Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4480 results about "Precast concrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Precast concrete is a construction product produced by casting concrete in a reusable mold or "form" which is then cured in a controlled environment, transported to the construction site and lifted into place ("tilt up"). In contrast, standard concrete is poured into site-specific forms and cured on site. Precast stone is distinguished from precast concrete using a fine aggregate in the mixture, so the final product approaches the appearance of naturally occurring rock or stone. More recently expanded polystyrene is being used as the cores to precast wall panels. This is lightweight and has better thermal insulation.

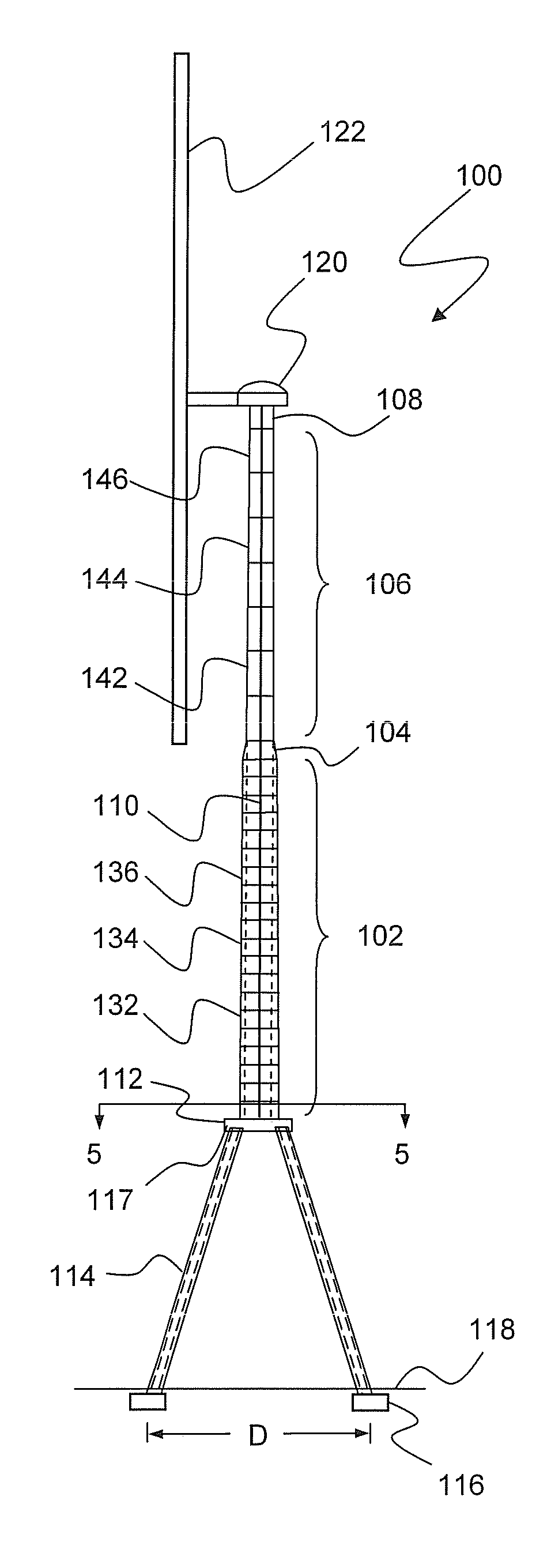

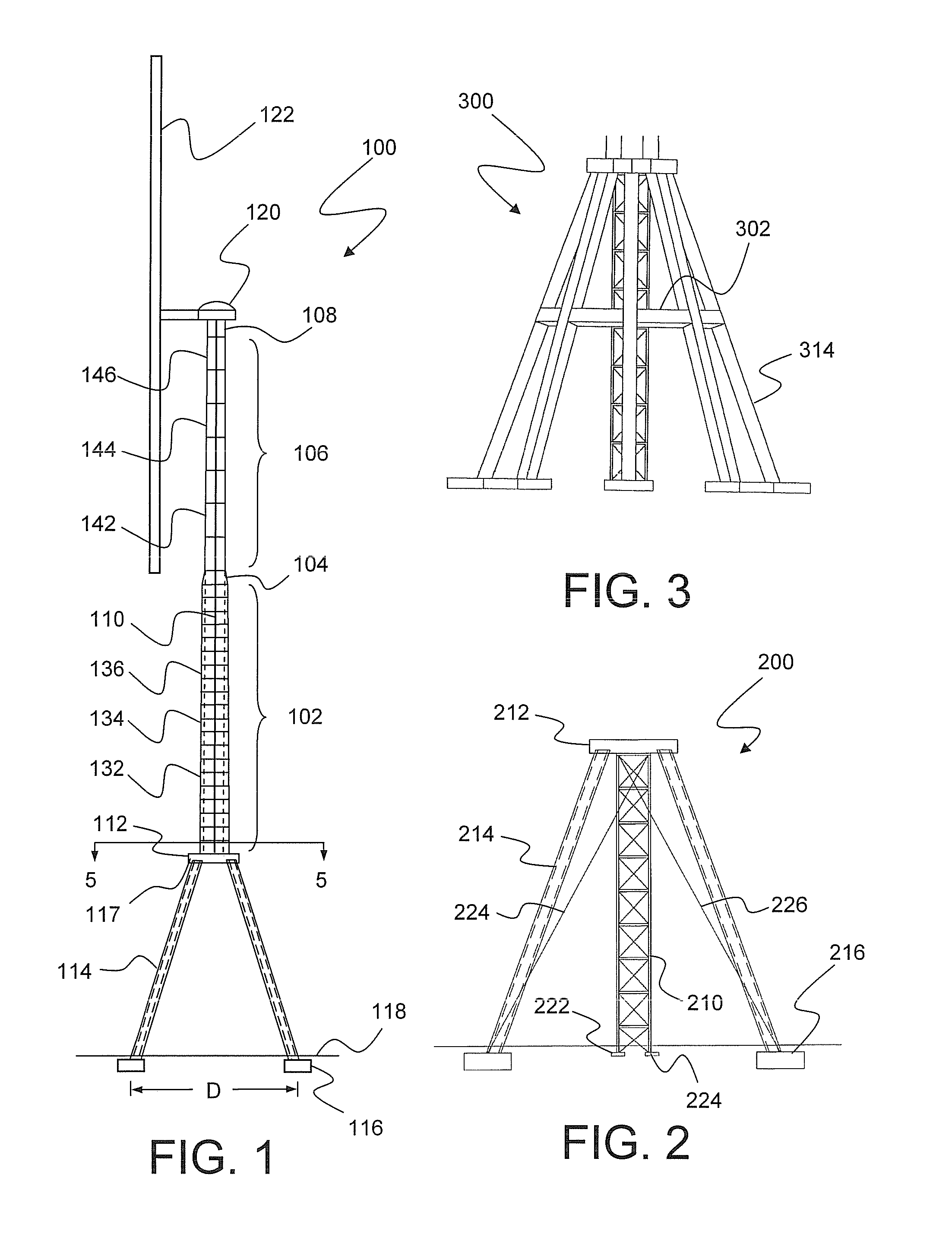

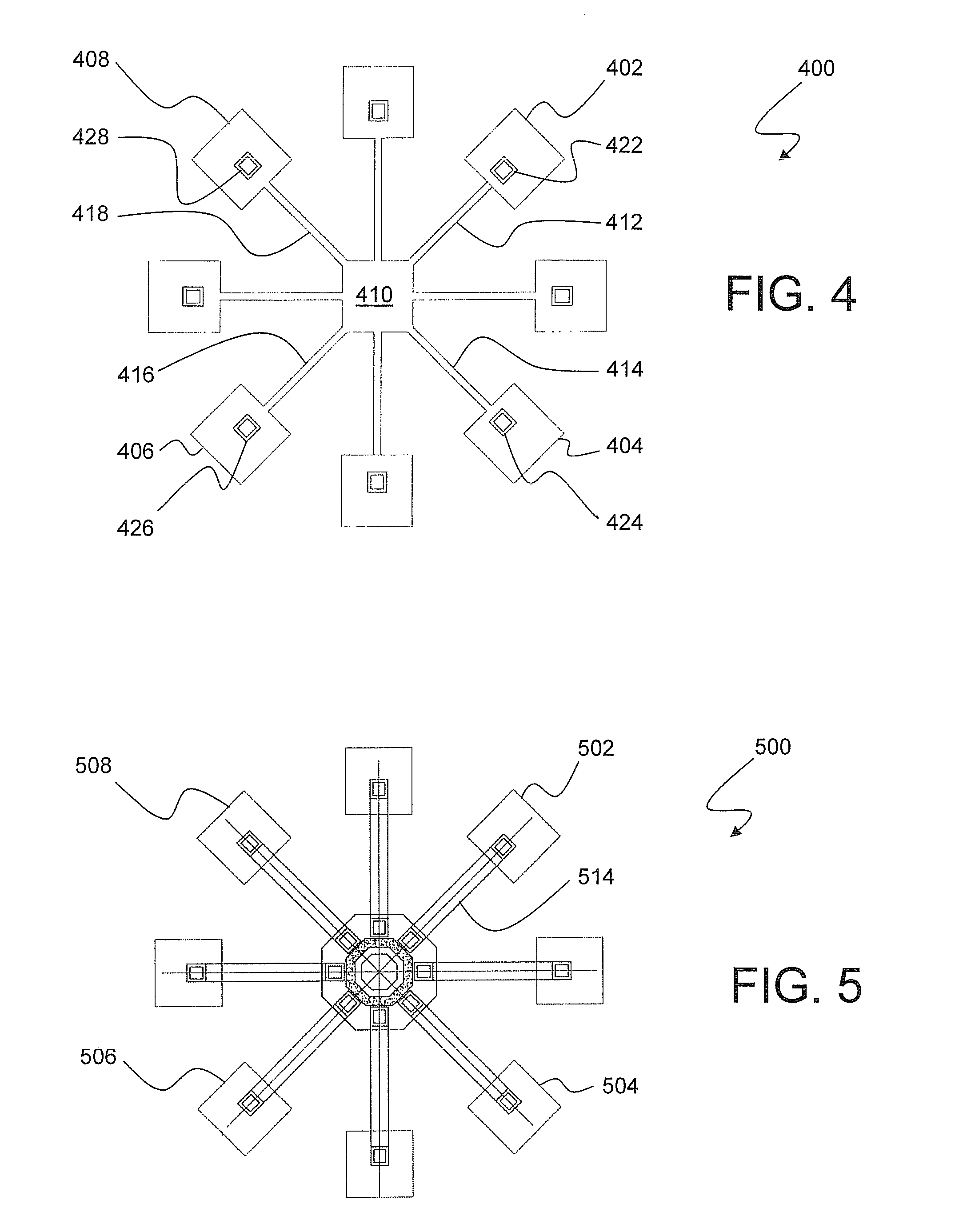

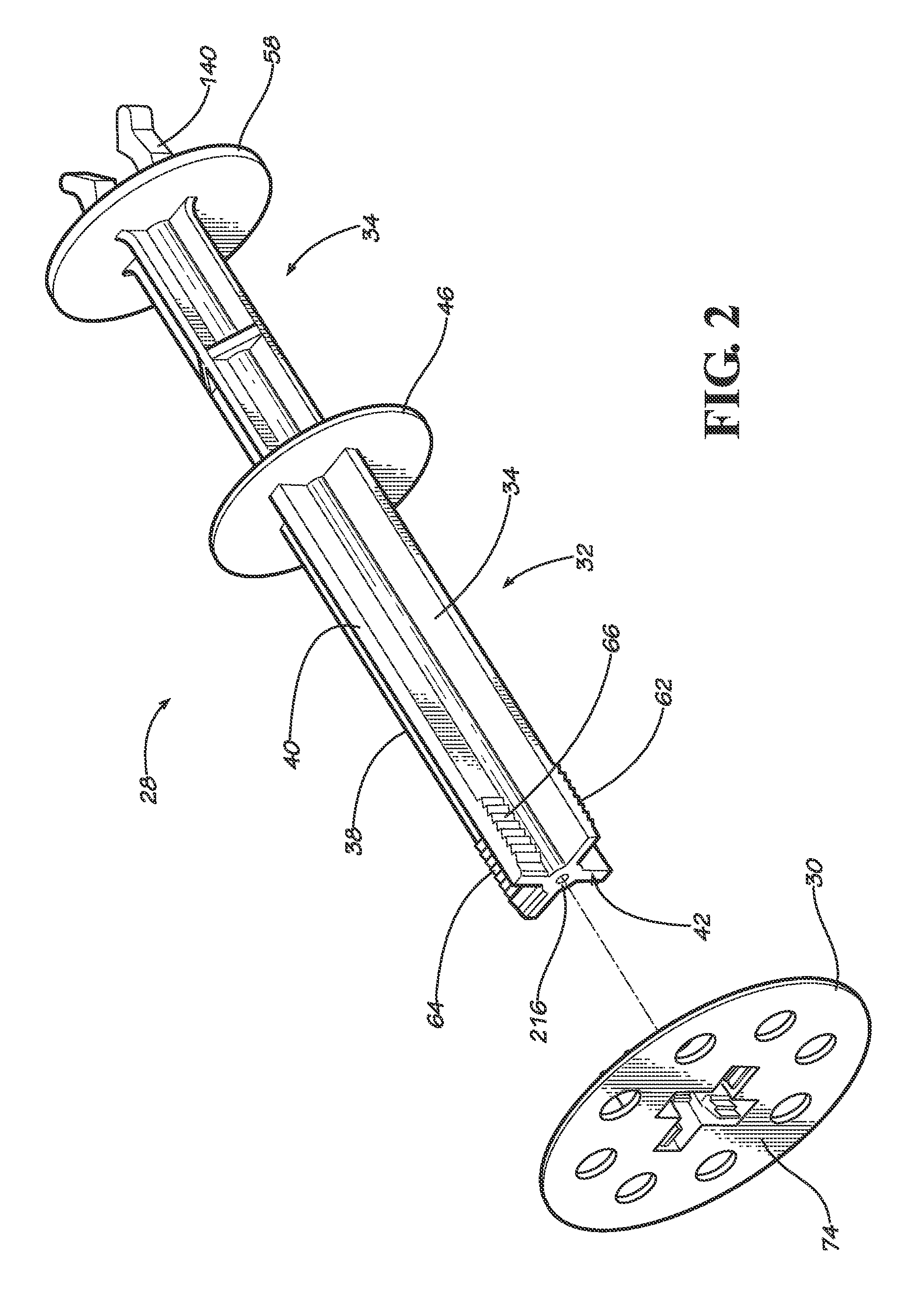

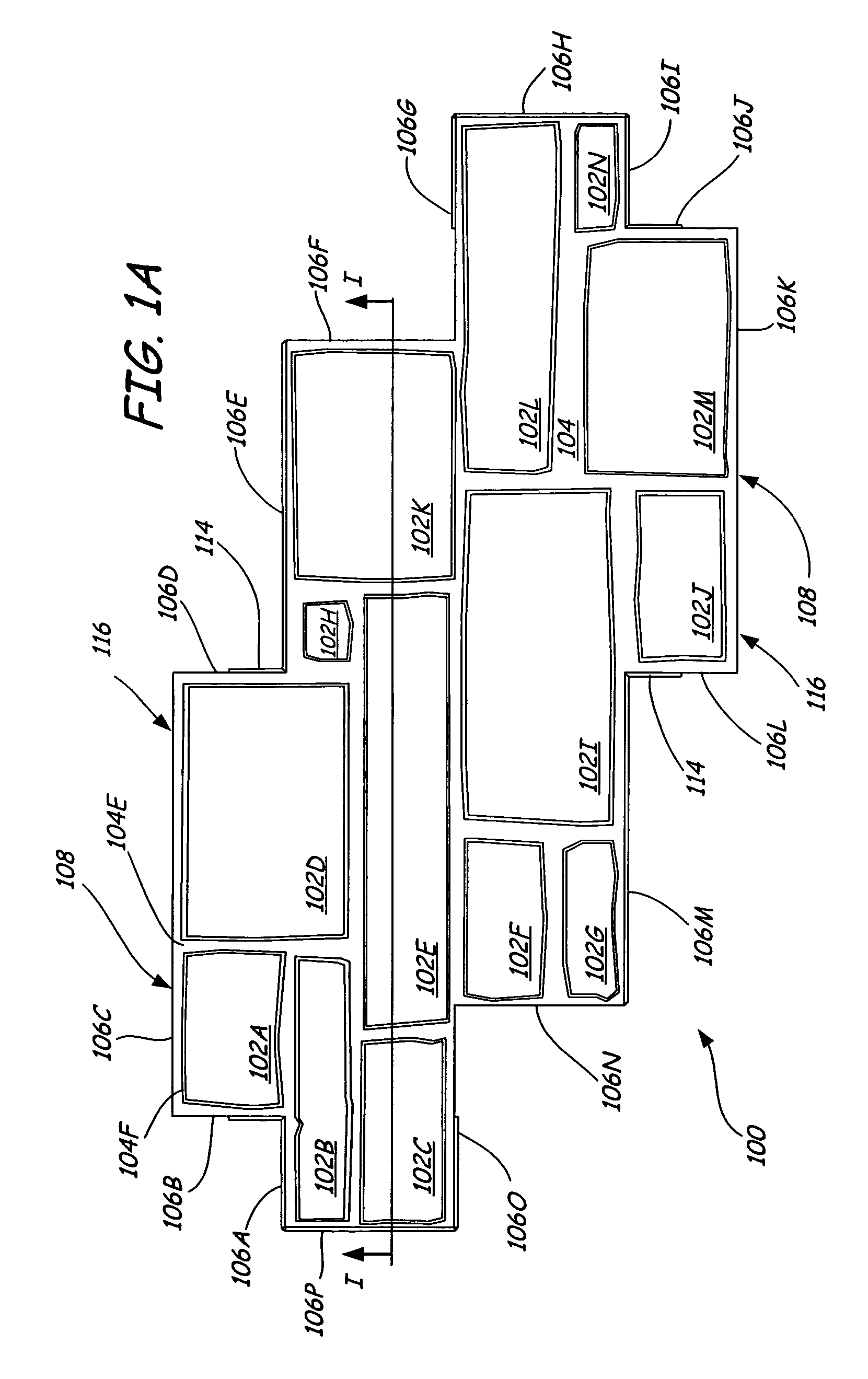

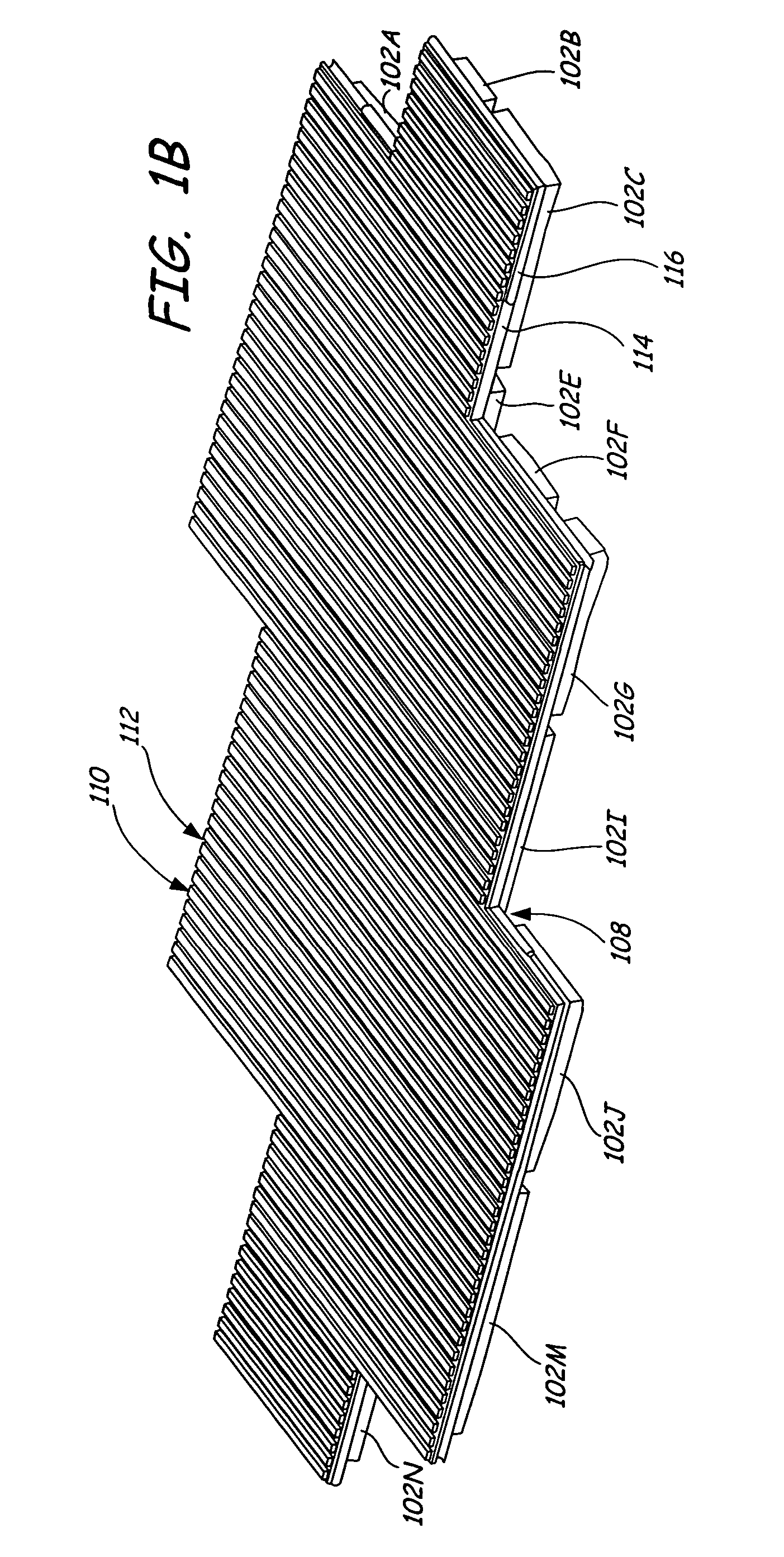

Base support for wind-driven power generators

Disclosed are apparatus and corresponding methodology for providing a base support, such as including concrete, and used such as for a wind-driven generator. Precast concrete cylinders are stacked in place upon a platform that may be partially precast and partially cast in place during assembly and supported, in certain embodiments, by plural concrete legs, the other ends of which are supported on a unitary or subdivided concrete foundation. In other embodiments, the platform may be supported by ribbed concrete panels. The concrete cylinders are glued together using an epoxy and then secured by an internal vertical post tension system extending from the platform to the upper most cylinder. Different types of concrete are used between upper and lower sections of the stacked cylinders. The lower section uses reinforced concrete while the upper section used ultra high performance fiber reinforced concrete.

Owner:TINDALL CORP

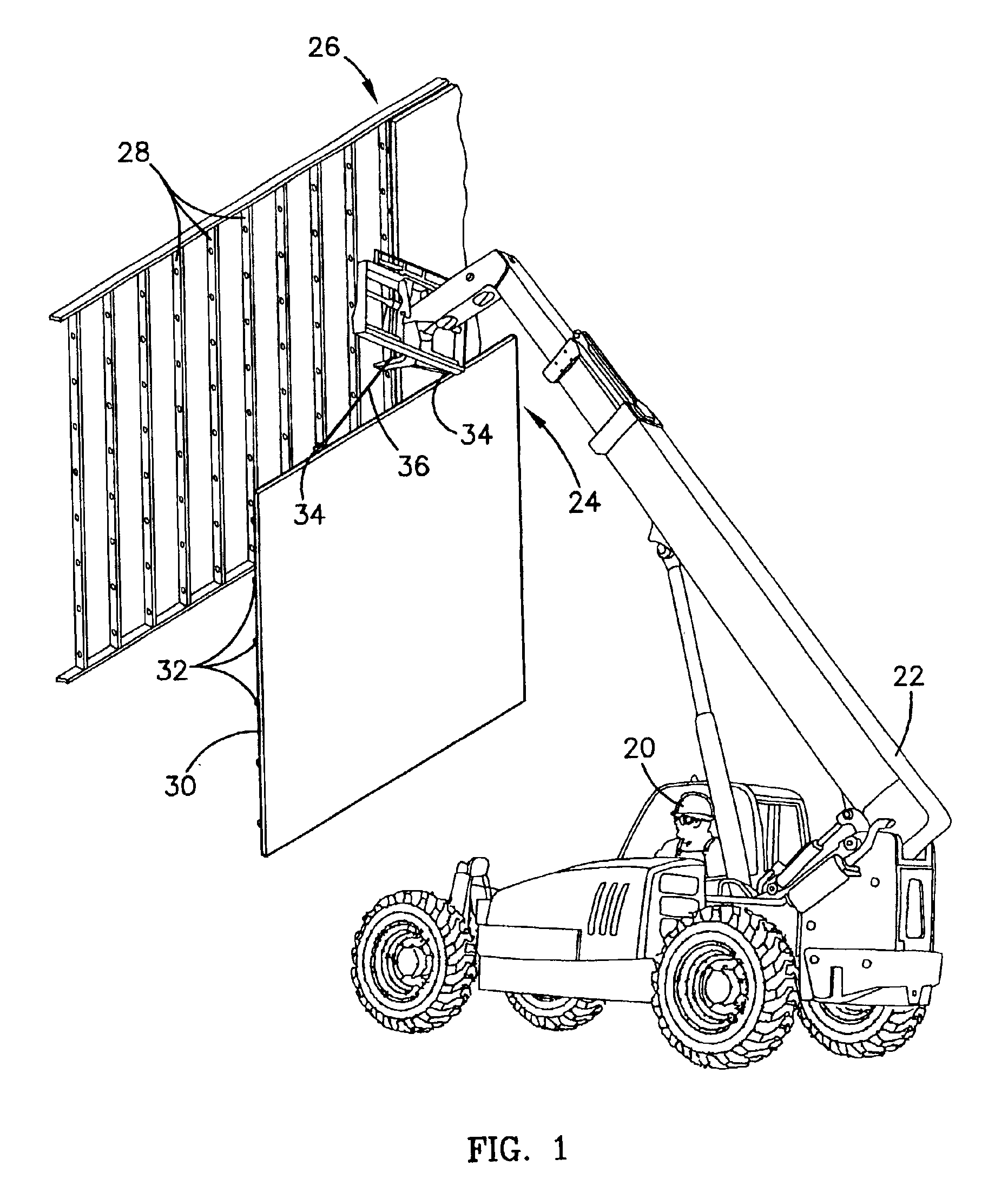

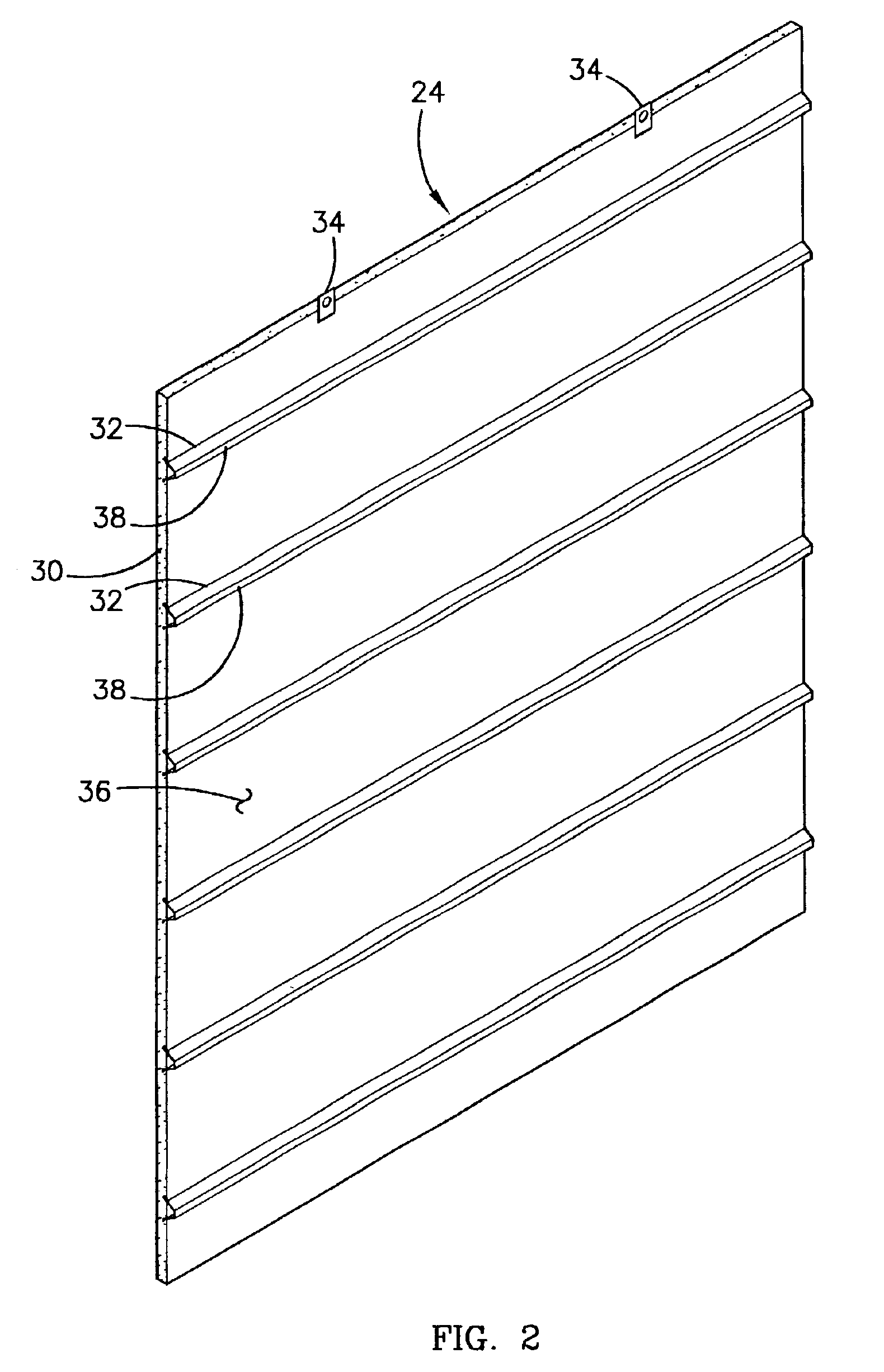

Lightweight precast concrete wall panel system

InactiveUS6837013B2Solve the lack of rigidityAvoid insufficient thicknessCeilingsConstruction materialPrecast concreteWall plate

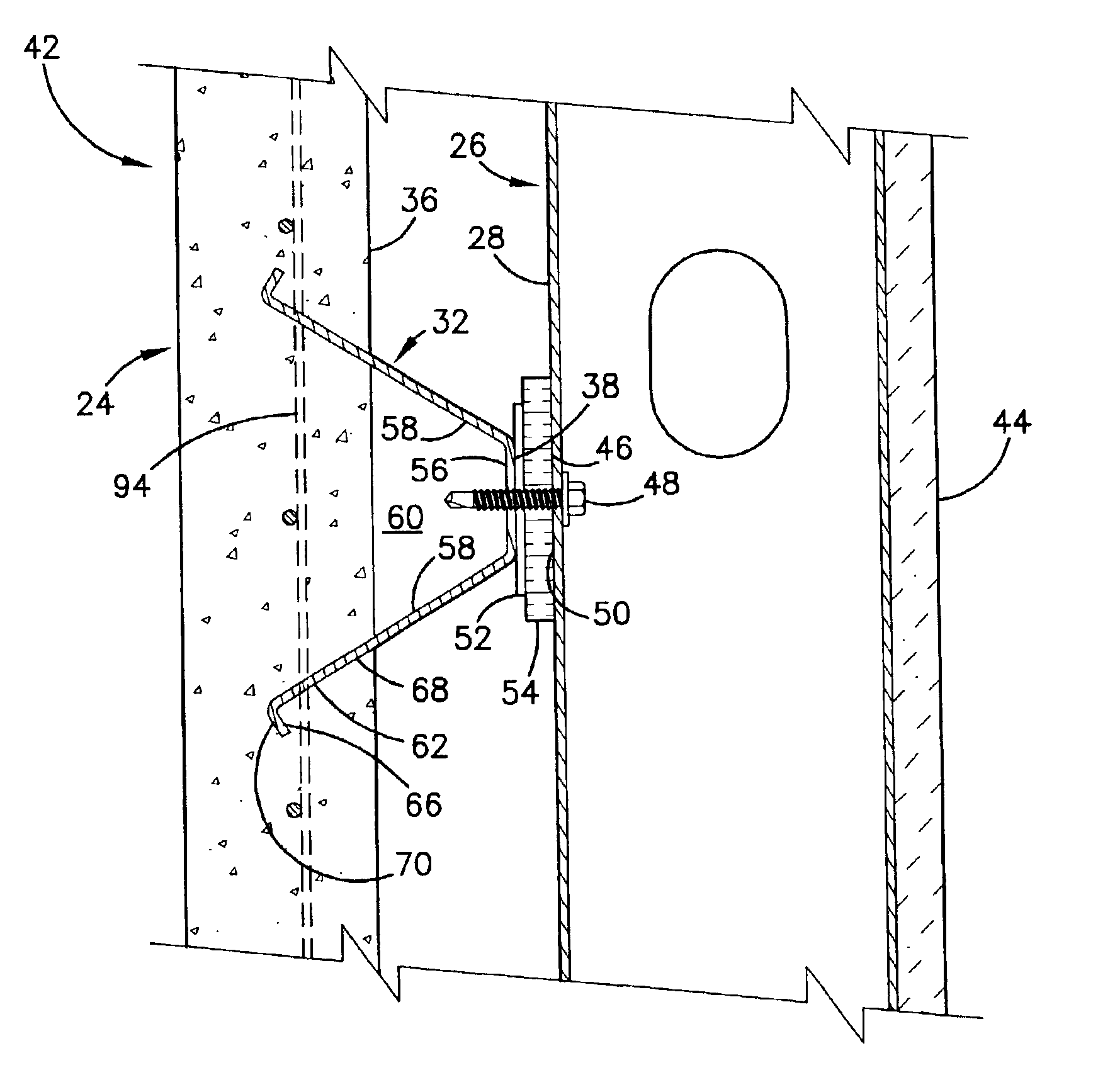

Wall system employing lightweight precast concrete wall panels. The precast wall panels include a concrete slab and a plurality of spaced-apart elongated generally parallel bent sheet metal channels that are partially embedded in the slab. Each wall panel can be coupled to a support wall by extending self-tapping screws through metallic wall framing members and the channels at locations where the framing members and channels cross.

Owner:FODERBERG JOEL +1

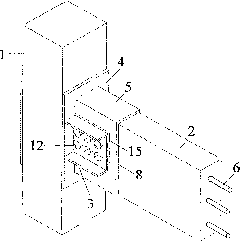

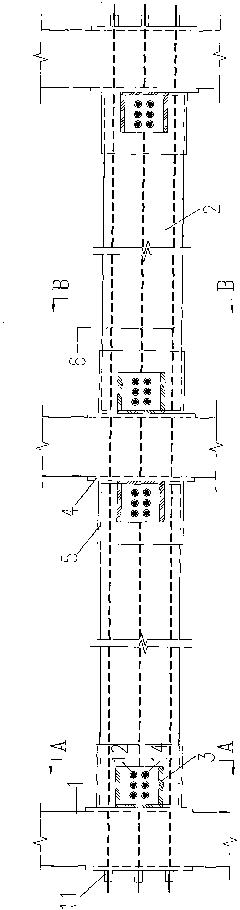

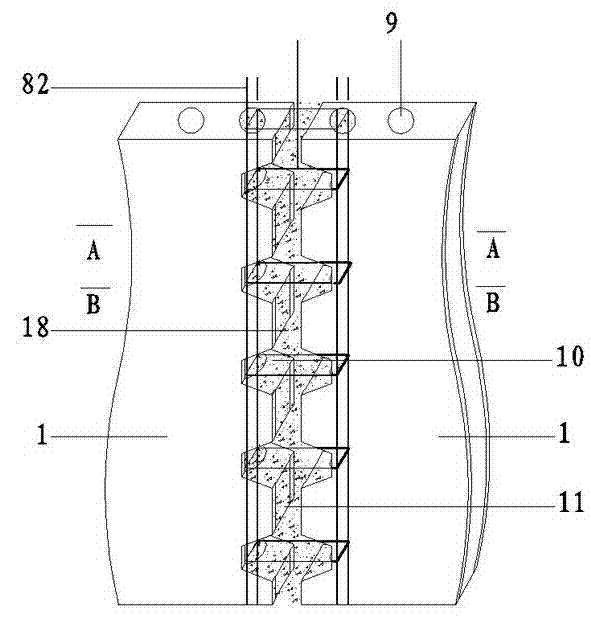

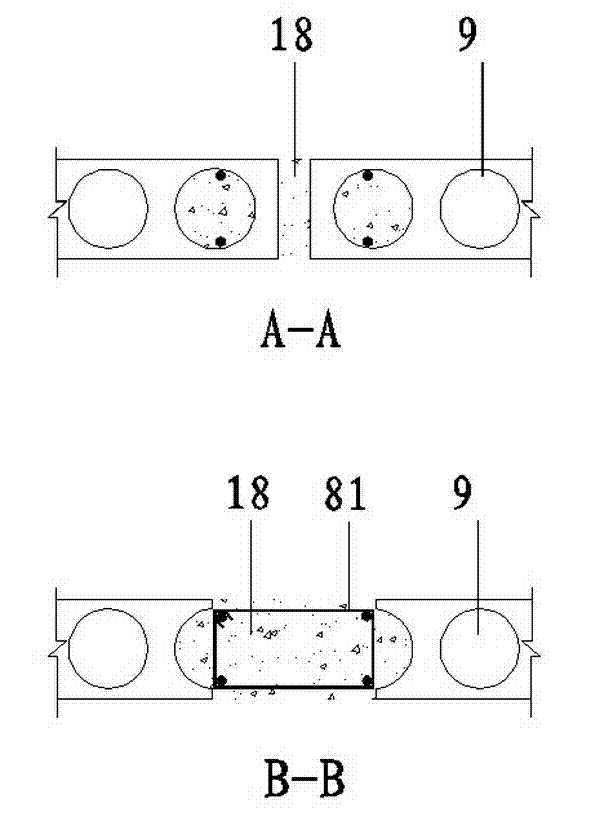

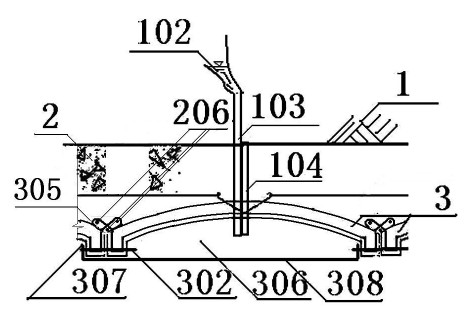

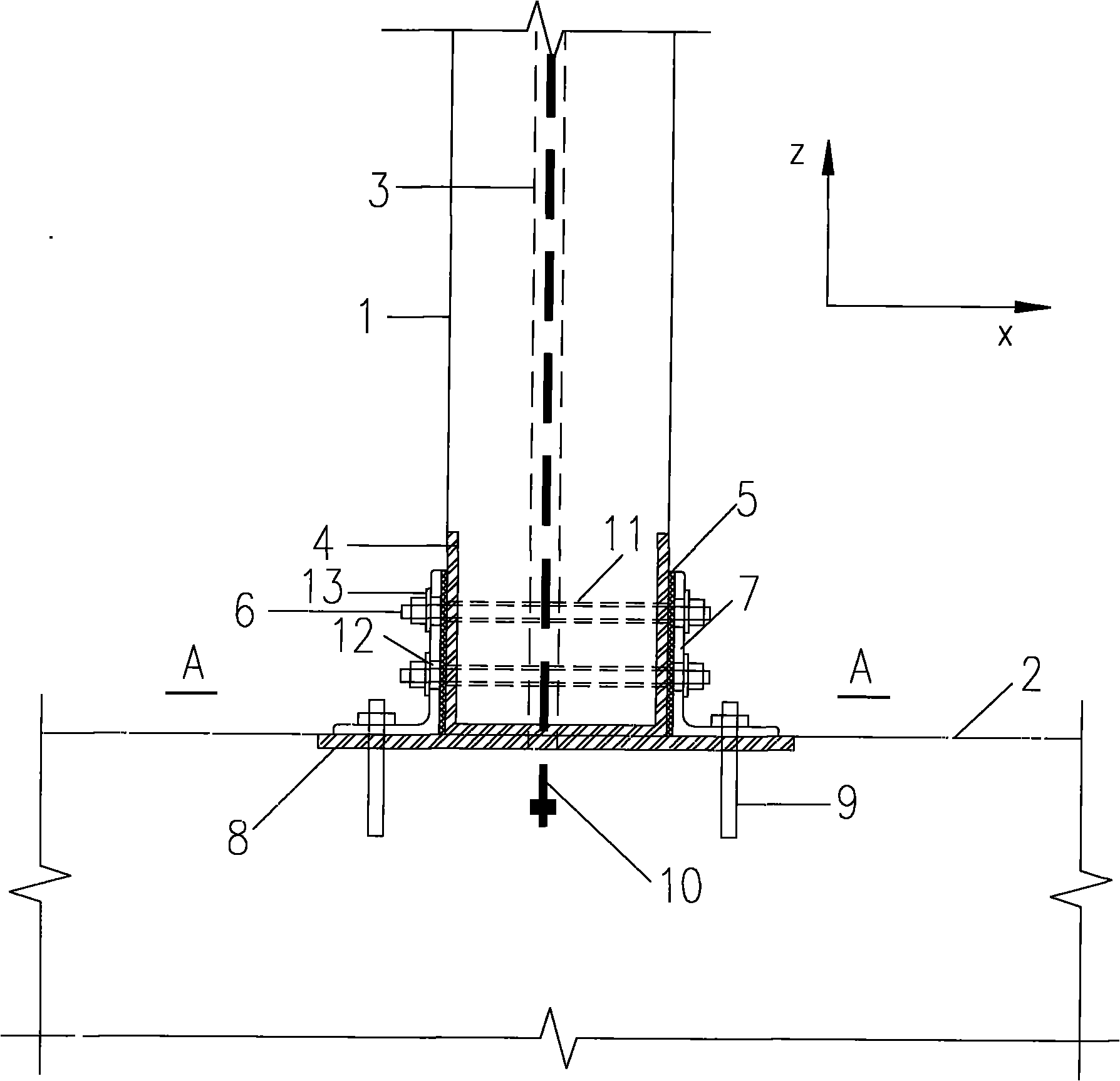

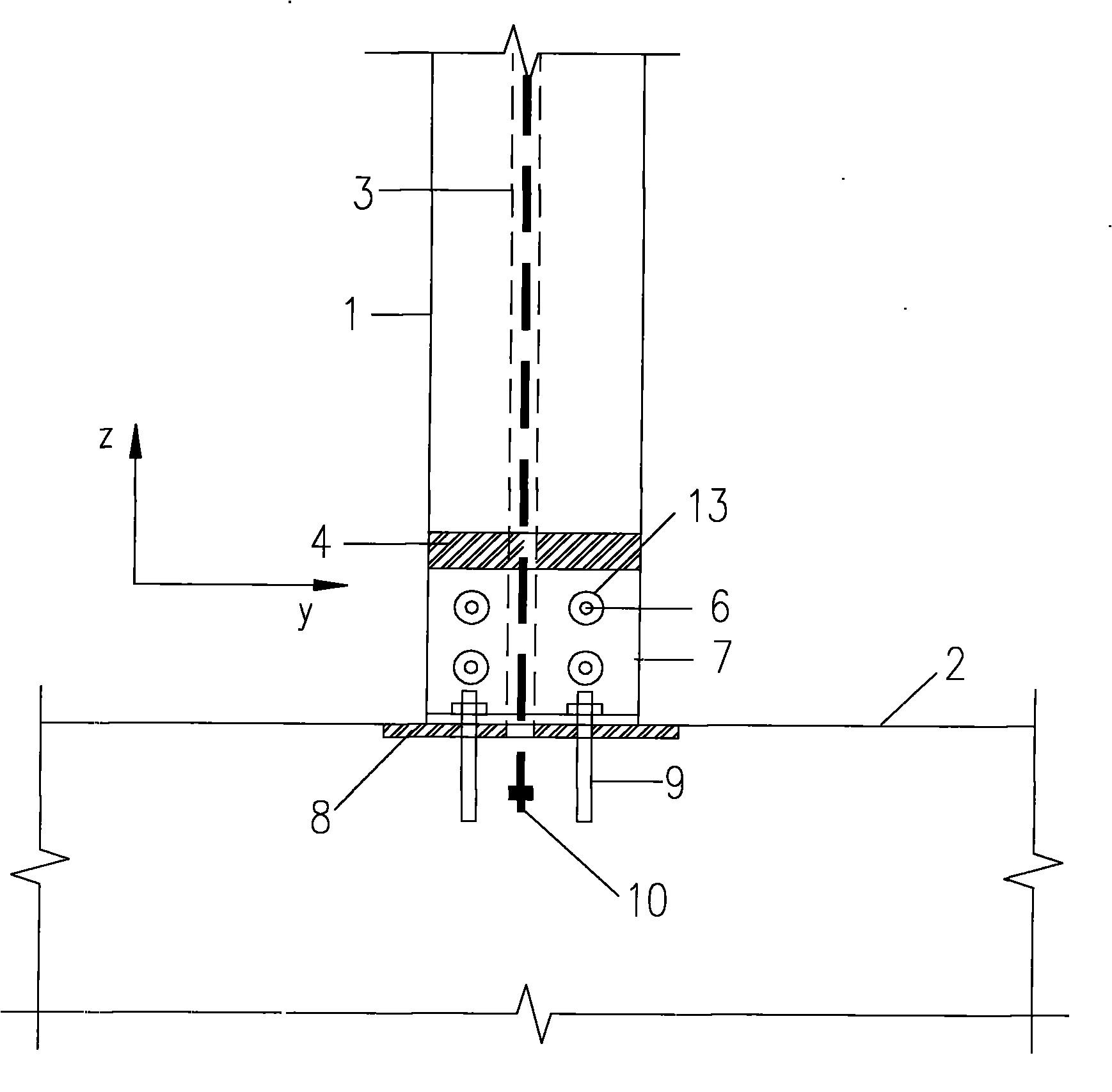

Node connection device for self-centering prestressed concrete frame

InactiveCN101798849ASolve local pressure problemsEliminate or reduce residual deformationShock proofingResidual deformationWhole body

The invention relates to a node connection device for a self-centering prestressed concrete frame. The node connection device is a device used for the connection between the beam and the column of a prefabricated reinforced concrete frame, and aims at improving energy consumption of a frame structure under seismic action and eliminating or reducing the residual deformation and damage of the frame structure. The connection device is characterized in that combined steel parts form an energy consuming device, two external friction steel plates (3) are arranged in the energy consuming device, are respectively and symmetrically arranged on the two sides of a column end reinforcing steel plate (4) and are connected with the column end reinforcing steel plate (4) into a whole body, two internal friction steel plates (8) are arranged between the two external friction steel plates (3), the upper end and the lower end of each internal friction steel plate (8) are respectively provided with a bean end reinforcing steel plate (5), friction discs (15) are respectively arranged between the two internal friction steel plates (8) and the two external friction steel plates (3), and friction-type high-strength bolts (12) penetrate through the external friction steel plates (3), the friction discs (15), the internal friction steel plates (8) and a prefabricated concrete beam (2) and connect all parts together.

Owner:SOUTHEAST UNIV

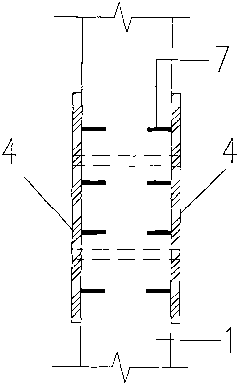

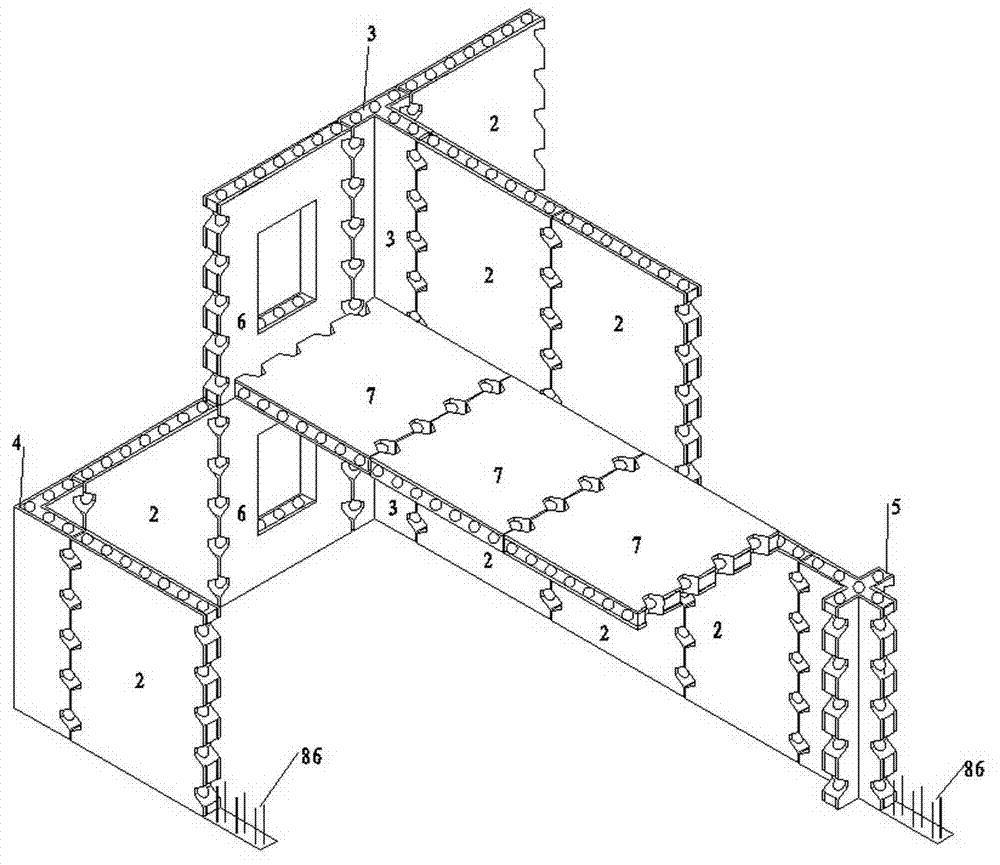

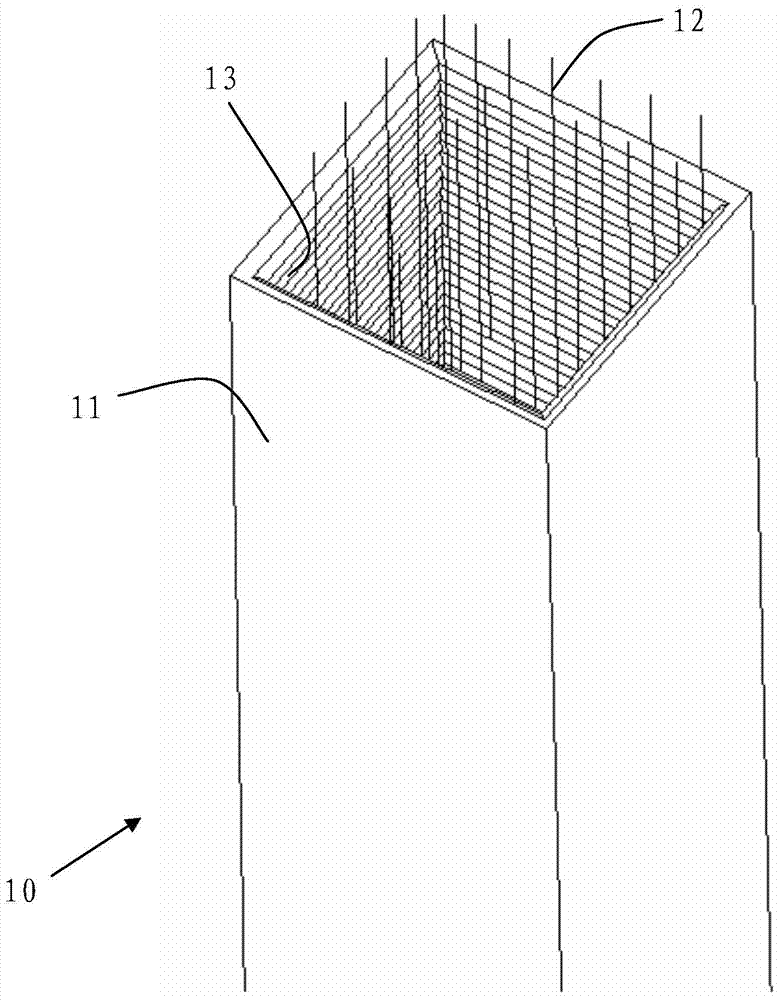

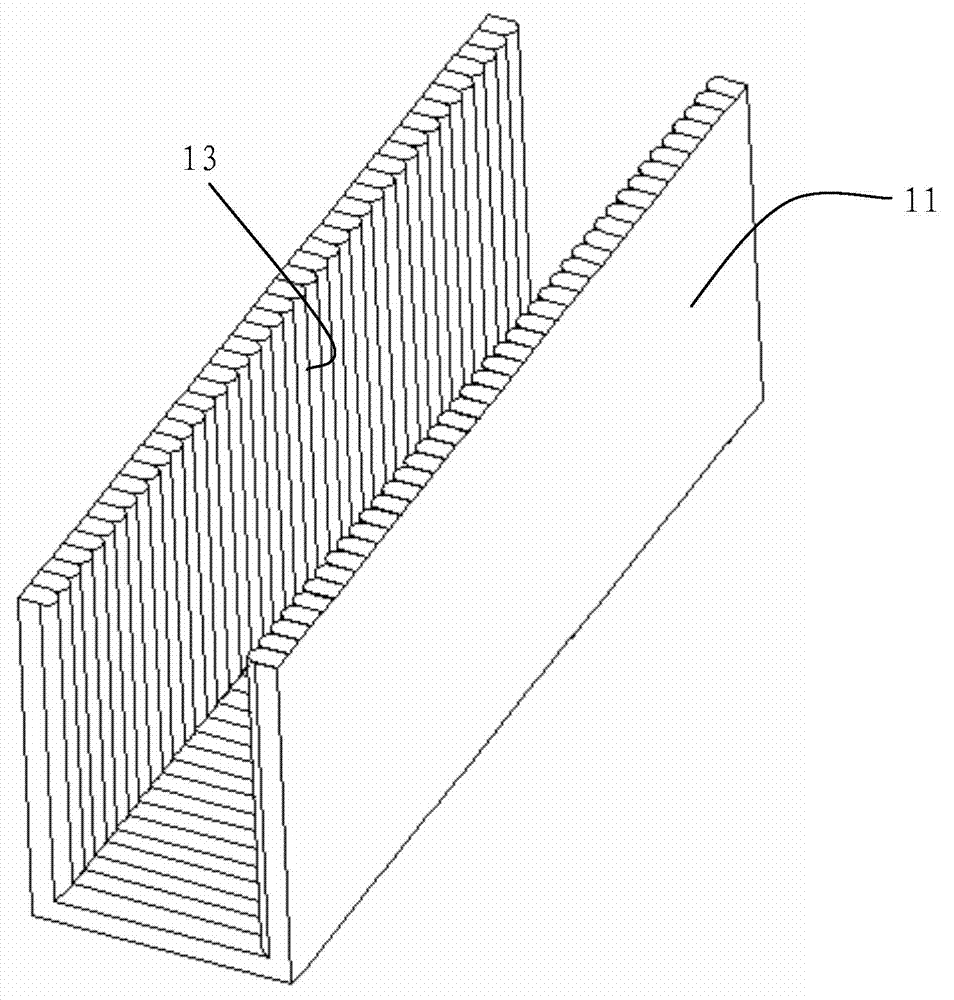

Assembled monolithic shear wall building structure and construction method thereof

InactiveCN102808450AImprove the level of industrializationIncrease productivityConstruction materialWallsTransverse grooveCross wall

The invention relates to an assembled monolithic shear wall building structure and a construction method thereof, and belongs to the technical field of buildings and construction thereof. The assembled monolithic shear wall building structure is formed by connecting prefabricated concrete members which comprise a prefabricated wall plate member, a floor member, a T-shaped wall column member, an L-shaped wall column member, a cross wall column member and a wall member with an opening. The structure is characterized in that a plurality of longitudinal through holes which are parallel to the surface are formed in each prefabricated concrete member; transverse grooves crossed with at least one longitudinal hole are formed on the longitudinal edge at intervals; transverse anchoring steel bars are arranged at the transverse grooves among different prefabricated members; longitudinal anchoring steel bars are arranged in the longitudinal holes; a layer of structural unit or a single-layer building structure is formed by filling concrete in the longitudinal holes and the transverse grooves; and a plurality of structural units are connected to form a multi-layer or high-rise assembled monolithic shear wall structure. The structure can be used in a multi-layer or high-rise shear wall building structure and a frame-shear wall building structure, the industrial level of the building structure can be improved, stress performance is improved, and resources are saved.

Owner:初明进

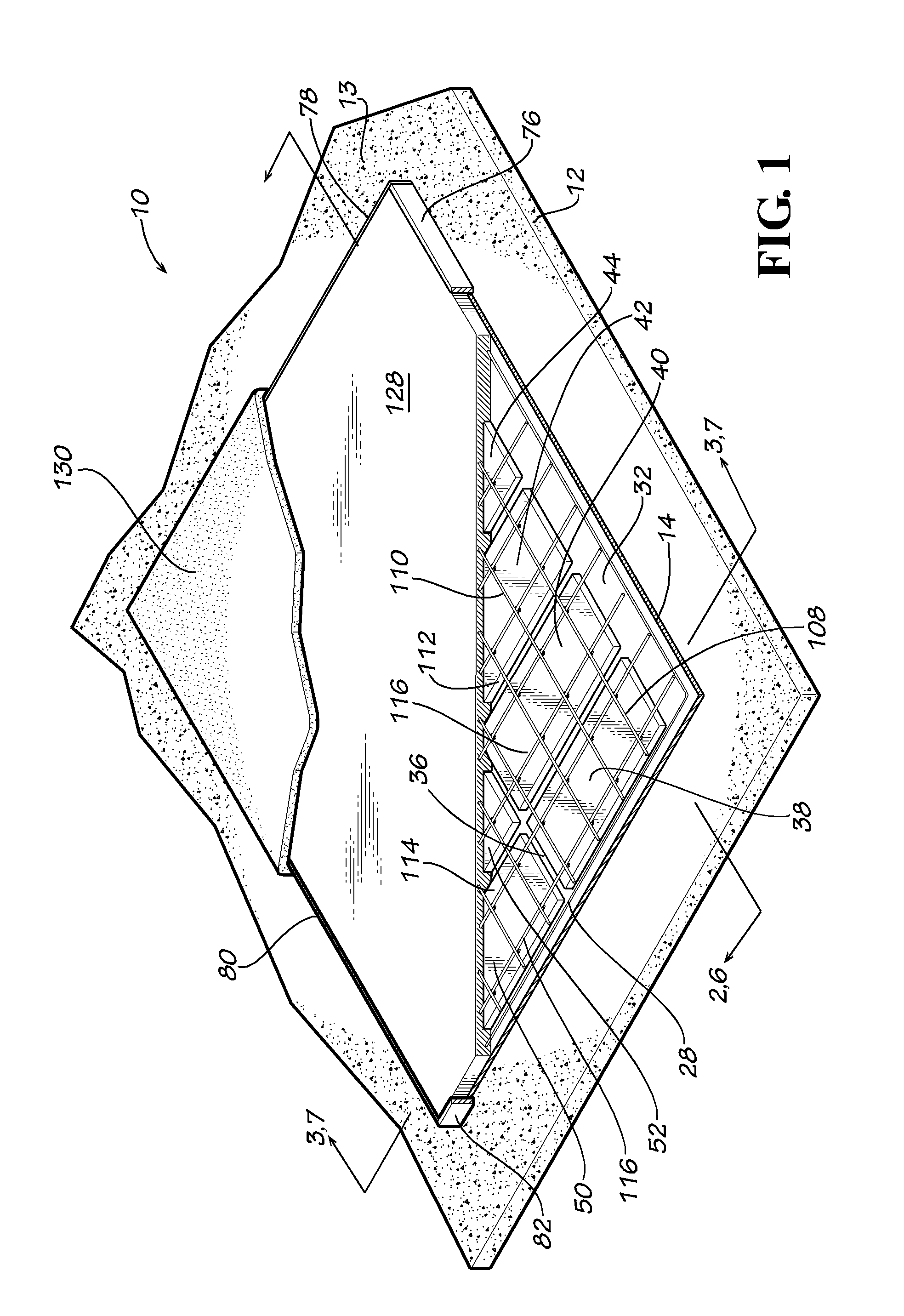

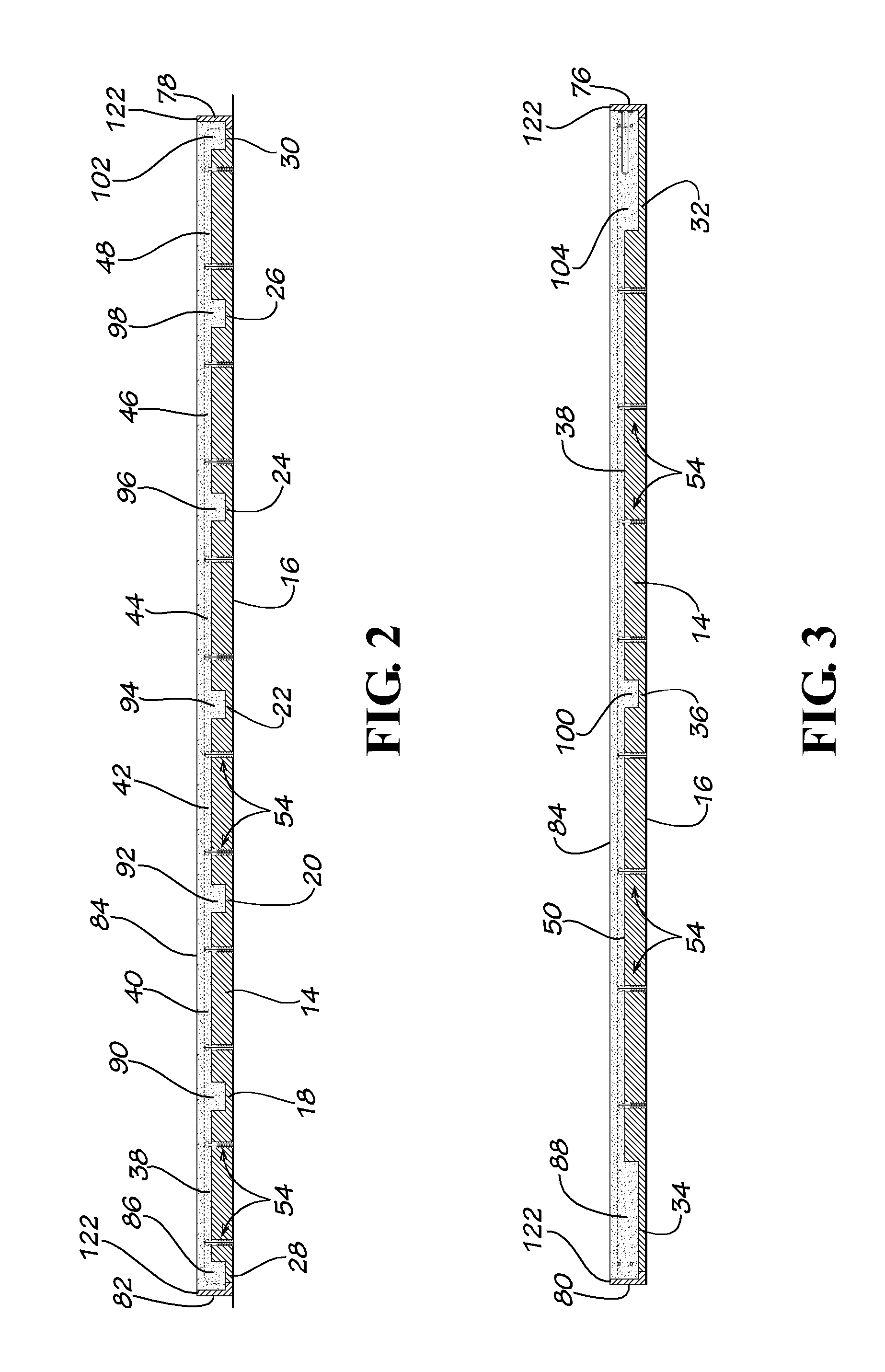

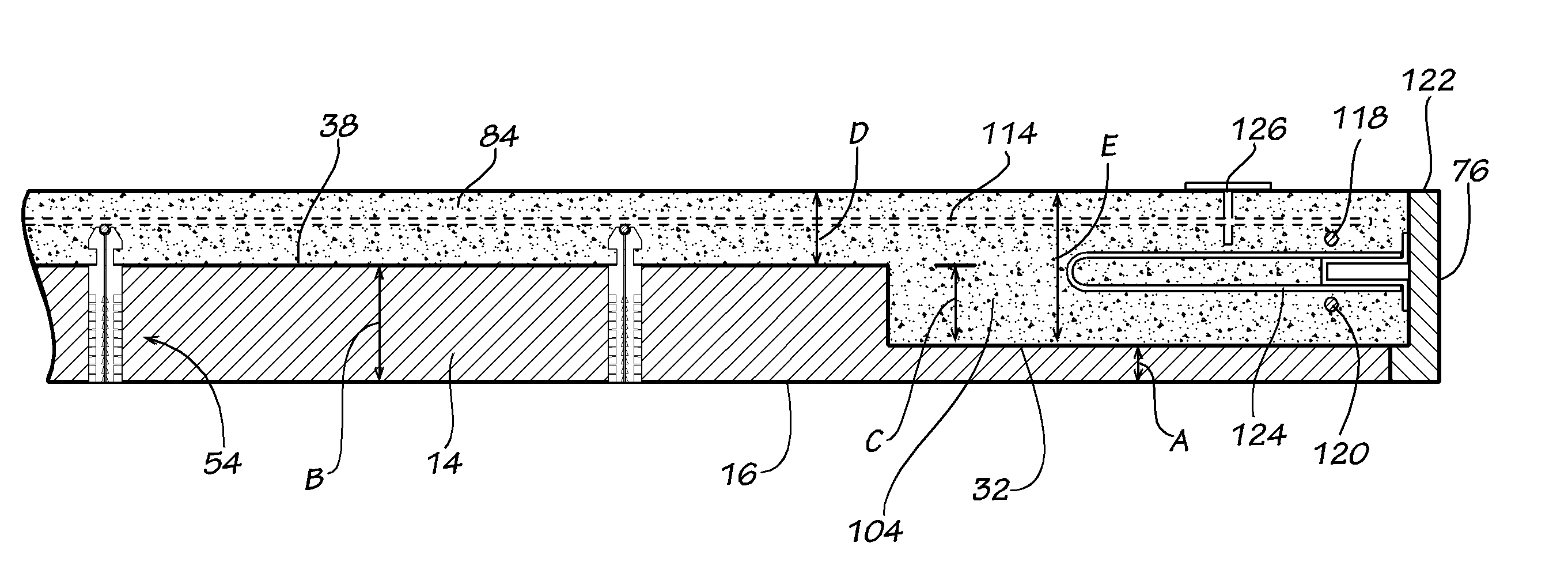

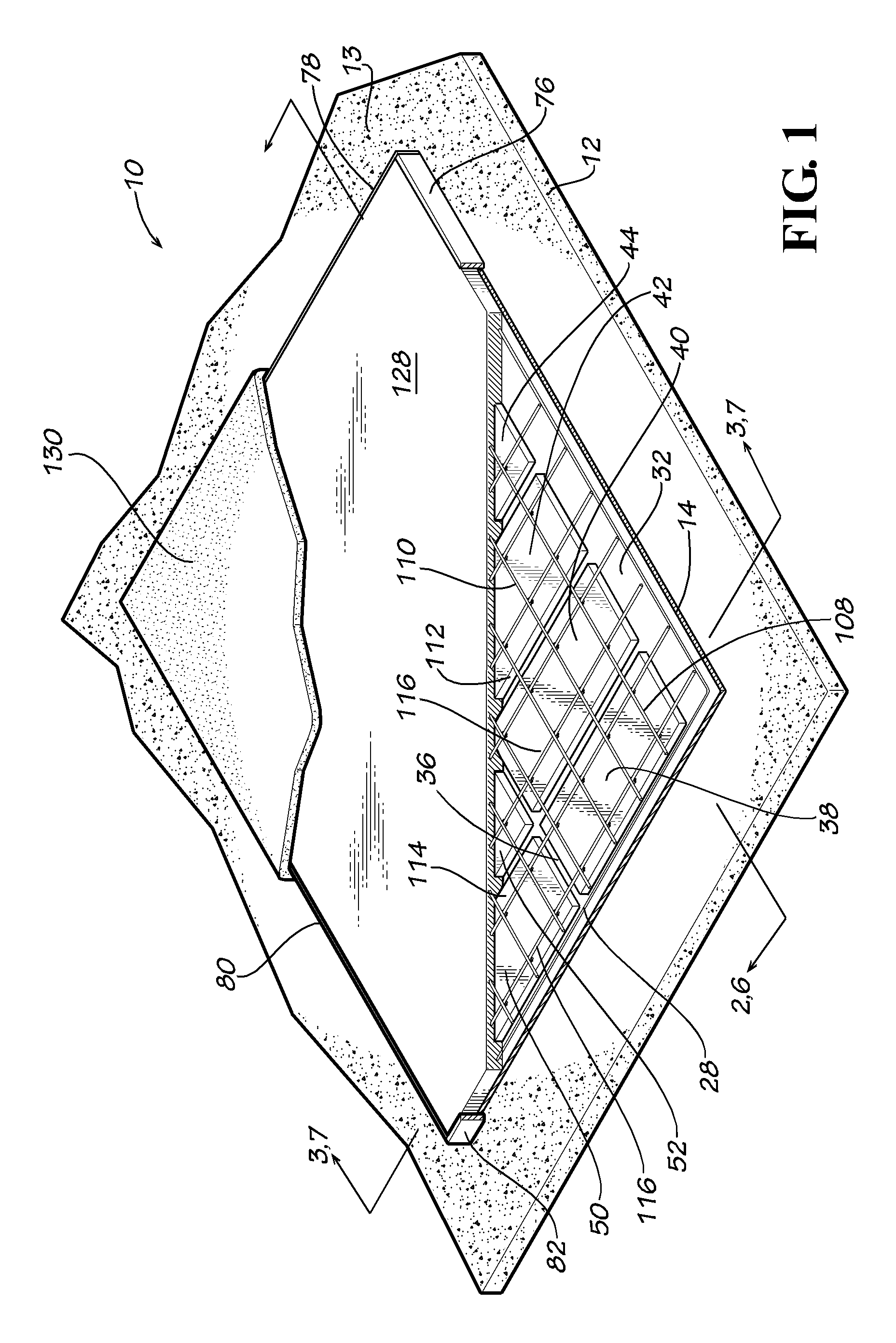

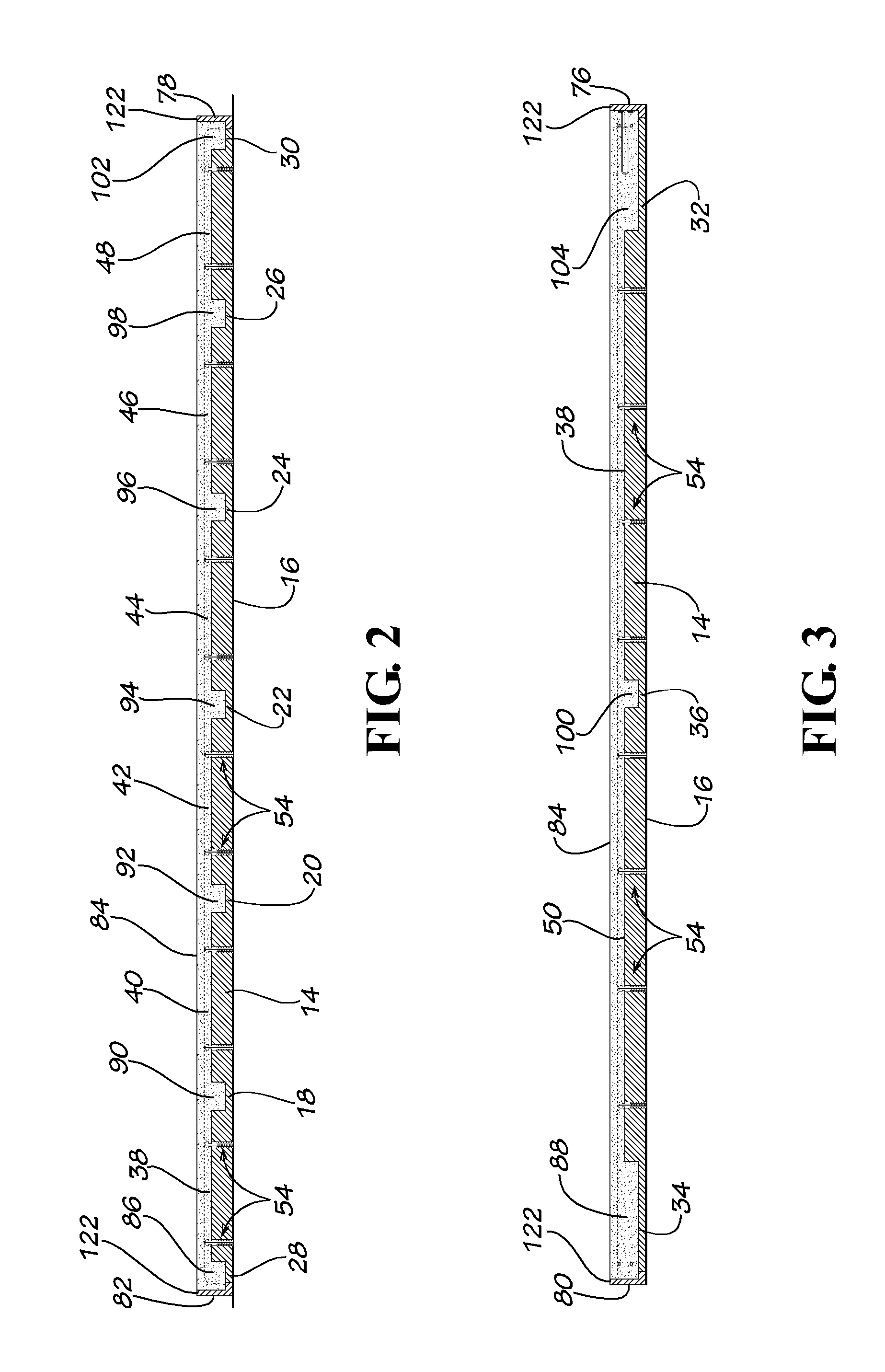

Precast concrete structures, precast tilt-up concrete structures and methods of making same

ActiveUS8555584B2Reduce internal stressReduce the amount requiredConstruction materialCovering/liningsPolystyreneExpanded polystyrene

Owner:CIUPERCA ROMEO ILARIAN

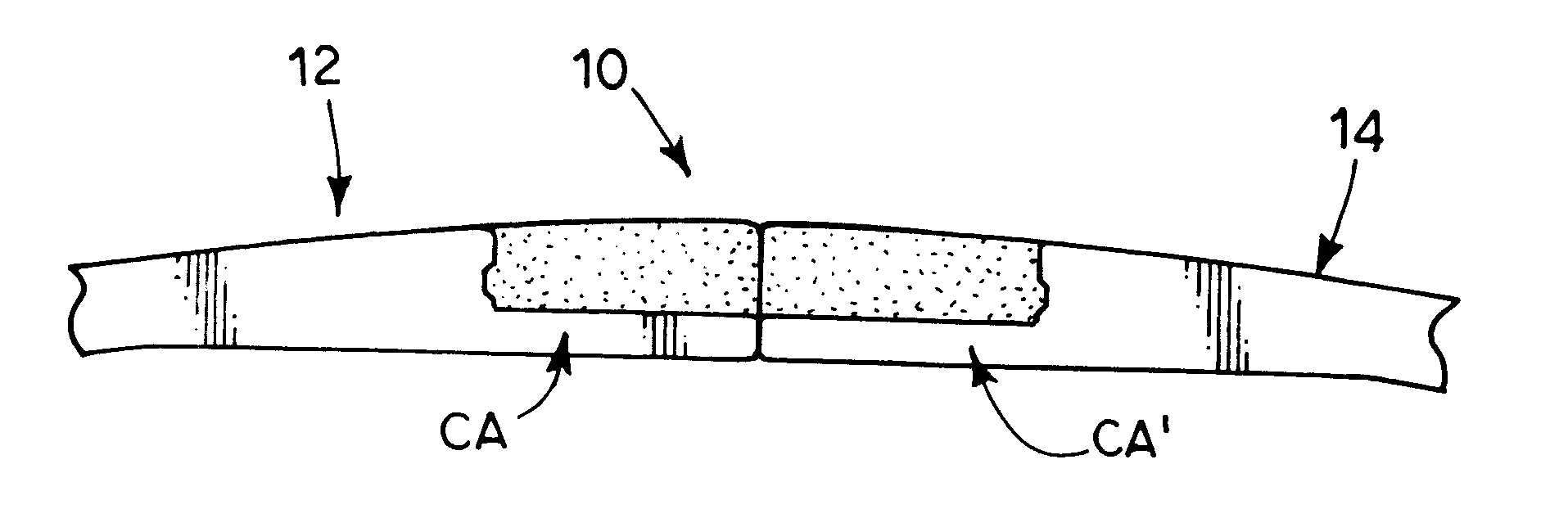

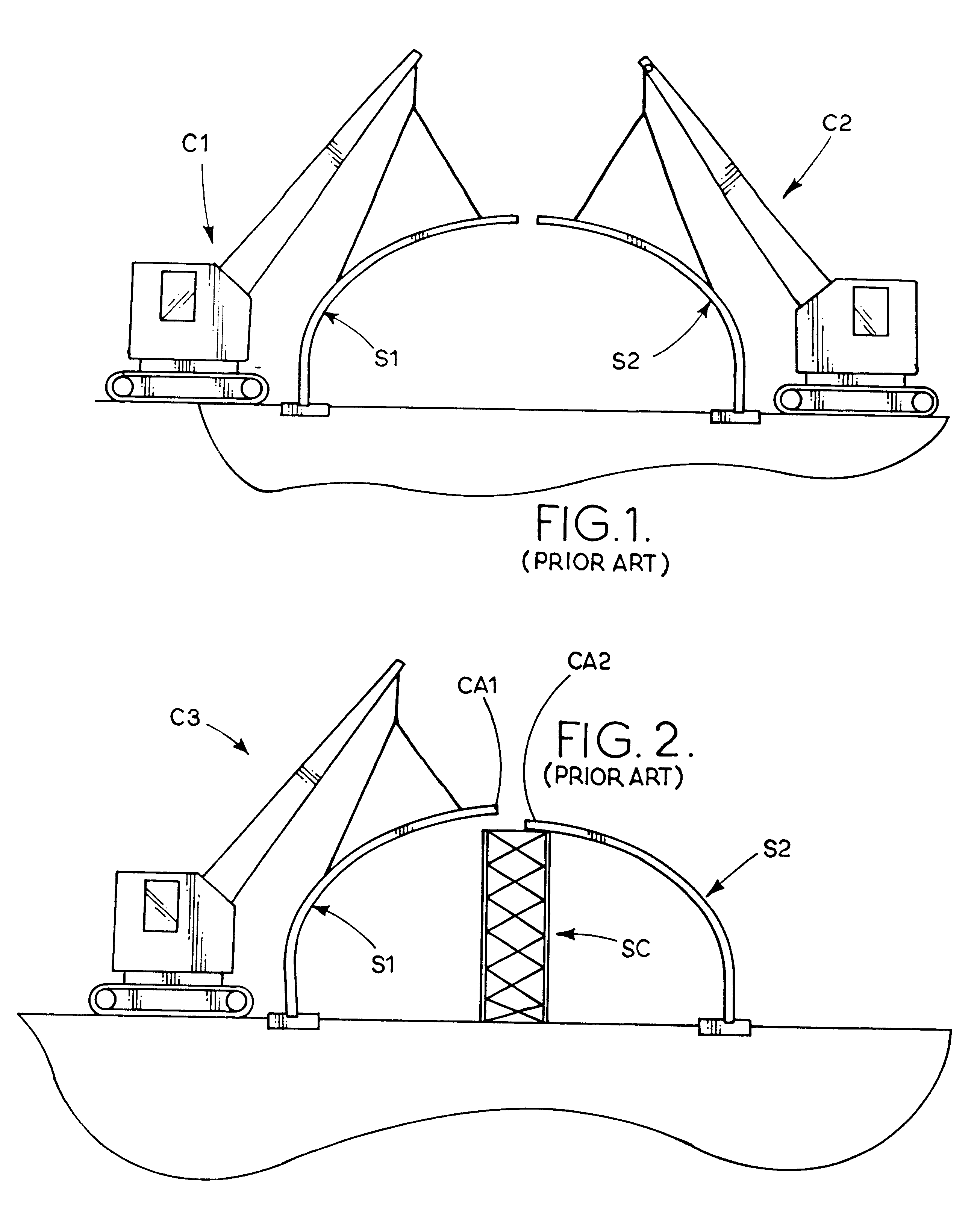

Joint for pre-cast concrete twin-leaf arch sections

InactiveUS6243994B1Efficiently and accurately formForming accuratelyUnderground chambersBuilding material handlingControl theoryPrecast concrete

A joint for pre-cast concrete twin-leaf arch sections is self-aligning when the two arch sections are initially brought into abutting contact with each other. The joint provides a rigid connection between the twin units and is achieved on site by means of re-inforced cast-in-place concrete. Reinforcement splices for the connection are lap splices, and the joint allows pouring the cast-in-place concrete without the need of formwork. For load distributing purposes, a continuous connection of individual arch rings in the longitudinal direction at the arch crown is possible. An initial abutting contact between the twin units is provided by the joint of the present invention. The contact provided by the joint of the present invention is self-aligning, locking, allows the controlled transmission of the abutting force and allows for a temporary connection. The joint includes mechanical elements for aligning and locking the two arch sections together. The mechanical elements include, in the preferred embodiment, a projection on one arch section and a depression on the other arch section. Cast-in-place concrete is placed in boxed-out, or step, sections located adjacent to the mechanical elements and completes the joint.

Owner:CONTECH ENGINEERED SOLUTIONS

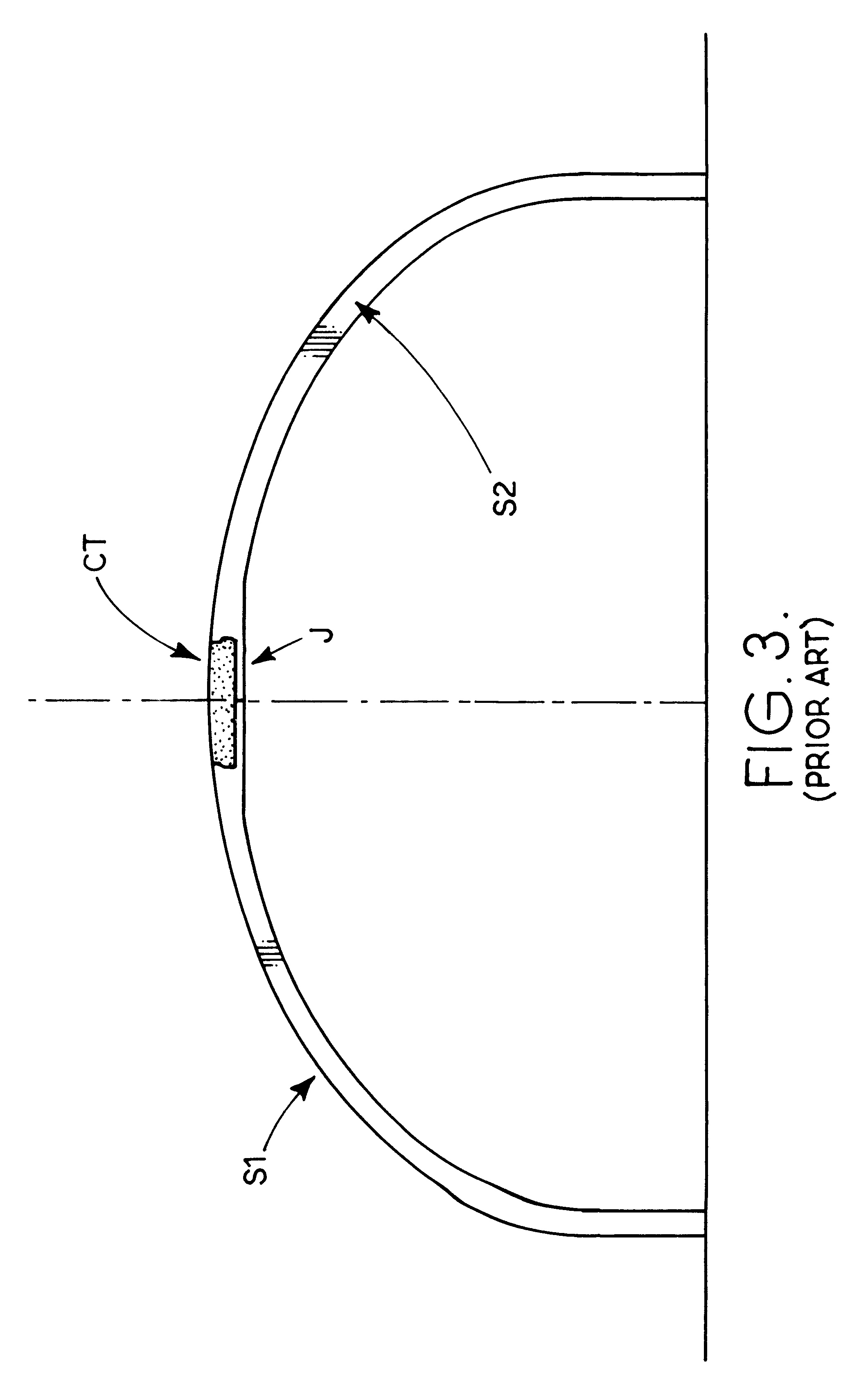

Slag concrete manufactured aggregate

Embodiments of the invention provide a slag manufactured aggregate suitable for inclusion in one or more of concrete, precast concrete, cellular concrete, or precast cellular concrete. Concretes, precast concretes, cellular concretes, and precast cellular concretes comprising the slag manufactured aggregate are also included in embodiments of the invention. Methods of making the foregoing aggregates and concretes are also included herein.

Owner:EXCELL TECH

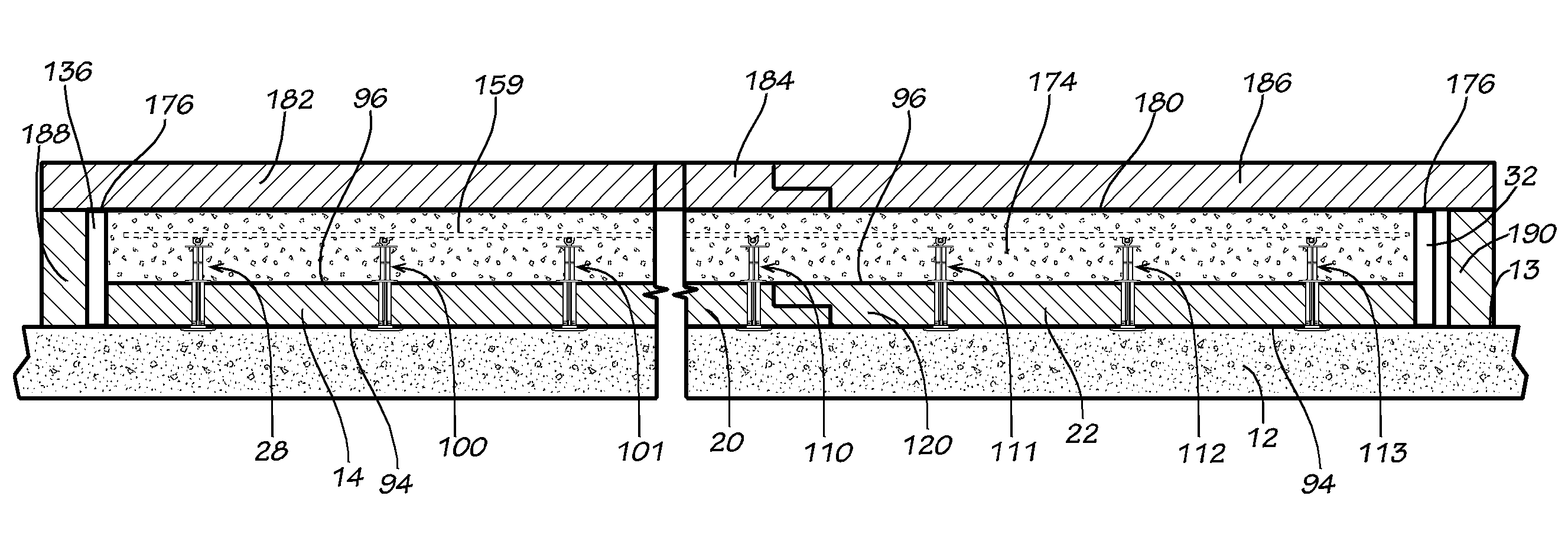

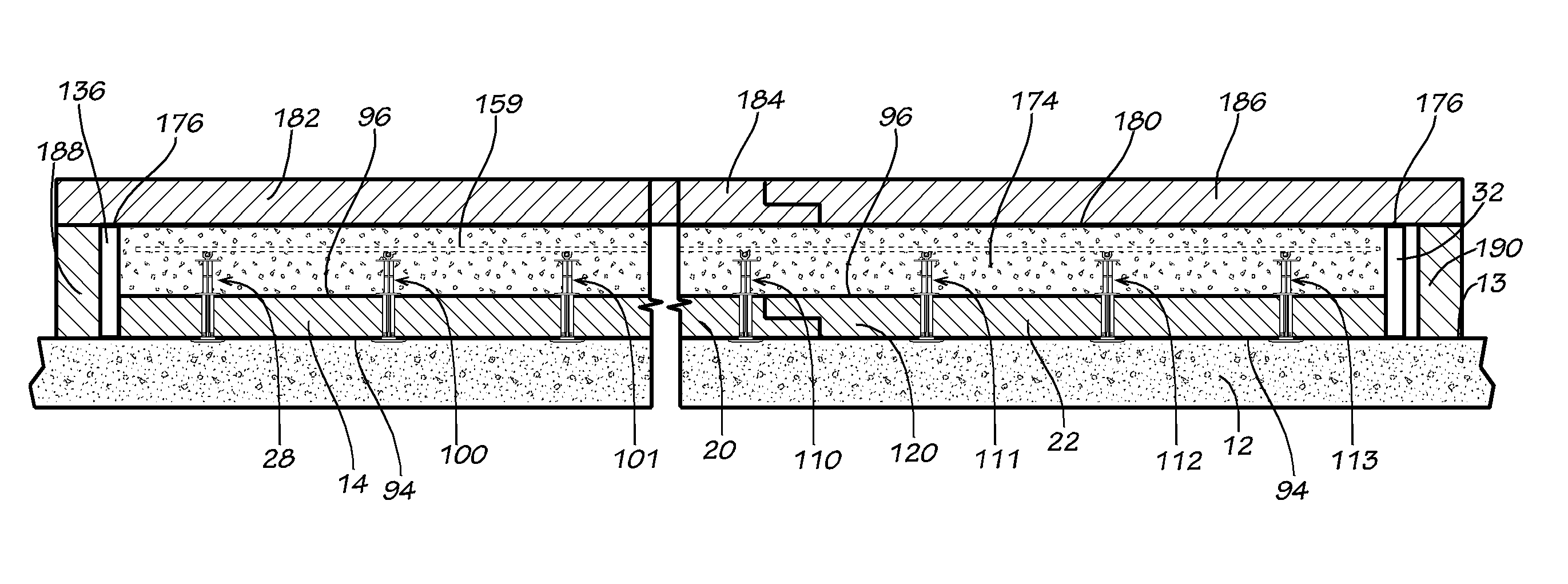

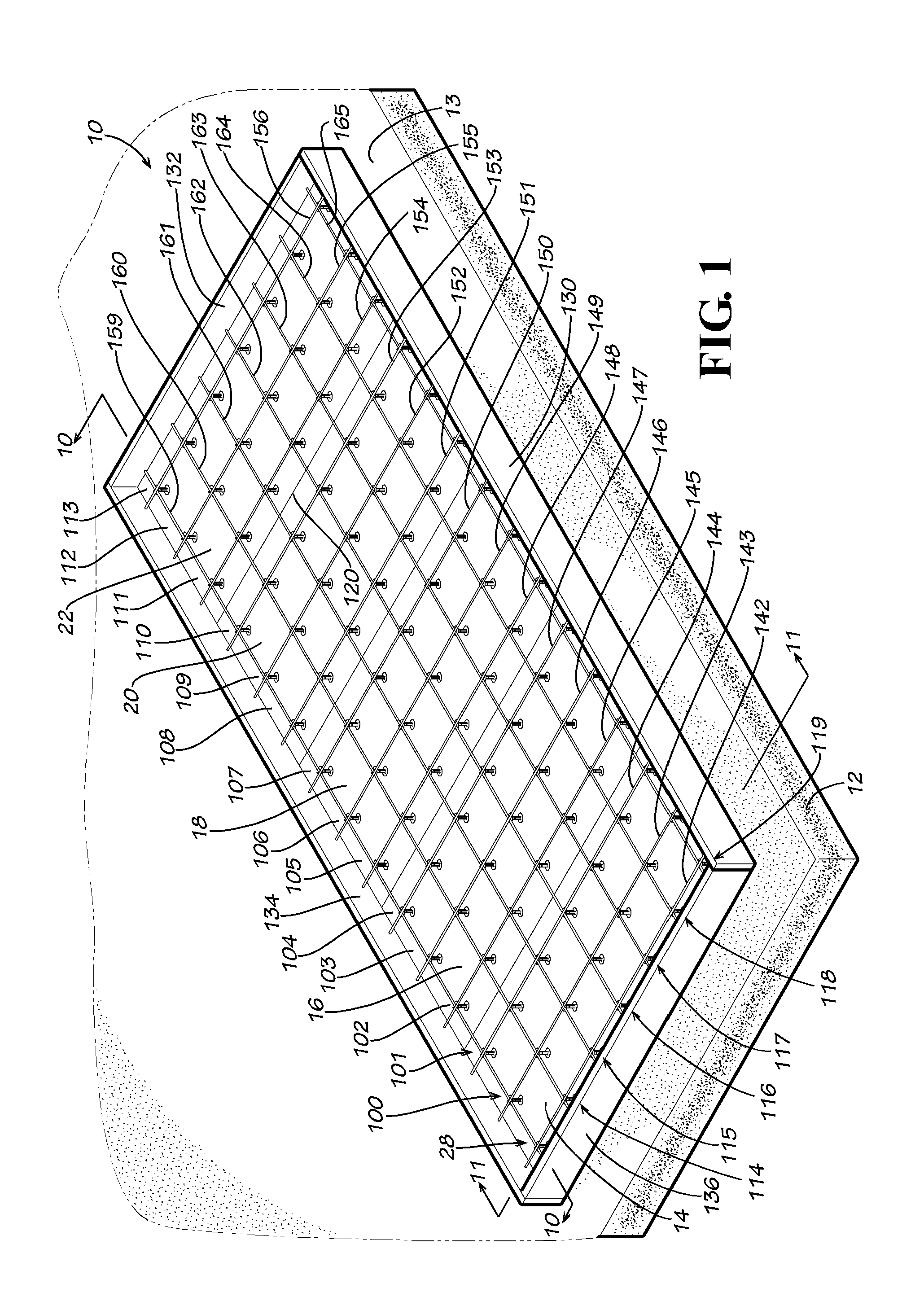

High performance, reinforced insulated precast concrete and tilt-up concrete structures and methods of making same

Owner:CIUPERCA ROMEO ILARIAN

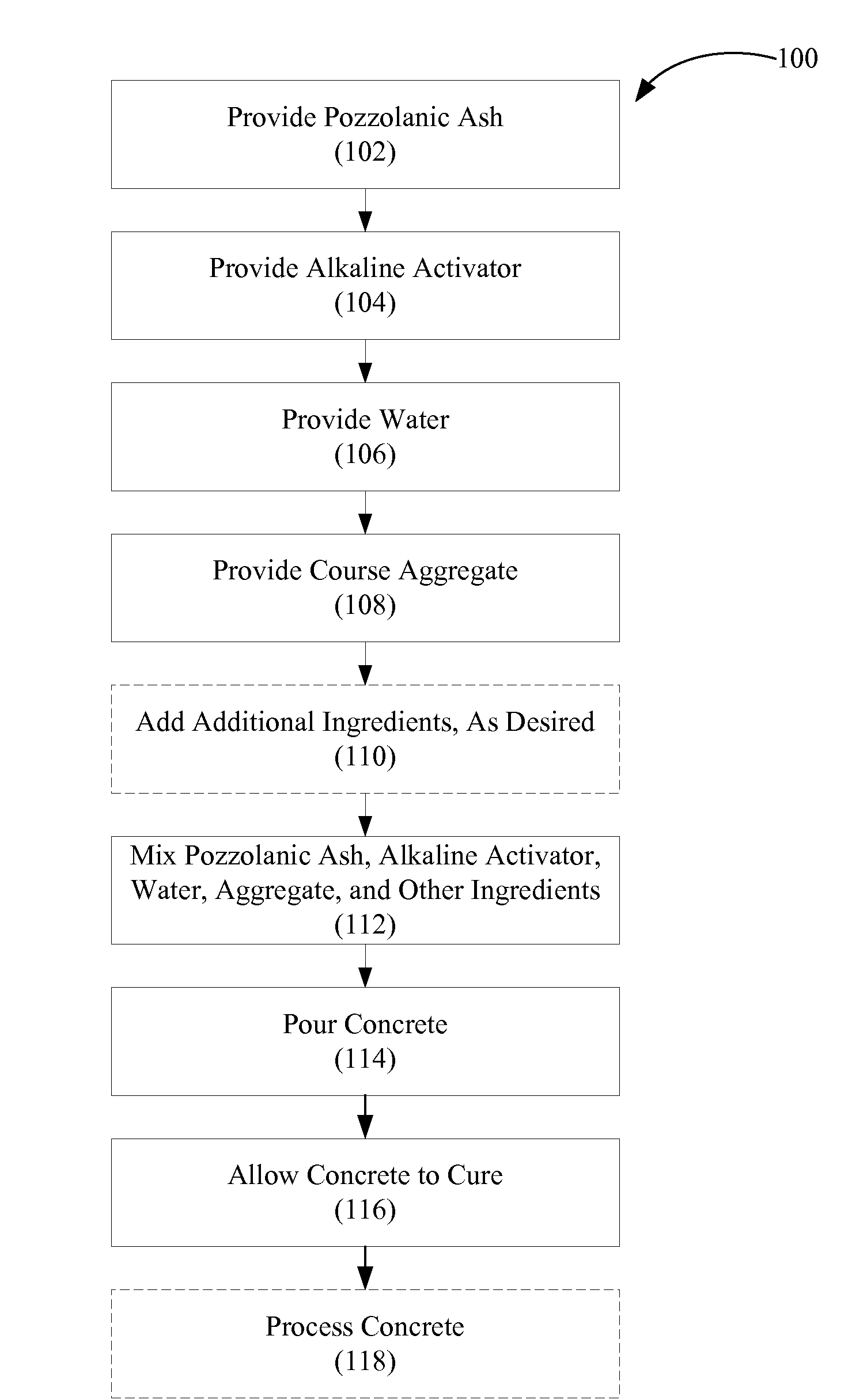

Previous concrete comprising a geopolymerized pozzolanic ash binder

ActiveUS20100058957A1Low costImprove performanceSolid waste managementCement productionAluminateCombustion

A process for making a pervious concrete comprising a geopolymerized pozzolanic ash. Generally, the process includes mixing a solid aggregate and a geopolymerized pozzolanic ash binder together to form a pervious concrete mixture. Some examples of suitable aggregates comprise recycled carpet, recycled cement, and aggregates of coal-combustion byproducts. The geopolymerized pozzolanic ash binder is made by combining a pozzolanic ash, such as fly ash, with a sufficient amount of an alkaline activator and water to initiate a geopolymerization reaction. The activator solution may contain an alkali metal hydroxide, carbonate, silicate, aluminate, or mixtures thereof. In some aspects, the final concrete forms a solid mass in the form of pavement or a pre-cast concrete shape. The solid mass of concrete may have a void content of between about 5% and about 35%.

Owner:CERAMTEC

High performance, reinforced insulated precast concrete and tilt-up concrete structures and methods of making same

Owner:CIUPERCA ROMEO ILARIAN

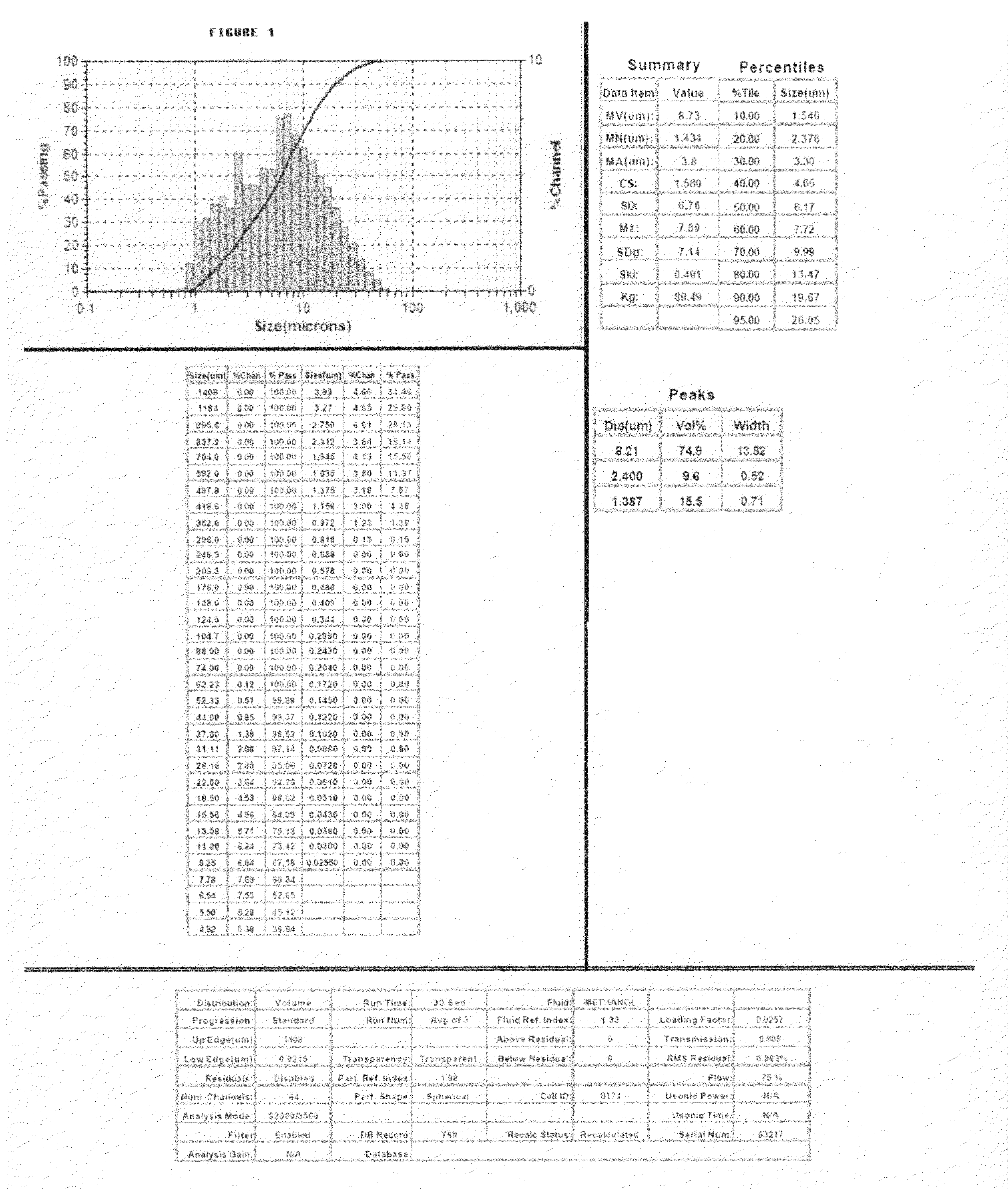

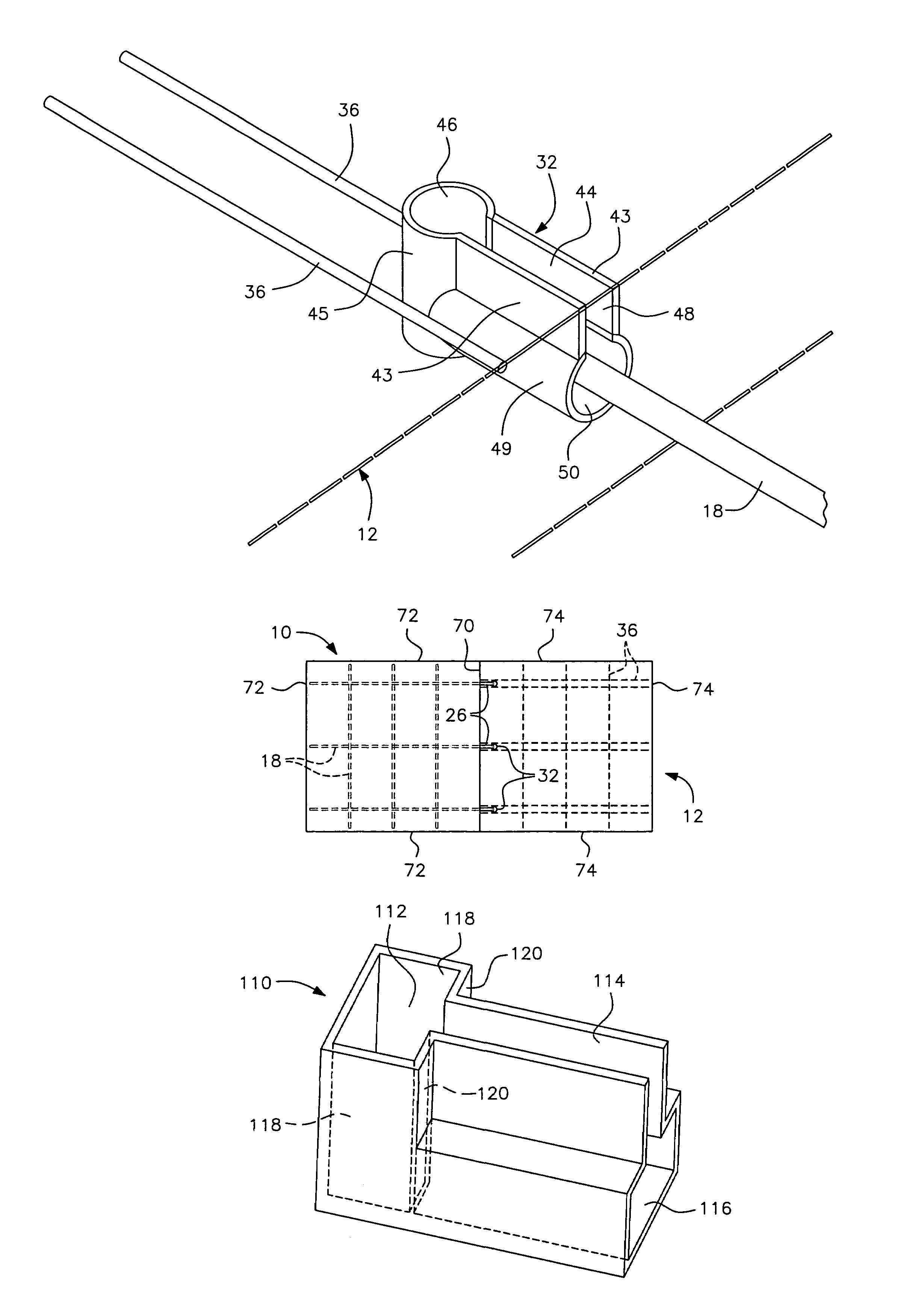

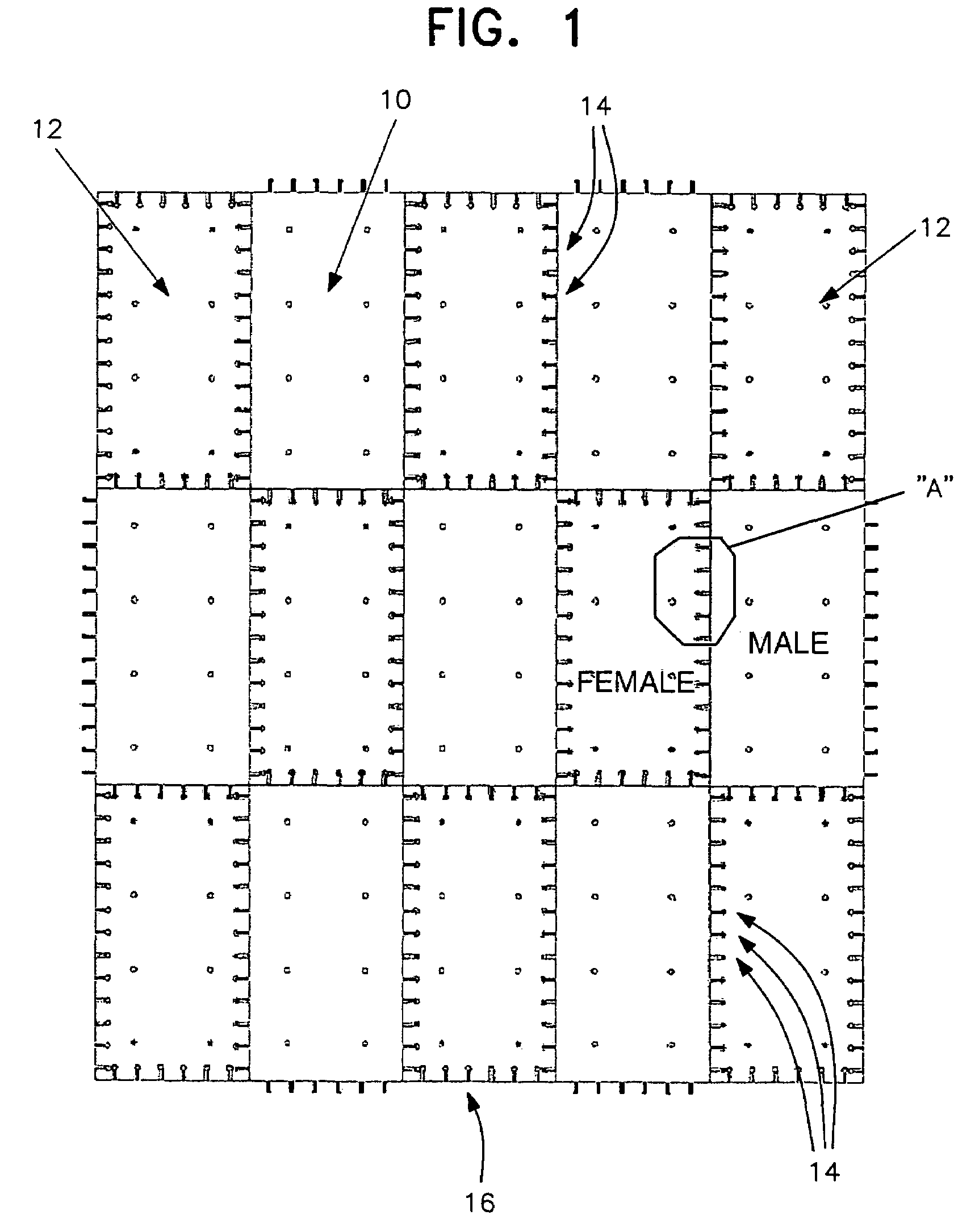

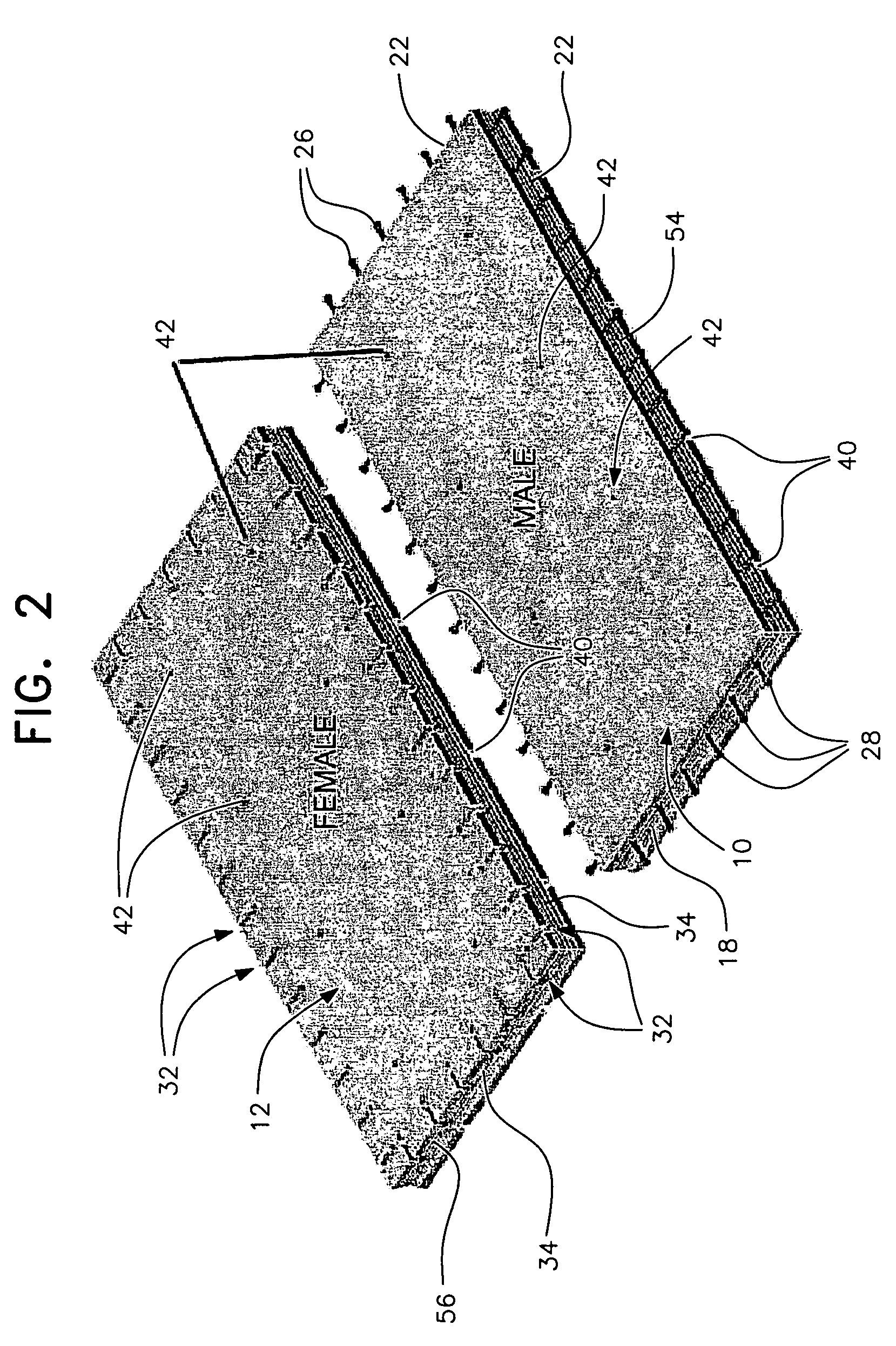

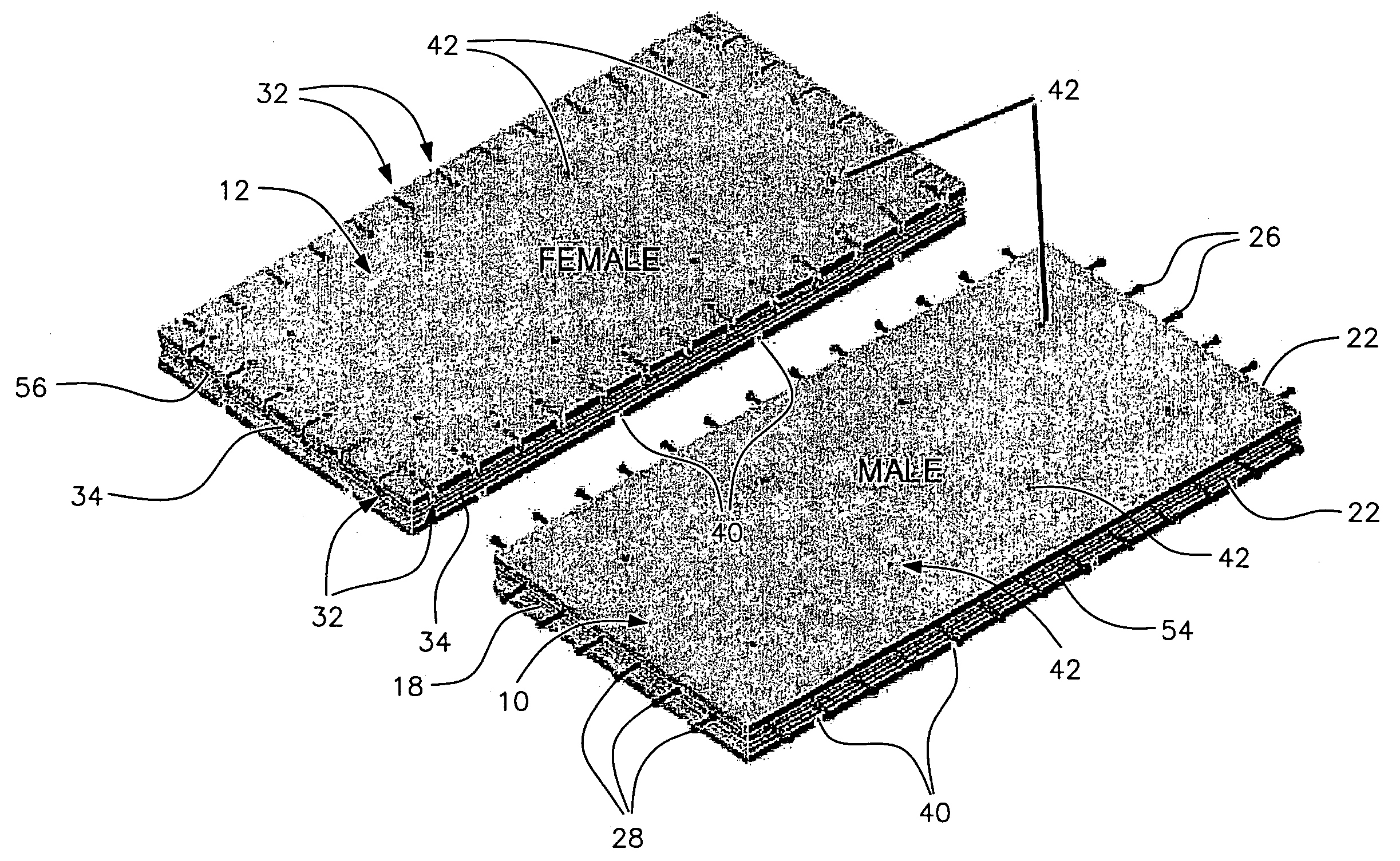

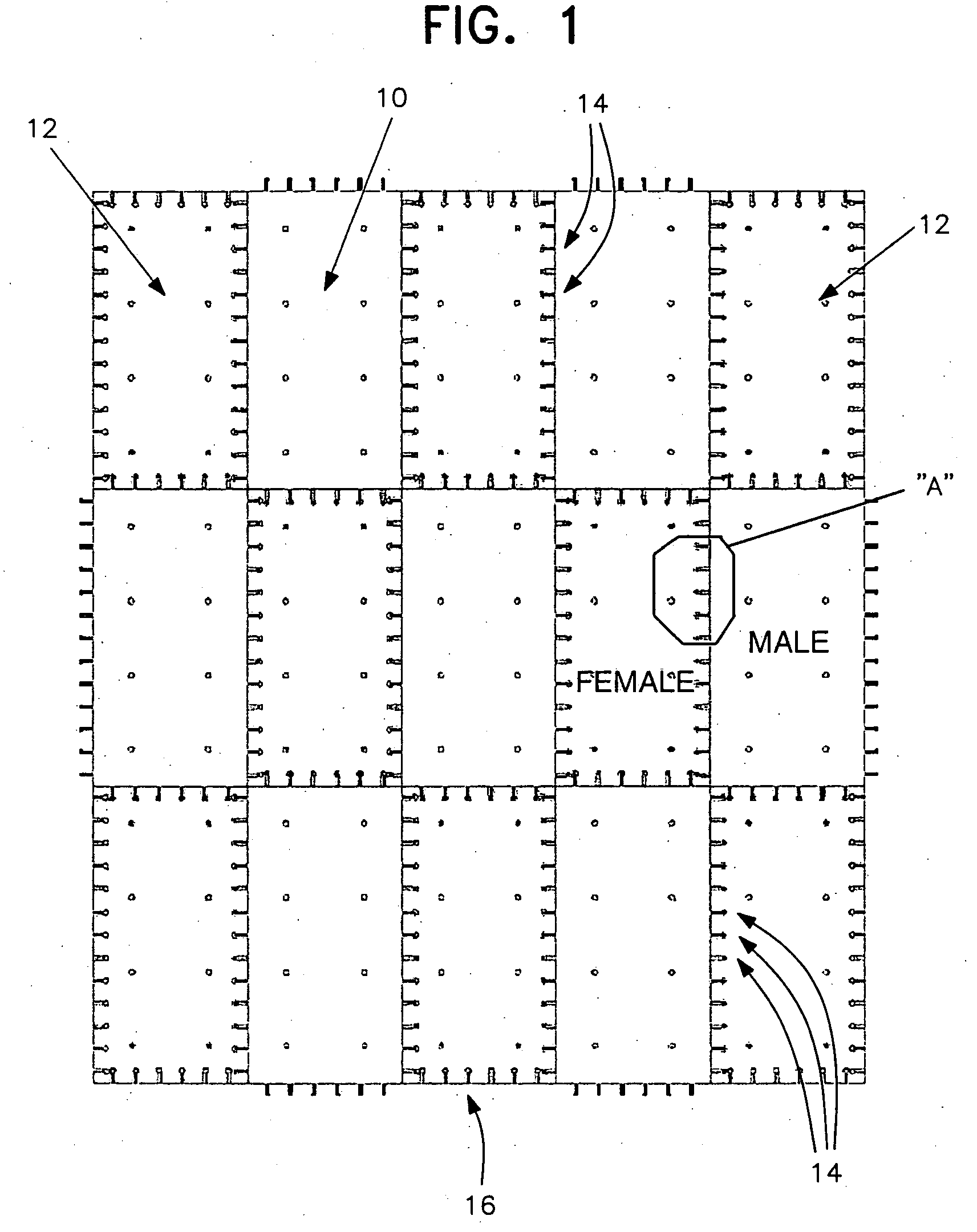

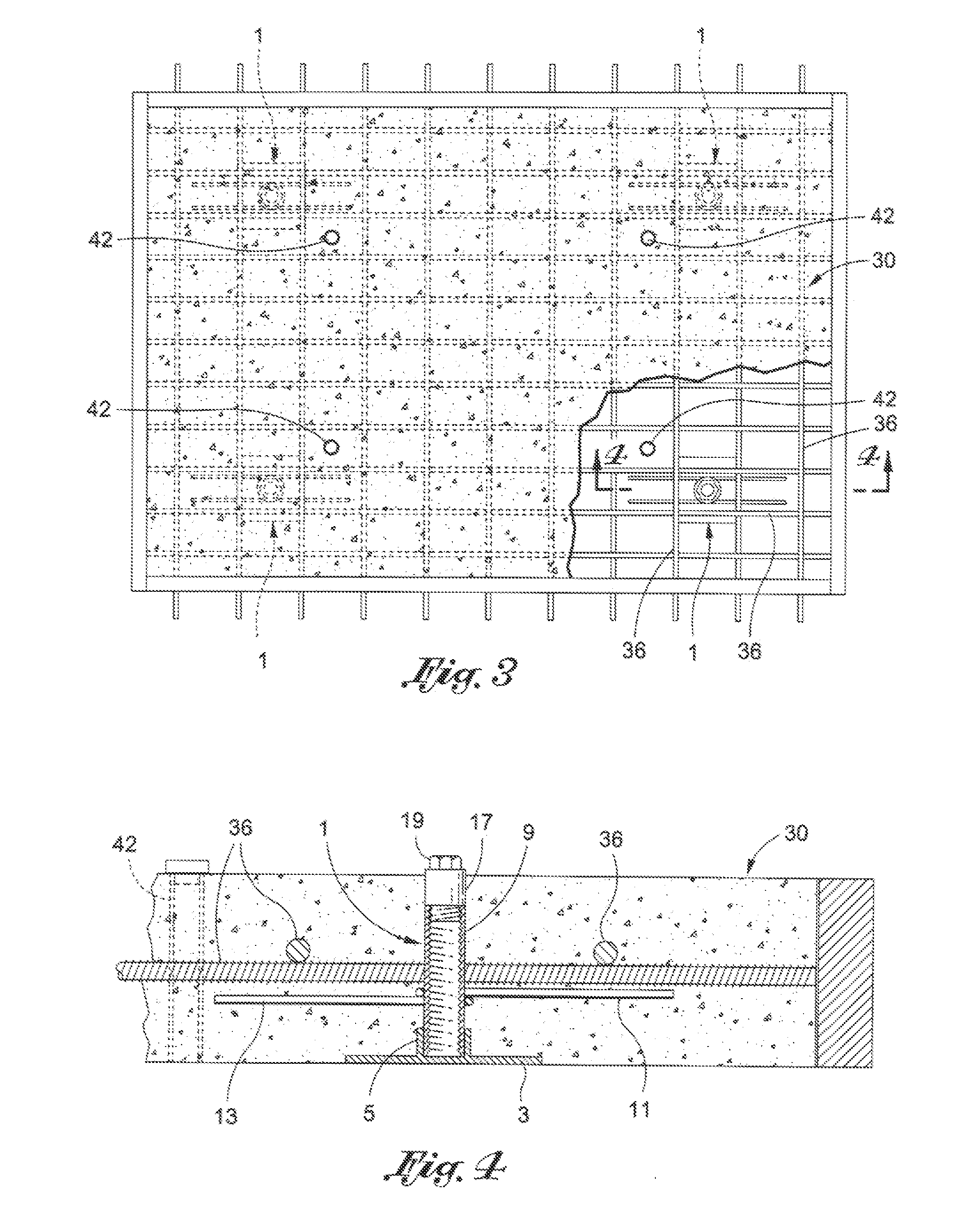

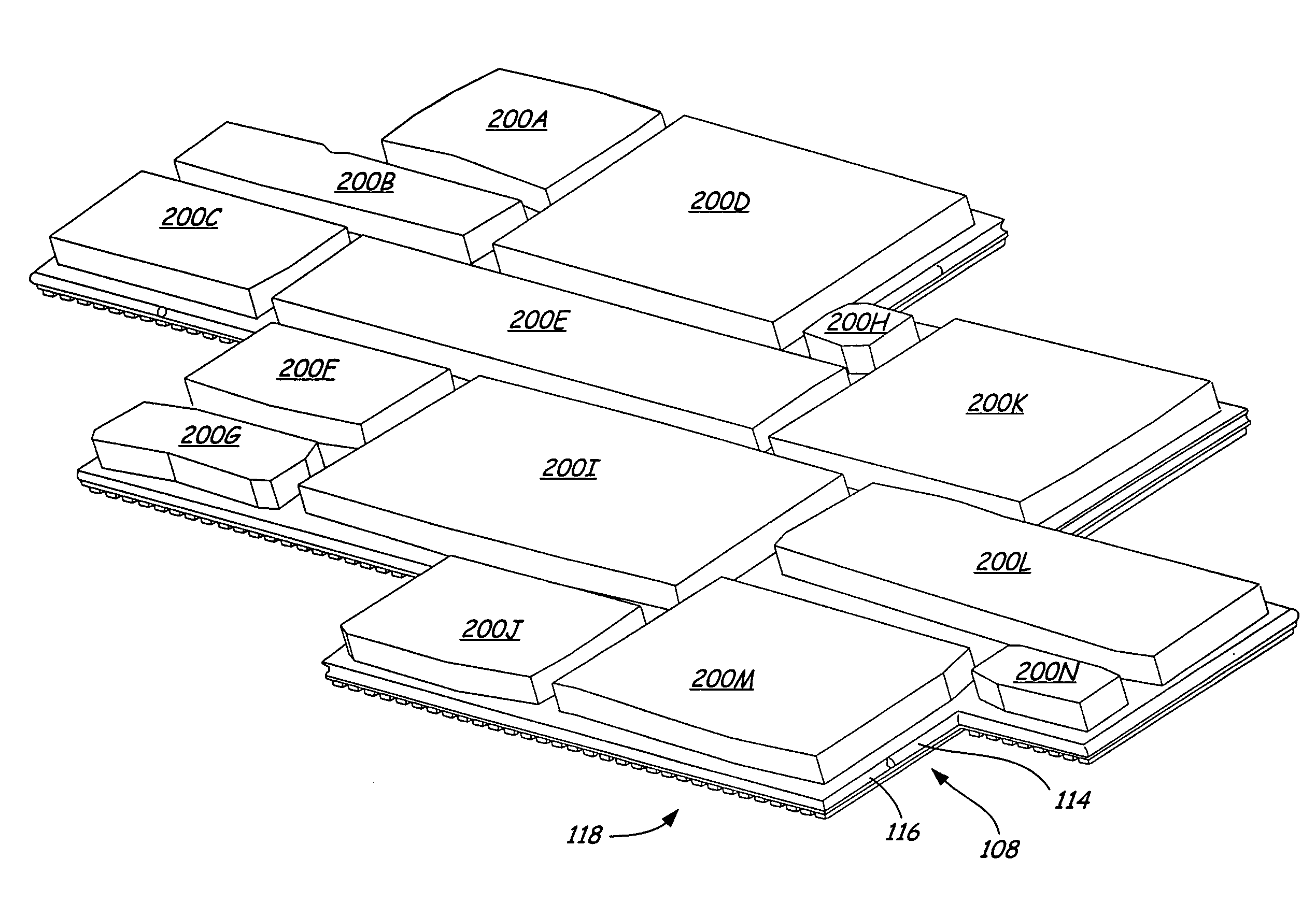

Precast concrete slab system and method therefor

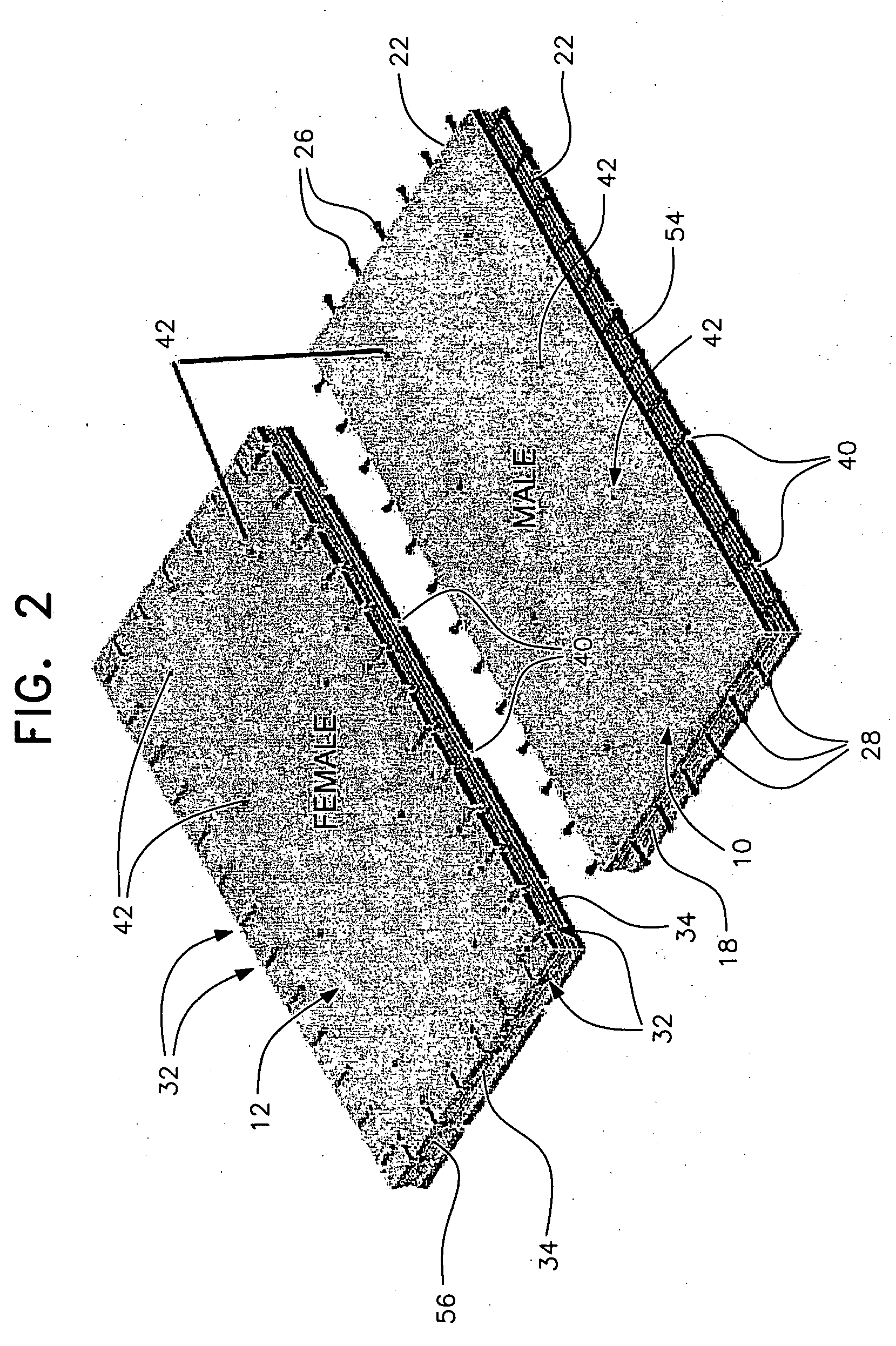

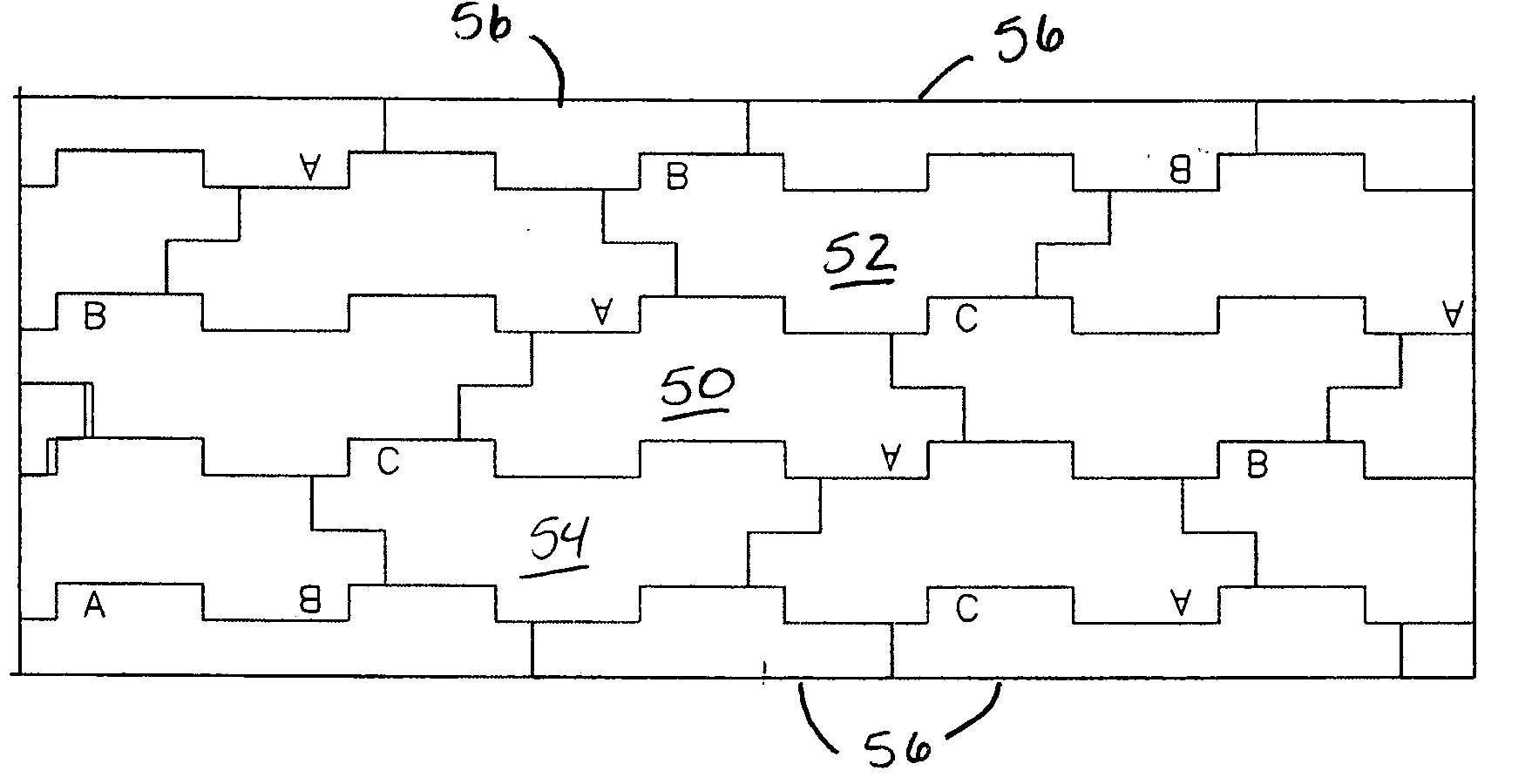

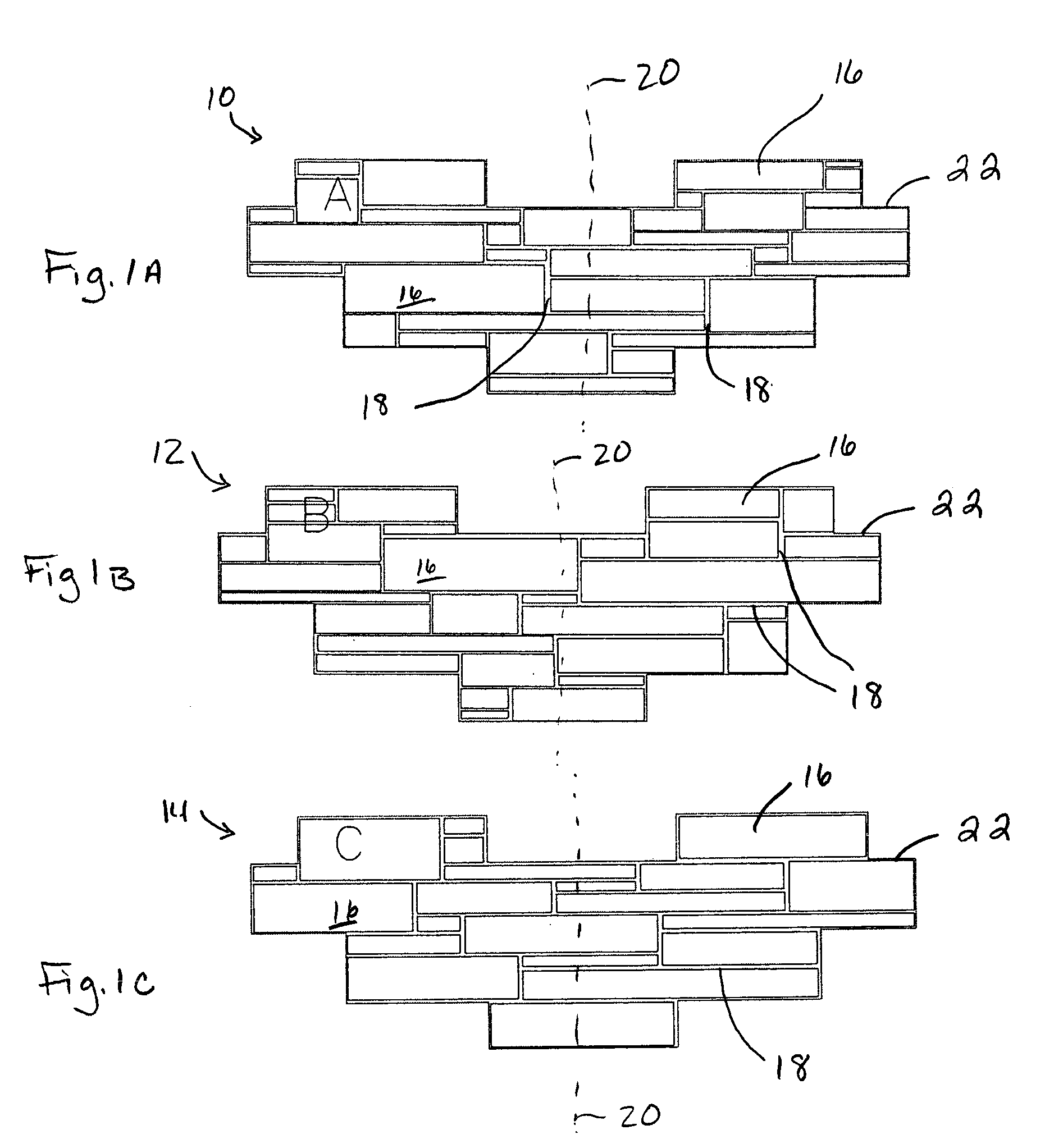

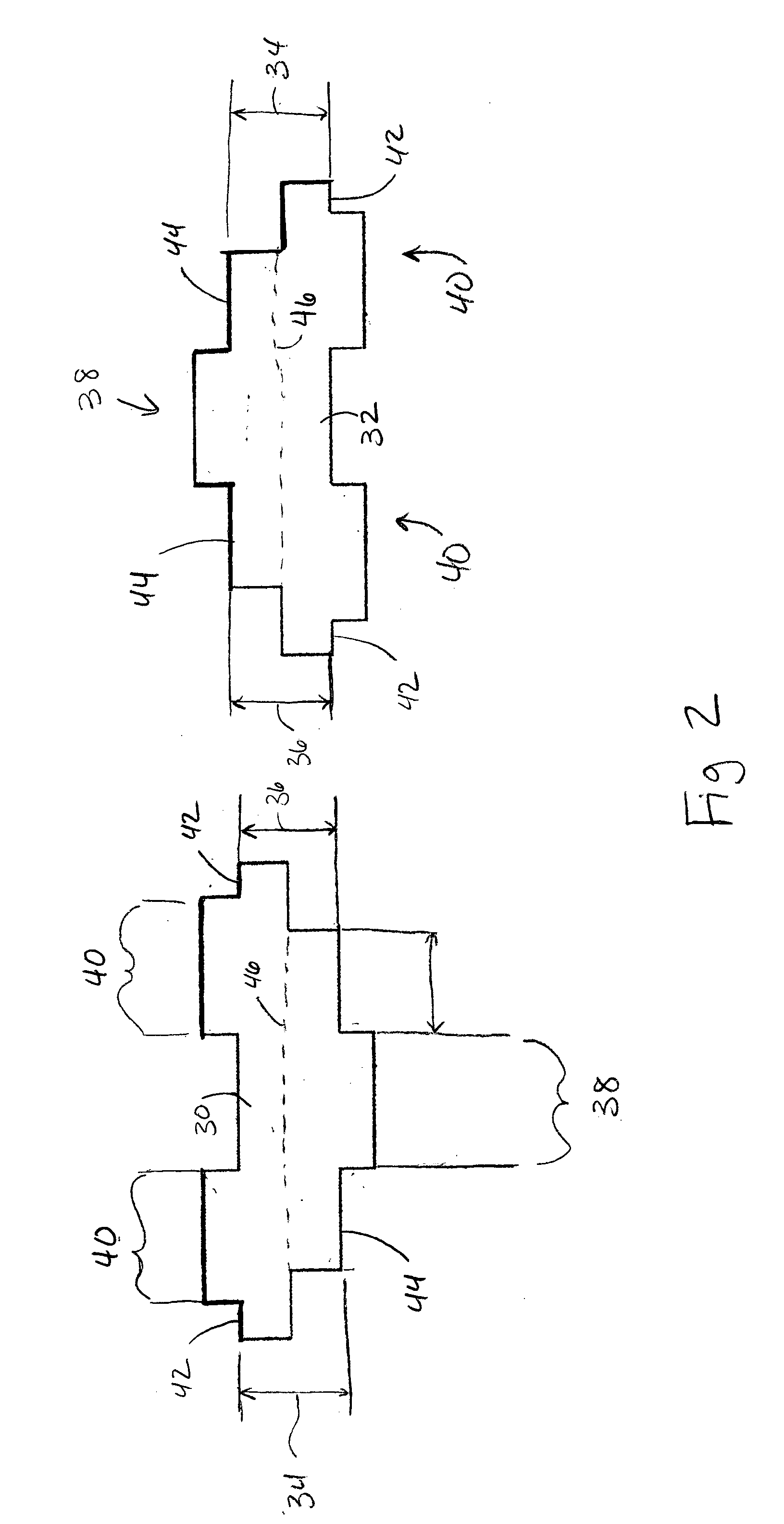

A pre-fabricated concrete slab system and method have matching rectangular male and female type slabs which fit adjacent to each other in a checkerboard fashion. The male slabs include spaced reinforcing rods extending longitudinally and transversely through the male slabs with the rods' distal ends protruding outwardly away from one or more side edges of the male slabs to form a plurality of male connectors. The female slabs include a plurality of corresponding female sockets on one or more sides of the female slab, each female socket receiving a corresponding male connector when dropped therein. Corresponding female sockets positioned on opposite side edges of the female slabs are interconnected by steel reinforcing bars in both the longitudinal and transverse directions in a configuration similar to the male slabs so that, when connected, a continuous tension reinforcement is established between male and female slabs in both the longitudinal and transverse directions.

Owner:ELIZABETH WONG YEE TRUSTEE OF THE ELIZABETH YEE REVOCABLE LIVING TRUST UNDER AGREEMENT DATED NOVEMBER 11 1981 AS AMENDED & RESTATED +1

Precast concrete slab system and method therefor

InactiveUS20050220539A1Quick installationIncrease the lengthWallsSingle unit pavingsEngineeringRebar

A pre-fabricated concrete slab system and method have matching rectangular male and female type slabs which fit adjacent to each other in a checkerboard fashion. The male slabs include spaced reinforcing rods extending longitudinally and transversely through the male slabs with the rods' distal ends protruding outwardly away from one or more side edges of the male slabs to form a plurality of male connectors. The female slabs include a plurality of corresponding female sockets on one or more sides of the female slab, each female socket receiving a corresponding male connector when dropped therein. Corresponding female sockets positioned on opposite side edges of the female slabs are interconnected by steel reinforcing bars in both the longitudinal and transverse directions in a configuration similar to the male slabs so that, when connected, a continuous tension reinforcement is established between male and female slabs in both the longitudinal and transverse directions.

Owner:ELIZABETH WONG YEE TRUSTEE OF THE ELIZABETH YEE REVOCABLE LIVING TRUST UNDER AGREEMENT DATED NOVEMBER 11 1981 AS AMENDED & RESTATED +1

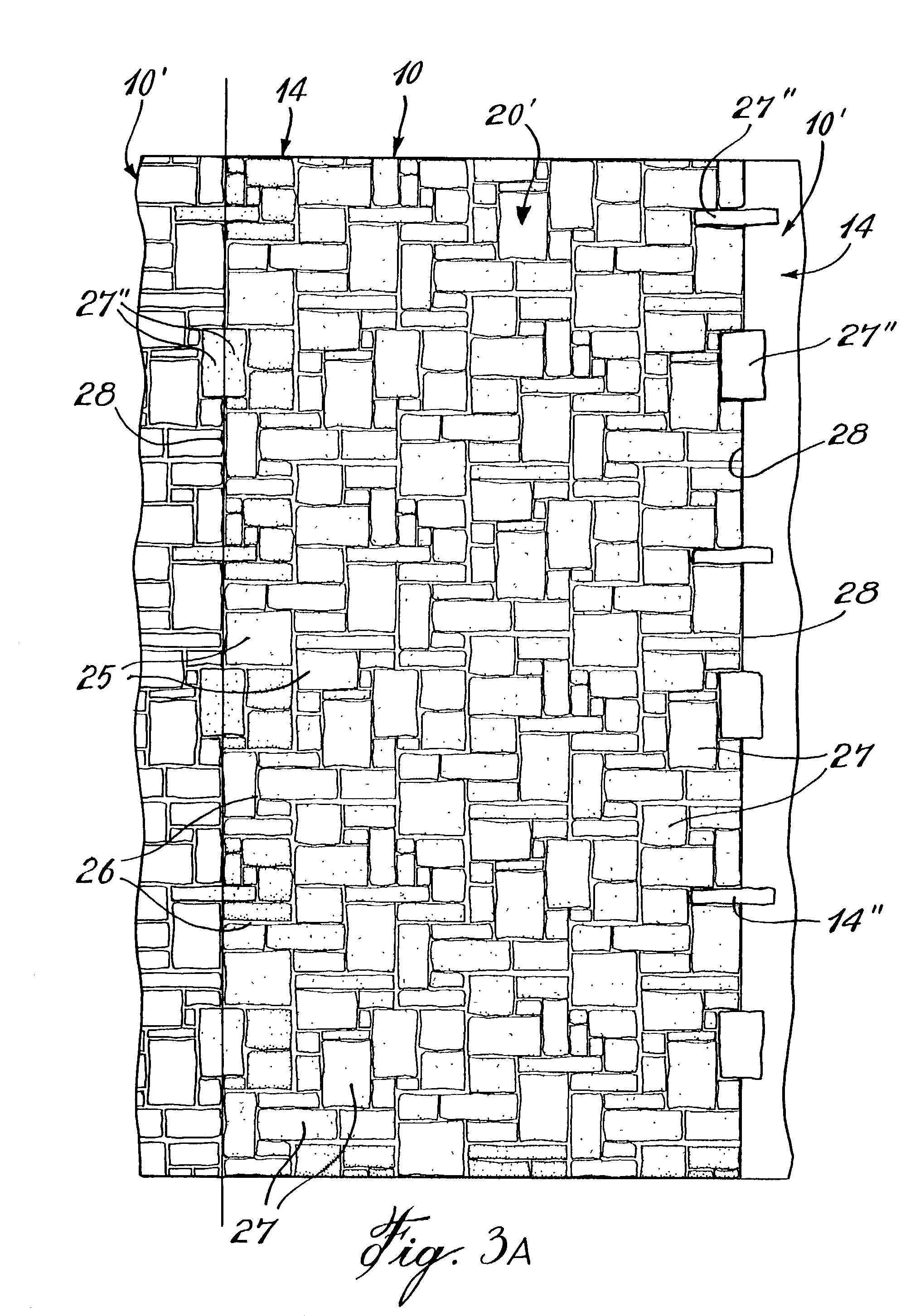

Precast concrete veneer panel system

InactiveUS20050210811A1Easily interconnect verticallyOptimize locationConstruction materialCovering/liningsEngineeringPrecast concrete

A pre-cast concrete veneer panel system for attaching to a wall surface. The pre-cast concrete veneer panels comprise a surface having simulated stone regions surrounded by simulated mortar regions. The concrete veneer panels are sized and shaped to allow the panels to interconnect both vertically and horizontally in a manner which results in a wall facade having a random pattern of unique stones.

Owner:NASVIK PAUL C

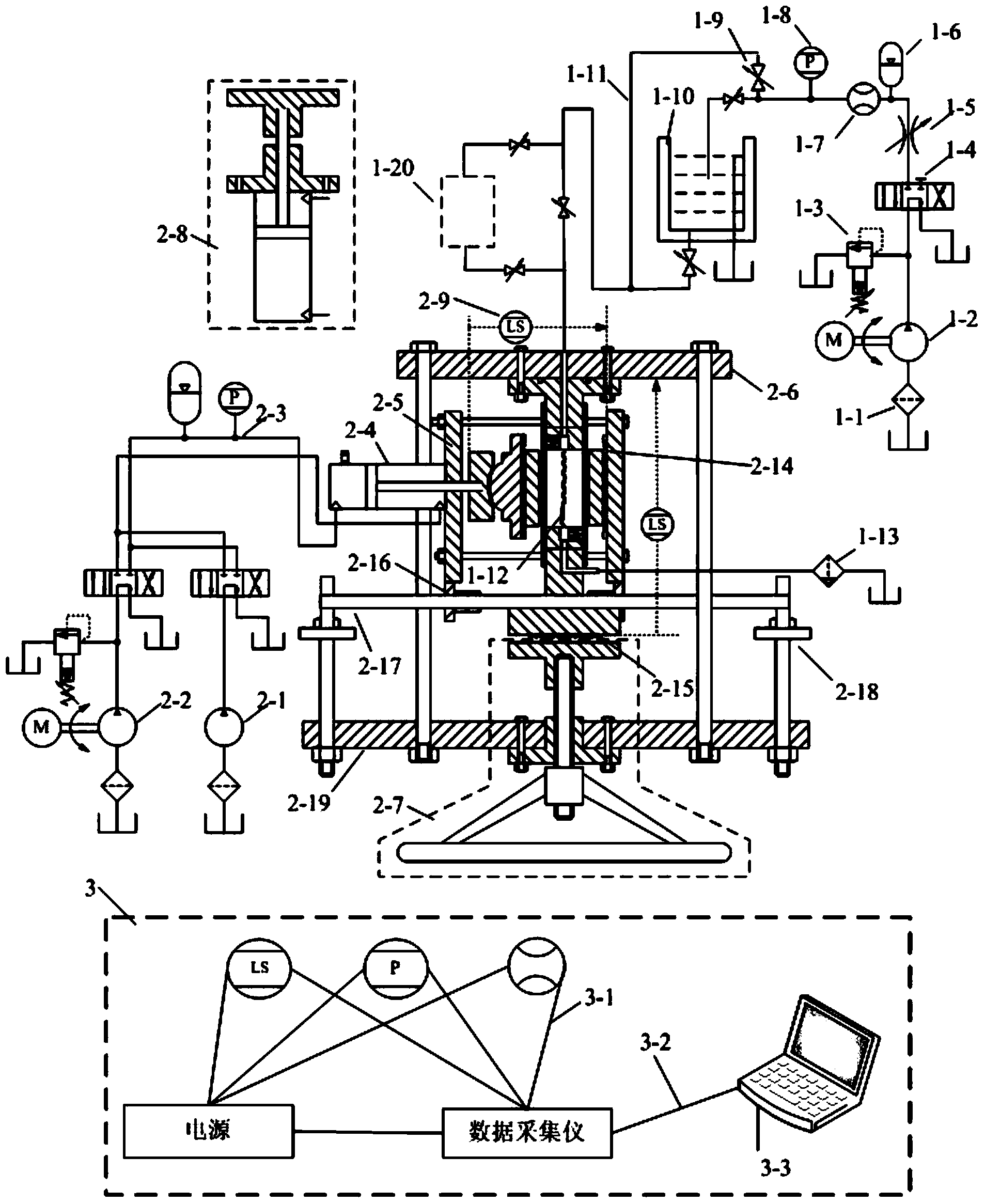

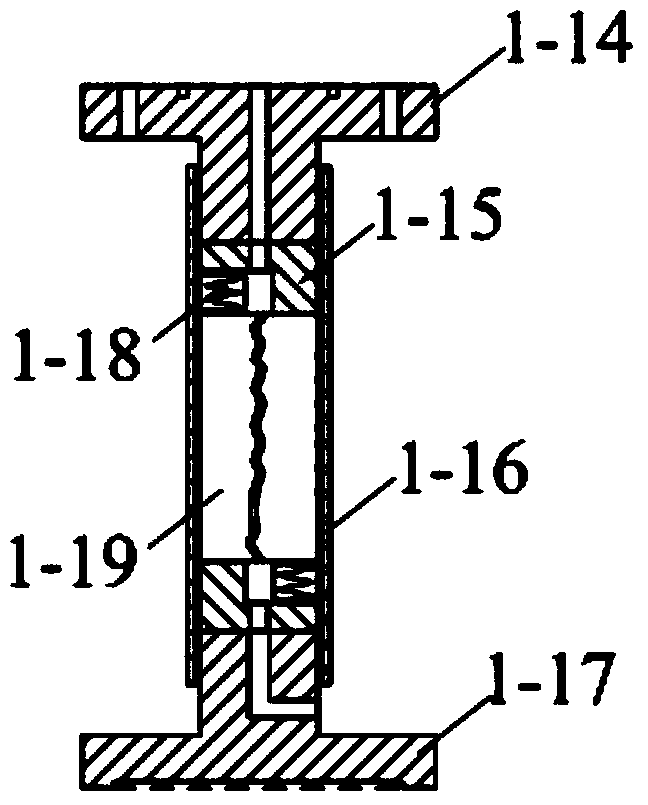

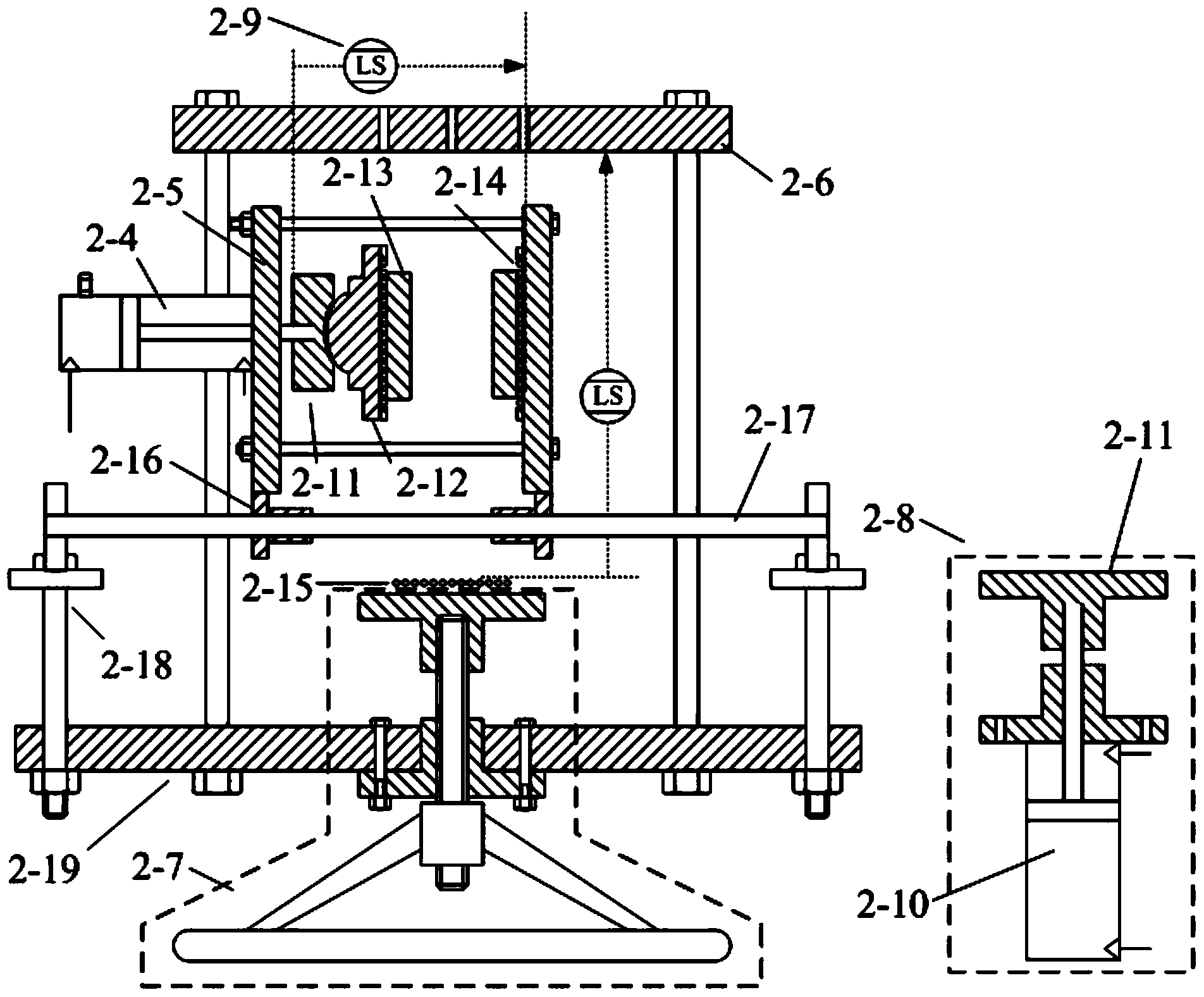

Fractured rock mass stress and seepage coupled testing system and method

InactiveCN104316447AEffective testing methodChange stress statePermeability/surface area analysisHydraulic cylinderThree degrees of freedom

The invention discloses a fractured rock mass stress and seepage coupled testing system and a fractured rock mass stress and seepage coupled testing method, belonging to testing systems and methods for fractured rock mass or pore medium seepage of rock and soil and geology. The system is divided into three parts, namely a seepage experiment device, a stress and displacement loading system and a data acquisition system, wherein the seepage experiment device can load square fractured rock mass or precast concrete crack samples, and a water pump provides power to form a test loop seepage channel; a control valve, an energy accumulator, a filtering device and a pressure and flow sensor are arranged on a water inlet / outlet pipe connected with the seepage experiment device; the stress and displacement loading system is equipped with a hydraulic cylinder driven by an oil pump and a trapezoidal screw; the hydraulic cylinder and the trapezoidal screw are matched with the pressure and flow sensor, so that the pressure and displacement can be accurately regulated and controlled; an unrelated three-degree-of-freedom sliding system is formed by a flange bearing, a cylindrical pin and a small ball, so that loading is not interfered by friction and other adverse factors; and moreover, all data in the experimental process is acquired and recorded by the data acquisition system in real time.

Owner:CHINA UNIV OF MINING & TECH

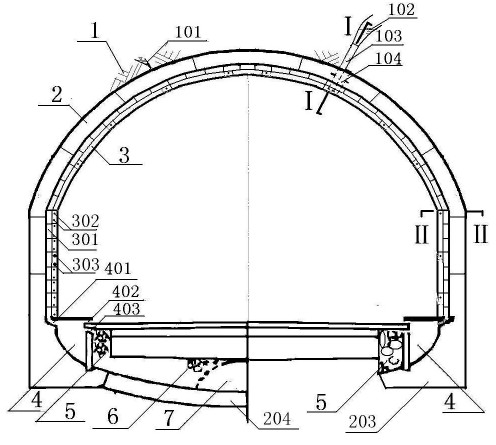

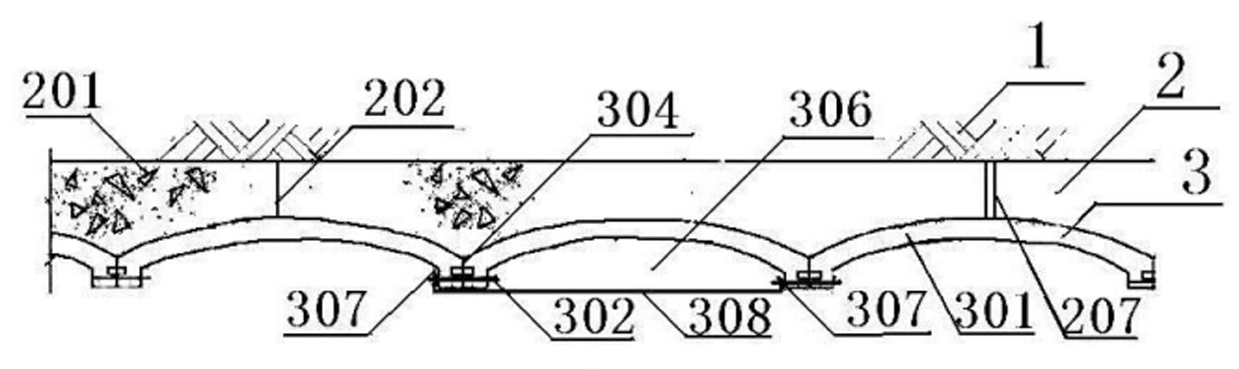

Tunnel lining self waterproof drainage system

InactiveCN102434175AGuaranteed reliabilityImprove waterproof qualityUnderground chambersDrainagePondingTube drainage

The invention relates to a tunnel lining self waterproof drainage system, which comprises a surrounding rock bearing arch, a cast-in-place cement main waterproof layer, a pre-cast cement arch sheet layer and longitudinal drainage channels. Arch sheet layer construction gaps and cast-in-place cement main waterproof layer construction gaps are interlaced. The tunnel lining self waterproof drainage system is characterized in that movable drainage grooves are fixedly arranged below the pre-cast cement arch sheet layer of centralized bursting water seepage points of loose surrounding rocks, and form arch sheet drainage spaces with an inwards concave surface of the pre-cast cement arch sheet layer, the parallel drainage spaces distributed along the section of a tunnel form a movable drainage channel, the longitudinal drainage channels are communicated and are arranged on two sides of the movable drainage channel and the pavement of the tunnel, pre-embedded water guiding pipes are arranged at the centralized bursting water seepage points, a water outlet end of each pre-embedded water guiding pipe is arranged on the inwards concave surface of the pre-cast cement arch sheet layer, and pre-embedded grouting pipes are arranged outside the pre-embedded water guiding pipes. The invention completely solves stubborn problems of the tunnel on cracking, seeping, frost heaving, ponding or freezing and the like on the premise of not arranging an interlayer waterproof layer and a hidden seepage water blind pipe drainage system, and the tunnel lining self waterproof drainage system disclosed by the invention has a simple structure and is convenient to construct.

Owner:中国市政工程西北设计研究院有限公司

Precast concrete structures, precast tilt-up concrete structures and methods of making same

ActiveUS20130074433A1Reduce internal stressReduce the amount requiredConstruction materialCovering/liningsExpanded polystyrenePrecast concrete

The invention comprises a method of forming a concrete structure. The method comprises placing plastic concrete in a form of a desired shape, encasing the concrete in insulating material having insulating properties equivalent to at least 1 inch of expanded polystyrene and allowing the plastic concrete to at least partially cure inside the insulating material. An insulated concrete form and a method of using the insulated concrete form are also disclosed.

Owner:CIUPERCA ROMEO ILARIAN

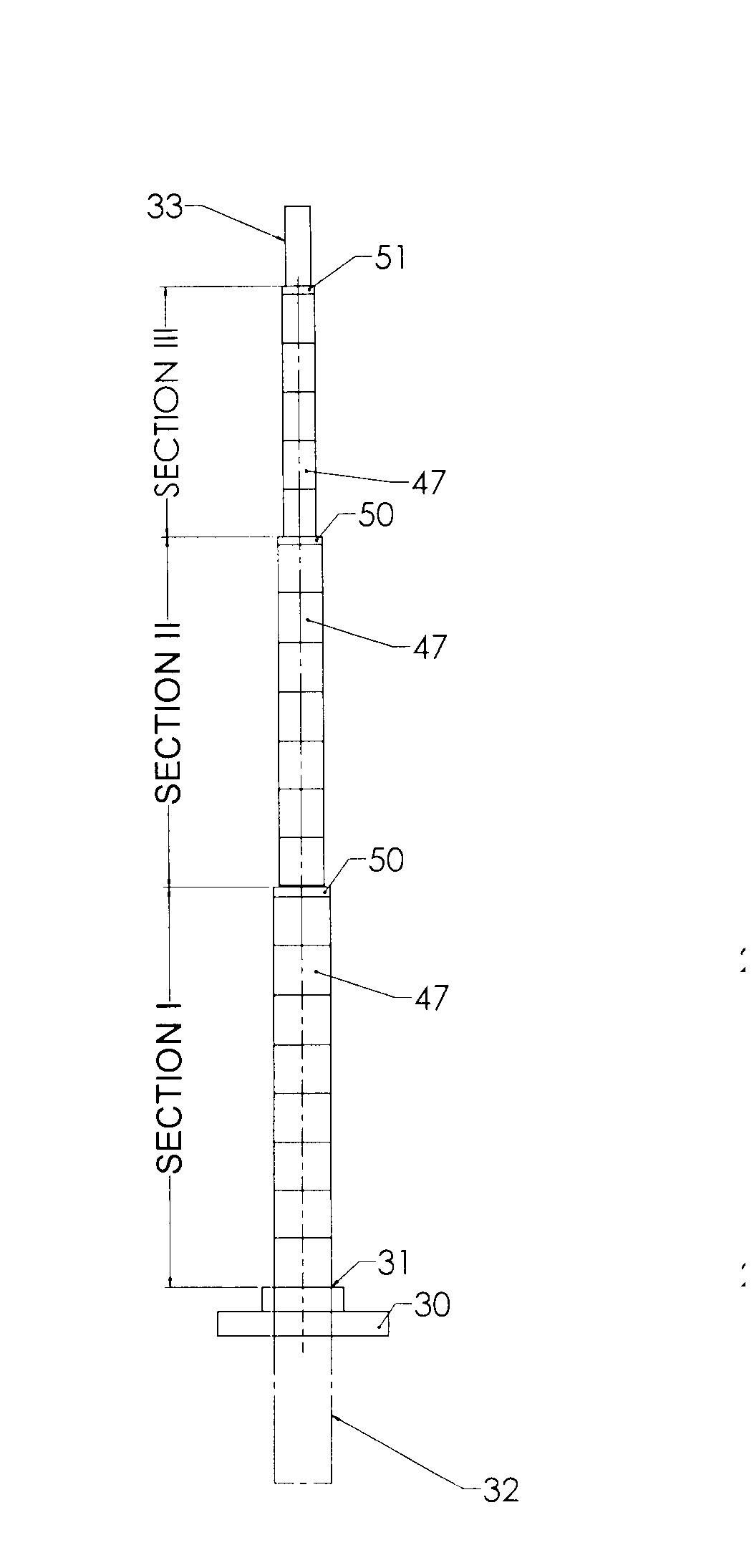

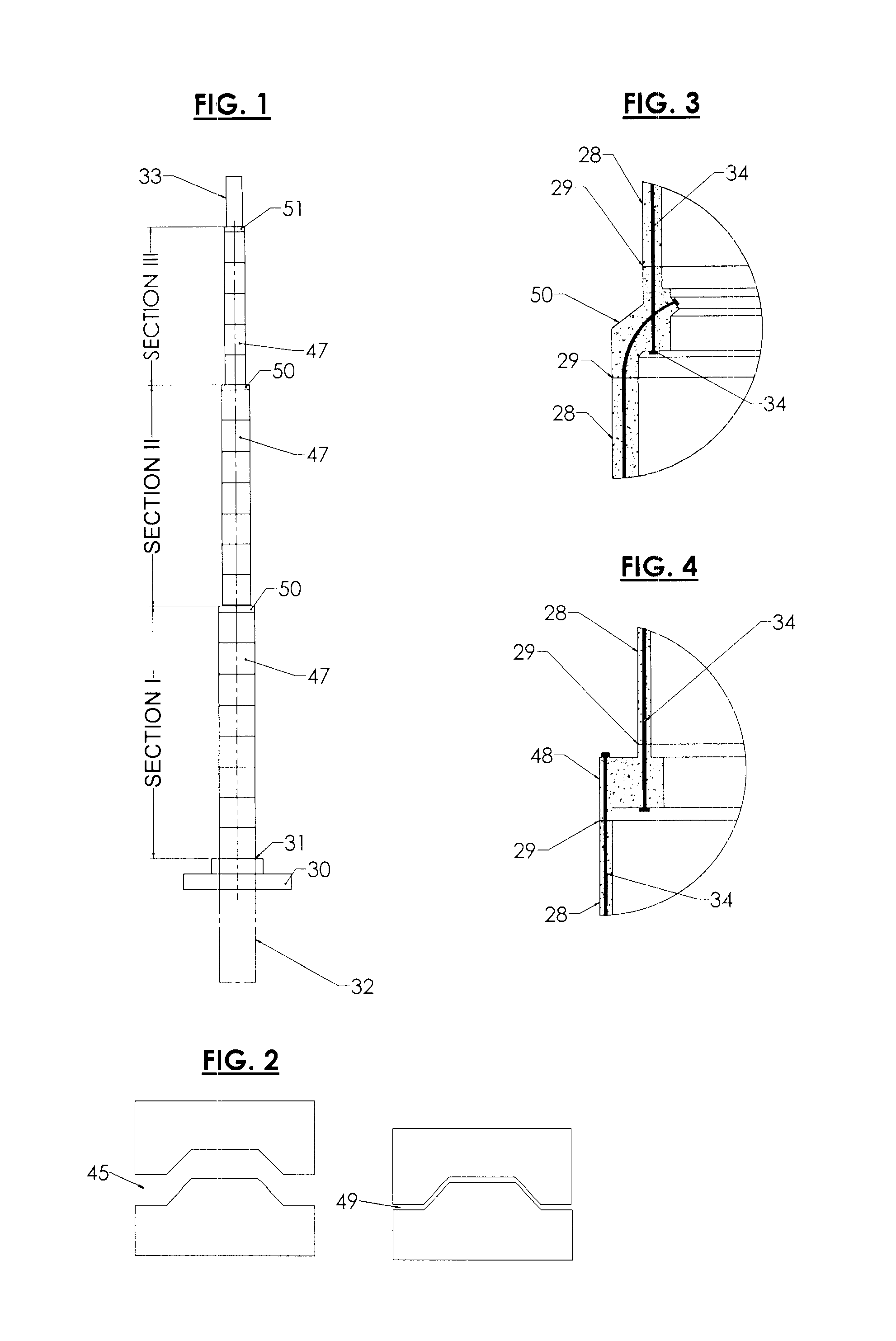

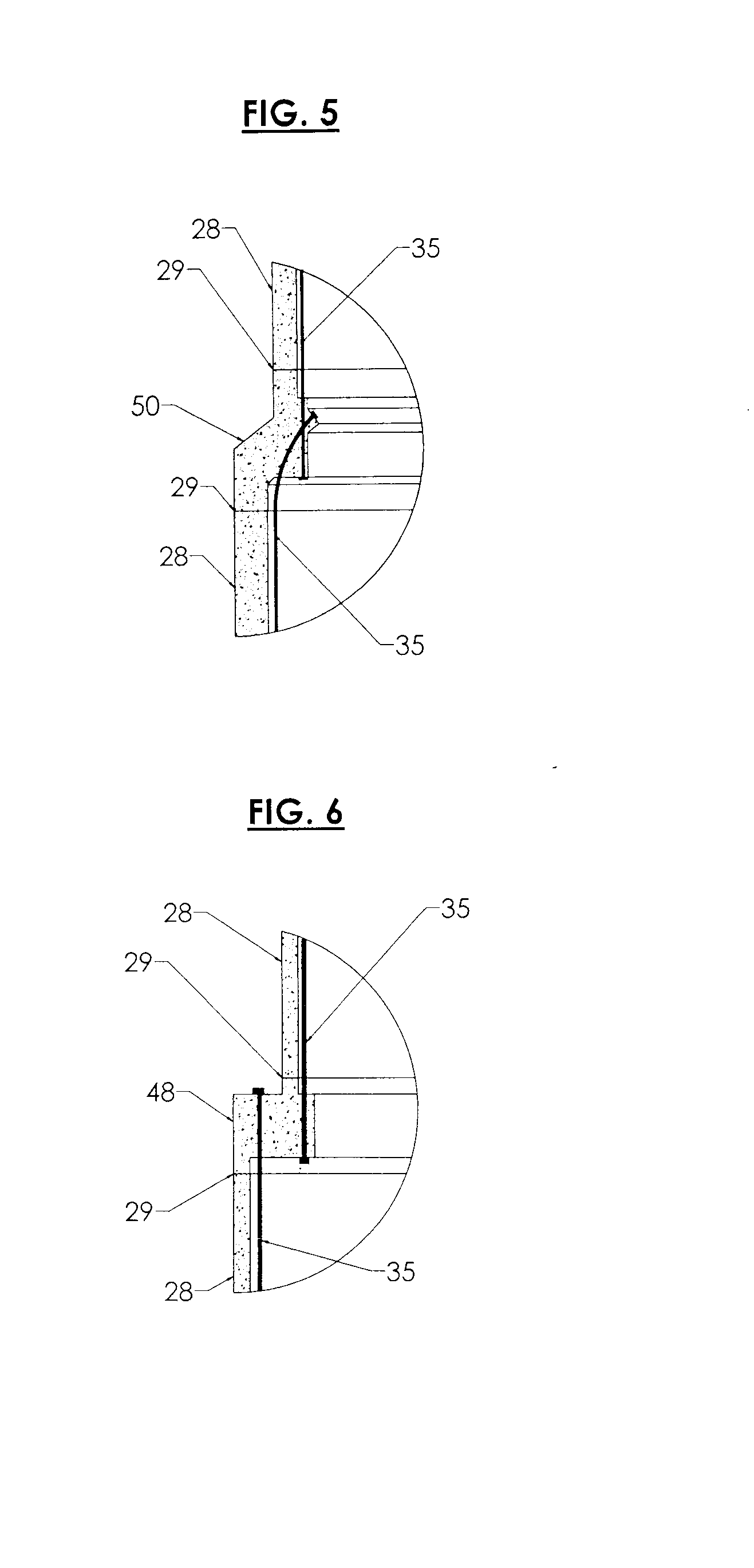

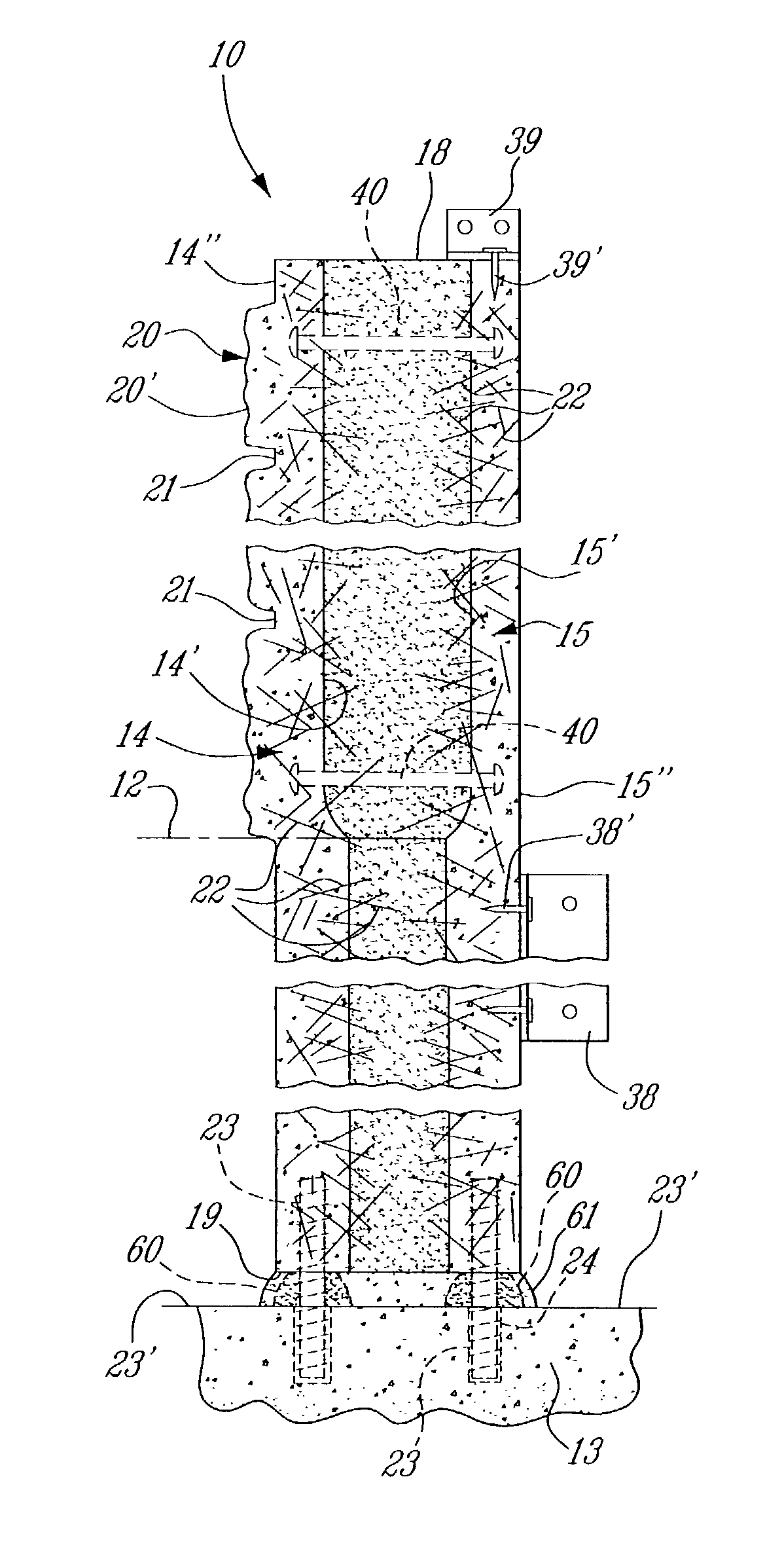

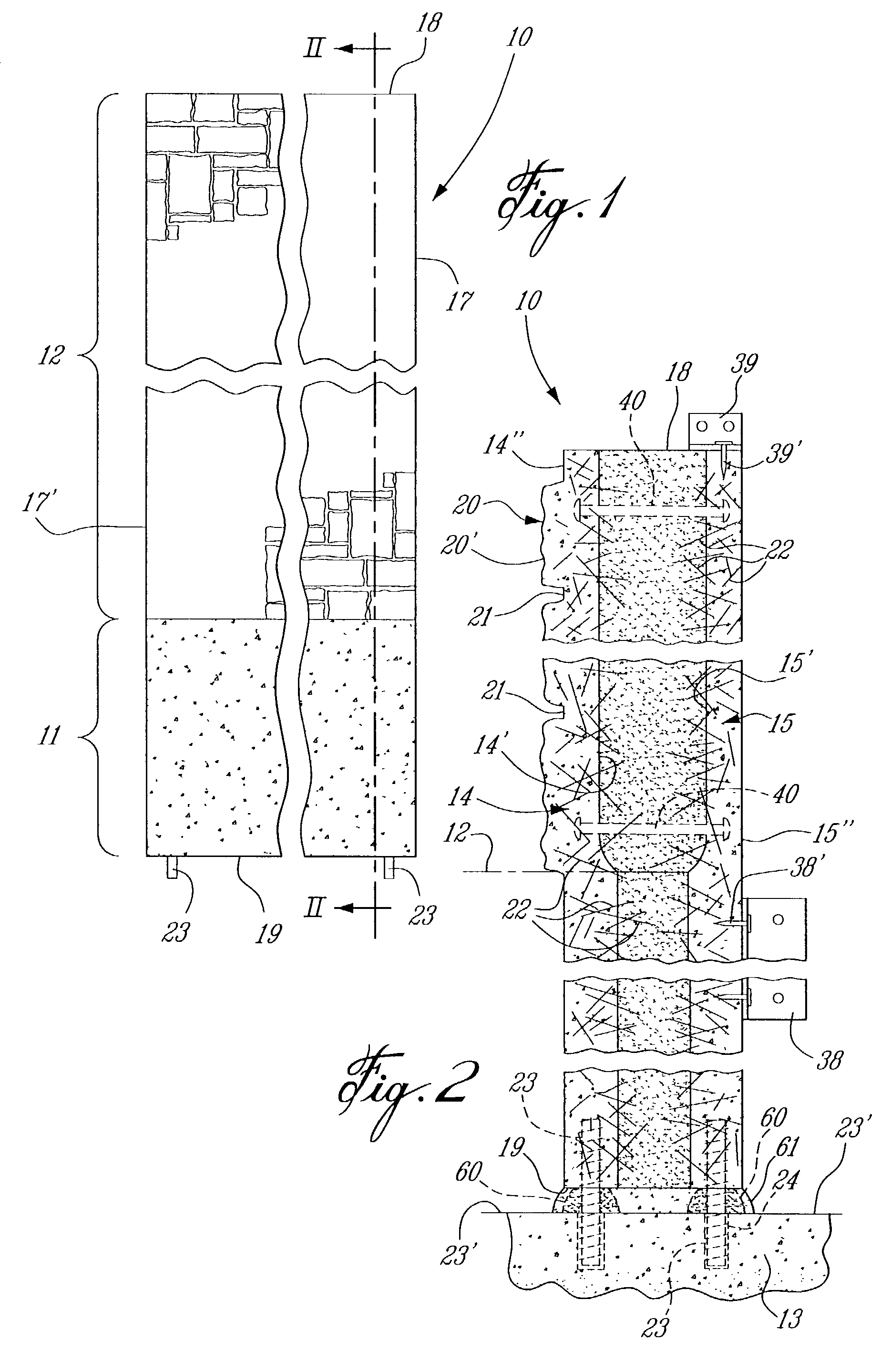

Precast concrete post tensioned segmented wind turbine tower

ActiveUS20140033628A1Easy constructionEliminate needWind motor supports/mountsMachines/enginesTowerTurbine

A post-tensioned precast segmental concrete tower has a stack of annular segments with uniform cross-sections which varies over the tower height. The transition between tower segments occurs in stages and is achieved using annular members or segments which support and anchor post-tensioning tendons that transfer loads passing through the tower as a result of a change in tower geometry. The tower segments are match cast against one another in fabrication to create tight matching opposing surfaces when placed into the tower and to create tight joints. The match casting eliminates the need for grout between precast segments, resulting in a faster tower erection time and high durability of the joints. All annular segments have horizontal joints and no vertical joints. The tower geometry simplifies the formwork system used to precast the segments, and the post-tensioning tendons tie all segments together and to the foundation.

Owner:WIND TOWER TECH

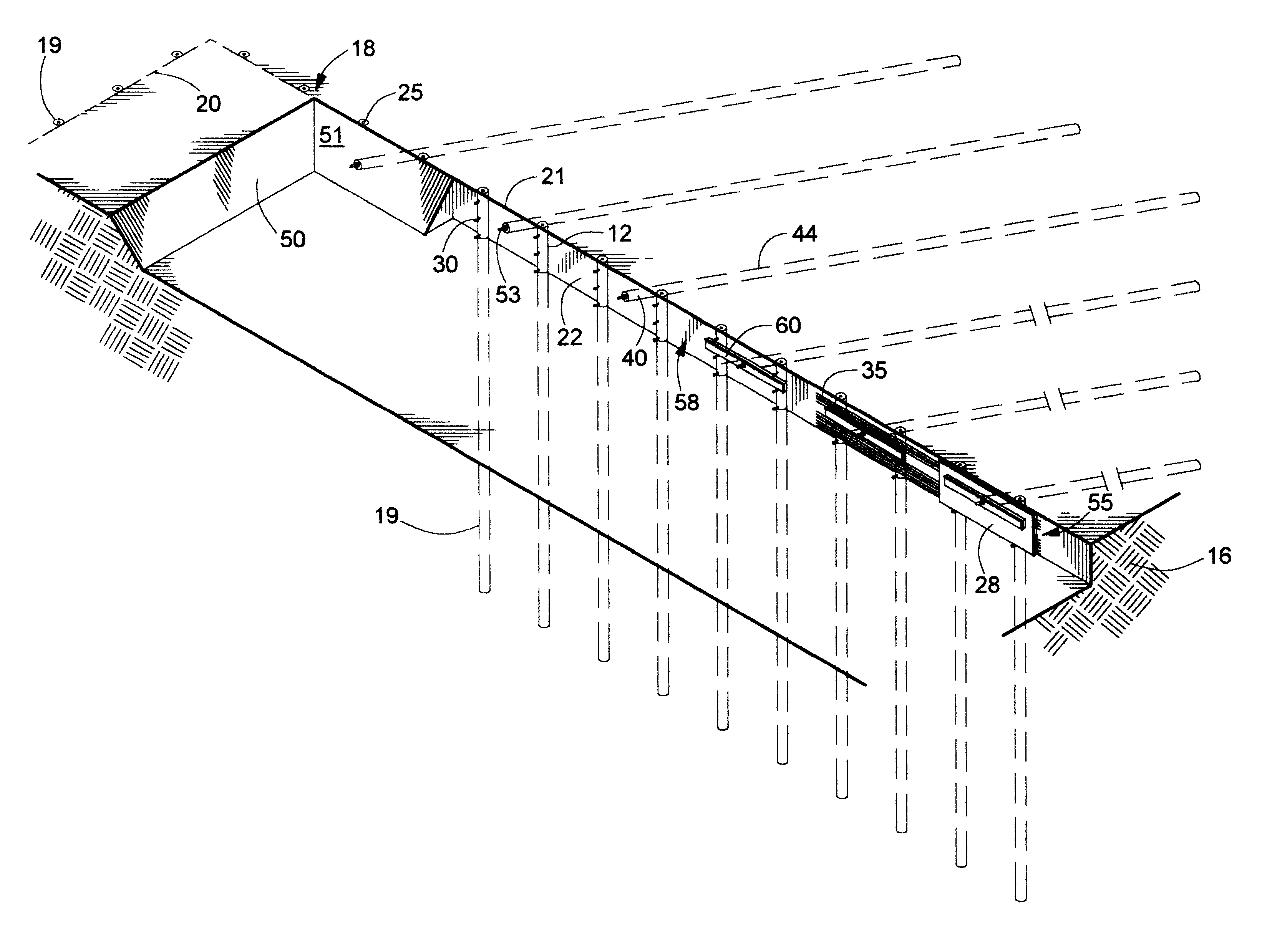

Method and apparatus for a shoring wall

InactiveUS6299386B1Improve face stabilityLarge and costly foundationArtificial islandsExcavationsSoil nailingRebar

A retaining element system is provided that improves face stability in poorer quality soils that are not suited to conventional soil nailing. The method includes inserting retaining elements substantially vertically into an earthen mass to shore the face of an excavation. The earthen mass can be any material or combination of materials, such as soil, clay or rock that requires excavation for the installation of a shoring wall. The plurality of retaining elements are placed side by side in a substantially linear arrangement. A plurality of soil nails are then inserted into the excavation plane, at the approximate midpoint between a pair of adjacent retaining elements. An exposed tip portion of each soil nail attaches to a wale, which is a substantially horizontal element that contacts a retaining element on both sides of each soil nail. The wale can be a beam, bracket, or a set of concrete reinforcement bars. The beam or bracket can either be a structural member, formed of steel or the like, or alternatively formed from a precast concrete. The concrete reinforcement bars can then receive a concrete fill to form a solid wale structure. Face stability is achieved with the pre-installed retaining elements, which with the wales provide complete facing support.

Owner:BYRNE R JOHN +1

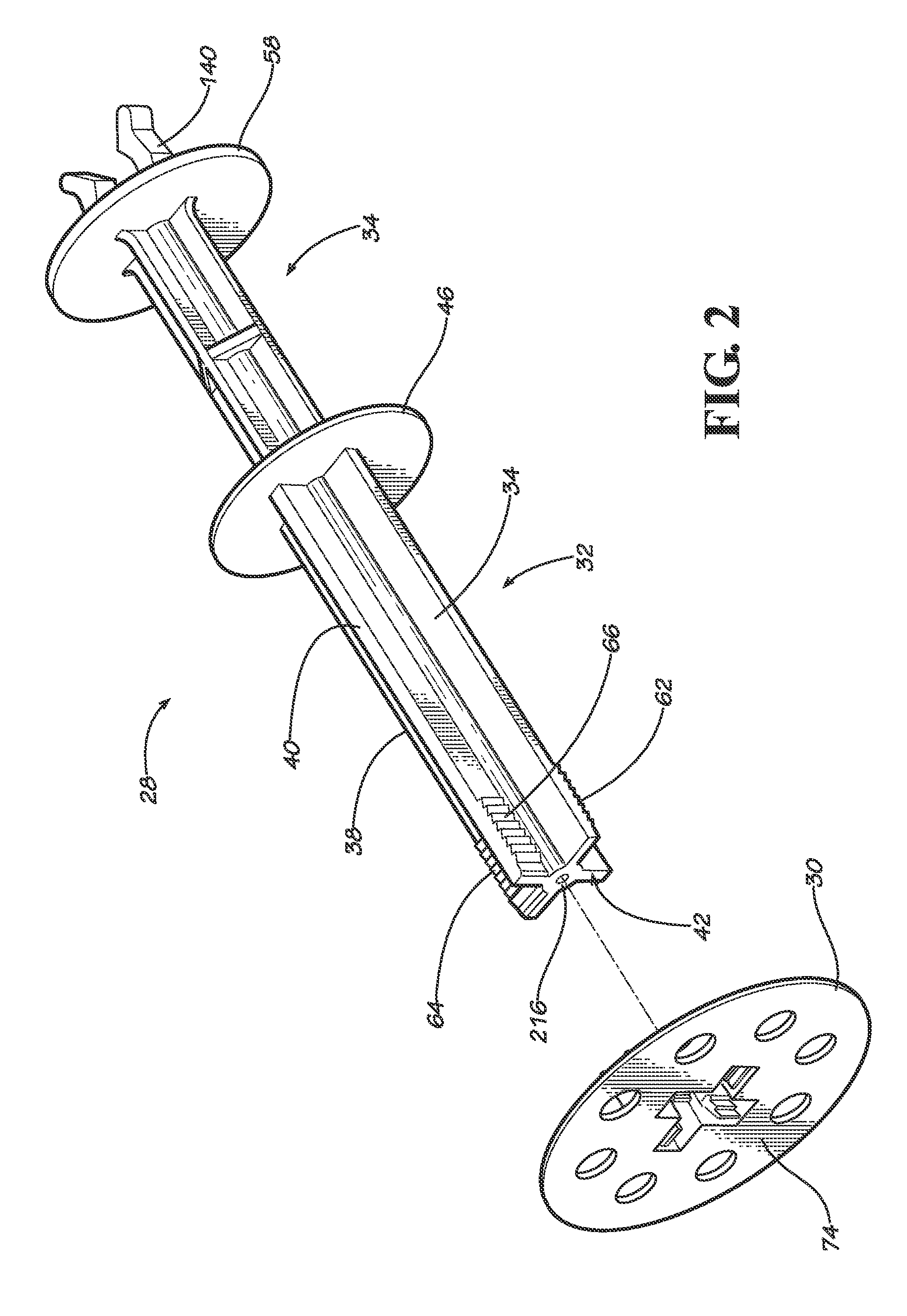

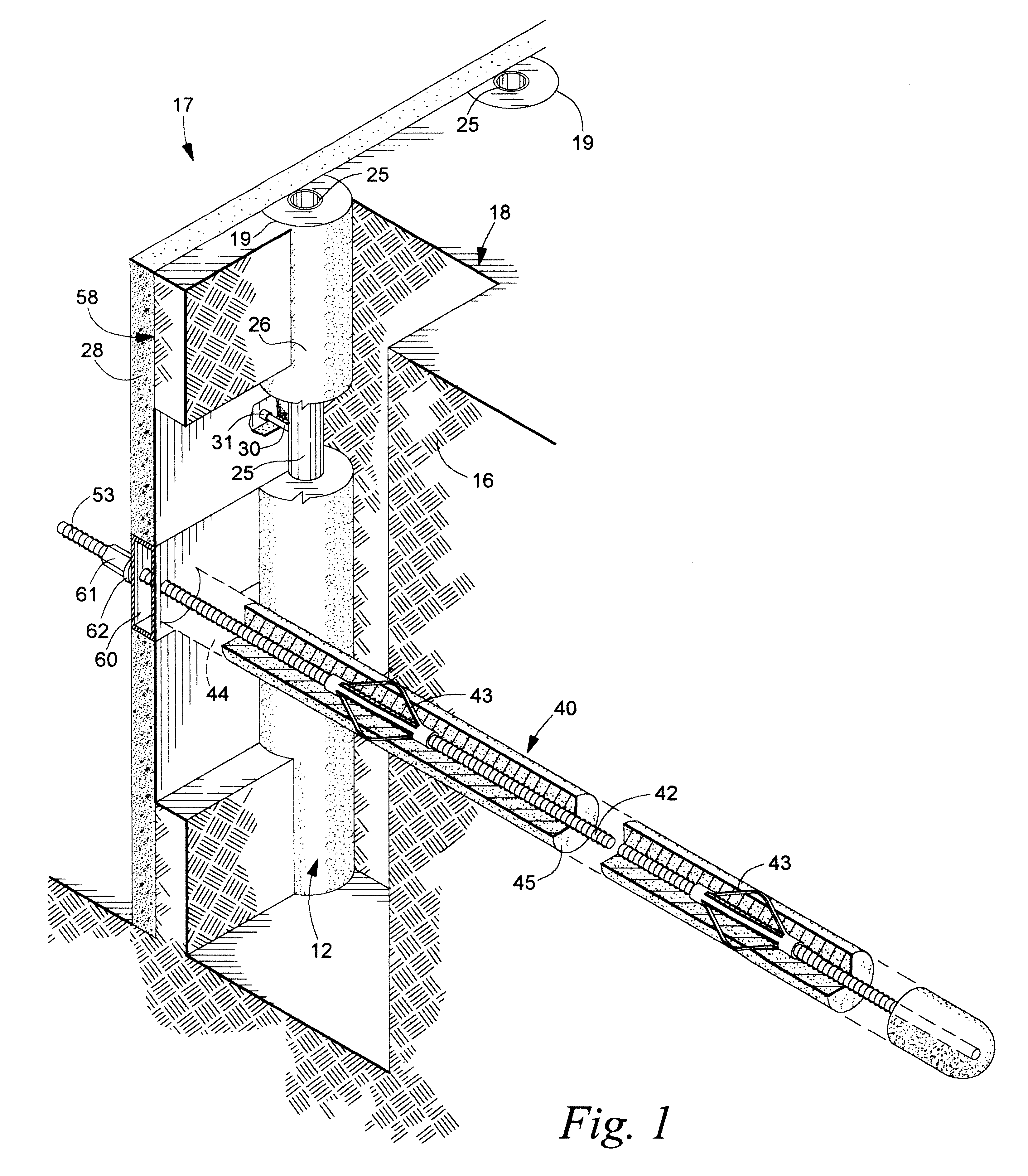

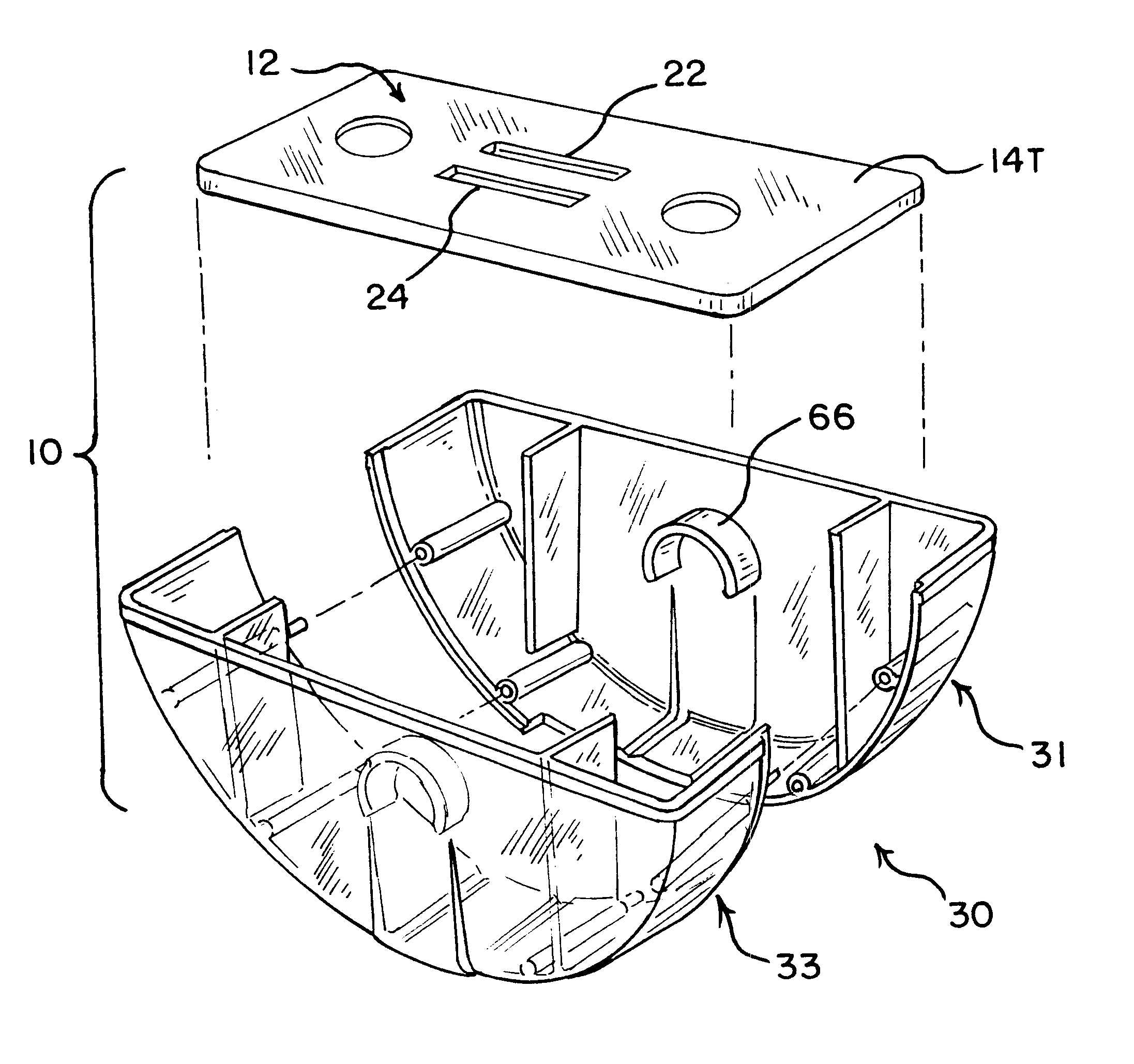

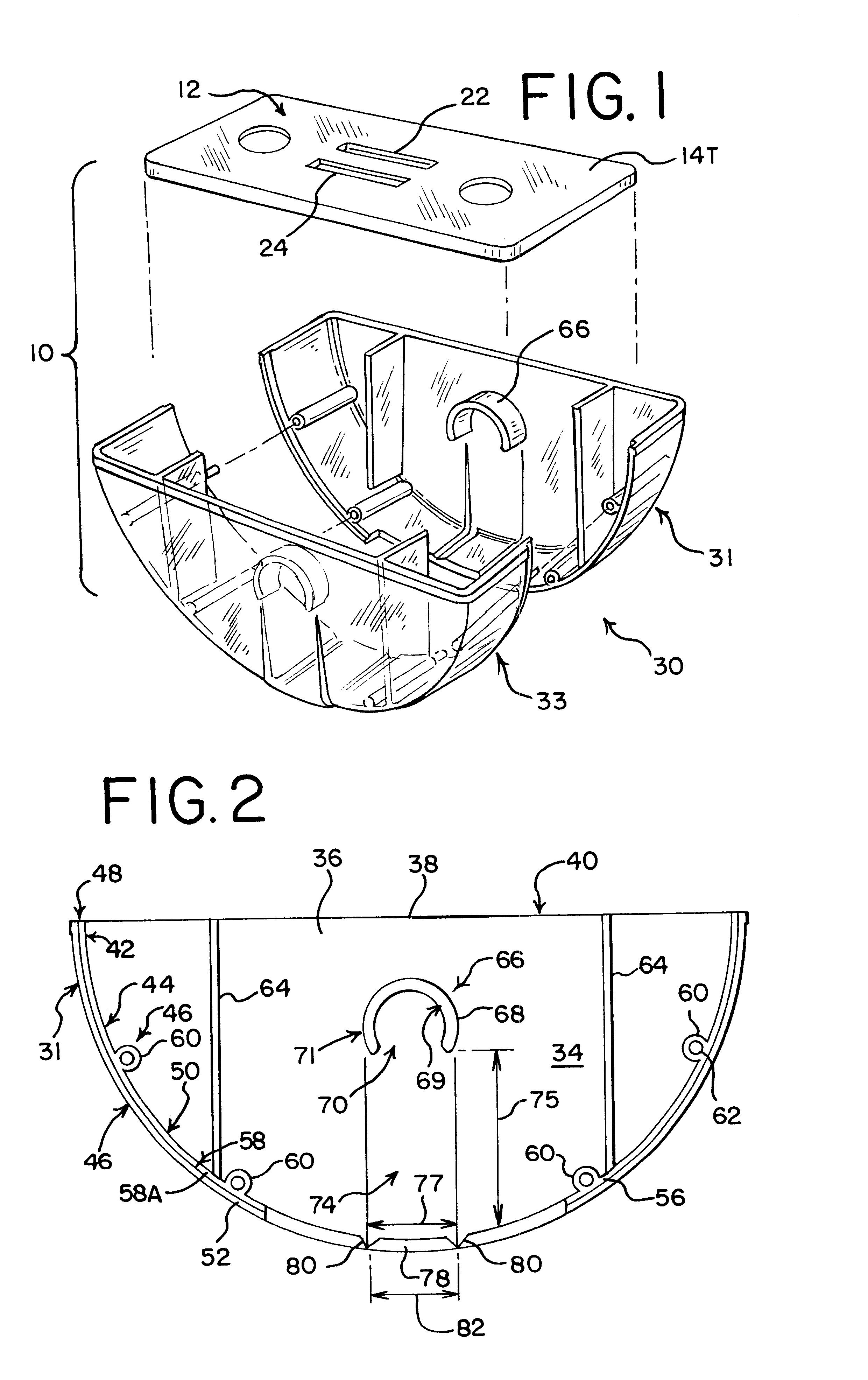

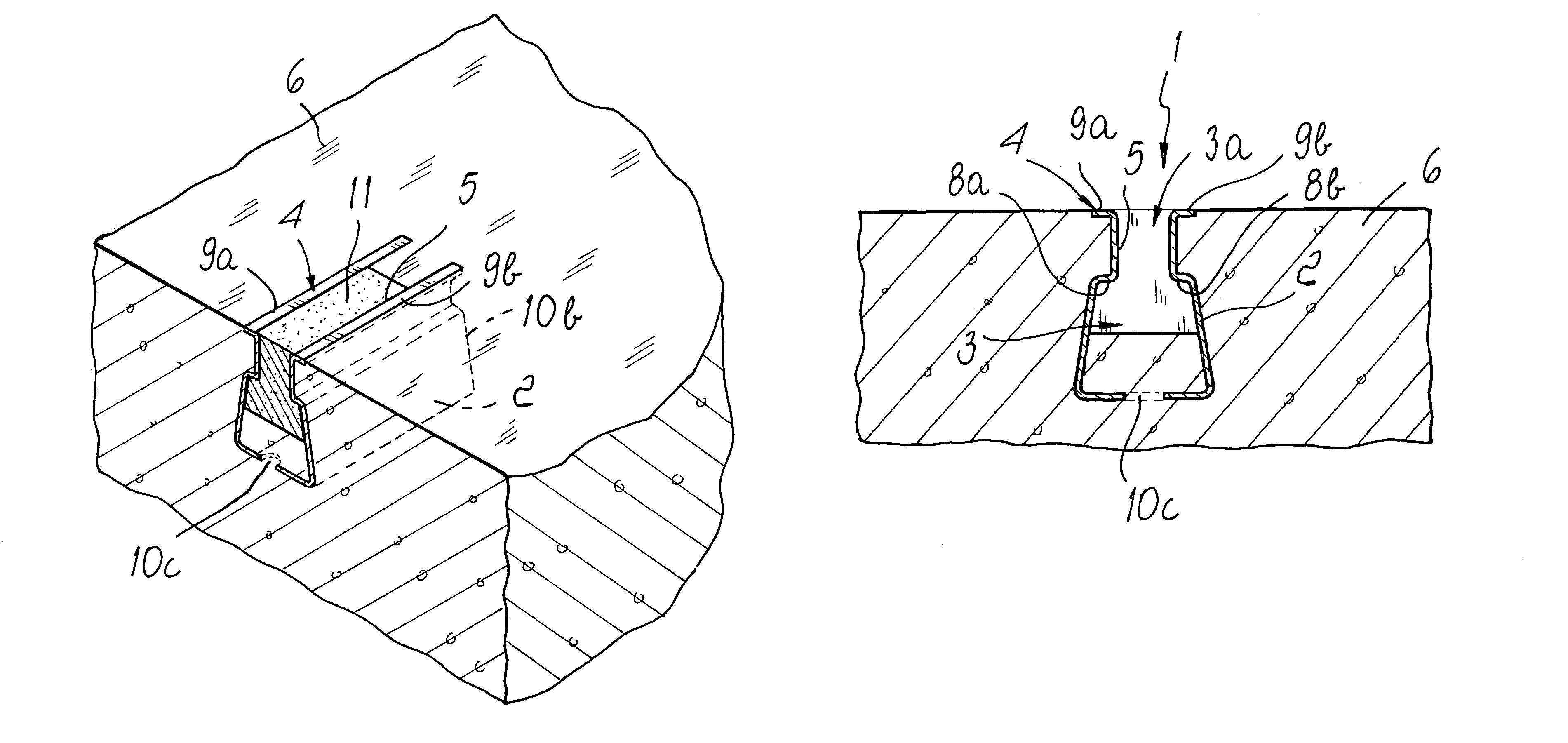

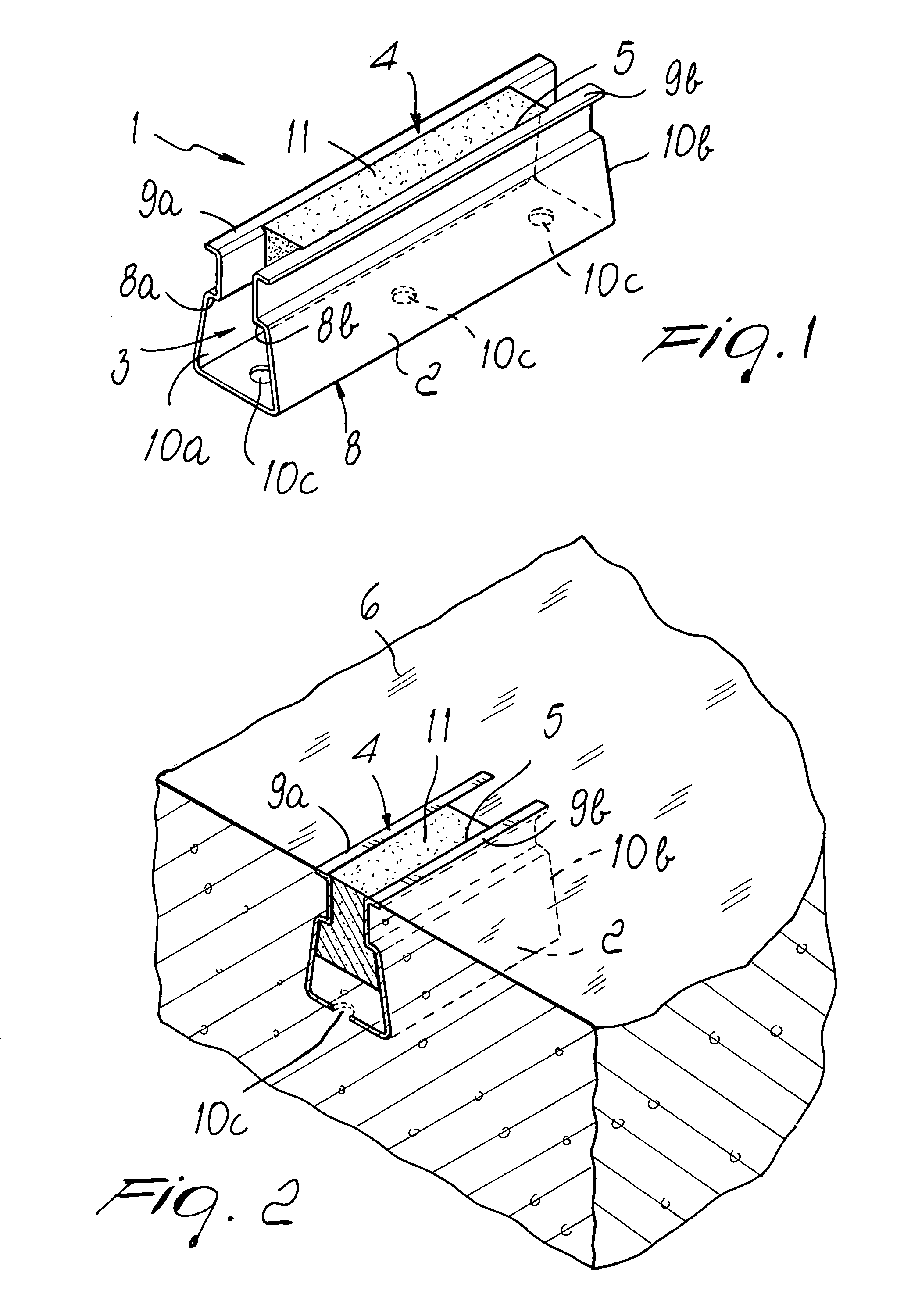

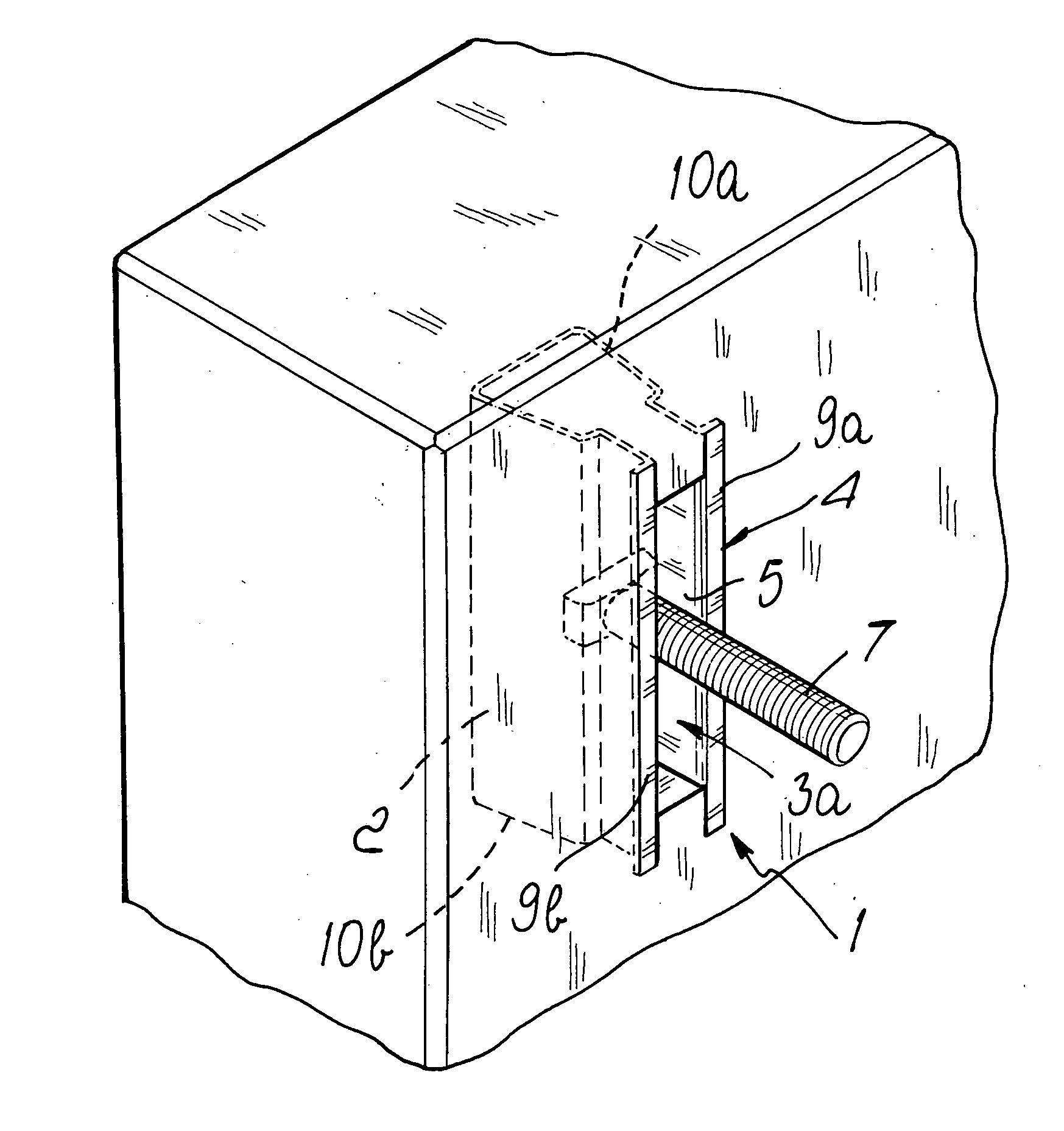

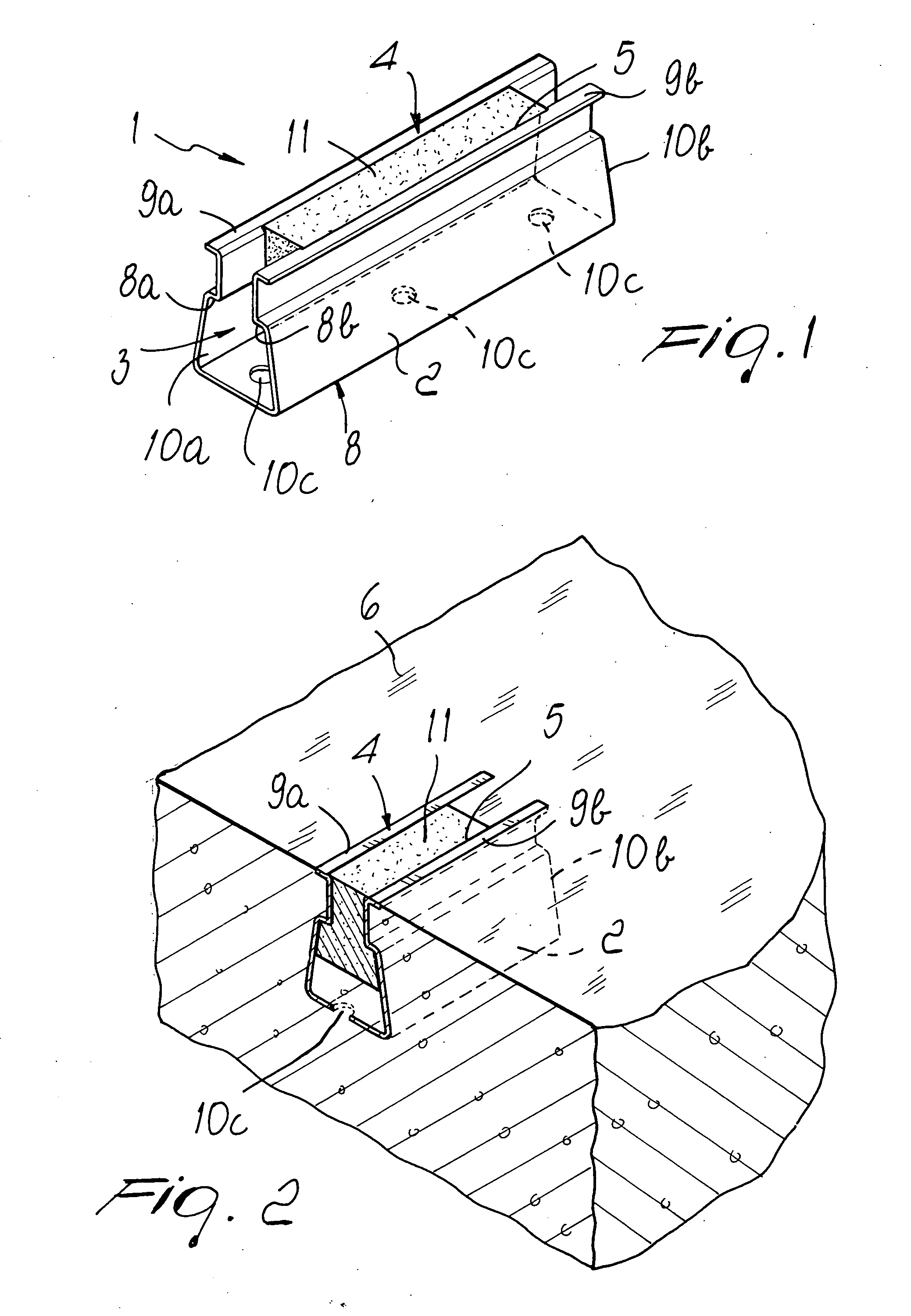

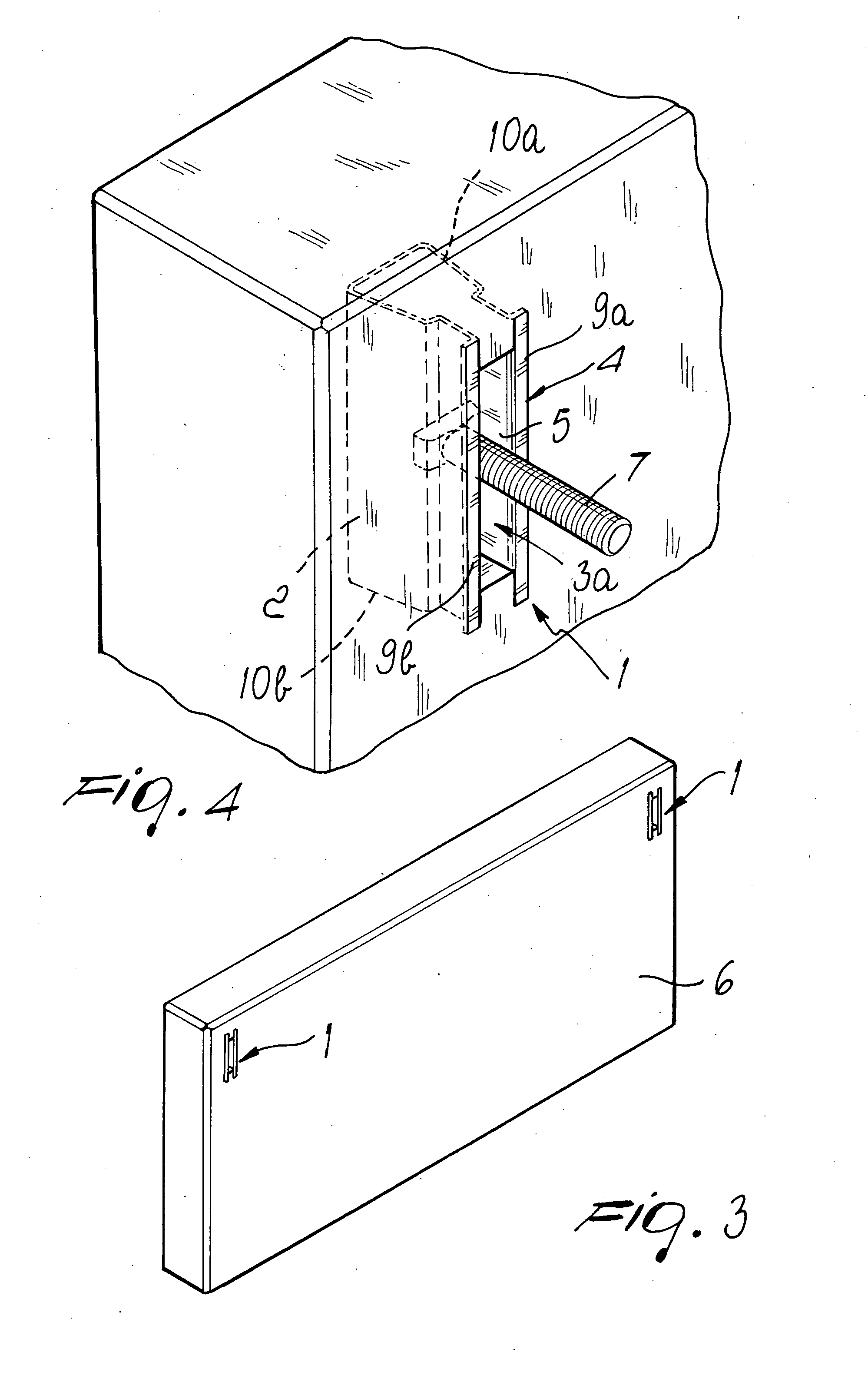

Removable insert for creating a void space, as in precast concrete panels

A removable and reusable insert assembly for positioning and supporting a lifting system within a panel to be formed from cast concrete, the insert assembly having a left and right portion which are detachably removable from each other, and a lid that is secured over the insert. The lid protects an interior space of the insert assembly.

Owner:FROMELIUS LAWRENCE

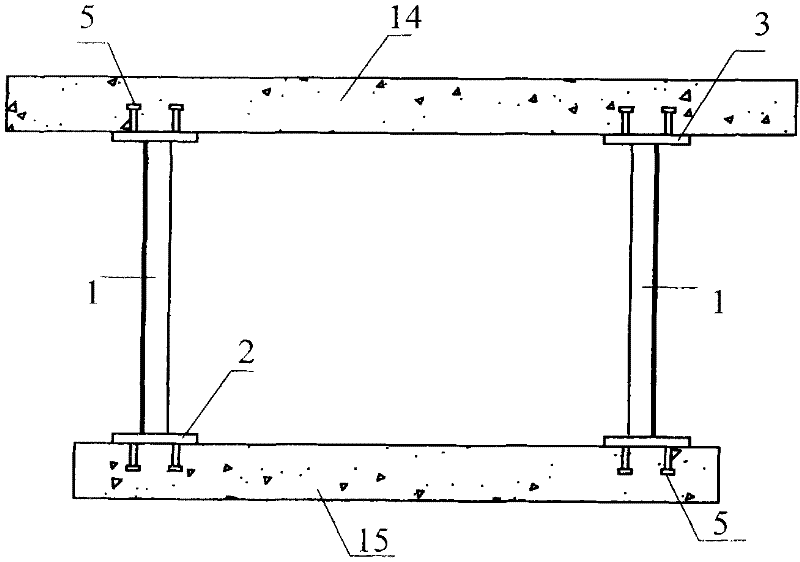

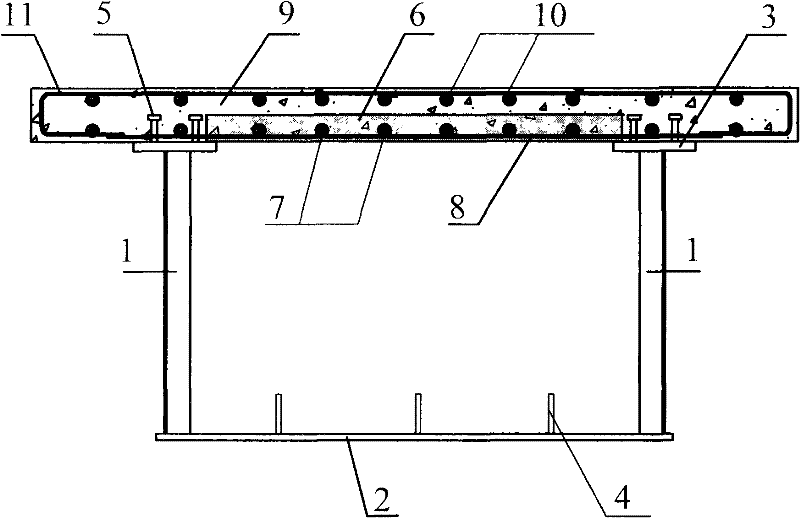

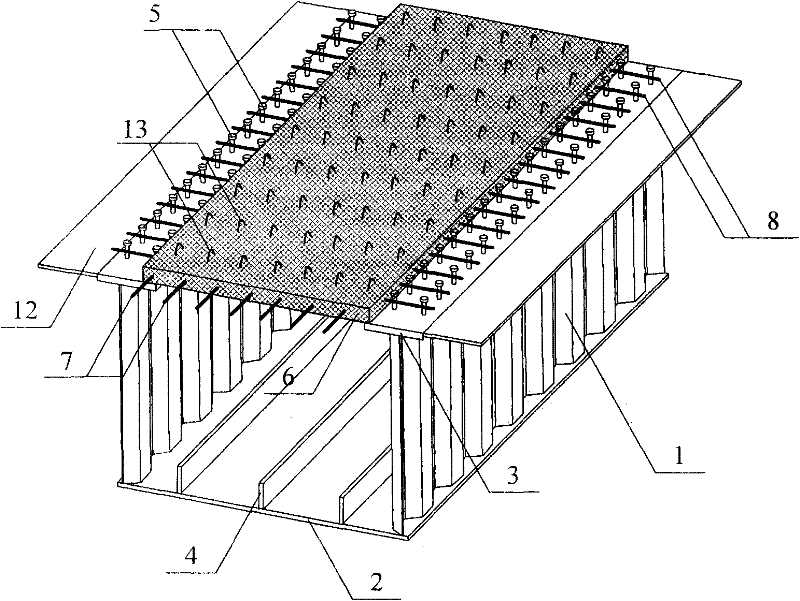

Steel-concrete composite beam adopting corrugated steel web and construction method thereof

The invention discloses a steel-concrete composite beam adopting a corrugated steel web, which relates to a corrugated steel web composite beam capable of being applicable to highway bridges and railway bridges. The beam comprises a top flange concrete composite plate, a corrugated steel web plate, a top flange steel plate, a box beam bottom plate and male pin connecting pieces, wherein the top flange comprises a precast concrete slab and a cast-in-place concrete layer; and the top flange concrete composite plate is connected with the top flange steel plate into a whole through the male pin connecting pieces welded on the top flange steel plate. By adopting the structure, the problems that the site workload and the construction difficulty for casting a bottom flange concrete slab of a traditional corrugated steel web composite beam are large, the construction quality is difficult to guarantee and the like are overcome on the premise that the quantity of steel is hardly increased, meanwhile, the tensile property of the steel plate is fully played, the bearing capacity, the rigidity and the cracking resistance of the structure are improved, and the durability of the structure is improved, therefore, the corrugated steel web composite beam has the advantages of simple structure, reasonable stress, quick and convenient construction, and good technical and economic benefits.

Owner:TSINGHUA UNIV

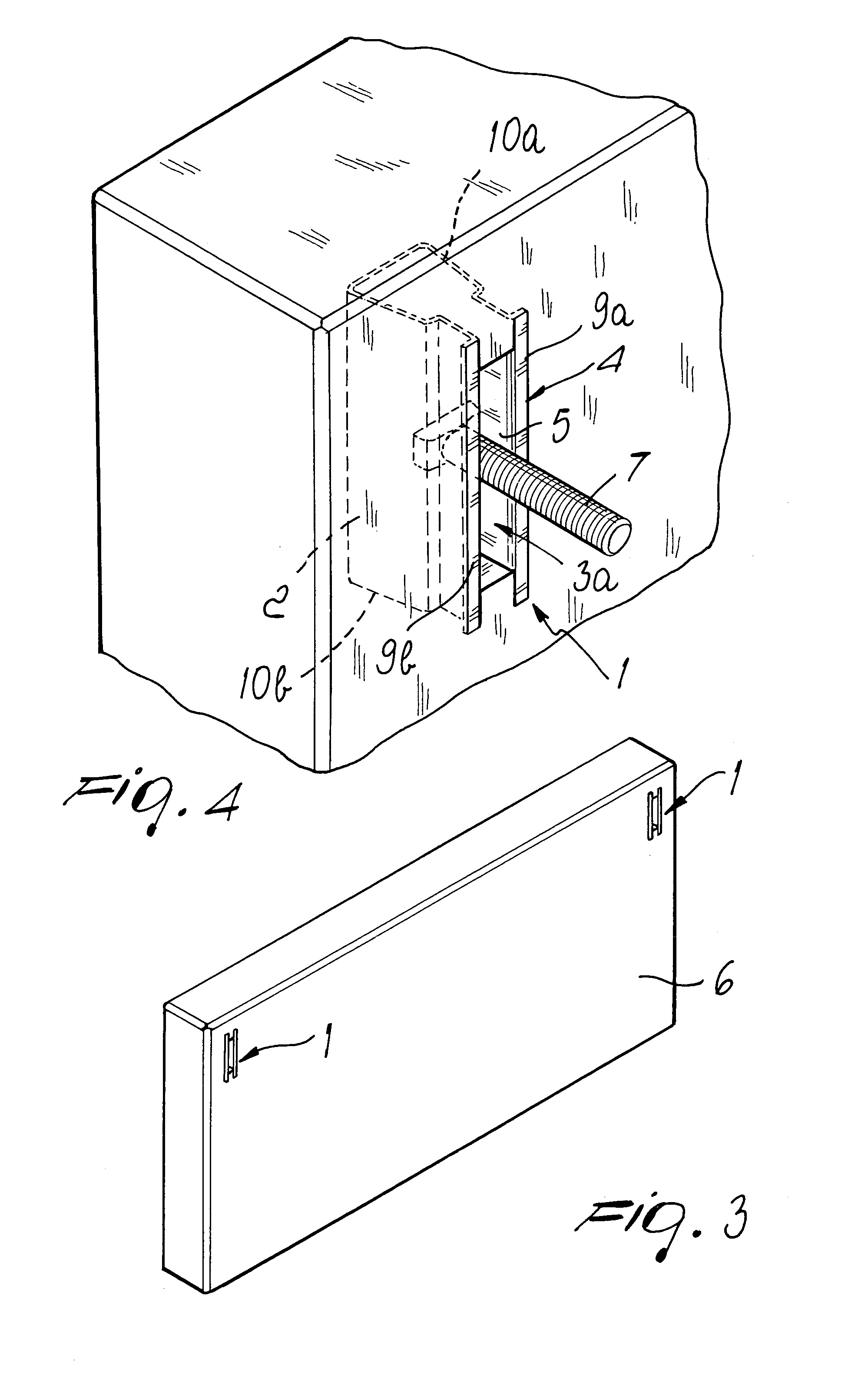

Anchoring insert for embedding in a concrete component and concrete component provided therewith

InactiveUS7654057B2Competitive manufacturing costEasy to useNutsBoltsOperating energyMechanical engineering

Owner:ZAMBELLI SERGIO +1

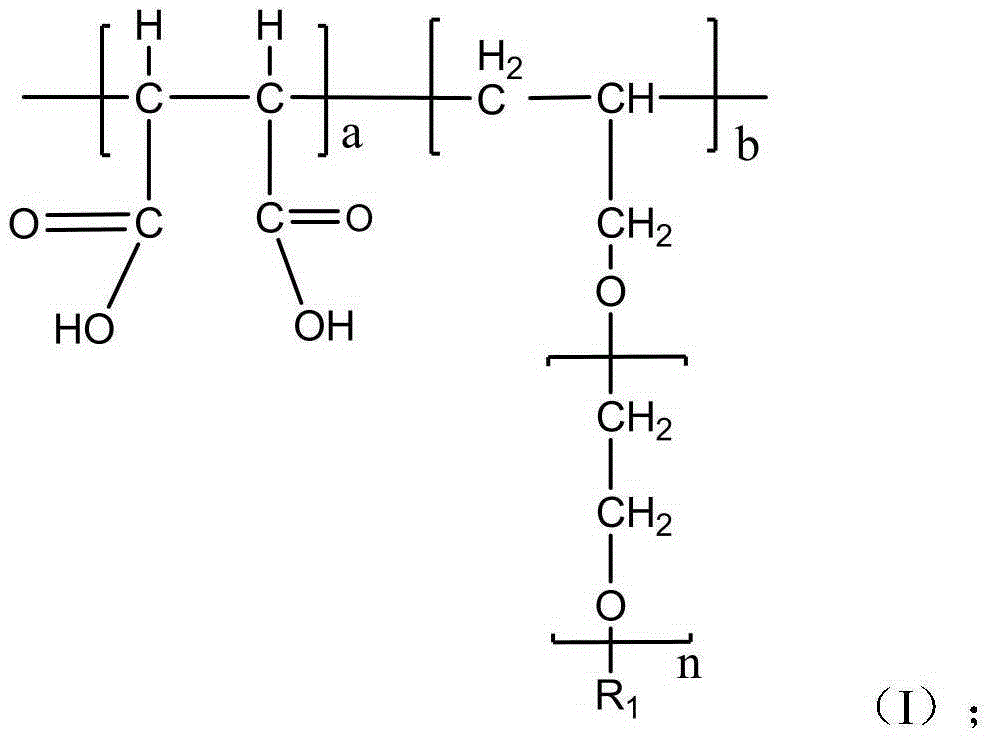

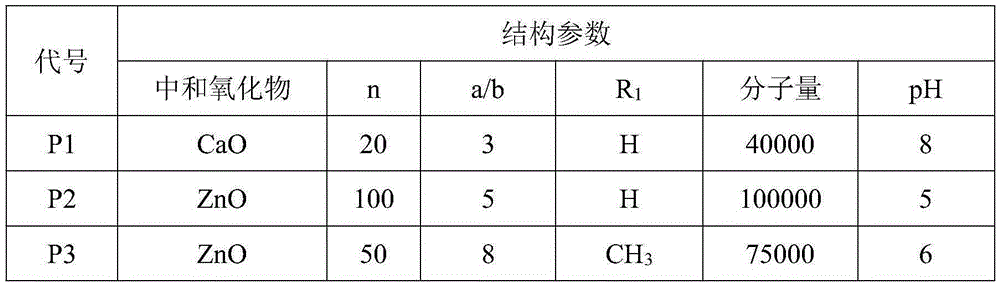

Nano suspension liquid concrete early strength agent and preparation method thereof

The invention provides a nano suspension liquid concrete early strength agent and a preparation method thereof. The nano suspension liquid concrete early strength agent is prepared from transition metal element doped nano calcium metasilicate suspension liquid, the suspension liquid is mainly composed of nanometer silicon particles, the chemical structure of the nanometer silicon particles is aCaO.bAl2O3.cZnO.SiO2.6H2O, 1<=a<=2, 0.50<=b<=1, and 0.25<=c<=0.50. The nanometer silicon particles are prepared from soluble calcium salt, soluble silicate, soluble aluminum salt, soluble zinc salt and a high polymer dispersing agent. On the one hand, the early strength agent contains no chlorine salt and has no corroding function on steel bars in concrete; on the other hand, an extremely stable suspension liquid system is achieved, adding is facilitated, and the early strength agent can be evenly dispersed easily in the concrete preparation process. The early strength of concrete can be remarkably improved, the early strength effect on concrete adopting highly-doped mineral admixtures is especially obvious, the early strength agent is especially suitable for production of precast concrete components, and a steam maintenance process can be effectively reduced and even omitted.

Owner:JIANGSU SOBUTE NEW MATERIALS

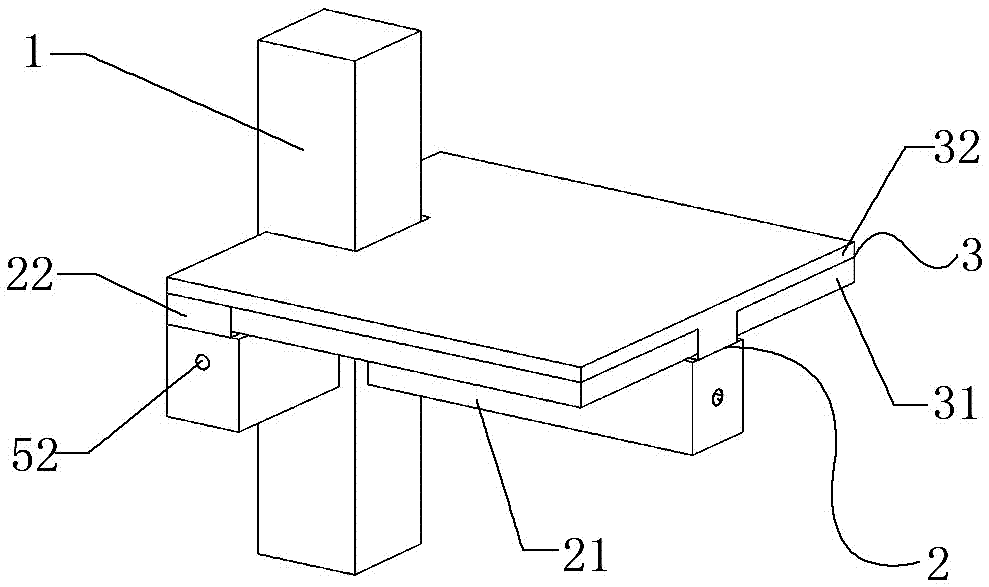

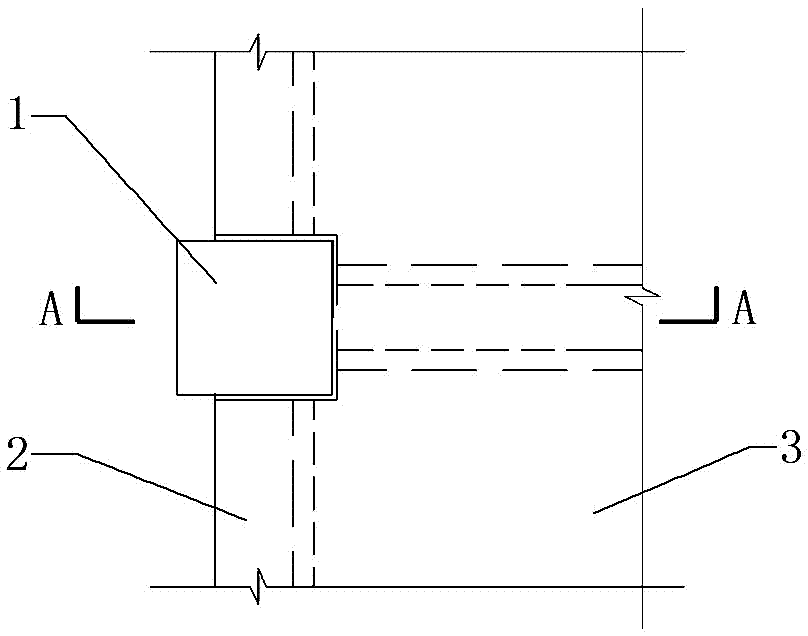

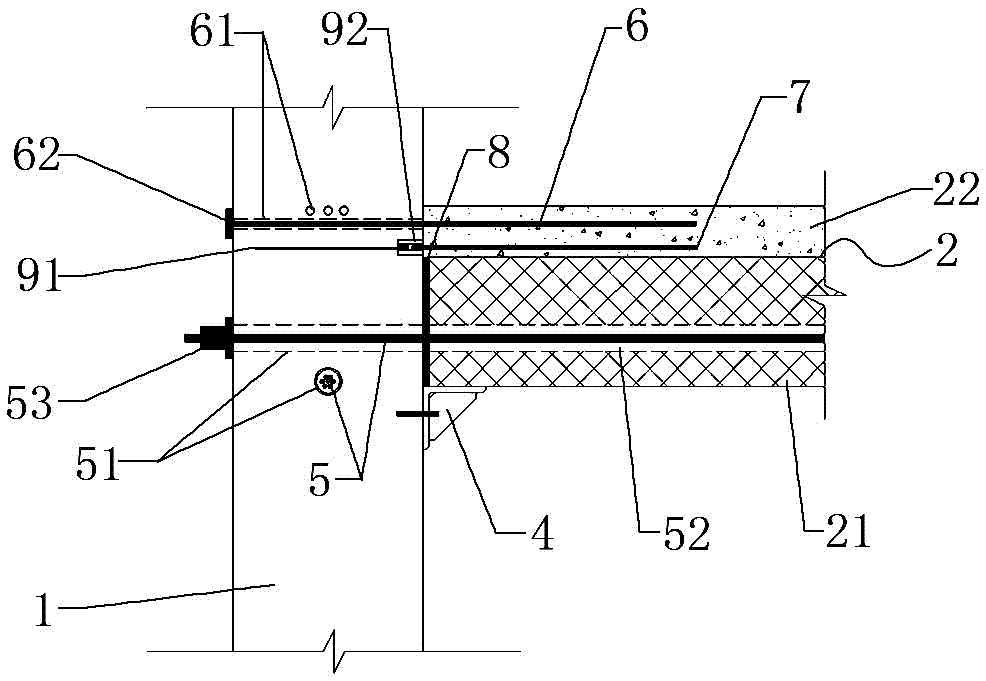

Pre-stressing-force fabricated concrete-frame-joint connecting structure and construction method thereof

PendingCN107165272AImprove integrityImprove energy consumptionGirdersProtective buildings/sheltersFloor slabPre stress

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Prefabricated thin wall concrete panel

Owner:PAUL BAILLARGEON ARCHITECTE

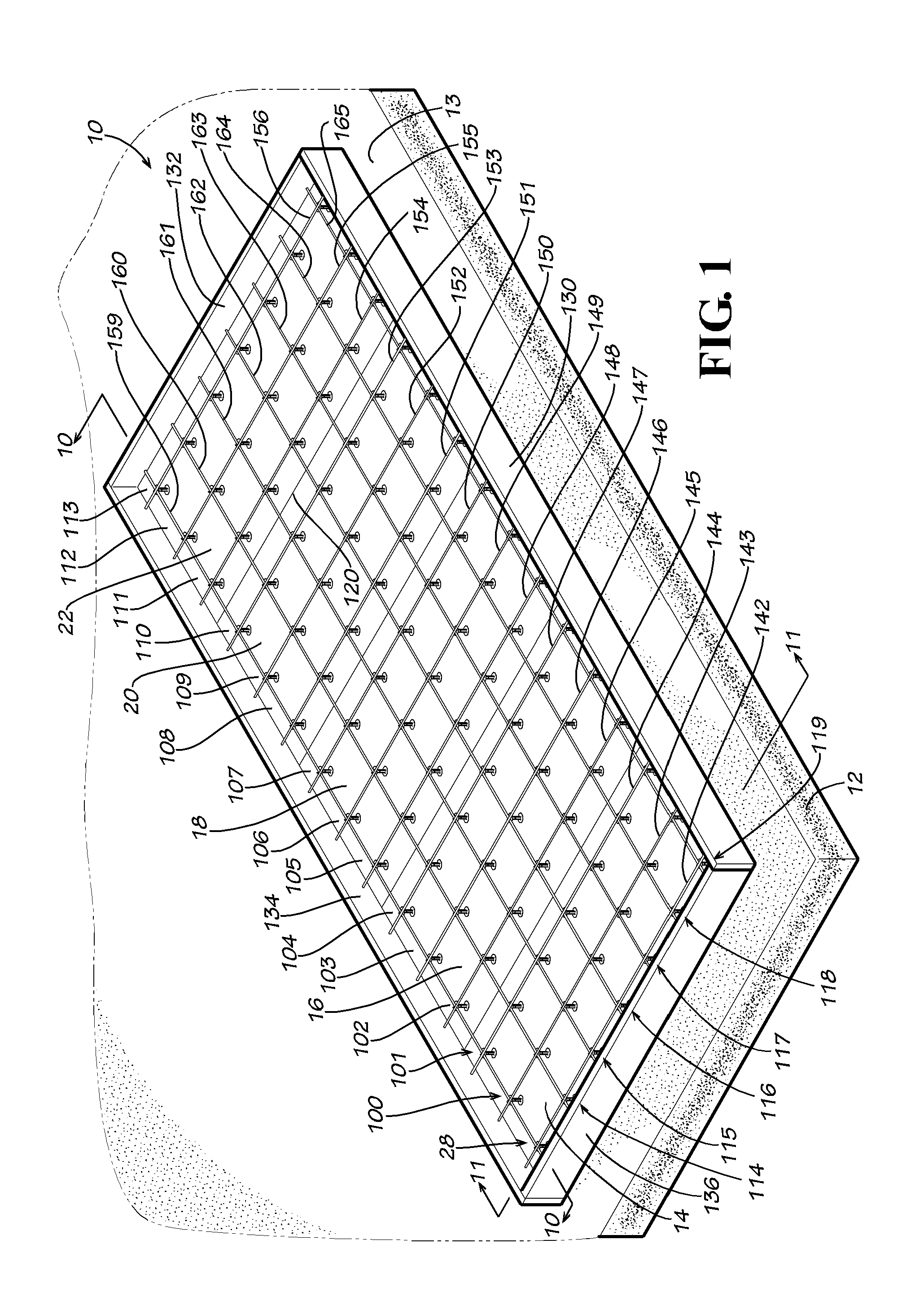

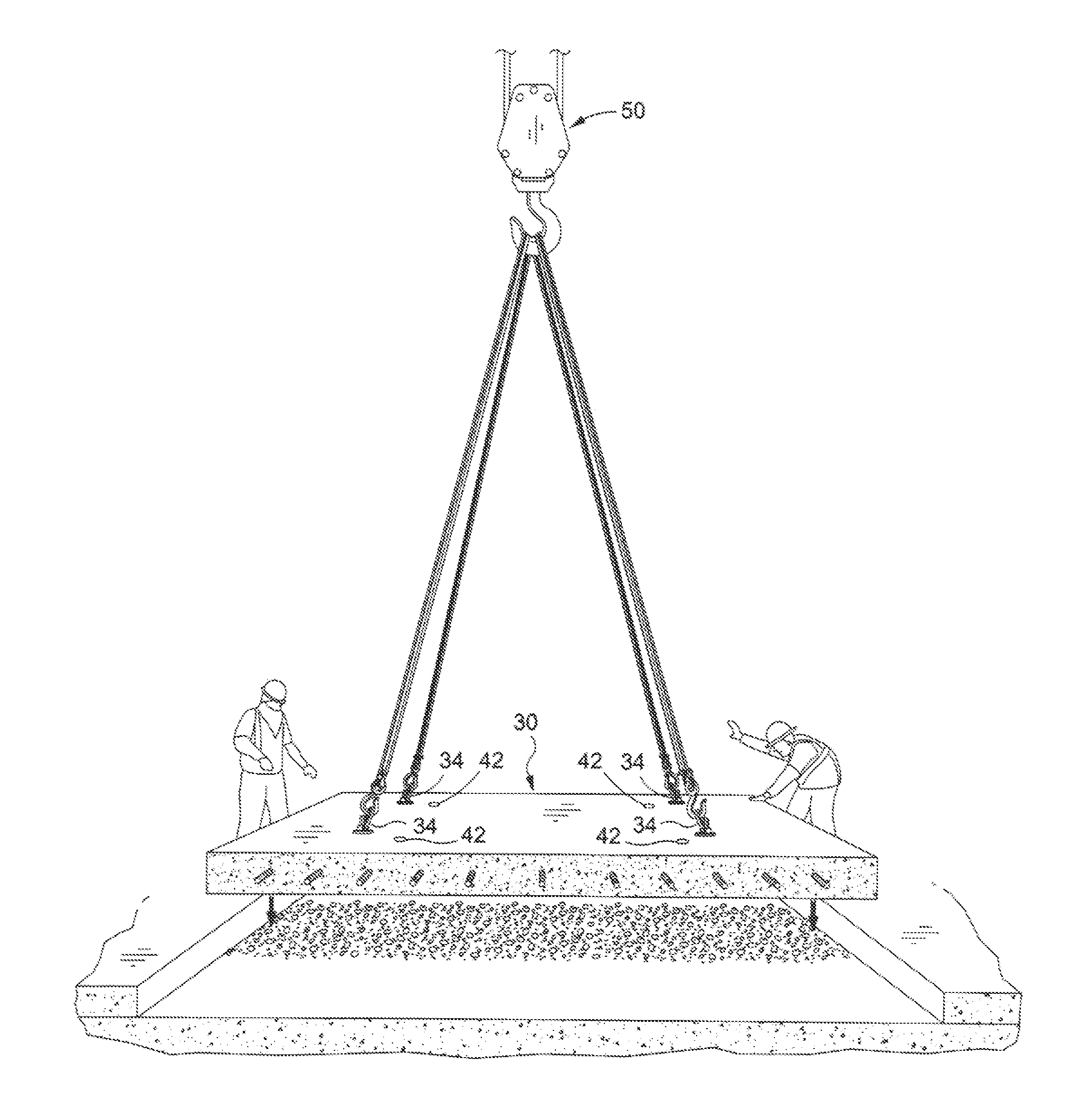

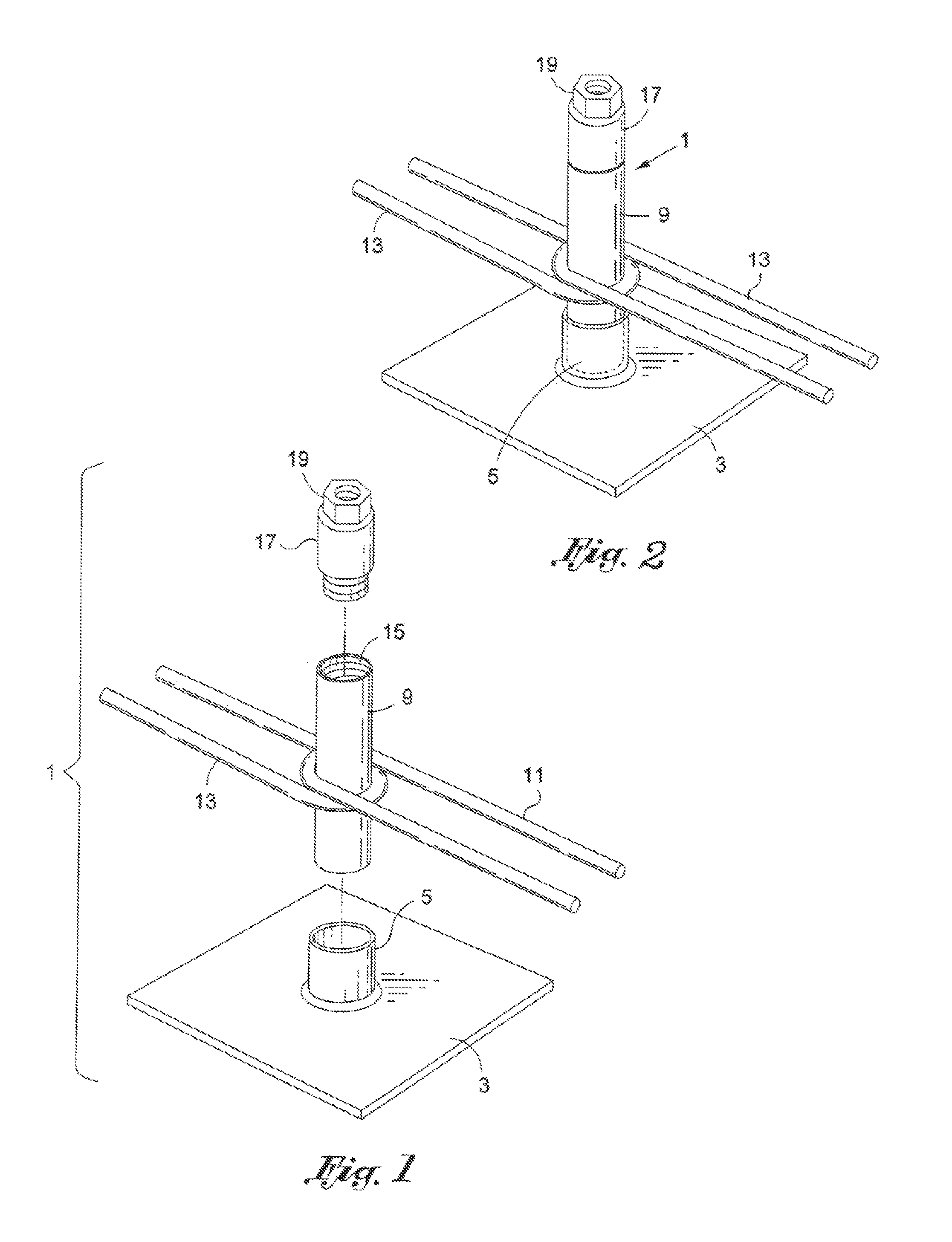

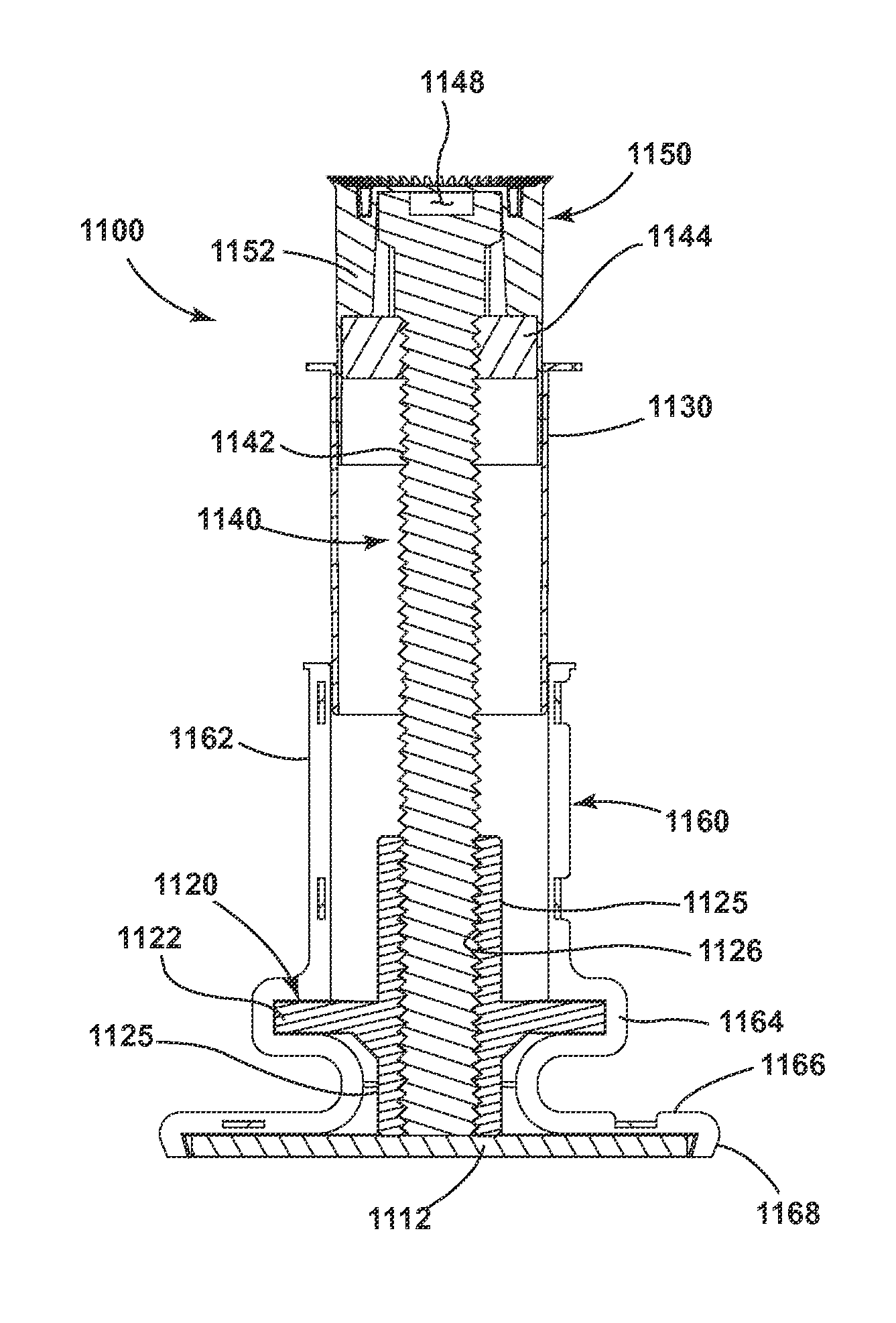

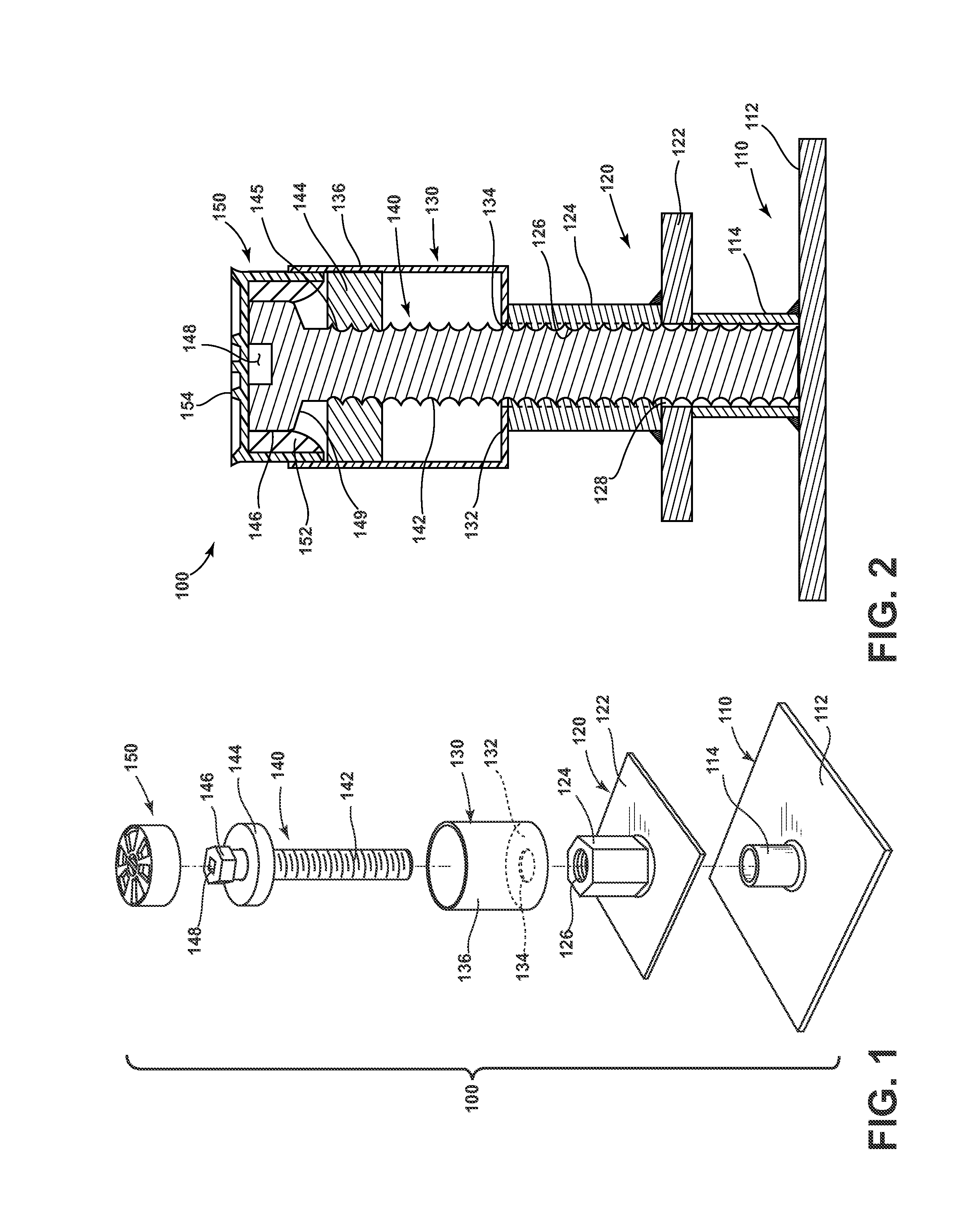

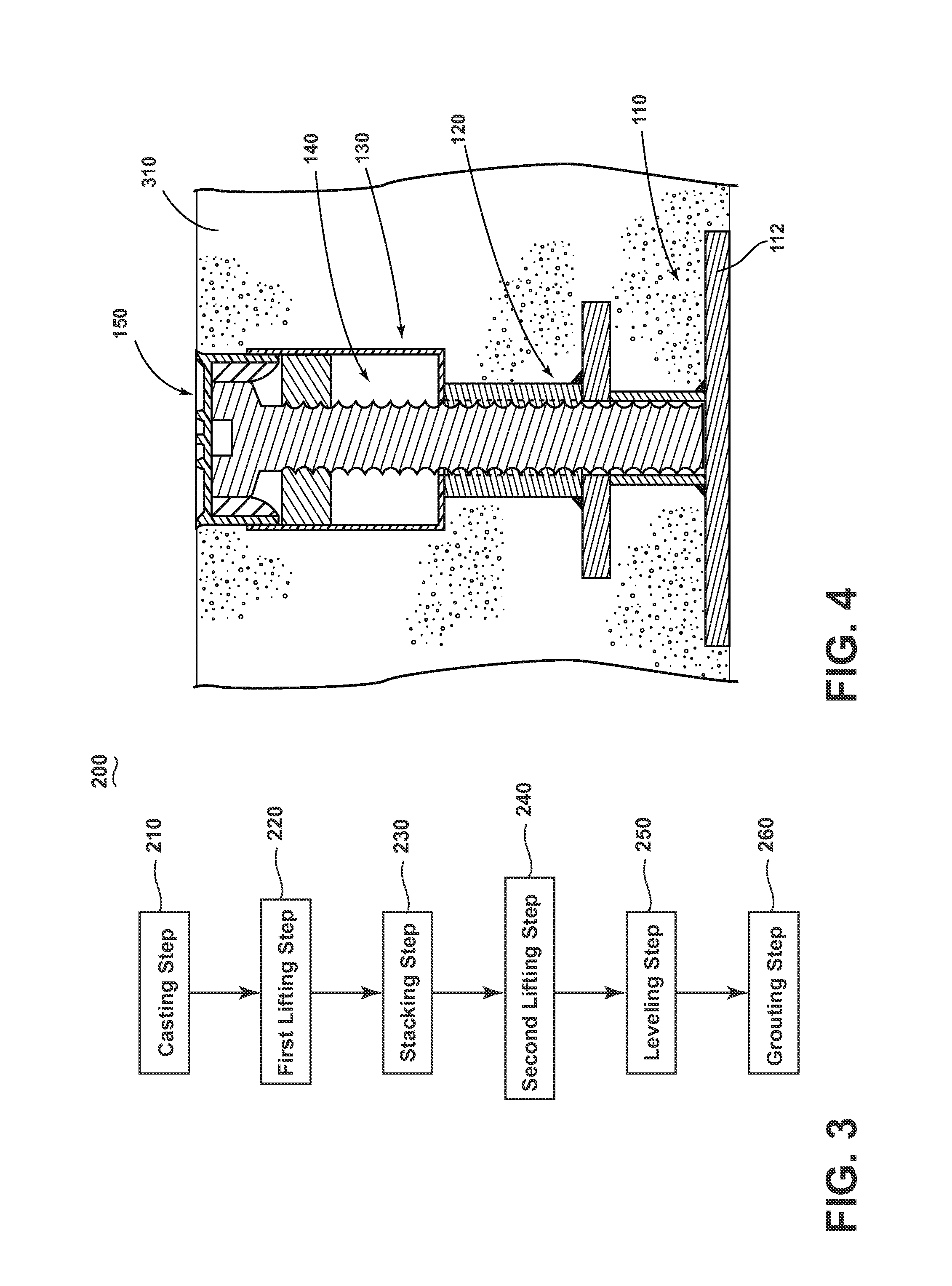

Method and apparatus for lifting and leveling a concrete panel

ActiveUS20140053475A1Convenient and reliable lifting pointQuickly and easily liftedSingle unit pavingsBuilding repairsRoad surfaceEngineering

A lifting apparatus to be embedded within a precast concrete panel or slab to enable the panel to be lifted, positioned atop a road bed, and elevated above the road bed. A lifting apparatus is located at each corner of the panel. Each lifting apparatus has a threaded sleeve extending through the panel to receive a removable threaded lifting bolt by which to establish a lifting point at which a lifting force is applied to lift and position the panel. When the threaded lifting bolt is rotated completely through the threaded sleeve, a pushing force is applied against a base plate, whereby to elevate the panel above the road bed as is necessary to make the panel level with adjacent panels during the construction or repair of a roadway. Grout is pumped through the panel to fill the space between the panel and the road bed.

Owner:SIQUEIROS BALTAZAR

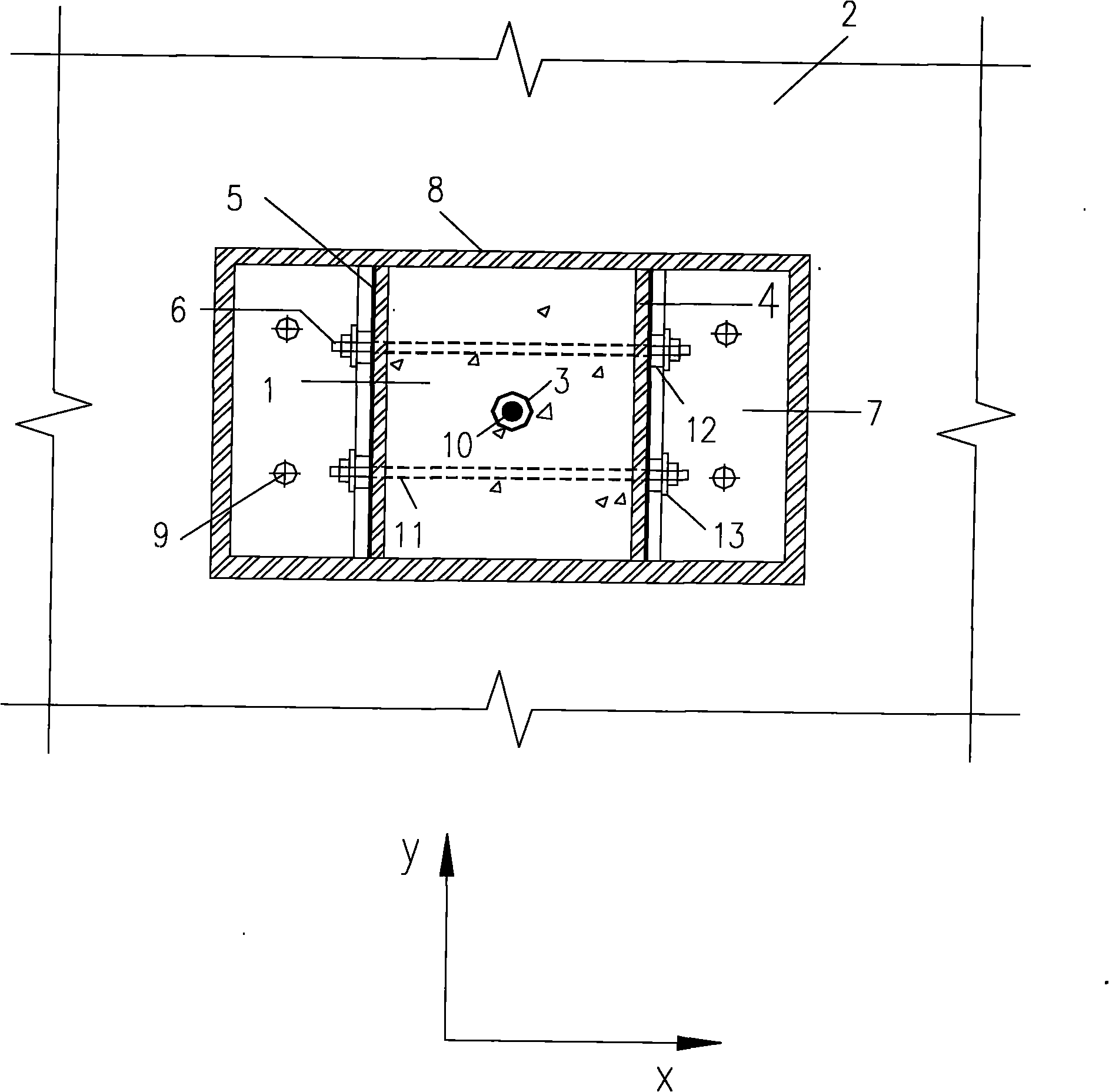

Friction energy consumption type node connection device for self-centering pier column structure

InactiveCN101936043AImprovement of local pressure problemsImprove performanceShock proofingPile capResidual deformation

The invention relates to a friction energy consumption type node connection device for a self-centering pier column structure, which is a device used for connecting a bridge pier or a frame column with a pile cap (a foundation), so as to improve the energy consumption of the pier column structure under the action of earthquake and eliminate or reduce the residual deformation and the injuries of the structure. The device comprises a pier column strengthening steel plate, a foundation pre-embedded steel plate, an angle steel, a friction bolt, a friction plate, unbonded prestressed tendons, an anchor bolt and the like. The device can connect a concrete pier column and the foundation into a whole through the unbonded prestressed tendons which are vertically arranged. When the earthquake strength achieves a certain degree, the pier column-foundation contact surface is open, and the pier column can produce a certain rotation relative to the foundation. A friction device can dissipate earthquake energy through friction at this time, and the prestress provided by the prestressed tendons can recover the structure to the initial position after the earthquake. A pre-embedded part at the end part of the pier column is used for improving the local bearing pressure of the concrete when the pier column rotates relatively.

Owner:SOUTHEAST UNIV

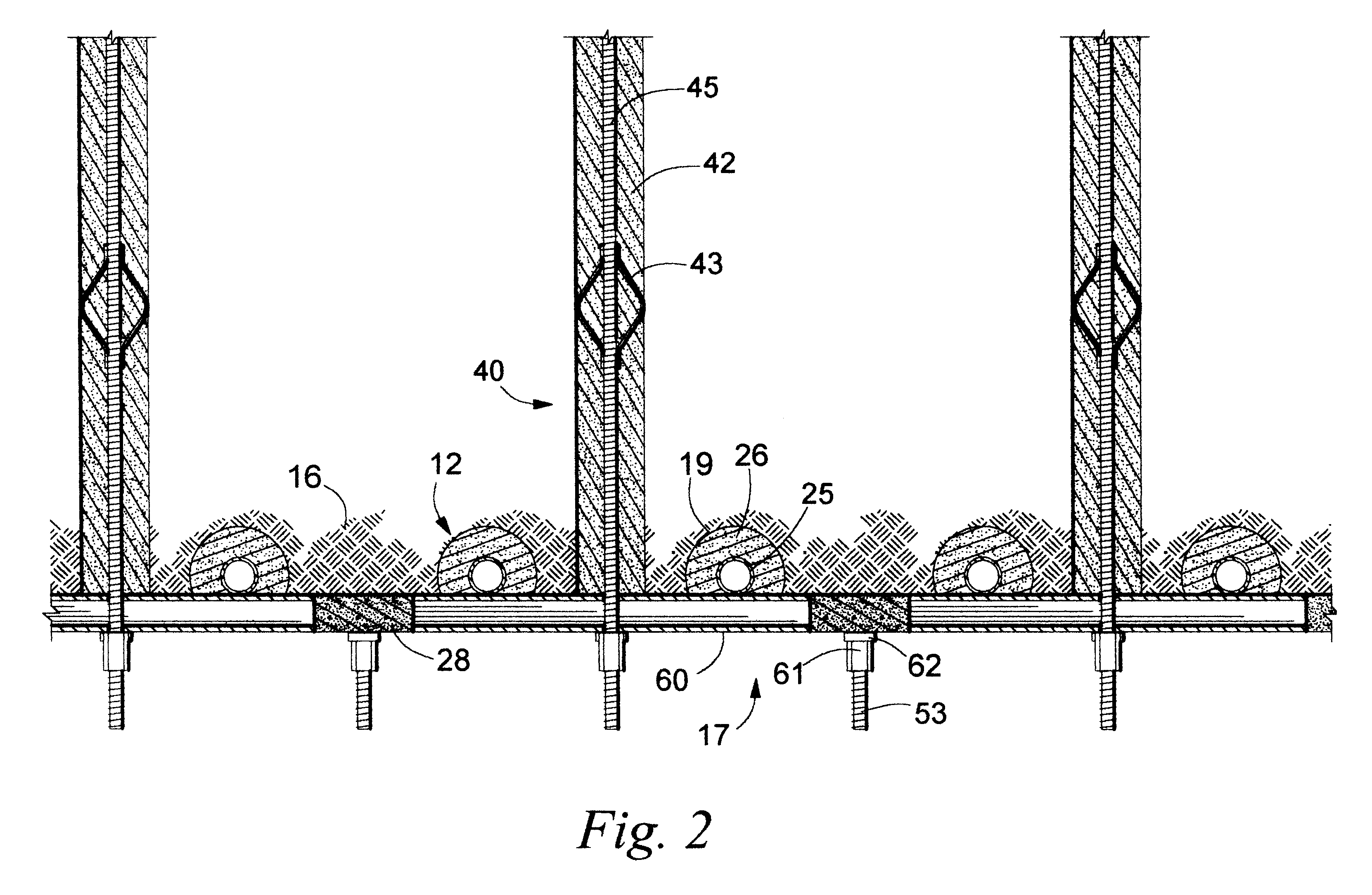

Lifting and leveling assembly for precast concrete slabs and method

ActiveUS9347232B1Improve the level ofReduce adhesionConstruction materialFloorsEngineeringScrew thread

A lifting and leveling assembly configured to be embedded in a precast concrete slab for lifting a leveling a precast concrete slab includes a base plate, a threaded sleeve, an anchor plate, a thread protecting sleeve, a threaded lifting bolt and an end cap. Rotating the threaded lifting bolt in a first direction positions a bolt head on the threaded lifting bolt above a top surface of a precast concrete slab to accommodate the attachment of a lifting device. Rotating the threaded lifting bolt in a second direction positions the bolt head beneath the top surface of the concrete slab and causes the threaded shaft to exert a force on the base plate to level the precast concrete slab.

Owner:FRANCIES III SIDNEY E

Anchoring insert for embedding in a concrete component and concrete component provided therewith

InactiveUS20070039281A1Competitive manufacturing costEasy to useNutsBoltsOperating energyEngineering

Owner:ZAMBELLI SERGIO +1

Pre-cast concrete veneer system with insulation layer

InactiveUS7647738B2Easily fixed to wall and surfacePlace safeCovering/liningsRoofingInsulation layerEngineering

A multi-layered panel comprises a first layer made of concrete, a second layer made of foam and an edge perimeter region. The first layer is a thin concrete layer of near uniform thickness that is cast onto the second layer. The exterior surface of the concrete layer simulates an exterior surface of a building. The front of the foam layer has dimensions designed to accommodate the application of the concrete layer. The back of the foam layer has features that assist in mounting the panel on an exterior surface of a building. The edge perimeter region includes a system for interconnecting adjacent multi-layered panels.

Owner:NASVIK PAUL C

Reinforced concrete structure based on 3D printing and structure construction method

The invention discloses a reinforced concrete structure based on 3D printing and a structure construction method. The method comprises the following steps that a foundation bottom plate is constructed, and a connection section is reserved on the foundation bottom plate; a steel bar structure of a structural column is bound to the connection section; a first prefabricated concrete outer shell is manufactured by adopting 3D printing, and concave-convex lines are formed in the inner surface of the first prefabricated concrete outer shell; the first prefabricated concrete outer shell is arranged on the steel bar structure of the structural column in a sleeved mode; a steel bar structure of a structural beam is bound, and the steel bar structure of the structural beam is bound to the steel bar structure of the structural column; a second prefabricated concrete outer shell is manufactured by adopting 3D printing; the second prefabricated concrete outer shell is mounted on the steel bar structure of the structural beam; concrete is poured in the second prefabricated concrete outer shell, and the structural beam and the structural column are completed. The prefabricated concrete outer shells are formed integrally by adopting a 3D printing technology, the continuous concave-convex lines are formed in the inner surfaces of the prefabricated concrete outer shells, the contact surfaces between the concrete poured in the prefabricated concrete outer shells and the inner surfaces of the prefabricated concrete outer shells are enlarged, compared with a smooth inner surface, friction is increased, bonding strength is improved, and a shell disengagement phenomenon is avoided.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com