Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

188results about How to "Enable formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

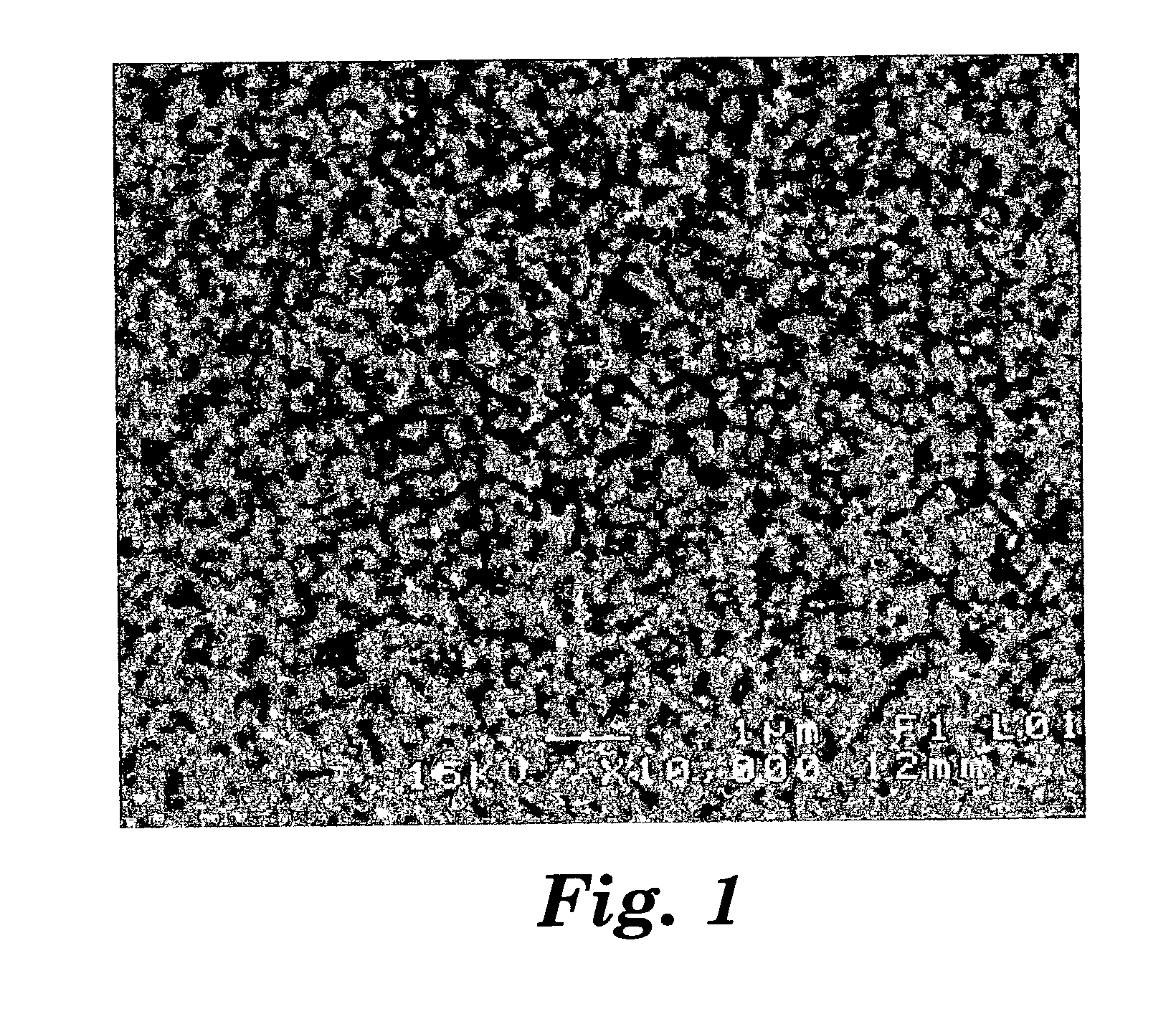

Abrasive particles, and methods of making and using the same

InactiveUS20030110707A1Facilitates formation and homogeneityOxide formationGlass drawing apparatusGlass forming apparatusAbrasive

Owner:3M INNOVATIVE PROPERTIES CO

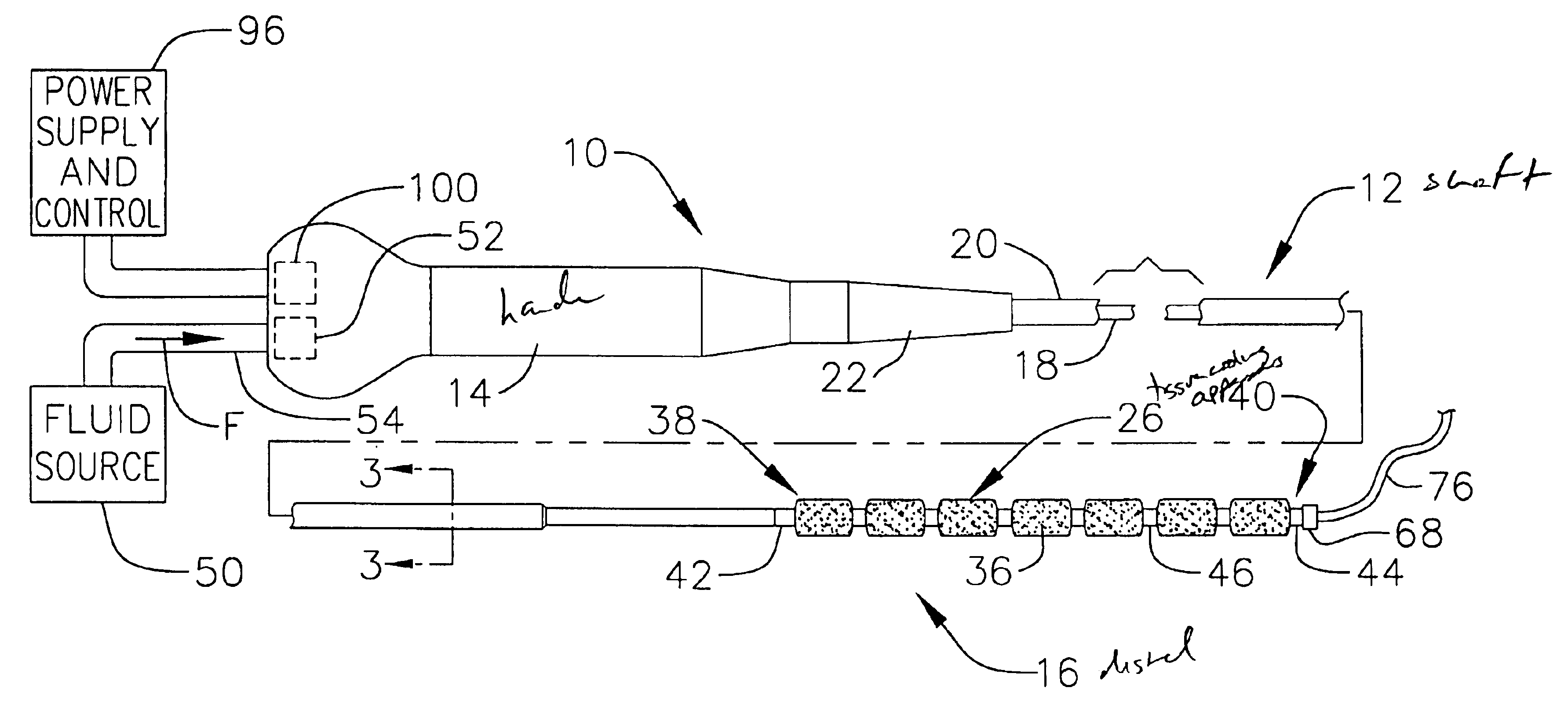

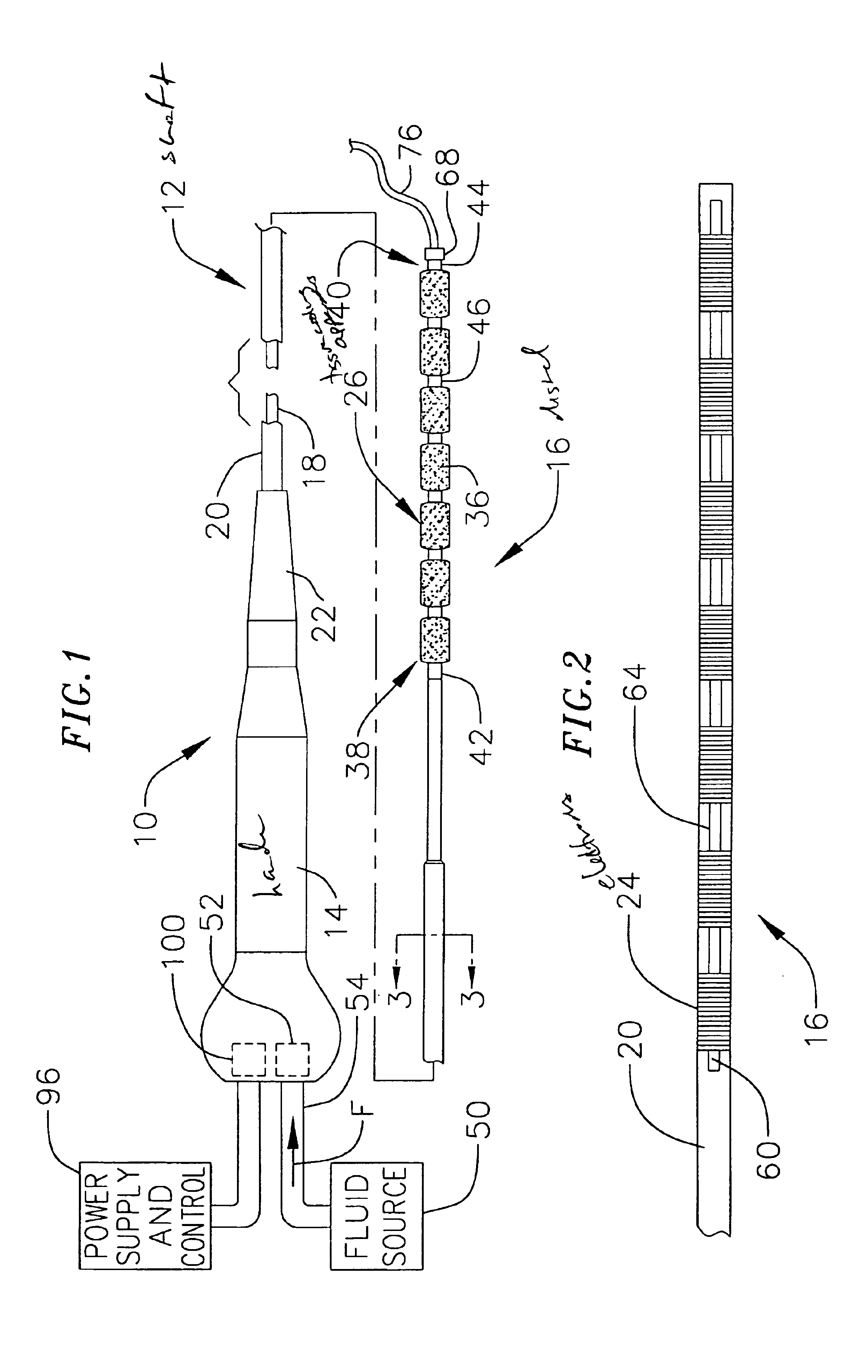

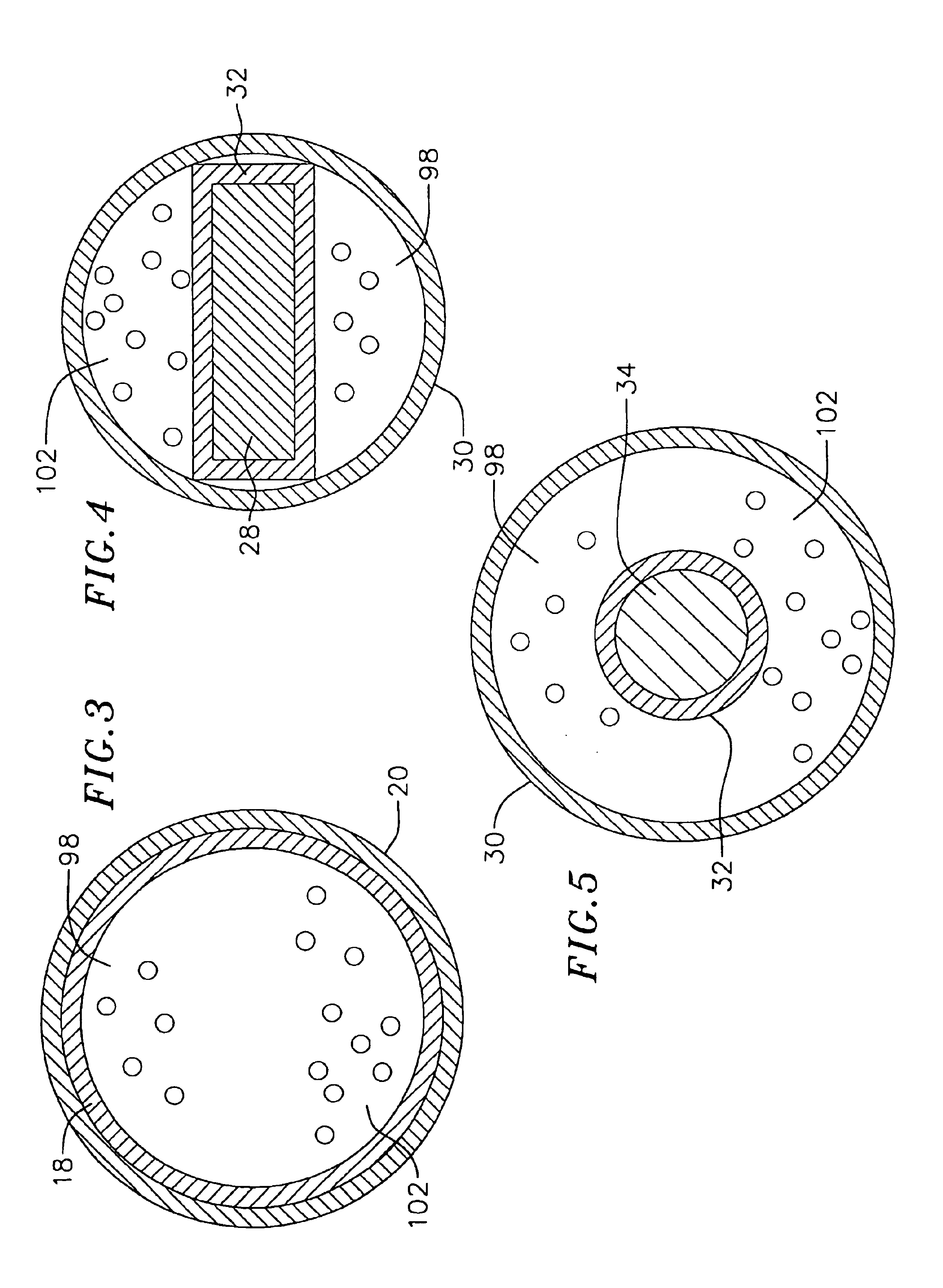

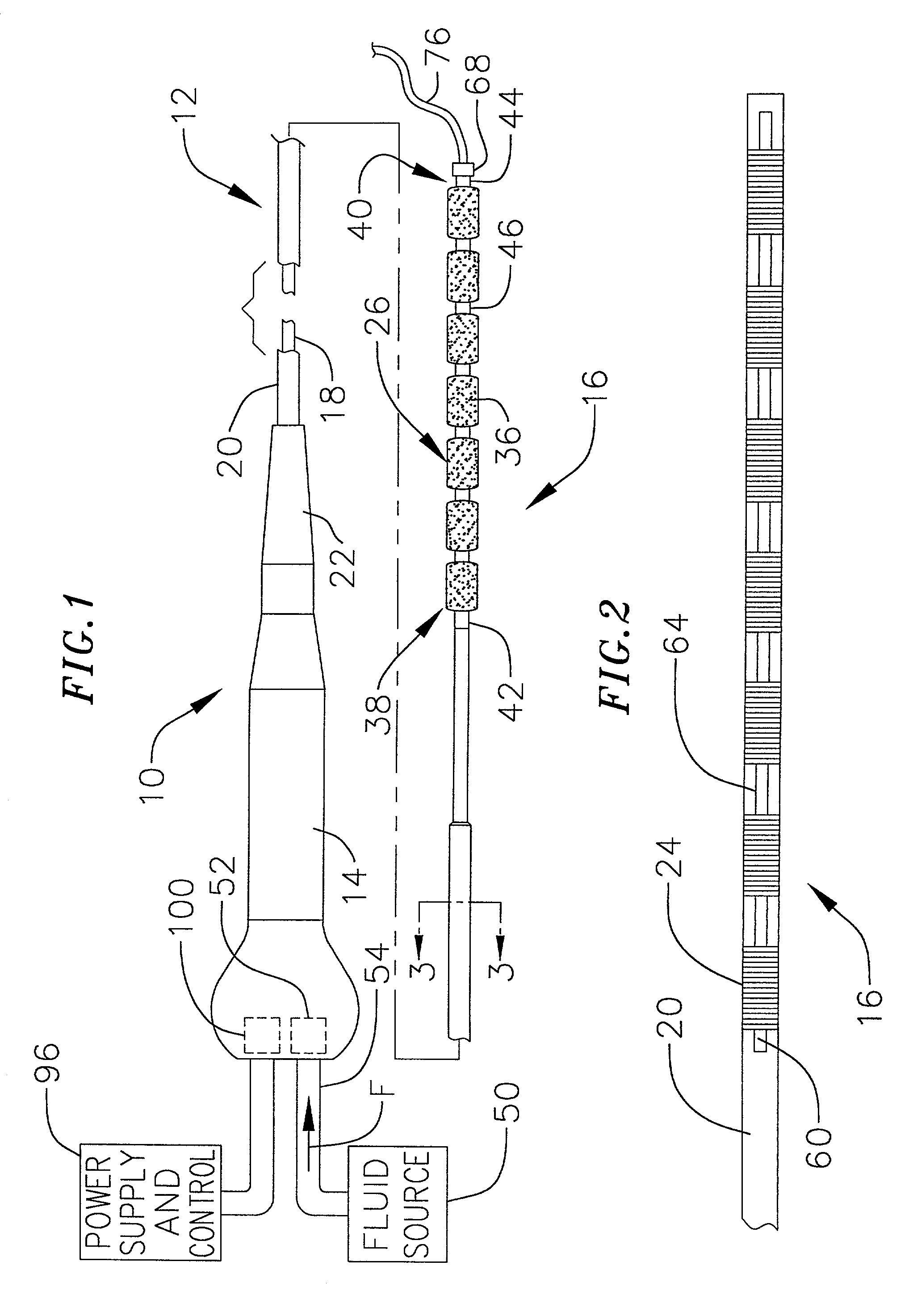

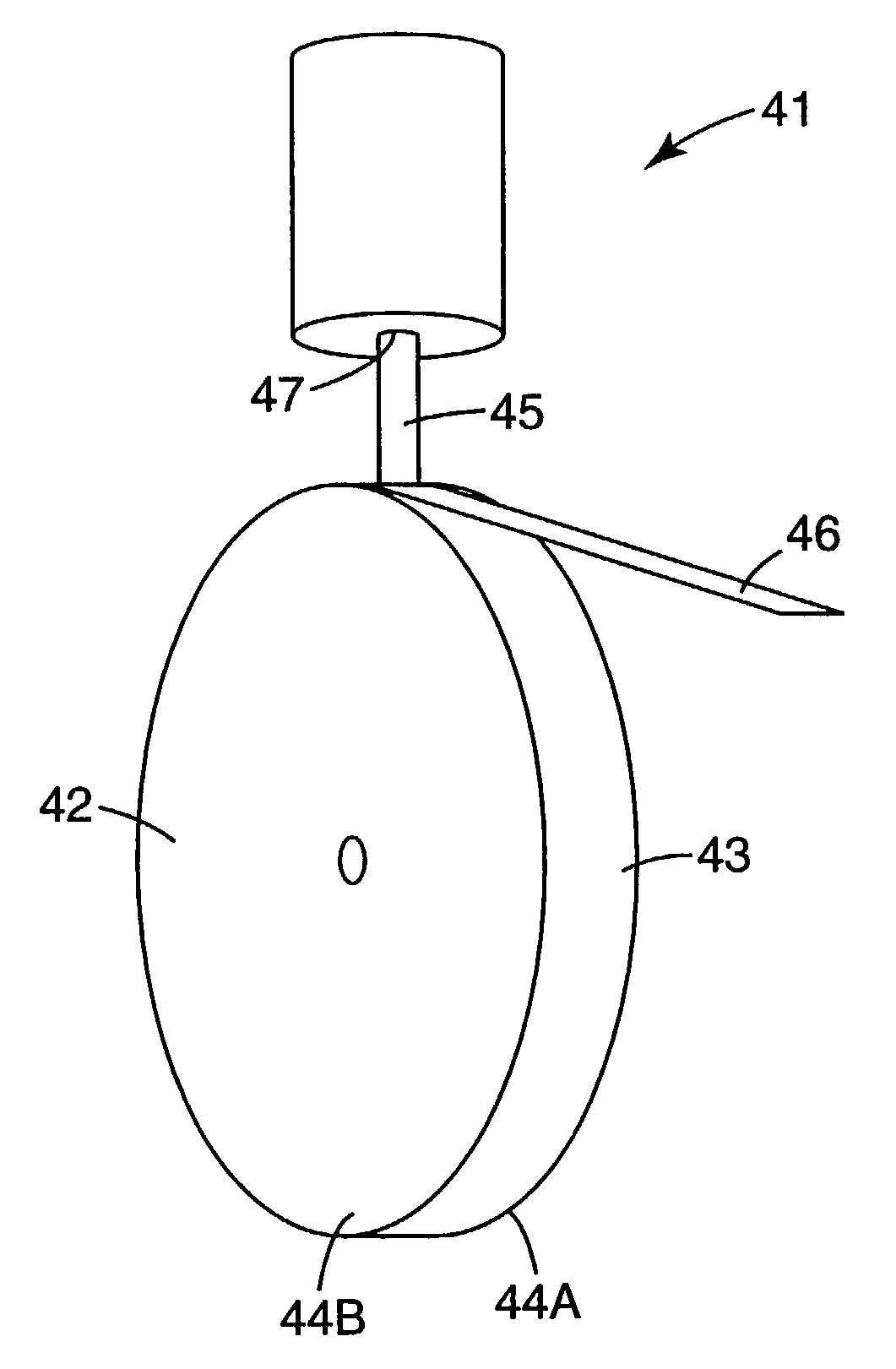

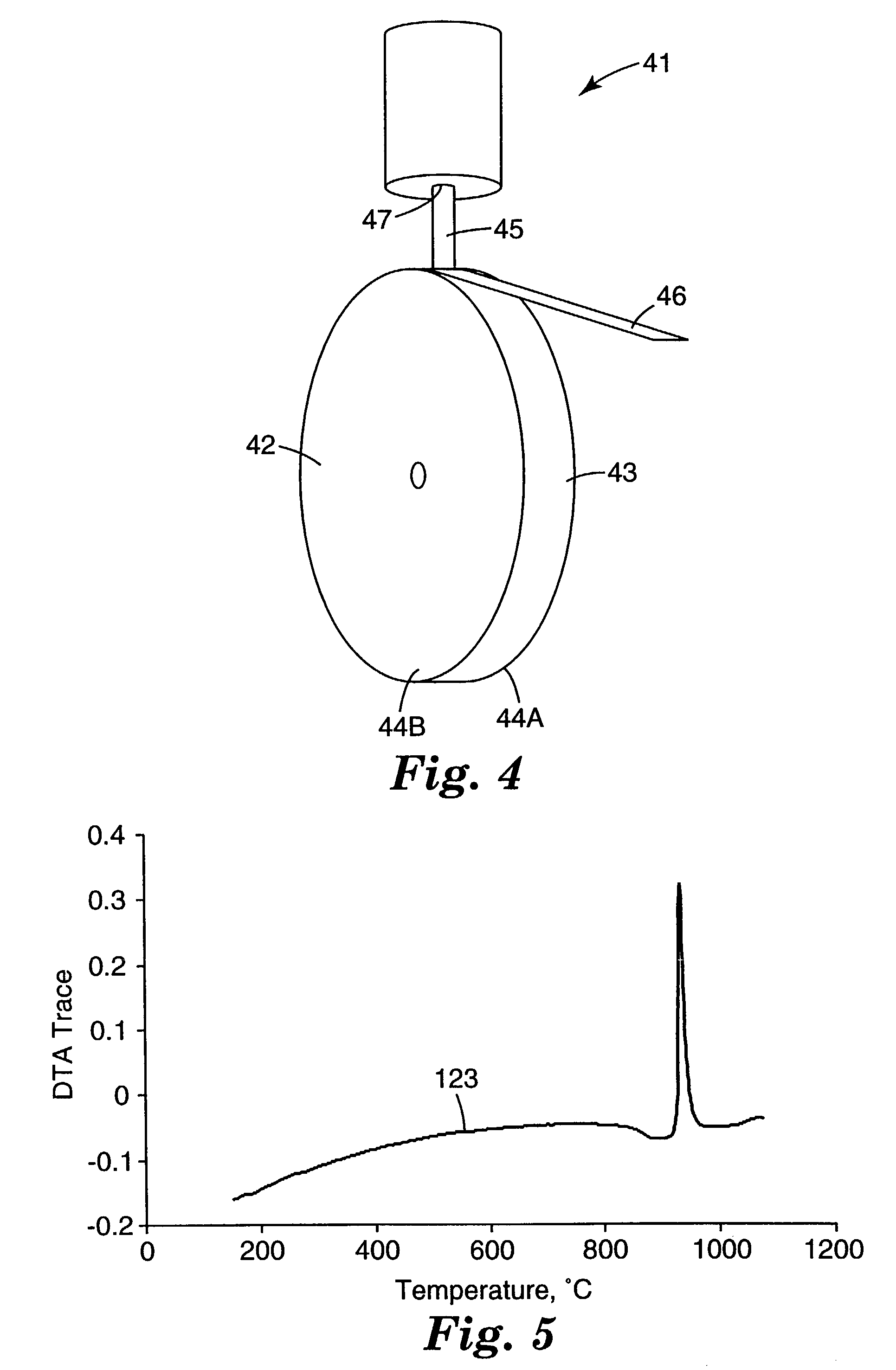

Fluid cooled apparatus for supporting diagnostic and therapeutic elements in contact with tissue

InactiveUS6942661B2Avoid problemEfficient mannerDiagnosticsInstrument handpiecesBiomedical engineeringOrgan surface

Surgical methods and apparatus for positioning diagnostic an therapeutic elements on the epicardium or other organ surface. The apparatus includes a tissue cooling apparatus.

Owner:BOSTON SCI SCIMED INC

Soft extensible nonwoven webs containing multicomponent fibers with high melt flow rates

InactiveUS20050164587A1Improve acceleration performanceEnable formationFilament/thread formingWoven fabricsFiberPolymer science

The present invention provides nonwoven webs comprising multicomponent fibers that enable the nonwoven web to possess high extensibility. The multicomponent fibers will comprise a first component comprising a polypropylene composition having a melt flow rate of from about 100 to about 2000 grams per 10 minutes and a second component comprising a polymer composition having a melt flow rate lower than the melt flow rate of the first component. The first component comprises at least about 10% of a surface of the multicomponent fiber.

Owner:THE PROCTER & GAMBLE COMPANY

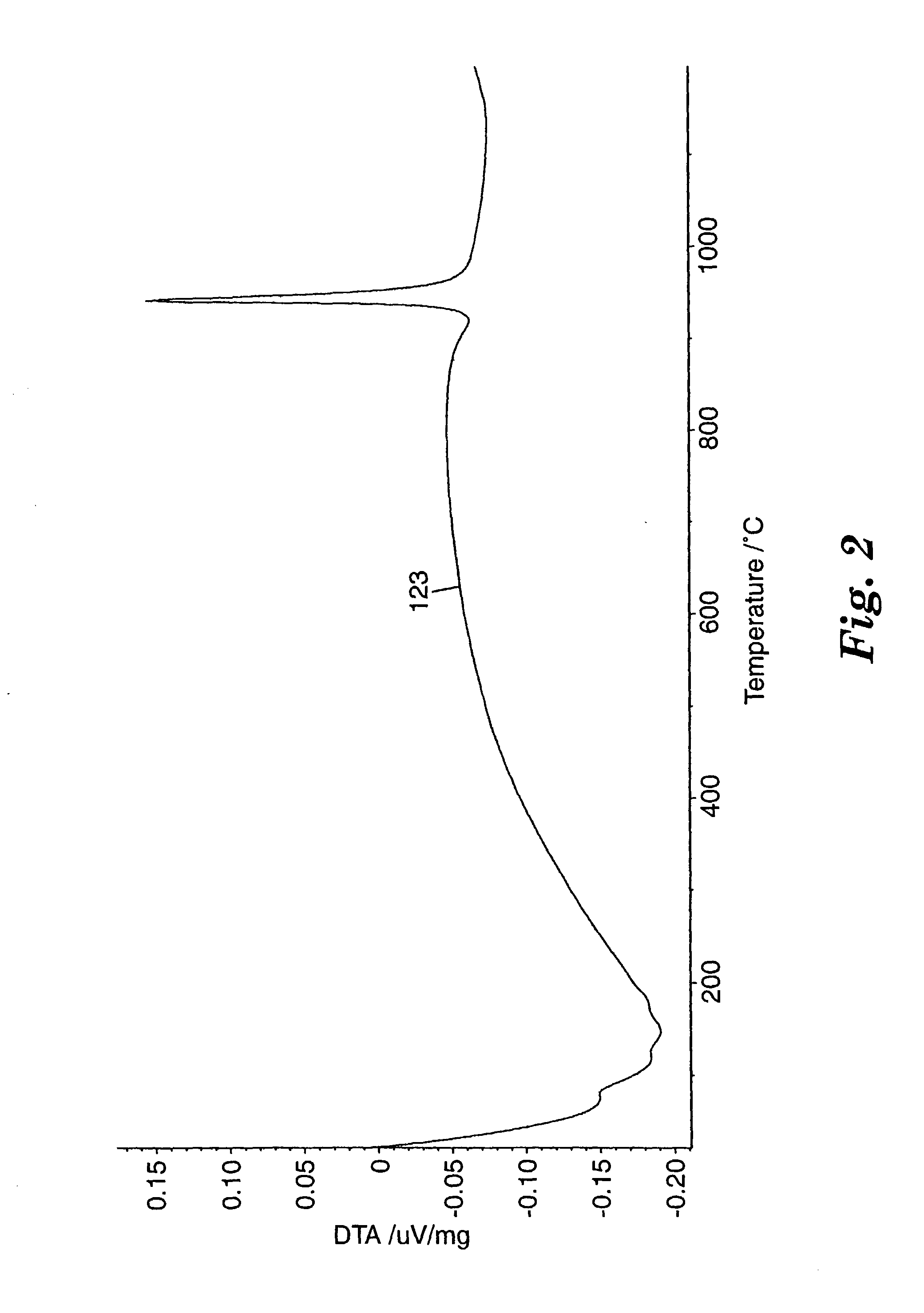

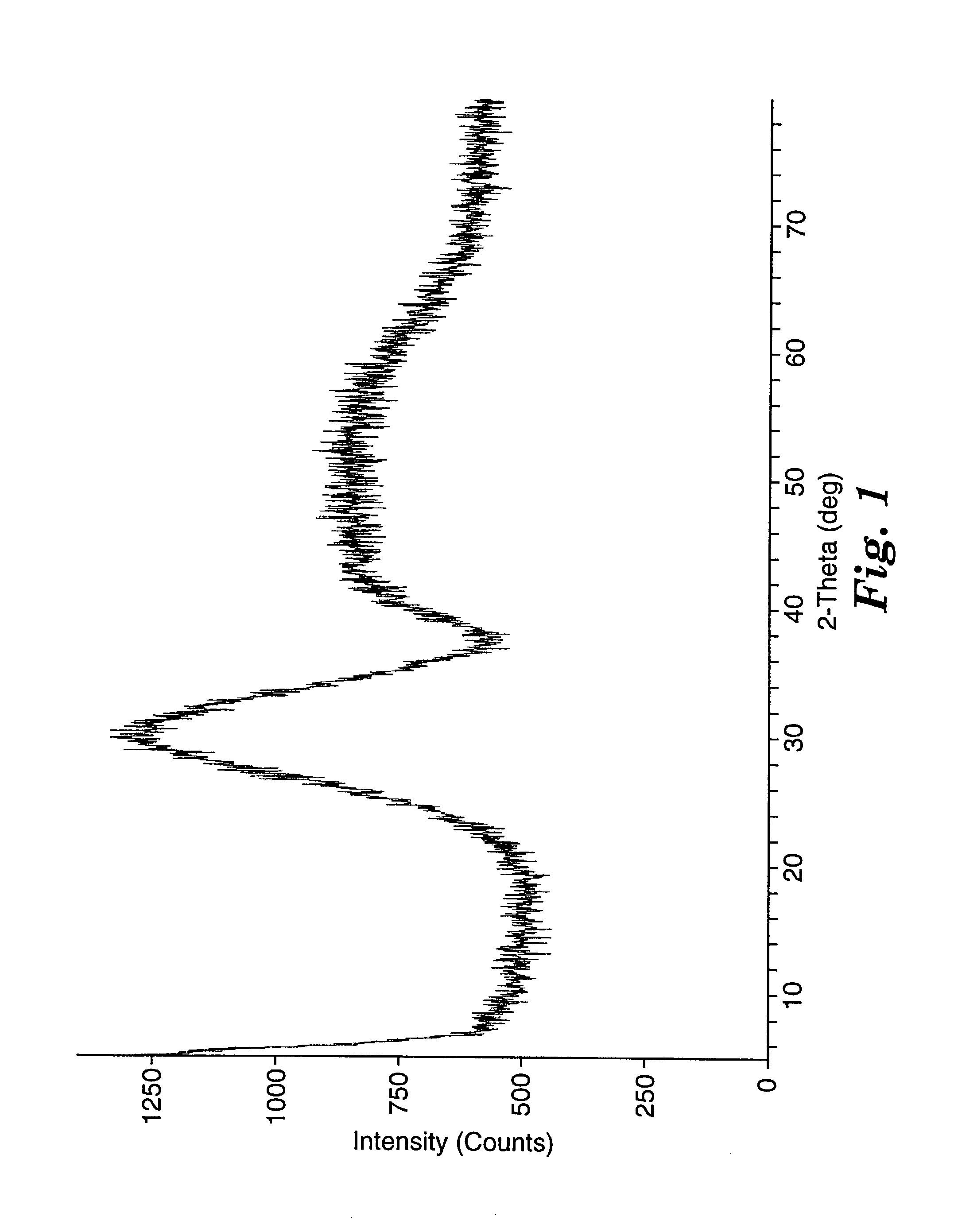

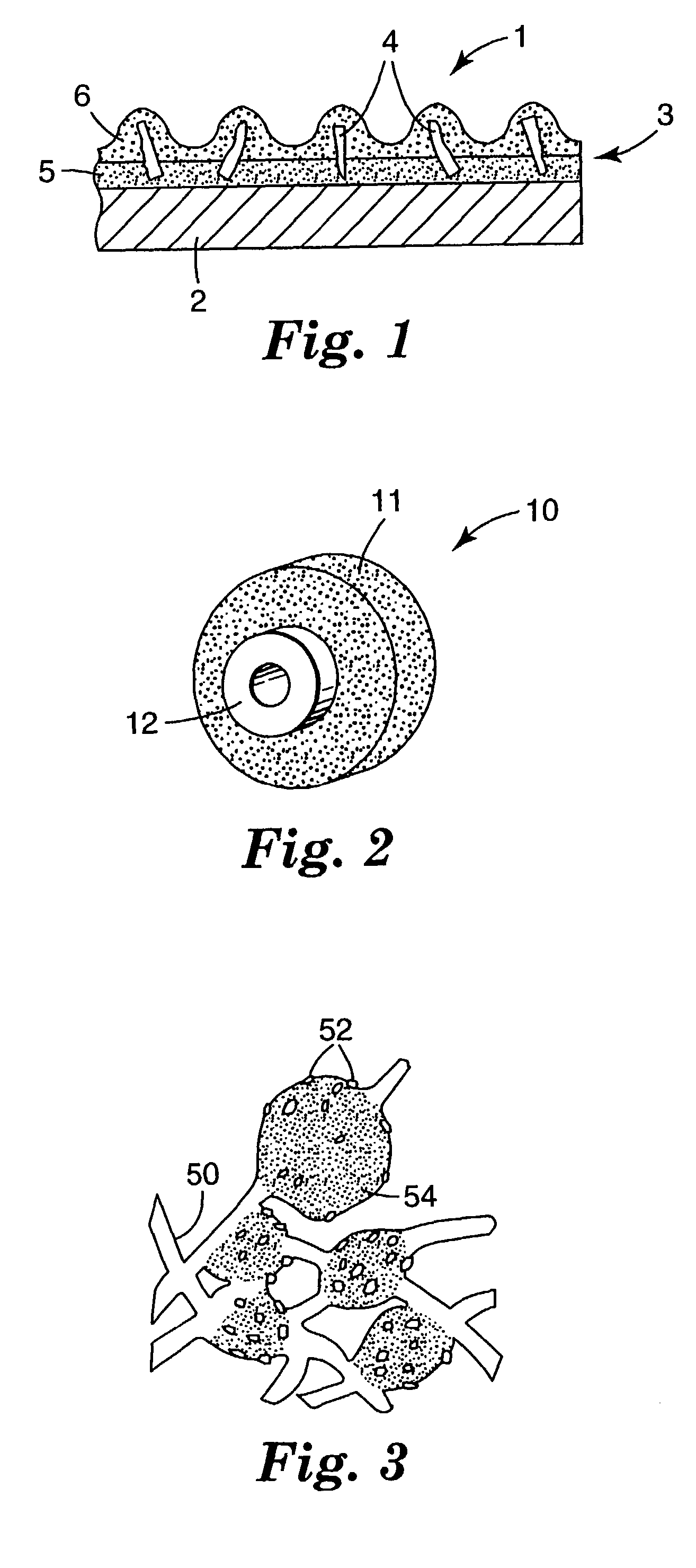

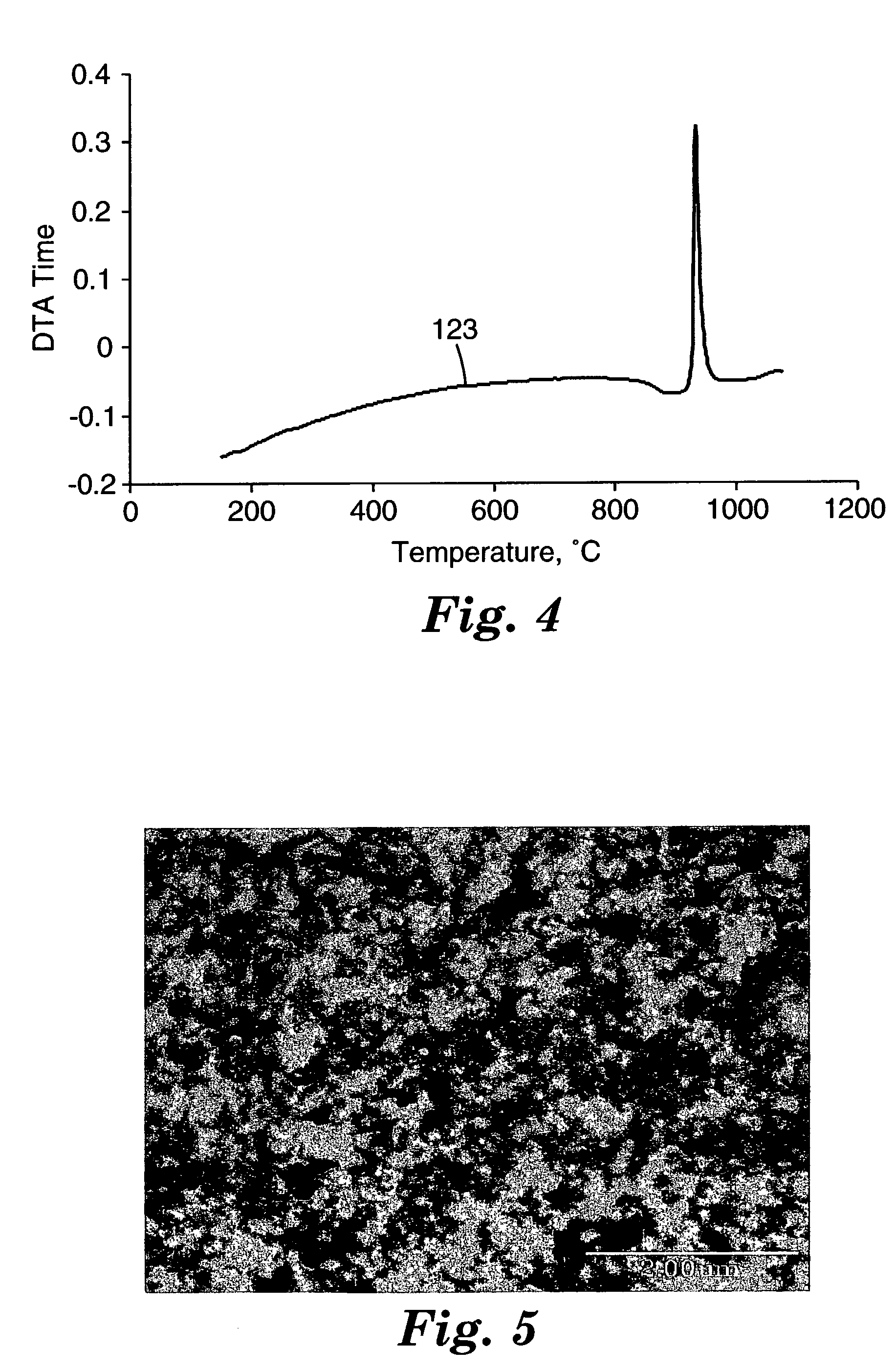

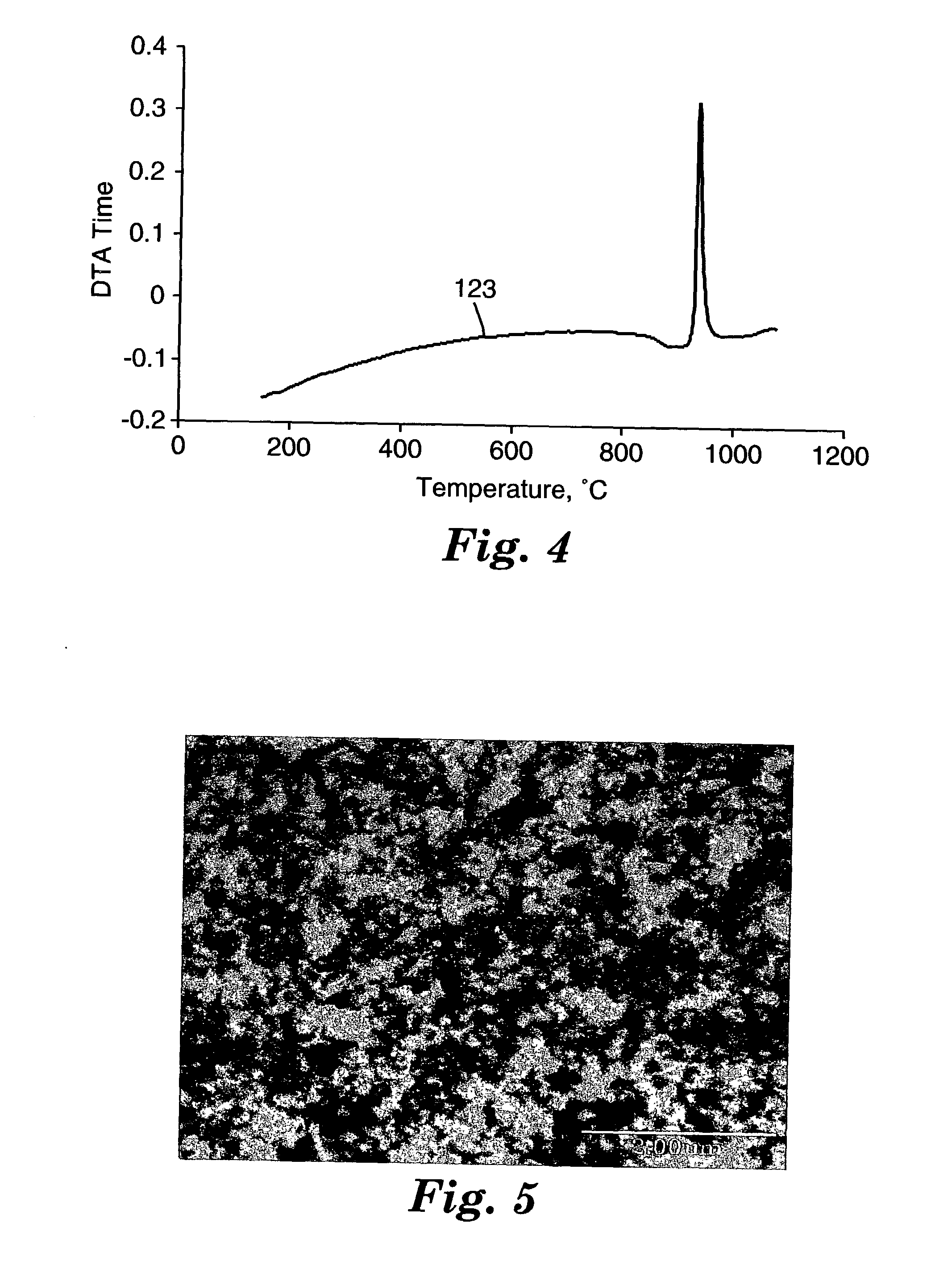

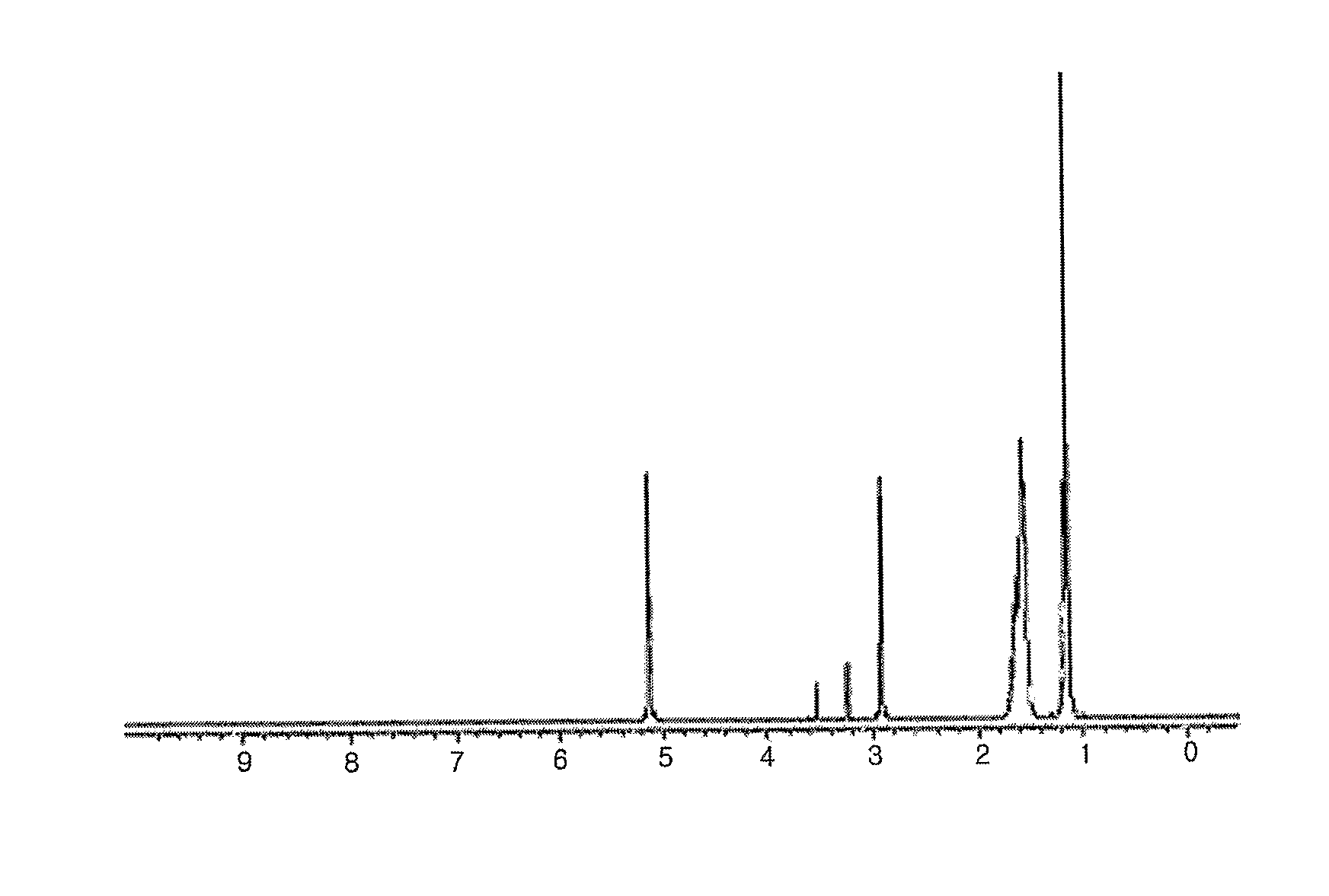

Al2O3-Y2O3-ZrO2/HfO2 materials, and methods of making and using the same

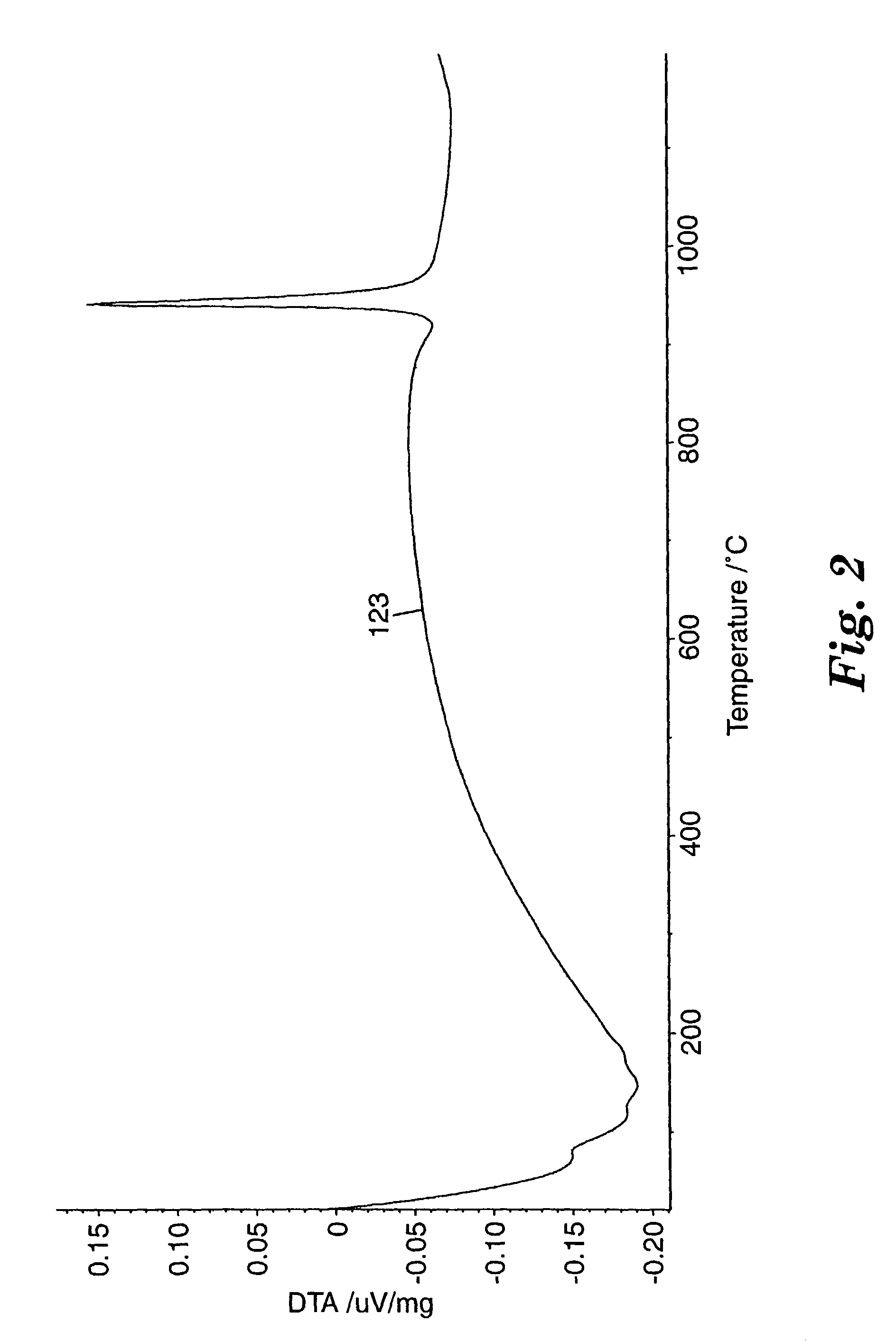

InactiveUS7507268B2Facilitates formation and homogeneityEliminates and minimizes heat transferPigmenting treatmentGlass drawing apparatusFiberThermal insulation

Al2O3—Y2O3—ZrO2 / HfO2 ceramics (including glasses, crystalline ceramics, and glass-ceramics) and methods of making the same. Ceramics according to the present invention can be made, formed as, or converted into glass beads, articles (e.g., plates), fibers, particles, and thin coatings. The particles and fibers are useful, for example, as thermal insulation, filler, or reinforcing material in composites (e.g., ceramic, metal, or polymeric matrix composites). The thin coatings can be useful, for example, as protective coatings in applications involving wear, as well as for thermal management. Certain ceramic particles according to the present invention can be are particularly useful as abrasive particles.

Owner:3M INNOVATIVE PROPERTIES CO

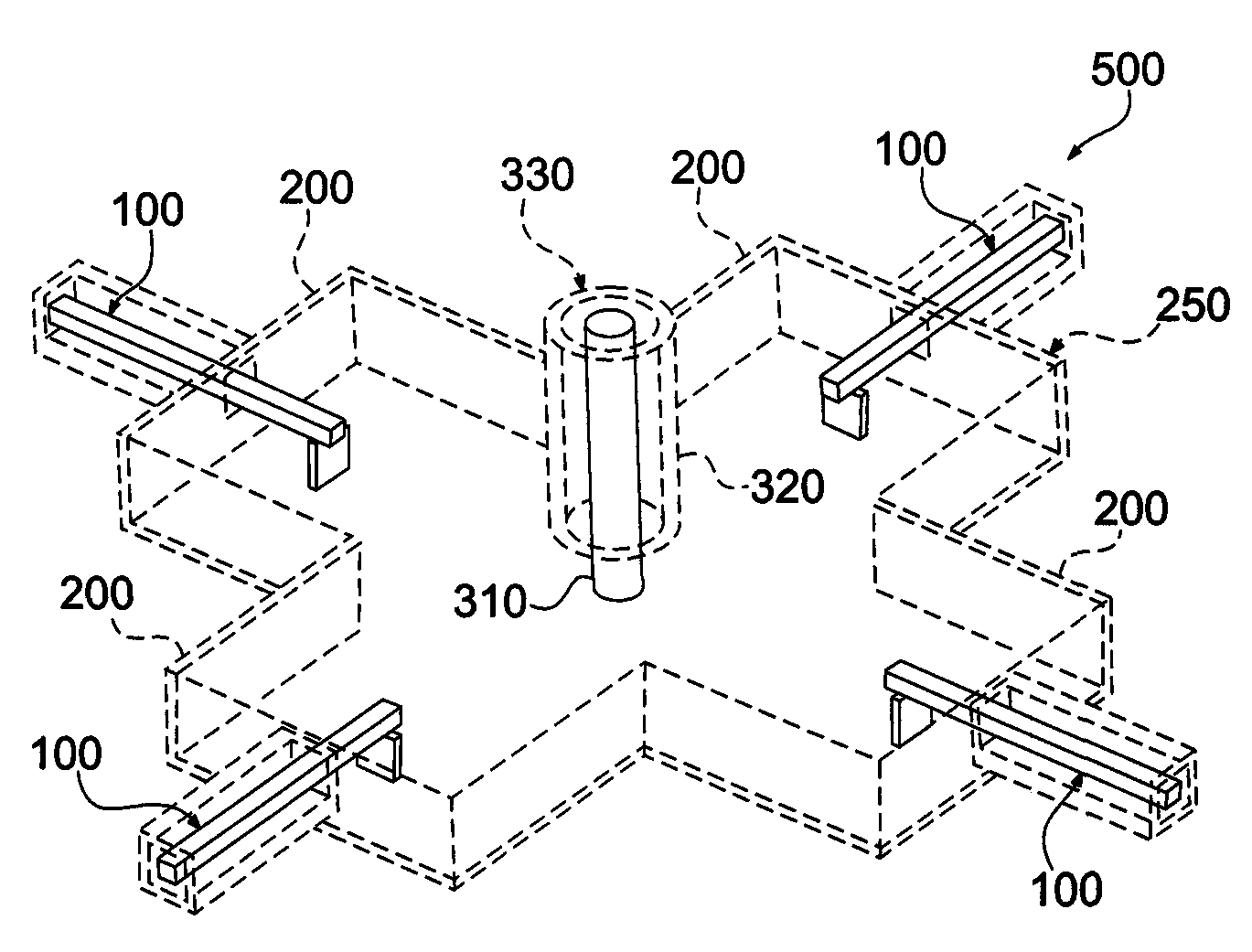

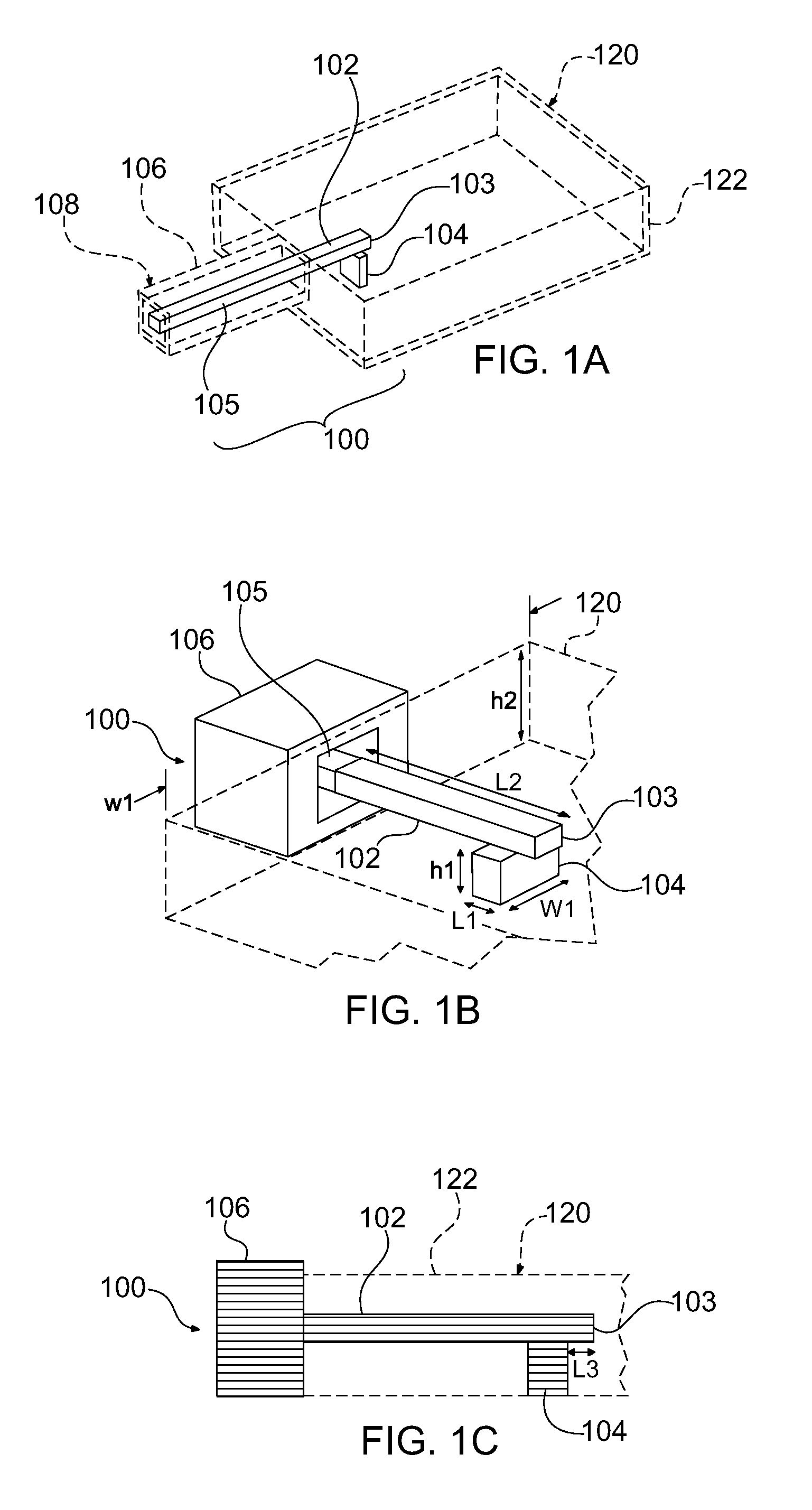

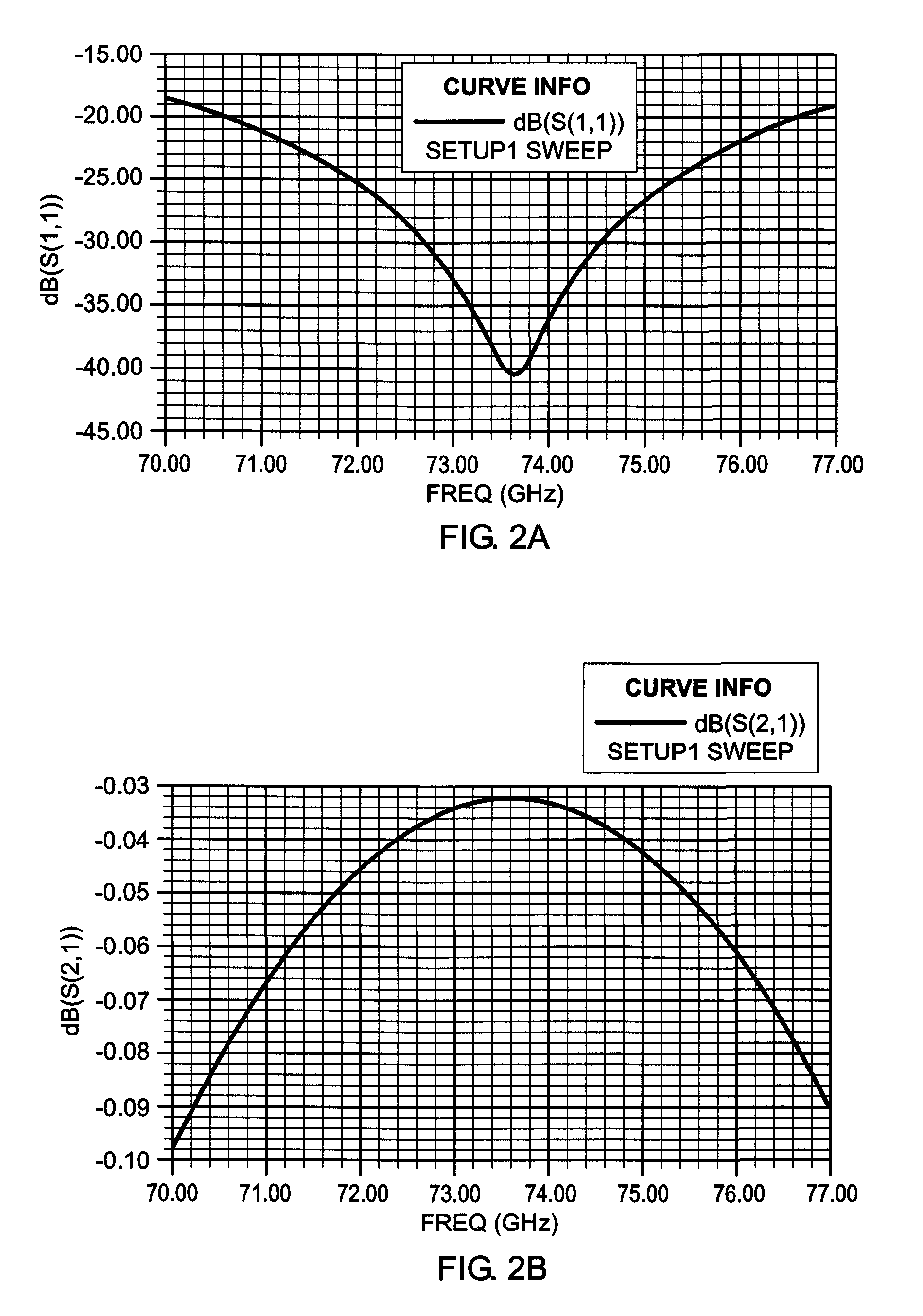

High frequency power combiner/divider

InactiveUS9065163B1Improve isolationOverall SSPA may be improvedPower amplifiersWaveguidesPower combinerHigh frequency power

Radio frequency (RF) power amplifiers are provided which may include high power, wideband, microwave or millimeter-wave solid state power amplifiers based on waveguide power combiner / dividers.

Owner:CUBIC CORPORATION

Fluid cooled apparatus for supporting diagnostic and therapeutic elements in contact with tissue

InactiveUS7303558B2Create efficientlyWider and deep lesionDiagnosticsInstrument handpiecesOrgan surfaceBiomedical engineering

Surgical methods and apparatus for positioning diagnostic an therapeutic elements on the epicardium or other organ surface. The apparatus includes a tissue cooling apparatus.

Owner:BOSTON SCI SCIMED INC

Al2O3-Y2O3-ZrO2/HfO2 materials, and methods of making and using the same

InactiveUS20030110708A1Facilitates formation and homogeneityOxide formationPigmenting treatmentGlass drawing apparatusFiberThermal insulation

Al2O3-Y2O3-ZrO2 / HfO2 ceramics (including glasses, crystalline ceramics, and glass-ceramics) and methods of making the same. Ceramics according to the present invention can be made, formed as, or converted into glass beads, articles (e.g., plates), fibers, particles, and thin coatings. The particles and fibers are useful, for example, as thermal insulation, filler, or reinforcing material in composites (e.g., ceramic, metal, or polymeric matrix composites). The thin coatings can be useful, for example, as protective coatings in applications involving wear, as well as for thermal management. Certain ceramic particles according to the present invention can be are particularly useful as abrasive particles.

Owner:3M INNOVATIVE PROPERTIES CO

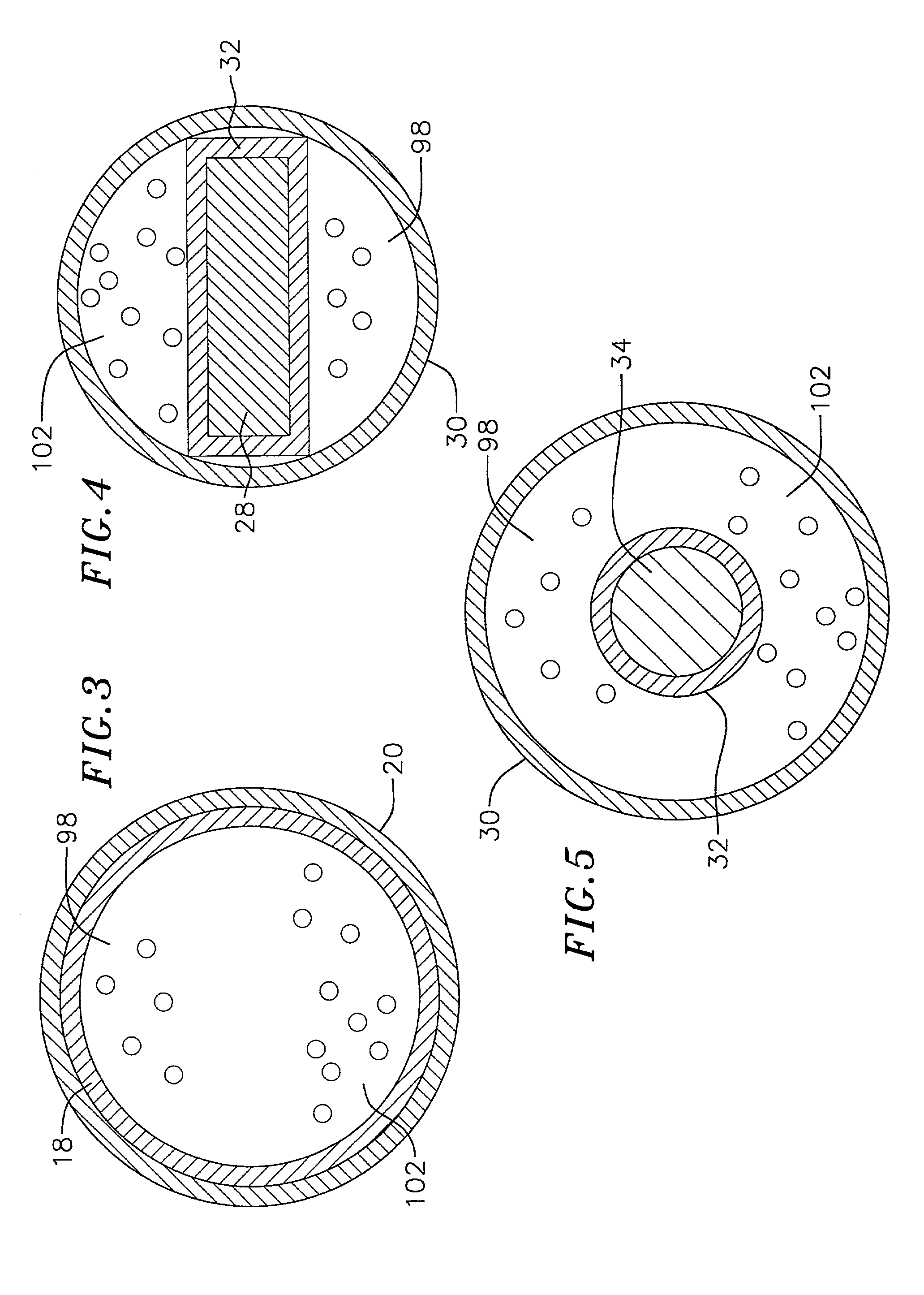

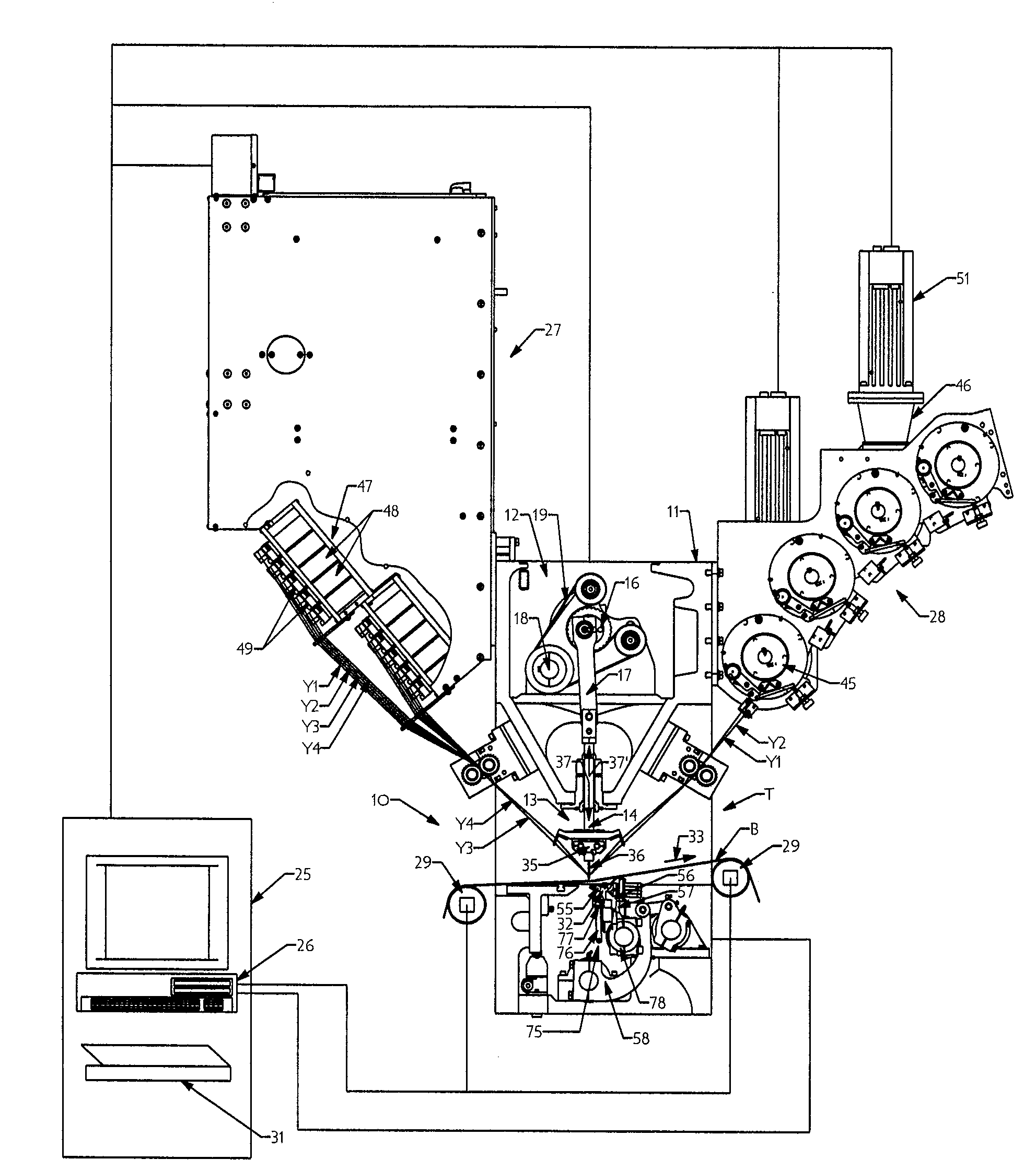

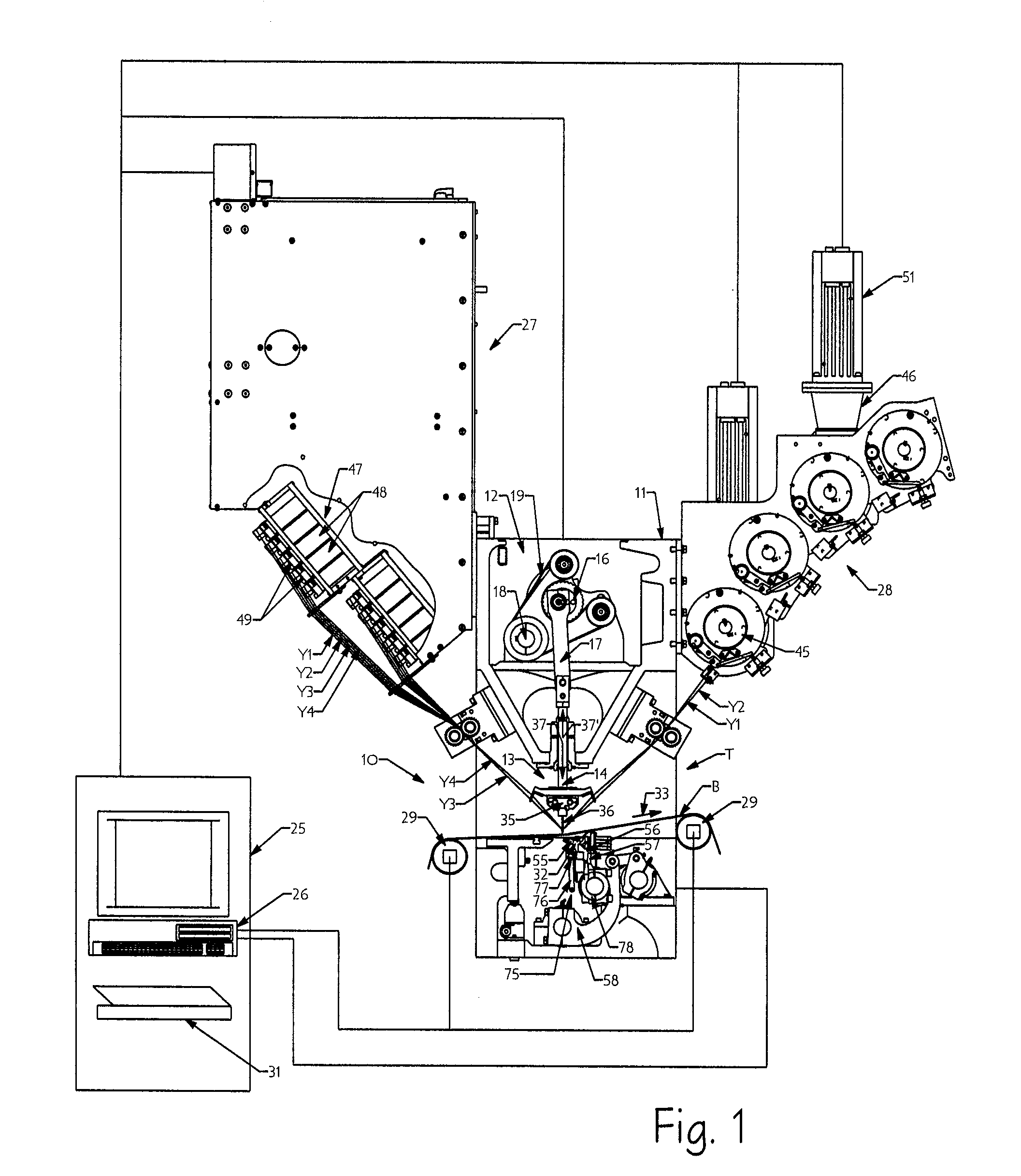

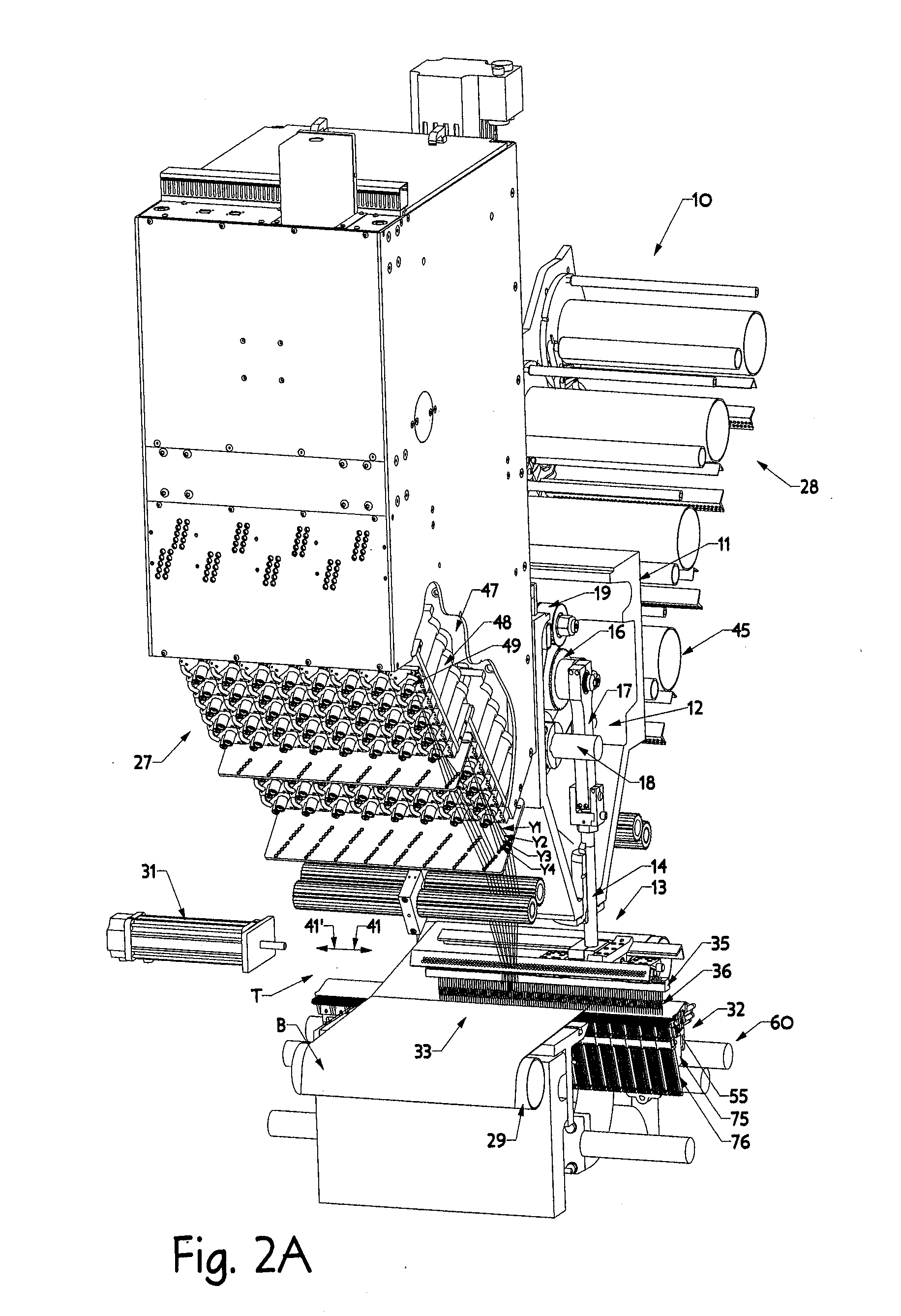

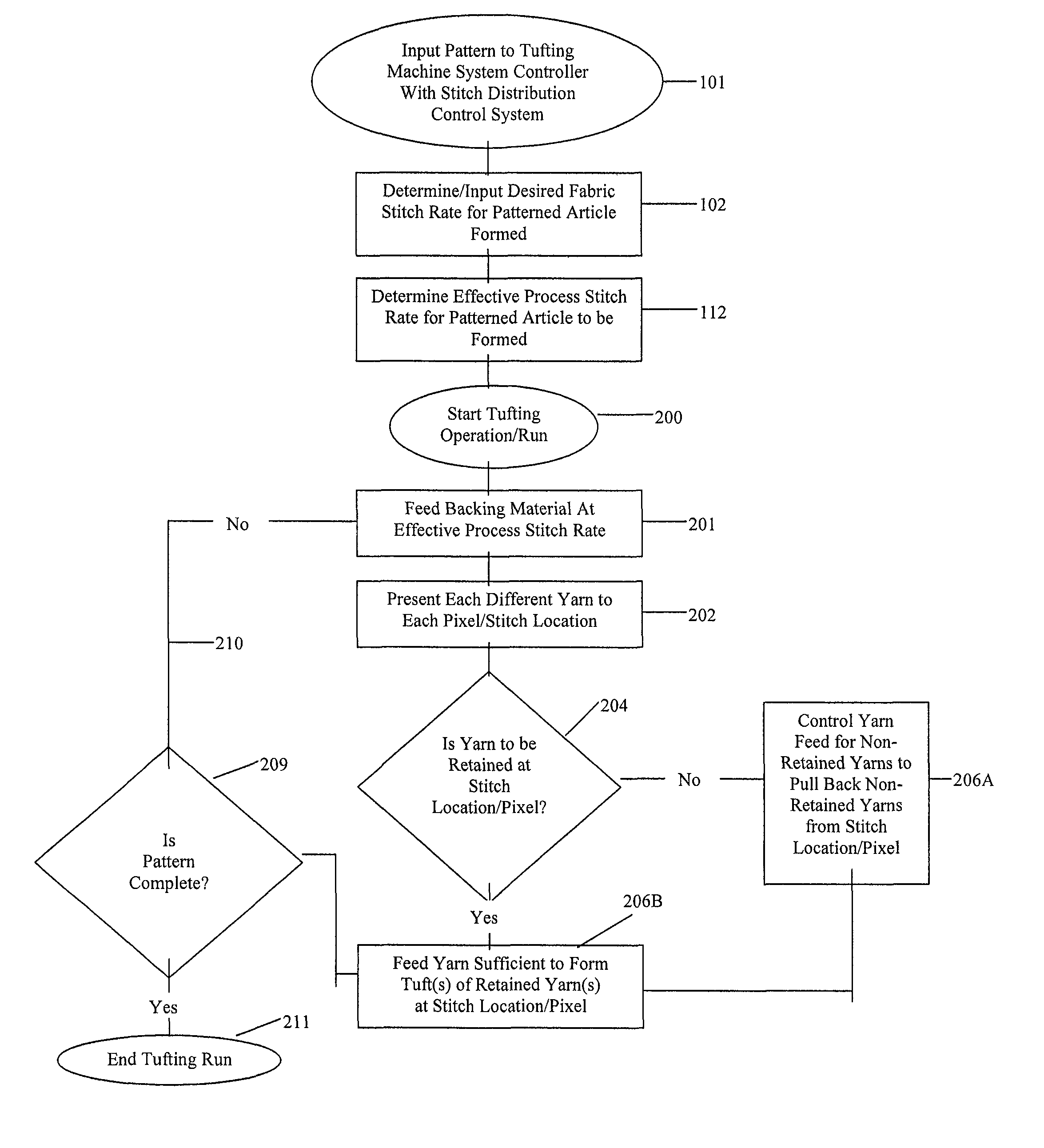

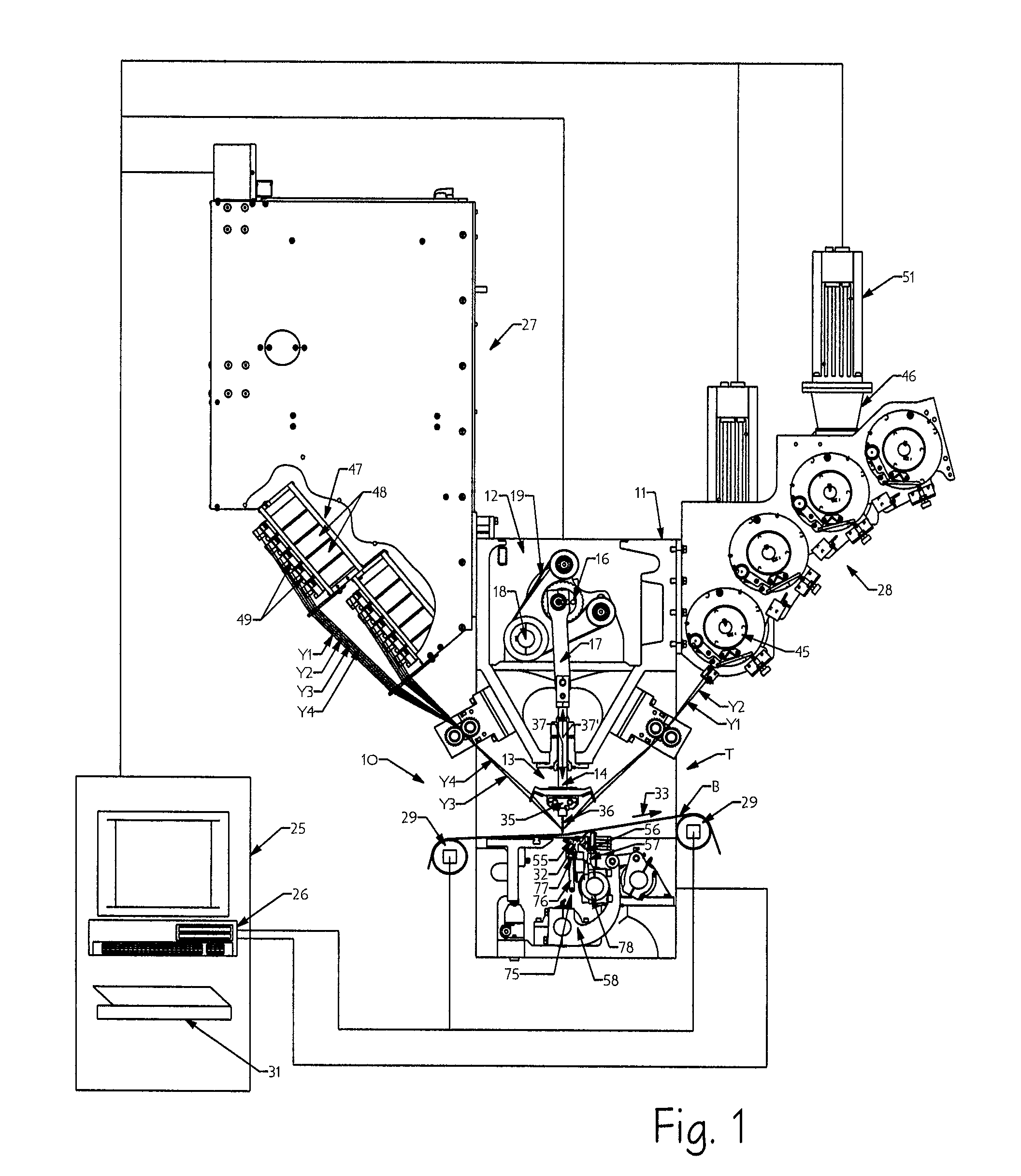

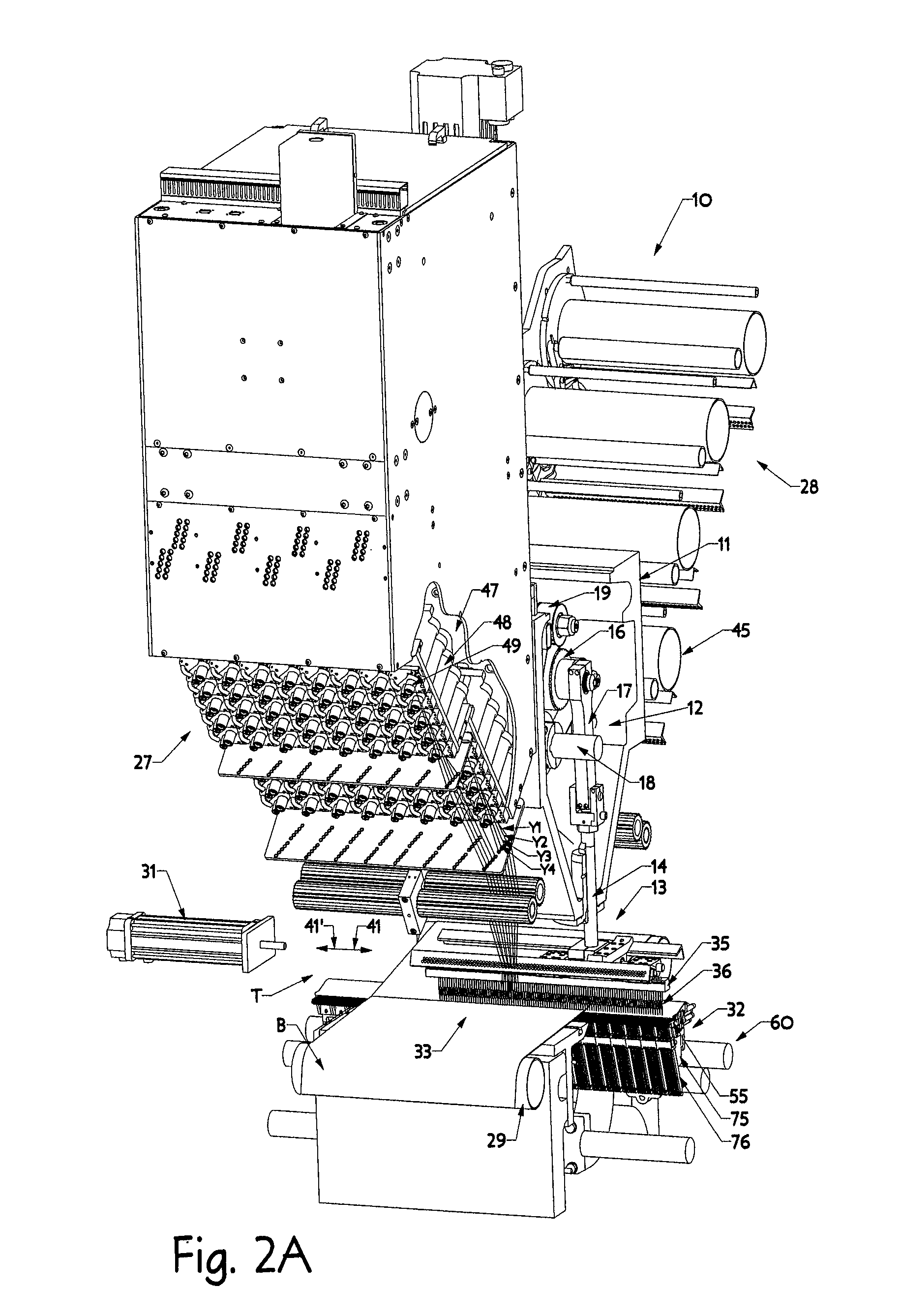

Stitch distribution control system for tufting machines

ActiveUS20090260554A1Sufficient enhanced densityHigh selectivityTufting apparatusYarnDistribution control

A stitch distribution control system for a tufting machine for controlling placement of yarns being fed to the needles of the tufting machine by yam feed mechanisms to form a desired pattern. A backing material is fed through the tufting machine at an increased stitch rate as the needles are shifted according to calculated pattern steps. A series of loopers or hooks engage and pick loops of yarns from the needles. The yarn feed mechanisms further can be controlled so that selected loops of yarns can be back-robbed so as to be hidden from view in the finished patterned tufted article.

Owner:CARD MONROE

Al2O3-rare earth oxide-ZrO2/HfO2 materials, and methods of making and using the same

InactiveUS20030126803A1Facilitates formation and homogeneityOxide formationPigmenting treatmentOther chemical processesFiberThermal insulation

Al2O3-rare earth oxide-ZrO2 / HfO2 ceramics (including glasses, crystalline ceramics, and glass-ceramics) and methods of making the same. Ceramics according to the present invention can be made, formed as, or converted into glass beads, articles (e.g., plates), fibers, particles, and thin coatings. The particles and fibers are useful, for example, as thermal insulation, filler, or reinforcing material in composites (e.g., ceramic, metal, or polymeric matrix composites). The thin coatings can be useful, for example, as protective coatings in applications involving wear, as well as for thermal management. Certain ceramic particles according to the present invention can be are particularly useful as abrasive particles.

Owner:3M INNOVATIVE PROPERTIES CO

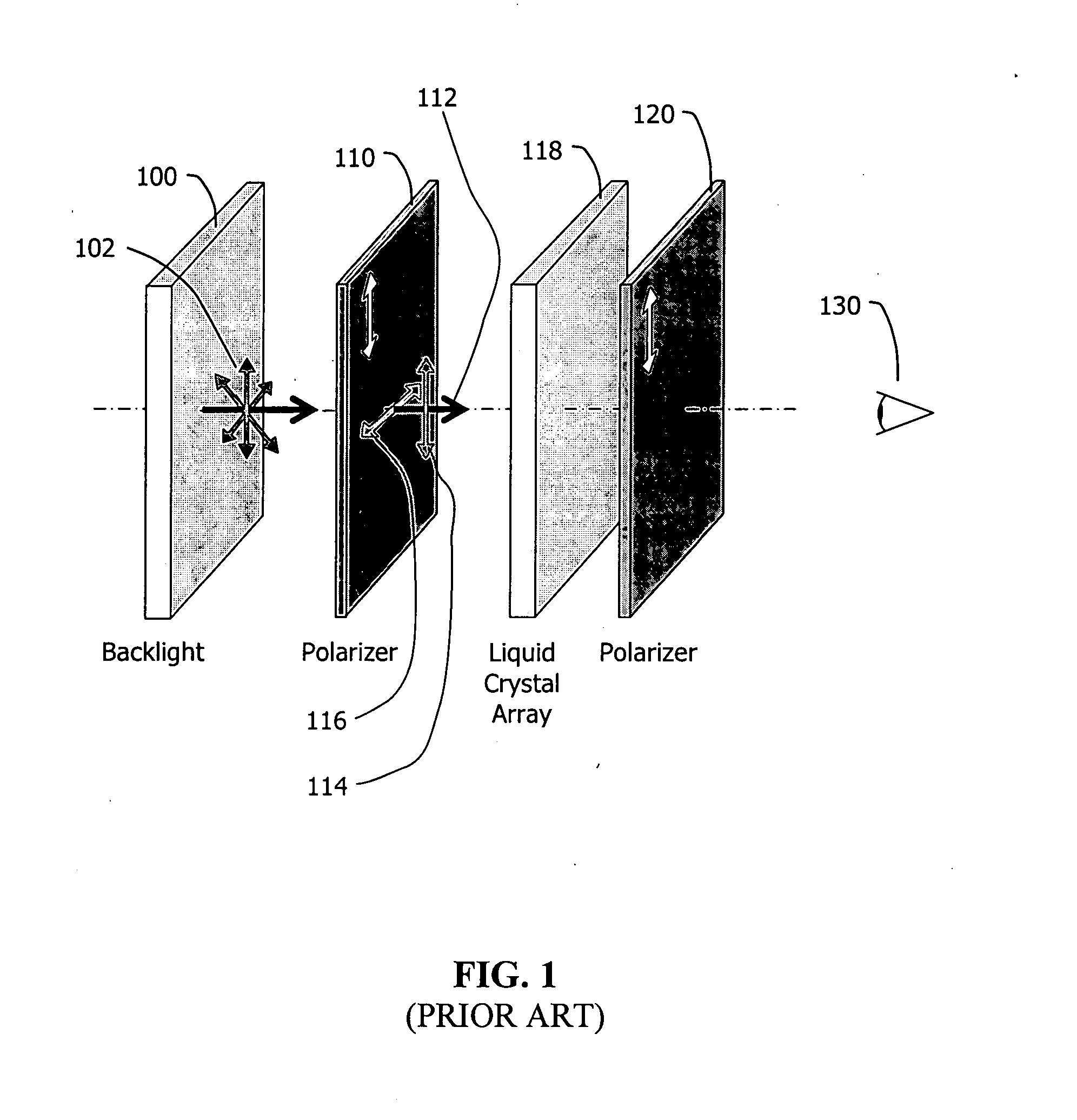

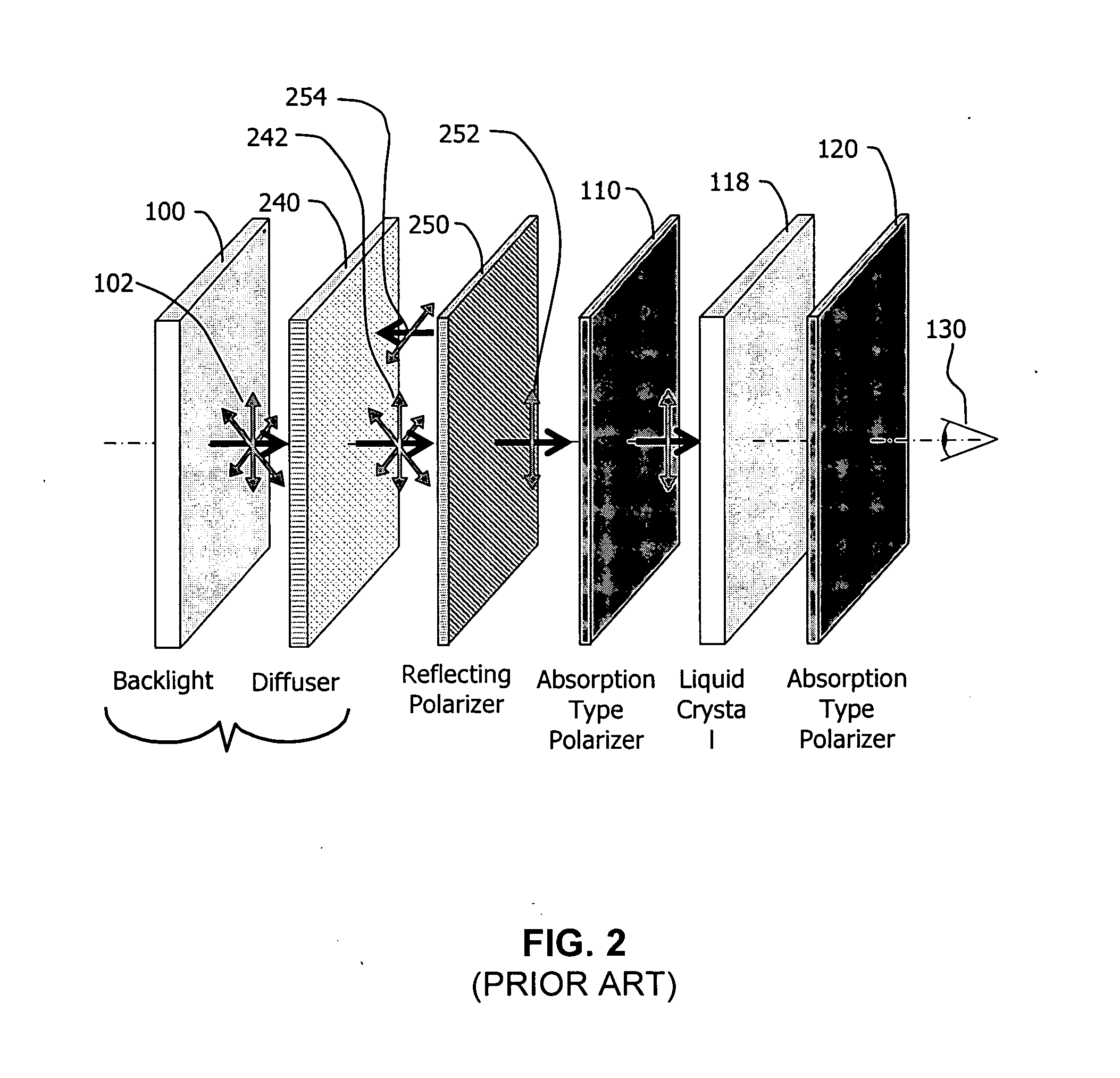

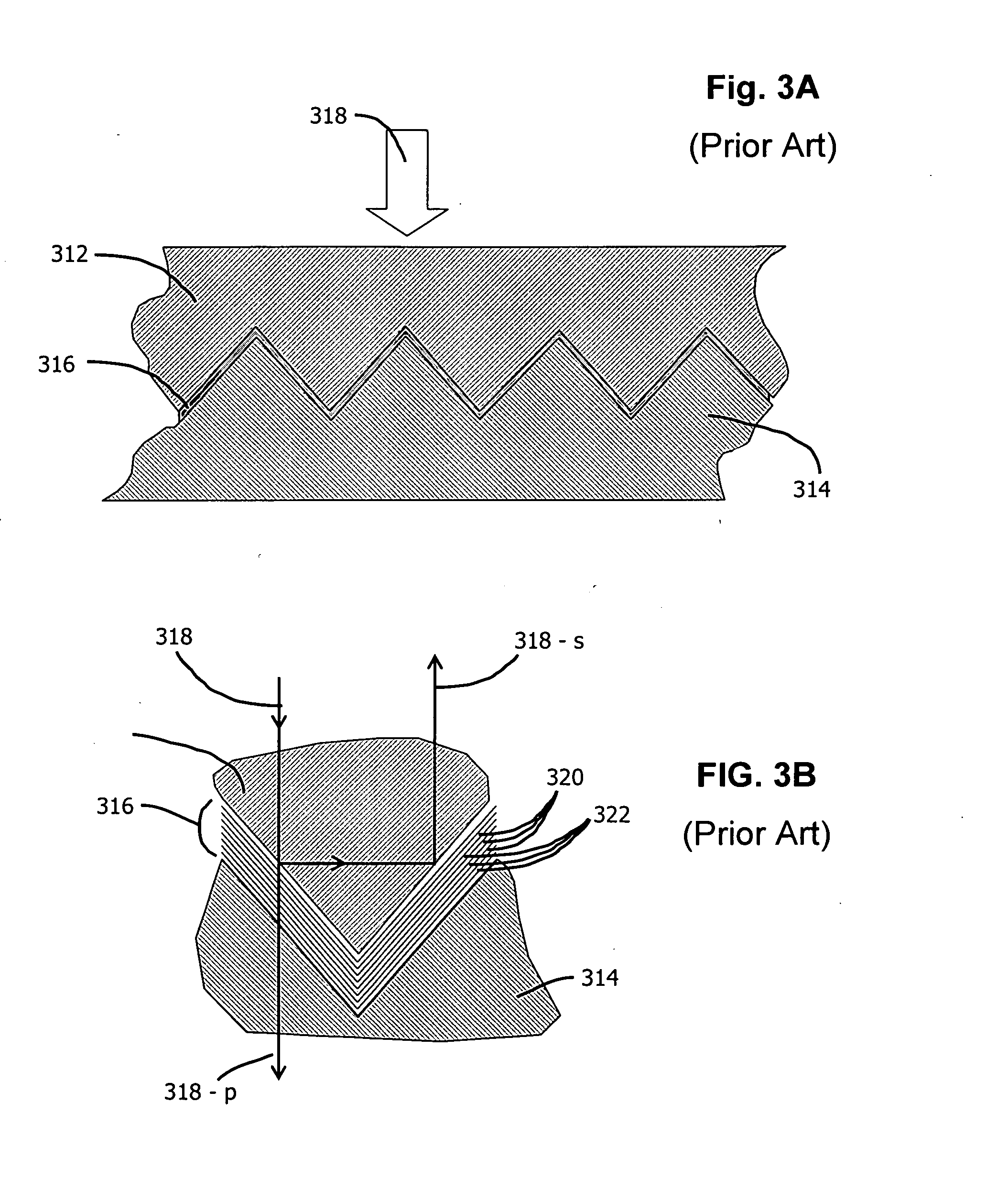

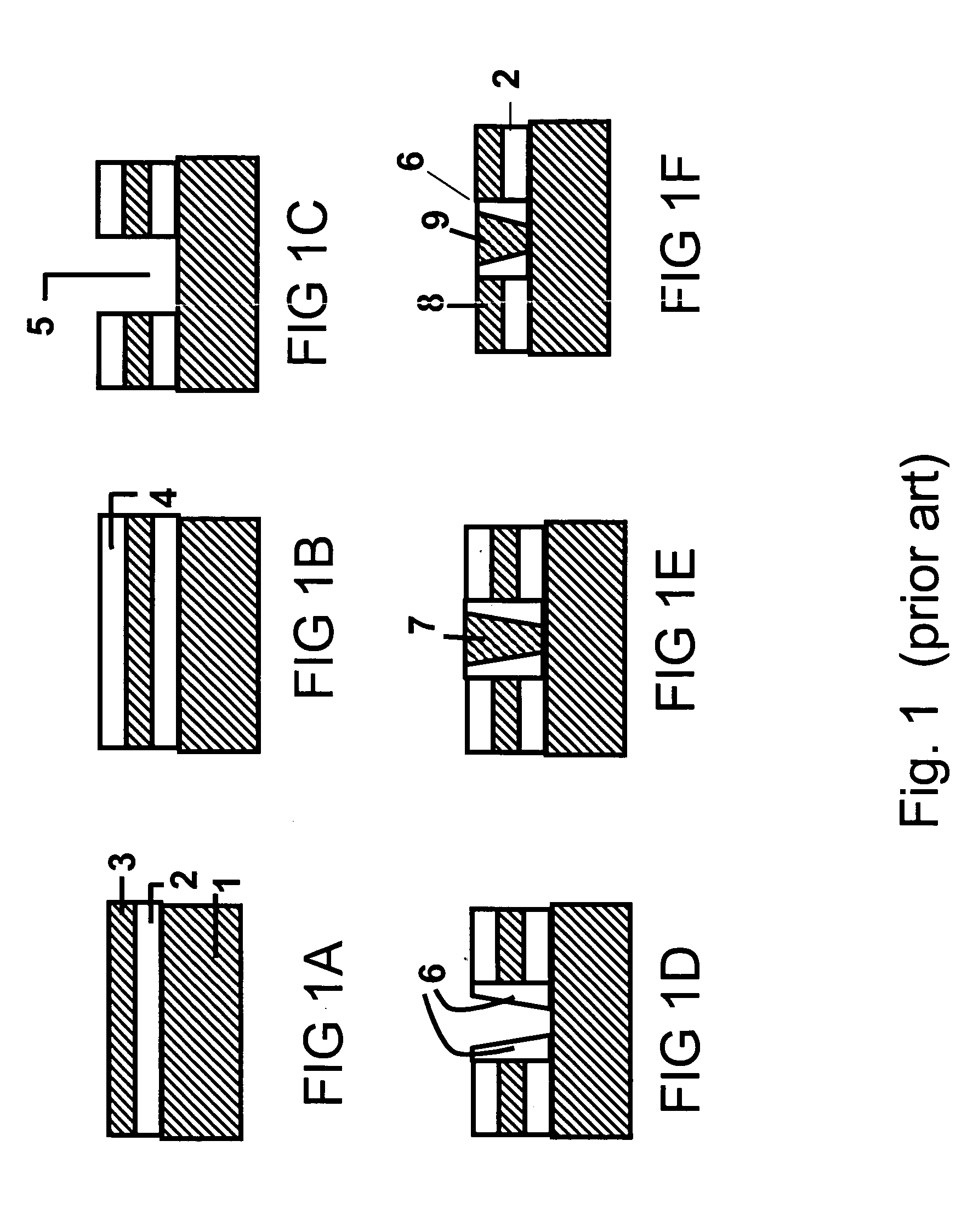

Applications and fabrication techniques for large scale wire grid polarizers

InactiveUS20060118514A1Enable formationMaterial nanotechnologyDecorative surface effectsWire gridElectrical conductor

A wire grid polarizer may be fabricated by forming plurality of substantially-straight metallic lines of predetermined periodicity Λ on a thin film substrate A plurality of substantially straight nanometer-scale periodic surface relief structures is created on a surface of the substrate. The periodic surface relief structures cover a region greater than about 4 centimeters in length and greater than about 4 centimeters in width, wherein the periodicity Λ is between about 10 nanometers and about 500 nanometers. One or more layers of material are formed on the periodic relief structures. The one or more layers include one or more conductor materials that form the plurality of substantially straight metallic lines over a region of the substrate greater than about 4 centimeters in length and greater than about 4 centimeters in width.

Owner:AGOURA TECH

Method of making amorphous and ceramics via melt spinning

InactiveUS20040020245A1Desired characteristicSpeed up the processOther chemical processesGlass forming apparatusCeramicMelt spinning

Owner:3M INNOVATIVE PROPERTIES CO

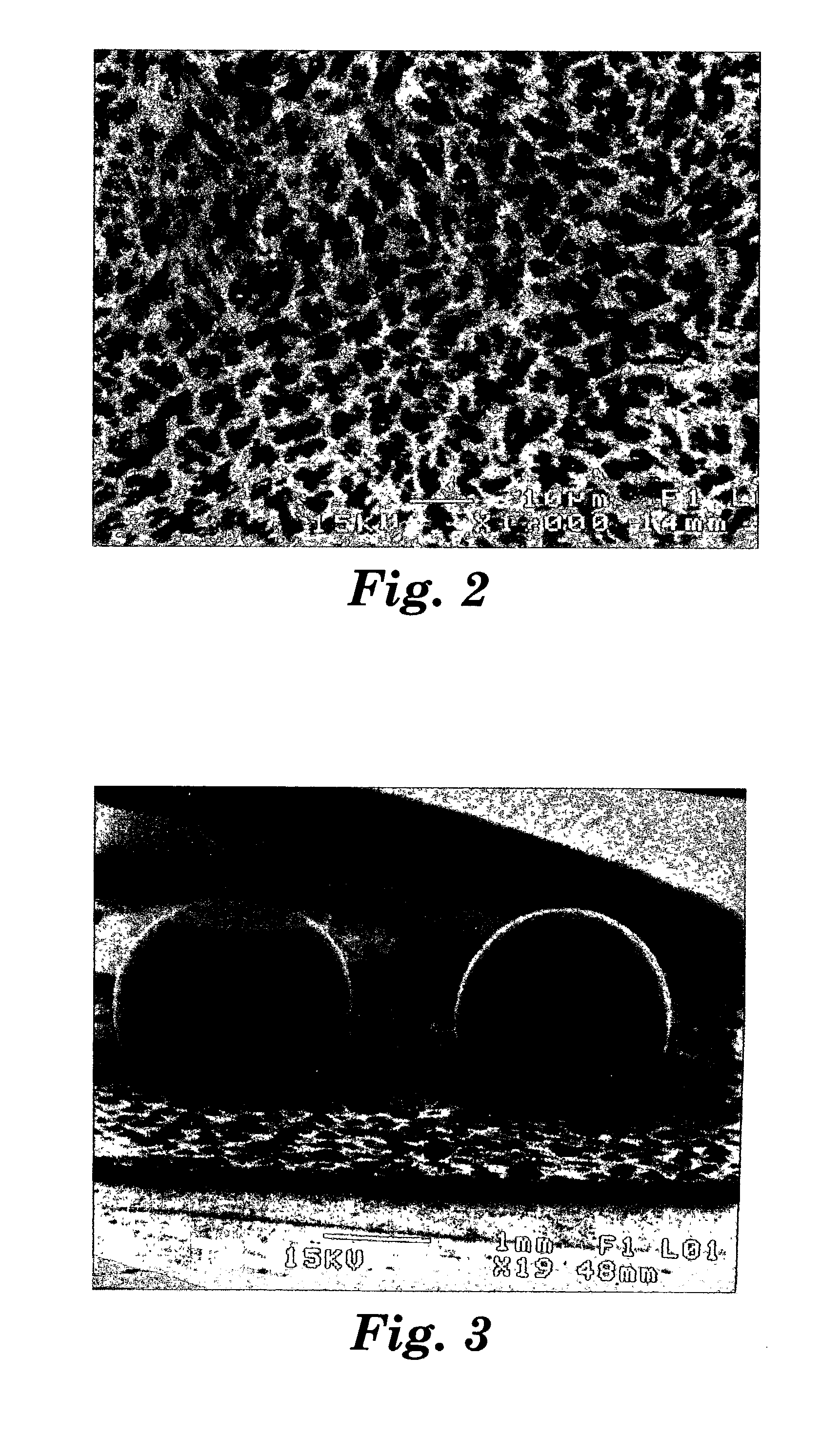

Ceramic materials, abrasive particles, abrasive articles, and methods of making and using the same

InactiveUS20030126802A1Facilitates formation and homogeneityOxide formationOther chemical processesInorganic pigment treatmentGlass-ceramicMaterials science

Owner:3M INNOVATIVE PROPERTIES CO

Stitch distribution control system for tufting machines

ActiveUS8359989B2High selectivityEnable formationProgramme-controlled sewing machinesTufting apparatusYarnDistribution control

Owner:CARD MONROE

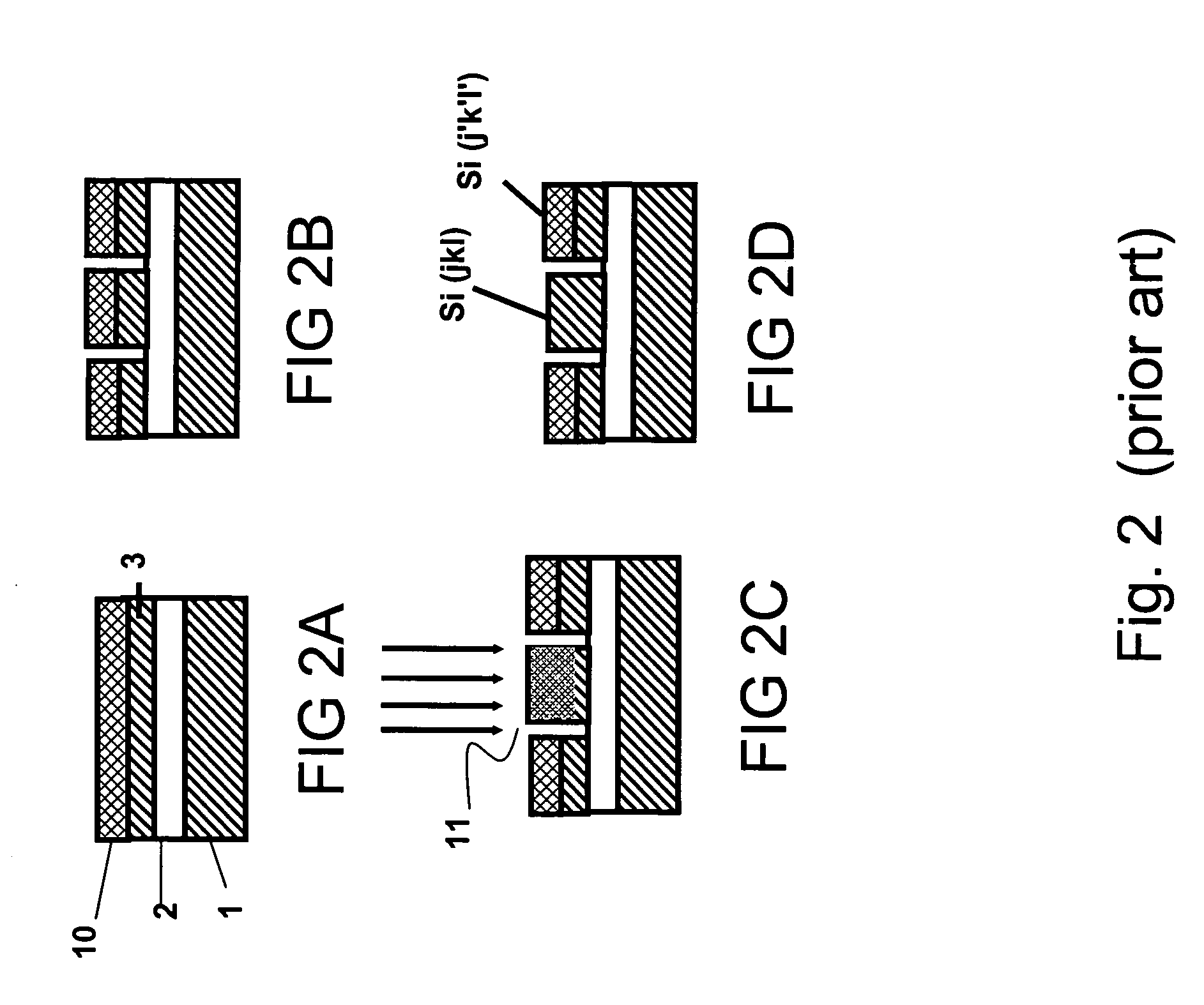

Mixed orientation and mixed material semiconductor-on-insulator wafer

InactiveUS20050277260A1Enable formationFrom solid stateSolid-state devicesCMOSSemiconductor materials

The present disclosure relates, generally, to a semiconductor substrate with a planarized surface comprising mixed single-crystal orientation regions and / or mixed single-crystal semiconductor material regions, where each region is electrically isolated. In accordance with one embodiment of the disclosure CMOS devices on SOI regions are manufactured on semiconductors having different orientations. According to another embodiment, an SOI device is contemplated as having a plurality of semiconductor regions having at least one of a different semiconductor material, crystalline lattice constant or lattice strain. Methods and processes for fabricating the different embodiments of the invention is also disclosed.

Owner:GLOBALFOUNDRIES INC

Method of making amorphous materials and ceramics

InactiveUS20030110709A1Facilitates formation and homogeneityEliminates and minimizes heat transferWood working apparatusCeramic shaping apparatusCeramicAbrasive

Owner:3M INNOVATIVE PROPERTIES CO

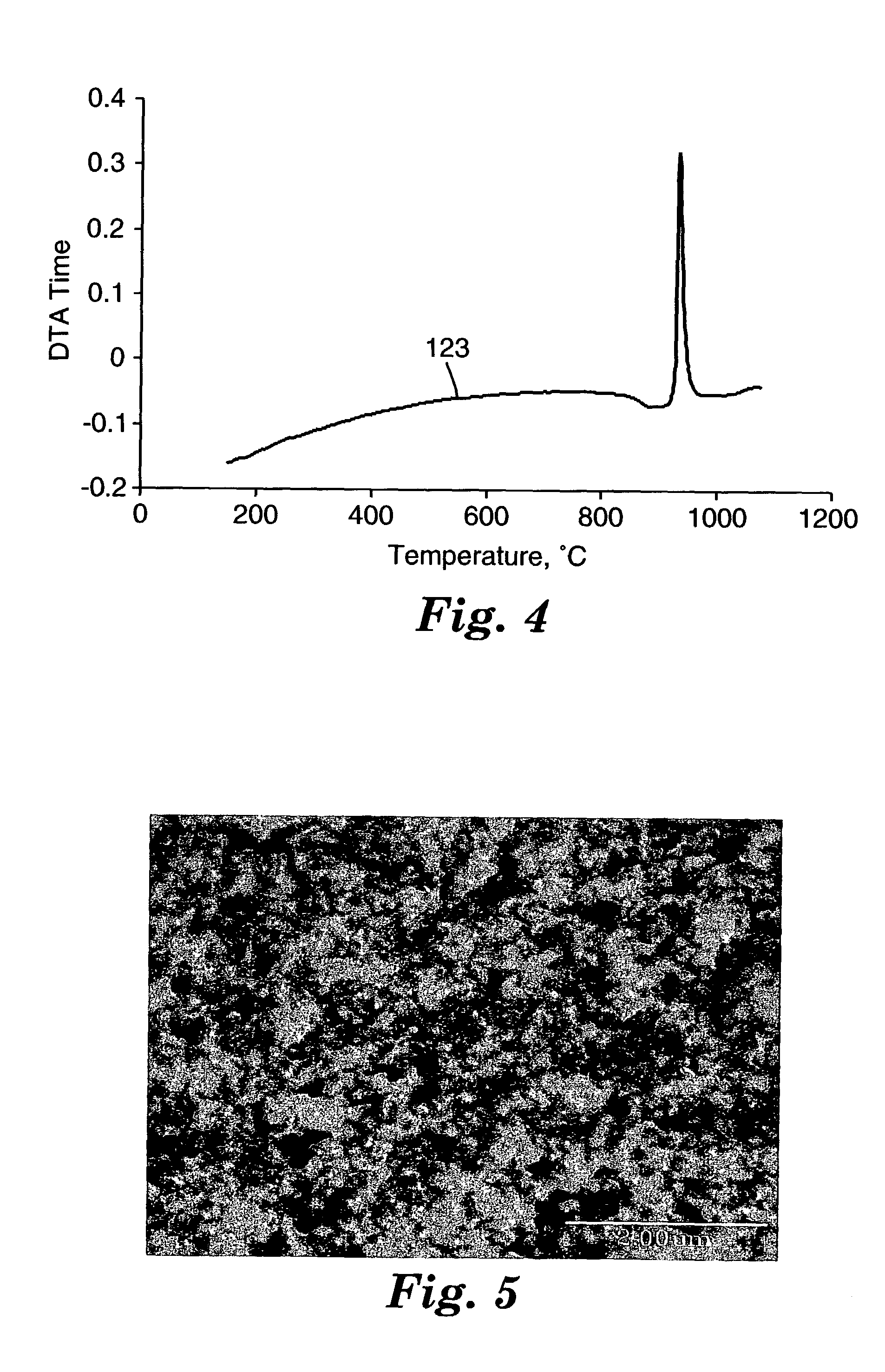

Abrasive particles and methods of making and using the same

InactiveUS20030110706A1Facilitates formation and homogeneityOxide formationPigmenting treatmentOther chemical processesOxideMetal

Abrasive particles comprising ceramic (including glasses, crystalline ceramics, and glass-ceramics) comprising (on a theoretical oxide basis) Al2O3 and at least one other metal oxide (e.g., REO and; REO and at least one of ZrO2 or HfO2) and methods of making the same. The abrasive particles can be incorporated into a variety of abrasive articles, including bonded abrasives, coated abrasives, nonwoven abrasives, and abrasive brushes.

Owner:3M INNOVATIVE PROPERTIES CO

Abrasive particles, abrasive articles, and methods of making and using the same

InactiveUS20030115805A1Facilitates formation and homogeneityOxide formationOther chemical processesInorganic pigment treatmentAbrasive

Owner:3M INNOVATIVE PROPERTIES CO

Organic silver complexes, their preparation methods and their methods for forming thin layers

ActiveUS8226755B2Superior stability and solubilityEasy to prepareGroup 1/11 organic compounds without C-metal linkagesRadiation applicationsThin layerAmmonium carbonate

Owner:INKTEC CO LTD

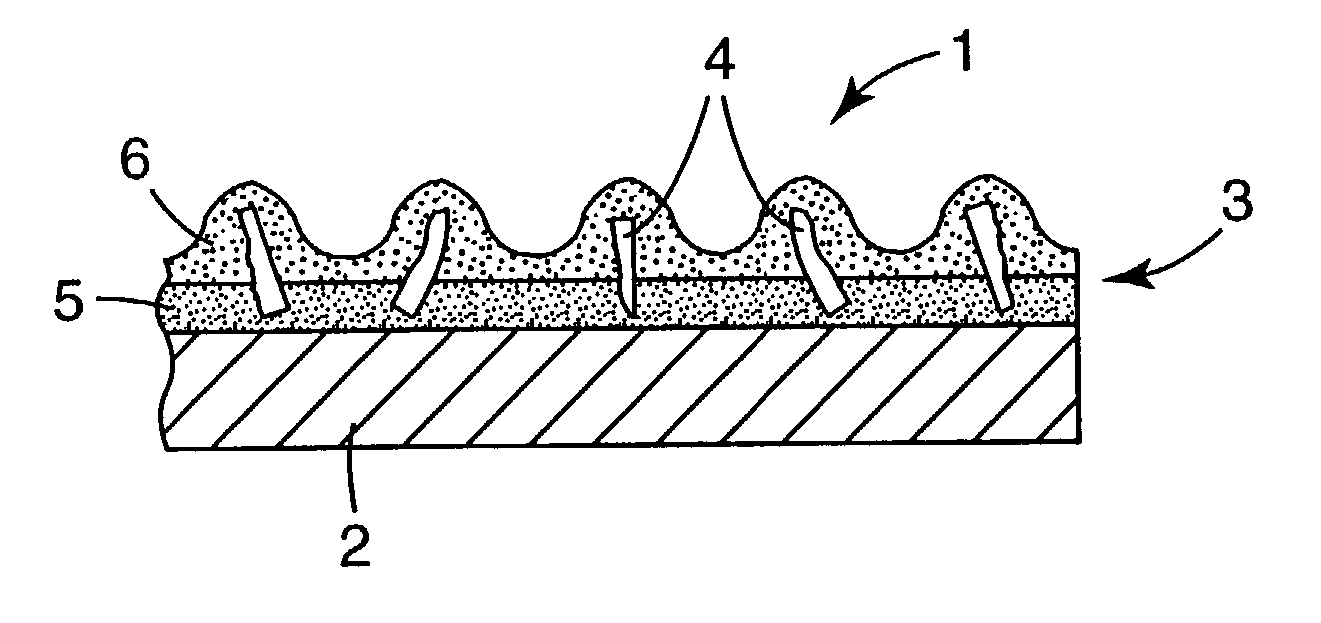

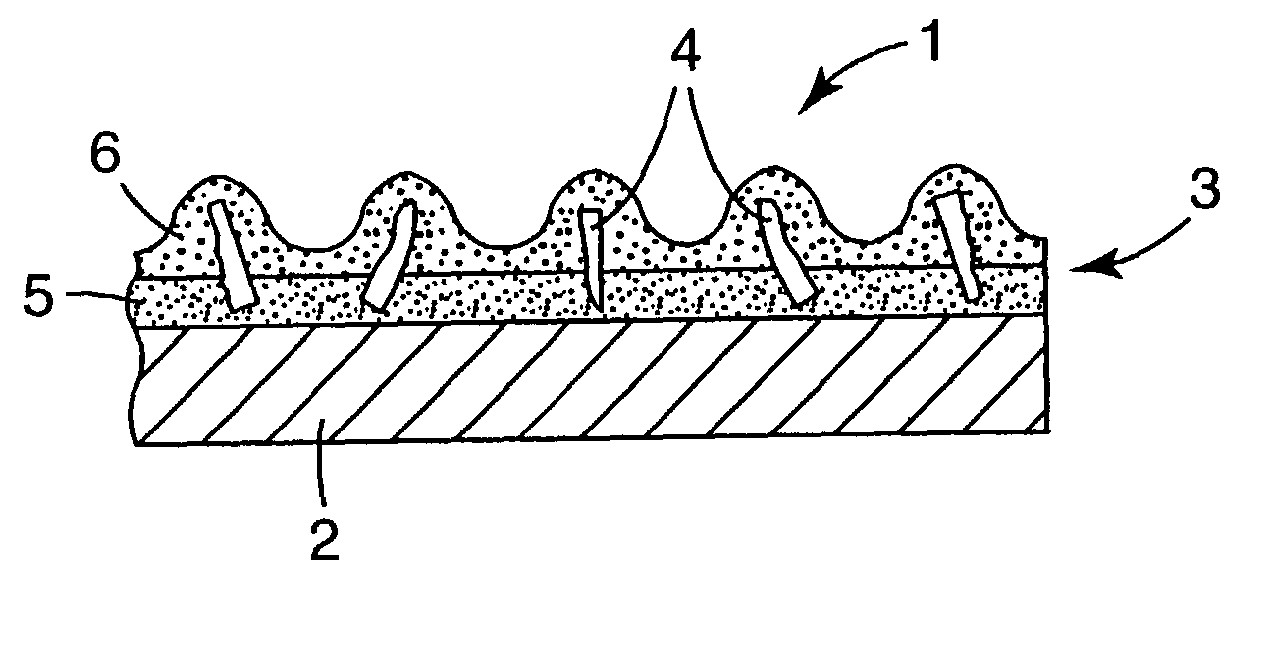

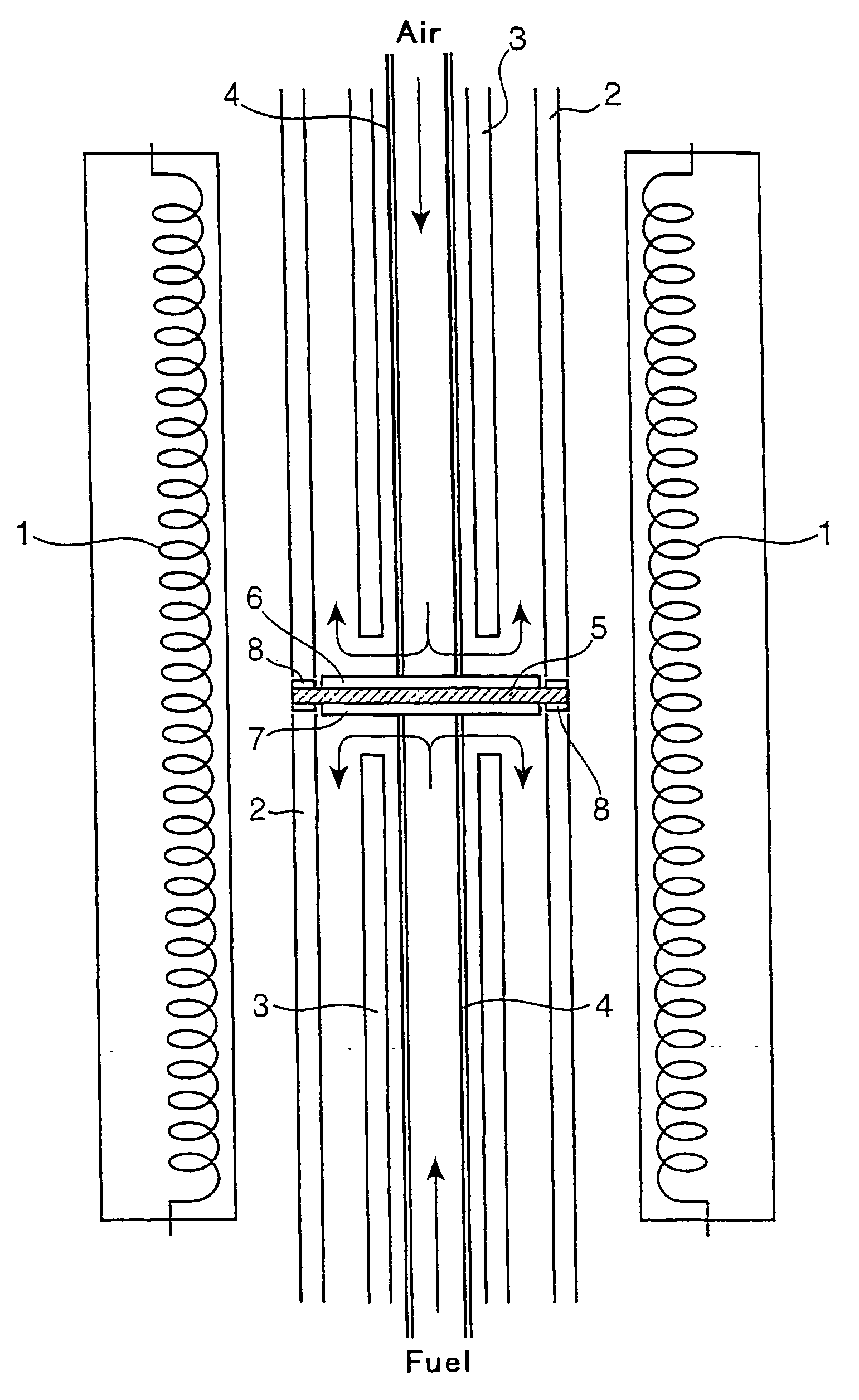

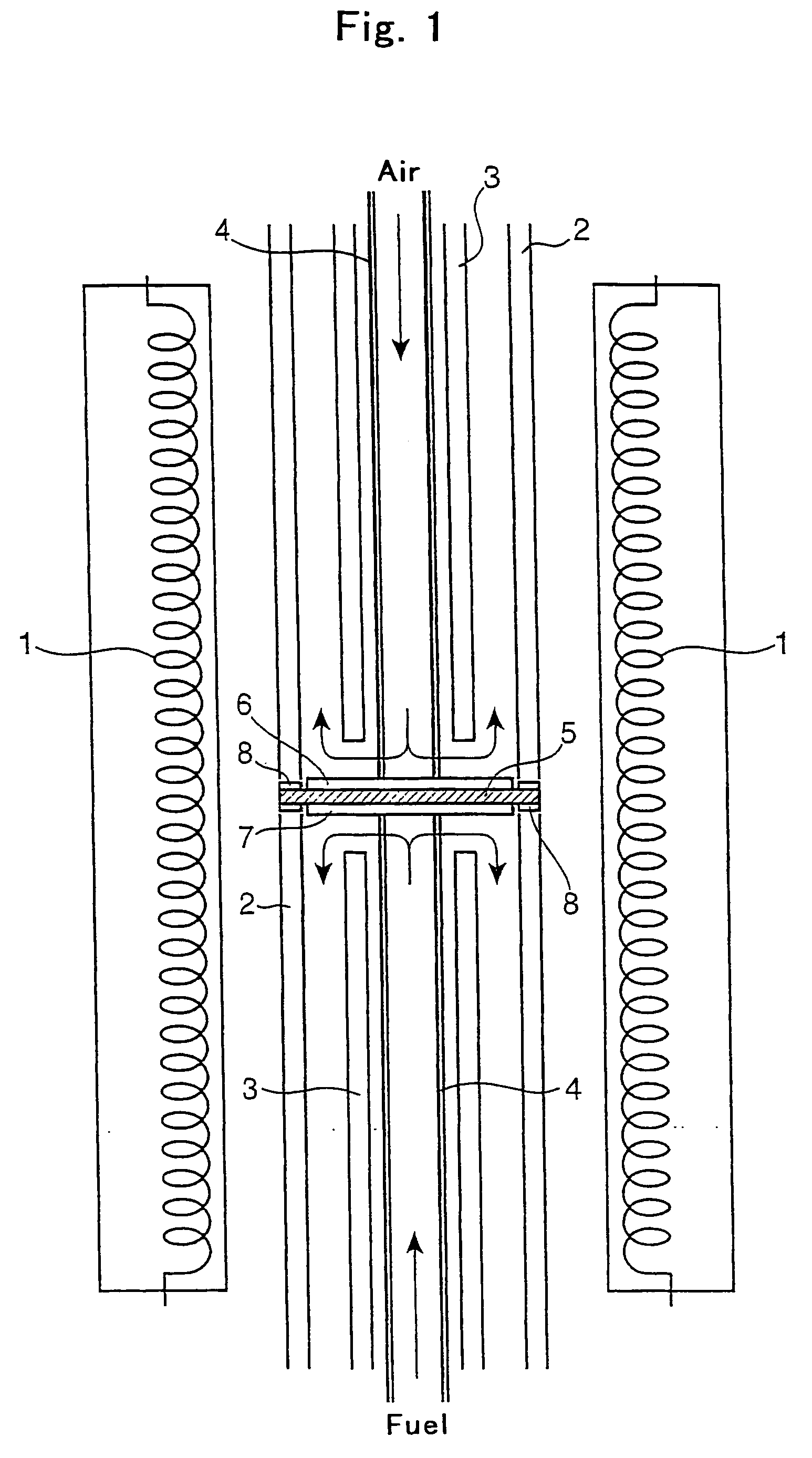

Electolyte sheets for solid oxide fuel cell and method for manufacturing same

InactiveUS20050271919A1Reduce warpingImprove productivitySolid electrolytesCell electrodesFuel cellsSurface roughness

The present invention provides electrolyte sheets for solid oxide fuel cells, the electrolyte sheets being able to improve their adhesion to electrode films formed on both surfaces thereof and being also able to improve electric power generation characteristics of fuel cells by an increase in their electrode reaction areas. There is disclosed an electrolyte sheet for solid oxide fuel cells including a sintered sheet, wherein surface roughness of the sheet as measured by an optical and laser-based non-contact three-dimensional profile measuring system is 2.0 to 20 μm in Rz and 0.20 to 3.0 μm in Ra, and wherein a ratio of Rz of one surface (having a greater Rz and a greater Ra) to Rz of the other surface having a smaller Rz and a smaller Ra is in a range of 1.0 to 3.0, and a ratio of Ra of one surface (having a greater Rz and a greater Ra) to Ra of the other surface having a smaller Rz and a smaller Ra is in a range of 1.0 to 3.0, and a ratio of Rmax to Rz (Rmax / Rz ratio) of at least one surface is in a range of 1.0 to 2.0.

Owner:NIPPON SHOKUBAI CO LTD

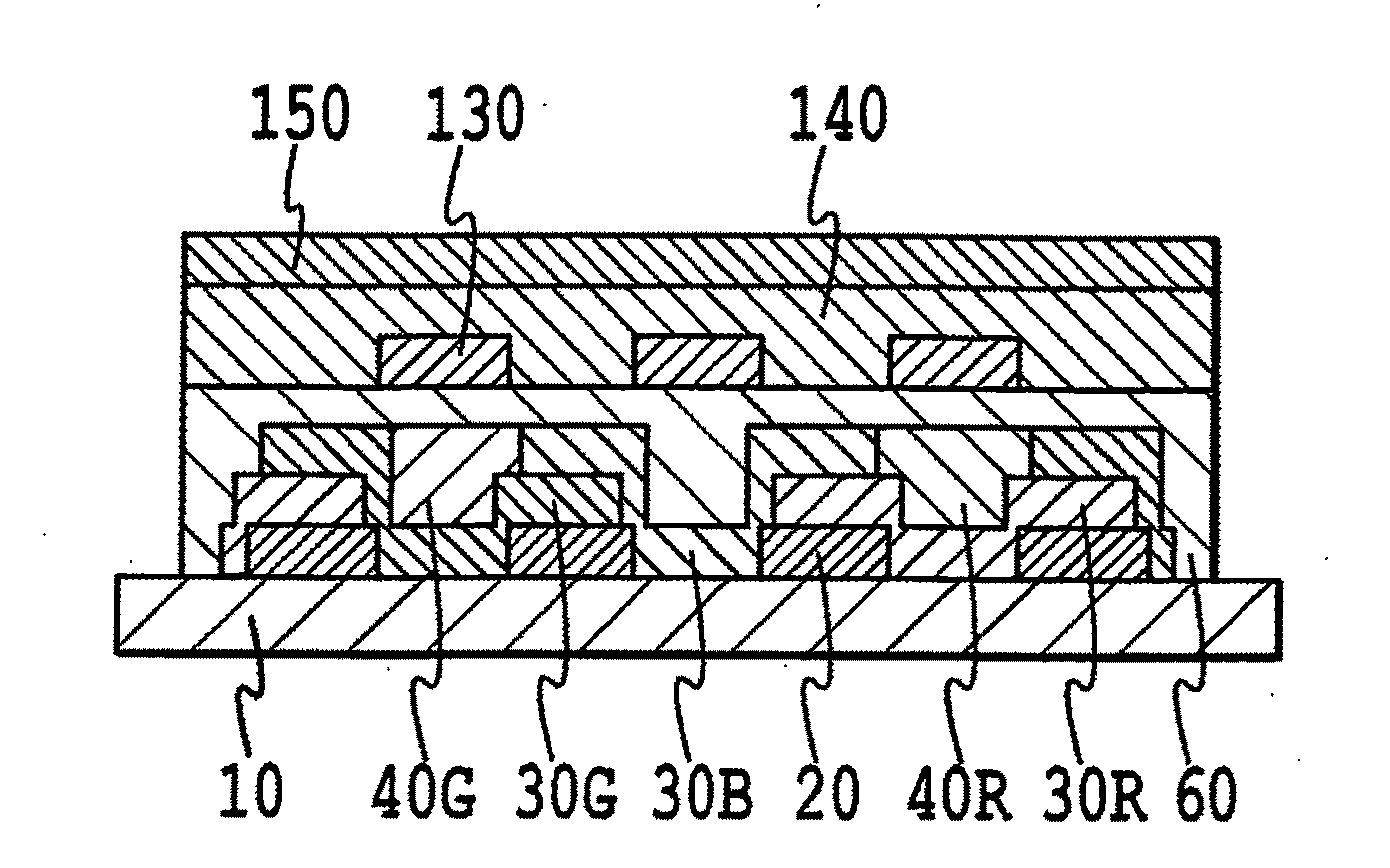

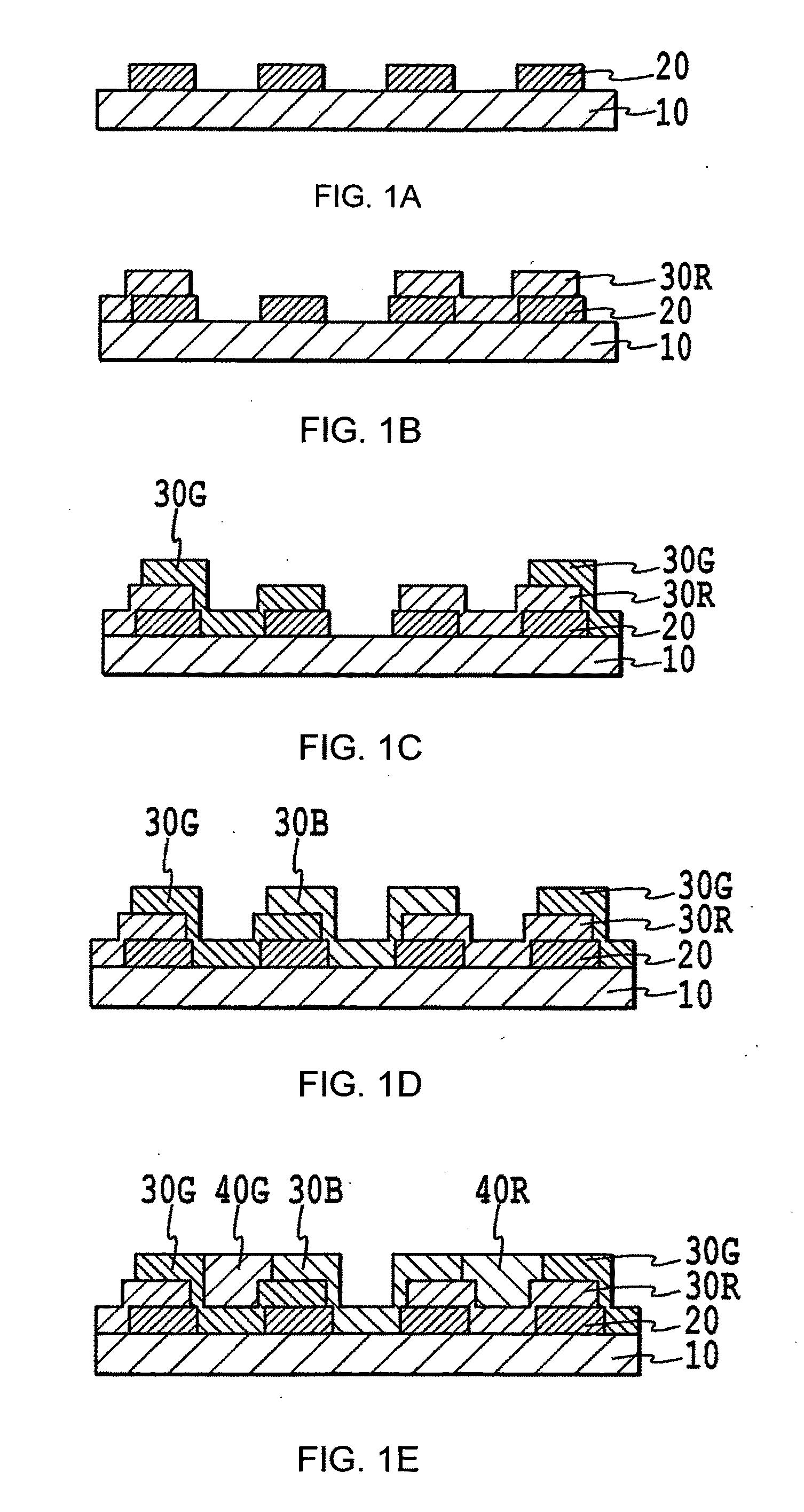

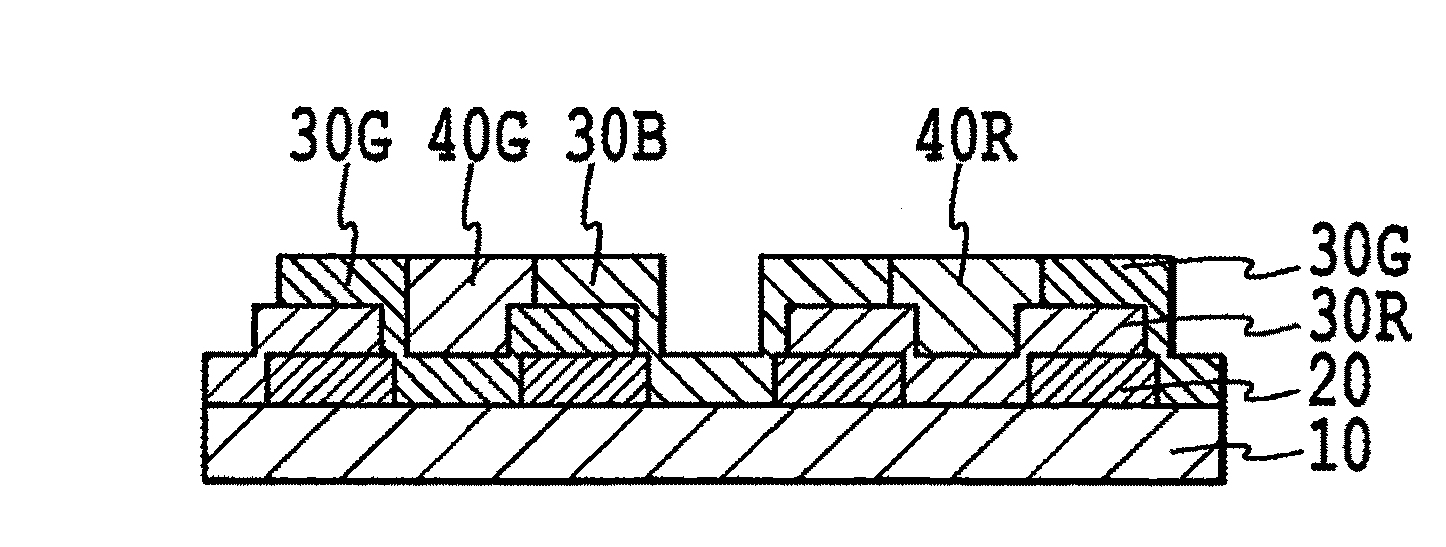

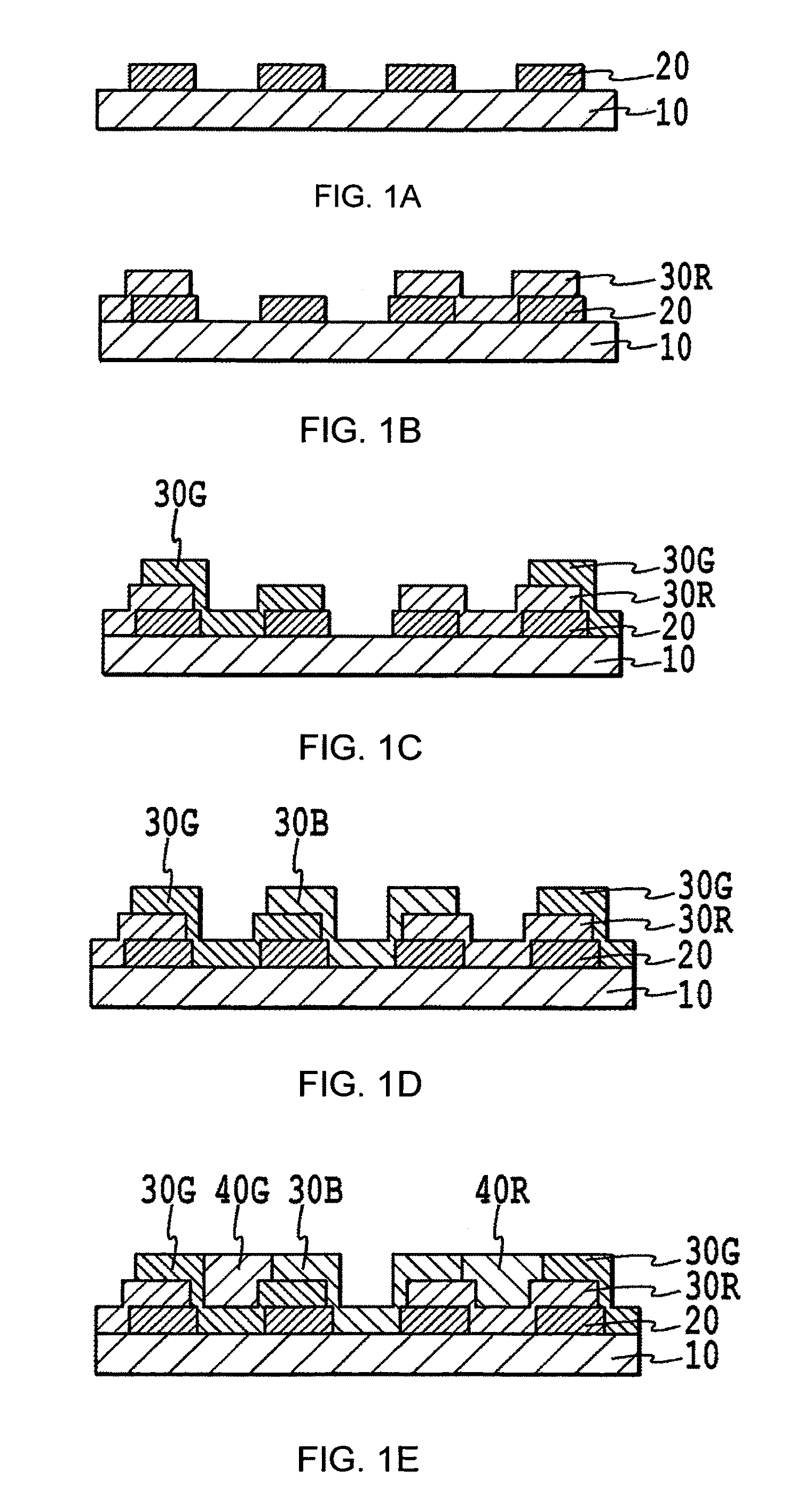

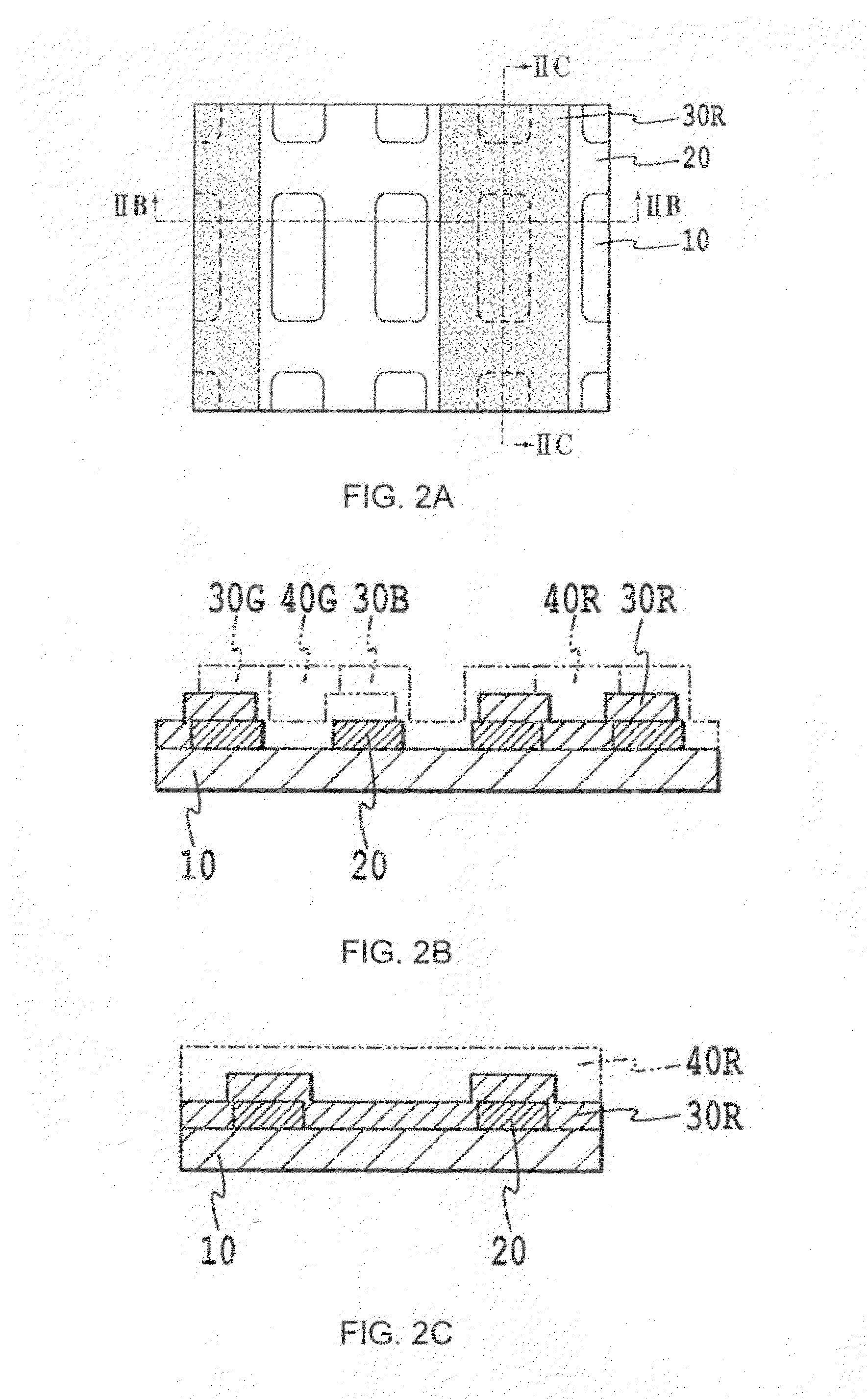

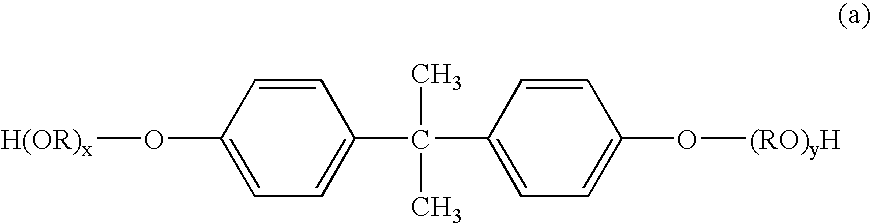

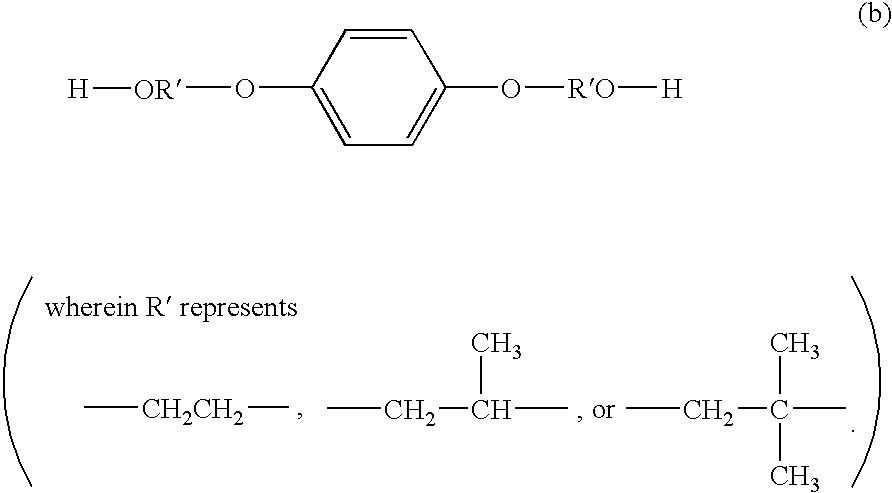

Color conversion filter and manufacturing method of the organic el display

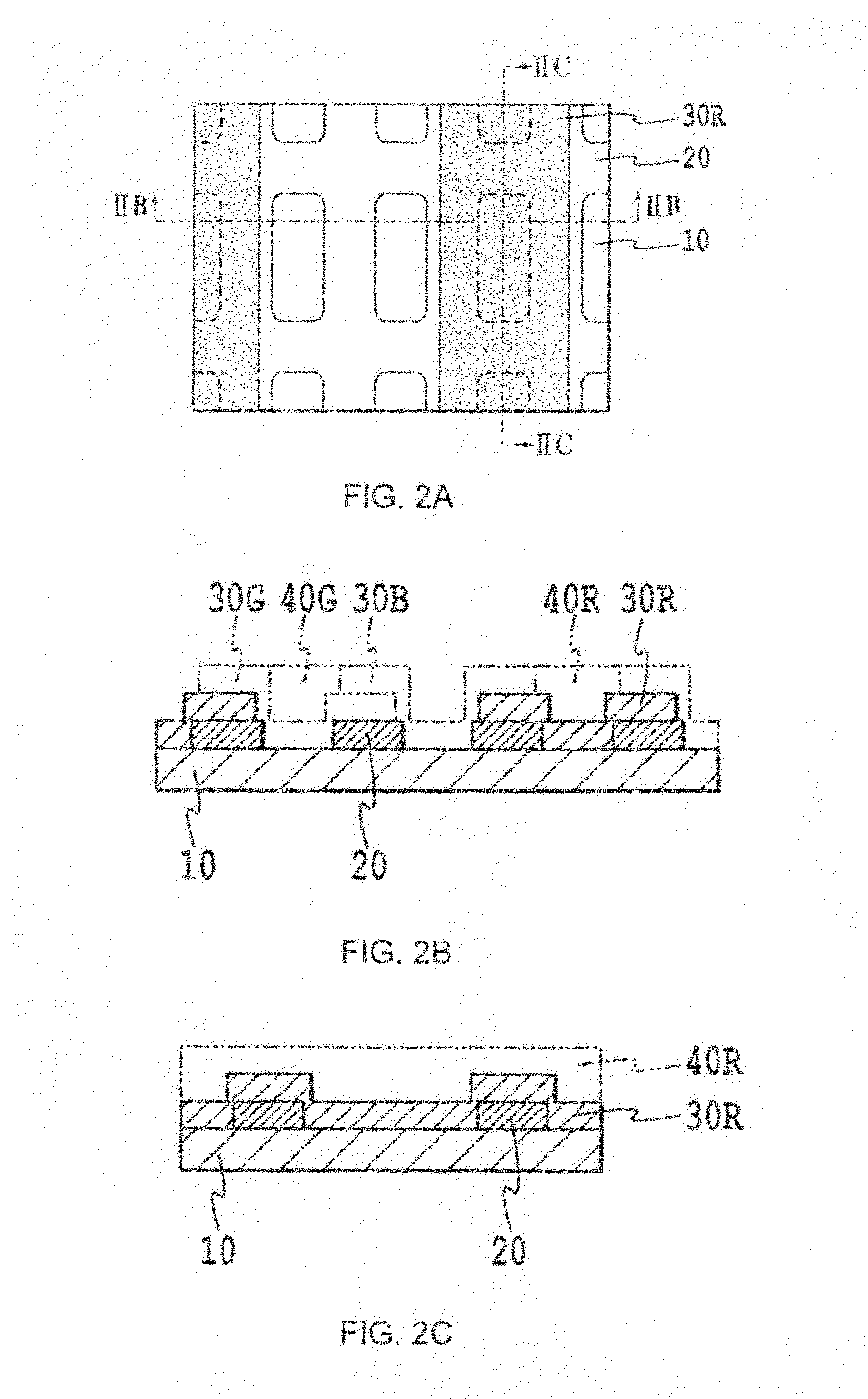

ActiveUS20110155296A1Enable formationInhibited DiffusionLamination ancillary operationsSolid-state devicesEngineeringColor filter array

A process for producing a color conversion filter uses an ink jet recording method, which can form a color conversion layer at a desired position without the need to separately form partition walls, and a process for producing an organic EL display. The process for producing a color conversion filter includes forming a black matrix having a plurality of opening parts on a transparent substrate, forming at least two types of color , filter layers independently of each other on a black matrix to which dissimilar color filter layers are adjacent, to form a partition wall, at least two of the color filter layers being superimposed on top of each other, and forming a color conversion layer by ink jet recording onto at least one of the color filter layers.

Owner:SHARP KK

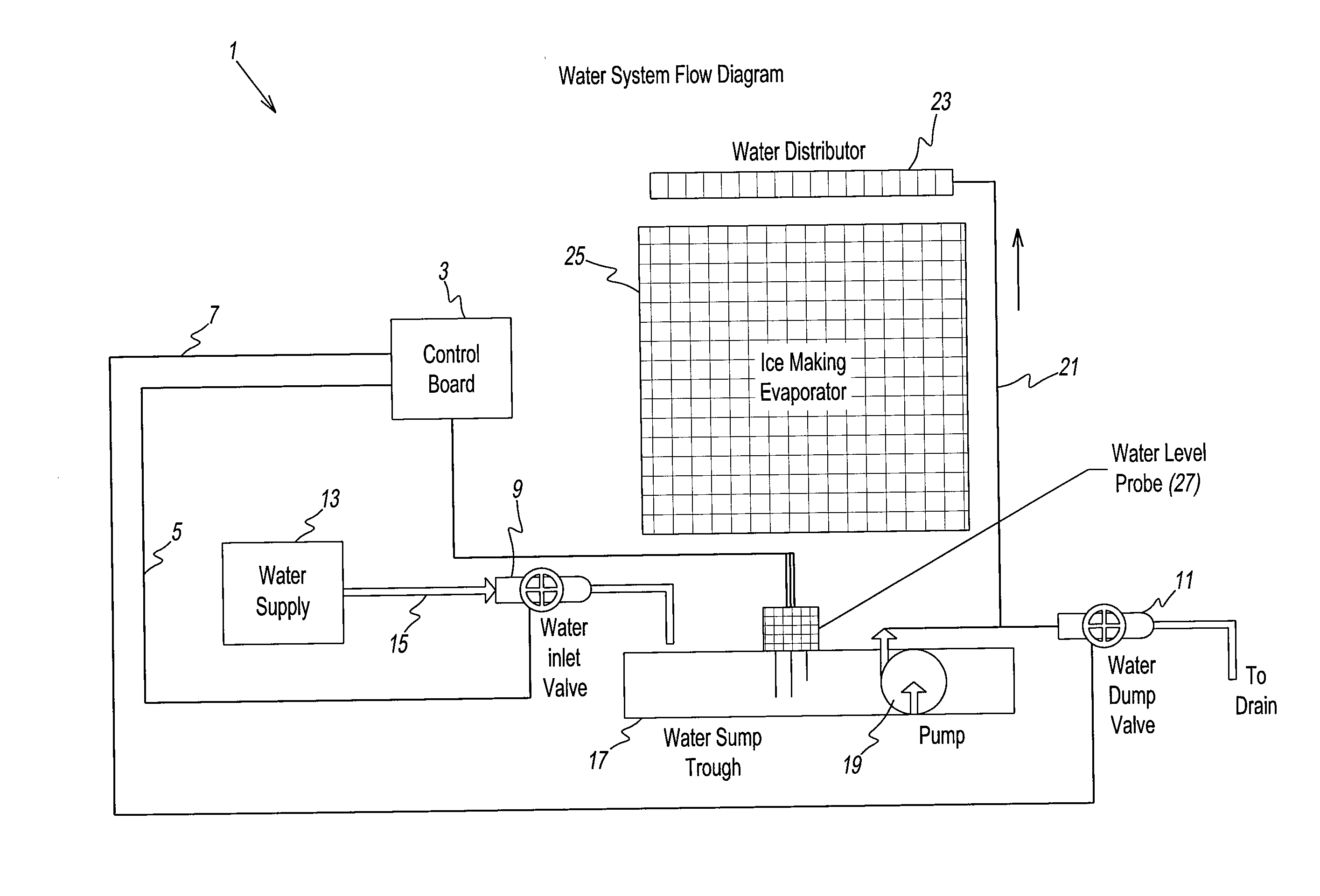

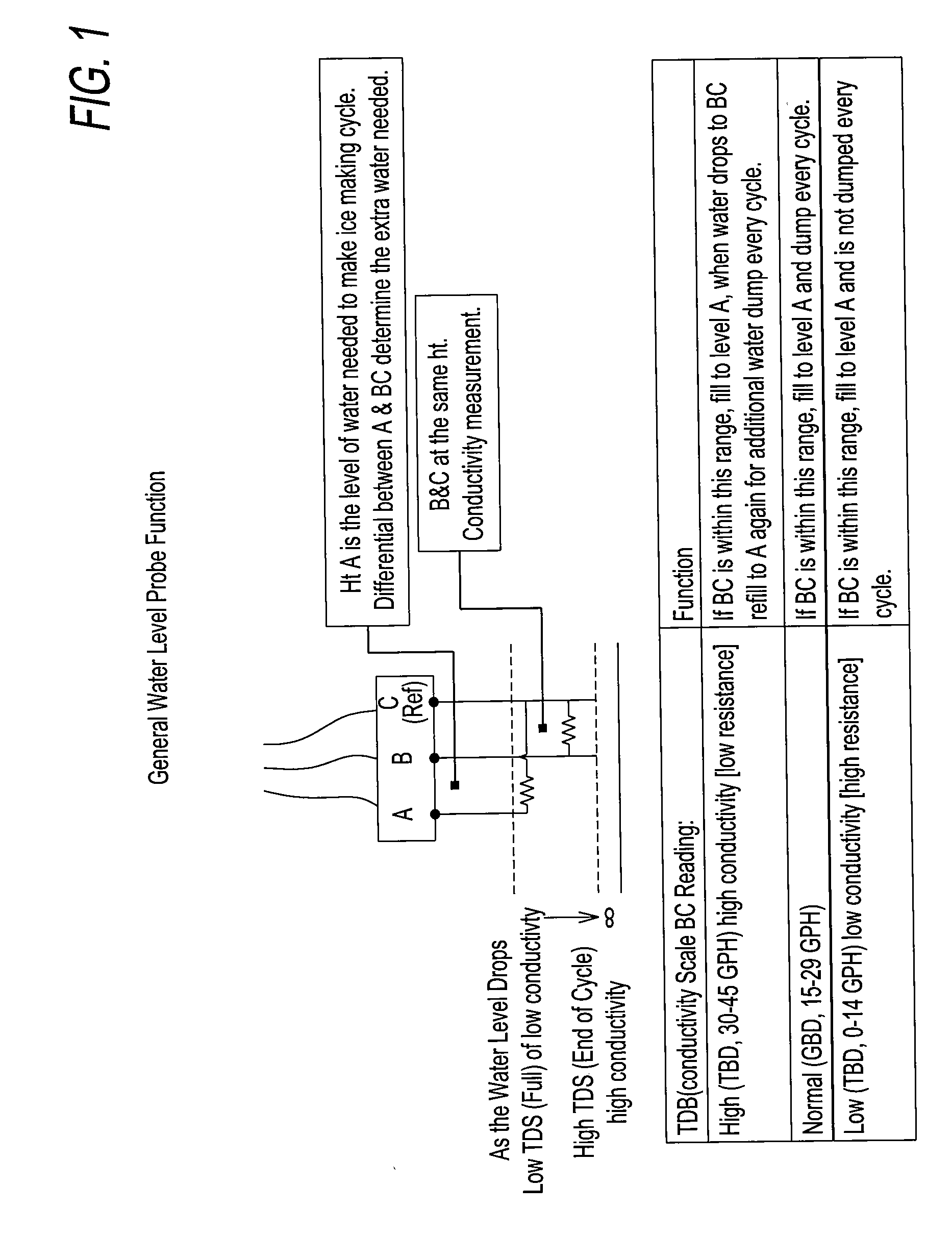

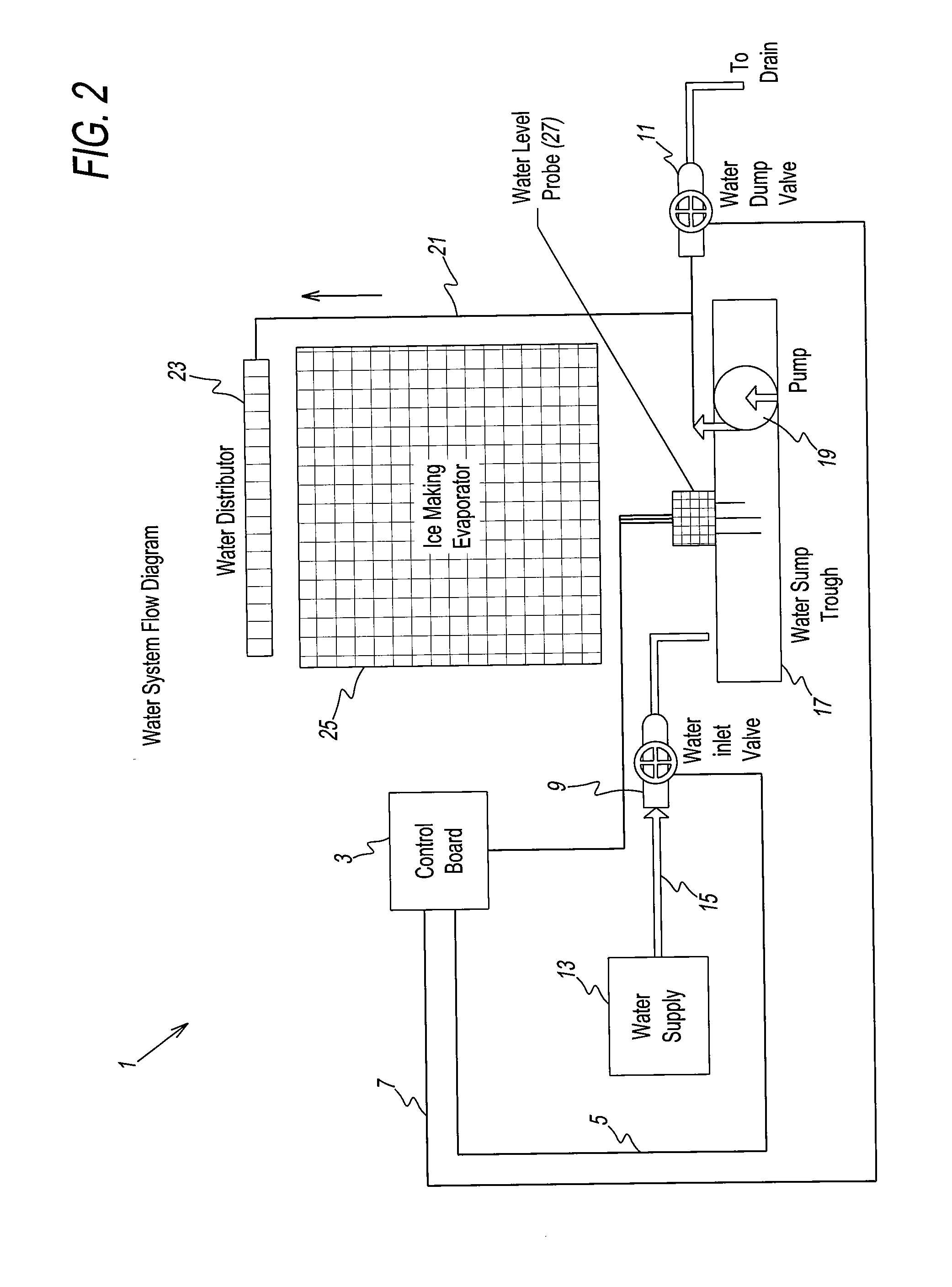

Method and system for producing clear ice

InactiveUS20120031114A1Reducing TDS level of waterEnable formationIce productionRefrigeration safety arrangementEnvironmental engineeringWater level

A method for making clear ice comprising: filling a water sump to a predetermined level; contacting a refrigerant to an evaporator; circulating water from the sump over the evaporator to form ice on the evaporator; monitoring the water level in the sump; and monitoring the conductivity of the water in the sump to determine if the conductivity of the water is equal to or greater than a predetermined conductivity valve, (i) if the conductivity is not equal to or greater than the predetermined conductivity valve and if the water level reaches a predetermined lower water level, then complete the ice making cycle and initiate the harvest cycle; or (ii) if the conductivity is equal to or greater than the predetermined conductivity valve and if the water level has not reached a predetermined lower water level, then add additional water to the water sump.

Owner:PENTAIR FLOW SERVICES

Soft extensible nonwoven webs containing fibers with high melt flow rates

InactiveUS20050170727A1Improve acceleration performanceEnable formationLayered productsFilament/thread formingFiberPolymer science

Owner:PROCTER & GAMBLE CO

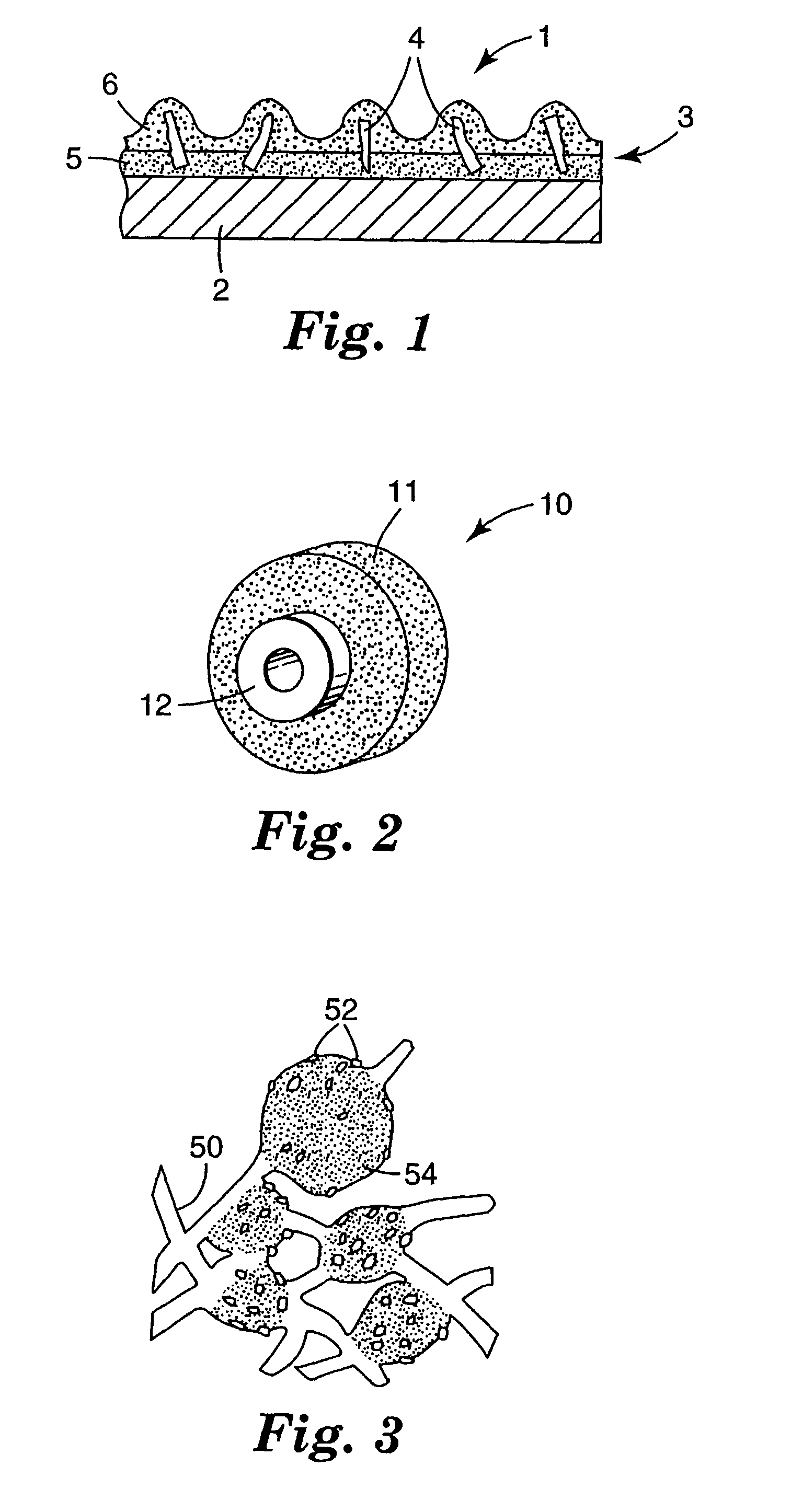

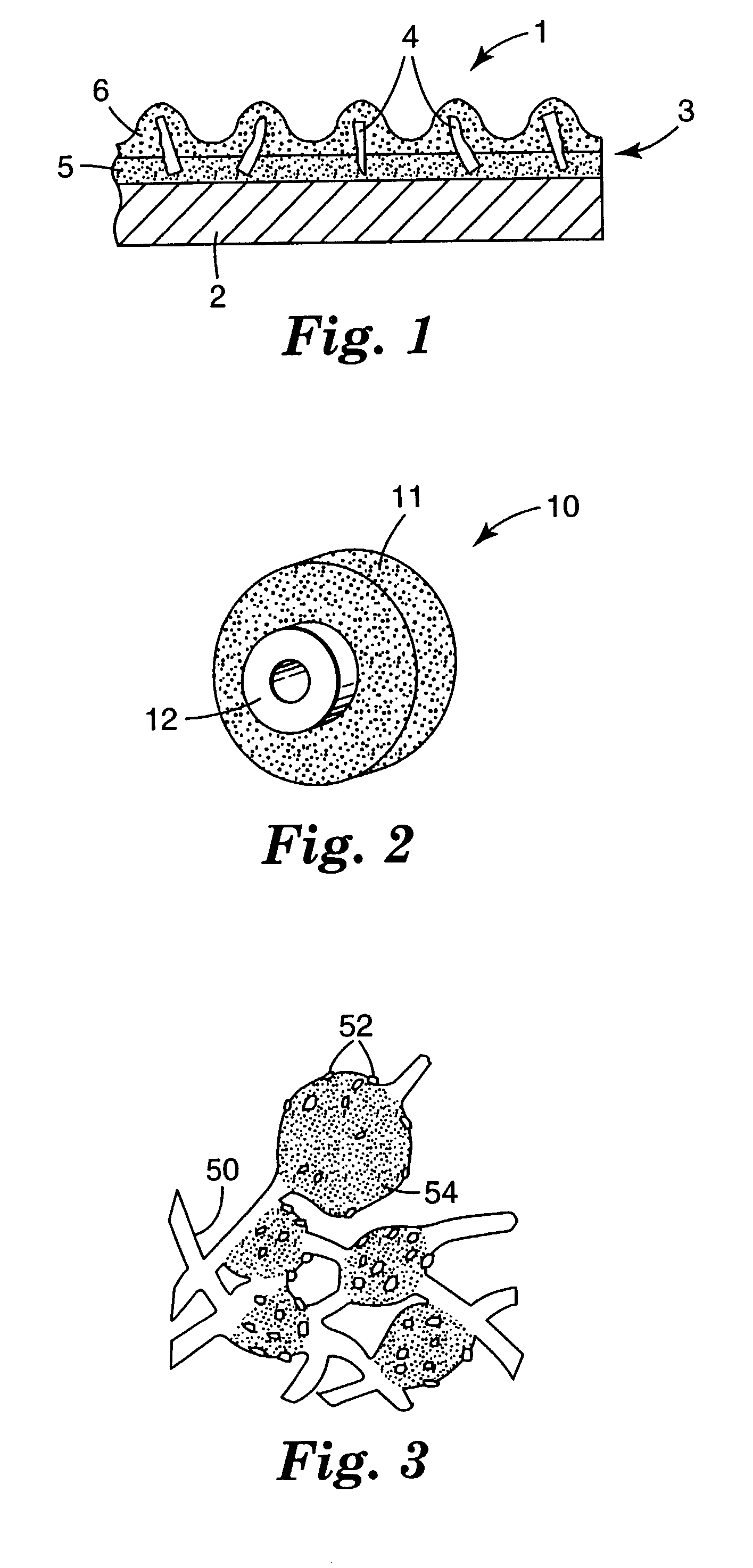

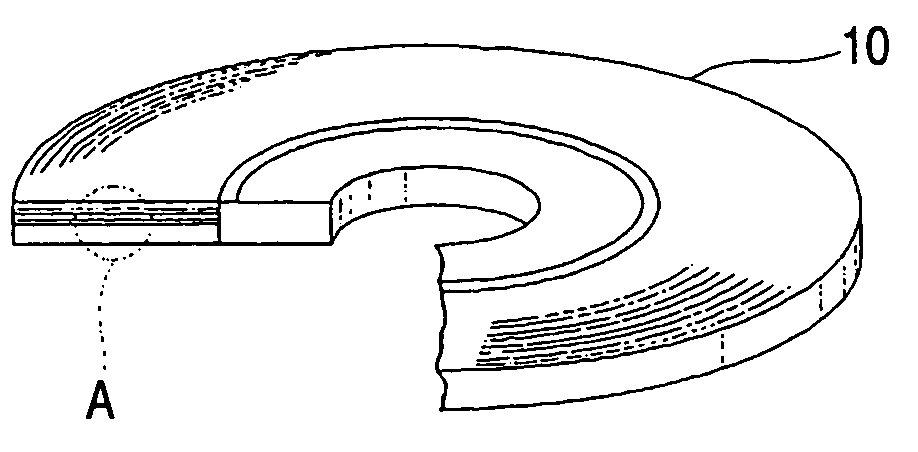

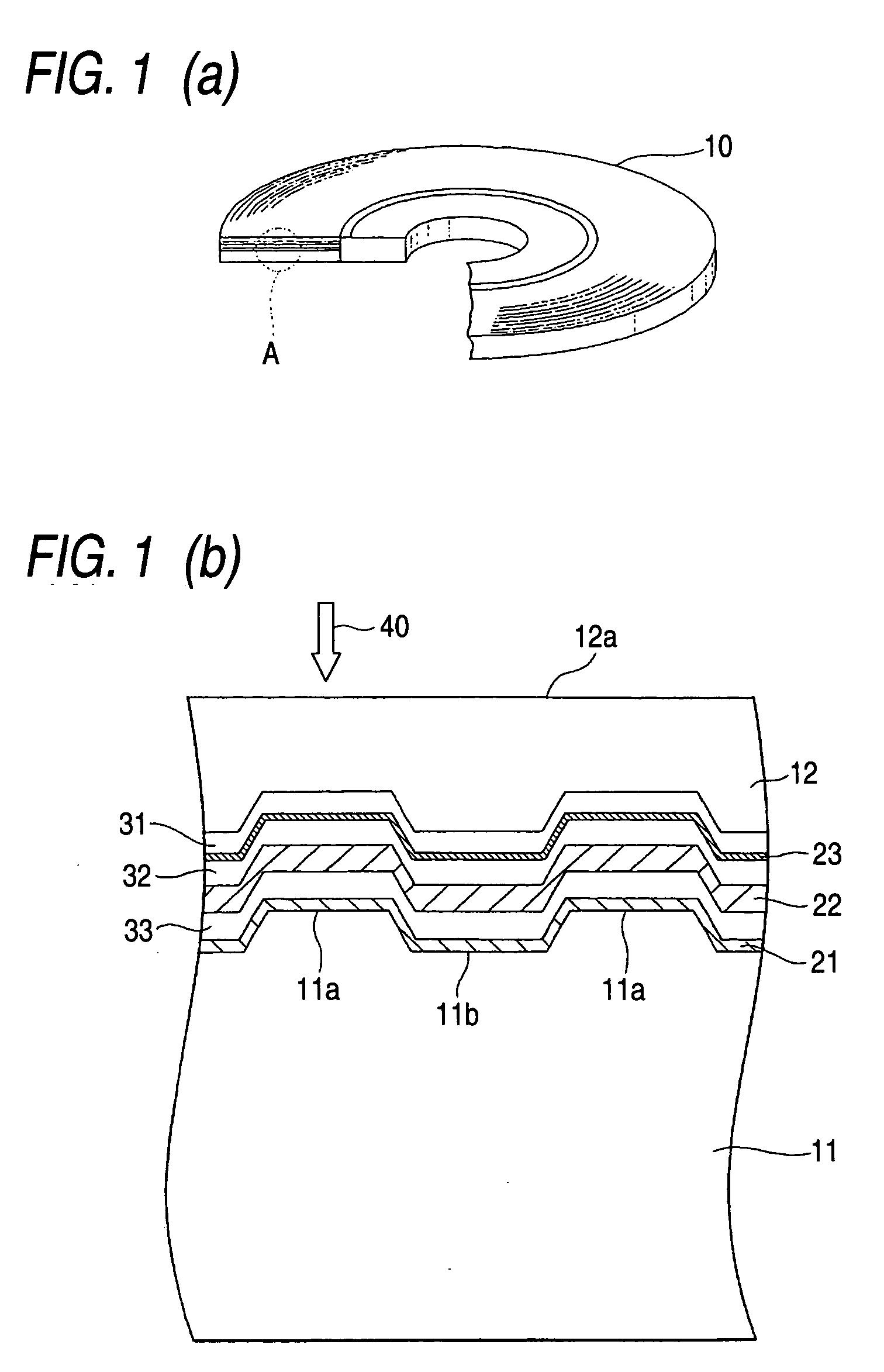

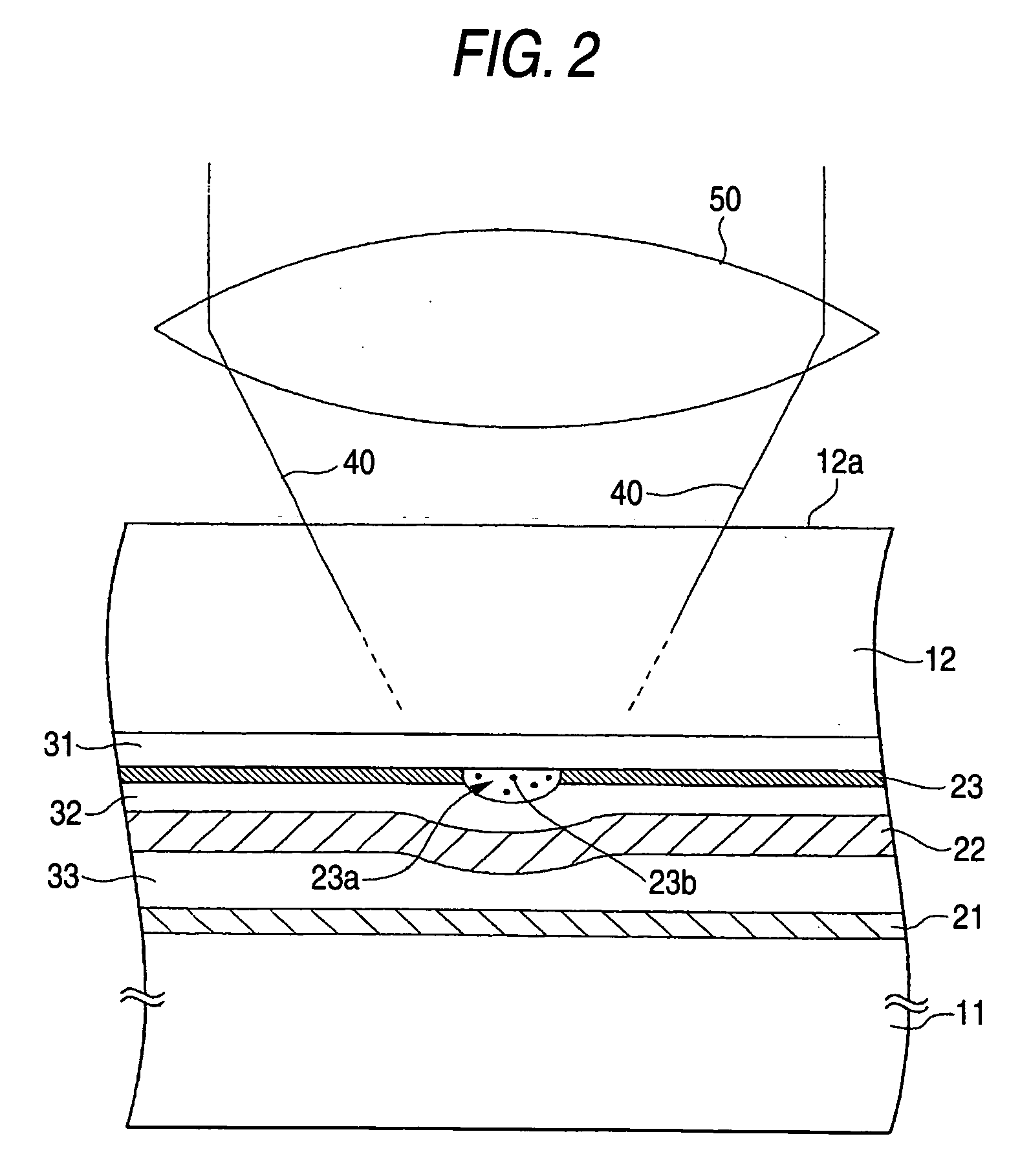

Optical recording medium and process for producing the same, and data recording method and data reproducing method for optical recording medium

InactiveUS20060245339A1Enable formationRecording involving bubble/bump formingRecord information storageOptical recordingData recording

An optical recording medium 10 of the present invention has a support substrate 11 and a light-transmitting layer 12, and further has a first dielectric layer 31, a noble metal nitride layer 23, a second dielectric layer 32, a light absorption layer 22, a third dielectric layer 33, and a reflection layer 21, all of which are interposed between the light-transmitting layer 12 and the support substrate 11. In the optical recording medium of the present invention, a laser beam 40 is irradiated on the substrate from the light entrance face 12a, to thus locally decompose the noble metal nitride layer 23, so that record marks can be formed by means of resultant bubble pits. In this case, a gas filling the bubble pits, which are to form the record marks, is a chemically-stable nitrogen gas (N2). The risk of this gas oxidizing or corroding other layers is very remote, and high storage reliability can be achieved.

Owner:TDK CORPARATION

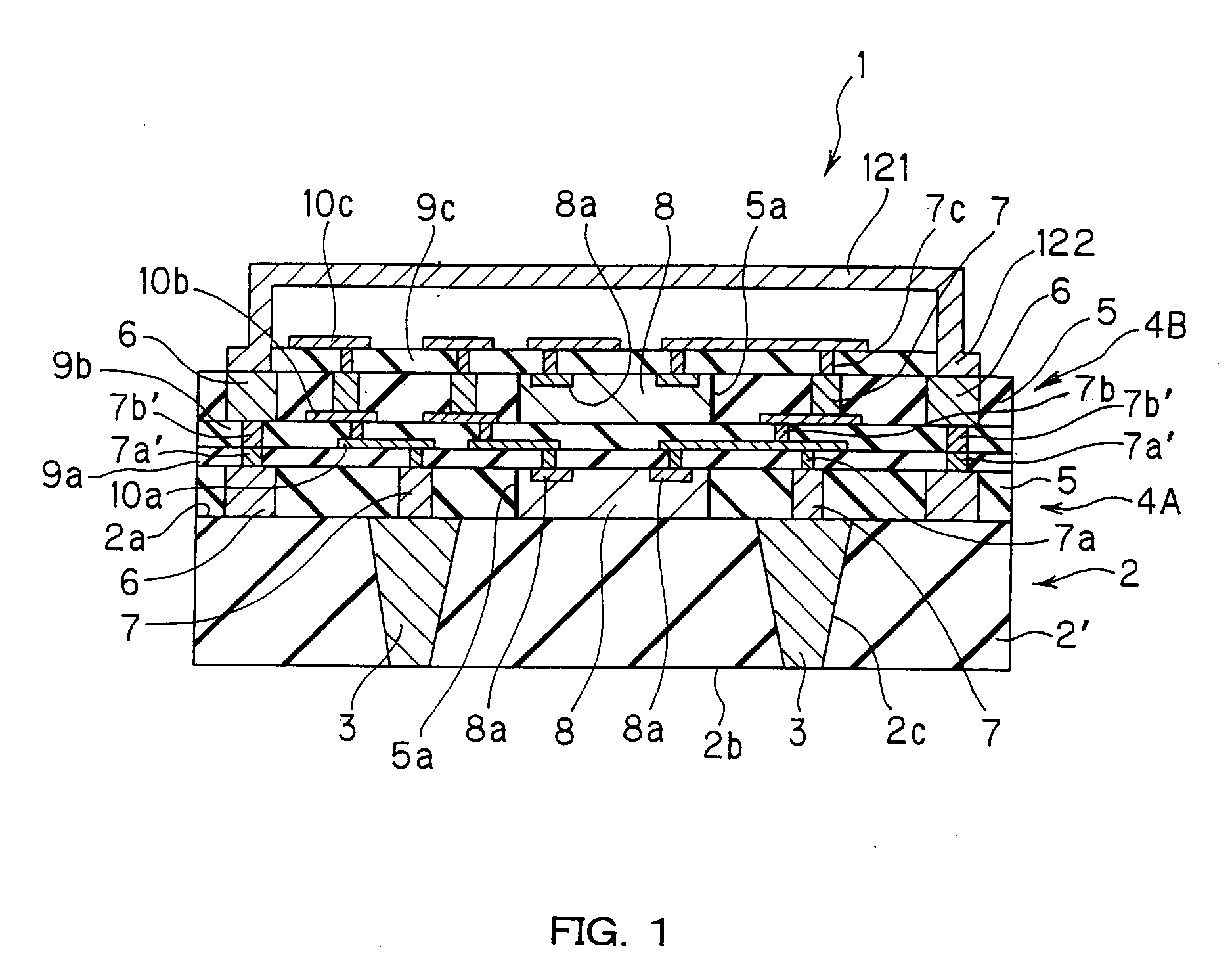

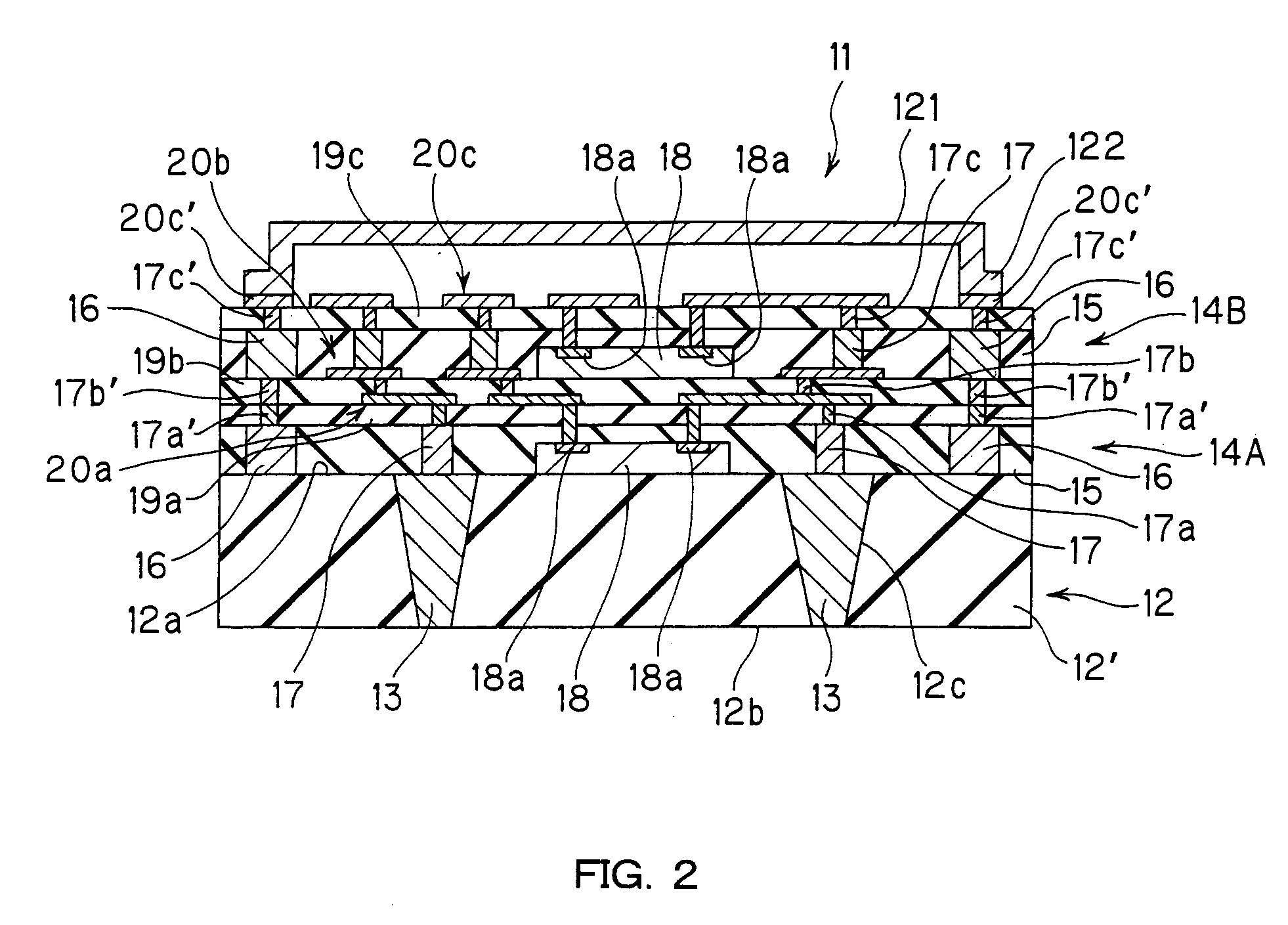

Electronic device and production method thereof

ActiveUS20070287230A1Small sizeHigh densitySemiconductor/solid-state device detailsSolid-state devicesHigh densityEngineering

An object is to provide an electronic device of a multilayer structure with high density and high reliability that can be reduced in size while incorporating an electronic component therein, and further provide a production method for easily producing such an electronic device. An electronic device of the present invention includes wiring layers and electrically insulating layers stacked on a core board and establishes predetermined electrical conduction between the wiring layers through upper-lower side conducting vias provided in the electrically insulating layers. An electronic component incorporating layer formed by directly forming a lower layer and insulating resin layer having a cutout portion for receiving an electronic component therein and upper-lower side conducting vias and by incorporating the electronic component in the cutout portion is provided at least between one of the wiring layers and one of the electrically insulating layers and / or between the core board and the electrically insulating layer. At least the uppermost-layer electronic component incorporating layer of electronic incorporating layers has a metal frame body surrounding the electronic component and the upper-lower side conducting vias, and a metal cap having a flange portion fixed to the metal frame body of the uppermost-layer electronic component incorporating layer is provided.

Owner:DAI NIPPON PRINTING CO LTD

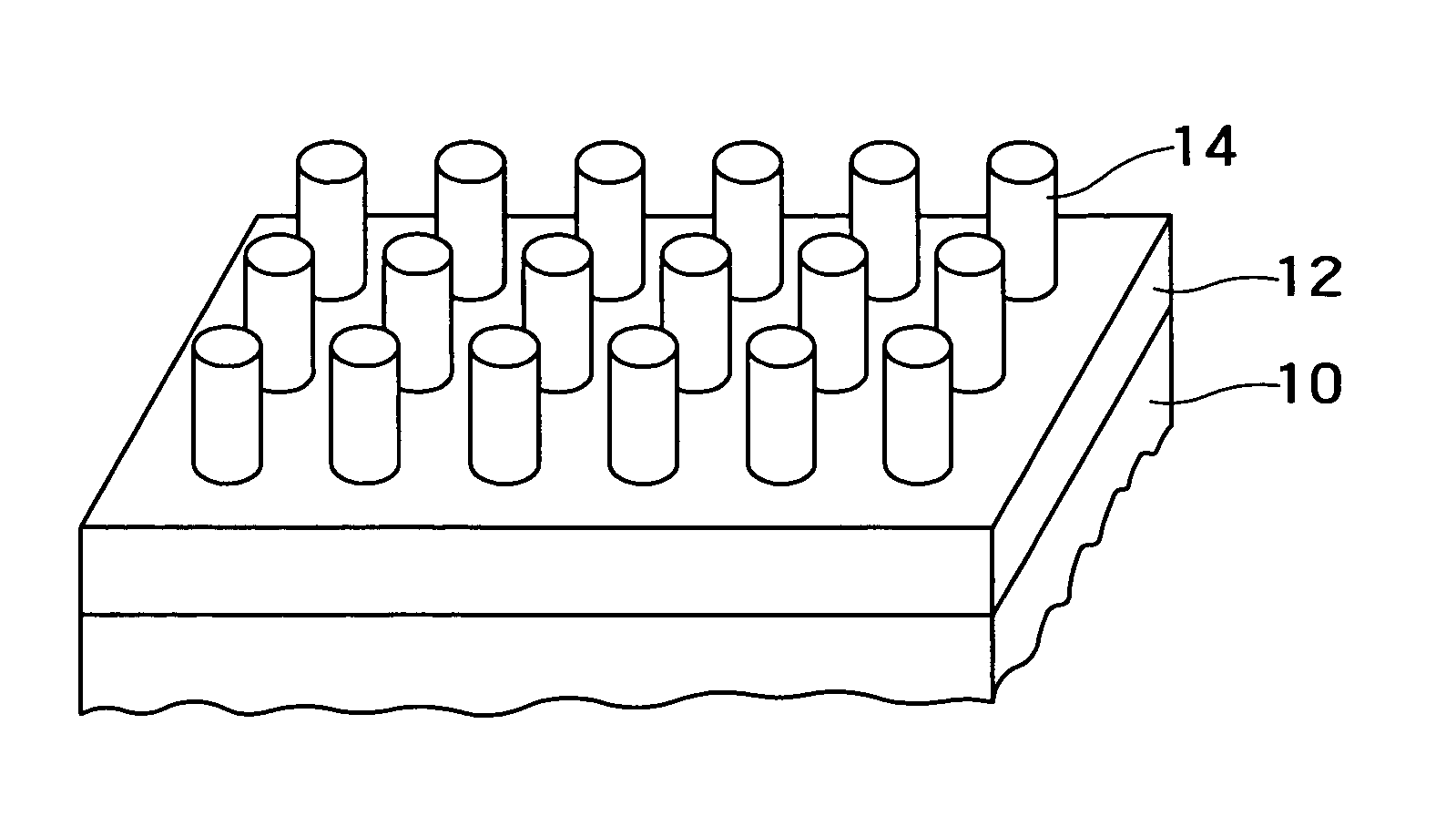

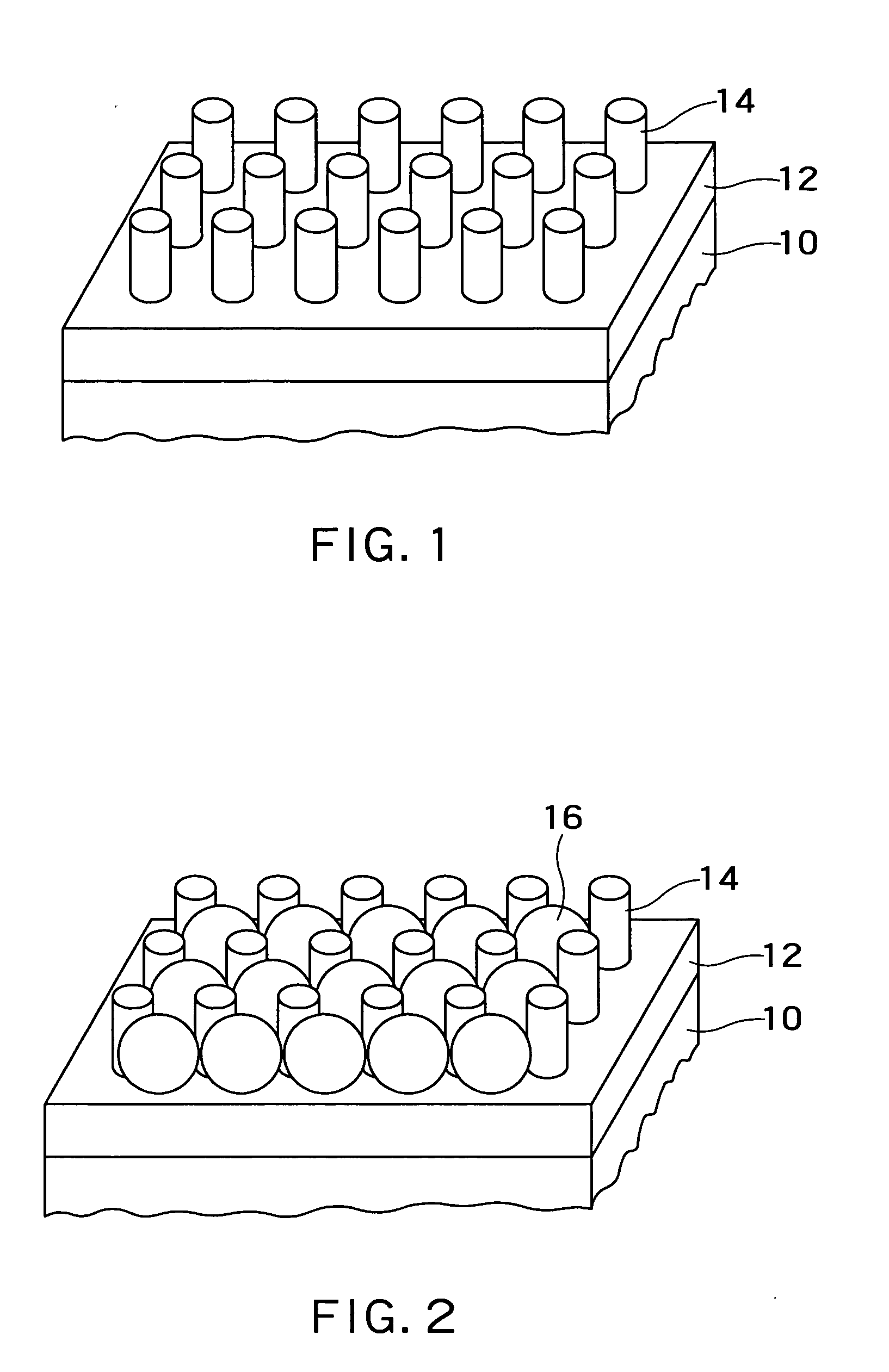

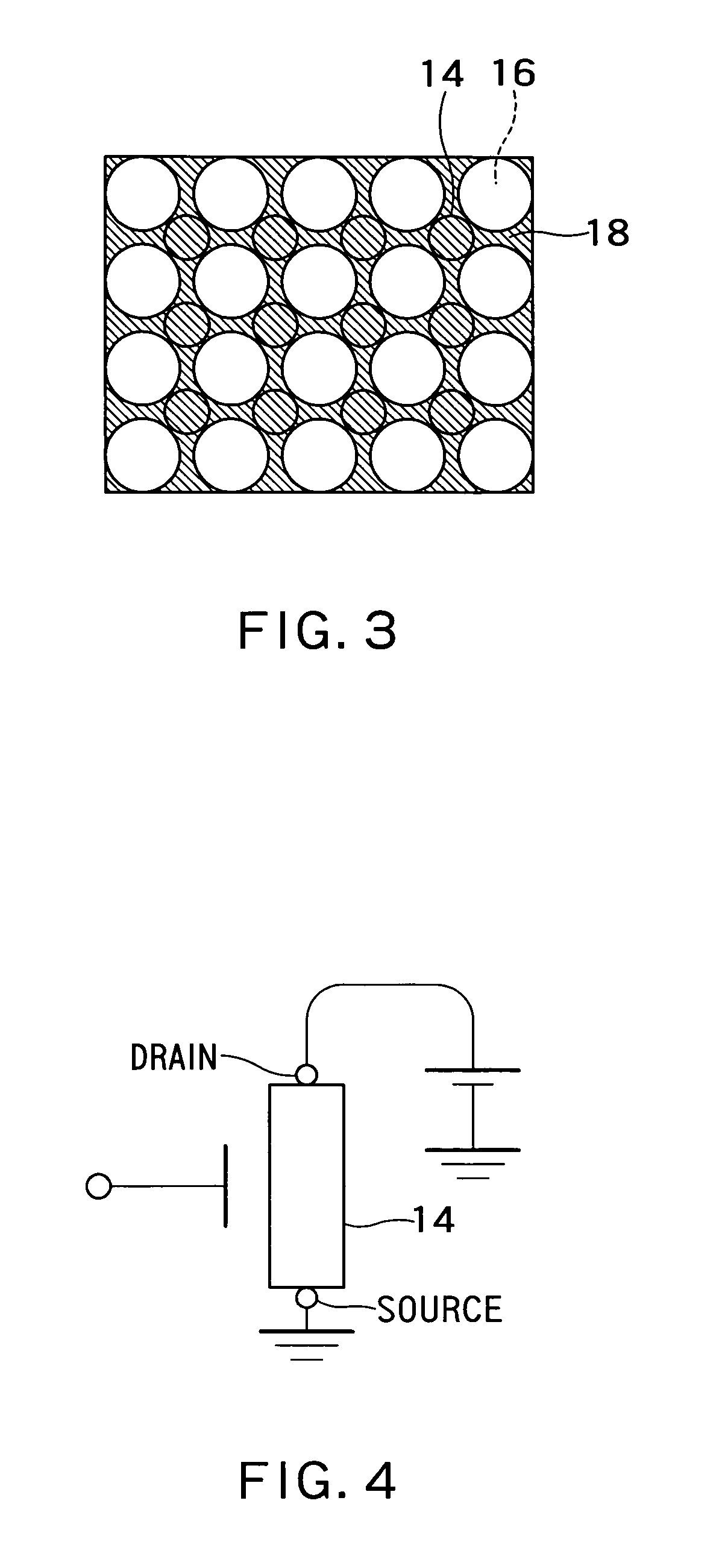

Electrode manufacturing method

An electrode manufacturing method comprises: forming plural protruding portions on a surface of a substrate; introducing first particles having a size that changes according to heat, light, or a first solvent between said plural protruding portions; changing the size of the first particles by applying heat, light, or the first solvent to said first particles; and depositing an electrode material onto the surface of said substrate.

Owner:KK TOSHIBA

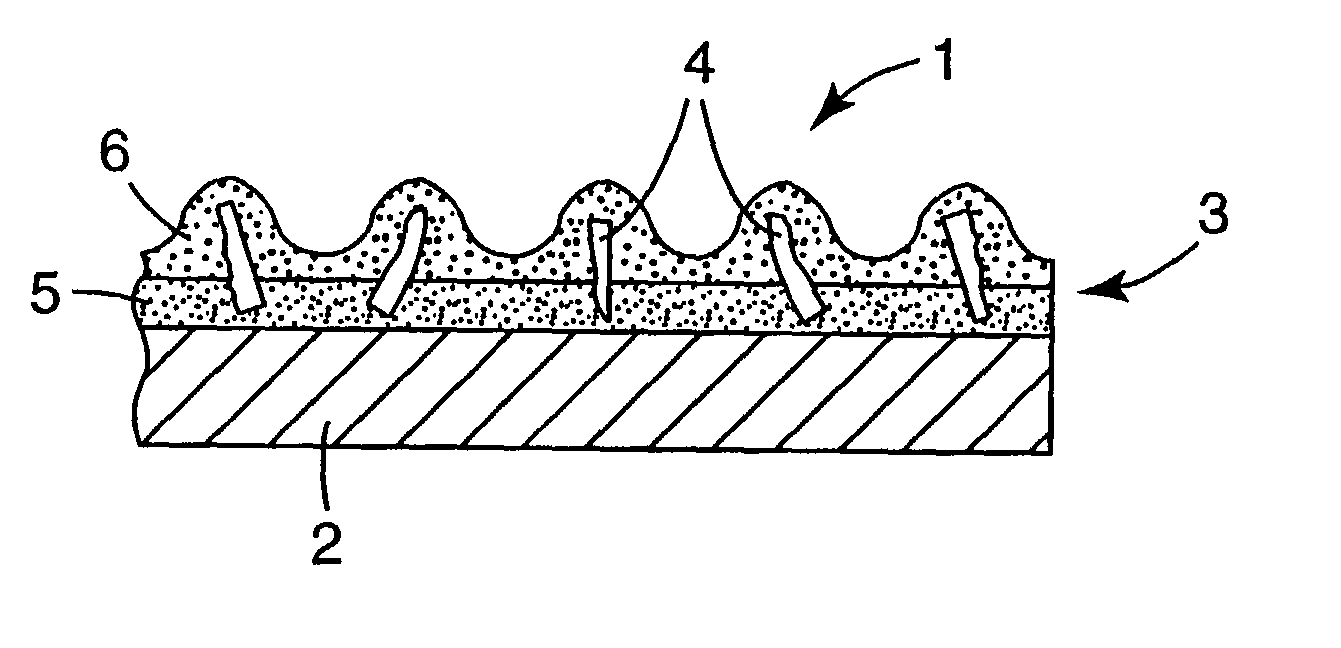

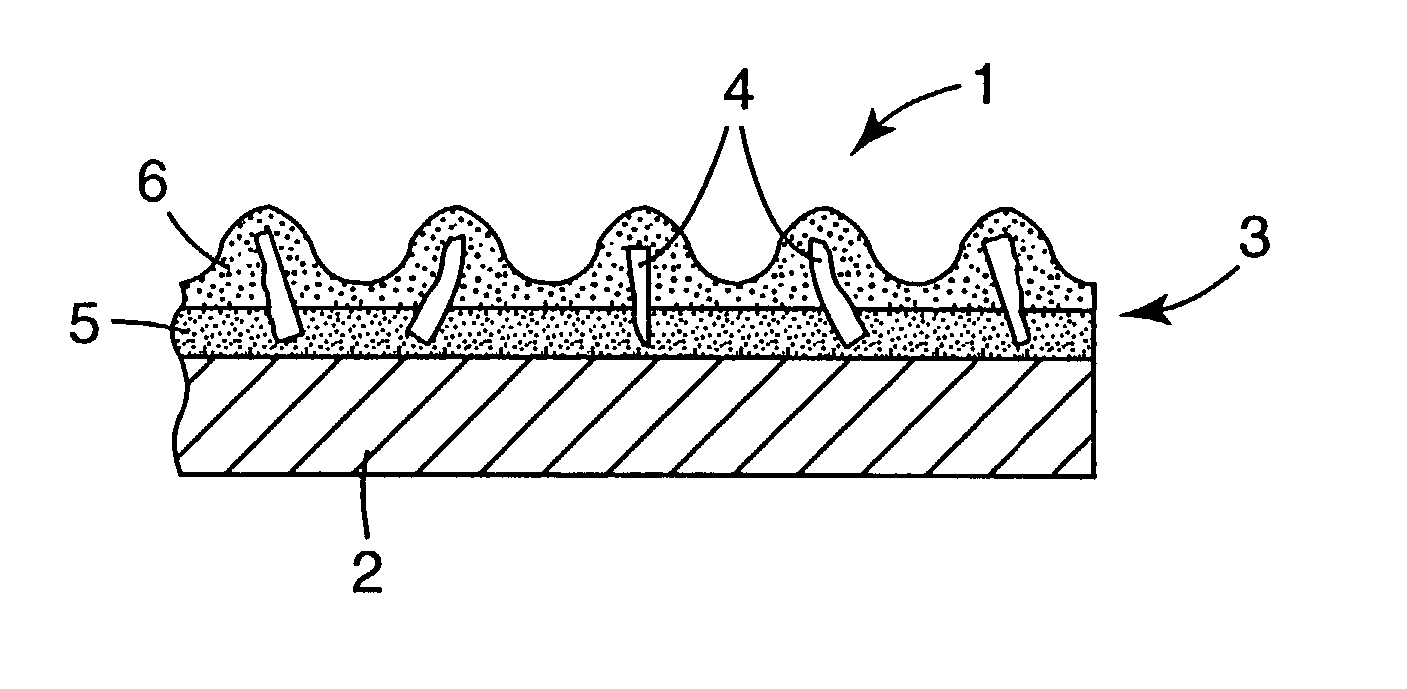

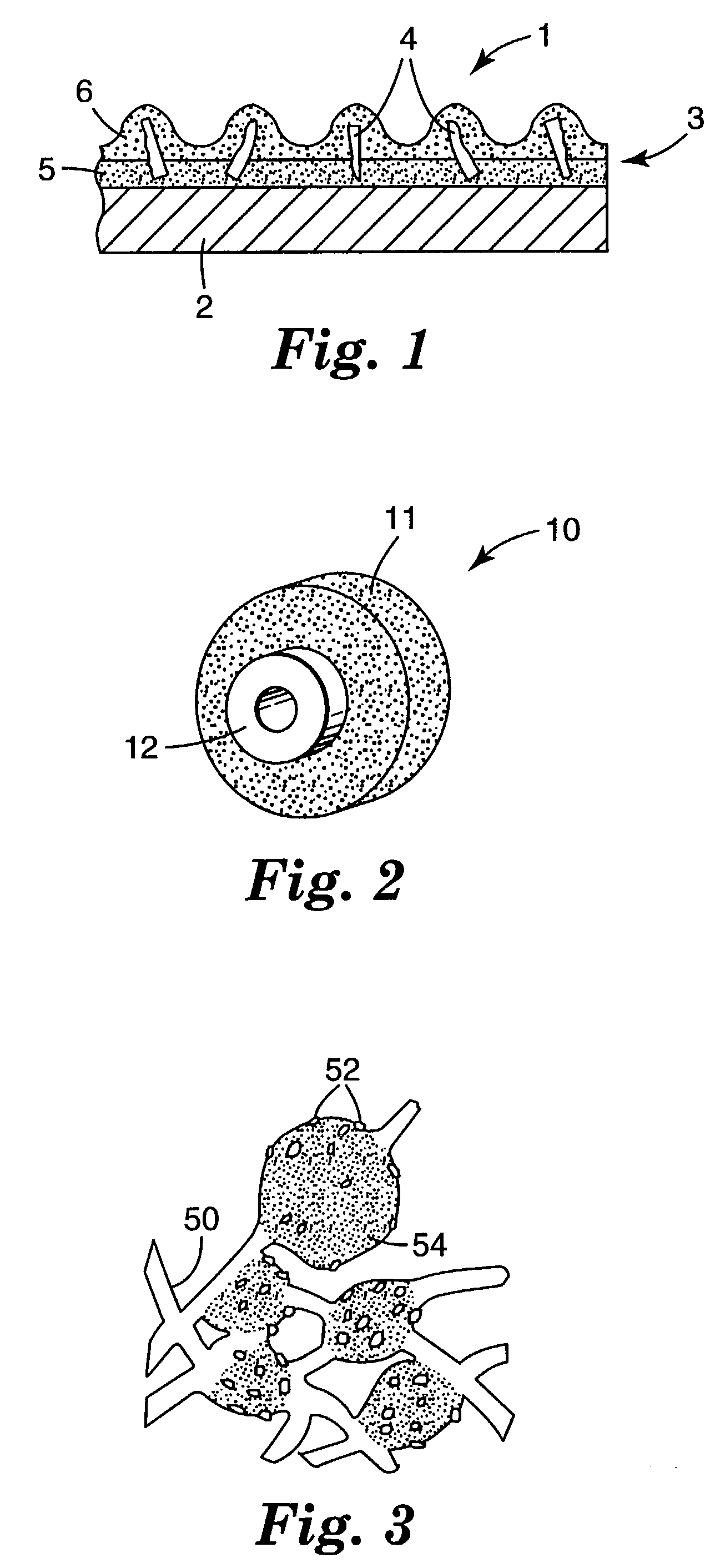

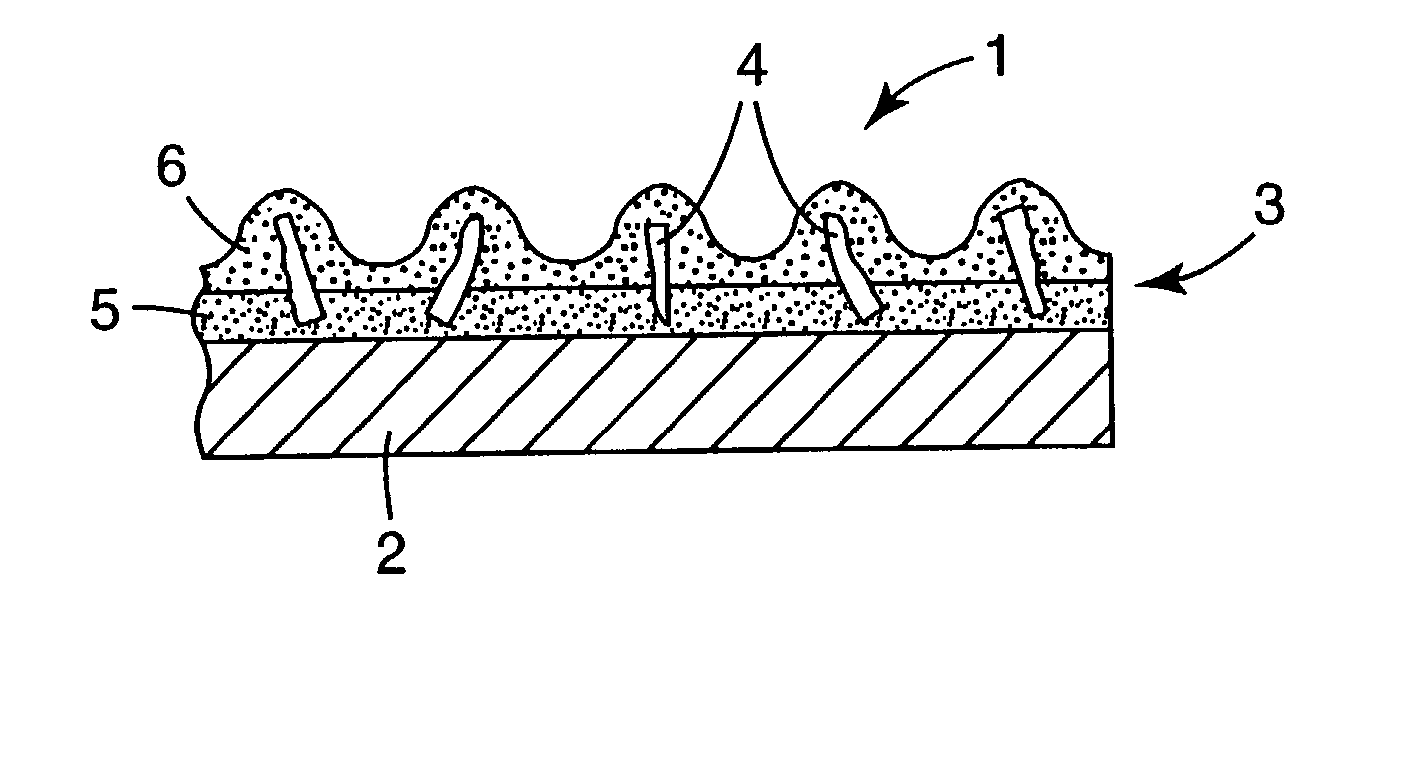

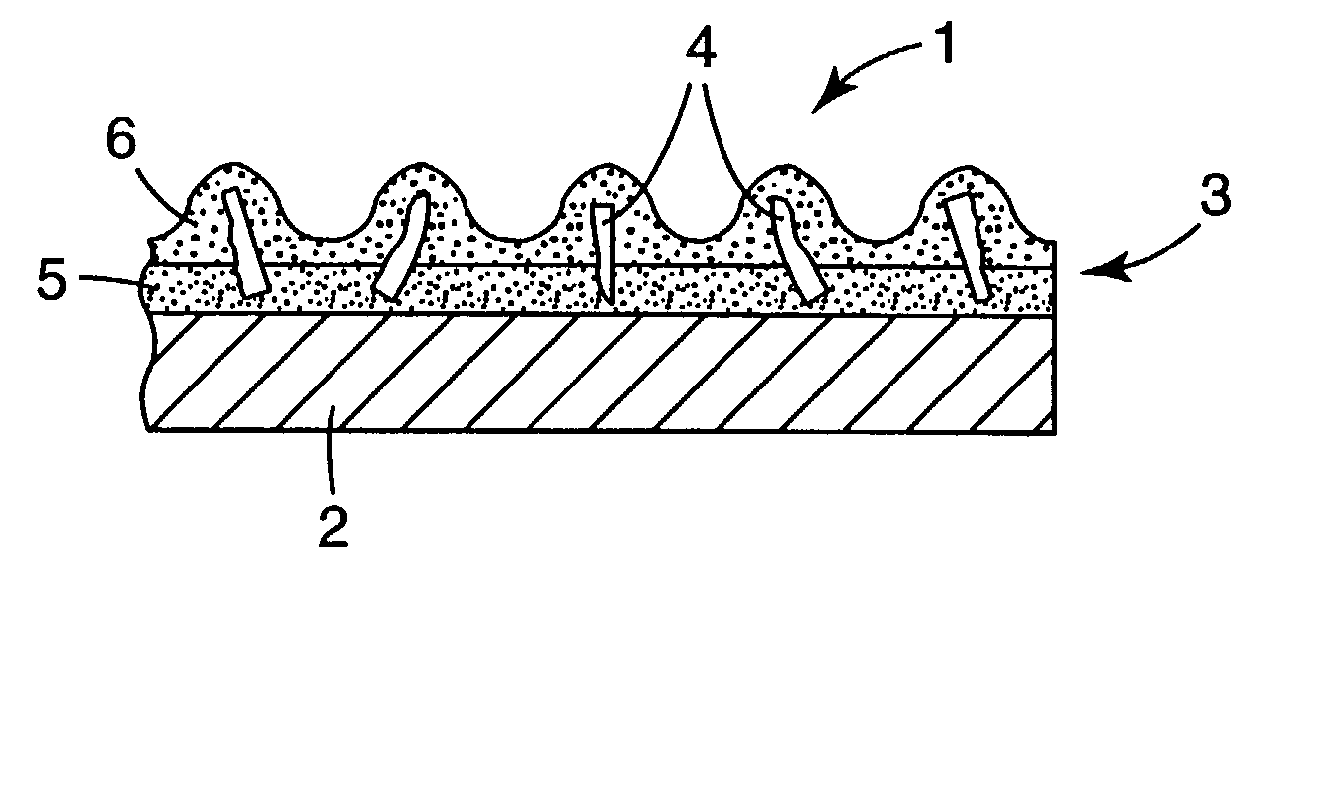

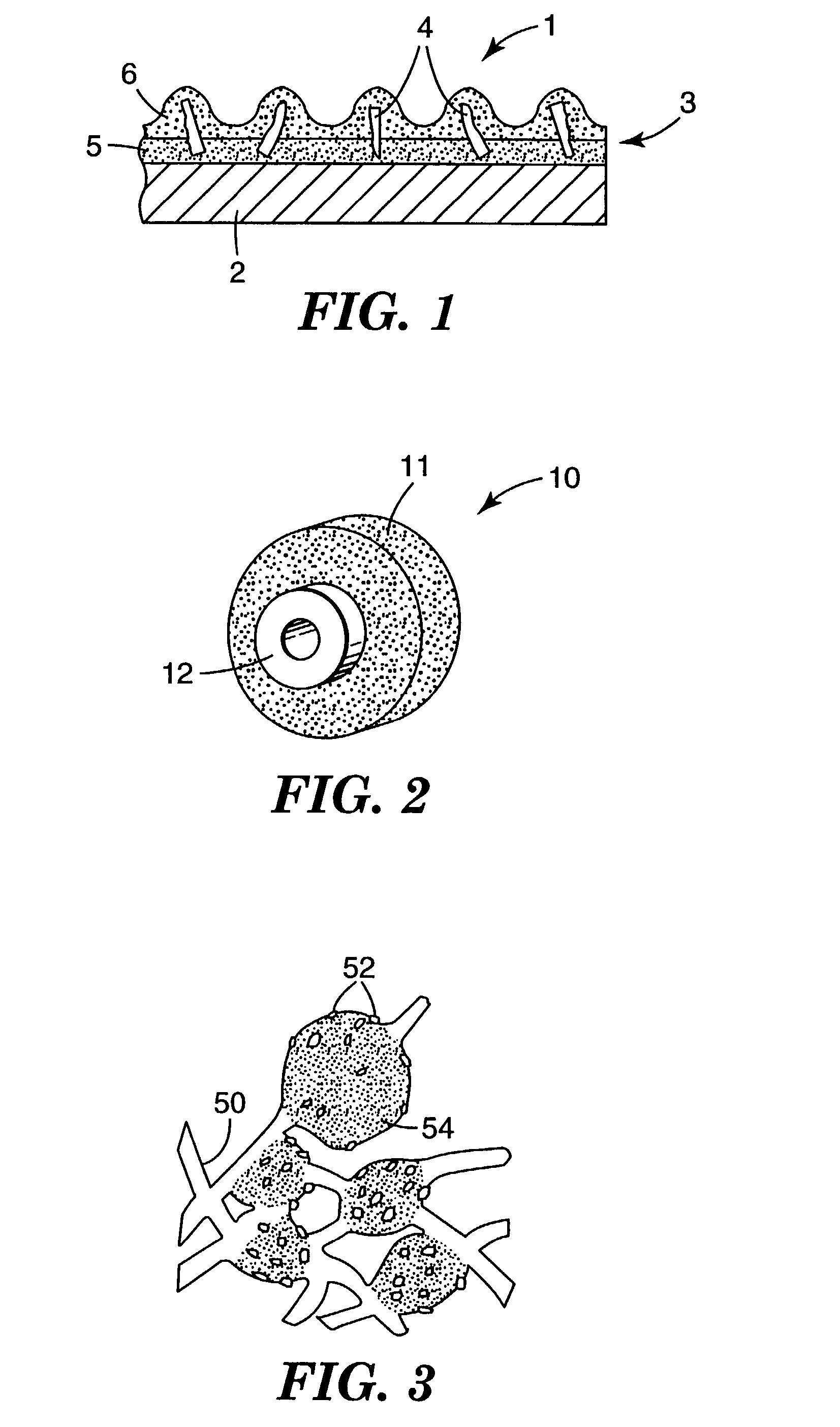

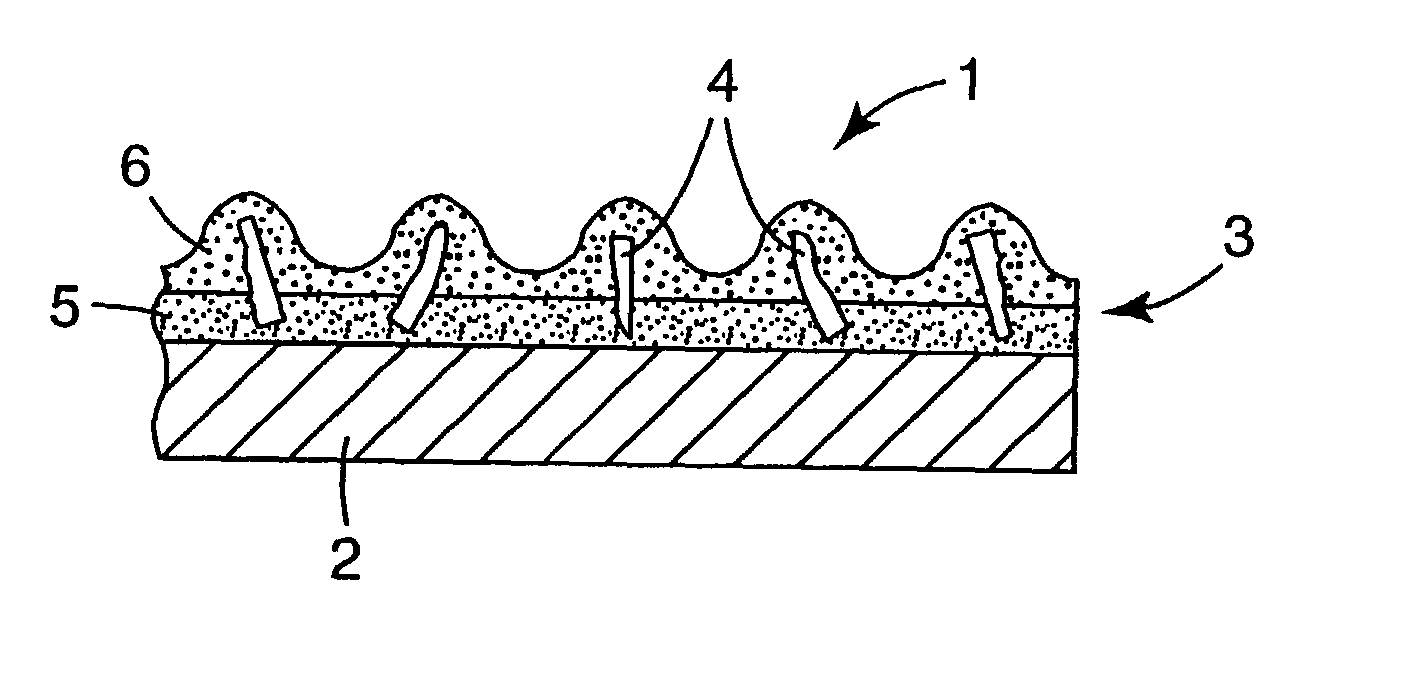

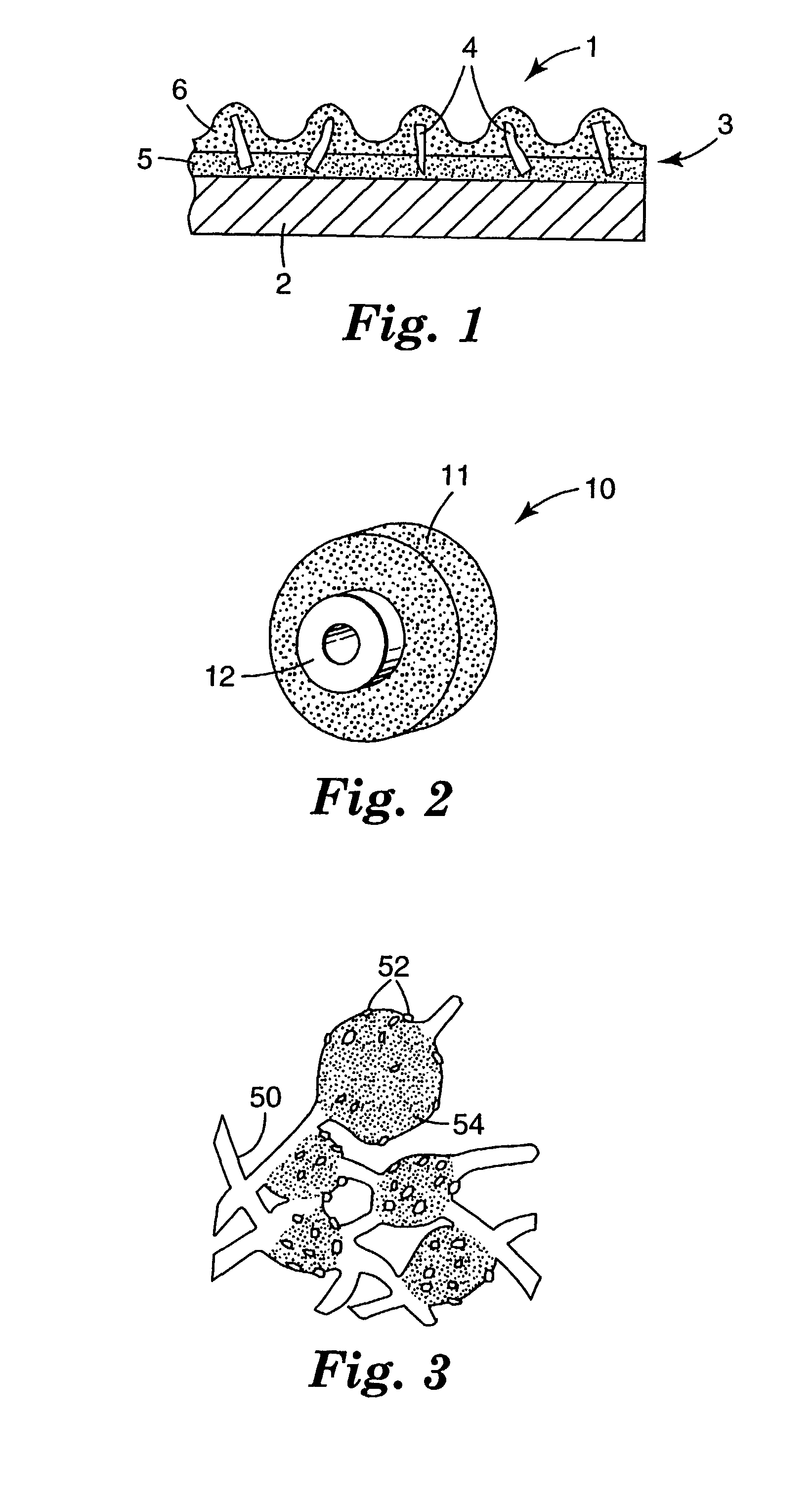

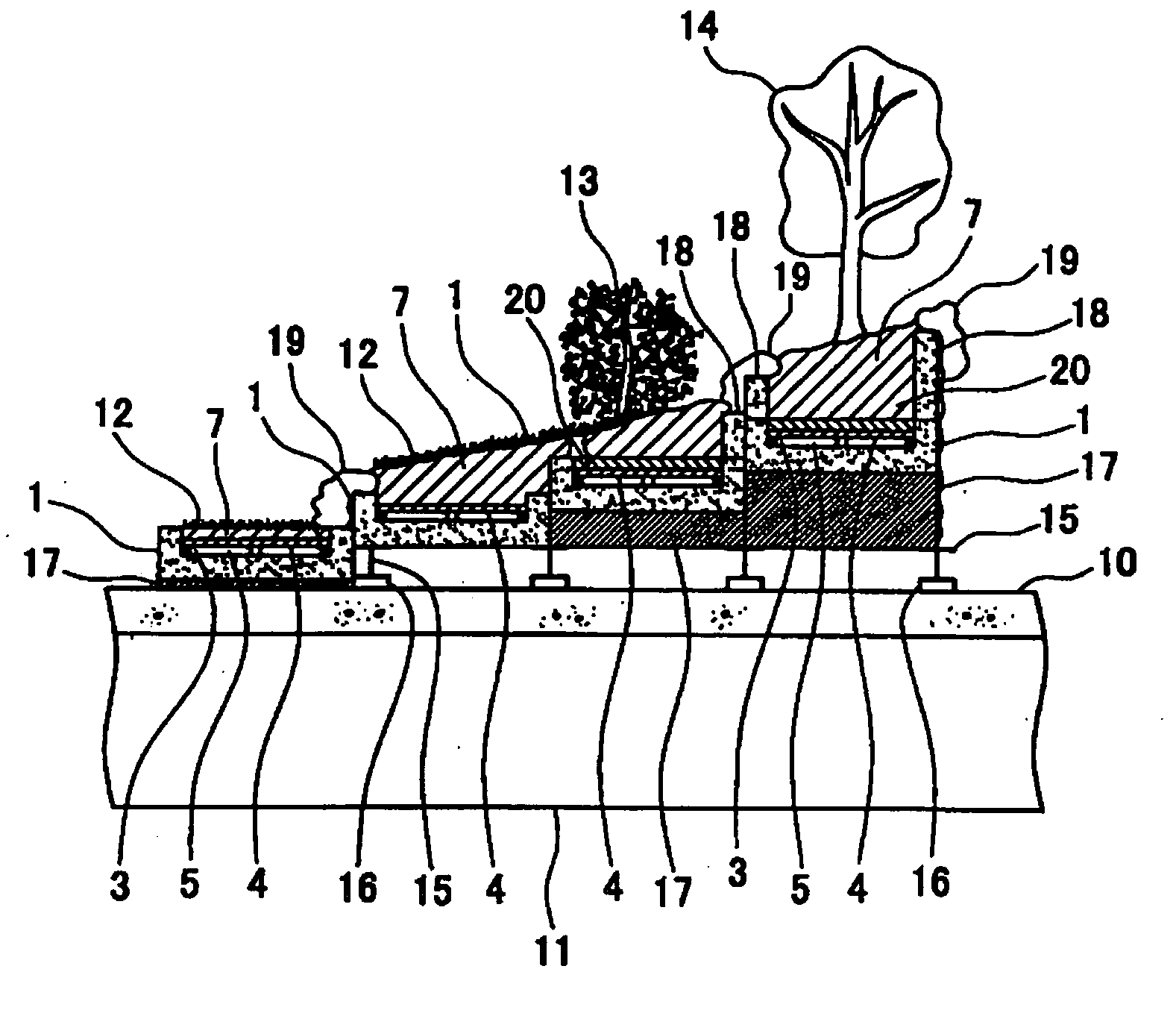

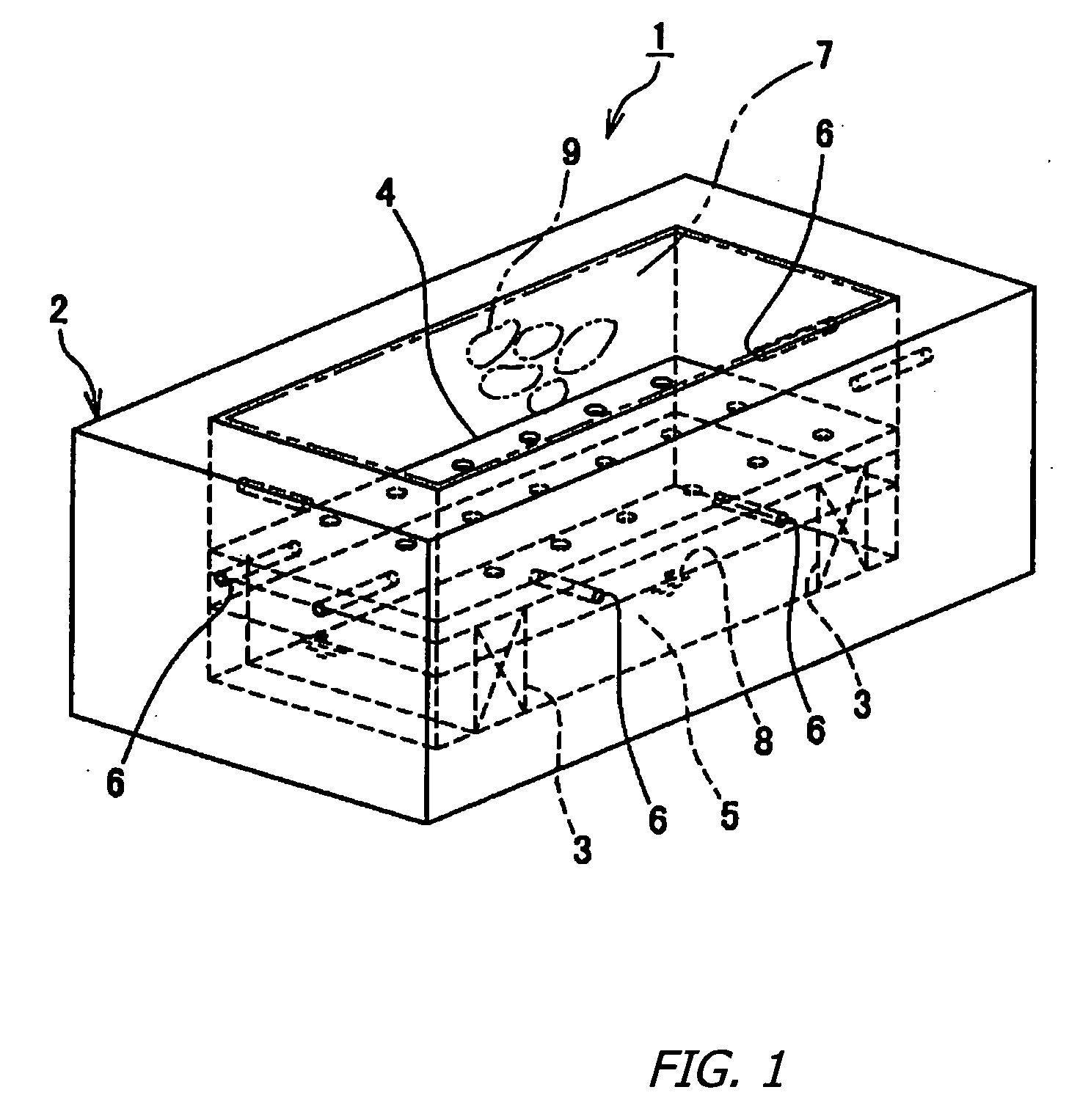

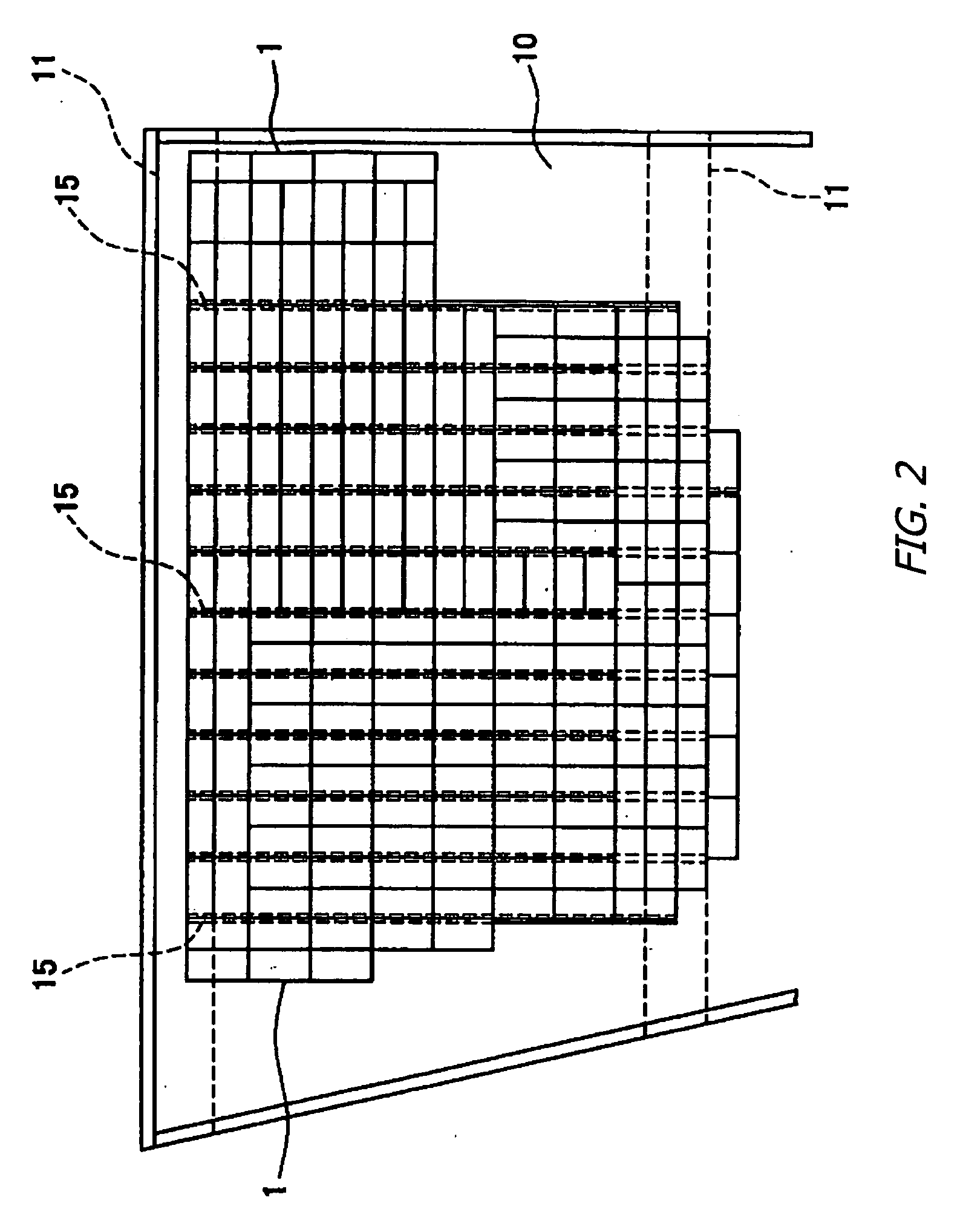

Greening system

ActiveUS20060070299A1Improve breathabilityMinimize presenceSelf-acting watering devicesGreenhouse cultivationEvaporationEngineering

A greening system us disclosed for enabling plants / vegetation to grow only with natural rainfall, without any particular irrigation facilities, enabling a full-blown garden to be constructed on building rooftops, minimizing the applicable loads on the building, and free from the risk of leakage. Planting container 1 comprises box 2 with stickers 3 to carry perforated partition panel 4. The lower half of the container is constituted as water storage 5, and drain holes 6 are opened on sides of the container. Soil layer 7 placed on partition panel 4 is formed of light woody soil-based on charcoal 9 and humus timber chips for absorbing moisture transported from the water 8 stored in water storage 5 by evaporation or difference in humidity, to have a large water capacity letting less water evaporate into the air. Charcoal 9 absorbs water from the air inside the lower half of the container to water the plants. Water storage 5 assures an amount of water necessary for plants to grow.

Owner:KAWADA CONSTR

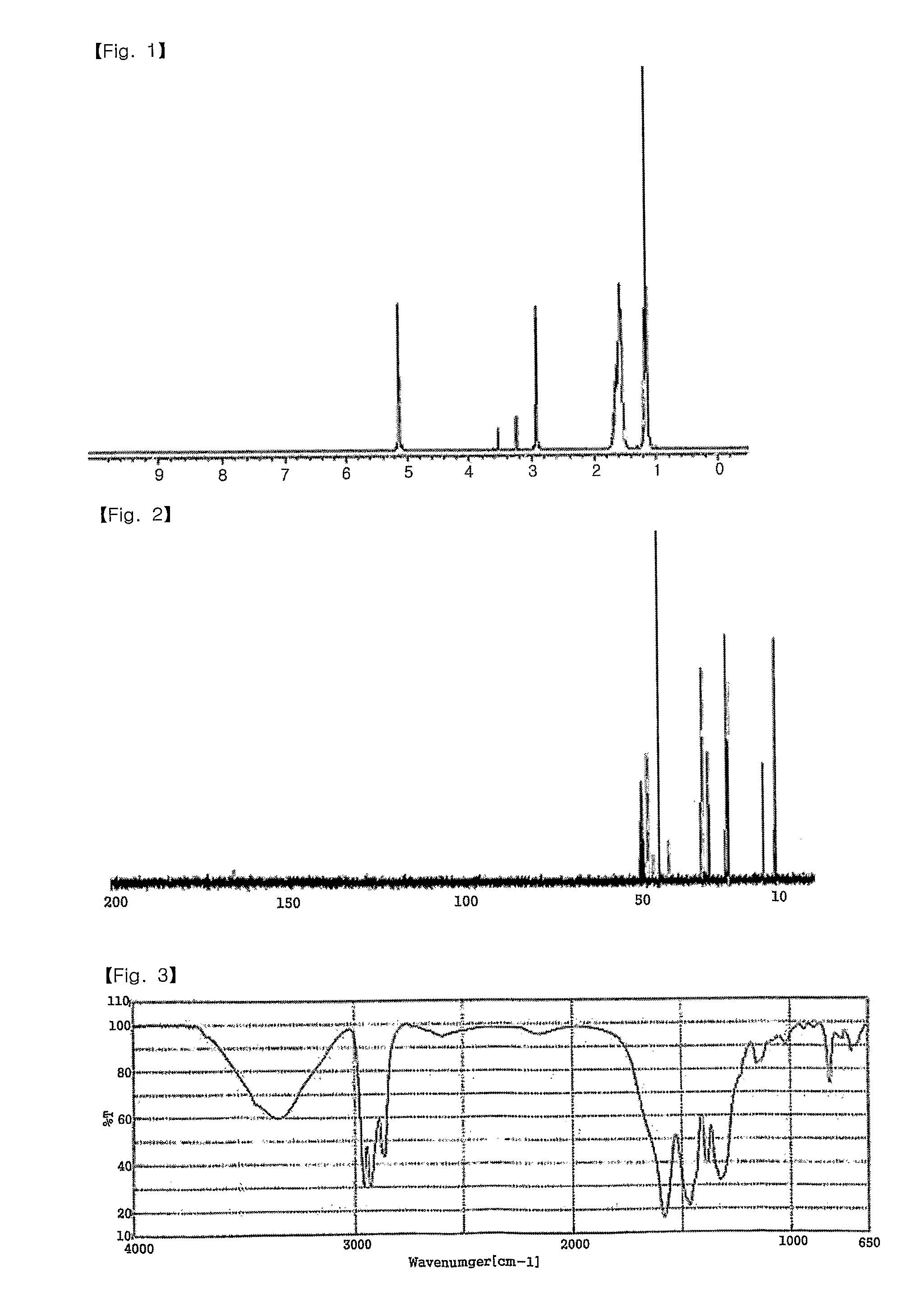

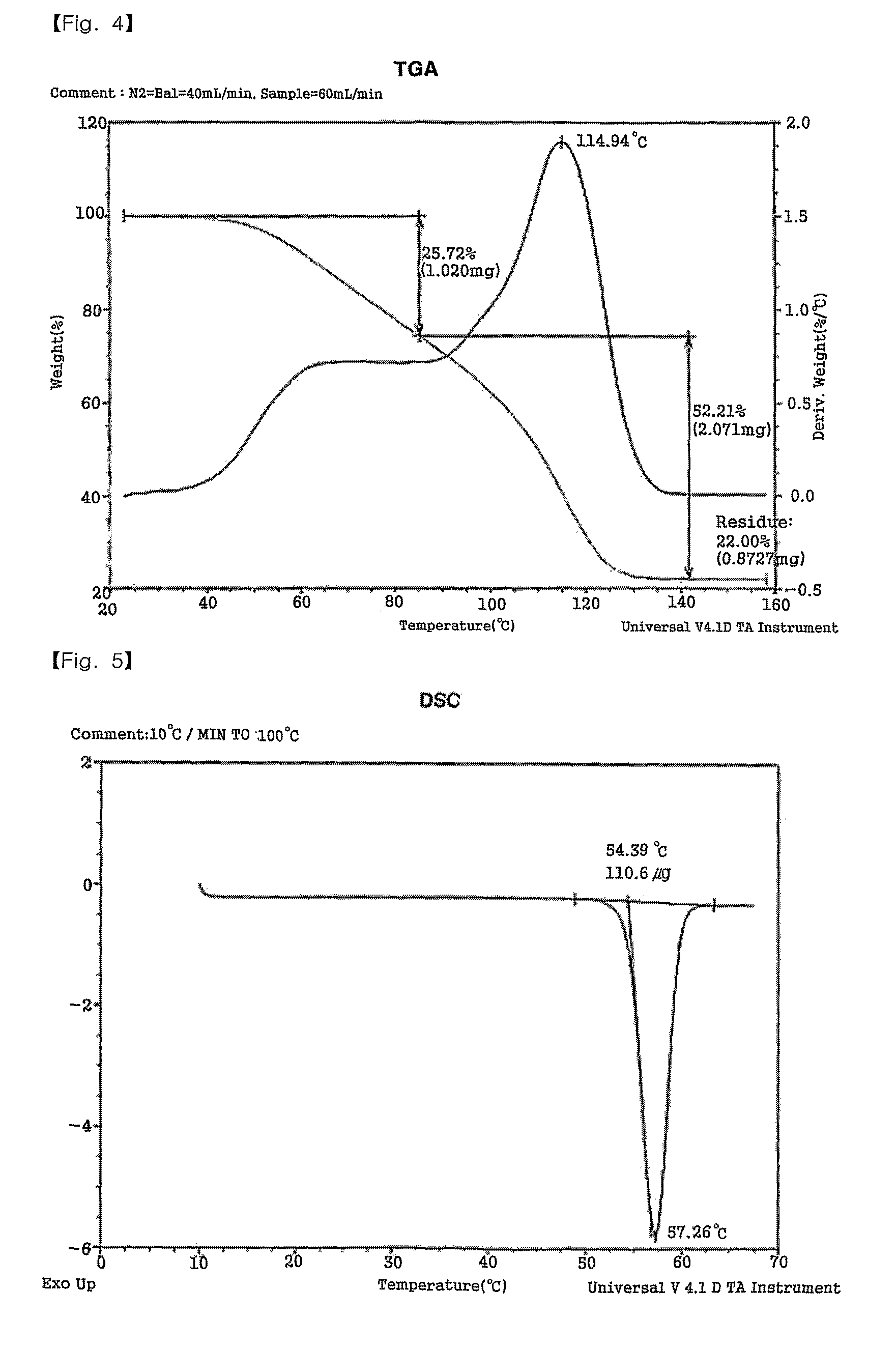

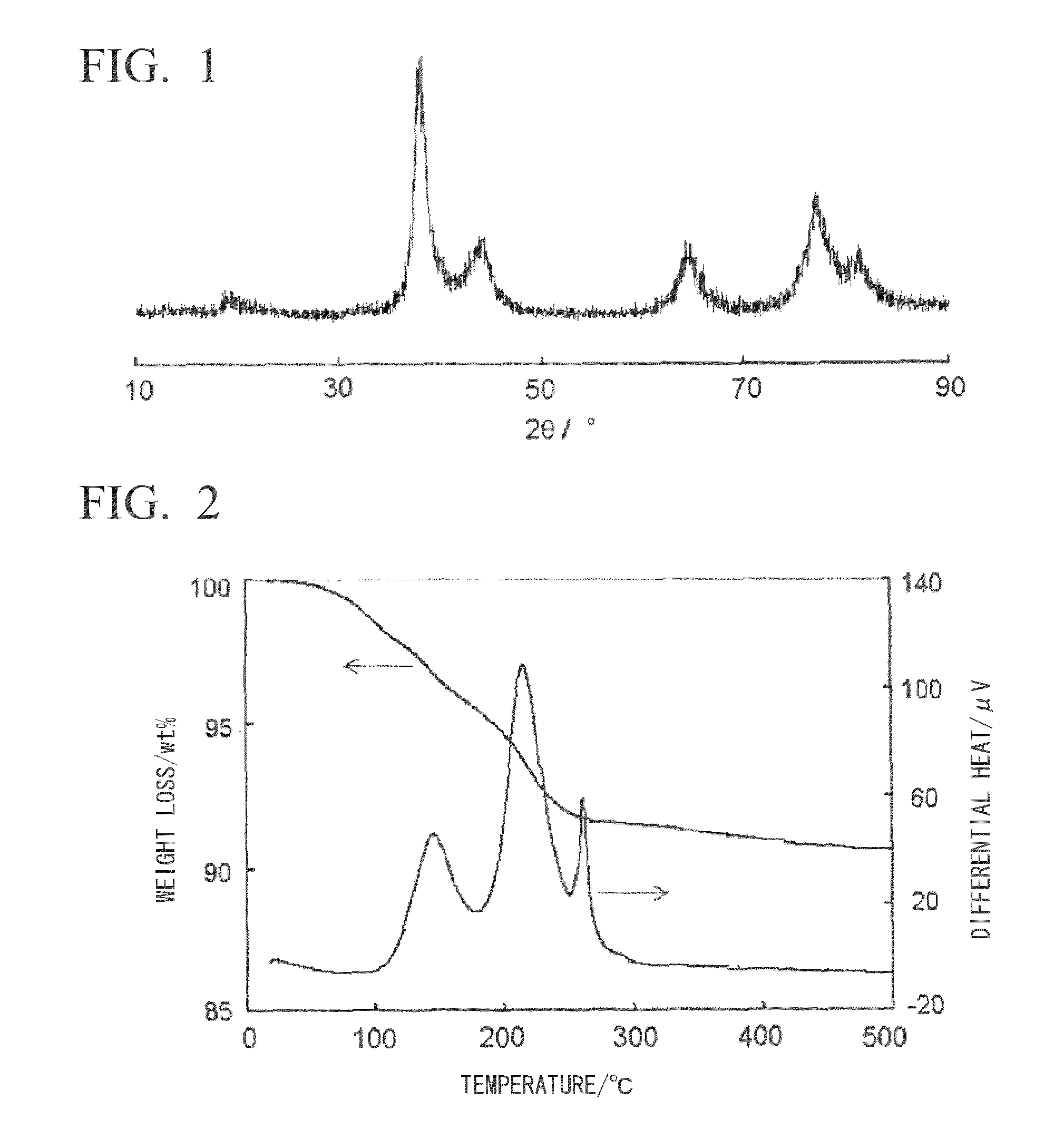

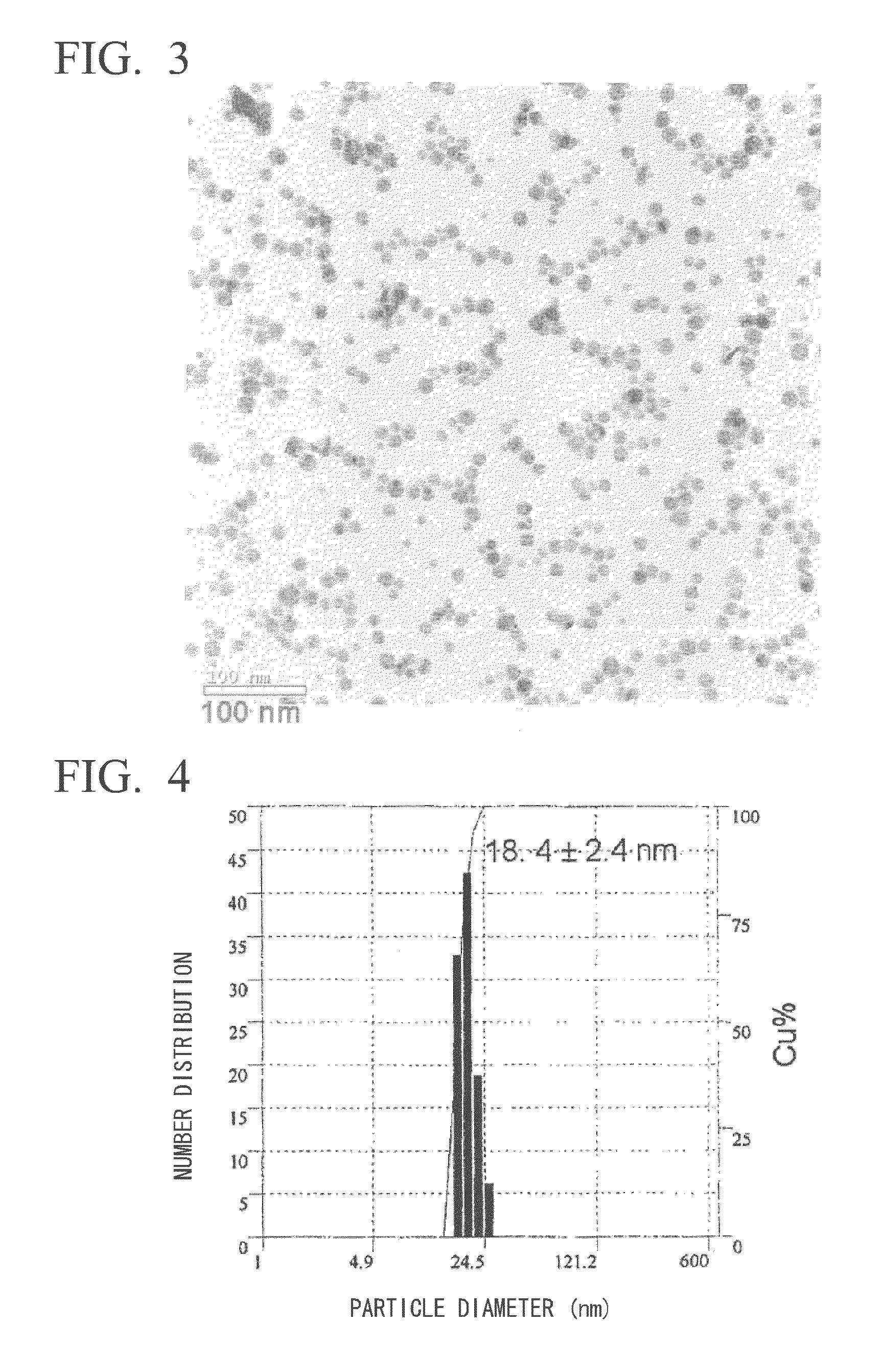

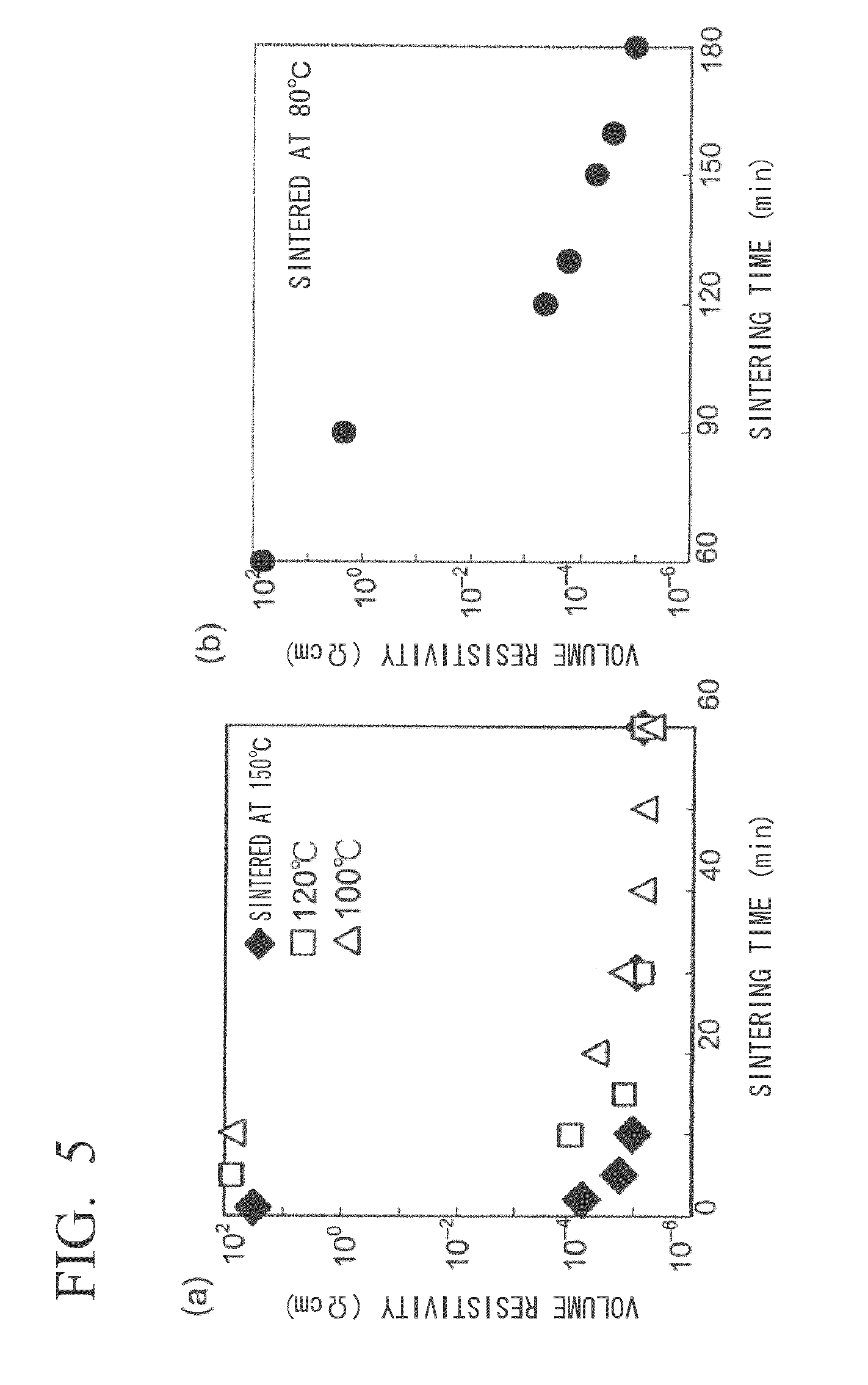

Coated silver nanoparticles and manufacturing method therefor

ActiveUS20120043510A1Enable formationReduce energy consumptionMaterial nanotechnologyNanostructure manufactureHeat resistanceConductive materials

The present invention provides coated silver nanoparticles for use as an electrically conductive material capable of sintering at lower temperatures that is able to be used even with flexible printed substrates having low heat resistance, and a manufacturing method therefor. The coated silver nanoparticles of the present invention have a mean particle diameter of 30 nm or less and are coated with protective molecules amine, and are characterized in that the weight loss rate when heated to 160° C. in thermogravimetric measurement is 30% or more. The coated silver nanoparticles of the present invention are also characterized in that a silver-colored sintered film can be formed by sintering at a temperature of 100° C. or lower for 1 hour or less. These coated silver nanoparticles are manufactured by mixing a silver compound that forms metallic silver when decomposed by heating, an alkylamine and an alkyldiamine to prepare a complex compound, and by thermally decomposing the silver compound by heating the complex compound.

Owner:YAMAGATA UNIVERSITY

Color conversion filter and manufacturing method of the organic EL display

ActiveUS8304265B2Enable formationInhibited DiffusionSolid-state devicesSemiconductor/solid-state device manufacturingColor transformationPhysical chemistry

Owner:SHARP KK

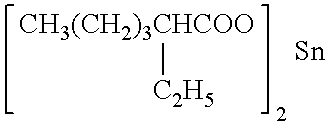

Magnetic toner

ActiveUS7160660B2High image densityExcellent low temperature fixabilityDevelopersVehicle componentsPolyesterLatent image

In a magnetic toner having toner particles containing at least a binder resin and a magnetic material, the binder resin is chiefly composed of a resin having a polyester unit synthesized using as a catalyst a tin compound represented by the following Formula (1), and the magnetic material has a number-average particle diameter of form 0.1 μm to 0.3 μm:(RCOO)2Sn Formula (1)wherein R represents an alkyl group having 5 to 15 carbon atoms. This magnetic toner can attain a stable image density without dependence on environment and enables formation of high-grade images over a long period of time without causing scratches of latent image bearing members.

Owner:CANON KK

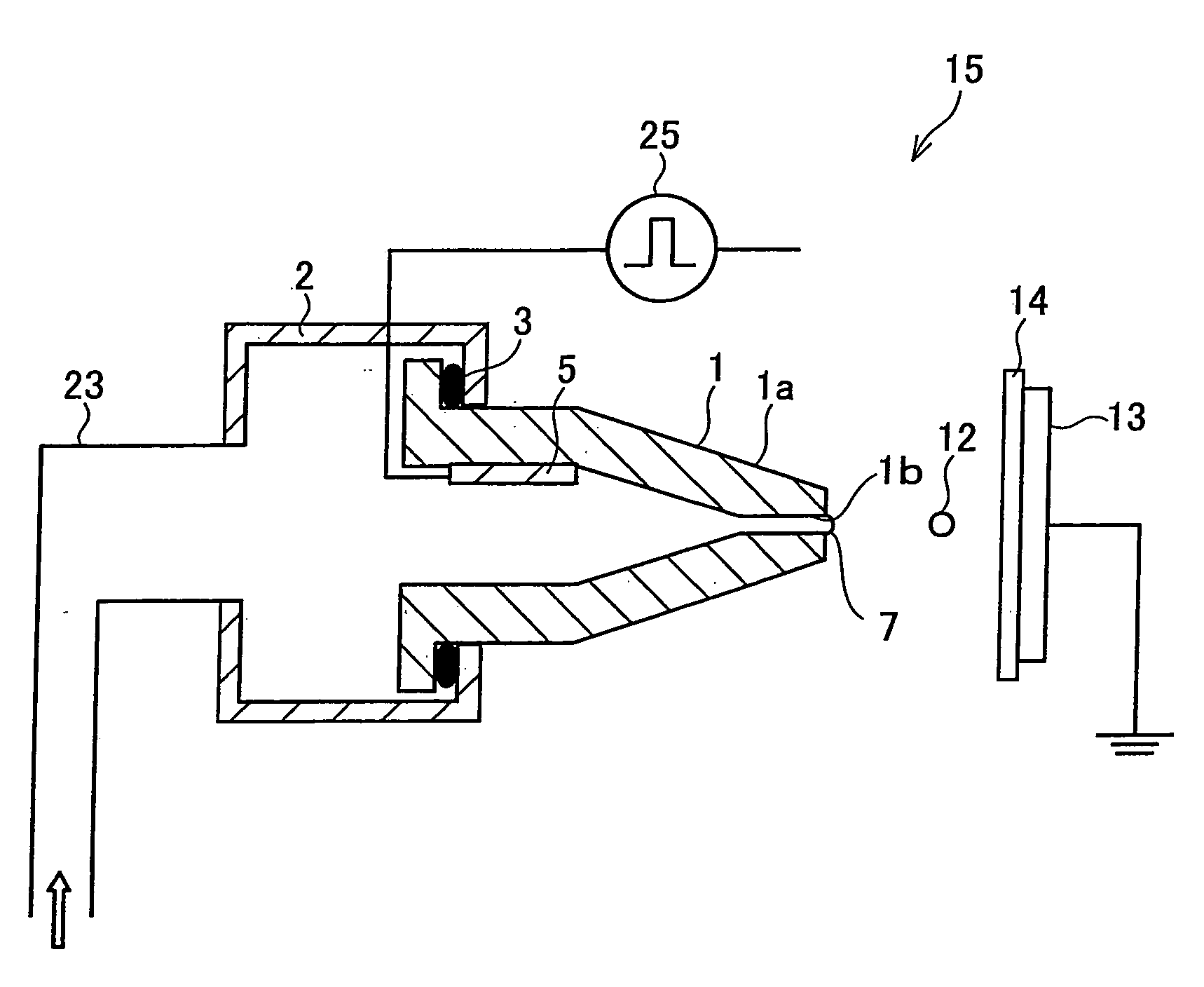

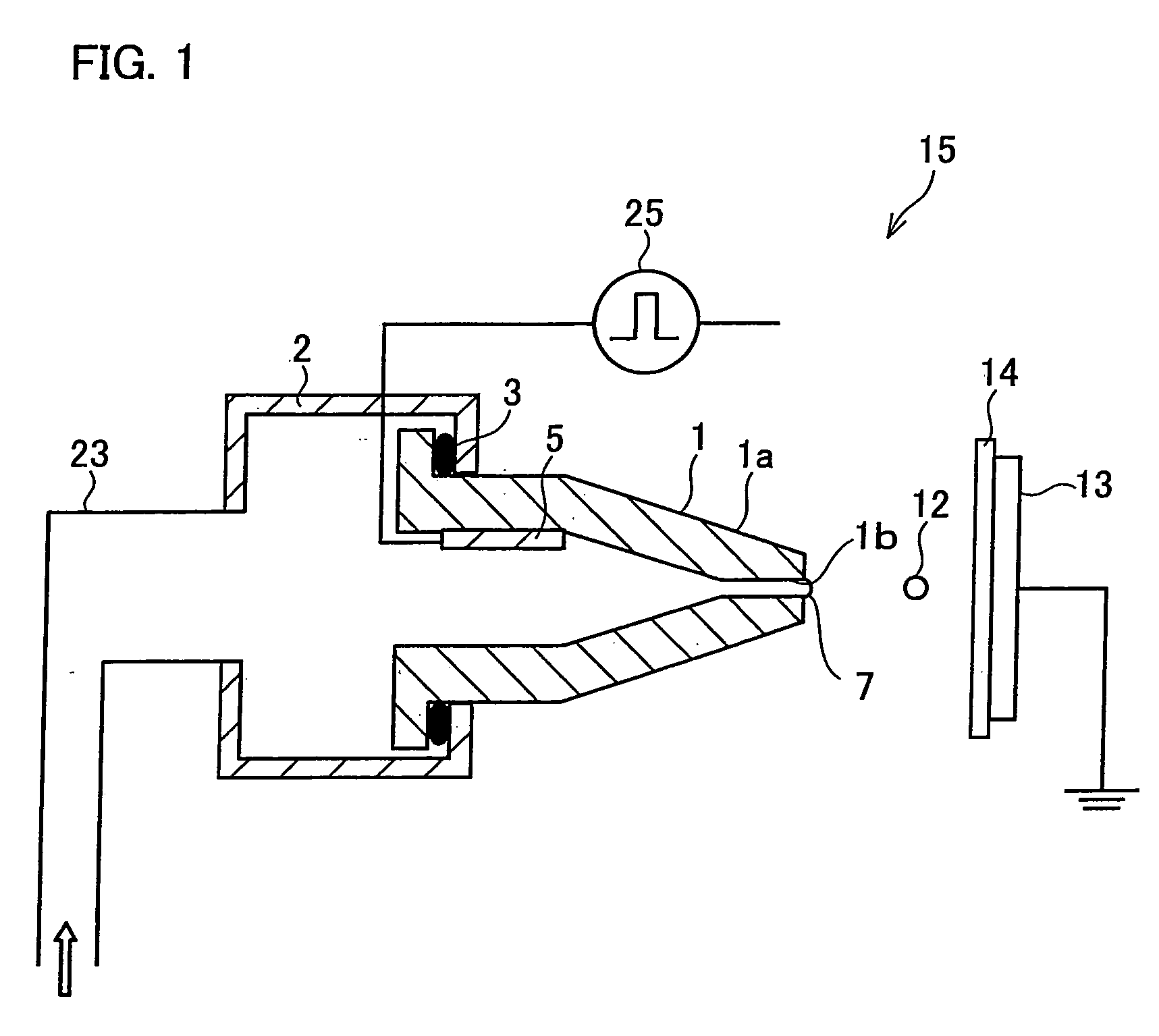

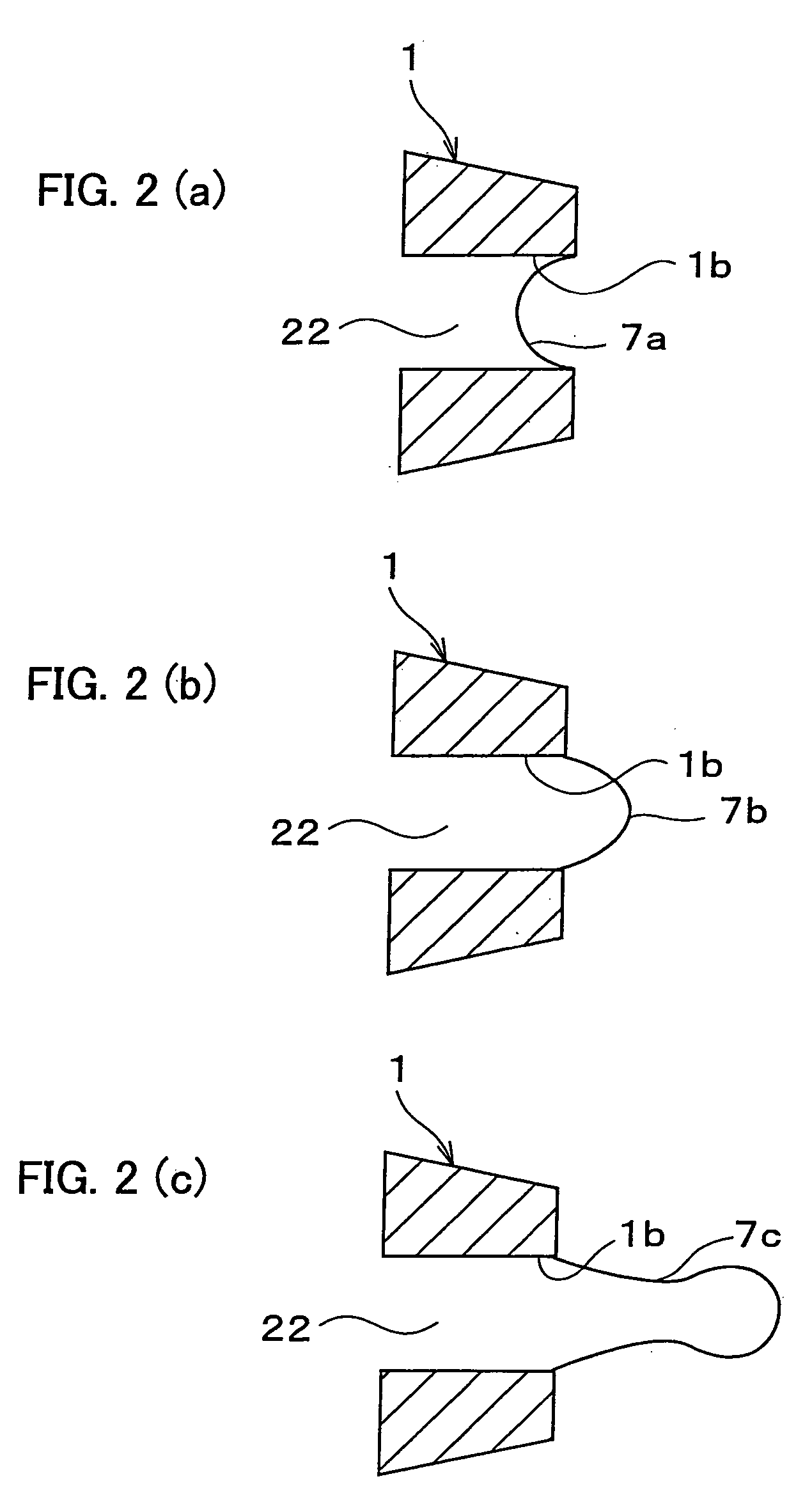

Method and apparatus for manufacturing active-matrix organic el display, active matrix organic el display, method for manufacturing liquid crystal array, liquid crystal array, method and apparatus for manufacturing color filter substrate, and color filter substrate

InactiveUS20060125363A1Accurate and easy formationEasy formationInking apparatusLiquid surface applicatorsElectrostatic attractionLiquid crystal

A method is for producing an active matrix organic EL display element by an inkjet method to eject droplets (12) of a liquid via an ejection hole of a nozzle so as to form an organic EL layer. The liquid contains an organic EL layer material. An electrostatic attraction type inkjet apparatus (15) is used whose ejection hole (1b) has a diameter smaller than a diameter of the droplets (12). The droplets are ejected from the nozzle of the electrostatic attraction type inkjet apparatus (15) in such a manner that each of the droplets is 1 pl or less in amount. With this arrangement, the landed droplet dries quickly, and movement of the landed droplet is restricted. This makes it possible to form an organic EL layer accurately with low cost.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com