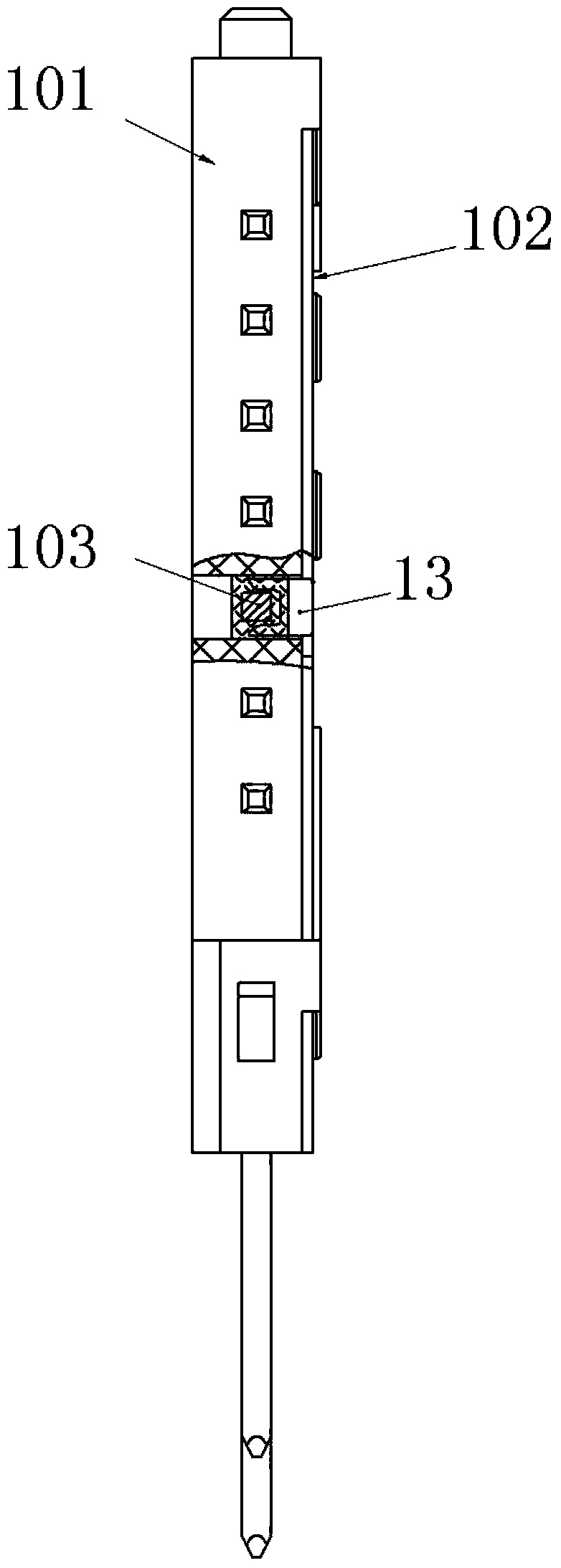

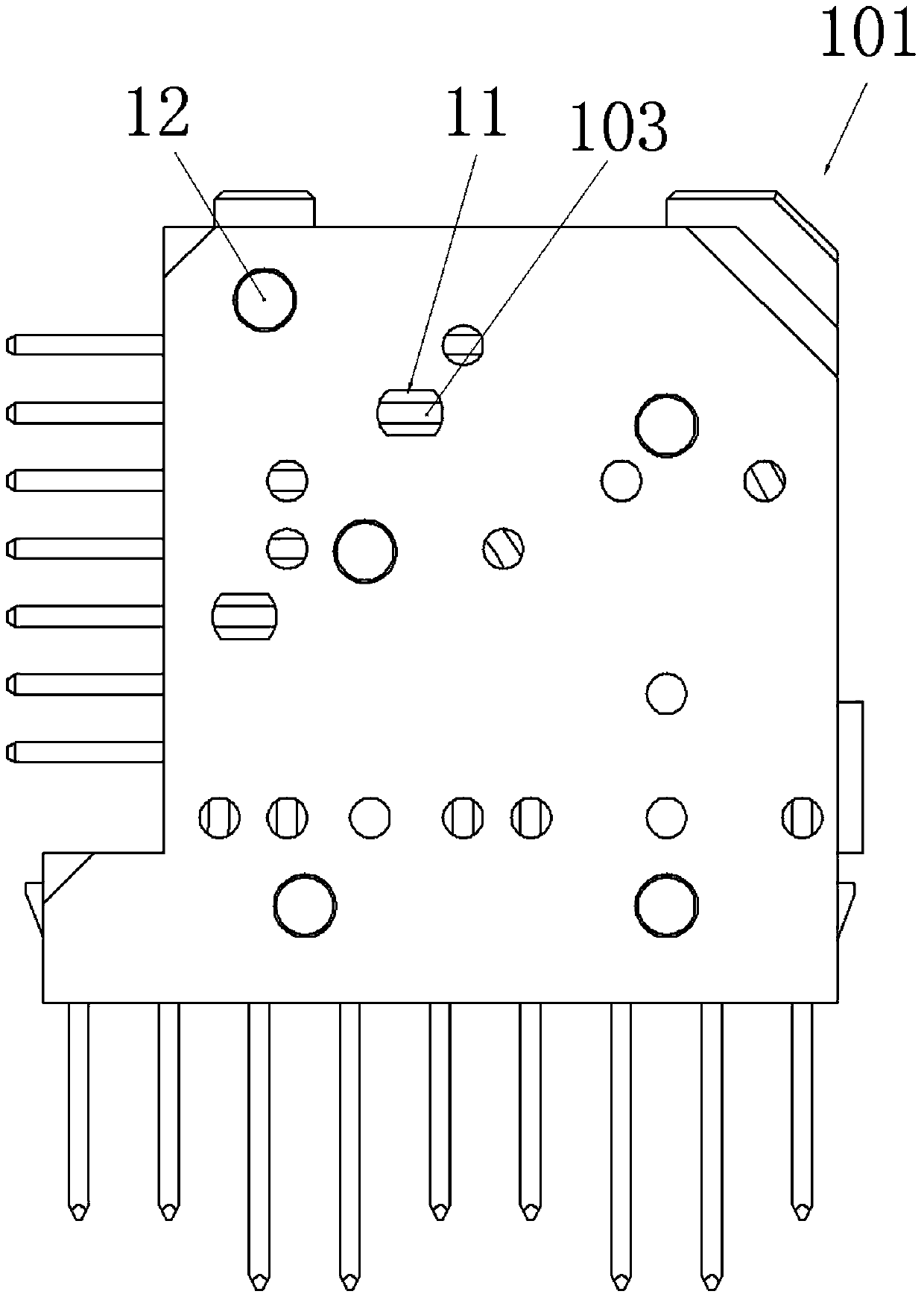

Contact module of high-speed electric connector and manufacture method of module

ActiveCN104183990AImprove reliabilityConvenient welding workContact member assembly/disassemblyCoupling device detailsElectricityGround contact

The invention relates to the field of an electric connector and especially relates to a contact module of a high-speed electric connector and a manufacture method of the module. The contact module of the high-speed electric connector comprises an insulator, grounding contacts packaged in the insulator and a shielding piece pasted on the upper side surface of the insulator. The shielding piece is provided with internally-protruding contact fingers. The contact fingers stretch downwards to the insulator. Each grounding contact is fixedly welded with the at least one contact finger of the shielding piece. In the contact module of the high-speed electric connector, since the shielding piece is provided with the contact fingers, the welding place of the grounding contact and the shielding piece is directly transferred to the insulator, larger space is provided for a connecting structure, cooperation surface between the touch fingers and the grounding contacts is enlarged, and the problem that the shielding piece of the conventional contact module for a high-speed electric connector at present is prone to be loosen is solved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

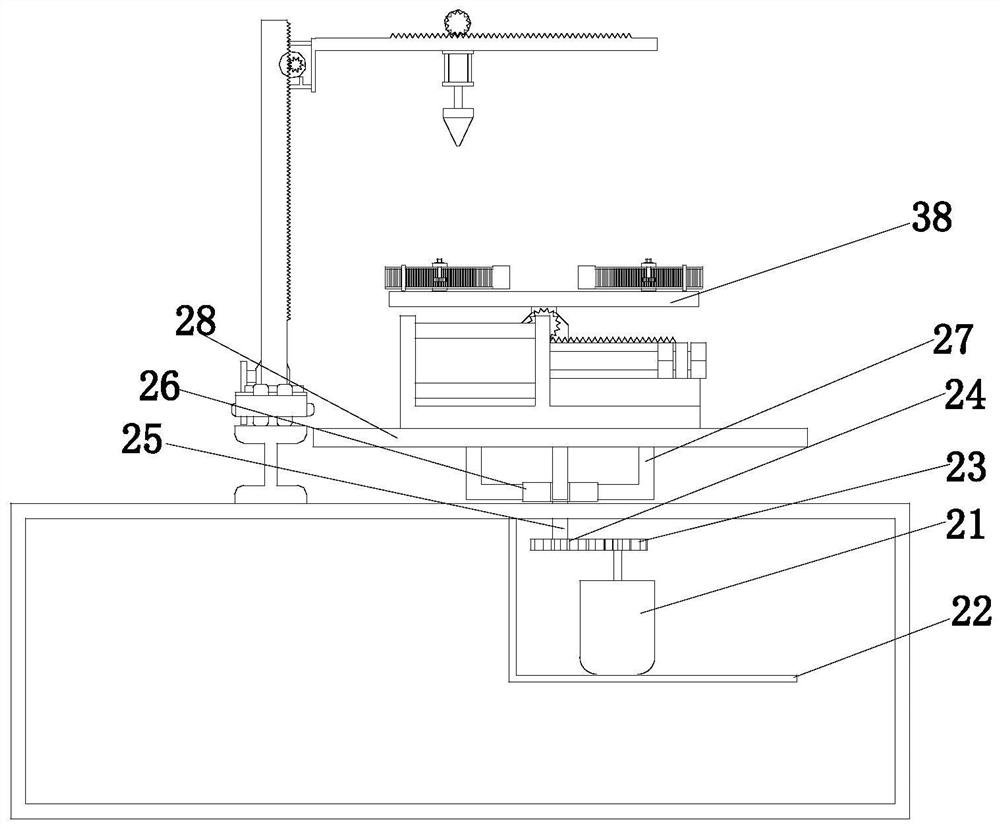

Double station annular pipe fitting circumferential laser welding machine and method

InactiveCN110653492AEasy to unloadConvenient reprocessing operationMetal working apparatusLaser beam welding apparatusPipe fittingLaser soldering

The invention discloses a double station annular pipe fitting circumferential laser welding machine and a method. The double station annular pipe fitting circumferential laser welding machine comprises a mounting bracket mounted on the surface of a wall. Two first clamping shells are symmetrically arranged at the lower end of the mounting bracket, a connecting plate is jointly and fixedly connected to the middle positions of the upper ends of the two first clamping shells, a lifting mechanism for moving the first clamping shells up and down is arranged between the connecting plate and the mounting bracket, two ends of each first clamping shell are rotatably connected to second clamping shells through rotating shafts, closing mechanisms are arranged between the first clamping shells and thesecond clamping shells, device slots are formed in the inner sides of the first and second clamping shells, and the device slots are formed circumferentially in a spaced manner. The double station annular pipe fitting circumferential laser welding machine is simple in structure, can carry out laser welding to annular pipefittings of different models, and is suitable for welding and processing ofvarious pipefittings of different apertures, so that the annular pipefitting is welded favorably and the structural stability is good.

Owner:南理工泰兴智能制造研究院有限公司

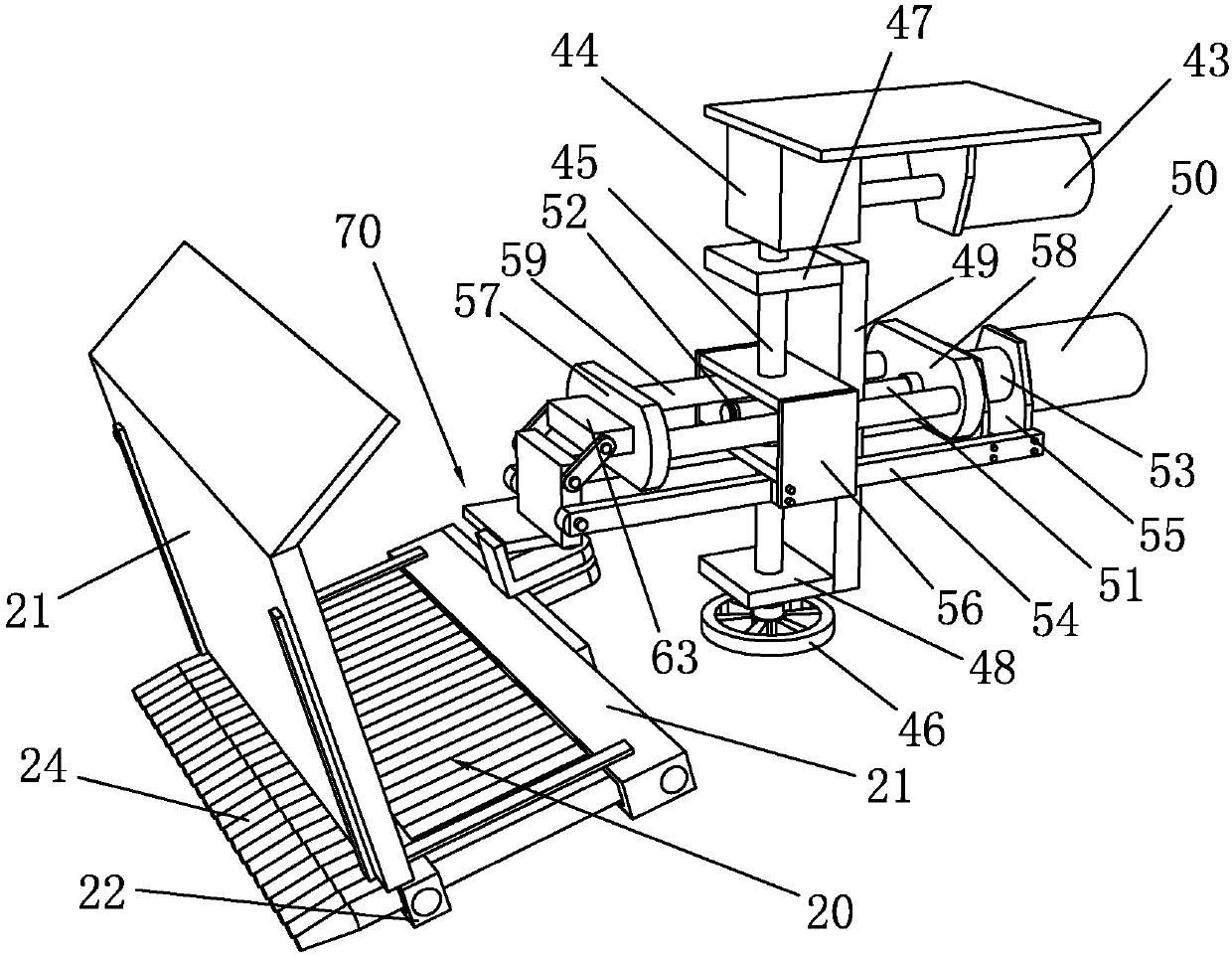

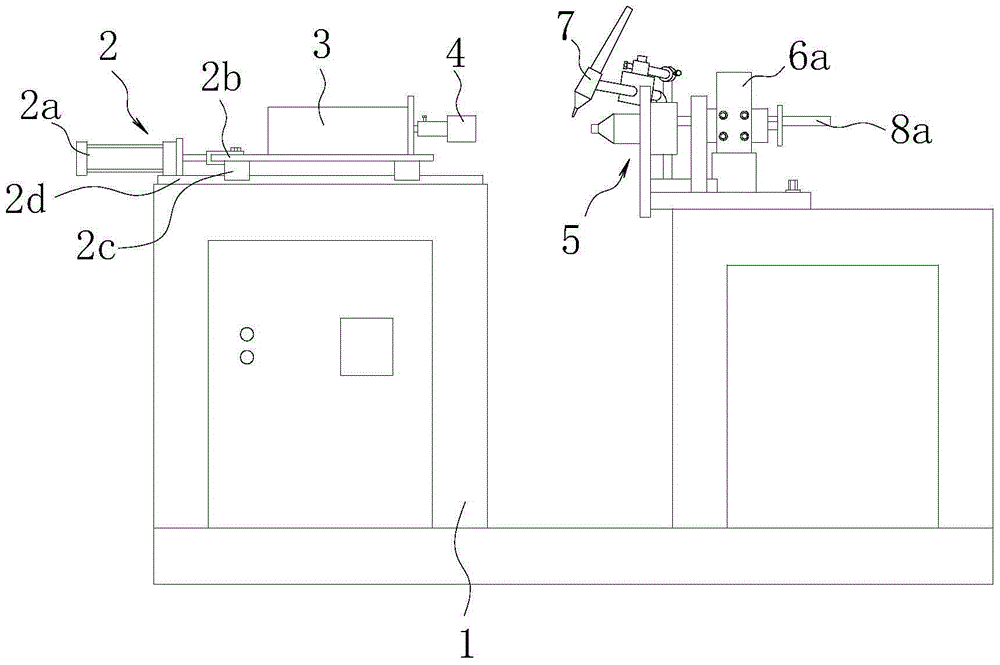

Linear flame welding machine and welding method thereof

ActiveCN107717171AEasy to handleIncrease feeding rateGas flame welding apparatusOperation safetyOperations security

The invention discloses a linear flame welding machine. The linear flame welding machine comprises a feeding mechanism, a welding mechanism and a discharging mechanism; the feeding mechanism comprisesa feeding table, a storing table and a pushing device; the welding mechanism comprises a welding room supporting frame and welding assemblies; each welding assembly comprises a welding head set, a longitudinal adjusting assembly and a transverse adjusting assembly; and the discharging mechanism comprises a discharging table, a material conveying device and a material table. A welding method comprises the following steps of (1) feeding of welded workpieces; (2) adjustment of the height of the welding assemblies; (3) adjustment of the position of the welding head sets; (4) welding; and (5) discharging of the welded workpieces. The linear flame welding machine is ingenious and reasonable in structural design, and convenient and rapid to use and operate, achieves automatic treatment operationof workpiece feeding and discharging through the feeding mechanism and the discharging mechanism, relieves labor intensity, improves operation safety performance, can conduct welding on the workpieces at the same time through design of the multiple welding assemblies, effectively increases the welding rate, and improves the work efficiency.

Owner:XINCHANG KECHUANG AUTOMATION EQUIP

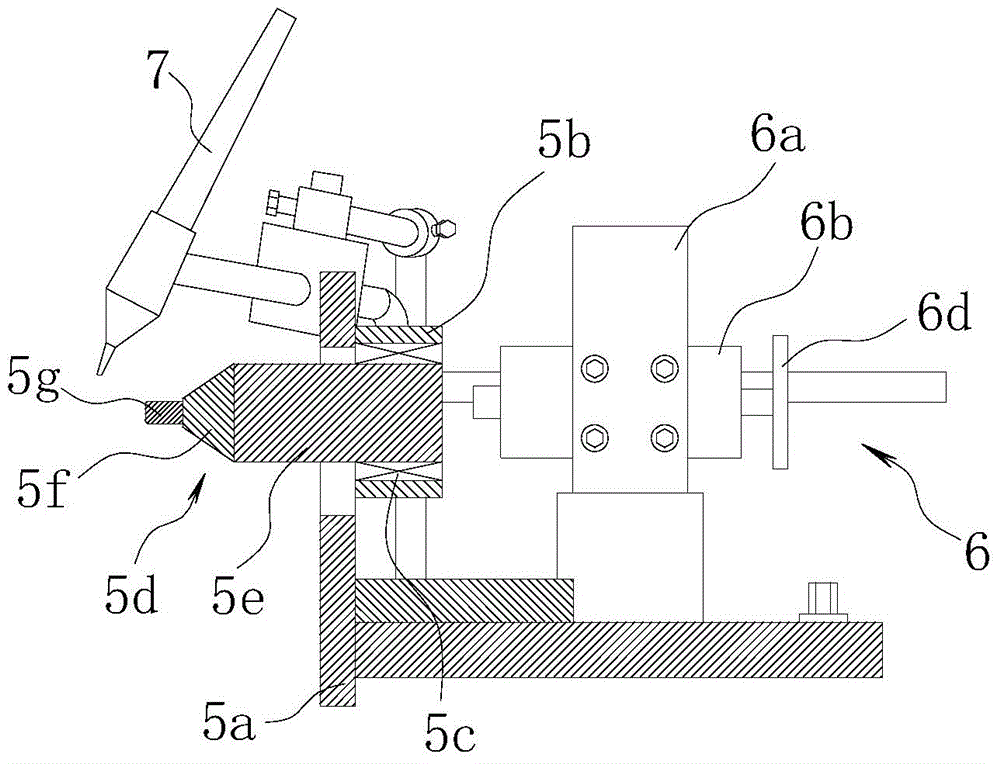

Automatic welding device for stainless steel water segregator

InactiveCN105171295AConvenient welding workPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringBlock match

The invention discloses an automatic welding device for a stainless steel water segregator, and belongs to the technical field of welding equipment. The automatic welding device for the stainless steel water segregator is characterized in that a rack is included, the rack is provided with a horizontal driving unit, the horizontal driving unit is provided with a rotating driving mechanism, the driving end of the rotating driving mechanism is provided with an arc-shaped block matched with the outer wall of the water segregator to be machined, the rack is provided with a rotating seat matched with the arc-shaped block, and the arch-shaped block is matched with the rotating seat to fix the water segregator to be machined; the rack is provided with a regulating mechanism, and the free end of the regulating mechanism is provided with a welding gun opposite to the to-be-welded portion of the water segregator to be machined. The automatic welding device for the stainless steel water segregator is convenient to use and good in effect and is used for welding the water segregator.

Owner:GUANGDONG HAIBO JIM STAINLESS STEEL MFG CO LTD

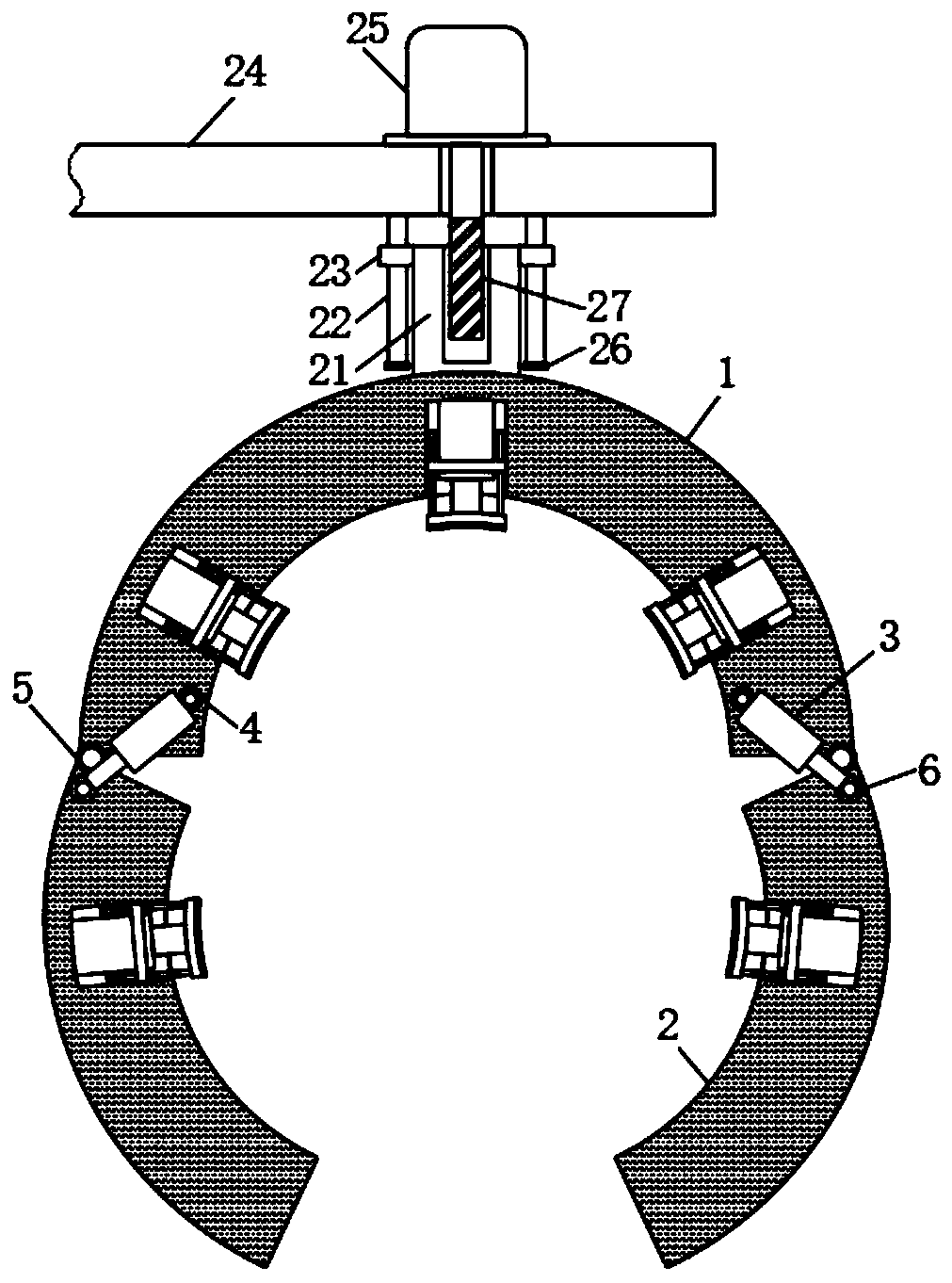

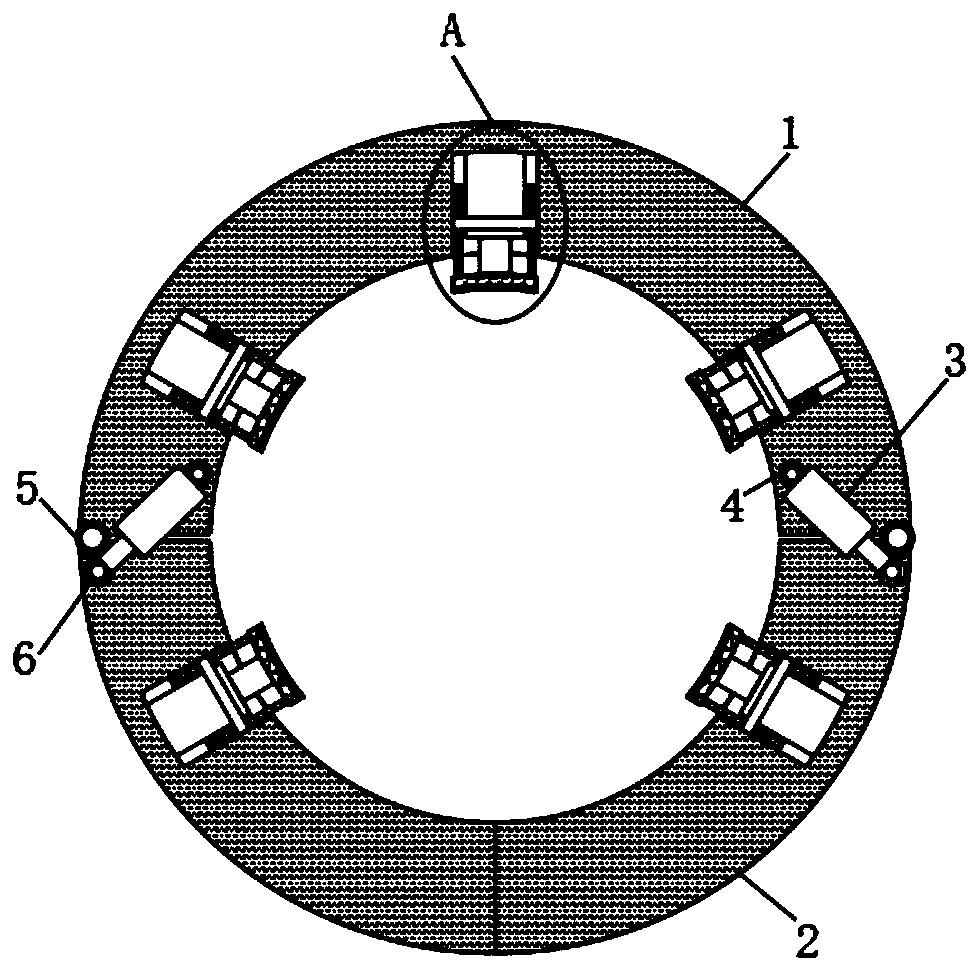

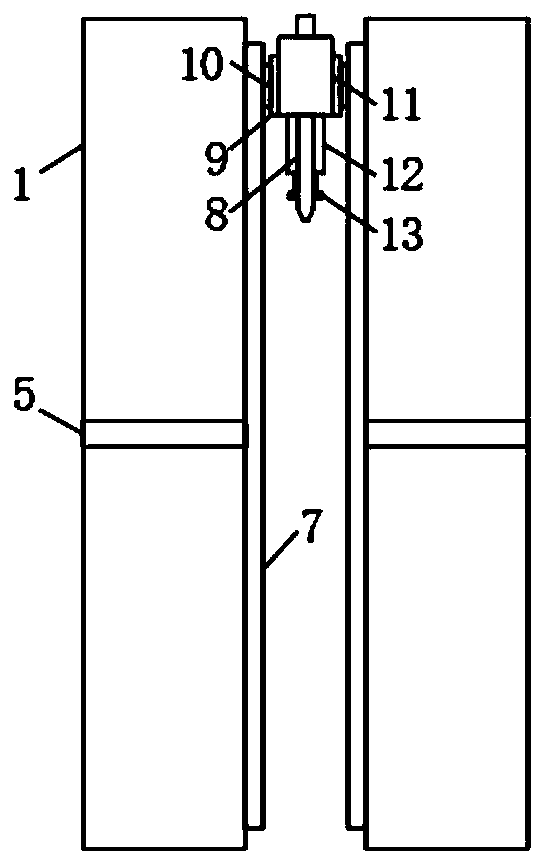

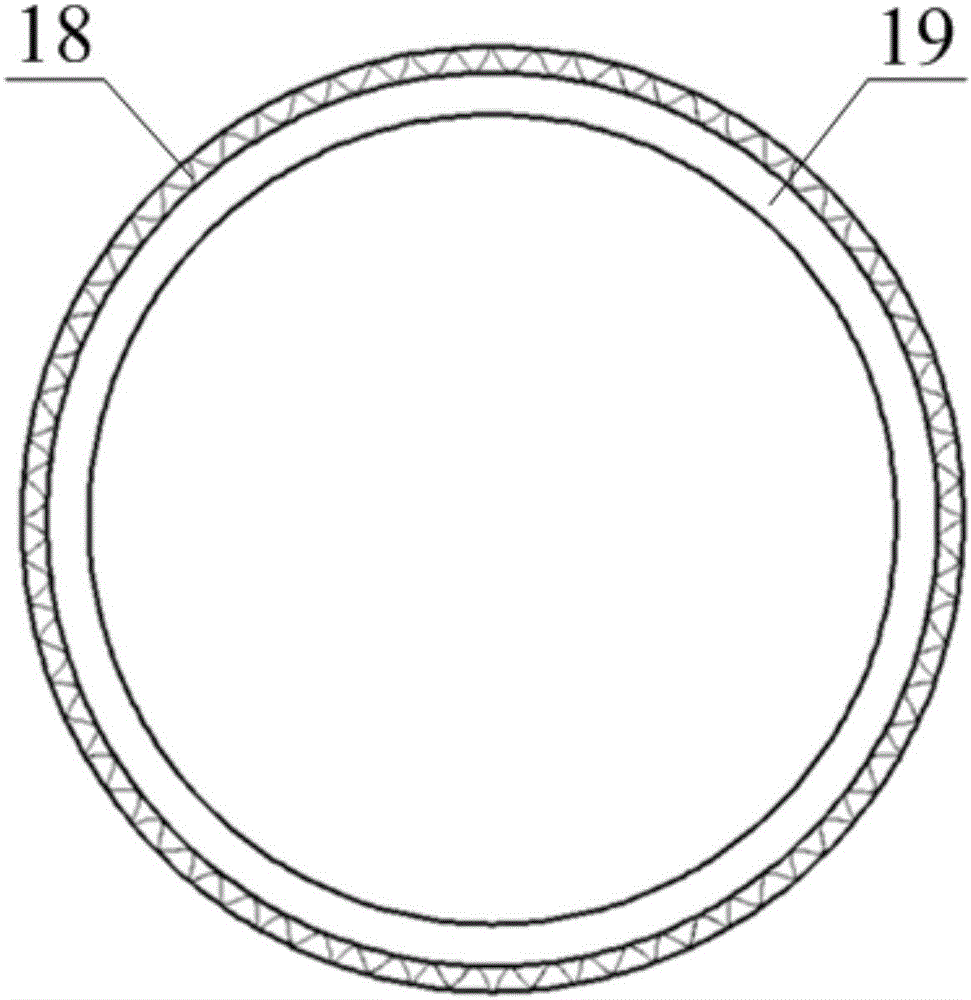

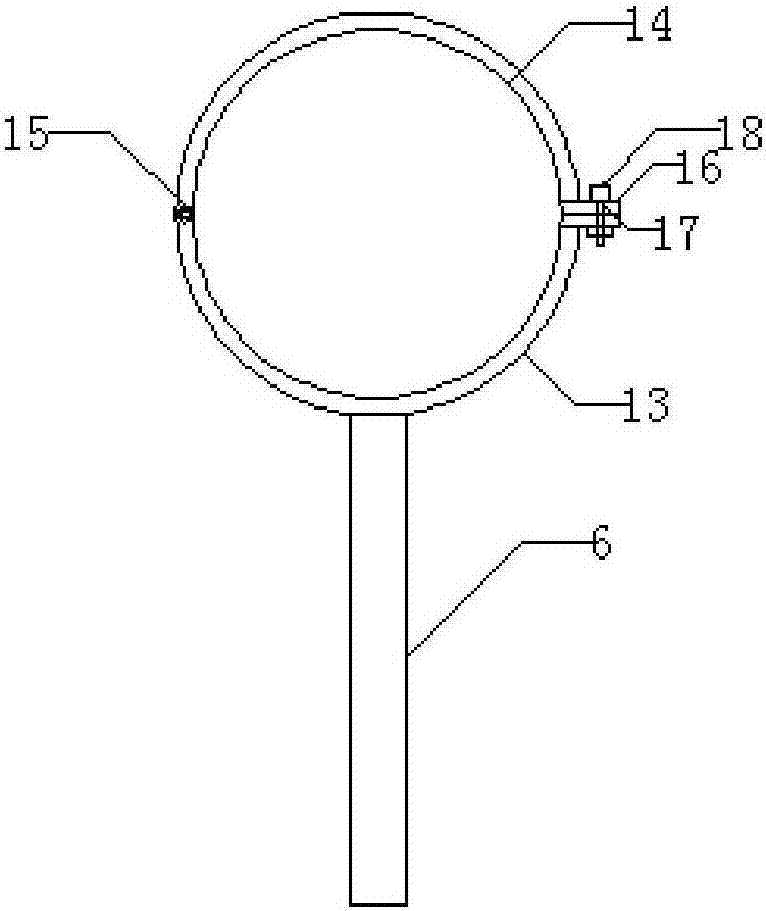

Preheating welding apparatus and method for marine equipment pile leg

ActiveCN106041378AImprove general performanceThere is no problem of temperature difference between inside and outsideWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMarine equipment

The invention discloses a preheating welding apparatus for a marine equipment pile leg, comprising a welding system and a base platform; the welding system includes a tubular electromagnetic heating device sleeving the pile leg, the electromagnetic heating device is peripherally provided with an induction coil, the tubular wall of the electromagnetic heating device is provided with an open groove with the outer wall provided with an automatic welding device; the base platform is provided with a driving device for driving the electromagnetic heating device to rotate relative to the pile leg and a guide support structure for supporting the electromagnetic heating device, and the base platform may slide relative to the pile leg. The pile leg is preheated by means of electromagnetic induction heating, and the apparatus may heat pile legs with different shapes and diameters, is highly universal and high in heating efficiency, and no interior and exterior temperature difference problem occurs to the pile leg. The electromagnetic heating device and the automatic welding device are rotated, with better simplicity and convenience and improved welding efficiency and welding quality provided. The invention also discloses a preheating welding method for a marine equipment pile leg.

Owner:GUANGDONG UNIV OF TECH

Multi-angle welding device for motor machining

InactiveCN112692395AConvenient welding workExpand the welding rangeWelding/soldering/cutting articlesMetal working apparatusElectric machineryEngineering

The invention discloses a multi-angle welding device for motor machining, and relates to the technical field of welding. The multi-angle welding device for motor machining comprises a work box, a rotating mechanism, a turnover mechanism, fixing mechanisms, a moving mechanism, a lifting mechanism and a welding mechanism, wherein the rotating mechanism is arranged on the work box; the output end of the rotating mechanism is arranged on the inner side of the work box; the turnover mechanism is fixedly arranged on the rotating mechanism; the two groups of fixing mechanisms are fixedly and symmetrically arranged on the turnover mechanism; the moving mechanism is fixedly arranged on the work box and is arranged on one side of the turnover mechanism; the lifting mechanism is arranged on the moving mechanism; and the moving mechanism is arranged on the lifting mechanism. According to the multi-angle welding device for motor machining provided by the invention, the different mechanisms are arranged, and a motor is moved, so that the welding work of the welding device is facilitated, and multi-angle welding is completed.

Owner:南京法贝登数码科技有限公司

Automatic assembling and welding device for heat pipe radiator machining

InactiveCN112139706AConvenient welding workImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesPower cableElectric machinery

The invention discloses an automatic assembling and welding device for heat pipe radiator machining. The automatic assembling and welding device comprises a case, a support base, a control panel, a power cable, a rack, a fixed rear frame, a first motor, a lead screw, a welding head, a direction overturning device, a welding base, an angle adjusting mechanism, a sliding block and a position adjusting mechanism. Through arrangement of the direction overturning device, an overturning frame drives the welding head to conduct overturning adjustment in the direction; the angle adjusting mechanism isarranged, so that the angle of the welding base can be adjusted; meanwhile, the position adjusting mechanism is arranged, and can enable the position of the welding base to be adjusted up and down, so that the welding head and the welding base can conduct welding work in different directions, angles and positions, and the welding efficiency is improved.

Owner:泉州市高谦机械产品有限公司

Welding clamp with convenient position adjustment function for welding of heat supply pipes

InactiveCN111421295ANo time consumingConvenient welding workWelding/cutting auxillary devicesAuxillary welding devicesElectric machineMechanical engineering

The invention discloses a welding clamp with a convenient position adjustment function for welding of heat supply pipes. The welding clamp comprises a baseplate, a motor and a retractable block. The middle of the exterior of the baseplate is provided with the motor, a limit base is integrally installed on the surfaces of the outer walls of the two sides of the baseplate, the top end of a limit bolt is clamped into the limit base, and the exterior of the limit bolt is connected with the inner wall of a preformed groove through a second torsional spring. The preformed groove runs through the middle of a connection plate, a fixing cover is connected to the upper portion of the top end of the baseplate through a connection rod, and the bottom of the connection rod is slidingly connected with the upper portion of the baseplate. When the welding clamp with the convenient position adjustment function for welding of the heat supply pipes is used, the effect of clamping the pipes can be easilyachieved, during clamping, it can be guaranteed that the two pipes in butt joint are on the same straight line, convenience is provided for welding the pipes, and the whole clamp clamps the pipes.

Owner:周口易圣热力供应有限公司

Composite steel pipe welding equipment

InactiveCN106853564AConvenient welding workSimple structureWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringPipe welding

The invention provides a composite steel pipe welding equipment, the bottom of the welding base is provided with a universal wheel, the universal wheel is provided with a brake device, the top of the welding base is provided with a chute, and at least four positioning sliders are provided in the chute , the positioning slider can move left and right along the chute, any positioning slider is provided with a positioning rod, and the end of the positioning rod is fixed with a positioning clamp; the top of the welding base is fixed with a welding bracket, and the top of the welding bracket is equipped with a welding bracket. The center of the ring, the welding ring and the positioning clamp are on the same straight line. There is a ring slide rail inside the welding ring, and an electric slider is installed inside the ring slide rail. The electric slider is slidingly connected with the ring slide rail. An electric welding torch pointing to the axis position is fixed, and the electric welding torch is connected with the electric welding control module fixed on the welding support. The invention has the beneficial effects of automatic welding, saving time and effort.

Owner:TIANJIN HAOHANG COMPOSITE PIPE

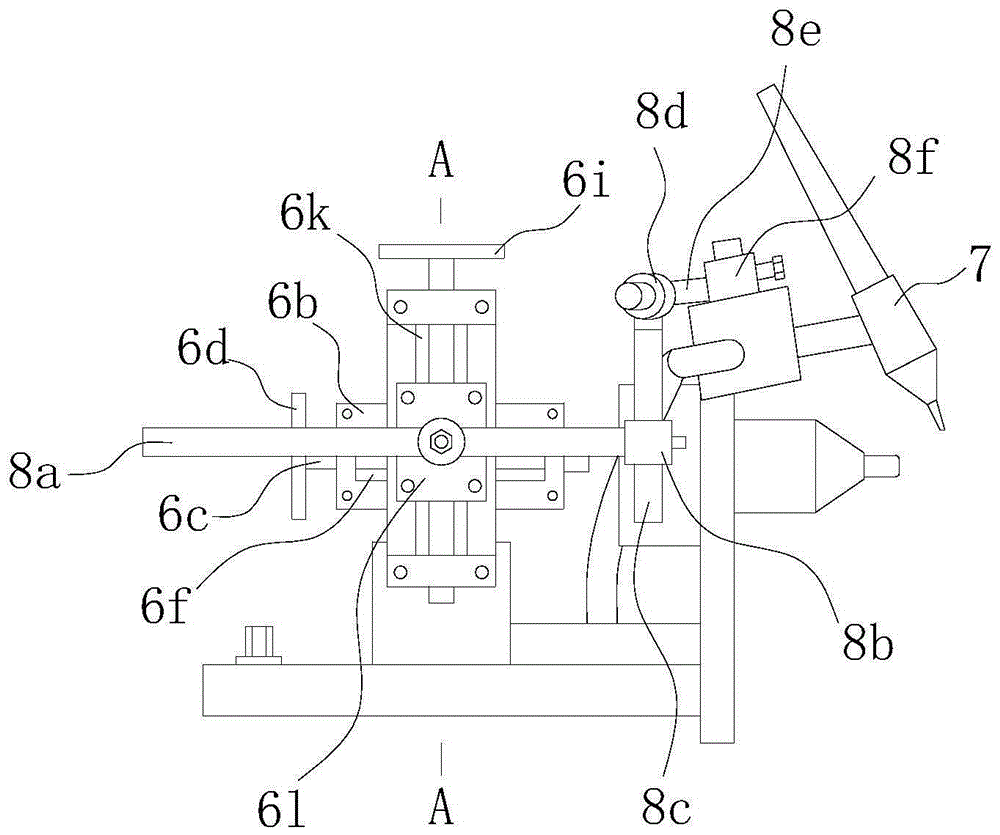

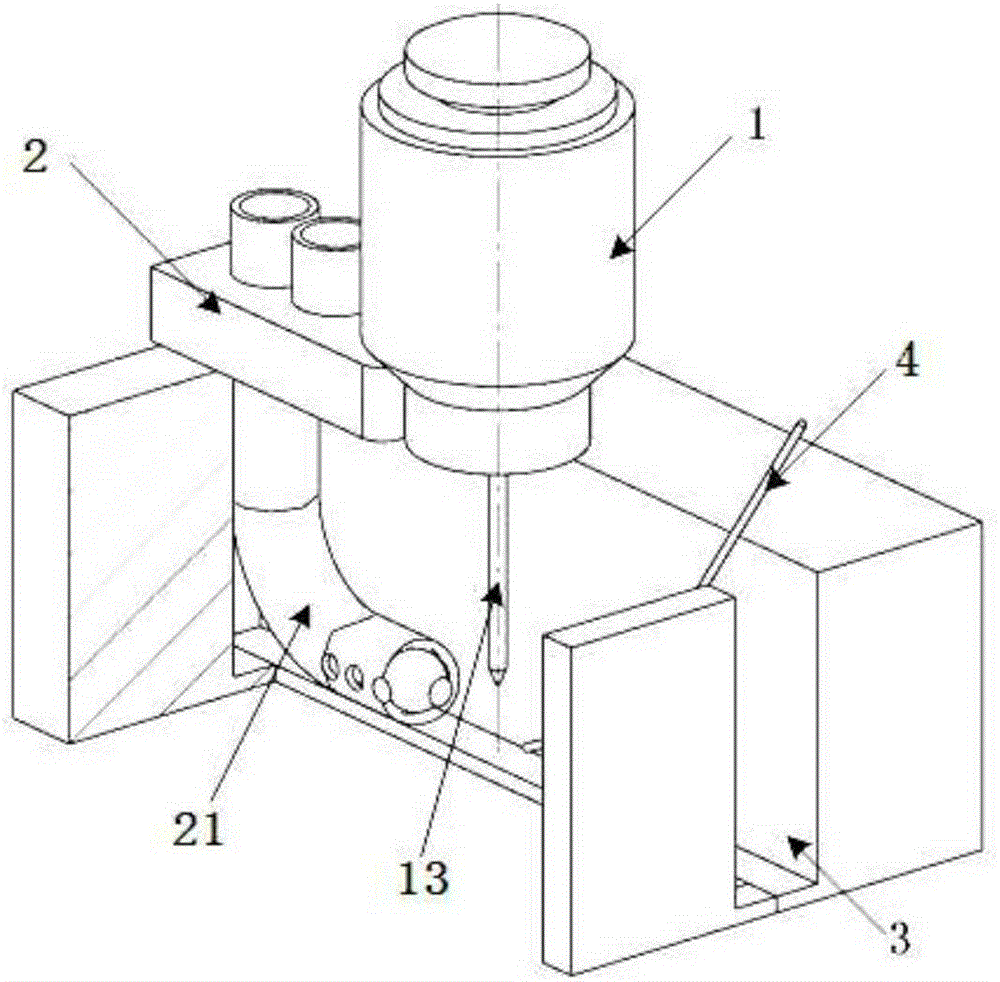

Tungsten inert gas (TIG) welding device and method applicable to narrow-gap groove

ActiveCN105312739AImprove welding qualityConvenient welding workElectrode supporting devicesEngineeringNarrow gap

The invention discloses a tungsten inert gas (TIG) welding device and method applicable to a narrow-gap groove. The welding device comprises a welding gun (1) and a protective unit (2) located on the rear side of the welding gun (1), wherein the protective unit (2) is used for spraying protective gas to carry out gas protection on a welding area of the welding gun (1); a tungsten electrode (13) of the welding gun (1) can be directly inserted into the bottom of the narrow-gap groove (3) during welding. According to the TIG welding device and method applicable to the narrow-gap groove, the defect that the welding position of a traditional welding gun is unreachable during narrow-gap welding is overcome, gas protection is conducted on the welding area, and the TIG welding device and method applicable to the narrow-gap groove have the advantages of being simple in structure, reasonable in design, low in manufacturing cost, good in welding effect and the like.

Owner:BEIJING GUOWANG OPTICAL TECH CO LTD

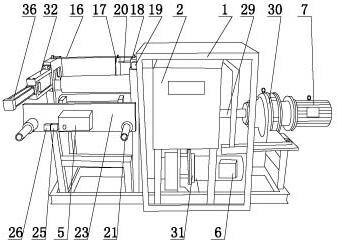

A fire extinguisher bottle automatic rolling machine

The invention relates to an automatic circle-rolling machine for a fire extinguisher bottle and belongs to the field of manufacturing machinery of fire extinguisher bottles. The automatic circle-rolling machine comprises an electric cabinet, a driving roller, a driven roller, a feeding cylinder, a transmission motor A, a transmission motor B and the like, wherein the electric cabinet is arranged in the middle of a frame; the transmission motor A and the transmission motor B are arranged on one side of the electric cabinet; the driving roller and the driven roller are arranged on the other side of the electric cabinet; the driving roller is connected to the transmission motor B; and the transmission motor A is in engaged and connected with a cam shaft through a transmission gear. The automatic circle-rolling machine can work orderly according to a preset program by virtue of various approach switches and various cylinders mounted on the automatic circle-rolling machine, thereby improving the working efficiency. A rejected material pushing plate 17 on the frame 1 is used for achieving the purpose of automatically discharging after a workpiece is formed, thereby relieving the labor intensity of the staff. The automatic circle-rolling machine for the fire extinguisher bottle has the advantages that the operation is simple and convenient, the working precision is high, and the automatic circle-rolling machine is especially suitable for rolling the cylindrical body of the fire extinguisher bottle.

Owner:湖北江荆消防科技股份有限公司

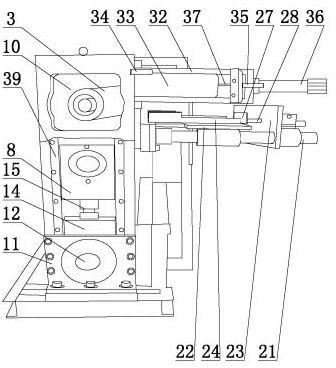

Welding clamp of steel cylinder base

InactiveCN104972264AConvenient welding workSimple structureWelding/cutting auxillary devicesAuxillary welding devicesLocknutEngineering

The invention discloses a welding clamp of a steel cylinder base. The welding clamp comprises a base and a plurality of sets of clamp assemblies of the same structure, wherein the multiple sets of clamp assemblies are evenly arranged in parallel in the width direction of the rack; each clamp assembly comprises a linear guide rail, two sliding blocks matched with the linear guide rail, two supporting rods and two supporting rollers; the linear guide rails extend in the length direction of the rack, two supporting rods are arranged in a crossing manner, and the crossing positions are movably connected; one end of each supporting rod is hinged to the corresponding sliding block, and two supporting rollers are movably mounted at the other ends of the two supporting rods; an adjusting component is arranged at the position, corresponding to each sliding block, of the rack, and comprises a fixed seat and an adjusting rod; the adjusting rods are in threaded connection with the fixed seats, and the bottom ends of the adjusting rods abut against the corresponding sliding blocks; and locking nuts are arranged on the adjusting rods, and abut against the fixed seats. The welding clamp can be suitable for clamping steel cylinders of different specifications, welding tool of a base is facilitated, and the welding clamp is simple in structure, low in cost and convenient to operate.

Owner:LIUZHOU SHANTAI GAS

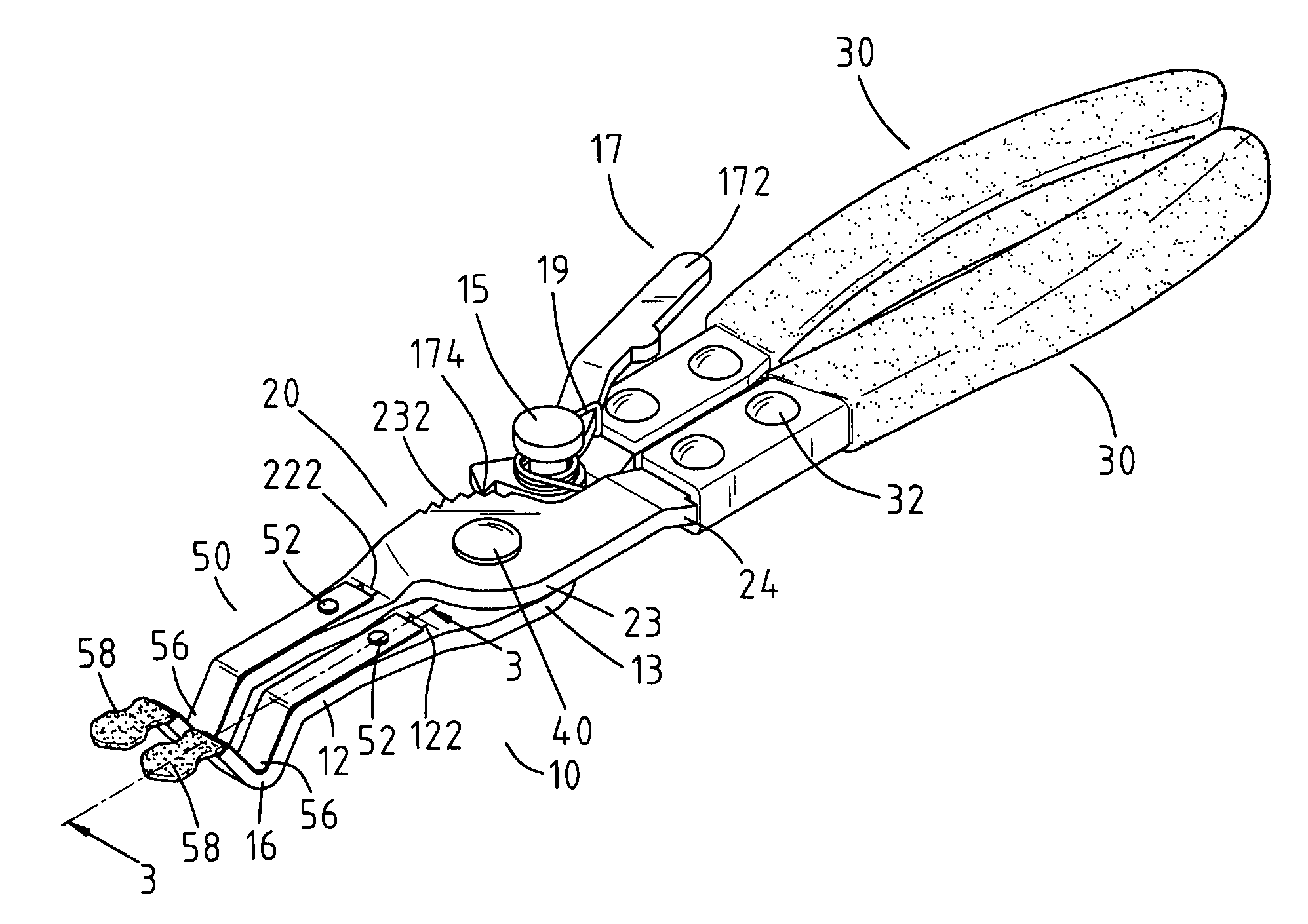

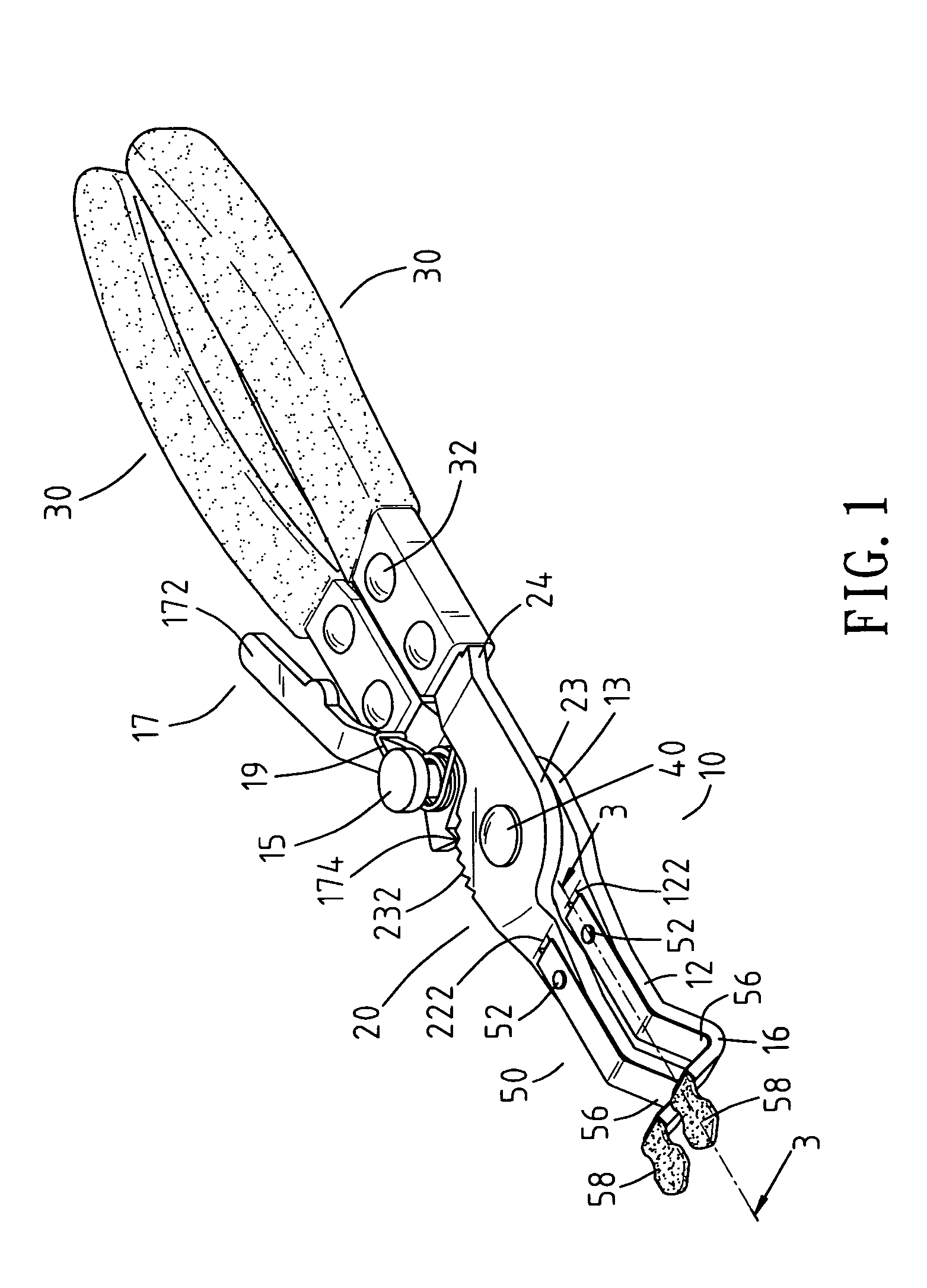

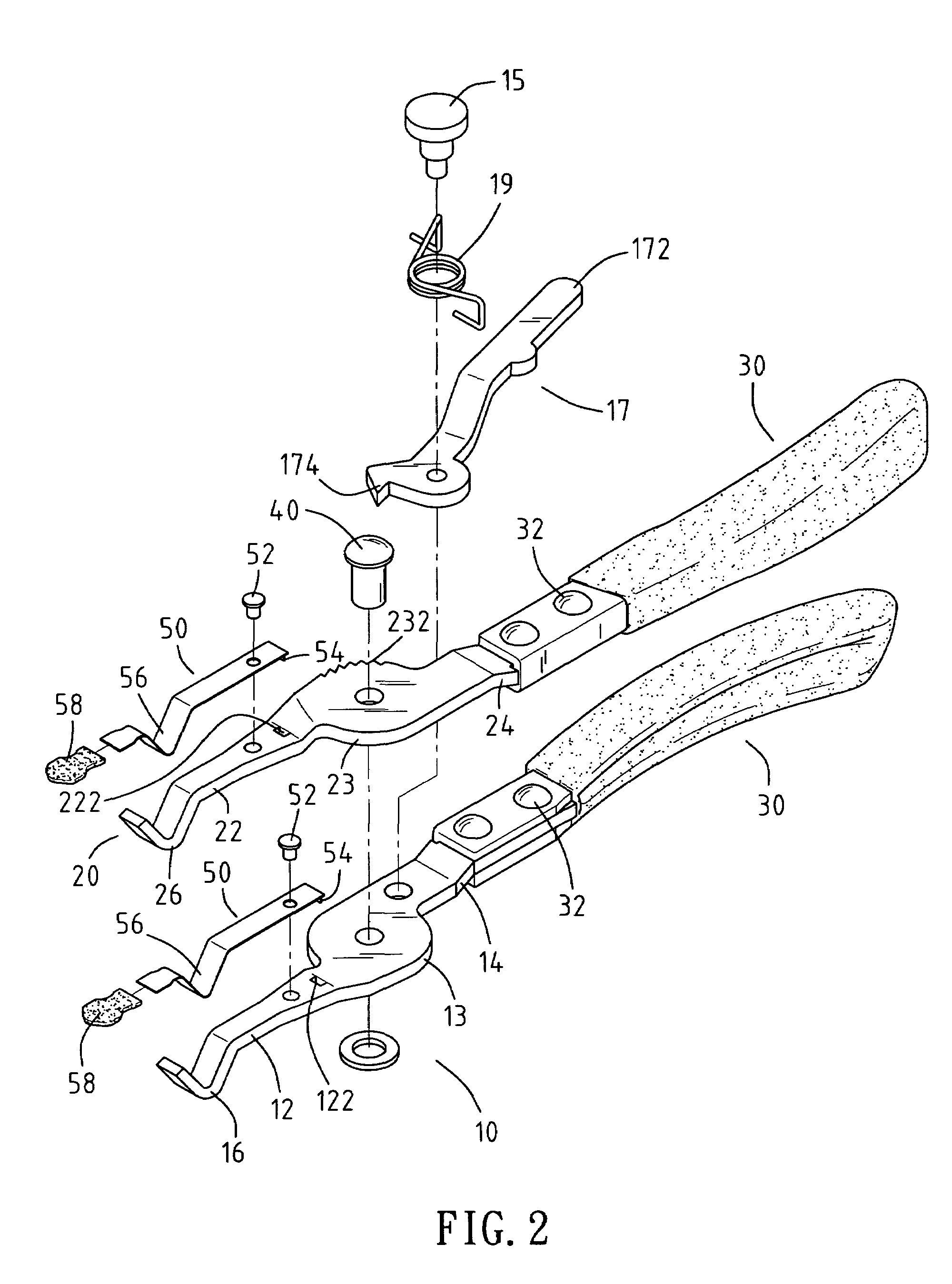

Auxiliary soldering tool

InactiveUS7156278B2Mitigate and obviate disadvantageConvenient welding workWelding/cutting auxillary devicesSemiconductor/solid-state device manufacturingEngineeringSoldering

An auxiliary soldering tool includes a first jaw plate having a first holding portion and a first holding portion, a second jaw plate having a second holding portion and a second holding portion, and two elastic press plates each respectively rested on the first holding portion of the first jaw plate and the second holding portion of the second jaw plate. Thus, the auxiliary soldering tool facilitates the soldering work of two wires, so that the worker can solder and connect the two wires easily and conveniently.

Owner:WU PI LIANG

Reversible welding clamp

InactiveCN108927631ASmooth rotationConvenient welding workWelding/cutting auxillary devicesAuxillary welding devicesBiochemical engineeringWelding

The invention provides a reversible welding clamp and relates to the technical field of welding clamps. The reversible welding clamp comprises a clamp bottom plate seat. A first supporting column anda second supporting column are separately arranged at two ends of the clamp bottom plate seat; one end of the first supporting column and one end of the second supporting column are arranged on the clamp bottom plate seat; a rectangular frame reversing clamp plate is movably arranged between the other end of the first supporting column and the other end of the supporting column; a plurality of parallel fixed bars are also movably arrange in the rectangular frame reversing clamp plate; the fixed bars are rectangular bars; a plurality of clamping air cylinders are also arranged on the rectangular frame reversing clamp plate and the fixed bars; rotary shafts are also separately arranged at two ends of the rectangular frame reversing clamp plate; and the reversing clamp plate is rotatably arranged between the other end of the first supporting column and the other end of the supporting column. The reversible welding clamp provided by the invention has the advantages of welding multiple faces of a product only by reversing the rectangular frame reversing clamp plate and the like.

Owner:TECH TRANSFER CENT CO LTD NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com