Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

207results about How to "Improve the level of industrialization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

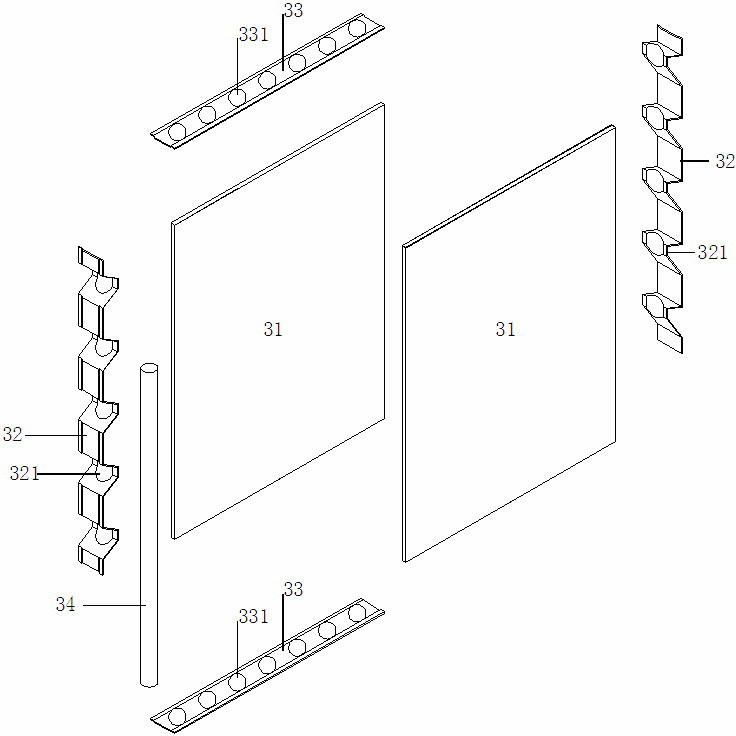

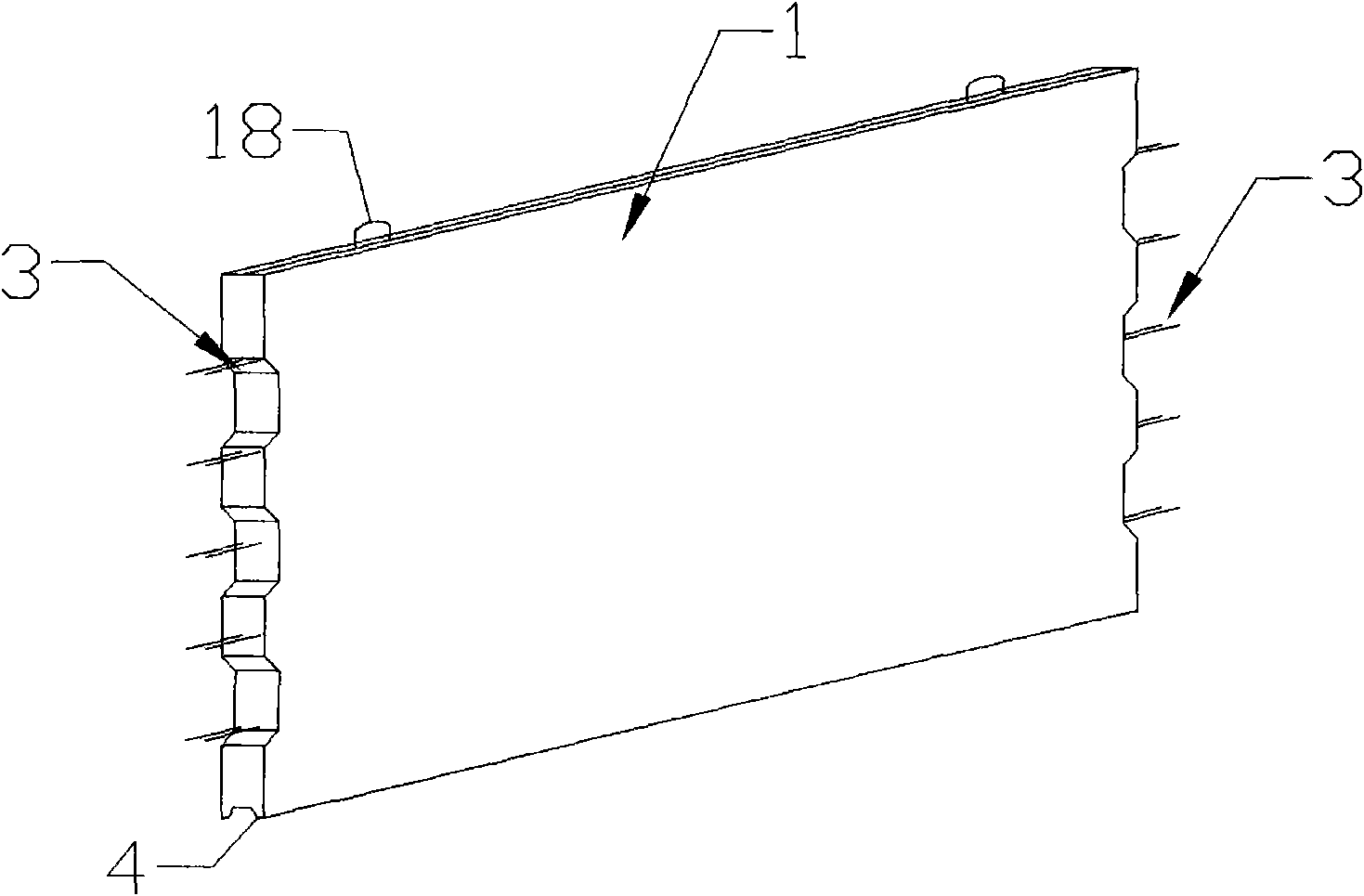

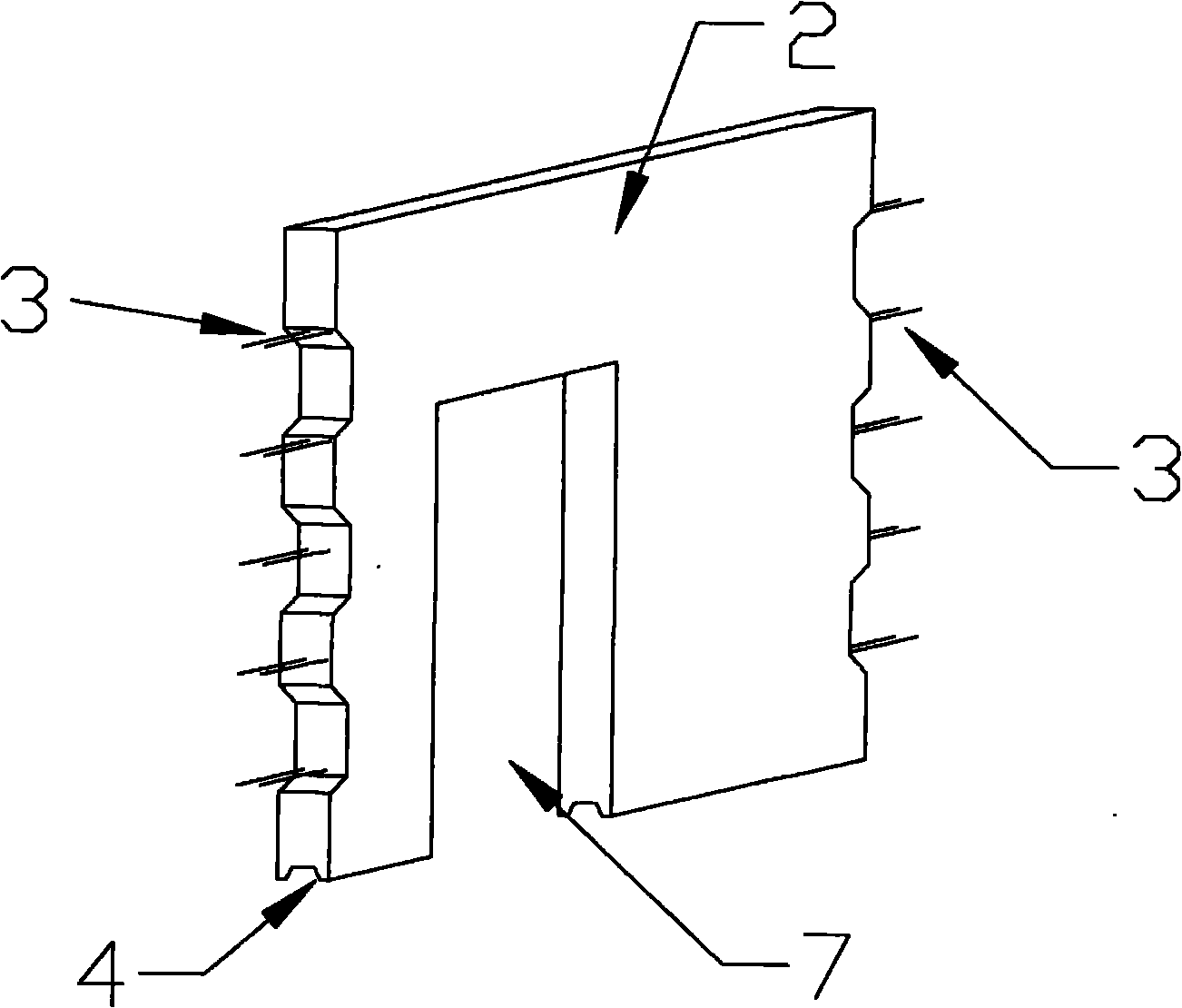

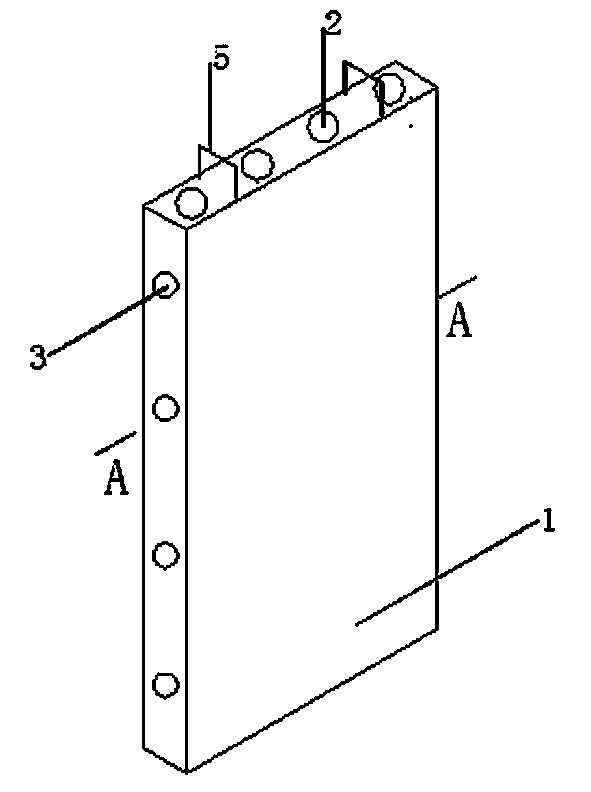

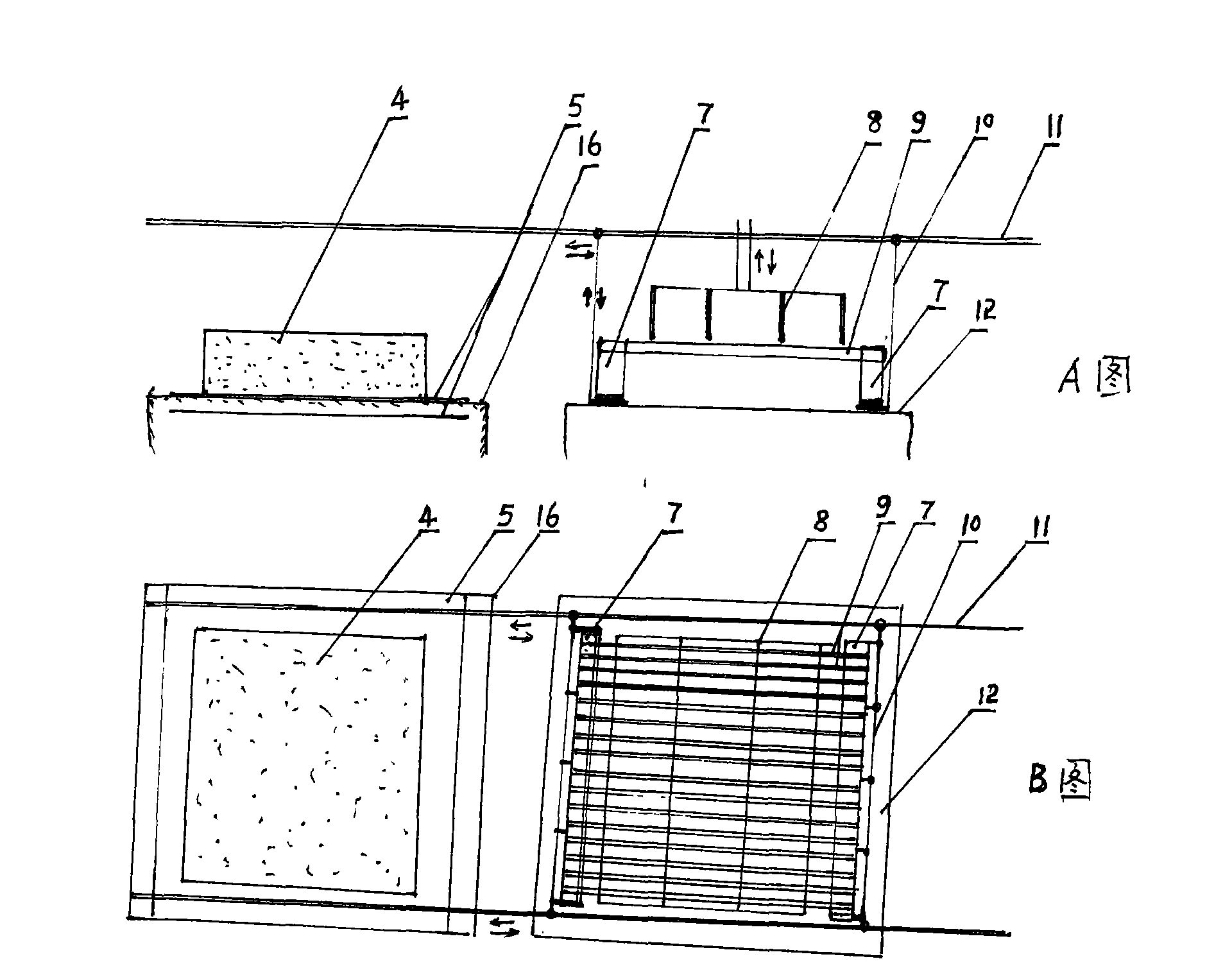

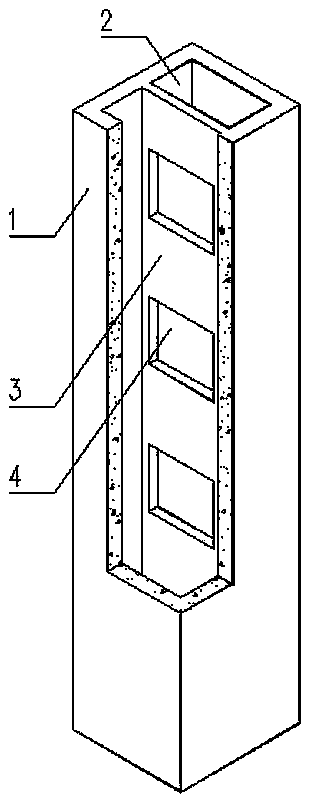

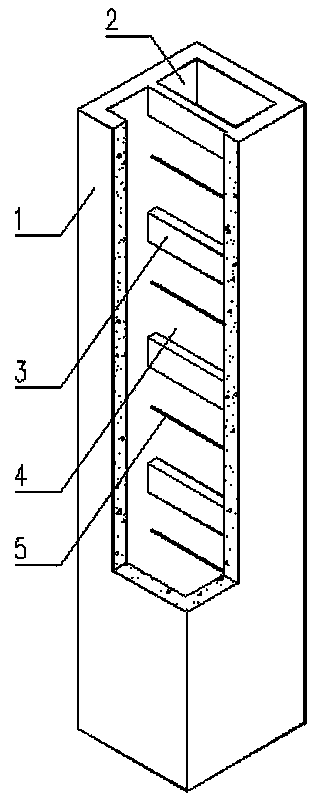

Prefabricated reinforced concrete component with grooves and manufacturing method thereof

ActiveCN102635197AIncrease productivityQuality improvementConstruction materialWallsReinforced concreteVertical edge

The invention relates to a prefabricated reinforced concrete component with grooves and a manufacturing method thereof and belongs to the technical field of components in a prefabricated reinforced concrete structure. The component uses a cored slab prefabricated by reinforced concrete; and transverse grooves are arranged at the vertical edge of the reinforced concrete prefabricated slab at intervals, and are interacted with vertical holes parallel to the surface in the prefabricated slab. The manufacturing method provided by the invention comprises the following steps of: combining templates, such as a bottom die, a top die, a side die, a steel pipe inner die and the like on a production field of prefabricated slabs; arranging reinforcing meshes; then pouring concrete; drawing a steel pipe before hardening the concrete; and dismounting the templates after the concrete reaches to the expected strength. According to the prefabricated reinforced concrete component and the manufacturing method thereof provided by the invention, the industrial level of a building structure is improved, the load-carrying capability is improved, and resources can be saved. The prefabricated reinforced concrete component can be applied to various wall body bearing structures.

Owner:初明进

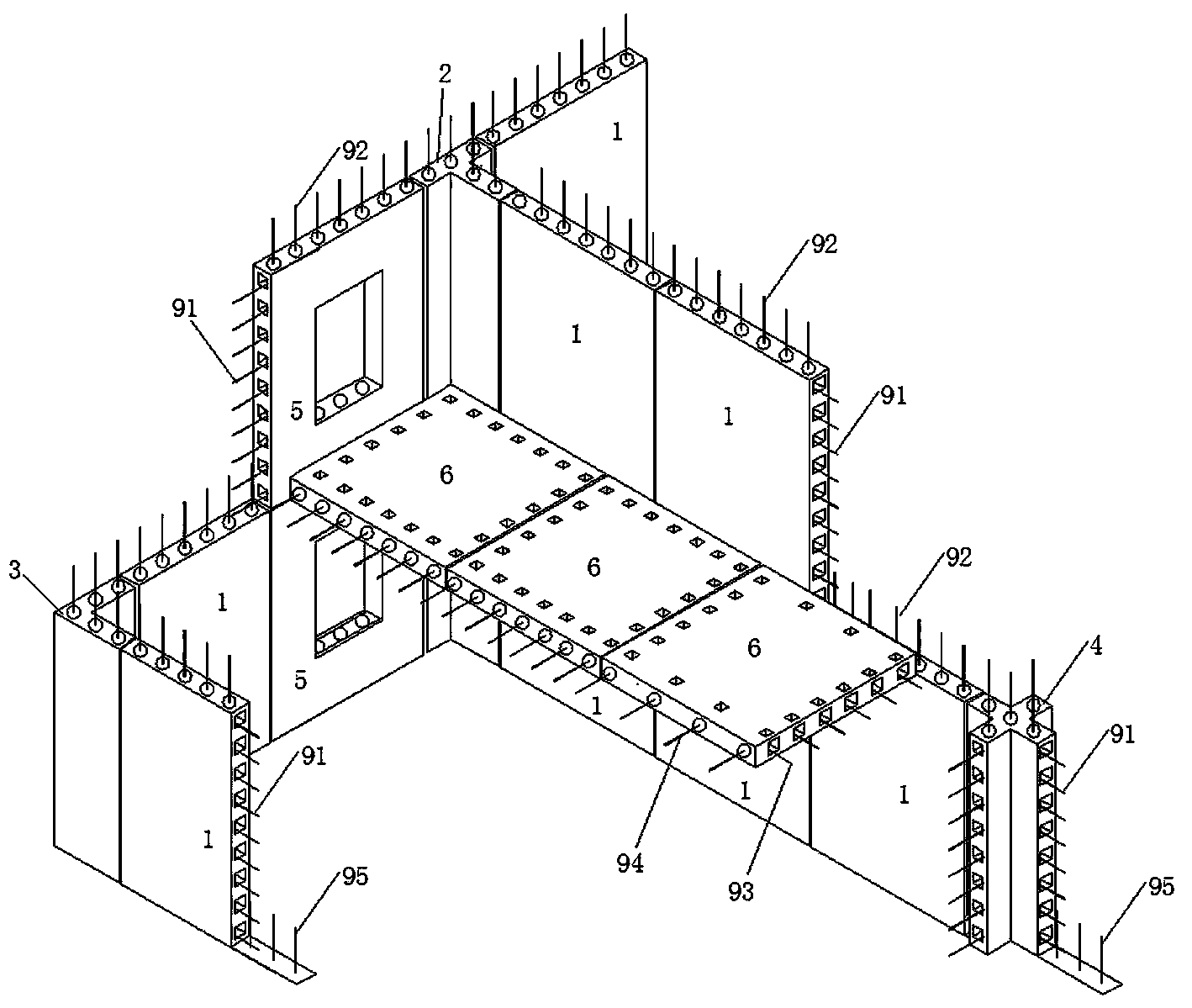

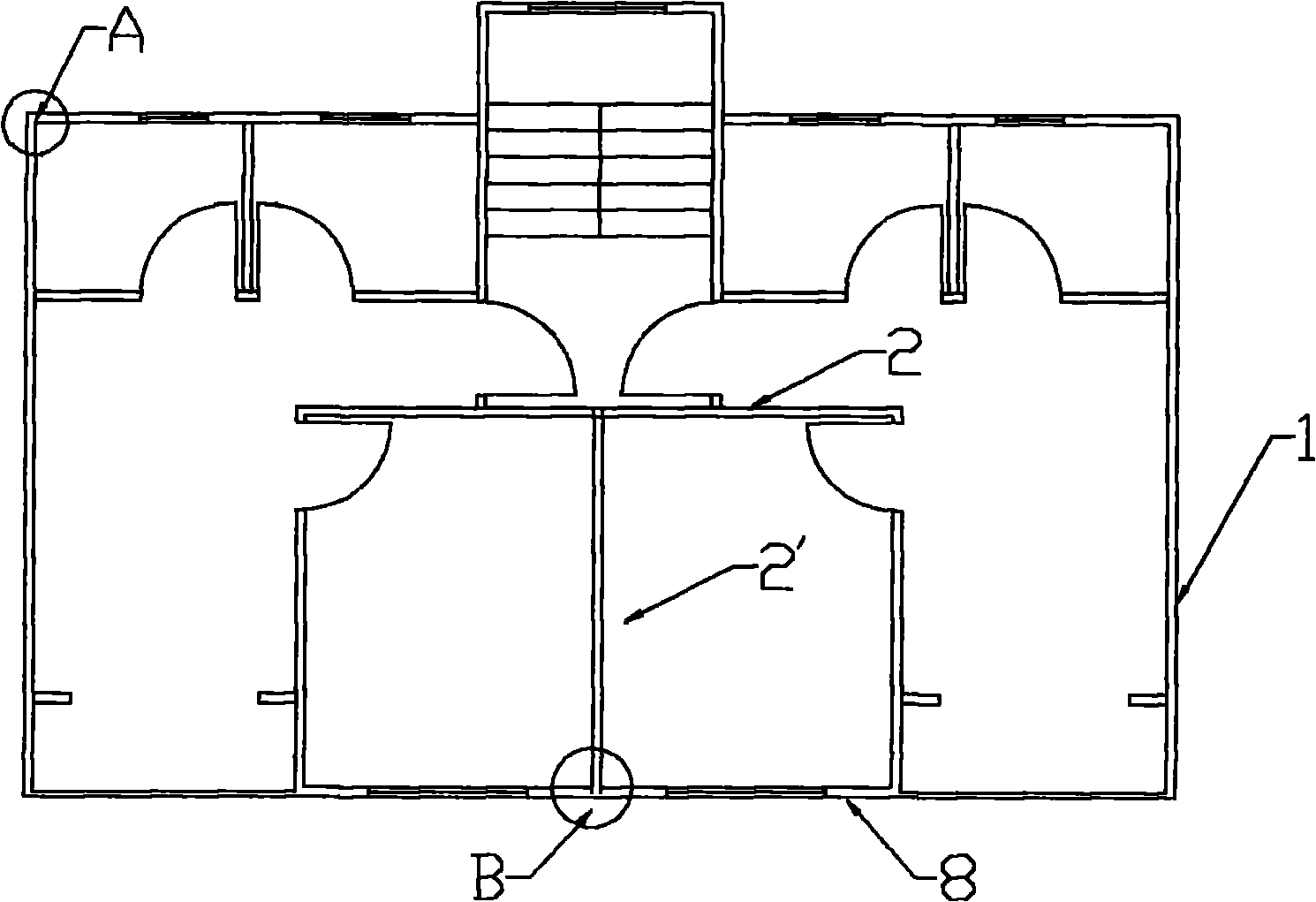

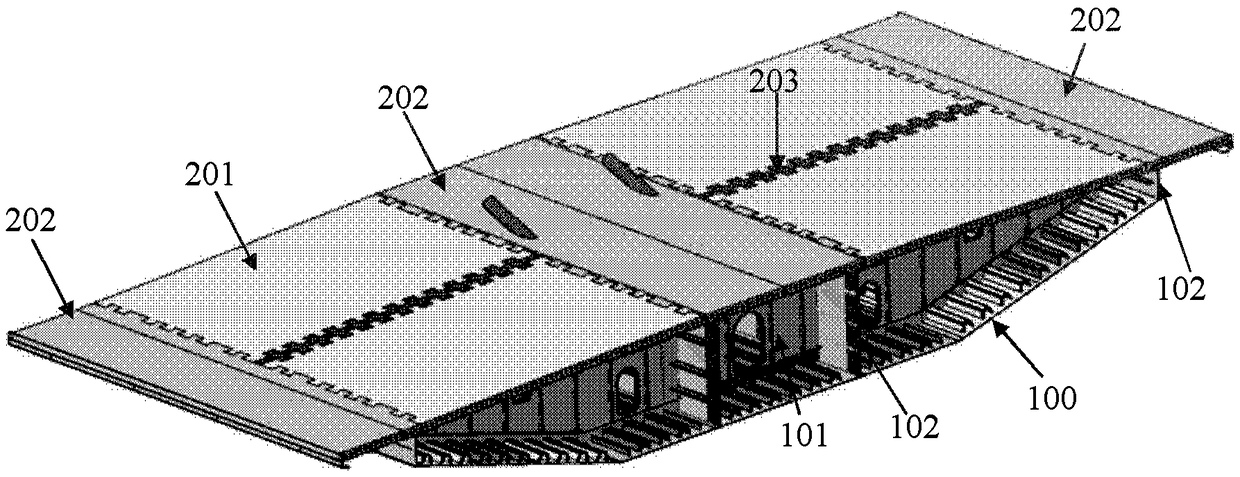

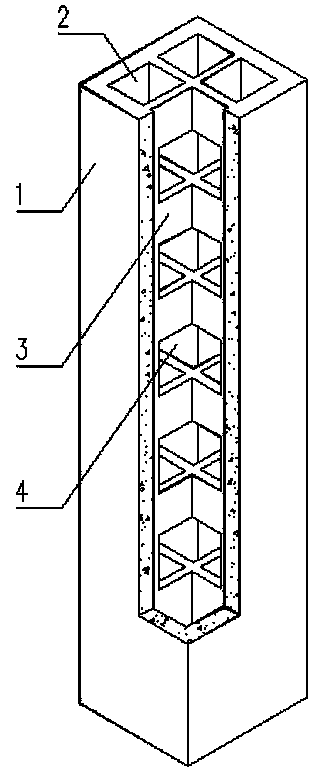

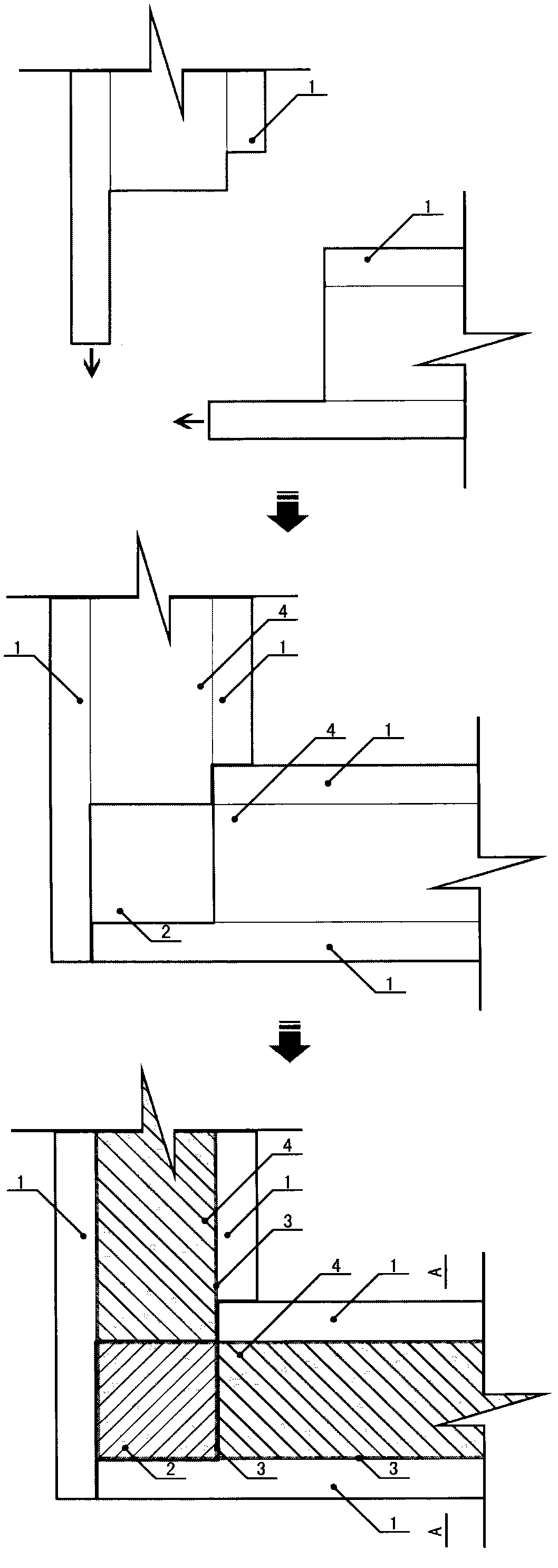

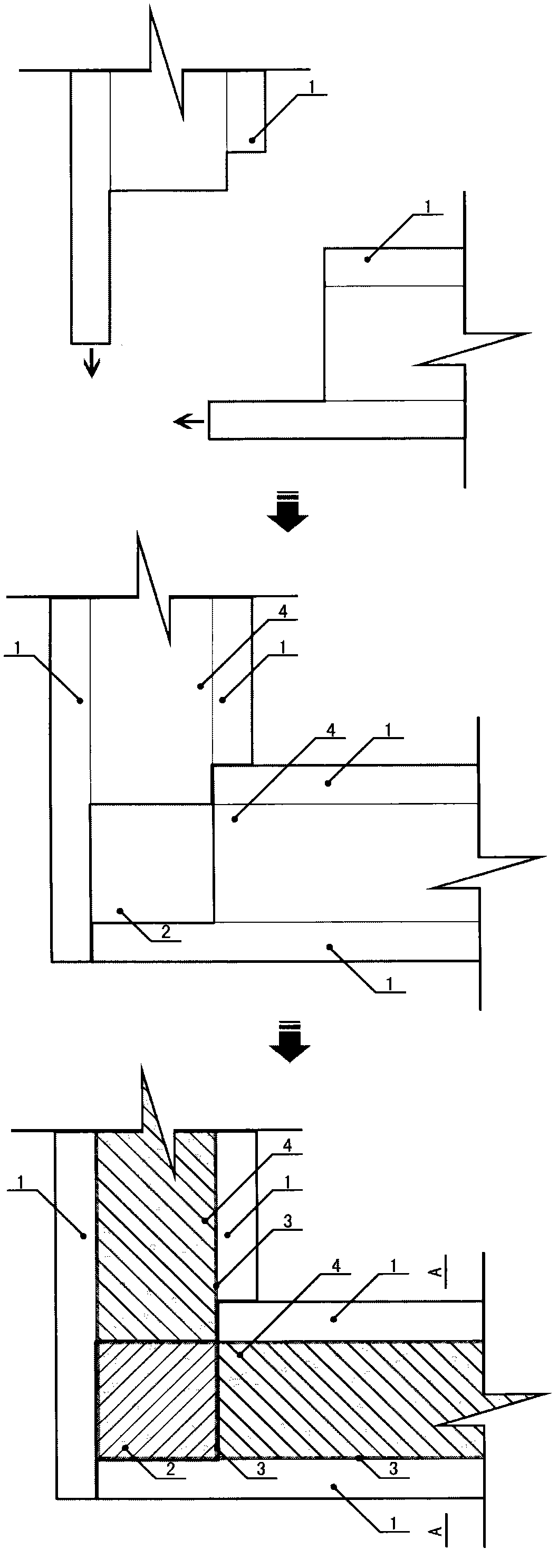

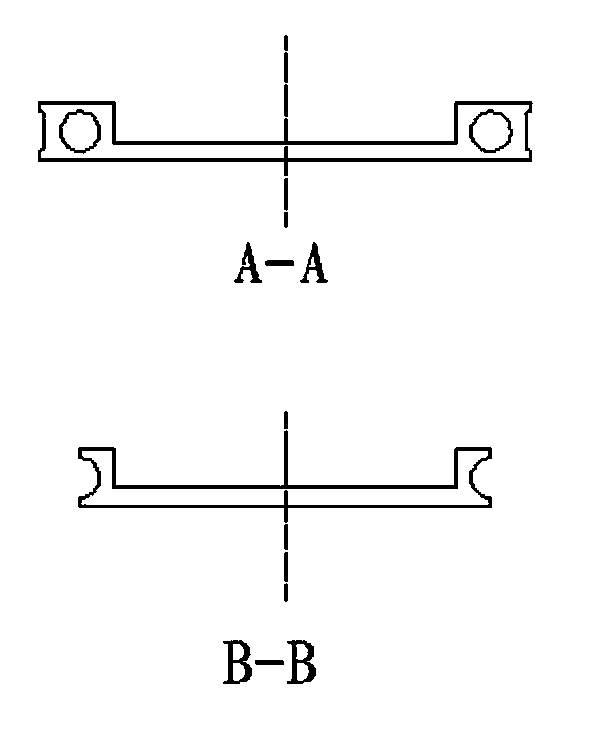

Assembly integral shear wall building structure and building method

ActiveCN103669559AImprove the level of industrializationIncrease productivityWallsBuilding material handlingRebarHigh rise

The invention relates to an assembly integral shear wall building structure and a building method and belongs to the field of buildings and construction technologies of the buildings. The shear wall building structure is formed by connecting prefabricated concrete hollow components through steel bars and cast-in-place concrete, wherein the prefabricated concrete hollow components include prefabricated wall body components, floor board components, T-shaped wall pillar components, L-shaped wall pillar components, cross-shaped wall pillar components and wall body components with holes. Multiple parallel lengthwise through holes are formed in the prefabricated hollow components in the length direction and multiple parallel transverse non-through holes communicated with the lengthwise through holes are formed in the prefabricated hollow components in the width direction. Horizontal anchor connection steel bars inserted into the transverse holes are arranged among the different prefabricated components. Lengthwise anchor connection steel bars are arranged in the lengthwise holes, wherein one end of each lengthwise anchor connection steel bar protrudes out of the surface of the corresponding prefabricated component by a certain length. The concrete is filled into the lengthwise holes and the transverse holes to form a layer of structural unit or a single-layer building structure. Multiple structure units are connected to form a multiple-layer or high-rise assembly integrated shear wall structure. The assembly integral shear wall building structure and the building method can be applied to the multiple-layer or high-rise shear wall building structures and frame-shear wall building structures. Thus, the industrial level of the building structures can be improved, stress performance can be improved and resources are saved.

Owner:初明进

Board-mixing structure assembly type house and building method thereof

InactiveCN101967851APromote the development of circular economyImprove the level of industrializationBuilding constructionsThermal insulationWall plate

The invention discloses a board-mixing structure assembly type house and a building method thereof. The house is characterized in that an inner wall board, an outer wall board and superimposed floor boards which are prefabricated are connected with constructional columns and floors which are cast in site so as to form a whole; and the inner wall board, the outer wall board, the superimposed floor boards and the constructional columns are prefabricated or cast by adopting green concrete. The house can improve the industrial level of house construction and the whole level of house buildings greatly and reduce the construction difficulty and cost, is beneficial to solving the node waterproofing problem, improving the thermal insulation level and durability of thermal insulating materials and reducing the laying of reinforcing steel bars on the floors and laying of templates, and is beneficial to realizing standardized production and greatly shortening the construction period.

Owner:董杨

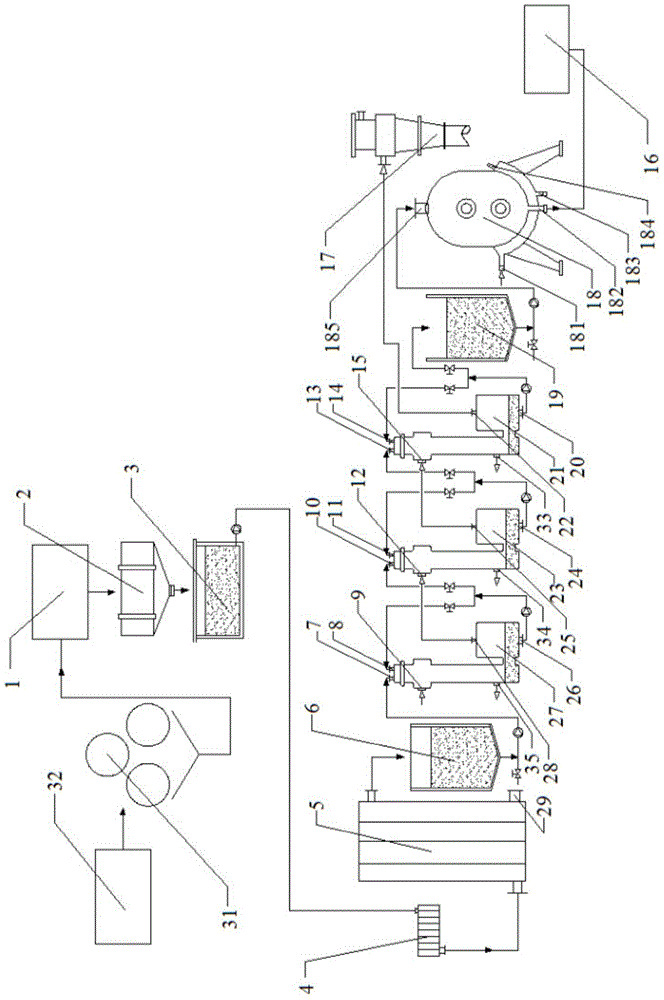

Heat radiation frame for mounting of battery pack

ActiveCN102013463ASolve the difficulty of installation and maintenanceImprove the level of industrializationSecondary cellsCell component detailsElectrical batteryRadiation

The invention provides a heat radiation frame for the mounting of a battery pack, comprising a plurality of battery supporting frames with the lower ends opened, and a baffle matched with the opened ends, wherein horizontal convex edges are correspondingly arranged at the opened lower ends and the upper ends of the supporting frames as well as the two sides of the baffle; the opened end of one of the battery supporting frames is provided with the baffle, and the other supporting frames are vertically piled at the upper end of the frame; the supporting frame, the baffle and the piled supporting frames are connected through bolts in the corresponding horizontal convex edges; a battery location groove is formed between the supporting frame and the inner wall of the baffle; a convex strip is longitudinally arranged on the outer wall of the baffle along the axial direction of the battery location groove; and a heat exchange channel is formed by penetrating the convex strip on the outer wall and the battery location groove on the inner wall. By providing a fire-new thought to solve more than one battery pack, the difficult discharging problem of the heat generated in the work is solved, and the difficult mounting and maintaining problems of the battery pack are solved in the process aspect and the technical aspect.

Owner:GUANGDONG HUACHAN RES INST OF INTELLIGENT TRANSPORTATION SYST CO LTD

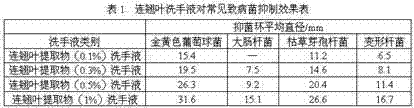

Forsythia suspensa leaf hand sanitizer and preparation method thereof

InactiveCN103767965AExtensive resourcesWide range of materialsAntibacterial agentsCosmetic preparationsAsparagus cochinchinensisAdditive ingredient

The invention relates to the field of daily cosmetics, and particularly relates to a mild type Chinese medicinal herb hand sanitizer with bacteriostatic, antibacterial and skin moisturizing effects, including a Chinese medicinal herb composition and an extraction process thereof and a preparation method of the hand sanitizer. A Forsythia suspensa leaf hand sanitizer comprises a functional component, a surfactant, a thickener, a humectant, a pH regulator, an anti-hard water agent, an aromatic, a pigment, a pearling agent and deionized water, wherein the functional component is Forsythia suspensa leaf extract, traditional Chinese medicine mixed extract, and Dioscorea opposita powder, and the traditional Chinese medicine mixed extract is mixed extract of Scutellaria baicalensis, Astragalus membranaceus and Asparagus cochinchinensis. The hand sanitizer provided by the invention has cleaning and antibacterial, skin moisturizing and skin caring effects, and does not cause dry hand skin, skin injury and other adverse effects even after frequent hand cleaning.

Owner:左权县桐峪镇嘉百岁农民专业合作社

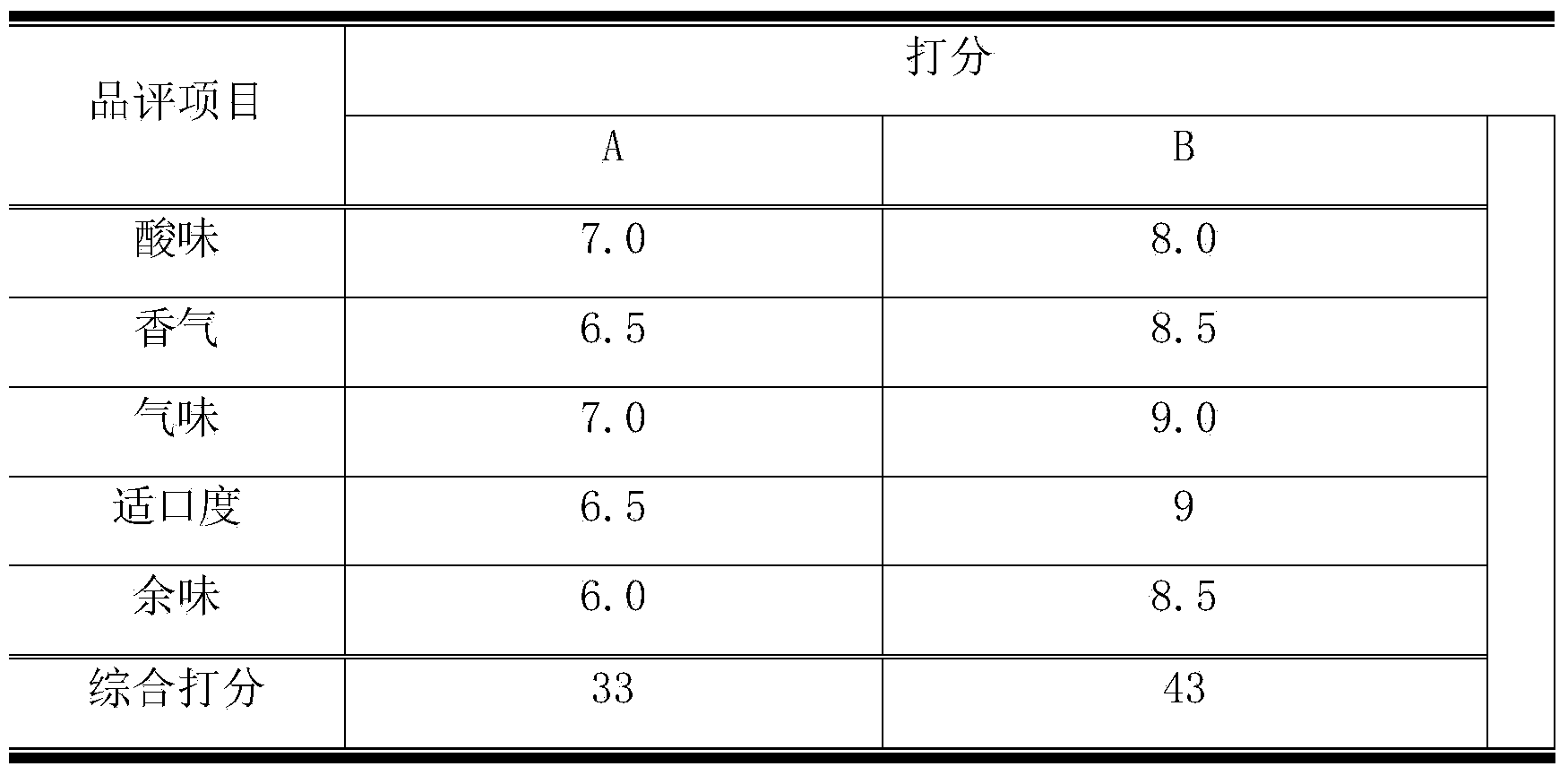

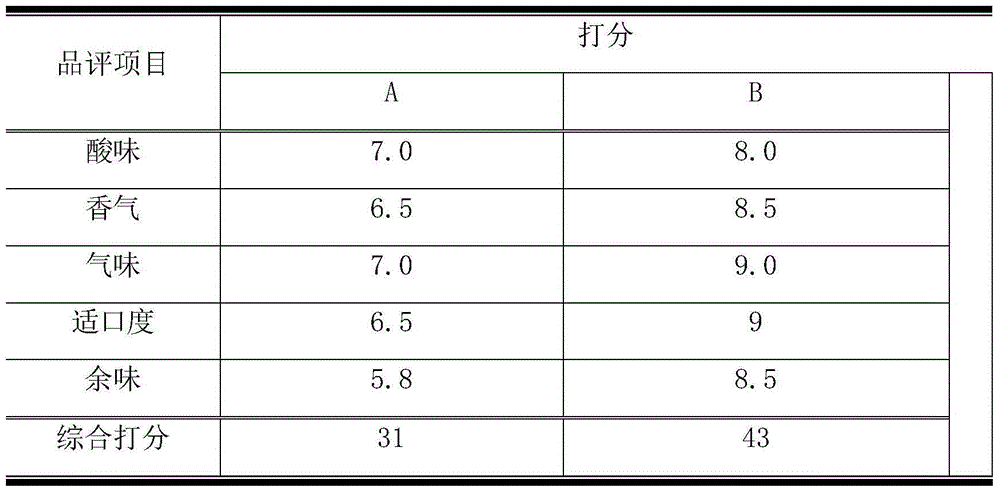

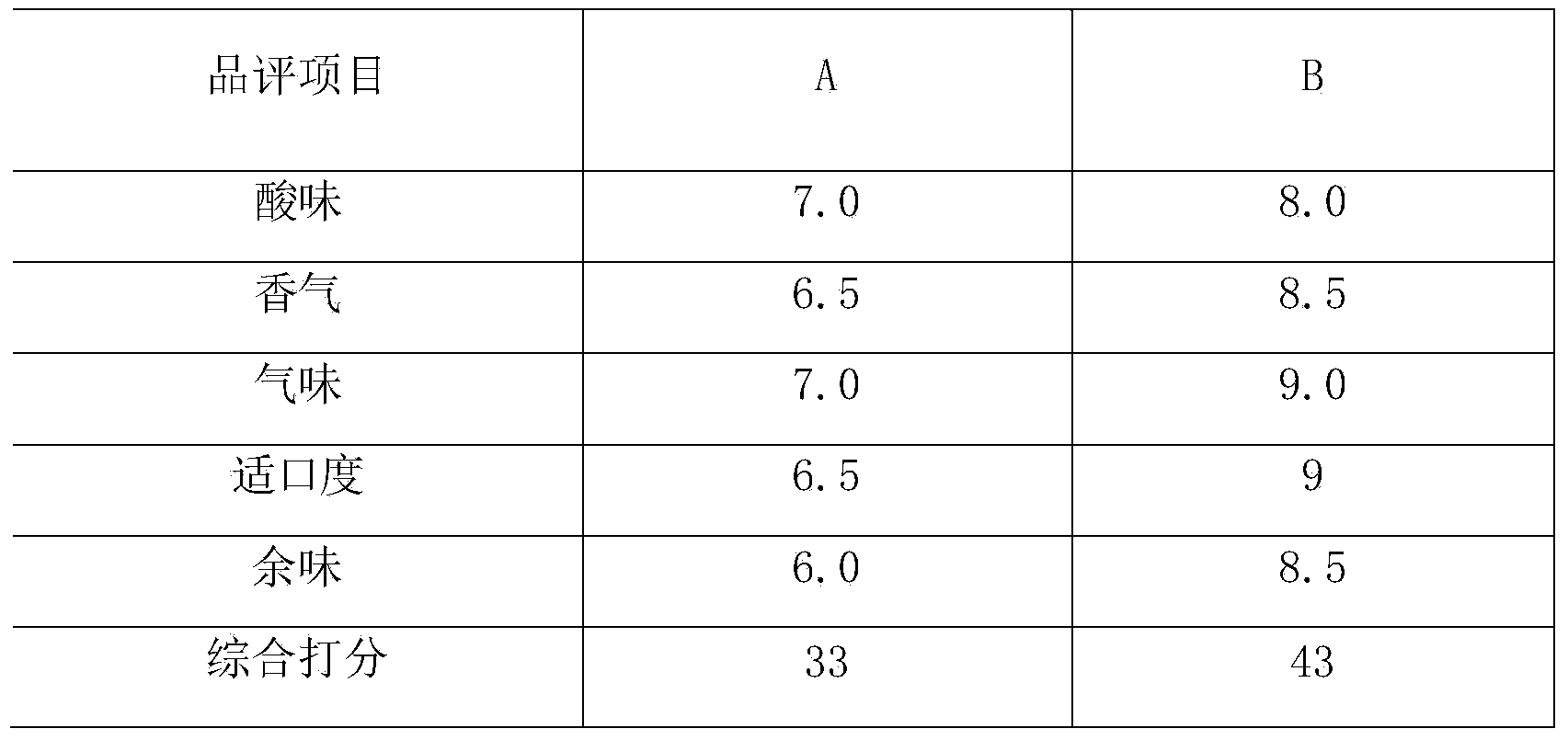

Microbial agent for producing pickles

ActiveCN104293706AKeep the flavorSolve the problem of subculture starterFungiBacteriaMicrobial agentMicrobiology

The invention discloses a microbial agent for producing pickles, belonging to the field of production of microbial preparations. The microbial agent product contains lactobacillus plantarum CGMCC NO.9405, and consists of the following agents: lactobacillus plantarum CGMCC NO.9405, bacillus aceticus and saccharomycetes. The preparation method comprises the following steps: singly culturing the lactobacillus plantarum, bacillus aceticus and saccharomyces cerevisiae strains, centrifuging to collect the thallus after culturing by a preset period of time, and preparing microbial powder of each strain by utilizing a conventional microbial preparation production method; and mixing and blending the prepared microbial powder according to a ratio. According to the selection and ratio of the strains, the production speed, good flavor and quality of pickle products are guaranteed, so that the production safety of the pickles is high, and the product is standard and consistent, can be suitable for large-scale industrial production and manual workshop type production and has wide application market.

Owner:拜肯生物科技(上海)股份有限公司

Vegetable fermentation composite bacterial agent product

InactiveCN104312941AKeep the flavorSolve the problem of subculture starterFungiBacteriaBiotechnologyProduction rate

The invention discloses a vegetable fermentation composite bacterial agent product for pickled vegetable production, and belongs to the microbial preparation production field. The vegetable fermentation composite bacterial agent is composed of the following bacterial agents: lactobacillus plantarum CGMCC No.9405, lactobacillus rhamnosus, bacillus aceticus, and yeast. Firstly, lactobacillus plantarum, bacillus aceticus, lactobacillus rhamnosus and saccharomyces cerevisiae strains are cultured individually, are cultured for a predetermined time and then are centrifuged to collecting thalli, and powdered microbial powders of the strains are prepared by using a conventional microbial preparation production method; the prepared stain powders are mixed and blended according to the proportion, wherein the composition ratio of the stains is also obtained through carefully experimental investigation; selection and proportioning of the strains guarantee the production rate of pickled vegetable products, excellent flavor of the pickled vegetable products and good quality of the pickled vegetable products.

Owner:宁波北仑锐晟明杰生物科技发展有限公司

Azalea tissue culture seedling out-bottle rooting method

ActiveCN103371093ASolve the technical bottleneck of the rooting of seedlingsSave spaceCultivating equipmentsHorticulture methodsAzaleaSeedling

The invention relates to an azalea tissue culture seedling out-bottle rooting method which includes the steps of 1) selecting out-bottle rooting time and site; 2) hardening bottle seedlings; 3) preparing substrate; 4) cutting tissue culture seedlings; 5) seedling hardening after cutting and light and water management. An effective azalea tissue culture seedling out-bottle rooting generic technology is provided, the bottleneck that some azalea subgenus tissue culture seedlings are difficult in rooting is solved, and the method is applicable to most azalea subgenus and varieties. By the method, an azalea tissue culture rapid propagation system is completed, tissue culture in-bottle rooting is unnecessary, tissue culture space is saved by more than 50%, cost of tissue culture seedlings is saved by more than 30%, tissue cycle is shortened greatly, tissue culture seedling out-bottle rooting rate can be reach to 80-95%, and great significance is provided for improving tissue culture industrialization level.

Owner:HANGZHOU BOTANICAL GARDEN

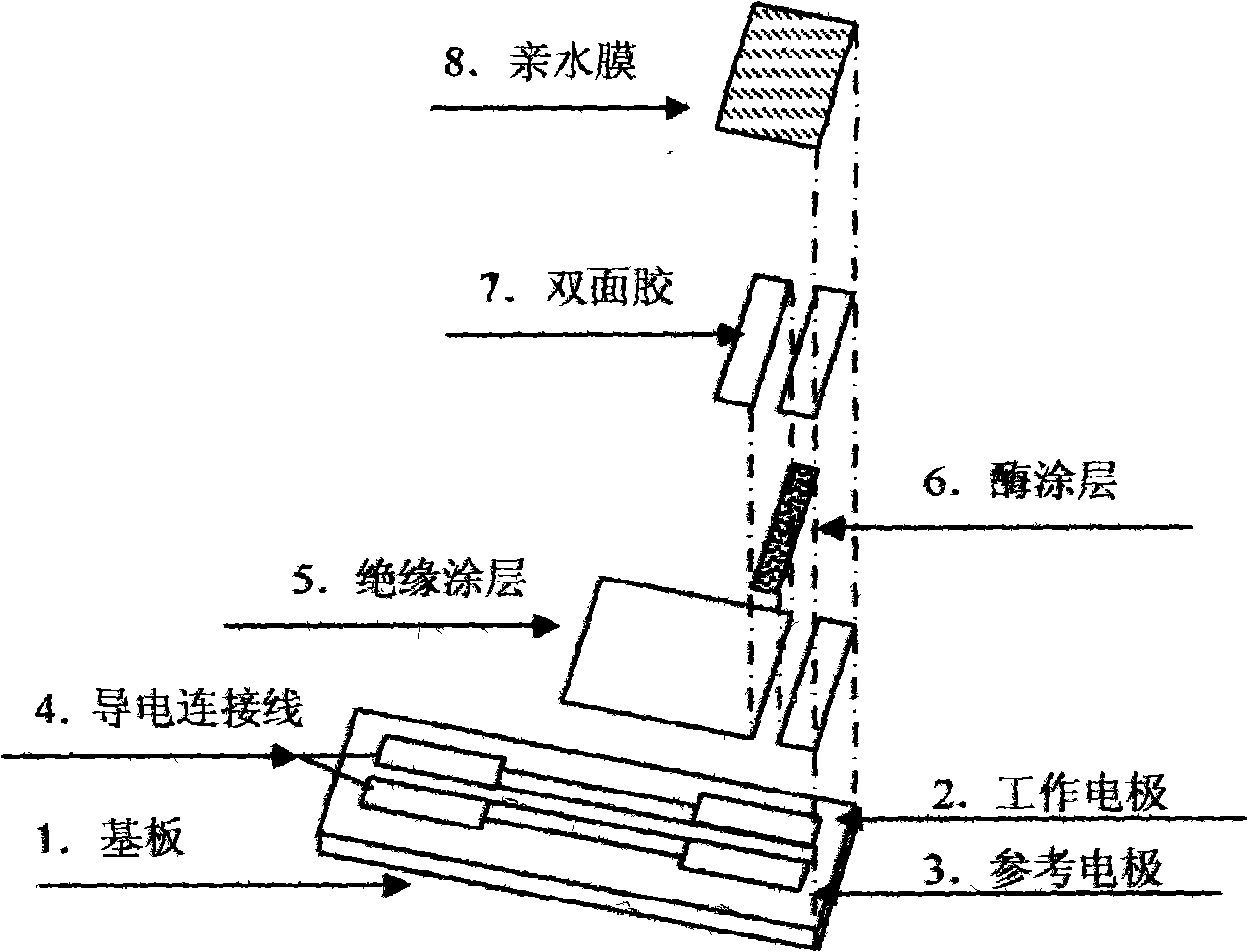

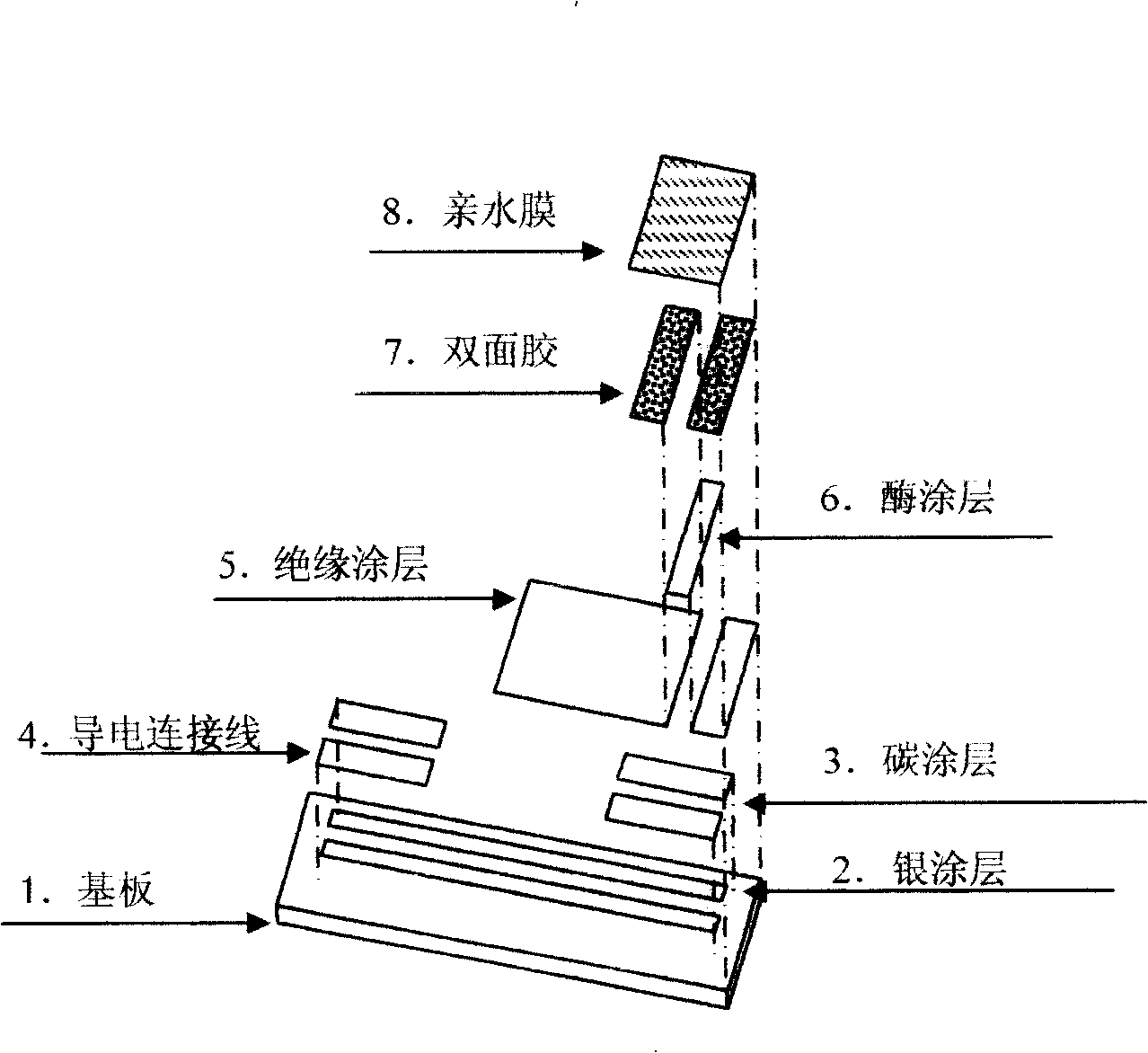

Method for manufacturing rapid blood sugar test paper

InactiveCN101303357ASimplify multi-layer printingEasy to readMicrobiological testing/measurementMaterial analysis by electric/magnetic meansMatching testSiphon

The invention discloses a matching test paper for a glucose tester and a preparation method thereof, which pertain to the technical field of bio-sensor. The substrate of the test paper is printed with a working electrode, a reference electrode and an electrical circuit; one end of the substrate is printed with a conducting wire connected with a read-out instrument; the working electrode and the reference electrode are carbon coatings which are printed on the substrate at once and printed with biological enzyme, a medium and an adhesive. The method adopts bio-sensor and electrochemical principle, produces the test paper by screen printing which is not restricted to a conductive circuit as well as prints relatively sensitive bio-components directly on an electrode holder; screen printing area is fully controlled by a screen printing machine. The encapsulation of the test paper adopts siphon encapsulation which limits reaction space. Once the test paper of the invention contacts human blood, a limited quantity of blood is sucked into a reaction tank and accurate results can be obtained conveniently and visually from a corresponding matching testing instrument. The glucose test paper has the advantages of simple production method, high accuracy and low cost and is convenient for later process and encapsulation and good for scale production.

Owner:胡军

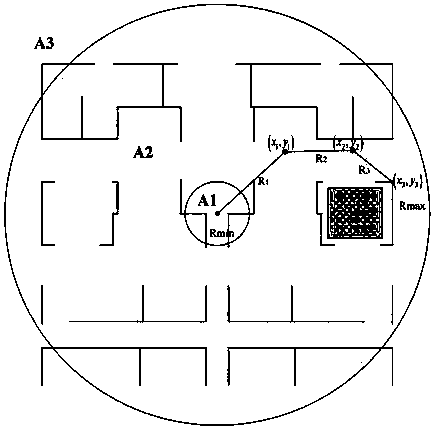

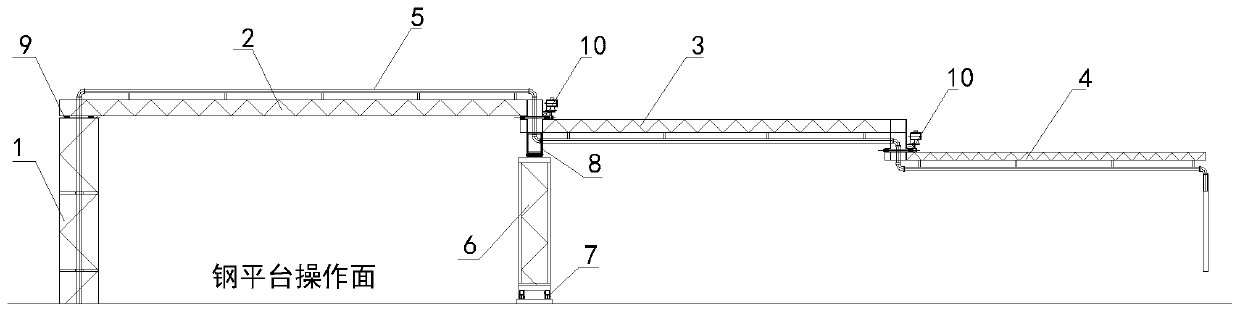

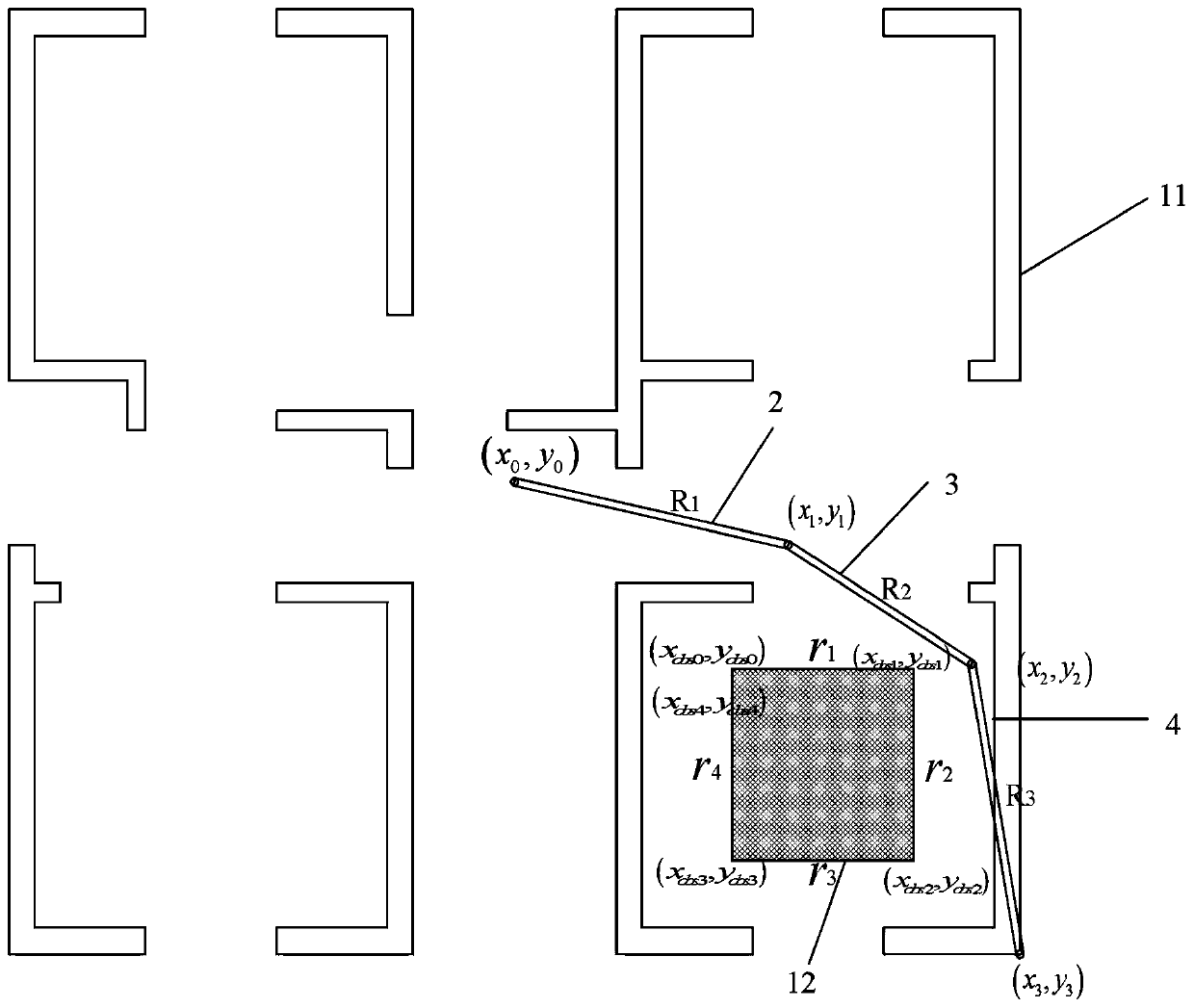

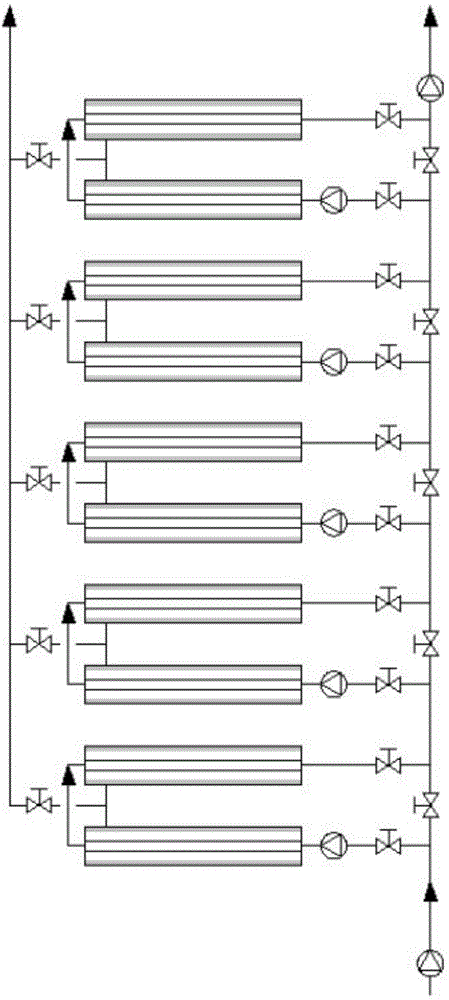

Intelligent concrete distribution control system and method for transverse folding arm concrete spreader

ActiveCN111058637AImprove cloth efficiencyImprove pouring qualityBuilding material handlingDistribution controlControl system

The invention discloses an intelligent concrete distribution control system and method for a transverse folding arm concrete spreader, and belongs to the field of construction engineering machinery. The intelligent concrete distribution system comprises an intelligent terminal, a PLC, a first driver, a second driver, a flow valve, an angle sensor and a flow sensor. According to the system and method, control parameters are sent to the PLC through the intelligent terminal, the first driver and the second driver are controlled by the PLC, and angle control over a rotary mechanism and opening degree control over the flow valve are realized, so that automatic intelligent concrete distribution can be realized through the horizontal folding arm concrete spreader, the concrete distribution position and flow can be precisely controlled, the labor cost is reduced, the concrete distribution efficiency is improved, and the industrialization level of the construction concrete spreader is improved.Meanwhile, the rotation angle of an arm frame, the concrete pouring flow, the position of a discharging port of a pump pipe and the concrete pouring progress can be monitored, precise concrete pouring is achieved, and the concrete pouring quality is improved.

Owner:SHANGHAI CONSTRUCTION GROUP

Lightweight steel-coarse aggregate reactive powder concrete composite beam structure

PendingCN109137718AReduce thicknessLose weightBridge structural detailsBridge engineeringProcess quality

The present disclosure provides a lightweight steel-coarse aggregate reactive powder concrete composite beam structure which comprises a plurality of segments, each segment comprising: a steel box girder comprising a bottom plate, a plurality of steel box girder webs and a plurality of steel box girder diaphragms. A coarse aggregate reactive powder concrete bridge deck comprises a plurality of precast bridge decks, a longitudinal wet joint and a transverse wet joint. A plurality of T-shaped pre-embedded steel plates are arranged on the bottom surface of the pre-fabricated bridge deck, the webplate thereof is connected with the steel box girder cross diaphragm plate, the top surface of the T-shaped pre-embedded steel plate is welded with a shear connector, and the shear connector is pre-embedded in the pre-fabricated bridge deck, so that the T-shaped pre-embedded steel plate and the pre-fabricated bridge deck form an integral whole. The invention can improve the mechanical performanceof the steel-concrete composite beam, enlarge the applicable span and scope, improve the construction speed and process quality of the bridge engineering, and overcome the problems of self-weight of the traditional steel-concrete composite beam and easy cracking of the bridge deck without reducing the mechanical performance of the concrete bridge deck.

Owner:CCCC HIGHWAY CONSULTANTS +1

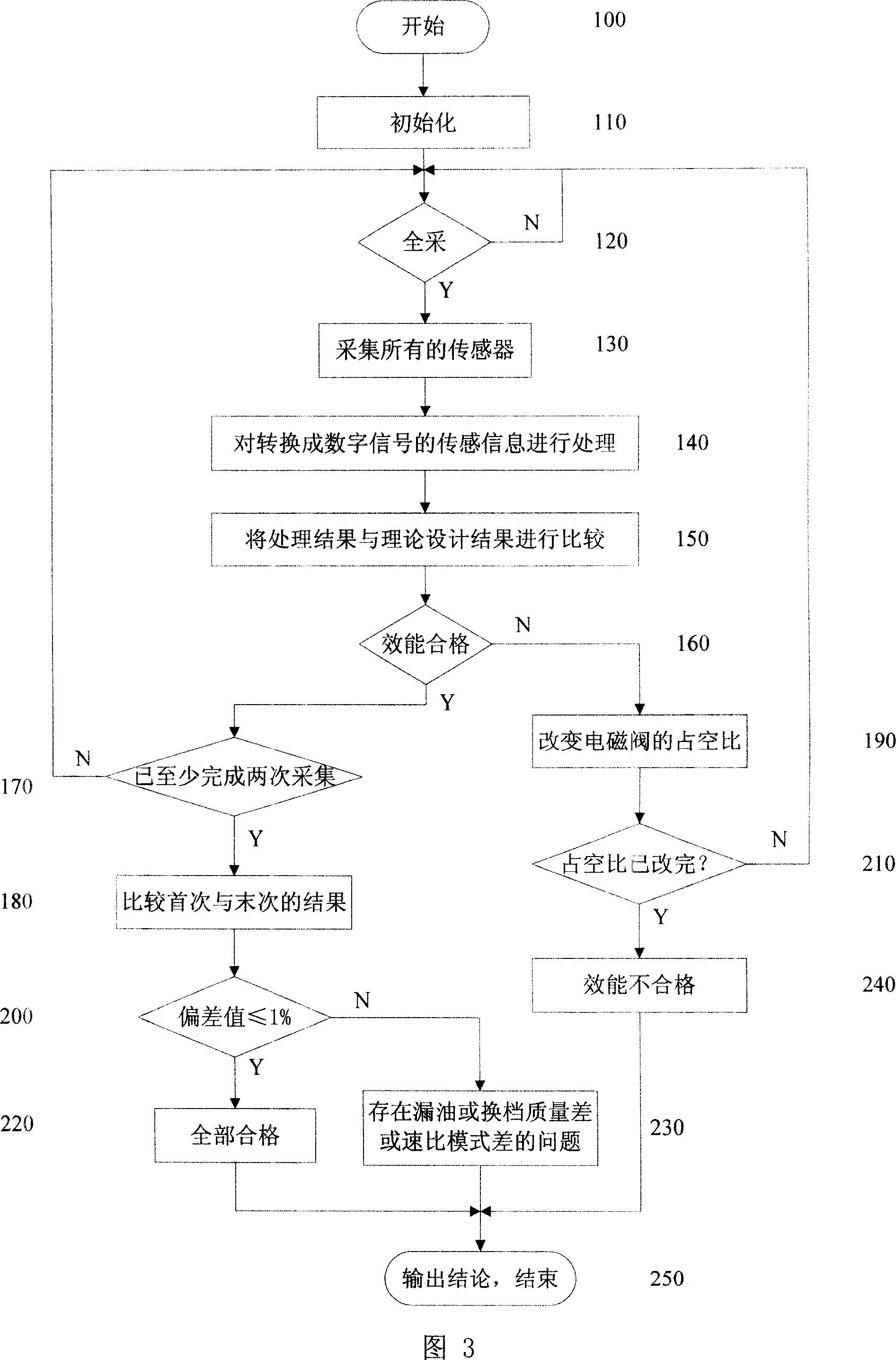

CVT stepless speed changer slope starting performance test method

ActiveCN101266195AReduce labor intensityImprove identityMachine gearing/transmission testingEngineeringSpur gear

The invention discloses a method for testing CVT (continuously variable transmission) slope-starting performance, comprising: step (a) tests on slope-starting capability respectively comprise: firstly testing starting performance respectively at D gear and R gear on flat road; then testing starting at slope with various gradients; testing forward starting performance and backward starting performance after halting the vehicle; test on slope practicality comprises: test for maximal halting gradient, idle vibration test for slope halting at D gear, test for impact and collision noise occurring during forward starting and backward starting at slope with various gradients; test on outdoor running; test to judge whether the speed ratio transformation works smoothly, whether the gear shifting position malfunction or disengagement occurs, whether the oil leakage occurs on air plug and whether the oil pump pressure reduces when normally running on outdoor long range slope; step (b) comparing recorded data with designed theoretical value of CVT in order to judge whether it meets the requirement. The invention has advantages of simple, rapid, compact, reasonable and convenient.

Owner:WUHU WANLIYANG TRANSMISSION CO LTD

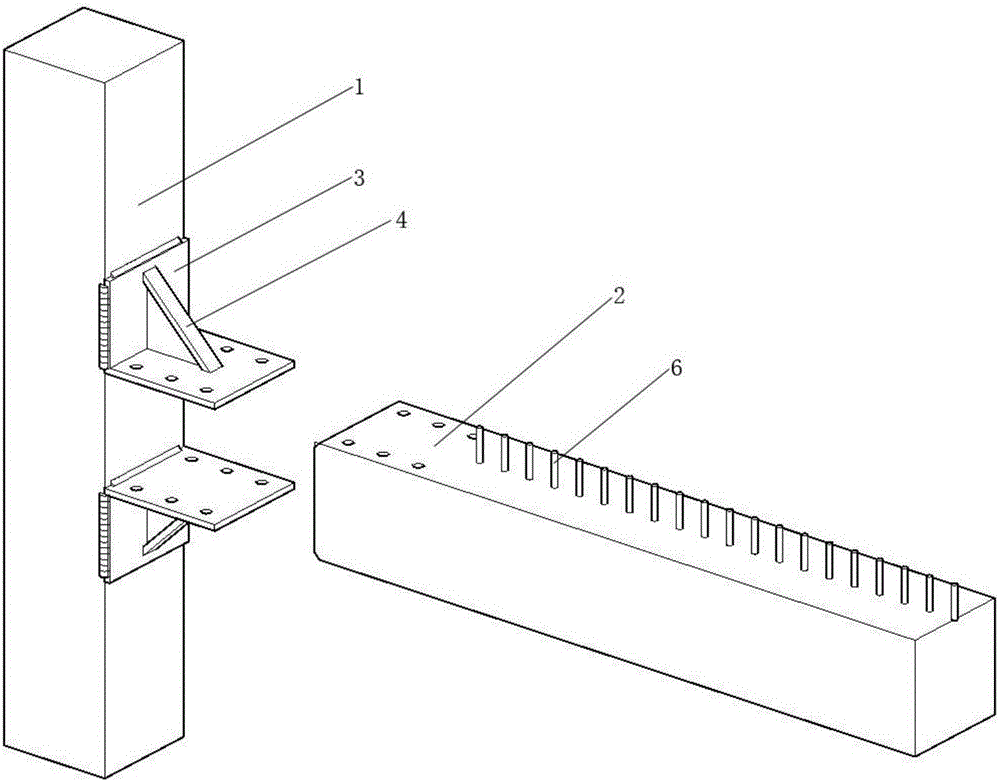

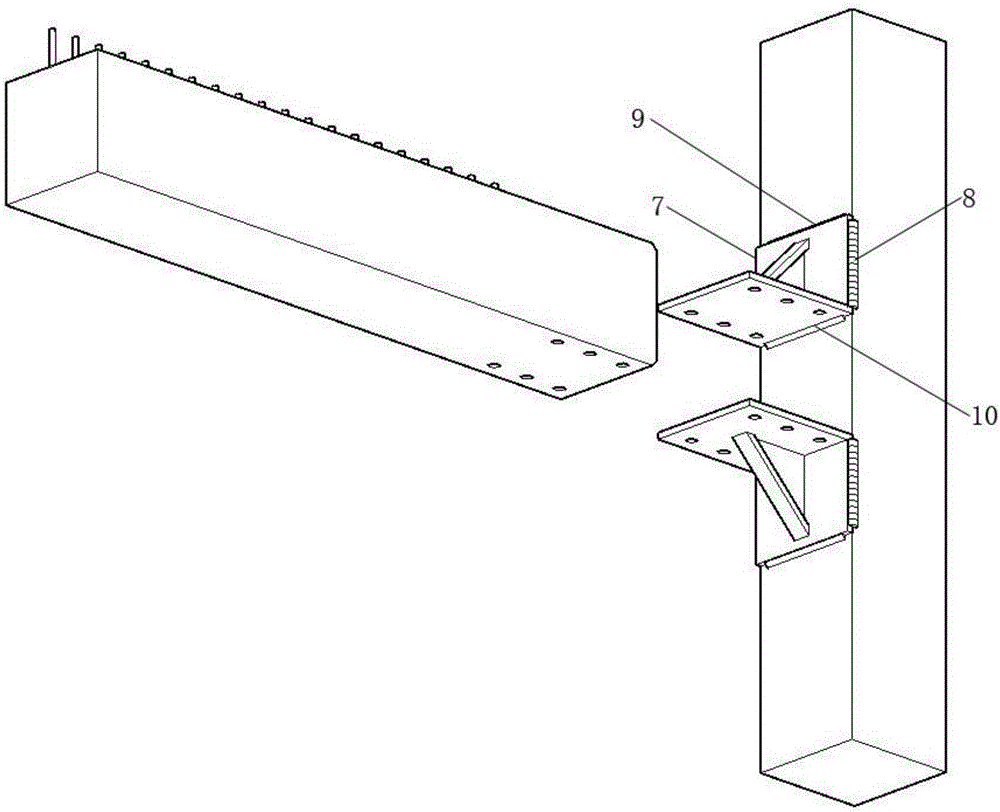

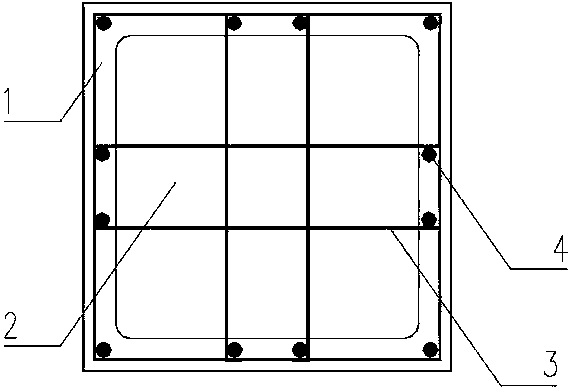

Connection node construction of concrete-filled square steel tube column and rectangular section steel beam

InactiveCN106703184ANode structure is simpleFlexible layoutBuilding constructionsLocal failureArchitectural engineering

The invention discloses a connection node construction of a concrete-filled square steel tube column and a rectangular section steel beam. The connection node construction is formed by the concrete-filled square steel tube column, the rectangular section steel beam, a right-angle connecting plate, a T-shaped triangle rib plate, a high-strength bolt, and a toggle pin on the top face of the steel beam. The connection node construction is simple, and the stress is clear. The amount of the steel for the connection node construction is less, and the connection node construction is only installed at one side of the column provided with the beam, so the composite cost is lower. The design of the beam column connection node is the ductile failure mode that the beam end is damaged by the tension, the obvious symptom and the duration time are existent before the damage, and the whole structure cannot be collapsed by the local failure. The connection of the steel beam and the concrete-filled steel tube column is firm, the integrality is good, the node rigidity is large, the assembly is simple and the construction period is short. New building rubbishes are not generated, and the requirements of housing industrialization and environmental protection are satisfied. The connection node construction is a novel node connection mode suitable for the connection of the current lower-layer and multi-layer light steel frame housing construction beam columns.

Owner:BEIJING UNIV OF TECH

Silk screen printing method for producing blood sugar test paper

InactiveCN101246175AImprove toughnessImprove insulation performanceMaterial analysis by electric/magnetic meansBiological testingCarbon coatingAdhesive

The invention provides a blood glucose testing instrument and the producing method thereof, which belongs to the field of bio-sensor technology. The substrate of the testing paper is printed with working electrode, reference electrode and electrical circuit which are formed by carbon-coating, one end of the substrate is printed with wire connected with readout instrument, the working electrode and reference electrode are respectively printed on carbon-coating above substrate conductive silver layer, the working electrode is also printed with enzyme, medium and adhesive. According to bio-sensor and electrochemical principle, the testing paper is made through silk-screen process, not only conductive circuit is printed, but also sensitive bio-element is directly printed on electrode supporter, the print amount of the print material and print area are totally and exactly controlled by computer. Once the testing paper contacts human body fluid, the testing result can be easily and directly read out on corresponding matching instrument, the producing method is easy, and has high precision, low cost, which is convenient for later process and encapsulation, and is good for large-scale production.

Owner:胡军

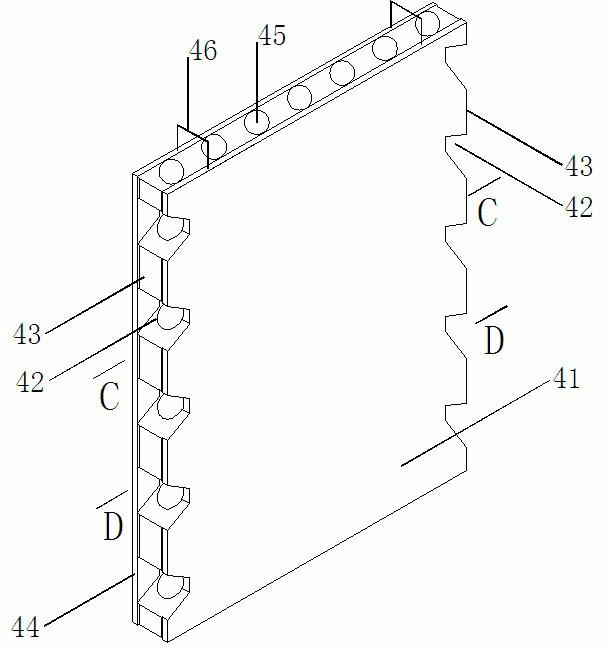

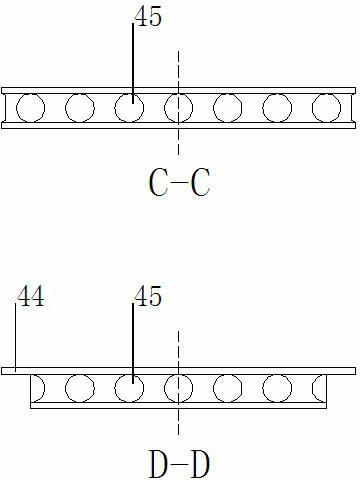

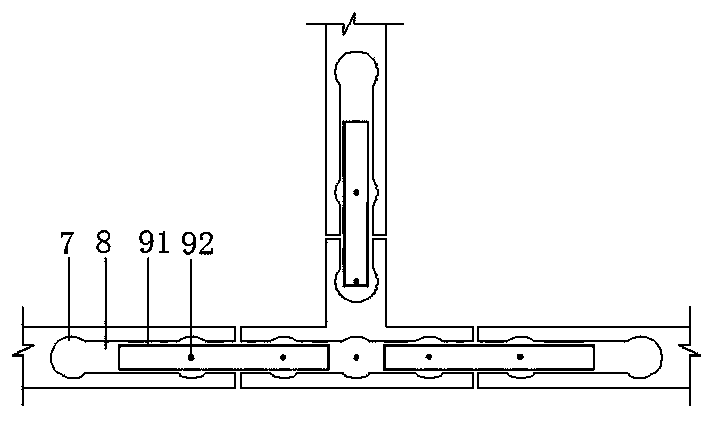

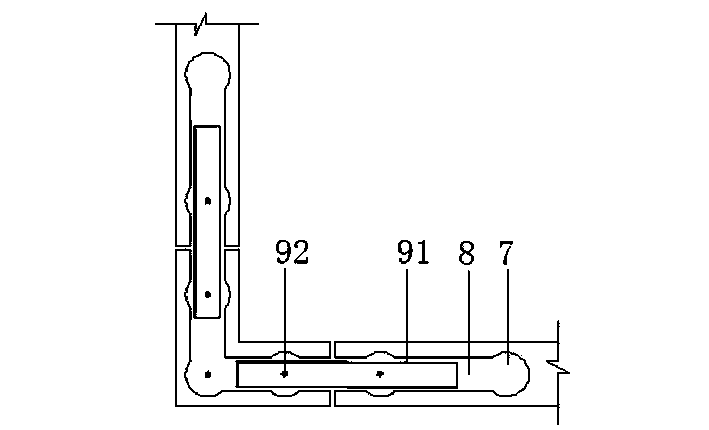

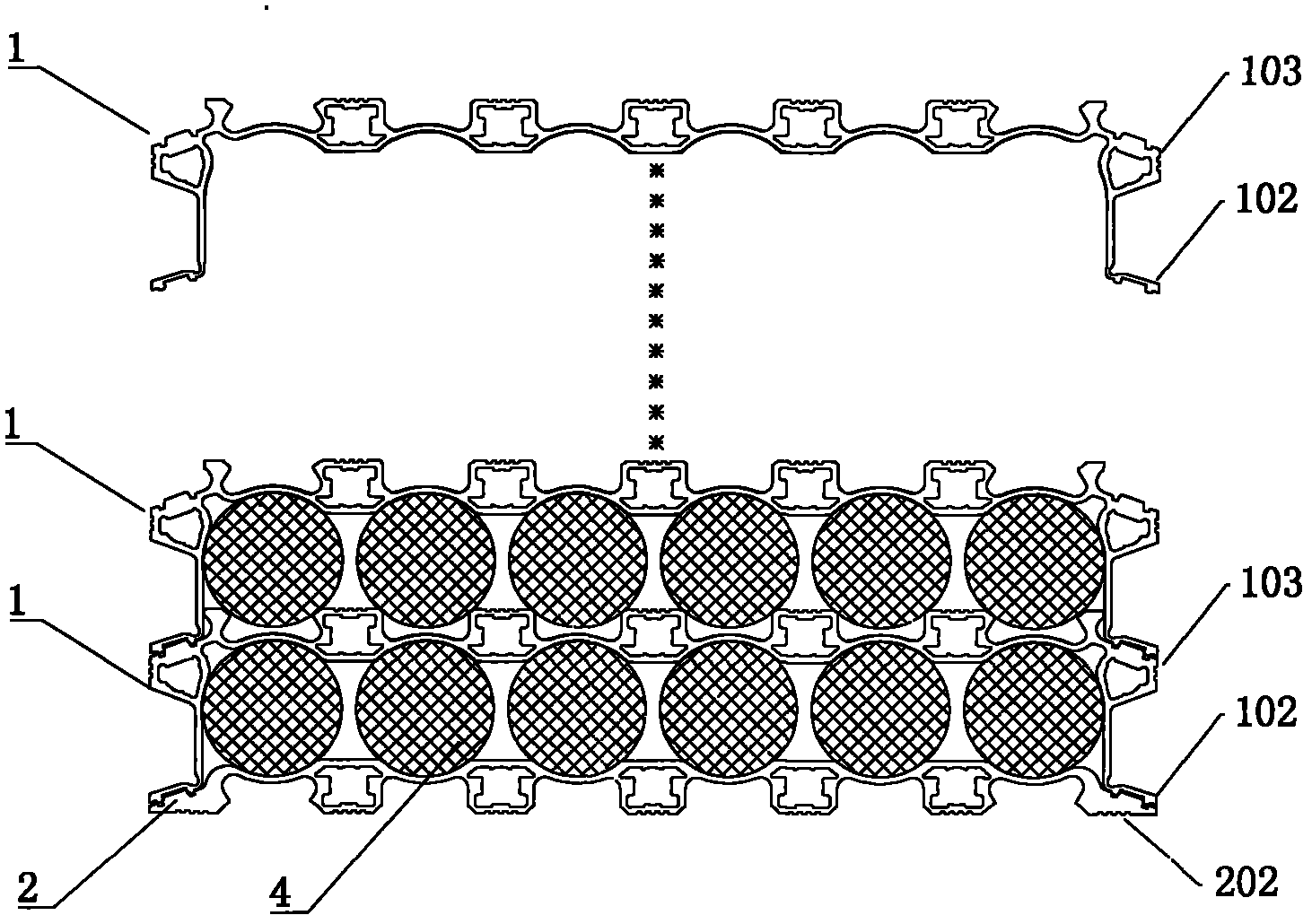

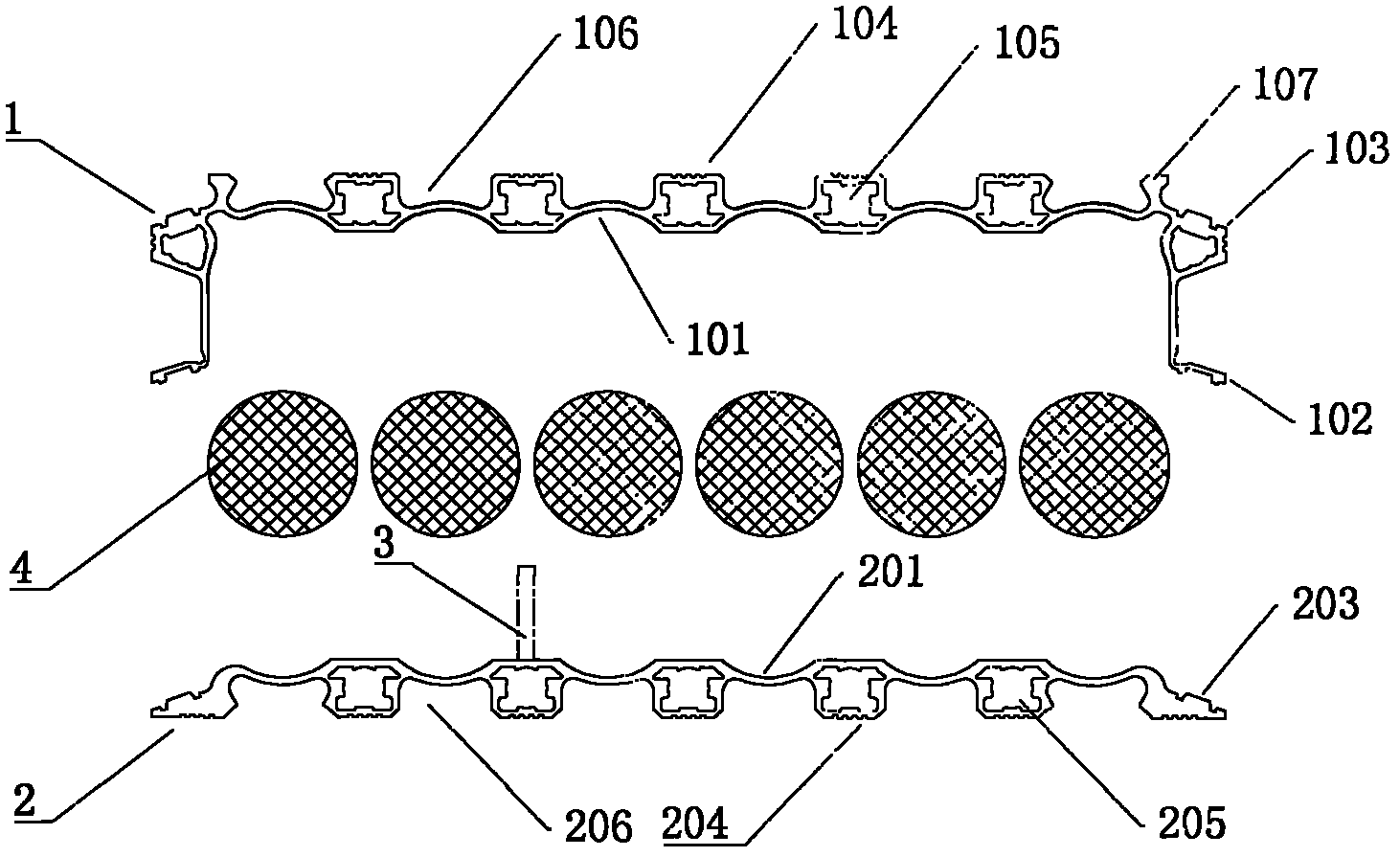

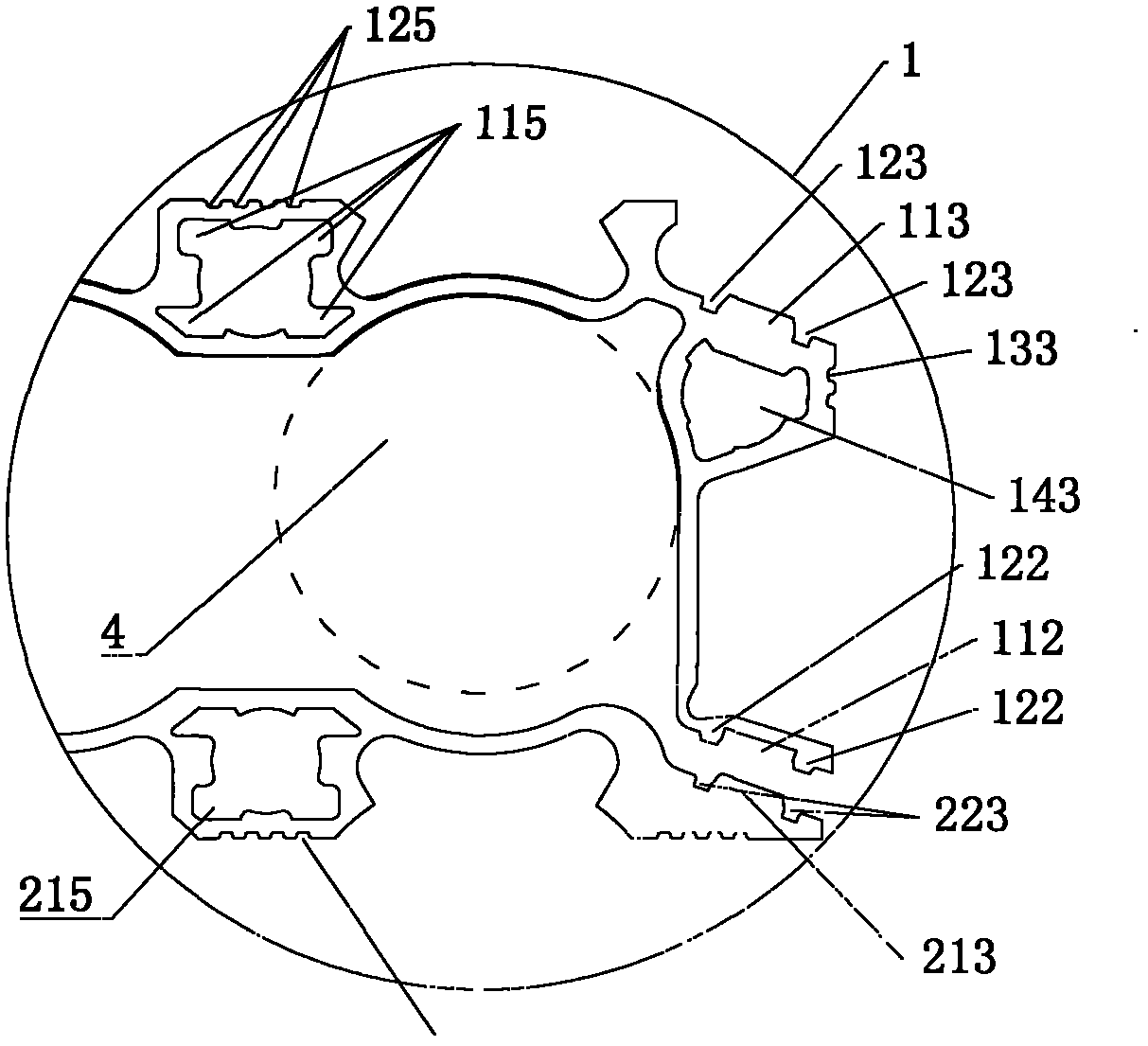

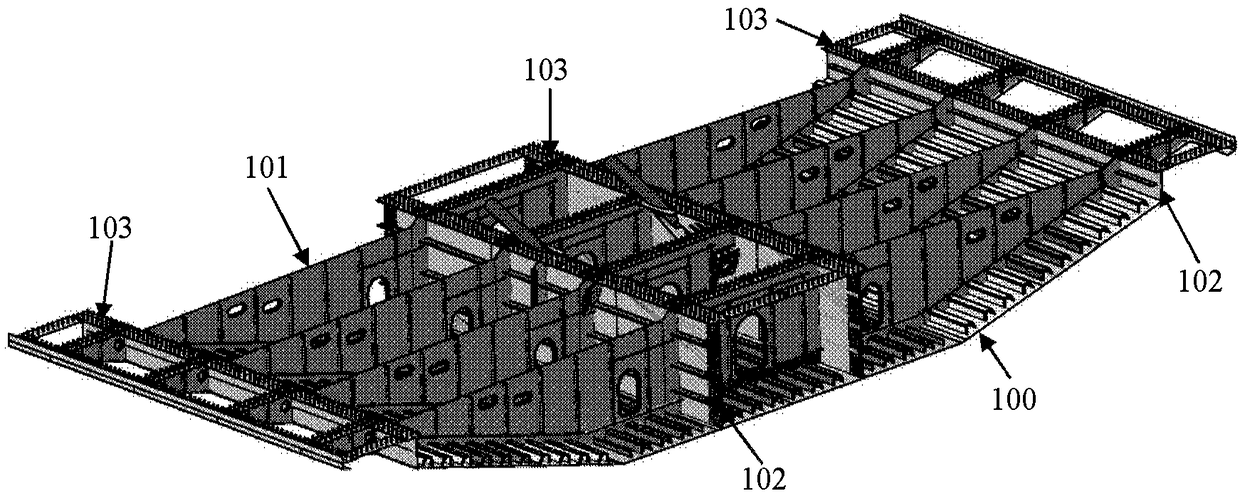

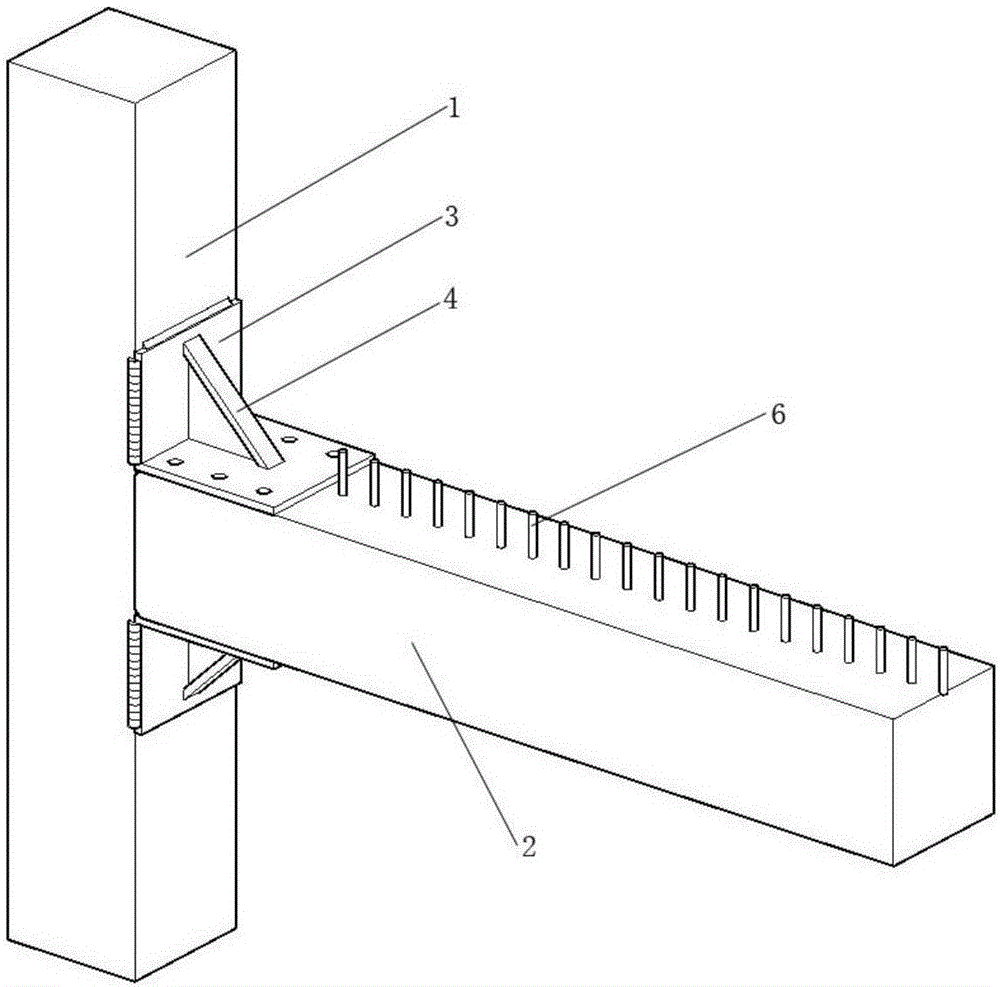

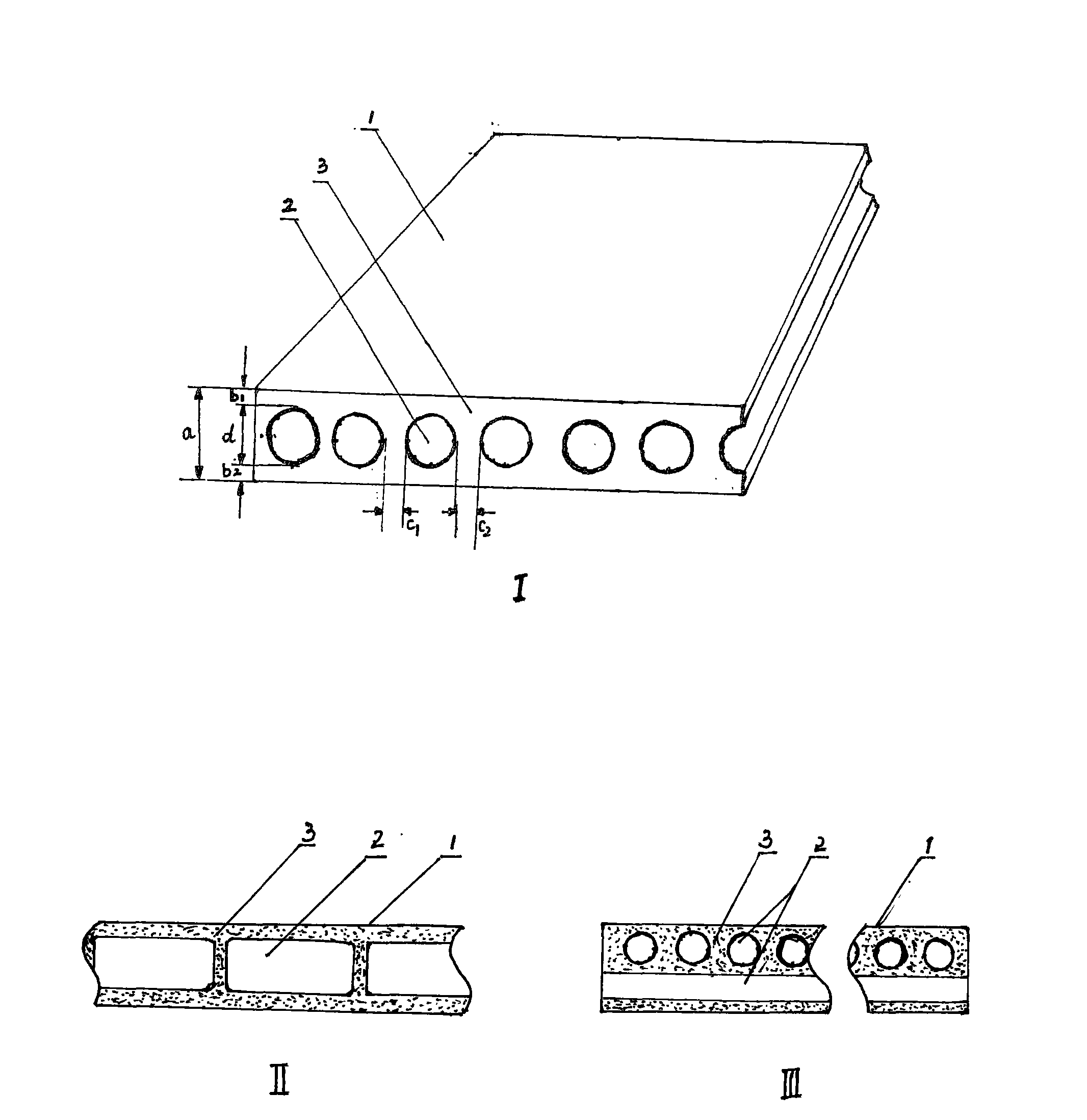

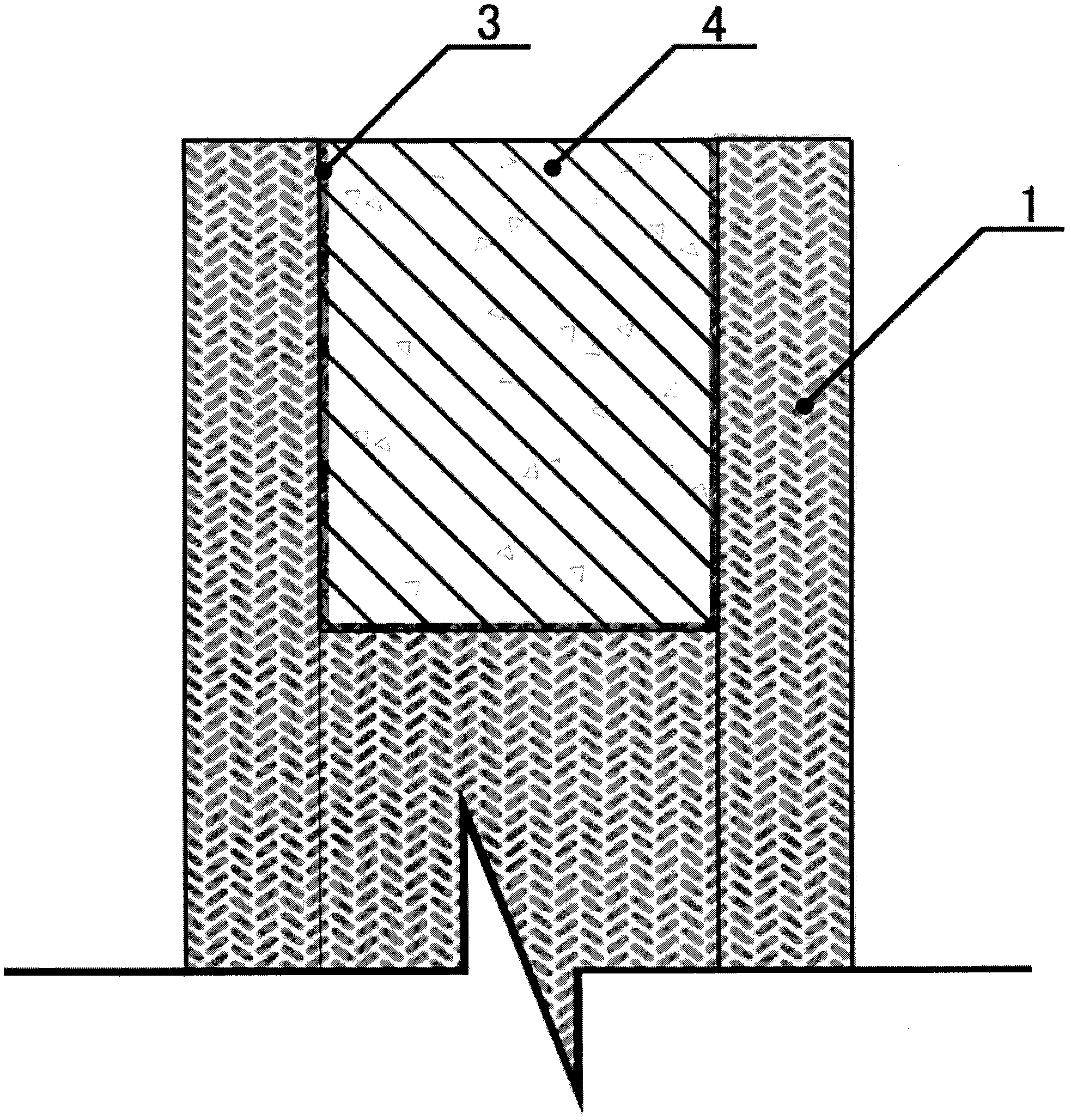

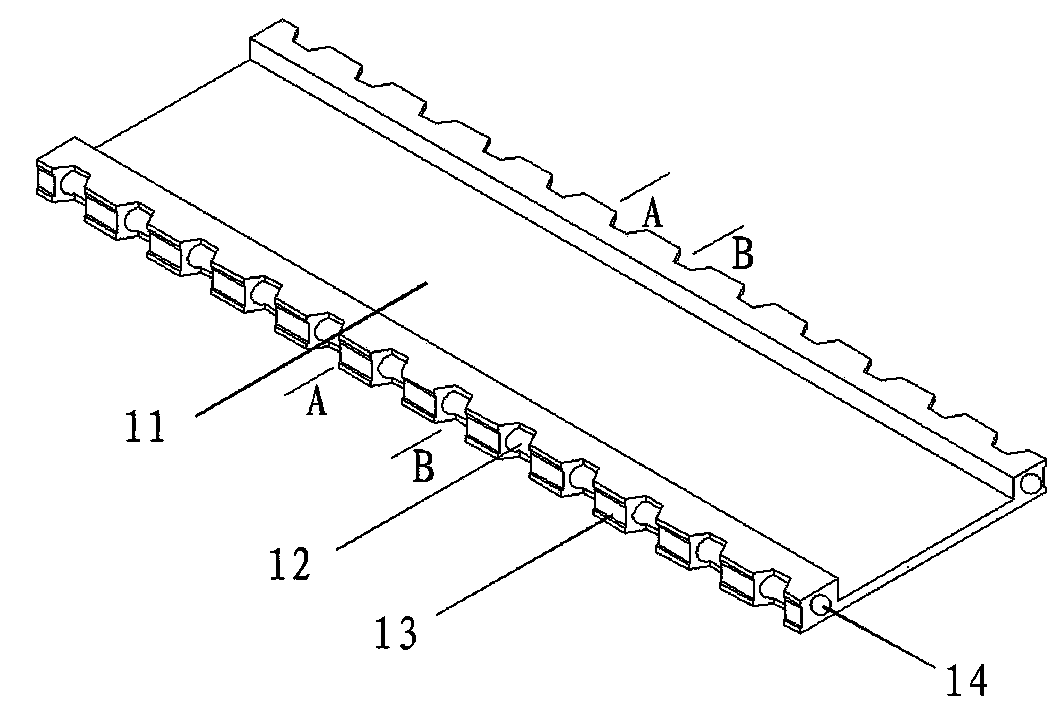

Precast concrete hollow component, and manufacturing method thereof

InactiveCN103628618AImprove the level of industrializationIncrease productivityStrutsConstruction materialReinforced concreteCross wall

The invention relates to a precast concrete hollow component, and a manufacturing method thereof, and belongs to the technical field of precast reinforced concrete structural components. The precast concrete hollow component comprises a precast wall plate component, a floor component, a T-shaped wall post component, an L-shaped wall post component, a cross wall post component and a wall body component provided with a hole; the precast concrete hollow component is internally provided with a plurality of longitudinal through holes along the length direction, and a plurality of horizontal non-through holes communicated with the longitudinal through holes along the width direction, wherein the longitudinal through holes are arranged parallelly to each other, and the horizontal non-through holes are arranged parallelly to each other. The manufacturing method comprises following steps: combining templates, such as a bottom die, a top die, a side die, a steel pipe inner die and the like, on a production field of precast slabs; arranging reinforcing meshes; then pouring concrete; drawing out a steel pipe after the strength of the concrete reaches to a certain degree; and dismounting the templates after the concrete reaches to an expected strength degree. The precast concrete hollow component can be used in multilayered, high-rise shear wall and frame-shear wall building structures, thus improving industrial level of the building structures, improving structural behaviors and saving sources.

Owner:初明进

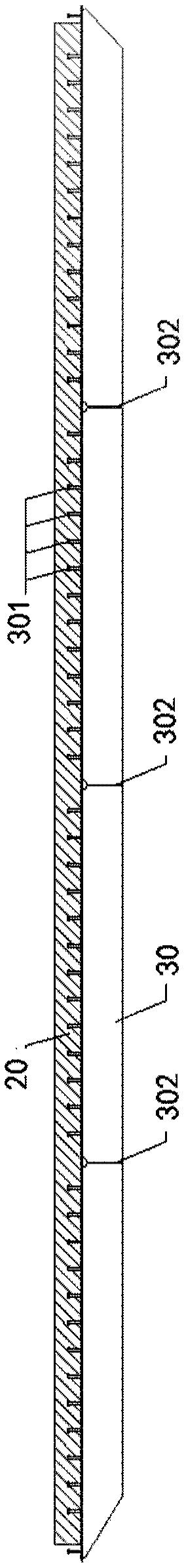

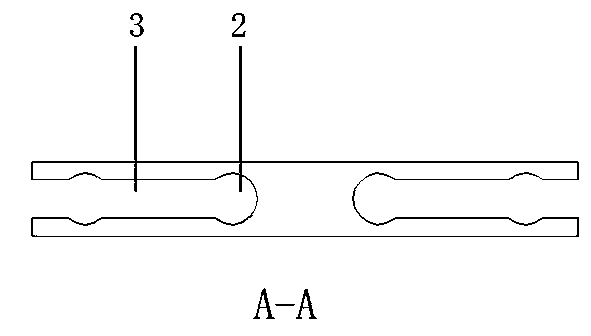

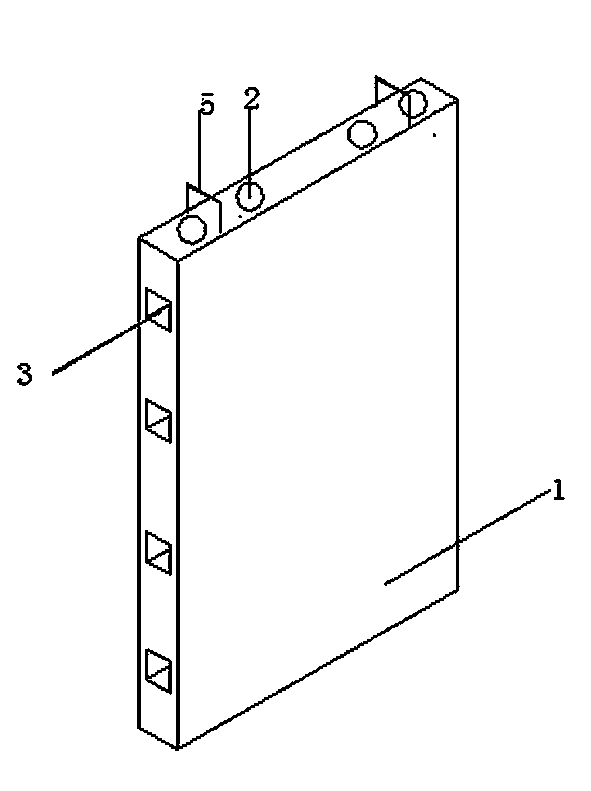

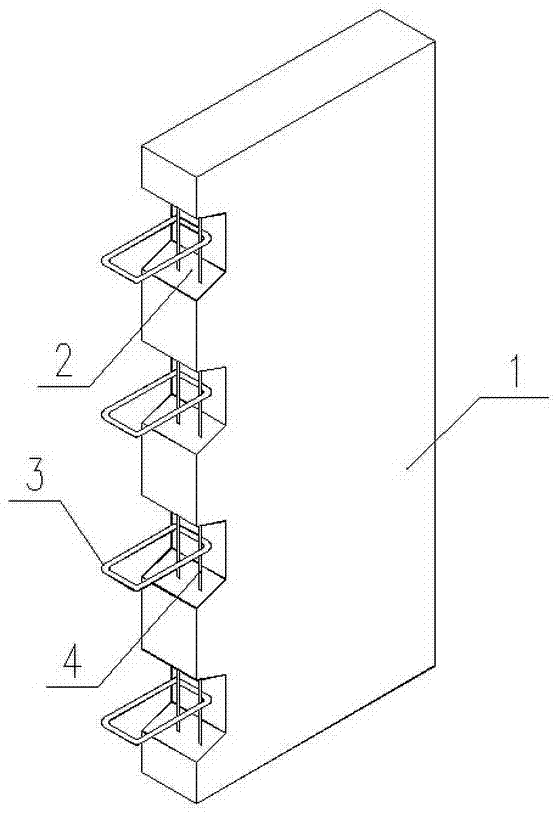

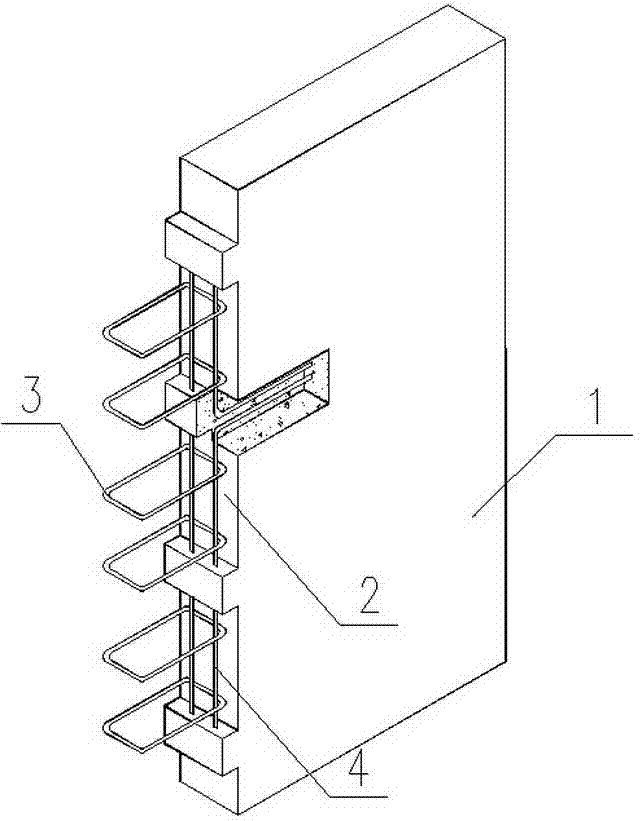

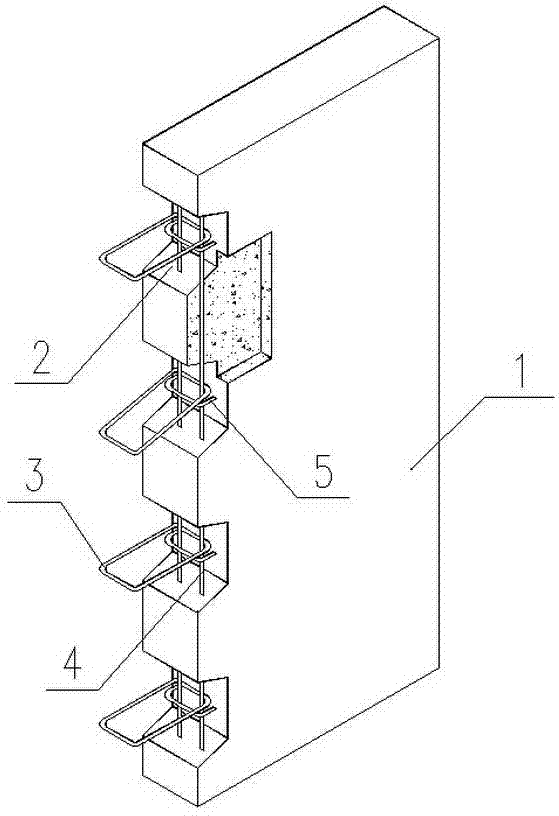

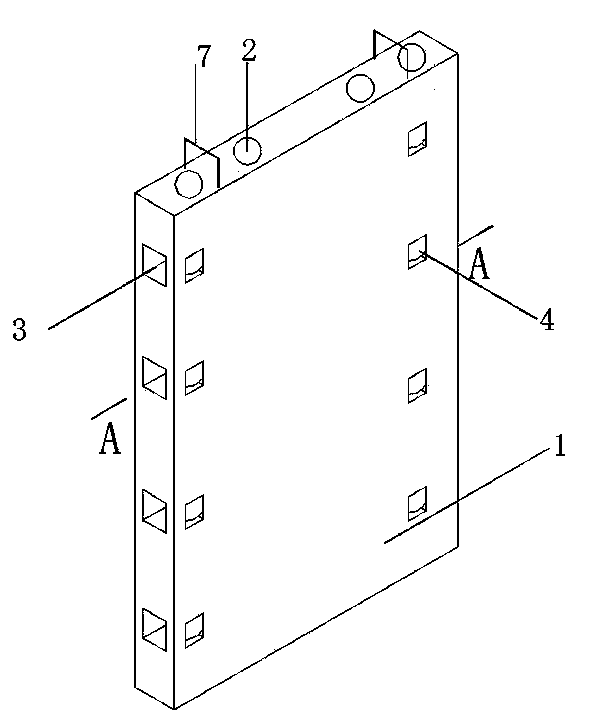

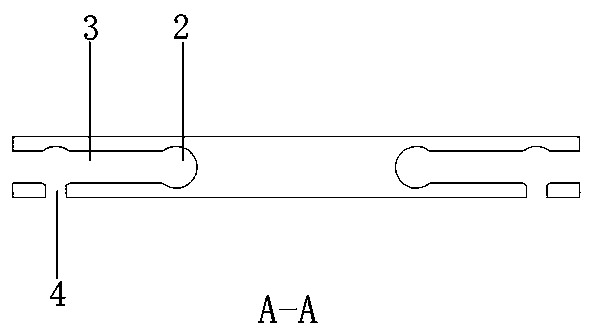

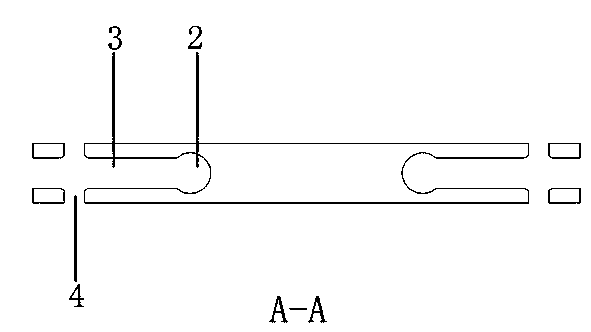

Prefabricated concrete component with connecting rings

InactiveCN103669698AImprove mechanical performanceImprove the level of industrializationConstruction materialReinforced concreteTransverse groove

The invention relates to a prefabricated concrete component with connecting rings and belongs to the technical field of prefabricated armoured concrete structural components. One or more transverse grooves are formed in one side surface of the prefabricated concrete component, the two side surfaces of the transverse grooves are connected with longitudinal ribs, and steel bar rings are hung on the longitudinal ribs. The prefabricated concrete component with the connecting rings boosts the industrial level of building structures, improves the force bearing performance, and saves resources.

Owner:初明进

Liquid culture medium for culturing mematophagous fungi and method for preparing chlamydospore of the same

A liquid culture medium for culturing Duddingtonia flagrans and a preparation method of chlamydospore thereof belongs to the field of prevention and treatment technology of gastrointestinal parasitic disease of livestock. The liquid culture medium mainly contains potato juice and trace amount of salt, and is filled in a 100 to 1,000 mL triangular flask or a 5 to 15 L fermentation tank by a volume of 1 / 3 to 1 / 5 of the container volume. The liquid culture medium can be used for preparing seeds of Duddingtonia flagrans and enlarging fermentation production after high-pressure sterilization. The technology has abundant and cost-effective raw materials, which facilitates the reduction of production cost, the alleviation of labor intensity, the improvement of a strain preparation as well as the improvement of scale production and industrialization level of the preparation. The technology can be used for fermentatively culturing Duddingtonia flagrans, which can provide seeds for batch production of chlamydospore of Duddingtonia flagrans and can be directly used for the production of chlamydospore.

Owner:王治才

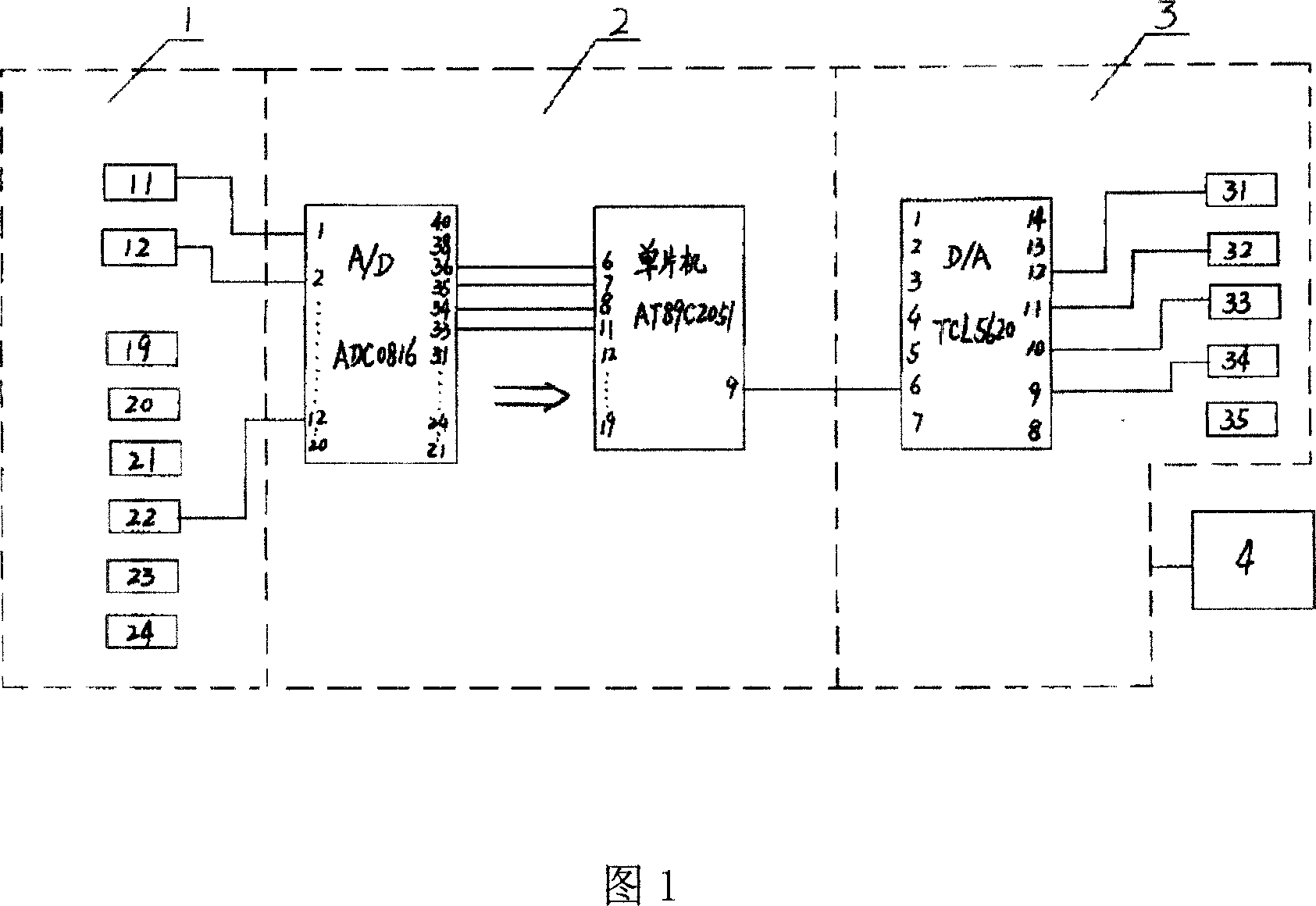

Device for testing cooling performance of liquid controlled stepless speed changer and its testing method

ActiveCN101000277AQuick analysisEasy to handleMachine gearing/transmission testingMicrocontrollerSolenoid valve

The invention discloses liquid control non-stage transmission cooling performance detecting device and method. The device includes sensing component connected in series, control component contains analog to digital converter ADC0816 and SCM AT89C2051, executing component contains digital to analog converter TCL5620 and solenoid valve, electrical source, and liquid flow rate adjusted by the solenoid valve according to the control signal. The method includes the following steps: respectively setting and collecting sensor output time slice, solenoid valve duty ratio, duty ratio adjusted step size; confirming collecting time according to the object and output value to process data converted into digital signal; comparing the curve gained under the condition that cooler inlet oil temperature is not more than 150 degree centigrade with theoretic one; storing the result and sending to output device. It can automatically verify and detect CVT efficiency, the matching of the wind cooler and hydraulic system.

Owner:WUHU WANLIYANG TRANSMISSION CO LTD

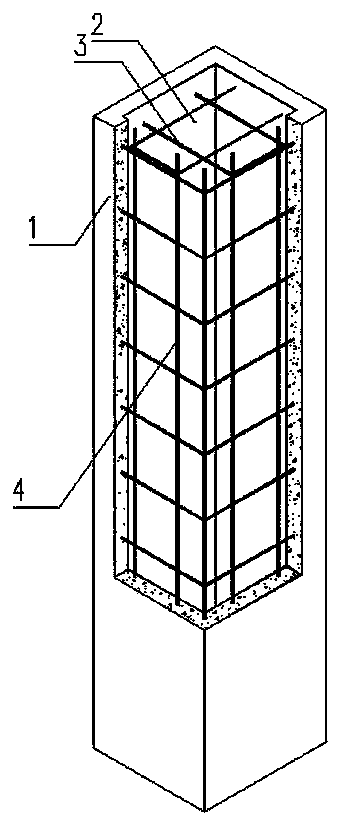

Prefabricated reinforced concrete hollow column template and making method thereof

ActiveCN103737718AMature technologyImprove the level of industrializationMouldsReinforced concrete columnEngineering

The invention provides a prefabricated reinforced concrete hollow column template. A plurality of stirrups are arranged on the column template, a longitudinally penetrating hollow duct is arranged in the column template, and part of the stirrups penetrate through the hollow duct. The invention further provides a making method for the prefabricated reinforced concrete hollow column template. The prefabricated column template provided by the invention can be used for manufacturing various reinforced concrete columns and can be widely used for various engineering structures.

Owner:初明进

Domestic sludge aerobic composting method and system thereof

PendingCN107089847AOptimizing dosageGuaranteed unobstructedBio-organic fraction processingClimate change adaptationSludgeSlag

The invention provides a domestic sludge aerobic composting method, which can solve the technical problems that the existing aerobic composting method is long in one-time composting period, and poor in sludge reduction effect. The method comprises the following steps: I. adding a conditioning agent for hardening and tempering, and then performing deep dehydration treatment to obtain a mud cake; II. crashing the mud cake to obtain mud cake particles; and III. composting and fermenting the mud cake particles. The composting method is characterized in that the conditioning agent contains a curing agent and a filtering aid, the addition quantity of each of the curing agent and the filtering aid is 10%-30% of solid content of sludge; the curing agent contains the following raw materials in percentage by mass: 5% -15% of incineration furnace slag, 50%-70% of carbide slag, and 20% -35% of desulfurization plaster, and the filtering aid is a porous biomass material. In addition, the invention further provides a domestic sludge aerobic composting system for realizing the method.

Owner:WUXI GUOLIAN ENVIRONMENTAL SCI & TECH

Method for manufacturing hollow medium density fiberboards and special equipment

InactiveCN101664953AImprove efficiencyQuality improvementWood working apparatusFlat articlesFiberProduction line

The invention relates to a method for manufacturing hollow medium density fiberboards and used equipment. At present, the fiberboards produced by a medium density fiberboard production line are all solid. In the invention, a part of special equipment is added in the medium density fiberboard production line so as to efficiently manufacture the hollow medium density fiberboards. The hollow medium density fiberboards can greatly save fiber materials, lighten the weight of board bodies, reduce the cost of each board, keep the good performances of the medium density fiberboards such as large breadth, fine fiber, attractive appearance, stable dimension and the like, and are of great application value in the fields of furniture, architectural decoration, wooden doors, vehicles and ships and thelike.

Owner:唐善学

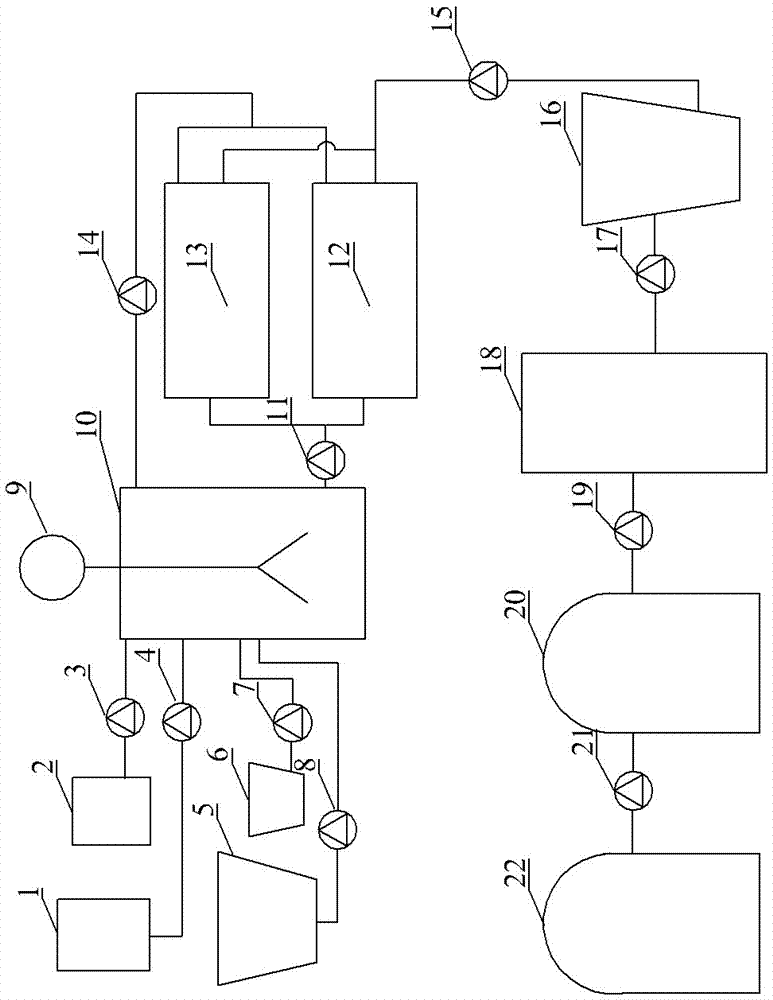

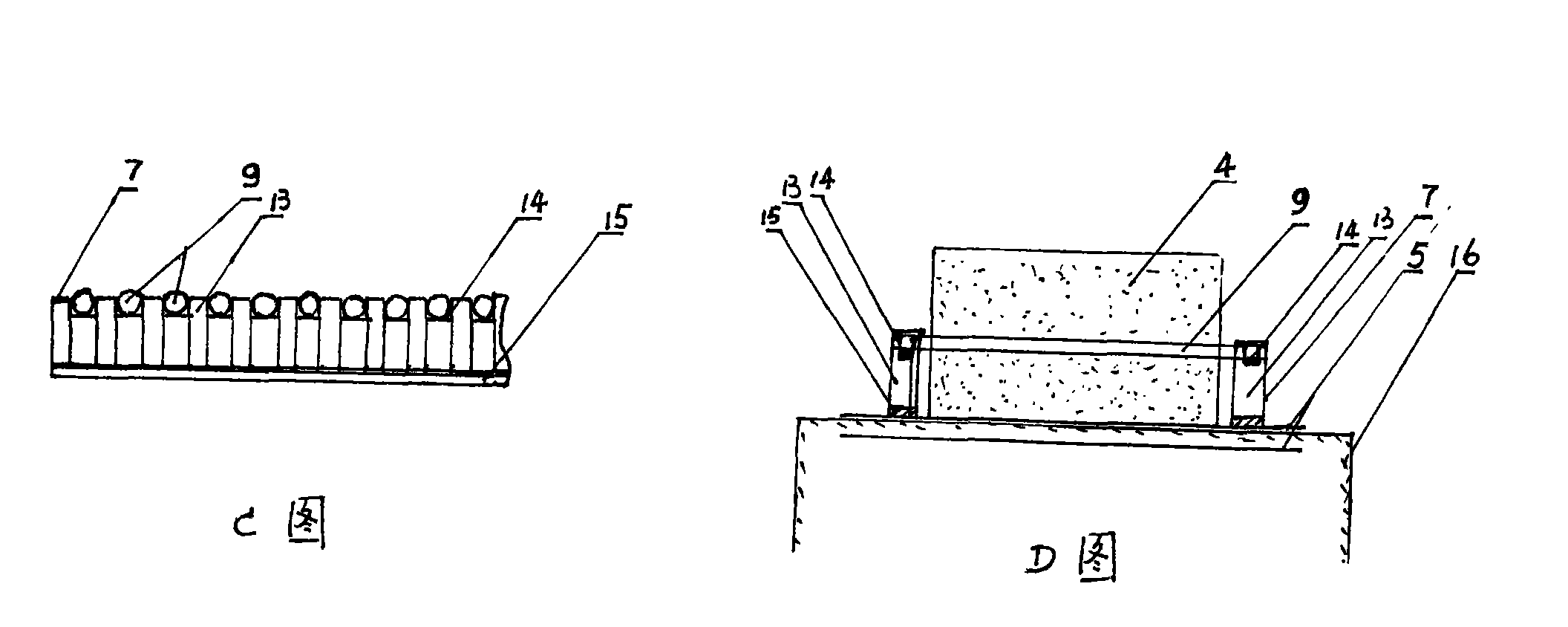

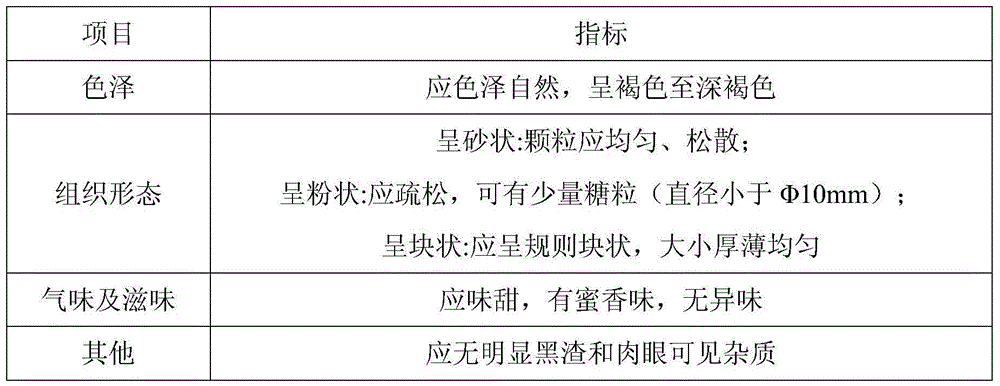

Originally ecological black sugar processing device

ActiveCN104805224ATroubleshoot filter clarification issuesEfficient removalSugar dryingSugar productsAdditive ingredientUltrafiltration

An originally ecological black sugar processing device comprises a squeezing rough-filtration device, a heat exchanger, a multistage ceramic membrane ultrafiltration device, a falling-film type three-effect vacuum evaporation system, a water jet condenser, a jacketed iron pot and a graining drying forming device, which are sequentially connected, wherein a clarified sugarcane juice box is connected between the multistage ceramic membrane ultrafiltration device and the three-effect vacuum evaporation device; a syrup box is connected between the falling-film type three-effect vacuum evaporation system and the jacketed iron pot. The black sugar prepared through the device provided by the invention is small in grain, brown-dark brown and natural in color, contains fewer impurities, has a natural caramel charcoal burning fragrance, is rich in flavor, sweet, delicious, and fine and smooth in mouthfeel, retains the nutritional ingredients of sugarcane to the greatest extent, and has a high nutritional value; the turbidity is less than 0.5 NTU after the black sugar is dissolved to 11.5 degrees Bx, so that the problem that black residues exist after the black sugar is dissolved is solved and the quality of the black sugar is improved.

Owner:广西百桂堂食品科技有限公司

Prefabricated concrete hollow member and preparation method thereof

InactiveCN103628616AImprove the level of industrializationIncrease productivityConstruction materialRebarCoupling beam

The invention relates to a prefabricated concrete hollow member and a preparation method thereof, and belongs to the technical field of prefabricated reinforced concrete structure members. The prefabricated concrete hollow member comprises a prefabricated panel member, a floorslab member, a T-shaped wall column member, an L-shaped wall column member, a cross-shaped wall column member and a wall member with holes. The wall member with the holes comprises the holes, a coupling beam at the upper portion of the holes and walls on two sides of each hole. Multiple communicated and longitudinal holes are arranged in the prefabricated concrete hollow member along the length direction and are parallel to each other, and multiple non-through horizontal holes are arranged in the prefabricated concrete hollow member along the width direction. Board holes are arranged at the joints of the longitudinal holes and the horizontal holes. The prefabricated concrete hollow member can be applied in a multi-storey and high-rise shear wall building structure and a framework-shear wall construction wall, and therefore industrialization level of a building structure can be improved, stress property is improved, and resource is saved.

Owner:初明进

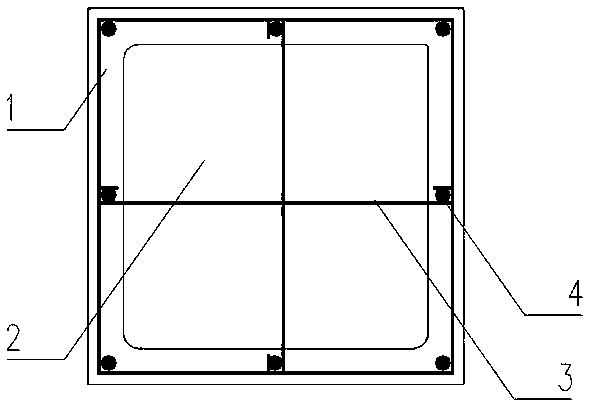

Prefabricated reinforced concrete column template and making method thereof

ActiveCN103741883AImprove the level of industrializationIncrease productivityStrutsCeramic shaping apparatusReinforced concrete columnEngineering structures

The invention provides a prefabricated reinforced concrete column template. The prefabricated reinforced concrete column template comprises a cylindrical outer wall and a longitudinal inner partition board, wherein the interior of the prefabricated reinforced concrete column template is separated into at least two longitudinally through hollow ducts by the inner partition board, and at least one lateral hole for communicating the hollow ducts on the two sides of the inner partition board is formed in the inner partition board. The invention further provides a making method of the prefabricated reinforced concrete column template. The prefabricated column template provided by the invention can be used for making various reinforced concrete columns and can be widely used for various engineering structures.

Owner:初明进

Composite bacterial agent product for fermentation of pickled vegetable and preparation method thereof

InactiveCN104388332AFast preparationShorten the production cycleFungiBacteriaBiotechnologyArray data structure

The invention relates to a composite bacterial agent product for fermentation of pickled vegetable and preparation method thereof, and belongs to the field of production of microbe preparations. The composite bacterial agent product for fermentation of pickled vegetable is composed of the following bacteria in parts by weight: 10-20 parts of plant lactobacillus CGMCC NO.9405, 2-4 parts of leuconostoc mesenteroide, 5-8 parts of lactobacillus rhamnosus, 1-5 parts of acetobacter aceti and 0.1-0.4 part of yeast. The employed bacterial strain is obtained through long-term test research, the obtained bacterial strain is especially suitable for fermentation production of pickled vegetable, and is used to prepare a directly-poured type bacterial powder special for fermentation of pickled vegetable. The bacterial powder is capable of rapidly preparing pickled-vegetable products, the production period is short, the product is good in quality, excellent in flavor and high in safety, and the product standards are consistent. The composite bacterial agent product is suitable for industrial large-scale production, also is applicable to manual workshop type production, and the product has relatively large application market.

Owner:天津天绿健科技有限公司

Straw wall body-based frame column/beam template-less construction technology

InactiveCN102322144AImprove reusabilityImprove the level of industrializationBuilding material handlingEngineeringShock resistance

The invention discloses a straw wall body-based frame column / beam template-less construction technology, wherein Chinese character 'kou'-shaped frame column spaces and U-shaped frame beam spaces are assembled at corners by using prefabricated external wallboards, and the frame columns and the frame beams are made by casting concrete or other substances with the same intensity. The construction technology disclosed by the invention has the advantages of being beneficial to protecting environment and effectively utilizing waste raw materials, such as straws and the like, enhancing the level of heat preservation and heat insulation and the recyclability of the materials, creating a new situation for the application of straw wall bodies, being beneficial to standardized production, and greatly enhancing the level of industrialization for the construction of buildings and the overall level and the shock resistance of building construction; and the template-less laying is adopted, so that the difficulty and the cost for construction are lowered, and the construction period is greatly shortened.

Owner:赵之昆 +2

Composite microbial preparation for pickle production and preparation method thereof

The invention discloses composite bacterial powder for pickle production and a preparation method thereof, belonging to the field of production of microbial preparations. The composite bacterial powder comprises the following components in parts by weight: 1-5 parts of bacillus aceticus, 1-2 parts of saccharomycetes, 5-10 parts of lactobacillus rhamnosus and 8-15 parts of lactobacillus plantarum. According to the composite bacterial powder, the number ranges of viable cells in each strain are that each gram of lactobacillus rhamnosus contains (0.1-10.0)*10<9> viable cells, each gram of bacillus aceticus contains (0.01-6.0)*10<9> viable cells, each gram of saccharomycetes contains (0.01-5.0)*10<8> viable cells, and each gram of lactobacillus plantarum contains (1-50)*10<8> viable cells. The pickle products can be rapidly prepared, the production period is short, and the product is high in quality, good in flavor, high in safety and consistent in standard, is suitable for large-scale industrial production, can be used for manual workshop type production and has large application market.

Owner:田岗

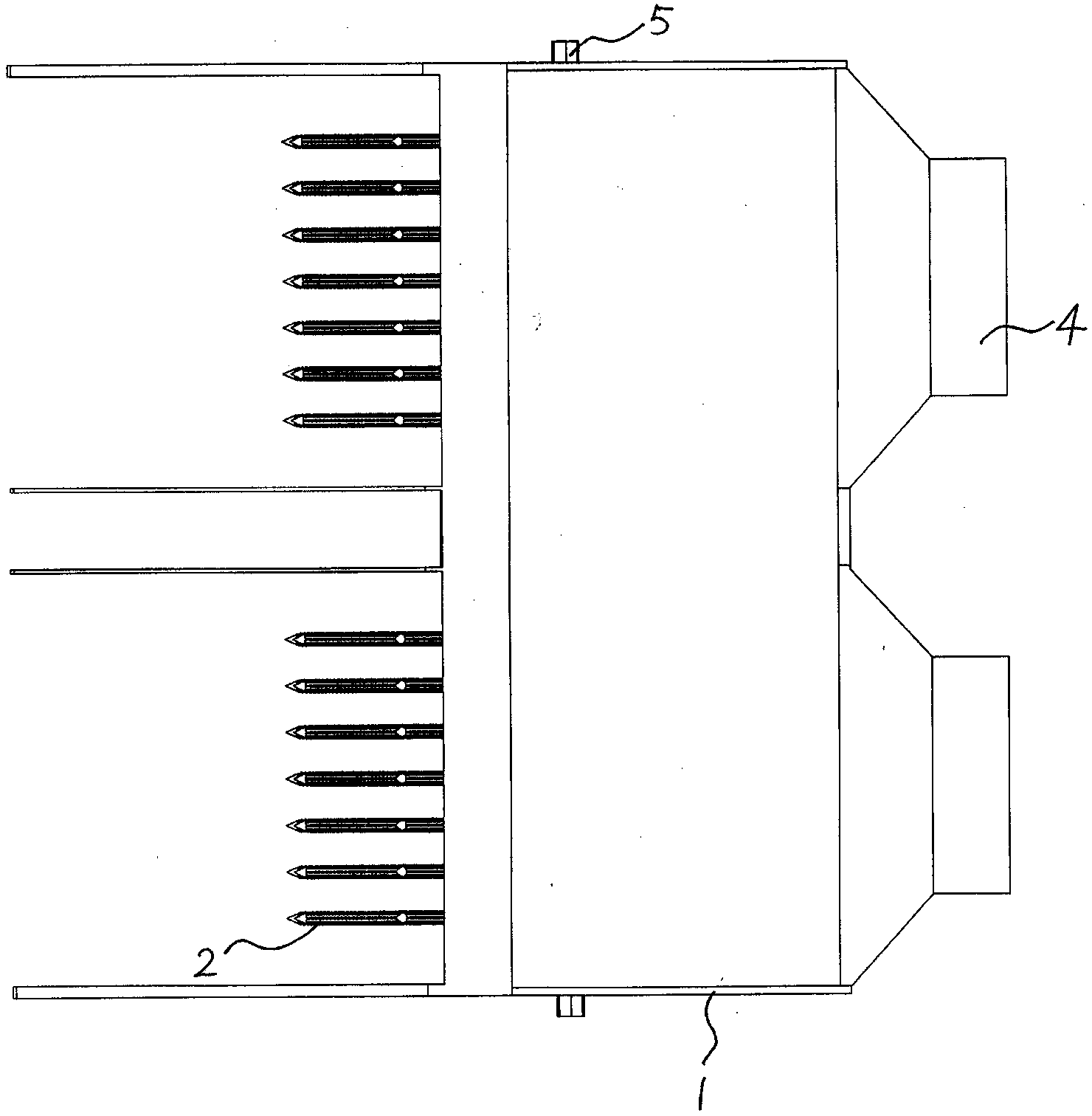

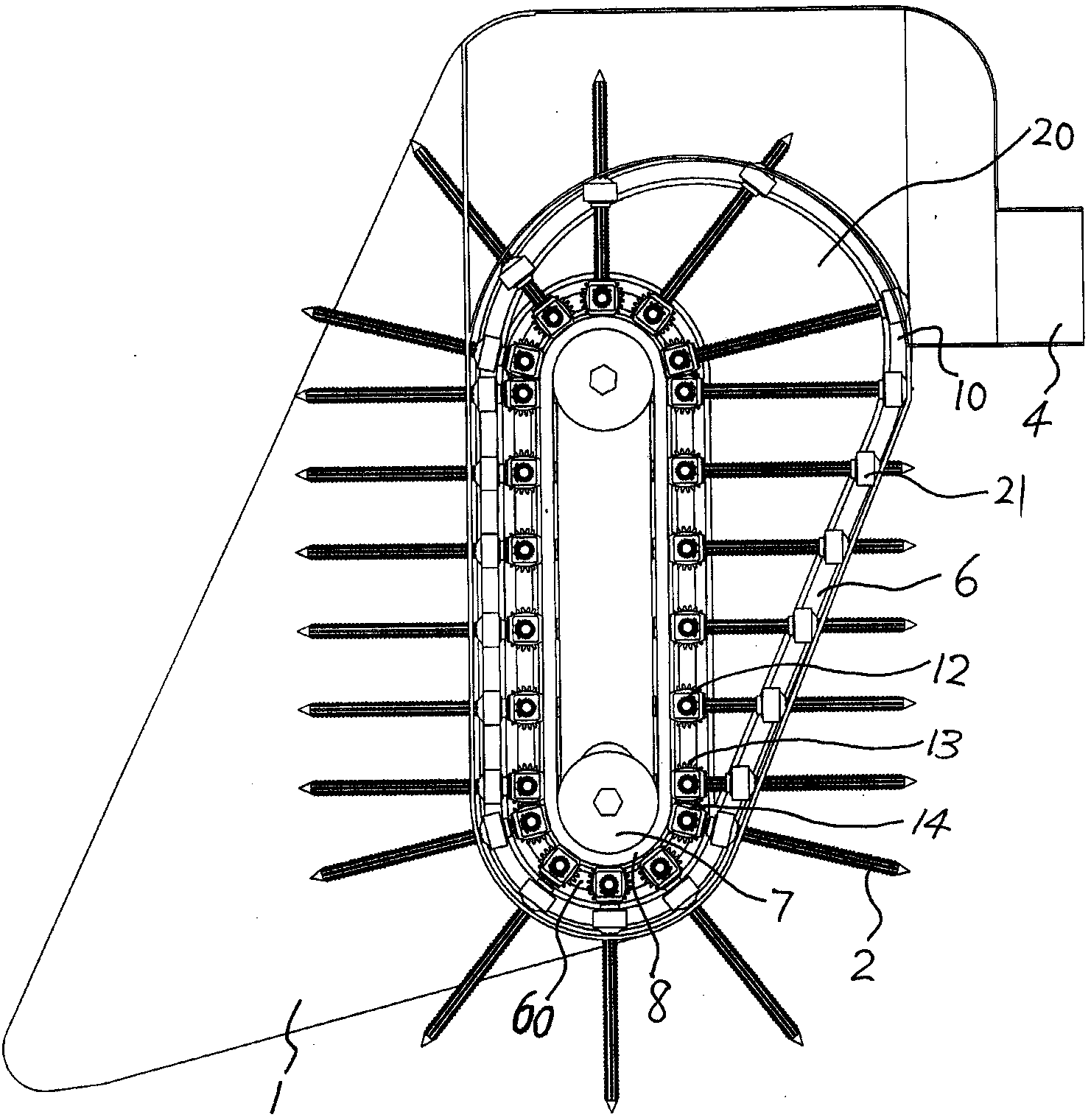

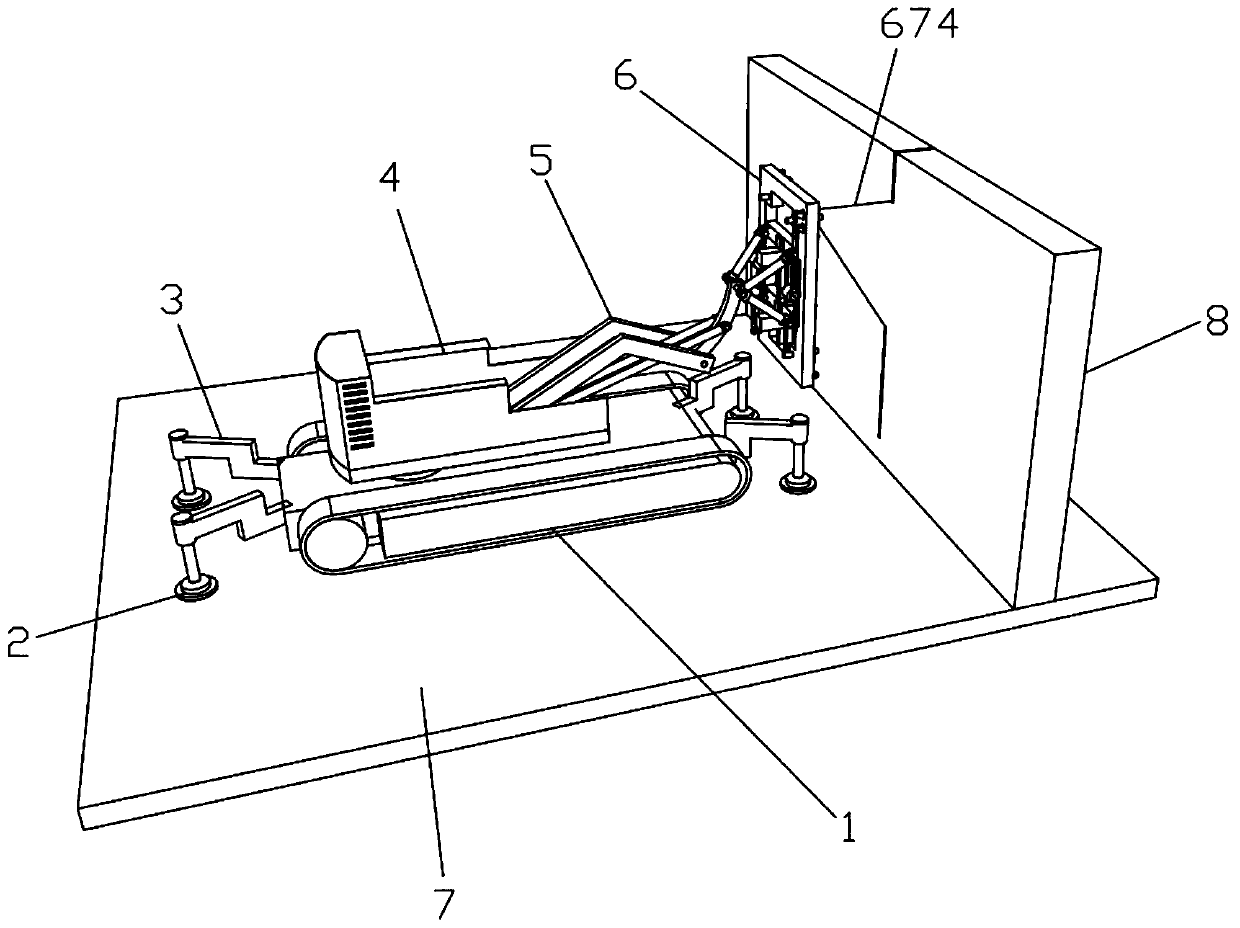

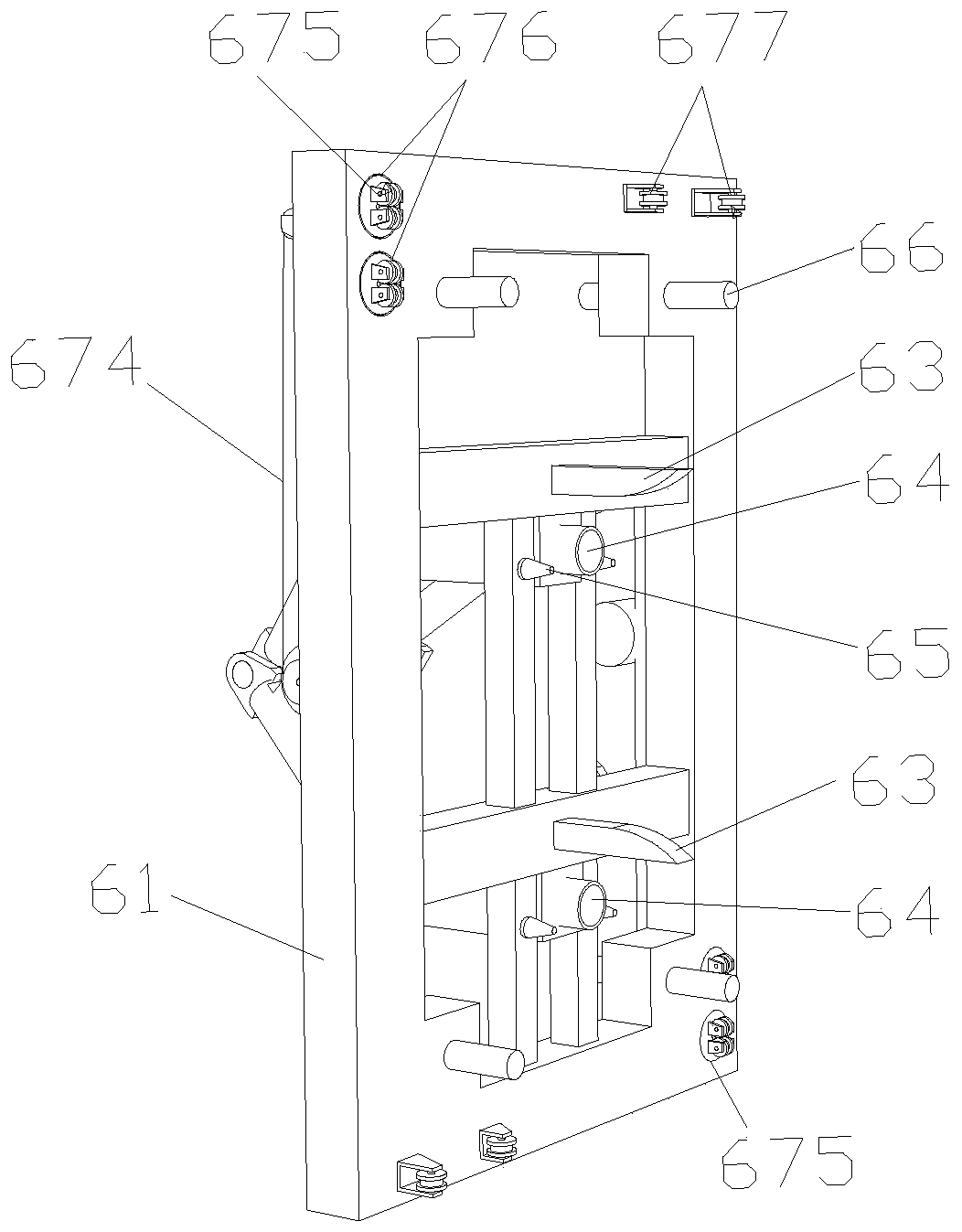

Cotton picking needle and mechanical cotton picking device provided with same

ActiveCN102090213BEasy to removeAvoid the disadvantages of being easy to pick and not easy to take offPicking devicesFiberBiomedical engineering

The invention aims at providing a cotton picking needle and a mechanical cotton picking device provided with the cotton picking needle. The axial periphery of the body of the cotton picking needle is uniformly provided with a plurality of grooves at intervals, an axial convex edge between two adjacent grooves is uniformly provided with triangle cotton picking teeth which are arranged from the needle head to the needle tail at intervals, and the convex sharp corners of the cotton picking teeth are all close to the needle head. The cotton picking needle provided by the invention is arranged on a cotton picking needle base, the cotton picking needle base moves from bottom to top along a driving belt arranged in the shell of a cotton picking device, meanwhile the cotton picking needle rotates when being driven by a center shaft in the cotton picking needle base to wind cotton fibers onto the cotton picking needle, and finally the cotton fibers are easily removed by a cotton carding loop sheathed on the cotton picking needle in sliding fit and are sucked by a cotton sucking port arranged behind the upper part of the cotton picking device. The invention is reasonable in structure, the operation is smooth, the cotton picking rate is high, and the market prospect is wide.

Owner:新疆华冠绿野农业科技有限公司

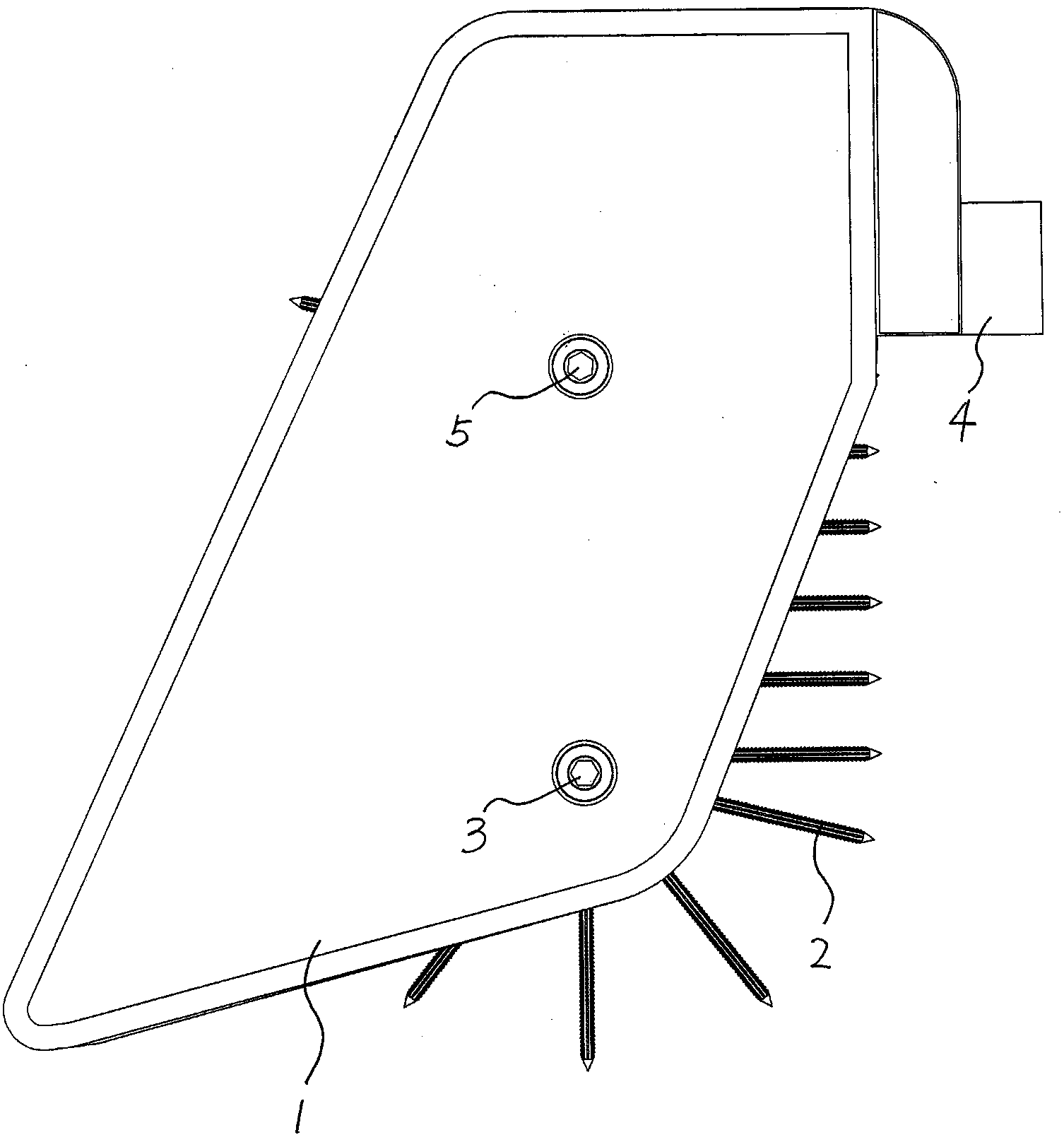

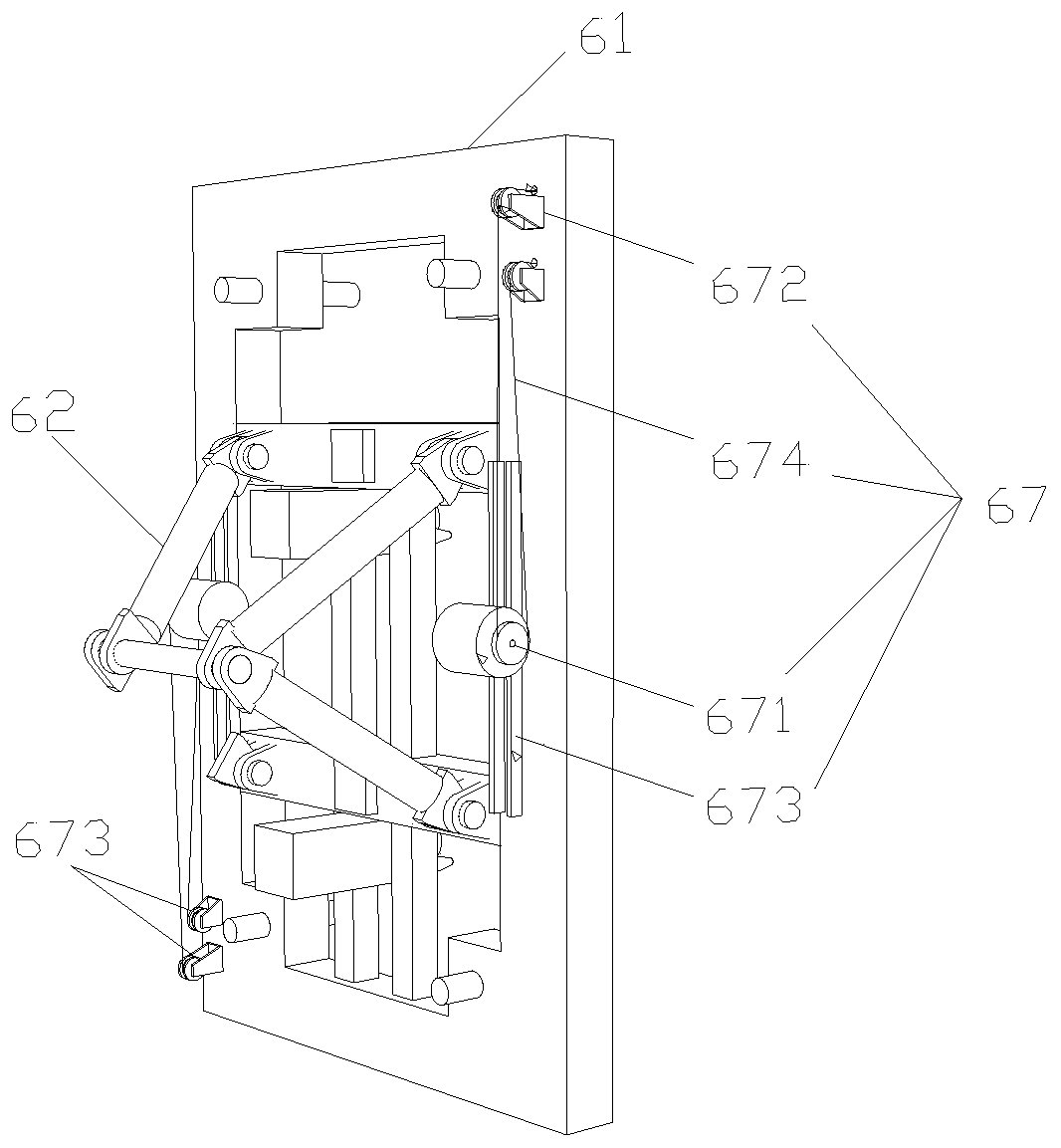

Fixing device of building component construction equipment

ActiveCN110905231AImprove the level of industrializationRealize drilling workBuilding repairsArchitectural engineeringBlock and tackle

The invention discloses a fixing device of building component construction equipment. The fixing device comprises a bracket, a mechanical arm connecting frame, a telescopic fixed pin, a static cuttingdrill bit and a rope saw assembly; and the rope saw assembly comprises a driving motor, two positioning pulleys which are arranged up and down in a spaced manner, a guide rail, a rope saw chain and two guide pulley blocks. The fixing device realizes trepanning, fixing and cutting integrated construction of a building component, has the advantages of low cost, high construction efficiency, convenience in use, high adaptability and the like, can be applied to small building component disassembling machinery and increases the industrialization level of building component disassembling operation.

Owner:SHANGHAI NO 4 CONSTR

Prefabricated channel plate

ActiveCN103572891AImprove the level of industrializationImprove performanceConstruction materialFloor slabPrecast concrete

Owner:山东艾科福建筑科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com