Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

870 results about "Wire grid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

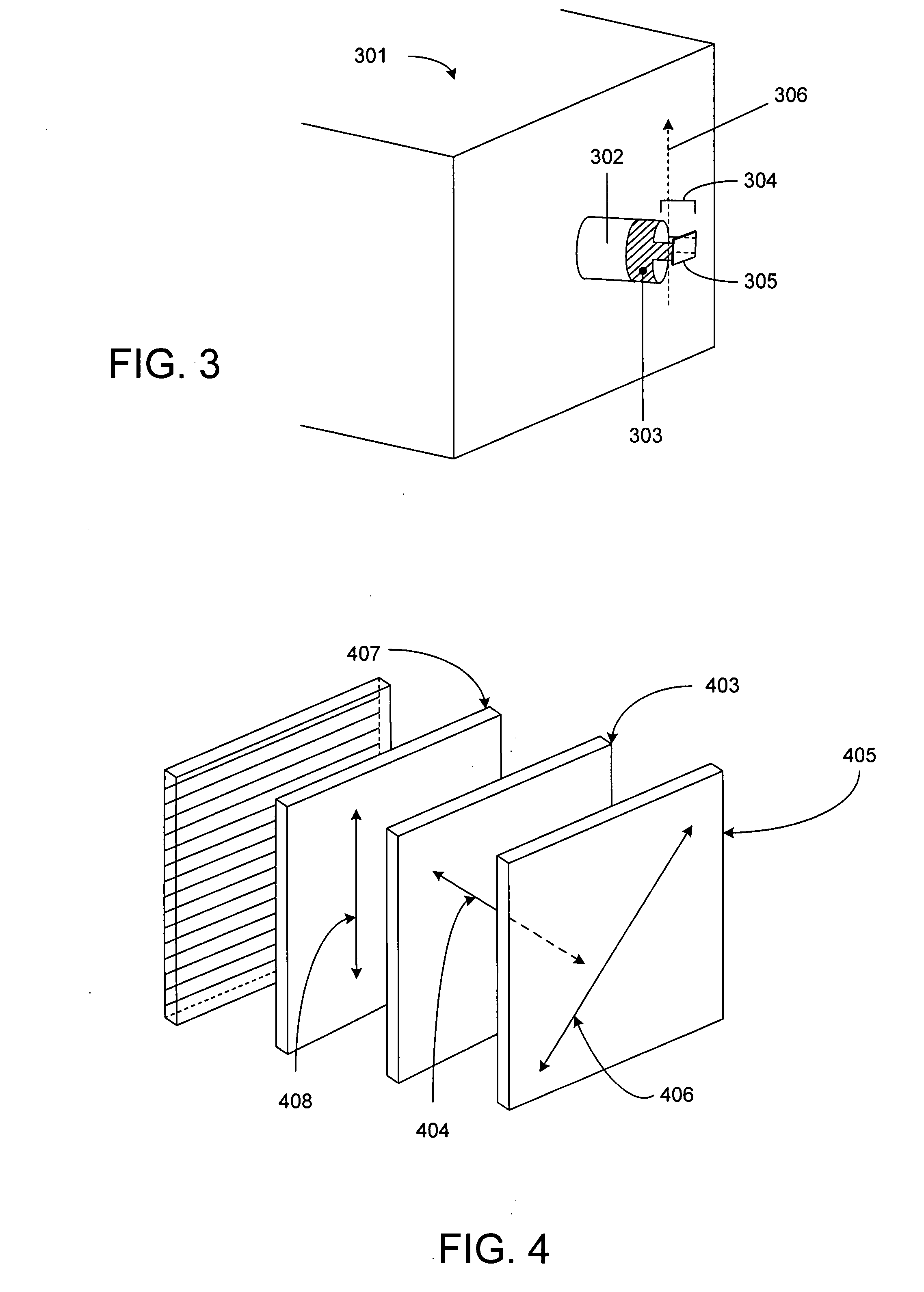

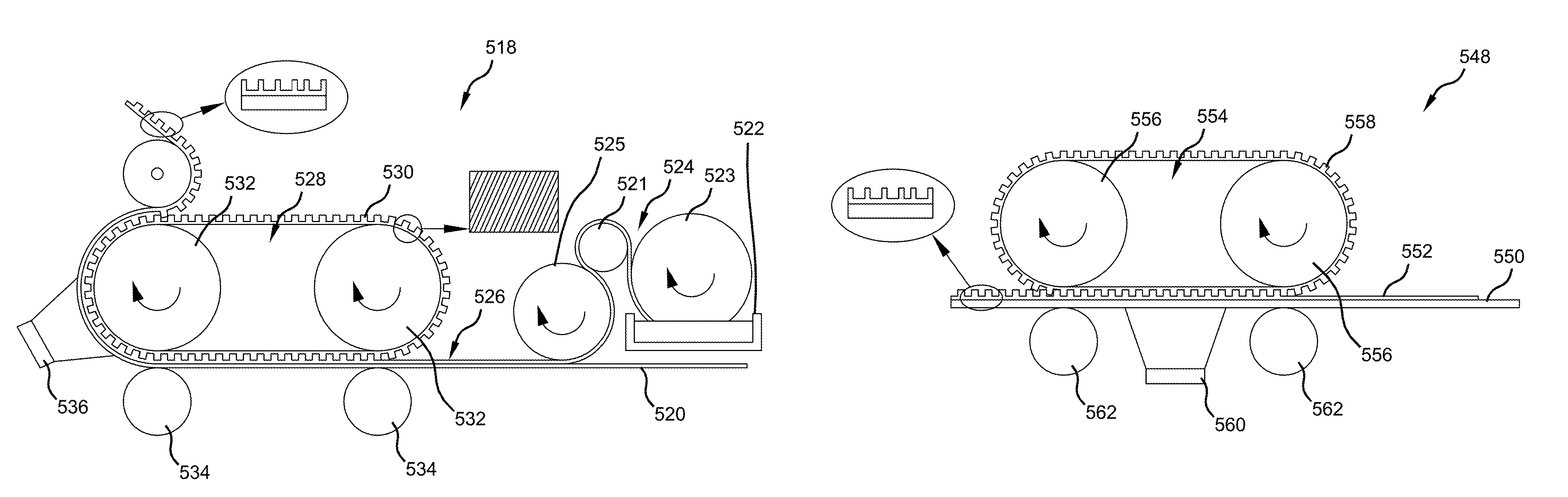

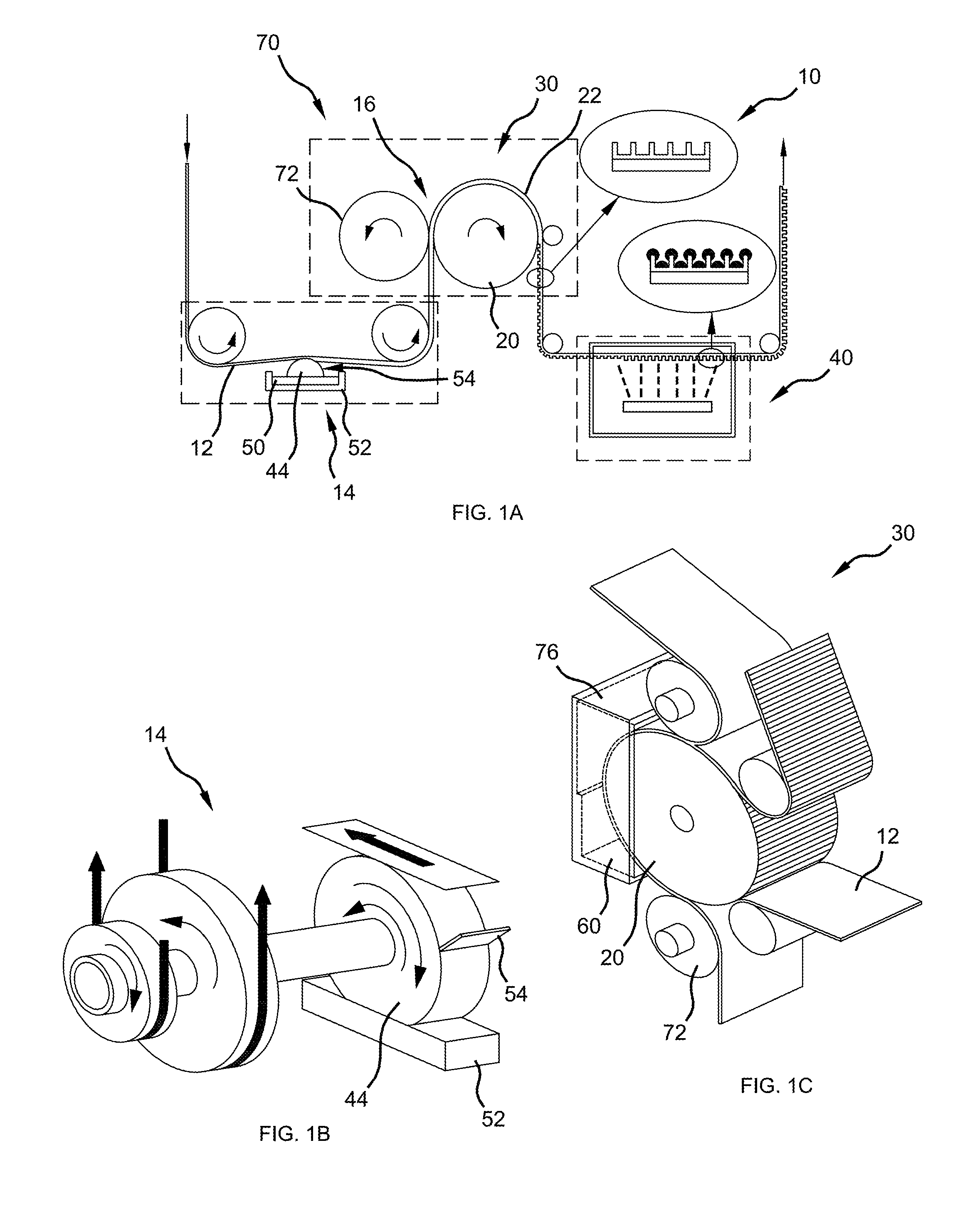

Roll to roll nanoimprint lithography

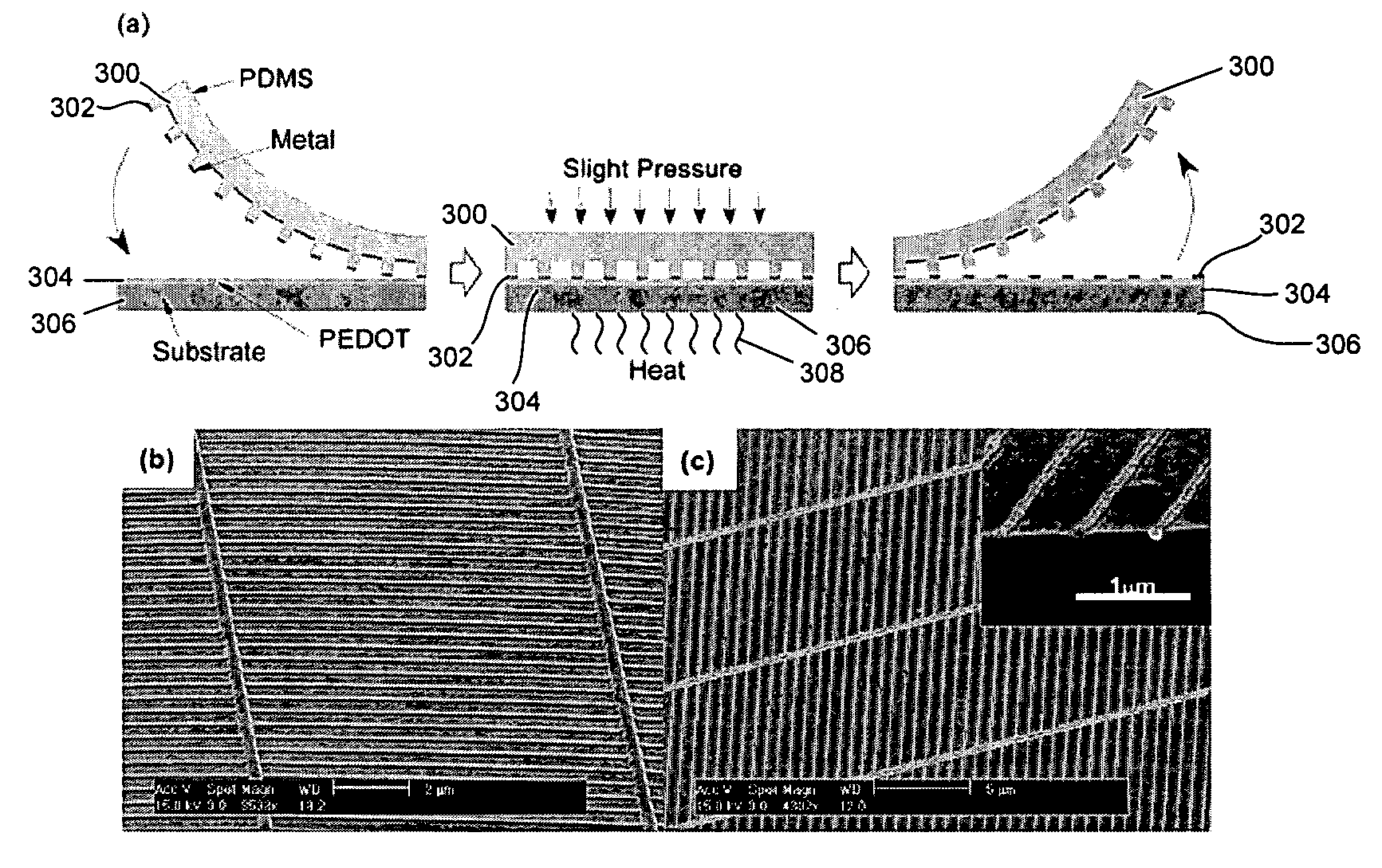

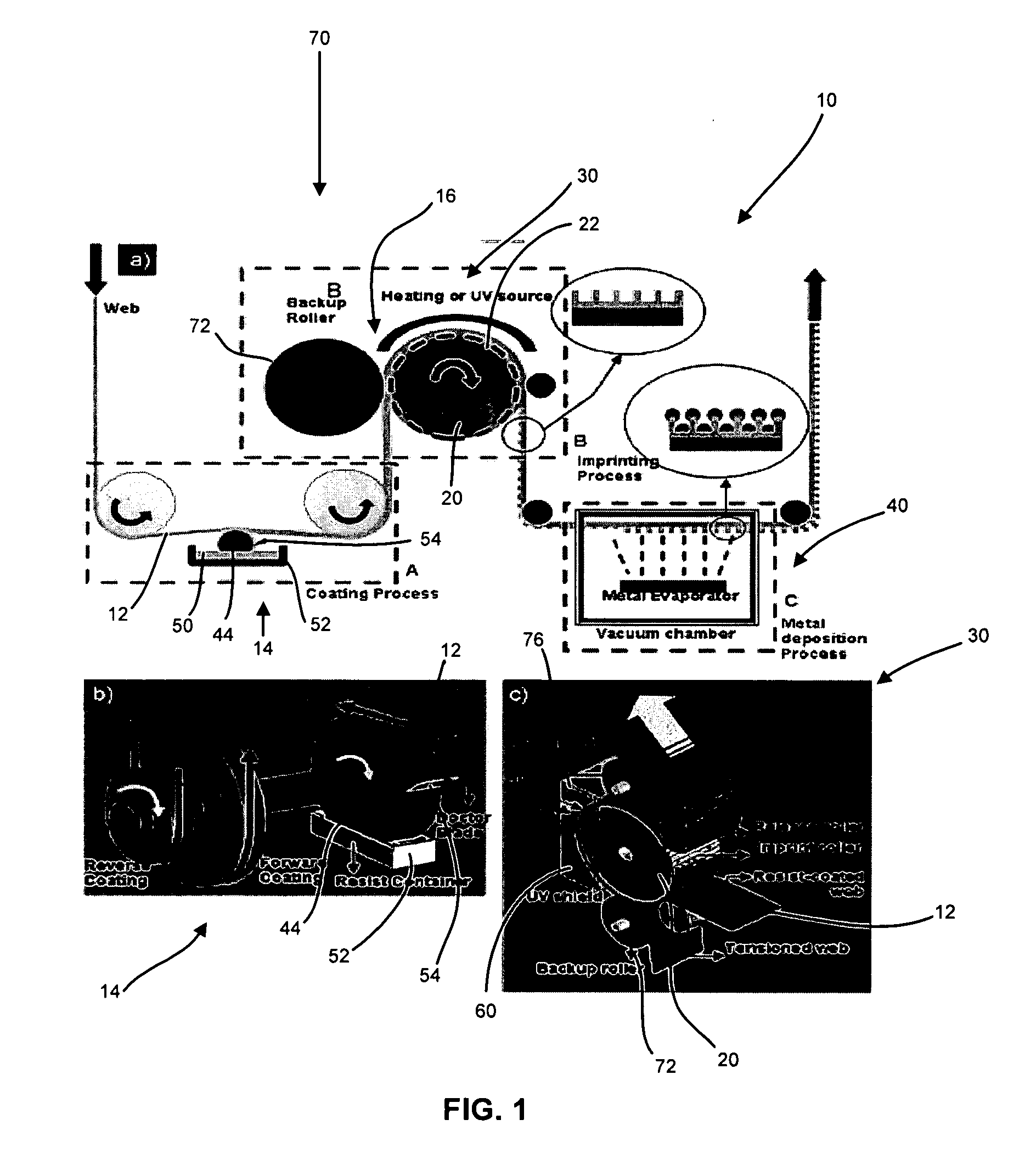

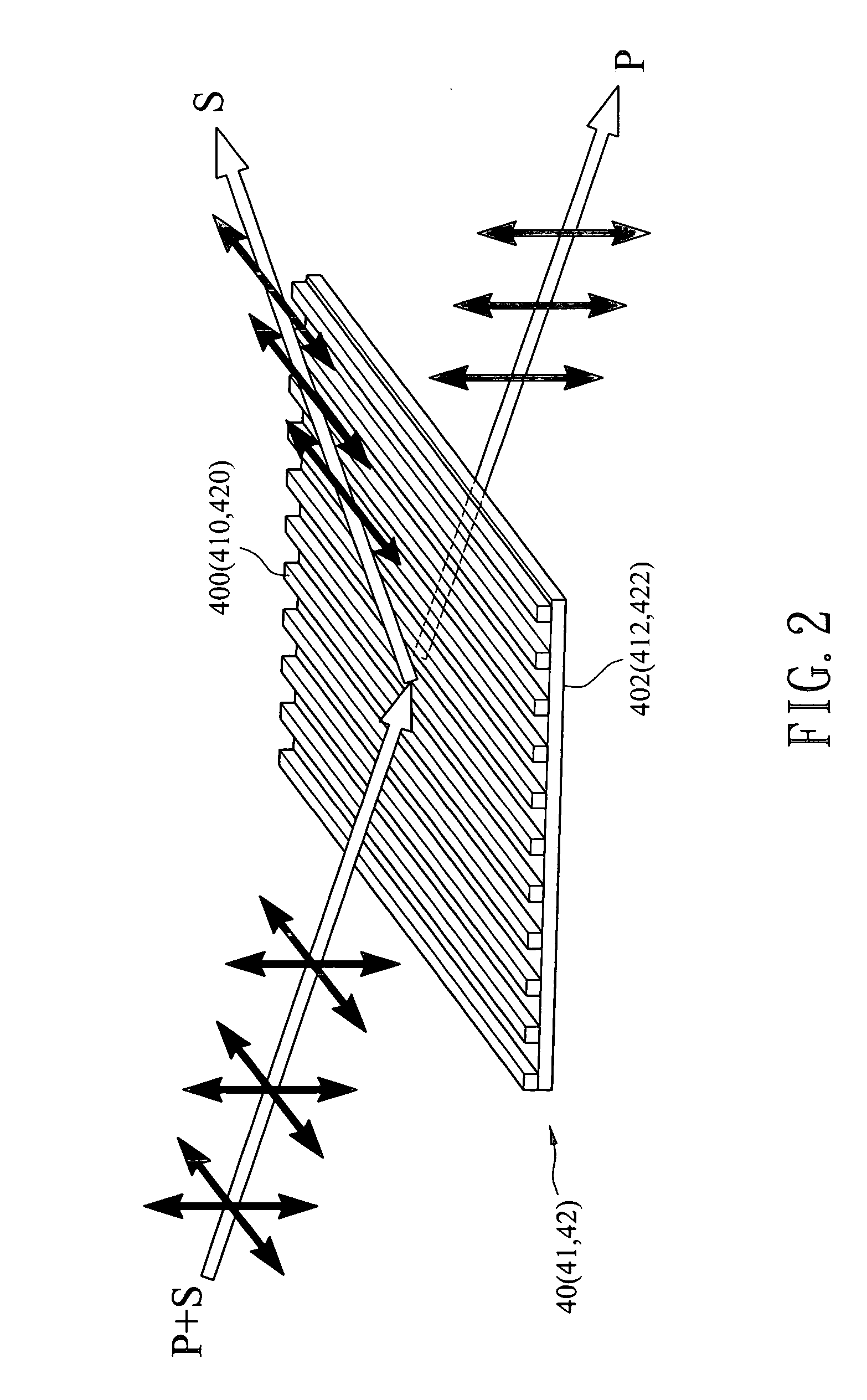

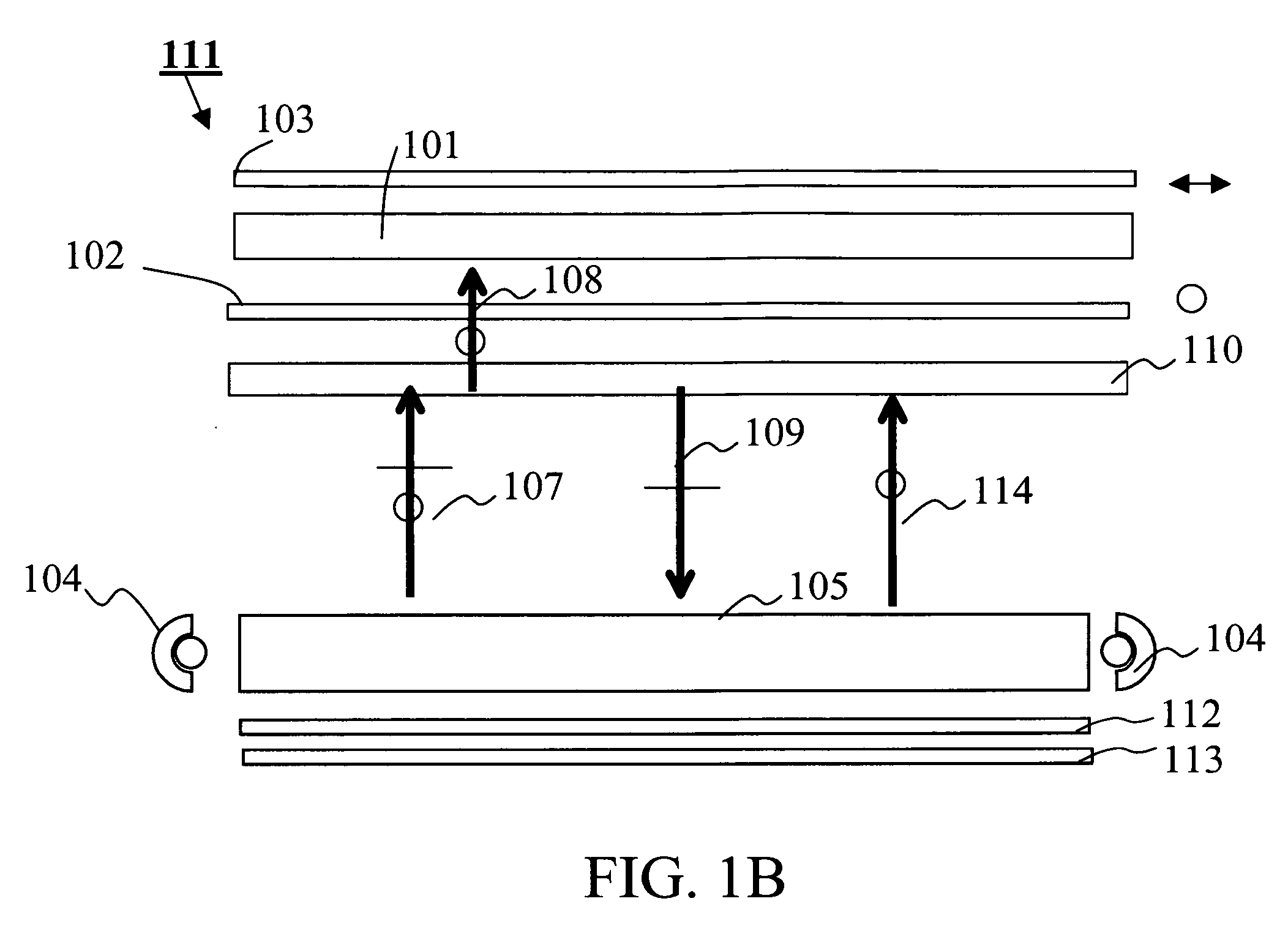

Apparatus and methods for a nano-patterning process to fabricate nanostructures. A roller type mold is used to continuously imprint nanostructures onto a flexible web or a rigid substrate. The process includes a coating and an imprinting module, which rotate the web synchronously. Liquid resist materials are used for imprinting and the patterns are set by thermal or UV curing. The process is used to produce bilayer metal wire-grid polarizers, organic solar cells, and organic light emitting diodes.

Owner:RGT UNIV OF MICHIGAN

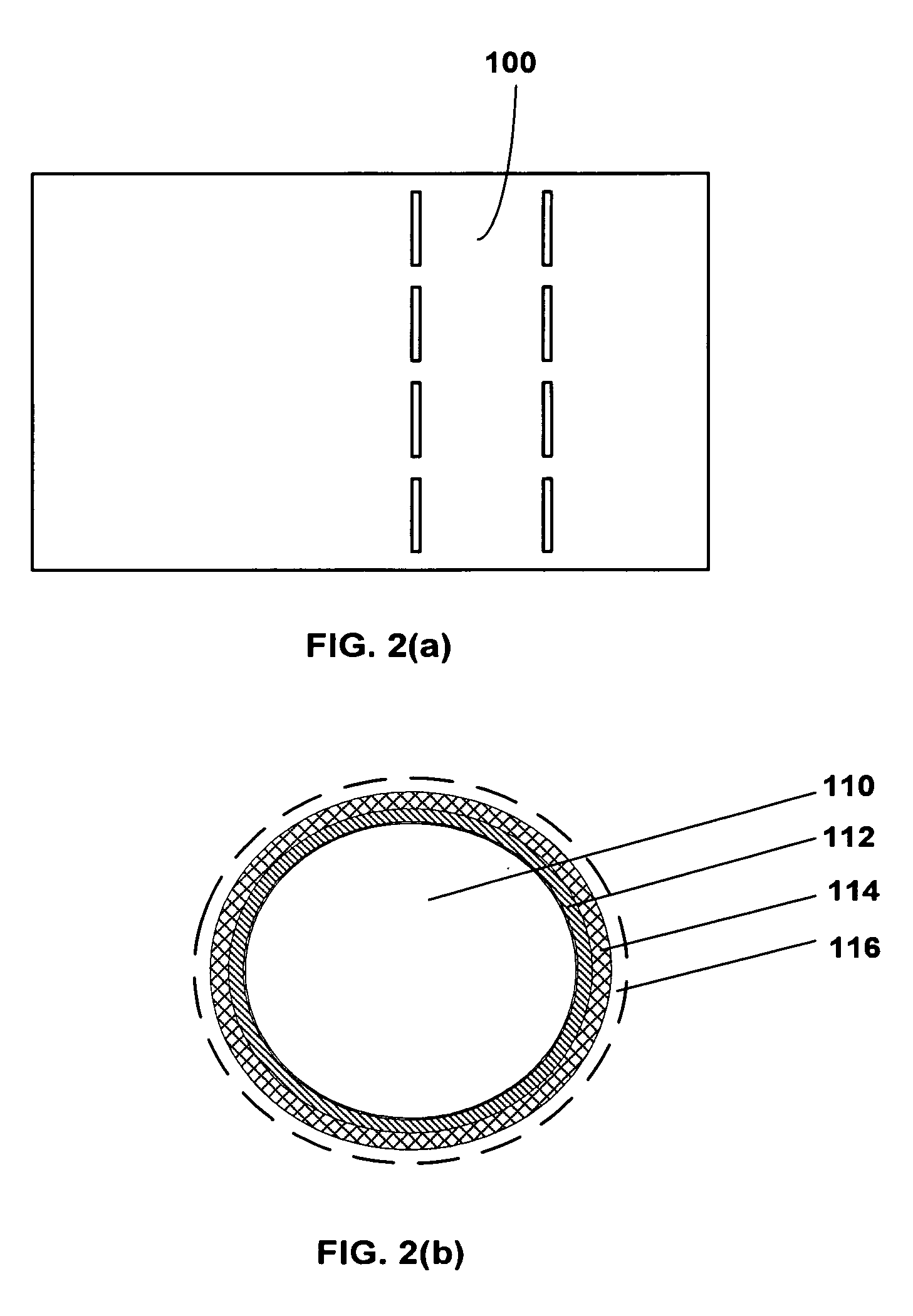

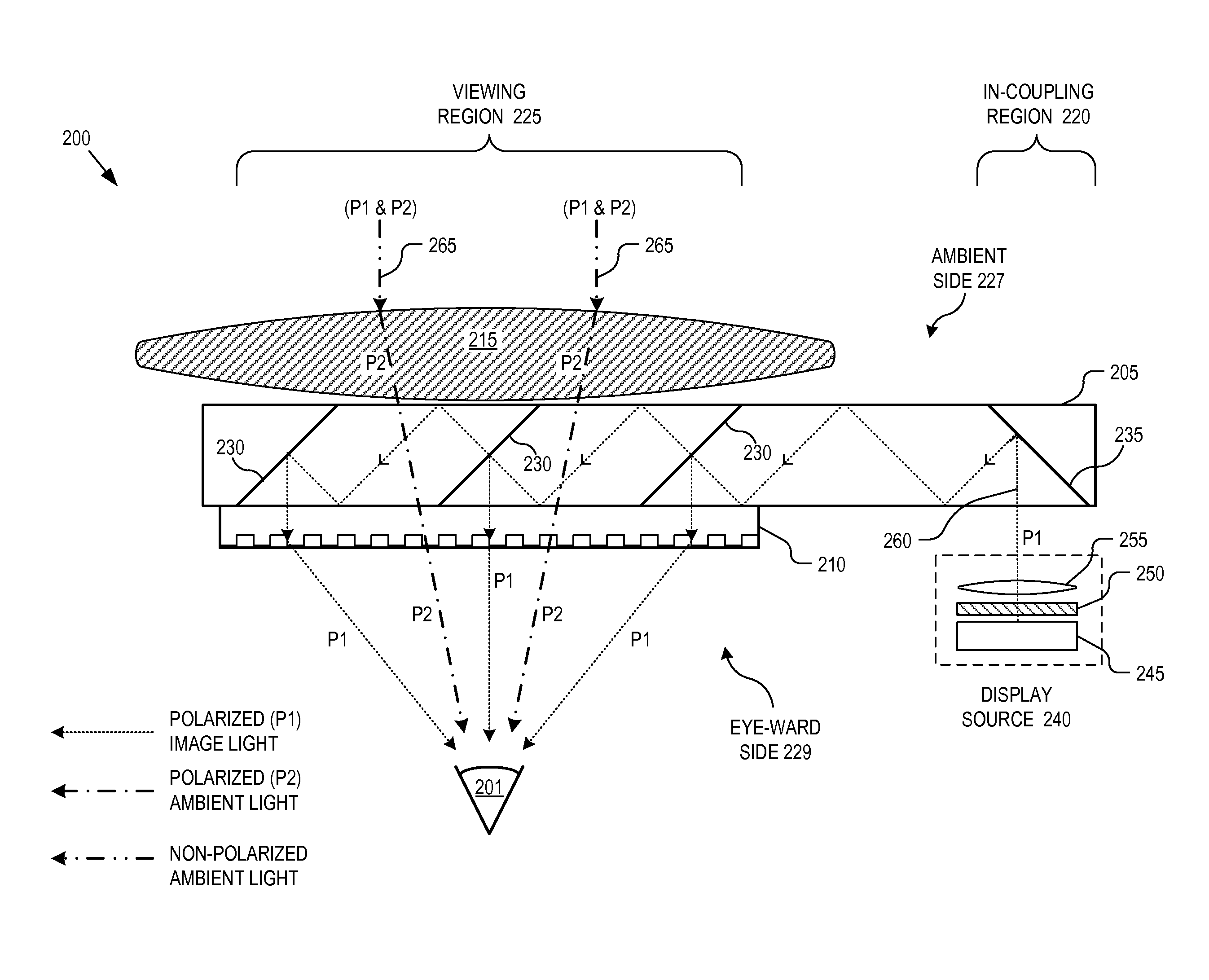

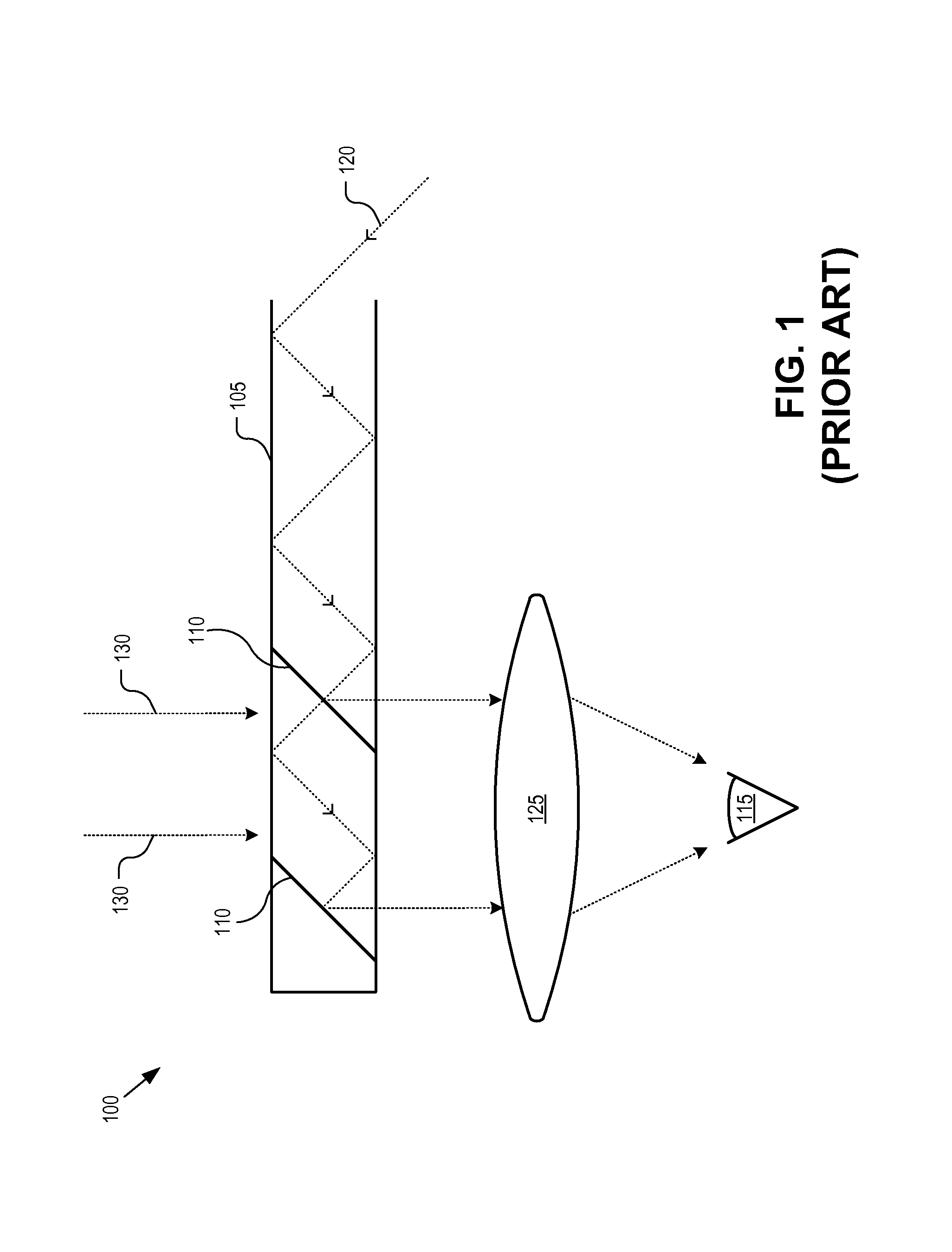

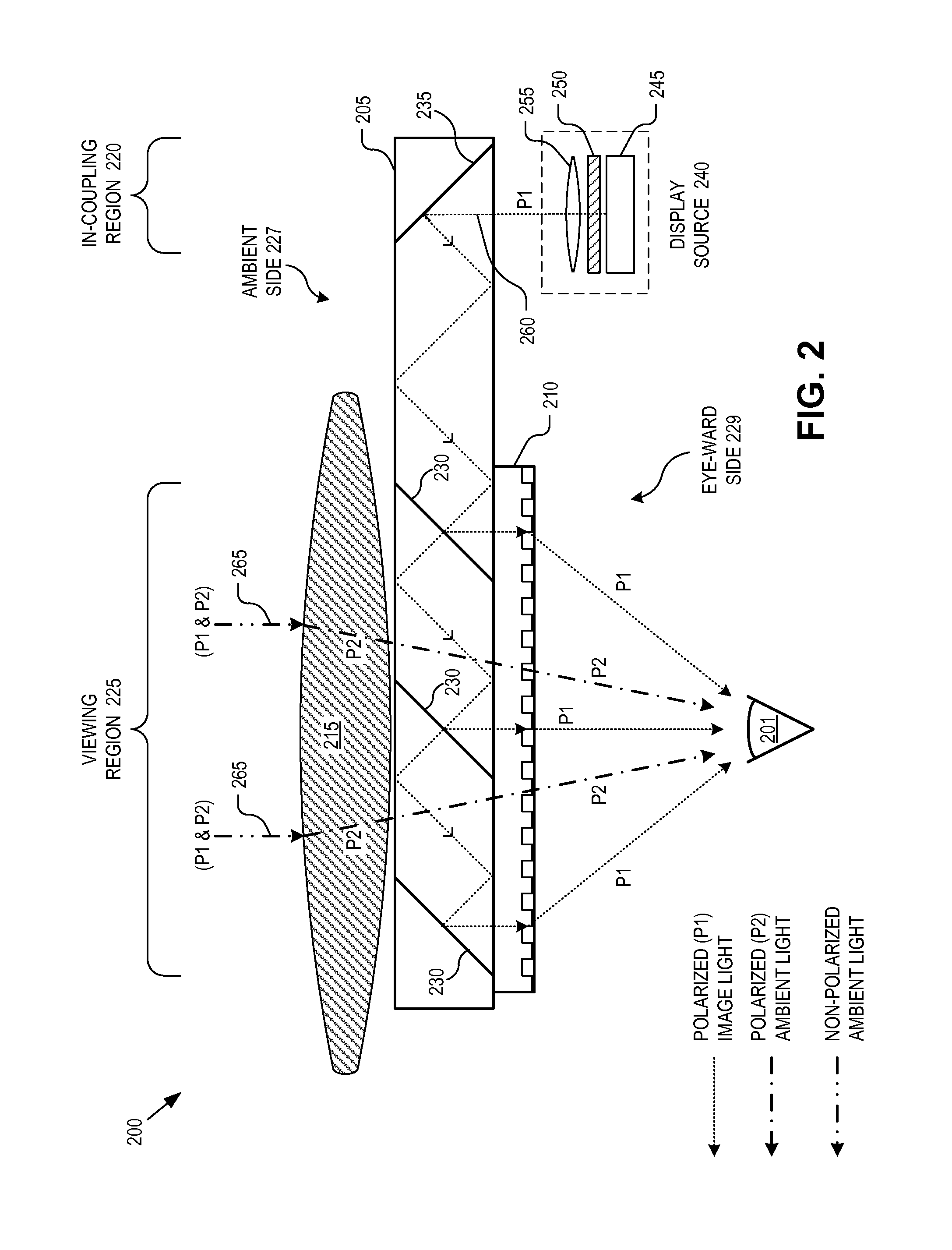

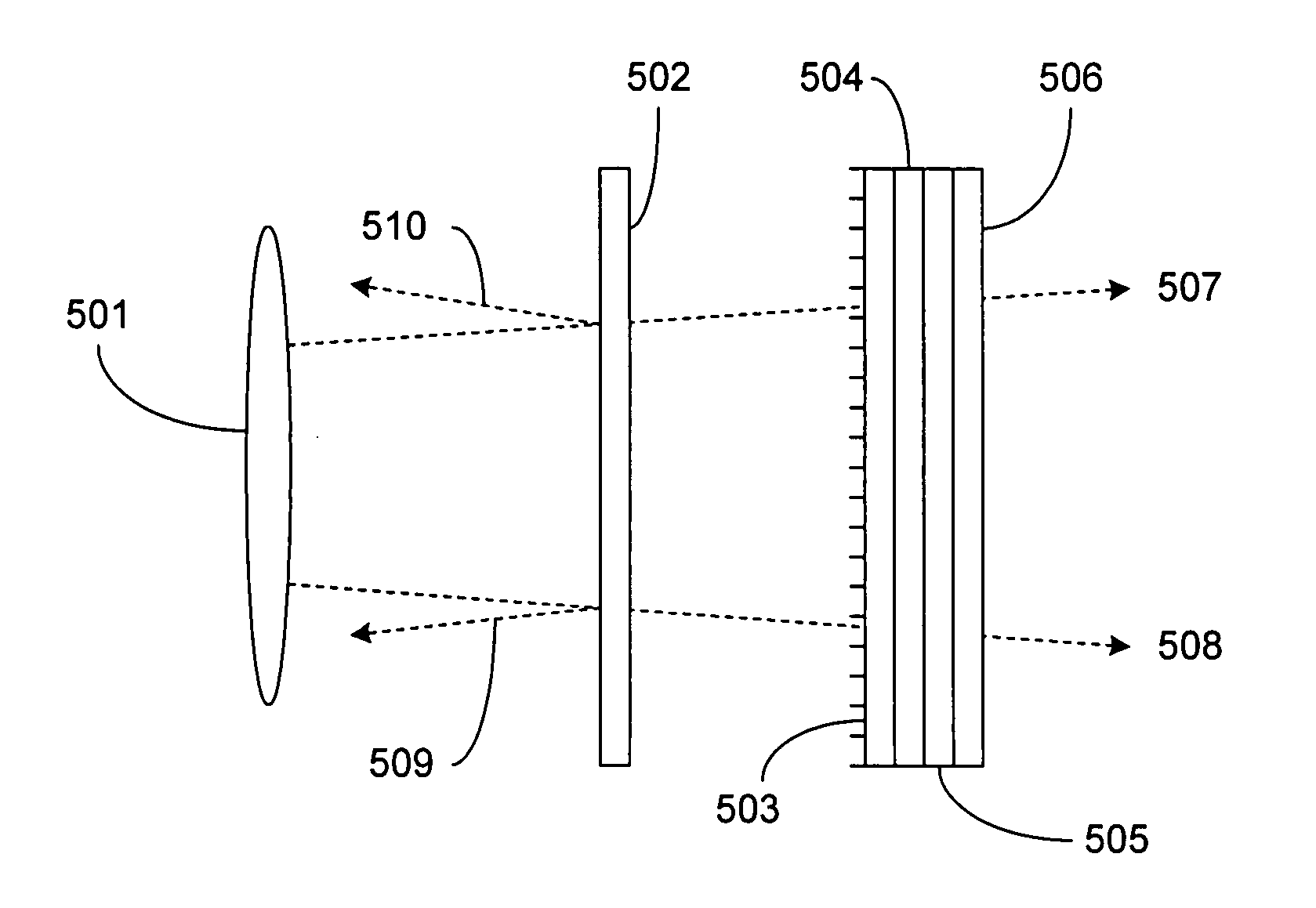

Near-to-eye display with diffractive lens

An eyepiece for a HMD includes a waveguide, an ambient light polarizer, and a wire grid polarizer with a diffraction lens having a lens function patterned into the wire grid polarizer. Polarized image light is guided between eye-ward and ambient sides of the waveguide from a display source to a viewing region of the waveguide where the polarized image light is directed out of the waveguide through the eye-ward side. The viewing region passes ambient light incident on the ambient side through to the eye-ward side. The ambient light polarizer is disposed adjacent to the ambient side to polarize the ambient light into polarized ambient light having a second polarization orthogonal to the first polarization. The wire grid polarizer is disposed adjacent to the eye-ward side along the viewing region. The wire grid polarizer is oriented to applying the lens function to the polarized image light via diffraction.

Owner:GOOGLE LLC

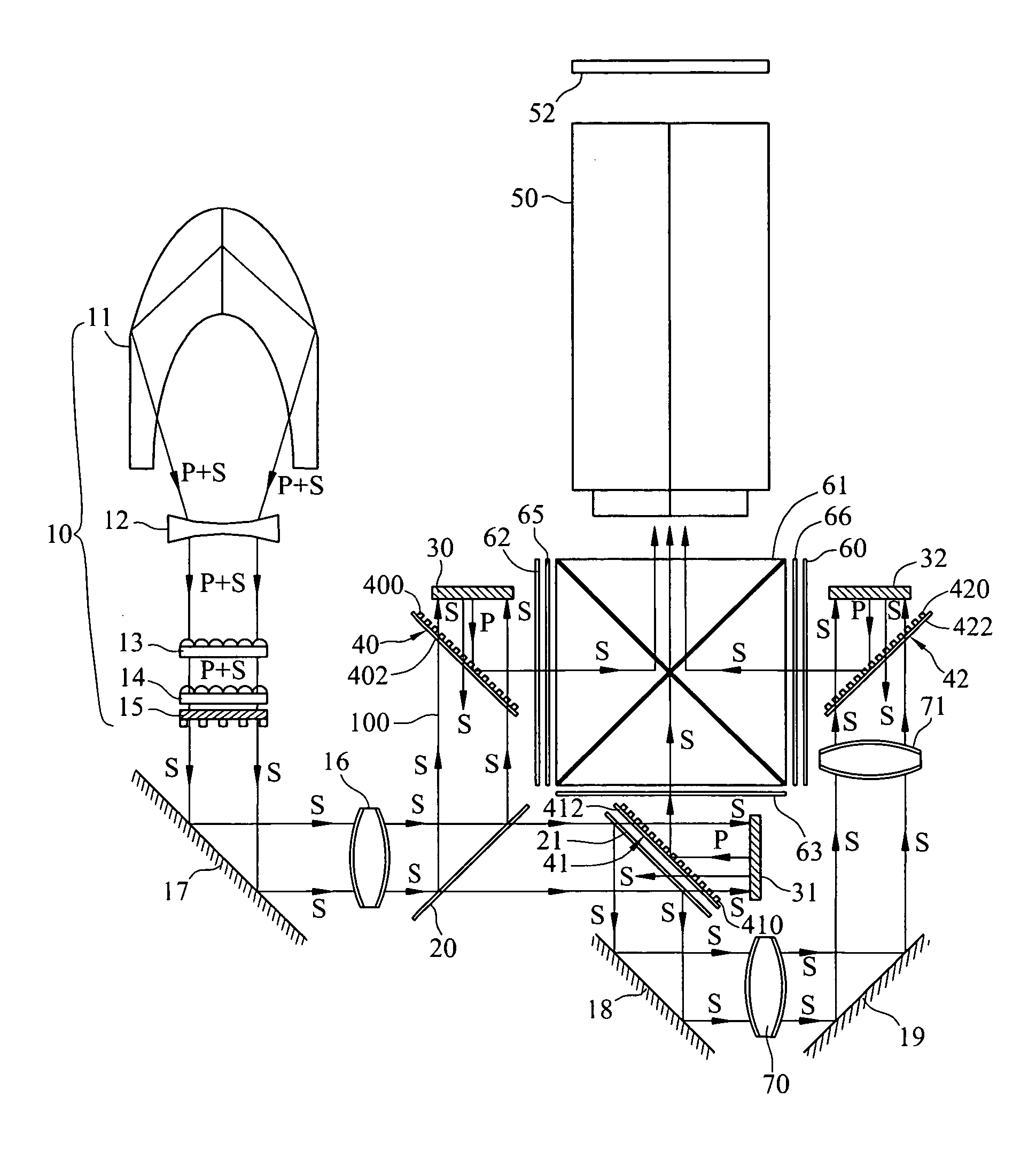

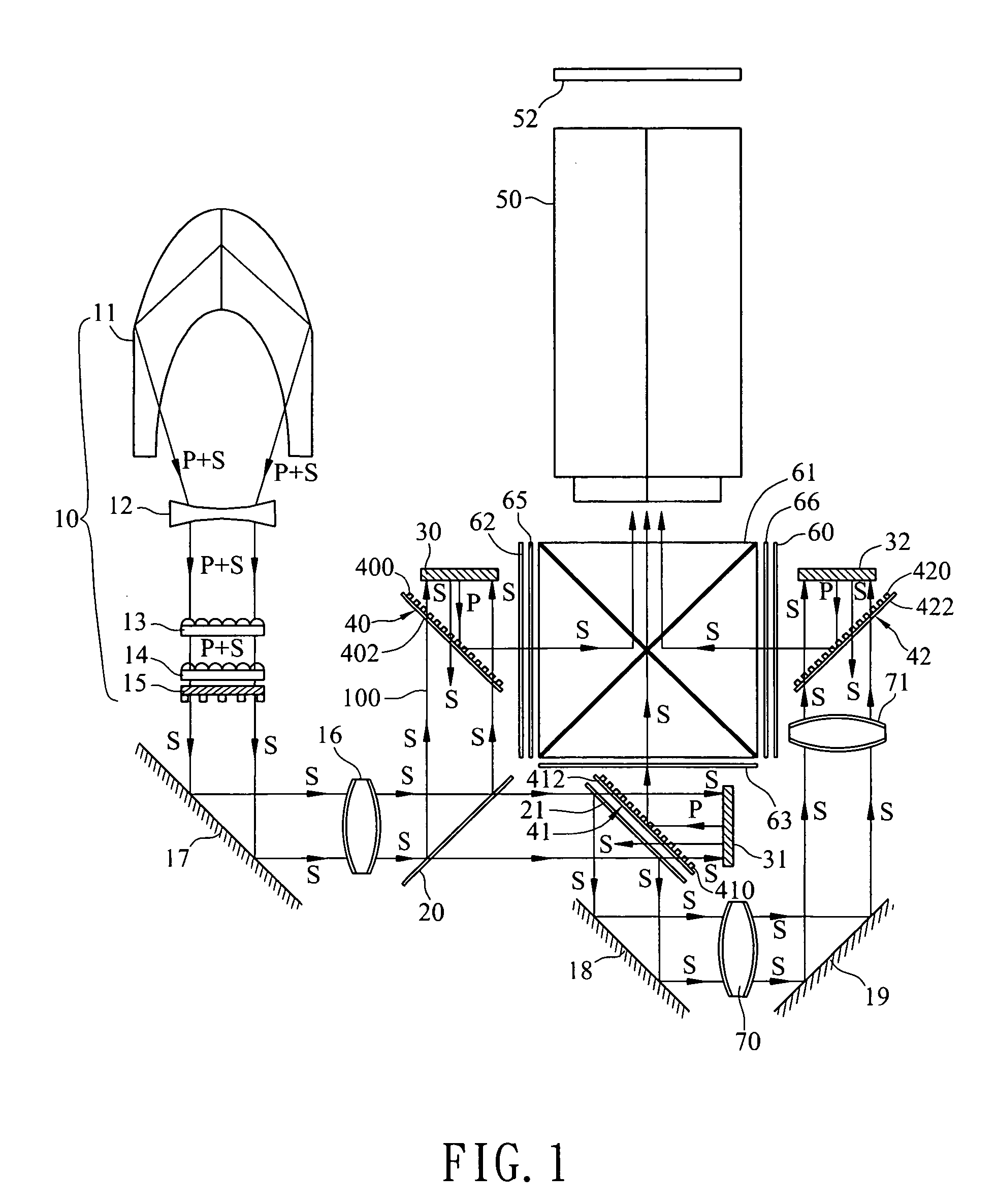

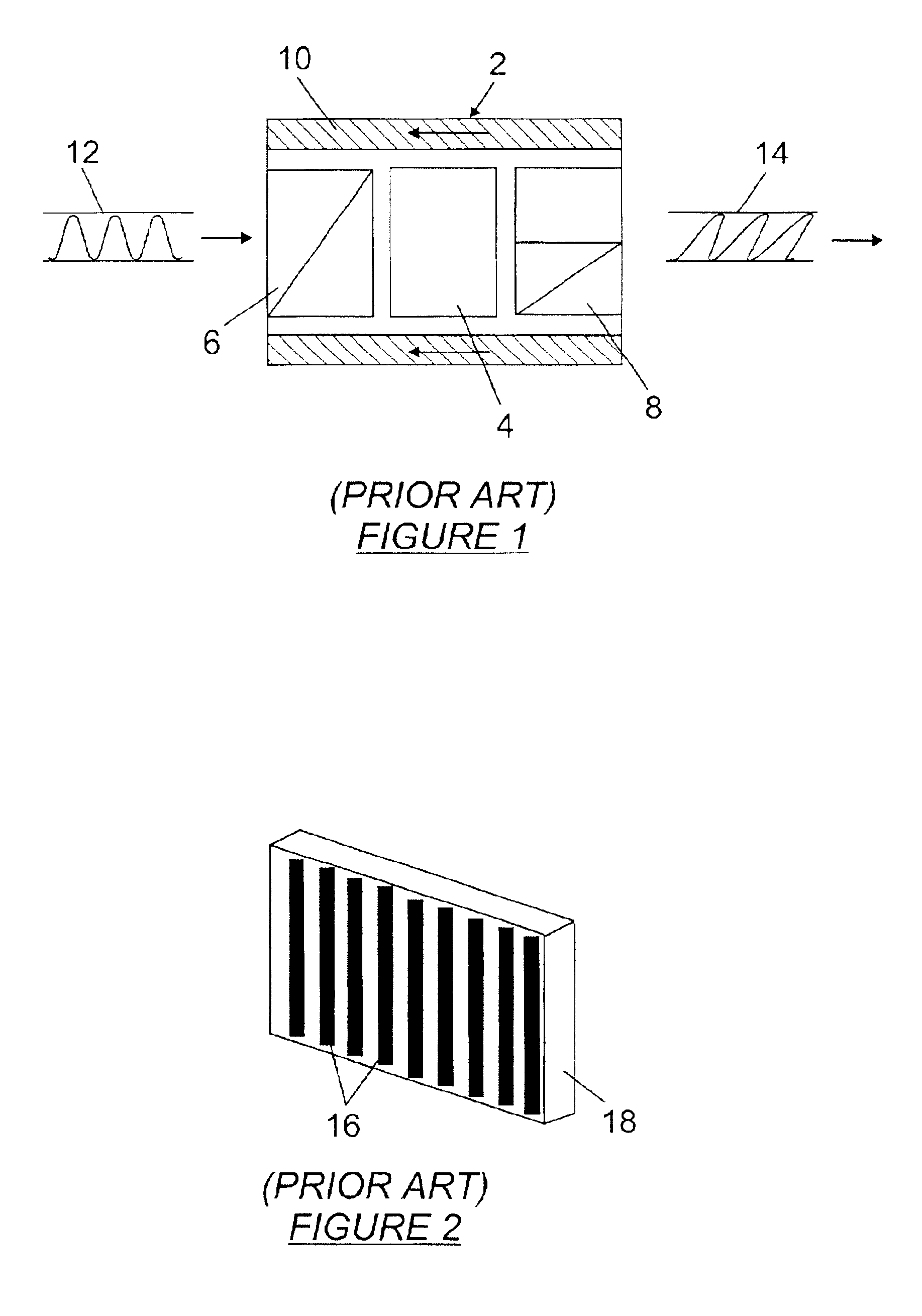

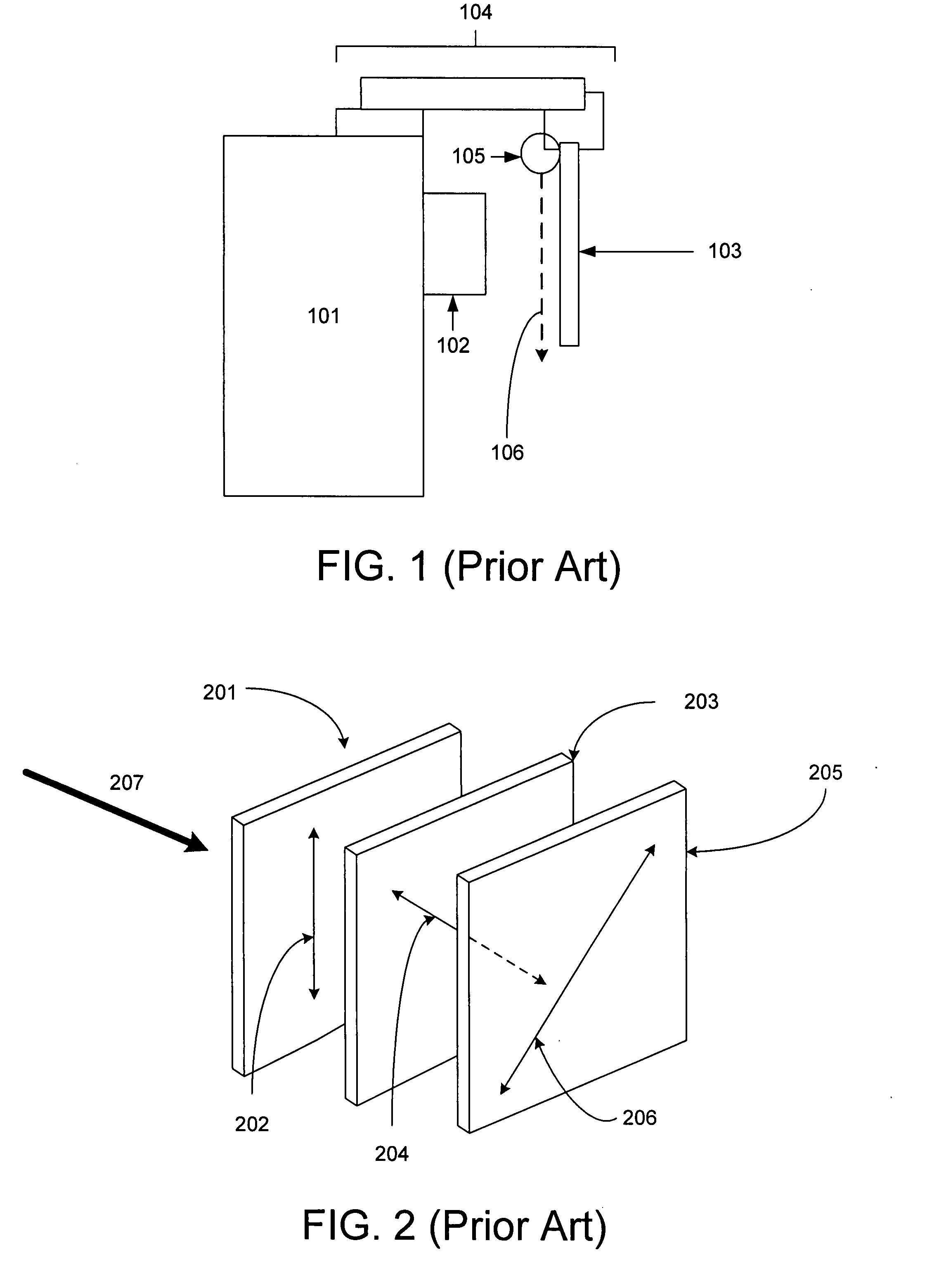

Reflective polarization valve engine and projection display using the same

InactiveUS20050024591A1High imaging performanceLow costProjectorsPolarising elementsDisplay devicePrism

Reflective polarization valve engine and projection display are disclosed. Instead of prism PBS, the projector applies wire-grid polarizers with advantages of higher heat-resistance, no limitation of the incident angle and no birefringence effects, to provide excellent contrast luminance. The light source in the projector utilizes an elliptical lamp under a telecentric optical system to achieve higher efficiency and avoid color gradient. In addition, the light paths are in special arrangement. The original beam is first splitted into RGB, and then proceeding with color-recombining right after being polarized via wire-grid polarizers and analyzed by reflective polarization valves. Hence, the analyzed beams finally are recombined images with superior performances.

Owner:DELTA ELECTRONICS INC

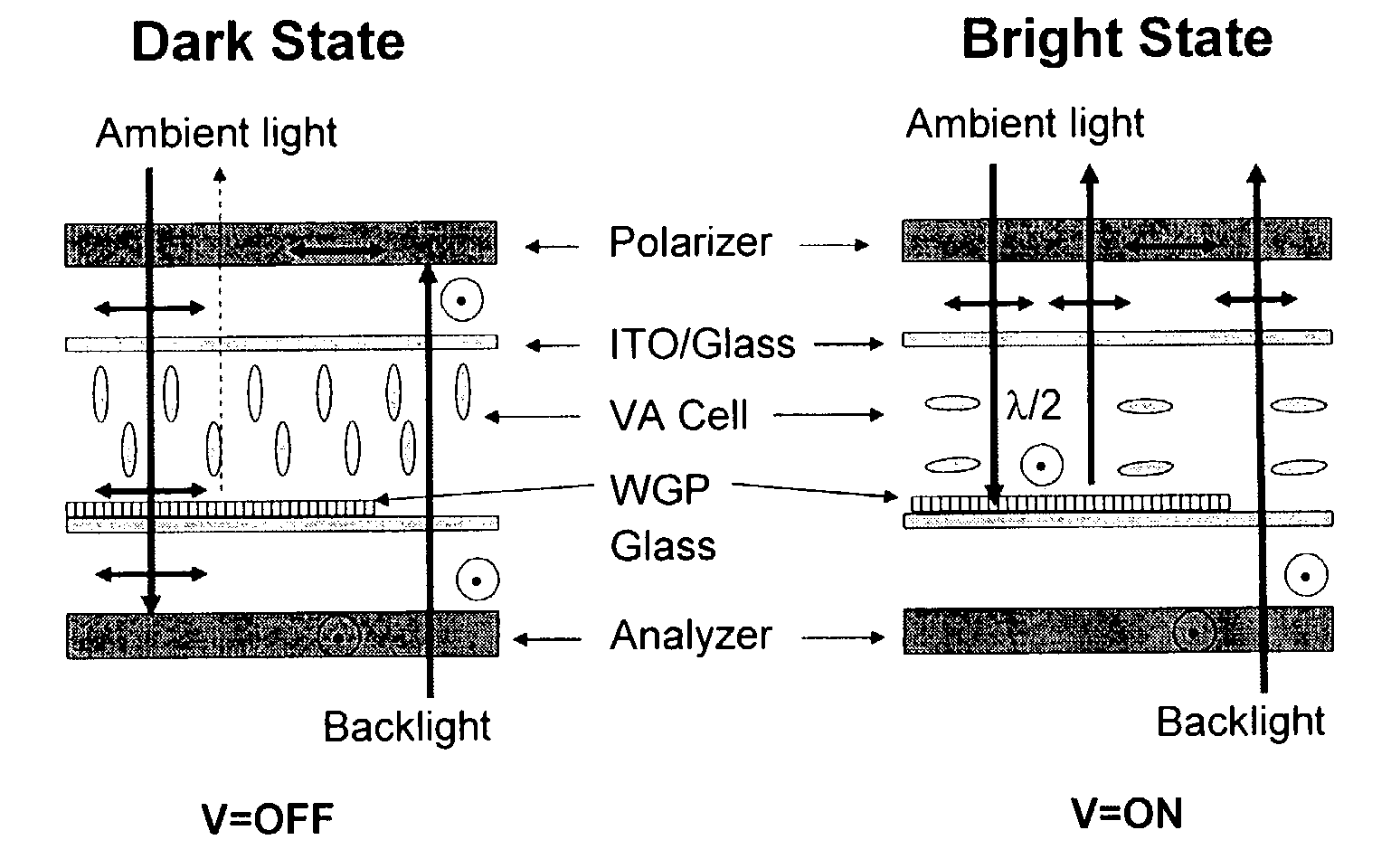

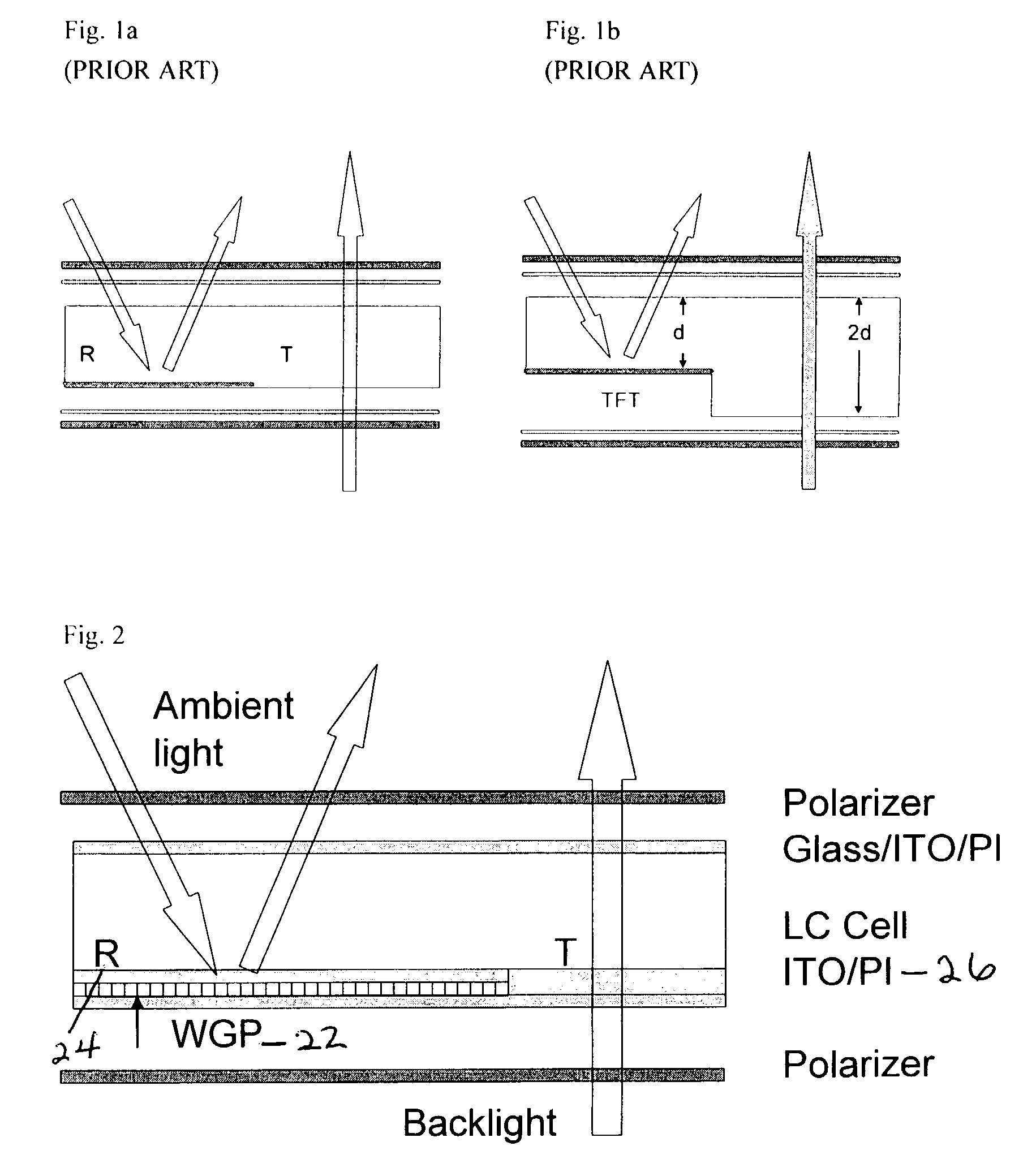

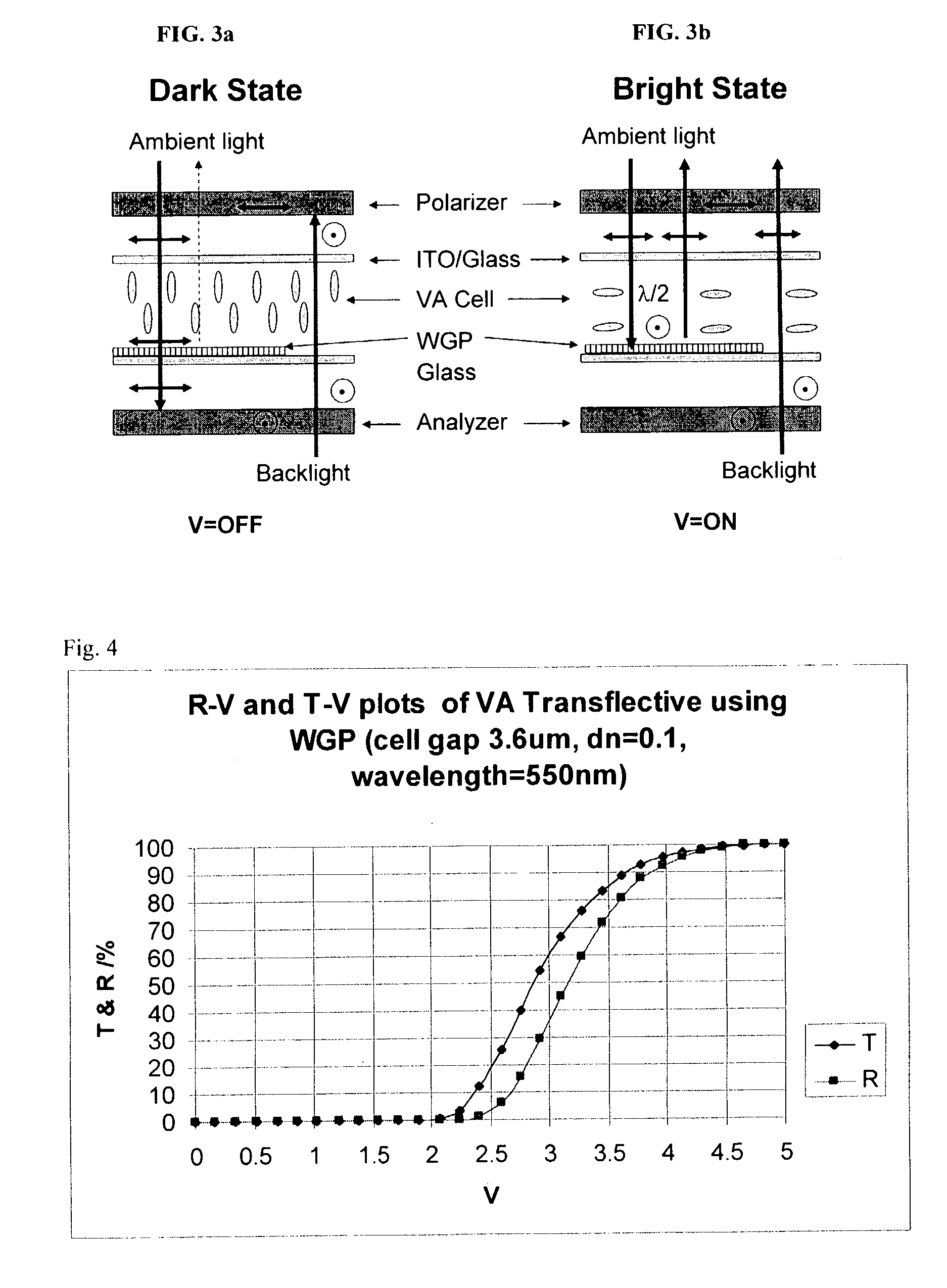

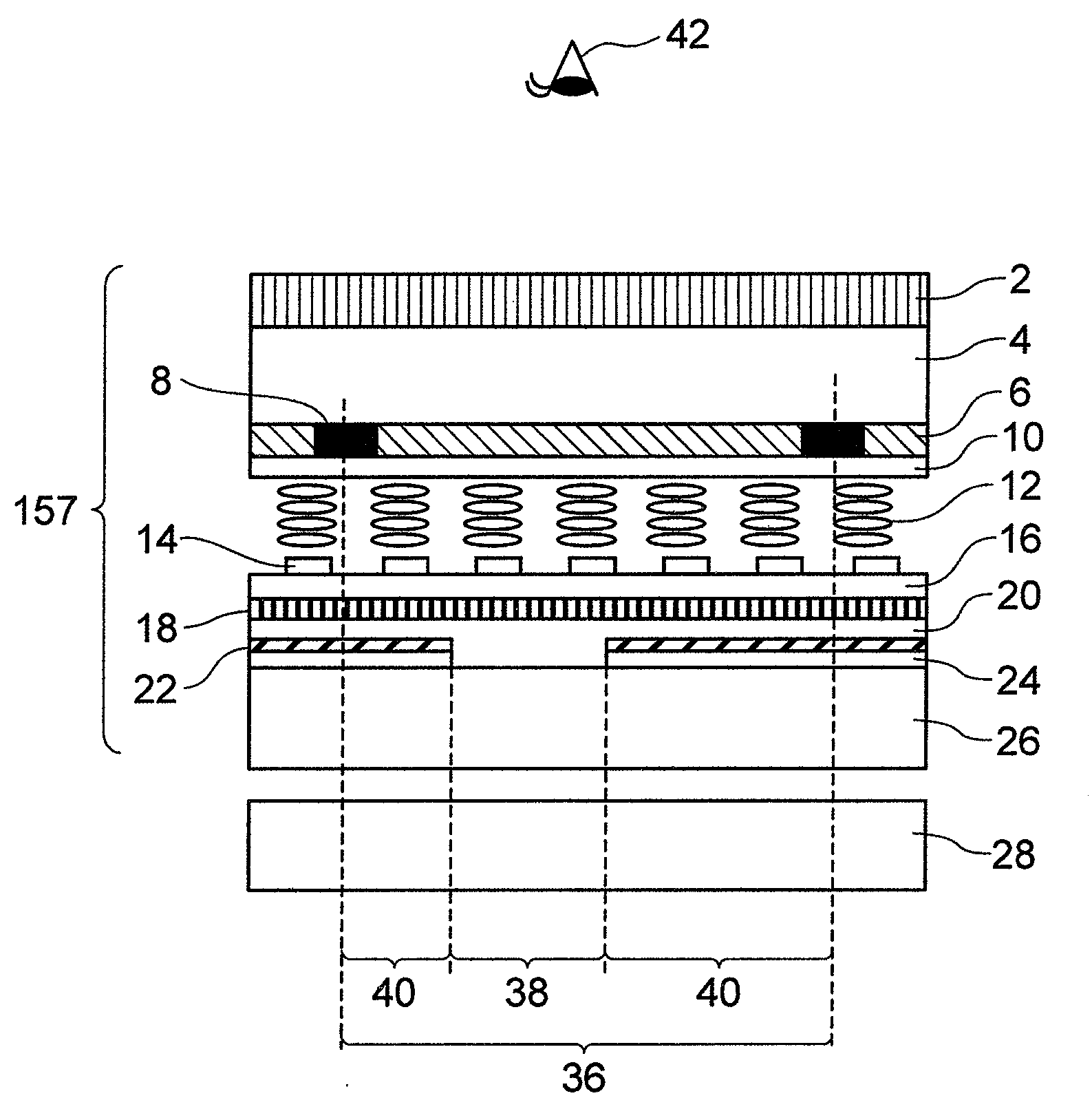

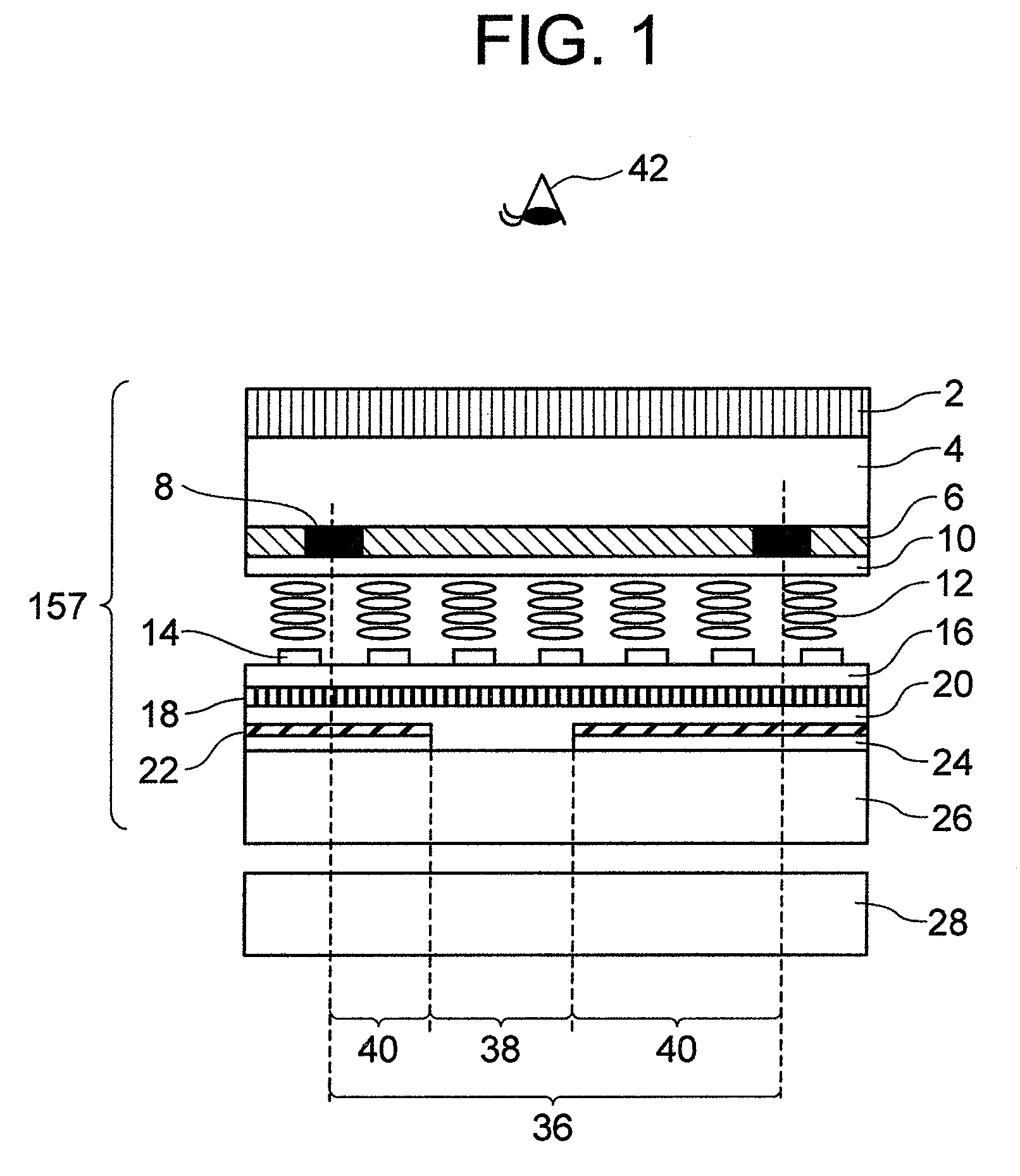

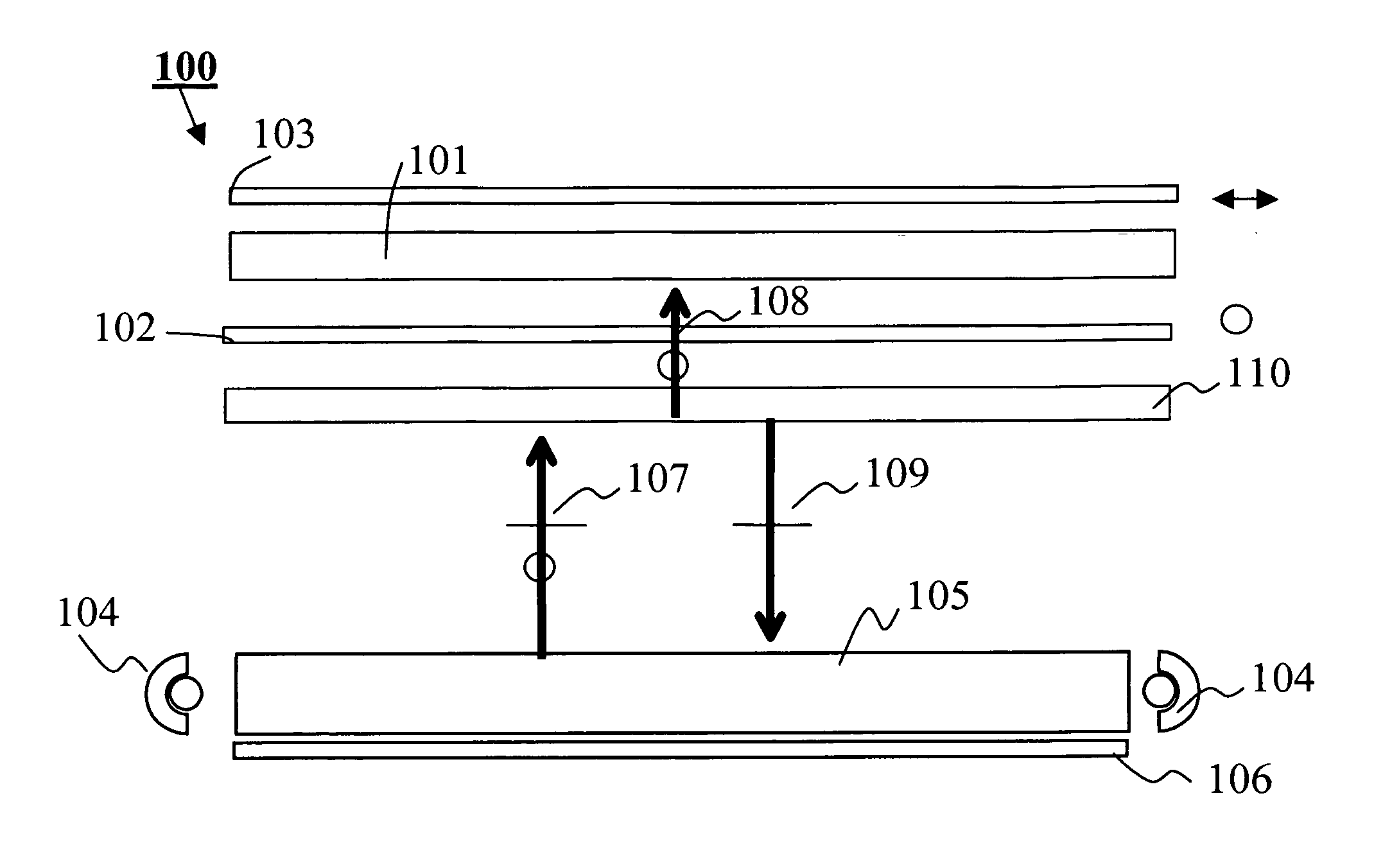

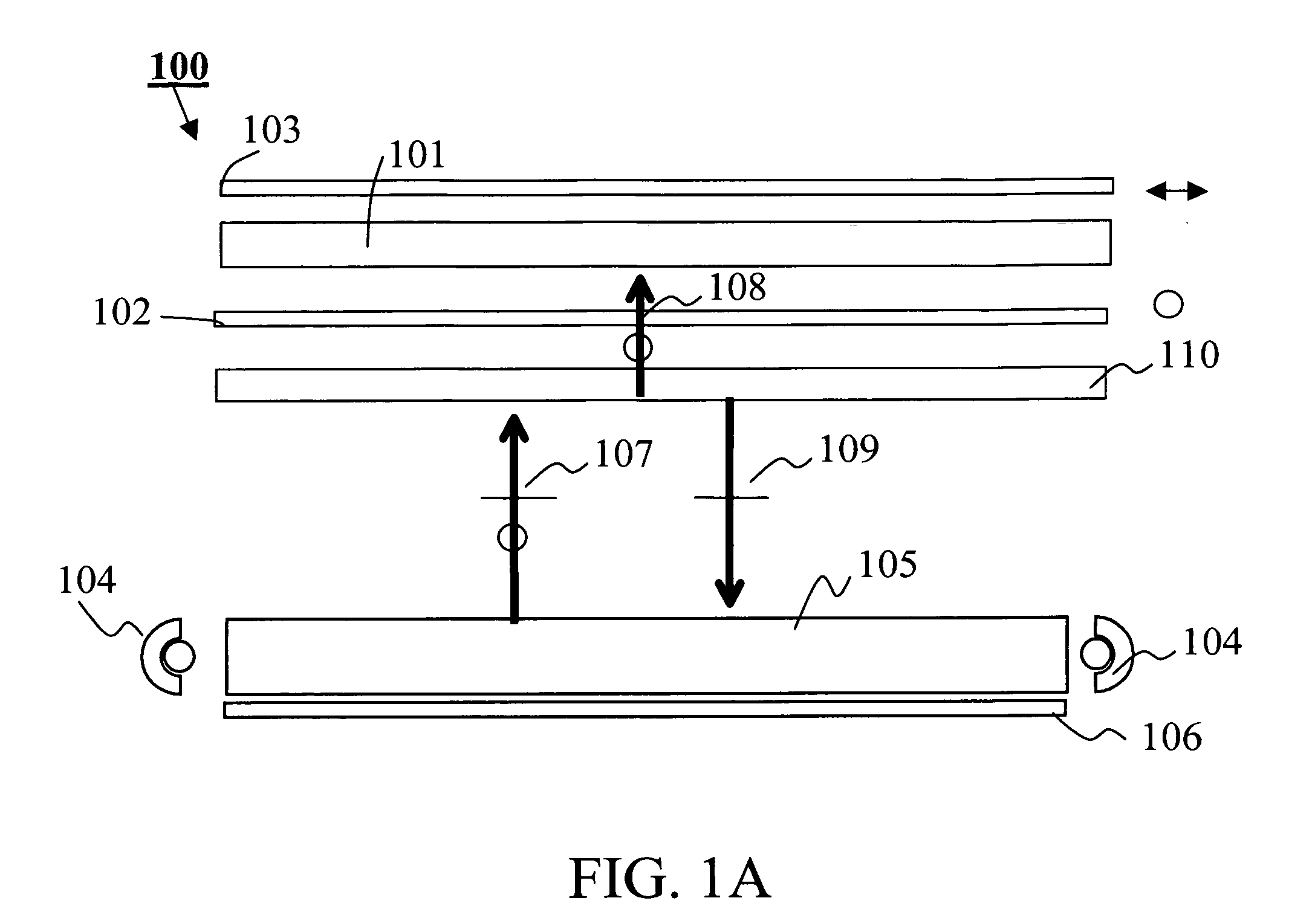

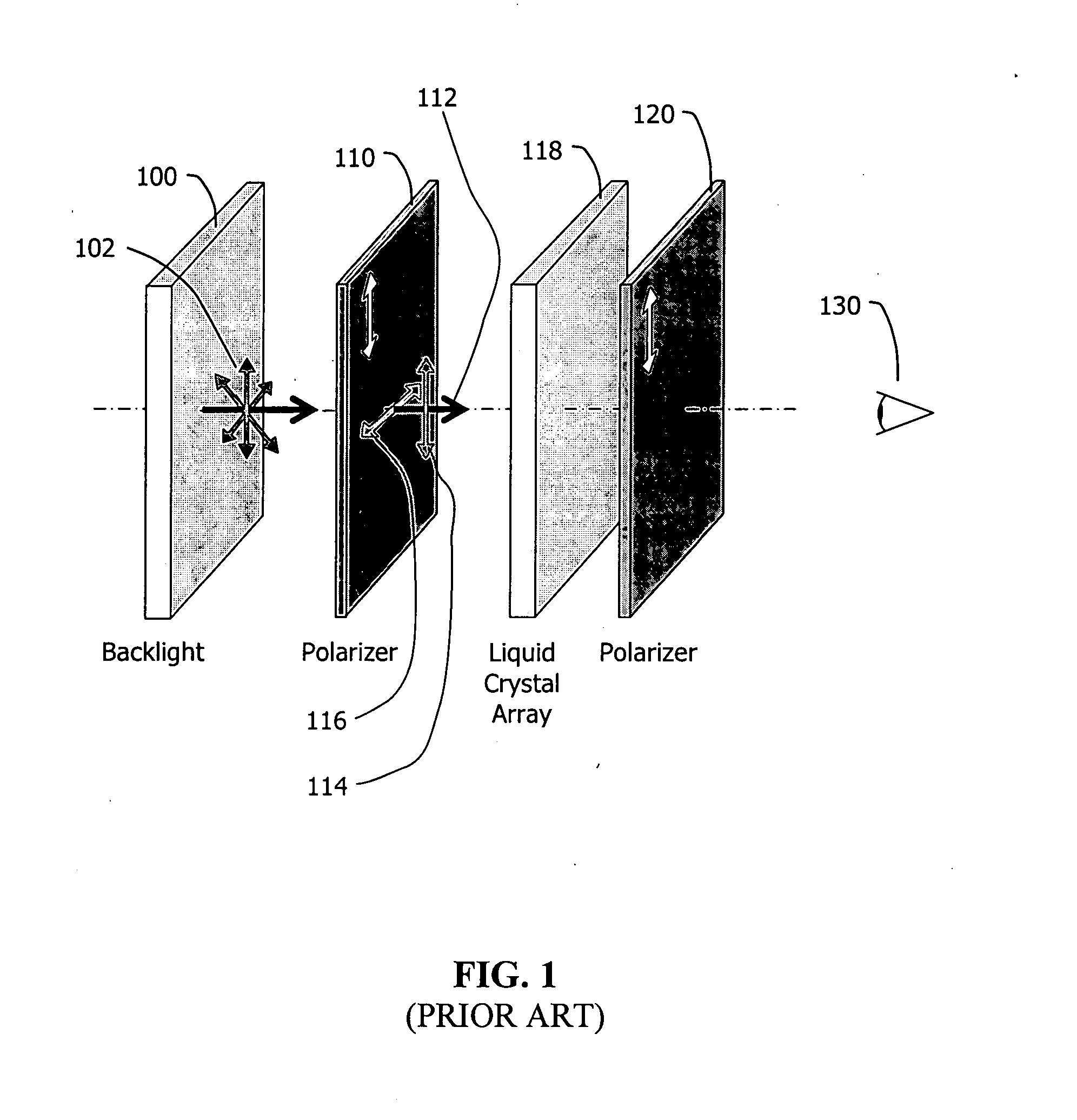

Reflective and transflective liquid crystal display using a wire grid polarizer

A device structure for single cell gap reflective and transflective liquid crystal displays (TF-LCDs). For an entirely reflective LCD, the imbedded wire-grid polarizer (WGP) serves as a polarization-dependent for the ambient light. For a transflective TF-LCD, the WGP only covers the reflective pixels. The disclosure also includes a method of using single cell gap liquid crystal displays (LCDs) without phase retardation films by providing a single cell gap LCD having reflective pixels and transmissive pixels, covering solely the reflective pixels, with at least one of: a wire grid polarizer and a broadband cholesteric reflector (BCR), reflecting ambient light off the reflective pixels; and passing back light through the transmissive pixels whereby the cell gap LCD obtains high contrast ratios without using phase retardation films.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

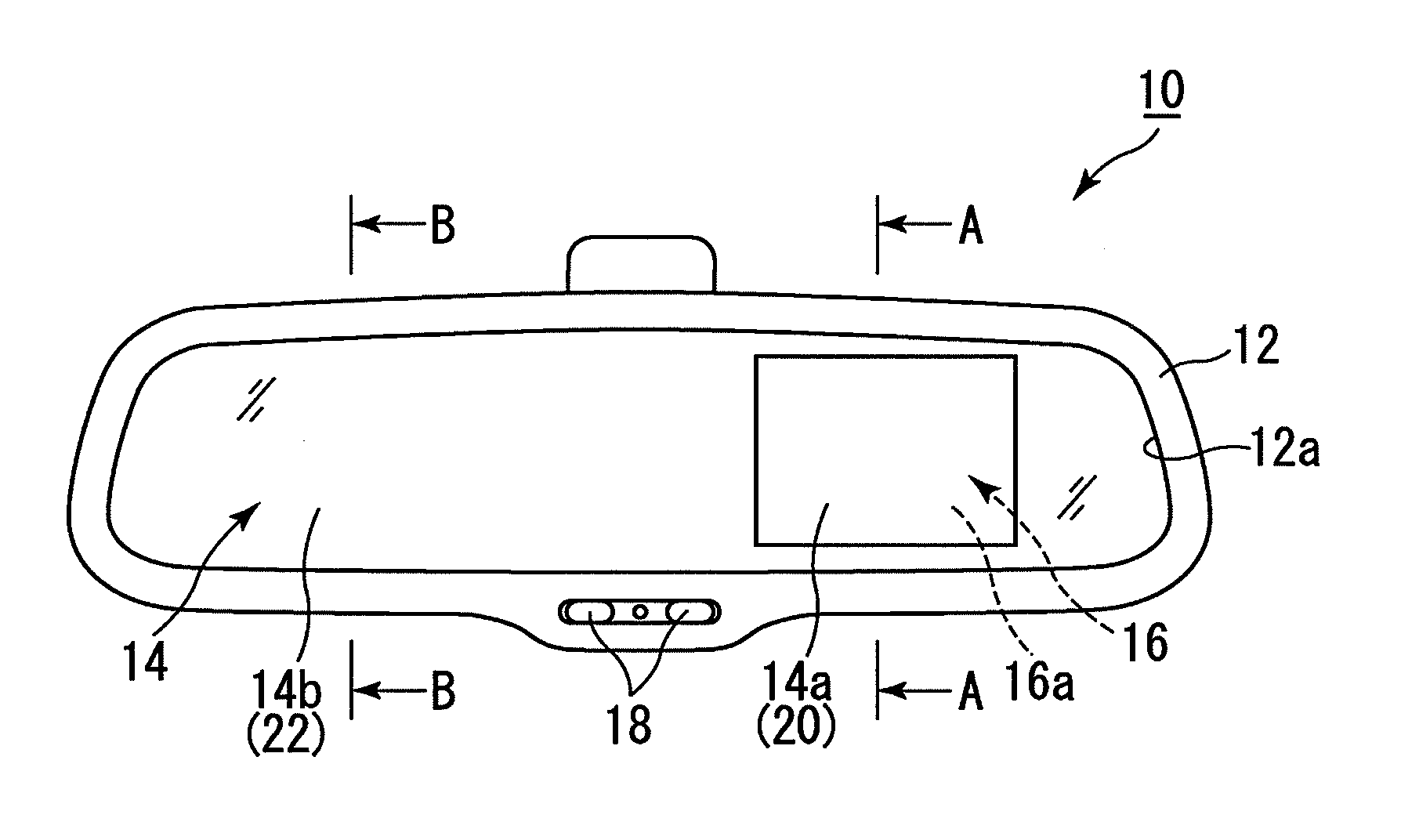

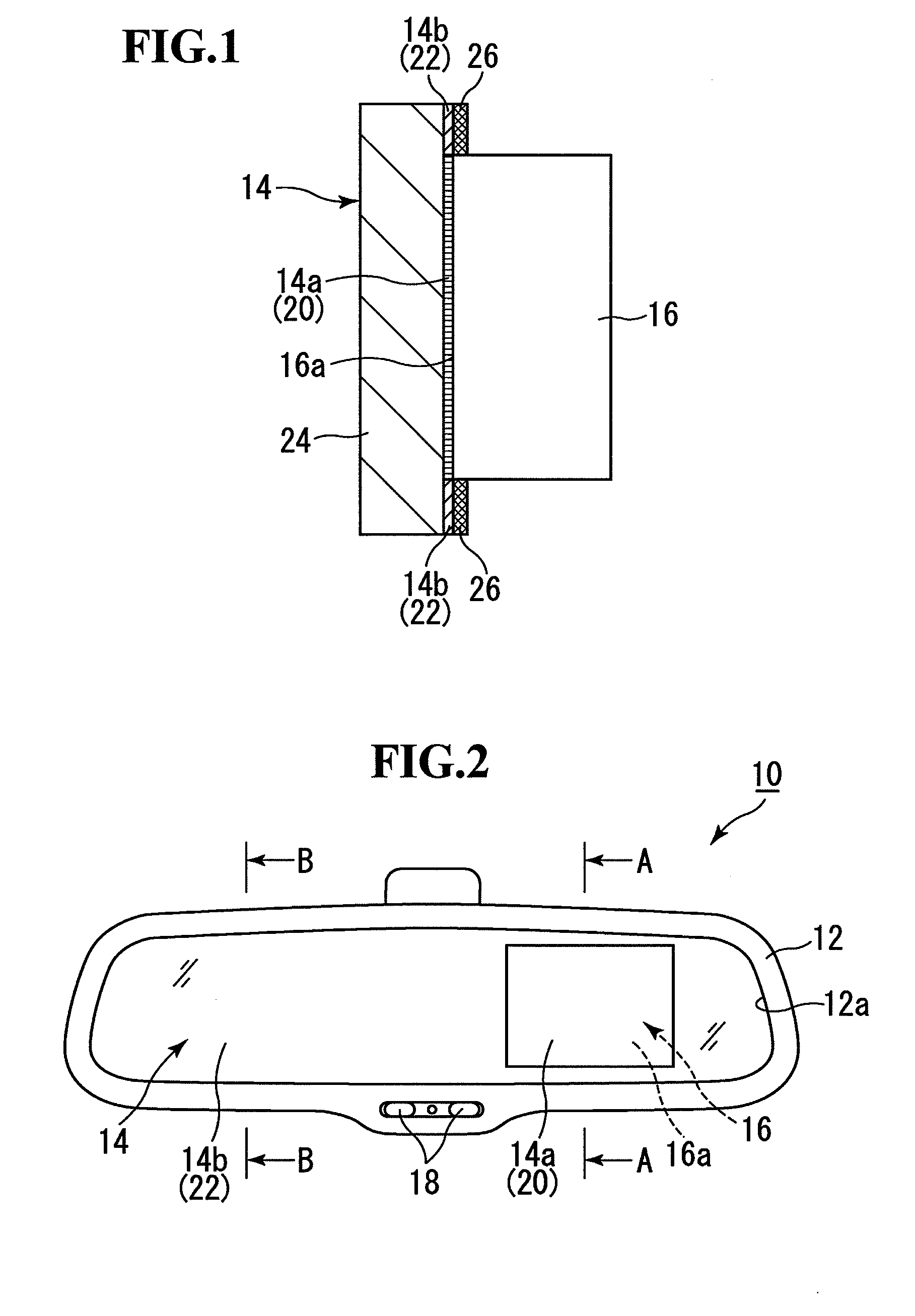

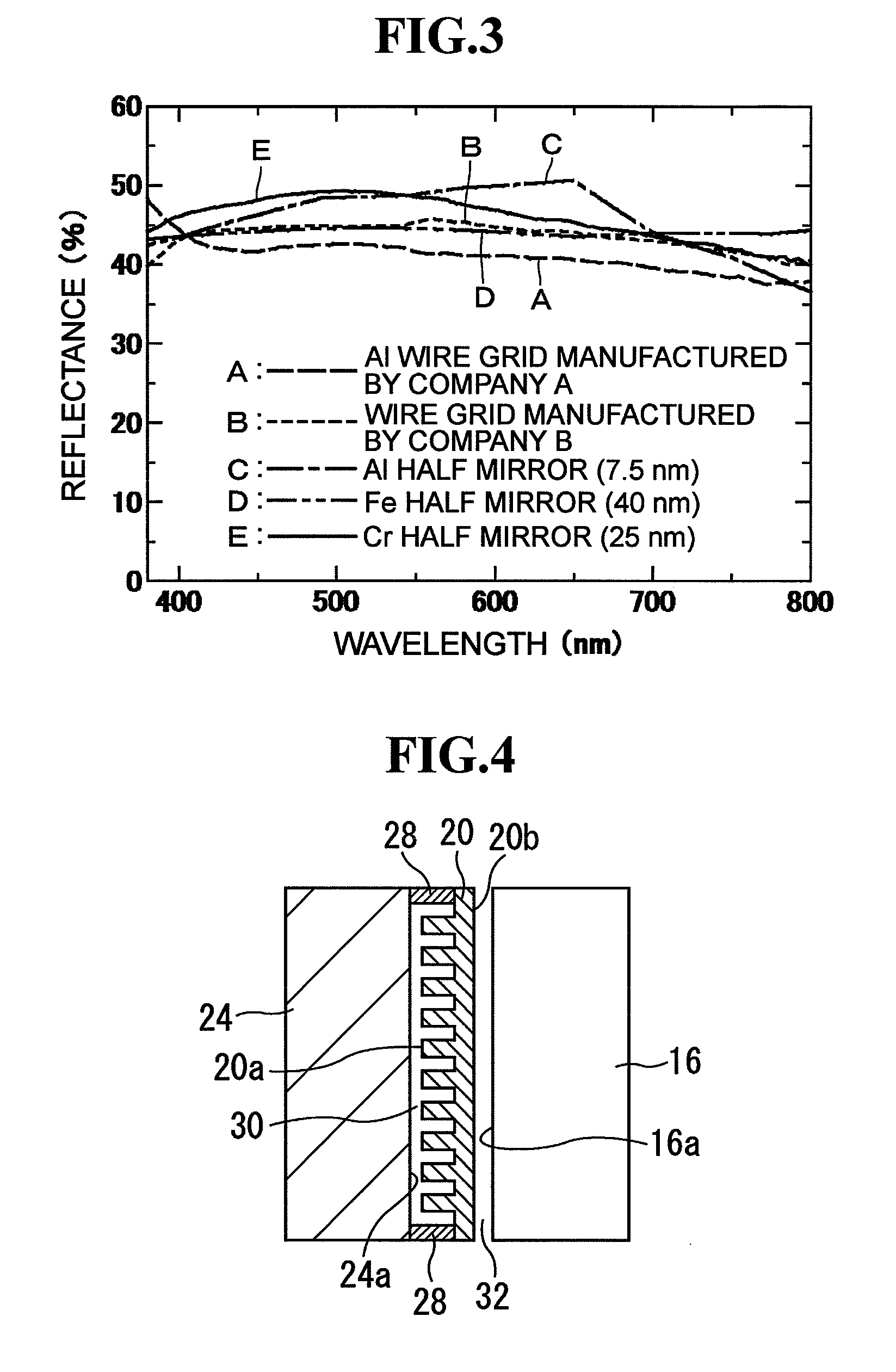

Mirror with monitor for vehicle

InactiveUS20100245701A1Increase volumeImprove visibilityPolarising elementsNon-linear opticsWire gridDark color

Owner:MURAKAMI CORP

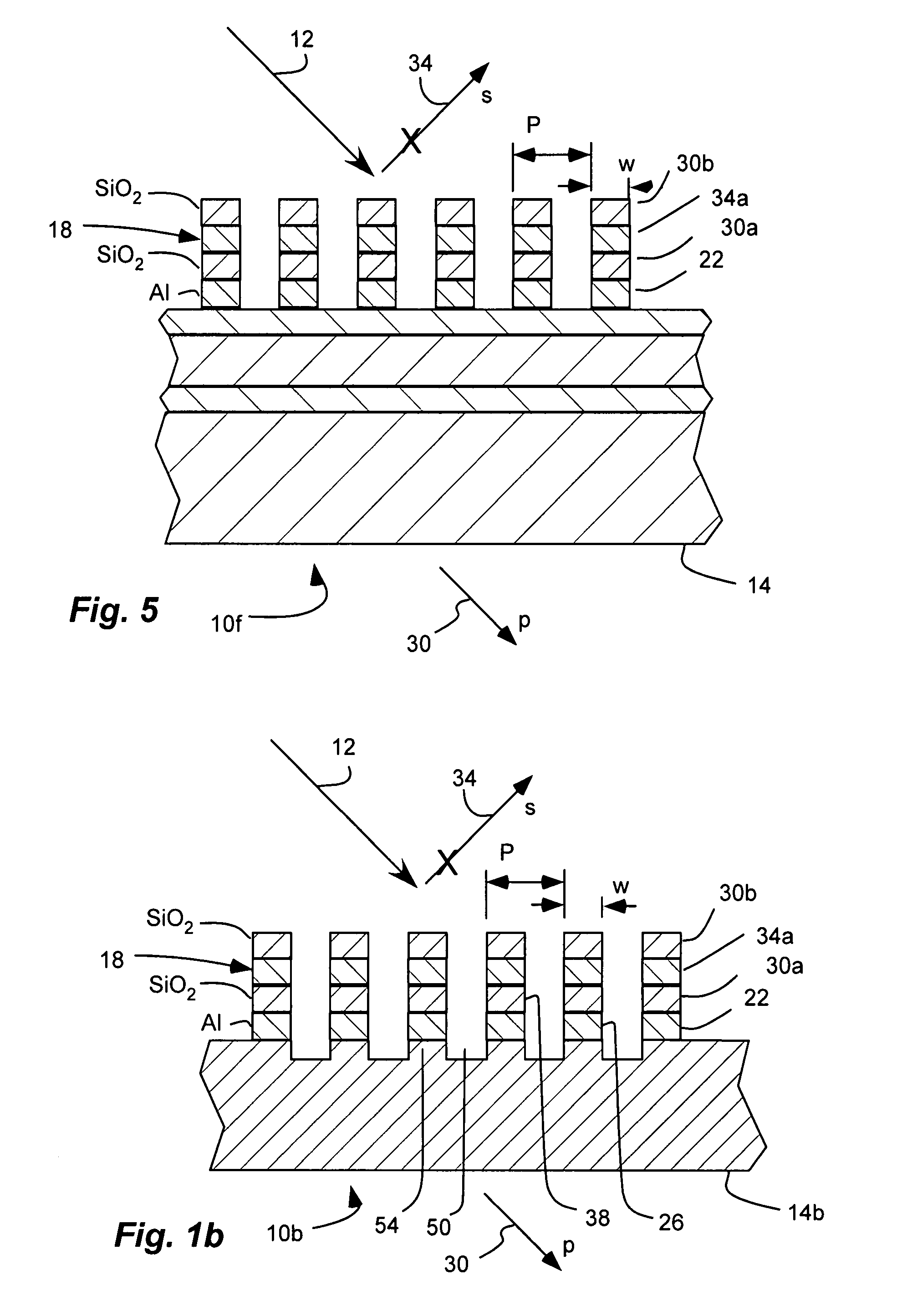

Method for fabricating an integrated optical isolator and a novel wire grid structure

InactiveUS6813077B2Inhibition reflexLow cost without sacrificing performanceDecorative surface effectsPolarising elementsResistWire grid

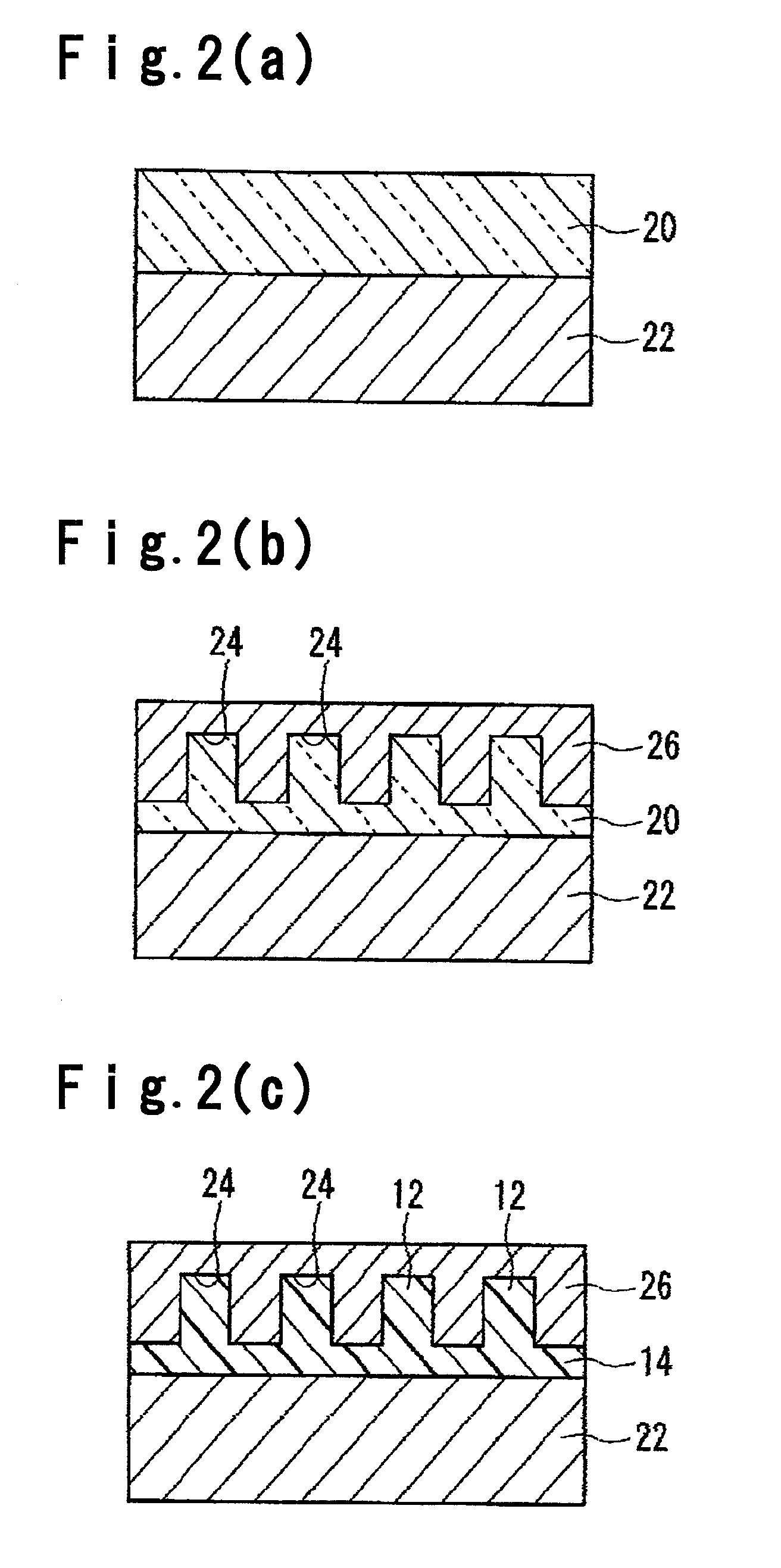

A method for fabricating an integrated optical isolator includes depositing a wire grid material on a magneto-optical substrate and depositing a resist film on the wire grid material. The method further includes bringing a mold with a wire grid pattern on contact with the resist film and compressing the mold and resist film together so as to emboss the wire grid pattern in the resist film. The method further includes transferring the wire grid pattern in the resist film to the wire grid material on the magneto-optical substrate by etching.

Owner:CORNING INC

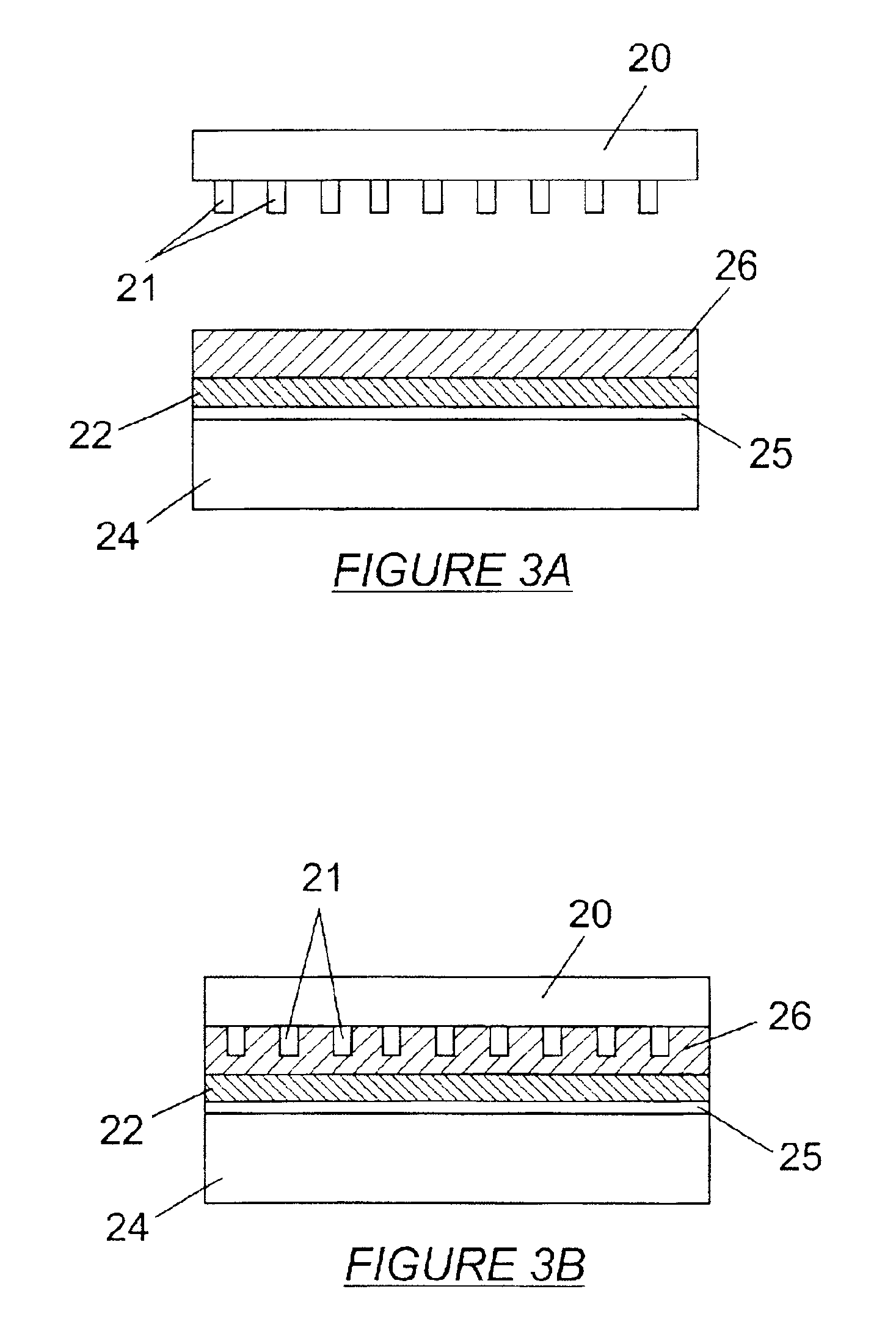

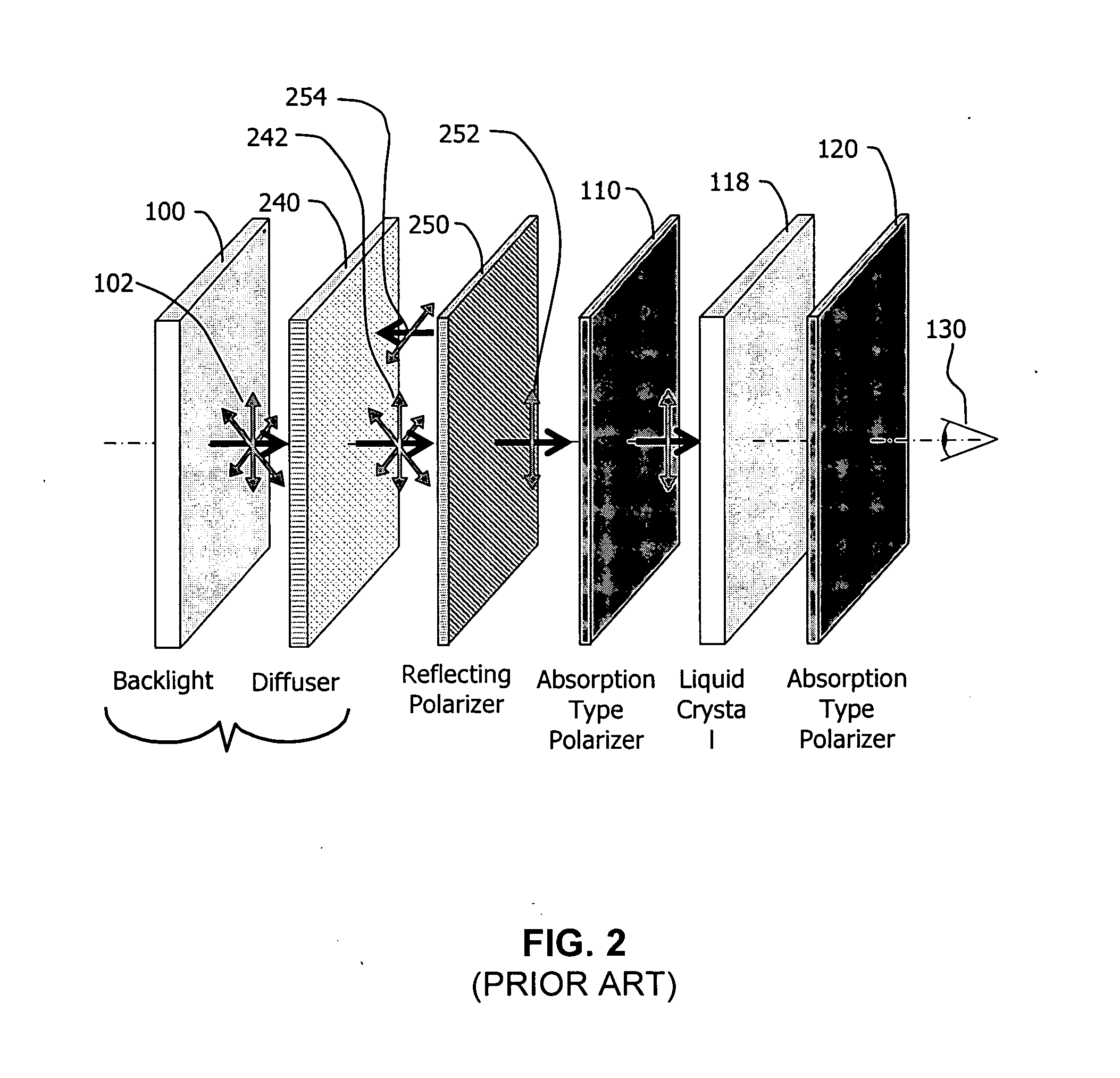

Wire grid polarized and liquid crystal display device using the same

ActiveUS20080094547A1Brightness in display can be increasedLow costPolarising elementsNon-linear opticsLiquid-crystal displayOptical property

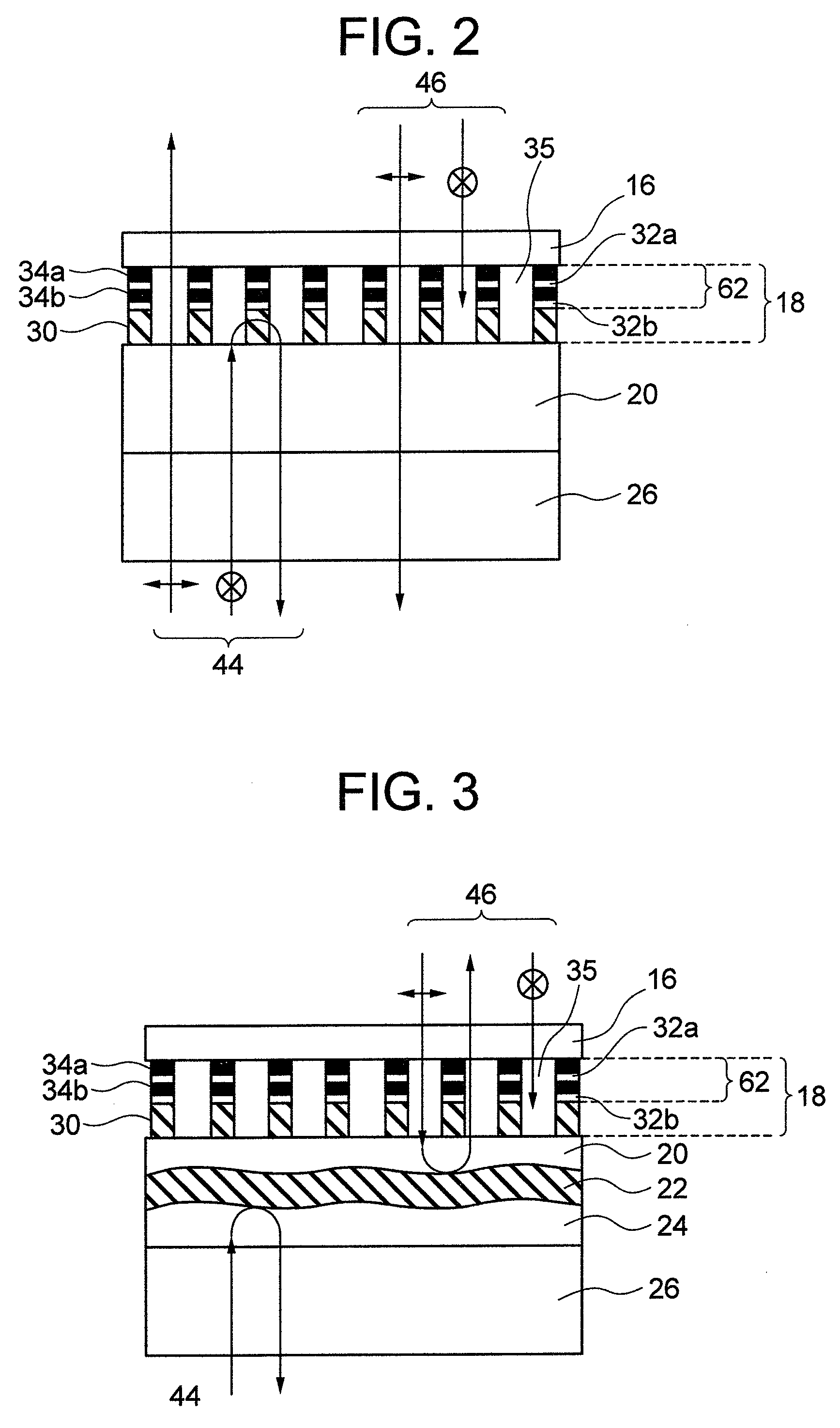

An image is displayed by modulating TM-polarized light between the polarizer 2 and the wire grid polarizer 18 through the variation of the optical characteristic of the liquid crystal layer 12 interposed between the transparent plate 4 and the transparent plate 26. Degradation of contrast in the bright ambience is avoided by providing an absorption layer for absorbing TE-polarized light on that surface of the wire grid polarizer 18 which faces the liquid crystal layer 12.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

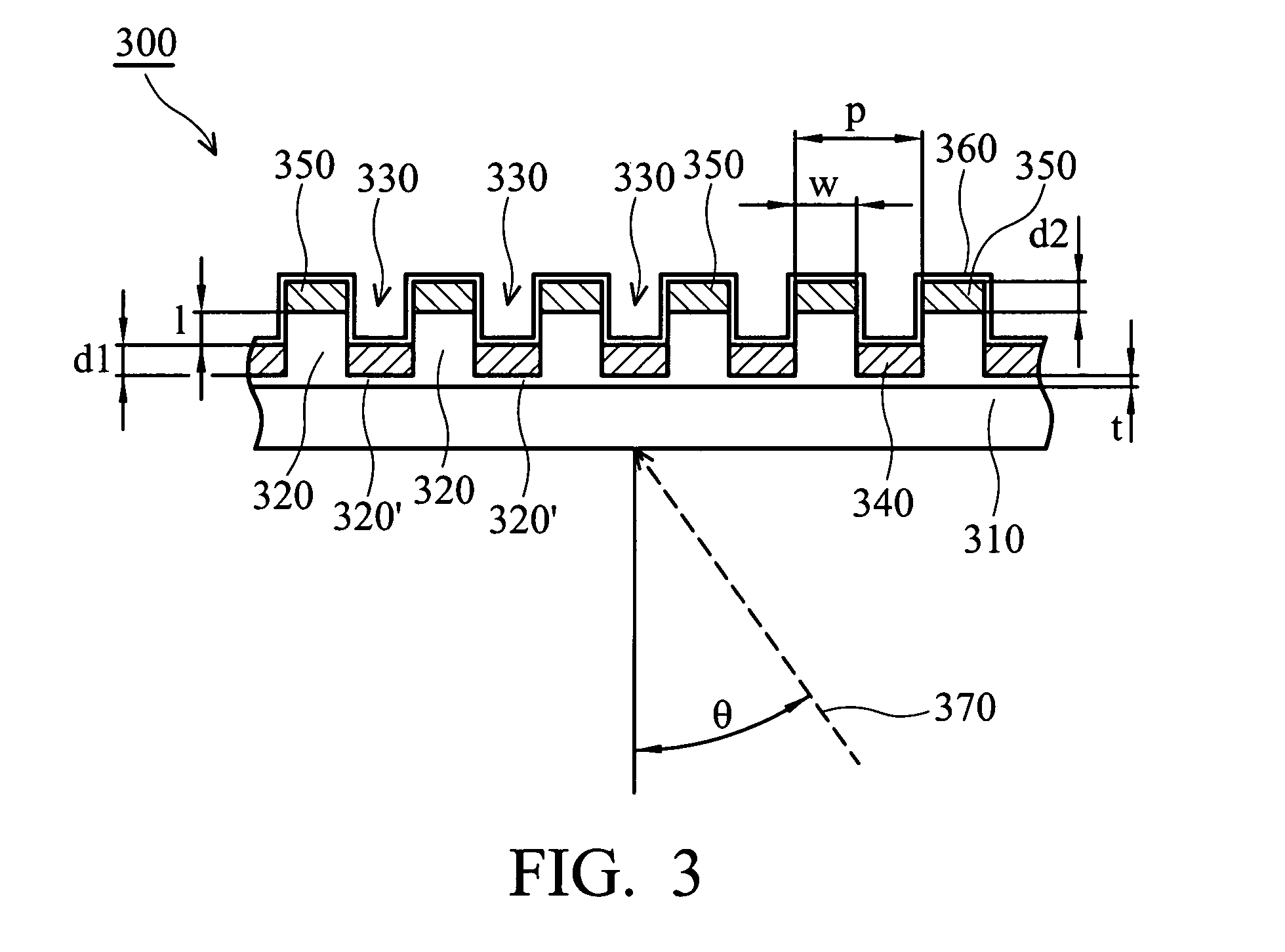

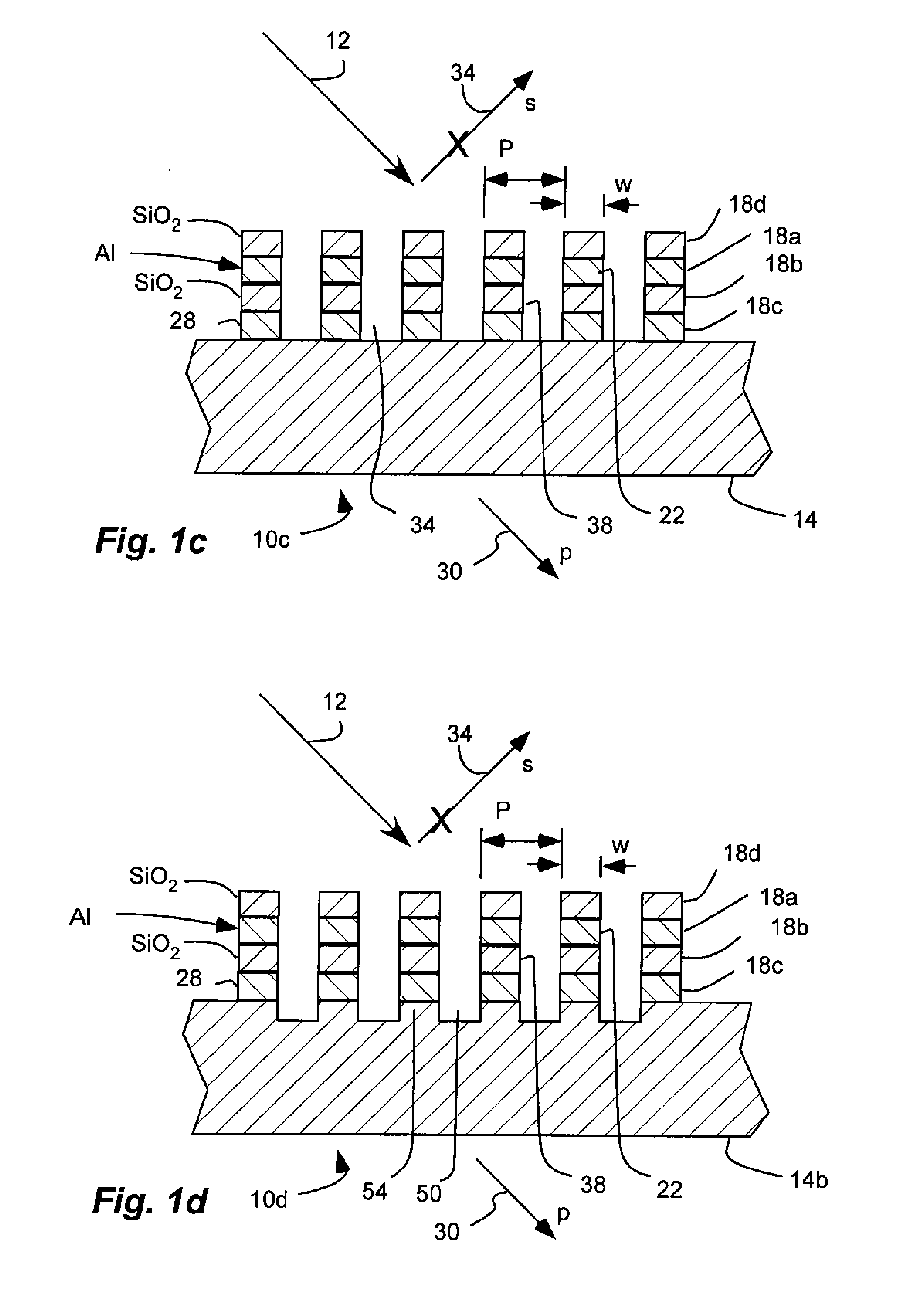

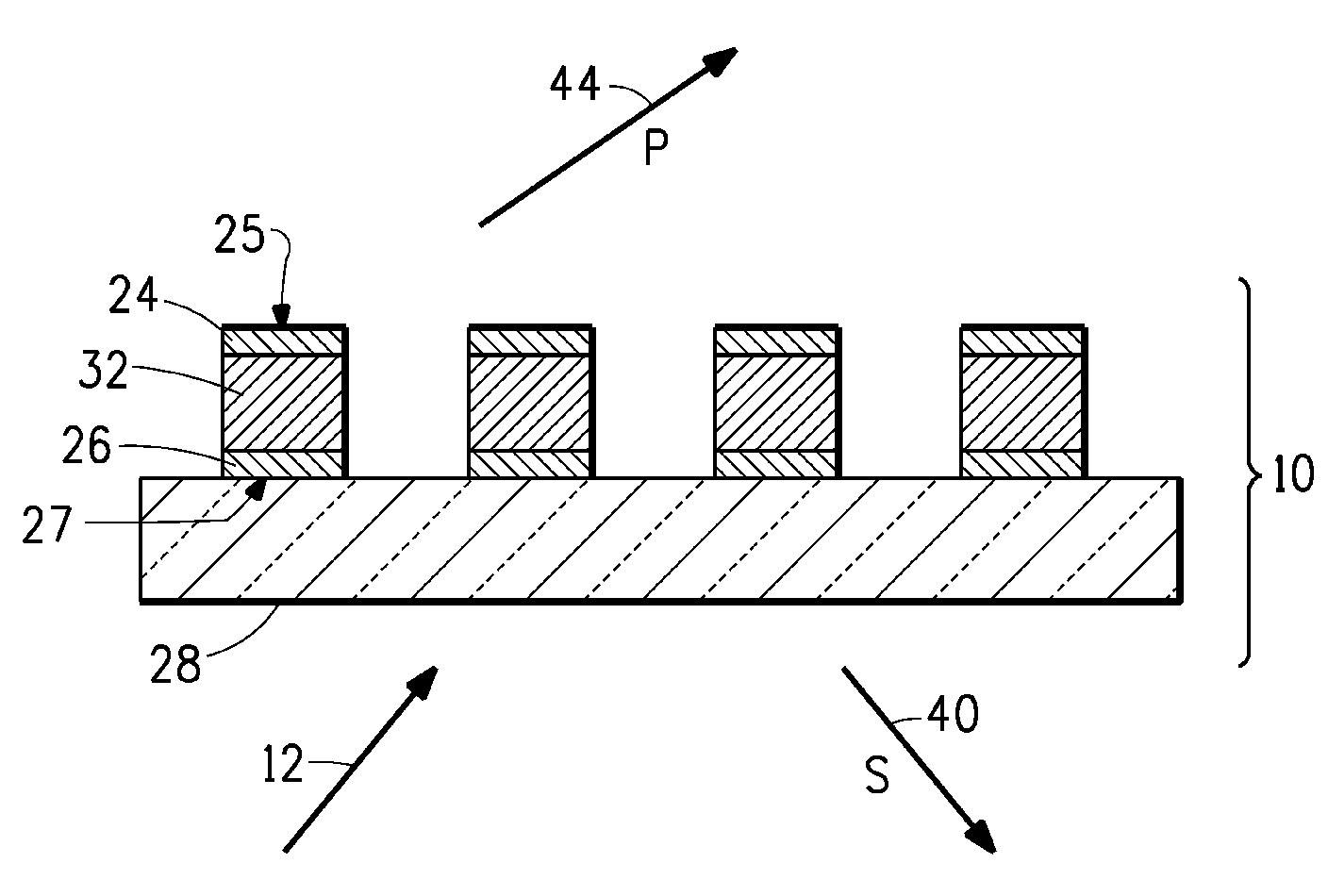

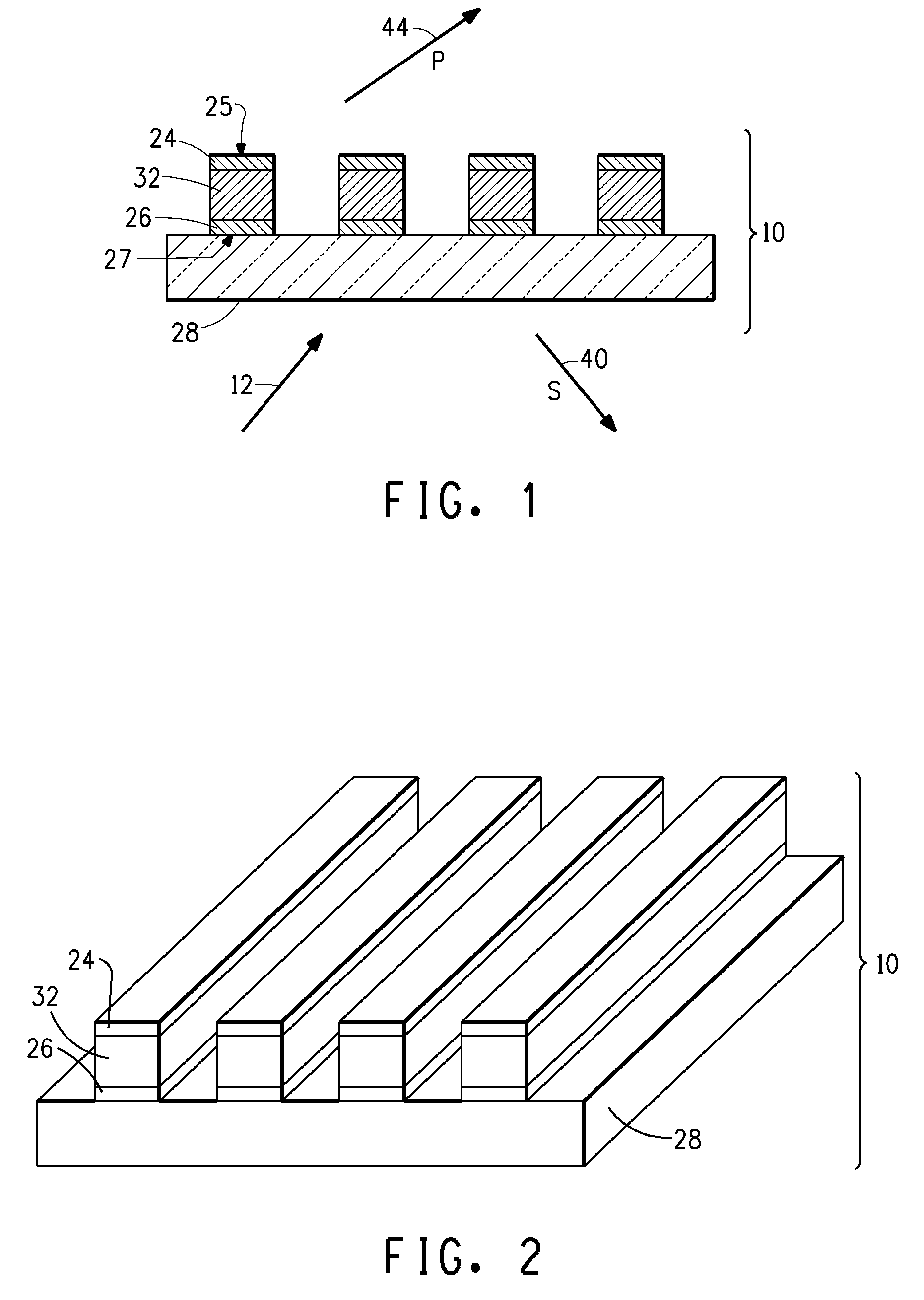

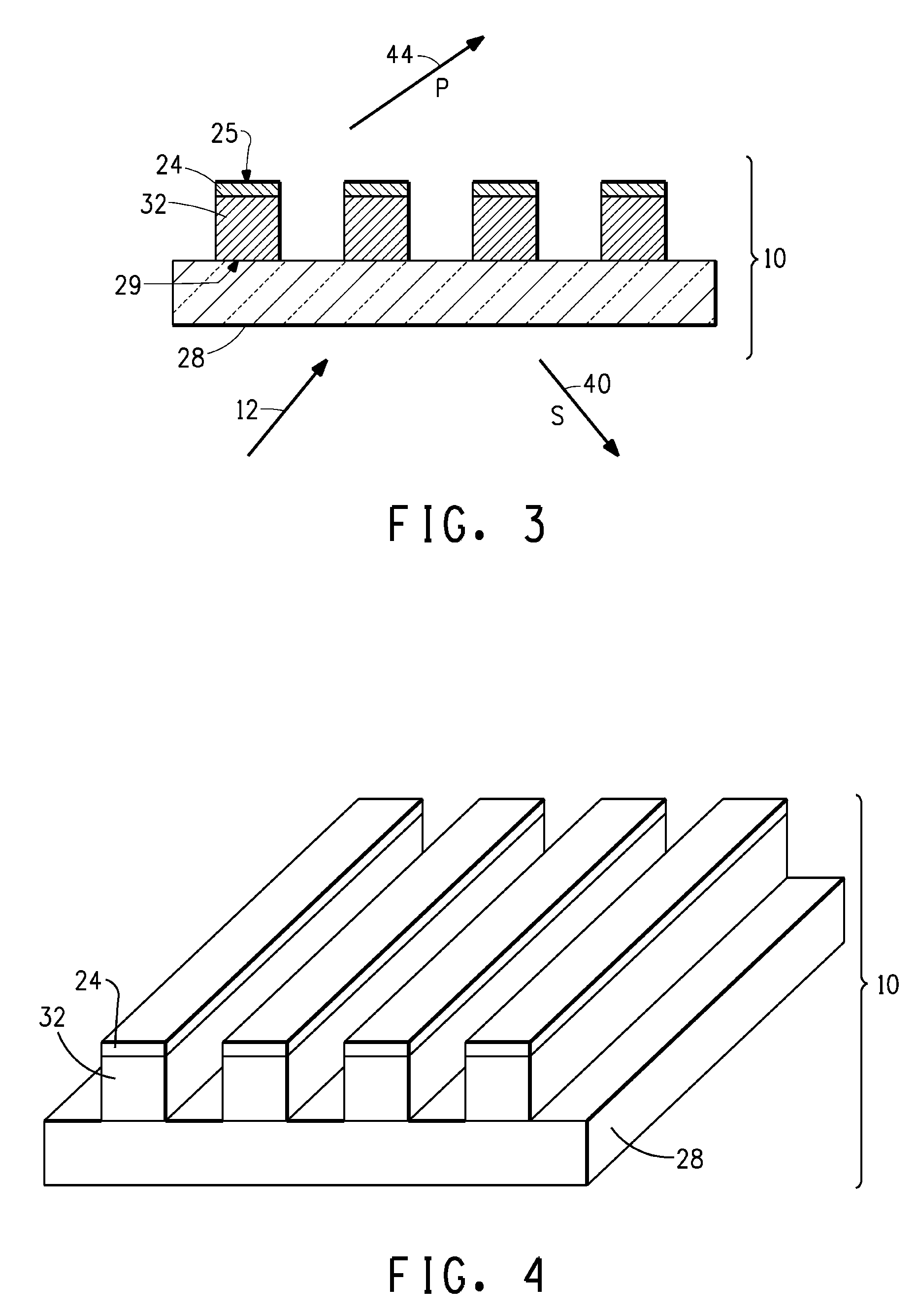

Low fill factor wire grid polarizer and method of use

In an example embodiment, a wire grid polarizer includes a plurality of parallel conductors having a pitch (P), a width (W), and a height (H). In example embodiments, a fill-factor (W / P) is greater than approximately 0.18 and less than approximately 0.25. In another example embodiment, a display system includes a light source and a light-valve. The display system also includes a wire grid polarizer that includes a plurality of parallel conductors having a pitch (P), a width (W), and a height (H). In example embodiments, a fill-factor (W / P) is greater than approximately 0.18 and less than approximately 0.25.

Owner:SK MICROWORKS SOLUTIONS CO LTD

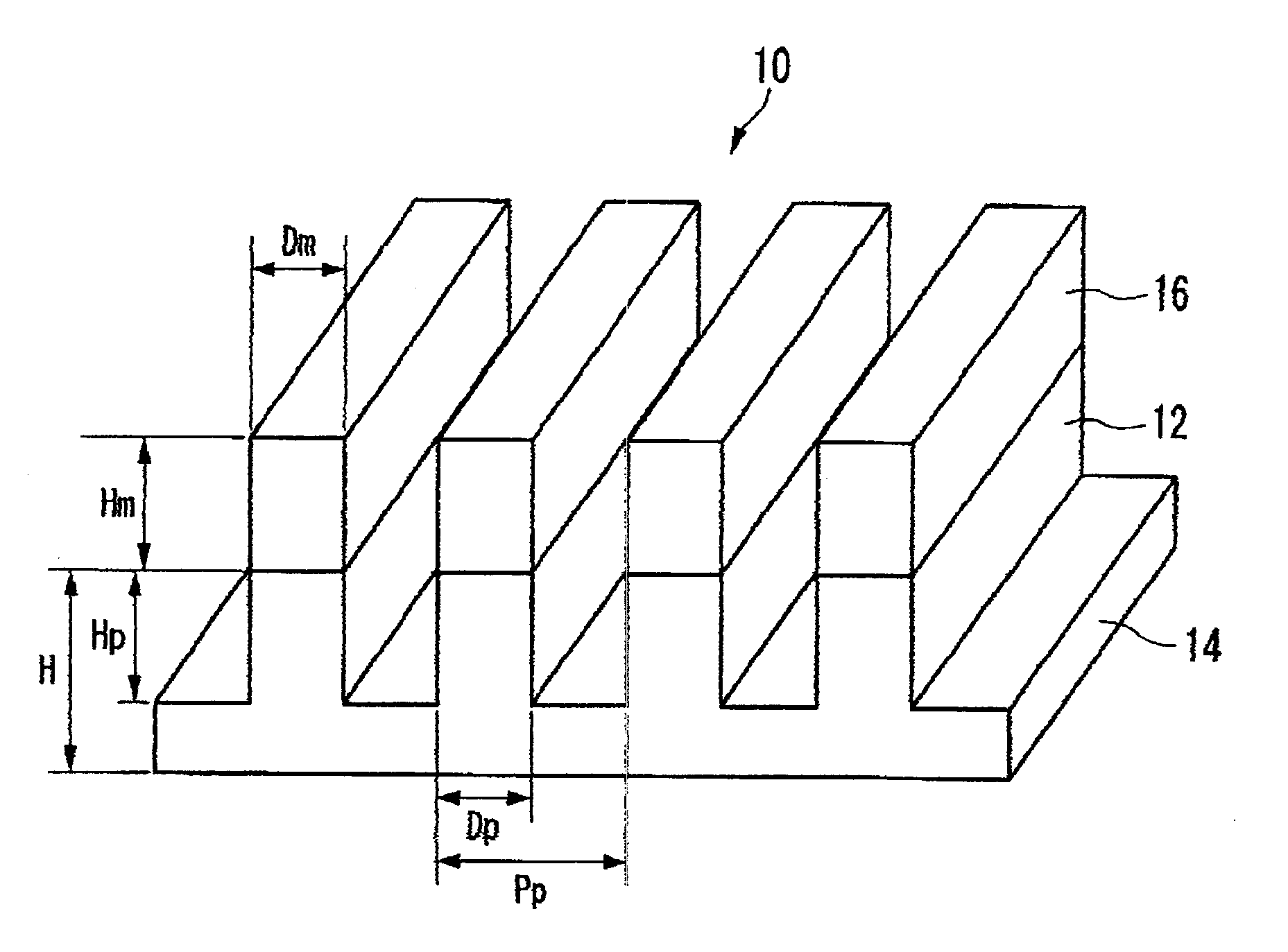

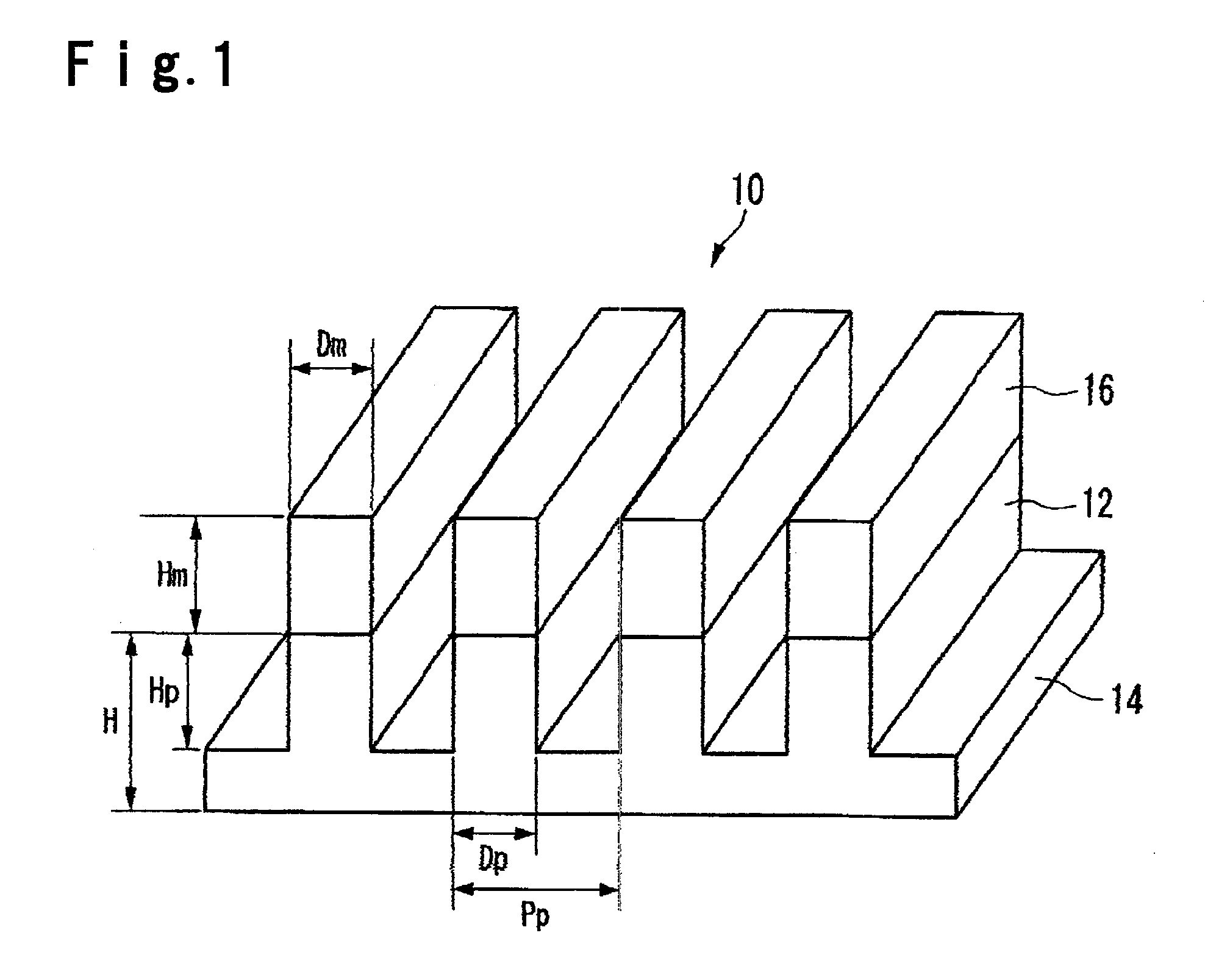

Wire grid polarizer and liquid crystal display device using the polarizer

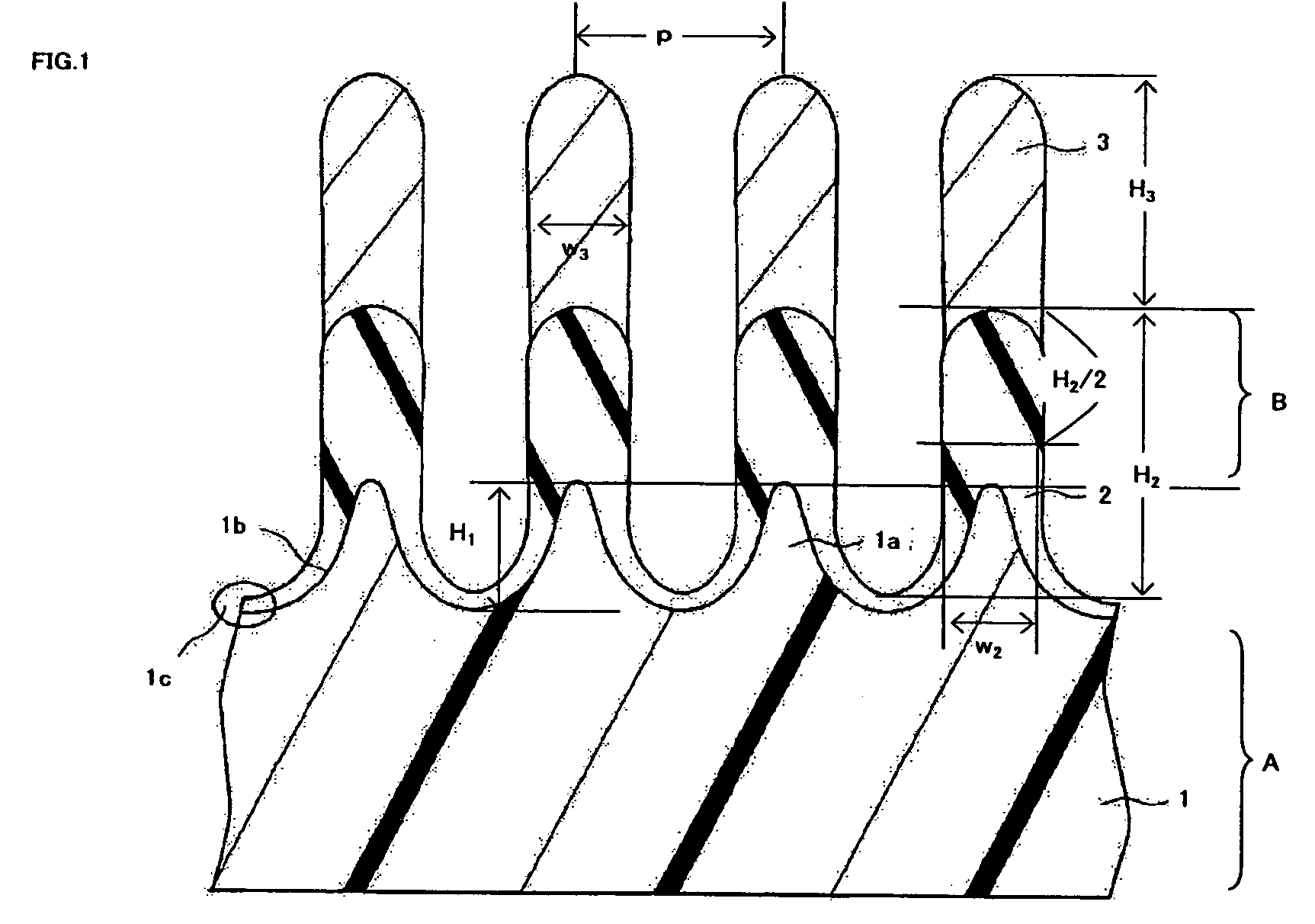

ActiveUS7605883B2Easy to disassembleNon-linear opticsOptical elementsLiquid-crystal displayWire grid

A wire grid polarizer has a resin substrate having grid-shaped convex portions, a dielectric layer provided to cover the grid-shaped convex portions of the resin substrate and at least part of side faces of the portions, and metal wires provided on the dielectric layer. The wire grid polarizer has a microstructural concavo-convex grid structure having grid-shaped convex portions, is not limited in structure, and has both the excellent degree of polarization and excellent transmittance over a wide range in the visible region.

Owner:ASAHI KASEI KK

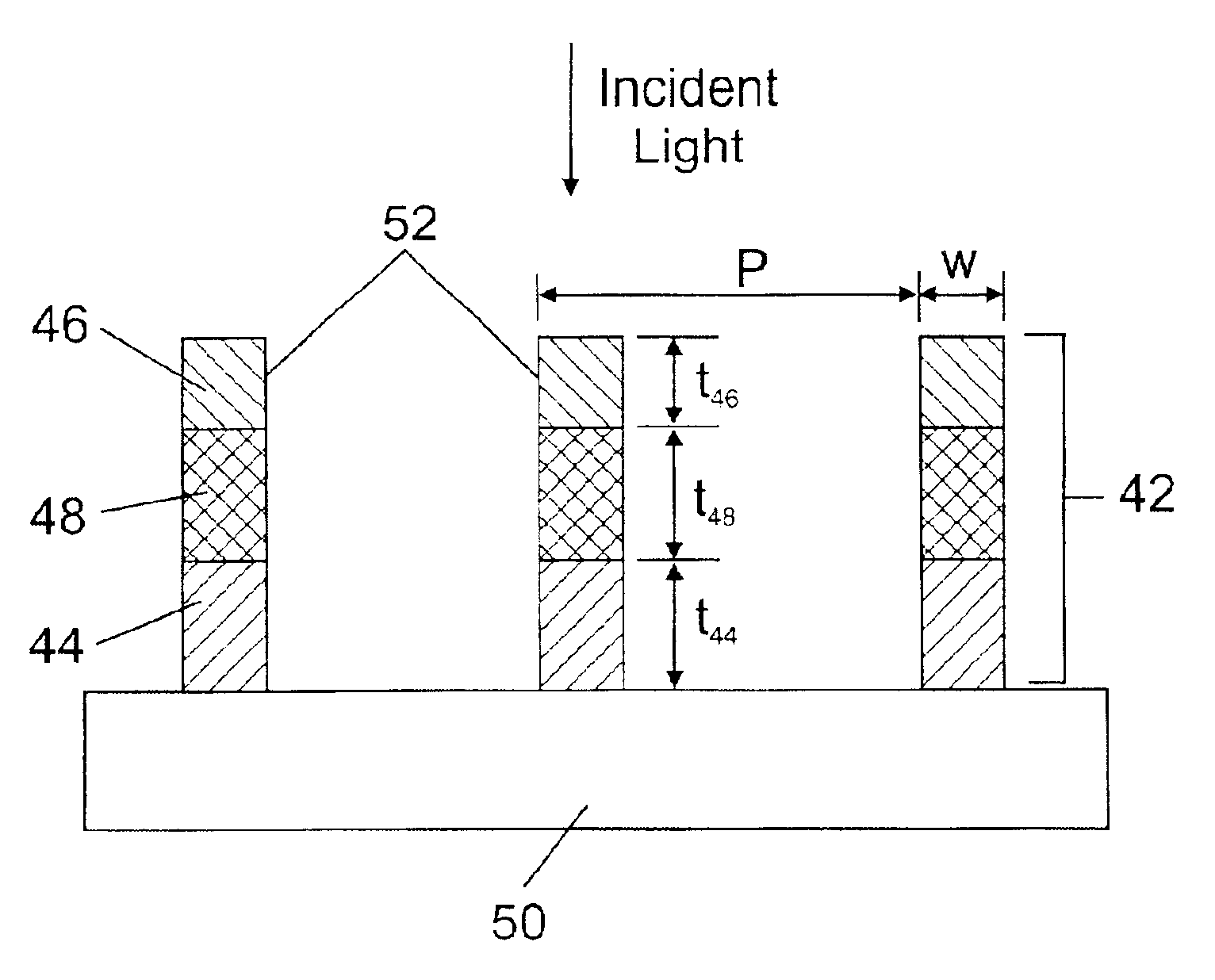

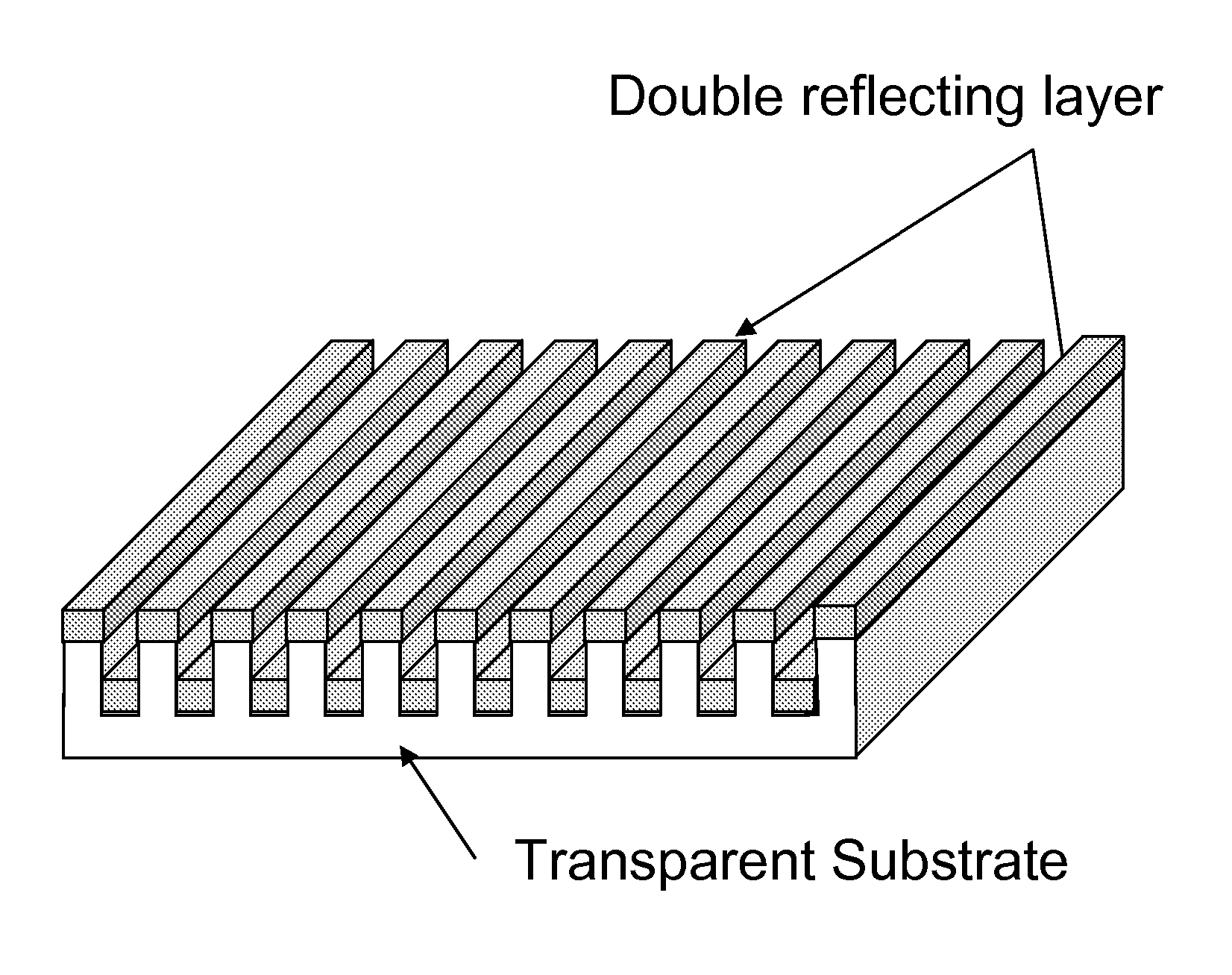

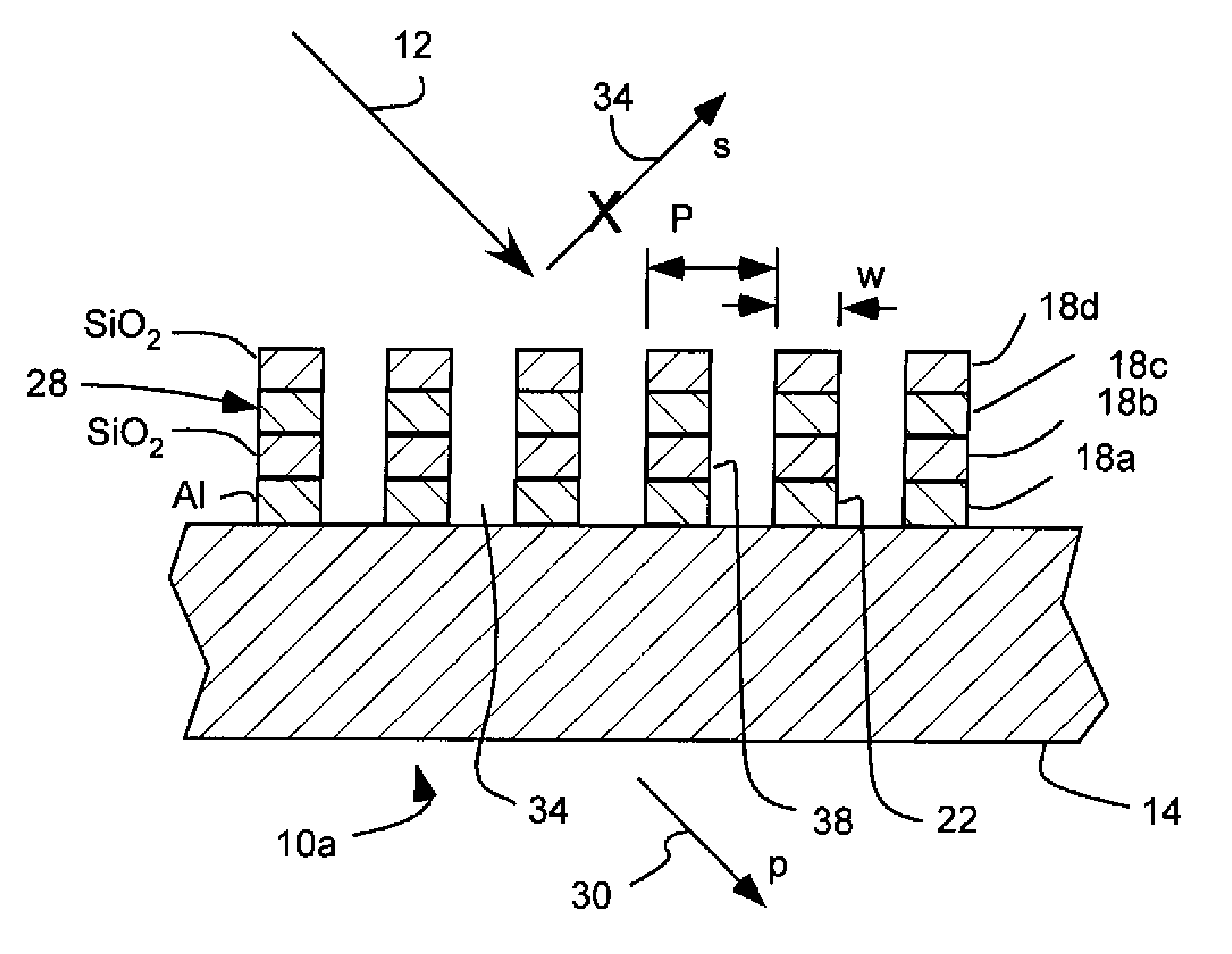

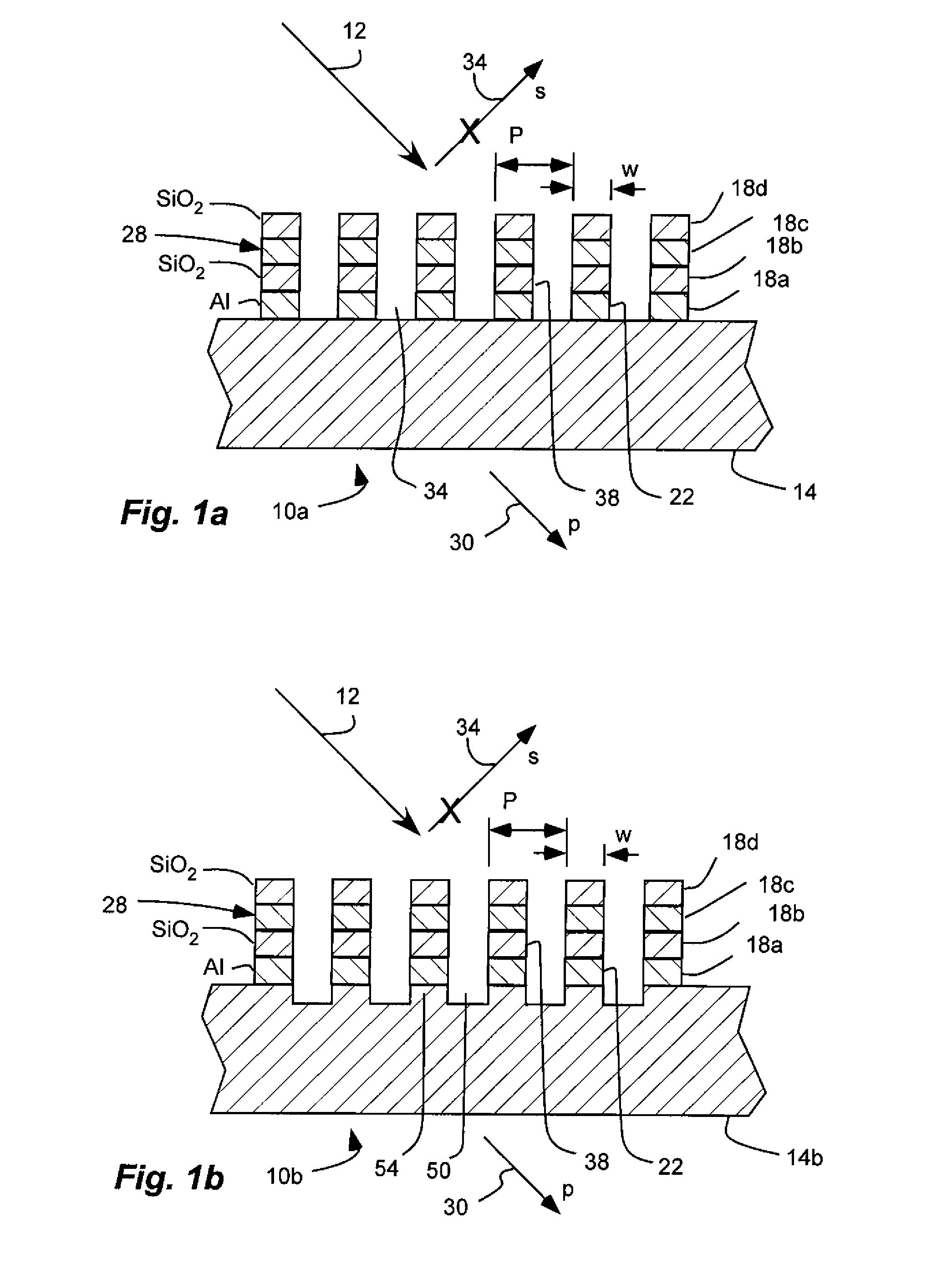

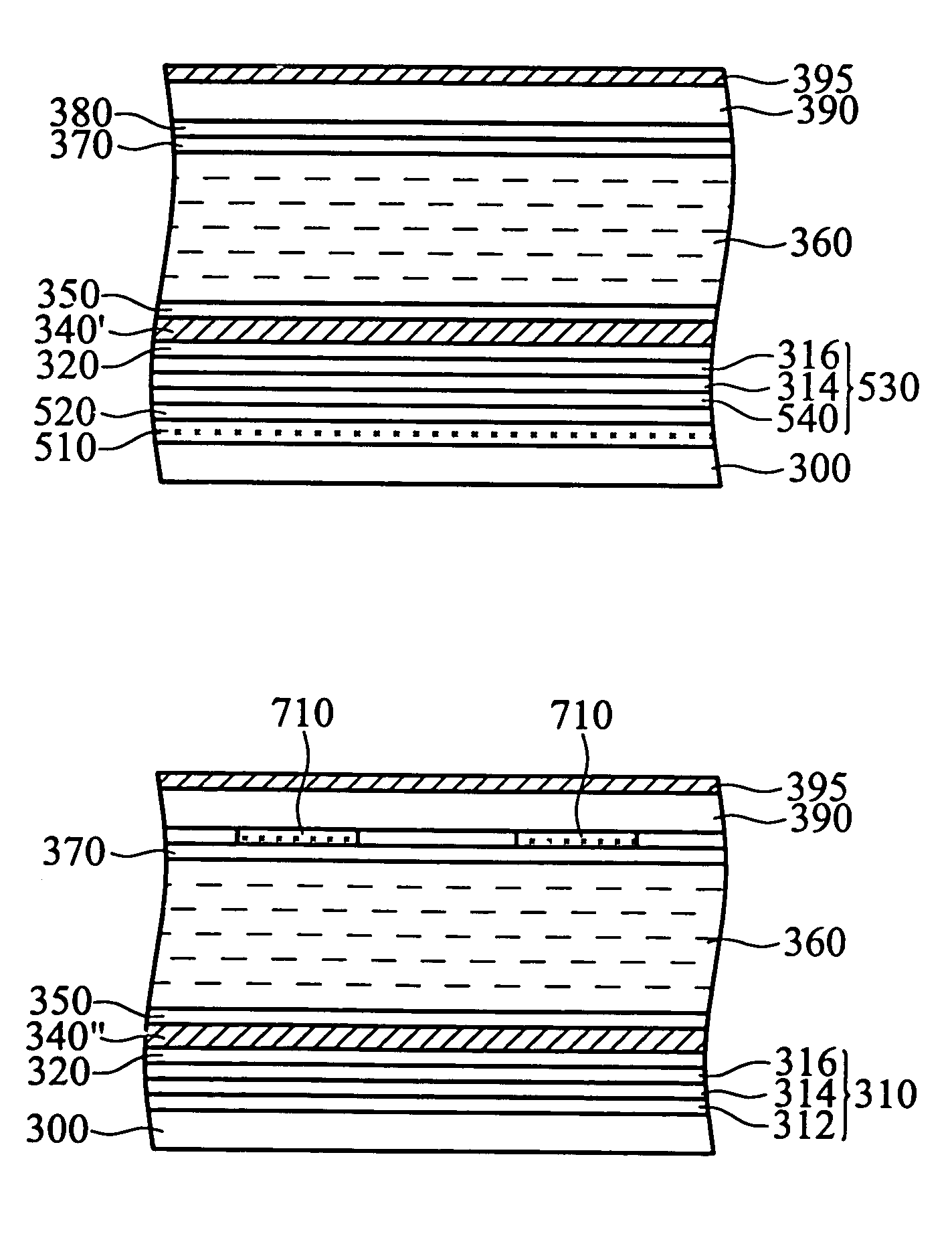

Selectively absorptive wire-grid polarizer

A selectively absorptive, mulitlayer wire-grid polarizer for polarizing incident light includes a stack of thin film layers disposed over a substrate, including a wire-grid array of elongated metal elements having a period less than half the wavelength of the light. One of the layers can include a thin film layer with a refractive index greater than a refractive index of the substrate. One of the thin film layers can include a dielectric array of non-metal elements. One of the layers includes a material that is optically absorptive to the incident light.

Owner:MOXTEK INC

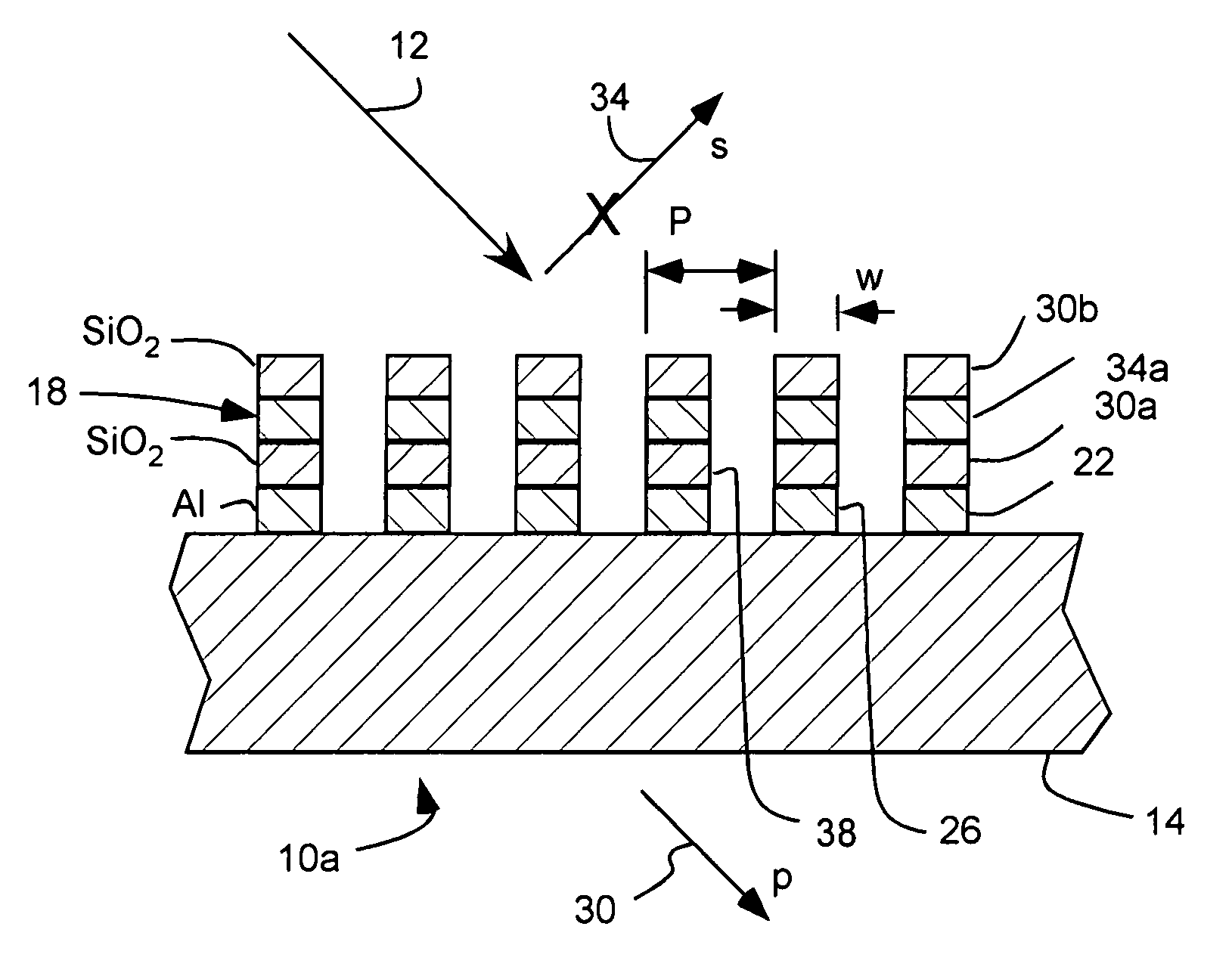

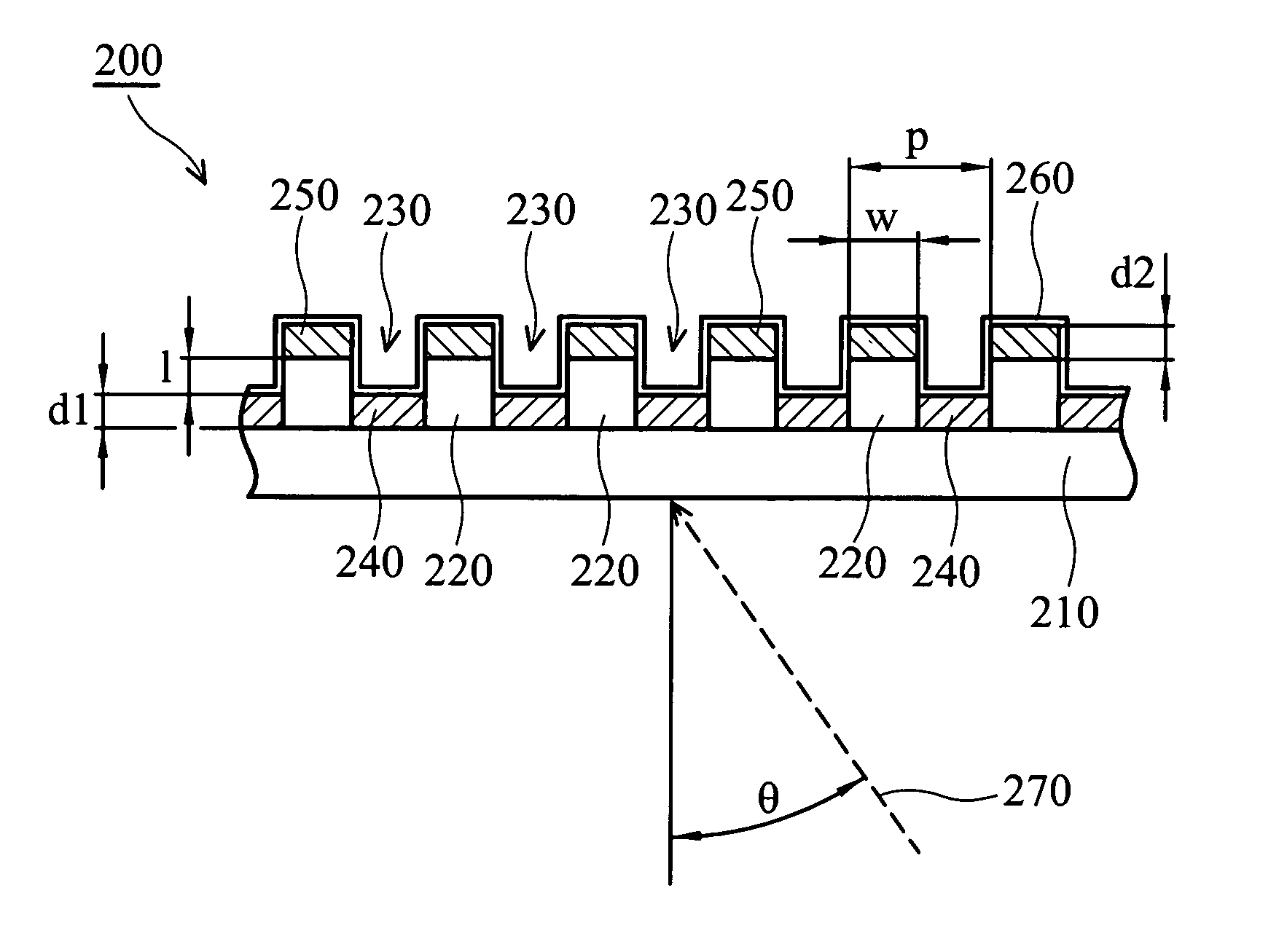

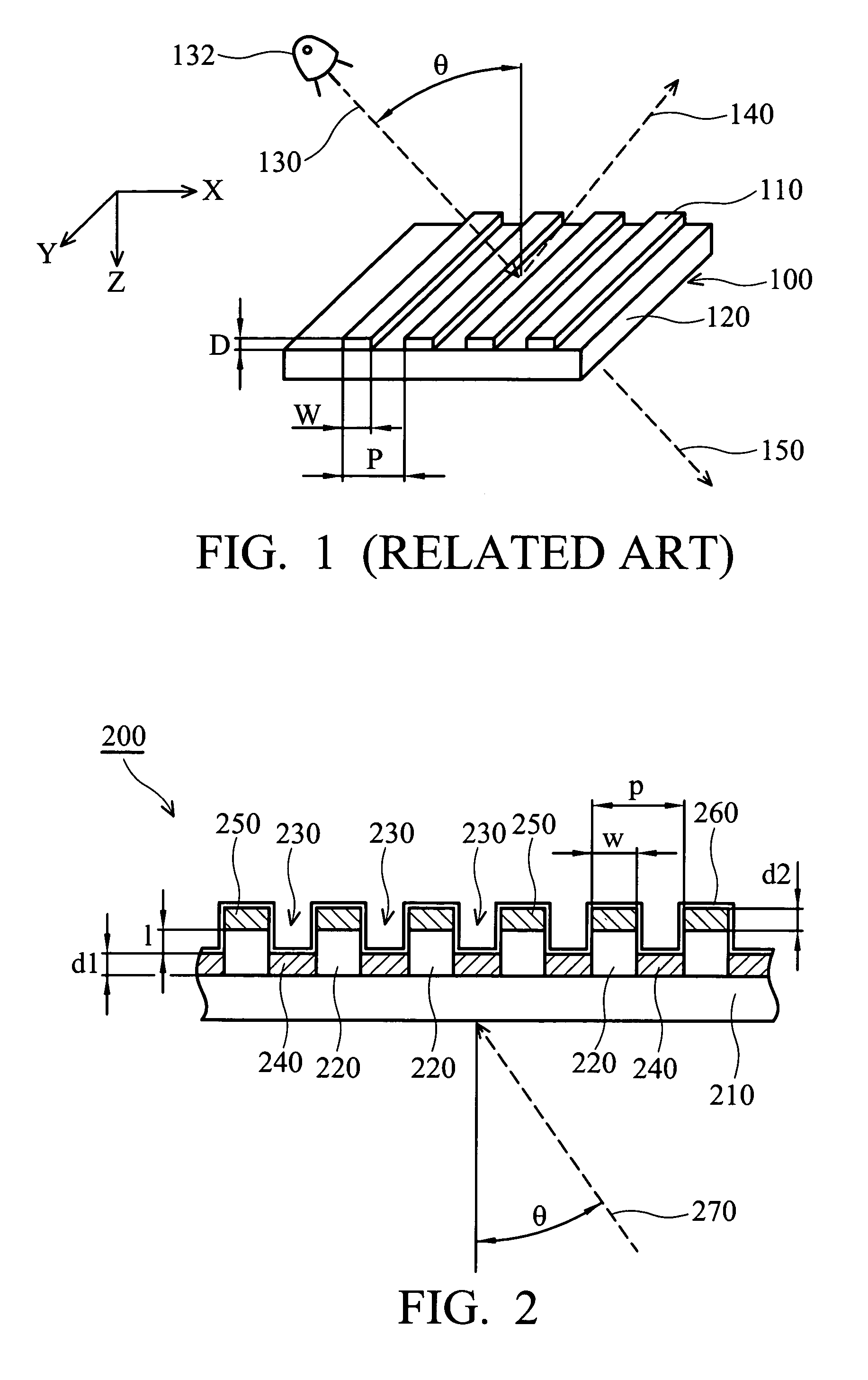

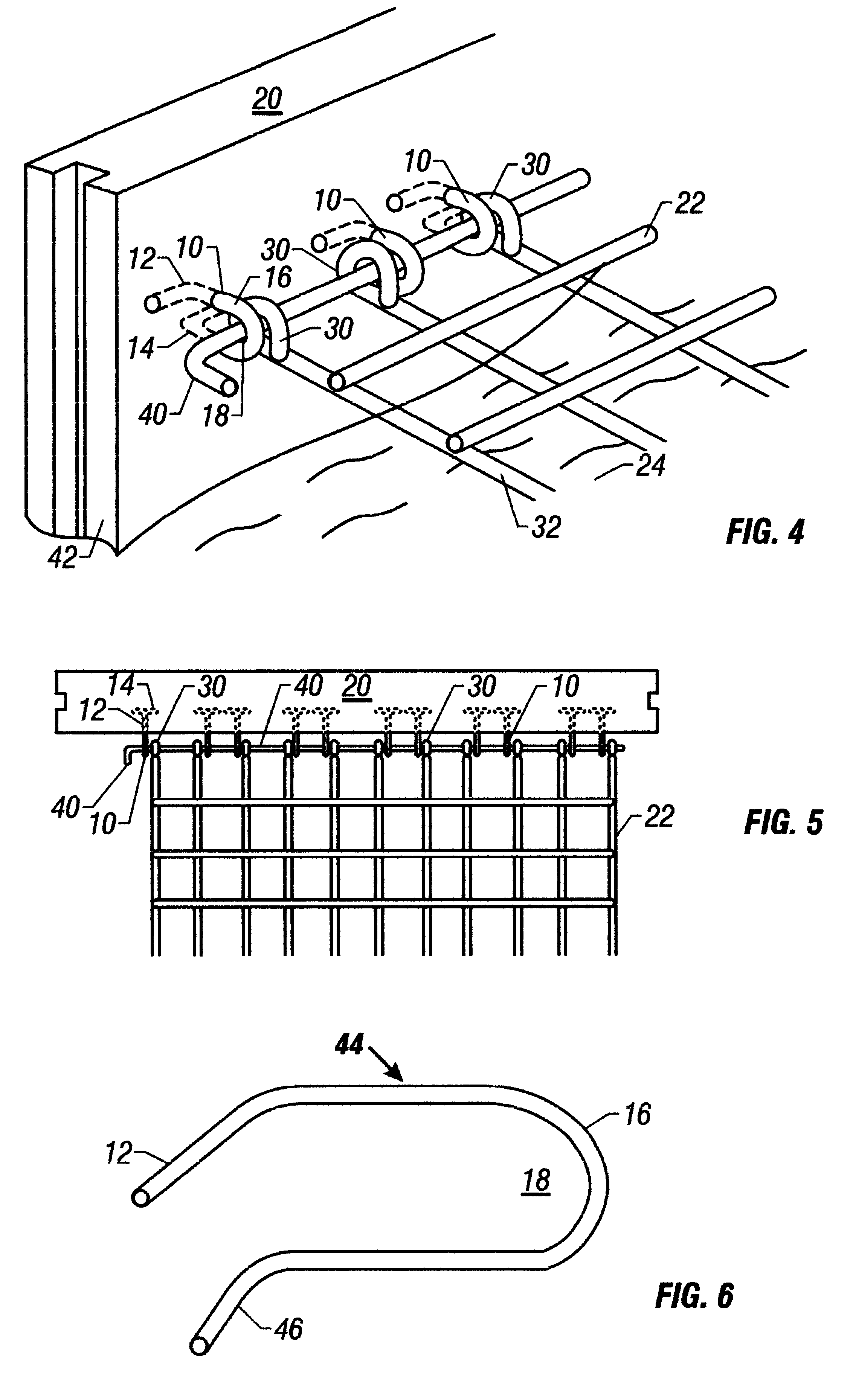

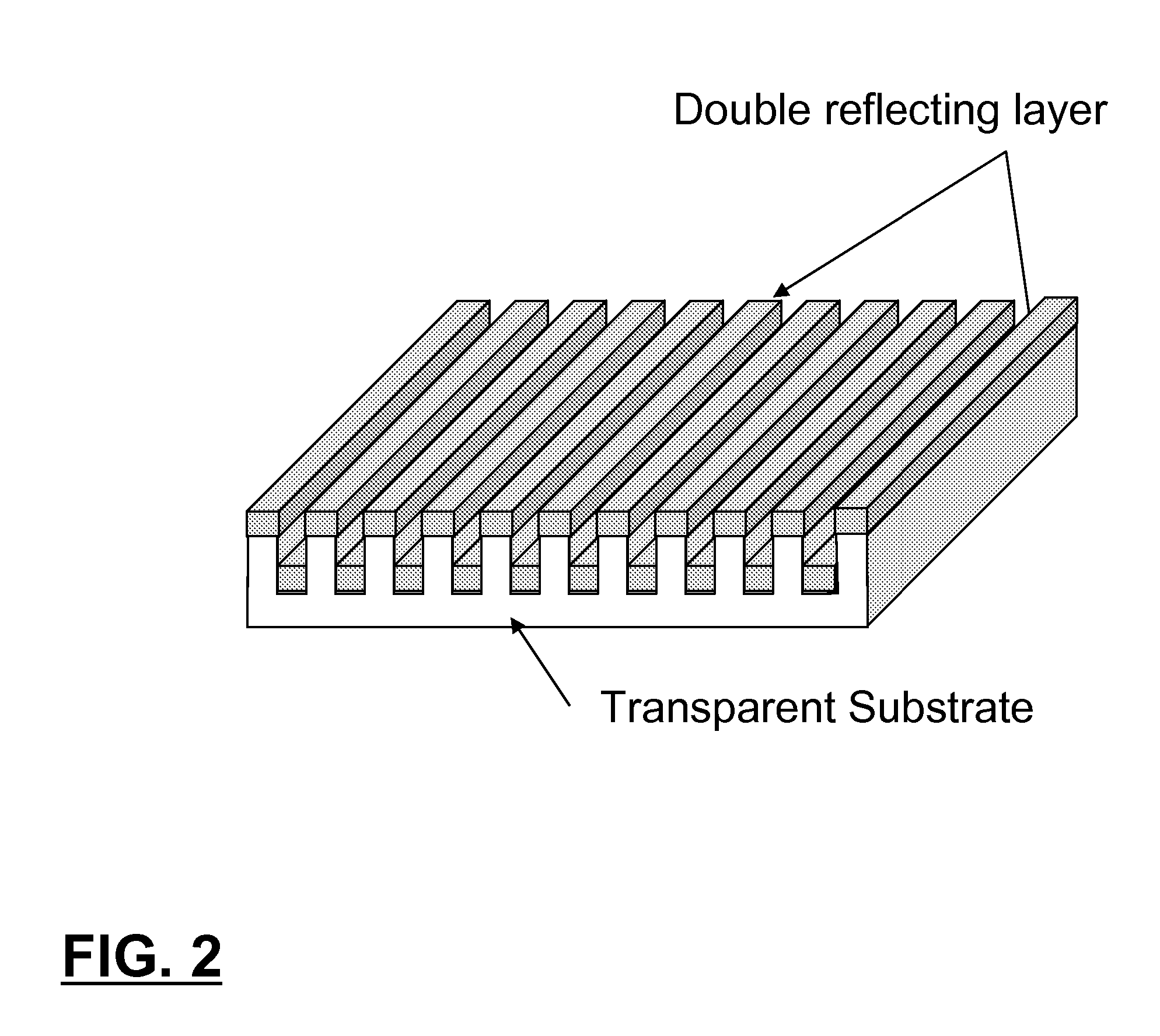

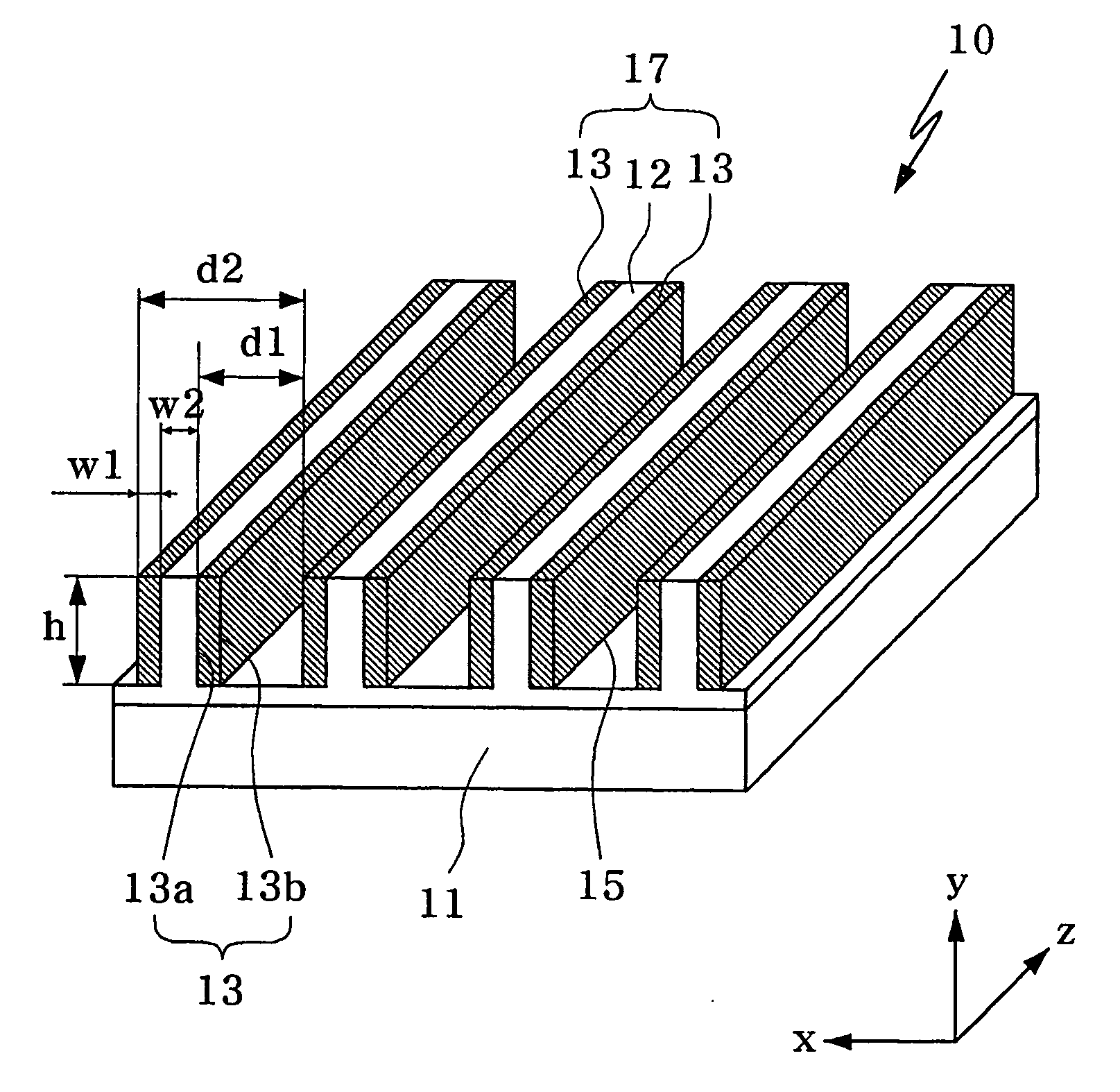

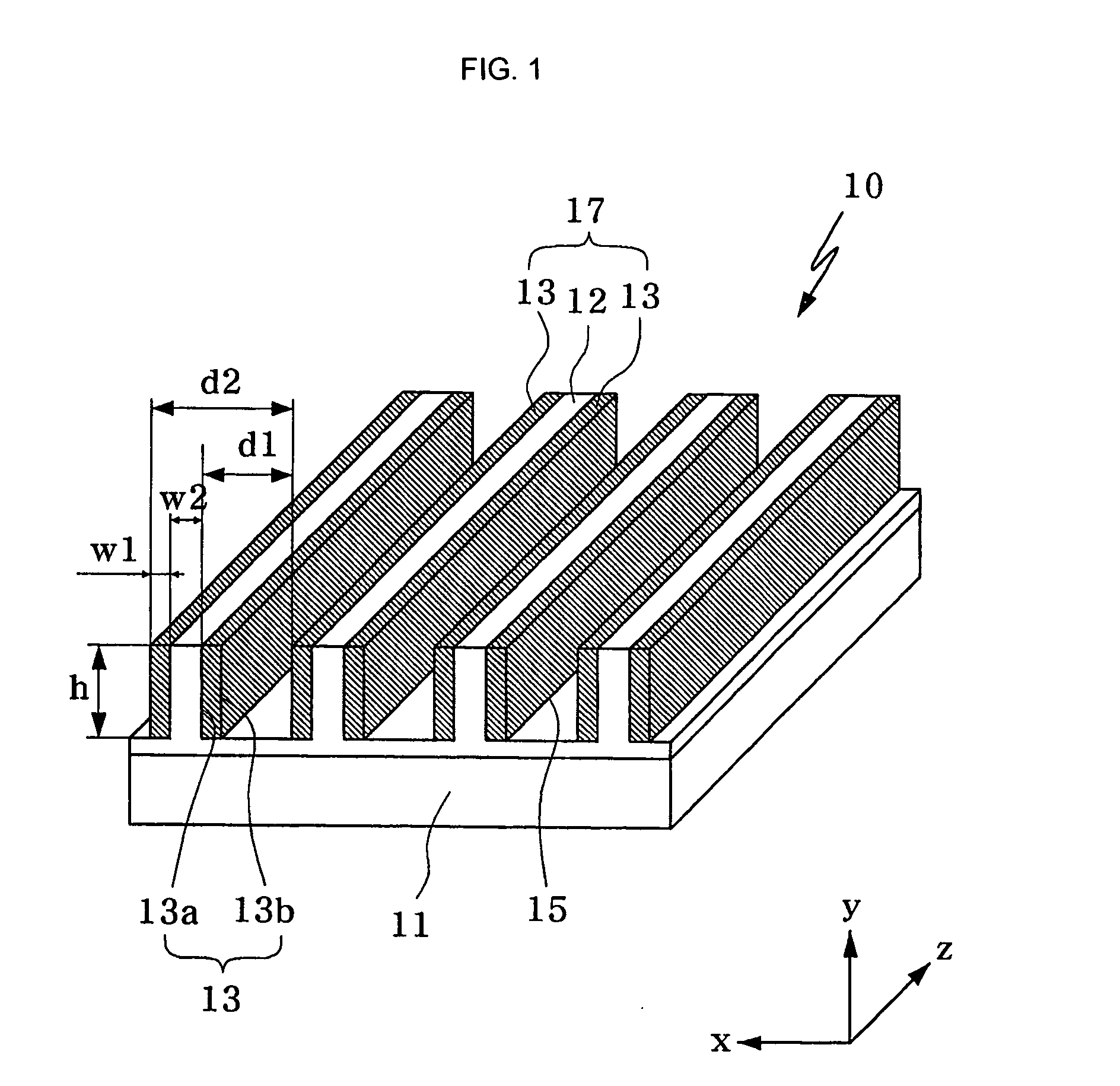

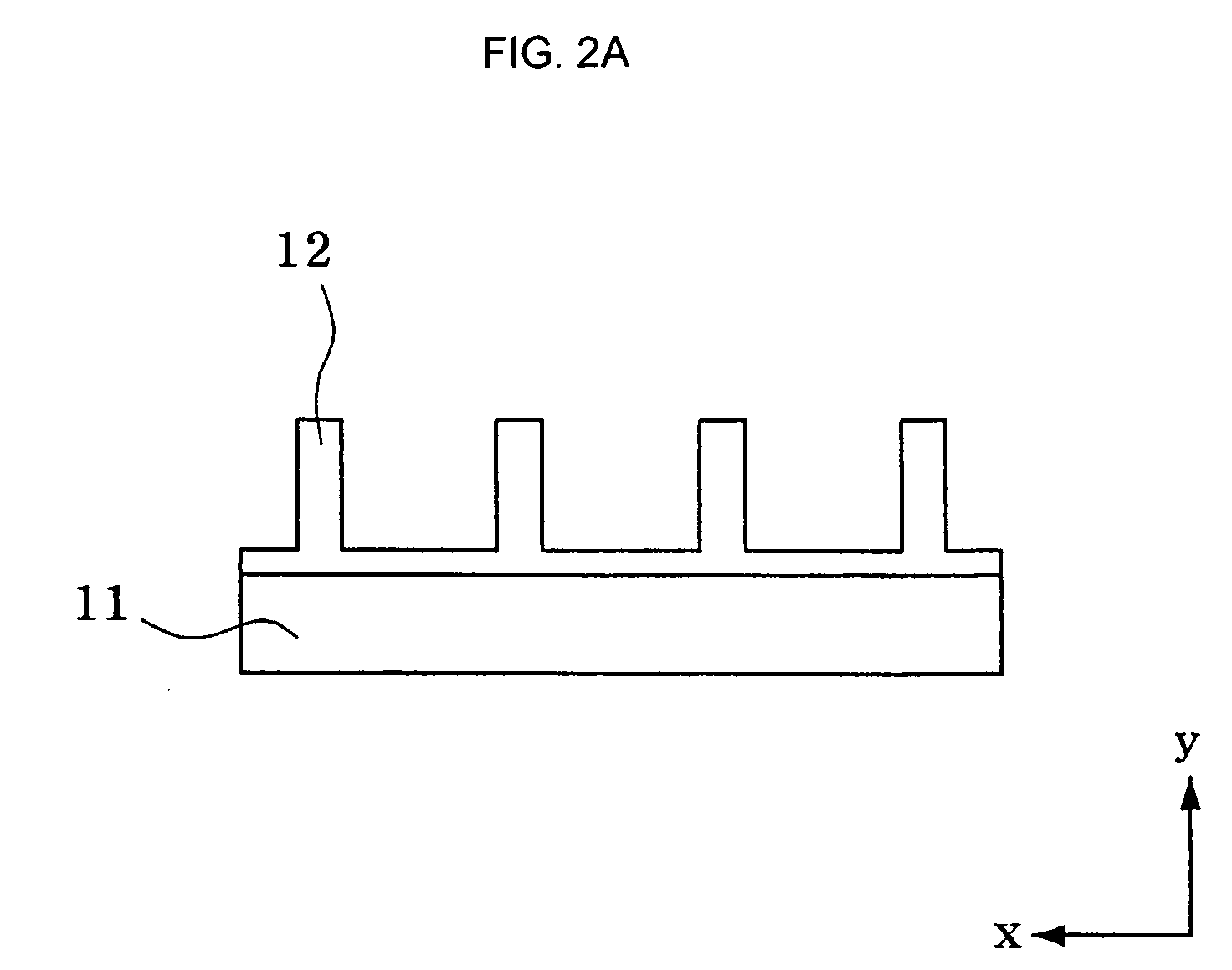

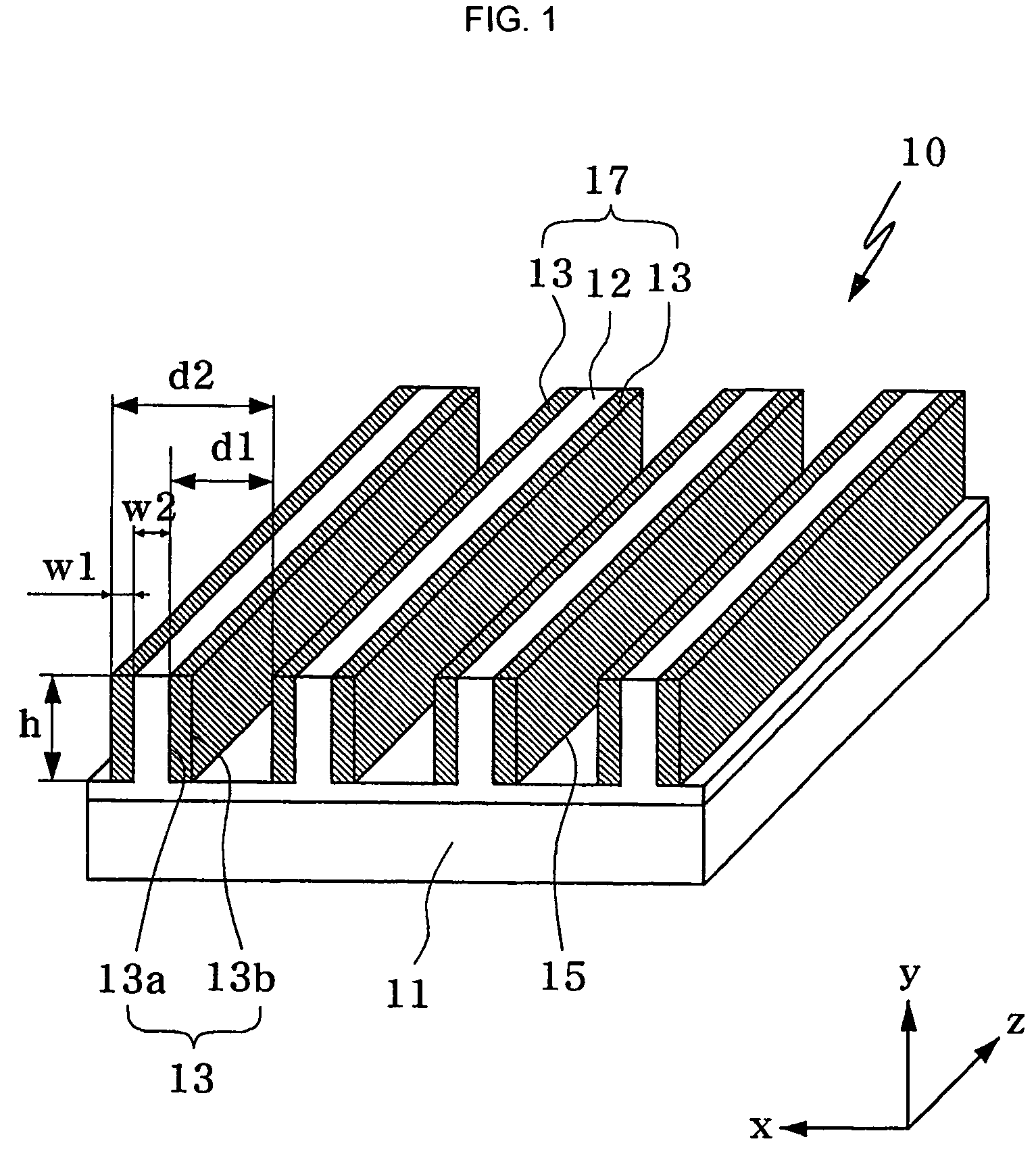

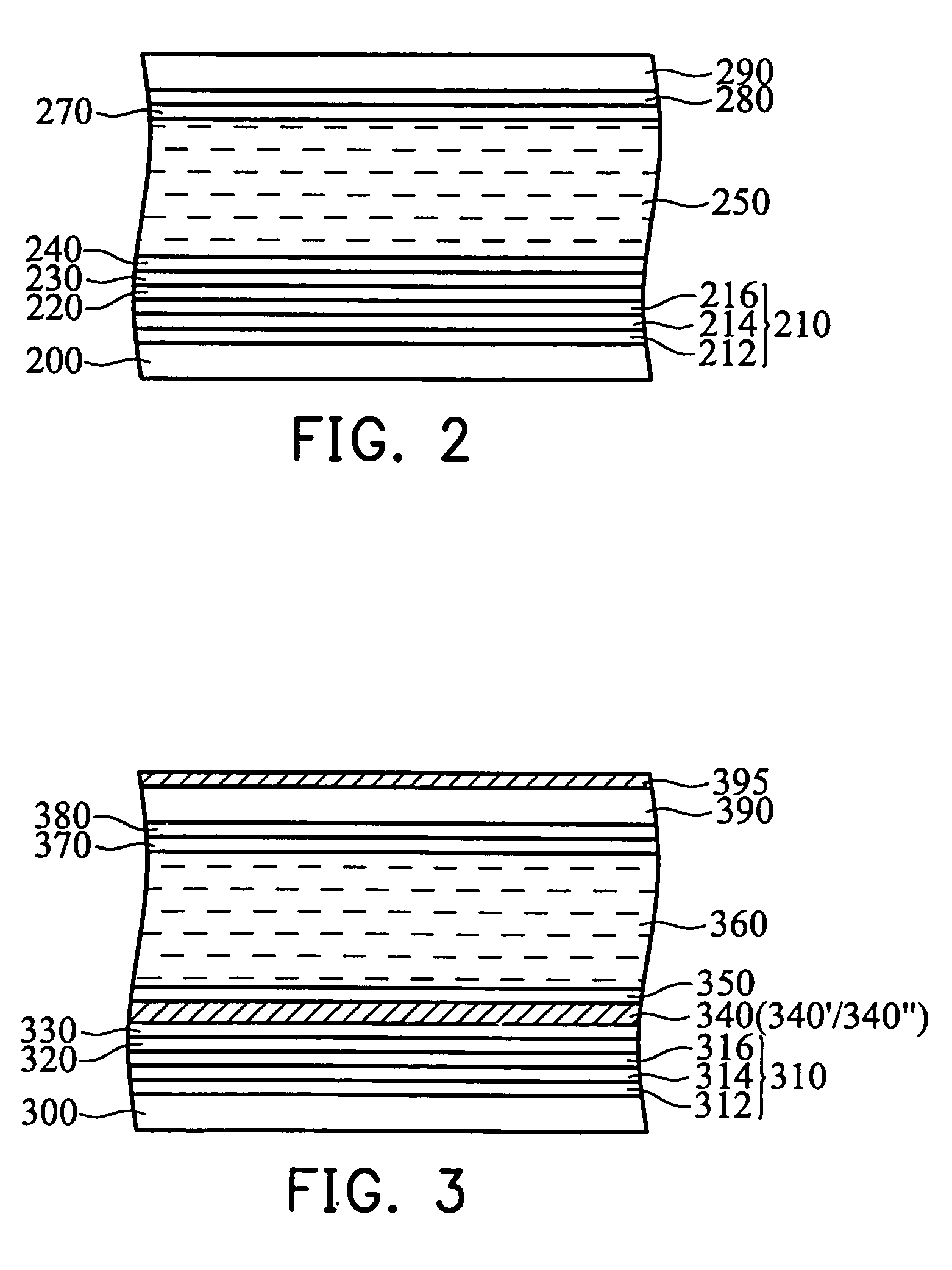

Wire grid polarizer with double metal layers

ActiveUS7158302B2High extinction ratioImprove disadvantagesPolarising elementsDiffraction gratingsWire gridDielectric layer

A wire grid polarizer with double metal layers for the visible spectrum. Parallel dielectric layers having a period (p) of 10˜250 nm and a trench between adjacent dielectric layers overlie a transparent substrate. A first metal layer having a first thickness (d1) of 30˜150 nm is disposed in the trench. A second metal layer having a second thickness (d2) of 30˜150 nm and a width (w) overlies on the top surface of each dielectric layer. The first and second metal layers are separated by a vertical distance (l) of 10˜100 nm. The first thickness (d1) is the same as the second thickness (d2). A ratio of the width (w) to the period (p) is 25˜75%.

Owner:IND TECH RES INST

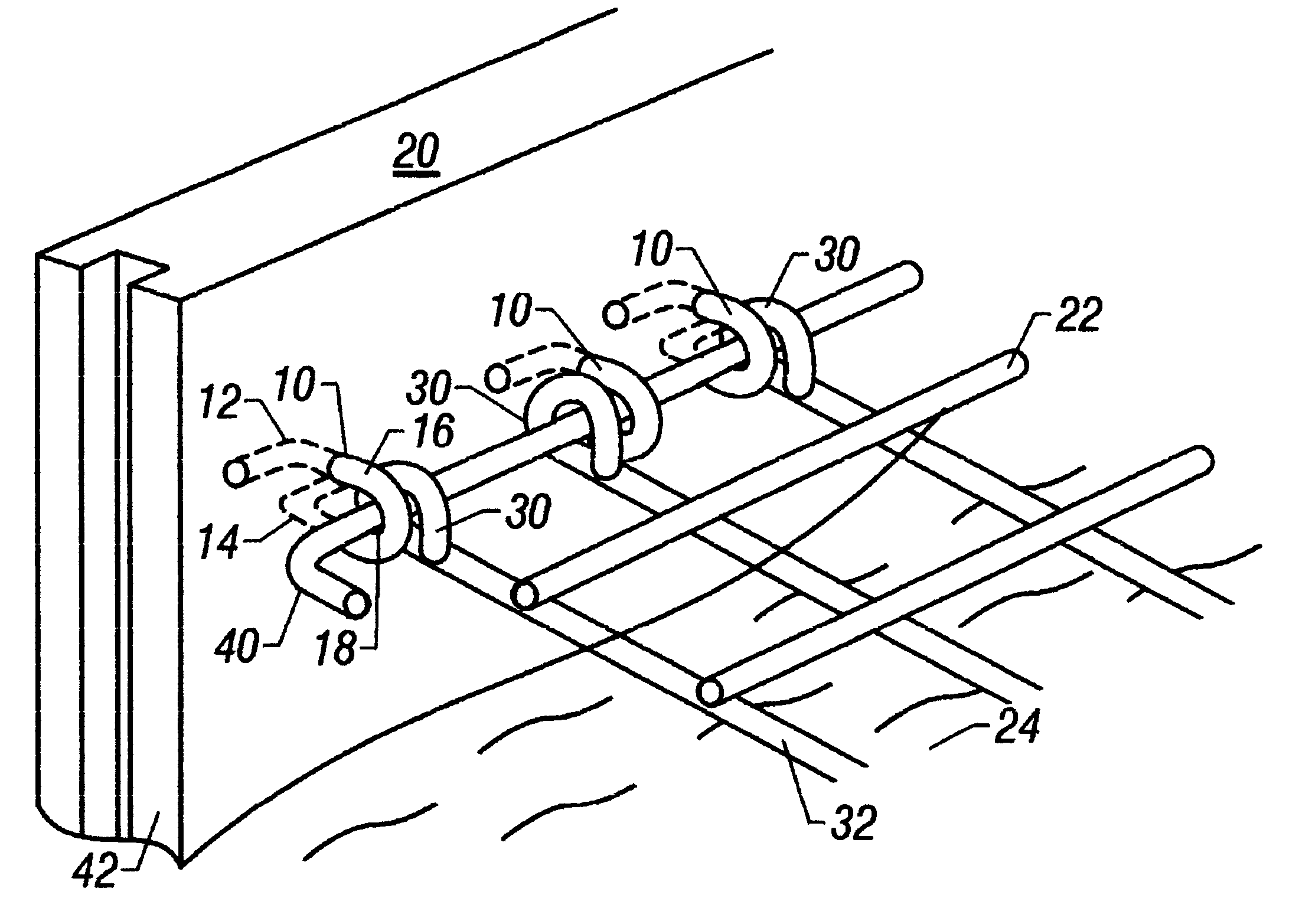

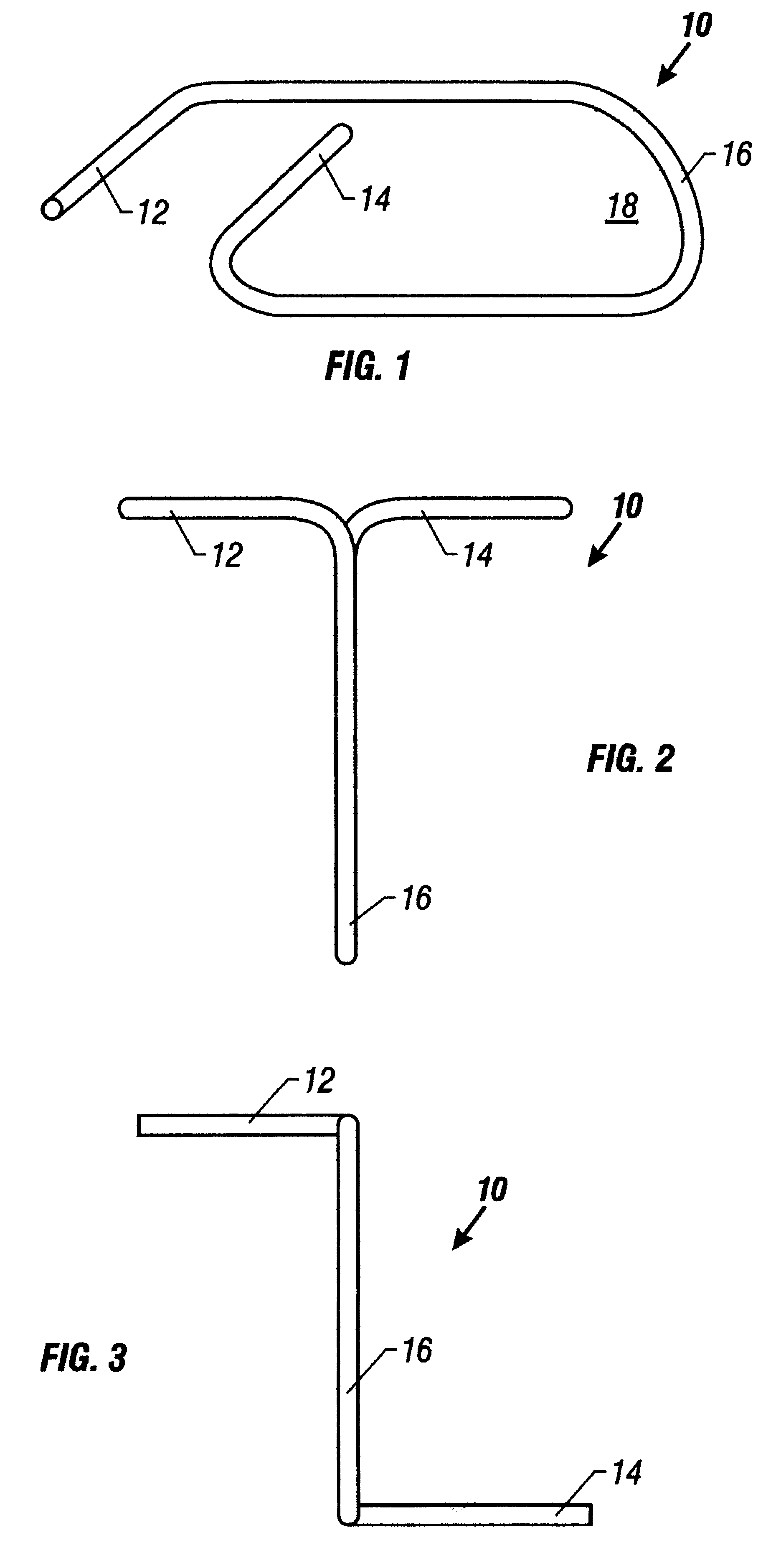

Mechanical interlocking means for retaining wall

An improved method and system for attaching a welded wire grid-work panel to a plurality of face panels of a retaining wall. The method first begins by providing a plurality of stackable face panels, each face panel having a plurality of anchor links fixed within a back portion of the face panels. Each of the anchor links forms a vertical loop extending outwardly generally perpendicular to the back portion of the face panels. Additionally, each anchor link includes two legs extending laterally from each anchor link within the face panel. Next, a first tier of the face panels is disposed at the bottom of the embankment being erected. Soil is then back-filled behind the first tier of panels to a level of the anchor links disposed within the first tier of face panels. A welded wire grid-work panel, which extends perpendicularly from the back portion of the face panels into a soil embankment, is positioned so that a plurality of wire loops at the edge of the grid-work panel aligns with the vertical loops. A connector rod is extended through the vertical loops of the anchor links and the wire loops of the grid-work panel. Next, additional soil is back-filled behind the first tier of face panels and over the anchor links, vertical loops, wire loops, and grid-work panel to a level at a top edge of the first tier of face panels. The method is repeated until the desired height of the embankment is attained.

Owner:SCR STI LLC

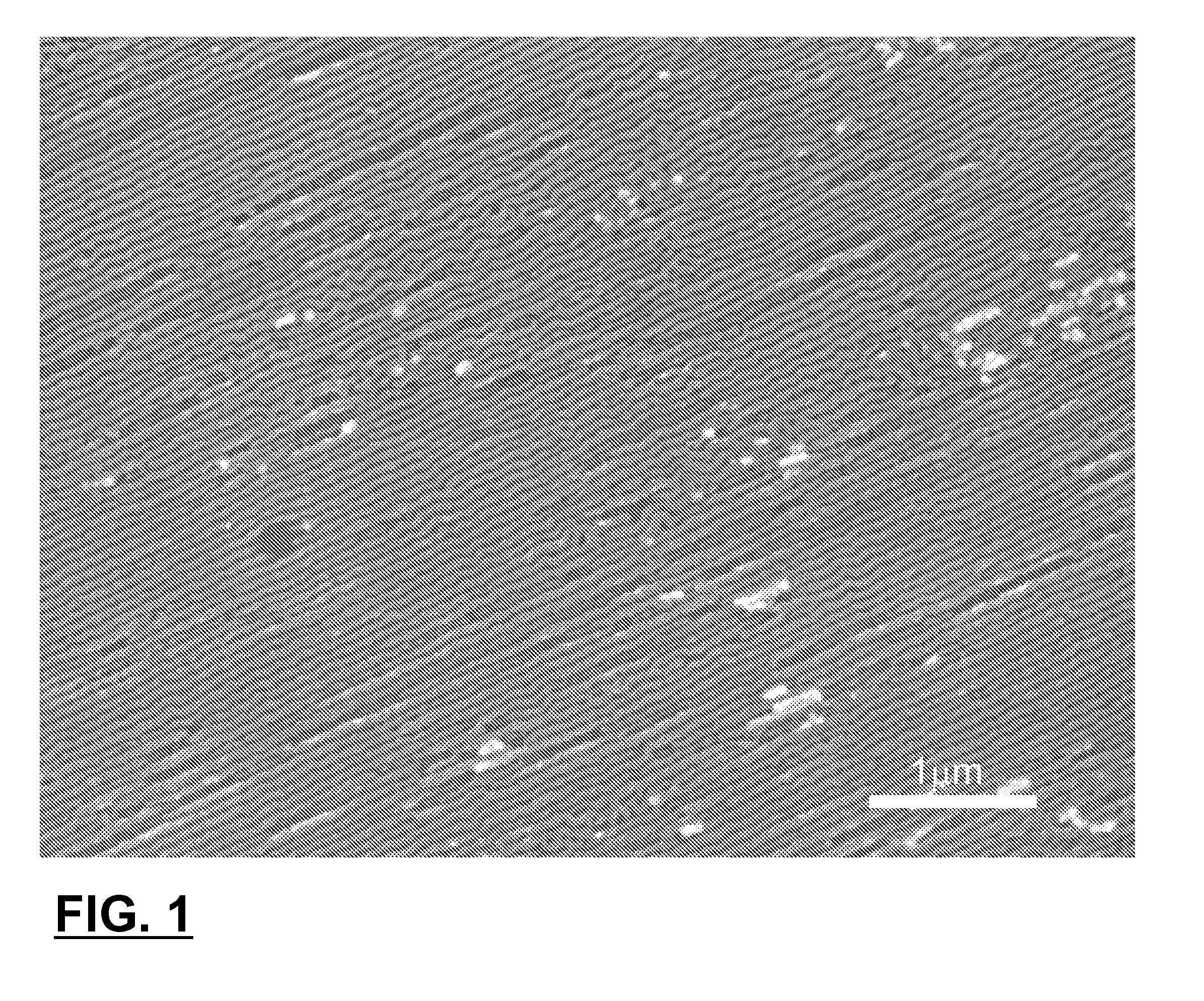

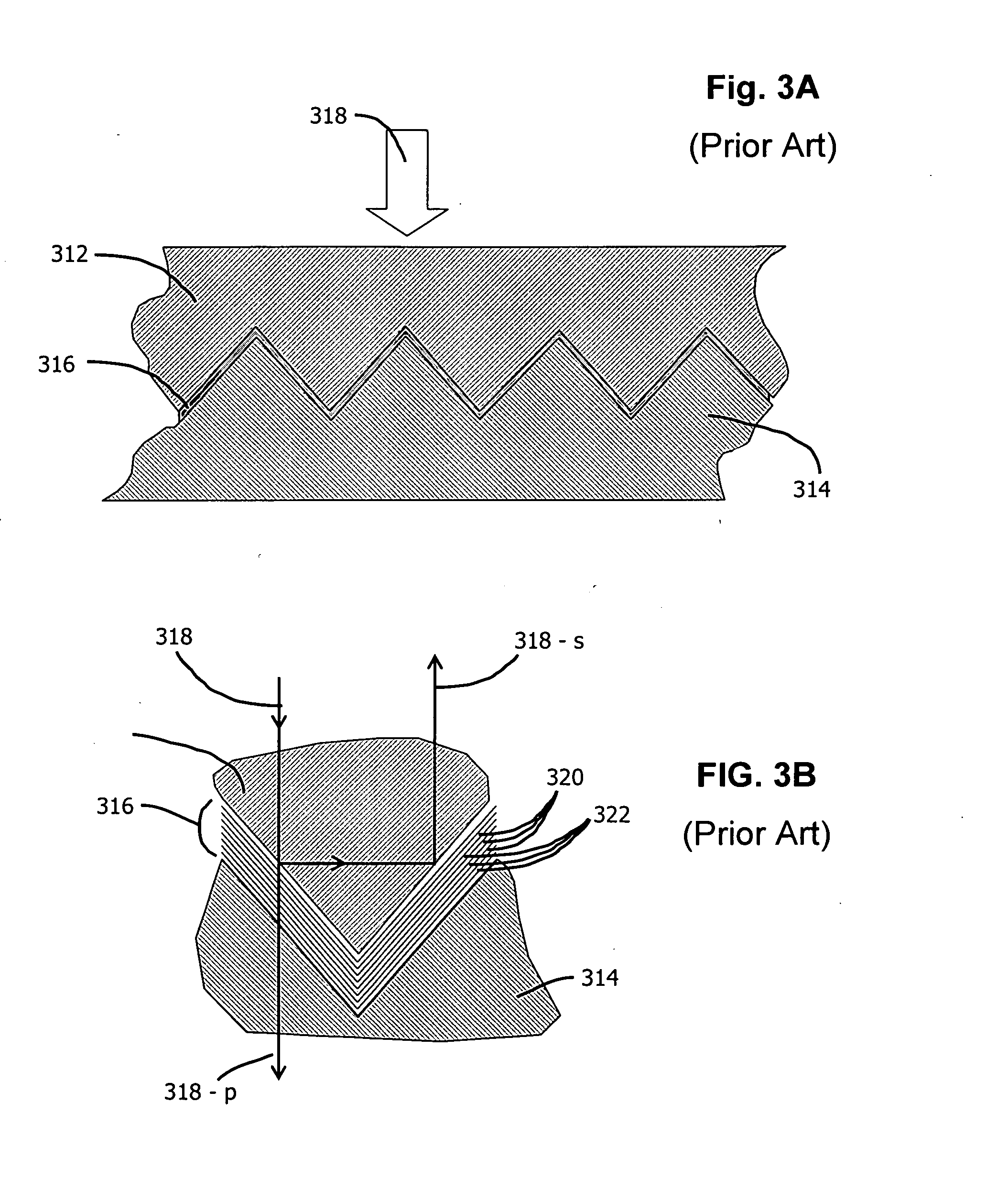

Short-wavelength polarizing elements and the manufacture and use thereof

While gold wire grids have been used to polarize infrared wavelengths for over a hundred years, they are not appropriate for shorter wavelengths due to their large period. With embodiments of the present invention, grids with periods a few tens of nanometers can be fabricated. Among other things, such grids can be used to polarize visible and even ultraviolet light. As a result, such wire grid polarizers have a wide variety of applications and uses, such as, e.g., in the fabrication of semiconductors, nanolithography, and more.

Owner:PRINCETON UNIV +1

Reflection-Repressed Wire-Grid Polarizer

A reflection repressed wire-grid polarizer device for polarizing incident visible or infrared light and selectively repressing a reflected polarization includes at least three layers disposed on a substrate. A polarizing wire-grid layer has an array of parallel metal wires with a period less than half the wavelength of the incident light. A reflection-repressing layer or grid includes an inorganic and non-dielectric material which is optically absorptive of visible or infrared light. A dielectric layer or grid includes an inorganic and dielectric material.

Owner:MOXTEK INC

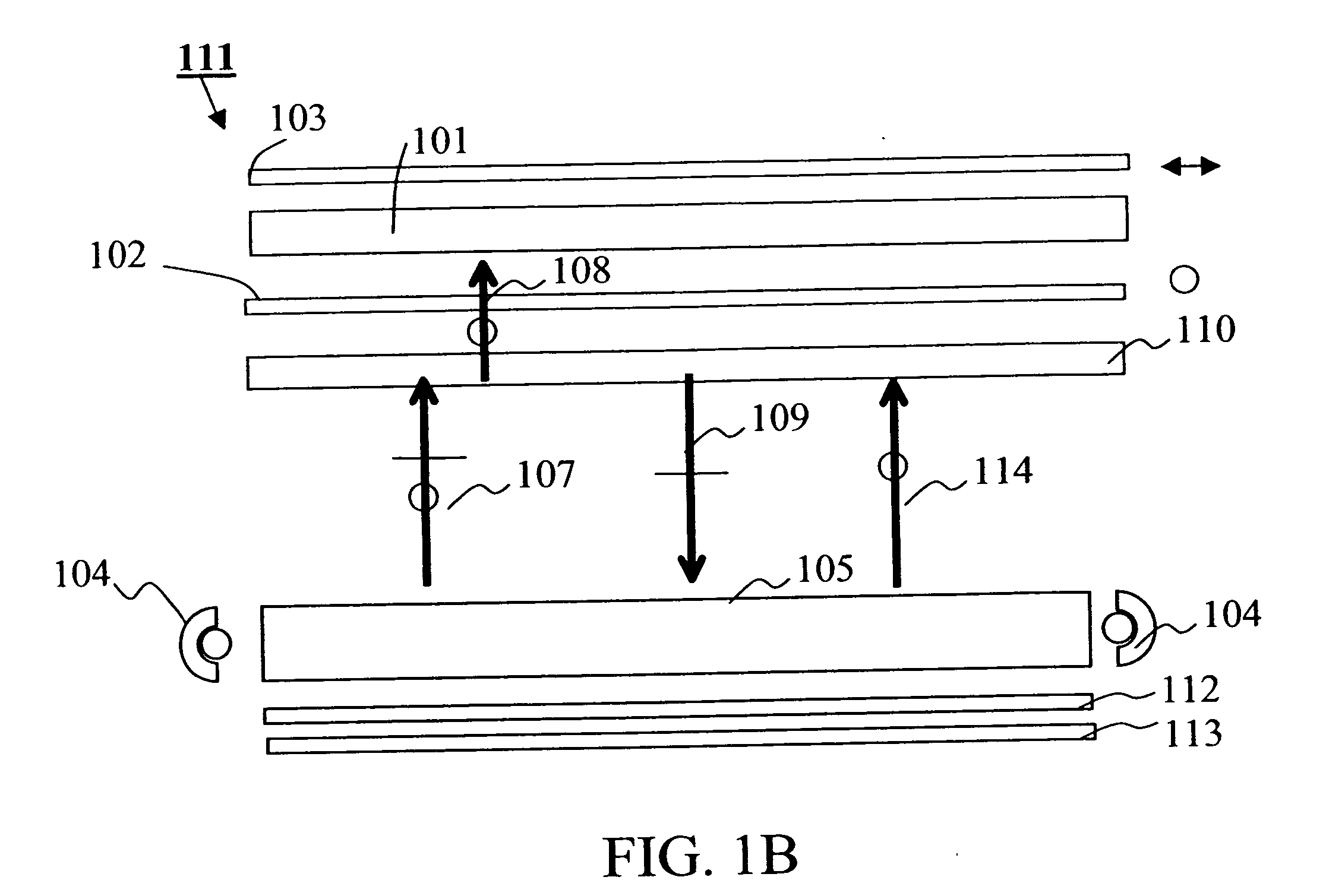

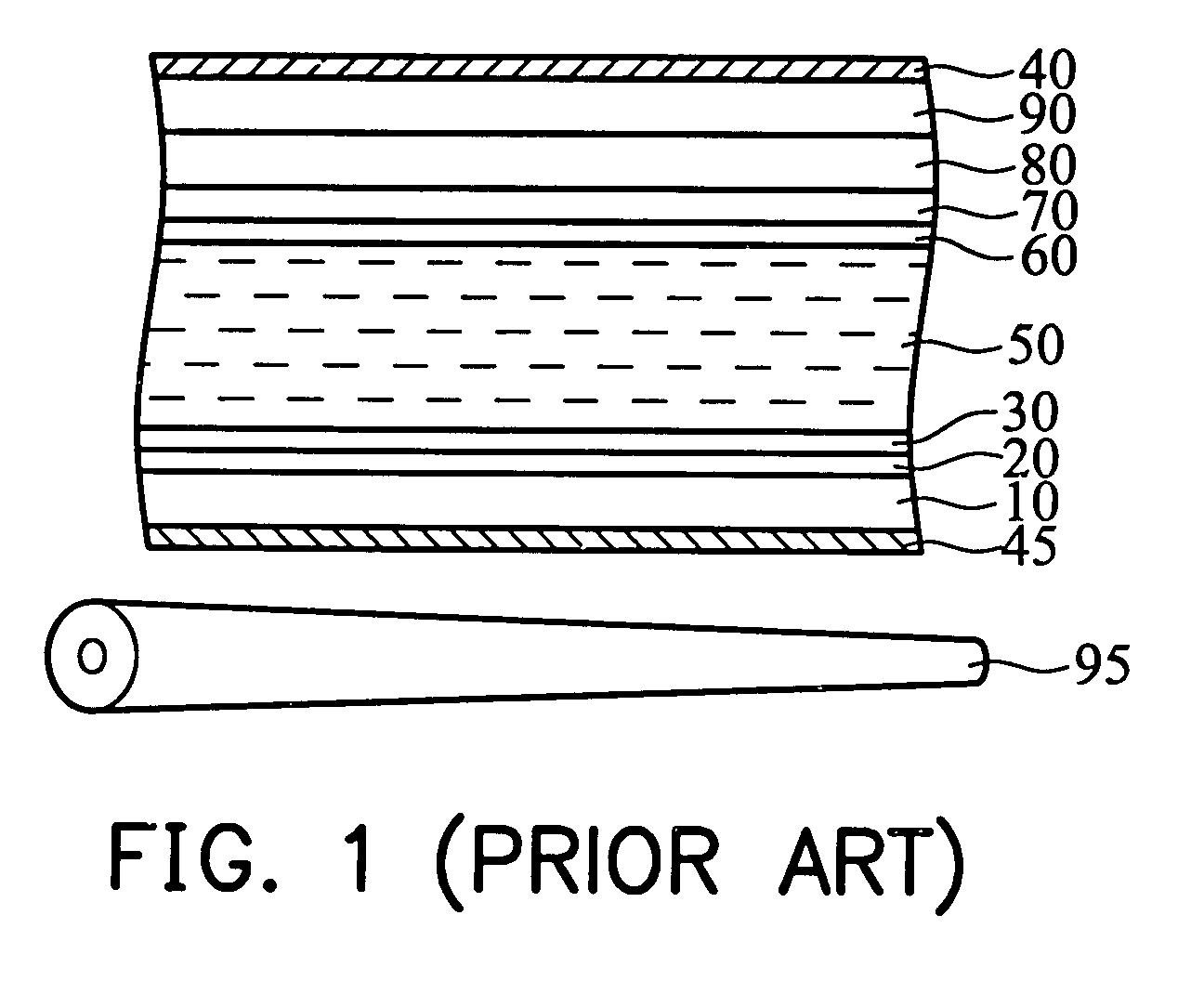

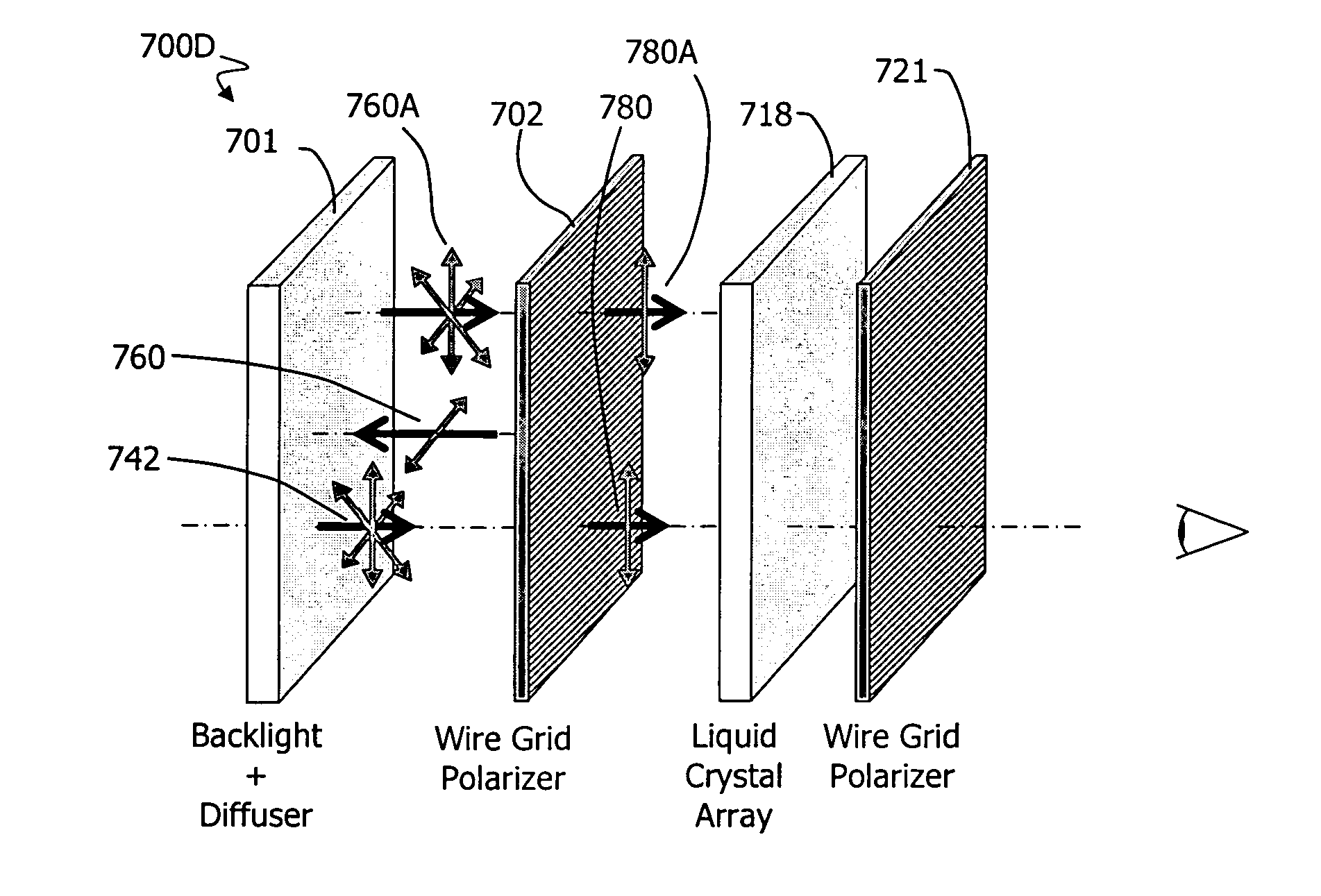

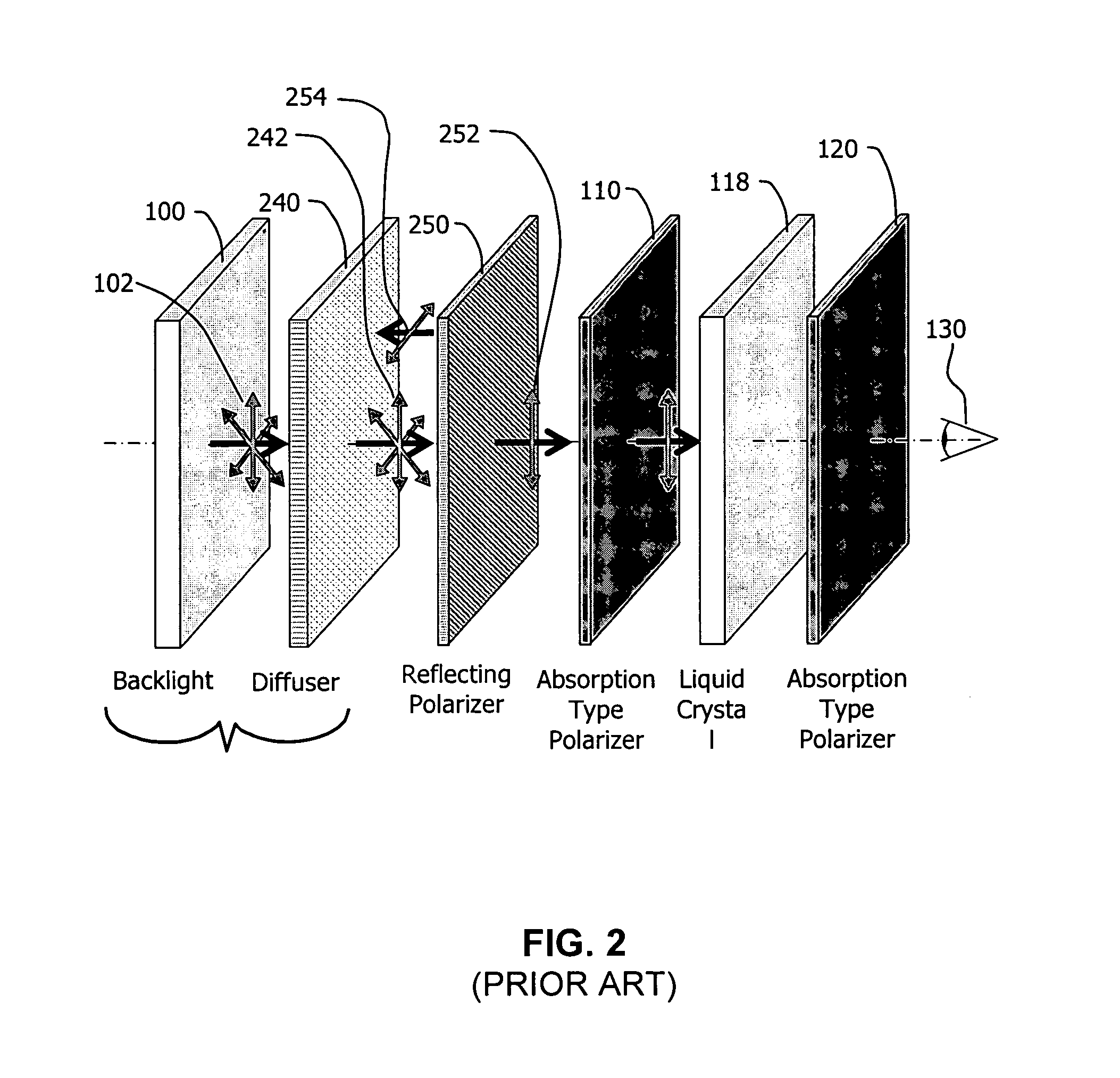

Wire-grid polarizers, methods of fabrication thereof and their use in transmissive displays

Wire-grid polarizers (WGPs) and their use in transmissive displays are disclosed. The displays containing these WGPs possess high contrast and brightness characteristics in comparison to prior art displays.

Owner:EI DU PONT DE NEMOURS & CO

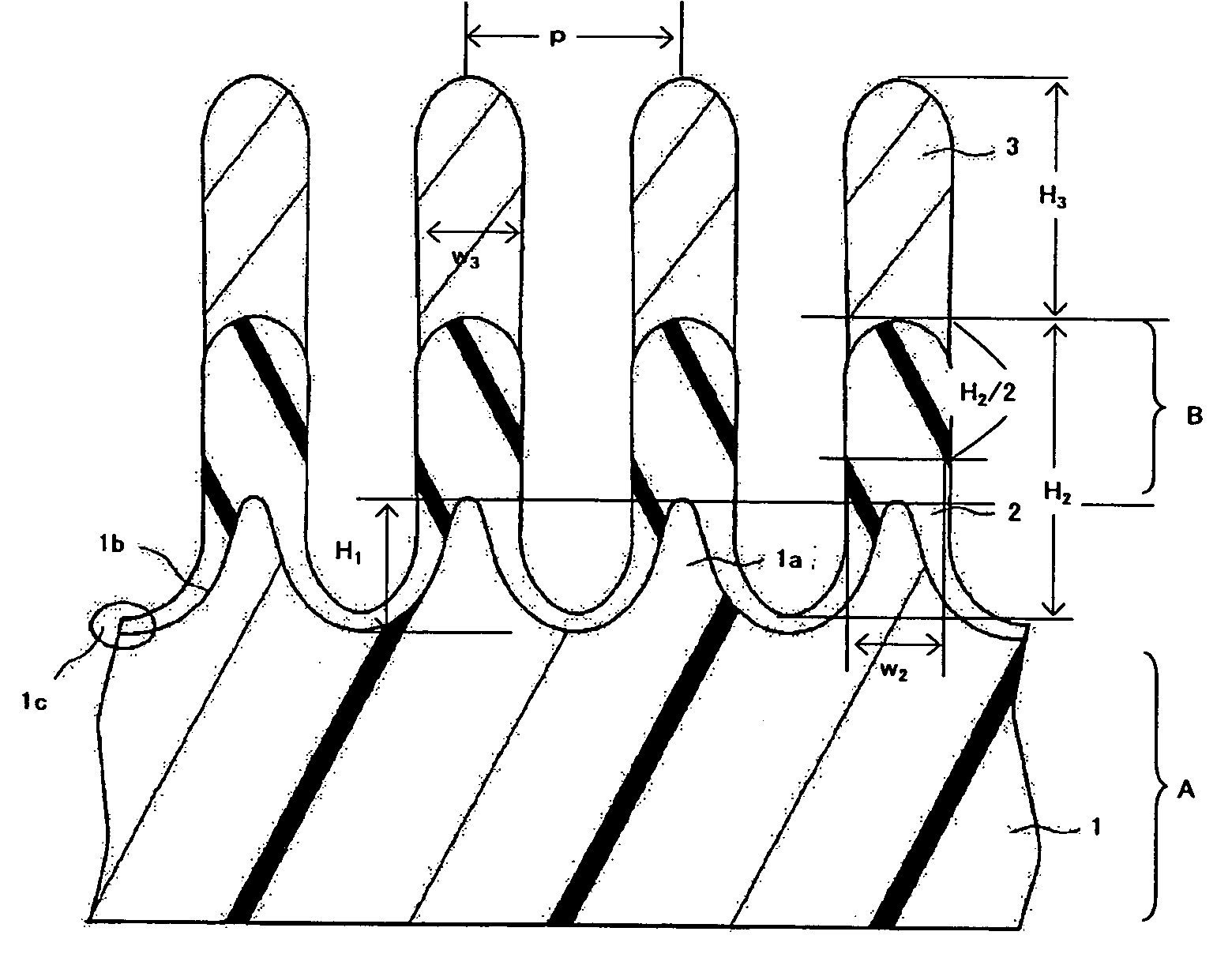

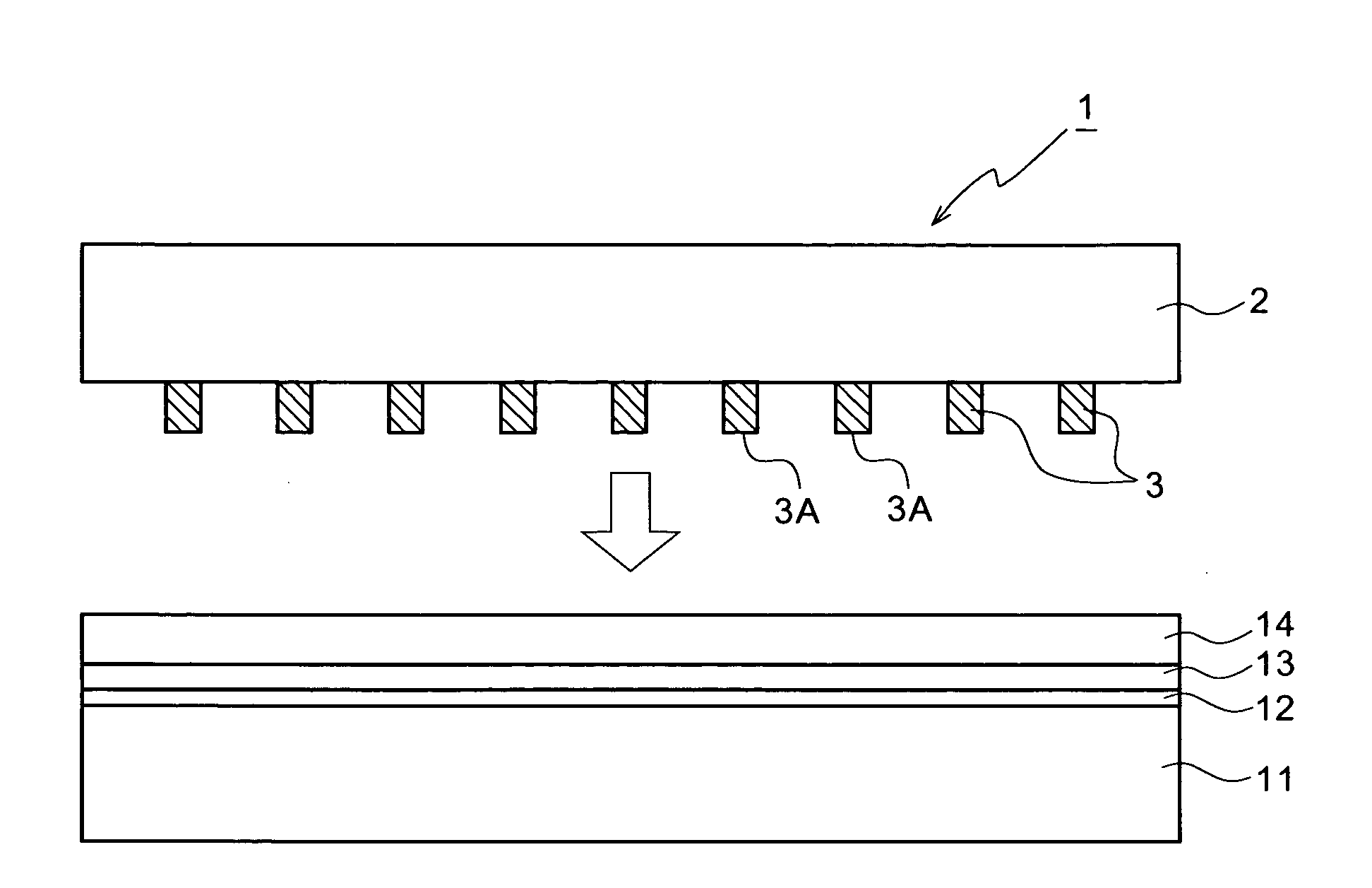

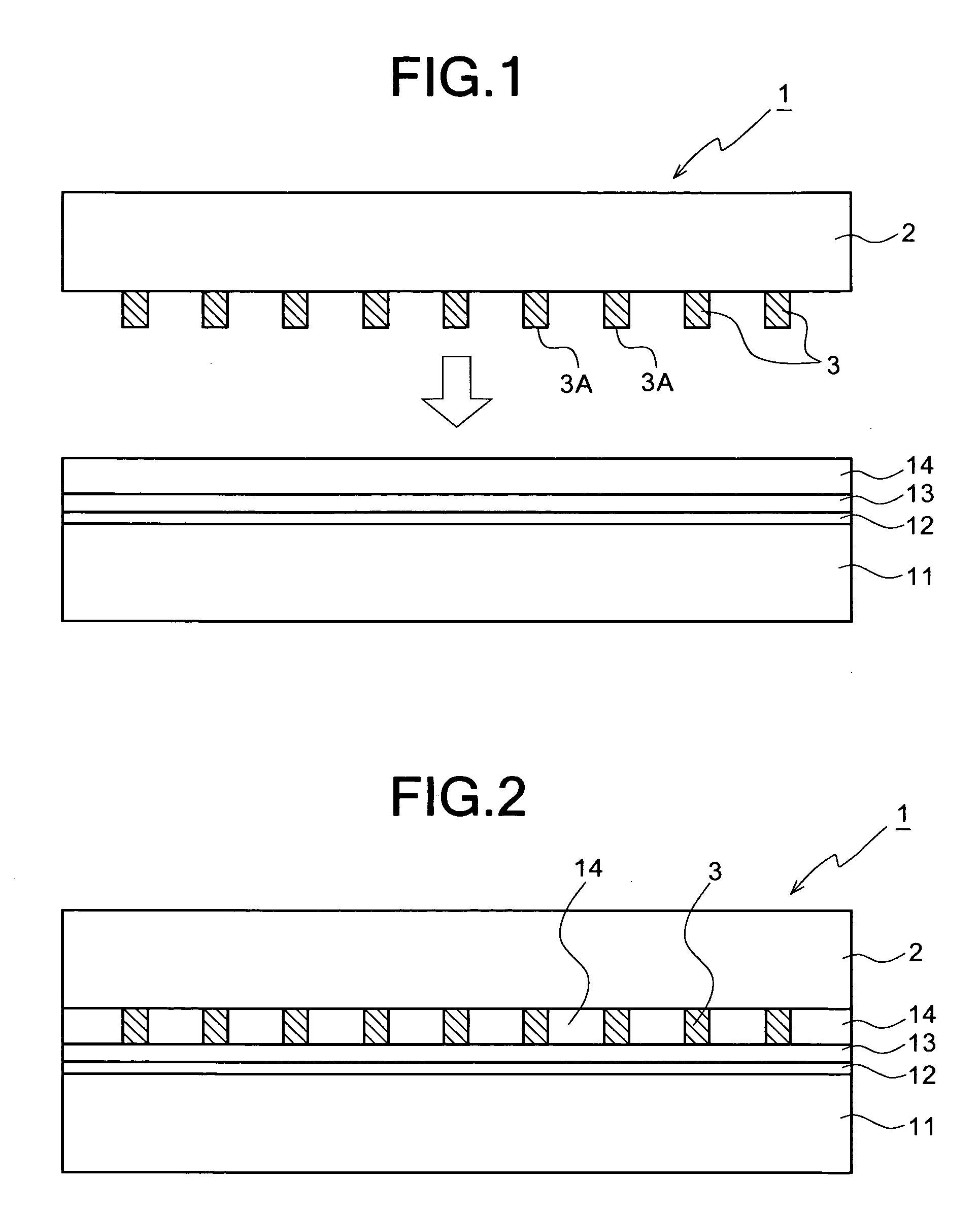

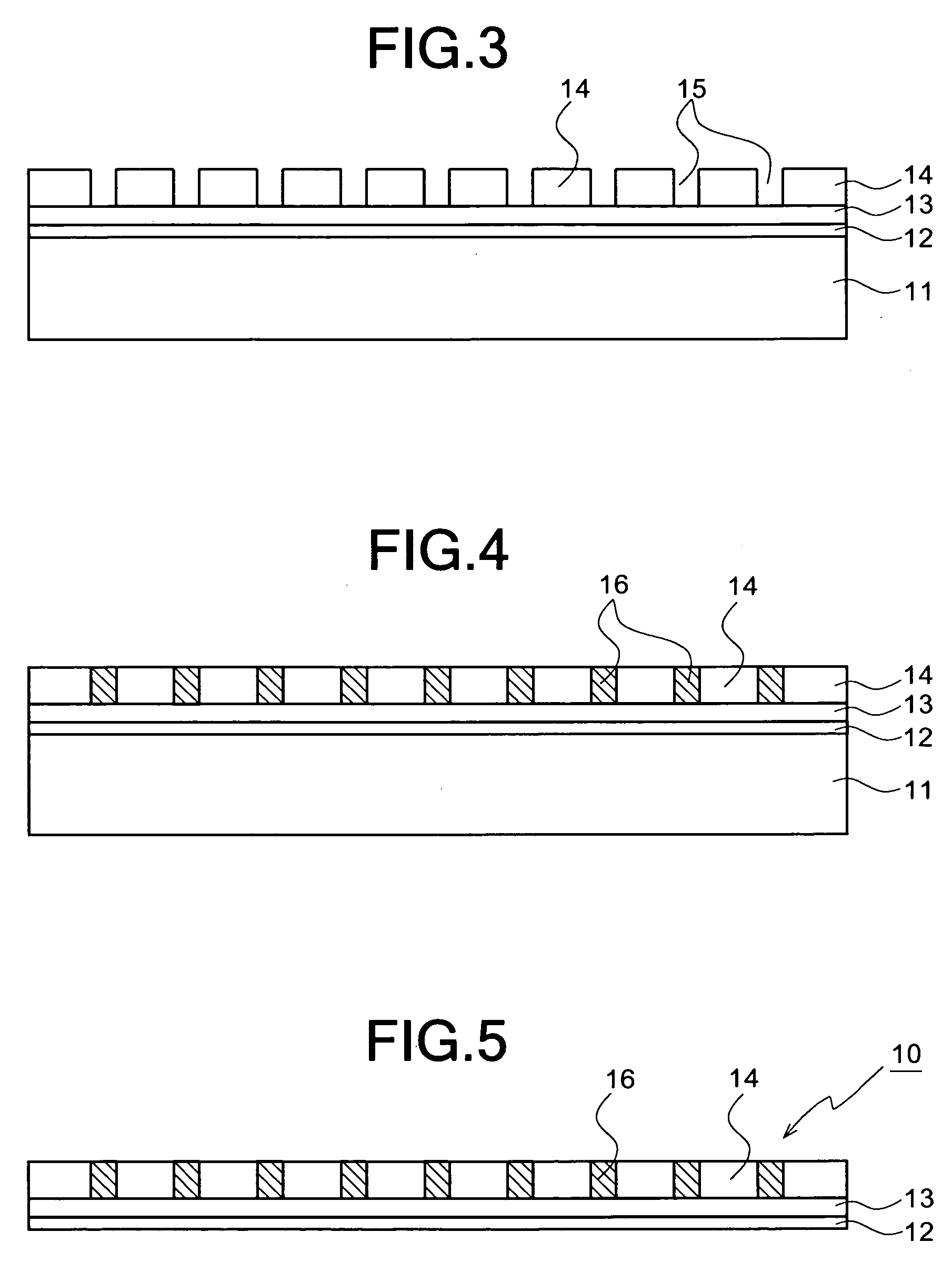

Wire grid polarizer and method for producing same

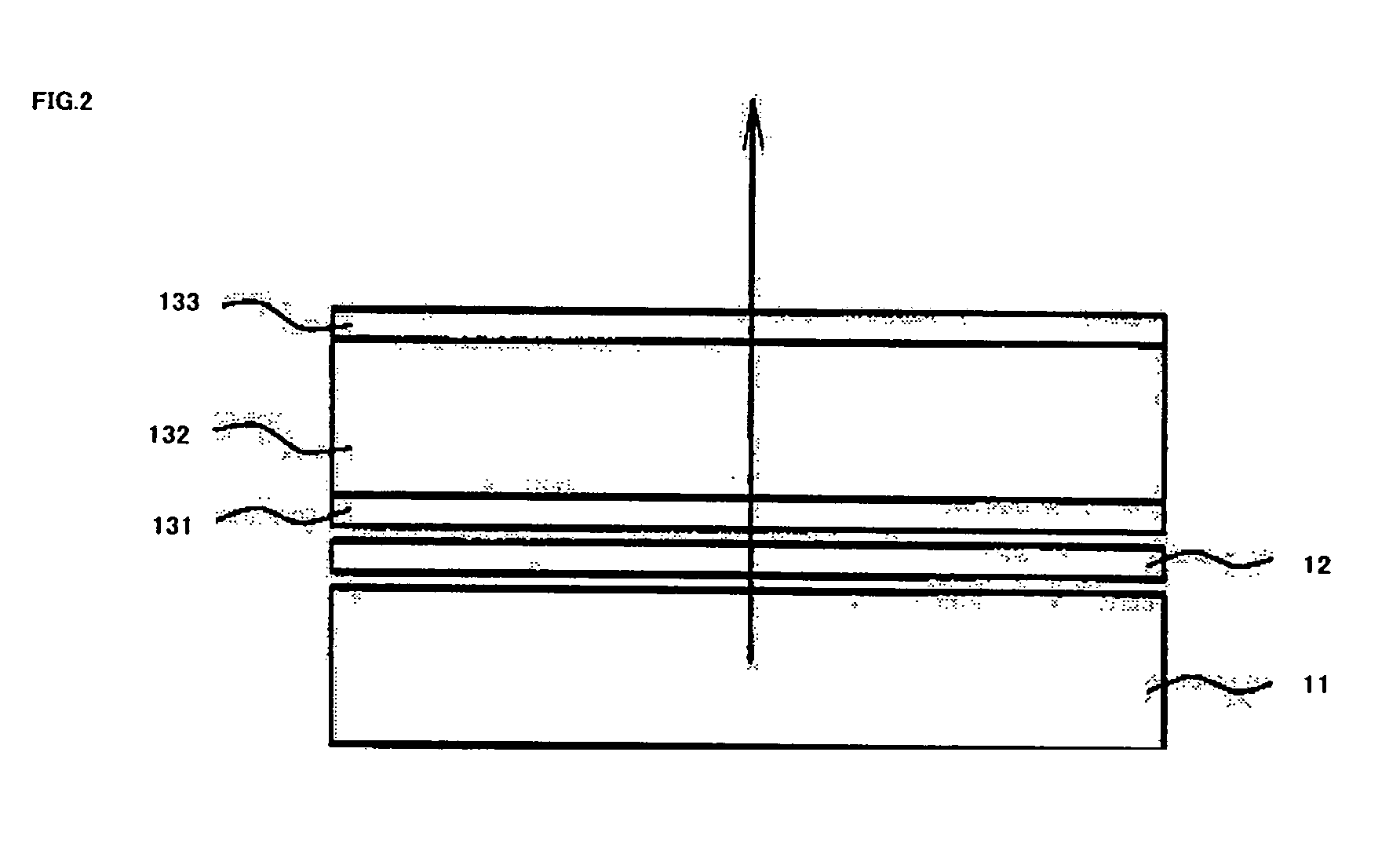

ActiveUS20050046943A1High light transmittanceLow costPolarising elementsOptical articlesWire gridLithographic artist

There are provided a thin wire grid polarizer having a high transmittance, a high quenching ratio and a high degree of polarization, and a method for producing the same at low costs. A fluoridated polyimide thin film 12, a hydrophilic thin film 13 and a hydrophobic thin film 14 are sequentially stacked on a glass substrate 11 to be pressed by a die 1 from the side of the hydrophobic thin film 14 to transfer the fine pattern of groove forming protrusions 3 of the die 1 to the hydrophobic thin film 14 and hydrophilic thin film 13 by the nano-imprinted lithography technique, and then, metal fine wires are caused to grow by plating.

Owner:ENPLAS CORP

ZScreen® modulator with wire grid polarizer for stereoscopic projection

ActiveUS20080316375A1Improve performanceStereoscopic photographyNon-linear opticsCamera lensWire grid

A projection design configured for use with a projector having a projector lens is provided. The device includes at least one pi-cell or pi-cell electro-optical modulator in combination with a wire grid polarizer mounted proximate the pi-cell(s). The design may include a cleanup polarizer between the pi-cell(s) and the wire grid polarizer and optionally a protective window between the wire grid projector and projection lens. The device may be oriented at an angle substantially differing from the axis of the projector lens. The resultant device includes spacing for airflow and can offer improved performance, particularly in heating, over designs previously available.

Owner:REAID INC

Wire grid polarizers with optical features

InactiveUS20060215263A1Improve optical efficiencyLess sensitive to heatPolarising elementsNon-linear opticsWire gridOptoelectronics

The invention relates to an optical element comprising a substrate, a wire grid on one side of said substrate, and prismatic light collimating features on the other side of said substrate

Owner:SKC HI TECH & MARKETING CO LTD CO REGISTRATION NO 161511 0225312

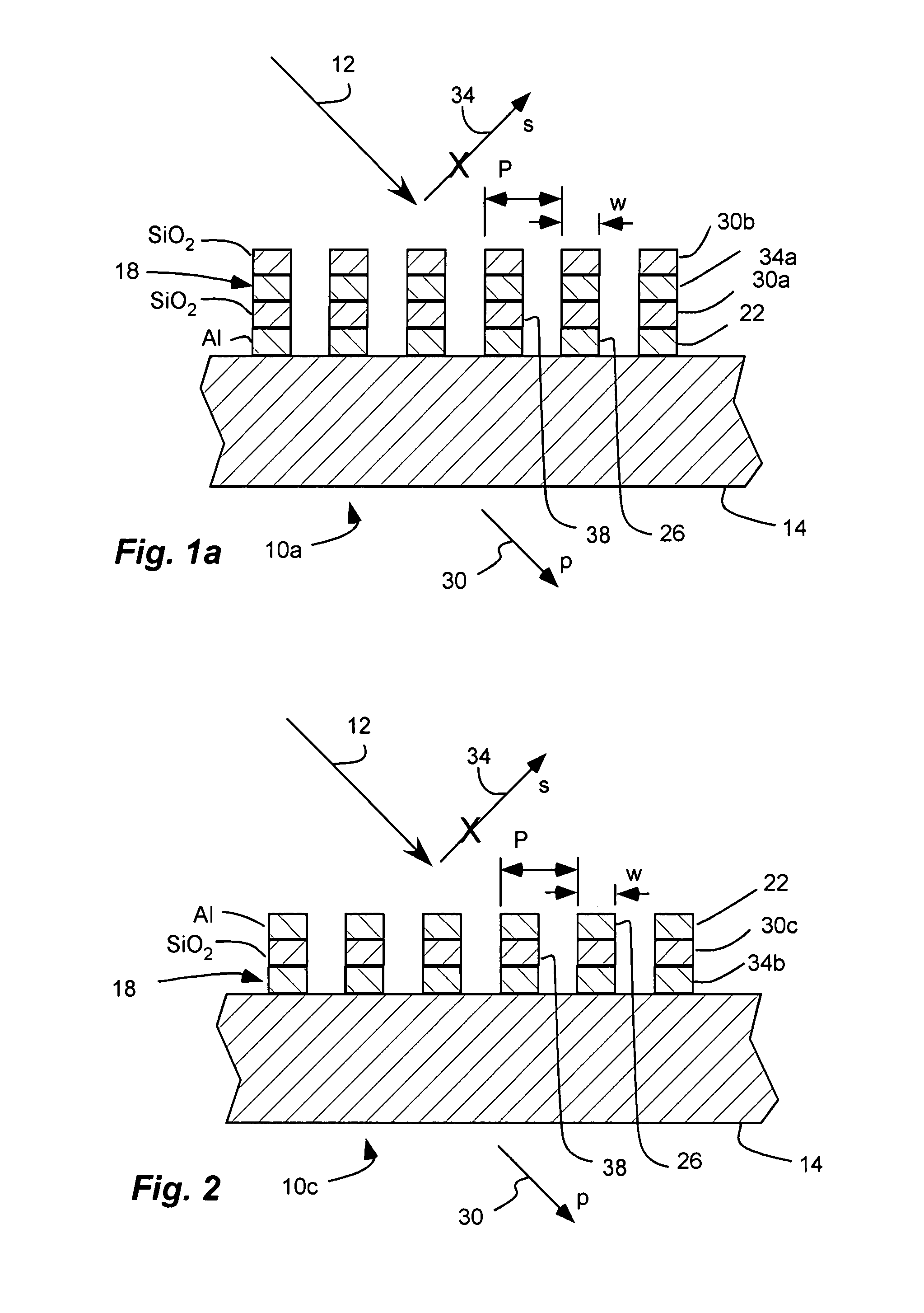

Wire grid polarizer and method of manufacturing the same

InactiveUS20080137188A1High light transmittanceHigh extinction ratioPolarising elementsOptical articlesWire gridEngineering

A wire grid polarizer includes a substrate adapted to transmit predetermined wavelengths of light, a plurality of dielectric wires extending parallel to one another along a first direction on the substrate, the dielectric wires including a dielectric material adapted to transmit the predetermined wavelengths of light, and a plurality of metal wires extending along the first direction between the dielectric wires, wherein sidewalls of the metal wires include portions in contact with sidewalls of the dielectric wires and portions not in contact with the sidewalls of the dielectric wires.

Owner:CHEIL IND INC

Roll to roll nanoimprint lithography

Apparatus and methods for a nano-patterning process to fabricate nanostructures. A roller type mold is used to continuously imprint nanostructures onto a flexible web or a rigid substrate. The process includes a coating and an imprinting module, which rotate the web synchronously. Liquid resist materials are used for imprinting and the patterns are set by thermal or UV curing. The process is used to produce bilayer metal wire-grid polarizers, organic solar cells, and organic light emitting diodes.

Owner:RGT UNIV OF MICHIGAN

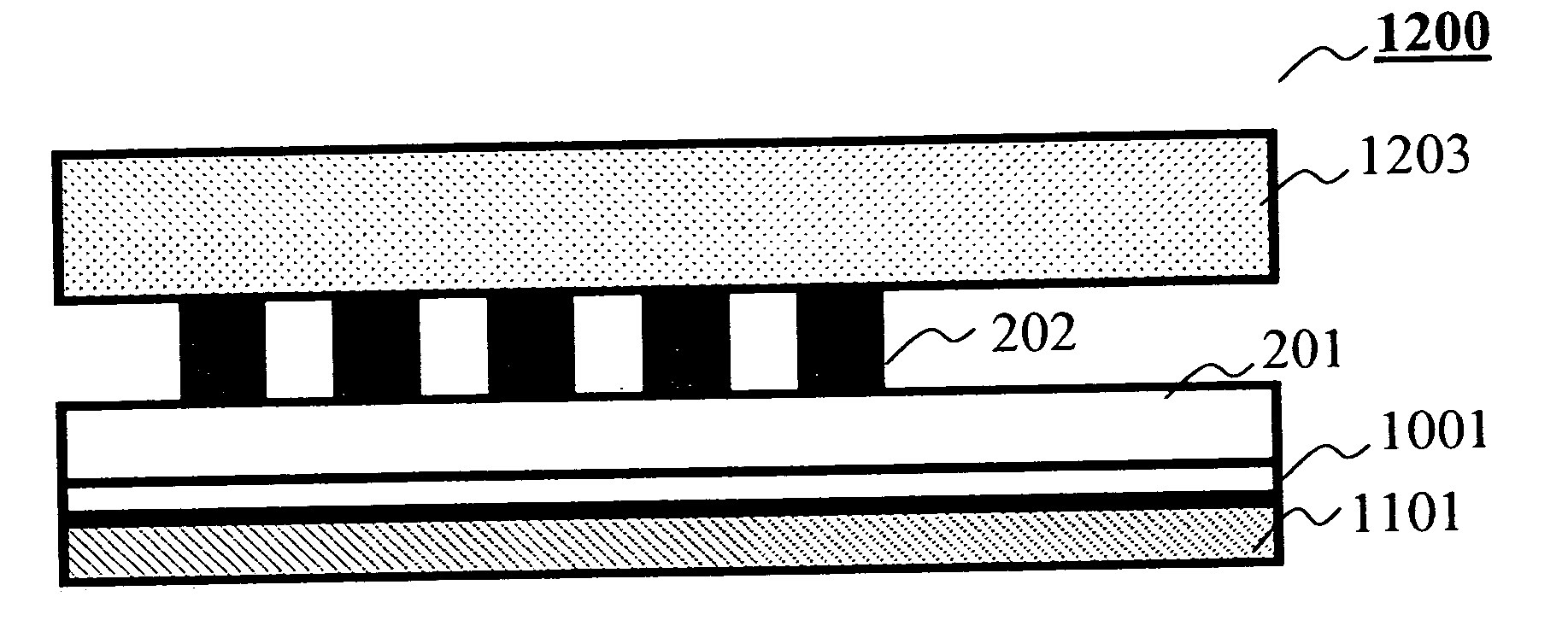

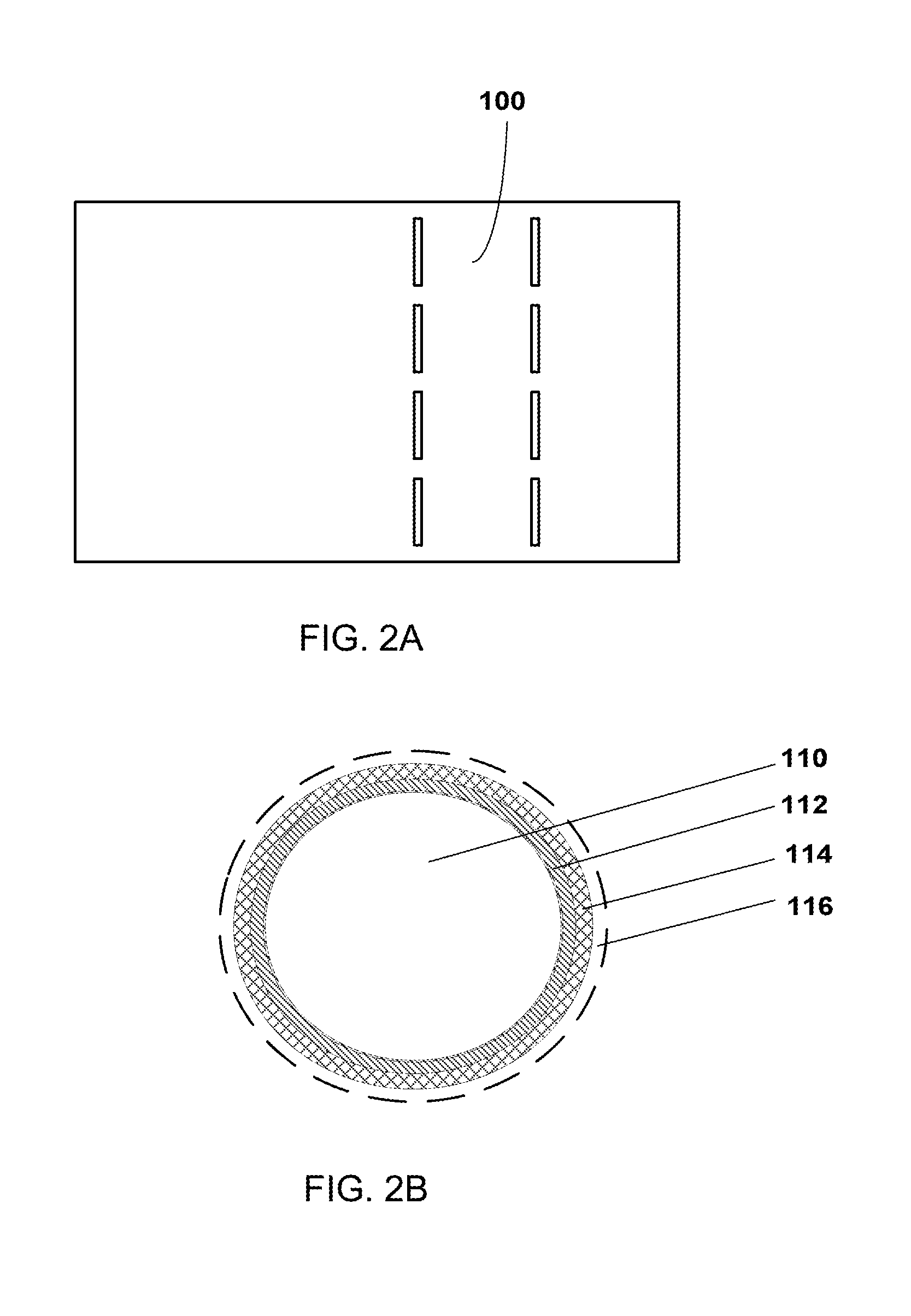

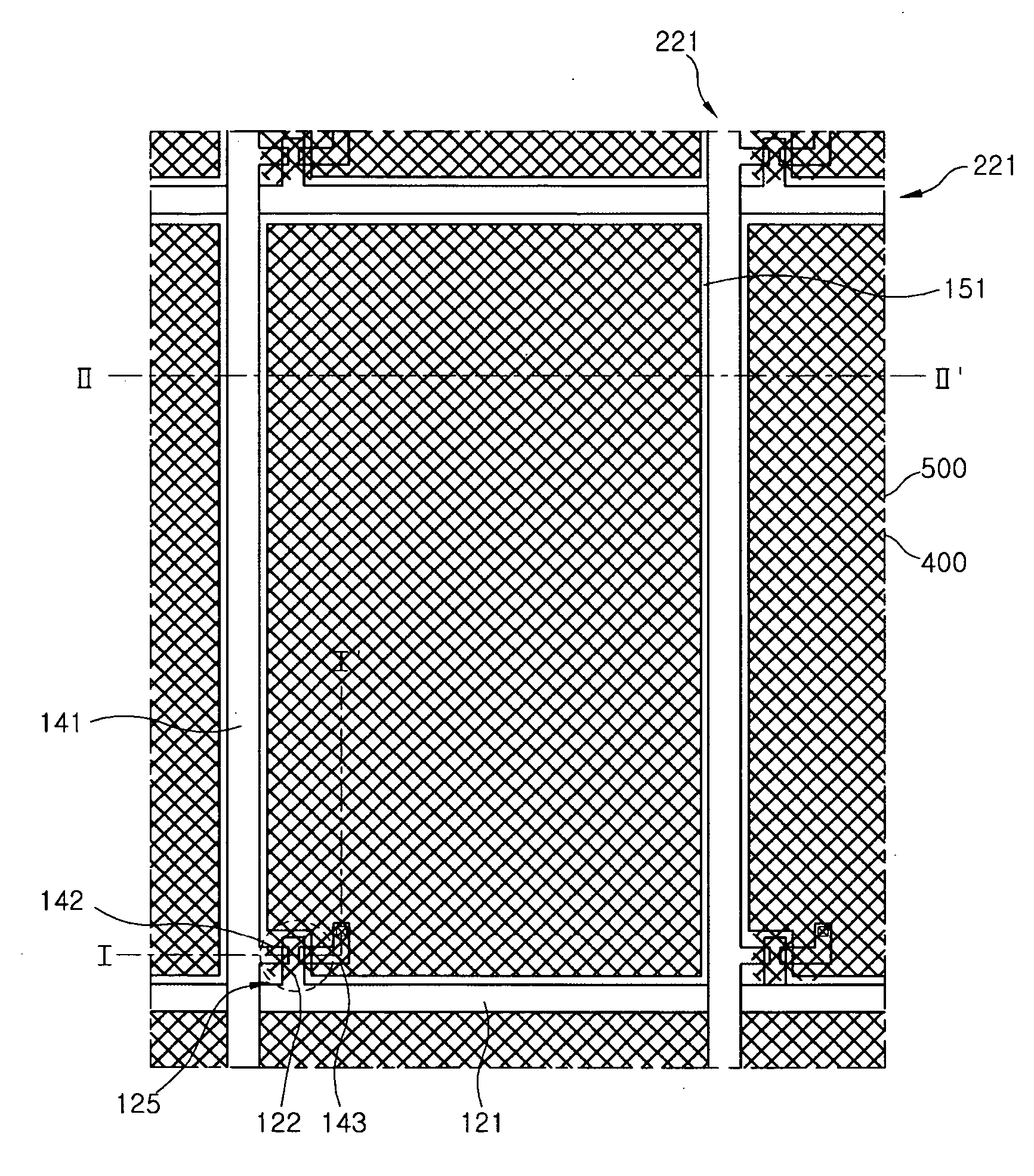

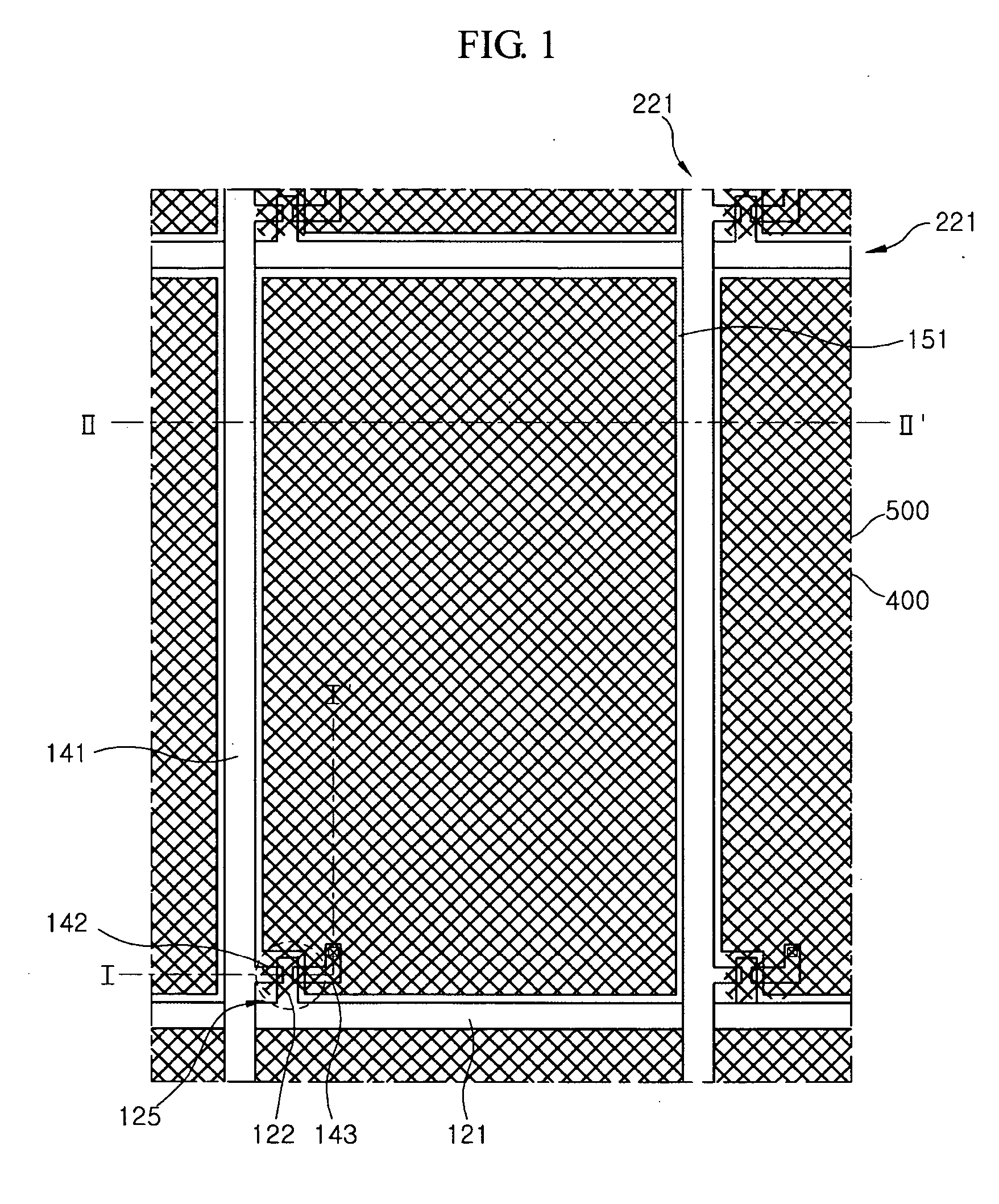

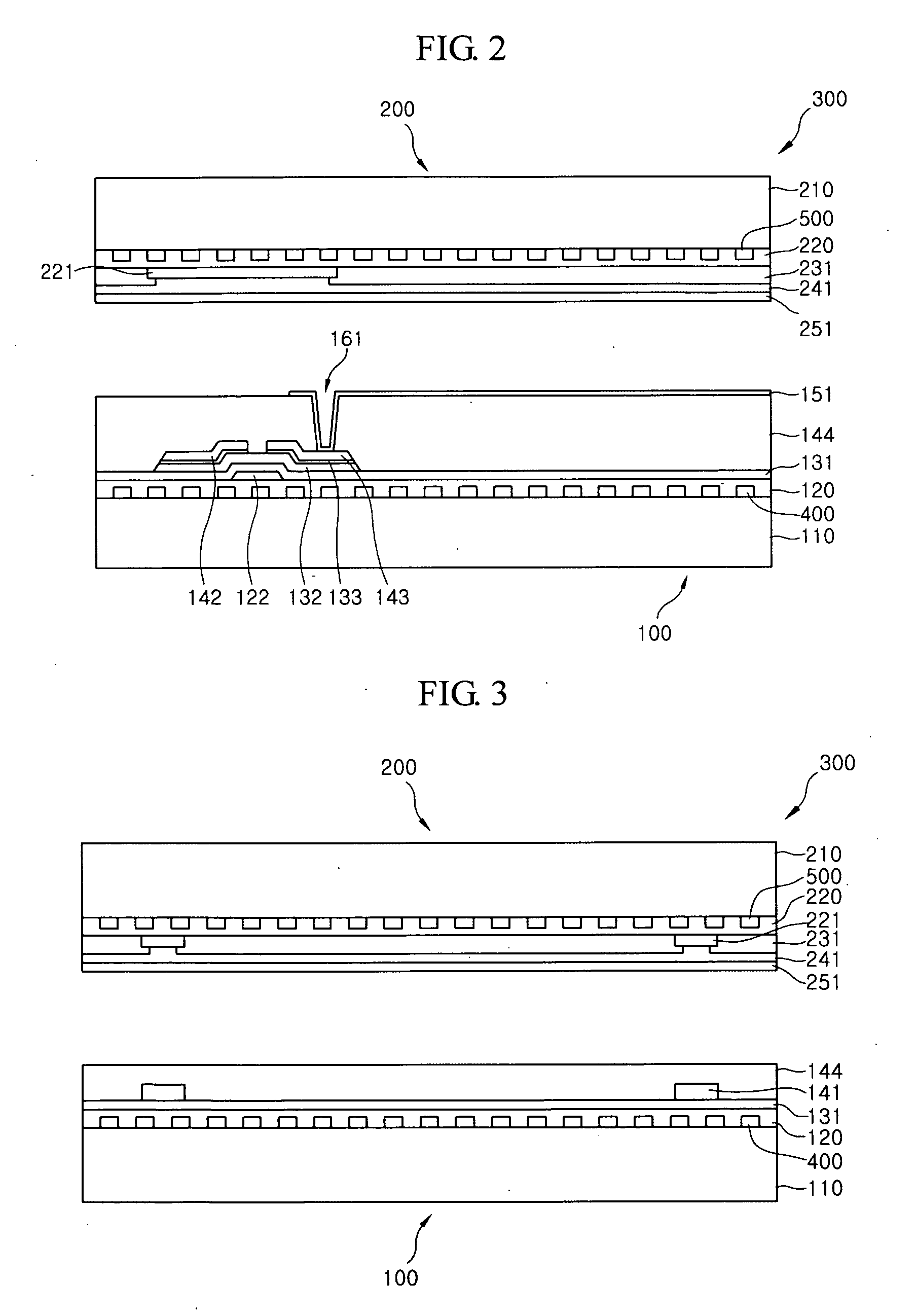

Liquid crystal display

ActiveUS20080100781A1Reduce thicknessLow costPolarising elementsNon-linear opticsLiquid-crystal displayWire grid

The present invention relates to a liquid crystal display (LCD) and a method of manufacturing the same. In the present invention, a wire grid polarizing pattern is formed on at least one of thin film transistor and color filter substrates in a manufacturing process thereof. According to the present invention, the thickness of an LCD panel can be reduced as compared with a method of attaching an existing polarizer to an LCD panel, and the wire grid polarizing pattern can be built in an LCD panel without increasing the number of masking processes.

Owner:SAMSUNG DISPLAY CO LTD

Wire-grid polarizer and process for producing the same

InactiveUS20090052030A1High polarization separation abilityIncreased durabilityNanoinformaticsPhotomechanical apparatusProduction rateWire grid

The present invention provides a wire-grid polarizer showing high polarization separation ability in the visible light region and is excellent in heat resistance and durability; and a process for producing such a wire-grid polarizer with high productivity, which enables to produce a polarizer of large area.A process for producing a wire-grid polarizer, comprising a step of coating a supporting substrate with a photocurable composition, a step of pressing a mold having a plurality of parallel grooves at a constant pitch against the photocurable composition so that the grooves contact with the photocurable composition, a step of curing the photocurable composition in a state that the mold is pressed against the photocurable composition, to form a light-transmitting substrate having a plurality of ridges corresponding to the grooves of the mold, a step of separating the mold from the light-transmitting substrate, and a step of forming fine metalic wires on the ridges of the light-transmitting substrate.

Owner:ASAHI GLASS CO LTD

Apparatus and test device for the application and measurement of prescribed, predicted and controlled contact pressure on wires

ActiveUS20060073712A1Effective controlTemperature compensation modificationSemiconductor/solid-state device detailsWire rodContact pressure

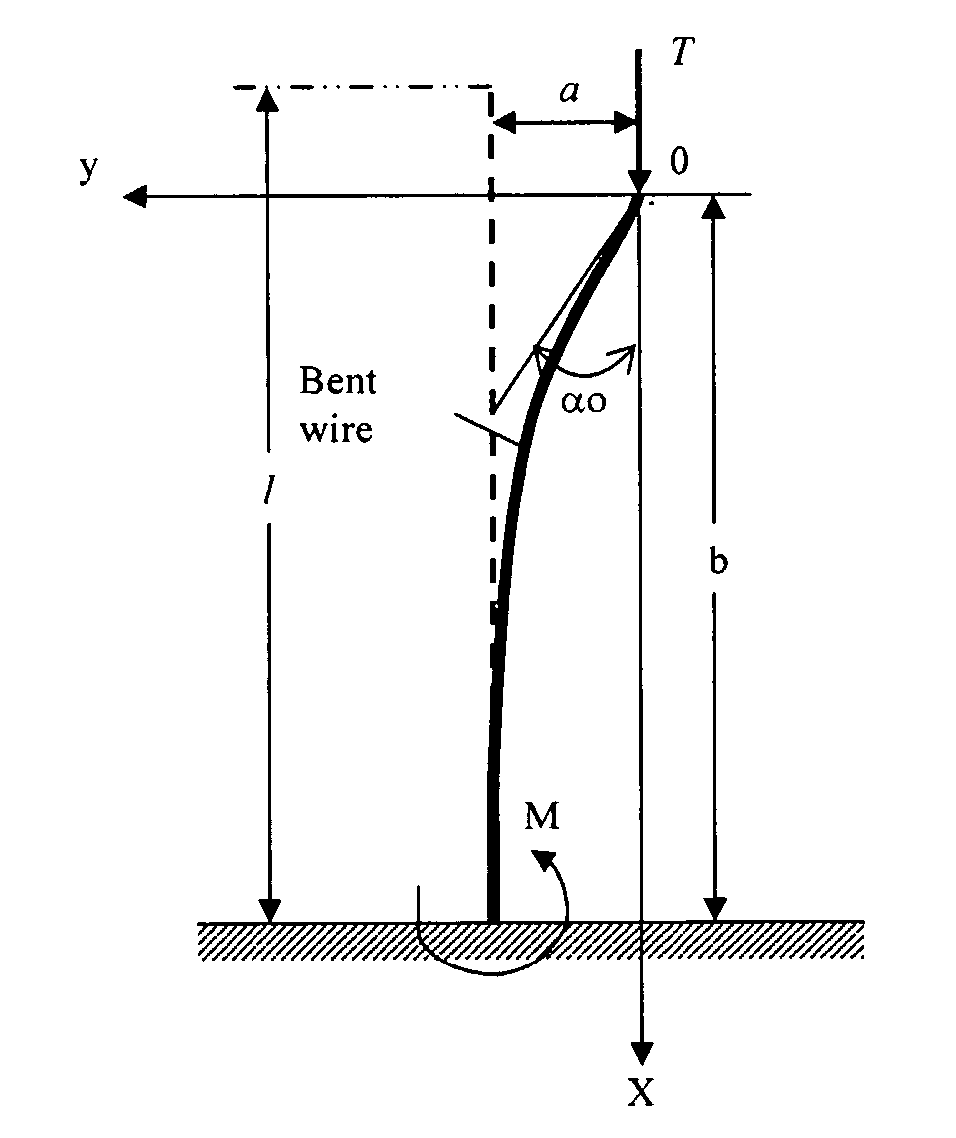

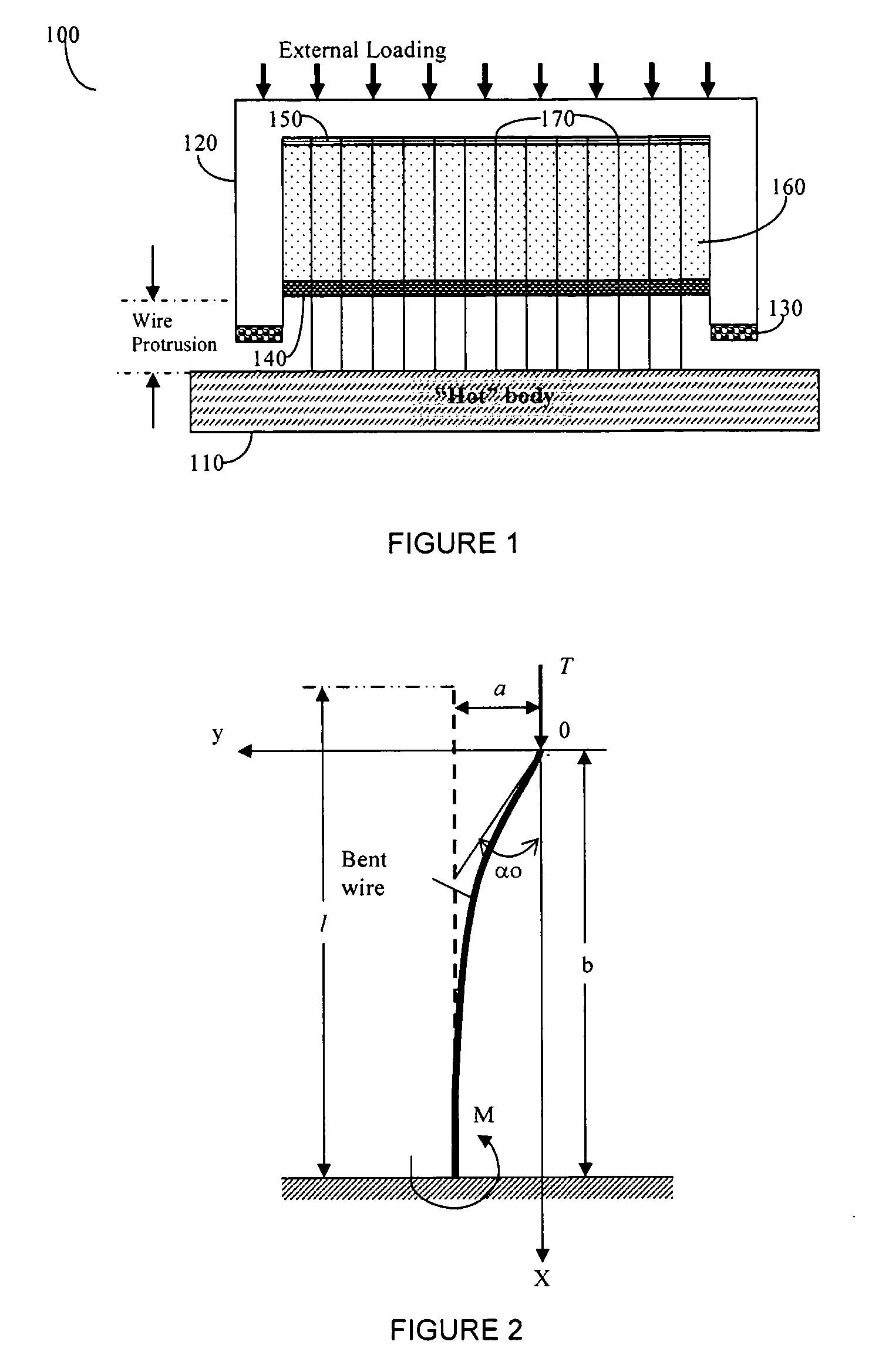

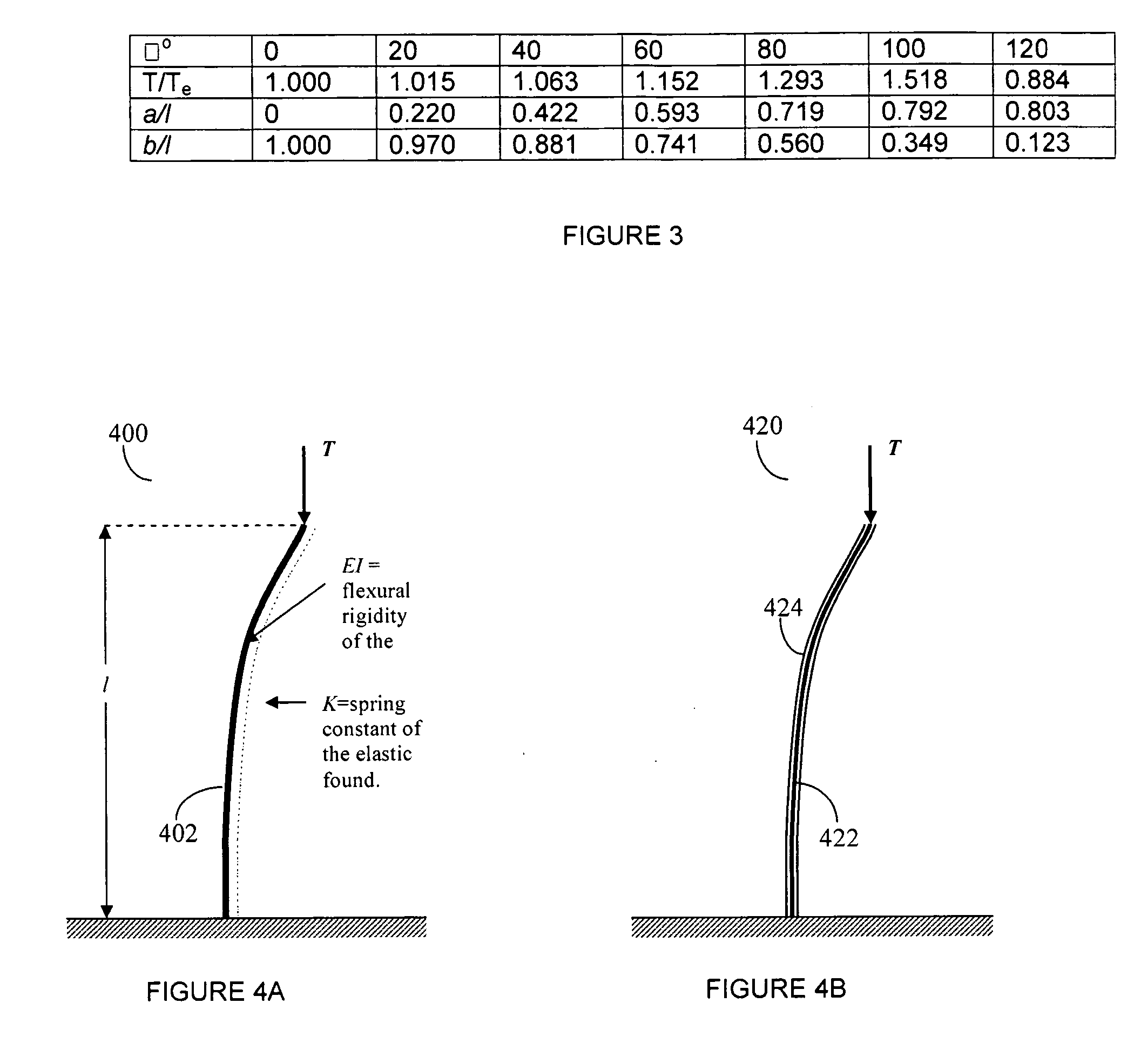

The mechanical behavior of wires subjected to axial loading and experiencing bending deformation is used to ensure effective control of the contact pressure in mechanical and / or heat removing devices, and similar structures and systems. An apparatus for taking advantage of the characteristics of wires in packaging of a device, such as a semiconductor device, is disclosed, as well as a test device for identifying the accurate contact pressure required in same. Methods for the prediction of such a behavior for pre-buckling, buckling, and post-buckling conditions in wires, carbon nanotubes (CNTs), and similar wire-grid-array (WGA) structures, for example are also disclosed.

Owner:SAMSUNG ELECTRONICS CO LTD

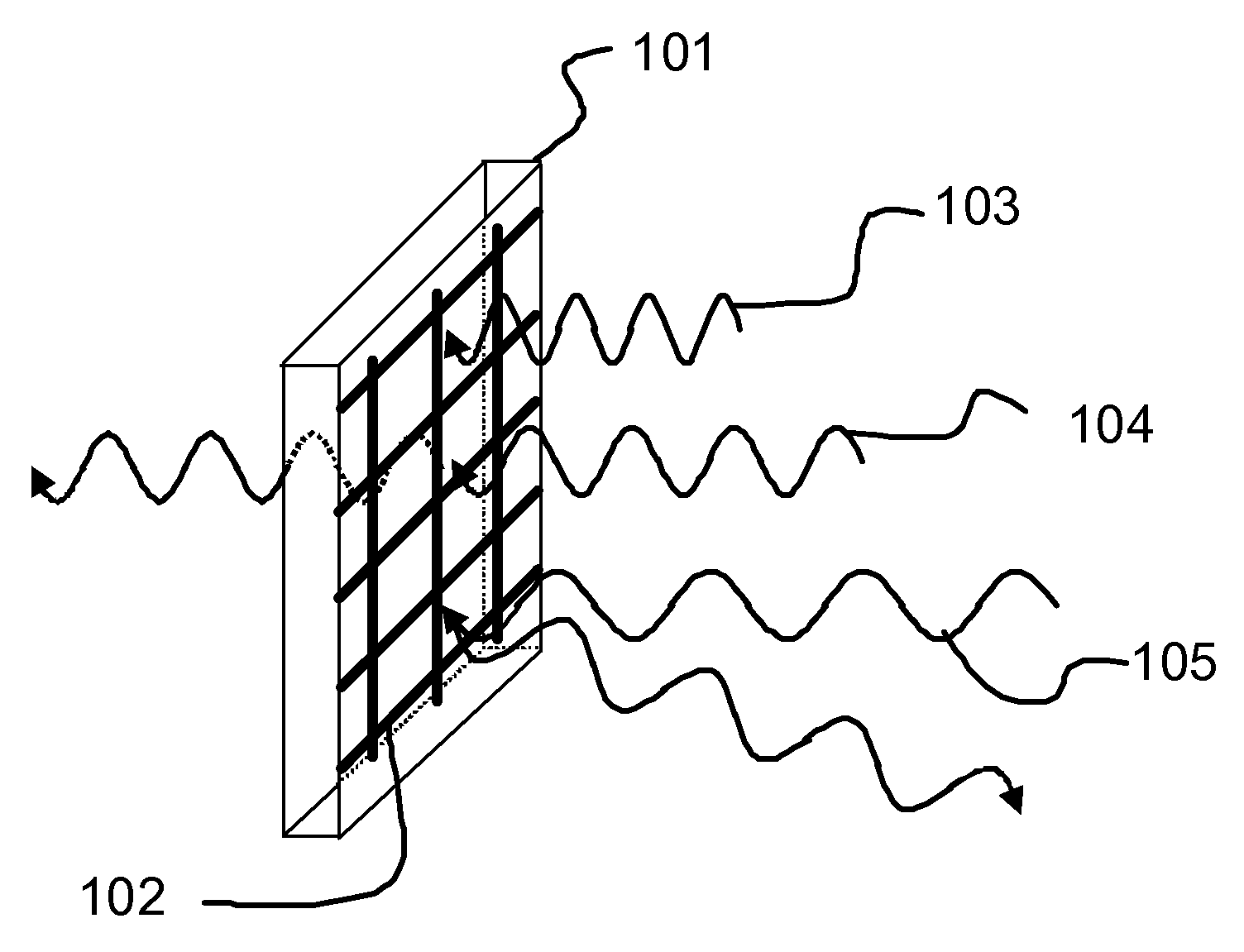

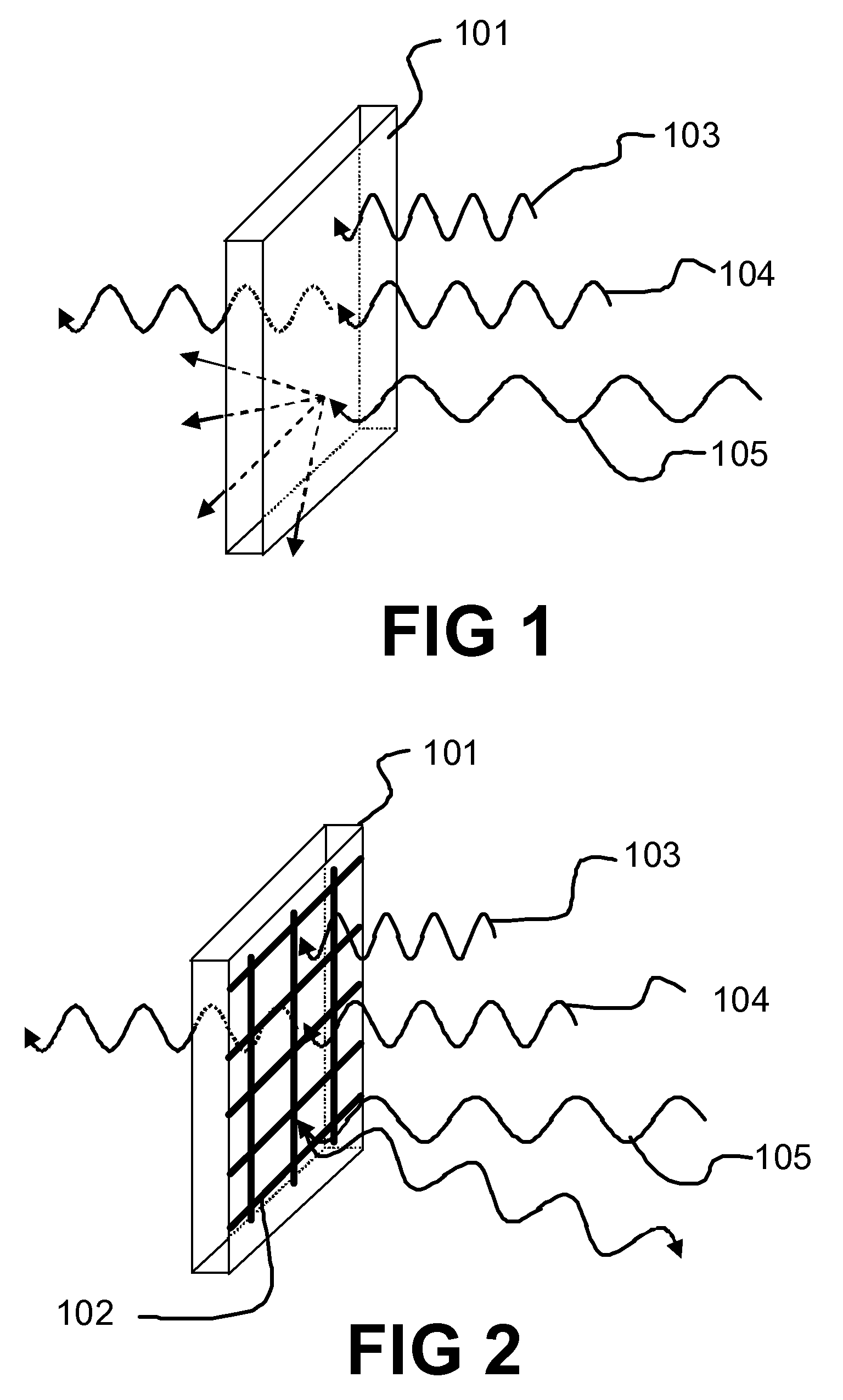

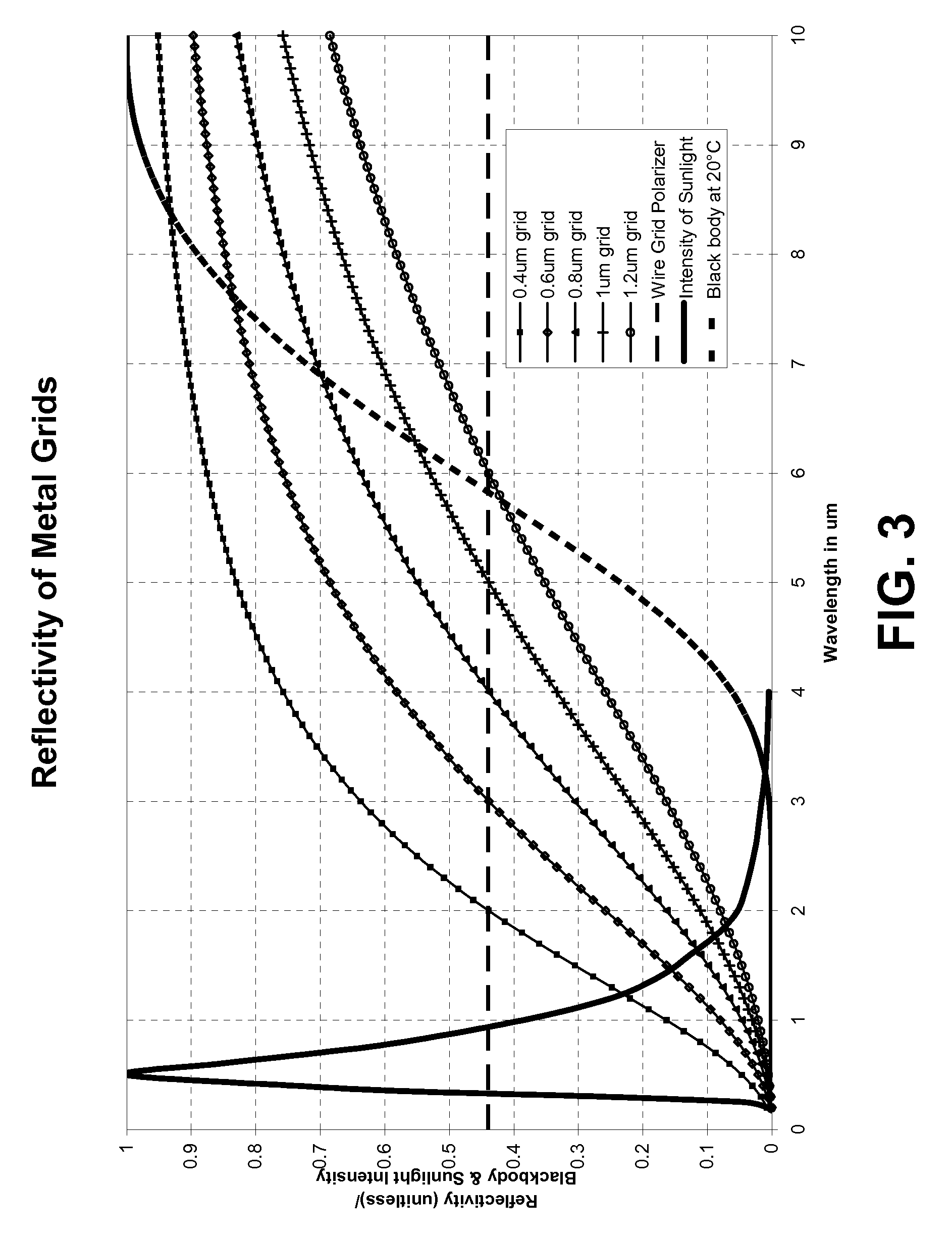

Low-emissivity window films and coatings incorporating nanoscale wire grids

InactiveUS20090128893A1Increasing effective insulation valueDecreased emissivityMirrorsDecorative surface effectsGratingBlack-body radiation

A high-transparency, low-emissivity window film or coating is designed to maximize so-called greenhouse heating. This effect is achieved through the use of conductive grids and / or gratings whose width and spacing has been selected such that the grid appears as a uniform conductive film to long-wavelength infrared (blackbody) radiation. The conductive grid film reflects the blackbody radiation strongly, and such that the grid appears highly transparent to visible and near-infrared light, and therefore transmits it.

Owner:RAVENBRICK

Wire grid polarizer and method of manufacturing the same

InactiveUS7692860B2High light transmittanceHigh extinction ratioOptical articlesPolarising elementsWire gridEngineering

Owner:CHEIL IND INC

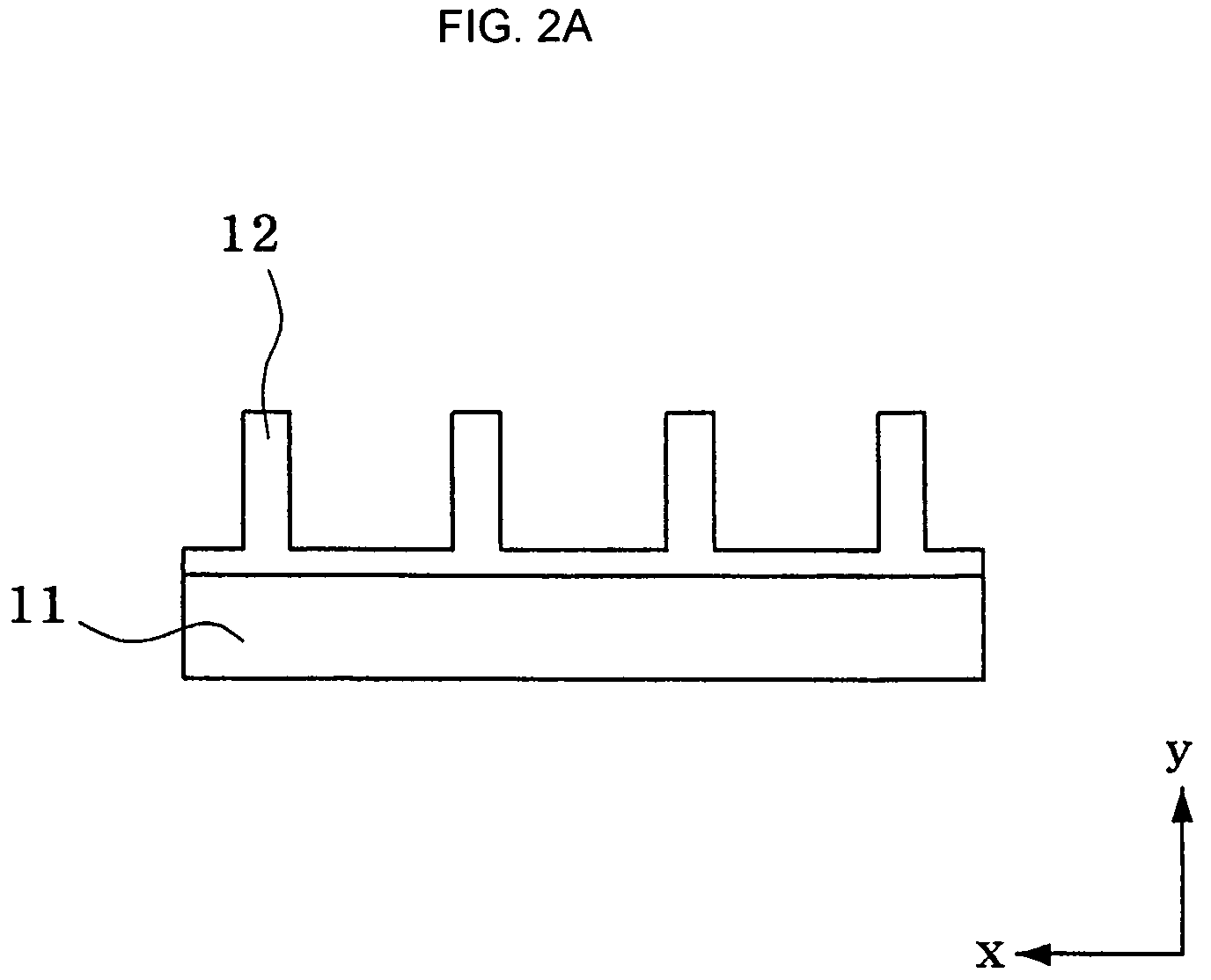

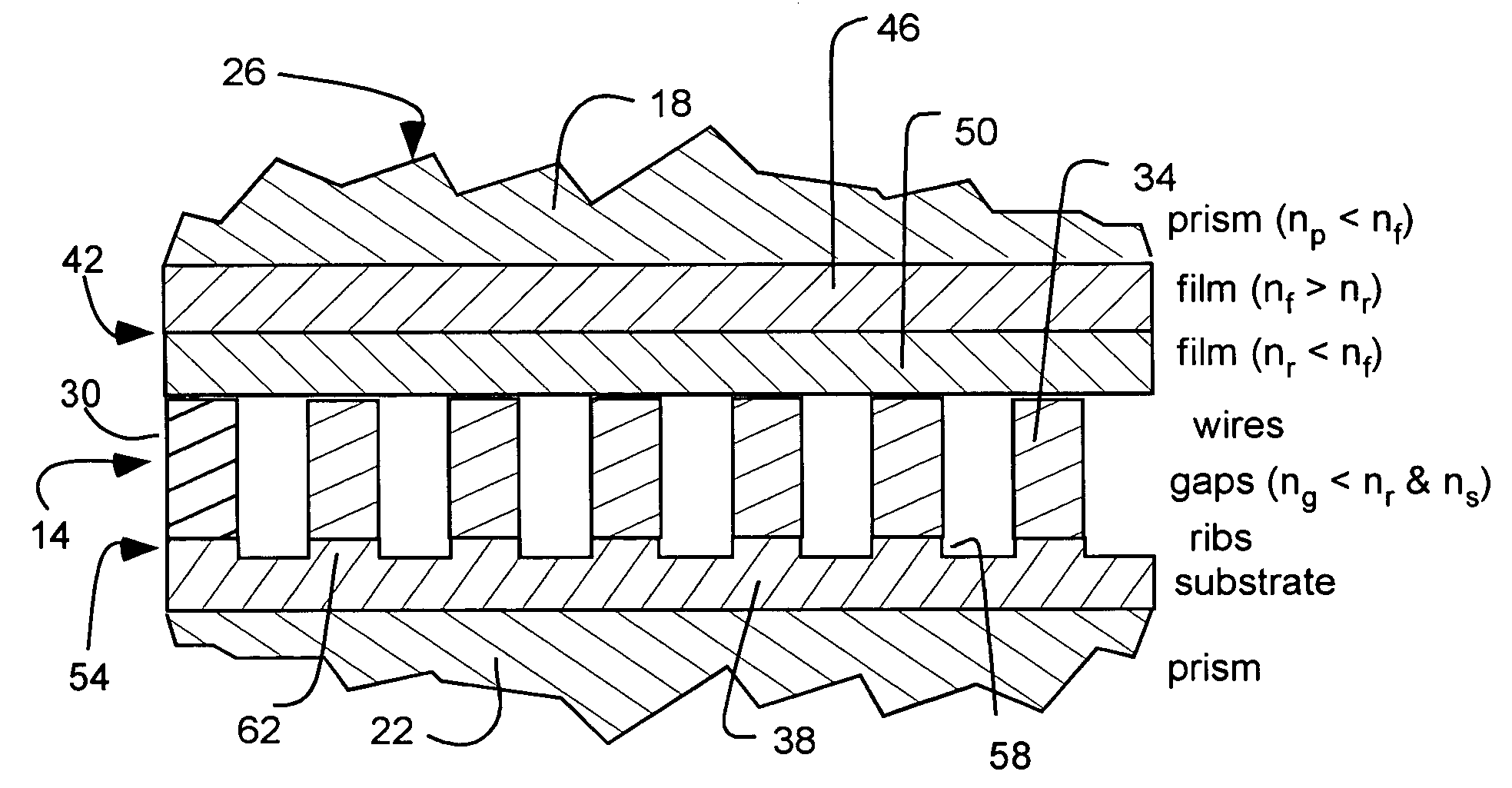

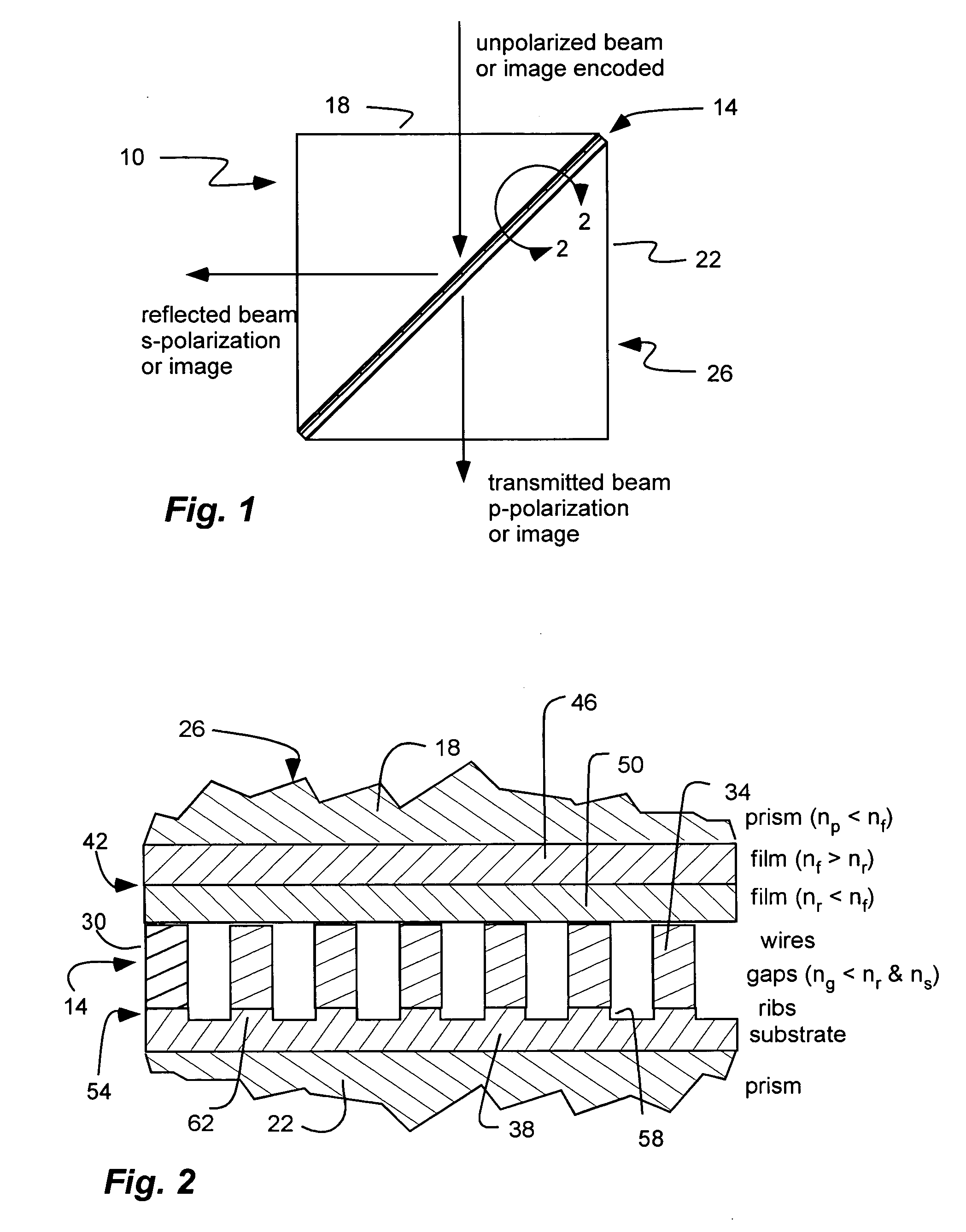

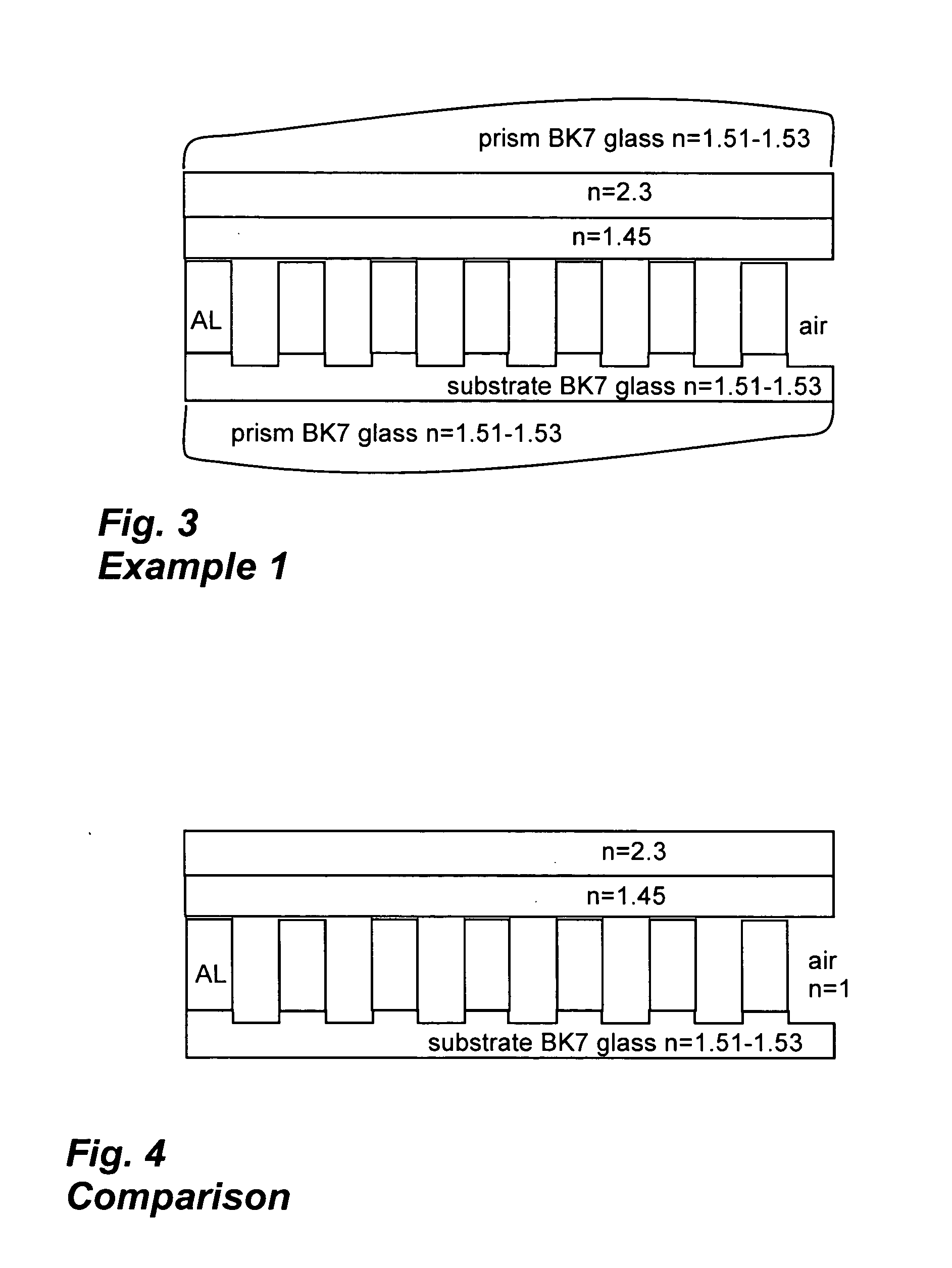

Cube wire-grid polarizing beam splitter

A cube wire-grid polarizing beam splitter includes a pair of prisms secured together to form a cube. An array of parallel conductive wires is disposed between the pair of prisms. A pair of continuous film layers is disposed on one side of the wires between the wires and one of the pair of prisms with an intermediate film layer adjacent the prism having a refractive index greater than both i) a refractive index of a rear film layer adjacent the plate wire grid polarizer, and ii) a refractive index of an adjacent prism. A layer of ribs is disposed on another side of the wires between the wires and another of the pair of prisms, the ribs being aligned with and supporting the array of parallel conductive wires.

Owner:MOXTEK INC

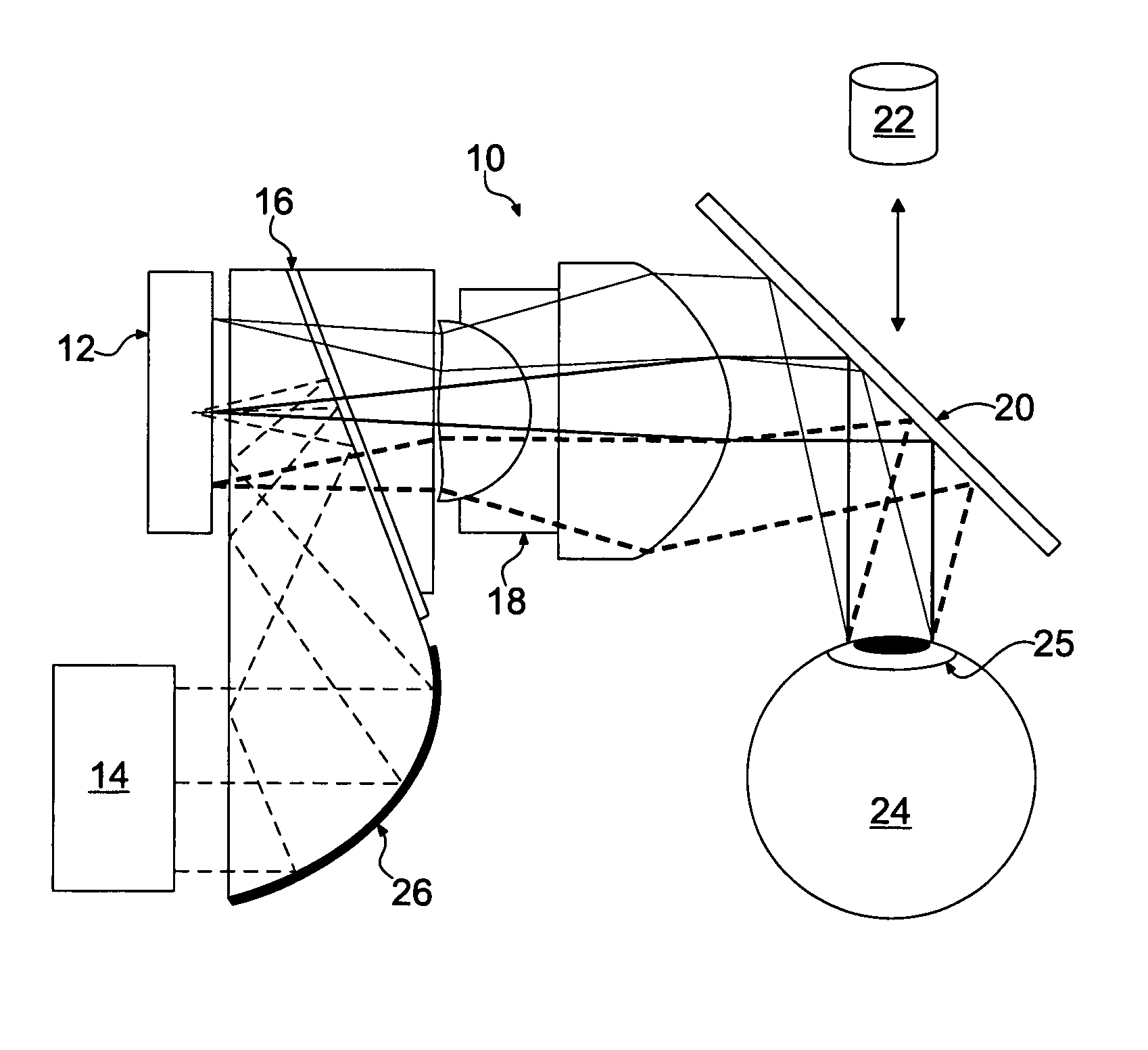

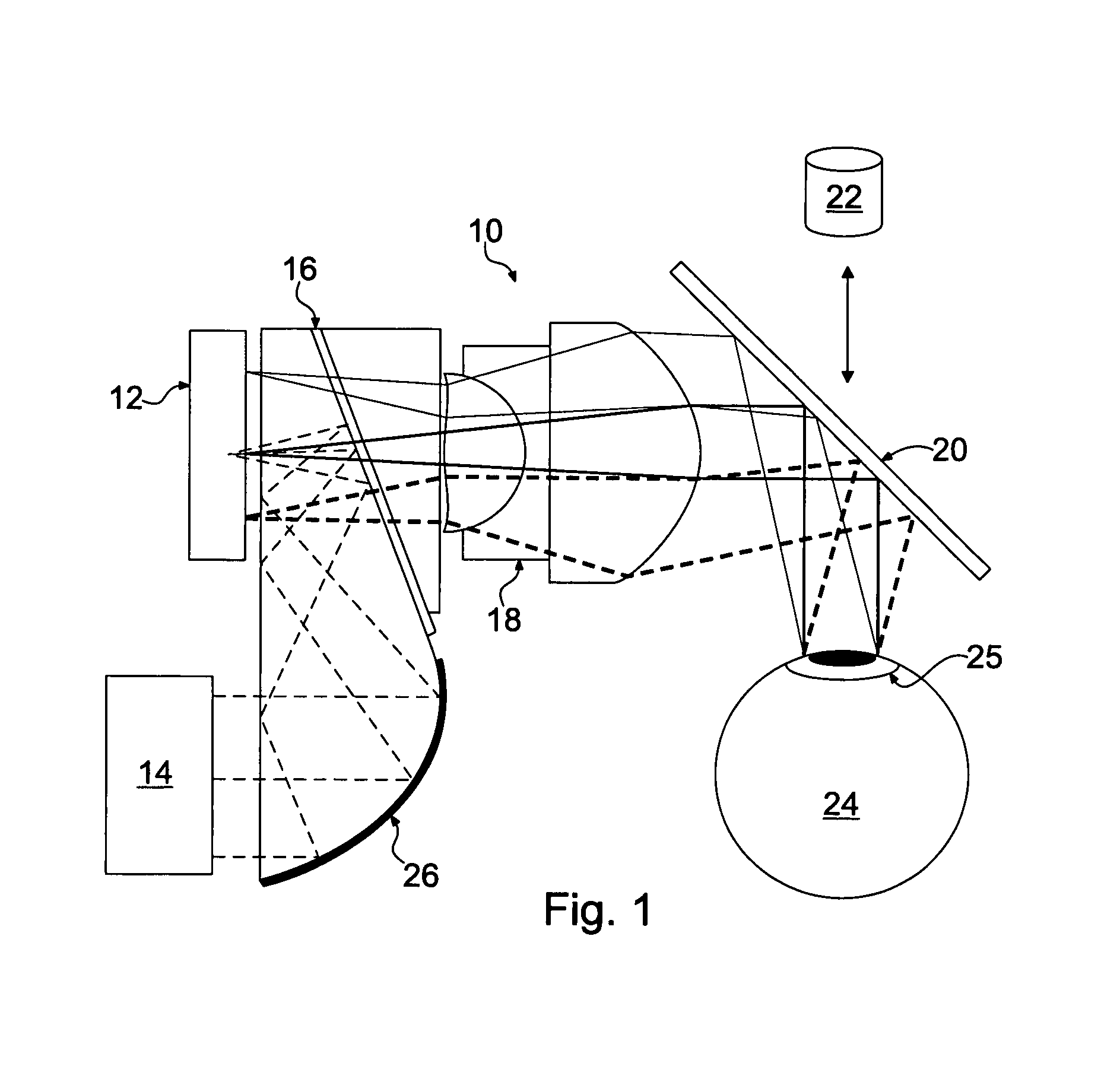

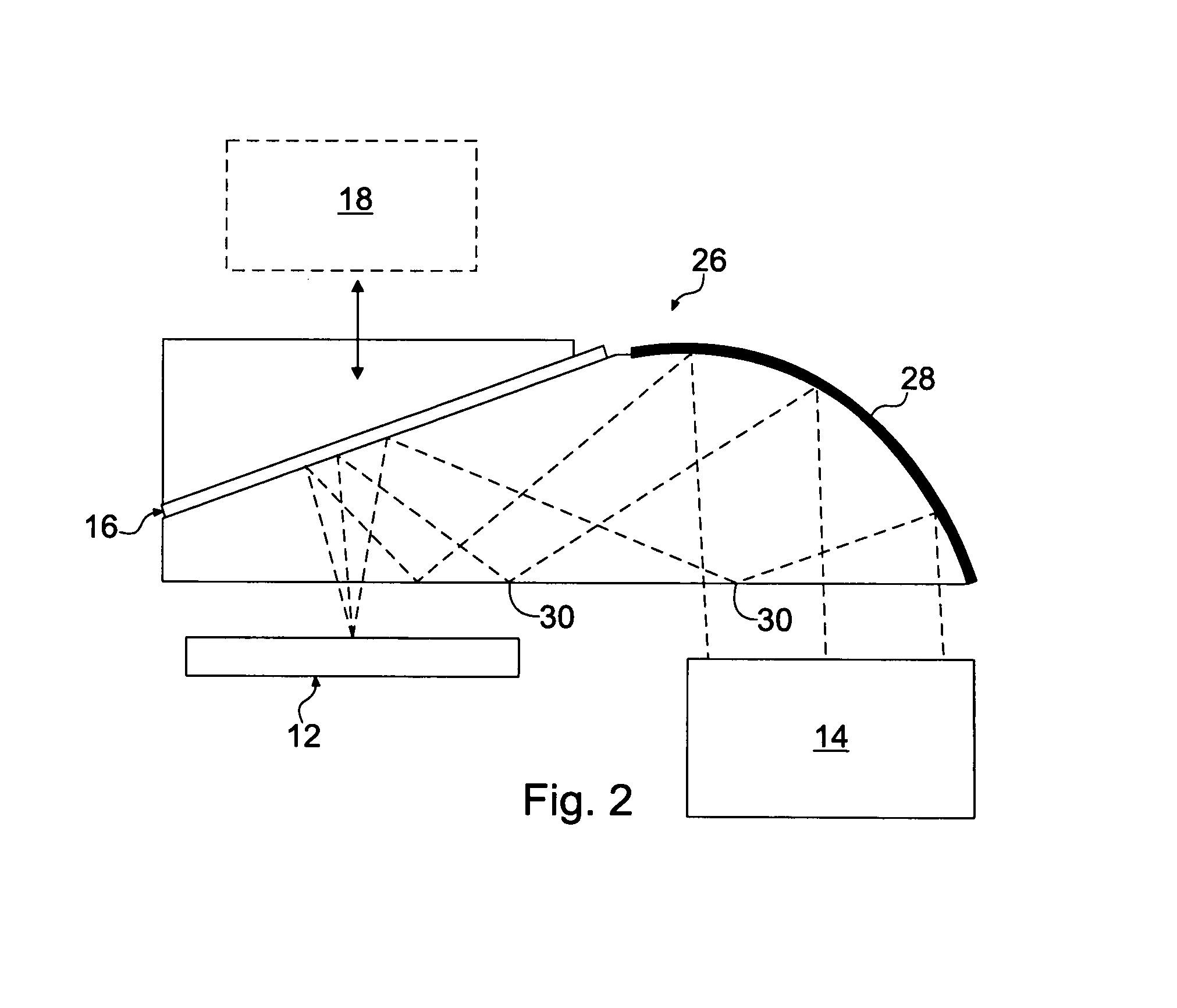

Wearable display system

InactiveUS7545571B2Large field of viewBrighter imagePolarising elementsCathode-ray tube indicatorsWire gridOptical power

A wearable display system, such as a Head Mounted Display, having a display engine producing light, preferably linearly polarized light, which defines a synthetic image that is relayed to a wire grid polarizing combiner which overlays the synthetic image onto a real image of an object of the outside world, and wherein the real image is contemporaneously viewed through the wire grid polarizing combiner by the wearer of the system. The wire grid polarizing combiner can be curved in at least one axis, and preferably two axis such that optical power is added to the wire grid polarizing combiner.

Owner:CONCURRENT TECH

Liquid crystal display device

ActiveUS6987547B2Light utilization efficiencyThin thicknessNon-linear opticsWire gridLiquid-crystal display

A liquid crystal display (LCD) device, with an organic electroluminescent display (OLED) element serving as a light source, a common electrode, and a polarizer which is a wire grid polarizer or a thin film polarizer are formed on a lower substrate. A pixel electrode is formed on an upper substrate. According to the invention, a thinner integrated LCD device with improved light utilization efficiency is obtained.

Owner:HANNSTAR DISPLAY CORPORATION

Applications and fabrication techniques for large scale wire grid polarizers

InactiveUS20060118514A1Enable formationMaterial nanotechnologyDecorative surface effectsWire gridElectrical conductor

A wire grid polarizer may be fabricated by forming plurality of substantially-straight metallic lines of predetermined periodicity Λ on a thin film substrate A plurality of substantially straight nanometer-scale periodic surface relief structures is created on a surface of the substrate. The periodic surface relief structures cover a region greater than about 4 centimeters in length and greater than about 4 centimeters in width, wherein the periodicity Λ is between about 10 nanometers and about 500 nanometers. One or more layers of material are formed on the periodic relief structures. The one or more layers include one or more conductor materials that form the plurality of substantially straight metallic lines over a region of the substrate greater than about 4 centimeters in length and greater than about 4 centimeters in width.

Owner:AGOURA TECH

Applications and fabrication techniques for large scale wire grid polarizers

InactiveUS7561332B2Material nanotechnologyDecorative surface effectsManufacturing technologyElectrical conductor

A wire grid polarizer may be fabricated by forming plurality of substantially-straight metallic lines of predetermined periodicity Λ on a thin film substrate A plurality of substantially straight nanometer-scale periodic surface relief structures is created on a surface of the substrate. The periodic surface relief structures cover a region greater than about 4 centimeters in length and greater than about 4 centimeters in width, wherein the periodicity Λ is between about 10 nanometers and about 500 nanometers. One or more layers of material are formed on the periodic relief structures. The one or more layers include one or more conductor materials that form the plurality of substantially straight metallic lines over a region of the substrate greater than about 4 centimeters in length and greater than about 4 centimeters in width.

Owner:AGOURA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com