Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1037 results about "Thin wire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

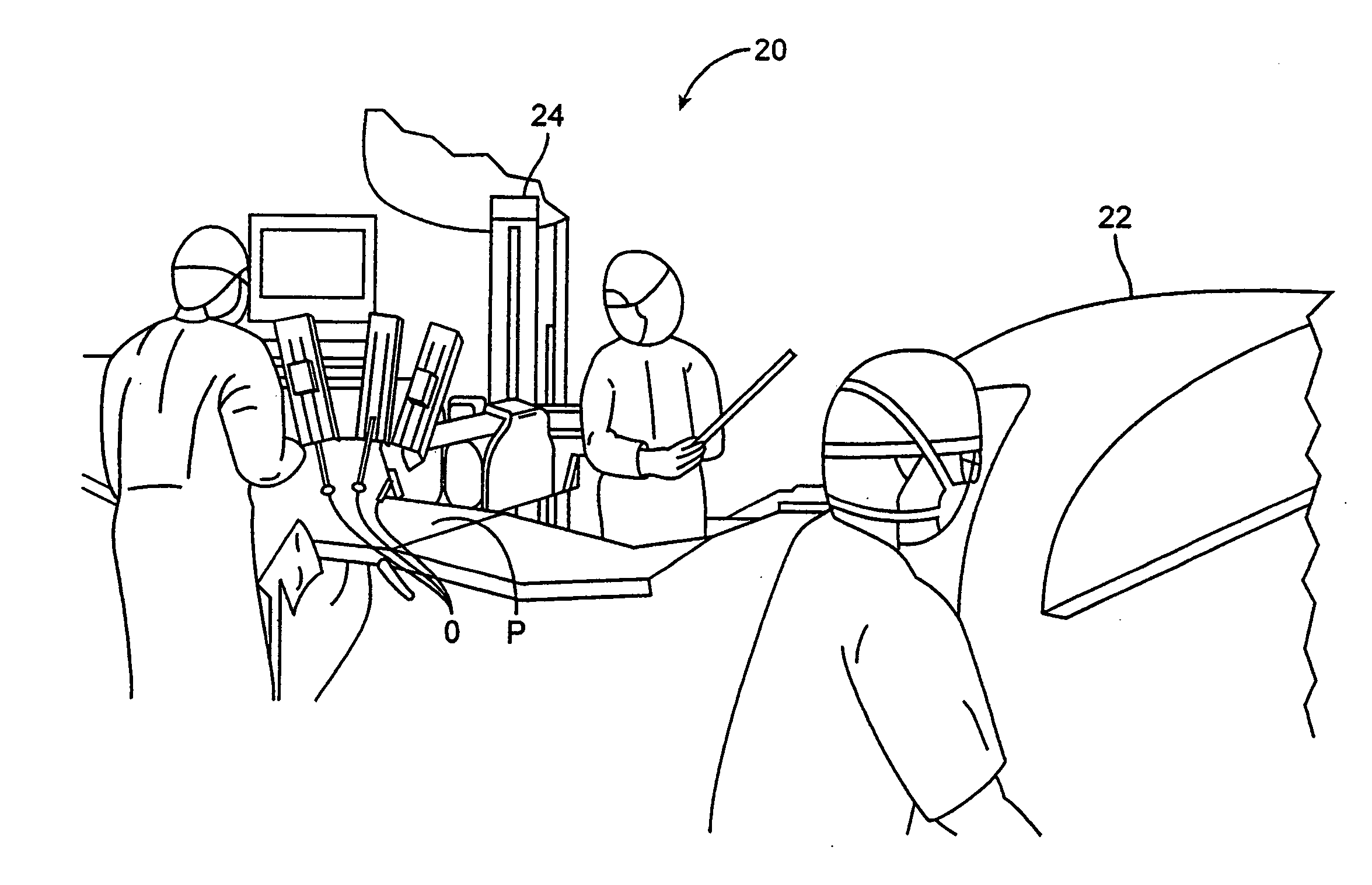

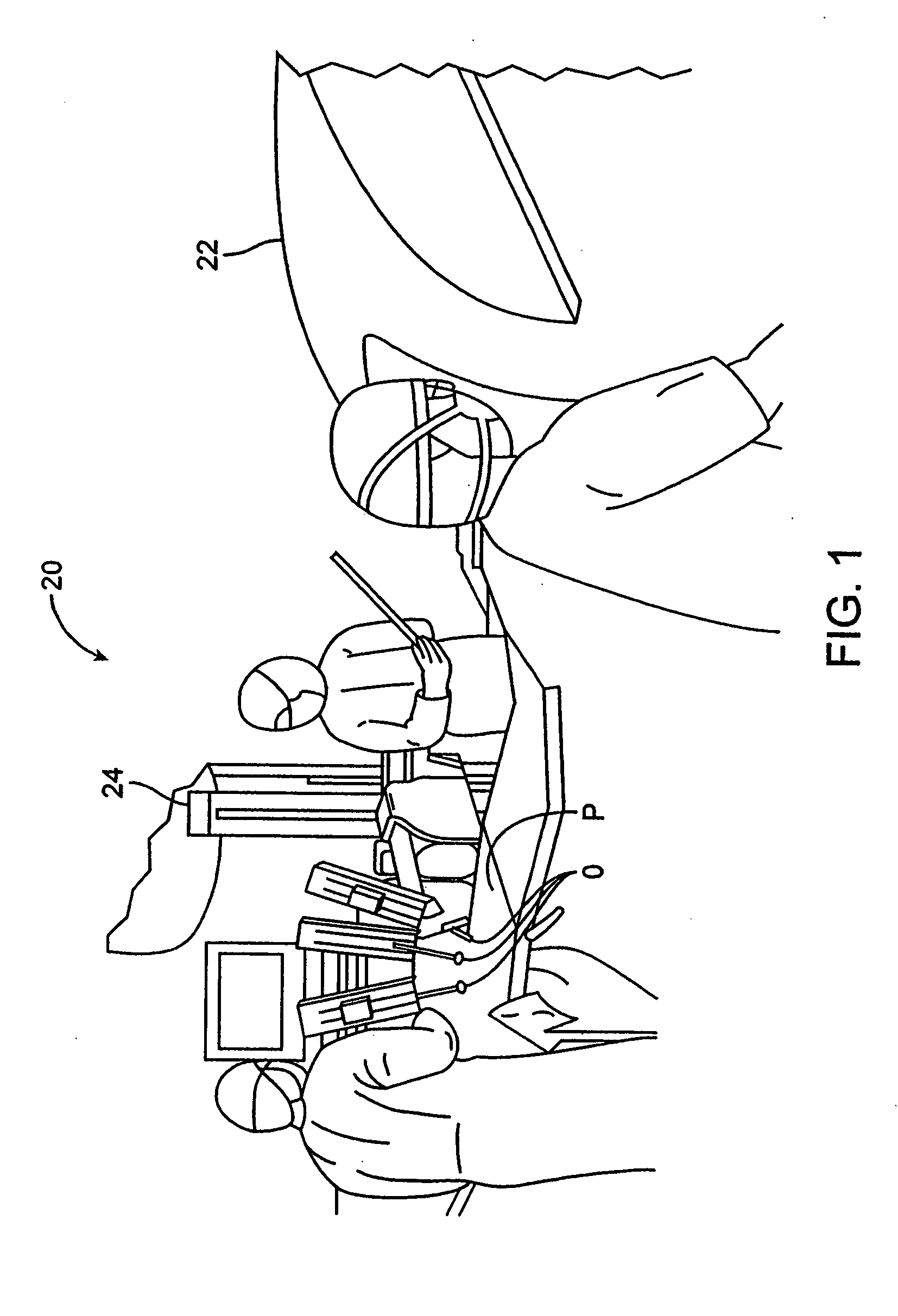

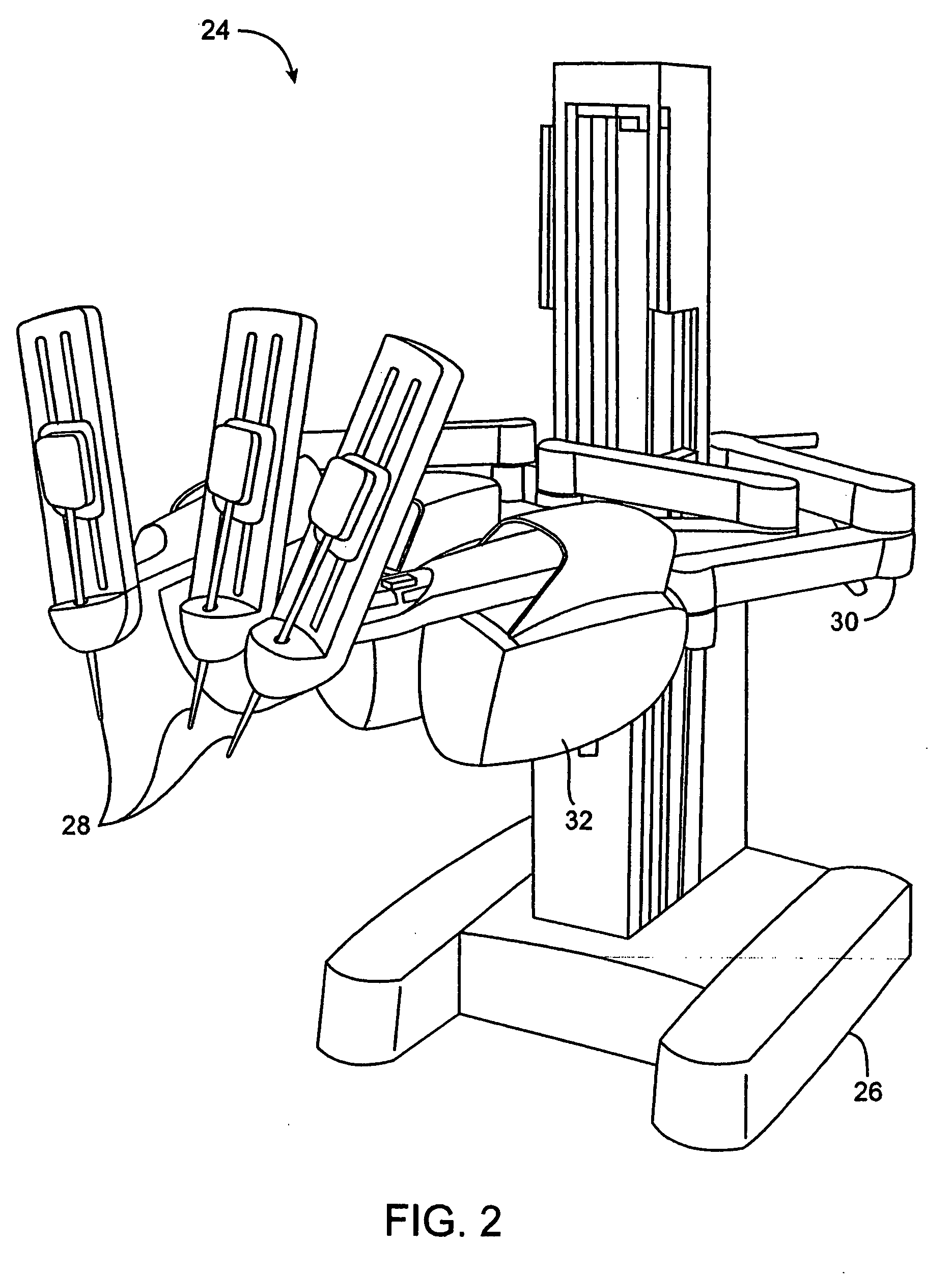

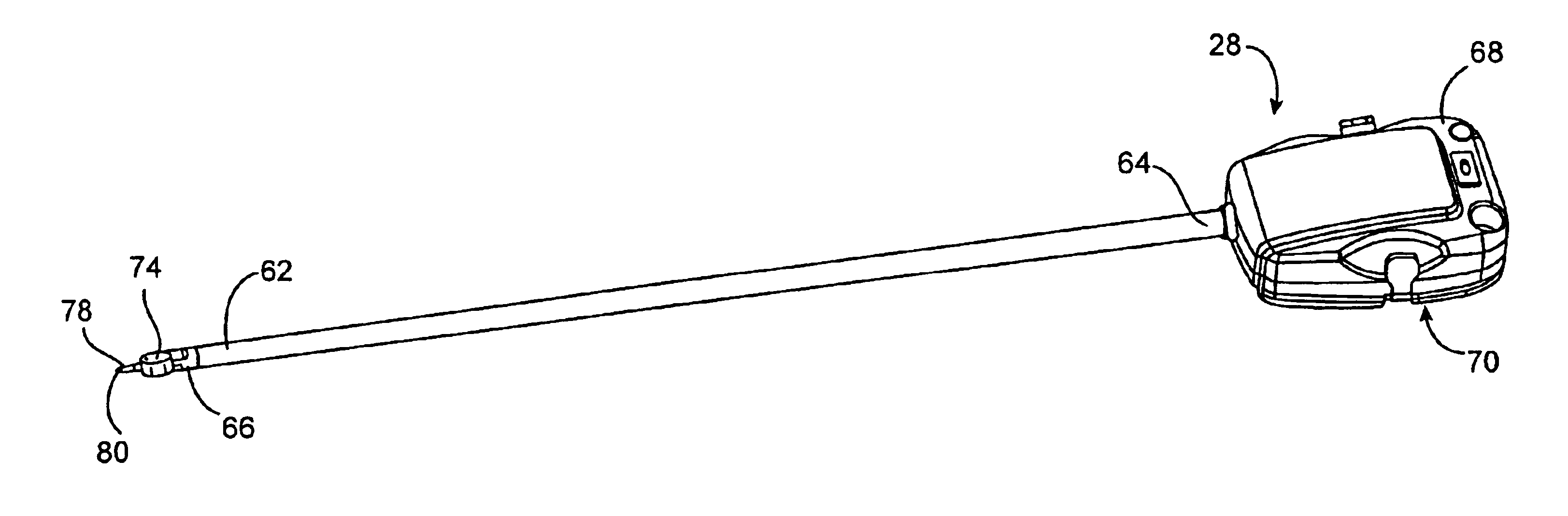

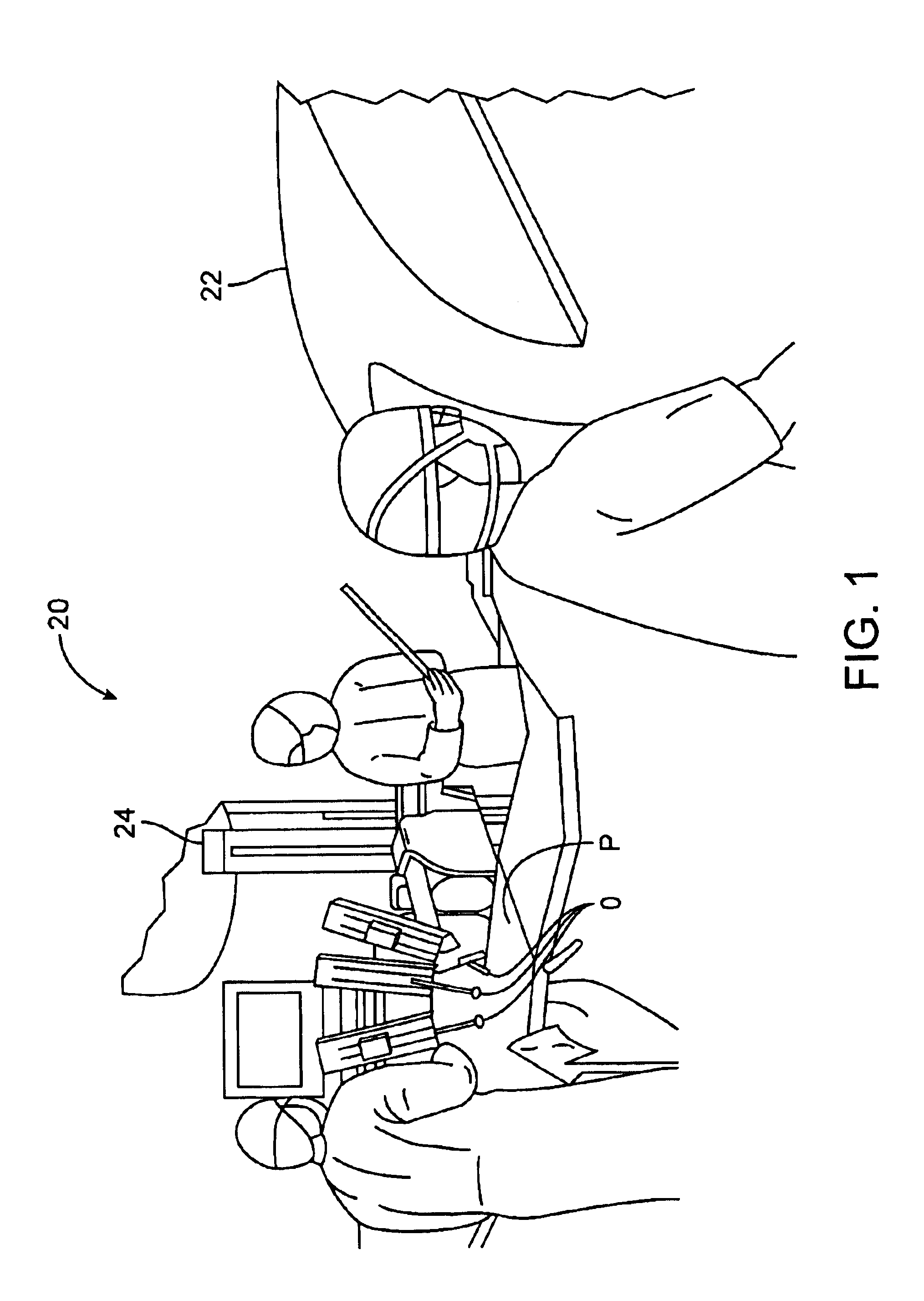

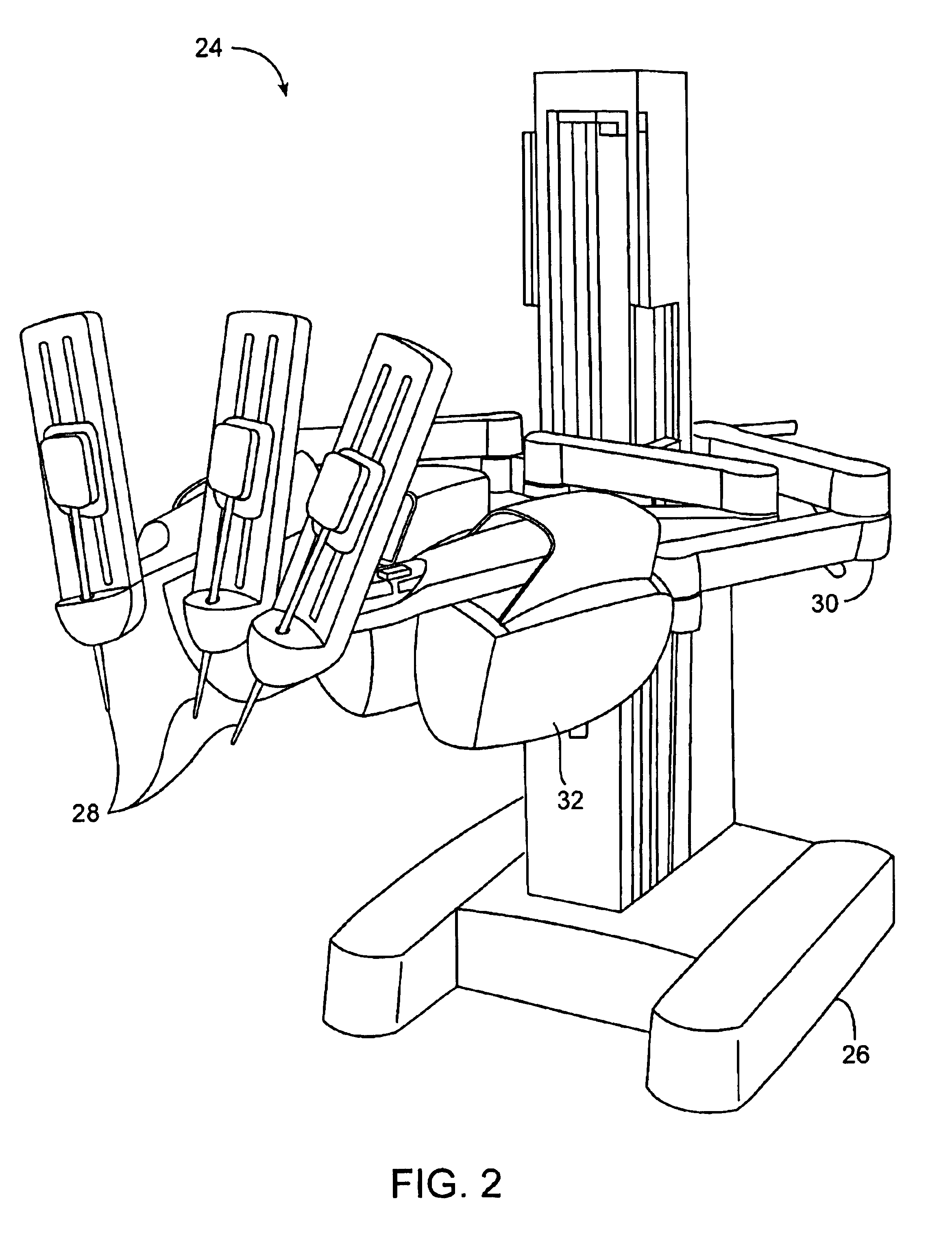

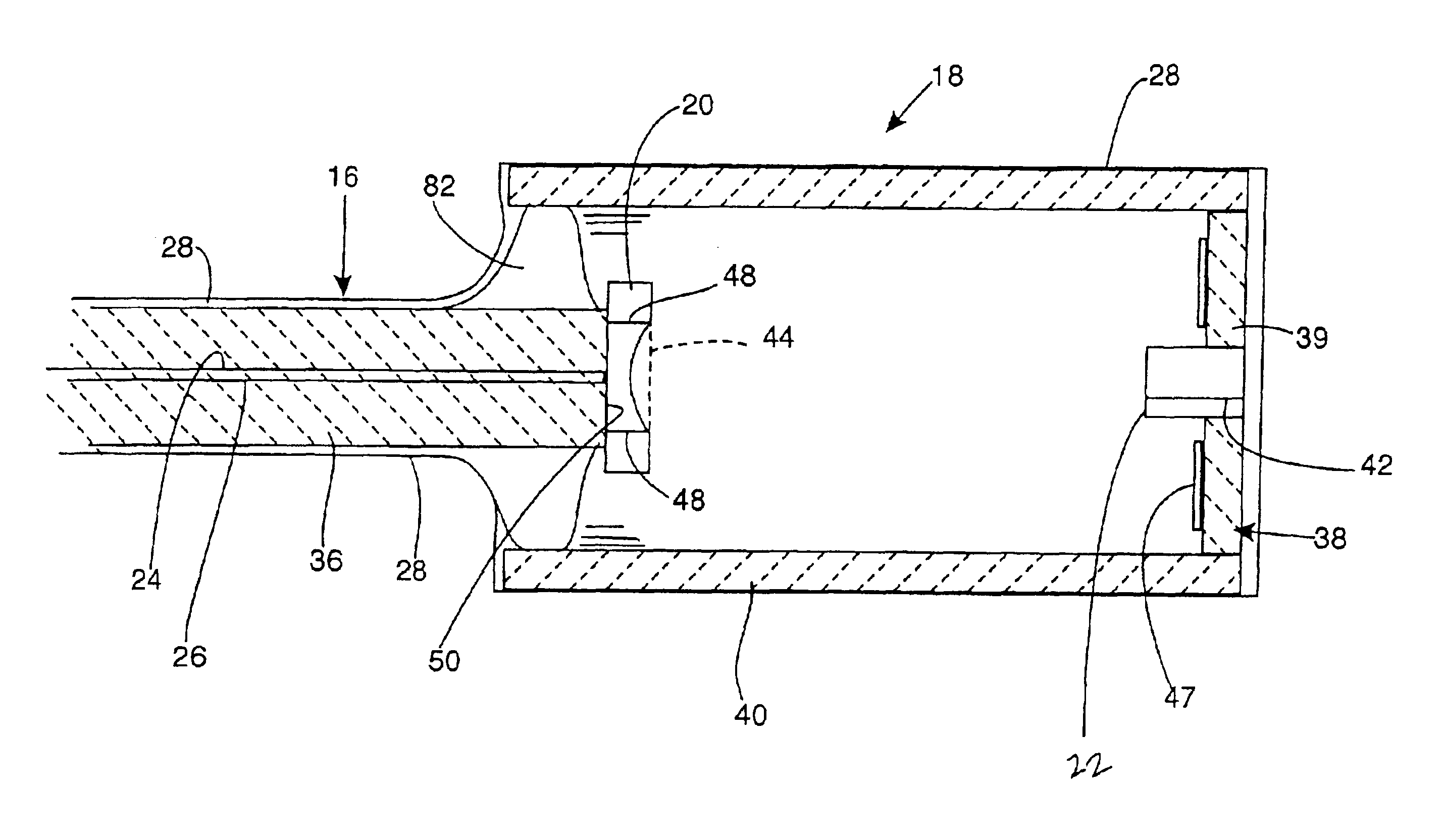

Bipolar cauterizing instrument

A bipolar surgical instrument that includes opposing grips that can engage the tissue. A current is delivered from an electrosurgical power source to electrodes disposed on the grips to cauterize the tissue. The electrode configurations provide efficient cauterization of the tissue. In some embodiments, the positive and negative electrodes will be offset from each other to prevent shorting and to provide a thin line of coagulation heating to the gripped tissue. In some embodiments the electrodes are removably coupled to the grips through nonconductive sleeves. In some embodiments, the first electrode is disposed in a groove and the second electrode is disposed on a boss.

Owner:INTUITIVE SURGICAL

Bipolar cauterizing instrument

A bipolar surgical instrument that includes opposing grips that can engage the tissue. A current is delivered from an electrosurgical power source to electrodes disposed on the grips to cauterize the tissue. The electrode configurations provide efficient cauterization of the tissue. In some embodiments, the positive and negative electrodes will be offset from each other to prevent shorting and to provide a thin line of coagulation heating to the gripped tissue. In some embodiments the electrodes are removably coupled to the grips through nonconductive sleeves. In some embodiments, the first electrode is disposed in a groove and the second electrode is disposed on a boss.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Self-expandable medical instrument for treating defects in a patient's heart

Owner:JENAVALVE TECH INC

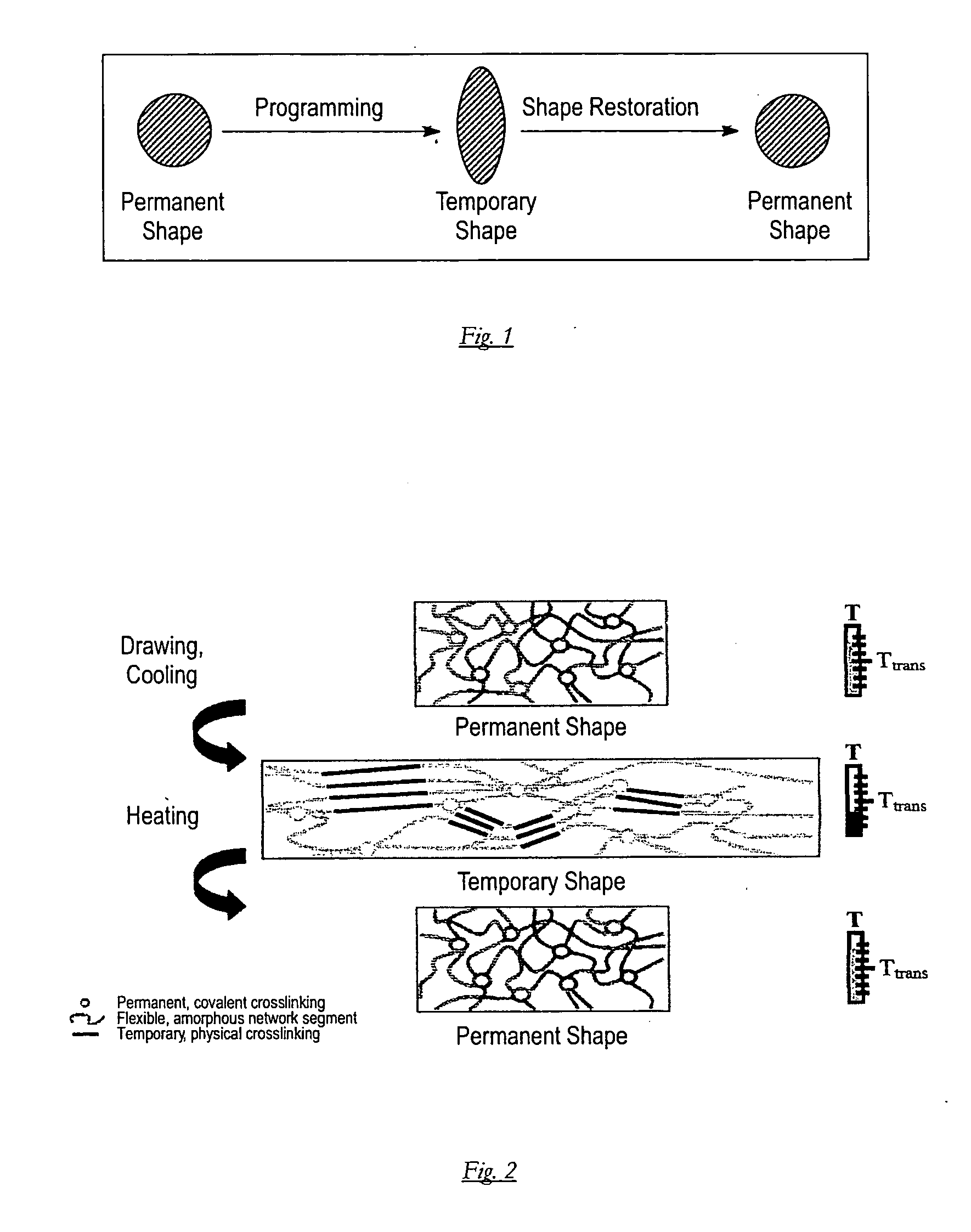

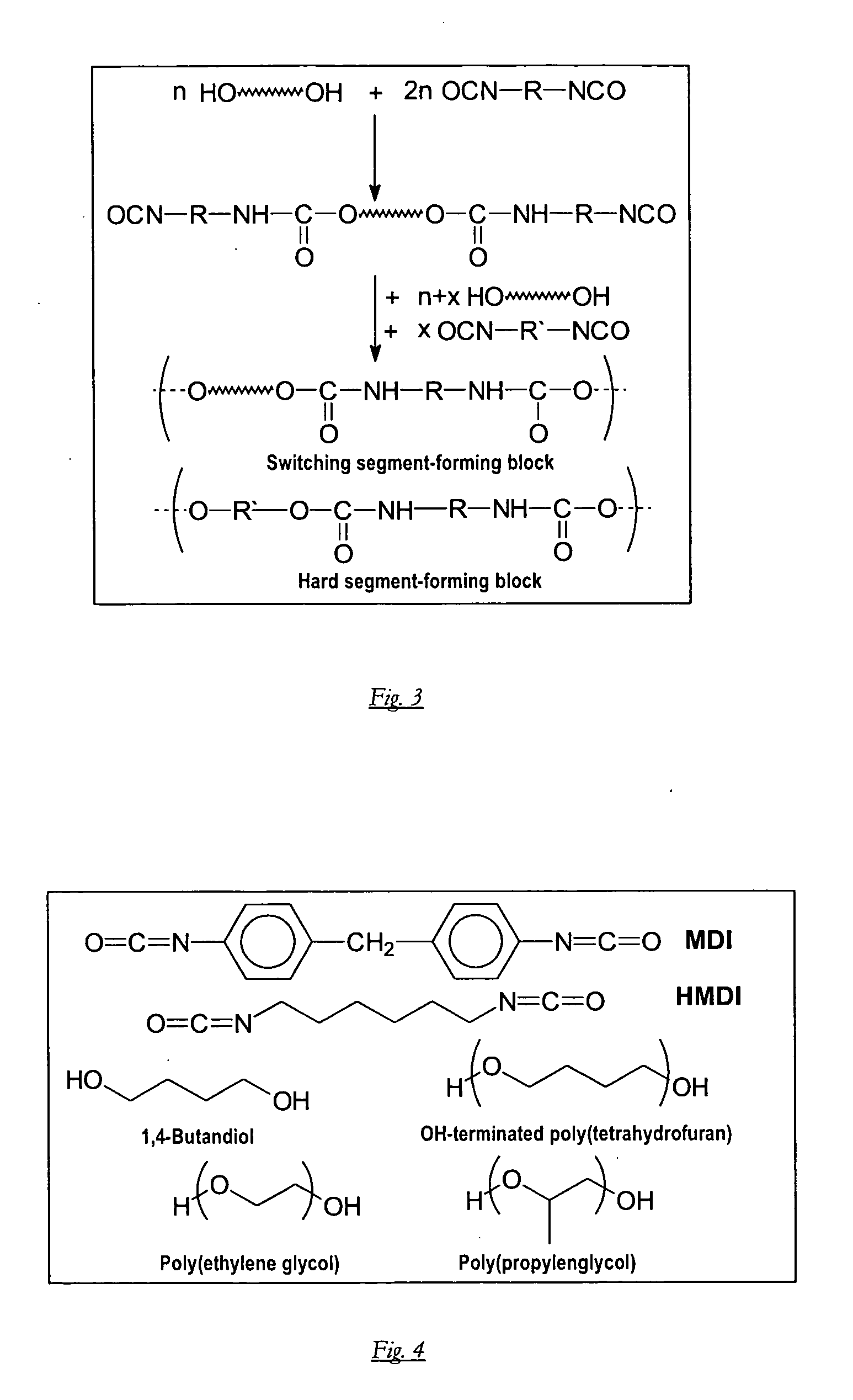

Self-expanding medical occlusion device

InactiveUS20070167980A1Good shape memoryImprove deformation abilitySuture equipmentsEar treatmentMedicineSurgery

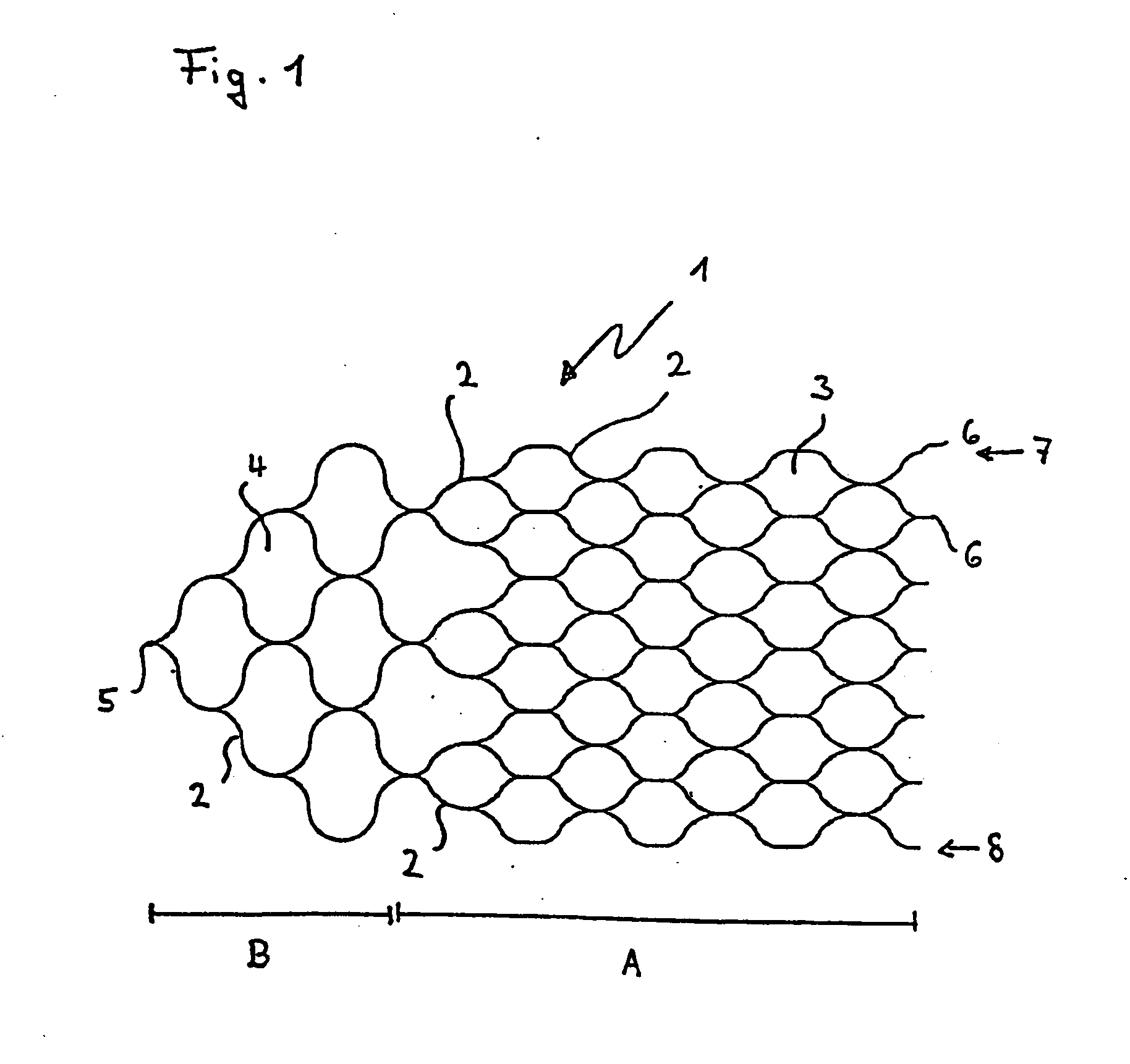

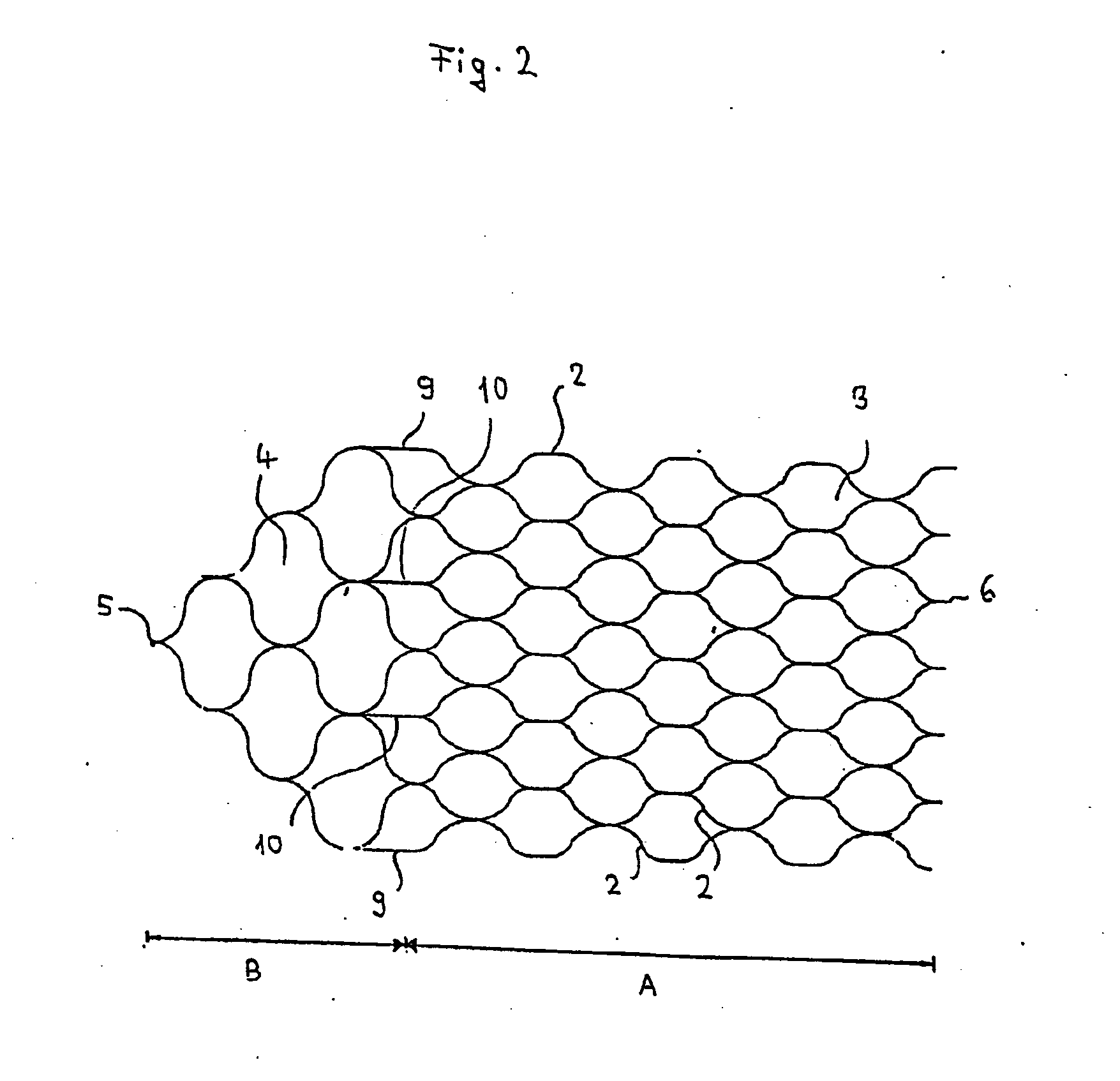

A self-expanding medical occlusion device treats a heart defect in a patient and is inserted into the body in minimally invasive fashion using a catheter system, and includes a braiding of thin threads which exhibits a first preliminarily definable shape as the occlusion device is being inserted into the patient's body and a second preliminarily definable shape in the implanted state, whereby the occlusion device is in a collapsed state in the first shape of the braiding and in an expanded state in the second shape of the braiding. The threads of braiding are composed of a shape memory polymer composite such that braiding deforms from a temporary shape to a permanent shape in consequence of an external stimulus, whereby the temporary shape is given in a first profile form of the braiding and the permanent shape is given in a second profile form of the braiding.

Owner:OCCLUTECH HLDG

Sternum suture wire with teardrop ring

InactiveUS20050021087A1No invasiveness onto the sternumEasy to operateSuture equipmentsInternal osteosythesisMedicineBreast bone

Owner:KOSEKI TOMOAKI

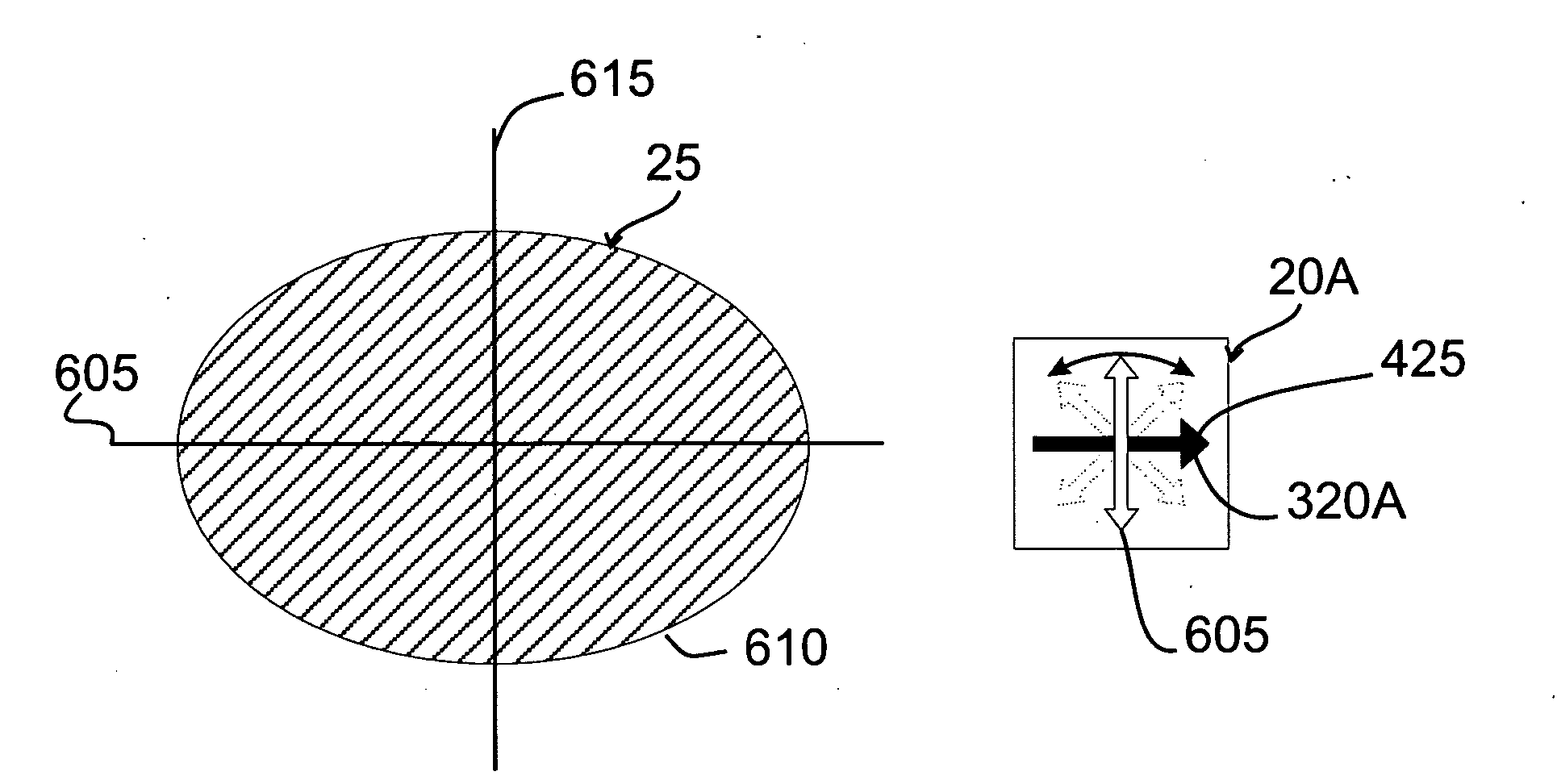

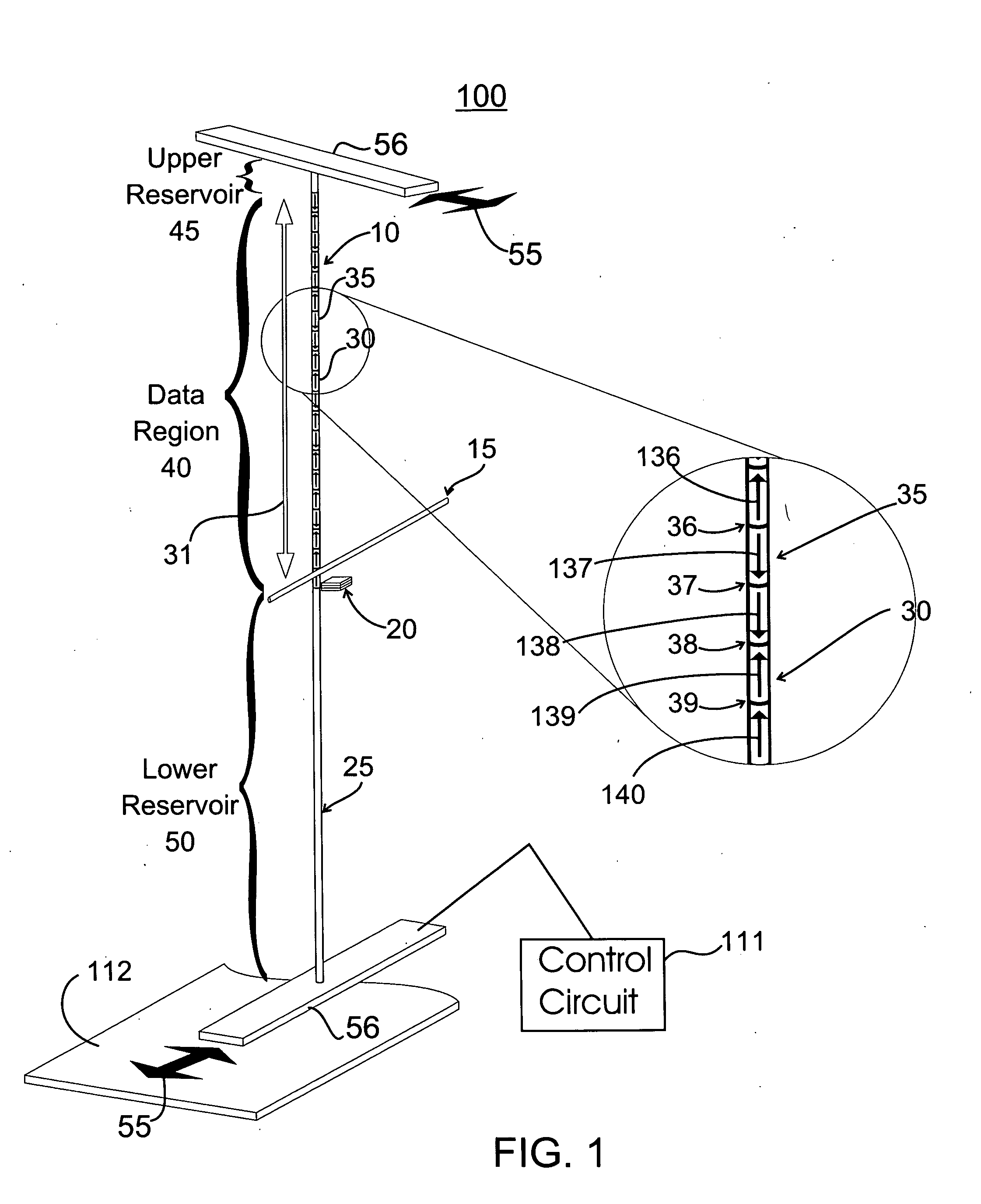

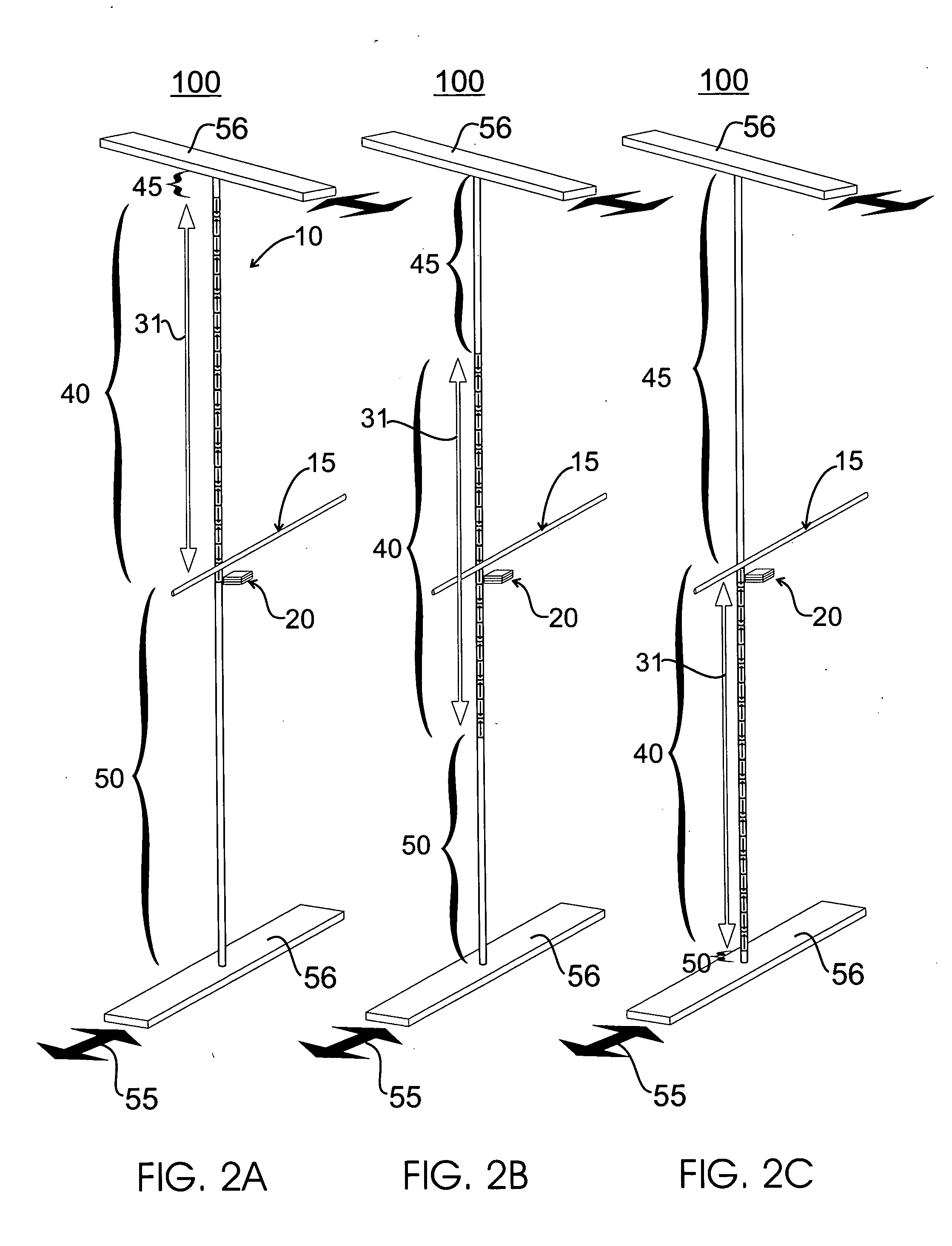

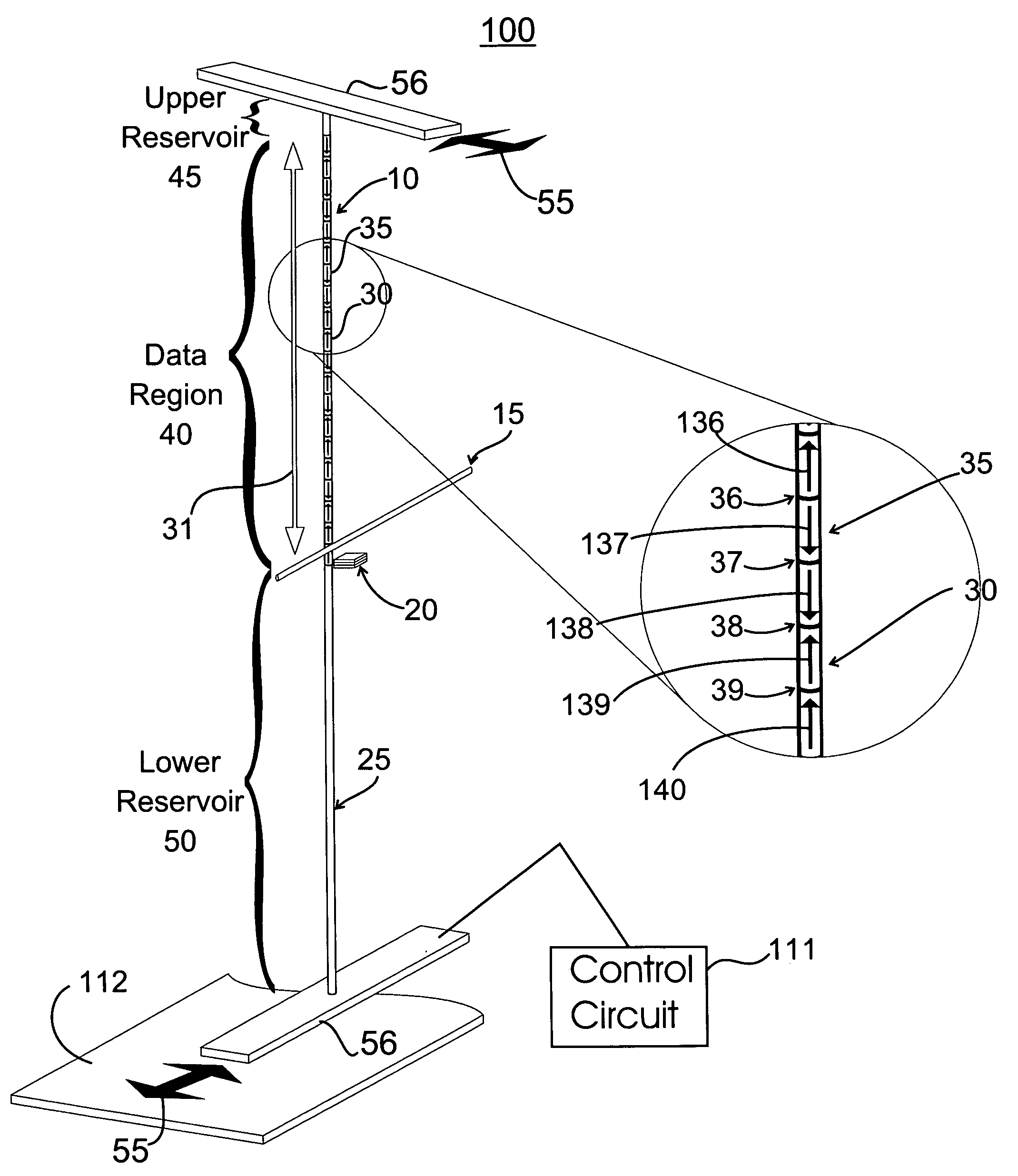

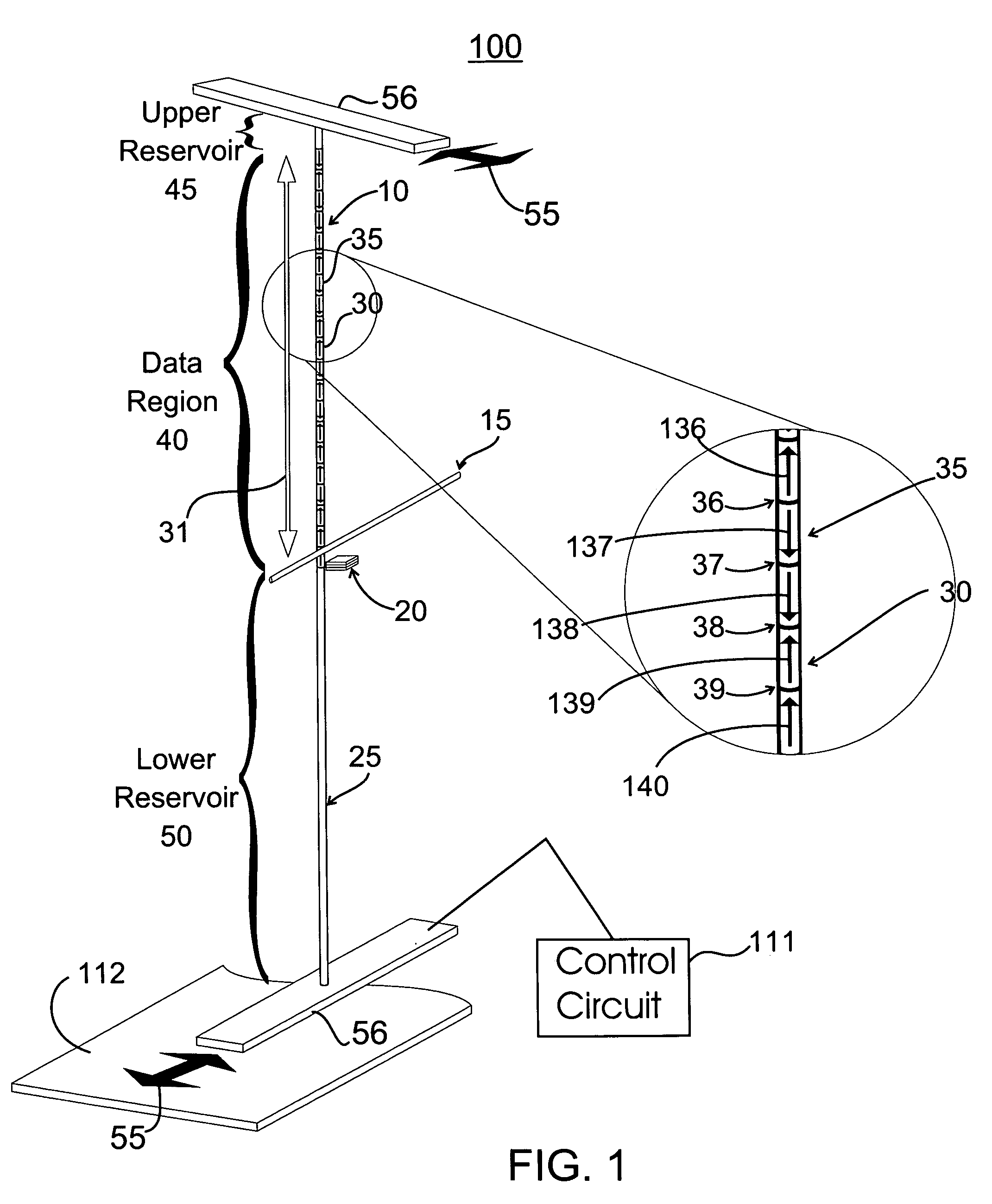

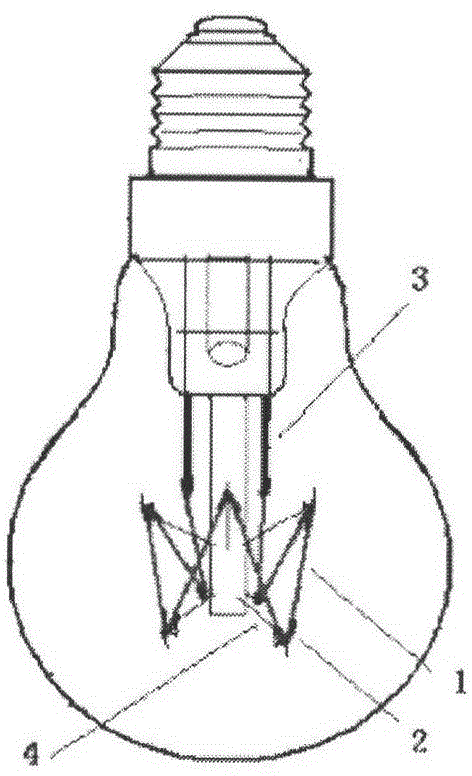

System and method for transferring data to and from a magnetic shift register with a shiftable data column

InactiveUS20060120132A1Magnitude fringing fieldEasy to operateDigital storageShift registerData storing

A magnetic shift register utilizes a data column comprising a thin wire of magnetic material. A writing element selectively changes the direction of the magnetic moment in the magnetic domains to write the data to the data column. Associated with each domain wall are large magnetic fringing fields concentrated in a very small space. These magnetic fringing fields write to and read from the magnetic shift register. When the domain wall is moved close to another magnetic material, the fringing fields change the direction of the magnetic moment in the magnetic material, effectively “writing” to the magnetic material. A reading element similar to a tunneling junction comprises a free layer and a pinned layer of magnetic material. Fringing fields change the direction of the magnetic moment in the free layer with respect to the pinned layer, changing electrical resistance of the reading element and “reading” data stored in the magnetic shift register.

Owner:GLOBALFOUNDRIES US INC

Medical implant having a curlable matrix structure

A medical implant, having a proximal and a distal end, that is preformed to assume a superimposed structure at an implantation site but can be made to take on a volume-reduced form making it possible to introduce it by means of a micro-catheter and a guide wire arranged at the proximal end, with the implant in its superimposed structure assuming the form of a longitudinally open tube and having a mesh structure of interconnected strings or filaments. The implant has a tapering structure at its proximal end where the strings or filaments converge at a connection point.

Owner:USSC MEDICAL GMBH

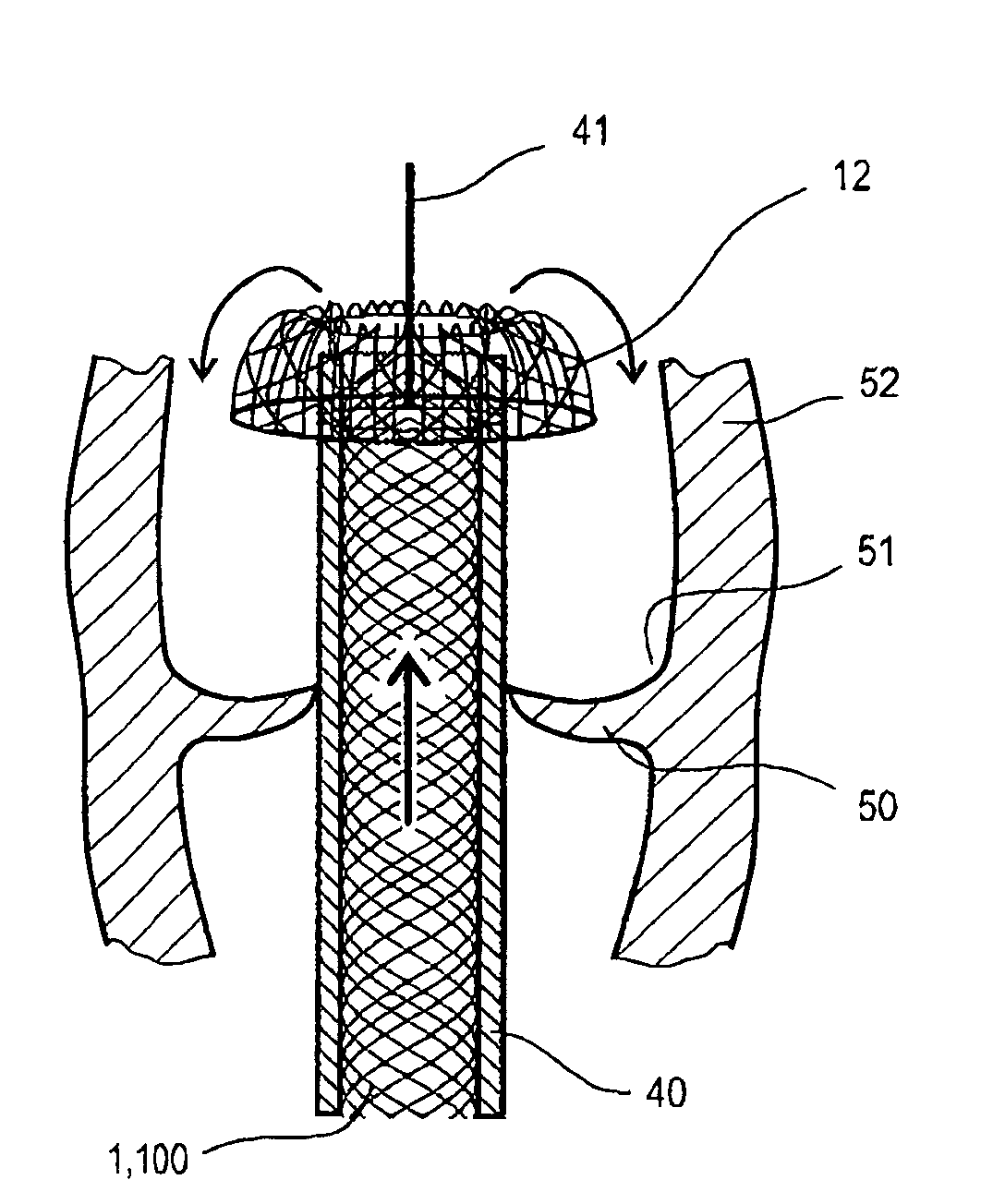

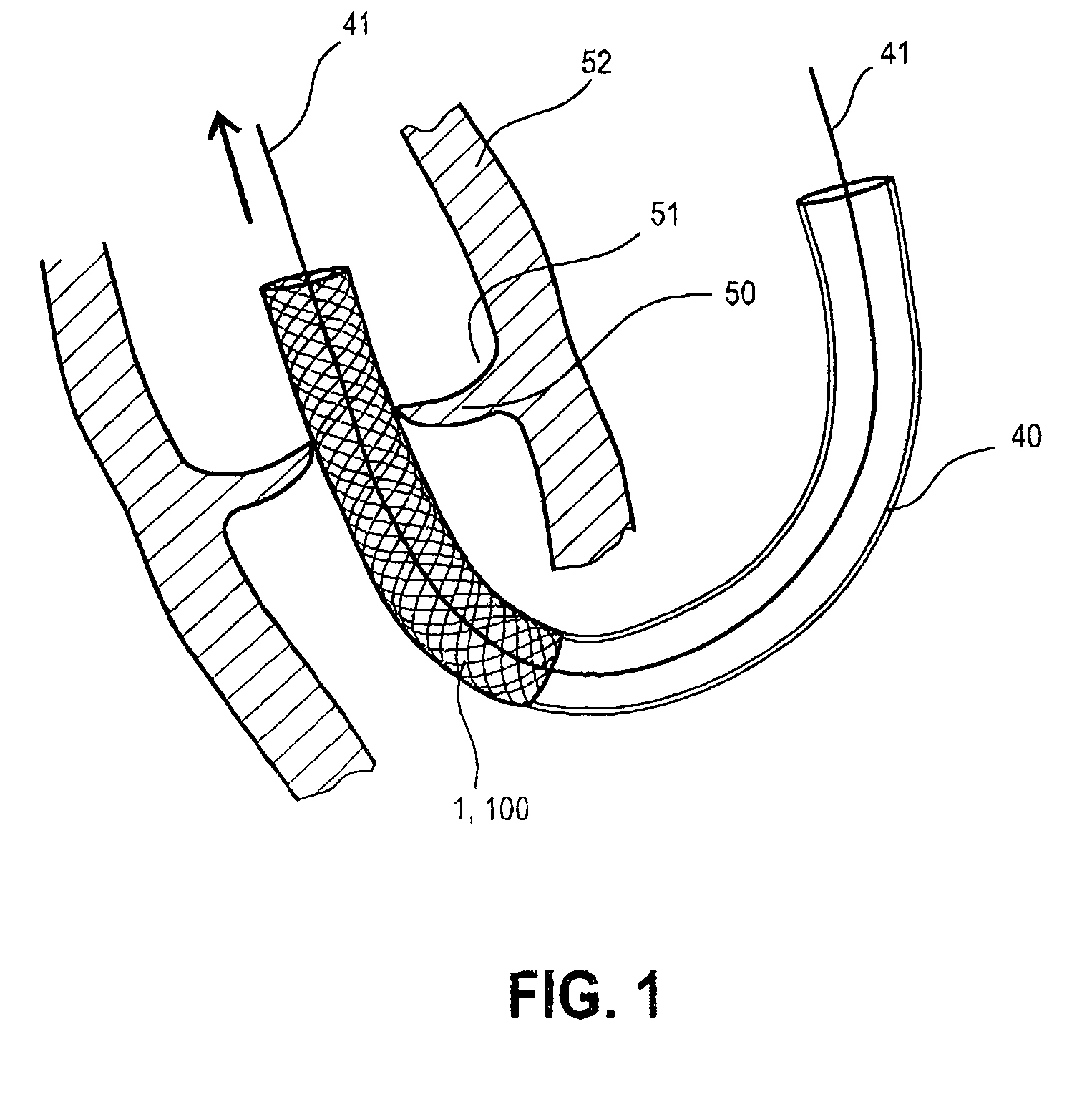

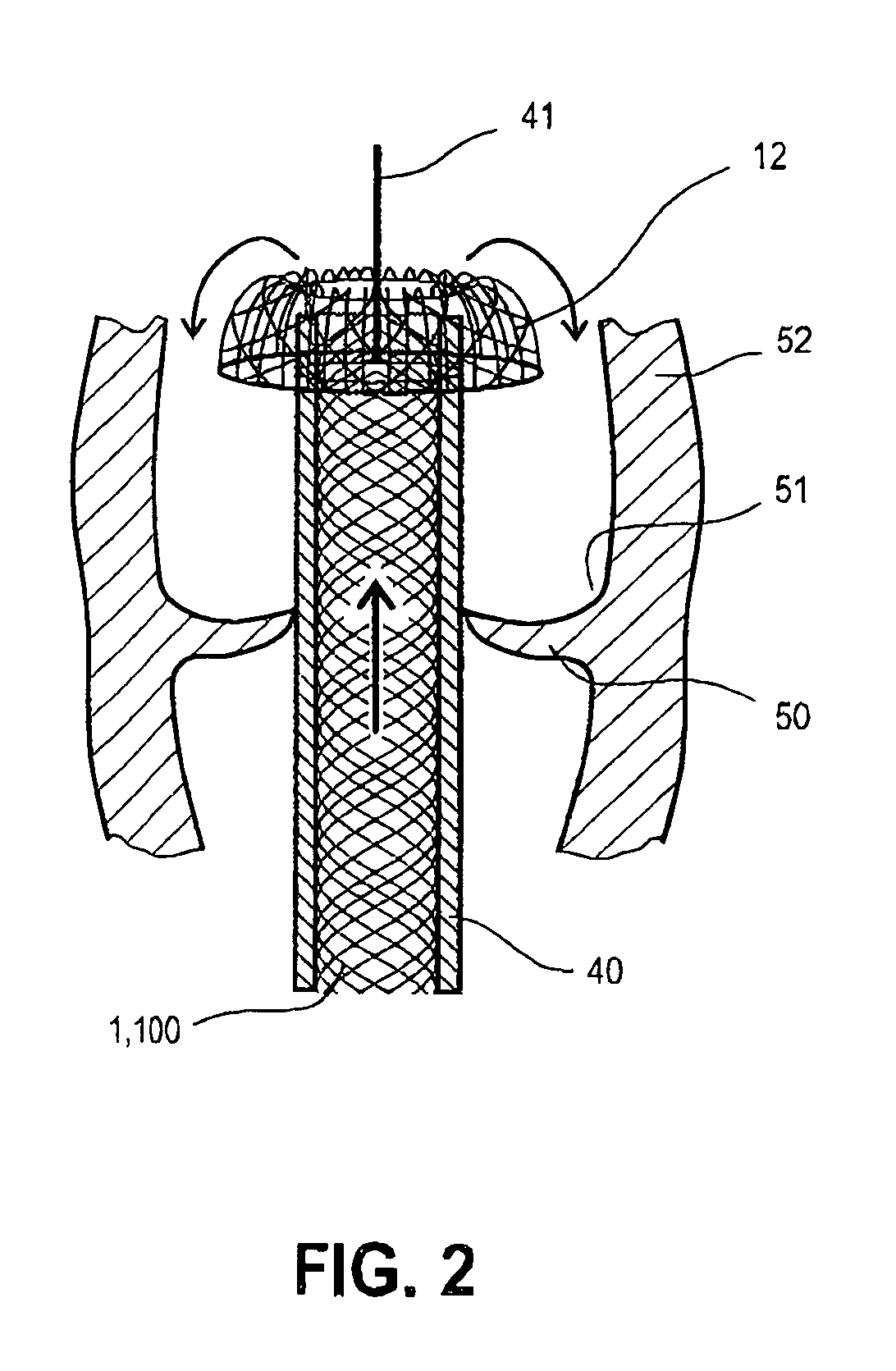

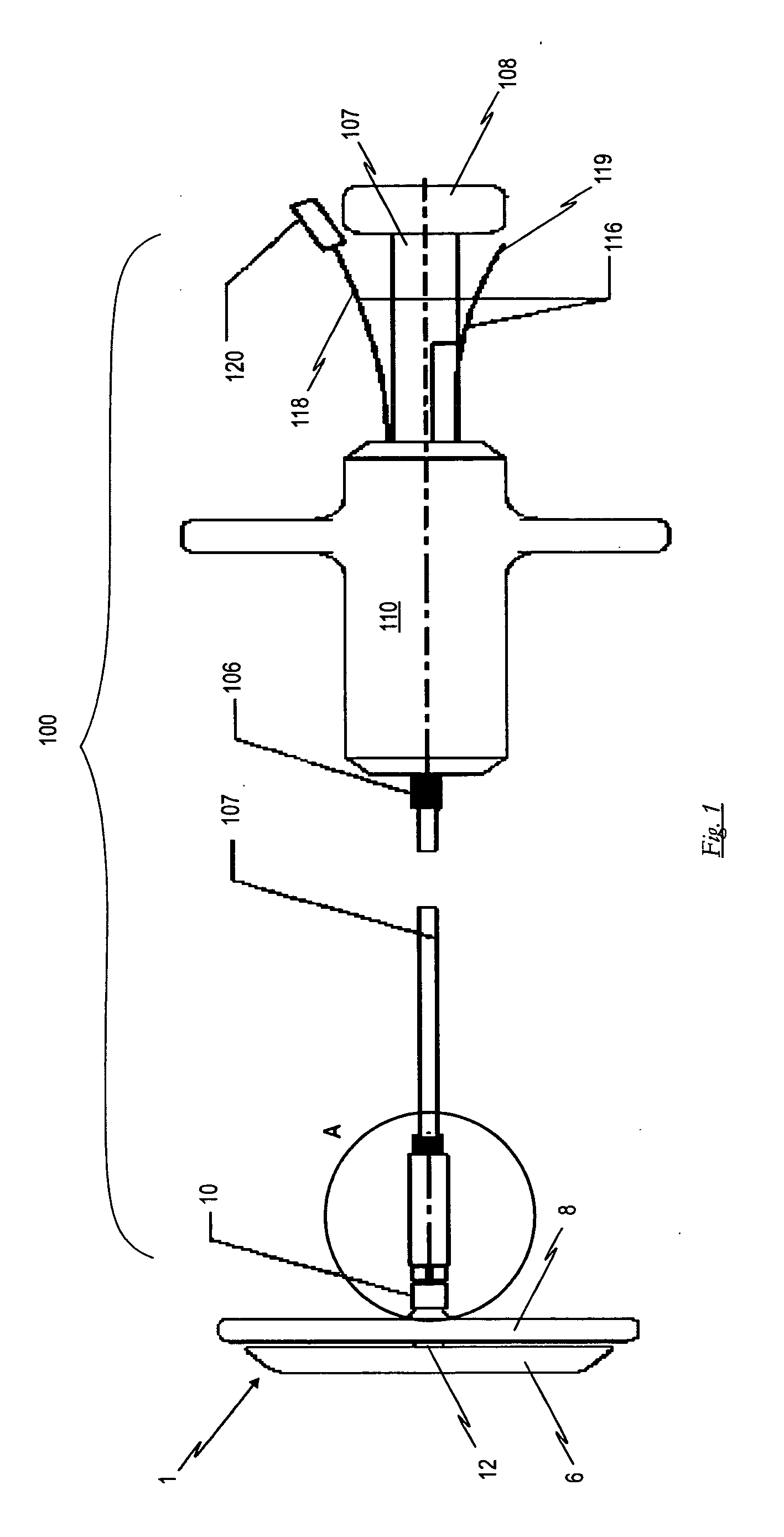

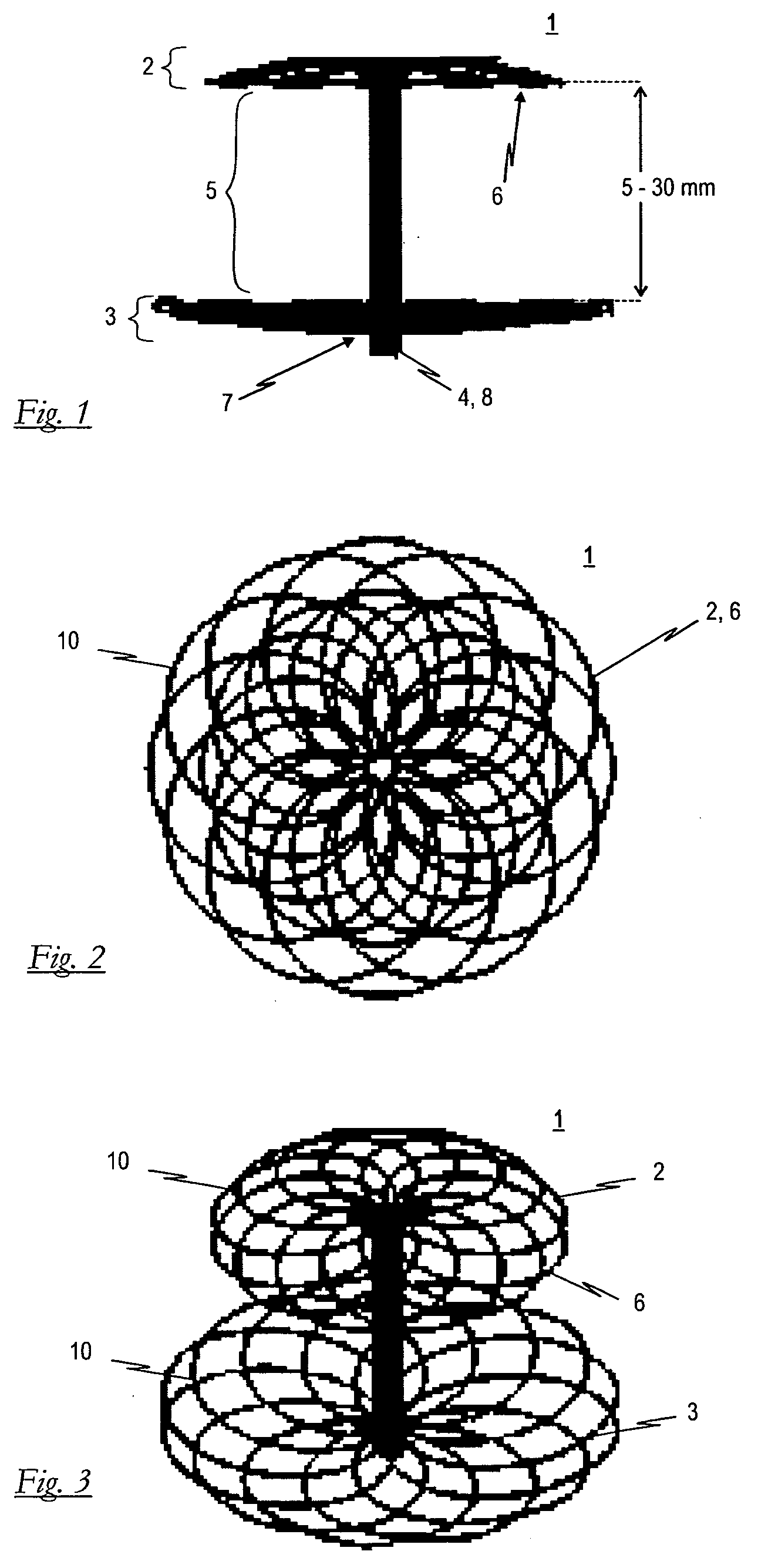

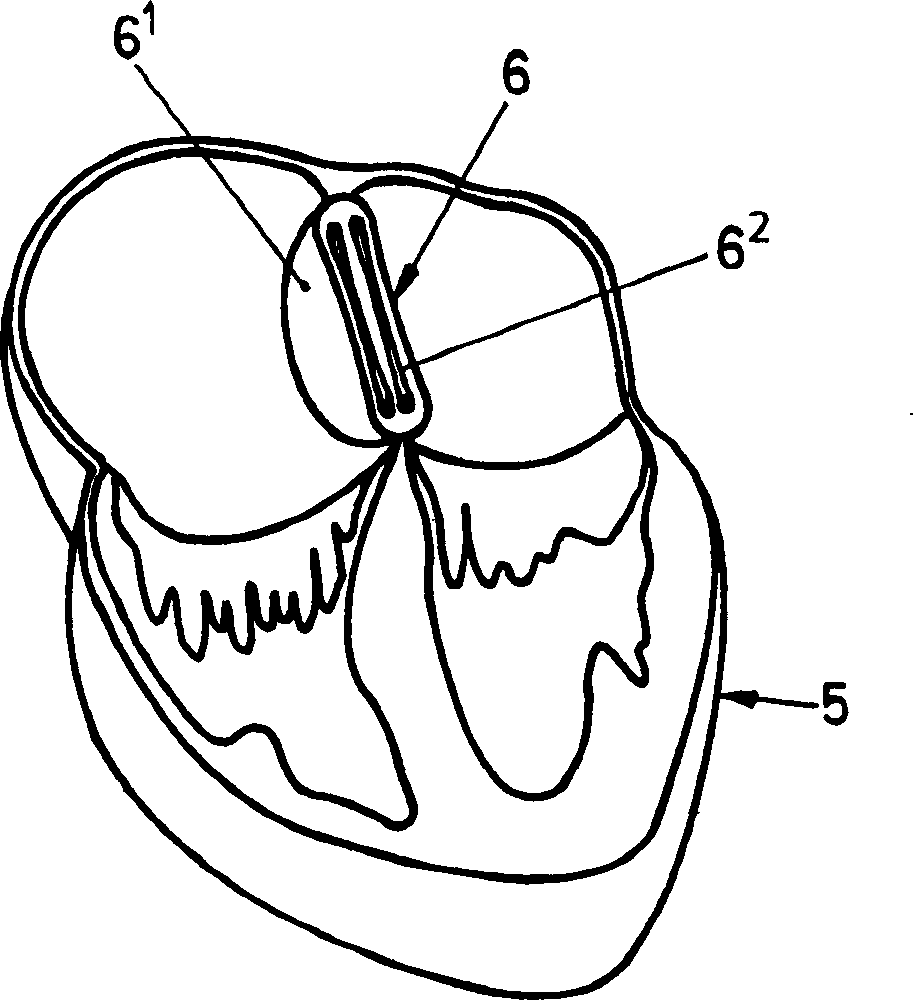

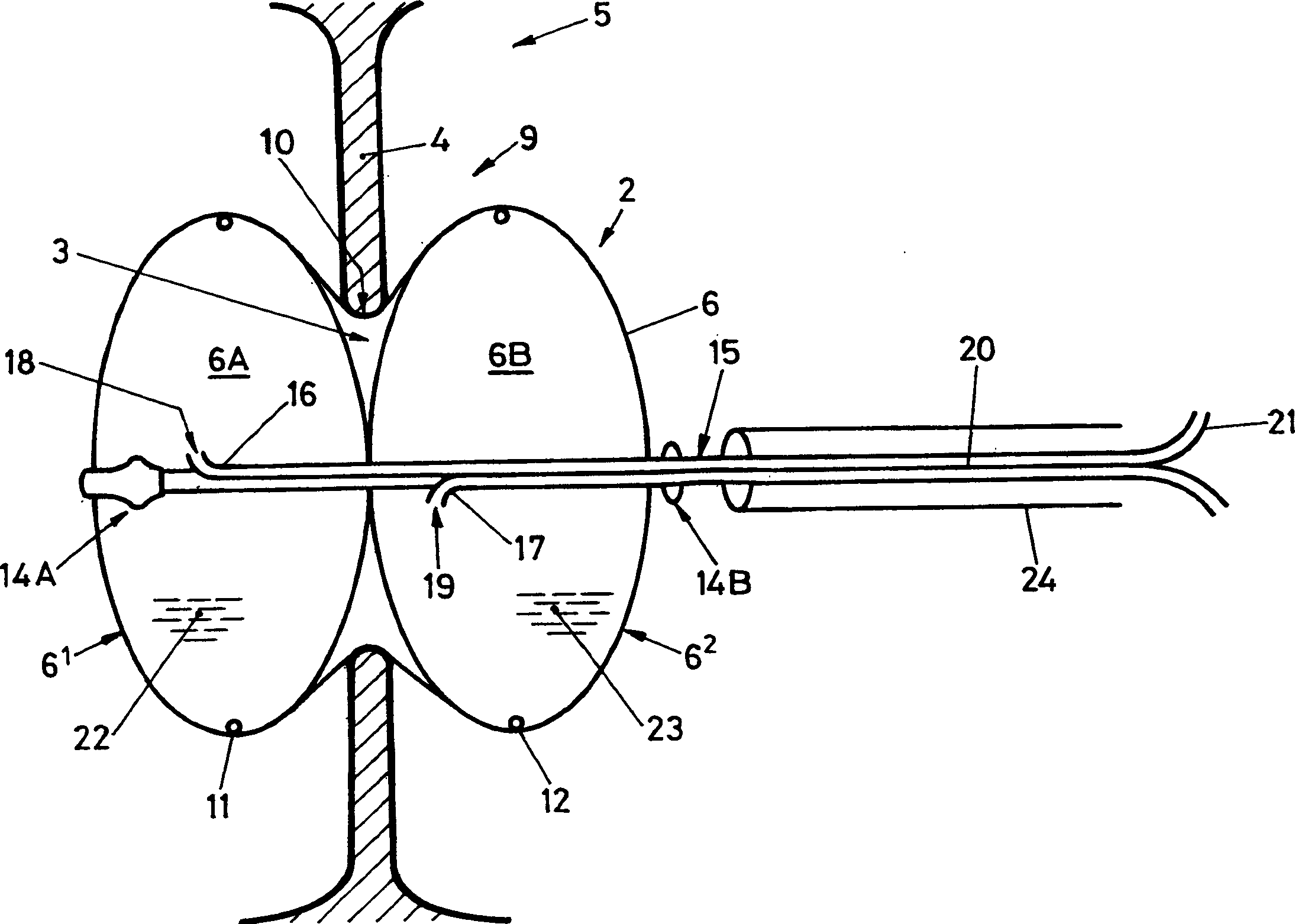

Occlusion device and surgical instrument and method for its implantation/explantation

InactiveUS20070112381A1Easy to operateSeating of the implant can be checkedSurgical veterinaryWound clampsSurgical departmentBlood vessel

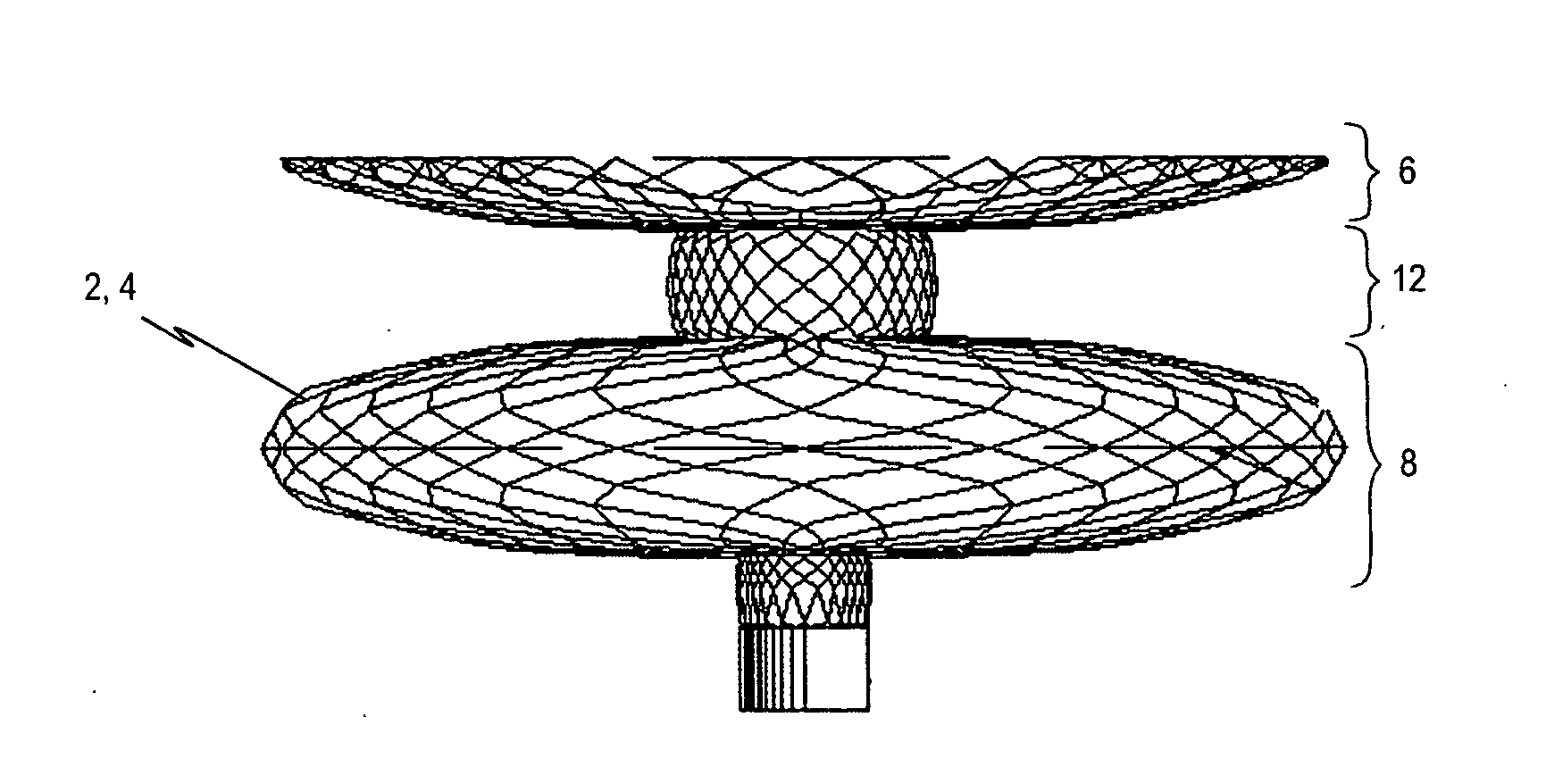

An occlusion device includes a braiding of thin wires or threads tapering to the diameter of a catheter used for an intravascular implantation / explantation procedure and having a proximal retention area, a distal retention area at which ends of the wires or threads converge into a holder, and a cylindrical crosspiece interposed between the proximal retention area and the distal retention area, whereby the two retention areas are positioned on two sides of a shunt to be occluded in a septum following implantation while the crosspiece transverses the shunt. The holder exhibits a head section at its free end having an eyelet as a cross-hole which can be gripped and held in form-fit fashion by an implantation / explantation instrument. A surgical instrument having such a holder includes gripper tongs with gripping jaws which open and close by a push / pull system, and which force-fit grips the head section of the holder.

Owner:OCCLUTECH HLDG

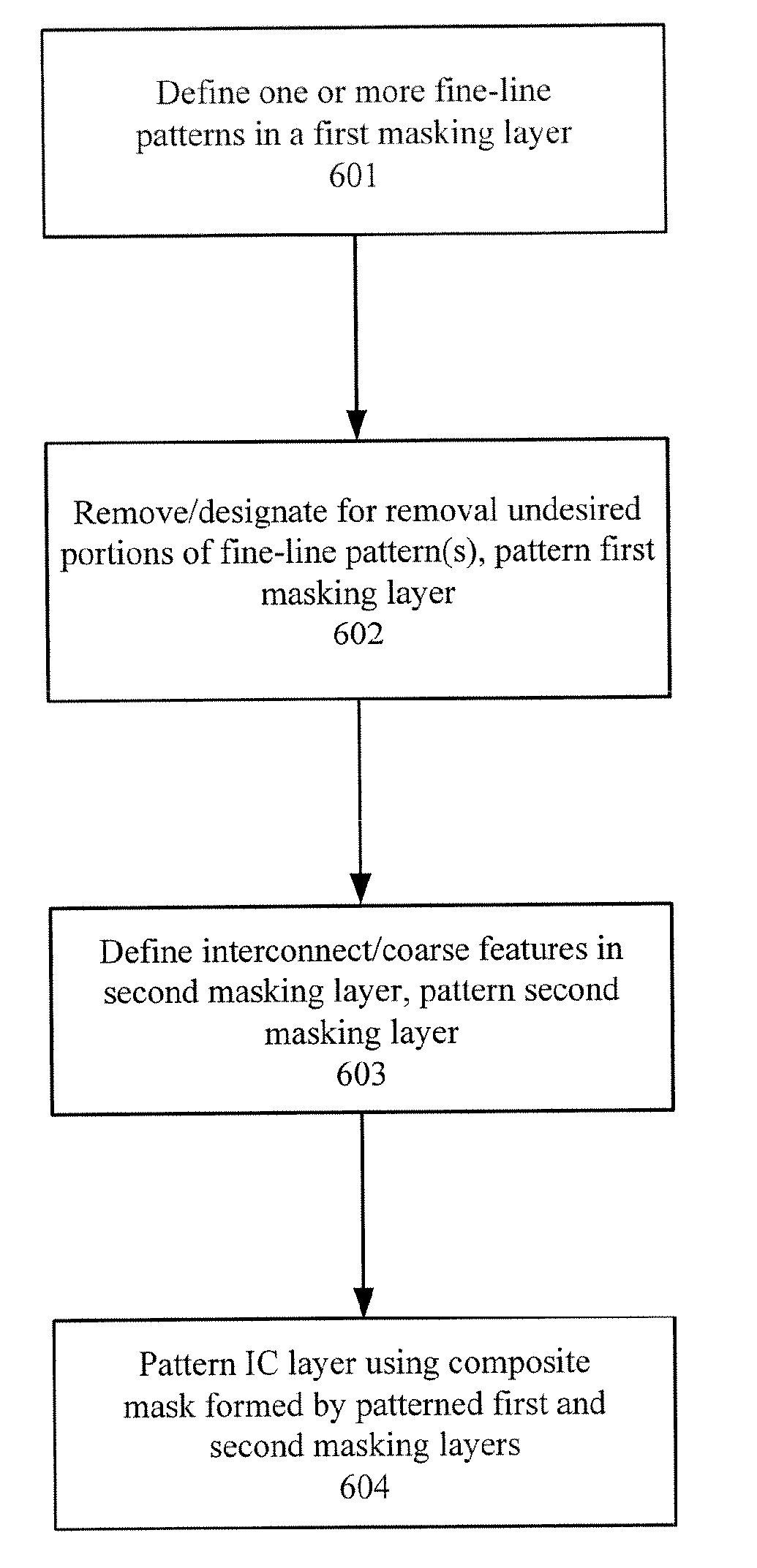

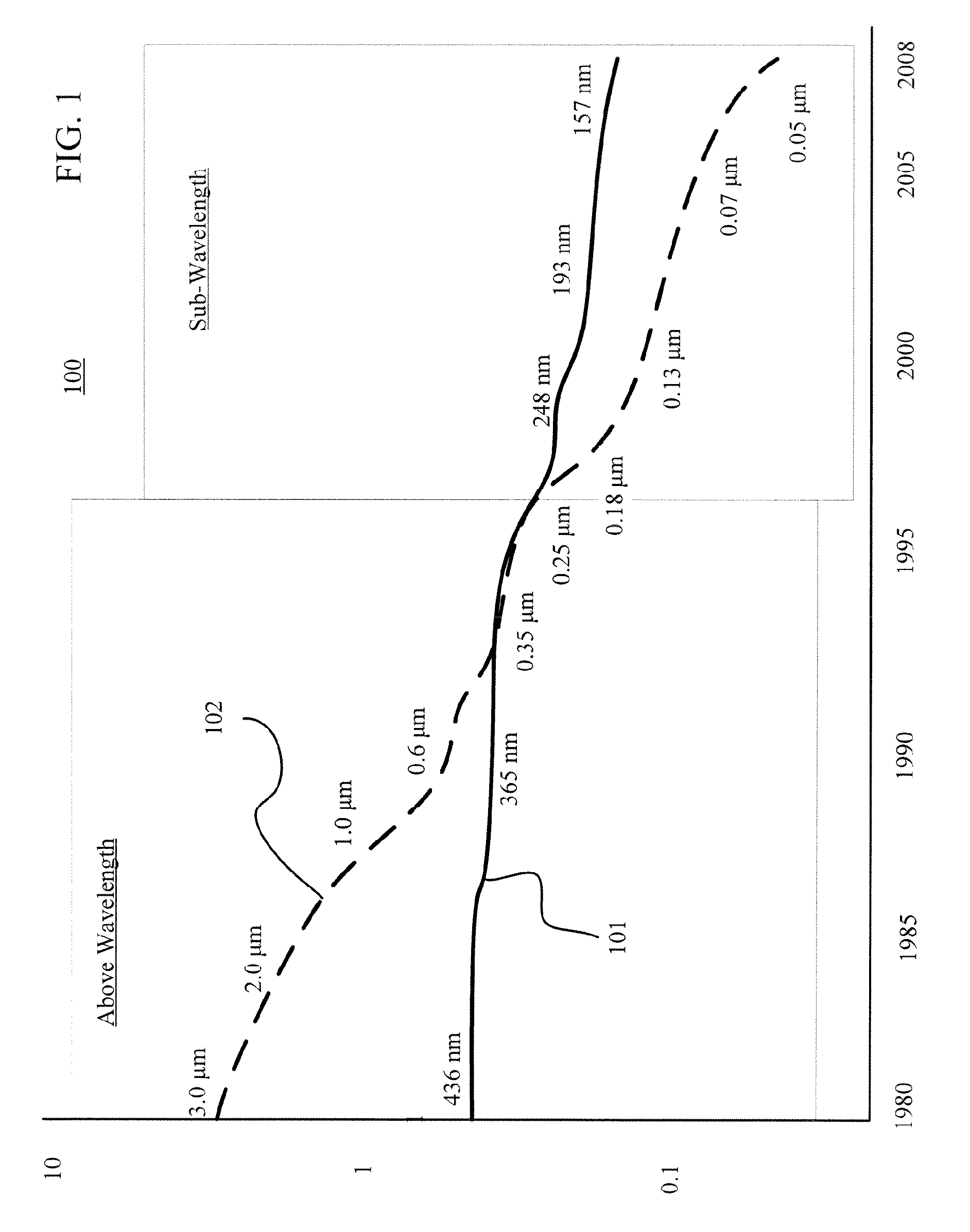

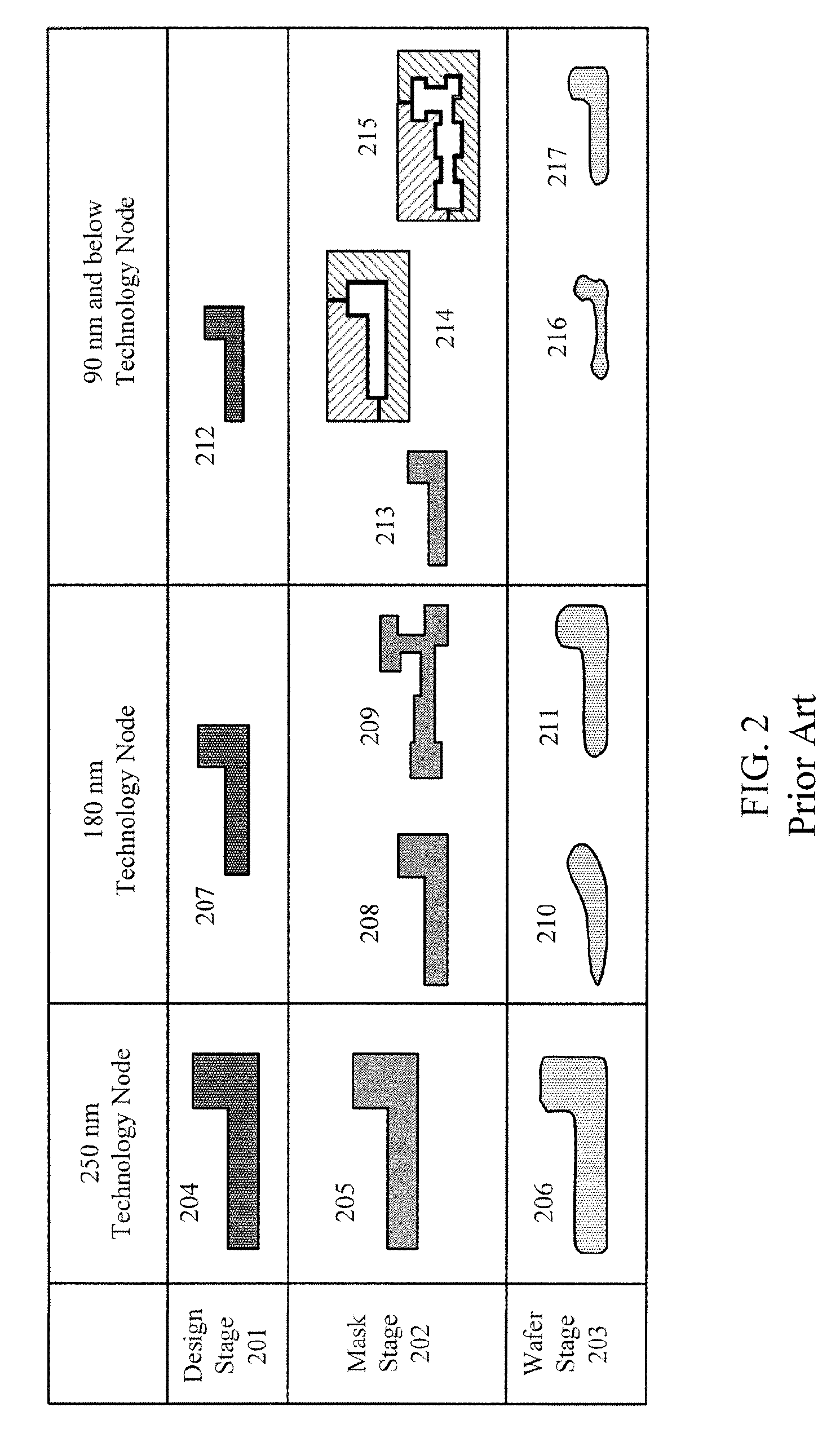

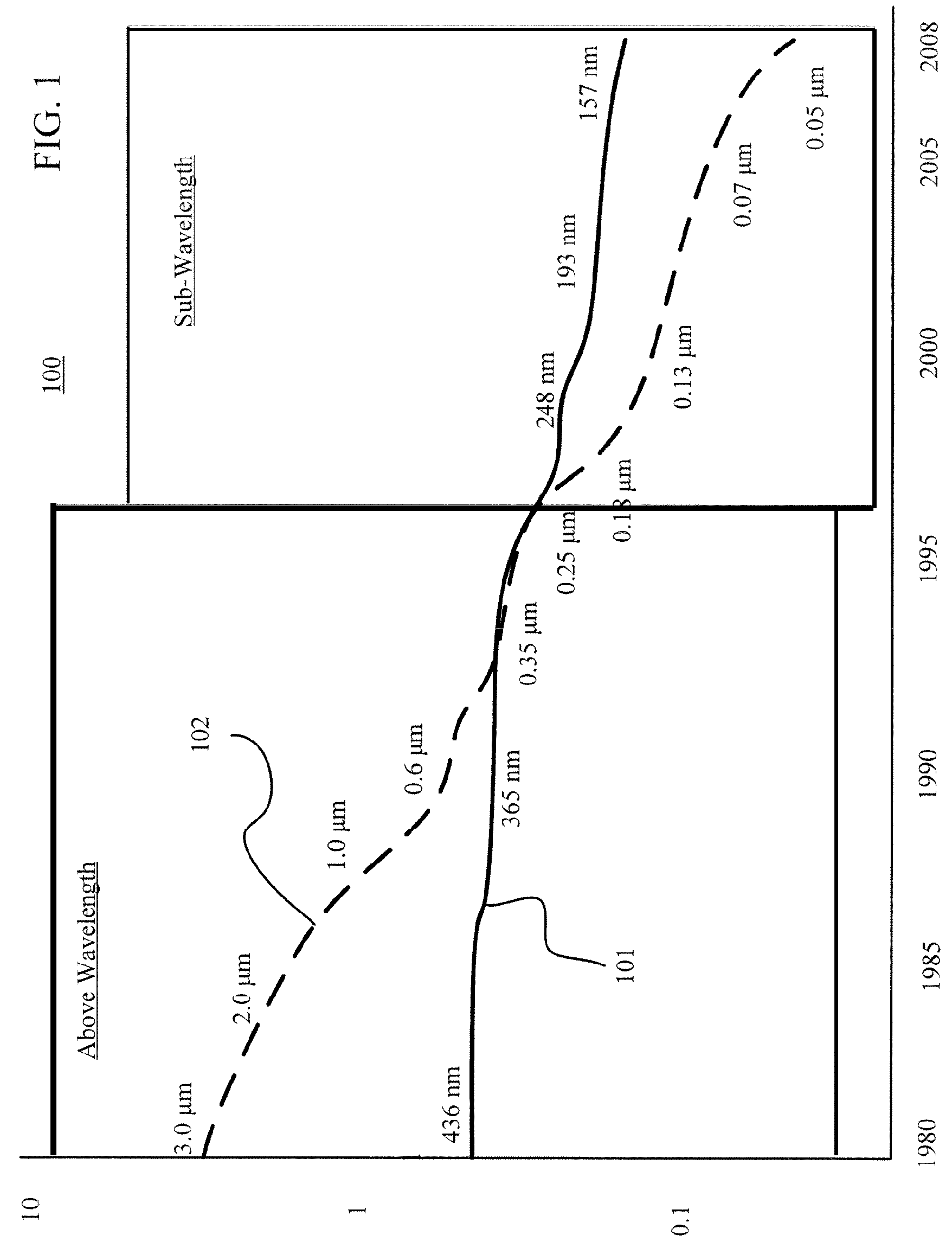

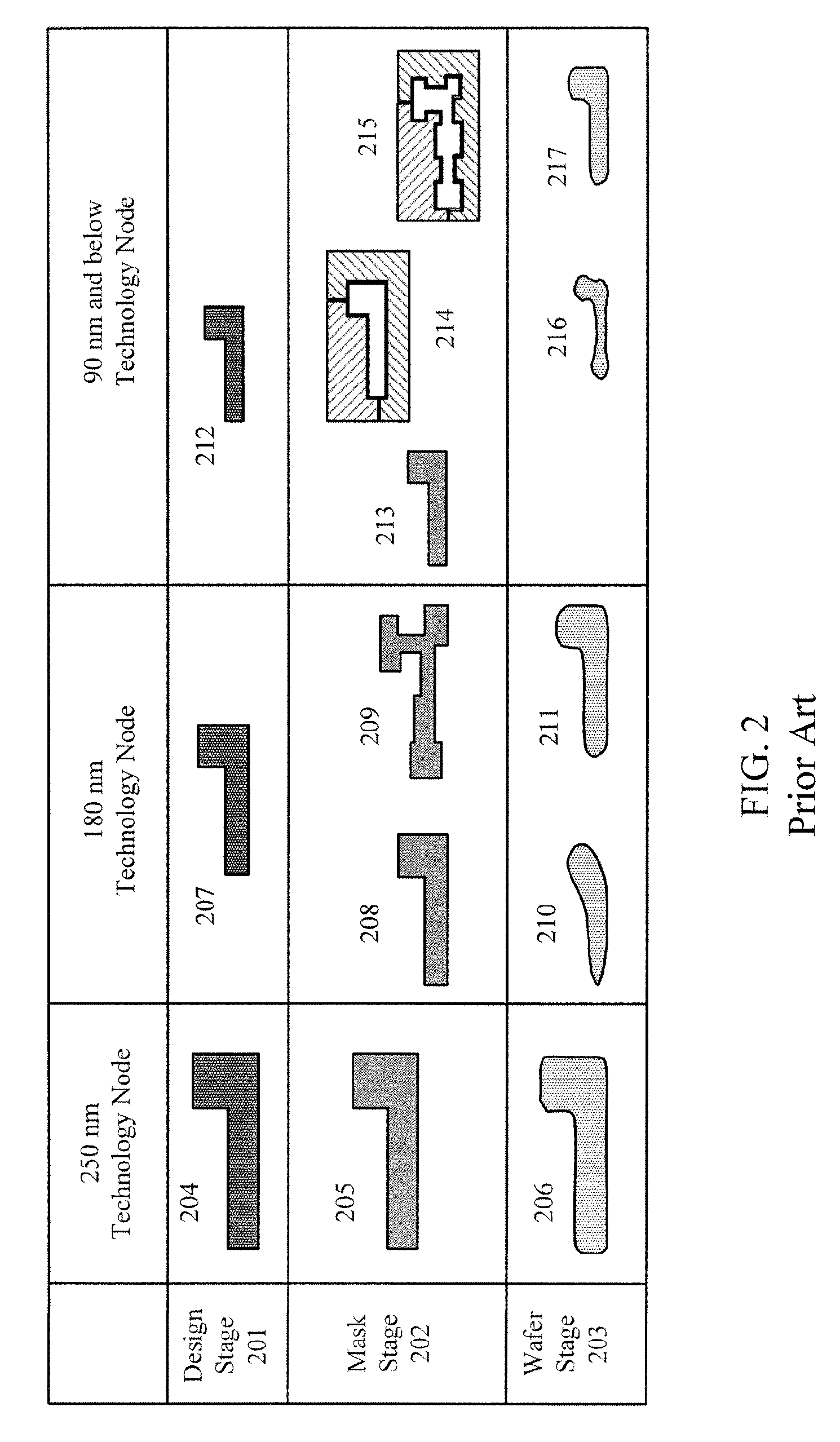

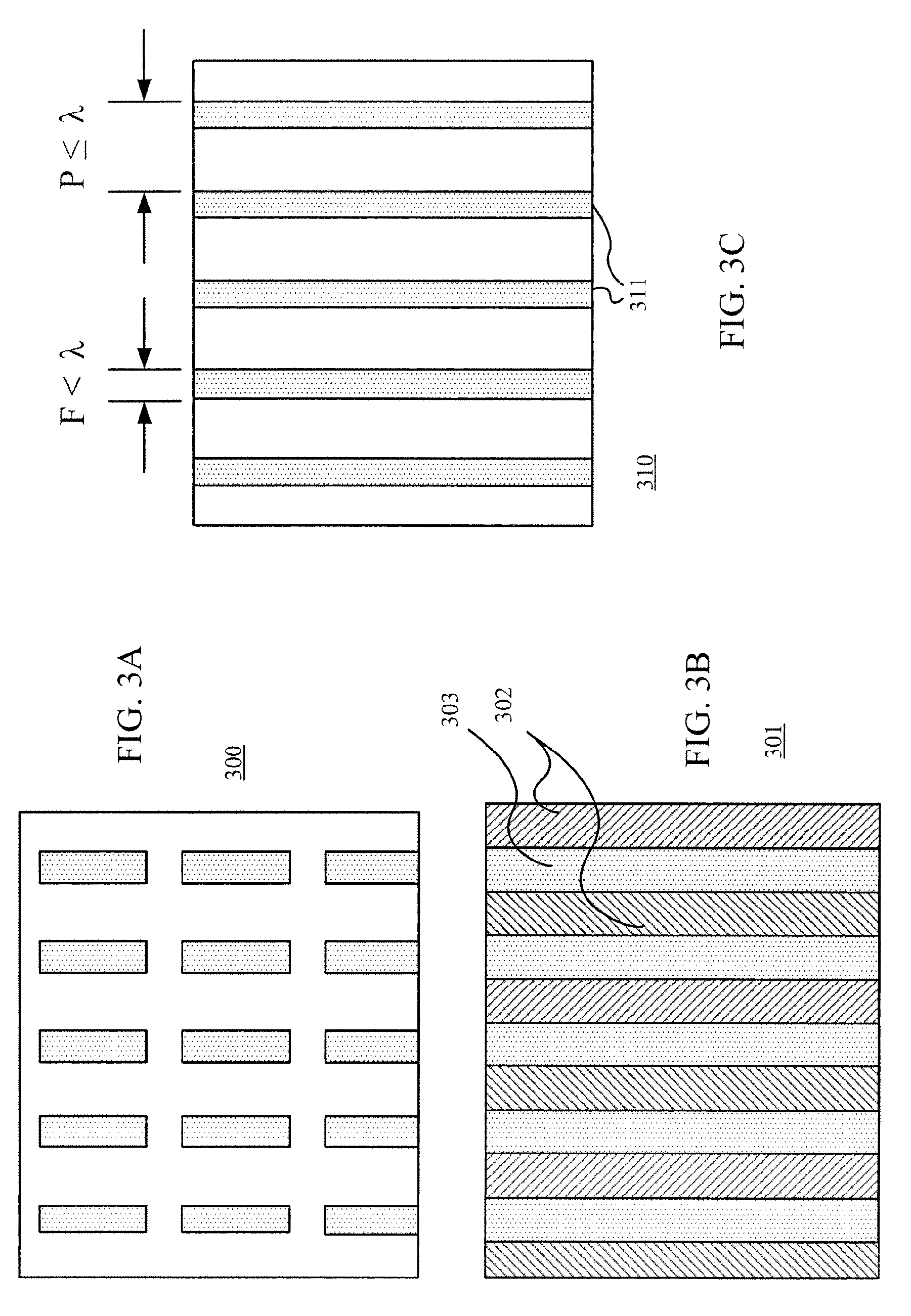

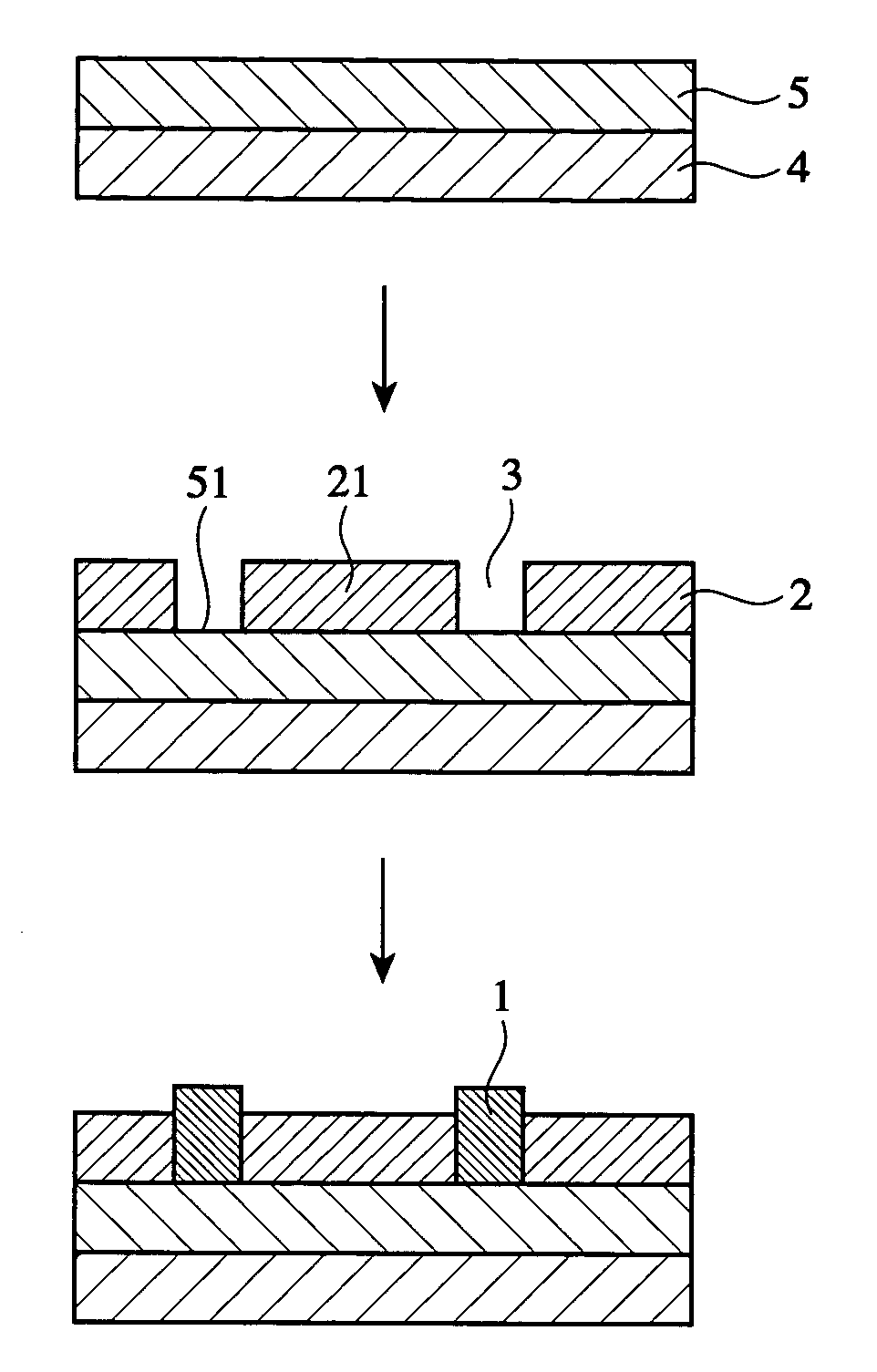

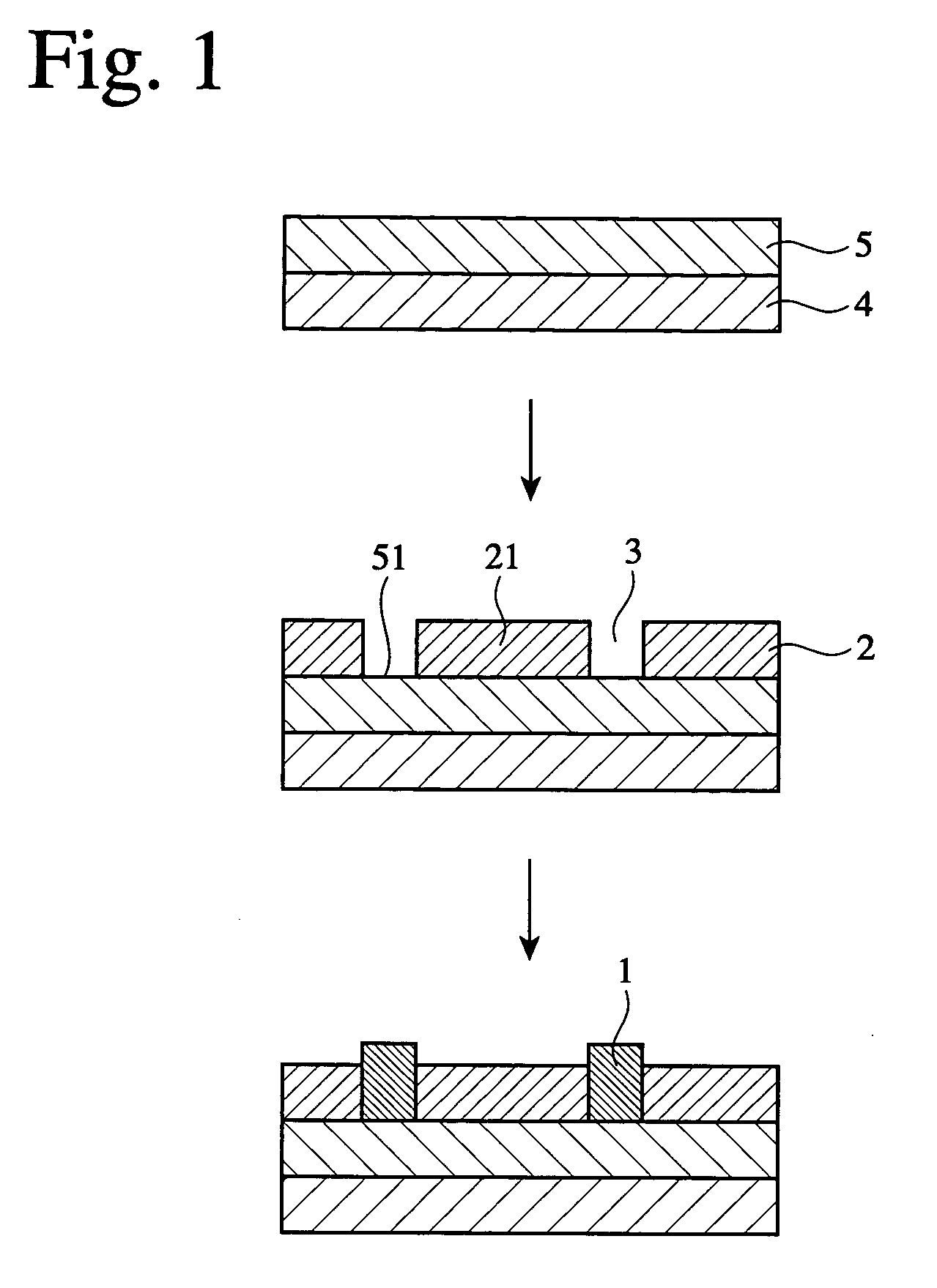

Patterning A Single Integrated Circuit Layer Using Multiple Masks And Multiple Masking Layers

ActiveUS20070275309A1Increase productionEasy to useSemiconductor/solid-state device manufacturingPhotosensitive material processingResolution enhancement technologiesLength wave

A multiple mask and a multiple masking layer technique can be used to pattern a single IC layer. A resolution enhancement technique can be used to define one or more fine-line patterns in a first masking layer, wherein each fine-line feature is sub-wavelength. Moreover, the pitch of each fine-line pattern is less than or equal to that wavelength. The portions of the fine-line features not needed to implement the circuit design are then removed or designated for removal using a mask. After patterning of the first masking layer, another mask can then be used to define coarse features in a second masking layer formed over the patterned first masking layer. At least one coarse feature is defined to connect two fine-line features. The IC layer can be patterned using the composite mask formed by the patterned first and second masking layers.

Owner:SYNOPSYS INC

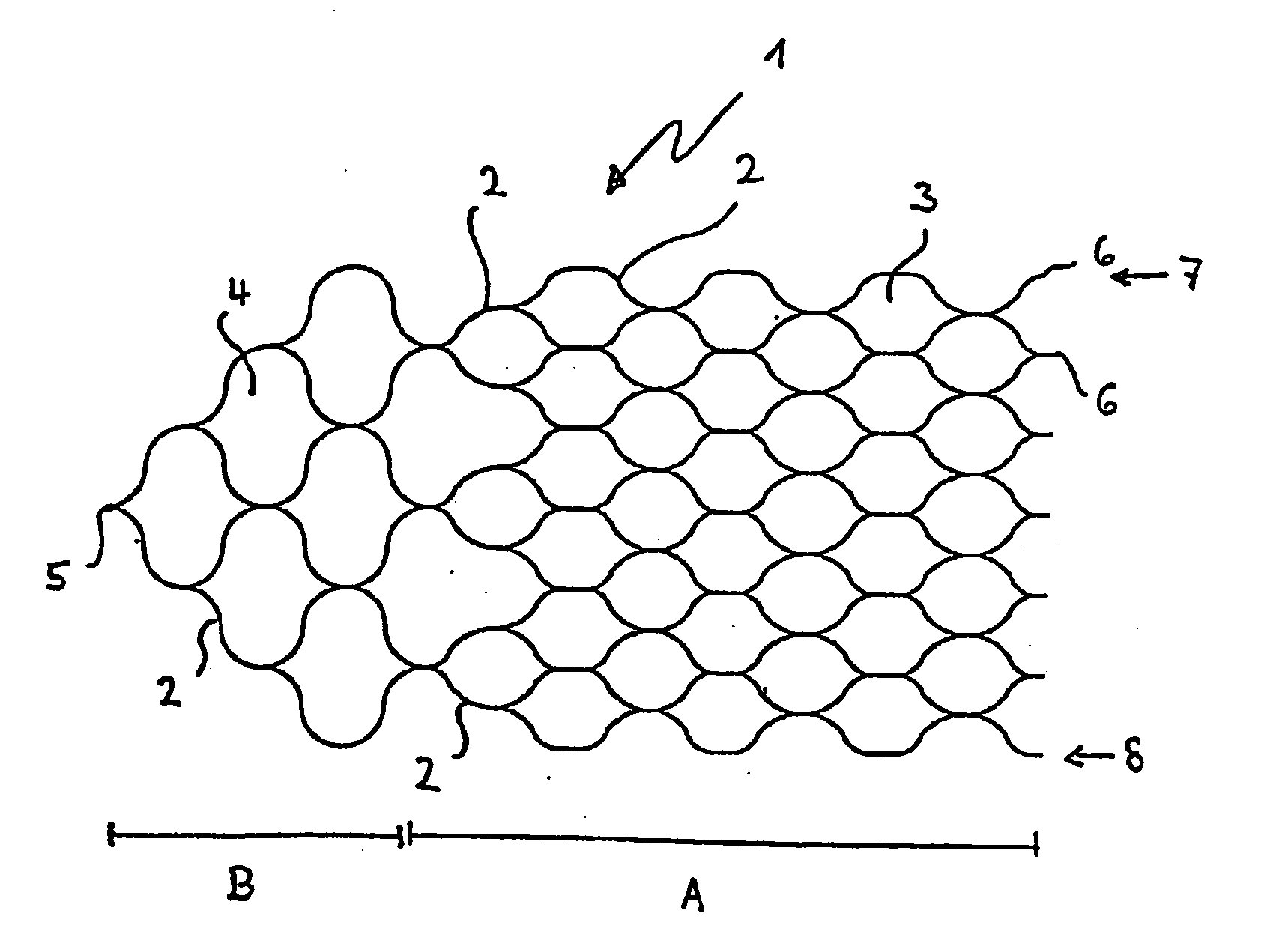

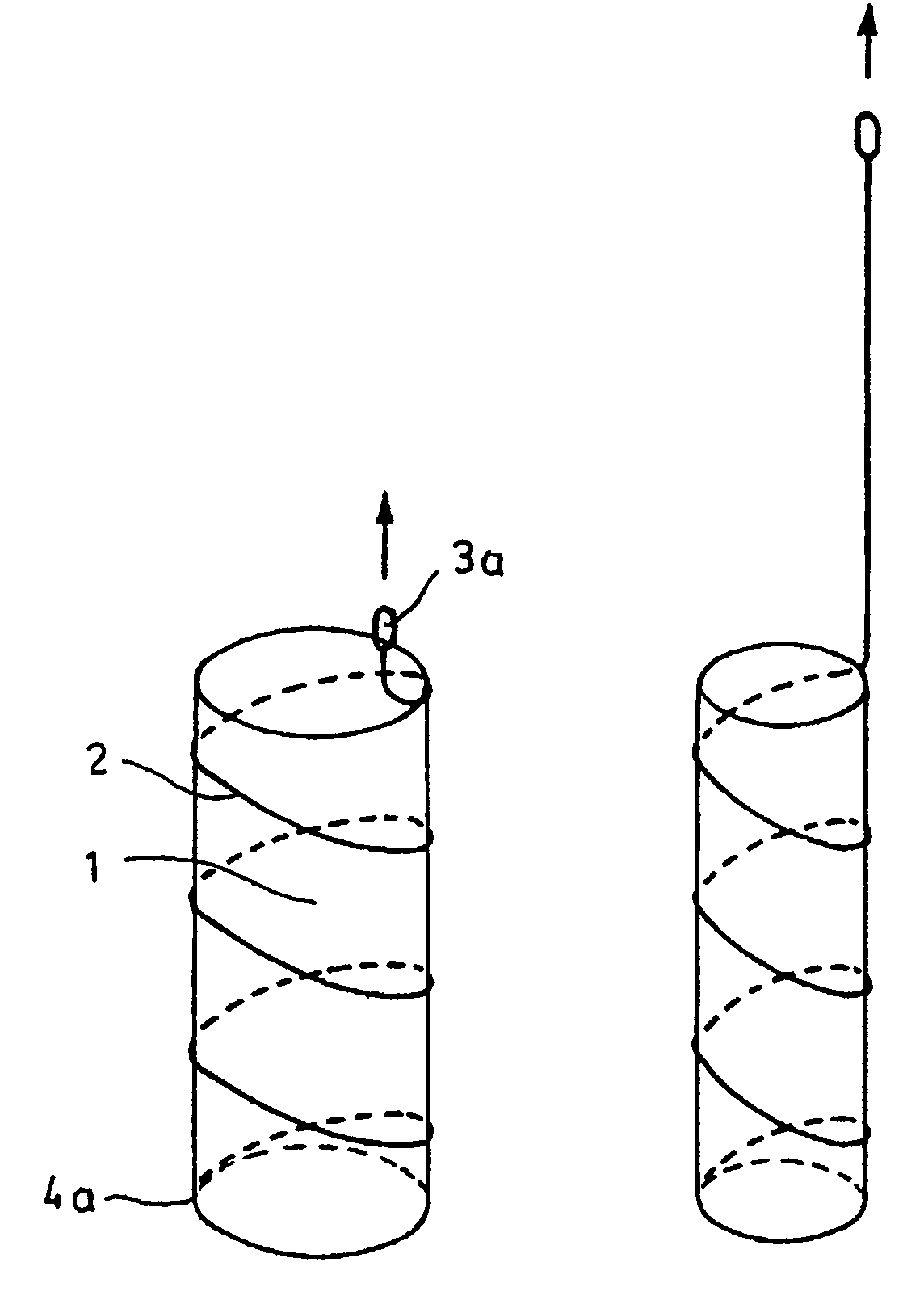

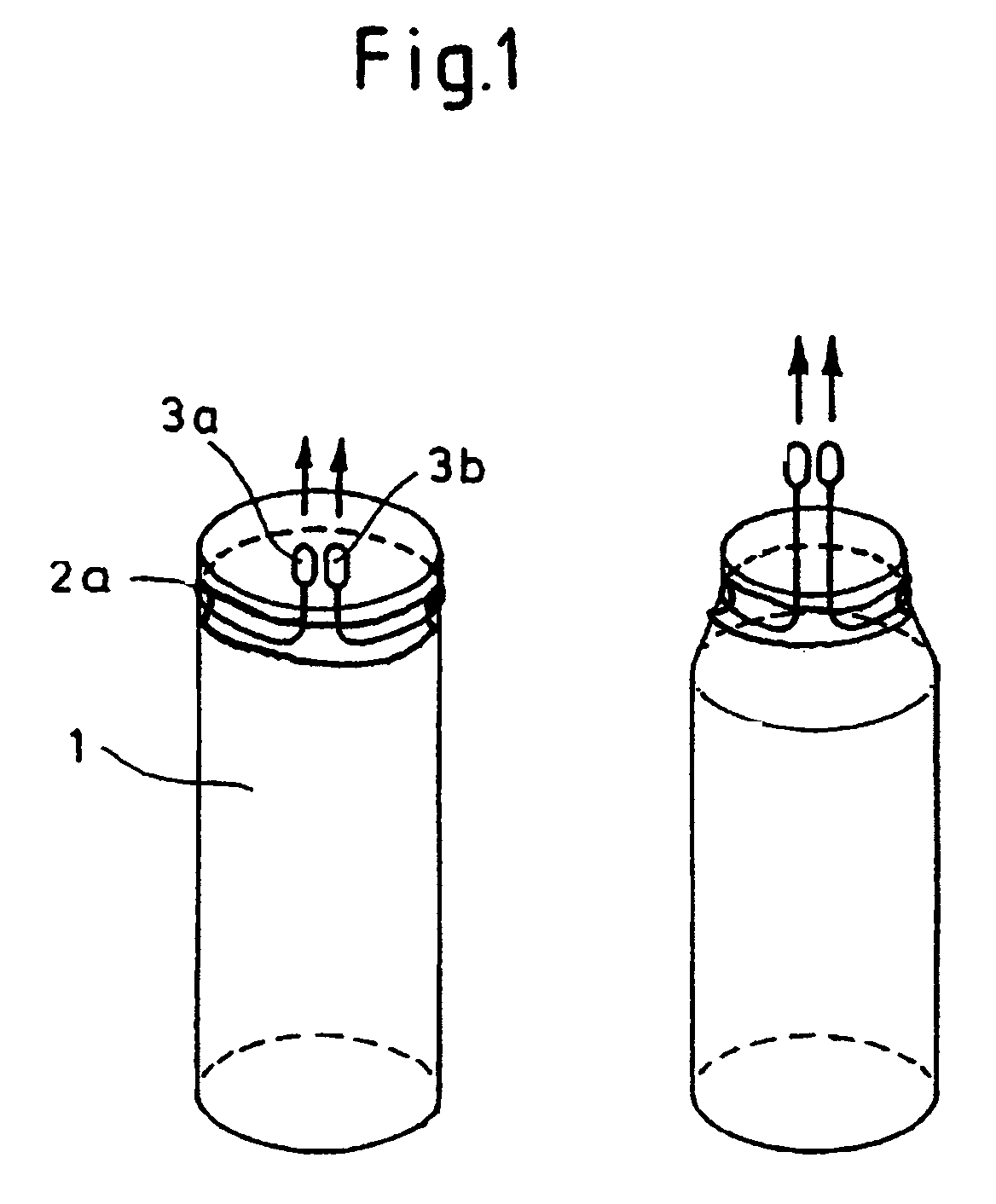

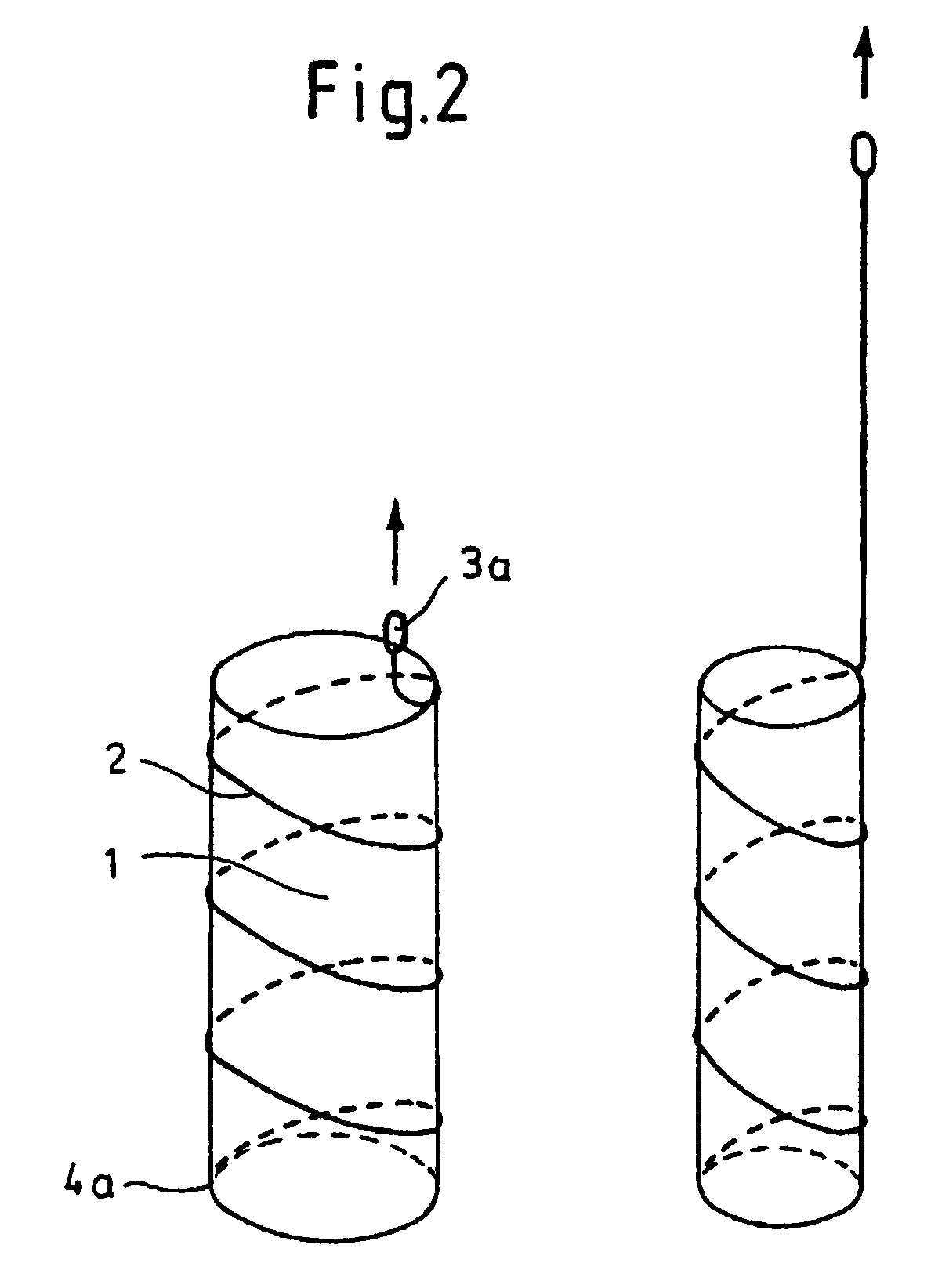

Removable essentially cylindrical implants

InactiveUS7252680B2Little complicationReduce the overall diameterStentsEar treatmentEngineeringCylindrical lens

The invention relates to removable, essentially cylindrical implants which are characterized in that they can be reduced in diameter and are wrapped once or several times at one or more levels by one or more elastic, thin wire-shaped structure(s) (2a, 2b) which include(s) a catch device (3a, 3b) at least on one end thereof.

Owner:MERIT MEDICAL SYST INC

Patterning a single integrated circuit layer using multiple masks and multiple masking layers

ActiveUS7537866B2Low costEasy to controlSemiconductor/solid-state device manufacturingPhotosensitive material processingResolution enhancement technologiesWavelength

A multiple mask and a multiple masking layer technique can be used to pattern a single IC layer. A resolution enhancement technique can be used to define one or more fine-line patterns in a first masking layer, wherein each fine-line feature is sub-wavelength. Moreover, the pitch of each fine-line pattern is less than or equal to that wavelength. The portions of the fine-line features not needed to implement the circuit design are then removed or designated for removal using a mask. After patterning of the first masking layer, another mask can then be used to define coarse features in a second masking layer formed over the patterned first masking layer. At least one coarse feature is defined to connect two fine-line features. The IC layer can be patterned using the composite mask formed by the patterned first and second masking layers.

Owner:SYNOPSYS INC

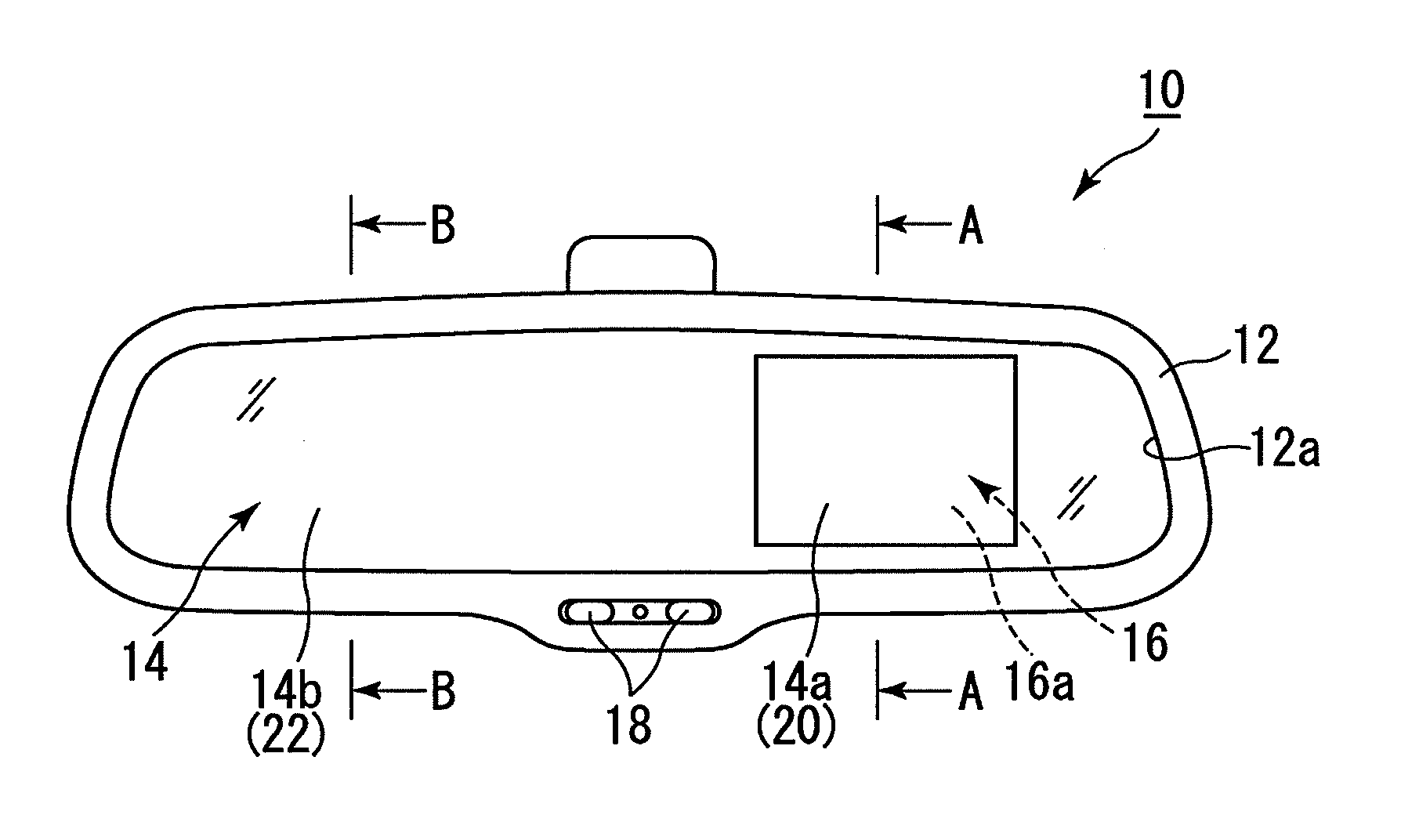

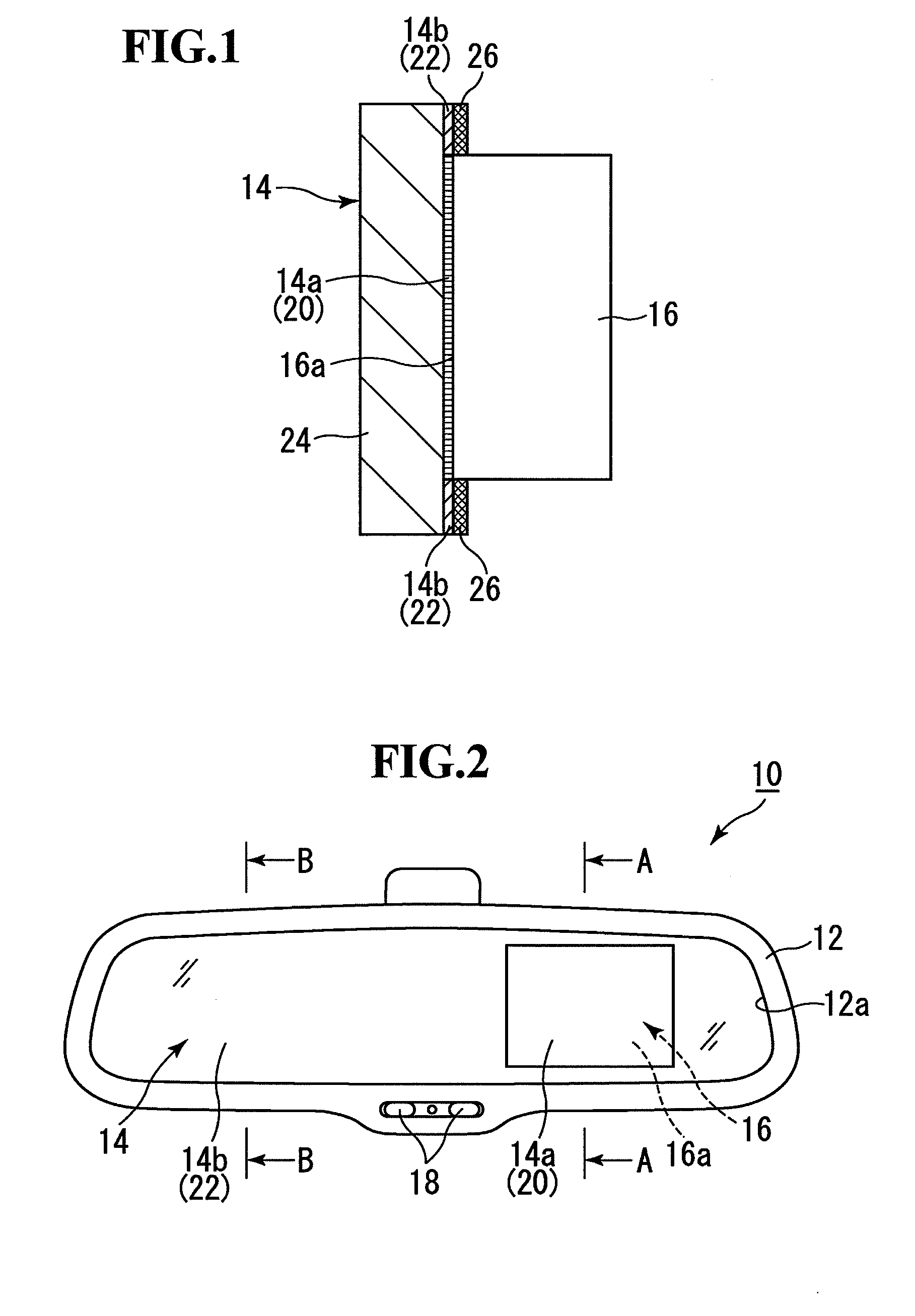

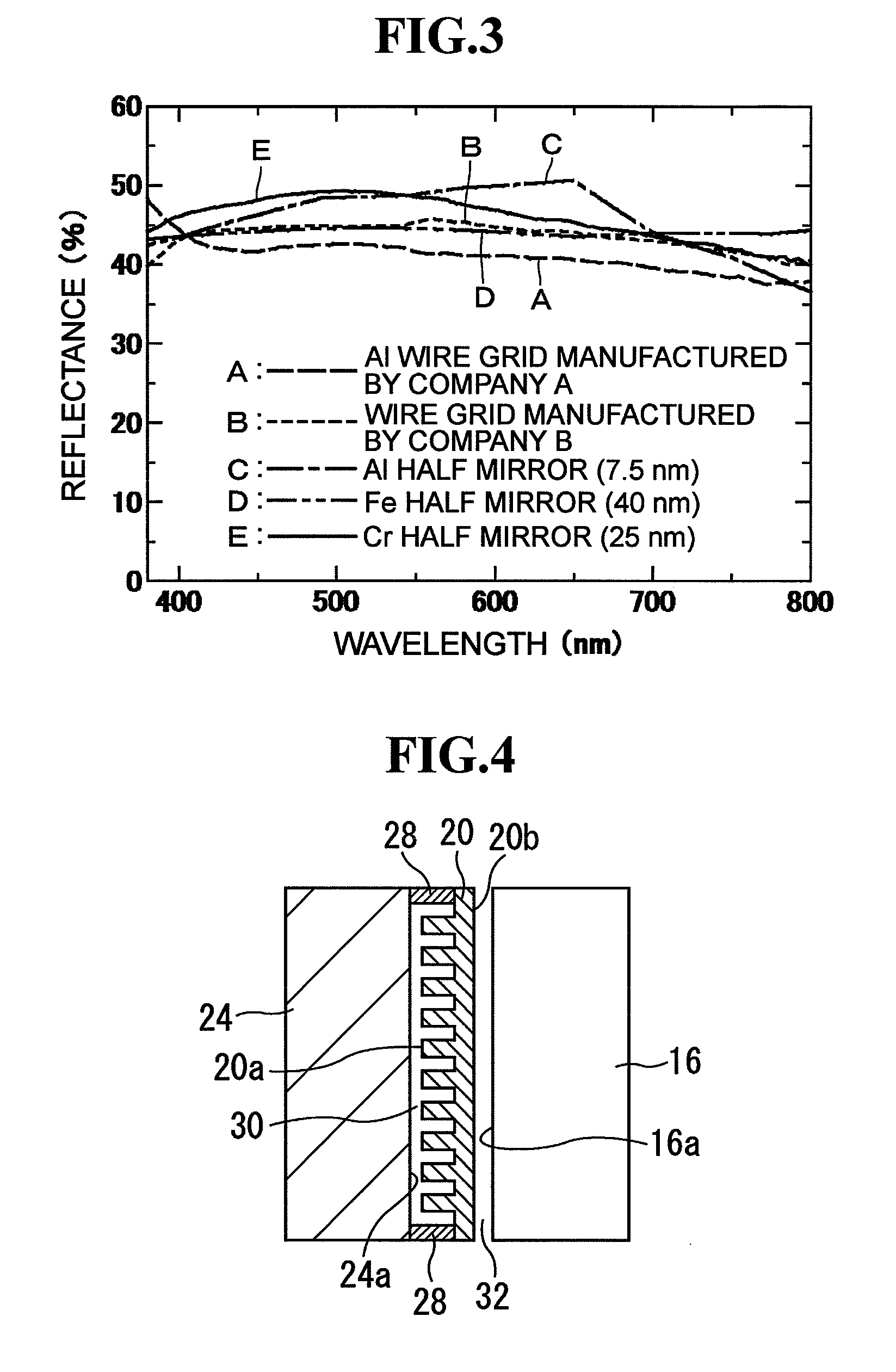

Mirror with monitor for vehicle

InactiveUS20100245701A1Increase volumeImprove visibilityPolarising elementsNon-linear opticsWire gridDark color

Owner:MURAKAMI CORP

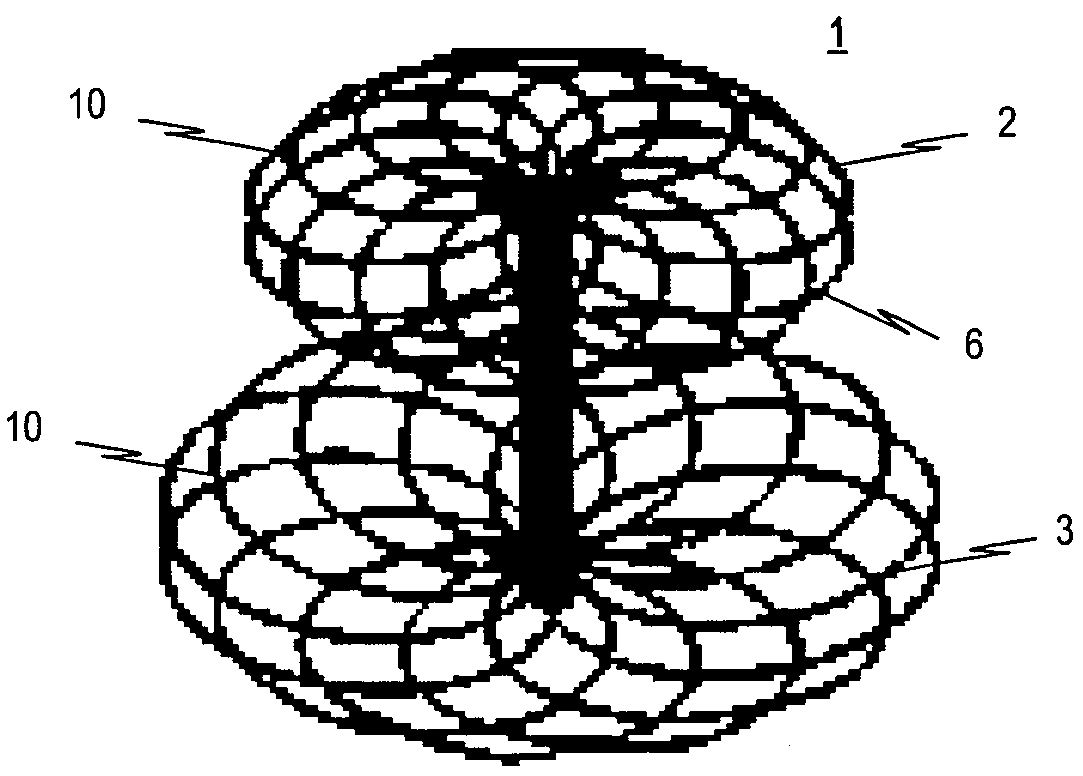

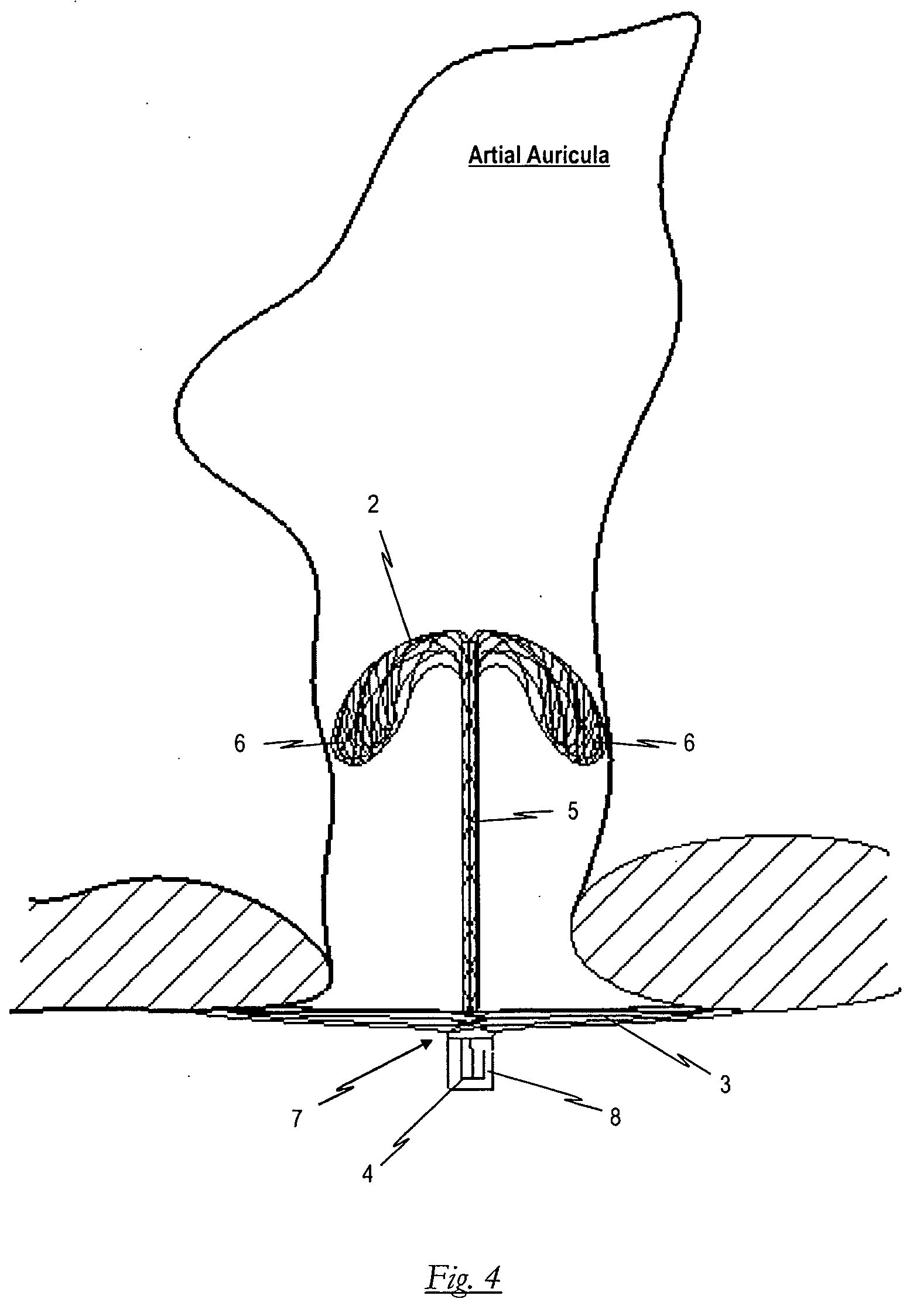

Occlusion device for occluding an atrial auricula and method for producing same

A self-expanding occlusion device for occluding an atrial auricula in the heart of a patient includes a braiding of thin wires or threads given a suitable profile form by means of a molding and heat treatment procedure. The occlusion device includes a proximal retention area, a distal retention area and a center section. The occlusion device holds securely in the atrial auricula of a patient in its expanded and implanted state without damaging the tissue of the patient's heart. The proximal retention area has a flanged area which positions at the inner walls of the atrial auricula when the occlusion device is in an expanded state in the atrial auricula to be occluded, and forms a force-fit connection with the inner walls of the atrial auricula, thus holding the implanted and expanded occlusion device in the atrial auricula, whereby the distal retention area closes the opening in the atrial auricula.

Owner:OCCLUTECH GMBH

System and method for transferring data to and from a magnetic shift register with a shiftable data column

InactiveUS7236386B2More sensitivityMagnitude fringing fieldDigital storageShift registerProcessor register

A magnetic shift register utilizes a data column comprising a thin wire of magnetic material. A writing element selectively changes the direction of the magnetic moment in the magnetic domains to write the data to the data column. Associated with each domain wall are large magnetic fringing fields concentrated in a very small space. These magnetic fringing fields write to and read from the magnetic shift register. When the domain wall is moved close to another magnetic material, the fringing fields change the direction of the magnetic moment in the magnetic material, effectively “writing” to the magnetic material. A reading element similar to a tunneling junction comprises a free layer and a pinned layer of magnetic material. Fringing fields change the direction of the magnetic moment in the free layer with respect to the pinned layer, changing electrical resistance of the reading element and “reading” data stored in the magnetic shift register.

Owner:GLOBALFOUNDRIES U S INC

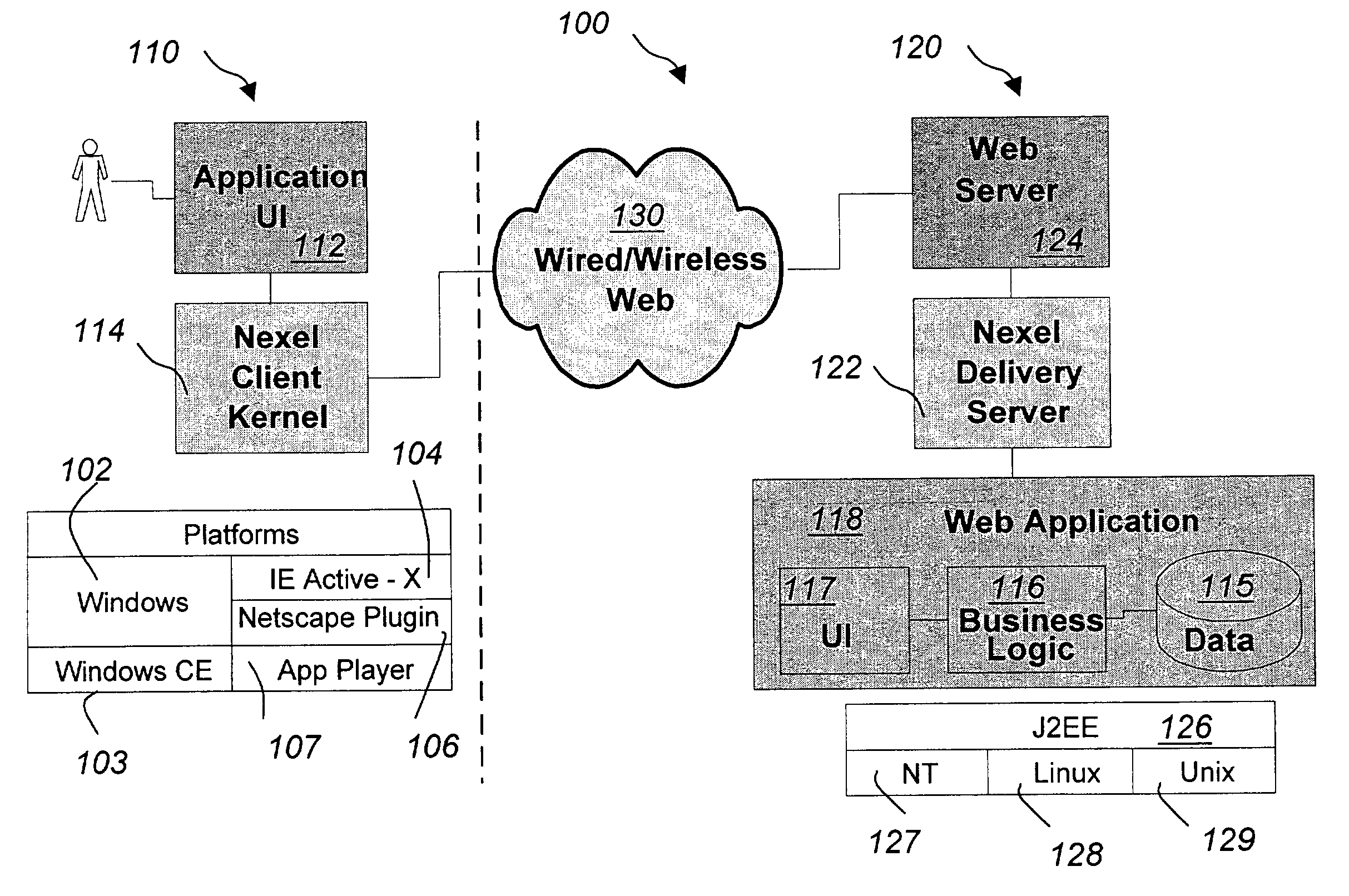

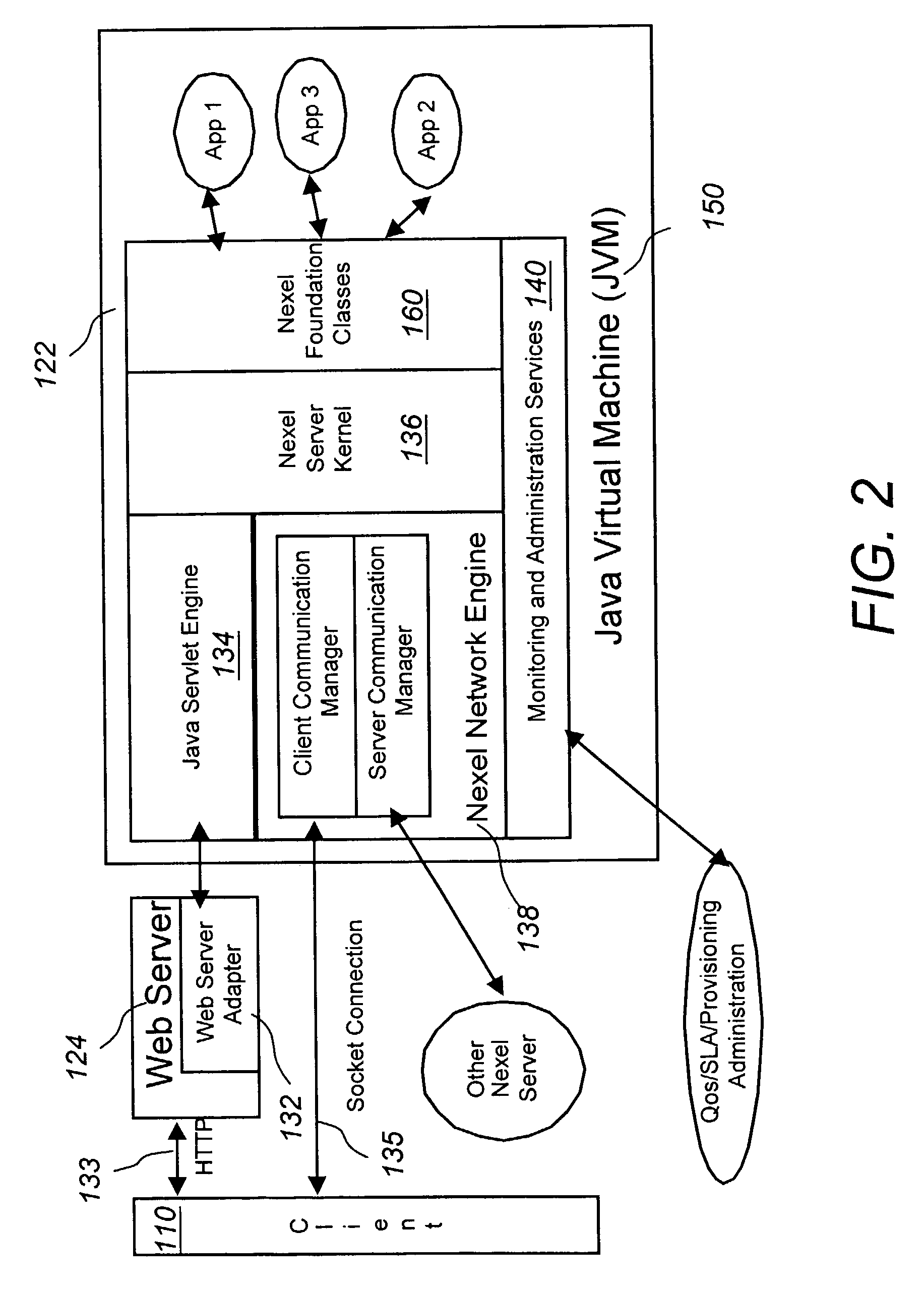

Methods and techniques for delivering rich Java applications over thin-wire connections with high performance and scalability

ActiveUS7596791B2Interprogram communicationMultiple digital computer combinationsNetwork connectionApplication software

A method for delivering applications over a network where the application's logic runs on the backend server and the application's user interface is rendered on a client-device, according to its display capabilities, thought a network connection with the backend server. The application's GUI API and event processing API are implemented to be network-aware, transmitting application's presentation layer information, event processing registries, and other related information a between client and server. The transmission is a high, object level format, which minimizes network traffic. Client-side events are transmitted to the server for processing via a predetermined protocol, the server treating such events and inputs as if locally generated. The appropriate response to the input is generated and transmitted to the client device using the format to refresh the GUI on the client.

Owner:EMC IP HLDG CO LLC

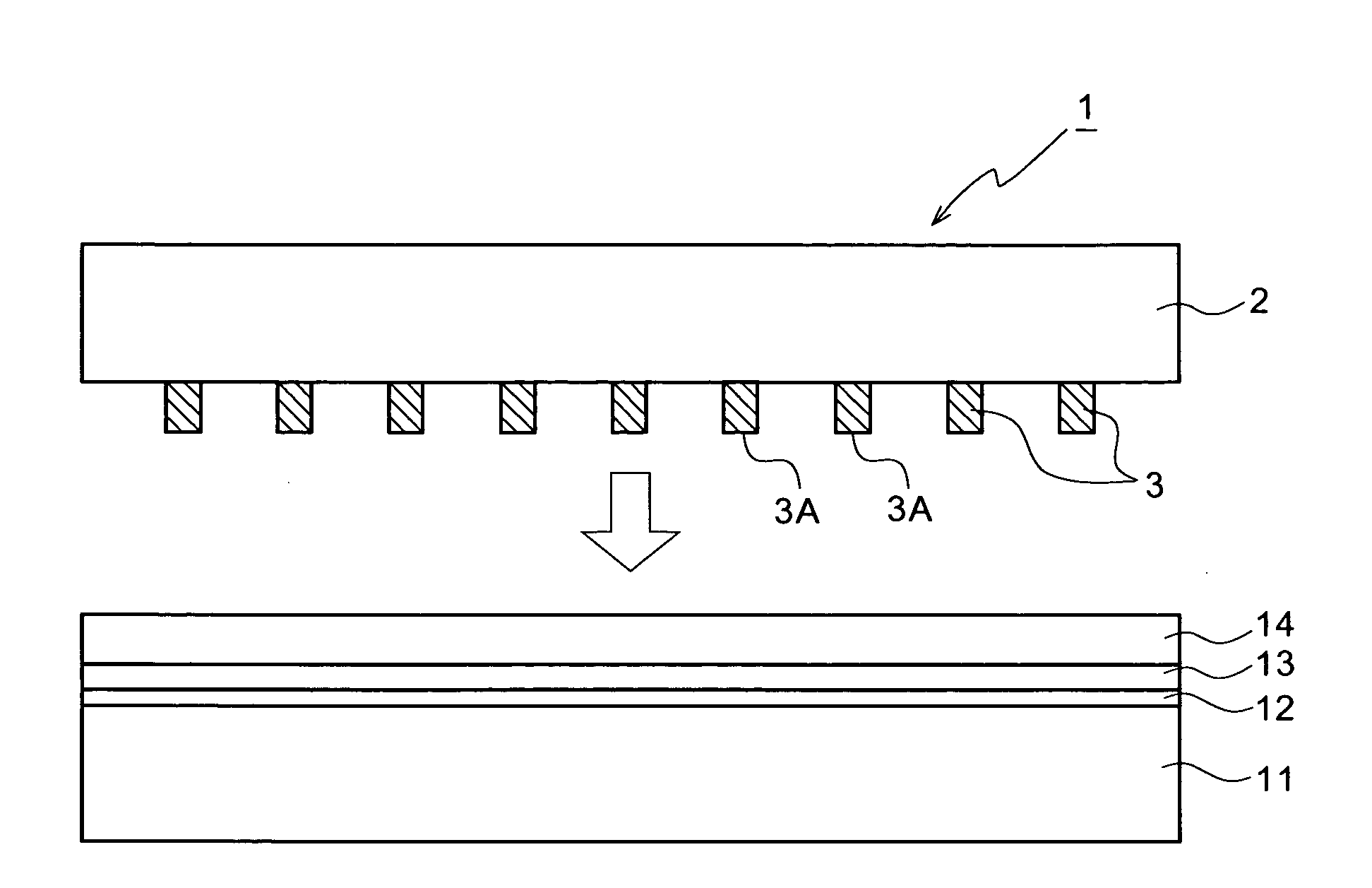

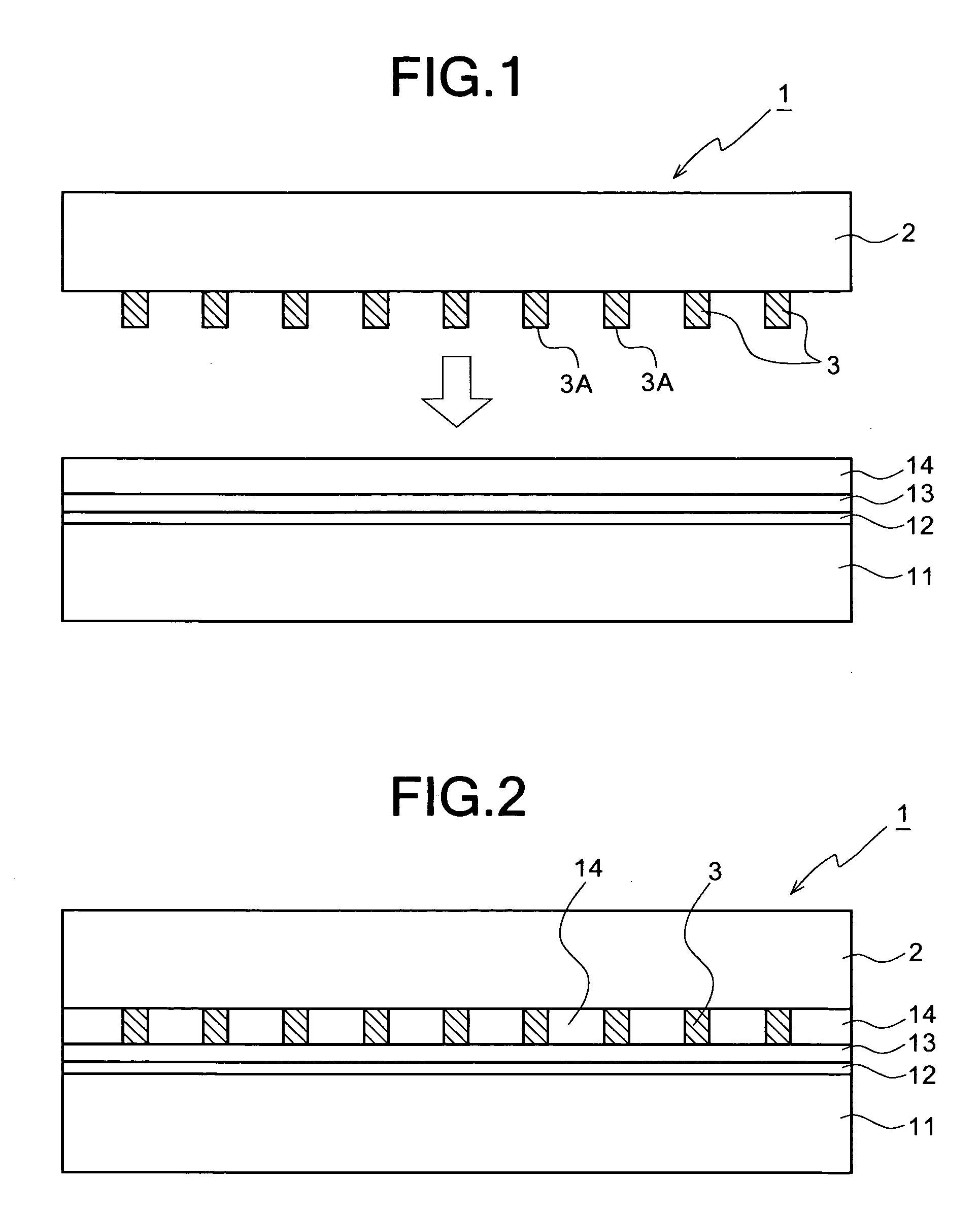

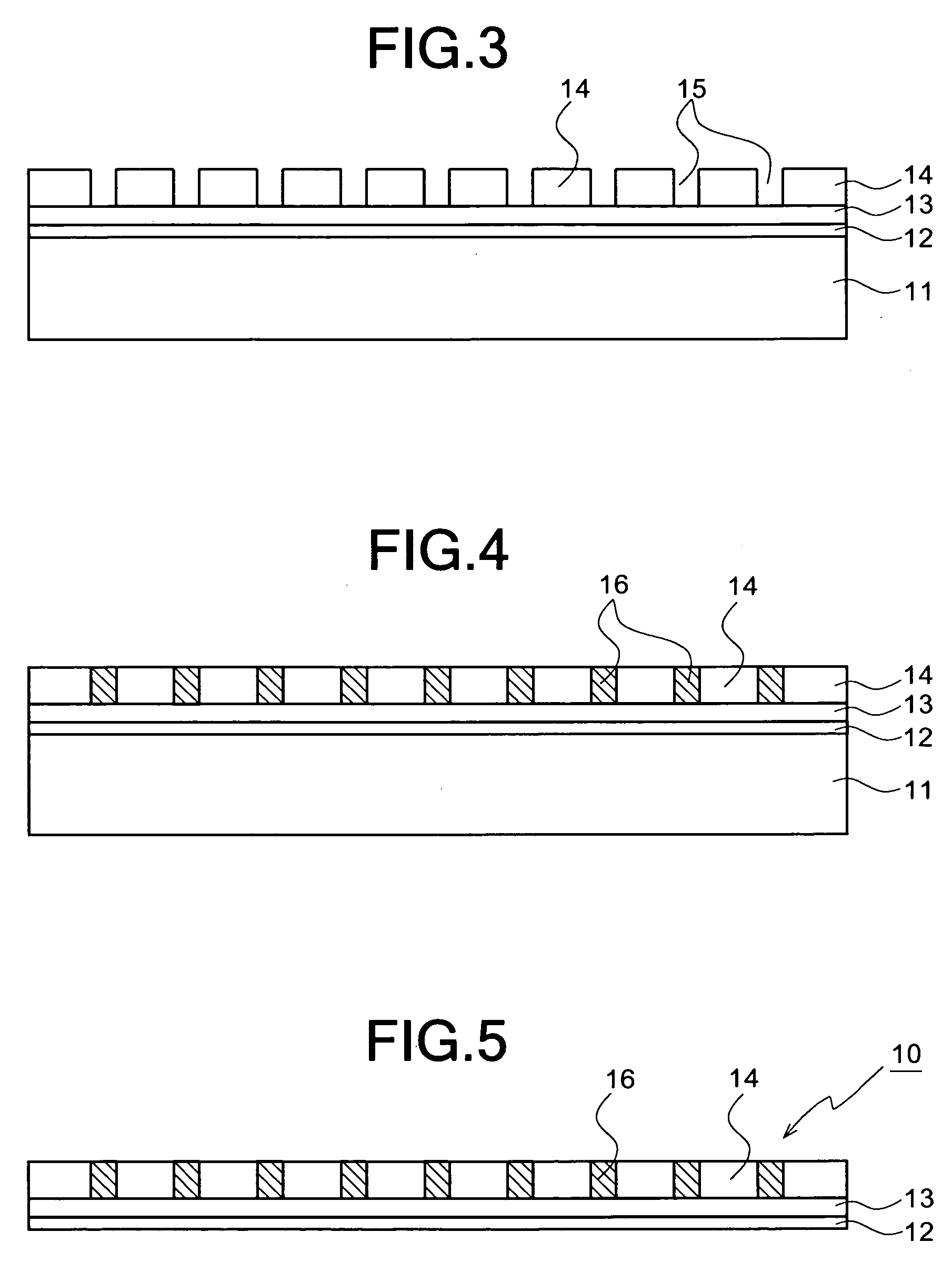

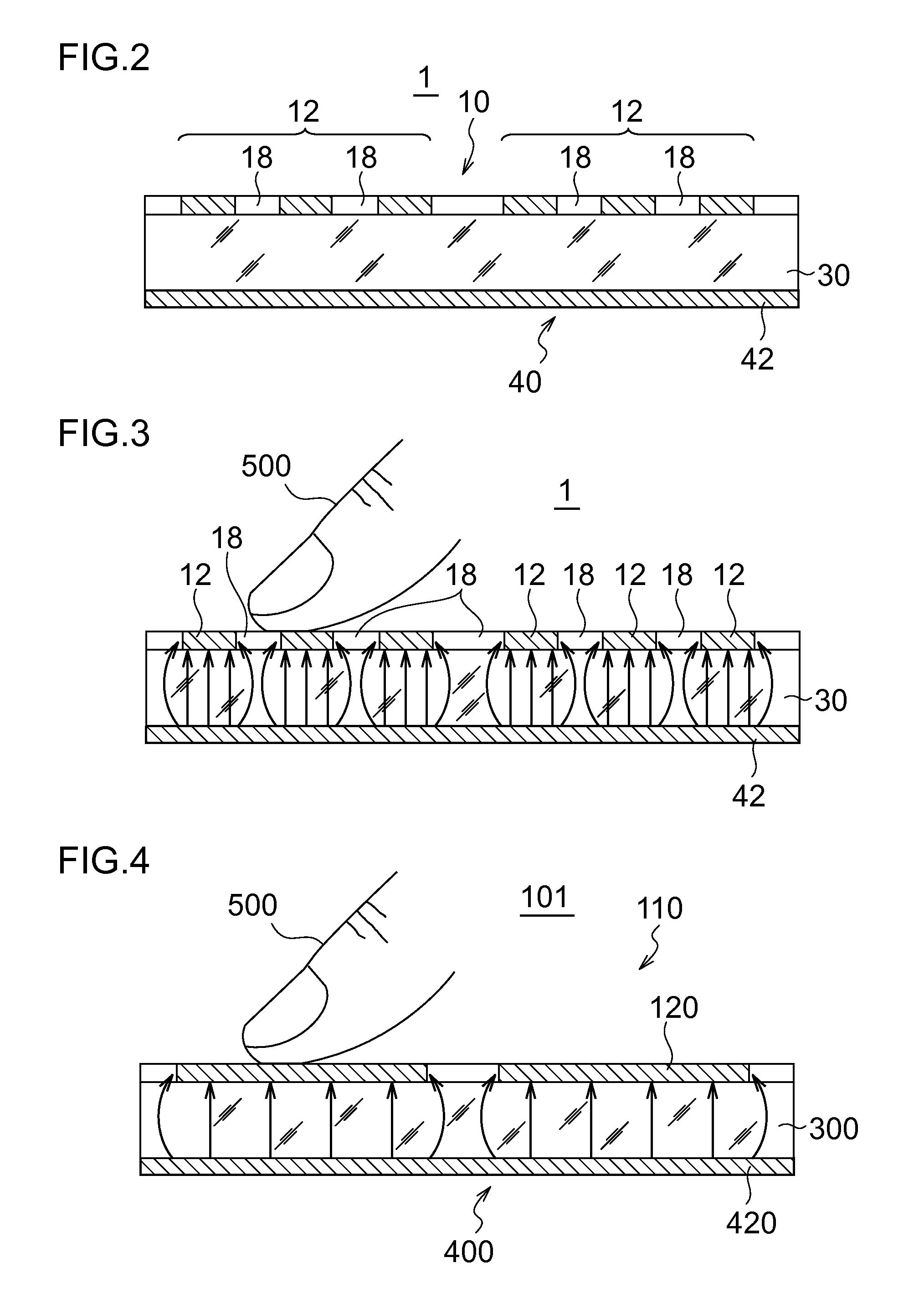

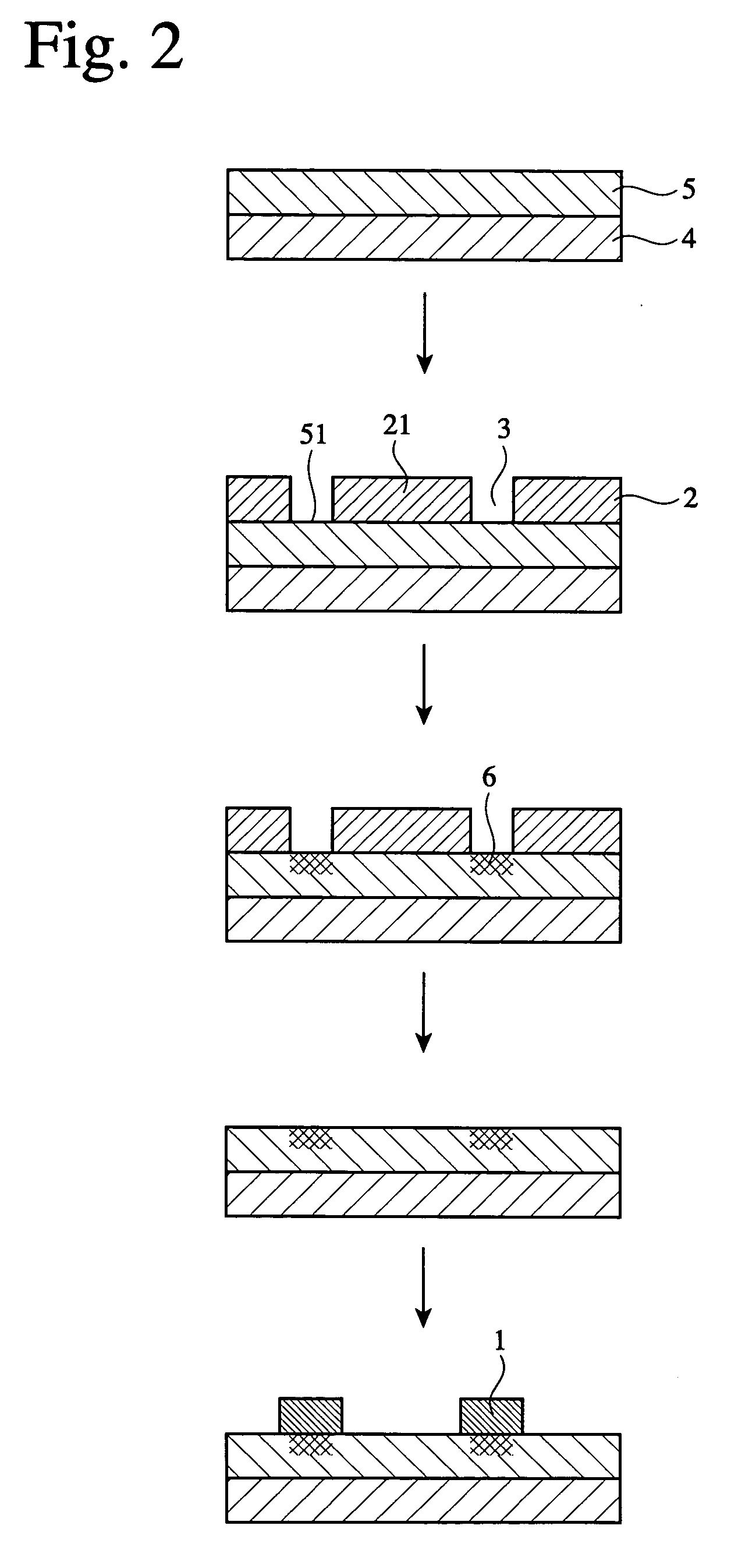

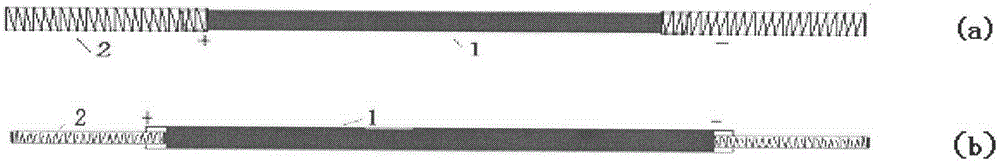

Wire grid polarizer and method for producing same

ActiveUS20050046943A1High light transmittanceLow costPolarising elementsOptical articlesWire gridLithographic artist

There are provided a thin wire grid polarizer having a high transmittance, a high quenching ratio and a high degree of polarization, and a method for producing the same at low costs. A fluoridated polyimide thin film 12, a hydrophilic thin film 13 and a hydrophobic thin film 14 are sequentially stacked on a glass substrate 11 to be pressed by a die 1 from the side of the hydrophobic thin film 14 to transfer the fine pattern of groove forming protrusions 3 of the die 1 to the hydrophobic thin film 14 and hydrophilic thin film 13 by the nano-imprinted lithography technique, and then, metal fine wires are caused to grow by plating.

Owner:ENPLAS CORP

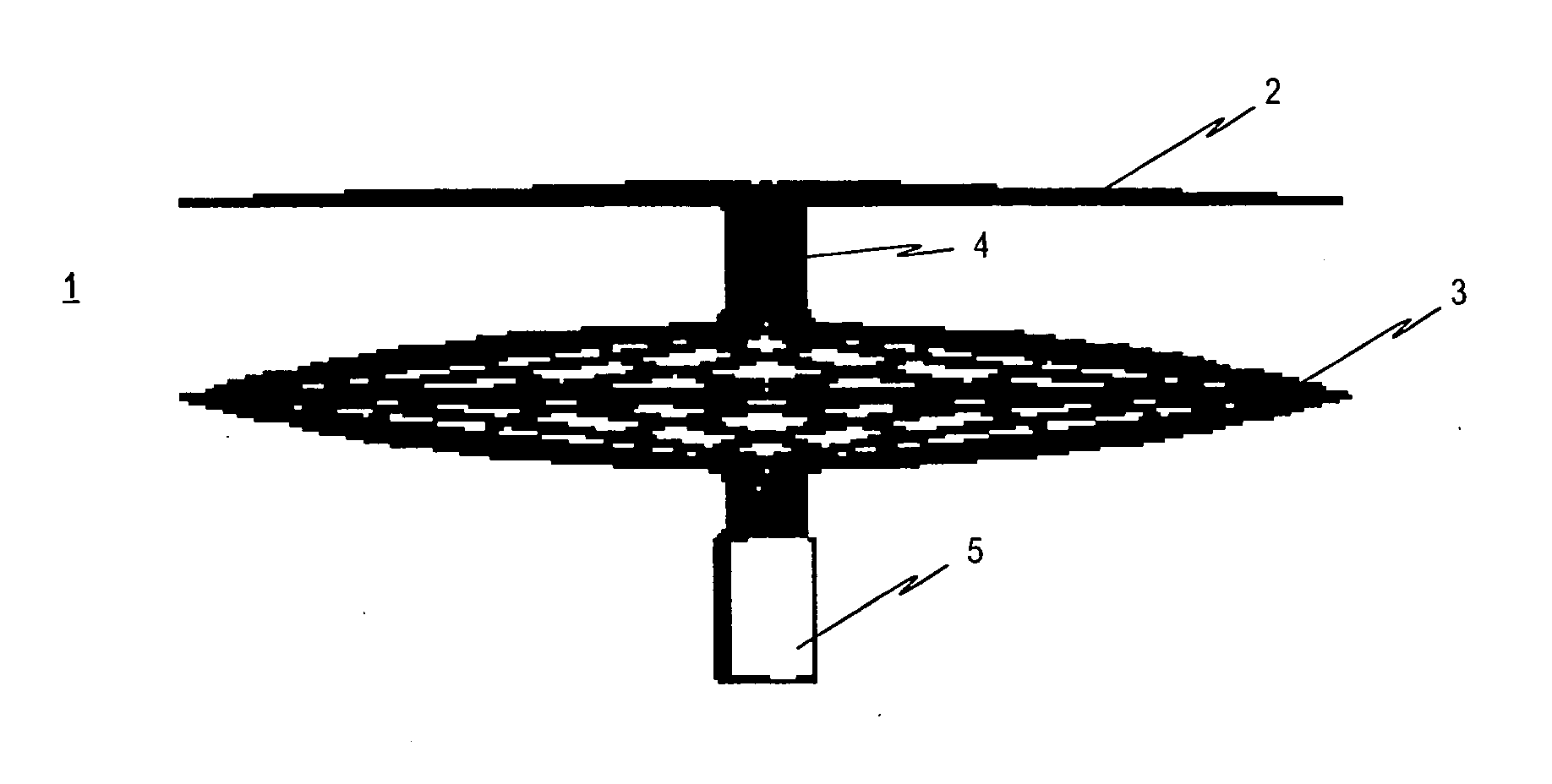

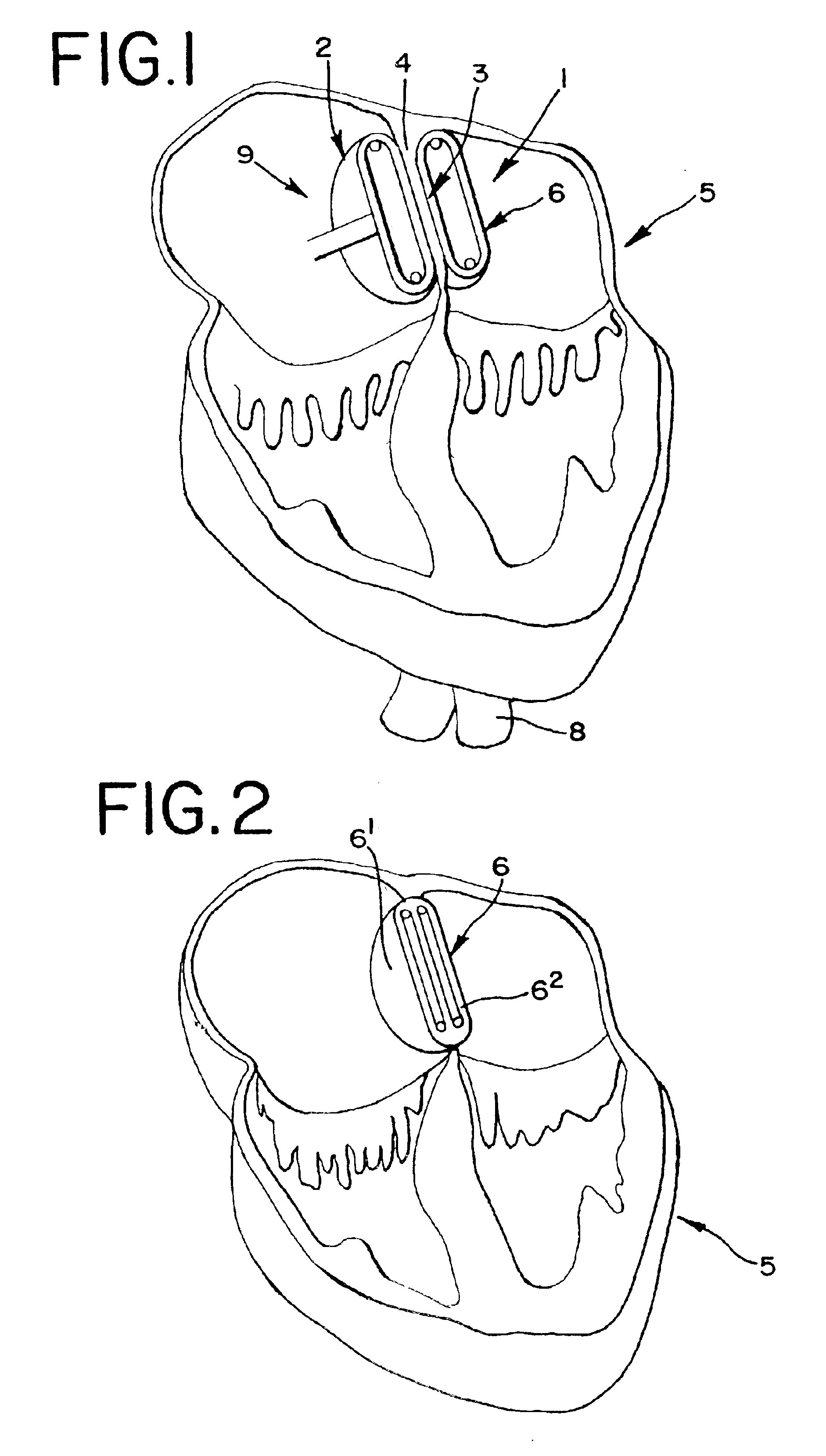

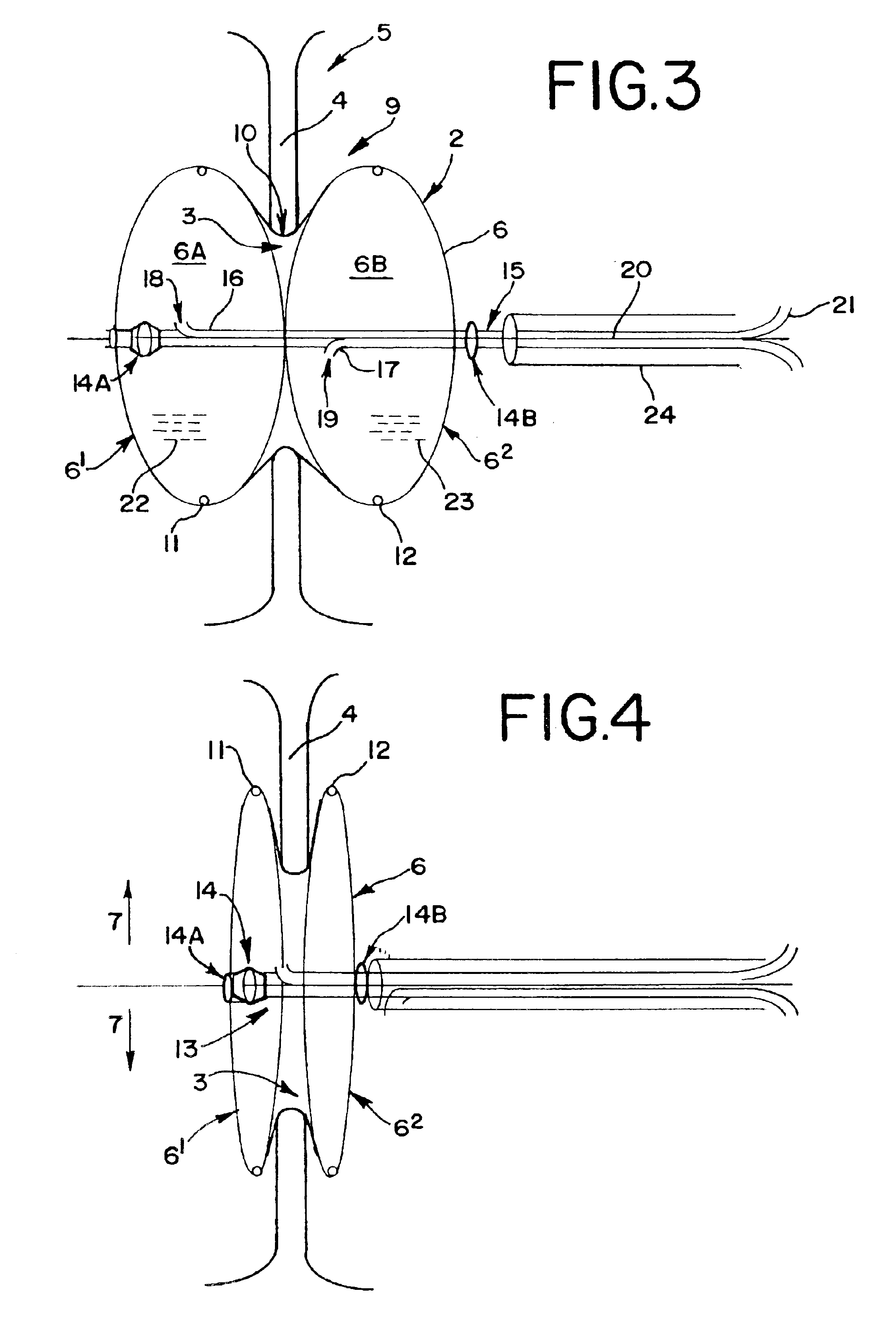

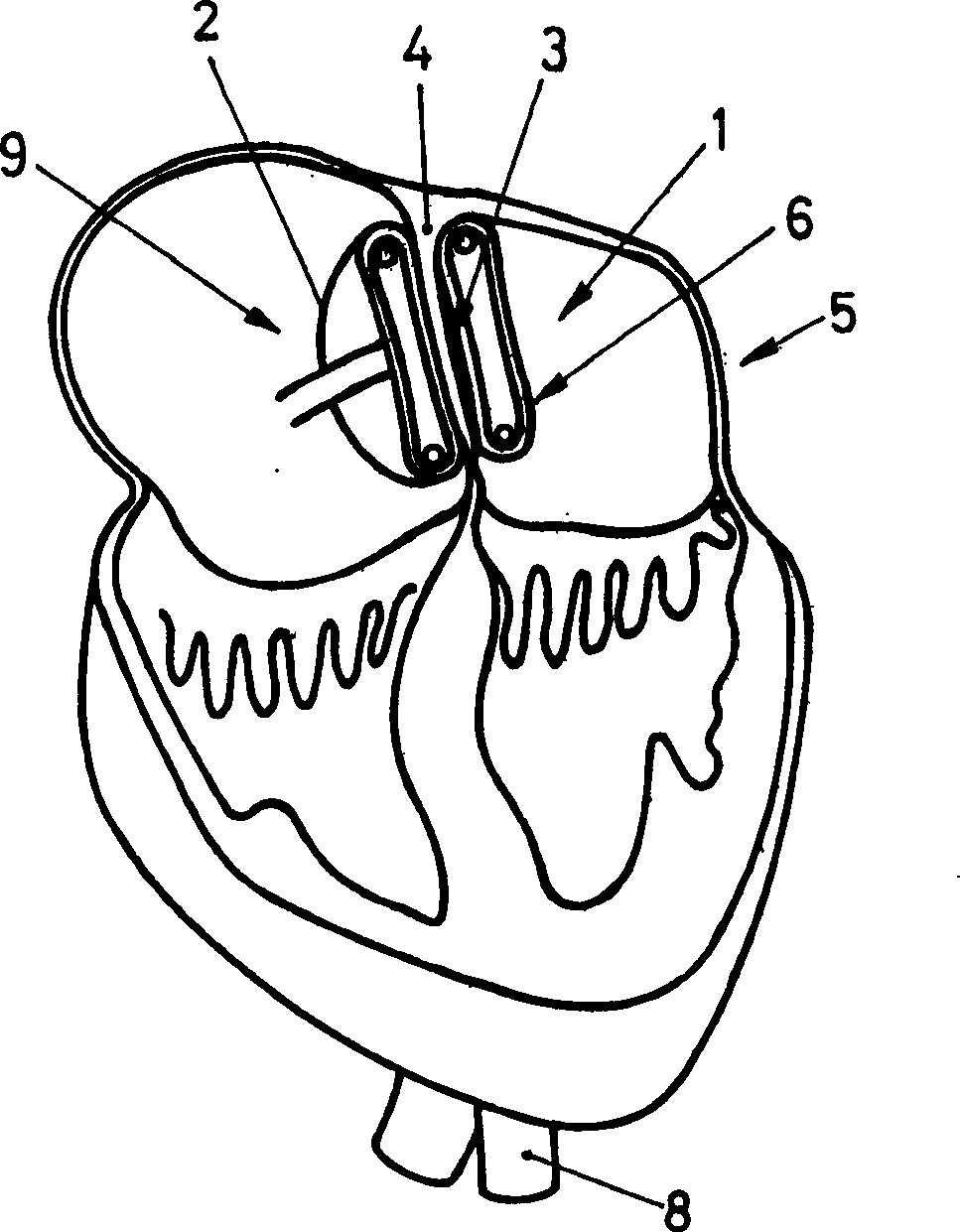

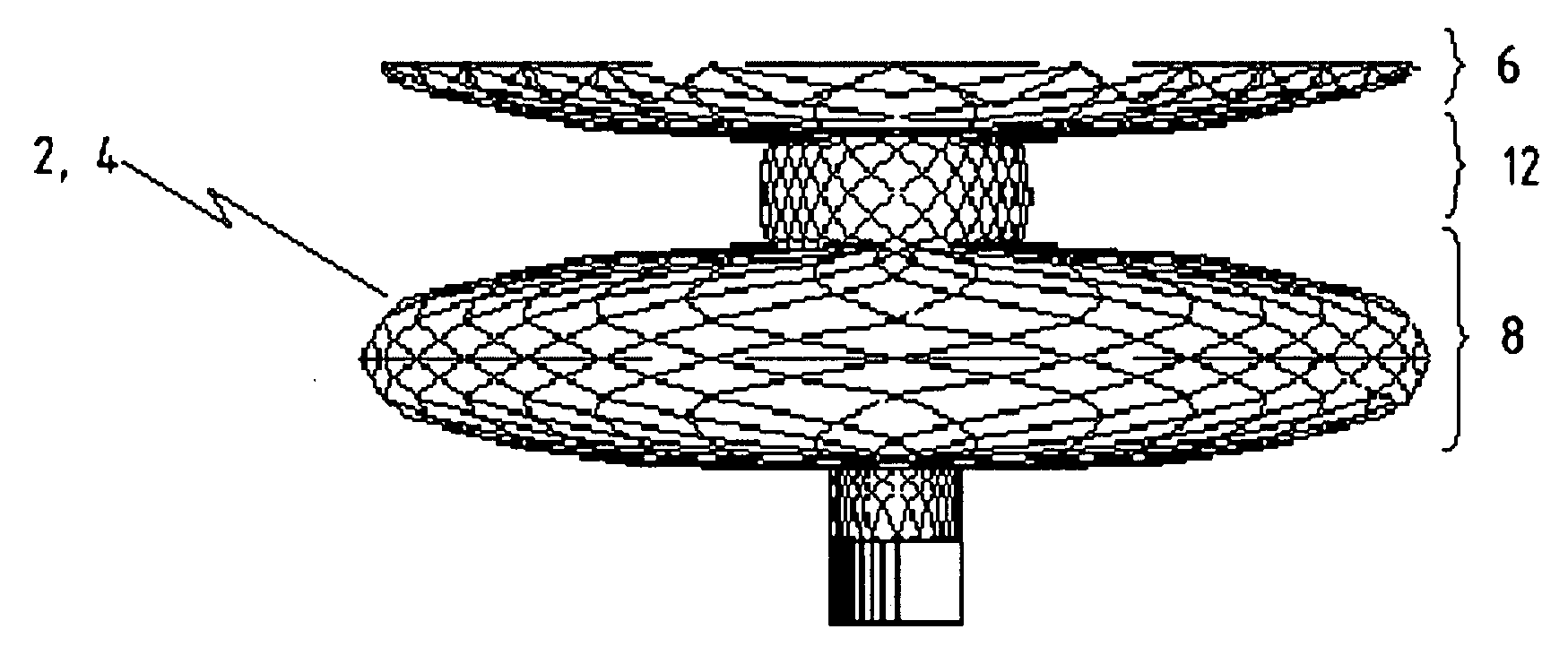

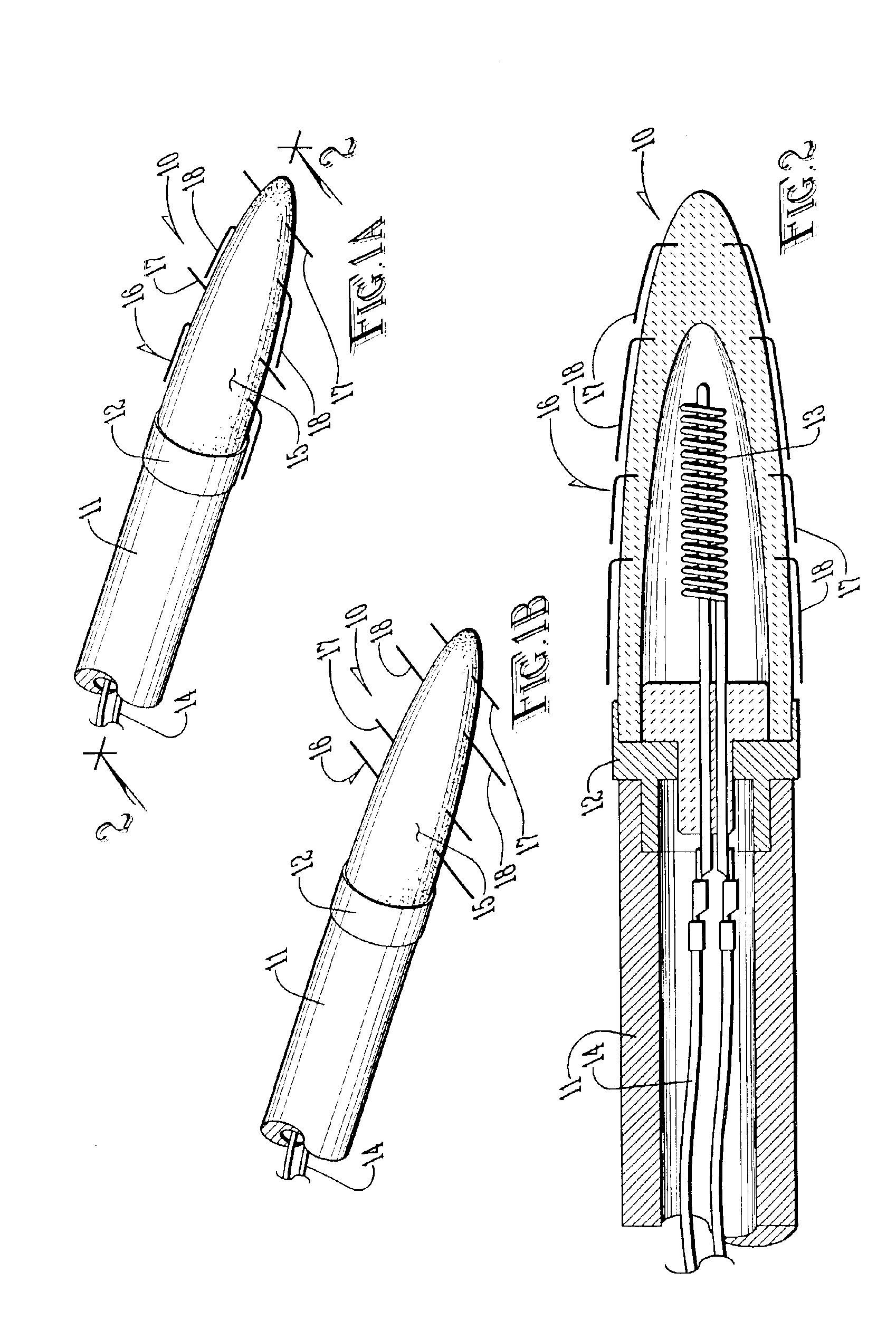

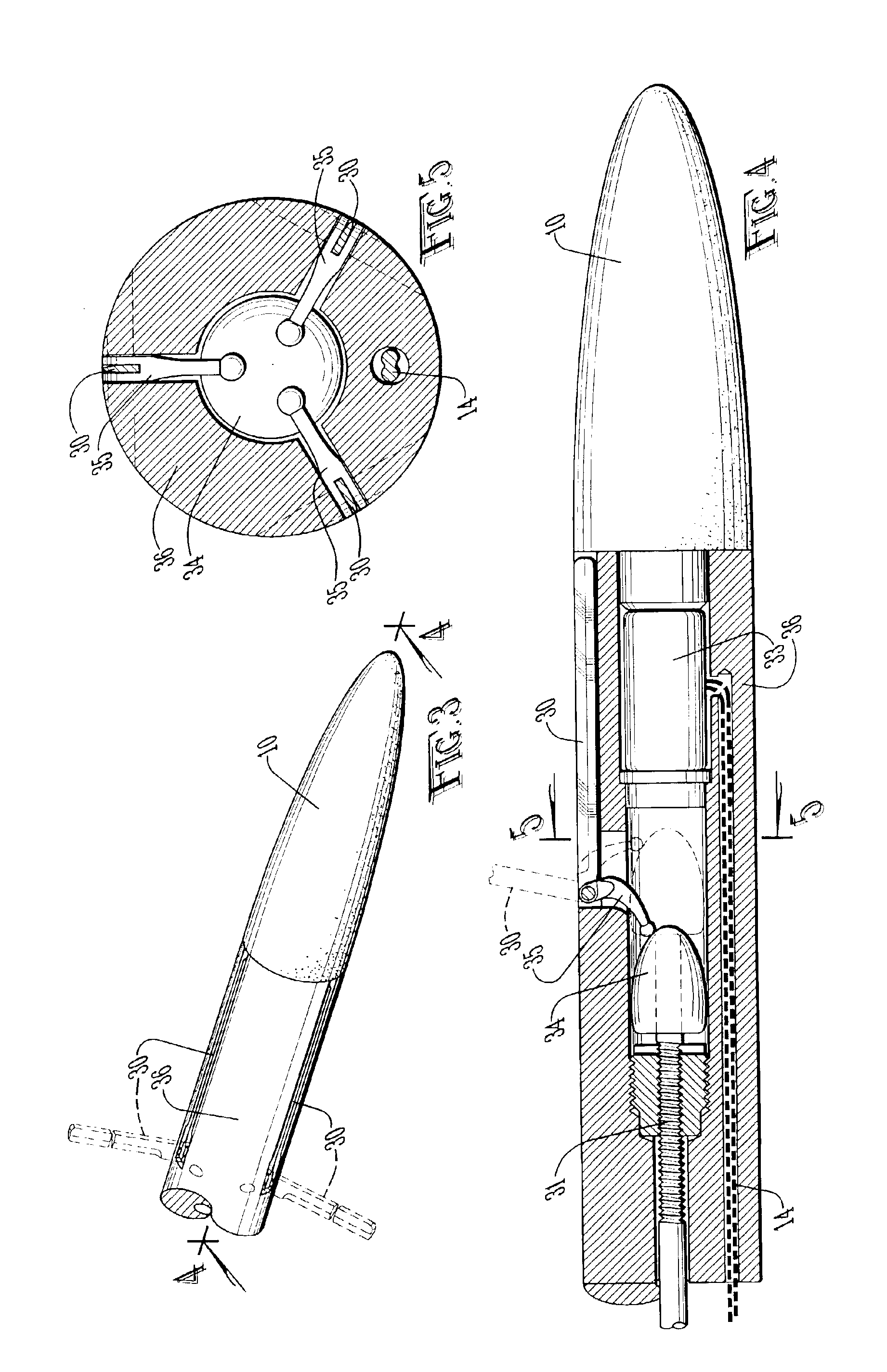

Device for plugging an opening such as in a wall of a hollow or tubular organ including biodegradable elements

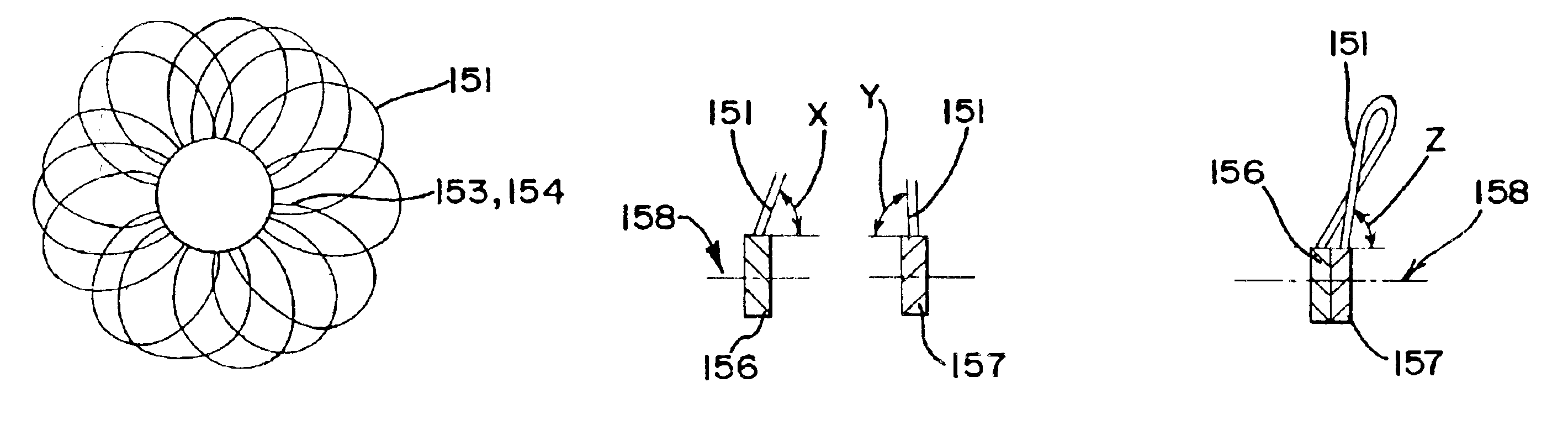

An implant for occluding a passage in a circulatory system is provided. The implant in one form includes a plurality of thin wire-like members each having a proximal and a distal end and a first holder to which the distal ends of the members are attached. The proximal ends of the members are attached to a second holder. The implant includes an expansible occluding body attached to the members at a point intermediate the first and second holders. A carrier rod is releasably attached to the first holder and upon which the second holder is slidably received. A driving implement is located on the carrier rod, the driving implement contacting the second holder and movable toward the first holder along the carrier rod. The members are attached to the first and second holders in a manner to cause the members to execute a twisting motion relative to the longitudinal axis to yield a plurality of generally radially extending loops combining to form a first fixation structure adjacent the distal face of the occluding body, and a second fixation structure of generally radially extending loops adjacent the proximal face of the occluding body. In another form, the implant includes a balloon structure which is expanded from within by a spring-like mechanism in situ, or by the foregoing radially extending loop mechanism.

Owner:CARAG AG

A device for plugging an opening such as in a wall of a hollow or tubular organ

An implant for occluding a passage in a circulatory system is provided. The implant in one form includes a plurality of thin wire-like members each having a proximal and a distal end and a first holder to which the distal ends of the members are attached. The proximal ends of the members are attached to a second holder. The implant includes an expansible occluding body attached to the members at a point intermediate the first and second holders. A carrier rod is releasably attached to the first holder and upon which the second holder is slidably received. A driving implement is located on the carrier rod, the driving implement contacting the second holder and movable toward the first holder along the carrier rod. The members are attached to the first and second holders in a manner to cause the members to execute a twisting motion relative to the longitudinal axis to yield a plurality of generally radially extending loops combining to form a first fixation structure adjacent the distal face of the occluding body, and a second fixation structure of generally radially extending loops adjacent the proximal face of the occluding body. In another form, the implant includes a balloon structure which is expanded from within by a spring-like mechanism in situ, or by the foregoing radially extending loop mechanism.

Owner:CARAG AG

Occlusion device and surgical instrument and method for its implantion/explantation

InactiveUS20080015619A1Seating of the implant can be checkedEasy to operateSurgical veterinaryWound clampsSurgical departmentBlood vessel

An occlusion device includes a braiding of thin wires or threads tapering to the diameter of a catheter used for an intravascular implantation / explantation procedure and having a proximal retention area, a distal retention area at which ends of the wires or threads converge into a holder, and a cylindrical crosspiece interposed between the proximal retention area and the distal retention area, whereby the two retention areas are positioned on two sides of a shunt to be occluded in a septum following implantation while the crosspiece transverses the shunt. The holder exhibits a head section at its free end having an eyelet as a cross-hole which can be gripped and held in form-fit fashion by an implantation / explantation instrument. A surgical instrument having such a holder includes gripper tongs with gripping jaws which open and close by a push / pull system, and which force-fit grips the head section of the holder.

Owner:OCCLUTECH GMBH

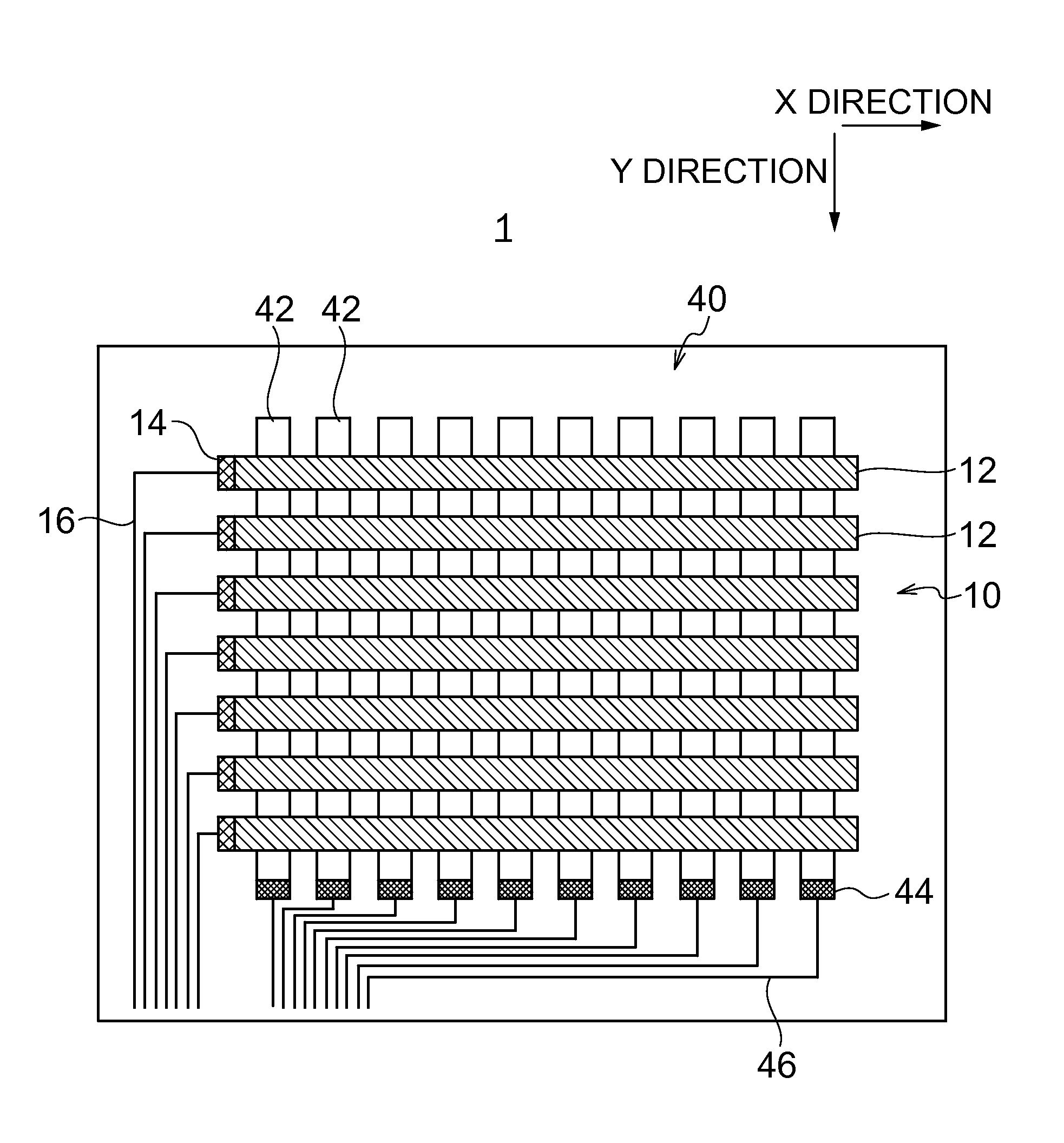

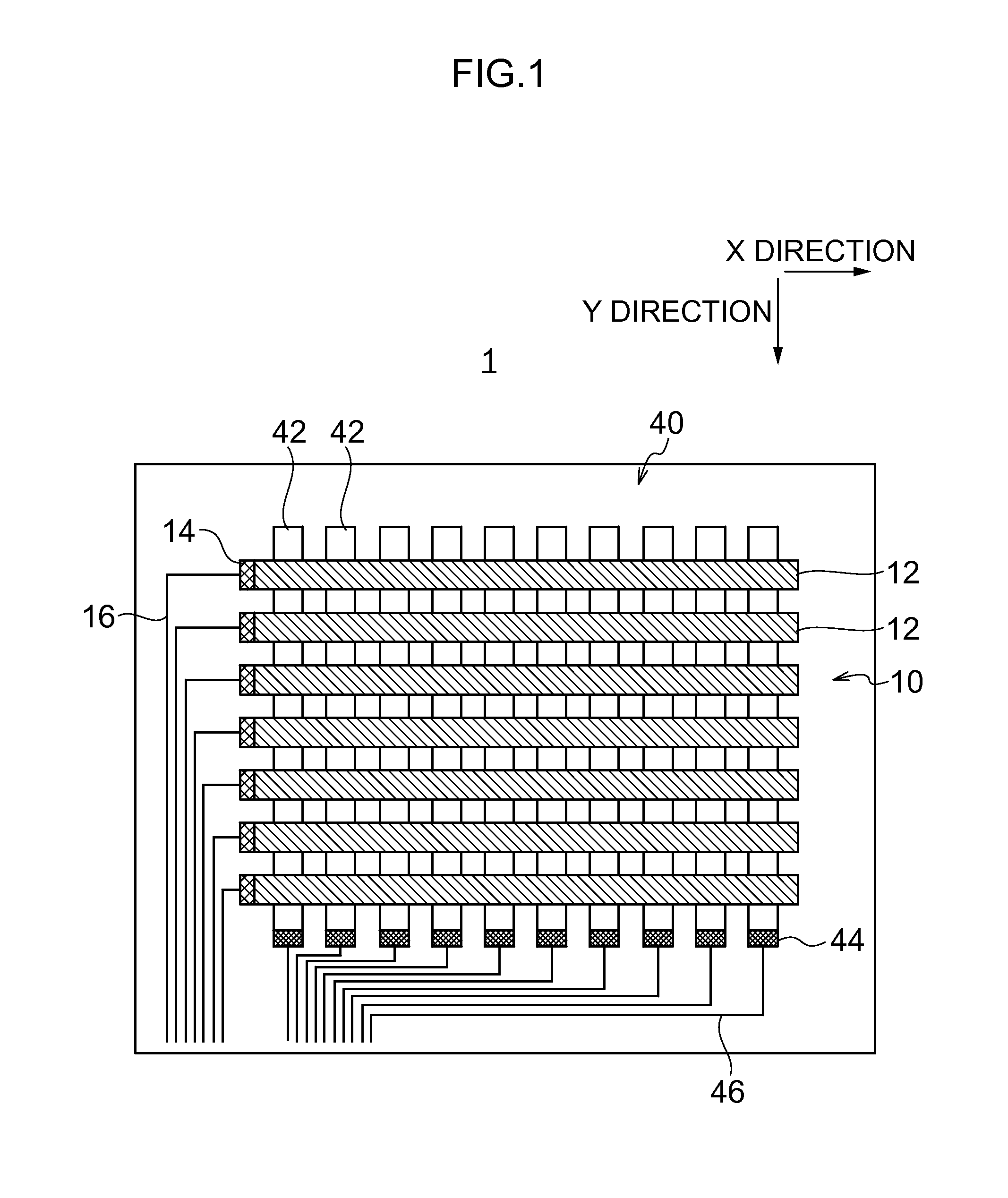

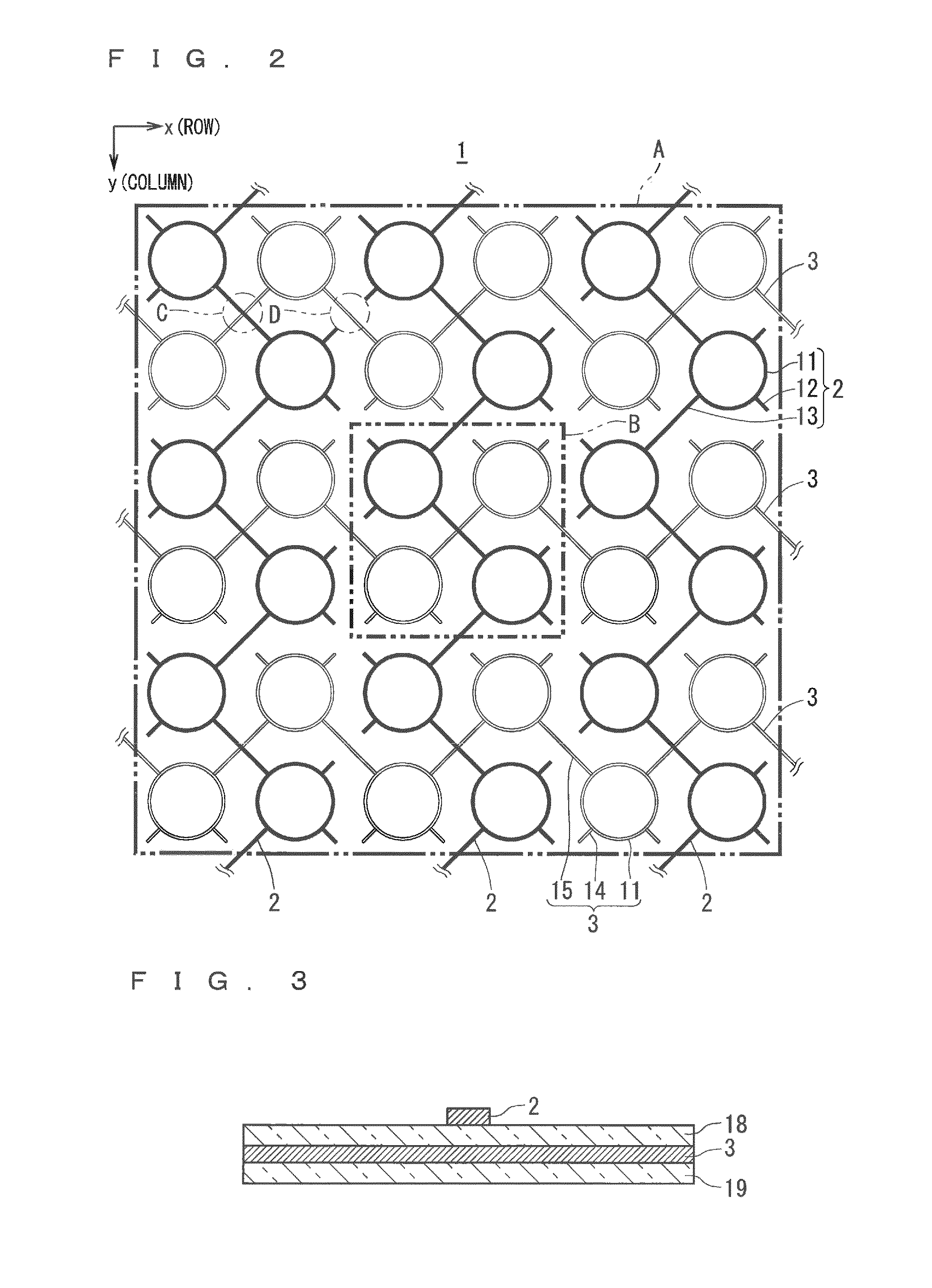

Conductive sheet and touch panel

ActiveUS20140299361A1Improve visibilityImprove detection accuracyCircuit optical detailsTransparent dielectricsEngineeringTouch panel

A conductive sheet includes: a substrate having a first main surface and a second main surface; and a first electrode pattern placed on the first main surface of the substrate. The first electrode pattern is made of metal thin wires, and includes a plurality of first conductive patterns that extend in a first direction. Each first conductive pattern includes, at least, inside thereof, a sub-nonconduction pattern that is electrically separated from the first conductive pattern. An area A of each first conductive pattern and an area B of each sub-nonconduction patterns satisfy a relation of 5%<B / (A+B)<97%. Accordingly, a conductive sheet and a touch panel having a high detection accuracy can be provided.

Owner:FUJIFILM CORP

Transparent camera calibration tool for camera calibration and calibration method thereof

InactiveUS20050280709A1Accurate CalibrationTelevision system detailsImage analysisLight beamComputer vision

The calibration tool of the present invention is a transparent camera calibration tool in which a plurality of indicator points is spatially distributed and fixed, wherein the indicator points are formed as intersecting points of thin wires extended to the frame by varying the position of the thin wires in the thickness direction and the indicator points are formed as groups of intersecting points of thin wires rendered by extending a plurality of parallel thin wire groups in different directions. The indicator groups are arranged in at least two sets in a non-coplanar relationship and embodied by distributing distinguishable minute particles in a transparent raw material or by marks or similar in the surface of the raw material. Further, a plurality of cameras arranged separately from one another are calibrated in the same coordinate system by using the transparent camera calibration tool, plate tools that are added thereto, and light beams.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

Network conductor and its production method and use

ActiveUS20040150326A1Excellent charge injection propertyLow resistivityConductive layers on insulating-supportsDischarge tube luminescnet screensNetwork structureEngineering

A network conductor has an irregular network structure with as thin lines as 10 nm to 10 mum. The network conductor is obtained by forming a thin film on a substrate; forming microcracks in a network manner in the thin film; and forming a layer of a conductive material in the microcracks. The network conductor can be used for a positive electrode and / or a negative electrode of an organic electroluminescence device.

Owner:FUJIFILM CORP +1

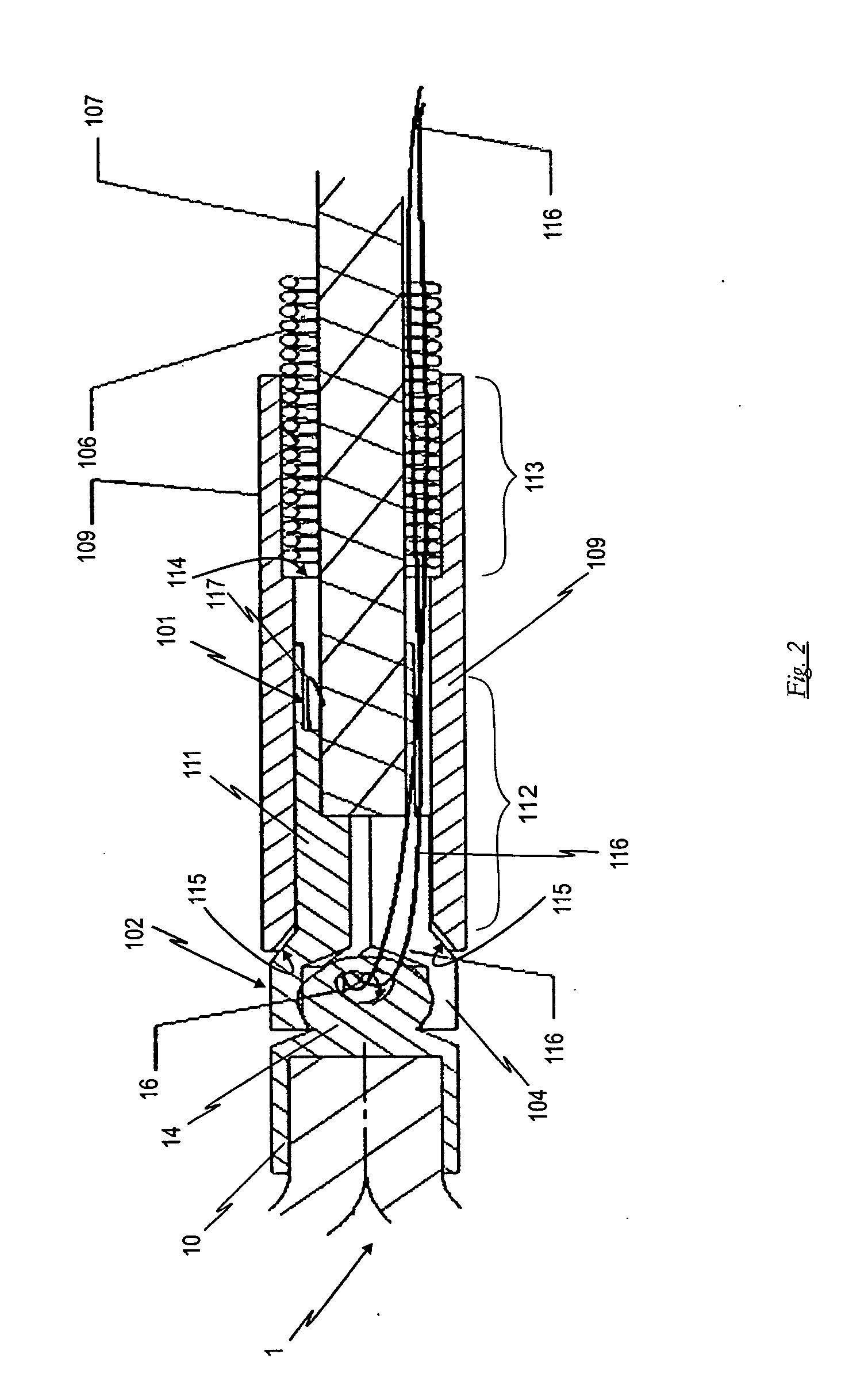

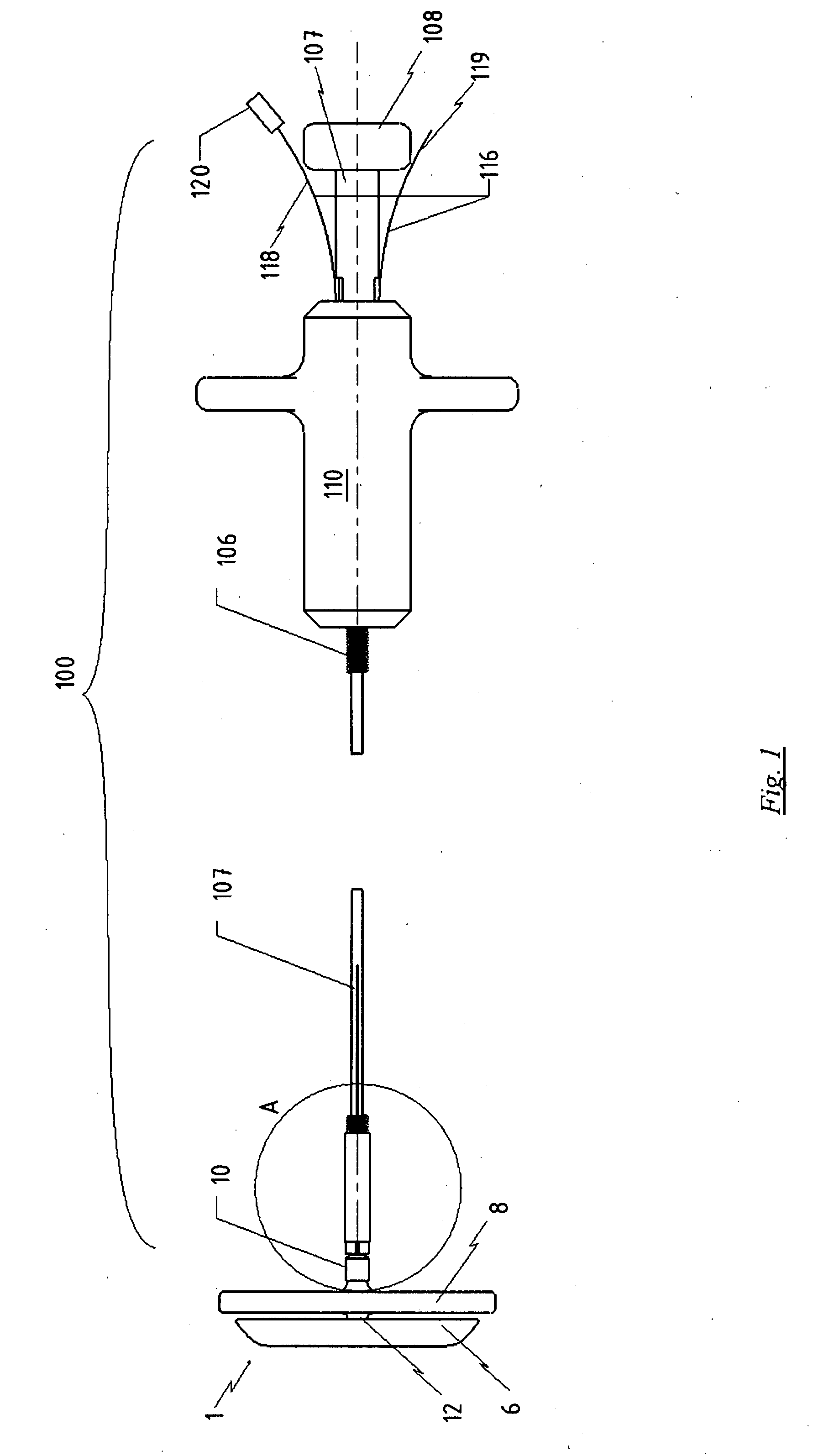

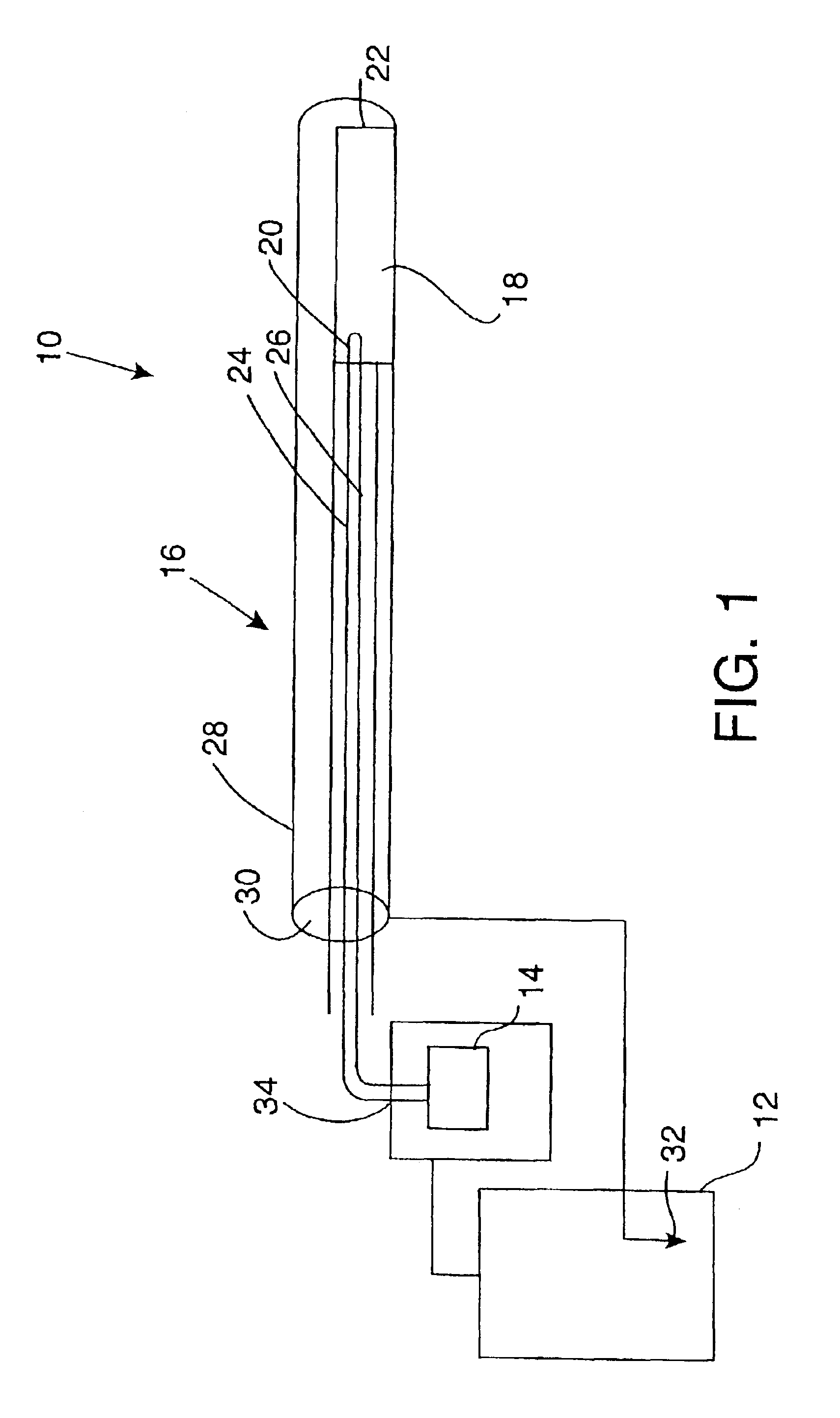

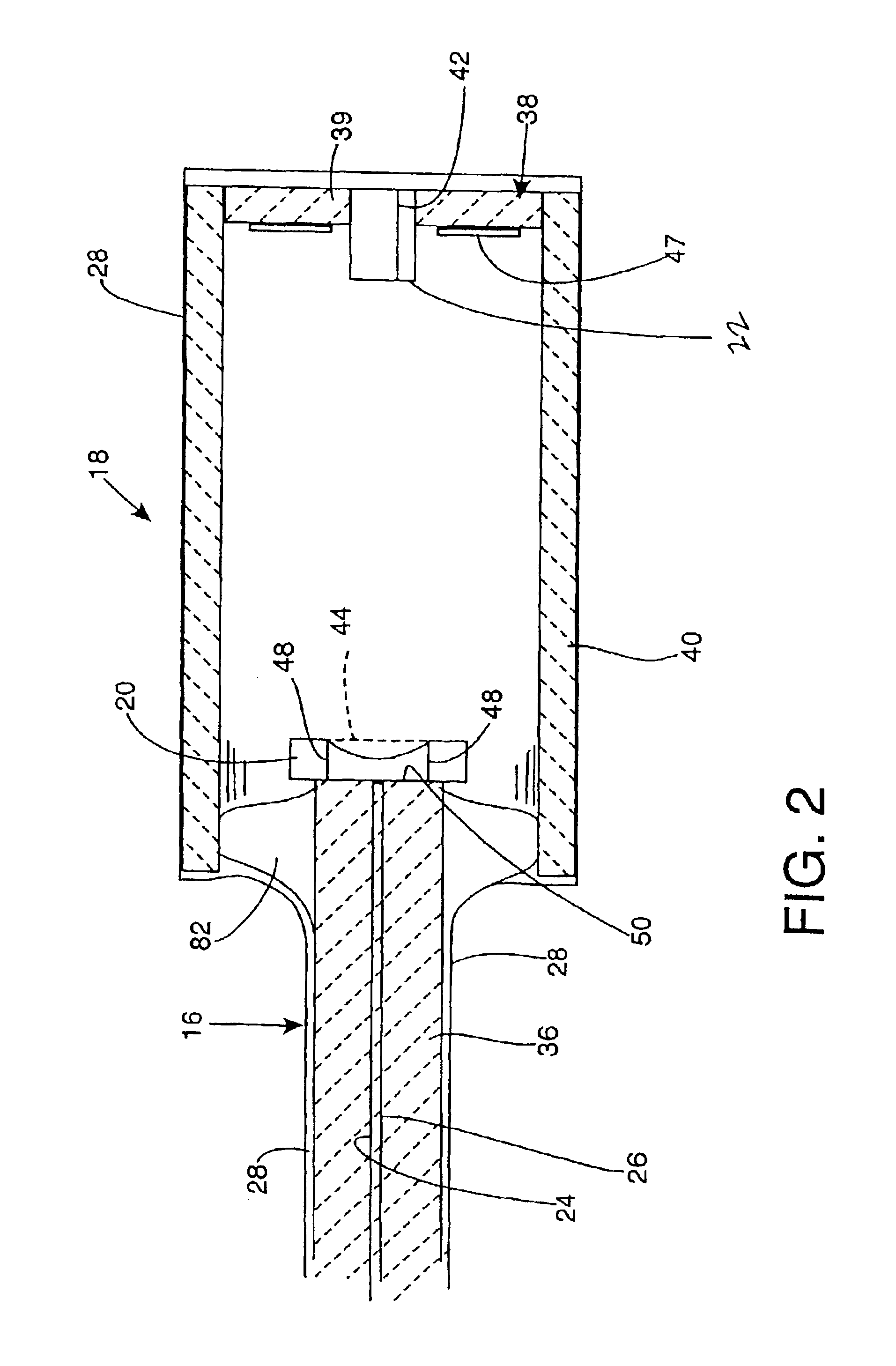

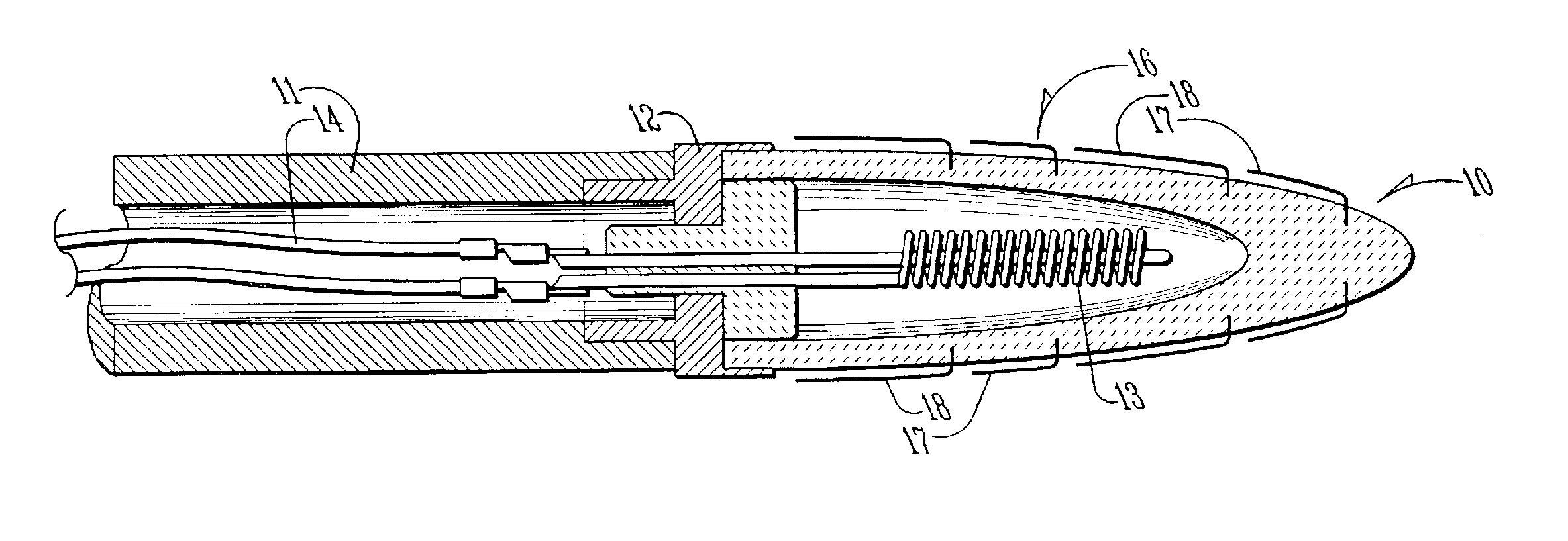

Miniature x-ray tube with micro cathode

ActiveUS6987835B2Reduces conductor size requirementHigh field gradientX-ray tube electrodesVessels or leading-in conductors manufactureElectricityElectrical conductor

A miniature x-ray tube capable of intra vascular use, has a micro cathode preferably formed by MEMS techniques. The very fine wire of the cathode filament is formed on a semiconductor base and draws a current sufficiently low that lead wires in a cathode heater circuit, passing through a probe line connected to the x-ray tube, can be very small wires, which helps maintain sufficient dielectric spacing in the high voltage circuit handled by the same probe line. In a preferred embodiment the probe line comprises a glass fiber, held at a small diameter to allow flexibility for navigating small-radius turns within the vessels. In a preferred embodiment the fiber is overcoated with a high-dielectric polymer to significantly increase the dielectric strength of the overall cable, without adding significantly to stiffness. The high voltage ground conductor is a coaxial sheath on the outside of the polymer. Exterior to the ground conductor is a further flexible layer having paths for coolant.

Owner:XOFT INC

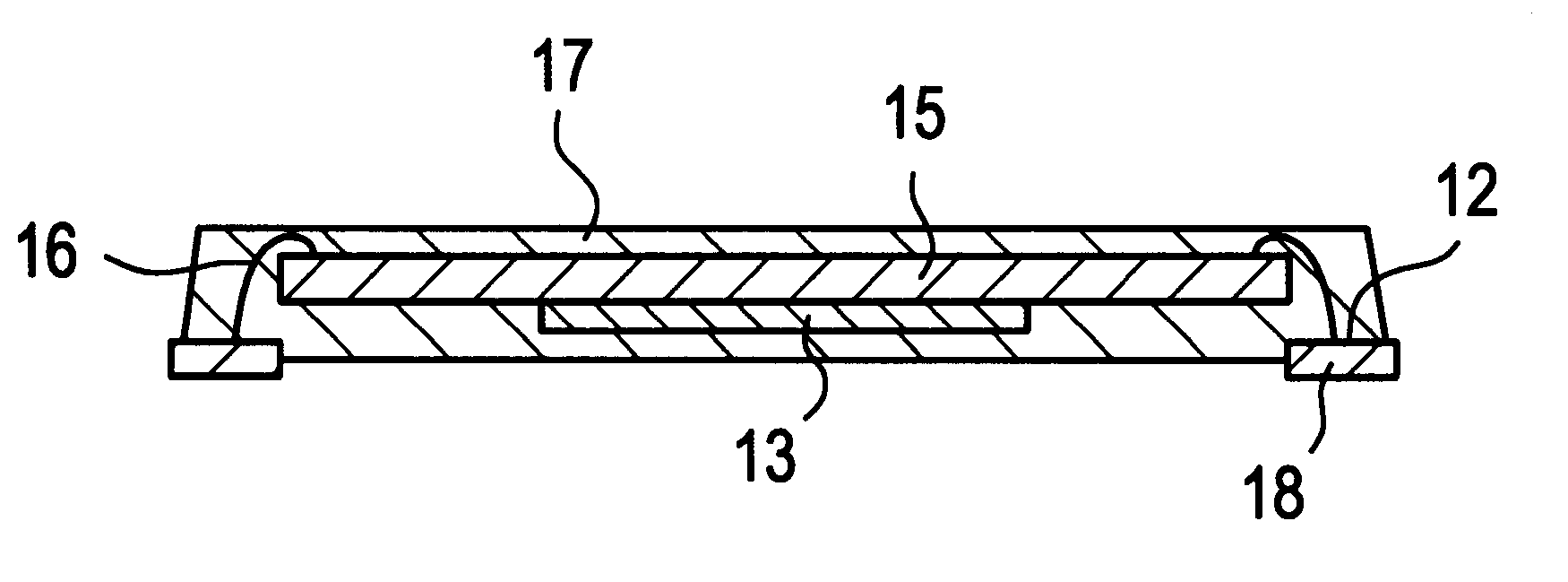

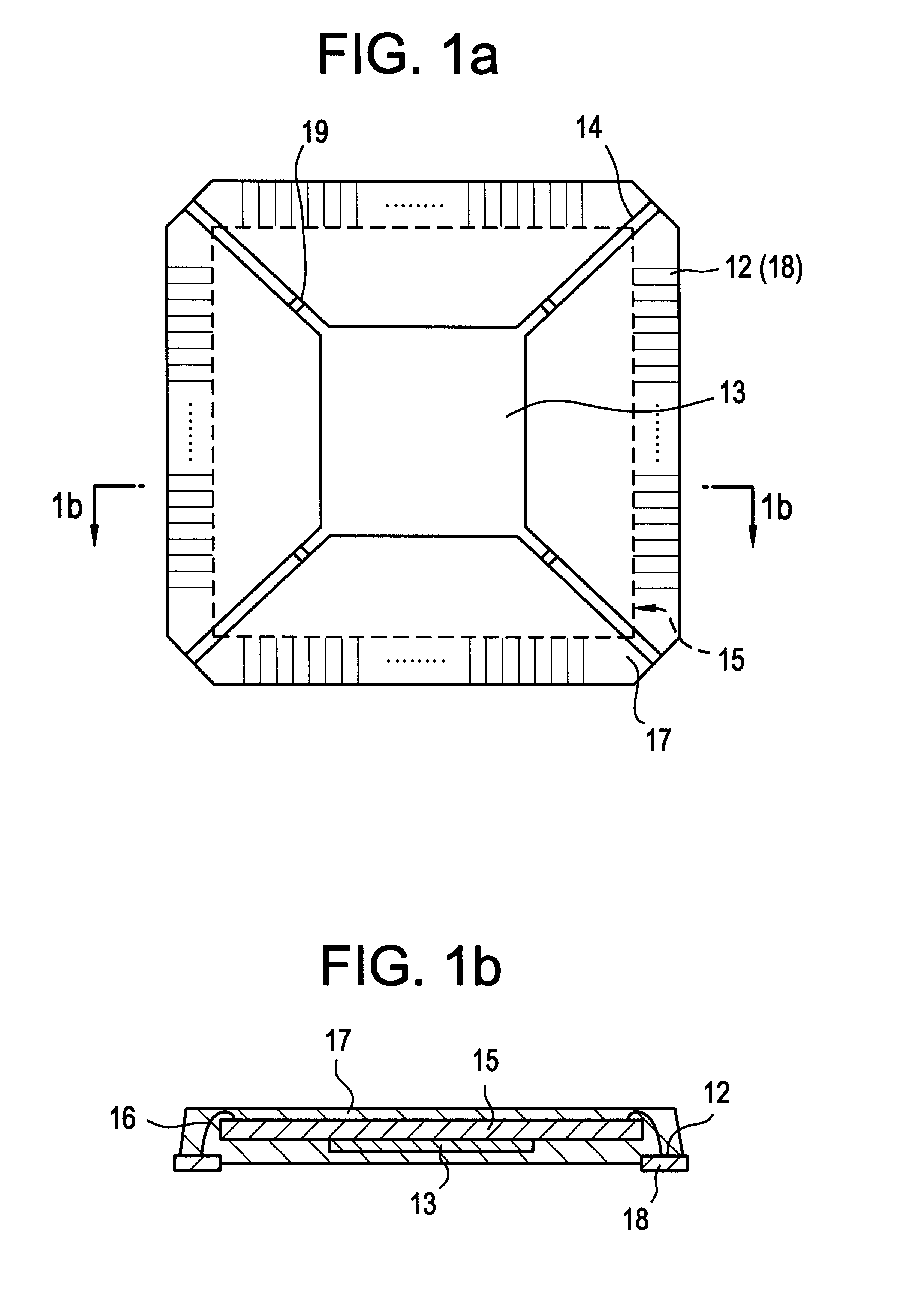

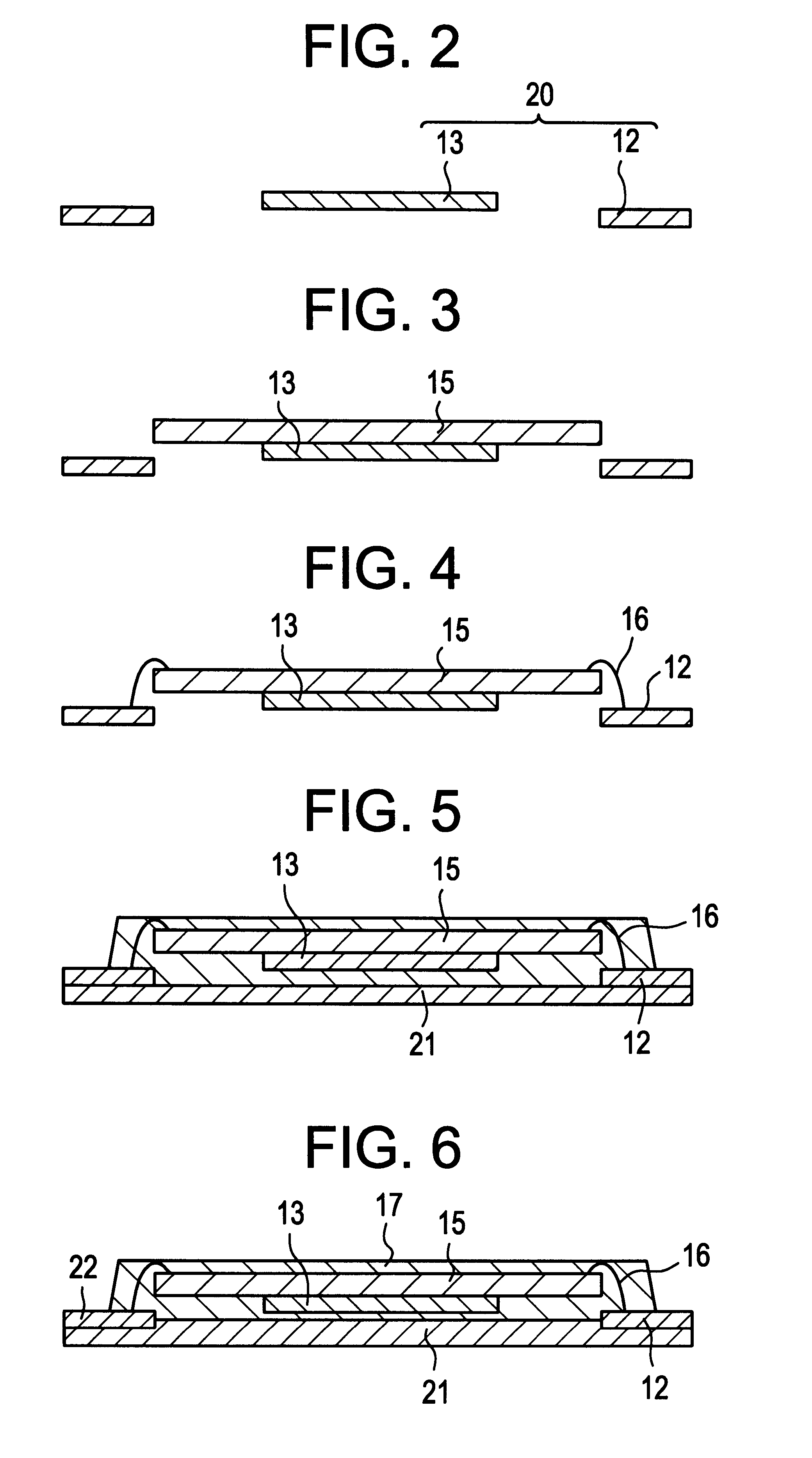

Resin molded semiconductor device and method for manufacturing the same

InactiveUS6291274B1Well formedHigh strengthSemiconductor/solid-state device detailsSolid-state devicesShell moldingSemiconductor chip

A method for manufacturing a semiconductor chip (15) which is bonded on a die pad (13) of a leadframe, and inner leads (12) are electrically connected to electrode pads of the semiconductor chip (15) with metal fine wires (16). The die pad (13), semiconductor chip (15) and inner leads are molded with a resin encapsulant (17). However, no resin encapsulant (17) exists on the respective back surfaces of the inner leads (12), which protrude downward from the back surface of the resin encapsulant (17) so as to be external electrodes (18).

Owner:PANASONIC CORP

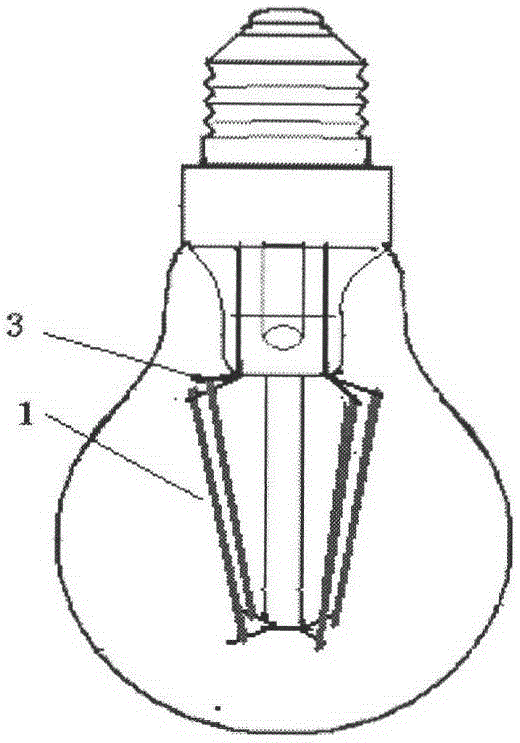

Connection and installation method for LED filaments

ActiveCN105371243AReduce damage rateReduce stressPoint-like light sourceLight fasteningsElectrical polarityEngineering

The invention provides a connection and installation method for LED filaments. The connection and installation method is used for assembling wicks in filament type LED bulbs. As the difference from the prior art of welding the lead-out ends of the LED filaments to a guide wire of a glass core column through a spot welding method, the electrode lead-out ends of the LED filaments are connected through elastic metal thin wire spiral parts, and therefore the LED filaments are connected in series one by one in an end-to-end manner according to the polarity to form a multi-joint LED filament series-connection system which can be bent. Then, the metal thin wire spiral parts at the head lead-out end and the tail lead-out end of the filament series-connection system are clamped on and fixed to corresponding core column side rod guide wires, and the metal thin wire spiral parts between the adjacent filaments are placed on corresponding filament hooks on the core column one by one so that the filaments can be arranged in order. By means of the connection and installation method, the defects that in the prior art, due to spot welding, the production efficiency is low, the finished product rate is low, and filament stress is large are overcome, and the production efficiency of filament type LED bulbs can be easily improved and the finished product rate of the filament type LED bulbs can be easily increased.

Owner:厦门银旭工贸有限公司

Lightning strike protection system for aircraft fuel tanks made of low electrical conductivity composite material

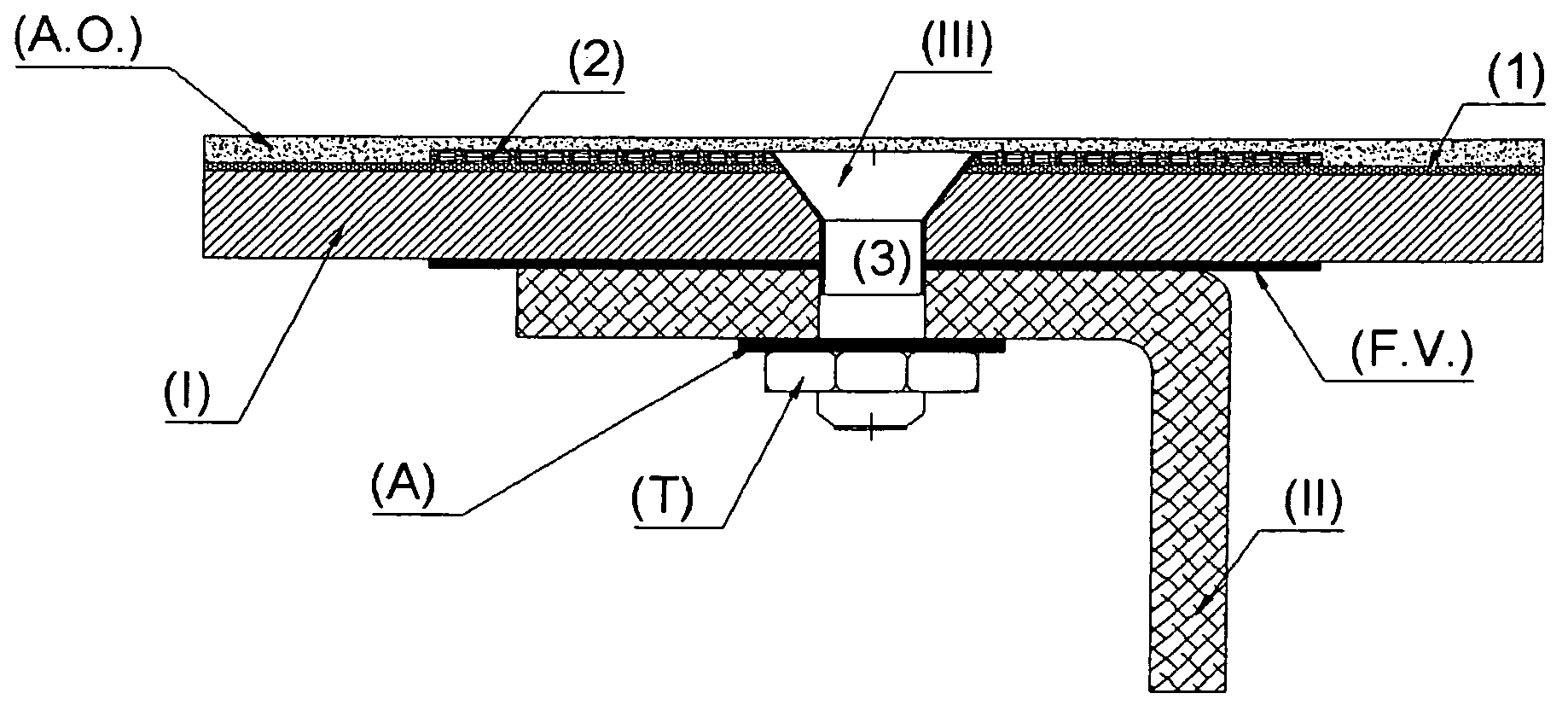

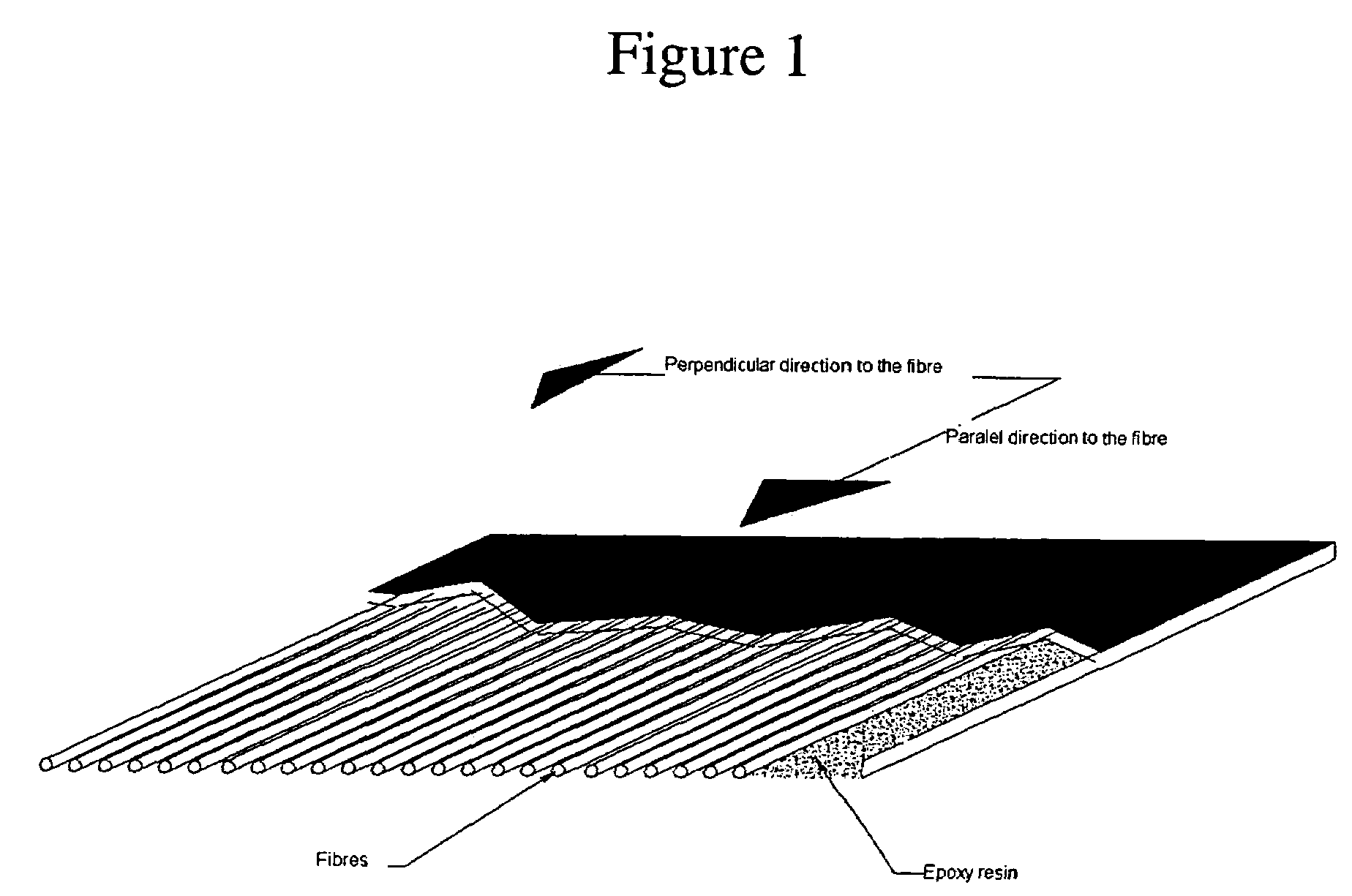

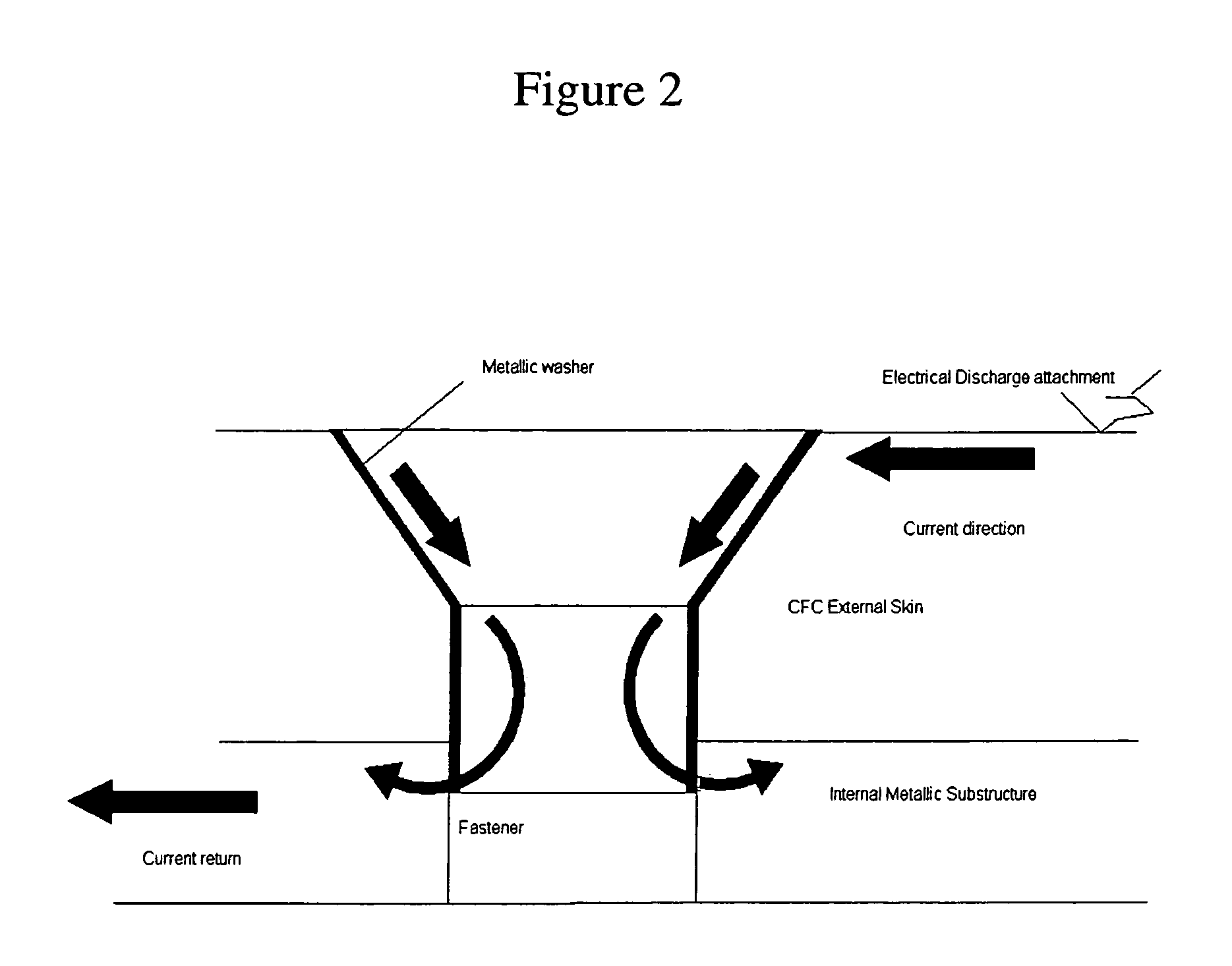

ActiveUS7307825B2Severe structural damage can be avoidedMinimize damageFuel tank safety measuresAircraft lighting protectorsLightning strikeFuel tank

Lightning strike protection system for aircraft fuel tanks made of low electrical conductivity composite material. The system comprises an electrical conductive thin wire mesh (1) that covers the whole external surface of the tank outer skin (I) made of composite and a thick wire metallic mesh (2) overlapping the mesh (1) at a minimum distance of 50 mm to both sides of a row of fasteners (III) joining the said outer skin (I) to one internal part (II) of either composite or metallic material. Both metallic meshes (1, 2) maintain electrical contact by their installation / assembly and by means of metallic countersunk head washers (3) connected to bonding points and set to the gap existing between the fastener (III) and the outer skin (I). The corresponding fabrication process is also described.

Owner:AIRBUS OPERATIONS SL

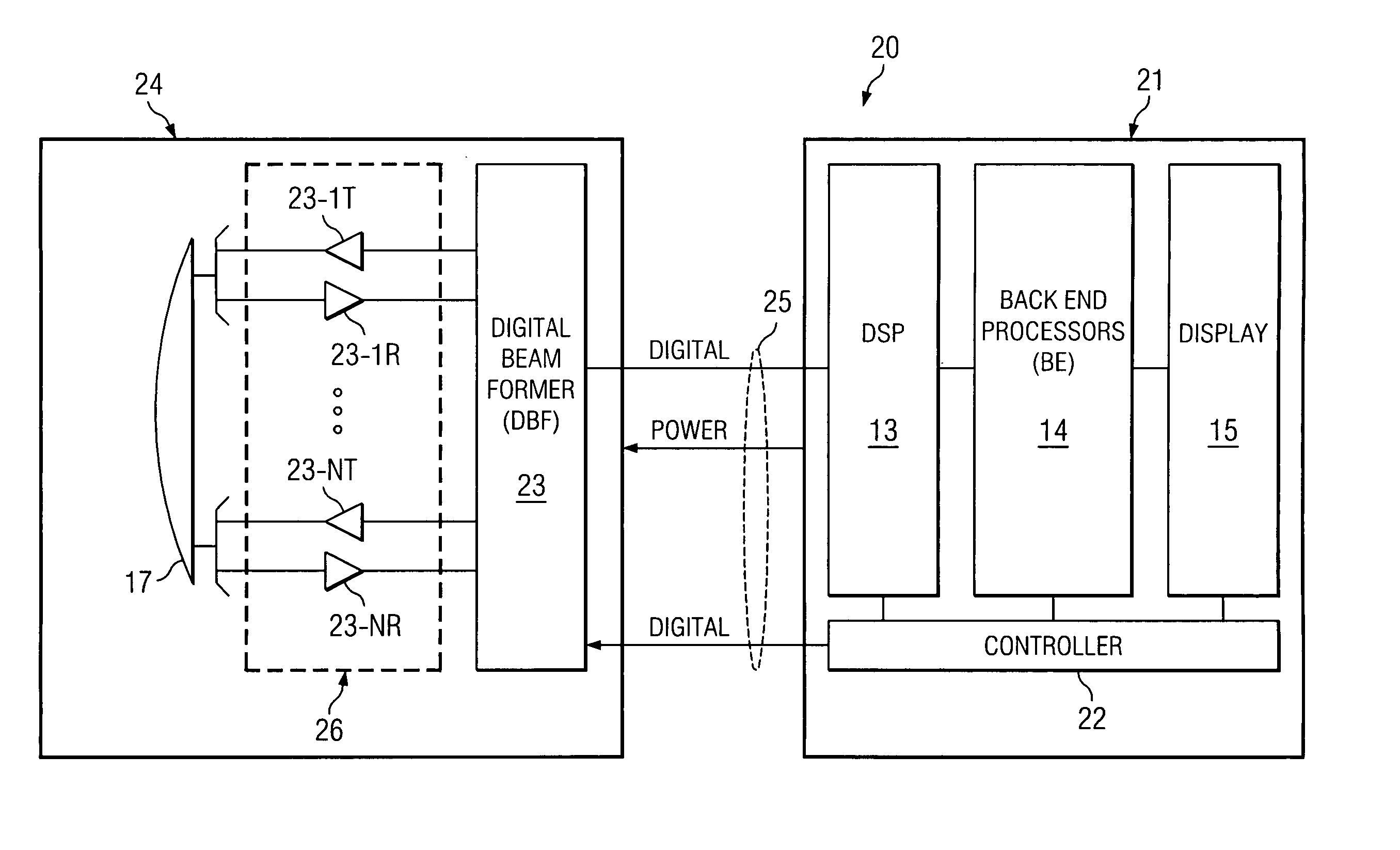

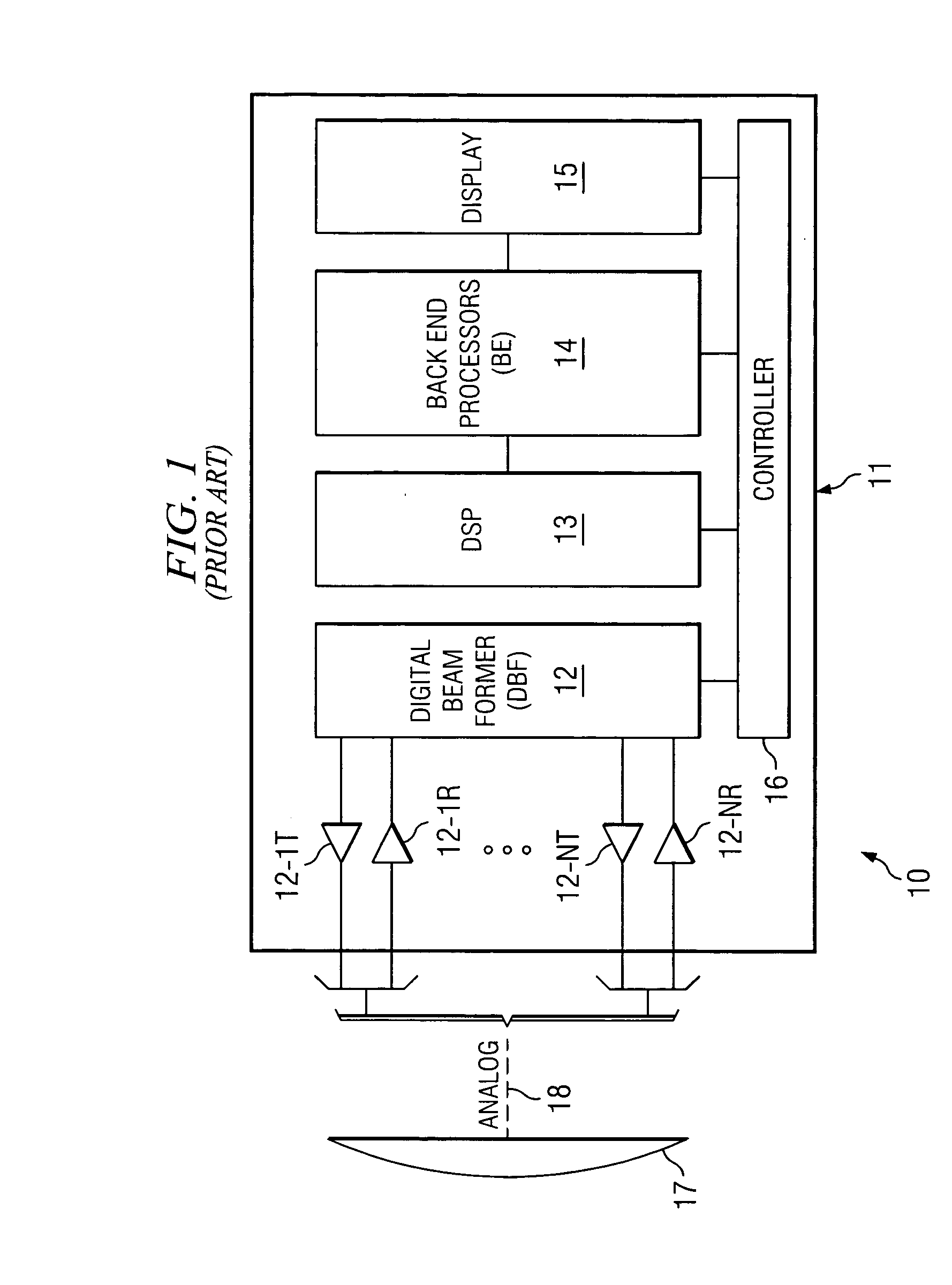

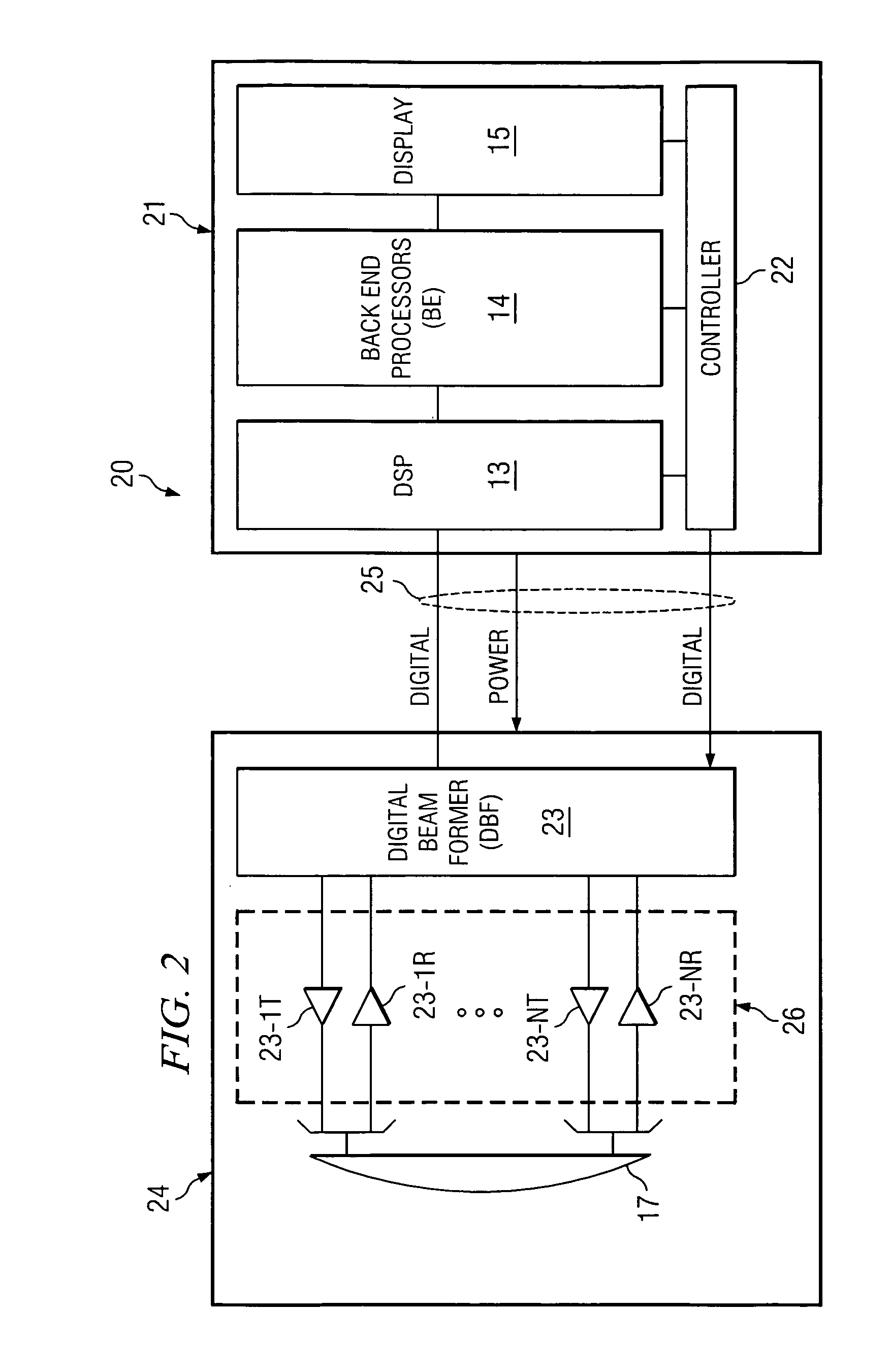

Ultrasonic transducer having a thin wire interface

InactiveUS20060058655A1Highly integratedReduce needInfrasonic diagnosticsSonic diagnosticsUltrasonic sensorSonification

The present invention is directed to an ultrasound system and method which, in one embodiment, partitions the main body processing such that a portion of the processing is contained within the transducer thereby reducing the need for a multiplicity of high performance cables running between the transducer and the main body. This is possible through the use of a unique architecture to allow for proper power management given the small transducer size and an architecture that exploits the high levels of integration possible on integrated circuit technologies allowing for its implementation in a few highly integrated circuits with virtually no external components outside of the ICs.

Owner:SONOSITE

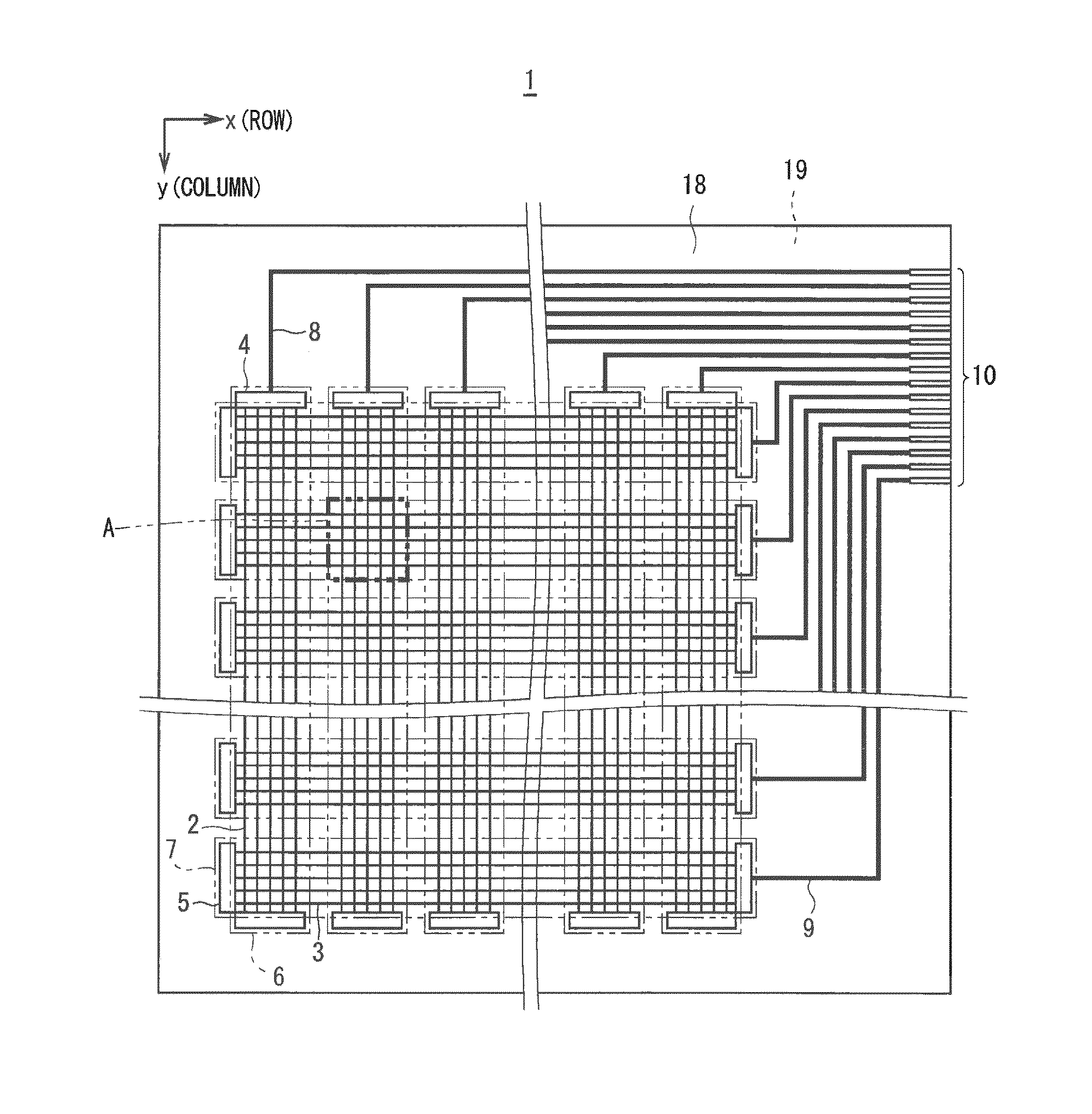

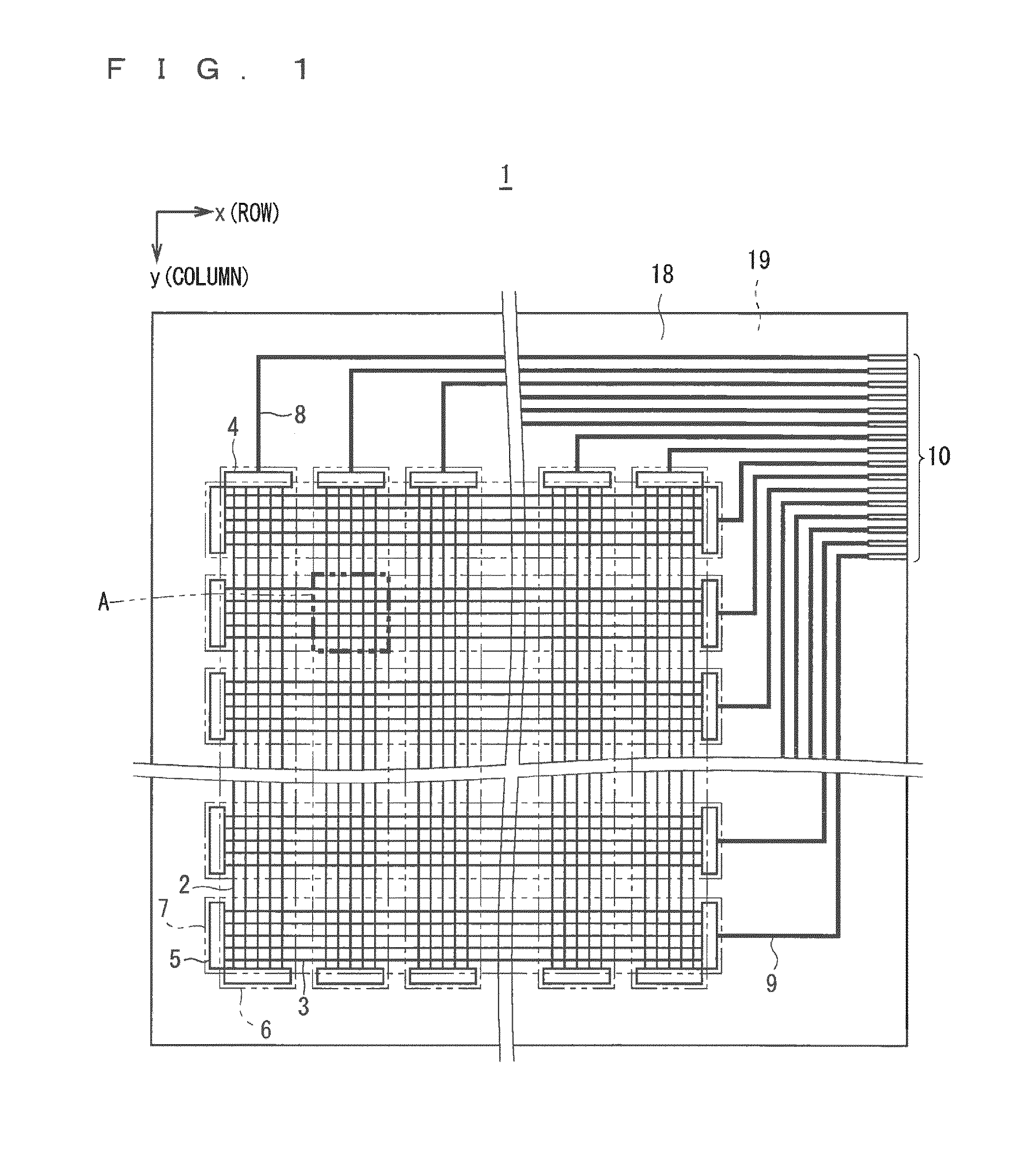

Touch screen, touch panel, display device and electronic device

ActiveUS20150002464A1Solve the broken effect is not goodReduce display unevennessCircuit optical detailsPrinted circuit aspectsDisplay deviceAlloy

Detection column wires and detection row wires are configured of thin wires made of a conductive material having light reflectivity, such as a metal or alloy including silver and aluminum. A predetermined plural number of detection column wires are electrically connected to form a plurality of column-direction bundle wires. A predetermined plural number of detection row wires are electrically connected to form a plurality of row-direction bundle wires. A reflected-light distribution pattern is further provided. When viewed in a direction vertical to the surface of the touch screen, the reflected-light distribution pattern includes a curved portion, and the normal lines of the curved portion head for all directions.

Owner:TRIVALE TECH LLC

Conductive interstitial thermal therapy device

InactiveUS6872203B2Highly predictable temperature distributionLimit on maximum temperatureSurgical instruments for heatingThermal probeFiber

An apparatus and method for thermally destroying tumors in which heat is generated by electrical resistance heating conducted to the target tissue. Computerized scanning is used to optimize the geometry of a thermal probe. The probe has a metal tip heated by a remote laser. The metal tip is mounted on the end of a wave guide fiber for transmitting the laser radiation to the metal tip. The tip is coated with a thin layer of biocompatible ceramic to avoid coagulated tissue sticking to the tip. The tip has one or more thin, thermally-conductive elements which deploy in stages to coagulate the tumor. The conductive elements may be thin wires or blades. On one embodiment, the conductive elements are composed of a shape memory material that is folded against the tip at lower temperatures and deploys at selected higher temperatures. In another embodiment, the conductive elements are blades that are deployed mechanically. The tip may be provided with a miniature thermocouple to provide temperature feedback information.

Owner:ARKANSAS CHILDRENS HOSPITAL RES INST +1

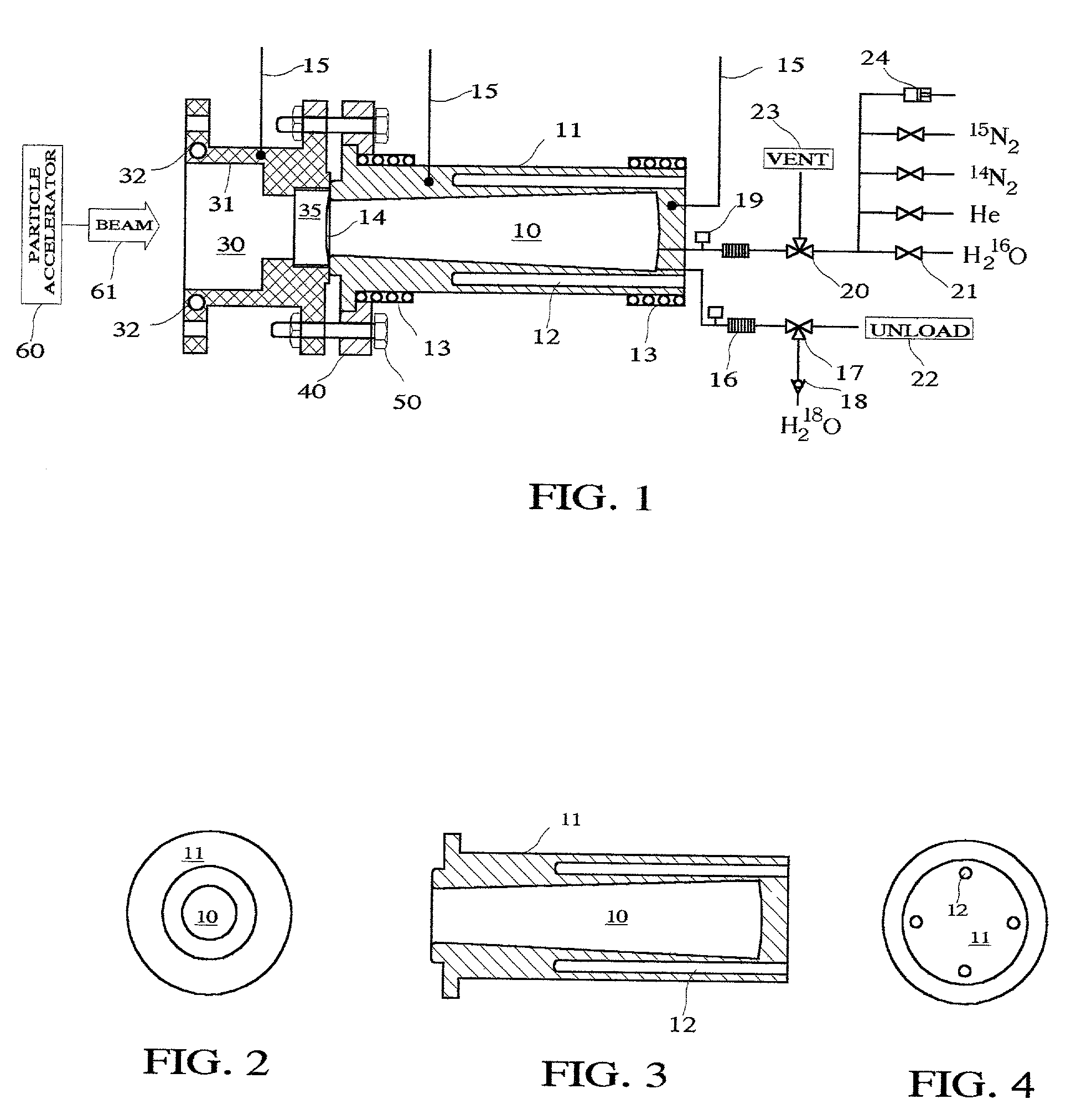

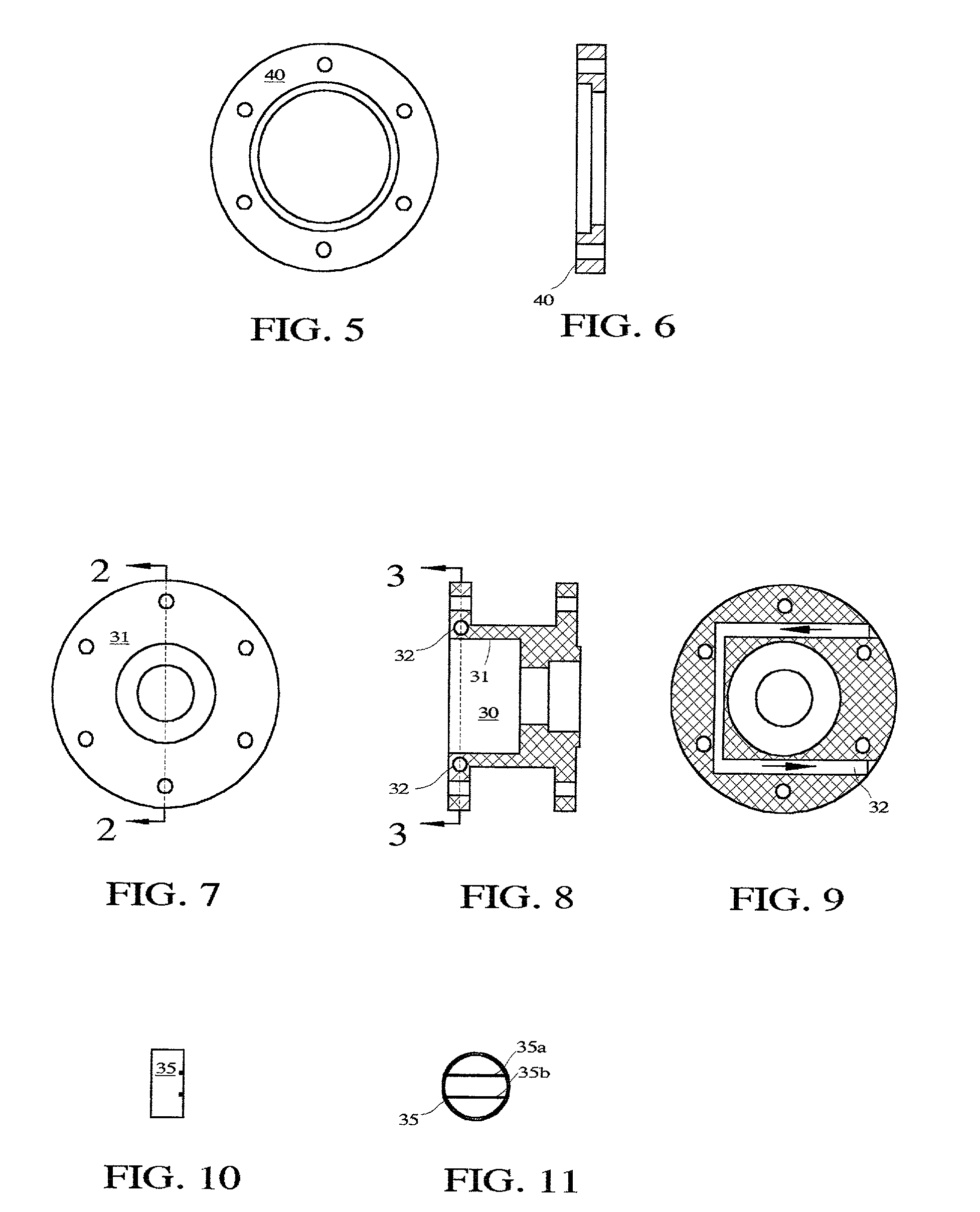

High power high yield target for production of all radioisotopes for positron emission tomography

InactiveUS20050061994A1Avoid low densitySuppress instabilityConversion outside reactor/acceleratorsNuclear monitoringCoolant flowInstability

A high power high yield target for the positron emission tomography applications is introduced. For production of Curie level of Fluorine-18 isotope from a beam of proton it uses about one tenth of Oxygen-18 water compared to a conventional water target. The target is also configured to be used for production of all other radioisotopes that are used for positron emission tomography. When the target functions as a water target the material sample being oxygen-18 water or oxygen-16 water is heated to steam prior to irradiation using heating elements that are housed in the target body. The material sample is kept in steam phase during the irradiation and cooled to liquid phase after irradiation. To keep the material sample in steam phase a microprocessor monitoring the target temperature manipulates the flow of coolant in the cooling section that is attached to the target and the status of the heaters and air blowers mounted adjacent to the target. When the target functions as a gas target the generated heat from the beam is removed from the target by air blowers and the cooling section. The rupture point of the target window is increased by a factor of two or higher by one thin wire or two parallel thin wires welded at the end of a small hollow tube which is held against the target window. One or two coils are used to produce a magnetic filed along the beam path for preventing the density depression along the beam path and suppression of other instabilities that can develop in a high power target.

Owner:AMINI BEHROUZ

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com