Method for improving expansive soil and construction method thereof

A construction method and expansive soil technology, applied in soil protection, chemical instruments and methods, fertilization devices, etc., to achieve excellent physical properties, increase compactness, and save engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

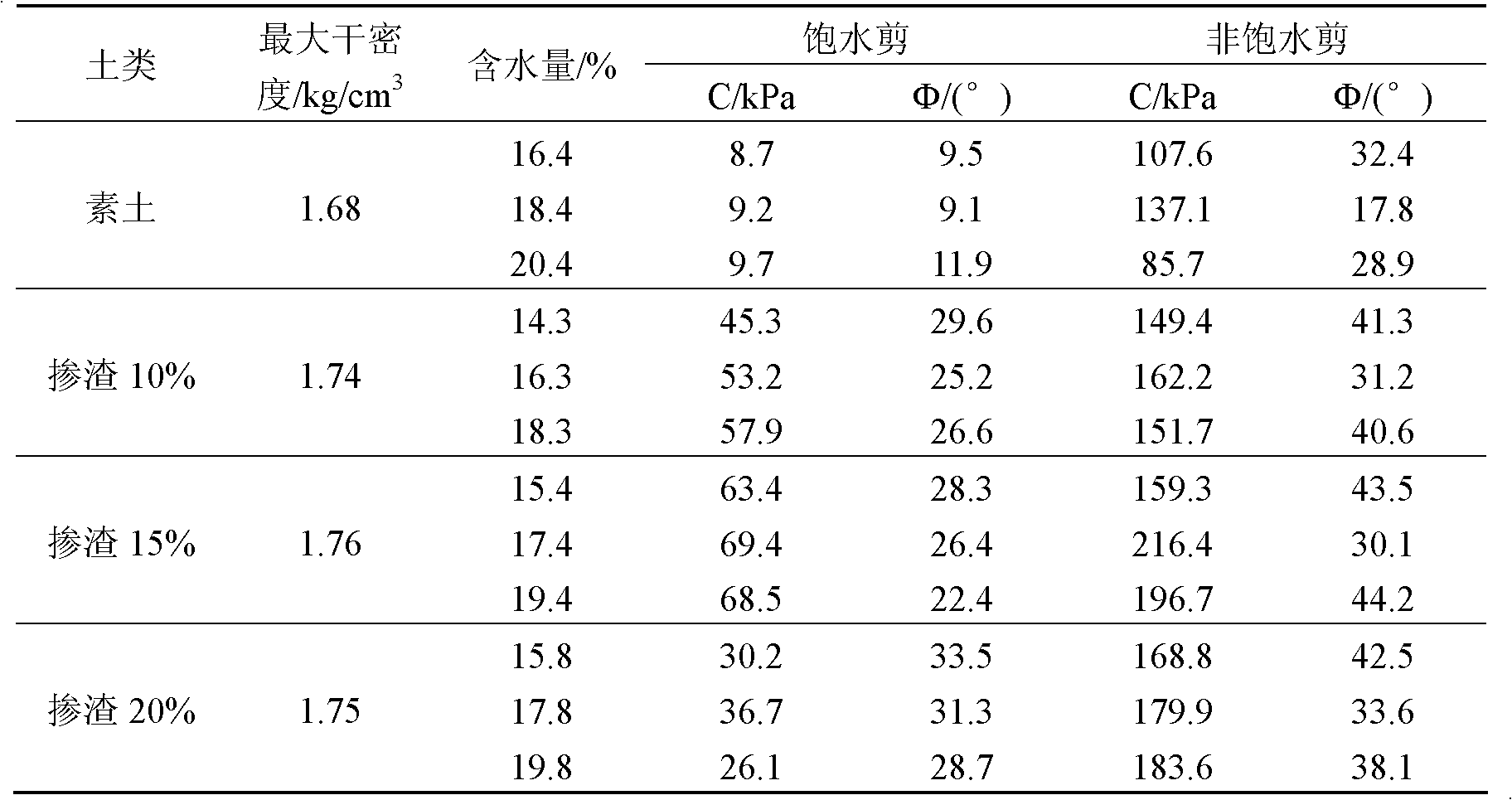

Embodiment 1

[0047] Mixed soil preparation, take the preparation of 1.15kg mixed soil as an example. The process steps of mixed soil preparation are as follows: (1) the dry soil mass of the expansive soil to be improved is 1.0 kg, and the required blast furnace slag mass is weighed at a ratio of 15% to 0.15 kg; After uniformity, the optimum moisture content obtained from the medium-duty compaction test of "Highway Soil Test Regulations" (JTJ-051-93) is 19%, and 1.15kg×0.19=218g of water is added to the mixed soil and mixed evenly The blast furnace slag-modified soil can be obtained by preventing the formation of pimples.

[0048] The steps of the improved construction method are: after unloading the modified blast furnace slag-modified soil to the designated place, spread it evenly, with a thickness of 30-35cm; after checking that the moisture content meets the requirements of the optimal moisture content, use a road roller to quickly statically press the soil And precise leveling; rollin...

Embodiment 2

[0067] A method for improving weak expansive soil with blast furnace slag, the steps are:

[0068] The first step is to weigh blast furnace slag and expansive soil at a ratio of 17% of the slag mixing rate, and mix them evenly;

[0069] The second step is to determine the optimum water content of the mixed soil through experiments;

[0070] The third step is to keep the water content of the mixed soil obtained in the first step at the optimum water content by digging, drying and adding water. After mixing evenly, it is stuffed under natural conditions for 5 to 7 days, so that you can get the soil after mixing. Modified soil after blast furnace slag improvement.

[0071] Using the method for improving expansive soil with blast furnace slag to obtain a construction method for improving expansive soil with blast furnace slag, the construction steps are:

[0072] The first step is to unload the modified blast furnace water slag modified soil to the designated place and spread it...

Embodiment 3

[0076] A method for improving expansive soil with blast furnace slag, the steps are:

[0077] The first step is to weigh blast furnace slag and expansive soil according to the ratio of 20% slag mixing rate, and mix them evenly;

[0078] The second step is to determine the optimum moisture content of the mixed soil sample through experiments;

[0079] The third step is to keep the water content of the mixed soil obtained in the first step at the optimum water content by digging, drying and adding water. After mixing evenly, it is stuffed under natural conditions for 5 to 7 days, so that you can get the soil after mixing. Modified soil after blast furnace slag improvement.

[0080] Using the method for improving expansive soil with blast furnace slag to obtain a construction method for blast furnace slag modified soil, the construction steps are:

[0081] The first step is to unload the modified blast furnace water slag modified soil to the designated place, spread evenly, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com