Heat source system

A heat source system and heating system technology, which is applied in the field of welding and manufacturing of electronic devices, can solve problems such as unsatisfactory thermal separation of components, and achieve the effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention are described below in conjunction with the accompanying drawings and examples. However, it should be understood that the following descriptions of specific embodiments are only for explaining implementation examples of the present invention, and do not limit the scope of the present invention in any way.

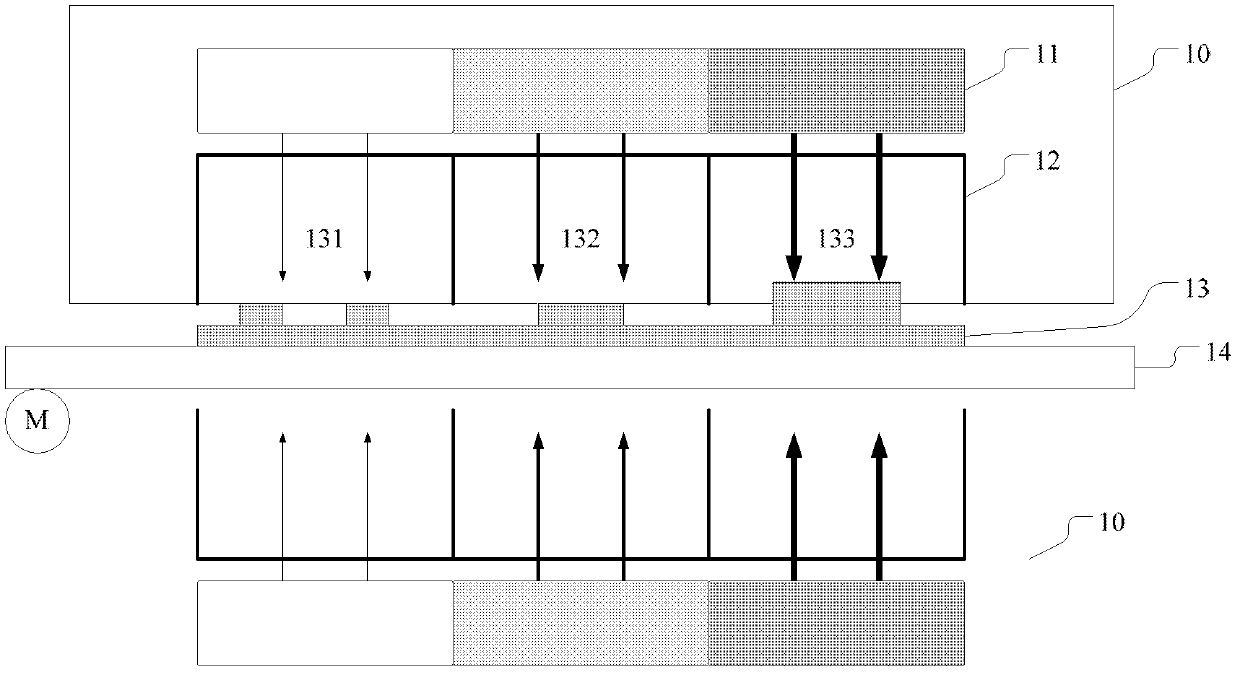

[0014] figure 1 A schematic structure of a heat source system according to an embodiment of the present invention is shown. Such as figure 1 As shown, a heat source system 10 according to an embodiment includes a heating system 11 and a heat distribution system 12 . The heating system 11 is used to provide non-uniform heating gas, such as figure 1 indicated by the middle arrow. Specifically, the thicker arrow on the right shows a more heated, higher temperature gas, and the thinner arrow on the left shows a less heated, lower temperature gas. Correspondingly, the heat distribution system 12 is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com