Packing apparatus for pressure type soil-nailing and soil-nailing construction method using the packing apparatus

a technology of packing apparatus and construction method, which is applied in the direction of soil preservation, bulkheads/piles, excavations, etc., can solve the problems of unavoidable development of steep slope districts, depreciation of construction efficiency, and longer construction period, so as to shorten construction term and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

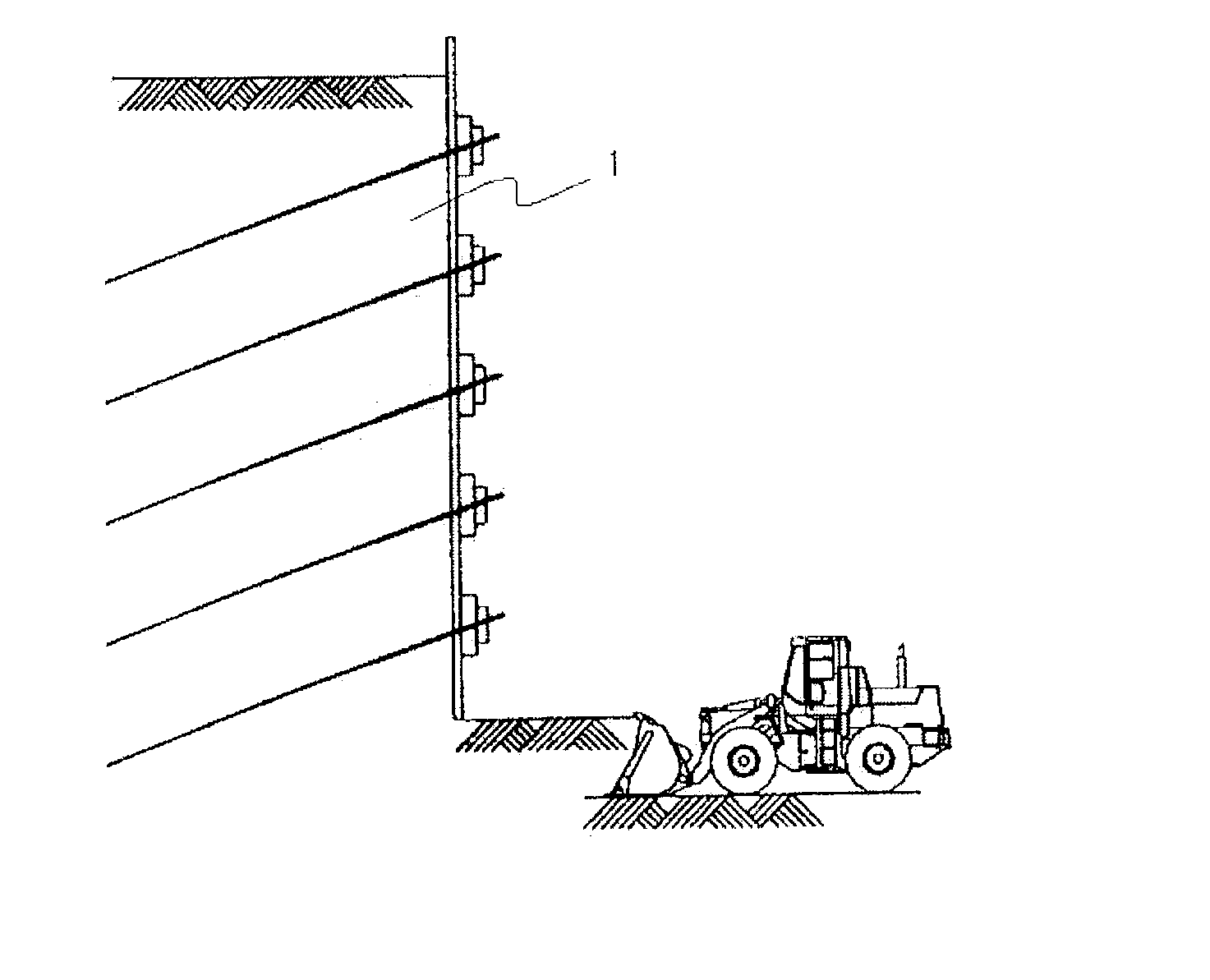

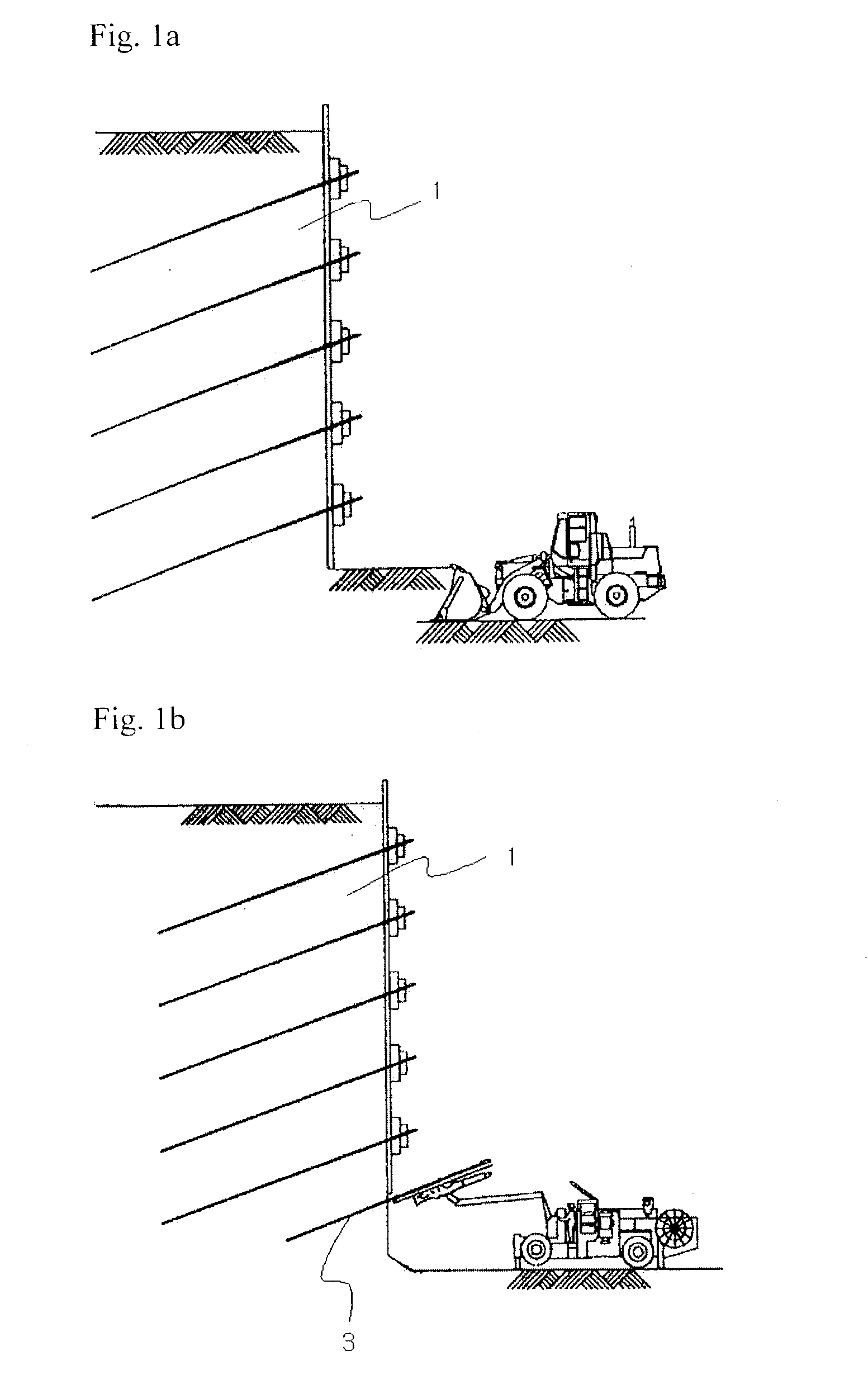

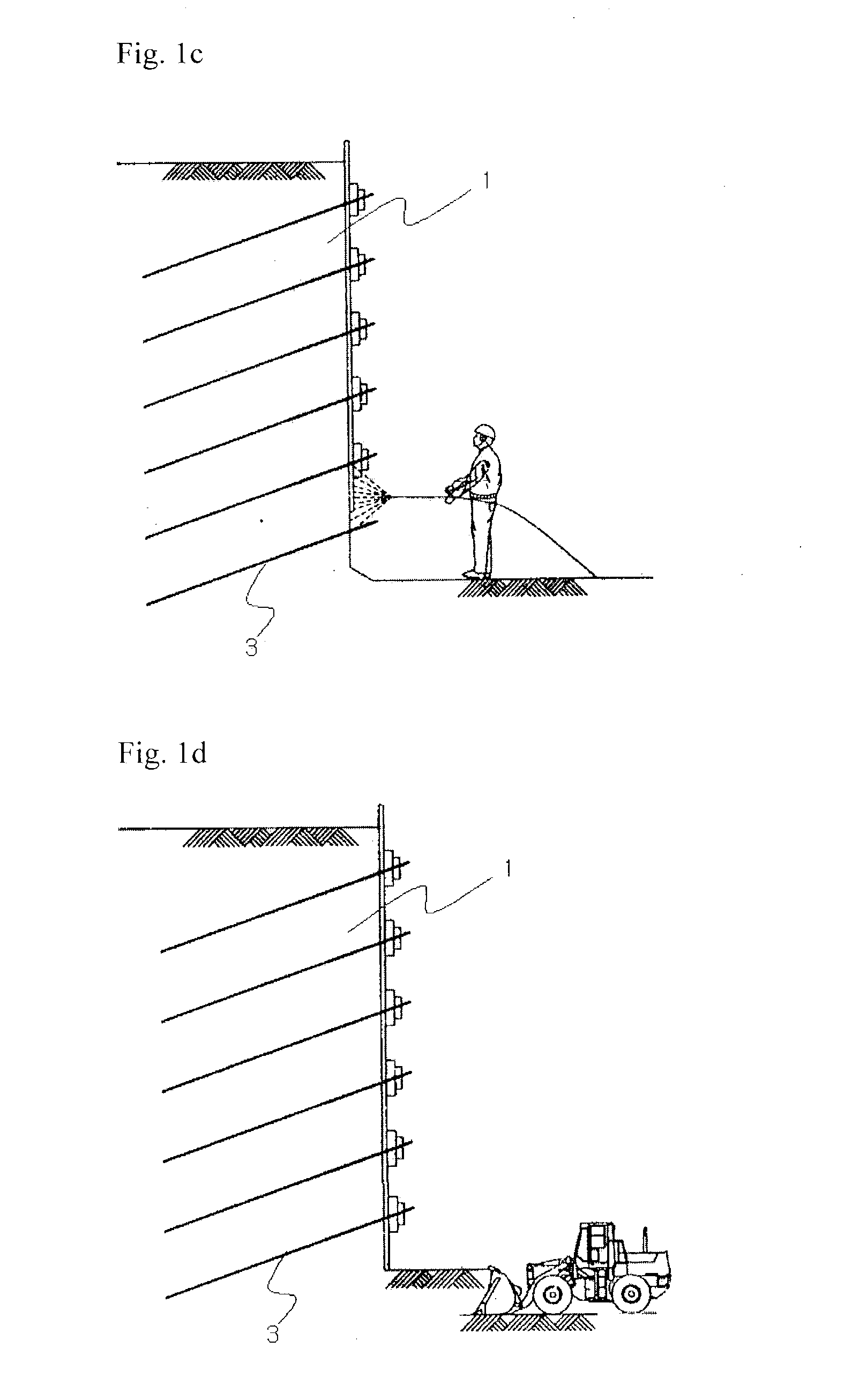

[0039] Below, the packing apparatus for pressure type soil-nailing of the present invention as described above will be explained in detail with reference to the accompanying drawings.

[0040] FIG. 3 is a perspective view of the packing apparatus for pressure type soil-nailing of the present invention, FIG. 4 is a perspective view with parts taken away of the packing apparatus for pressure type soil-nailing of the present invention, and FIG. 5 is a cross section of the ground for explaining the establishment state of the packing apparatus for pressure type soil-nailing of the present invention.

[0041] As illustrated to drawings, at the packing apparatus for pressure type soil-nailing of the present invention are inserted the first packing 33a and the second packing 33b at a predetermined interval mutually to a lengthwise direction of the nail 31 in which screw threads are formed on the circumferential surface.

[0042] Also, at the packing apparatus for pressure type soil-nailing of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com