Method and system for producing clear ice

a clear ice and production method technology, applied in the field of clear ice production methods and systems, can solve the problems of increasing the difficulty of harvesting ice cubes, affecting machine operation, and forming unsuitable ice deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

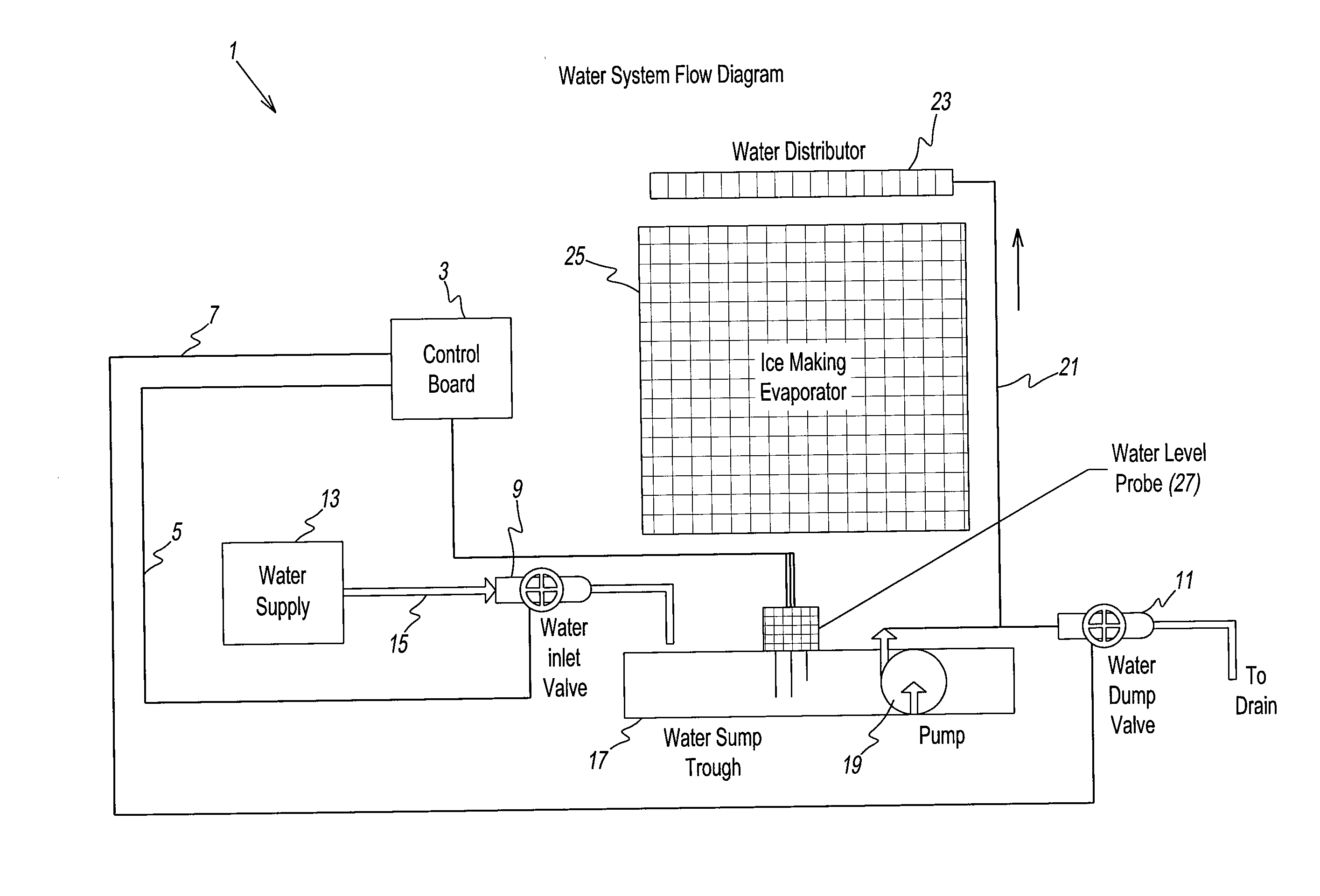

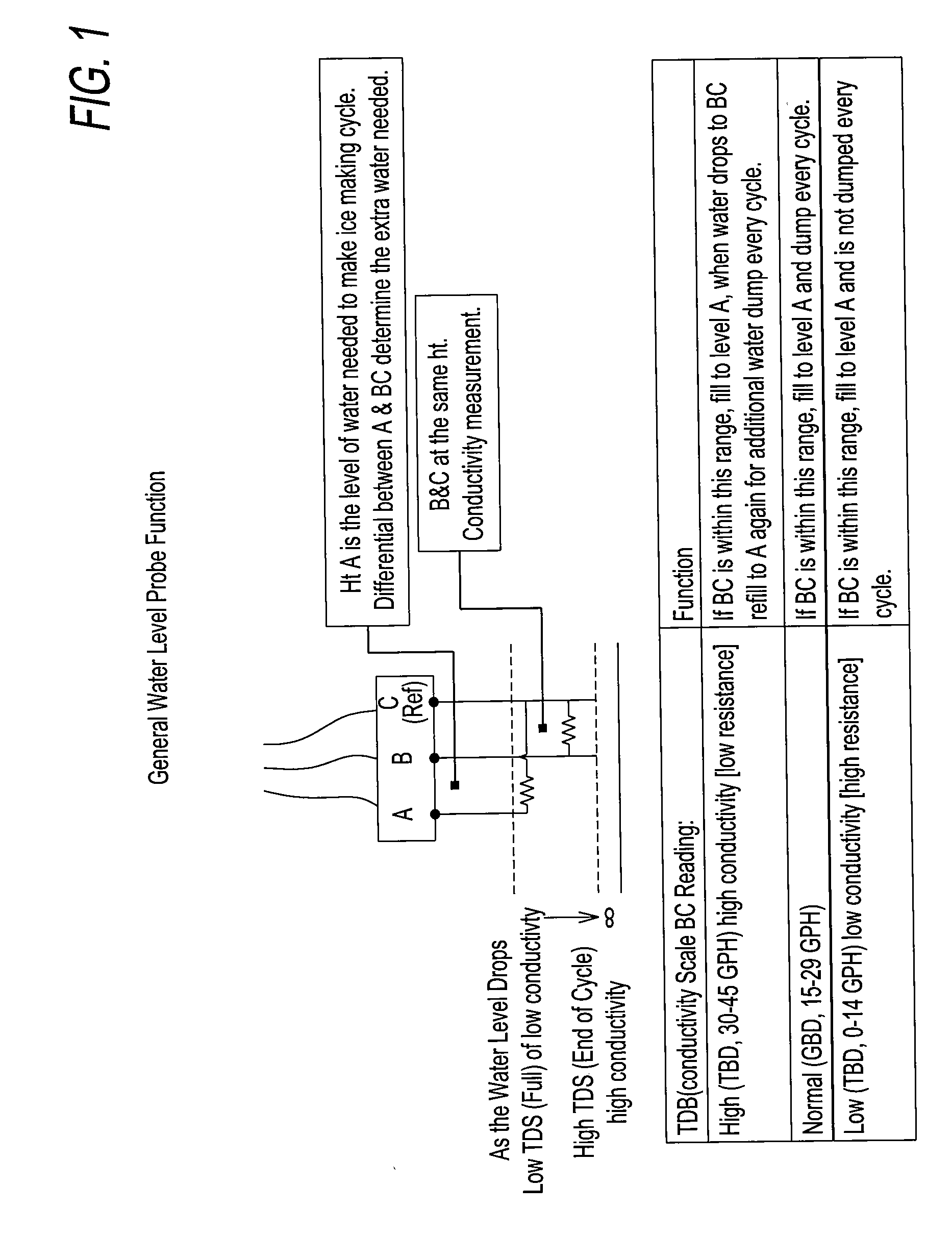

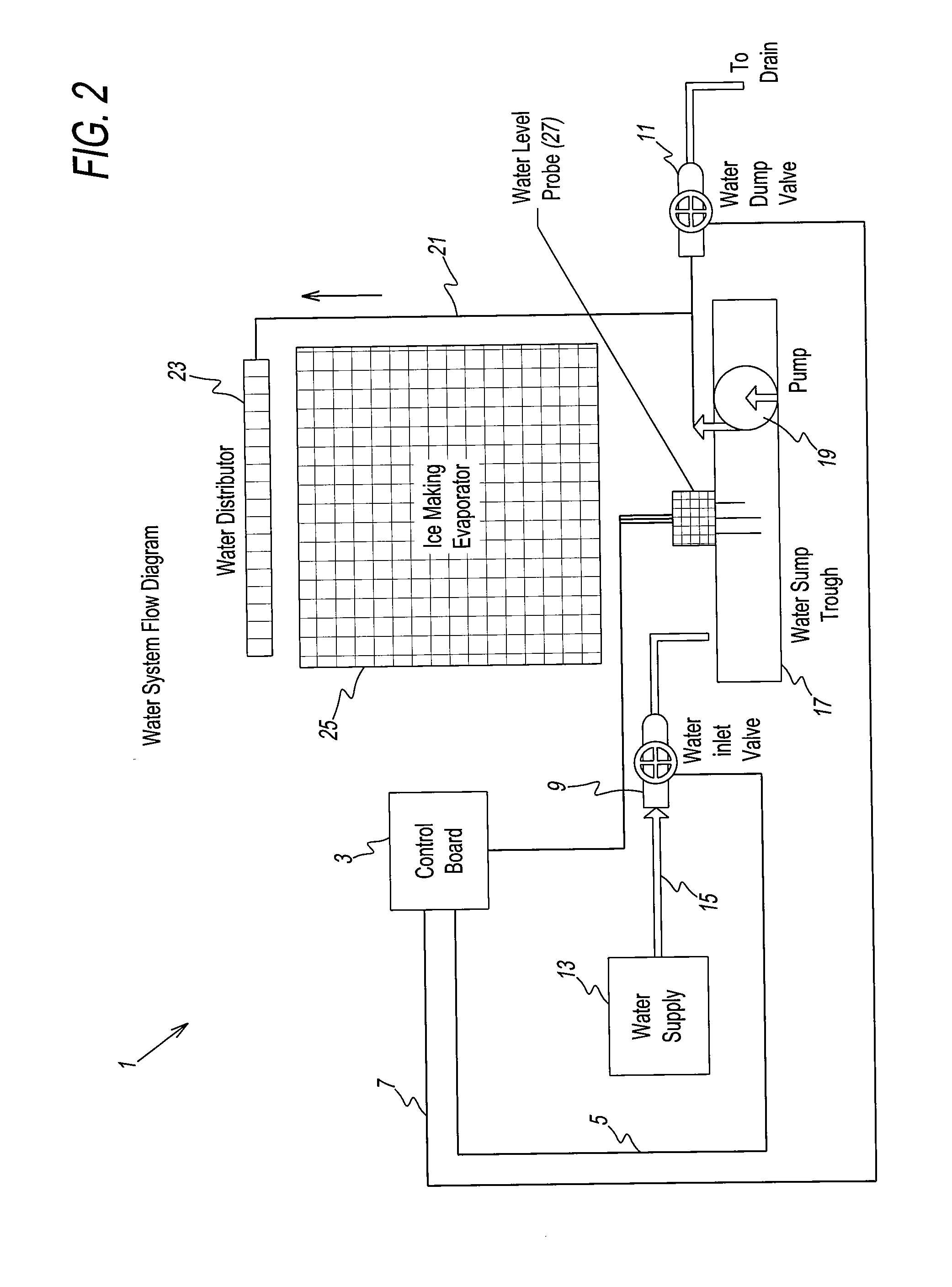

[0023]A system for making ice while controlling the water inlet and outlet based on the water conductivity in the sump trough. The water inlet valve is energized to bring all of the water in at one time prior to initiating the freeze cycle. Preferably, the amount of water is sufficient make a single batch of ice through one freeze and harvest cycle. And a conductivity measurement is made and depending upon the measurement the water valve may be energized again throughout the ice making or freezing cycle, as is necessary to maintain the conductivity or TDS level at or below a predetermined amount. During the freeze cycle, sensor readings are periodically taken of the water in the sump to determine if additional water needs to be added to reduce the TDS level, thereby producing substantially clear ice.

[0024]The system measures TDS of the supply water in the sump as water enters the system. If TDS is below the lower limit of normal, then no more water is brought into the sump and ice i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com