Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

20282results about "Artificial islands" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

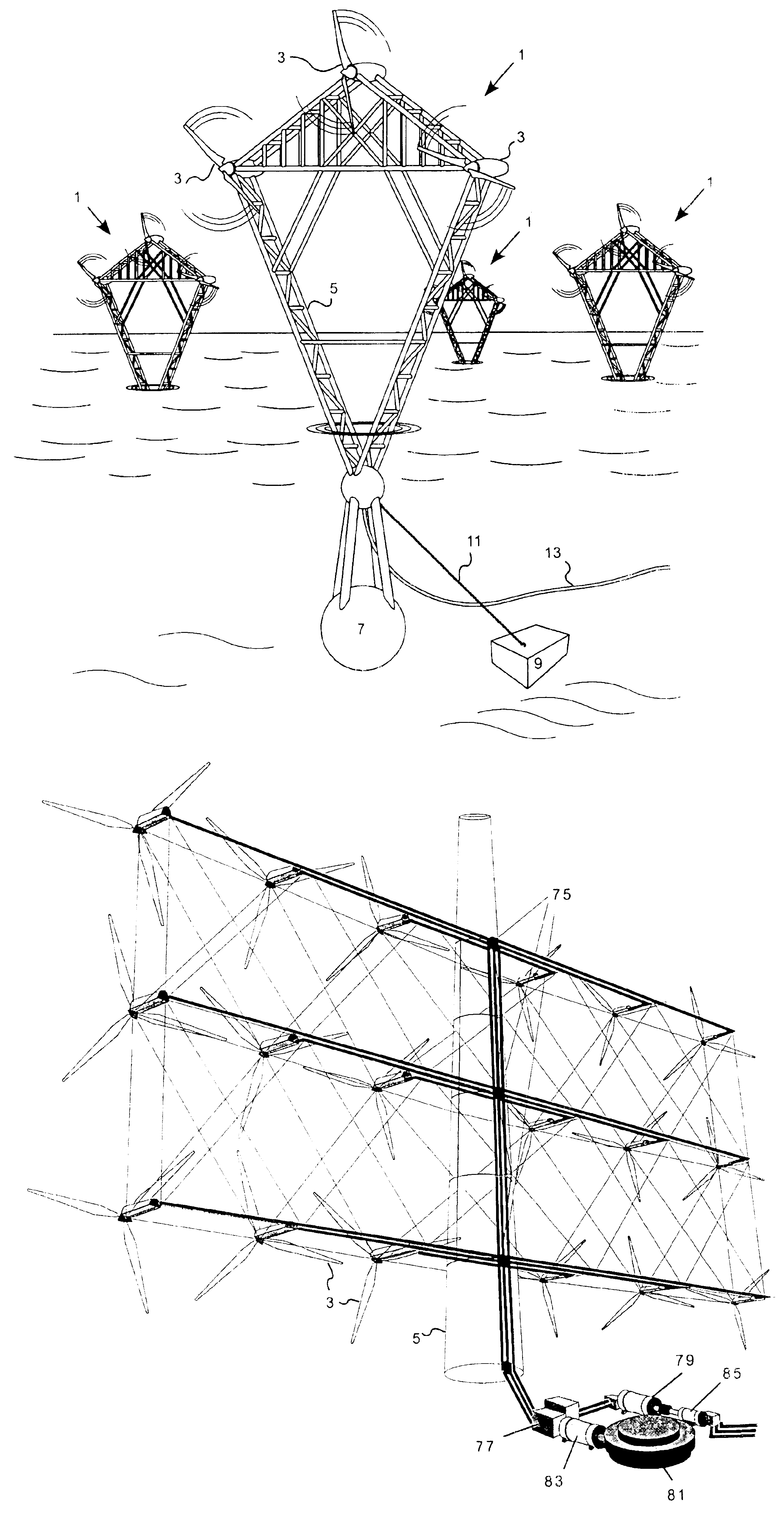

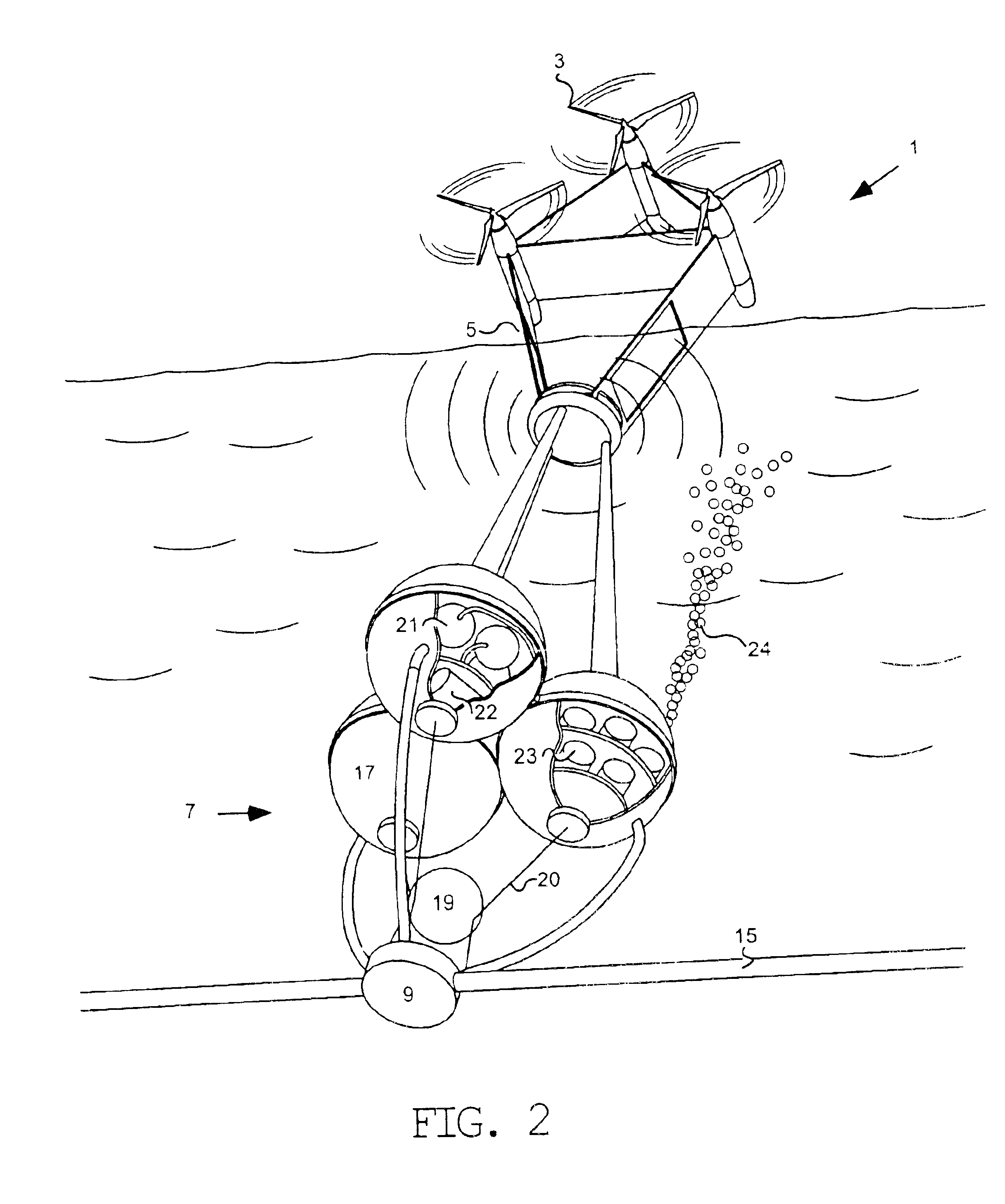

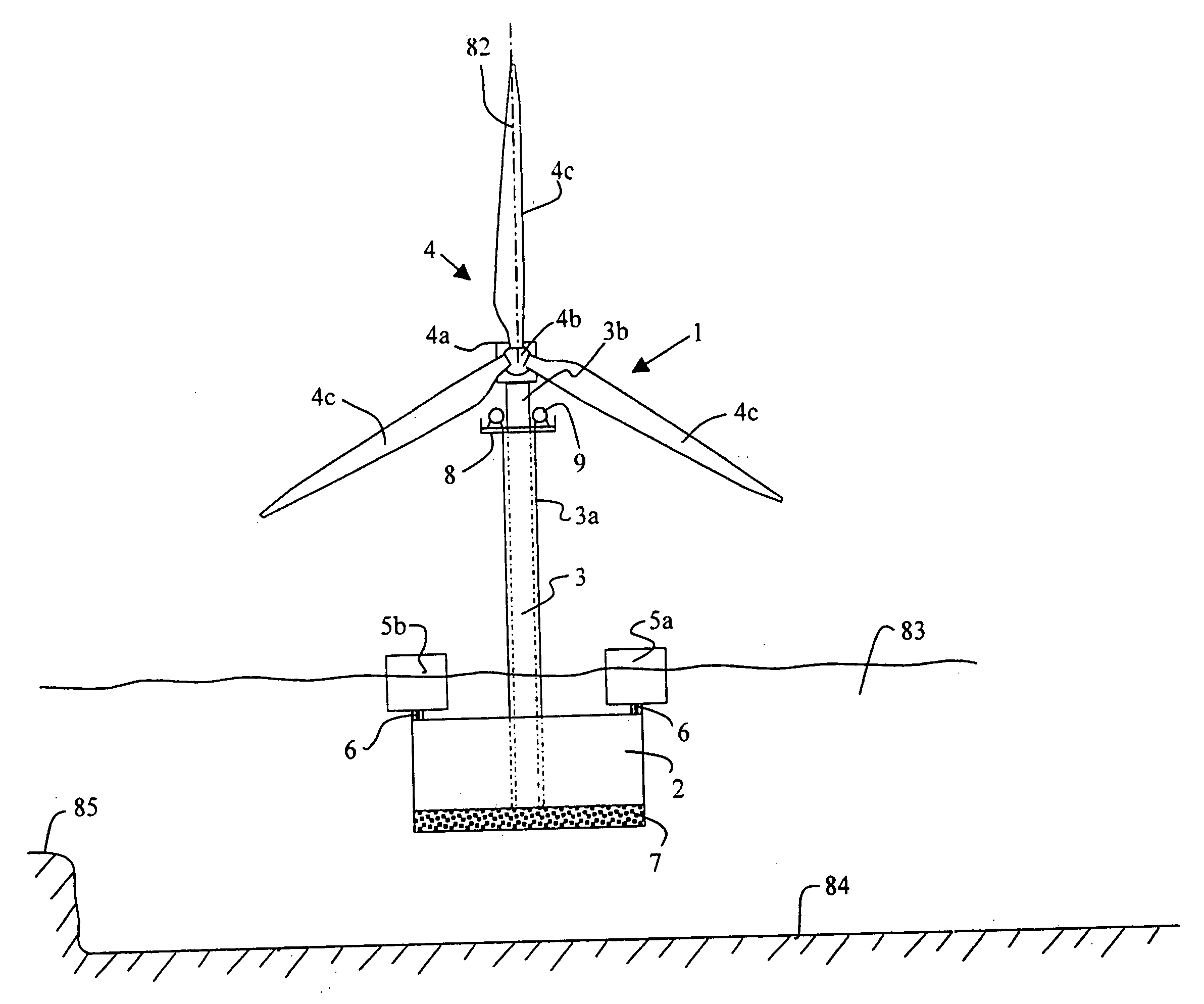

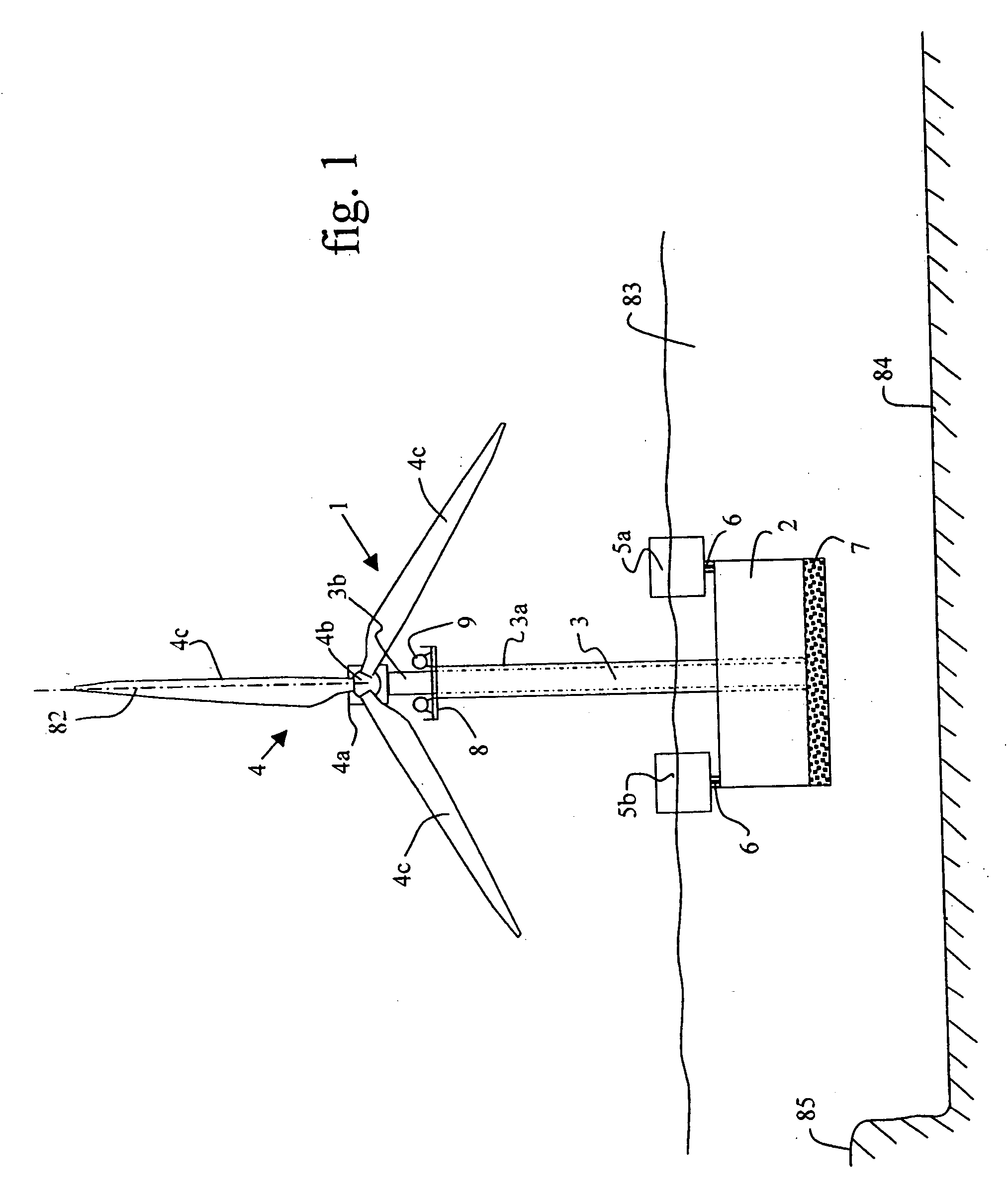

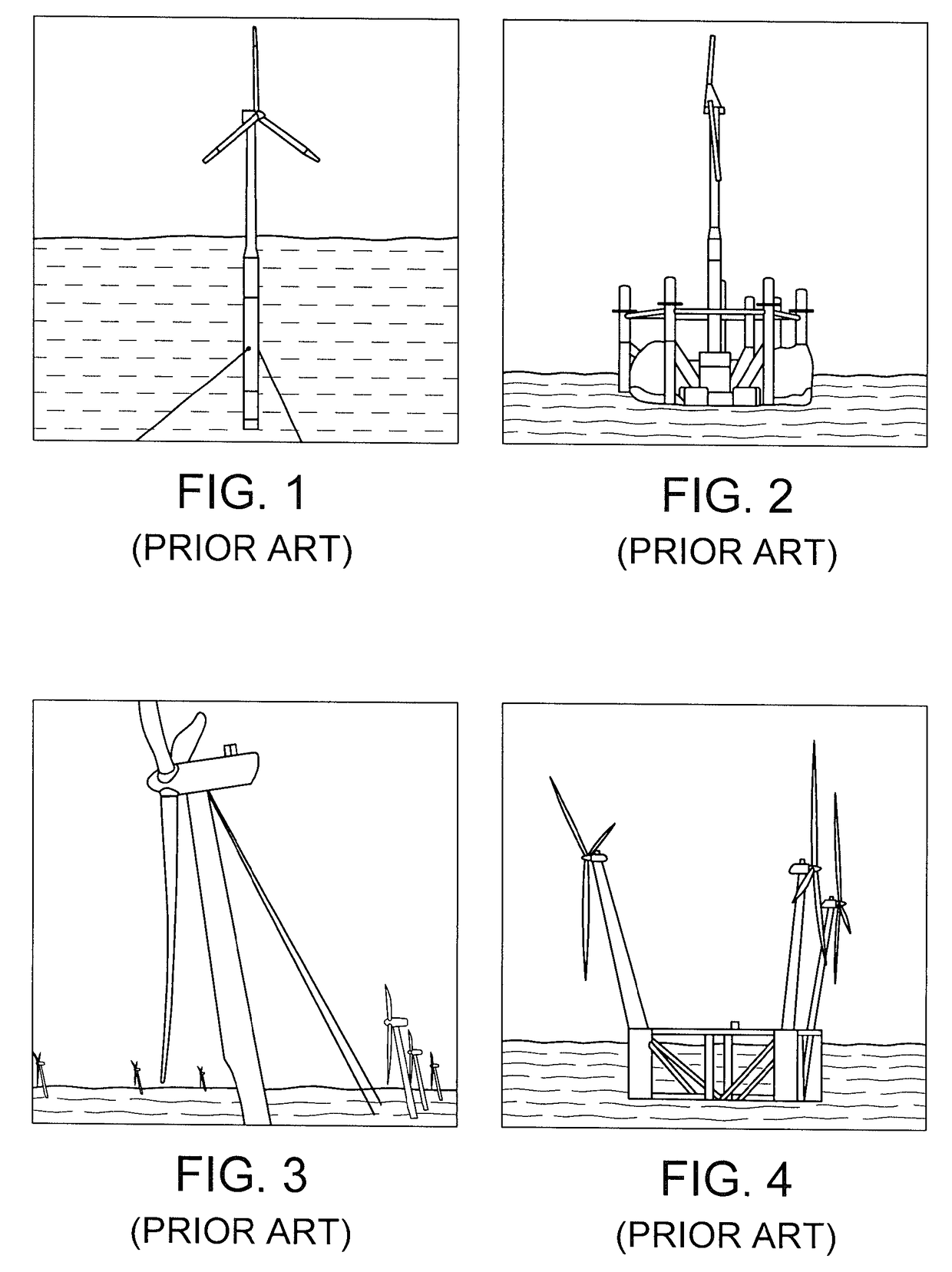

Offshore wind turbine with multiple wind rotors and floating system

ActiveUS7075189B2Reduce weightLean structureGeneral water supply conservationWind motor supports/mountsElectric power transmissionEngineering

A wind energy conversion system optimized for offshore application. Each wind turbine includes a semi-submersible hull with ballast weight that is moveable to increase the system's stability. Each wind turbine has an array of rotors distributed on a tower to distribute weight and loads and to improve power production performance where windshear is high. As much of the equipment associated with each rotor as possible is located at the base of the tower to lower the metacentric height. The equipment that may be emplaced at the bottom of the tower could include a power electronic converter, a DC to AC converter, or the entire generator with a mechanical linkage transmitting power from each rotor to the base of the tower. Rather than transmitting electrical power back to shore, it is contemplated to create energy intensive hydrogen-based products at the base of the wind turbine. Alternatively, there could be a central factory ship that utilizes the power produced by a plurality of wind turbines to create a hydrogen-based fuel. The hydrogen based fuel is transported to land and sold into existing markets as a value-added “green” product.

Owner:OCEAN WIND ENERGY SYST

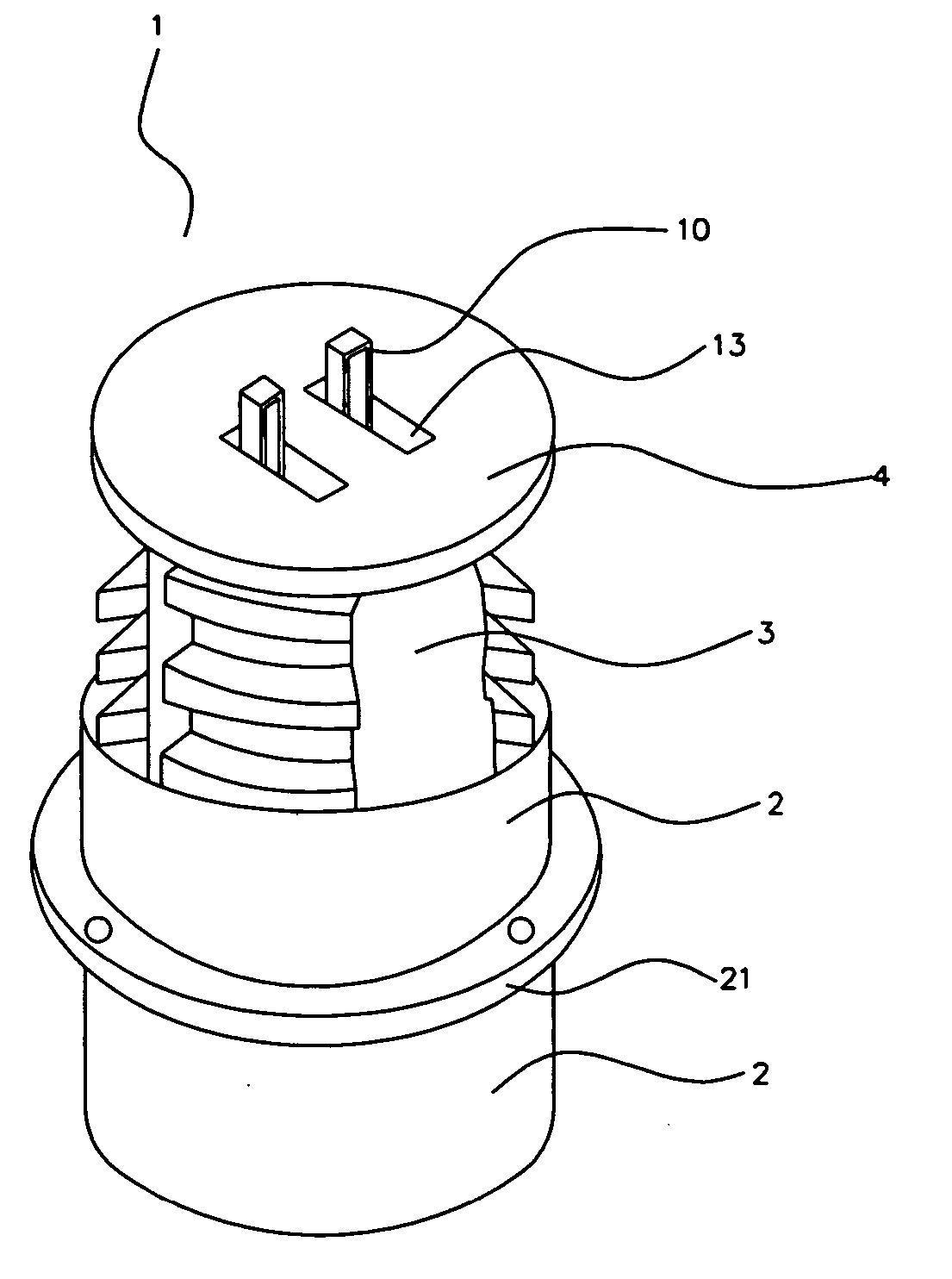

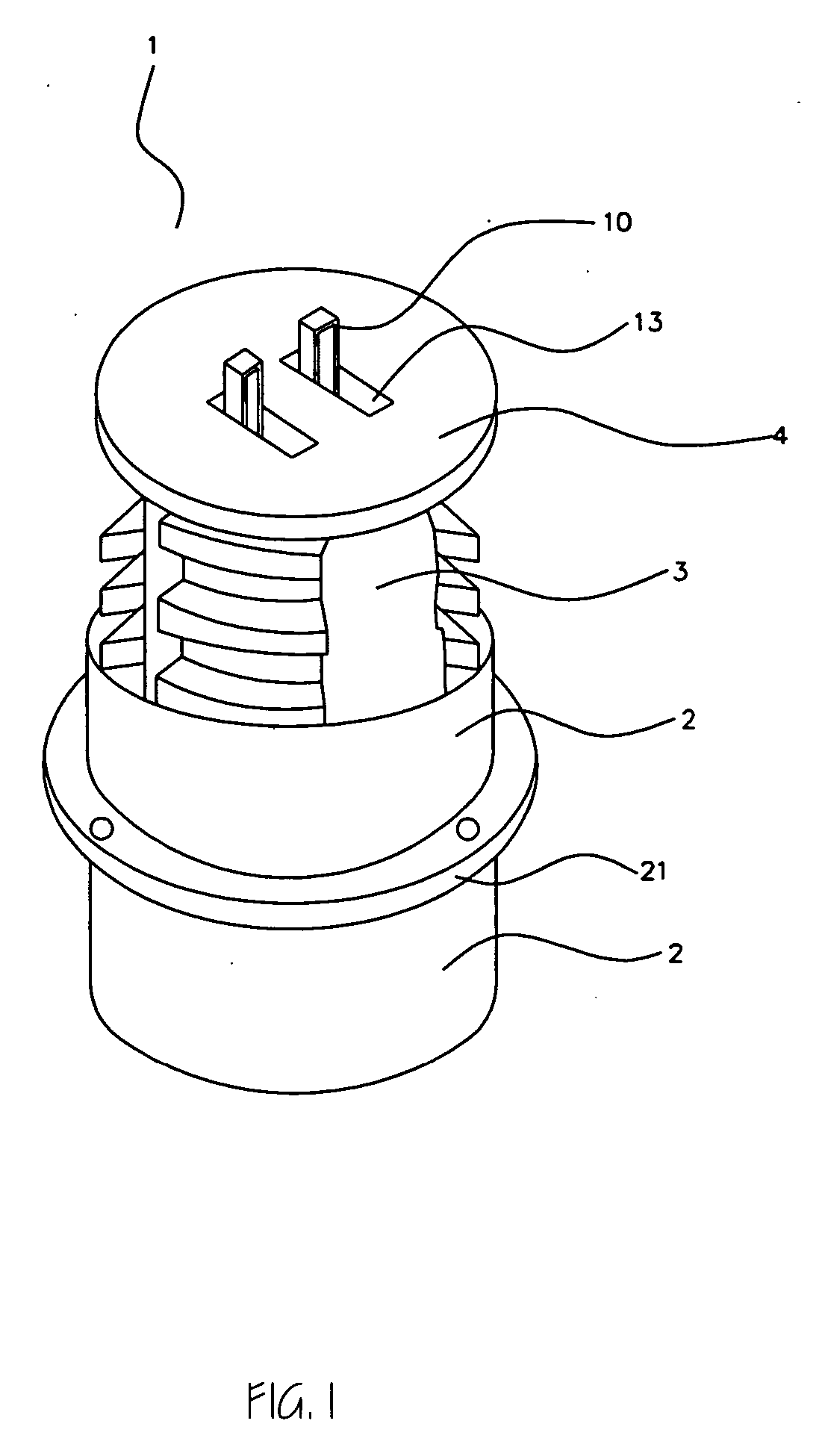

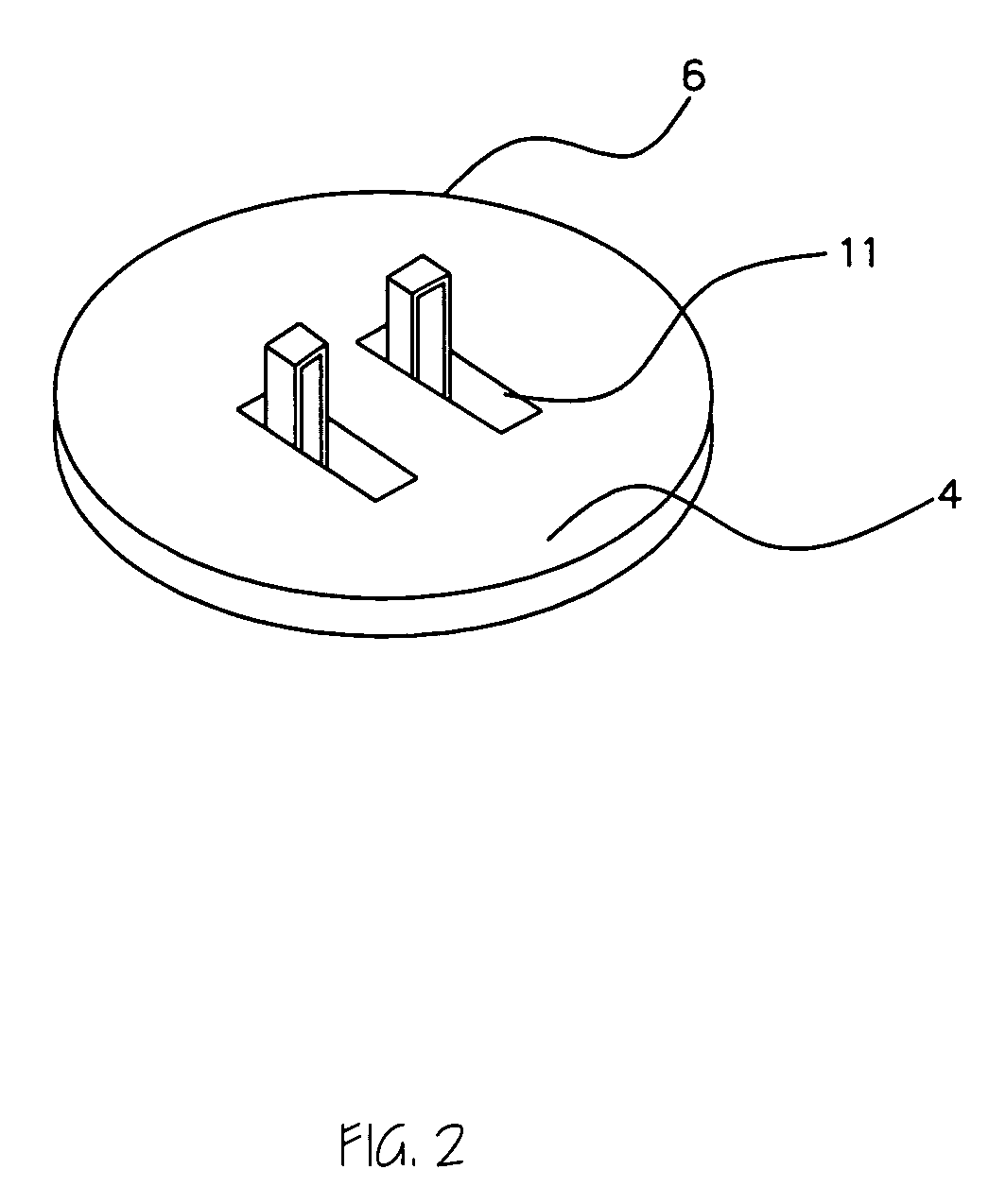

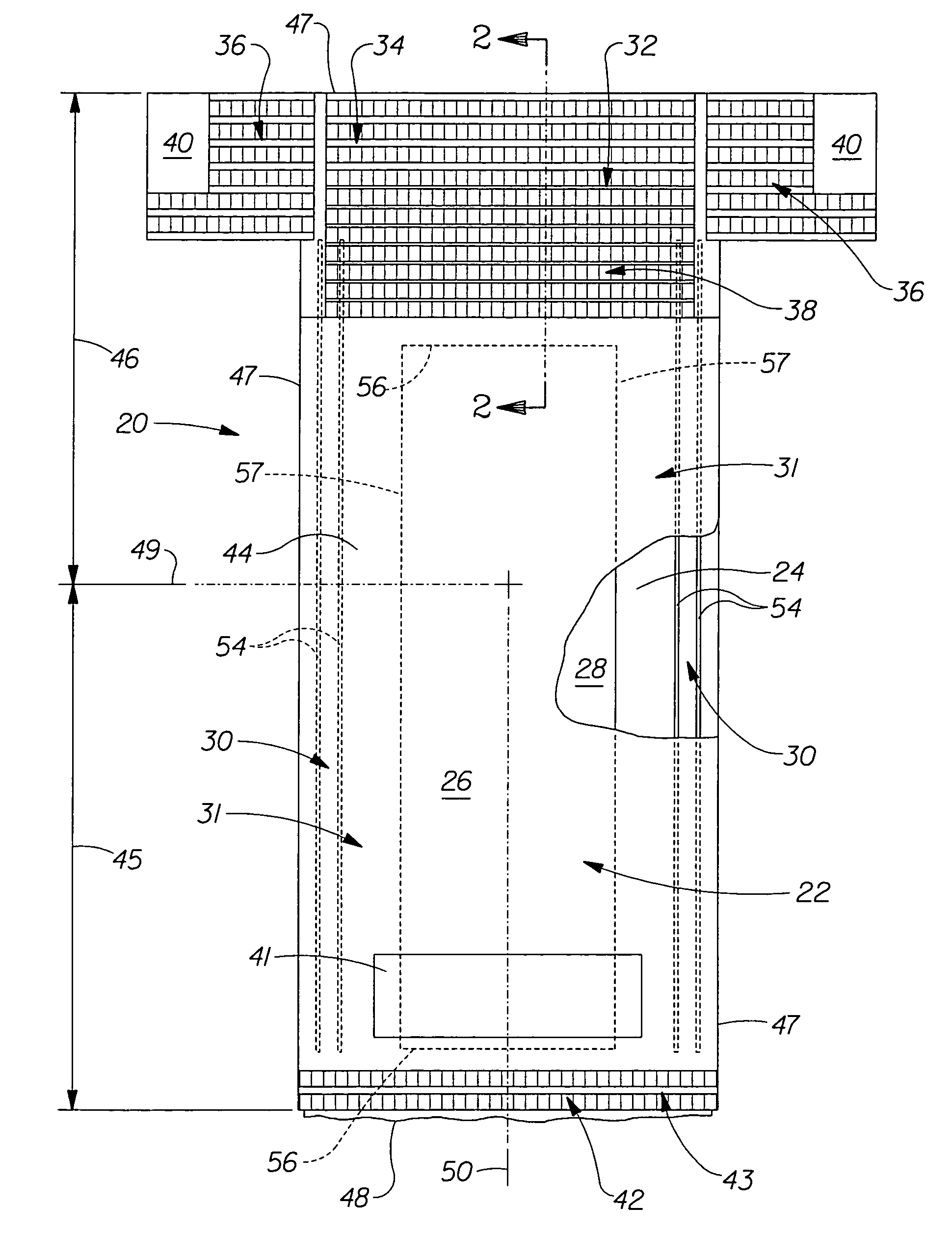

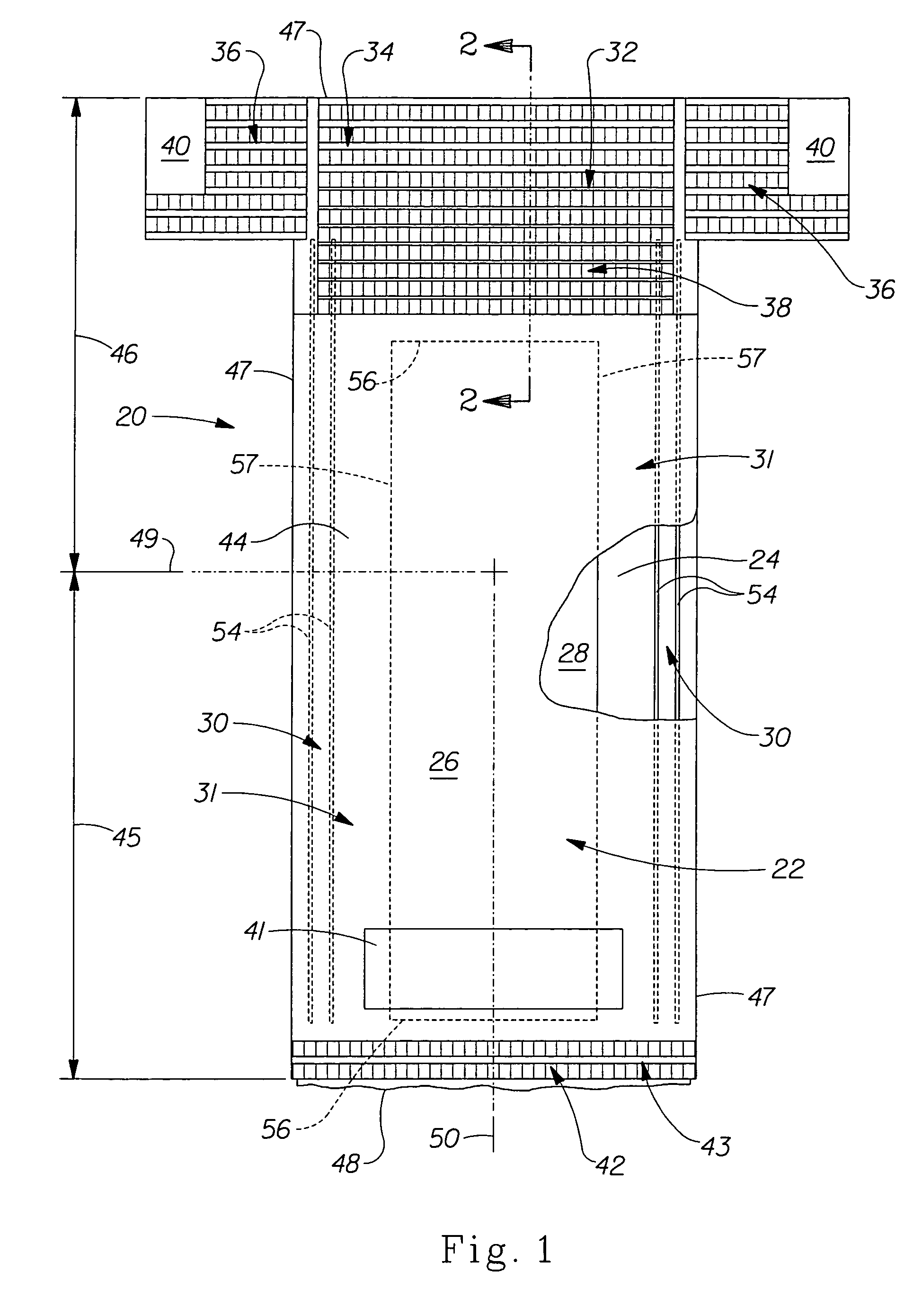

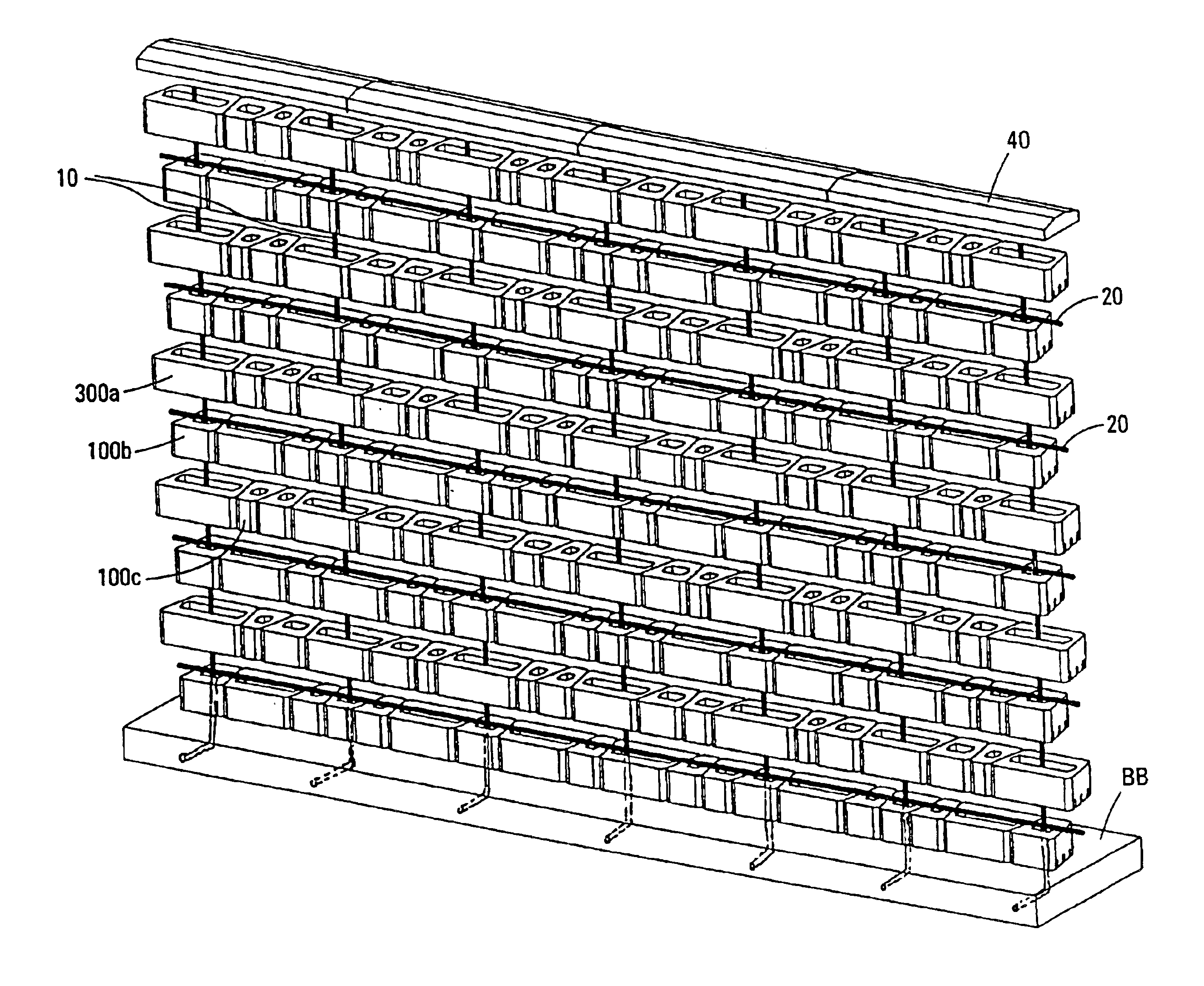

Four parts manhole enabling an easy install and height adjustment

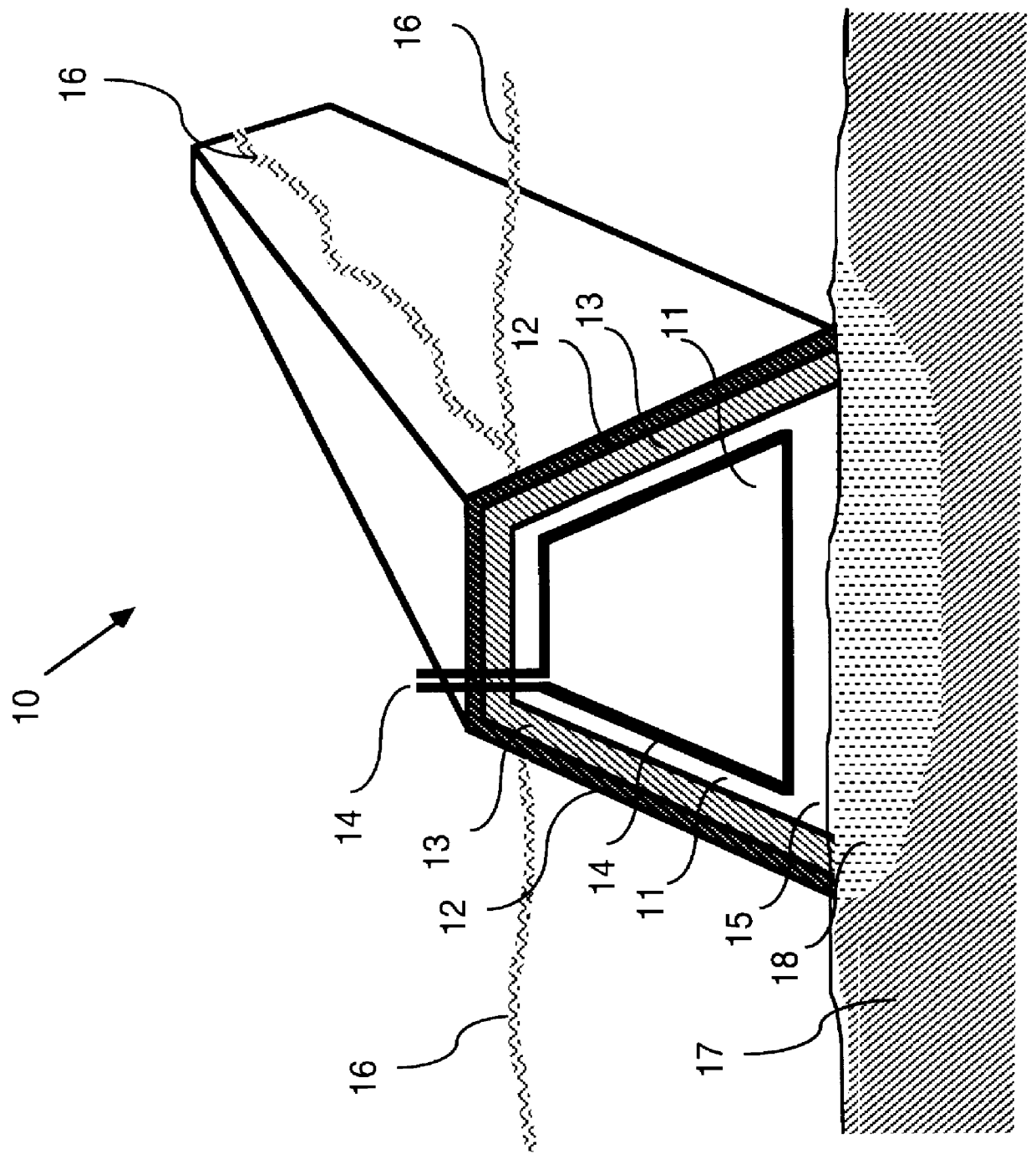

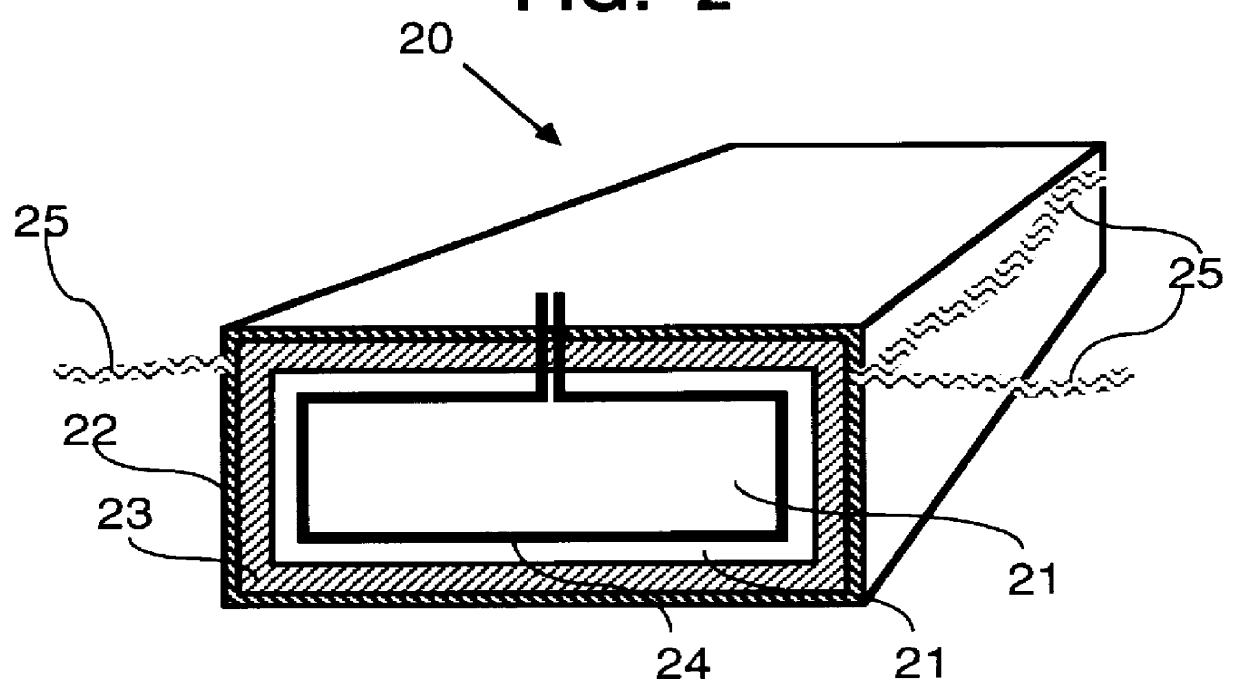

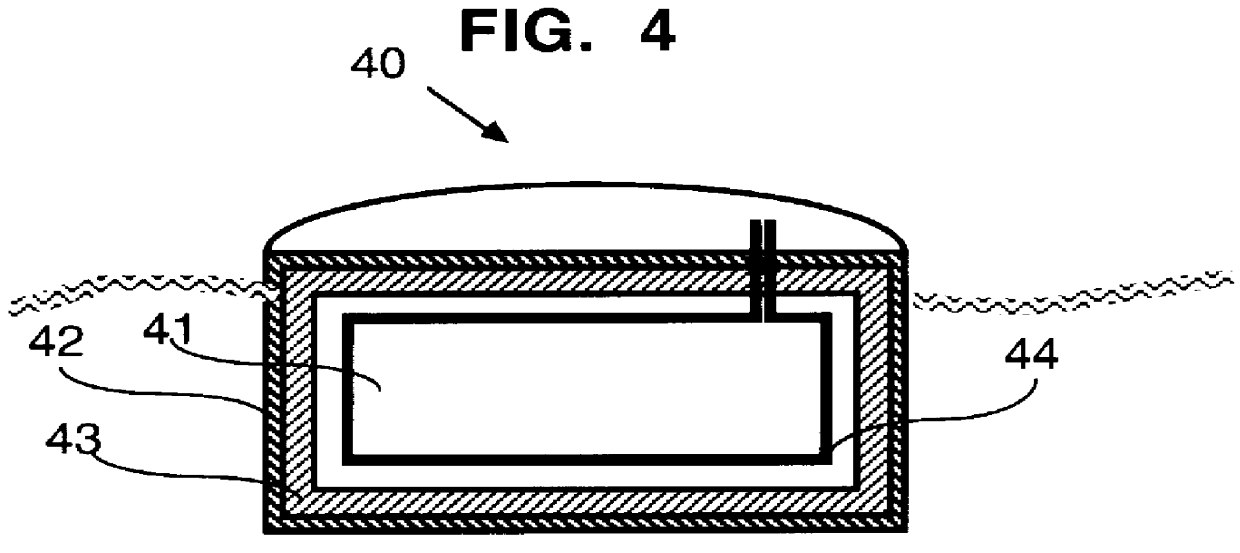

InactiveUS20070081857A1Easy to installEasy to adjustArtificial islandsUnderwater structuresBand shapeKnife blades

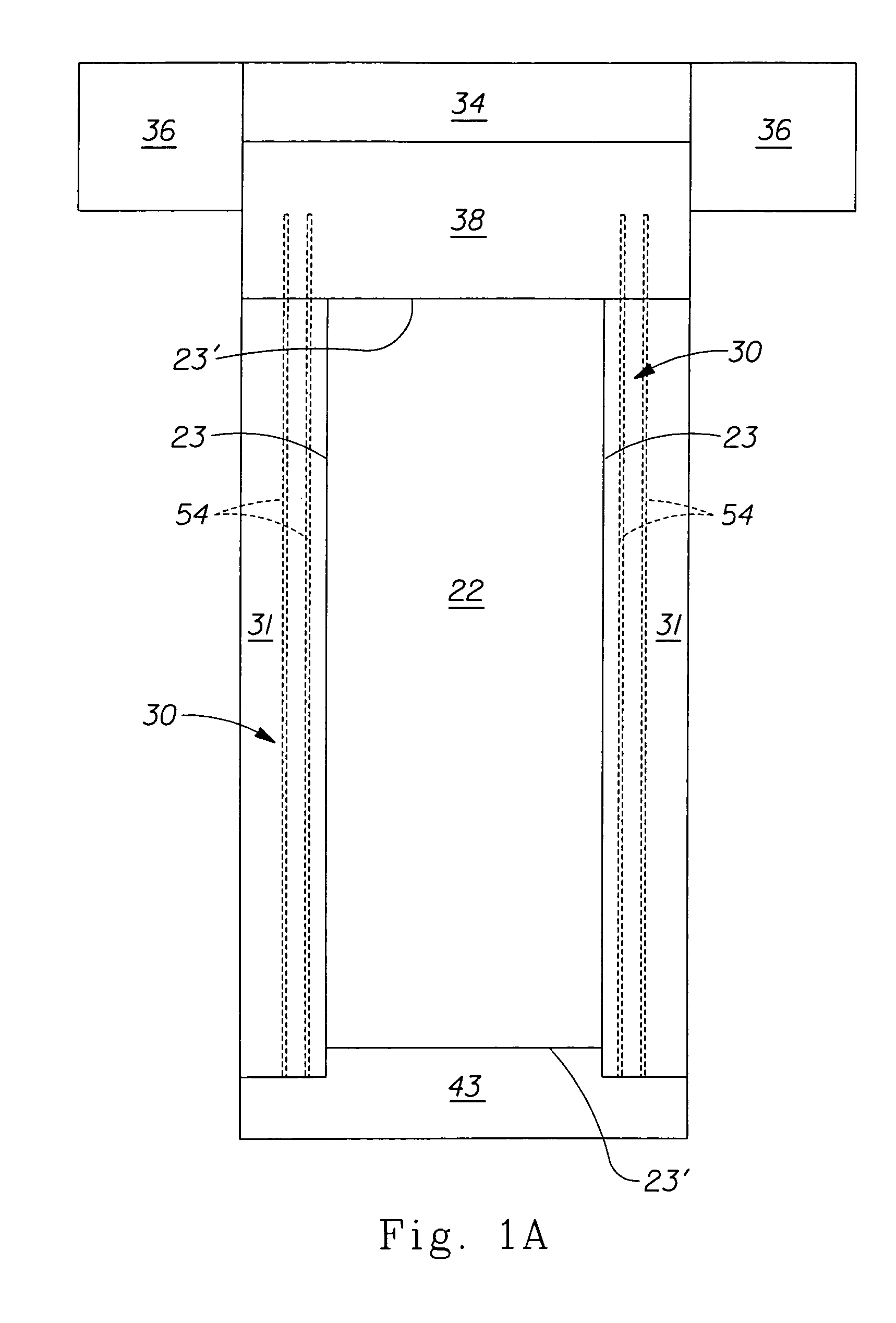

A manhole comprised of four parts is provided. The manhole is comprised of an outer-manhole pipe, an inner-manhole pipe, a manhole cover, and a support pipe. Pluralities of concave arc band shape blades are horizontally developed along the inner surface of the outer manhole pipe. Same number of convex arc band shape blades is horizontally developed along the outer surface of the inner manhole pipe. The inner-manhole pipe is inserted into the outer-manhole pipe vertically when the two kinds of arc shape blades aligned to make pass way for each other. When a desired height is reached, workers rotate the inner-manhole pipe 60 degrees horizontally and put down the inner-manhole pipe. Then the two kinds of blades are overlapped and fix the height of the manhole cover. A support pipe, comprised of two pieces of equal hemi-pipe connected one end, is engaged between the top flange of the inner-manhole pipe and top end of the outer manhole pipe to hold and support the distance between them.

Owner:YOON JUNG HO

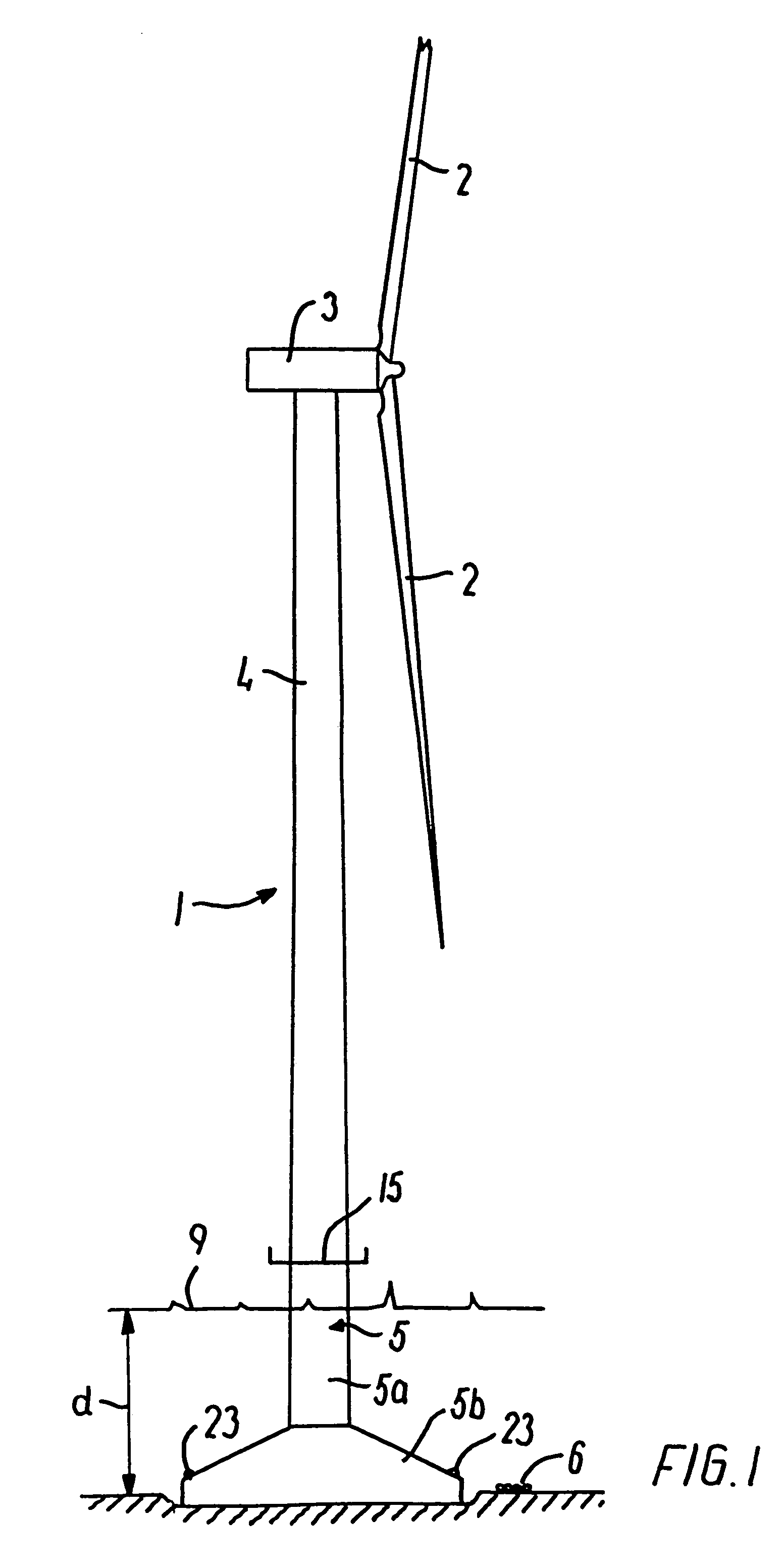

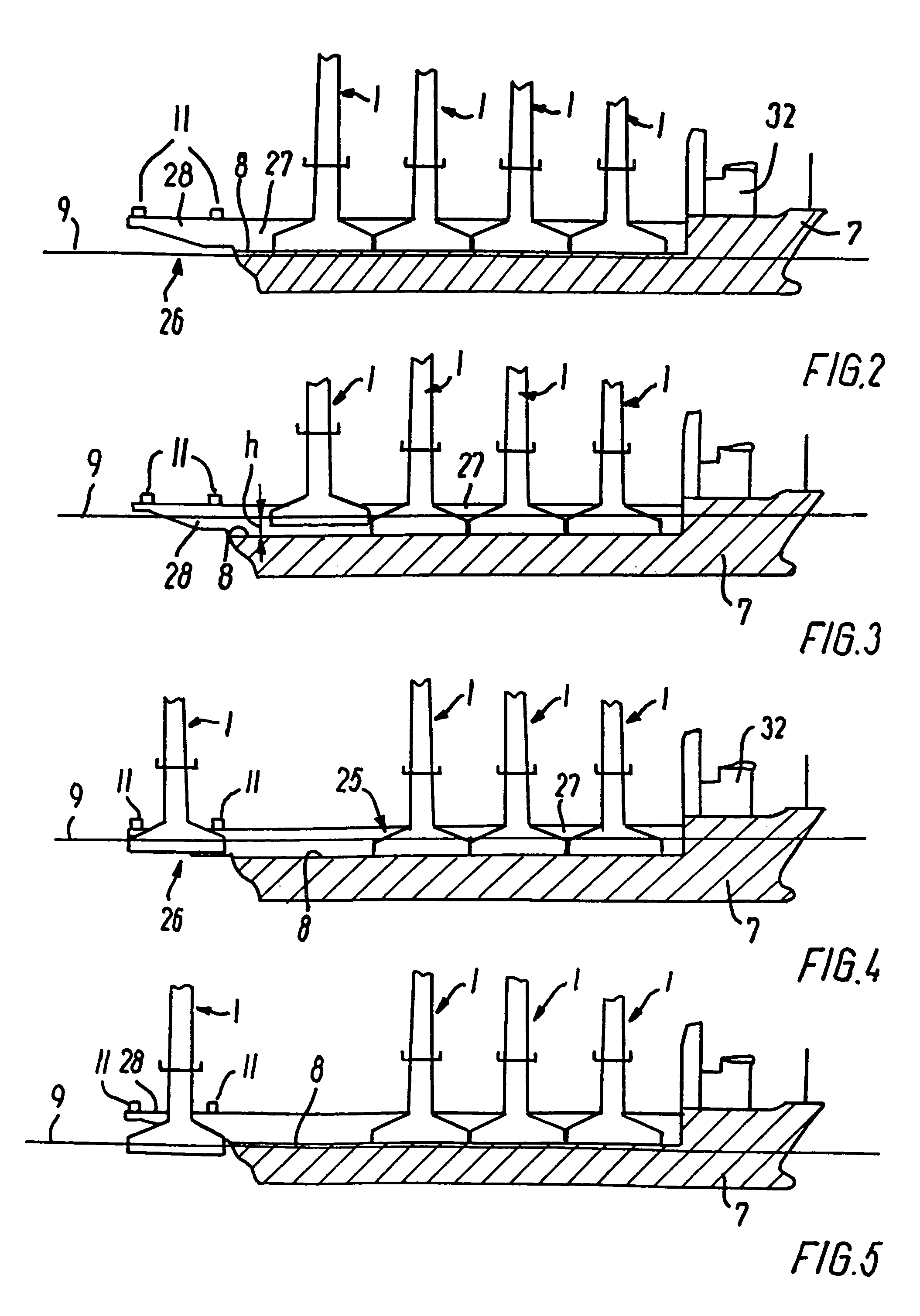

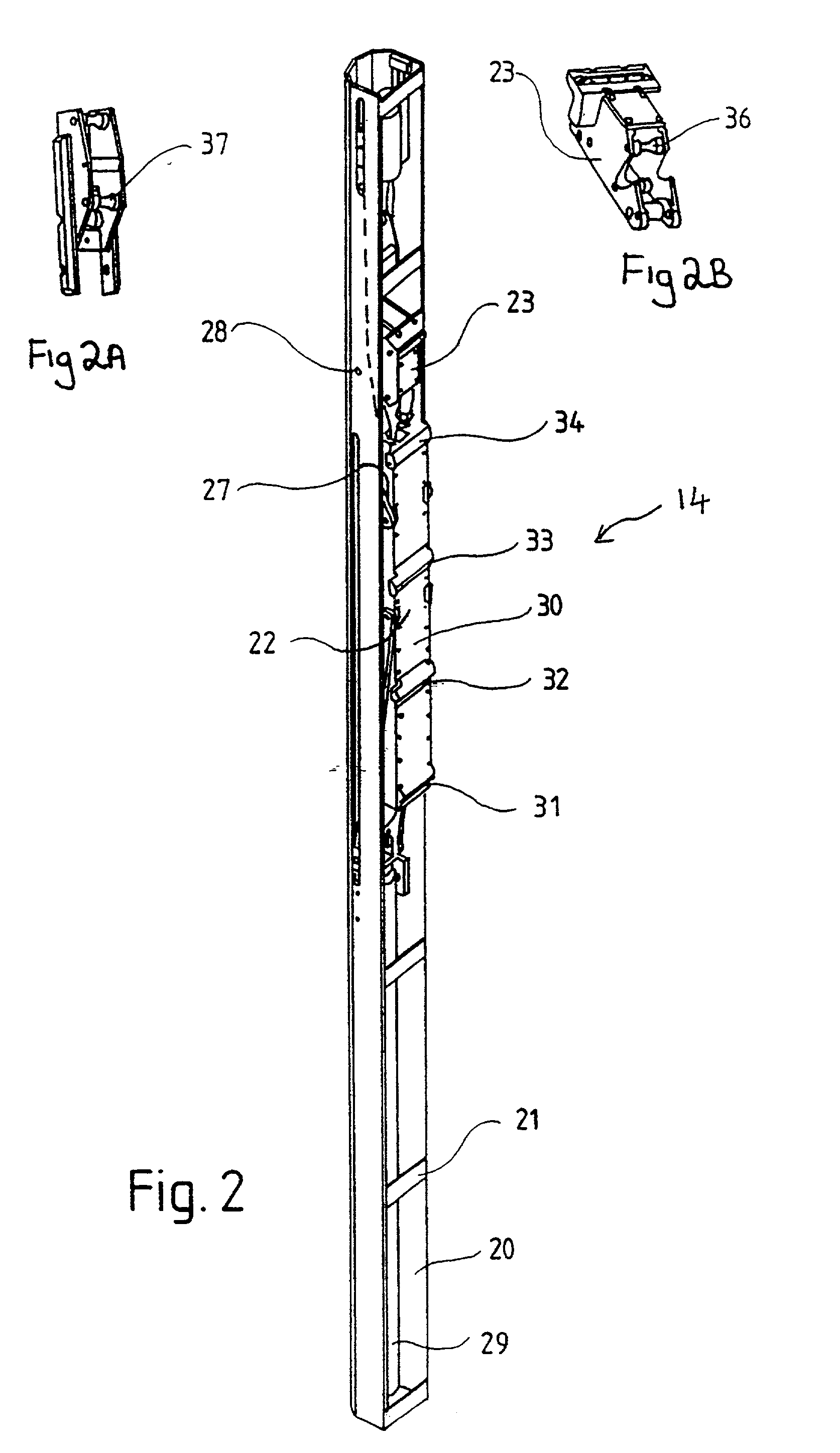

Offshore wind turbine and method for making same

InactiveUS20040169376A1Reduce usageEasy to transportEngine manufactureFinal product manufactureElectricityEngineering

The present invention relates to wind generators installed off-shore, in particular at sea, to support structures forming a part of such wind generators, and to methods of making and installing such wind generators. The technical field of the invention is that of making, transporting, and installing wind generators for producing electricity, more particularly off-shore, and in large numbers, so as to form wind "farms". The wind generator of the invention comprises a wind turbine and a deployable telescopic pylon or support supporting the turbine, and a gravity base supporting the pylon or support.

Owner:SAIPEM SA

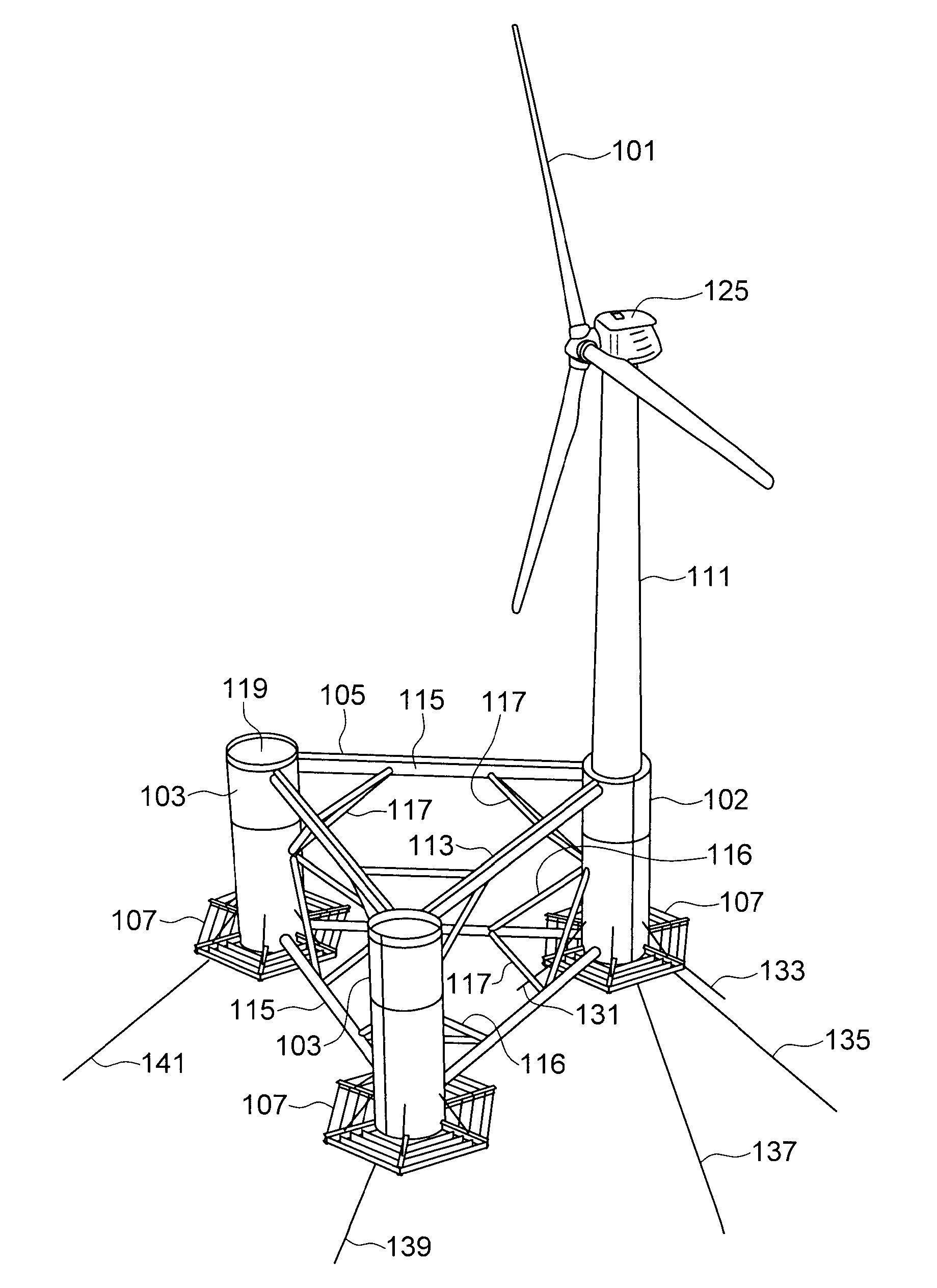

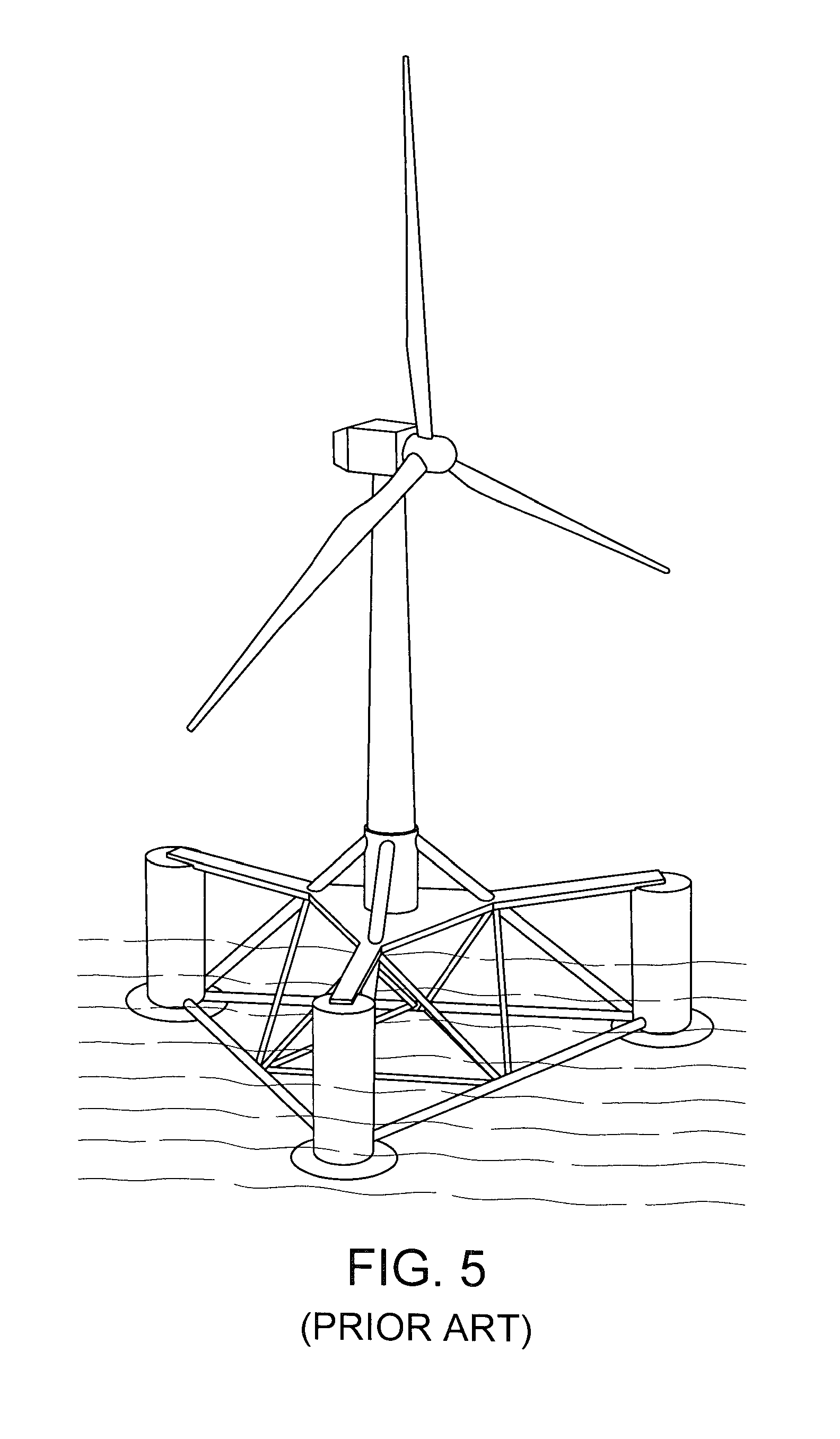

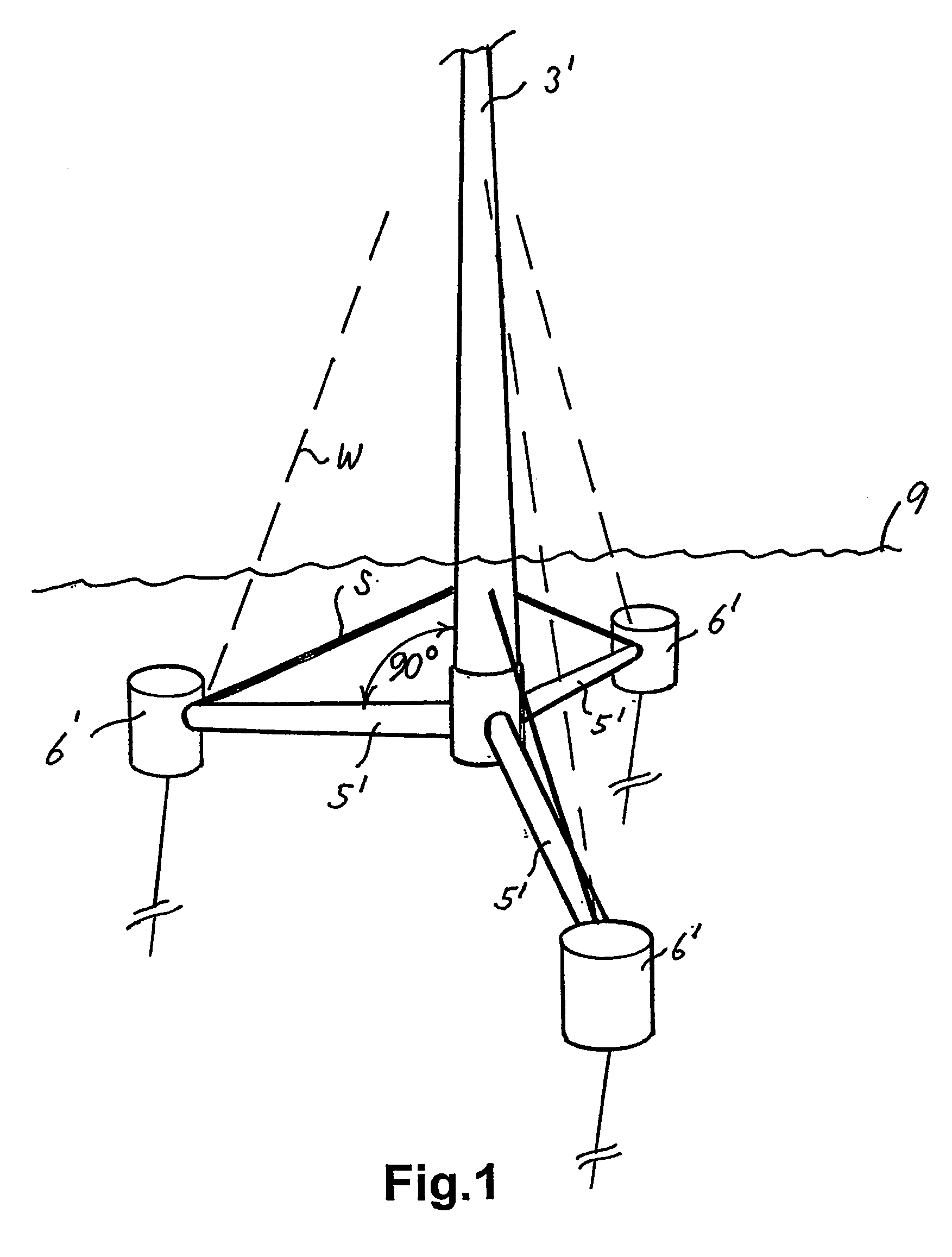

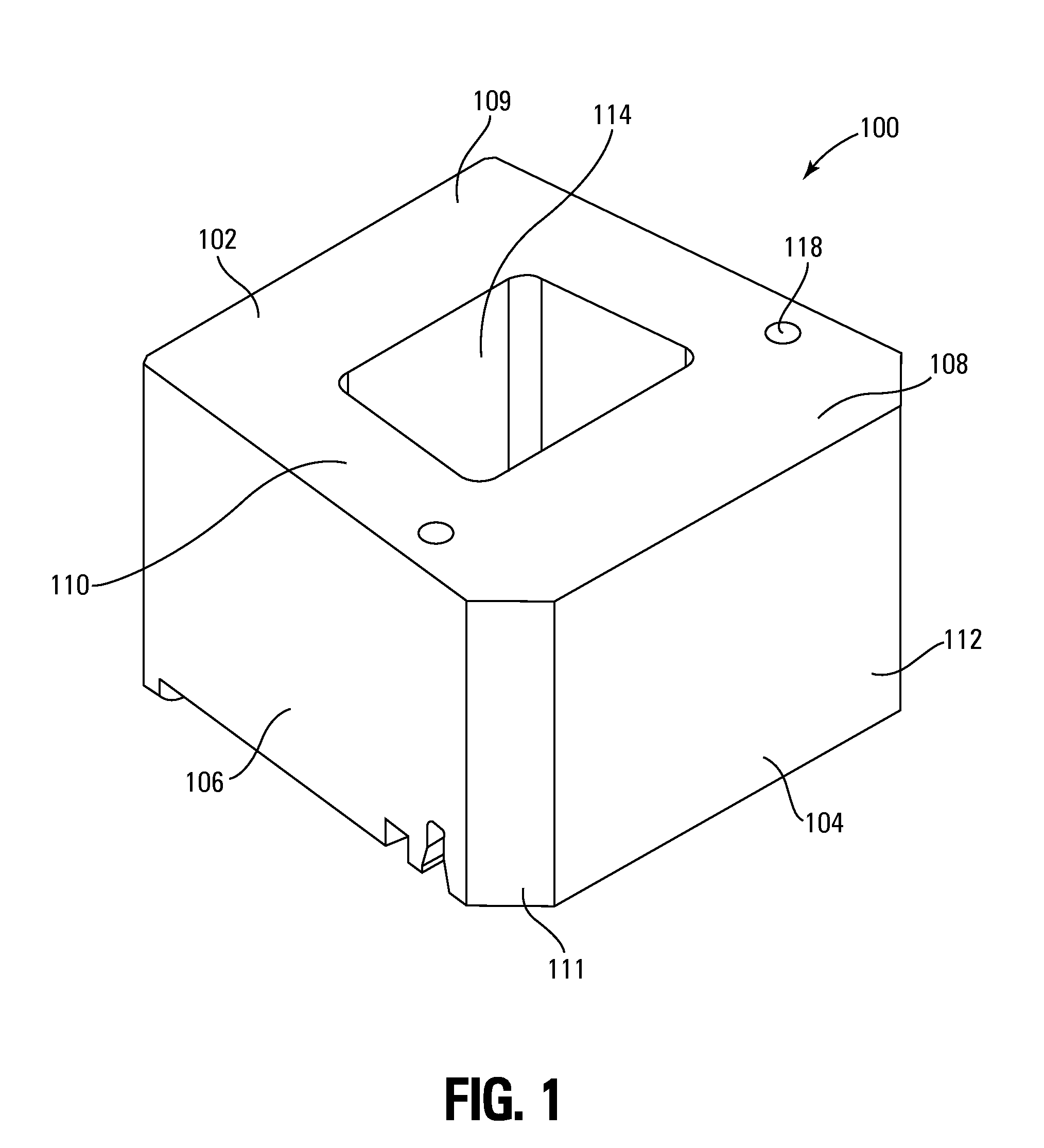

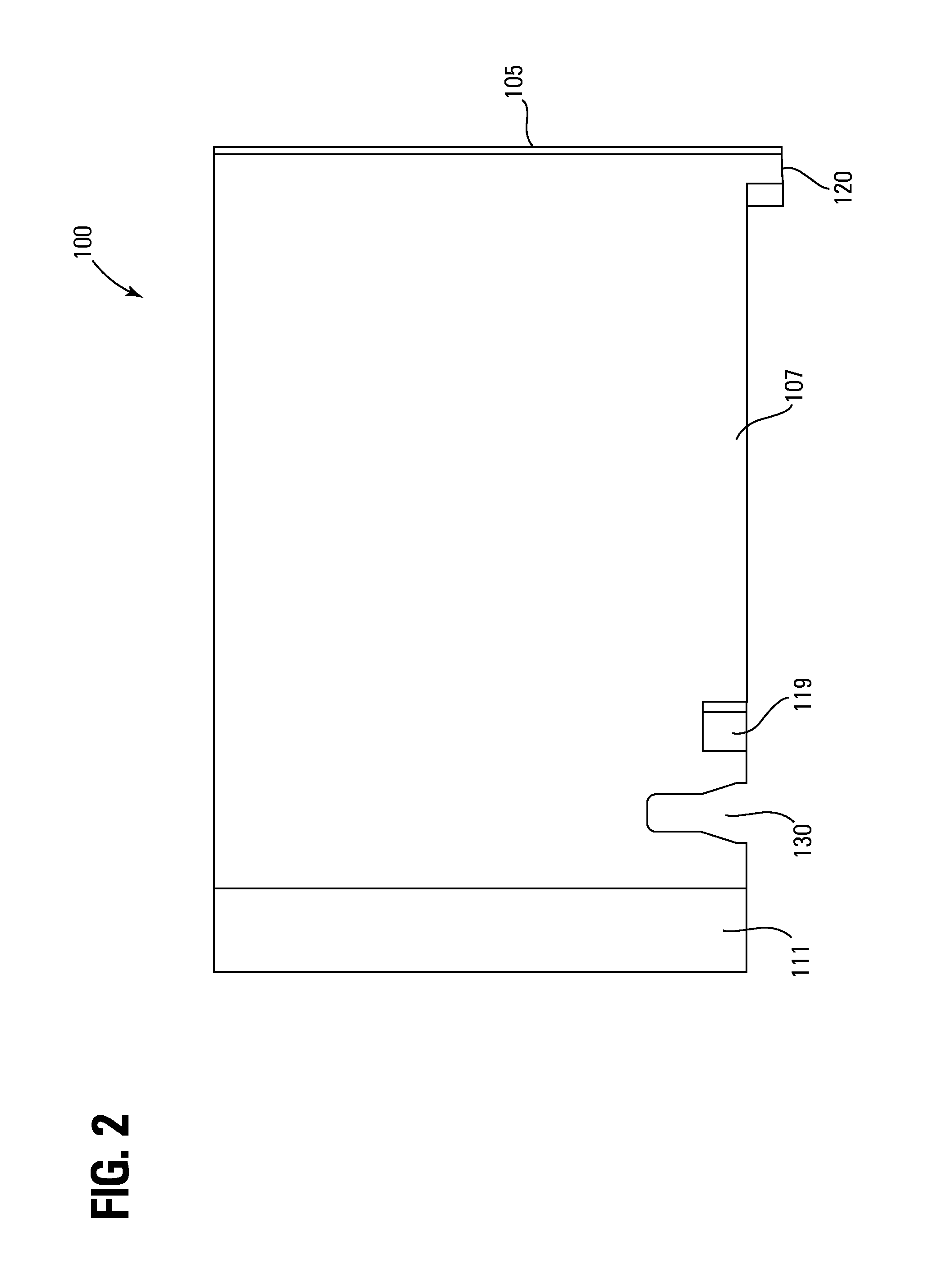

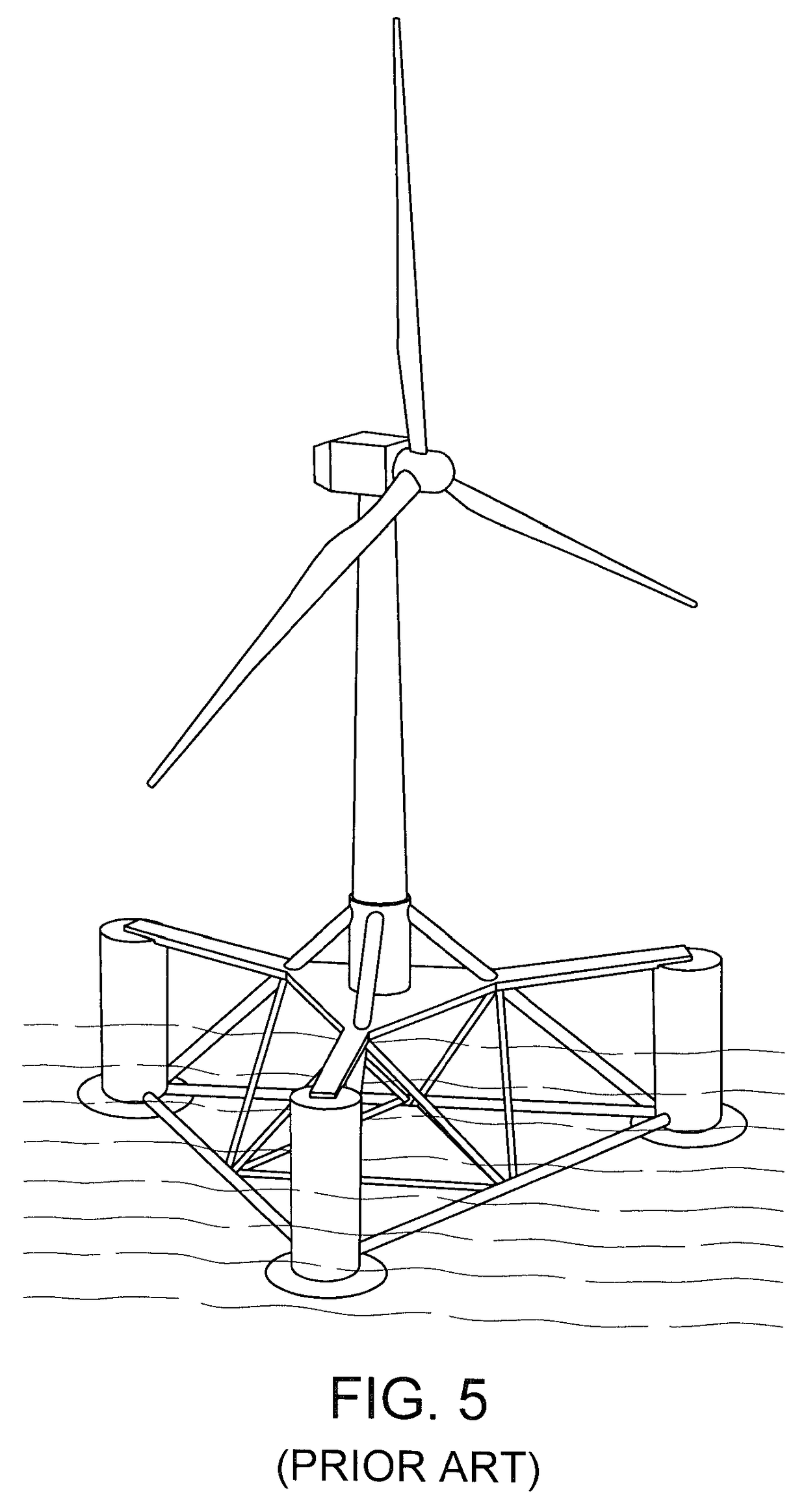

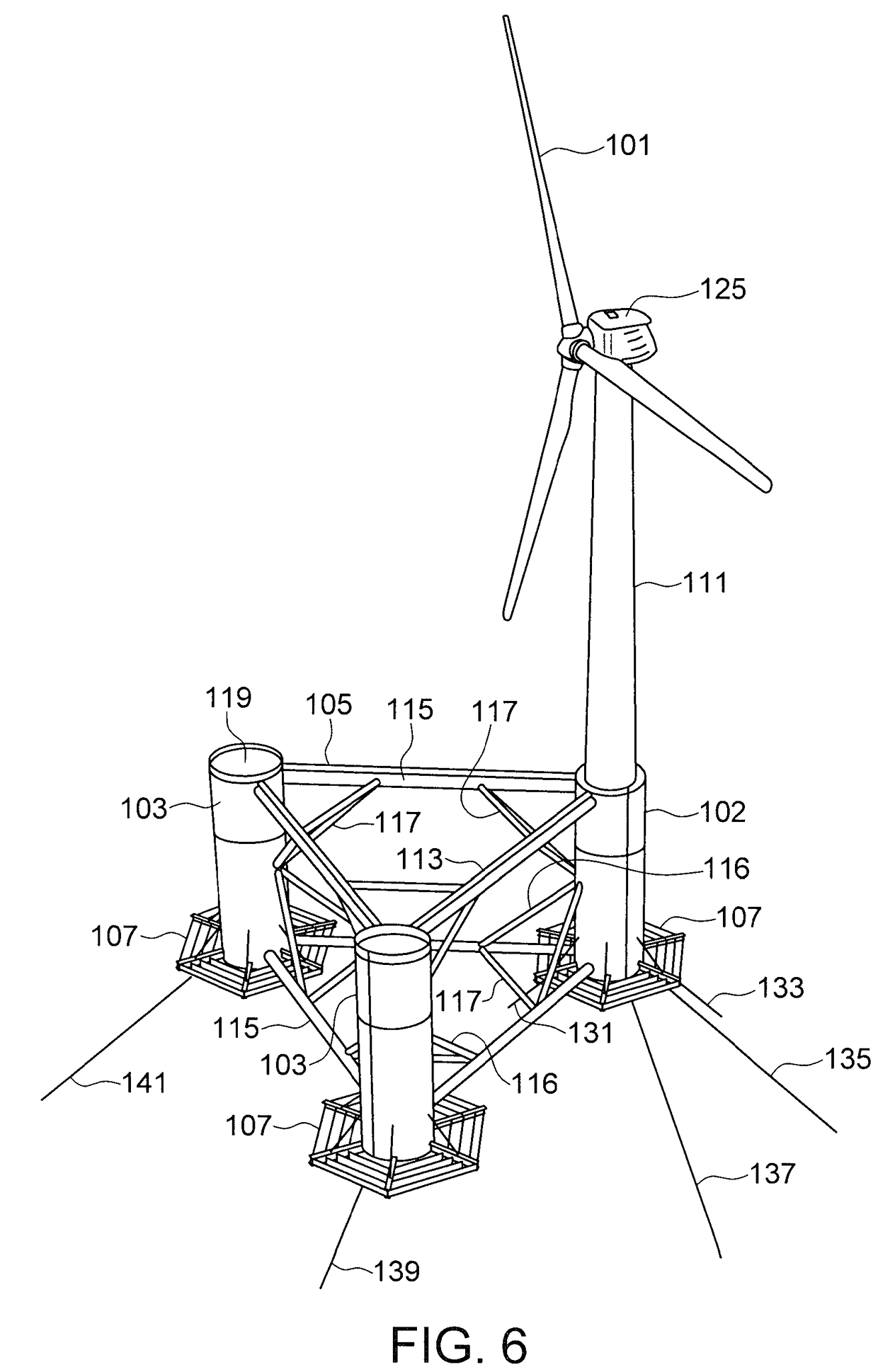

Column-stabilized offshore platform with water-entrapment plates and asymmetric mooring system for support of offshore wind turbines

ActiveUS20110037264A1Improve performanceEasy to produceWind motor controlWind motor assemblyNacelleMooring system

A floating wind turbine platform includes a floatation frame (105) that includes three columns (102, 103) that are coupled to each other with horizontal main beams (115). A wind turbine tower (111) is mounted above a tower support column (102) to simplify the system construction and improve the structural strength. The turbine blades (101) are coupled to a nacelle (125) that rotates on top of the tower (111). The turbine's gearbox generator and other electrical gear can be mounted either traditionally in the nacelle, or lower in the tower (111) or in the top of the tower-supporting column (102). The floatation frame (105) includes a water ballasting system that pumps water between the columns (102, 103) to keep the tower (111) in a 10 vertical alignment regardless of the wind speed. Water-entrapment plates (107) are mounted to the bottoms of the columns (102, 103) to minimize the rotational movement of the floatation frame (105) due to waves.

Owner:PRINCIPLE POWER

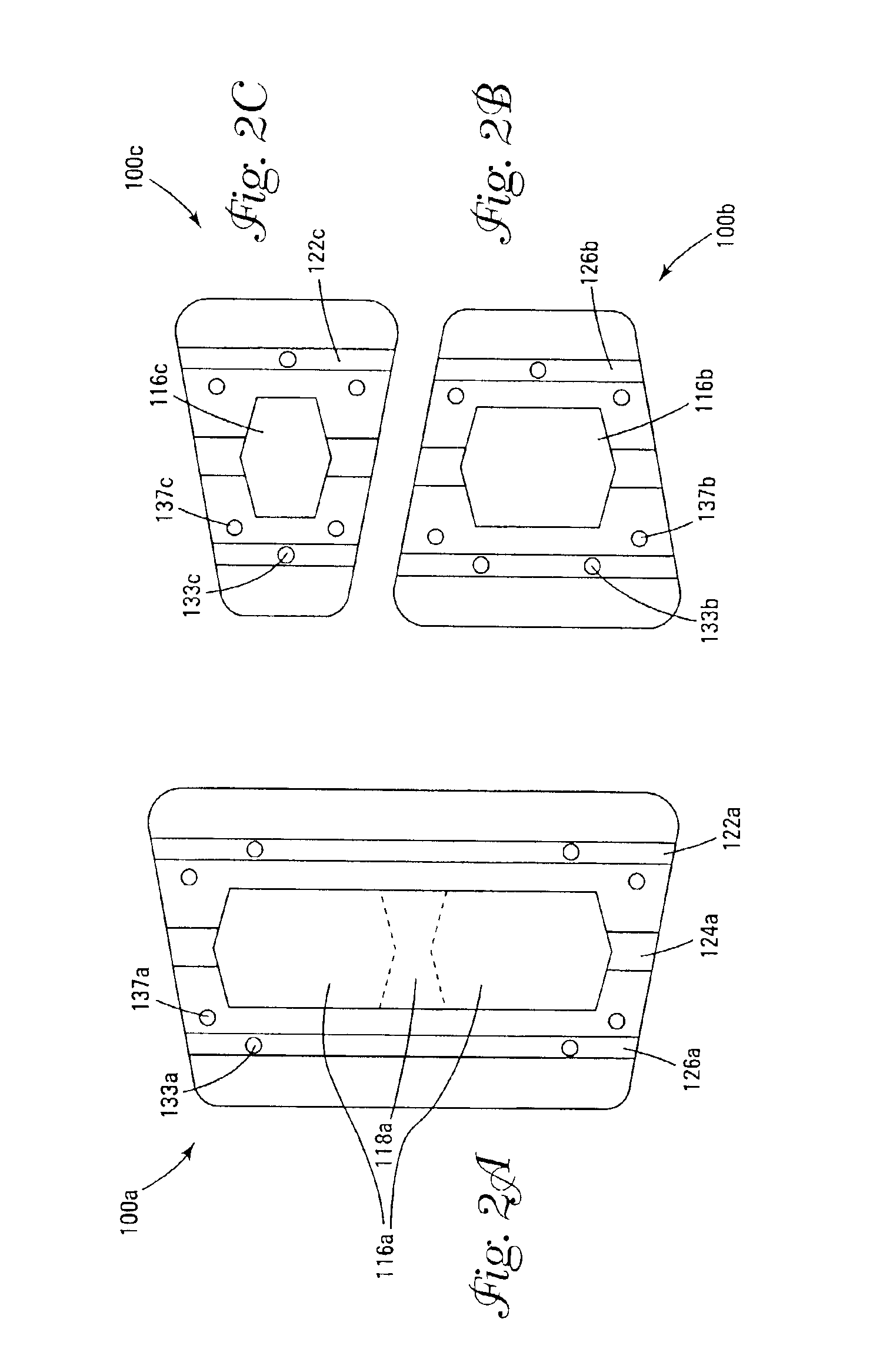

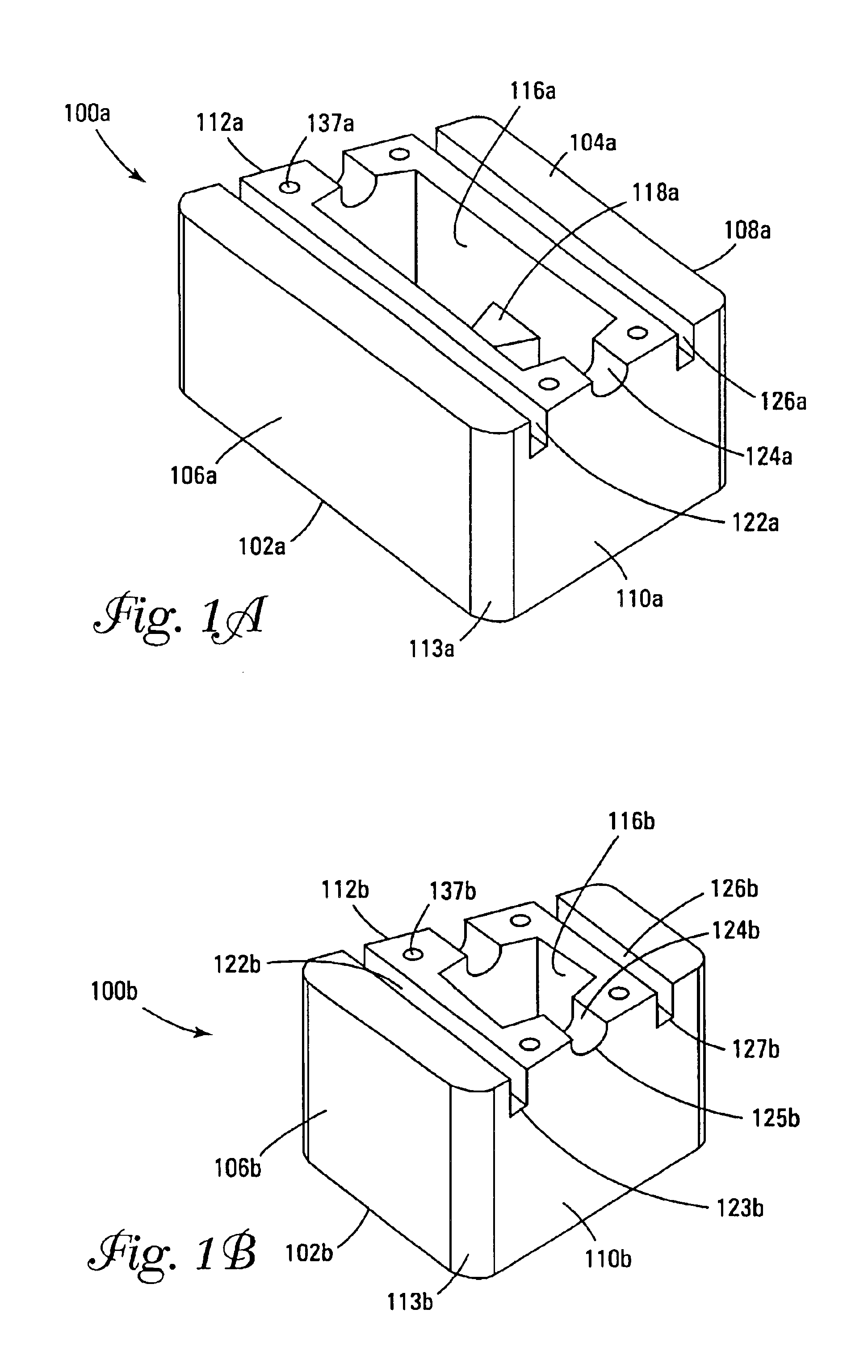

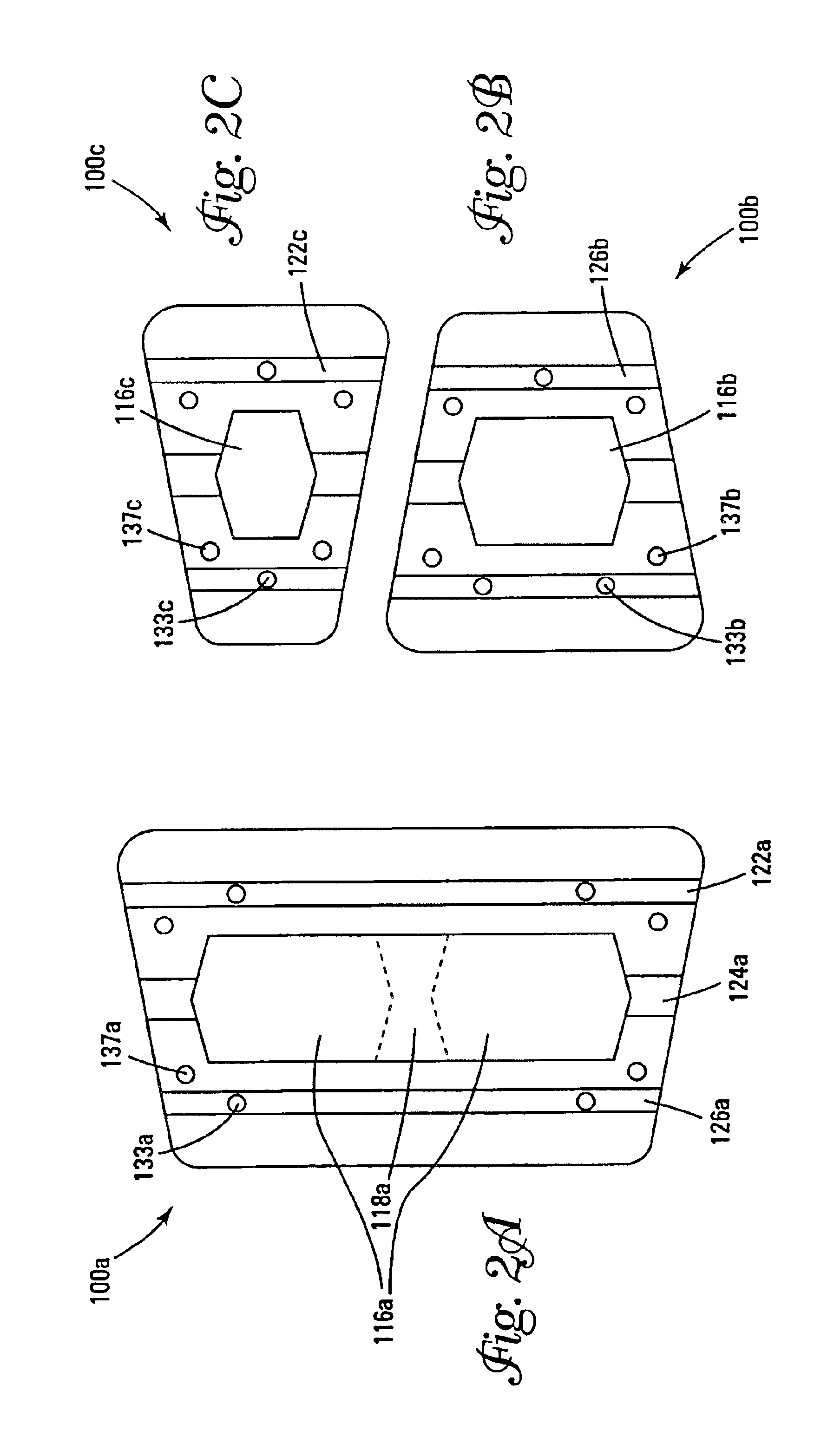

Retaining wall block with face connection

Single and multiple retaining wall blocks and block systems are disclosed. The blocks are provided with a face connection system which includes at least one front lip extending from a top surface of the block and a bottom channel formed into a front face and bottom surface of the block. The front lips have a length which is less than the width of the blocks.

Owner:CONTECH TECH

Fatigue reistant foundation system

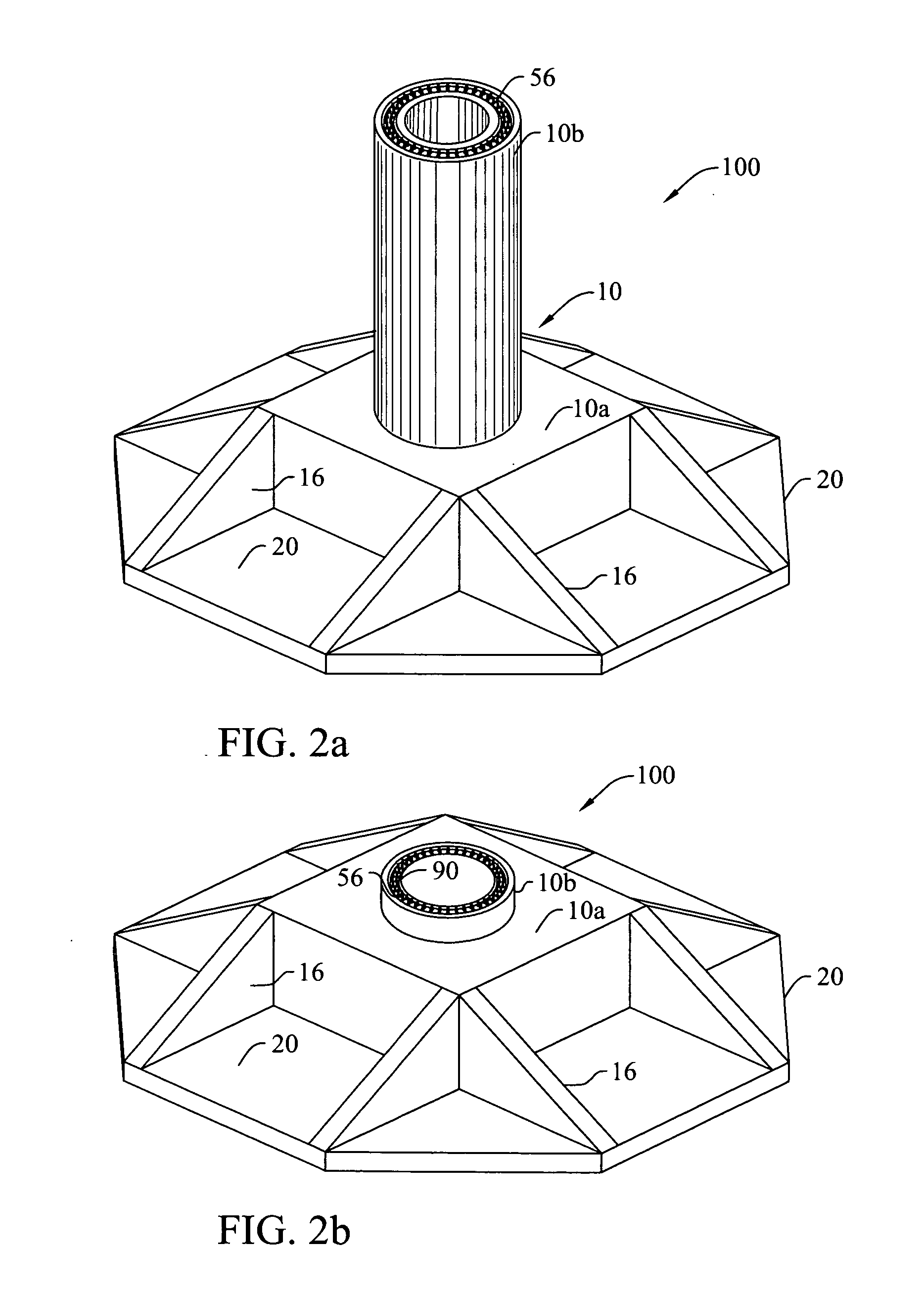

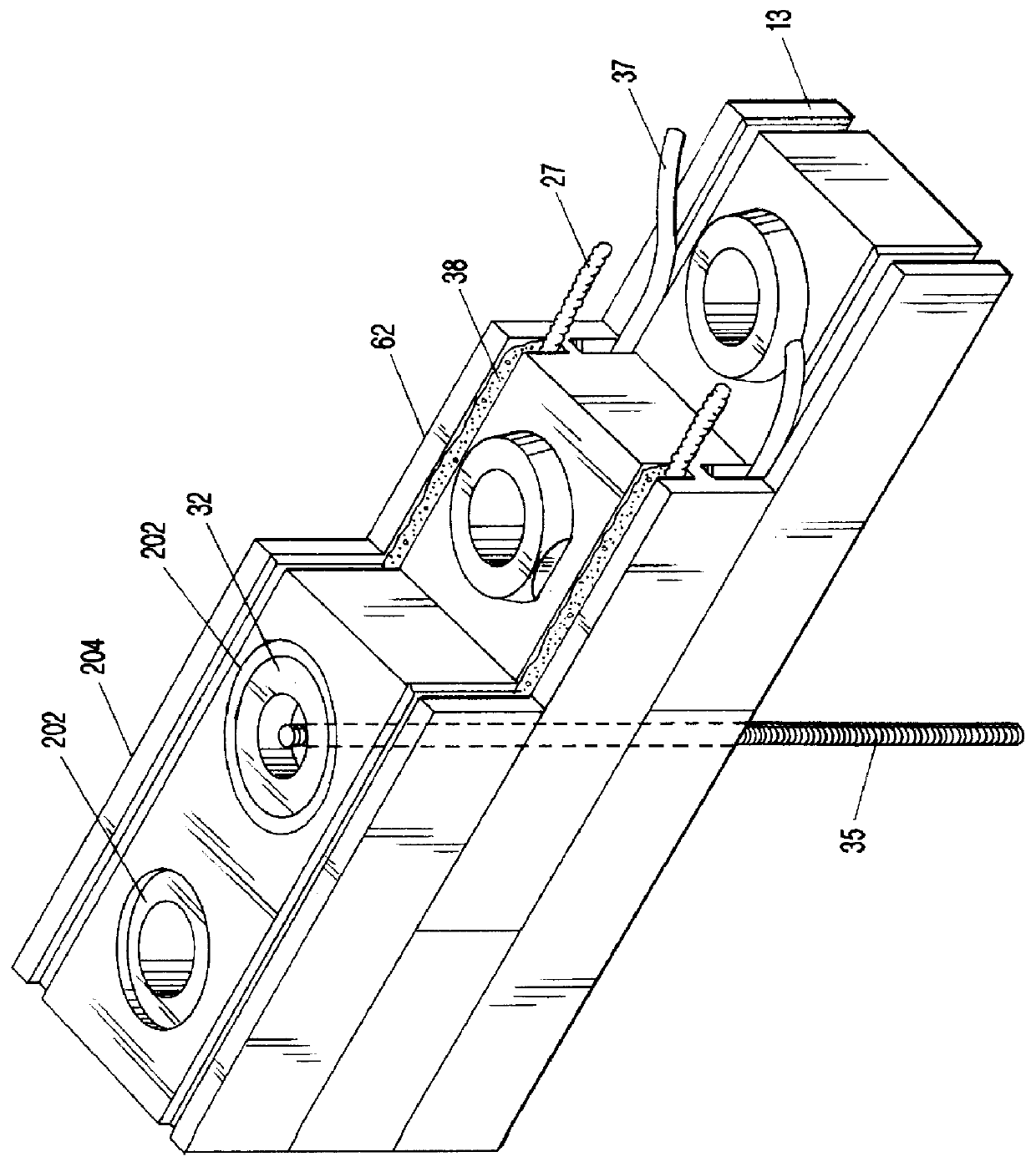

InactiveUS20110061321A1Reduce construction material and laborCost-effectiveArtificial islandsEngine manufactureHigh stiffnessTower

A fatigue resistant gravity based spread footing under heavy multi-axial cyclical loading of a wind tower having a central vertical pedestal, a substantially horizontal continuous bottom support slab with a stiffened perimeter, a plurality of radial reinforcing ribs extending radially outwardly from the pedestal and a three-dimensional network 500 of post-tensioning elements that keep the structural elements under heavy multi-axial post compression with a specific eccentricity that is intended to reduces stress amplitudes and deflections and allows the foundation to have a desirable combination of high stiffness and superior fatigue resistance. The foundation design reduces the weight and volume of materials used, reduces cost, and improves heat dissipation conditions during construction by having a small ratio of concrete mass to surface area thus eliminating the risk of thermal cracking due to heat of hydration.

Owner:PHULY AHMED

Structural elastic-like nonwoven web

Owner:PROCTER & GAMBLE CO

Settable fluids and methods for use in subterranean formations

The present invention relates to subterranean operations, and more particularly, to settable fluids comprising vitrified shale and hydrated lime and methods of using such settable fluids in subterranean applications. In an exemplary embodiment, the settable fluids of the present invention may be used as a displacement fluid. In another exemplary embodiment, the settable fluids of the present invention may be used as a drilling fluid.

Owner:HALLIBURTON ENERGY SERVICES INC

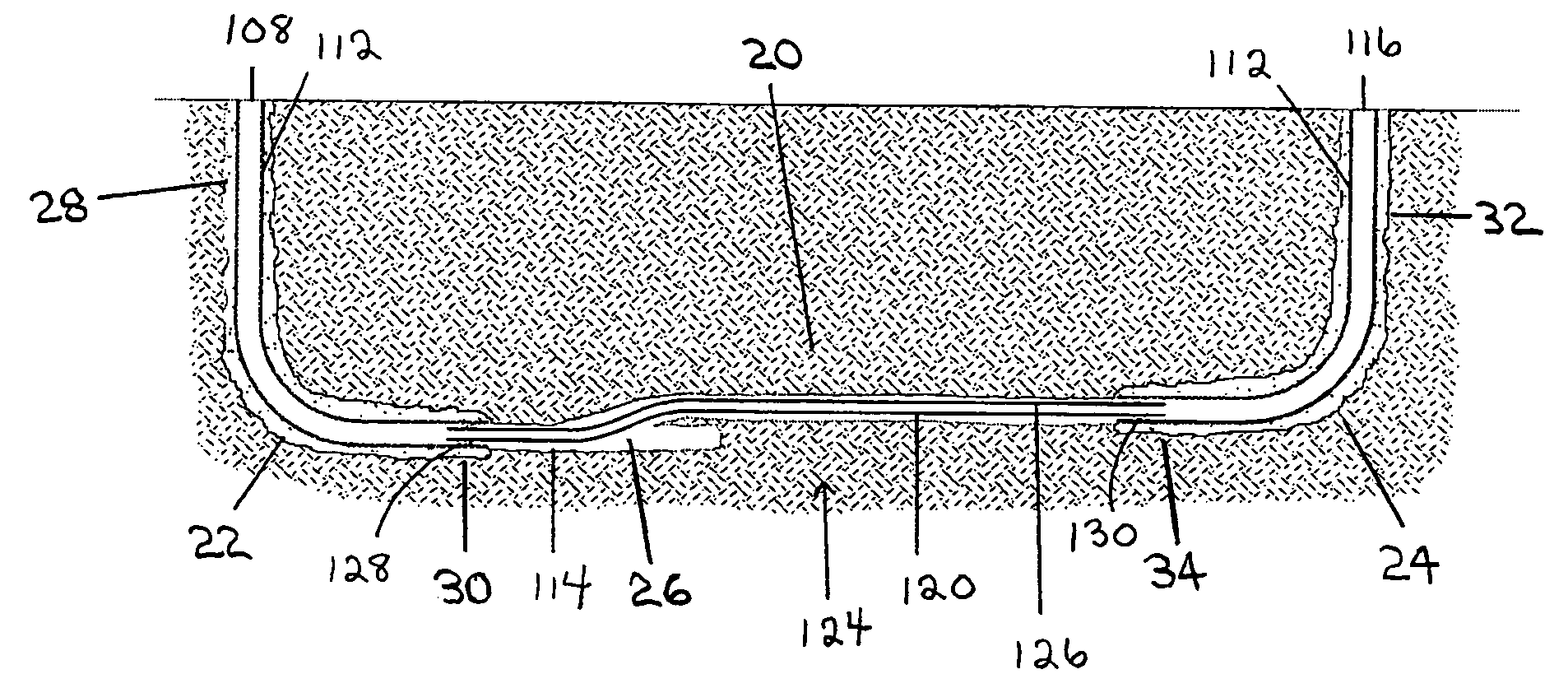

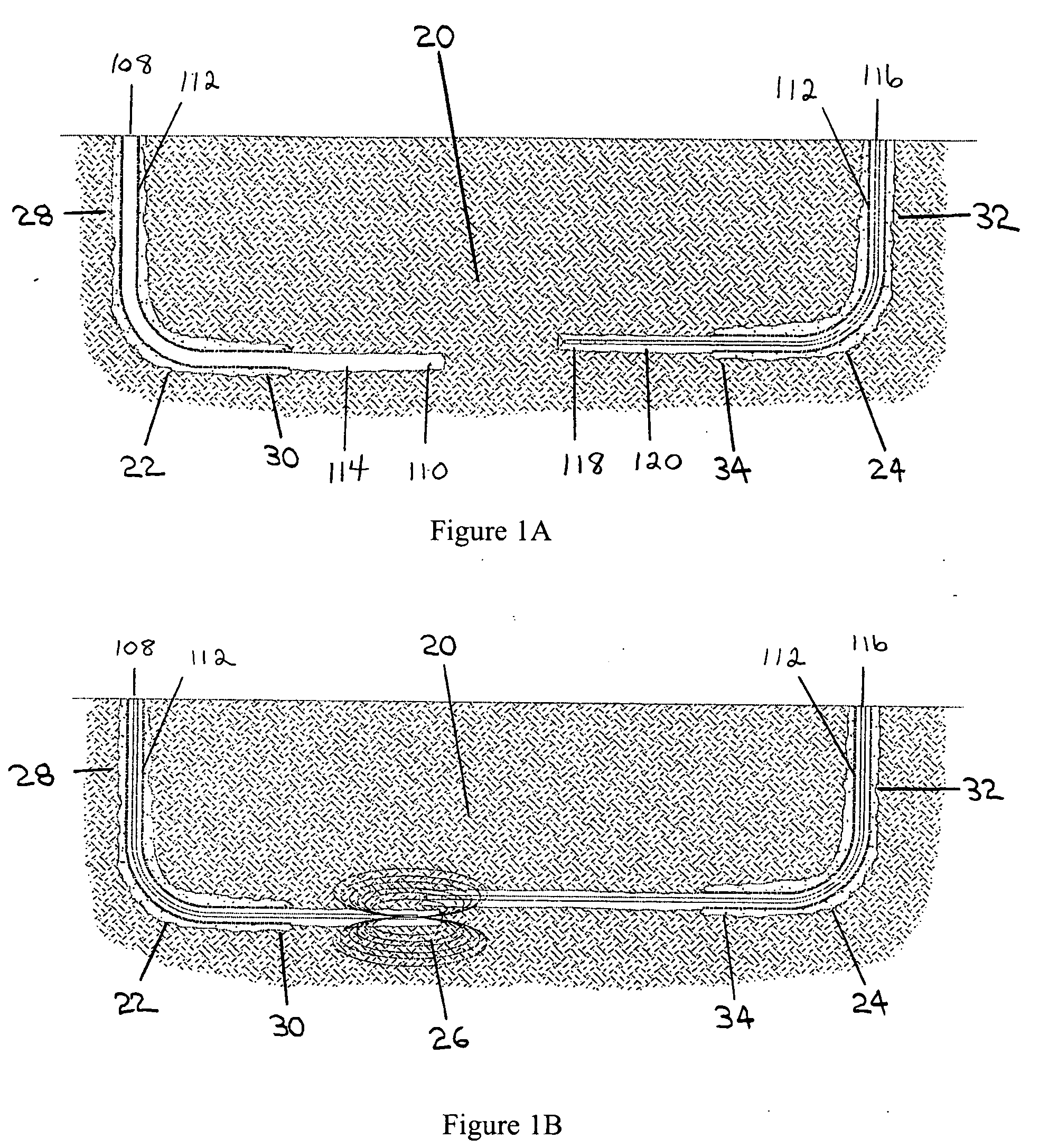

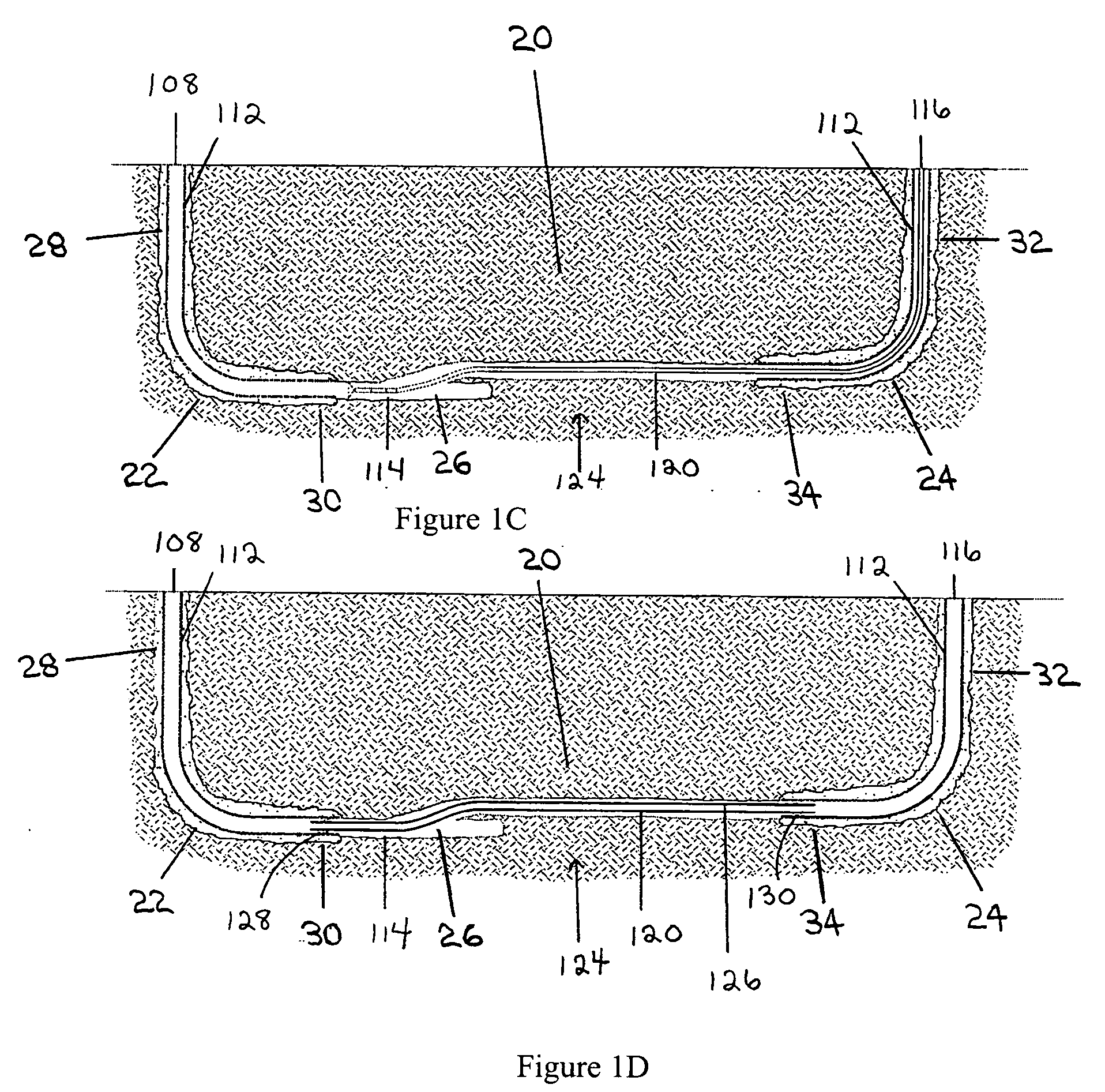

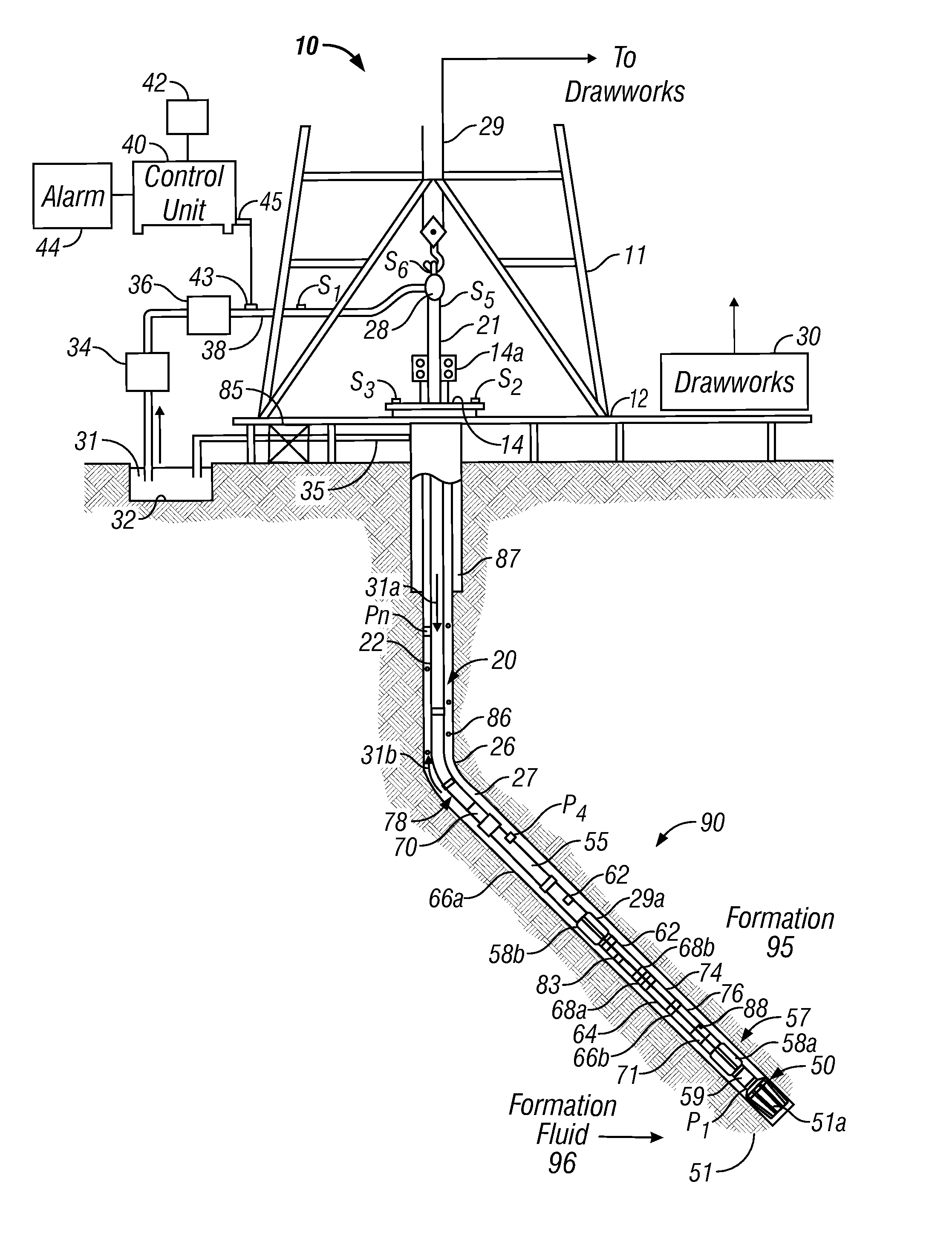

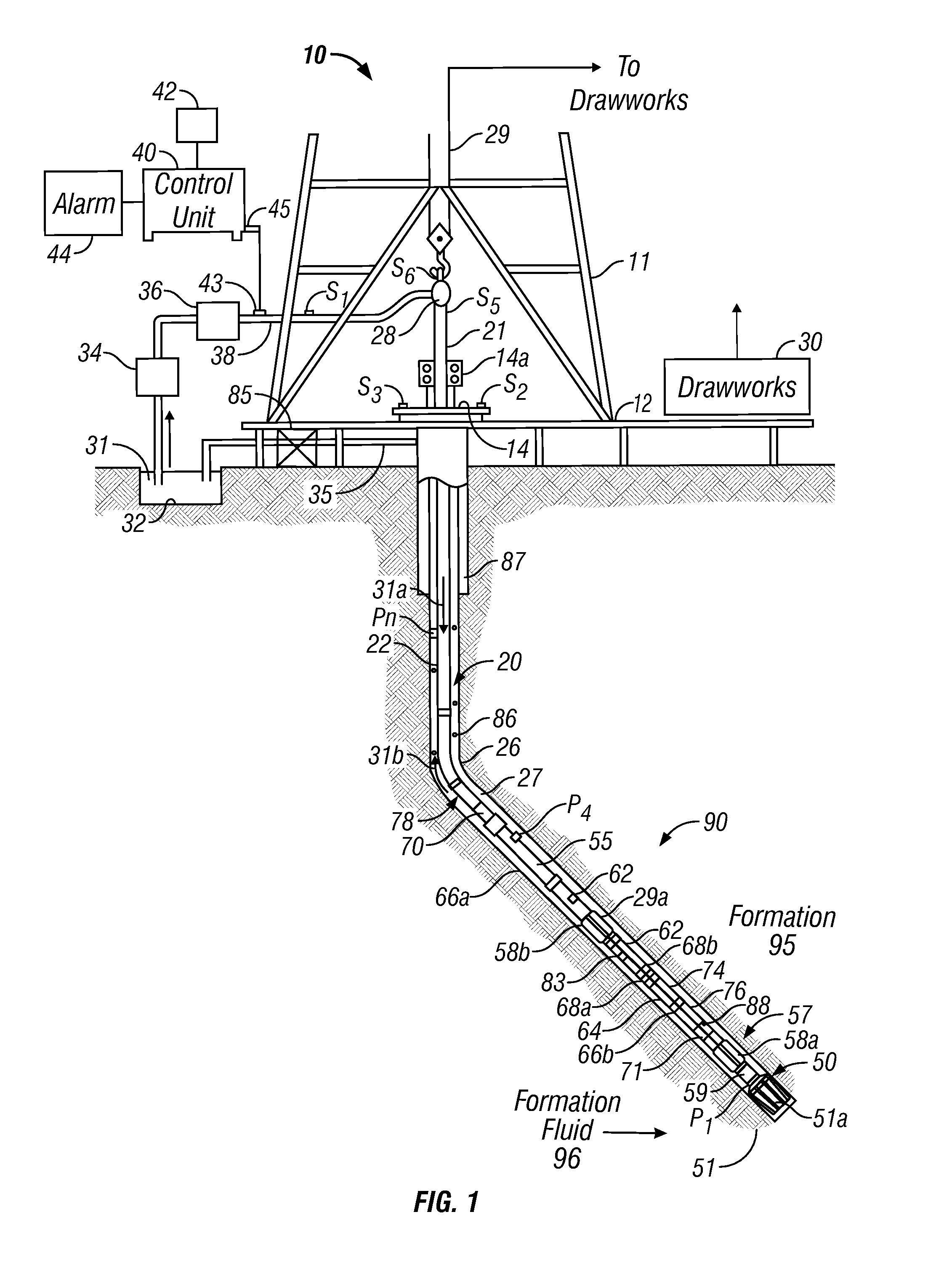

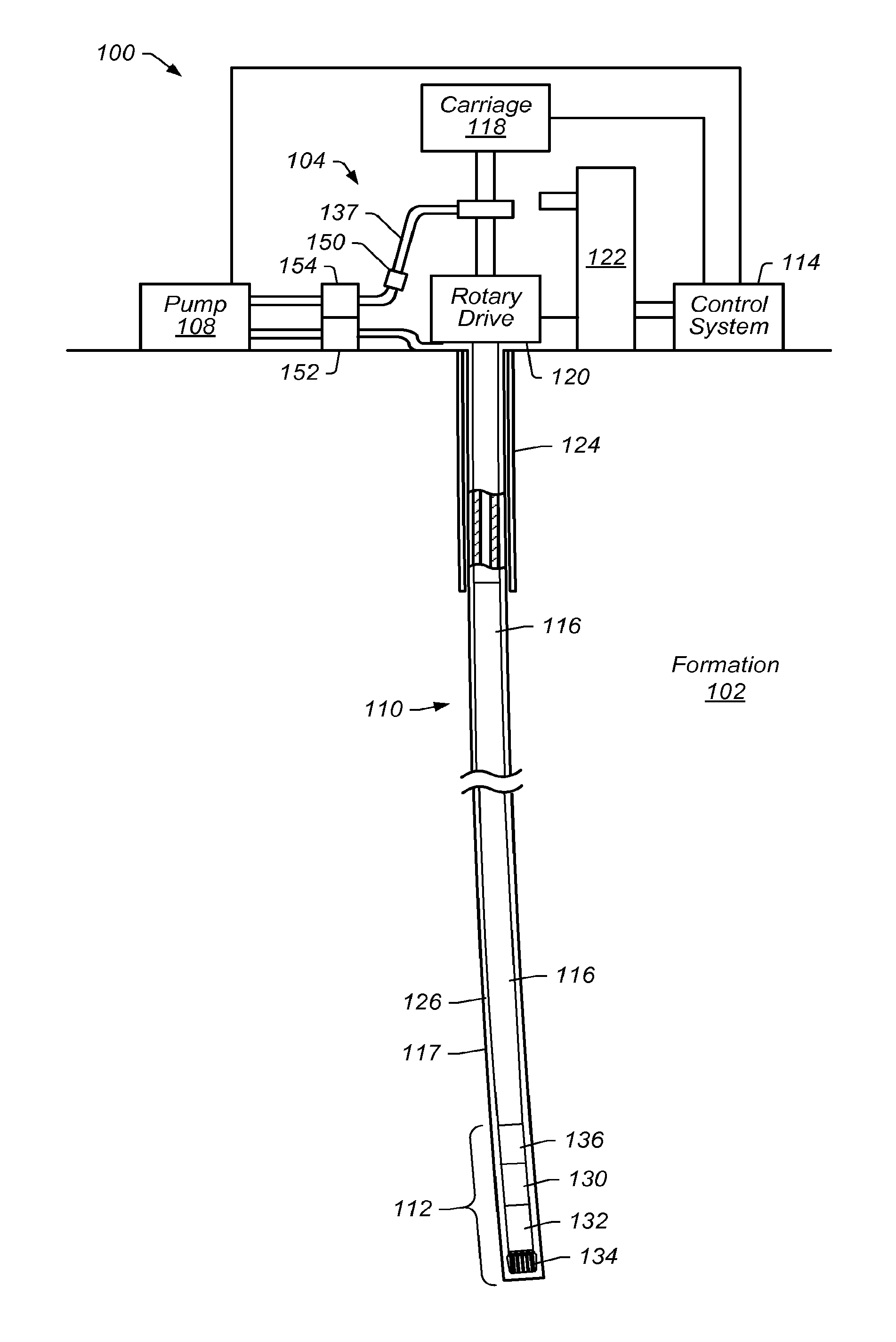

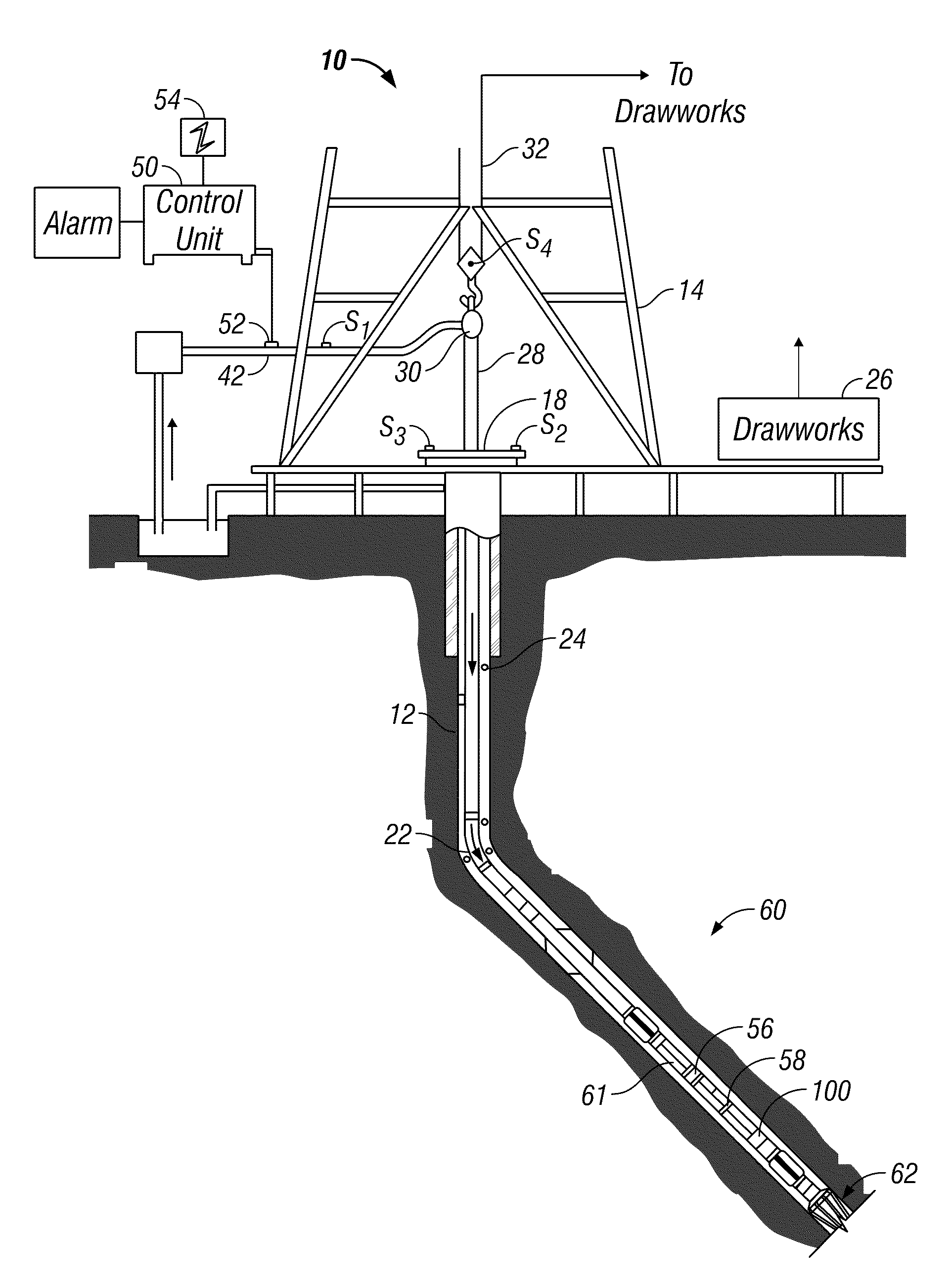

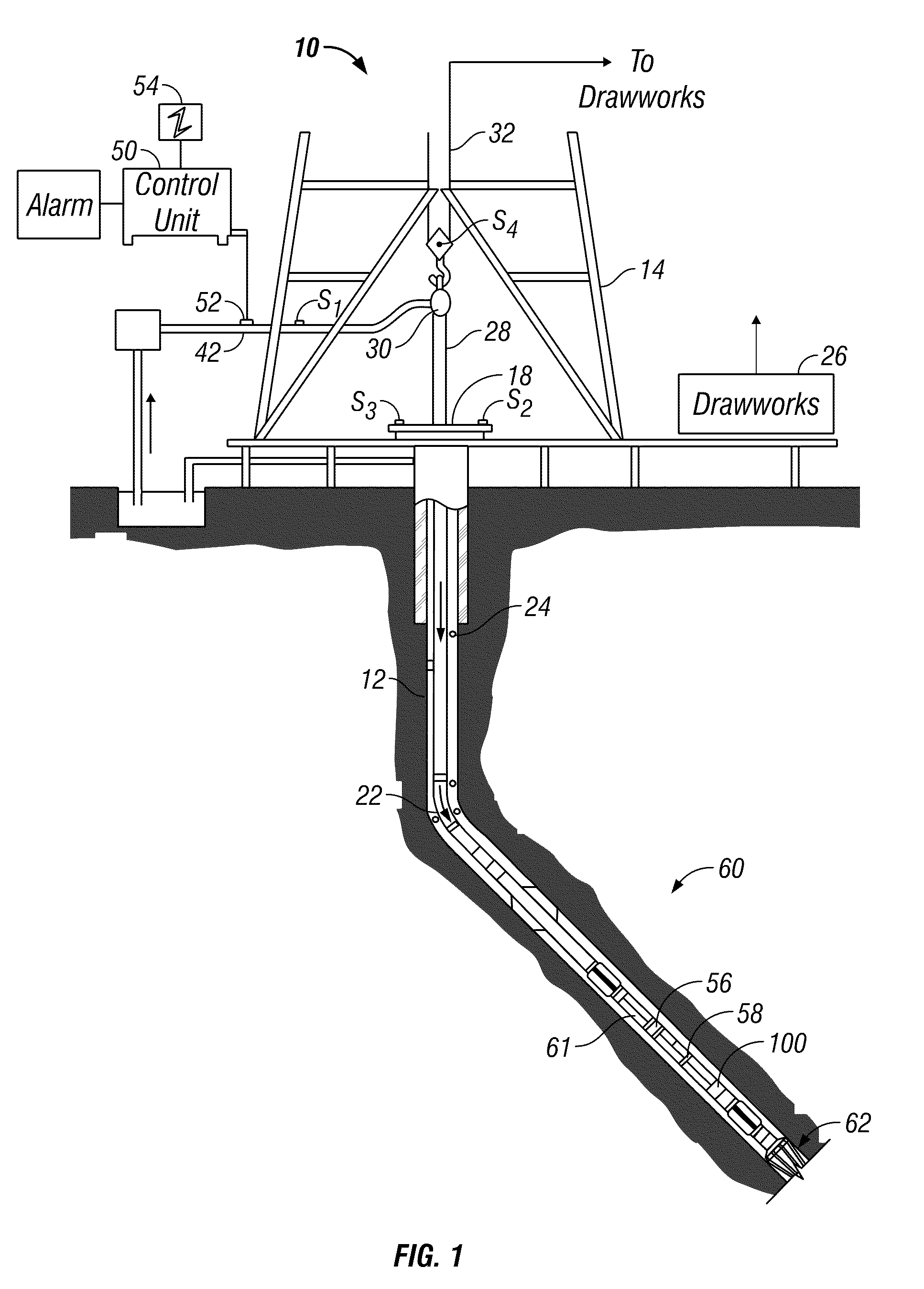

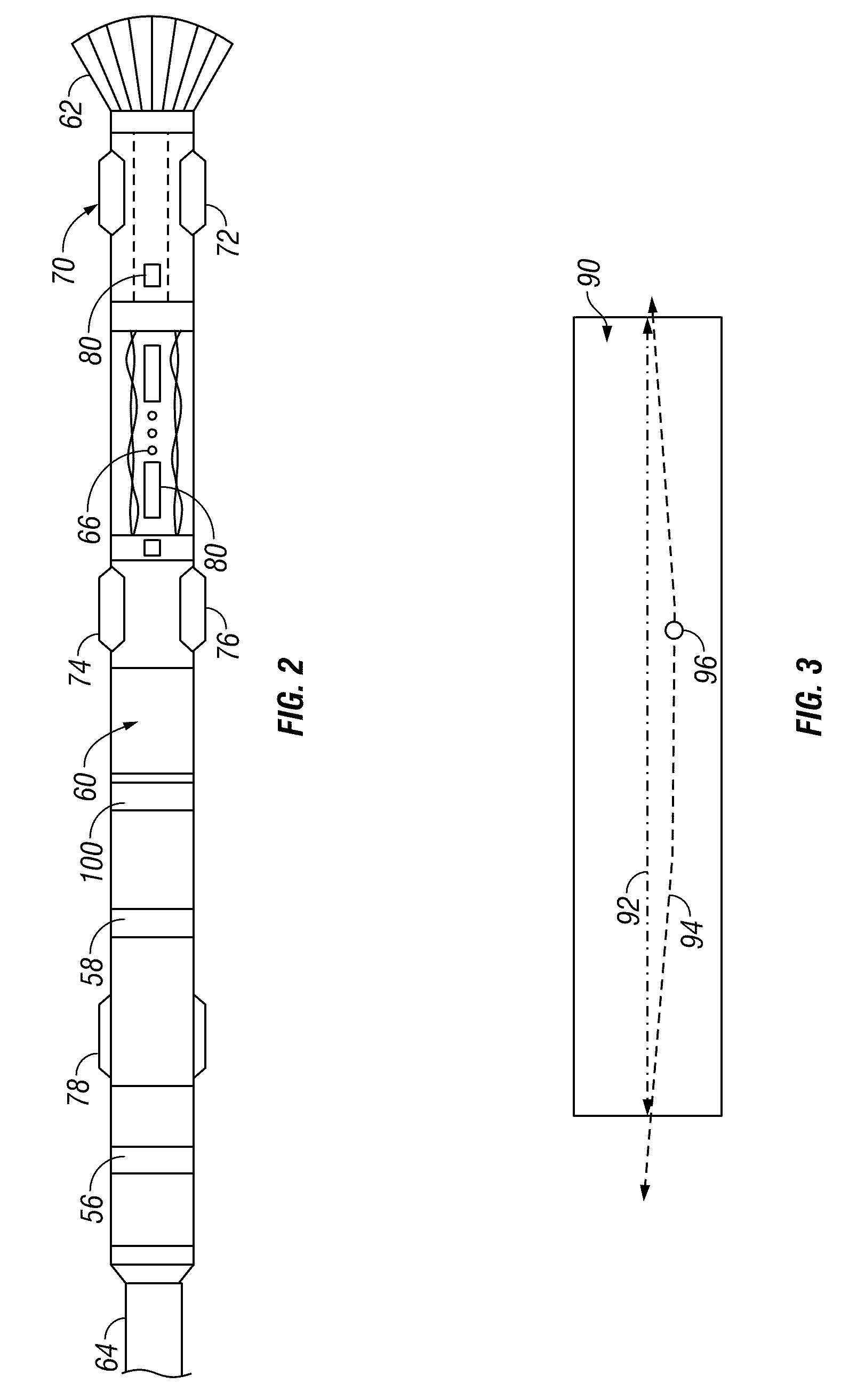

Methods and apparatus for drilling, completing and configuring U-tube boreholes

A borehole network including first and second end surface locations and at least one intermediate surface location interconnected by a subterranean path, and a method for connecting a subterranean path between a first borehole including a directional section and a second borehole including a directional section. A directional drilling component is drilled in at least one of the directional sections to obtain a required proximity between the first and second boreholes. An intersecting component is drilled, utilizing magnetic ranging techniques, from one directional section to provide a borehole intersection between the first and second boreholes, thereby connecting the subterranean path.

Owner:HALLIBURTON ENERGY SERVICES INC

Ice composite bodies

InactiveUS6099208AHigh purityEfficiency sometimes variesArtificial islandsDrilling rodsThermal insulationEngineering

PCT No. PCT / IE97 / 00002 Sec. 371 Date Jul. 10, 1998 Sec. 102(e) Date Jul. 10, 1998 PCT Filed Jan. 10, 1997 PCT Pub. No. WO97 / 25483 PCT Pub. Date Jul. 17, 1997An ice composite body has an inner ice core covered by a protective outer armor layer. Thermal insulation is provided between the inner core and the outer armor layer. Refrigeration is accomplished by a system of conduits for refrigerant are located within the body. The insulation and the refrigeration are adapted to maintain the ice core in a frozen condition relative to the ambient temperature. The base of the body cavity can be in direct contact with the water bed such that the ice core is freeze bonded to an advancing ice front in the water bed. The ice composite body provides structures of equal or greater strength than equivalent structures using conventional materials.

Owner:MCALISTER PADRAIG

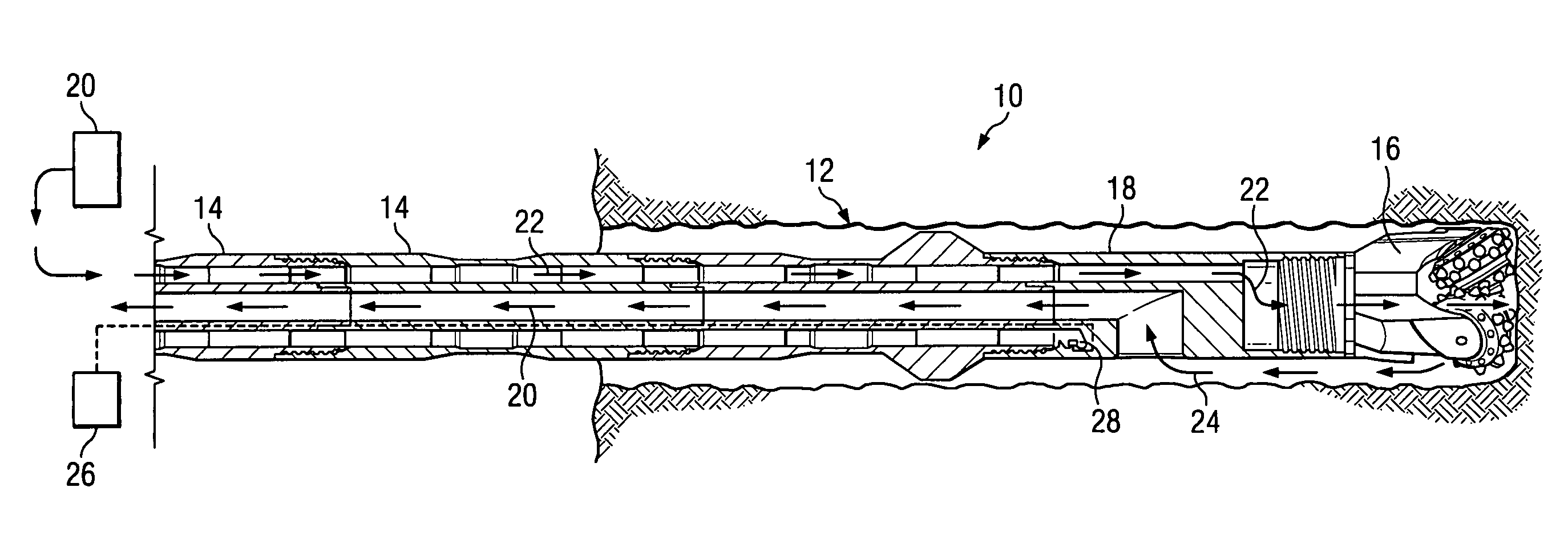

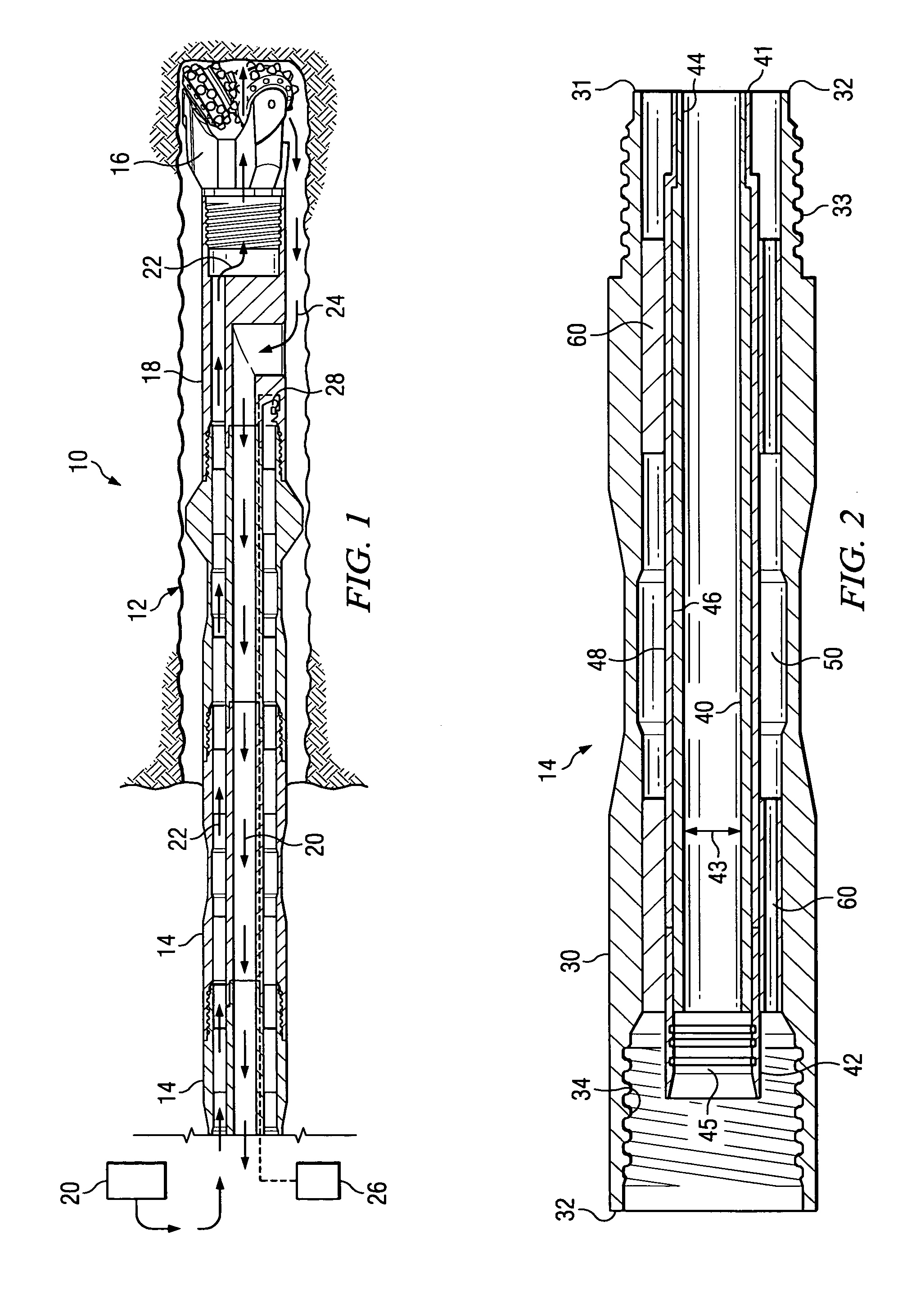

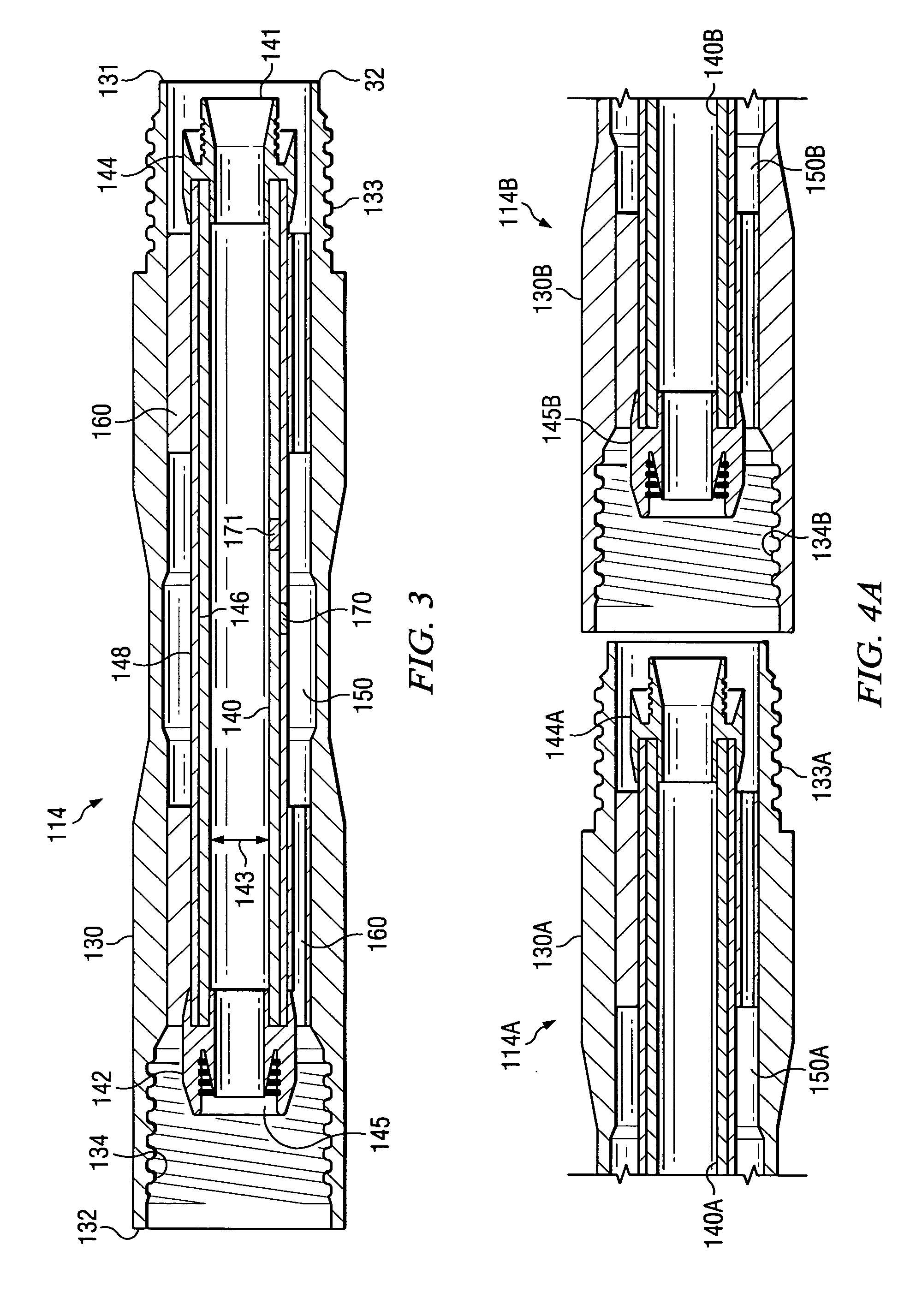

Dual wall drill string assembly

ActiveUS20050103527A1Little and no resistanceIncrease volumeDrilling rodsFlushingCoiled tubingEngineering

A coil tubing or jointed dual wall drill string assembly for subsurface drilling. The drill string assembly includes a metallic outer tube having an outer tube first end and an outer tube second end opposite the outer tube first end. The assembly also includes a flexible, substantially non-metallic inner tube that is substantially enclosed within and generally coaxially aligned with the outer tube. The flexible, substantially non-metallic inner tube has an inner tube first end, an inner tube second end opposite the inner tube first end, and an inner tube inner diameter. The inner tube and the outer tube define an annular channel therebetween. The drill string assembly also includes a means for conveying fluid through the annular channel toward the inner tube first end. The annular channel is adapted to convey drilling fluid under pressure toward the inner tube first end and the inner tube is adapted to convey cuttings toward the inner tube second end.

Owner:AMERICAN AUGERS +1

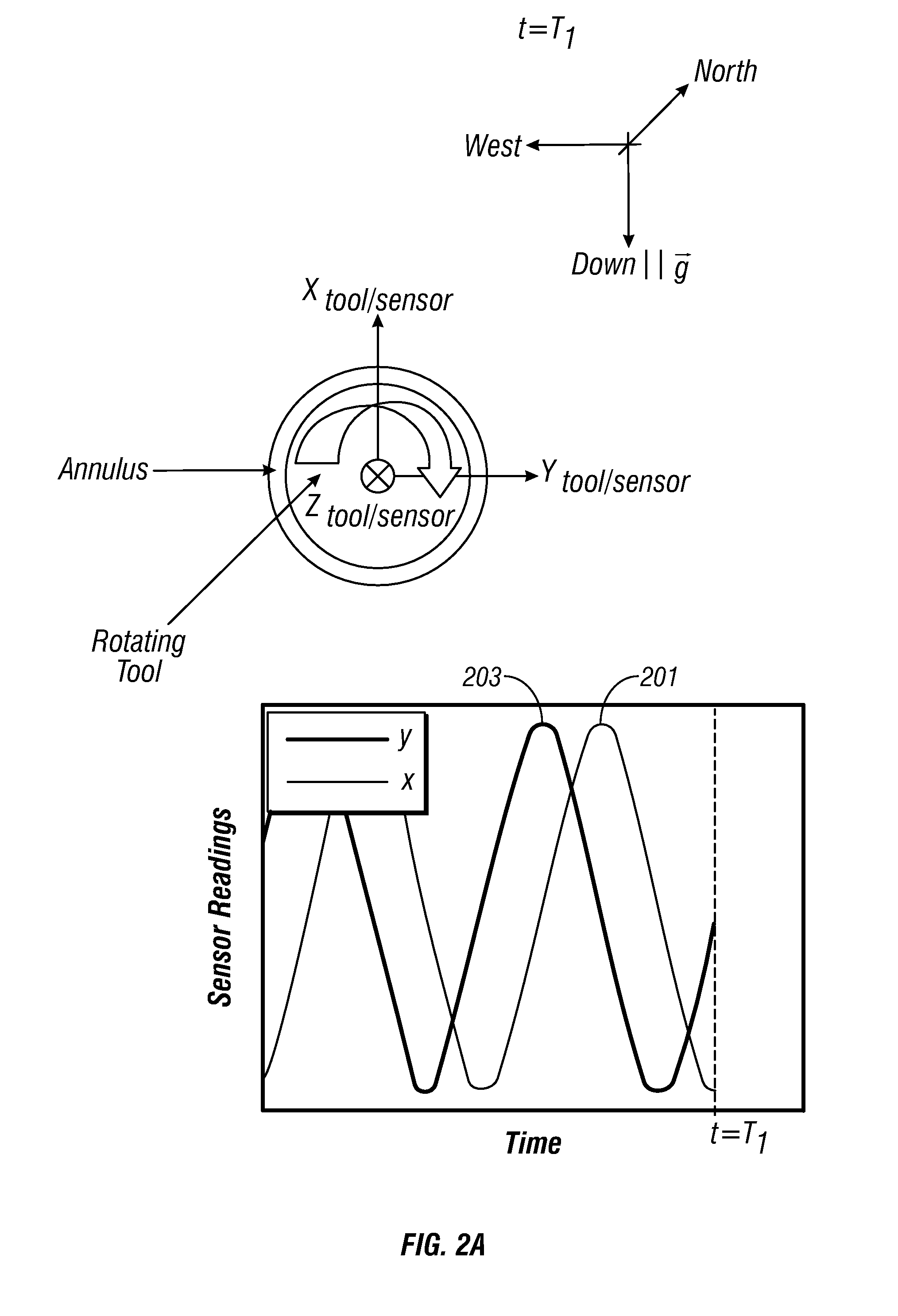

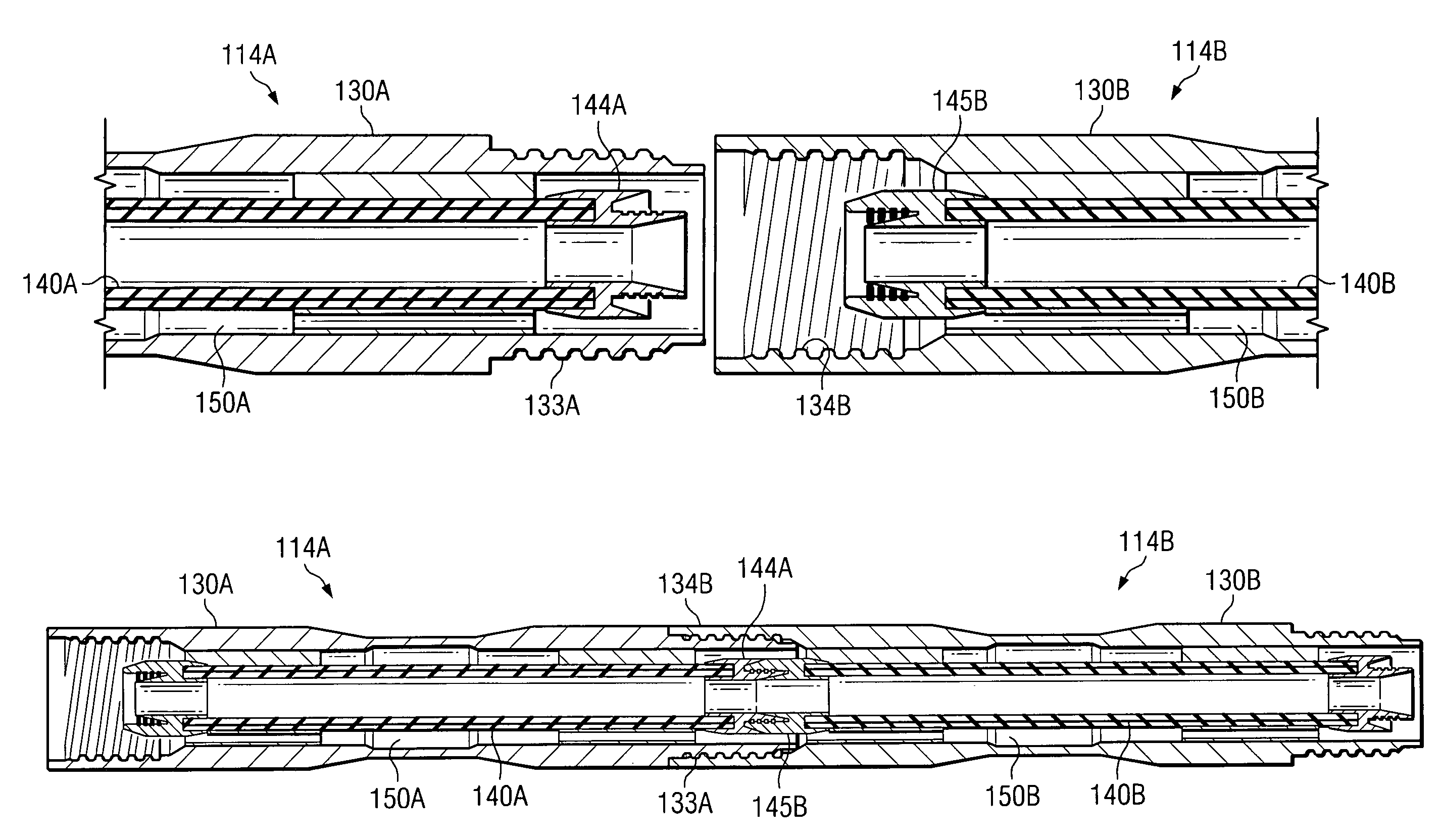

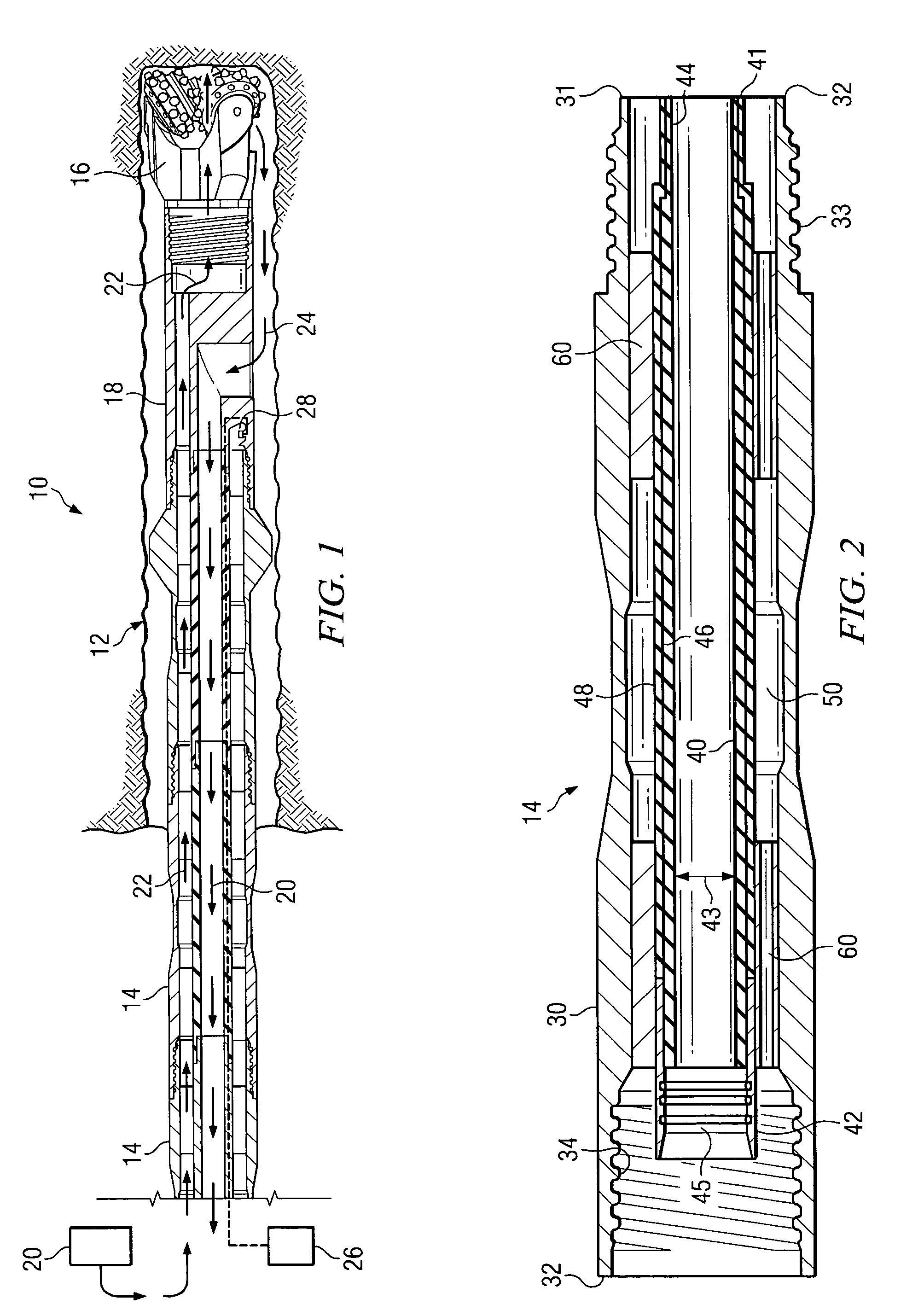

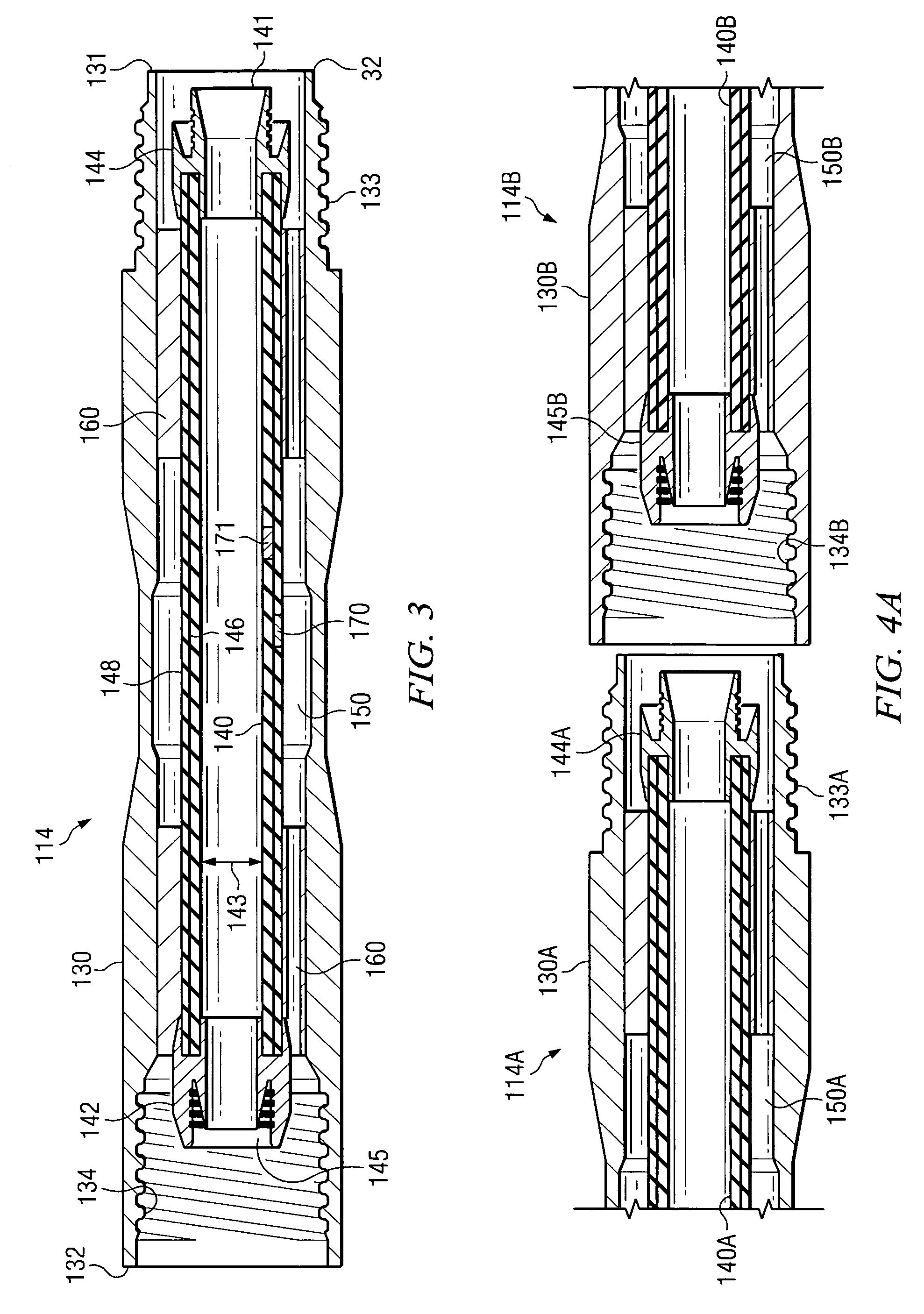

Phase Estimation From Rotating Sensors To Get a Toolface

Measurements made by a rotating sensor on a bottomhole assembly are used to determine the toolface angle of the BHA. The method includes using a phase locked loop (PLL) to determine a phase difference between the sensor output and a reference signal.

Owner:BAKER HUGHES INC

Dual wall drill string assembly

InactiveUS7152700B2Little and no resistanceIncrease volumeDrilling rodsFlushingCoiled tubingDrilling fluid

Owner:AMERICAN AUGERS +1

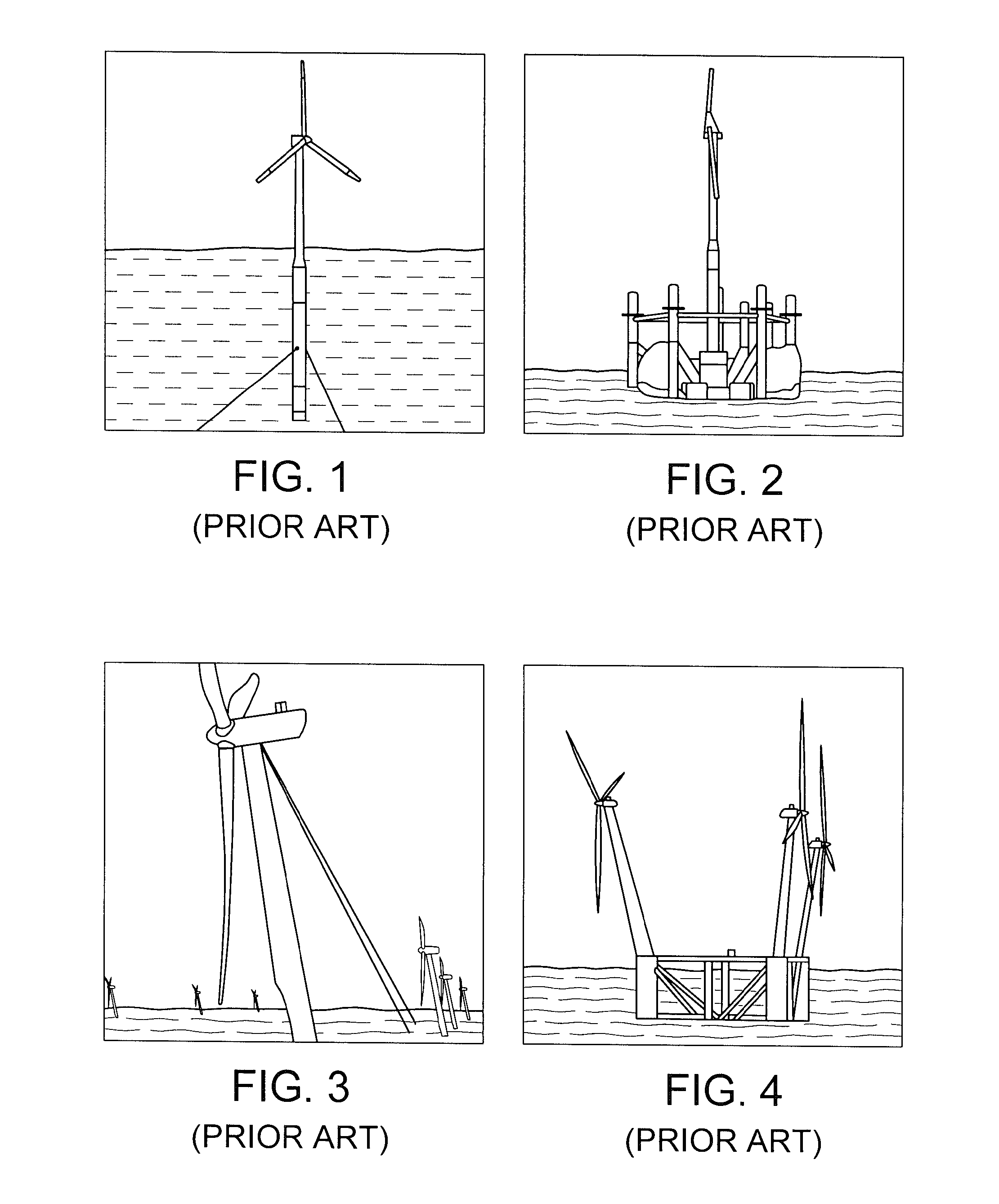

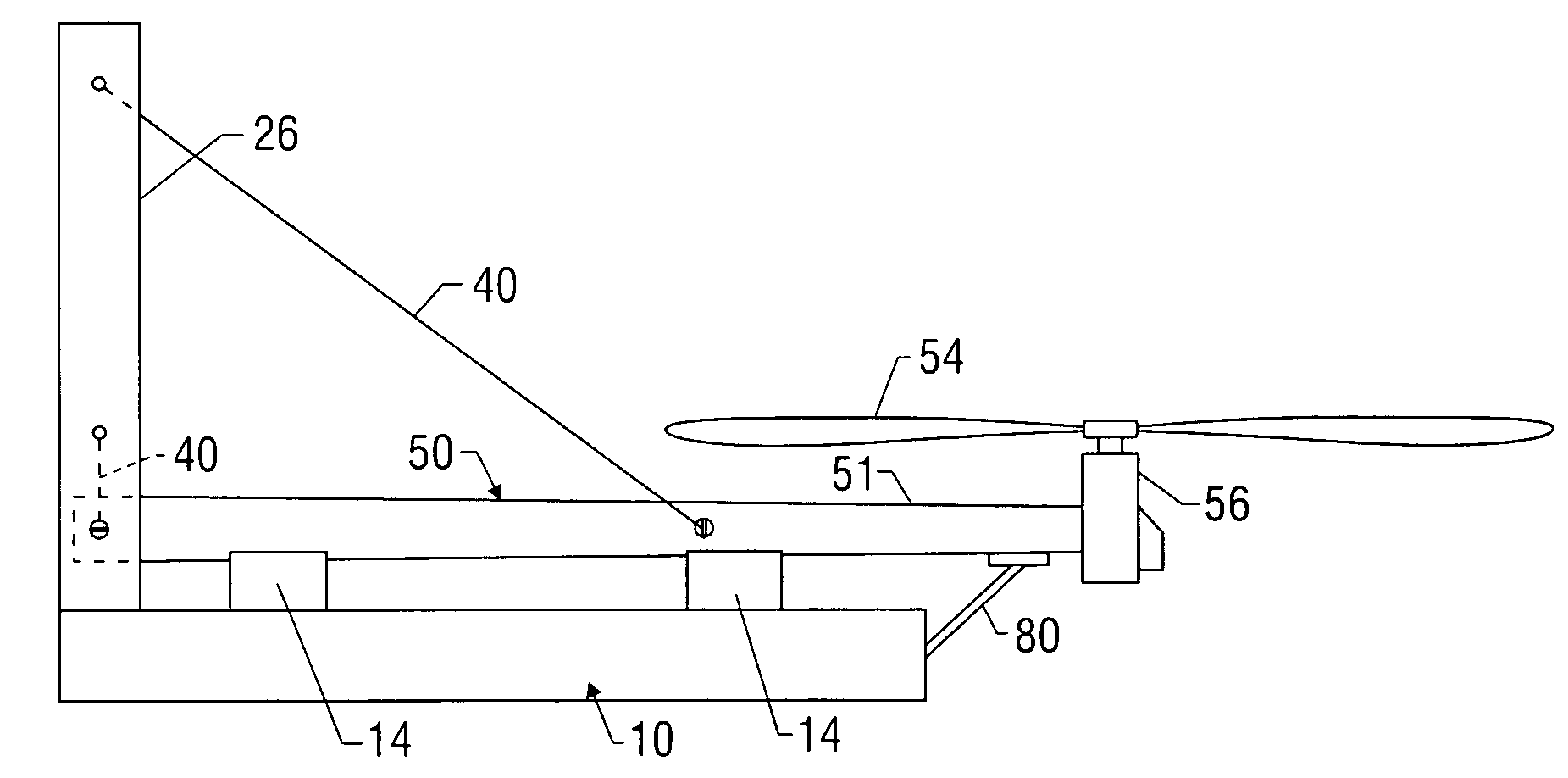

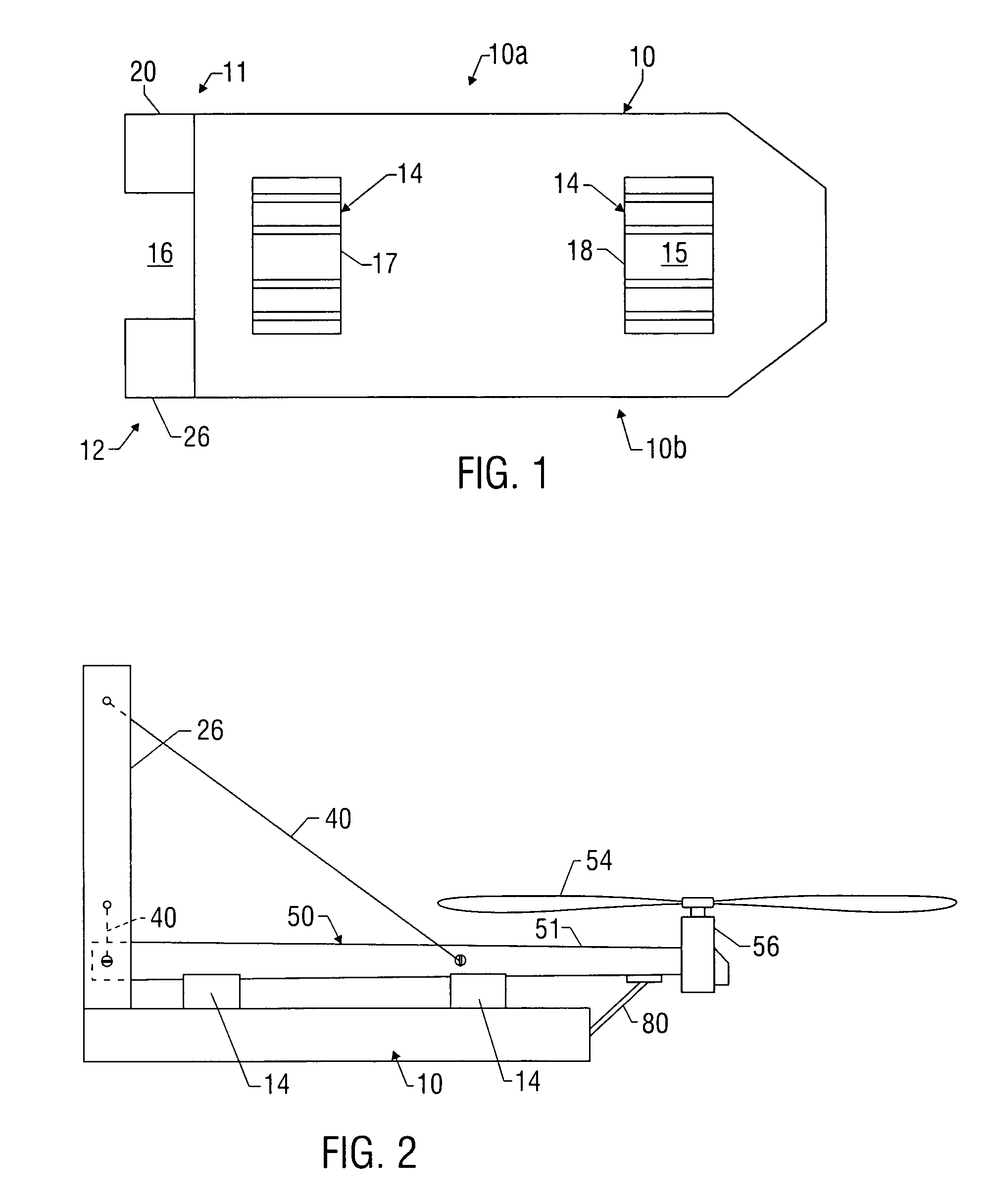

Apparatus, systems and methods for erecting an offshore wind turbine assembly

An embodiment of an apparatus useful for up-righting a wind turbine pillar at an offshore installation location includes a barge having first and second towers and an open area therebetween and which extends downwardly to the offshore installation location. At least two pulling lines extend from the towers to the pillar and are useful to assist in moving the pillar into a generally up-right orientation between the towers and lowering the pillar downwardly through the open area to the offshore installation location.

Owner:GEIGER WILLIAM CLYDE

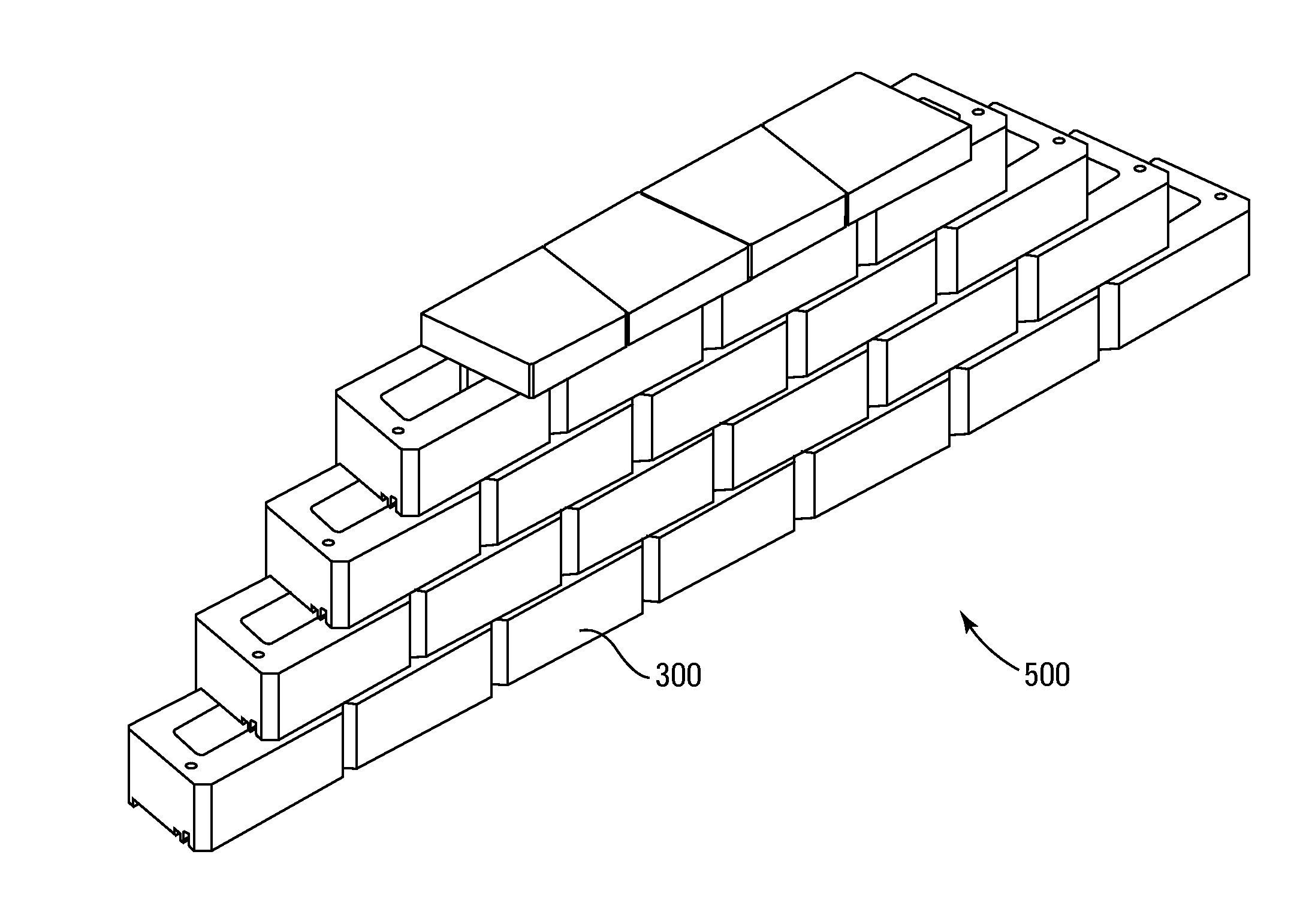

Modular building materials

Building materials of modules of at least one mortise and tenon and either a curvilinear side face or joinder of the modules at angles other than zero and ninety degrees. Lateral ends of the modules are flush with lateral ends of adjacent modules. Preferably, the modules are: (1) of a low density aggregate cementitious mix; and / or (2) have a hollow space extending from the mortise to the tenon and include a structural support member passing through the hollow space and a compression retainer securing the structural support member to the modules; and / or (3) have grooves circumscribing the modules and which are proximate corresponding grooves on modules placed on top or below. The modules are preferably sealed to one another with sealant placed in the grooves.

Owner:SIMMONS SCOTT +1

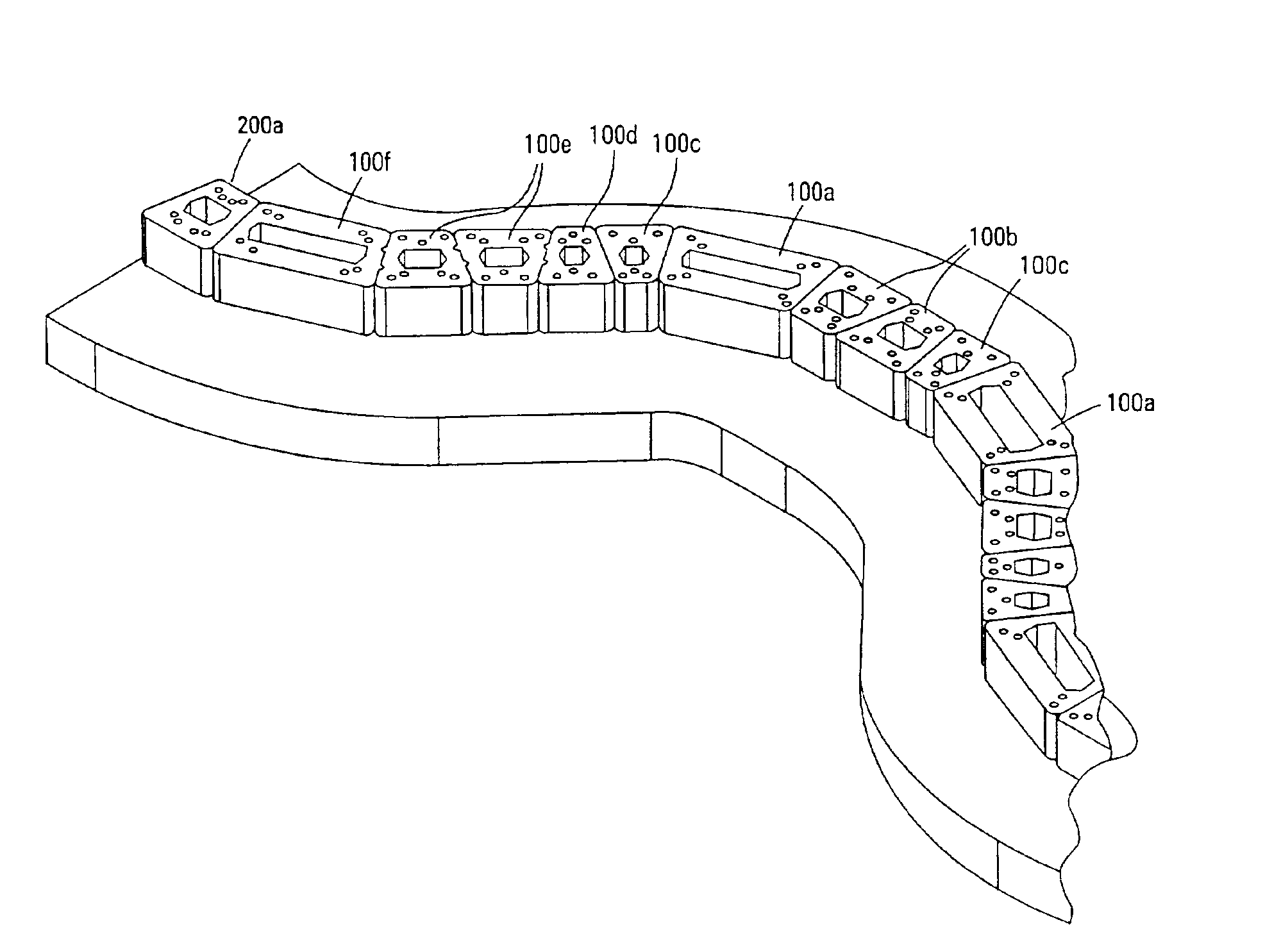

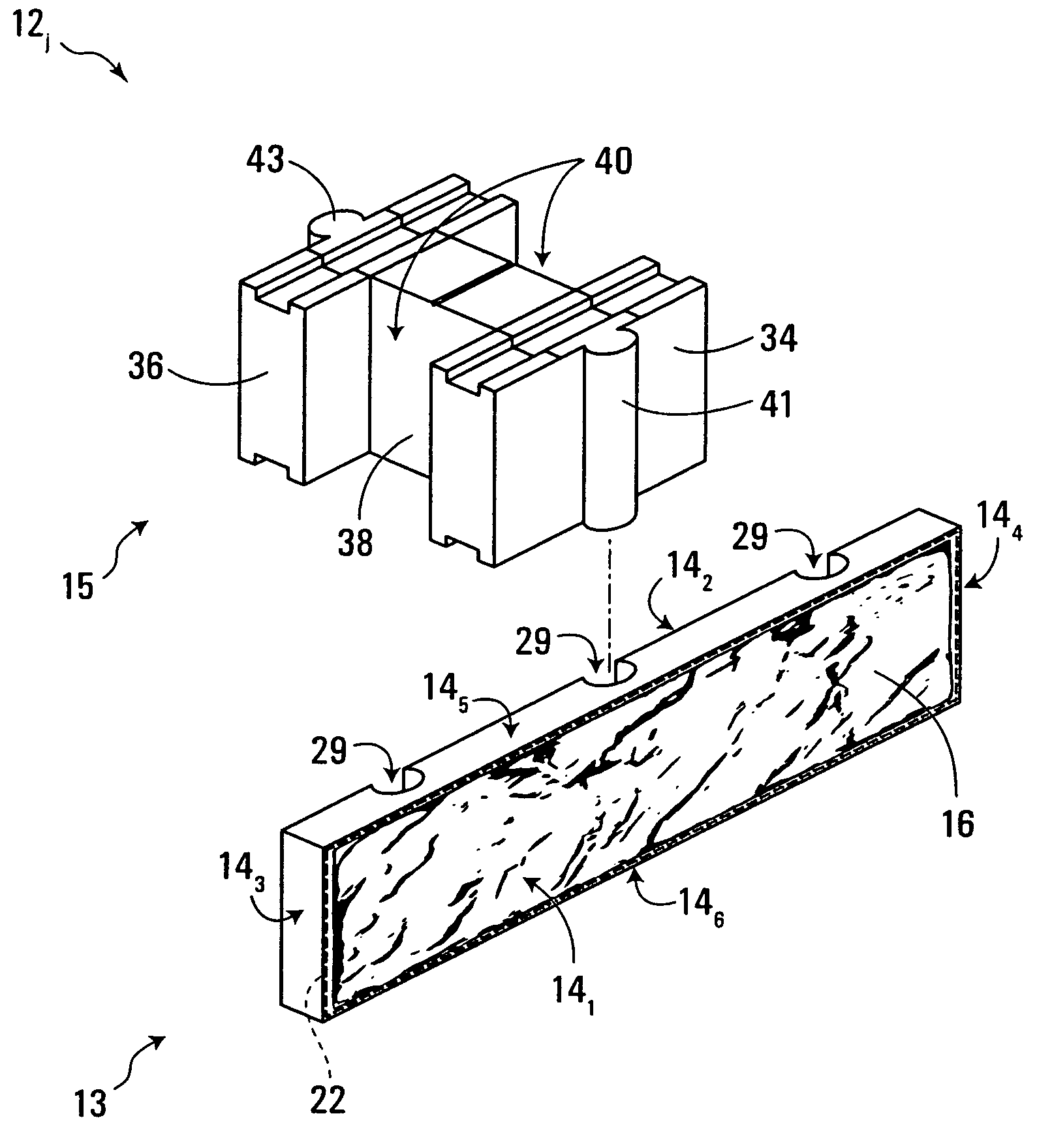

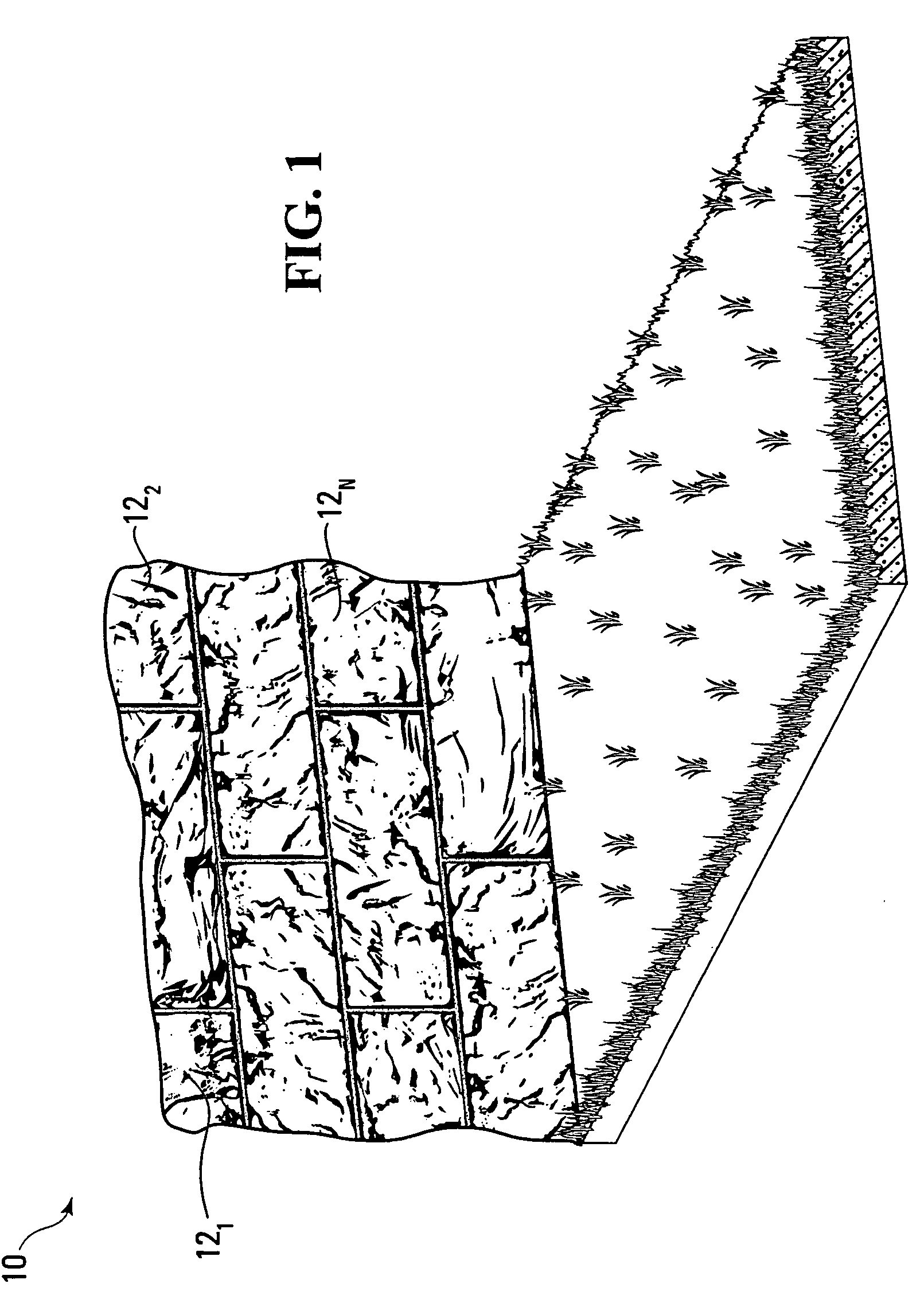

Multi-channel retaining wall block and system

A retaining wall block system having multiple sizes and shapes of blocks with differently dimensioned, interchangeable front and back faces. The blocks are used to construct an irregularly textured wall having a weathered, natural appearance. Multiple channels in the lower face of the block are used to engage pins in pin-receiving apertures to form an attachment system. A side connection system is particularly useful for stabilizing free-standing walls. Horizontal reinforcing members are also used in the channels and vertical reinforcing members are used in cores of adjacent blocks for reinforcing a wall. Reinforcing geosynthetic materials can also be firmly held in a wall by means of the pins or by connectors adapted to fit in the block channels.

Owner:KEYSTONE RETAINING WALL SYST

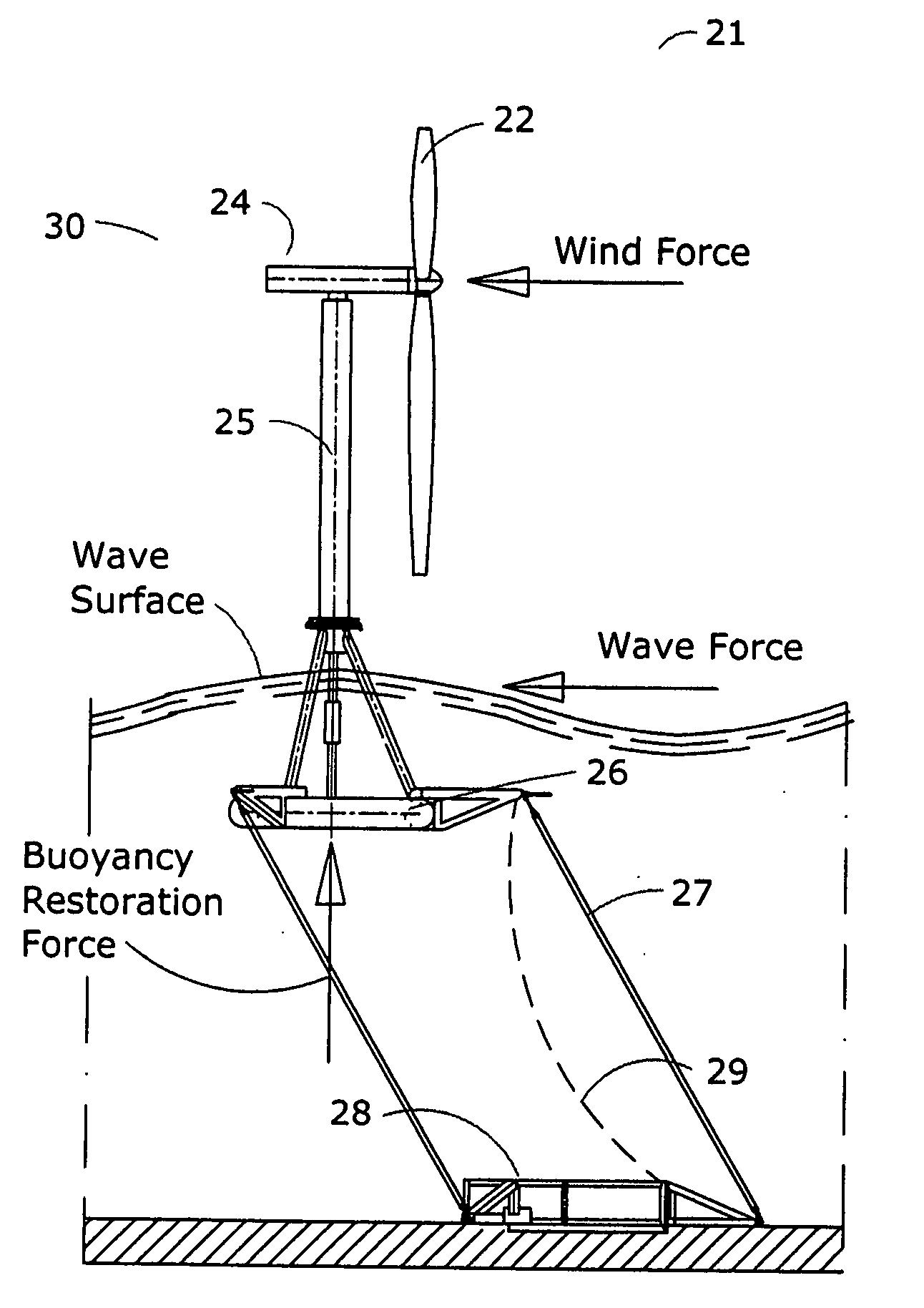

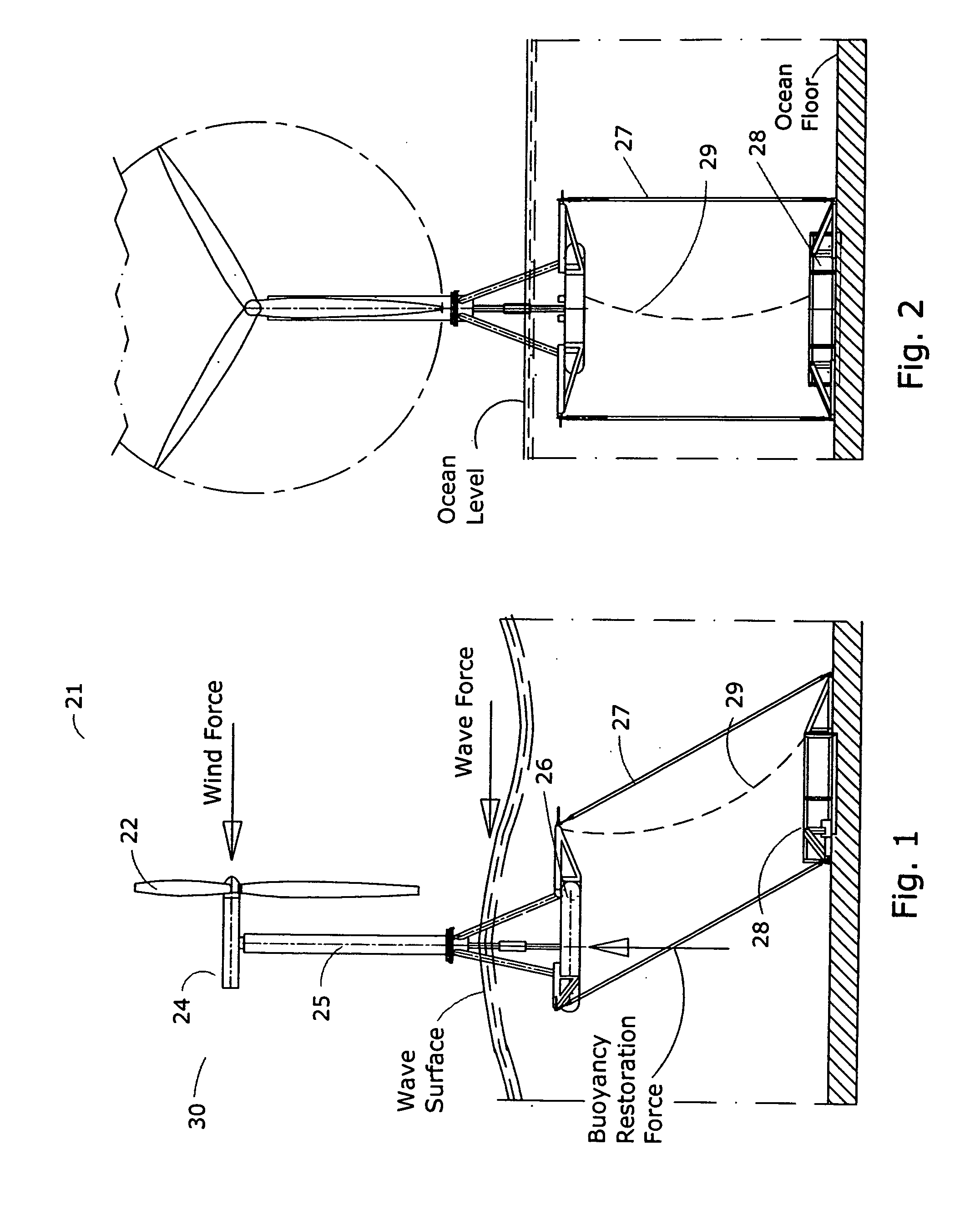

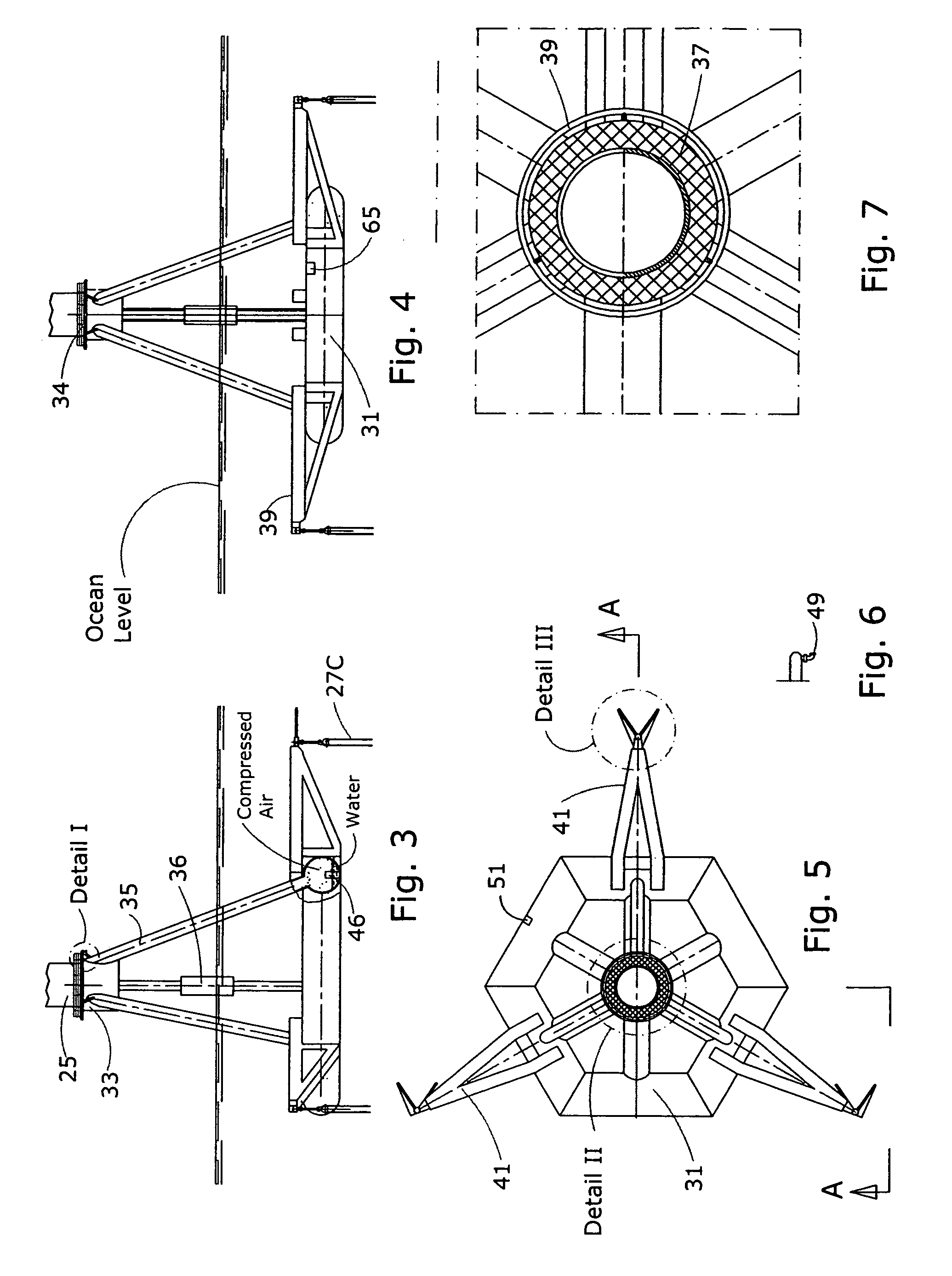

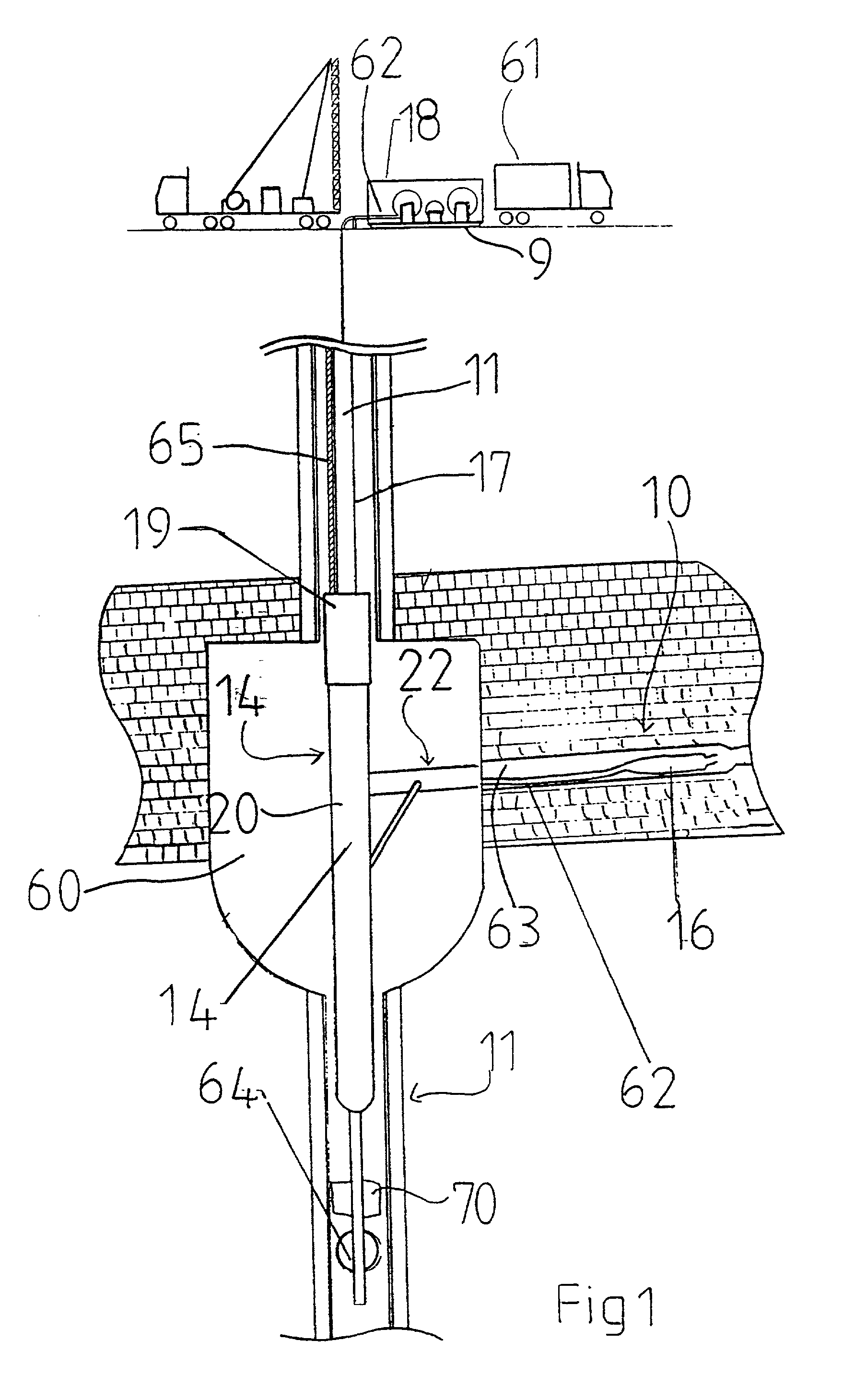

Assembly, transportation and installation of deepwater windpower plant

InactiveUS20080240864A1Reduce installationShorten assembly timeWind motor assemblyWind motor supports/mountsOcean bottomBuoy

A deepwater windpower plant (DWP) has a tension leg-type floating platform with an evacuable base for adjusting its buoyancy for installation at ocean depths ranging from 40 meters up to 1.5 kilometers and more. The DWP has a typical offshore wind turbine assembled close to shore which is then towed to a desired installation site on the ocean, and held in place by a gravity anchoring base (GAB), to which an evacuable portion or space of the DWP platform is anchored. The GAB has upwardly extending mooring tethers and a power cable which are brought to the ocean surface by attached buoys. The GAB is sunk to the ocean floor at the installation site under controlled conditions so that the GAB lands flat on the ocean floor. As the GAB sinks to the ocean floor, the mooring tethers and power cable are pulled to the surface by their respective buoys. The GAB is loaded with heavy ballast material that can be dropped from barges on the ocean surface into the upwardly open GAB below the barges.

Owner:DEEPWATER WIND

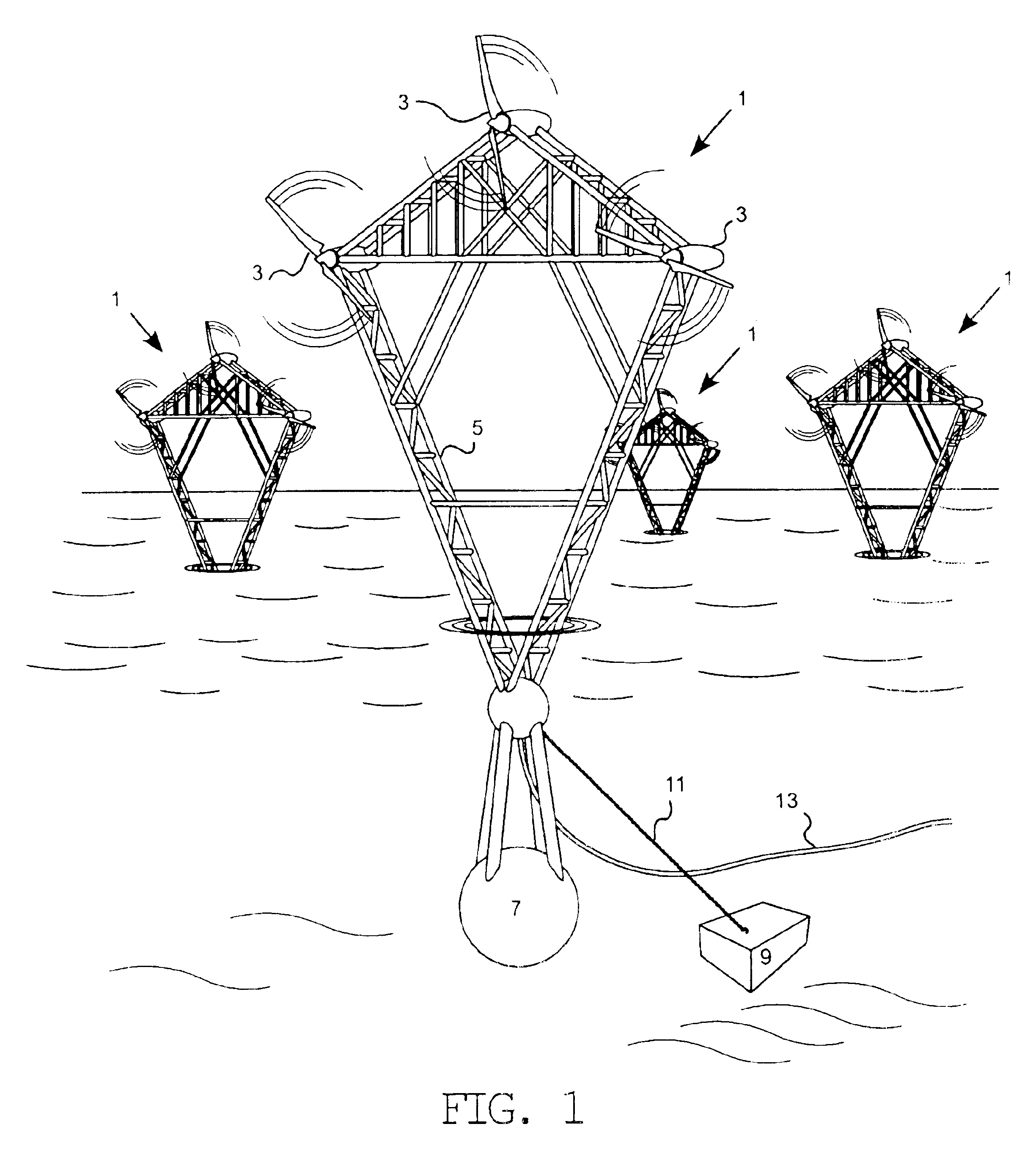

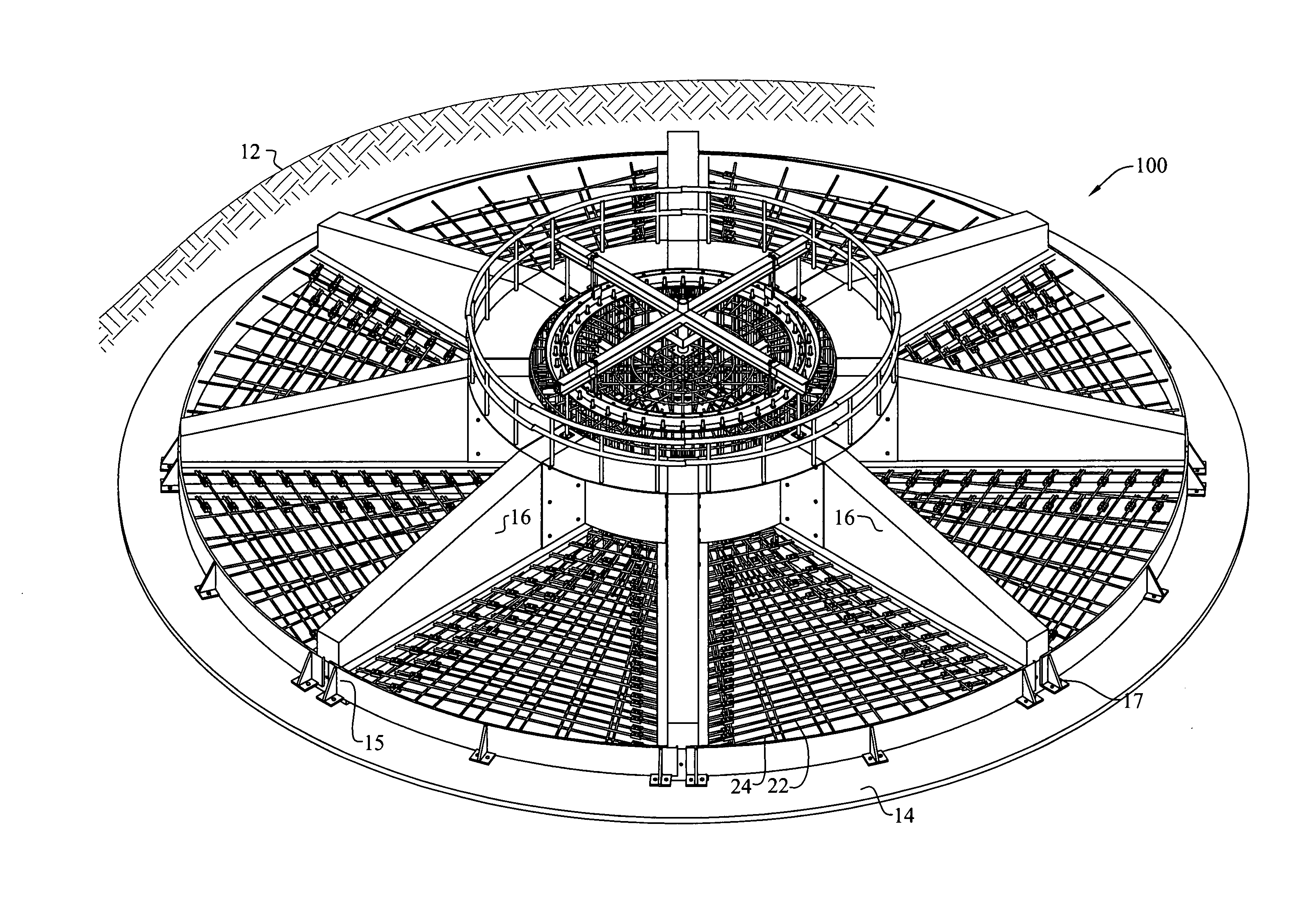

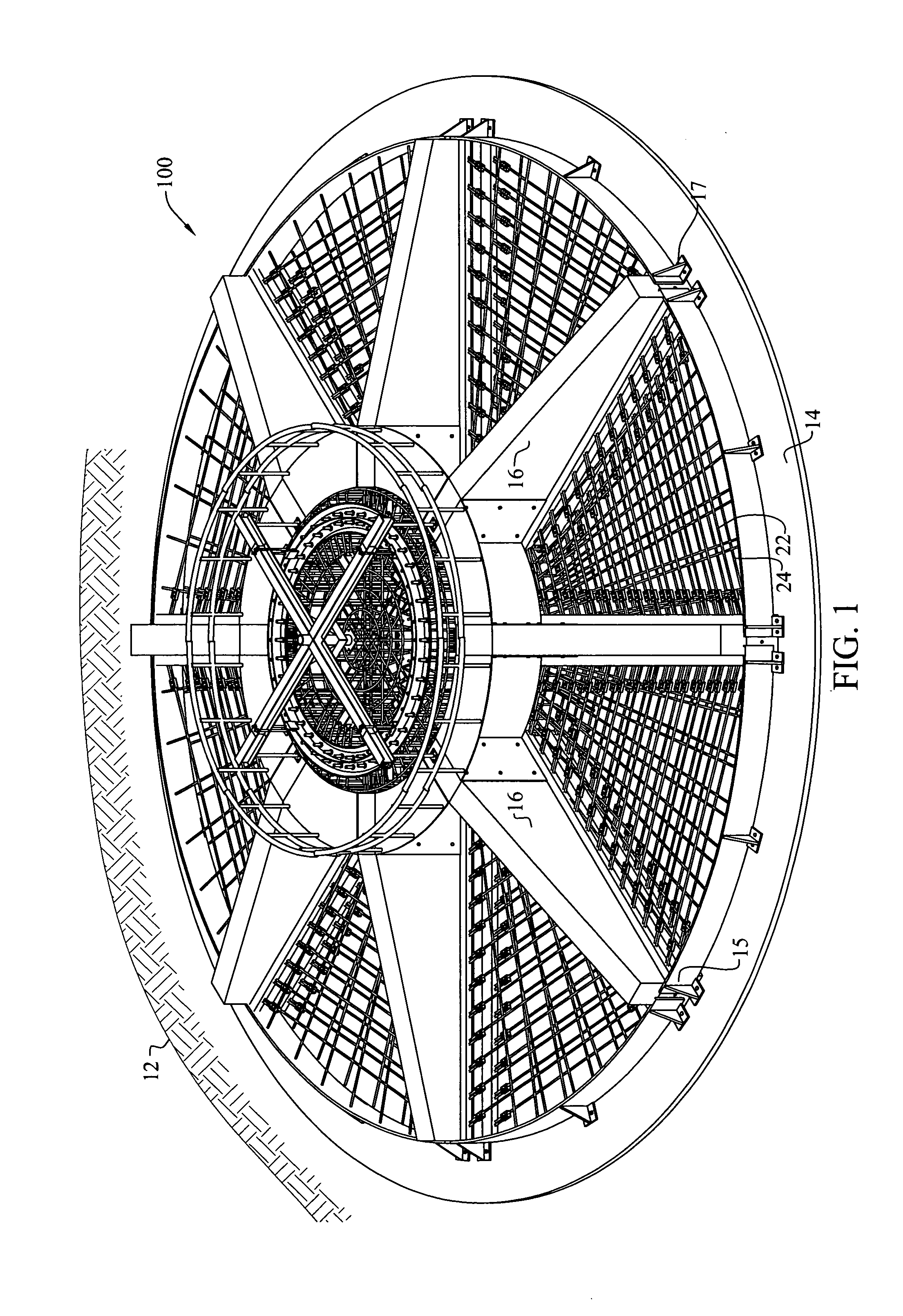

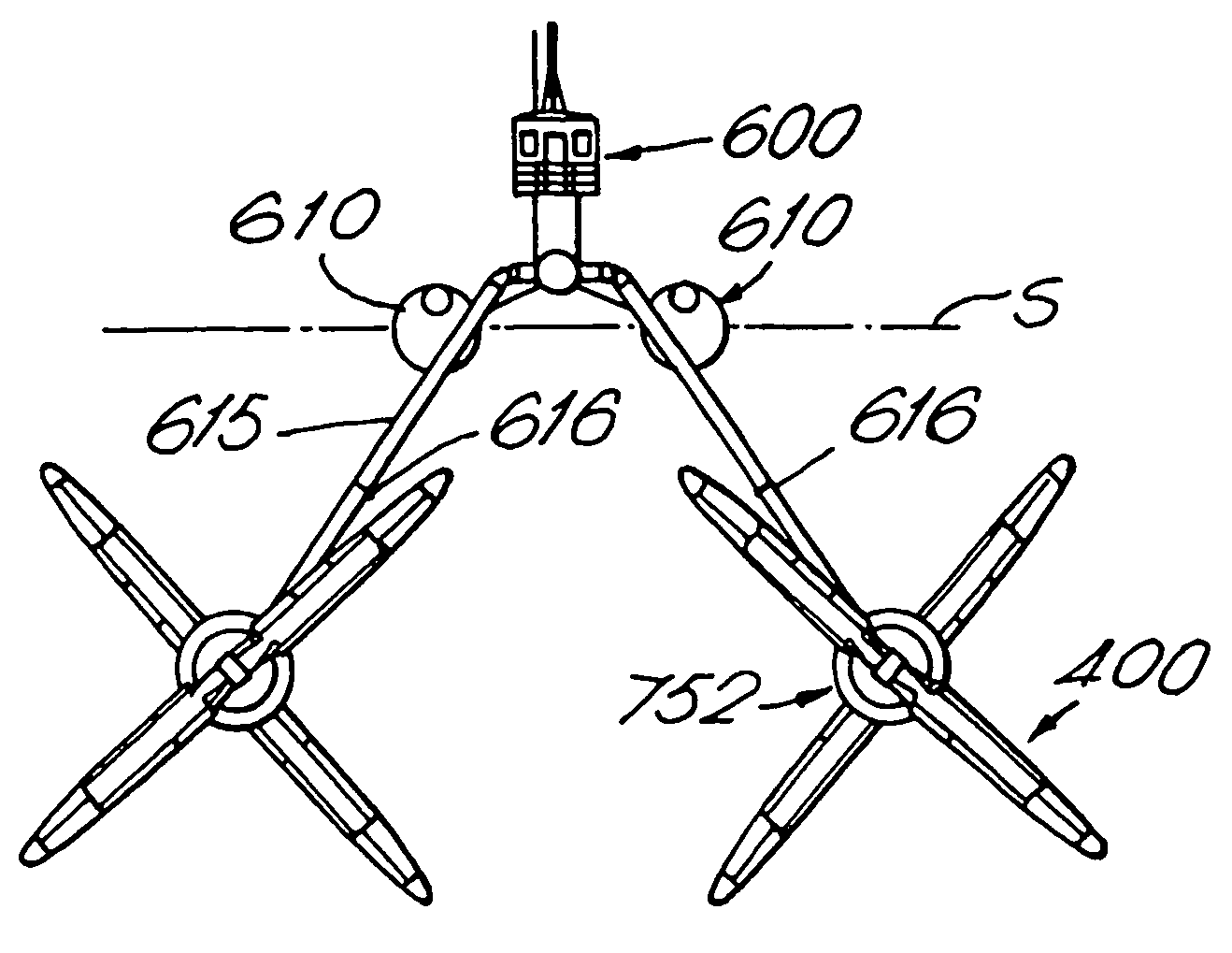

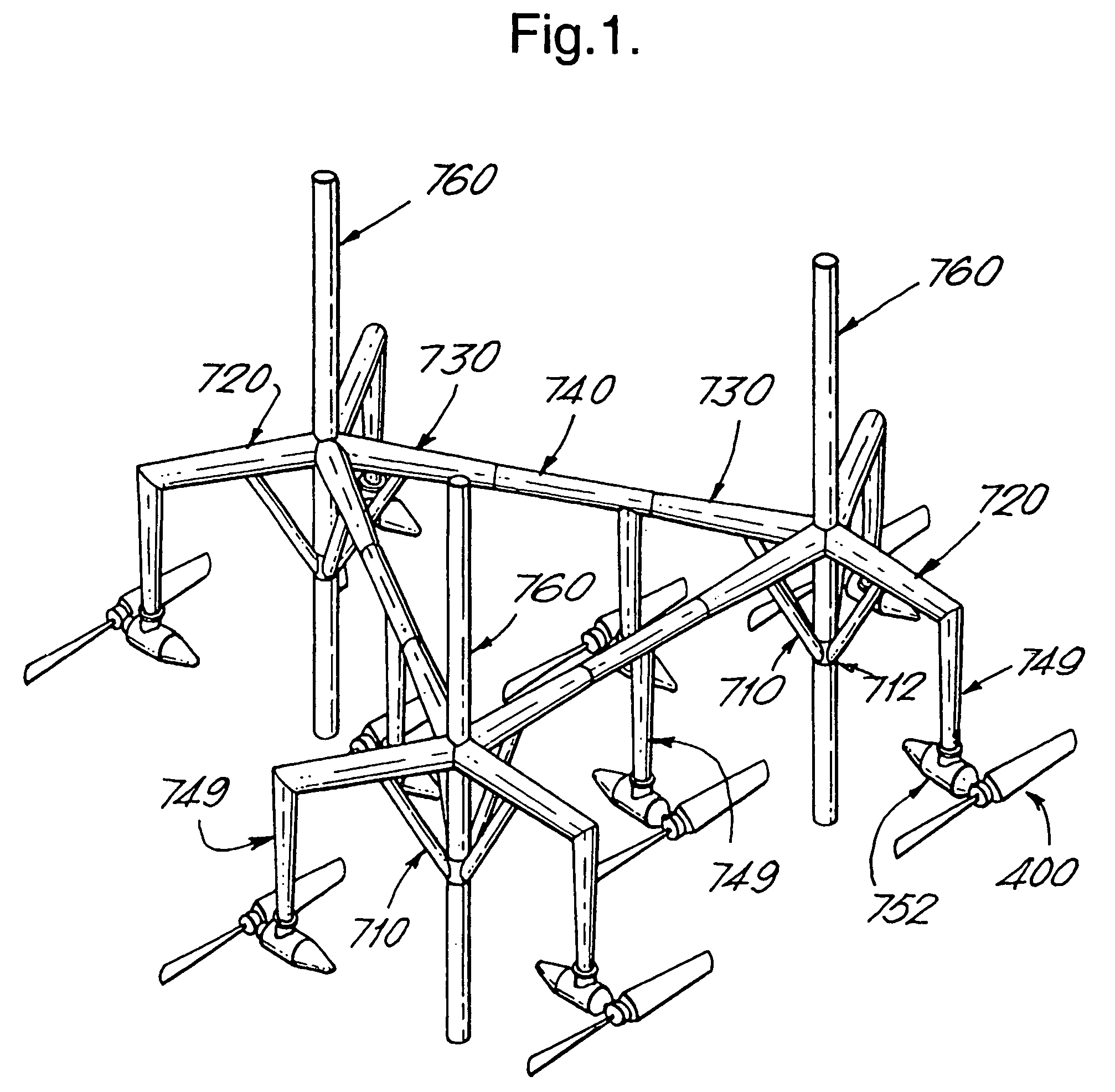

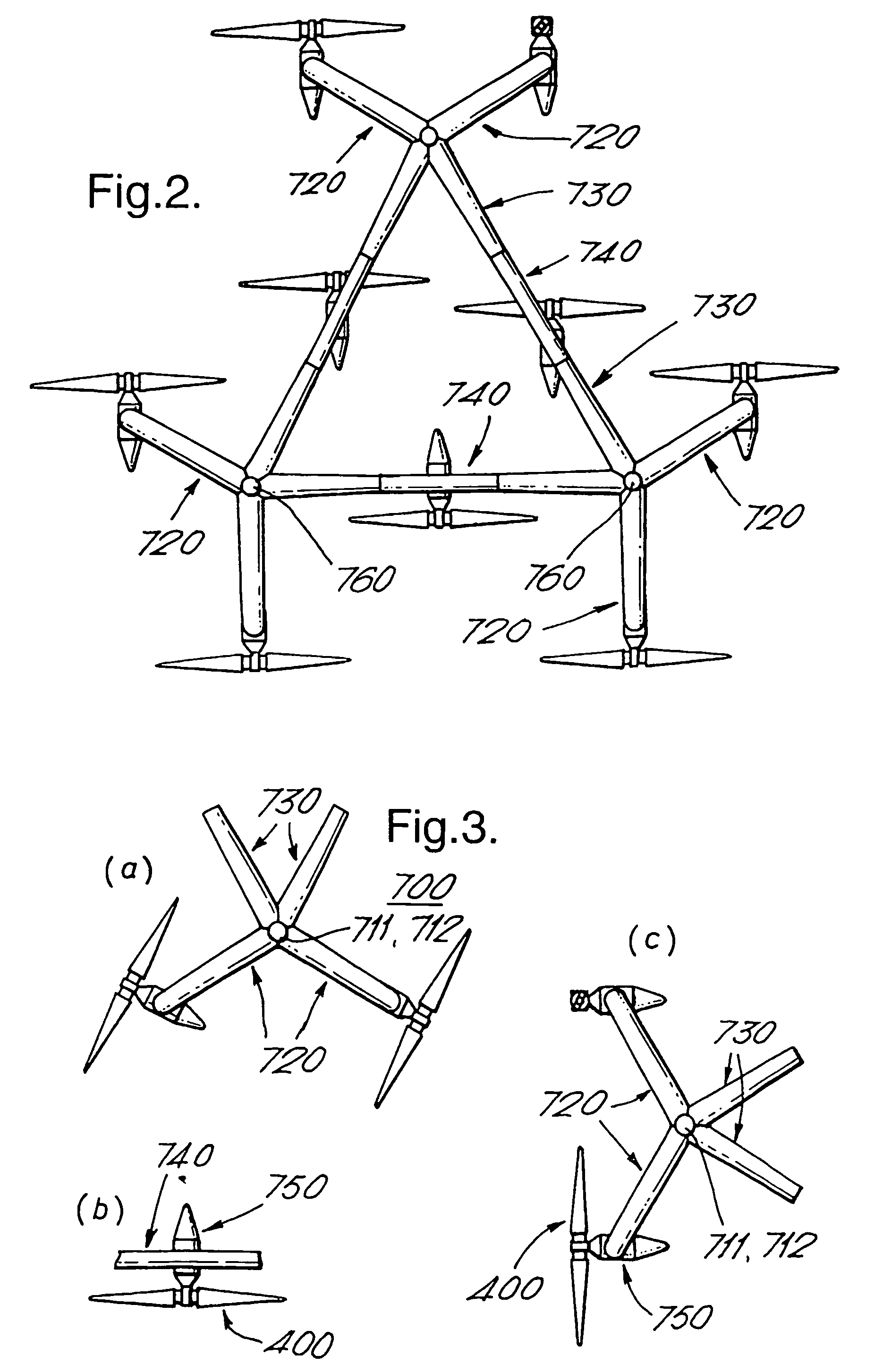

Plant, generator and propeller element for generating energy from watercurrents

A plant, generator and rotating member for the production of power from currents in a body of water, comprising a fixedly mounted of floating structure, and a plurality of replaceable generator units (750) supported by the structure and which are driven by the water currents. The structure comprises arms (615, 720, 730). The rotating member (400) comprises a plurality of member sections (410) rotatably mounted on a shaft (405) between an end piece (407) and a tip (406). The generator comprises a contra-rotating rotor (550) and stator (800) connected to respective shafts (500, 820) and bearings, where the stator frame (800) is axially supported (810) on the first shaft (500) and the first shaft (500) at one end thereof is axially supported (810) on the stator frame. The generator according to the invention can be used for the production of electric power, and as an electromotor for the production of mechanical rotational energy.

Owner:HYDRA TIDAL ENERGY TECH

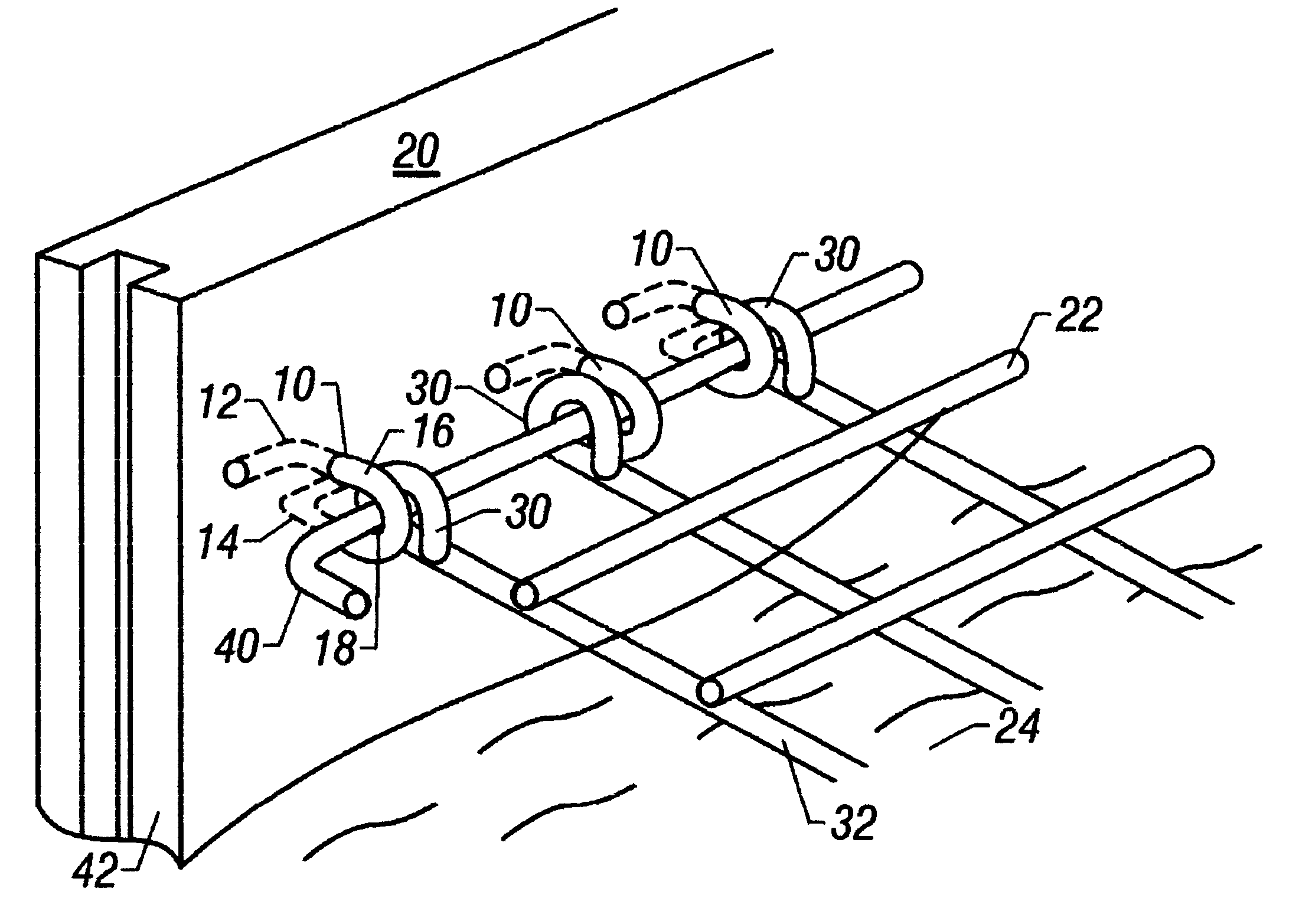

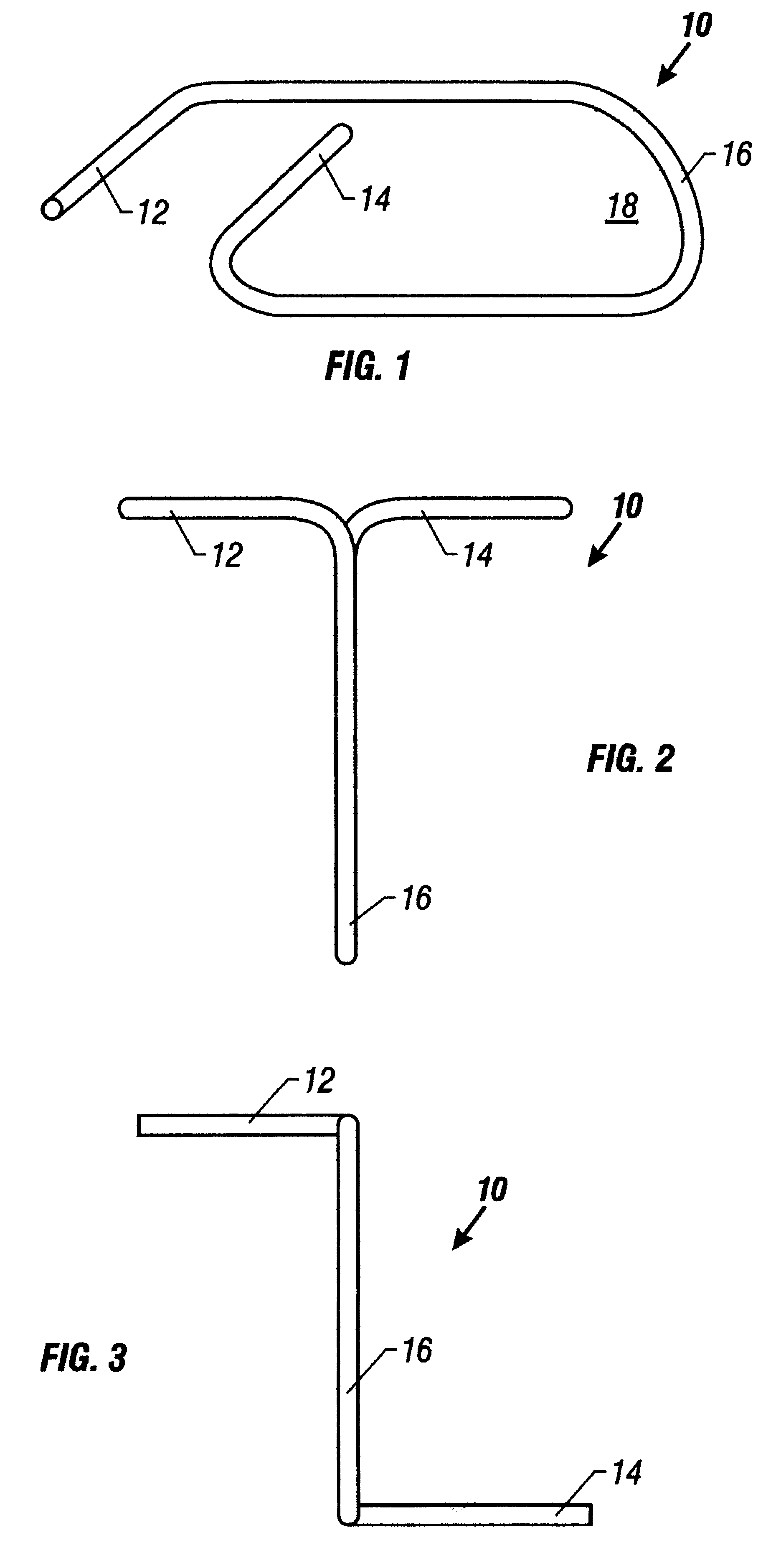

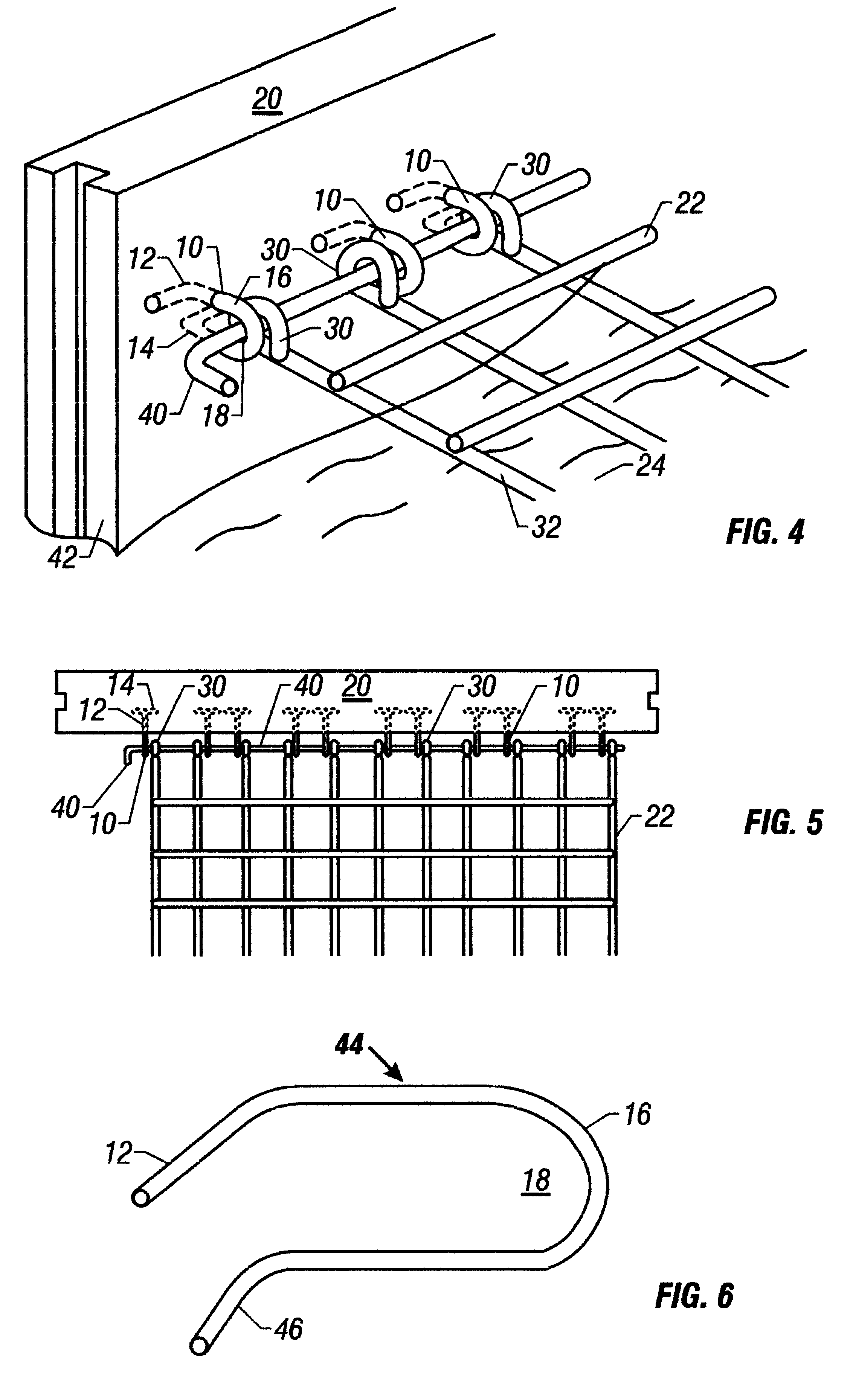

Mechanical interlocking means for retaining wall

An improved method and system for attaching a welded wire grid-work panel to a plurality of face panels of a retaining wall. The method first begins by providing a plurality of stackable face panels, each face panel having a plurality of anchor links fixed within a back portion of the face panels. Each of the anchor links forms a vertical loop extending outwardly generally perpendicular to the back portion of the face panels. Additionally, each anchor link includes two legs extending laterally from each anchor link within the face panel. Next, a first tier of the face panels is disposed at the bottom of the embankment being erected. Soil is then back-filled behind the first tier of panels to a level of the anchor links disposed within the first tier of face panels. A welded wire grid-work panel, which extends perpendicularly from the back portion of the face panels into a soil embankment, is positioned so that a plurality of wire loops at the edge of the grid-work panel aligns with the vertical loops. A connector rod is extended through the vertical loops of the anchor links and the wire loops of the grid-work panel. Next, additional soil is back-filled behind the first tier of face panels and over the anchor links, vertical loops, wire loops, and grid-work panel to a level at a top edge of the first tier of face panels. The method is repeated until the desired height of the embankment is attained.

Owner:SCR STI LLC

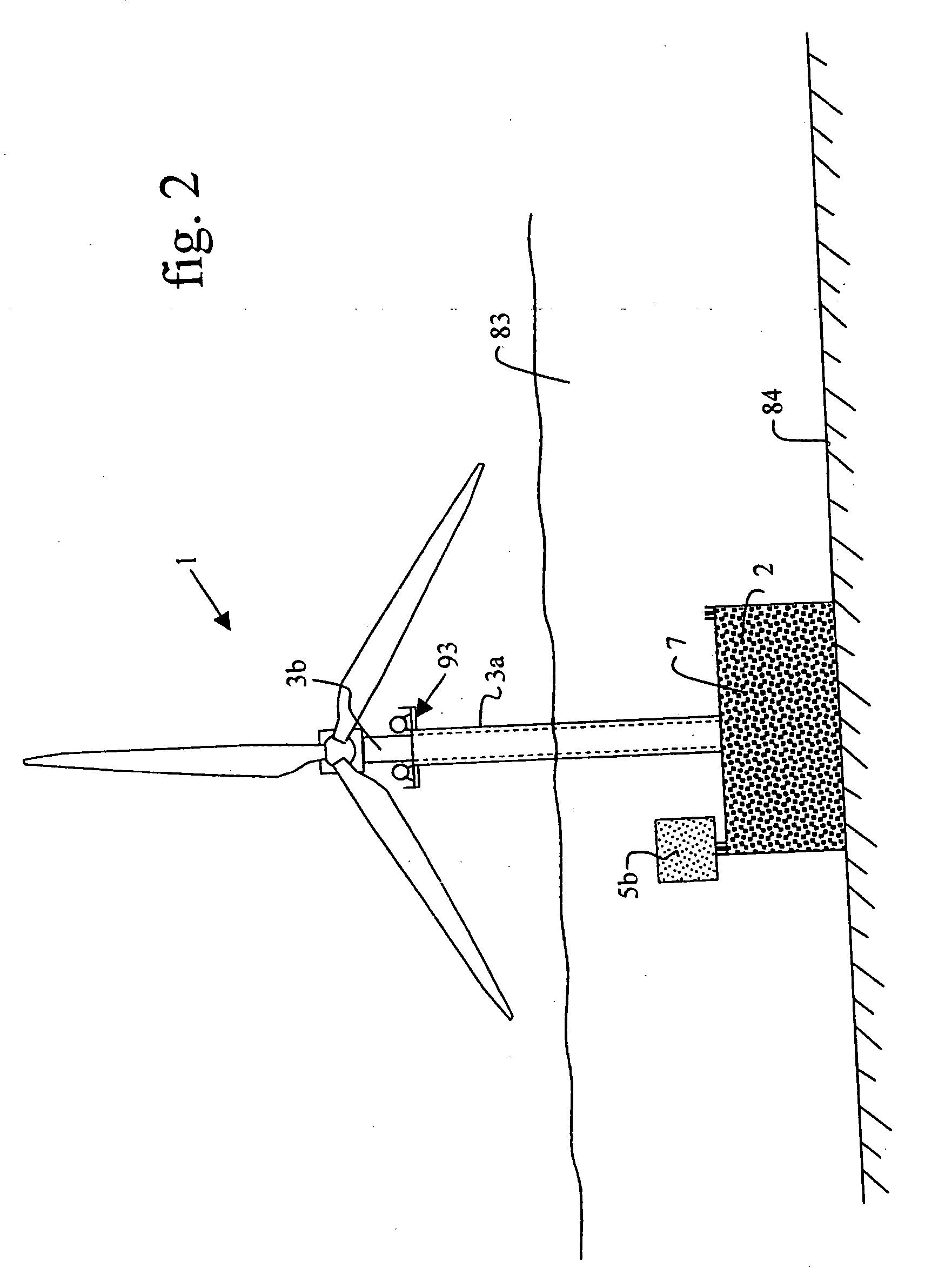

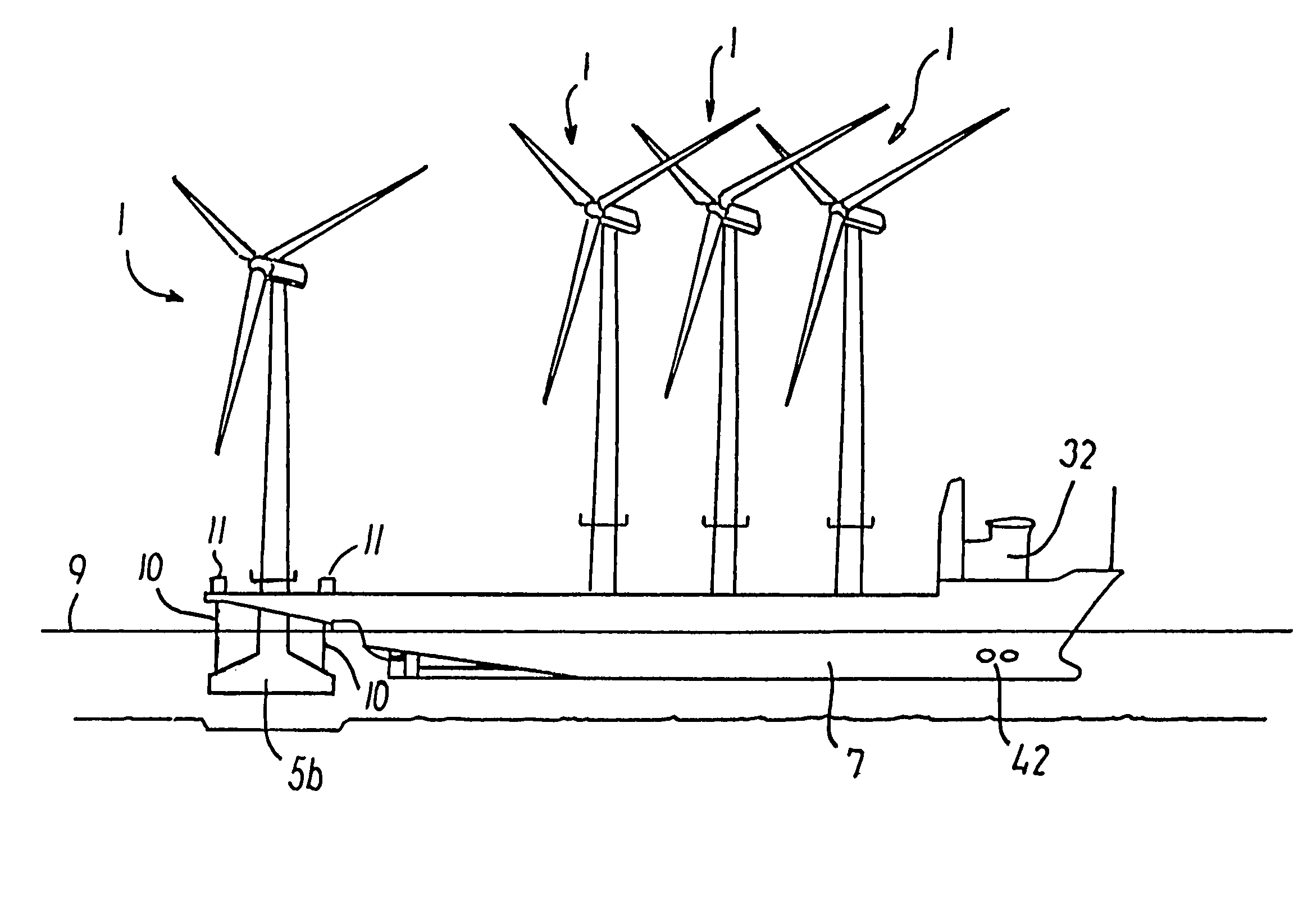

Vessel for transporting wind turbines, methods of moving a wind turbine, and a wind turbine for an off-shore wind farm

A wind turbine (1) has a base (5) divided into at least three ballast tanks (12). A vessel (7) has means for displacing the wind turbine between a loading space (25) and an unloading position (26). At its unloading position the vessel has winches (11) with at least three flexible lines (10) that can be connected with horizontally distanced lifting points (23) on the wind turbine base.

Owner:LOGIMA VSVEND ERIK HANSEN

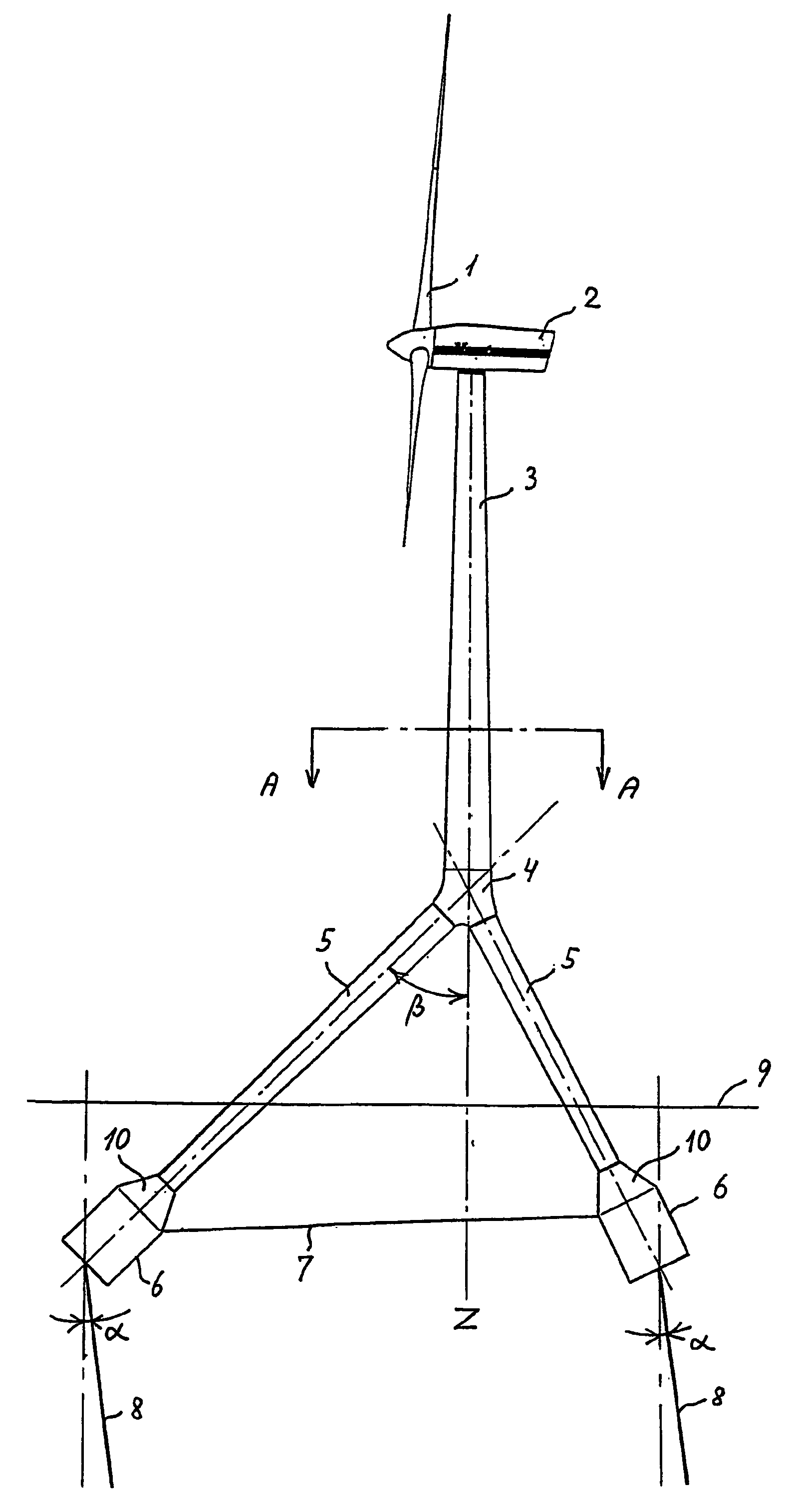

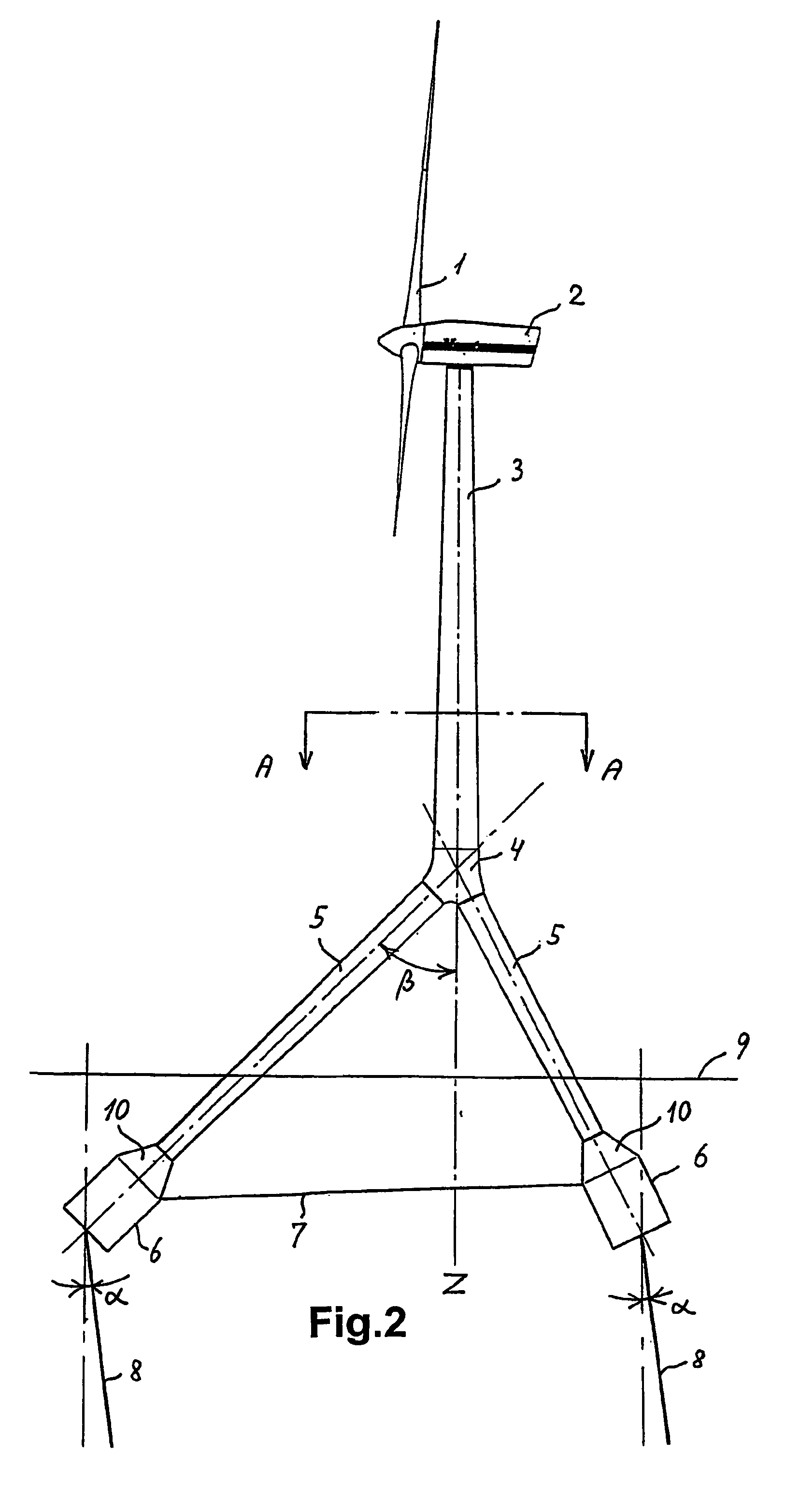

Wind turbine with floating foundation

InactiveUS7156586B2Reduce weightEasy to carryDrilling rodsWind motor supports/mountsStress concentrationTower

Owner:VESTAS WIND SYST AS

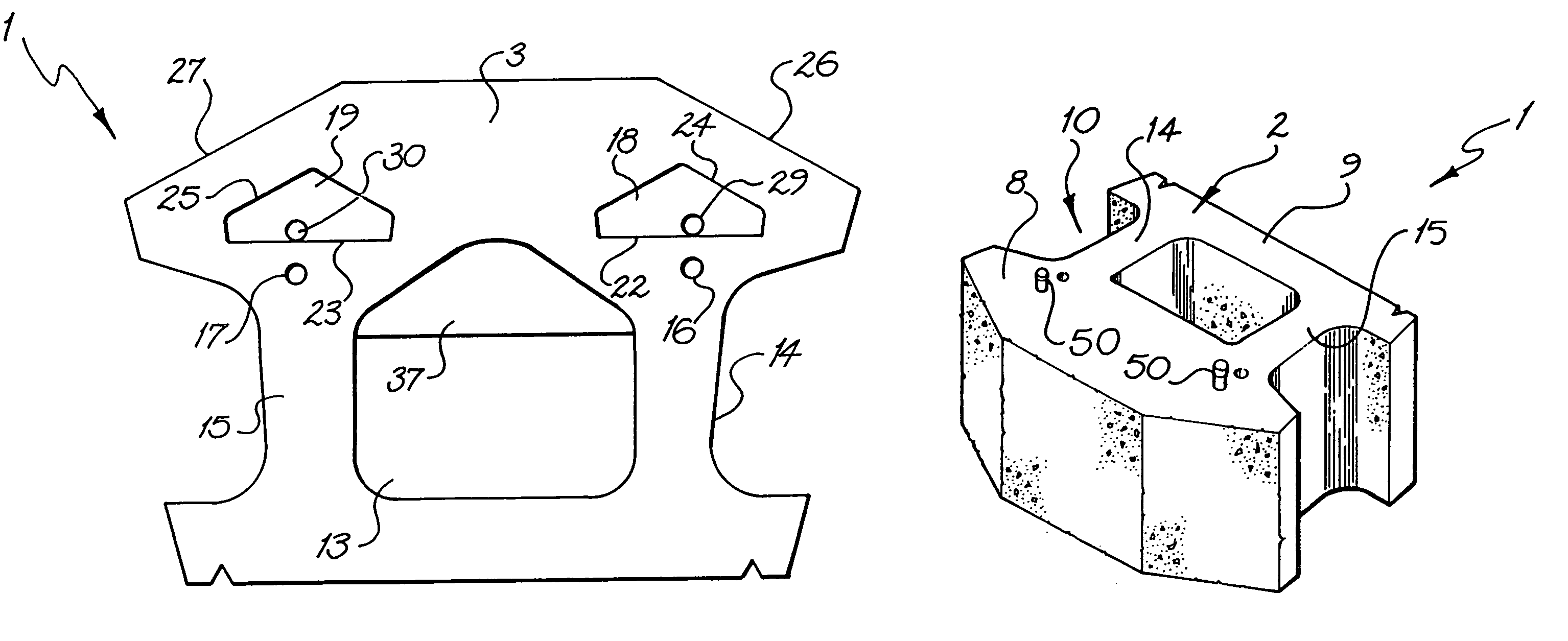

Retaining wall block

InactiveUS7168892B1Reduced and zero predetermined setbackArtificial islandsCoastlines protectionVertical planeEngineering

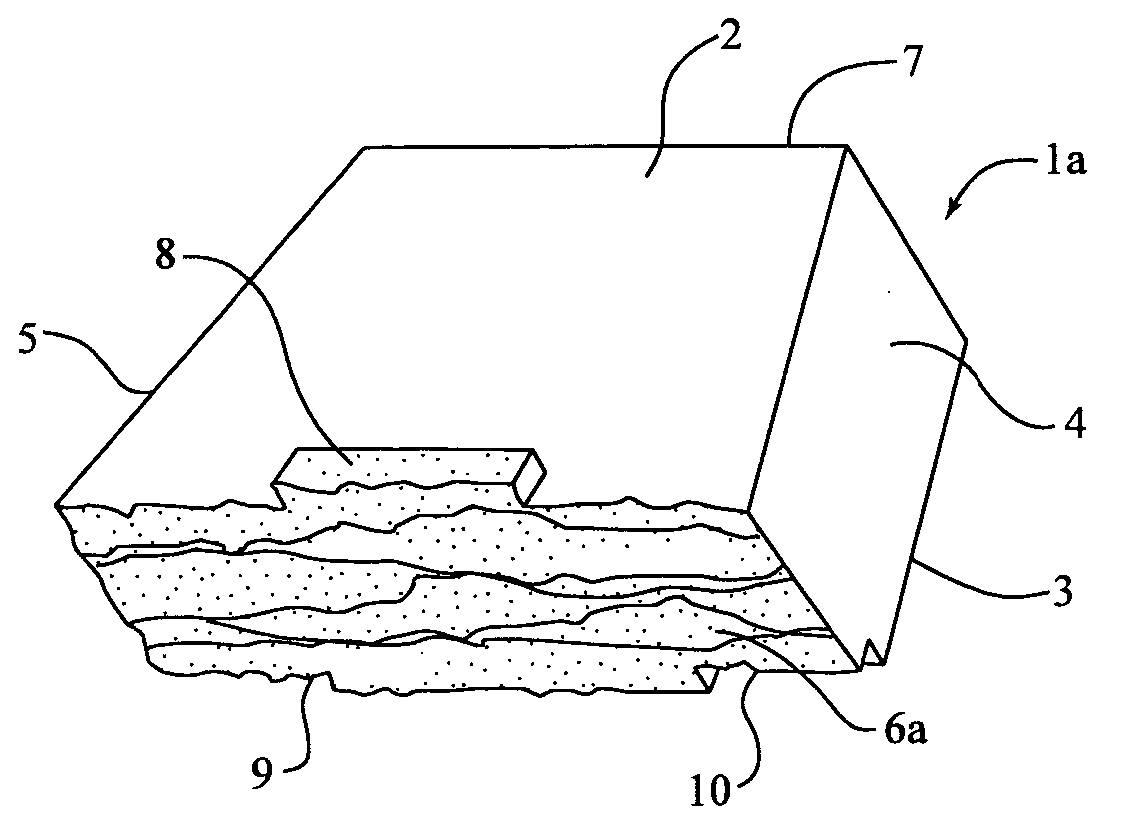

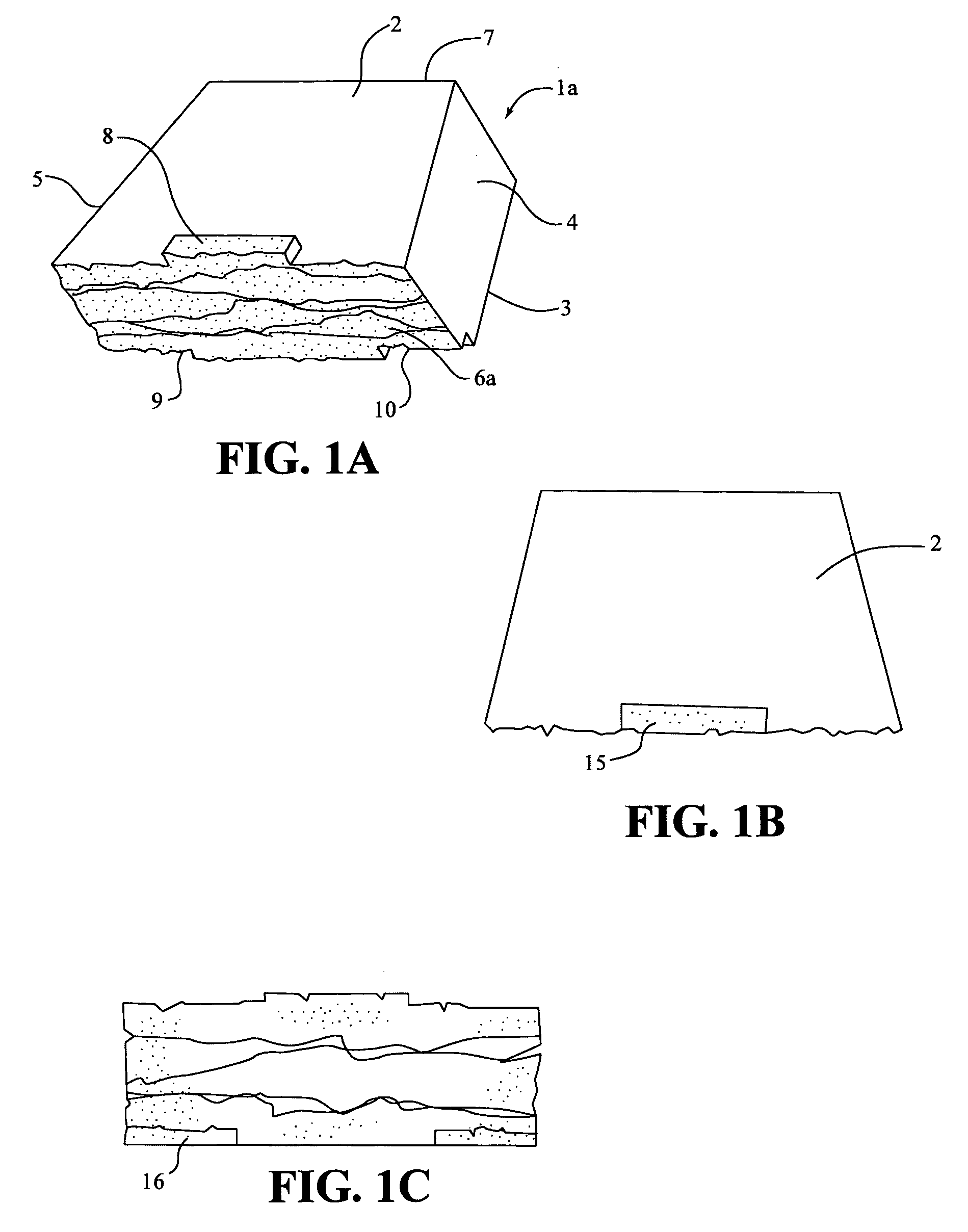

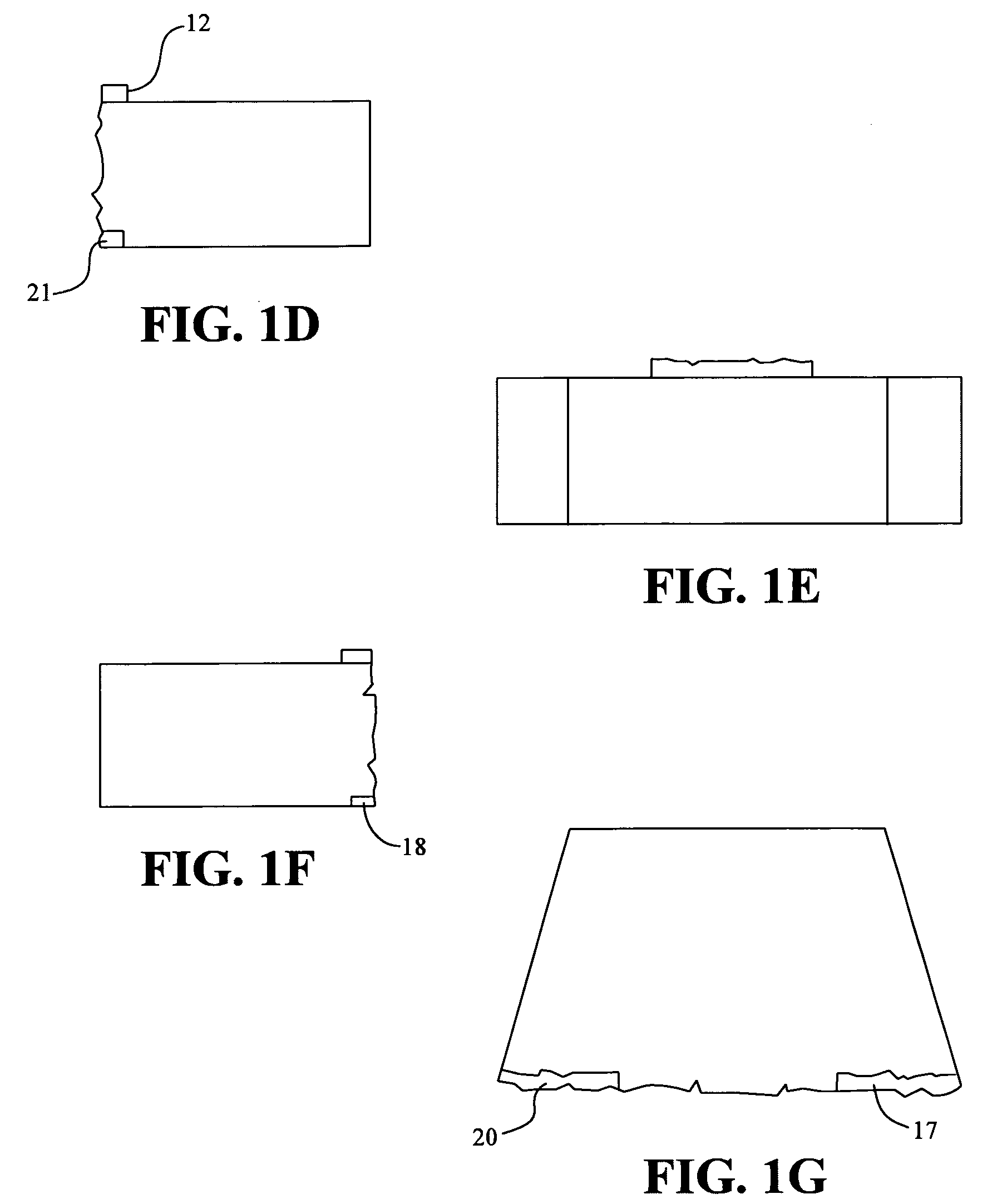

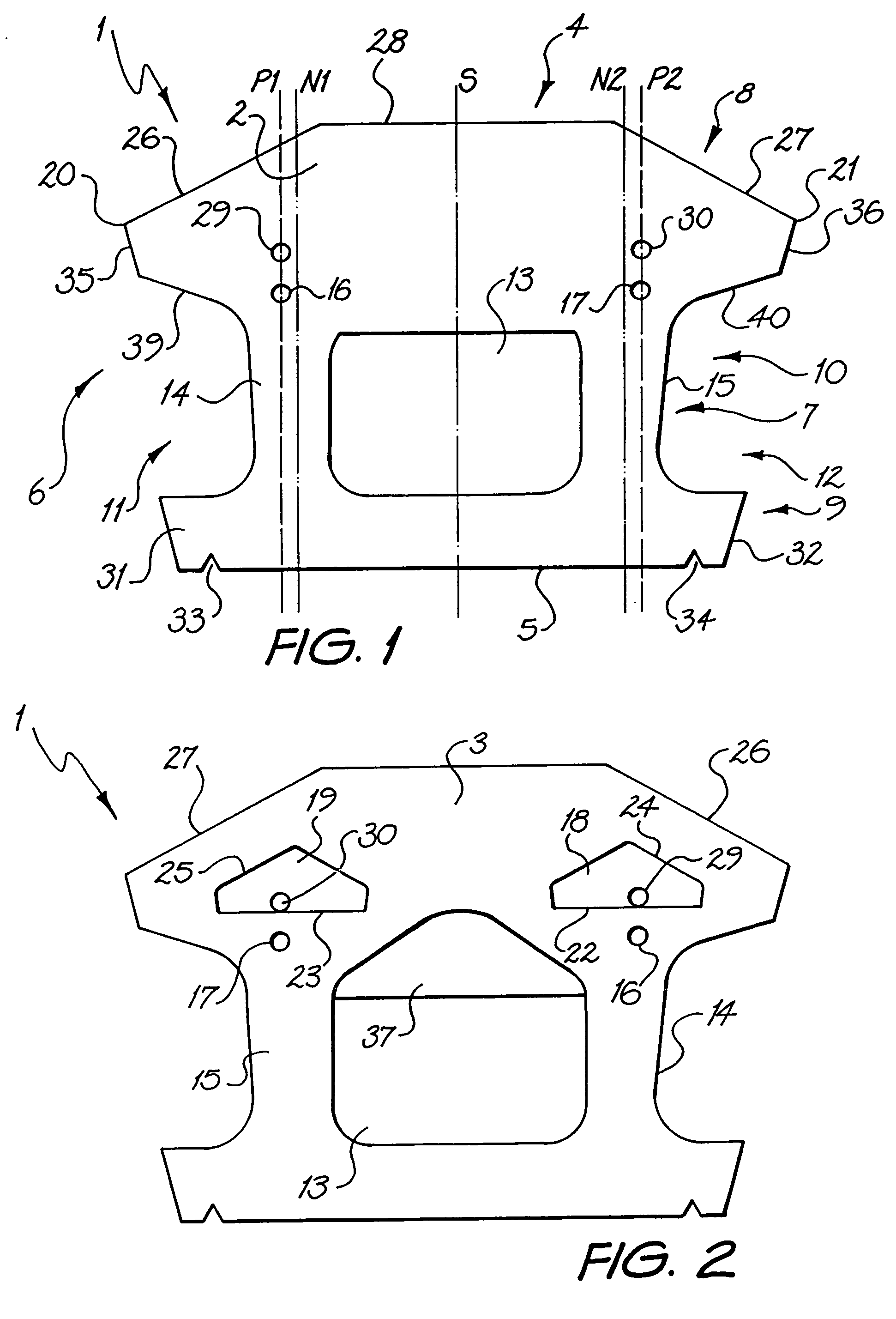

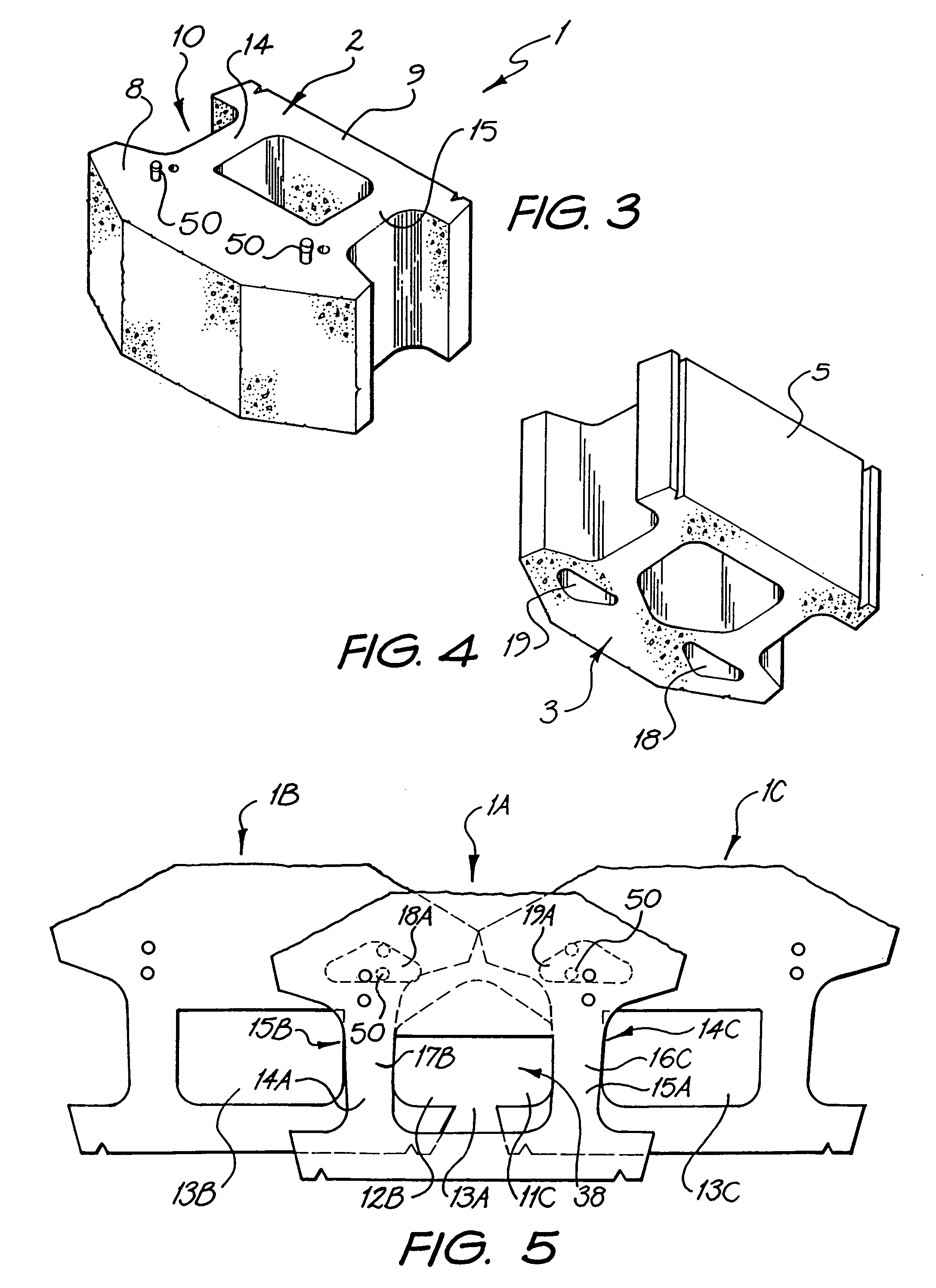

A retaining wall block (1) has parallel top and bottom faces (2, 3), a front face (4), a rear face (5), first and second side wall faces (6, 7) and a vertical plane of symmetry (S) extending between the front and rear faces (4, 5). The block (1) is formed as a body portion (8) including the front face (4), a head portion (9) including the rear face (5) and a neck portion (10) connecting the body portion (8) and the head portion (9). The body, head and neck portions (8, 9, 10) each extend between the top and bottom faces (2, 3) and between the first and second side wall faces (6, 7). An opening (13)′ extends through the neck portion (10) from the top face (2) to the bottom face (3), dividing the neck portion (10) into first and second neck wall members (14, 15) extending rearwardly from the body portion (8) to the head portion (9). First and second pin holes (16 and 17) are each disposed in the body portion (8) and open onto the top face (2) for receiving a pin (50, 51) with a free end of the pin protruding beyond the top face. First and second pin receiving cavities (18, 19) are each disposed in the body portion (8) and open onto the bottom face (3) for receiving the free end of a pin (50, 51) received in a pin hole (16 and 17) of an adjacent block (1) disposed therebeneath so as to interlock the blocks (1) with a predetermined setback. The neck wall members (14, 15), pin holes (16 and 17) and pin receiving cavities (18, 19) are positioned such that a first plane (P1) extending parallel to the plane of symmetry (5) passes through the first pin receiving cavity (18), first pin hole (16) and first neck wall member (14) and a second plane (P2) extending parallel to the plane of symmetry (5) passes through the second pin receiving cavity (19), second pin hole (17) and second neck wall member (15).

Owner:MELLON BANK N A

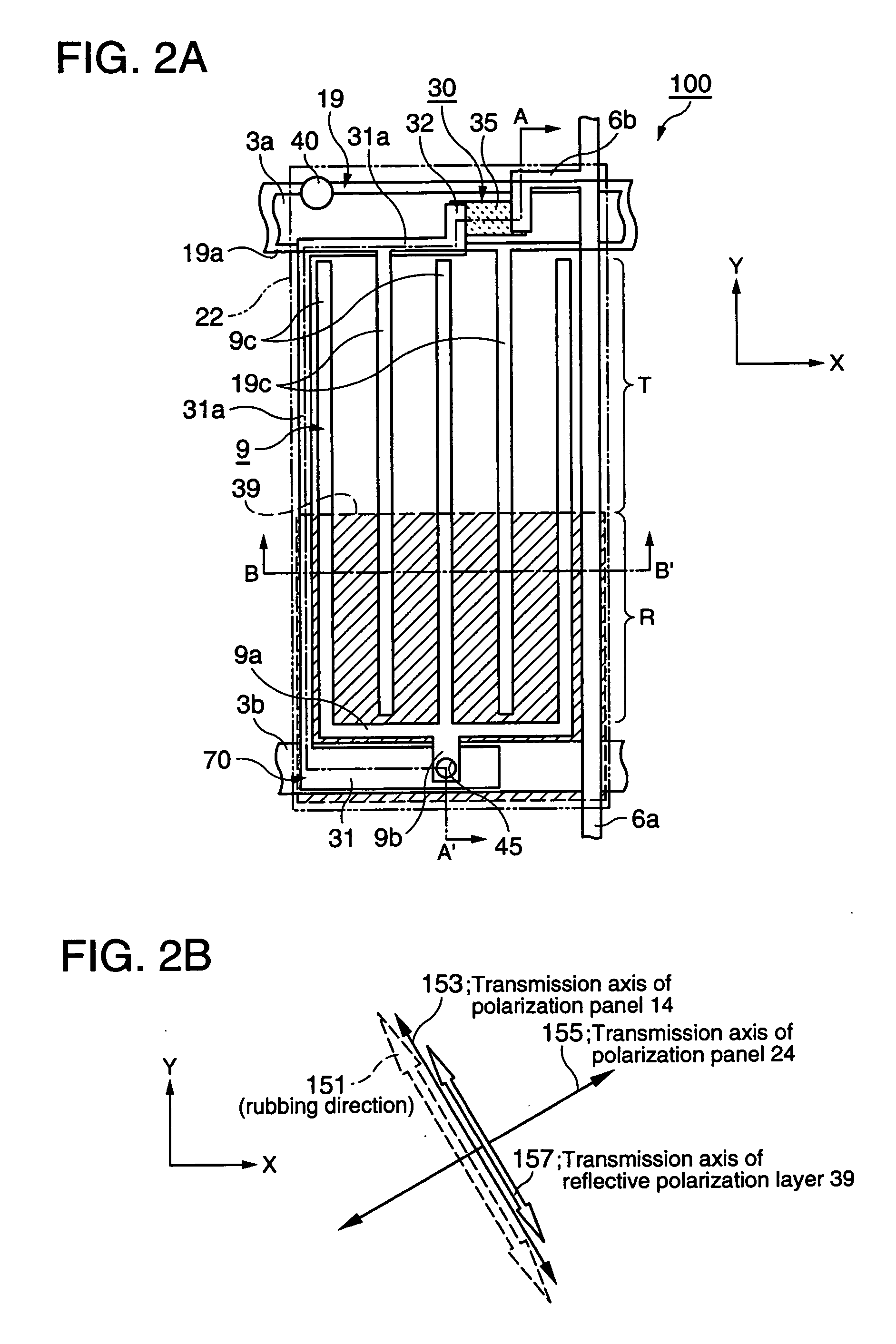

Liquid crystal device and electronic equipment

InactiveUS20060215086A1High quality displayArtificial islandsNon-linear opticsElectronElectric field

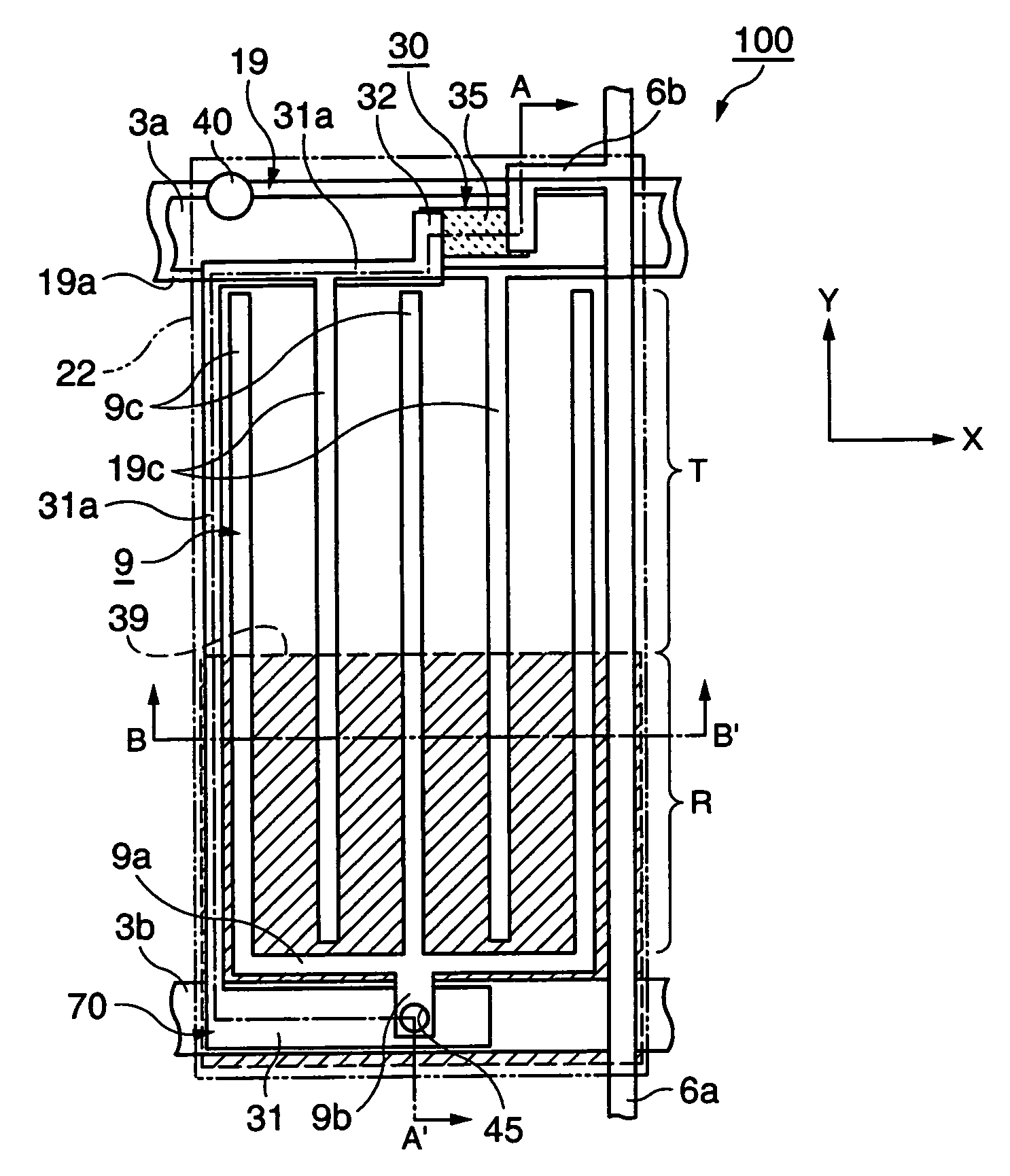

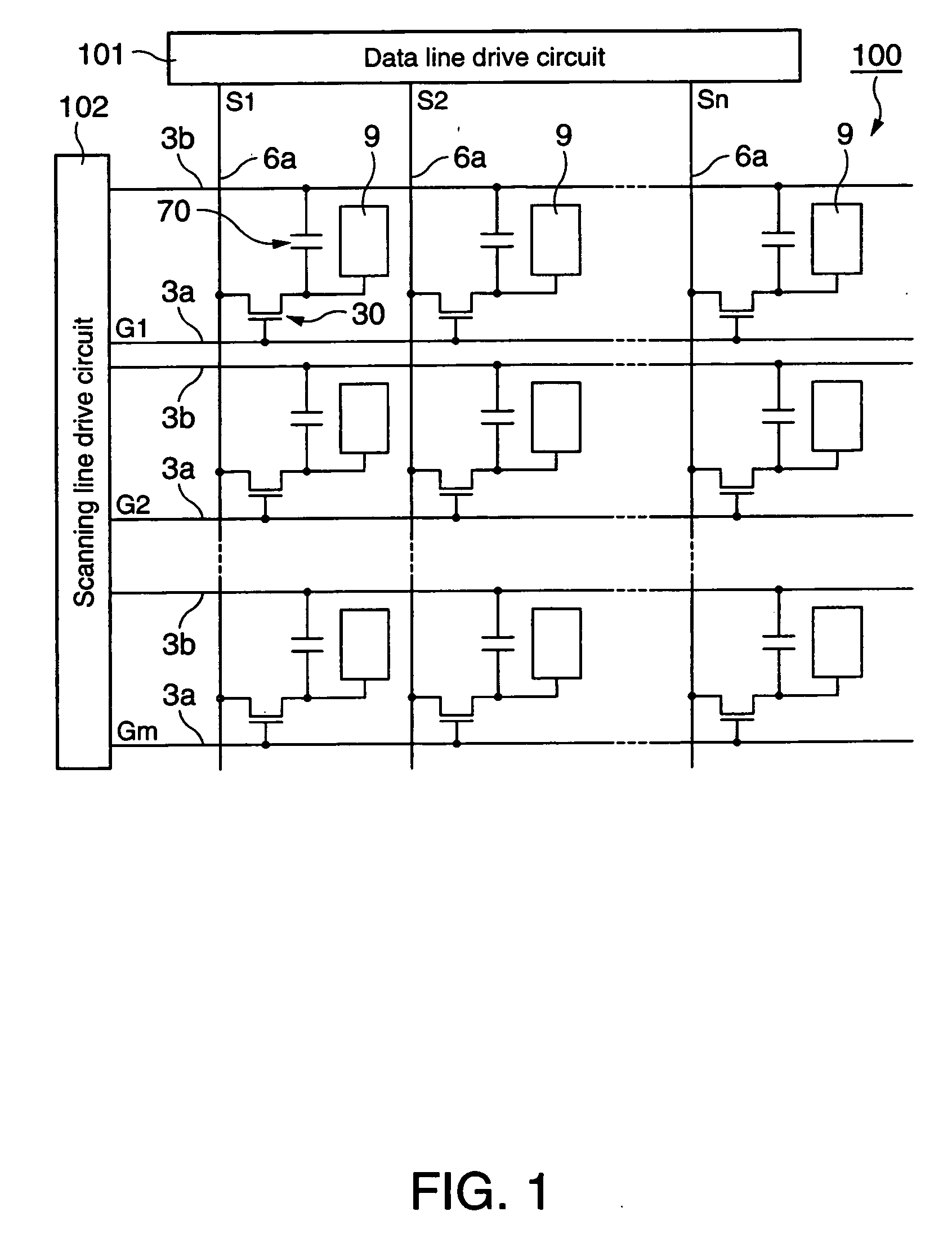

A semi-transmissive reflective liquid crystal device includes a first substrate, a second substrate disposed opposite to the first substrate, a liquid crystal layer disposed between the first substrate and the second substrate, a plurality of sub-pixel regions at which reflective display and transmissive display are performed, each of the sub-pixel regions being the smallest display unit, a first electrode and a second electrode disposed in each of the sub-pixel regions at the liquid crystal layer side of the first substrate for driving the liquid crystal layer by an electric field generated between the first electrode and the second electrode, and a reflective polarization layer disposed at the first substrate or the second substrate, the reflective polarization layer including a transmission axis and a reflection axis perpendicular to the transmission axis, for reflecting a portion of an incident light, which is a polarized light component parallel with the reflection axis, and transmitting the remainder of the incident light, which is a polarized light component parallel with the transmission axis.

Owner:JAPAN DISPLAY WEST

Multi-channel retaining wall block and system

A retaining wall block system having multiple sizes and shapes of blocks with differently dimensioned, interchangeable front and back faces. The blocks are used to construct an irregularly textured wall having a weathered, natural appearance. Multiple channels in the lower face of the block are used to engage pins in pin-receiving apertures to form an attachment system. Horizontal reinforcing members are also used in the channels and vertical reinforcing members are used in cores of adjacent blocks for reinforcing a wall. Reinforcing geosynthetic materials can also be firmly held in a wall by means of the pins or by connectors adapted to fit in the block channels.

Owner:KEYSTONE RETAINING WALL SYST

Concrete block system

A dry-cast concrete block system for use in a structure. The dry-cast concrete block system comprises a support block comprising a first coupling part and a face block comprising a second coupling part. The first coupling part and the second coupling part enable the face block to be coupled to the support block. The face block comprises a surface adapted to be exposed when the face block is coupled to the support block and the dry-cast concrete block system is positioned in the structure. In one embodiment, at least a portion of the surface has a cast texture with a natural stone appearance. In one embodiment, the structure is a wall and the concrete block system is a wall block system. For example, the wall may be a retaining wall and the wall block system may be a retaining wall block system. In another embodiment, the structure is a column and the concrete block system is a column block system. In yet another embodiment, the structure is steps and the concrete block system is a steps block system.

Owner:OLDCASTLE BUILDING PROD CANADA INC

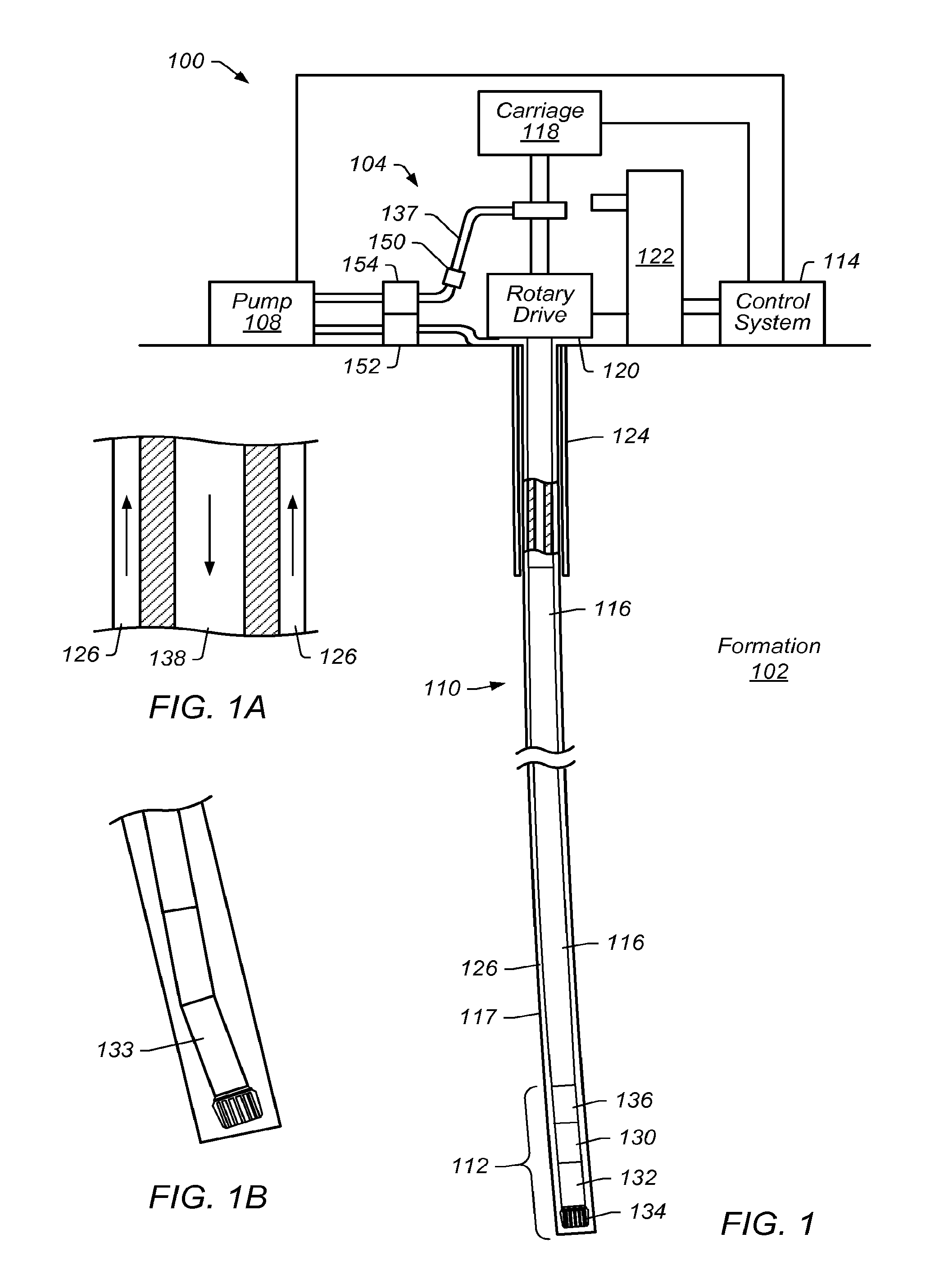

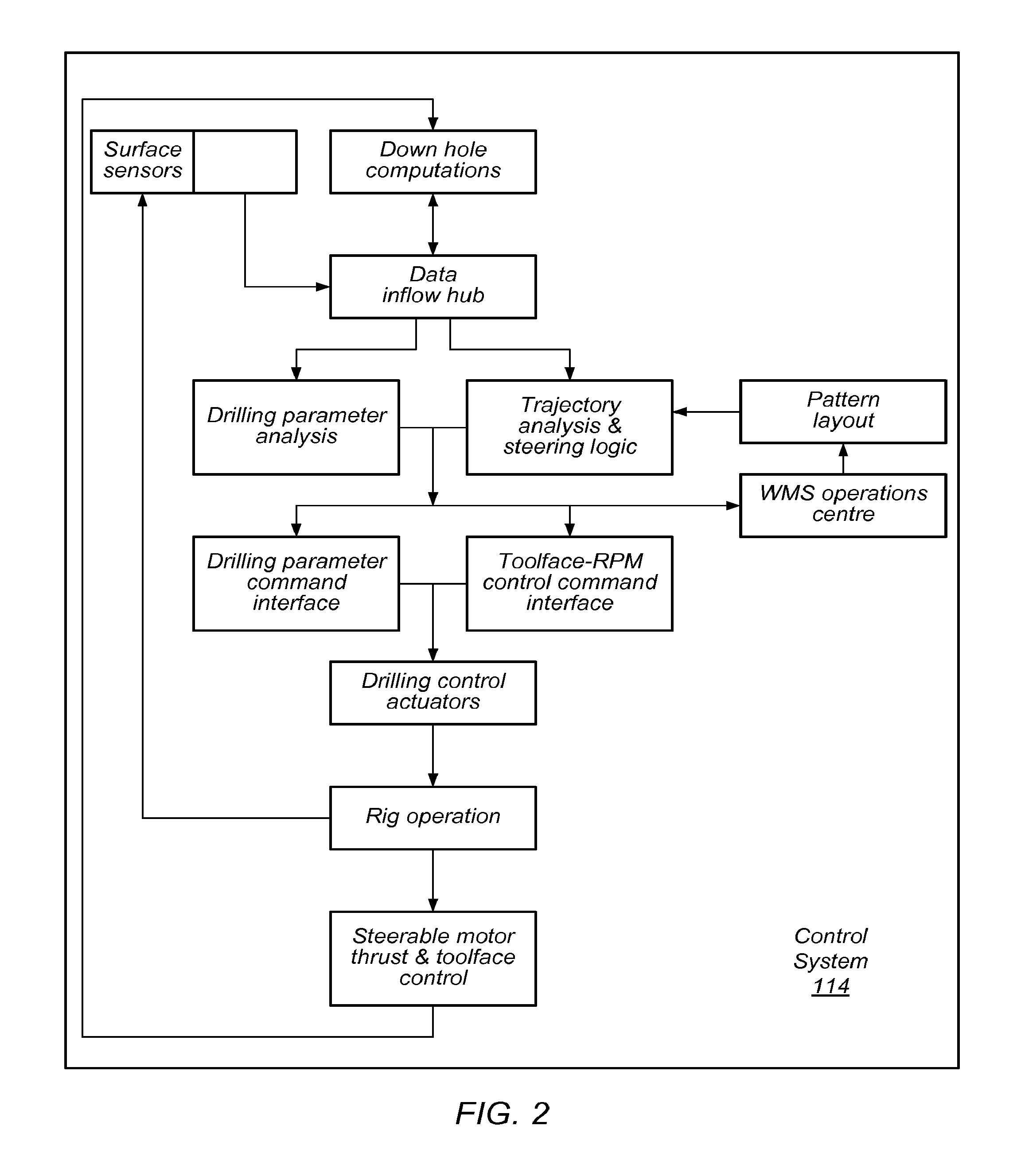

Methods and systems for drilling

A method of steering a drill bit to form an opening in a subsurface formation, comprises a) determining a distance from design of a well, and b) determining an angle offset from design of the well wherein angle offset from design is the difference between the inclination and azimuth of the hole and the inclination and azimuth of plan, c) wherein at least one distance from design and at least one angle offset from design are determined in real time based, at least in part, on a position of the hole at the last survey, a position at a projected current location of the bit, and a projected position of the bit.

Owner:SHELL USA INC

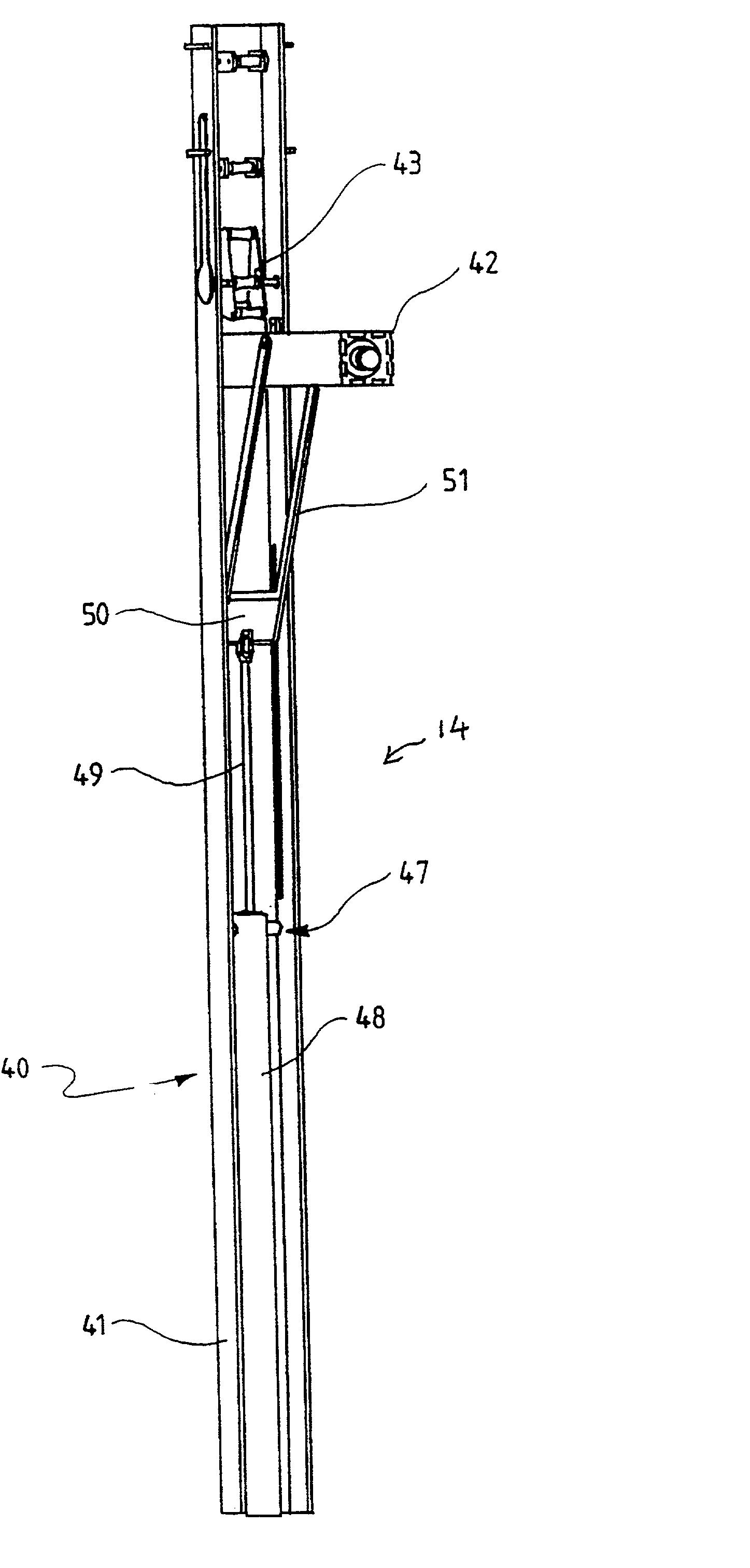

Erectable arm assembly for use in boreholes

InactiveUS20020043404A1Avoid interferencePrecise positioningArtificial islandsSurveyEngineeringDrill string

An erectable arm assembly for use in a borehole, the erectable arm assembly comprising a main body and an arm member, the arm member being able to move between a collapsed position in which the assembly can be removed from the borehole and an erected position, the erectable arm assembly being adapted to house a fluid drilling assembly comprising a fluid cutting device and a flexible hose drill string such that the arm member during erection can contain at least part of the fluid drilling assembly, and when in the erected position the arm member is able to guide the fluid cutting device towards the borehole wall, the assembly further including at least one sensor for monitoring the arm member or the fluid drilling assembly.

Owner:TRUEMAN ROBERT +2

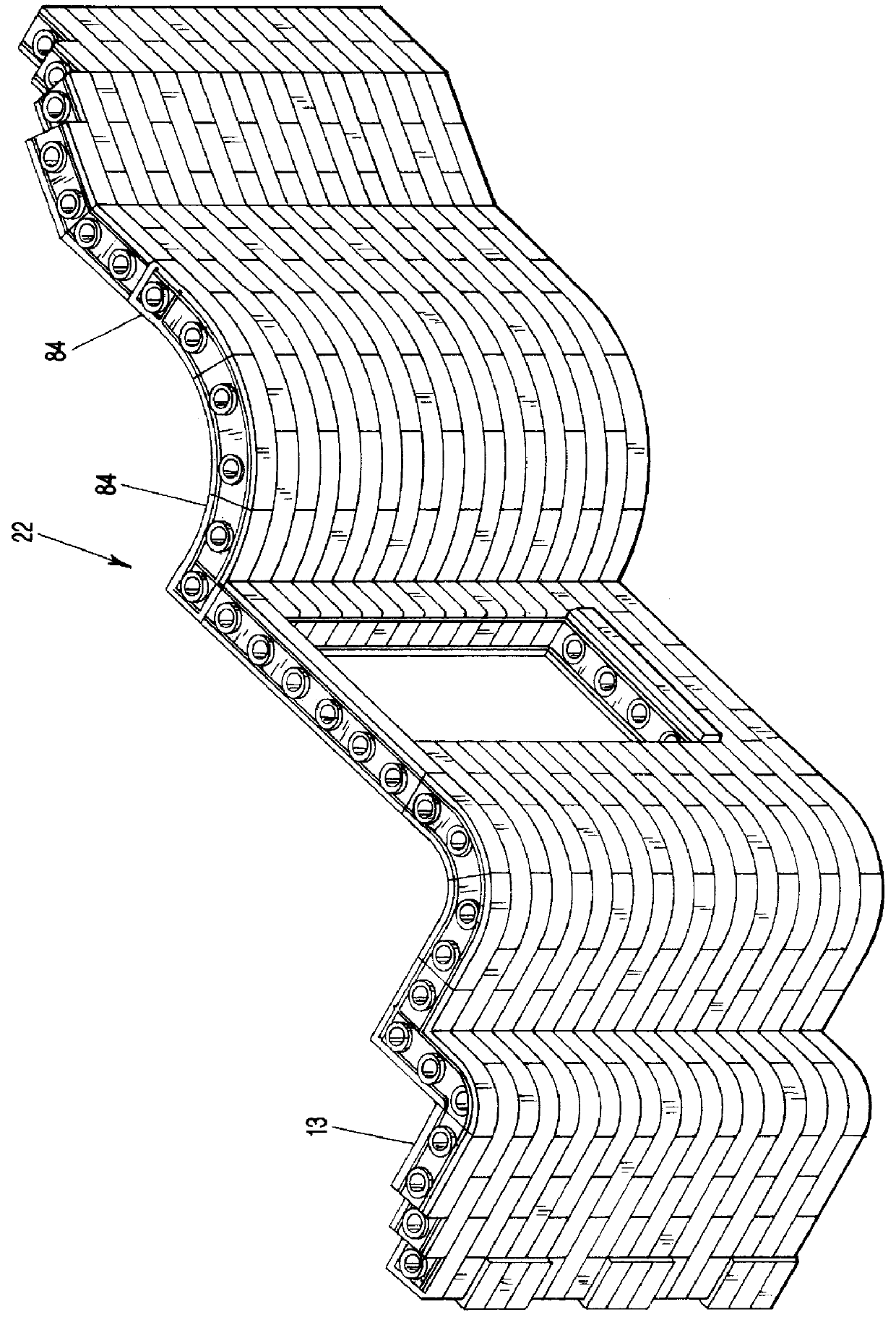

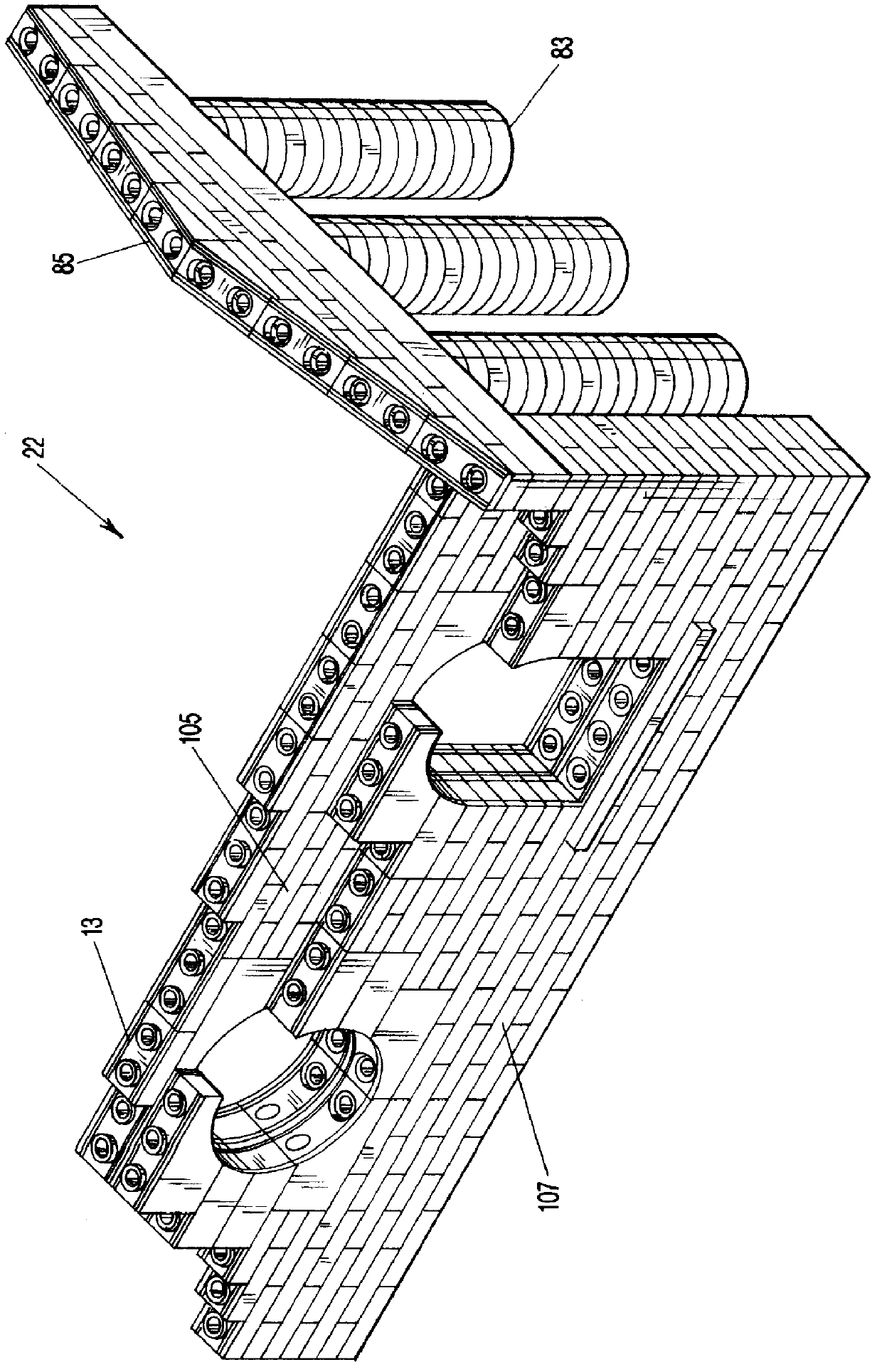

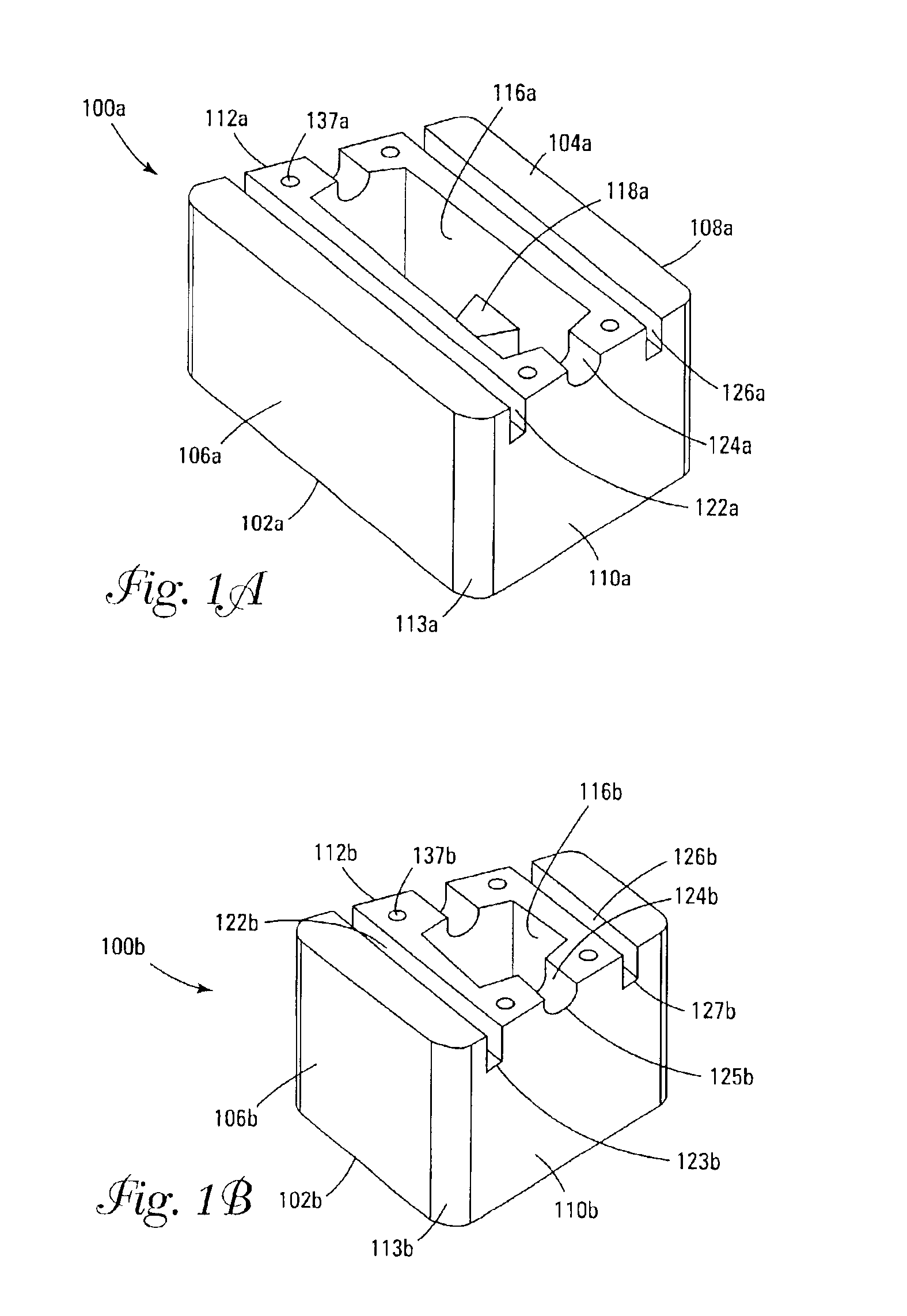

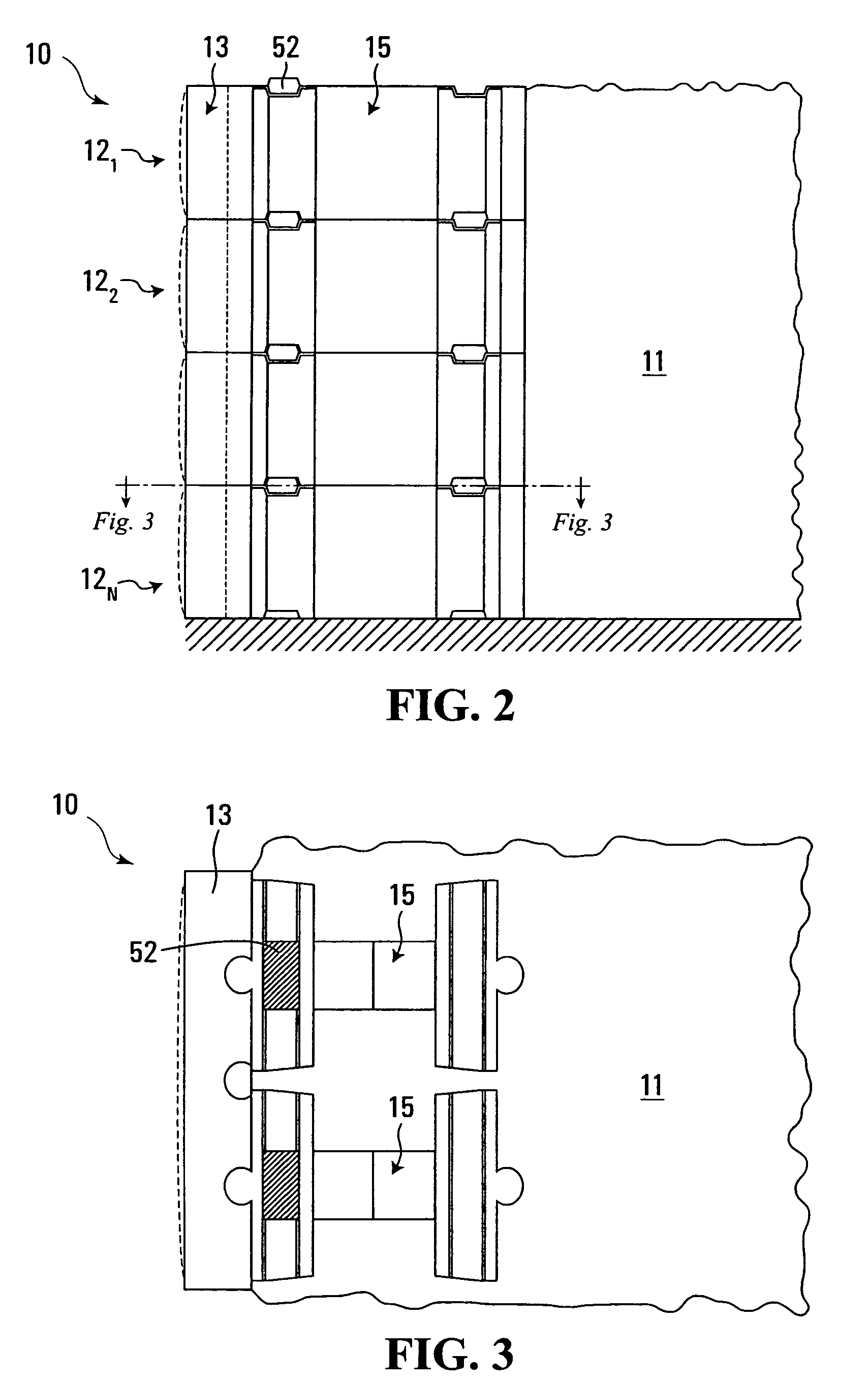

Retaining wall block system

InactiveUS20110217127A1Improves Structural IntegrityAvoid displacementArtificial islandsStrutsEngineeringMechanical engineering

A wall block having a block body having opposed front and rear faces, opposed first and second side walls, and opposed and substantially parallel top and bottom faces, one or more pin holes that open onto the top face of the block, and one or more lugs that extend from the bottom face, each lug having a back surface that extends contiguously from the rear face of the block. A corner block for use with the wall block. A retaining wall comprising a plurality of wall blocks including at least one lower course and at least one upper course.

Owner:KEYSTONE RETAINING WALL SYST

Column-stabilized offshore platform with water-entrapment plates and asymmetric mooring system for support of offshore wind turbines

ActiveUS8471396B2Improve performanceEasy to produceWind motor controlWind motor assemblyNacelleMooring system

A floating wind turbine platform includes a floatation frame that includes at least three columns that are coupled to each other with horizontal main beams. A wind turbine tower is mounted above a tower support column to simplify the system construction and improve the structural strength. The turbine blades are coupled to a nacelle that rotates on top of the tower. The turbine's gearbox generator and other electrical gear can be mounted either traditionally in the nacelle, or lower in the tower or in the top of the tower-supporting column. The floatation frame includes a water ballasting system that pumps water between the columns to keep the tower in a vertical alignment regardless of the wind speed. Water-entrapment plates are mounted to the bottoms of the columns to minimize the rotational movement of the floatation frame due to waves.

Owner:PRINCIPLE POWER

Real Time Misalignment Correction of Inclination and Azimuth Measurements

A method for determining wellbore trajectory includes determining survey parameters in the wellbore; measuring force parameter(s) in the wellbore; and correcting the survey parameters using the measured force parameter(s). The downhole measured force parameters may include forces associated with an operation of a steering device such as an internal reaction force, and / or a bending moment. In variants, the method may include measuring a wellbore temperature; measuring a wellbore parameter in addition to the temperature; and correcting a survey parameter using the measured parameter and the measured temperature. These methods may include correcting survey parameters using measured wellbore diameters. Also, a processor in the wellbore may be programmed to perform the correction while in the wellbore and / or control a steering device using measurements provided by a sensor for measuring internal reaction forces.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com