Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

305 results about "Soil nailing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soil nailing is a construction remedial measure to treat unstable natural soil slopes or as a construction technique that allows the safe over-steepening of new or existing soil slopes. The technique involves the insertion of relatively slender reinforcing elements into the slope – often general purpose reinforcing bars (rebar) although proprietary solid or hollow-system bars are also available. Solid bars are usually installed into pre-drilled holes and then grouted into place using a separate grout line, whereas hollow bars may be drilled and grouted simultaneously by the use of a sacrificial drill bit and by pumping grout down the hollow bar as drilling progresses. Kinetic methods of firing relatively short bars into soil slopes have also been developed. Bars installed using drilling techniques are usually fully grouted and installed at a slight downward inclination with bars installed at regularly spaced points across the slope face. A rigid facing (often pneumatically applied concrete, otherwise known as shotcrete) or isolated soil nail head plates may be used at the surface. Alternatively a flexible reinforcing mesh may be held against the soil face beneath the head plates. Rabbit proof wire mesh and environmental erosion control fabrics and may be used in conjunction with flexible mesh facing where environmental conditions dictate.

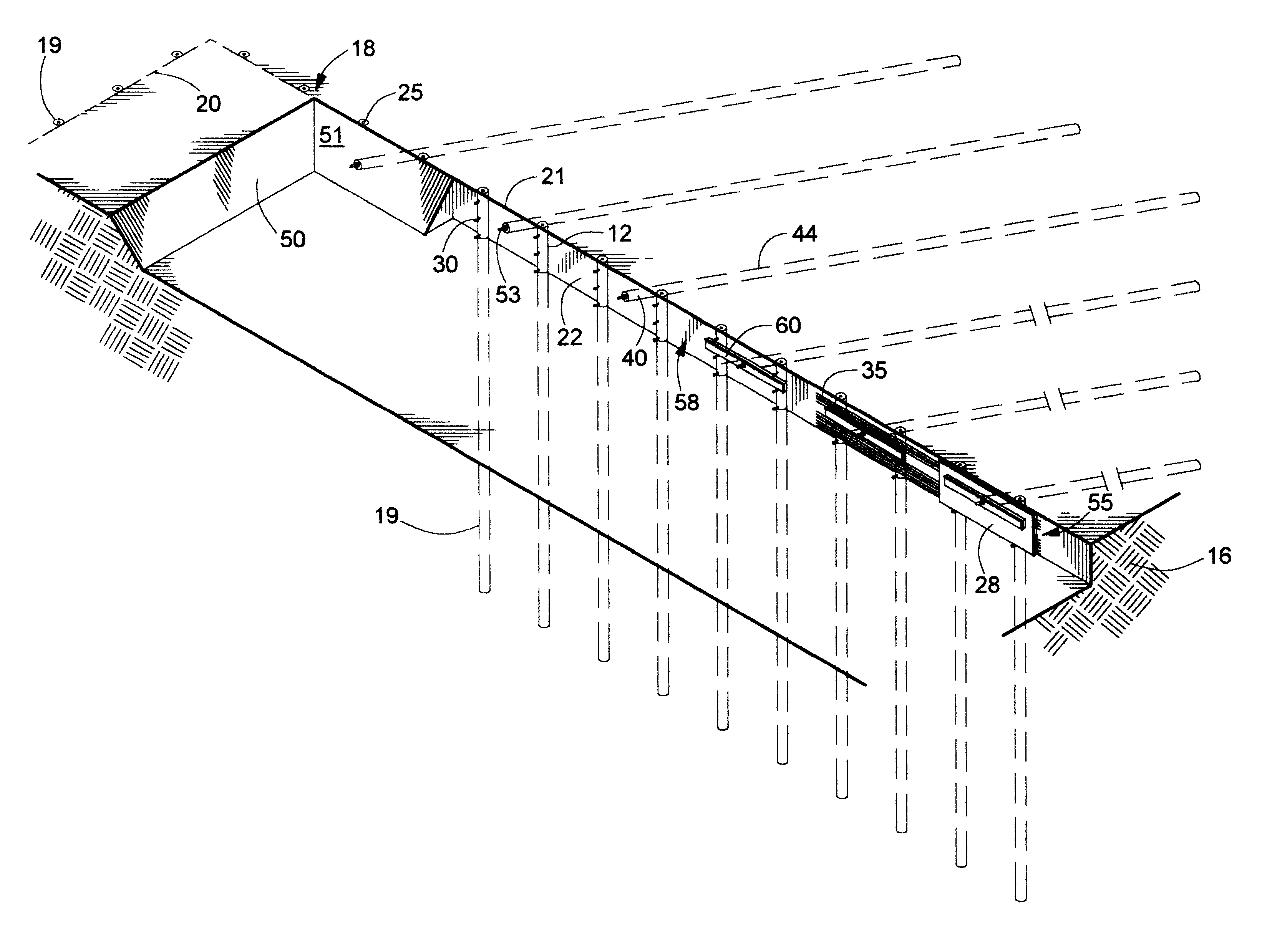

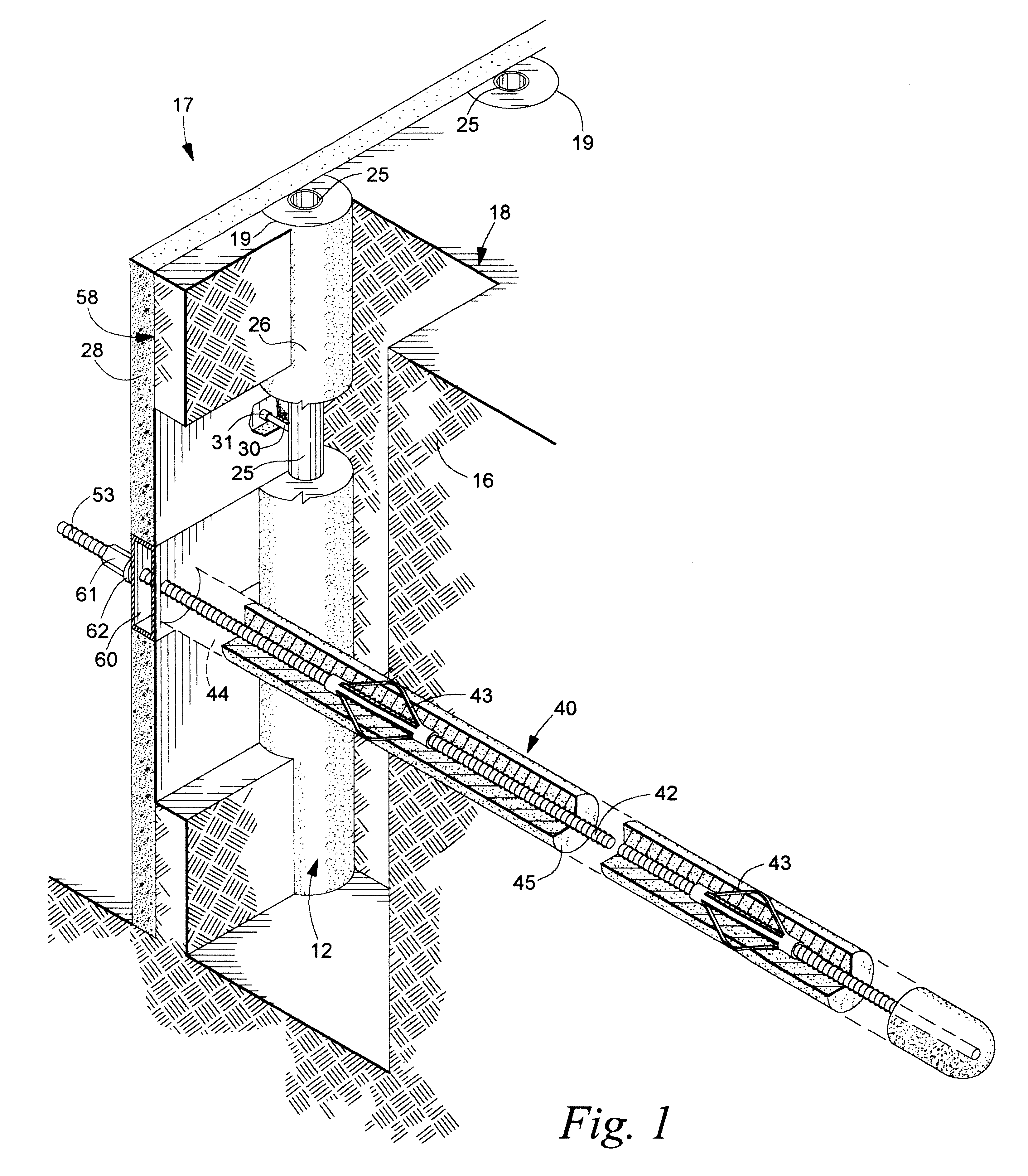

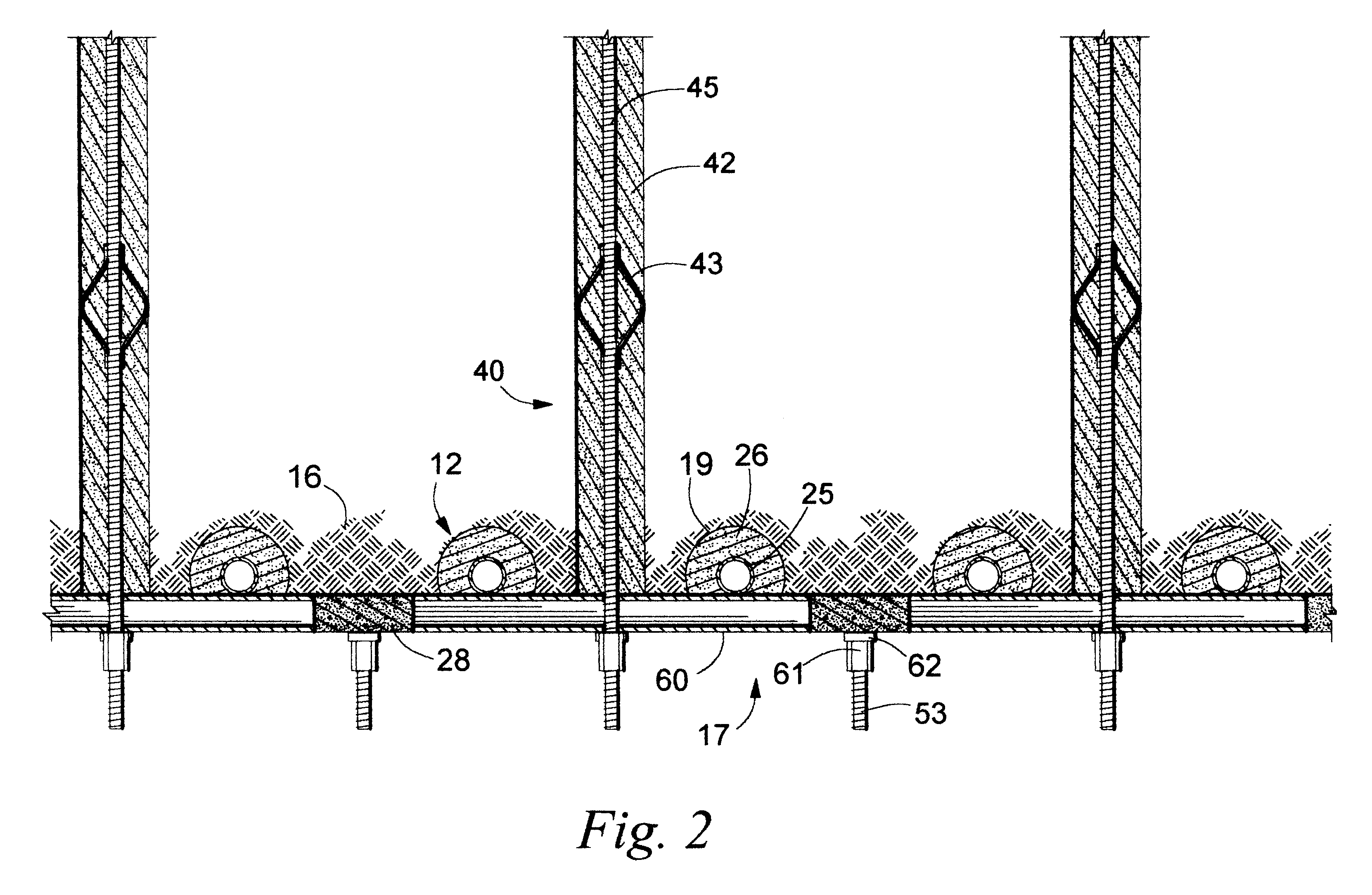

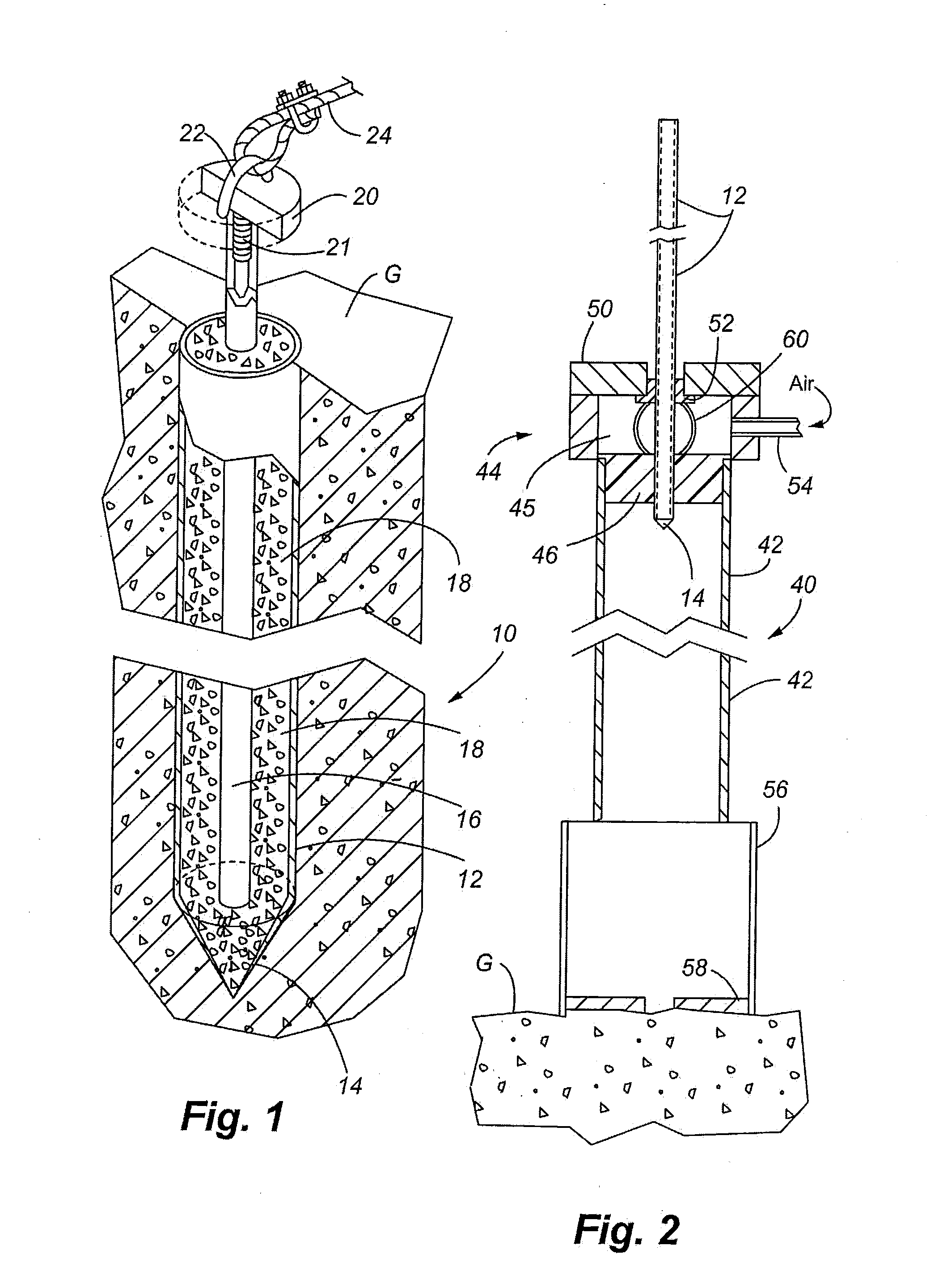

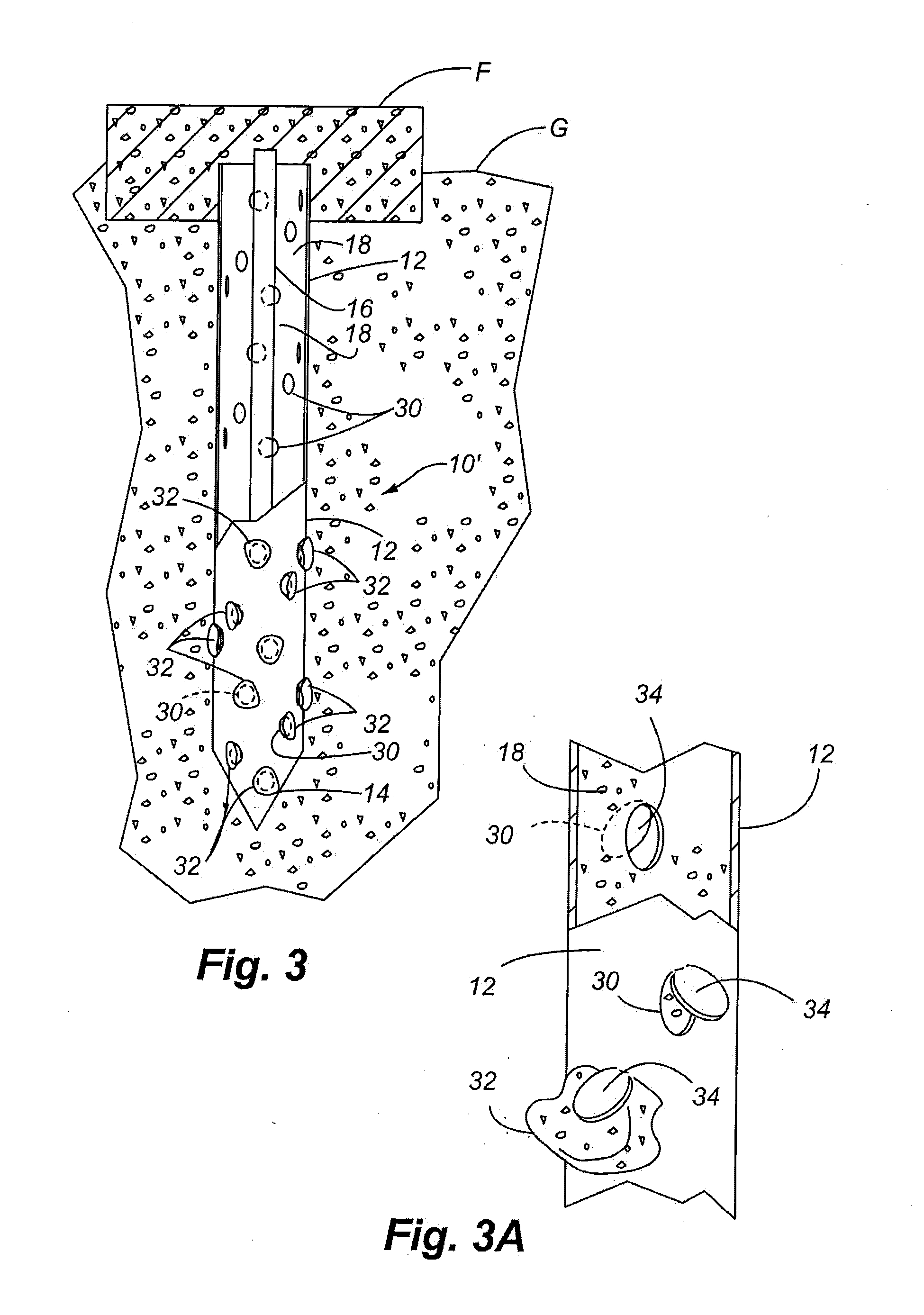

Method and apparatus for a shoring wall

InactiveUS6299386B1Improve face stabilityLarge and costly foundationArtificial islandsExcavationsSoil nailingRebar

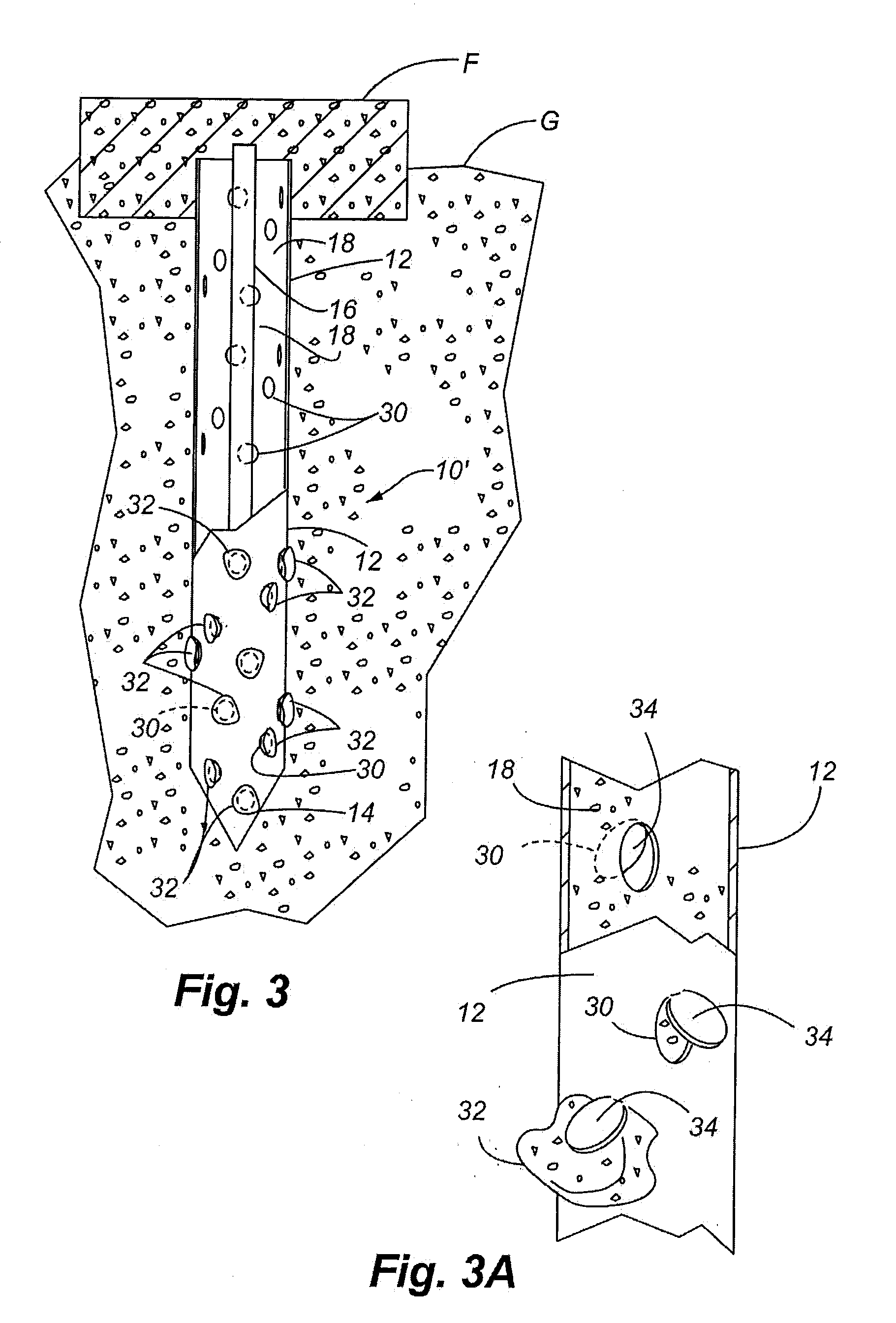

A retaining element system is provided that improves face stability in poorer quality soils that are not suited to conventional soil nailing. The method includes inserting retaining elements substantially vertically into an earthen mass to shore the face of an excavation. The earthen mass can be any material or combination of materials, such as soil, clay or rock that requires excavation for the installation of a shoring wall. The plurality of retaining elements are placed side by side in a substantially linear arrangement. A plurality of soil nails are then inserted into the excavation plane, at the approximate midpoint between a pair of adjacent retaining elements. An exposed tip portion of each soil nail attaches to a wale, which is a substantially horizontal element that contacts a retaining element on both sides of each soil nail. The wale can be a beam, bracket, or a set of concrete reinforcement bars. The beam or bracket can either be a structural member, formed of steel or the like, or alternatively formed from a precast concrete. The concrete reinforcement bars can then receive a concrete fill to form a solid wale structure. Face stability is achieved with the pre-installed retaining elements, which with the wales provide complete facing support.

Owner:BYRNE R JOHN +1

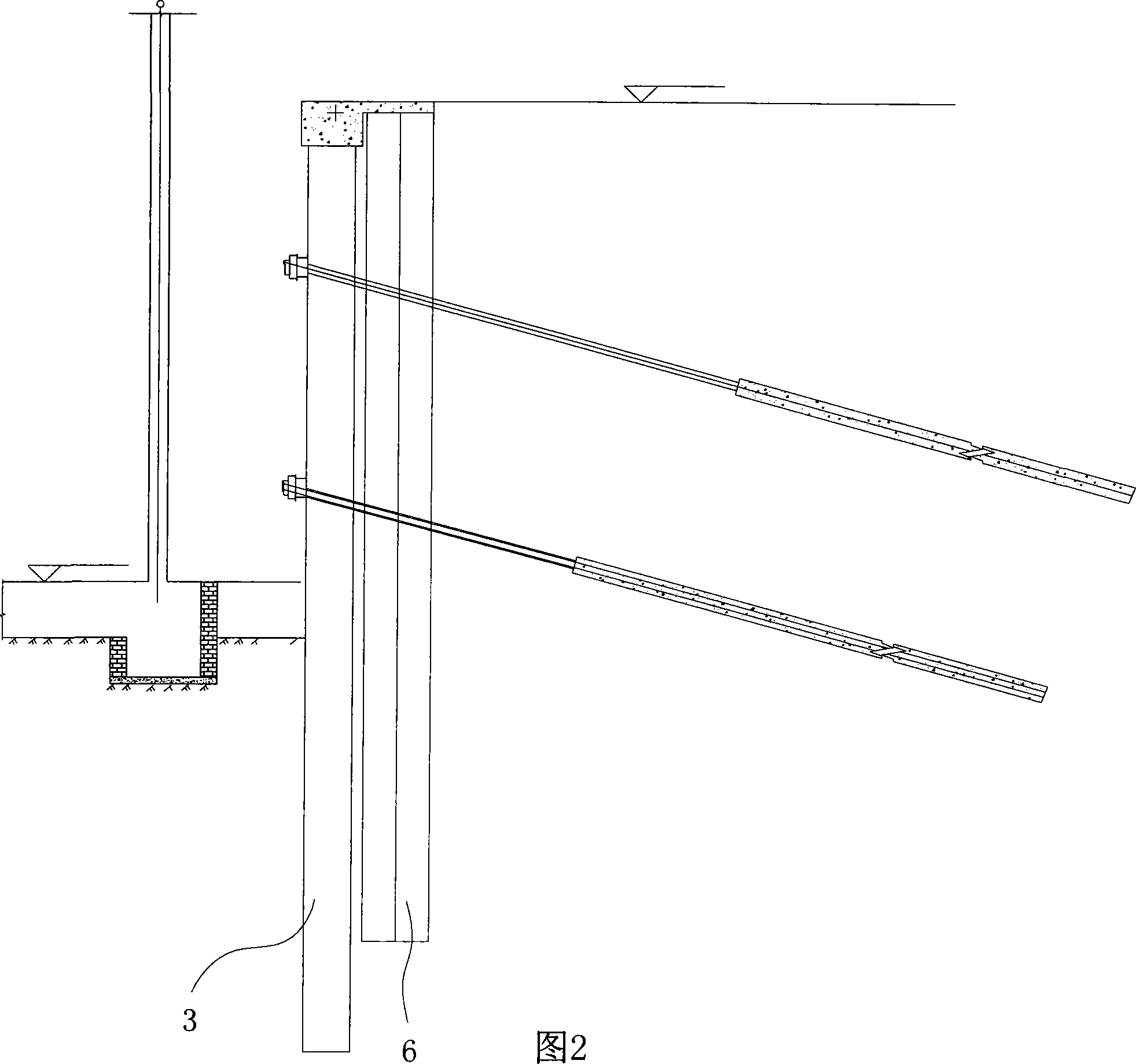

Foundation pit support device and construction method

The invention relates to a foundation pit support device and a construction method. For different address conditions, two or more of an SMW (soil mixing wall) construction method pile system, an internal supporting system, a concrete revetment system and a soil nailing wall revetment system are comprehensively applied. A concrete circuit girt is arranged at the top end of an SMW construction method pile; and profiled bars are inserted into the pile, and have equal or unequal lengths. The internal support system is a slanting steel pipe support or a horizontal support. The soil nailing wall revetment system is formed in a way that: a concrete revetment is arranged on the inner side, from the pit top to the pit bottom, of a foundation pit, and is paved with a reinforced concrete surface layer; and soil nails are inserted into soil around the foundation pit vertical to the reinforced concrete surface layer. The foundation pit support device and the construction method have the advantages of effectively reducing foundation pit support cost and construction cost and accelerating the construction, and are particularly suitable for the support of the large-area foundation pits and construction plants of which infrared spaces between subsurface structures and the ground are small.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD +1

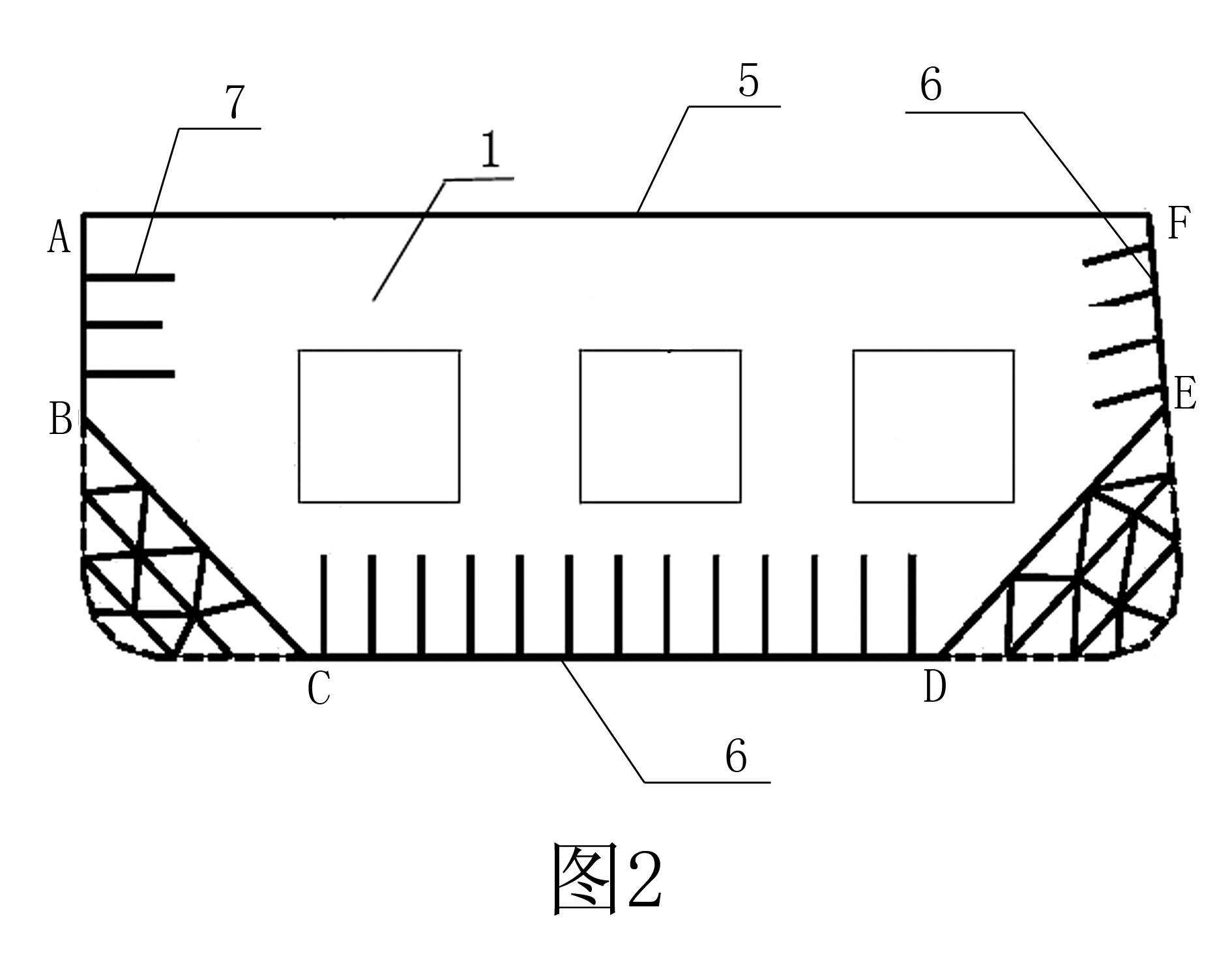

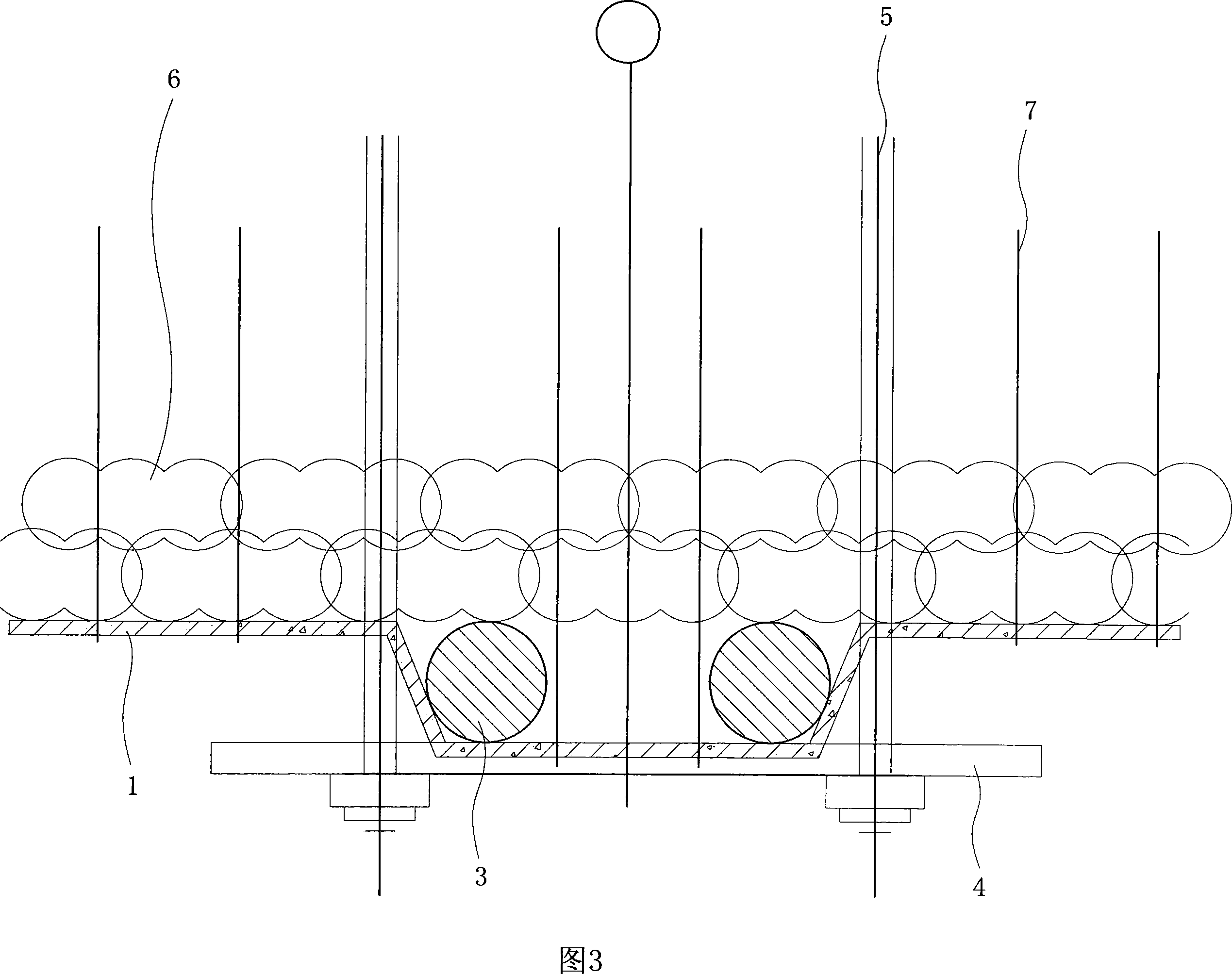

Soil nailing wall foundation pit support and construction method

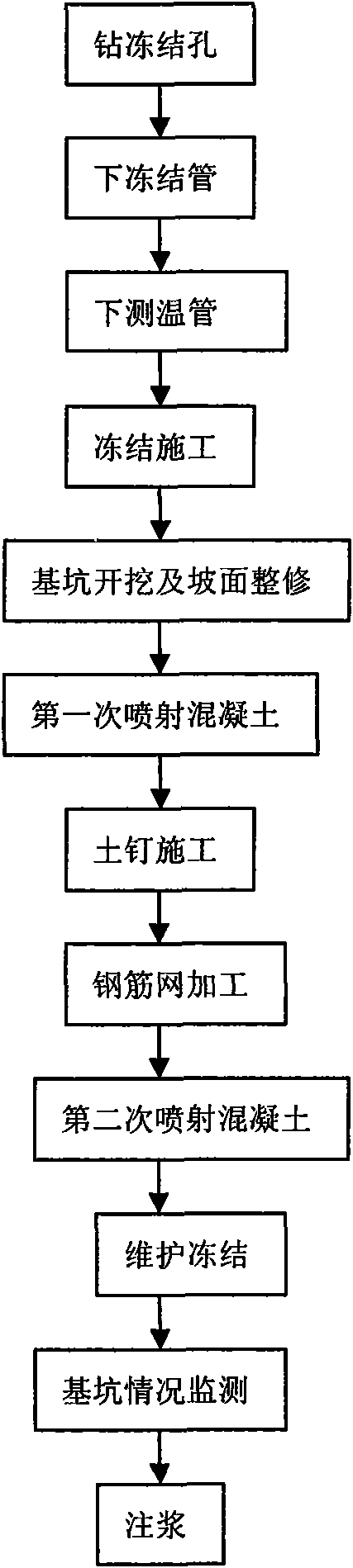

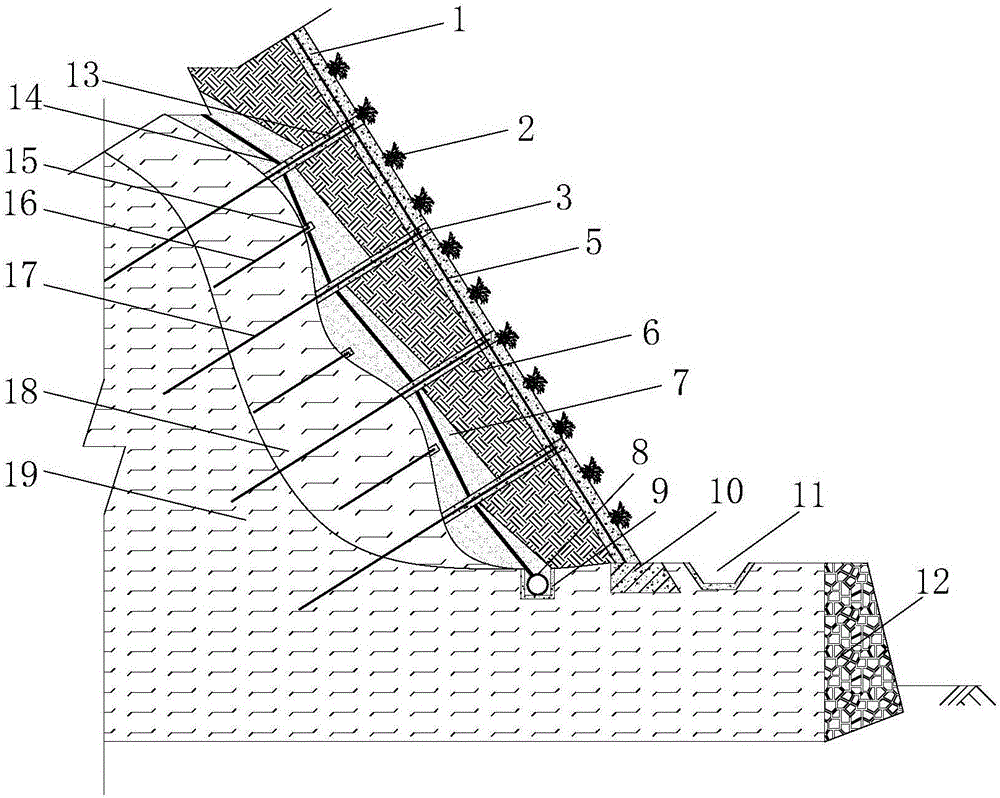

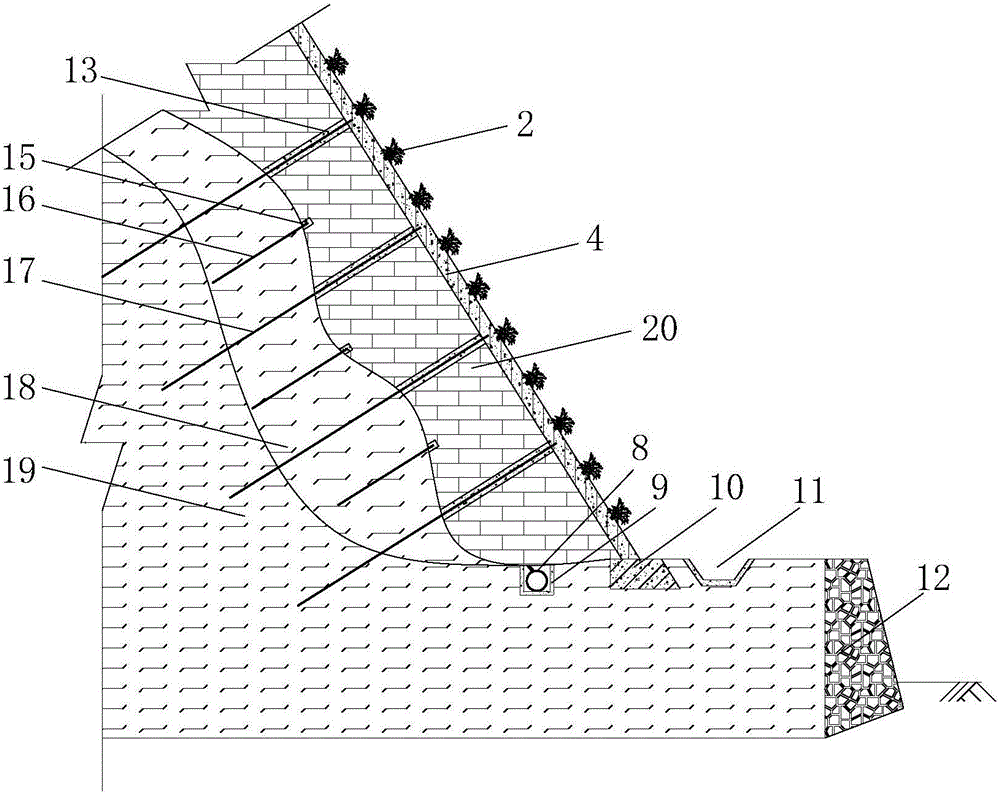

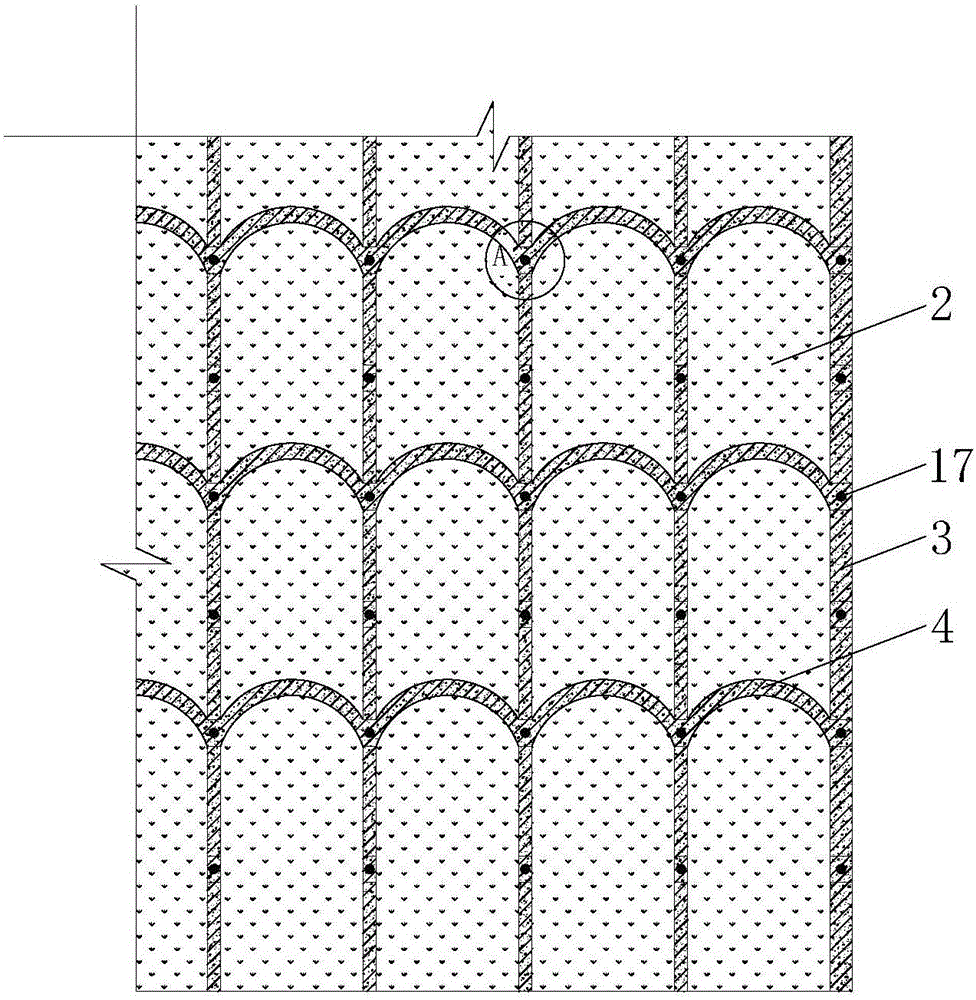

The invention discloses a soil nailing wall foundation pit support and a construction method. The construction method is characterized by comprising the steps of drilling freezing holes, arranging freezing pipes, arranging temperature tubes, performing the freezing construction, performing the pit excavation and ramp finishing, spraying concrete for the first time, performing the soil nailing construction comprising the processes of positioning, pore forming, reinforcement bar inserting and mortar pouring, processing a reinforcement net, spraying the concrete for the second time, maintaining the freezing; monitoring the foundation pit condition and pouring mortar. The invention is secure and reliable, and the stability and water sealing property of the foundation pit can be improved.

Owner:ANHUI TONGJI CONSTR GRP

Environmental-friendly grass concrete highway slope protection structure and construction method thereof

ActiveCN106013191AImprove stabilityGood economic and technical benefitsExcavationsBulkheads/pilesSoil nailingDitch

The invention relates to an environmental-friendly grass concrete highway slope protection structure which mainly comprises grass concrete, prefabricated framed girders, anchor rods, soil nails, a mortar flag stone wall, a hillslope drainage system and a gravity retaining wall. The soil nails are arranged in an unstable rock mass of an original highway slope. Concrete piers are arranged at anchor heads. The mortar flag stone wall is additionally arranged on an original hillslope. The interior of the mortar flag stone wall is sequentially filled with a gravel bed, a clay bed and the grass concrete from bottom to top. The prefabricated framed girders are mounted at the top of the mortar flag stone wall. The anchor rods are arranged at the intersections of the prefabricated framed girders. Concrete inclusions are arranged at the peripheries of the anchor rods. The hillslope drainage system is arranged in the gravel bed. A drainage channel is arranged at a slope bottom. The gravity retaining wall is arranged on the outer side of a highway subgrade side ditch at a slope foot. The environmental-friendly grass concrete highway slope protection structure is high in integrality and stability, and combines safety embankment with environment protection really, and the traffic environment is effectively improved. The invention further provides a construction method of the environmental-friendly grass concrete highway slope protection structure.

Owner:ANHUI ROAD & BRIDGE GRP

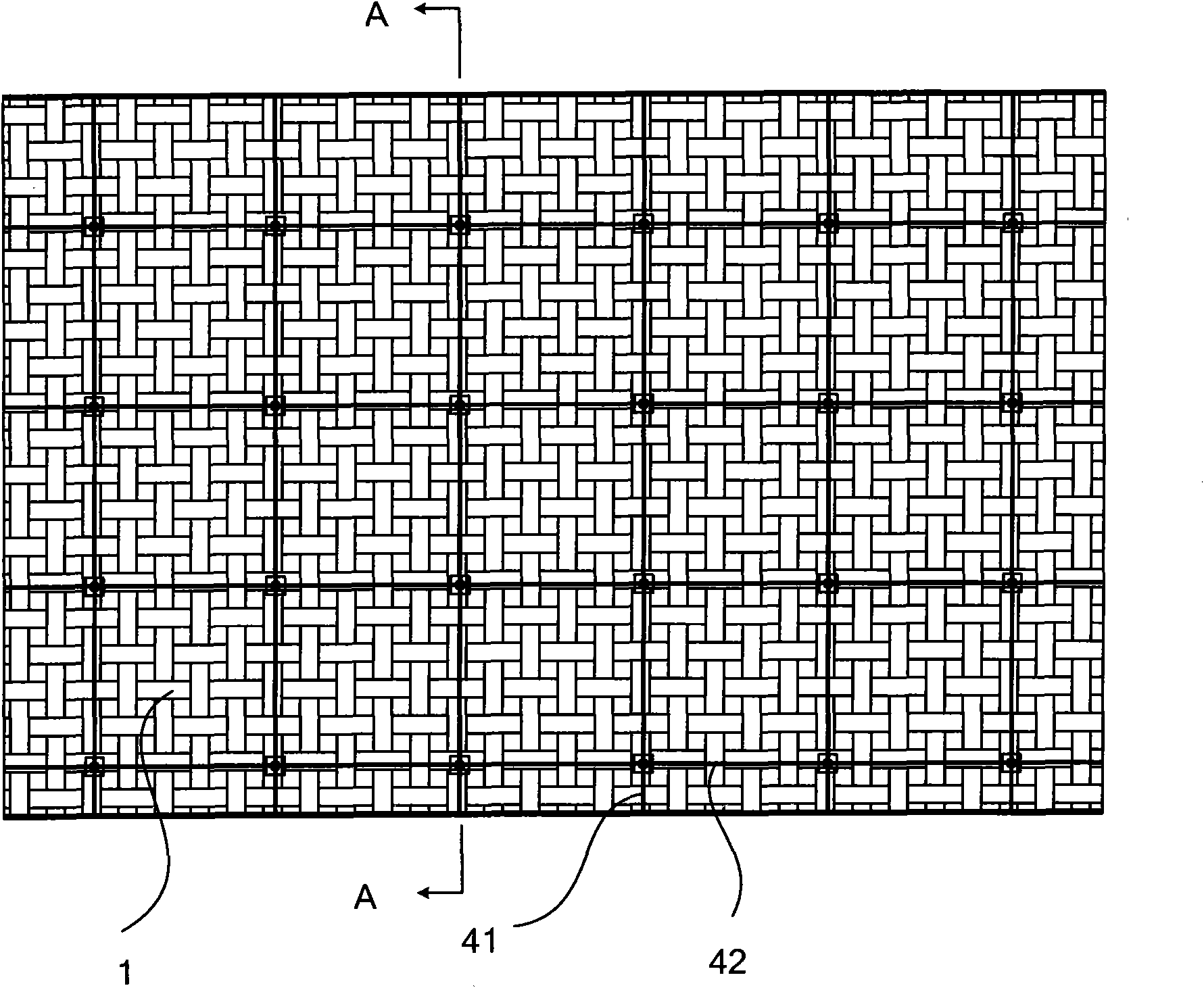

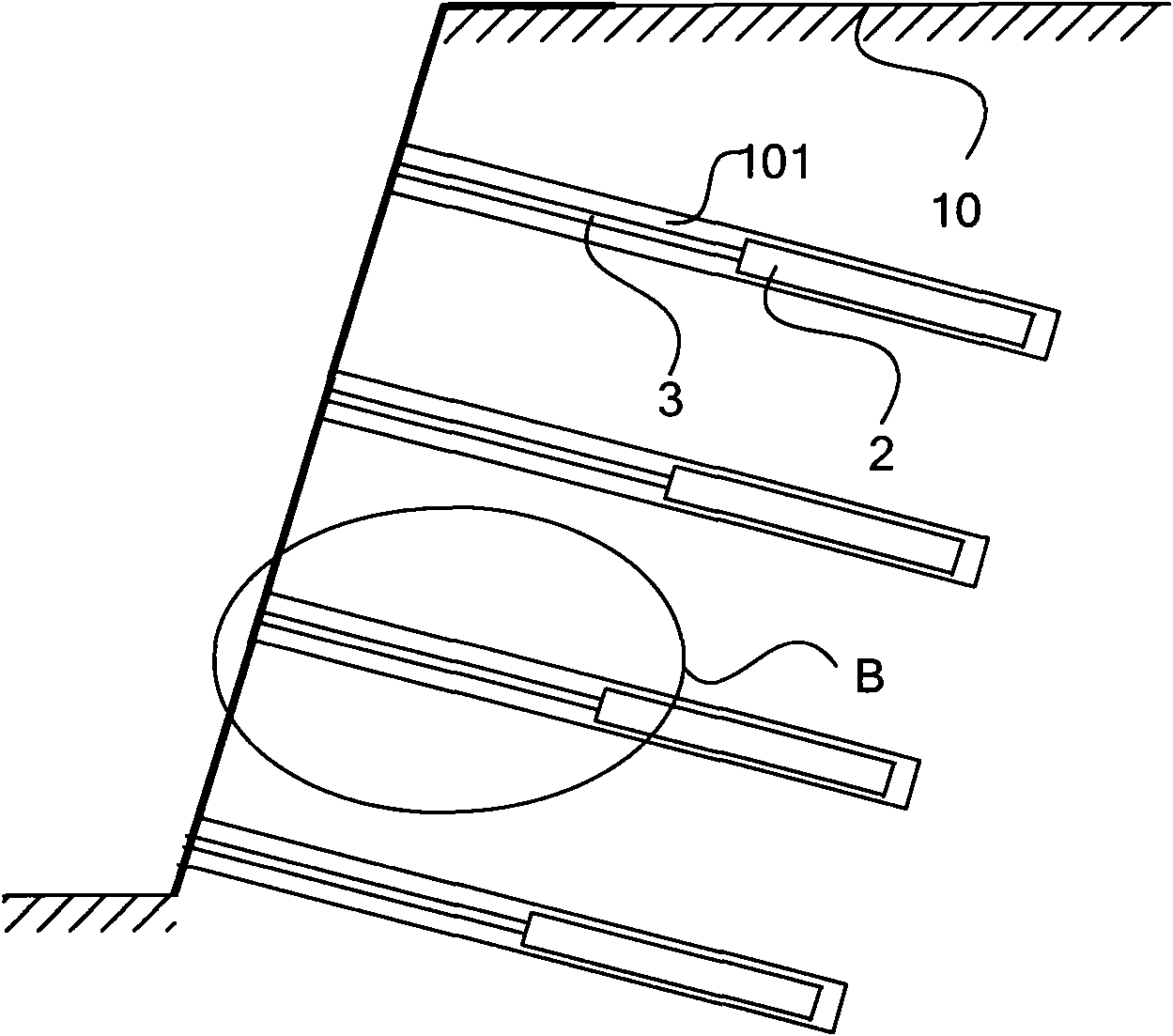

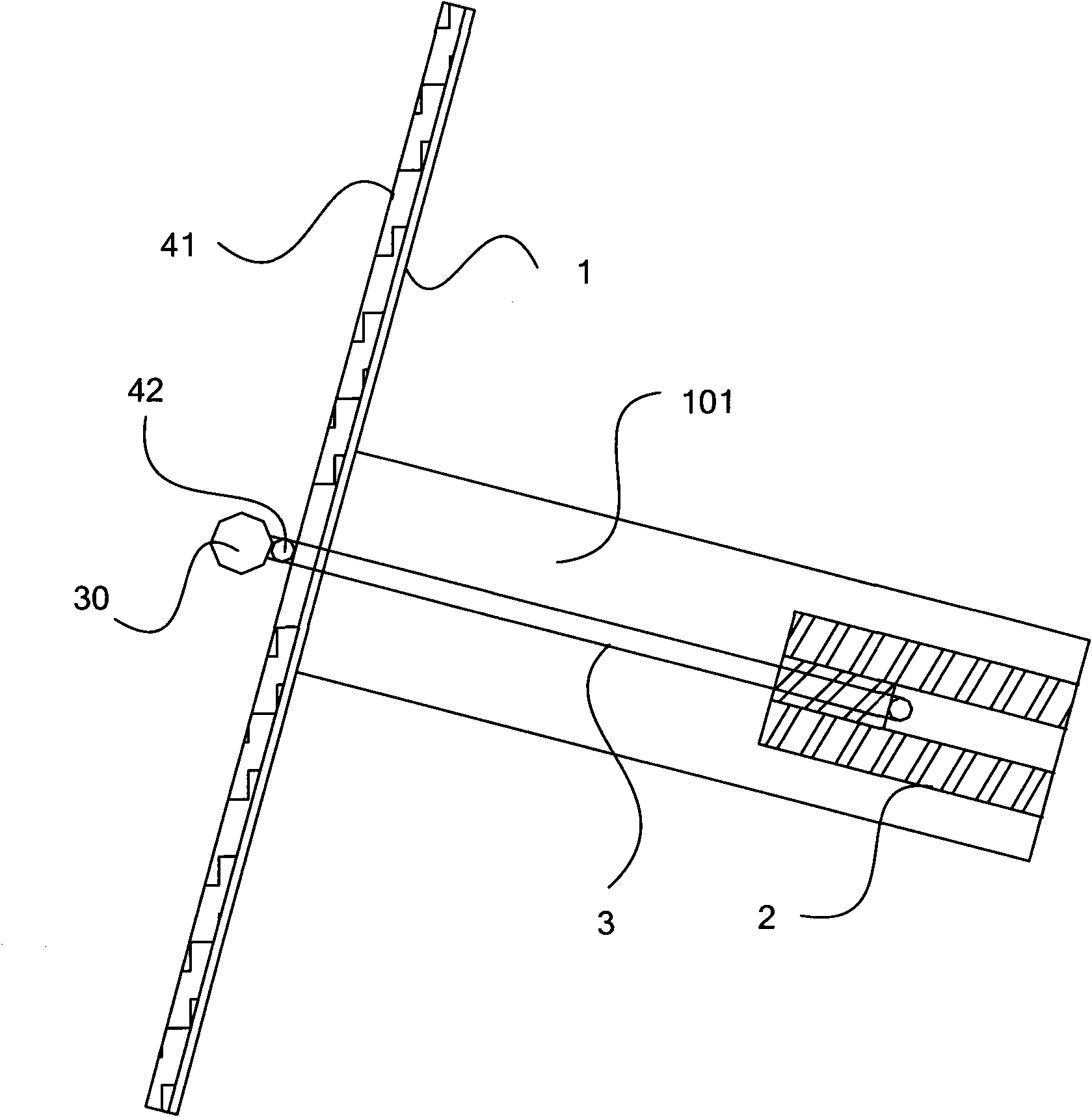

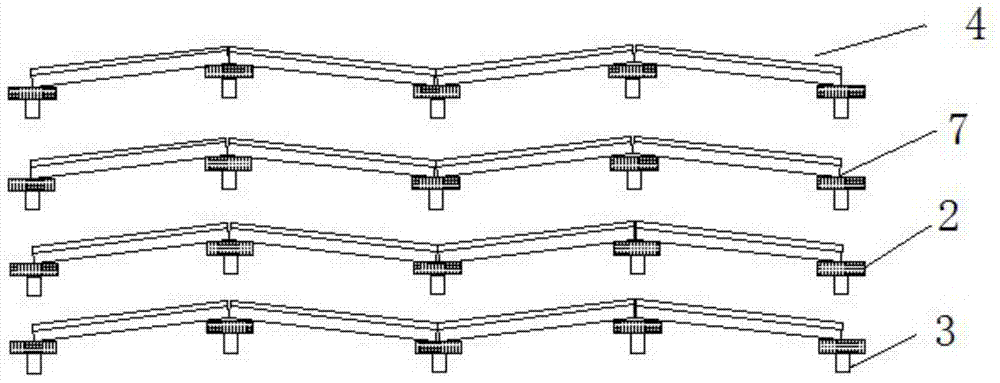

Flexible surface layer soil nailing wall support system and construction method thereof

The invention provides a flexible surface layer soil nailing wall support system and a construction method thereof. The flexible surface layer soil nailing wall support system comprises a plurality of soil nails, a plurality of connecting structures and a flexible surface layer, wherein one end of each connecting structure is fixedly connected with a corresponding soil nail, and the other end of the connecting structure is fixedly connected with the flexible surface layer; the soil nails are fixed in drill holes which are formed on a side slope; and the flexible surface layer is covered on the surface of the side slope. The soil nails are fixed in the drill holes which are formed on the side slope by grouting, the flexible surface layer is connected with the soil nails through the connecting structures and appropriate pre-stressing force can be applied during connection of the flexible surface layer and the soil nails, so that the flexible surface layer is covered on the side slope after being tensioned and the aim of lowering engineering cost on protection of the side slope through the flexible surface layer soil nailing wall support system is fulfilled.

Owner:孙涛

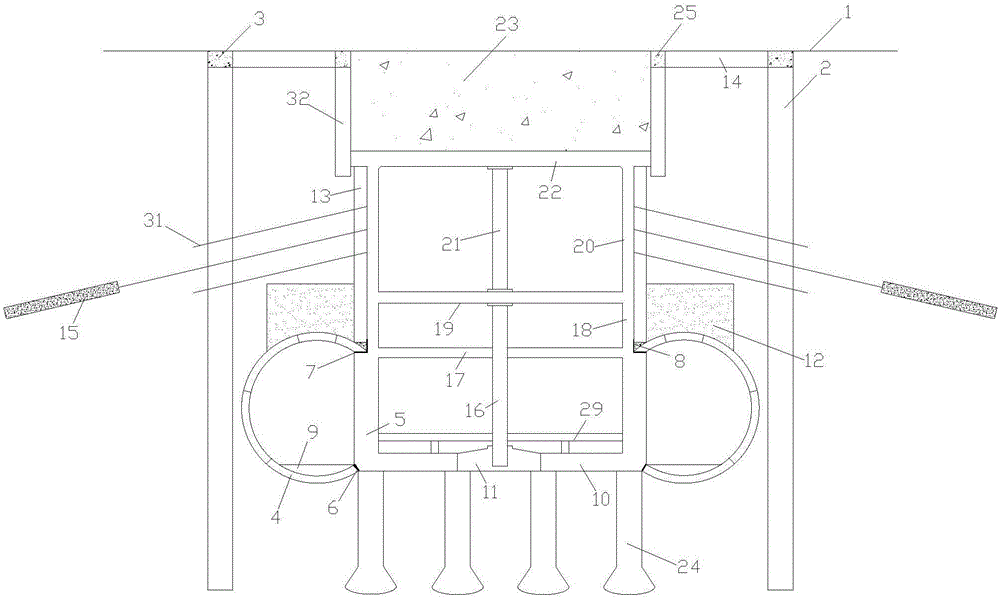

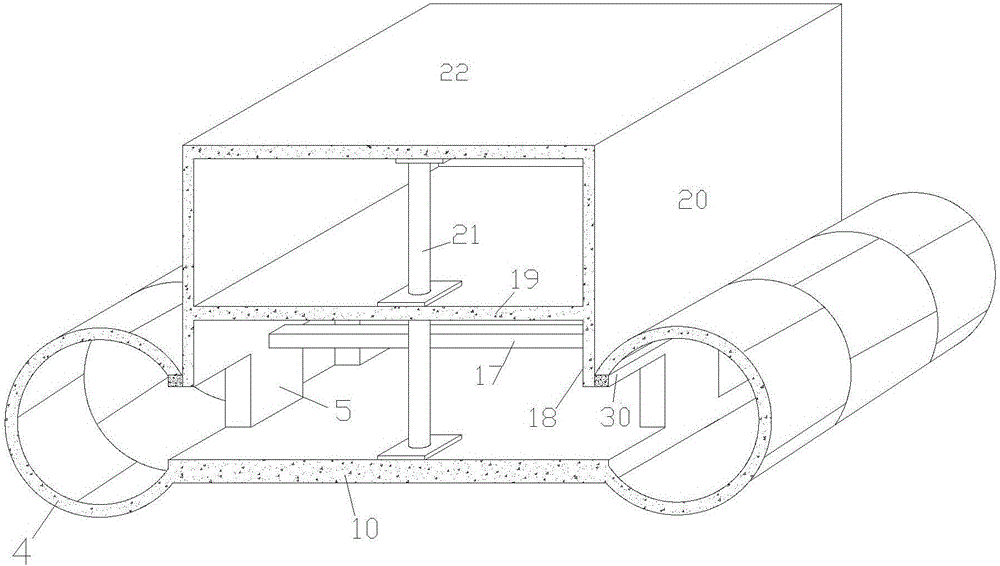

Reversed construction method for expanding and excavating stations on sectional shield tunnel foundations of subways

InactiveCN105003272AImprove construction efficiencyGuaranteed stabilityUnderground chambersTunnel liningSlurry wallSoil nailing

The invention discloses a reversed construction method for expanding and excavating stations on sectional shield tunnel foundations of subways. The expanded and excavated stations are simply supported frame wall column type double-layer subway stations in structural forms. The reversed construction method includes retaining soil and water by the aid of piles in rows and waterproof curtains or underground diaphragm walls, and resisting lateral deformation of soil mass; excavating the soil mass between openings of parallel shield tunnel segments and constructing cross passages; grouting and reinforcing the soil mass above tunnels, building foundation pit excavation supporting structures and short supporting piles of station bodies and connecting the tops of the foundation pit excavation supporting structures and the short supporting piles with the outer piles in the rows or the outer underground diaphragm walls by connecting beams; constructing the structures of the station bodies by the aid of cover and excavation top down processes, filling the station bodies with the soil mass and recovering road surfaces. Foundation pit slopes can be supported by the aid of composite soil nailing supporting technologies in excavation procedures. The reversed construction method has the advantages that the reversed construction method is reasonable and feasible, is high in operability and has important engineering application value and an important development prospect, and huge economic, social and environmental benefits can be brought by application of the reversed construction method.

Owner:BEIJING UNIV OF TECH

Method for deep excavation pit combination support construction close to subway station

InactiveCN103114592AShort construction periodReduce construction costsExcavationsSoil nailingArchitectural engineering

The invention discloses a method for deep excavation pit combination support construction close to a subway station. The method is safe, reliable, short in construction period and low in construction cost and comprises the following steps that (1) two rows of reinforced concrete cast-in-place concrete piles are arranged at the outer side of an underground structure of an entrance and an exit of the subway station for blocking soil; (2) a single row of reinforced concrete cast-in-place concrete piles are arranged at the inner side of the underground structure of the exit and the entrance of the subway station; (3) coupling beams at the top of the reinforced concrete cast-in-plate concrete piles are constructed; and (4) when each coupling beam reaches to strength, earth excavation to a deep excavation pit is performed and in the process of excavation, a plurality of rows of steel tube inner supports are arranged transversally from top to bottom between the single row of reinforced concrete cast-in-place concrete piles and the deep excavation pit and meanwhile and meanwhile, soil nailing wall reinforce is adopted to the bottom of the underground structure of the exit and the entrance of the subway station in a matched mode until the earth excavation is performed to the bottom of the deep excavation pit.

Owner:LONGXIN CONSTR GRP

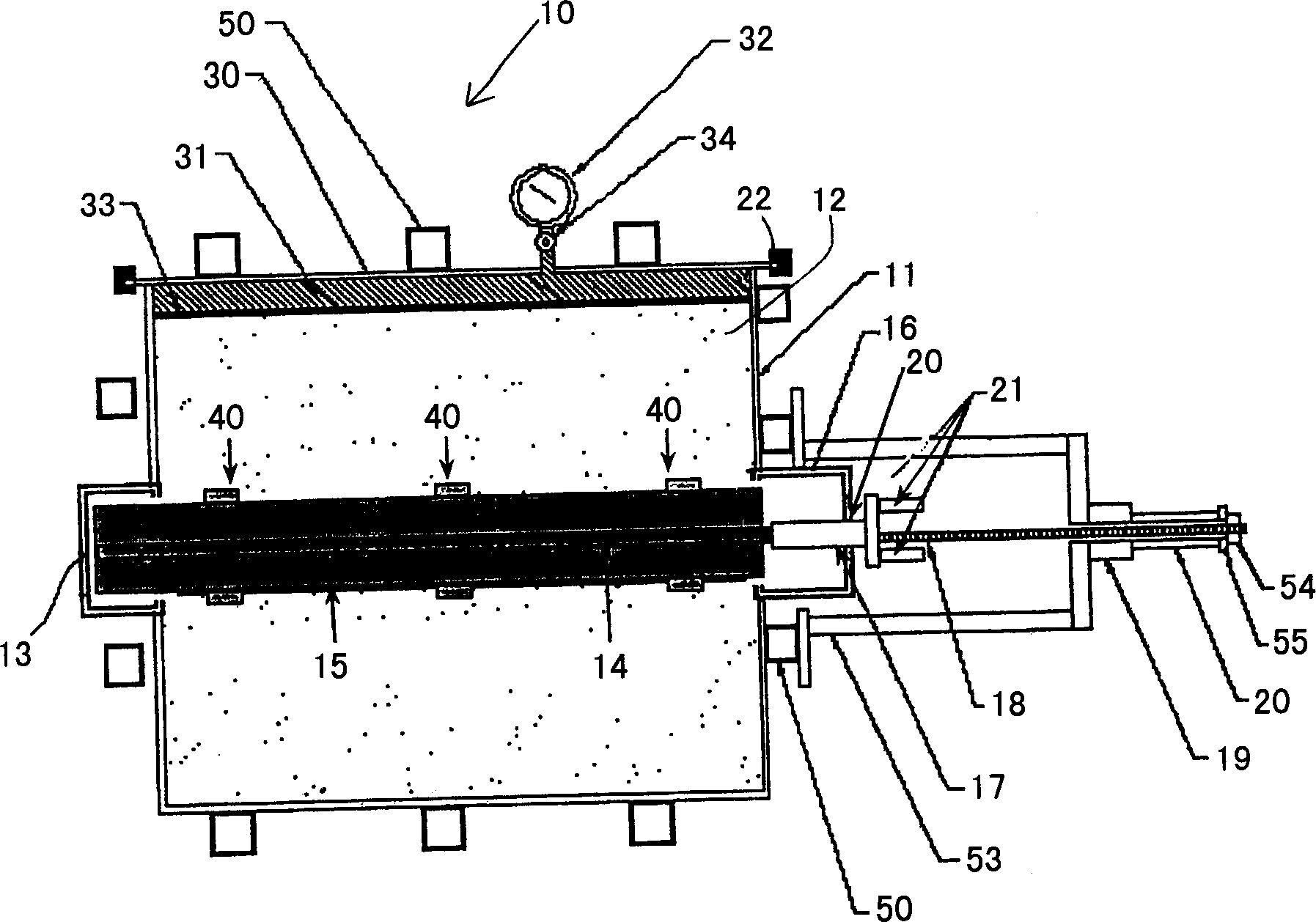

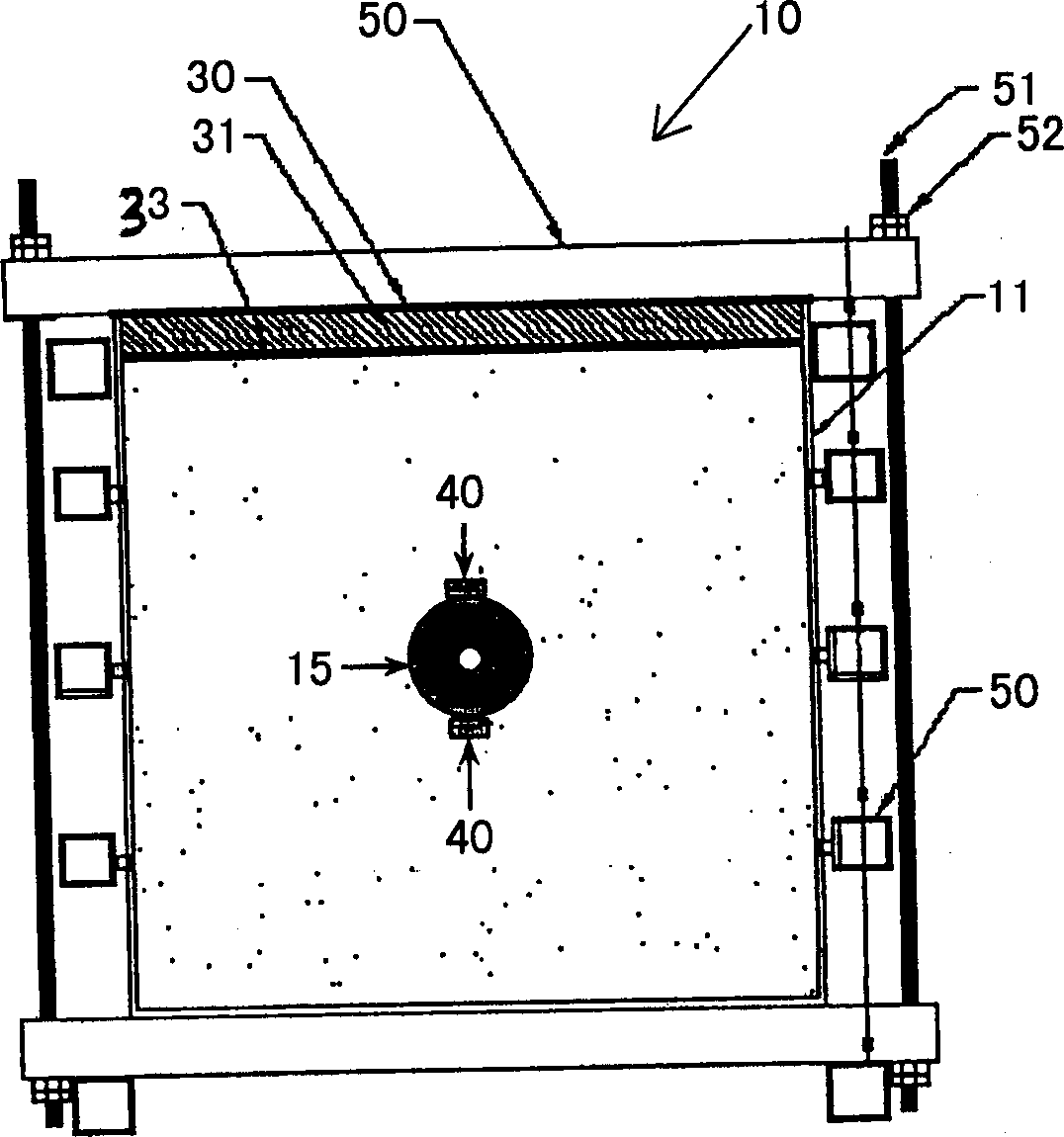

Testing box for measuring anti-pulling force of soil nailing mechanical property

ActiveCN1773241AIncrease water saturationUniform rock pressureMaterial strength using tensile/compressive forcesUsing mechanical meansSoil nailingPull force

Owner:THE HONG KONG POLYTECHNIC UNIV

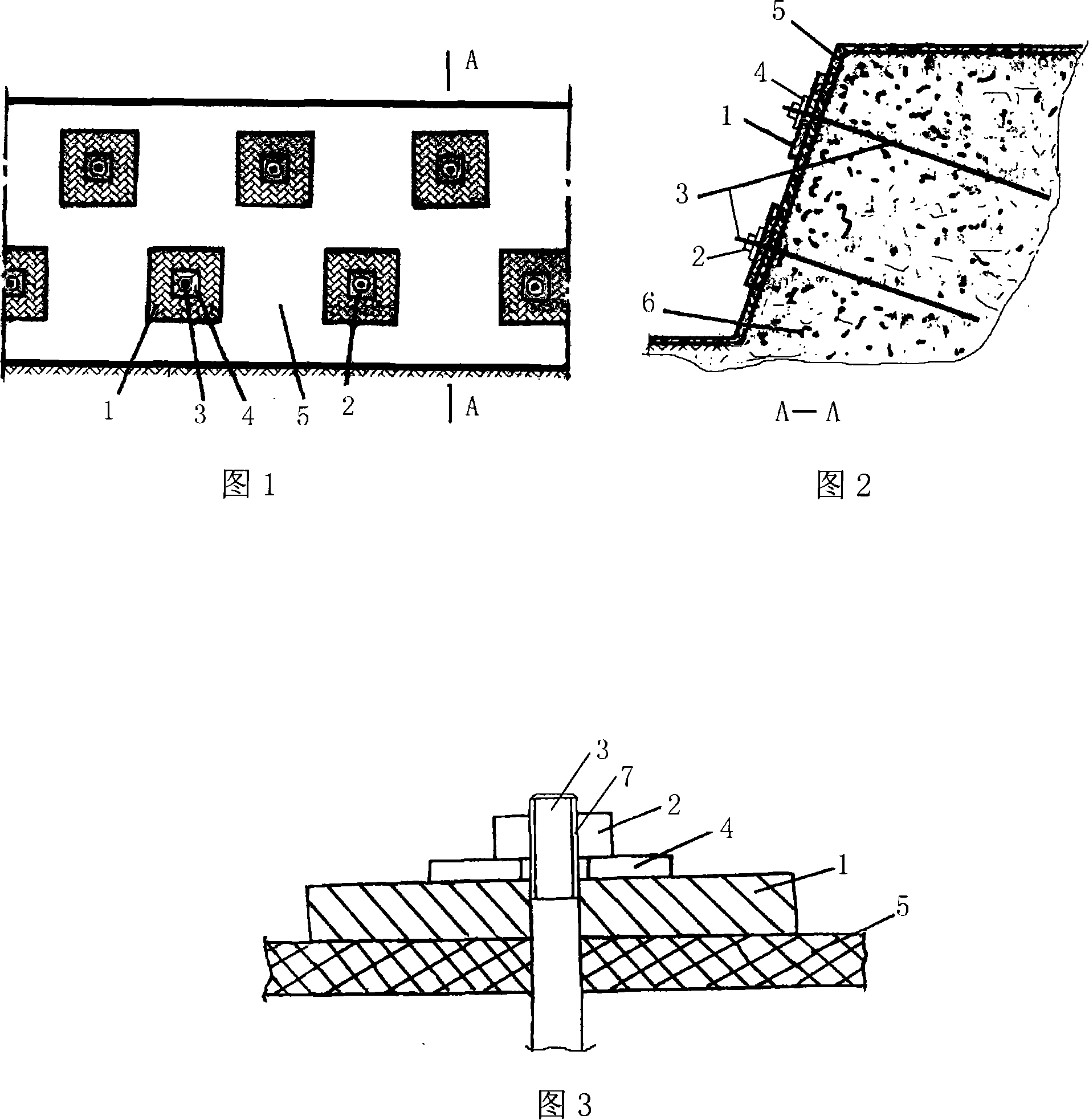

Demountable composite material face plate brad supporting system

ActiveCN101122132AEasy constructionFast and convenient construction speedExcavationsBulkheads/pilesResin matrixEngineering

The invention discloses a detachable composite material panel soil nail support system, which belongs to the technical field of building auxiliary engineering. The soil nails are fixed on the wall of the foundation pit, and the detachable composite panels are fixed on the wall of the wall foundation pit by detachable anchors and soil nails, and are connected by waterproof devices between the panels. After the service period is over, the composite panel can be disassembled to continue serving for the next project. The detachable composite panel is made of resin-based fiber composite material, mainly because of its light weight, high specific strength, large specific modulus, and good fatigue resistance. Compared with the traditional soil nail wall construction, the construction speed of the detachable composite panel support system is fast and saves time: the detachable composite panel soil nail support system is better than the traditional one in controlling the distribution of the plastic zone of the foundation pit and the deformation of the foundation pit. Soil nailed wall, good safety.

Owner:CHINA RAILWAY CONSTR GROUP +1

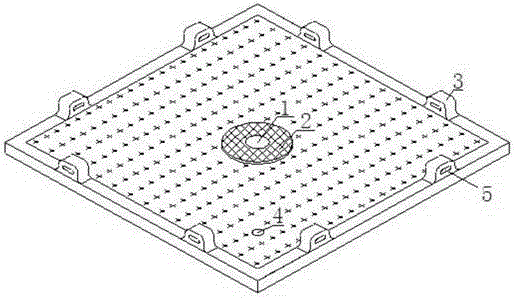

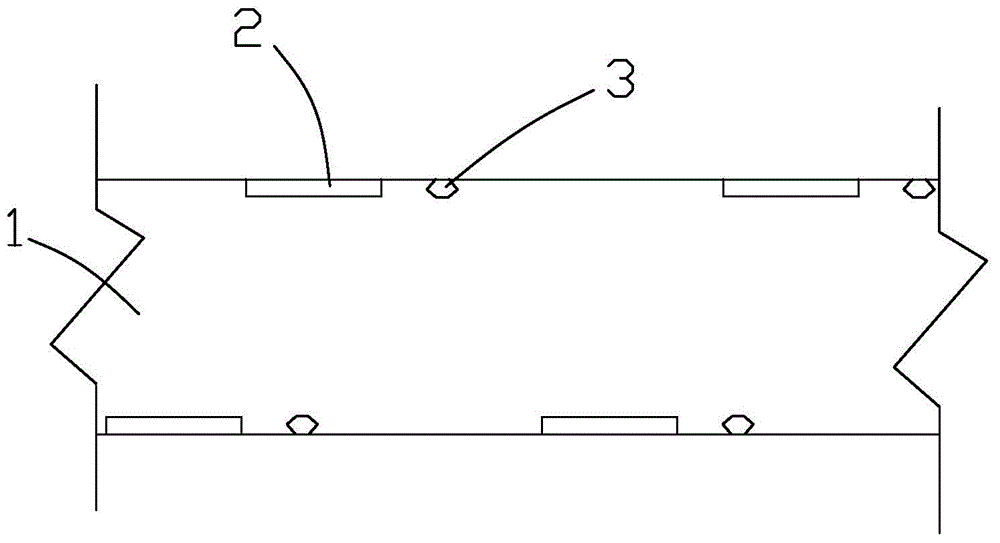

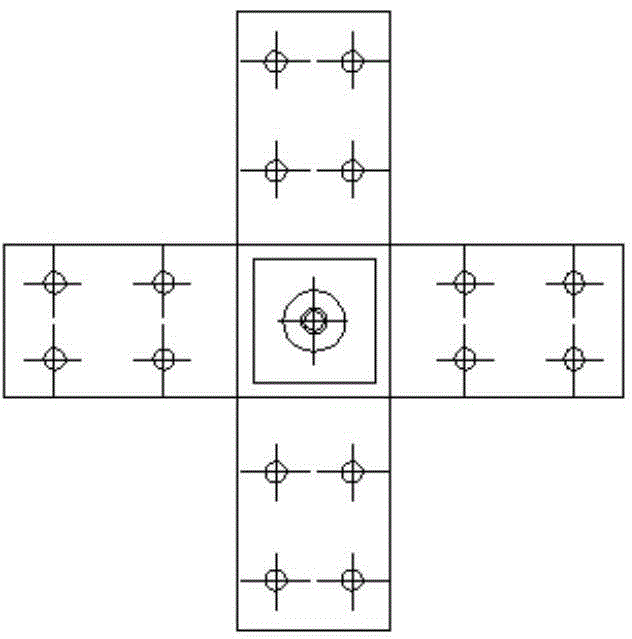

Reusable composite-material soil nailing wall supporting face plate and construction method thereof

ActiveCN103912000AOvercoming weak connectionsEasy to useExcavationsBulkheads/pilesSoil nailingWater leakage

The invention discloses a reusable composite-material soil nailing wall supporting face plate and a construction method thereof and relates to the technical field of anchoring structural parts or wall protection devices. The supporting face plate comprises a plate body, splicing connection portions for connecting two adjacent supporting face plates are arranged at the edges of the plate body, and soil nail holes and water leakage holes penetrating the body are formed in the plate body. The supporting face plate is used for soil nailing wall construction and has the advantages of being firm in construction, capable of preventing wasting of construction materials and preventing construction materials from polluting the underground and reusable.

Owner:中勘冶金勘察设计研究院有限责任公司

Scattered row piles-brad wall combination supporting method

InactiveCN101126241AImprove stabilityReduce stabilityExcavationsBulkheads/pilesSoil nailingEngineering

The invention discloses a scattered row pile-soil-nailed wall combination supporting method, which is characterized in that: the excavation and support sequence is that: a. the scattered pile is constructed according to certain pile spacing and the ratio of the pile spacing to the pile diameter, the pile is an arch foot pile; b. the pile is constructed with the technology of mixing pile or rotary jet grouting pile and a water-stopping curtain is applied to stop the water between the piles; c. the earthwork layer by layer is excavated for the construction of soil-nailed wall; d. pile support construction or bolt construction is made if the pile support or the bolt is encountered; e. the beam is constructed or the pillar is support; f. the support is sustained or stretch the bolt is stretched; g. the concrete spraying of soil nail is excavated layer by layer; h. the procedure b-g is repeated until the pit bottom is reached. The scattered row pile-soil-nailed wall combination support structure can effectively maintain the stability of the foundation pit and the side slope and control the displacement of the foundation pit and the side slope.

Owner:吴忠诚

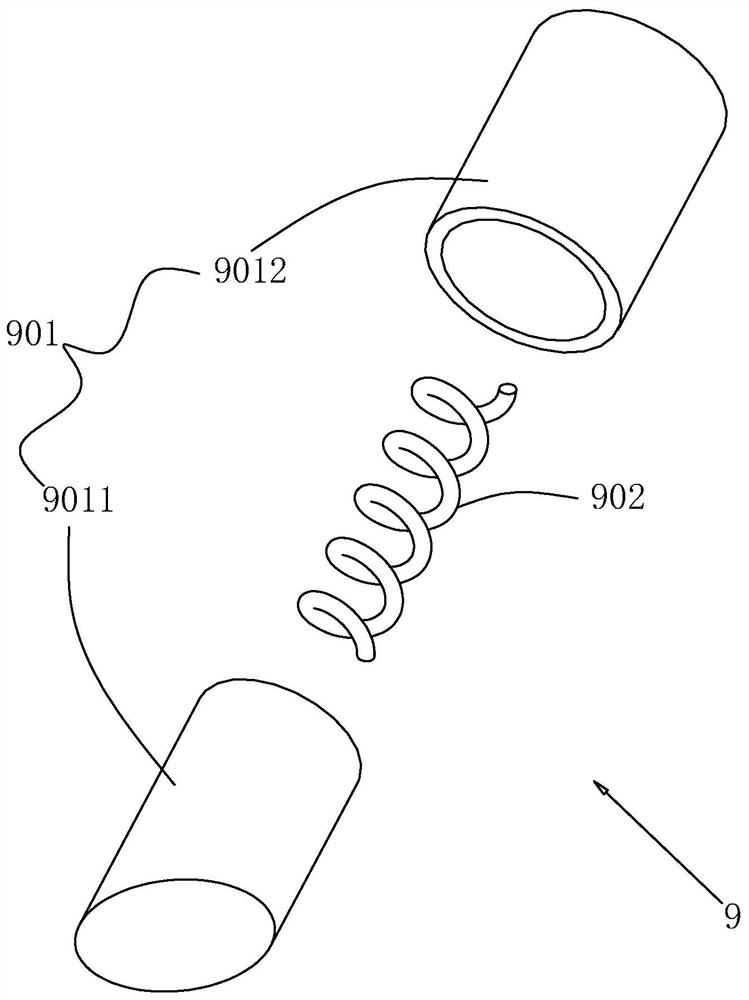

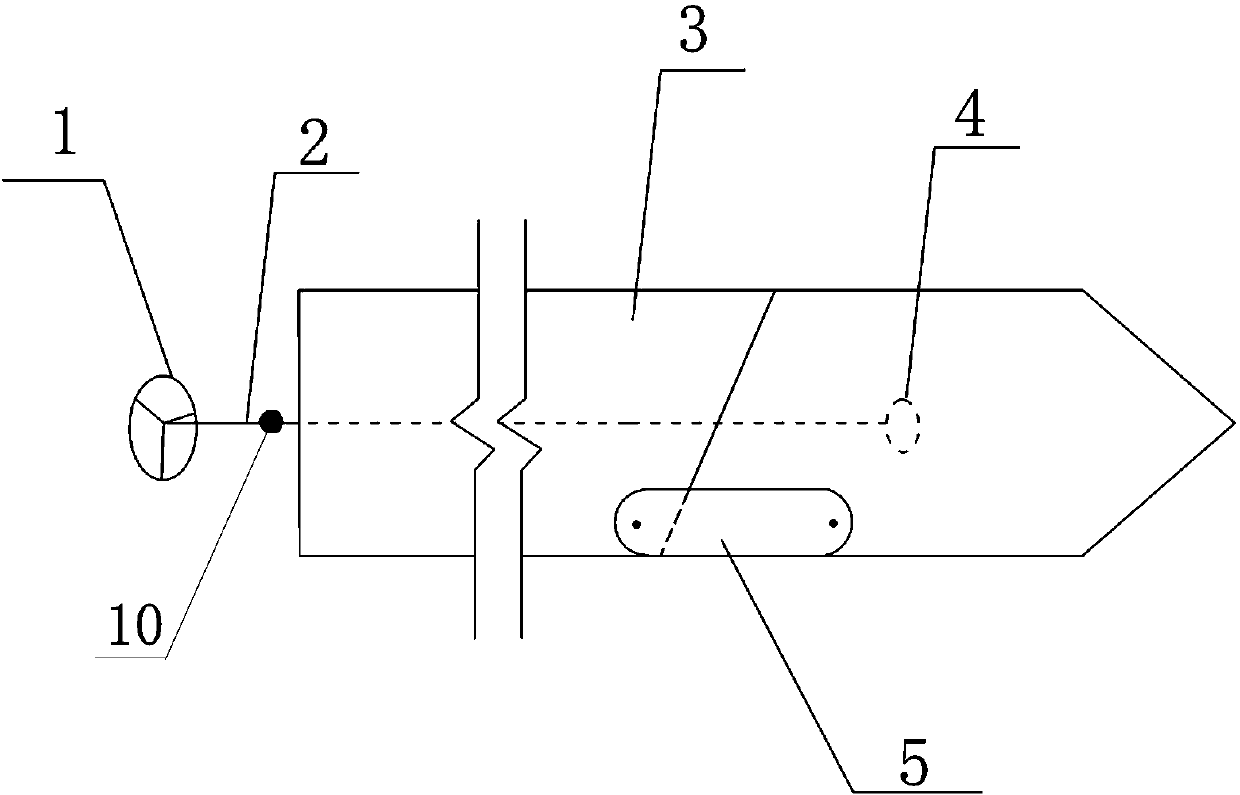

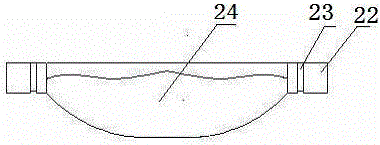

Packing apparatus for pressure type soil-nailing and soil-nailing construction method using the packing apparatus

InactiveUS20030235472A1Reduce constructionImprove construction efficiencyExcavationsOrganic fertilisersSoil nailingGrout

The present invention relates to a packing apparatus for pressure type soil-nailing and soil-nailing construction method using the apparatus, can shorten a grouting time through pressure type grouting which seals completely grouting area, and can improve stability of a ground reinforcing body by filling liquid grout to even a gap between a boring hole and the ground and void of the ground.

Owner:KOREA LAND COPORATION +2

Building foundation pit supporting construction

The invention discloses a foundation pit support structure of buildings which comprises a soil nailing wall surrounding a foundation pit and a prestressed anchor rod which is inserted into the soil body by the soil nailing wall. The invention is characterized in that the pier column structure is arranged on the soil nailing wall every 5 meters to 10 meters; wherein, the pier column structure comprises a filling pile group which is perpendicular to the bottom of the foundation pit, the prestressed anchor rod at the two sides of the filling pile group and a level channel steel which is connected with the anchor rod at the two sides and is arranged at the outside terminal of the soil nailing wall; the filling pile group is packed in the soil nailing wall and consists of at least two filling piles in homogeneous alignment. The invention makes use of the pier column structure to divide the large-area foundation pits into small-area foundation pits; the combination of a filling pile, a prestressed anchor rod and the soil nailing wall raises the ability of the pit support in anti-deforming and anti-displacement and realizes the supporting to the foundation pit; besides, the construction cost is just 60 percent of rigid perfusion row piles.

Owner:ZHONGYIFENG CONSTR GRP

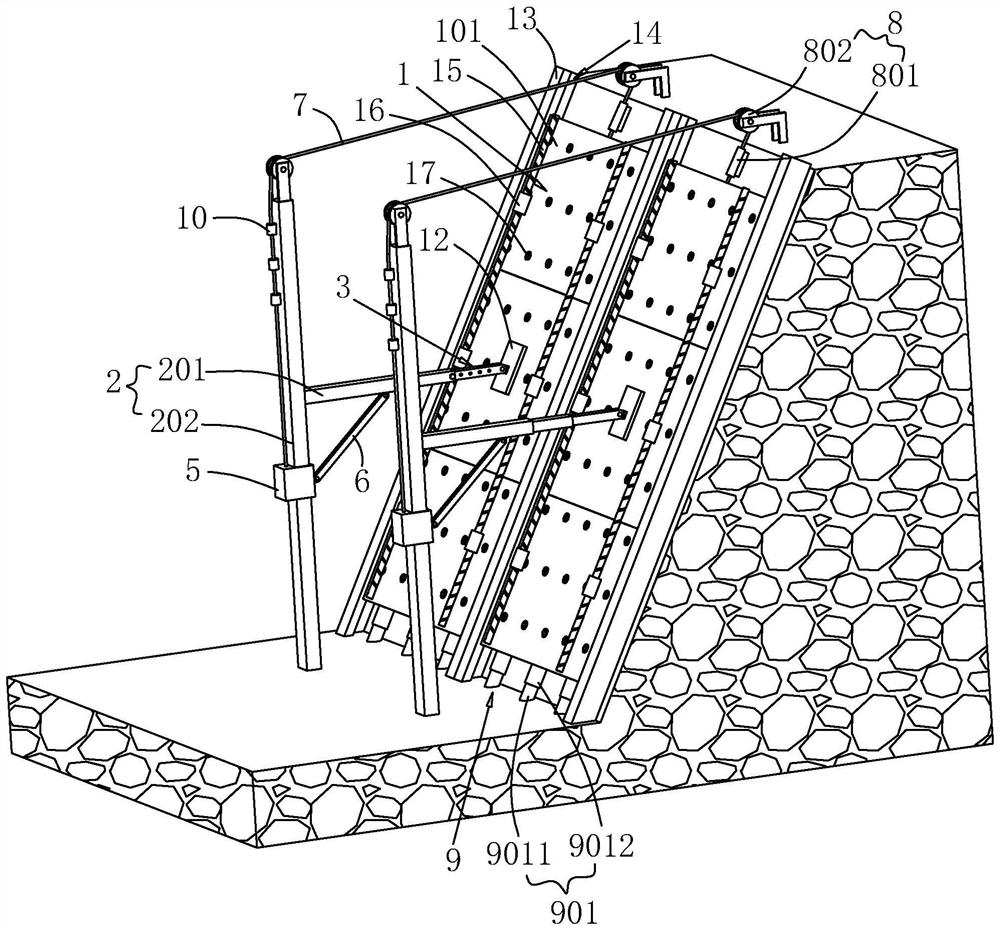

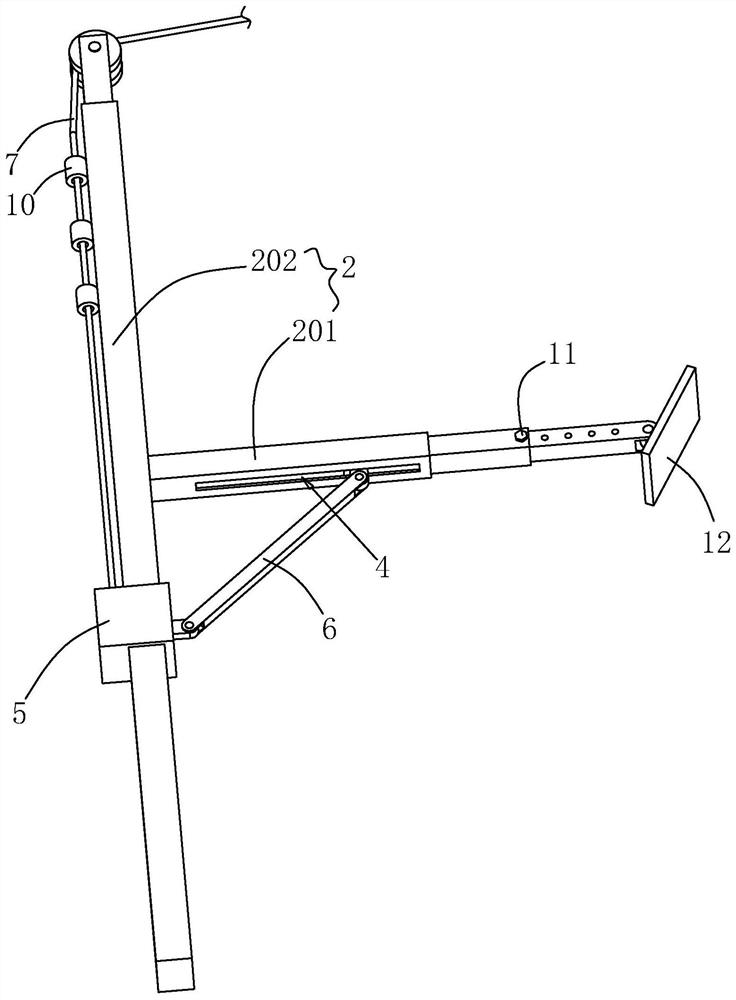

Soil nailing wall supporting structure

The invention relates to a soil nailing wall supporting structure. The soil nailing wall supporting structure comprises an abutting plate and a supporting device used for abutting against the abuttingplate, wherein the supporting device comprises a supporting transverse rod and a supporting vertical rod vertically arranged in a foundation pit; the supporting transverse rod is perpendicularly connected to the supporting vertical rod, and one end of the supporting transverse rod points to the abutting plate; the supporting transverse rod is hollow, and a sliding rod used for abutting against the abutting plate is movably arranged in the supporting transverse rod in a penetrating mode; an open groove communicating with the interior of the supporting transverse rod is formed in the lower endface of the supporting transverse rod in the length direction of the supporting transverse rod; the supporting vertical rod is sleeved with and slidably connected with a sleeve below the supporting transverse rod; the sleeve penetrates through the open groove and the end, away from the abutting plate, of the sliding rod through an oblique rod; the two ends of the oblique rod are rotationally connected with the sleeve and the sliding rod correspondingly; the upper end of the abutting plate is connected with the sleeve through a connecting rope; and a guiding assembly used for guiding the connecting rope is arranged on the portion, above the abutting plate, of a side slope in the inclination direction of the side slope. The soil nailing wall supporting structure has the effects that the construction efficiency is improved, and construction is convenient.

Owner:成都城投建筑工程有限公司

Full-thread fiber resin rod body soil nailing wall and construction method thereof

InactiveCN102352630ACorrosion resistantEasy to resist corrosionExcavationsBulkheads/pilesFiberSoil nailing

The invention relates to a full-thread fiber resin rod body soil nailing wall and a construction method thereof; a soil nail rod body of a soil nailing wall is a full-thread fiber resin rod body, auxiliary reinforcement ribs are arranged at positions situated on the upper part of an interior segment of a concentrate surface layer of the soil nail rod body, and continuous cross pressing ribs are arranged on the lower part thereof; the fastening nut is a resin nut; the lining plate is a resin lining plate injected by a resin material and is fastened on the outer surface of the concentrate surface layer; and ring locators are sleeved on the parts stretched into the side slope soil of the full-thread fiber resin rod body at intervals. Compared with the present soil nailing wall, the invention has the advantages of simple and convenient construction, energy saving, consumption reduction and larger application range of resin rod body; and the nut and lining plate situated on the end part of the rod body are situated at the outside of the concentrate surface layer, so the stress is more reasonable. Meanwhile, an expanding head is arranged at a position situated in the side slope of the rod body according to the actual engineering to form a reinforced expanding head soil nail, so that the plasticity is strong. The invention can be extensively applied in the construction of side slope soil nailing wall technique.

Owner:CHINA XINXING CONSTR & DEV CO LTD

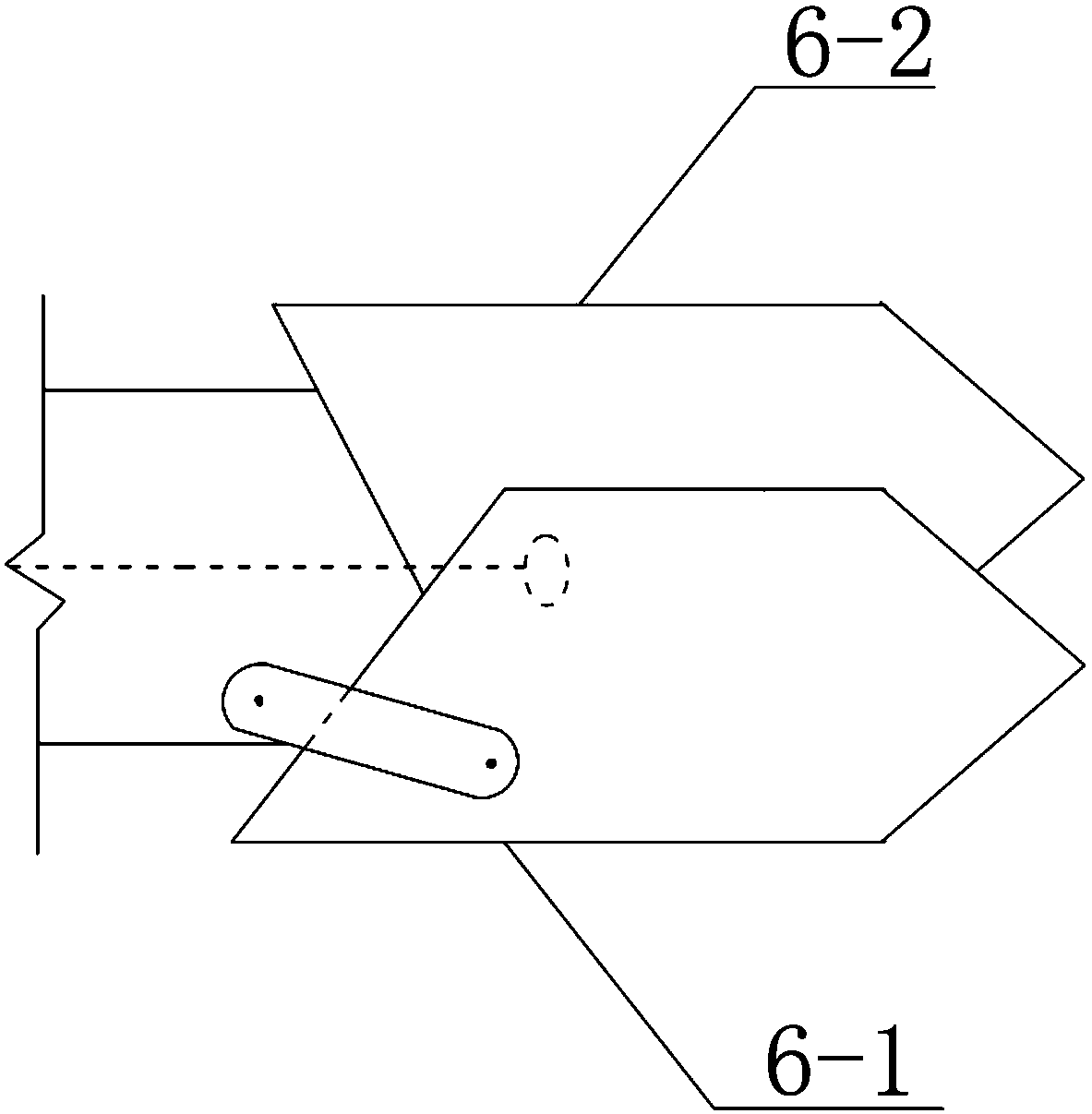

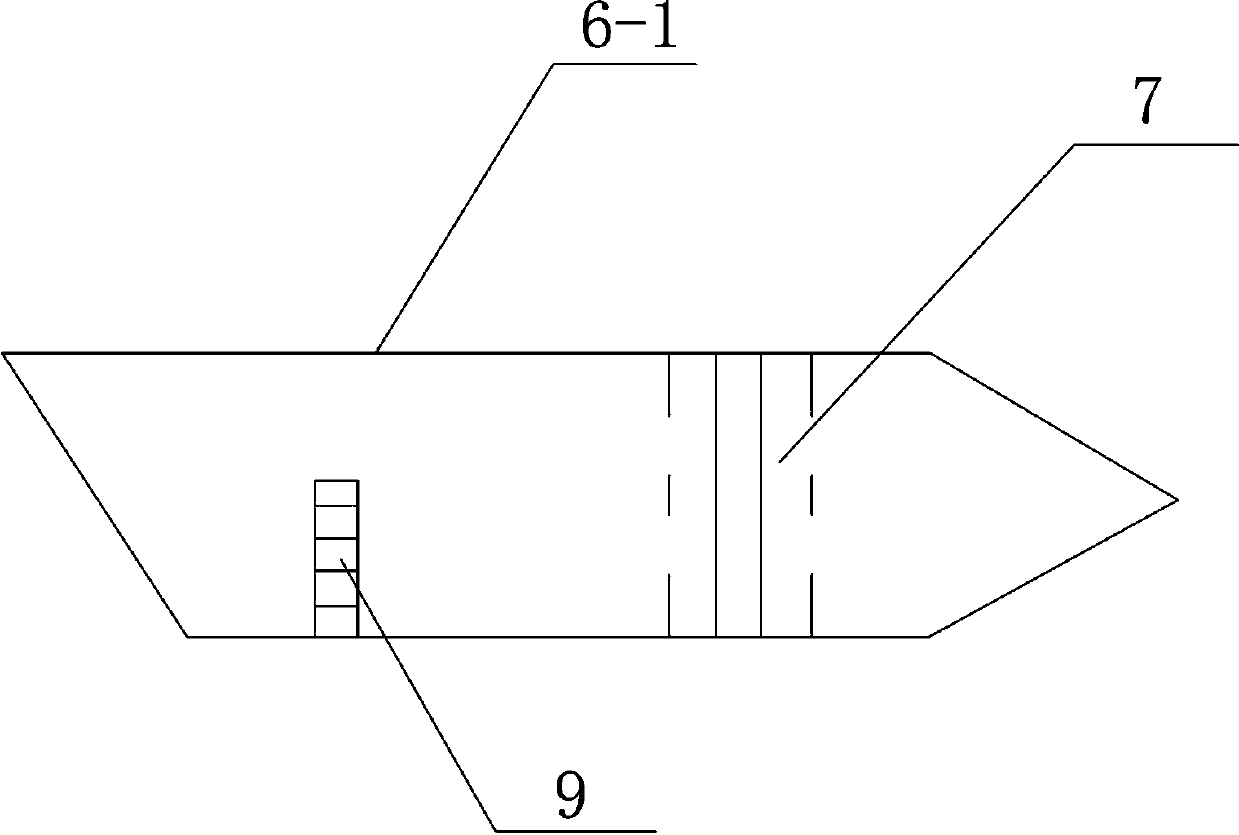

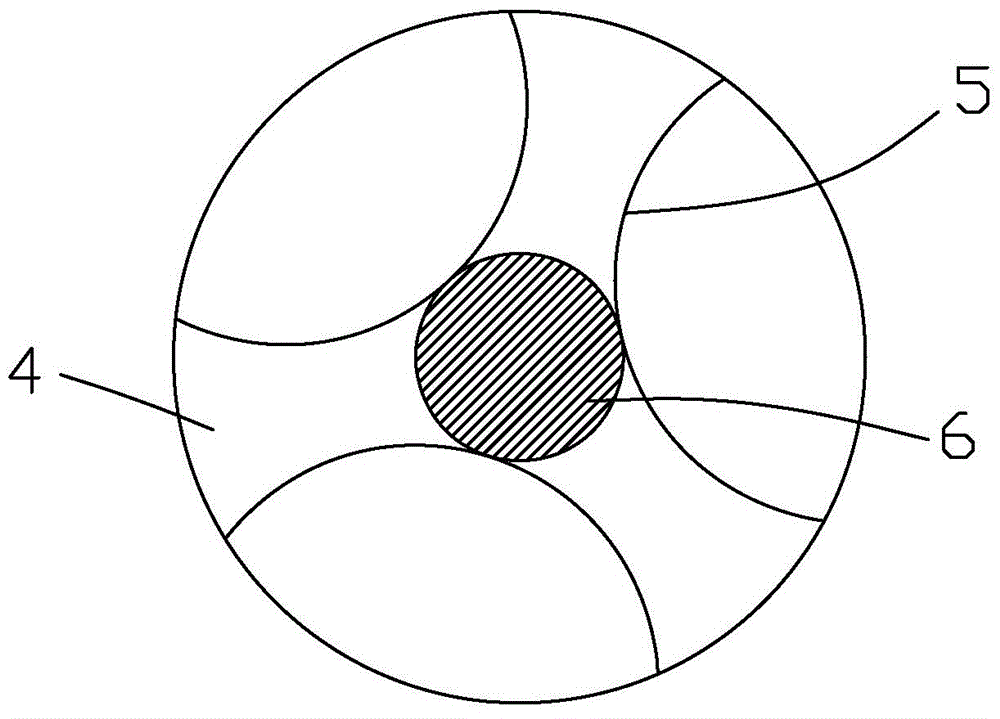

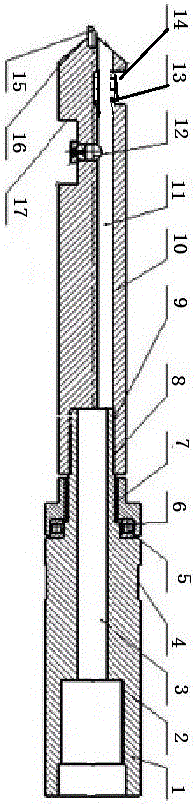

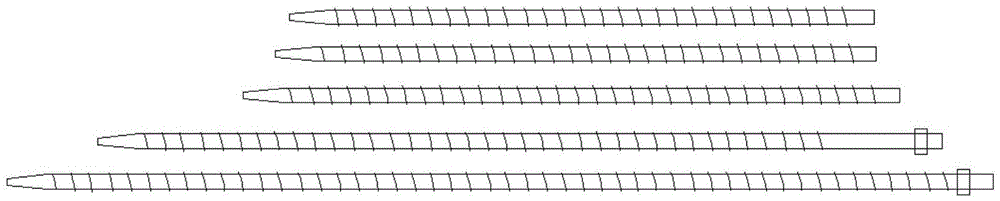

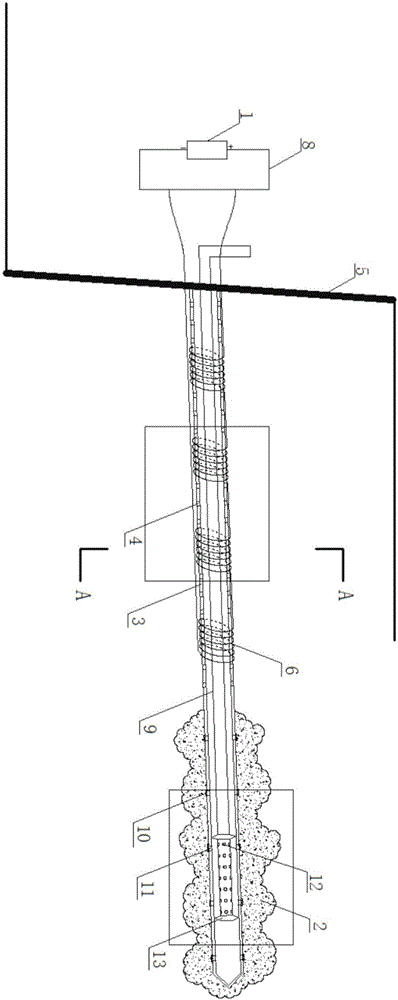

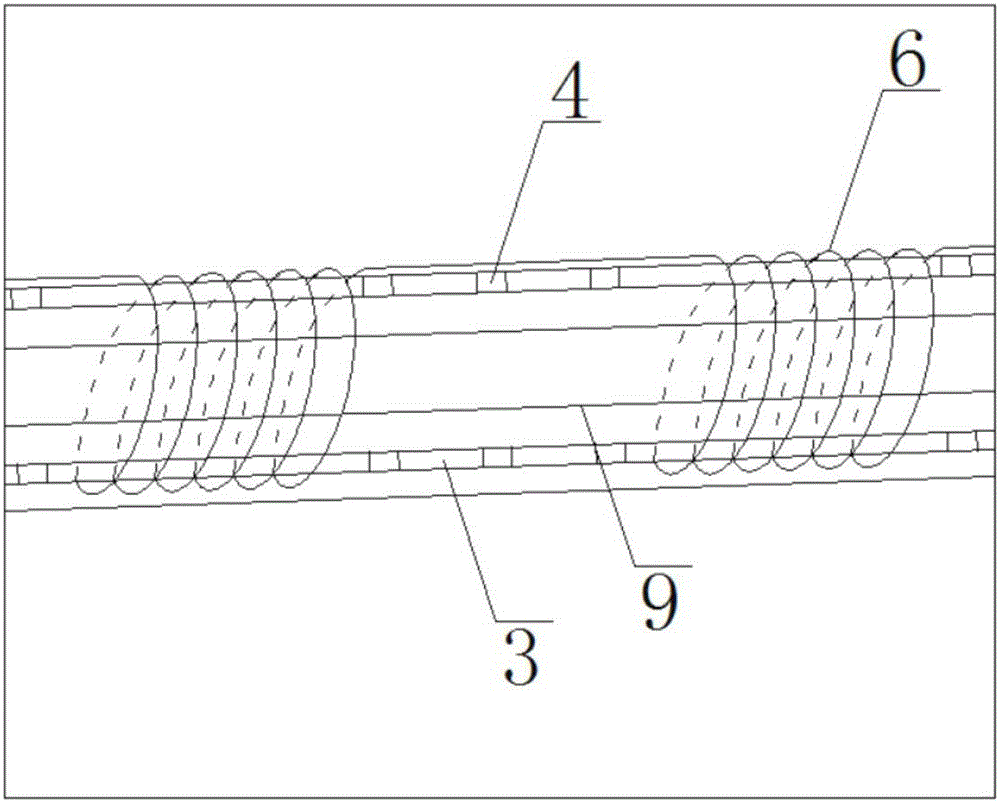

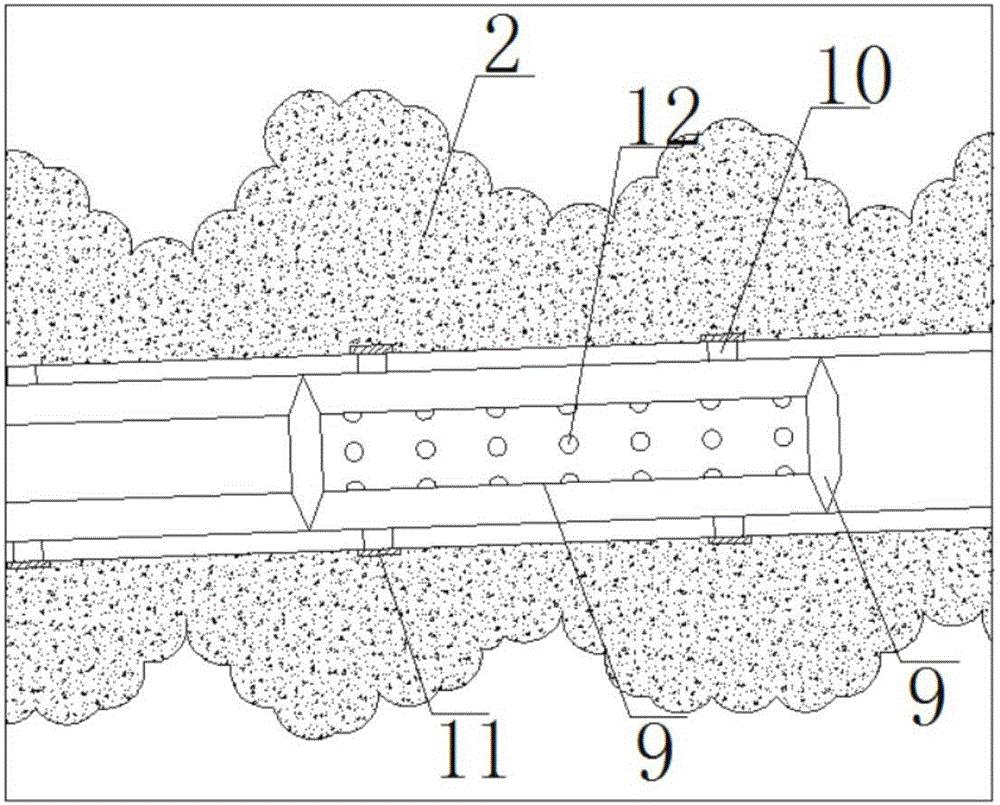

Novel soil nail diameter expanding device and diameter expanding method

InactiveCN104179185AEconomic design purposeSecurity Design PurposeExcavationsBulkheads/pilesEngineeringDrill

The invention provides a novel soil nail diameter expanding device which comprises a core shaft knob, a core shaft, a core shaft knob advance and retreat control device, a drill rod and a cylindrical gear, wherein the core shaft knob and the cylindrical gear are connected through the core shaft; the cylindrical gear is positioned inside the drill rod; the novel soil nail diameter expanding device further comprises a first diameter expanding wing and a second diameter expanding wing; the first diameter expanding wing and the second diameter expanding wing are respectively connected onto the drill rod through connecting parts; a gear rack is respectively arranged on each of the first diameter expanding wing and the second diameter expanding wing; the gear racks are meshed with the cylindrical gear. The invention further provides a soil nail diameter expanding method. According to the novel soil nail diameter expanding device and diameter expanding method, the diameter of a soil nail hole at a soil nail anchorage section can be very conveniently enlarged to the size meeting the design requirement, so that the design purposes of economy, safety and reasonableness of a supporting structure can be achieved, and the construction cost is reduced.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

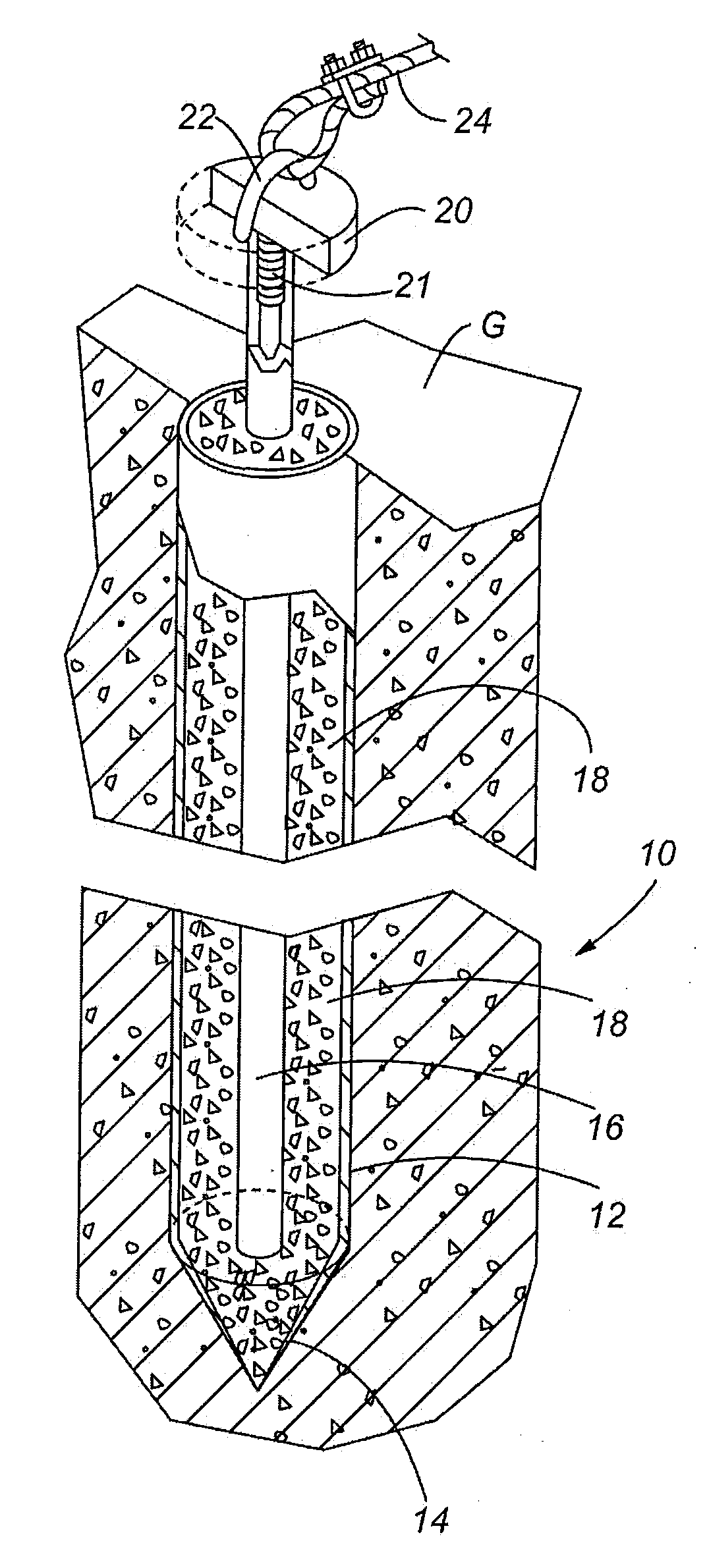

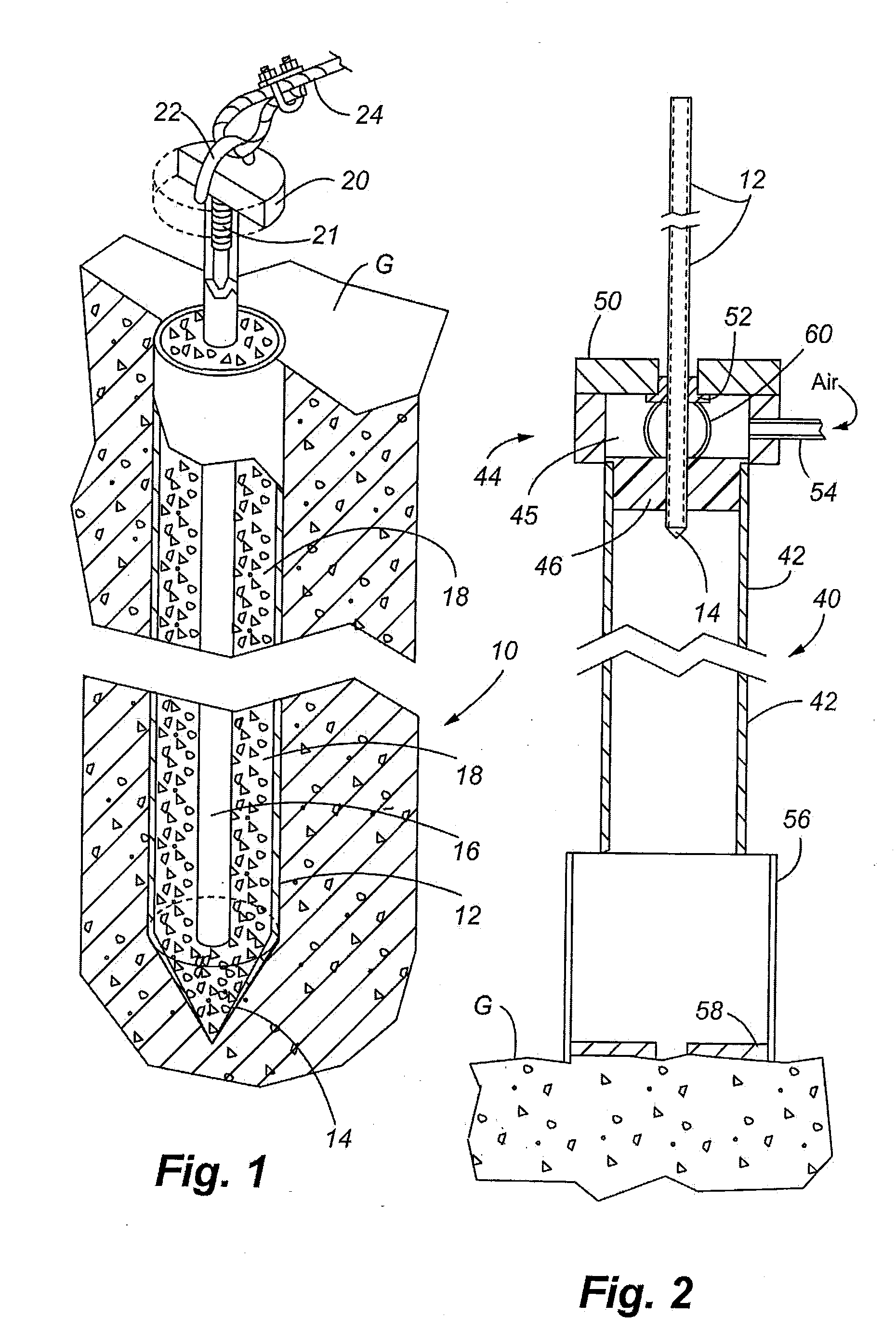

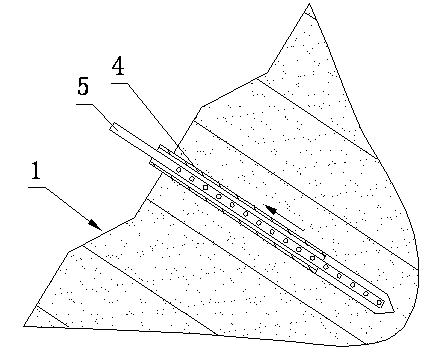

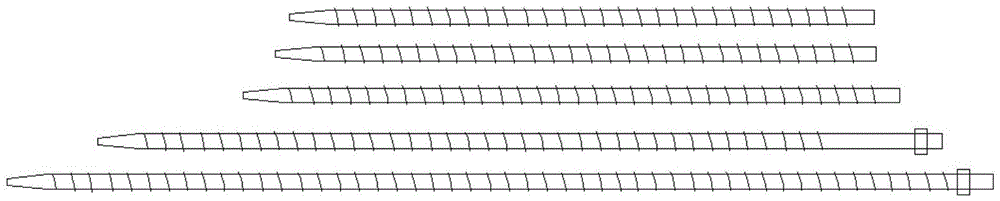

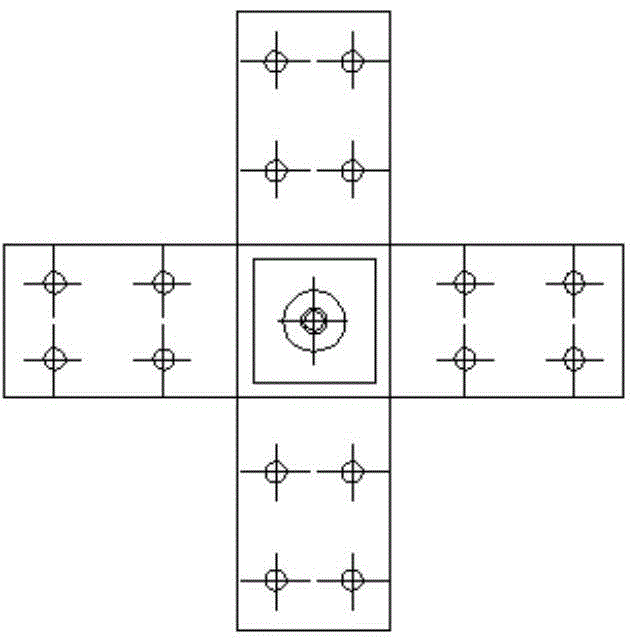

Self-centralizing soil nail and method of creating subsurface support

ActiveUS20100166505A1Improve corrosion resistanceHigh speedBulkheads/pilesAnchoring boltsComposite constructionGlass fiber

A subsurface support is provided comprising a soil nail having an outer member and an inner member placed within the outer member. The soil nail includes features that maintain a uniform spaced relationship between the inner and outer members. The soil nail may be installed by drilling or launching through a launching device. The spaced relationship between the inner and outer members may be achieved by crimping the outer member, or by use of an insert installed between the inner and outer members. In other embodiments, the support is made of composite construction materials, and having a self-drilling capability. The soil nail has two primary members, namely, an outer threaded member, and an inner threaded member that is placed through the outer member The outer member is made from fiberglass, and a metallic drill bit is secured to a distal end of the soil nail. The inner member is preferably steel. The dual piece construction provides superior tensile and compressive strength, particularly for applications in which a coupler is used to join outer members to extend a length of the soil nail. A method is also provided to improve pull-out capacity by galvanizing the inner and outer members

Owner:SOIL-NAIL HLDG LLC

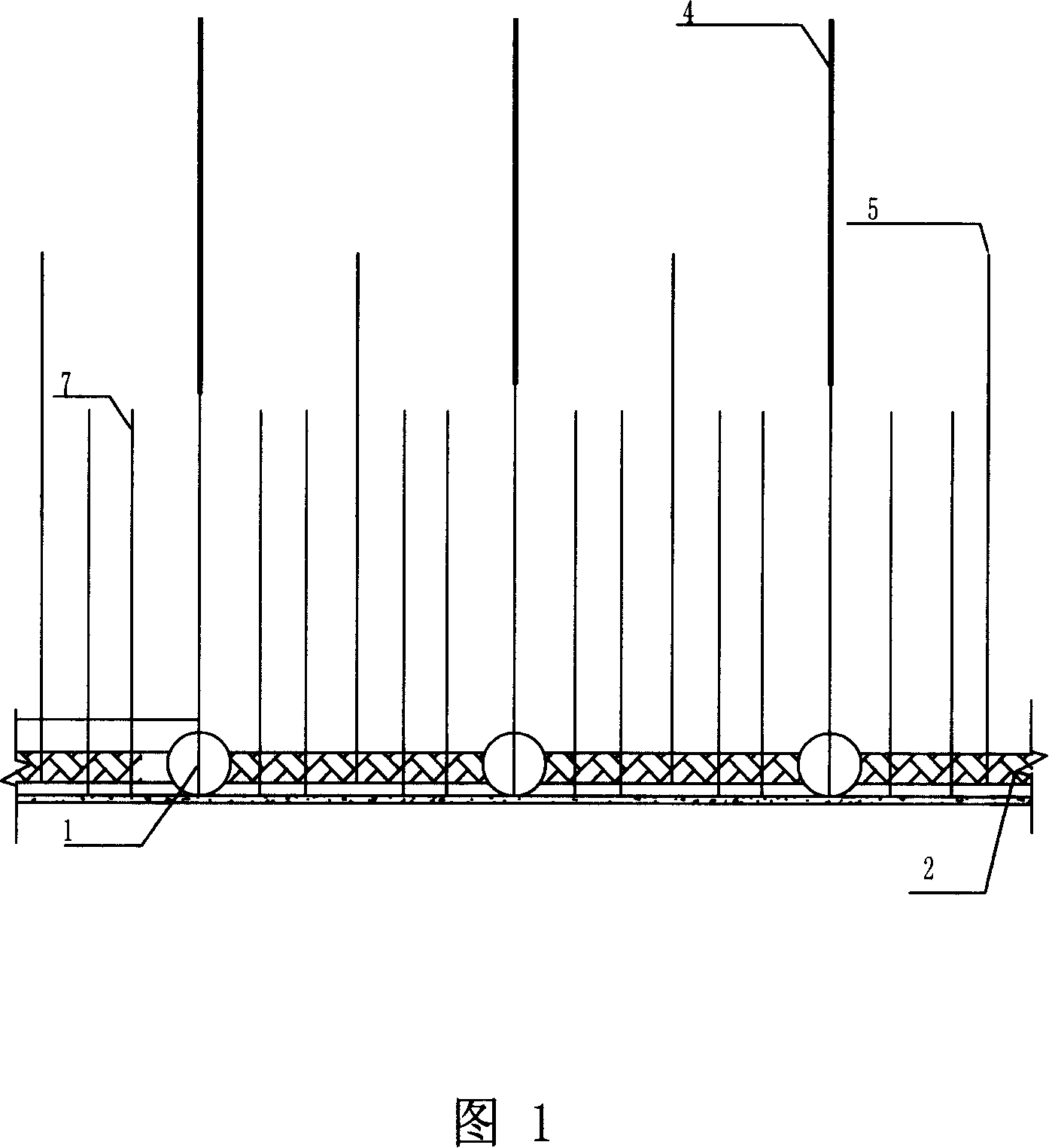

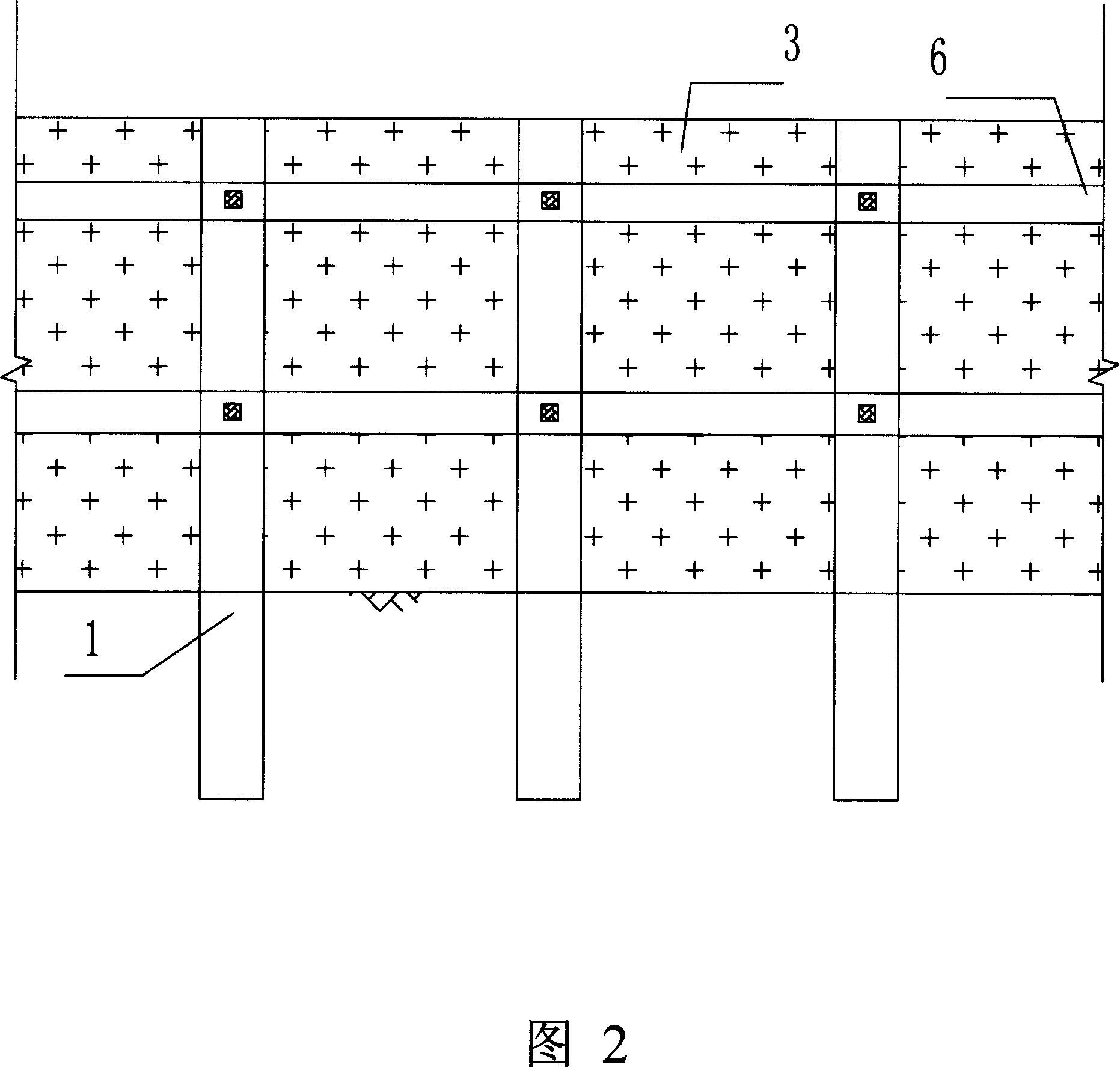

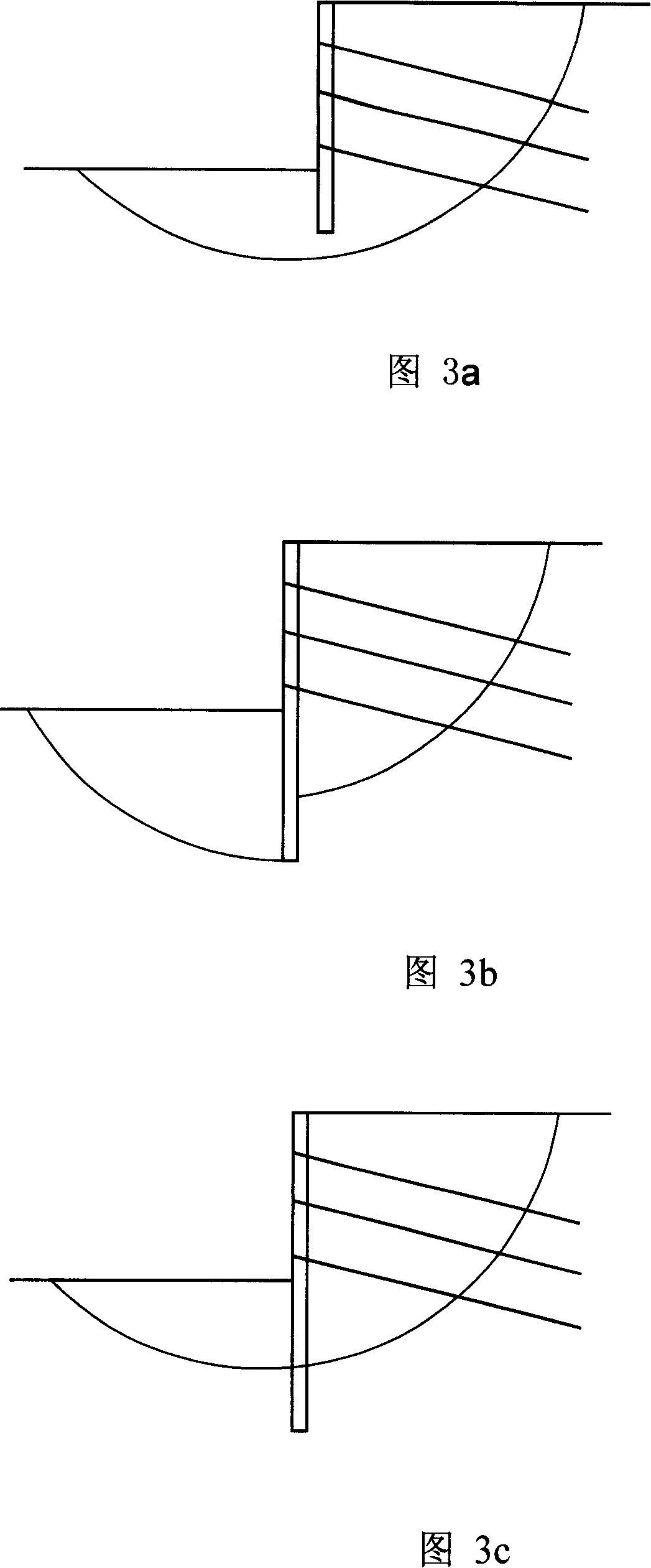

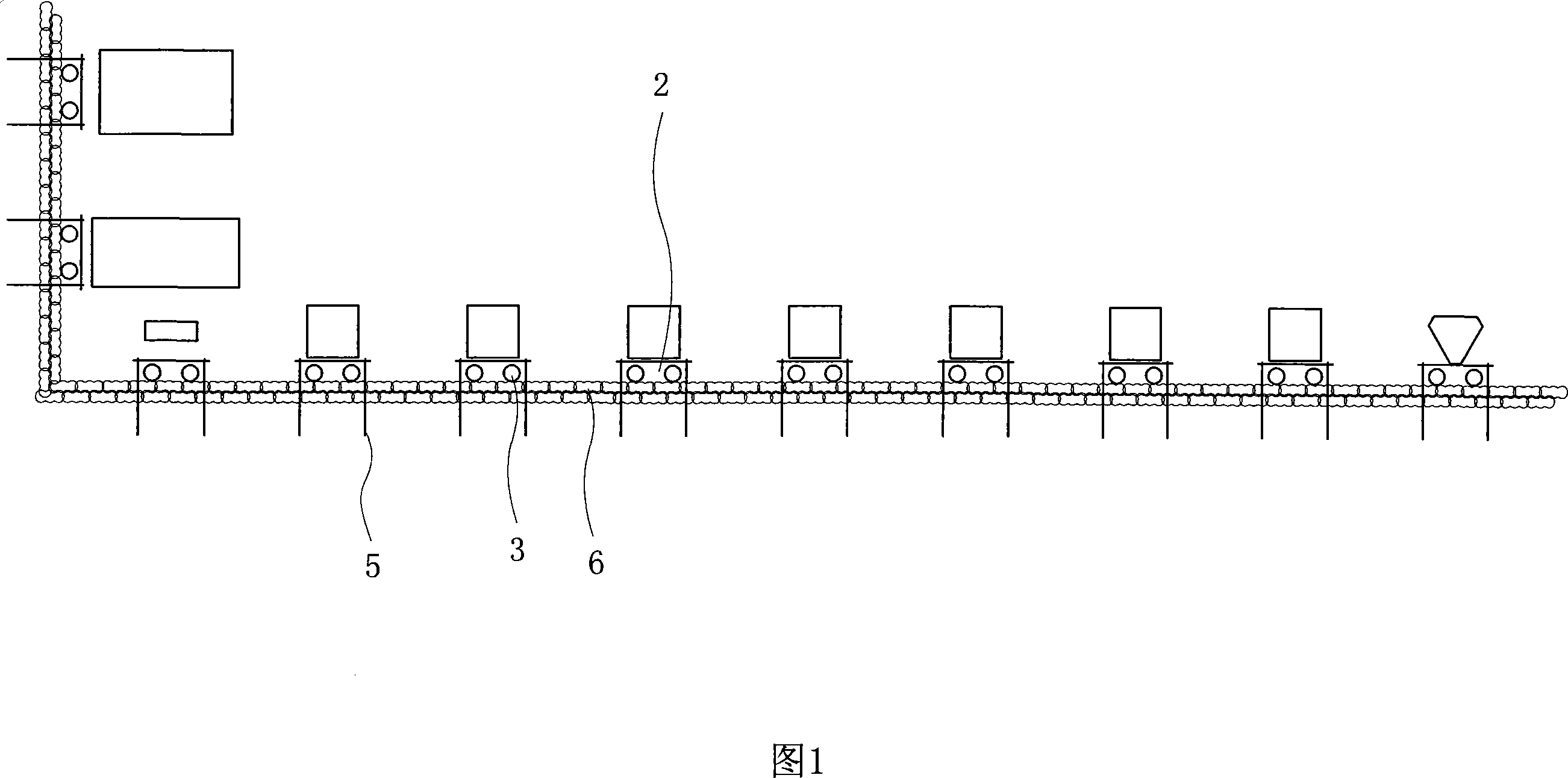

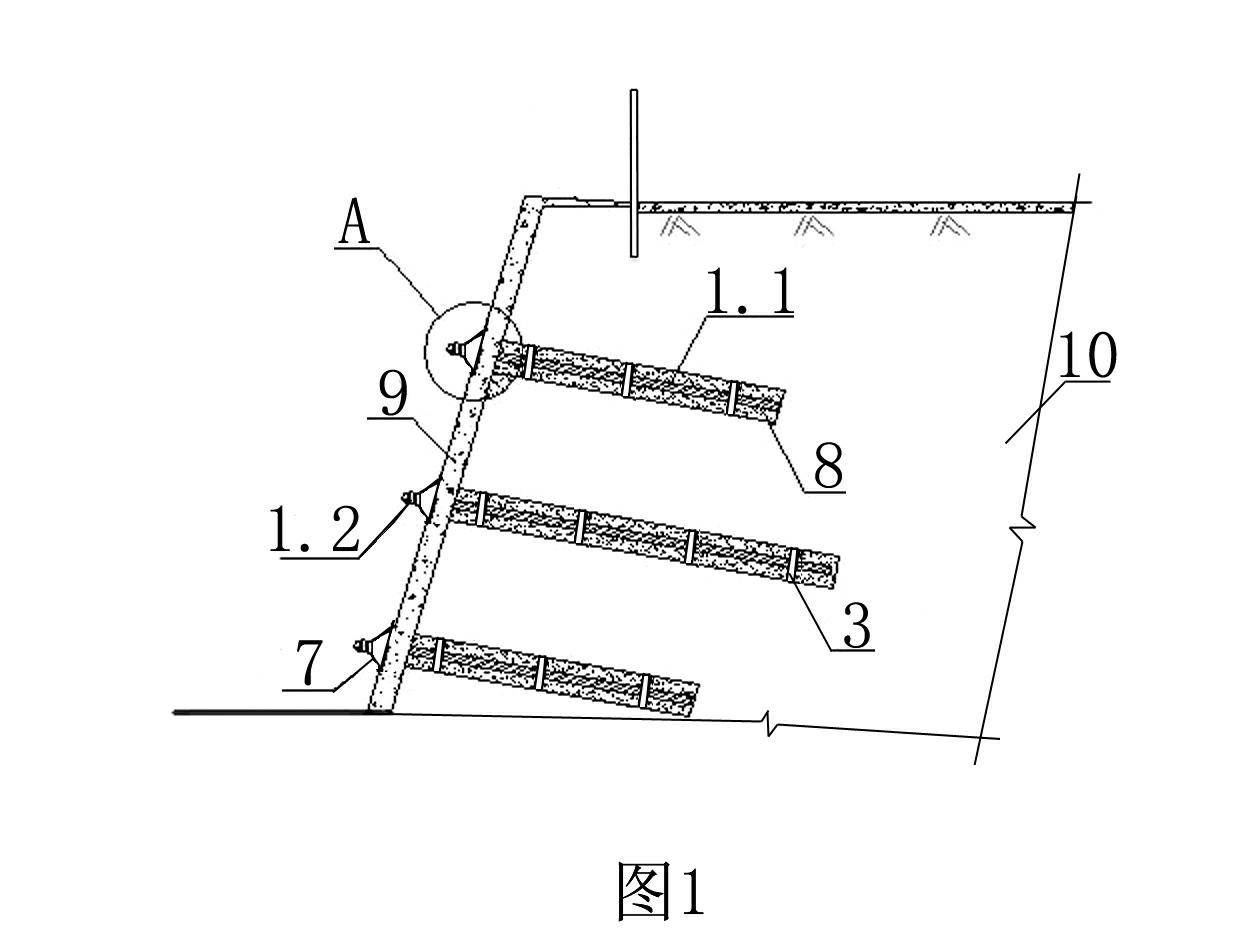

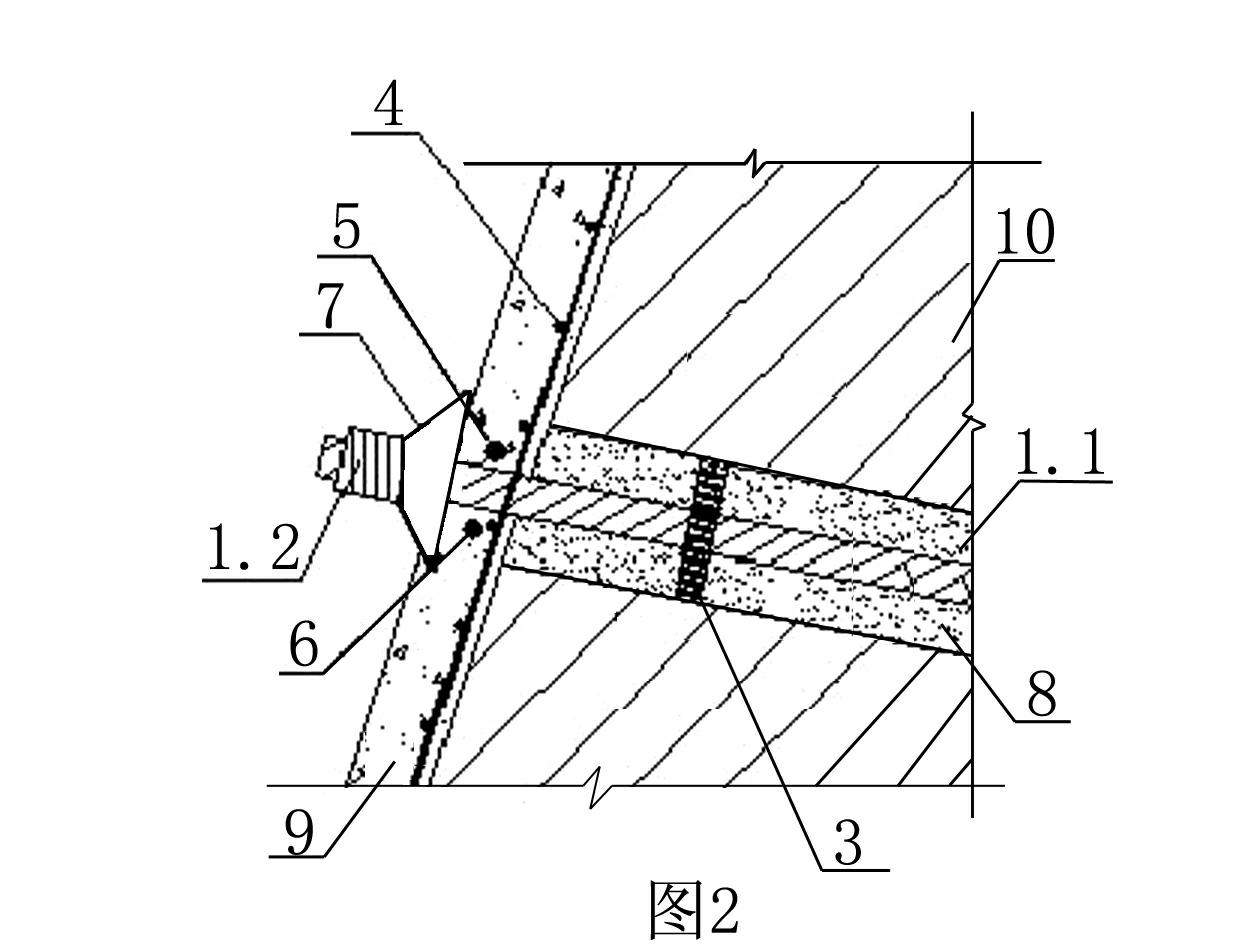

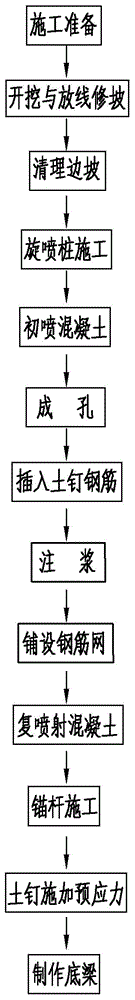

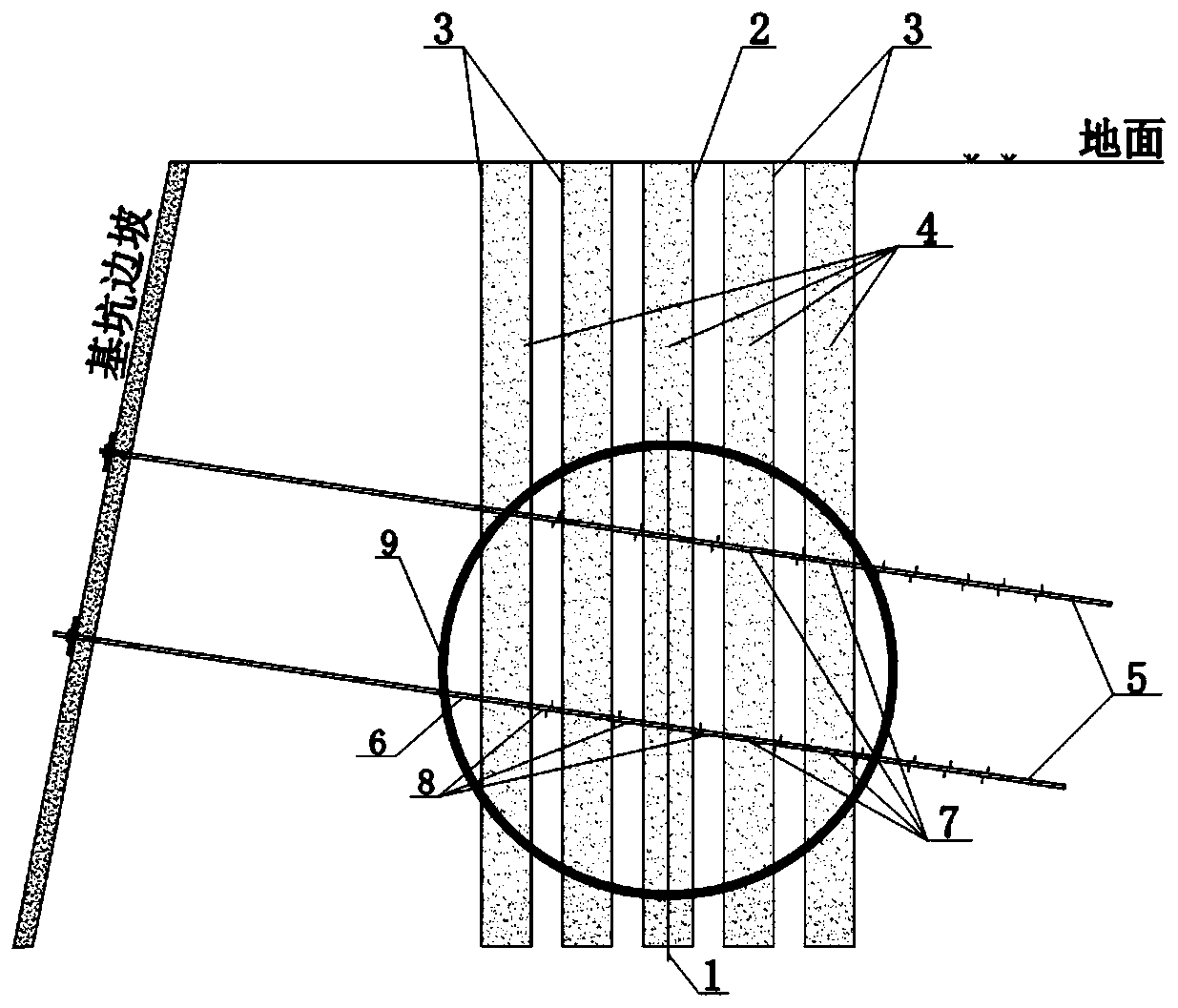

Construction method of jet-grouting pile and composite soil-nailed wall support for deep foundation pit construction

ActiveCN104831734AReduce the impactSimple and easy to makeExcavationsBulkheads/pilesSoil nailingShotcrete

The invention discloses a construction method of jet-grouting pile and composite soil-nailed wall support for deep foundation pit construction. The construction method comprises the following steps of (1) preparing for construction; (2) excavating, paying off, and finishing slopes; (3) cleaning side slopes; (4) constructing a jet-grouting pile; (5) spraying concrete for the first time; (6) forming holes; (7) inserting soil nail steel bars; (8) grouting; (9) laying steel bar nets; (10) spraying concrete for the second time; (11) constructing anchor rods; (12) applying prestress on soil nails; (13) manufacturing bottom beams. According to the construction method, the jet-grouting pile and a soil-nailed wall are combined for support, so that the bearing capacity is greatly increased, additionally, the self-bearing capacity of a soil body is reasonably utilized, and the soil body is used an integral part of a support structure; the structure has the advantages of light weight, large flexibility, good vibration resistance and malleability, stability, reliability, small displacement of support rear side slopes, strong overload capacity and short total construction time and can be excavated and supported at any time; compared with other deep foundation pit support types, the construction method has the advantages of low cost and high economic benefit.

Owner:ZHENGJIAN CONSTR CO LTD

Narrow site deep foundation pit excavation supporting construction method

The invention relates to a narrow site deep foundation pit excavation supporting construction method, and belongs to the field of building construction. The construction method includes the following contents that the depth of a foundation pit is 12.1 m; the depth of underground water in a the foundation pit is 30 m; the depth of underground water outside the foundation pit is 30 m; and the coefficient for importance of a supporting structure is 1.0. The construction method comprises the steps that (1) a soil nailing and anchor spraying method is adopted for slope supporting of the foundation pit; (2) a support pile and anchor cable method is adopted for non-sloping space supporting of a forwarding station and a gallery; and (3) the support pile and anchor cable method is adopted for foundation pit supporting. According to the narrow site deep foundation pit excavation supporting construction method, it is guaranteed that surface water outside the foundation pit does not flow into the foundation pit, accumulated water inside the foundation pit and on a slope face is drained out of the foundation pit in time, and stagnantblocked water on a shallow layer of the side wall of the foundation pit can be smoothly drained out; and a retention wall is arranged on the periphery of the foundation pit, it is guaranteed that rainwater cannot wash the slope, and it is guaranteed that the accumulated water can be drained out in time.

Owner:CHINA CHEM ENG SECOND CONSTR

Soil nailing wall supporting construction method based on assembly type recoverable process

The invention relates to a soil nailing wall supporting construction method based on the assembly type recoverable process in the field of civil engineering. A supporting structure is composed of recoverable soil nails and assembly type prefabricated panels. A plurality of joints are arranged on the slope face in a multi-straight-line mode. The soil nails are arranged on the joints. Keels are arranged between the adjacent joints. The panels are installed among multiple straight lines. A foundation pit is excavated layer by layer to the pit bottom, and the joints, the soil nails, the keels and the panels are arranged layer by layer to finish construction of assembly type soil nailing supporting; supporting materials are disassembled and recovered; the panels, the keels, the joints and the soil nails are disassembled layer by layer after the foundation pit function is finished, and therefore the supporting materials can be recovered and reutilized. Assembly type construction can be achieved, the supporting materials can be machined in factories, and can be recovered and reutilized, and the purpose of environmental protection is achieved.

Owner:SHANDONG UNIV +1

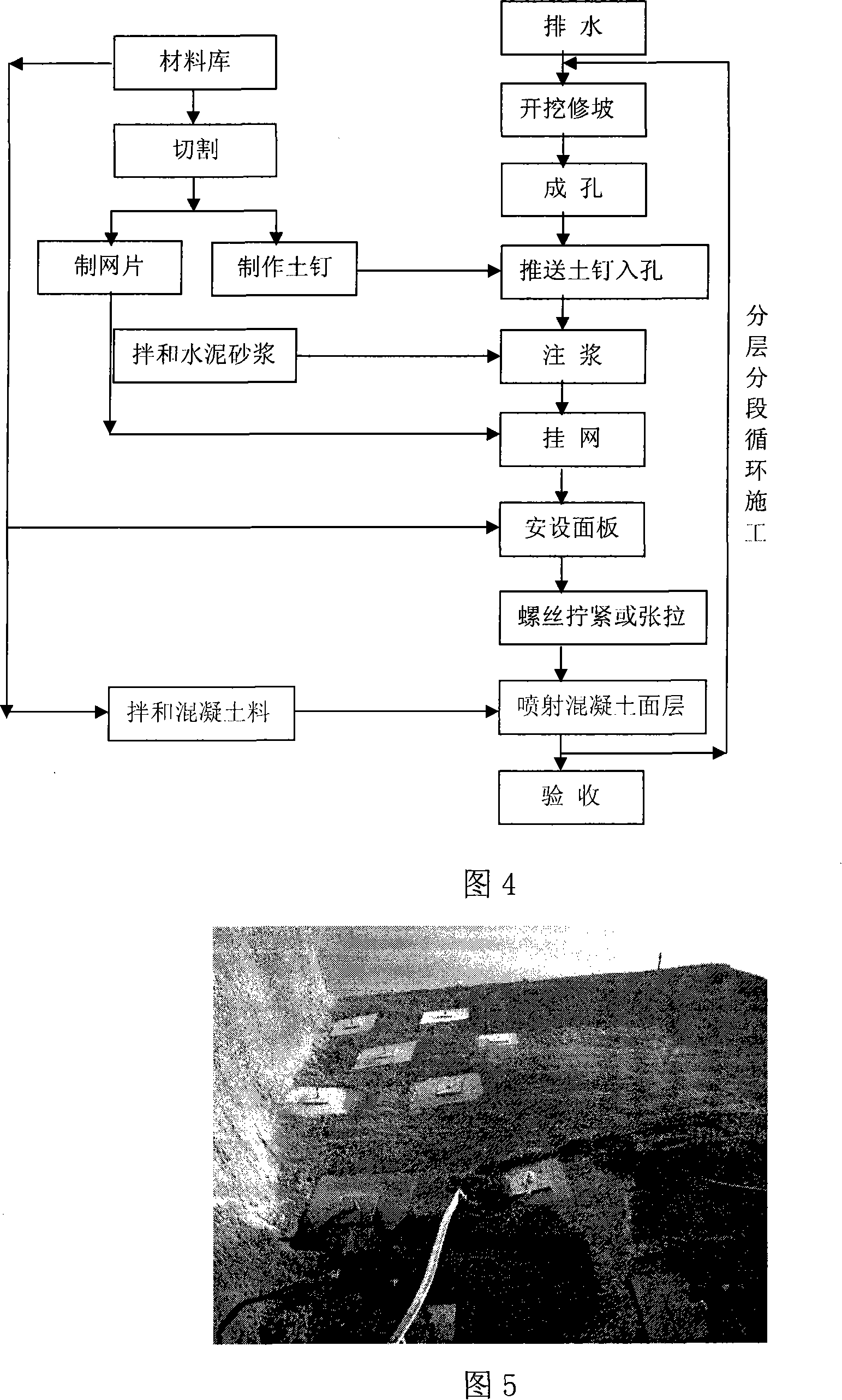

Composite soil nailing wall slope support method

InactiveCN103321235AImprove construction qualityImprove securityExcavationsBulkheads/pilesSoil nailingSlurry

The invention discloses a composite soil nailing wall slope support method. The composite soil nailing wall slope support method comprises the following steps that (1) a drilling position is confirmed; (2) holes are formed, wherein a drill is aligned to the drilling position, a drill rod is driven by a drilling machine and the drill is driven to drill, in the drilling process, a follow-up sleeve sleeved outside the drill rod is gradually pressed inwards along with the drill rod until a design depth requirement is satisfied, and then the drill rod and the drill are backed out; (3) slurry injecting is conducted, wherein a butted molten steel spark pipe is inserted in the drilled hole, and slurry is injected in the molten steel spark pipe through a slurry jacking pump, in the process that the slurry is injected in the molten steel spark pipe, the follow-up sleeve is pulled outwards while slurry injecting is conducted, and the follow-up sleeve is completely backed out of the formed hole until slurry injecting in the molten steel spark pipe is finished. The composite soil nailing wall slope support method is suitable for high slope support of various slopes (particularly suitable for slope support of a backfilling loose ground surface or slope support under a high weathered geological condition), installment is easy to conduct, safety is high, operations are easy to conduct, and the construction cost is low.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

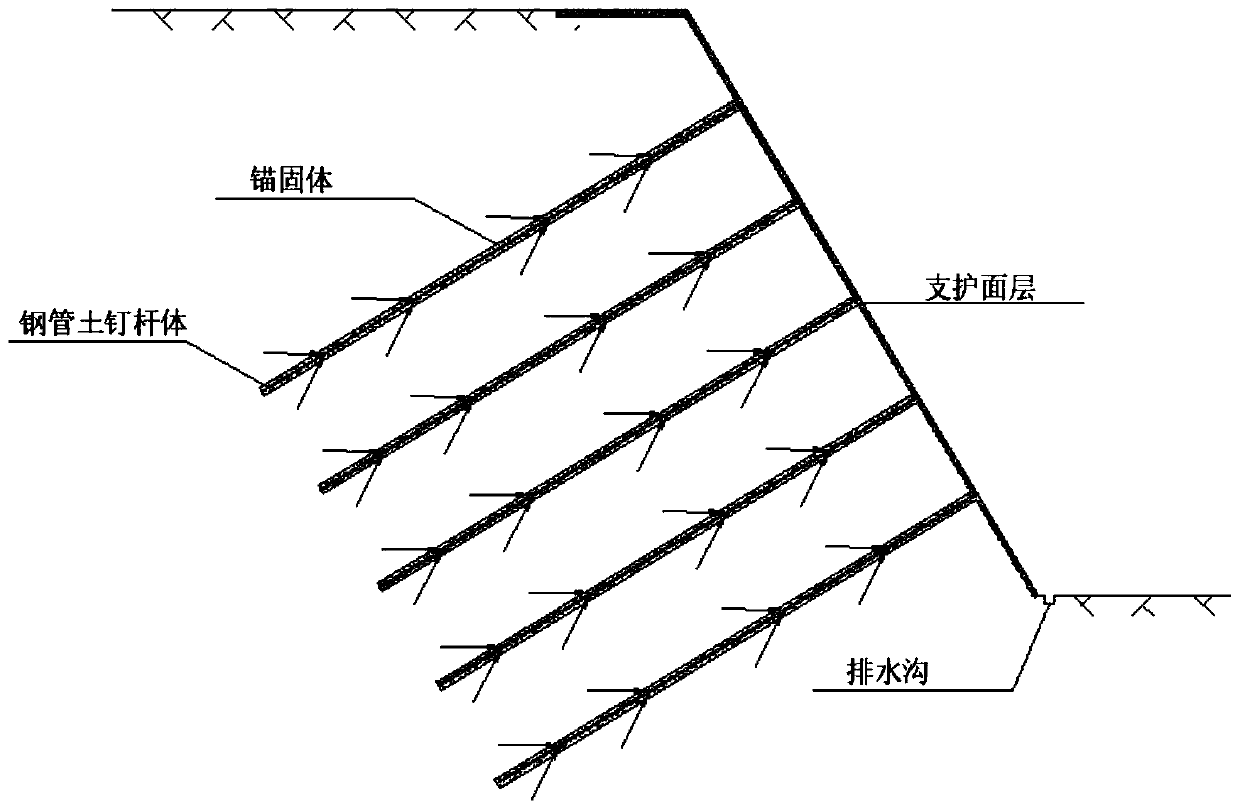

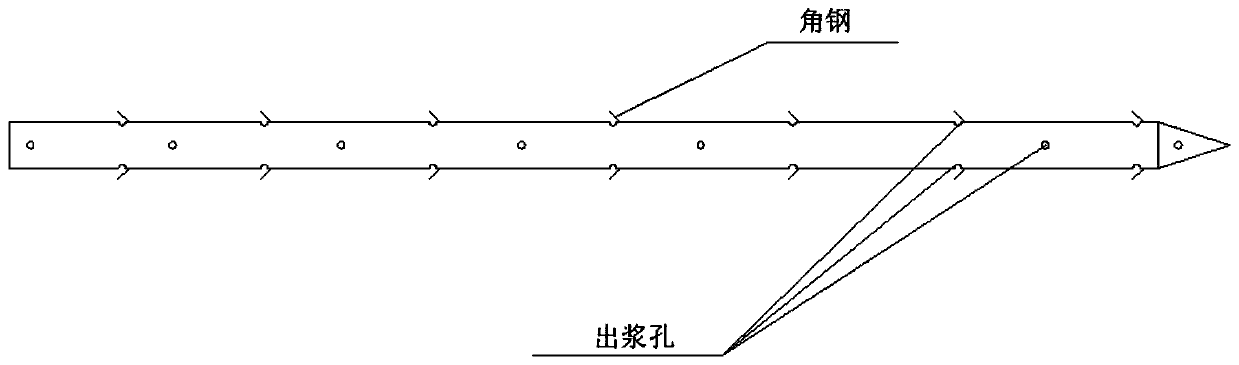

Microorganism curing striking-in type steel pipe soil nail and construction method thereof

InactiveCN110528533AImprove mechanical propertiesImprove integrityExcavationsSoil preservationSoil nailingNutrient solution

The invention discloses a microorganism curing striking-in type steel pipe soil nail and a construction method thereof. The steel pipe soil nail mainly comprises a steel pipe and angle iron. The steelpipe comprises a pipe head and a pipe body. The construction method mainly includes the steps that the steel pipe soil nail is manufactured, and the steel pipe soil nail is struck into mud through apneumatic down-the-hole hammer; sporosarcina pasteurii is activated and subjected to enlarge cultivation, and a microorganism bacterium solution is obtained; the obtained microorganism bacterium solution is injected into the soil nail through the steel pipe soil nail so that the microorganism bacterium solution can be spread in sandy soil; a composite nutrient solution is prepared and includes 0.5mol / L of urea and 0.5 mol / L of calcium salt; the composite nutrient solution is injected into the steel pipe soil nail and a slope face, and an anchoring body is formed; and the above steps are repeated till the strength of the soil nail reaches the design requirement, and the microorganism curing striking-in type steel pipe soil nail is obtained. By means of the microorganism curing striking-intype steel pipe soil nail and the construction method thereof, the sandy soil in the soil nail is cemented through a cementing effect of microorganisms, the mechanical property of a slope soil body isimproved, the integrity and self stability of the slope soil body are improved, and the slope can be more stable.

Owner:GUANGDONG UNIV OF TECH

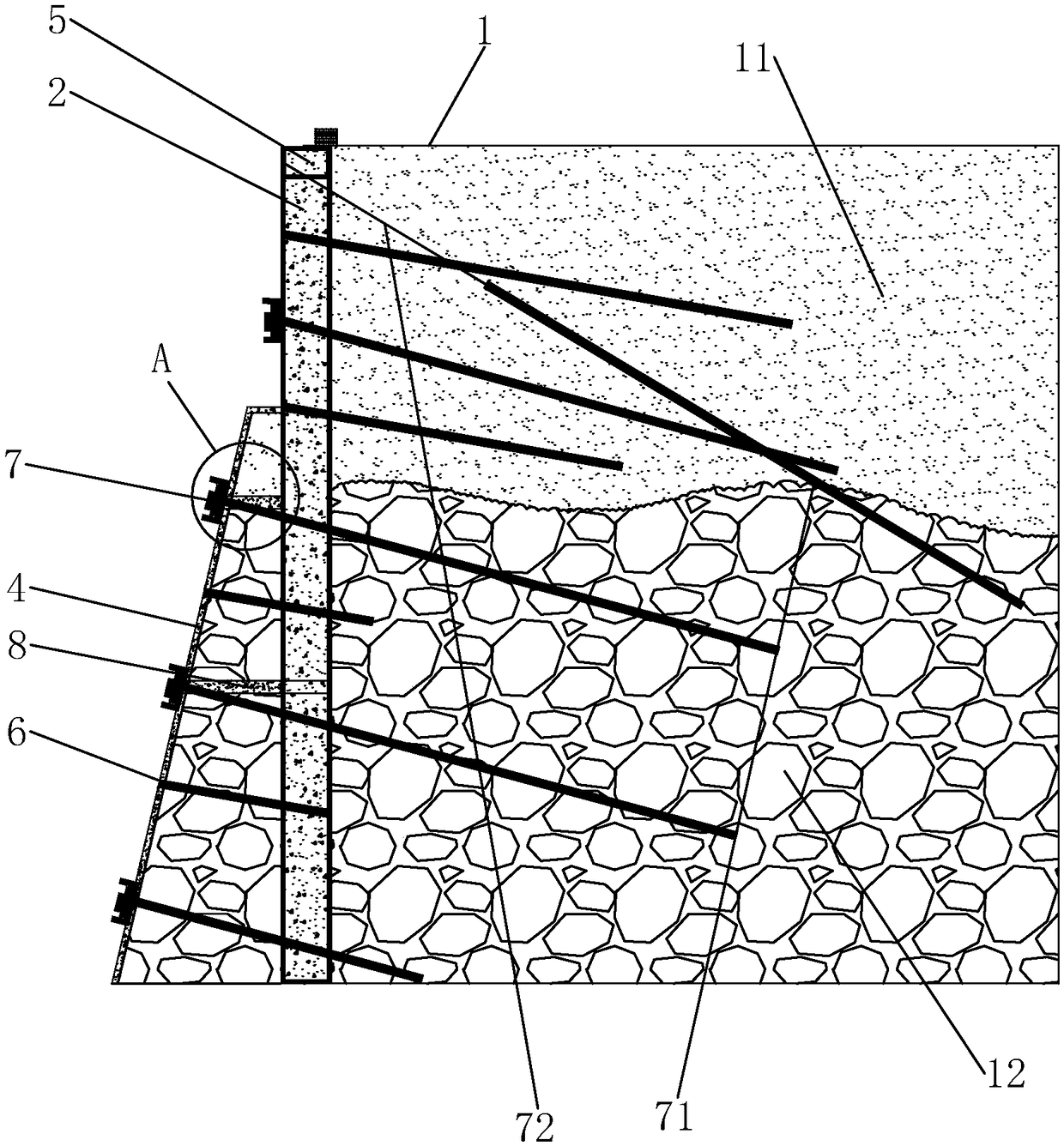

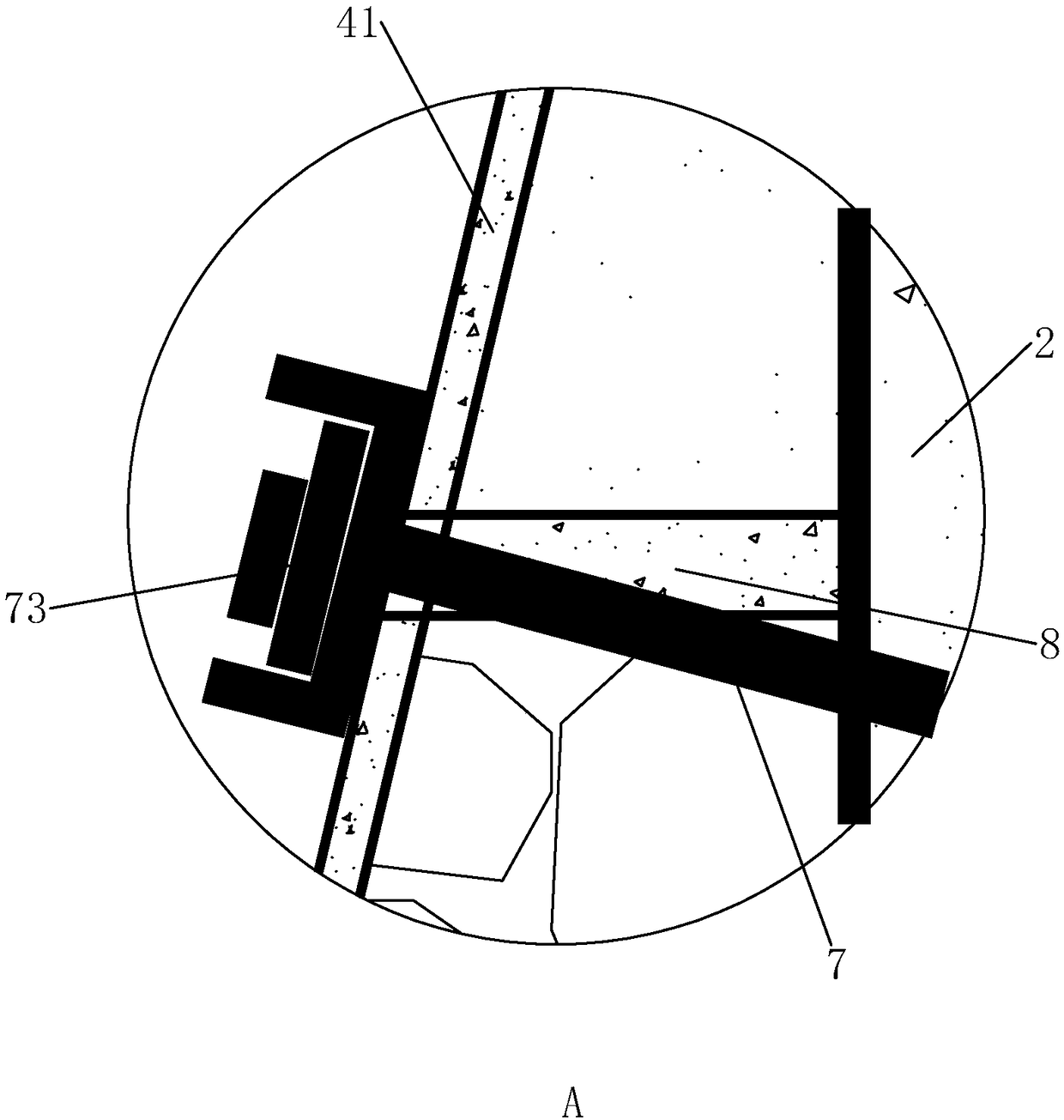

Composite soil nailing wall and pile-anchor support compound support structure and construction method

The invention discloses a composite soil nailing wall and pile-anchor support compound support structure and a construction method. A composite soil nailing wall and a pile-anchor support are used ina combined manner; the composite soil nailing wall fully utilizes the available space in a foundation pit to perform moderate grading, therefore the density of slope protection piles in the pile-anchor support is lowered, and the construction cost is lowered; and meanwhile, a proper number of steel pipes are inserted among the slope protection piles to assist the slope protection piles, and foundation pit supporting is performed according to an advanced supporting concept. Meanwhile, for deep backfill which is loose and soft in soil texture, to achieve the effect that the pile-anchor support and the composite soil nailing wall can both give play to the actual supporting effect, one ends of pre-stressed anchor rods close to the upper portion of the foundation pit are locked into a top beam,and the other ends are inserted into a pebble bed under the backfill stratum in a large-angle inclined inserting manner to form a reliable tension effect. The steel pipes are additionally arranged between the ends of the pre-stressed anchor rods of the grading segment and the slope protection piles, so that the tension force of the pre-stressed anchor rods is transferred to the slope protection piles without damaging a grading boss.

Owner:北京爱地地质工程技术有限公司

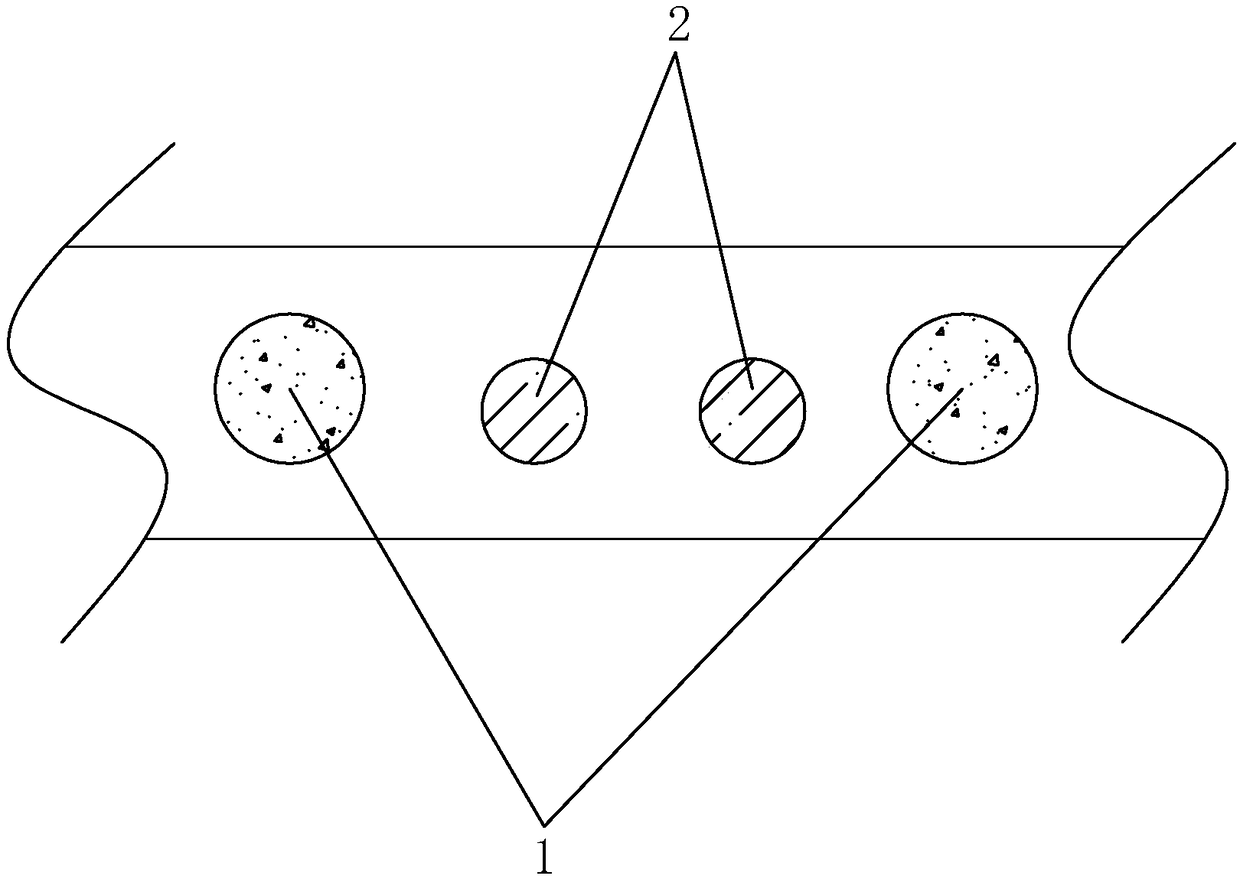

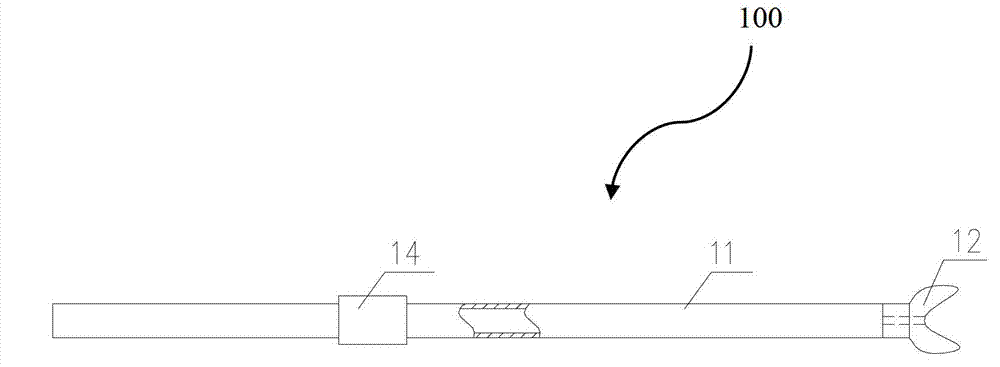

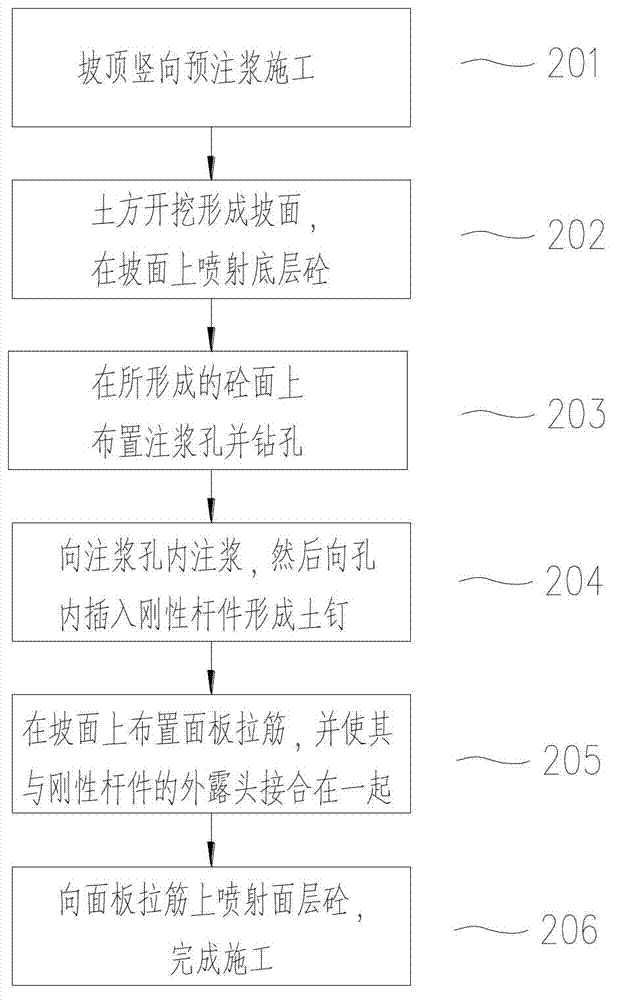

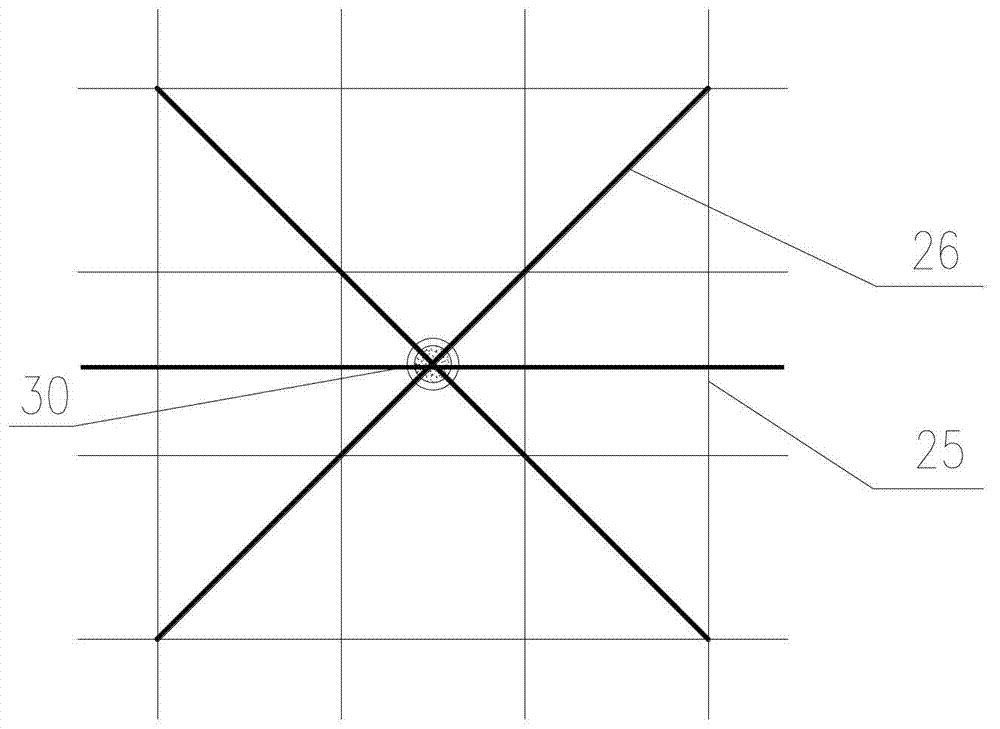

Combined soil nailing construction method

ActiveCN102877470AControl Diffusion RadiusAvoid churnExcavationsBulkheads/pilesSoil nailingSurface layer

The invention relates to a combined soil nailing construction method, which belongs to the field of geotechnical engineering, and includes the steps as follows: step 1, preliminary grouting is vertically performed at the top of a slope; step 2, earth is excavated to form a sloping surface, and bottom layer concrete is sprayed on the sloping surface; step 3, injected holes are distributed in a concrete surface formed in the step 2 and holes are drilled, wherein drill stems of drilling tools are steel pipes, and the steel pipes are left in the holes to serve as grouting pipes after the holes are formed; step 4, the grouting pipes are grouted, then rigid rod pieces are inserted in the pipes to form combined soil nails; step 5, panel tie pieces are placed on the sloping surface, and are enabled to be jointed with exposed heads of the rigid rod pieces in the step 4; and step 6, surface layer concrete is sprayed on the panel tie pieces, and the construction is completed. The method provided by the invention solves the supporting problem of soil layers with poor soil strength, and has the advantages of low construction cost and short construction period.

Owner:HUNAN HENGDUN GEOTECHN GROUTING TECH +2

Sleeve-valve-pipe grouting and draining soil-nailing retaining device and construction method thereof

The invention discloses a sleeve-valve-pipe grouting and draining soil-nailing retaining device which is characterized by comprising a steel sleeve valve pipe, a grouting pipe, cement soil, coils and epoxy resin; one end of the steel sleeve valve pipe is opened, the other end of the steel sleeve valve pipe is closed, drain holes and grouting holes are distributed in the surface of the steel sleeve valve pipe on which the coils are wound, and the coils are connected with conducting lines and a high-frequency alternating-current power supply; each of the inner and outer sides of the steel sleeve valve pipe is coated with an epoxy resin protective layer by which the coils are covered; a slope surface is provided with a steel bar wire mesh, and cement slurry is sprayed on the slope surface, so that a cement soil surface layer is formed, and the cement soil covers the steel bar wire mesh; and the steel sleeve valve pipe is grouted at high pressure to form a grouting body. By using the steel sleeve valve pipe with the coils, an electromagnetic field and electromagnetic heating can act in a soil body around an anchor rod, so that the viscosity of water in the soil body is reduced and the draining efficiency is increased under the combined action of the electromagnetic field and a temperature field.

Owner:CHONGQING UNIV

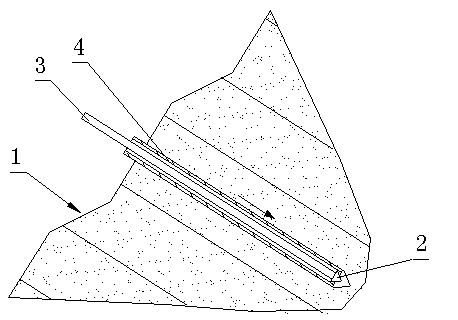

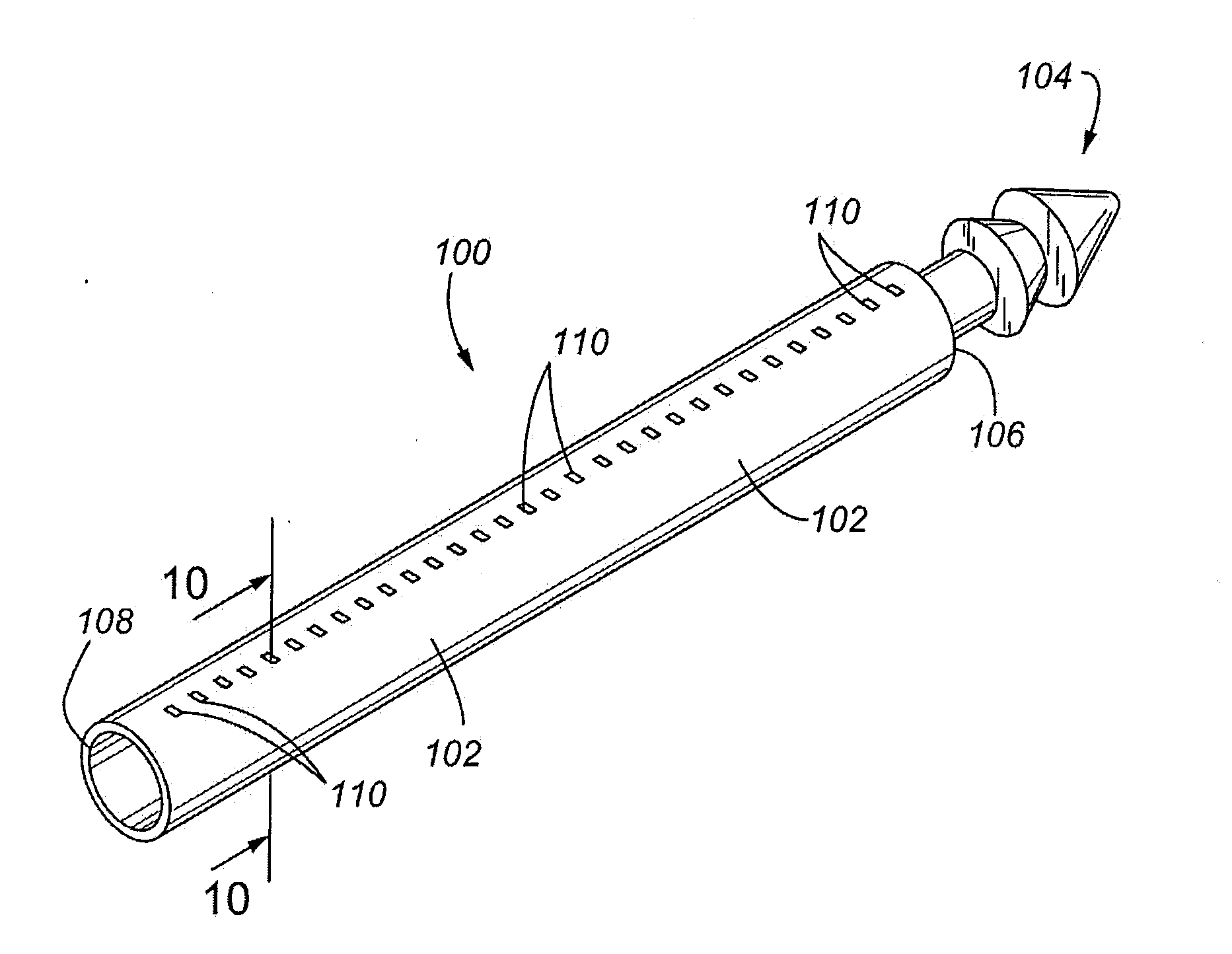

Composite self-drilling soil nail and method

ActiveUS20100166506A1Improve corrosion resistanceImprove abilitiesBulkheads/pilesAnchoring boltsComposite constructionGlass fiber

A subsurface support is provided comprising a soil nail having an outer member and an inner member placed within the outer member. The soil nail includes features that maintain a uniform spaced relationship between the inner and outer members. The soil nail may be installed by drilling or launching through a launching device. The spaced relationship between the inner and outer members may be achieved by crimping the outer member, or by use of an insert installed between the inner and outer members. In other embodiments, the support is made of composite construction materials, and having a self-drilling capability. The soil nail has two primary members, namely, an outer threaded member, and an inner threaded member that is placed through the outer member The outer member is made from fiberglass, and a metallic drill bit is secured to a distal end of the soil nail. The inner member is preferably steel. The dual piece construction provides superior tensile and compressive strength, particularly for applications in which a coupler is used to join outer members to extend a length of the soil nail. A method is also provided to improve pull-out capacity by galvanizing the inner and outer members

Owner:SOIL-NAIL HLDG LLC

Construction method for water-rich sand layer shield to pass through steel tube soil nail area

ActiveCN110630271ASignificantly superior effectReduce wearUnderground chambersTunnel liningSoil nailingShield tunneling

The invention discloses a construction method for a water-rich sand layer shield to pass through a steel tube soil nail area. According to the method, a steel tube soil nail is cut and twisted off with the adoption of a high-power rotary digging drilling-jumping hole, the cutting-off sole pressing steel tube is directly pressed into a space below 500 mm of the bottom of a tunnel, the length of theretained steel tube left in the tunnel is not greater than 500 mm, the discharge requirement of the shield is met, the drilling engineering quantity of a transverse barrier clearing hole is reduced to the greatest extent, a drilling hole is backfilled by mortar, excavation parameters of the shield are controlled, and the shield excavates through the steel tube soil nail area; and the method is easy to operate, abrasion of a cutter head and a cutting tool due to the fact that the shield directly passes through the steel tube area is reduced, and the situation that major accidents of surface collapse, building damage and the like happen due to the fact that direct excavation of the shield results in winding of the steel tube soil nail on the cutter head of the shield and causes disturbanceof a soil body is avoided. The problem that a shield tunneling machine is difficulty in construction and high in construction cost when passing through a barrier area.

Owner:POWERCHINA RAILWAY CONSTR

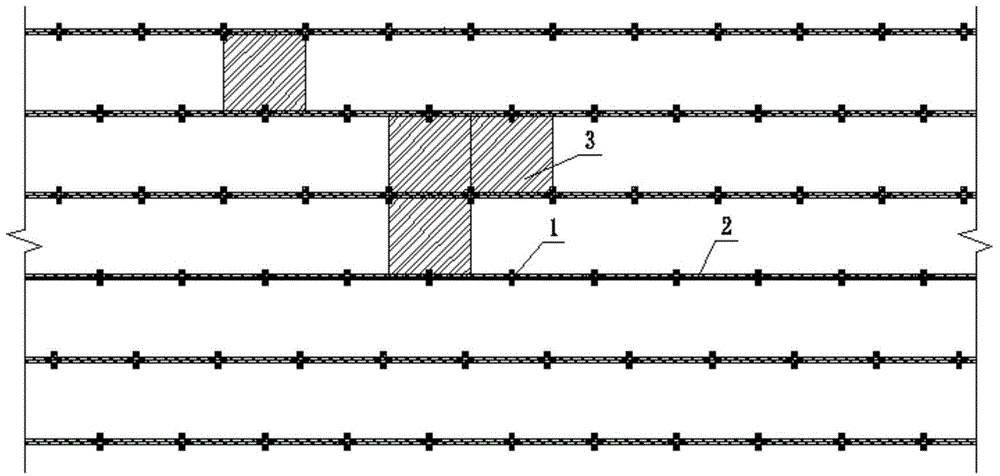

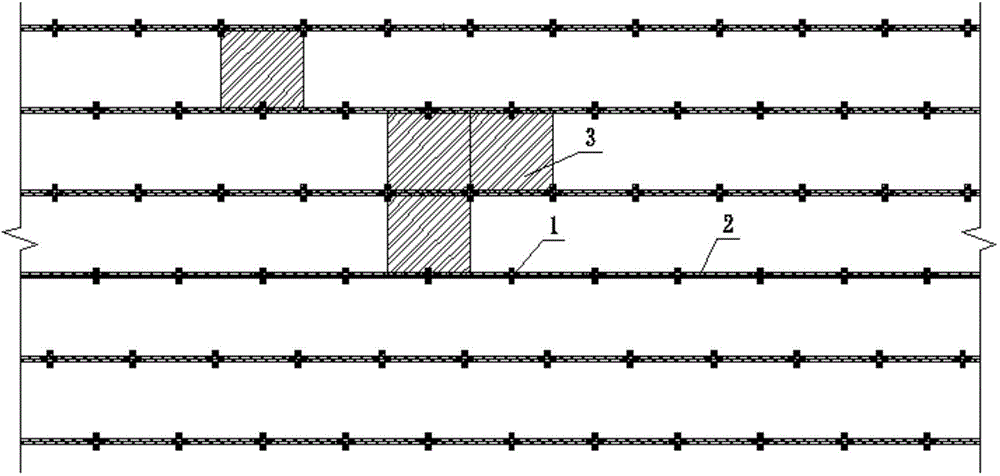

Soil nailing wall supporting system based on assembly type recoverable process

InactiveCN104947662AAchieve recyclabilityGood repeatabilityExcavationsBulkheads/pilesSoil nailingSupporting system

The invention relates to a soil nailing wall supporting system based on the assembly type recoverable process in the field of civil engineering. The system comprises a plurality of soil nails, a plurality of joints, a plurality of keels and a plurality of panels. The joints are laid on the slope face as a horizontal straight line and spaced by a set distance. The joints cover the slope face one layer by one layer. One ends of the soil nails penetrate through holes of the joints and are inserted into the slope face. Every two adjacent joints in the same layer are connected through the keels. The panels are fixed between the two adjacent layers. The supporting system is high in structural stability, and all the supporting structural members can be machined in factories, and can be assembled for construction; supporting materials can be recovered and reutilized, and in this way, resources can be saved; the construction cost is saved, and in addition, the supporting materials will not be left underground.

Owner:SHANDONG UNIV +1

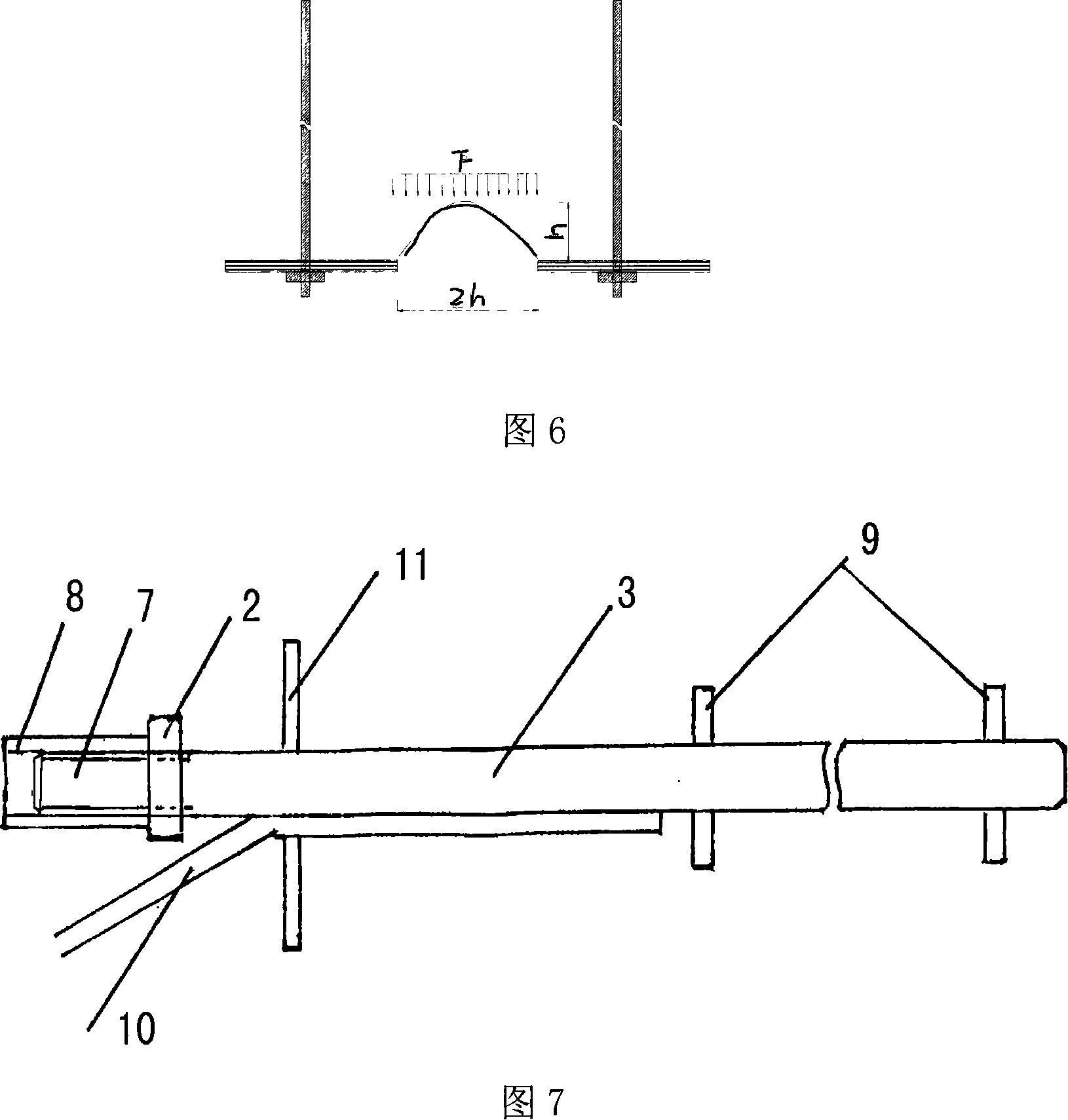

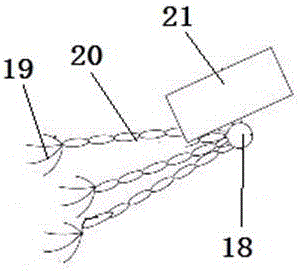

Rock slope combined type protective structure and method

InactiveCN104294829ALow costSolve problems such as crackingExcavationsReceptacle cultivationSoil nailingSoil science

The invention discloses a rock slope combined type protective structure and method. The protective structure comprises prefabricated grooves and multiple soil nailing unit rows. Each soil nailing unit row is composed of soil nailing units which are driven into a slope and arranged in a staggered mode high and low. Each soil nailing unit is composed of a horizontal soil nail and a vertical soil nail which are perpendicular to each other. One end of each horizontal soil nail is fixed to the corresponding vertical soil nail, each horizontal soil nail is driven into the slope in the horizontal direction, each vertical soil nail is driven into the slope in the vertical direction, and the top end of each vertical soil nail is higher than the horizontal line where the corresponding horizontal soil nail is located. The angle between a plane formed by the horizontal soil nails of the adjacent soil nailing units in each soil nailing unit row and the horizontal plane ranges from 4 degrees to 7 degrees and the prefabricated grooves are formed in the horizontal soil nails of the adjacent soil nailing units in the soil nailing unit rows. According to the structure and method, construction is convenient and rapid, the engineering manufacturing cost can be remarkably reduced, and the structure and method are suitable for protection of the rock slope generated in the manual digging process in traffic civil engineering.

Owner:CHONGQING COMM CONSTR GRP

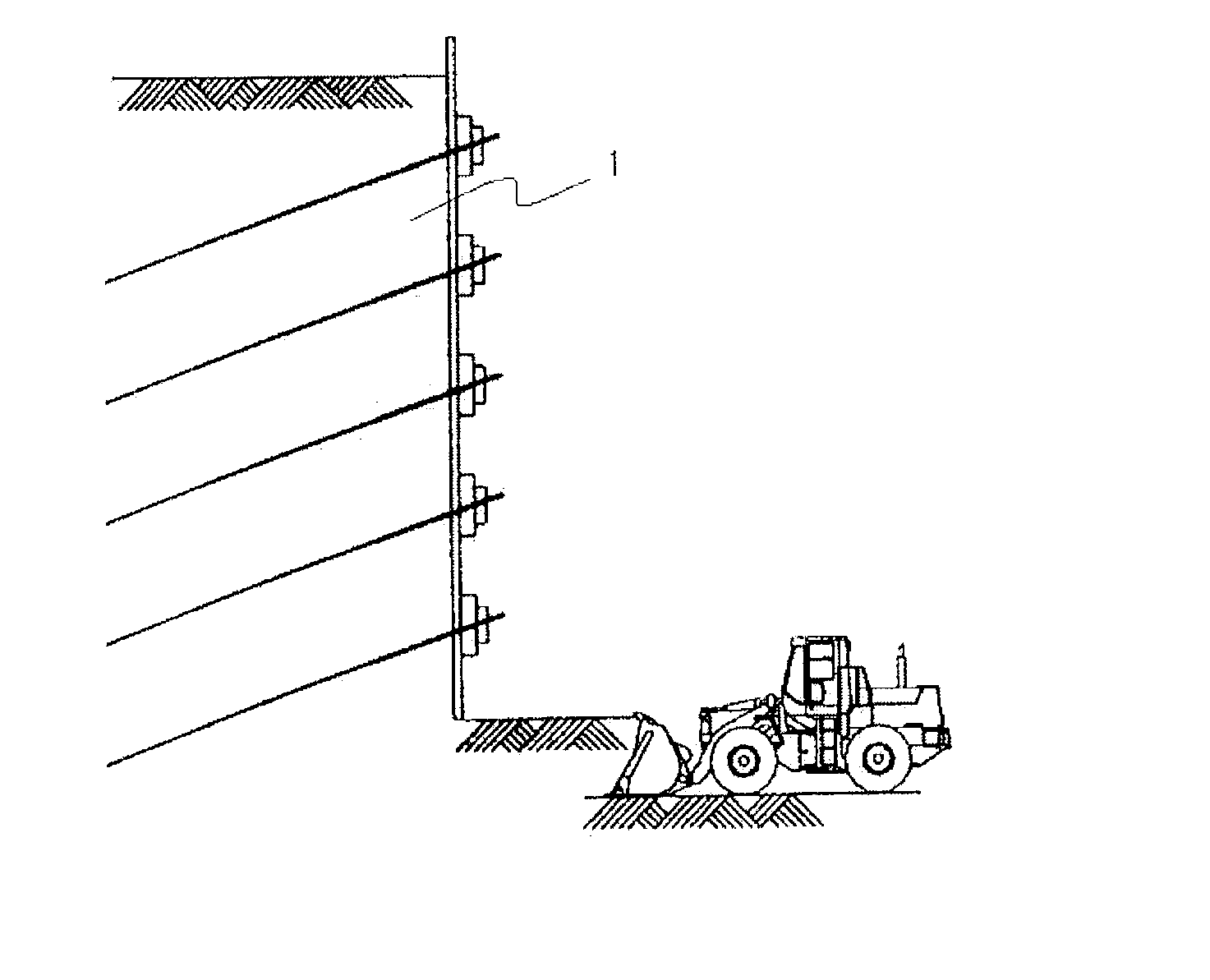

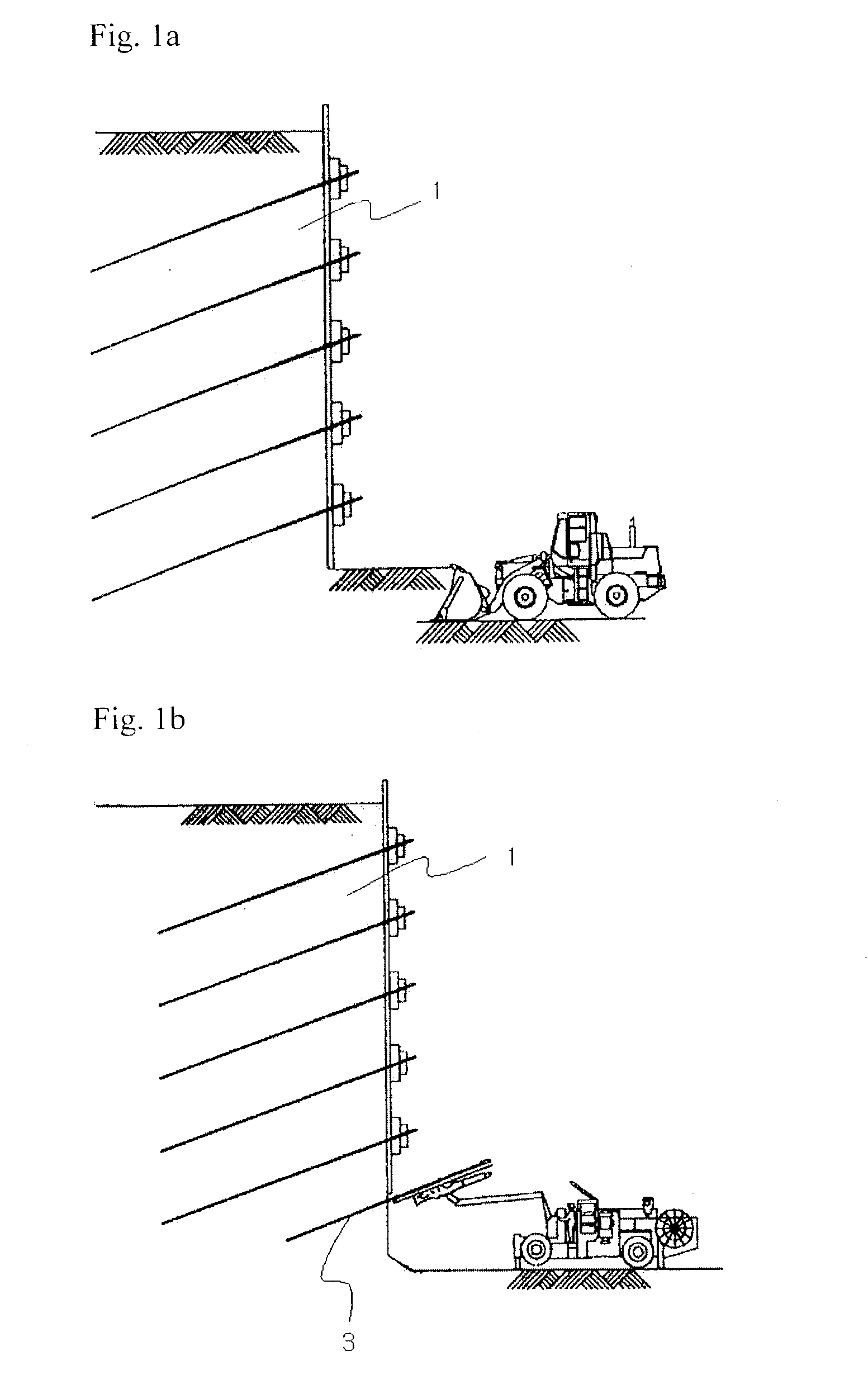

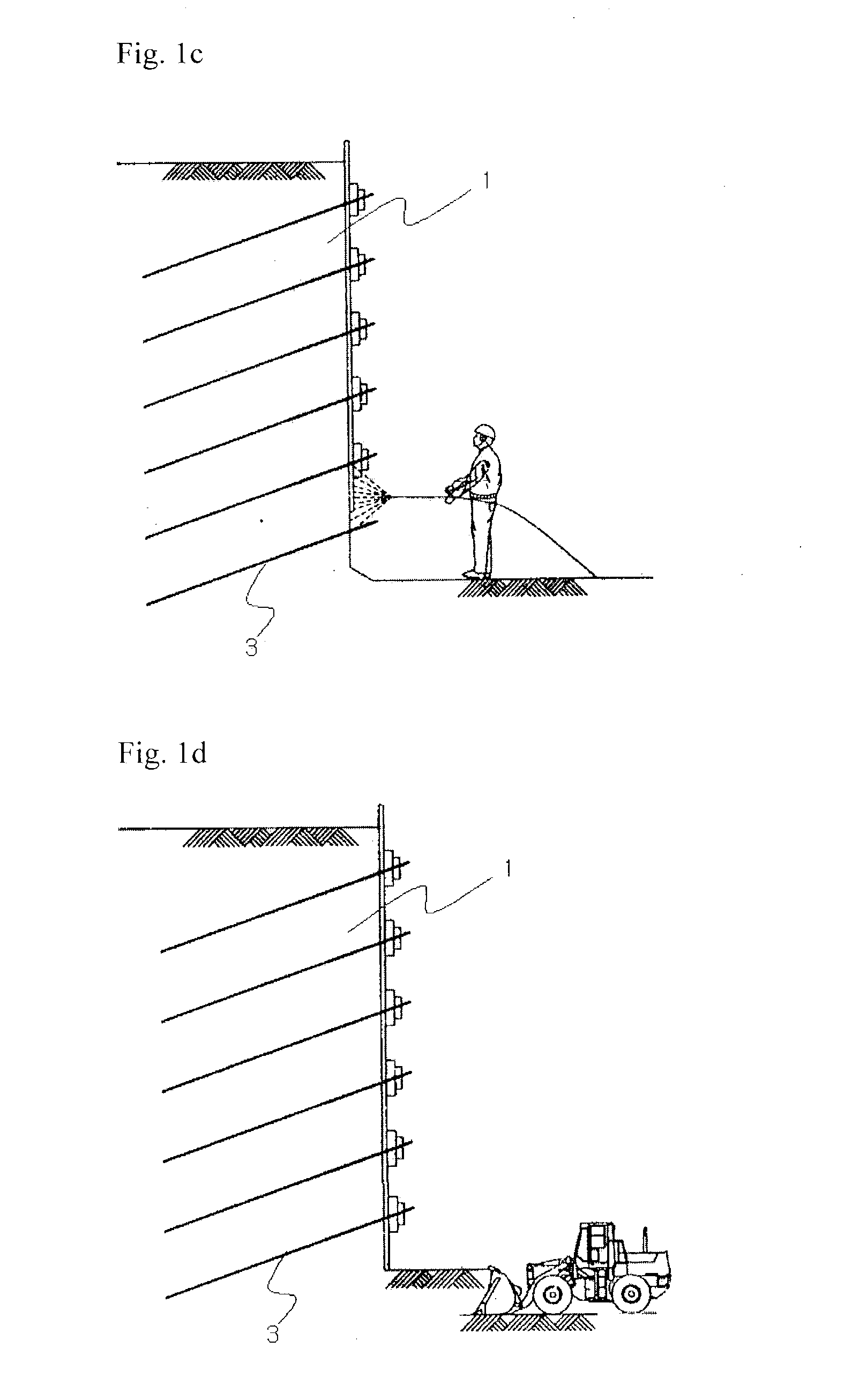

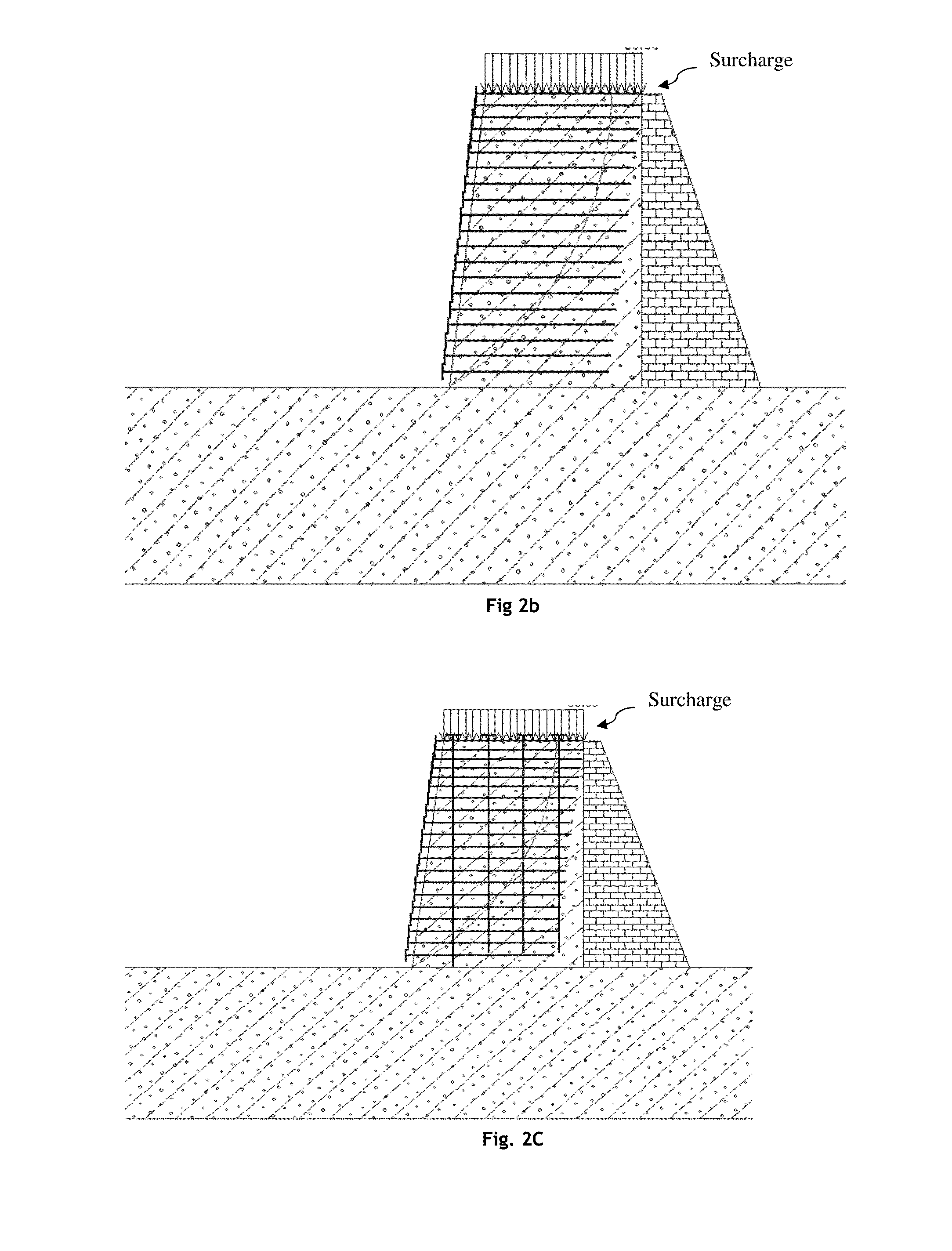

Stepwise repeated destabilization and stabilization of highly collapsible soil mass by 'soil nailing technique' used for construction of railway/road underpass

ActiveUS20150197895A1Prevention of sudden collapseInexpensively and safely constructionRoadwaysProtective foundationSoil nailingInstability

The excavations of side vertical walls for building and underpasses must be shored so that the excavations adjacent to the neighboring properties do not cave in during the constructions. A Soil Nailing system has been used for stabilization of excavations and natural slopes for the last few decades in India and Abroad. Soil Nailing Technique used steel anchor rods inserted directly into the soil mass as a driven nails and when Nails are placed in pre-drilled holes to form grouted nails. In both the cases, it restrained load and the side deformations. In the present study, an innovative technique of ‘Soil Nailing’ has been developed for stepwise vertical de-stabilization and stabilization of compacted collapsible sandy soil for the construction of railway underpasses in live railway loading conditions. This technique is successfully implemented first time in the world for controlled destabilization of vertical cut slope and again stabilization for creating a space for pushing of box for railway underpasses for the length of 22 m and 50 m at two sites, namely Yamuna Bazzar and Apsara border, respectively, in Delhi, India. This Soil Nailing Technique of controlled destabilization of soil and again stabilization in steps has proved a superficial method of stabilization with the other methods for such kind of dynamic loading situations.

Owner:COUNCIL OF SCI & IND RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com