Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

547 results about "Size determination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sample size determination. Sample size determination is the act of choosing the number of observations or replicates to include in a statistical sample. The sample size is an important feature of any empirical study in which the goal is to make inferences about a population from a sample.

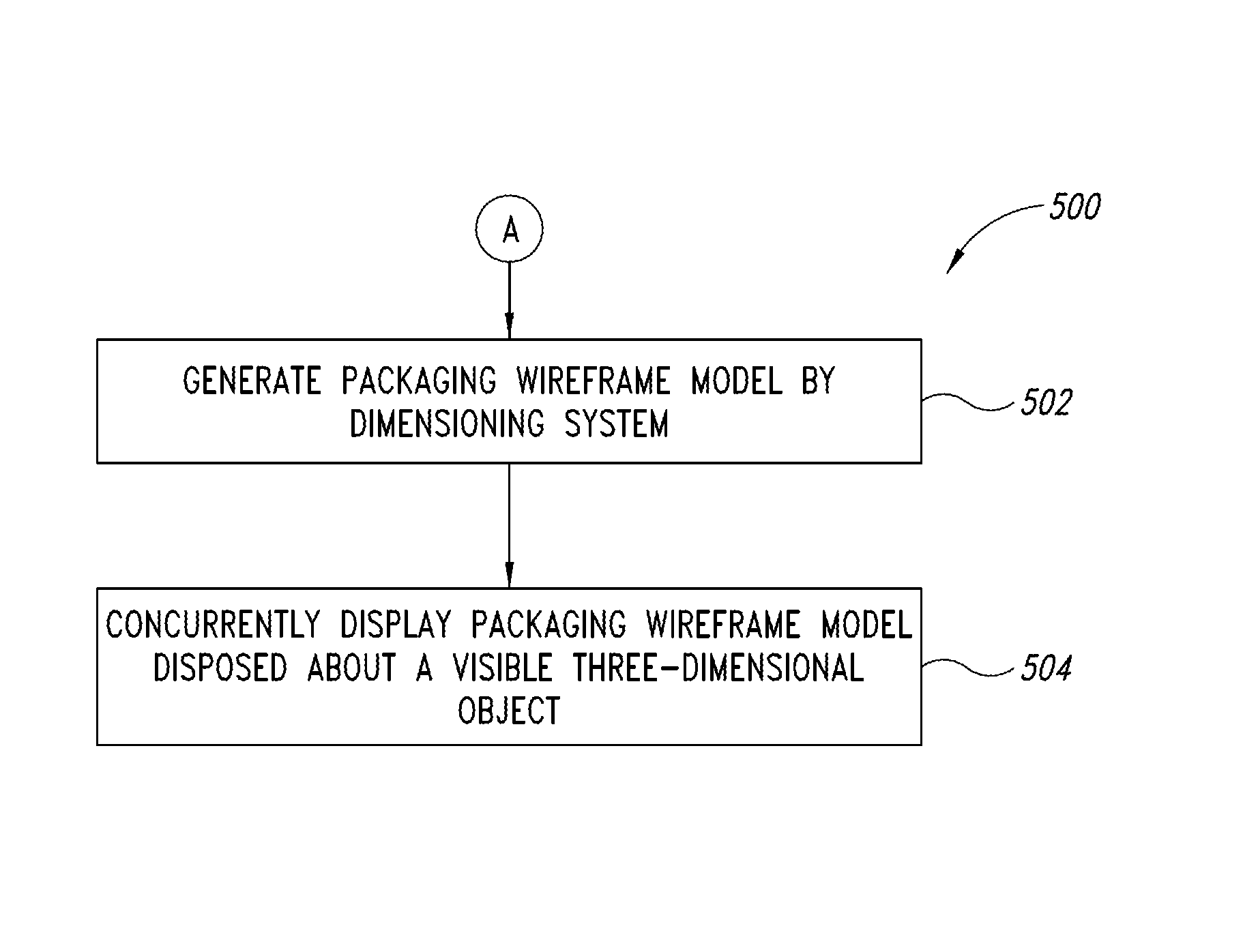

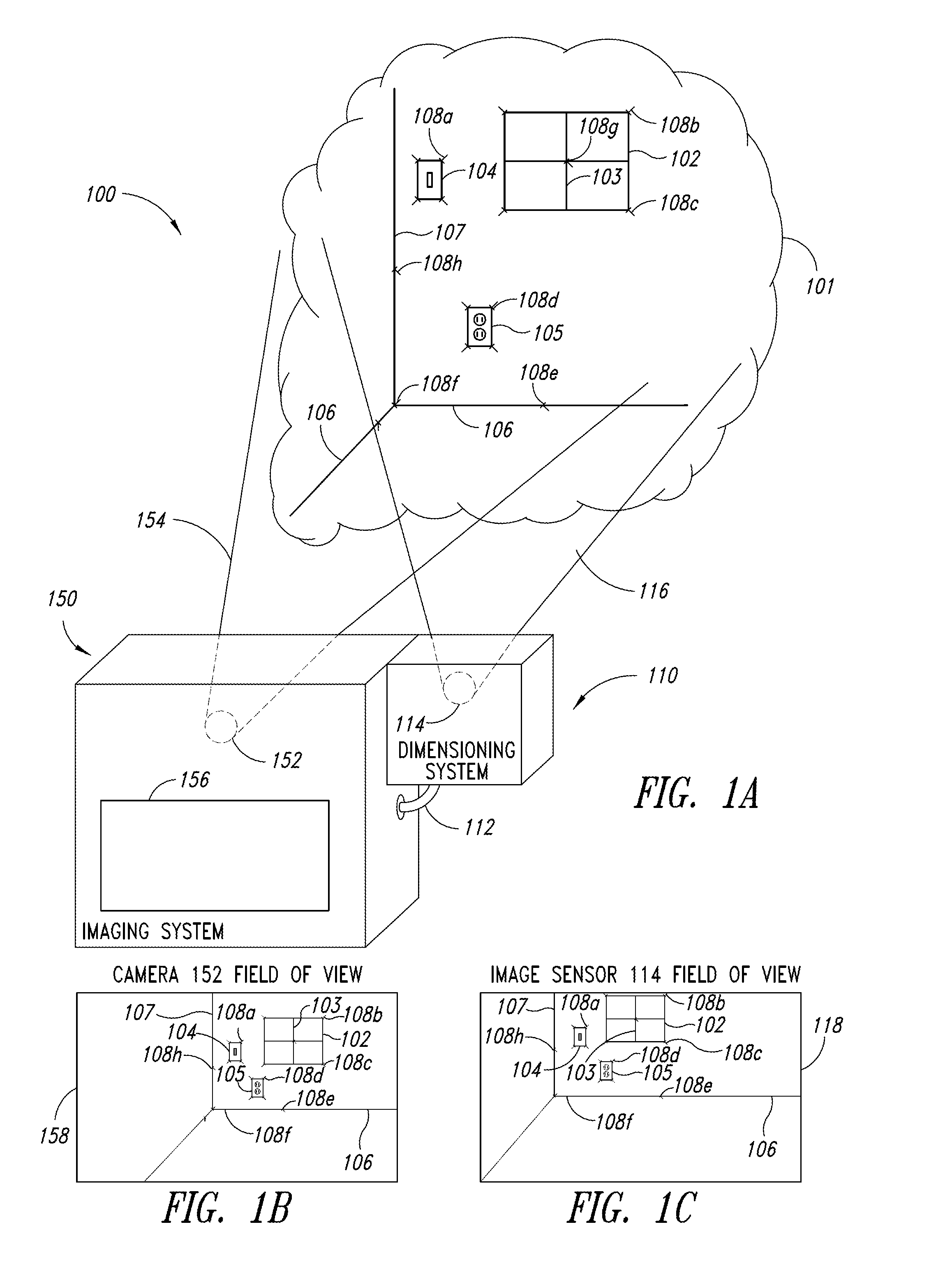

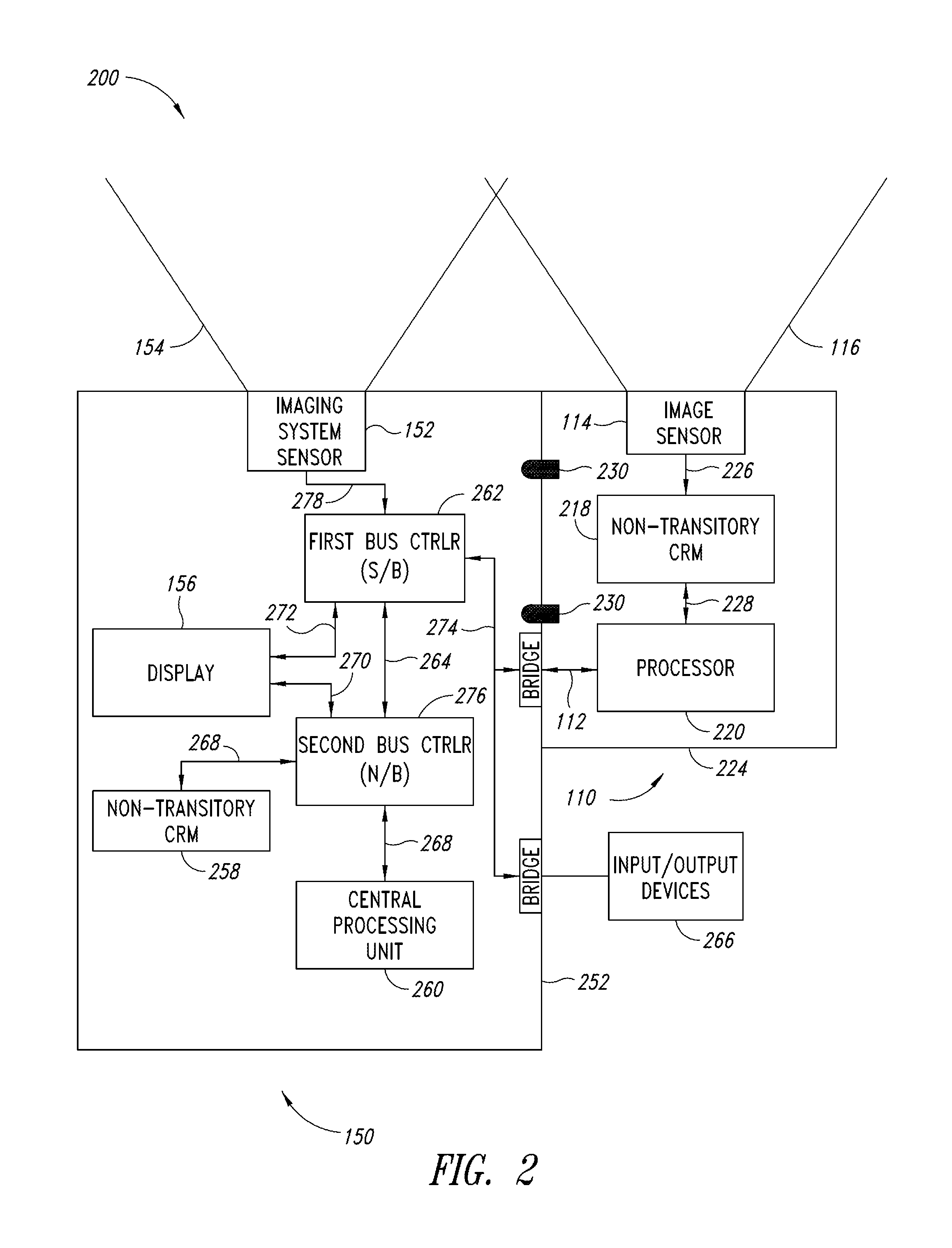

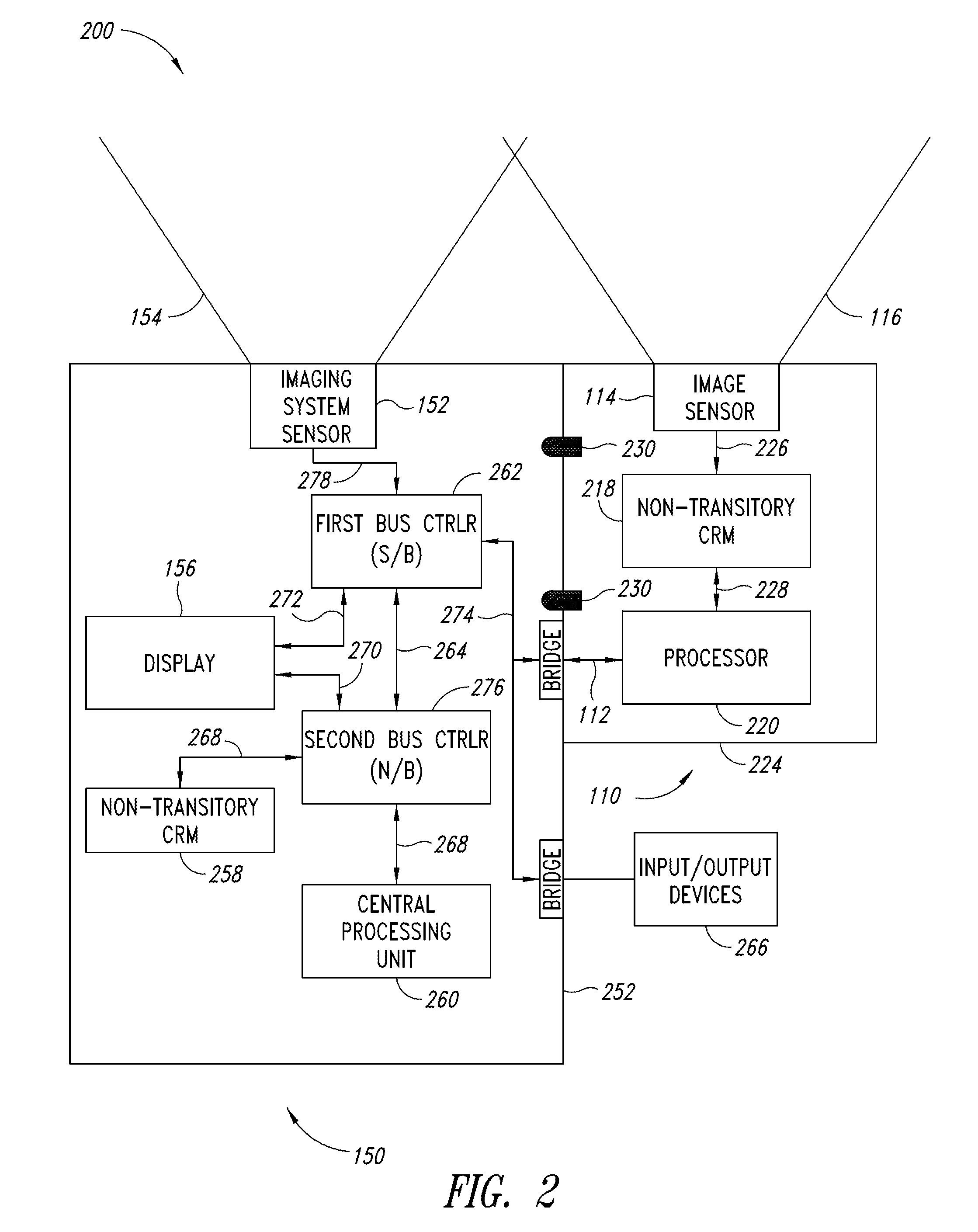

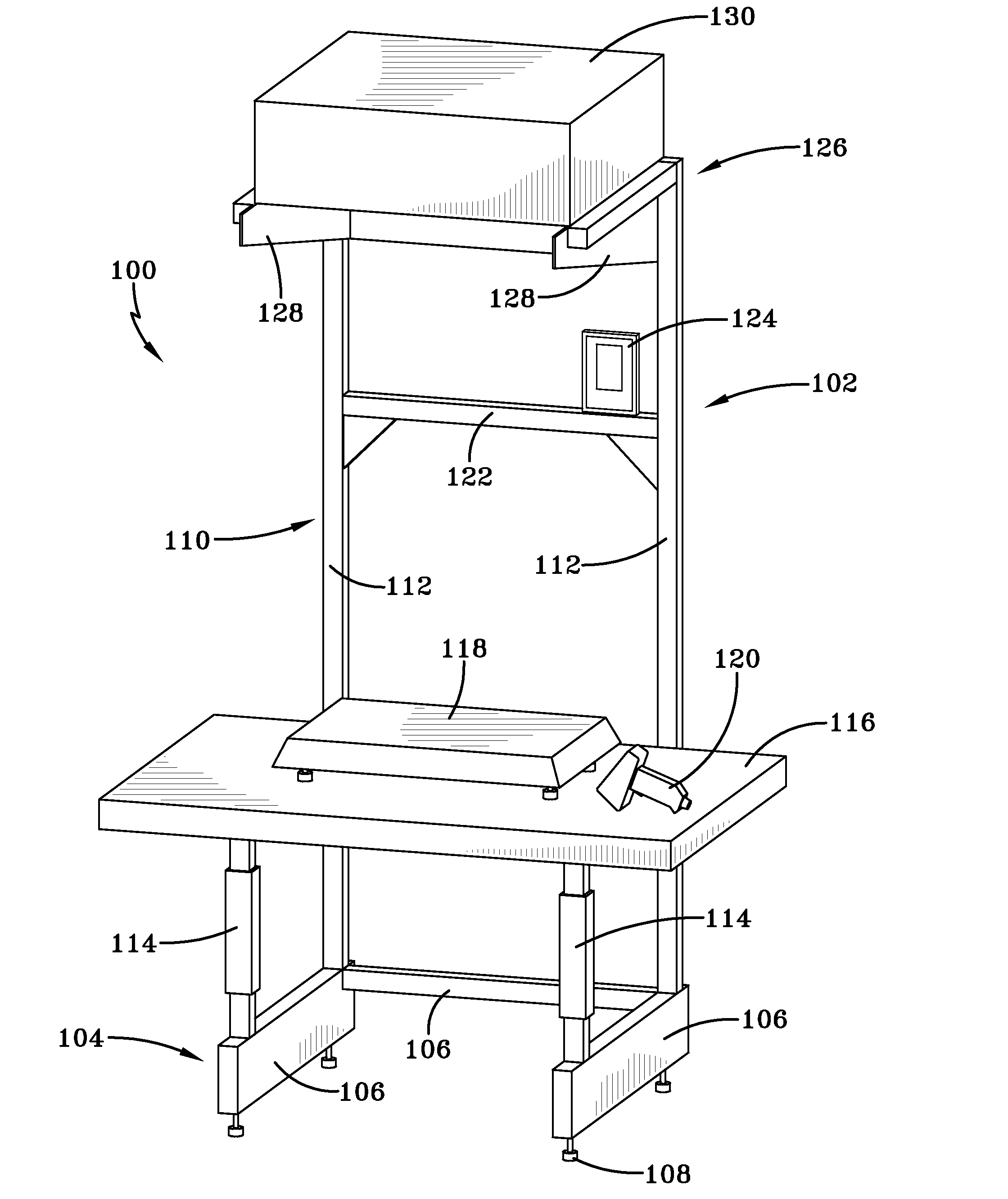

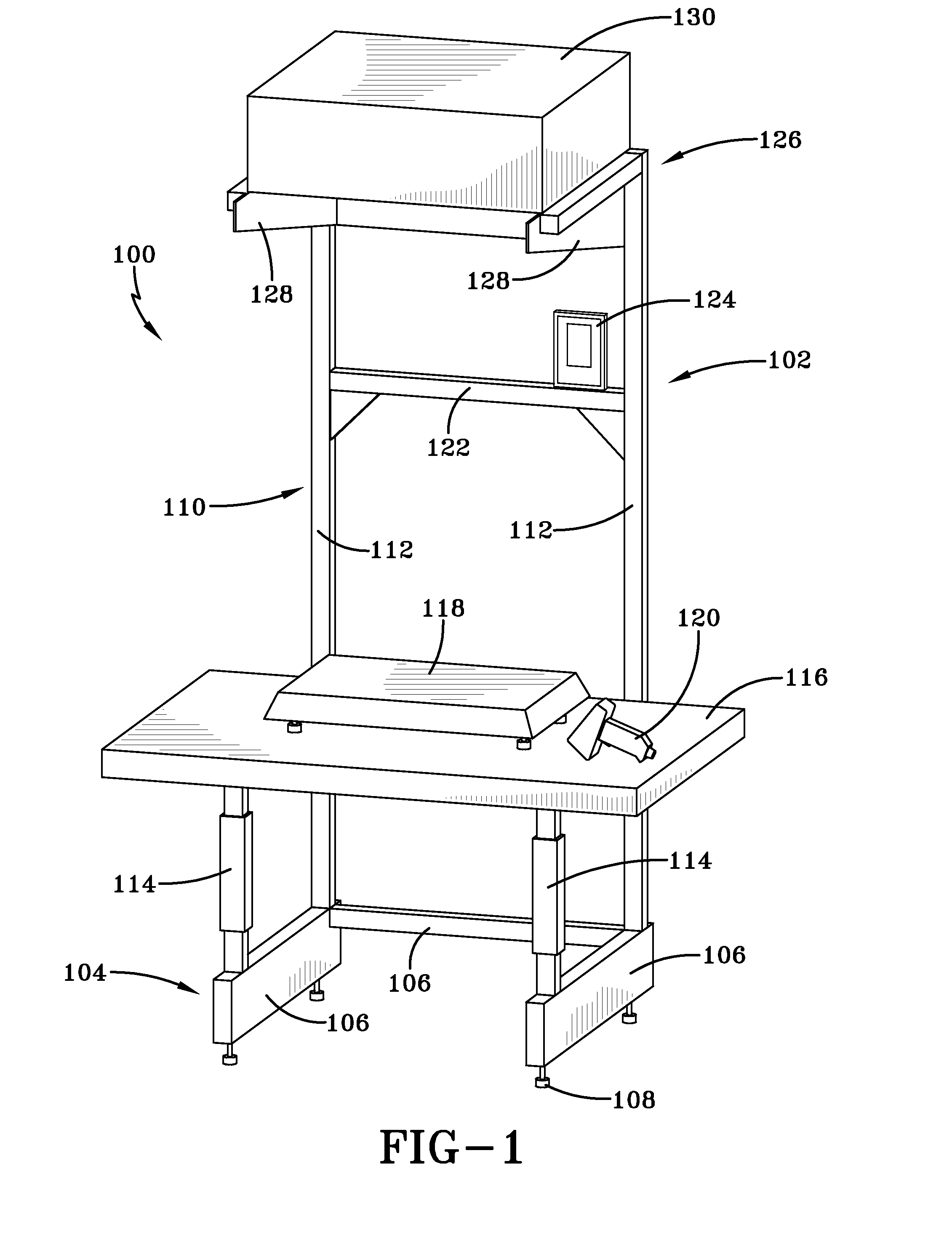

Dimensioning system calibration systems and methods

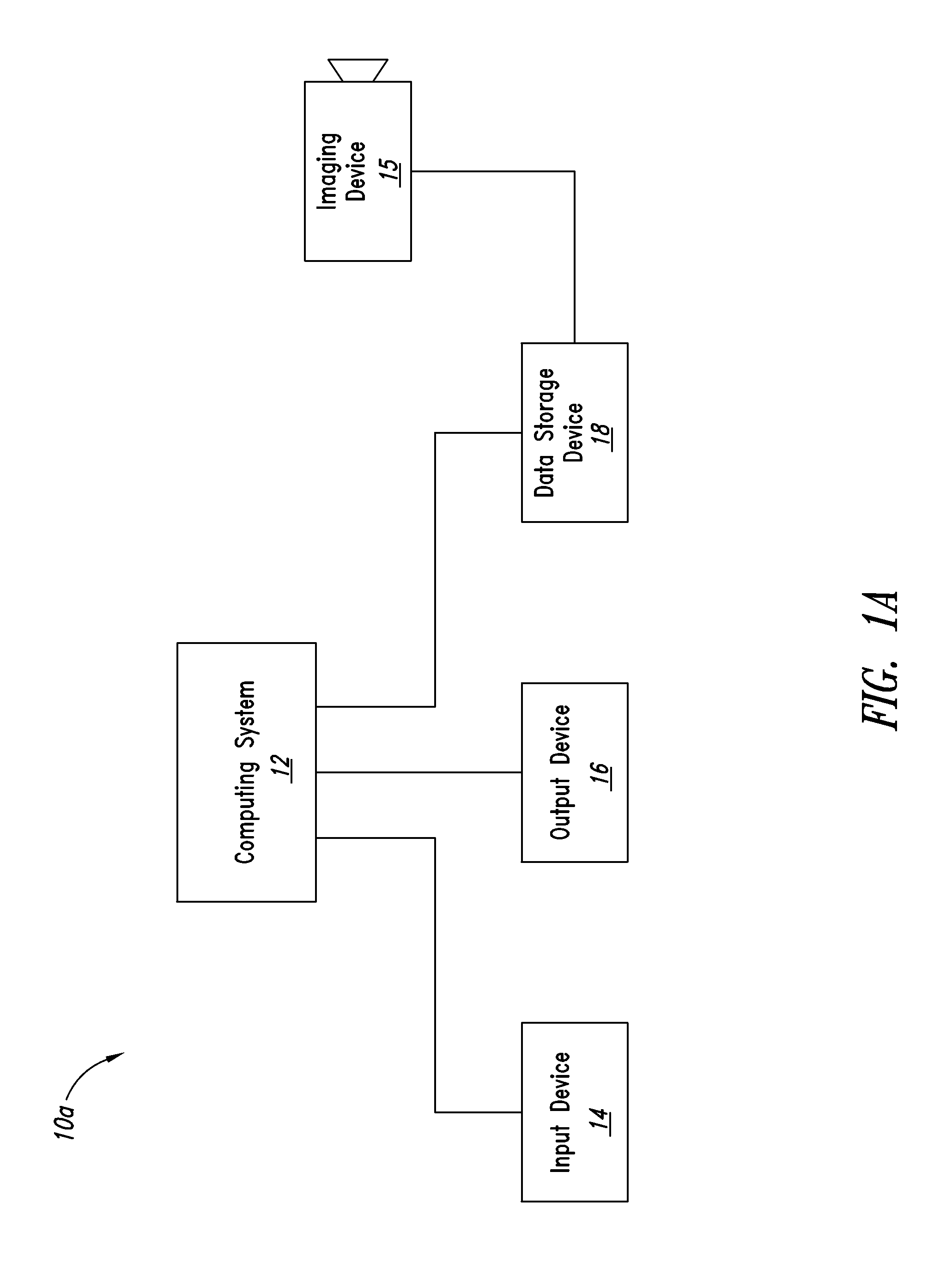

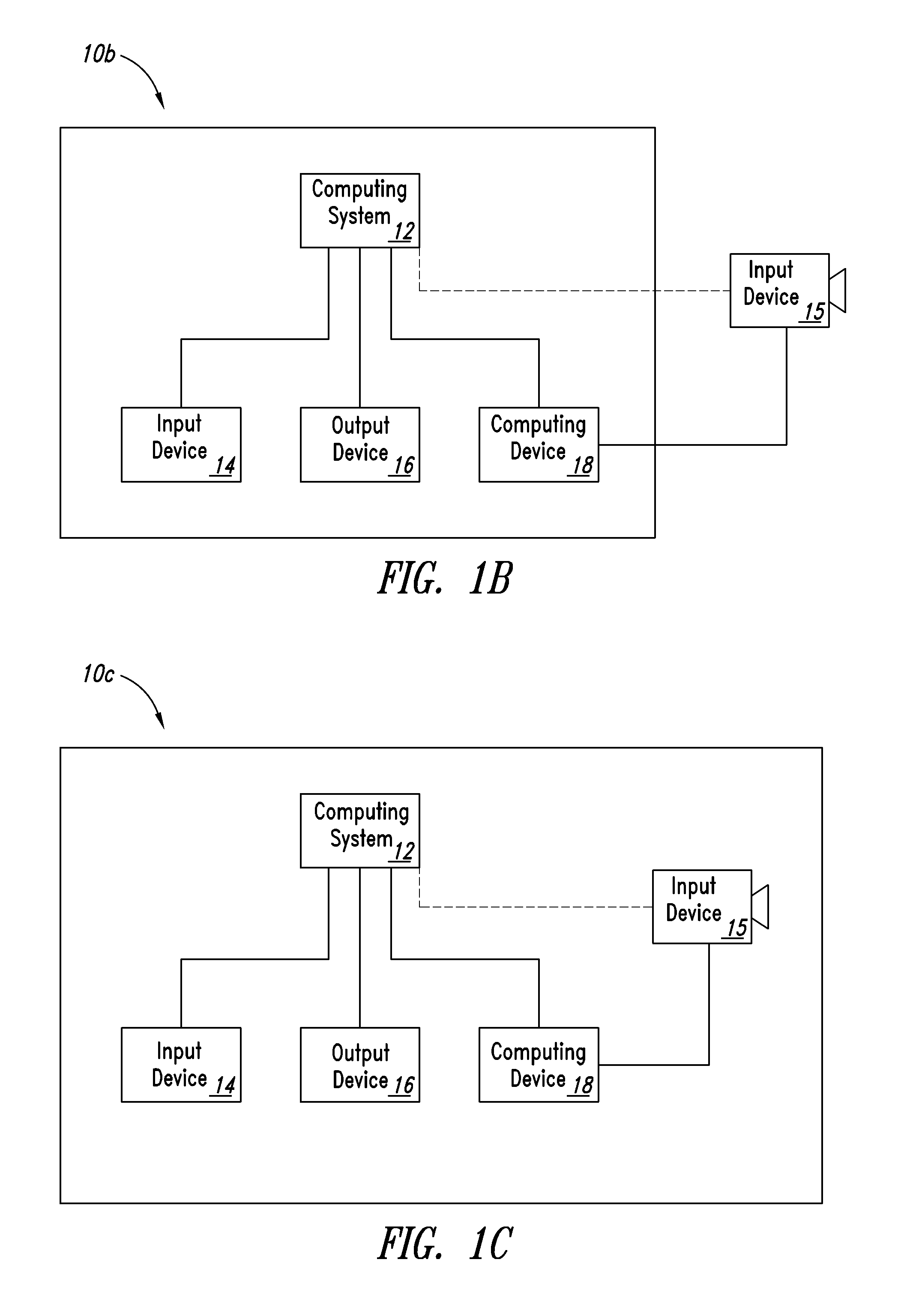

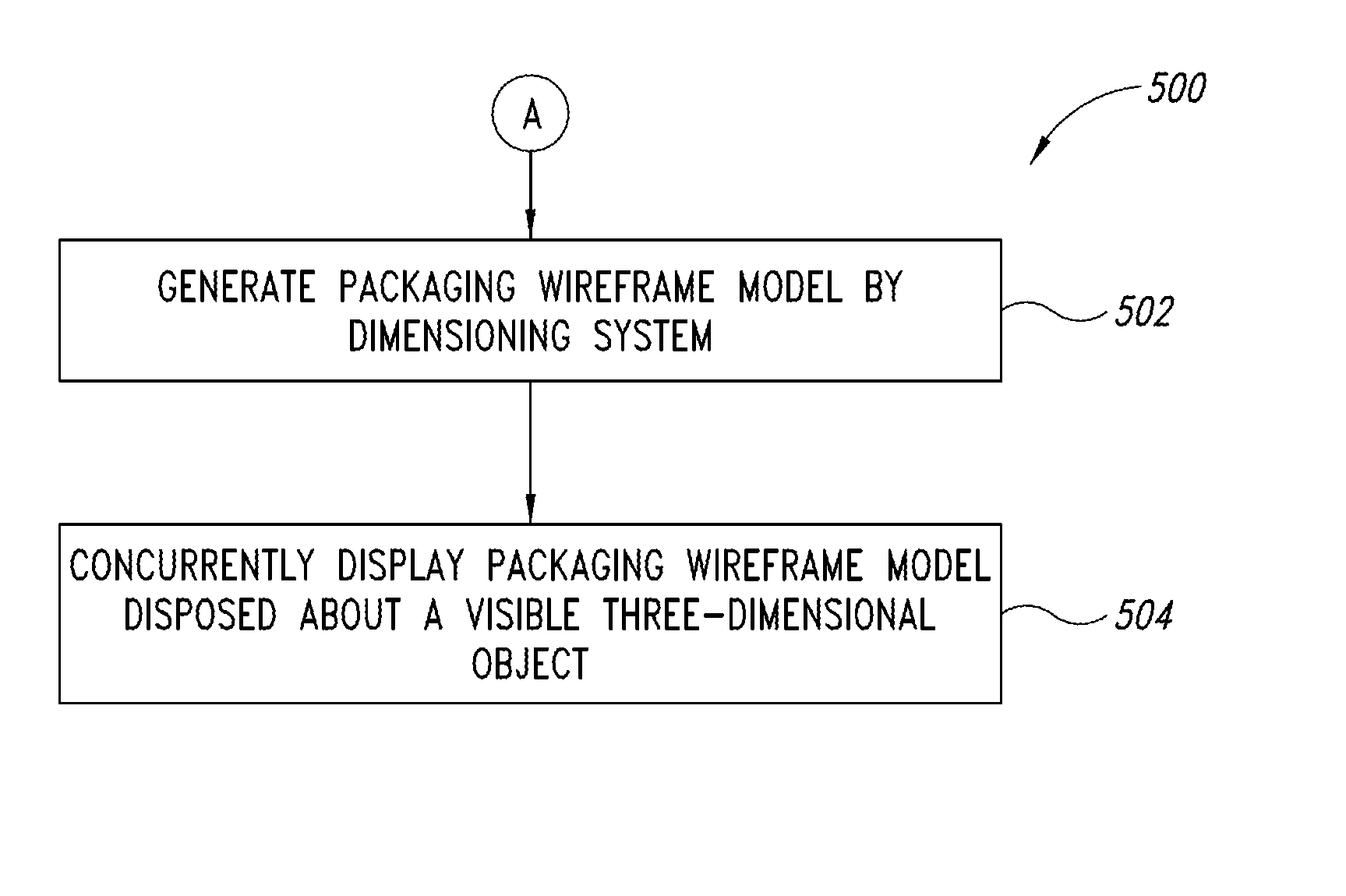

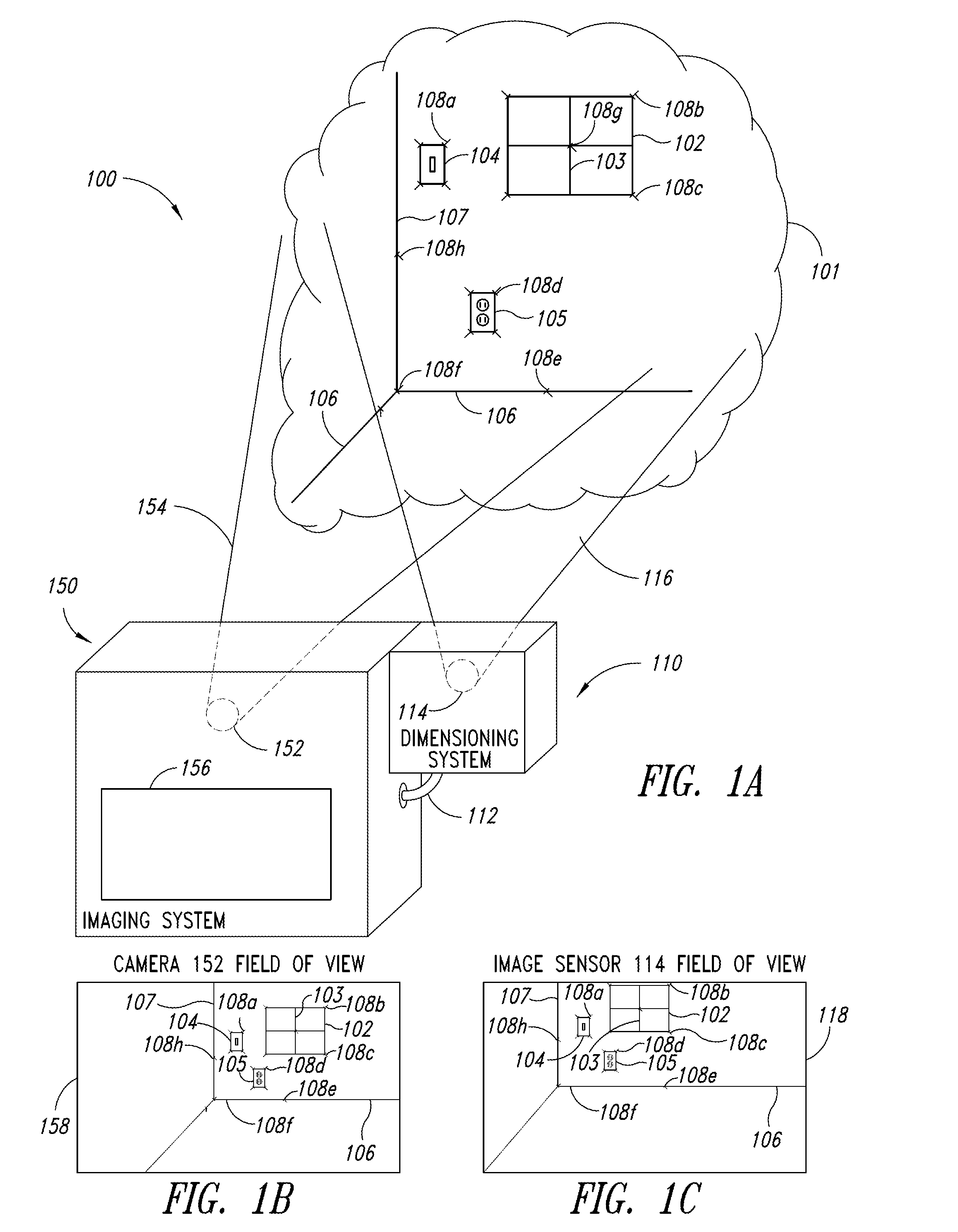

Systems and methods of determining the volume and dimensions of a three-dimensional object using a dimensioning system are provided. The dimensioning system can include an image sensor, a non-transitory, machine-readable, storage, and a processor. The dimensioning system can select and fit a three-dimensional packaging wireframe model about each three-dimensional object located within a first point of view of the image sensor. Calibration is performed to calibrate between image sensors of the dimensioning system and those of the imaging system. Calibration may occur pre-run time, in a calibration mode or period. Calibration may occur during a routine. Calibration may be automatically triggered on detection of a coupling between the dimensioning and the imaging systems.

Owner:INTERMEC IP

Semi-automatic dimensioning with imager on a portable device

A method of operating a dimensioning system to determine dimensional information for objects is disclosed. A number of images are acquired. Objects in at least one of the acquired images are computationally identified. One object represented in the at least one of the acquired images is computationally initially selected as a candidate for processing. An indication of the initially selected object is provided to a user. At least one user input indicative of an object selected for processing is received. Dimensional data for the object indicated by the received user input is computationally determined.

Owner:INTERMEC IP CORP

Dimensioning system calibration systems and methods

Systems and methods of determining the volume and dimensions of a three-dimensional object using a dimensioning system are provided. The dimensioning system can include an image sensor, a non-transitory, machine-readable, storage, and a processor. The dimensioning system can select and fit a three-dimensional packaging wireframe model about each three-dimensional object located within a first point of view of the image sensor. Calibration is performed to calibrate between image sensors of the dimensioning system and those of the imaging system. Calibration may occur pre-run time, in a calibration mode or period. Calibration may occur during a routine. Calibration may be automatically triggered on detection of a coupling between the dimensioning and the imaging systems.

Owner:INTERMEC IP

Crystal growth devices and systems, and methods for using same

Owner:FLUIDIGM CORP

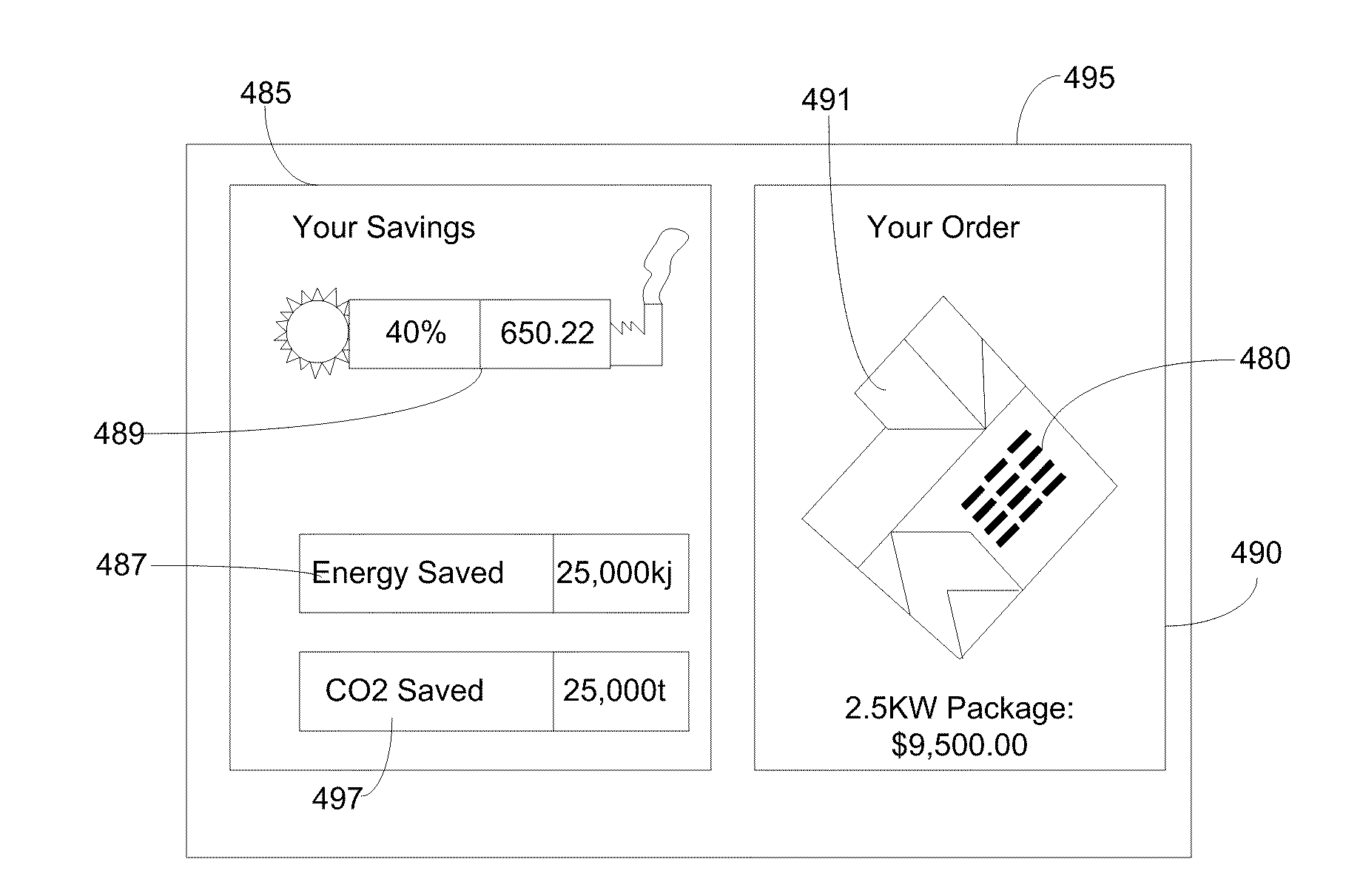

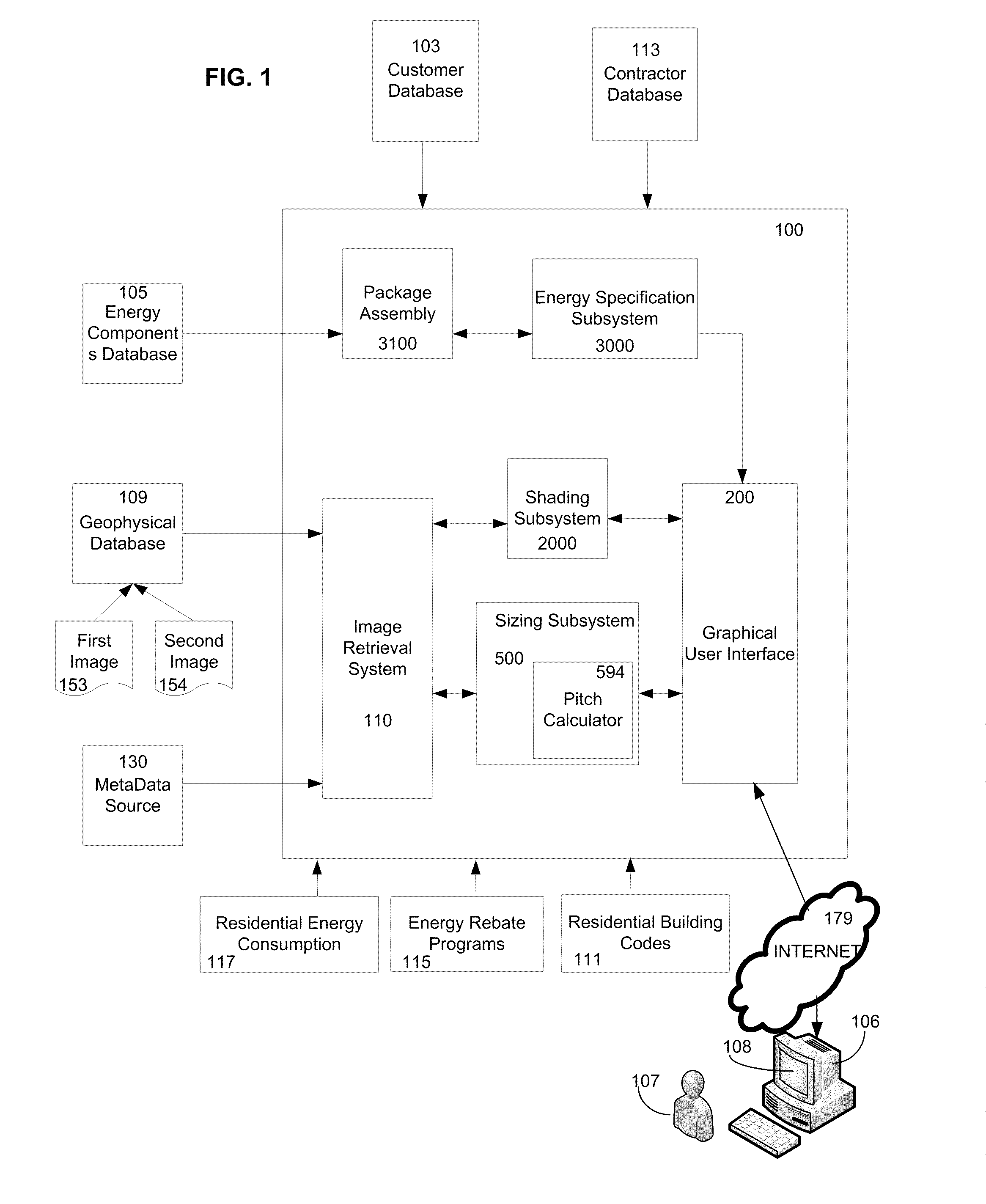

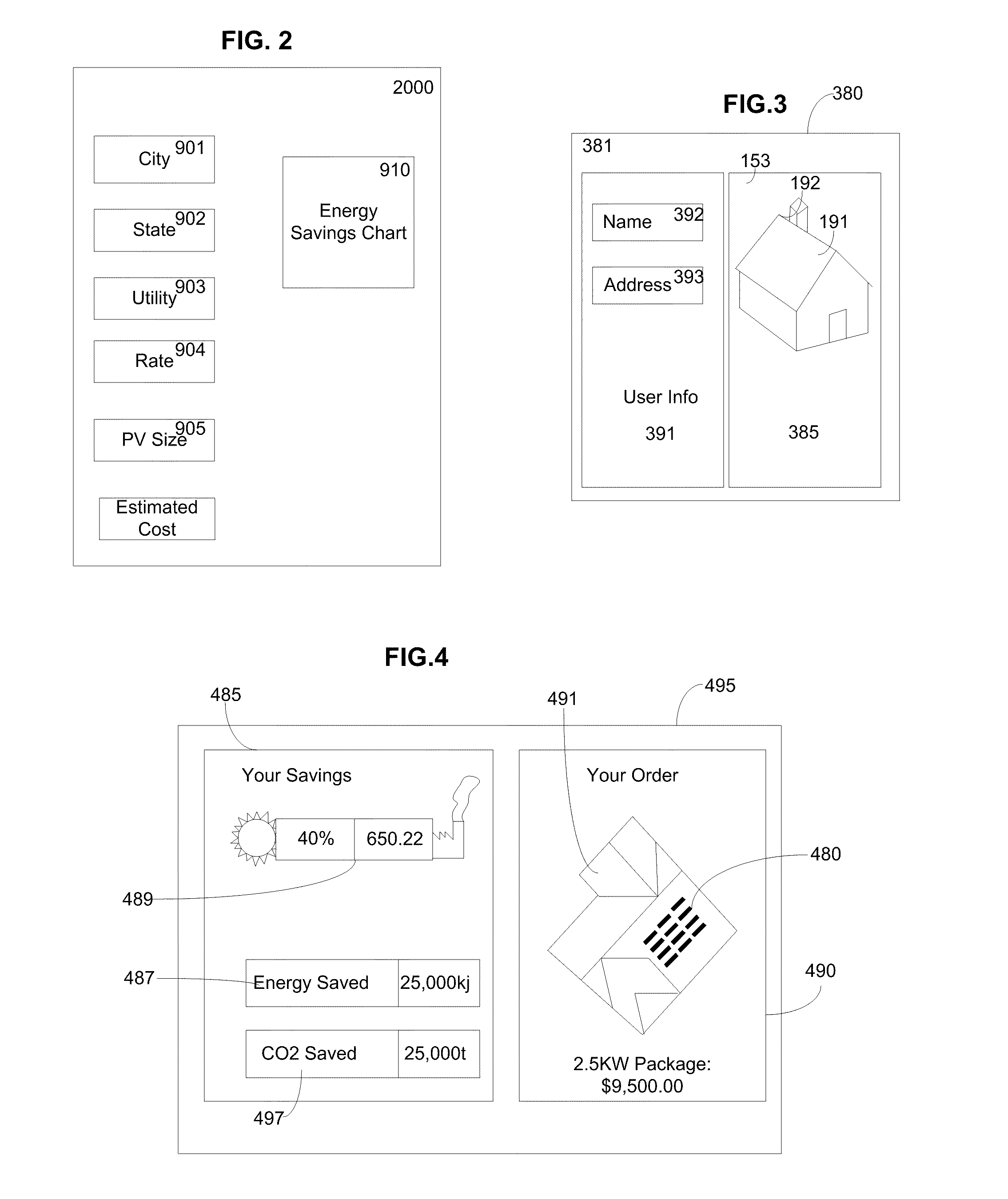

Methods and Systems for Provisioning Energy Systems

ActiveUS20090304227A1Solar heating energySolar heat simulation/predictionThird partySize determination

The invention provides consumers, private enterprises, government agencies, contractors and third party vendors with tools and resources for gathering site specific information related to purchase and installation of energy systems. A system according to one embodiment of the invention remotely determines the measurements of a roof. An exemplary system comprises a computer including an input means, a display means and a working memory. An aerial image file database contains a plurality of aerial images of roofs of buildings in a selected region. A roof estimating software program receives location information of a building in the selected region and then presents the aerial image files showing roof sections of building located at the location information. Some embodiments of the system include a sizing tool for determining the size, geometry, and pitch of the roof sections of a building being displayed.

Owner:SUNGEVITY

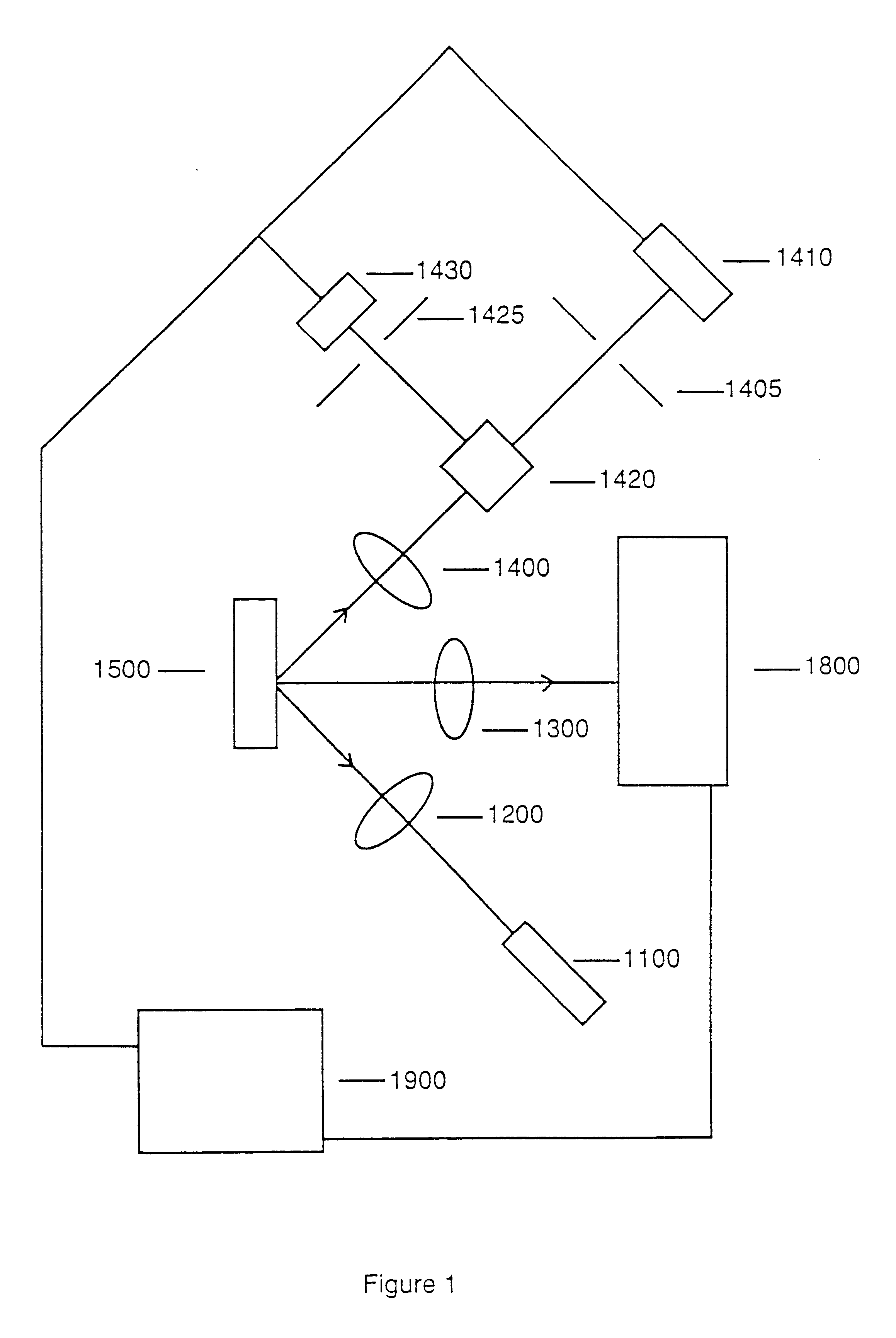

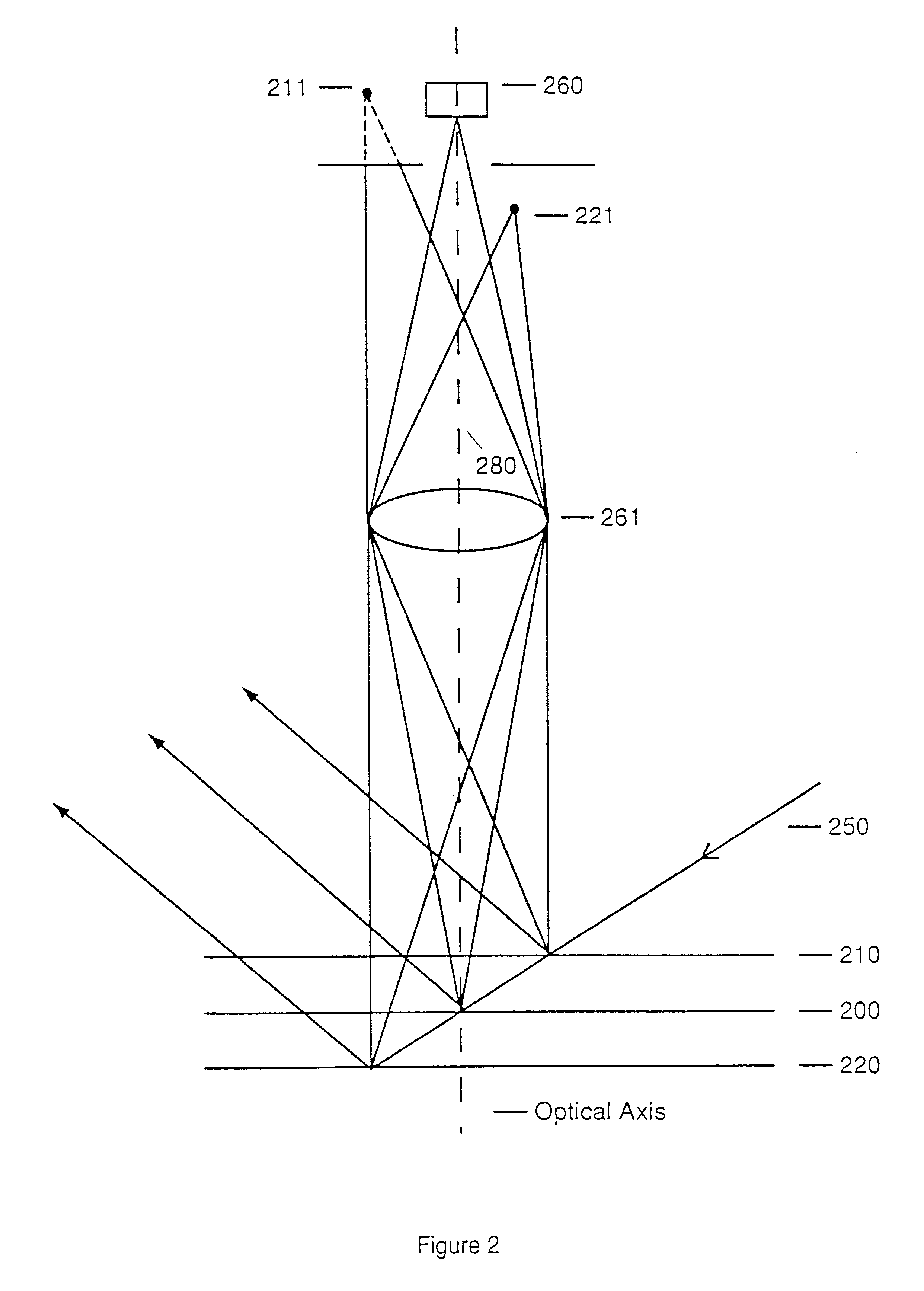

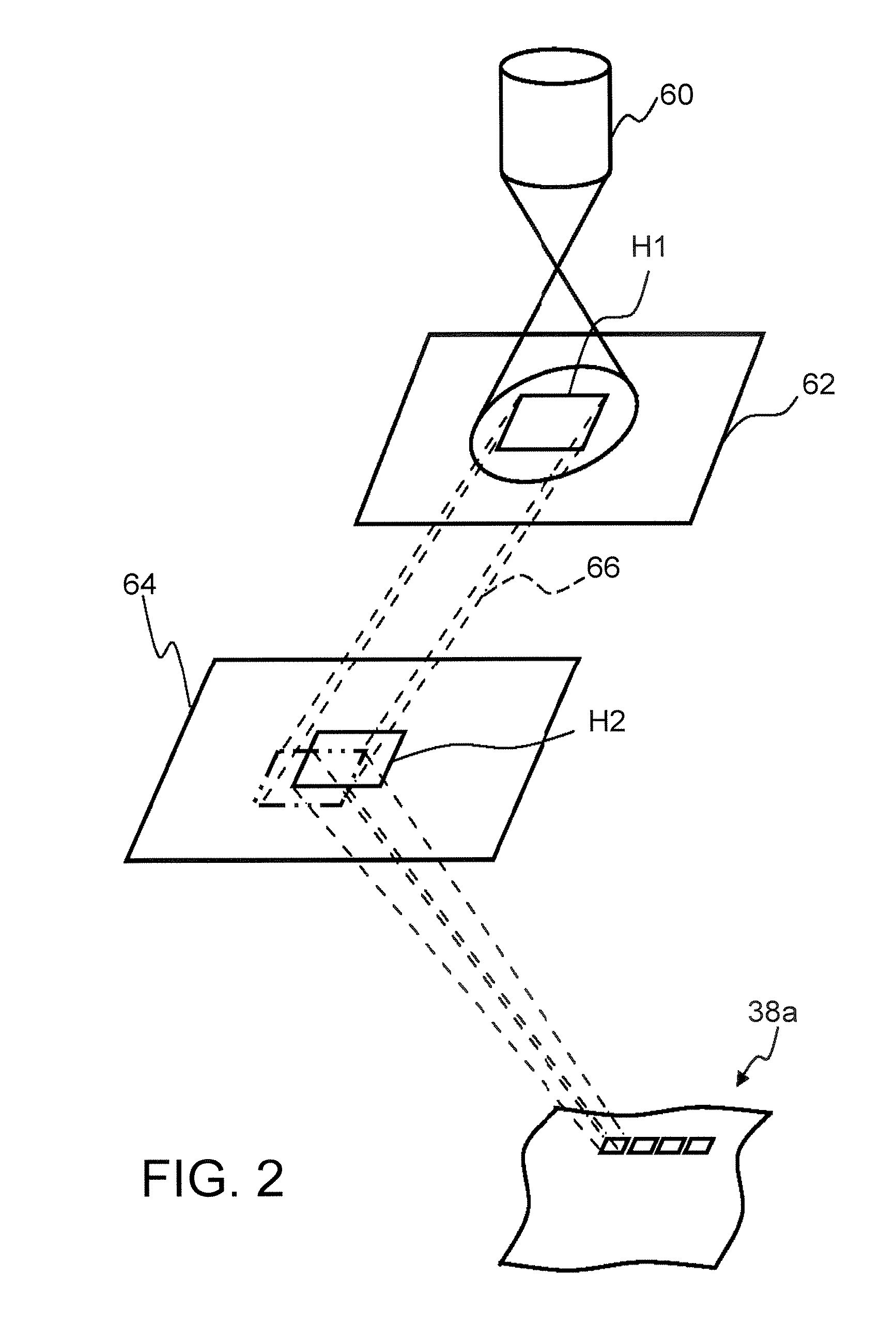

Method and apparatus for imaging a sample on a device

InactiveUS6252236B1Good depth discriminationChemical library matterPhotometrySize determinationResponse radiation

A method and apparatus for imaging a sample are provided. An electromagnetic radiation source generates excitation radiation which is sized by excitation optics to a line. The line is directed at a sample resting on a support and excites a plurality of regions on the sample. Collection optics collect response radiation reflected from the sample I and image the reflected radiation. A detector senses the reflected radiation and is positioned to permit discrimination between radiation reflected from a certain focal plane in the sample and certain other planes within the sample.

Owner:AFFYMETRIX TECH

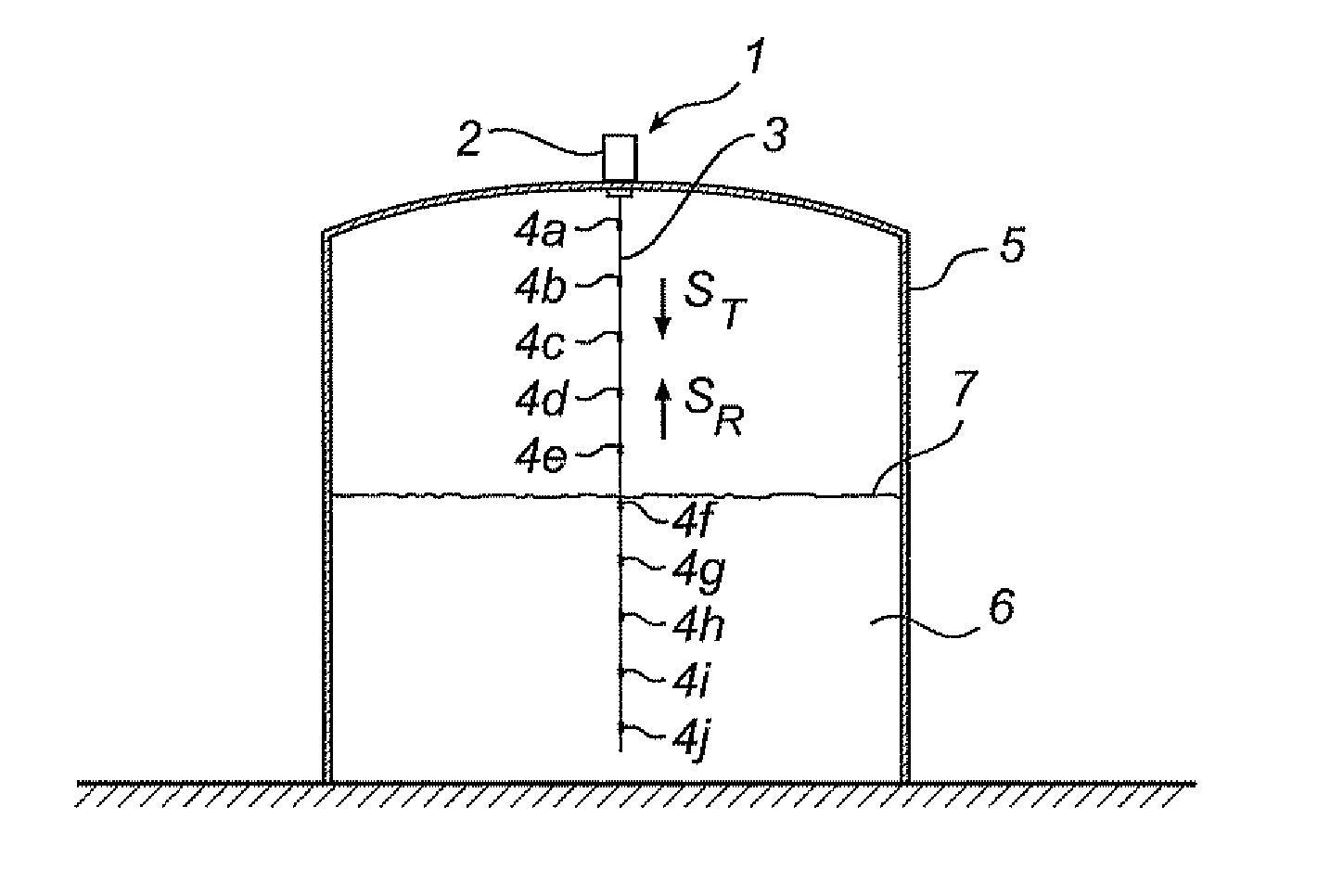

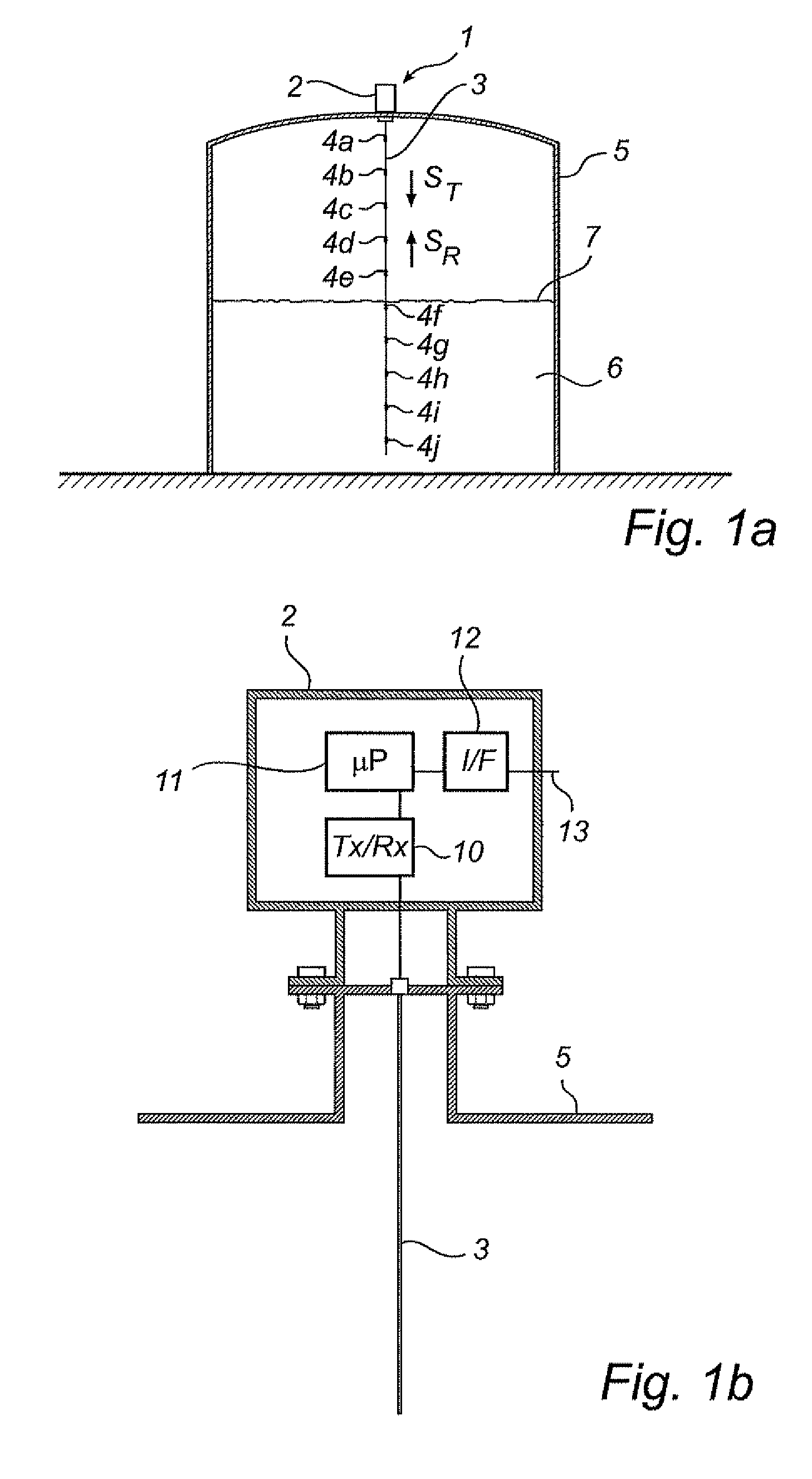

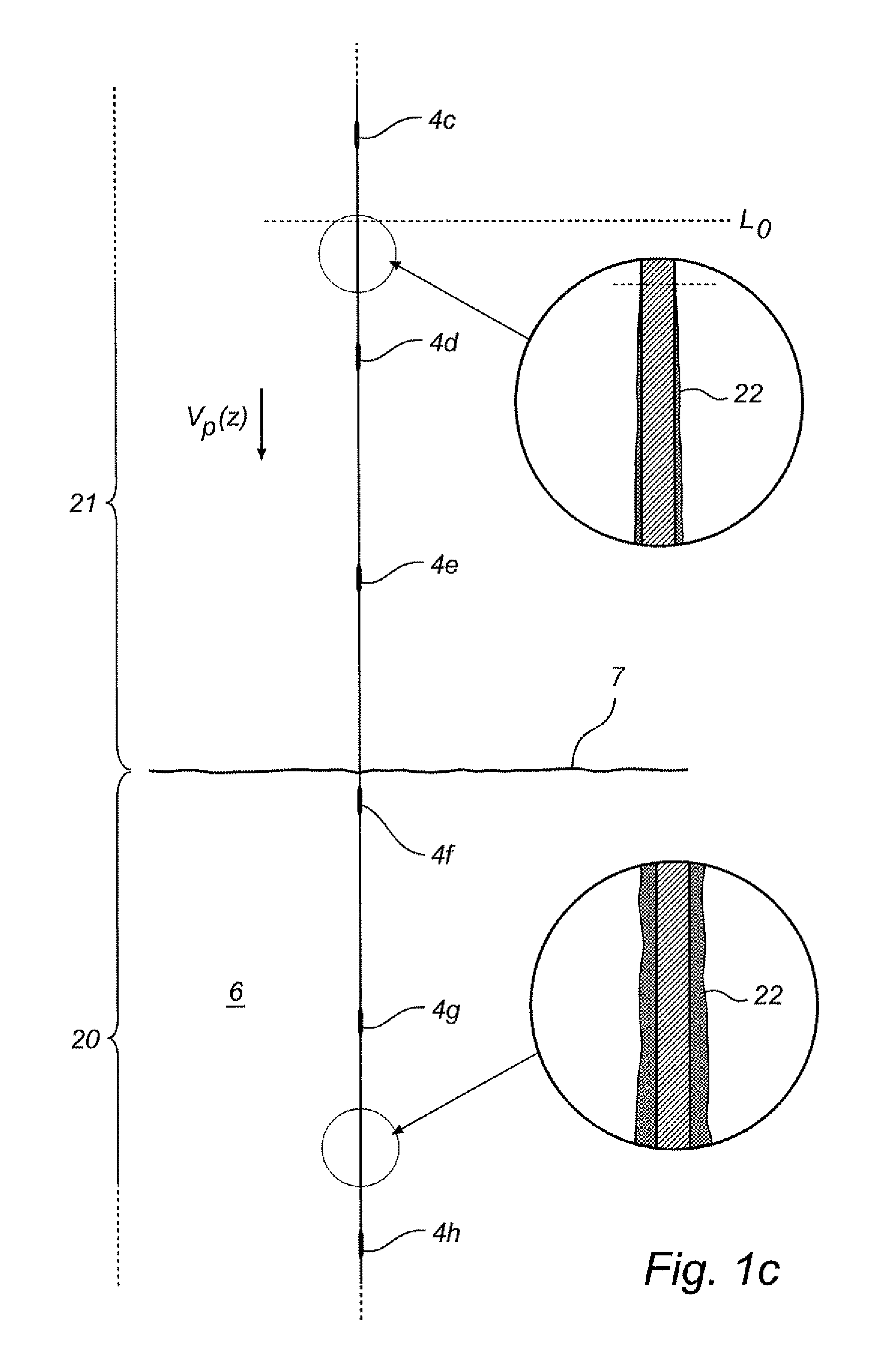

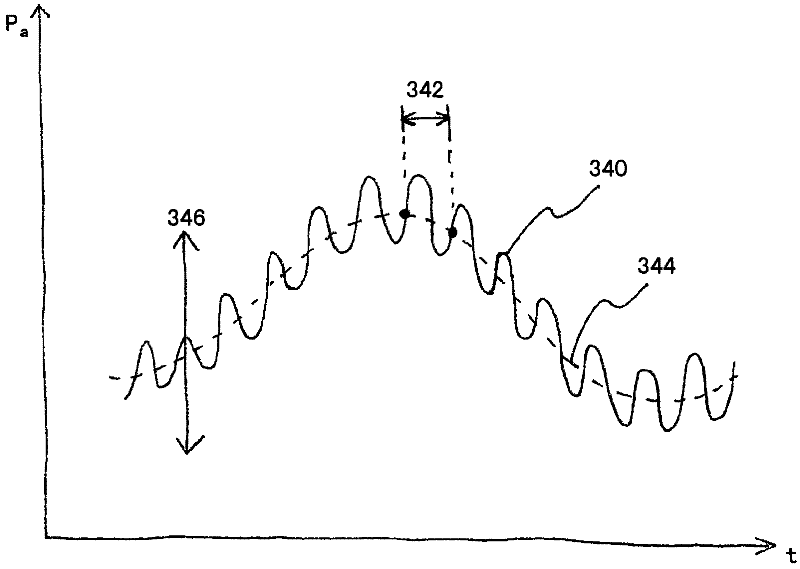

System and method for filling level determination

A method for determining a filling level of a product contained in a tank, by means of a radar level gauge system comprising a transceiver for generating, transmitting and receiving electromagnetic signals; a probe connected to the transceiver and arranged to guide a transmitted electromagnetic signal from the transceiver towards and into the product inside the tank, and to return a reflected electromagnetic signal resulting from reflection of the transmitted electromagnetic signal by a surface of the product back towards the transceiver; and a plurality of reference reflectors each being arranged at a respective known position along the probe and being configured to reflect a portion of the transmitted electromagnetic signal back towards the transceiver. The method comprises the steps of identifying, based on received electromagnetic signals reflected by the reference reflectors, a set of reference reflectors located above the surface of the product; selecting first and second reference reflectors comprised in the set of reference reflectors; determining a propagation velocity compensation factor based on a known distance between the first and second reference reflectors and a distance therebetween determined using received electromagnetic signals reflected by the first and second reference reflector, respectively; and determining the filling level based on a received electromagnetic signal reflected by the surface of the product, and the propagation velocity compensation factor.

Owner:ROSEMOUNT TANK RADAR

Semi-automatic dimensioning with imager on a portable device

A method of operating a dimensioning system to determine dimensional information for objects is disclosed. A number of images are acquired. Objects in at least one of the acquired images are computationally identified. One object represented in the at least one of the acquired images is computationally initially selected as a candidate for processing. An indication of the initially selected object is provided to a user. At least one user input indicative of an object selected for processing is received. Dimensional data for the object indicated by the received user input is computationally determined.

Owner:INTERMEC IP

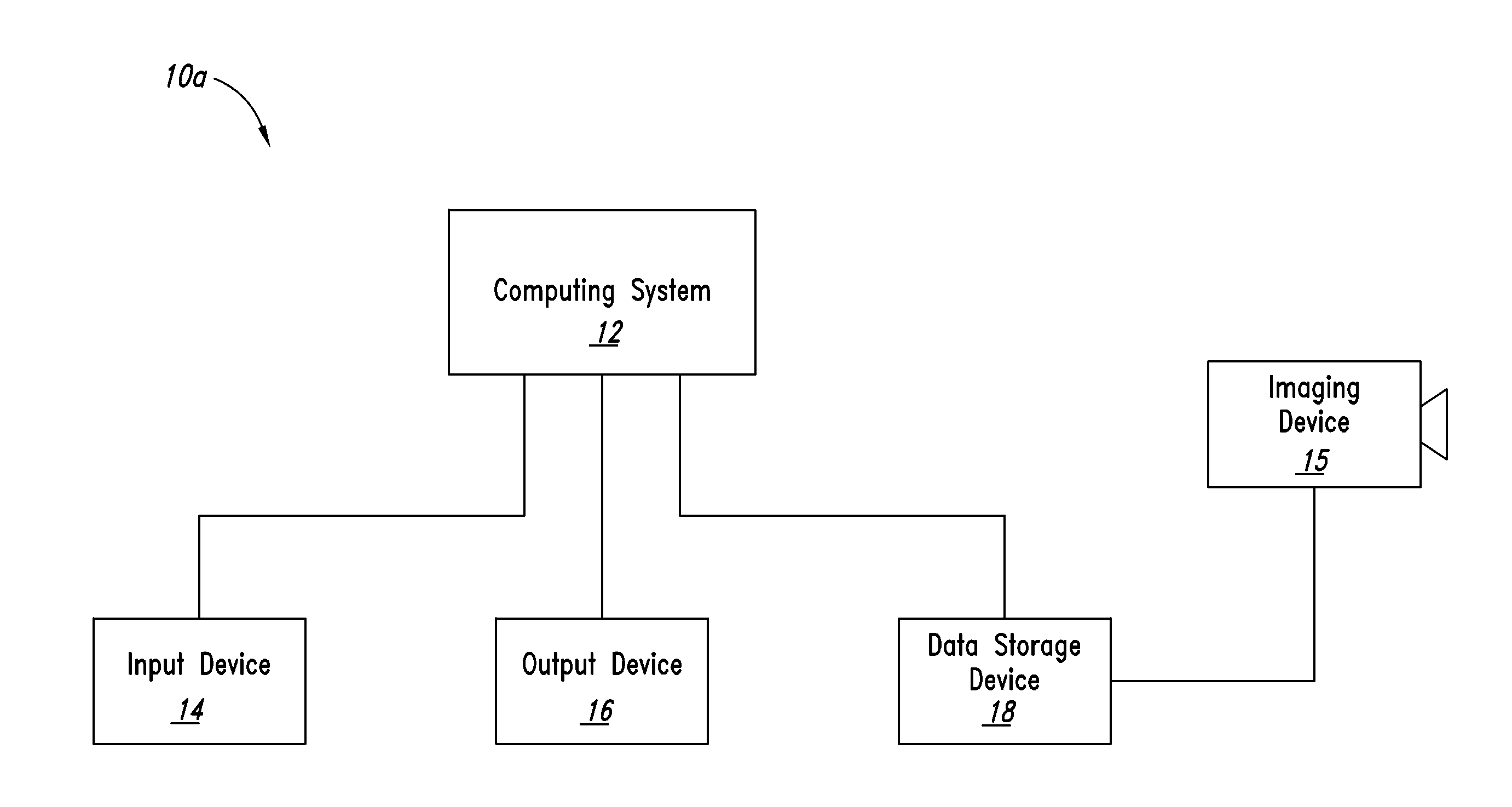

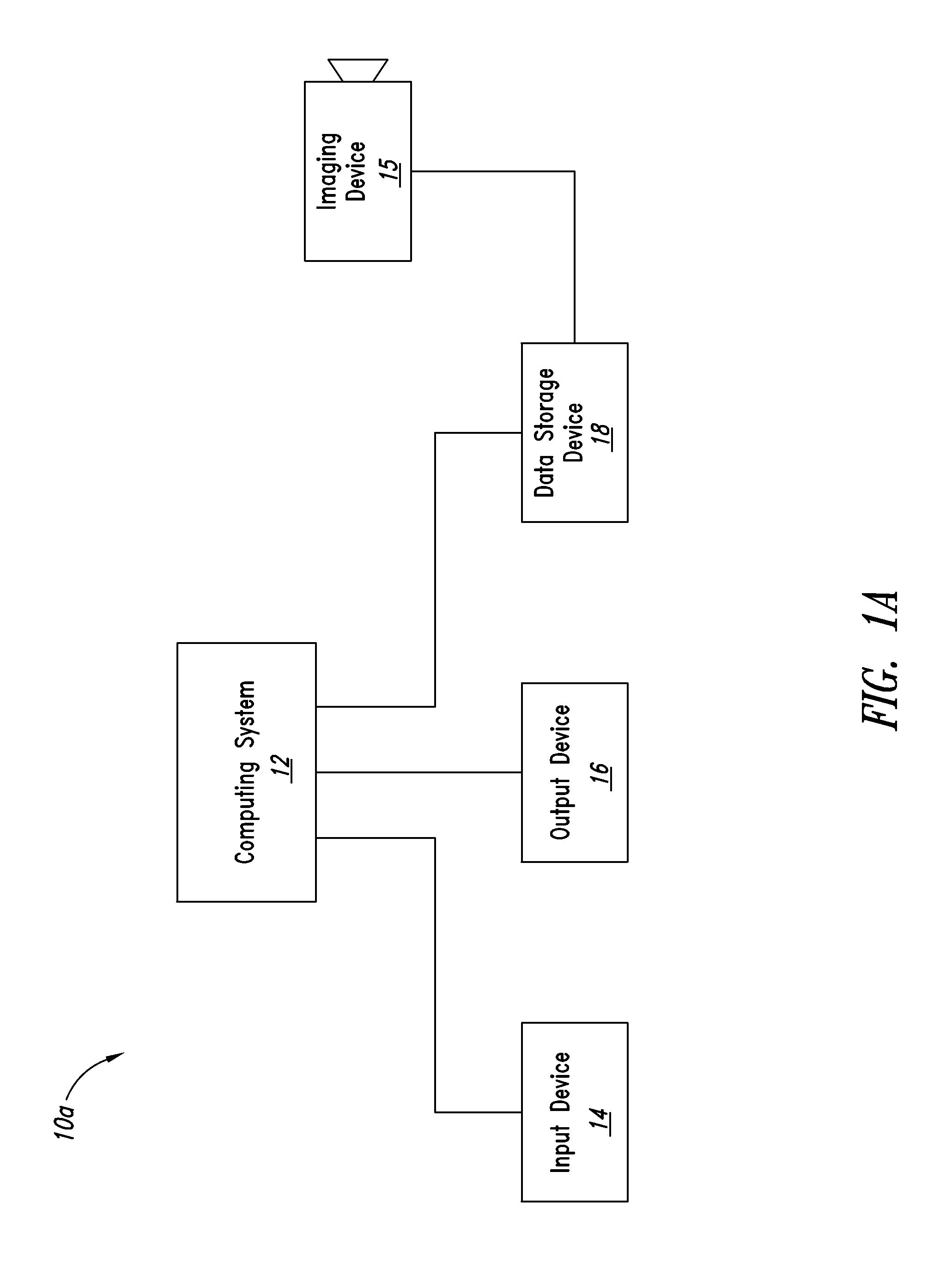

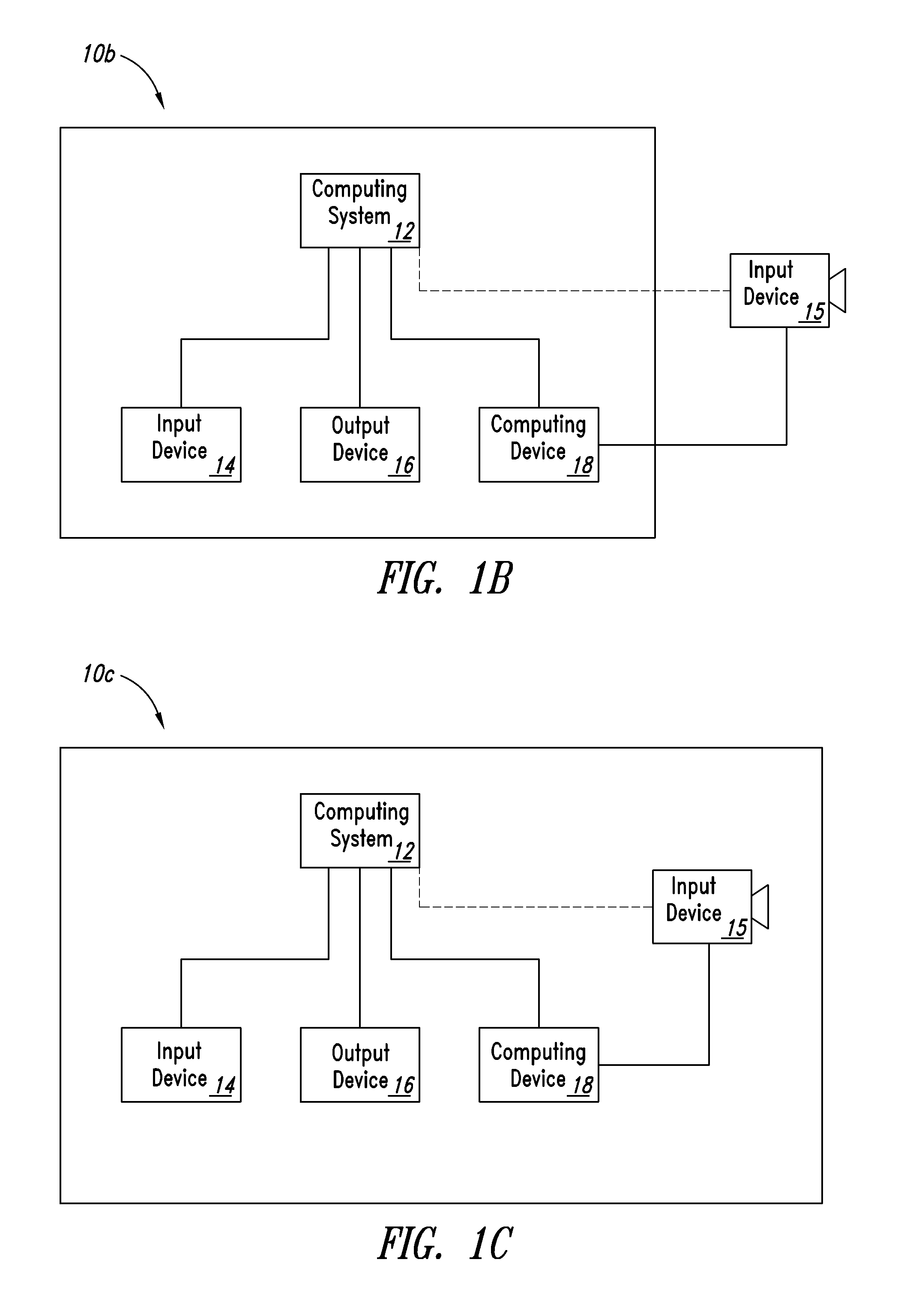

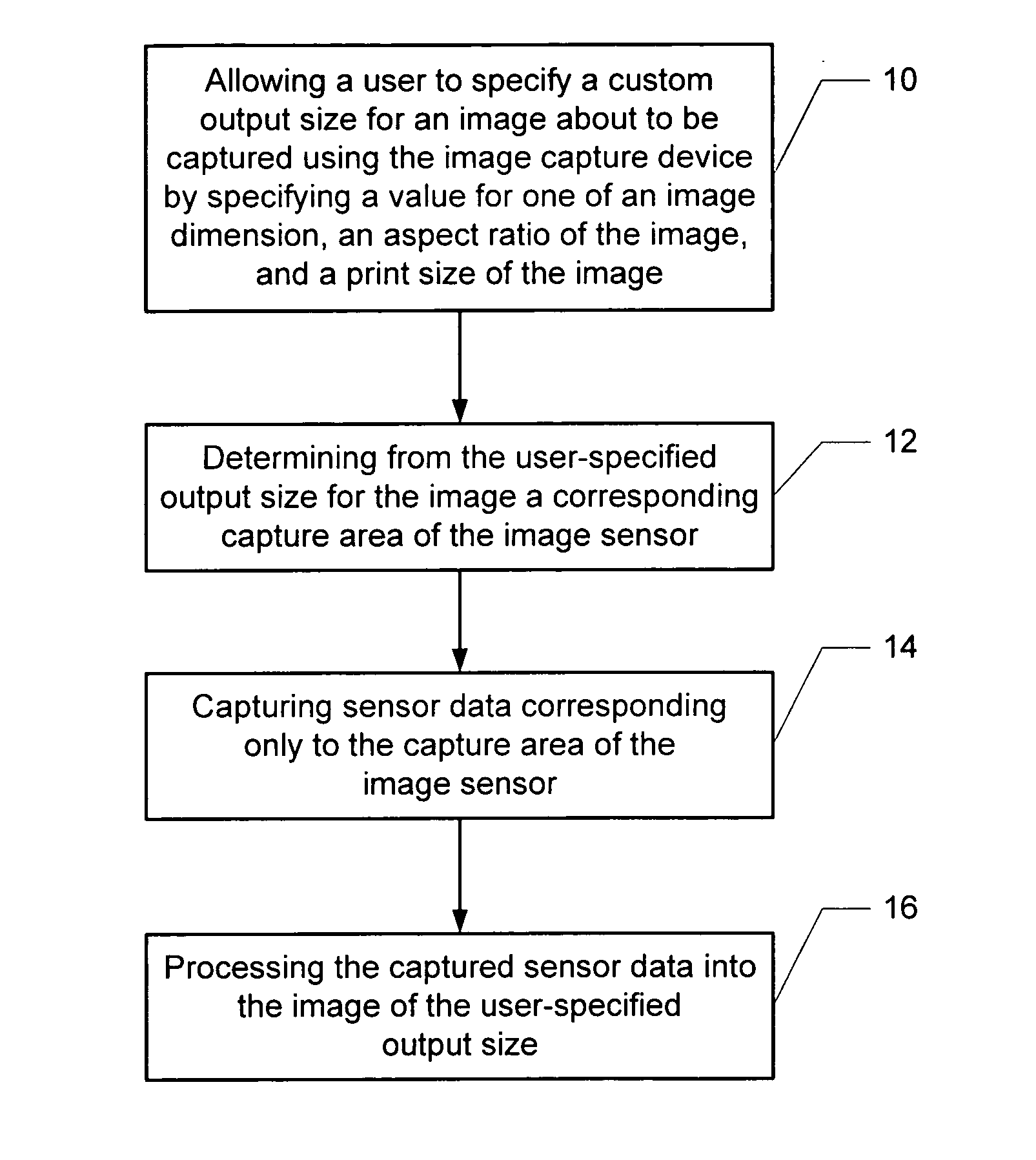

User established variable image sizes for a digital image capture device

InactiveUS20060221198A1High resolution imageSignificant to useTelevision system detailsColor television detailsSize determinationDigital image

Methods and apparatus for allowing a user to establish variable image sizes in a digital image capture device having an image sensor are described. Aspects of the present invention include allowing the user to specify a custom output size for an image about to be captured using the image capture device by specifying a value for one of an image dimension, an aspect ratio of the image, and a print size of the image; determining from the user-specified output size for the image a corresponding capture area of the image sensor; capturing sensor data corresponding only to the capture area of the image sensor; and processing the captured sensor data into the image of the user-specified output size.

Owner:SCENERA TECH

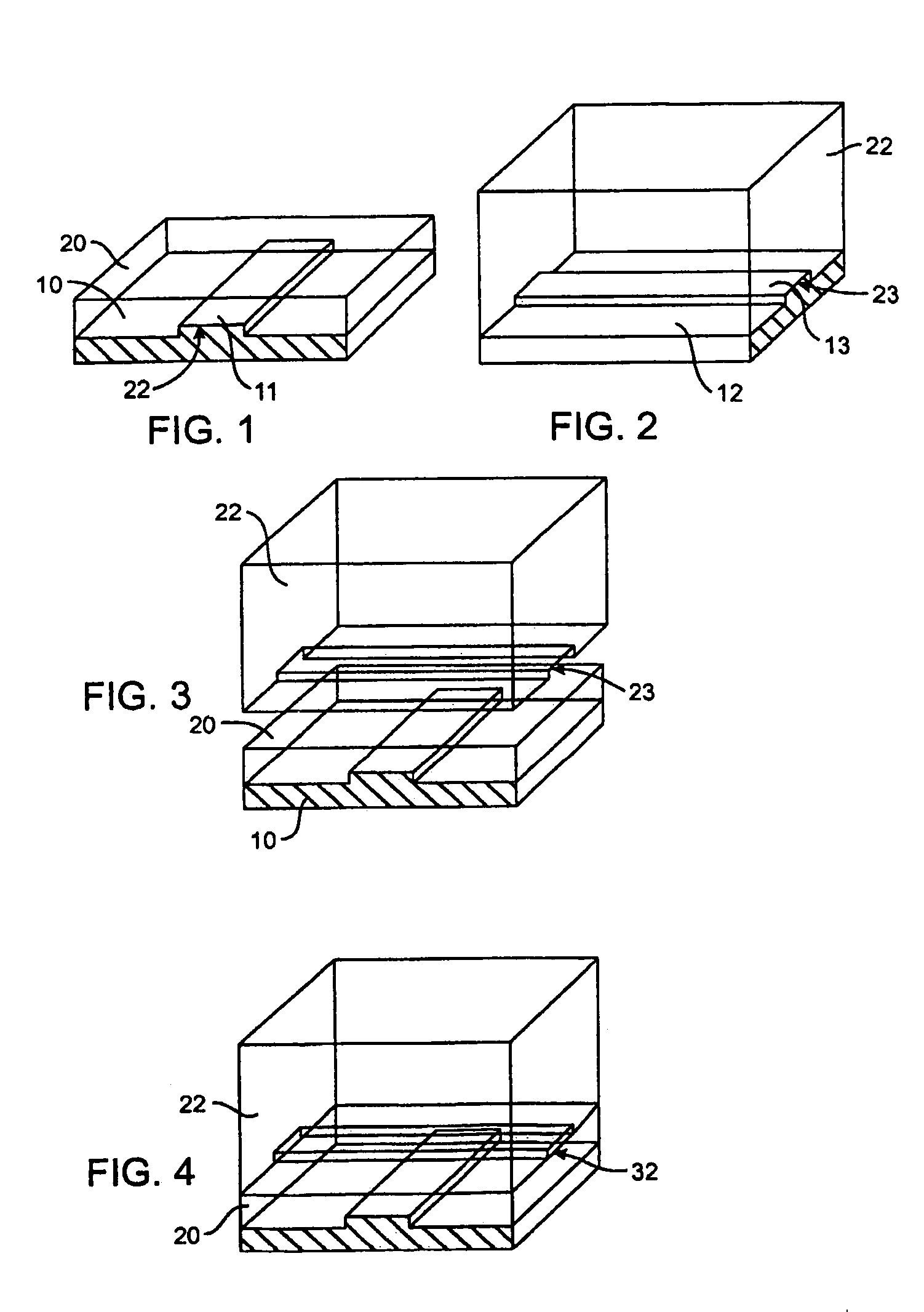

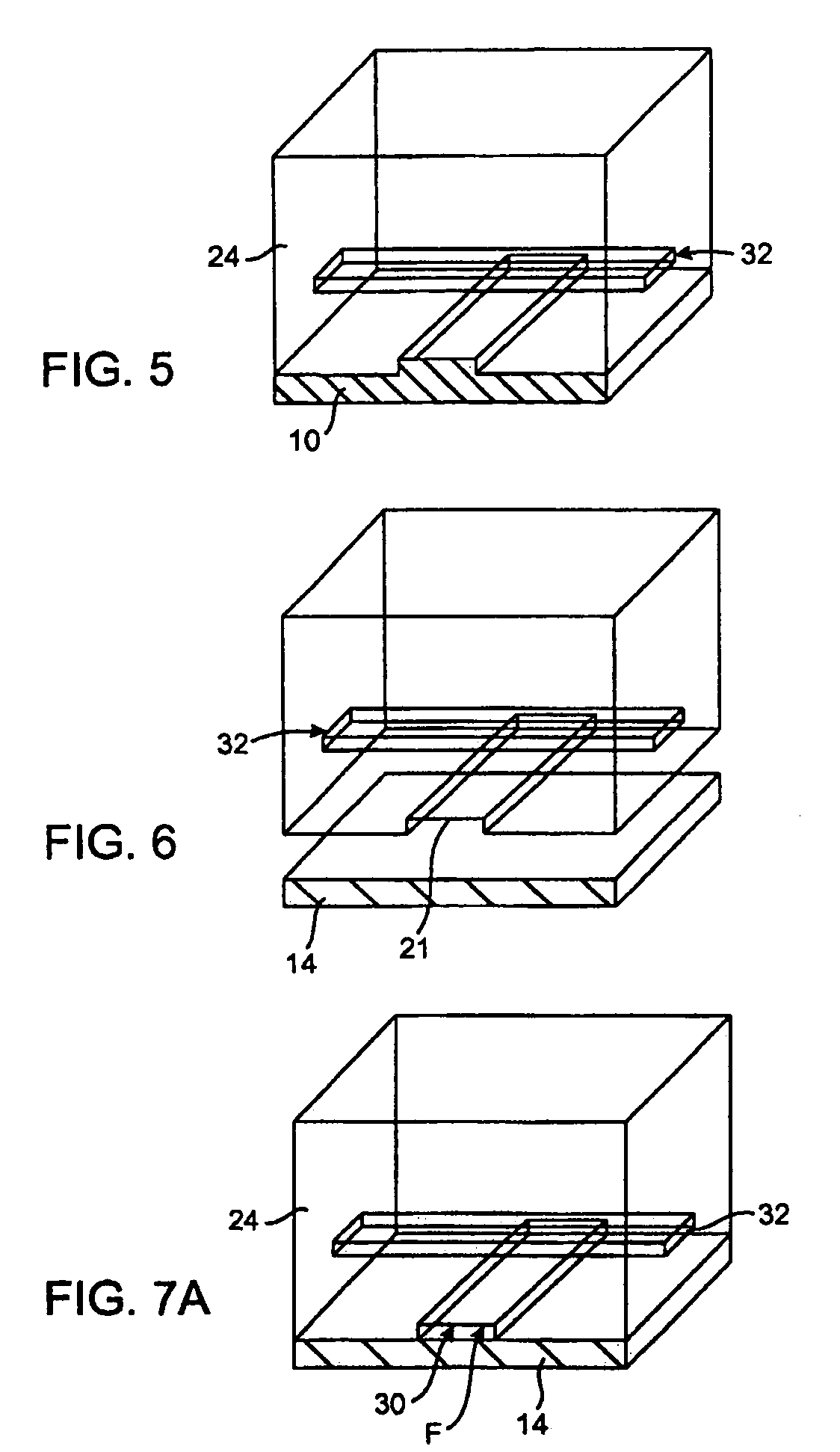

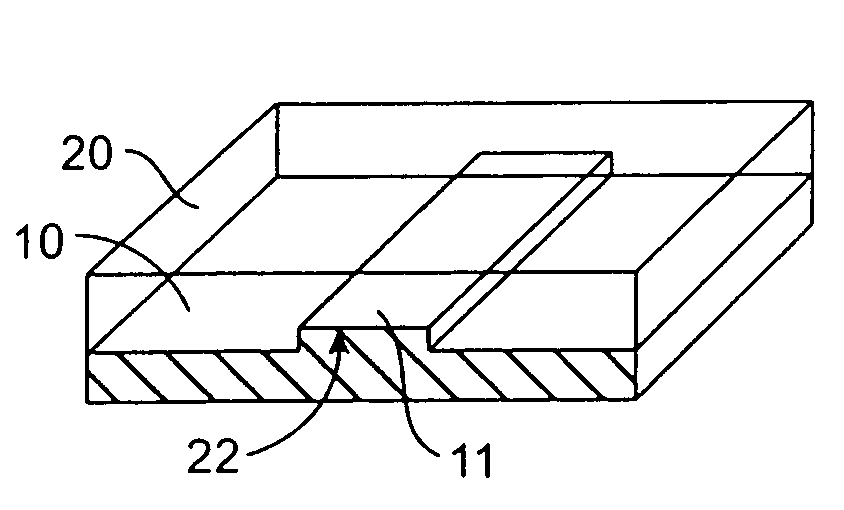

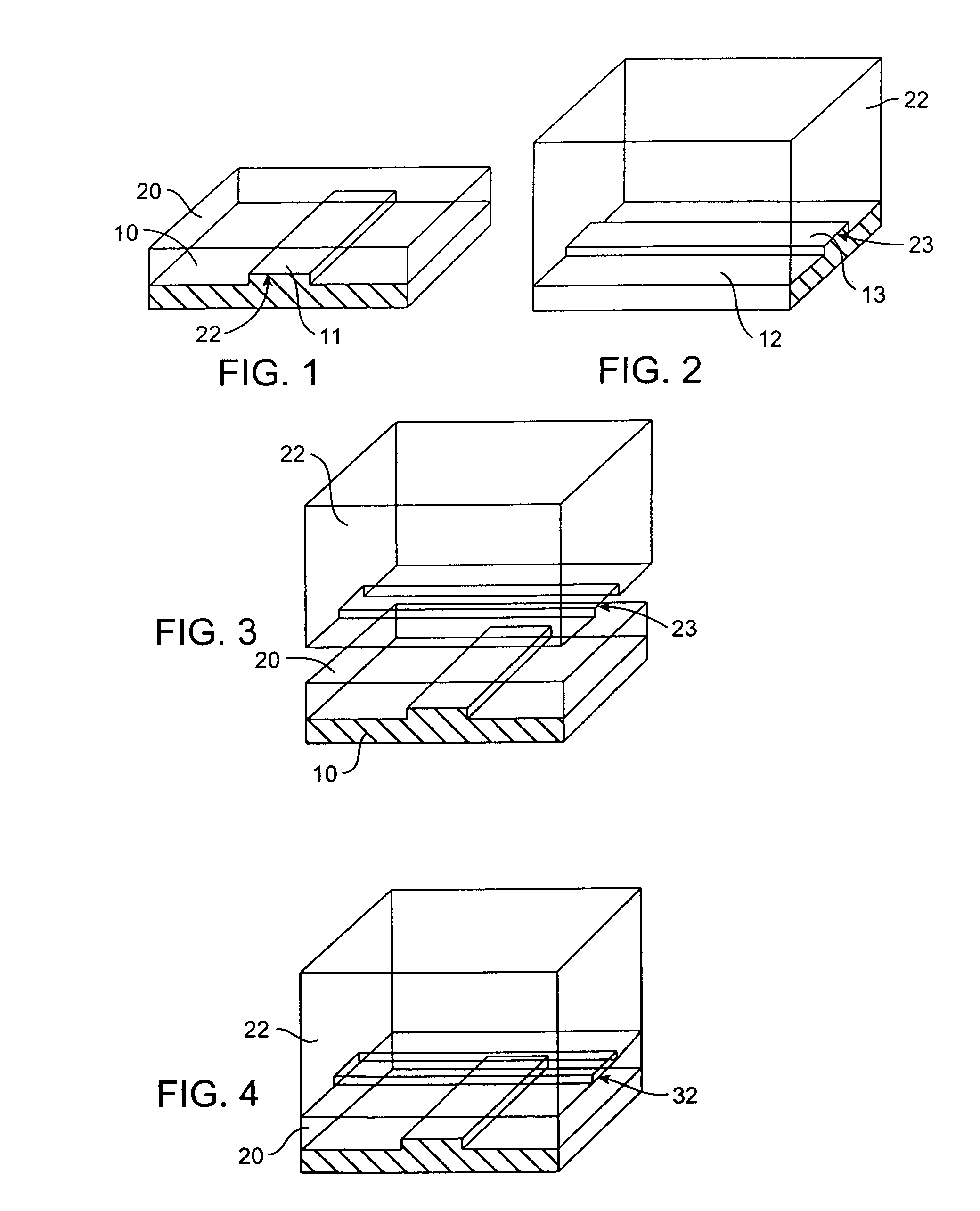

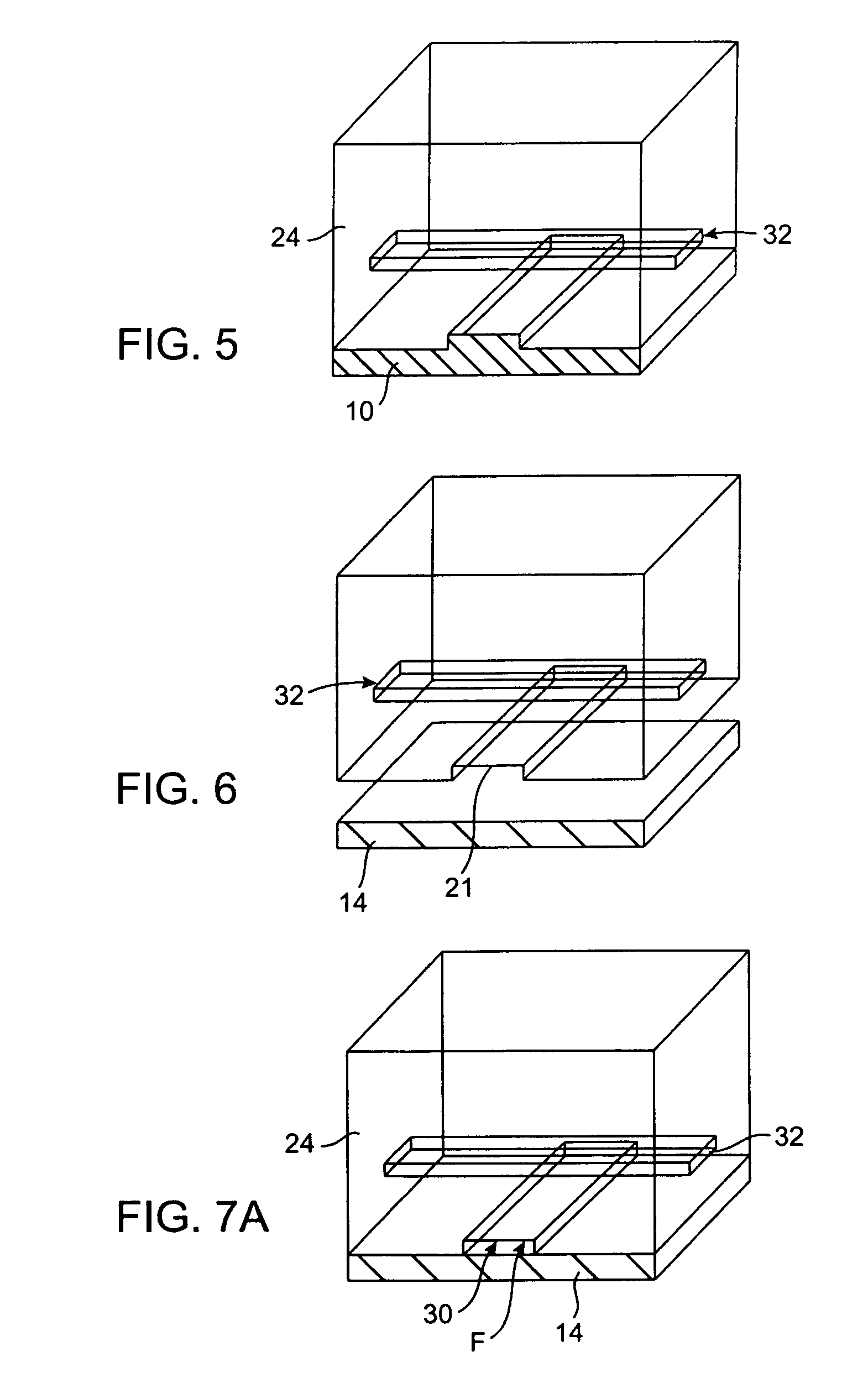

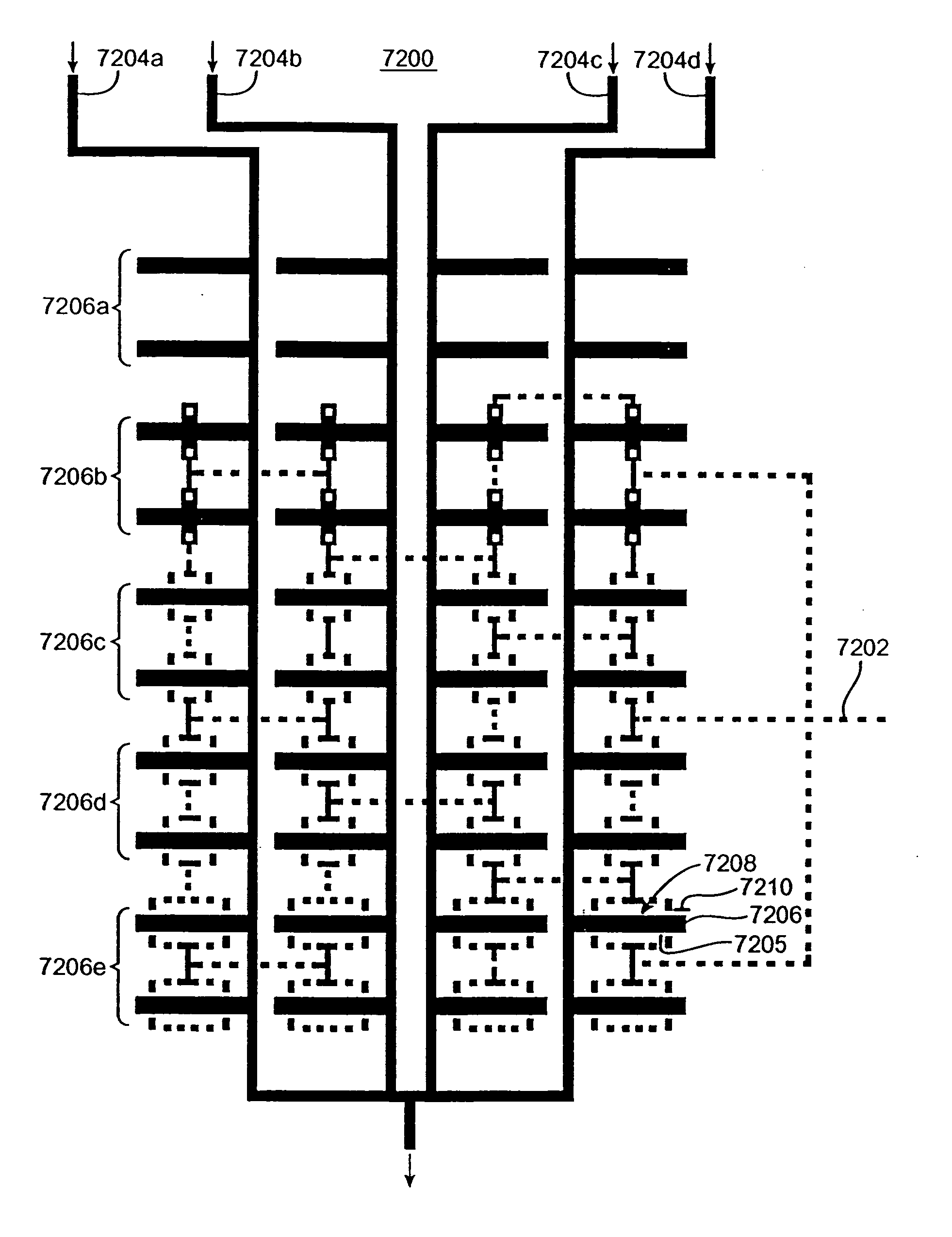

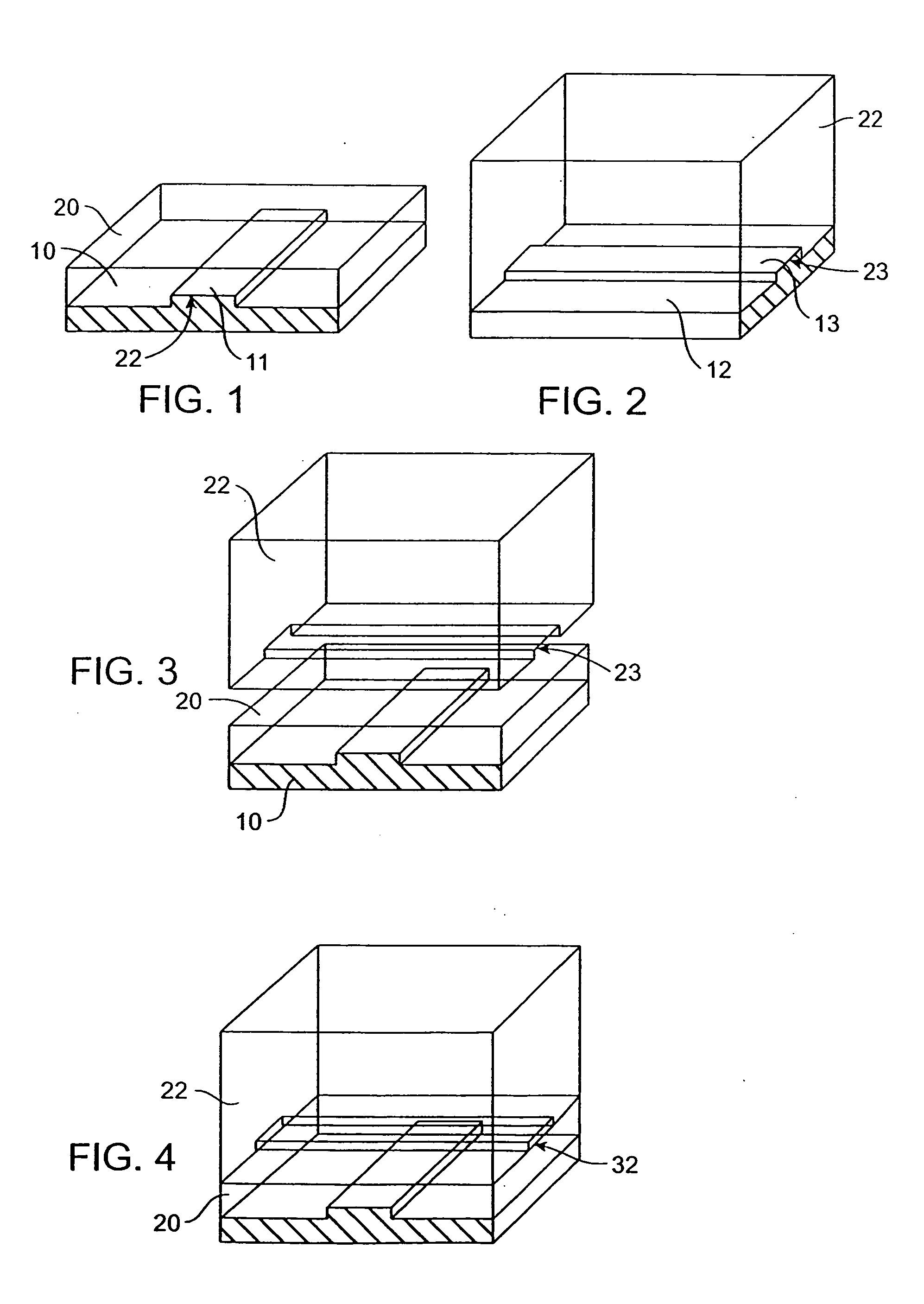

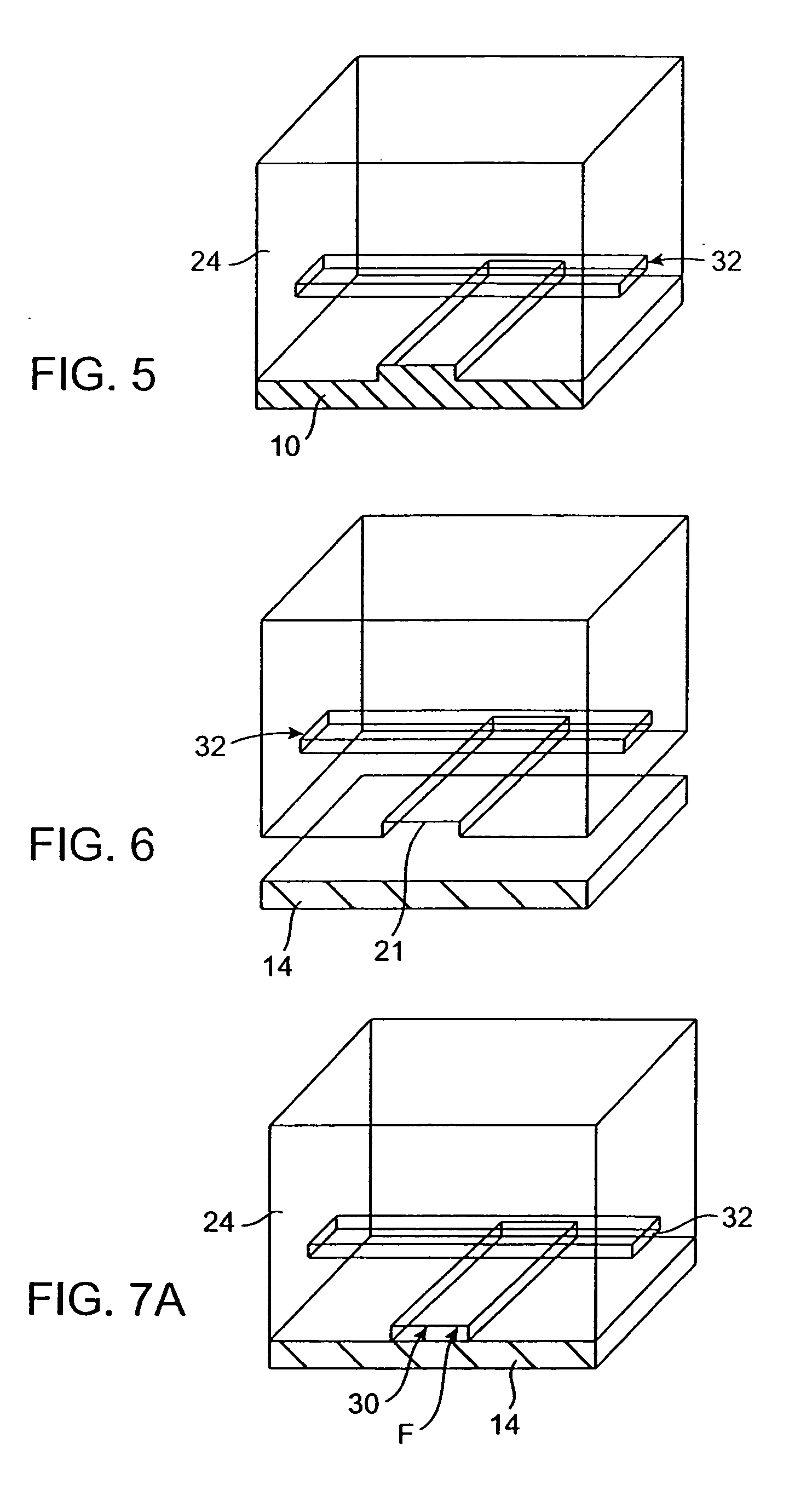

High throughput screening of crystallization of materials

InactiveUS7052545B2Sequential/parallel process reactionsFrom normal temperature solutionsHigh-Throughput Screening MethodsSize determination

High throughput screening of crystallization of a target material is accomplished by simultaneously introducing a solution of the target material into a plurality of chambers of a microfabricated fluidic device. The microfabricated fluidic device is then manipulated to vary the solution condition in the chambers, thereby simultaneously providing a large number of crystallization environments. Control over changed solution conditions may result from a variety of techniques, including but not limited to metering volumes of crystallizing agent into the chamber by volume exclusion, by entrapment of volumes of crystallizing agent determined by the dimensions of the microfabricated structure, or by cross-channel injection of sample and crystallizing agent into an array of junctions defined by intersecting orthogonal flow channels.

Owner:RGT UNIV OF CALIFORNIA +1

Device determination

A method of operating a server for determining the model of a mobile device and for delivering configuration parameters to the mobile device (114) consistent with the model determined. The application server (106) captures the mobile device's phone number and associates it with a generated unique identifier (206). The unique identifier is sent to the mobile device as part of a URL (212). When the mobile device (114) accesses the URL, the request (216) sent to the application server includes the unique identifier as well as a user agent header (218). The model number of the mobile device can be extracted from the user agent header, and thus the model number can be tied to the mobile device's phone number by way of the unique identifier. The model number and phone number association can be used to correctly configure applications for use on the mobile device (114).

Owner:BRITISH TELECOMM PLC

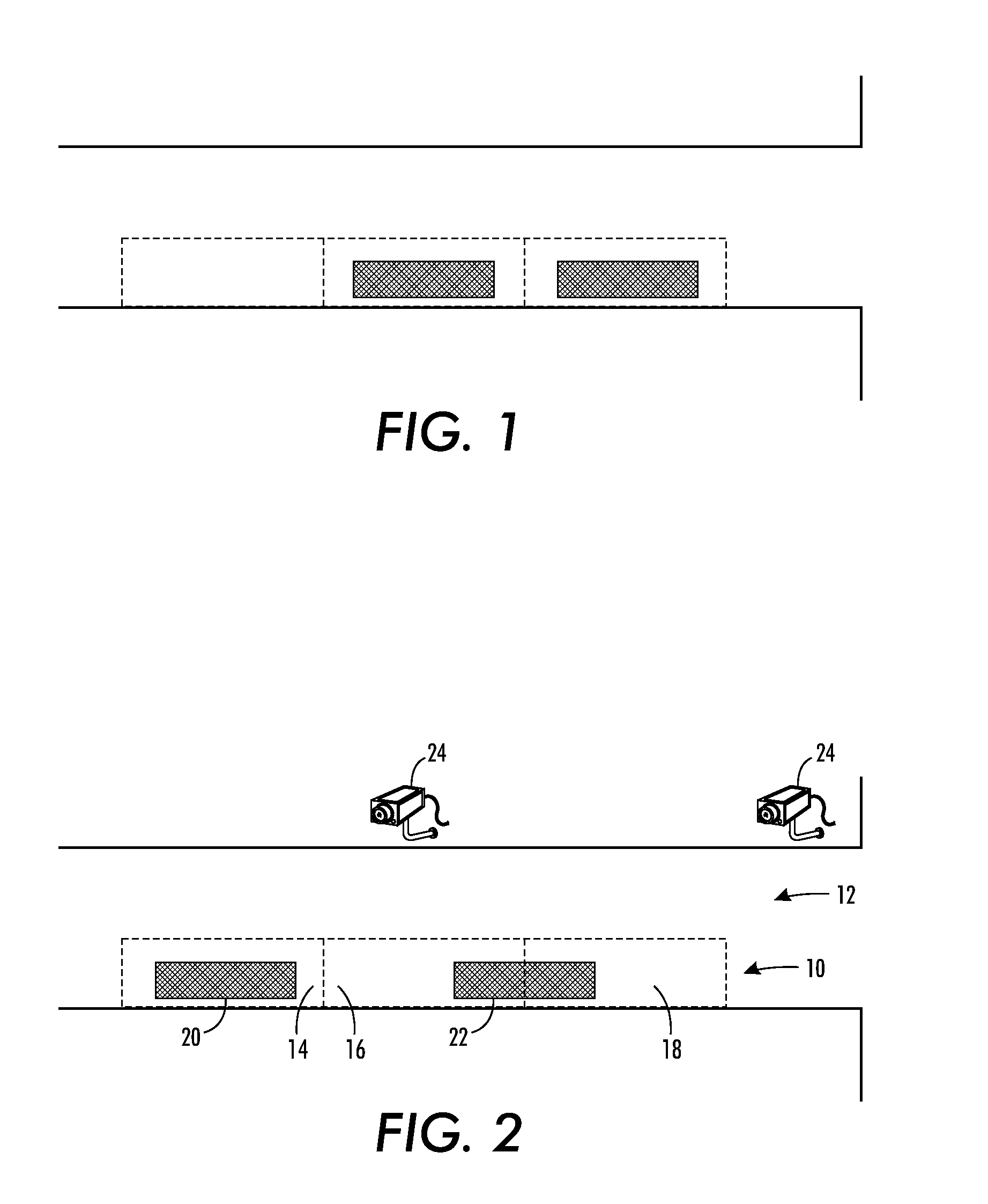

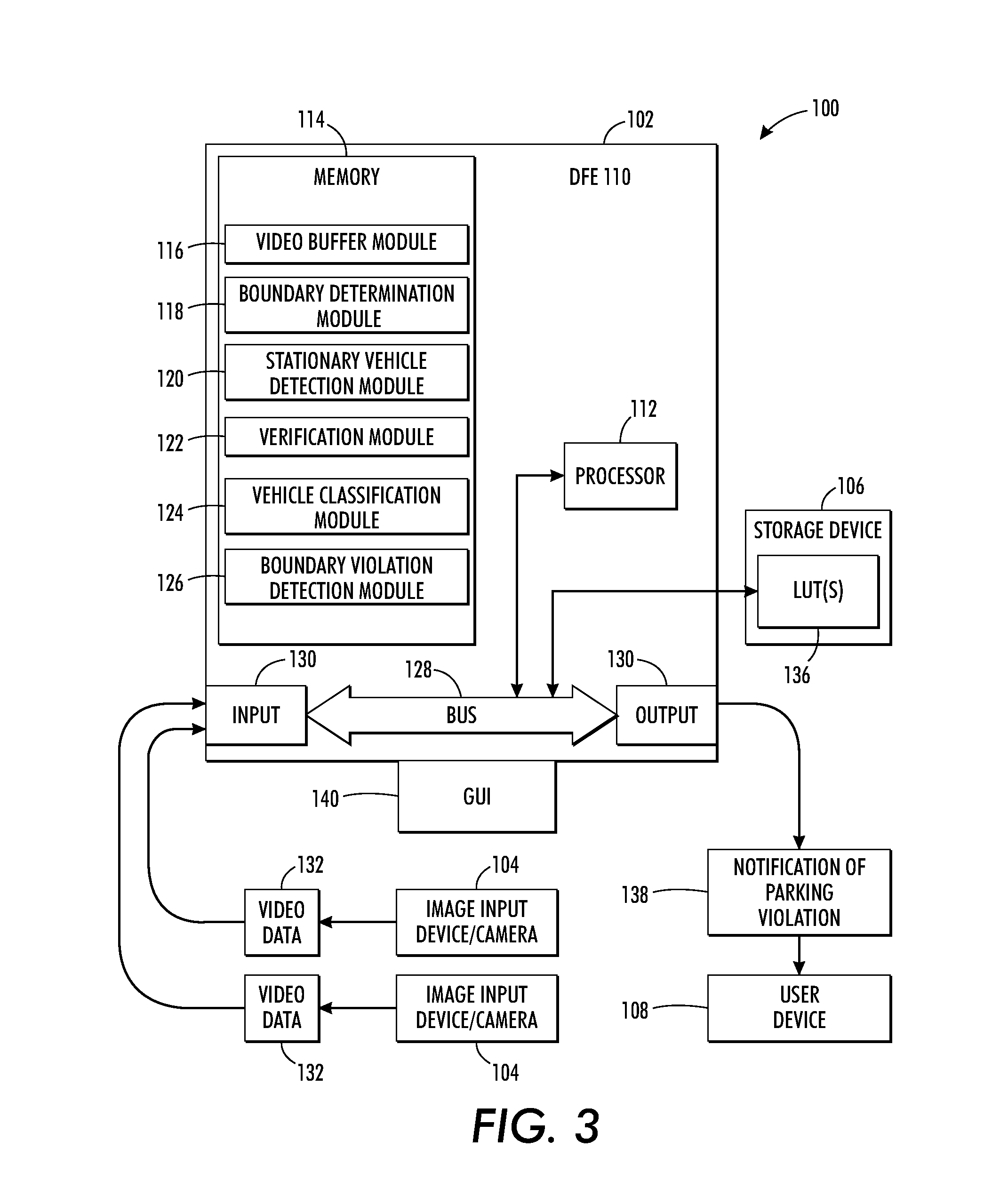

Video-based method for detecting parking boundary violations

A method and a system for determining a parking boundary violation includes receiving video data from a sequence of frames taken from an image capture device monitoring a parking area including at least a single parking space. A boundary is determined for defining at least one parking space in the parking area. A vehicle is detected in the parking area. A determination is made whether the detected vehicle is violating a parking regulation based on a position and size of the vehicle within the boundary.

Owner:CONDUENT BUSINESS SERVICES LLC

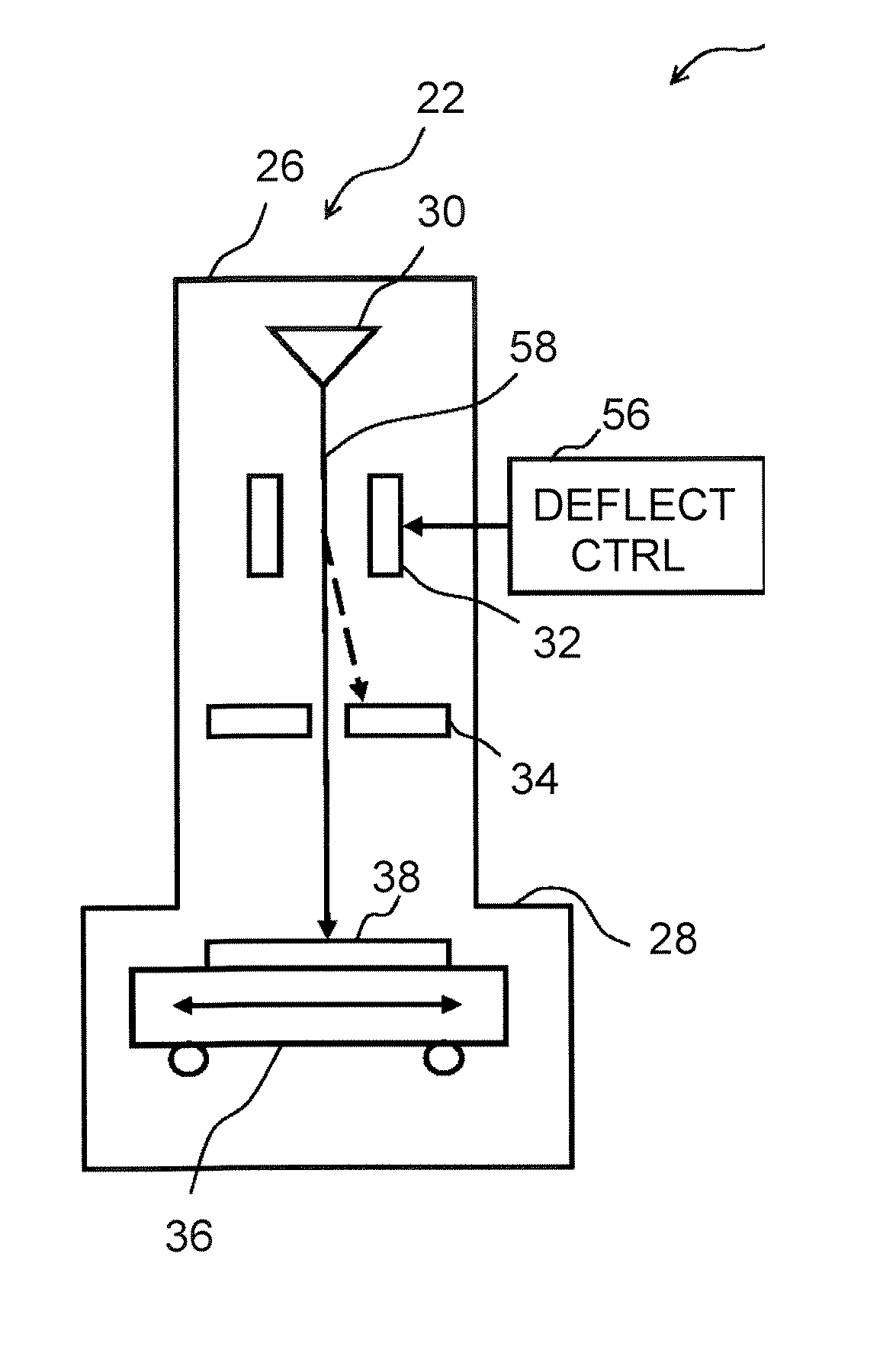

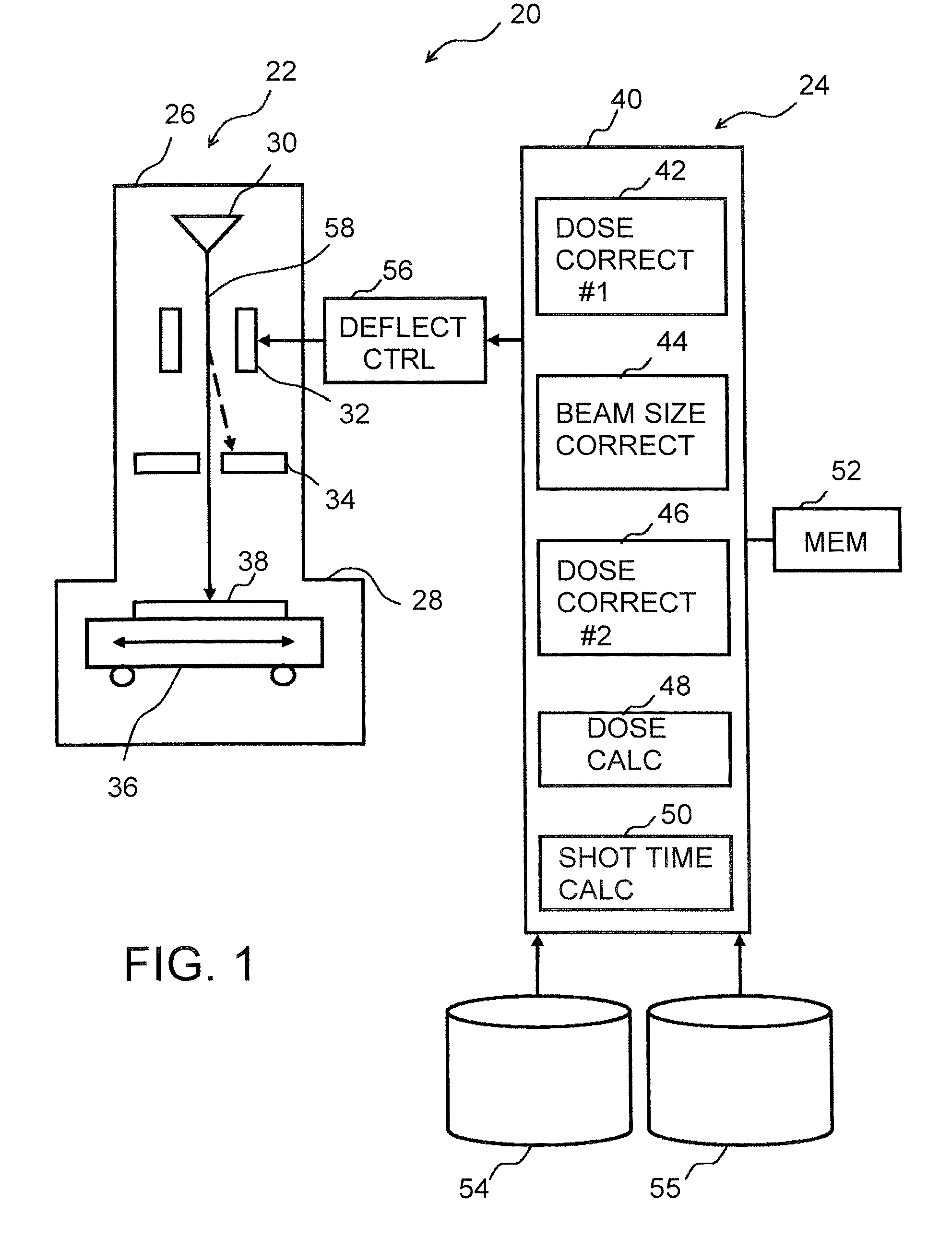

Beam dose computing method and writing method and record carrier body and writing apparatus

A beam dose computing method includes specifying a matrix of rows and columns of regions as divided from a surface area of a target object to include first, second and third regions of different sizes, the third regions being less in size than the first and second regions, determining first corrected doses of a charged particle beam for correcting fogging effects in the first regions, determining corrected size values for correcting pattern line width deviations occurring due to loading effects in the second regions, using said corrected size values in said second regions to create a map of base doses of the beam in respective ones of said second regions, using said corrected size values to prepare a map of proximity effect correction coefficients in respective ones of said second regions, using the maps to determine second corrected doses of said beam for correction of proximity effects in said third regions, and using the first and second corrected doses to determine an actual beam dose at each position on the surface of said object.

Owner:NUFLARE TECH INC

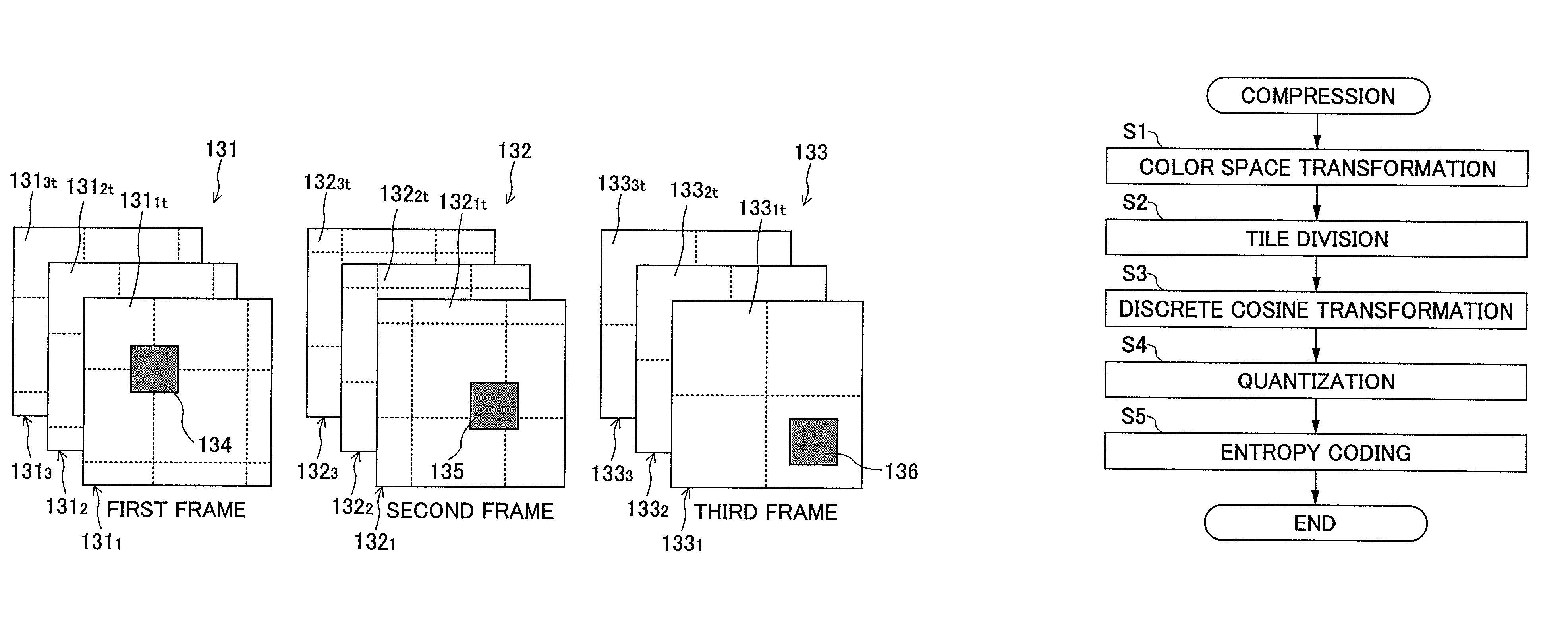

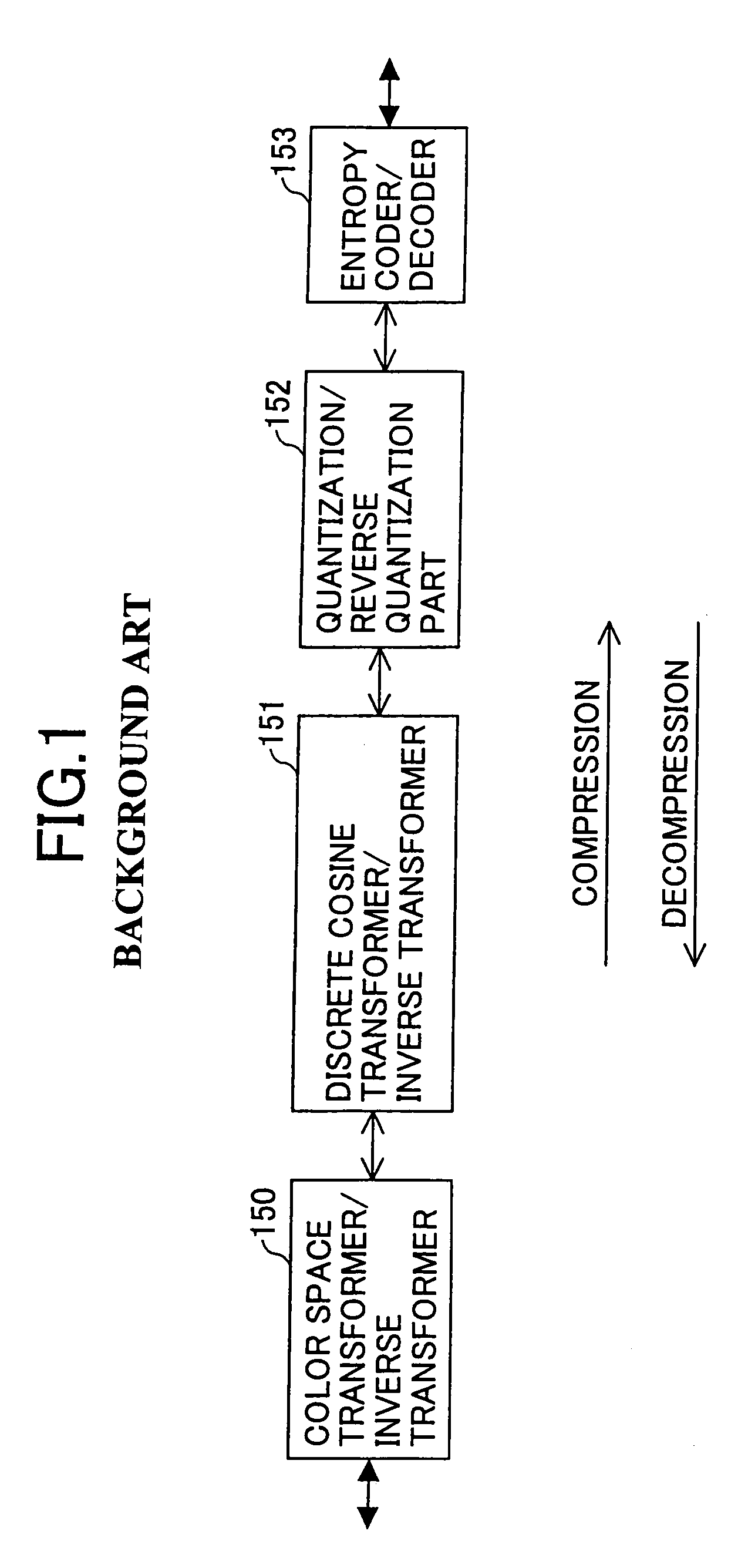

Image compression with tile alignment

InactiveUS7158679B2Control the elicitation of borders of tiles soReduce decreaseColor television with pulse code modulationCode conversionComputer graphics (images)Size determination

An image compression apparatus includes a tile size determiner, an image divider and an image compression processor. The tile size determiner determines an arbitrary size of a rectangular tile for each component of a still image having a plurality of components. The image divider divides the image using the rectangular tiles the sizes of which are determined by the tile size determiner. The image compression processor performs an irreversible compression process on the image divided by said image divider.

Owner:RICOH KK

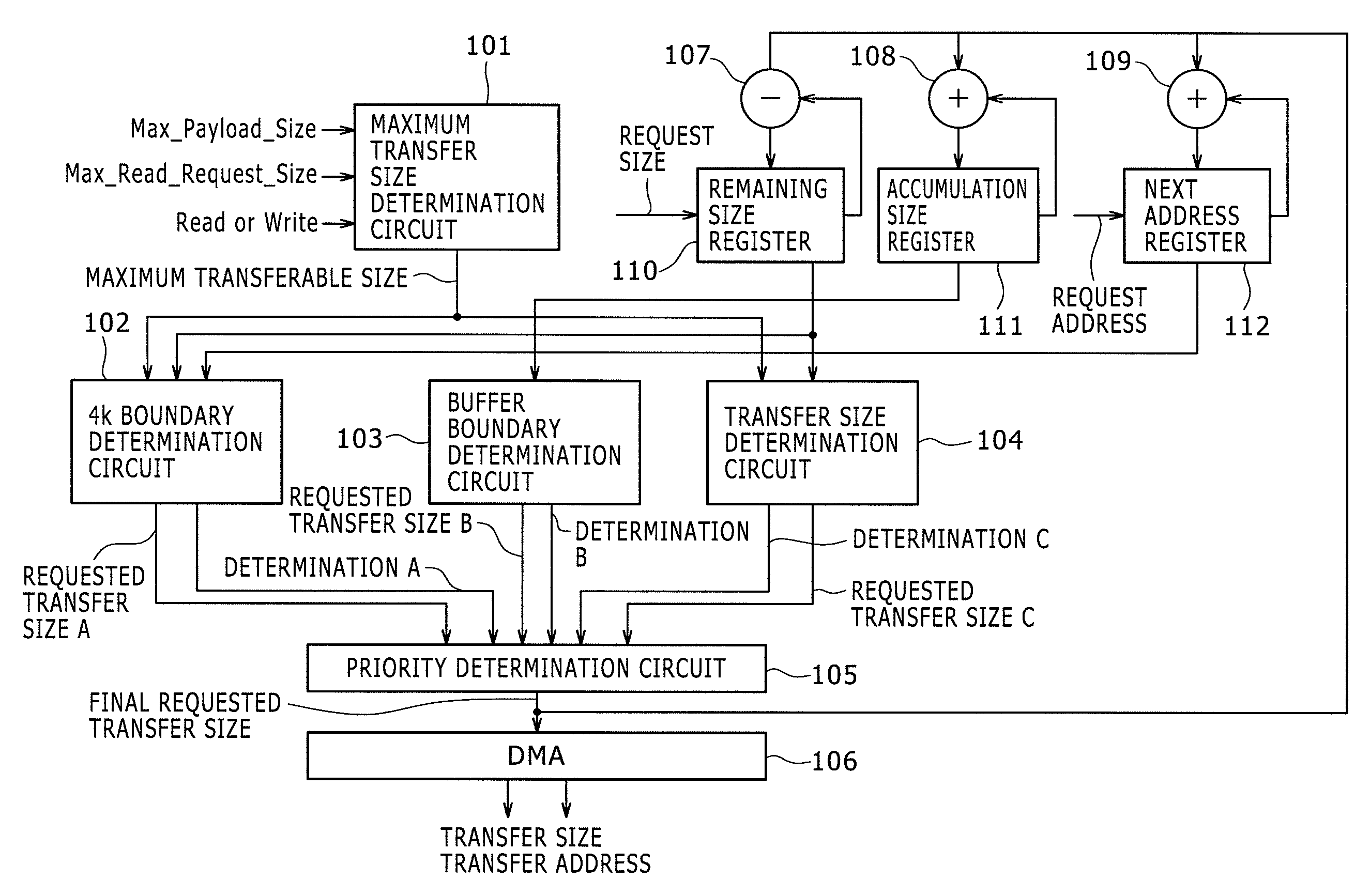

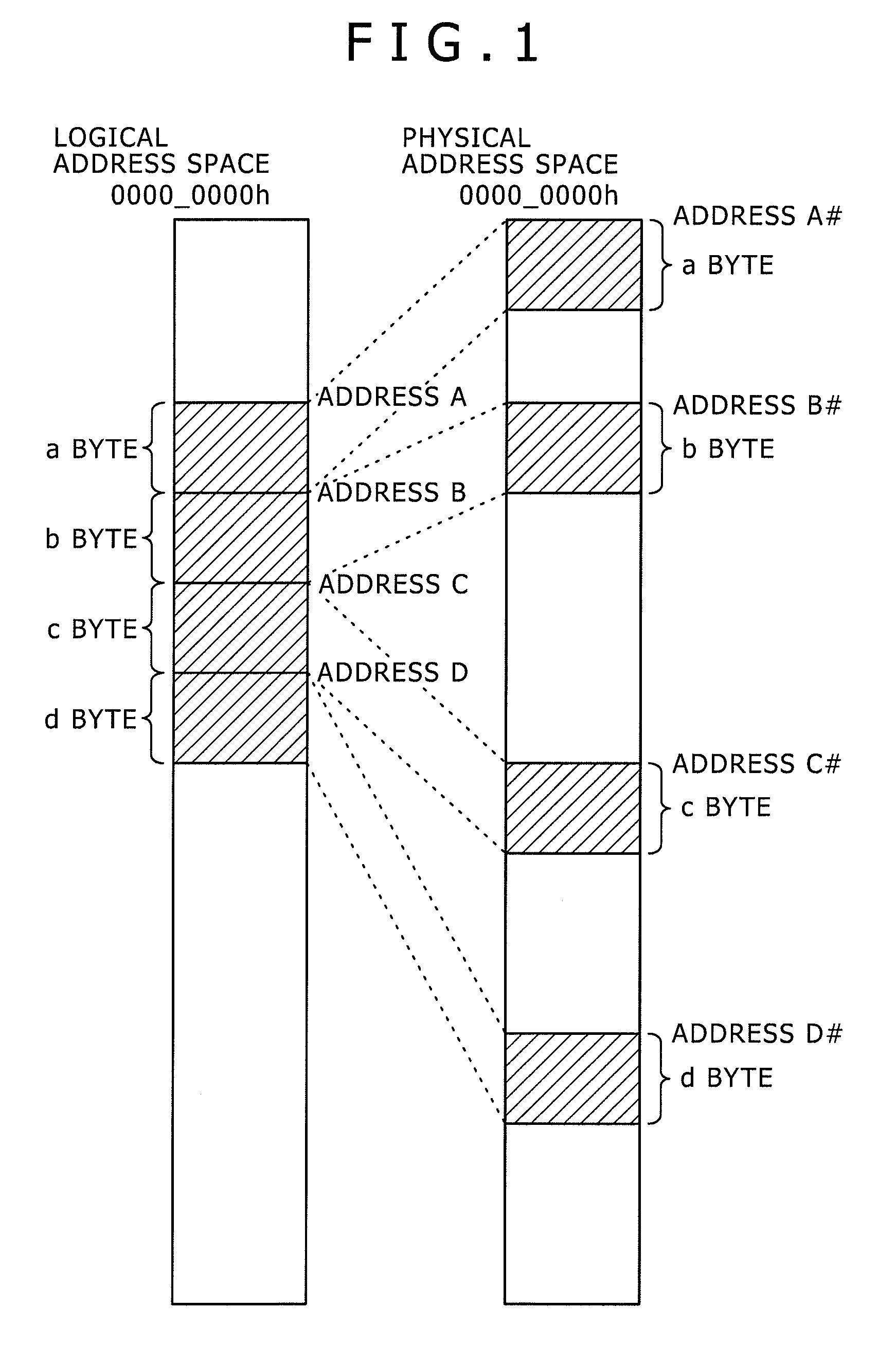

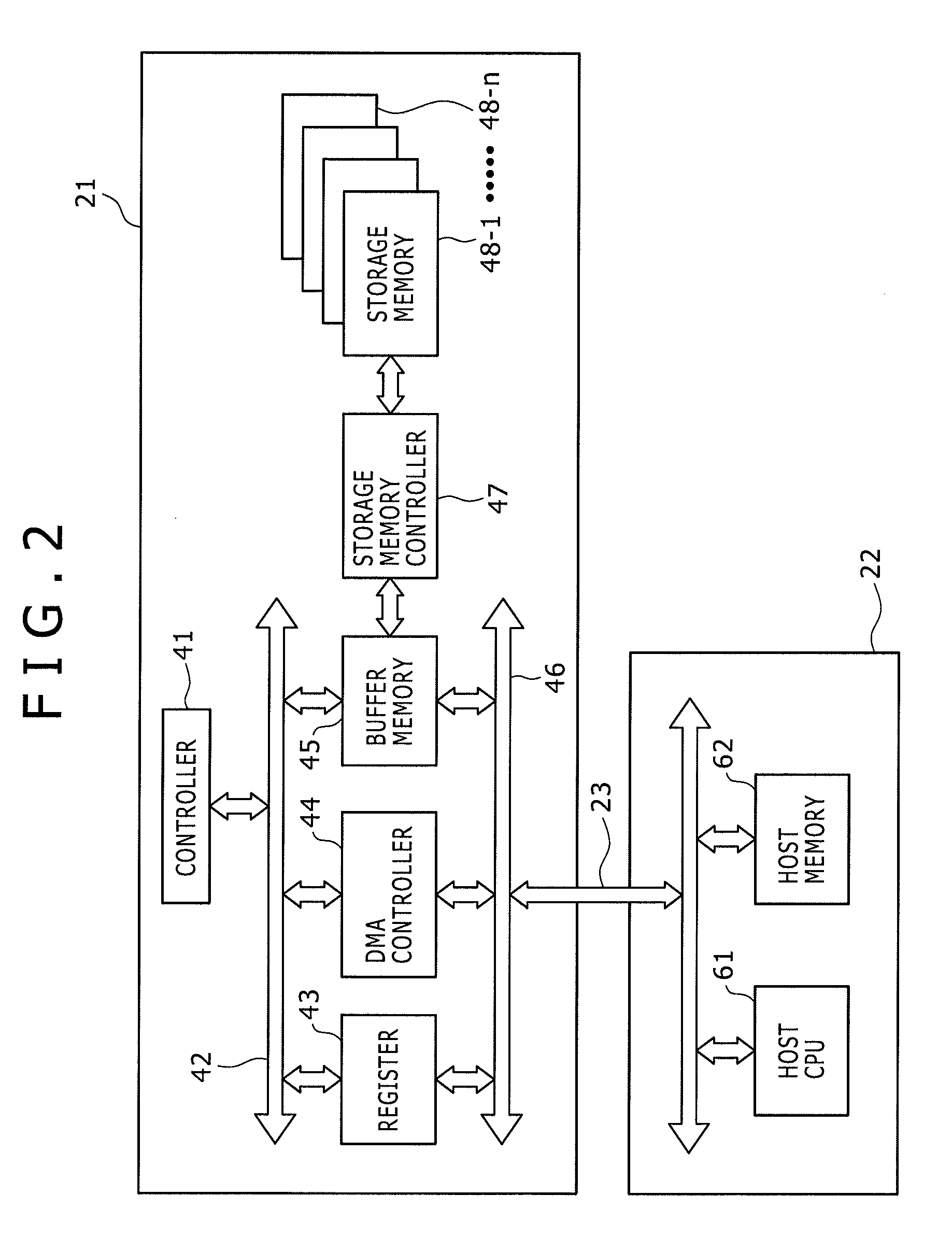

Information processing apparatus and method, and program

InactiveUS20080263307A1Reduce the amount requiredReduce processMemory adressing/allocation/relocationInformation processingSize determination

Disclosed herein is an information processing apparatus, including: setting means for setting, a maximum transfer size; calculation means for subtracting a second data amount from a first data amount to calculate a third data amount; boundary determination means for determining whether this transfer will involve a page boundary being extended across; buffer boundary determination means for determining whether this transfer will involve a buffer size being exceeded; transfer size determination means for determining whether or not the third data amount is equal to or less than the maximum transfer size; and determination means for determining a data amount of data to be transferred within limits of the third data amount, based on a first determination made by the boundary determination means, a second determination made by the buffer boundary determination means, and a third determination made by the transfer size determination means.

Owner:SONY CORP

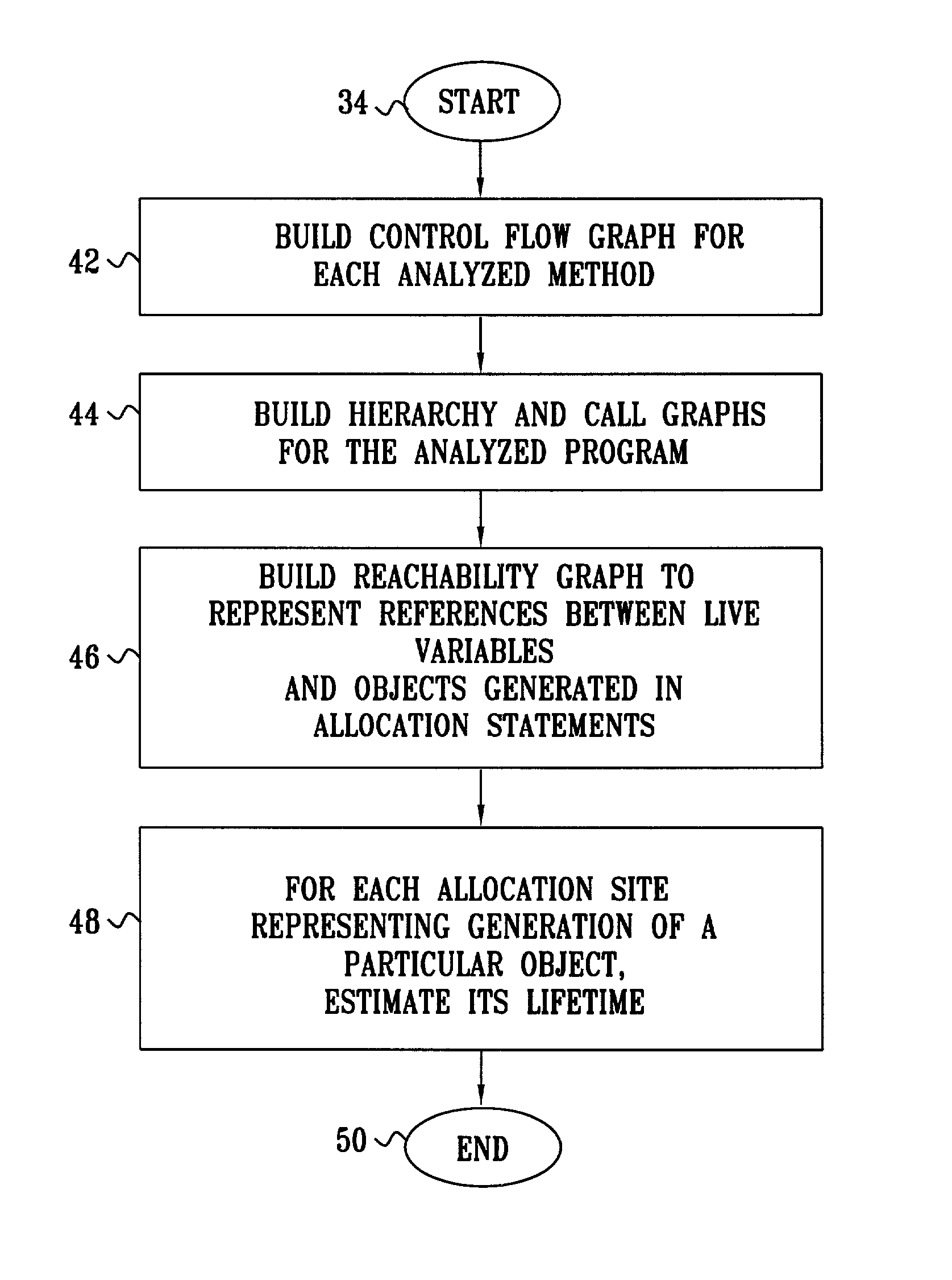

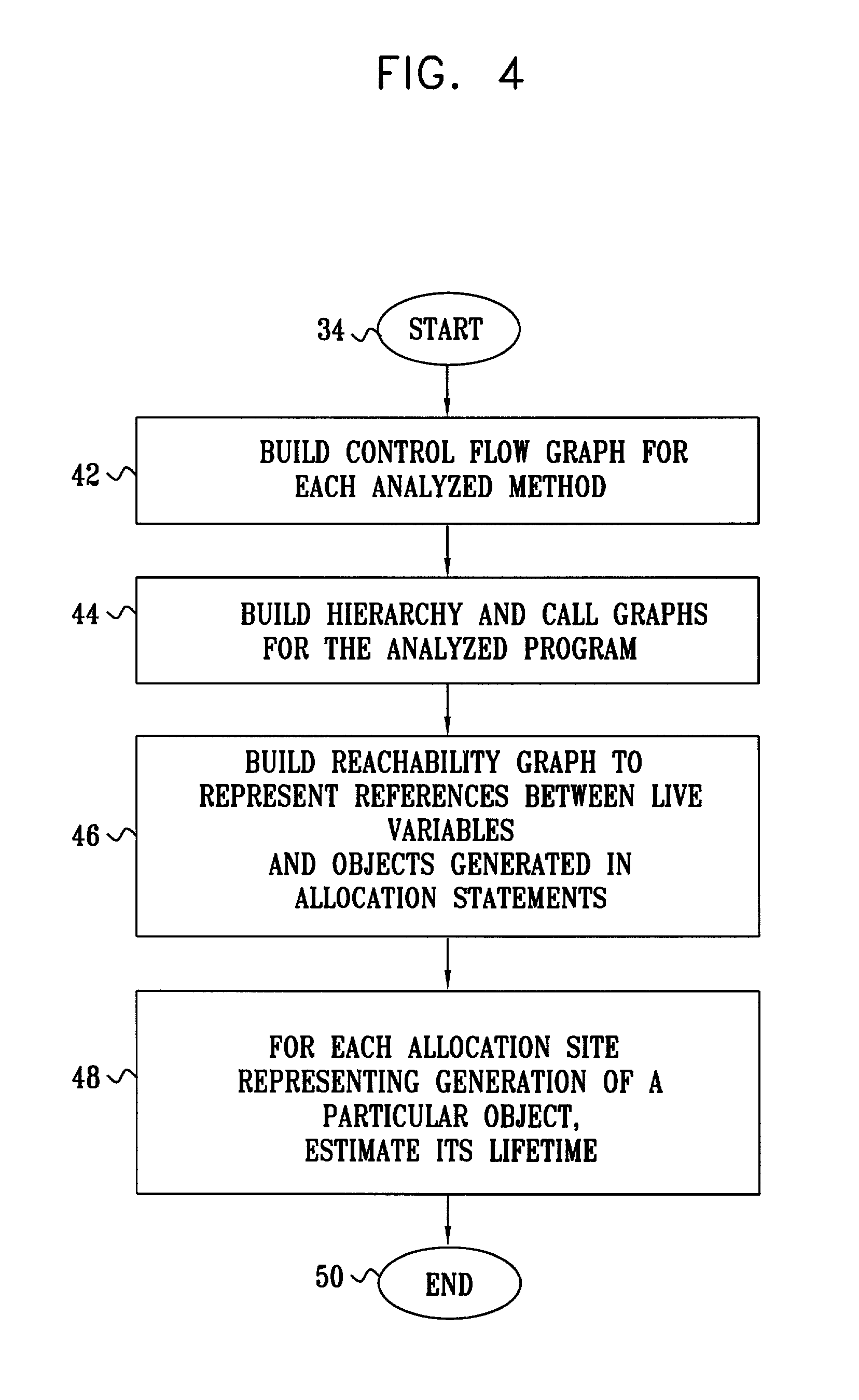

Estimation of object lifetime using static analysis

InactiveUS20020129343A1Improve performanceGood estimateData processing applicationsSoftware engineeringStatic timing analysisObject lifetime

A computer implemented technique for the static evaluation of the lifetime of objects allocated in memory is presented, which find application in reducing the overhead of generational garbage collection. The method combines pointer alias analysis with static object size determination, from which accurate generational assignment of newly created objects can be accomplished.

Owner:LINKEDIN

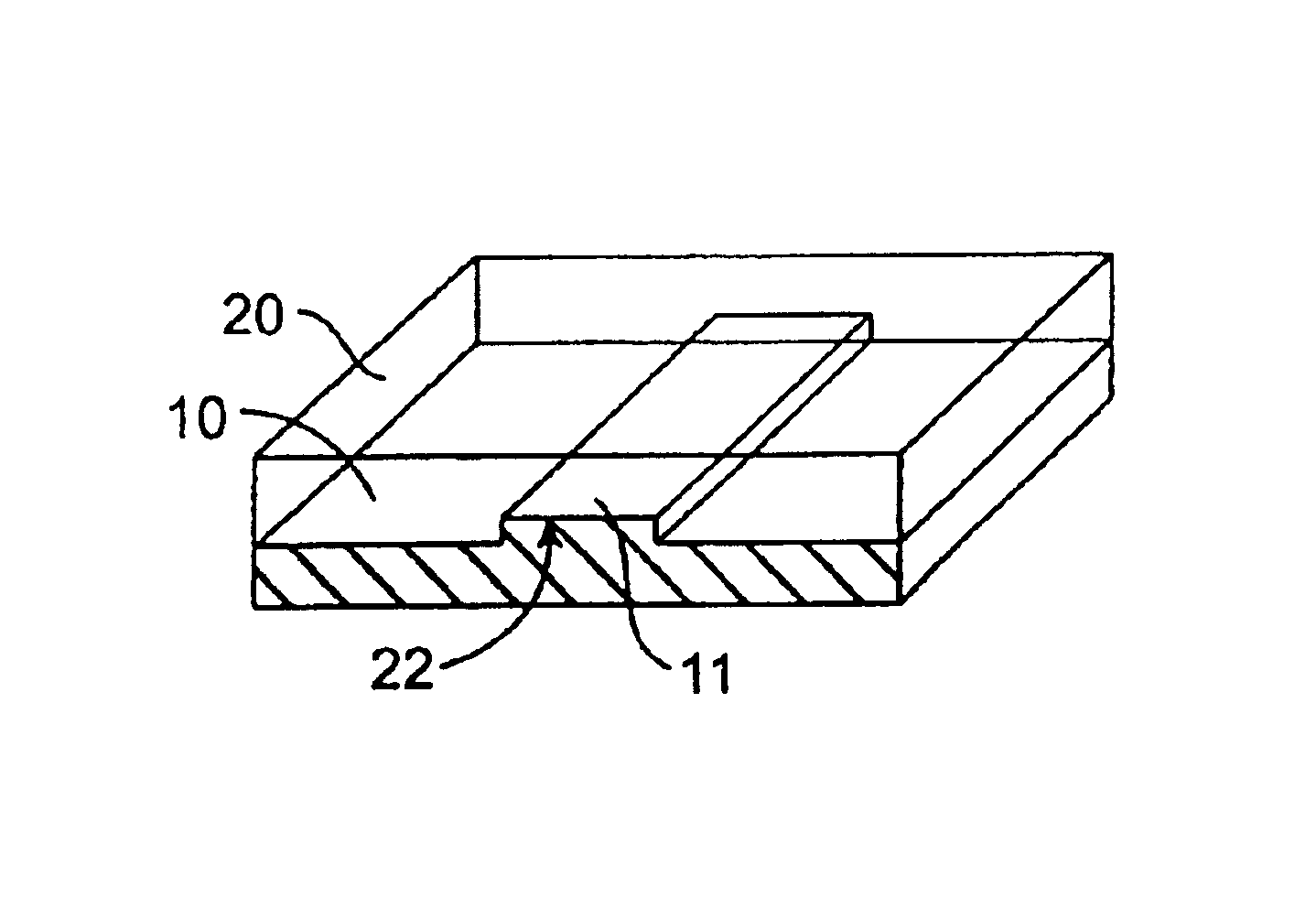

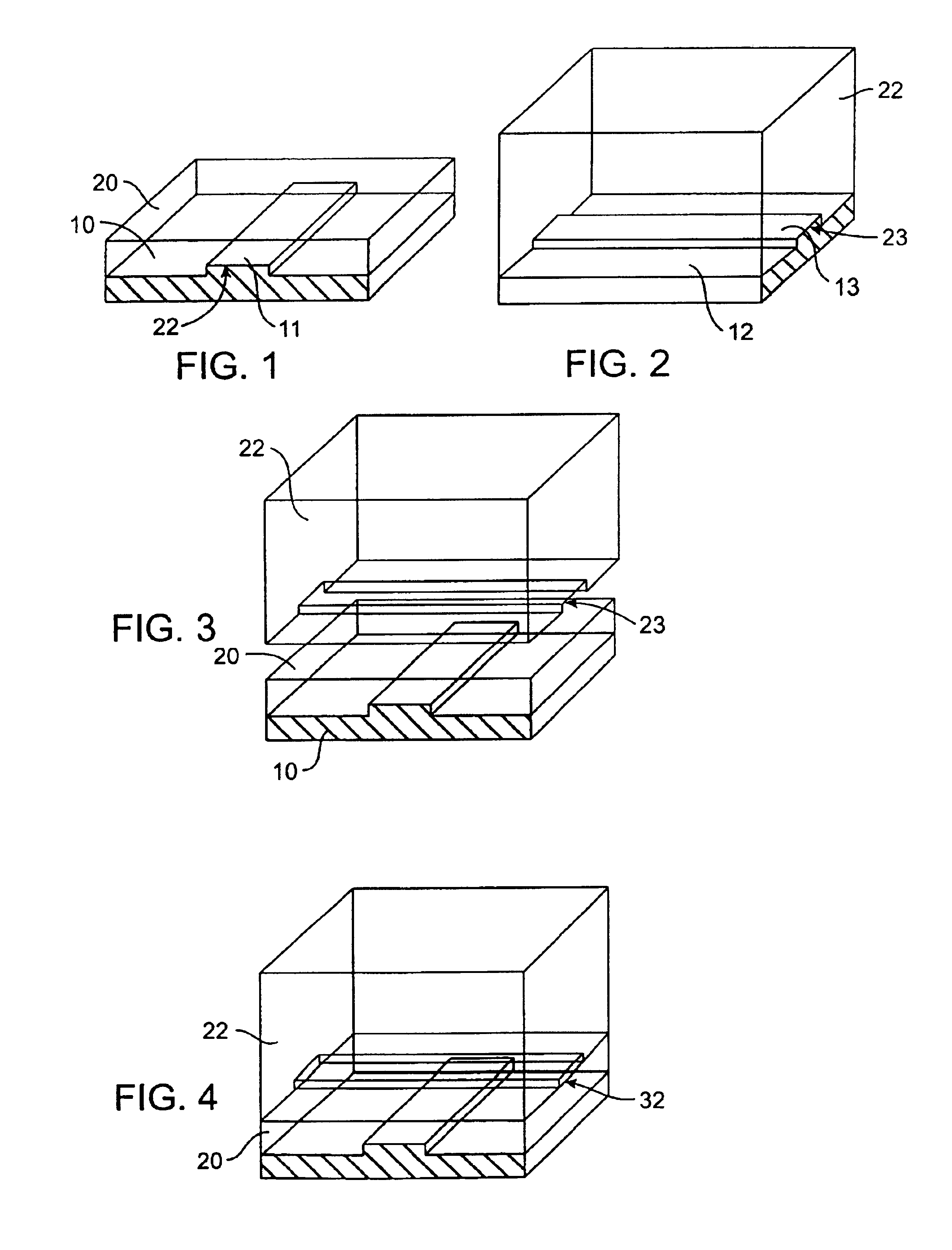

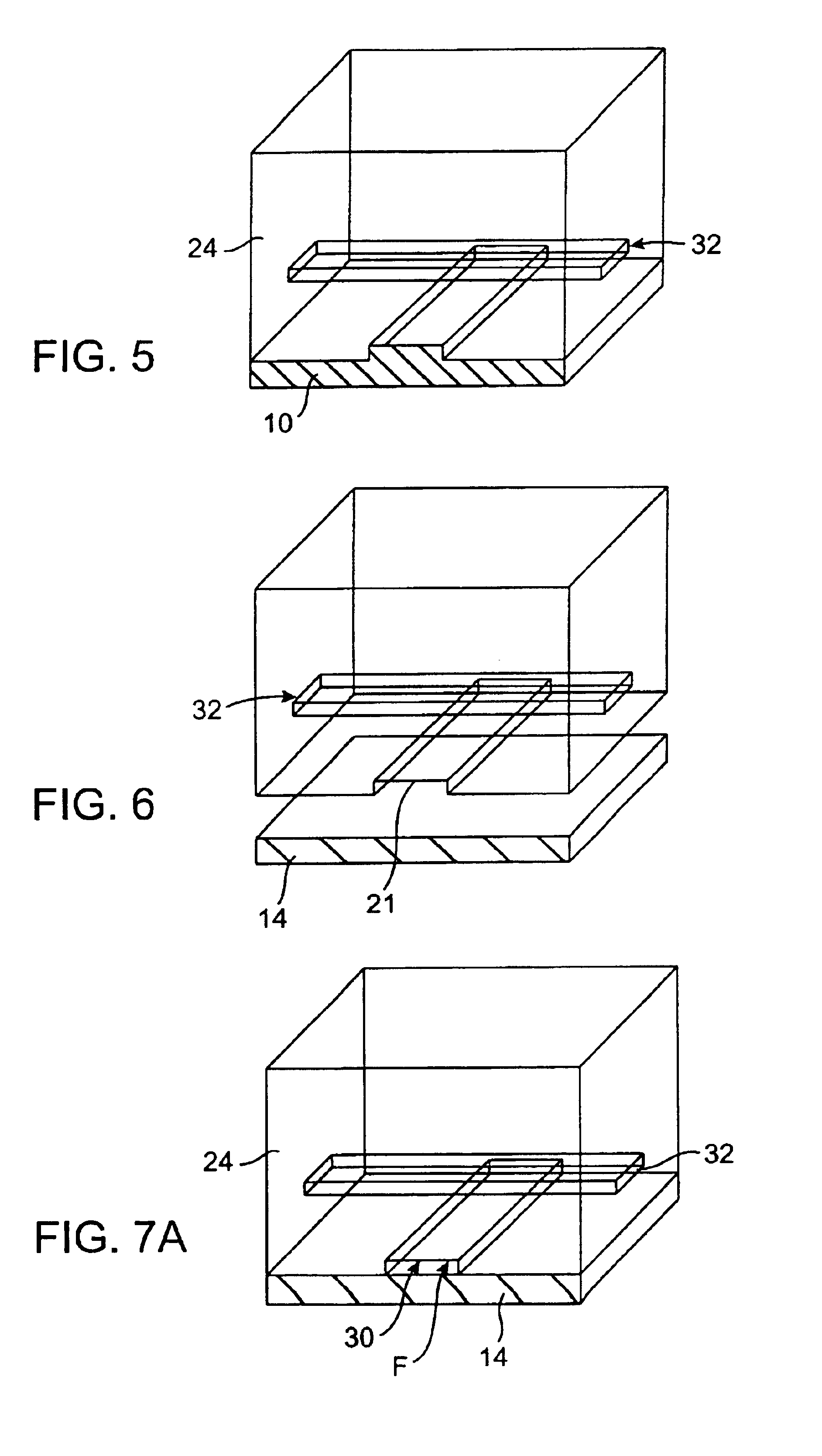

High throughput screening of crystallization of materials

InactiveUS7195670B2From normal temperature solutionsFixed microstructural devicesHigh-Throughput Screening MethodsSize determination

High throughput screening of crystallization of a target material is accomplished by simultaneously introducing a solution of the target material into a plurality of chambers of a microfabricated fluidic device. The microfabricated fluidic device is then manipulated to vary the solution condition in the chambers, thereby simultaneously providing a large number of crystallization environments. Control over changed solution conditions may result from a variety of techniques, including but not limited to metering volumes of crystallizing agent into the chamber by volume exclusion, by entrapment of volumes of crystallizing agent determined by the dimensions of the microfabricated structure, or by cross-channel injection of sample and crystallizing agent into an array of junctions defined by intersecting orthogonal flow channels.

Owner:CALIFORNIA INST OF TECH +1

High throughput screening of crystallization of materials

InactiveUS20050229839A1Sequential/parallel process reactionsFrom normal temperature solutionsHigh-Throughput Screening MethodsSize determination

High throughput screening of crystallization of a target material is accomplished by simultaneously introducing a solution of the target material into a plurality of chambers of a microfabricated fluidic device. The microfabricated fluidic device is then manipulated to vary the solution condition in the chambers, thereby simultaneously providing a large number of crystallization environments. Control over changed solution conditions may result from a variety of techniques, including but not limited to metering volumes of crystallizing agent into the chamber by volume exclusion, by entrapment of volumes of crystallizing agent determined by the dimensions of the microfabricated structure, or by cross-channel injection of sample and crystallizing agent into an array of junctions defined by intersecting orthogonal flow channels.

Owner:CALIFORNIA INST OF TECH +1

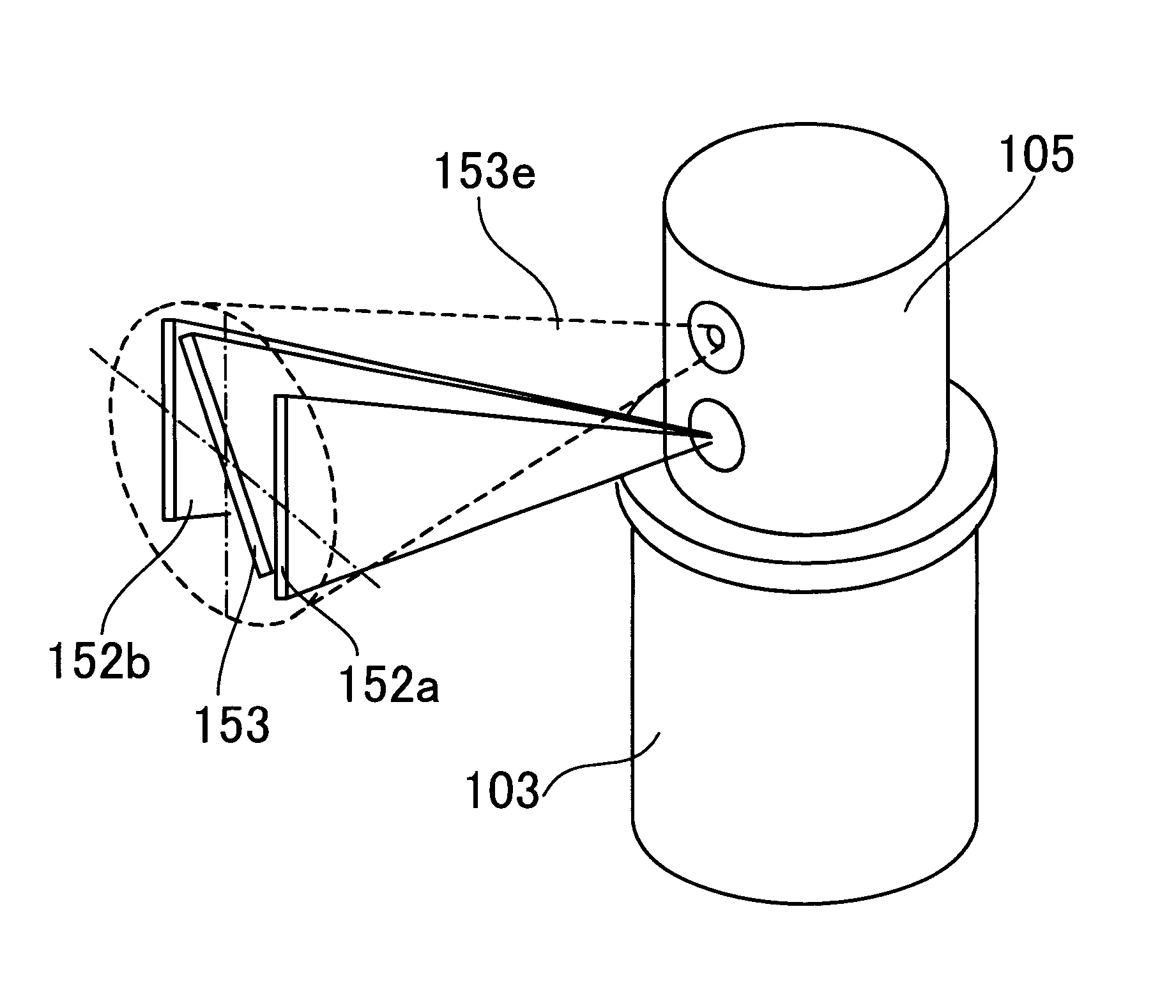

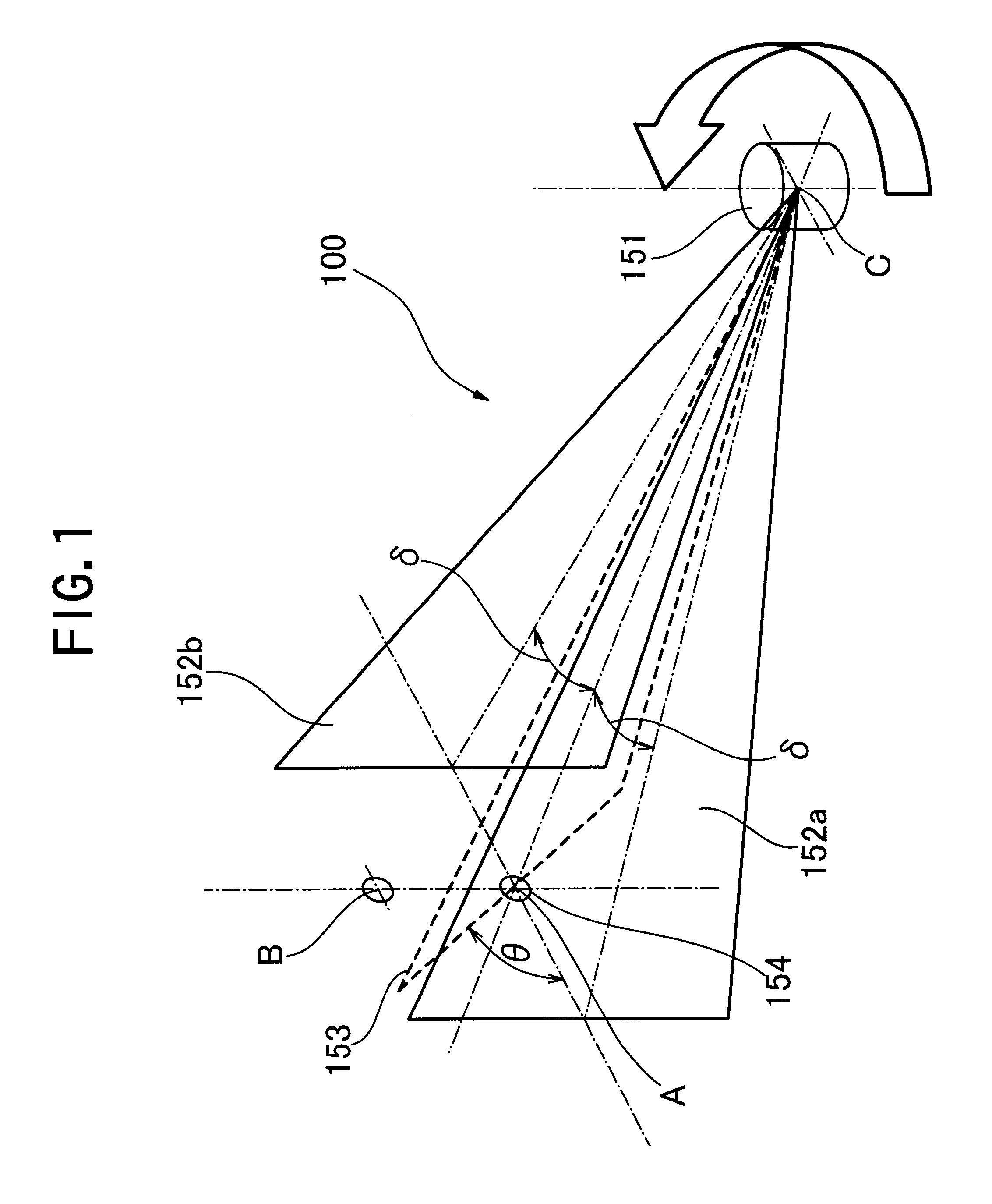

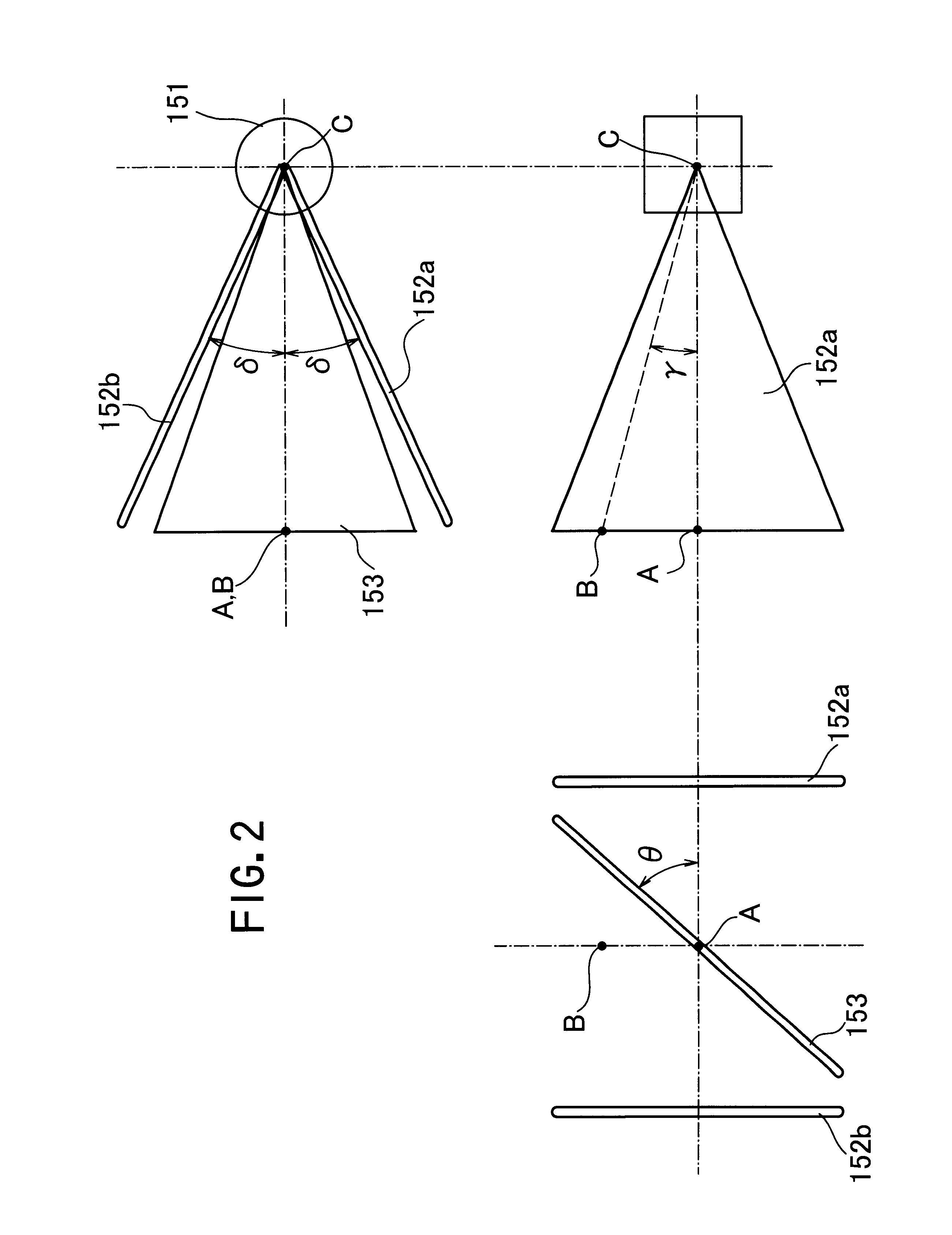

Position determination and adjustment system and light sensing device used for the same

A position determining system is disclosed, which has a simplified configuration capable of producing a plurality of phantom planes simultaneously. The improved system according to the present invention consists of a light receiving and sensing device that includes a body having means for sending data on elevation- and depression-angles and horizontal angles, and a phantom plane determining function for determining phantom planes, so as to display or output differential angles of elevations and depressions in relation with the phantom surfaces produced from the data received from the body.

Owner:KK TOPCON

Self-calibrating position determination system

A position determination system comprises a first measuring apparatus and a second measuring apparatus. The first measuring apparatus includes a first sensing device having a sensing field for obtaining positional data of a first testing target, a calibration target rigidly linked to the first sensing device, wherein the positional relationship between the first sensing device and the calibration target is known. The system has a repositioning mechanism for repositioning the sensing field of the first sensing device. The second measuring apparatus includes a second sensing device having a sensing field for obtaining positional data of a second testing target, a calibration sensing device rigidly linked to the second sensing device for obtaining positional data of the calibration target, wherein the positional relationship between the second sensing device and the calibration sensing device is known, and a repositioning mechanism for repositioning the sensing field of the second sensing device. Depending on different needs, the repositioning mechanism readjust the viewing fields of the sensing devices such that the testing targets are properly within the sensing fields of the sensing devices.

Owner:SNAP ON INC

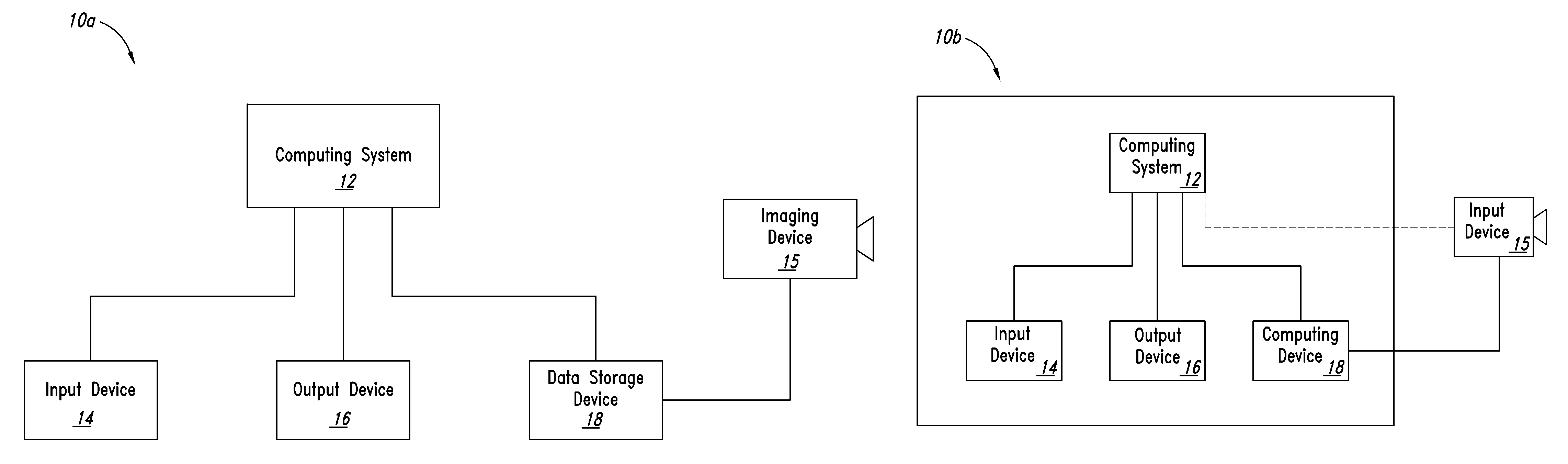

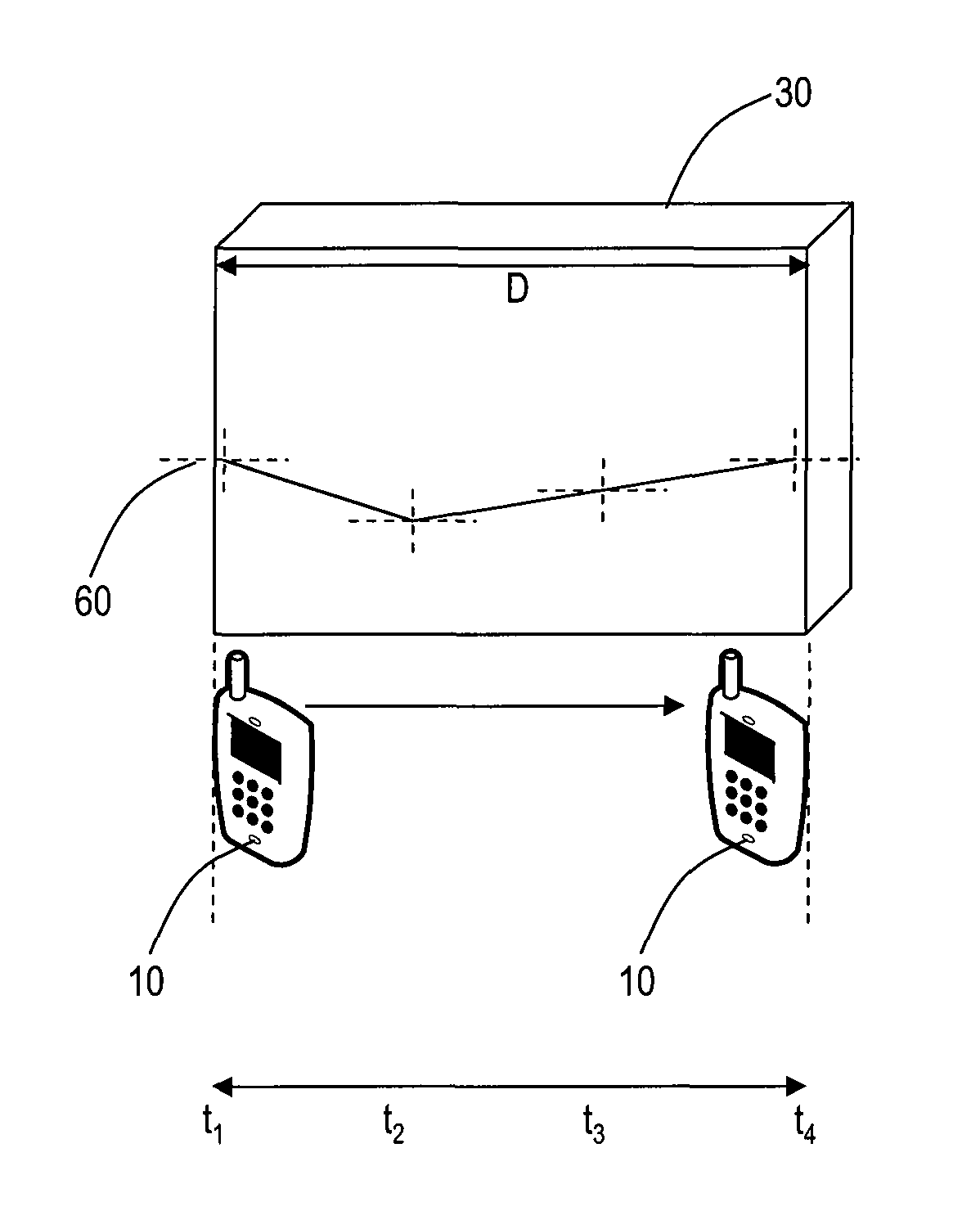

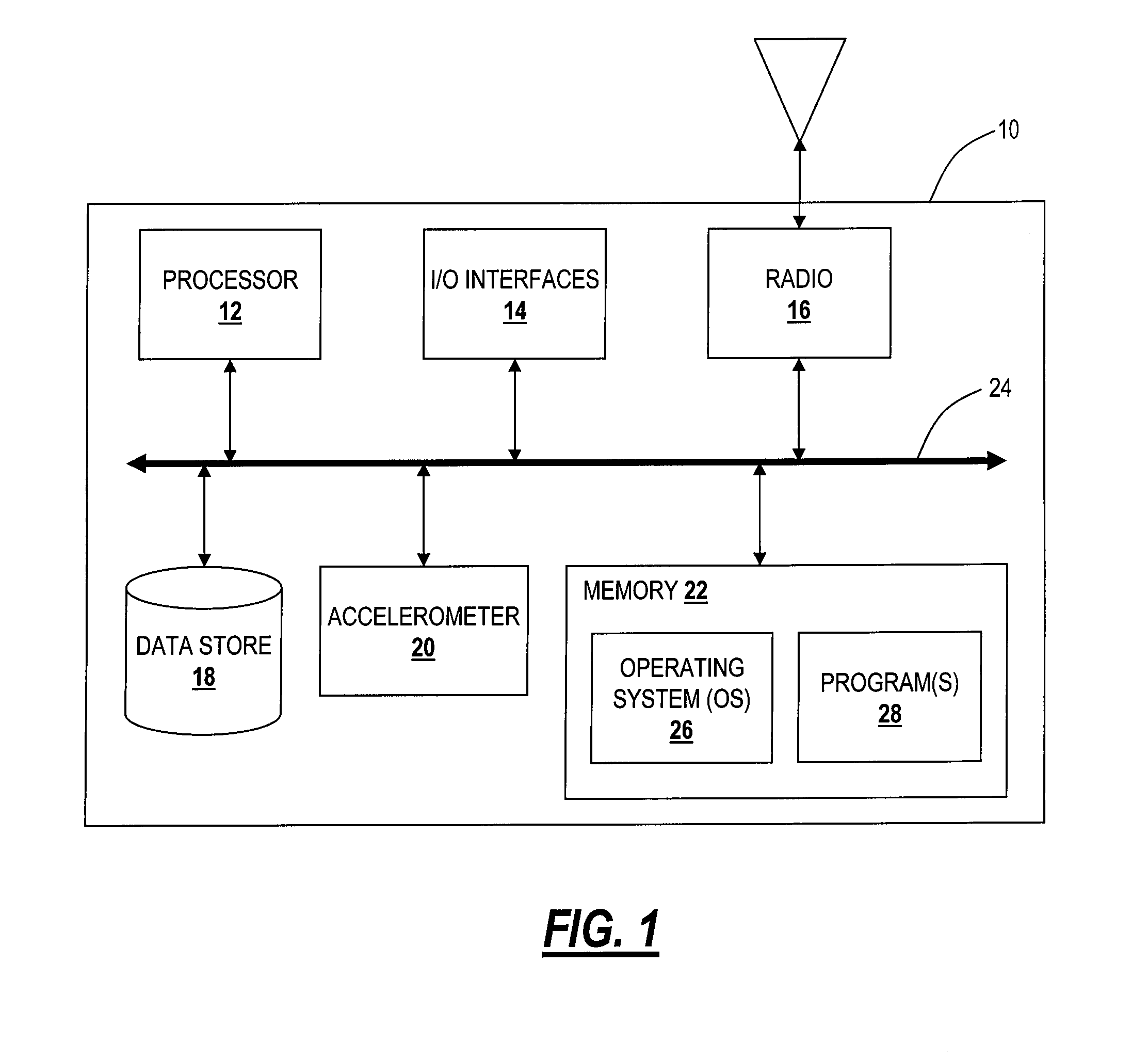

Interactive sensor systems and methods for dimensioning

ActiveUS8265895B2Character and pattern recognitionIncline measurementSize determinationThree axis accelerometer

The present disclosure relates to interactive systems and methods for dimensioning with a mobile device. The mobile device can include an accelerometer, imager, and a corresponding algorithm configured to compute dimensions based on a plurality of inputs from the accelerometer, imager, etc. Specifically, the accelerometer allows the mobile device to measure acceleration and time, and the algorithm is configured to convert these measurements into distances. Additionally, with a three-axis accelerometer, the user can move the device off an axis being measured and still receive an accurate measurement, i.e. the algorithm can compensate for off-axis movement. Further, the present invention can incorporate an imager on the mobile device to provide additional compensation supplementing the algorithm and allowing the user additional freedom to be positioned away from the starting and end-point of a measurement.

Owner:SYMBOL TECH LLC

Weighing and dimensioning system and method for weighing and dimensioning

InactiveUS20070272732A1Visual presentationWeighing auxillary devicesSize determinationComputer science

A system and method for weighing and dimensioning an object is described. The system may include a weighing apparatus and a dimensioner. The dimensioner may begin dimensioning the object after receiving a signal from the weighing apparatus. In one exemplary embodiment, a terminal may send the signal. The terminal may also receive and display the results received from the weighing apparatus and dimensioner.

Owner:METTLER TOLEDO INC

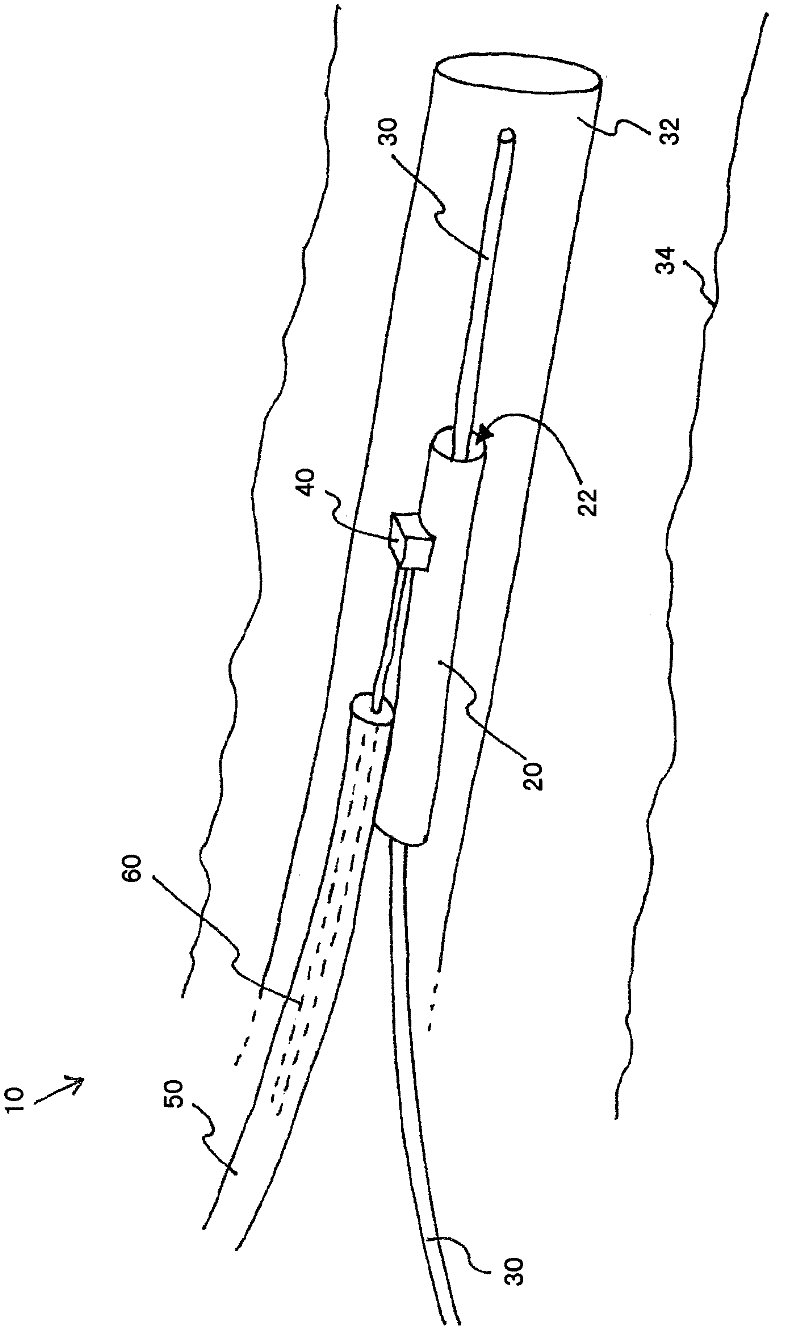

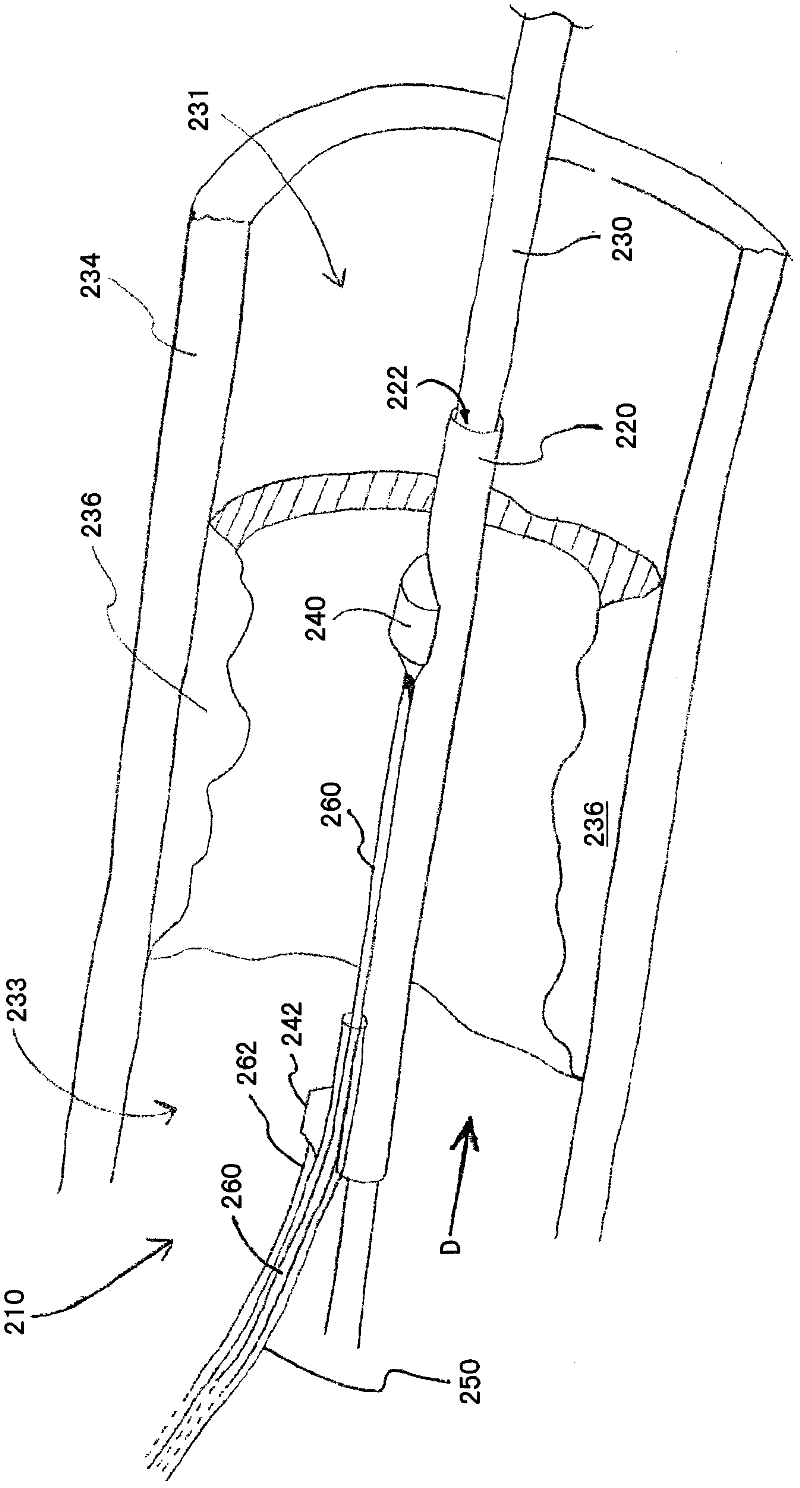

Physiological sensor delivery device and method

Owner:ACIST MEDICAL SYST

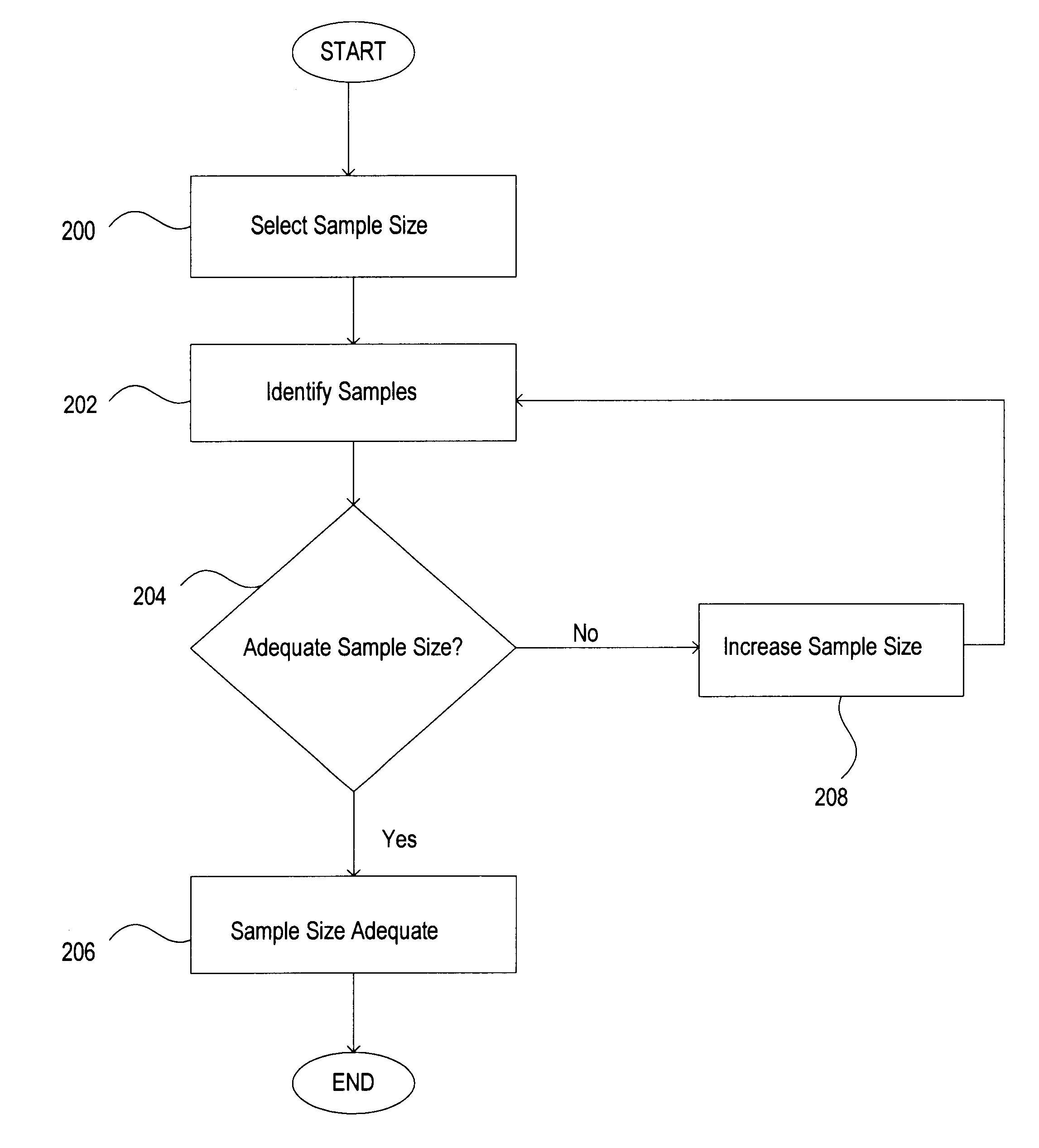

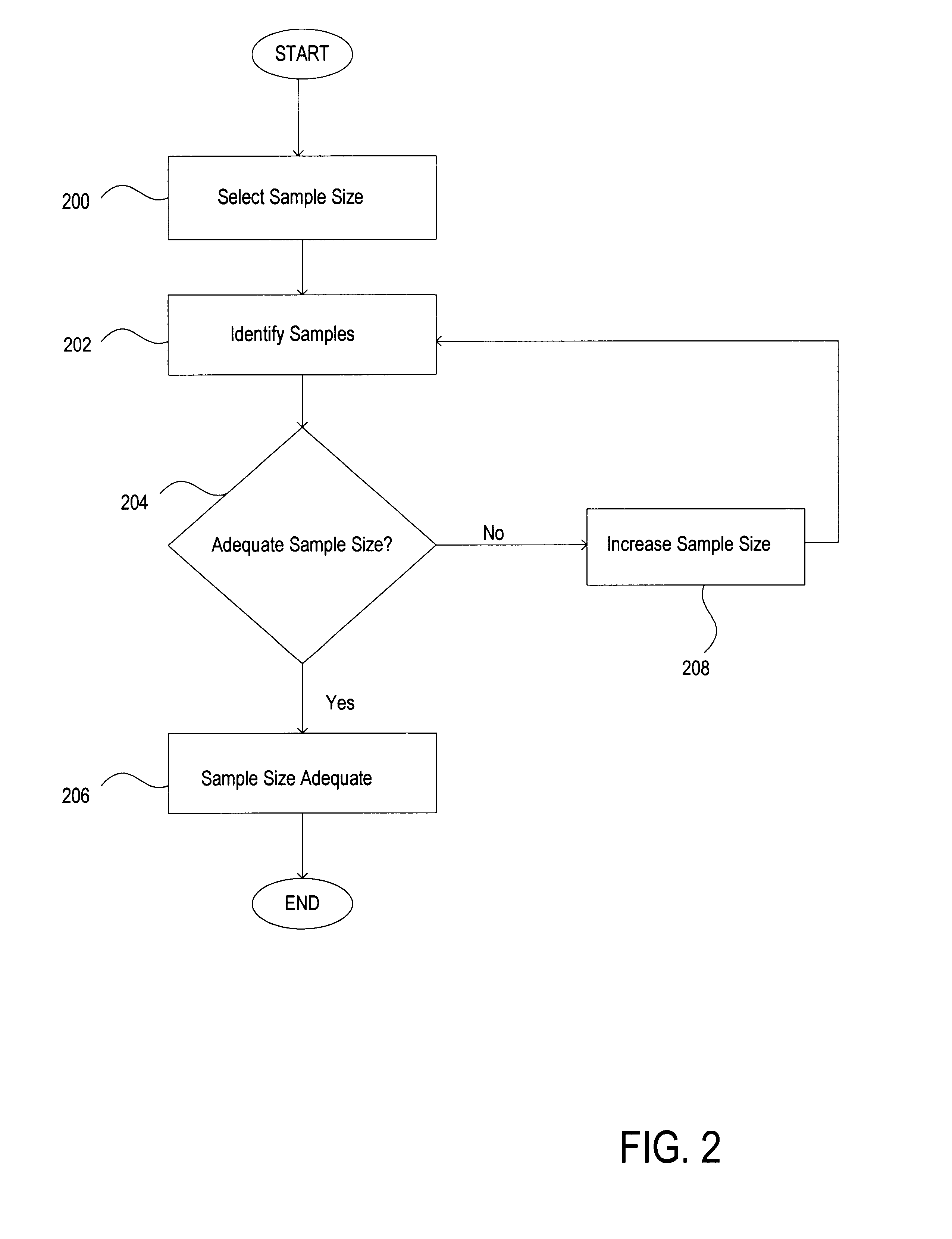

Method and system for sample size determination for database optimizers

InactiveUS6732085B1Quickly and efficiently executedEfficient executionData processing applicationsDigital data information retrievalSmall sampleIterative methodology

A system and method for determining an adequate sample size for statistics collection is disclosed. A mechanism for automatically determining an adequate sample size for both statistics and histograms is provided. The sample size determination is accomplished via an iterative approach where the process starts with a small sample, and for each attribute which may need more data, the sample size is increased while restricting the information collected to only those attributes that require the larger sample.

Owner:ORACLE INT CORP

Method for manufacturing direct shear test structural plane model

ActiveCN101718644ALong sampling costLow efficiencyPreparing sample for investigationFeeding arrangmentsSize determinationOperability

The invention relates to a method for manufacturing a direct shear test structural plane model. The method comprises the following steps of: (1) the selection and the processing of a virgin rock structural plane: selecting a virgin rock structural plane to be used as a sample, and leveling an original structural plane of the rock mass; then coating a mould release agent at a selected position determined according to the specific size of a structural plane model, and spreading an isolating membrane; (2) putting a lower mould on the selected position of the original structural plane, and pouring a uniformly stirred mixed material into the lower mould; after carrying out water retention maintenance on the sample, turning over a lower disk structural plane sample together with the lower mould, and removing the used isolating membrane on the lower disk structural plane; (3) coating the mould release agent on the prepared lower disk structural plane, and spreading the isolating membrane; centering and putting an upper mould on a lower mould, and then pouring a uniformly stirred mixed material of weighed raw materials into the upper mould again; and (4) demoulding. The method has specific principle, strong maneuverability, low cost and good use effect.

Owner:GUANGZHOU FULI CONSTR & INSTALLATION ENG

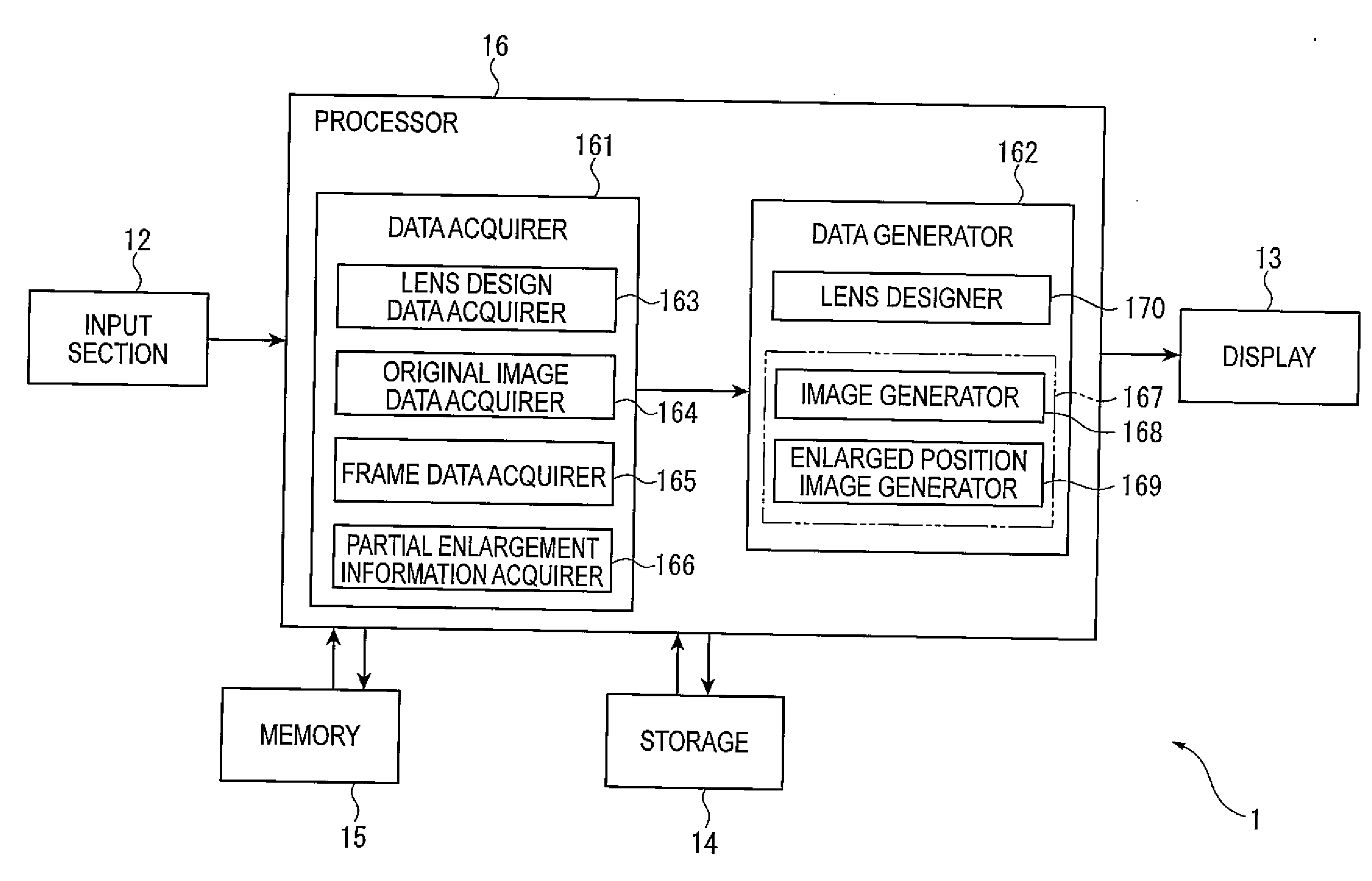

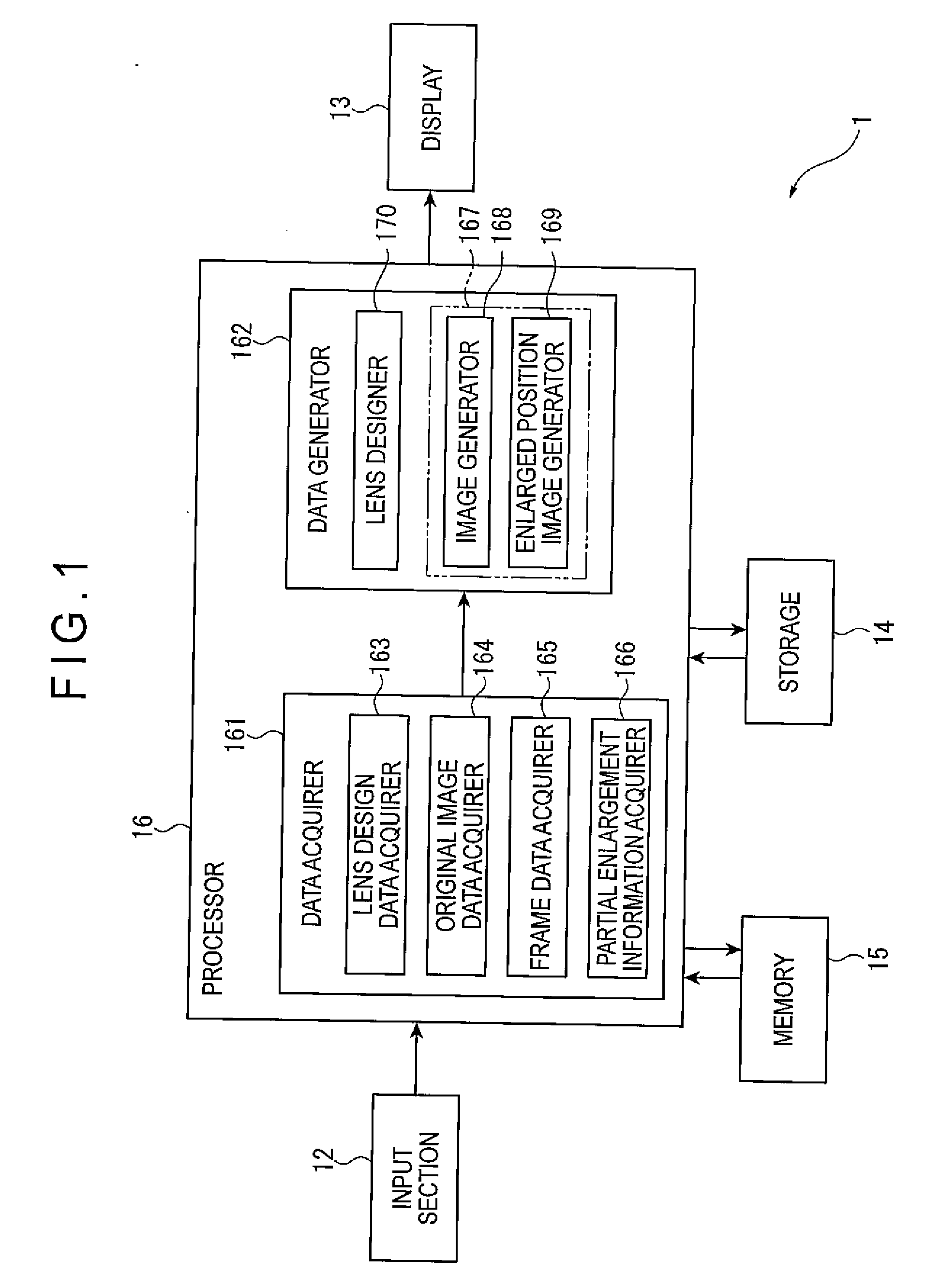

Visual Simulator for Spectacle Lens, Visual Simulation Method for Spectacle Lens, and Computer Readable Visual Simulation Program for Spectacle Lens

InactiveUS20100114540A1Accurate displayUser-friendliness is enhancedComputation using non-denominational number representationEye diagnosticsCamera lensData display

A visual simulator for a spectacle lens including: a lens design data acquirer that acquires lens design data on design items of a spectacle lens including a prescription for a spectacle wearer's naked eye; a lens designer that designs the spectacle lens based on the lens design data; an original image data acquirer that acquires an original image data for the simulation; an image processor that processes the original image data acquired by the original image data acquirer and generates image data representing an image viewed through a lens processed based on the frame data; a display that comprises a screen that displays the image based on the image data generated by the image processor; a partial enlargement information acquirer that acquires partial enlargement information of a visual field, the partial enlargement information including a distance from a spectacle lens wearer to the screen of the display and a dimension of the screen, wherein a processing mode of the image processor includes: an entire display mode in which the visual field based on the shape data is entirely displayed on the screen of the display; and a partial display mode in which a part of the visual field determined by the distance from the spectacle wearer to the screen of the display and the dimension of the screen acquired by the partial enlargement information acquirer.

Owner:HOYA LENS MFG PHILIPPINES +1

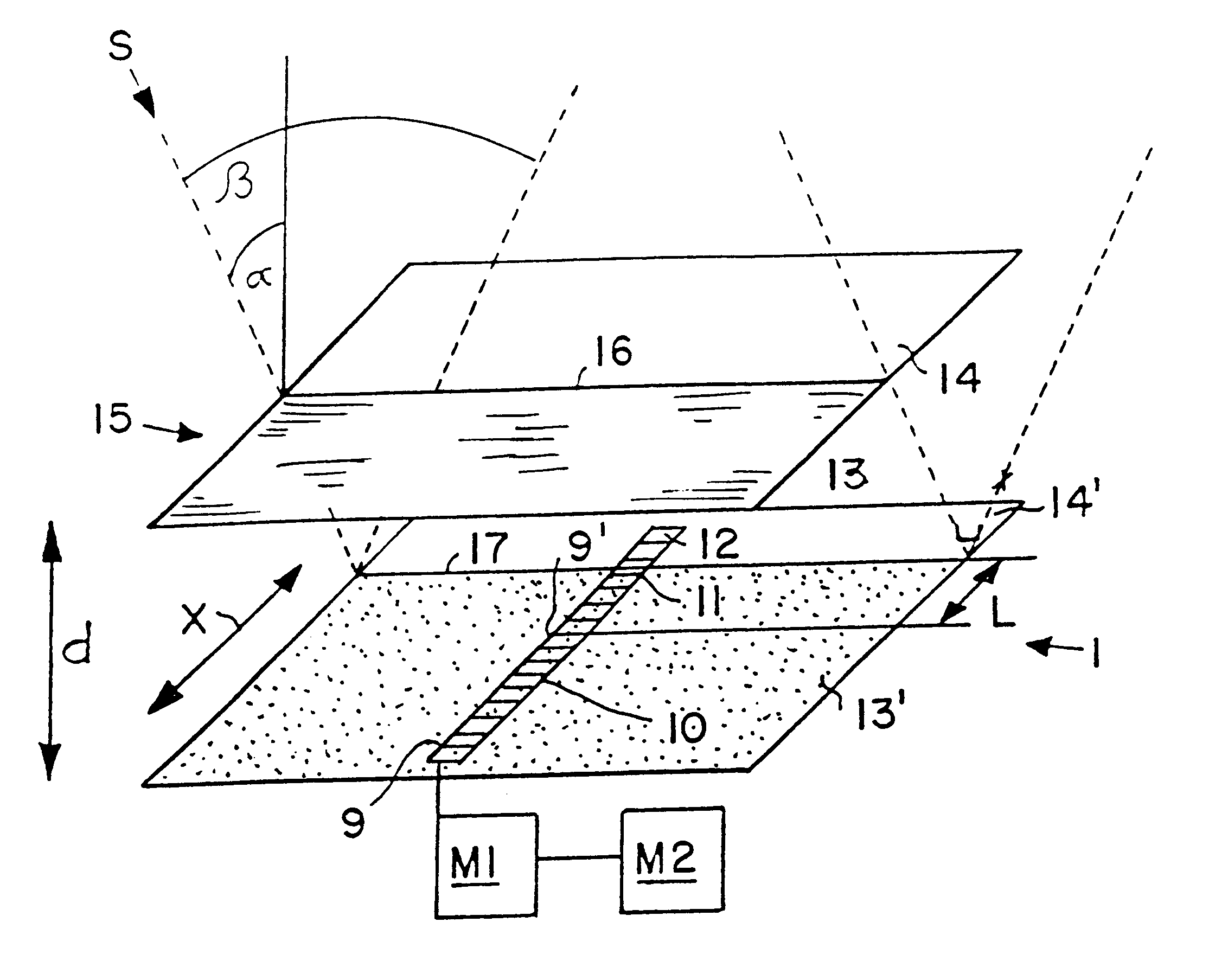

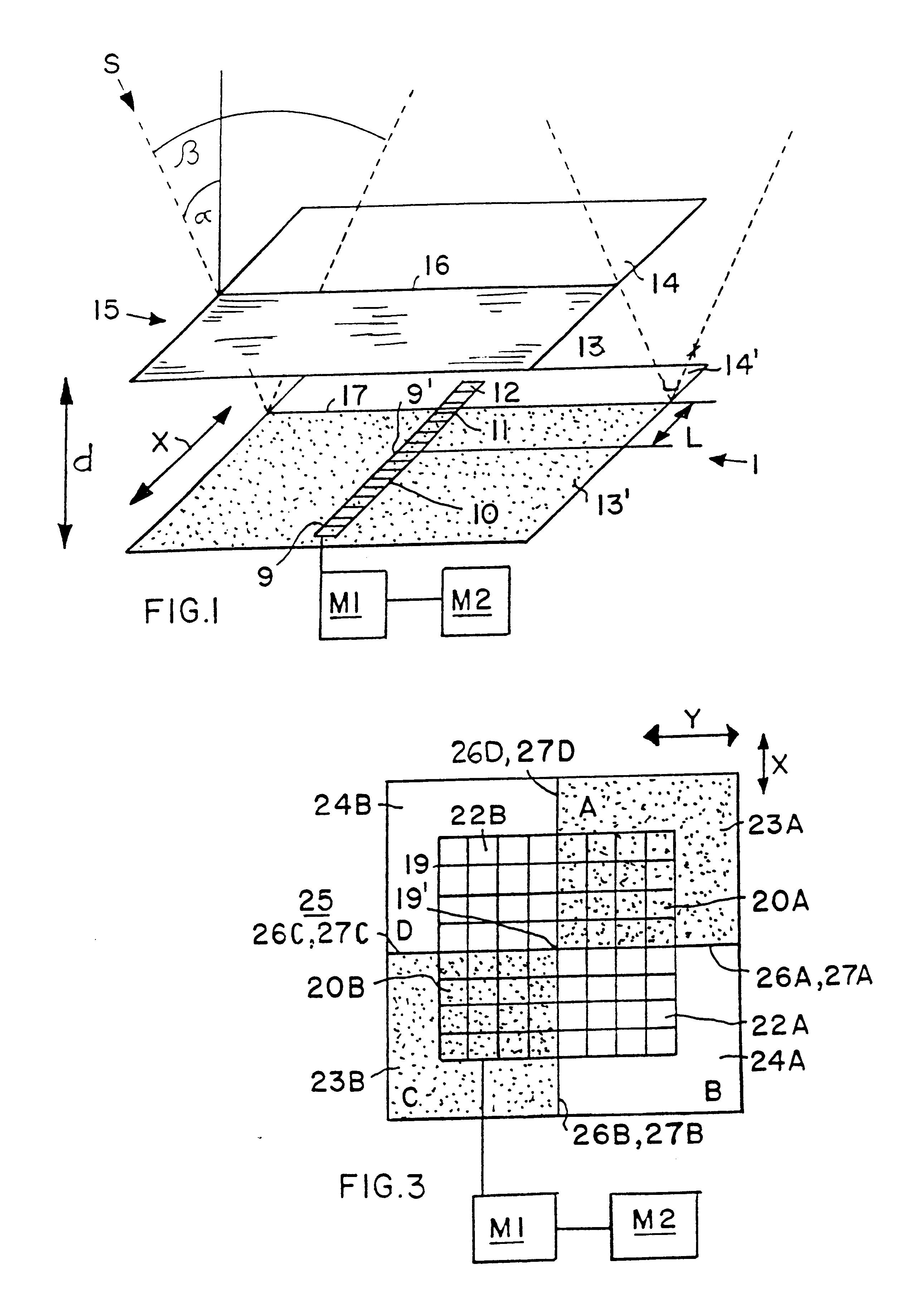

Arrangement for determining the incidence angle of radiation and especially solar radiation

InactiveUS6274862B1Easy constructionSmall sizeAngle measurementPhotometry using reference valueAngle of incidenceSize determination

A device for determining the angle of incidence (alpha) of incident radiation and particularly sunlight (S) includes an array of light sensitive elements (10, 11 and 12) and a shadow mask (15) arranged above the elements. The shadow mask (15) includes a transparent region (14) and a non-transparent region (13) with a linear boundary or edge (16) therebetween. The linear edge (16) is arranged above the center of the linear array (9) of light sensitive elements (10, 11 and 12) so as to extend at a right angle relative to the linear direction of the array. To determine the angle of incidence (alpha), a coarse determination of the number of completely shaded light sensitive elements (10), and a fine determination of the fractional shading portion of the partially shaded light sensitive element (11) immediately adjacent to the completely shaded elements, are carried out. In this manner, a very high precision and accuracy can be achieved, exceeding the physical resolution determined by the size of the individual light sensitive elements, while still maintaining a simple and reliable construction. The angles of incidence (alpha) and (beta) in two perpendicular planes can be determined by providing a two-dimensional array of light sensitive elements in connection with a shadow mask having a two-dimensional checkerboard pattern of transparent regions and non-transparent regions.

Owner:DAIMLER AG

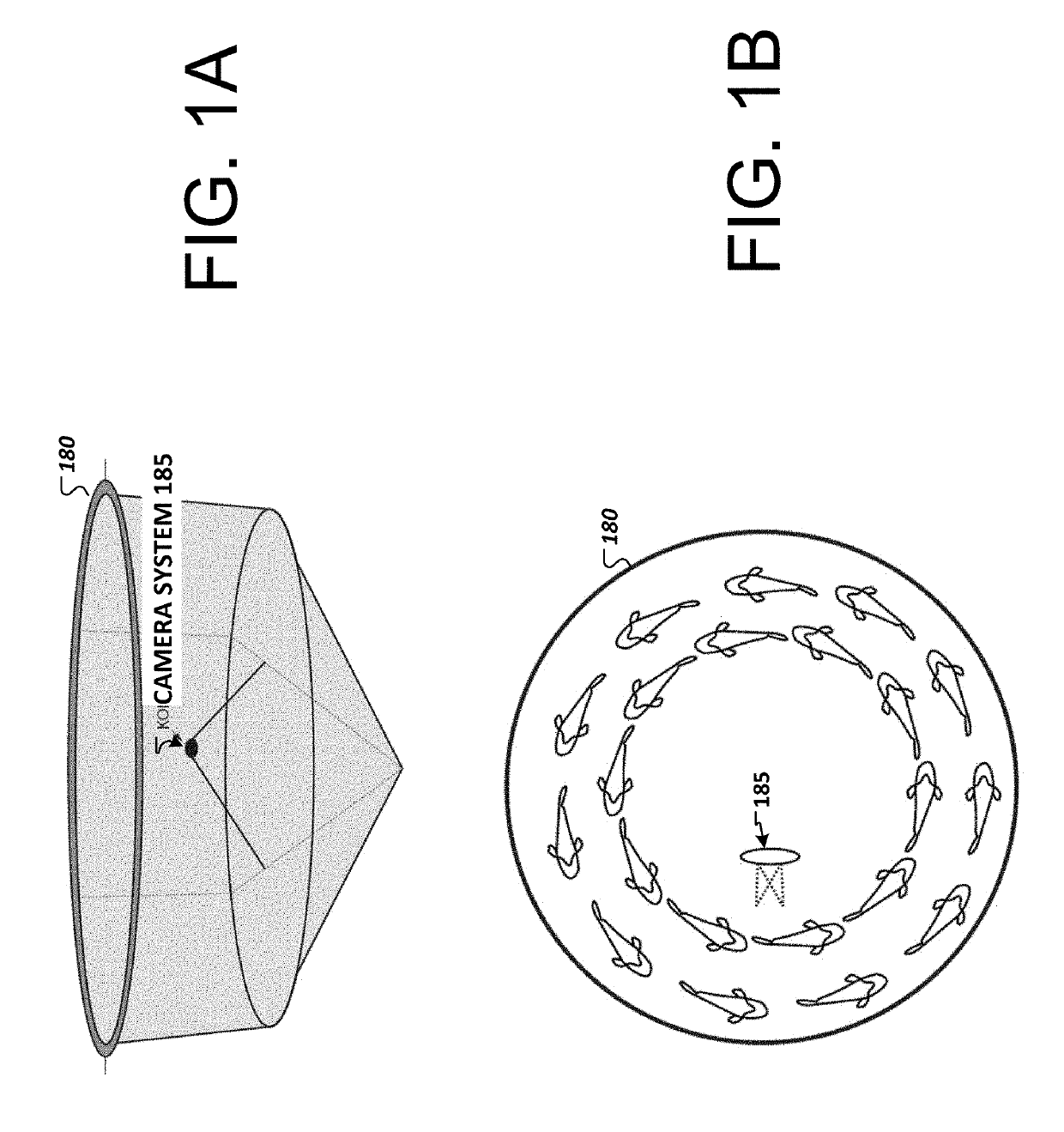

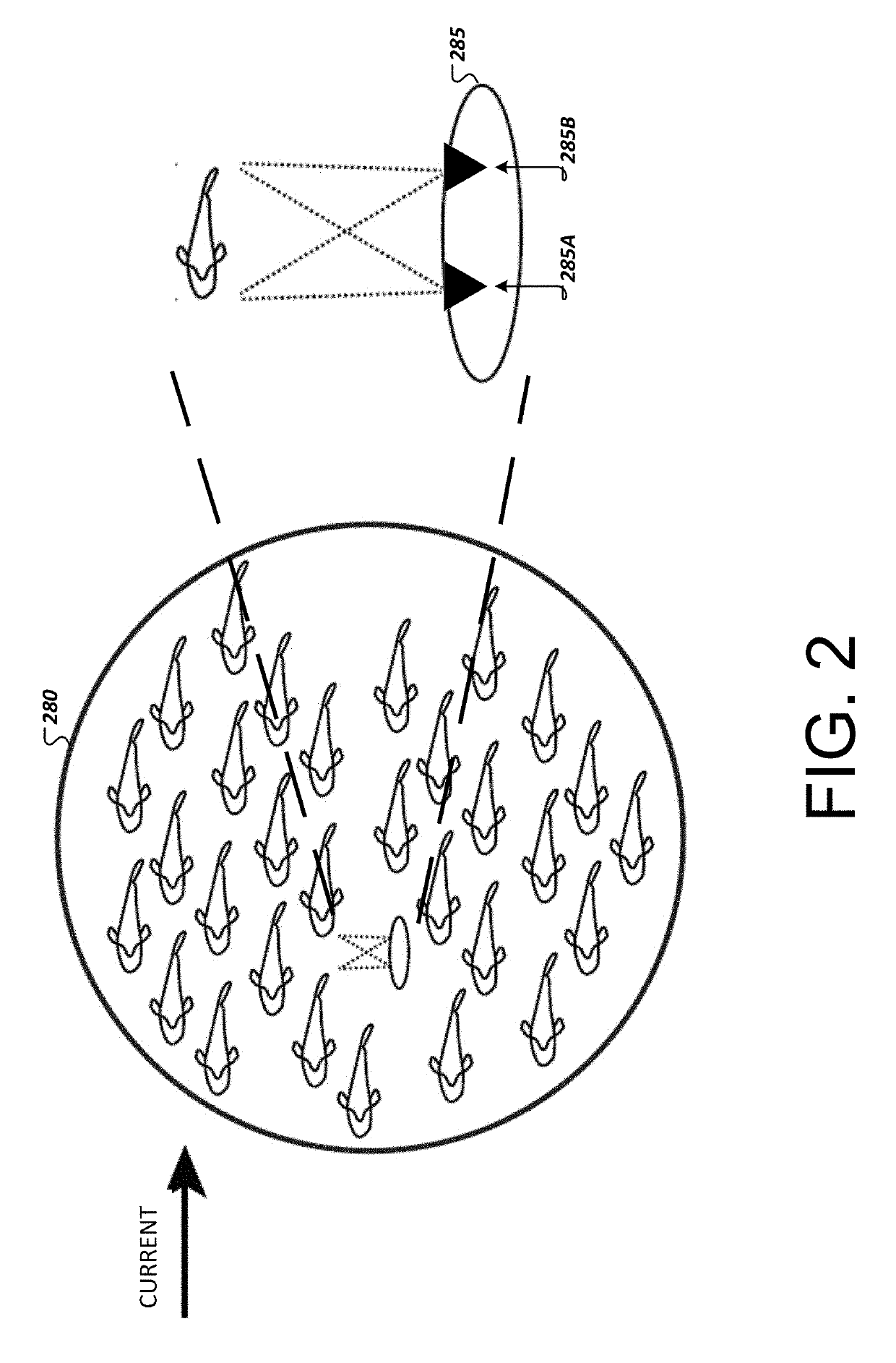

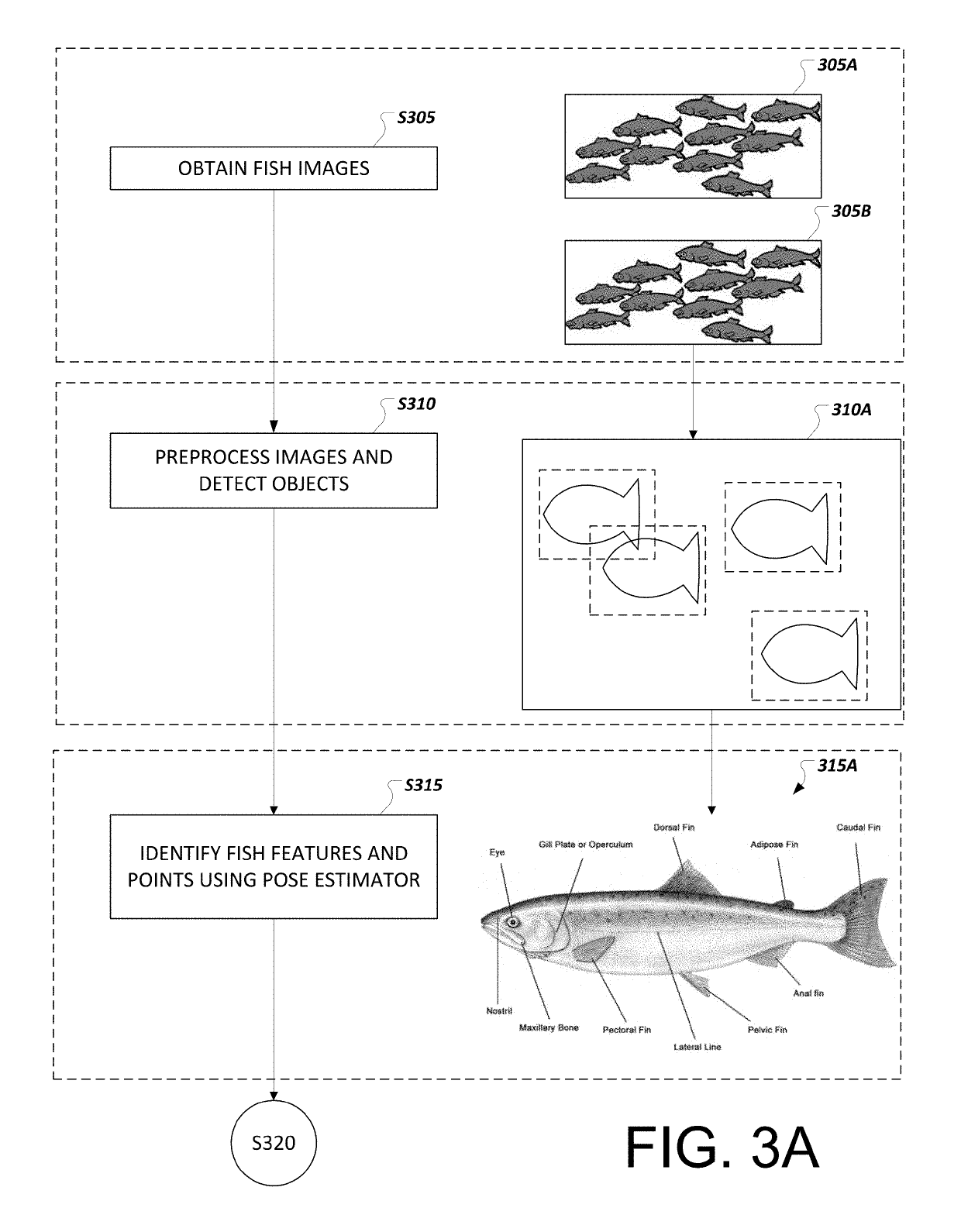

Fish biomass, shape, and size determination

ActiveUS20190228218A1Improve accuracyImprove consistencyImage enhancementImage analysisSize determinationStereo cameras

Methods, systems, and apparatuses, including computer programs encoded on a computer-readable storage medium for estimating the shape, size, and mass of fish are described. A pair of stereo cameras may be utilized to obtain right and left images of fish in a defined area. The right and left images may be processed, enhanced, and combined. Object detection may be used to detect and track a fish in images. A pose estimator may be used to determine key points and features of the detected fish. Based on the key points, a three-dimensional (3-D) model of the fish is generated that provides an estimate of the size and shape of the fish. A regression model or neural network model can be applied to the 3-D model to determine a likely weight of the fish.

Owner:X DEV LLC

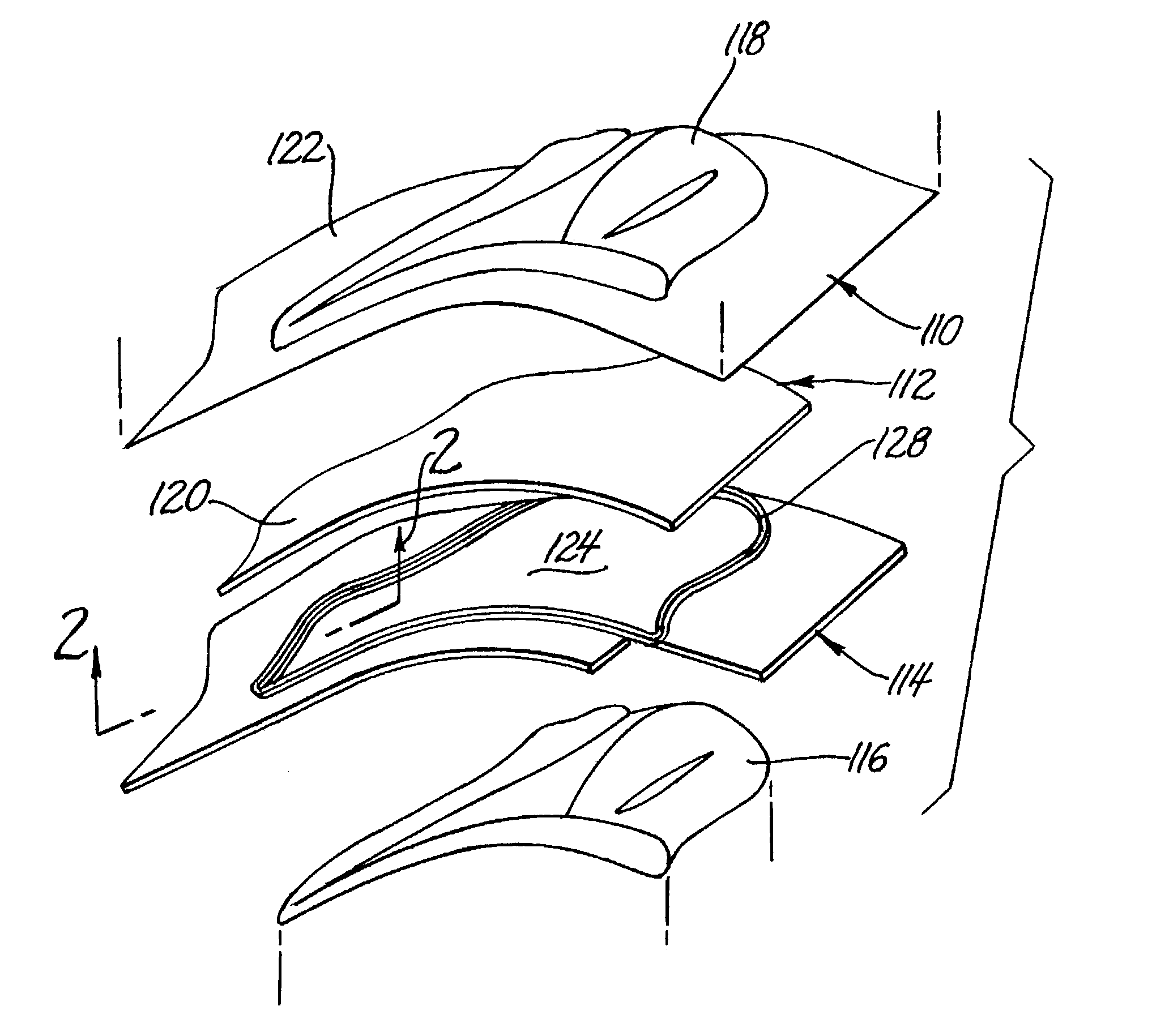

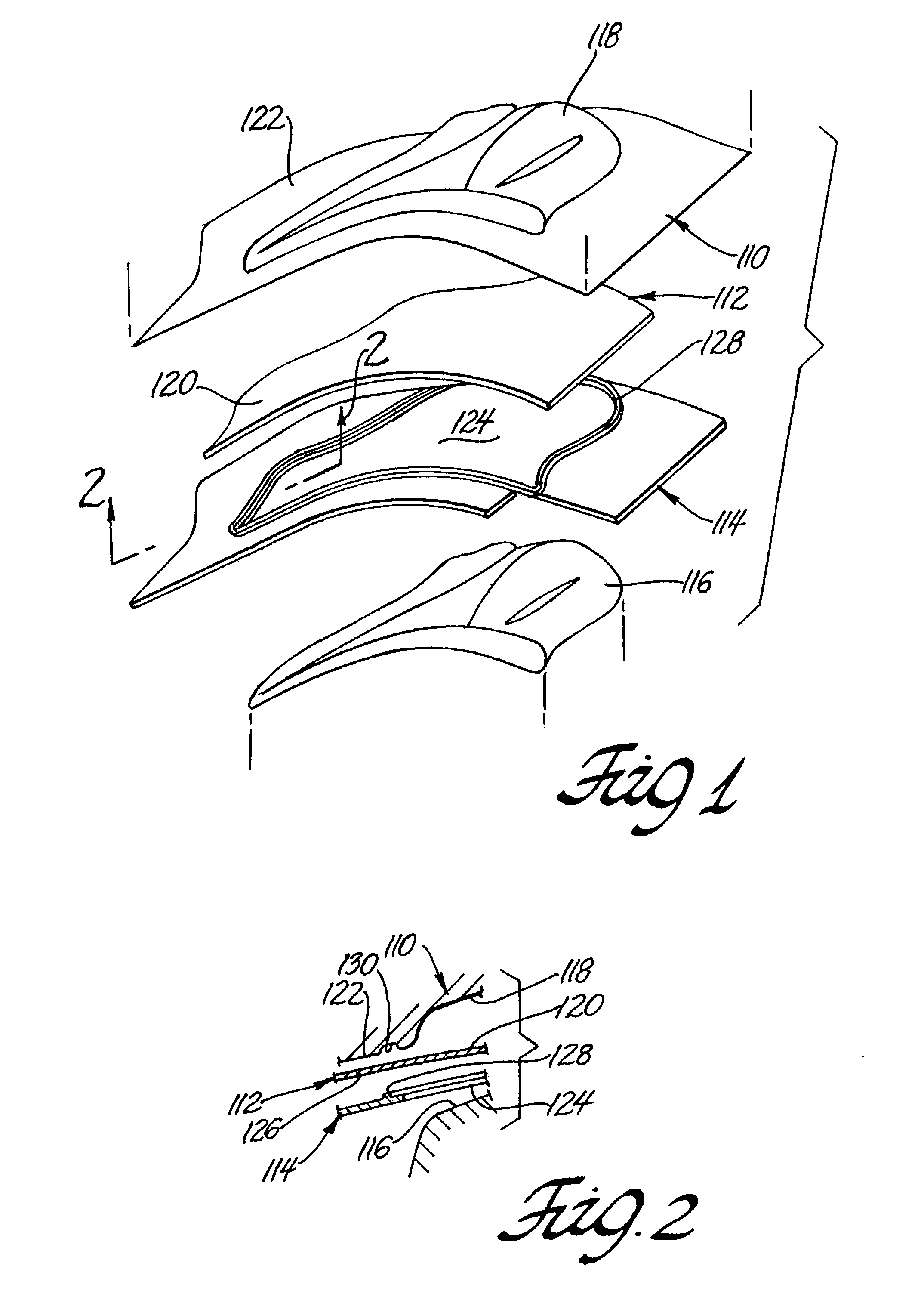

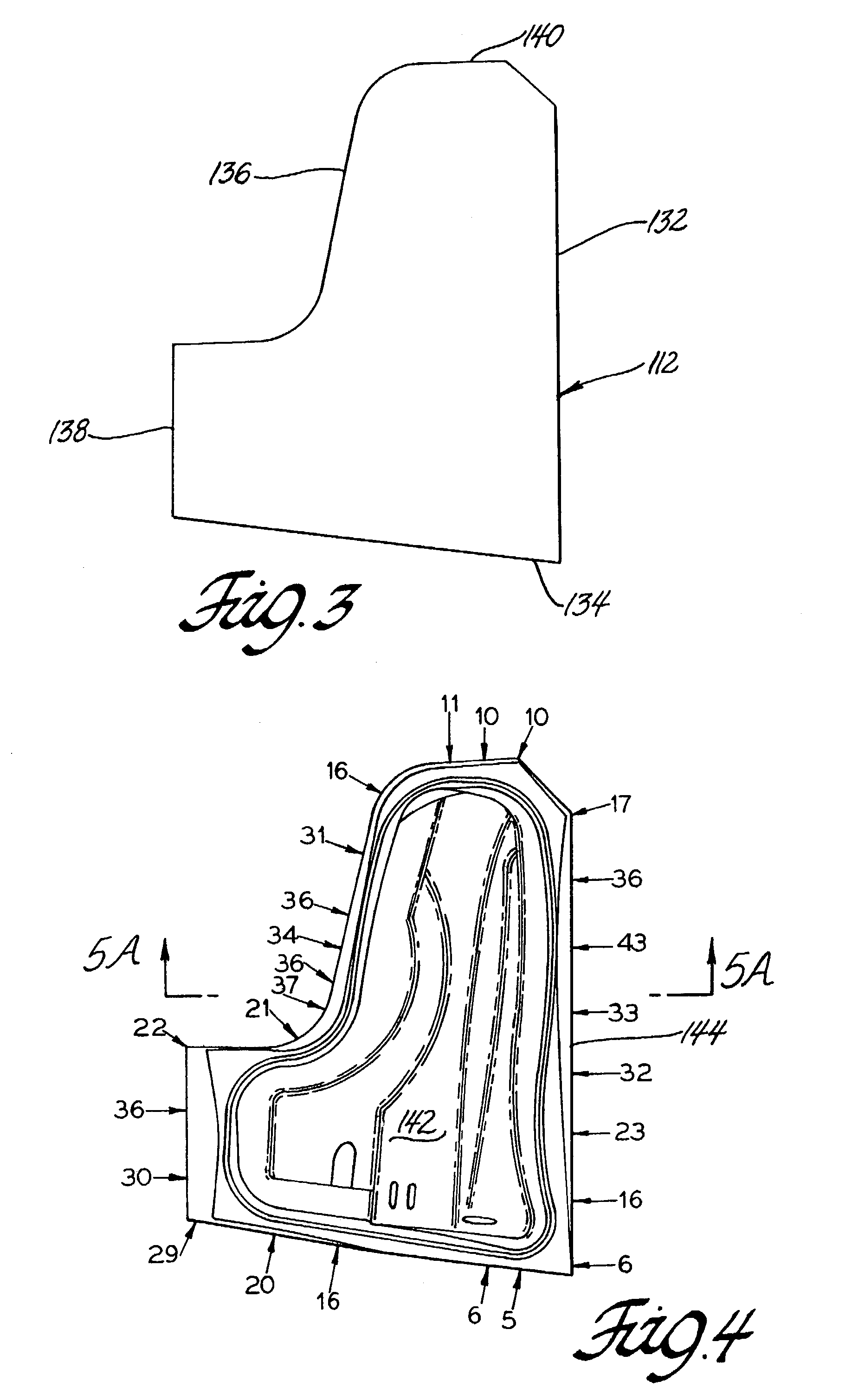

Draw-in map for stamping die tryout

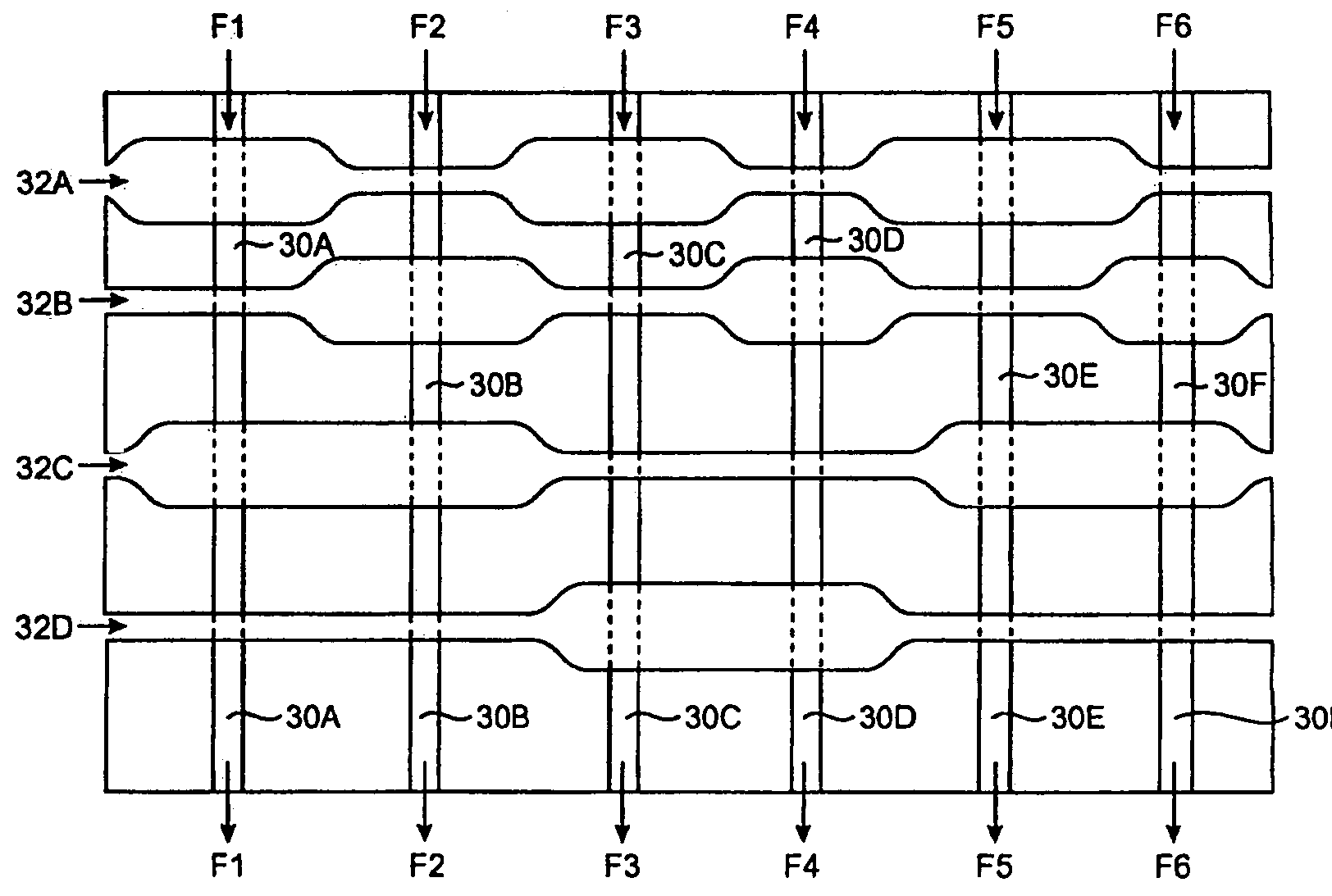

ActiveUS7130708B2Rapid productionMinimum effortShaping toolsSpecial data processing applicationsMetal formingSize determination

Sheet metal forming is a manufacturing process in which flat sheet metal is drawn into a die cavity to form a product shape. Draw-in amount is the single most important stamping index that controls all forming characteristics (strains and stresses), formability failures (splits, wrinkles) and surface quality (distortions) on a panel. Adaptation of a new die set for repetitively stamping sheet metal parts to a part design specification is simplified by using a math-based simulation of the stamping operation under specified engineering stamping conditions for the specified part. The stamping simulations are used to create an engineered draw-in map comparing selected locations on the peripheral edge of the stamped part with corresponding locations on the peripheral edge of its original sheet metal blank. The resulting map of sheet metal draw-in dimensions reflect suitable displacements of the metal sheet between the binder ring and binder surface of the female die member at all such locations as the punch member of the die set executes its stamping operation. The engineered draw-in dimensions for a simulated part identify specific locations for adjustment of the binder ring / binder surface system in adapting the die set for production of parts.

Owner:GM GLOBAL TECH OPERATIONS LLC

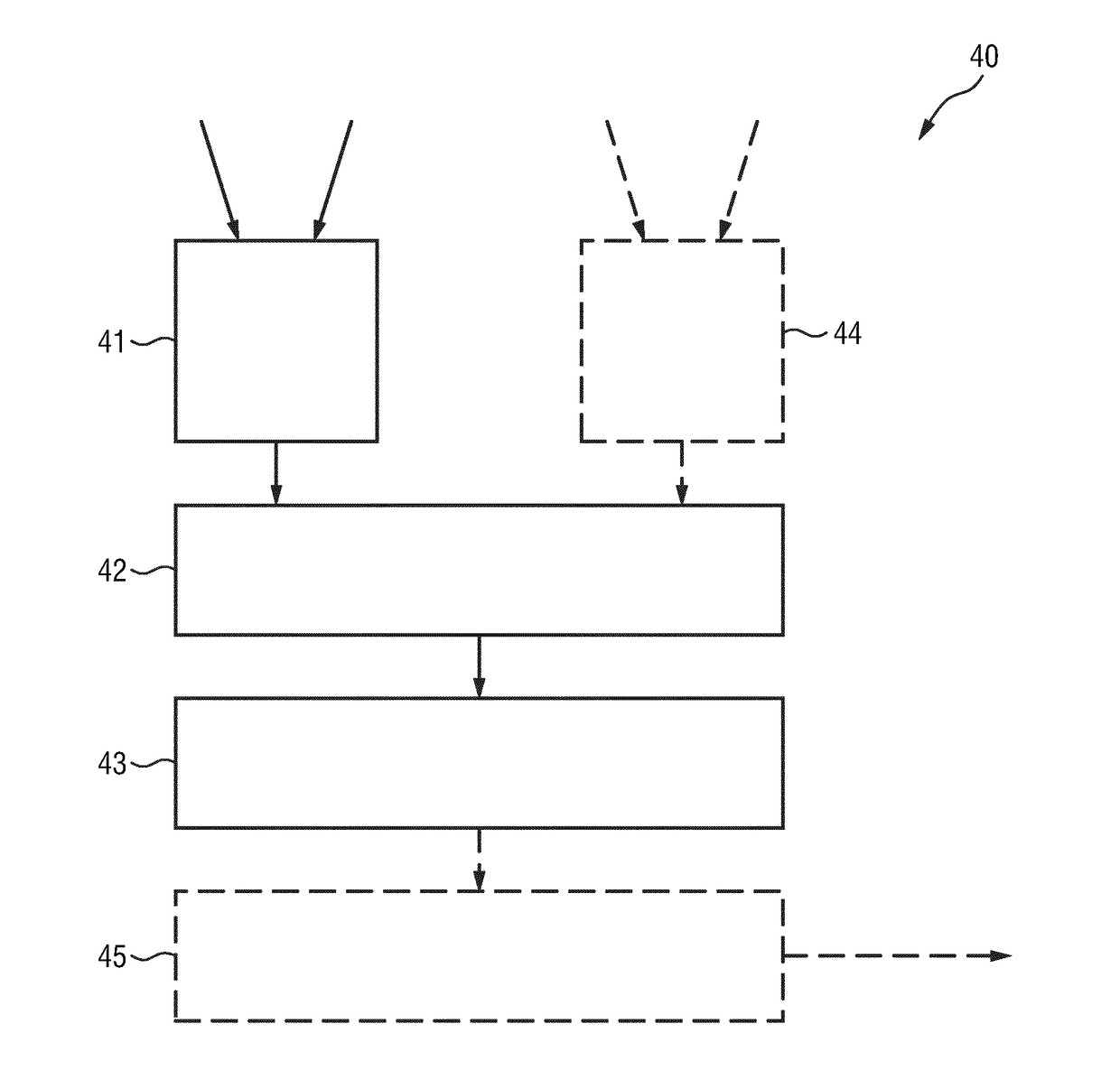

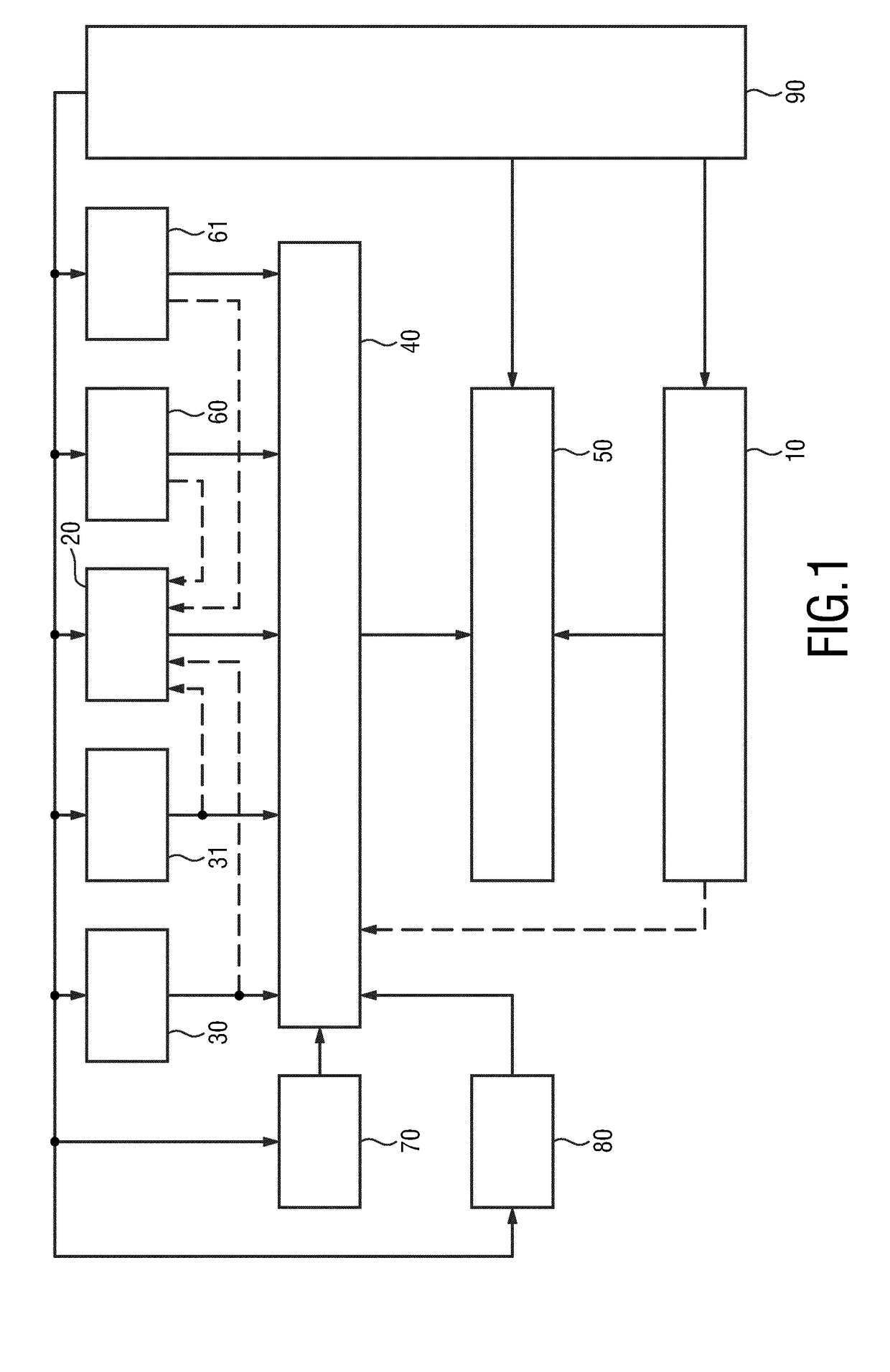

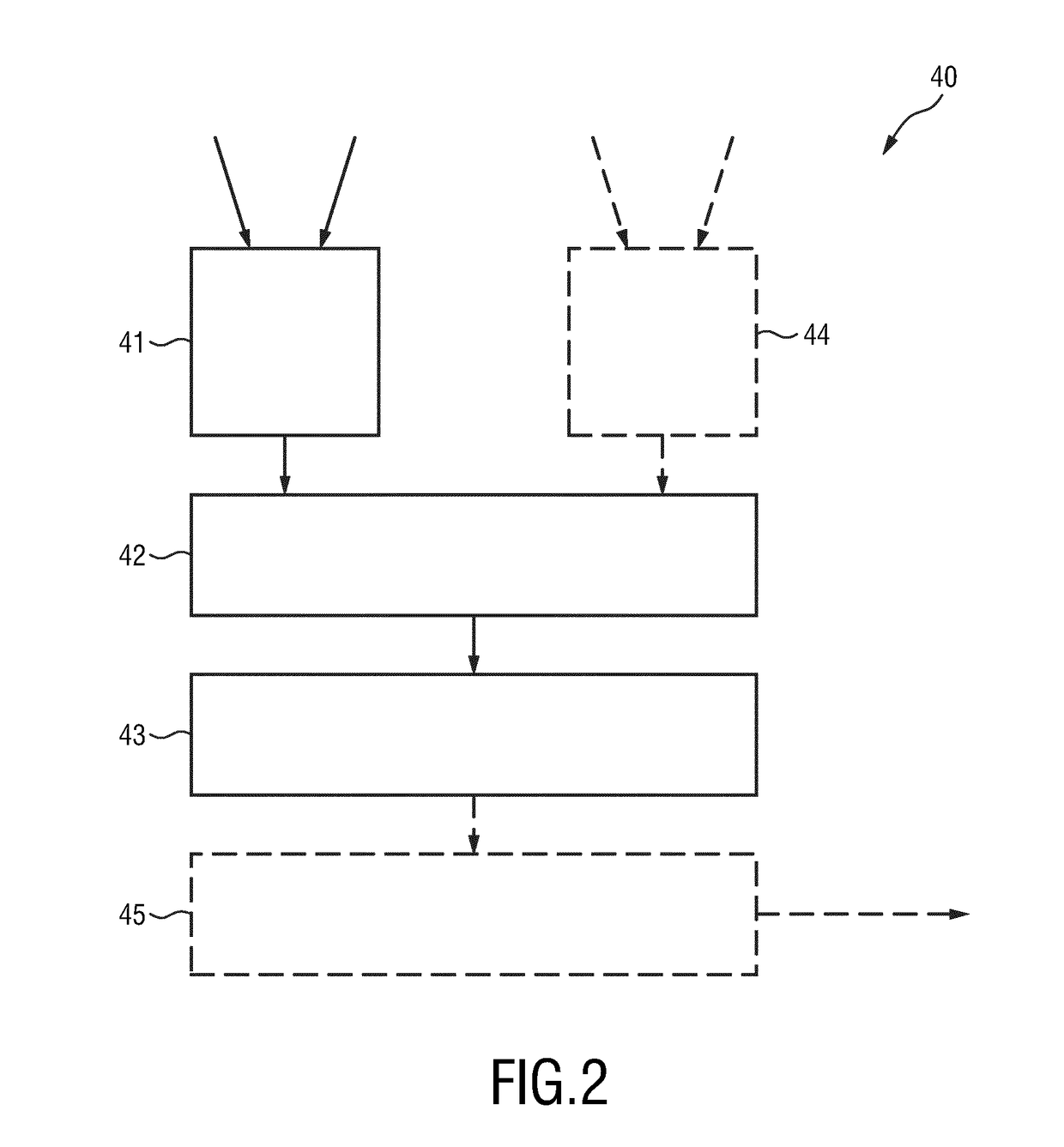

Device and method for suv determination in emission tomography

ActiveUS20180289340A1Less cumbersomeMore comfortable for the patientRadiation diagnosis data transmissionComputerised tomographsRadioactive tracerSize determination

The invention relates to a device (40) for standard uptake value, SUV, determination during an emission tomography imaging procedure of a patient. The device receives SUV-related data required for SUV determination, and event data relating to one or more events that may affect the SUV determination. The SUV-related data includes a time of administration of the radiotracer dose to the patient. The event data includes at least one of: a time at which an emission tomography imaging procedure of the patient is performed, patient motion data, patient position data, and patient vital signs data. An anomalous event determination unit (42) determines, based on the event data, anomalous event information indicative of one or more anomalous events that affect the SUV determination. An SUV determination unit (43) determines the SUV based on said SUV-related data taking into account the anomalous event information.

Owner:KONINKLJIJKE PHILIPS NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com