Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1045 results about "Chemical Ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ingredient labels for food and other products we use every day, like toothpaste or soap, often include unfamiliar chemical names – even basic ingredients like salt, water and baking soda are often identified on a product label by technical names: sodium chloride, aqua and sodium hydrogen carbonate.

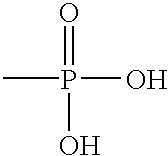

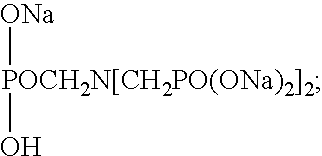

Alkaline detergent containing mixed organic and inorganic sequestrants resulting in improved soil removal

InactiveUS6150324ASoften waterImprove organic soil removal propertyInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsWater useAlkalinity

Solid block alkaline detergent compositions are disclosed comprising a source of alkalinity, and other detergent additives including sequestrants. The solid block detergents of the invention used a mixed inorganic and organic sequestrant composition that successfully softens service water used in manufacturing aqueous detergents from the composition, but also obtains substantially improved organic soil removal on dishware or flatware. The solid block detergents of the invention comprise large masses of the chemical ingredients having a weight of greater than about 500 grams in a solid block product format that is typically dispensed using a spray on water dispenser that creates an aqueous concentrate that is used in a washing machine.

Owner:ECOLAB USA INC

Transparent lead-free fritted glaze with low expansion coefficient and preparation method thereof

The invention relates to a transparent lead-free fritted glaze with low expansion coefficient and a preparation method thereof. The fritted glaze comprises the following chemical ingredients of: 59 to 66 percent of SiO2, 10 to 15 percent of Al2O3, 5 to 10 percent of B2O3, 3 to 6 percent of CaO, 4 to 8 percent of MgO, 0 to 3 percent of K2O, 0 to 2 percent of Na2O, 0 to 1 percent of Li2O, 1 to 5 percent of ZnO and 0 to 2 percent of SrO; and the fritted glaze comprises the raw materials of: 10 to 25 percent of kaolin, 15 to 30 percent of quartz, 10 to 25 percent of potassium feldspar, 0 to 8 percent of dolomite, 2 to 6 percent of grammite, 10 to 20 percent of roasted talc, 1 to 6 percent of zinc oxide, 2 to 8 percent of boric acid, 5 to 15 percent of calcium borate, 1 to 5 percent of alumina, 0 to 2 percent of lithium carbonate and 0 to 3 percent of strontium carbonate. The expansion coefficient of the fritted glaze is 3.7-4.5*10-6 / DEG C (RT to 500 DEG C), the melted temperature is 1400 DEG C to 1500 DEG C, the glaze firing temperature is 1130 DEG C to 1230 DEG C; and the transparent lead-free fritted glaze has fine and bright glaze surface, high transparency, low expansion coefficient as well as no lead precipitation and is particularly suitable for double-fired hard porcelain body with lower expansion coefficient.

Owner:JINGDEZHEN CERAMIC INSTITUTE

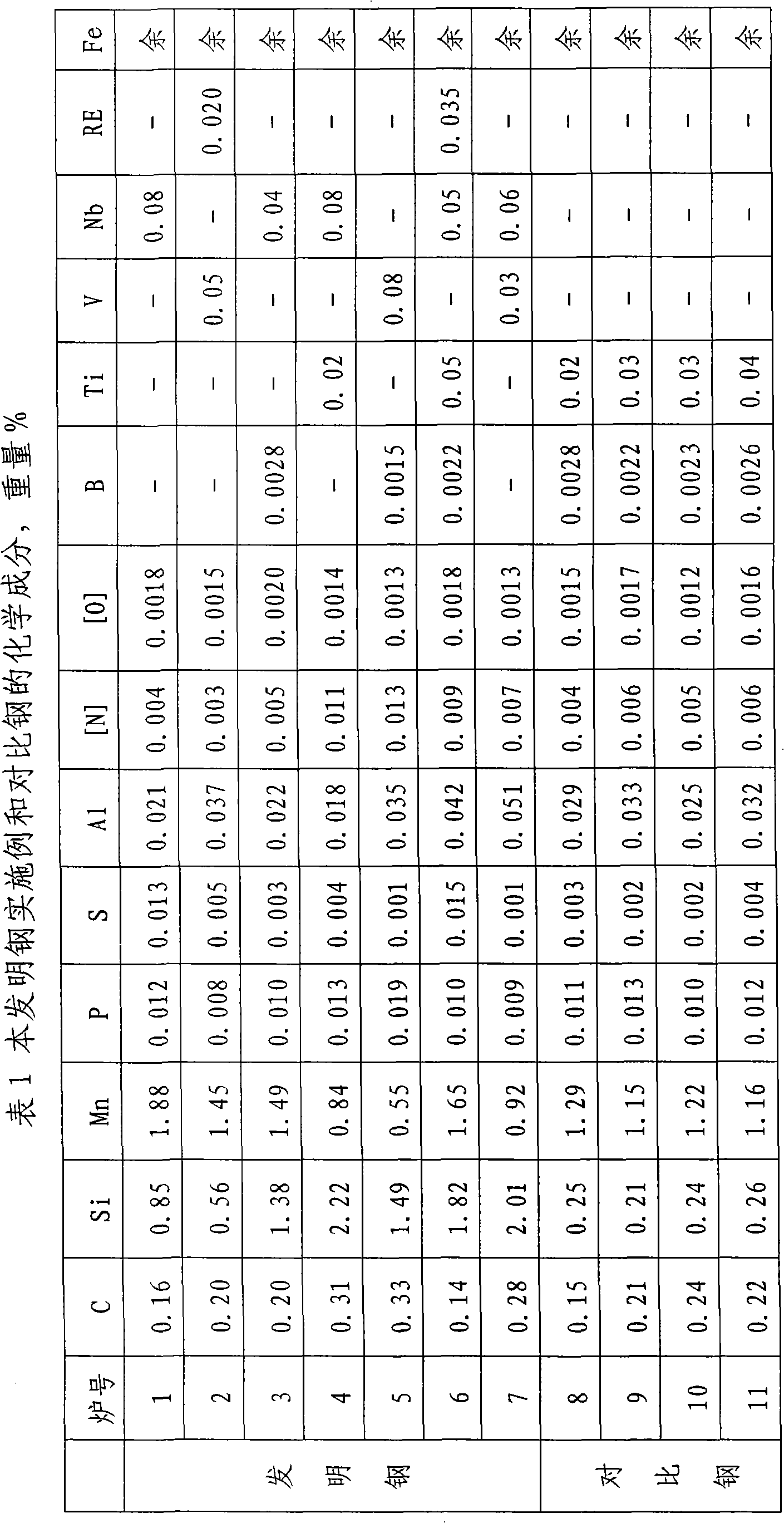

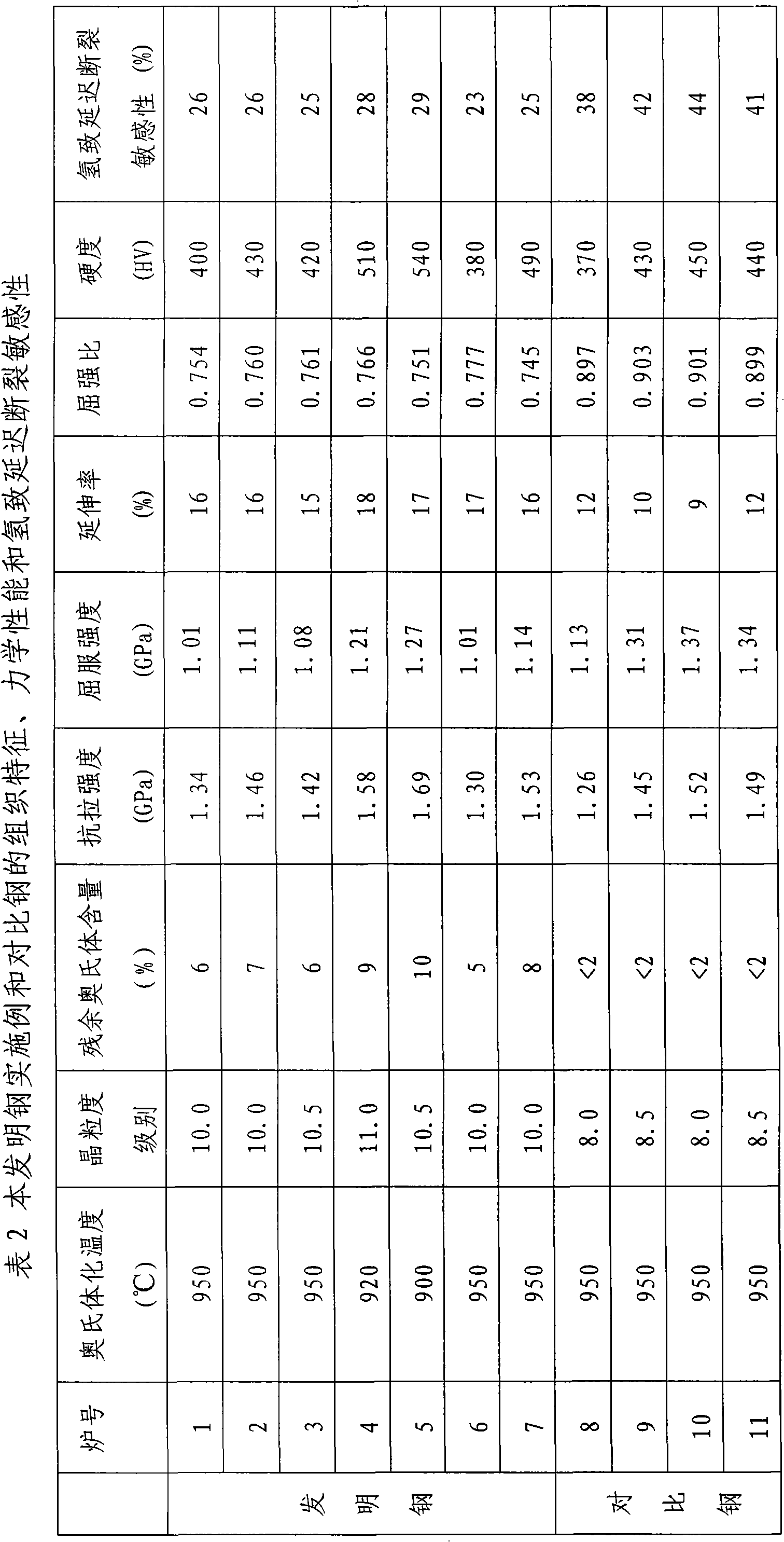

Hotforming martensitic steel

The invention belongs to the field of alloy steel, more particularly relates to thermal forming martensitic steel, which is mainly suitable for the steel for thermal punching forming accessory with thin thickness whose tensile strength ranges from 1.3 to 1.7GPa. The mainly chemical ingredients (weight %) of the steel are: C 0.10-0.33%, Si, 0.50-2.30%, Mn 0.50-2.00%, P <= 0.020%, S <= 0.015%, Al 0.015-0.060%, [O] <= 0.002%, [N] 0.002-0.015%, the rests are Fe and unavoidable impurities. In addition, the steel is also added with any or more than one of the group consisting of B 0.0005-0.0050%, Ti 0.02-0.10%, Nb 0.02-0.10%, V 0.02-0.15% and RE 0.001-0.050%. Compared with the current thermal forming martensitic steel 22MnB5, the steel of the invention not only has the tensile strength enhanced from 1.0-1.5GPa to 1.3 to 1.7GPa, but also has good plasticity, the coefficient of extension is more than 15%, and hydrogen-induced delayed fracture sensitivity is obviously reduced, thus making the vehicle having lighter weight and higher secure performances become true.

Owner:CENT IRON & STEEL RES INST

Vermicular graphite cast iron for producing brake drum of high-speed and heavy-load automobile

The invention discloses alloyed vermicular graphite cast iron produced by alloying the ordinary vermicular graphite cast iron. The cast iron comprises an alloy of two or more of elements such as Cu, Cr, Mo, Ni, Sn, Sb, B, Ti, Al, V and the like. The vermicular graphite cast iron comprises the following chemical ingredients in percentage by weight: 3.00-3.80 percent of C, 2.00-2.80 percent of Si, 0.45-0.95 percent of Mn, less than 0.06 percent of P, less than or equal to 0.02 percent of S, and 0.02-0.60 percent of alloy ingredient. The technical indexes of the vermicular graphite cast iron are that: VG is more than or equal to 80 percent, Rm is more than or equal to 380 MPa, hardness is between 180 HBW and 258 HBW, cast pearlite is more than or equal to 60 percent, and elongation rate is between 1 percent and 2 percent. The vermicular graphite cast iron has the advantages of high intensity, high heat conductivity, high wear resistance, high thermal fatigue resistance, small deformation, simple casting process and easiness in mechanical production. The service life of a produced brake drum for a high-speed and heavy-load automobile is remarkably prolonged, and safety is ensured.

Owner:罗云

High-plasticity magnesium alloy and preparation method thereof

The invention relates to the field of metal materials, in particular to a high-plasticity magnesium alloy and a preparation method thereof. The alloy comprises the following chemical components in percentage by mass: 0.1 to 6.0 percent of aluminum, 0.1 to 3.0 percent of tin, 0.01 to 2.0 percent of manganese, 0.01 to 2.0 percent of strontium and the balance of magnesium and other inevitable impurities; simultaneously, the magnesium alloy can also contain one or more of additional elements such as zinc and stibium and rare earth elements. The preparation method comprises the following steps of: melting the magnesium and the aluminum, adding the tin, the additional elements, the rare earth elements and the strontium in turn, stirring and refining, and preparing a melt into a plate by a cast-rolling and rolling process; or directly pouring the melt into a cast ingot; or pouring the melt into the cast ingot, extruding the cast ingot into a section or a thick plate and rolling the thick plate into a thin plate. The preparation method enhances the intensity and toughness of the alloy and overcomes the defects that a cast magnesium alloy is difficult to adapt to a deformation condition and a deformed magnesium alloy is difficult to adapt to a casting condition.

Owner:JILIN UNIV

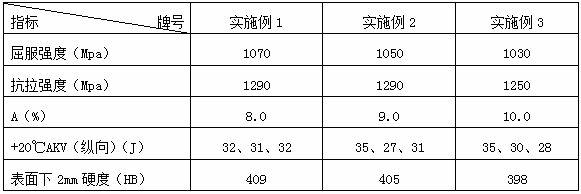

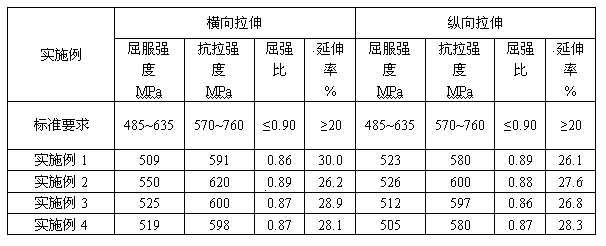

Hardening and tempering high-strength steel plate for wood based panel equipment and production method of tempering high-strength steel plate

The invention relates to a hardening and tempering high-strength steel plate for wood based panel equipment and a production method of the steel plate, and belongs to the field of manufacturing low-alloy high-strength structural steel. The steel plate consists of the following chemical components in percentage by weight: 0.18 to 0.24 percent of C, 0.20 to 0.50 percent of Si, 0.80 to 1.20 percent of Mn, more than or equal to 0.02 percent of P, more than or equal to 0.01 percent of S, 0.20 to 0.50 percent of Mo, 0.20 to 0.50 percent of Ni, 0.70 to 1.00 percent of Cr, more than or equal to 0.003percent of B, 0.017 to 0.030 percent of Nb, 0.040 to 0.050 percent of V, 0.017 to 0.026 percent of Ti, and the balance of Fe and inevitable impurities. The production method of the steel plate comprises the following steps of: electric furnace smelting, vacuum decarburization / vacuum arc decarburization (VD / VOD) furnace vacuum decarburization, ladle furnace (LF) furnace refining, continuous casting (die casting), billet steel (ingot) clearing, heating, plate rolling, hardening and tempering, steel plate checking and polishing, tempering, sampling inspection, and warehousing. The hardening andtempering high-strength steel plate for the wood based panel equipment adopts Cr-Ni-Mo-B system micro-alloy elements for composite strengthening, and acquires good obdurability matching through a reasonable heat treatment process, and simultaneously the welding performance of a thick plate is not reduced.

Owner:WUYANG IRON & STEEL +1

Alkaline detergent containing mixed organic and inorganic sequestrants resulting in improved soil removal

InactiveUS6436893B1Improve propertiesImprove removabilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsEnvironmental engineeringChemical Ingredients

Owner:ECOLAB USA INC

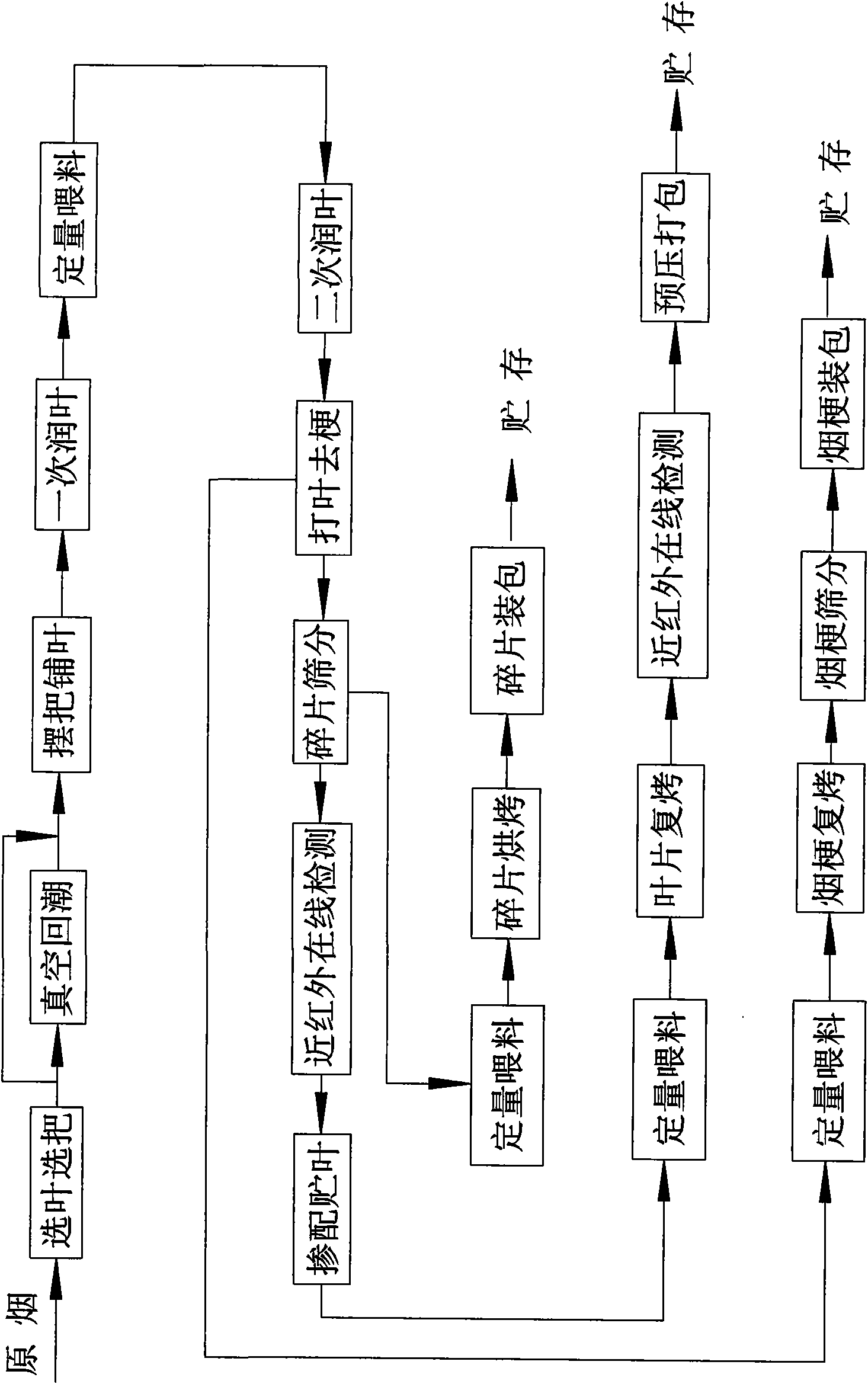

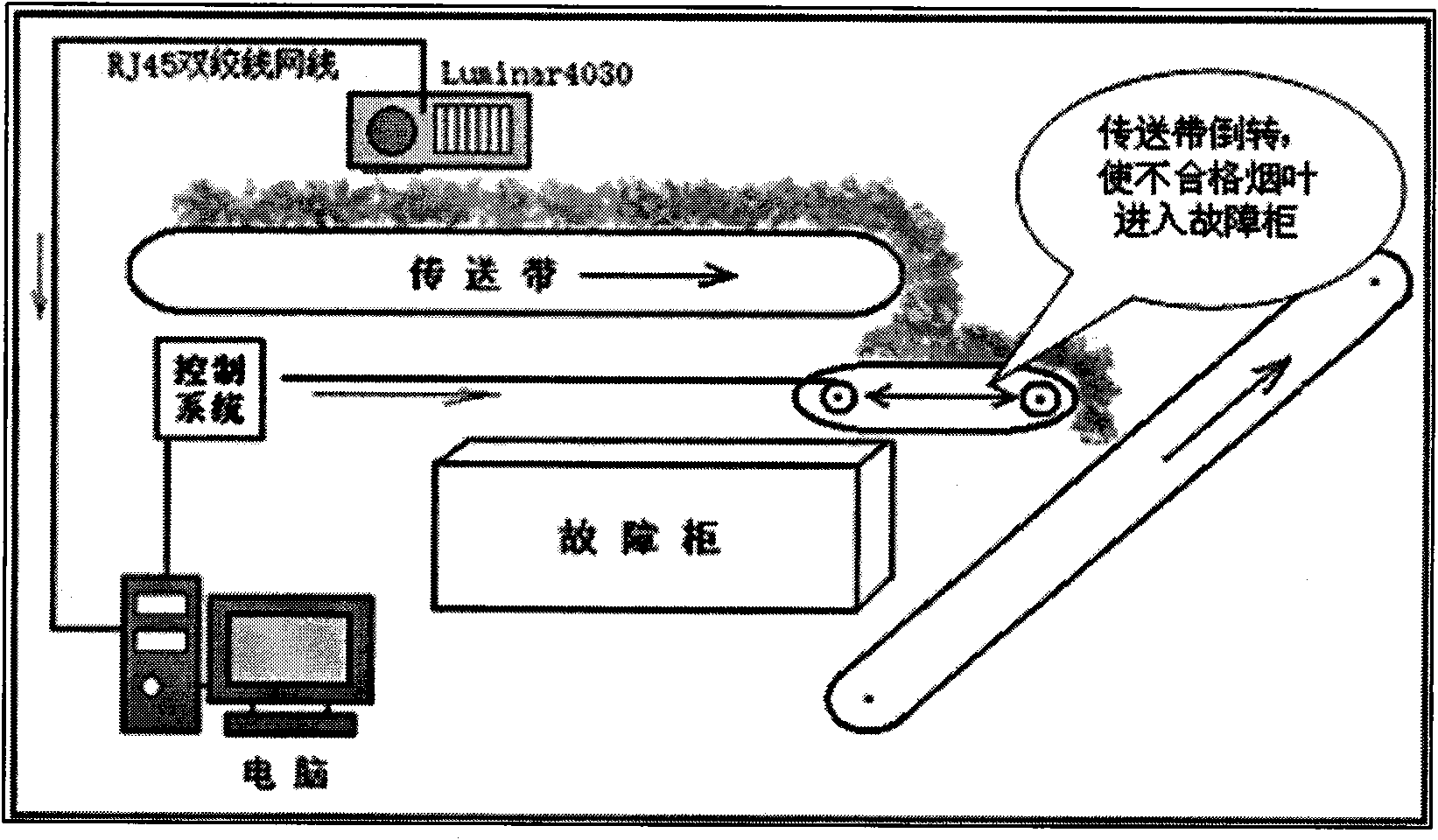

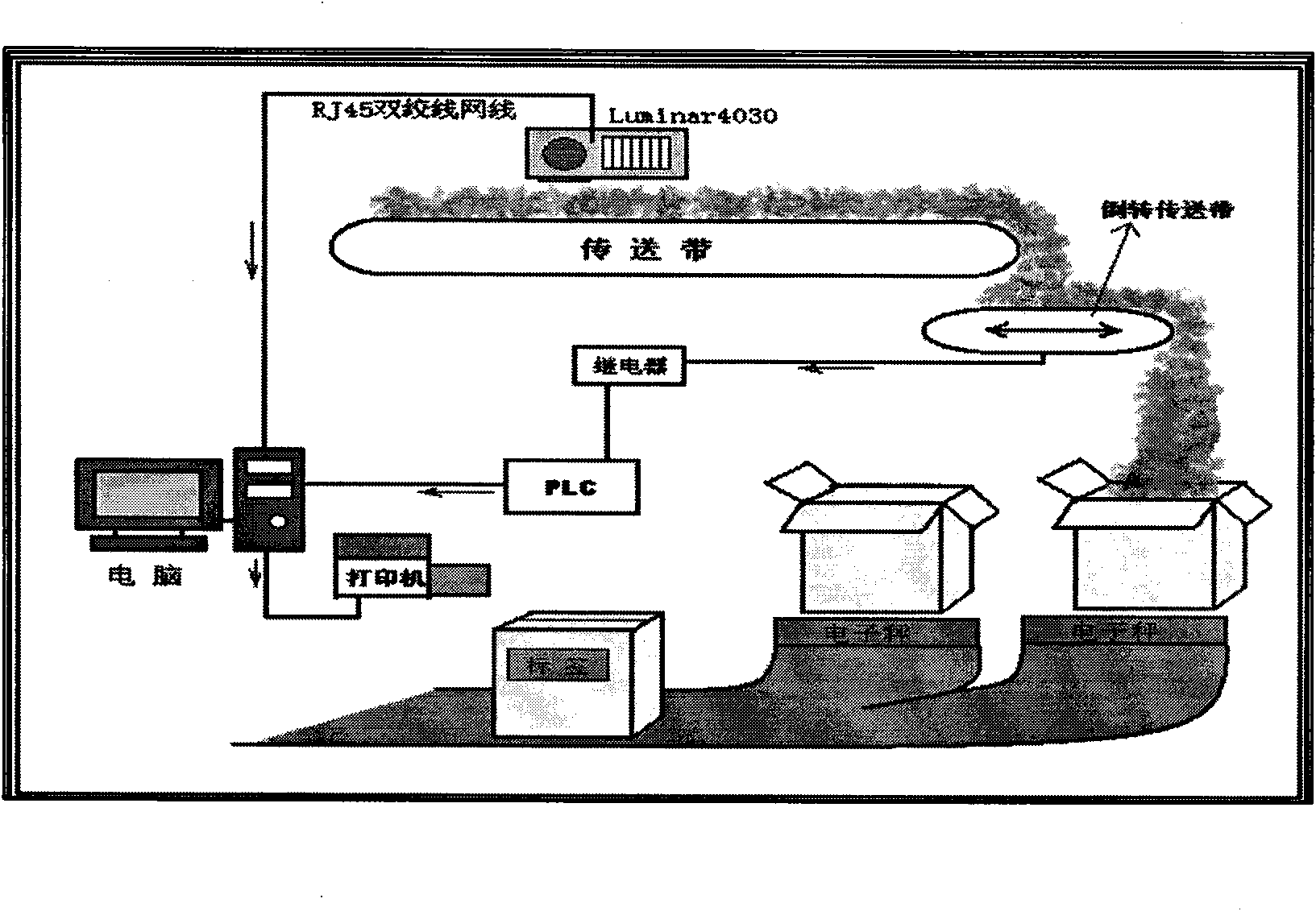

New mean production control type threshing and redrying method

ActiveCN101564199AEasy to detectEasy to controlTobacco preparationTobacco treatmentComputer control systemLoop control

The invention discloses a new mean production control type threshing and redrying method, which comprises a raw material preparation process, a threshing process, a redrying process and a packaging process. A process for the near infrared online detection of chemical ingredient contents of tobacco leaves is added before the threshing and redrying and after the threshing and redrying respectively, and the online detection of a near infrared spectrometer cooperates with a computer control system before redrying and links with threshing and redrying equipment to form closed-loop control. In the invention, the addition of the near infrared online detection process before leaf redrying realizes the mean management of threshing and redrying line, eliminates the defect of the past threshing and redrying technique that the control indexes of inner quality are short, thus laying a good foundation for threshing and redrying enterprises to improve processing level and satisfying the requirements of cigarette processing enterprises. The addition of the near infrared online detection after redrying ensures that each box of products have labels of chemical ingredient content data, thus providing powerful data reference for tobacco alcoholization and cigarette prescription, and leading all jobs to have relatively accurate chemical index data as basis.

Owner:BAOFENG REDRYING FACTORY OF TIANCHANG INT TOBACCO CO LTD

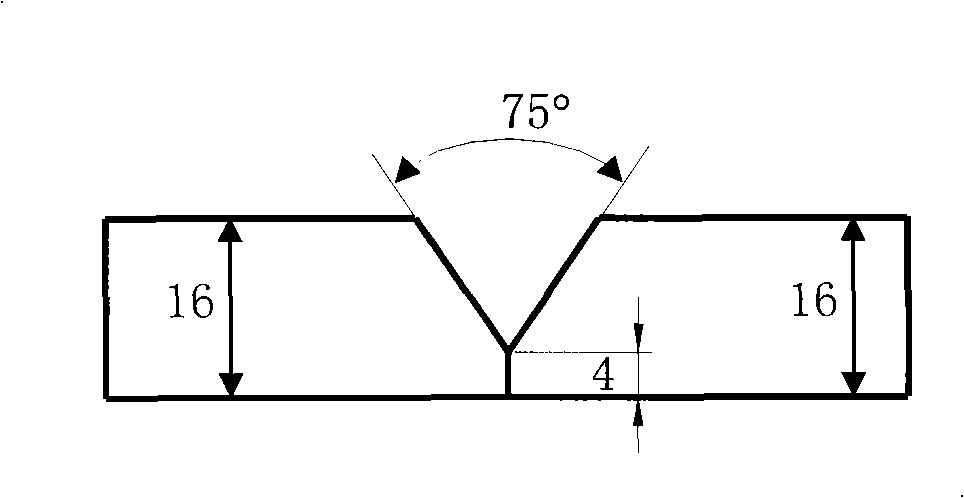

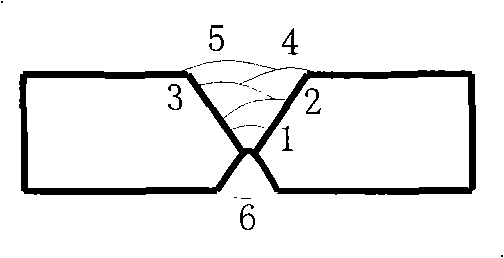

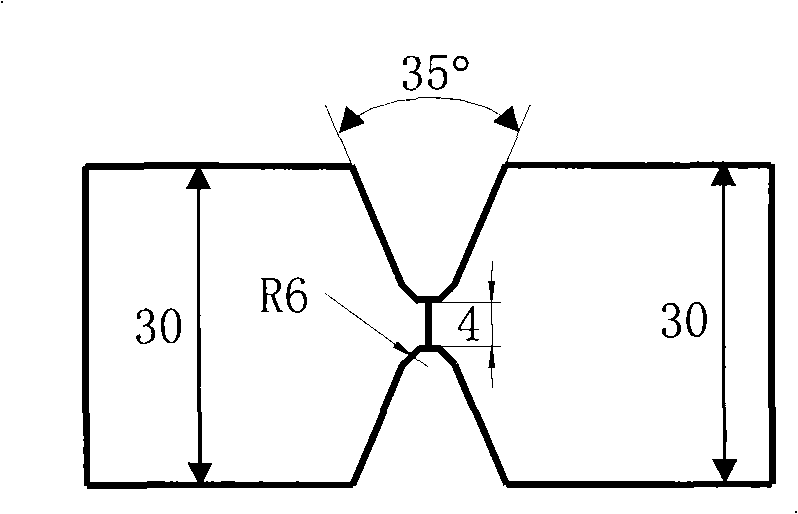

Welding method of Q420qE grade ultra-low-carbon bainite steel for bridges

InactiveCN101513695AImprove mechanical propertiesImprove welding efficiencyWelding/soldering/cutting articlesMetal working apparatusChemical IngredientsWeld line

The invention discloses a welding method of Q420qE grade ultra-low-carbon bainite steel for bridges, comprising the following steps: 1. the special chemical ingredients and technical conditions of Q420qE grade ultra-low-carbon bainite steel for bridges related to the welding method; 2. the pre-heating temperature before welding related to the steel and thickness specification of the steel; 3. welding line energy related to the steel; 4, the groove form and welding method related to the joint form and the plate thickness of the steel; 5. welding materials related to the steel, the joint form, groove form and welding method of the steel; and 6. welding process parameters related to the steel, the joint form, groove form, welding method and welding materials of the steel. The welding method covers the typical joint forms and thickness specifications of the bridge structure, and is simple and practical, the implementation effect of which complies with the related standards of the present bridge steel and the bridge structure, thus being practically applied to welding of the bridge steel structure.

Owner:YANSHAN UNIV +1

Nb-Ti microalloying steel suitable for large line energy welding and smelting method therefor

InactiveCN1962916AImprove toughnessSimple production processWelding/cutting media/materialsSoldering mediaSheet steelPre treatment

The invention discloses an Nb-Ti microalloy steel for large line power welding, which comprises the following parts: 0.06%-0.12% C, 0.10%-0.50% Si, 0.40%-1.8% Mn, not more than 0.015% P, not more than 0.010% S, 0.020%-0.050% Nb, 0.006%-0.030% Ti, 0.0030%- 0.0100% N, one or more of not more than 0.40% Mo, not more than 0.06% V, not more than 1.0% Ni, not more than 1.0% Cr, and not more than 0.50% Cu and Fe and inevitable impurity, wherein the Ceq is C+Mn / 6+Si / 24+Ni / 40+Cr / 5+Mo / 4+V / 14<=0.45%; the [Ti%]T is not less than 2.667[N%]T-0.004667%. The smelting method comprises the following steps: predisposing molten iron; smelting through rotary furnace; removing S in the LF furnace; refining in the VD or RH; adding Ti and Nb in the VD or RH. The steel board possesses excellent flexibility in the welding heat influencing region when it is welded at 50-150KJ / cm.

Owner:ANGANG STEEL CO LTD

High-strength steel plate for 800MPa hydropower station pressure pipeline and production method thereof

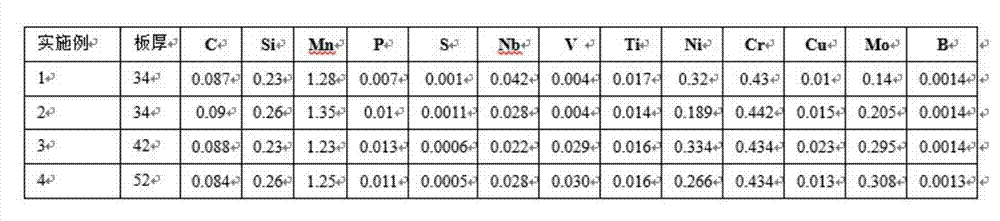

The invention provides a high-strength steel plate for an 800MPa hydropower station pressure pipeline and a production method thereof, and belongs to the technical field of steel for hydropower stations. The steel is composed of the following chemical ingredients in percentage by weight: 0.08-0.10% of C, not larger than 0.25% of Si, 1.2-1.6% Mn, not larger than 0.013% of P, not larger than 0.02% of S, 0.01-0.03% of Nb, not larger than 0.03% of V, 0.01-0.02% of Ti, 0.15-0.50% of Ni, 0.20-0.60% of Cr, 0.05-0.30% of Mo, 0.0010-0.0015% of B and the balance of Fe and inevitable impurities. Since element ingredients are reasonably combined and designed and corresponding rolling and heat treatment techniques are matched, the steel plate has excellent welding adaptability while having excellent strength, plasticity and low-temperature impact toughness, and the welding cold cracking sensitivity index Pcm is not larger than 0.22%.

Owner:SHOUGANG CORPORATION

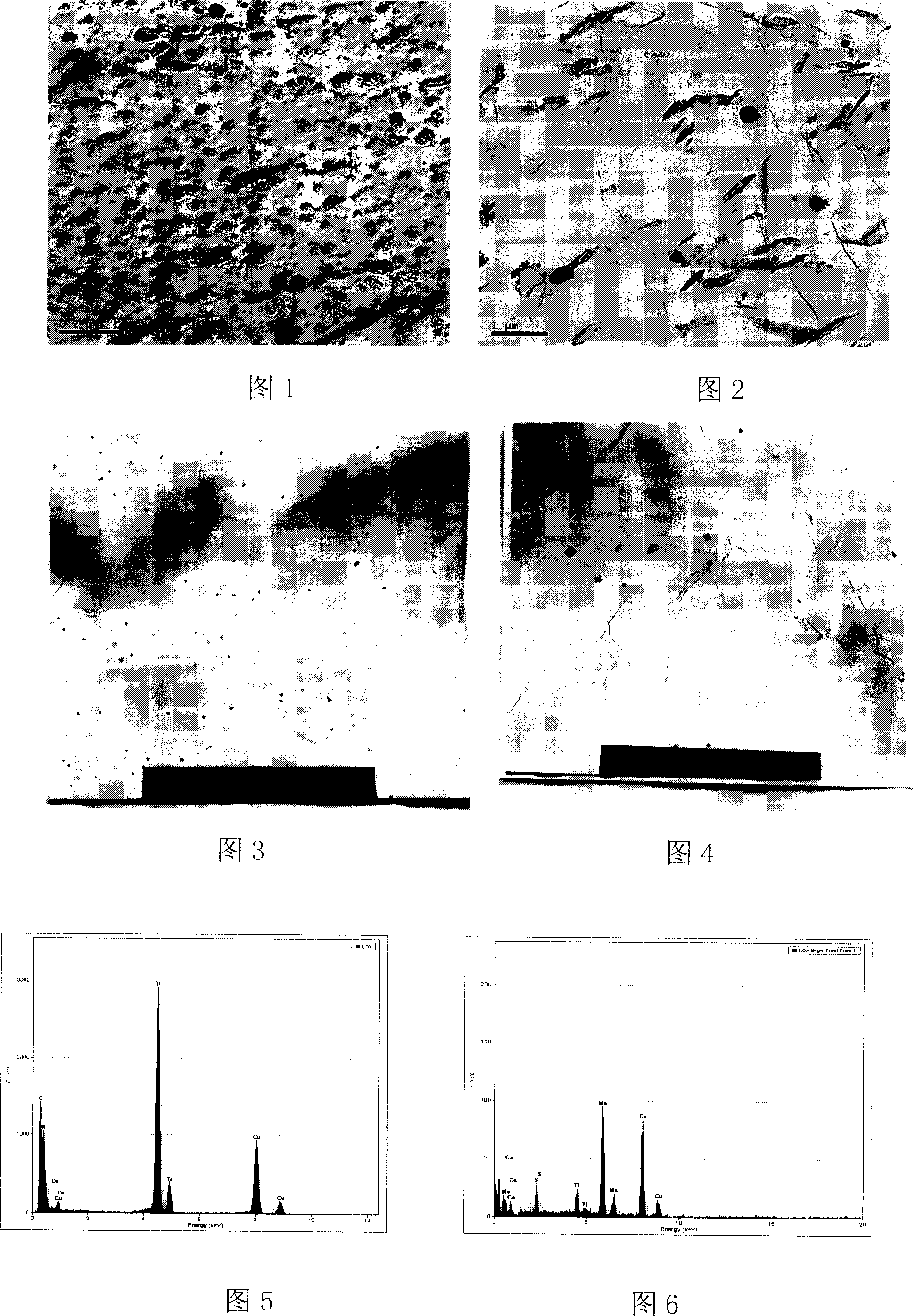

Low-alloy high-strength steel with yttrium-based rare earth and manufacturing method thereof

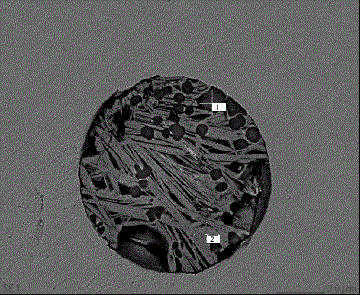

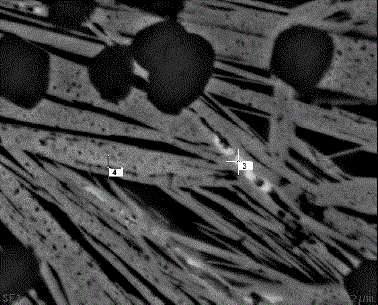

The invention discloses low-alloy high-strength steel with yttrium-based rare earth. The low-alloy high-strength steel with the yttrium-based rare earth comprises the following chemical ingredients in percentage by mass: 0.08-0.19% of C, 0.15-0.55% of Si, 1.20-1.70% of Mn, not greater than 0.040% of P, not greater than 0.040% of S, not greater than 0.040% of Nb, not greater than 0.18% of V, not greater than 0.020% of Ti, not greater than 0.40% of Ni, not greater than 0.30% of Cr, not greater than 0.30% of Cu, not greater than 0.08% of Mo, not greater than 0.050% of Alt, not greater than 0.012% of N, 0.002-0.003% of O, and balance iron Fe, rare earth and inevitable impurities, wherein the rare earth is the yttrium-based rare earth; the steel comprises the following dissolved solid matters: 0.004-0.010% of Y, and 0.014-0.025% of Ce, and the residues exist in the form of combining Y and Ce with O, Mg, Al and S in the steel to form small dispersed compound inclusions; the compound inclusion component contains, in percentage by mass, 25.40-70.10% of Y, and 3.25-19.15% of Ce; and a matrix structure of the steel is a fine ferrite and perlite structure. The low-alloy high-strength steel disclosed by the invention is improved by utilizing the yttrium-based rare earth for exerting the effects of purification, modification, microalloying and oxide metallurgy in the steel.

Owner:JIANGXI UNIV OF SCI & TECH +1

Preparation method of golden red temmku kiln fancy glaze Western-style food dinnerware

The invention provides a preparation method of a golden red temmku kiln fancy glaze Western-style food dinnerware. In the preparation method, the used ground enamel comprises the following components: 61.4-7.02 of SiO2, 8.6-14.6 of Al2O3, 7.6-13.1 of CaO, 2.9-8.3 of K2O, 1.4-5.9 of Fe2O3, 0.3-2.4 of Na2O, 0.3-1.5 of MnO2, 0.2-1.2 of B2O3, 0.2-1.0 of MgO, 0.09-0.2 of Li2O and less than or equal to0.7 of other components; and the cover glaze comprises the following components: 53.4-58.1 of SiO2, 12.4-20.9 of ZnO, 5.1-14.9 of Al2O3, 3.5-10.6 of CaO, 2.2-8.7 of B2O3, 1.9-7.4 of K2O, 1.1-4.0 of Na2O, 0.4-1.4 of TiO2, 0.4-1.0 of BaO, 0.1-0.8 of MgO and less than or equal to 0.7 of other inevitable components. The process flow is as follows: preparing the green body of the dinnerware; carrying out ball-milling on the ground enamel and the cover glaze slurry; adding 5-10 parts of red zirconium silicate-coated cadmium sulfide selenide pigment in the cover glaze slurry; and glazing on the green body, and finally, completing calcination.

Owner:JIANGSU GAOCHUN CERAMICS

System for controlling the loading of one or more foods into a self-propelled mixing unit by means of a mechanical shovel mounted to a motor vehicle

A system for controlling the loading of at least one food for animal use into one or more self-propelled mixing units by means of a mechanical shovel, which is mounted to a motor vehicle for collecting the food and unloading the food into the self-propelled unit. The system includes a testing apparatus, which is mounted to the shovel to determine a series of chemical-physical information related to the chemical components contained in the food present in the shovel and a weighing apparatus, which is installed in the self-propelled unit to measure the weight of the food contained in the self-propelled unit and is adapted to establish a wireless communication with the testing apparatus to receive the chemical-physical information related to the components contained in said food; the weighing apparatus including a processing module which determines, at each loading and according to the received chemical-physical information, the weight of a remaining amount of food to be loaded into the self-propelled unit so that each chemical-physical component of the food inside the self-propelled unit, once the loading has been completed, fulfils a predetermined condition.

Owner:DINAMICA GENE

Ferrite stainless steel cold-rolled steel band and manufacturing method thereof

ActiveCN101649418AEasy to processReduced processing performanceTemperature control deviceManufacturing convertersSS - Stainless steelMolten steel

The invention relates to a ferrite stainless steel cold-rolled steel band and a manufacturing method thereof. The ferrite stainless steel cold-rolled steel band comprises the following chemical ingredients in percentage by weight: 0.02%-0.04% of C, 0.10%-0.50% of Si, 0.10%-1.00% of Mn, 14.0%-19.0% of Cr, less than or equal to 0.030% of P, less than or equal to 0.010% of S, more than 0% while lessthan or equal to 0.030% of N, more than 0% while less than or equal to 0.60% of Ni, and the balance of Fe and unavoidable impurities. The manufacturing method comprises the following steps: (1) smelting, i.e. smelting liquid steel according to the requirement of the steel band; (2) continuous casting, i.e. casting into a continuous casting billet; (3) casting billet hot rolling, i.e. rolling the casting billet into a hot rolled coil; (4) hot coiling annealing, i.e. preserving the temperature at 800 DEG C-880 DEG C for the temperature preserving time of 10-13 hours, freely reducing the temperature to 600 DEG C after the temperature preservation is completed; (5) cold rolling, i.e. adopting once cold rolling or twice cold rolling among cold rolled finished products; and (6) cold coiling annealing, i.e. controlling annealing temperature at 860+ / -20 DEG C, and controlling annealing time according to 2-5 minutes / mm. The ferrite stainless steel cold-rolled steel band has good cold processingforming property and excellent crinkling and breaking resistance.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

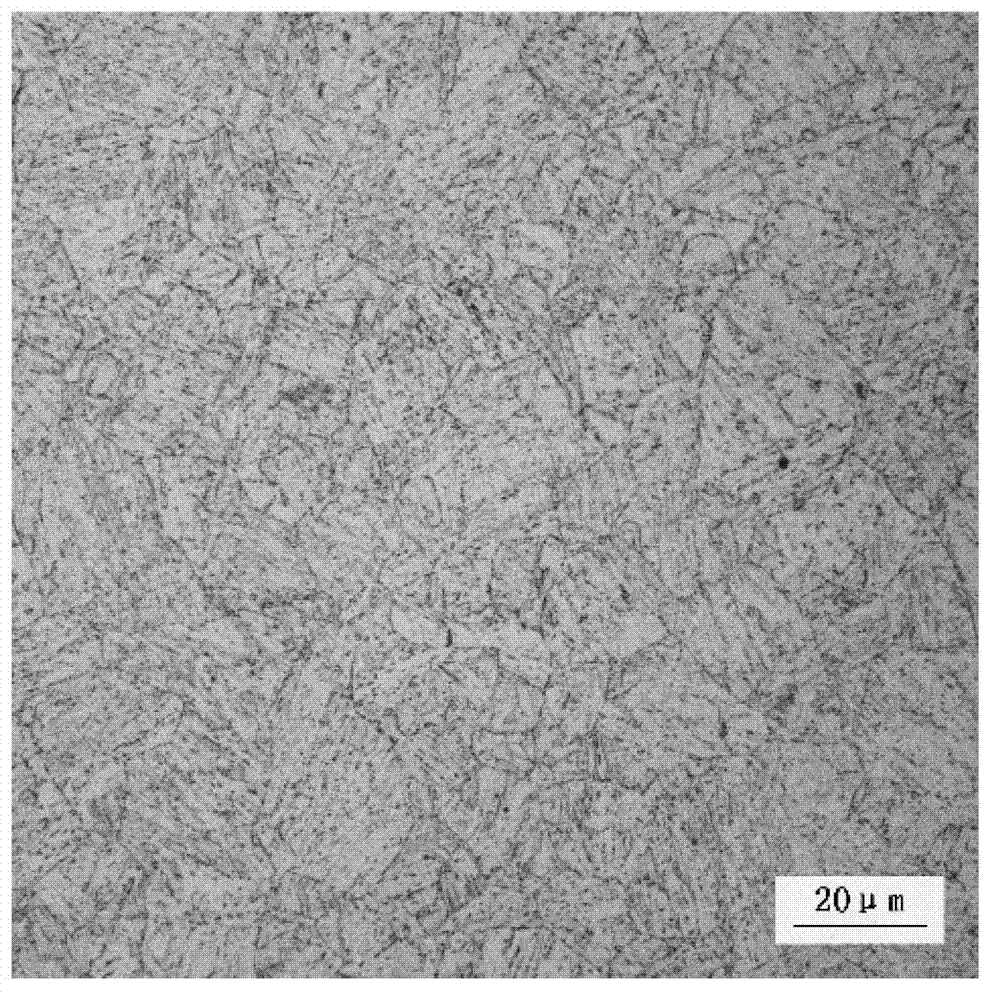

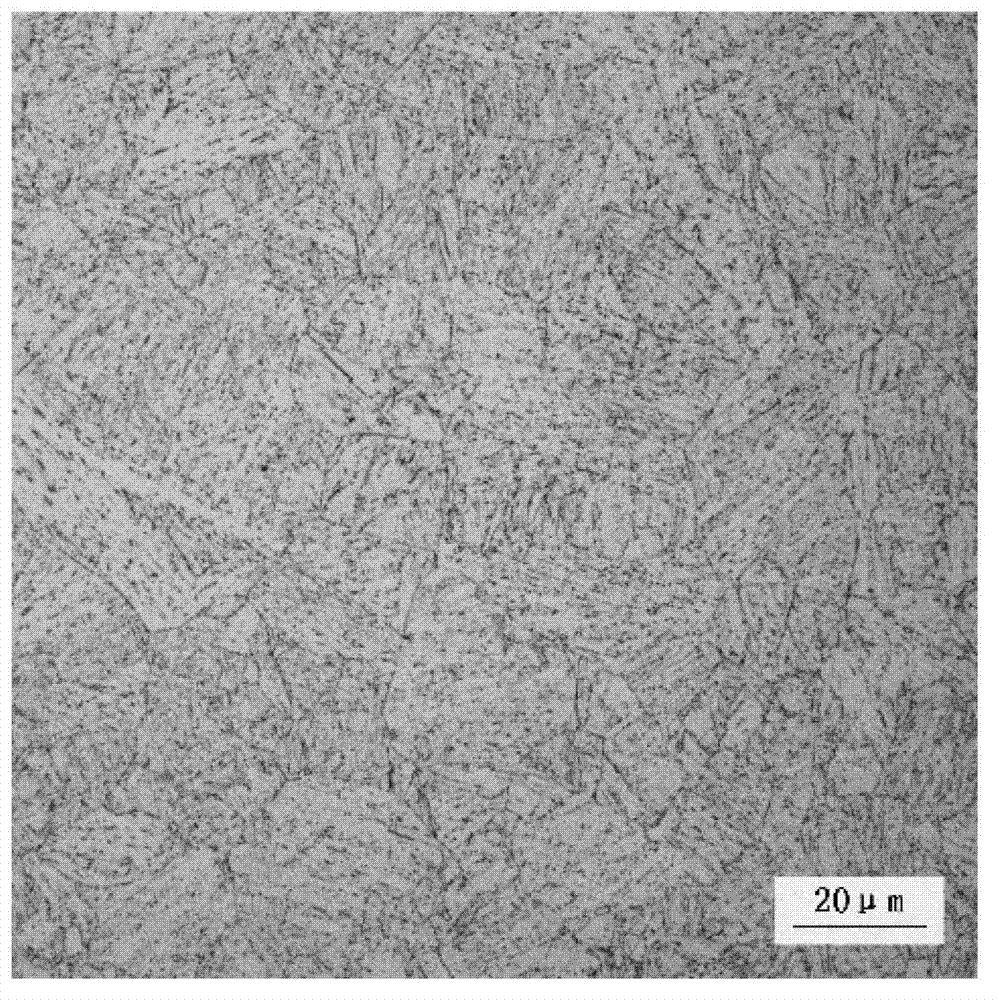

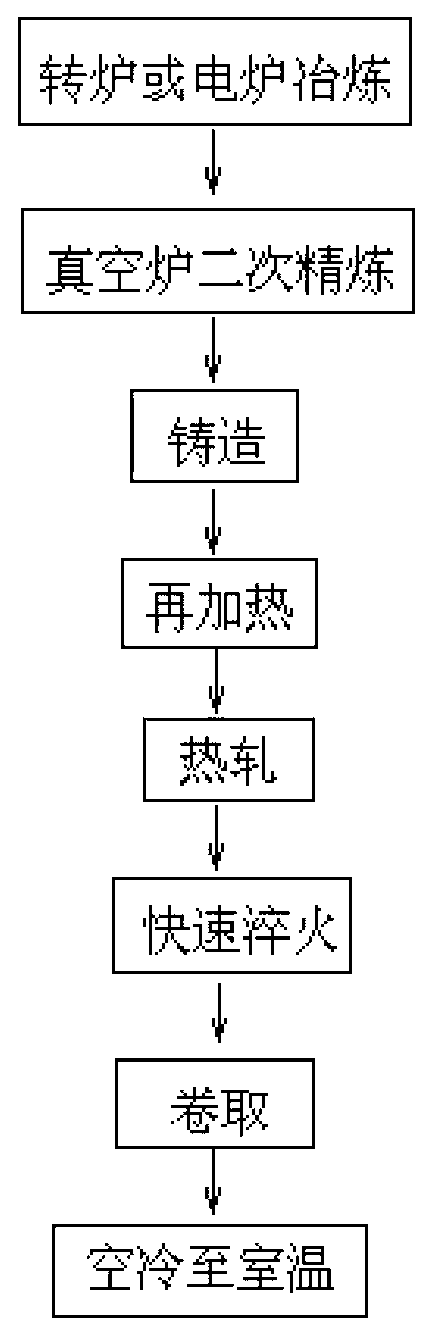

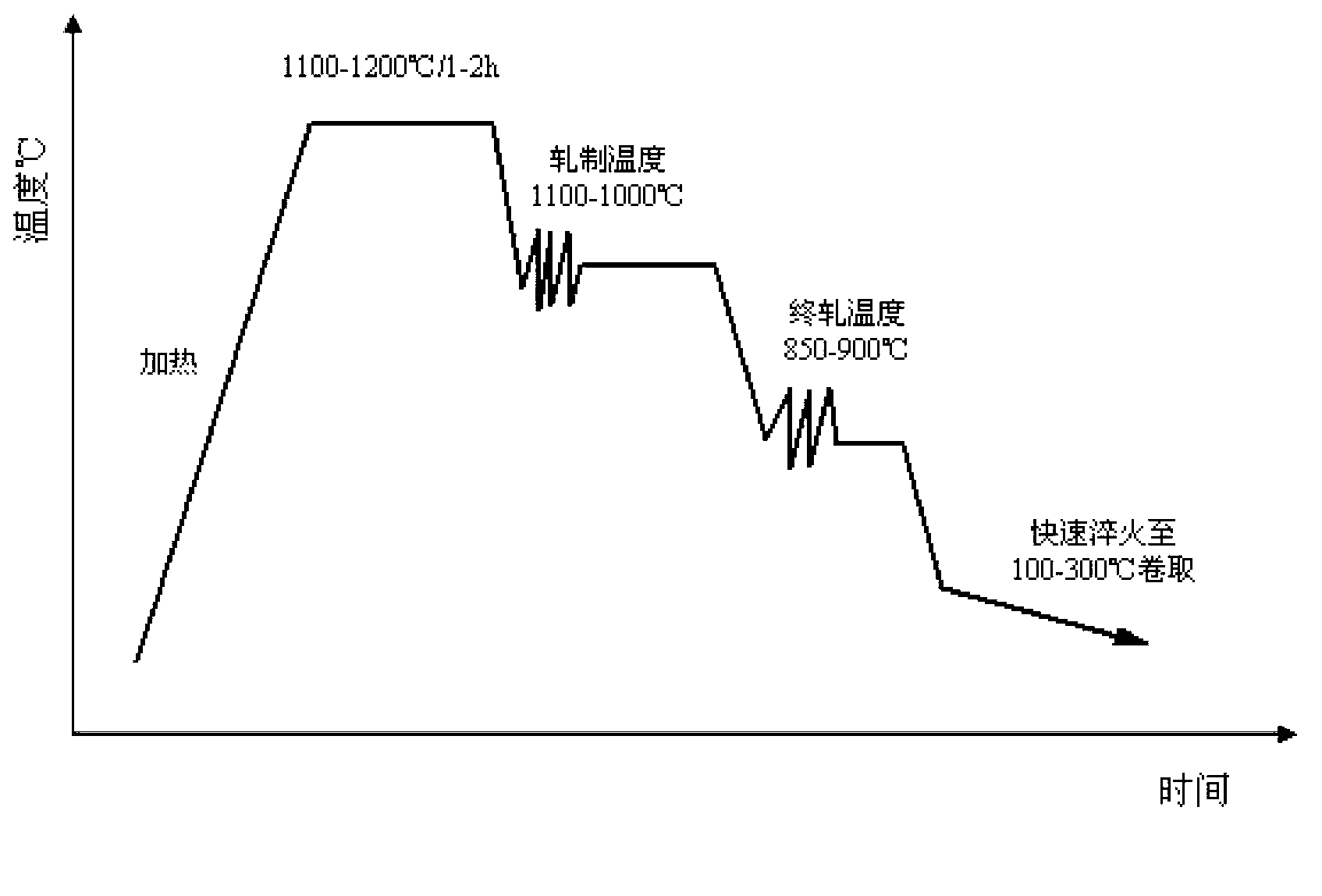

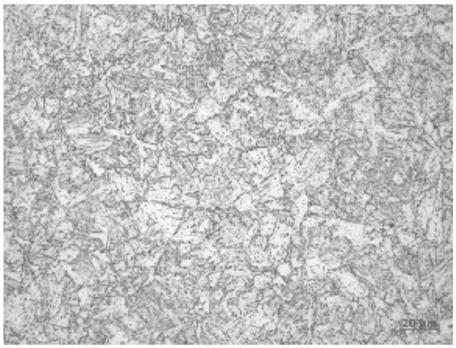

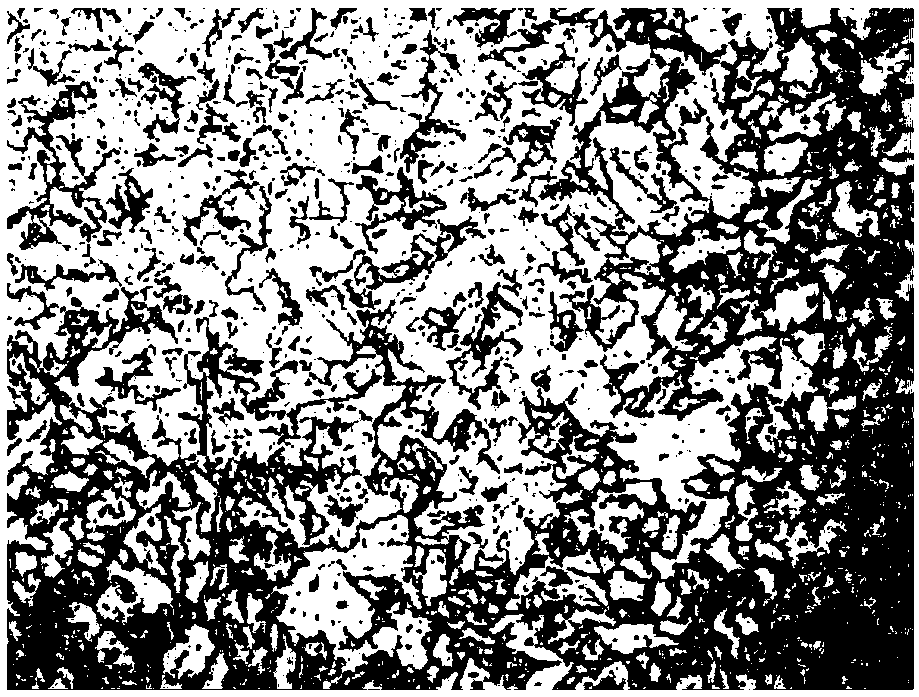

High-strength and high-toughness hot-rolled wear-resistant steel and preparation method thereof

The invention discloses high-strength and high-toughness hot-rolled wear-resistant steel and a preparation method thereof. The high-strength and high-toughness hot-rolled wear-resistant steel comprises the following chemical ingredients in percentage by weight: 0.20-0.50% of C, 0.8-2.0% of Si, 1.5-3.0% of Mn, not greater than 0.015% of P, not greater than 0.005% of S, 0.02-0.08% of Al, not greater than 0.006% of N, not greater than 30 ppm of O, 0.005-0.015% of Ti, 0.5-2.0% of Ni, and the balance of Fe and inevitable impurities, wherein the sum of Mn and Ni is 3.2-3.6%; the microscopic structure is composed of lath martensites and retained austenites, and the volume percentage content of the retained austenites is 5.0-15.0%; and the high-strength and high-toughness wear-resistant steel obtained by the processes of hot continuous rolling and rapid quenching has a tensile strength of greater than 1500 MPa, a yield strength of 1150-1400 MPa, a thickness of 3-12 mm, a good ductility (of greater than 10%), and a good low-temperature impact toughness (impact energy of 38-48 J at minus 20 DEG C), and shows excellent strong-plastic matching.

Owner:BAOSHAN IRON & STEEL CO LTD

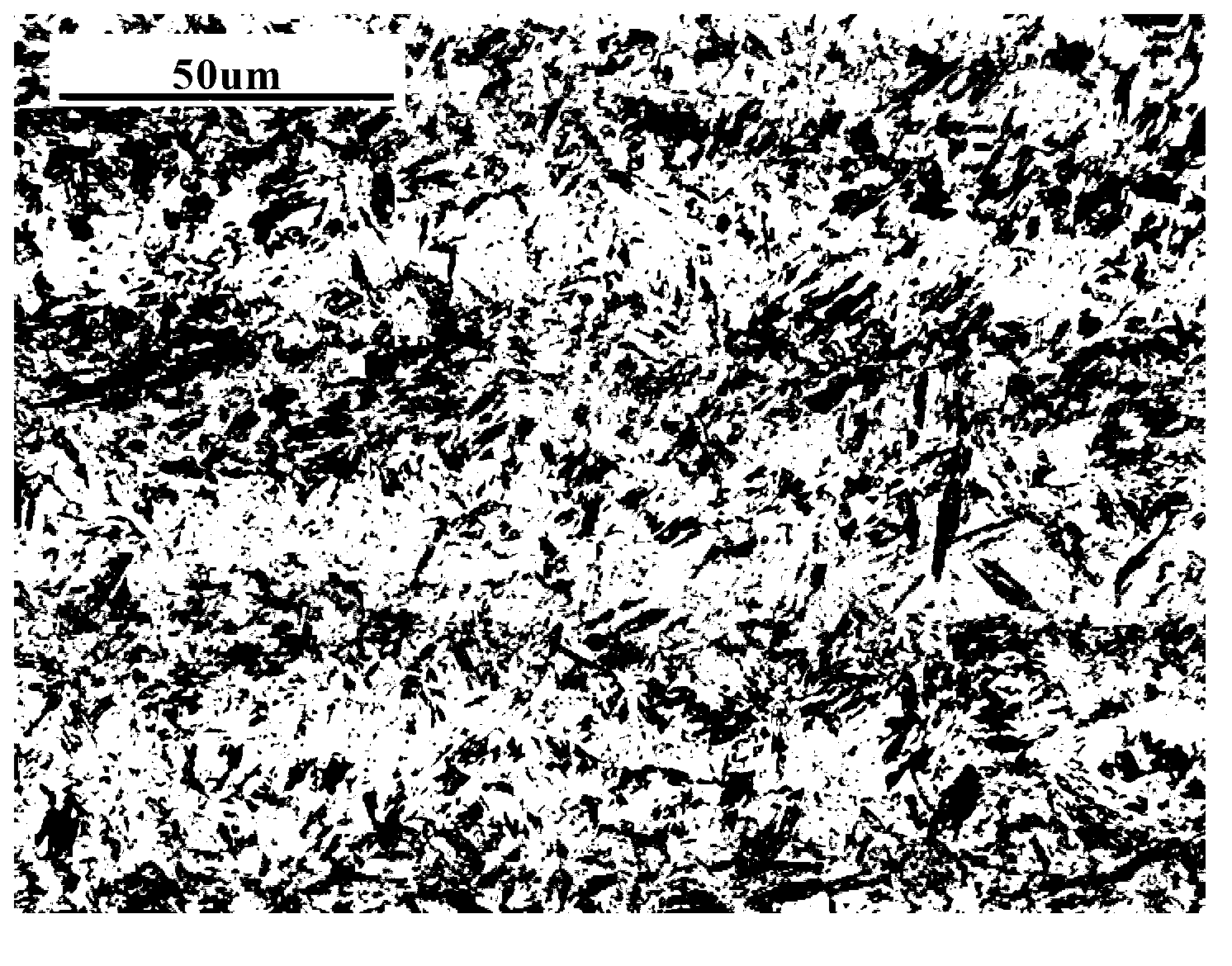

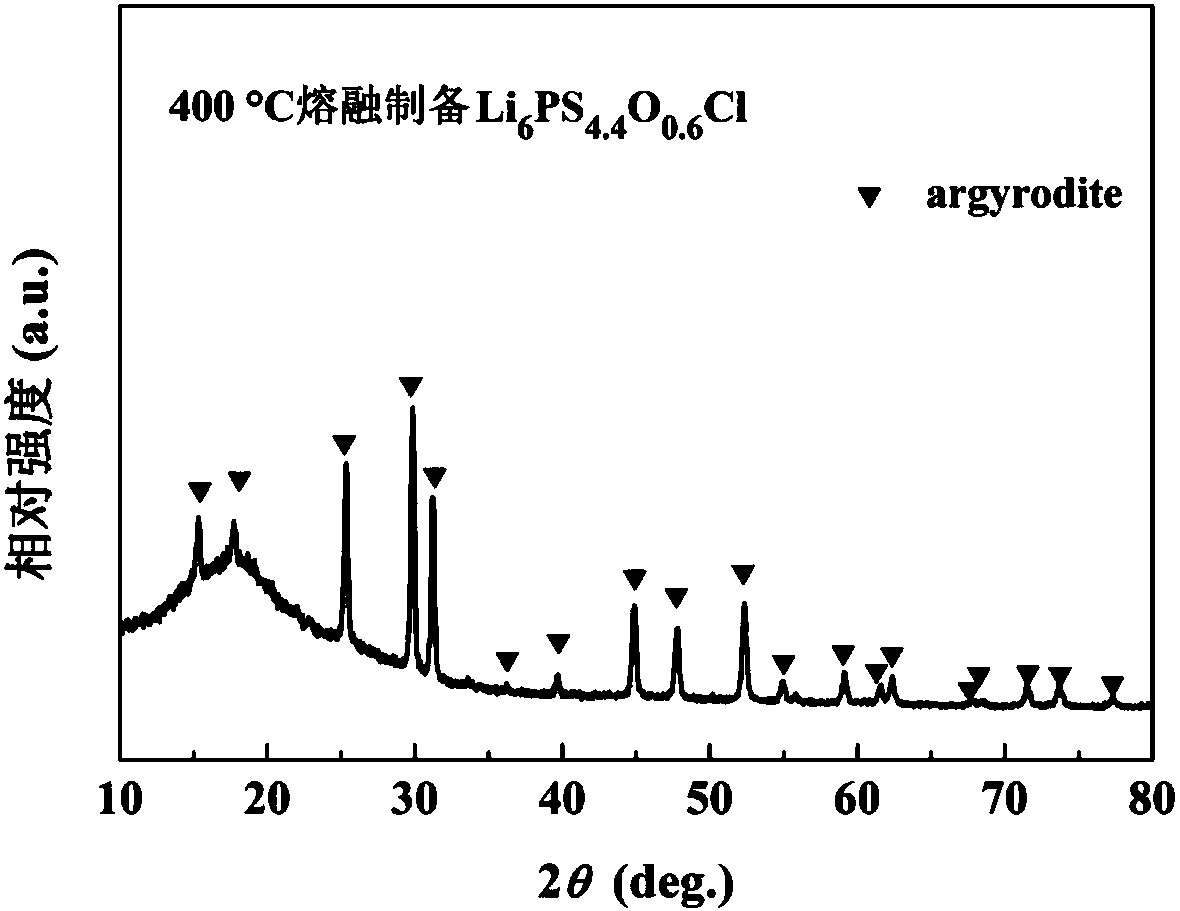

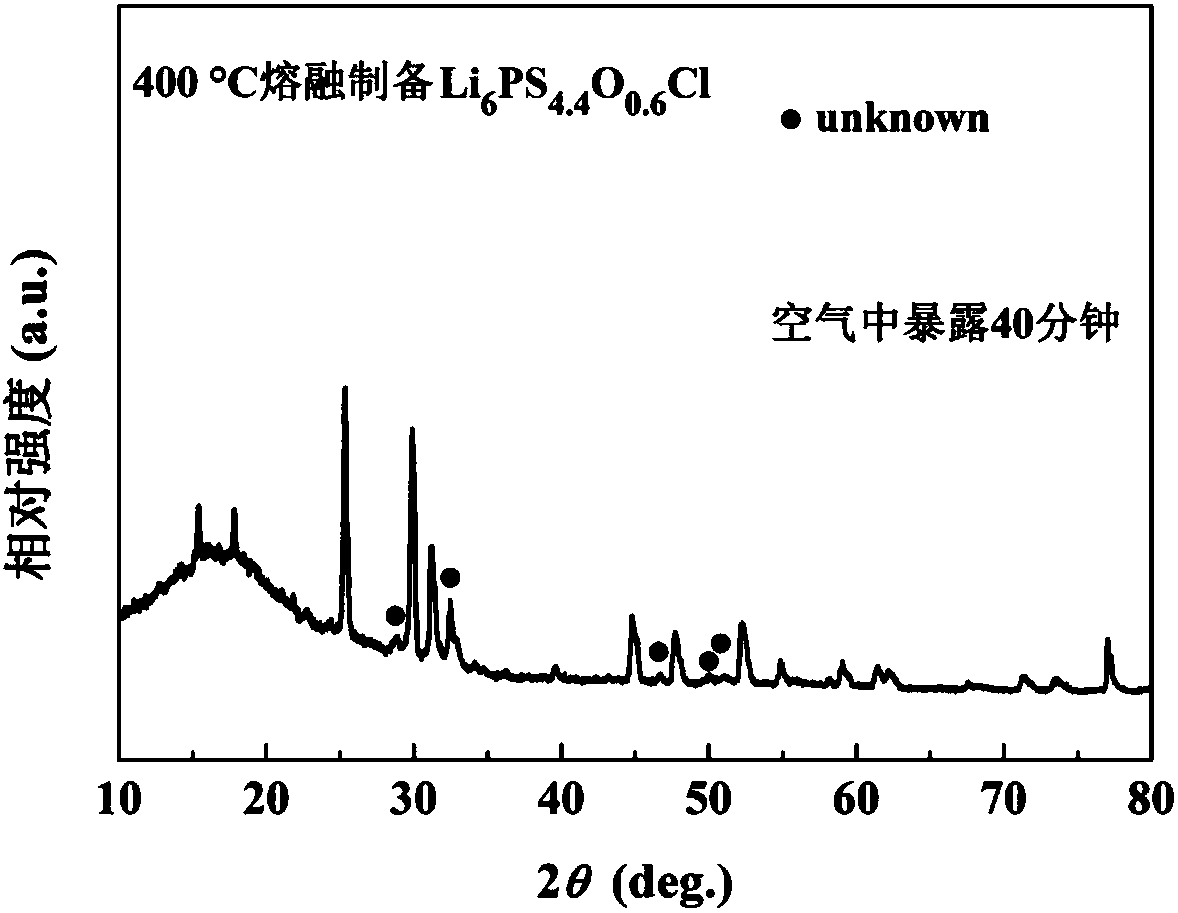

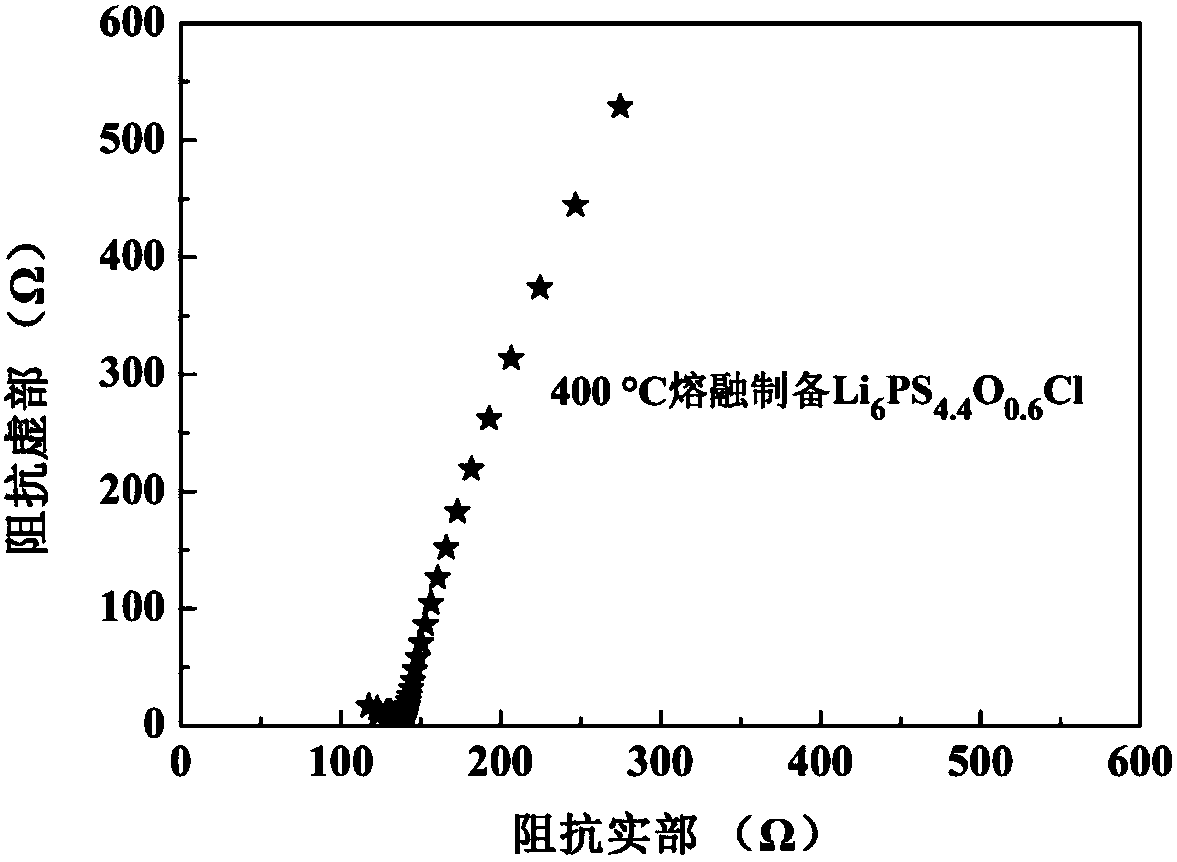

Sulfide solid electrolyte based on oxygen doping and preparation method of sulfide solid electrolyt

ActiveCN108493479AImprove stabilityImprove ionic conductivitySolid electrolytesLi-accumulatorsLithium chloridePhosphorus pentasulfide

The invention provides a sulfide solid electrolyte based on oxygen doping. The sulfide solid electrolyte is prepared from the chemical ingredients, in percentage by mass: 36-60% of lithium sulfide orlithium selenide, 18-48% of phosphorus pentasulfide or phosphorus selenide, 1-23% of metal oxide or specific nonmetallic oxide and 8-37% of lithium chloride, lithium bromide or lithium iodide. The preparation method of the sulfide solid electrolyte mainly comprises the steps that the raw materials are sufficiently blended and subjected to tabletting, then placed in a quartz tube to be burned and sealed, the product is placed in a muffle furnace and heated to be 400-600 DEG C at a slow heating rate, the optimal heating rate is 0.3 DEG C / minute, heat preservation is conducted for 12-48 hours, and then the product is cooled to reach the room temperature; and the product is ground to be powder, and the sulfide solid electrolyte based on oxygen doping is prepared. The sulfide solid electrolyteis easy to prepare and high in repeatability, the prepared solid electrolyte has the high ionic conductivity and good stability to the air and positive and negative electrodes.

Owner:YANSHAN UNIV

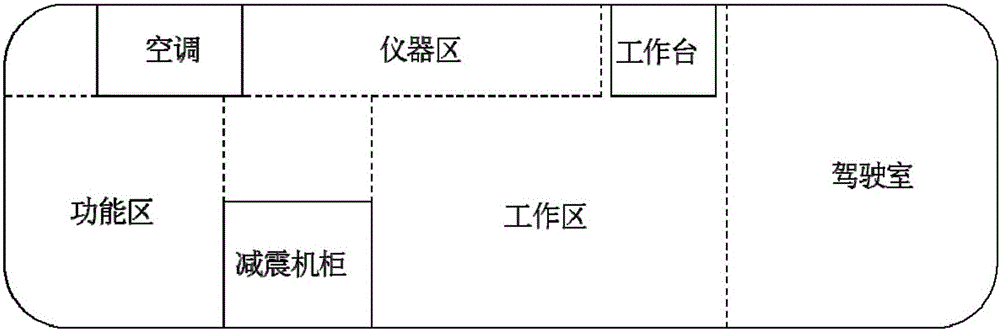

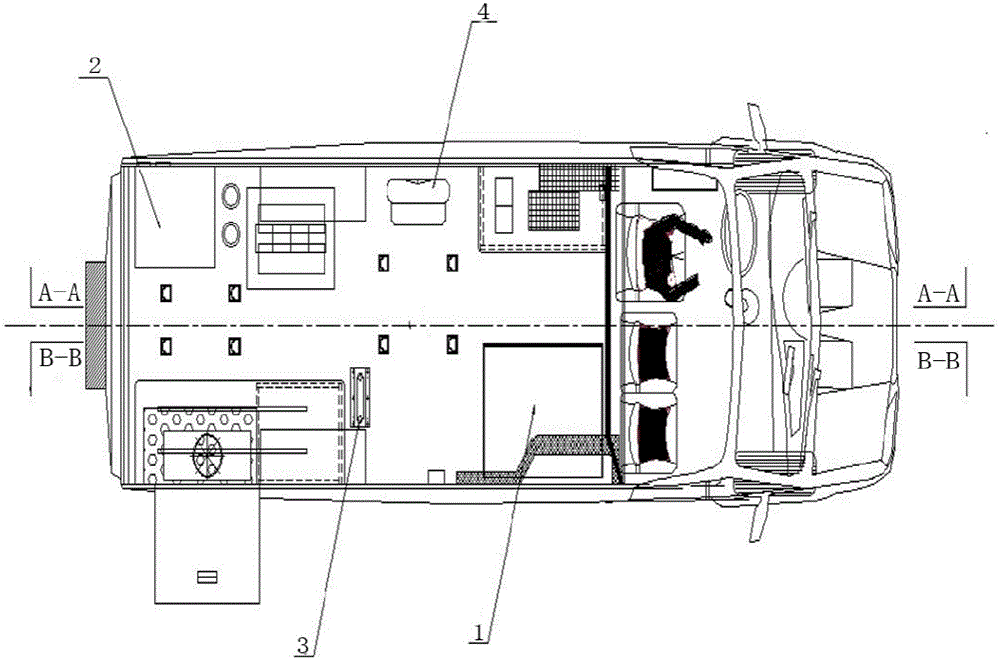

Vehicle-mounted dust-haze pollutant real-time on-line monitoring system and vehicle-mounted dust-haze pollutant real-time on-line monitoring method

InactiveCN105136631ARich dataMaterial analysis by electric/magnetic meansParticle size analysisParticulatesAdditive ingredient

The invention discloses a vehicle-mounted dust-haze pollutant real-time on-line monitoring system and a vehicle-mounted dust-haze pollutant real-time on-line monitoring method. The monitoring system includes a PM2.5 online mass spectrum detection system, a VOCs online mass spectrum detection system and a VOCs online spectrum detection system which are arranged on a moving monitoring vehicle. The monitoring method includes the steps of performing on-line measurement to particulate matters in atmosphere through PM2.5 online time of flight mass spectrum to obtain number concentration of the particulate matters, spectrogram of particle size and online mass spectrum data, classifying the ingredients of the particle matters through an ART-2a method to obtain chemical ingredient data of single particle under different time resolutions and particle sizes, analyzing the source of the particulate matters through a mass spectrum direct analysis technology to determine the source of the particulate matters, directly performing online measurement to VOCs in atmosphere through the VOCs online time of flight mass spectrum to obtain the ingredient and concentration characters of the VOCs, and directly performing online measurement to the VOCs in atmosphere through VOCs online spectrum to obtain the ingredient and concentration characters of the VOCs.

Owner:JINAN UNIVERSITY

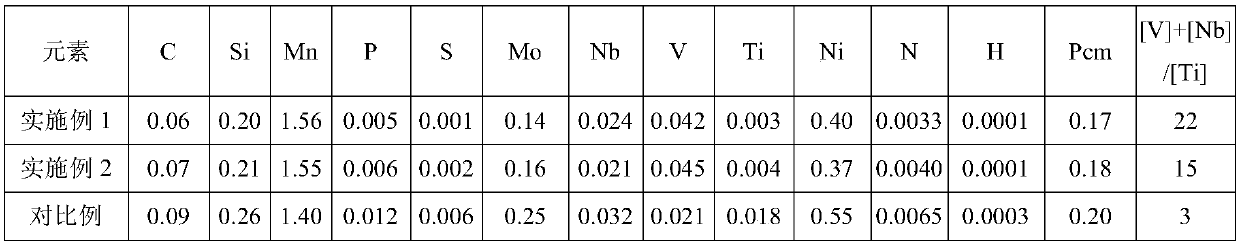

Easy-to-weld container plate with thickness ranging from 40 millimeters to 60 millimeters and excellent center low-temperature toughness, and making method thereof

The invention relates to an easy-to-weld container plate with the thickness ranging from 40 millimeters to 60 millimeters and the excellent center low-temperature toughness, and a making method thereof. The steel plate comprises the chemical ingredients, by mass, 0.04% to 0.09% of C, equal to or smaller than 0.40% of Si, 1.00% to 1.60% of Mn, equal to or smaller than 0.008% of P, equal to or smaller than 0.002% of S, 0.12% to 0.30% of Mo, equal to or smaller than 0.10% of the sum of Nb, V and Ti, 0.20% to 0.60% of Ni, 25 ppm to 55 ppm of N, equal to or smaller than 2ppm of H, the balance Fe and unavoidable impurity elements. Meanwhile, the steel plate meets the conditions that Pcm is equal to or smaller than 0.20%, w(Nb+V) / w(Ti) ranges from 10 to 30, the yield strength of the steel plate is larger than or equal to 490MPa, the tensile strength Rm of the steel plate is larger than or equal to 620MPa, the elongation A is larger than or equal to 21%, the yield ratio is equal to or smallerthan 0.88, the side knock power minus 50 DEG C KV2 of the position of one fourth of the thickness of the plate is larger than or equal to 220 J, and the side knock power minus 50 DEG C KV2 of the position of one second of the thickness of the plate is larger than or equal to 100 J. The method comprises the following working steps of molten iron pretreatment, converter smelting, ladle furnace refining, vacuum treatment, continuous casting, casting blank cover cooling, casting blank heating, controlled rolling, controlled cooling, stack retarded cooling, quenching, tempering, flaw detection andperformance examination. The easy-to-weld container plate with the thickness ranging from 40 millimeters to 60 millimeters and the excellent center low-temperature toughness not only has the excellenttoughness matching, but also has the excellent center low-temperature impact toughness, and thereby meeting the requirements on steel for a large spherical tank.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Ultra-high strength strapping raw sheet and manufacturing method thereof

The invention provides an ultra-high strength strapping raw sheet and a manufacturing method thereof. The raw sheet comprises the following chemical components by weight percent: 0.15-0.60% of C, 0.25-1.80% of Si, 1.0-3.5% of Mn, the balance of Fe and inevitable impurities, wherein one or more of 0.05-1.00% of Cr, 0.05-0.50% of Ni, 0.01-0.50% of Mo, 0.002-0.010% of B, 0.01-0.10% of Ti, 0.01-0.10% of V, and 0.01-0.10% of Nb also can be added to the steel. The manufacturing method of the raw sheet mainly adopts the processes of smelting, casting, hot rolling, pickling and cold rolling; the hot rolling finishing temperature is 850-950 DEG C; the hot-rolling coiling temperature is 550-750 DEG C; and the cold rolling reduction ratio is 50-70%. The tensile strength of the raw sheet disclosed by the invention after the process of isothermal quenching, or quenching and tempering can achieve over 1250 MPa; the extensibility can be up to over 12%; the requirements of wool and cotton packaging on the high strength and high tenacity are met; the section size of the strapping steel is reduced; consumption of steel products is reduced; and the ultra-high strength strapping raw sheet has a broad popularization and application prospect.

Owner:ANGANG STEEL CO LTD

High-wear-resisting stainless steel coffee maker material and preparation method thereof

The invention relates to the technical field of a coffee maker material, and particularly relates to a high-wear-resisting stainless steel coffee maker material and a preparation method thereof. The high-wear-resisting stainless steel coffee maker material comprises the following elements in percentage by weight: 0.08-0.12% of C, 0.06-0.1% of N, 0.15-0.55% of Si, 0.6-1% of Mn, 11.5-13.5% of Cr, 0.1-0.3% of Ni, 0.6-1% of Mo, 0.2-0.6% of Al, 0.05-0.25% of Zr, 0.01-0.05% of Y, 0.6-1% of Nb, 0.05-0.15% of Ti and the balance of Fe and impurities. The high-wear-resisting stainless steel coffee maker material has relatively high hardness and wear resistance by strictly controlling the content of each element, is low in production cost and also has relatively high strength, toughness, heat resistance, corrosion resistance and excellent combination property.

Owner:WANBAOLI STAINLESS STEEL PRODS DONGGUAN

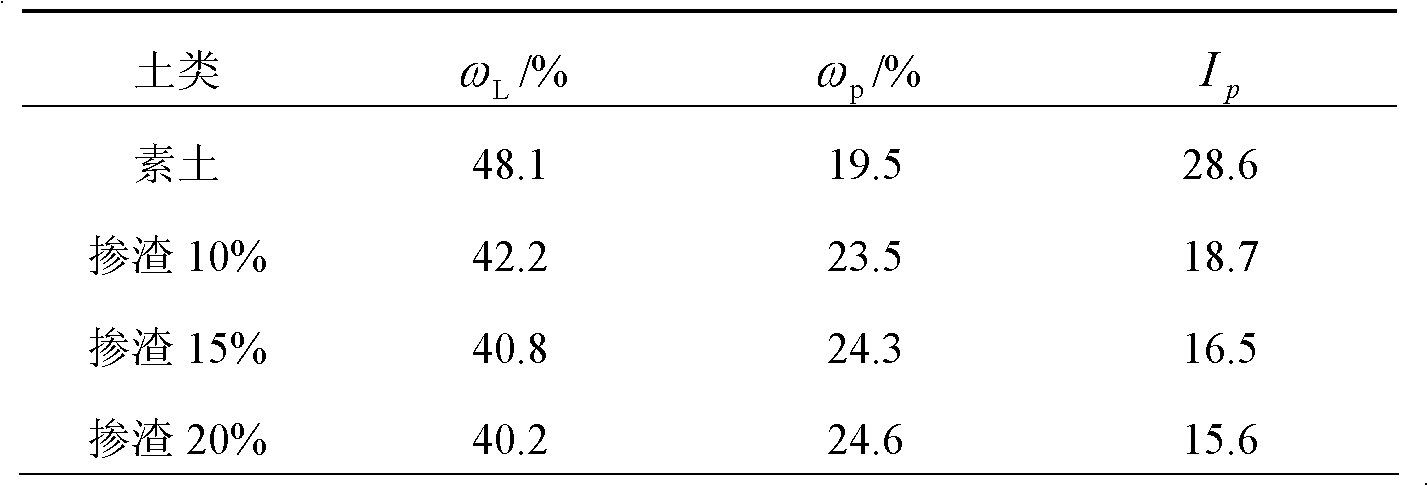

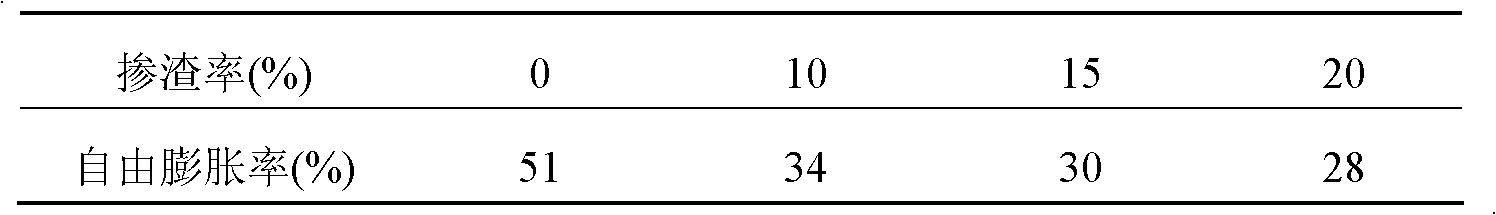

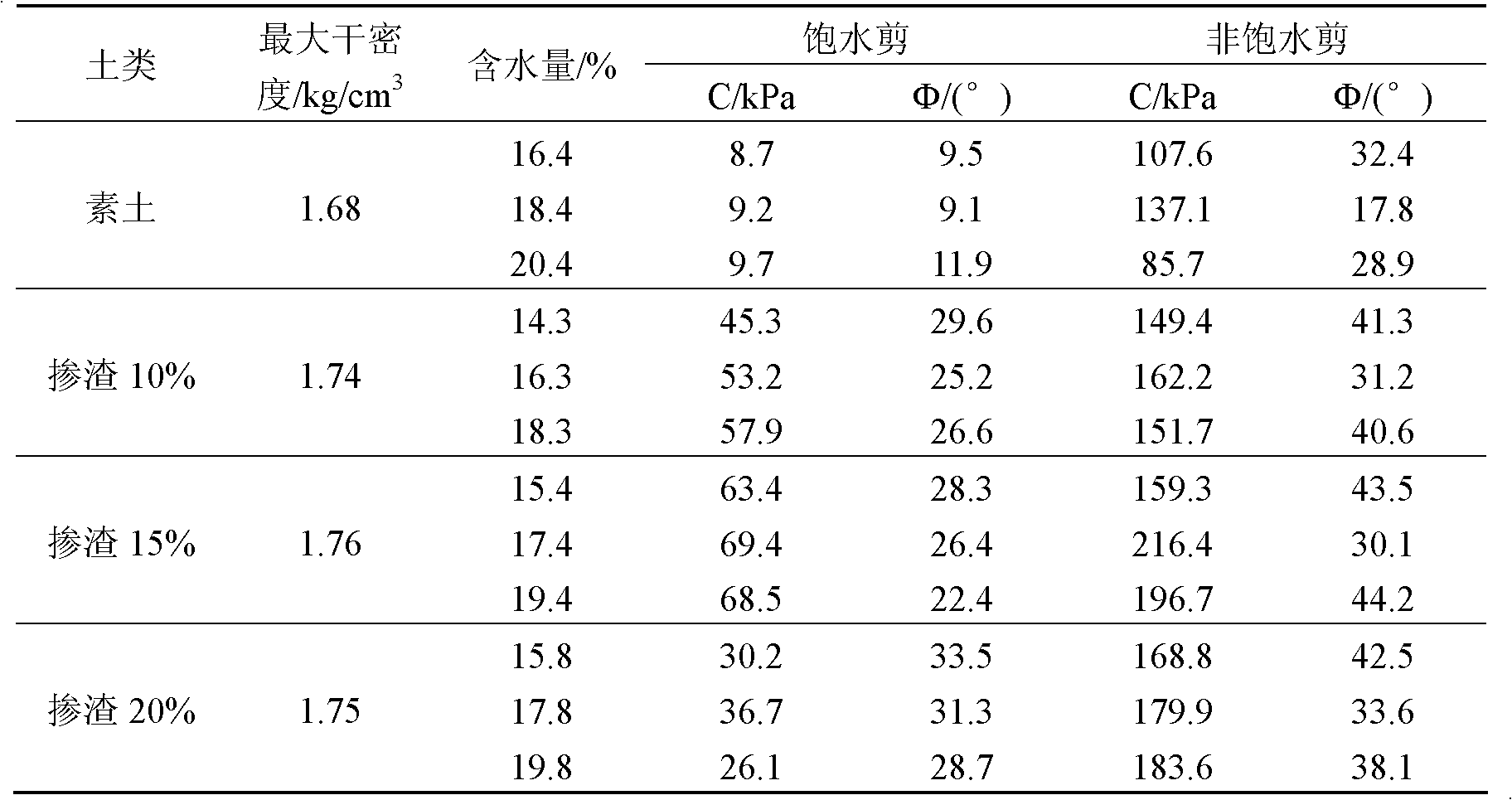

Method for improving expansive soil and construction method thereof

InactiveCN103184733AReduce swelling effectImprove water stabilityBuilding constructionsOrganic fertilisersSoil scienceSlag

The invention discloses a method for improving expansive soil and a construction method thereof. The method for improving expansive soil comprises the following steps of: 1) at the mass ratio of 15-20% of modifying agent and dry soil, evenly stirring the modifying agent and expansive soil to obtain composite soil; 2) determining the optimal moisture content of the composite soil; 3) regulating the moisture content of the composite soil obtained in step 1) to keep at the optimal moisture content; and under the natural condition, tightly covering materials to obtain the improved expansive soil. The method is characterized in that the modifying agent is blast furnace grain slag, and the blast furnace grain slag comprises the following main chemical ingredients in parts by mass: 38-43% of CaO, 33-38% of SiO2, 15-16% of Al2O3 and 4-8% of MgO. According to the improved expansive soil, the expansibility of the expansive soil can be eliminated, the water stability of the expansive soil is improved, and the strength required by the engineering is satisfied.

Owner:HOHAI UNIV

High-strength welding wires of gas shielded welding needing thermal refining after welding

InactiveCN101722382AGood mechanical propertiesImprove low temperature toughnessFurnace typesWelding/cutting media/materialsAbsorbed energyHigh intensity

The invention relates to welding wires, in particular to high-strength welding wires needing hardening and tempering after welding, comprising the following chemical components by weight percent: 0.03-0.12 wt% of C, 0.30-0.80 wt% of Si, 1.2-2.2 wt% of Mn, 1.0-2.0 wt% of Ni, 0.05-0.30 wt% of Cu, 0.10-0.50 wt% of Cr, 0.20-0.80 wt% of Mo, 0.03-0.20 wt% of Ti, equal to or less than 0.015 wt% of S, less than or equal to 0.020 wt% of P, and the balance Fe and inevitable impurity elements. As for the welding wires after rich Ar gas shielded welding, under the thermal refining state, the mechanical property of the obtained welded metal is follows: yield strength ReL is equal to or greater than 630MPa, tensile strength Rm is equal to or greater than 780MPa, elongation A is equal to or greater than 20%, and absorbed energy Akv is equal to or greater than 60J under the temperature of -40 DEG C. The welded metal of the welding wires has high strength, good low-temperature toughness and favorable welding technological property after hardening and tempering.

Owner:BAOSHAN IRON & STEEL CO LTD

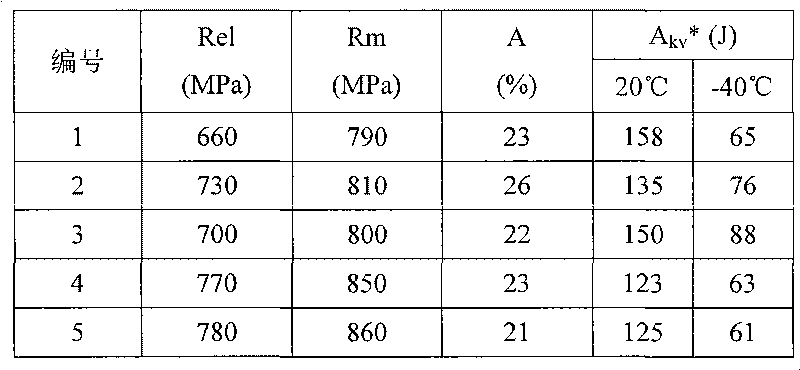

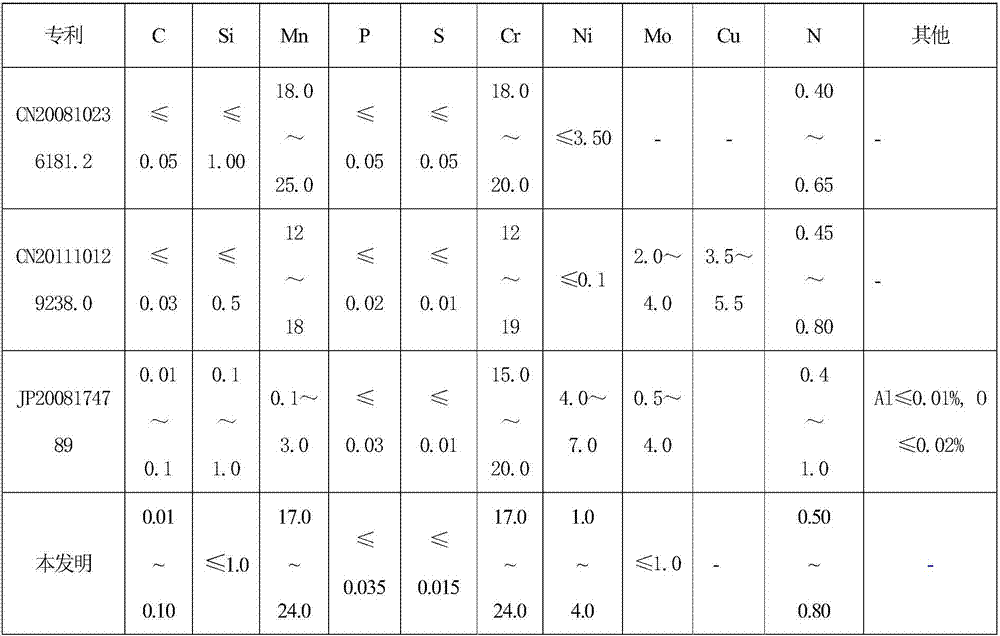

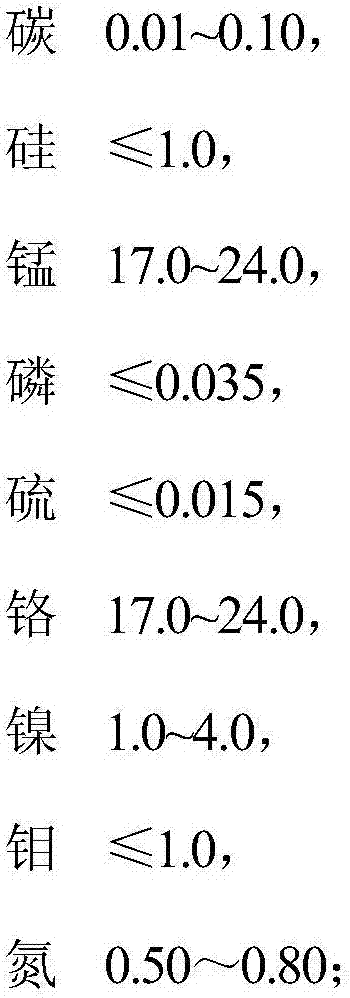

High-nitrogen non-magnetic austenitic stainless steel and manufacturing method thereof

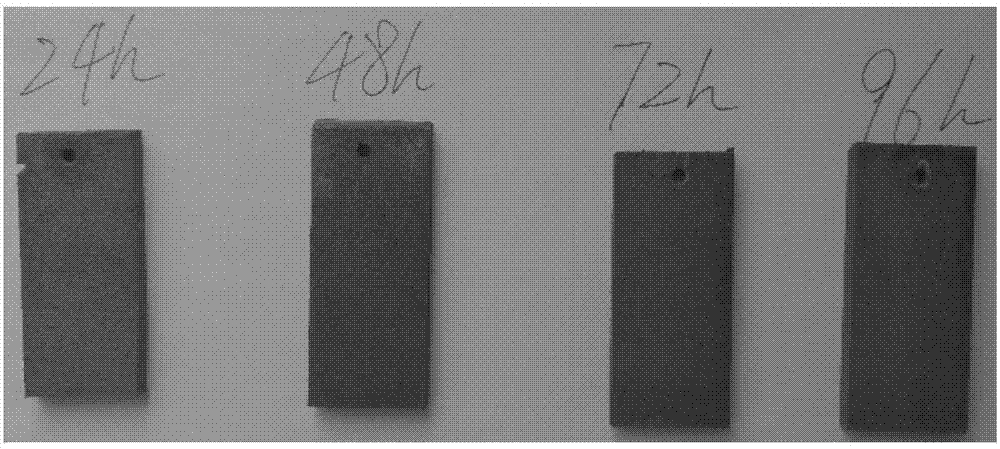

The invention relates to high-nitrogen non-magnetic austenitic stainless steel. The high-nitrogen non-magnetic austenitic stainless steel comprises following chemical components including, by weight percent, 0.01% to 0.10% of C, not larger than 1.0% of Si, 17.0% to 24.0% of Mn, not larger than 0.035% of P, not larger than 0.015% of S, 1.0% to 4.0% of Ni, 17.0% to 24.0% of Cr, not larger than 1.0%of Mo, 0.50% to 0.80% of N and the balance Fe and inevitable impurities. The manufacturing method comprises the steps that the electric furnace+AOD+LF manner is adopted for smelting, continuous casting or die casting is adopted for making a slab ingot, and during continuous casting, the superheat degree is controlled to be smaller than 50 DEG C; a continuous casting blank or die casting slab ingotis put into a stepping type heating furnace to be heated, hot rolling on a rolling machine is carried out to form a board of the needed specification, the final rolling temperature ranges from 800 DEG to 950 DEG C, the hot-rolled board is subject to acid pickling, and the high-nitrogen non-magnetic austenitic stainless steel hot-rolled board finished product is obtained. The product has high yield strength, good ductility and toughness, corrosion resistance and wide application field and has no magnetism.

Owner:宝武特种冶金有限公司

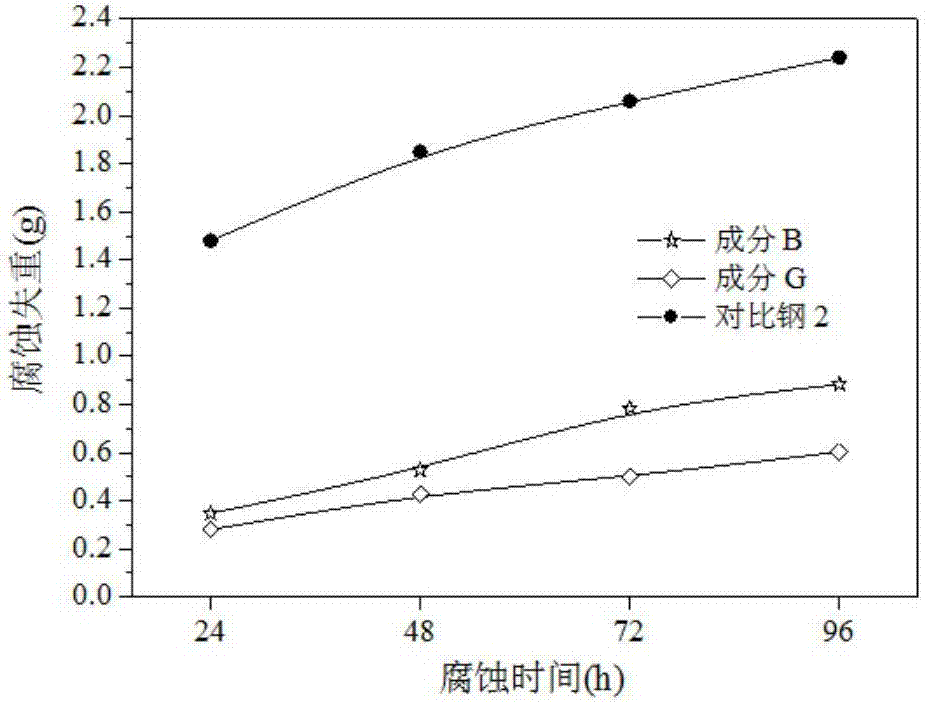

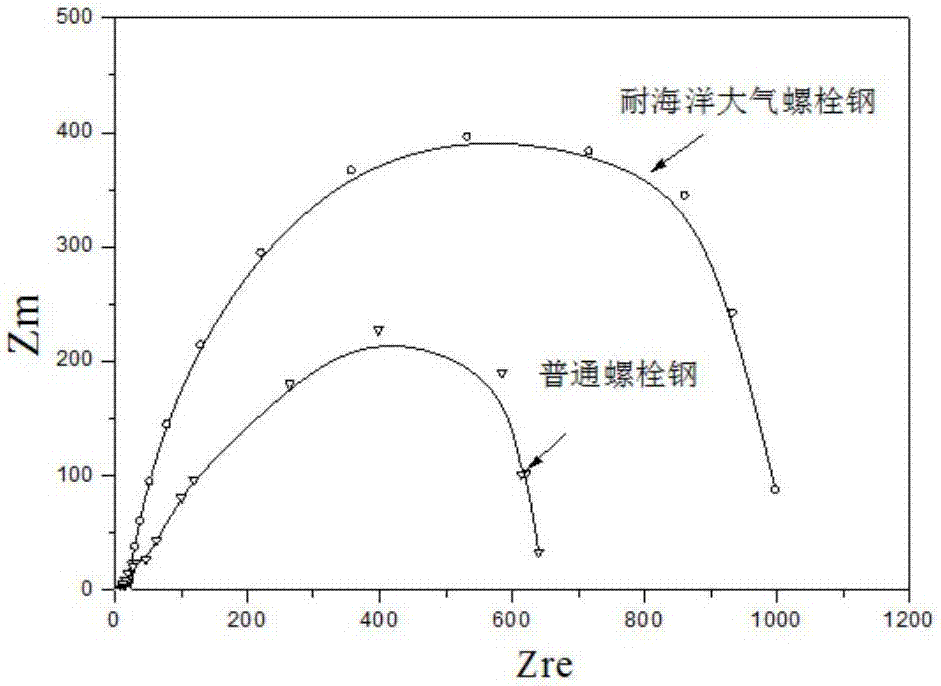

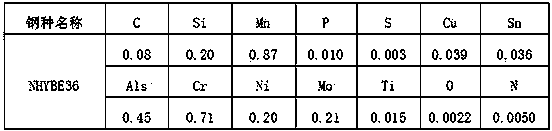

Coating-free ocean atmospheric corrosion resisting high-strength bolt steel for bridge structure and manufacturing method

InactiveCN107022718AAccelerated corrosionImprove low temperature resistanceFurnace typesHeat treatment furnacesToughnessImpurity

The invention discloses ocean atmospheric corrosion resisting high-strength bolt steel for a coating-free bridge structure and a manufacturing method, and belongs to the technical field of steel for bridge structure connection. The steel is prepared from, by weight, 0.16%-0.45% of C, 0.01%-2.2% of Si, 0.3%-2.5% of Mn, 0.001%-0.024% of P, 0.002%-0.025% of S, 0.0005%-0.0100% of B, 0.01%-0.50% of Ti, 0.01%-0.20% of V, 0.001%-0.15% of Al, 0.35%-3.2% of Cr, 0.2%-0.6% of Cu, 0.2%-2.5% of Ni and the balance Fe and trace impurities. The corrosion resisting index I, calculated according to a chemical ingredient prediction formula, of the high-strength weather-proof bolt steel is larger than or equal to 6.3, the properly produced bolt specification range is M16-30 mm, after the bolt steel is beaten into bolts through a bolt machining factory, oil hardening of 840 DEG C to 920 DEG C and tempering of 380 DEG C to 625 DEG C are included in a quenched-tempered heat treatment system, and optimum high toughness matching is obtained. The bolt steel has the beneficial effects that the 10.9-grade high-strength bolts are used for matching connection of coating-free bridge structure plates and profiles, and have excellent ocean atmospheric corrosion and low temperature resisting performance.

Owner:SHOUGANG CORPORATION

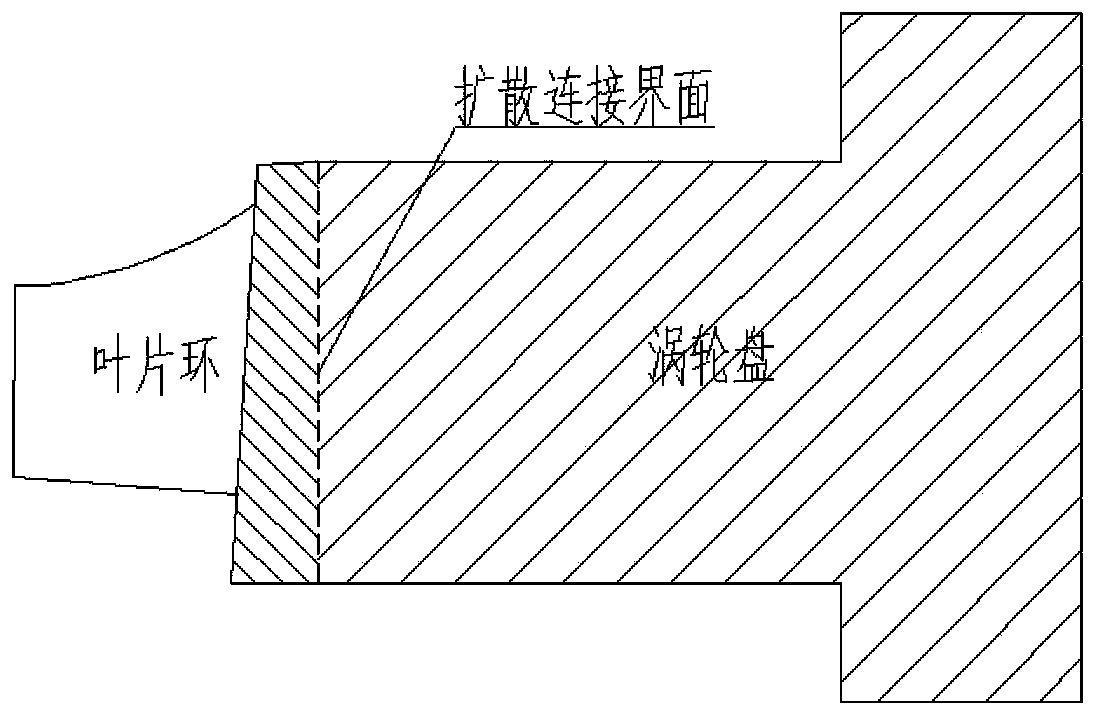

Method for using hot isostatic pressing to produce double-alloy blisk

ActiveCN103447759AQuality improvementReduce difficultyNon-electric welding apparatusGranularitySuperalloy

Owner:CENT IRON & STEEL RES INST

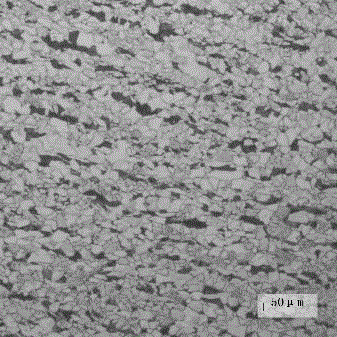

Steel plate with low density and high marine environment resistance and production technology thereof

The invention relates to a steel plate with low density and high marine environment corrosion resistance and a production technology thereof. The steel plate contains the following chemical ingredients by weight: 0.03-0.10 of C, 0.1-0.8 of Si, 0.5-1.5 of Mn, not more than 0.015 of P, not more than 0.005 of S, 0.1-2.0 of Al, 0.01-0.30 of Sn, 0.1-0.8 of Cr, 0.1-0.5 of Ni, 0.05-0.45 of Mo, 0.01-0.05 of Ti and the balance of Fe and unavoidable impurities. The production technology comprises a rotary furnace smelting procedure, an LF refining procedure, a vacuum degassing procedure, a continuous casting procedure, a controlled-rolling and controlled-cold procedure and the like. The structure type of the steel plate is theoretically a single-phase polygonal ferrite fine structure, but contains an extreme small quantity of unavoidable pearlite structure during actual industrial production. The marine environment (marine atmosphere, tidal range, total immersion and the like) corrosion resistance can be improved by near 70% than that of an EH36 ship structure in the same service environment, and the steel plate has excellent obdurability matching and welding performance. The steel plate has the advantages of simple production technology, low production cost, stable performance, excellent surface quality and great improvement on marine environment corrosion resistance.

Owner:UNIV OF SCI & TECH BEIJING +1

High-hardenability medium-carbon low-alloy round steel for fastener and manufacturing method of high-hardenability medium-carbon low-alloy round steel

ActiveCN106521316AImprove hardenabilityReduce manufacturing costFurnace typesHeat treatment furnacesChemical IngredientsContinuous casting

The invention relates to high-hardenability medium-carbon low-alloy round steel for a fastener. Chemical ingredients of the high-hardenability medium-carbon low-alloy round steel comprise, by mass, 0.36-0.44% of C, 0.15-0.40% of Si, 0.80-1.00% of Mn, 1.00-1.15% of Cr, 0.05-0.25% of Mo, 0.05-0.25% of Ni, 0.05-0.25% of Cu, 0.015-0.050% of Al, 0.0010-0.0050% of B, 0.020-0.050% of Ti and the balance Fe. The largest diameter of the round steel is 65 mm. The production process comprises converter steel making, LF refining, RH / VD degassing, Ti wire and ferroboron feeding, continuous casting, bar rolling, and quenching and tempering treatment, and therefore the quenched and tempered round steel is obtained. The quenched and tempered round steel can be directly used for machining fasteners such as 10.9-level bolts which meet the ISO 898-1 standards.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Titanium carbide ceramic-enhanced visible arc self-shielded flux-cored wire for high-chromium cast iron

InactiveCN102248325AEasy to use on siteImprove wear resistanceWelding/cutting media/materialsSoldering mediaMachine partsWear resistant

The invention discloses a titanium carbide ceramic-enhanced visible arc self-shielded flux-cored wire for high-chromium cast iron, and the flux-cored wire provided by the invention comprises the following chemical components in percentage by weight (wt%): 60 to 70% of high-carbon ferrochrome, 1 to 2% of high-carbon ferromanganese, 1 to 3% of ferrosilicon, 1 to 3% of ferrovanadium, 1 to 3% of ferromolybdenum, 2 to 8% of TiC, 15 to 25% of graphite, and 1 to 2% of aluminum / magnesium powders; and the flux-cored wire has a low-carbon steel strip serving as an outer wrapper. The flux-cored wire is made by use of flux-cored wire production equipment which has a flux powder filling rate of 37%to 45%, and drawn by a wire drawing machine 2 to 5 times until the outside diameter of the flux-cored wire reaches the level F4. The flux-cored wire disclosed by the invention can be applied to overlay-welding under the conditions of no preheating before welding and no heat treatment after welding, and is very convenient in on-site use. By virtue of overlay-welding using the flux-cored wire disclosed by the invention, deposited metals have a high hardness up to HRC63-67 and better wear resistance andare not liable to stripping, and the service lives of large-sized high-chromium cast iron wear-resistant parts are 2 to 4 times those of integrally-machined parts.

Owner:YANSHAN UNIV

Super-thick X70 pipeline steel and manufacturing method thereof

The invention discloses super-thick X70 pipeline steel and a manufacturing method thereof, wherein the pipeline steel is 30-32mm thick, and the pipeline steel comprises the following chemical ingredients in percentage by mass: 0.03-0.06% of C, 0.1-0.30% of Si, 1.30-1.60% of Mn, less than or equal to 0.010% of P, less than or equal to 0.0050% of S, 0.030-0.050% of Nb, 0.008-0.020% of Ti, 0.10-0.30% of Ni, 0.l0-0.30% of Cr, 0.10-0.30% of Cu and the balance being Fe and inevitable impurity elements. smelting raw materials are sequentially subjected to KR molten iron pretreatment, converter smelting, LF refining and RH vacuum degassing to obtain molten steel which is relatively high in purity, and then the pipeline steel, which is high in thickness, high in strength, narrow in strength interval, excellent in low-temperature toughness, and excellent in both low-temperature resistant aging performance and HIC resistance, is obtained through a controlled rolling and controlled cooling process.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com