Sensing system for detecting presence of an ink container and level of ink therein

a technology of ink supply container and sensor system, which is applied in the direction of liquid/fluent solid measurement, instruments, machines/engines, etc., can solve the problems of damage to the associated printhead, no prior art reference includes means, and the reliance on prior art references is relatively high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

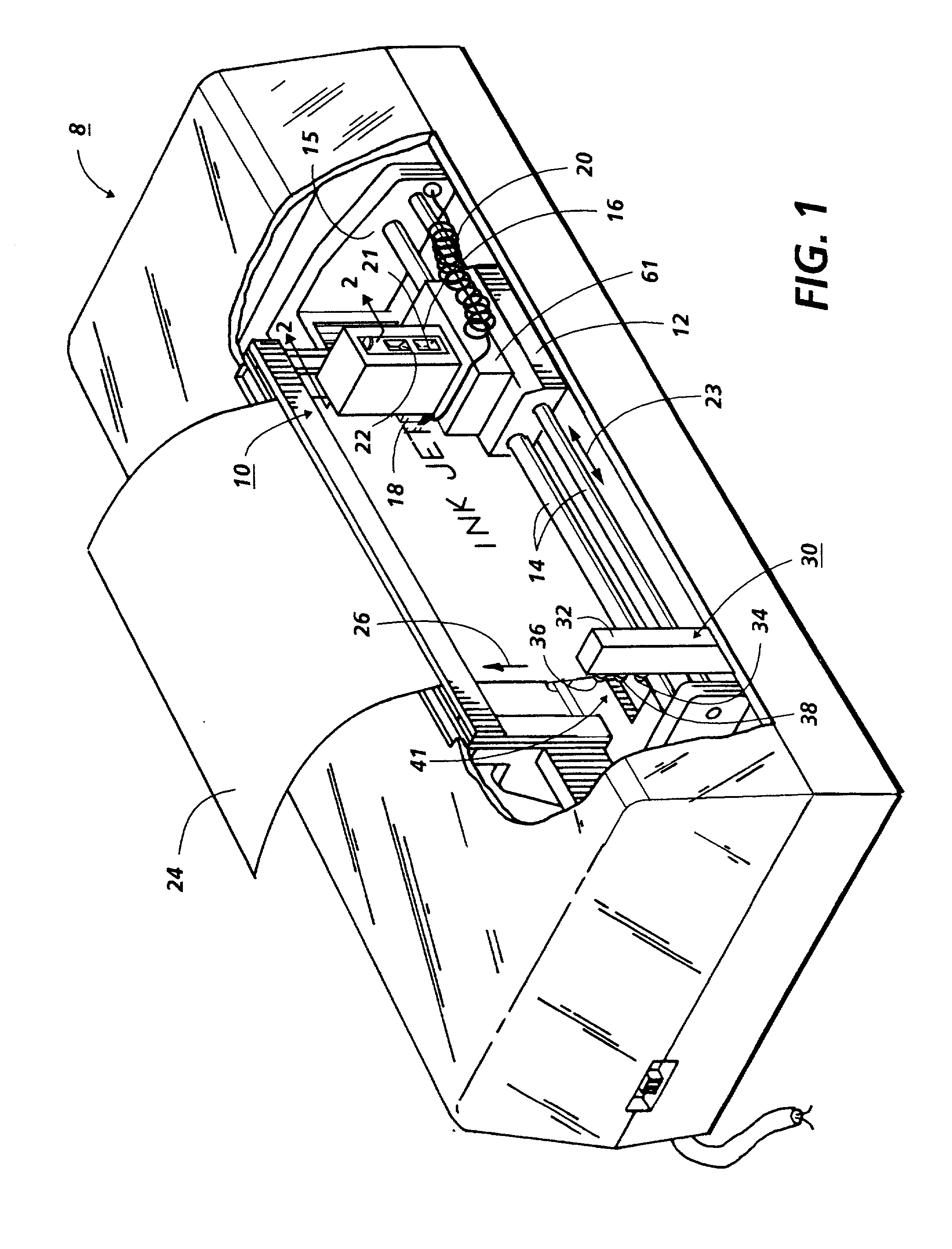

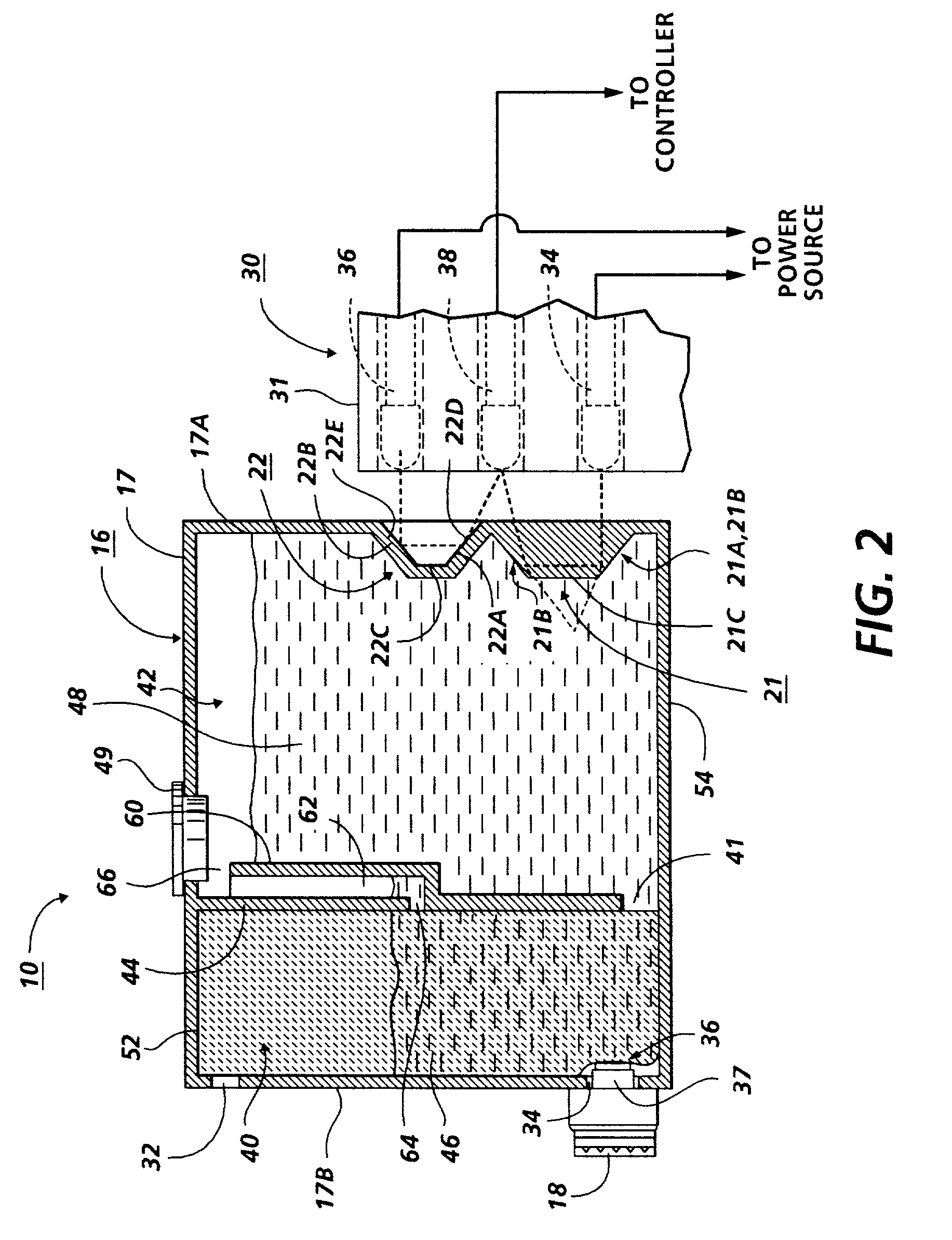

[0049] FIG. 1 illustrates a perspective view of a thermal ink jet printer 8 which incorporates a preferred embodiment of the ink container and low ink detection system of the present invention. Printer 8 is exemplary only. The invention can be practiced in other types of thermal ink jet printers as well as other reproduction devices such as piezoelectric printers, dot matrix printers and ink jet printers driven by signals from a document Raster Input Scanner. Printer 8 includes an ink jet printhead cartridge 10 mounted on a carriage 12 supported by carriage rails 14. The carriage rails are supported by a frame 15 of the ink jet printer 8. The printhead cartridge 10 includes a container 16 shown in detail in FIG. 2, containing ink for supply to a thermal ink jet printhead 18 which selectively expels droplets of ink under control of electrical signals received from a controller 50 (FIG. 4) of the printer 8 through an electrical cable 20. Container 16 comprises a housing 17 having a wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com