Contact module of high-speed electric connector and manufacture method of module

A technology for electrical connectors and contacts, which is applied to components of connecting devices, assembly/disassembly of contacts, circuit/current collector components, etc. Insufficient, grounding failure of the shielding sheet, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

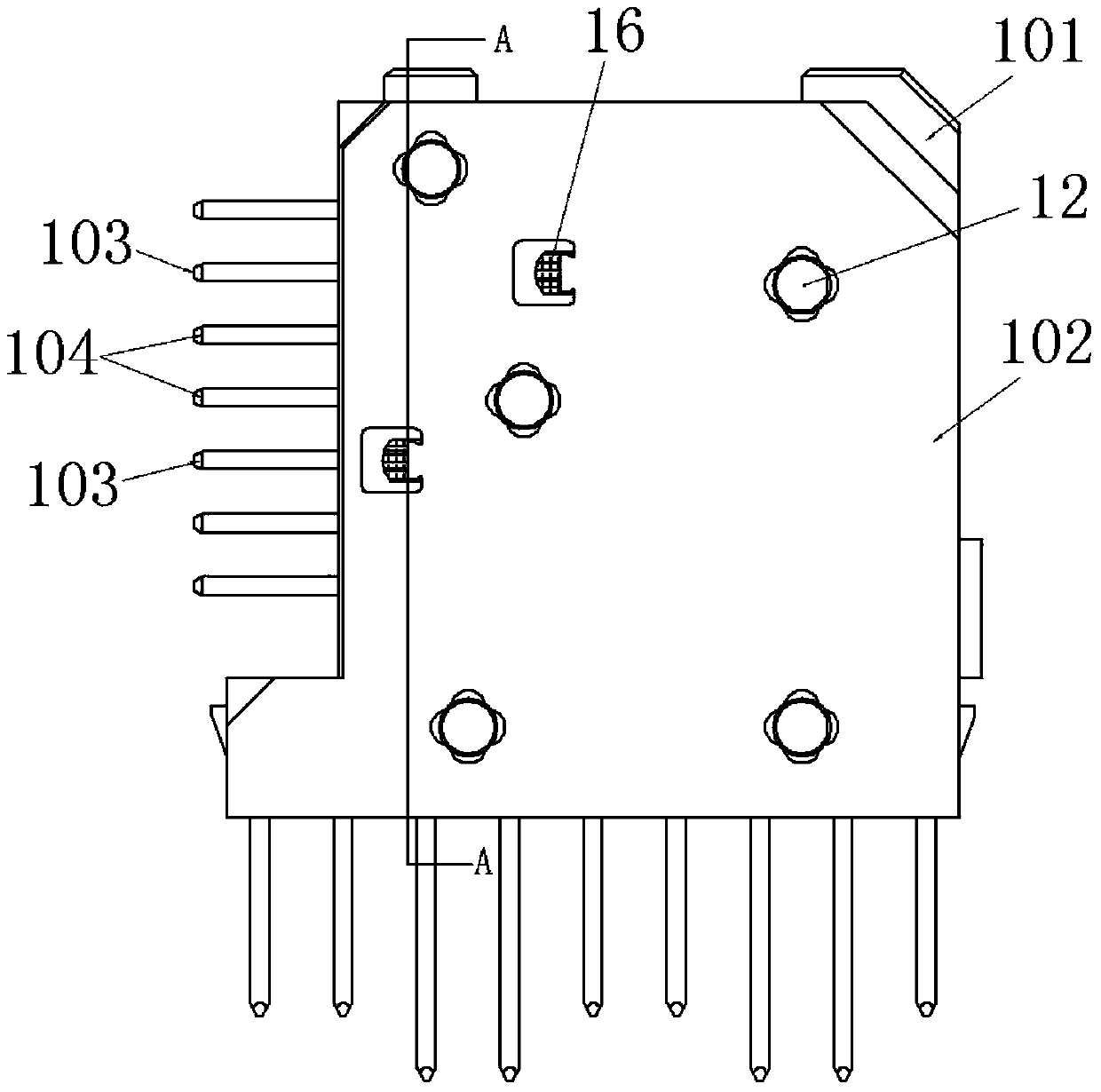

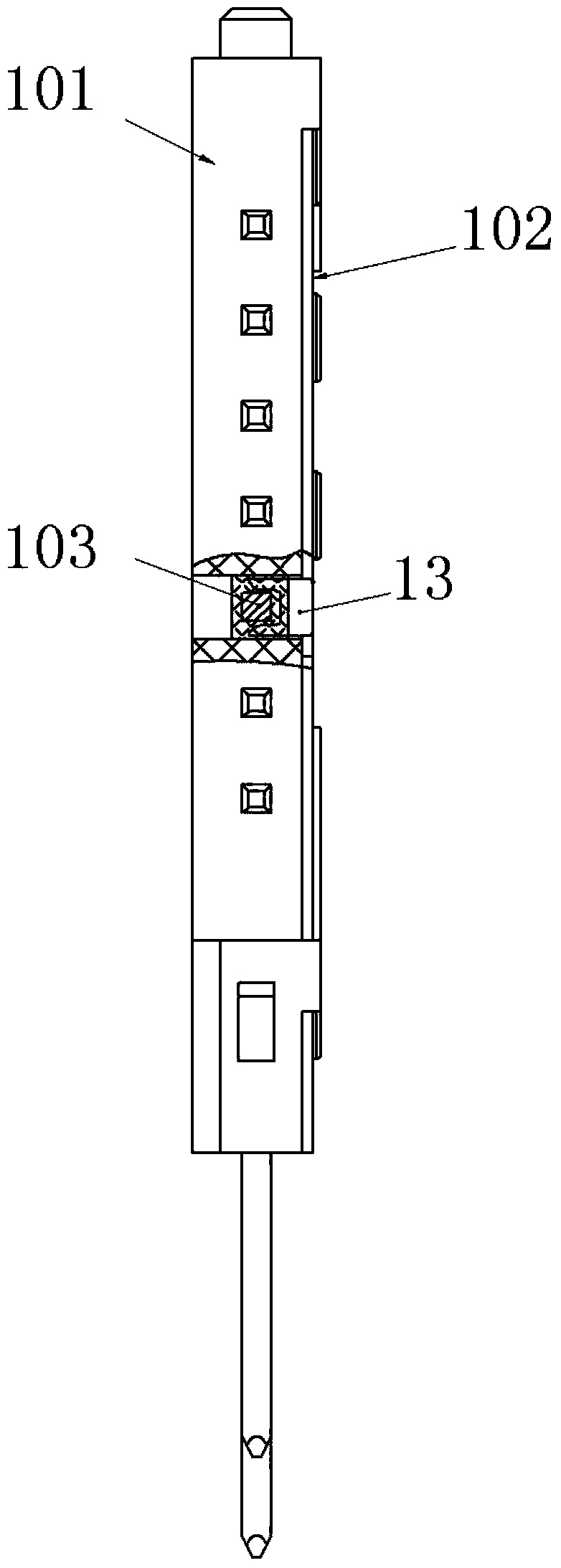

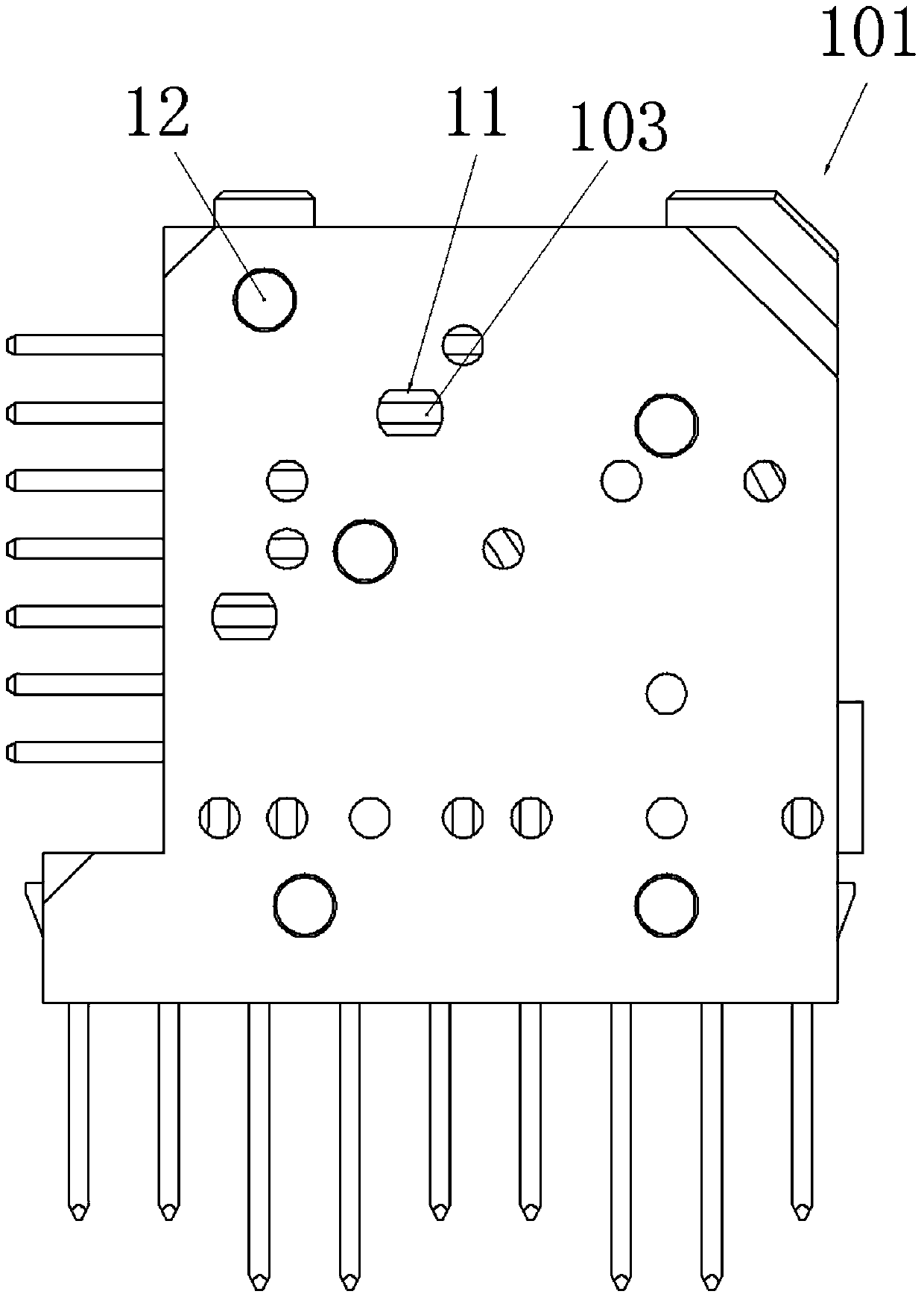

[0024] Embodiments of contact modules of high-speed electrical connectors, such as Figure 1-5 As shown, the contact module includes a contact, an insulator 101 and a shield 102 .

[0025] The contacts are divided into ground contacts 103 and signal contacts 104. In this embodiment, the ground contacts 103 are ground pins, and the signal contacts 104 are differential pairs.

[0026] The insulator 101 is in the shape of a sheet, and the shape of its outer contour is the same as that of the prior art. In this embodiment, the insulator 101 is made by injection molding. During the manufacturing process, the signal contacts 104 and the ground contacts 103 are encapsulated in the insulator 101 at the same time. The insulator 101 is provided with an insertion hole 11, and each ground There is at least one insertion hole directly above the contact piece 103 , and the insertion hole 11 exposes the corresponding part of the ground contact piece 103 to the outside. In this embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com