Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11222 results about "Structural unit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In polymer chemistry, a structural unit is a building block of a polymer chain. It is the result of a monomer which has been polymerized into a long chain. There may be more than one structural unit in the repeat unit. When different monomers are polymerized, a copolymer is formed. It is a routine way of developing new properties for new materials.

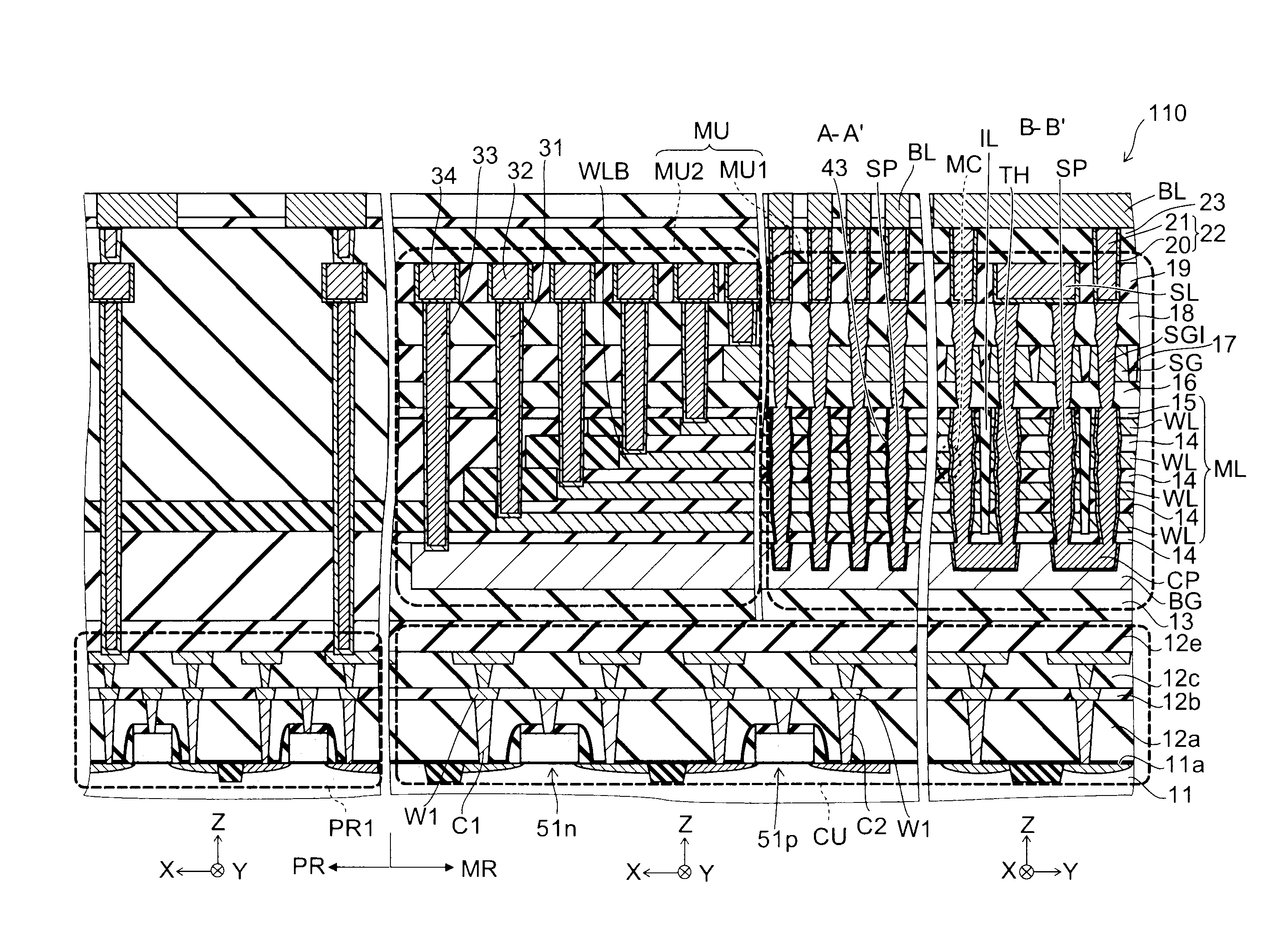

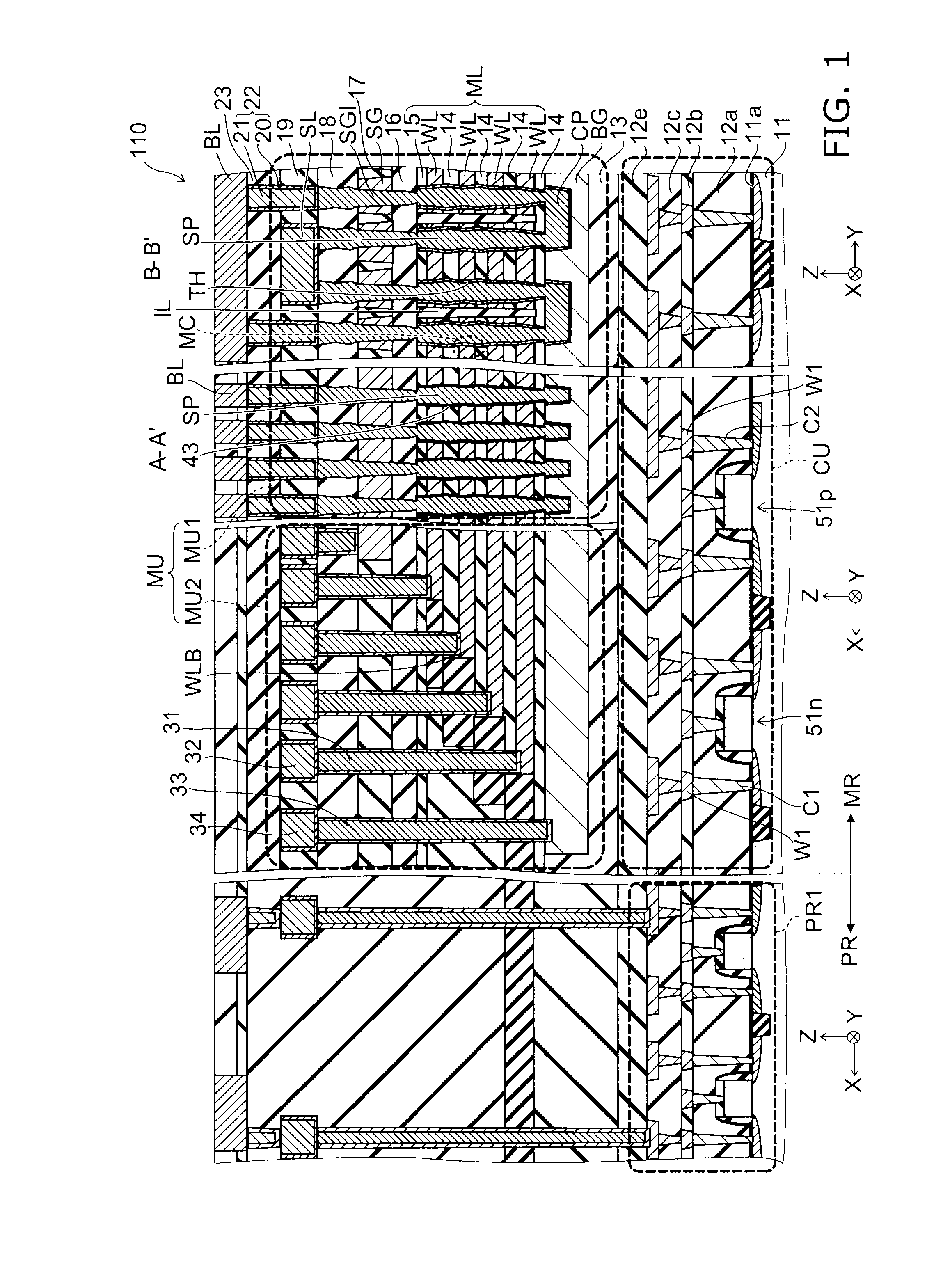

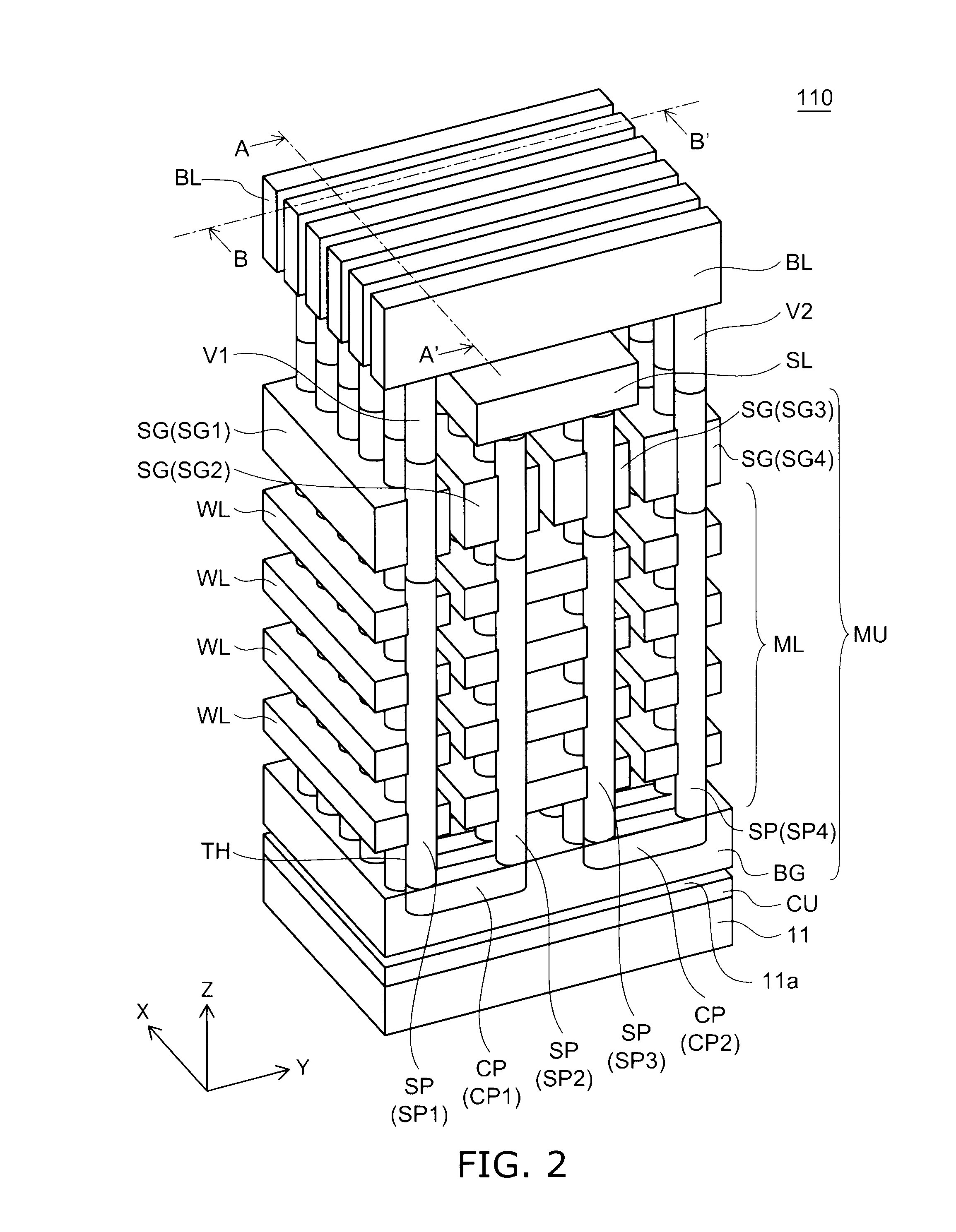

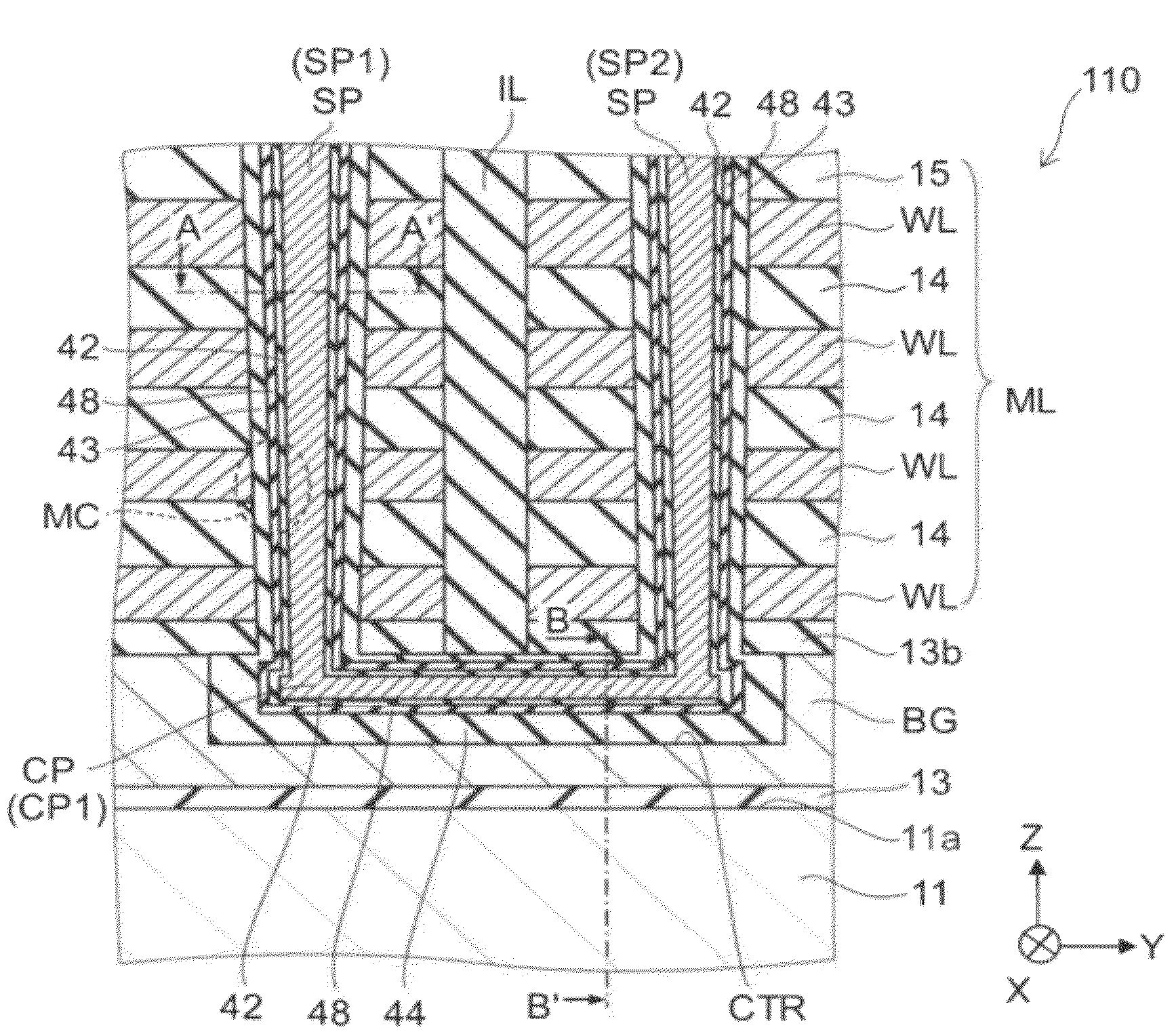

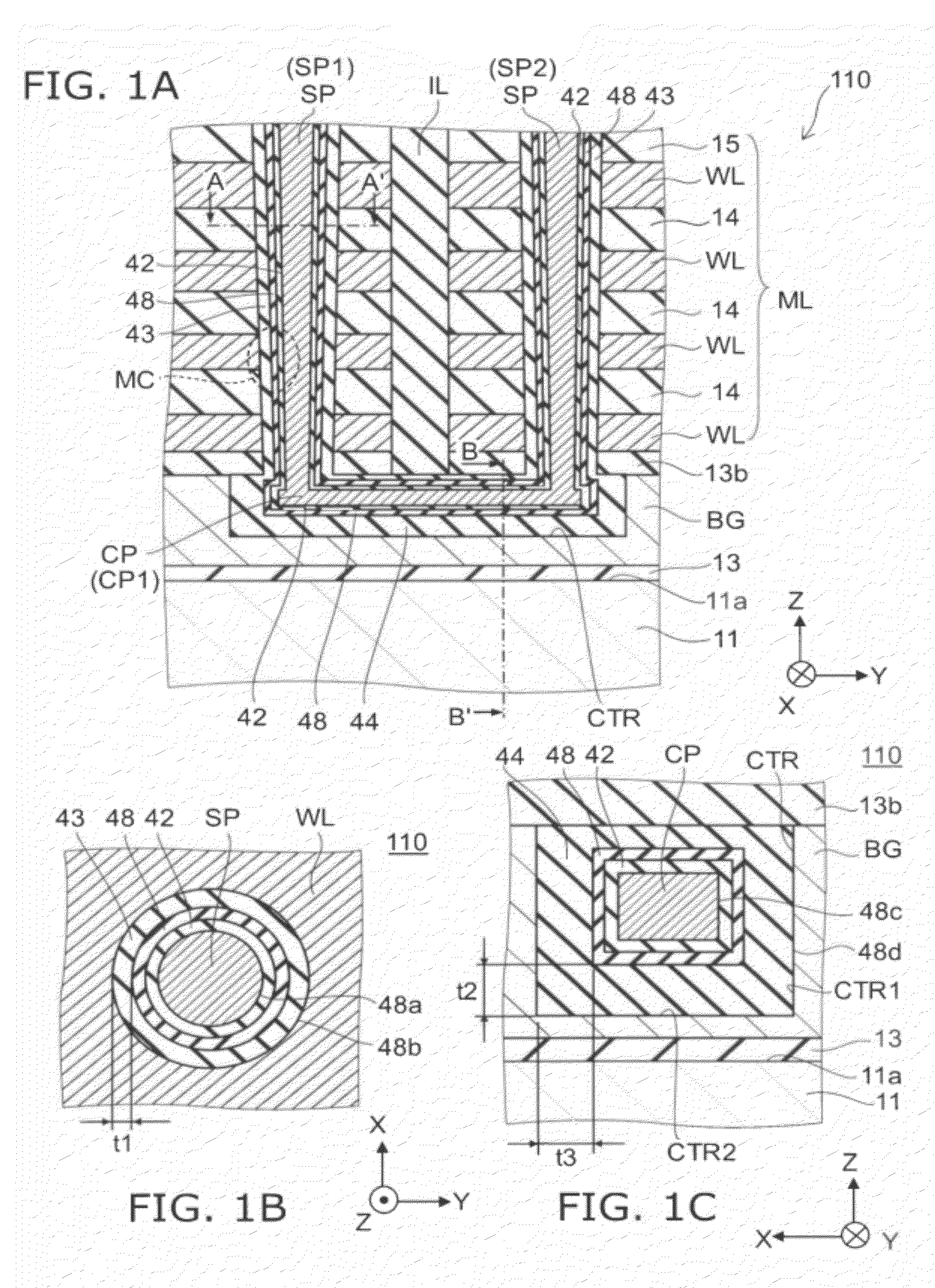

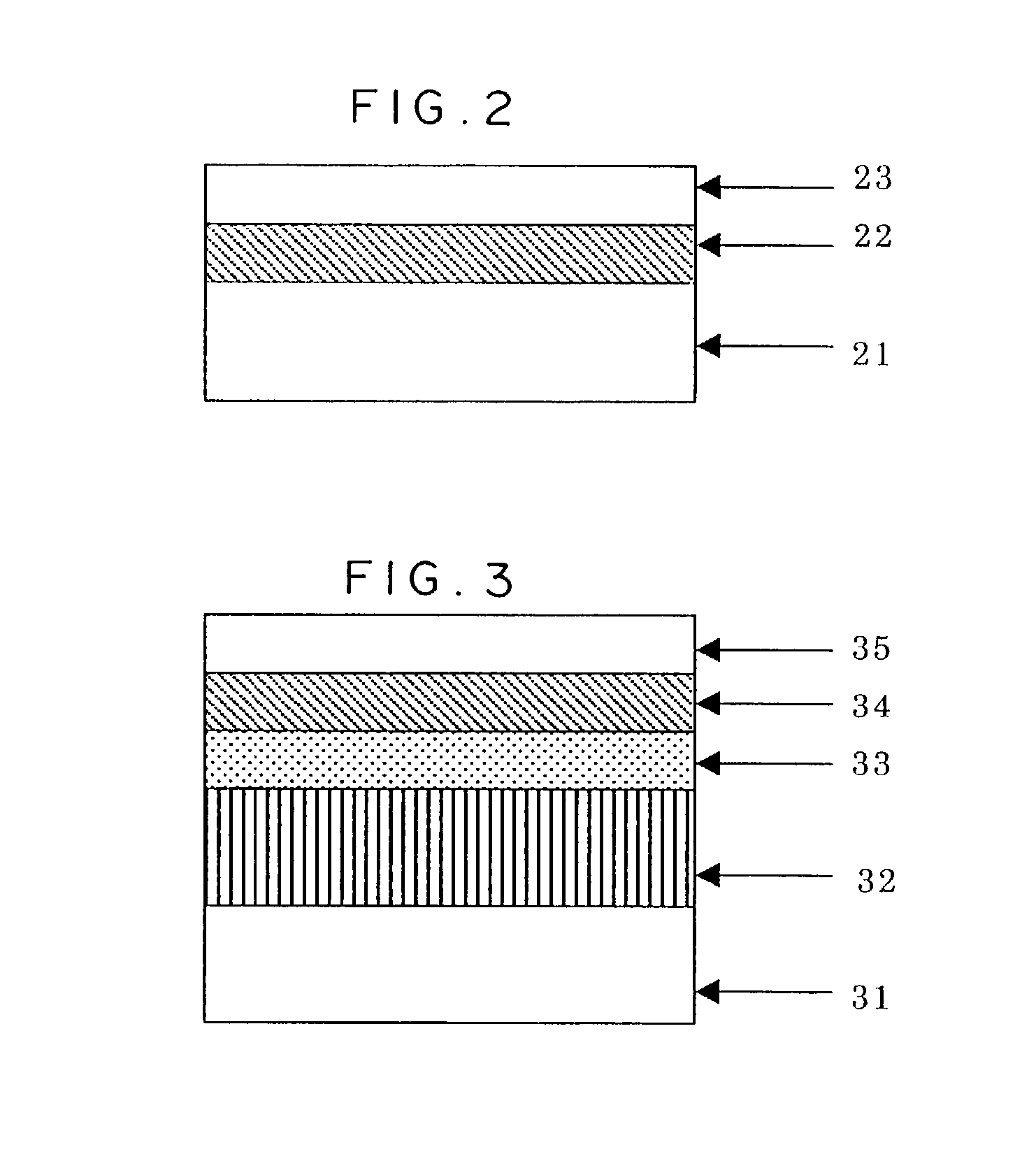

Nonvolatile semiconductor memory device and method for manufacturing same

InactiveUS20100320526A1Semiconductor/solid-state device detailsSolid-state devicesStructural unitSemiconductor

A nonvolatile semiconductor memory device includes: a semiconductor substrate; a memory unit; and a circuit unit provided between the semiconductor substrate and the memory unit. The memory unit includes: a stacked structural unit having electrode films alternately stacked with inter-electrode-film insulating films; a semiconductor pillar piercing the stacked structural unit; and a storage unit provided corresponding to an intersection between the electrode films and the semiconductor pillar. The circuit unit includes first and second transistors having different conductivity type, a first interconnect, and first and second contact plugs. The first interconnect includes silicide provided on a side of the first and second transistors opposite to the semiconductor substrate. The first contact plug made of polysilicon of the first conductivity type connects the first interconnect to the first transistor. The second contact plug made of polysilicon of the second conductivity type connects the first interconnect to the second transistor.

Owner:KK TOSHIBA

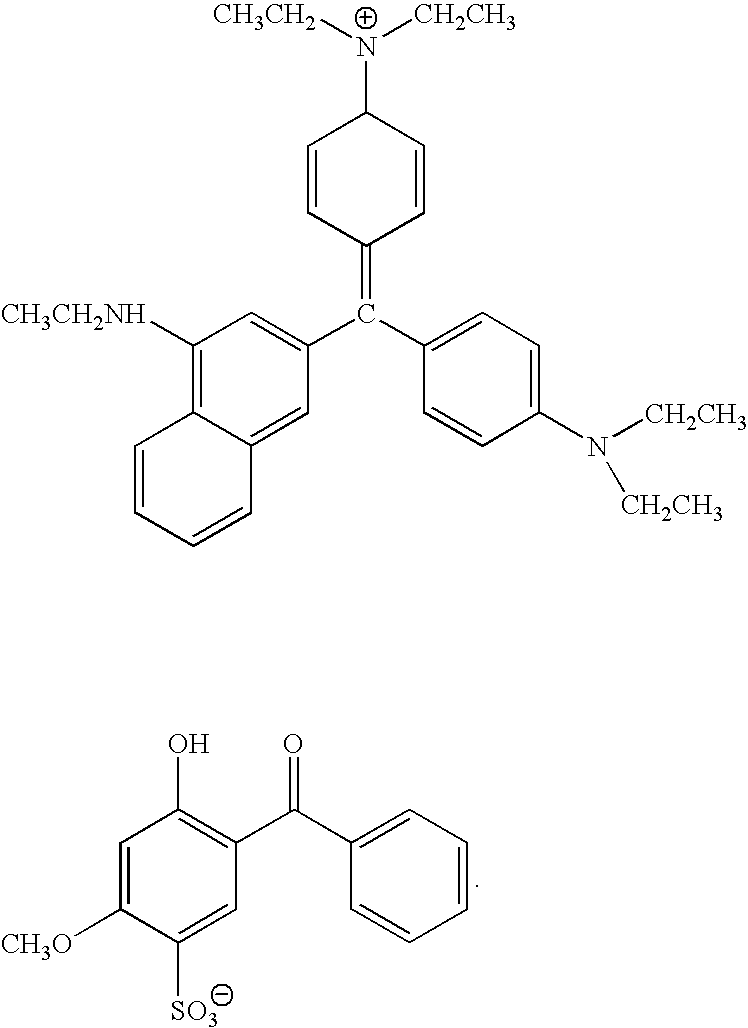

Water-developable infrared-sensitive printing plate

ActiveUS20050123853A1Semiconductor/solid-state device manufacturingPhotosensitive material auxillary/base layersPendant groupAqueous solution

The present invention provides an imageable element including a lithographic substrate and an imageable layer disposed on the substrate. The imageable layer includes a radically polymerizable component, an initiator system capable of generating radicals sufficient to initiate a polymerization reaction upon exposure to imaging radiation, and a polymeric binder having a hydrophobic backbone and including constitutional units having a pendant group including a hydrophilic poly(alkylene oxide) segment. The imageable element can be developed using an aqueous developer solution. Alternatively, the imageable element can be developed on-press by contact with ink and / or fountain solution.

Owner:KODAK POLYCHROME GRAPHICS

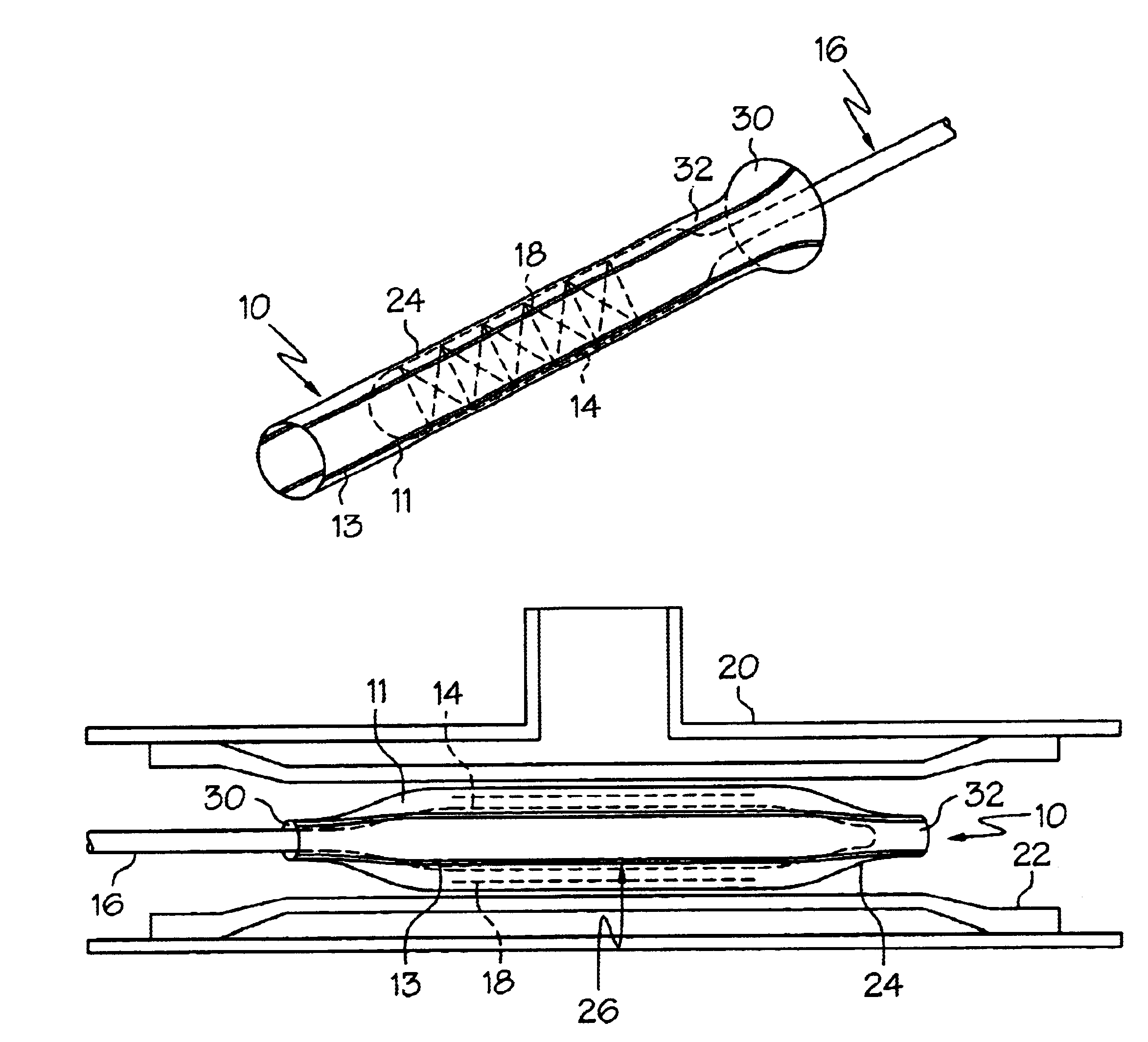

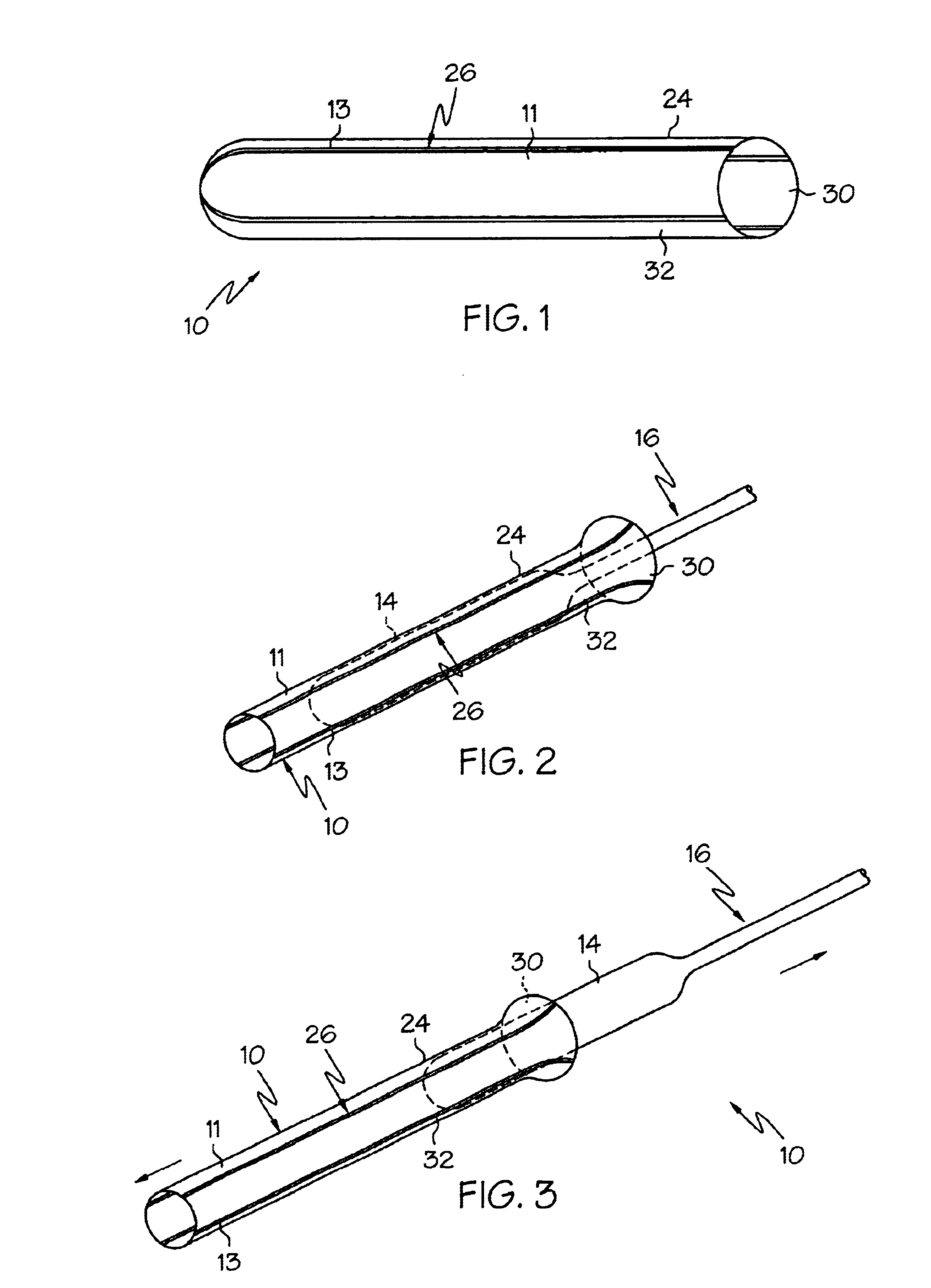

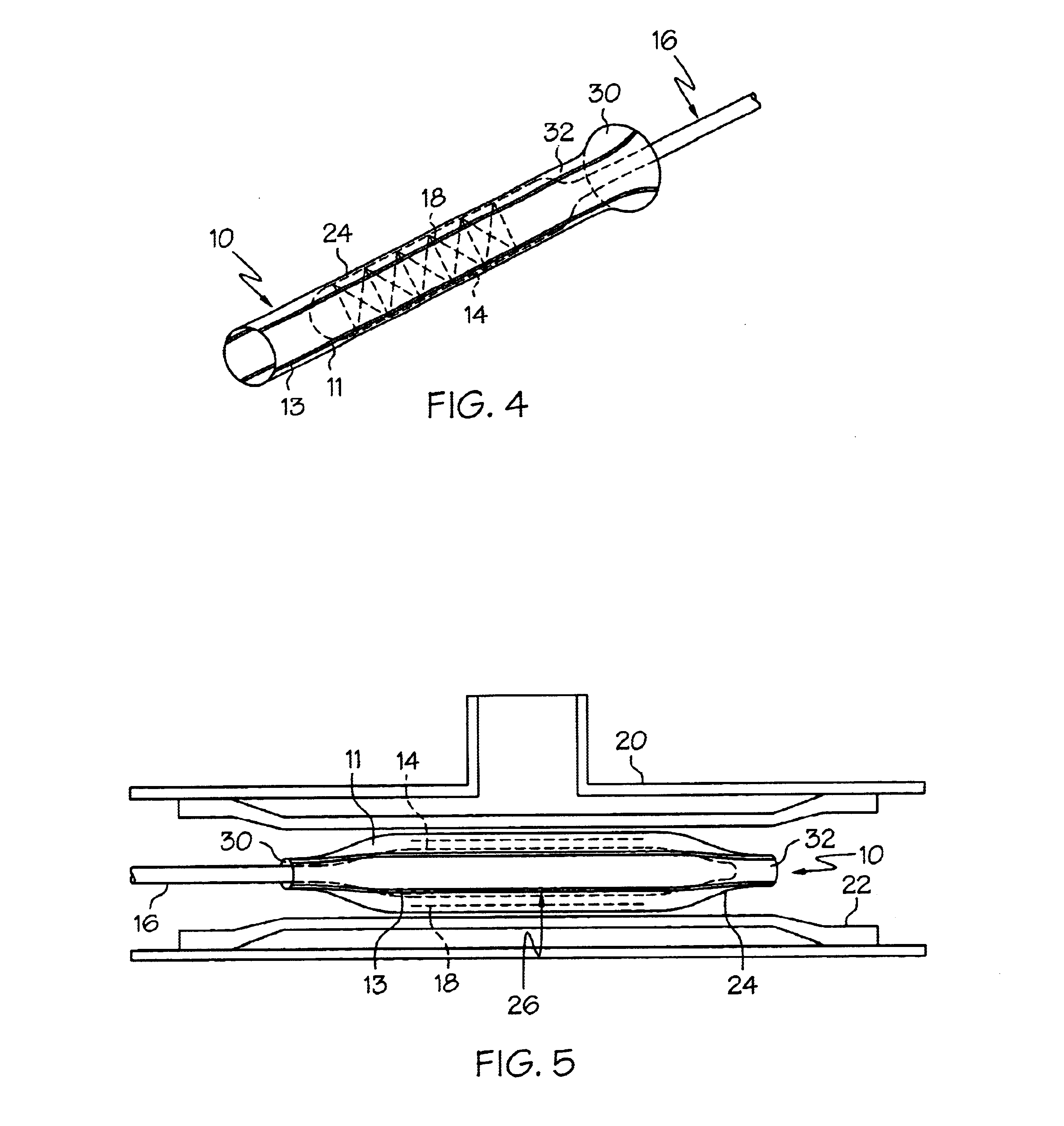

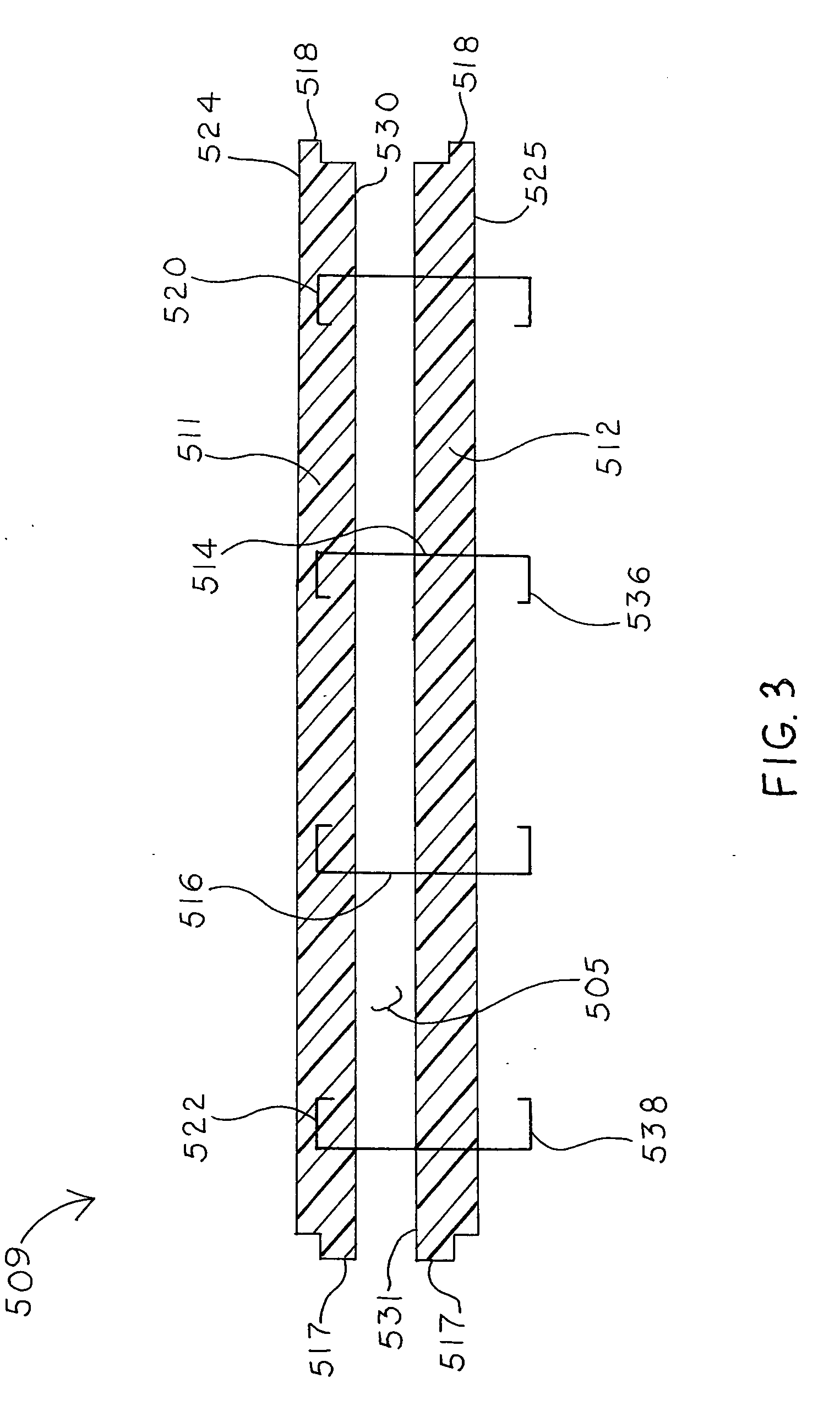

Crimpable balloon/stent protector

InactiveUS6783542B2Reduce the overall diameterIncrease flexibilityStentsBalloon catheterAcetoacetatesStructural unit

A protective sleeve for a catheter assembly comprising a tubular member composed of a first material. The first material having a first predetermined modulus of elasticity. The tubular member having at least one stripe of a second material engaged thereto. The second material having a greater modulus of elasticity than the first material. The tubular member having a loading state and being crimpable to a reduced state. In the loading state the tubular member being sized to disposingly engage the balloon of a catheter assembly wherein the balloon has a first diameter. When the tubular member is in the reduced state the tubular member is disposingly and retainingly engaged to the balloon. When the tubular member is in the reduced state the balloon has a second diameter which is less than the first diameter.

Owner:BOSTON SCI SCIMED INC

Nonvolatile semiconductor memory device and method for manufacturing same

A nonvolatile semiconductor memory device, includes: a stacked structural unit including electrode films alternately stacked with inter-electrode insulating films; first and second semiconductor pillars piercing the stacked structural unit; a connection portion semiconductor layer electrically connect the first and second semiconductor pillars; a connection portion conductive layer provided to oppose the connection portion semiconductor layer; a memory layer and an inner insulating film provided between the first and semiconductor pillars and each of the electrode films, and between the connection portion conductive layer and the connection portion semiconductor layer; an outer insulating film provided between the memory layer and each of the electrode films; and a connection portion outer insulating film provided between the memory layer and the connection portion conductive layer. The connection portion outer insulating film has a film thickness thicker than a film thickness of the outer insulating film.

Owner:KK TOSHIBA

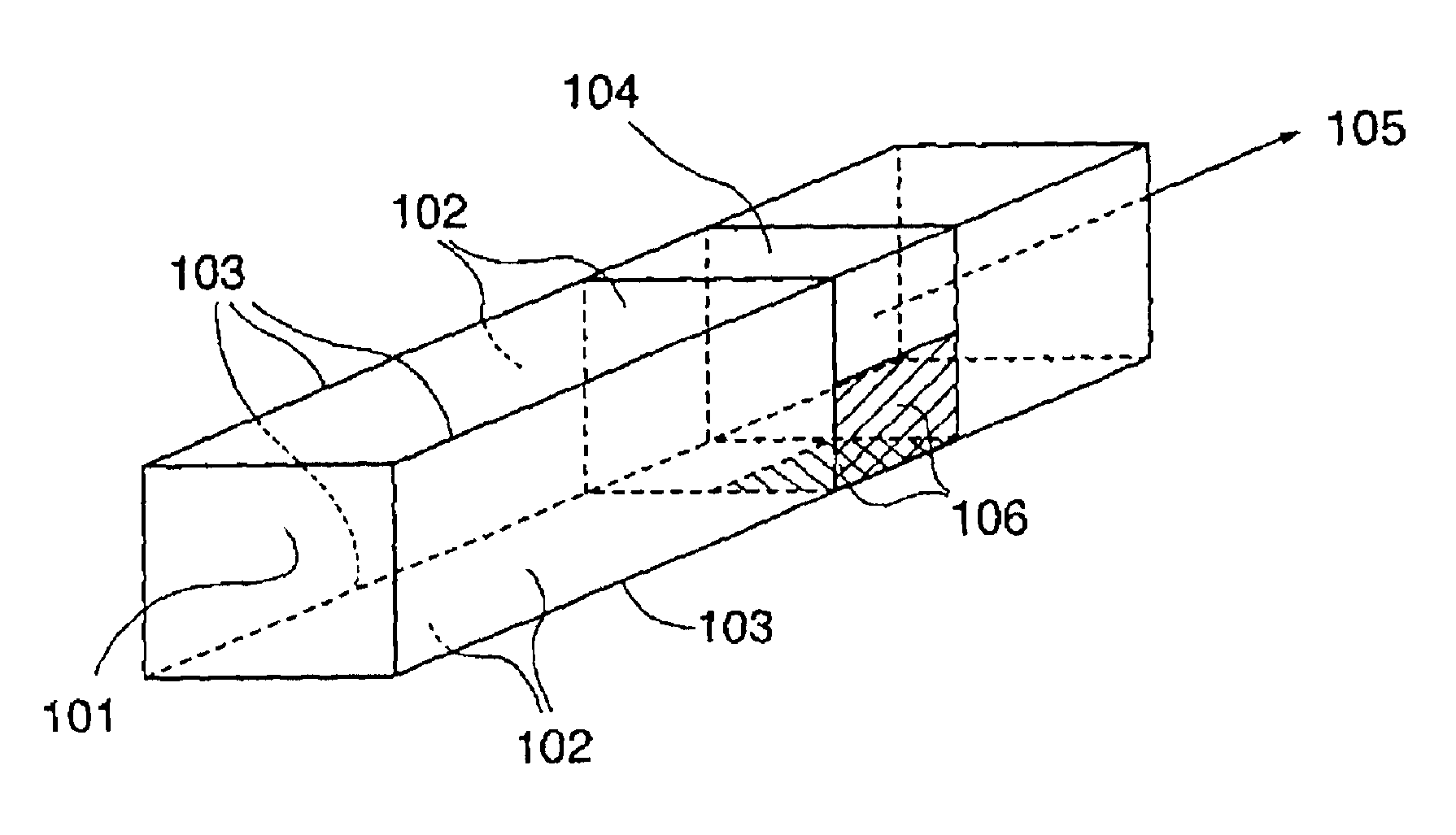

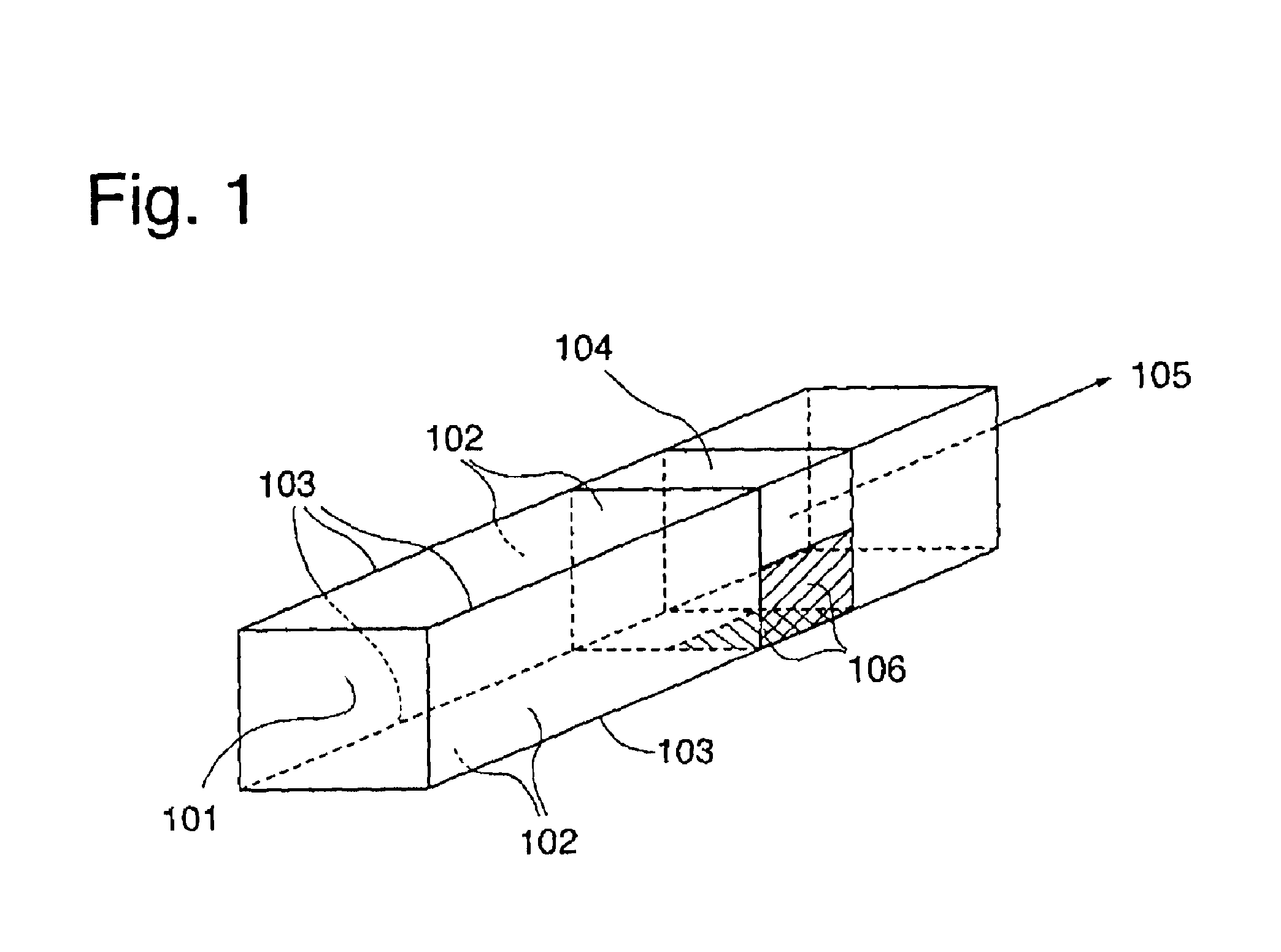

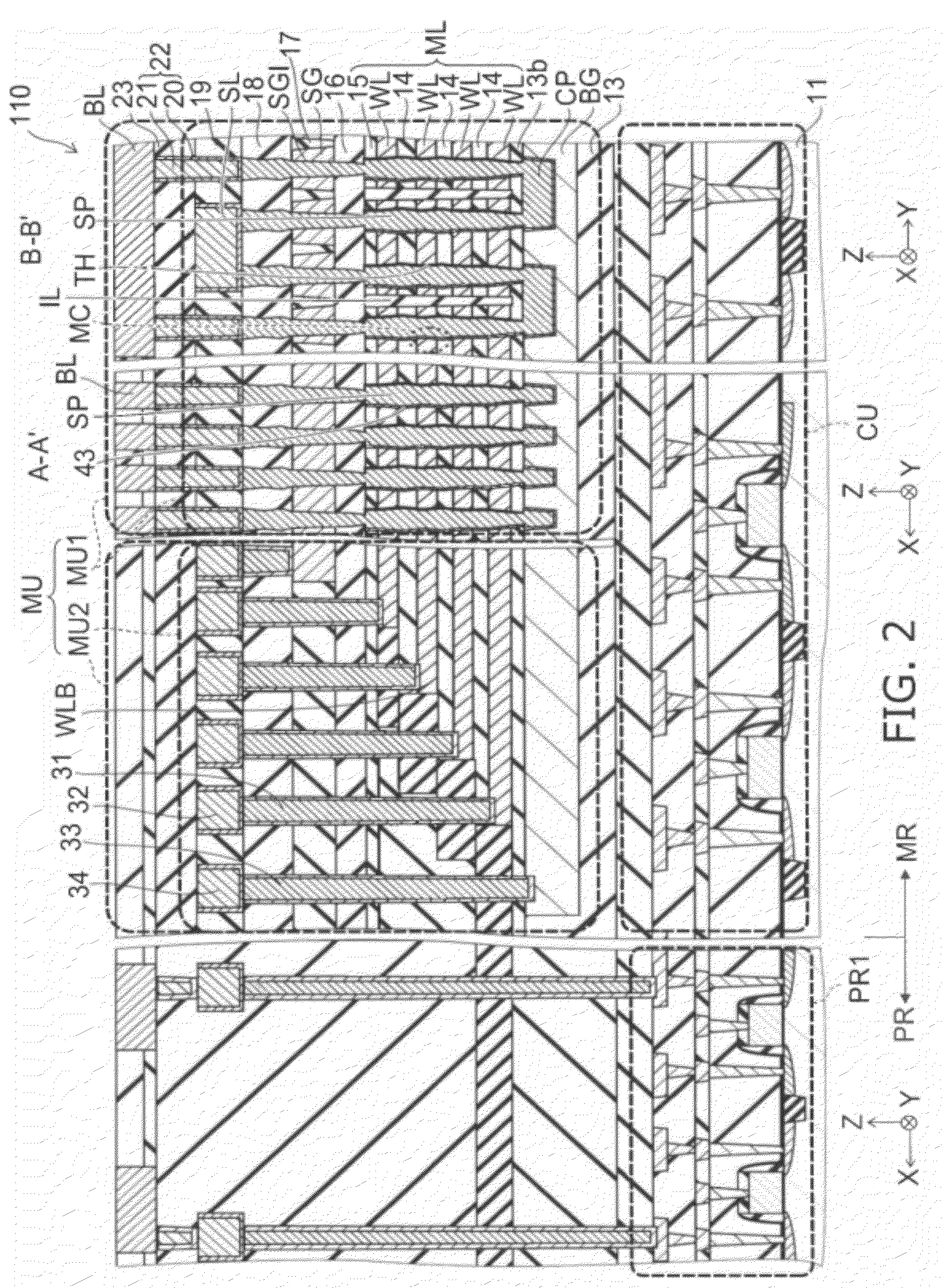

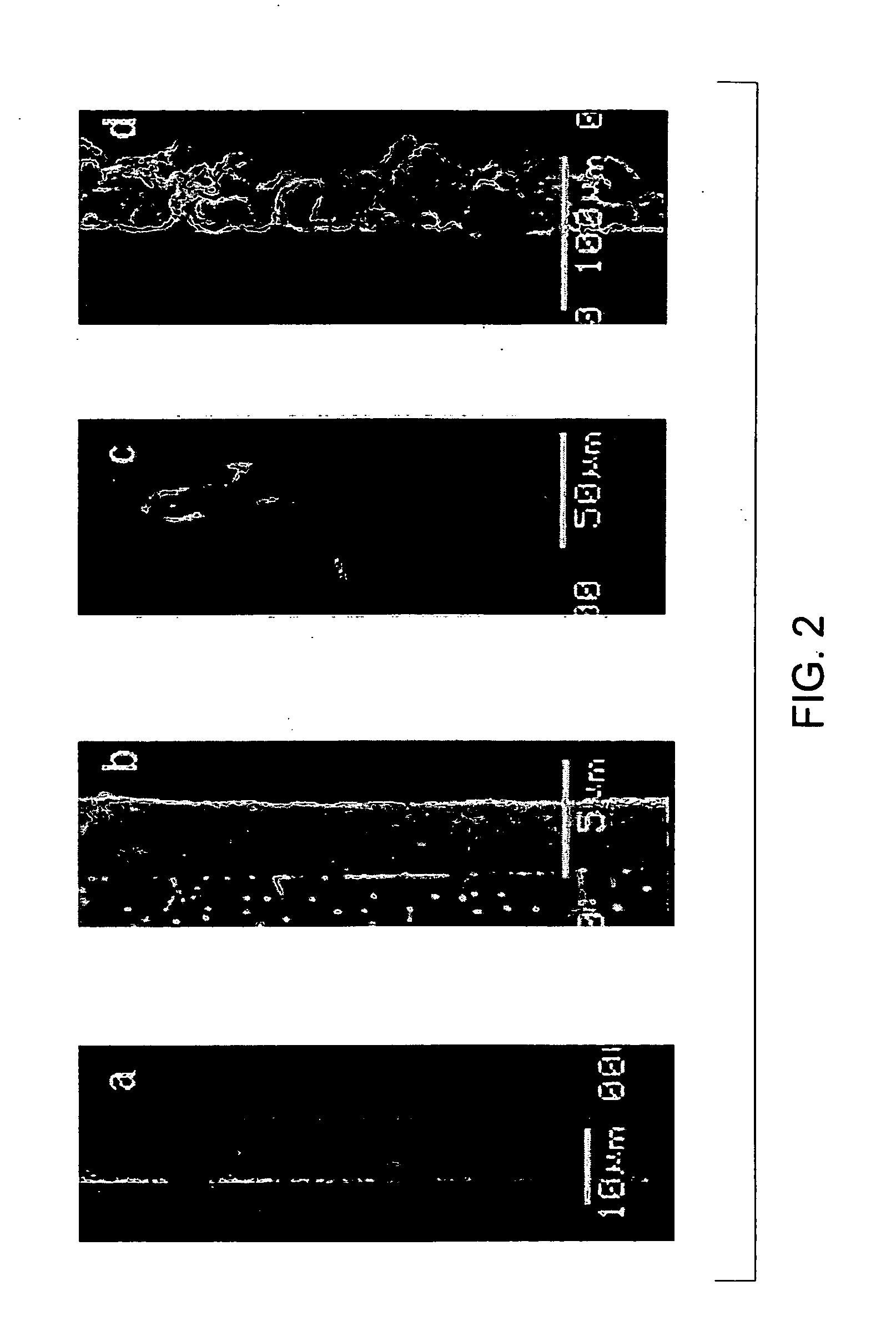

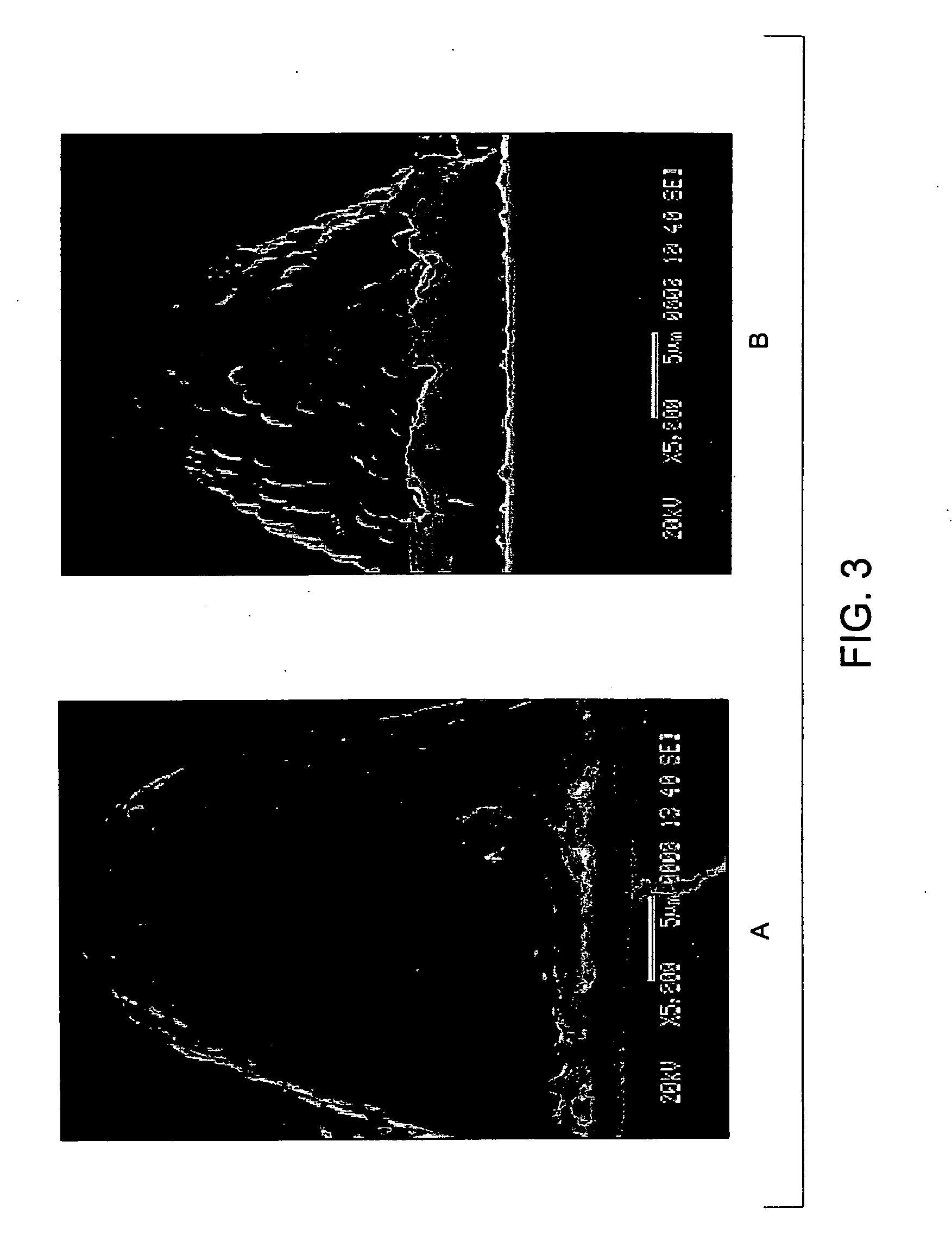

Methods for forming improved self-assembled patterns of block copolymers

ActiveUS7347953B2Easy alignmentReduce defectsMaterial nanotechnologyRadiation applicationsSemiconductor structureStructural unit

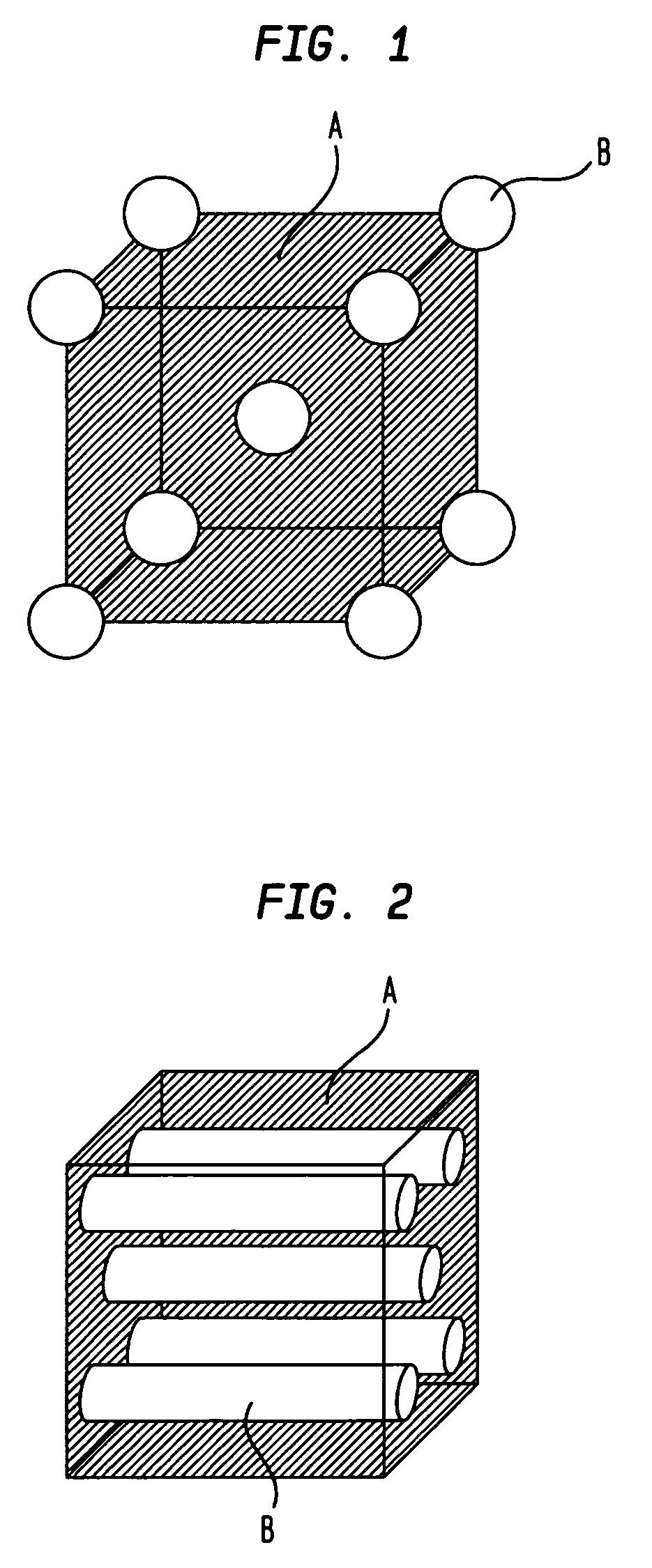

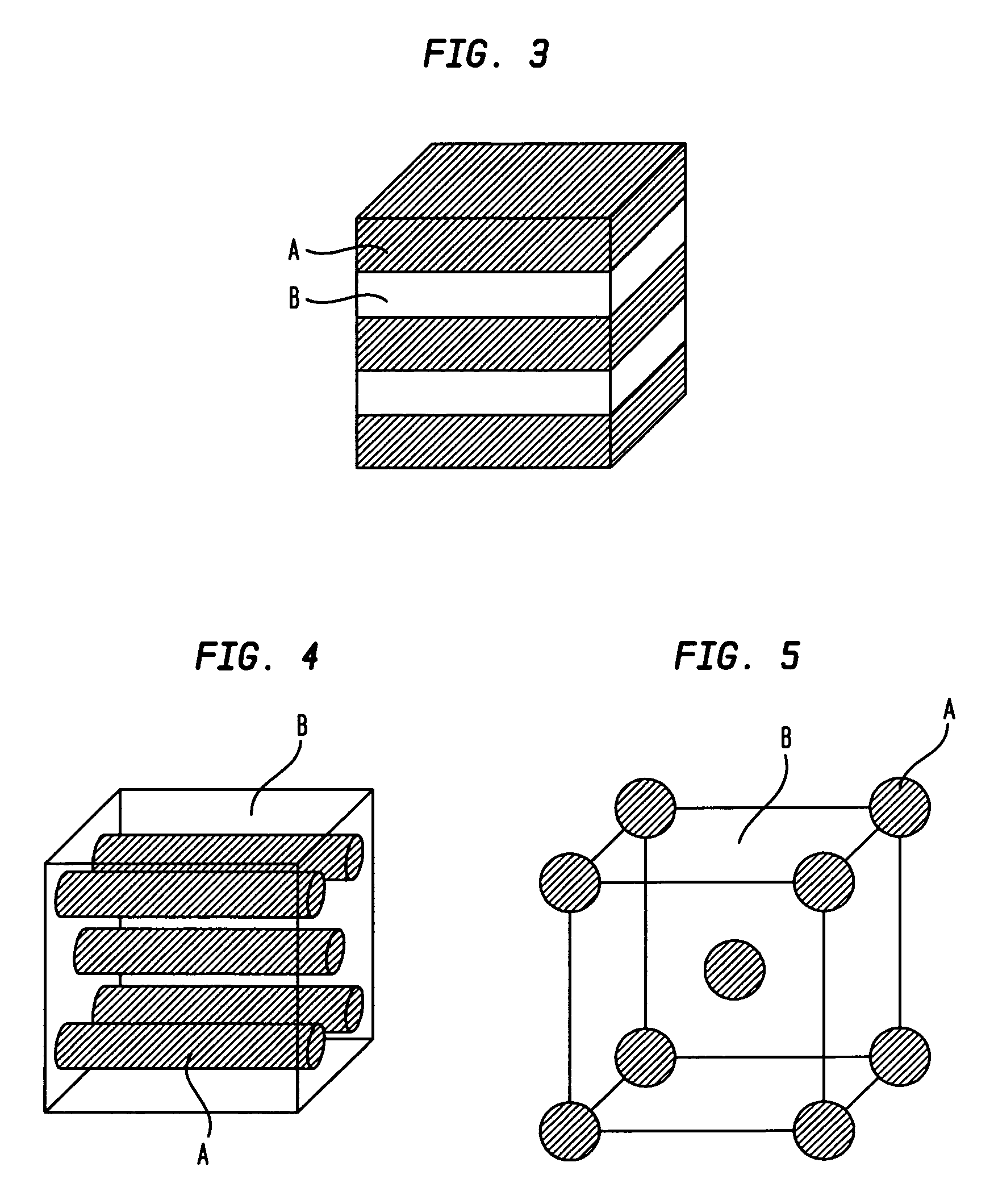

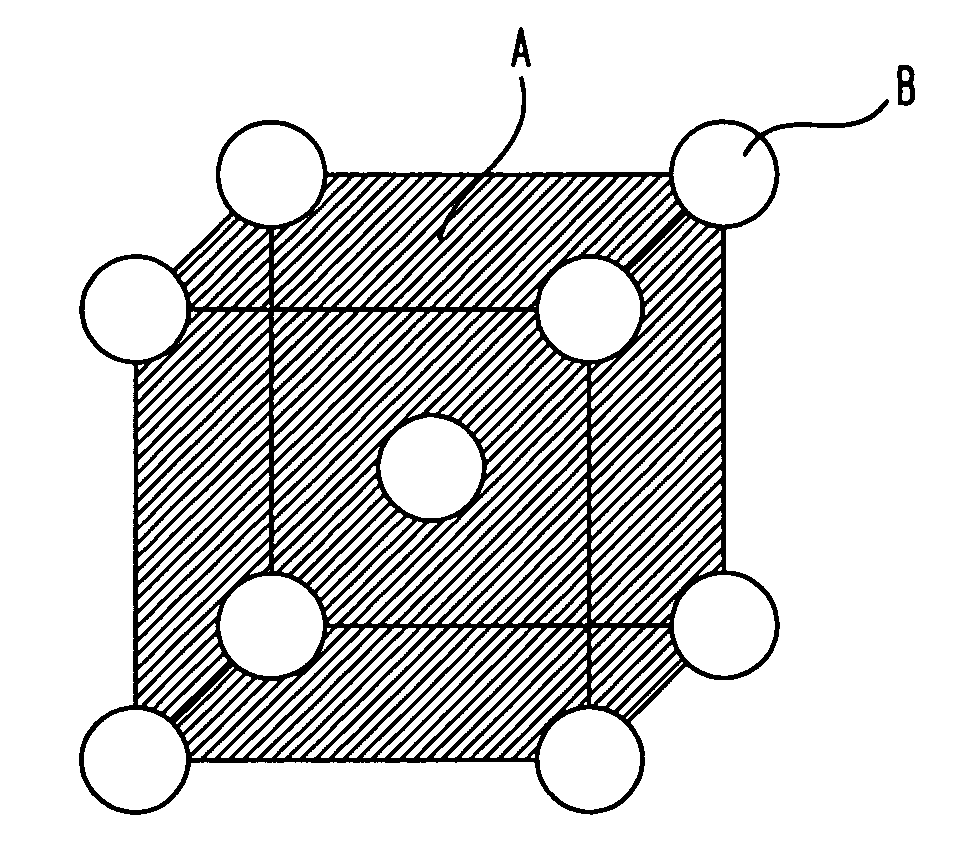

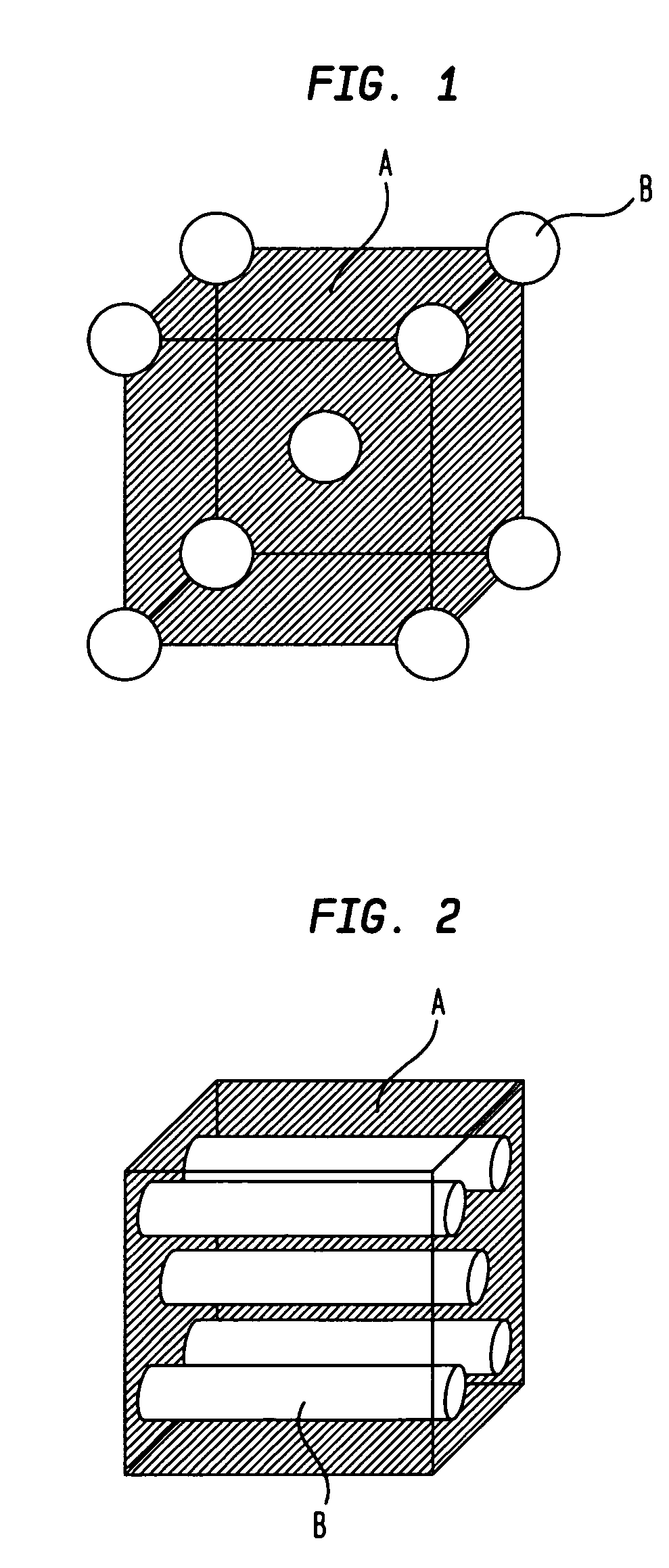

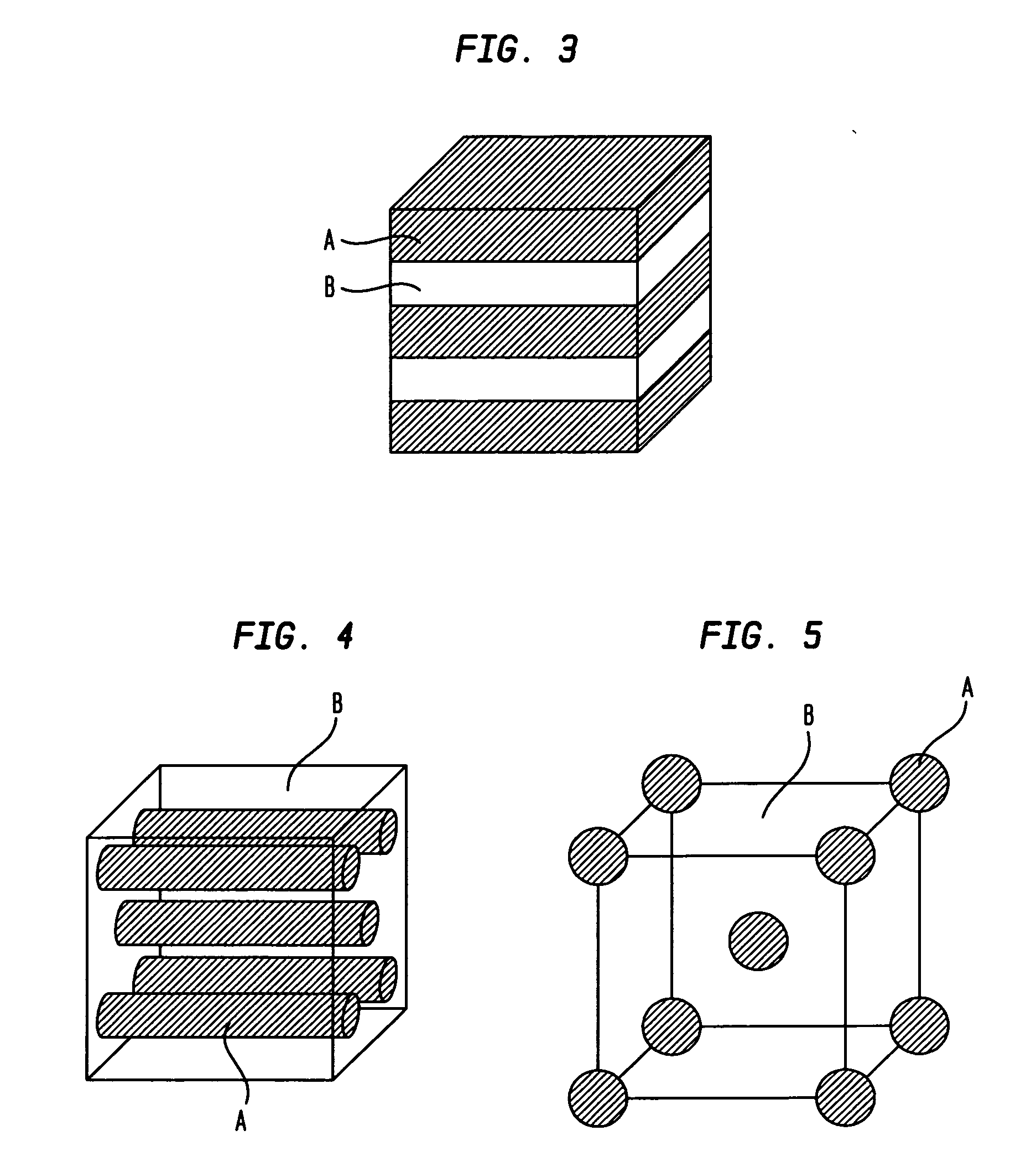

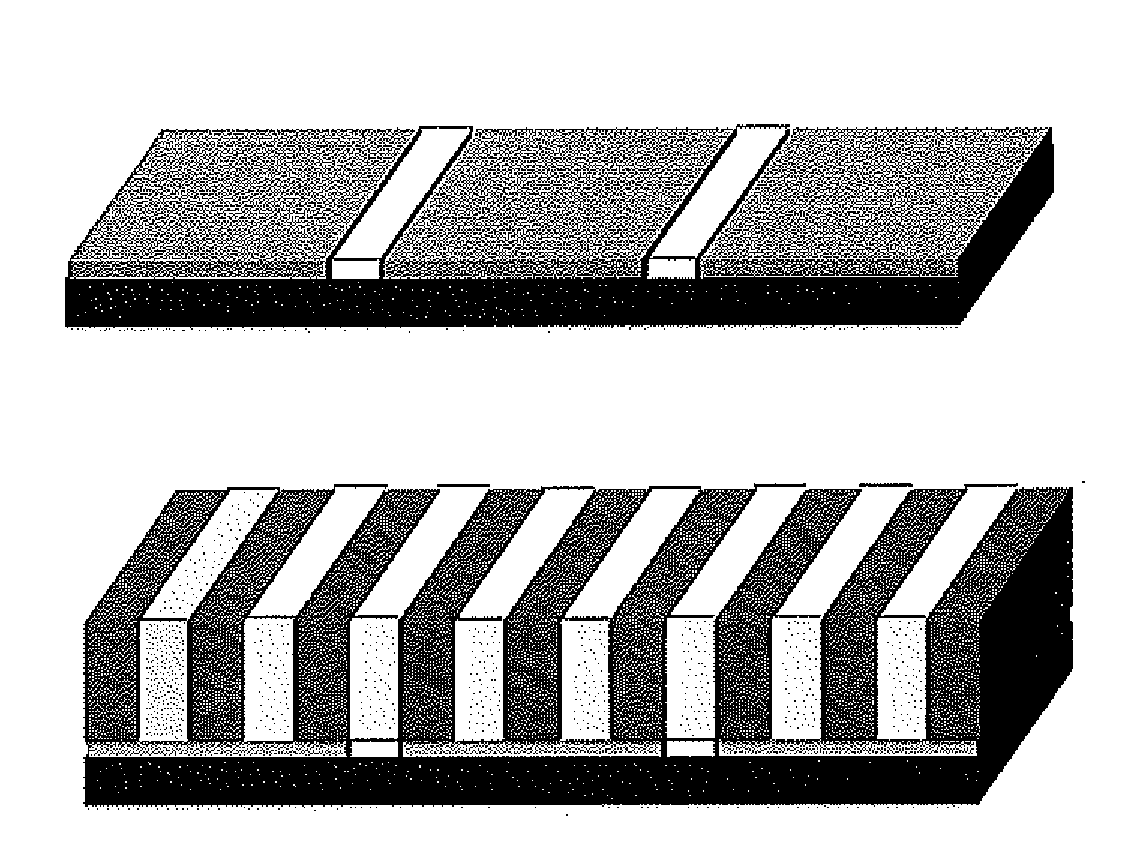

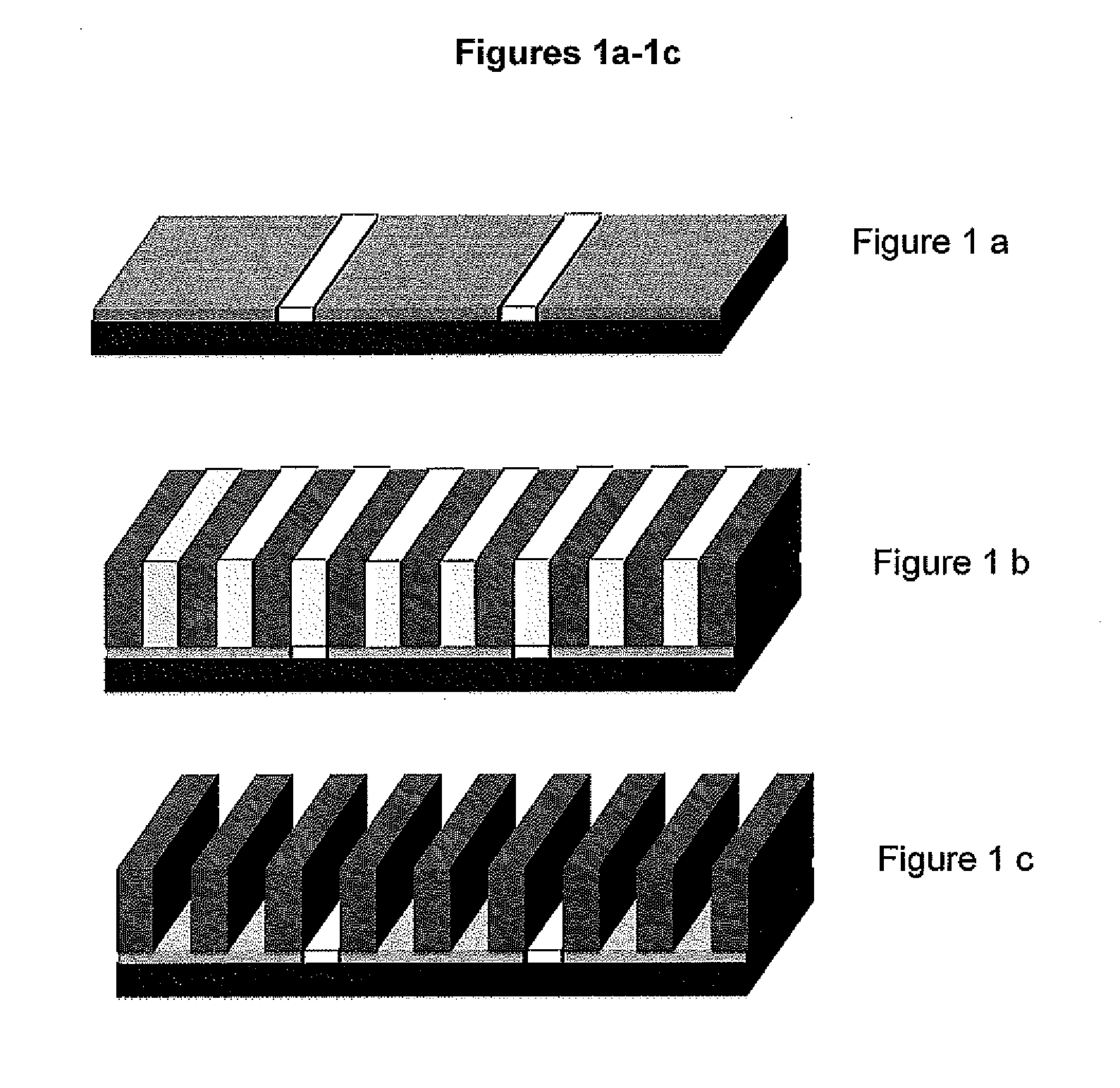

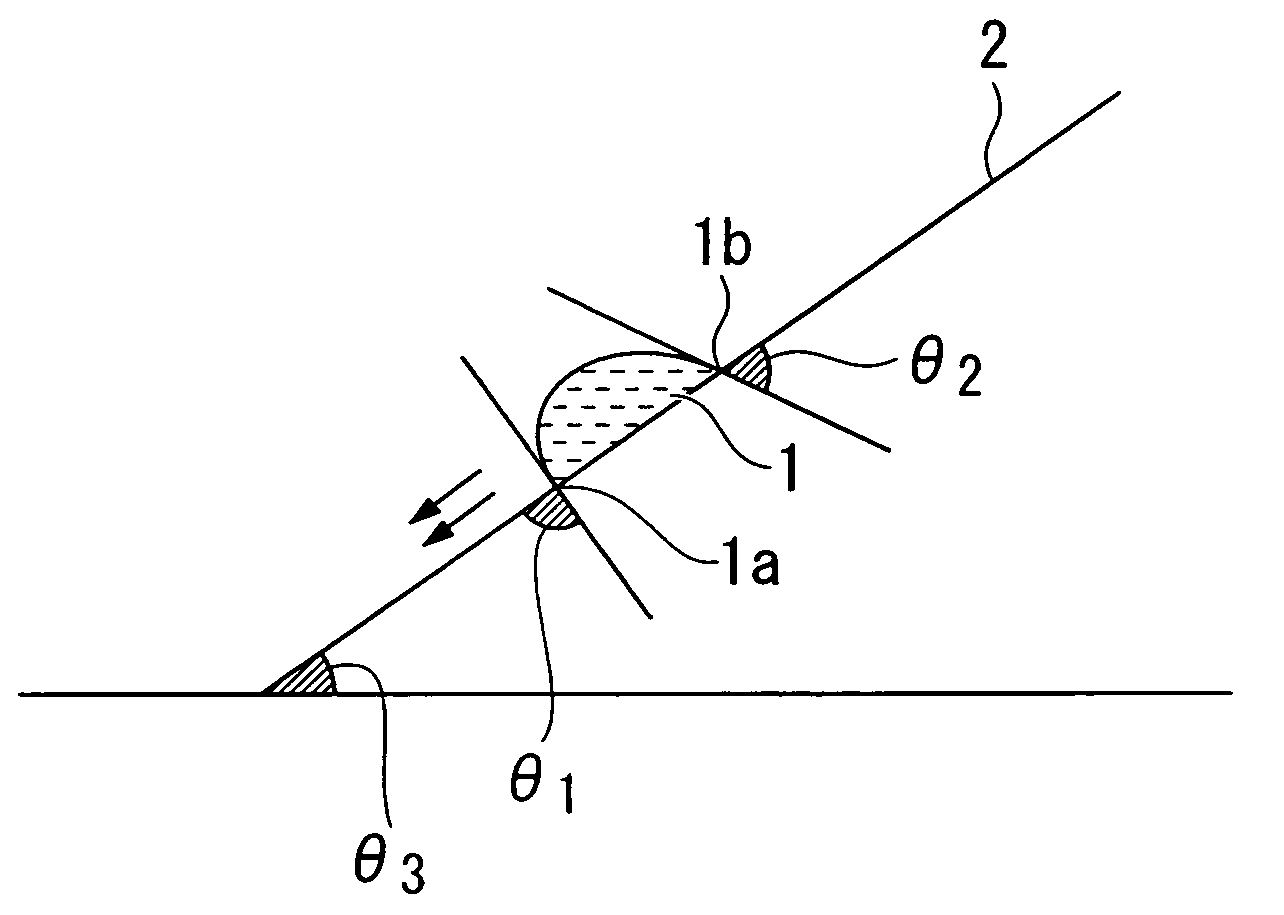

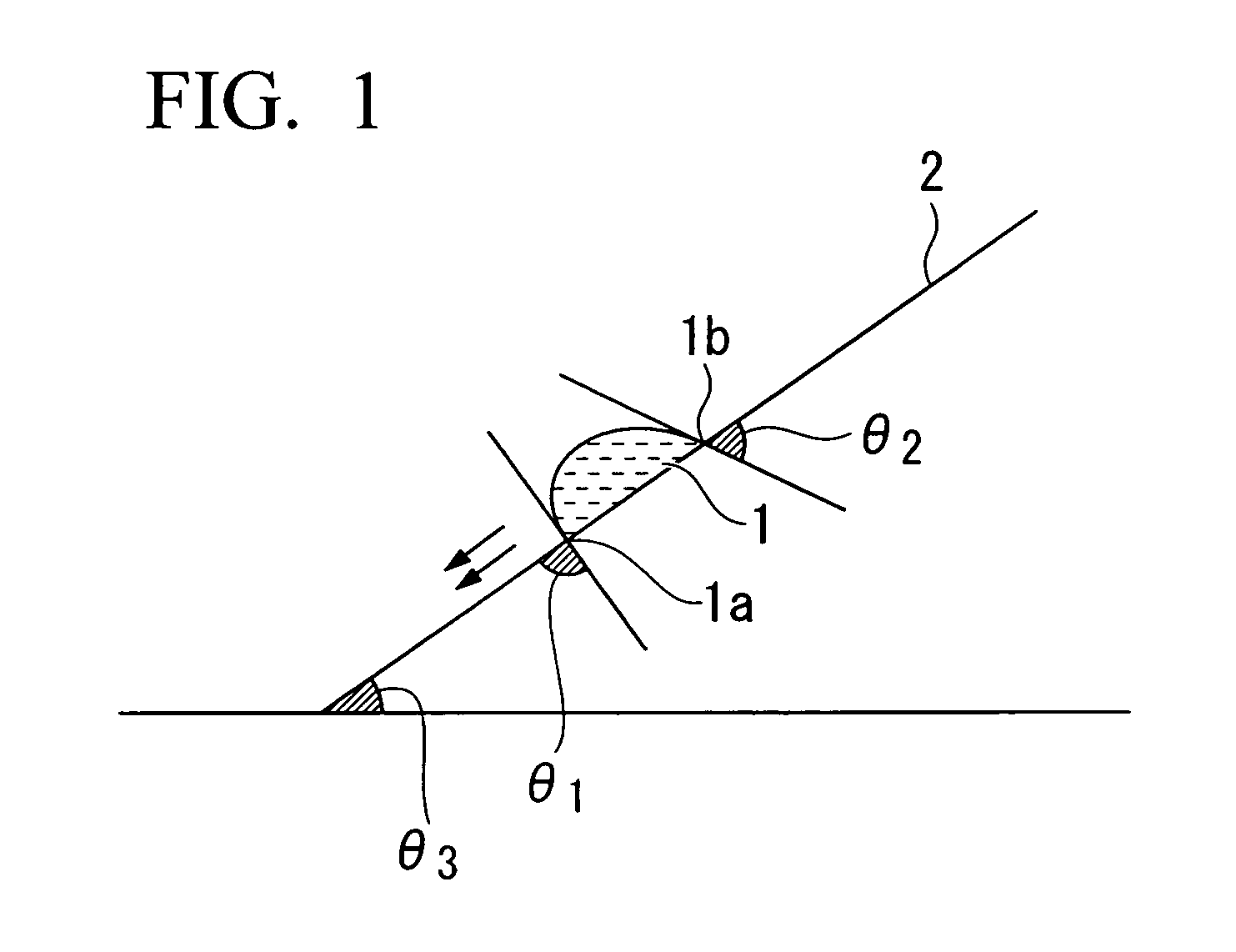

A method for forming self-assembled patterns on a substrate surface is provided. First, a block copolymer layer, which comprises a block copolymer having two or more immiscible polymeric block components, is applied onto a substrate that comprises a substrate surface with a trench therein. The trench specifically includes at least one narrow region flanked by two wide regions, and wherein the trench has a width variation of more than 50%. Annealing is subsequently carried out to effectuate phase separation between the two or more immiscible polymeric block components in the block copolymer layer, thereby forming periodic patterns that are defined by repeating structural units. Specifically, the periodic patterns at the narrow region of the trench are aligned in a predetermined direction and are essentially free of defects. Block copolymer films formed by the above-described method as well as semiconductor structures comprising such block copolymer films are also described.

Owner:GLOBALFOUNDRIES US INC

Methods for forming improved self-assembled patterns of block copolymers

ActiveUS20070175859A1Easy alignmentReduce defectsMaterial nanotechnologyRadiation applicationsSemiconductor structureStructural unit

A method for forming self-assembled patterns on a substrate surface is provided. First, a block copolymer layer, which comprises a block copolymer having two or more immiscible polymeric block components, is applied onto a substrate that comprises a substrate surface with a trench therein. The trench specifically includes at least one narrow region flanked by two wide regions, and wherein the trench has a width variation of more than 50%. Annealing is subsequently carried out to effectuate phase separation between the two or more immiscible polymeric block components in the block copolymer layer, thereby forming periodic patterns that are defined by repeating structural units. Specifically, the periodic patterns at the narrow region of the trench are aligned in a predetermined direction and are essentially free of defects. Block copolymer films formed by the above-described method as well as semiconductor structures comprising such block copolymer films are also described.

Owner:GLOBALFOUNDRIES US INC

Polymer wood composite

InactiveUS6015612AHigh modulusHigh compressive strengthWood working apparatusRecord information storageFiberThermoplastic

The invention relates to a composition comprising a polymer and wood fiber composite that can be used in the form of a linear extrudate or thermoplastic pellet to manufacture structural members. The polymer and wood fiber composite structural members can be manufactured in an extrusion process or an injection molding process. The linear extrudate or pellet can have a cross-section of any arbitrary shape, or can be a regular geometric. The pellet can have a cross-section shape having a volume of at least about 12 mm3. Preferably the pellet is a right cylindrical pellet having a minimum radius of about 1.5 mm and a minimum length of 1 mm weighing at least 14 mg. The invention also relates to an environmentally sensitive recycle of waste streams. The polymer and wood fiber composite contains an intentional recycle of a waste stream comprising polymer flakes or particles or wood fiber. The waste stream can comprises, in addition to polymer such as polyvinyl chloride or wood fiber, adhesive, paint, preservative, or other chemical stream common in the wood-window or door manufacturing process, or mixtures thereof. The initial mixing step before extrusion of the composite material insures substantial mixing and melt contact between molten polymer and wood fiber. The extruded pellet comprises a consistent proportion of polymer, wood fiber and water. During the extrusion, water is removed intentionally to dry the material to a maximum water content of less than about 10 wt-% based on the pellet weight. To make a structural unit, the pellet is introduced into an extruder or injection molding apparatus wherein, under conditions of temperature and pressure, the composite pellet material is shaped into a useful cross-section. Alternatively, the extruded thermoplastic mass, in the form of a elongated linear extrudate without a pelletizing step, can be immediately directed after formation into an extruder or injection molding apparatus.

Owner:ANDERSEN CORPORATION

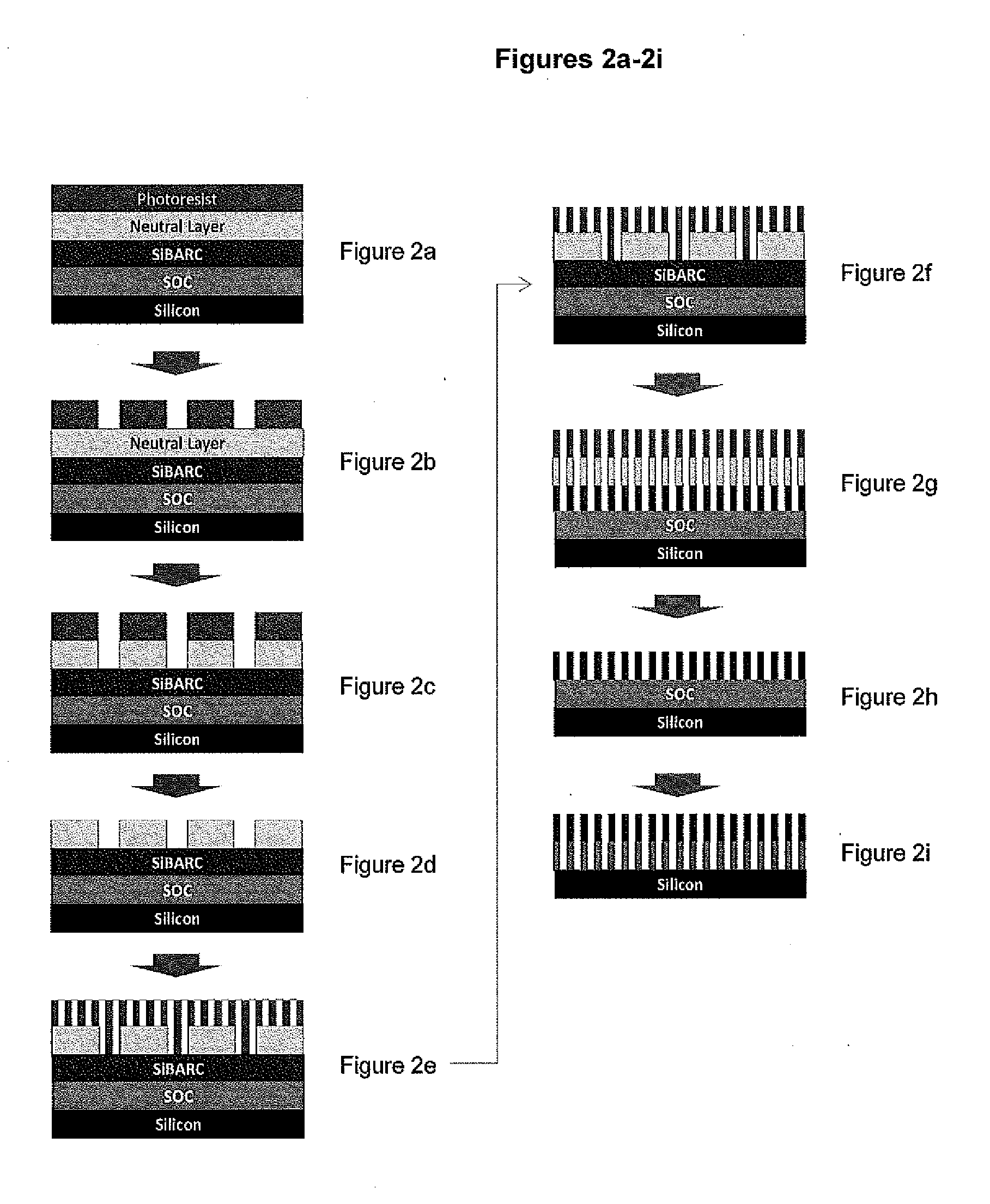

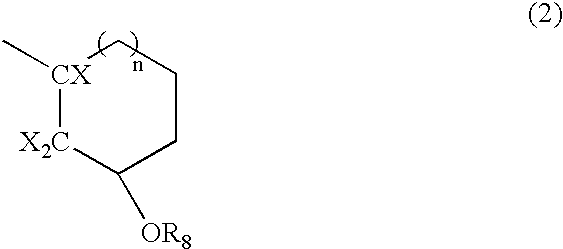

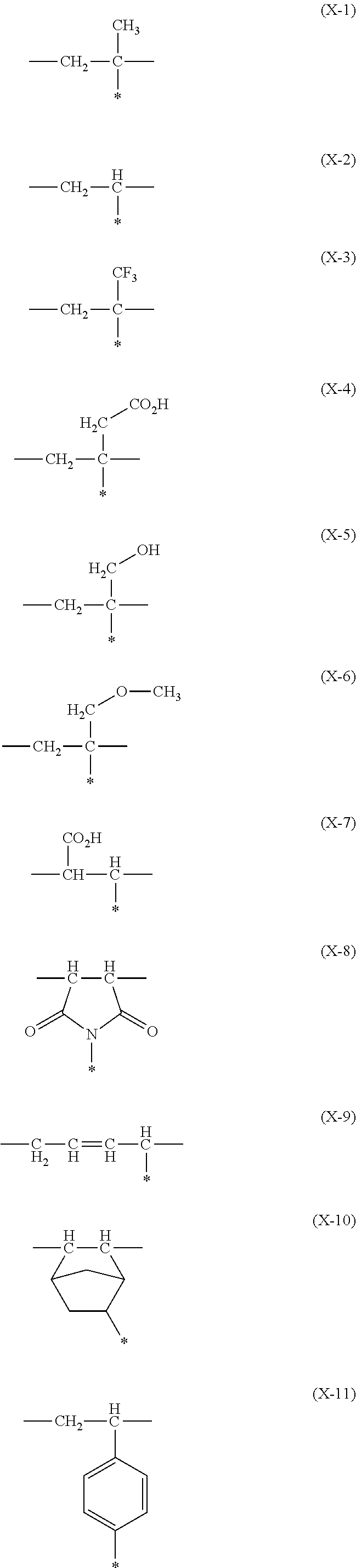

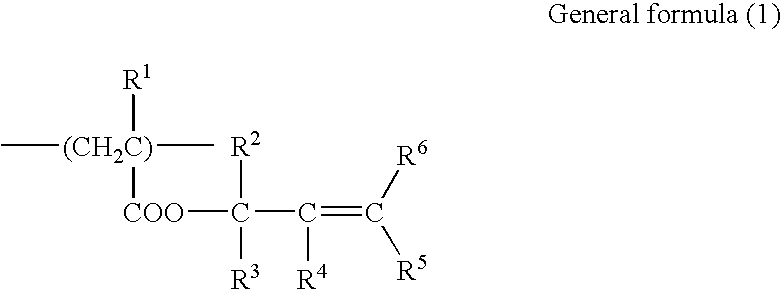

Compositions of neutral layer for directed self assembly block copolymers and processes thereof

ActiveUS20130078576A1High resolutionHigh pattern definitionElectric discharge tubesNanoinformaticsPolymer scienceMoiety

The present invention relates to novel neutral layer compositions and methods for using the compositions. The neutral layer composition comprises at least one random copolymer having at least one unit of structure (1), at least one unit of structure (2) and at least one unit of structure (3)where R1 is selected from the group consisting of a C1-C8 alkyl, C1-C8 fluoroalkyl moiety, C1-C8 partially fluorinated alkyl, C4-C8 cycloalkyl, C4-C8 cyclofluoroalkyl, C4-C8 partially fluorinated cycloalkyl, and a C2-C8 hydroxyalkyl; R2, R3 and R5 are independently selected from a group consisting of H, C1-C4 alkyl, CF3 and F; R4 is selected from the group consisting of H, C1-C8 alkyl, C1-C8 partially fluorinated alkyl and C1-C8 fluoroalkyl, n ranges from 1 to 5, R6 is selected from the group consisting of H, F, C1-C8 alkyl and a C1-C8 fluoroalkyl and m ranges from 1 to 3.

Owner:MERCK PATENT GMBH

Advanced compatible polymer wood fiber composite

InactiveUS6210792B1Improve compatibilityGood material compatibilitySynthetic resin layered productsCellulosic plastic layered productsThermoplasticFiber

The invention relates to a composition comprising a thermoplastic polymer and wood fiber composite that can be used in the form of a linear extrudate or thermoplastic pellet to manufacture structural members. The polymer, the fiber or both can be modified to increase compatibility. The wood fiber composite structural members can be manufactured in an extrusion process or an injection molding process. The linear extrudate or pellet can have a cross-section of any arbitrary shape, or can be a regular geometric. The pellet can have a cross-section shape having a volume of at least about 12 mm3. Preferably the pellet is a right cylindrical pellet having a minimum radius of about 1.5 mm and a minimum length of 1 mm weighing at least 14 mg. The invention also relates to an environmentally sensitive recycle of waste streams. The polymer and wood fiber composite contains an intentional recycle of a waste stream comprising polymer flakes or particles or wood fiber. The waste stream can comprises, in addition to polymer such as polyvinyl chloride or wood fiber, adhesive, paint, preservative, or other chemical stream common in the wood-window or door manufacturing process, or mixtures thereof. The initial mixing step before extrusion of the composite material insures substantial mixing and melt contact between molten polymer and wood fiber. The extruded pellet comprises a consistent proportion of polymer, wood fiber and water. During the extrusion, water is removed intentionally to dry the material to a maximum water content of less than about 10 wt-% based on the pellet weight. To make a structural unit, the pellet is introduced into an extruder or injection molding apparatus wherein, under conditions of temperature and pressure, the composite pellet material is shaped into a useful cross-section. Alternatively, the extruded thermoplastic mass, in the form of a elongated linear extrudate without a pelletizing step, can be immediately directed after formation into an extruder or injection molding apparatus.

Owner:ANDERSEN CORPORATION

Imageable element with solvent-resistant polymeric binder

InactiveUS7261998B2Enhances on-press solvent resistanceProlong lifeRadiation applicationsSemiconductor/solid-state device manufacturingPolymer scienceBackbone chain

The present invention provides an imageable element including a lithographic substrate and an imageable layer disposed on the substrate. The imageable layer includes a radically polymerizable component, an initiator system capable of generating radicals sufficient to initiate a polymerization reaction upon exposure to imaging radiation, and a polymeric binder having a hydrophobic backbone and including both constitutional units having a pendant cyano group attached directly to the hydrophobic backbone, and constitutional units having a pendant group including a hydrophilic poly(alkylene oxide) segment. When the imageable element is imaged and developed, the resulting printing plate may exhibit improved on-press solvent resistance and longer press life.

Owner:KODAK POLYCHROME GRAPHICS

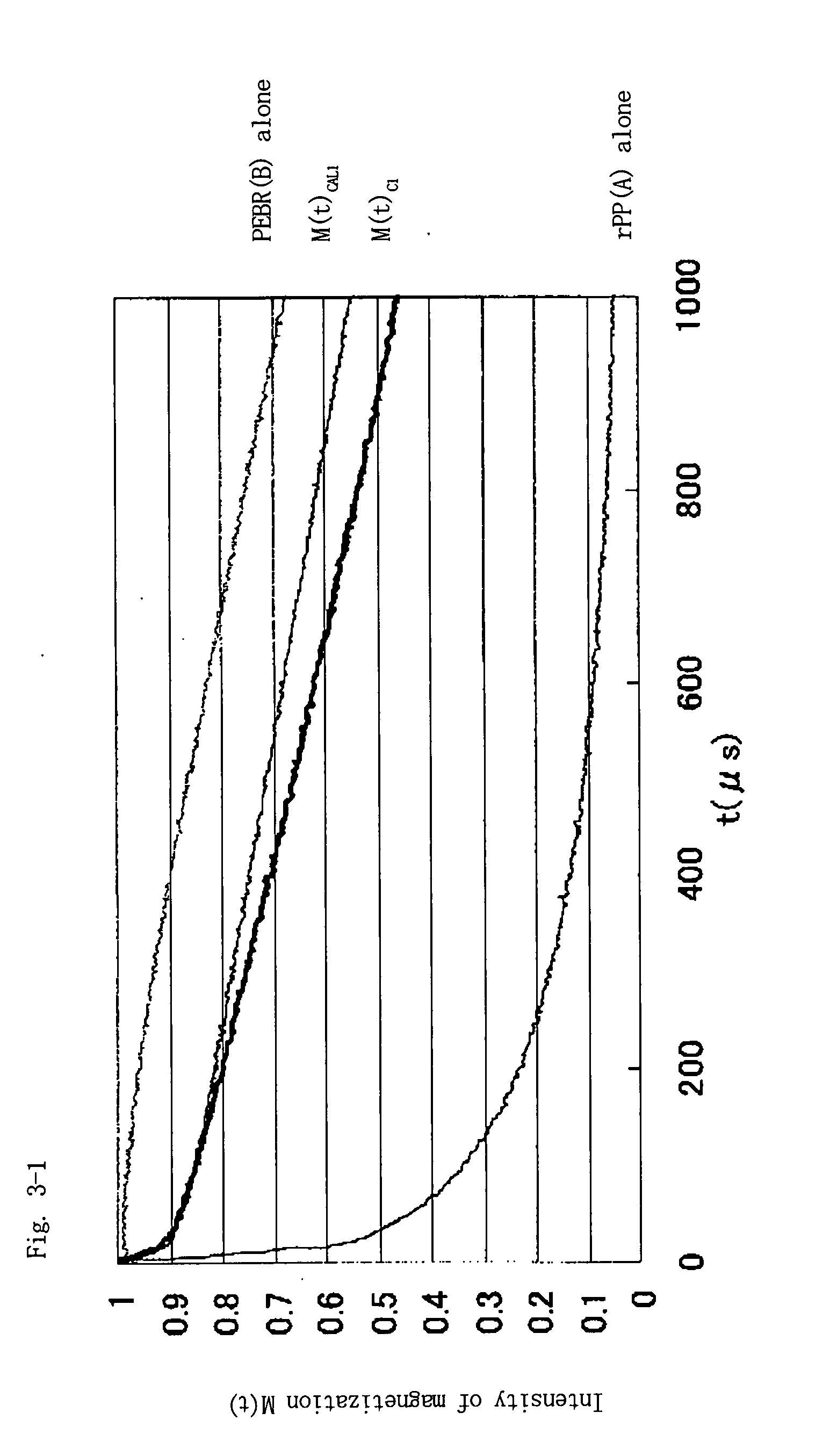

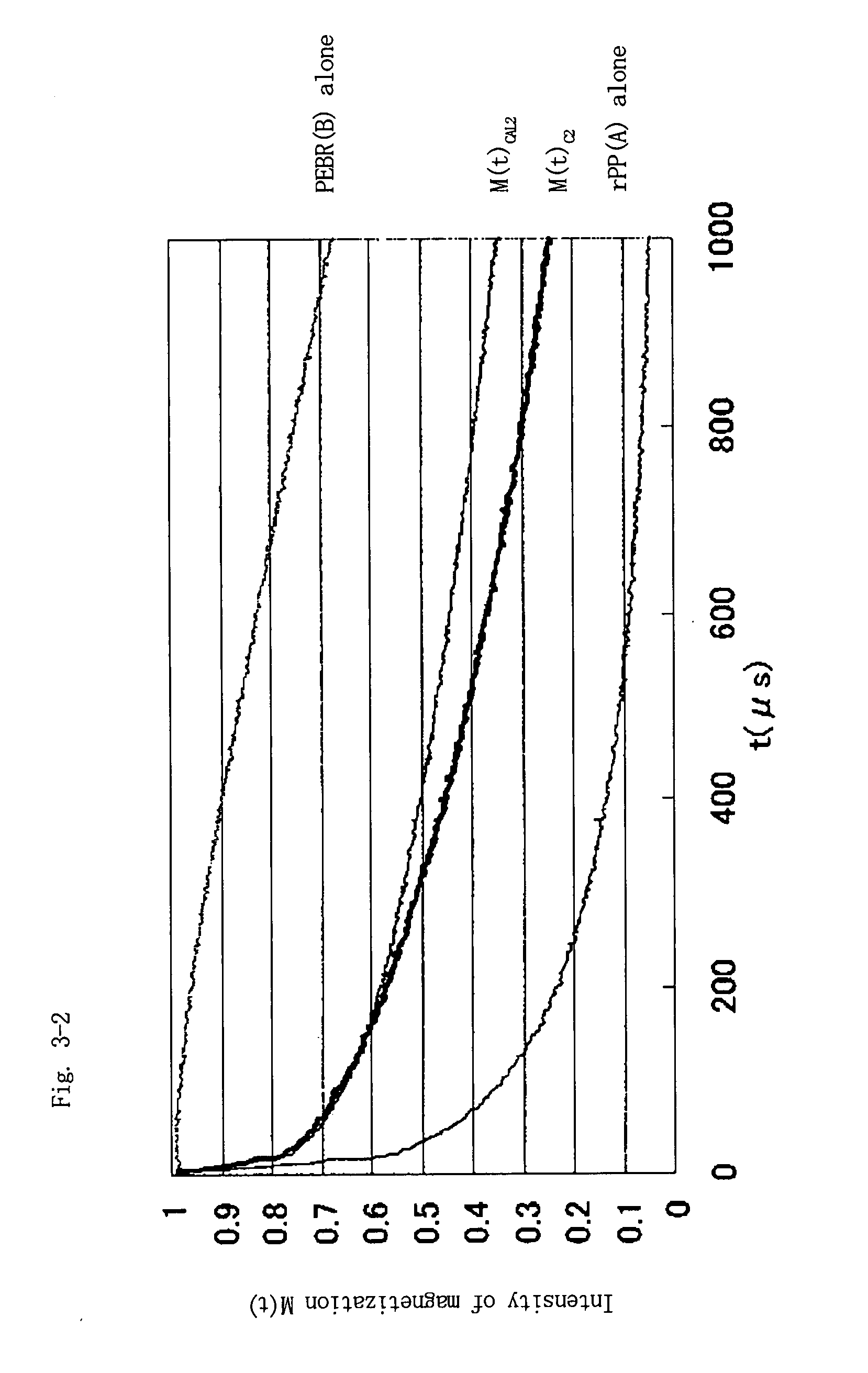

Propylene resin composition and use thereof

ActiveUS20070251572A1Improve mechanical propertiesGood rubber elasticitySolesPlastic/resin/waxes insulatorsElastomerAlpha-olefin

The thermoplastic resin composition (Xi) of the present invention comprises (A1), (B1), (C1), and optionally (D1) below: 1 to 90 wt % of an isotactic polypropylene (A1); 9 to 98 wt % of a propylene / ethylene / α-olefin copolymer (B1) containing 45 to 89 mol% of propylene-derived structural units, 10 to 25 molt of ethylene-derived structural units, and optionally, 0 to 30 mol% of C4-C20 α-olefin-derived structural units (a1); 1 to 80 wt % of a styrene-based elastomer (C1); and 0 to 70 wt % of an ethylene / α-olefin copolymer (D1) whose density is in the range of 0.850 to 0.910 g / cm3, wherein (A1)+(B1)+(C1)+(D1)=100 wt %.

Owner:MITSUI CHEM INC

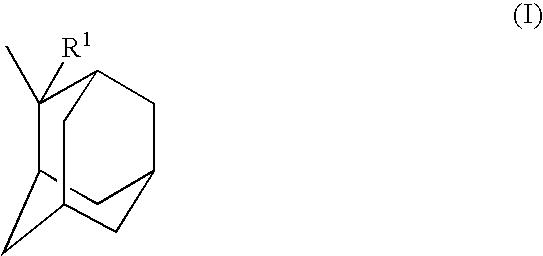

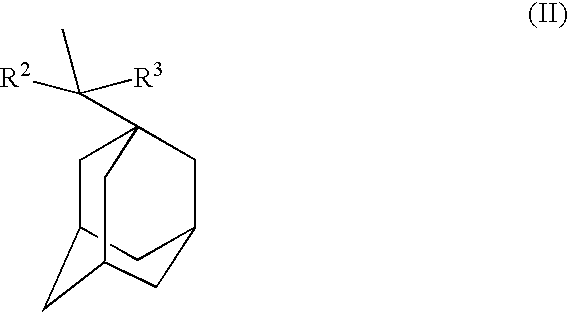

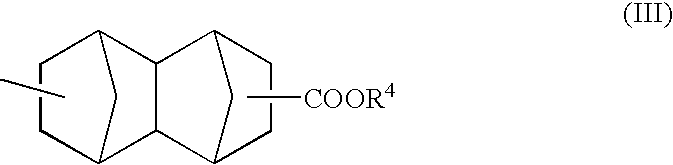

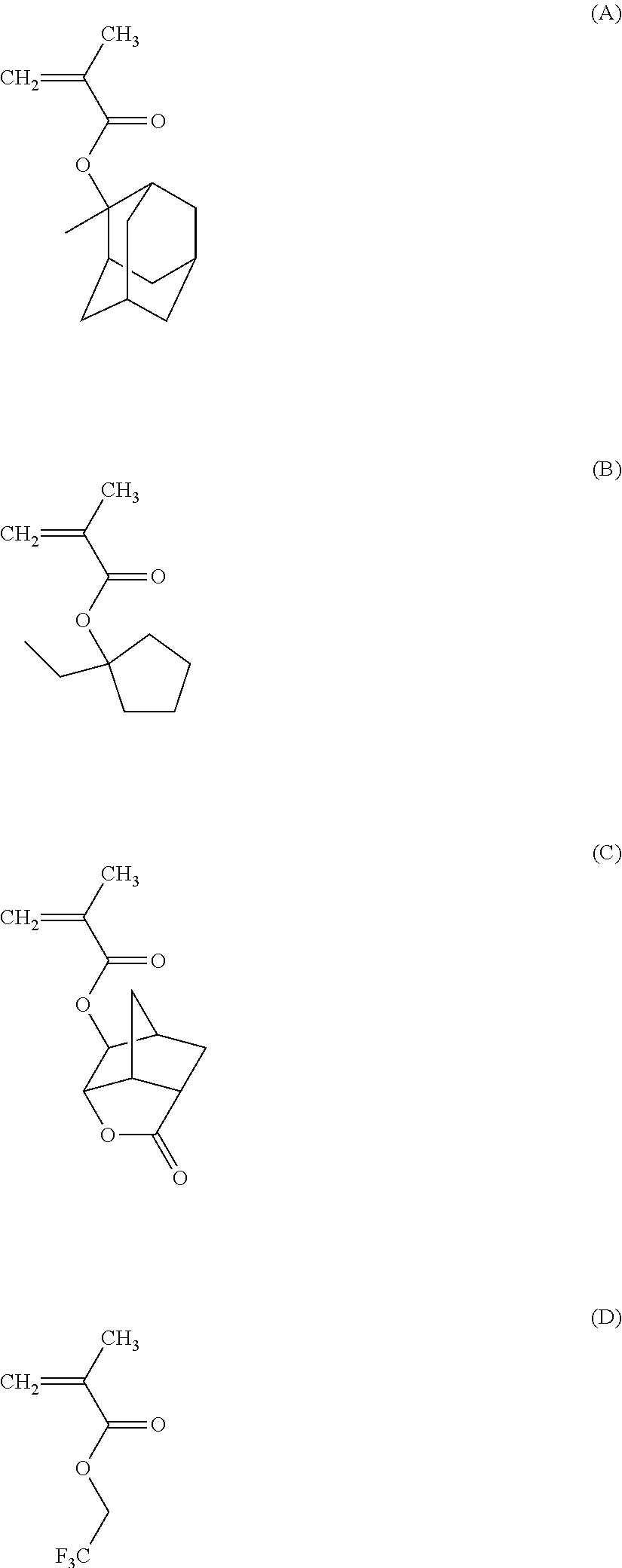

Positive resist composition and method of forming resist pattern from the same

InactiveUS20040110085A1Small line edge roughnessHigh resolutionRadiation applicationsSemiconductor/solid-state device manufacturingSolubilityMethacrylate

There is provided a positive type resin composition comprising (A) a resin component comprising within the principal chain a structural unit derived from a (meth)acrylate ester and incorporating an acid dissociable, dissolution inhibiting group containing a polycyclic group on an ester side chain section, for which the solubility in alkali increases under the action of acid, (B) an acid generator component which generates acid on exposure, and (C) an organic solvent, wherein the component (A) comprises both a structural unit derived from a methacrylate ester and a structural unit derived from an acrylate ester. According to such a resist composition, a resist pattern can be formed which displays little surface roughness and line edge roughness on etching, and also offers excellent resolution and a wide depth of focus range.

Owner:TOKYO OHKA KOGYO CO LTD

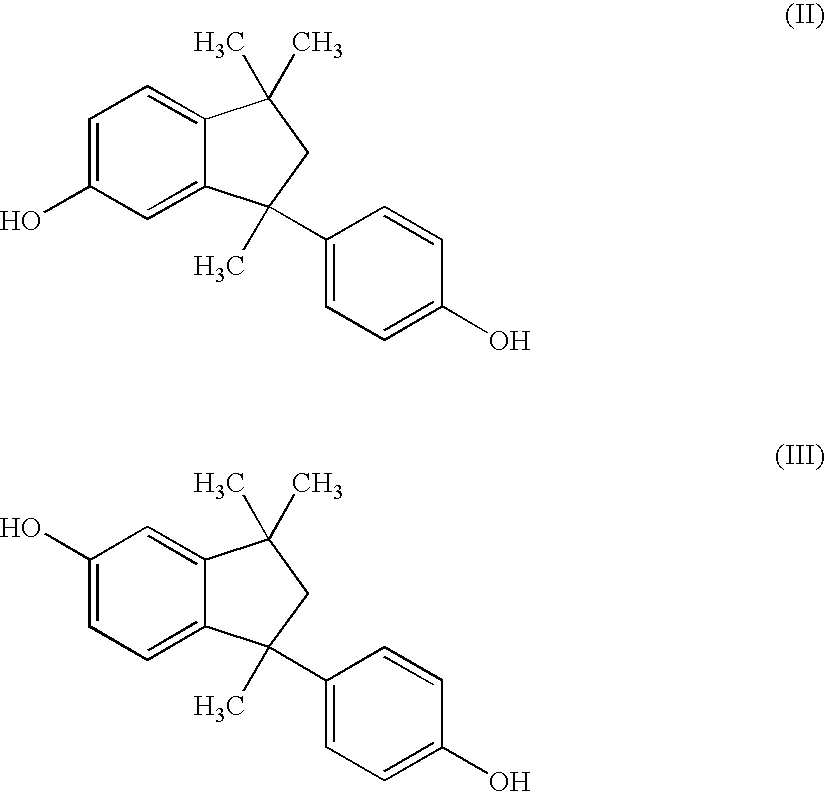

Biodegradable polyesters

InactiveUS6120895AMonocomponent copolyesters artificial filamentPolyurea/polyurethane coatingsFiberPolymer science

PCT No. PCT / EP97 / 04908 Sec. 371 Date Mar. 17, 1999 Sec. 102(e) Date Mar. 17, 1999 PCT Filed Sep. 19, 1997 PCT Pub. No. WO98 / 12242 PCT Pub. Date Mar. 20, 1998Biodegradable polyesters based on A) 95-99.99 mol % of at least one polyester A containing as monomeric building blocks of an acid component comprising a11) 20-95 mol % of at least one aliphatic or cycloaliphatic dicarboxylic acid or its ester-forming derivative and a12) 5-80 mol % of at least one aromatic dicarboxylic acid or its ester-forming derivative and at least one dihydroxy compound or at least one amino alcohol or their mixtures, and B) 0.01-5 mol % of a mixture comprising mono-, bi-, tri-, tetra- and higher-nuclear isocyanurates or corresponding compounds containing two, three or four functional groups capable of reacting with the end groups of polyester A, or mixtures of the isocyanurates and the corresponding compounds, as well as molding compositions comprising said polyesters, their manufacture and their use in the manufacture of moldings, filsm, fibers and coatings.

Owner:BASF AG

Positive resist composition

InactiveUS20030194639A1High light transmittanceHigh resolutionPhotosensitive materialsRadiation applicationsResistAlicyclic Hydrocarbons

Owner:FORTINET +1

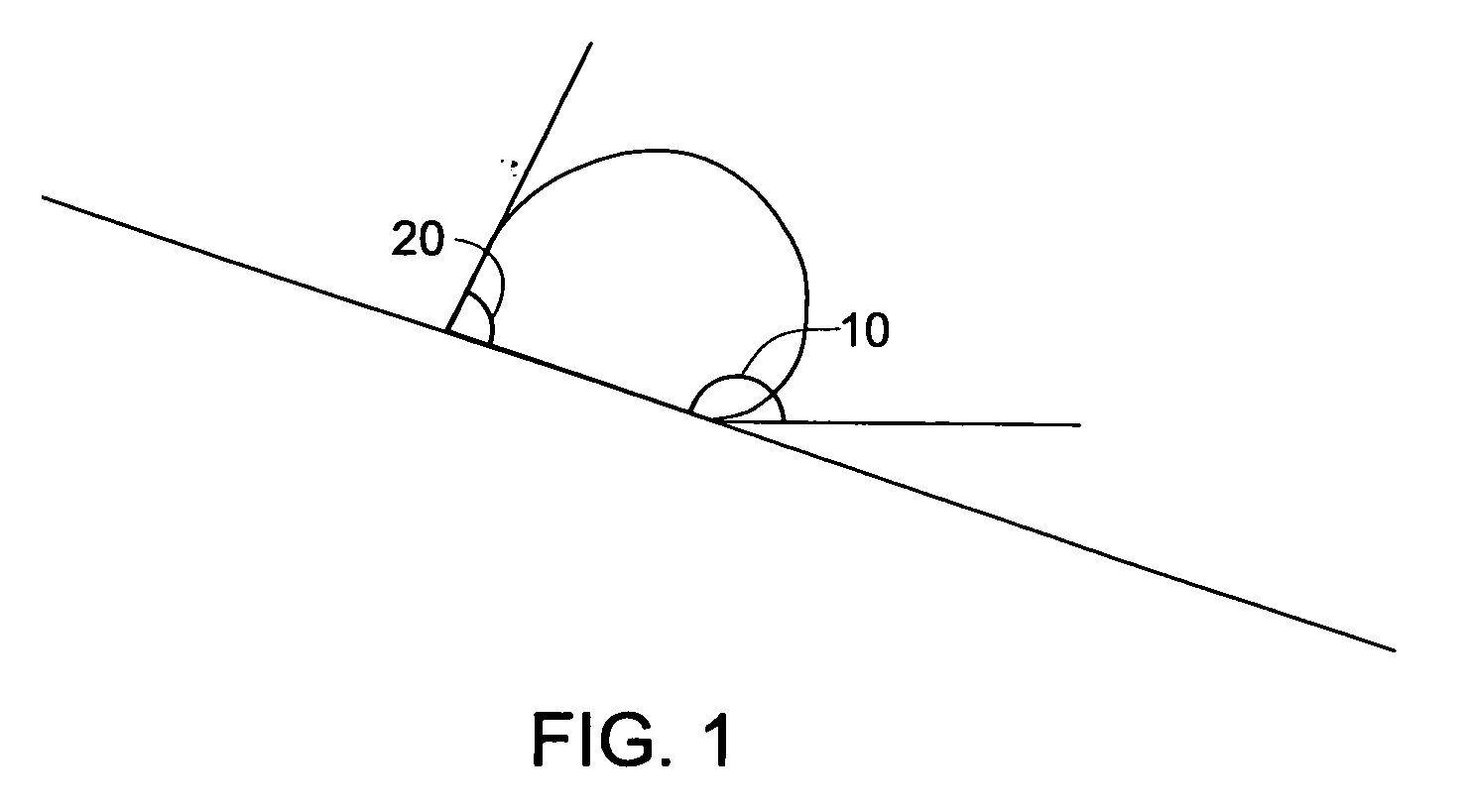

Superhydrophobic coating composition and coated articles obtained therefrom

A coating composition is provided comprising: (i) a fluorinated polymer comprising (a) structural units having the formula (I):—CR1R2—CFX— (I)wherein R1 and R2 are each independently an alkyl group, a fluorine atom, a chlorine atom, a hydrogen atom or a trifluoromethyl group, and X is a fluorine atom, a chlorine atom, a hydrogen atom or a trifluoromethyl group, and (b) structural units comprising at least one type of crosslinkable functional group; (ii) a crosslinking agent; and (iii) a plurality of particles functionalized with a functional group, wherein the functional group on the particles is essentially non-reactive with the fluorinated polymer and with the crosslinking agent. Articles comprising a coating composition described in embodiments of the invention are also provided.

Owner:GENERAL ELECTRIC CO

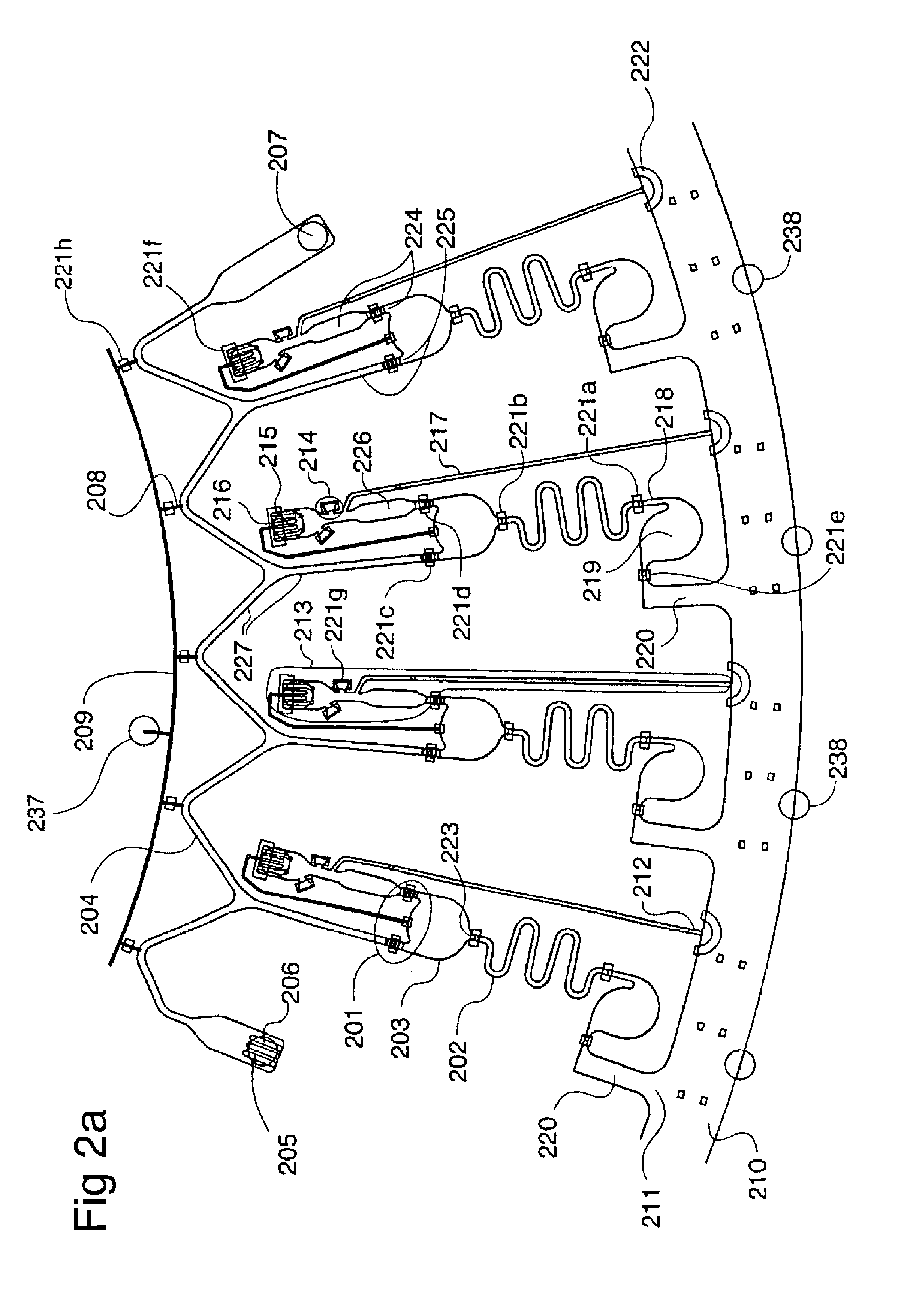

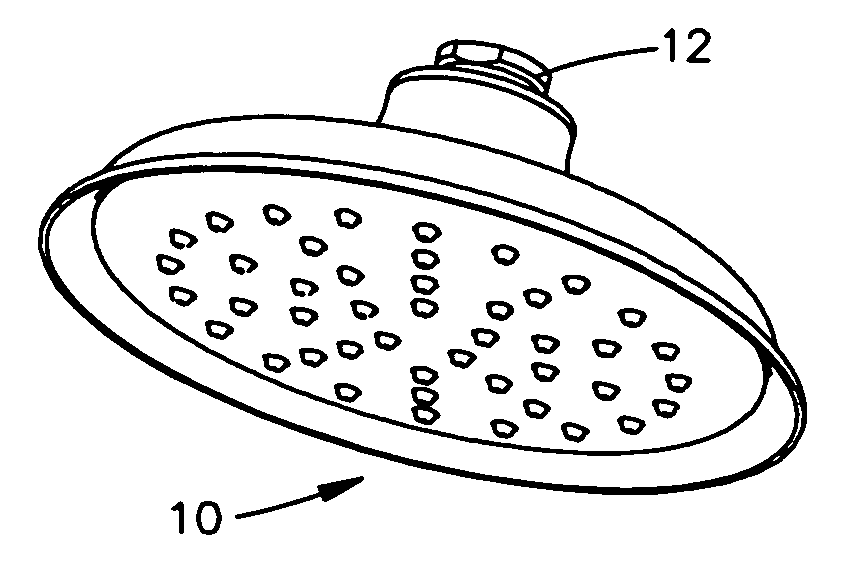

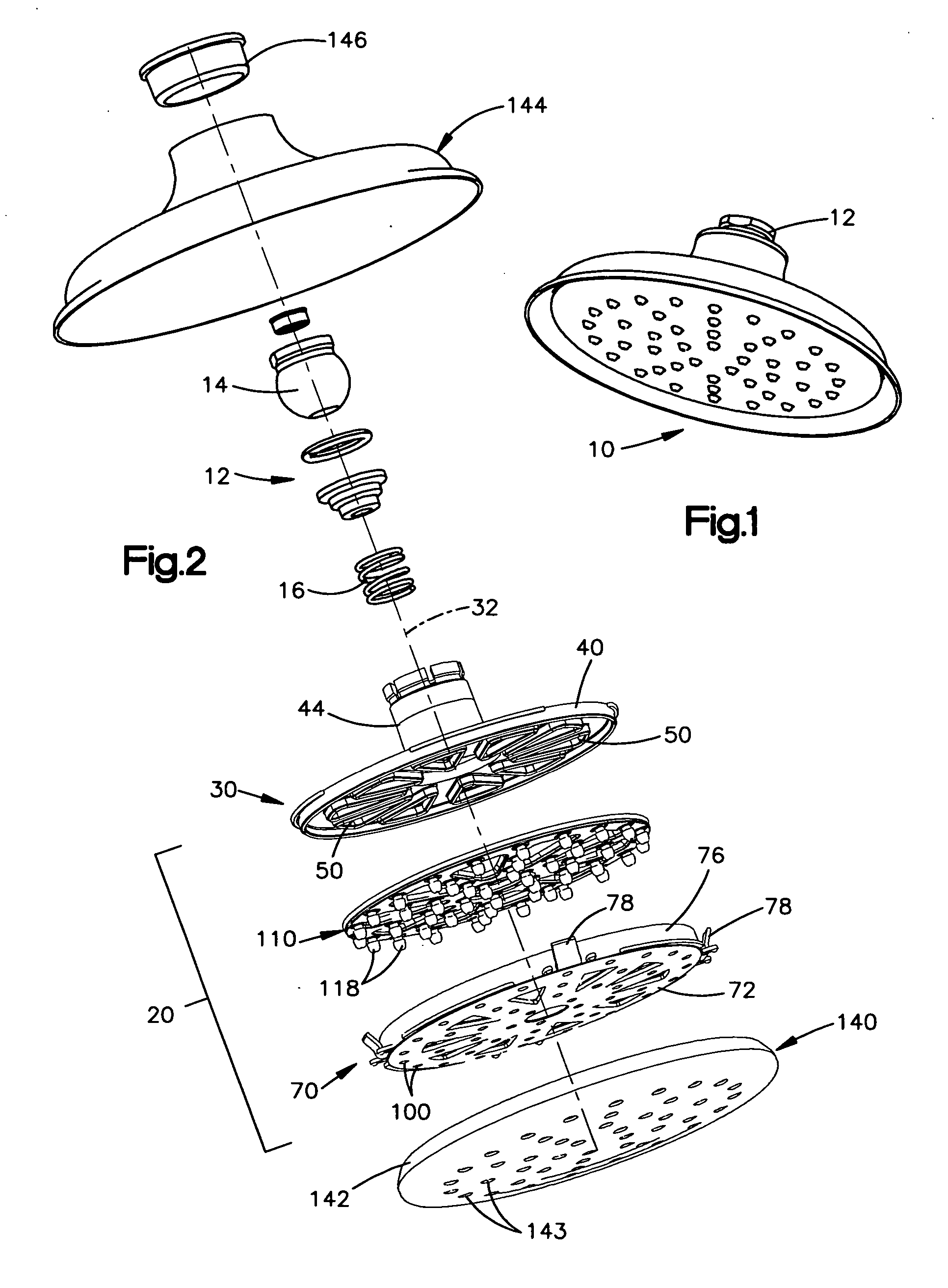

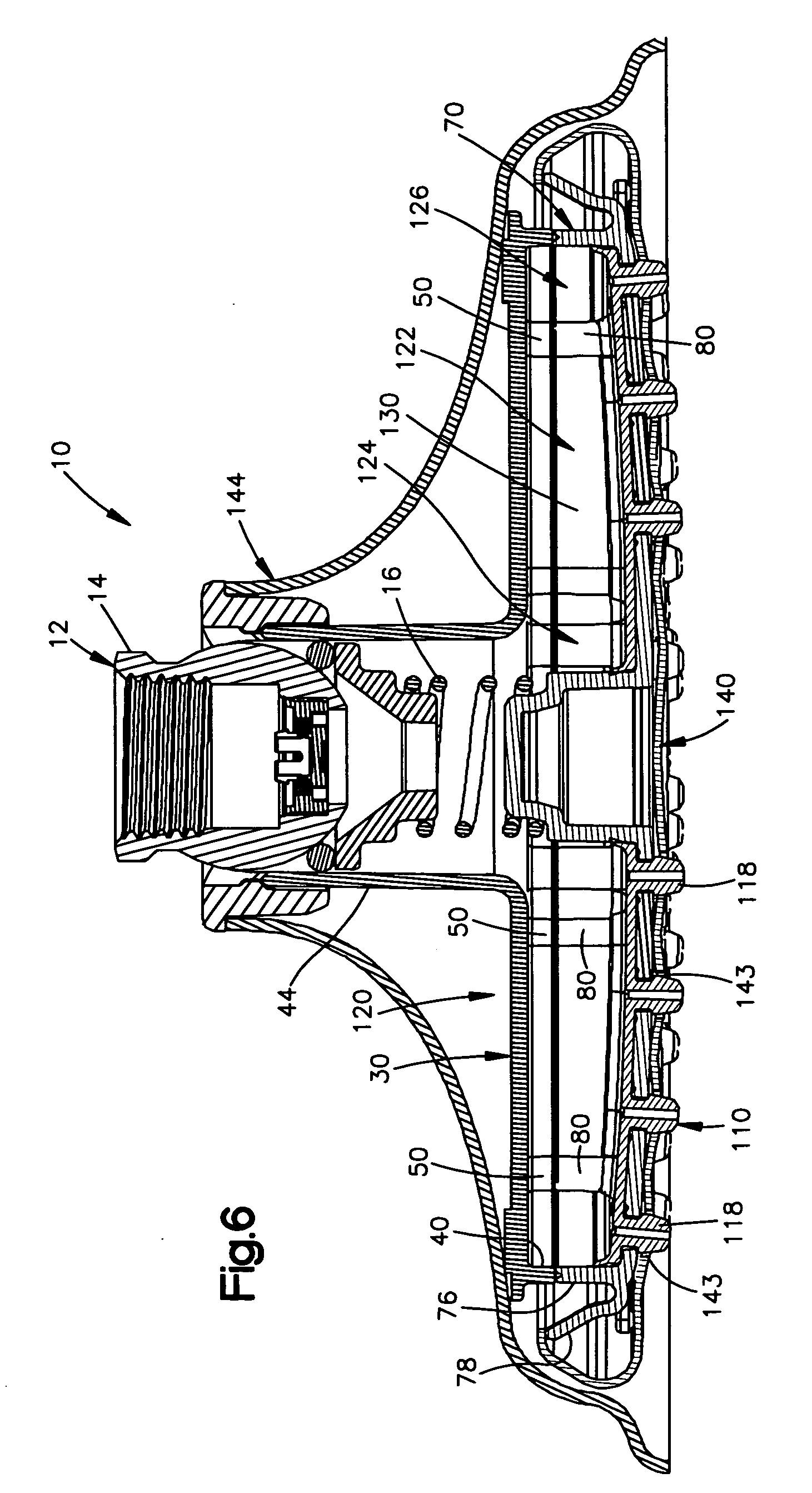

Showerhead

A showerhead includes a base connected with a water supply assembly. The base has a front wall with a plurality of water outlets; a plurality of waterways for directing water from the water supply assembly to the water outlets; and a plurality of cavities between the waterways that are not pressurized with water when the showerhead is operated. The showerhead may optionally include a front cover releasably supported on the base, and having a plurality of openings through which water from the water outlets of the base flows. If so, the front cover may be decorative and not pressurized with water when the showerhead is operated. A non-adjustable showerhead includes a structural unit having waterways that limit the surface area of the structural unit that is exposed to water pressure thereby limiting the force on the structural unit. The front wall of the structural unit may be exposed and serve not only a structural function but also as the esthetic part of the showerhead.

Owner:MOEN INC

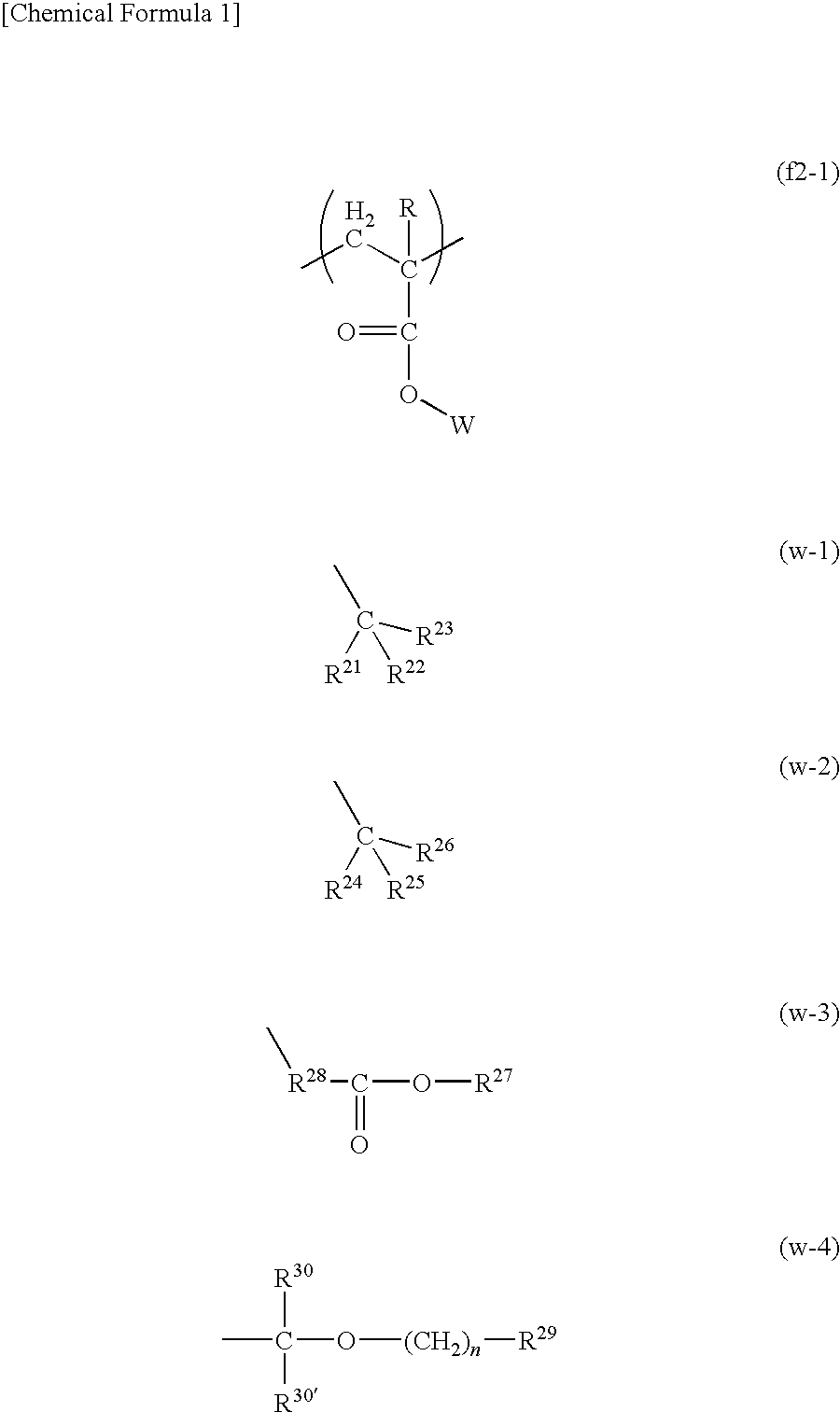

Resist composition for immersion exposure, method of forming resist pattern, and flourine-containing polymeric compound

ActiveUS20090317743A1Affect propertyImprove hydrophobicityPhotosensitive materialsRadiation applicationsCompound aResist

A resist composition for immersion exposure including: a fluorine-containing polymeric compound (F) containing a structural unit (f1) having a base dissociable group and a structural unit (f2) represented by general formula (f2-1) (wherein R represents a hydrogen atom, a lower alkyl group or a halogenated lower alkyl group; and W is a group represented by any one of general formulas (w-1) to (w-4)); a base component (A) that exhibits changed solubility in an alkali developing solution under the action of acid; and an acid generator component (B) that generates acid upon exposure.

Owner:TOKYO OHKA KOGYO CO LTD

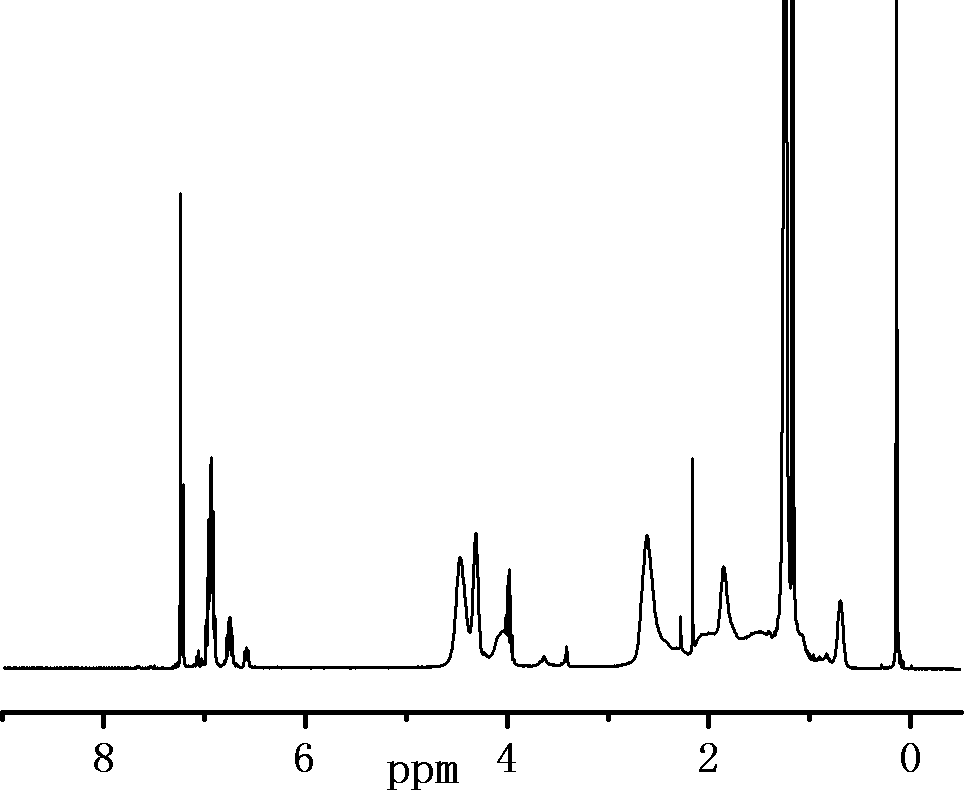

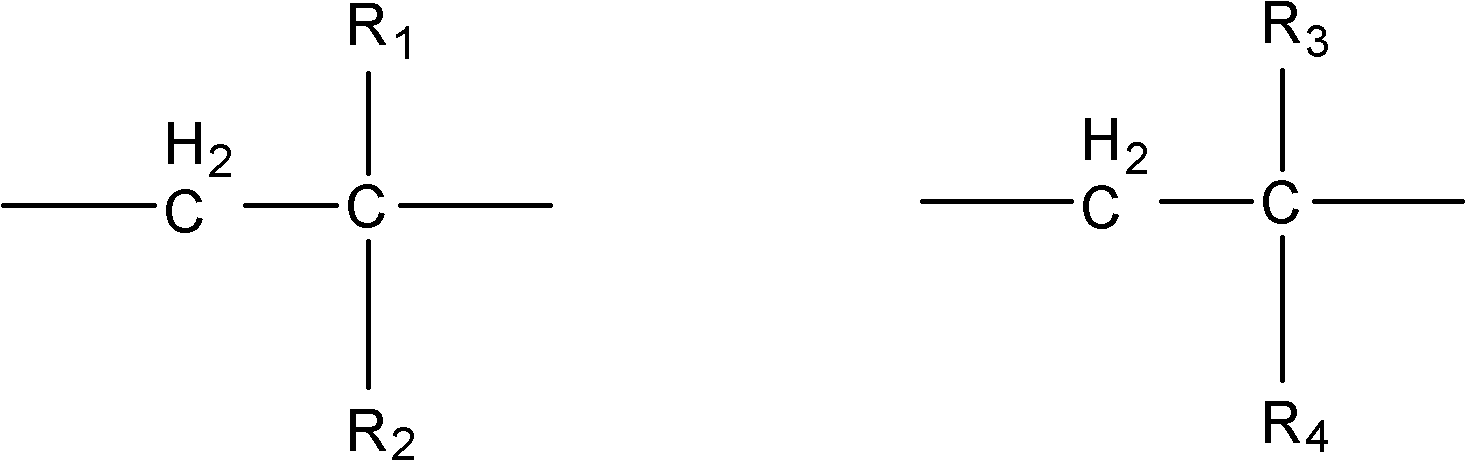

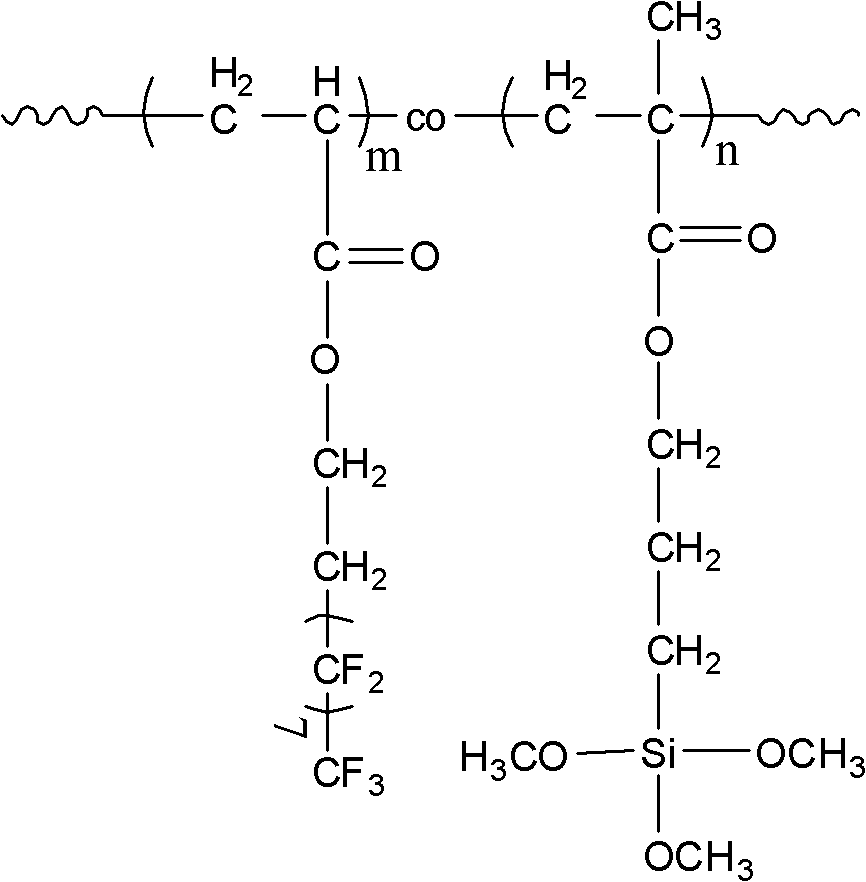

Super-amphiphobic polymer and super-amphiphobic surface prepared from super-amphiphobic polymer

InactiveCN102432742AGood scrub resistanceAccelerated corrosionWater-repelling agents additionPaper/cardboardPolymer scienceMicrosphere

The invention belongs to the field of macromolecule super-amphiphobic materials and discloses a super-amphiphobic polymer and a super-amphiphobic surface. The super-amphiphobic polymer is a random copolymer composed of structural units shown as a formula I and a formula II. The super-amphiphobic surface is obtained by comprising the following steps of: pre-processing a substrate material; placinga micro-balloon in a fluorine-containing solvent, and ultrasonically dissolving to obtain a micro-balloon supernatant solution; adding the super-amphiphobic polymer, a hydrochloric acid tetrahydrofuran solution and water into the micro-balloon solution while stirring, placing the substrate material, and reacting for 5-24 h; and taking out the substrate material, washing by using the fluorine-containing solvent, methanol and water in turn, drying in vacuum, and obtaining the super-amphiphobic surface. The super-amphiphobic polymer disclosed by the invention can give good surface hydrophobic ability and oleophobic ability to the substrate. Because the polymer has the characteristics of the fluorine-containing polymer so that the polymer can be chemically bonded with the surface of the substrate, the obtained super-amphiphobic surface has good scrubbing resistant property and corrosion resistant property.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

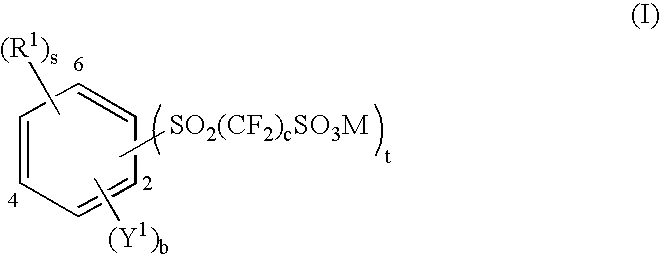

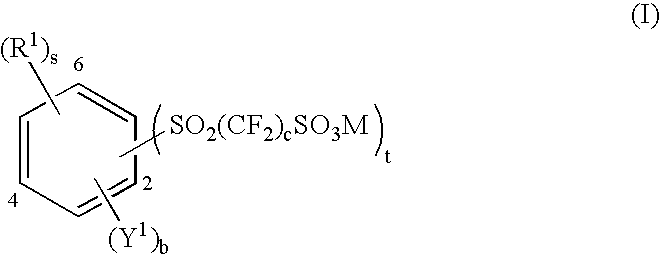

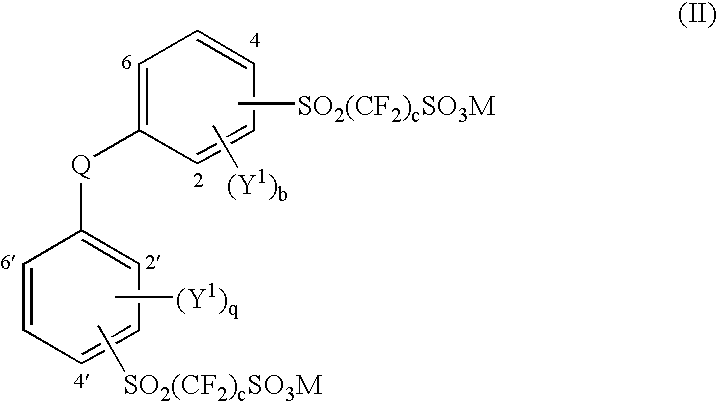

Aromatic polyethers

An aromatic polyether comprising structural units derived from a halosulfone sulfonate having structure (I):wherein R1 is a C3-C25 aromatic radical, a C3-C25 cycloaliphatic radical, or a C1-C10 aliphatic radical; M is hydrogen or a charge balancing cation; Y1 is independently at each occurrence a halogen; “t” is an integer having a value of 1 or 2; “s” is an integer having a value 0 to 3, “b” is an integer having a value 1 to 4; and “c” is an integer having a value 1 to 20. Also provided are methods of preparing the aromatic polyethers, and compositions including the aromatic polyethers.

Owner:GENERAL ELECTRIC CO

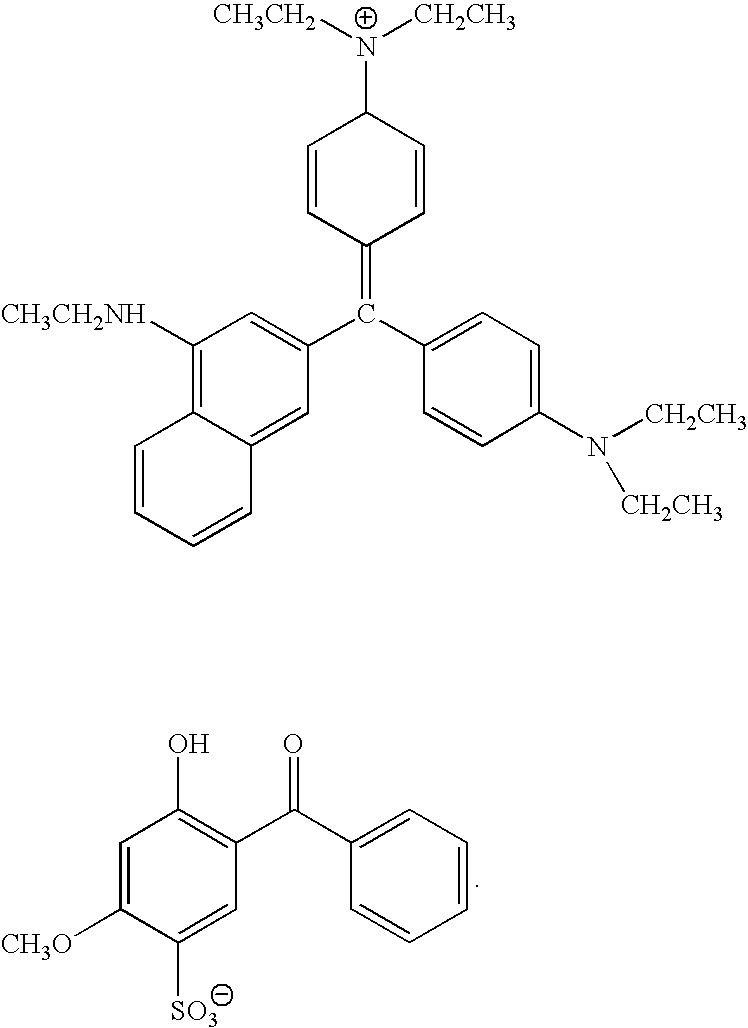

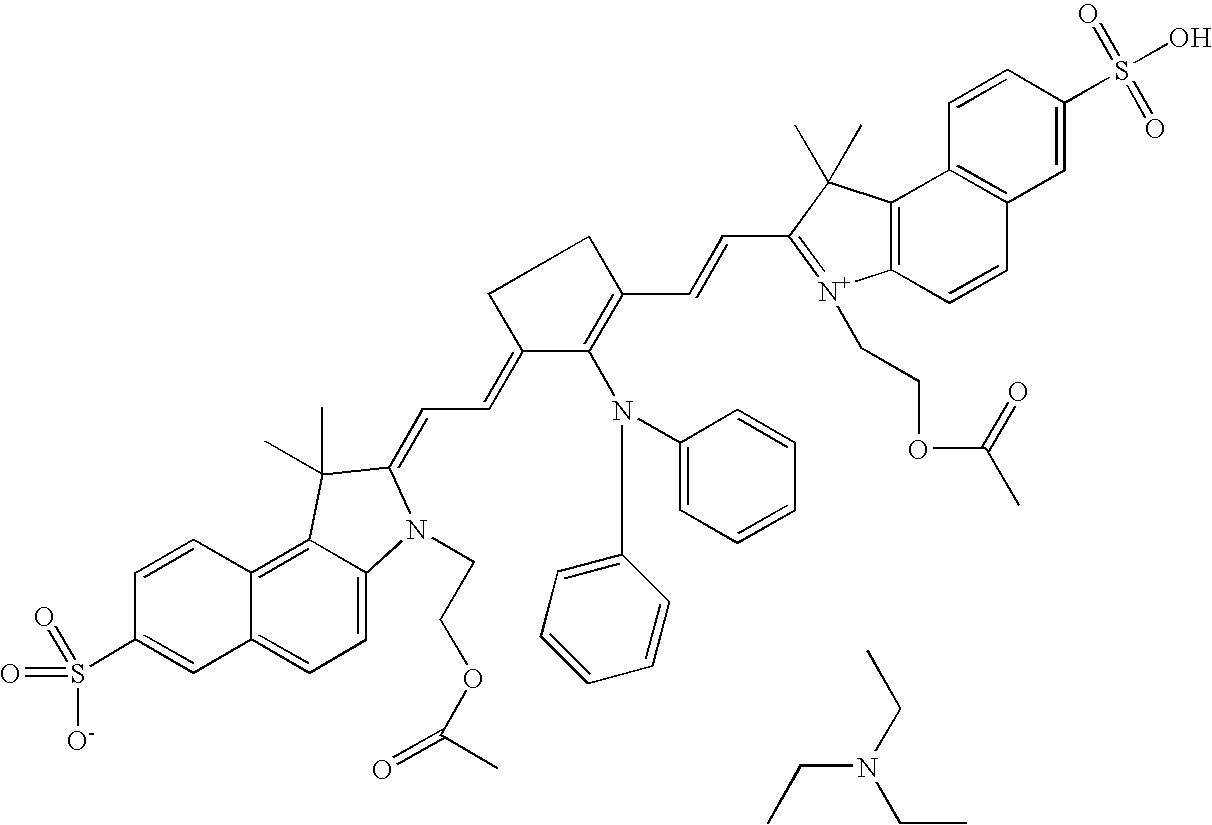

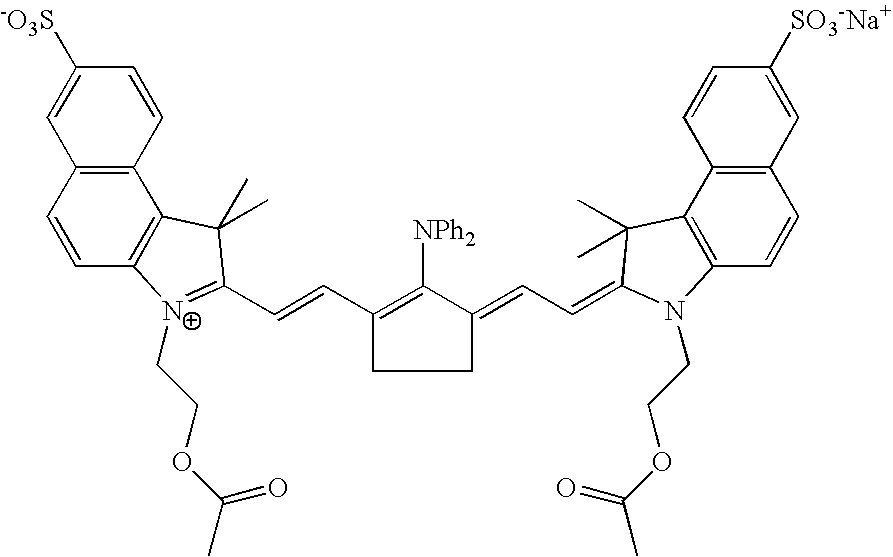

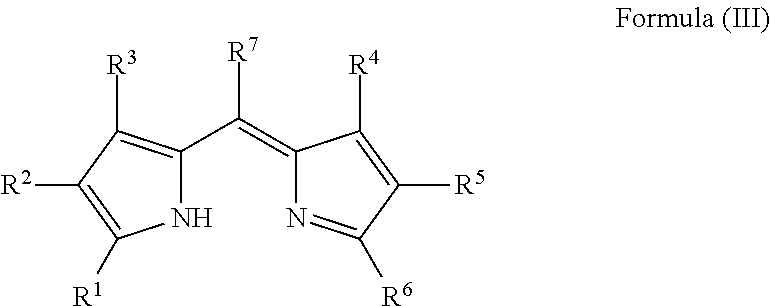

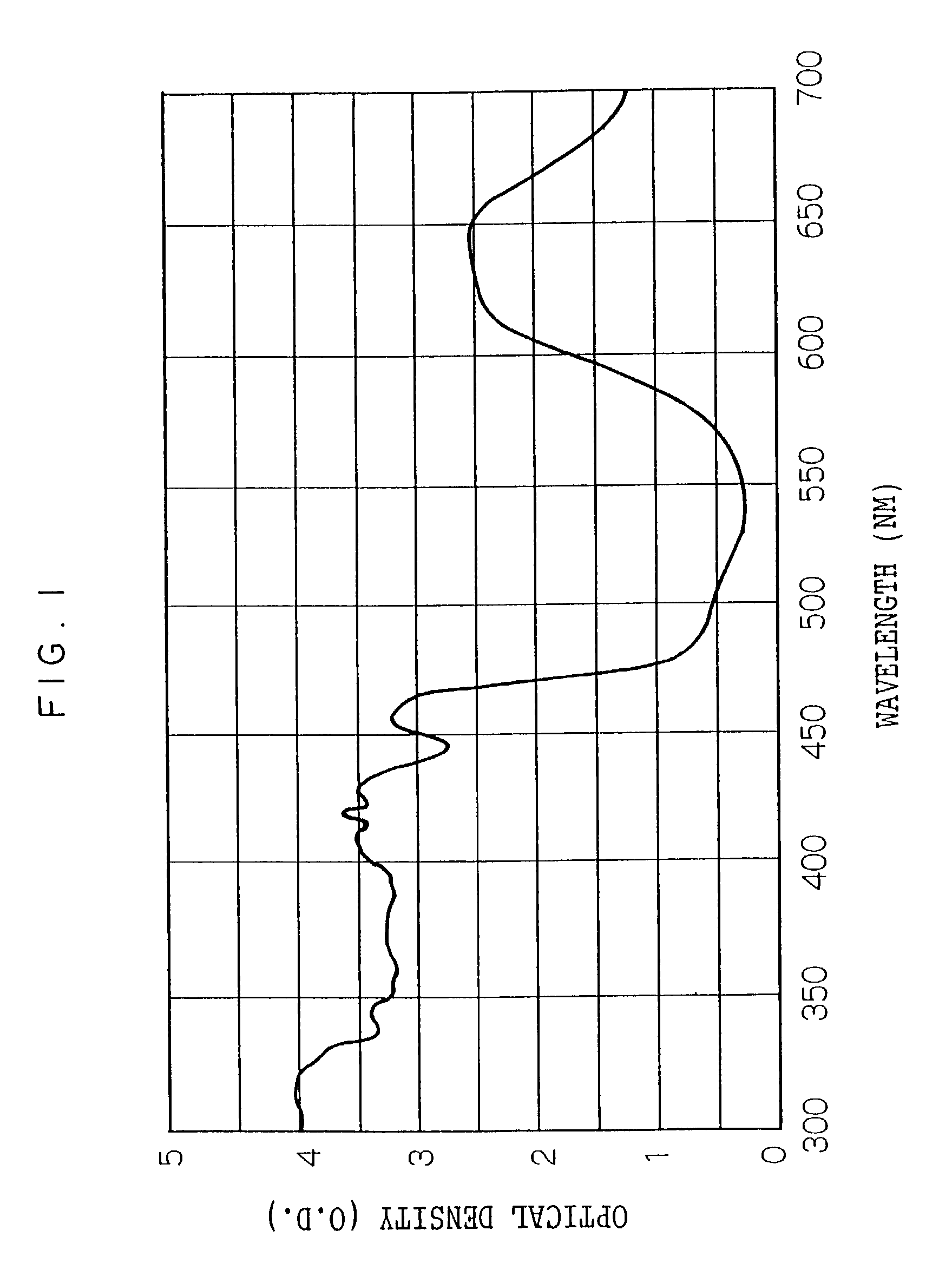

Radiation-sensitive colored composition, color filter, method for producing a color pattern, method for producing color filter, solid-state imaging device, and liquid crystal display apparatus

ActiveUS20120242940A1Improve hydrophilicityImproved development propertyPhotosensitive materialsSolid-state devicesLiquid-crystal displayRadiation sensitivity

Provided is a radiation-sensitive colored composition that enables formation of color cured films in which color concentration unevenness is inhibited and which have uniform color and exhibit a superior development property and excellent pattern formability in the formation of color patterns.The radiation-sensitive colored composition contains (A) a dye polymer containing a structural unit having a dye structure polymerized using a chain-transfer agent having a LogP value of 5 or less, and (B) a solvent.

Owner:FUJIFILM CORP

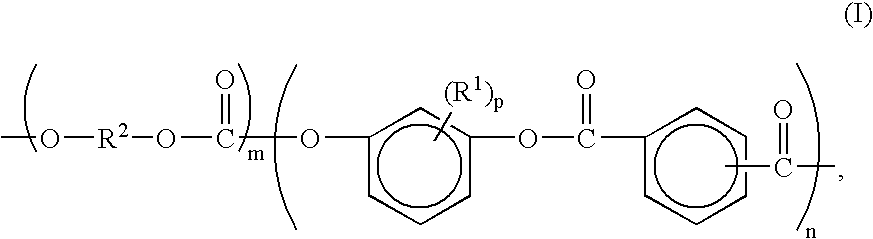

Copolyester as well as preparation method and application thereof

InactiveCN102030893AImprove dyeing effectLow investment costMonocomponent copolyesters artificial filamentDisperse dyeSide chain

The invention discloses copolyester and a preparation method and application thereof. The copolyester comprises binary acid components and binary alcohol components, wherein in the binary acid components, the content of the terephthalic acid structural unit is more than 90mol%; and in the binary alcohol components, the content of the ethylene glycol structural unit is 70-99mol%, and the content of the aliphatic dihydric alcohol structural unit which contains side chains and less than 6 carbon atoms is 1-30mol%. The copolyester also comprises a polyethylene glycol structural unit. Because the aliphatic dihydric alcohol structural unit which contains side chains and less than 6 carbon atoms and the polyethylene glycol structural unit are added to the copolyester, the copolyester can be made into fiber with the known method, and the fiber can be made into fabric. The prepared finished product has good dyeing property on disperse dye at normal temperature and pressure, thus the high equipment investment and operation cost resulted from high-temperature and high-pressure dying can be reduced.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

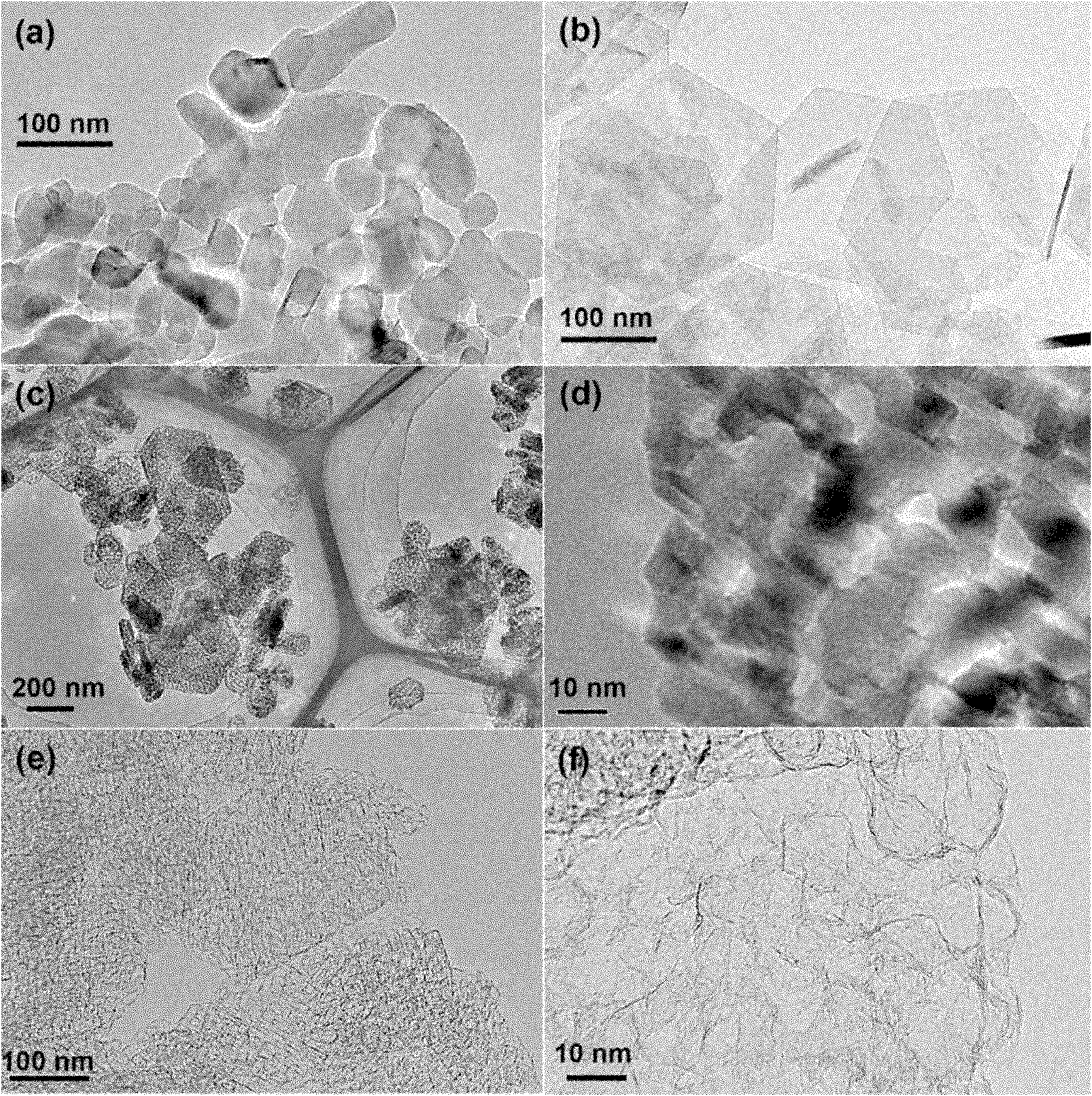

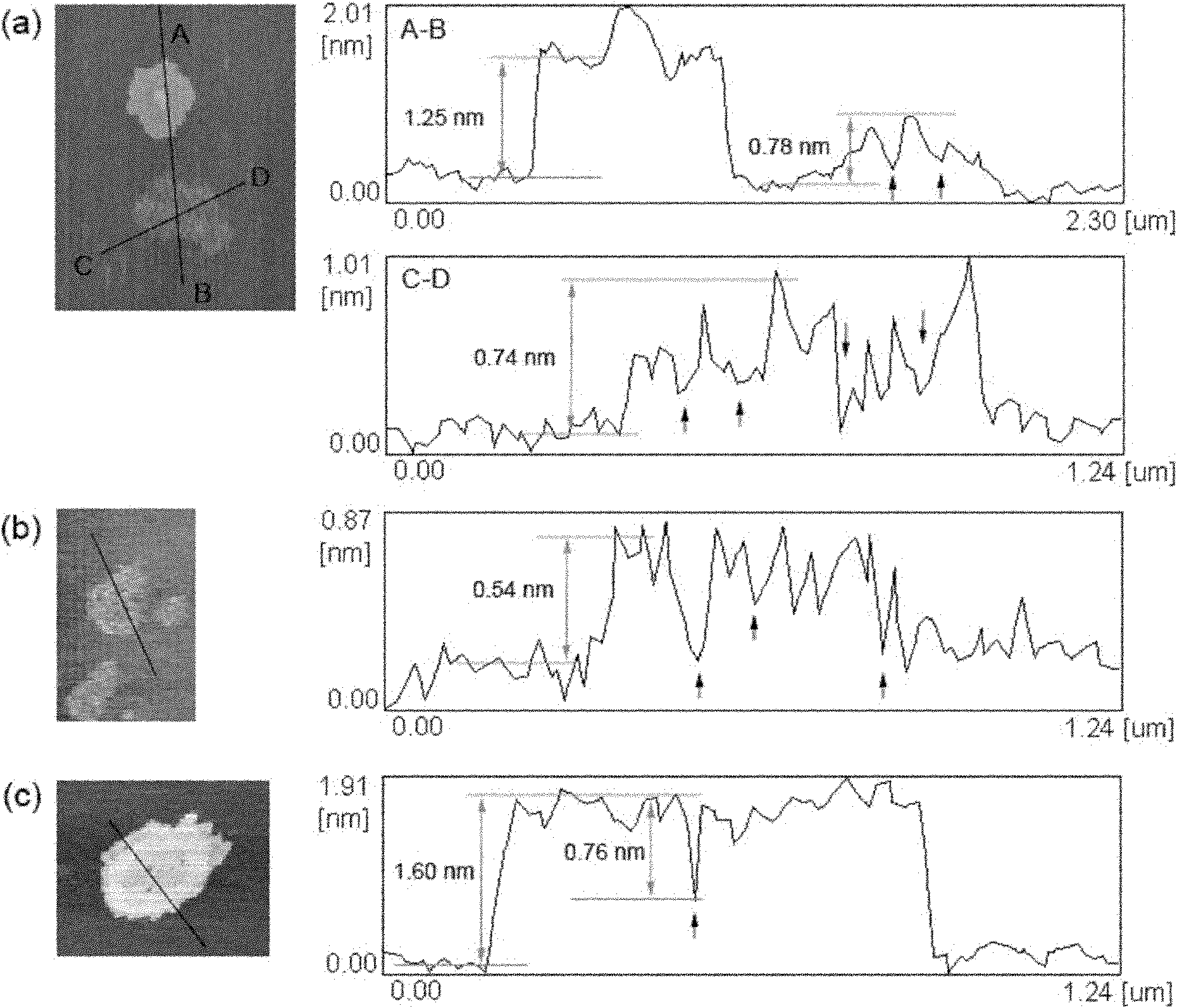

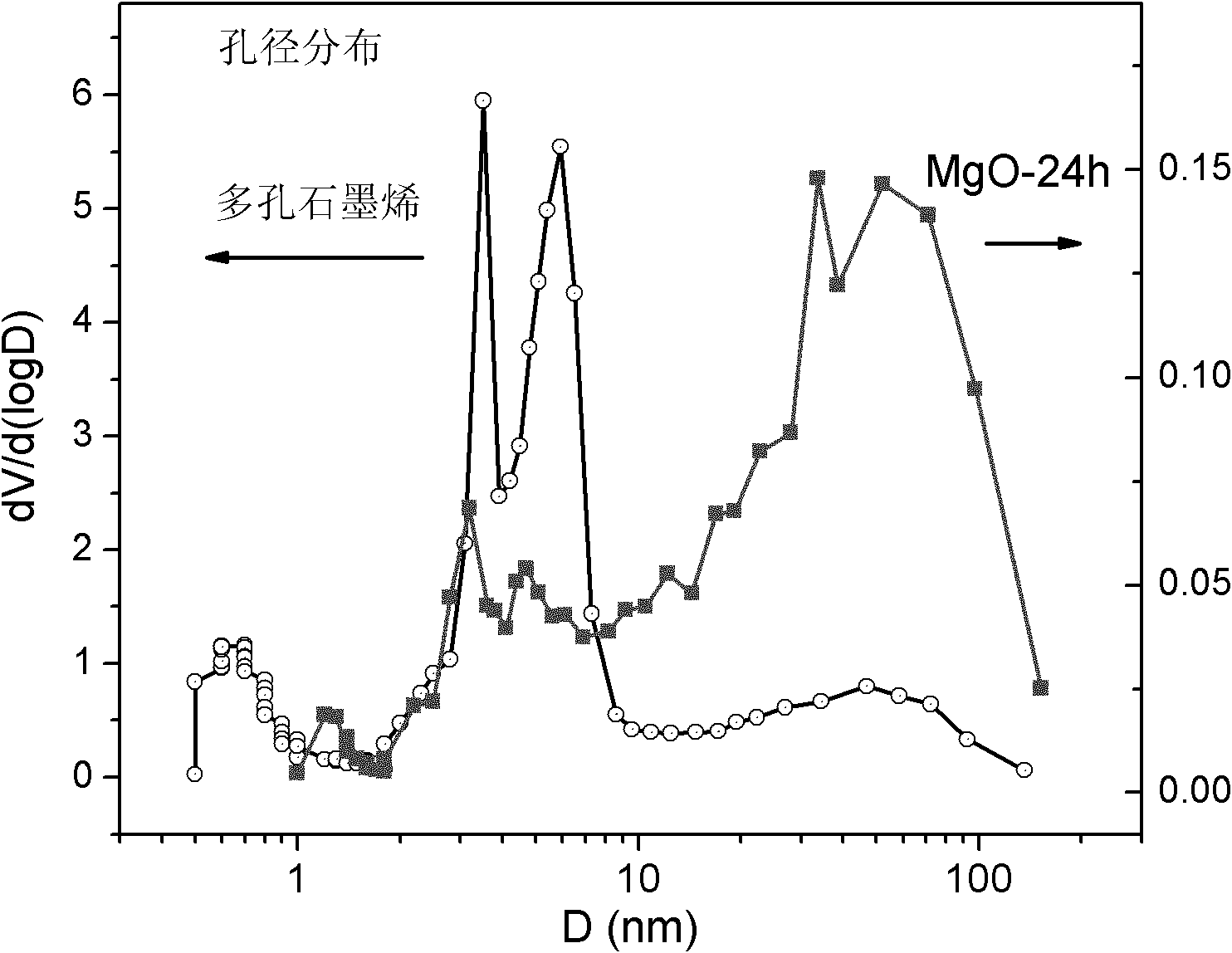

Graphene with porous structure and preparation method of graphene

The invention discloses a graphene with a porous structure and a preparation method of the graphene. The porous grapheme consists of a single-layer or multi-layer graphene structure unit, the single-layer or multi-layer grapheme structure unit has a pore-shaped structure (pore diameter is 0.1-200 nm) and a large specific surface area (300-2000 m<2> / g), thus the graphene has potential application value in the aspects of super-capacitors, conductive filling materials and the like. The preparation method of the porous grapheme is characterized in that MgO, Mg(OH)2, Al2O3, Al(OH)3, hydrotalcite compounds and / or corresponding calcined products of the substances are used as catalysts, or MgO, Mg(OH)2, Al2O3, Al(OH)3, hydrotalcite compounds and / or corresponding calcined products of the substances are used as carriers so as to further load one or more active components of Fe, Co, Ni and Mo and then the obtained substance is used as the catalyst ( the pore diameter of the catalyst is 1-200 nm, and the specific surface area is 10-300 m<2> / g); and then at the temperature of 300-1000 DEG C, the graphene is prepared by using inert gases such as nitrogen, argon, helium and the like and using a hydrocarbon chemical gas phase deposition method.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

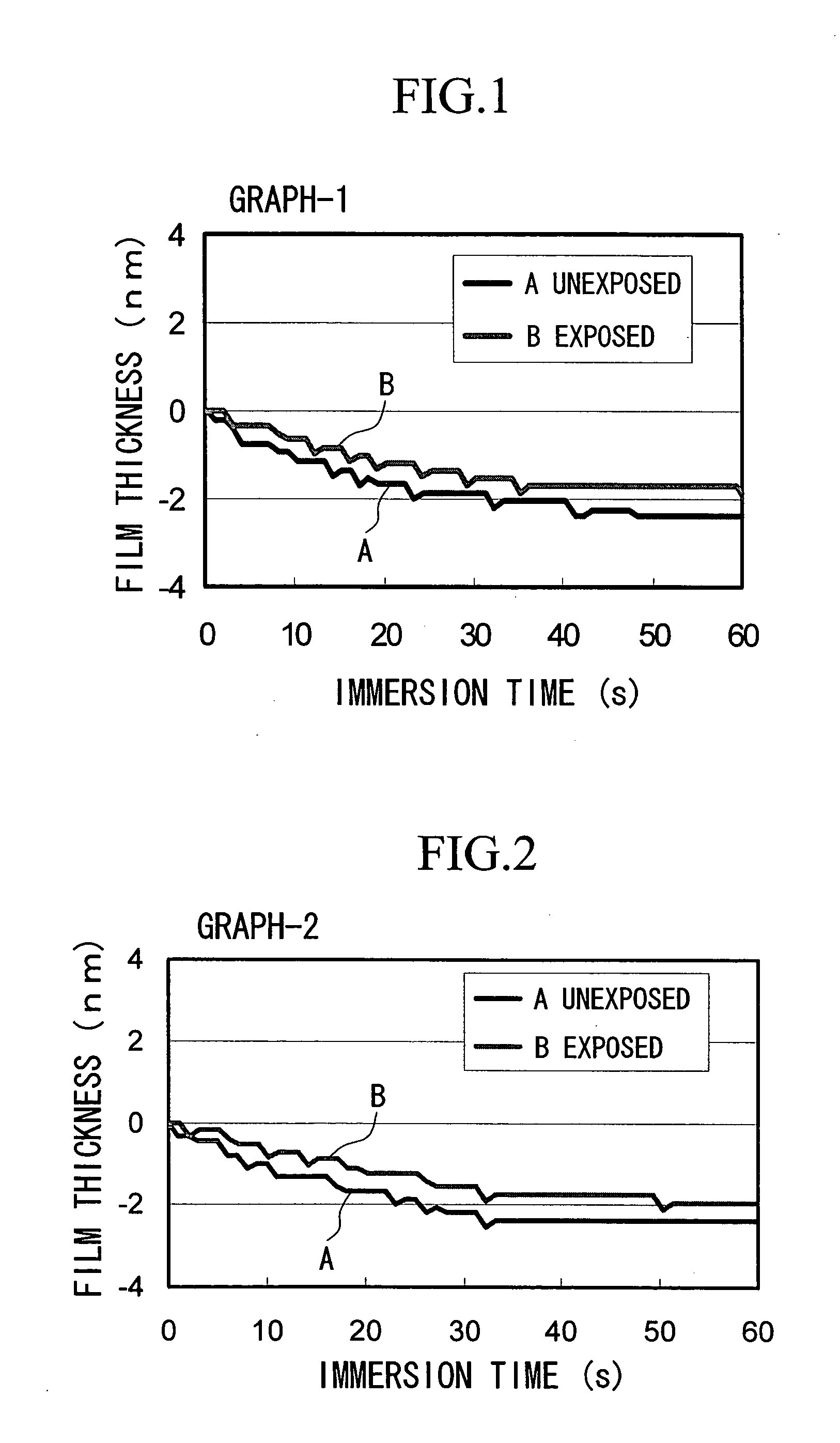

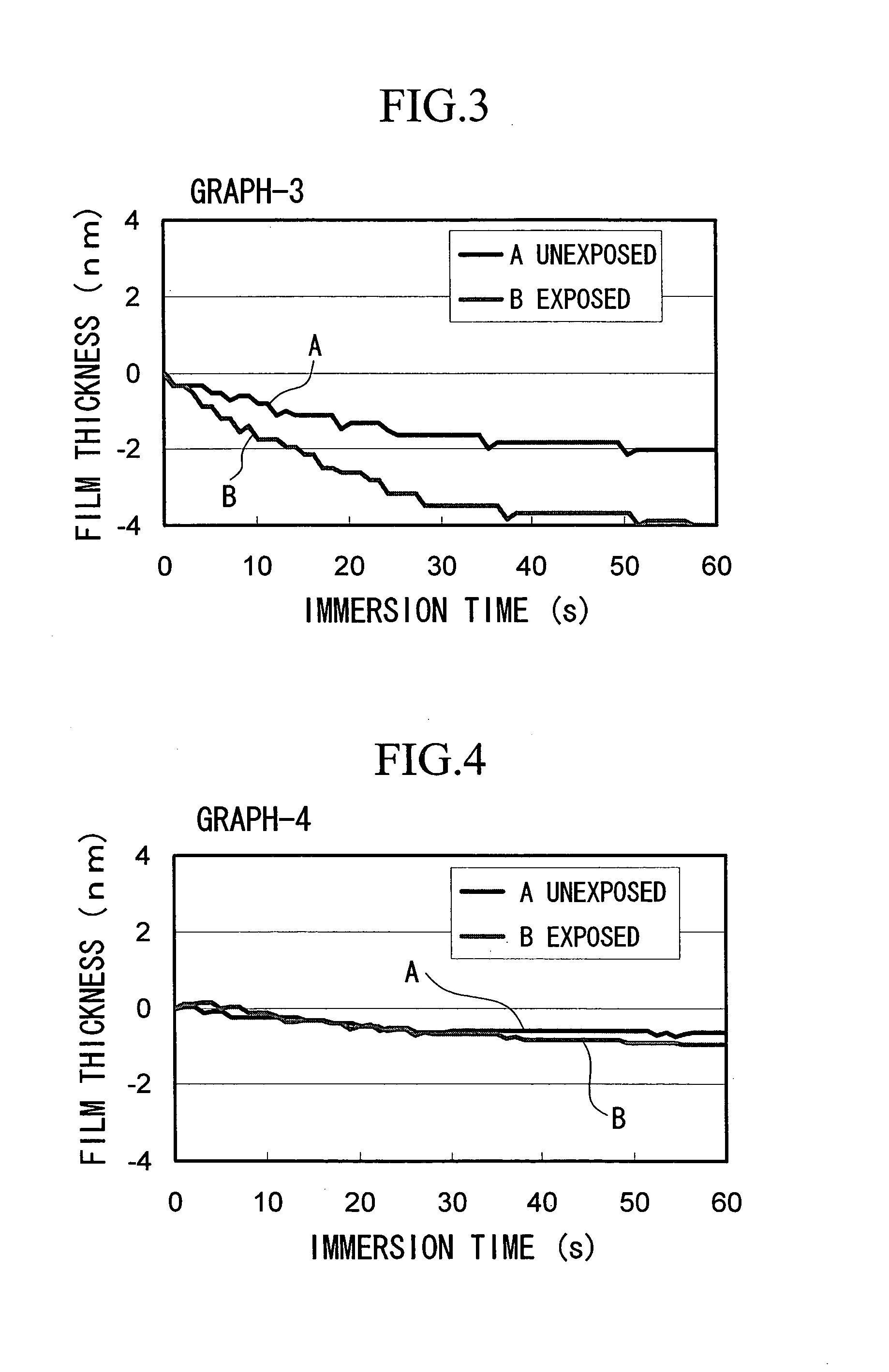

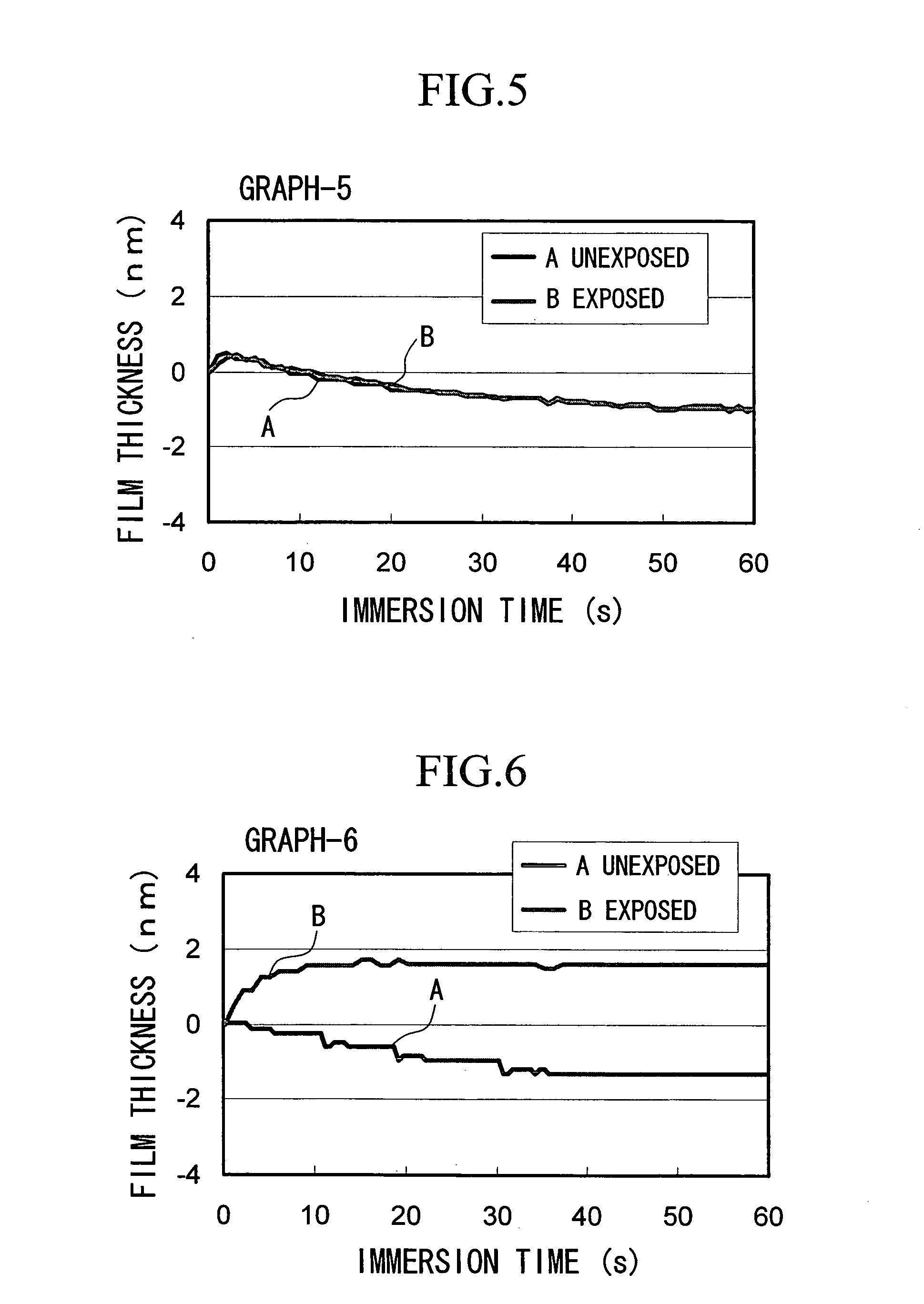

Resist composition

ActiveUS20050014090A1Minimal deterioration in sensitivitySmall swellingRadiation applicationsSemiconductor/solid-state device manufacturingMethacrylateSolubility

A resist composition which is stable relative to solvents used in immersion lithography processes and displays excellent sensitivity and resist pattern profile, and a method of forming a resist pattern that uses such a resist composition are provided. The resist composition is in accordance with predetermined parameters, or is a positive resist composition comprising a resin component (A) which contains an acid dissociable, dissolution inhibiting group and displays increased alkali solubility under the action of acid, an acid generator component (B), and an organic solvent (C), wherein the component (A) contains a structural unit (a1) derived from a (meth)acrylate ester containing an acid dissociable, dissolution inhibiting group, but contains no structural units (a0), including structural units (a0-1) containing an anhydride of a dicarboxylic acid and structural units (a0-2) containing a phenolic hydroxyl group.

Owner:TOKYO OHKA KOGYO CO LTD

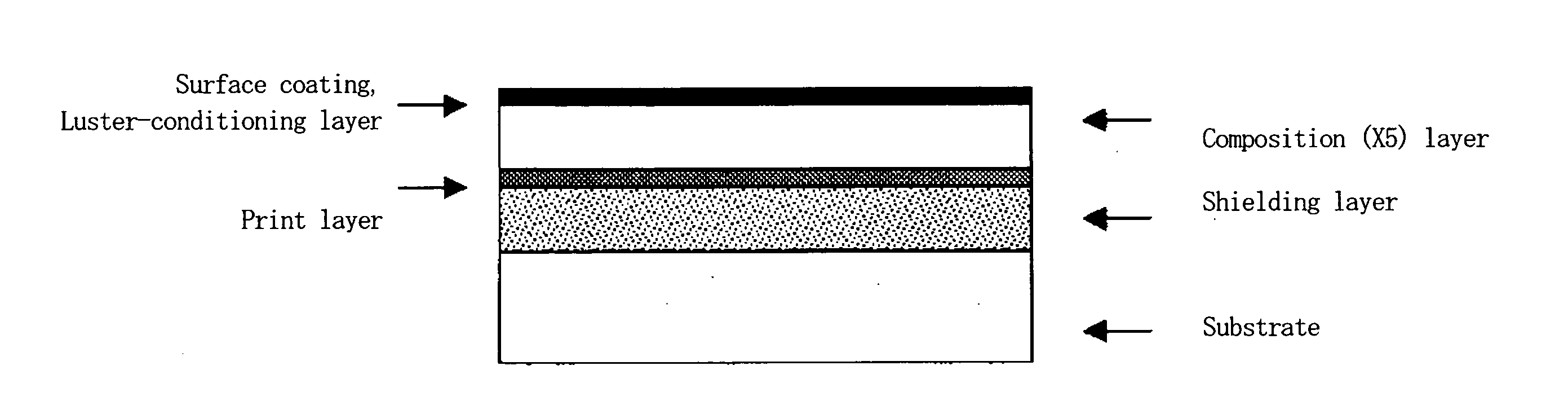

Photosensitive resin composition, transfer material, image forming method, color filter and producing method thereof and photomask and producing method thereof

InactiveUS7041416B2Improve performanceHigh resolutionPhotography auxillary processesPhotosensitive materialsArylMeth-

The invention provides a colored photosensitive resin composition for forming a colored image on a transparent substrate, the colored photosensitive resin composition comprising: an alkali-soluble binder, one of a monomer and an oligomer having at least two ethylenic unsaturated double bonds, one of a photopolymerization initiator and a photopolymerization initiating system, and a pigment, said alkali-soluble binder comprising a copolymer including a structural unit having a carboxyl group, a structural unit represented by the following general formula (1), and a structural unit comprising a (meth)acrylate having at least one of an aromatic ring and an alicyclic ring:wherein R1 represents one of a hydrogen atom and a methyl group; and each of R2 to R6 independently represents one of a hydrogen atom, a substituted and unsubstituted alkyl group, a substituted and unsubstituted aryl group, a halogen atom and a cyano group.

Owner:FUJIFILM CORP +1

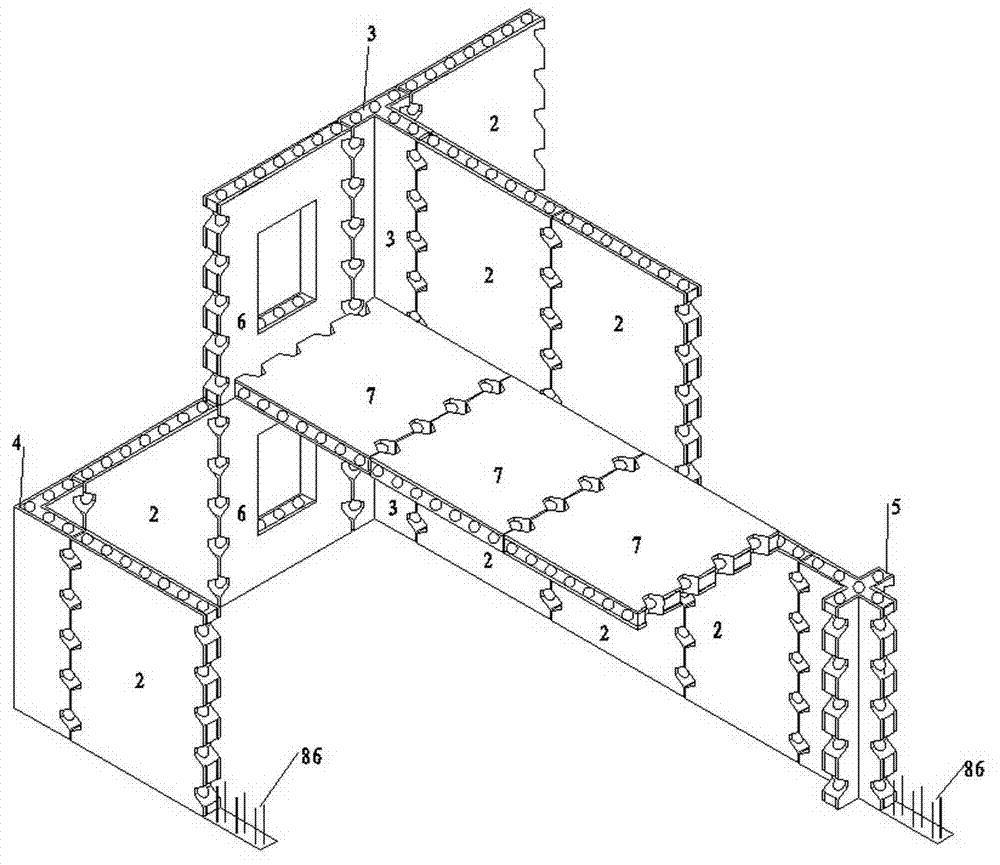

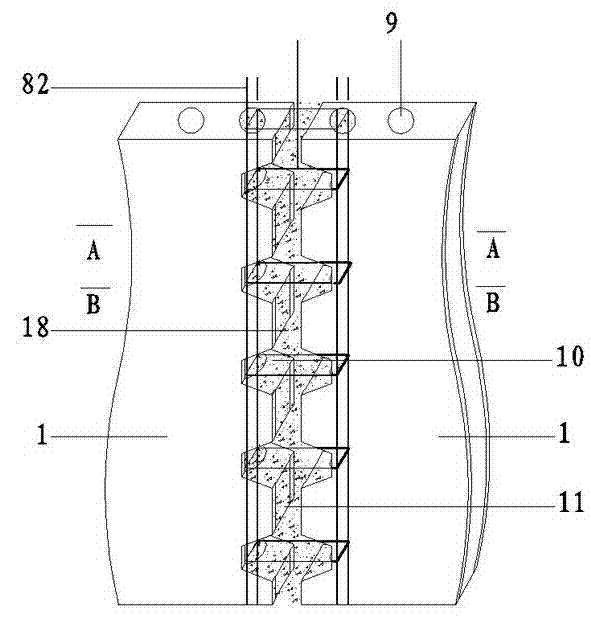

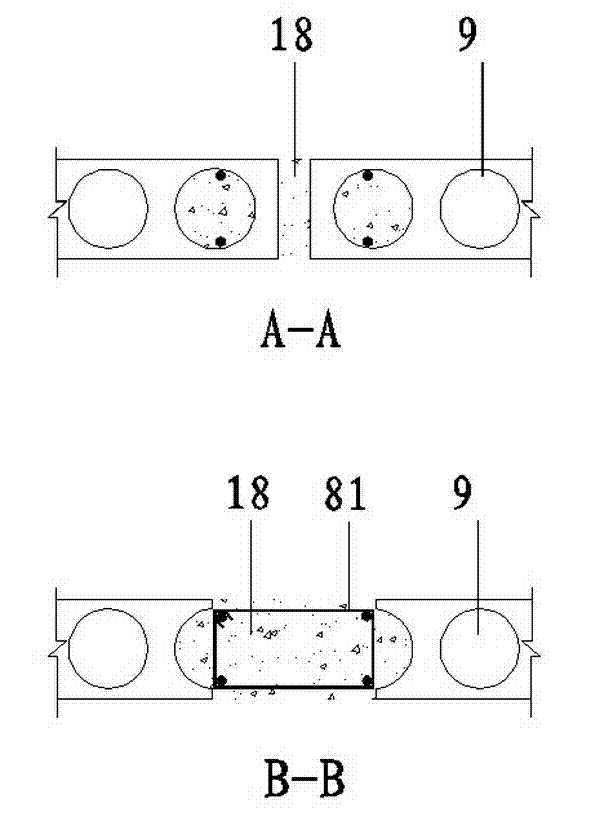

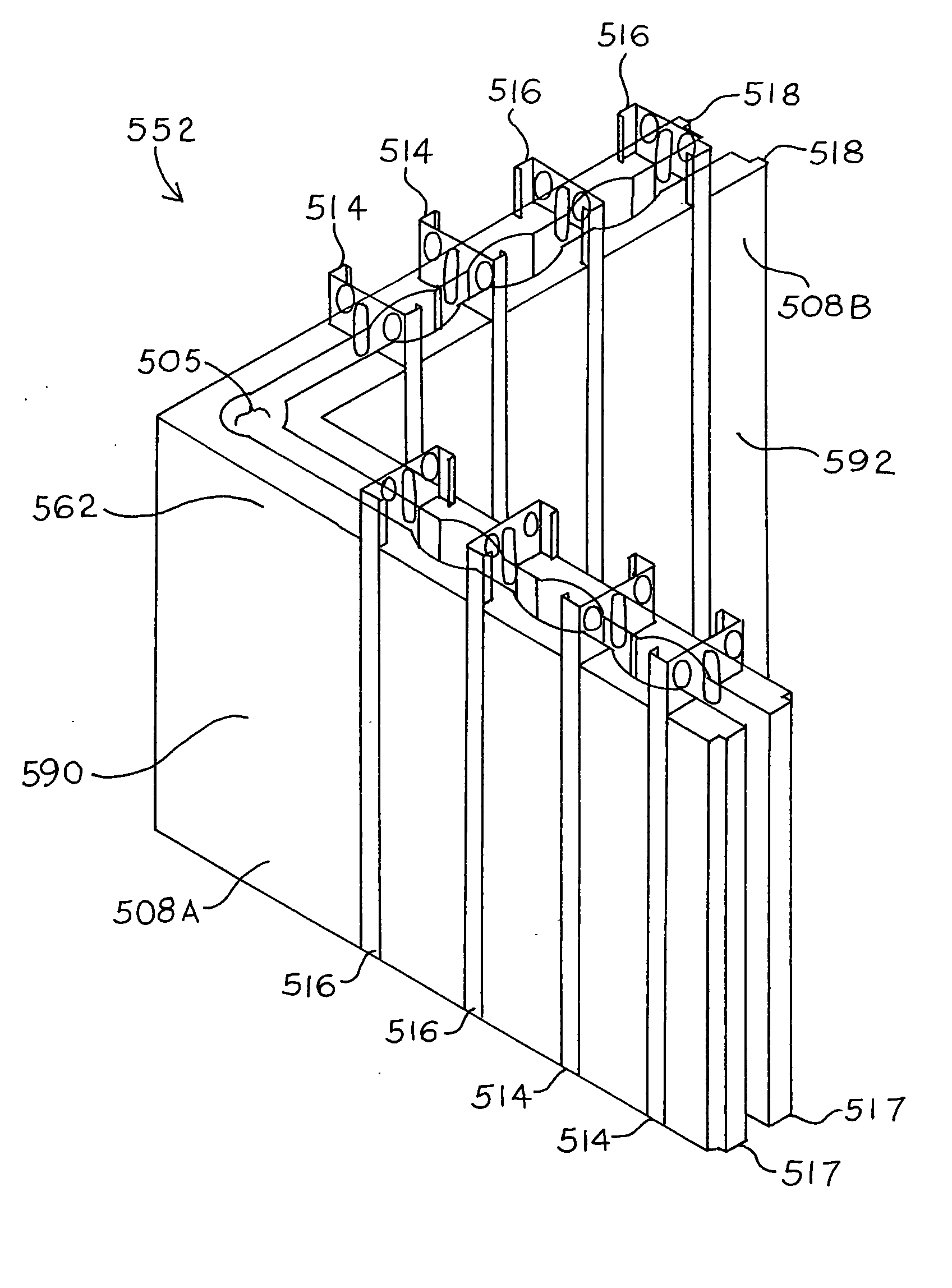

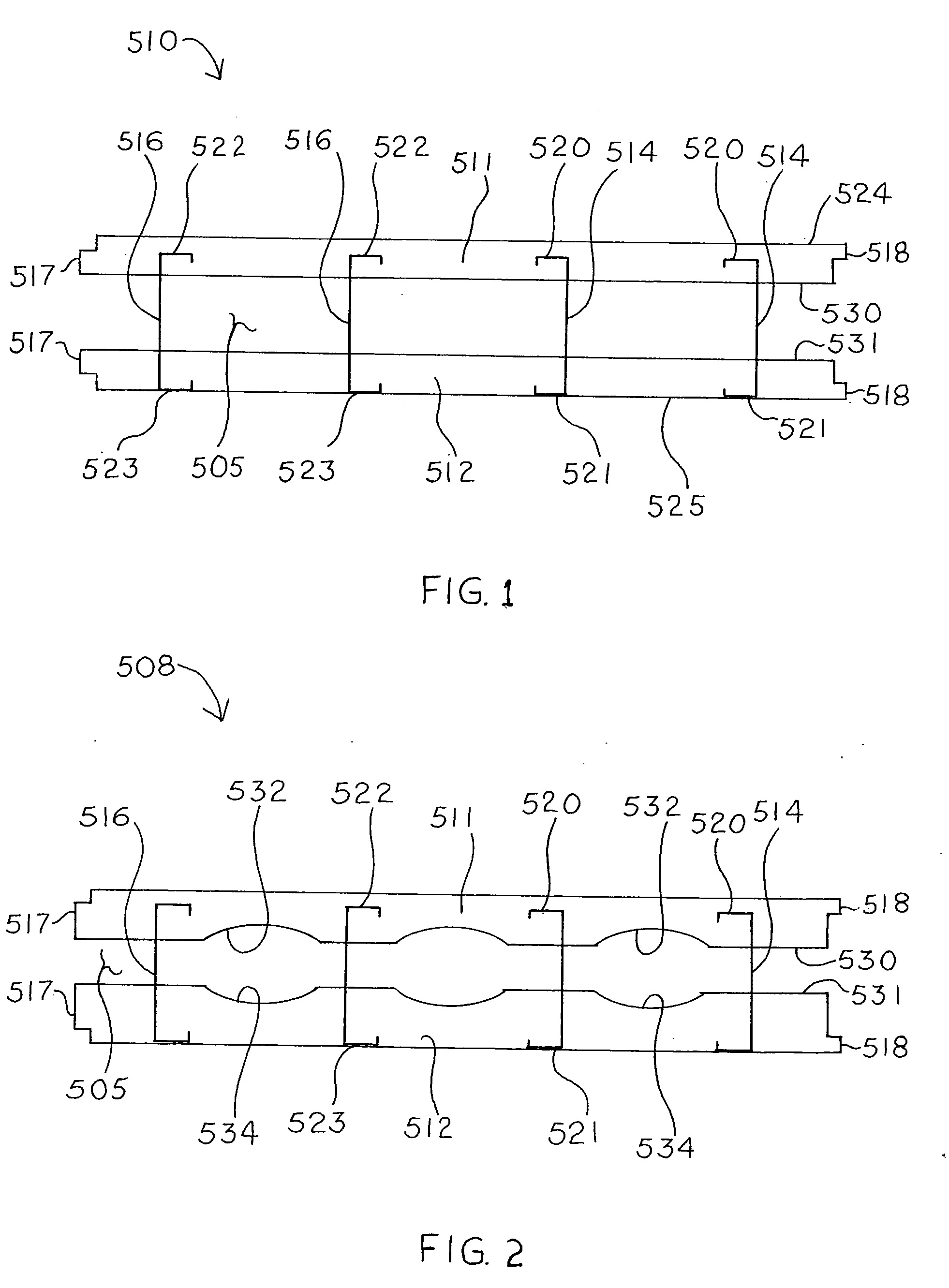

Assembled monolithic shear wall building structure and construction method thereof

InactiveCN102808450AImprove the level of industrializationIncrease productivityConstruction materialWallsTransverse grooveCross wall

The invention relates to an assembled monolithic shear wall building structure and a construction method thereof, and belongs to the technical field of buildings and construction thereof. The assembled monolithic shear wall building structure is formed by connecting prefabricated concrete members which comprise a prefabricated wall plate member, a floor member, a T-shaped wall column member, an L-shaped wall column member, a cross wall column member and a wall member with an opening. The structure is characterized in that a plurality of longitudinal through holes which are parallel to the surface are formed in each prefabricated concrete member; transverse grooves crossed with at least one longitudinal hole are formed on the longitudinal edge at intervals; transverse anchoring steel bars are arranged at the transverse grooves among different prefabricated members; longitudinal anchoring steel bars are arranged in the longitudinal holes; a layer of structural unit or a single-layer building structure is formed by filling concrete in the longitudinal holes and the transverse grooves; and a plurality of structural units are connected to form a multi-layer or high-rise assembled monolithic shear wall structure. The structure can be used in a multi-layer or high-rise shear wall building structure and a frame-shear wall building structure, the industrial level of the building structure can be improved, stress performance is improved, and resources are saved.

Owner:初明进

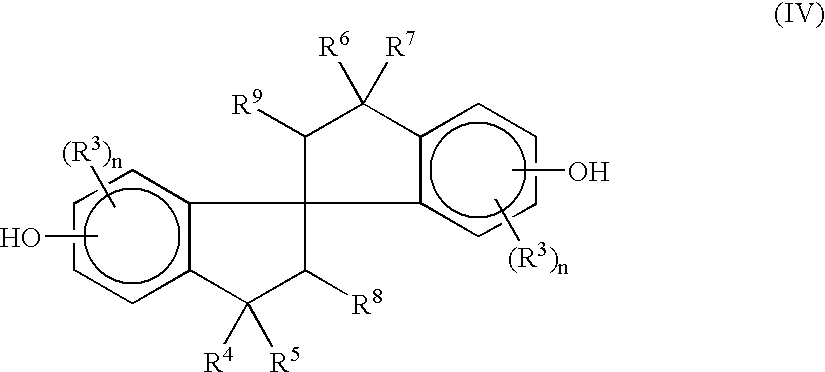

Weatherable multilayer articles and method for their preparation

InactiveUS20040253428A1Avoid insufficient thicknessRelieve stressSynthetic resin layered productsThin material handlingPolyesterPolymer science

Disclosed are weatherable multilayer articles comprising (i) a coating layer comprising a block copolyestercarbonate comprising structural units derived from at least one 1,3-dihydroxybenzene and at least one aromatic dicarboxylic acid, (ii) a second layer comprising a polymer comprising carbonate structural units, (iii) an adhesive layer comprising a polyester with structural units derived from at least one glycol and at least one dibasic carboxylic acid, and (iv) a substrate layer, wherein the coating layer is in contiguous contact with the second layer, and the adhesive layer is in contiguous contact with the second layer and the substrate layer. Also disclosed is a method for making the multilayer article.

Owner:SABIC INNOVATIVE PLASTICS IP BV

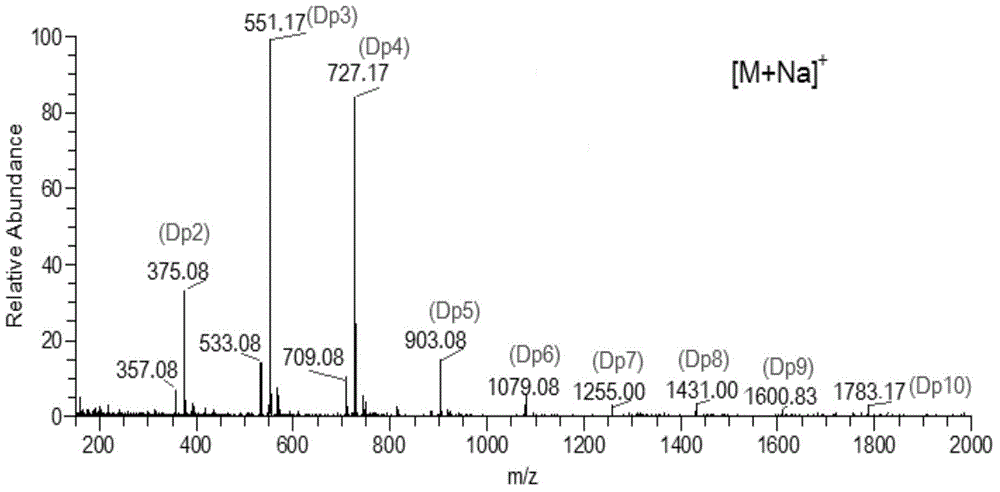

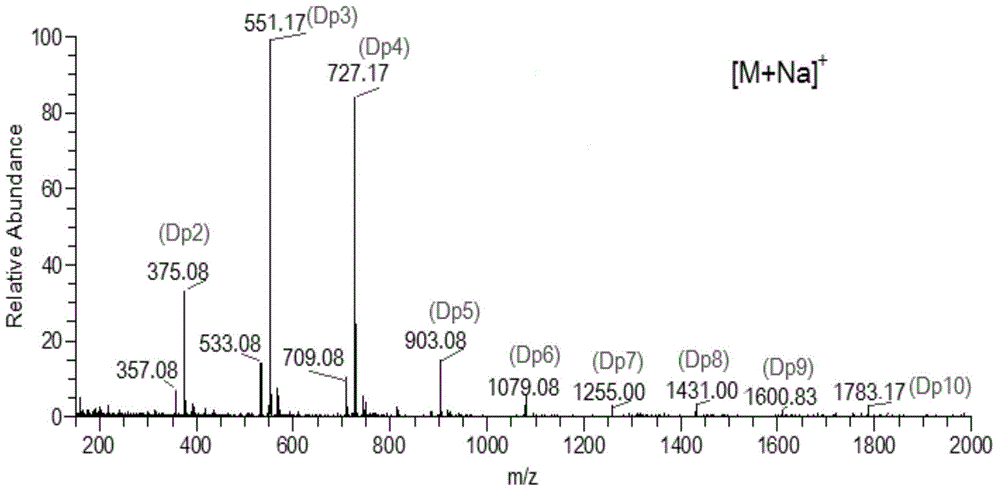

Sodium alginate oligosaccharide coated slow-release fertilizer and preparation and application thereof

ActiveCN104649806AWide variety of sourcesLow priceFertilising methodsLayered/coated fertilisersIntroduced organismsPlant growth

The invention discloses a sodium alginate oligosaccharide coated slow-release fertilizer. Coated materials of the slow-release fertilizer contain sodium alginate oligosaccharide and an auxiliary coated material, wherein sodium alginate oligosaccharide is composed of two structural units, namely a-L-mannuronic acid and b-D-guluronic acid. The two structural units are linked in three ways by 1,4-glucosidic bond, so as to form a unbranched linear segmented copolymer. The coated slow-release fertilizer is mainly applied in commercial crops, fruit and vegetable crops, grain crops, economic forest, flowers and plants, traditional Chinese medicinal materials, lawn and the like. By introducing organism-derived sodium alginate oligosaccharide into the coated materials of the slow-release fertilizer, nutritive elements required by plant growth and development can be supplemented by a slow-release approach, and the plant growth promoting effect of sodium alginate oligosaccharide also can be performed so as to finally achieve the yield-increasing effect. In addition, a medicament prepared by using sodium alginate oligosaccharide as the main coated material composition is safe and nontoxic and has advantages of low cost, small application amount and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

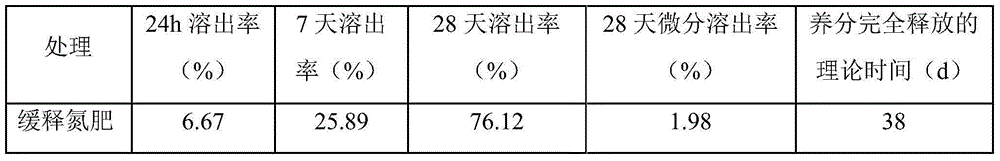

Resist composition and method for producing resist pattern

ActiveUS20120052443A1Great DOFFew defectPhotosensitive materialsRadiation applicationsAliphatic hydrocarbonMethyl group

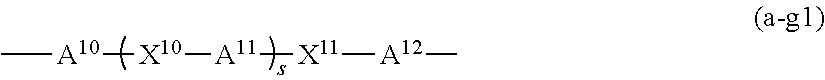

A resist composition contains; a resin having a structural unit derived from a compound represented by the formula (a); and an acid generator.wherein R1 represents a hydrogen atom or a methyl group; R2 represents an optionally substituted C1 to C18 aliphatic hydrocarbon group; A1 represents an optionally substituted C1 to C6 alkanediyl group or a group represented by the formula (a-g1);wherein s represents 0 or 1; A10 and A12 independently represent an optionally substituted C1 to C5 aliphatic hydrocarbon group; A11 represents a single bond or an optionally substituted C1 to C5 aliphatic hydrocarbon group; X10 and X11 independently represents an oxygen atom, a carbonyl group, a carbonyloxy group or an oxycarbonyl group; provided that a total number of the carbon atom of A10, A11, A12, X10 and X11 is 6 or less.

Owner:SUMITOMO CHEM CO LTD

Lightweight compositions and articles containing such

A lightweight cementitious composition containing from 22 to 90 volume percent of a cement composition and from 10 to 78 volume percent of particles having an average particle diameter of from 0.2 mm to 8 mm, a bulk density of from 0.03 g / cc to 0.64 g / cc, an aspect ratio of from 1 to 3, where after the lightweight cementitious composition is set it has a compressive strength of at least 1700 psi as tested according to ASTM C39. The cementitious composition can be used to make concrete masonry units, construction panels, road beds and other articles and can be included as a layer on wall panels and floor panels and can be used in insulated concrete forms. Aspects of the lightweight cementitious composition can be used to make lightweight structural units.

Owner:SYNTHEON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com