Reinforced concrete structure based on 3D printing and structure construction method

A 3D printing and construction method technology, applied in truss structures, building structures, joists, etc., can solve the problems of easy shelling and low bonding ability, save formwork, save construction procedures, and facilitate the industrialization of construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

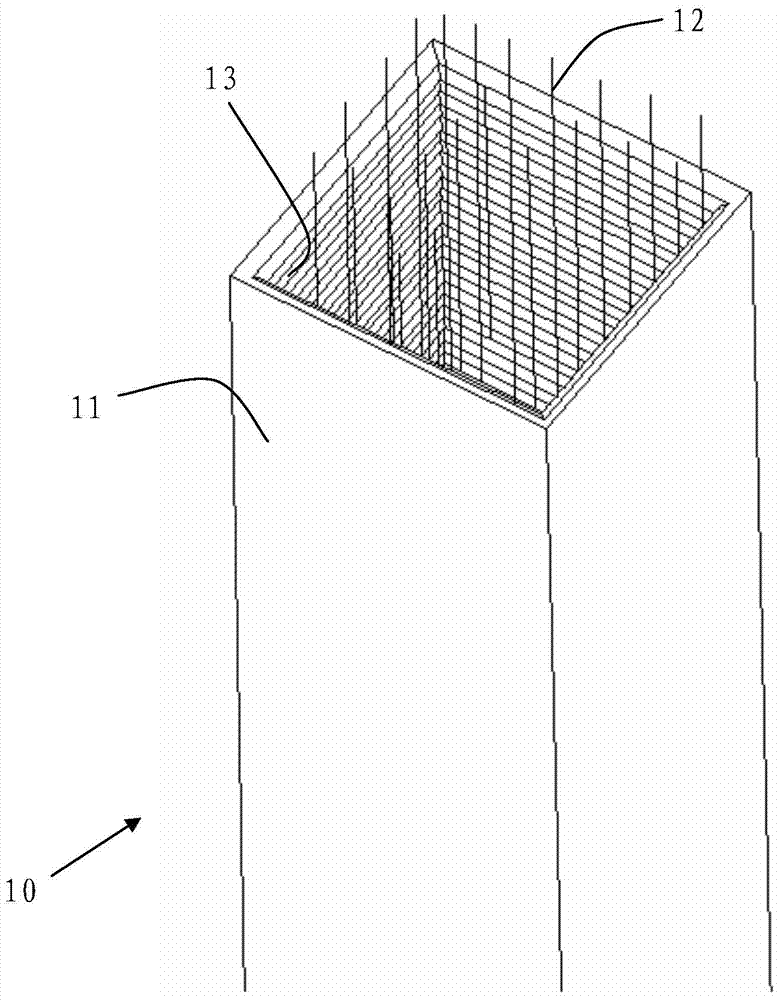

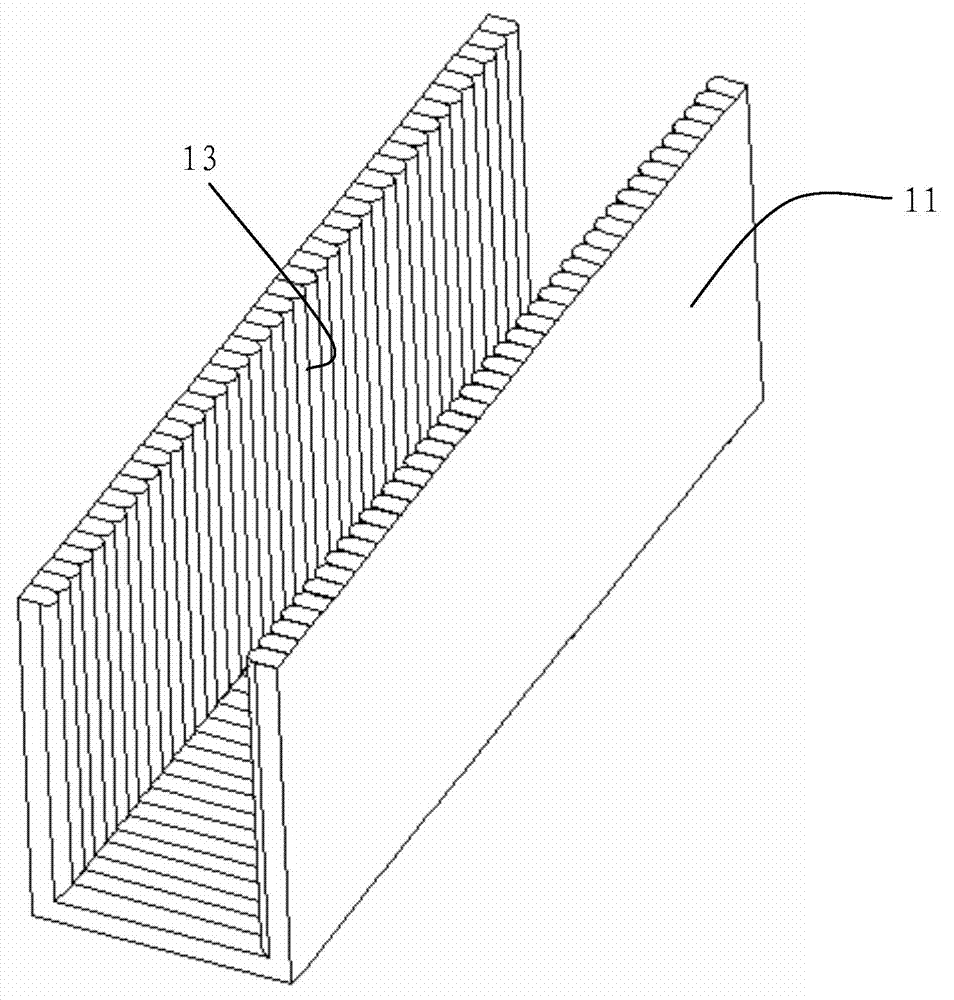

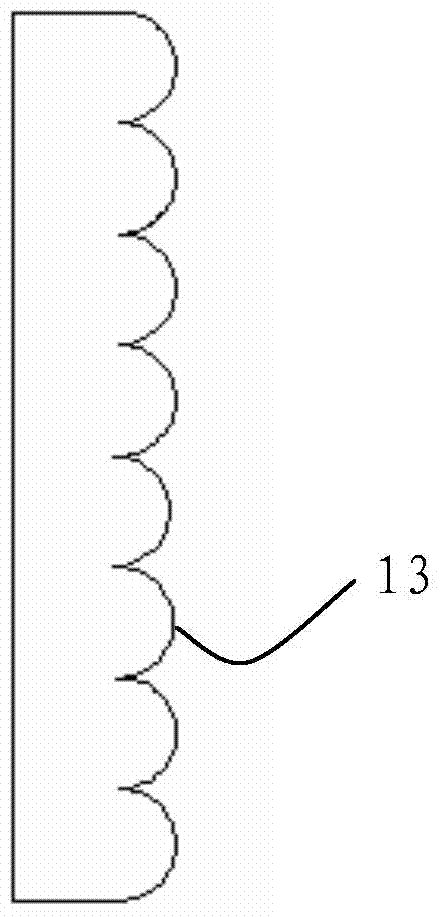

[0027] see first figure 1 As shown, a reinforced concrete structure 10 based on 3D printing of the present invention is mainly composed of a precast concrete shell 11 , a steel structure 12 set in the precast concrete shell 11 , and concrete poured in the precast concrete shell 11 . Cooperate figure 2 and image 3 as shown, figure 2 It is a prefabricated concrete shell 11 of a beam. The prefabricated concrete shell 11 is integrally formed by 3D printing, and the inner surface is continuously formed with concave-convex lines 13. The concave-convex lines 13 are arc-shaped, which can increase the distance between the concrete and the inner surface of the precast concrete shell 11. The contact surface, compared with the smooth inner surface, increases the friction, improves the bonding strength, and avoids shelling. Cooperate imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com