Environmental-friendly grass concrete highway slope protection structure and construction method thereof

A kind of concrete and environment-friendly technology, applied in the direction of foundation structure engineering, excavation, sheet pile wall, etc., can solve problems such as difficult to meet the requirements of protection and masonry, uncoordinated natural landscape, damage to land resources, etc., achieve outstanding economic and technical benefits, and avoid environmental pollution. Destruction and environmental secondary pollution, and the effect of improving the traffic environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In this embodiment, the prefabrication process requirements of the prefabricated sash beams, ecological anti-shock blocks, etc., the technical requirements of the prestressed anchor cable tensioning construction, the construction process requirements of concrete pouring, and the types of plants on the slope will not be described in detail, and the present invention will be focused on The implementation mode of the involved cast-in-situ planting type ecological concrete slope protection structure construction.

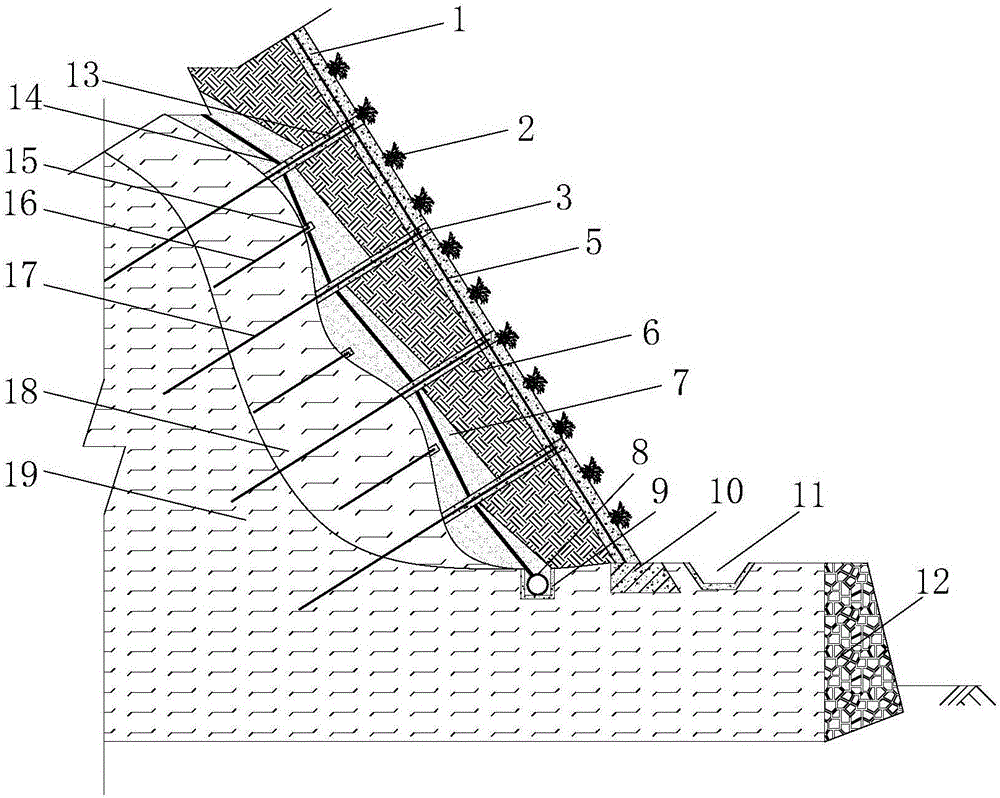

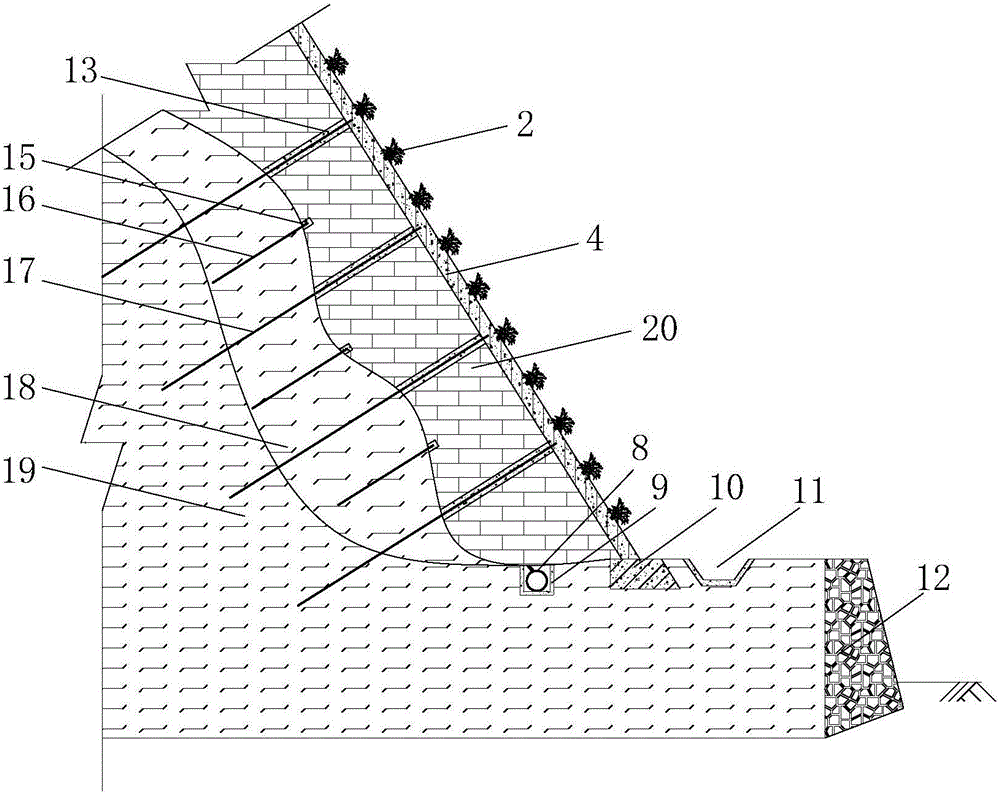

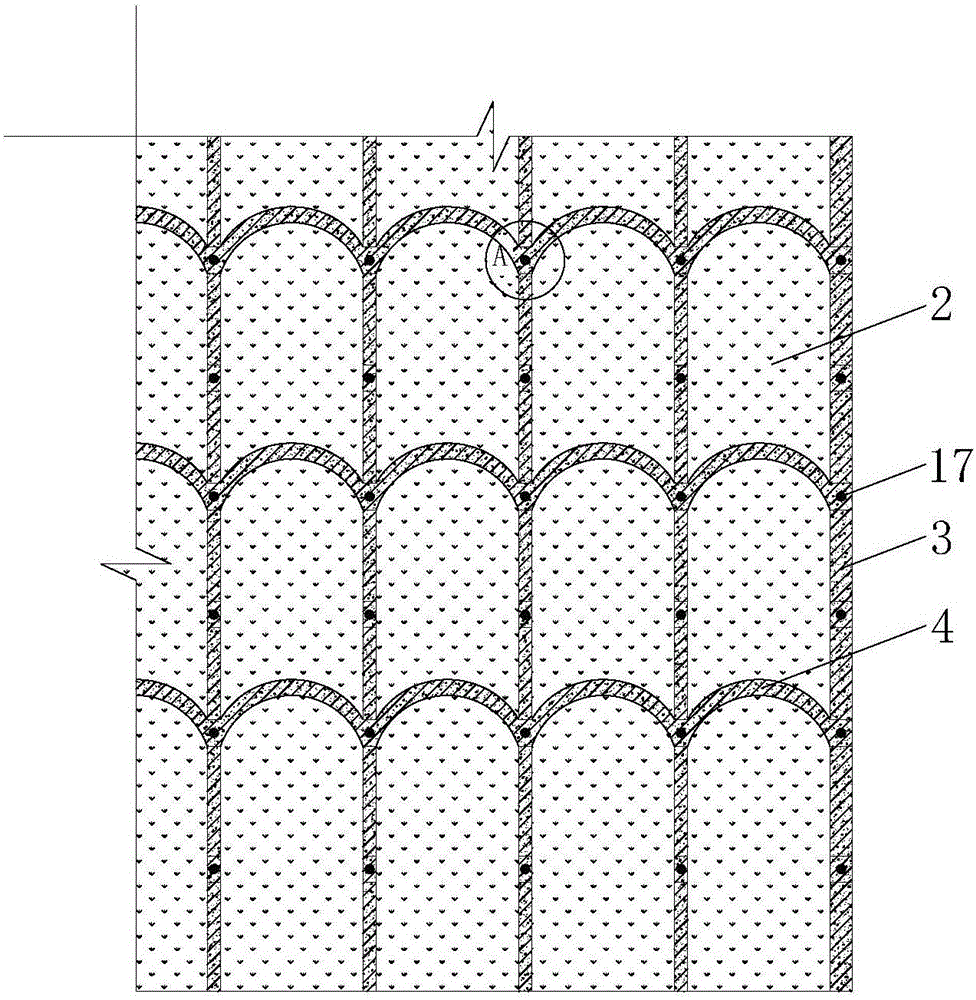

[0040] figure 1 It is the front view of the environmental protection type grass-planting concrete road slope protection structure of the present invention, figure 2 It is the I-I sectional view of the environmental protection type grass-planting concrete road slope protection structure of the present invention, image 3 It is the II-II sectional view of the environmental protection type grass-planting concrete road slope protection structure of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com