Welding process of ultrahigh-strength steel and heterogeneous high-strength steel

An ultra-high-strength steel, welding technology, applied in welding media, welding equipment, welding equipment and other directions, can solve the problems of low welding efficiency, different physical properties, high cost, improve production efficiency, high degree of automation, simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The welding process of ultra-high-strength steel and dissimilar high-strength steel includes the following steps:

[0029] 1. Material selection:

[0030] 1) Ultra-high-strength steel workpiece 1 is made of Tenaris S690 steel pipe with a wall thickness of 15.9 mm and a pipe diameter of Ф457.2 mm. This material has the advantages of high strength and good toughness, but the weld is prone to softening and embrittlement in the heat-affected zone , Welding cold cracks and other problems, this type of steel is widely used in important structures in marine engineering, shipbuilding and other industries.

[0031] 2) The material of dissimilar high-strength steel workpiece 2 is 15CrNiMoV, which is a kind of forged steel with a plate thickness of 140 mm.

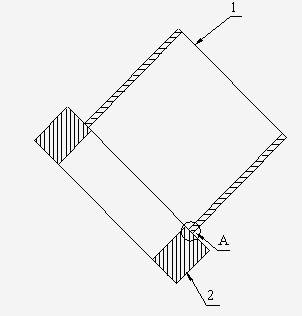

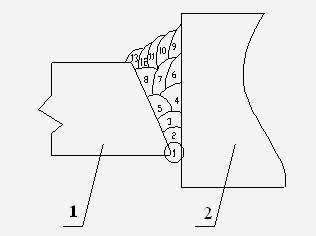

[0032] 2. The welding process is as follows: before welding, dry the welding material at 360°C-410°C for 2 hours, if figure 1 , 2 As shown, first set a V-shaped groove on the end face of the ultra-high-strength steel workp...

Embodiment 2

[0039] A welding process for ultra-high-strength steel and dissimilar high-strength steel, comprising the following steps:

[0040] 1. Material selection:

[0041] 1) Ultra-high-strength steel workpiece 1 is made of 30CrMnSiNi2A, with a wall thickness of 16.5mm and a pipe diameter of Ф460.5mm.

[0042] 2) The material of dissimilar high-strength steel workpiece 2 is 35CrMoV, which is a kind of forged steel with a plate thickness of 100mm. The length and width of the test material taken are both 600mm.

[0043] 2. The welding process is as follows: before welding, dry the welding material at 360°C-410°C for 2 hours, if figure 1 The welding position is shown. Firstly, the end face of the ultra-high-strength steel is set with a V-shaped groove at an angle of 40°; then, the molten electrode mixed gas shielded welding is used, and the Lincoln STT technology is used to make the bottom. Welding requires one-sided welding and double-sided forming. AWS A5.28 ER80S-G (Φ1.0mm) solid w...

Embodiment 3

[0049] A welding process for ultra-high-strength steel and dissimilar high-strength steel, comprising the following steps:

[0050] 1. Material selection:

[0051] 1) Ultra-high-strength steel workpiece 1 is made of S460NH steel pipe with a wall thickness of 25.4 mm and a pipe diameter of Ф457.2 mm. This material has the advantages of high strength and good toughness, but the weld is prone to softening and embrittlement in the heat-affected zone. Welding cold cracks and other problems, this type of steel has a wide range of applications in important structures in marine engineering, shipbuilding and other industries.

[0052] 2) The material of dissimilar high-strength steel workpiece 2 is 15CrNiMoV, which is a kind of forged steel with a plate thickness of 140 mm.

[0053] 2. The welding process is as follows: before welding, dry the welding material at 360°C-410°C for 2 hours, if figure 1 The welding position is shown. First, set the V-shaped groove on the end face of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com