Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4051results about "Level indicators by physical variable measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

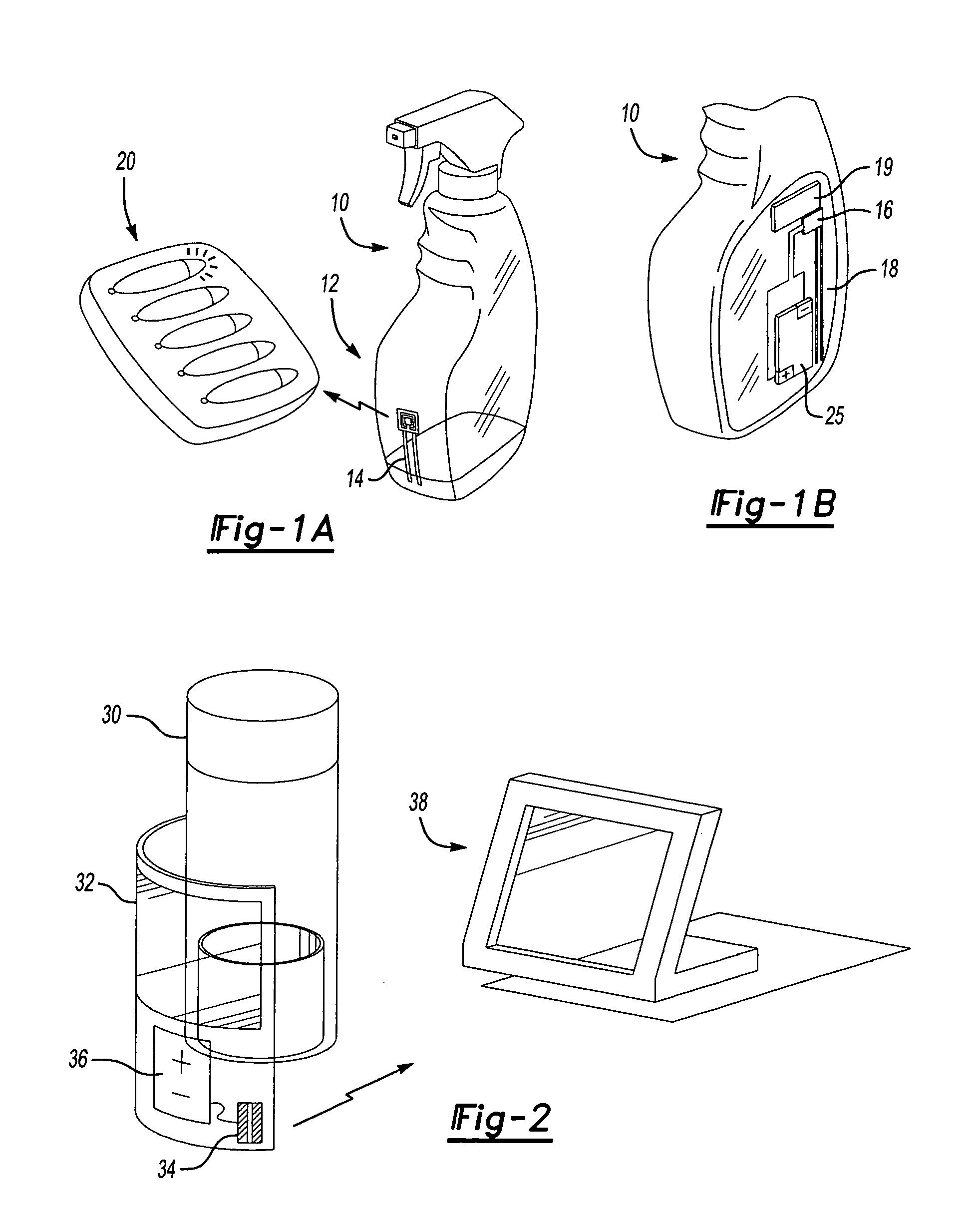

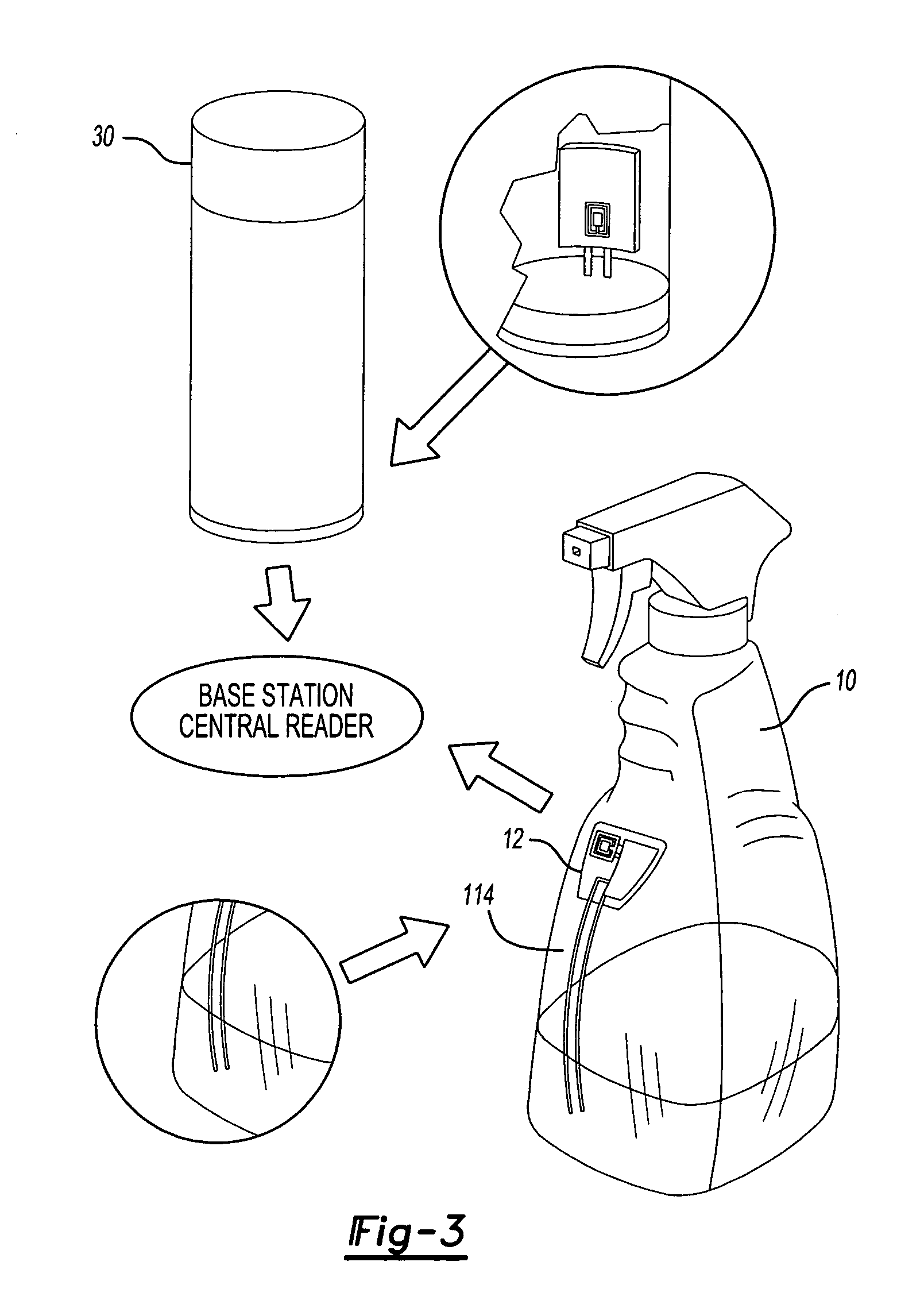

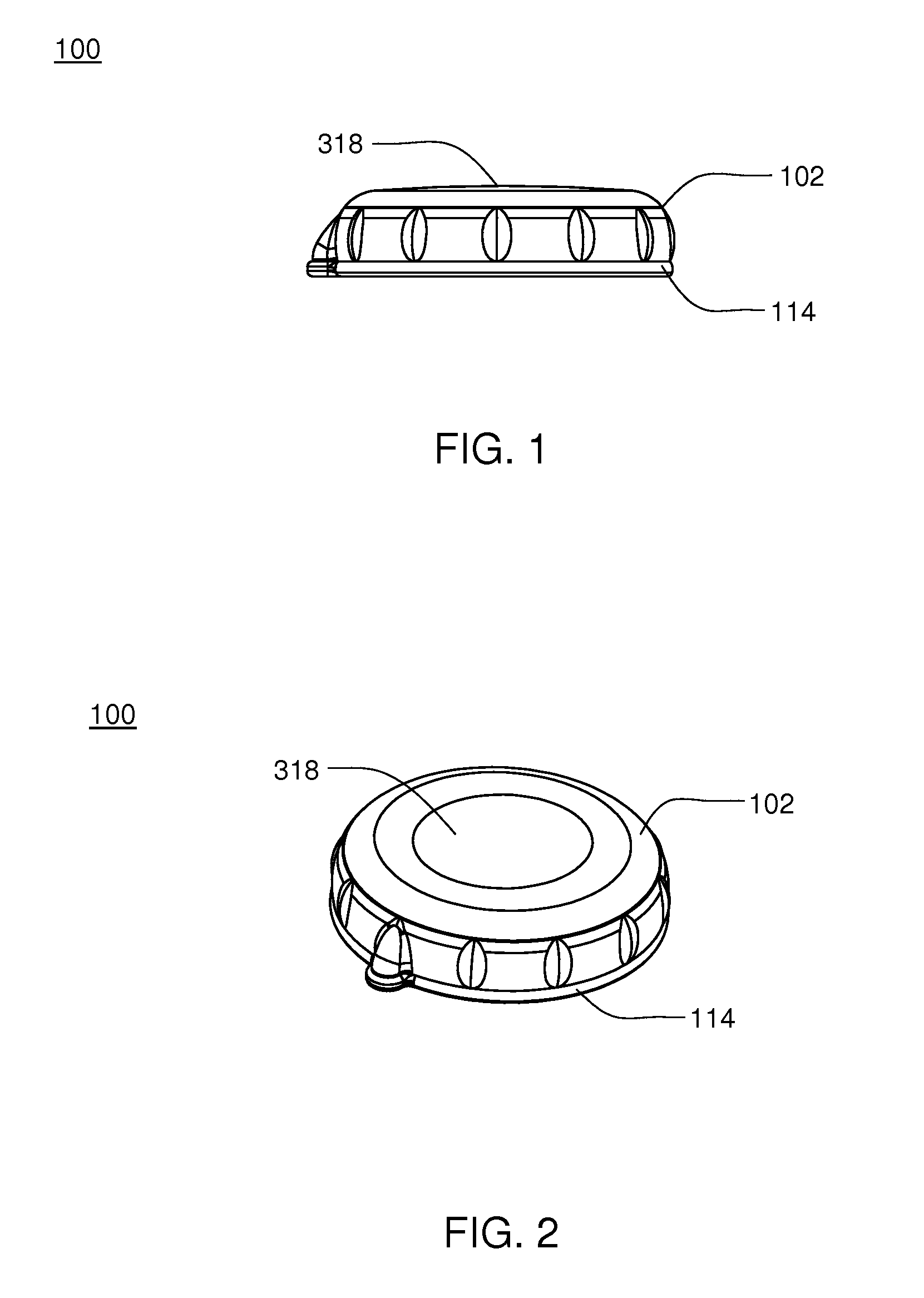

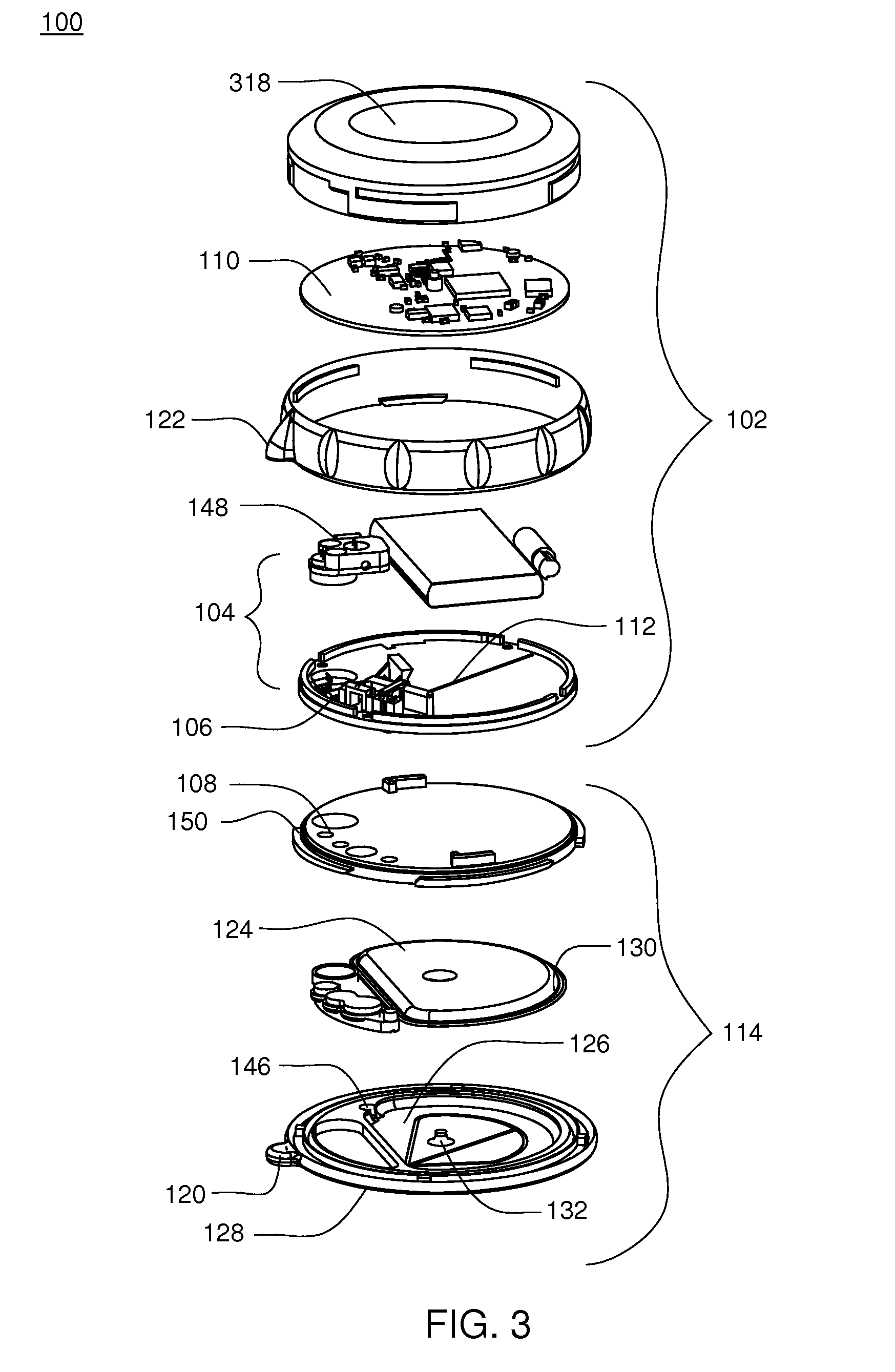

Point of sale inductive systems and methods

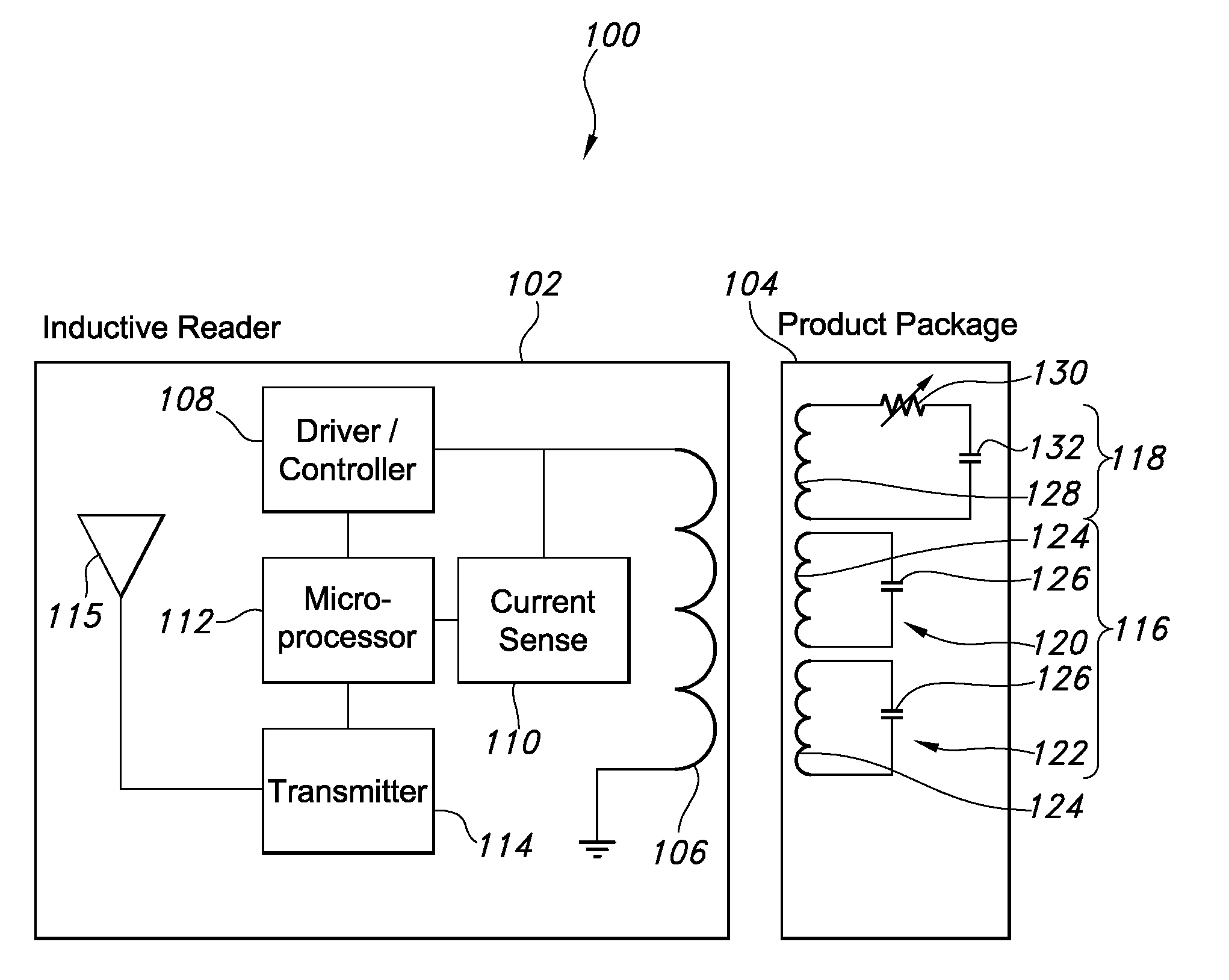

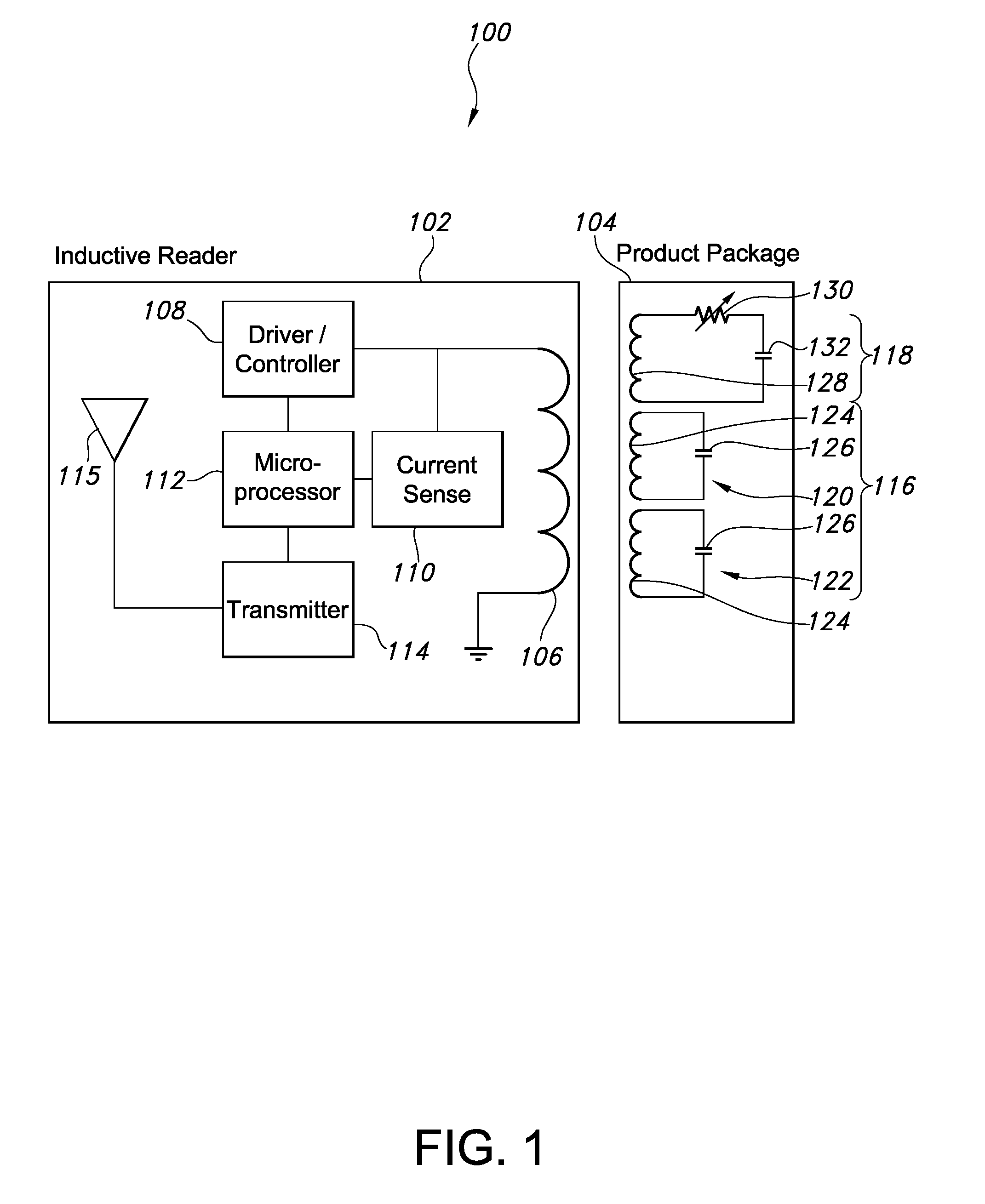

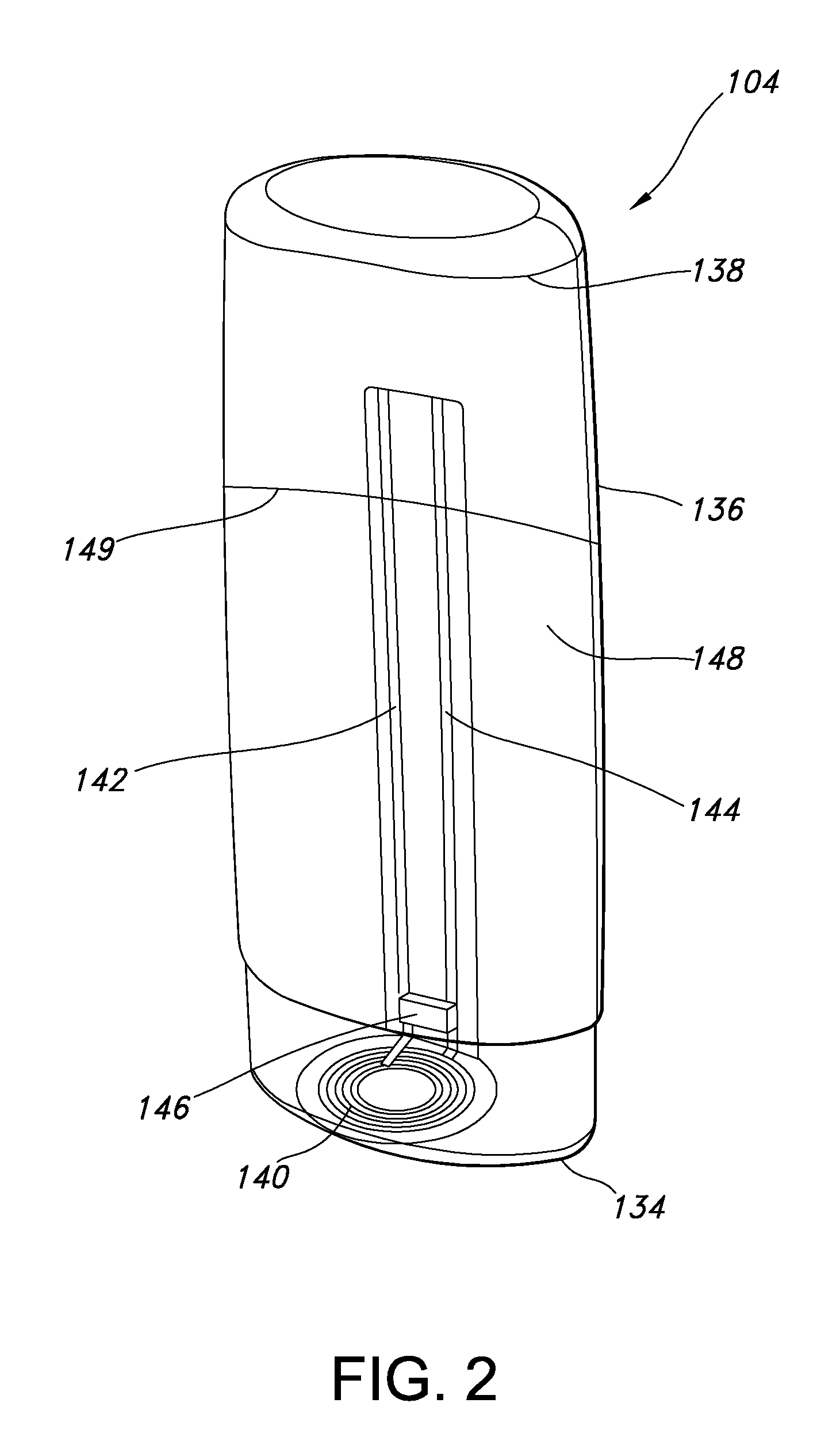

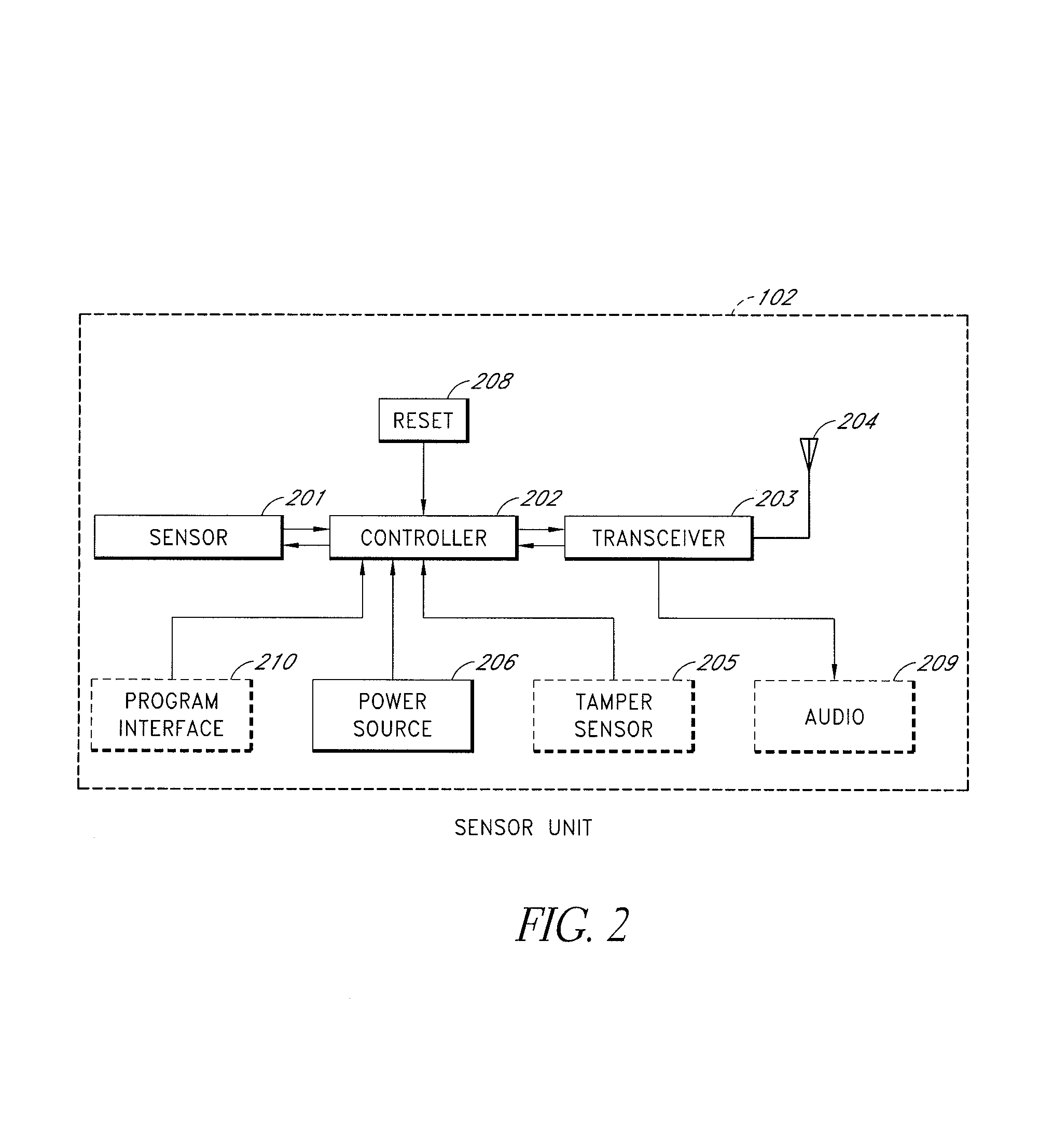

Systems and methods for the identification, powering and control of products and product packaging. The systems can include a point of sale display having a contactless power supply. The contactless power supply can provide a source of wireless power for products and product packaging. The products and product packaging can include light emitting diodes, e-ink displays and printed speaker circuits that activate as the operating frequency of the contactless power supply varies. Other embodiments include product level sensors, inductive reader networks, printed temperature sensors, product alignment systems, passive identification circuits and methods for controlling operation of the same.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Product dispensing controlled by RFID tags

ActiveUS7009519B2Provide informationContainer decorationsLevel indicationsTimerManufacturing engineering

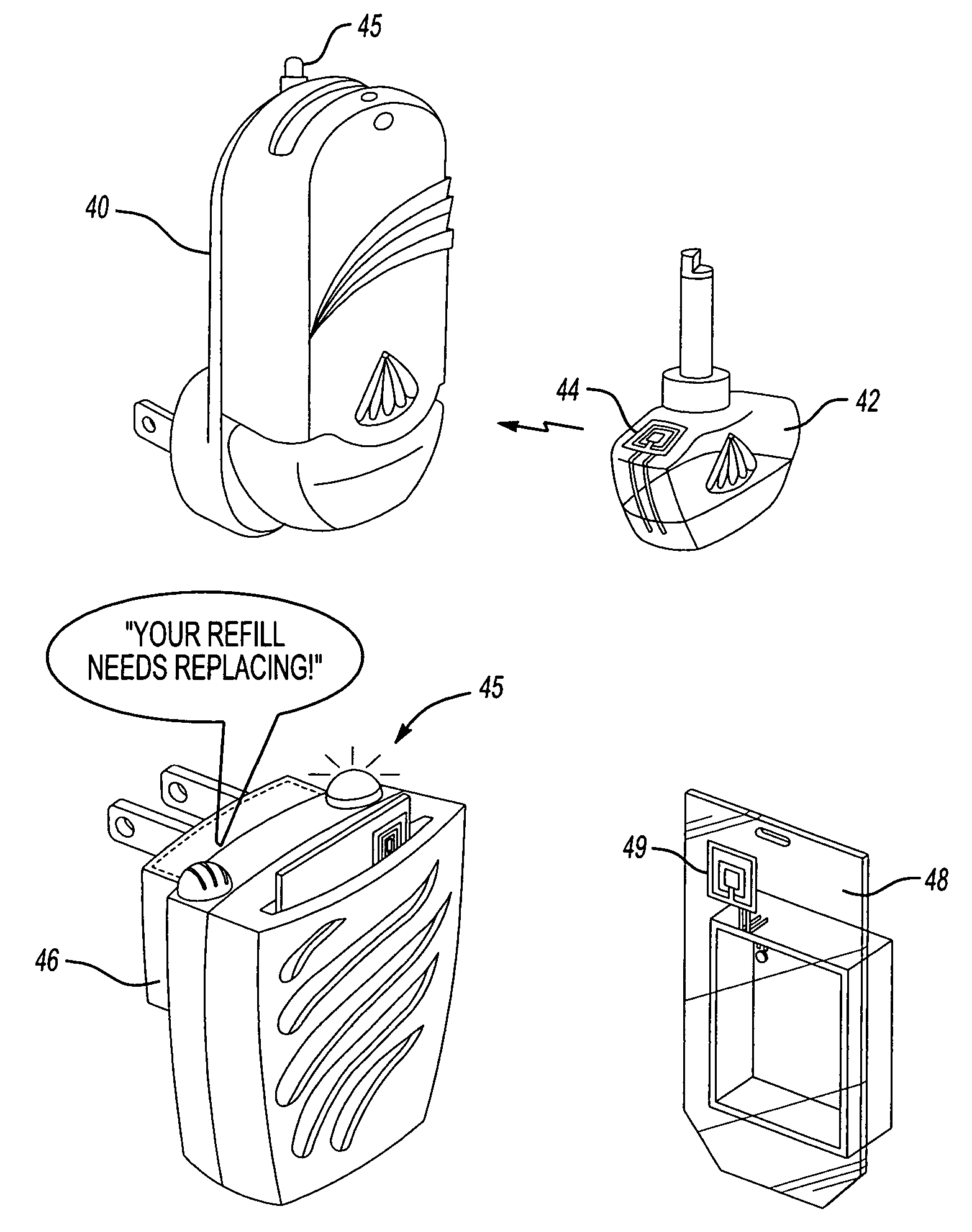

RFID tags attached to a product contain information regarding the product and communicate this information to a reader. This information can include the age of the product, the amount of product left and preparation or care instructions for the product. To record the age of a product, a timer is initiated in the RFID tag. Thereafter, the elapsed time on the timer can be read and displayed by the reader. For other products, the RFID tag can have contacts monitoring the level of remaining product. Once the contacts sense that the amount of product is low, this information can be transmitted and communicated by the reader. Preparation and care instructions are prerecorded on the tag. Instructions can also be communicated between a product and a base, such as a heater.

Owner:SC JOHNSON & SON INC

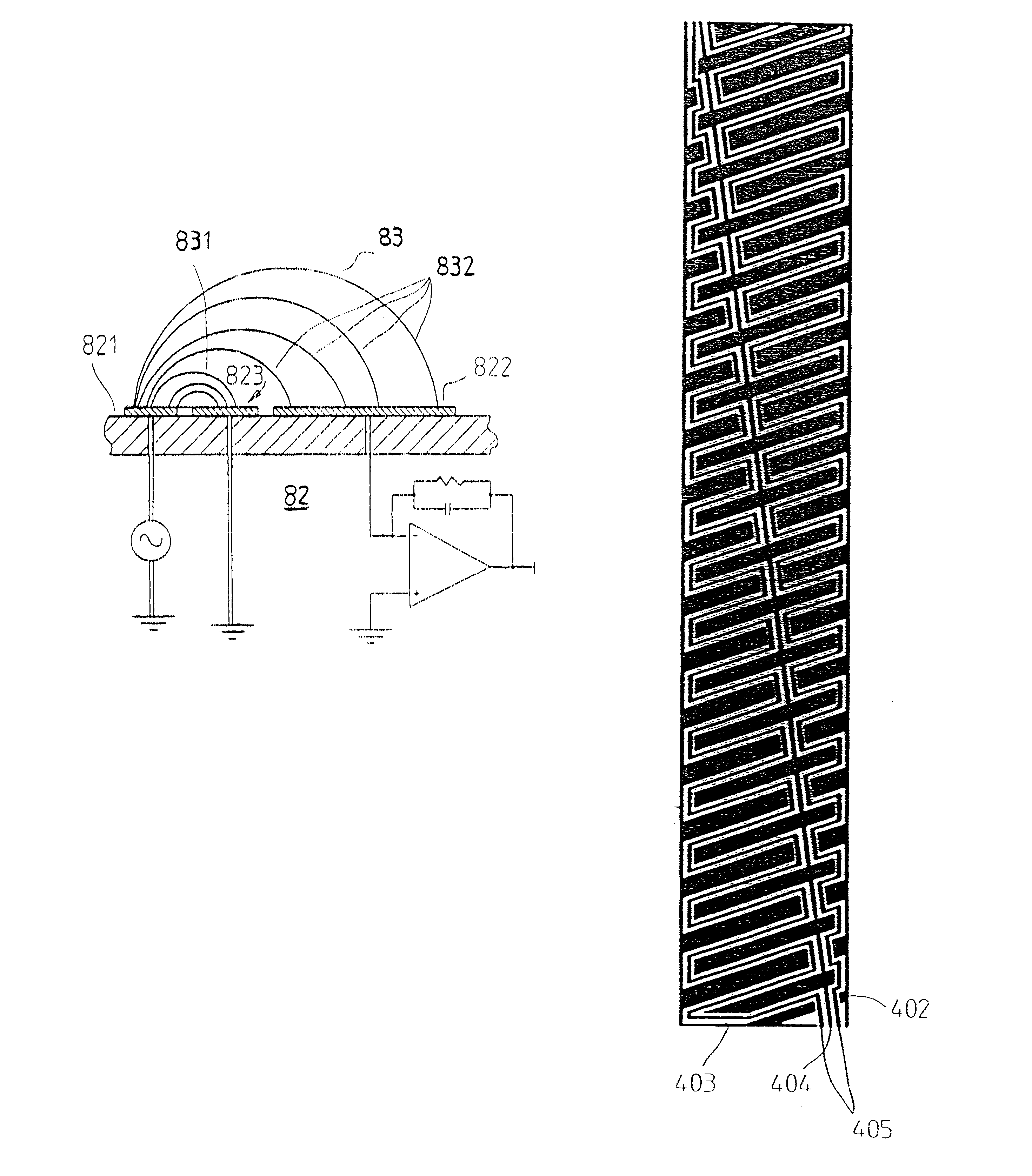

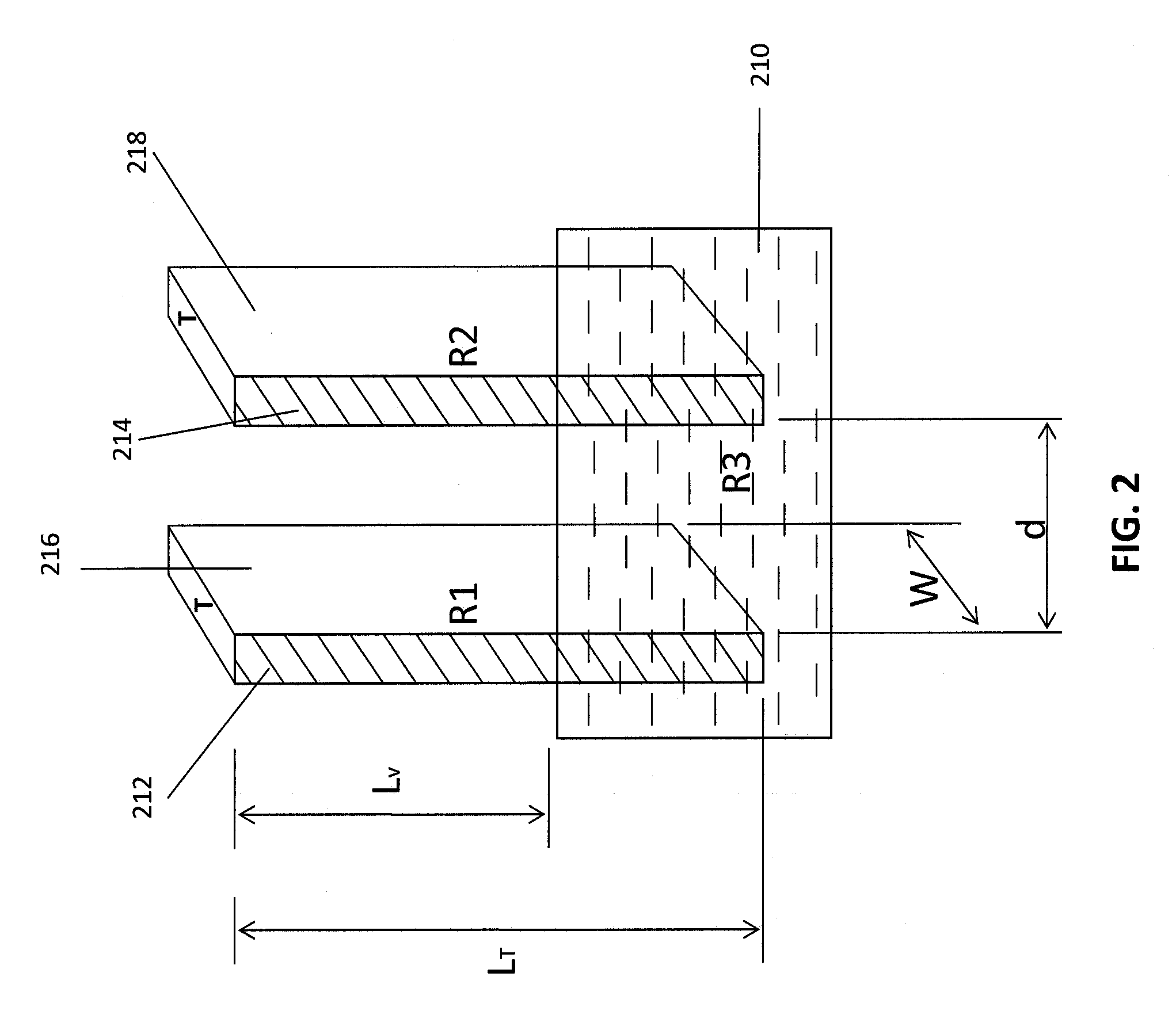

Compensated capacitive liquid level sensor

A fringing-field capacitive liquid level sensor comprising an electrically insulating substrate, having a first and a second pattern of conductive capacitance plates plated on the substrate. Each pattern constitutes a fringing-field capacitor having a capacitance the value of which is both dependent on the liquid level and dependent on the dielectric constant of the liquid. The ratio of the two capacitances, however, is proportional to the liquid level and independent of the dielectric constant of the liquid. The fringing-field capacitive liquid level sensor may be used for measurement of liquids of substantially any dielectric constant without requiring full-scale calibration or knowledge of, and calibration for, dielectric constant of the liquid to be measured. Compensation for tilt angle can be provided through the addition of a second level sensor.

Owner:TAMAR SENSORS LTD

Sensor for detecting the level of a medium

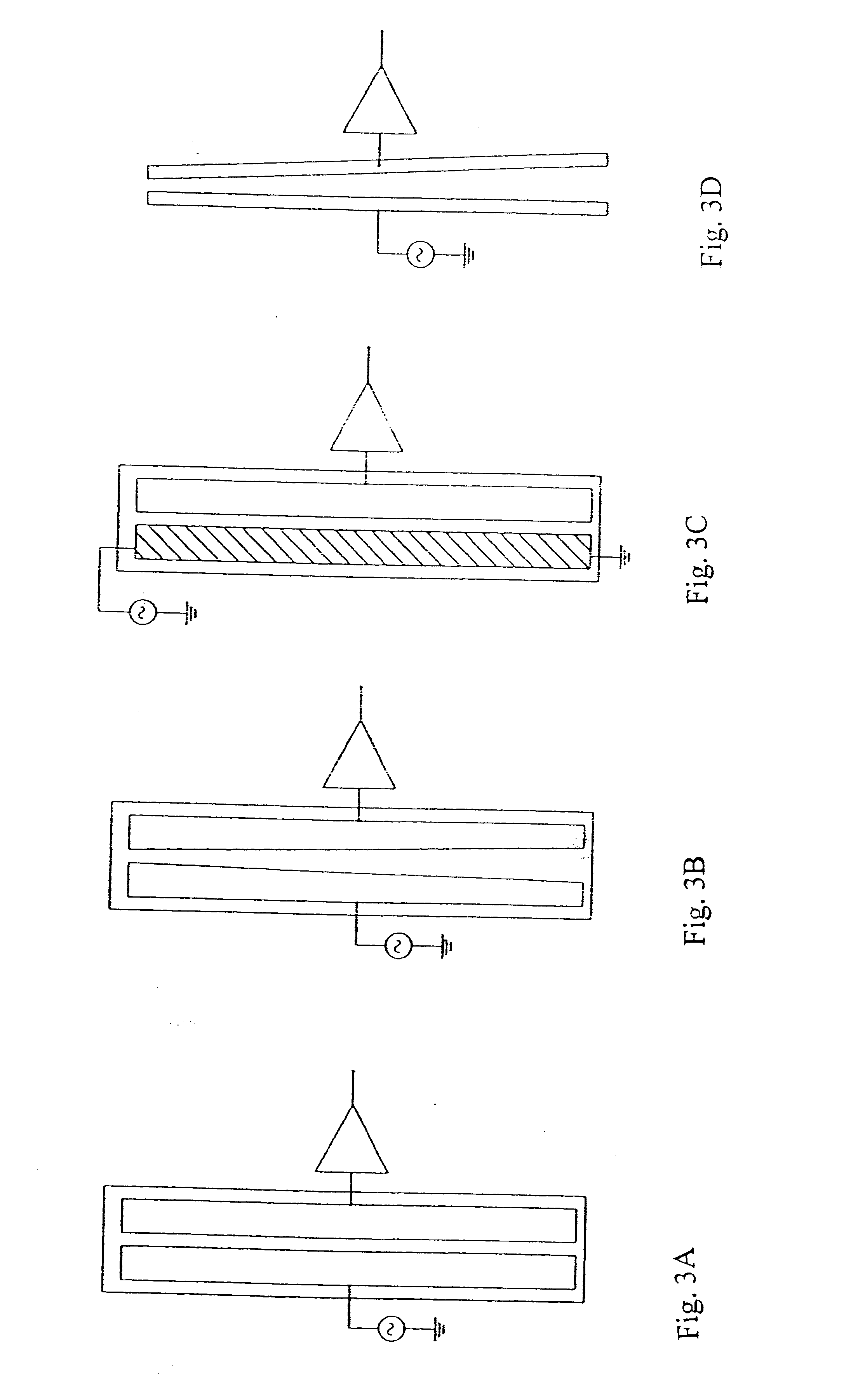

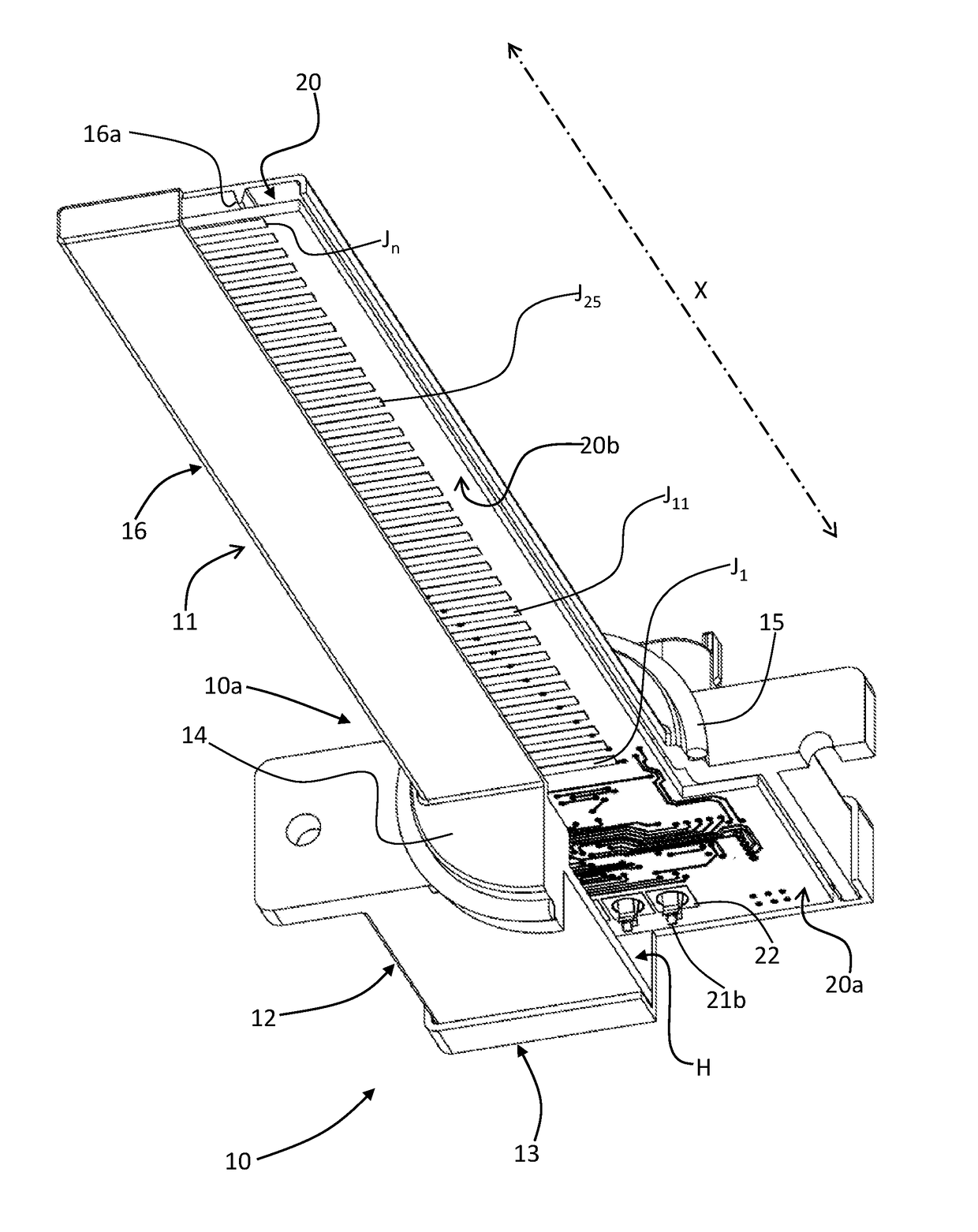

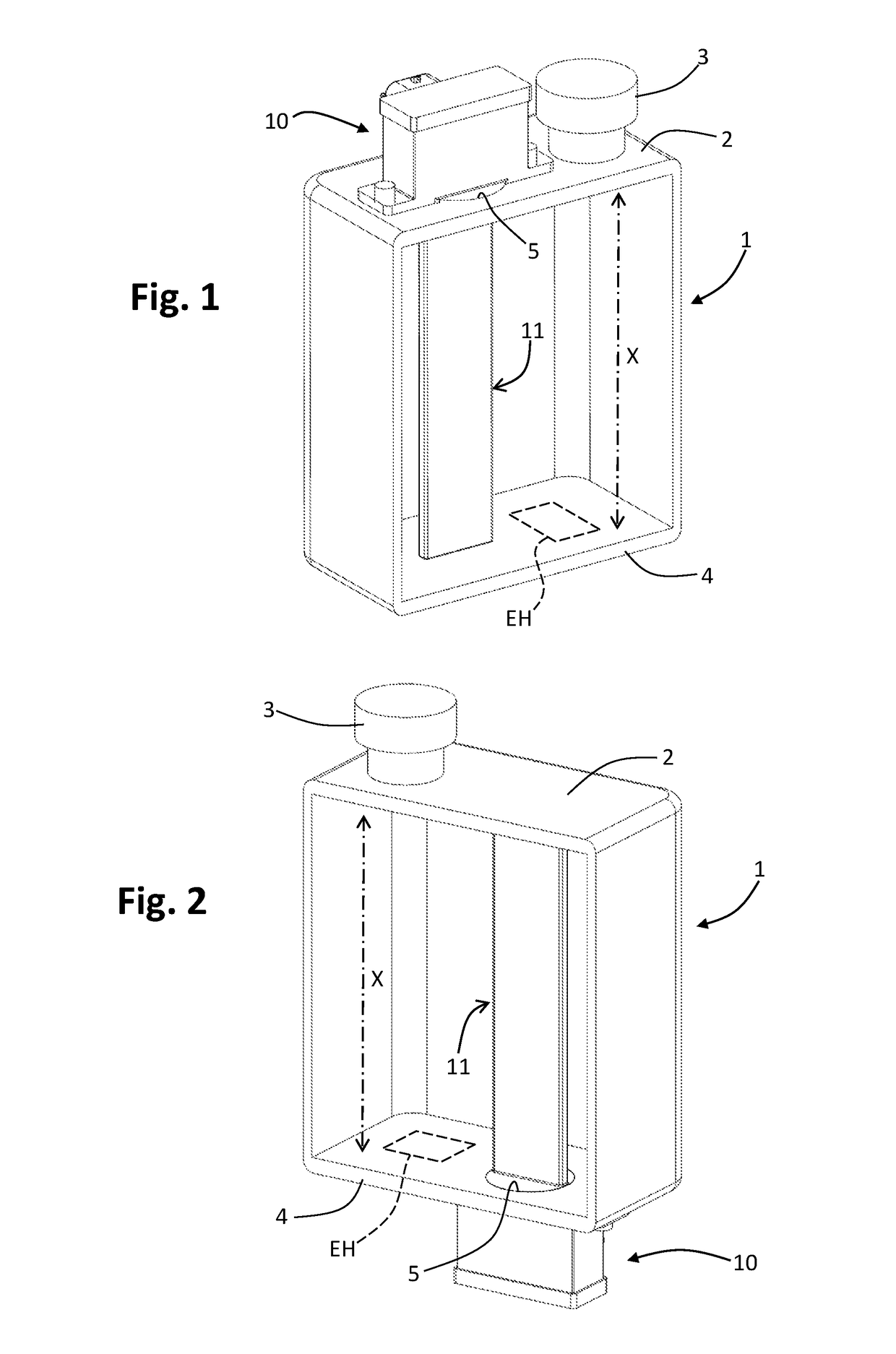

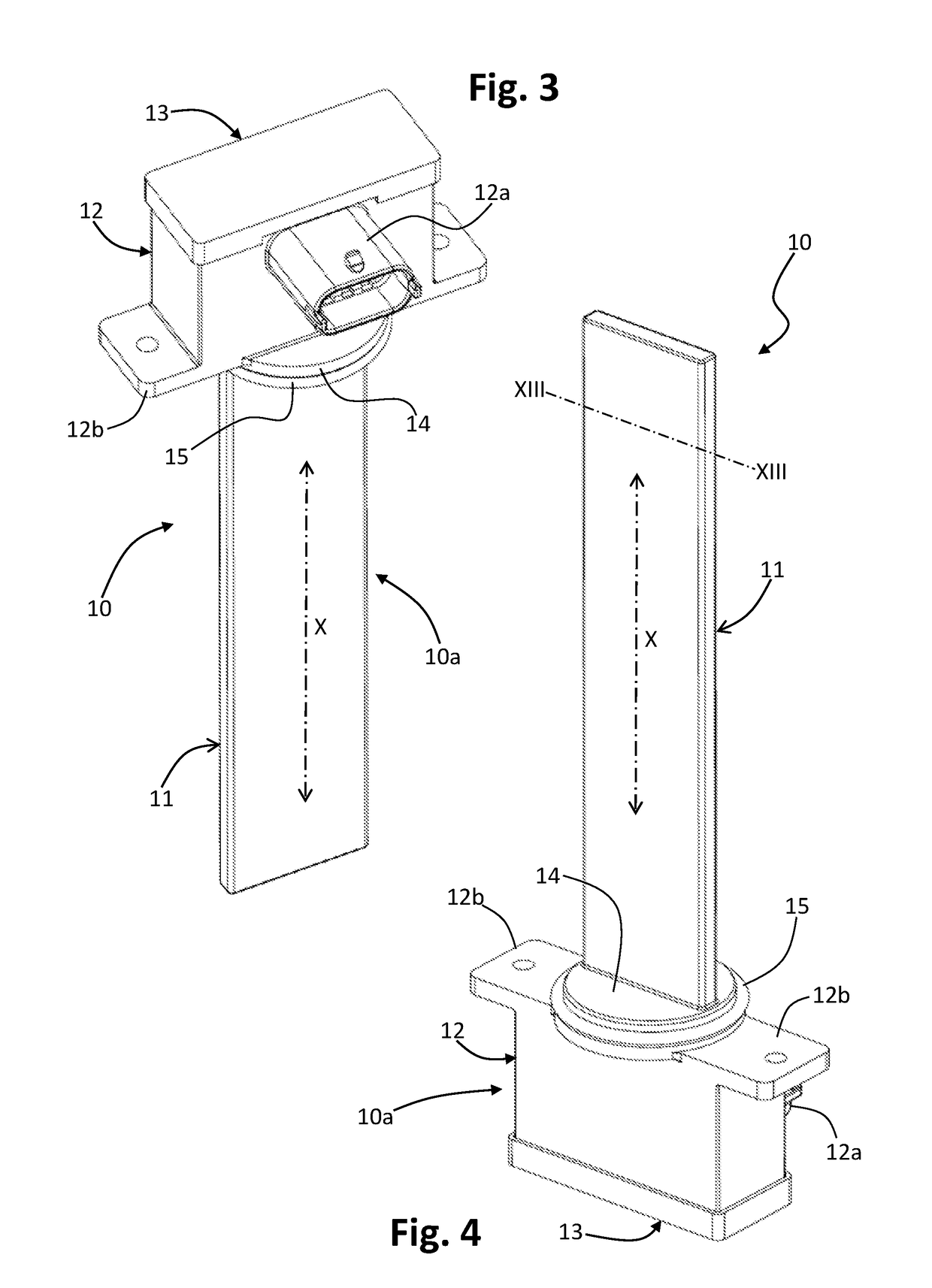

ActiveUS20170191861A1Increase flexibilityAccurate operationLevel indicators by physical variable measurementCapacitanceLevel sensor

A level sensor for detecting the level of a medium contained in a vessel comprises:an array of capacitive elements designed to be associated with the vessel (1), comprising a plurality of electrodes (J1-Jn), spaced apart from each other along an axis of detection (X),an insulation layer (16) for electrically insulating the electrodes (Ji-L) with respect to the inside of the vessel (1),a controller (24) having a plurality of inputs.Each capacitive element comprises at least one of a single electrode and a group of electrodes connected in common to each other, the single electrode or the group of electrodes being connected to a respective input of the plurality of inputs.The controller (24) is prearranged for discriminating a value of electrical capacitance associated with each electrode (J1-Jn) to deduce the level of the medium present in the vessel.

Owner:ELTEK

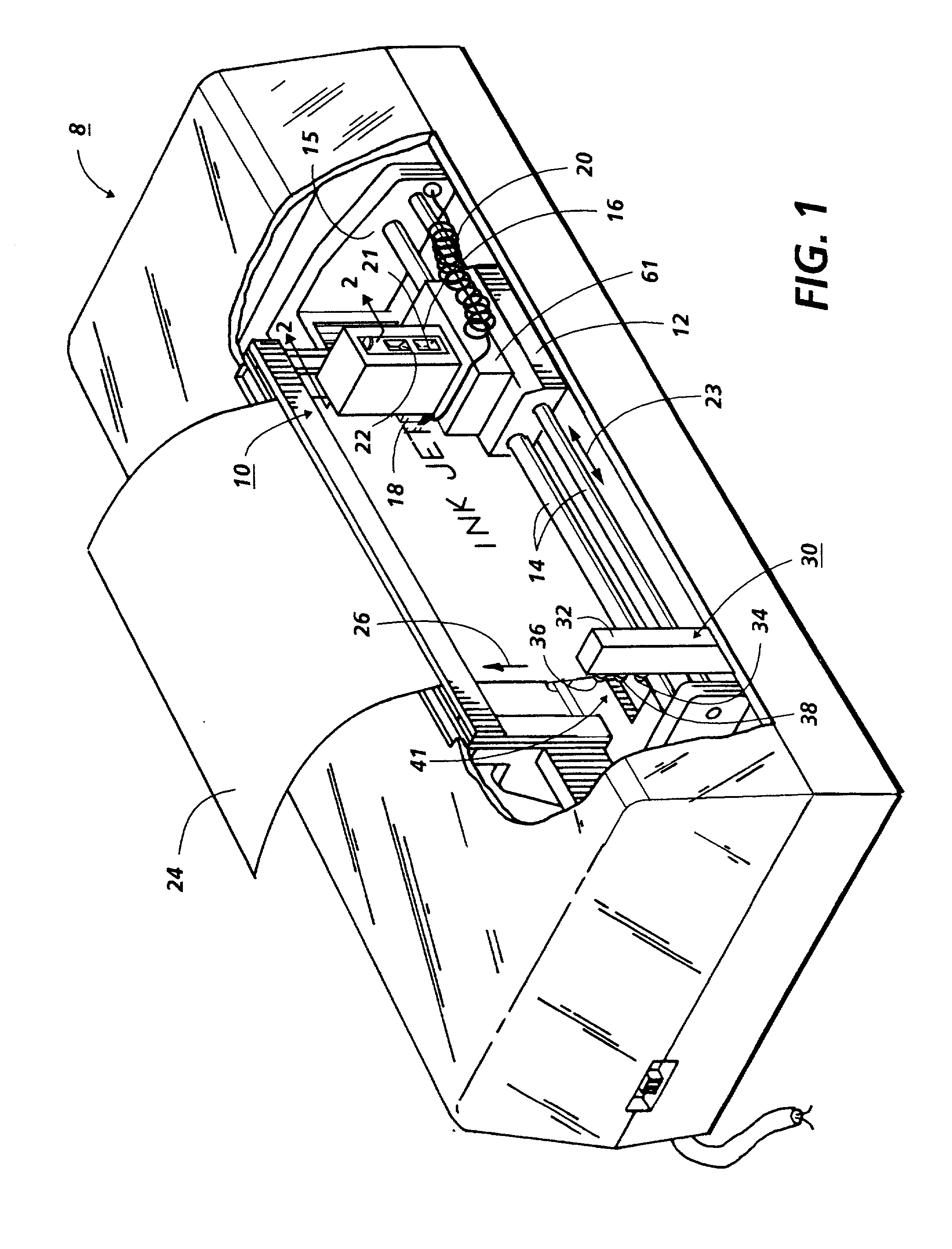

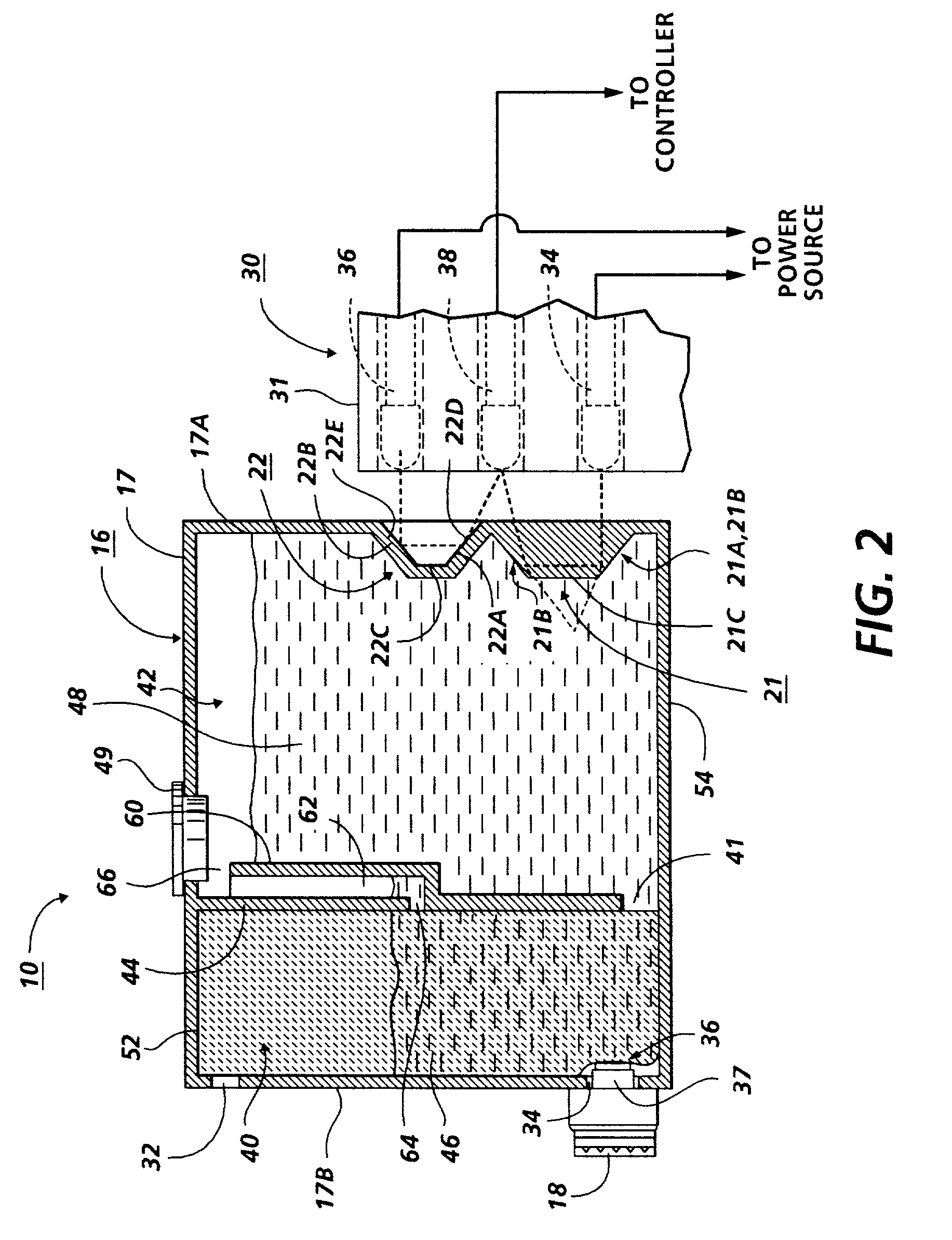

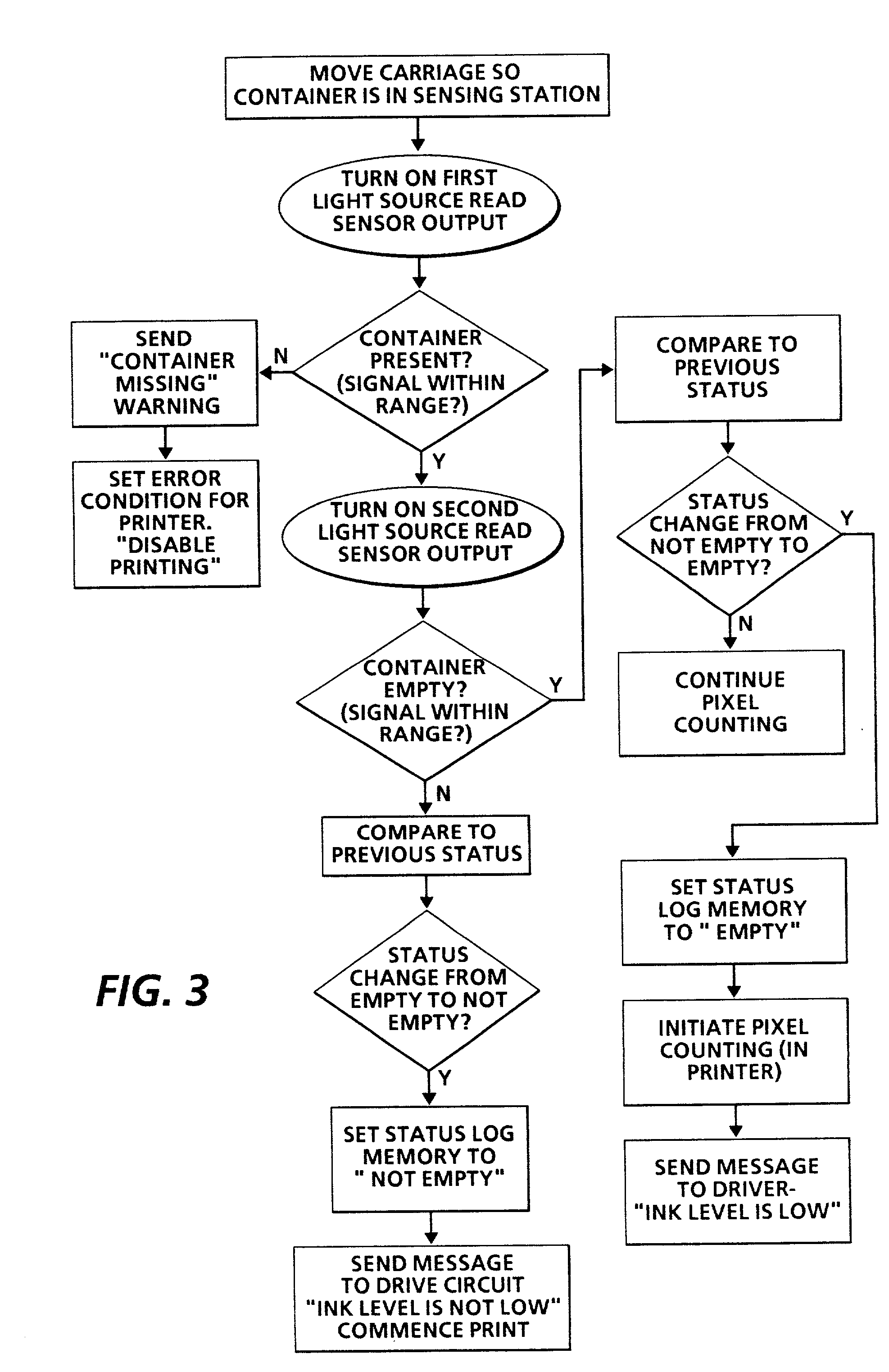

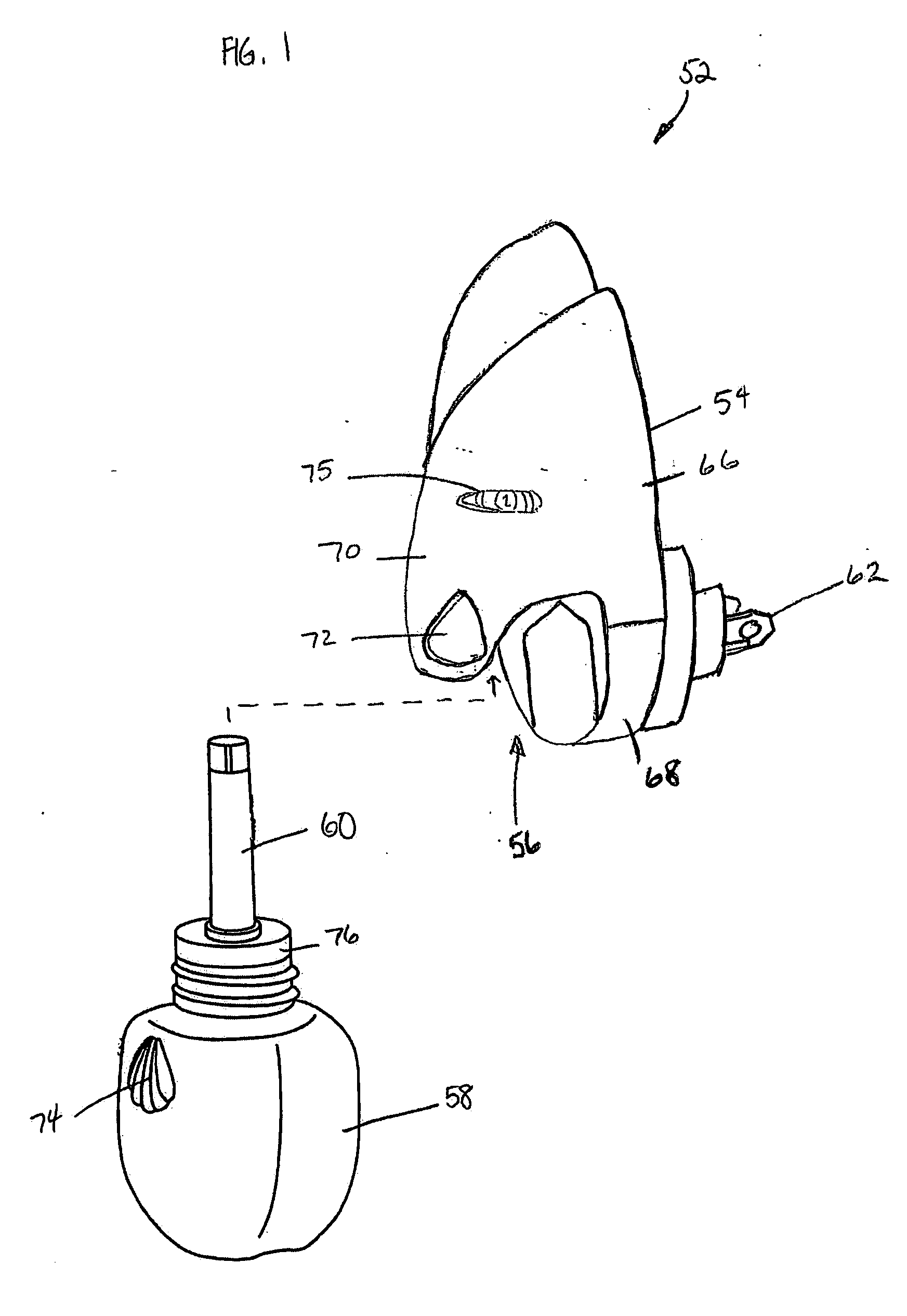

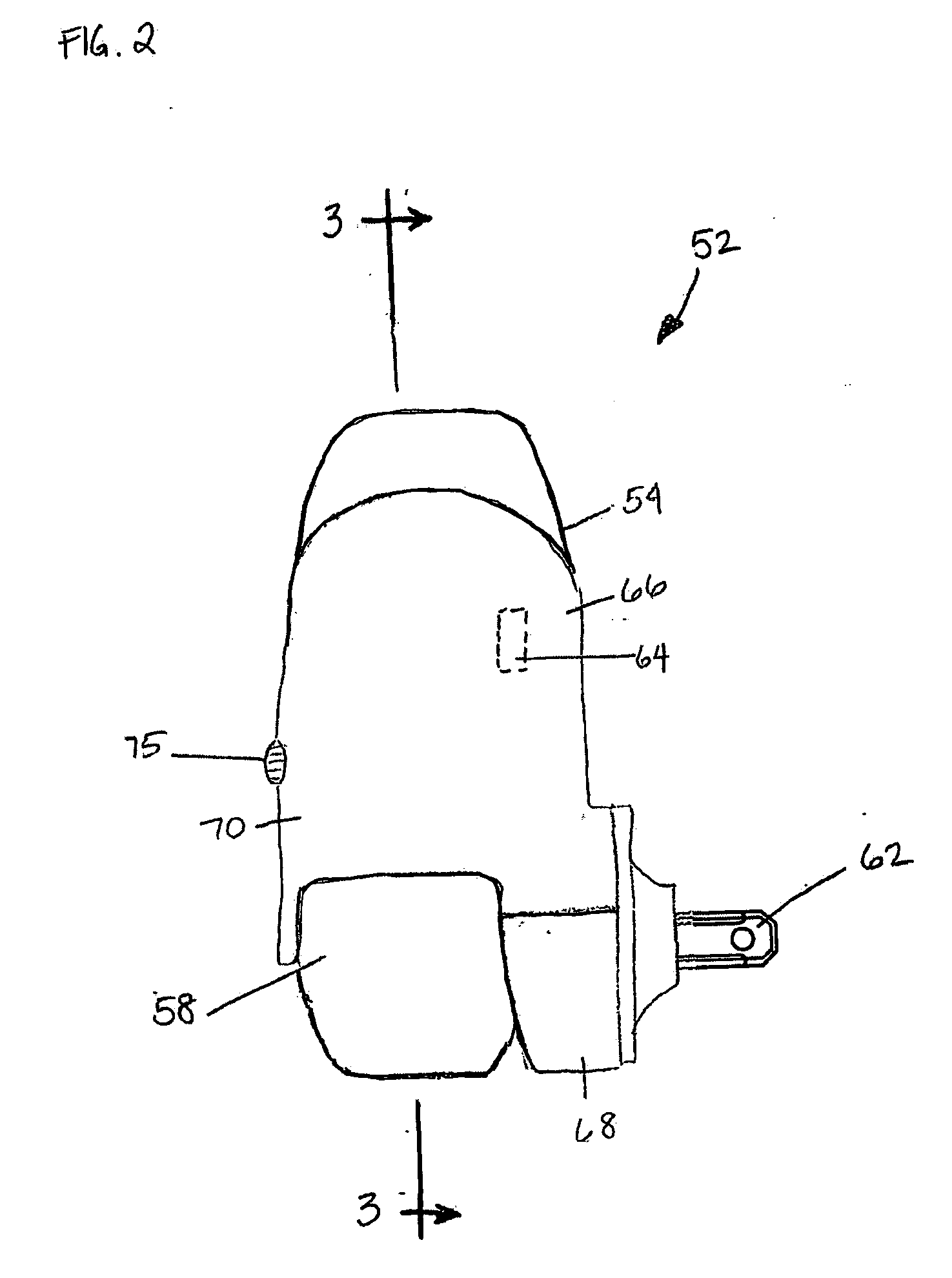

Sensing system for detecting presence of an ink container and level of ink therein

A low ink sensing system is combined with an ink cartridge detection system to enable a more efficient ink jet printer. An ink container which supplies ink to an associated printhead is modified by the incorporation of two light directing elements, in the preferred embodiment, a faceted prism and a roof mirror, into a transparent wall of the container housing. The cartridge, comprising the ink container and associated printhead, is mounted on a scan carriage. Periodically, the carriage is conveyed to a sensing station comprising a pair of light sources and a commonly used photosensor. A first light source is energized and a beam of light is directed to a location where the roof mirror, would be positioned if the cartridge is present. If the cartridge is absent, lack of a reflected return signal is sensed, indicating a cartridge has not been inserted. Print operation is halted until a cartridge is inserted. If a cartridge is properly inserted, the roof mirror returns most of the incident light to the photosensor which generates a signal indicating the presence of the cartridge. A second light source is then energized and directed towards the faceted prism, which is either immersed in ink or exposed to air within the interior of the container. If the latter, light is internally reflected by the prism facets back to the photosensor. If a print operation has been in progress, and the ink level has fallen, the common photosensor detects either a strong or weak redirected light component and initiates a status check and generates appropriate displays of low ink level or out of ink warnings.

Owner:SAMSUNG ELECTRONICS CO LTD

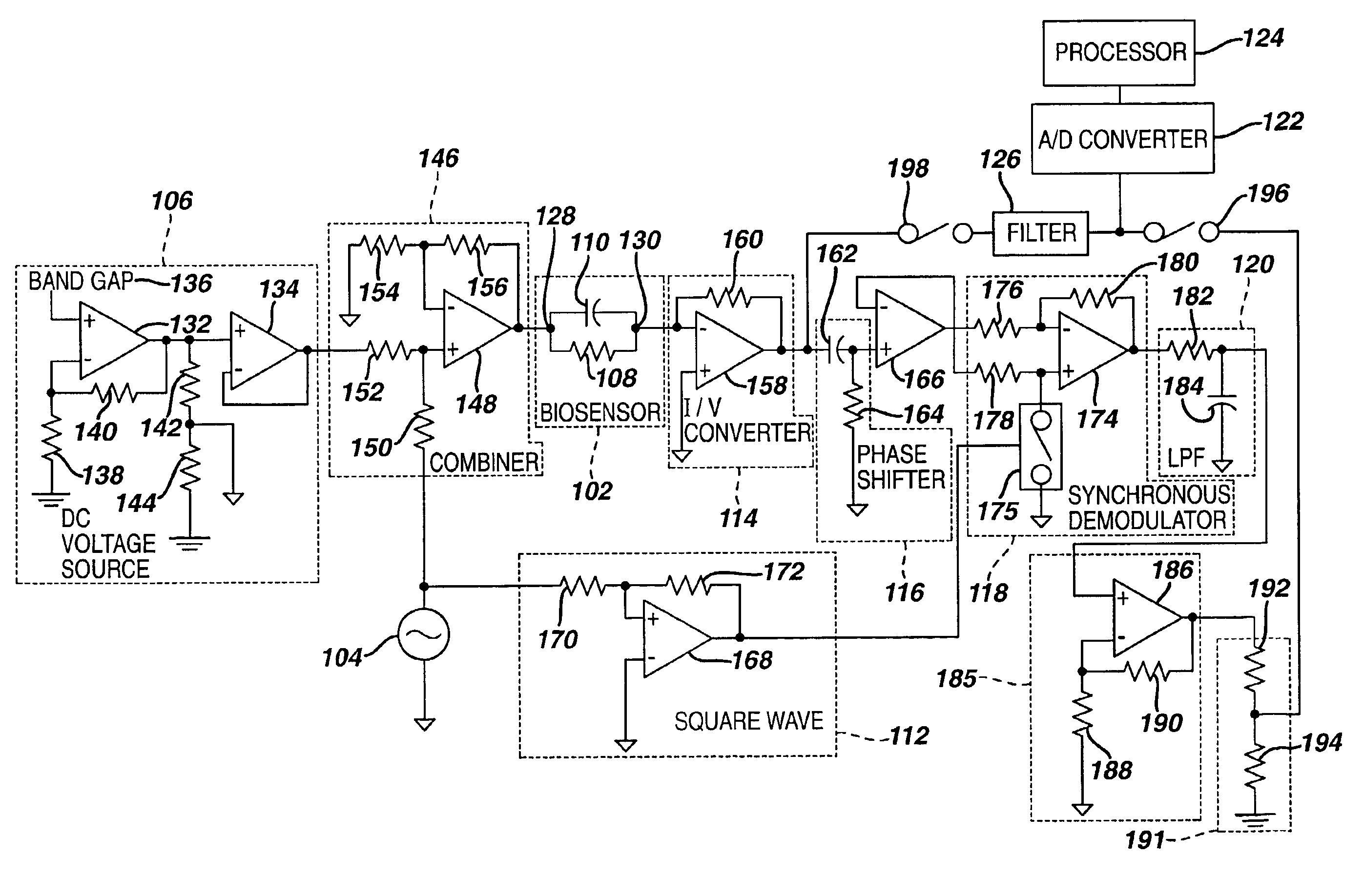

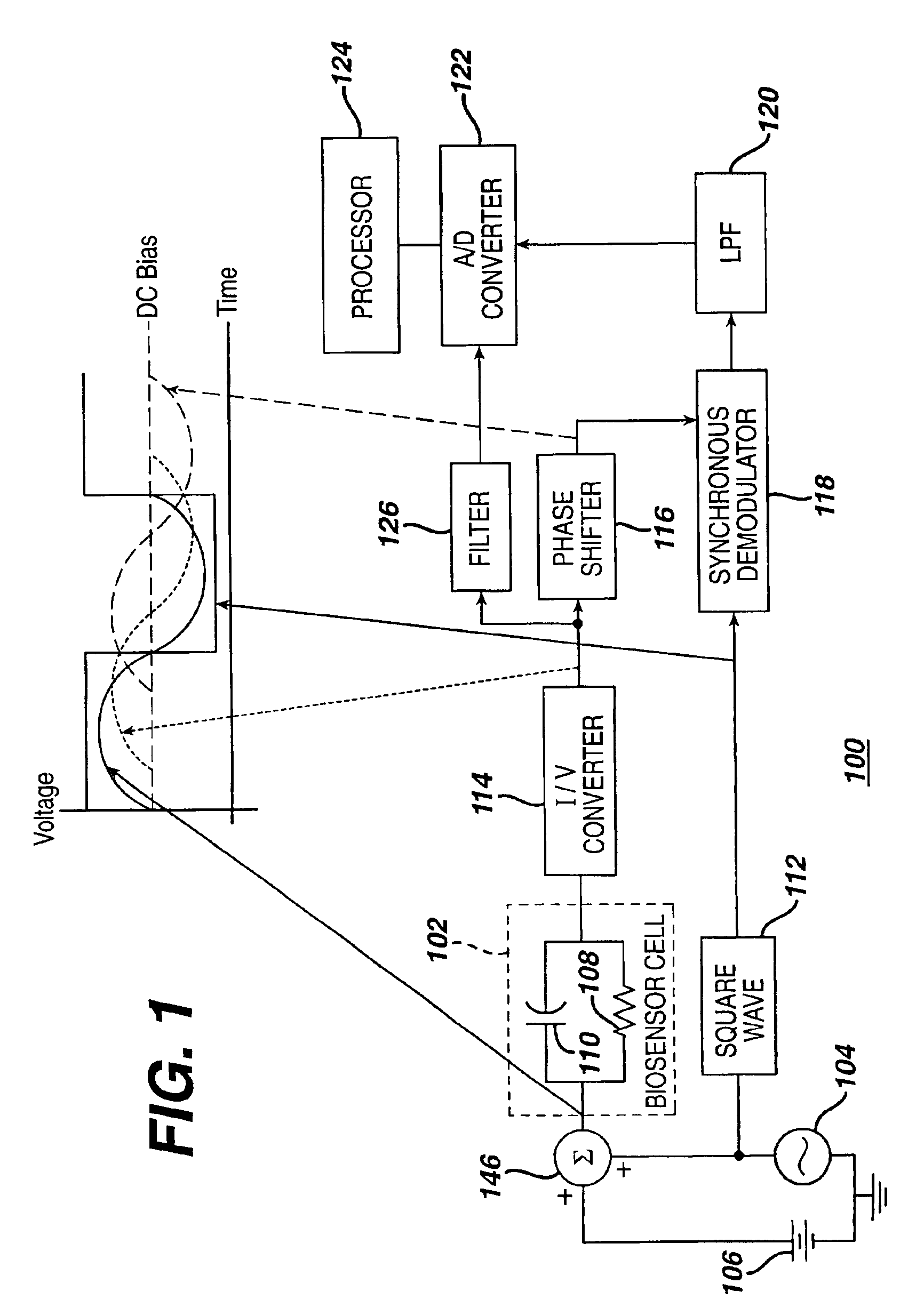

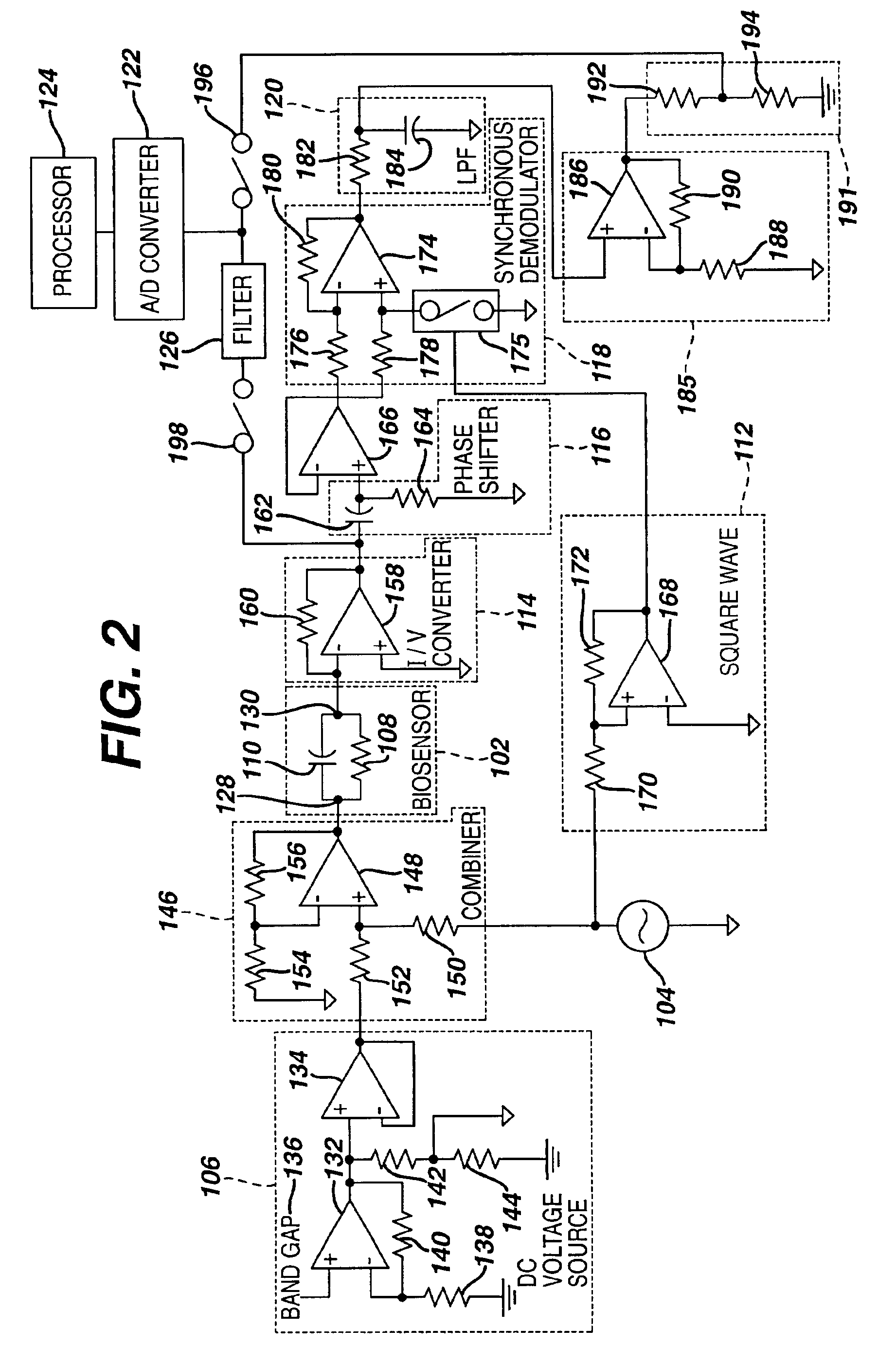

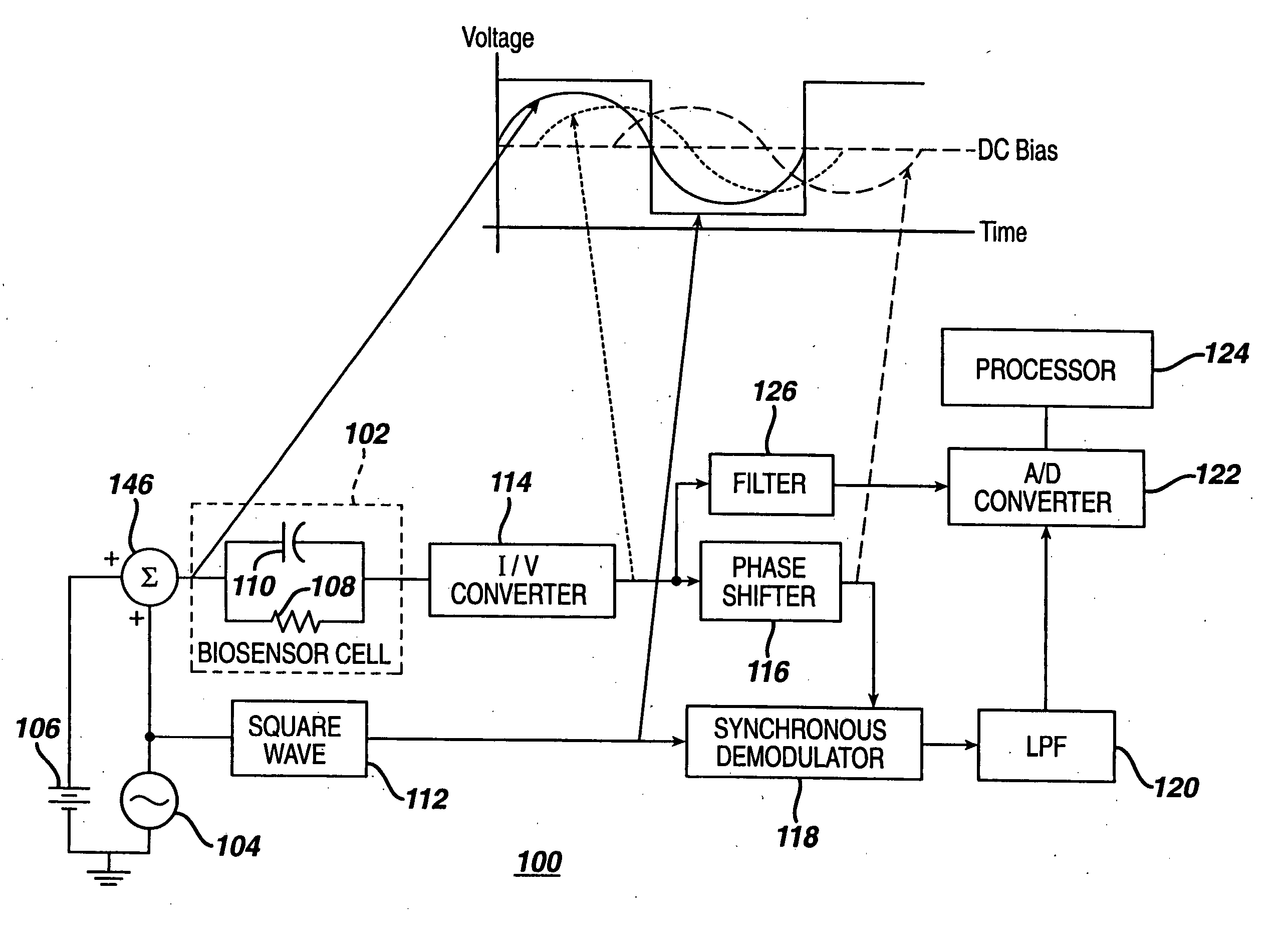

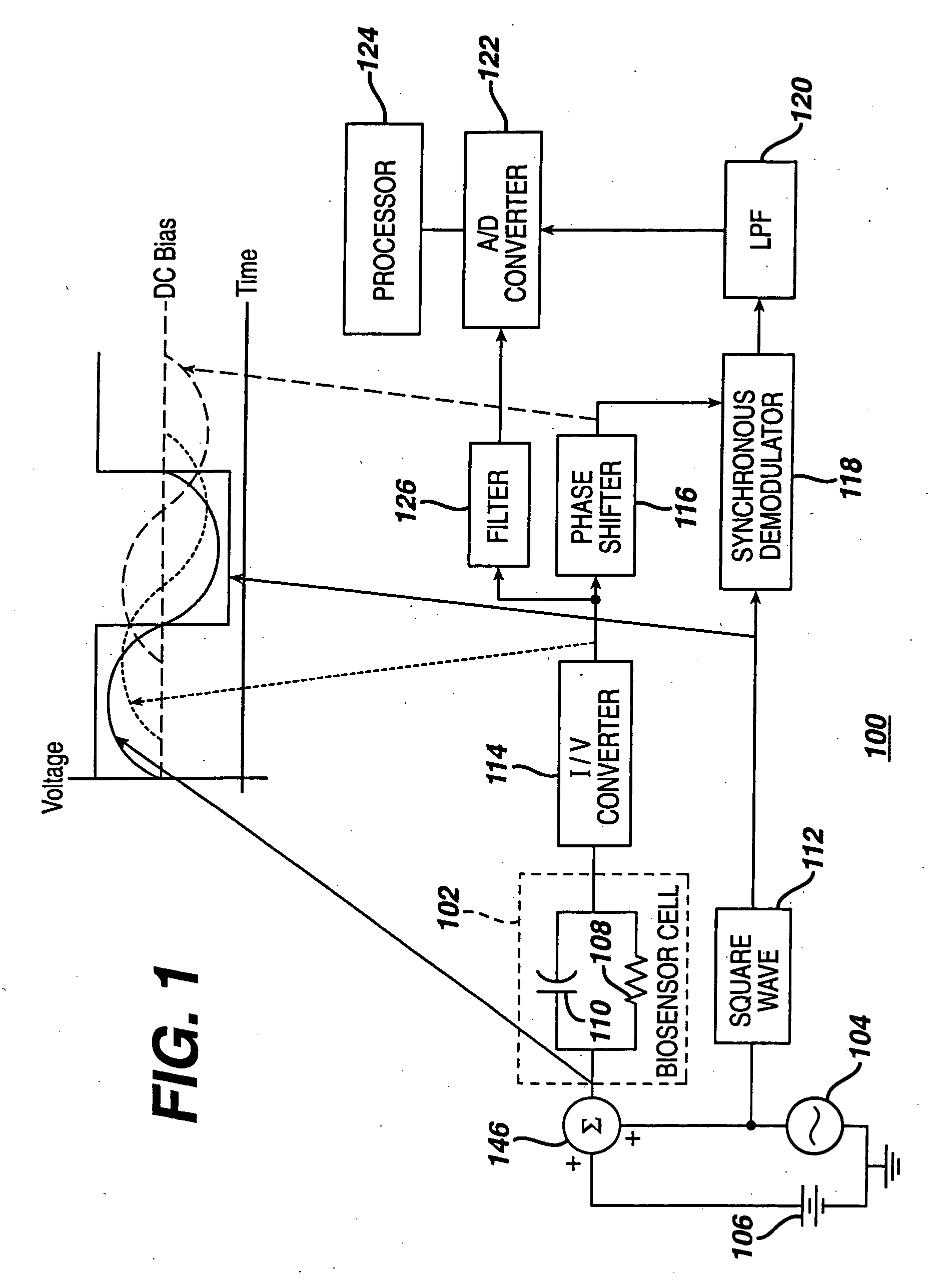

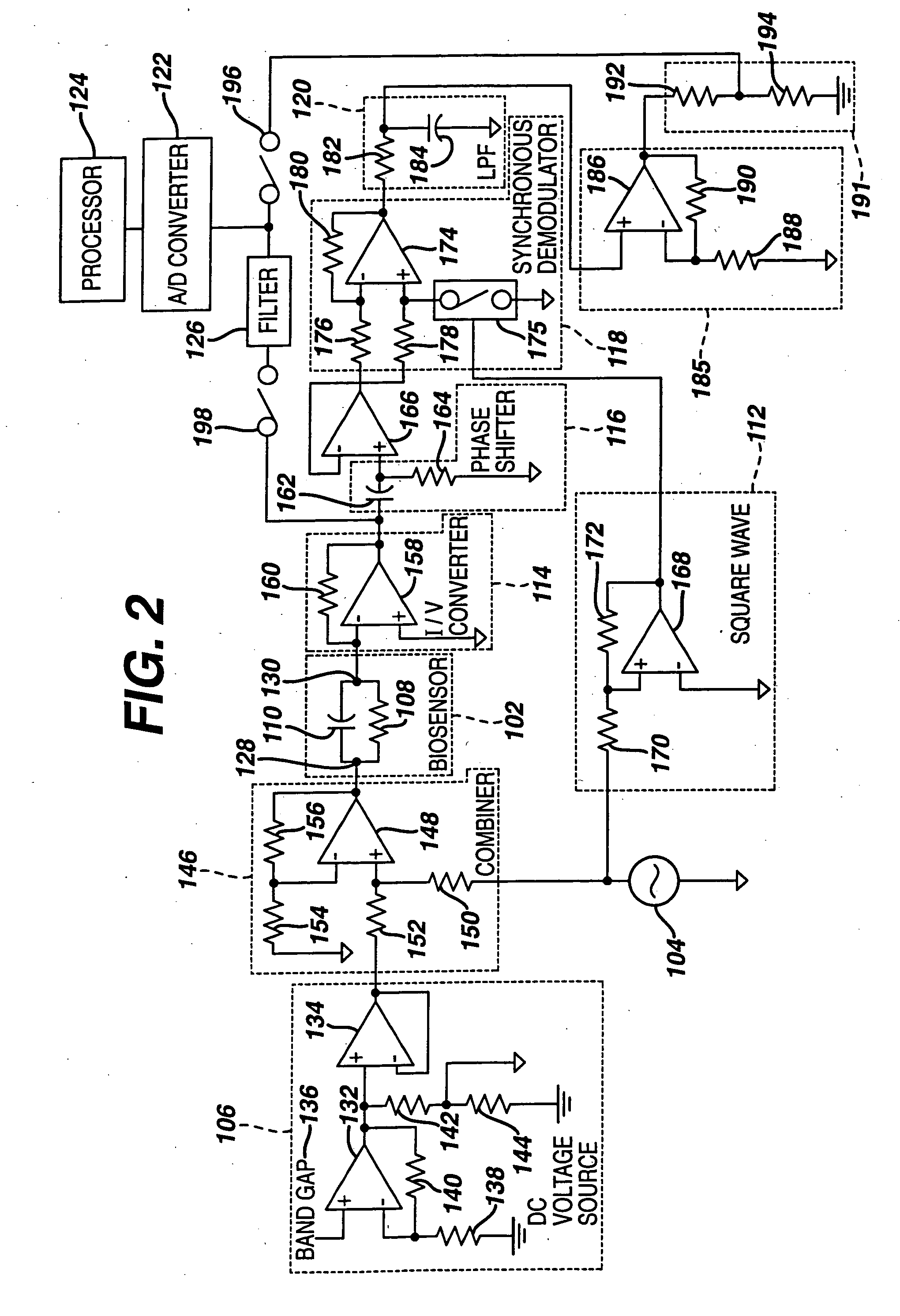

Biosensor apparatus and method with sample type and volume detection

A biosensor apparatus and method with sample type and cell volume detection. The apparatus includes a sine wave generator to apply an AC signal to a biosensor cell containing a sample, a current-to-voltage converter, a phase shifter, a square wave generator, a synchronous demodulator, and a low pass filter which yields a signal proportional to the effective capacitance across the biosensor cell, which is proportional to the volume of the sample. In addition, the current-to-voltage converter yields a signal indicative of the type of sample contained within the biosensor cell. The method includes applying a sine wave to the biosensor cell, shifting the phase of the resultant signal, generating a square wave synchronous with the sine wave, demodulating the resultant signal with the square wave, and filtering the demodulated signal to produce a signal proportional to the effective capacitance across the biosensor cell. The biosensor apparatus and method are capable of determining sample type and measuring glucose levels over a wide range of sample volumes.

Owner:LIFESCAN IP HLDG LLC

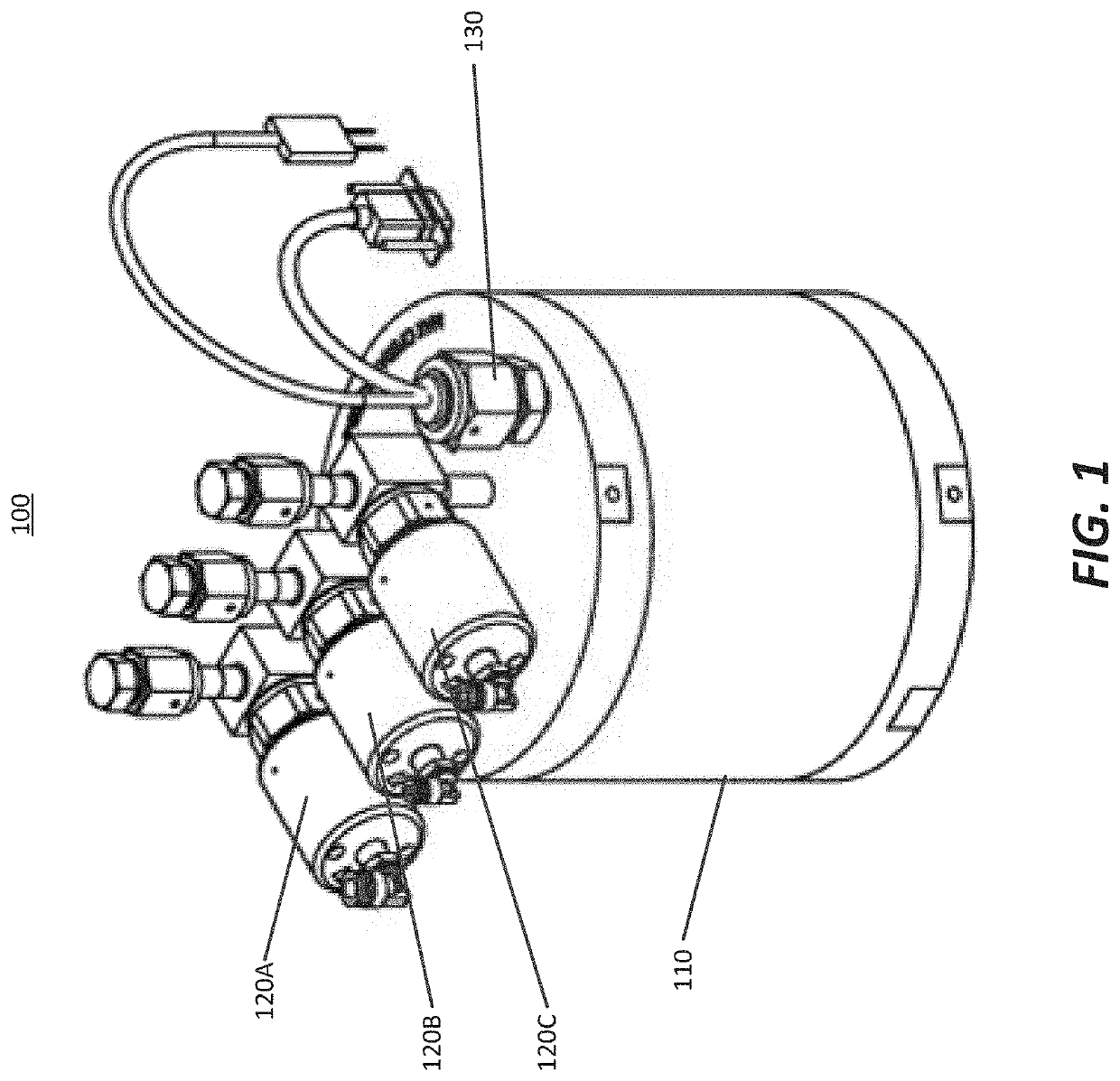

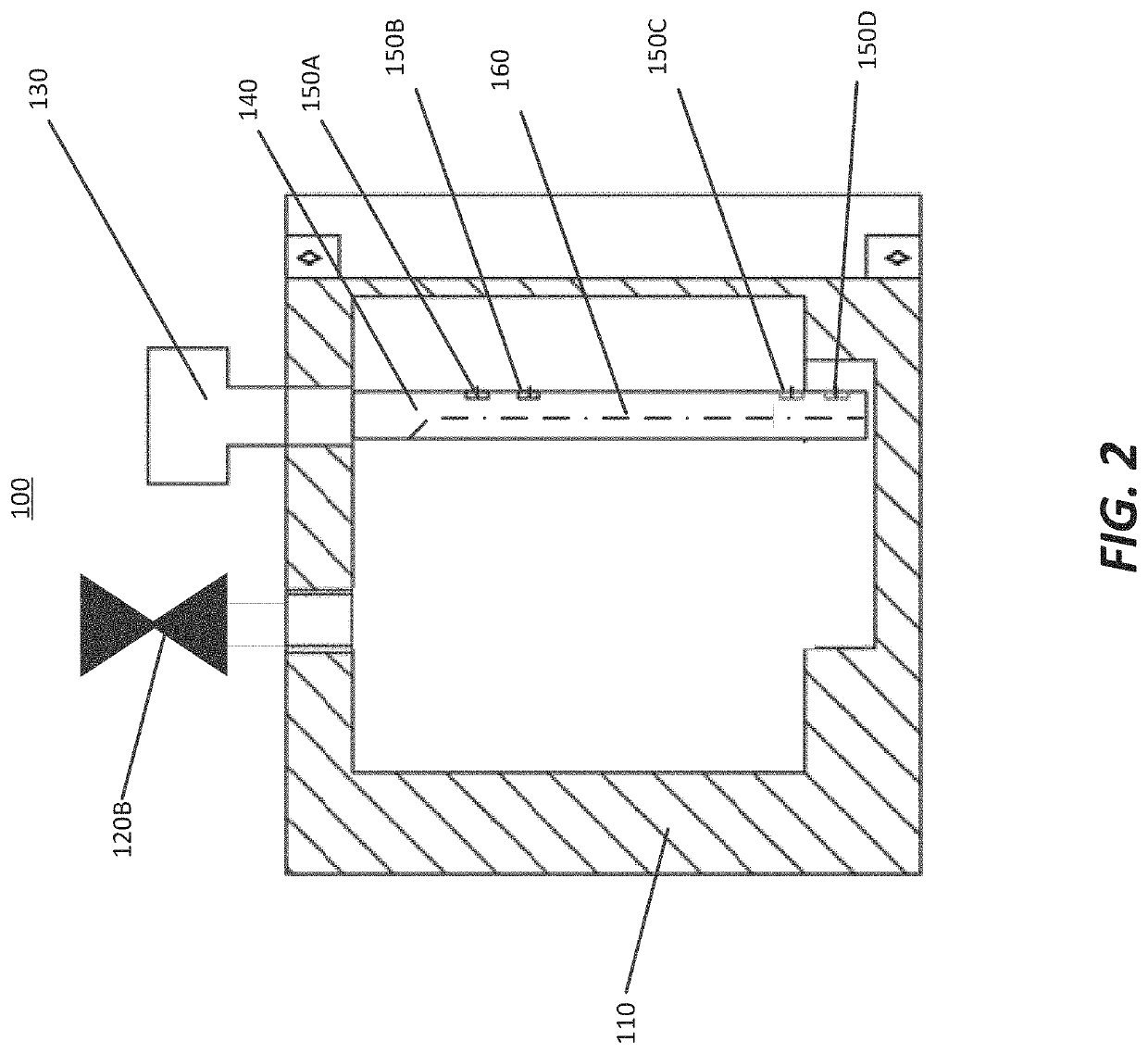

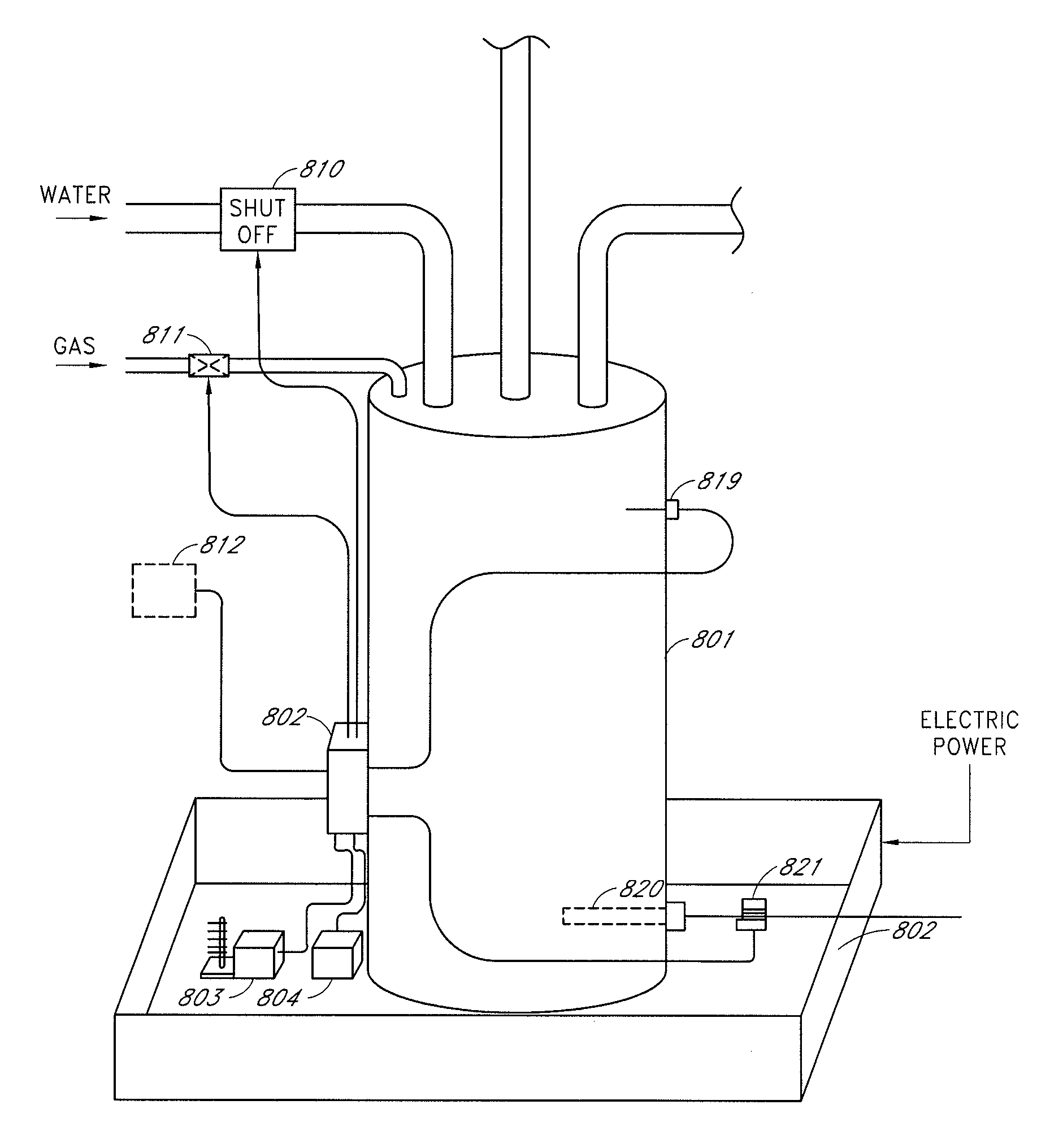

Liquid level sensor for a chemical source vessel

ActiveUS20210041284A1Well formedLiquid surface applicatorsLevel indicators by dip membersLiquid stateEngineering

A chemical vessel used for holding a liquid chemical precursor is disclosed comprising a liquid level sensor tube. The liquid level sensor tube is configured to operate in an environment where the liquid chemical precursor is heated to a point of boiling or vaporization. The liquid level sensor tube comprises housing with a slot built in to prevent any false readings of sensors disposed within the liquid level sensor tube.

Owner:ASM IP HLDG BV

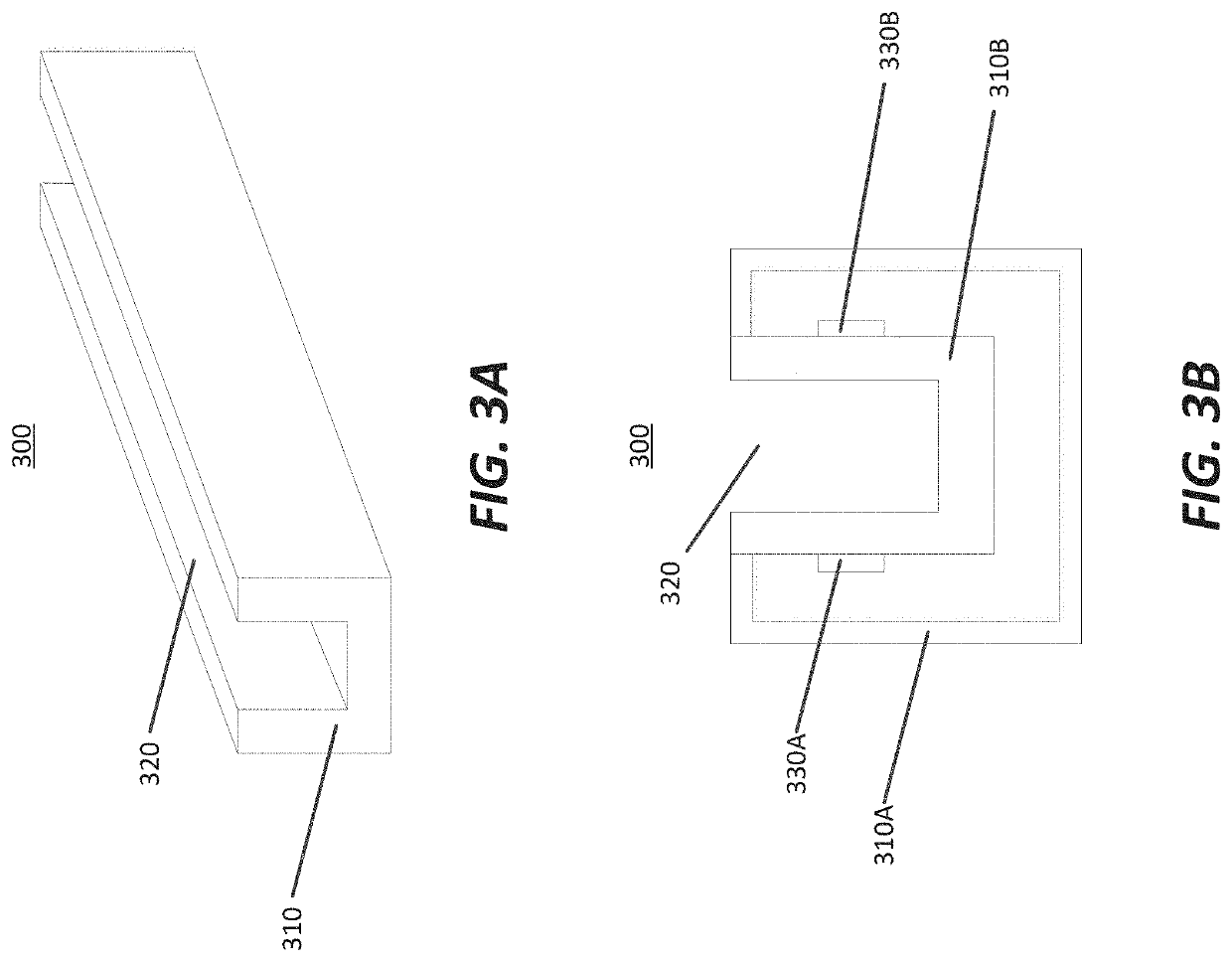

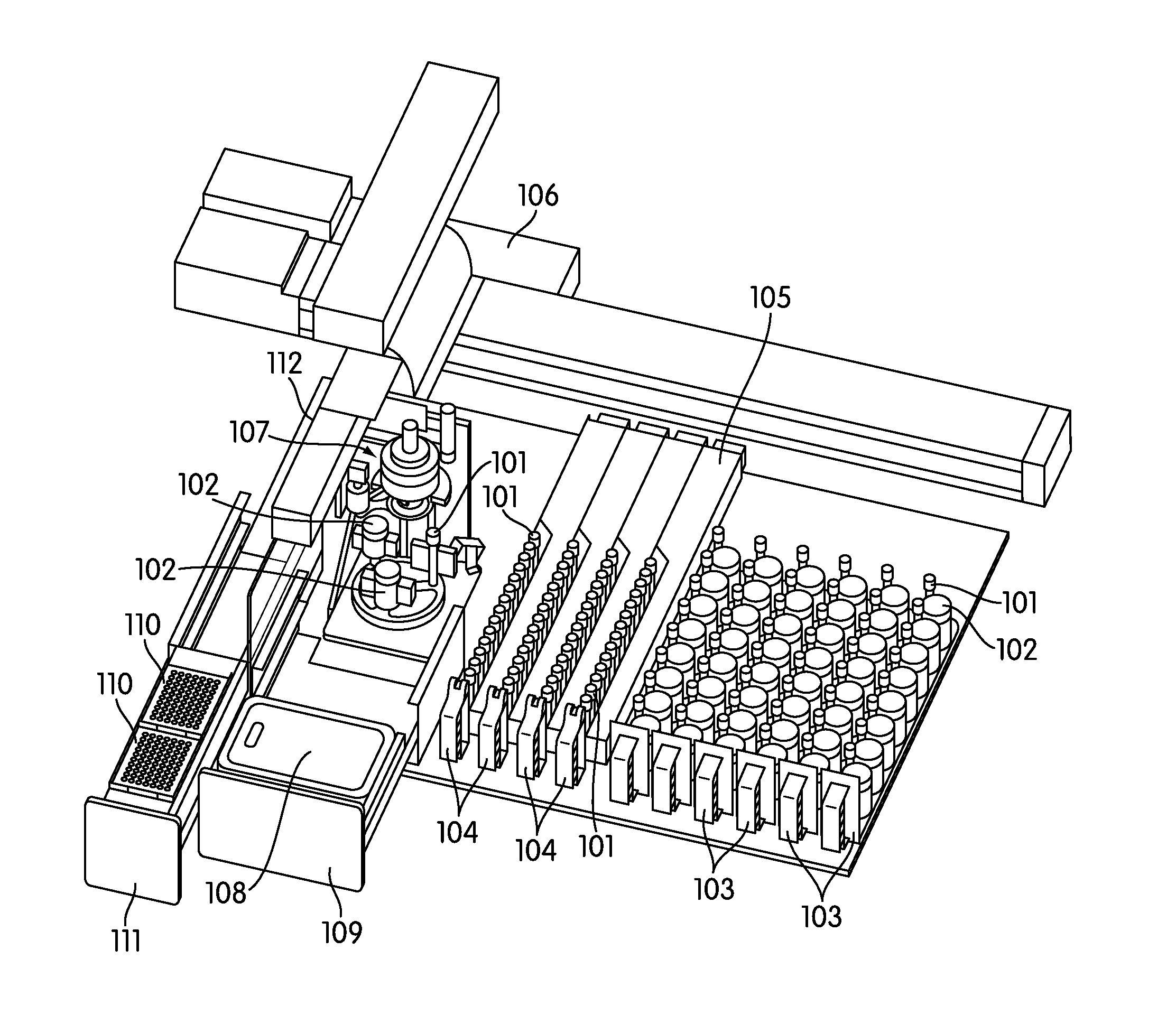

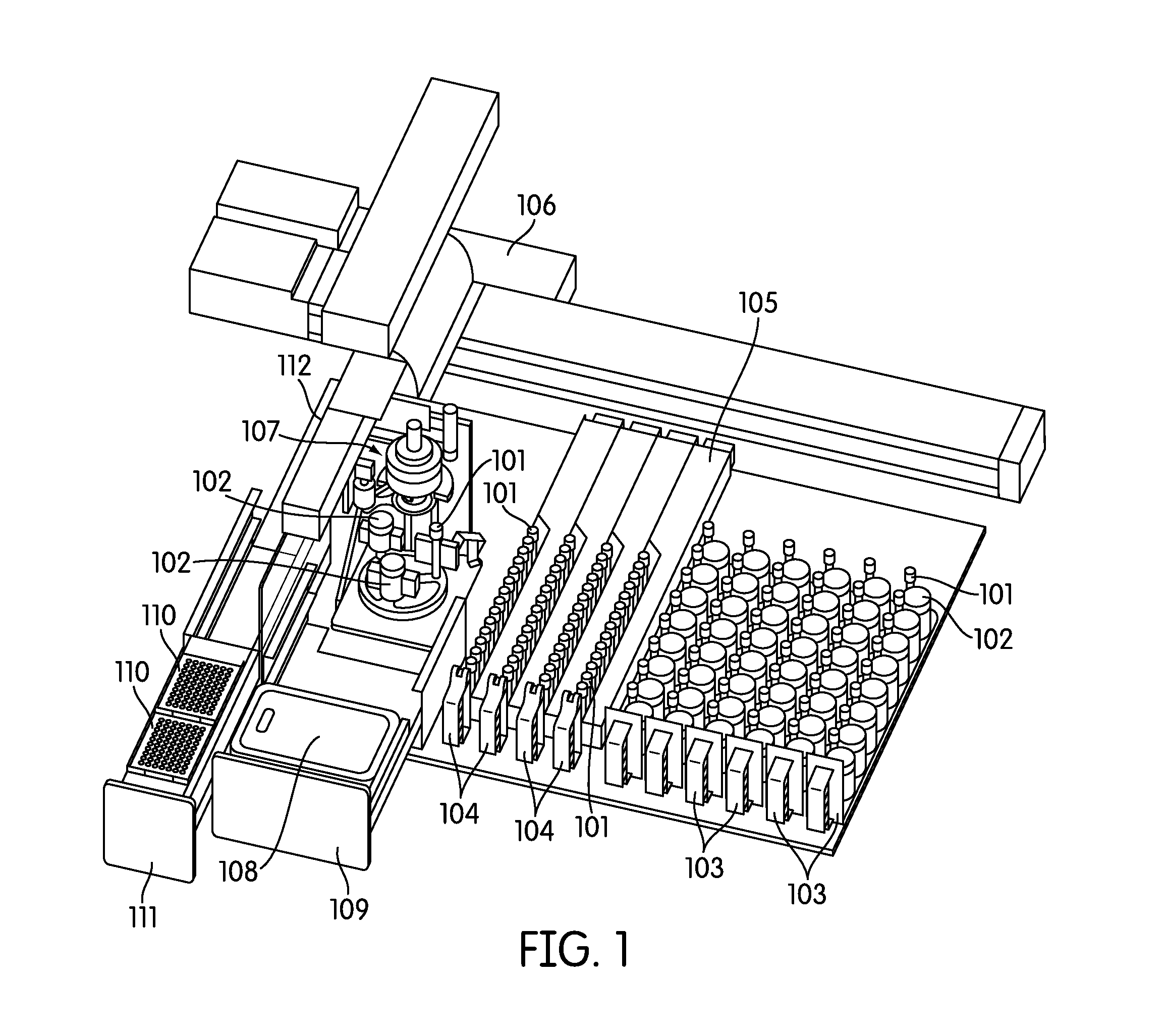

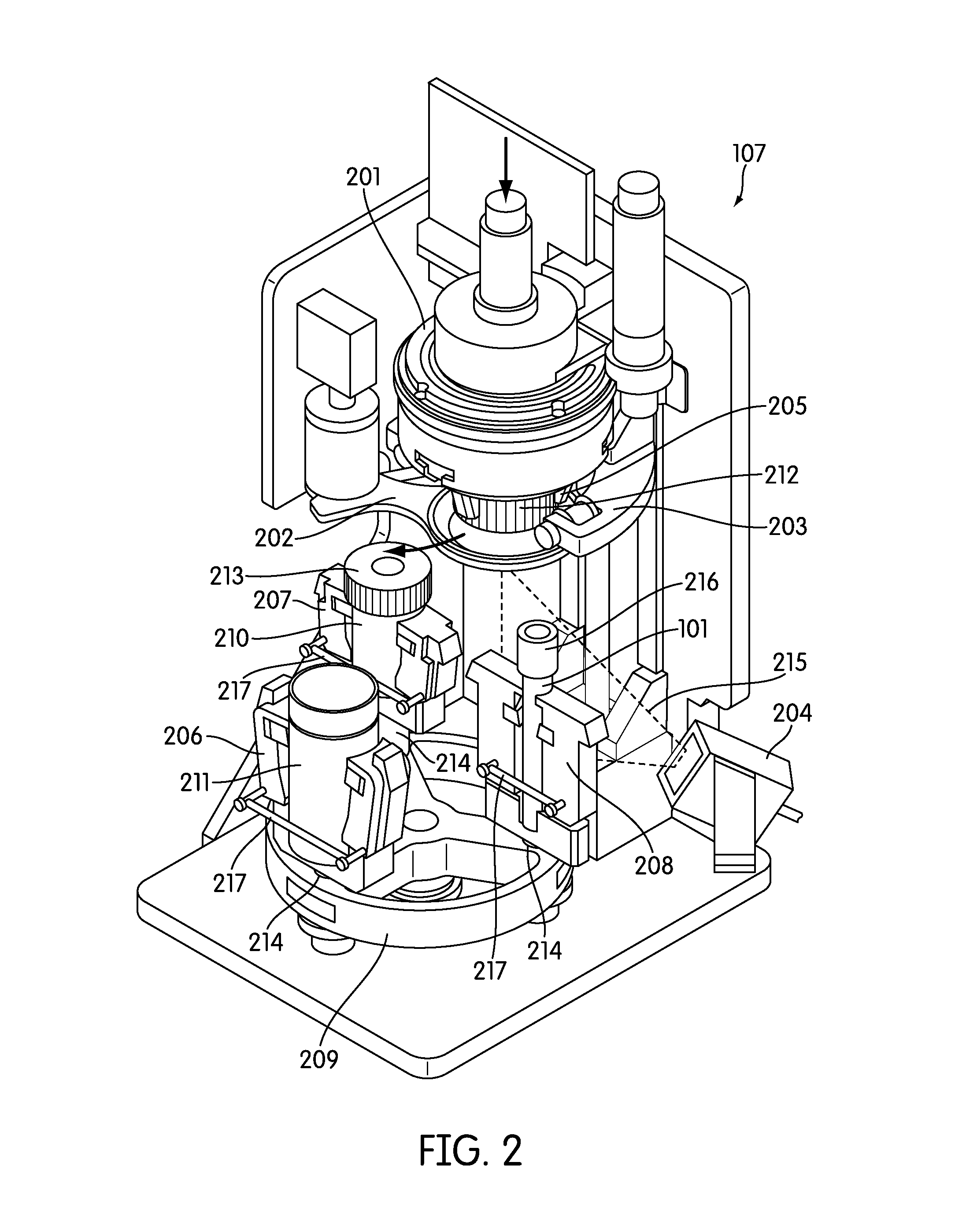

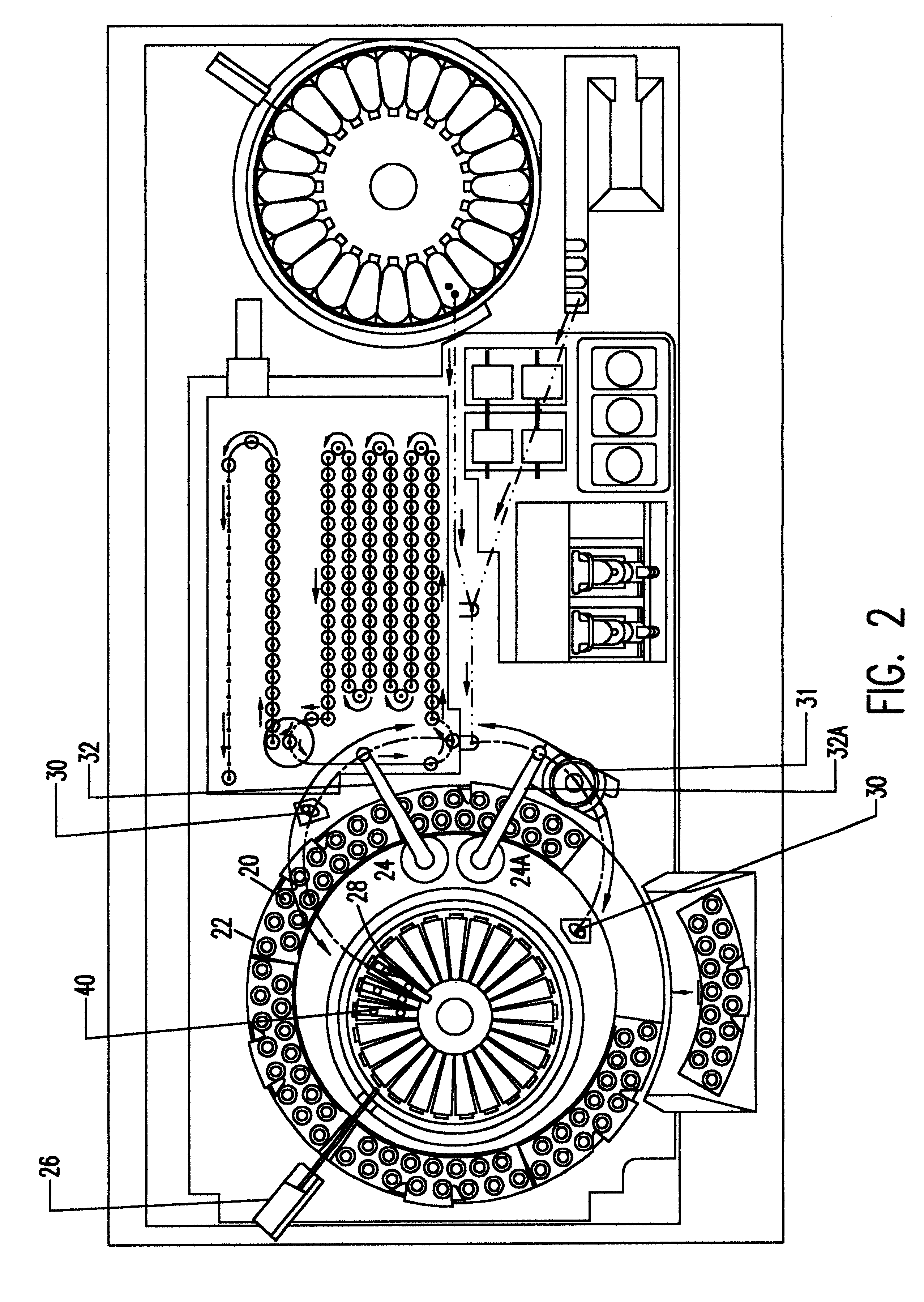

Automated sample handling instrumentation, systems, processes, and methods

The present invention provides a processing station for automatically processing a biological sample, a system for automated real-time inventory control of consumables within a biological sample handling or assay instrument, a high throughput random access automated instrument for processing biological samples, an automated instrument for processing or analysis of a sample, and processes for automated mucoid detection and elimination. Methods of using the disclosed instruments, mucoid detection processes, and systems to process and / or analyze samples are also disclosed.

Owner:GEN PROBE INC

Capacitance fluid volume measurement

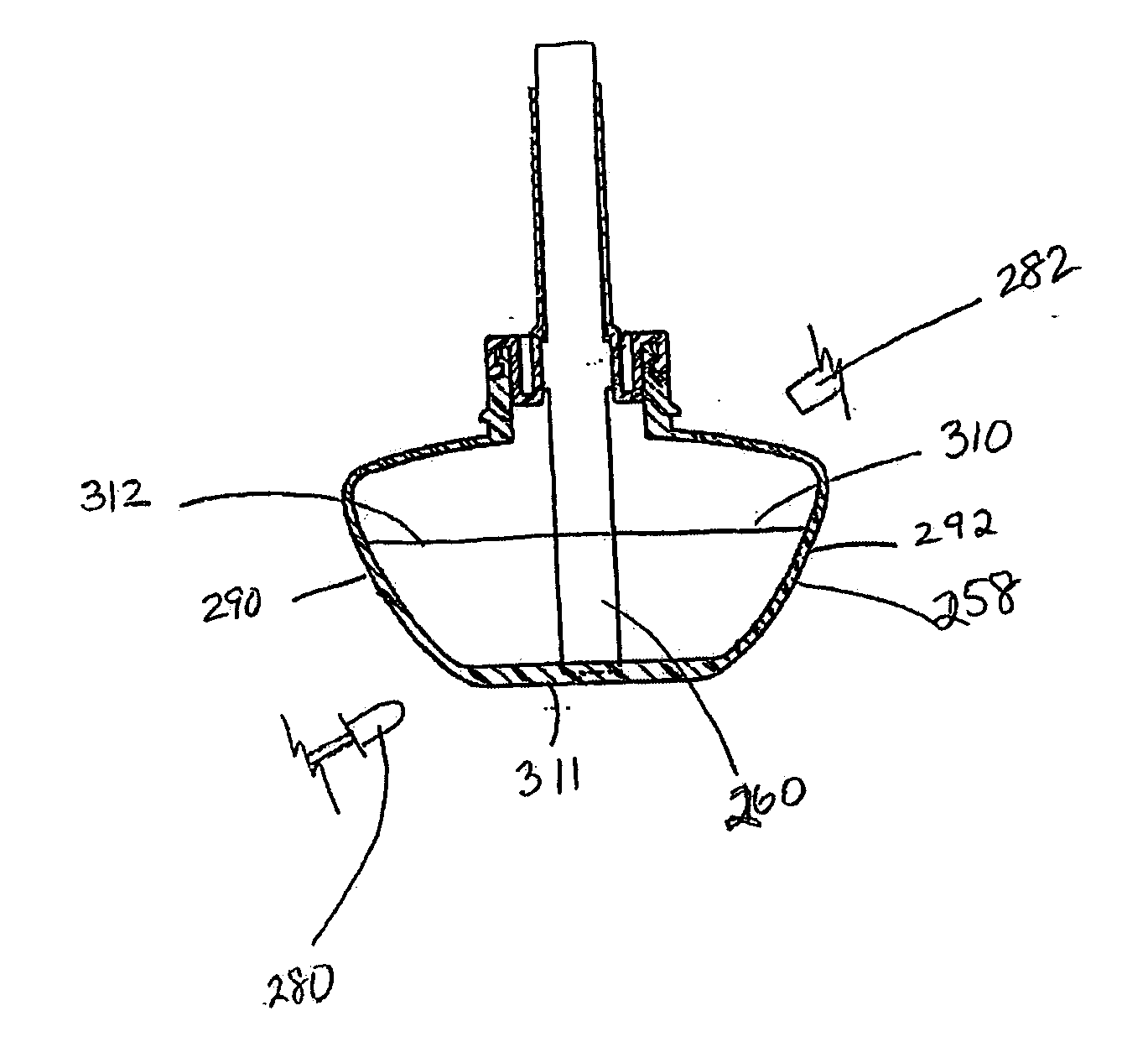

InactiveUS7107837B2Simple systemSimple methodVolume/mass flow measurementMedical devicesPump chamberEngineering

A fluid volumetric pumping system has a fluid pump and capacitor plates disposed around a pump chamber of the fluid pump. The capacitance between the capacitor plates changes as the volume of fluid in the pump chamber changes. An electrical circuit measures a change in the capacitance between the plates and outputs a signal indicative of the volume of fluid in the pump chamber. The pump having the capacitance sensor of the present invention fluidly connects to a patient. In an embodiment, a peritoneal dialysis system provides dialysate to the patient via the pump, and the capacitance sensor measures the volume of dialysate supplied to and drained from a peritoneal cavity of the patient.

Owner:BAXTER INT INC +1

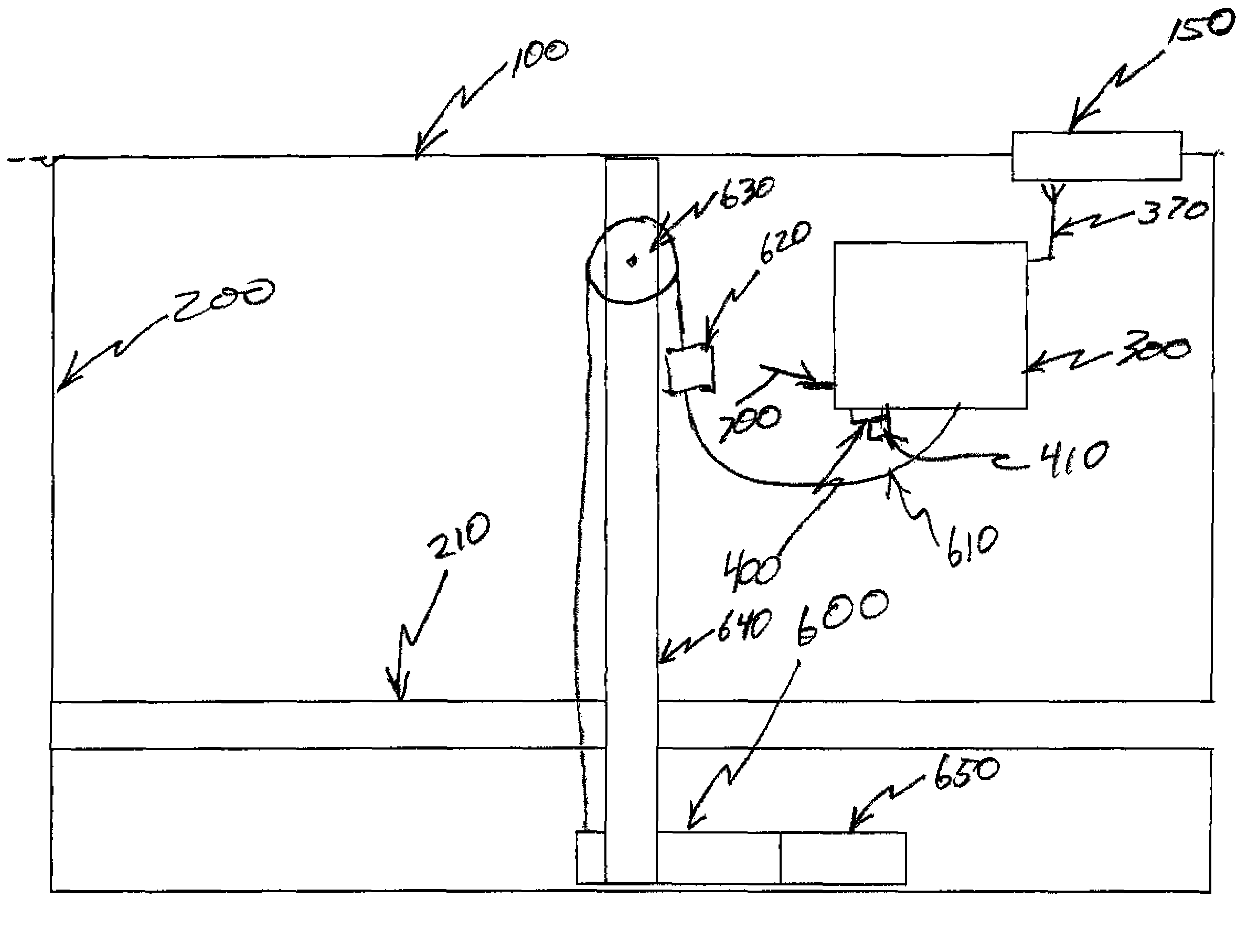

Fluid monitoring apparatus and method

A fluid monitoring apparatus and method is disclosed for use in an underground utility vault. Specifically, a system utilizing multiple sensors to determine the total amount and type of fluid present in a utility vault is disclosed. A first sensor located above the fluid detects and determines the overall depth of fluid present. A second sensor, relying on specific properties of the fluid(s) present, is located in contact with the fluids present. The information regarding specific fluid level and type is conveyed to a central location for monitoring.

Owner:WALKER ENG

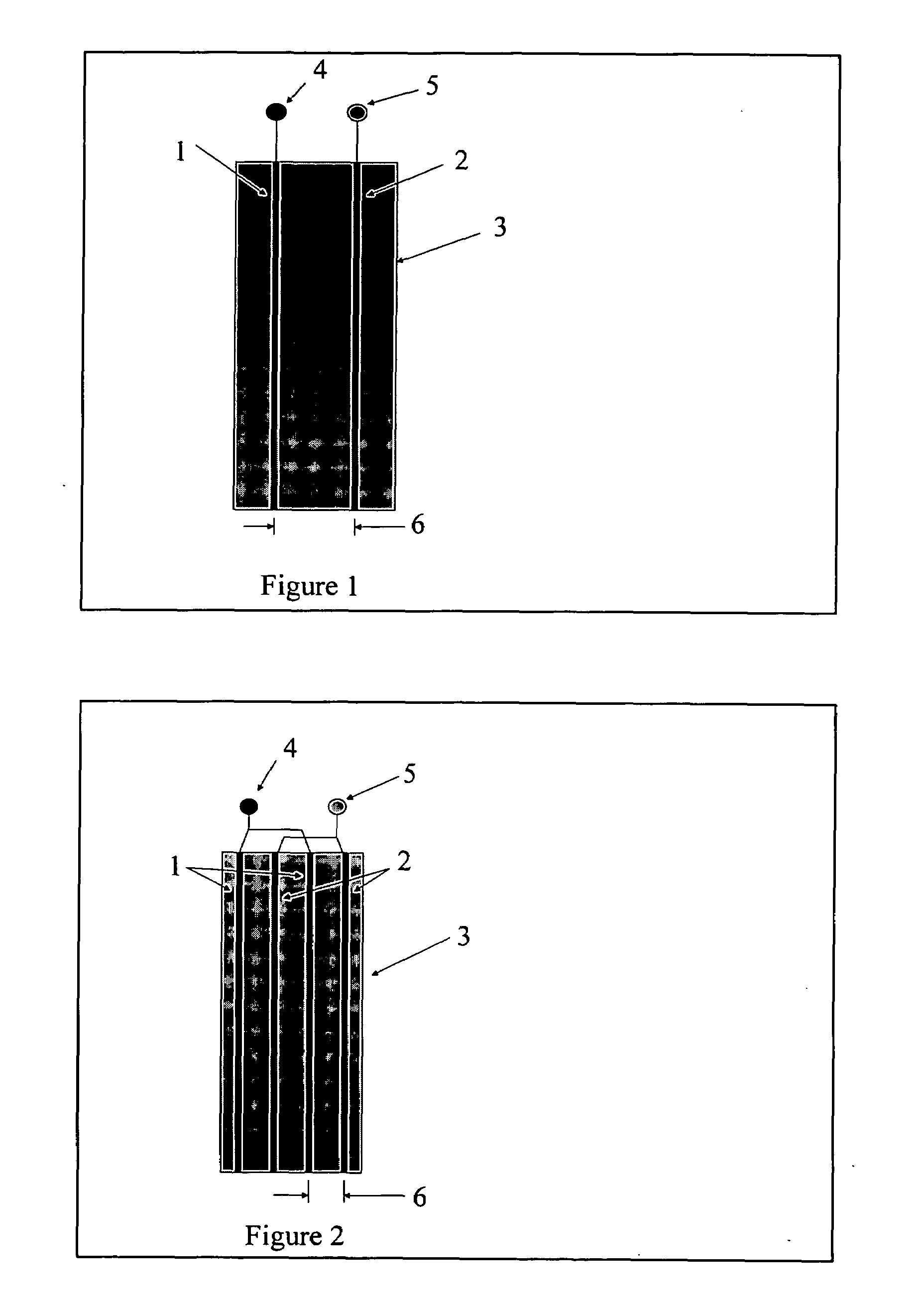

Capacitive liquid level indicator

A capacitive liquid level indicator having a capacitive sensor array superposed on each side of a dielectric substrate, wherein the sensor signal detection electronics are located immediately adjacent each capacitive sensor. These provisions result in high sensitivity of detection of submergence in the liquid, as well as essentially eliminating parasitic electric fields. The preferred capacitive sensors are interdigitated capacitors, and the preferred sensor signal detection circuit is an RC bridge and a comparator, wherein the comparator senses a voltage difference in the RC bridge between a sensor resistor and sensor capacitor of a first leg thereof and a reference resistor and reference capacitor of a second leg thereof. It is preferred for the capacitive liquid level indicator to be coated with a low dielectric conformal coating to thereby insulate the electronic components (inclusive of the capacitive sensors) thereof with respect to the liquid into which it is submerged. The sensitivity of the capacitive liquid level sensor according to the present invention is extremely high; as a result, a reference capacitive sensor is obviated, and there are no false indications of liquid due to any film of the liquid clinging to an exposed portion of the capacitive liquid level sensor.

Owner:GDM

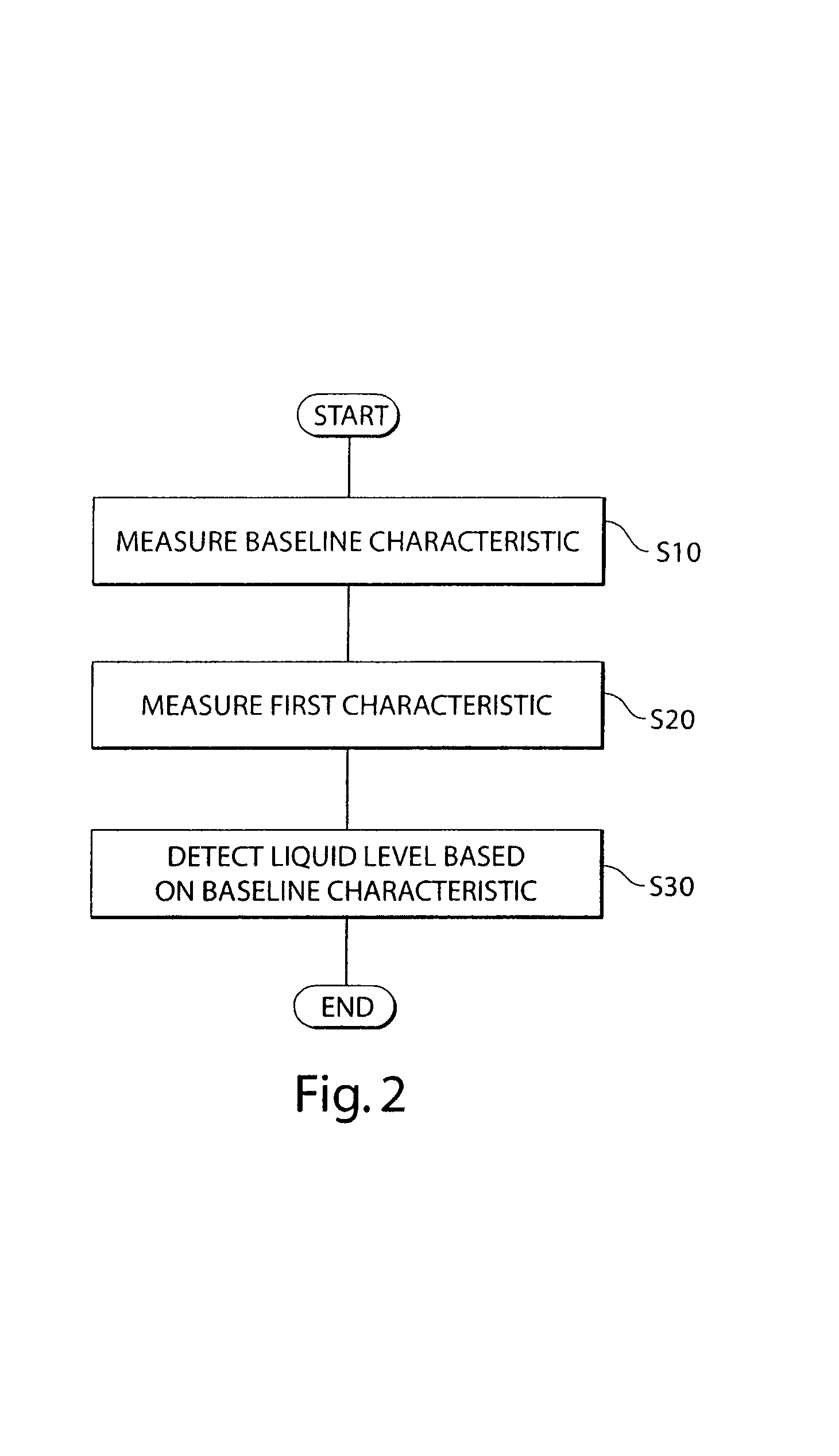

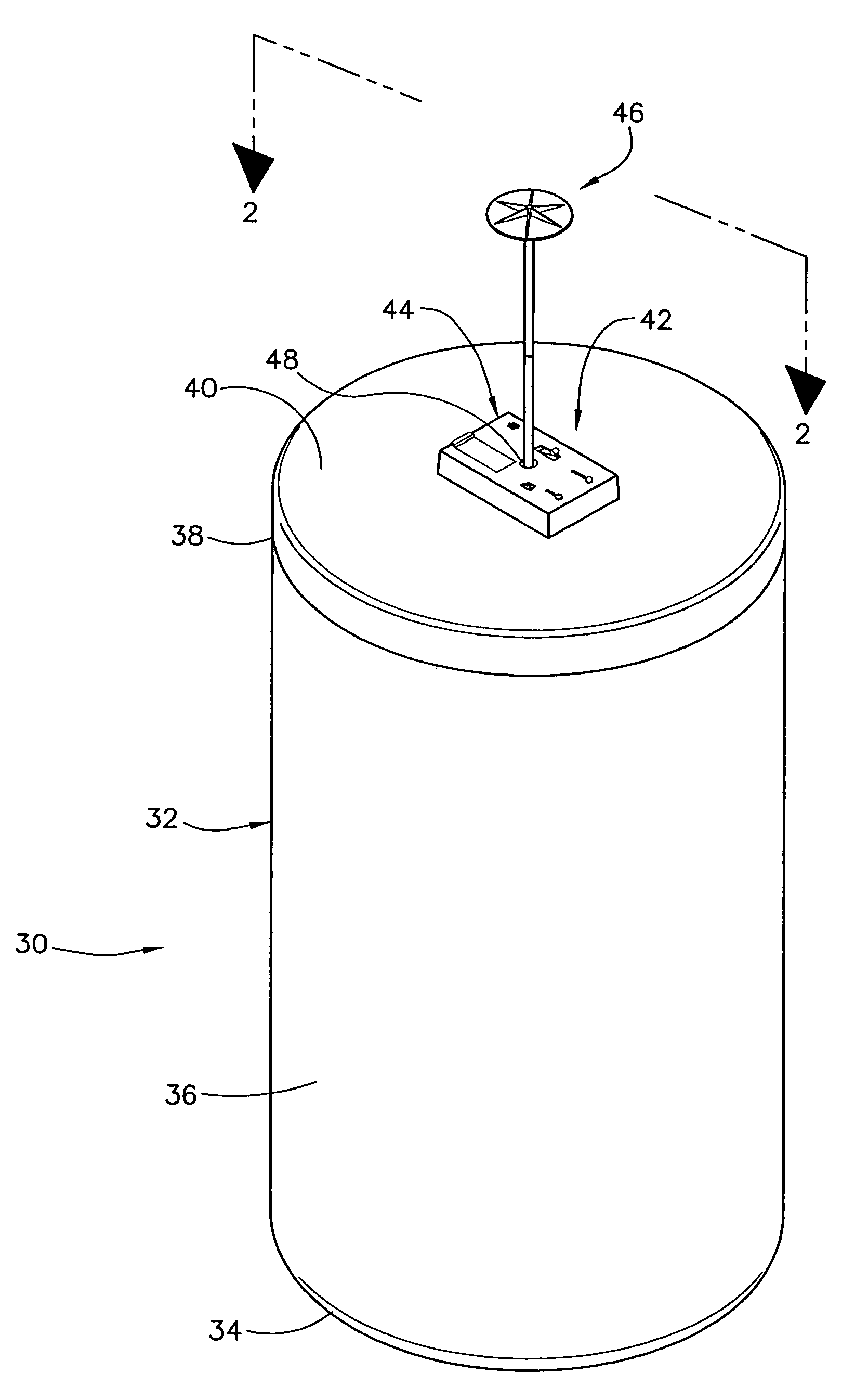

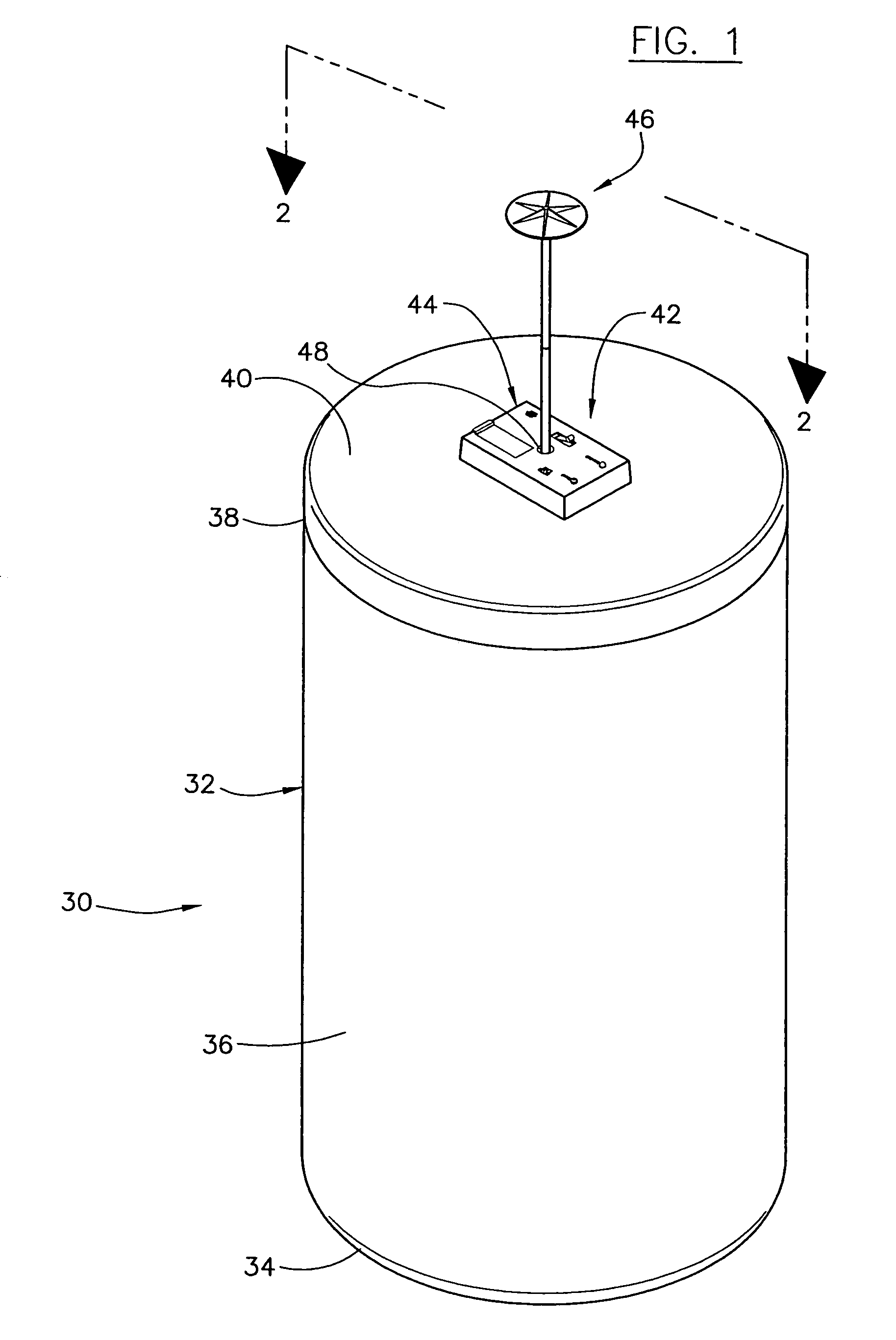

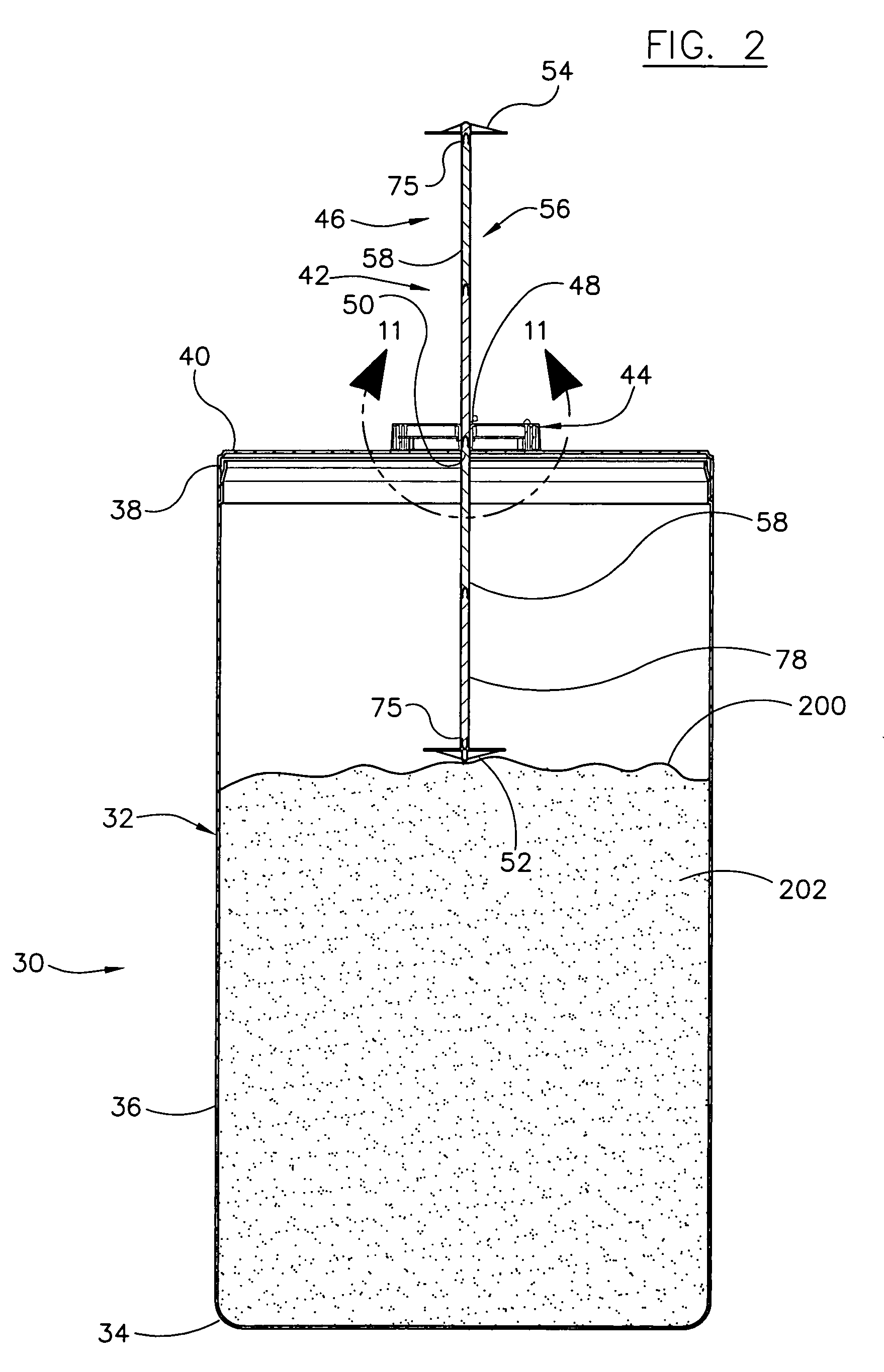

Method and apparatus for sensing liquid level using baseline characteristic

ActiveUS7360418B2Reliable detectionAccurate measurementBeverage vesselsMachines/enginesElectrical resistance and conductanceVoltage

A liquid level sensing arrangement using a probe uses a baseline probe circuit characteristic, e.g., a circuit resistance or voltage, that is measured when the probe is out of contact with the liquid in the tank. The baseline characteristic may be used to determine a liquid level in the tank, e.g., a determination whether the liquid level is below or at / above the probe. In one embodiment, the baseline characteristic may be compared to a circuit characteristic that is measured as the tank is being filled. A difference between the baseline characteristic and the other circuit characteristic may be used to determine whether or not the probe is in contact with the liquid.

Owner:KEURIG GREEN MOUNTAIN INC

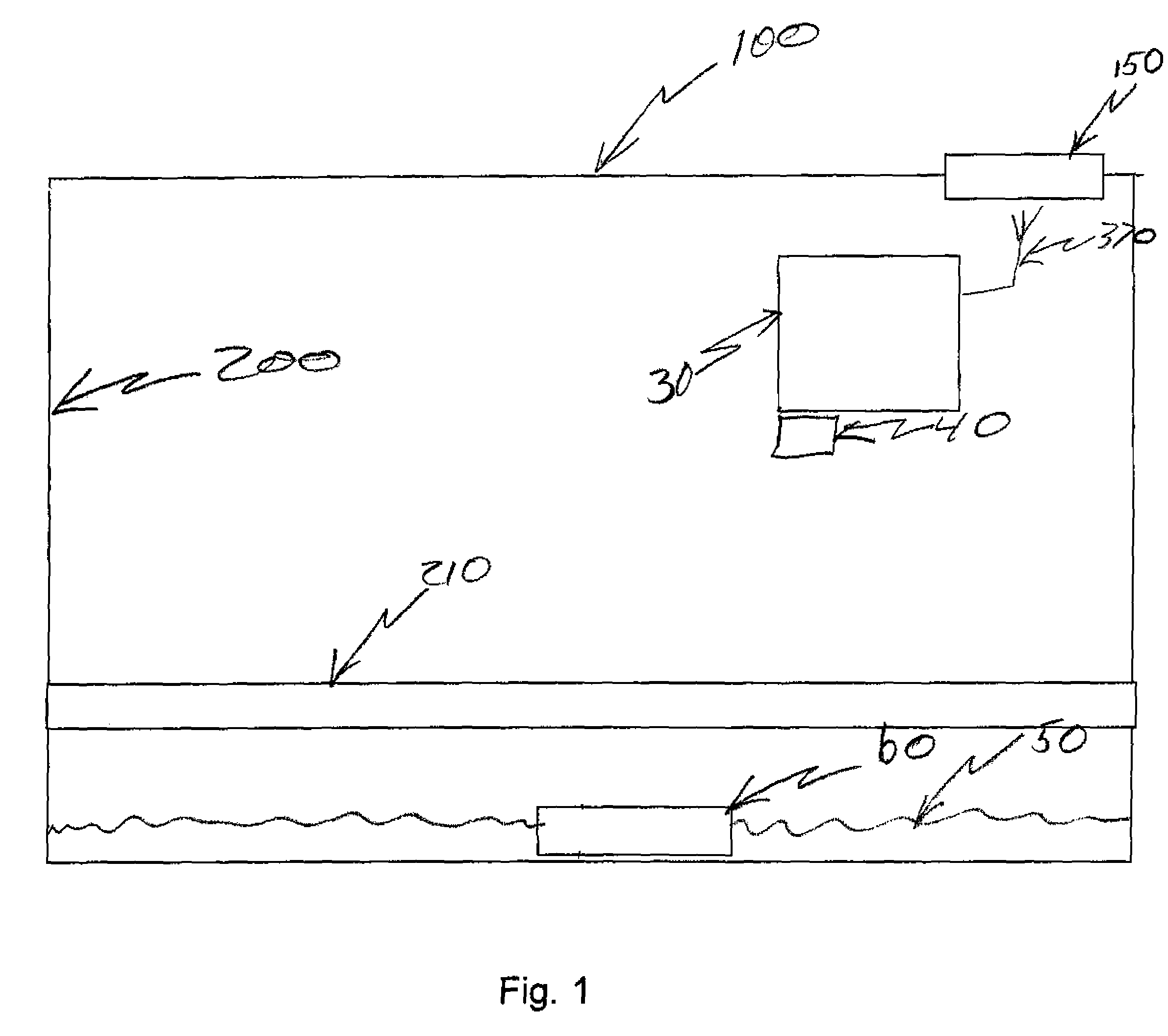

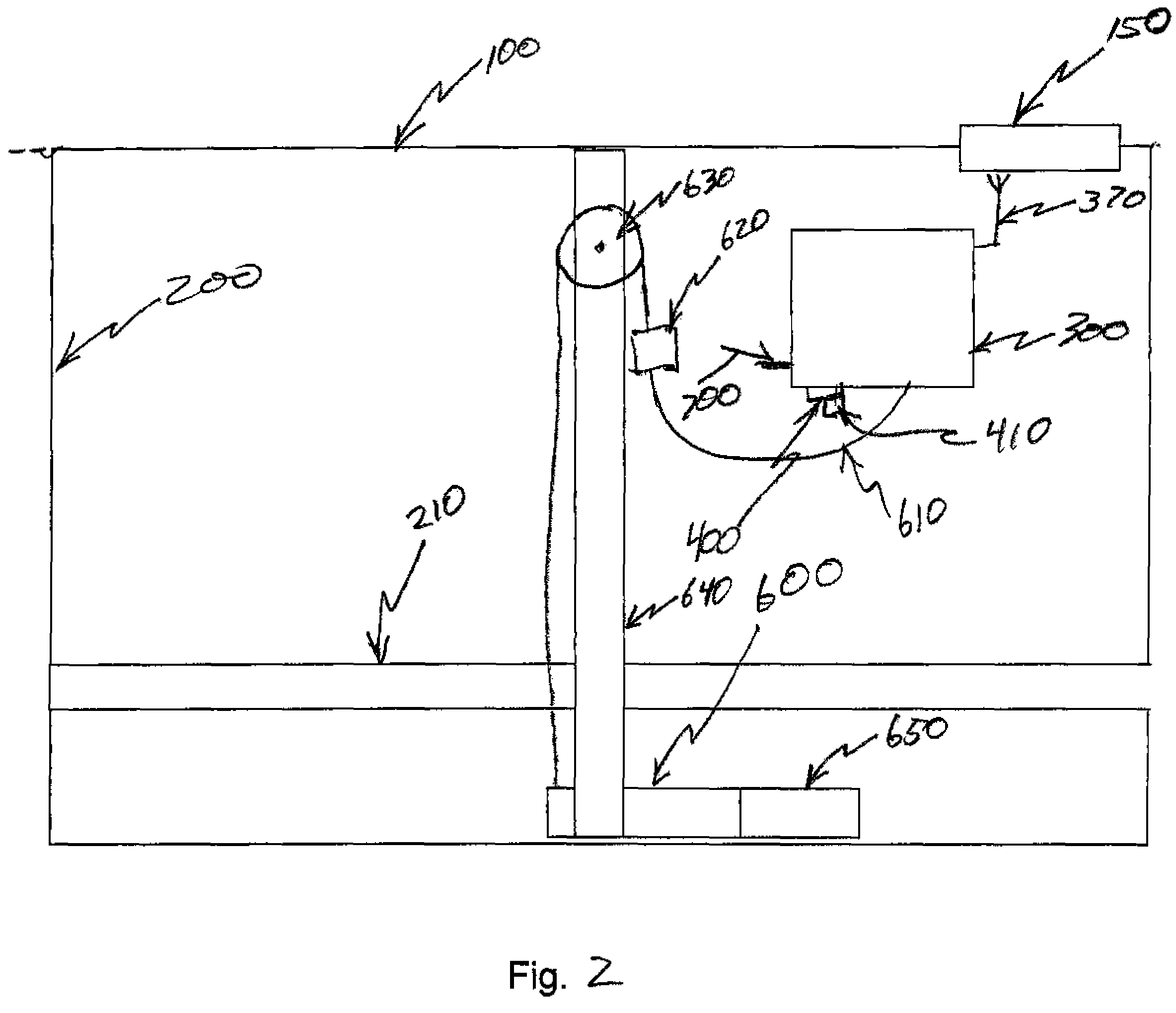

Water softener monitoring device

A device for monitoring the level or amount of a material within a container is provided. The device includes a detection mechanism that can be a direct detection mechanism or an indirect detection mechanism. When the detection mechanism senses an upper level of the substance in the container that is below a predetermined lower limit for the substance, the mechanism operates an alarm mechanism to emit an audible and / or visible alarm to alert an individual to the low level of the substance within the container. The alarm mechanism can be integrally formed with the detection mechanism, or can be spaced from the detection mechanism in order to provide a more accessible point for the viewing or hearing of the alarm emitted by the alarm mechanism.

Owner:WANIE ANDREW J

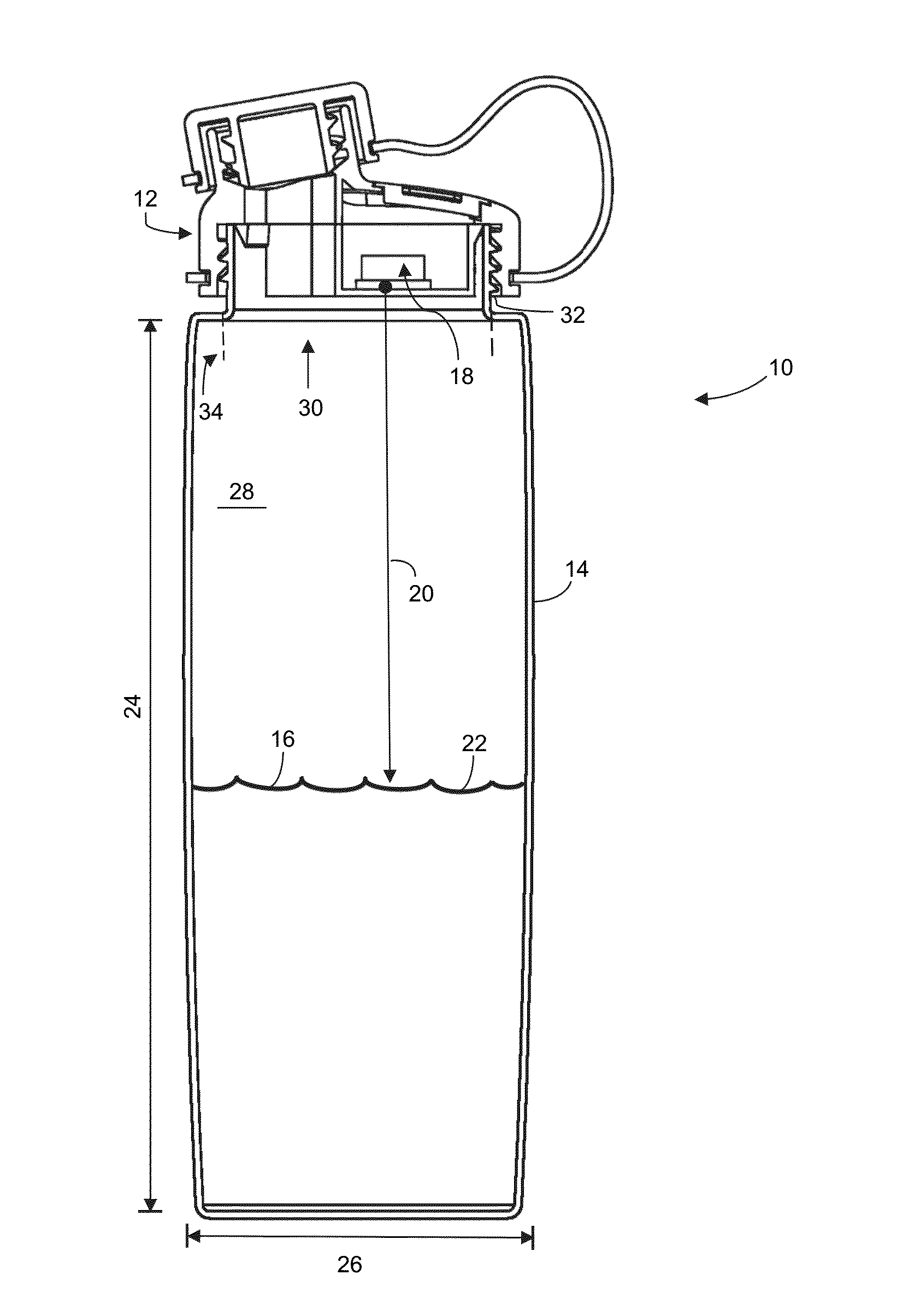

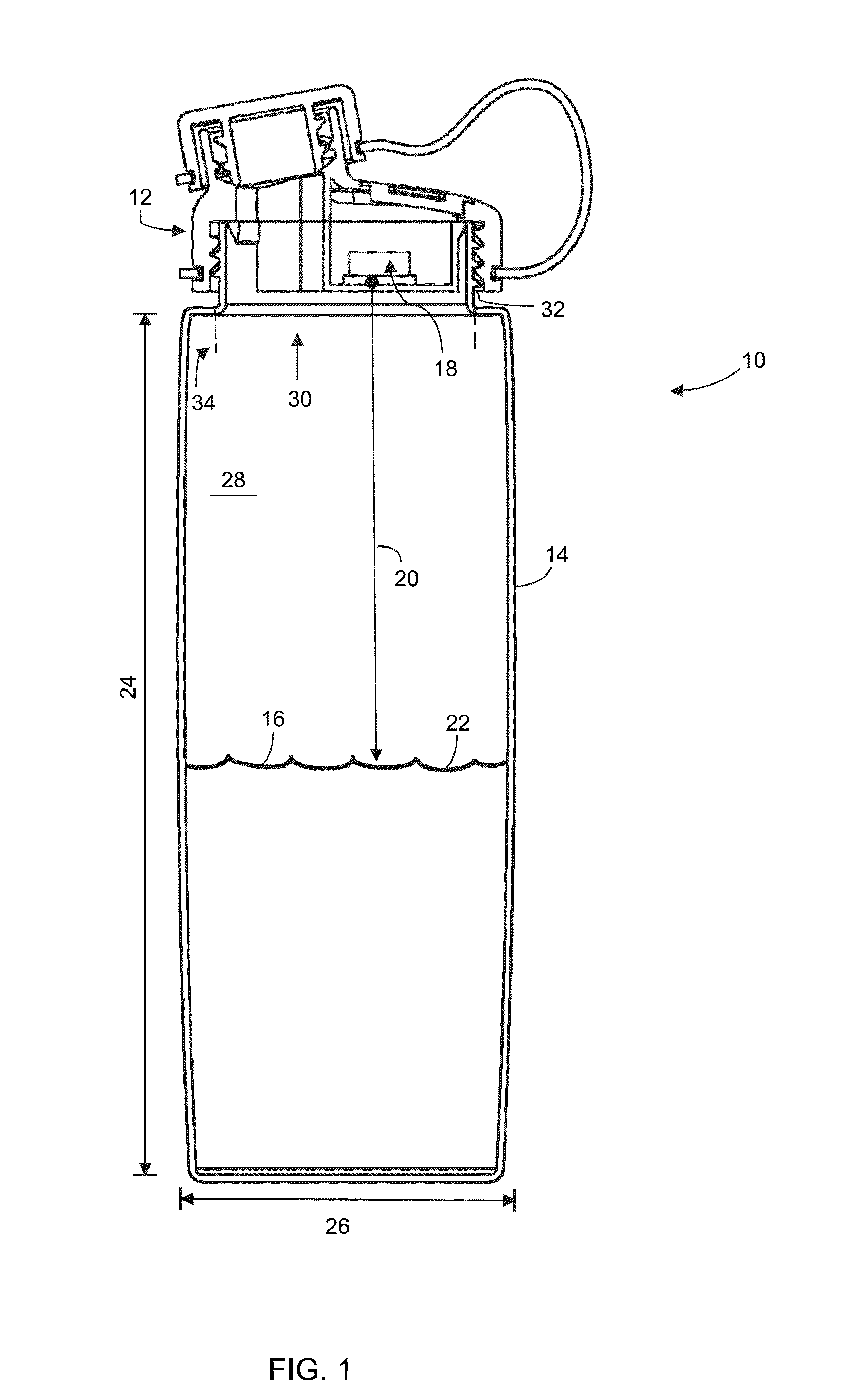

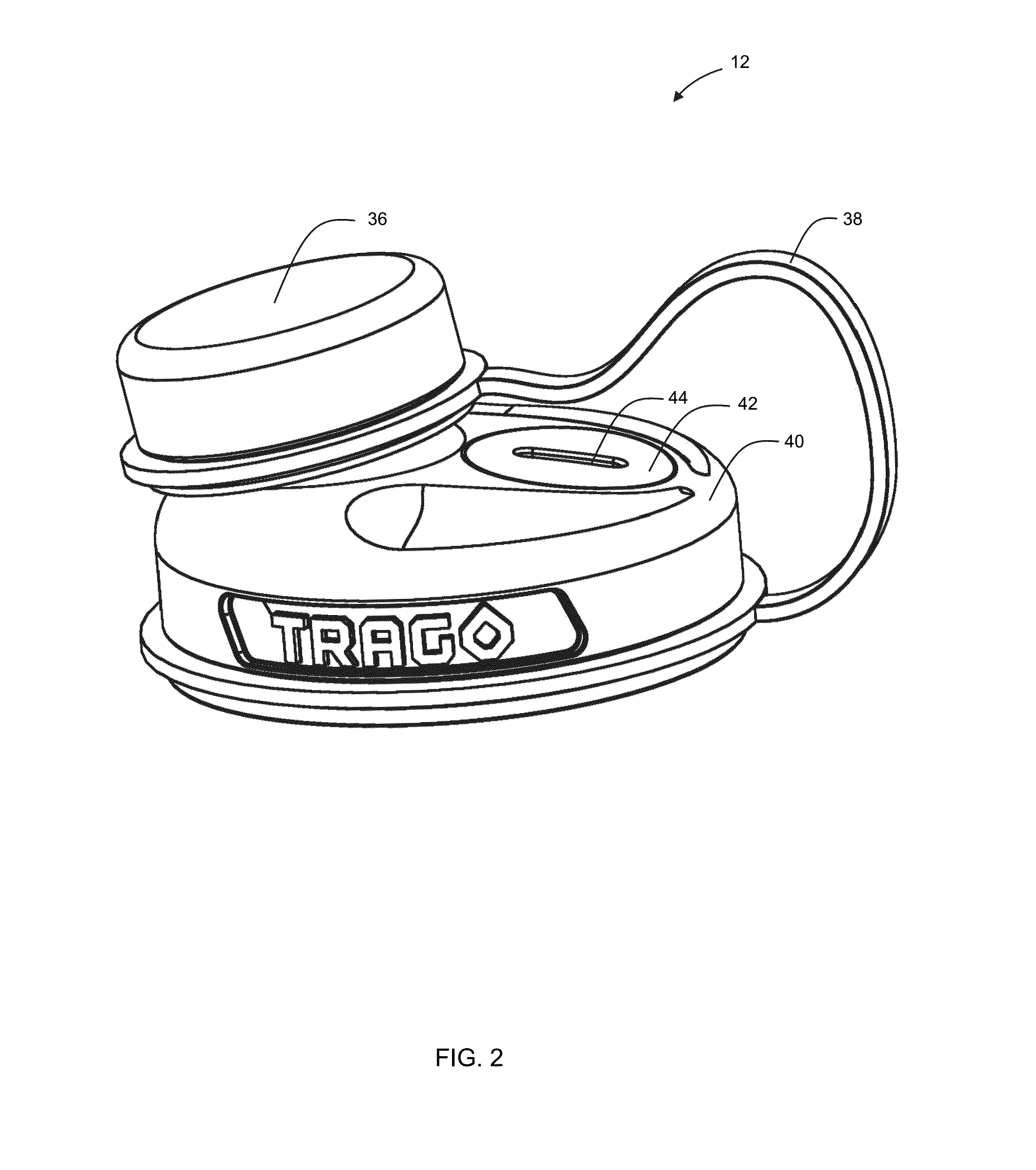

Liquid consumption tracker

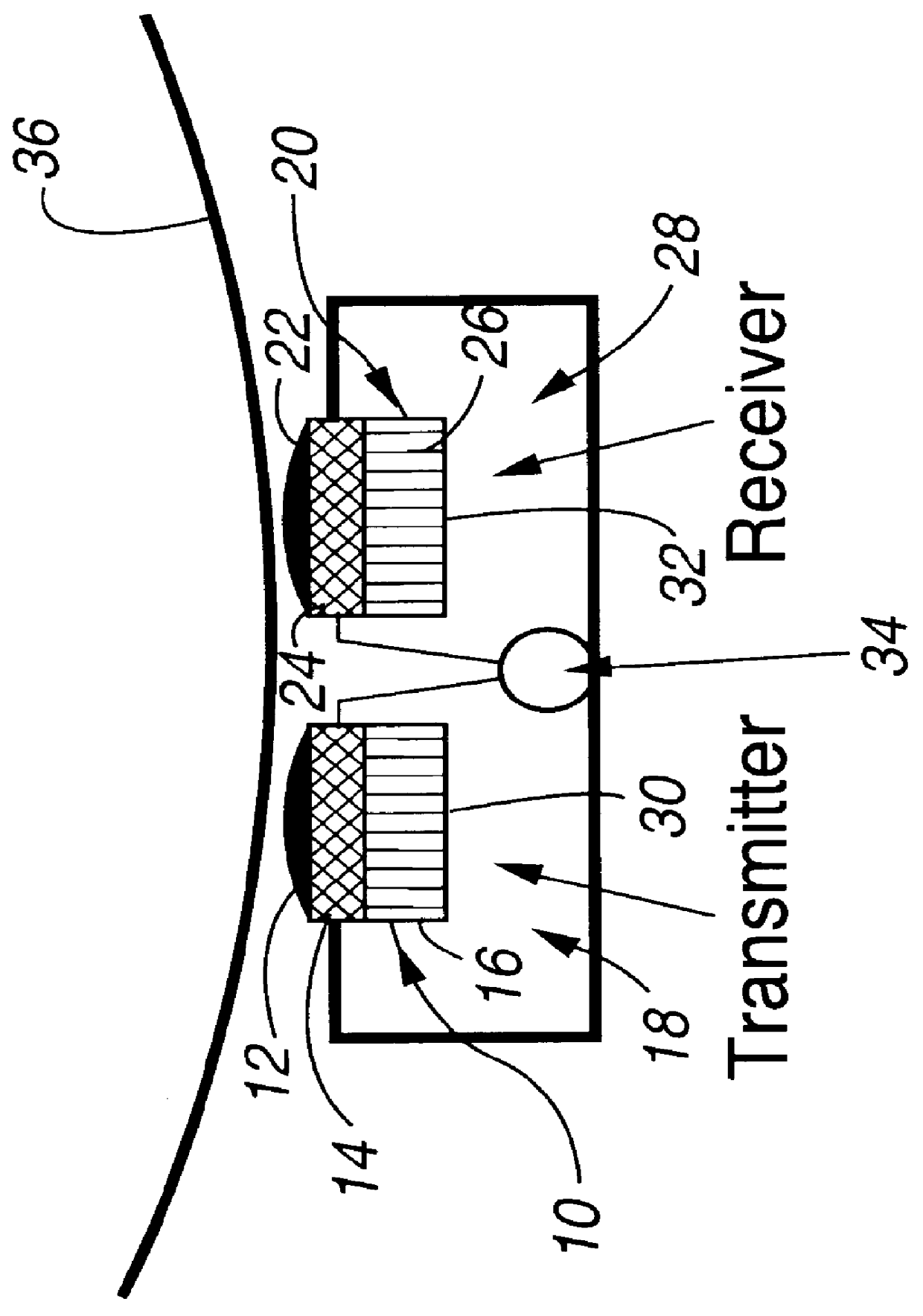

Provided is a sensor operative to track changes in a liquid level of a hand-held liquid container, the sensor comprising: an ultrasonic liquid-level sensor configured to indicate a liquid level of a liquid in a hand-held liquid container, wherein the ultrasonic liquid-level sensor is capable of indicating the liquid level when the surface of the liquid is less than 20 centimeters away from the ultrasonic liquid-level sensor; a radio transmitter; and a processor configured to draw power from a portable power source, receive liquid-level indications from the ultrasonic liquid-level sensor, and cause the radio transmitter to transmit data indicative of changes in the liquid level.

Owner:TRAGO

Infusion pump assembly

A wearable infusion pump assembly including a reservoir for receiving an infusible fluid, and a fluid delivery system configured to deliver the infusible fluid from the reservoir to an external infusion set. The fluid delivery system includes a volume sensor assembly configured to receive a quantity of the infusible fluid from the reservoir. The volume sensor assembly includes an acoustically contiguous region having a volume that varies based upon the quantity of infusible fluid received from the reservoir, and an acoustic energy emitter configured to provide acoustic energy at a plurality of frequencies to excite a gas included within the acoustically contiguous region.

Owner:DEKA PROD LLP

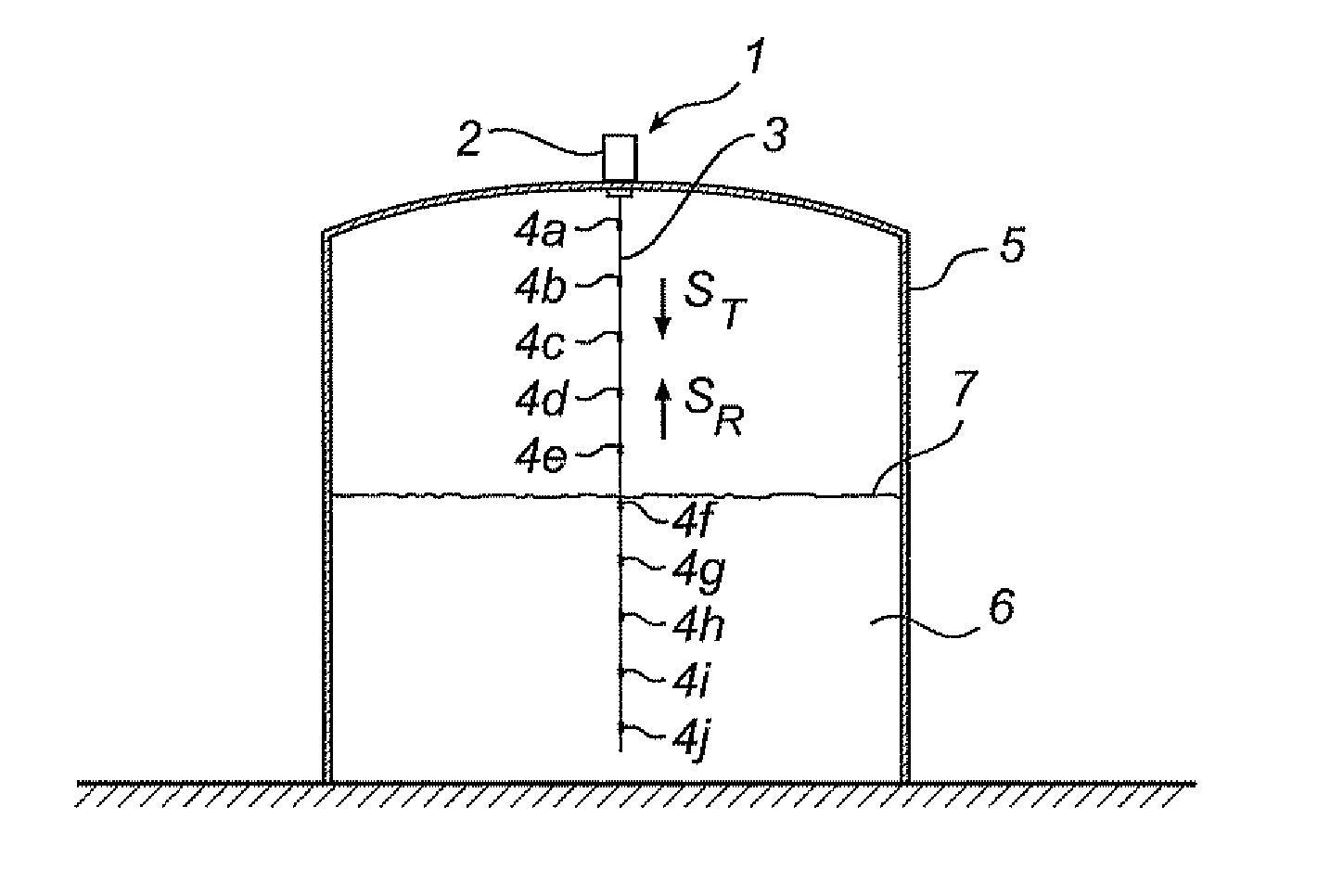

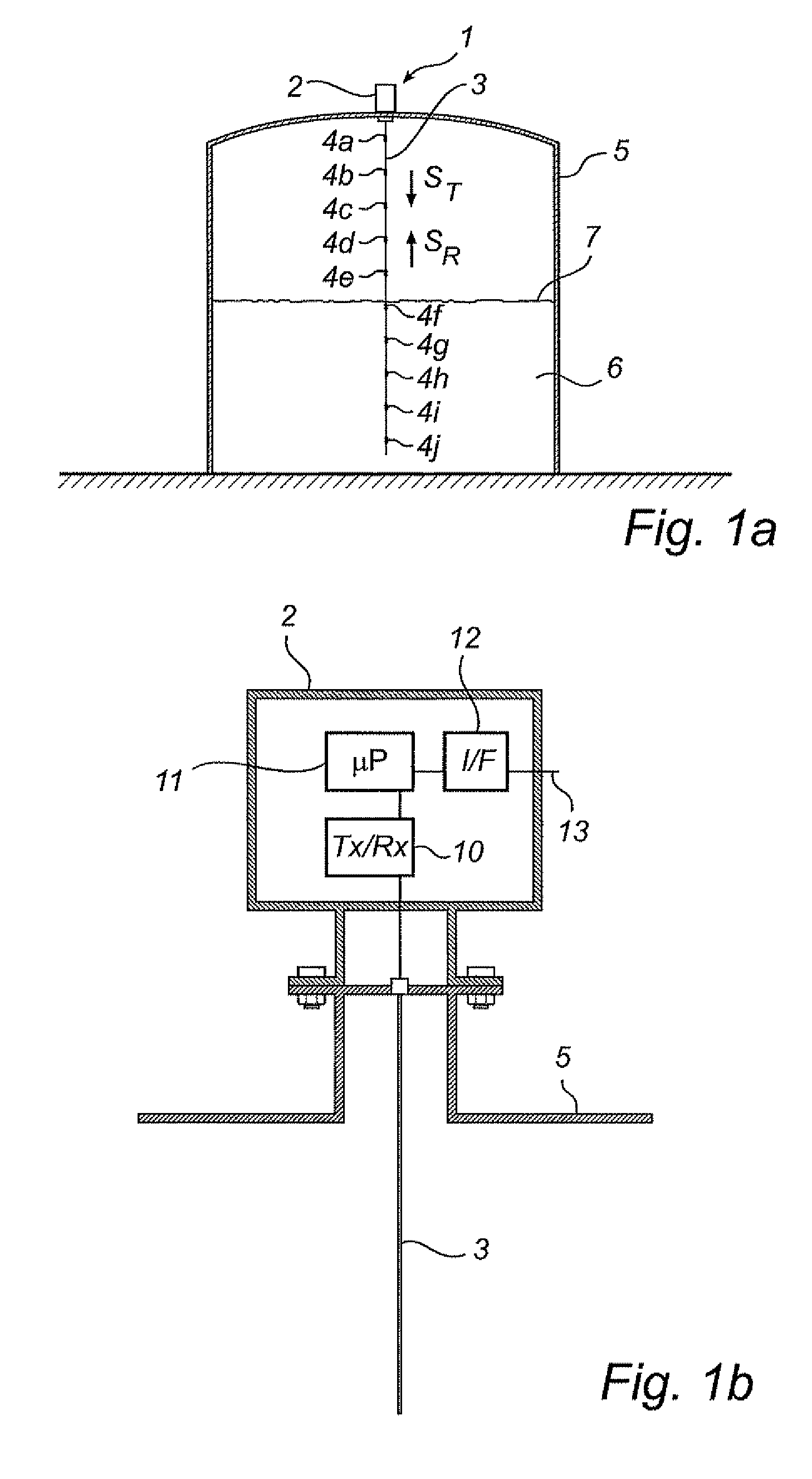

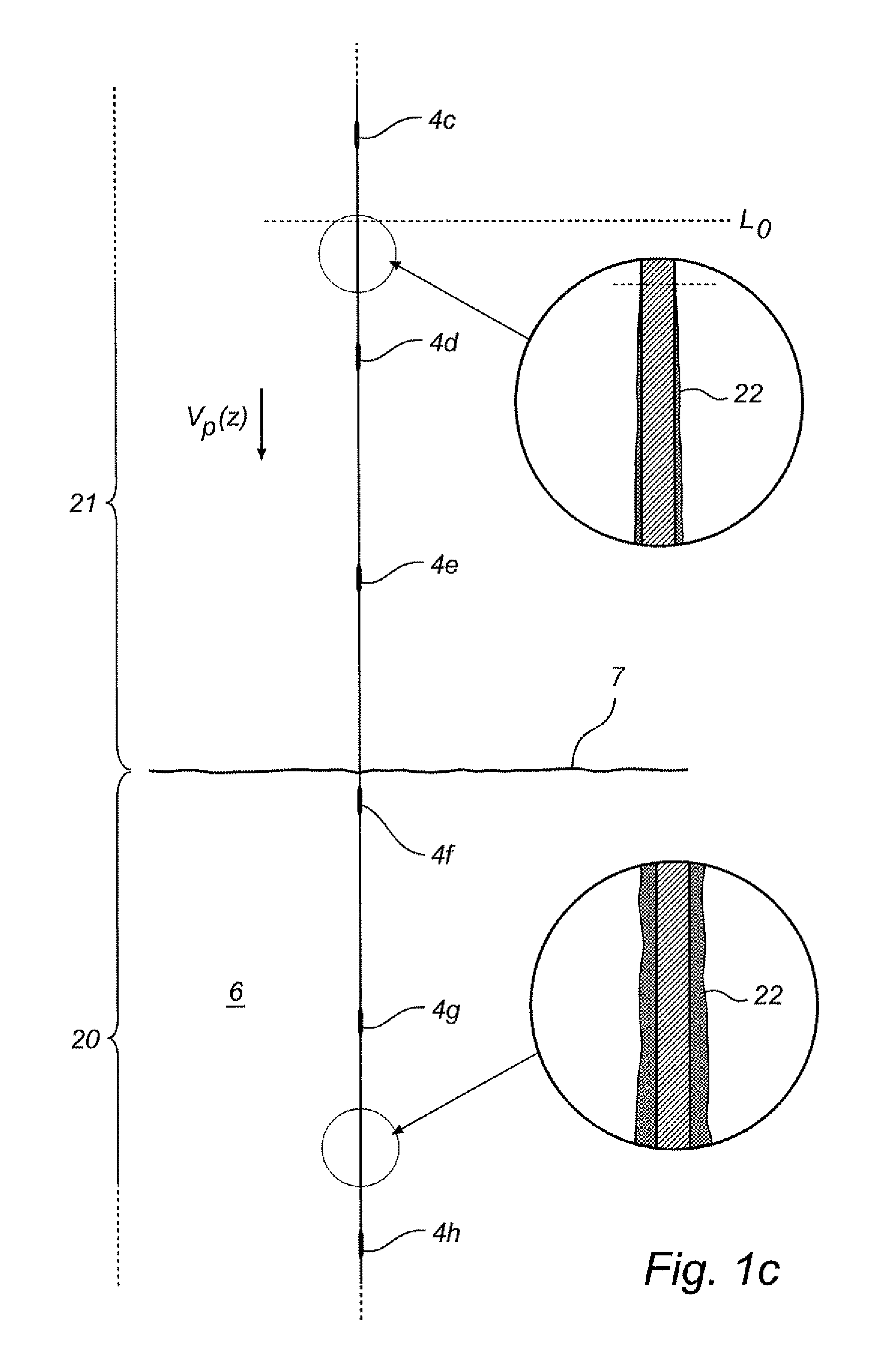

System and method for filling level determination

A method for determining a filling level of a product contained in a tank, by means of a radar level gauge system comprising a transceiver for generating, transmitting and receiving electromagnetic signals; a probe connected to the transceiver and arranged to guide a transmitted electromagnetic signal from the transceiver towards and into the product inside the tank, and to return a reflected electromagnetic signal resulting from reflection of the transmitted electromagnetic signal by a surface of the product back towards the transceiver; and a plurality of reference reflectors each being arranged at a respective known position along the probe and being configured to reflect a portion of the transmitted electromagnetic signal back towards the transceiver. The method comprises the steps of identifying, based on received electromagnetic signals reflected by the reference reflectors, a set of reference reflectors located above the surface of the product; selecting first and second reference reflectors comprised in the set of reference reflectors; determining a propagation velocity compensation factor based on a known distance between the first and second reference reflectors and a distance therebetween determined using received electromagnetic signals reflected by the first and second reference reflector, respectively; and determining the filling level based on a received electromagnetic signal reflected by the surface of the product, and the propagation velocity compensation factor.

Owner:ROSEMOUNT TANK RADAR

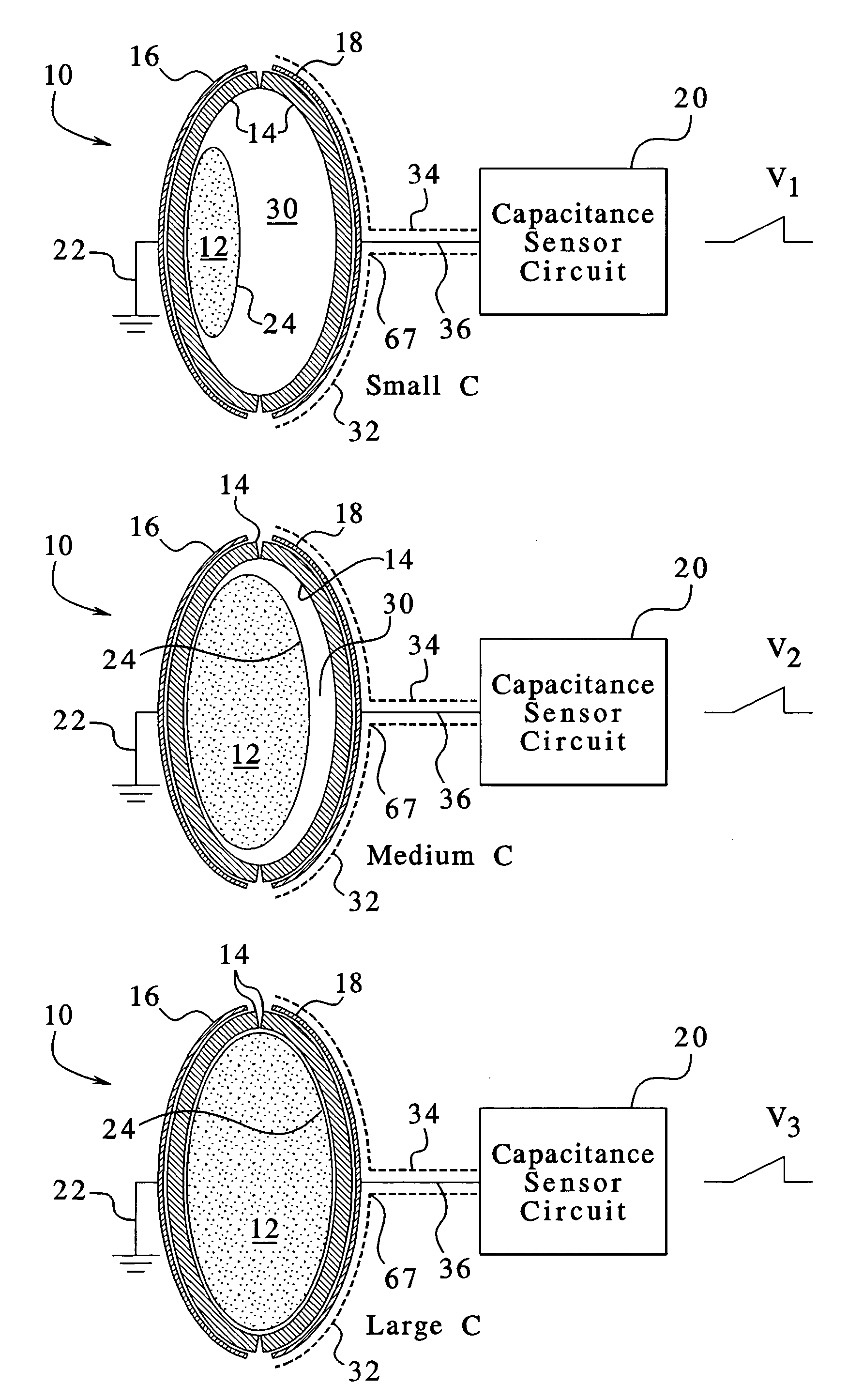

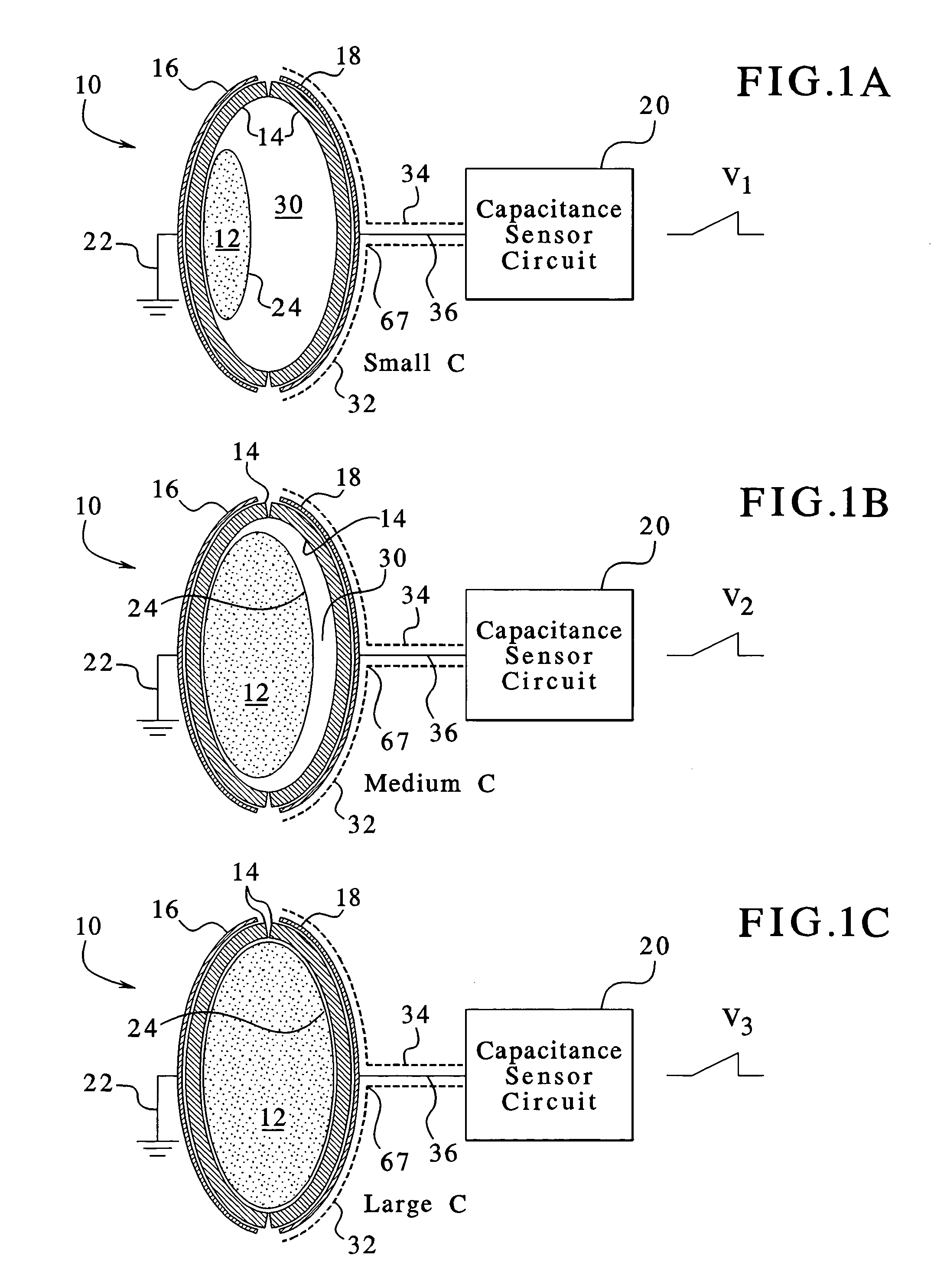

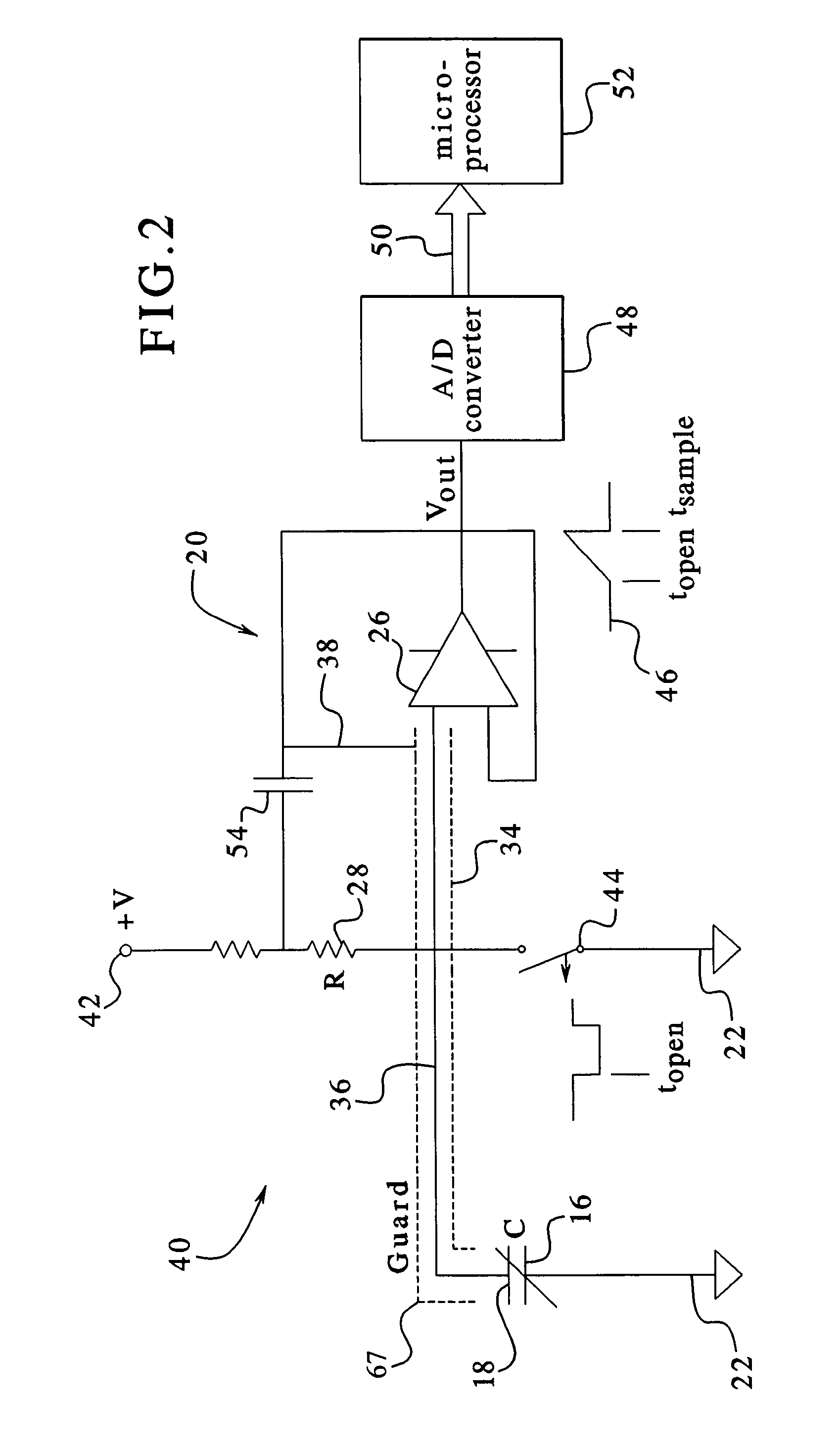

Isolated capacitive fluid level sensor

InactiveUS7258005B2Reliable separationEasy to addMachines/enginesLubrication indication devicesElectricityCapacitance

A capacitive fluid level sensor is disclosed that operates without the use of a float, wherein coplanar sensing electrodes disposed onto a dielectric substrate and positioned proximate a dielectric wall of a vessel containing a fluid, form a fringing field capacitance that changes in accordance with changes in the level of the fluid. The electrodes are electrically insulated from the measured fluid. The electrodes are sized and spaced to maximize response of the capacitance to changes in the level of the fluid, while minimizing the effects of the dielectric wall. The sensor is fabricated such that it can be positioned against the outside of a dielectric wall of a vessel, or embedded within a dielectric material. A low permitivity spacer and shield assembly are taught which reduces sensitivity to electric fields external to the vessel. An interdigital comb configuration of the electrodes is also disclosed in which depressions or gaps are formed into the dielectric substrate in an area of spacing of the electrodes.

Owner:NYCE DAVID SCOTT

System for detecting a container or contents of the container

ActiveUS20060219962A1Investigating moving fluids/granular solidsScattering properties measurementsMechanical engineeringEngineering

A system for detecting a container or contents of the container. The system includes a diffuser for retaining the container, where the container is configured to hold an active material therein and may include a wick extending therefrom. The system further includes a sensor positioned to detect, for example, the container retained in the diffuser and / or the contents of the container retained in the diffuser.

Owner:SC JOHNSON & SON INC

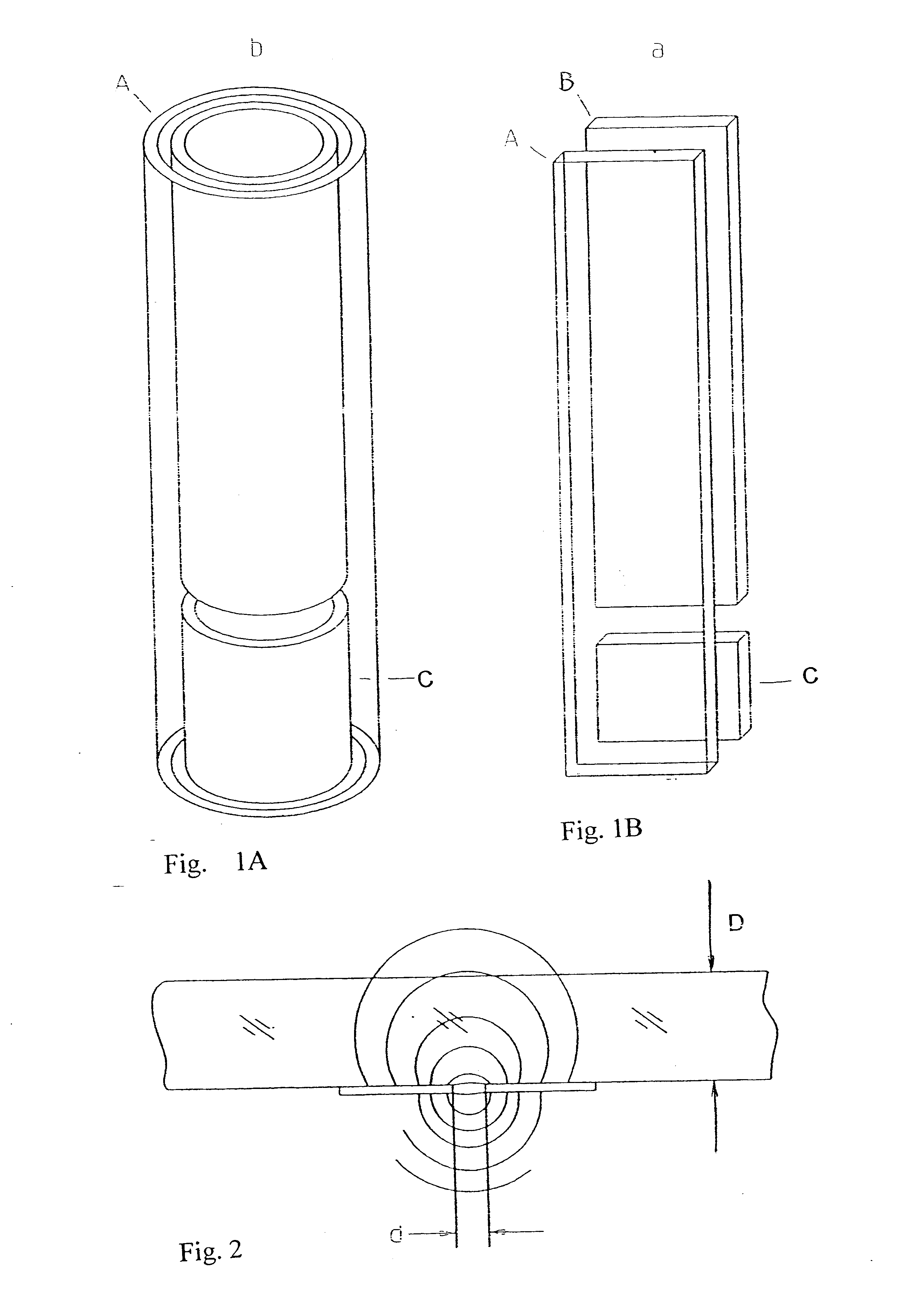

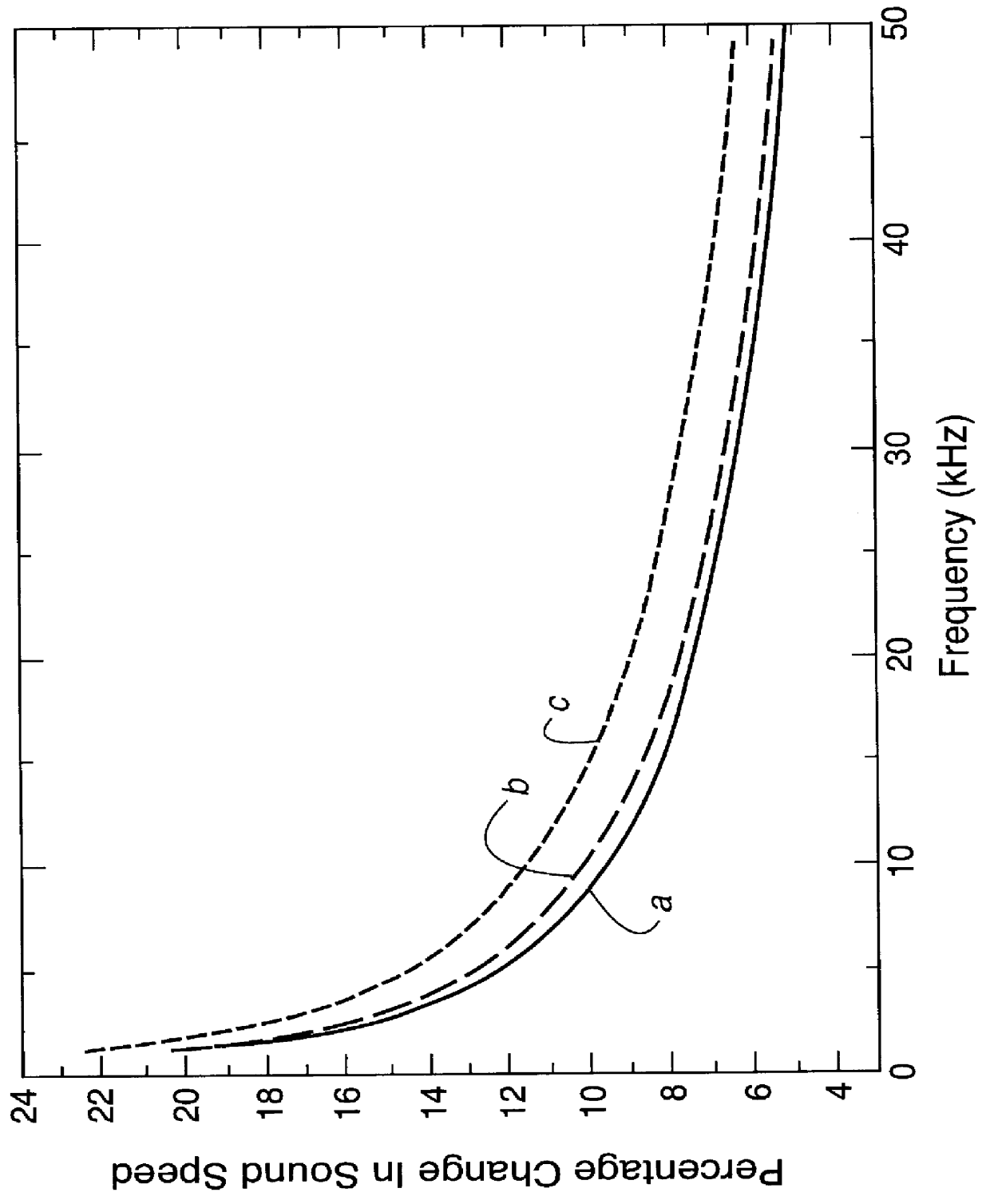

Noninvasive method for determining the liquid level and density inside of a container

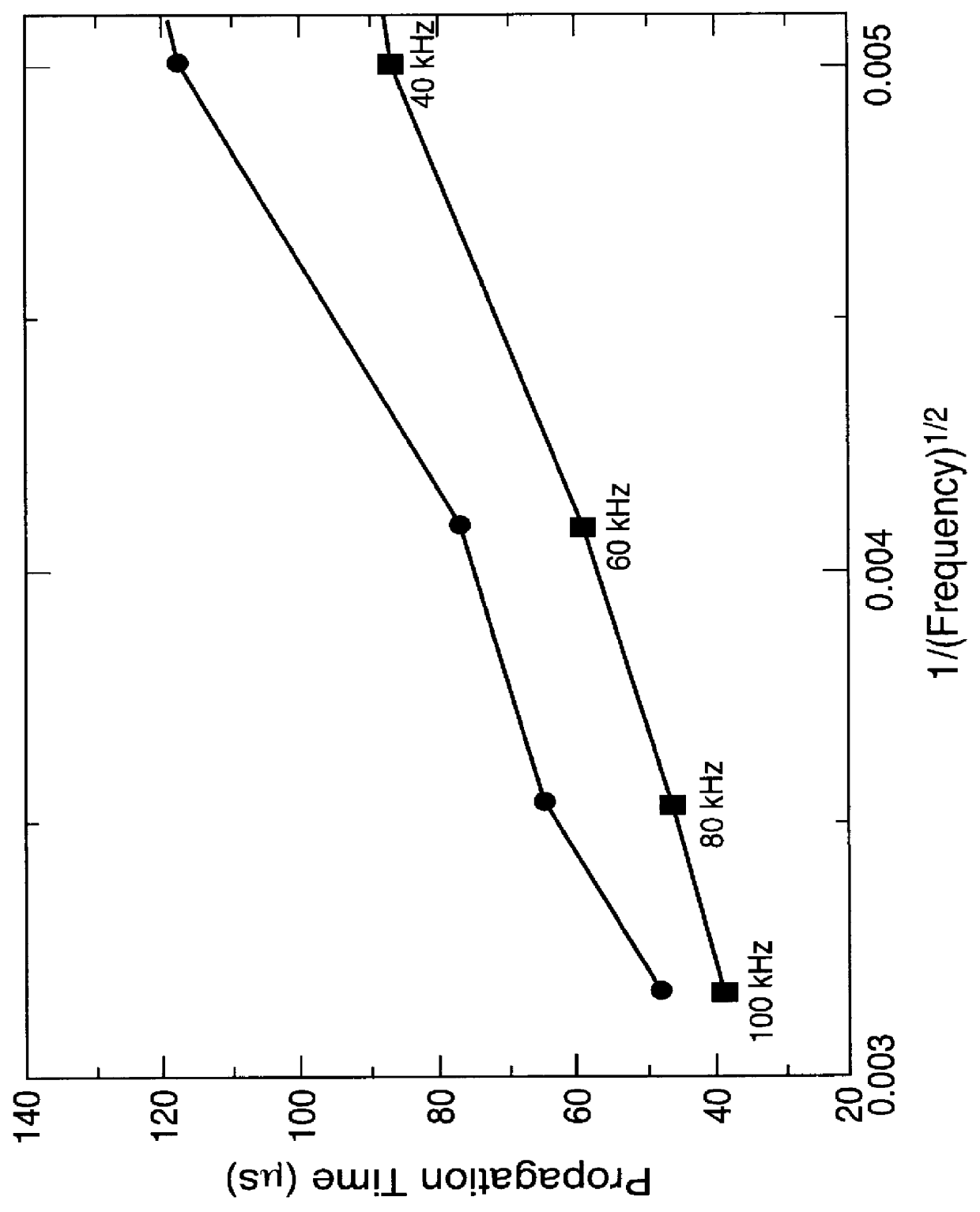

InactiveUS6053041AHigh resolutionMaterial analysis using sonic/ultrasonic/infrasonic wavesMachines/enginesPhase differenceWave detection

Noninvasive method for determining the liquid level and density inside of a container having arbitrary dimension and shape. By generating a flexural acoustic wave in the container shell and measuring the phase difference of the detected flexural wave from that of the originally generated wave a small distance from the generated wave, while moving the generation and detection means through the liquid / vapor interface, this interface can be detected. Both the wave generation and wave detection may be achieved by transducers on the surface of the container. A change in the phase difference over the outer surface of the vessel signifies that a liquid / vapor interface has been crossed, while the magnitude of the phase difference can be related to fluid density immediately opposite the measurement position on the surface of the vessel.

Owner:LOS ALAMOS NATIONAL SECURITY

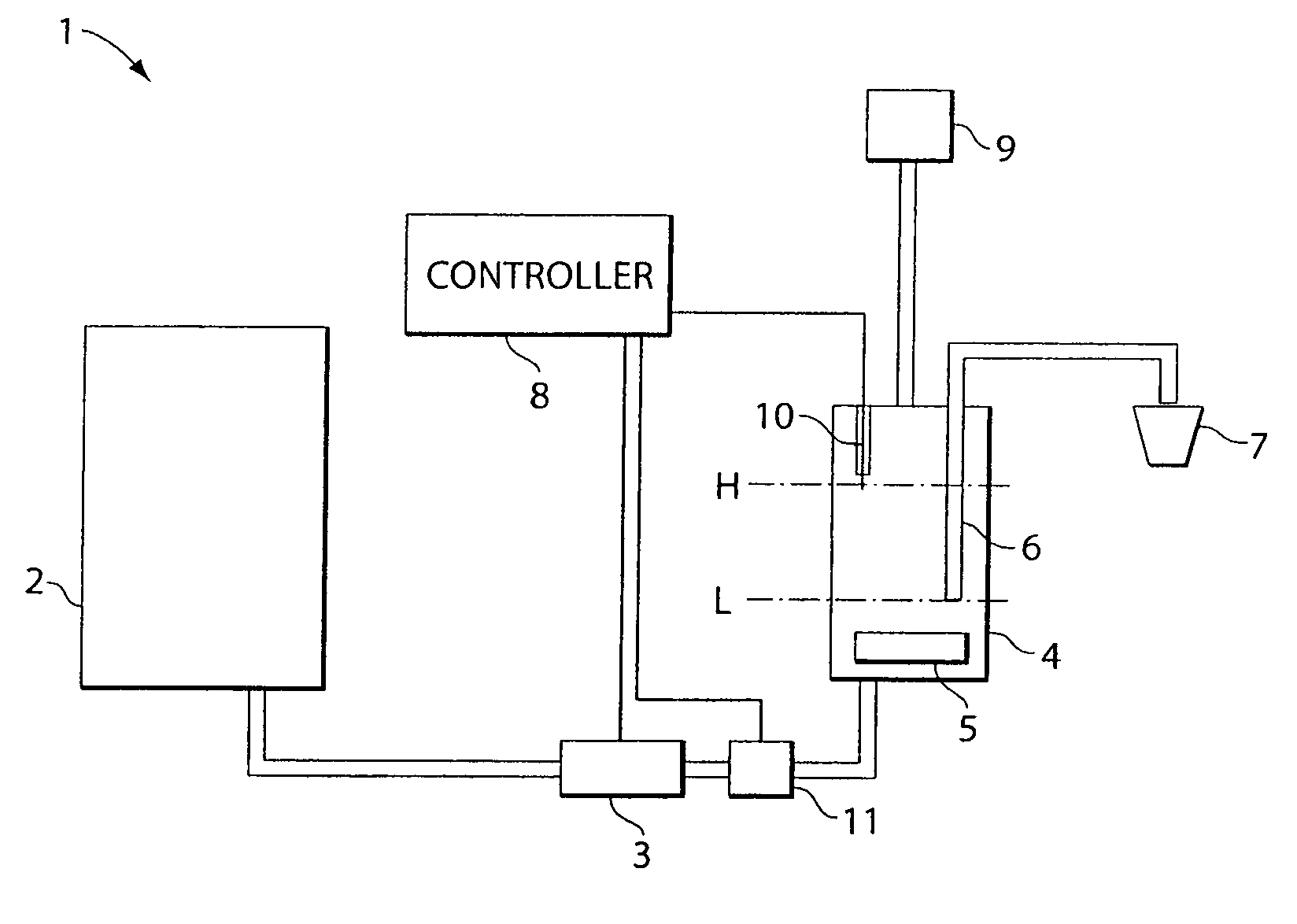

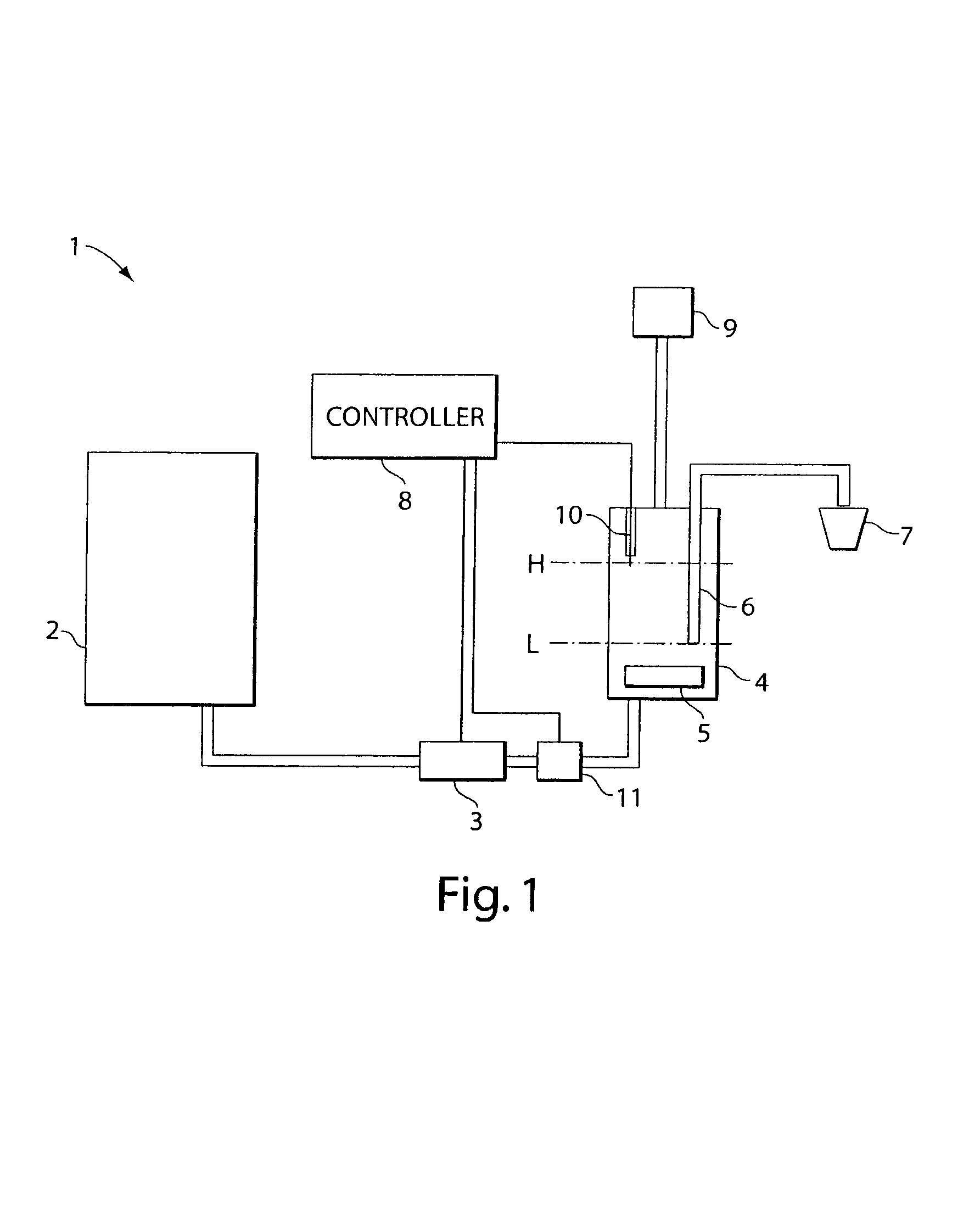

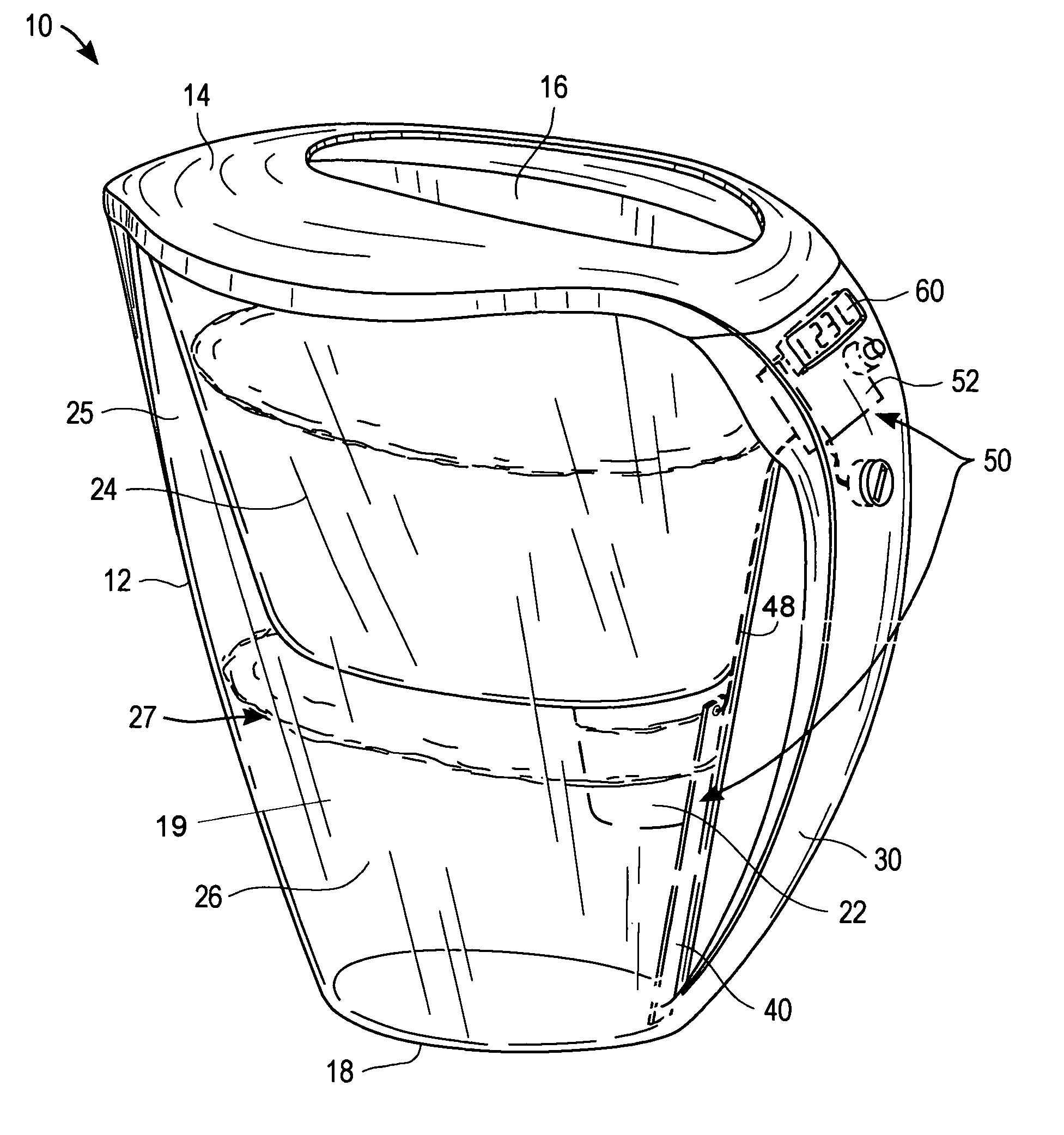

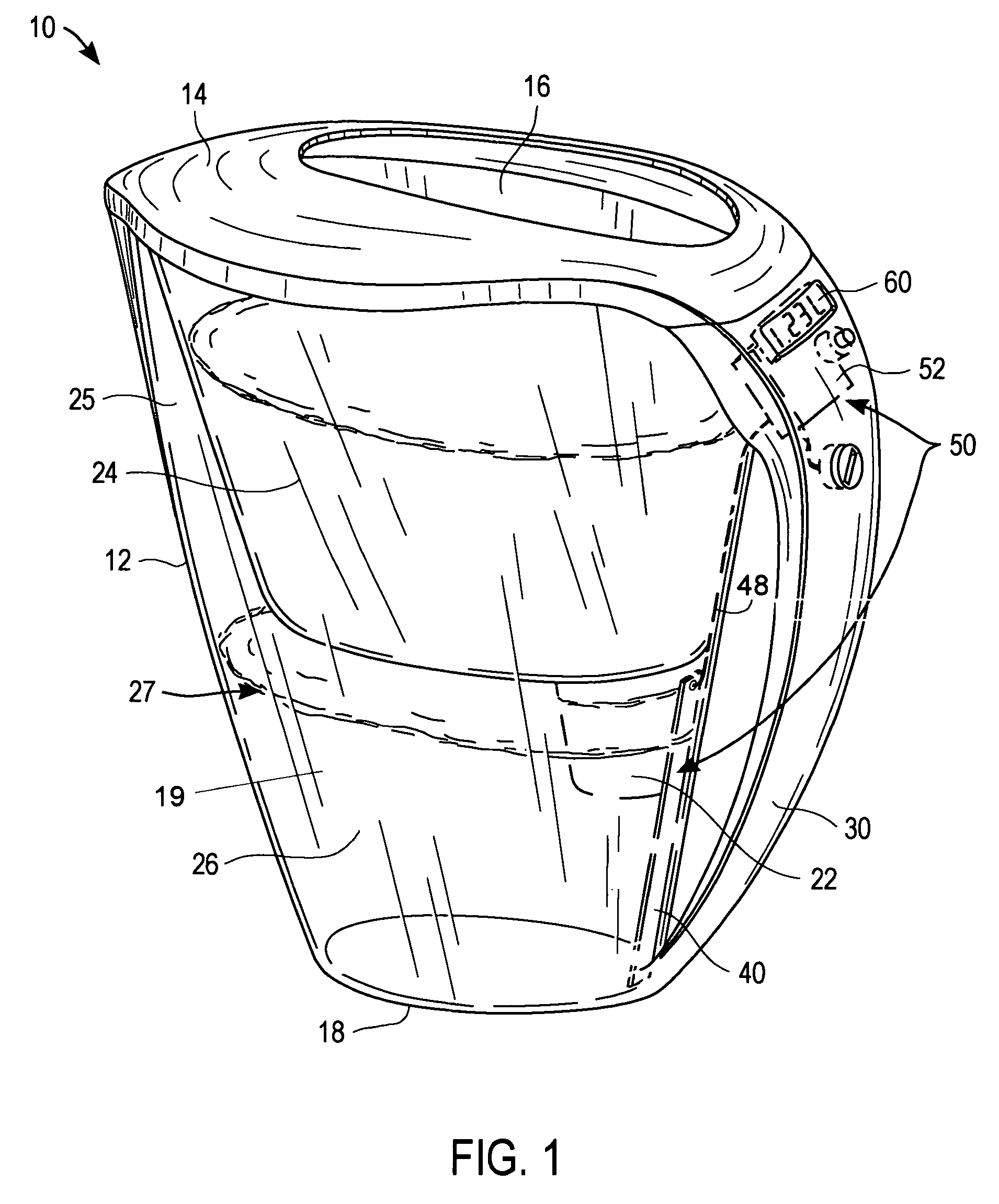

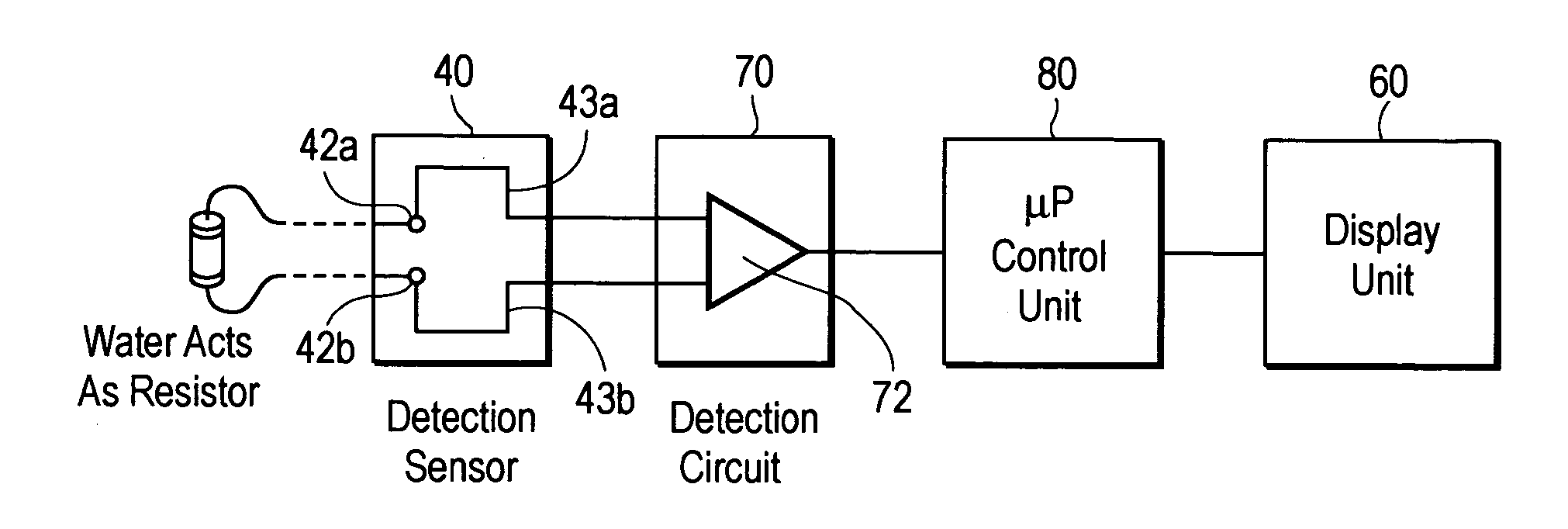

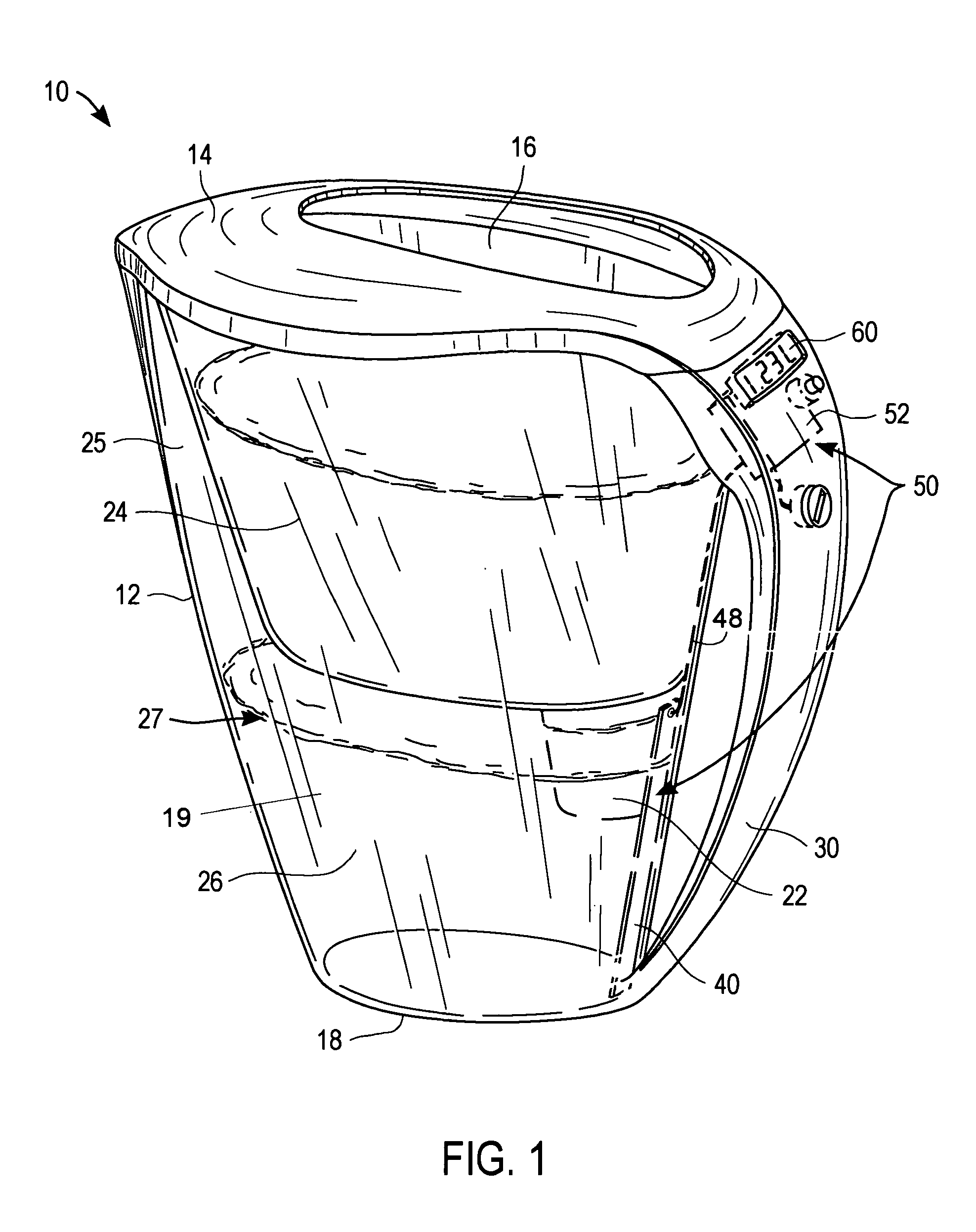

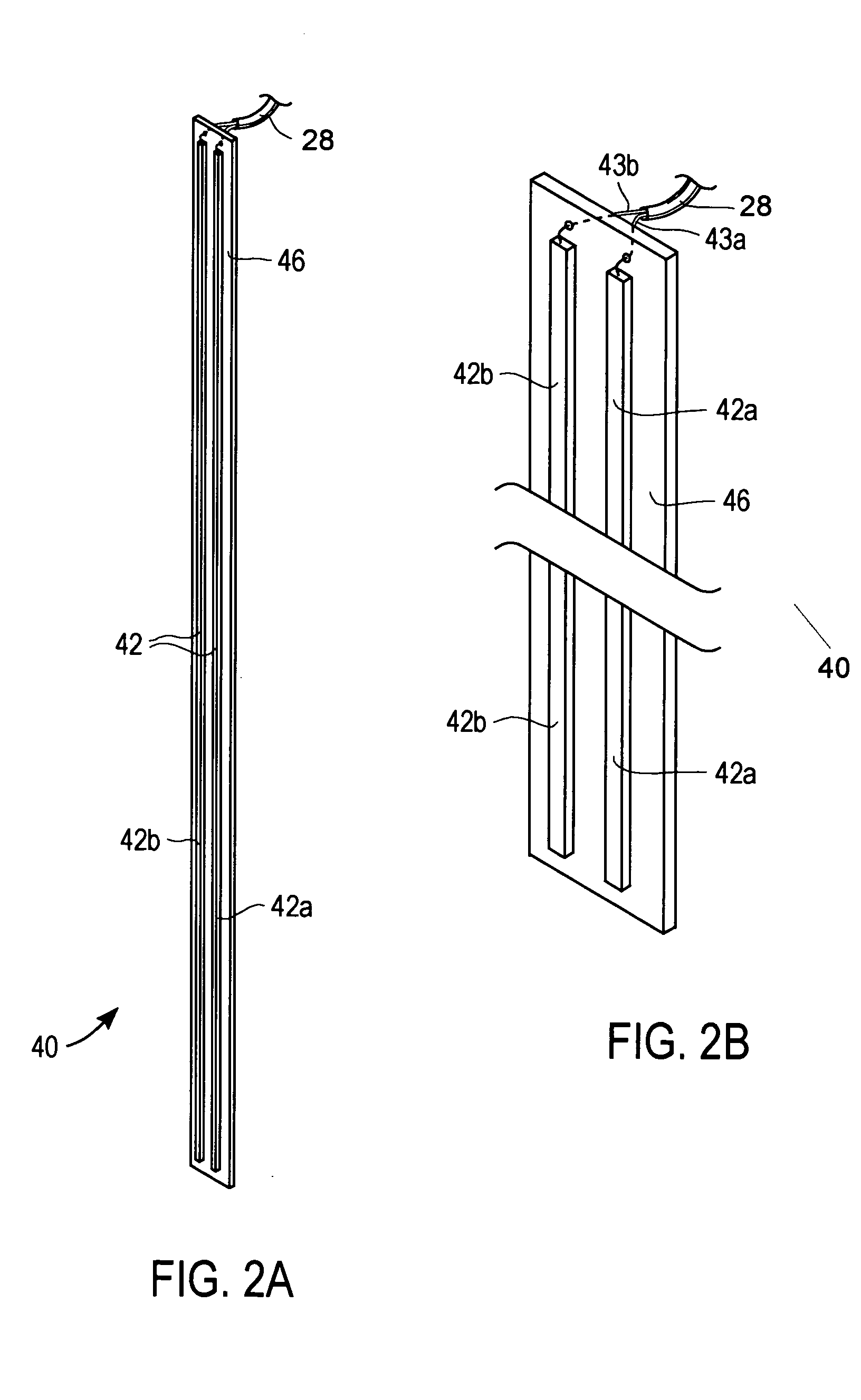

Apparatus and methods for monitoring water consumption and filter usage

InactiveUS7107838B2Water treatment parameter controlSpecific water treatment objectivesFilter mediaEnvironmental engineering

Apparatus and methods for employing electrical properties of water to indicate the level of filtered water in a filtered water container. The container is fitted with a hopper that holds unfiltered water. The hopper is fitted at its base with a removable and replaceable filter cartridge. Water is filtered by draining through the filter medium contained in the filter cartridge into the lower portion of the container. The water level in the lower portion of the container is monitored by means of one or more water level detector strips in the lower portion of the container. The detector strips are in electrical communication with a detection circuit and a control unit. The control unit uses the detection strips to monitor water level and uses such data to track filtered water consumption and to determine when the filter cartridge should be replaced.

Owner:FOOK TIN TECH

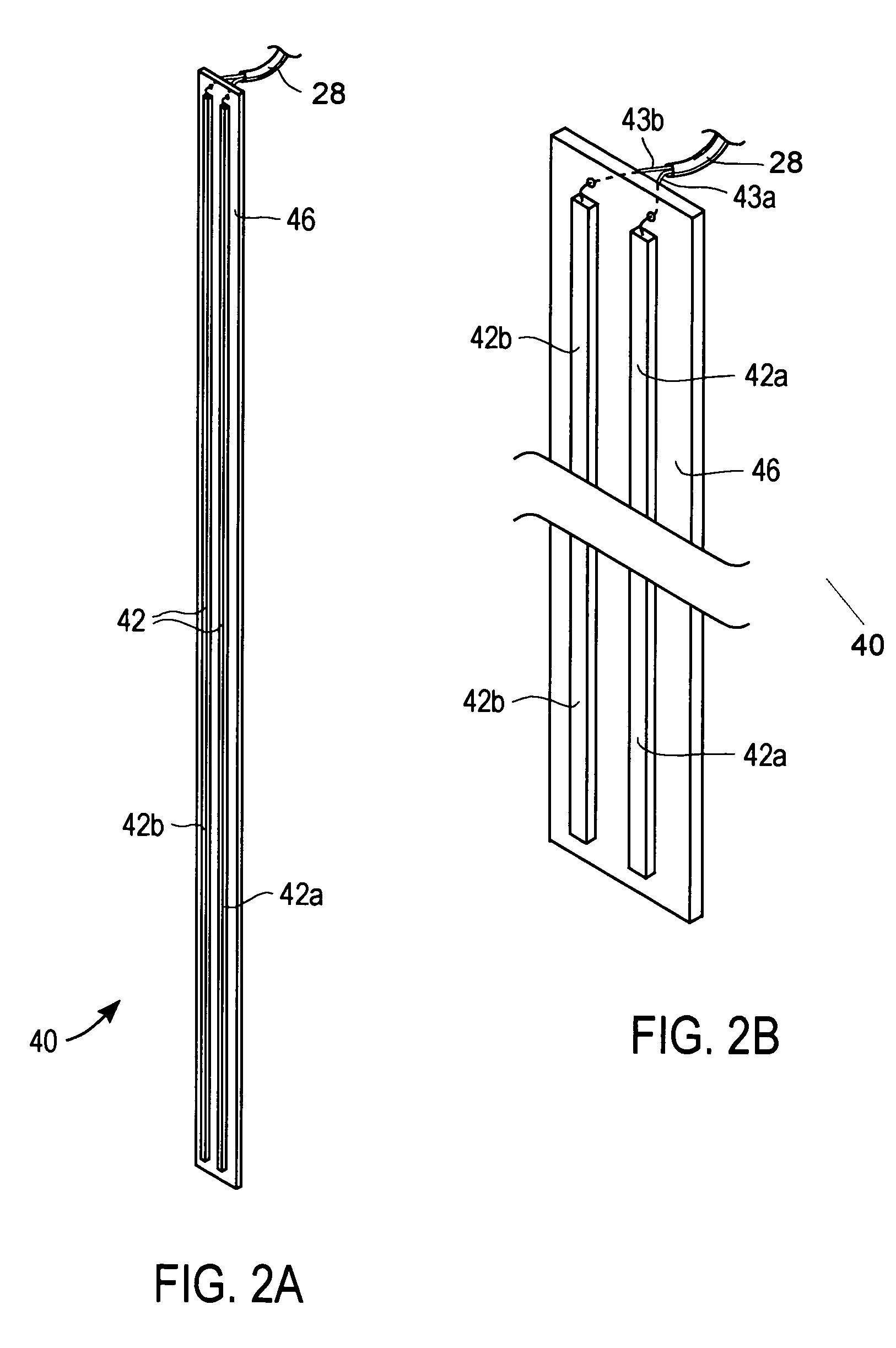

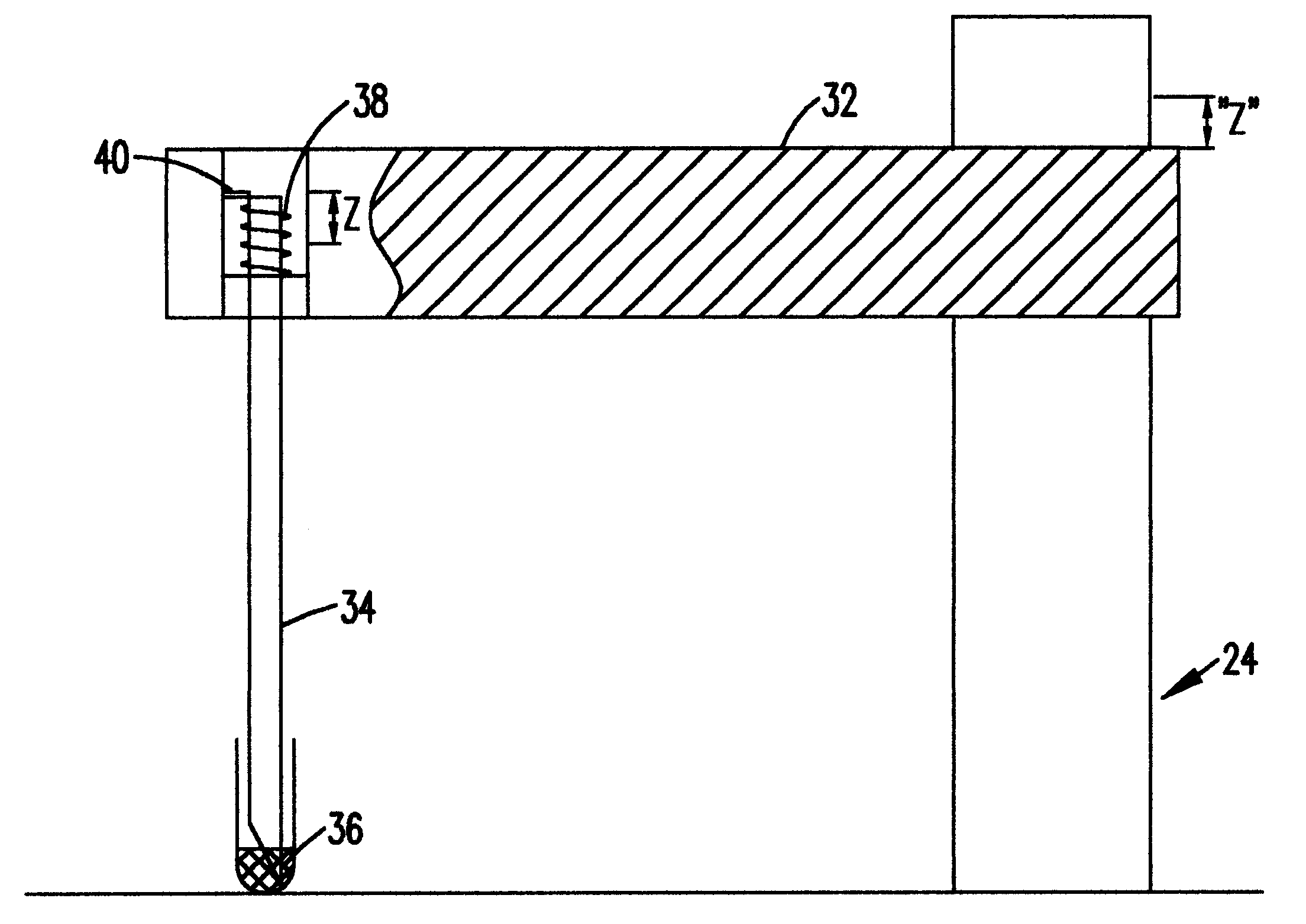

Tube bottom sensing for small fluid samples

InactiveUS6270726B1Withdrawing sample devicesMaterial analysis by optical meansEngineeringFluid level

A pipetting station having a bottom sensing device is provided in conjunction with one of any known liquid level sensing devices. The bottom sensing device includes a pipetting probe spring mounted to a pipetting arm of the pipetting station. The bottom sensing device also includes a sensor for determining when a pipetting tip of the pipetting probe is in contact with a bottom of a tube. The bottom sensing device permits the pipetting probe to measure an exact volume of fluid in the tube by allowing the pipetting tip to be lowered to the bottom of the tube beyond the sensed fluid level.

Owner:SIEMENS HEALTHCARE DIAGNOSTICS INC

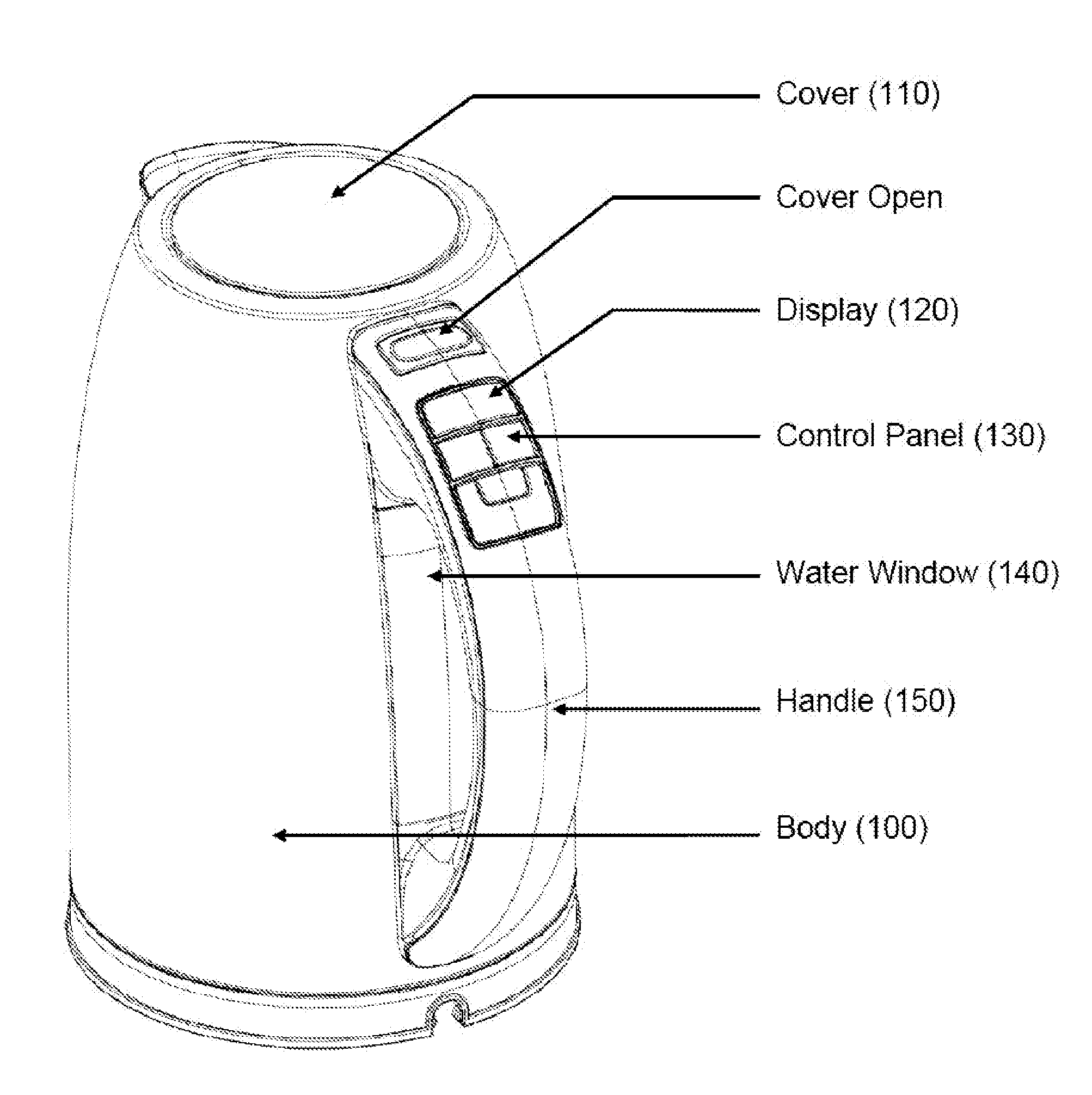

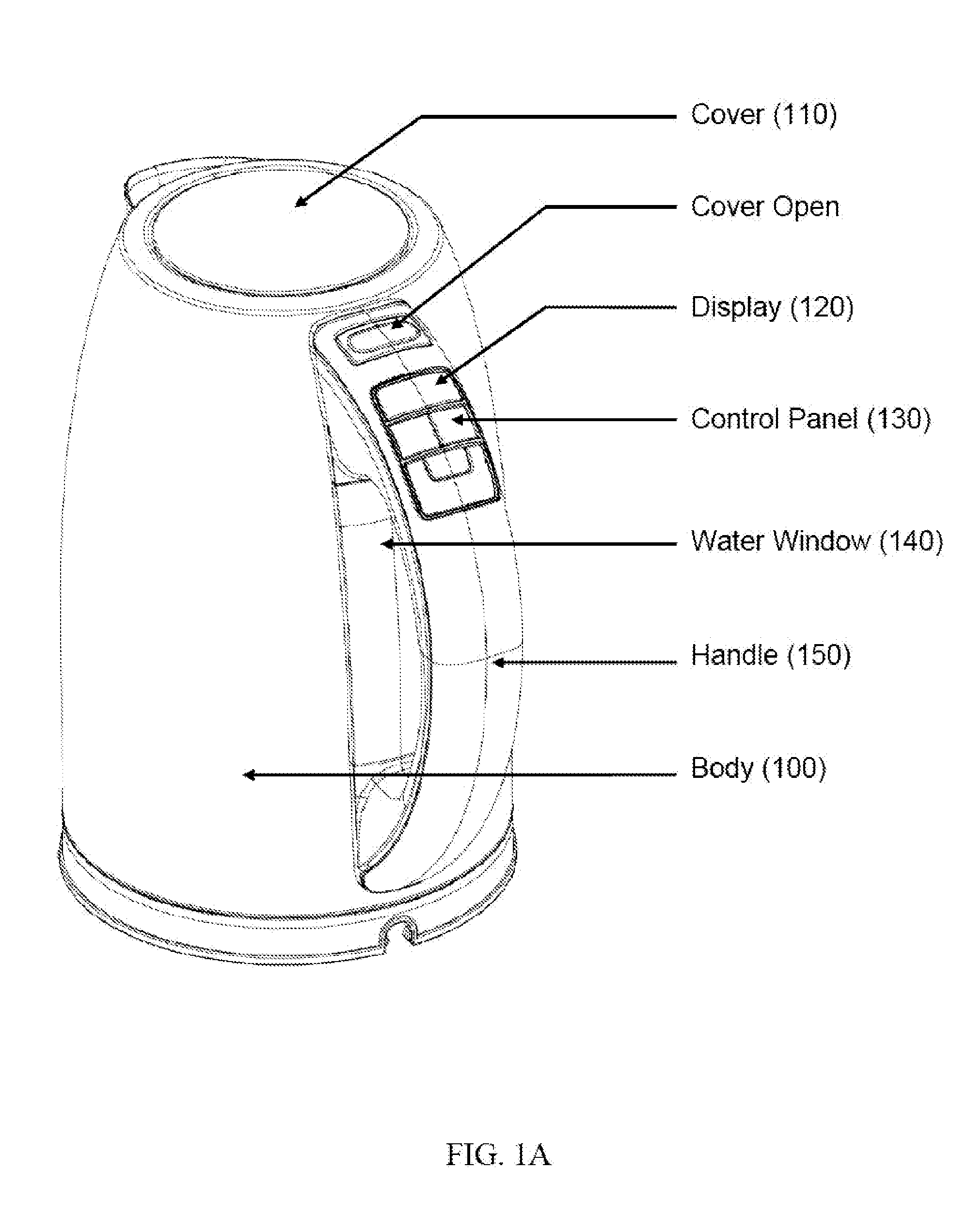

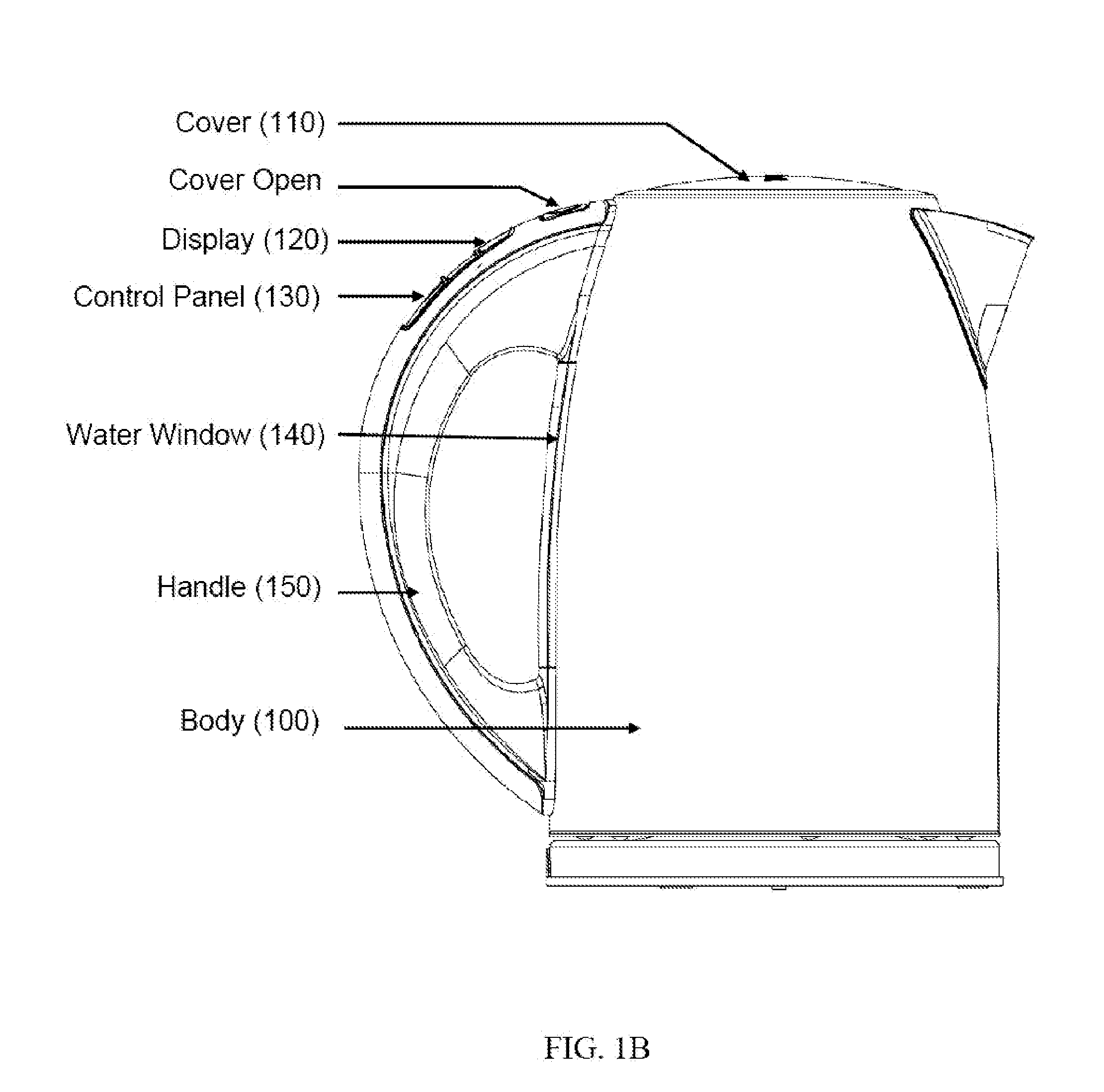

Non-contact liquid level sensing system for household electric appliances

A non-contact liquid level sensing system for an electric appliance is provided. The electric appliance includes a liquid container for containing liquid. The non-contact liquid level sensing system includes a micro-controller and a plurality of sensors vertically aligned and mounted to the inside of the liquid container. The micron-controller includes a non-volatile memory for storing data. Each of the sensors includes a circuit board, a sensor pad made of a conductive material mounted on the circuit board, and a cover plate made of a dielectric material covering and being in direct contact with the sensor pad. The micro-controller is electrically connected with the sensors, and configured to measure the capacitance between the sensor pad of each sensor and a reference electric potential, and to determine a liquid level in the liquid tank based on the measured capacitance and the data stored in the non-volatile memory of the micro-controller.

Owner:LI WING CHUNG

Biosensor apparatus and method with sample type and volume detection

InactiveUS20060119362A1Accurate detectionElectric/magnetic detection for well-loggingCapacitance measurementsCapacitanceLow-pass filter

A biosensor apparatus and method with sample type and cell volume detection. The apparatus includes a sine wave generator to apply an AC signal to a biosensor cell containing a sample, a current-to-voltage converter, a phase shifter, a square wave generator, a synchronous demodulator, and a low pass filter which yields a signal proportional to the effective capacitance across the biosensor cell, which is proportional to the volume of the sample. In addition, the current-to-voltage converter yields a signal indicative of the type of sample contained within the biosensor cell. The method includes applying a sine wave to the biosensor cell, shifting the phase of the resultant signal, generating a square wave synchronous with the sine wave, demodulating the resultant signal with the square wave, and filtering the demodulated signal to produce a signal proportional to the effective capacitance across the biosensor cell. The biosensor apparatus and method are capable of determining sample type and measuring glucose levels over a wide range of sample volumes.

Owner:LIFESCAN IP HLDG LLC

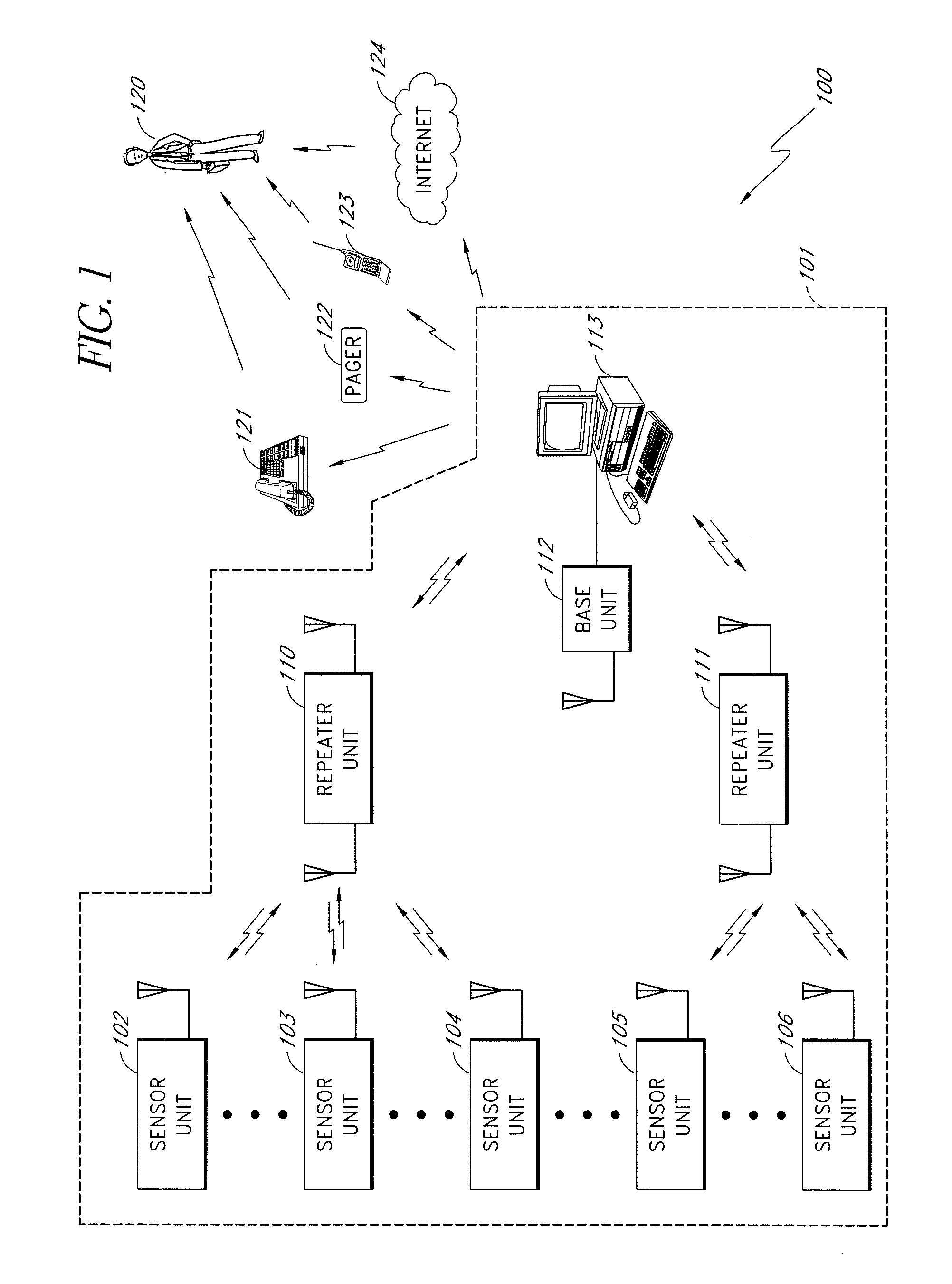

Method and apparatus for detecting severity of water leaks

InactiveUS7561057B2Low costIncrease rangeMeasurement of fluid loss/gain rateElectric testing/monitoringWater leakEngineering

A system for detecting water leaks is described. In one embodiment, the system includes a plurality of sensors, selected from a moisture sensor, a water level sensor, and / or a water temperature sensor. A processor collects moisture readings from the sensors. In one embodiment, the processor reports a possible water leak when a moisture sensor detects moisture above a moisture threshold value. In one embodiment, the processor reports a water leak when the water level reading exceeds a water threshold value and / or when the temperature reading exceeds a temperature threshold value.

Owner:GOOGLE LLC

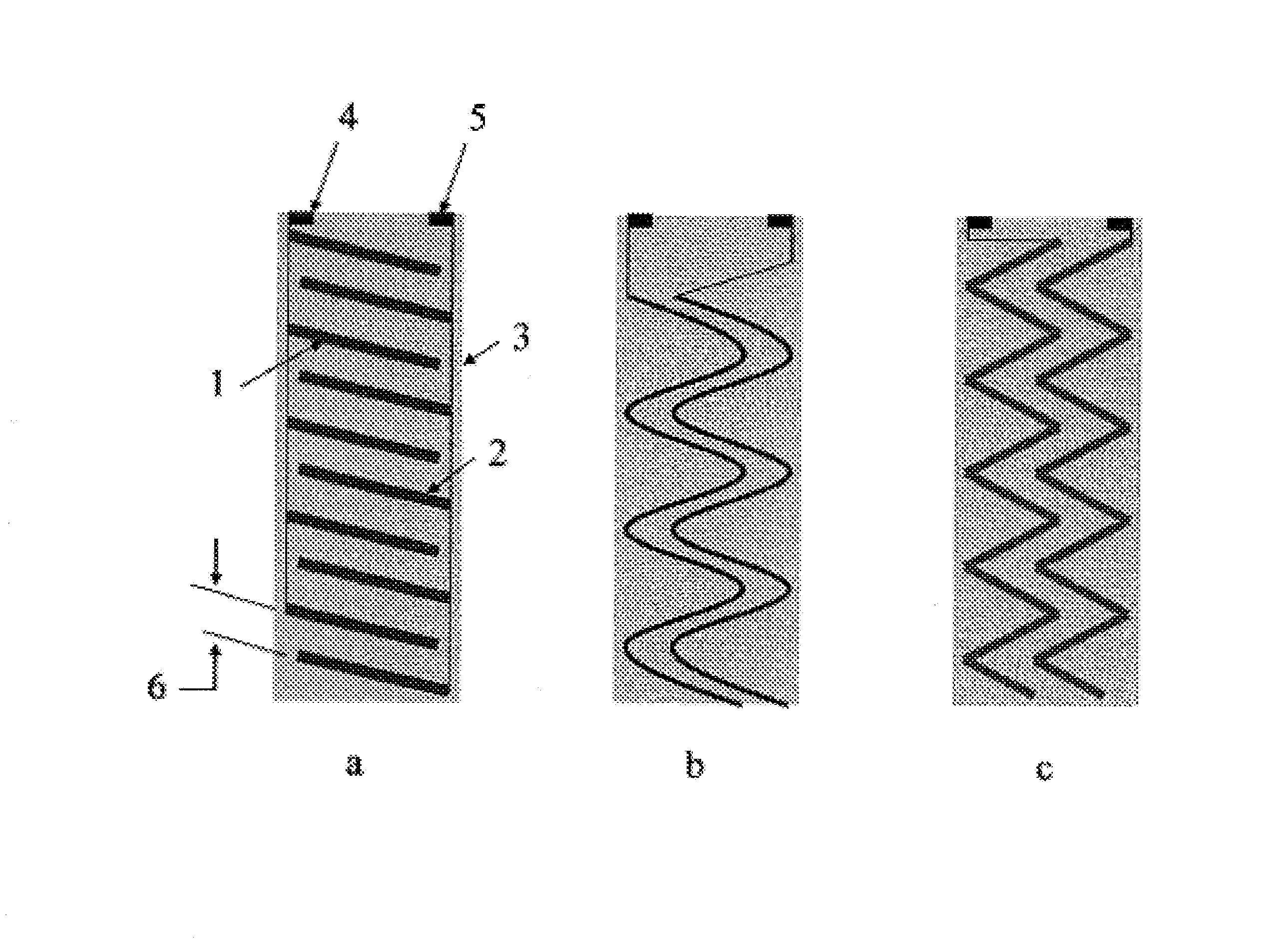

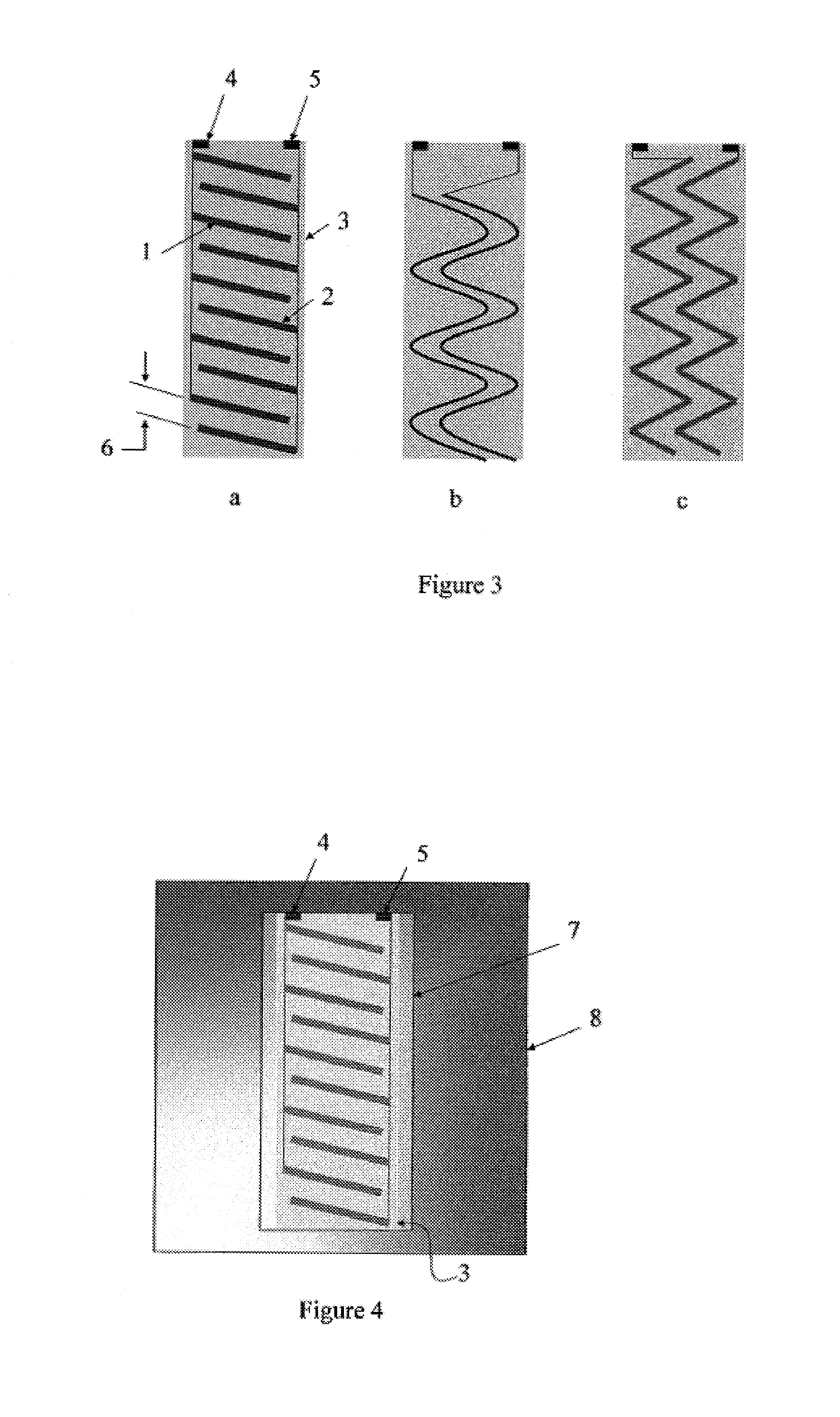

Proximity sensor for level sensing

A field effect sensor is adapted for use in sensing level of fluids and powders. The sensor uses elongated, parallel electrodes disposed on or within the side wall of a tank. The longitudinal axes of the electrodes are parallel to the surface of fluid or powder contained in the tank.

Owner:TOUCHSENSOR TECH

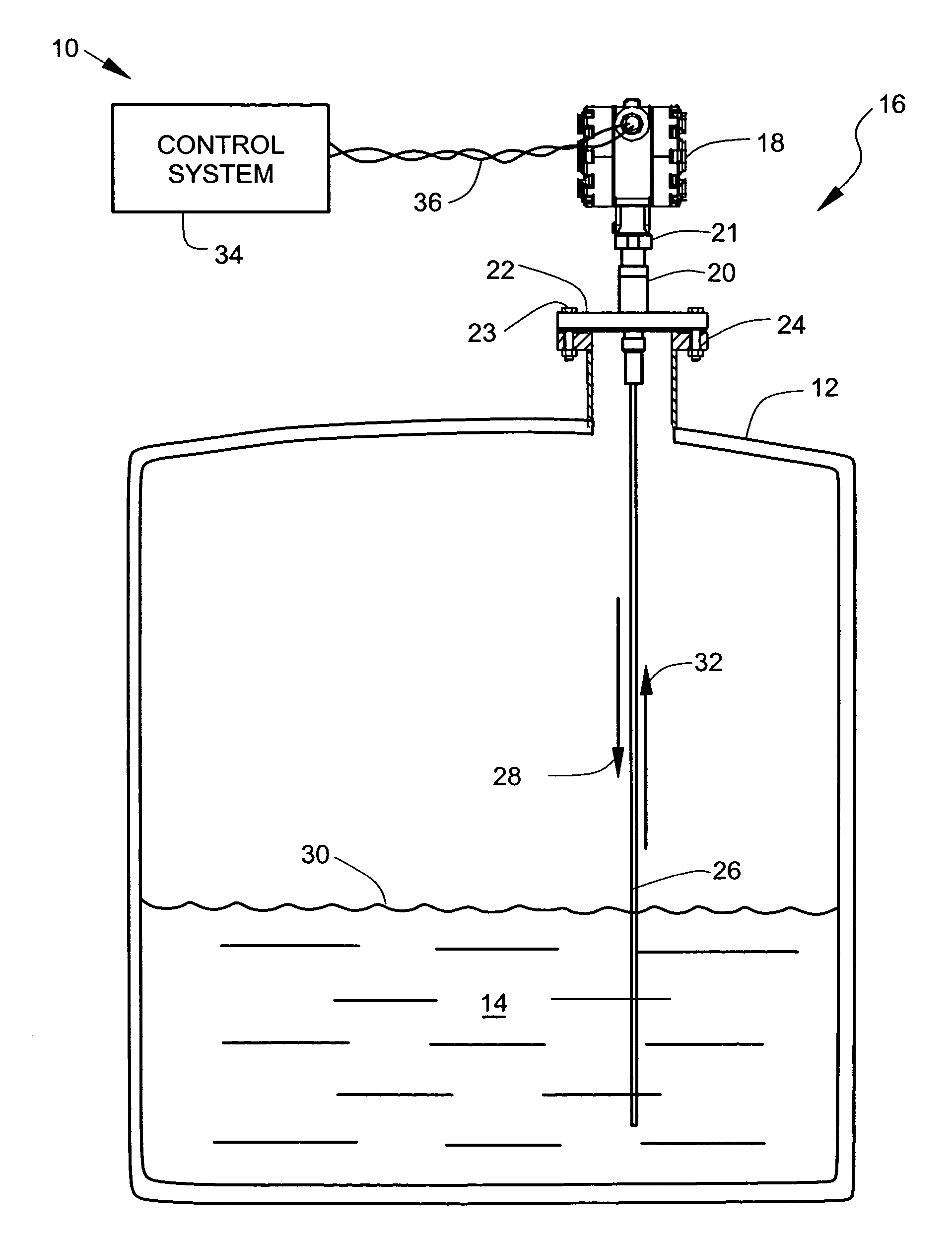

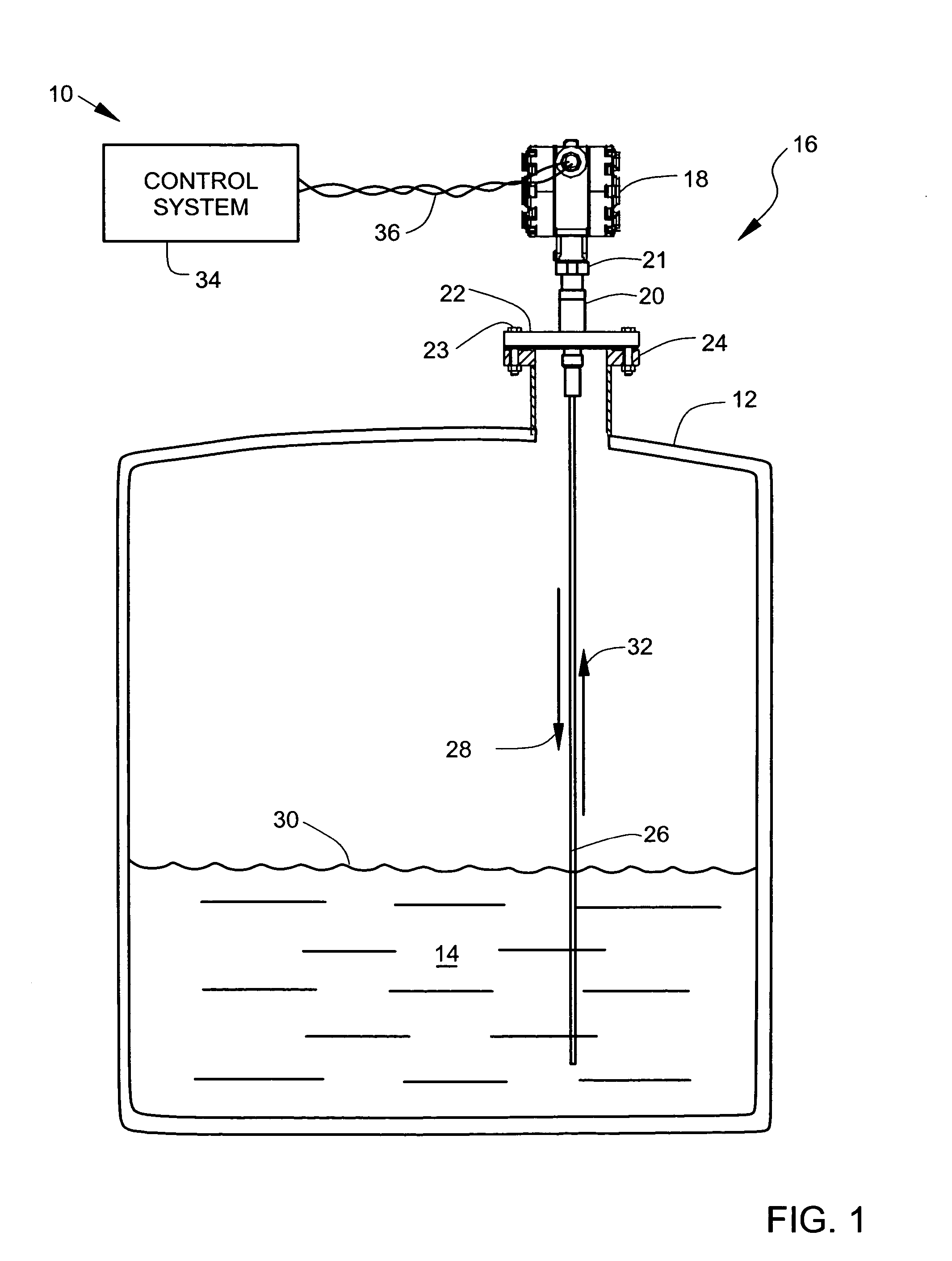

Tank seal for guided wave radar level measurement

A microwave level gauge for measuring a level of a process material in a tank includes a ceramic seal and a microwave conductor. The ceramic seal is disposed adjacent to an opening in the tank and adapted to isolate circuitry from the process material. The microwave conductor is electrically coupled to the circuitry and extends through the hermetic seal and into the process material in the tank. The ceramic seal and an isolating adapter cooperate to isolate the microwave conductor from the process fluid and from external forces.

Owner:ROSEMOUNT INC

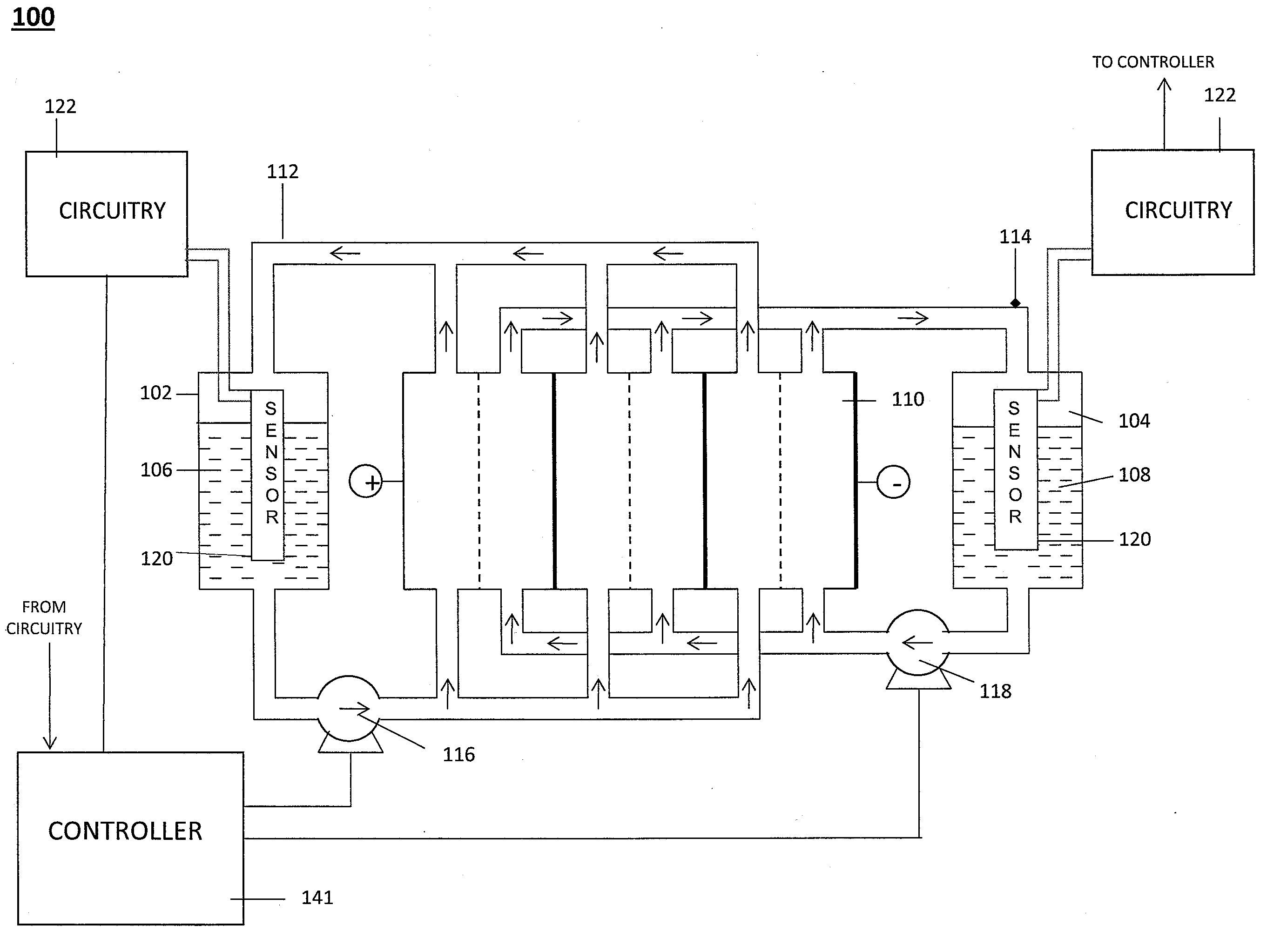

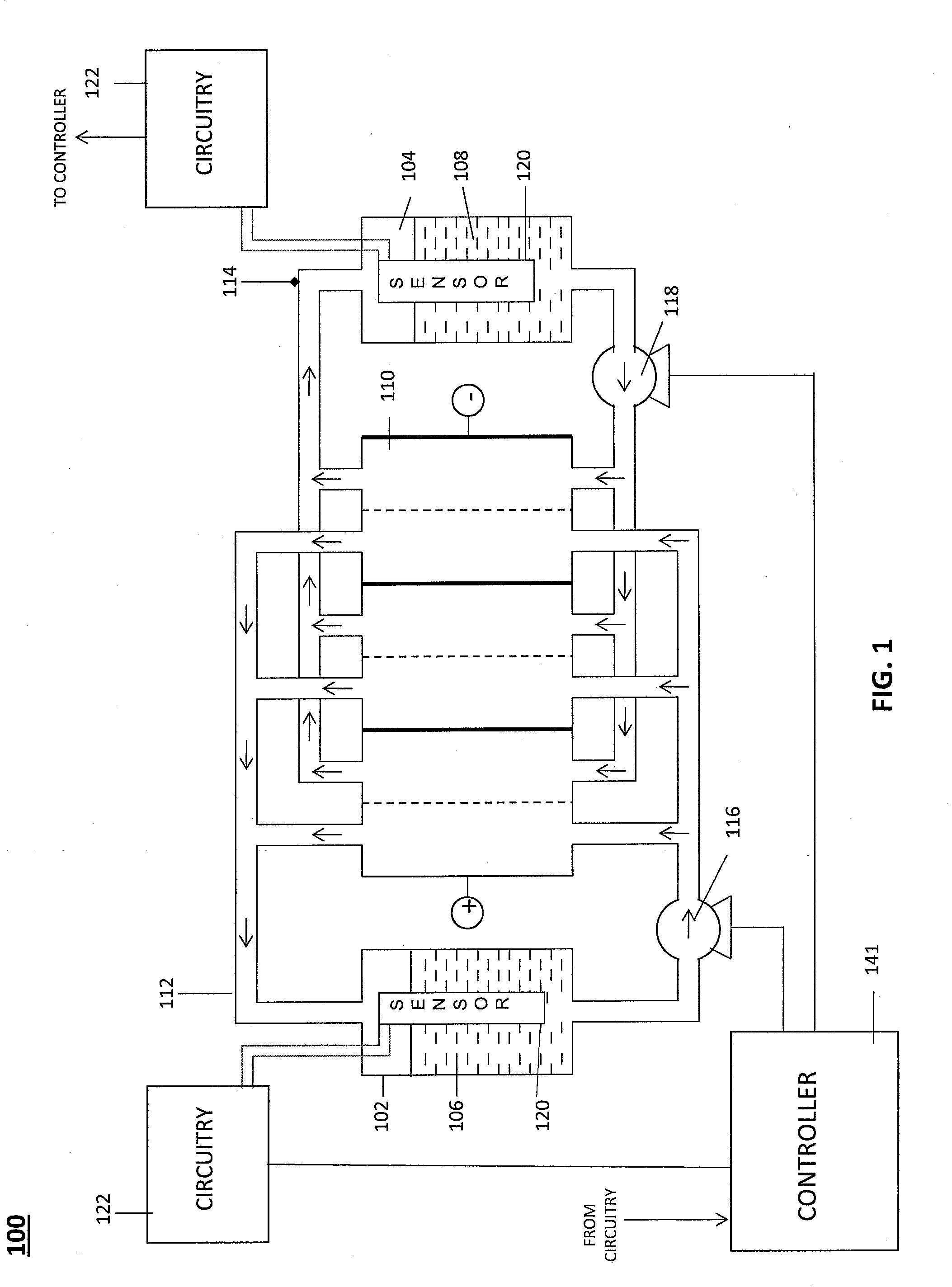

Level Sensor for Conductive Liquids

A sensor for measuring a level of a conductive liquid, is provided. The sensor includes at least two electrodes that can be positioned in a holding tank so as to be partially submerged in the conductive liquid, sensor leads coupled to the at least two electrodes, and circuitry and a controller for determining the properties of the electrolyte, the circuitry being coupled to the at least two electrodes via the sensor leads, and the controller being coupled to the circuitry. The sensor may be used as an electrolyte level sensor in a flow battery system.

Owner:IMERGY POWER SYST

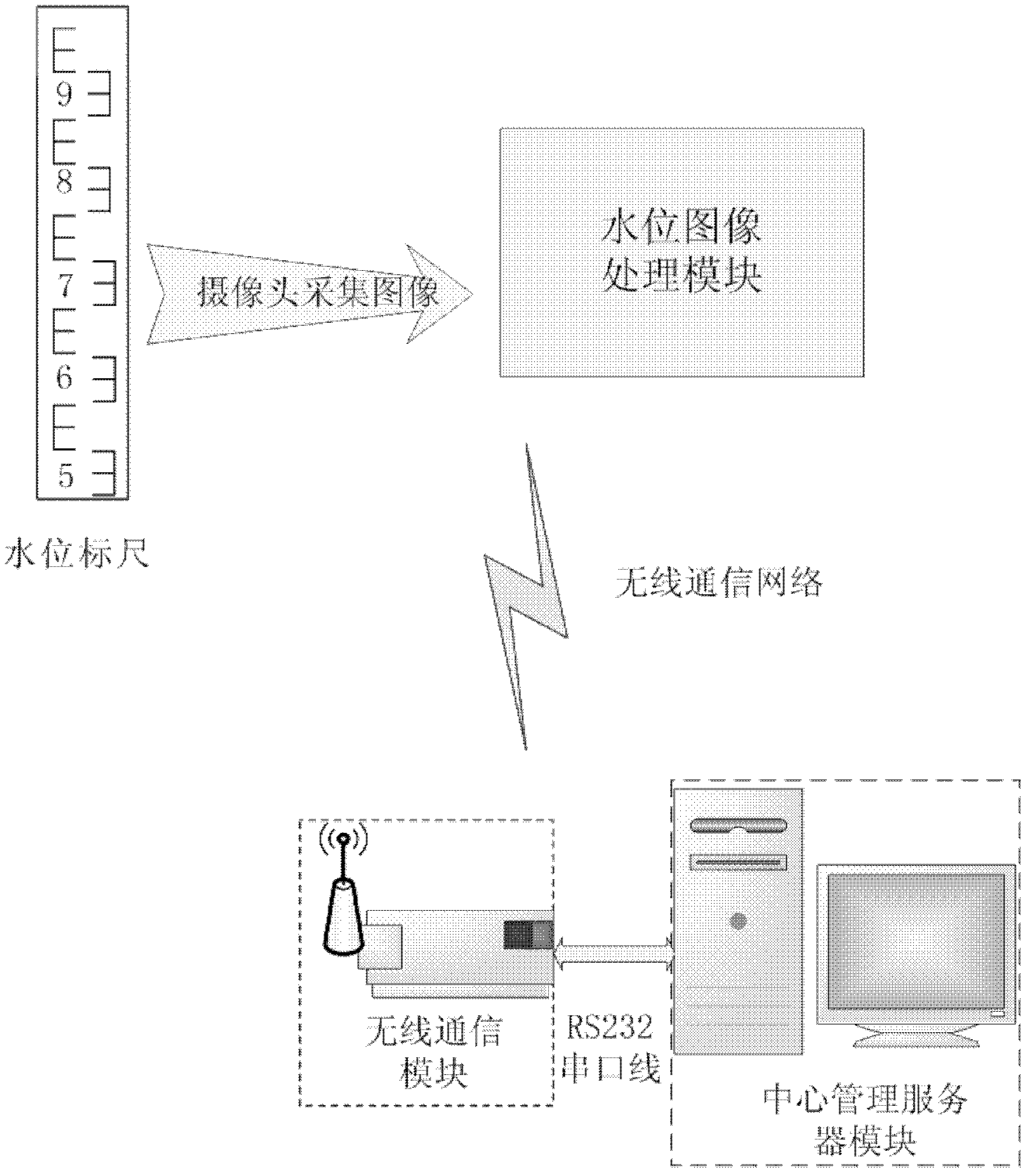

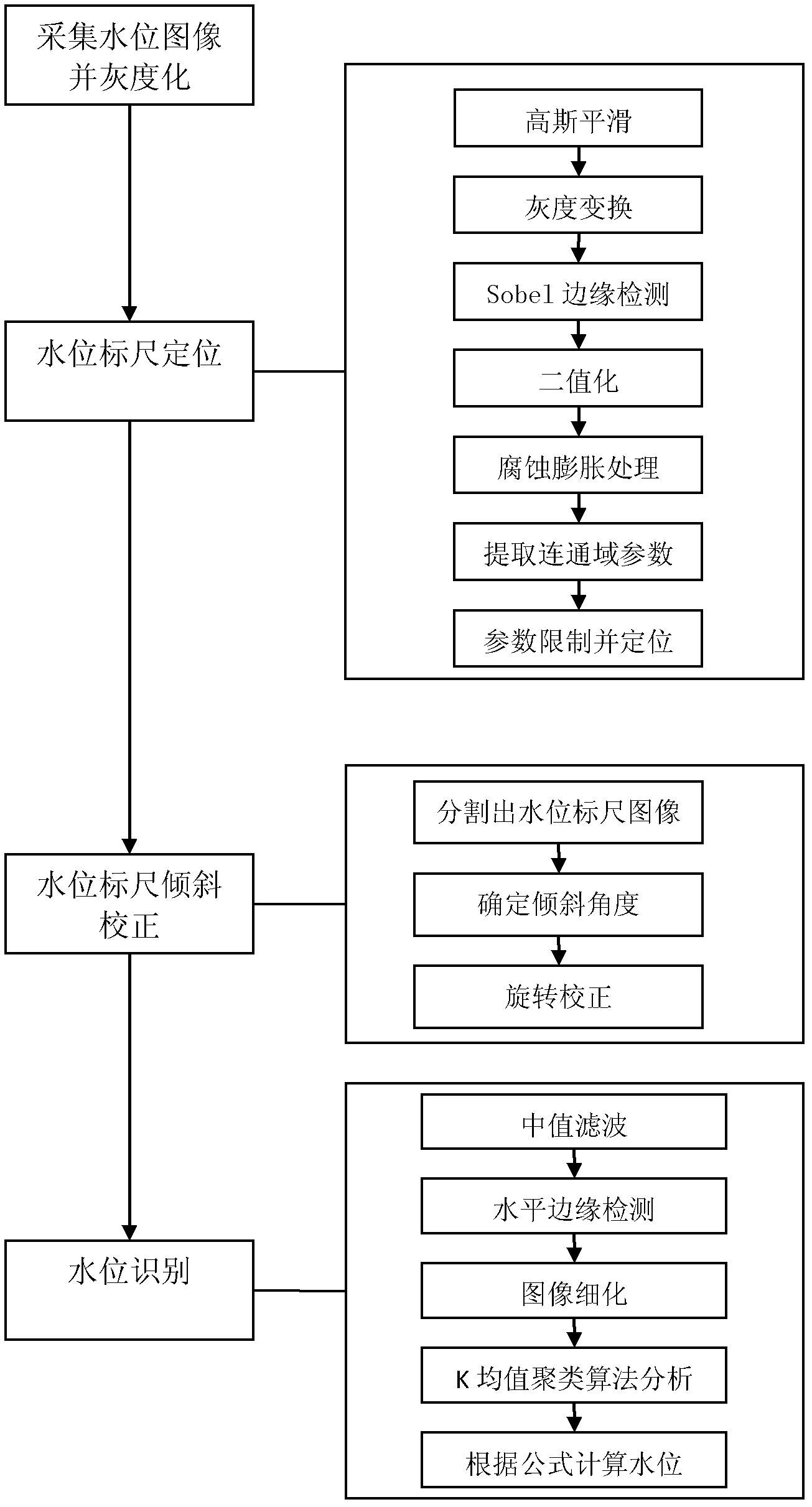

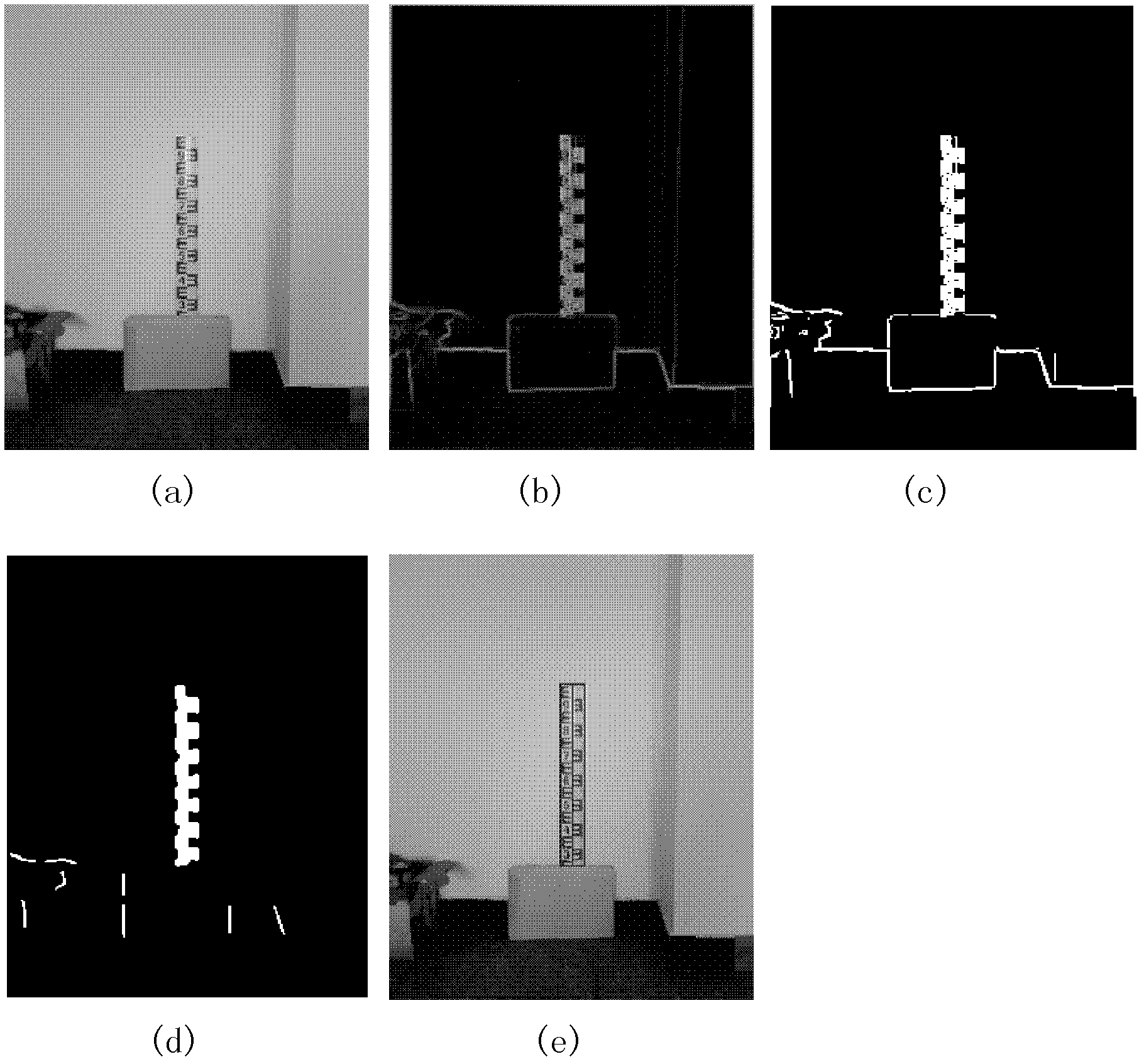

Water level monitoring system based on image processing and method

InactiveCN102494733AHigh speedHigh precisionImage enhancementLevel indicators by physical variable measurementImaging processingMonitoring system

The invention discloses a water level monitoring system based on image processing and a method, which mainly solve the problem that water level cannot be monitored automatically in the prior art. The water level monitoring system comprises a water level gauge, a water level image processing module, a wireless communication module and a central management server module. Working principle of the system is that: firstly the water level gauge is used for marking the water level, water level images marked by the water level gauge can be collected by a camera, the water level image processing module further performs automatic positioning, skew correcting and recognizing on the water level gauge in the water level images to obtain water level data and transmits the water level data to the wireless communication module through a wireless communication network, then the wireless communication module transmits the received water level data to the central management server module which stores the received water level data into a computer data base so as to draw current hydrograph in real time, when the current water level is higher than a preset water level, alarm information can be given out, and accordingly automatic monitoring of the water level can be achieved.

Owner:XIDIAN UNIV

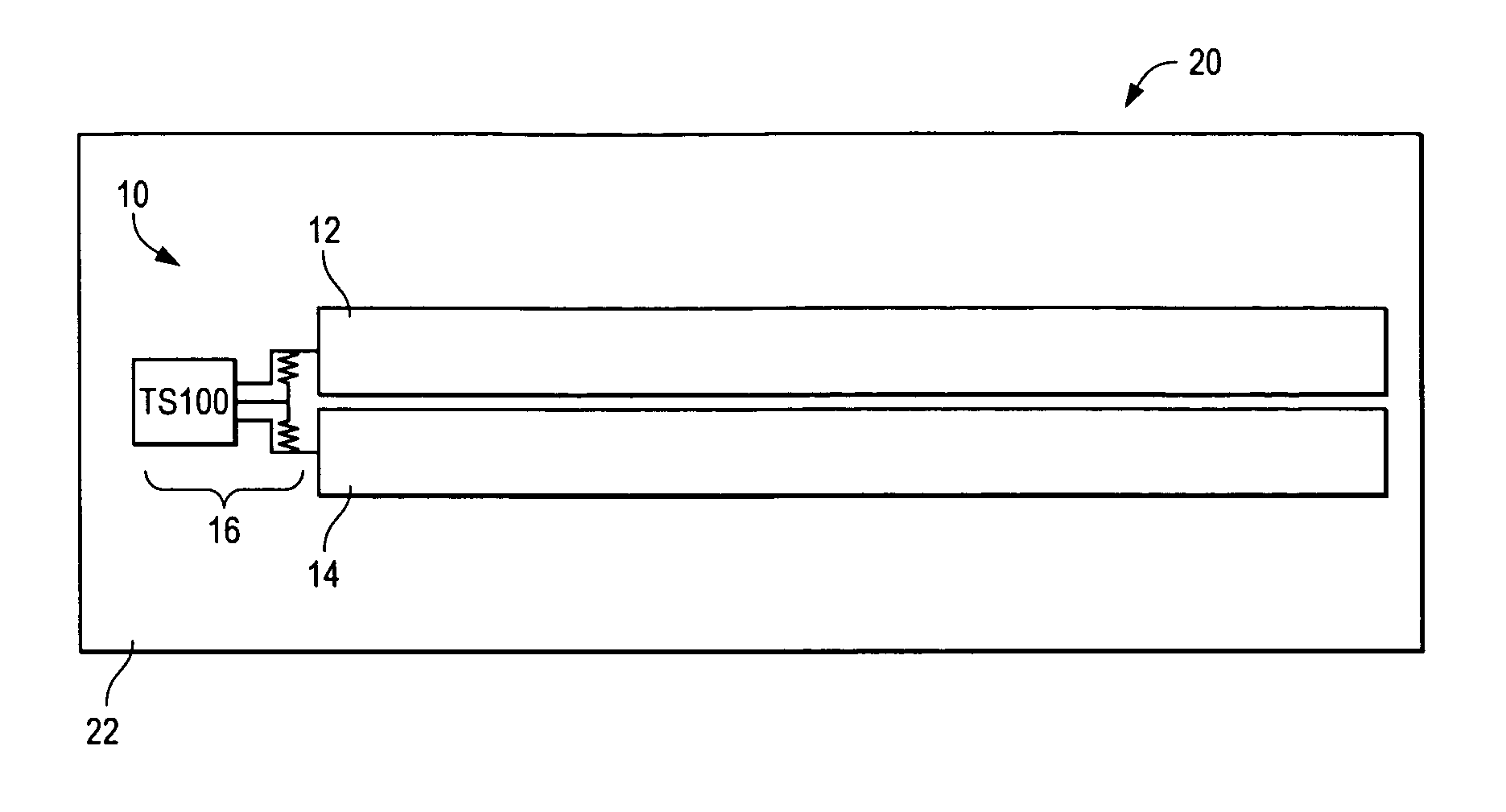

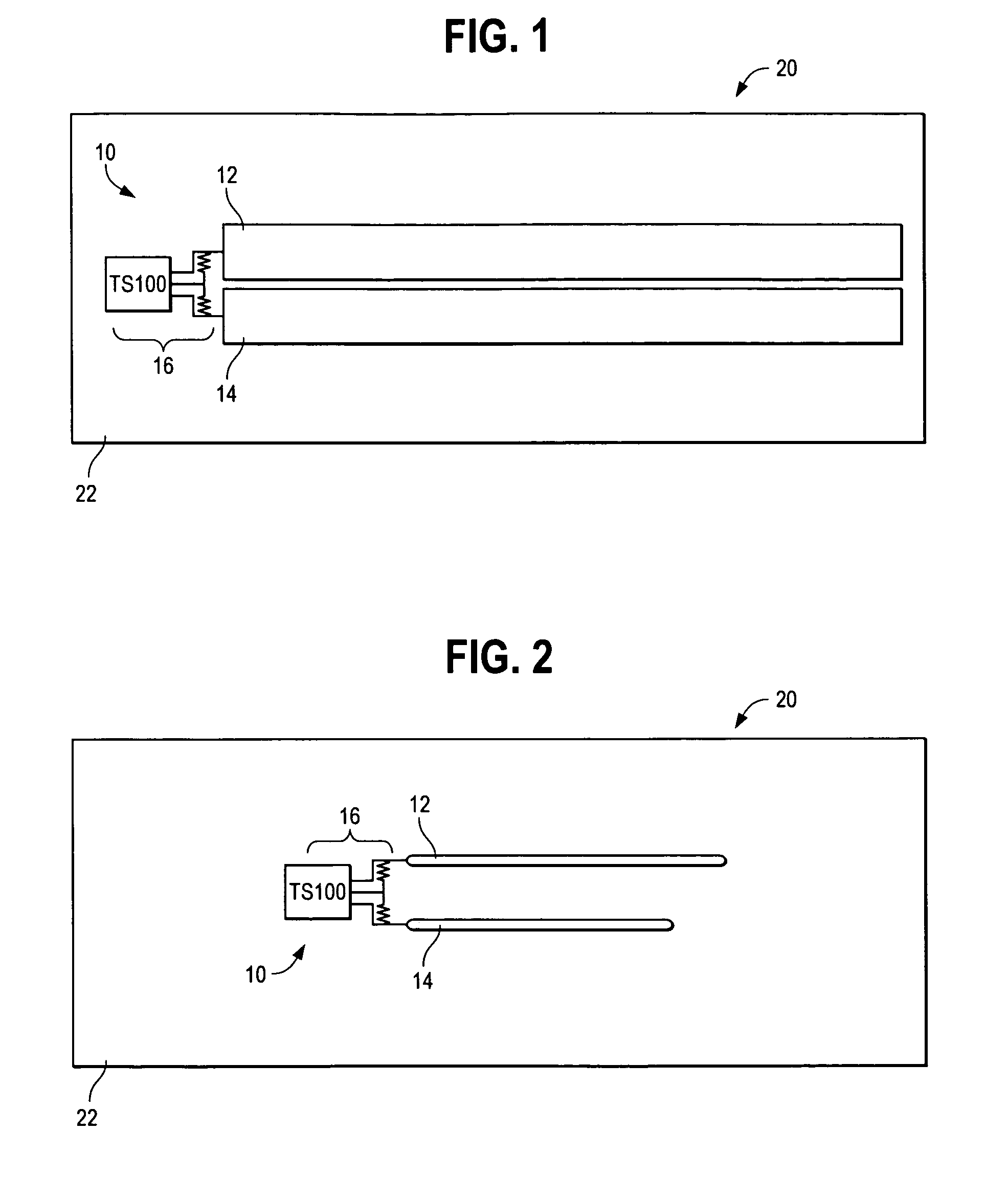

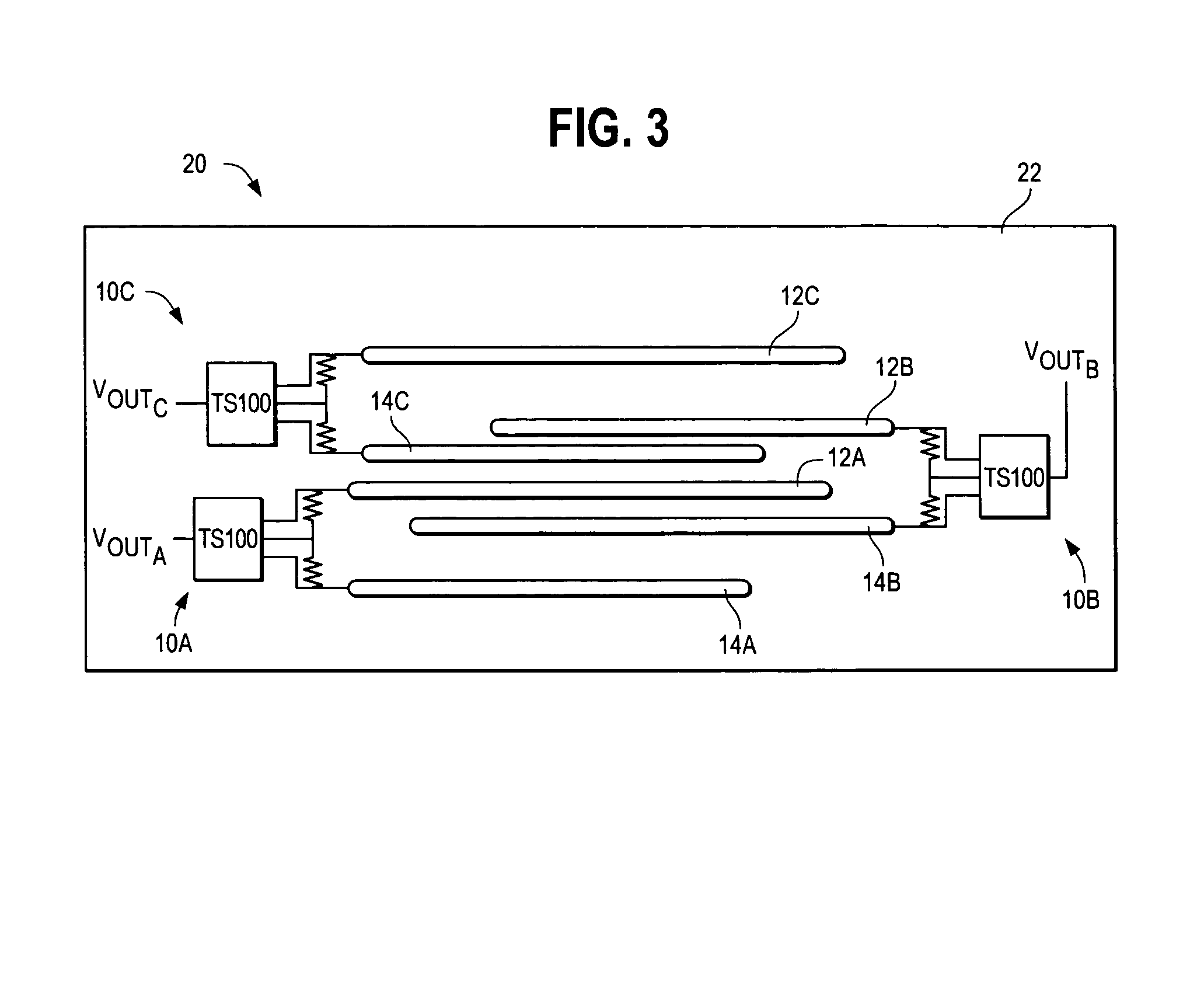

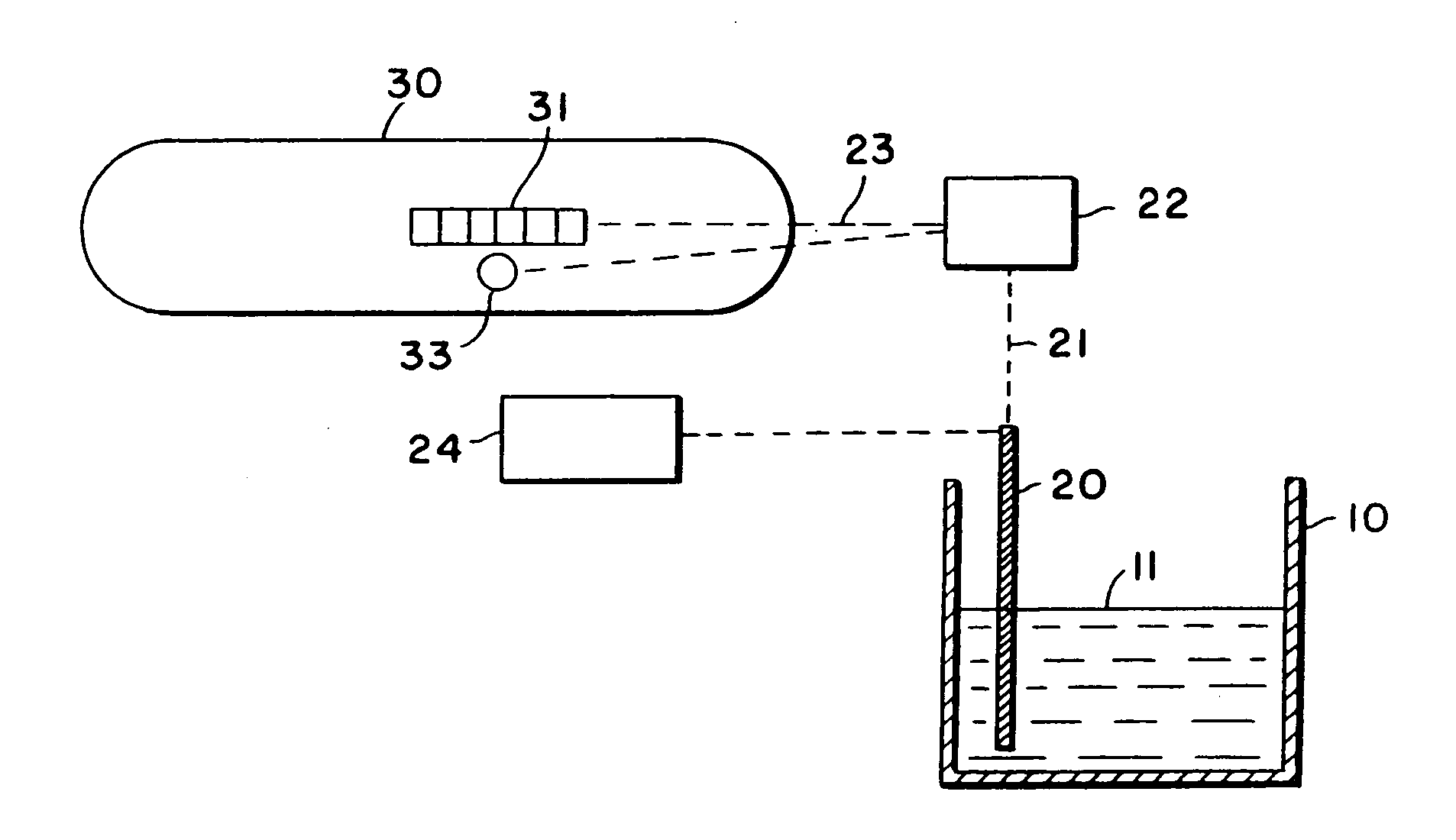

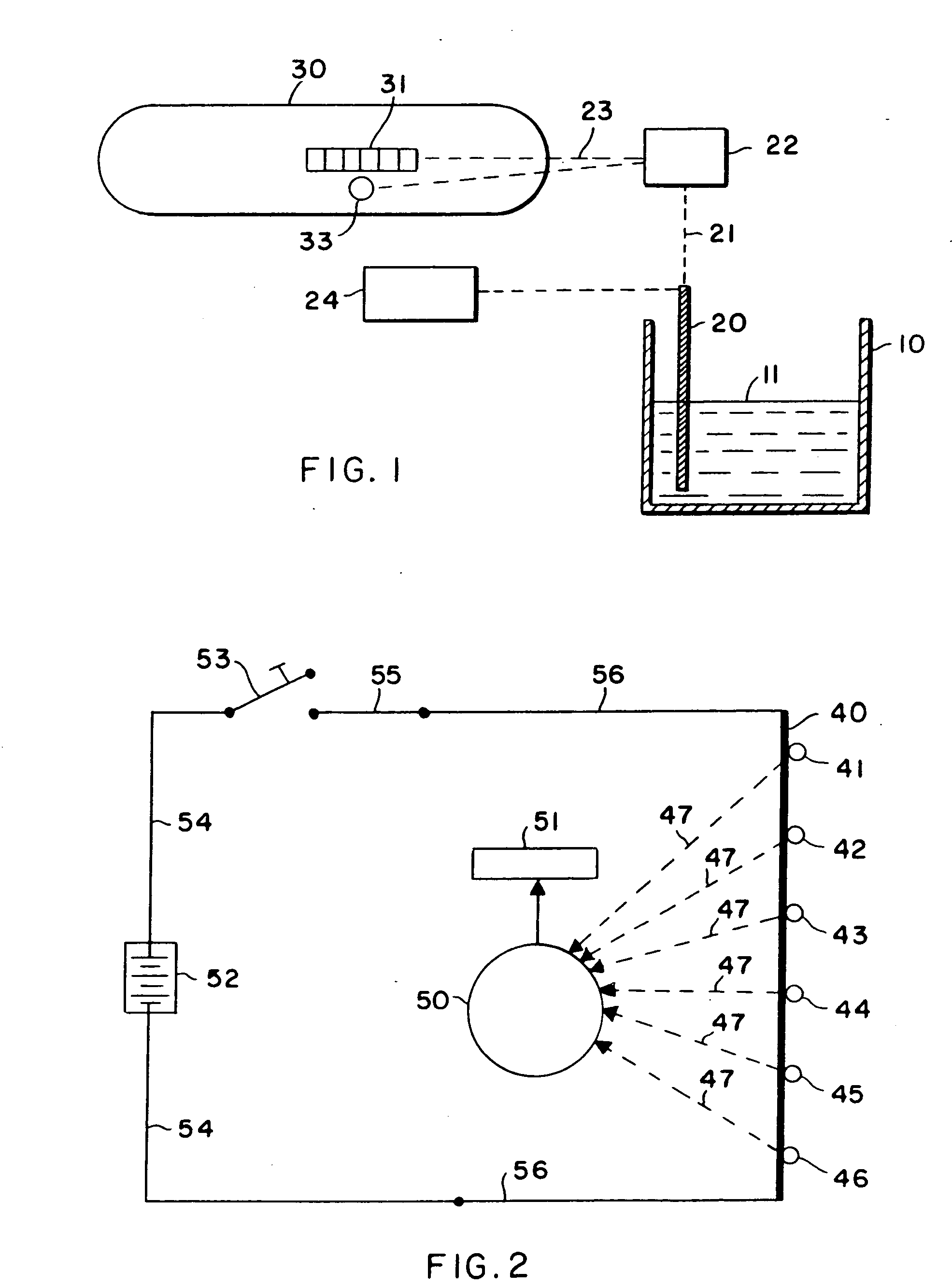

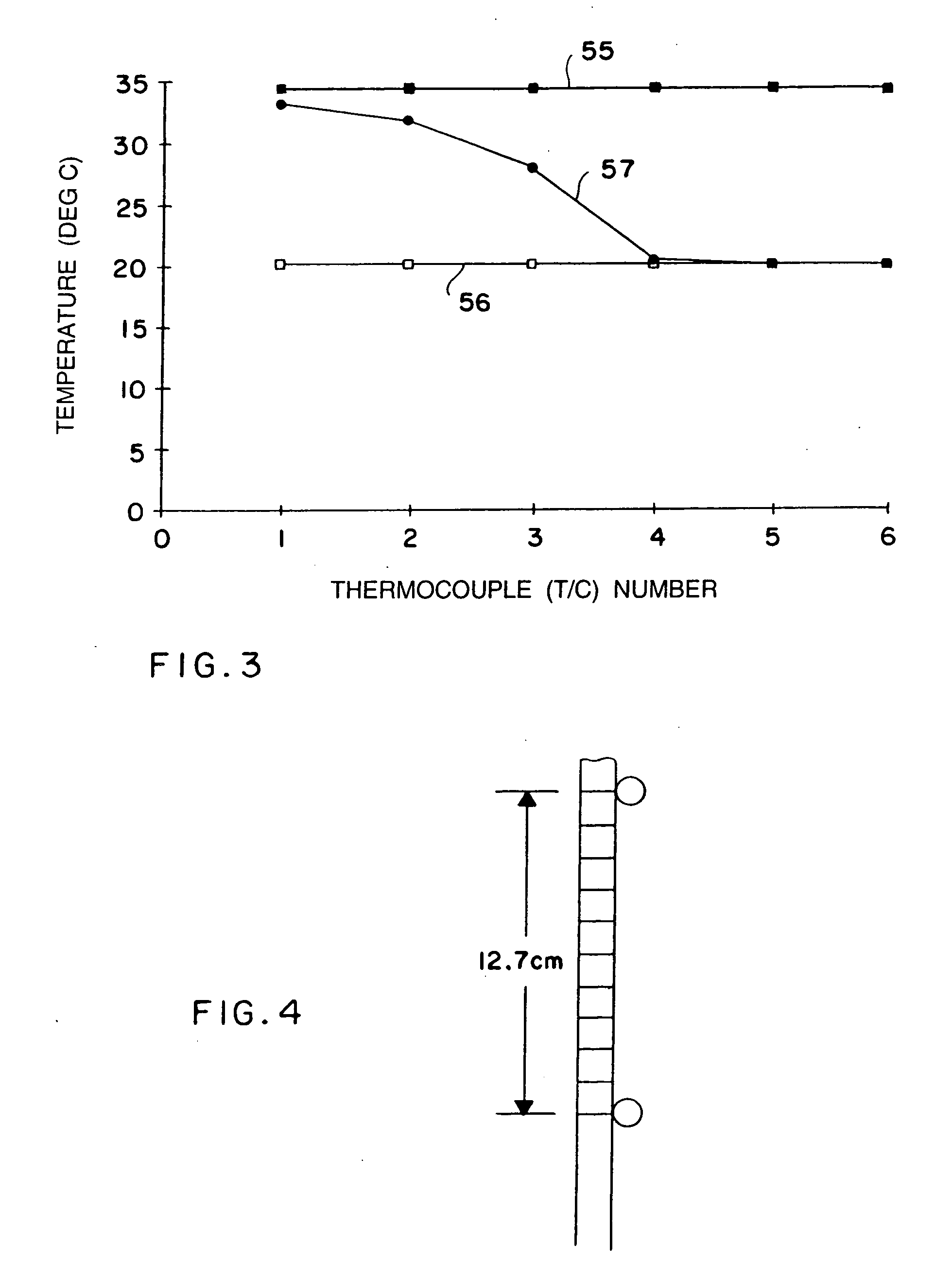

Liquid sensor and ice detector

InactiveUS20050126282A1Difference in efficiencyRemove heat moreMachines/enginesLubrication indication devicesScreen printingLiquid temperature

An improved apparatus and a method of measuring and interpreting reliably, simply and accurately the information on continuous liquid level, liquid temperature and other liquid properties within a vessel. The apparatus could be made of a powered heater element and temperature sensors can be screen-printed, vacuum deposited, etched, welded, soldered or plated on one or both sides of a single rigid or a flexible substrate. The geometry of the heater determines the curve shape, such as steepness or shallowness of a temperature profile along a heater. Various parallel and serial configurations of thermocouples or temperature sensors can be used to measure the temperature along a heater. Simultaneous measurements from all the temperature sensors, before and after heat is applied, are used to generate accurate temperature profiles for the entire heater. Different features of the temperature profiles will determine accurately the liquid level, liquid temperature and other liquid properties. Apparatus of the invention may also be used to detect ice formation.

Owner:MAATUK JOSEF

Apparatus and methods for monitoring water consumption and filter usage

InactiveUS20050229699A1Accurate and robust methodWear is exacerbatedWater treatment parameter controlSpecific water treatment objectivesElectricityFilter media

Apparatus and methods for employing electrical properties of water to indicate the level of filtered water in a filtered water container. The container is fitted with a hopper that holds unfiltered water. The hopper is fitted at its base with a removable and replaceable filter cartridge. Water is filtered by draining through the filter medium contained in the filter cartridge into the lower portion of the container. The water level in the lower portion of the container is monitored by means of one or more water level detector strips in the lower portion of the container. The detector strips are in electrical communication with a detection circuit and a control unit. The control unit uses the detection strips to monitor water level and uses such data to track filtered water consumption and to determine when the filter cartridge should be replaced.

Owner:FOOK TIN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com