Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Expand the welding range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

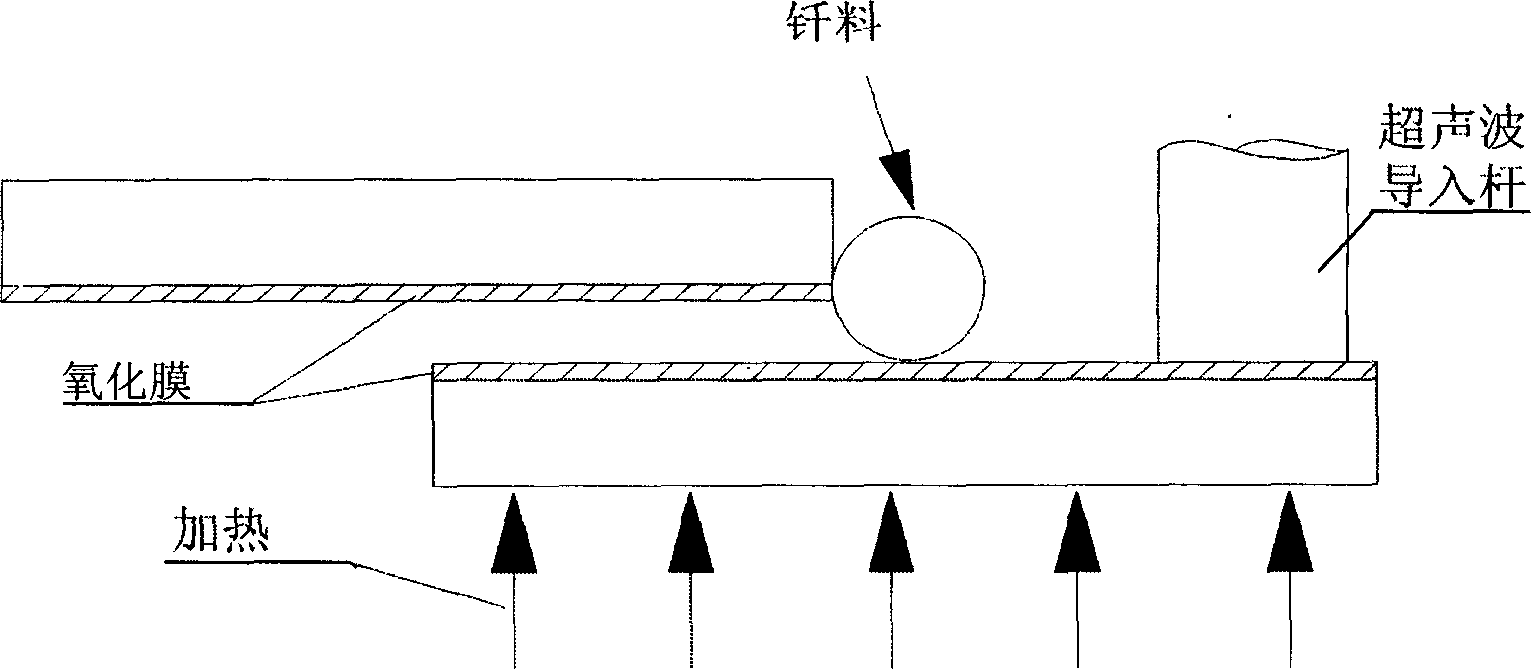

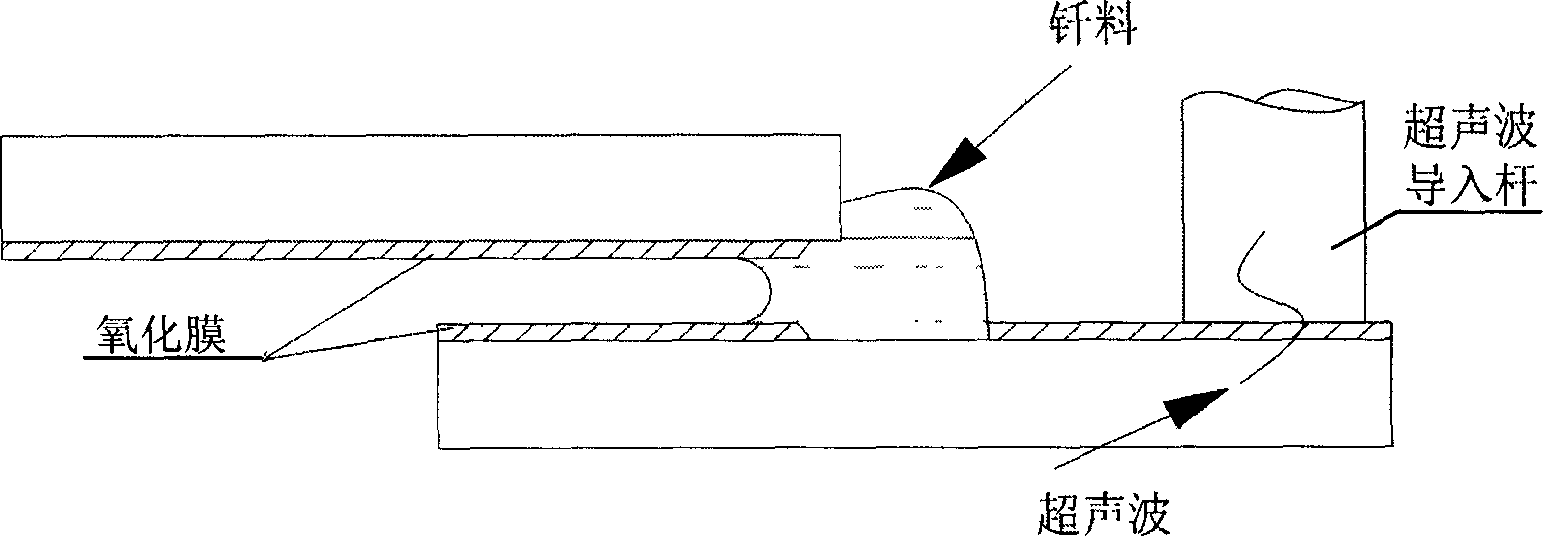

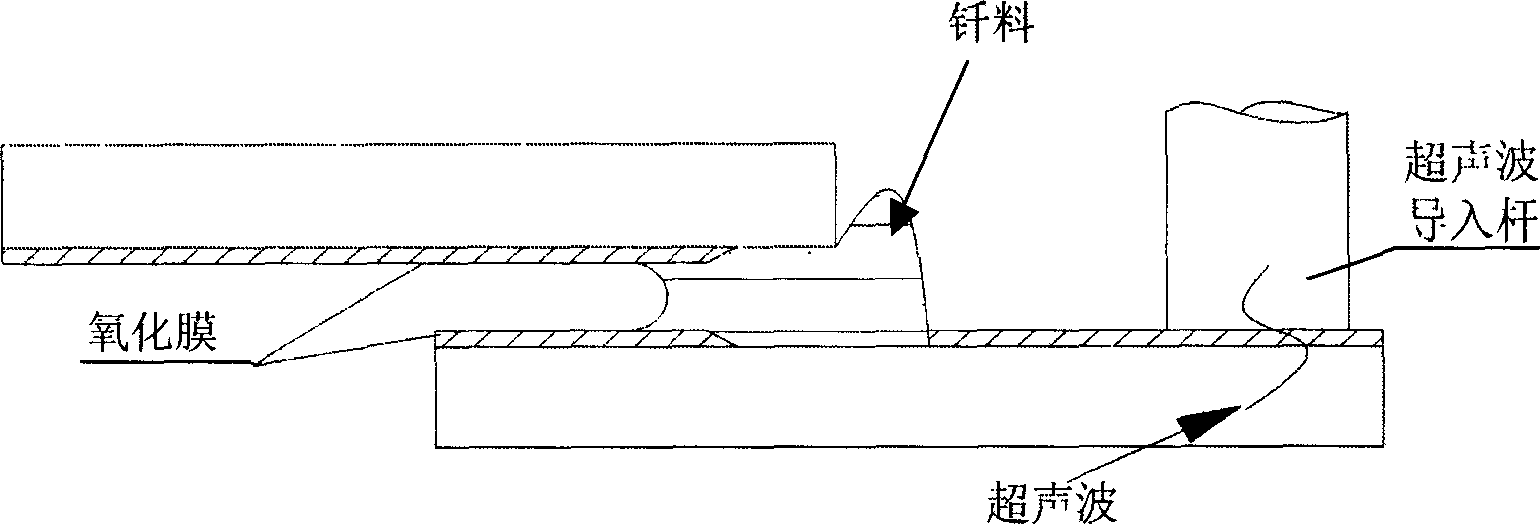

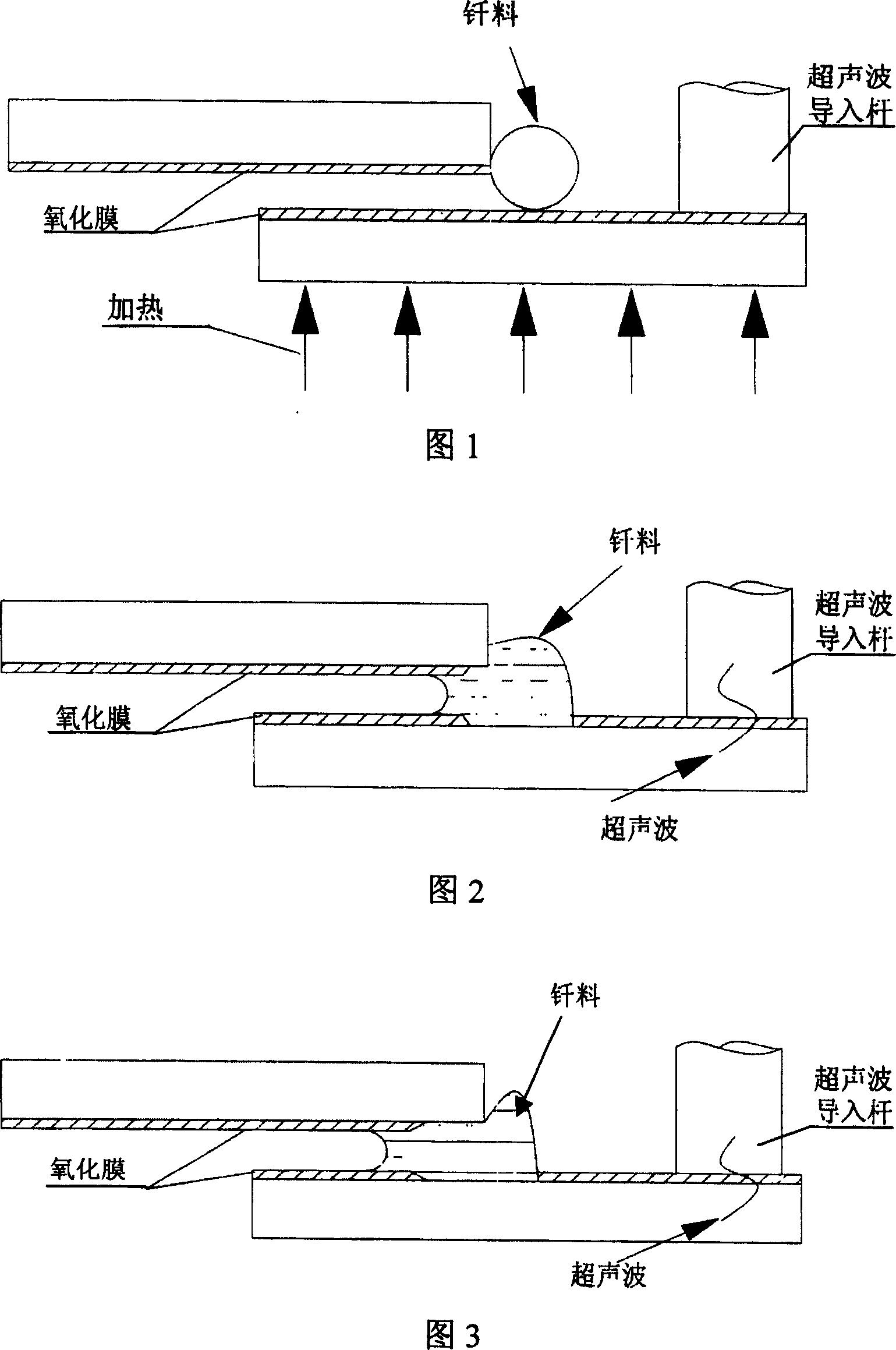

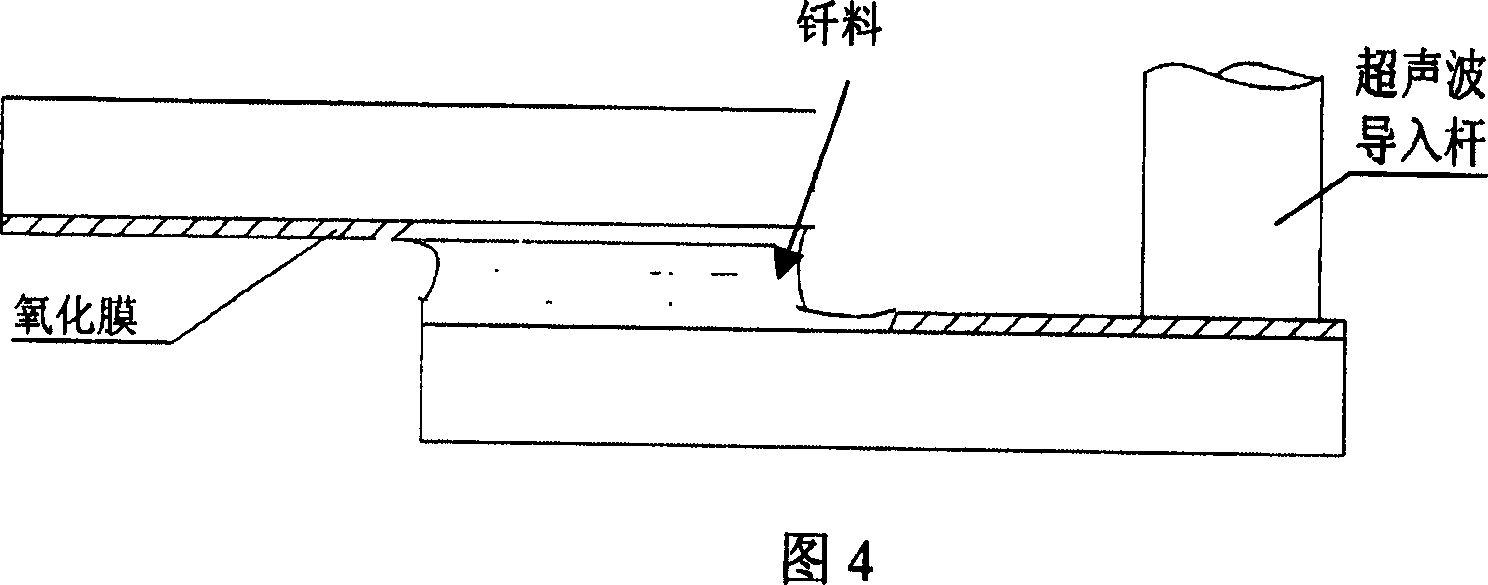

Aluminium base composite material ultrasonic wave fine welding method

InactiveCN1644291AAvoid WeldingEfficient weldingNon-electric welding apparatusUltrasonic vibrationMaterials science

An ultrasonic capillary welding method for the Al-base composite material includes such steps as arranging upper and lower parts to be welded in such manner that the gap between them is 10-300 microns, putting the flux close to lap end, heating to smelt the flux, holding the temp, pressing the ultrasonic head onto surface of the part to be welded, and applying ultrasonic vibration for 0.5-15 S. Its advantages are high welding quality, low welding temp, and high speed.

Owner:HARBIN INST OF TECH

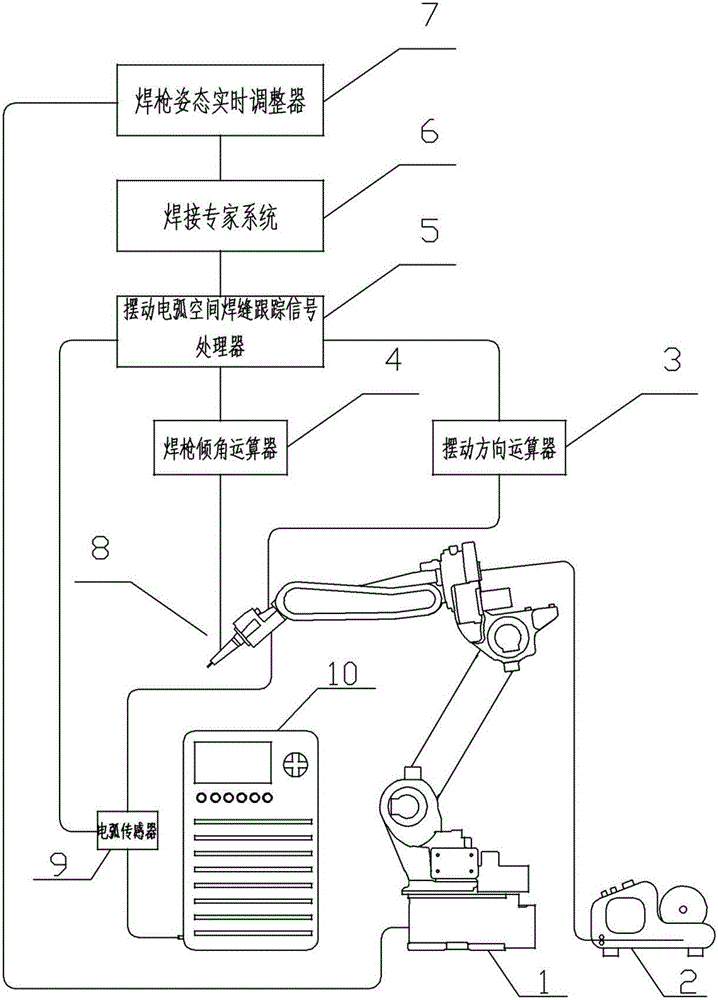

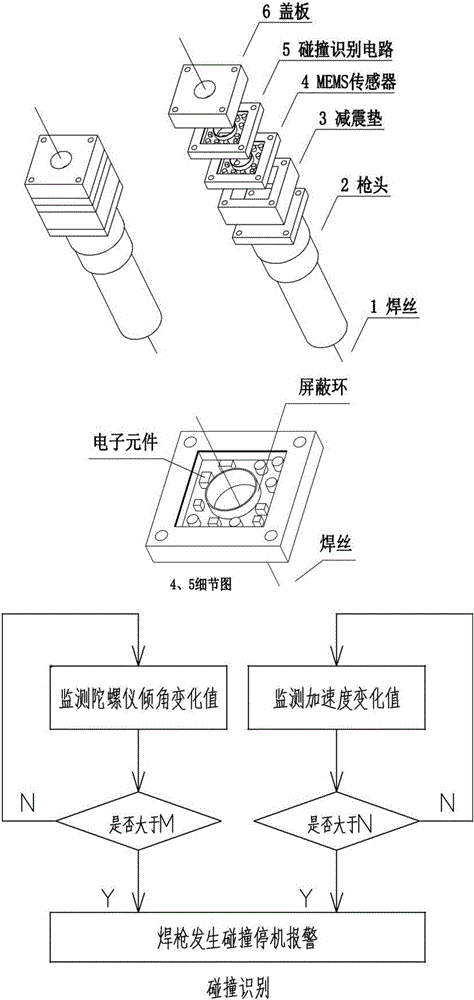

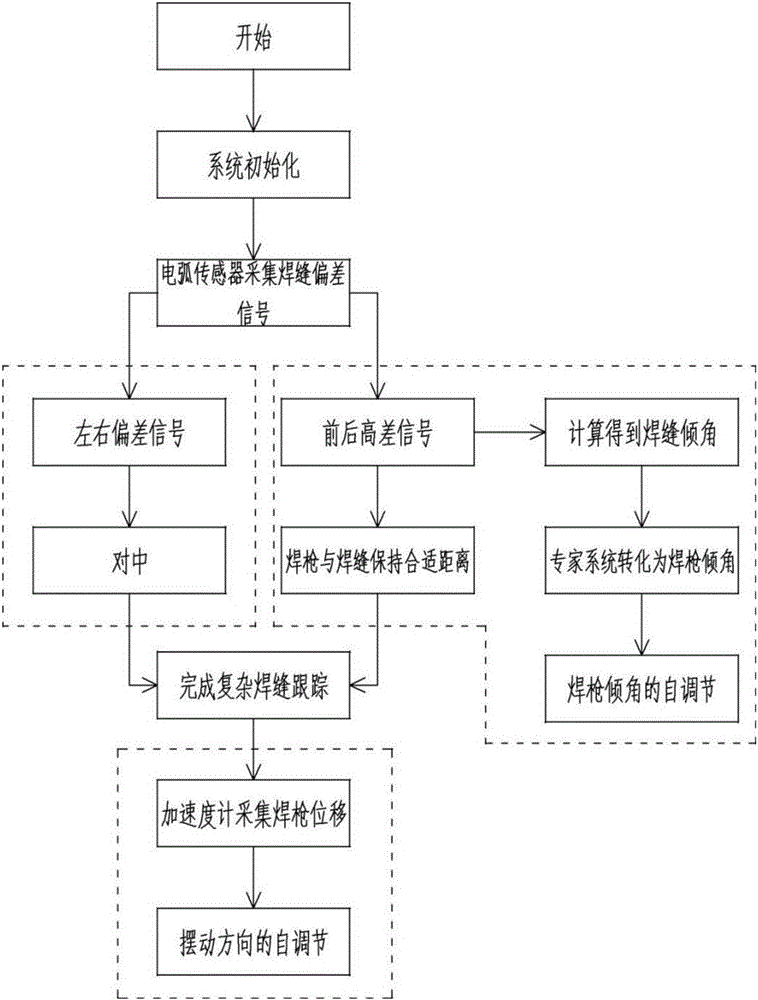

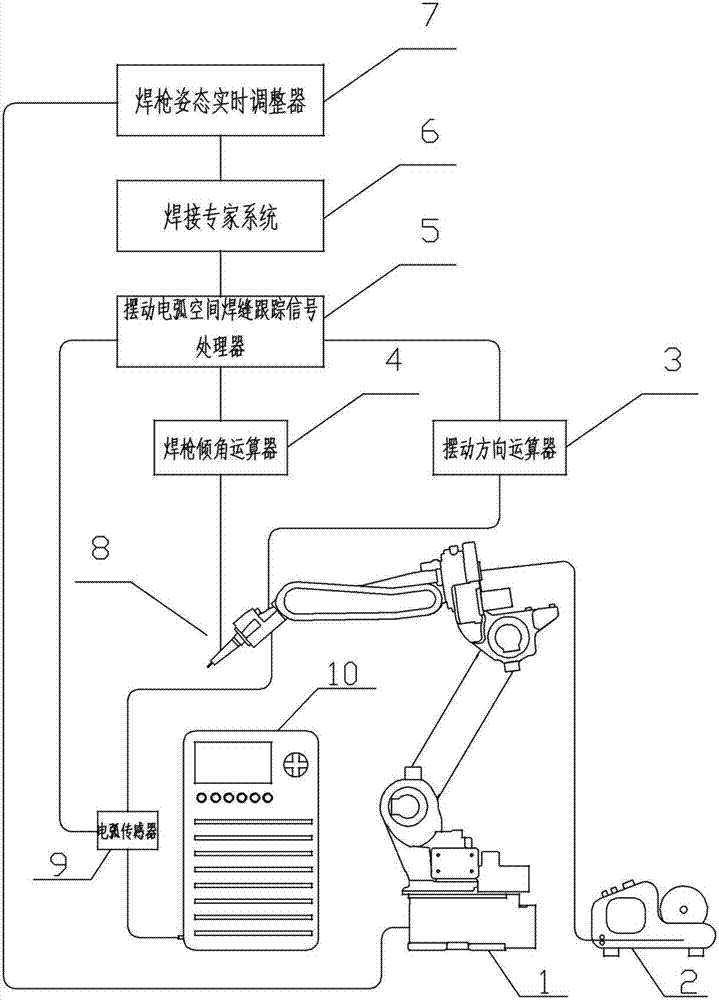

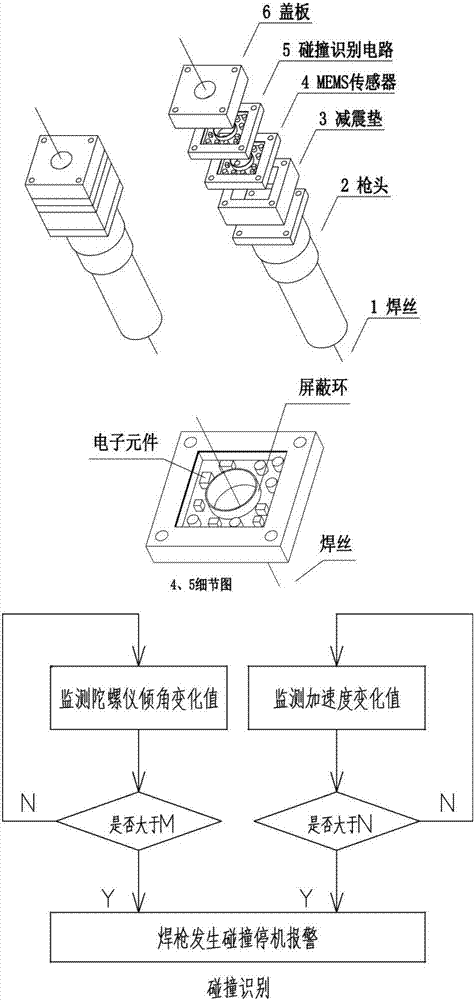

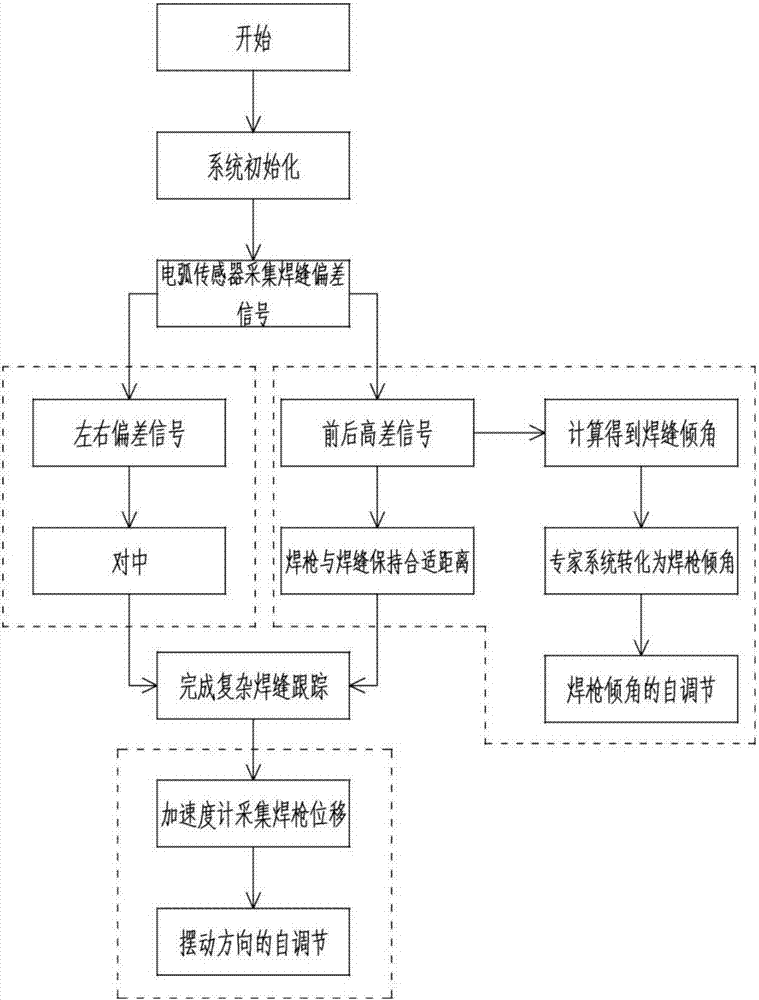

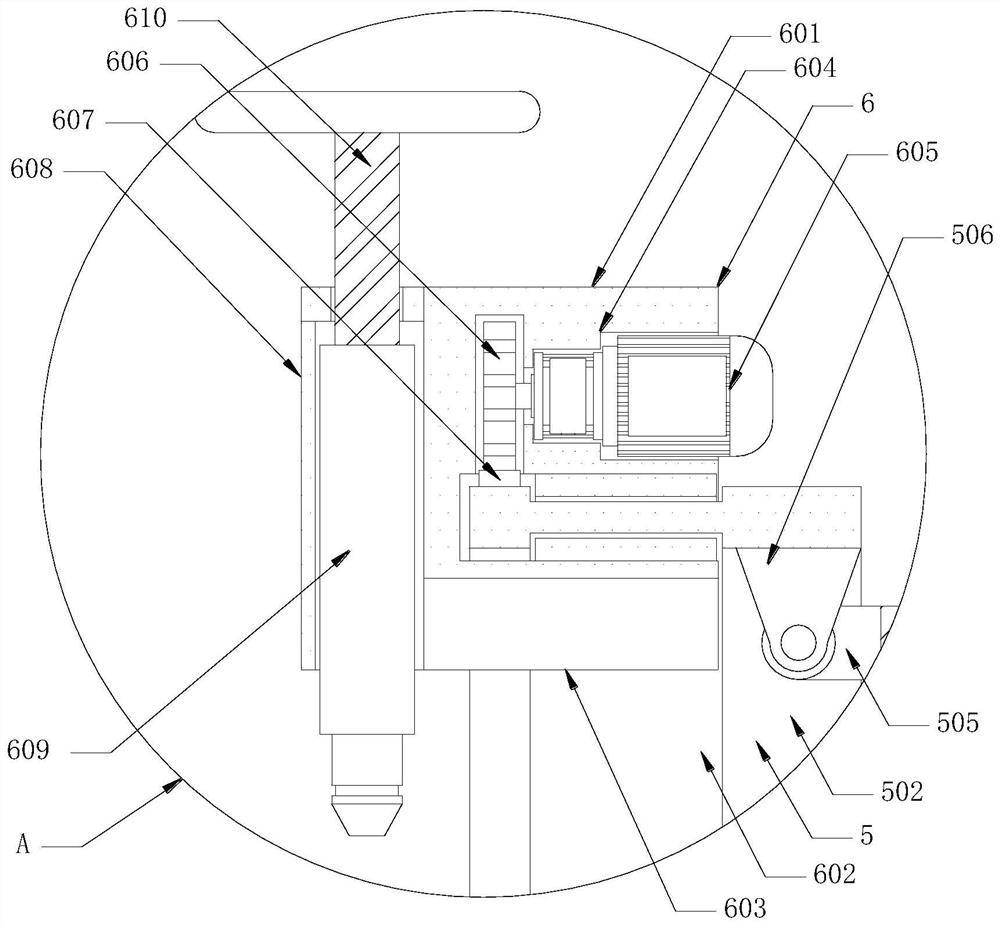

System and method for tracking weaving arc space weld based on MEMS (micro-electromechanical systems) sensor

ActiveCN105728904ASolving Seam Tracking IssuesExpand the welding rangeArc welding apparatusAccelerometerGyroscope

The invention discloses a system and a method for tracking a weaving arc space weld based on an MEMS (micro-electromechanical systems) sensor. The system comprises a manipulator, a welding power source, a wire delivery machine, an electric arc sensor, a built-in type MEMS sensor welding gun, a weaving arc space weld tracking signal processor, a welding gun tilting angle operator, a swinging direction operator, a welding gun attitude real-time adjuster, and a welding expert system. The system adopts a core principle that the space weld can be tracked by the weaving arc space weld tracking method based on the MEMS sensor, and has the advantage that the space attitude of the welding gun is collected by an arc sensor, a gyroscope and an accelerometer, and the tilting angle and swinging direction of the welding gun are automatically adjusted by weld angle differential identification, vertical displacement orientation and other methods, so that the real-time tracking of the space complicated weld is realized.

Owner:XIANGTAN UNIV

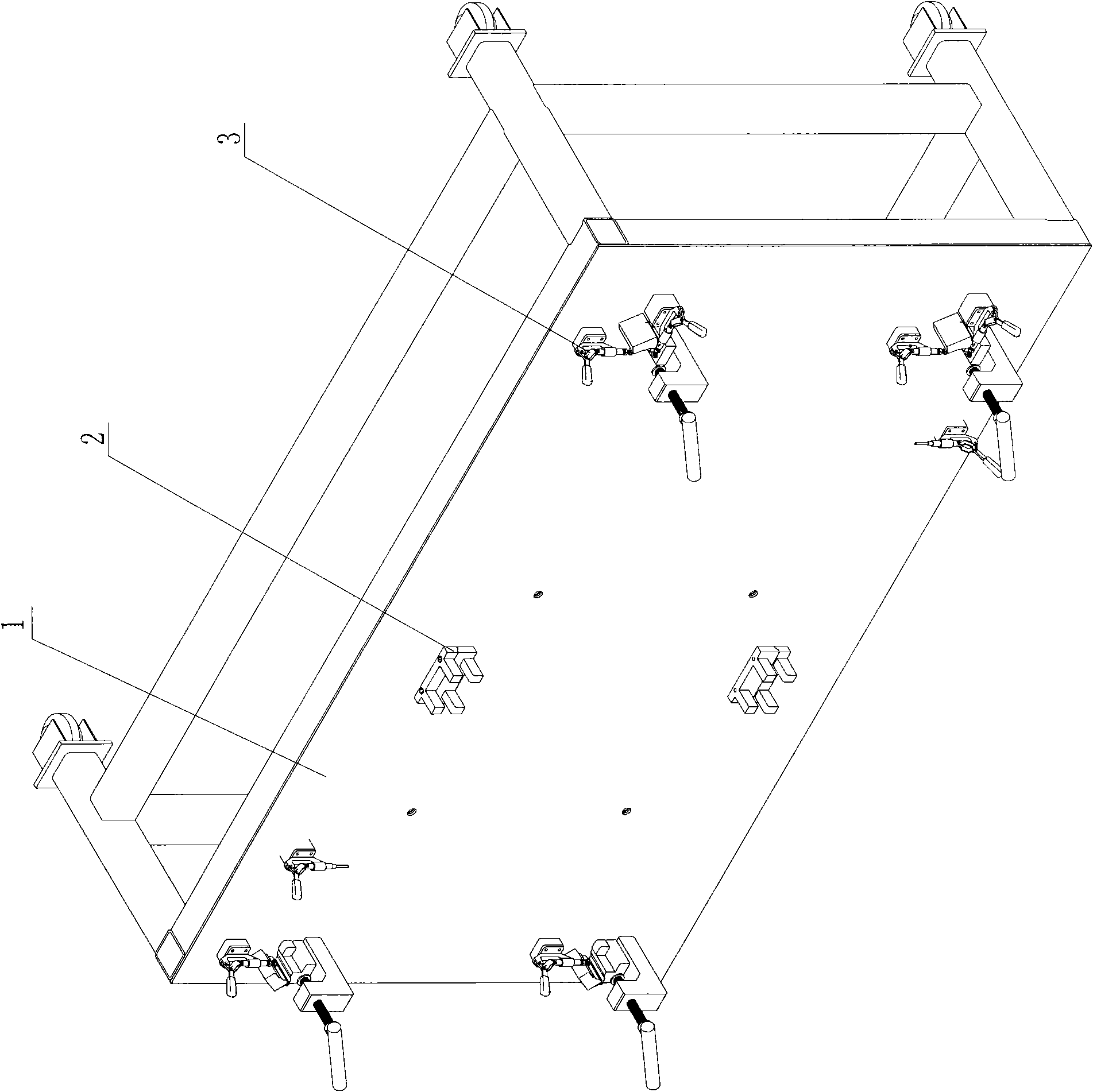

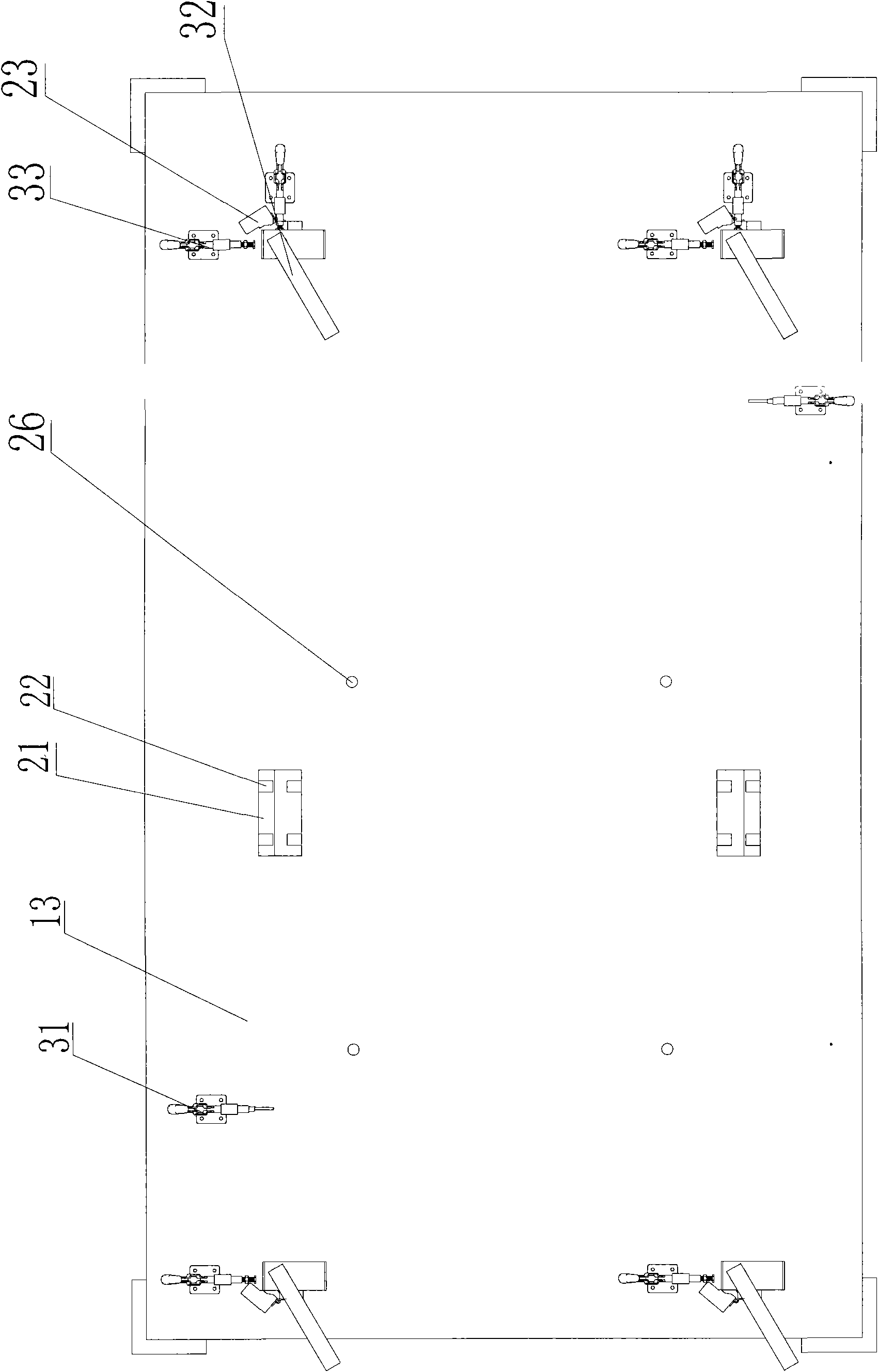

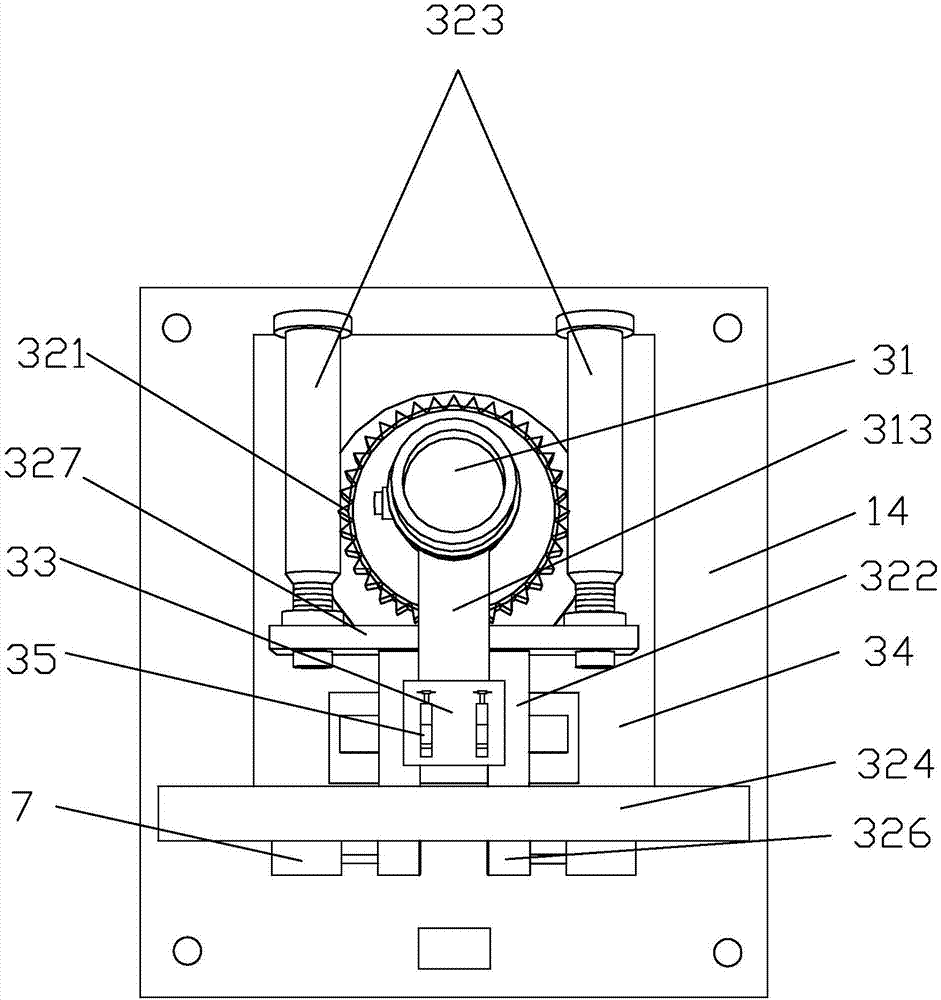

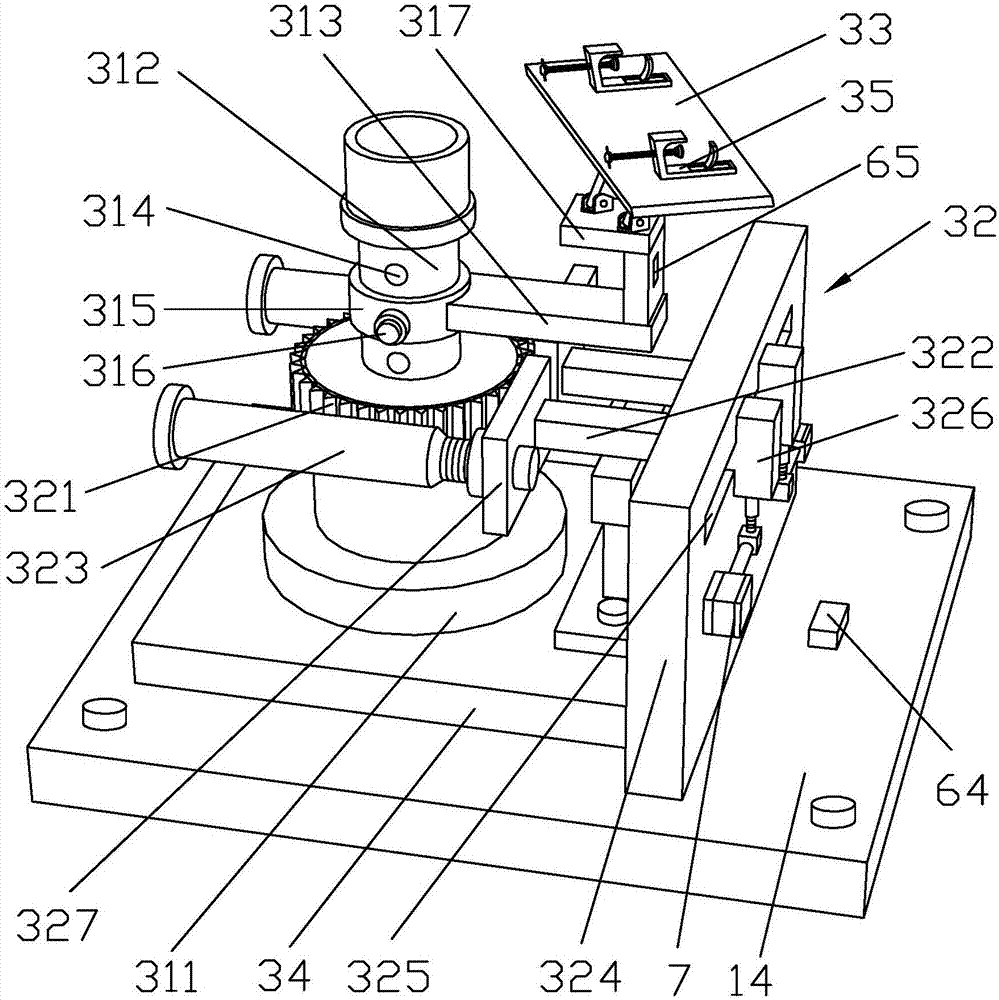

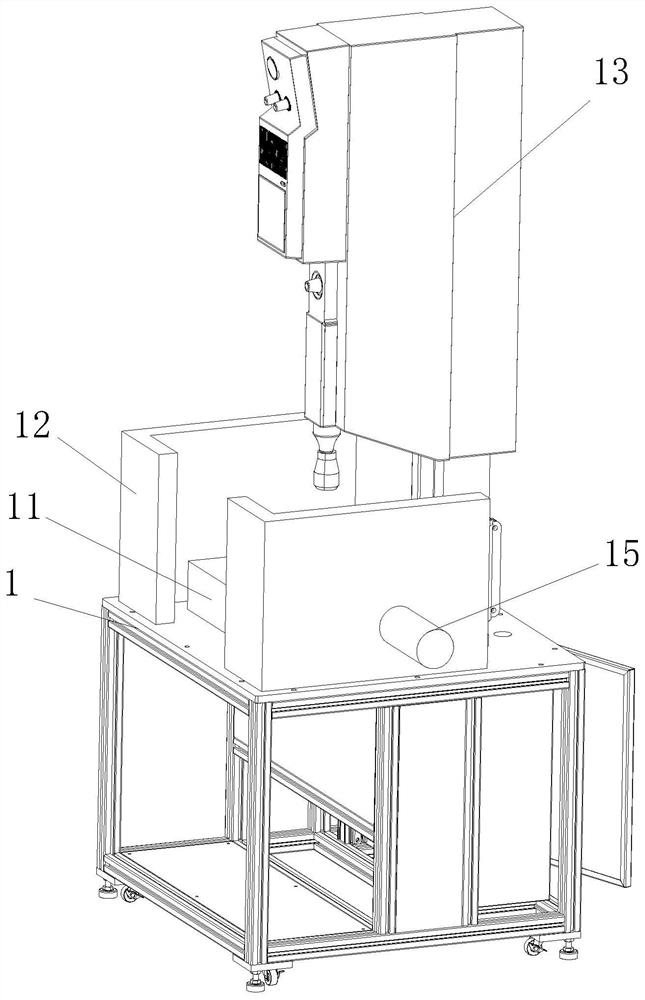

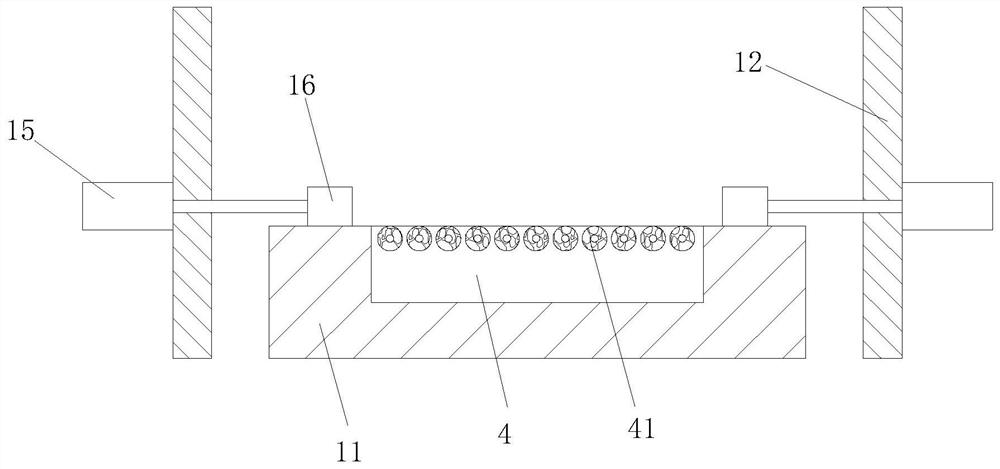

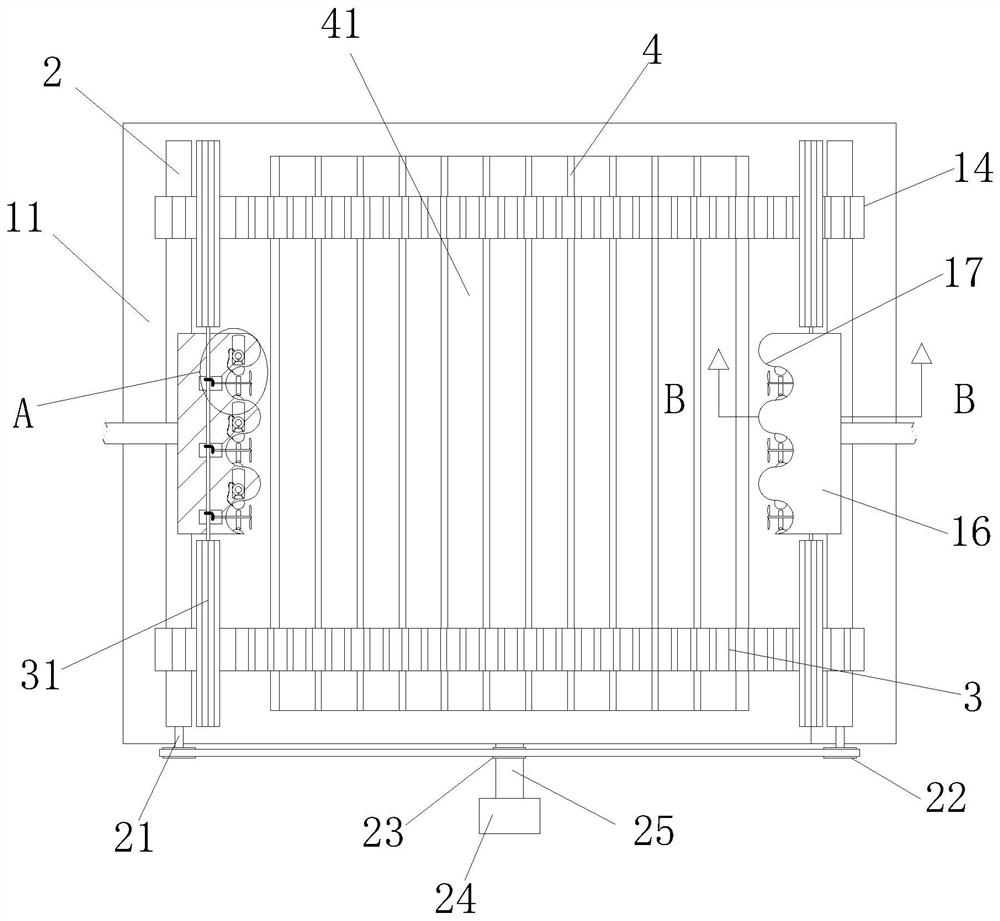

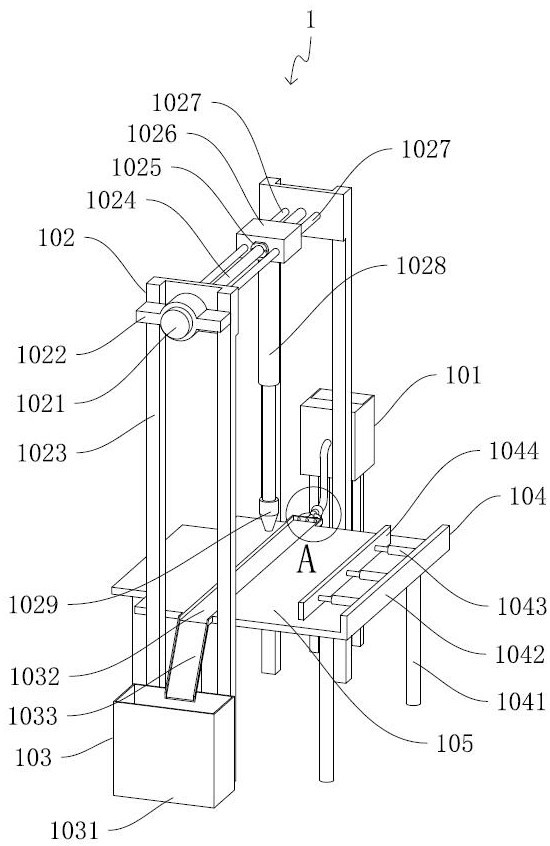

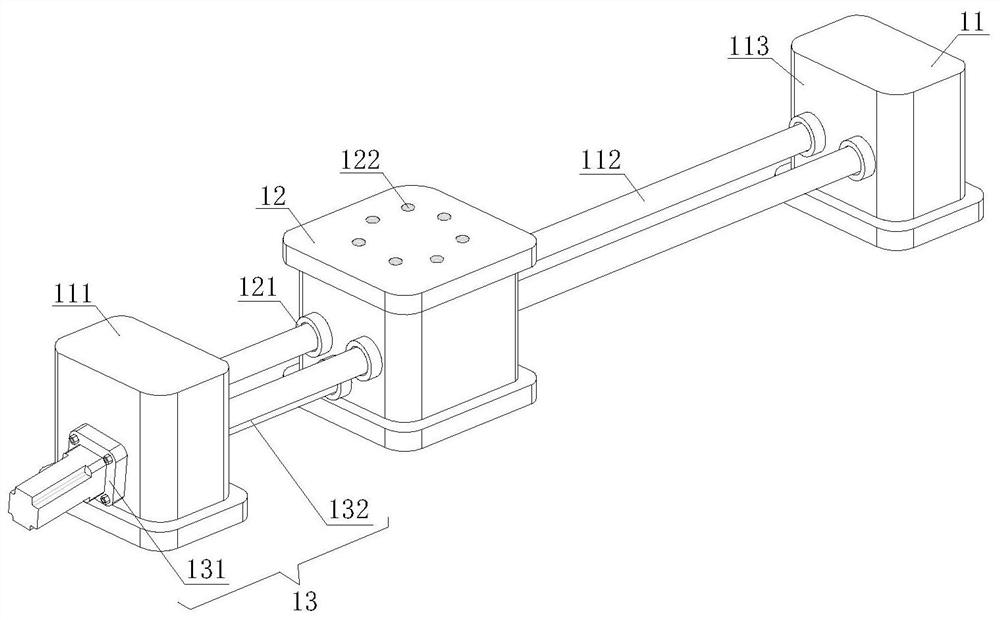

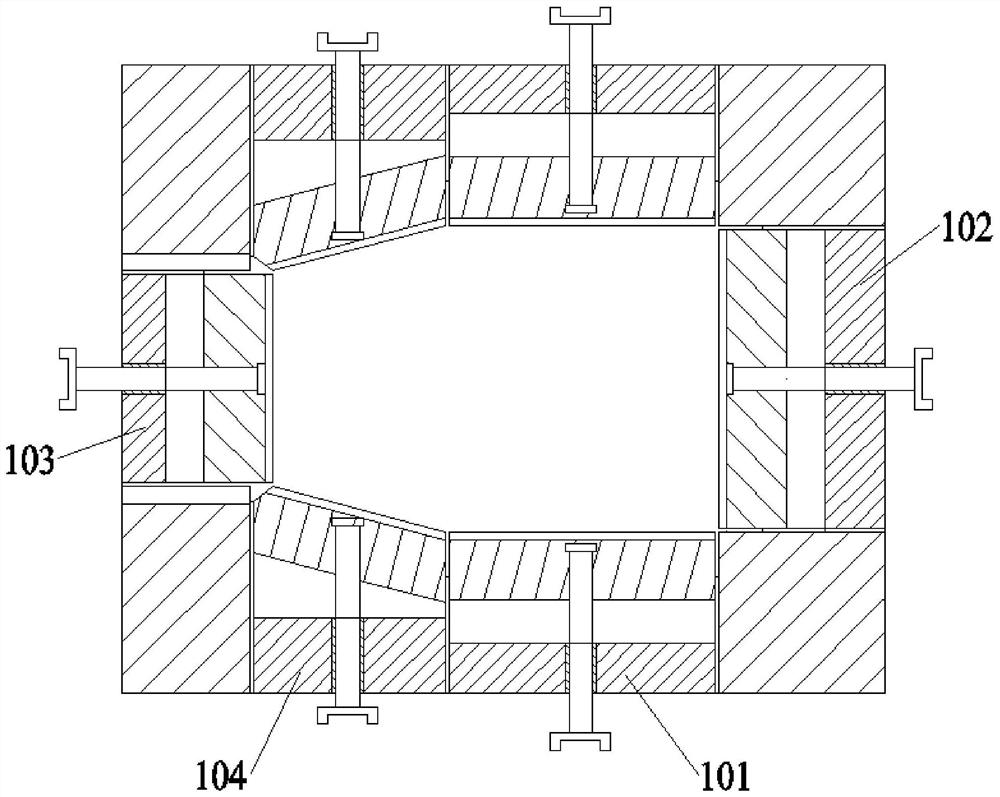

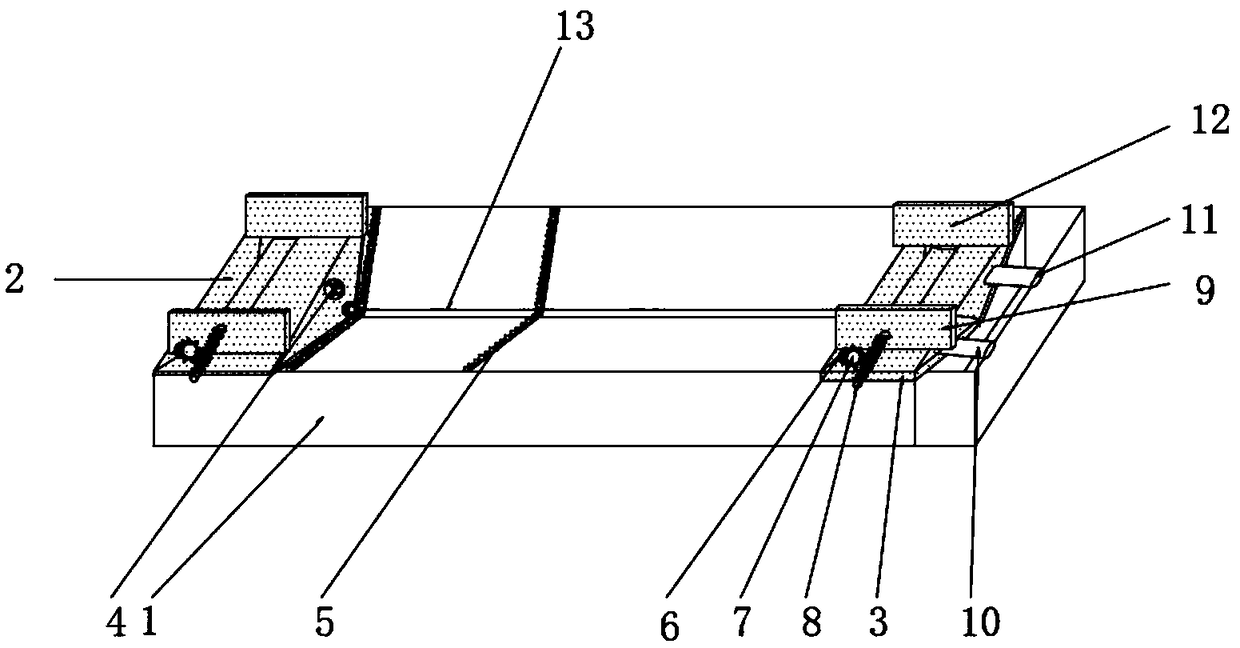

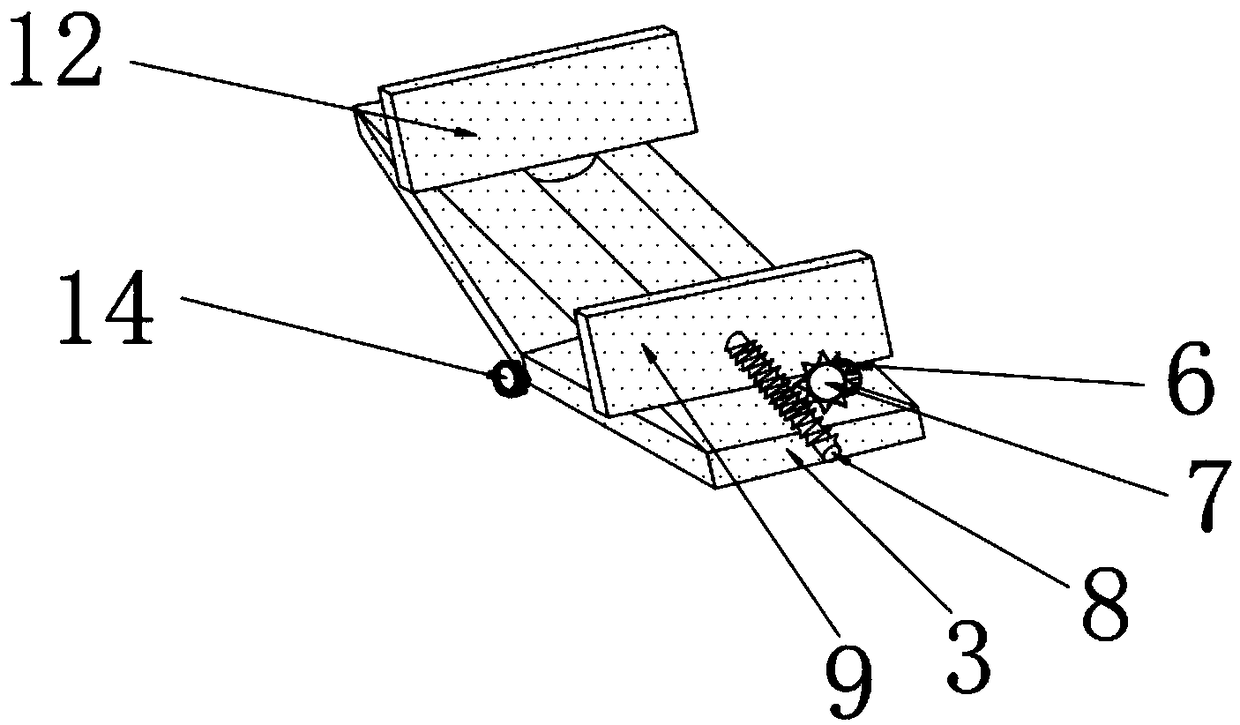

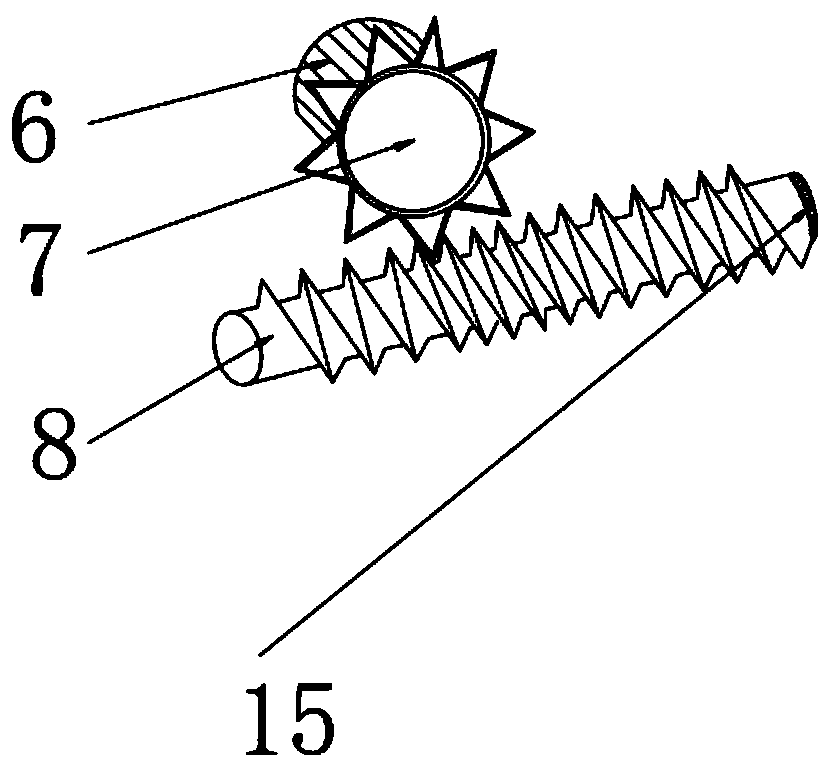

Method for assembling pedestal body of overhead cell support of hybrid vehicle and clamp thereof

ActiveCN101618493AReduce physical laborImprove assembly and welding efficiencyWelding/cutting auxillary devicesAssembly machinesInstabilityThermal deformation

The invention discloses a method for assembling a pedestal body of an overhead cell support of a hybrid vehicle and a used welding frock clamp thereof. The welding tool clamp comprises a clamp body (1), and the pedestal body of the overhead cell support of the hybrid vehicle comprises two pedestal crossbeams (11) and a plurality of middle supporting plates (12); the clamp is characterized in that a positioning element (2) is fixedly arranged at the upper end of the clamp body and horizontally limits the positions of the pedestal crossbeams (11), and a clamping device (3) is arranged at the outer sides of the pedestal crossbeams (11) and clamps the two pedestal crossbeams (11) and the middle supporting plates (12) arranged between the two pedestal crossbeams. The clamp greatly lightens the physical work of the operating staff, improves the assembling and welding efficiency, controls or eliminates the thermal deformation of workpieces caused by welding, and reduces the instability of manual welding.

Owner:苏州宝馨智能制造有限公司

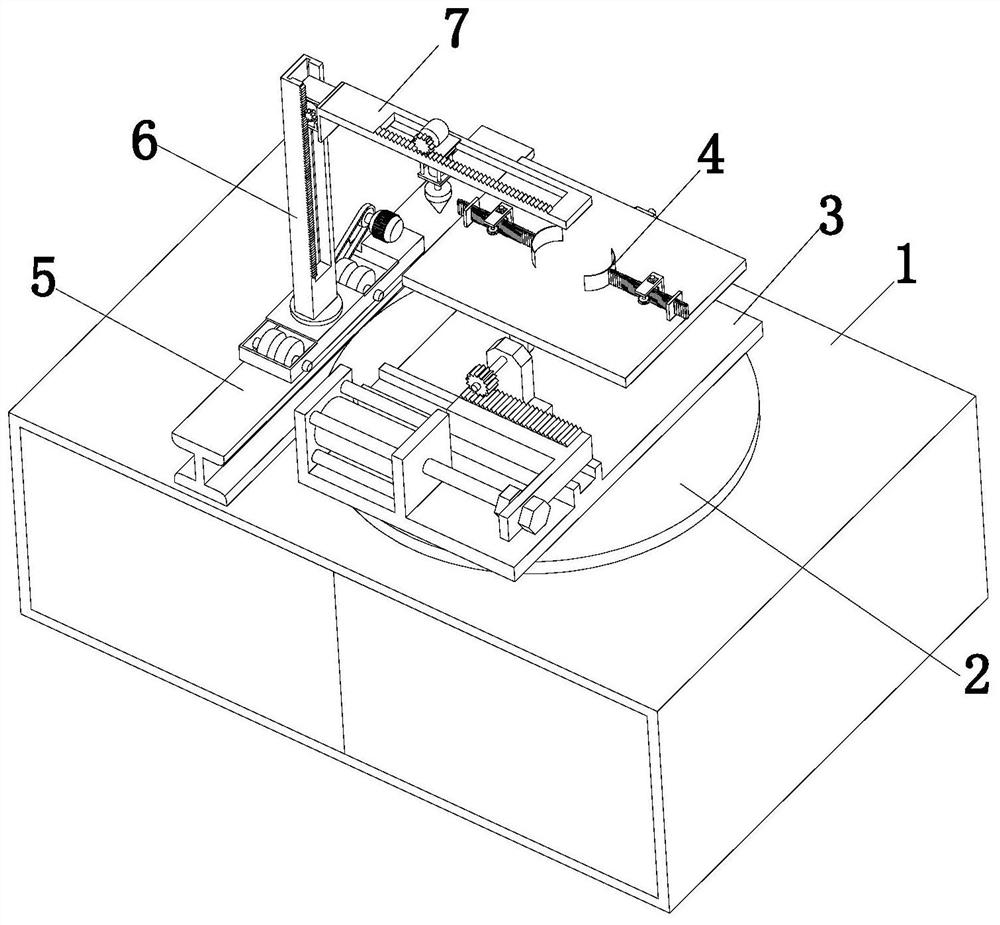

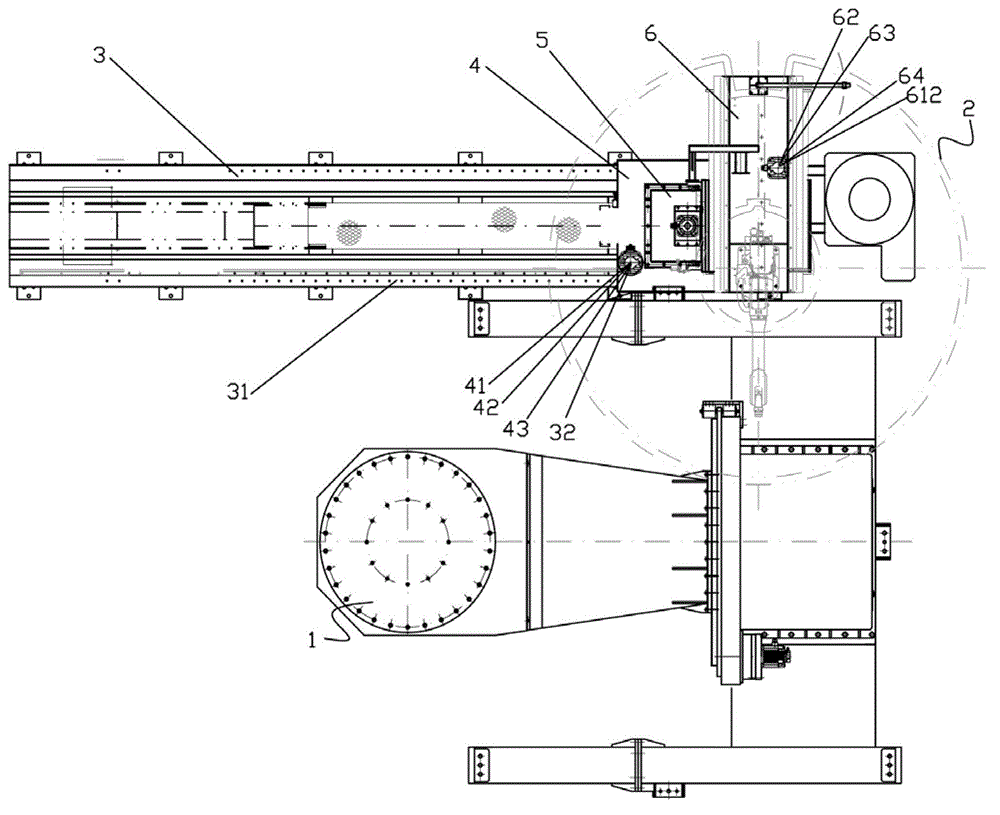

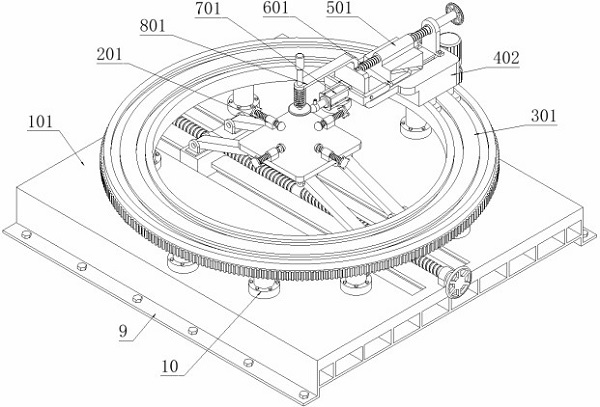

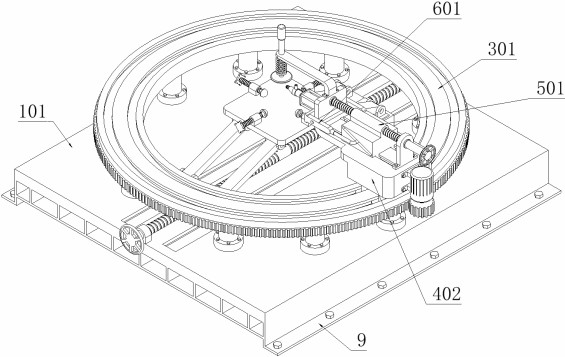

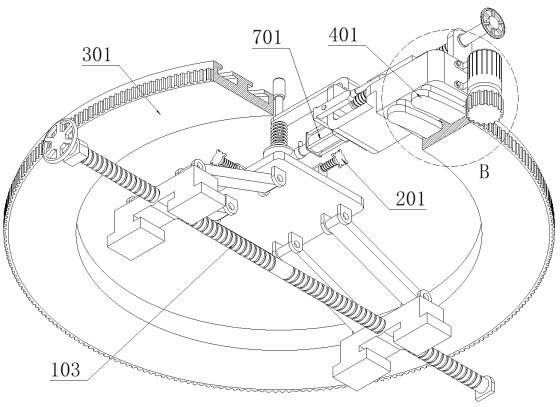

Turntable type flame welding machine

ActiveCN107378183AAvoid going off courseGuaranteed accuracyGas flame welding apparatusContinuous/uninterruptedInductor

The invention mainly discloses a turntable type flame welding machine. The technical scheme of the turntable type flame welding machine is characterized by comprising a workbench and a conveying rail, wherein a rotary table, a welding gun, a wire feeding gun and an induction device are arranged on the workbench; the rotary table is driven to rotate by a first driver, machining stations are distributed on the rotary table in the circumferential direction, and the machining stations are provided with machining clamps and induction switches; the machining clamps comprise rotating devices, locking devices and supporting plates, the rotating devices are driven by a second driver, and the supporting plates are used for fixing welding workpieces through fixing clamps; the welding gun and the wire feeding gun are connected with angle adjusting mechanisms respectively, and the wire feeding gun is further connected with a wire feeding device; and the induction device is connected with the first driver and the second driver, and the induction device comprises a first inductor and a second inductor. The turntable type flame welding machine is stable in work, accurate in positioning, capable of effectively improving the welding quality and ensuring the uniformity of welding joints, high in automation degree, capable of working continuously and reducing the labor intensity of workers, and capable of automatically welding large-batch products.

Owner:XINCHANG KECHUANG AUTOMATION EQUIP

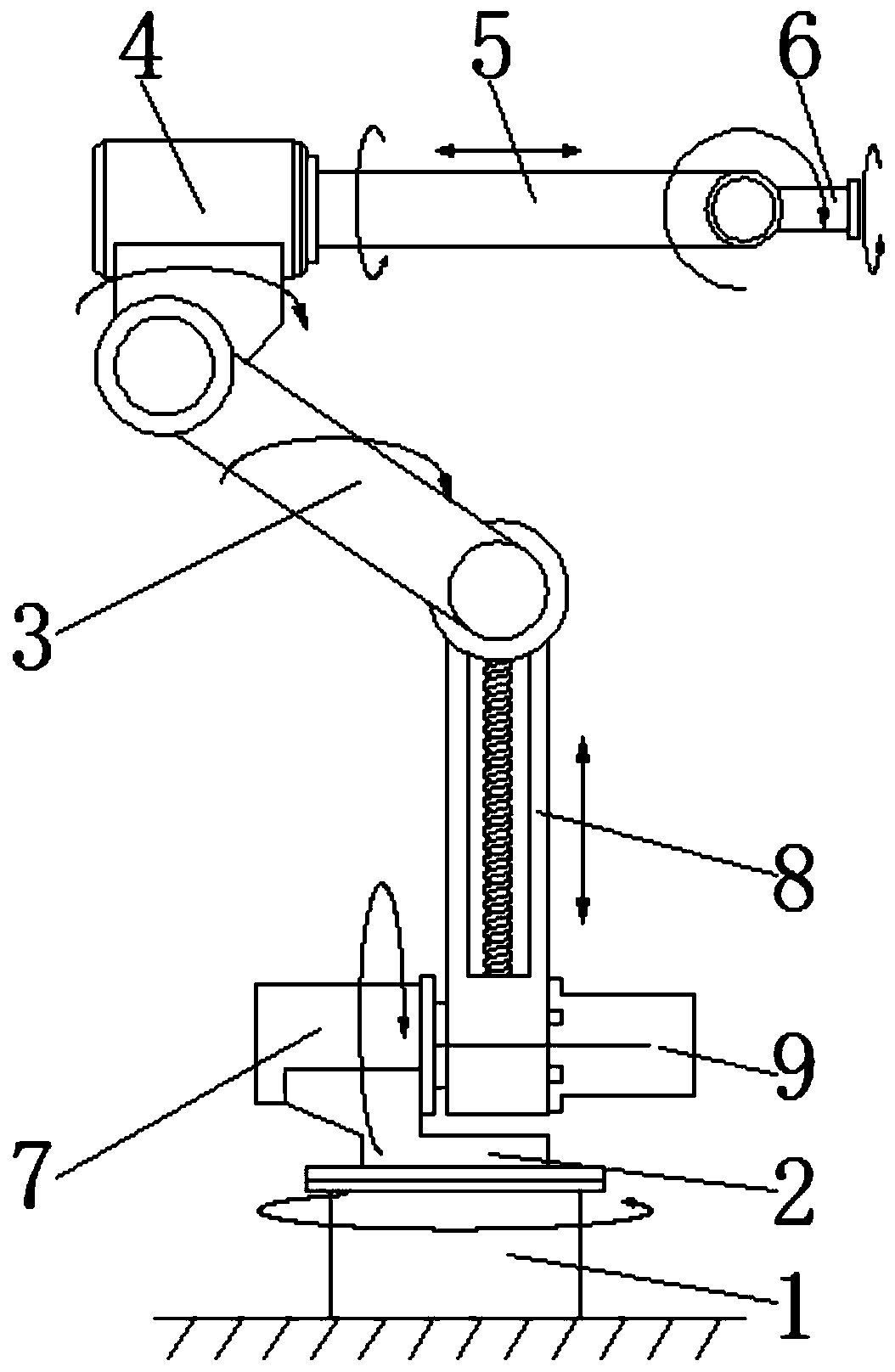

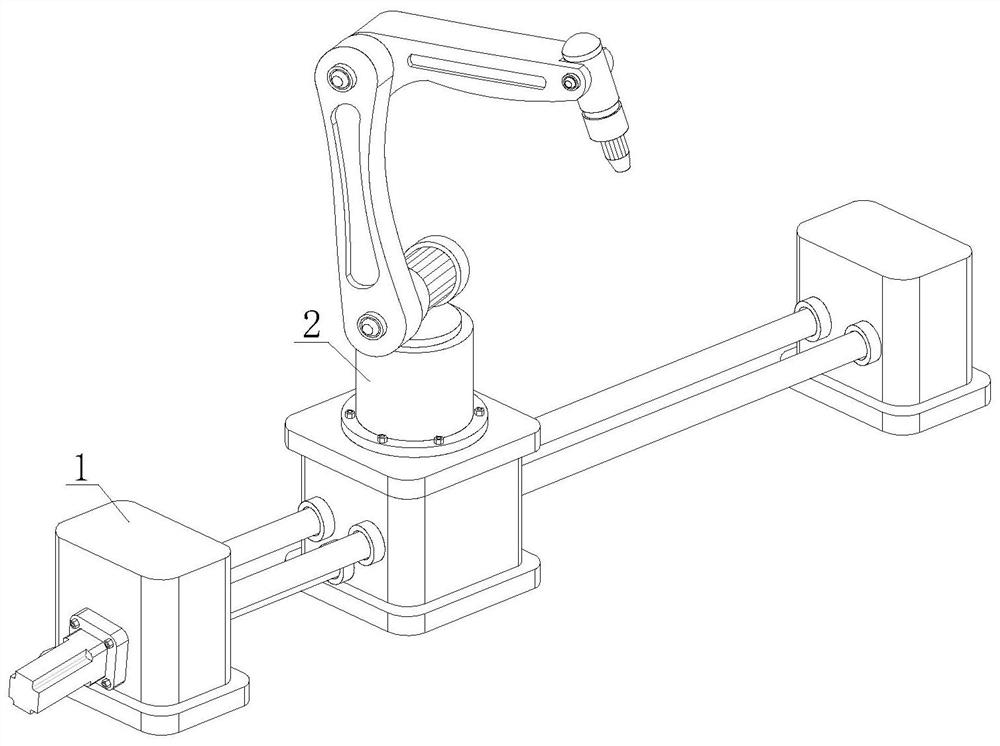

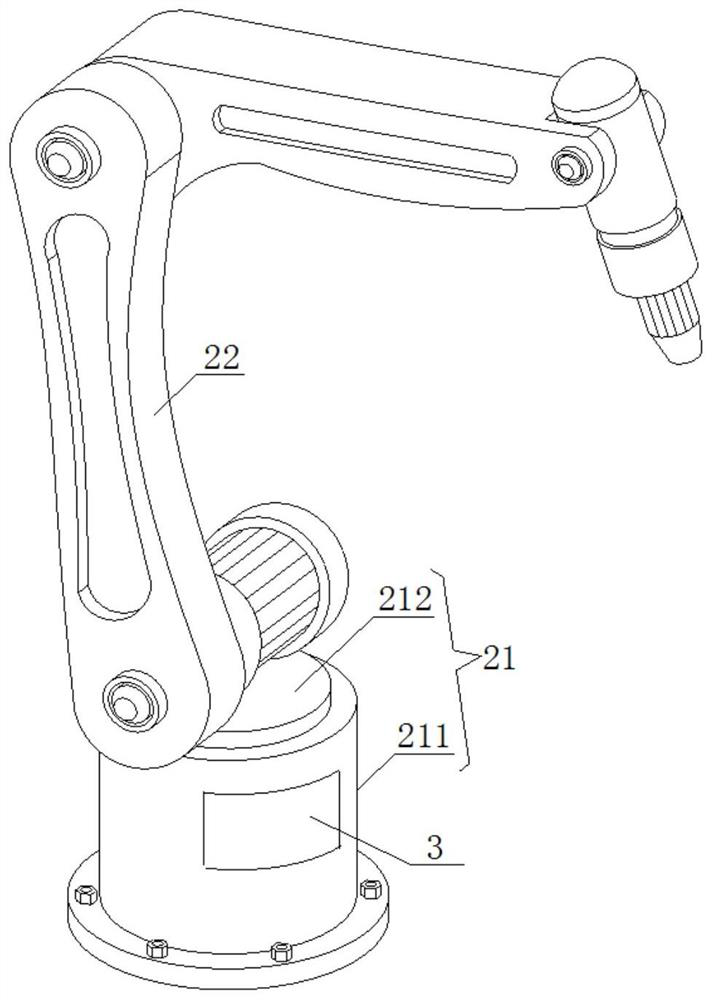

Robot mechanical arm

InactiveCN111151936AReduce usageRun fastProgramme-controlled manipulatorWelding/cutting auxillary devicesEngineeringIndustrial robotics

The invention relates to the technical field of industrial robots, and discloses a robot mechanical arm. The robot mechanical arm comprises a fixed base, a servo motor and a precise harmonic reducer.The mechanical arm can rotate in the YZ plane, a movable shoulder and a movable elbow are conveyed to the side edge of a large part, then the position and posture of a welding gun are adjusted throughthe movable shoulder, the movable elbow, a sliding rod and an executive part connecting rod so as to reach the position needing welding, the freedom degree of the welding robot is increased, the welding range is widened, and the limitation of the welding robot by the size of a welding part is reduced; meanwhile, due to the arrangement of the sliding rod, when the welding gun carries out linear welding on the welded part, direct control can be carried out through linear advancing, cooperative use of two or more mechanical arms is reduced, the complex degree of the moving track of the mechanical arms is reduced, and the calculated amount and workload of workers are reduced; and the complexity of program control is reduced, the operation speed of the mechanical arm is increased, and the welding efficiency and quality are improved.

Owner:盐城市沿海新能源汽车科技有限公司

Intelligent welding industrial robot

InactiveCN107617836AEmission reductionEnsure physical safetyAnalysing solids using sonic/ultrasonic/infrasonic wavesWelding/cutting auxillary devicesManipulatorUltimate tensile strength

The invention discloses an intelligent welding industrial robot comprising a base. A rotating seat is vertically installed on the base; a first telescopic rod is arranged at the upper end of the rotating seat and parallel to the base; a connecting shaft is installed on the first telescopic rod; a dust removing device is fixedly installed on the side face of the connecting shaft; a welding gun is installed at the lower end of the connecting shaft and connected with a welding machine arranged on the base; a main disc decelerating motor is further arranged on the base and located below the welding gun, and a main disc is connected to the upper portion of the main disc decelerating motor through an output shaft; and a manipulator assembly is further arranged on the base. The robot is safe, reliable and convenient to use, emission of poisonous gas is reduced, the welding angle can be adjusted, the labor intensity is reduced, the working efficiency is improved, and the ambient environment isprotected.

Owner:CHONGQING TECH & BUSINESS INST

Multi-angle welding device for motor machining

InactiveCN112692395AConvenient welding workExpand the welding rangeWelding/soldering/cutting articlesMetal working apparatusElectric machineryEngineering

The invention discloses a multi-angle welding device for motor machining, and relates to the technical field of welding. The multi-angle welding device for motor machining comprises a work box, a rotating mechanism, a turnover mechanism, fixing mechanisms, a moving mechanism, a lifting mechanism and a welding mechanism, wherein the rotating mechanism is arranged on the work box; the output end of the rotating mechanism is arranged on the inner side of the work box; the turnover mechanism is fixedly arranged on the rotating mechanism; the two groups of fixing mechanisms are fixedly and symmetrically arranged on the turnover mechanism; the moving mechanism is fixedly arranged on the work box and is arranged on one side of the turnover mechanism; the lifting mechanism is arranged on the moving mechanism; and the moving mechanism is arranged on the lifting mechanism. According to the multi-angle welding device for motor machining provided by the invention, the different mechanisms are arranged, and a motor is moved, so that the welding work of the welding device is facilitated, and multi-angle welding is completed.

Owner:南京法贝登数码科技有限公司

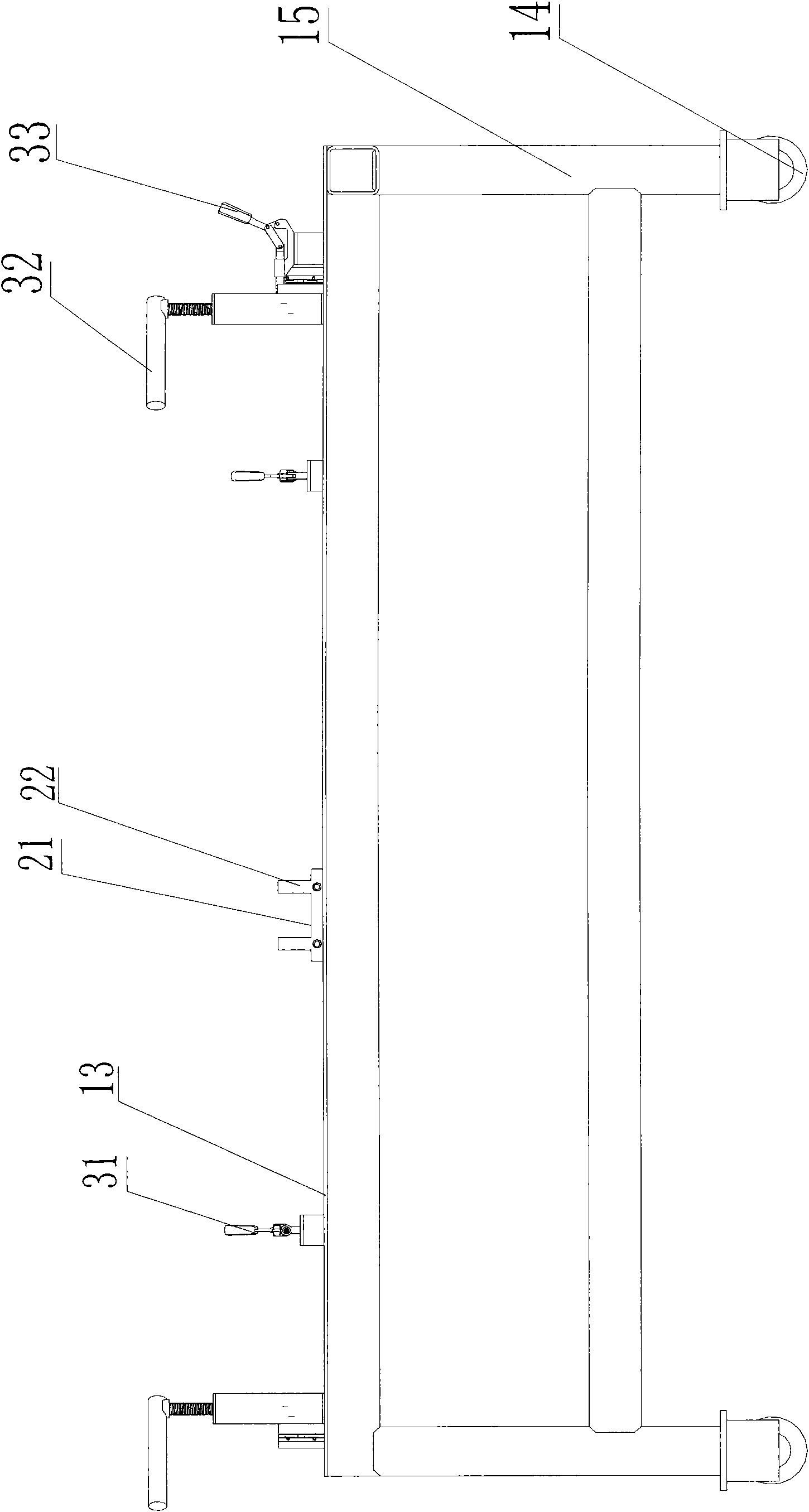

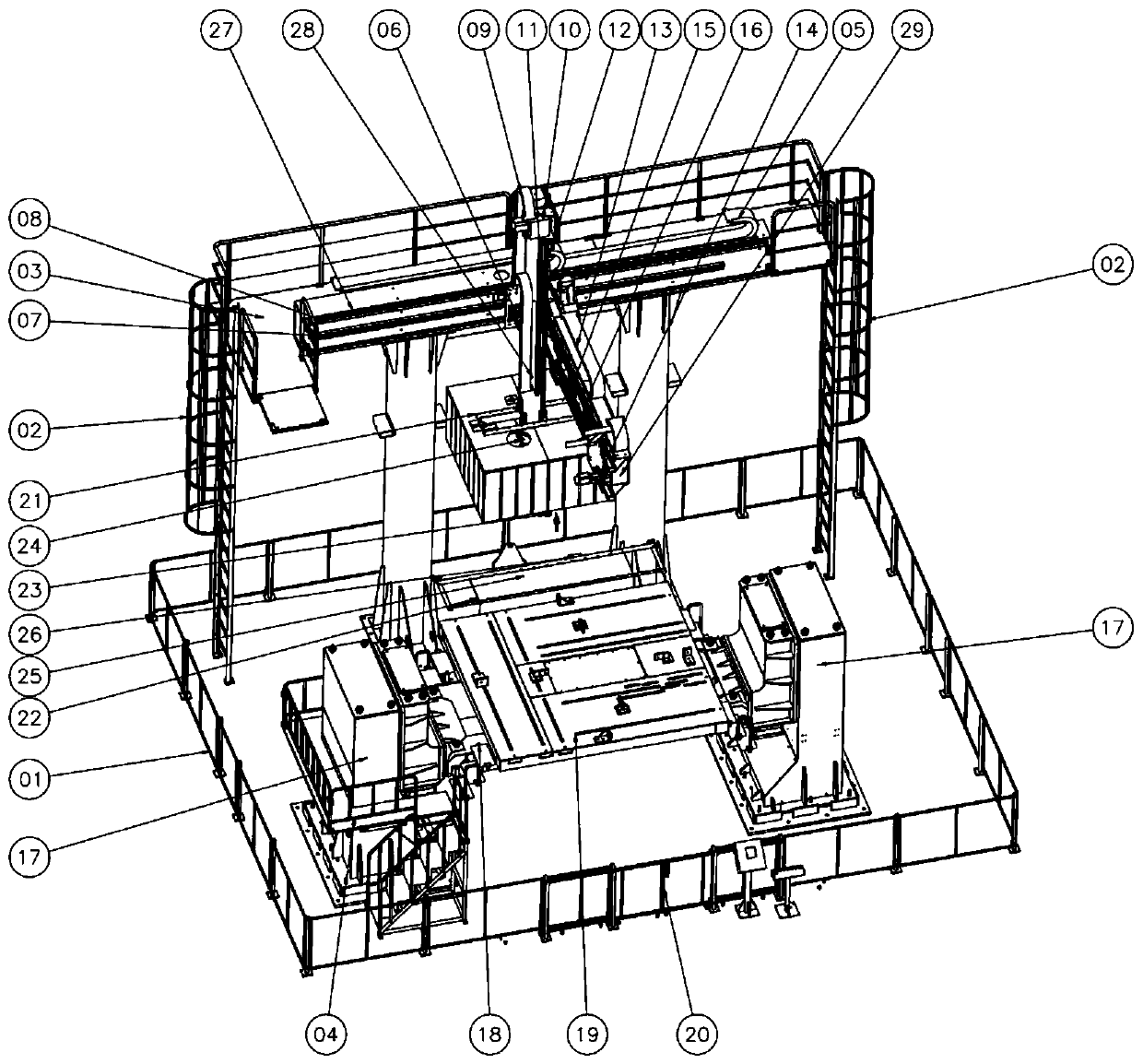

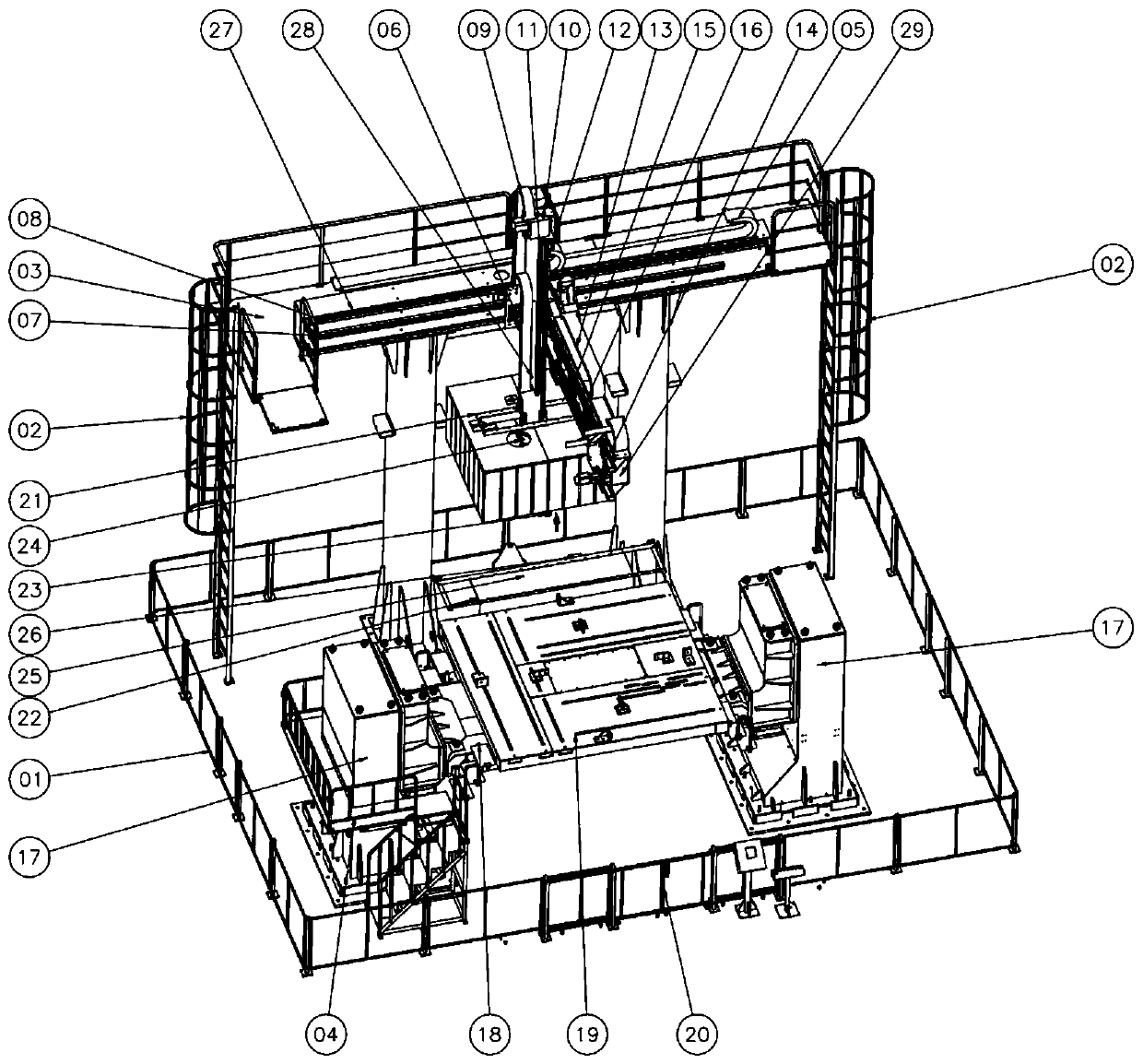

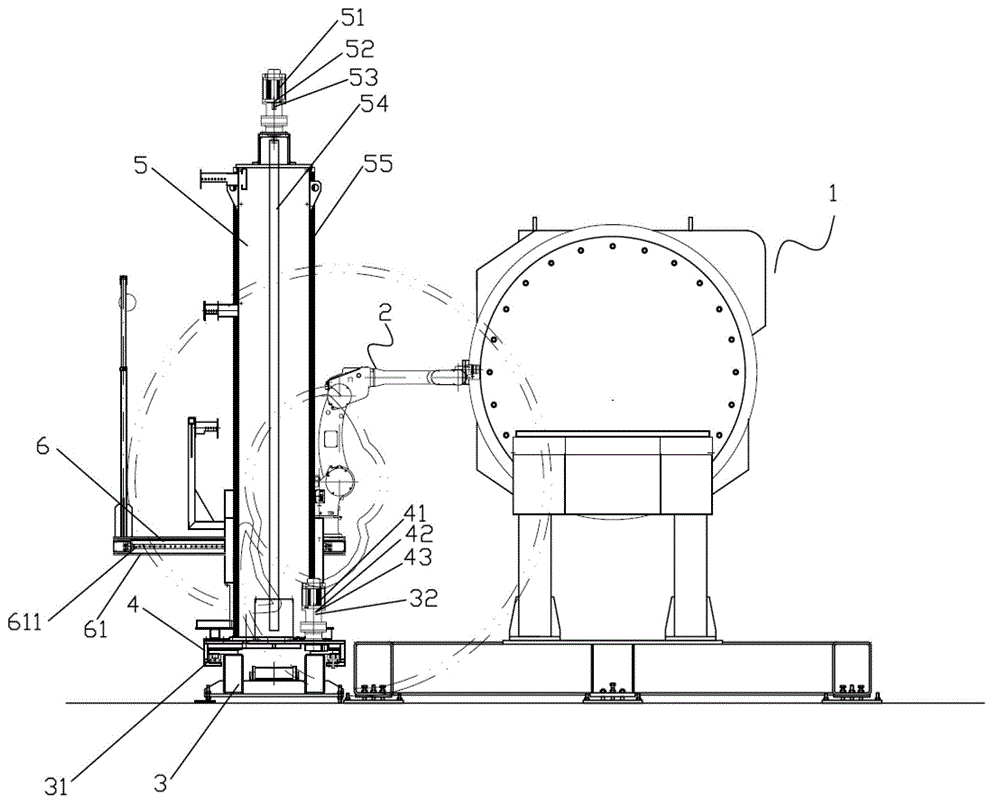

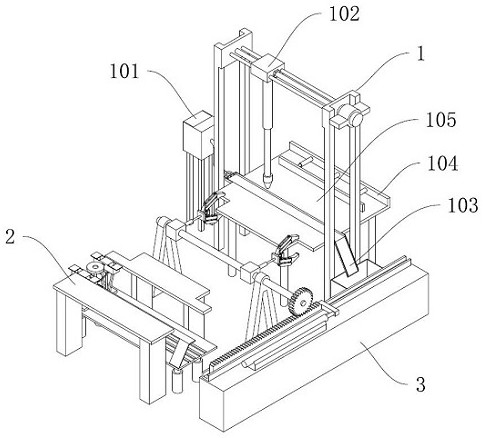

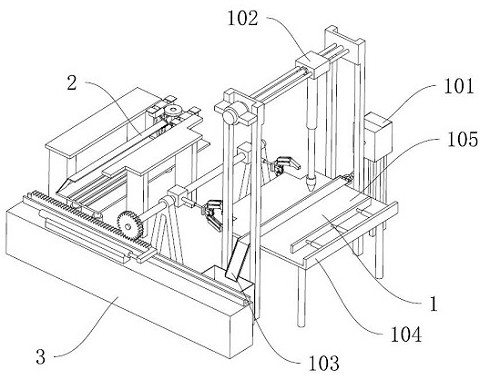

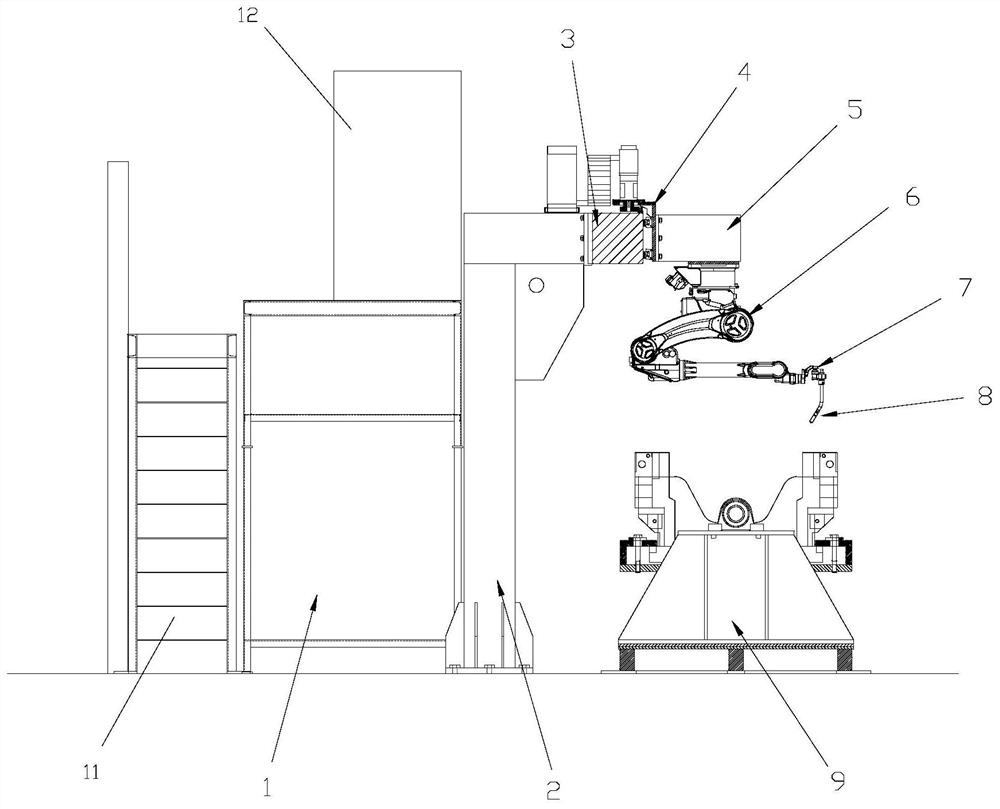

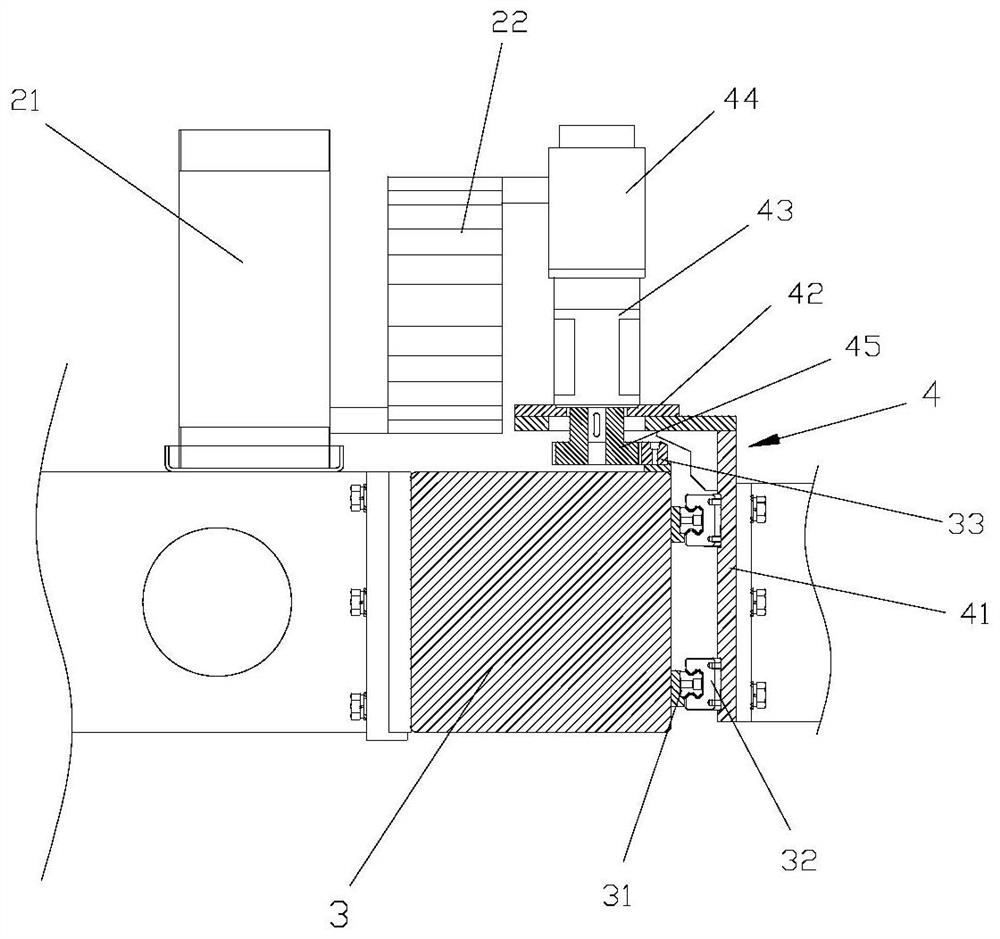

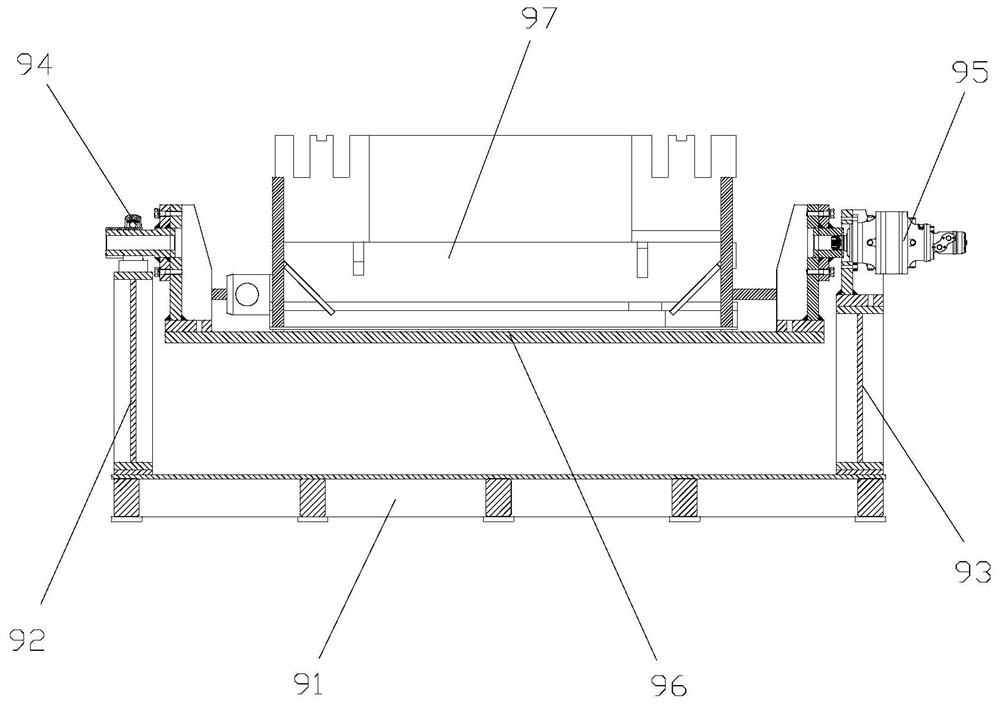

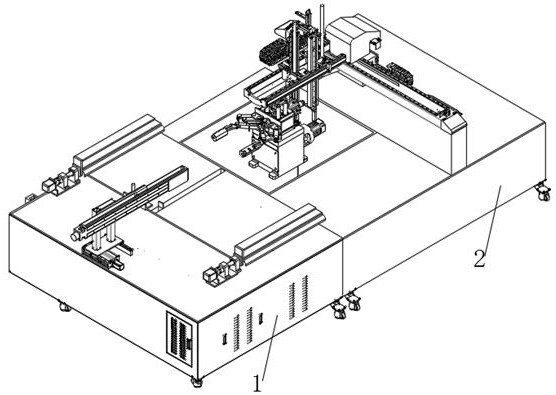

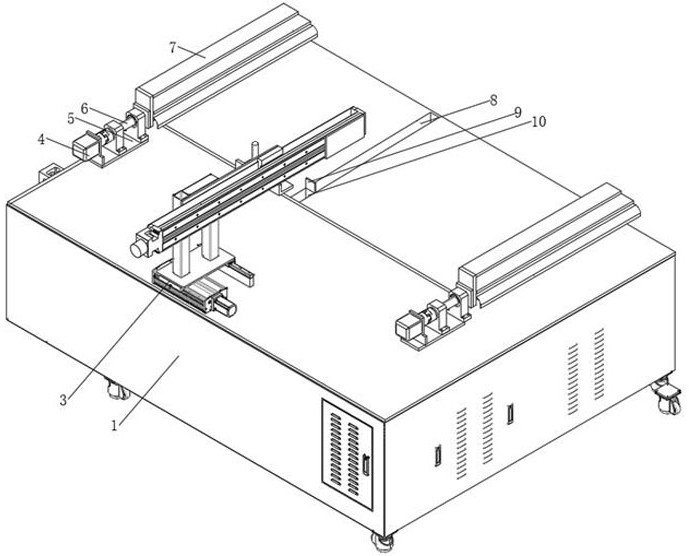

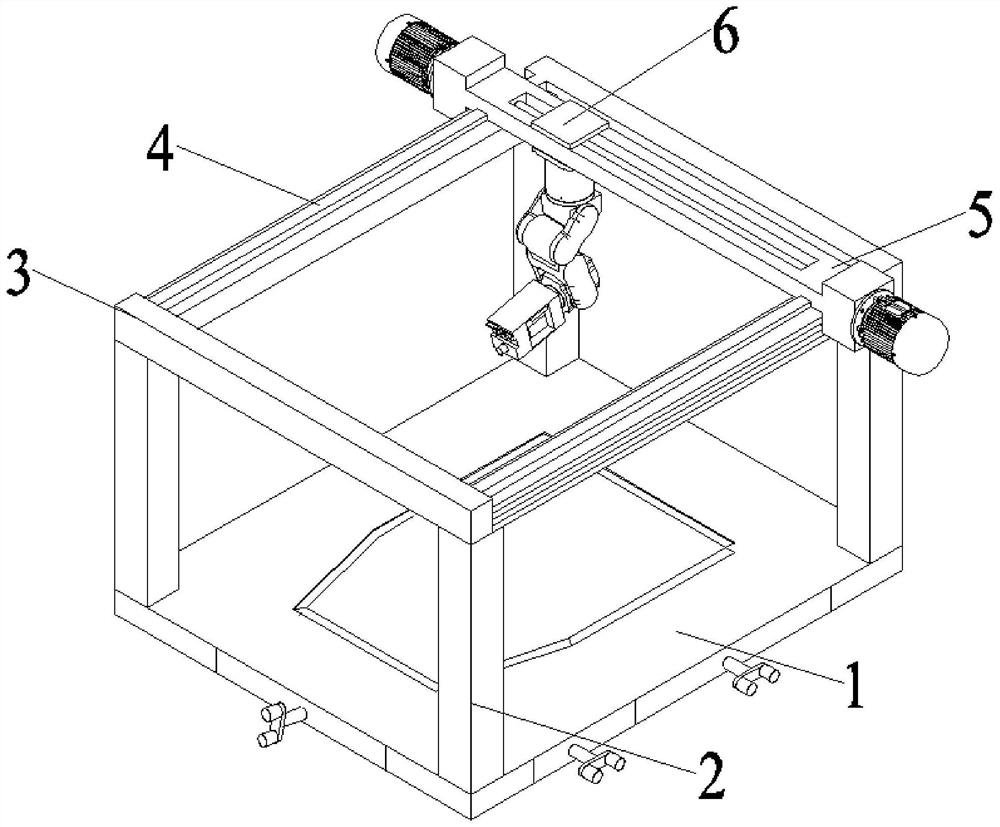

Large-sized robot welding workstation with flue dust treatment function

PendingCN109702291AExpand the welding rangeIncrease freedomWelding/cutting auxillary devicesAuxillary welding devicesControl systemDegrees of freedom

The invention discloses a large-sized robot welding workstation with a flue dust treatment function. The large-sized robot welding workstation comprises a safe enclosure of a welding workshop, a welding location control system, a workpiece turnover platform, a flue dust treatment robot welding system and a workstation controller, wherein the workpiece turnover platform and the flue dust treatmentrobot welding system are arranged in the safe enclosure of the welding workshop; the welding location control system is arranged above the flue dust treatment robot welding system; and the welding location control system, the workpiece turnover platform, the flue dust treatment robot welding system and the workstation controller are electrically connected. With the welding location control systemand the workpiece turnover platform, the welding range and the degree of freedom are extended, and the problem of small welding operation range of the welding robot is effectively solved; a high-pressure contact sensor is adopted for the welding robot, so that the actual weld joint position is determined automatically according to deformation in the welding process, and the optimal welding effectis achieved; and a flue dust treatment device improves the environment friendliness performance.

Owner:GUANGZHOU RUISONG INTELLIGENT TECH CO LTD

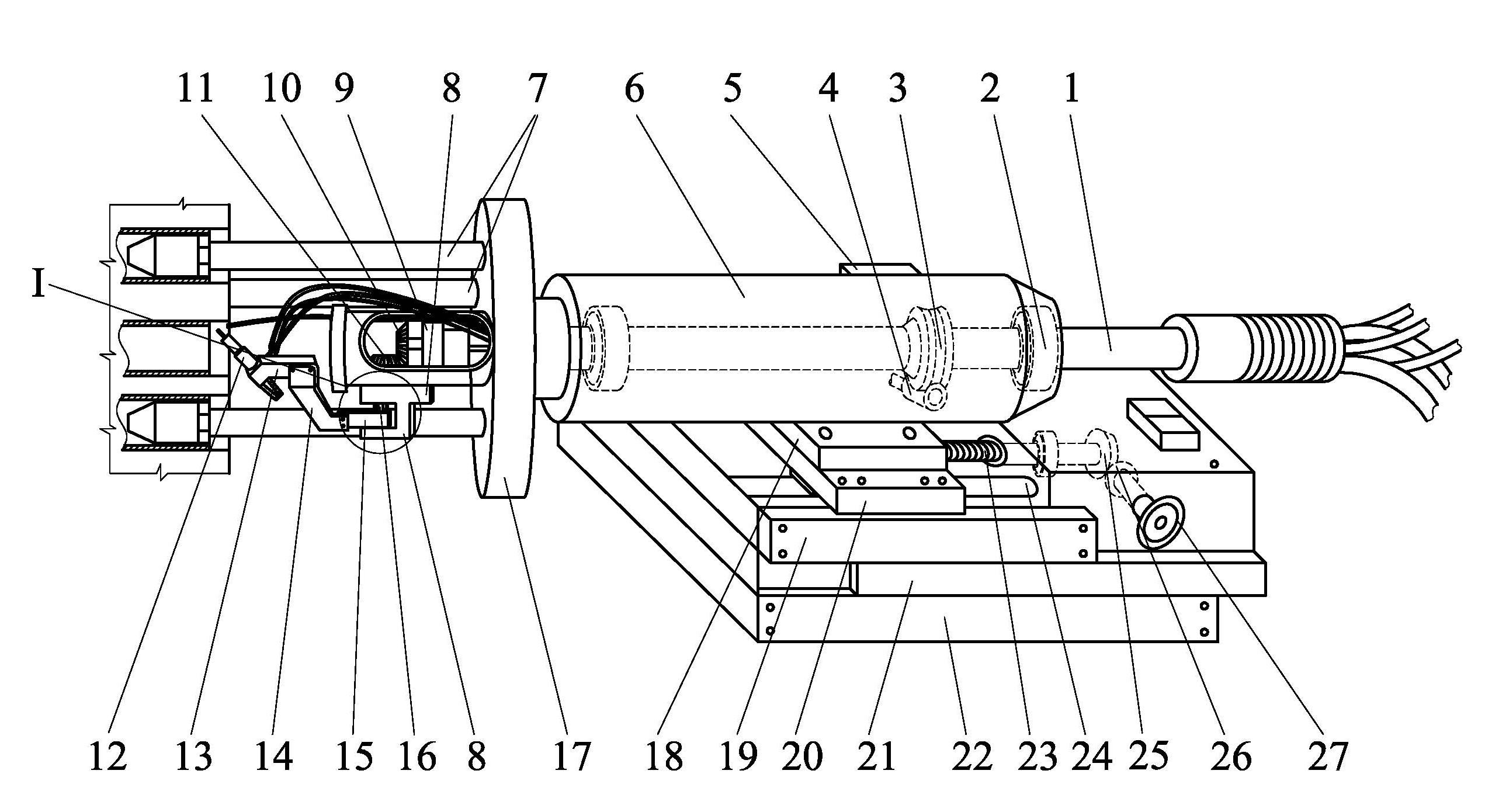

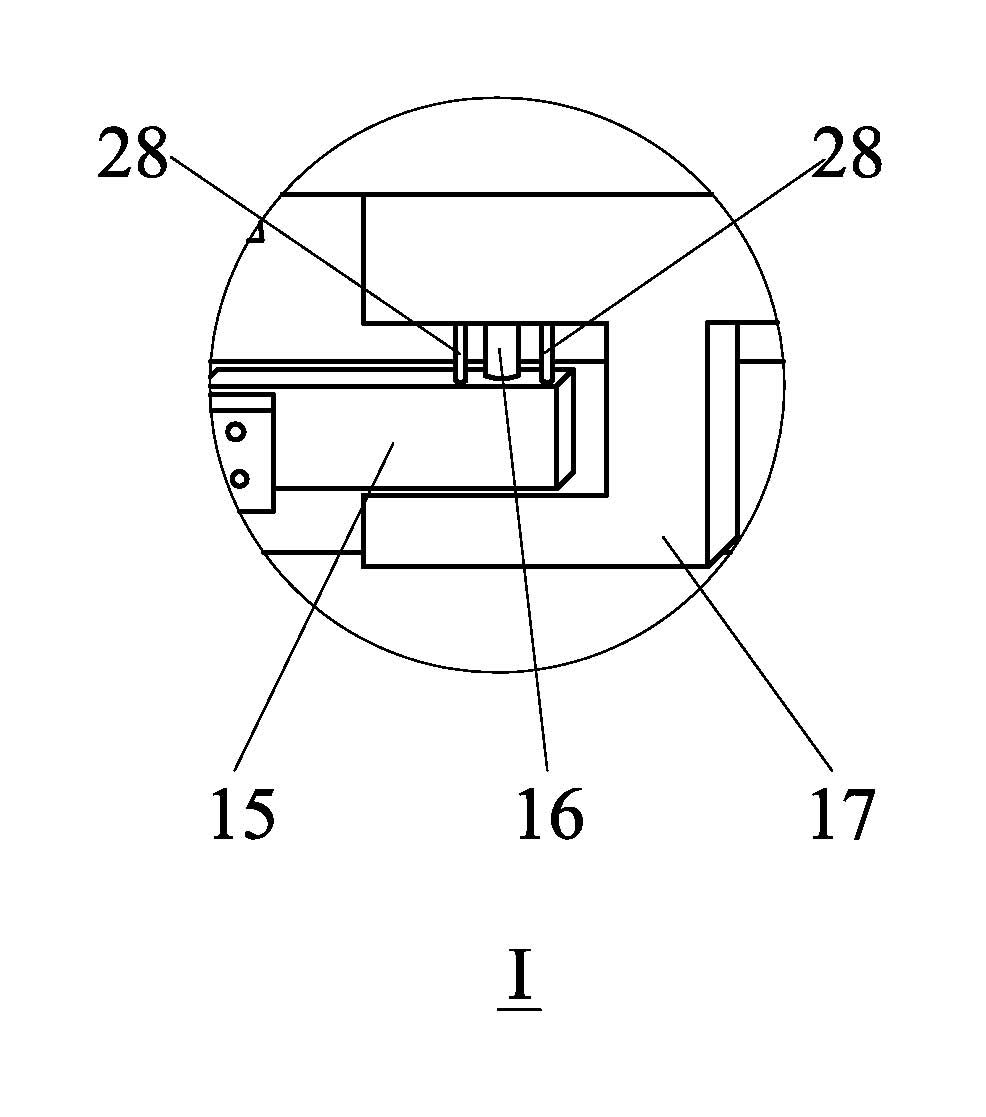

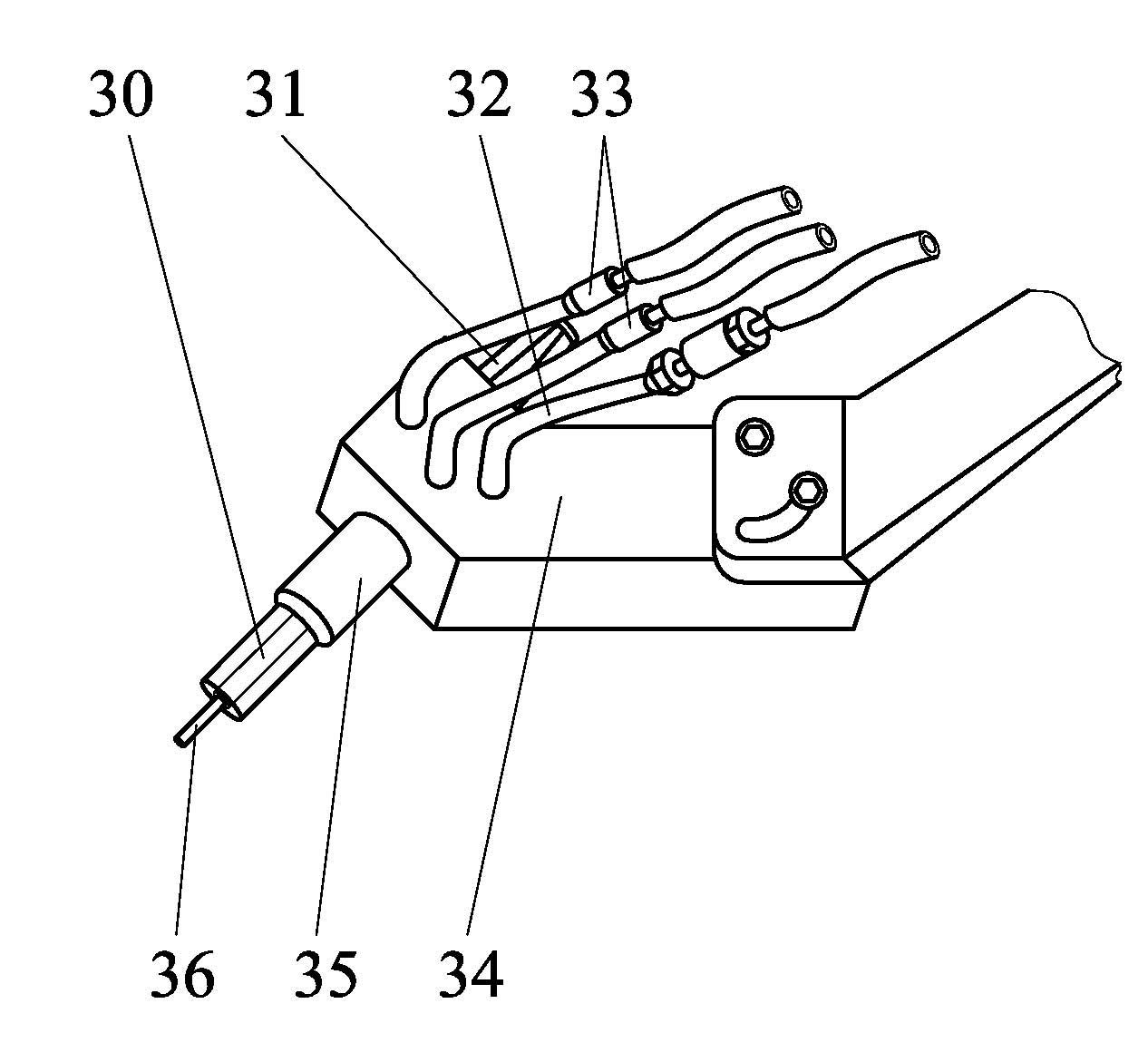

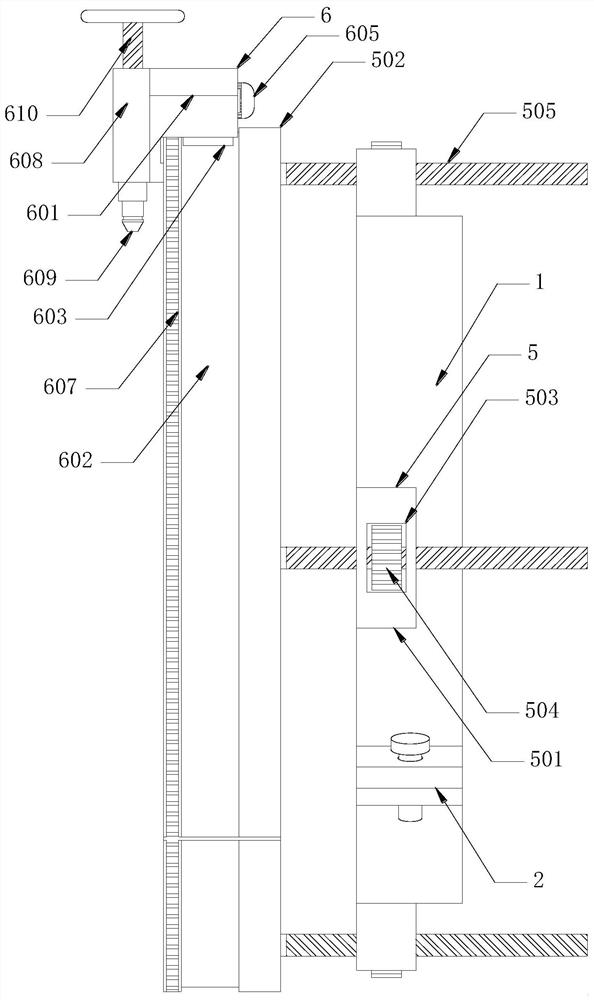

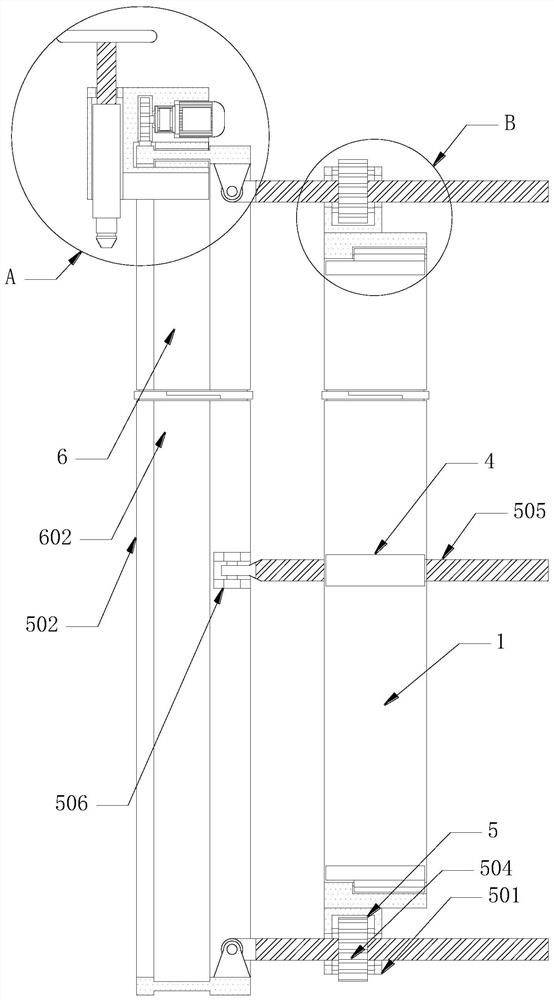

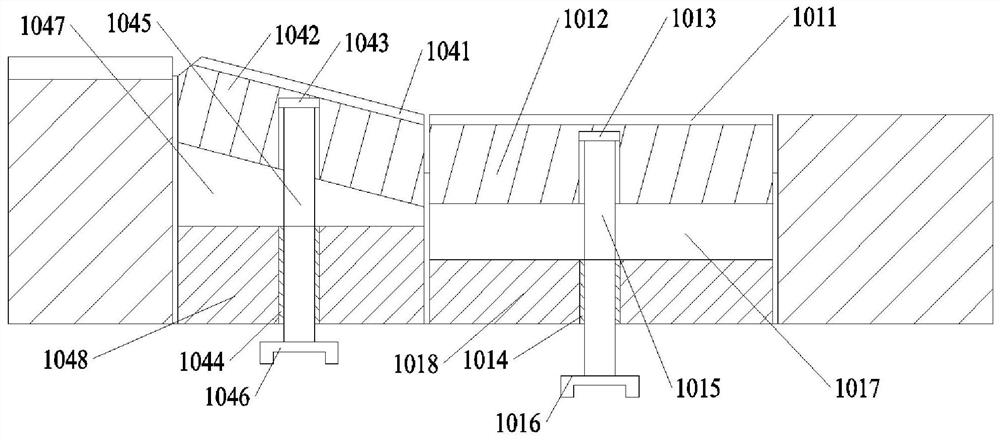

Recessed type tube head automatic welding machine

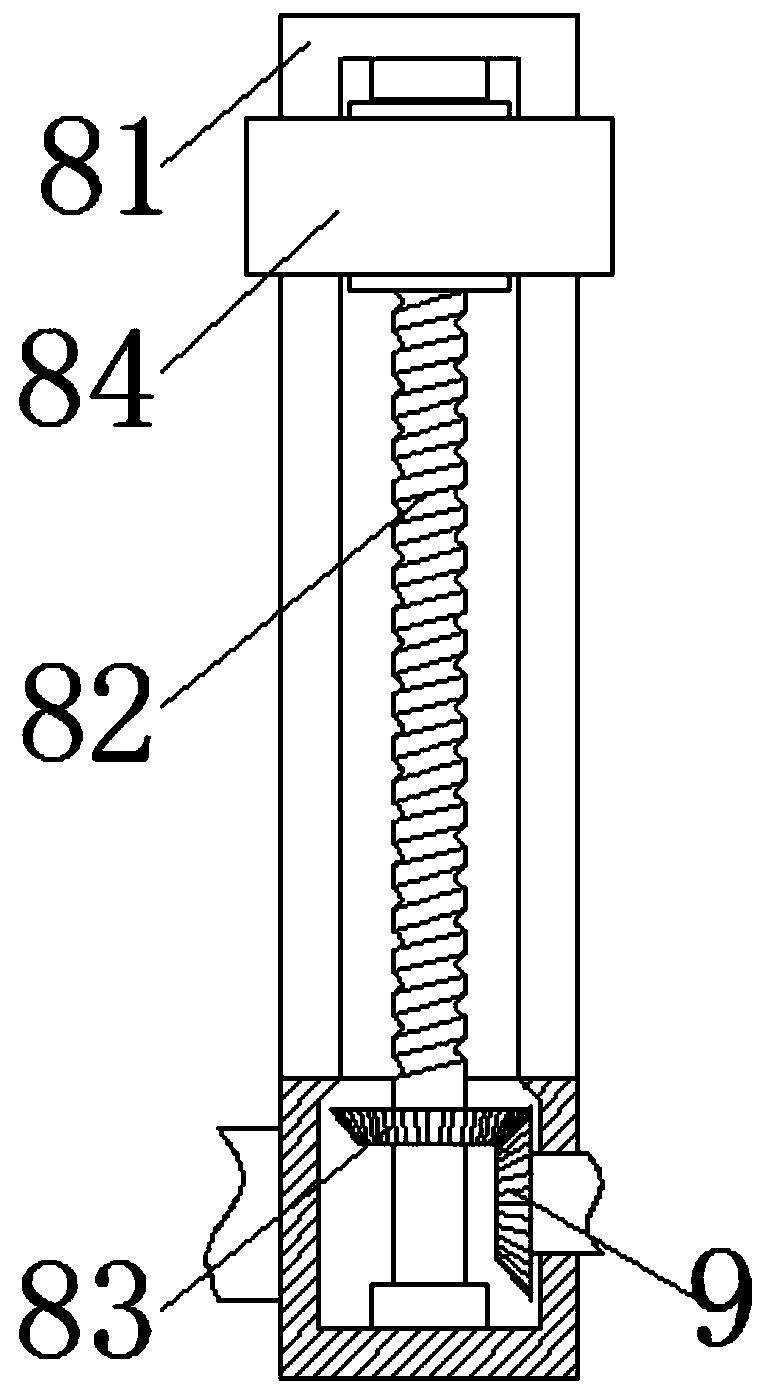

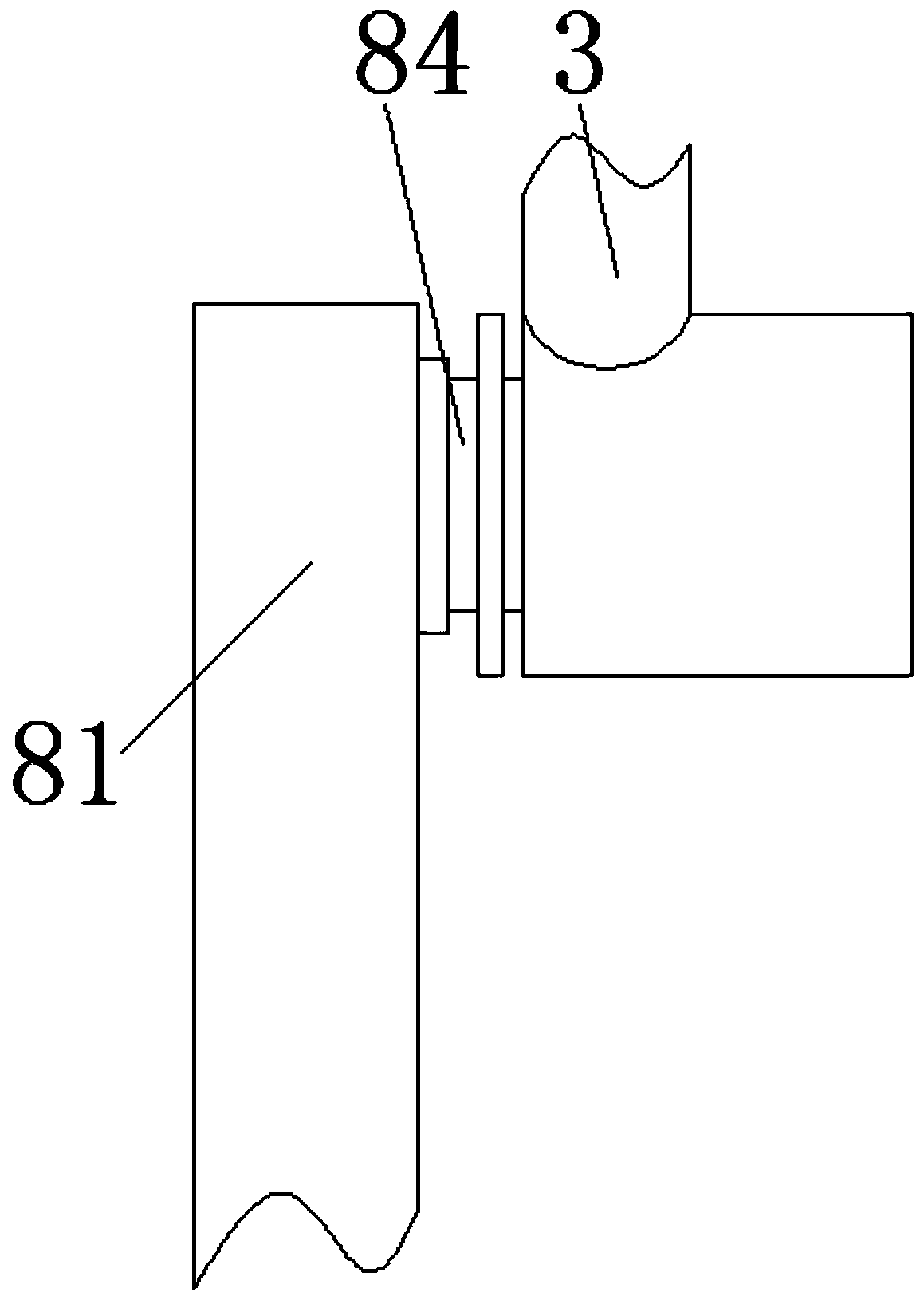

ActiveCN102019487AImprove stabilityHigh positioning accuracyWelding accessoriesShell and tube heat exchangerDrive motor

The invention relates to a recessed type tube head automatic welding machine, comprising a rotating spindle, a machine body, a welding gun and a welding gun connecting plate, wherein the rotating spindle is penetrated in the machine body; the welding gun connecting plate is connected with the front side of the machine body along the axial direction; the welding gun is arranged on the welding gun connecting plate; a rotating spindle driving device is arranged, and the rotating spindle driving device comprises a driving motor and a worm gearing connected with the driving motor in a driving way;an axial adjusting mechanism is arranged, and the axial adjusting mechanism is connected with the machine body; a radial adjusting mechanism is arranged, the radial adjusting mechanism is connected with the welding gun connecting plate and the welding gun; and the welding gun connecting plate is provided with at least three positioning legs. Because the axial adjusting mechanism and the radial adjusting mechanism are combined, recessed tube head welding of a shell-and-tube heat exchanger is realized, thus not only expanding the welding range of the tube hole depth, but also avoiding the influence of form and position deviation of the tube hole on the welding quality, and the automatic welding machine has the characteristics of large welding range, good welding quality, high welding accuracy and simple operation.

Owner:THE CHALLENGE PETROCHEM MACHINERY CORP

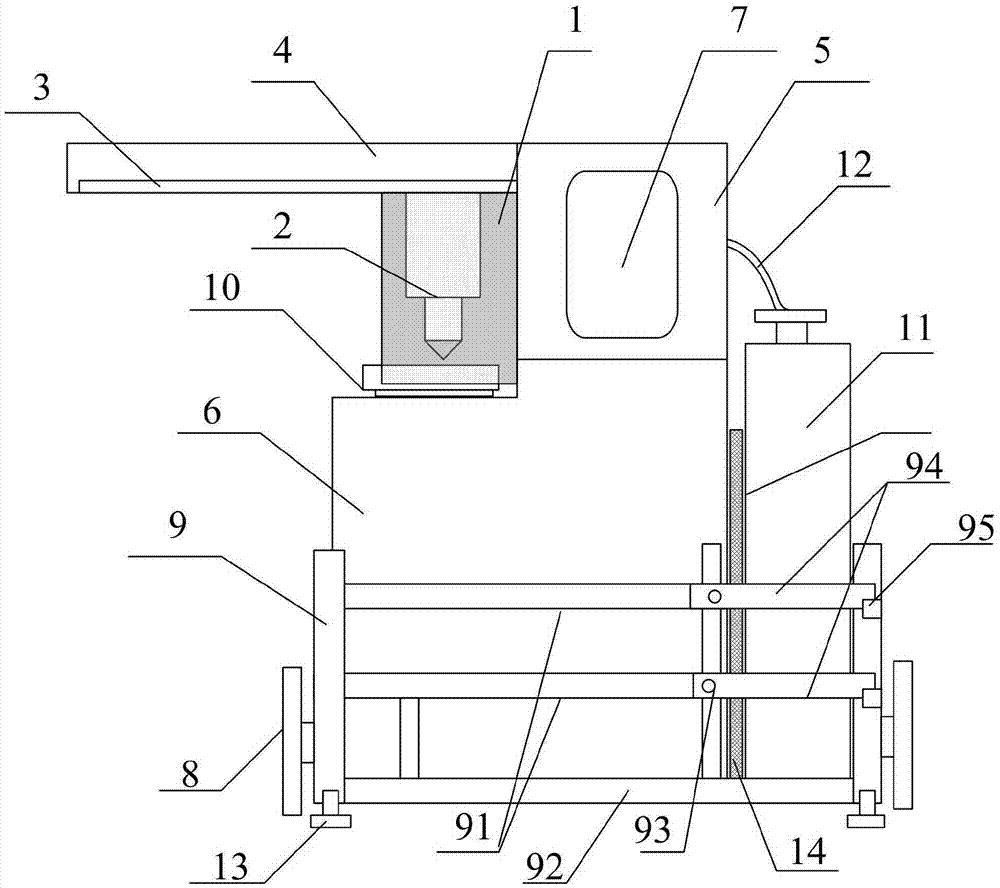

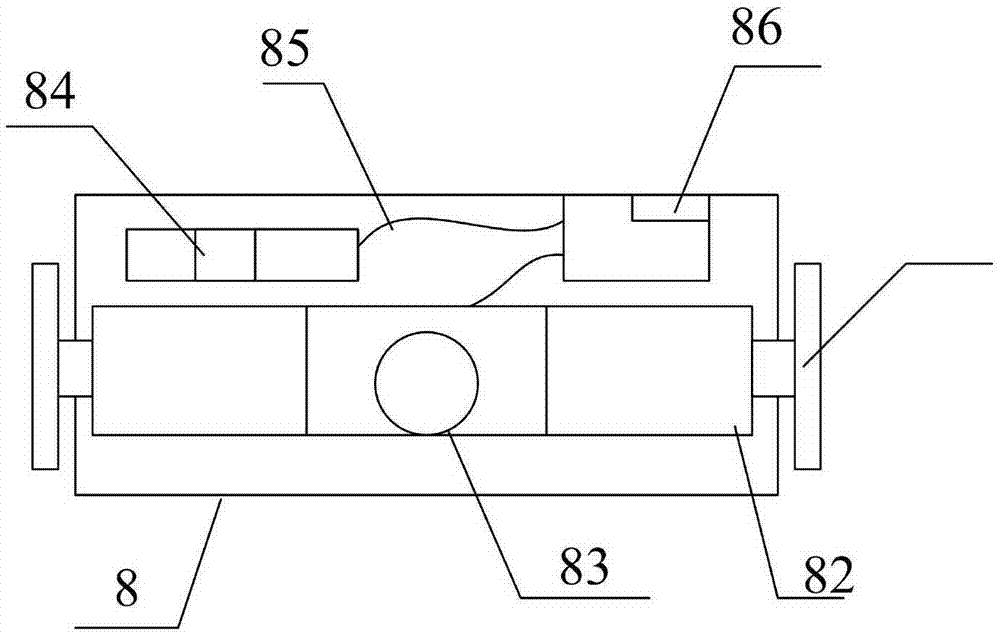

Double-layer telescopic welding robot system

ActiveCN103143863AExpand the welding rangeEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesAutomatic controlUltimate tensile strength

The invention relates to a double-layer telescopic welding robot system. The double-layer telescopic welding robot system comprises a positioner for overturning and / or rotating a workpiece to be processed, a trolley body, a travelling mechanism, a lifting mechanism, a double-layer telescopic mechanism, a welding robot and an automatic control circuit for controlling the welding robot system to weld, wherein the travelling mechanism is assembled on the trolley body and moves on the trolley body according to welding position requirements; the lifting mechanism is assembled at the upper end of the travelling mechanism; one end of the double-layer telescopic mechanism is mounted on the lifting mechanism; the welding robot is mounted at the other end of the double-layer telescopic mechanism; the positioner is arranged within an operating range of the welding robot in a matching manner; and the trolley body is arranged and fixed on a foundation. The welding robot system has the advantages that the welding robot system is simple and convenient to operate, time-saving, labor-saving, and high in working efficiency and safety, acts smoothly and reliably, reduces labor intensity, improves welding quality and saves production cost.

Owner:TAICANG ASAHI LINE AUTOMATIC SYST

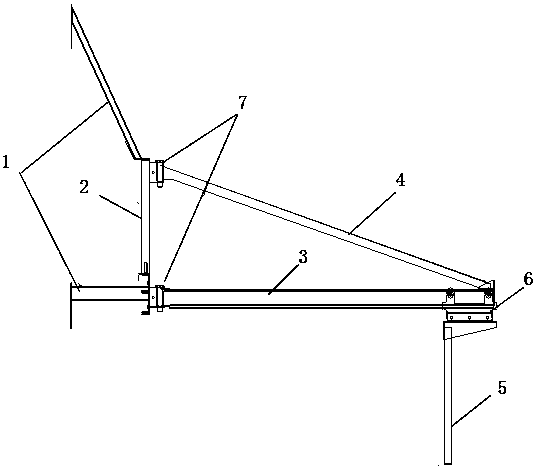

Welding machine suspension bracket

InactiveCN103418953AExpand the welding rangeAvoid inefficienciesWelding/cutting auxillary devicesAuxillary welding devicesContactorFixed frame

The invention provides a welding machine suspension bracket. The welding machine suspension bracket comprises a fixing frame connected to a base, an upper bridge frame, a sliding bridge frame and a welding machine suspension device. The welding machine suspension bracket is characterized in that the sliding bridge frame and the upper bridge frame are connected with the fixing frame through steering shafts component to form a triangular rotary pair, wherein the triangular rotary pair takes the fixing frame as an axis to rotate; the welding machine suspension bracket is arranged at the front end of the sliding bridge frame through a sliding block, and the welding machine suspension device can slide on the sliding bridge frame. Due to the fact that the steering shaft components and the sliding bridge frame are arranged, a welding machine can move on the suspension bracket, the welding range of the welding machine is effectively increased, and the problems that efficiency is low, lines are messed, contactors are loosened caused by frequent moving of the welding machine equipment during the practical operation process is solved.

Owner:WUXI ZHONGNENG JINGKE NEW ENERGY TECH

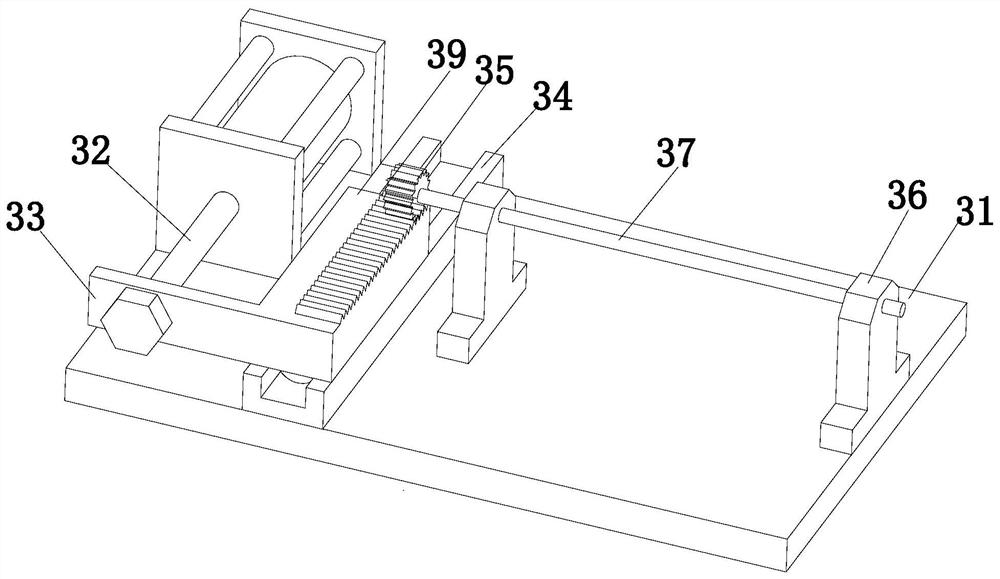

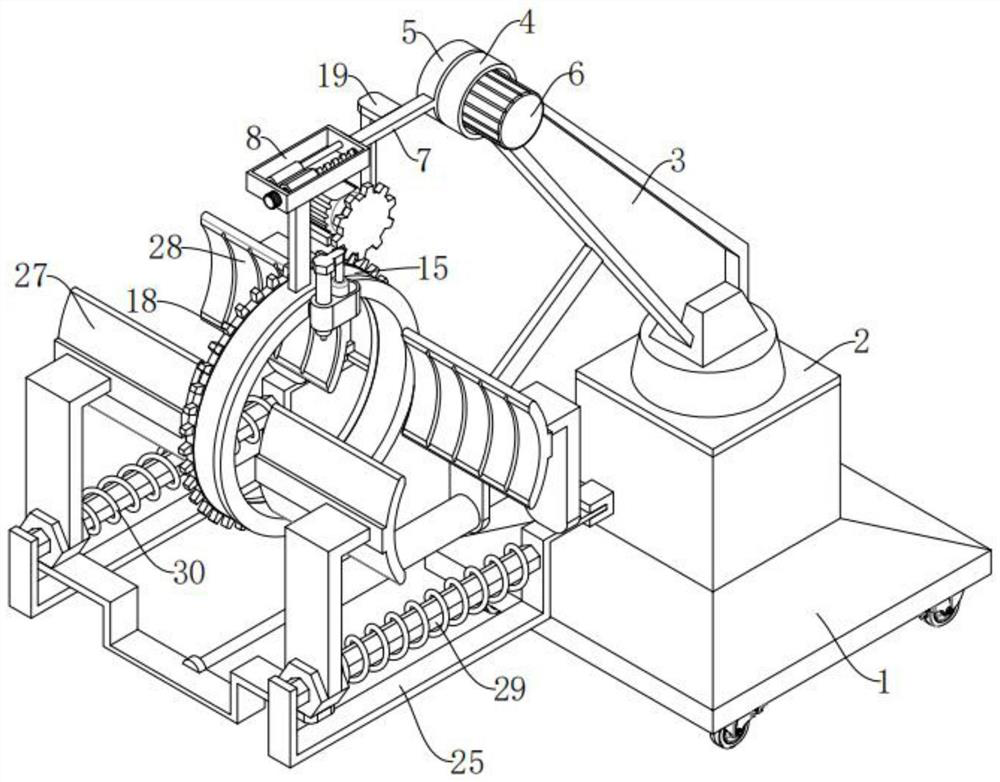

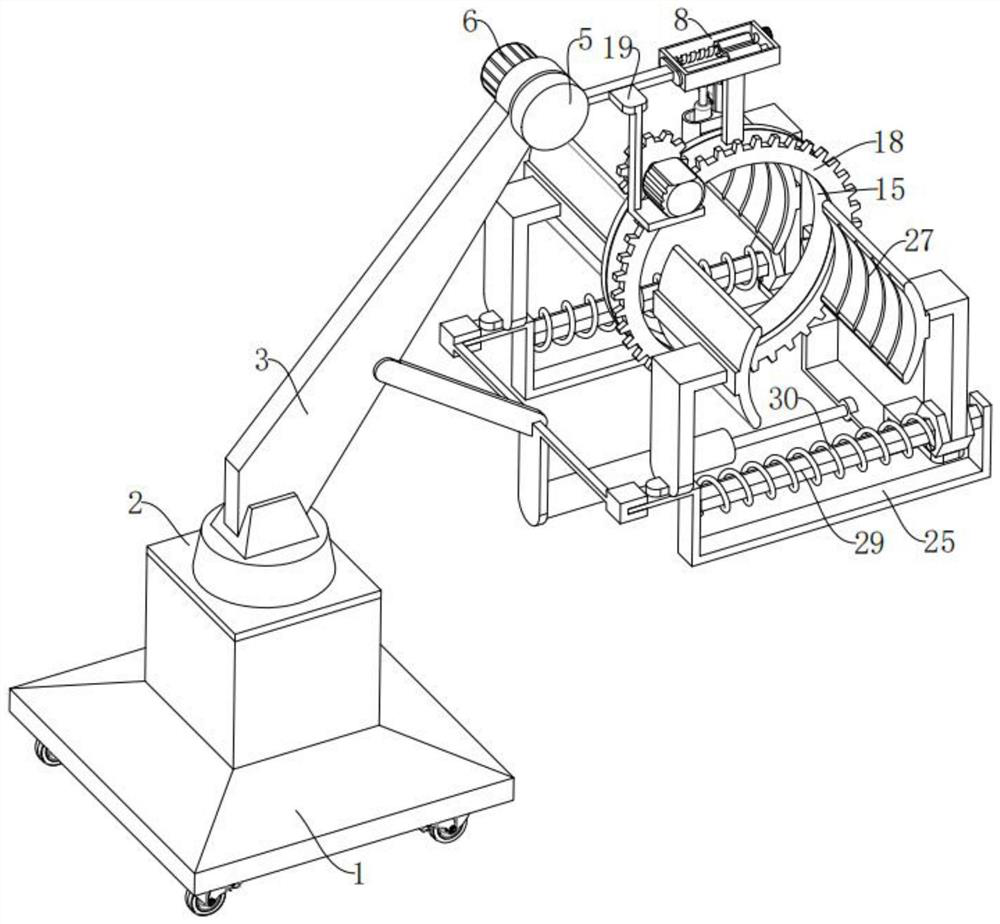

Full-automatic welding manipulator for steel pipe furniture and welding method of full-automatic welding manipulator

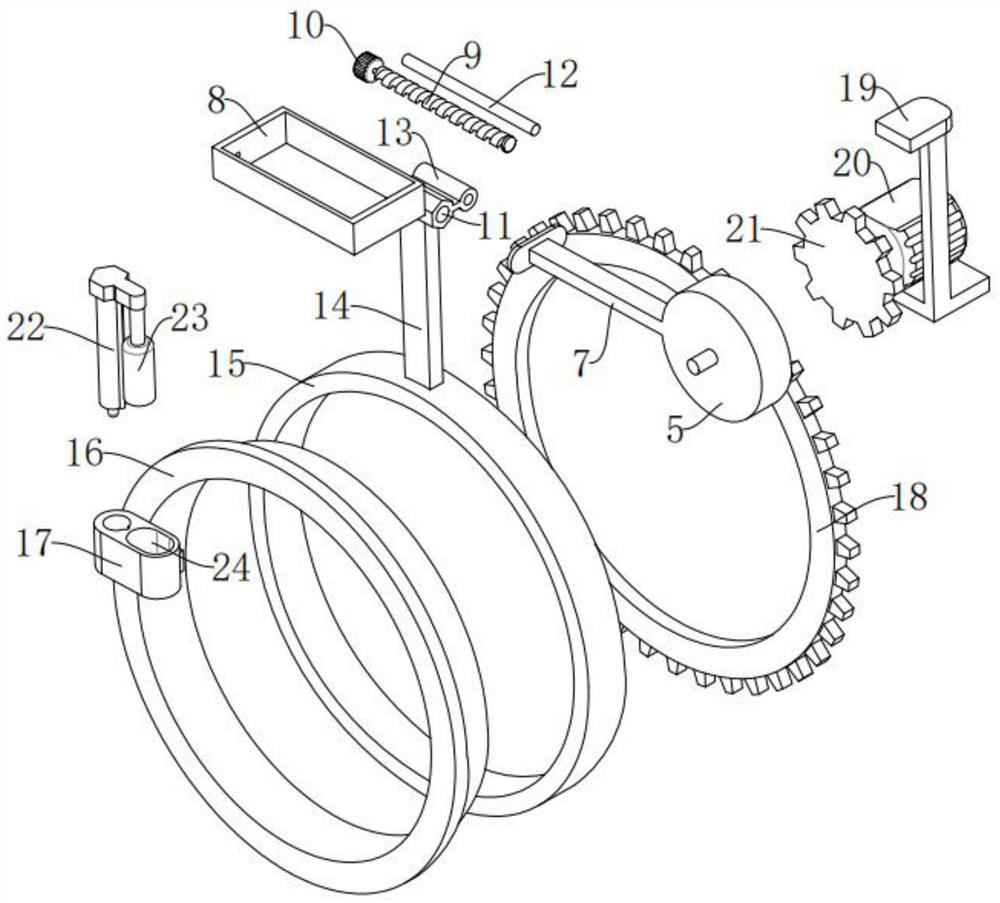

PendingCN113977157AConvenient distance weldingFlexible distance adjustmentWelding/cutting auxillary devicesAuxillary welding devicesGear wheelGravity center

The invention discloses a full-automatic welding manipulator for steel pipe furniture and a welding method of the full-automatic welding manipulator, and belongs to the technical field of steel pipe welding. The full-automatic welding manipulator comprises a gravity center base, a supporting assembly which comprises a mounting plate, a supporting arm, an extending arm and a mounting frame, wherein the mounting plate is fixedly connected to the upper end of the gravity center base, the supporting arm is fixedly connected to the upper end of the mounting plate, an adjusting assembly is arranged between one end of the extending arm and the supporting arm and used for adjusting the position of the mounting frame, and the mounting frame is fixedly connected to the other end of the extending arm; a rotating assembly which comprises a static mounting ring, a movable mounting ring and a large gear, wherein the static mounting ring is arranged on the lower side of the mounting frame, the movable mounting ring is rotationally connected into the static mounting ring, and a welding assembly is arranged on one side of the movable mounting ring; the full-automatic welding manipulator can slowly rotate around a welding point, welding is fast and stable, equidistant welding of a welding device is facilitated, the welding process is simplified, and a skilled welding technology is not needed.

Owner:漳州舒展家具有限公司

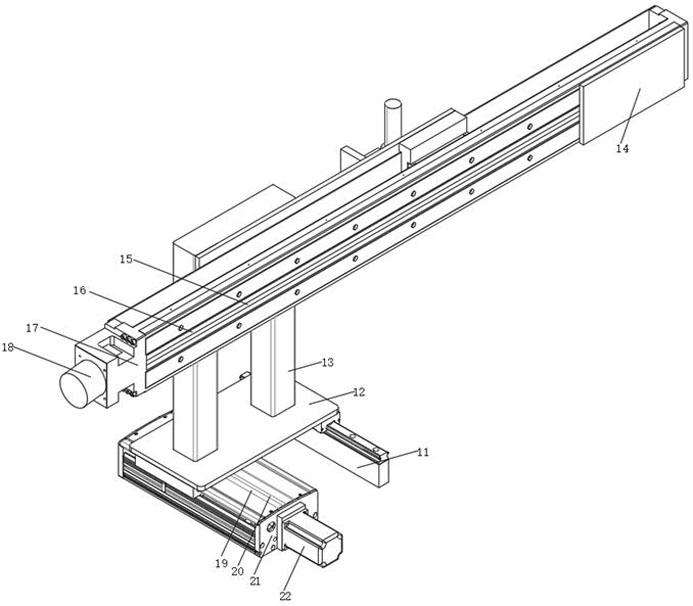

Small laser welding machine structure

The invention provides a small laser welding machine structure. A laser welding head of the small laser welding machine structure is connected with a driving air cylinder, and a laser focusing lens is connected with the laser welding head. According to a small laser welding machine, the welding head is connected with the driving air cylinder, and the driving air cylinder is a rotating air cylinder; in other words, the welding head can reciprocate in the longitudinal direction and can also swing back and forth in the left-and-right direction; in this way, when a workpiece is welded, the welding head is matched with a longitudinal moving sliding table and a transverse moving sliding table below a working table to move in the opposite directions, the welding range of the welding head can be effectively expanded accordingly, and some workpieces with large sizes can be welded on the small laser welding machine accordingly.

Owner:SUZHOU RECEN PRECISION MACHINERY CO LTD

Space seam tracking method of oscillating arc based on mems sensor

ActiveCN105728904BSolving Seam Tracking IssuesExpand the welding rangeArc welding apparatusGyroscopeAccelerometer

The invention discloses a system and a method for tracking a weaving arc space weld based on an MEMS (micro-electromechanical systems) sensor. The system comprises a manipulator, a welding power source, a wire delivery machine, an electric arc sensor, a built-in type MEMS sensor welding gun, a weaving arc space weld tracking signal processor, a welding gun tilting angle operator, a swinging direction operator, a welding gun attitude real-time adjuster, and a welding expert system. The system adopts a core principle that the space weld can be tracked by the weaving arc space weld tracking method based on the MEMS sensor, and has the advantage that the space attitude of the welding gun is collected by an arc sensor, a gyroscope and an accelerometer, and the tilting angle and swinging direction of the welding gun are automatically adjusted by weld angle differential identification, vertical displacement orientation and other methods, so that the real-time tracking of the space complicated weld is realized.

Owner:XIANGTAN UNIV

Positioning device for power electronic component production

InactiveCN113547256AShorten positioning timeImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderProcess engineering

The invention belongs to the technical field of power electronic component production, and particularly relates to a positioning device for power electronic component production. The positioning device comprises a workbench, a welding unit is mounted on the workbench, a placement seat is fixedly connected to the workbench, the placement seat is located right below the welding unit, a protective cover is fixedly connected to the workbench, the protective cover is arranged around the placement seat, hydraulic cylinders are fixedly connected to the side walls of the two sides of the protective cover, and the end parts of hydraulic rods of the hydraulic cylinders penetrate through the protective cover and are fixedly connected with positioning plates. The invention provides the positioning device for power electronic component production, and aims to solve the problems that when a square power electronic component is automatically welded by an intelligent welding machine, the component needs to be fixed at the center of a workbench by a positioning mechanism, then a welding program is input, automatic welding is carried out through the welding machine, however, an existing positioning mechanism is tedious, the positioning time is long, and the welding efficiency of the welding machine is affected.

Owner:江苏众利达自动化设备有限公司

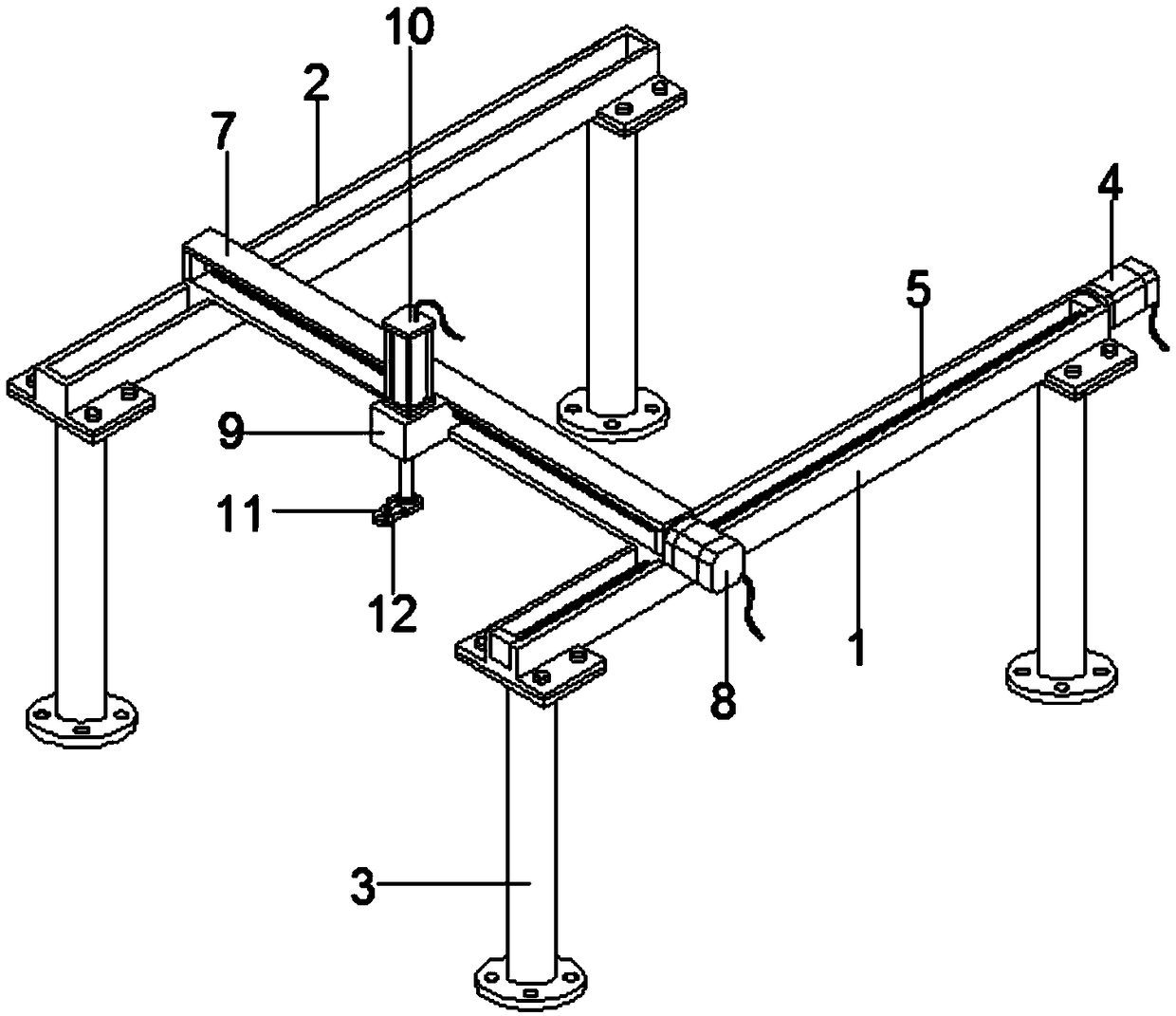

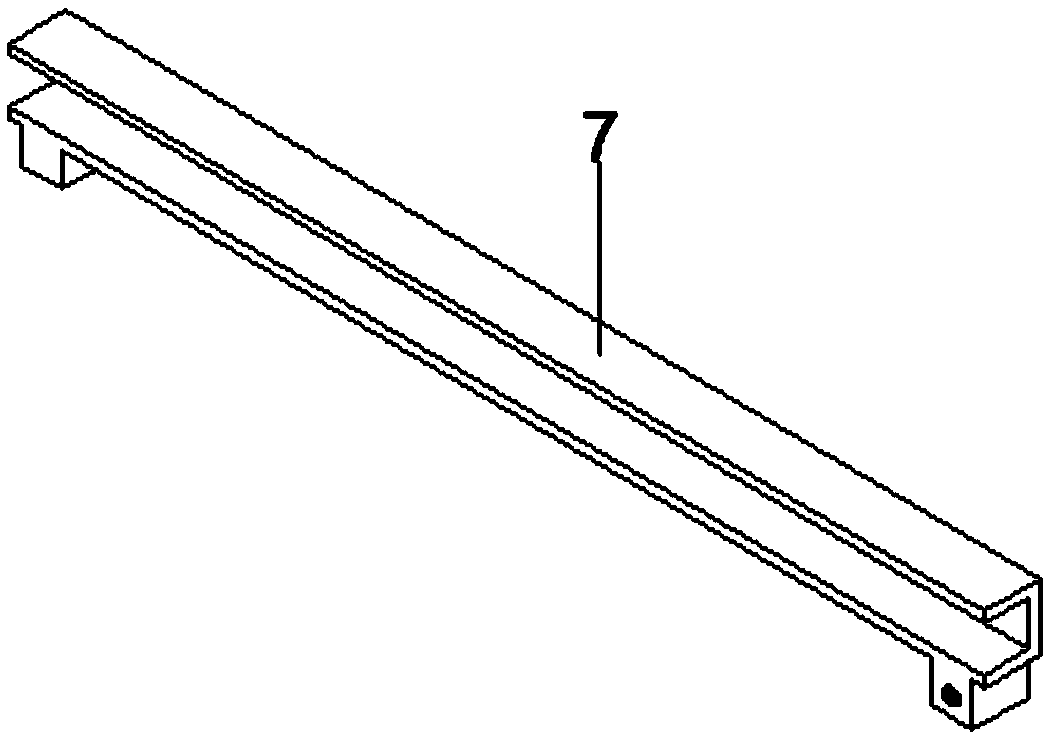

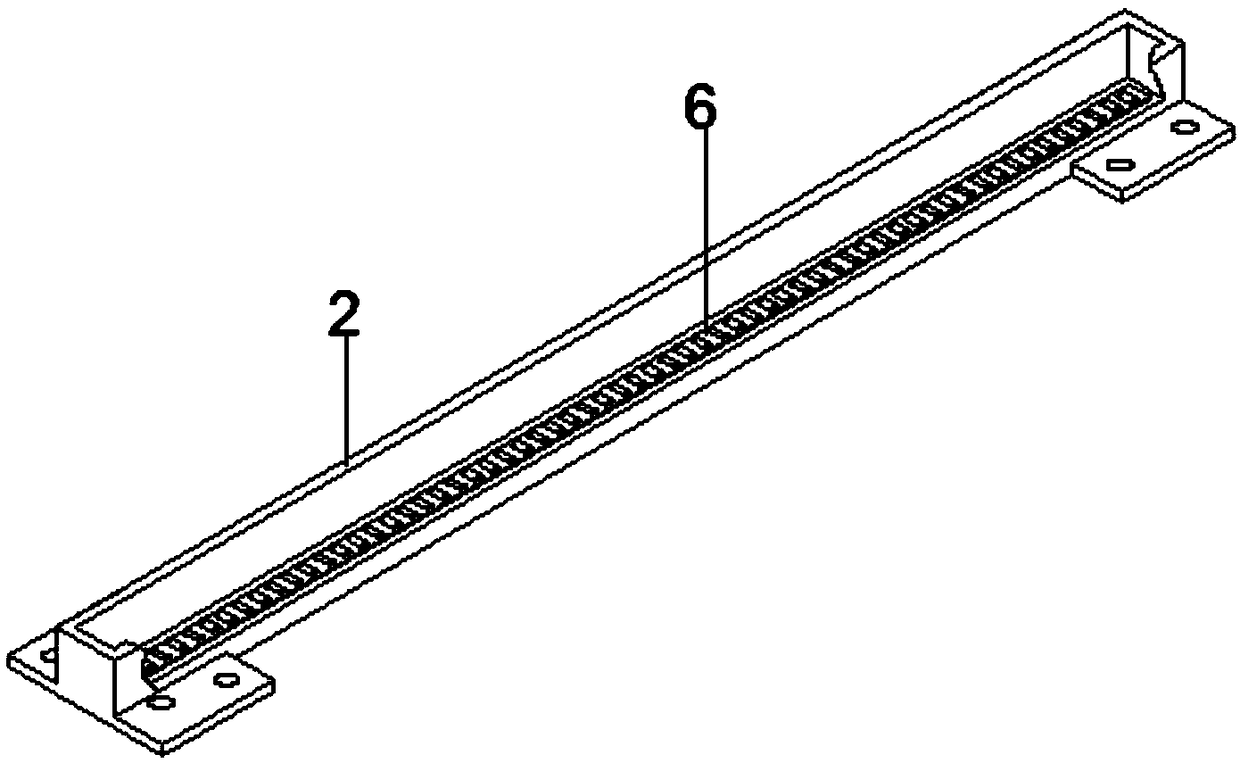

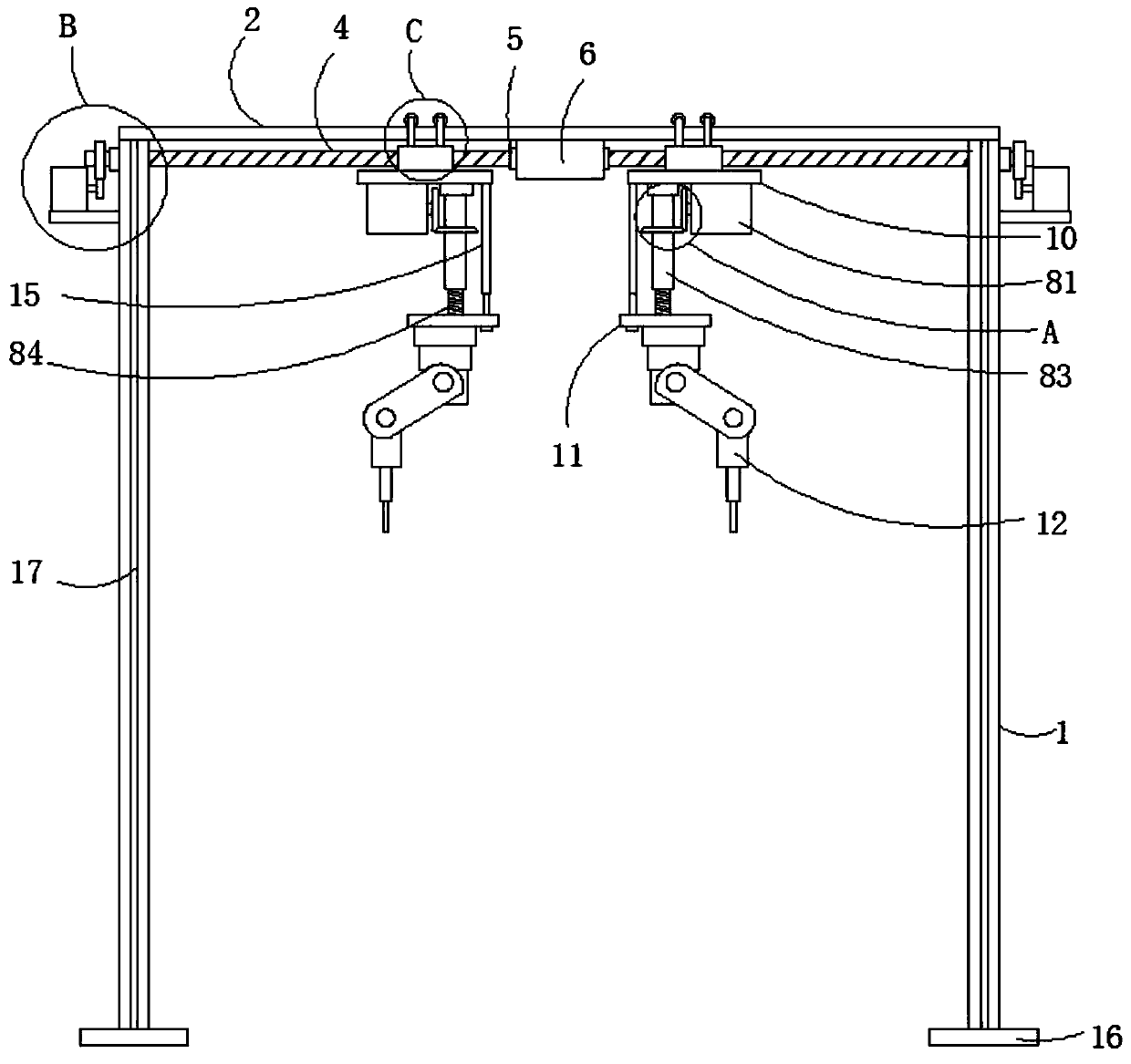

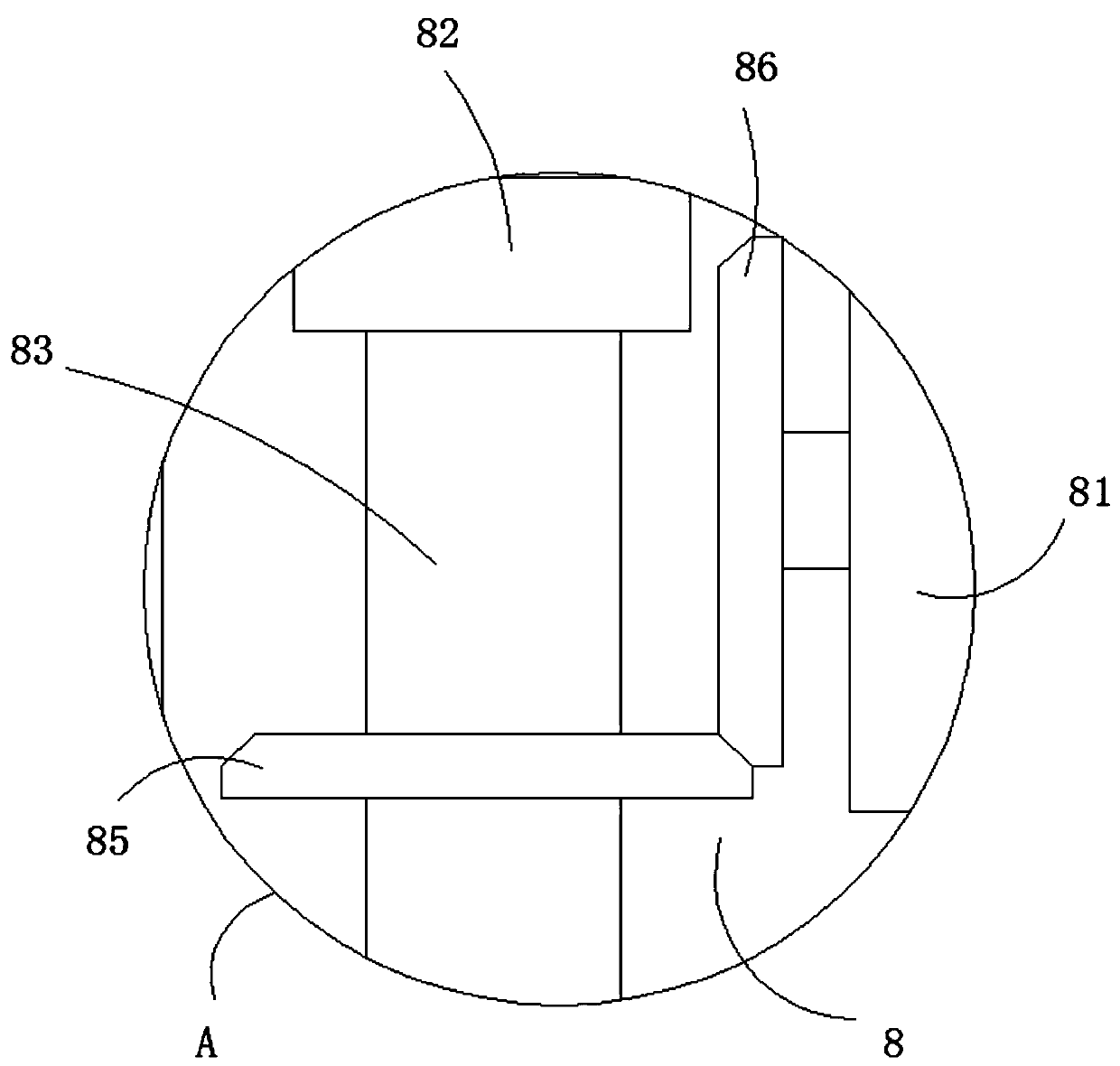

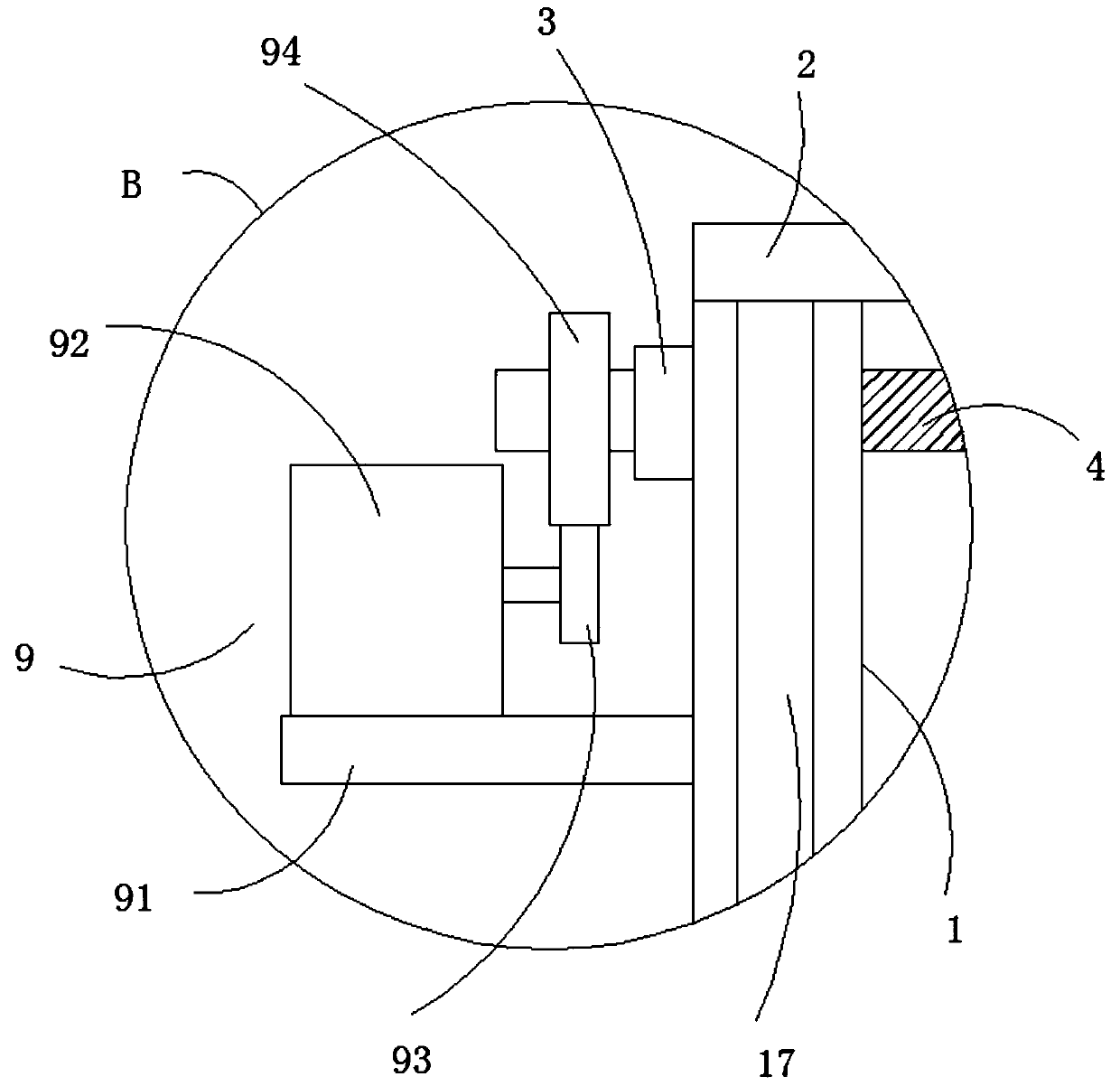

Truss type welding machine

InactiveCN108687472AWith bi-directional operation modeIncrease welding rangeWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringAutomation

The invention provides a truss type welding machine which comprises a first longitudinal beam, a second longitudinal beam and a transverse frame. The second longitudinal beam is arranged on one side of the first longitudinal beam, and the second longitudinal beam and the first longitudinal beam are connected through the transverse frame. Stand columns are arranged at the two ends of the bottom ofthe first longitudinal beam and the two ends of the bottom of the second longitudinal beam correspondingly, and the stand columns are connected with the first longitudinal beam and the second longitudinal beam in a bolt fixing manner. A Y-axis motor is arranged at one end of the first longitudinal beam and is connected with the first longitudinal beam in a bolt fixing manner. Lead screws are arranged in the first longitudinal beam and the transverse frame correspondingly and are connected with the first longitudinal beam and the transverse frame through a lead screw pair. Through the improvement on the machine, the advantages that the bidirectional operation manner is achieved, the welding range is widened, the welding height can be adjusted, and the function can be controlled based on automation are achieved; and therefore the problems and defects provided by the truss type welding machine in the background technology are effectively solved.

Owner:惠州市豪美仕智能技术有限公司

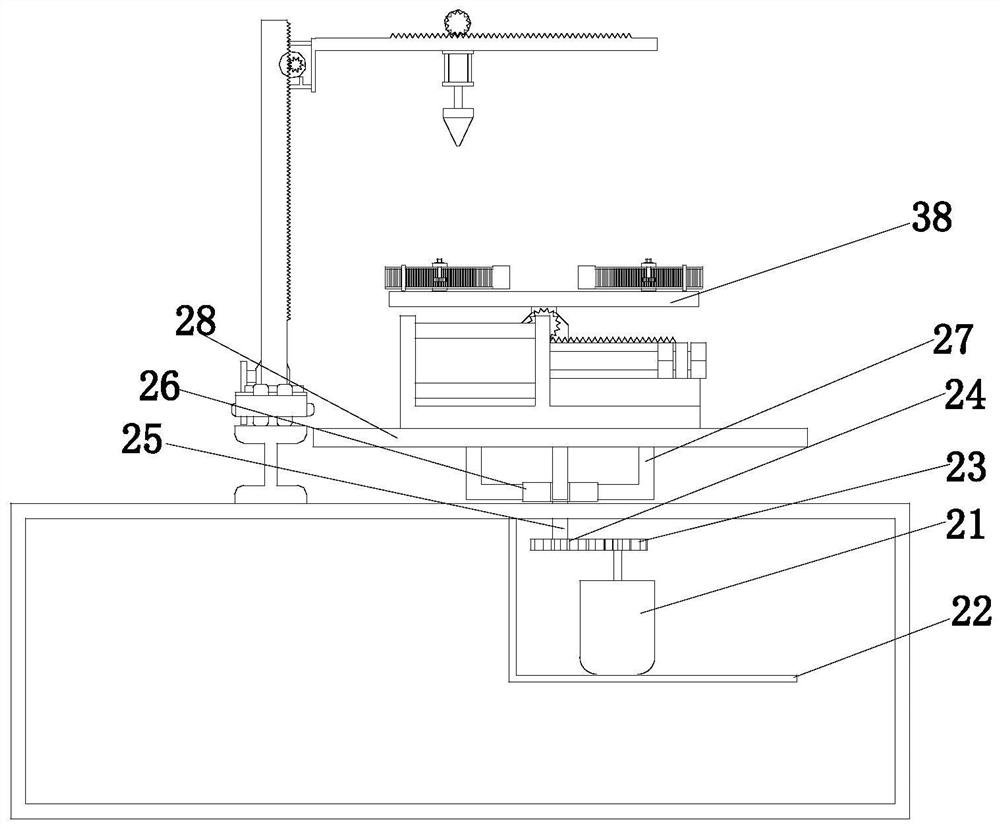

Bottom welding slag water-cooling collection type automobile sheet metal part welding device

ActiveCN114043225AReach water deliveryTo achieve the effect of not losing waterOther manufacturing equipments/toolsSlag (welding)Process engineering

The invention discloses a bottom welding slag water-cooling collection type automobile sheet metal part welding device which comprises a self-suction transverse moving type water-cooling welding assembly, a turnover type intermediate intervention type grinding assembly and a turnover driving and fixing assembly. The invention belongs to the technical field of automobile sheet metal welding, and particularly relates to a bottom welding slag water-cooling collection type automobile sheet metal part welding device which is efficient, energy-saving, convenient to operate and high in integration level. Under the condition that no water pump or driving unit exists, the siphonic effect principle and the pneumatic and hydraulic structure principle are combined, a large amount of carbon dioxide generated by dry ice gasification is utilized to pressurize a refrigeration box, and cooling water can be quickly conveyed into a siphon after the air pressure in the refrigeration box is increased, so that passive conveying of the cooling water is realized under the condition of no mechanical power source, by merely depending on a single driving unit, the grinding, transverse moving, cooling and dust falling functions of the turnover follow-up type reverse grinding device are achieved, use of some unnecessary driving units is avoided, and the effects of energy conservation and emission reduction are achieved.

Owner:徐州云陌机械科技有限公司

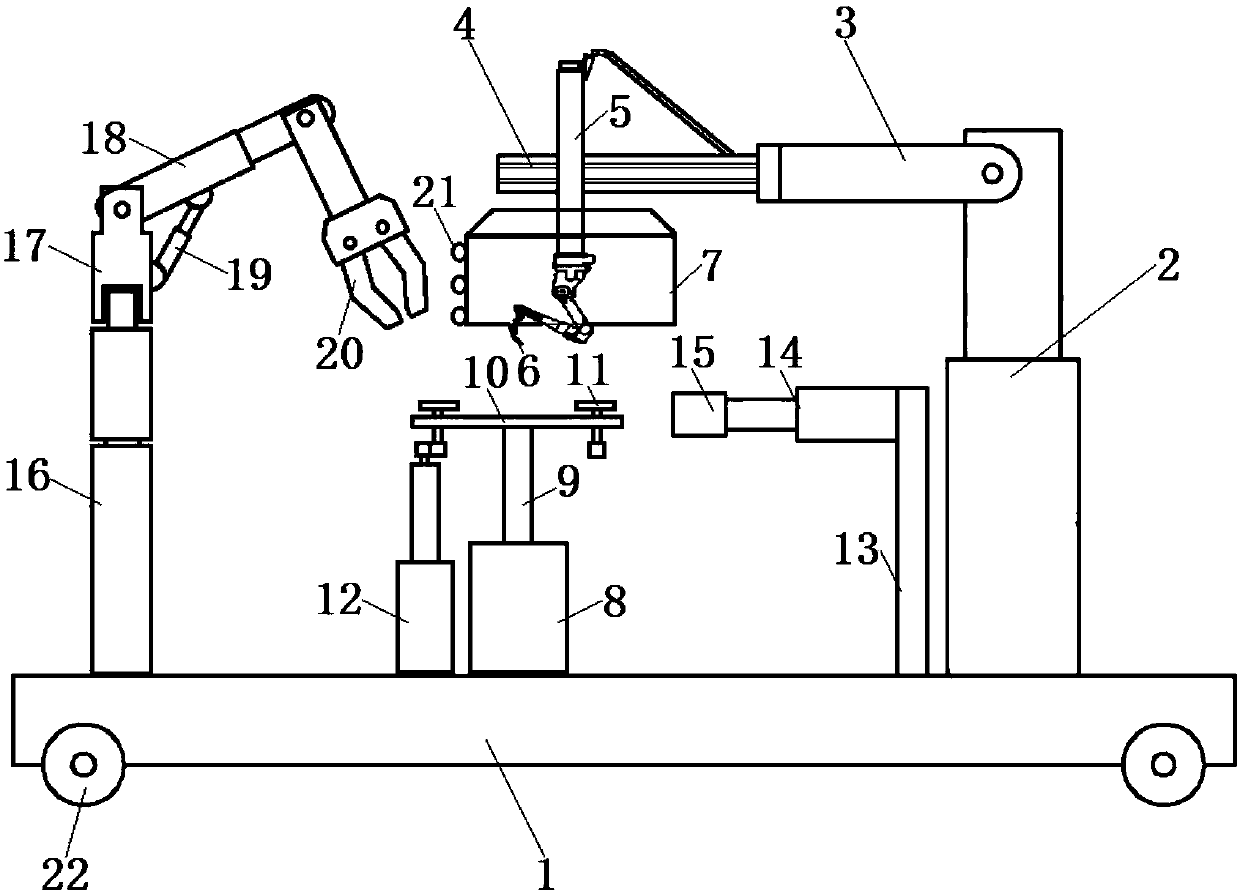

Vehicle body welding robot with temperature protection function

InactiveCN112917073AExpand the welding rangeStable supportWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderRobotic arm

The invention discloses a vehicle body welding robot with a temperature protection function. The vehicle body welding robot with the temperature protection function comprises a supporting and moving mechanism and a rotary welding manipulator mechanism, and the rotary welding manipulator mechanism is fixedly installed on the supporting and moving mechanism. A push rod is driven to move through stretching and retracting of the telescopic end of a hydraulic cylinder, so that the push rod pushes an installation sliding block to horizontally move left and right on a guide rail column; compared with a traditional welding robot fixed to the ground, the welding robot has the advantages that the welding range is enlarged in the welding process; a driving motor is fixedly mounted in a mounting shell, the output end of the driving motor penetrates through the mounting shell to be fixedly connected with a connecting circular truncated cone, the connecting circular truncated cone is arranged on the outer side of the mounting shell, meanwhile, a mechanical arm is fixedly mounted on the connecting circular truncated cone, the driving motor drives the connecting circular truncated cone to rotate, so that the working direction of the mechanical arm is adjusted; and the rotating angle of the mechanical arm is not limited any more, and welding is convenient.

Owner:盐城市昱博汽车零部件有限公司

Novel welding robot

PendingCN112276423AExpand the welding rangeReduce self-weight loadWelding/cutting auxillary devicesAuxillary welding devicesCantilevered beamRoboty

The invention discloses a novel welding robot. The novel welding robot comprises a workbench, two stand columns arranged on the side face of the workbench and symmetrically arranged in parallel, a cross beam arranged on the side faces of the top ends of the stand columns, a transverse moving mechanism arranged on the side face of the cross beam, a cantilever beam arranged at the movable end of thetransverse moving mechanism, a robot body arranged at the bottom of the cantilever beam and spirally fixed to the cantilever beam, a welding clamp arranged at the tail end of the robot body, a welding gun clamped and fixed through the welding clamp, and a hydraulic overturning clamping table arranged below the robot body. The novel welding robot has the technical effects that the transverse moving mechanism is matched with the robot body, so that the robot body can transversely move, the welding range is widened, large-size workpieces are welded, the welding freedom degree is improved throughthe synergistic effect of the robot body and the hydraulic overturning clamping table, and all-dimensional welding is achieved.

Owner:广东恒华重工有限公司

Aluminium base composite material ultrasonic wave fine welding method

InactiveCN1326658CAvoid WeldingEfficient weldingNon-electric welding apparatusUltrasonic vibrationMaterials science

Owner:HARBIN INST OF TECH

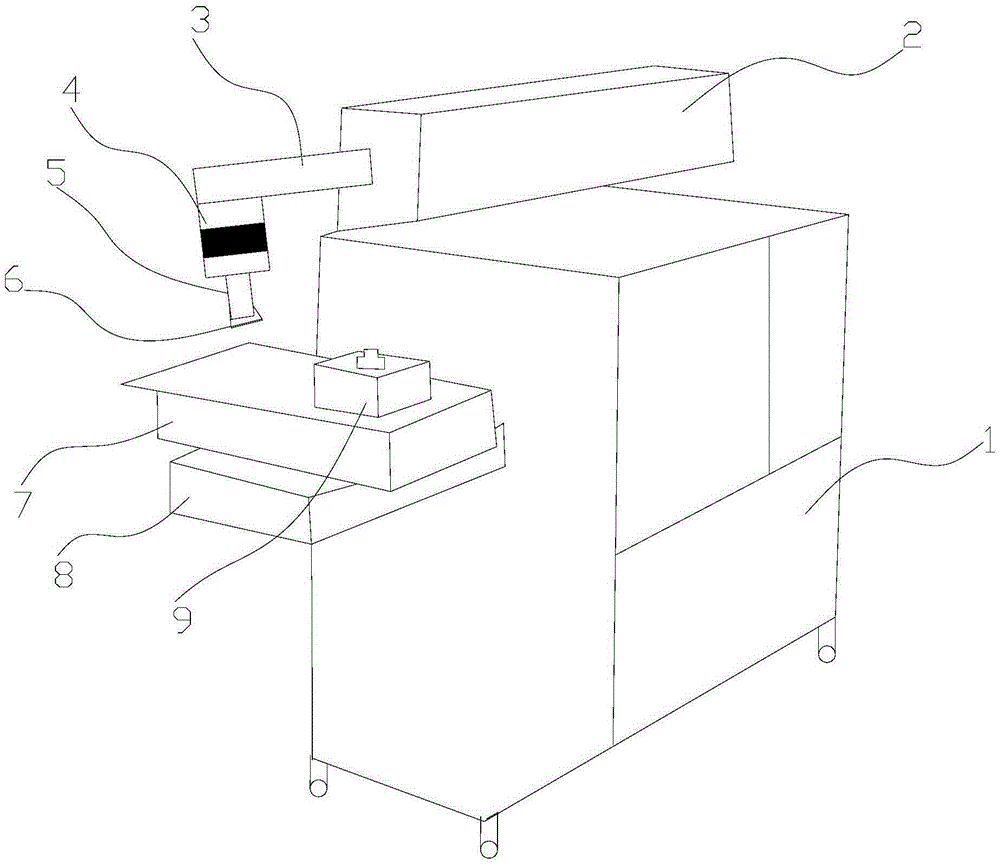

Welding surface detection device based on machine vision and detection method thereof

PendingCN112858316ARealize multi-directional movementEasy to moveOptically investigating flaws/contaminationMachine visionElectric machinery

The invention discloses a welding surface detection device based on machine vision and a detection method thereof. The welding surface detection device comprises a first bottom box, a second bottom box is fixedly connected to one side of the first bottom box, a welding structure is fixedly installed on one side of the top of the first bottom box, and three first sliding ways are formed in the other side of the top of the first bottom box; two motor mounting plates and two cover frames are fixedly mounted at the top of the first bottom box, a first driving motor is fixedly mounted at the top of each motor mounting plate, and a first threaded rod is fixedly connected to the driving end of each first driving motor. According to the welding surface detection device based on machine vision and the detection method thereof, automatic discharging of welded materials is achieved, welded workpieces are made to be away from a welding area, meanwhile, material clamping, namely welding surface detection of the workpieces is achieved, direct classified transportation is achieved after detection is completed, manual transfer is not needed, welding, unloading and detection are completed in one step, the process flow is reduced, and then the working efficiency is improved.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

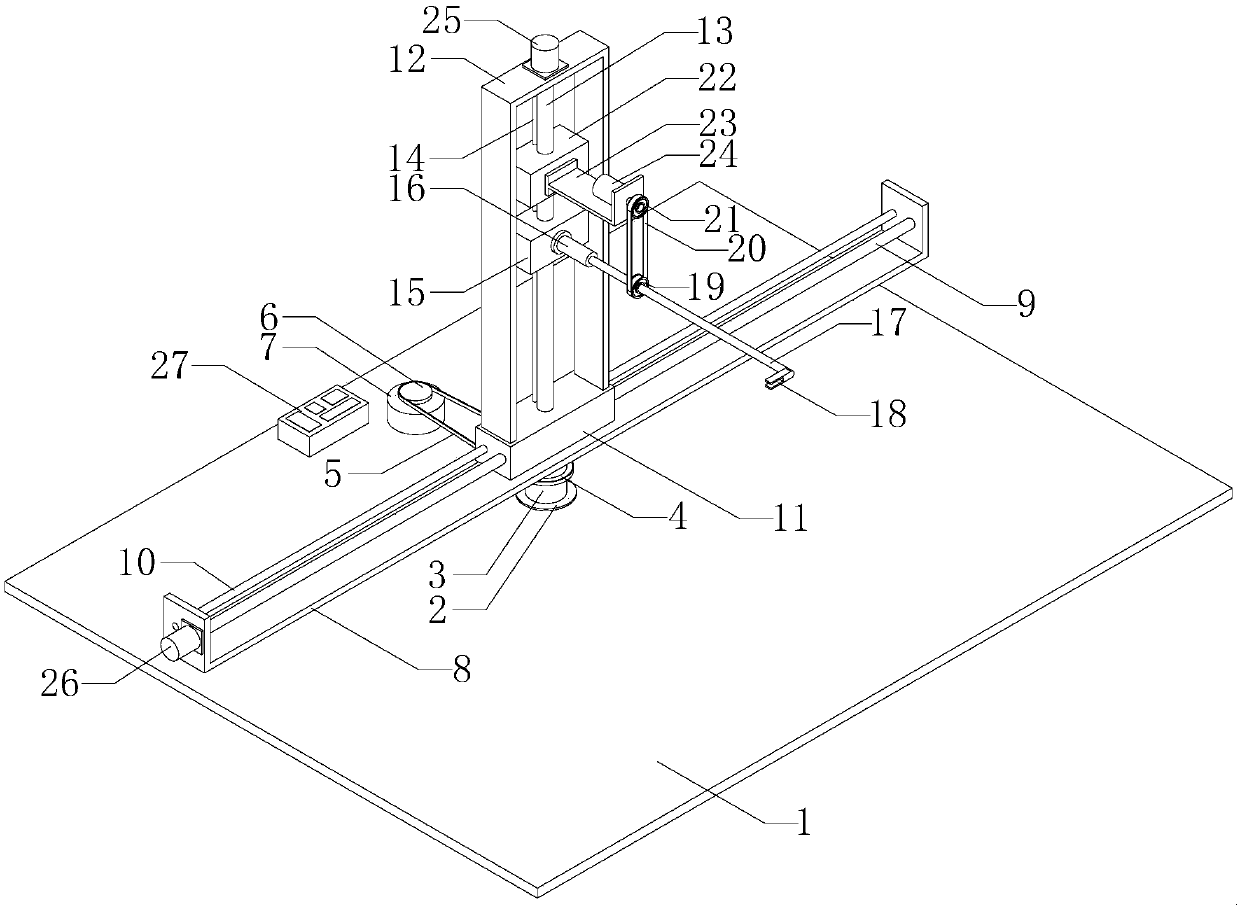

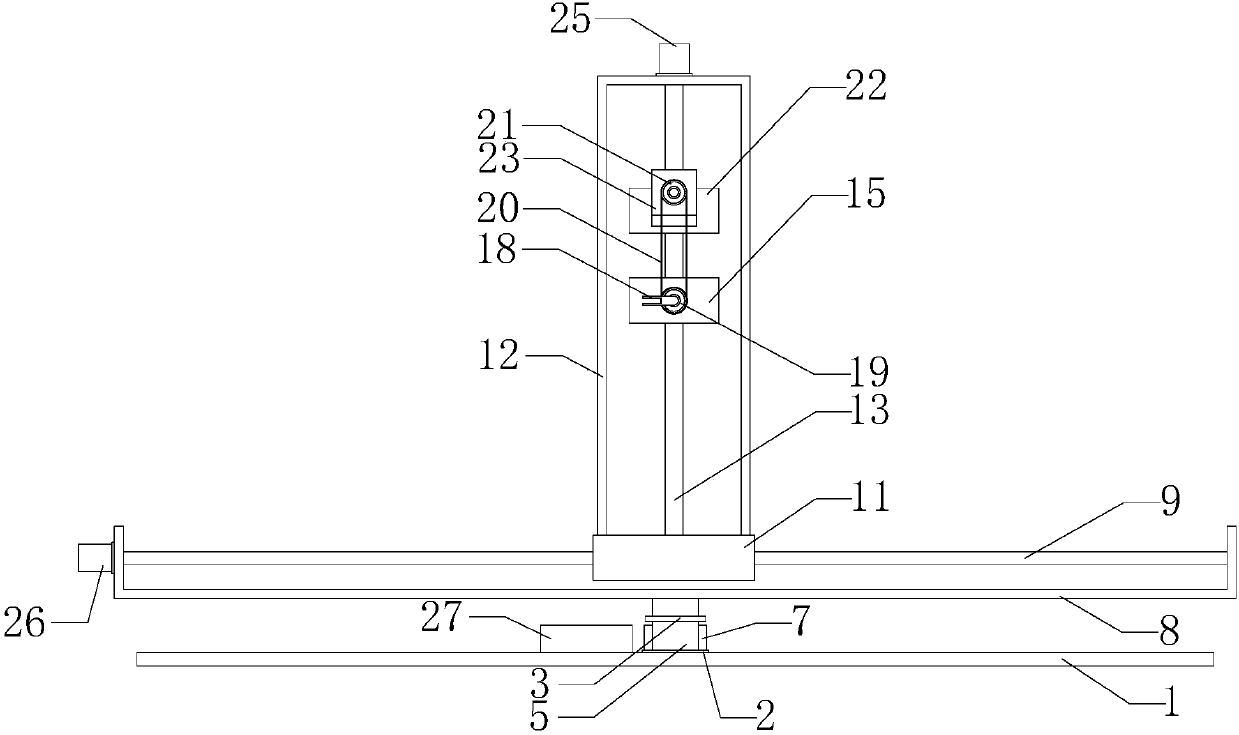

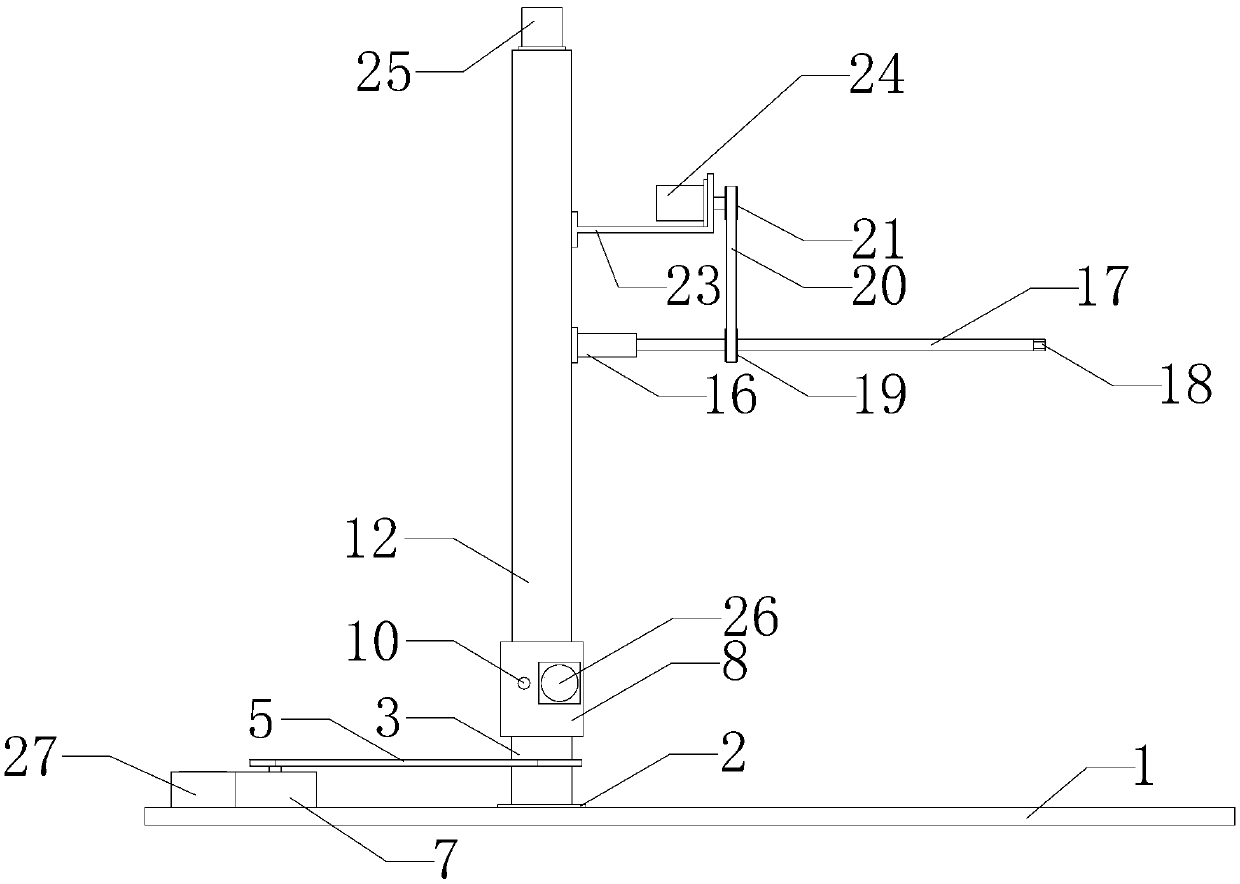

Multi-degree-of-freedom automatic welding device

InactiveCN108098104ASimple structureSimple and fast operationSoldering auxillary devicesVertical planeThrust bearing

The invention discloses a multi-degree-of-freedom automatic welding device. The multi-degree-of-freedom automatic welding device comprises a base plate. The base plate is fixedly connected with a stand column through a thrust bearing, and the stand column is fixedly connected with a translation support. A large belt pulley is arranged in the middle of the stand column and is in transmission connection with a small belt pulley through a driving belt, and the small belt pulley is fixedly connected with a first motor. A controller is arranged on the base plate, and the first motor, a second motor, a third motor and a fourth motor are electrically connected with the controller through wires. The multi-degree-of-freedom automatic welding device is simple in structure, easy and convenient to operate, low in cost and complete in function. A horizontal sliding block is driven by the fourth motor to move, finally a lifting support and a welding bar are driven to horizontally move, and movementis rapid and reliable. A lower sliding block and an upper sliding block are driven by the third motor to move, finally the welding bar is driven to vertically move, and motions are accurate and effective. Angle adjustment of a welding rod in the horizontal plane and the vertical plane is achieved through the first motor and the second motor correspondingly. The welding range is broad, and weldingis flexible and accurate.

Owner:董琴

Portable automatic welding device

InactiveCN106914716AEasy to moveImprove adaptabilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMobile device

The invention provides a portable automatic welding device. The portable automatic welding device comprises a protective cover, a welding head, a sliding way, a machine head, a control device, a machine body, a display screen, a moving device, a base, a workbench, a helium tank, a gas inlet pipe, supporting legs and a shock insulator. The protective cover and the welding head are installed on the lower portion of the machine head through the sliding way. The control device is installed on the upper portion of the machine body. The display screen is installed on the front side face of the control device. The moving device is installed on the lower portion of the base. The machine body or the helium tank is fixed to the upper portion of the base. The workbench is installed under the welding head. The gas inlet pipe enables the helium tank to be connected with the machine body. According to the portable automatic welding device, through the moving device, the base and the supporting legs, the portable automatic welding device is convenient to move, time and effort are saved, carrying is convenient, the work range is expanded, operation is convenient and rapid, the utilization rate of the portable automatic welding device is improved, and therefore the portable automatic welding device is convenient to apply and popularize on market.

Owner:迦融华艺(天津)科技有限公司

Steel pipe welding device for hardware machining and using method of steel pipe welding device

PendingCN112958992AExpand the welding rangeIn line with actual useWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPipe

The invention relates to the technical field of hardware machining, in particular to a steel pipe welding device for hardware machining and a using method thereof. The technical problems that the position of a welding machine is fixed, inclined section steel pipes are difficult to weld, large steel pipes are inconvenient to machine and taken out manually, time and labor are wasted, and the efficiency is affected are solved. In order to solve the technical problems, the steel pipe welding device for hardware machining and the using method thereof are provided. The steel pipe welding device for hardware machining is composed of an adjusting mechanism and a welding structure, the moving track of a welding gun is adjusted to be matched with the tangent plane of a steel pipe for welding, the welding range is expanded, and actual use is better met; the semi-clamping ring and the track ring are connected to the surface of the steel pipe in a sleeving mode for welding machining, a user is prevented from excessively moving the large steel pipe, machining is more convenient, the limitation of sites and equipment is reduced, the device can be directly disassembled after welding is completed, the steel pipe does not need to be treated, the time and labor are saved, and the machining efficiency is improved.

Owner:张景文

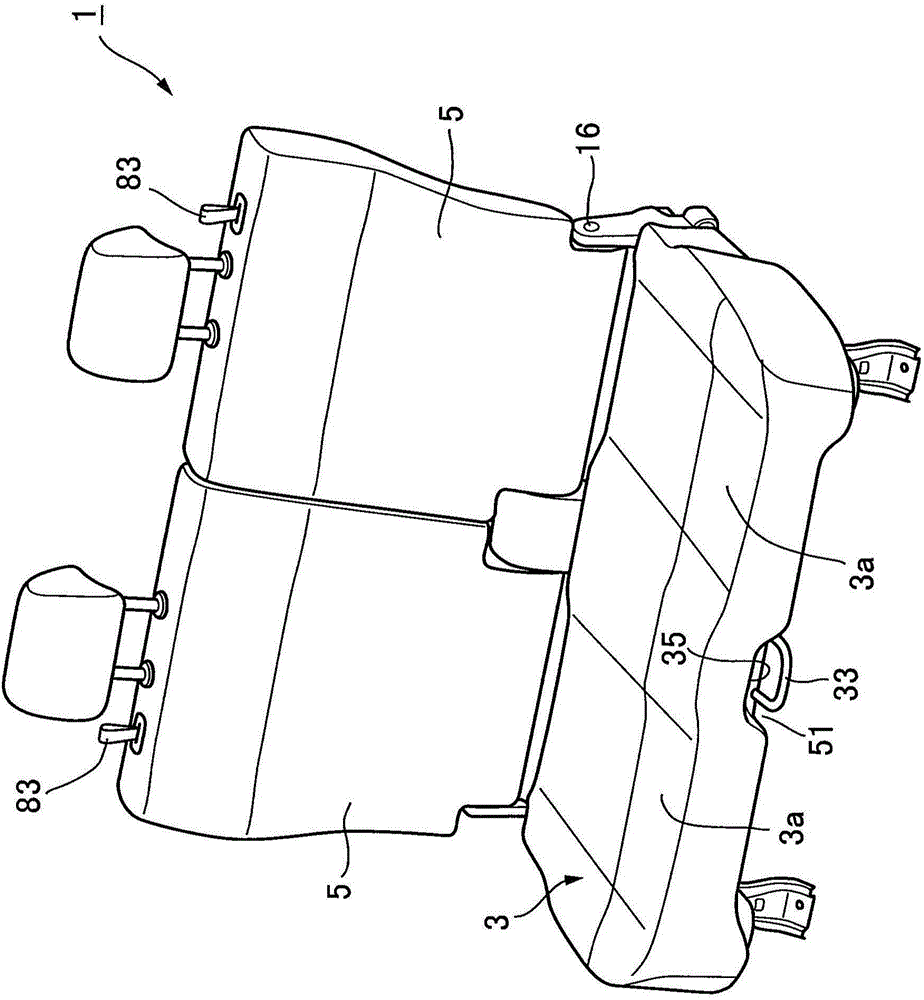

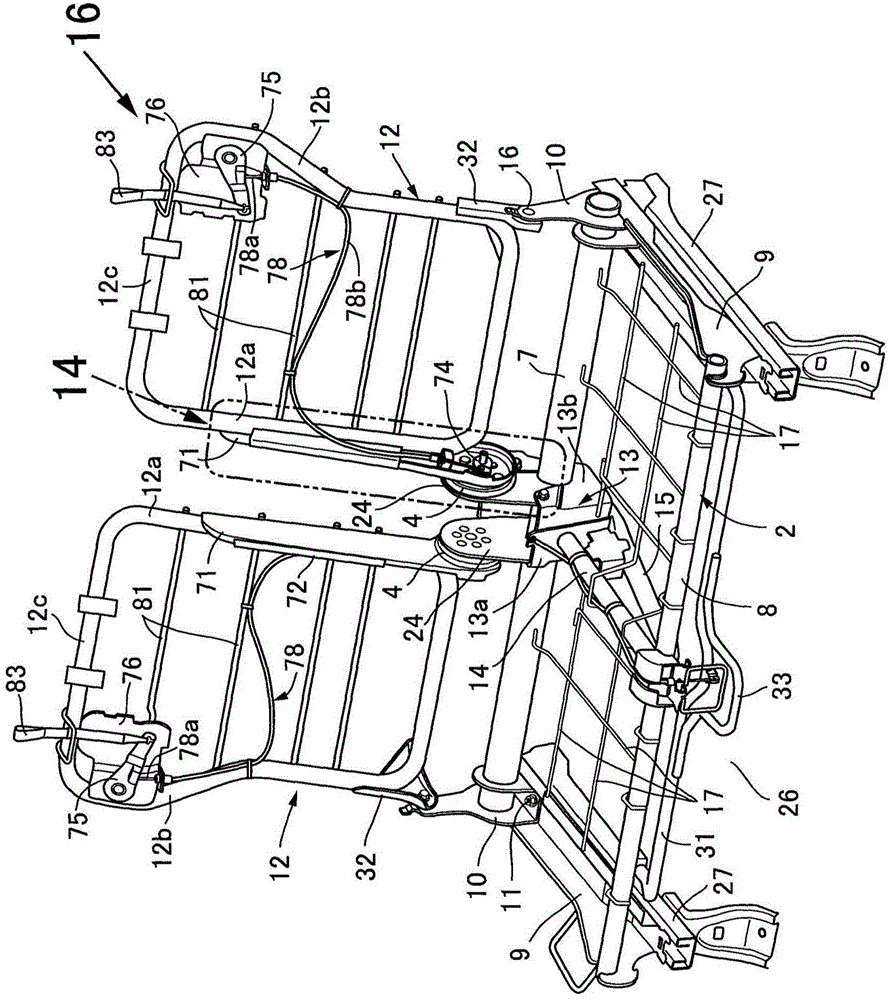

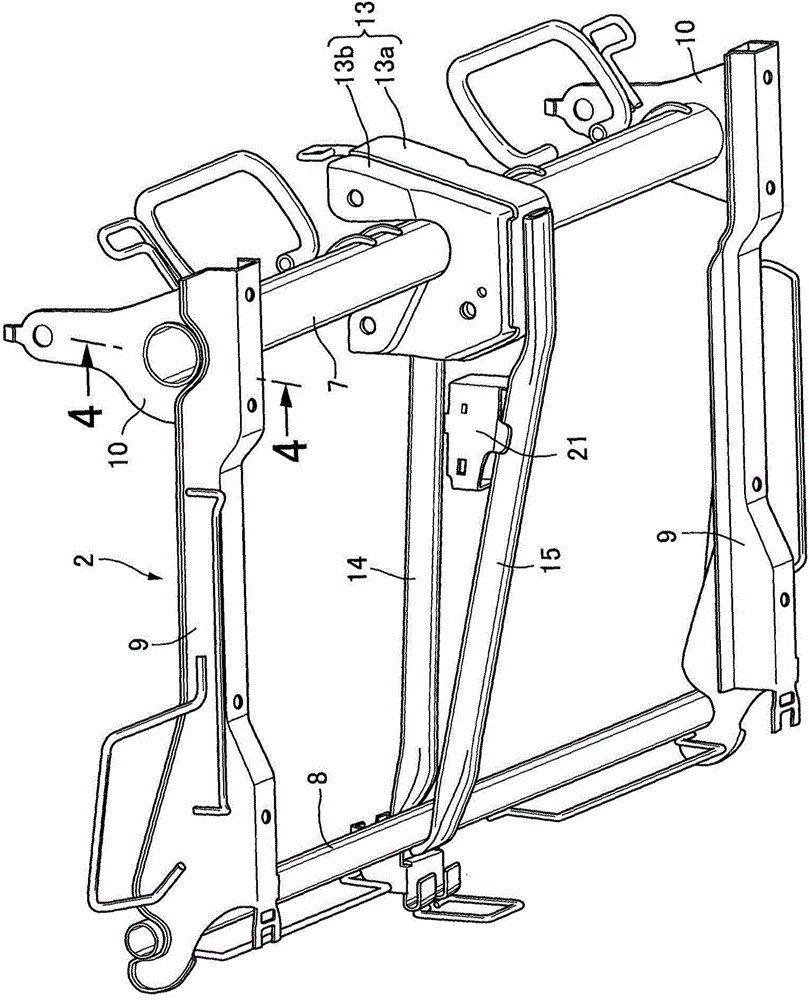

Frame structure for vehicle seat

ActiveCN104627044AHelps to reduce weightFully resistant to compressive stressSeat framesEngineeringUltimate tensile strength

The invention provides a frame structure for a vehicle seat, wherein the torque applied on a rear framework is effectively improved while the weight thereof is prevented from increasing. The structure comprises a seat cushion frame (2) and a seat back frame (12). The seat cushion frame (2) is provided with a rear frame (7), a front frame (8) and a lateral frame (9). One lateral part of the seat back frame (12) is connected with the seat cushion frame (2) through a pivot pin (16). The other lateral part of the seat back frame (12) is connected with the seat cushion frame (2) via a tilt mechanism.

Owner:TS TECH CO LTD

A welding equipment suitable for valve manufacturing

ActiveCN113560779BRealize multi-directional positioningHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringVALVE PORT

The invention provides a welding equipment suitable for the production and manufacture of valves, including a support device; two first mounting plates are fixedly connected to the bottom of the support device, ten support columns are installed on the support device, and the ten support columns are fixed The running track is connected; four positioning devices are fixedly connected to the supporting device, and the structures on the four positioning devices are the same; the driving device is installed on the running track, and the adjusting part is installed on the driving device; the driving device is installed with The upper mold positioning device; the welding support part, which is rotatably connected to the driving device; the welding part is installed on the welding support part, and the positioning device is installed, and the propulsion can be realized by rotating and positioning the propulsion shaft. The structure is simple and stable. By adjusting the four positioning propulsion shafts, the coaxiality of the valve parts and the running track can be adjusted, which effectively improves the welding accuracy of the valve, greatly reduces the defective rate, and avoids the occurrence of "virtual welding" at the same time.

Owner:合飞阀门有限公司

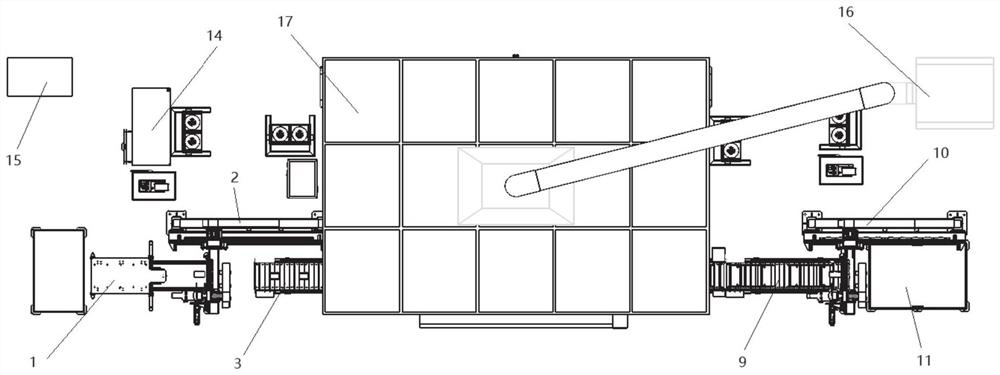

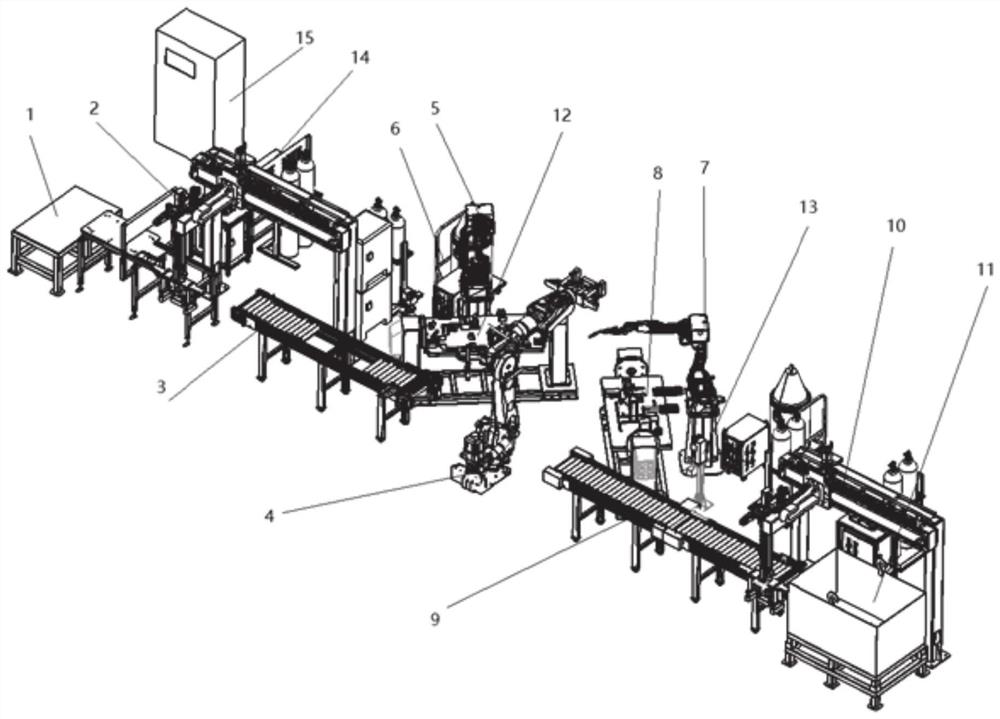

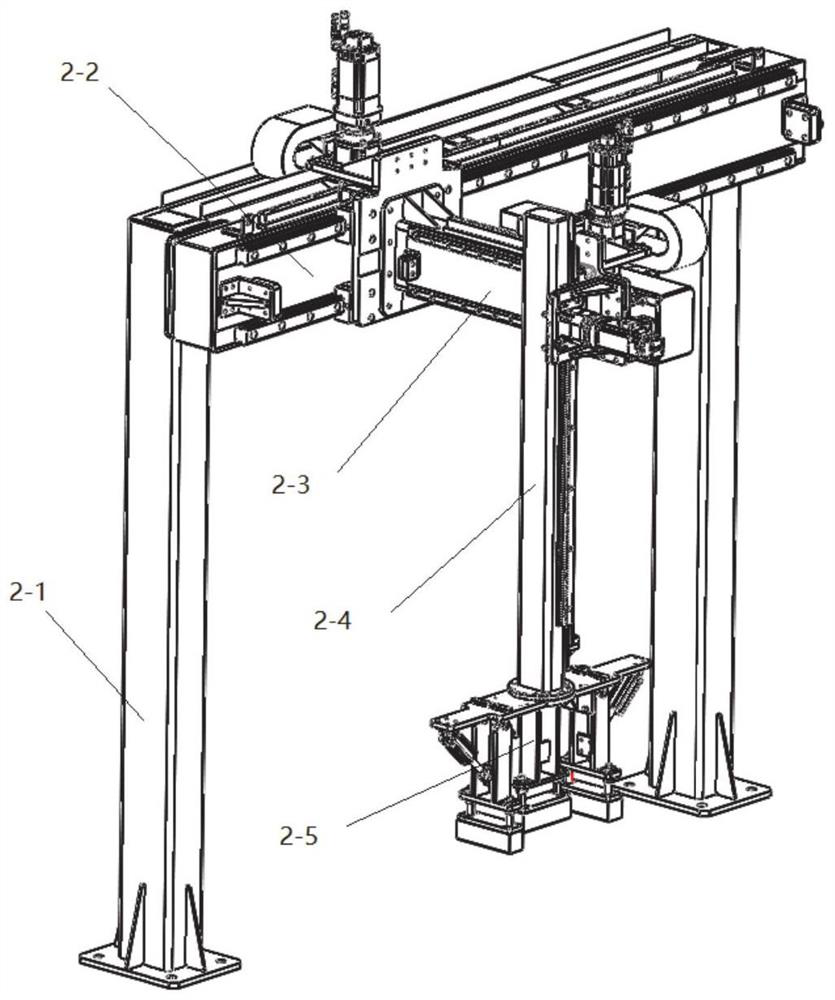

Flexible welding production line for small and medium-sized parts of railway wagon

PendingCN114227103AFlexible welding realizedRealize automatic unmannedWelding/cutting auxillary devicesAuxillary welding devicesProduction lineSpot welding

The invention relates to the technical field of production equipment for small and medium-sized parts of railway wagons, in particular to a flexible welding production line for small and medium-sized parts of railway wagons, which comprises a spot welding platform, a first carrying device, a feeding conveying device, a second carrying device, a discharging conveying device and at least one flexible welding device, the flexible welding device comprises a displacement device and an automatic welding device, the displacement device is provided with a swingable fixing plate and a plurality of welding stations arranged on the fixing plate, and each welding station is provided with a positioning device matched with different small and medium-sized components to be welded; full-automatic unmanned welding of small and medium-sized components can be achieved, the labor intensity of workers is reduced, and the automatic welding device is suitable for large-scale welding production of large-scale small and medium-sized components.

Owner:SHANGDONG TONGLIDA INTELLIGENT MACHINERY

Welding mechanism for rail transit

ActiveCN112108811AWide range of weldingWeld firmlyWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

The invention belongs to the technical field of rail transit equipment, and particularly relates to a welding mechanism for rail transit. The welding mechanism for rail transit comprises a base, foursets of supporting columns, a cross beam, a movable base and a welding assembly. The cross beam is fixedly installed on the base through a plurality of sets of supporting columns. The cross beam comprises two sets of cross rods and two sets of sliding rails; the two sets of cross rods are parallel and symmetrically arranged; and the two sets of sliding rails are parallel and symmetrically arranged; Two ends of the movable base are movably clamped to the two sets of sliding rails correspondingly. A clamping assembly is movably mounted on the movable base. The welding assembly is movably clampedonto the movable base, so that the welding assembly can reach any point in a plane projection formed by the sliding rails and the cross beam.

Owner:浙江泰邦电器有限公司

Welding tool for butting of cylinder bodies

InactiveCN108817626ARealize automatic dockingExpand the welding rangeWelding/cutting auxillary devicesAuxillary welding devicesWeldingStopped work

The invention discloses a welding tool for butting of cylinder bodes. The welding tool for butting of the cylinder bodies includes a tool seat, wherein a fixed fixture is fixedly connected to one sideof the tool seat, and a moving fixture is arranged on the other side of the tool seat. A stepping motor linear guide rail sliding table is arranged at the position, close to the fixed fixture, of oneside of the bottom end of the tool seat in an embedded mode. A rack is fixedly connected to the upper end of the stepping motor linear guide rail sliding table. Through the thrust generated by a first hydraulic rod and a second hydraulic rod acting on the moving fixture, the moving fixture is moved and close to the fixed fixture. By rotating a stepping motor to drive a second transmission gear torotate, the two cylinder bodies can be turned over synchronously, and thus the scope of welding is expanded. After the cylinder bodies are detected by an infrared sensor, a motor stops working so that the cylinder bodies can be clamped. The rack is moved by the stepping motor linear guide rail sliding table so that the two cylinder bodies can be turned over.

Owner:芜湖若科自动化科技有限公司

Frequency-variable and speed-adjustable gate-type automatic welding machine

PendingCN111438470AImprove welding efficiencyImprove ease of useWelding/cutting auxillary devicesAuxillary welding devicesRolling-element bearingEngineering

The invention relates to the technical field of welding machines, and discloses a frequency-variable and speed-adjustable gate-type automatic welding machine. The frequency-variable and speed-adjustable gate-type automatic welding machine comprises two gate posts, and the upper surfaces of the two gate posts are together fixedly connected with a connecting rod; the outer walls of the two gate posts are provided with through holes, the hole walls of the through holes are fixedly connected with first rolling bearings, and the inner walls of the first rolling bearings are fixedly connected with first threaded rods; the opposite ends of the two first threaded rods are fixedly connected with second rolling bearings in a sleeved manner, the outer walls of the second rolling bearings are togetherfixedly connected with a connecting cylinder, and the outer wall of the connecting cylinder is fixedly connected with the outer wall of the connecting rod; and the rod walls of the two first threadedrods are in threaded connection with threaded cylinders, and the lower surfaces of the threaded cylinders are fixedly connected with fixing plates. The frequency-variable and speed-adjustable gate-type automatic welding machine has the advantages that the welding efficiency of the gate-type automatic welding machine can be effectively improved, the use convenience of the gate-type automatic welding machine is improved, and meanwhile the labor intensity of working staff can be reduced.

Owner:ZHUHAI EASTERN HEAVY IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com