Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

650results about How to "Efficient welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

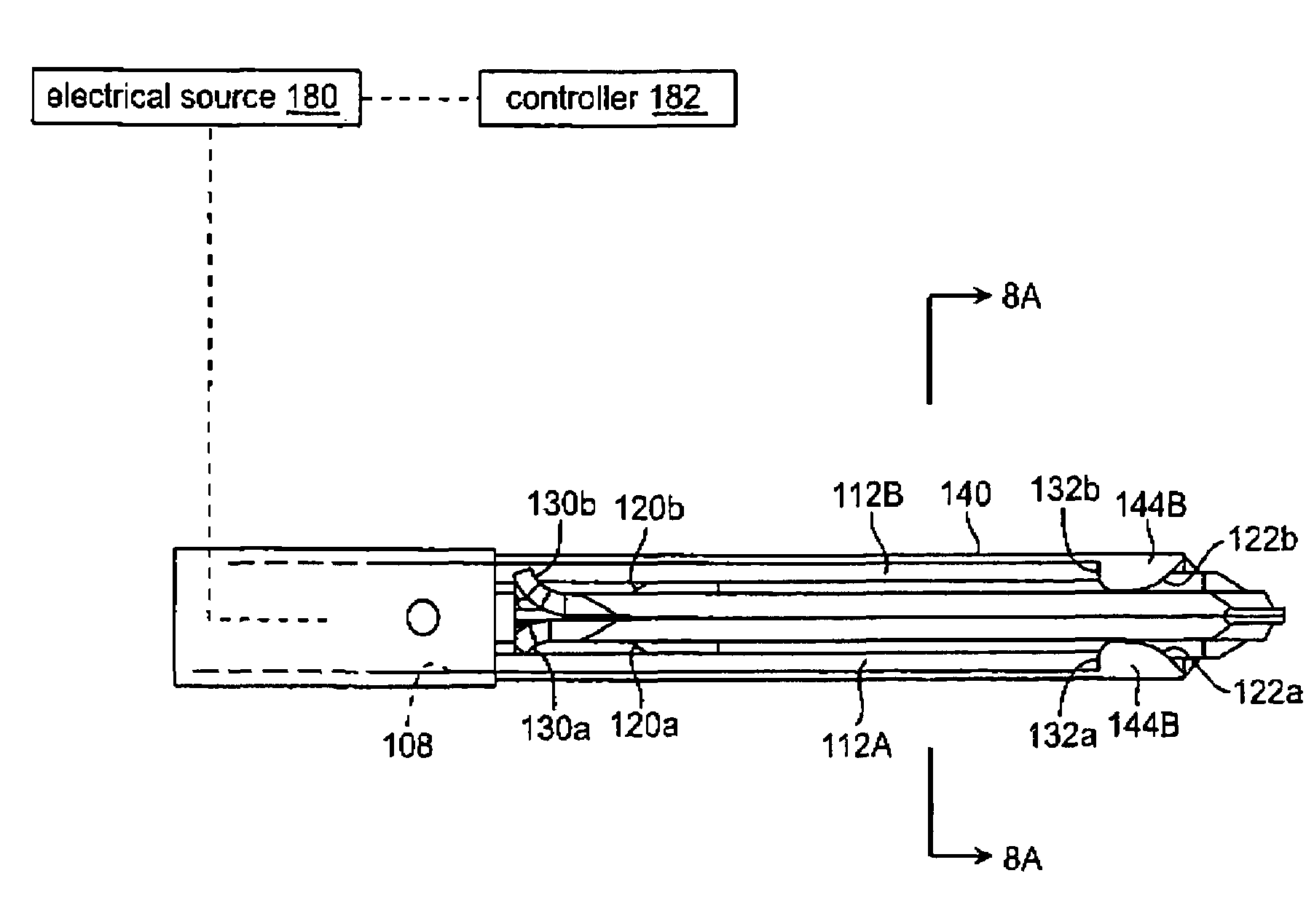

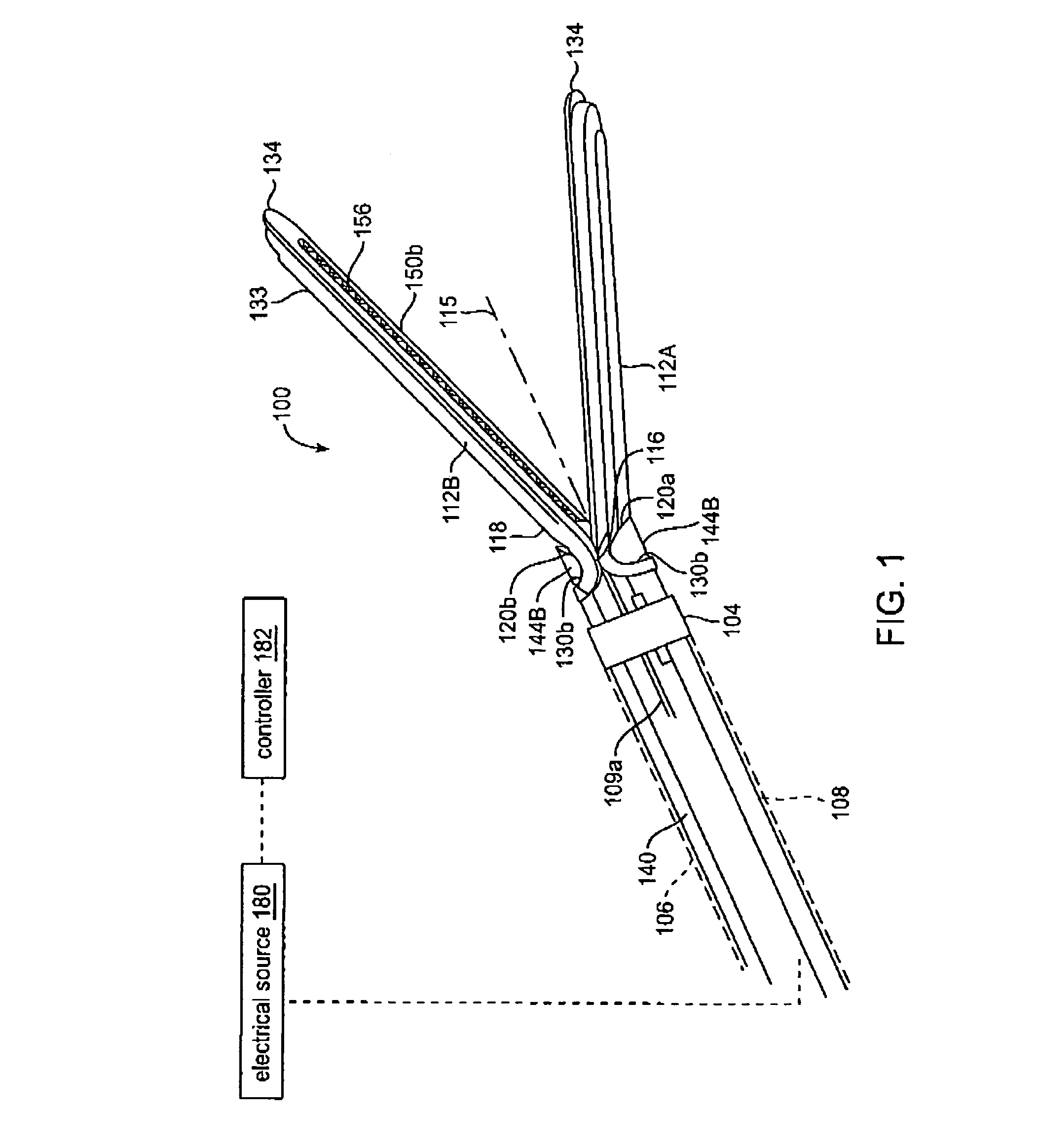

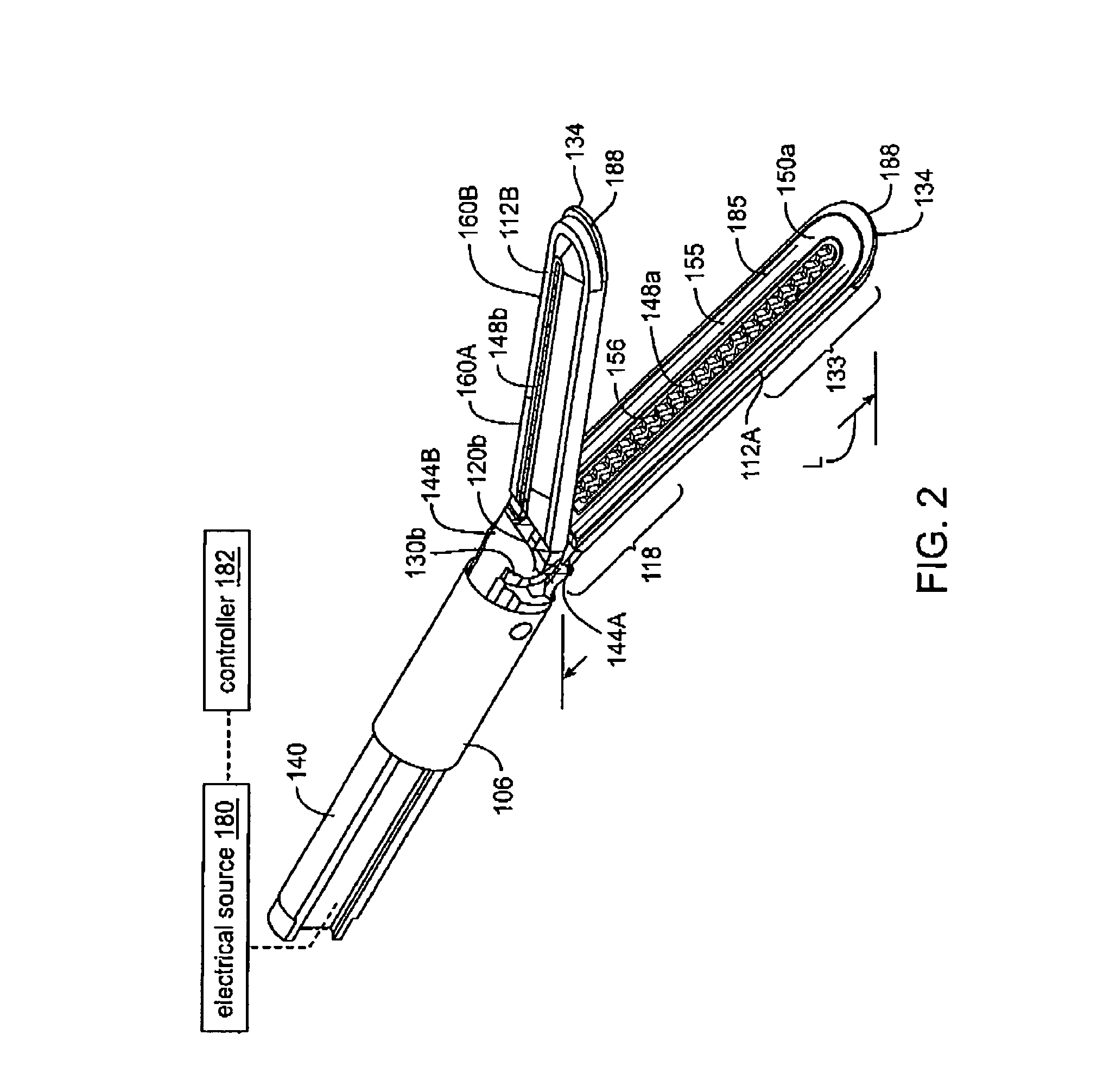

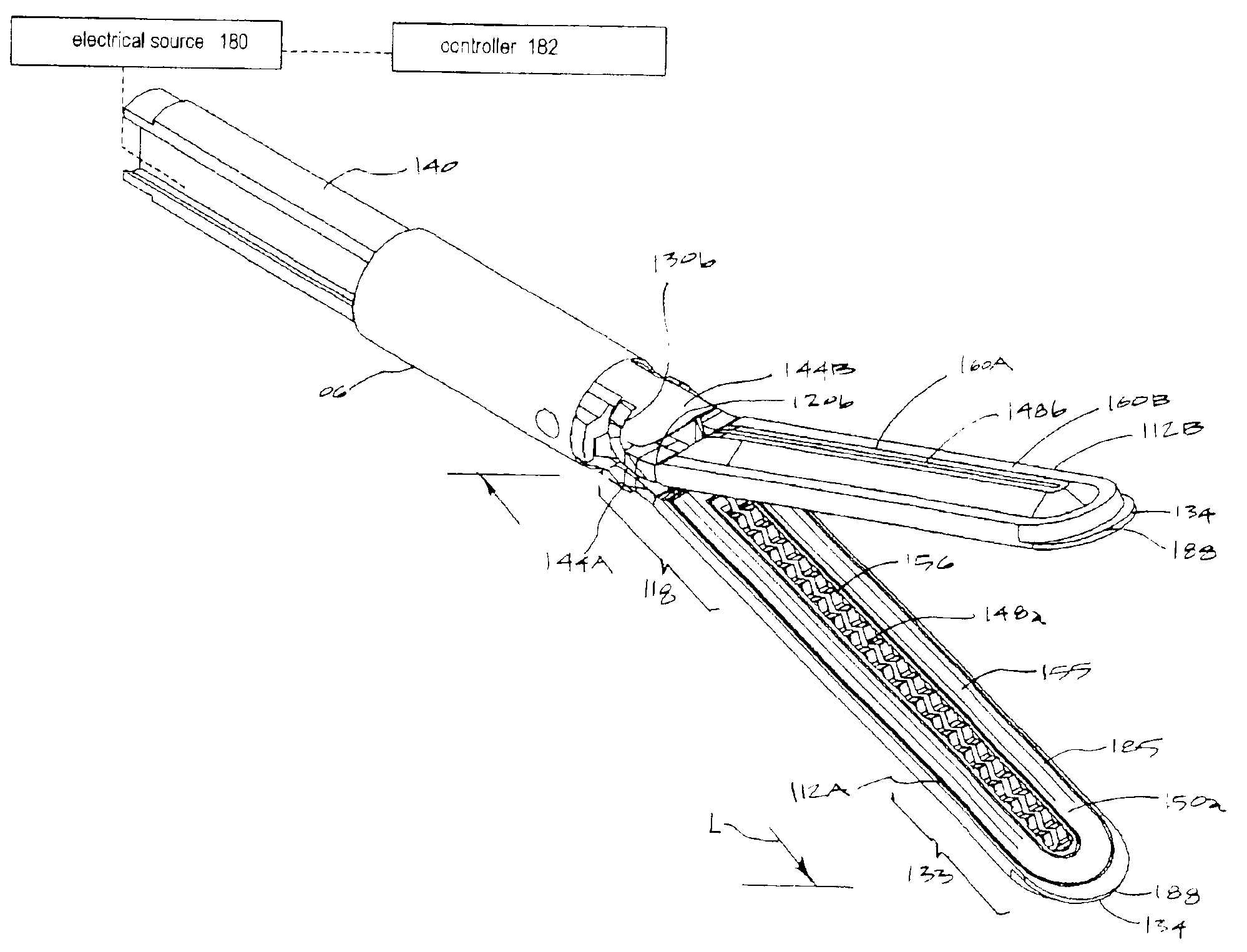

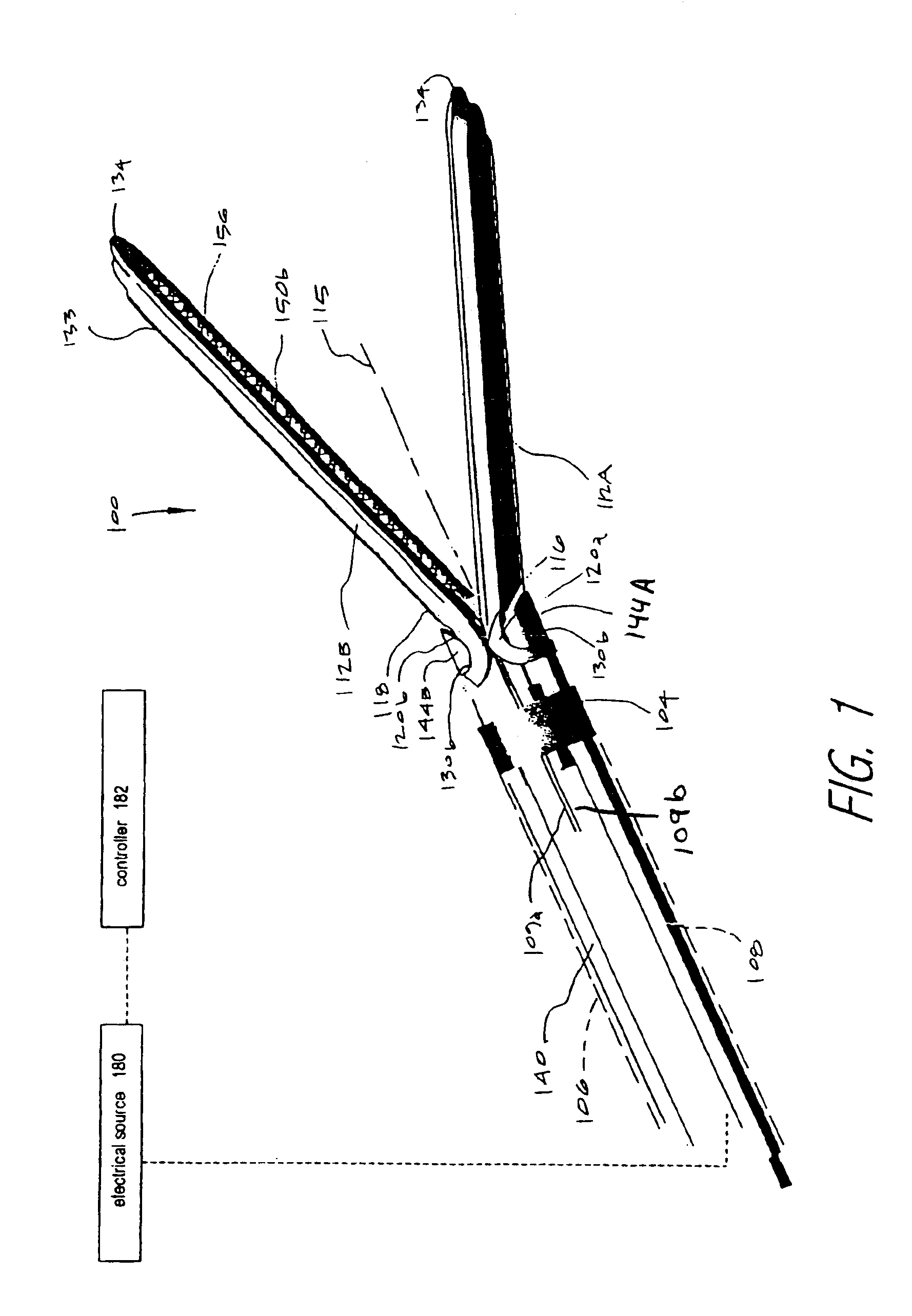

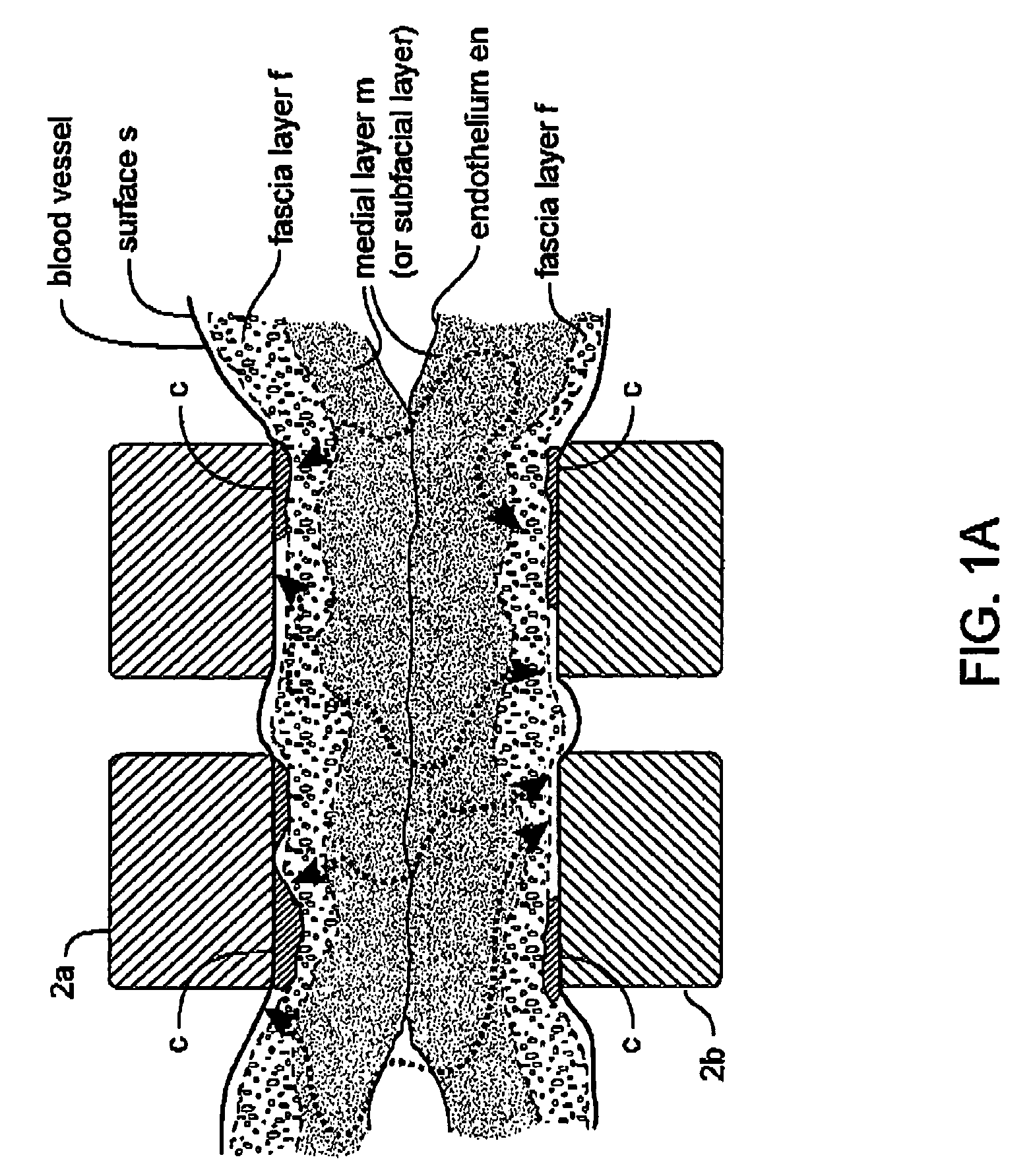

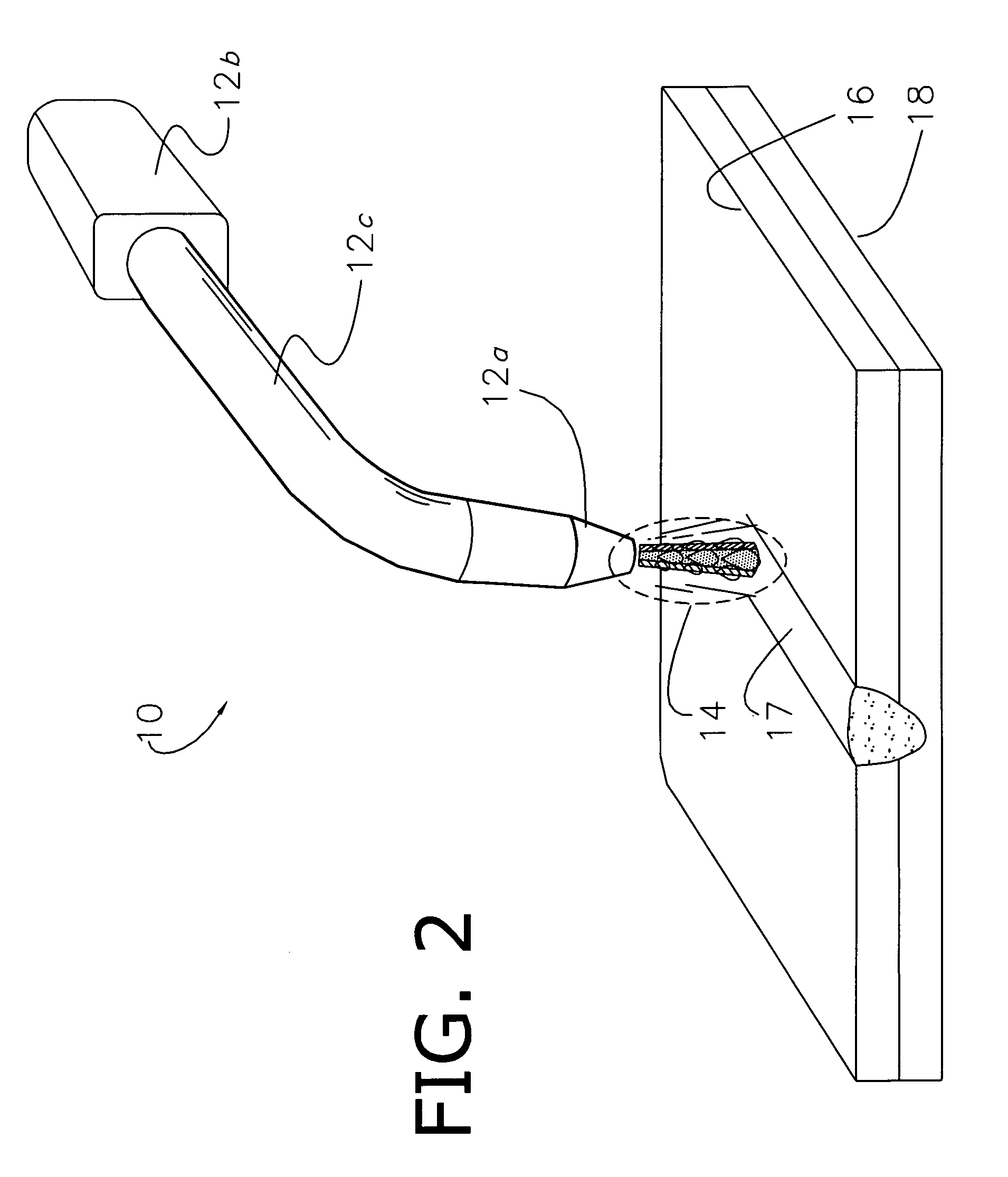

Jaw structure for electrosurgical instrument and method of use

InactiveUS7011657B2Improve the immunityEfficient weldingElectrotherapySurgical instruments for heatingTissue heatingVolumetric Mass Density

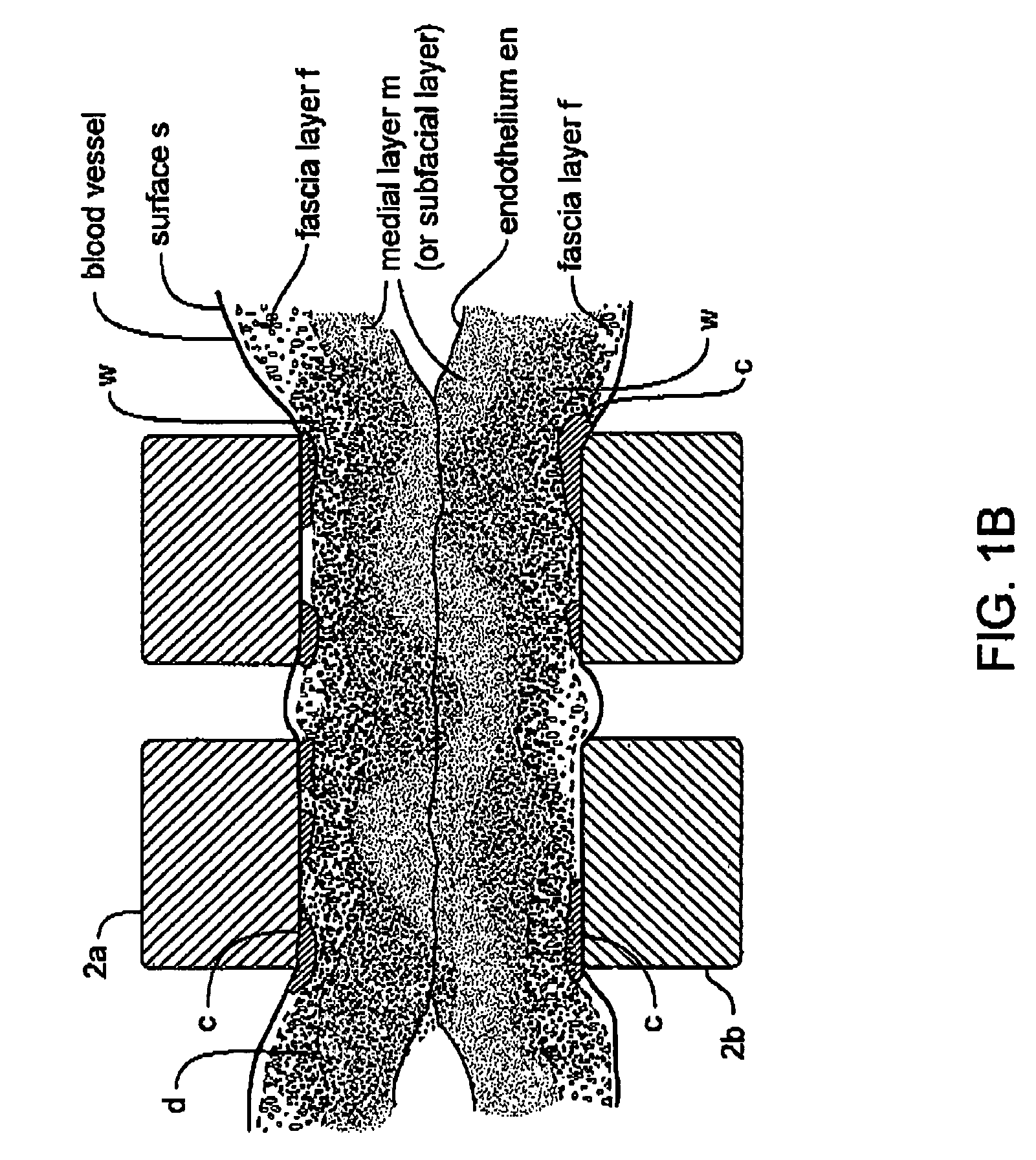

An electrosurgical medical device and technique for creating thermal welds in engaged tissue that provides very high compressive forces. In one exemplary embodiment, at least one jaw of the instrument defines a tissue engagement plane carrying first and second surface portions that comprise (i) an electrically conductive material and (ii) a positive temperature coefficient (PTC) material having a selected increased resistance that differs at each selected increased temperature over a targeted treatment range. One type of PTC material is a doped ceramic that can be engineered to exhibit a selected positively sloped temperature-resistance curve over about 37° C. to 100° C. The 70° C. to 100° C. range can bracket a targeted “thermal treatment range” at which tissue welded can be accomplished. The engineered resistance of the PTC matrix at the upper end of the temperature range will terminate current flow through the matrix. In one mode of operation, the engagement plane cause ohmic heating within tissue from Rf energy delivery tissue PTC matrix is heated to exceed the treatment range. Thereafter, energy density in the engaged tissue will be modulated as the conductivity of the second portion hovers within the targeted treatment range to thereby provide optical tissue heating for purposes of tissue welding.

Owner:ETHICON ENDO SURGERY INC

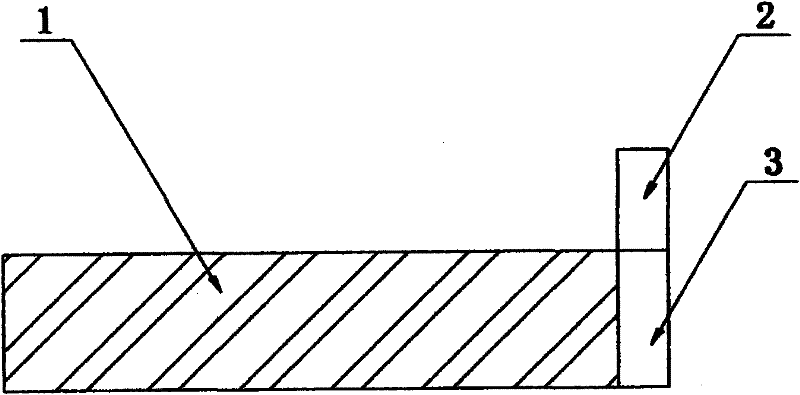

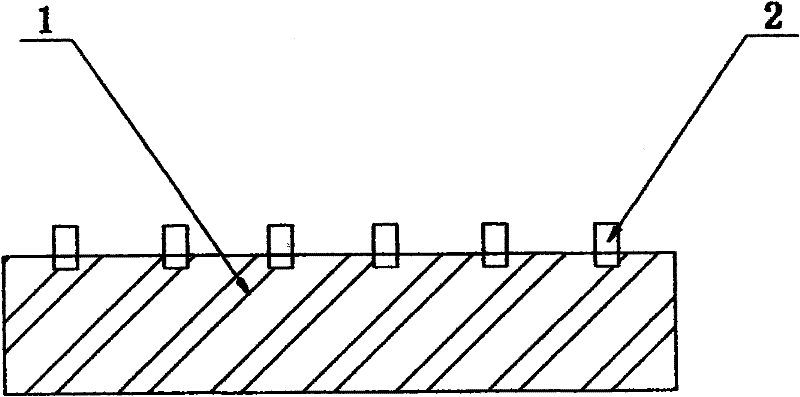

Jaw structure for electrosurgical instrument

InactiveUS6905497B2Efficient weldingPrevent any substantial dehydrationSurgical instruments for heatingCoatingsBiomedical engineeringInstrumentation

An electrosurgical medical device for creating thermal welds in engaged tissue that provides general grasping and dissecting functionality. In an exemplary embodiment, at least one jaw of the instrument defines a tissue engagement plane carrying electrosurgical energy delivery means. The jaw assembly, in one mode of operation, can be used for general grasping and dissecting purposes wherein the jaws close in a non-parallel manner so that the distalmost jaw tip only engage tissue with little movement of the actuator lever in the handle of the instrument. In another mode of operation, the jaw assembly closes close in a parallel manner under very high compression to enable tissue welding.

Owner:ETHICON ENDO SURGERY INC

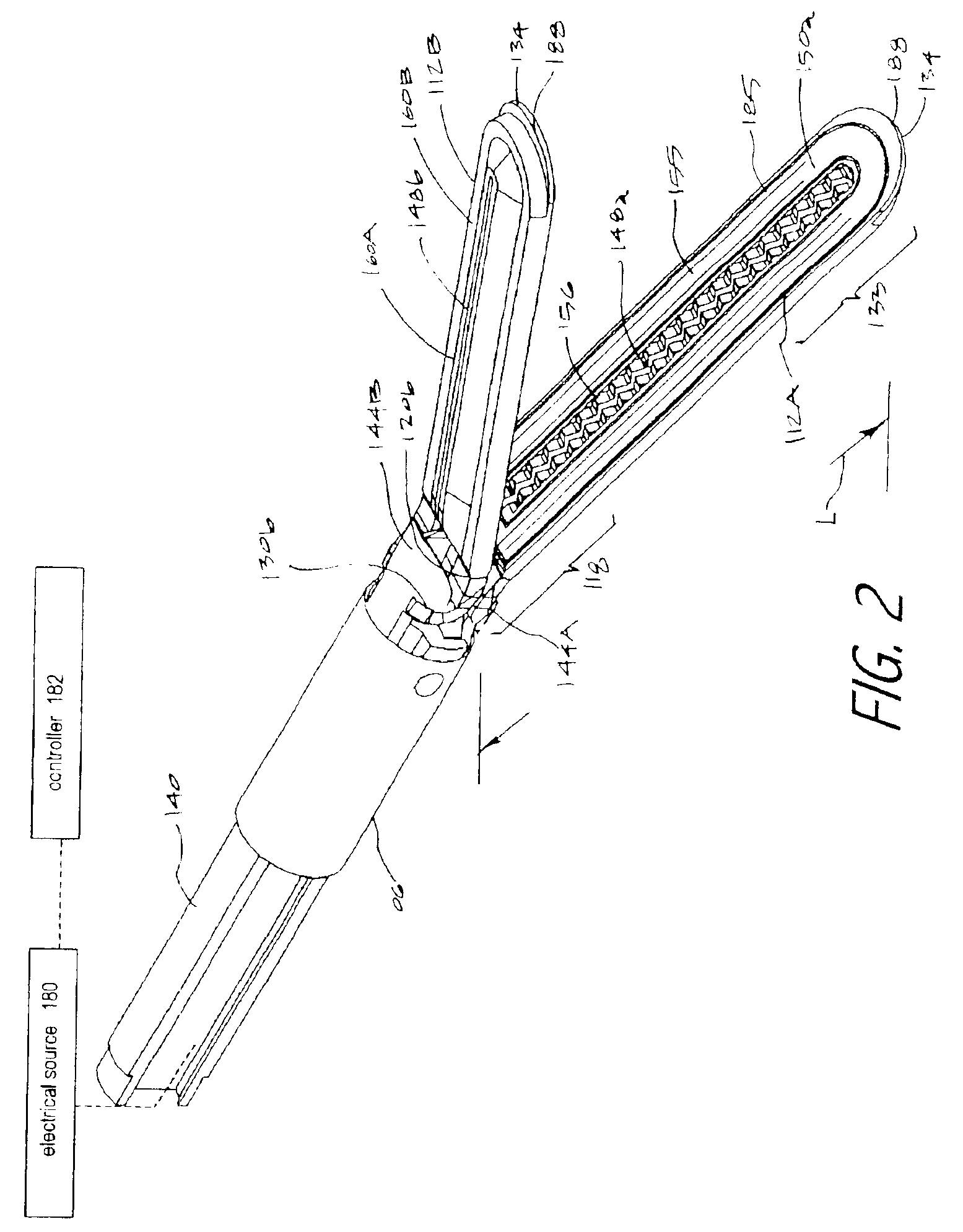

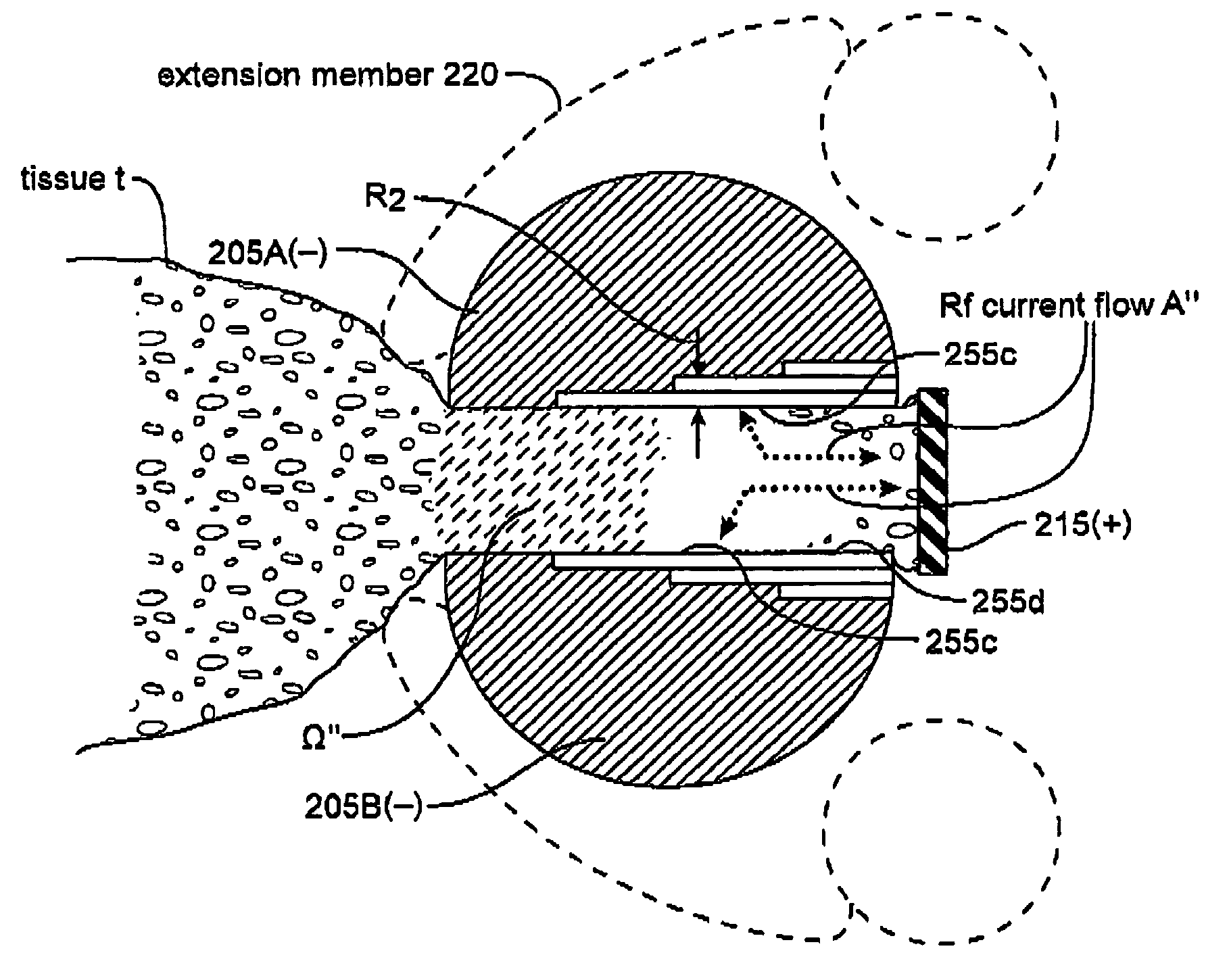

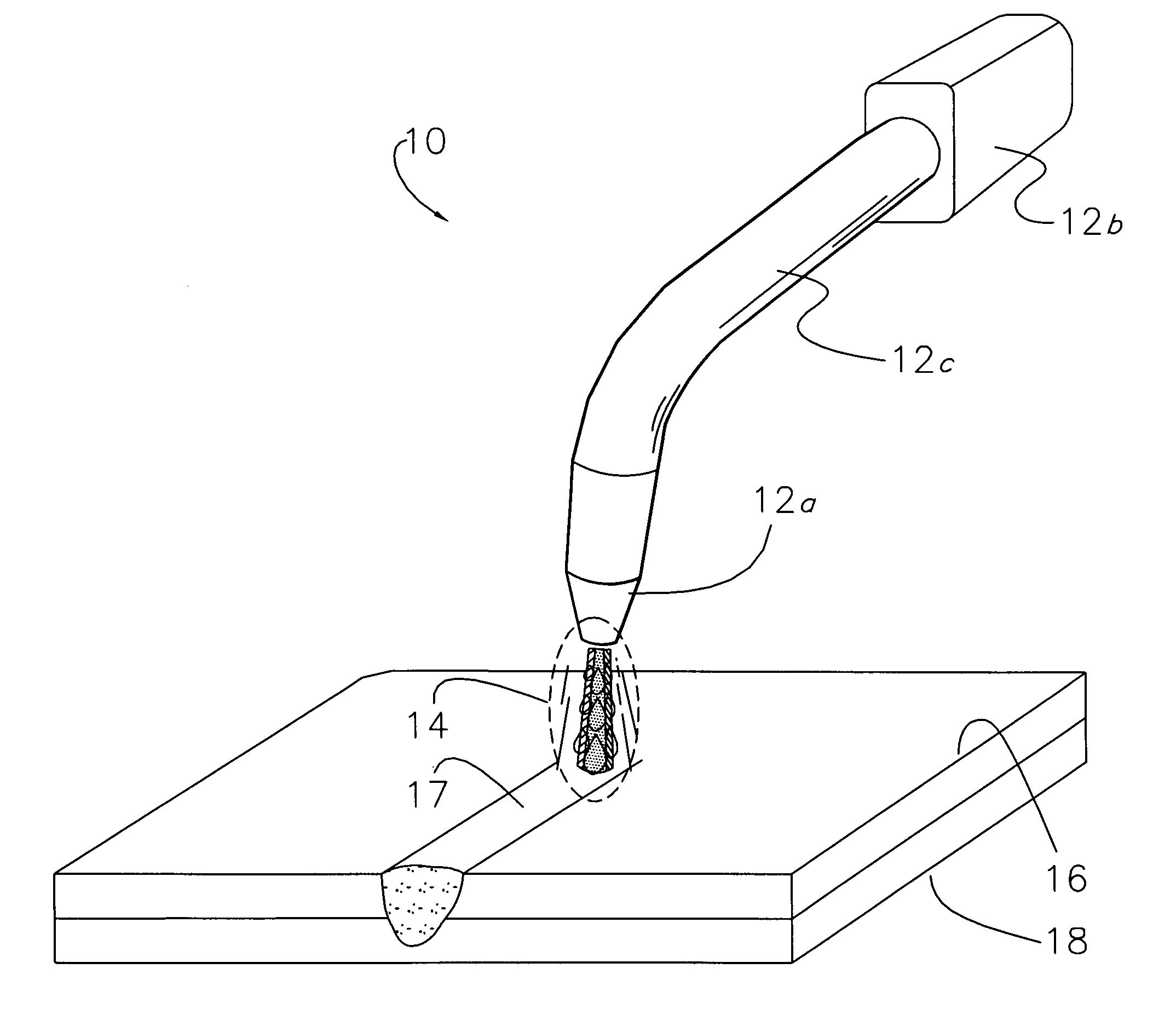

Electrosurgical instrument and method of use

InactiveUS20050267464A1Efficient weldingSpeed up the flowSurgical instruments for heatingSurgical forcepsElectrical resistance and conductanceEngineering

An embodiment of a method of the invention provides a method for welding tissue comprising providing a tissue welding device having first and second tissue engaging surfaces with at least one surface including an electrode surface that defines a plurality of surface portions having different resistances to electrical current flow therethrough. A target tissue volume is engaged with the tissue engaging surfaces. Rf energy is delivered to the target volume to create a substantially even temperature distribution across at least a portion of the target tissue volume to substantially uniformly weld at least a portion of the target tissue volume.

Owner:SURGRX

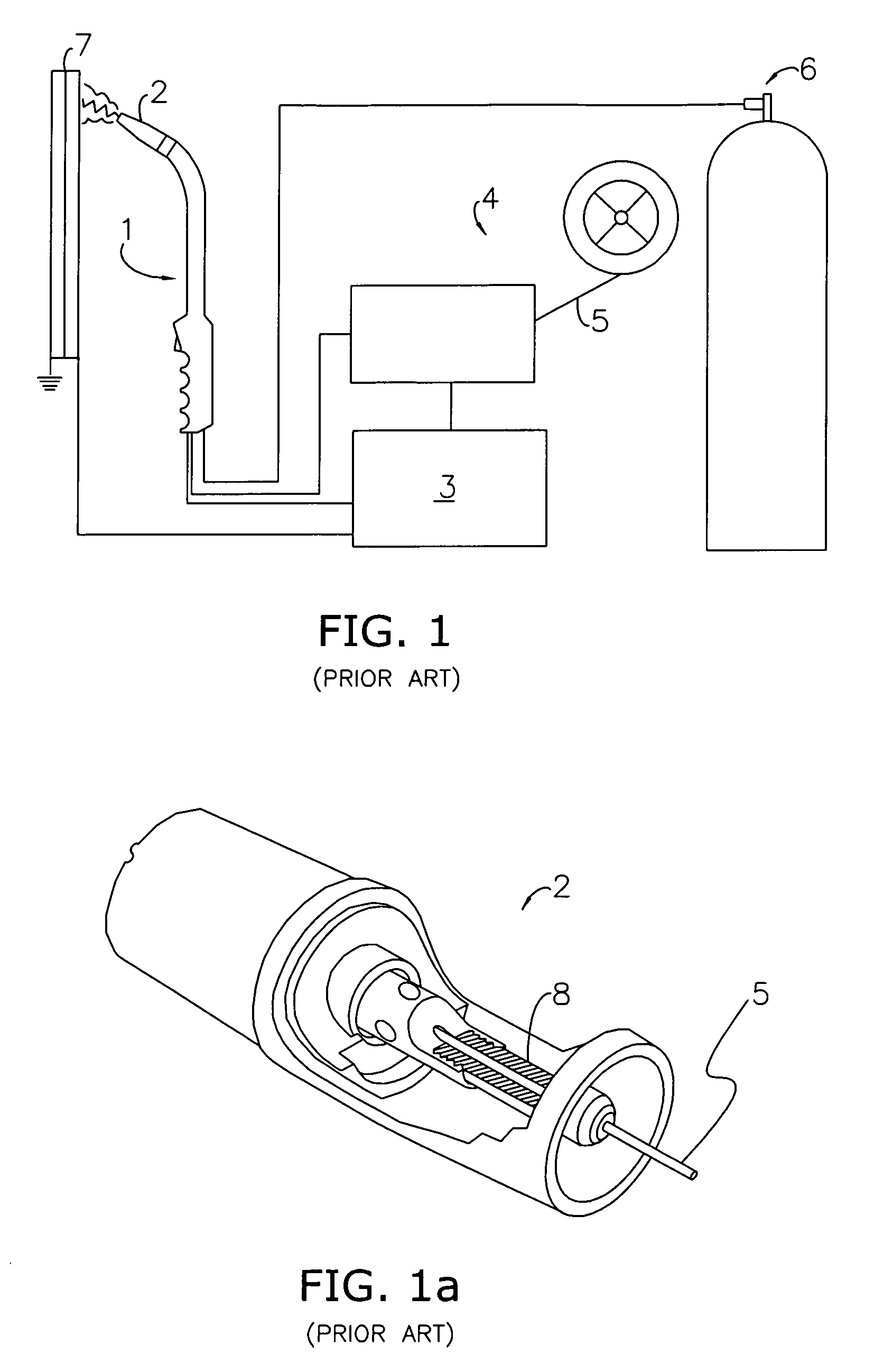

Laser welding control system

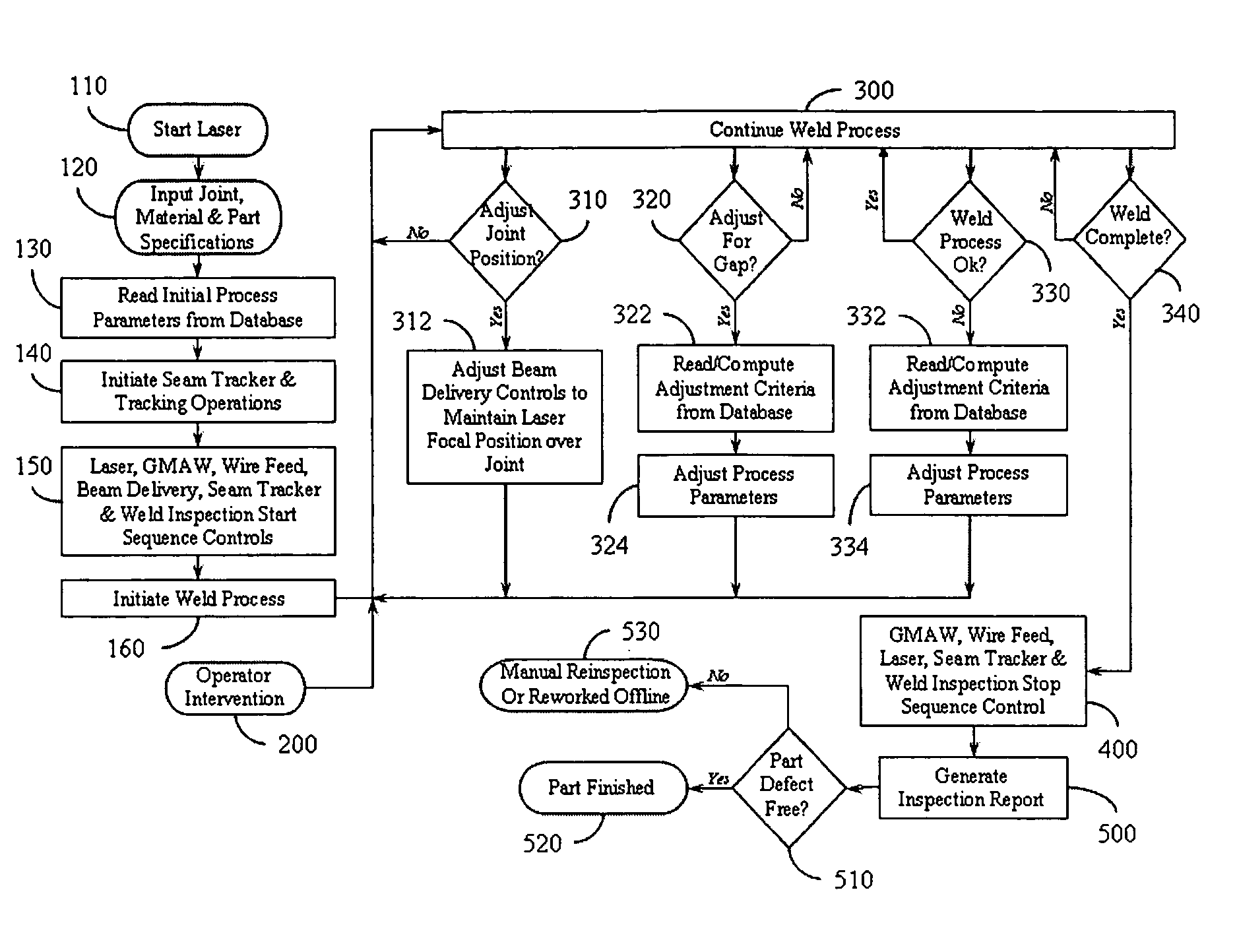

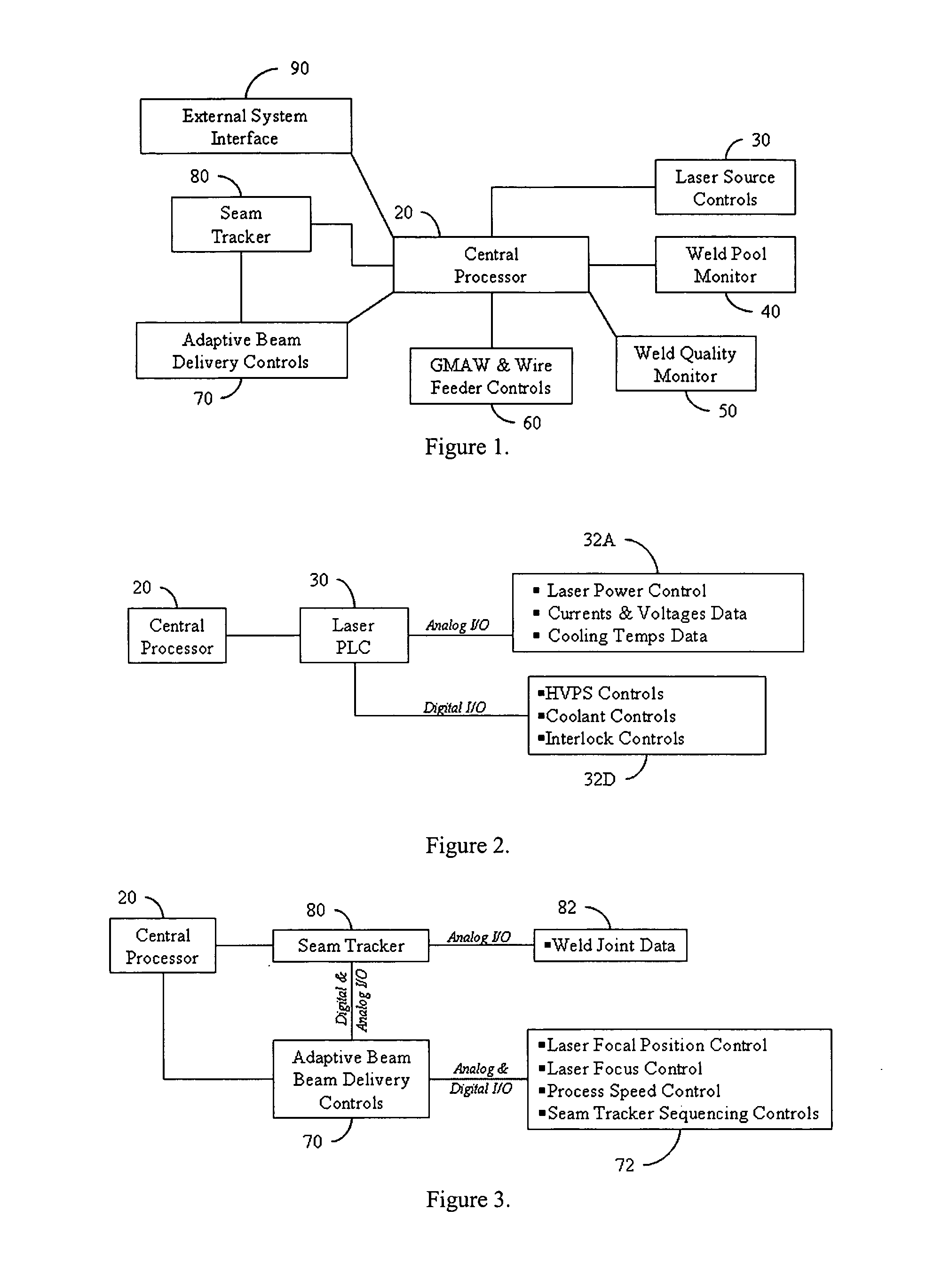

ActiveUS7107118B2Improve reliabilityReduce the amount requiredProgramme controlElectrical apparatusClosed loopVision based

A fully integrated automated laser weld process control system (LWPCS) and method of controlling the fabrication of structural parts, particularly for shipbuilding and other industries. The LWPCS defines joint and weld quality attributes as process control variables and integrates these weld quality variables, along with the more traditional process parameters such as laser power, wire feed, GMAW voltage and active seam tracking, into a closed-loop monitoring and control system. The LWPCS includes a central processor and a plurality of subsystems that control laser beam positioning, vision-based monitoring and image processing, active weld-quality monitoring and inspection, adaptive beam delivery, and seam tracking. Cross-communication between subsystems is managed by the central processor. In addition to process control, the system extracts weld quality attributes during the weld process and provides immediate documentation of the weld quality.

Owner:ESAB AB

Yield strength 700MPa grade atmospheric corrosion resistant steel and method for manufacturing same

ActiveCN101135029AImprove mechanical propertiesSuitable for thin designTemperature control deviceHeat treatment process controlSheet steelWeather resistance

The atmospheric corrosion resistant steel with yield strength of 700 MPa level has the chemical composition comprising C 0.05-0.10 wt%, Si not more than 0.50 wt%, Mn 0.8-1.6 wt%, P not more than 0.020 wt%, S not more than 0.010 wt%, Al 0.01-0.05 wt%, Cu 0.20-0.55 wt%, Cr 0.40-0.80 wt%, Ni 0.12-0.40 wt%, Ca 0.001-0.006 wt%, N 0.001-0.006 wt% and Fe and inevitable impurity for the rest. Its production process includes the following steps: 1. smelting and casting to form steel billet; 2. heating the steel billet to over 1200 deg.c, finish rolling at 950 deg.c in the final temperature lower than 910 deg.c and lowered with the increased plate thickness; and 3. cooling in the rate of 5-15 deg / s to 450-650 deg.c, winding and air cooling to room temperature. The atmospheric corrosion resistant steel has excellent comprehensive mechanical performance, yield strength over 700 MPa, high weather resistance and other advantages.

Owner:BAOSHAN IRON & STEEL CO LTD

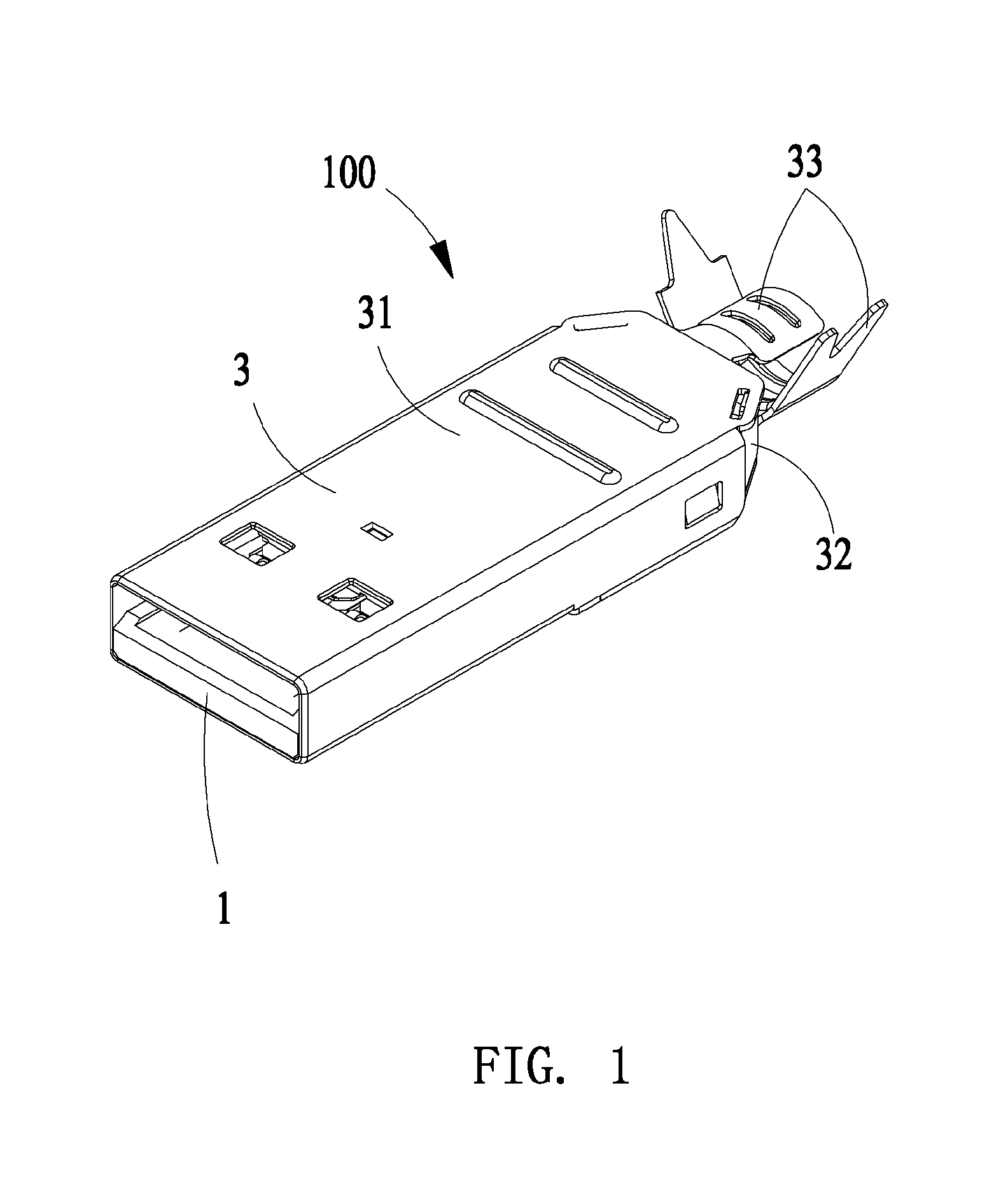

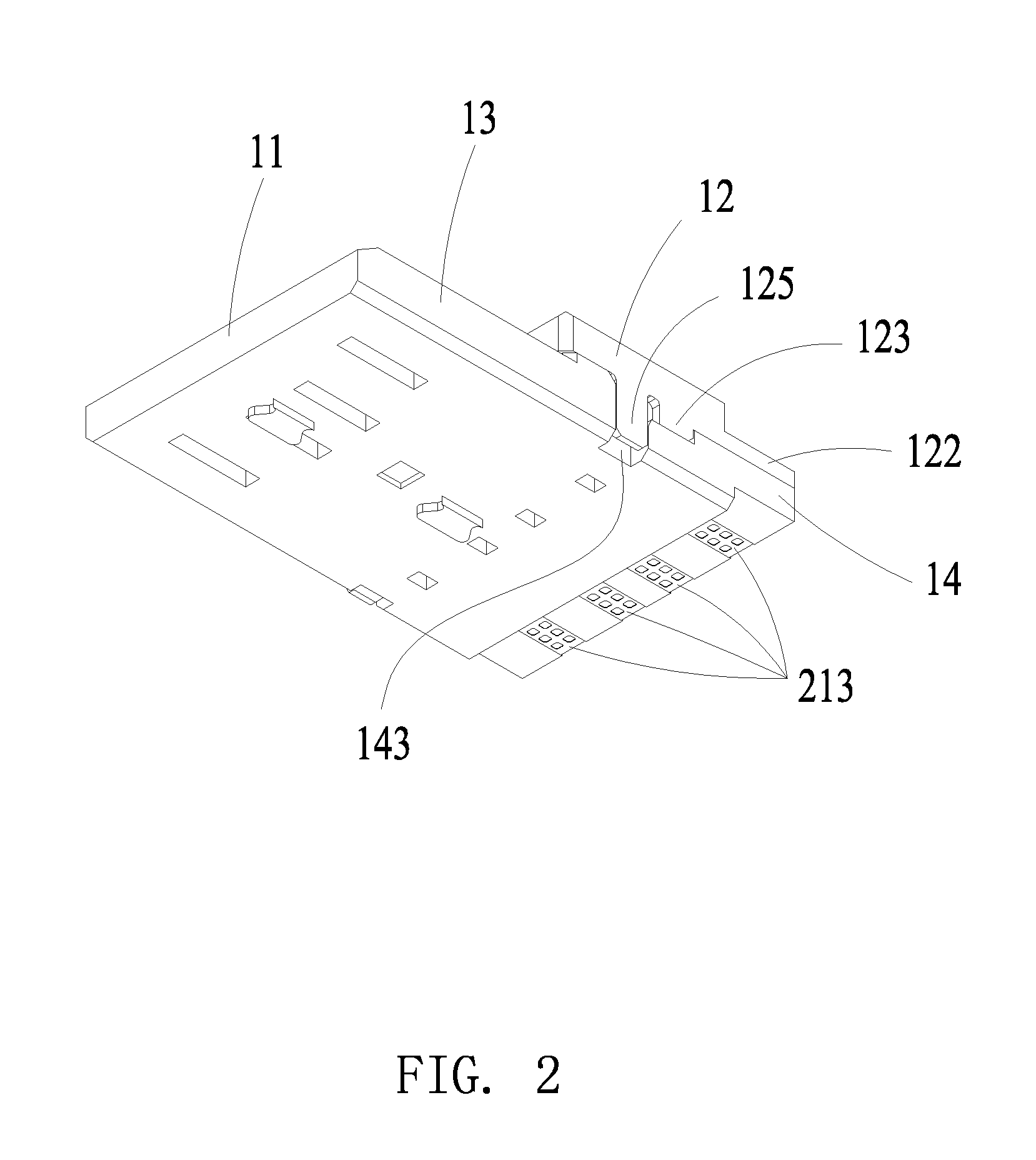

Electrical connector with grounding contact having forked soldering branches

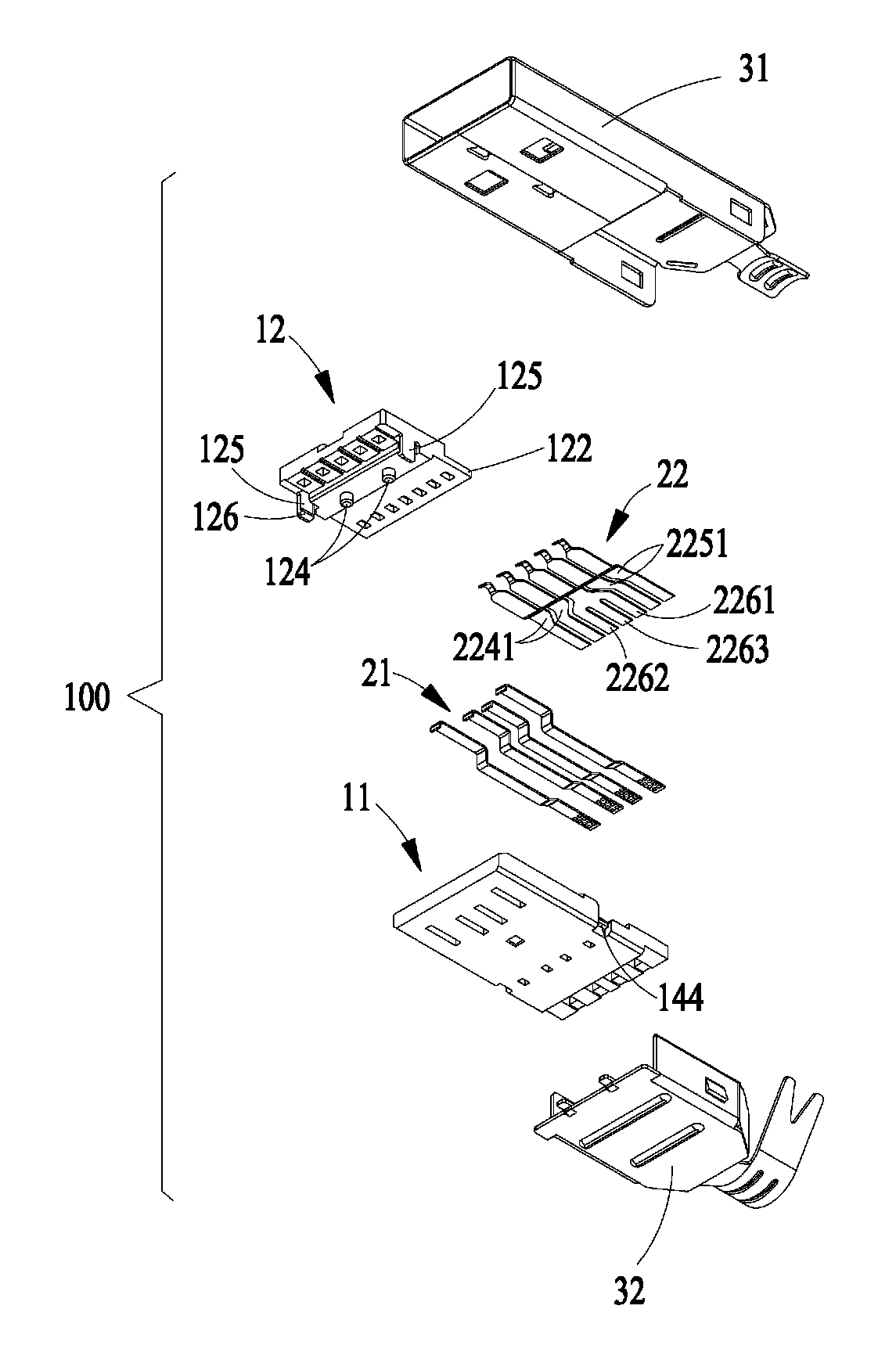

InactiveUS8708718B2Efficient weldingElectric discharge tubesSecuring/insulating coupling contact membersGround contactElectricity

A cable connector compatible to type-A USB 3.0 standard includes a number of contacts divided into a first contact group and a second contact group. The first contact group is compatible to USB 2.0 standard. The second contact group includes a number of second contacts having a first pair of high-speed differential signal contacts, a second pair of high-speed differential signal contacts and a grounding contact disposed between the first pair and the second pair of high-speed differential signal contacts. The second soldering section of the grounding contact is of a forked manner and includes at least a first branch and a second branch. As a result, it is more effective to solder the second soldering section of the grounding contact with a cable without any manual alignment work.

Owner:LUXSHARE PRECISION IND SHENZHEN

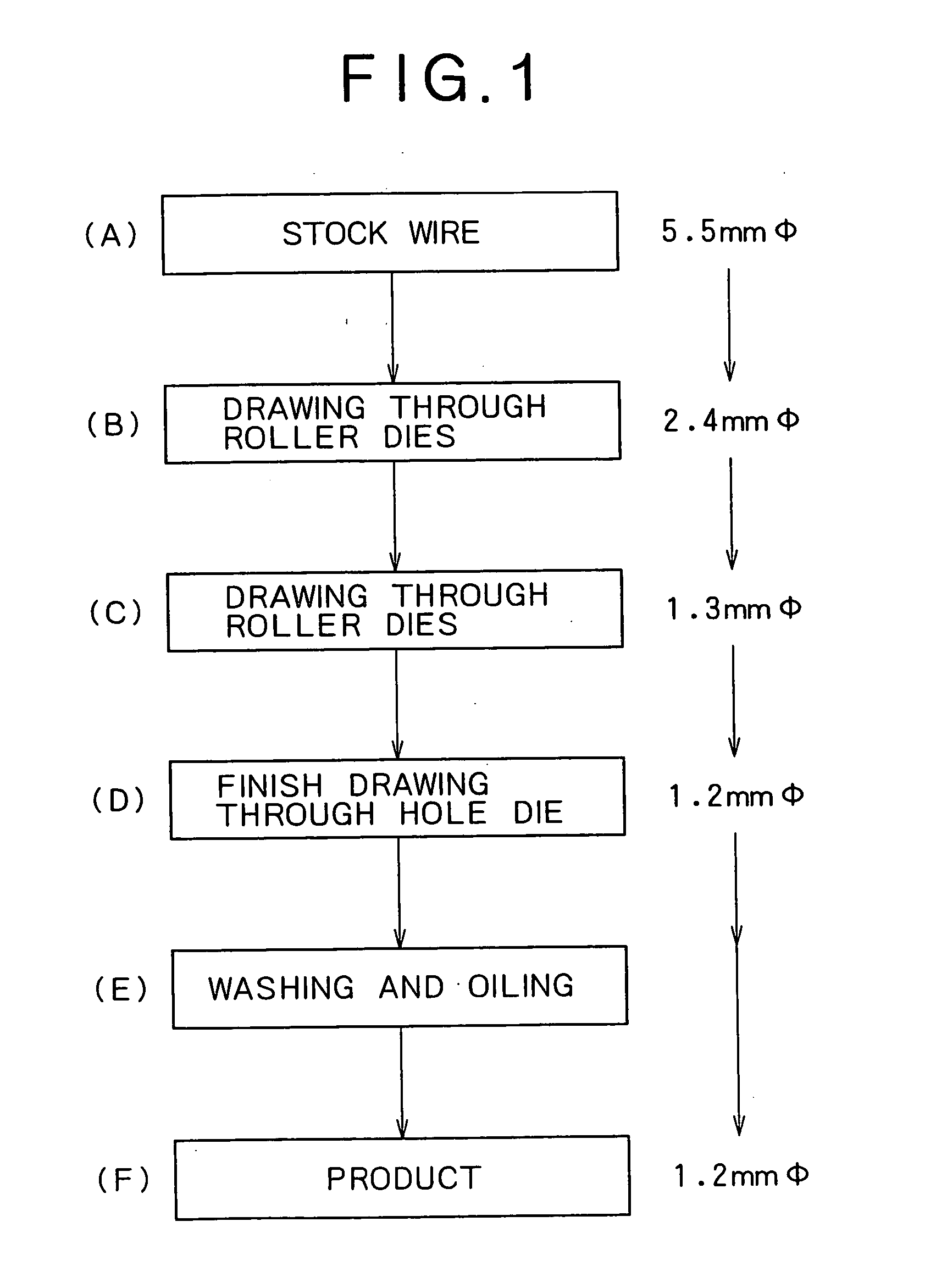

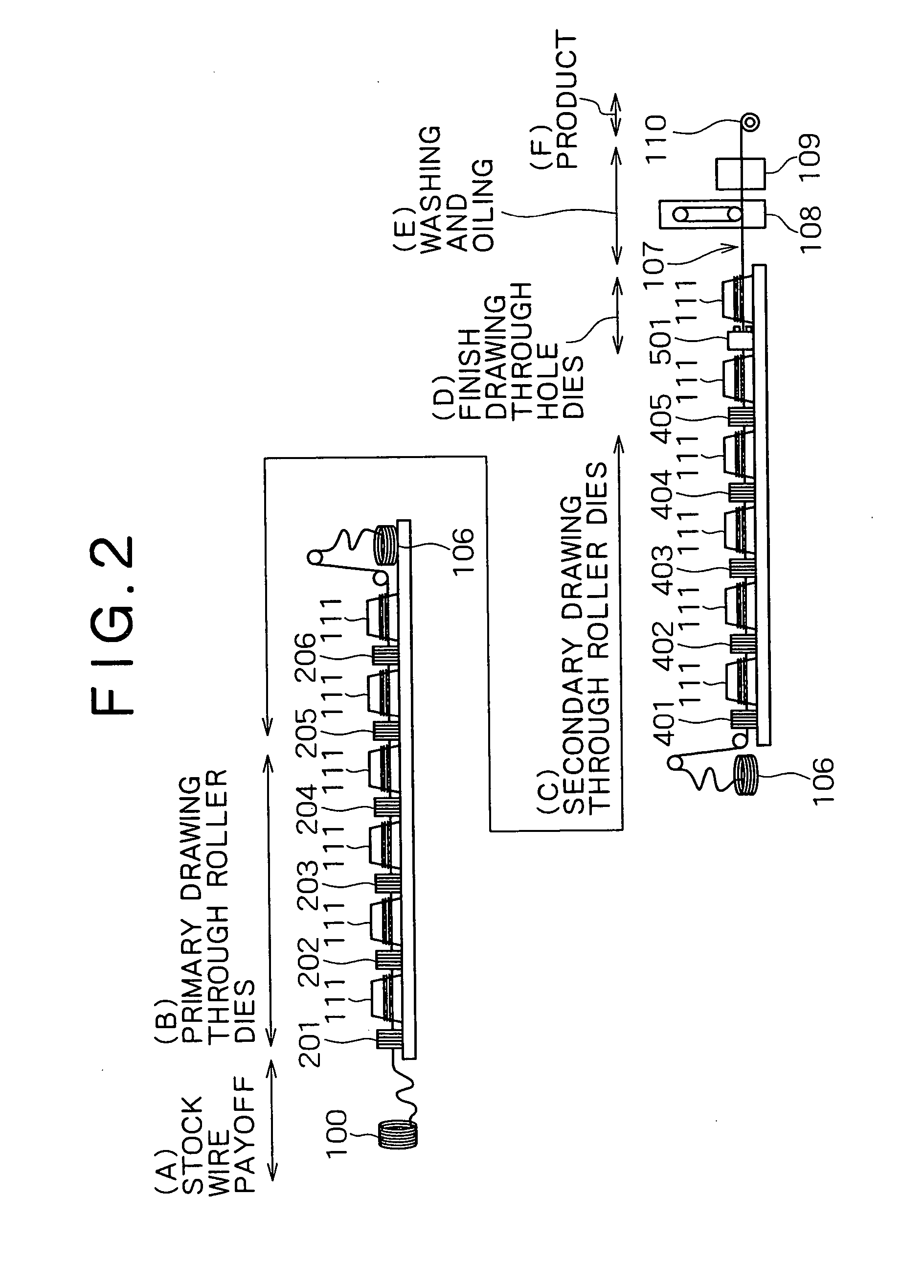

Method of producing solid wire for welding

ActiveUS20050045699A1Uniform applicationEfficient weldingDrawing diesArc welding apparatusCopper platingSodium stearate

A method for efficient production of a welding solid wire free of copper plating. The method consists of drawing by means of roller dies with the help of a dry solid lubricant for drawing which is at least either of sodium stearate or potassium stearate, removing the lubricant from the wire surface by means of a washing device, and applying a lubricant for wire feeding to the surface of the drawn wire by means of an oiling device. High-speed drawing by means of roller dies makes a stock wire into a welding solid wire having the diameter of the finished wire or nearly finished wire. The drawing step is followed by the washing step and the lubricant applying step, which are all accomplished in-line.

Owner:KOBE STEEL LTD

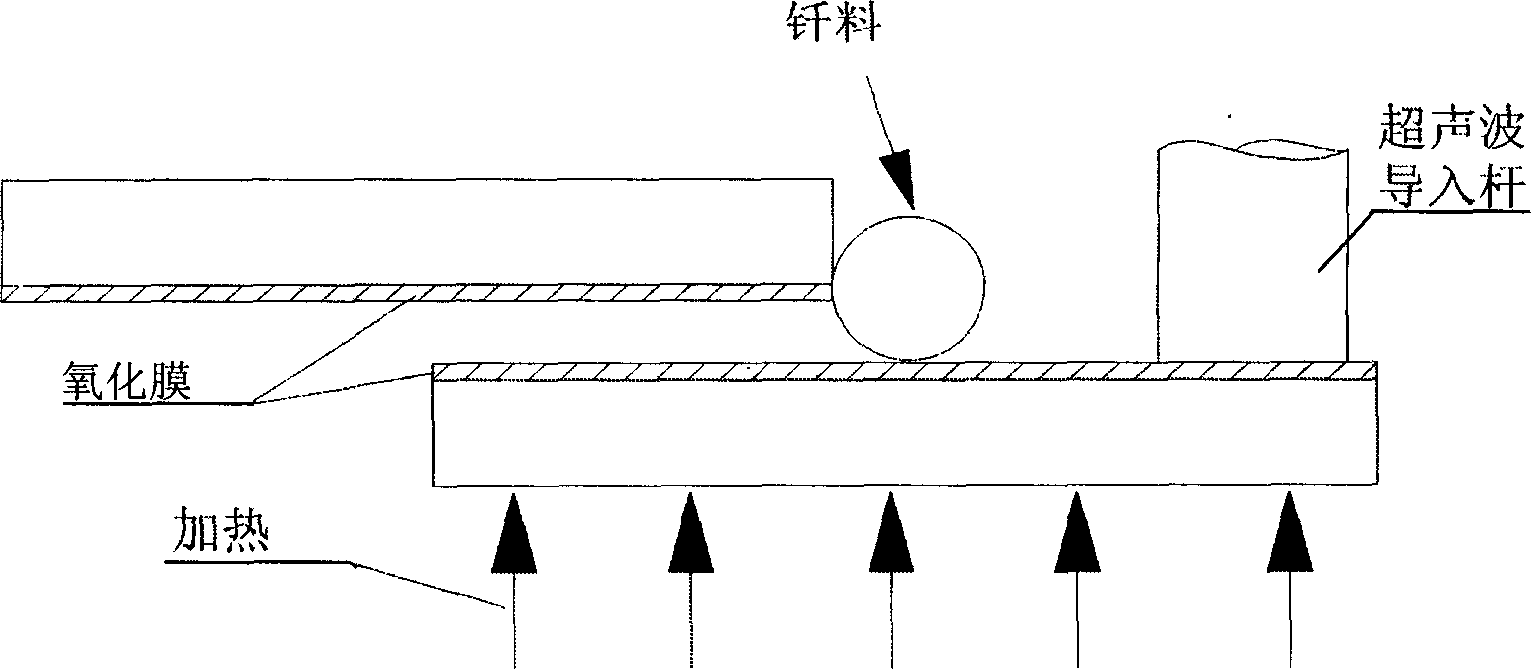

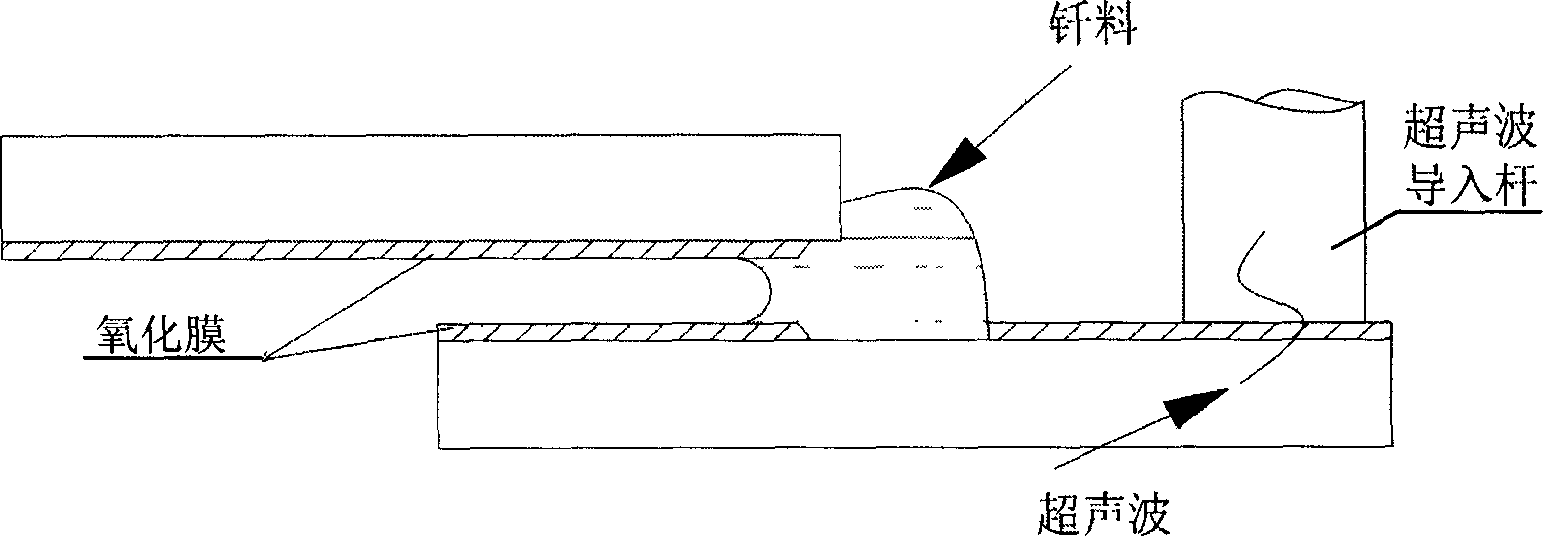

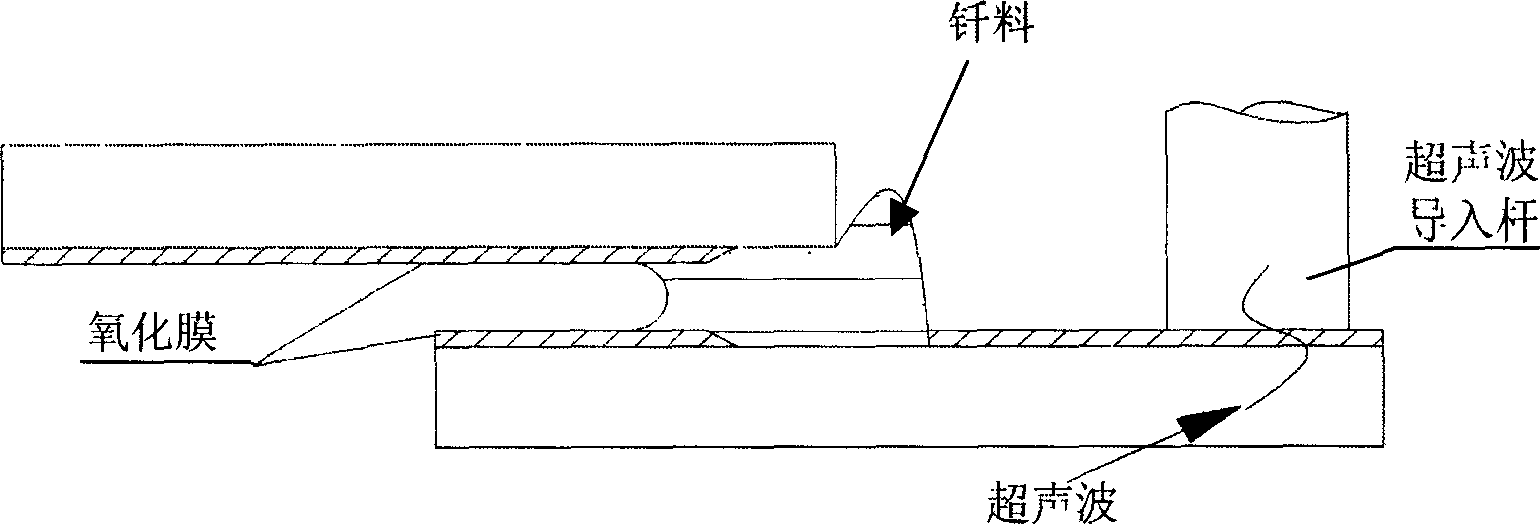

Aluminium base composite material ultrasonic wave fine welding method

InactiveCN1644291AAvoid WeldingEfficient weldingNon-electric welding apparatusUltrasonic vibrationMaterials science

An ultrasonic capillary welding method for the Al-base composite material includes such steps as arranging upper and lower parts to be welded in such manner that the gap between them is 10-300 microns, putting the flux close to lap end, heating to smelt the flux, holding the temp, pressing the ultrasonic head onto surface of the part to be welded, and applying ultrasonic vibration for 0.5-15 S. Its advantages are high welding quality, low welding temp, and high speed.

Owner:HARBIN INST OF TECH

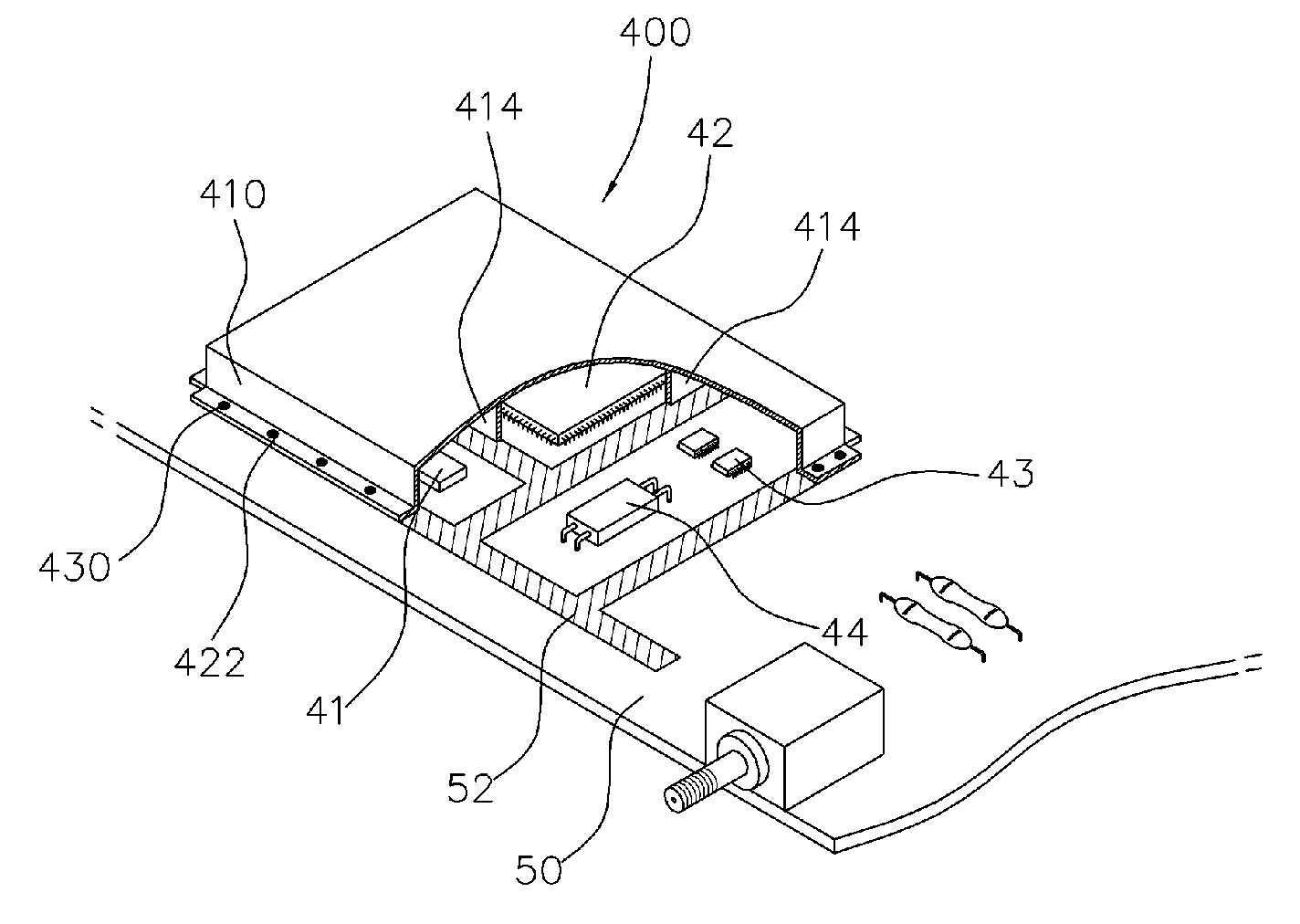

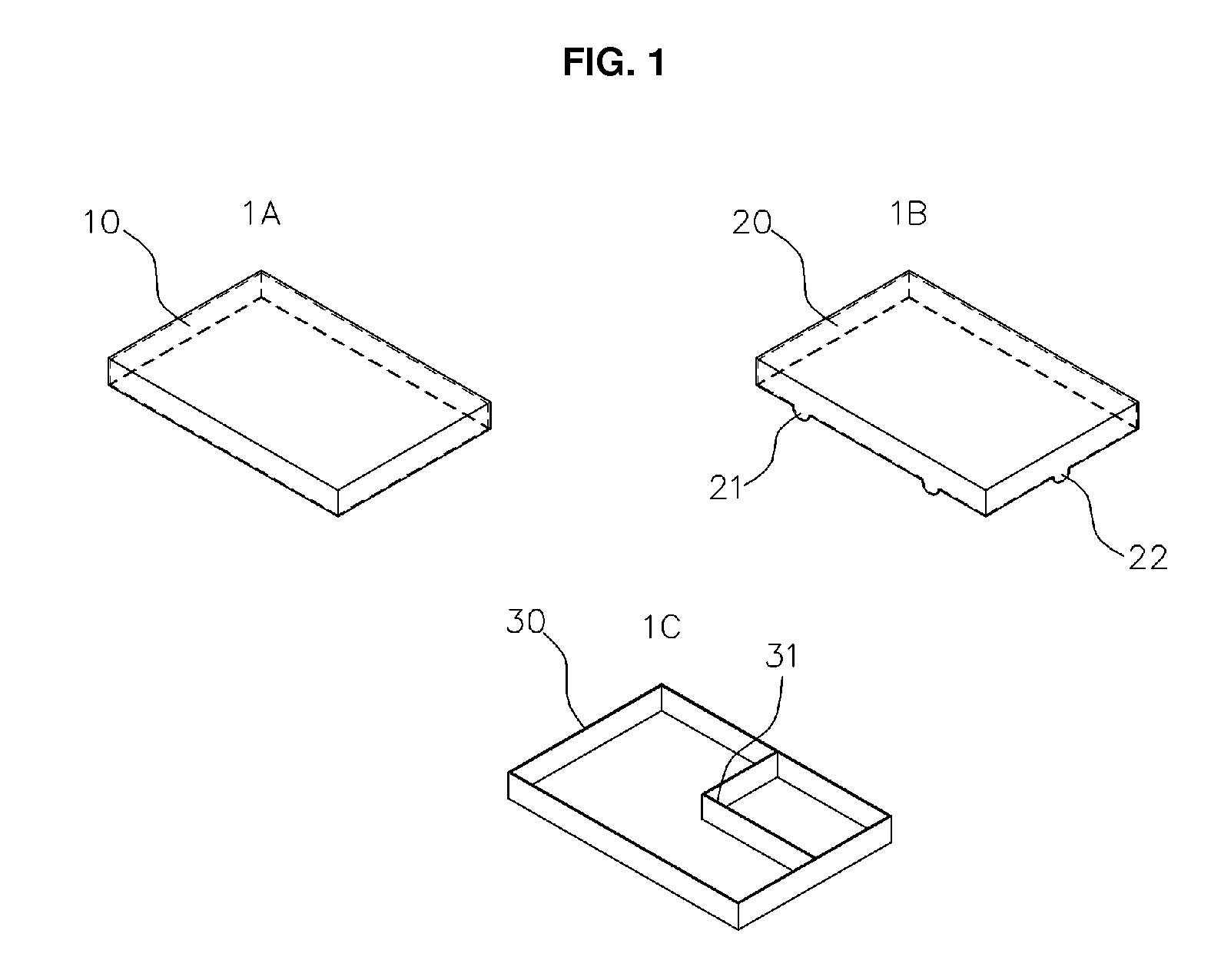

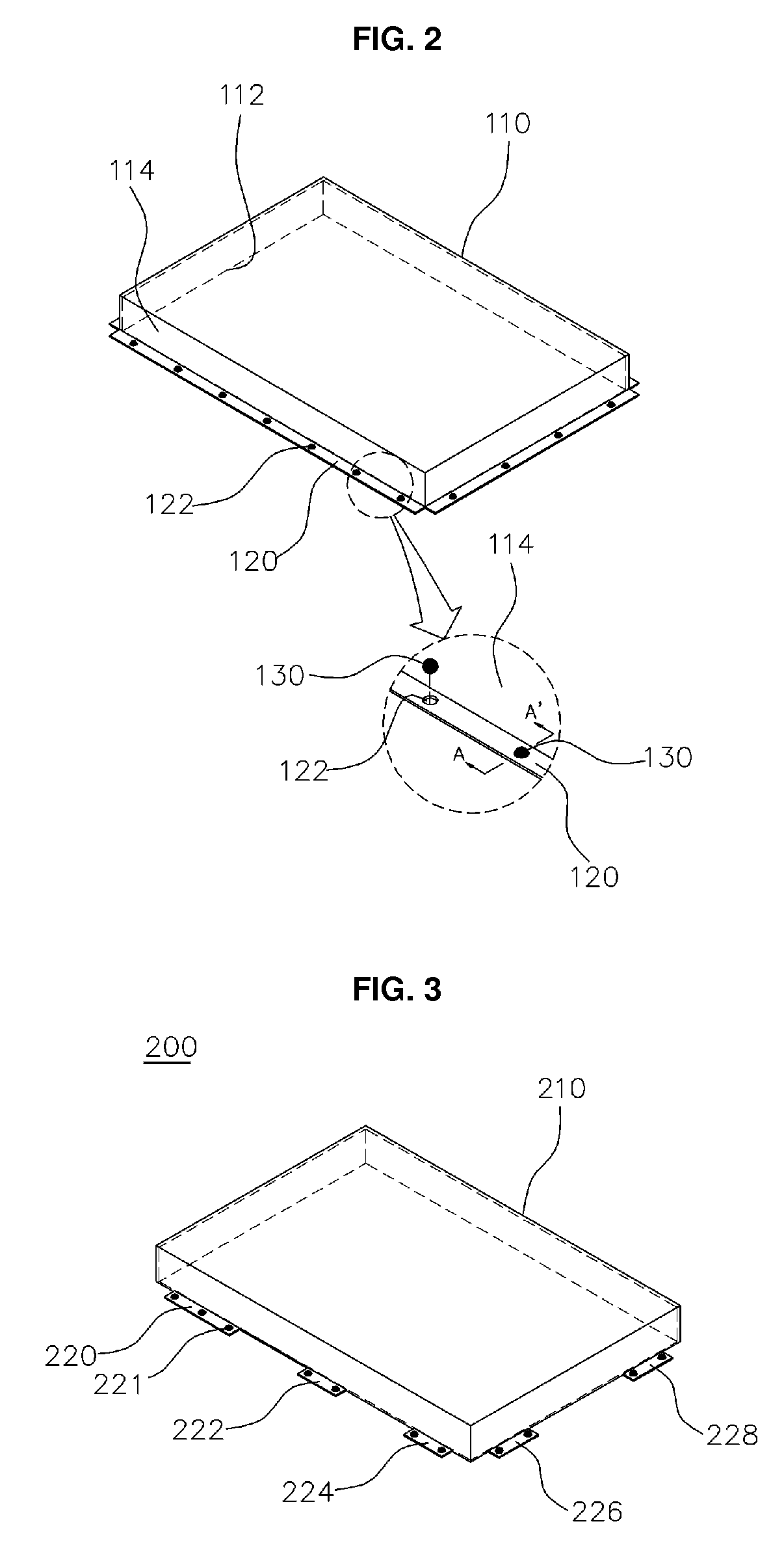

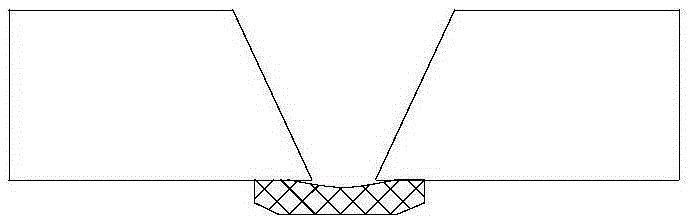

Easily solderable shield case for electromagnetic wave shielding

InactiveUS20120281386A1Ensure qualityEasy to processMagnetic/electric field screeningCasings/cabinets/drawers detailsElectromagnetic shieldingSoldering

An easily soldered shield case for electromagnetic-wave shielding comprises: a metal main body in the shape of a box of which the bottom surface is open; a flange which is formed extending integrally outward or inward from the open edge of the main body; a plurality of through holes formed along the flange or a plurality of recesses formed along the rear surface of the flange; and a solder member which is stably placed on the through holes or the recesses and projects in the thickness direction of the flange, wherein the shield case is mounted on a printed circuit board and the solder member is electrically and mechanically joined to the printed circuit board by means of soldering.

Owner:JOINSET

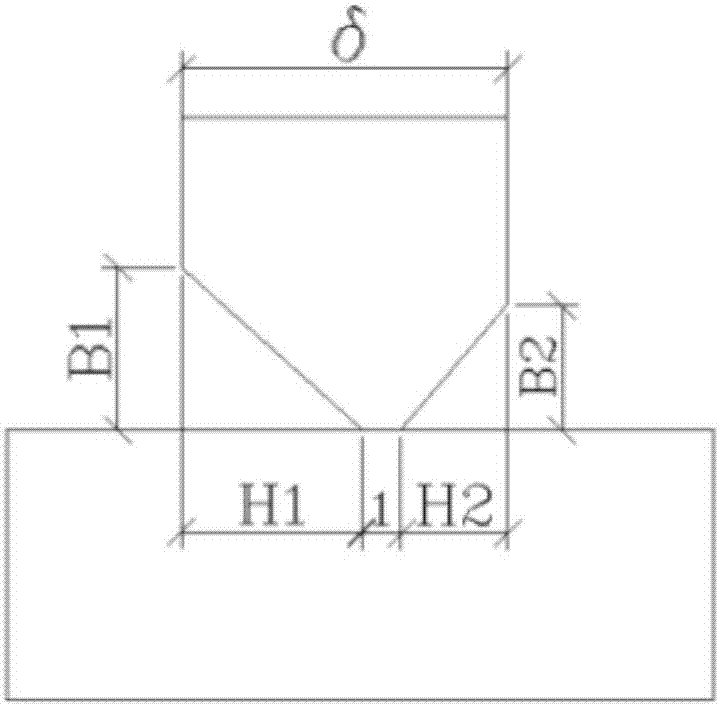

Welding method for high-performance weather-resistant steel which is at Q345qENH-Q420qENH level and used for bridges

InactiveCN105252122AGood mechanical propertiesImprove corrosion resistanceArc welding apparatusWelding/cutting media/materialsShielded metal arc weldingChemical composition

The invention discloses a welding method for high-performance weather-resistant steel which is at the Q345qENH-Q420qENH level and used for bridges. Welding connectors selected according to specific chemical components, mechanical properties, welding connector corrosion-resistant indexes, applicable technological conditions and different plate thickness specifications of the high-performance weather-resistant steel which is at the Q345qENH-Q420qENH level and used for bridges are in the type of a butt joint and a T-shaped connector (including a corner connector); a welding method includes submerged automatic arc welding, solid wire argon-rich gas protection semi-automatic welding, flux-cored wire CO2 gas protection semi-automatic welding and shielded metal arc welding; and preheating temperature before welding is determined according to different plate thicknesses. The welding method comprehensively covers the connector types and the plate thickness specifications of the bridge steel structure; the technical scheme is high in practicability; the implementation effect totally meets the technological requirements of structural steel for existing bridges and relevant standards in the steel bridge manufacturing field; and the welding method can be used for welding the high-performance weather-resistant steel which is at the Q345qENH-Q420qENH level and has a great effect on prompting popularization of high-level weather-resistant bridge steel.

Owner:中铁宝桥(扬州)有限公司

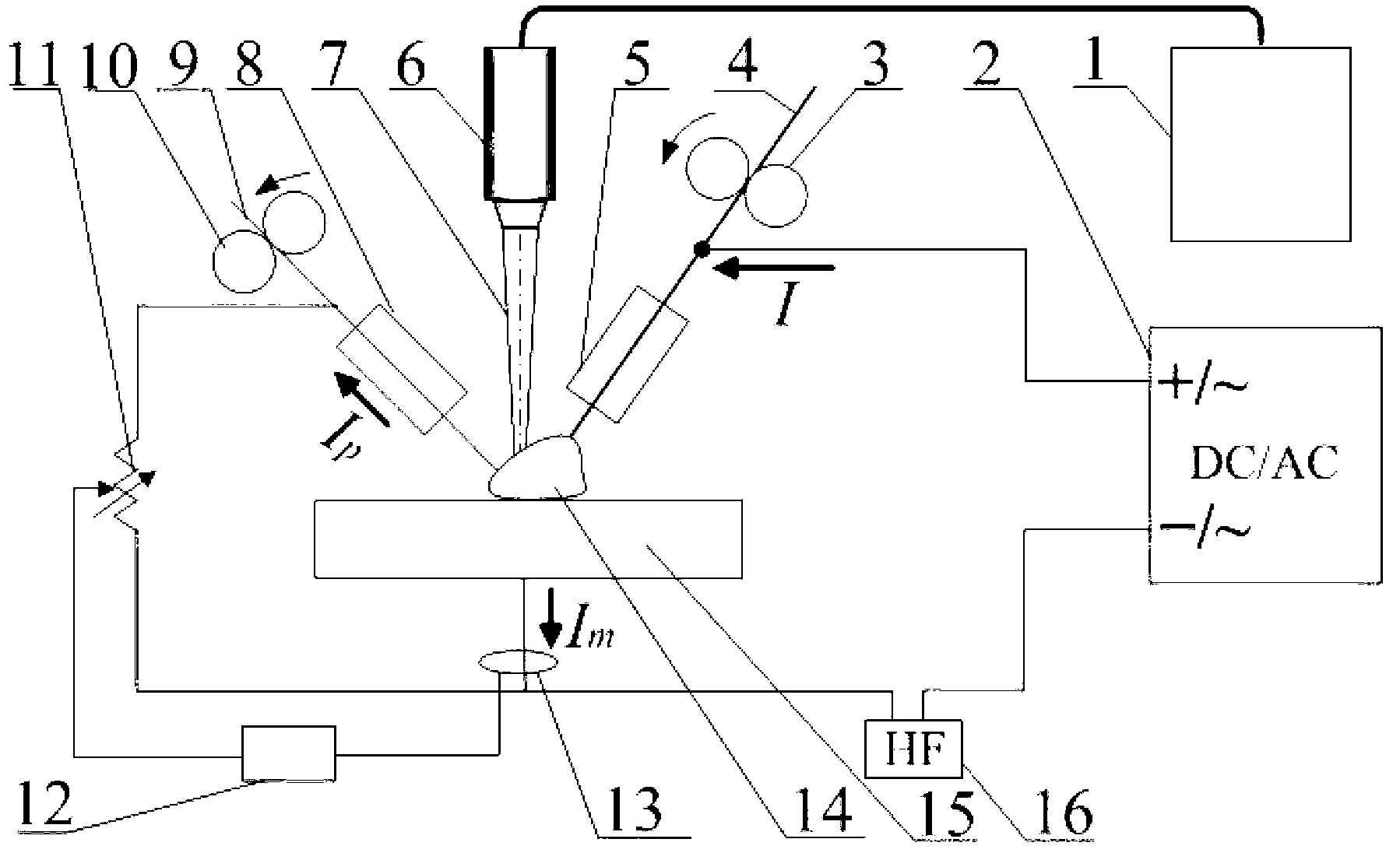

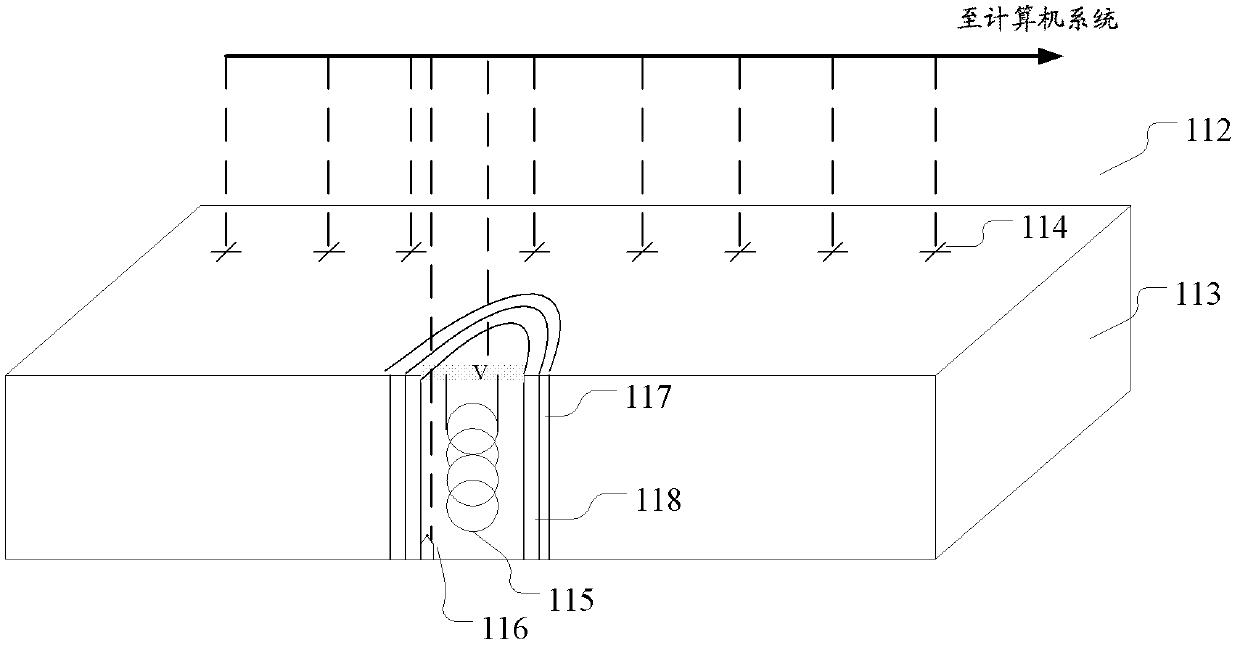

Ultrasonic assistec laser electric arc composite welding method of aluminum alloy

InactiveCN105710537AEfficient weldingPromote escapeWelding/soldering/cutting articlesLaser beam welding apparatusCavitationWelding residual stress

The invention relates to an ultrasonic assisted laser electric arc composite welding method of an aluminum alloy. On the basis of carrying out a welding scheme by combining TIG electric arc welding and laser welding, ultrasonic vibration pressure is introduced into a welding seam, wherein a designed vibration head is in direct contact with the welding seam, so that ultrasonic resources can be more sufficiently utilized, and gas in the welding seam can be rapidly escaped; most of gas in the welding seam is removed so that welding seam gas pore defects are reduced or avoided; tissue crystal grains of the welding seam are remarkably refined by utilizing cavitation effect and acoustic streaming effect caused by the fact that ultrasonic waves are transmitted in liquid, and furthermore, tissue alloy elements of the welding seam are more uniform, segregation is reduced, the strength and corrosion resistance performance of the welding seam are improved, and the performance of a welding connector is improved; and welding residual stress is effectively eliminated or reduced and the strength and corrosion resistance performance of the connector are enhanced, so that the efficient welding of the aluminum alloy is realized.

Owner:北京隆源自动成型系统有限公司

Composite combining silica thermal repairing material and preparation method thereof

The invention discloses a composite bonded silicious hot repair material, which belongs to the technical field of refractory materials. The repair material comprises the following compositions in percentage by weight: 45 to 55 percent of silicious clinker aggregate, 8 to 12 percent of silicious clinker powder, 20 to 30 percent of natural silica powder, 8 to 12 percent of complex binder, 3 to 5 percent of plasticizer, and 1 to 1.5 percent of dispersant. The silicious clinker aggregate and the silicious clinker powder are waste main crown silica bricks (SiO2 is more than or equal to 95 percent) and fused quartz tubes or fused quartz wedges (SiO2 is more than or equal to 98 percent), SiO2 is more than or equal to 96 percent in natural silica, the complex binder is formed by compounding an SiO2 ceramic bond and a phosphorous acid (phosphate) chemical bond, the plasticizer is white clay or bentonite, and the dispersant is silica fume. The repair material is processed according to the particle size. The invention can satisfy various conditions proposed by hot repair of a kiln to the repair material, can also realize the aims of saving energy sources and increasing the service life of the kiln, and can also be used for filling or building positions which are not suitable for silica brick masonry during the cold repair at the same time.

Owner:山西高科耐火材料股份有限公司

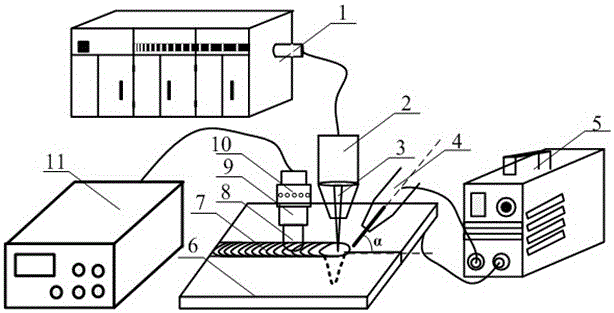

Laser-arc composite welding device based on heat input control and welding method

ActiveCN103071935ALow heat inputReduce thermal deformationLaser beam welding apparatusHeat-affected zoneInput control

The invention provides a laser-arc composite welding device based on heat input control and a welding method. The laser-arc composite welding device based on the heat input control comprises a laser device, a laser head, an arc-welding power supply, a main consumable-electrode welding gun and a wire feeding mechanism and also comprises a bypass welding gun and a rheostat, wherein the laser head is connected with the laser device, the laser head is arranged above a workpiece, the main consumable-electrode welding gun and the bypass welding gun are symmetrically placed at both sides of a laser beam formed by the laser head, the main consumable-electrode welding gun is connected with the positive pole of the arc-welding power supply, the electrifying end of the workpiece is connected with the negative pole of the arc-welding power supply, and the bypass welding gun is connected with the negative pole of the arc-welding power supply by the rheostat. According to the laser-arc composite welding device based on the heat input control and the welding method, the welding heat input of a composite laser-arc heat source can be controlled, the heat affected zone and the welding deformation are reduced, and the metallurgical performance and the microstructure of a welding seam are improved. The laser-arc composite welding device based on the heat input control and the welding method not only are suitable for the fusion welding of homogeneous metal but also are suitable for the braze (fusion) welding of dissimilar metal, such as aluminum or steel and magnesium or steel.

Owner:哈尔滨哈船特装科技发展有限公司

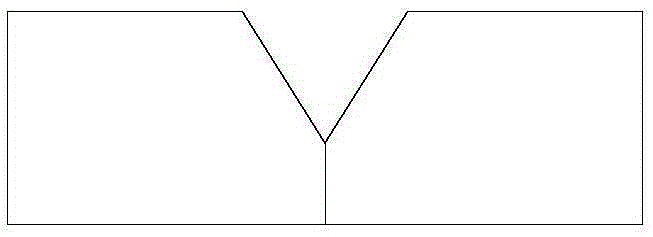

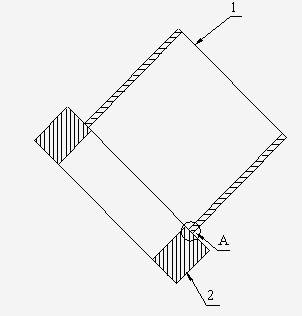

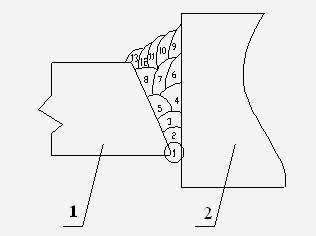

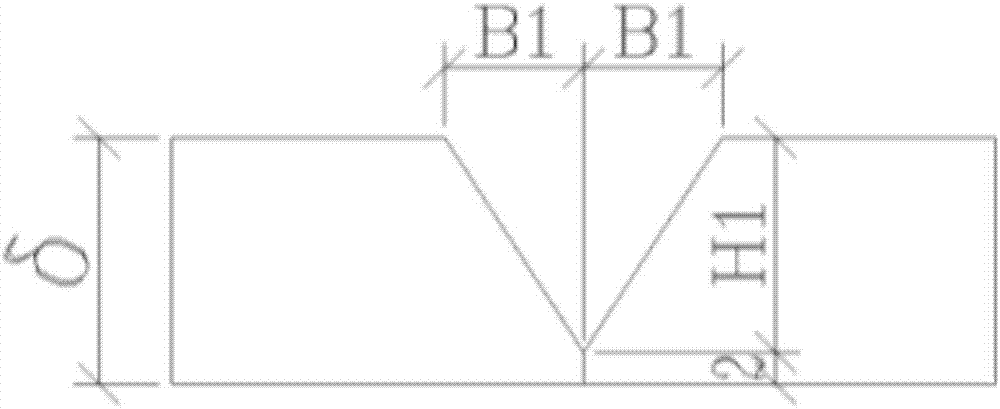

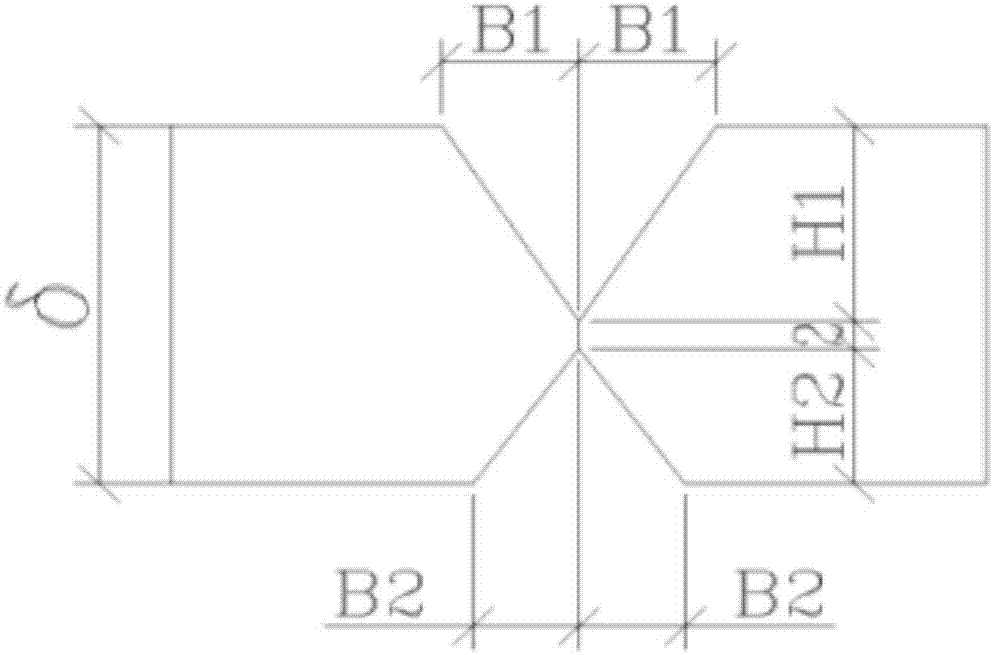

Welding process of ultrahigh-strength steel and heterogeneous high-strength steel

InactiveCN101954524AHigh degree of automationEasy to operateArc welding apparatusWelding/cutting media/materialsWelding defectManufacturing engineering

The invention relates to a welding process of ultrahigh-strength steel and heterogeneous high-strength steel, belonging to the field of welding and processing. For solving problems, the invention provides a welding process of ultrahigh-strength steel and heterogeneous high-strength steel to ensure that welded joints have favorable formation and no welding defects and the mechanical properties can meet the requirement on the product. The welding process comprises the following steps of: (1) groove form: setting the groove angle on the end surface of the ultrahigh-strength steel to 37 DEG-45 DEG, setting the end face of a heterogeneous high-strength steel forging to a vertical plane, and adopting appropriate root gaps and truncated edges; (2) selection of a welding method and a welding material: bottoming by adopting melting pole mixed gas metal arc welding (GMAW) with a Lincoln STT (Short Time Test) technology, wherein the welding requires single-face welding and double-face formation, welding wires adopt AWSA5.28ER80S-G, the protective gas is formed by mixing 80% of AR and 20% of CO2, and the gas flow is15-20 L / Min; and the filling and the cover face, wherein low-hydrogen shielded metal arc welding (SMAW) is adopted, and AWSA5.5E11018M is selected as a welding rod. The welding process is used for welding and processing the ultrahigh-strength steel and the heterogeneous high-strength steel.

Owner:PENGLAI JUTAL OFFSHORE ENG HEAVY IND CO LTD

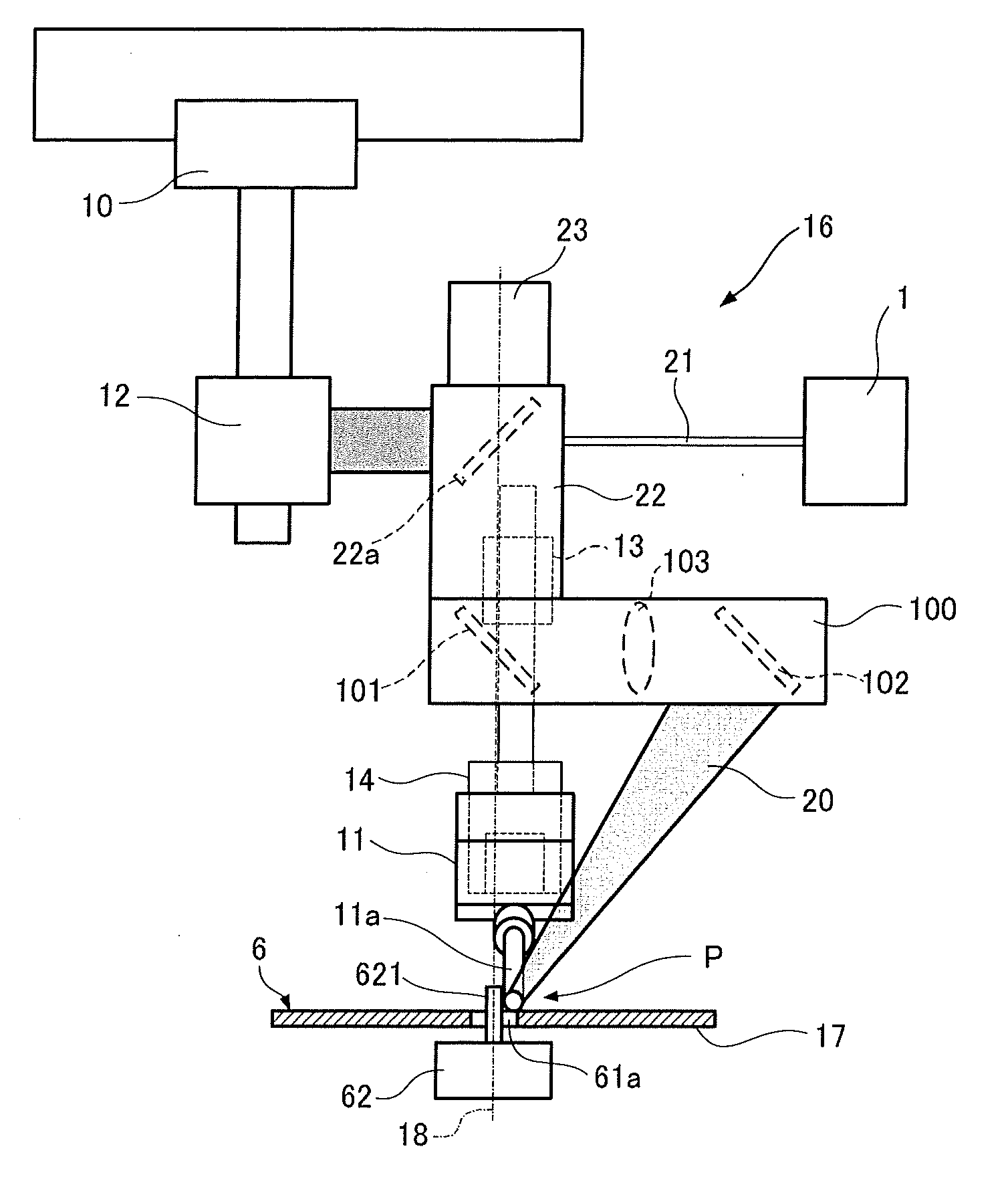

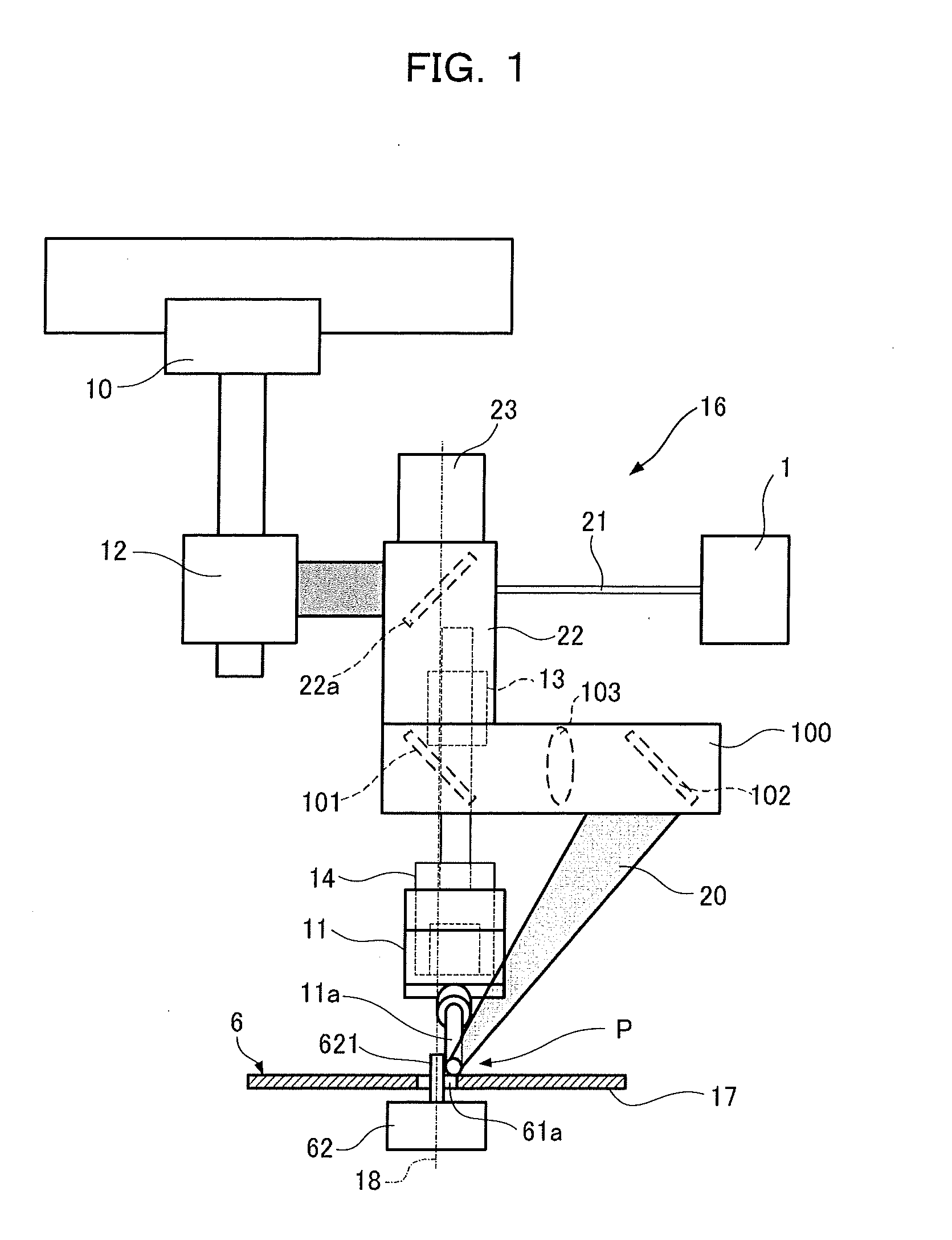

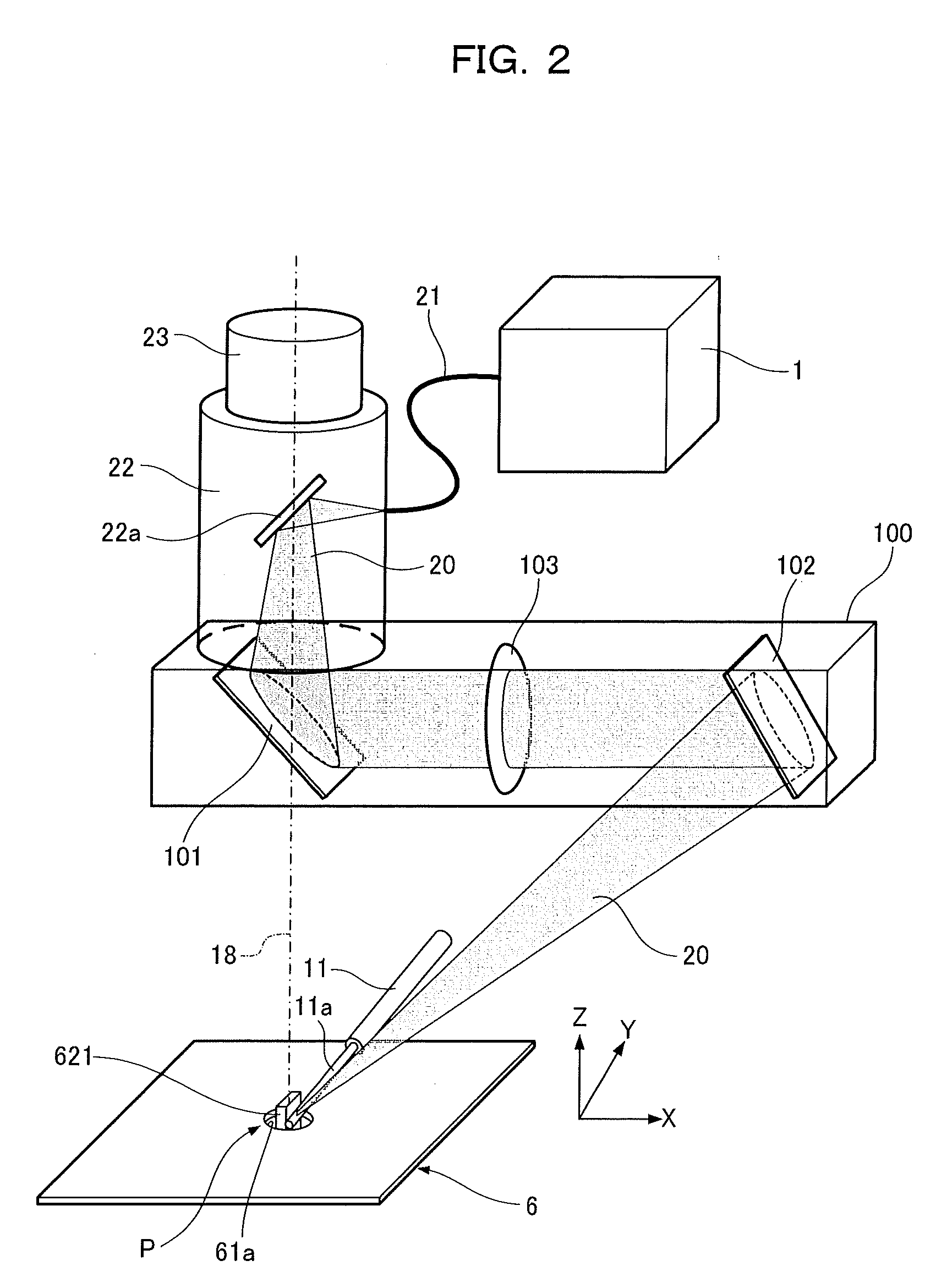

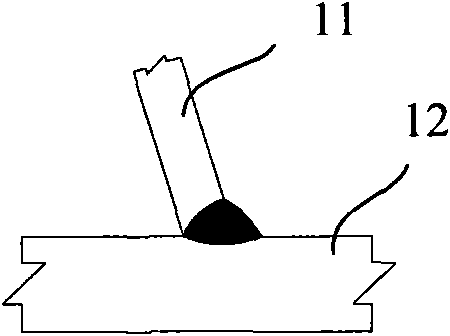

Laser soldering apparatus

InactiveUS20100206854A1Quality improvementIncrease speedPrinted circuit assemblingSoldering apparatusHeat resistanceLaser light

By irradiating laser light 20 obliquely onto a substrate 6, the laser soldering apparatus reduces the laser light passing through an insertion hole 61a in the substrate 6 and prevents damage to low-heat-resistance portions of a component 62 disposed on the rear surface side of the substrate 6. Moreover, the substrate 6 can be observed from a normal direction with a camera 23. Therefore, even if the insertion hole 61 for inserting a component lead or the like is provided in the substrate 6, the laser light does not leak out to the side of a component mounting surface 17 of the substrate 6.

Owner:PANASONIC CORP

Welding method for Q420qENH coating-free weathering steel for steel bridge

InactiveCN106956064AGuaranteed compatibility of ingredientsSolve weather resistanceArc welding apparatusWelding/cutting media/materialsFillet weldWeather resistance

A welding method of Q420qENH coating-free weather-resistant steel for steel bridges, the Q420qENH coating-free weather-resistant steel has an atmospheric corrosion resistance index I≥6.5, a welding sensitivity index Pcm≤0.23, and when the welded joint form is a butt weld, The combined welding process of solid wire gas-shielded welding for backing and submerged arc automatic welding for filling and covering is adopted; when the welding joint form is T-shaped penetration fillet weld, the gas-shielded welding process of flux-cored welding wire is adopted; the welding joint form is single-sided bridge deck When welding double-sided formed joint welds, a combined welding process of solid wire gas shielded welding for bottoming and submerged arc automatic welding for filling and covering is used. The atmospheric corrosion resistance index I of the welding wire in the present invention is ≥ 6.5, and the relative corrosion rate of the deposited metal is ≤ 8%, which ensures that the welding seam matches the composition of the steel plate, and solves the weather resistance of the welding seam of the coating-free weather-resistant steel. Coating the weather-resistant steel bridge solved the technical bottleneck.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

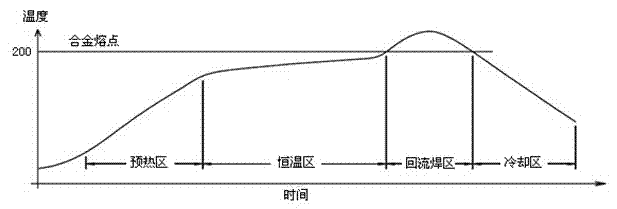

Reflow soldering method of SMD (Surface Mounted Device) components

InactiveCN104325205AReduce shockEfficient use ofPrinted circuit assemblingPrinted circuit aspectsLower limitSurface mounting

The invention discloses a reflow soldering method of SMD (Surface Mounted Device) components. The method comprises the following steps: stopping heat when the temperature is increased for 80-90 DEG C during a heating process of a preheating region, keeping for 8-10 seconds, and continuously heating to 150-200 DEG C at a slope rate of 4 DEG C / S; and controlling the temperature of the heating region to increase at a slope rate less than or equal to 4 DEG C / S until the temperature increases to 150-200 DEG C; fully preheating a workpiece at 150-200 DEG C, so that impact of heat in the heating process is decelerated, residual heat is effectively utilized, the preheating efficiency is improved and energy sources are saved; and keeping the temperature within a range of a peak temperature+ / -5 DEG C for not more than 10 seconds during a reflow soldering process of a reflow soldering region, reducing the temperature to the lower limit of a peak temperature range of 25-35 DEG C, and keeping for 10-20 seconds, so that workpiece damage caused by long-time continuous high temperature can be avoided and effective welding is achieved.

Owner:佛山市德艾光电科技有限公司

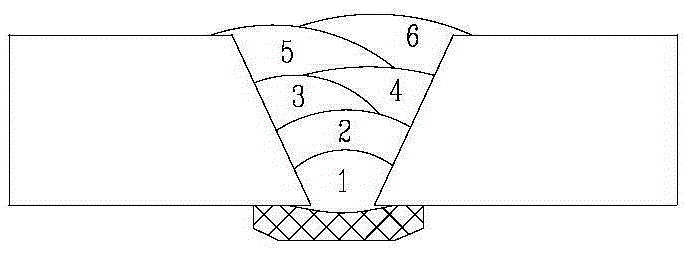

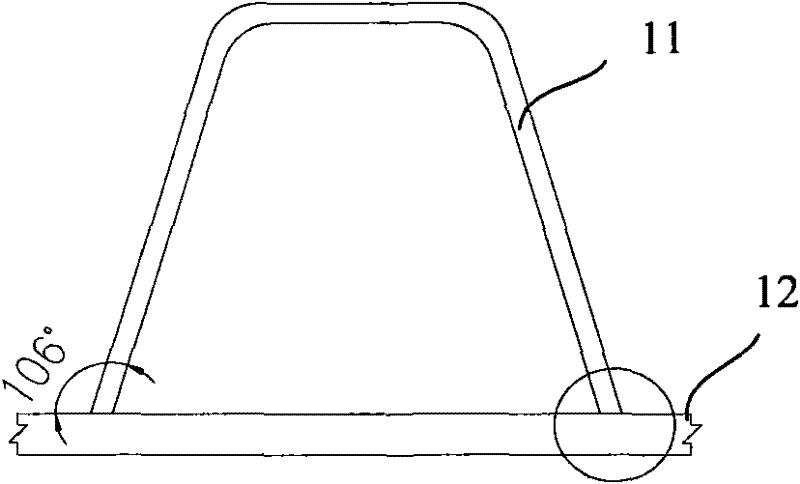

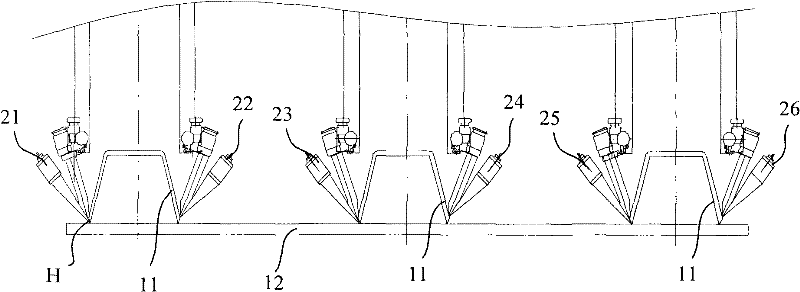

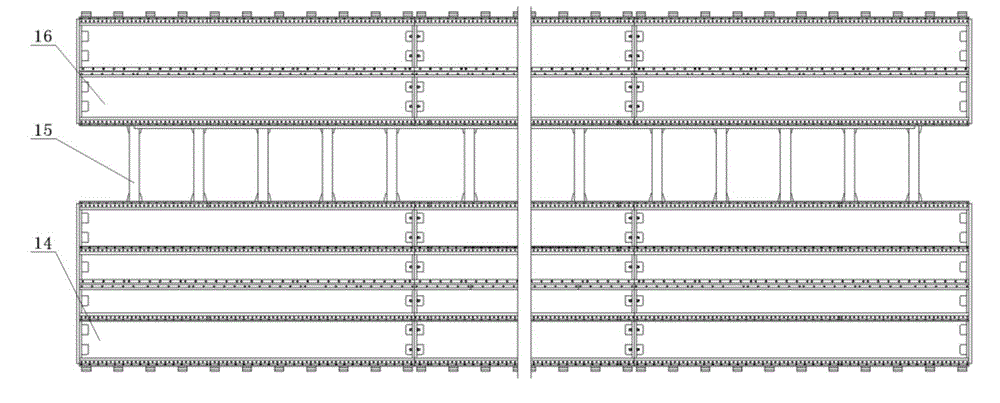

U-rib welding process of steel bridge deck

InactiveCN102275026AAchieving penetrationEfficient weldingArc welding apparatusWorkpiece edge portionsBridge deckStructural engineering

The invention relates to a U-rib welding process for a steel bridge deck, comprising the following steps. First, place the ends of the U-rib on the welded position of the steel bridge deck. Secondly, use the gas shielded welding head to perform gas shielded welding on the welding position in front, and at the same time use the submerged arc welding head to perform automatic submerged arc welding on the welding position. Therefore, on the premise that the thickness of the U rib plate reaches 12mm, the purpose of weld penetration rate of 80%-100% is realized.

Owner:SHANGHAI ZHENHUA HEAVY IND

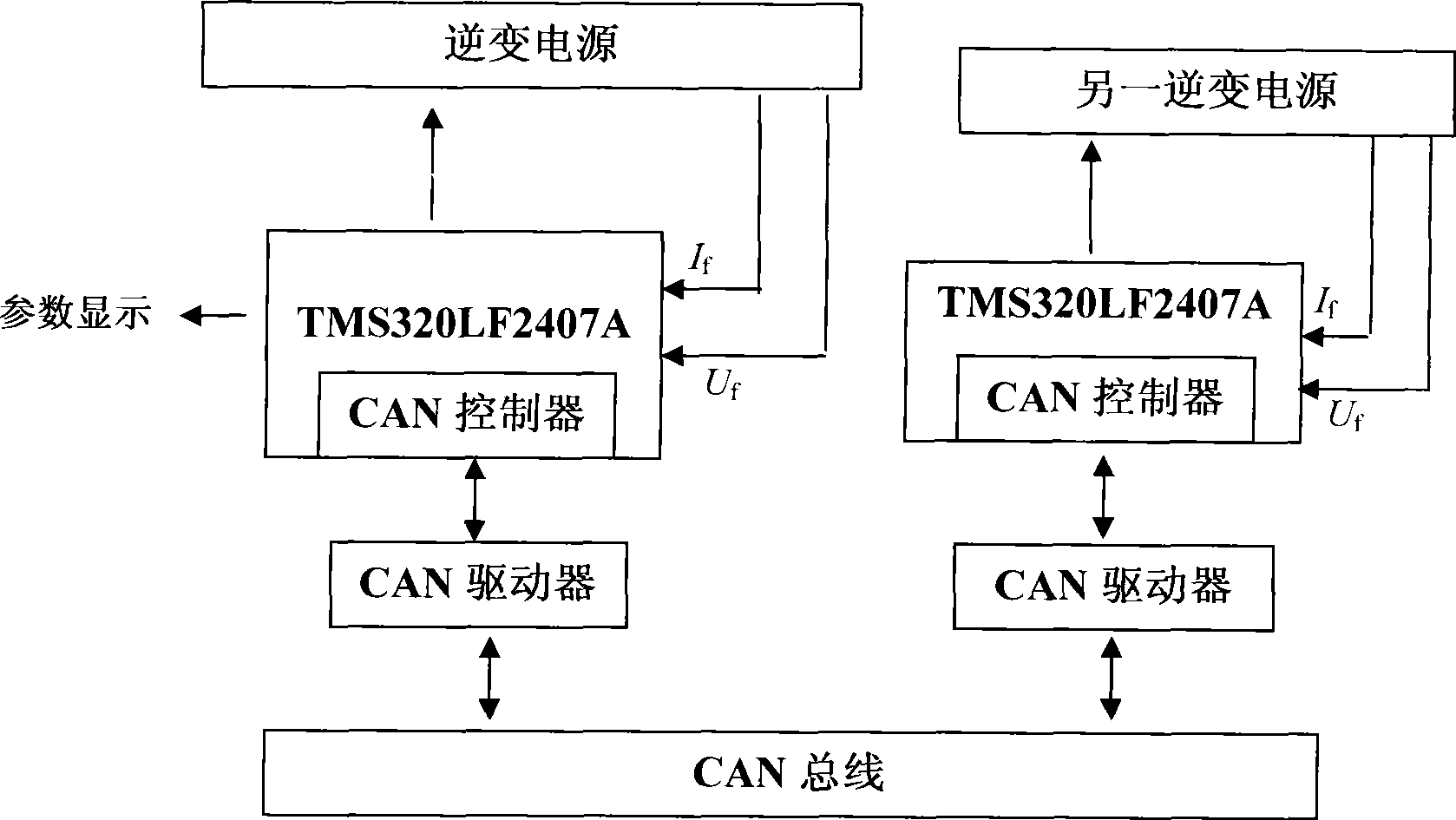

Double-wire bonding control method based on CAN bus

The invention relates to a dual-wire-welding control method based on a CAN bus, comprising the following steps: (1) when a first welding wire changes from a peak status to a base status, a second power supply controls a first DSP chip of the first welding wire to send out first triggering signals to a second DSP chip of a second welding wire controlled by a second power supply through the CAN bus, and the second welding wire enters the peak status; (2) after the second welding wire status is ended, the second DSP chip sends out second triggering signals to the first DSP chip through the CAN bus, and the first welding wire returns to the peak status again; and (3) the steps (1) and (2) are repeated. The invention maintains the phase difference of the output pulse welding current at 180 DEG, effectively reduces the interference between two arcs, achieves stable welding, increases the welding speed greatly while favorable welding line formation is obtained, achieves highly efficient welding and improves the production efficiency.

Owner:SHANGHAI HUGONG ELECTRIC WELDING MACHINE MFG

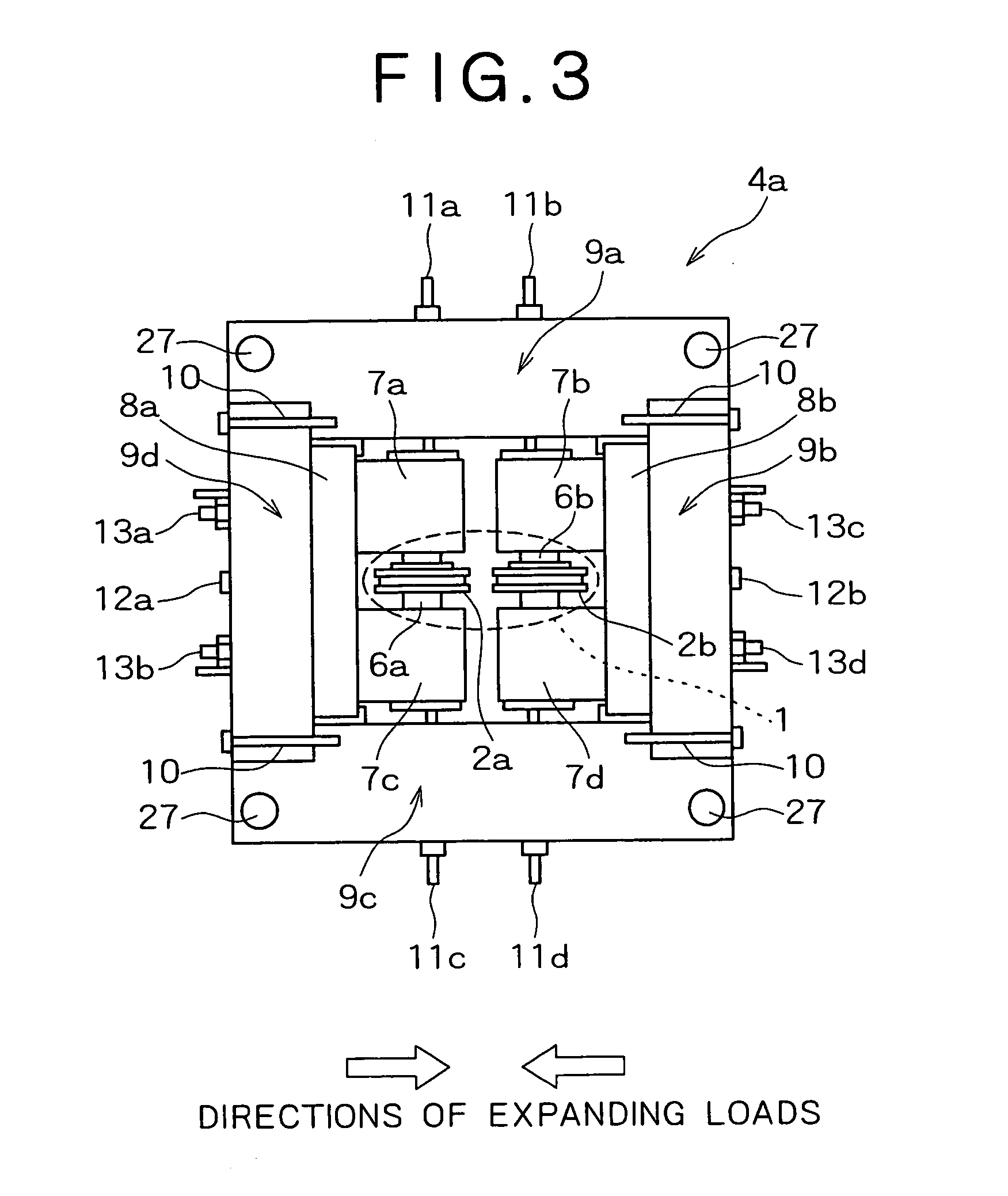

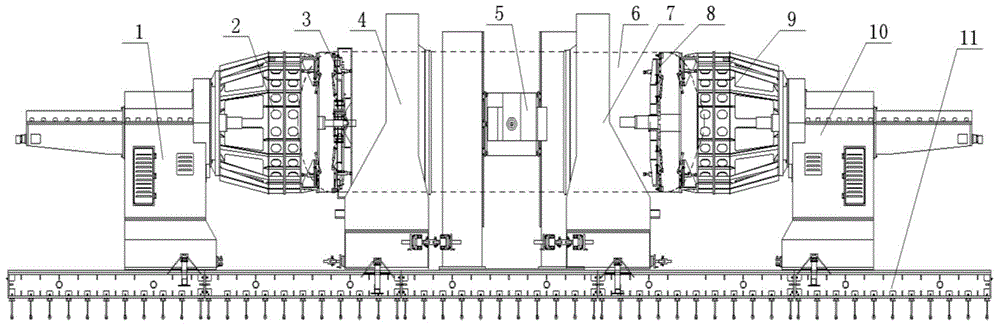

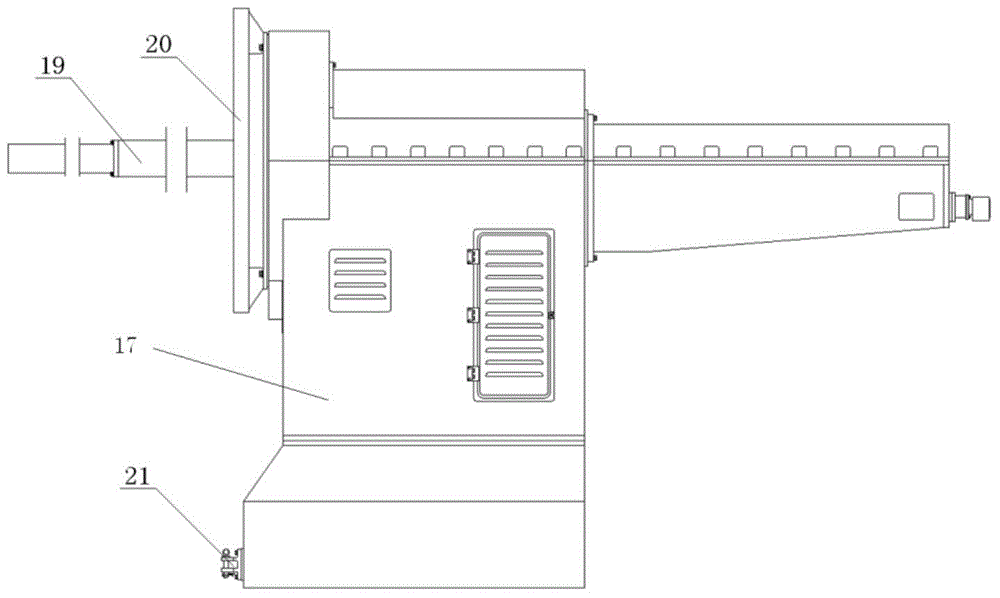

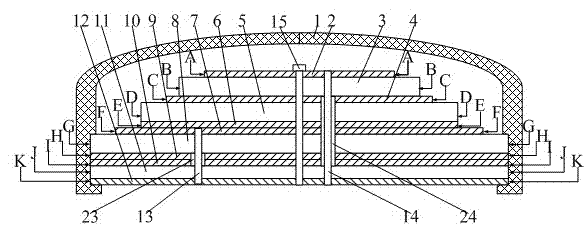

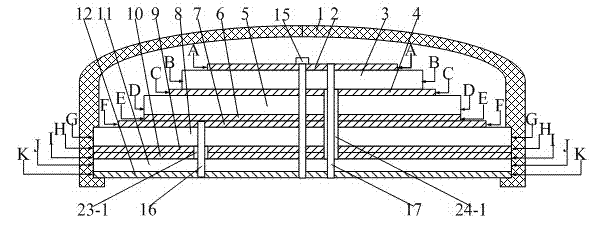

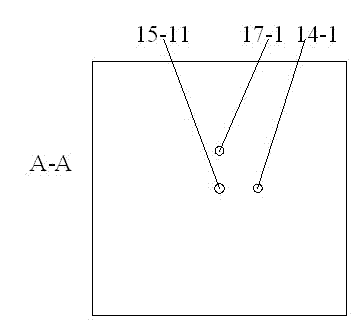

Horizontal device and method for friction-stir welding of circular seam of carrier rocket storage tank assembly

ActiveCN104400212AEfficient weldingHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRocket

The invention provides a horizontal device and a method for friction-stir welding of a circular seam of a carrier rocket storage tank assembly. The device comprises a bed body, wherein a bed head and a bed tail are respectively arranged at the two ends above the bed body; a front transition ring, an outer right positioning and compressing mechanism, an outer left positioning and compressing mechanism and a rear transition ring are arranged between the bed head and the bed tail in sequence; an inner supporting mechanism and a rod system supporting mechanism are respectively hung on a bed head telescopic shaft and a bed tail telescopic shaft and can move horizontally along with the telescopic shafts; a stirring host is arranged on the bed body. The method comprises the following steps of welding a front bottom with a first cylinder section, welding a front short shell with the front bottom, welding the rest cylinder sections with the cylinder section, welding the cylinder sections and a rear bottom, and welding a rear short shell and a rear bottom. According to the horizontal device and the method, one-time clamping, in-situ edge milling and welding of the storage tank can be realized; the assembling precision and the welding efficiency are greatly improved; high-precision and high-efficiency welding of a rocket storage tank can be realized; the effect is good.

Owner:CAPITAL AEROSPACE MACHINERY +2

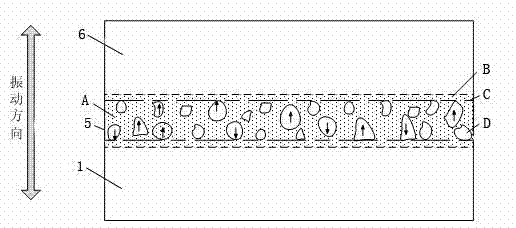

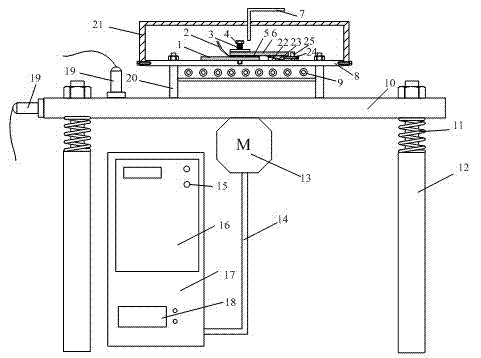

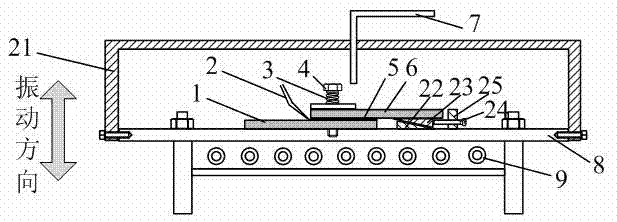

Heterogeneous semi-solid brazing method of aluminum alloy and magnesium alloy assisted by external vibration energy

InactiveCN102266994AAvoid serializationEfficient weldingSoldering apparatusRoom temperatureSemi solid

The invention provides a heterogeneous semi-solid brazing method for an aluminum alloy and a magnesium alloy under assistance of external vibration energy. According to the invention, the method comprises the following steps of: clamping an aluminum alloy weld member and a magnesium alloy weld member on a fixture and placing medium-temperature brazing filler metals of a Zn-Al or Al-Si series on two surfaces to be welded, wherein the brazing filler metals can be of flaky shapes or foil shapes, can be plating layers or can be sprayed on the surfaces to be welded in advance; heating the weld members so that the middle layer of brazing filler metal is in a semi-solid state; adjusting the pressure to be matched with the amplitude of the applied vibration; starting a vibrating device with amplitude of 0.01-2mm, wherein the brazing filler metals vibrate along with the two weld members, and the vibration time is 0.5-3 minutes according to actual requirements; stopping the vibration; and cooling the weld members to room temperature by air, wherein a certain pressure of 0.1-5 Mpa is always applied in the brazing process. According to the invention, high-efficiency, high-quality and economic connection between the aluminum alloy and the magnesium alloy can be realized.

Owner:CHONGQING UNIV OF TECH

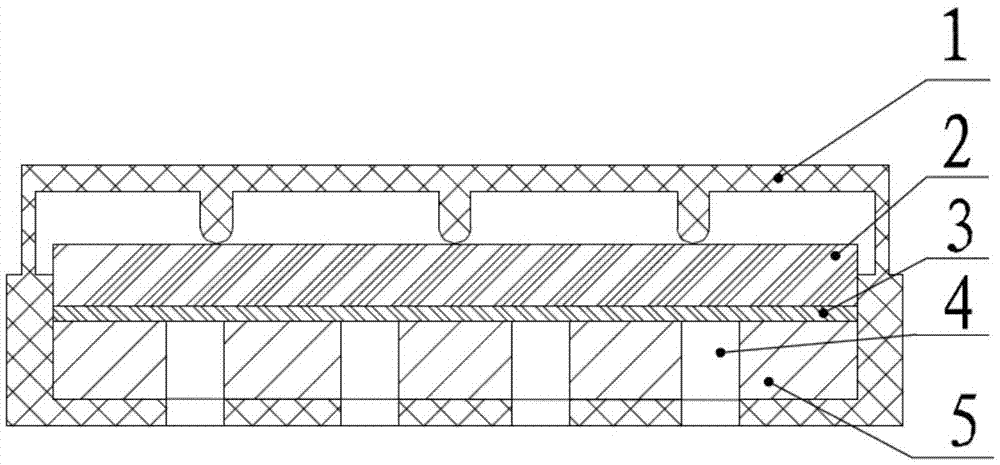

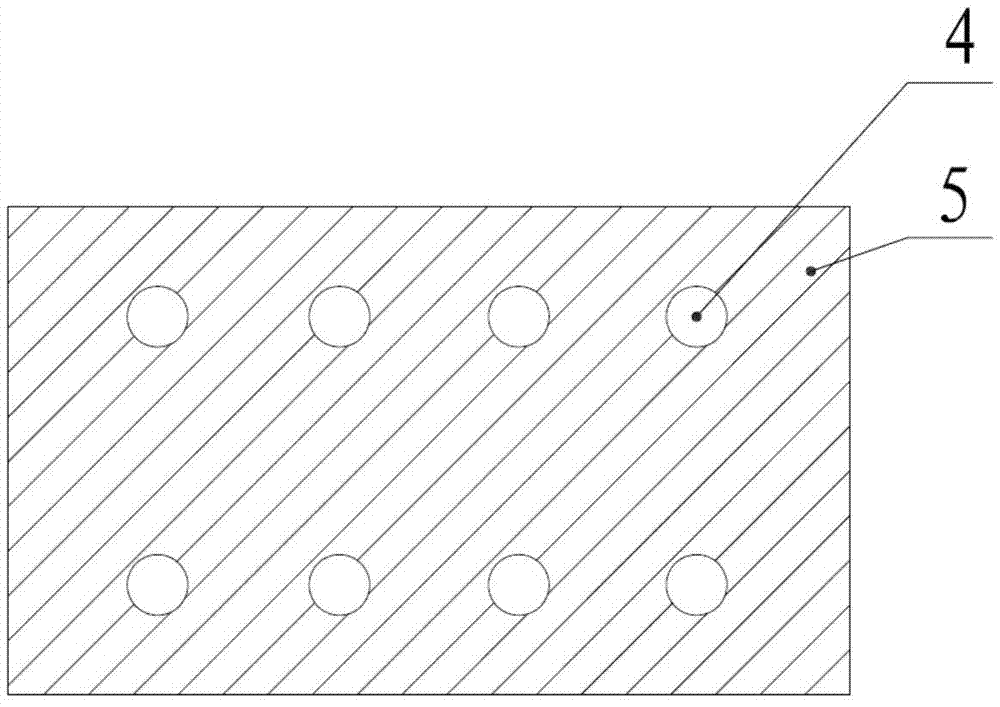

LTCC substrate component and eutectic sintering process method thereof

ActiveCN106876267AEfficient weldingAchieve high precision controlSemiconductor/solid-state device detailsSolid-state devicesSinteringCoating

The invention relates to a LTCC substrate component and a eutectic sintering process method thereof. The LTCC substrate component comprises a LTCC substrate (2), a 0.08mm-thickness preforming silver tin soldering sheet (3), a fuzz button installing hole (a CNA8 high temperature protection resistance welding glue coating position) (4) and a LTCC substrate structure component (5). The LTCC substrate component is placed into an elastic positioning tooling (1) so as to form a product component. The component and the method are suitable for multiple sizes of special-purpose elastic tooling and substrate voidage can be increased to over 90% from below 80%; a protection technology of the fuzz button installing hole is designed so as to realize accurate protection to a welding process of different connector installing holes and subsequent connector installation is not influenced; and simultaneously, a silver tin soldering sheet is served as a welding material so that high precision control of a solder amount can be realized and product consistency is increased.

Owner:LEIHUA ELECTRONICS TECH RES INST AVIATION IND OF CHINA

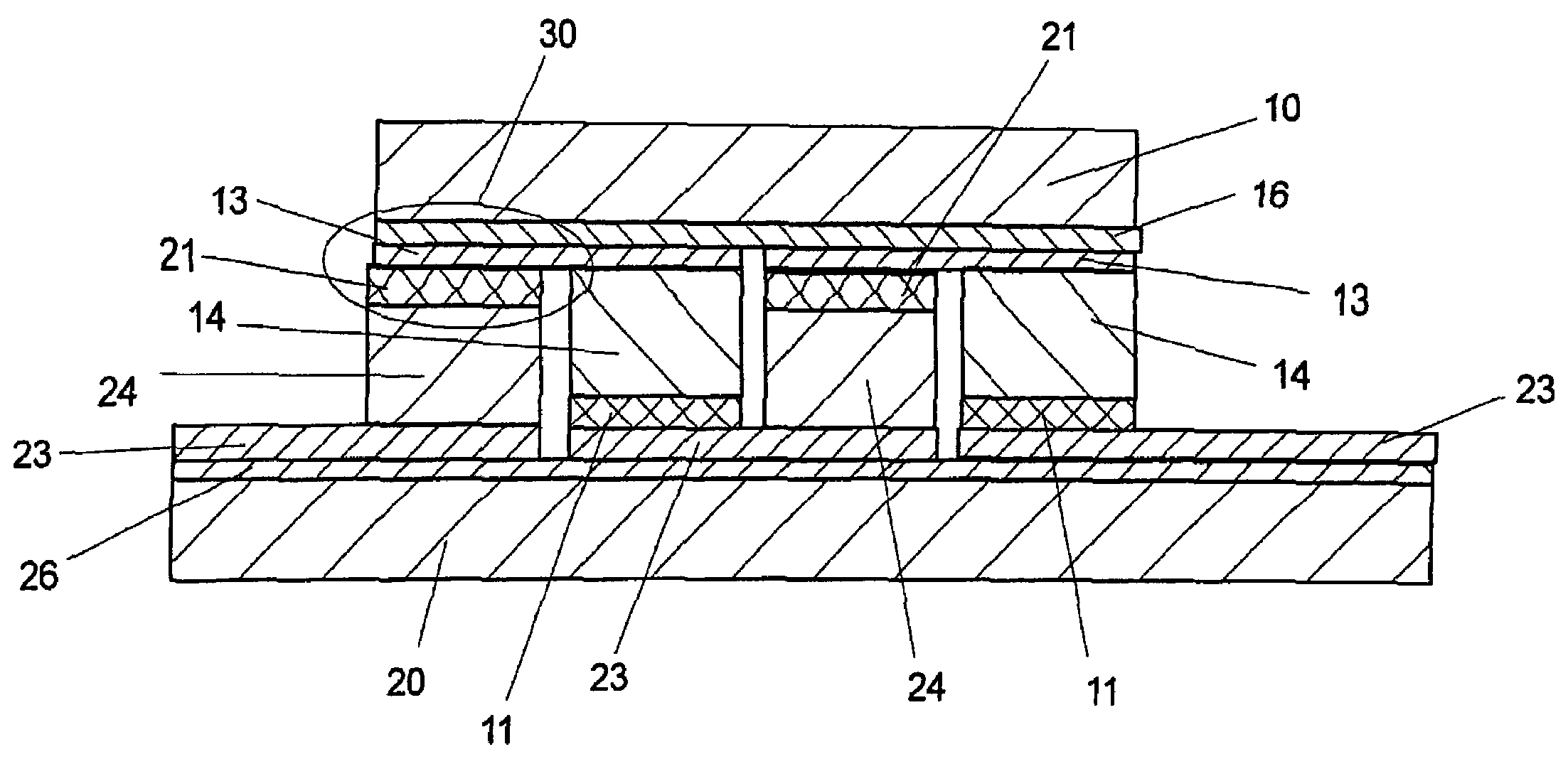

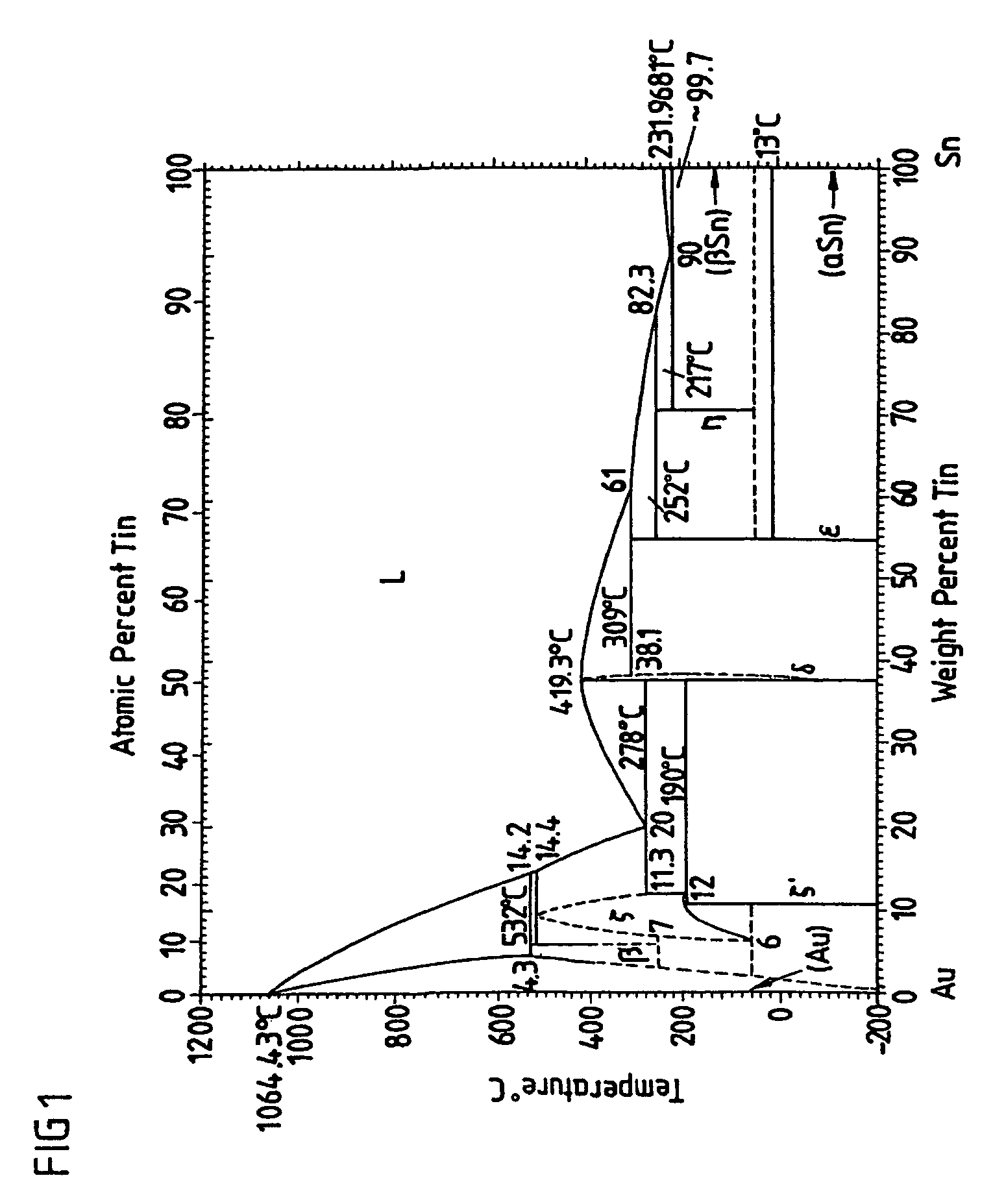

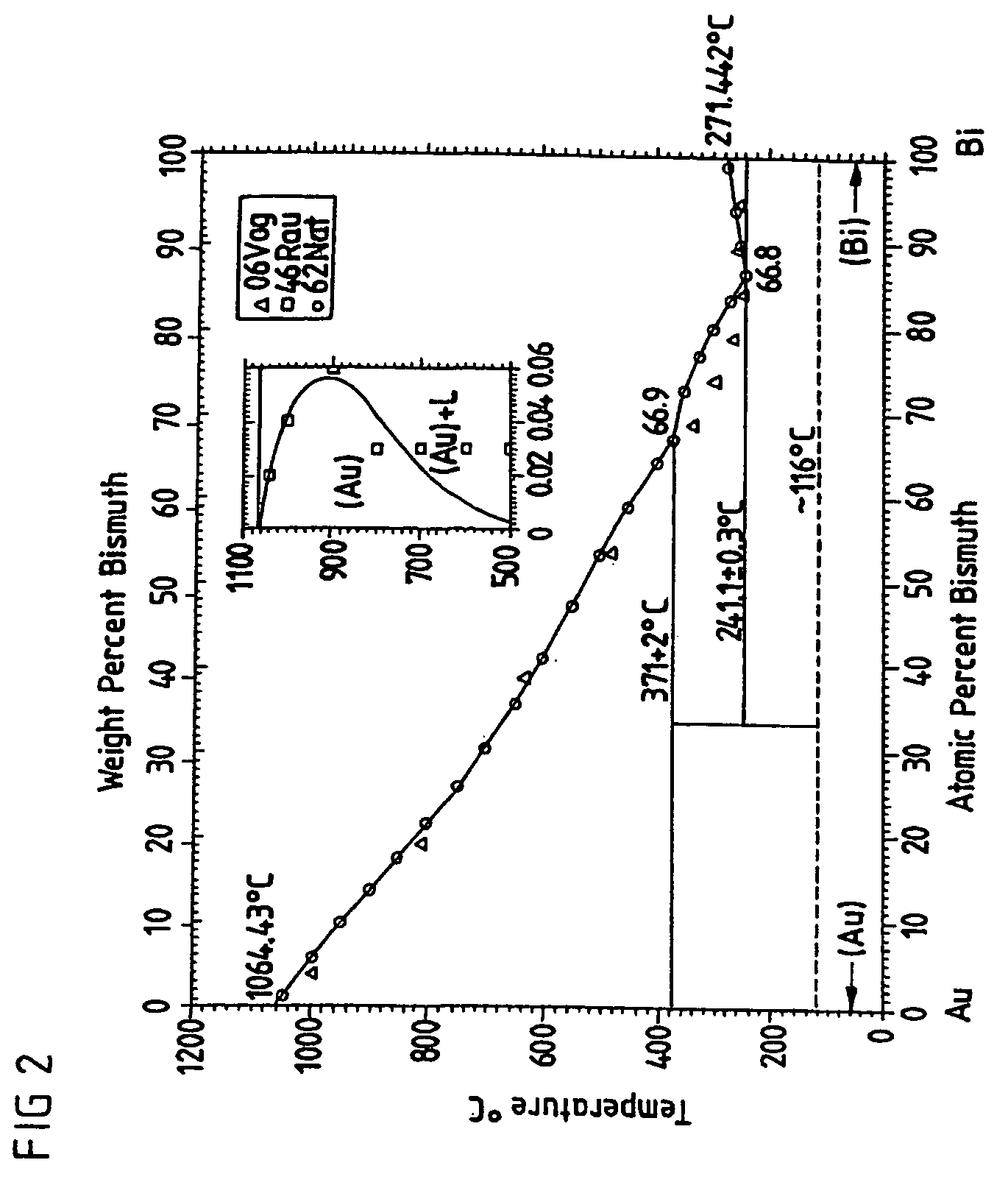

Solder, microelectromechanical component and device, and a process for producing a component or device

InactiveUS7402910B2Easy to processEasy to patternPrecision positioning equipmentSemiconductor/solid-state device detailsBismuth preparation

A solder, in particular a thin-film solder, for joining microelectromechanical components, wherein the solder is a eutectic mixture of gold and bismuth. Components and devices joined by a solder of this type are also disclosed, in addition to processes for producing such components or devices.

Owner:NAVAJO MFG +1

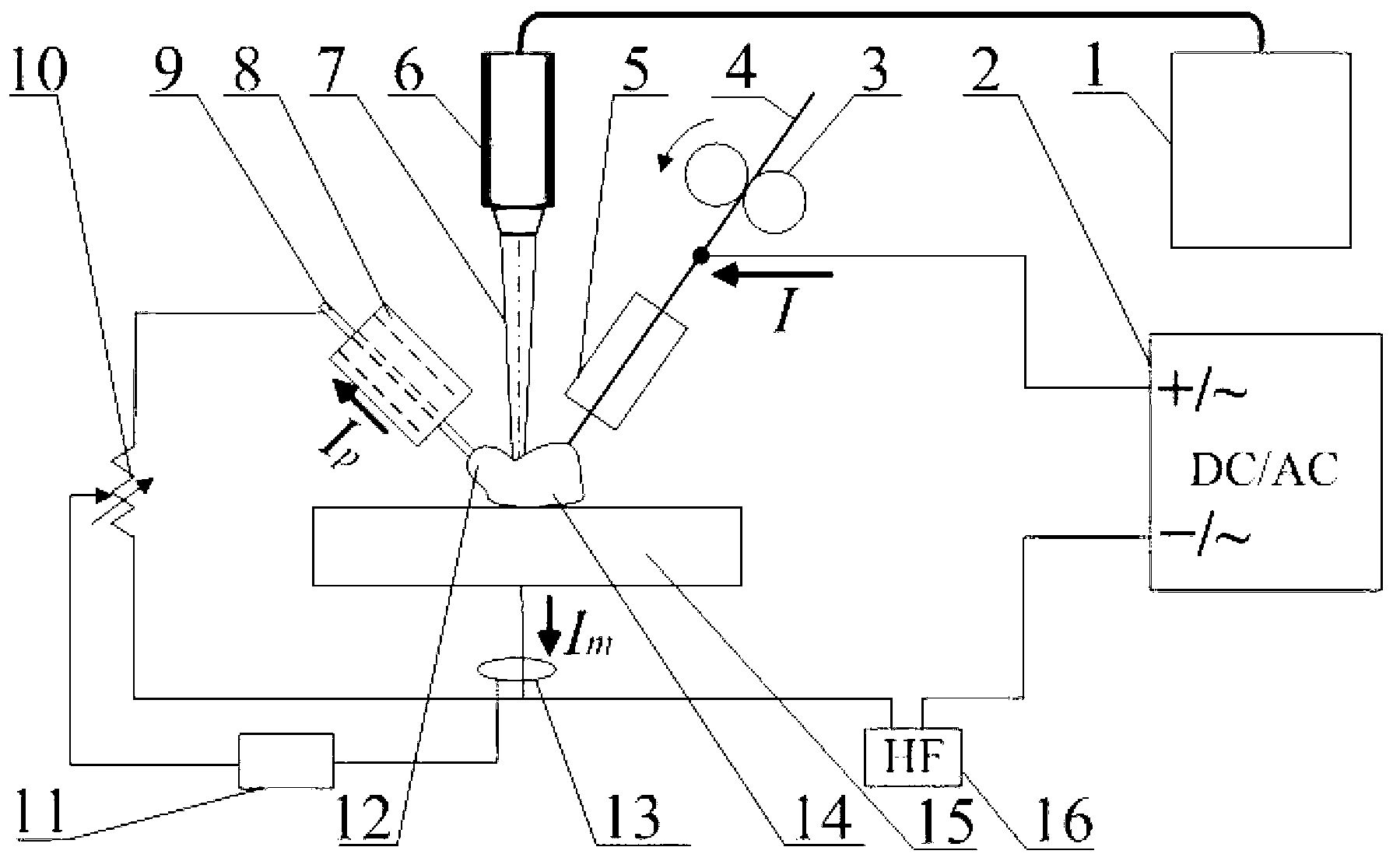

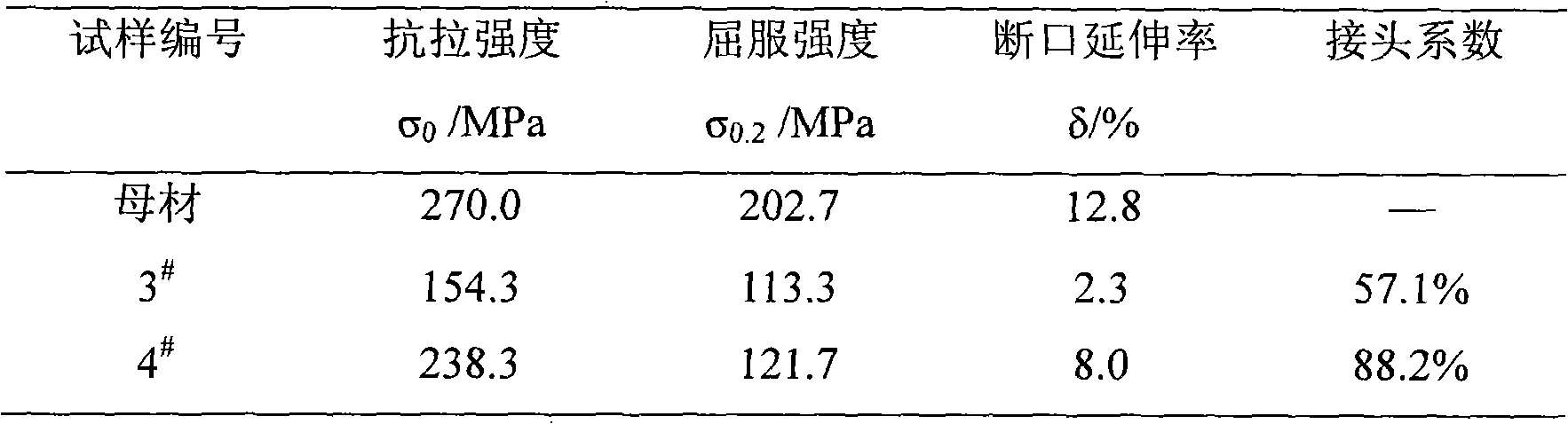

Electromagnetic direct-drive high-speed three-wire magnetic-field compound flux copper-gasket submerged arc welding device and method thereof

InactiveCN101745725AIncrease frictionImprove stabilityArc welding apparatusWelding power supplyTorch

The invention discloses an electromagnetic direct-drive high-speed three-wire magnetic-field compound flux copper-gasket submerged arc welding device and a method thereof. The device comprises a wire feed system, a welding power source, a magnetic field power source, a copper gasket system, a torch system, an electromagnetic compound system and a numerical control system, wherein the wire feed system is formed by integrating the rotor of the electromagnetic direct-drive rotating servomotor and the main wire feed rolls into an integral body; the torch system comprises an eccentric current contact nozzle which is divided into an upper part and a lower part; the electromagnetic compound system is integrated with the nozzle of the torch system and a water cooling system into an integral body; and the copper gasket system is an air-pressure copper-gasket one-side-welding double-side one-step molding system, the back side of which uses flux. The invention can cancel the mechanical transmission link between the traditional motor and the wire feed rolls, greatly enhances the wire feed stability and the control response precision, and eliminates the noise, oil sludge and vibration, thereby realizing the three-wire high-speed electromagnetic compound submerged arc welding one-side-welding double-side molding high-efficiency welding method. The method has the advantages of simple structure, small size, high stability and reliability, and precise numerical control, and can be used for welding huge and thick plates.

Owner:ANHUI HONGLU STEEL CONSTR (GROUP) CO LTD

Battery core of spiral lithium ion battery, and spiral lithium ion battery

InactiveCN102347515AReduce thicknessLower internal resistanceFinal product manufactureElectrode carriers/collectorsElectricityPower battery

The invention discloses a battery core of a spiral lithium ion battery, and a spiral lithium ion battery containing the battery core. The spiral lithium ion battery comprises a battery housing, and a spiral battery core and a battery upper cap positioned in the battery housing. The battery core comprises an anode sheet, a cathode sheet, a separating film, an anode flow concentrating plate, and a cathode flow concentrating plate. The upper end of the anode sheet and the lower end of the cathode sheet are provided with uncoated blank bands. After the anode sheet and the cathode sheet are separated by using the separating film and are rolled, the lower surface of the anode flow concentrating plate firmly contacts the circular blank band formed on the anode sheet, and the upper surface of the cathode flow concentrating plate firmly contacts the circular blank band formed on the cathode sheet. The anode flow concentrating plate is electrically connected to the upper cap of the battery. The cathode flow concentrating plate is electrically connected to the housing. The battery provided by the invention is advantaged in small internal resistance, uniformly distributed current, and long service life. The battery is especially suitable for power batteries of electric cars and the like.

Owner:XIANGTAN YINHE NEW ENERGY

GMAW System Having Multiple Independent Wire Feeds

InactiveUS20090188896A1Good flexibilityReduce splashSupport devices with shieldingWelding/cutting media/materialsGas metal arc weldingEngineering

A gas metal arc welding system comprising, and a method of welding a plurality of workpieces utilizing, a plurality of individually selectable and separately controlled wire feeds, wherein the feeds preferably present differing wire diameters and compositions and predetermined wire contributions are combined during welding so as to present a weld pool and joint having aggregate properties.

Owner:GM GLOBAL TECH OPERATIONS LLC

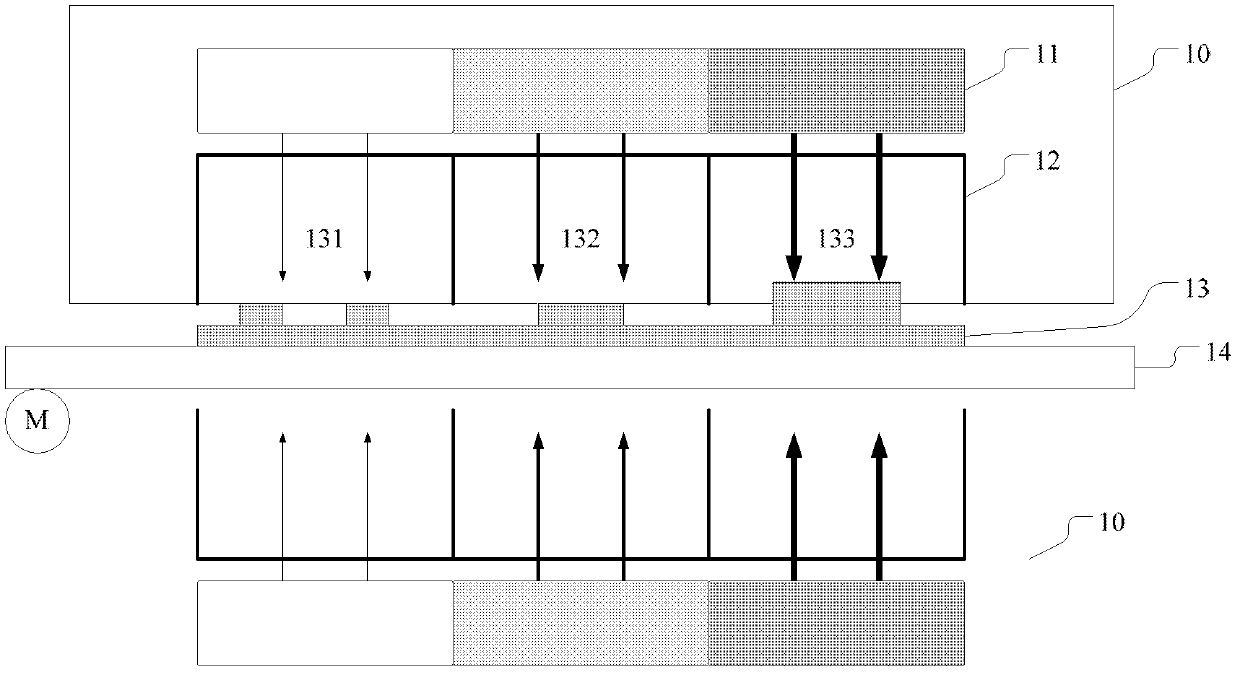

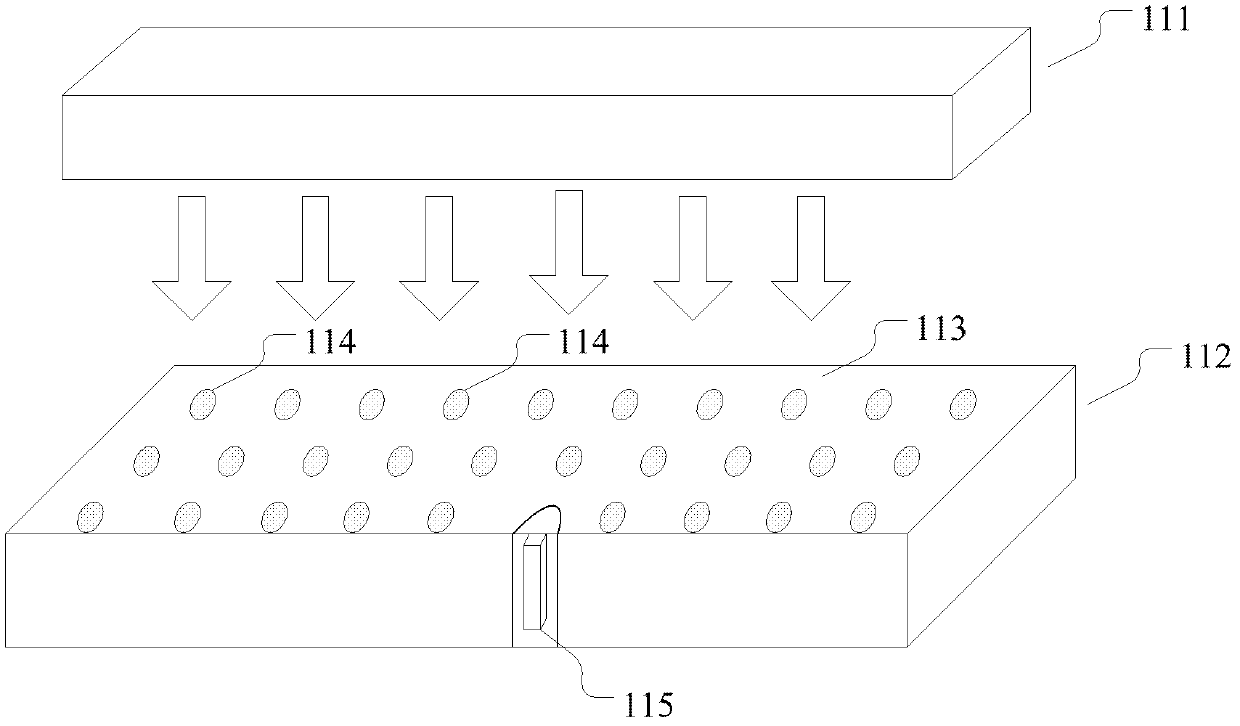

Heat source system

ActiveCN103286408AImprove welding efficiencyEfficient weldingPrinted circuit assemblingHeating appliancesHeat distributionHeating system

The invention provides a heat source system which comprises a heating system and a heat distribution system, wherein the heating system comprises a gas supply unit and a temperature control unit; the gas supply unit is used for supplying flow gas; the temperature control unit comprises a base plate, and a plurality of through holes are formed in the base plate so as to allow the flow gas to pass; a temperature regulation device is arranged aiming at least a part of the plurality of the through holes, and can regulate the temperature of the flow gas passing the corresponding through holes independently; and the heat distribution system comprises a partition device which divides the heat distribution system into a plurality of areas, so that the flow gas passing the plurality of through holes reaches to-be-heated objects in the plurality of areas. The heat source provided by the embodiment of the invention can provide non-uniform heating as required.

Owner:레노보인터내셔널리미티드

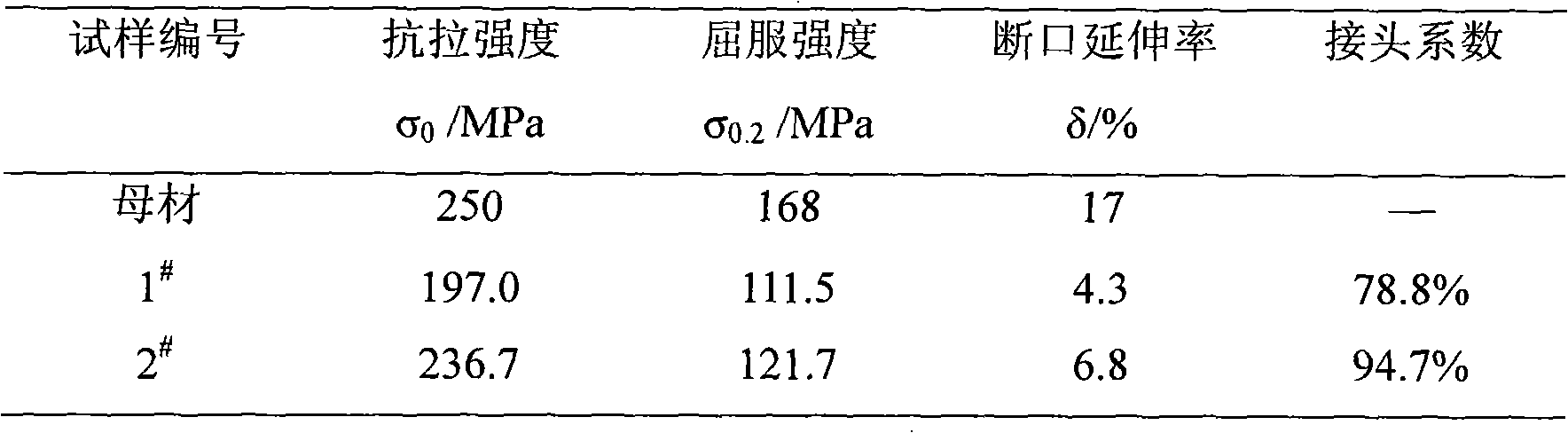

Friction stir welding method of medium plate AZ AZ1 magnesium alloy

InactiveCN101885109ABeautiful shapeNo surface cracksNon-electric welding apparatusMaterials processingFrustum

The invention relates to a friction stir welding method of a medium plate AZ AZ1 magnesium alloy, belongs to the technical field of welding process used in material processing projects, and particularly provides a friction stir welding method of a 10 to 20-millimeter-thick AZ31 magnesium alloy. The welding inclined angle of a stirring head is 2.5 to 3 DEG, the pressing depth is 0.1 to 0.2 millimeter, the rotation speed is 600 to 1,400r / min, and the welding speed is 100 to 200 mm / min; the shaft shoulder of the stirring head is concave and a stirring pin is frustum-shaped and spiral; the diameter of the shaft shoulder of the stirring head is 28 to 35 millimeters; the diameter of the root part of the stirring pin is 10.3 to 15.1 millimeters, and the diameter of the end part of the stirring pin is 7.8 to 9.3 millimeters; and the length of the stirring pin is 9.6 to 19.5 millimeter. By selecting reasonable welding parameters, the obtained joint is formed elegantly, the maximum tensile strength is up to 94.7 percent of that of a parent metal, and the well welding of the medium plate AZ AZ1 magnesium alloy.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Tri-band wide wave beam circular polarization microstrip antenna

ActiveCN102570017AReduce working frequency point deviationAvoid deviationSimultaneous aerial operationsRadiating elements structural formsPhysicsPhase shifted

The invention realizes a tri-band wide wave beam circular polarization microstrip antenna, which comprises an antenna cover, wherein a feed network layer, a first medium layer, a first metal layer, a second metal layer, a second medium layer, a third metal layer, a fourth metal layer, a third medium layer, a fifth metal layer, a fourth medium layer and a sixth metal layer are sequentially stackedin the antenna cover from bottom to top and penetrated and fixed by short-circuit screws; the third metal layer is connected with the fourth metal layer; a first metallization through hole and a second metallization through hole are formed in the second medium layer and connected to the third metal layer; a Wilkinson 90-degree phase shift power divider and a four-branch 90-degree phase shift power divider are arranged on the feed network layer; a first feed needle and a second feed needle are arranged between the third metal layer and the feed network layer; and a third feed needle and a fourth feed needle are arranged between the sixth metal layer and the feed network layer.

Owner:SUZHOU TIANYE MECHANICAL IND

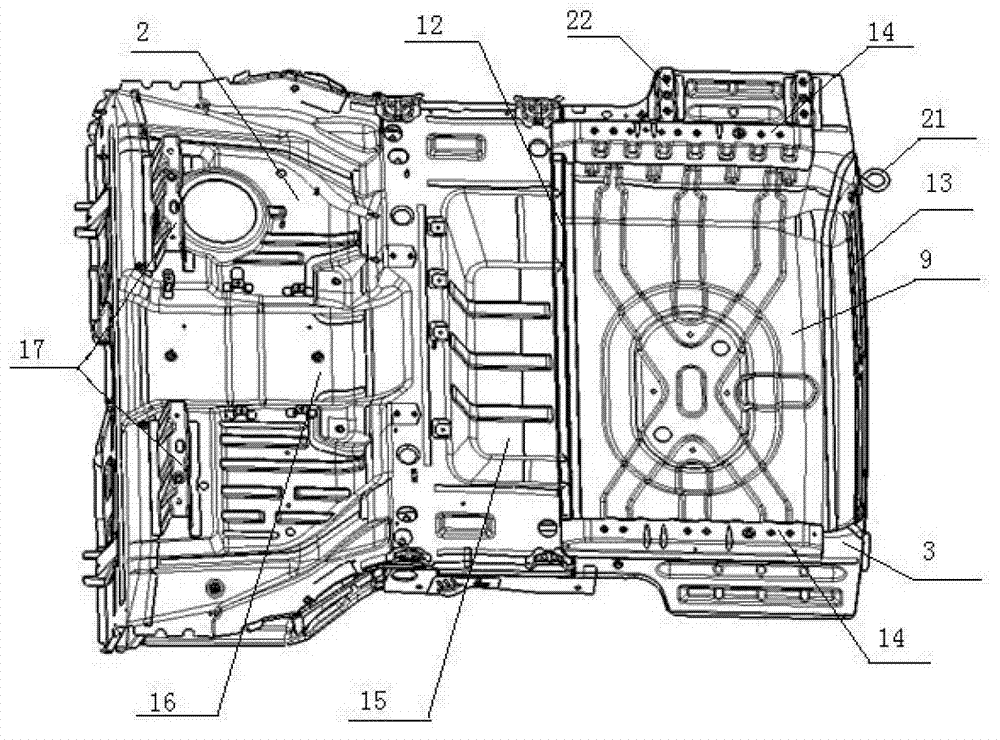

Rear floor assembly structure for plug-in hybrid electric vehicle

ActiveCN102897228AGuaranteed StrengthEnsure safetyElectric propulsion mountingSuperstructure subunitsStable fixationFuel tank

The invention discloses a rear floor assembly structure for a plug-in hybrid electric vehicle, which comprises a rear-floor front part and a rear-floor rear part, wherein a left side longitudinal beam and a right side longitudinal beam extending to the downside of the rear-floor rear part are respectively arranged on the two sides of the downside of the rear-floor front part, a cross beam is connected between the left side longitudinal beam and the right side longitudinal beam below the rear-floor front part and is connected with a fuel tank and an exhaust pipe muffler, a battery compartment is arranged on the rear-floor rear part between the left side longitudinal beam and the right side longitudinal beam, a battery pack is hung above the battery compartment, the front end of the battery pack is connected with a battery cooling system, and the battery cooling system is fixed above the rear-floor front part. According to the rear floor assembly structure, a mode of directly loading floors in the conventional thinking is abandoned, but the battery pack is hung above a rear floor at the bottom of a suitcase and loaded on the side longitudinal beams, so that the strength is ensured, and meanwhile a stable fixation state is formed; and through reasonable partitioning, spaces above and below the rear floor are fully used, so that the function components such as the battery pack and the cooling system thereof, the fuel tank and the exhaust pipe muffler are reasonably arranged on a vehicle body.

Owner:DONGFENG MOTOR CORP HUBEI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com