Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

746results about How to "Improve pouring quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

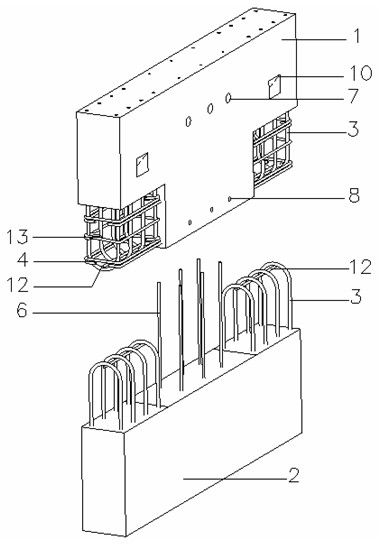

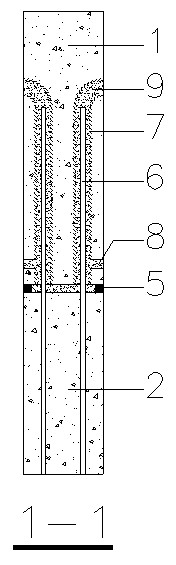

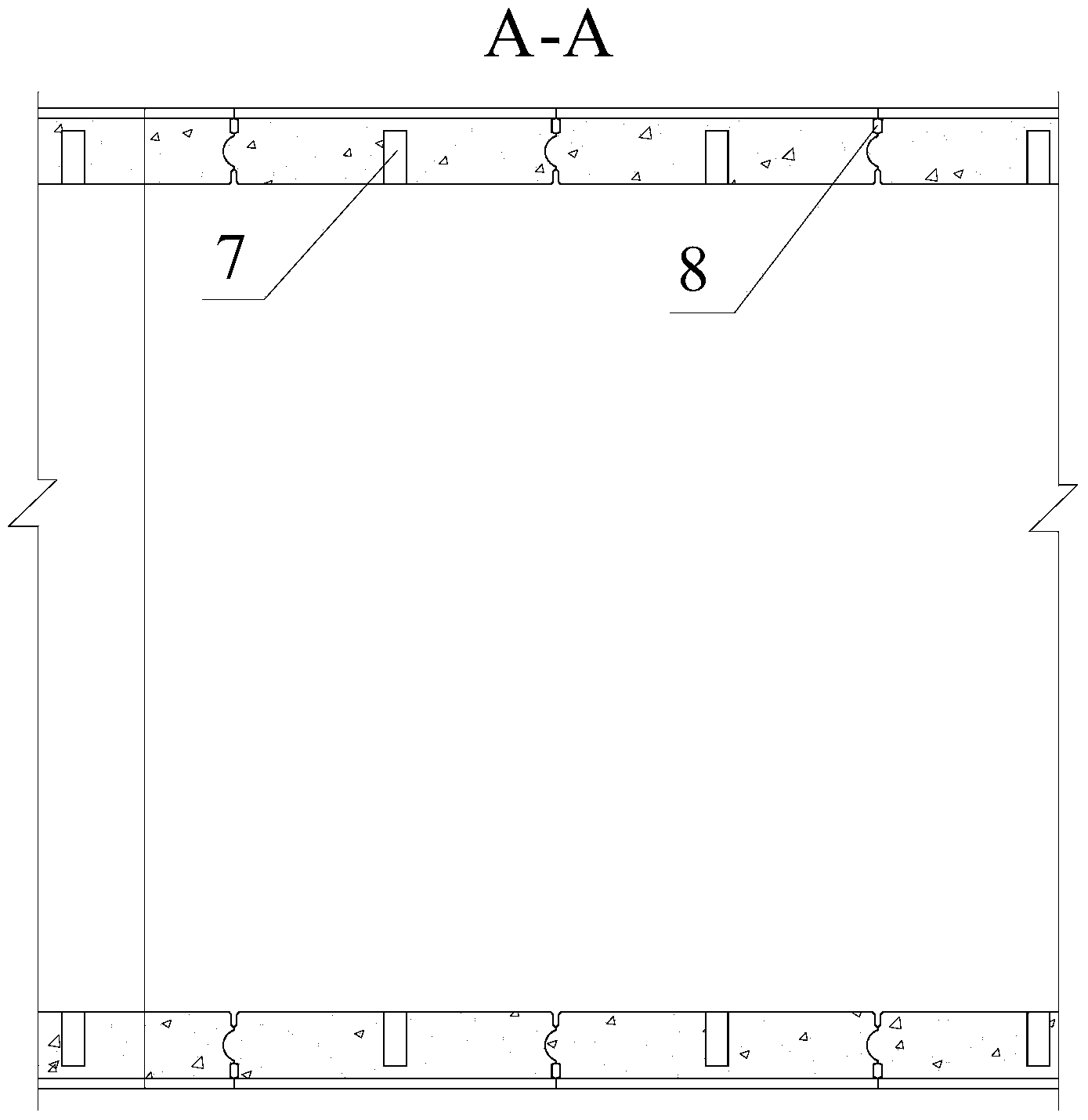

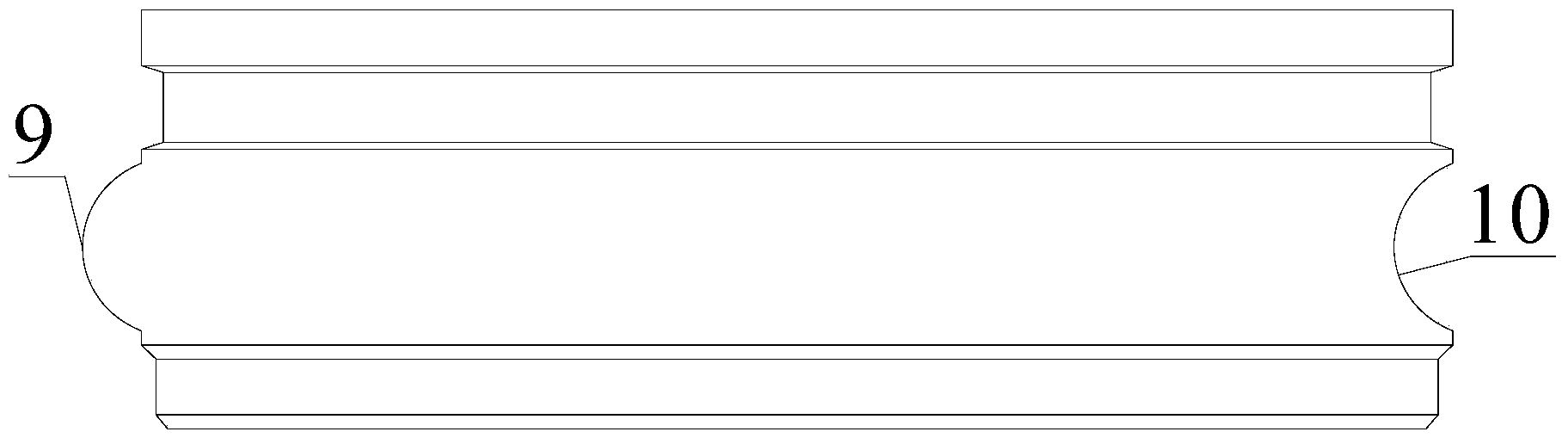

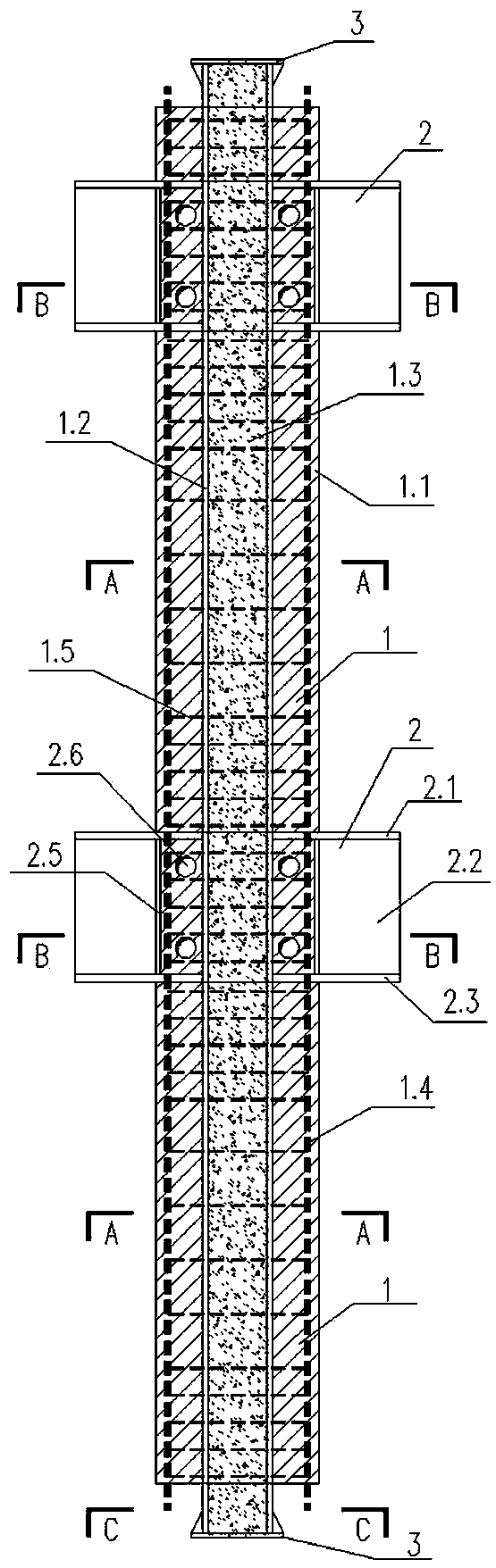

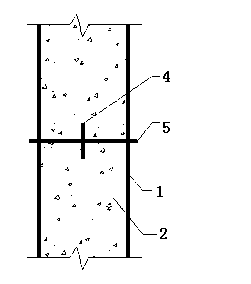

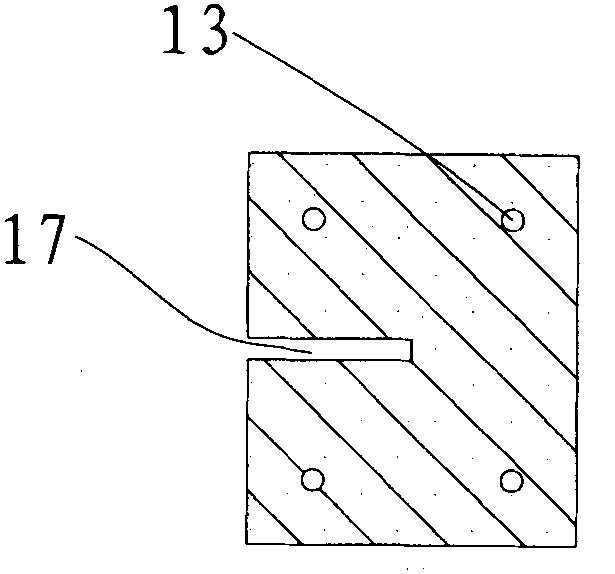

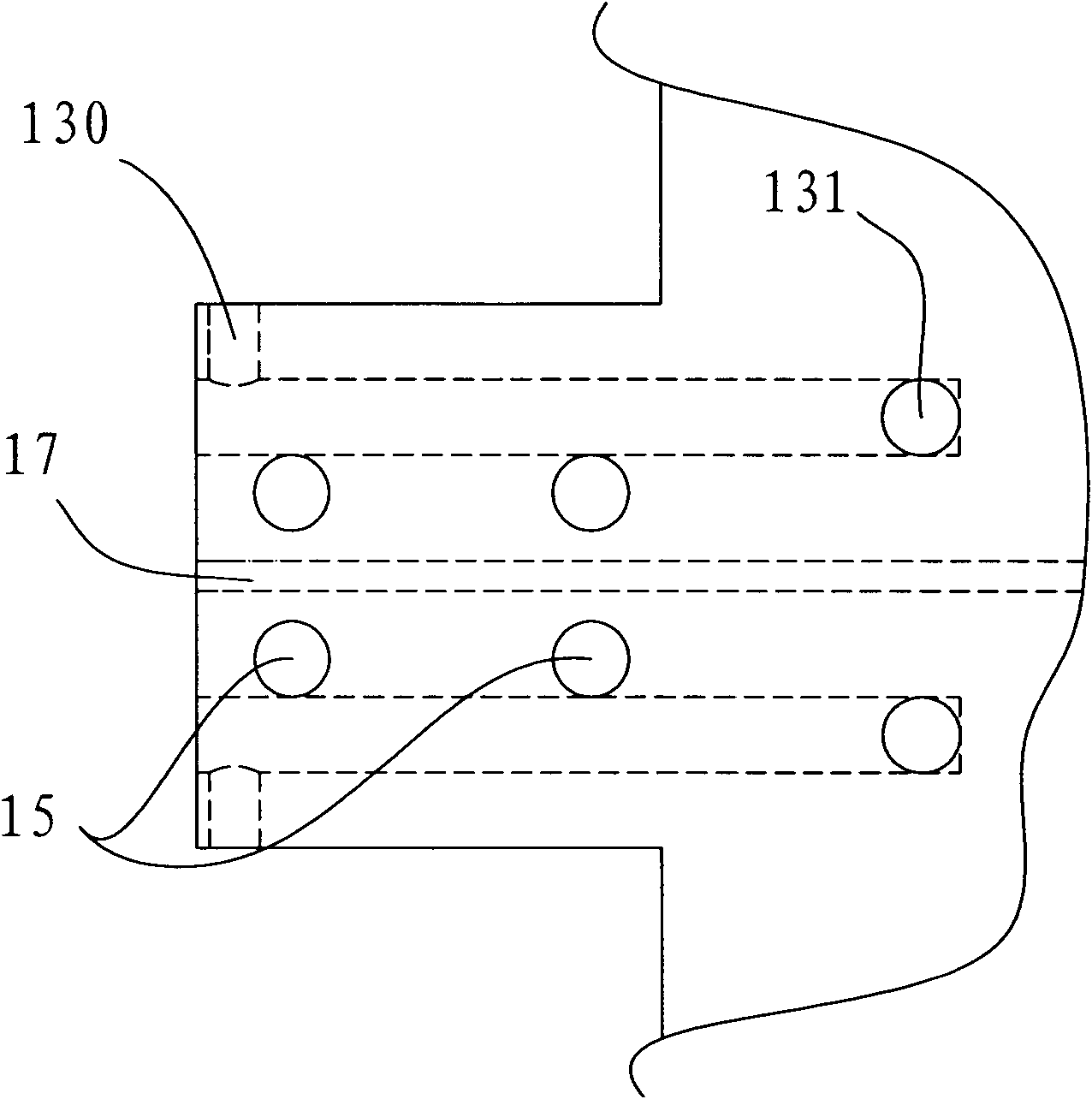

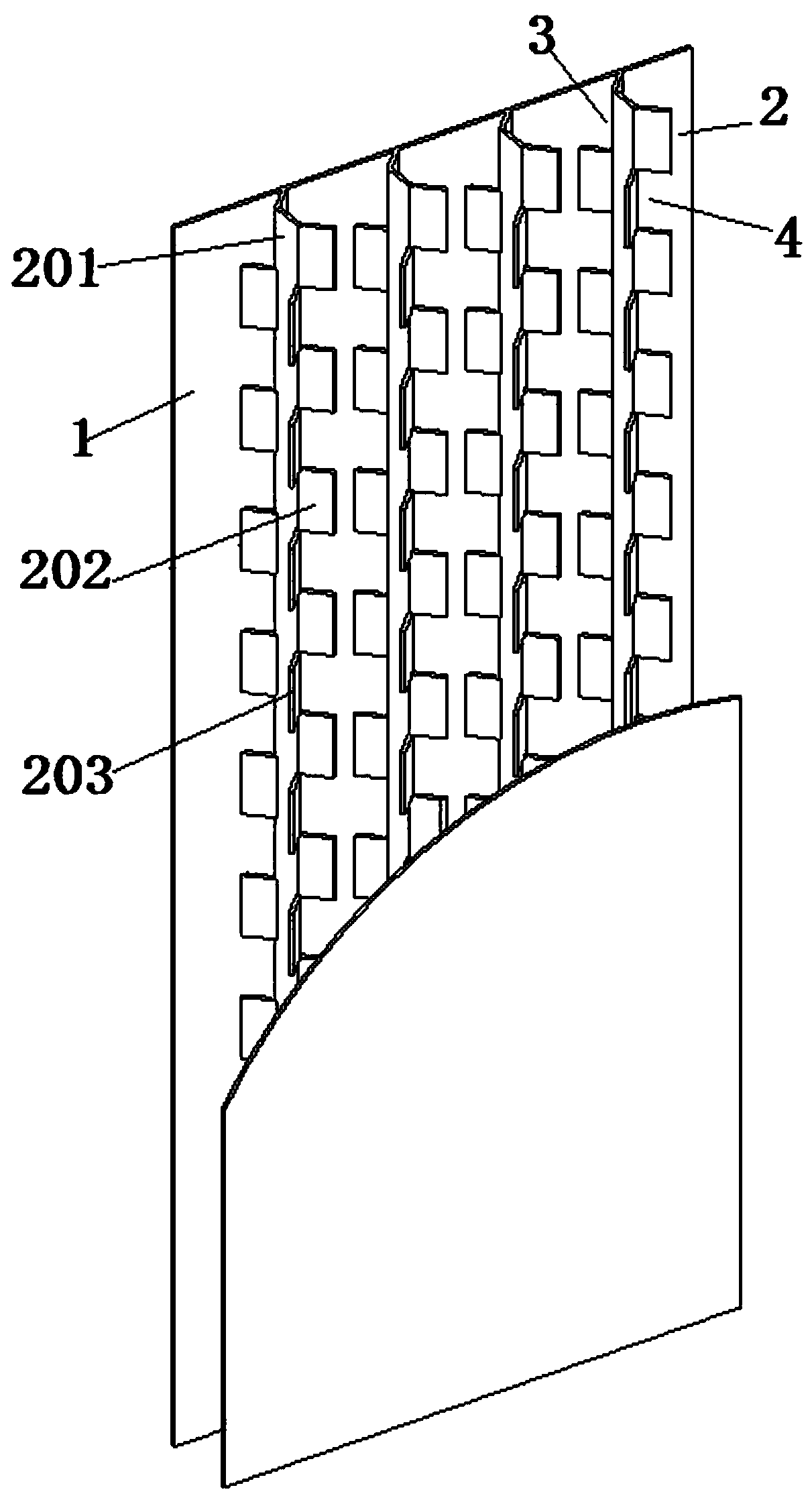

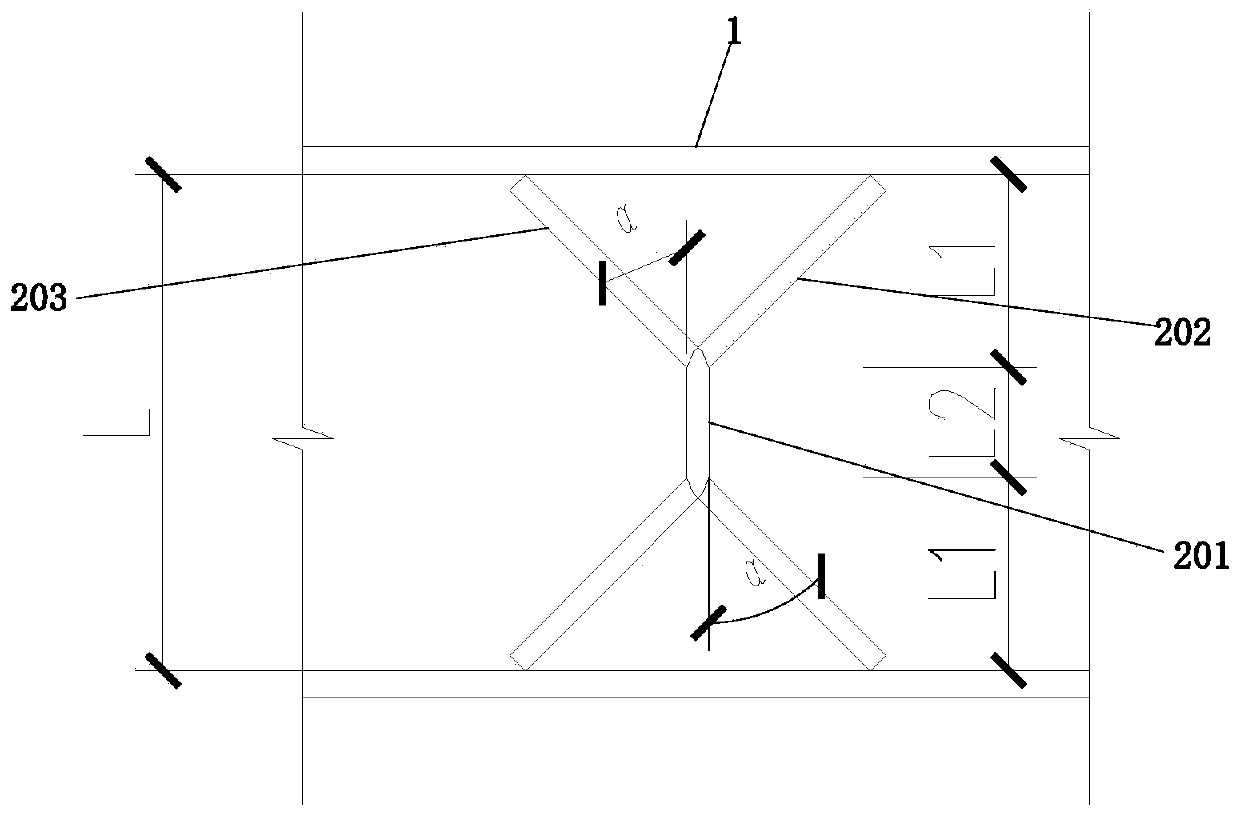

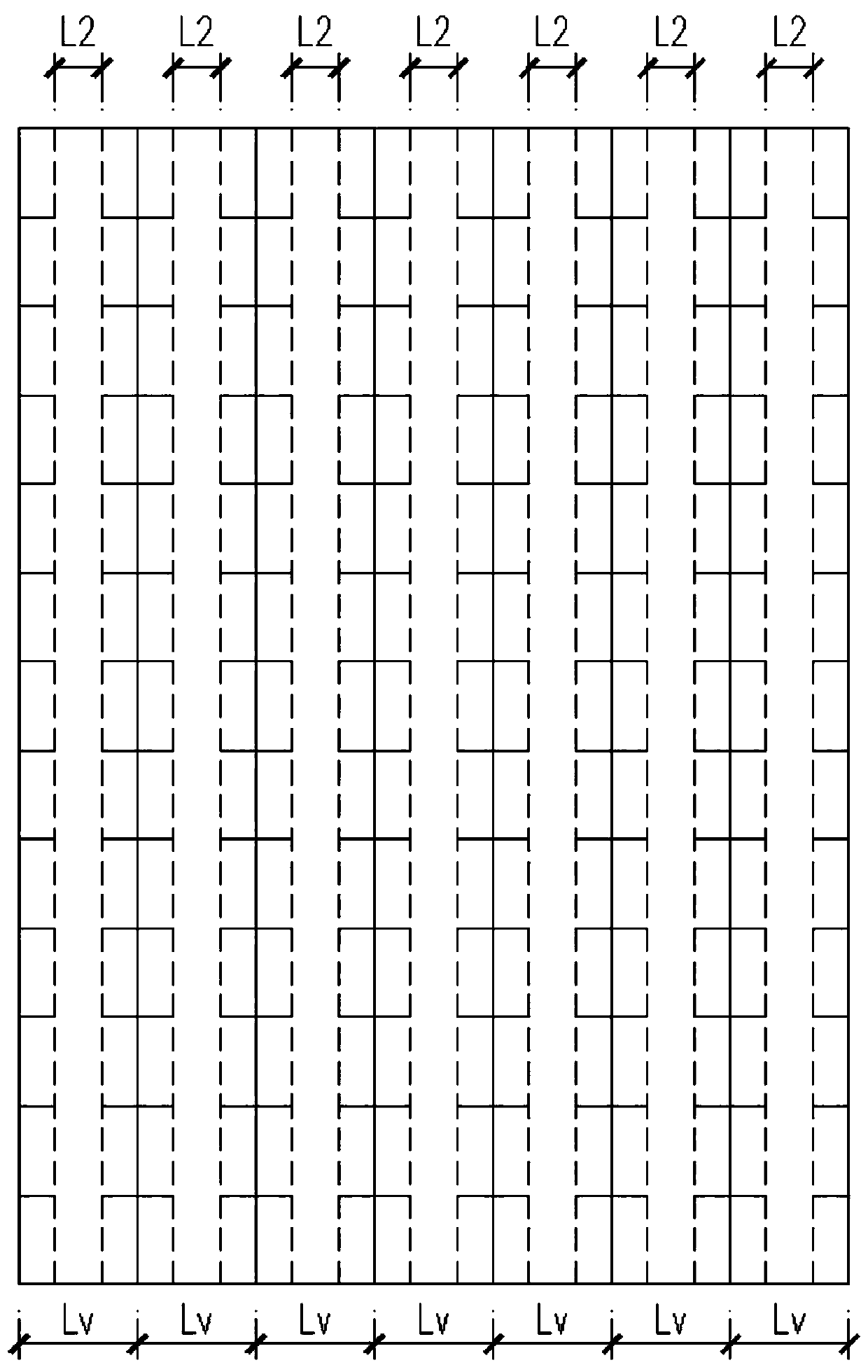

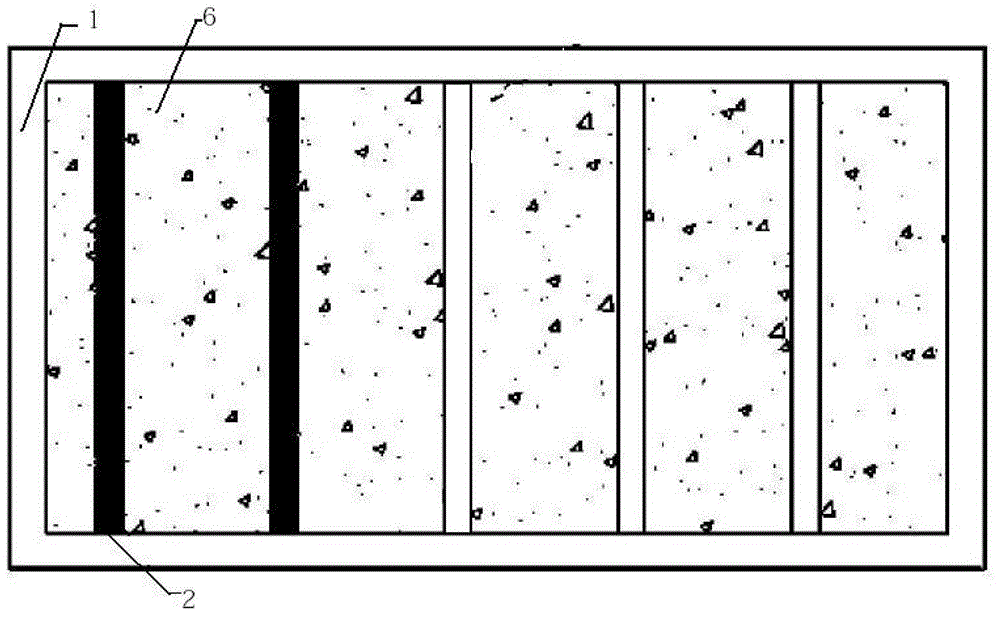

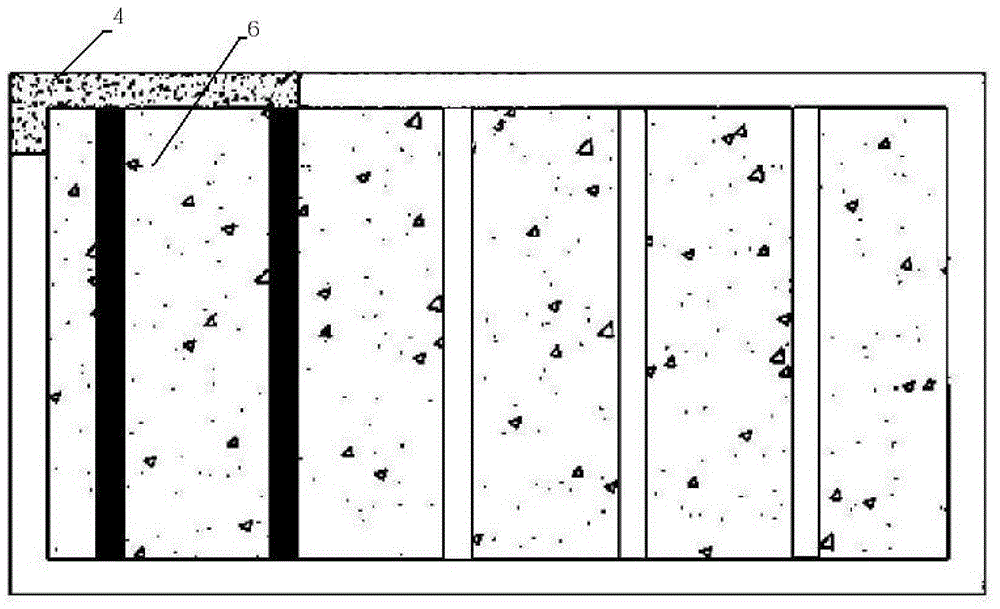

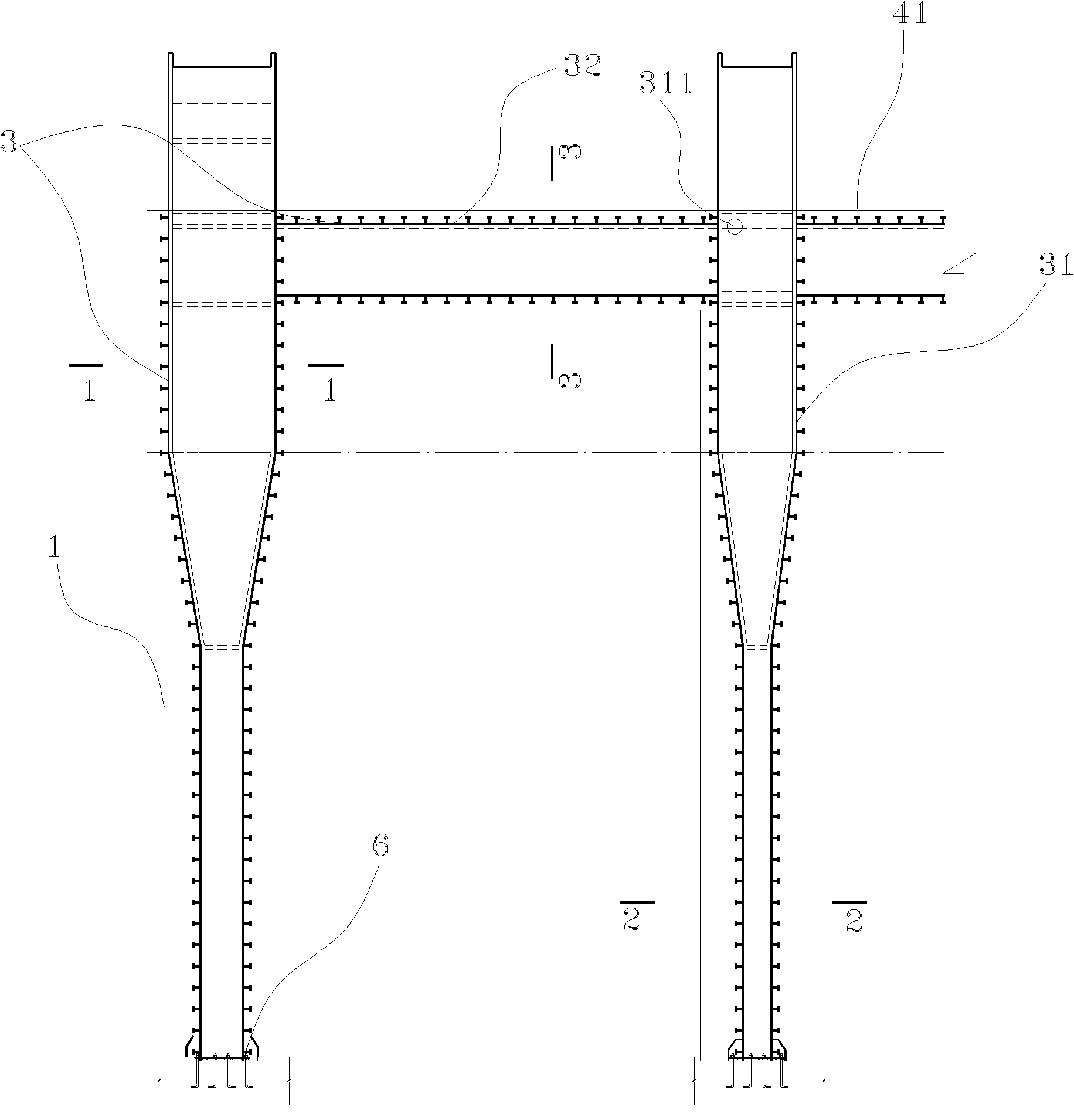

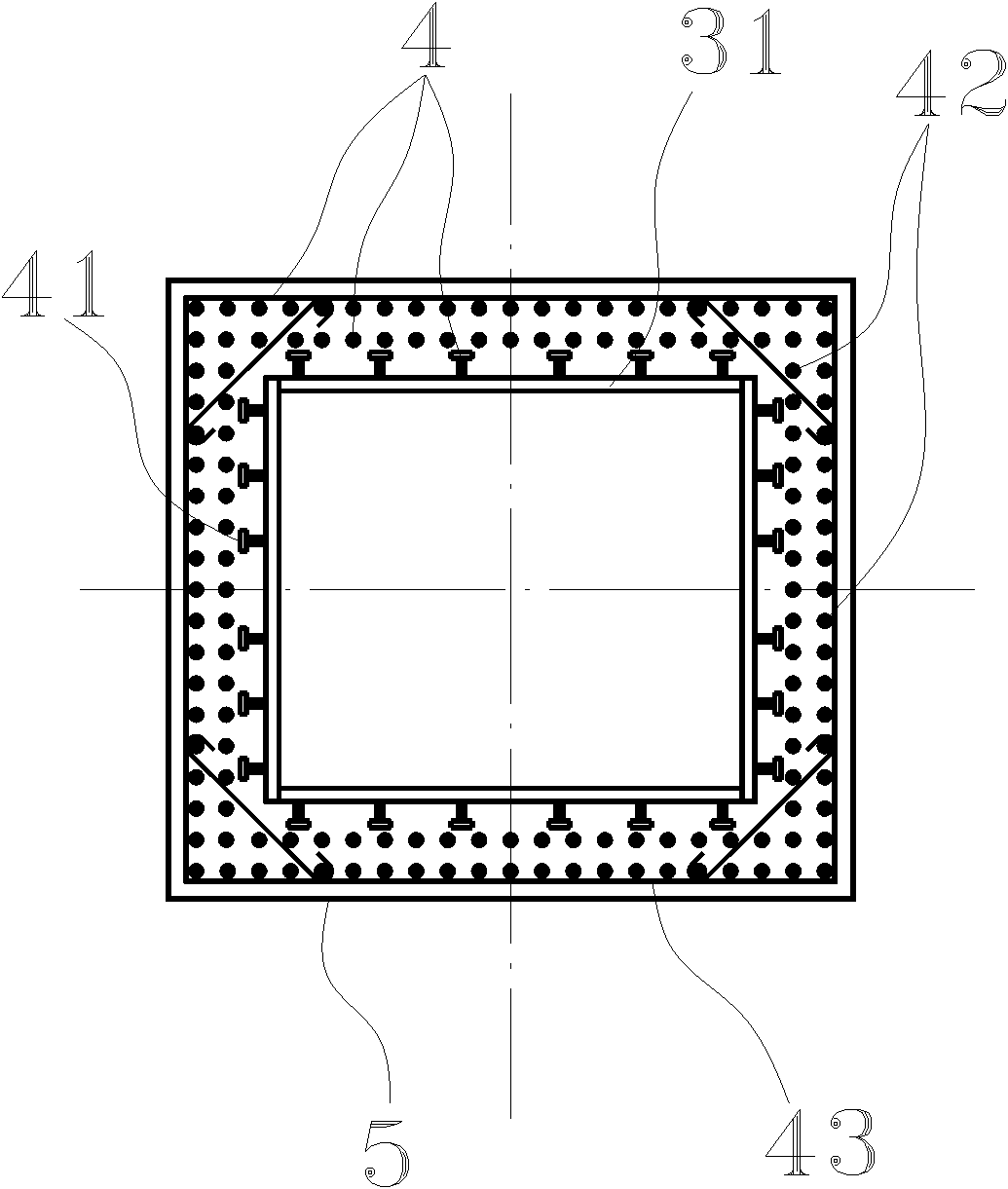

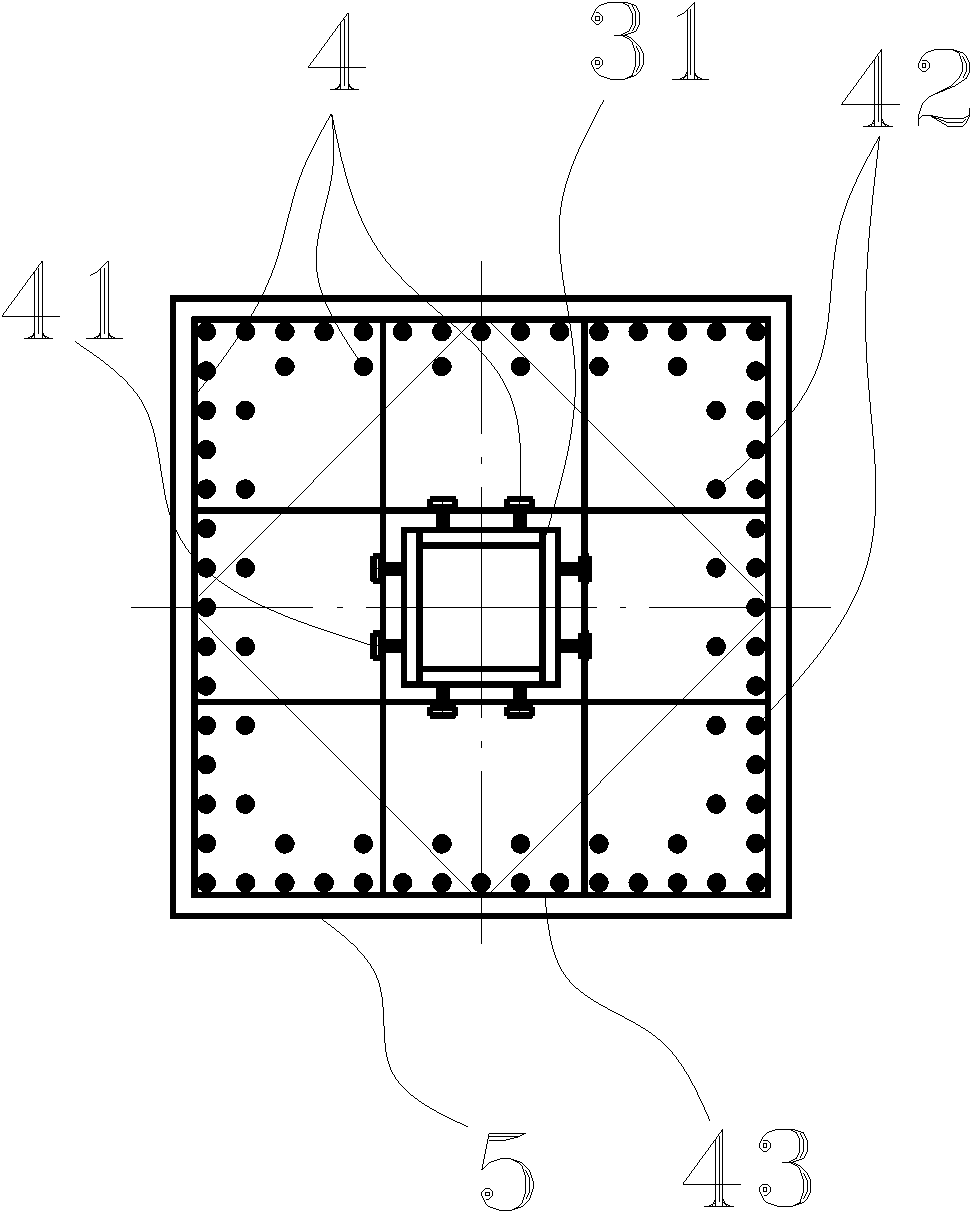

Vertical mixed connection structure and method of prefabricated internal wallboards for assembling shear wall structure

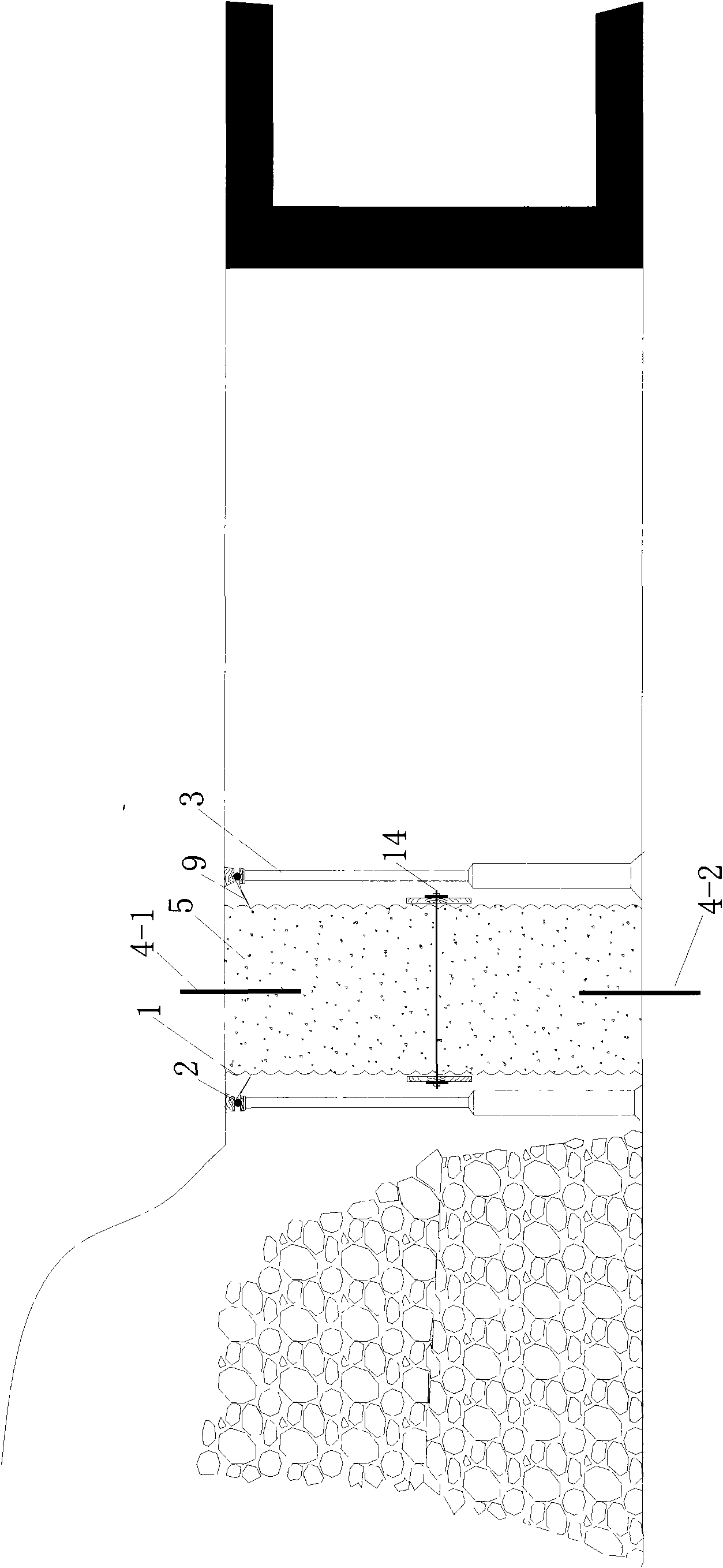

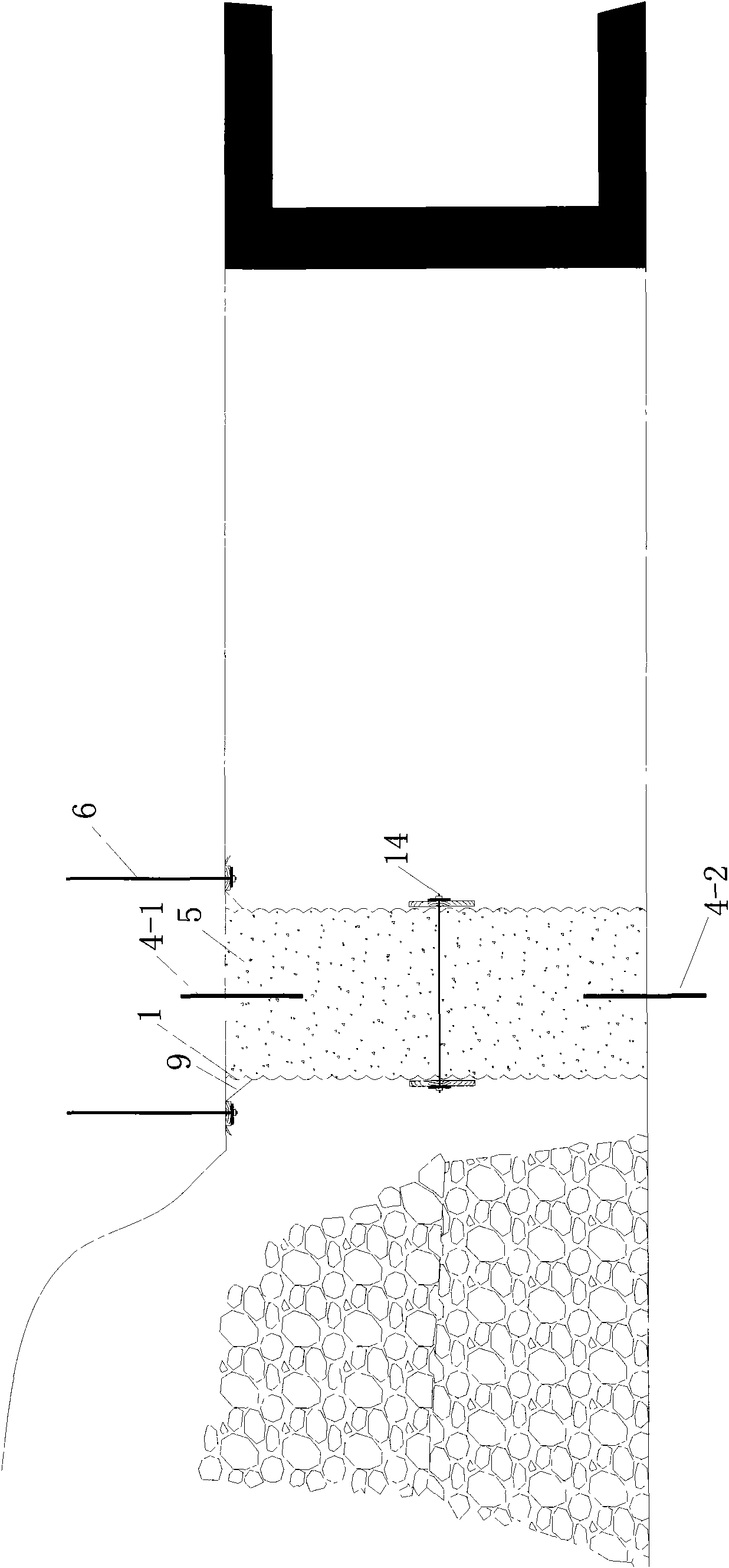

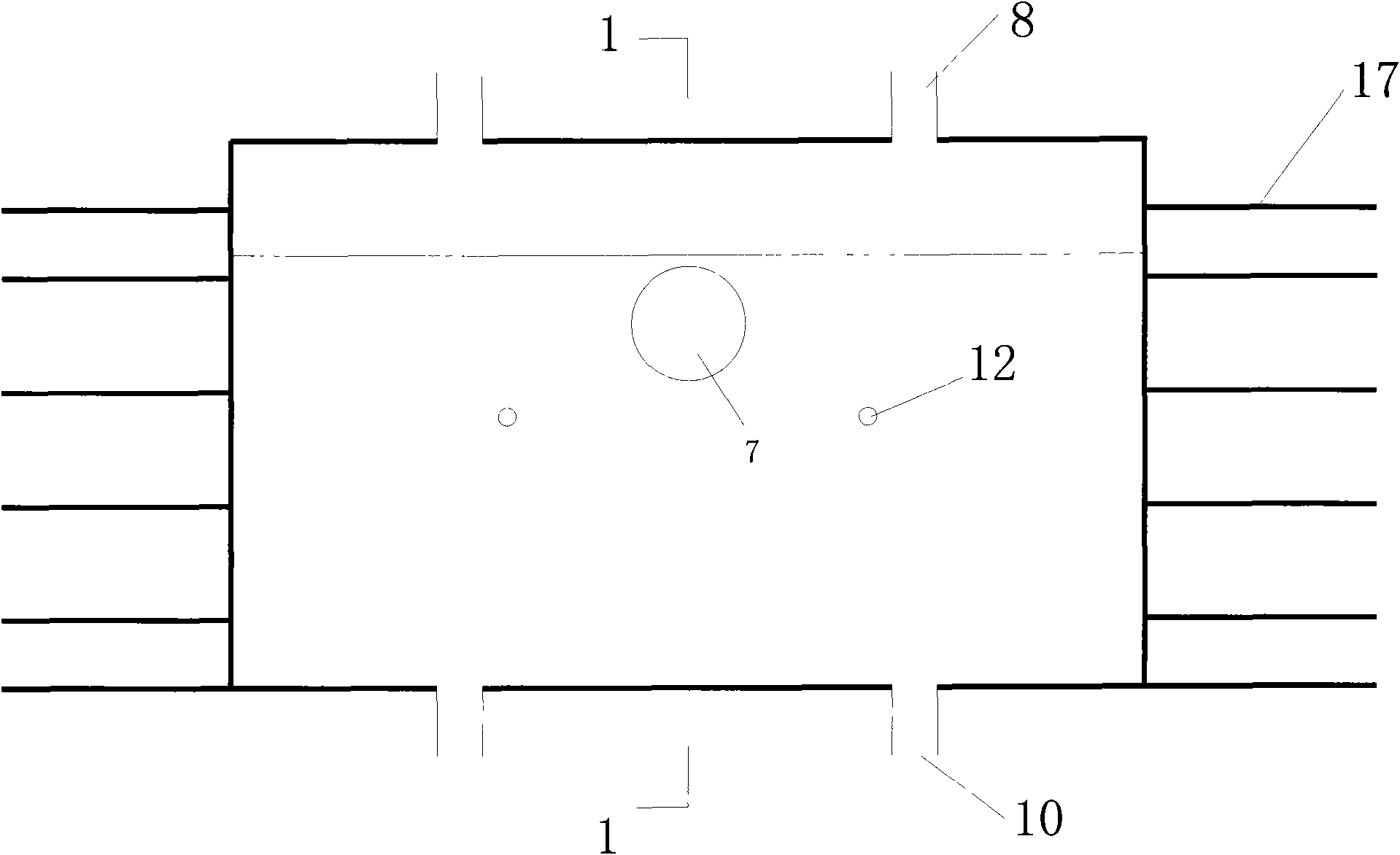

The invention discloses a vertical mixed connection structure and method of prefabricated internal wallboards for assembling a shear wall structure. On the structure, edge components of upper-layer and lower-layer prefabricated internal wallboard structures are overlapped through vertical steel bars and U-shaped ribs, and horizontal reinforcing ribs and local cast-in-place concrete are arranged in a closed ring so as to realize the edge components equivalent to the cast-in-place concrete, the vertically distributed steel bars at the middle part of the components are connected in a manner of indirect overlapping by use of mortar anchor steel bars of a retention metal mortar anchor pipe so as to form an entire shear wall. By utilizing the local cast-in-place concrete moist joint at the edgecomponent part formed by the mixed connection and the dry joint of bedding and grouting at the part of the vertically distributed steel bars, the shear strength and rigidity of the horizontal jointing part of the prefabricated internal wallboards are improved; casting holes reserved at the bottom of the edge components can be used for solving the problem of casting the local cast-in-place concrete; and the vertically distributed steel bars are connected in a manner of indirect overlapping by use of the mortar anchor, which facilitates the installation and temporary fixation of the wallboards on a concrete floor. The mixed connection structure of the prefabricated internal wallboards, provided by the invention, ensures the overall performance of the shear wall; and construction is convenient.

Owner:SOUTHEAST UNIV

Casting-curing insensitive high-explosion-heat explosive and preparation method thereof

ActiveCN103073369AImprove pouring qualityHigh Explosive Calorific ValueNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsWorking capacityAluminium

The invention discloses a casting-curing insensitive high-explosion-heat explosive which comprises the following components in parts by weight: 65 parts of hexogen, 21.5 parts of aluminum powder, 6-8 parts of binder, 2-3 parts of insensitive agent, 2.5-3.2 parts of plasticizer and 0.5-0.7 parts of curing agent. The hexogen is subjected to grain composition to improve explosive energy. The invention further discloses a preparation method of the explosive, which comprises the steps of batching, mixing, vacuum treatment and vacuum casting, and heating curing. The explosive has a higher explosion heat value, has good viability in hazardous environments such as shock, high temperature, bullets and detonation waves, and has the characteristics of high work capacity and high safety; and compared with PBXN-109 (plastic-bonded explosive-109), the solid content is higher, and the overall properties are equivalent.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

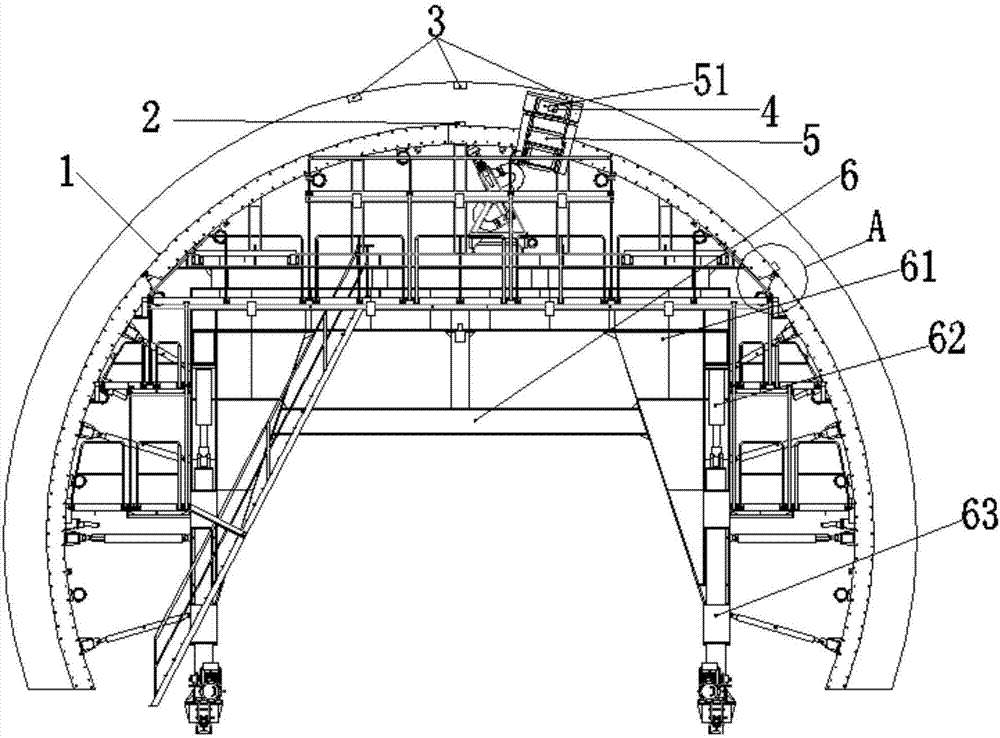

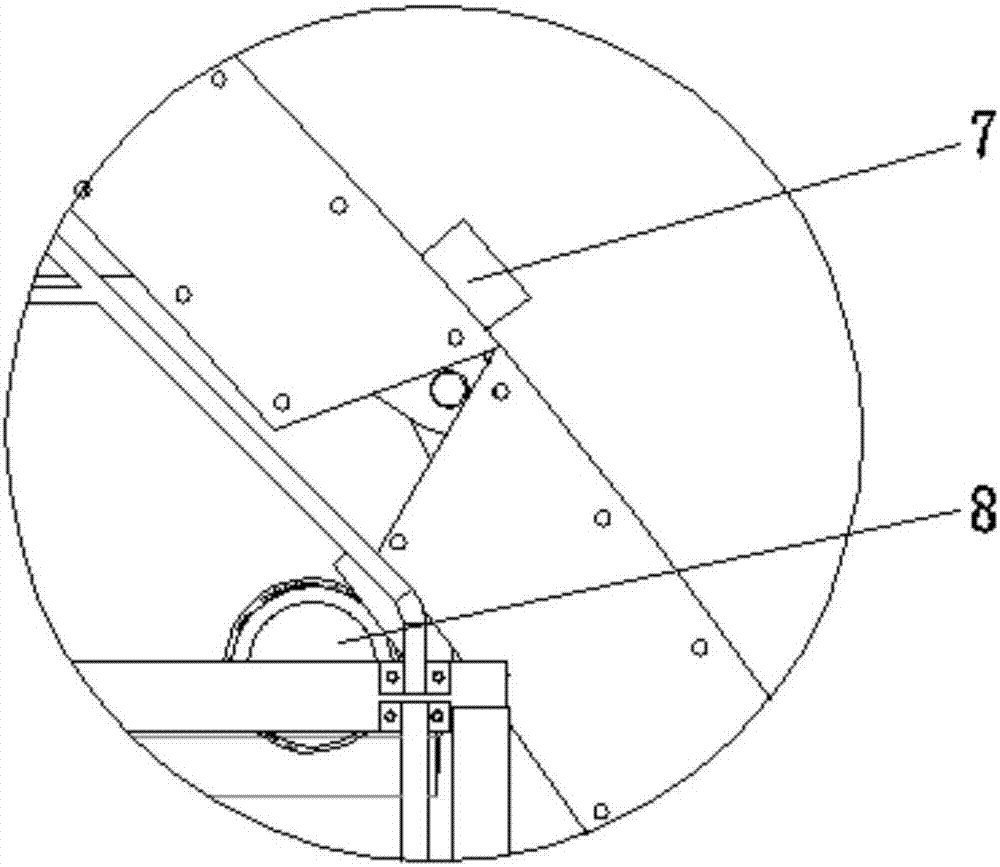

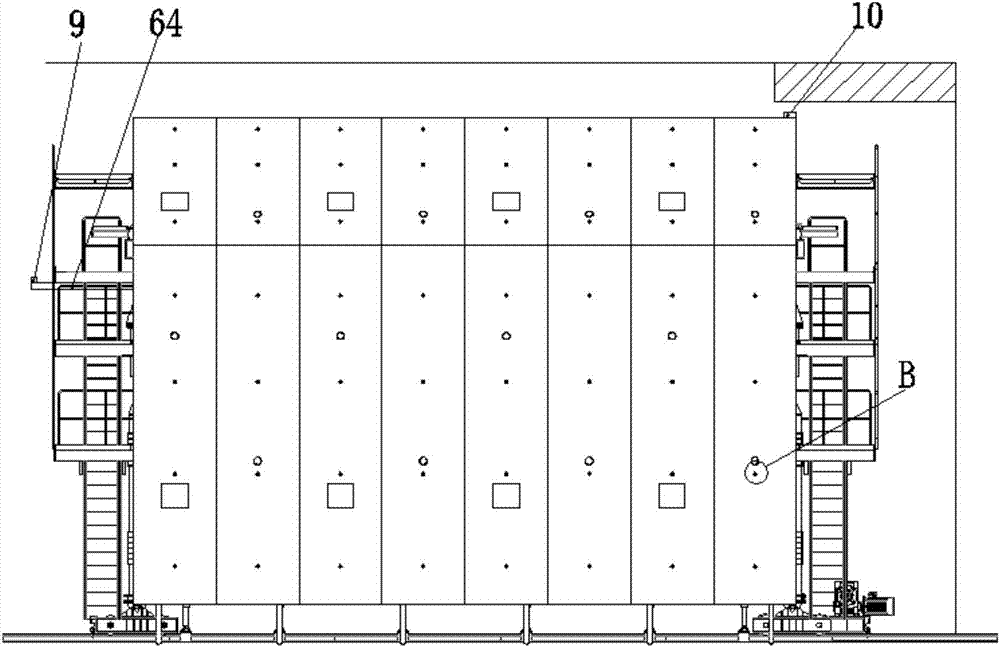

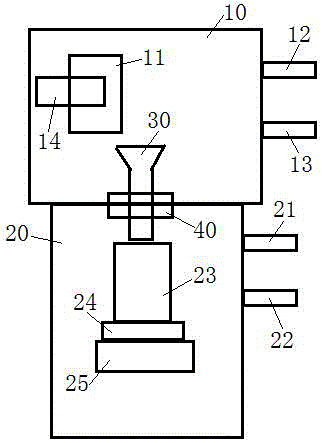

Intelligent tunnel lining trolley

PendingCN107956490AEasy loading and unloadingPlace stableUnderground chambersTunnel liningMonitoring systemSteel frame

Provided is an intelligent tunnel lining trolley, characterized by comprising a door-shaped main steel frame, a concrete pouring informationized monitoring system, an end template, a template cleaningand surface lubricating system, an automatic running gear, and a layered window-by-window pouring and cleaning system. The tunnel lining trolley is simple in structure and reasonable in design, and real-time monitoring of each parameter in a concrete pouring process is realized, automation degree of equipment is improved, cleaning and template surface lubrication operation flow are simplified. The intelligent tunnel lining trolley provides convenience for on-site management and construction, and has certain environmental protection property and very high security.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

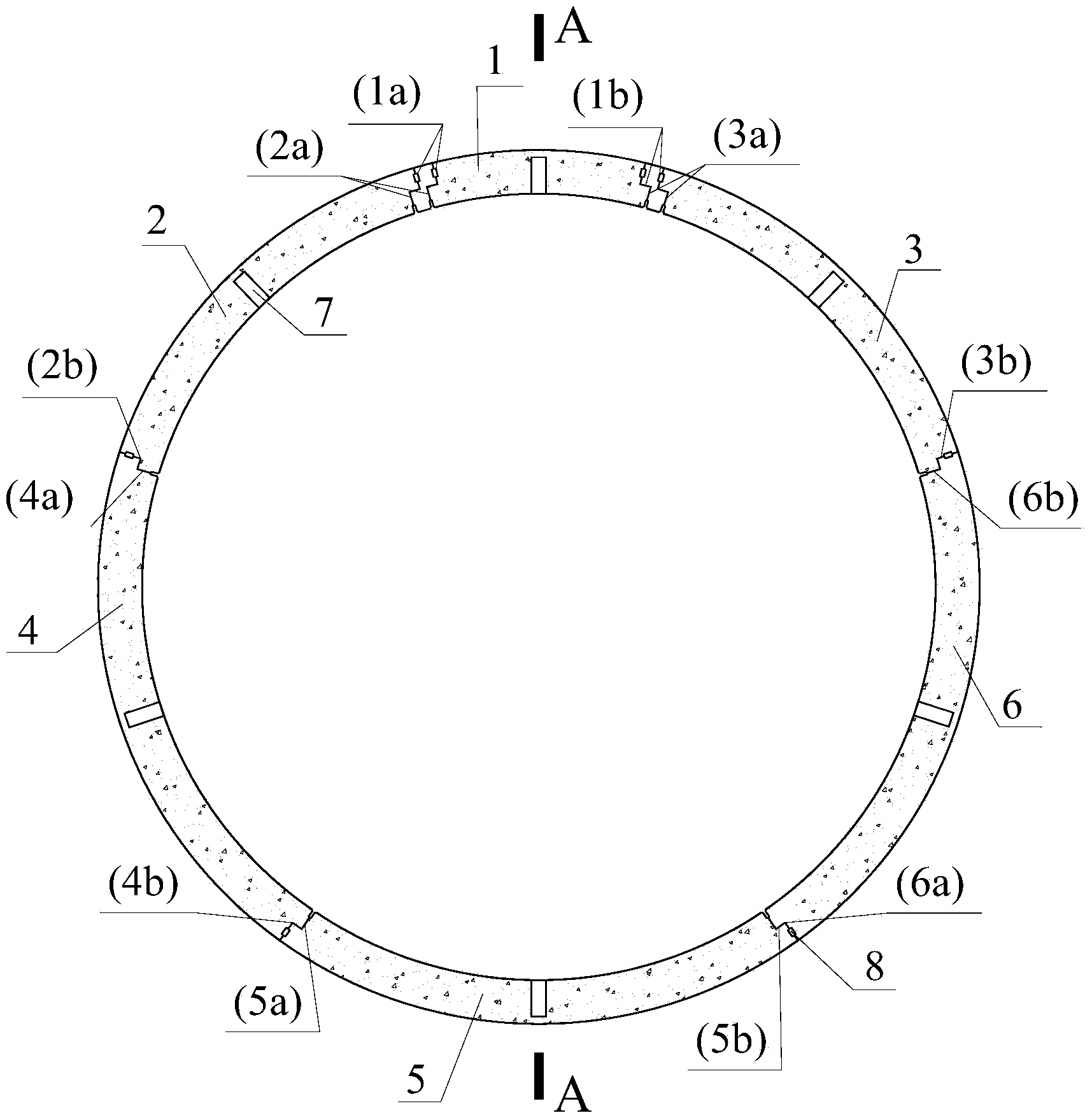

Prefabricated tunnel lining segment

ActiveCN103643966AImprove construction efficiencyImprove construction progressUnderground chambersTunnel liningWedge shapeTunnel construction

The invention discloses a prefabricated tunnel lining segment, belonging to the field of tunnel construction technology and aiming at simplifying the production and processing technique of prefabricated segments, optimizing the connection mode of segments and improving the prefabricated segment splicing and lining construction efficiency of a shield tunnel, especially round cross section, and the like. The concrete lining in the cross section of a round tunnel is divided into six prefabricated concrete segments, arcs are arranged on the cross sections of the six concrete prefabricated concrete segments, the six concrete prefabricated concrete segments include a top sealing block, two abutting blocks and three standard blocks, and two end surfaces of each block are provided with concave-convex steps which have symmetric or reverse structures; the top sealing block is shaped like a regular wedge which has a symmetrical structure, the two abutting blocks are both partially wedge-shaped and have reverse structures; the two standard block have reverse structures; after a circle of closed lining can be completed by splicing the six concrete prefabricated concrete segments, one ends, provided with bulges, of all segments in the circle are embedded in the cylindrical grooves of the spliced segments in the last circle so as to splice the segments. The prefabricated tunnel lining segment is mainly used for lining of the shield tunnel.

Owner:SOUTHWEST JIAOTONG UNIV

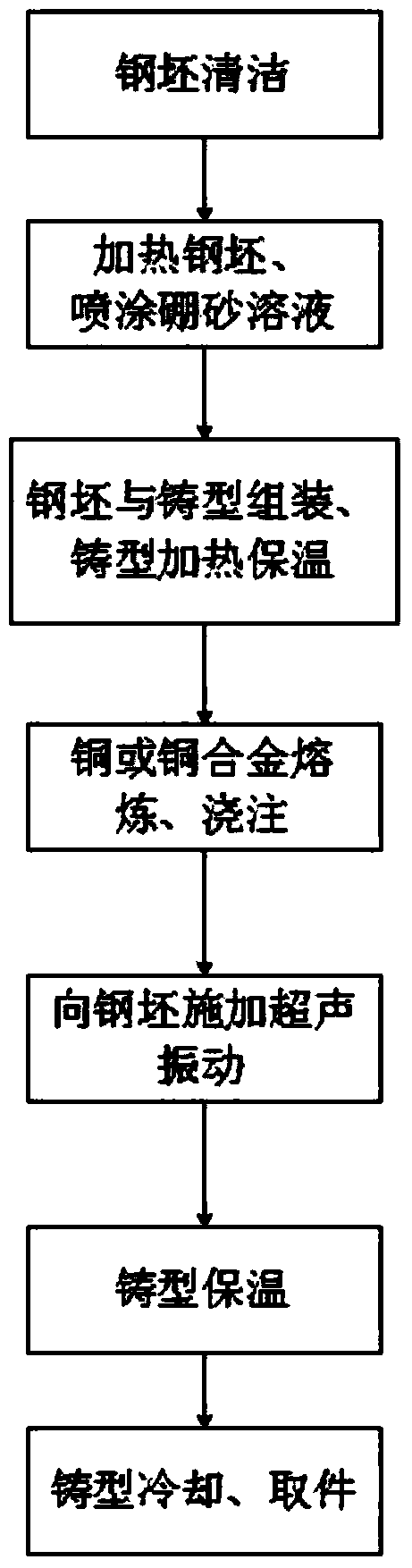

Copper-steel bimetal casting improved technology

The invention provides a copper-steel bimetal casting improved technology. Copper or copper alloy in a certain thickness is directly cast on a steel base body through a static cast type casting method, and the main technical process comprises the steps of: cleaning a steel billet, heating the steel billet and spraying a borax solution on the heated steel billet, combining the cast, heating and keeping the heat, melting and pouring the copper or copper alloy, performing ultrasonic vibration on the steel billet, and keeping the high temperature of the cast. Through the copper-steel bimetal casting improved technology provided by the invention, the ultrasonic vibration and stirring step is added on the basis of the static embedding process technology, a copper or copper alloy layer in a certain thickness and without segregation can be obtained by casting on steel billets in various types and various sizes, and good metallurgical bonding can be realized between the copper or copper alloy layer of the obtained cast and the steel billet.

Owner:GUIZHOU ANJI AVIATION PRECISION CASTING

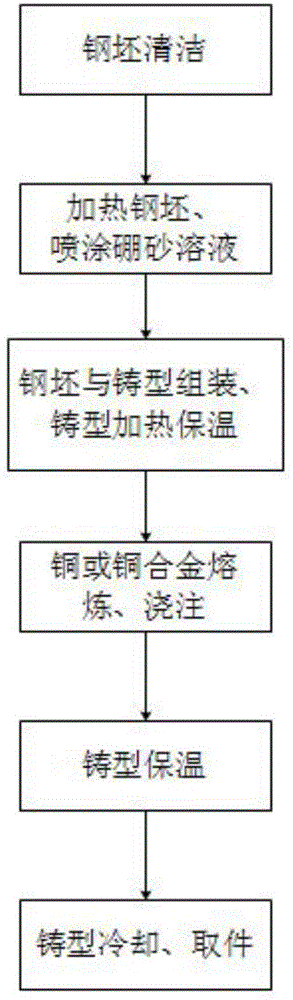

Copper and steel bimetallic casting application technology

The invention provides a copper and steel bimetallic casting application technology. Copper or copper alloy with certain thickness is directly cast on a steel base body by a static casting mold casting method. The technology mainly comprises the following steps of cleaning a steel billet, heating the steel billet, spraying a borax solution, combining a casting mold, heating and insulating heat, melting and casting the copper or the copper alloy, and insulating the heat of the casting mold at high temperature. The copper and steel bimetallic casting application technology has the advantages that a copper or copper alloy layer with certain thickness and without segregation can be cast on various shapes and various sizes of steel billets, and the good metallurgical combination between the copper or copper alloy layer of a casting and the steel billets is realized.

Owner:GUIZHOU ANJI AVIATION PRECISION CASTING

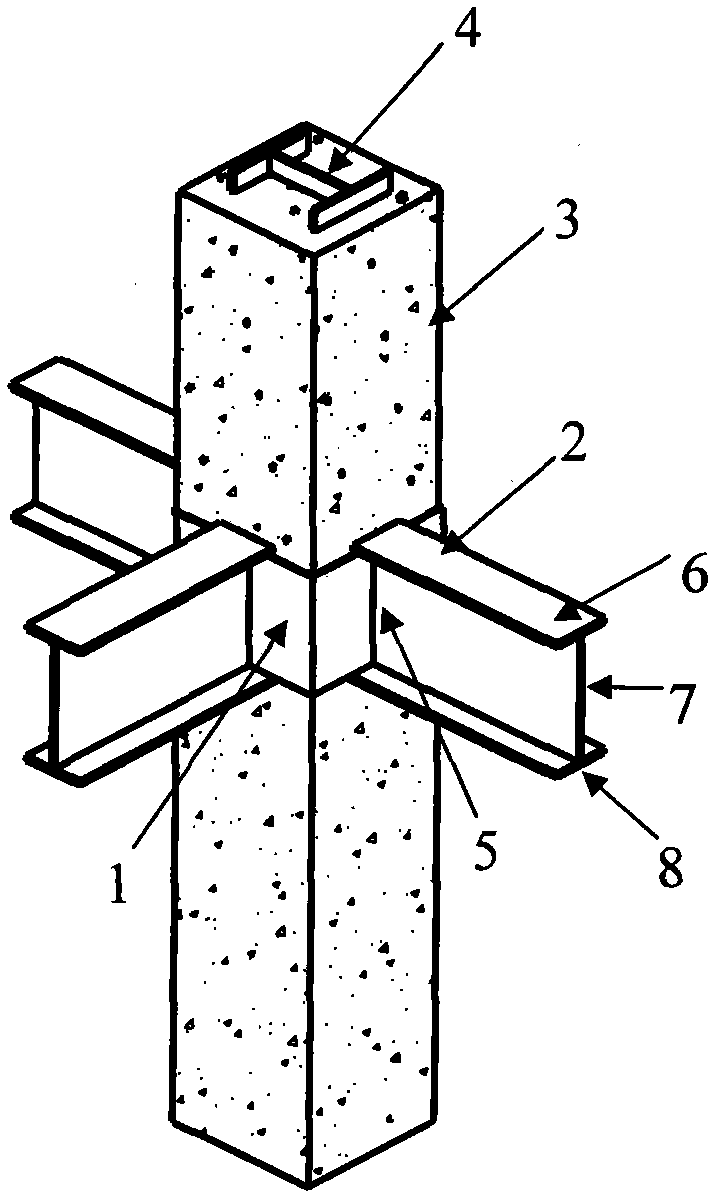

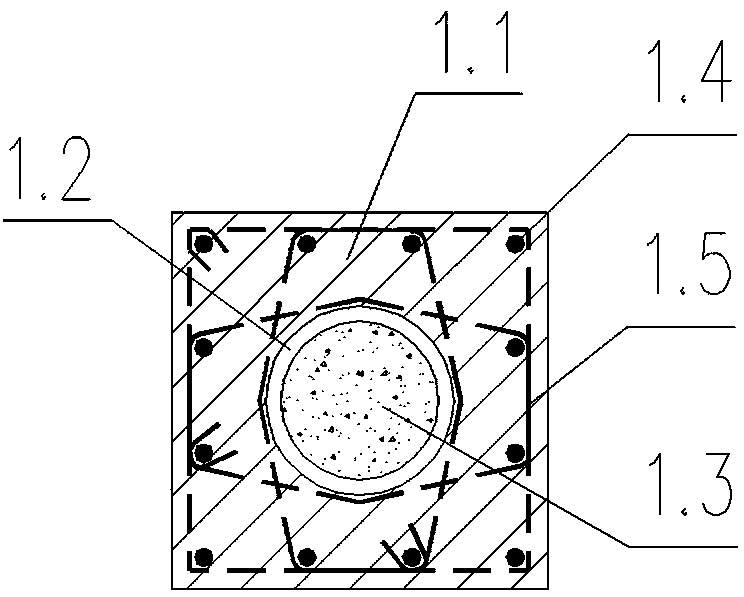

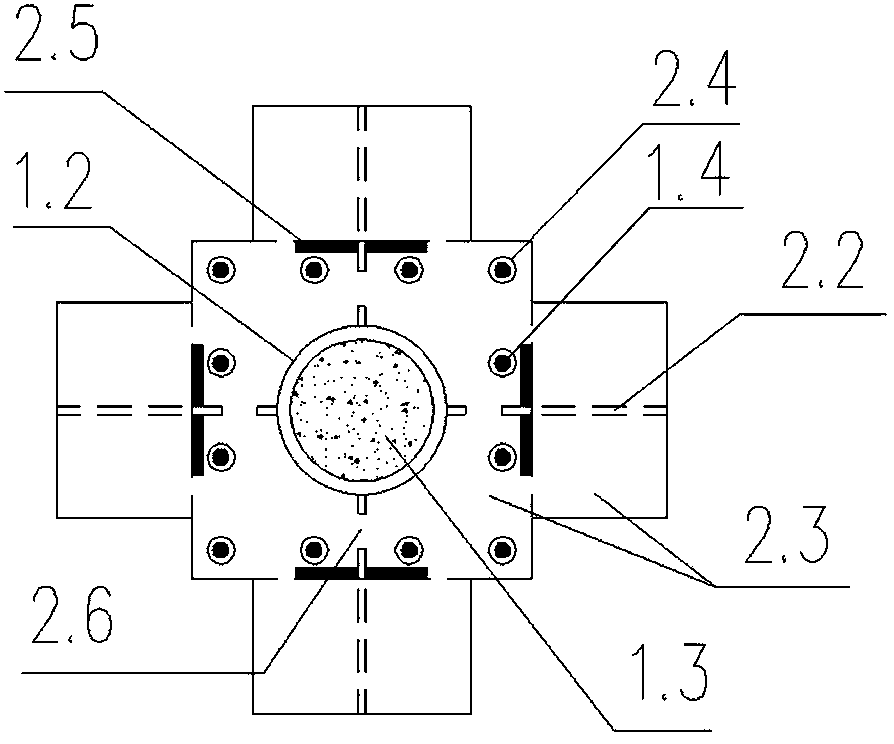

Section steel concrete column-steel girder node

The invention discloses a section steel concrete column-steel girder node which belongs to the technical field of building structures, solves the problem of high construction difficulty caused by field insertion of hoop reinforcement into a steel girder web plate and welding in a conventional section steel concrete column-steel girder node region. According to the technical scheme provided by the invention, the periphery of a node region section steel concrete column is provided with a steel pipe; the steel pipe is connected with the web plate of a node region horizontal steel girder; and the steel pipe is welded with the web plate on both sides connected with the steel girder web plate, so that the restriction effect of the node region is effectively enhanced and a remarkable effect is achieved. The section steel concrete column-steel girder node is a novel node form with the advantages of simple structure, convenience and quickness in constructing, capability of enhancing the concrete pouring quality of the node region, high shock resistance, high economic efficiency and high factory production degree.

Owner:HARBIN INST OF TECH

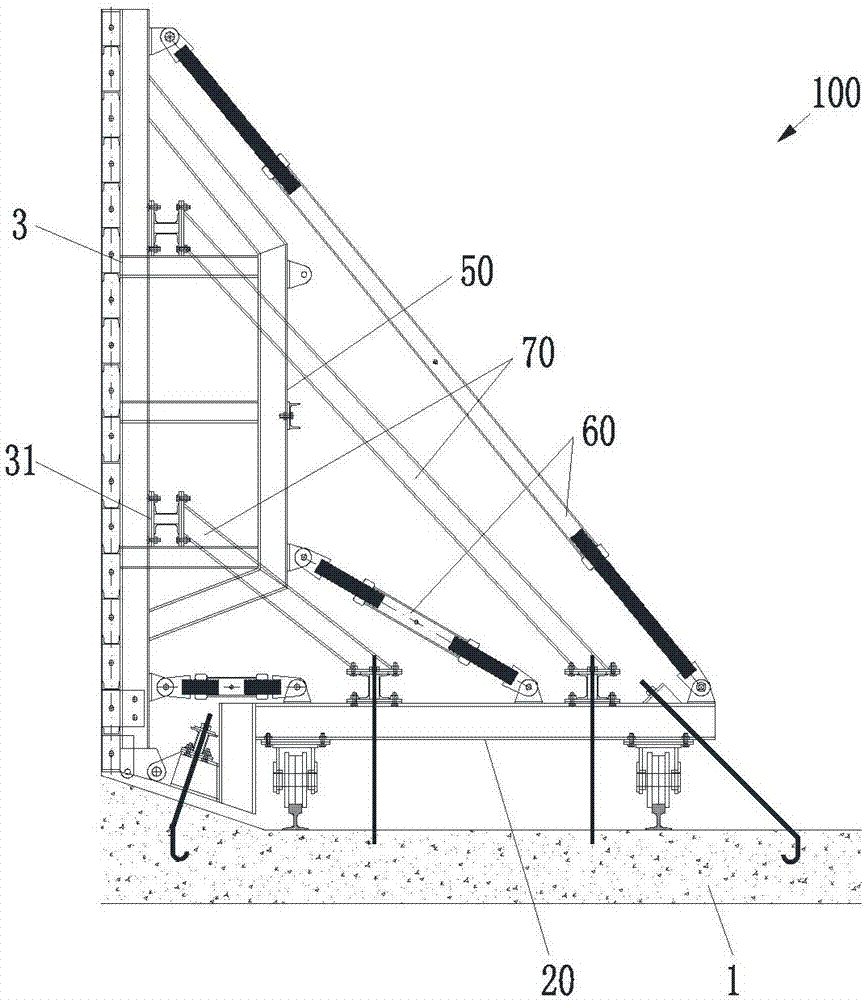

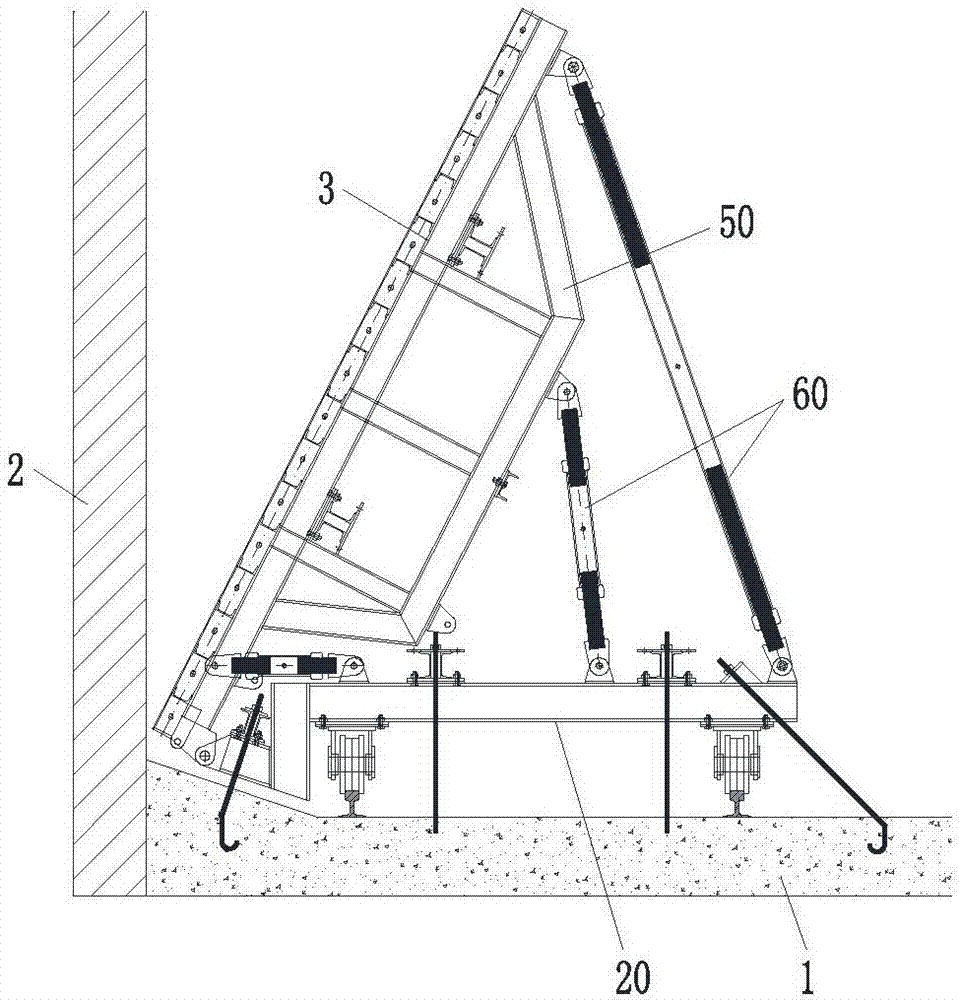

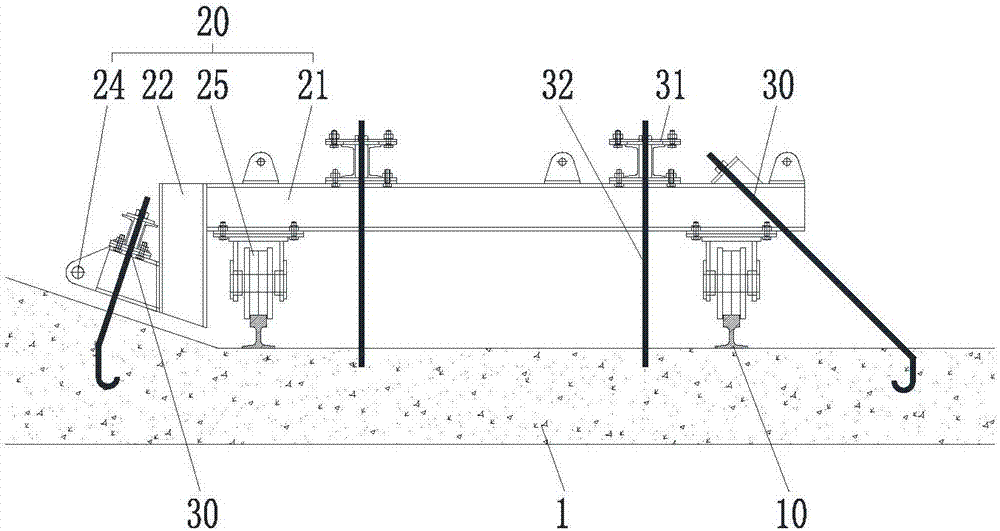

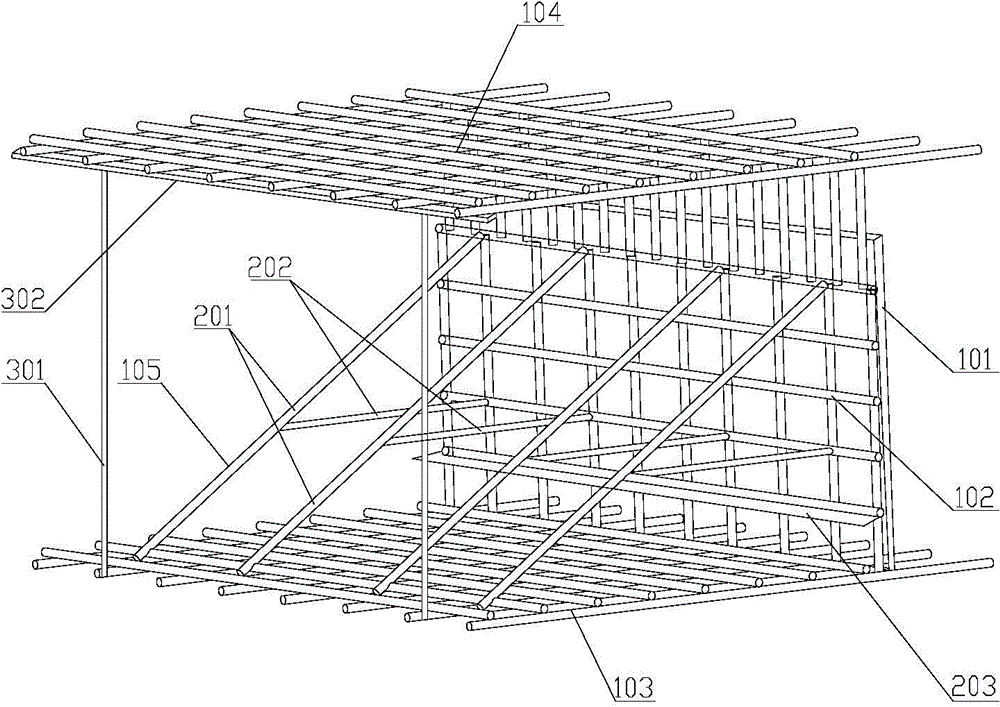

Basement outer wall single-side steel formwork supporting system and construction method thereof

PendingCN107313589AVerticality is easy to controlGuaranteed verticalityAuxillary members of forms/shuttering/falseworksBuilding material handlingSupporting systemArchitectural engineering

The invention provides a basement outer wall single-side steel formwork supporting system and a construction method thereof, and relates to the technical filed of constructional engineering equipment. Aiming at the problems that the labor intensity of construction personnel is high and formwork supporting work efficiency is low existing in the available supporting system, the basement outer wall single-side steel formwork supporting system and the construction method thereof are provided. The basement outer wall single-side steel formwork supporting system comprises a pair of tracks, bases, and a plurality of supporting trusses, wherein the pair of tracks is laid at a foundation slab and parallel to an outer wall steel formwork, the bases are arranged on the tracks and can slide along the tracks, and the multiple supporting trusses are vertically arranged at intervals and are connected with the outer wall steel formwork; and bottom parts of the supporting trusses are hinged to the bases, and the supporting trusses are detachably connected with top ends of the bases through a plurality of adjusting rod pieces. The construction method comprises the steps that the steel formwork supporting system is spliced and fixed, after outer wall concrete is poured, a ground anchor assembly and a diagonal bracing are disassembled, an adjusting rod piece is retracted, so that the demoulded outer wall steel formwork are made to be supported on the base, and the next working section is started to continue pouring construction of outer wall concrete.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

Device and method for casting concrete continuous walls along gob-side entry retaining by mining working face

ActiveCN101649744AGood top connection effectFilled tightlyUnderground chambersTunnel liningFiberSteel bar

The invention discloses a device and a method for casting concrete continuous walls along gob-side entry retaining by a mining working face. A fiber flexible template is in cuboid shape or in cubicalshape, which is formed by a main body template and a top joint template and is connected with a flange, a casting opening, a reinforcing steel bar implanting opening, a spacing hole and a tiepiece. The method comprises the following steps: the fiber flexible template is manufactured in advance; the flexible template is hung over on a top plate of a coal seam through an individual hydraulic prop oran anchor rod by the flange; the exposure end of the implanted reinforcing steel bar is inserted in the flexible template through the reinforcing steel bar implanting opening; a leading screw penetrates into the spacing hole and two ends thereof are fixed by tray nuts; the casting opening is inserted with a concrete conveying pipe and is bonded; concrete is poured into the flexible template through the conveying pipe by a concrete pump; and finally the concrete continuous walls are formed. The invention has simple structure, high-speed construction, high work efficiency, good impermeability,uneasily slurry leaking property, densely filled concrete and good top joint effect, can carry out mechanized operation, adapts to the change of gradient of the roof and floor, and can be widely usedin the following industries, such as coal mine, metallurgical mine, water conservancy, underground construction and national defense and the like.

Owner:SHAANXI PIONEERING ARCHITECTURAL TECH

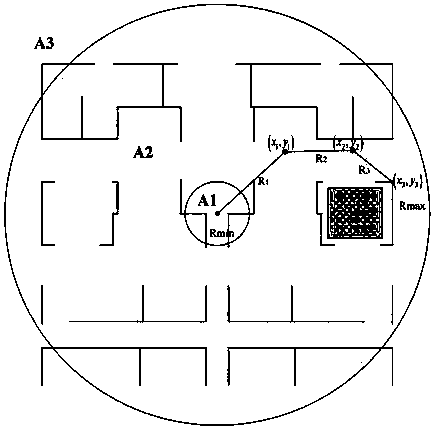

BIM (building information models)-based mass concrete real-time temperature monitoring and warning method

InactiveCN106768432AImprove pouring qualityThermometers using value differencesMeasuring instrumentComputer module

The invention discloses a BIM (building information models)-based mass concrete real-time temperature monitoring and warning method. The BIM-based mass concrete real-time temperature monitoring and warning method includes 1, carrying out BIM solid modeling on buildings according to design requirements; 2, establishing mass concrete pouring temperature field computing modules, concrete pouring temperature monitoring and warning modules and five-dimensional temperature field databases by means of BIM secondary development; 3, formulating temperature monitoring schemes; 4, arranging wireless temperature measuring instruments on sites according to the temperature monitoring schemes, transmitting five-dimensional temperature field variation of various monitoring points in real time, automatically processing transmission data by the aid of BIM and storing the transmission data in the temperature field databases; 5, retrieving concrete pouring five-dimensional temperature field data on the BIM by means of BIM secondary development; 6, automatically warning site constructors when the difference between the internal temperatures and the external temperatures of site concrete is higher than a warning threshold value and reminding the site constructors of curing the concrete. The BIM-based mass concrete real-time temperature monitoring and warning method has the advantages that temperature field variation in integral pouring procedures can be visually displayed by the aid of the BIM, and effective warning modes can be provided for timely guiding implementation of curing measures on the sites.

Owner:NANTONG SIJIAN CONSTR GRP

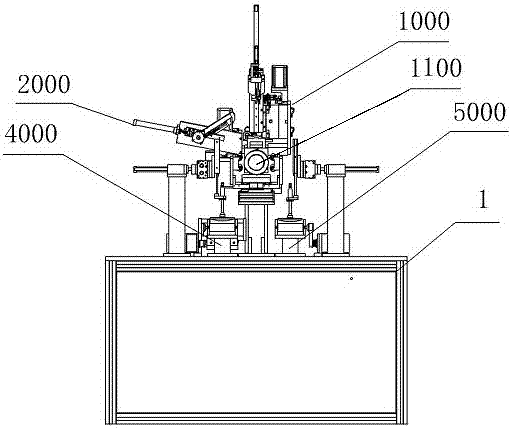

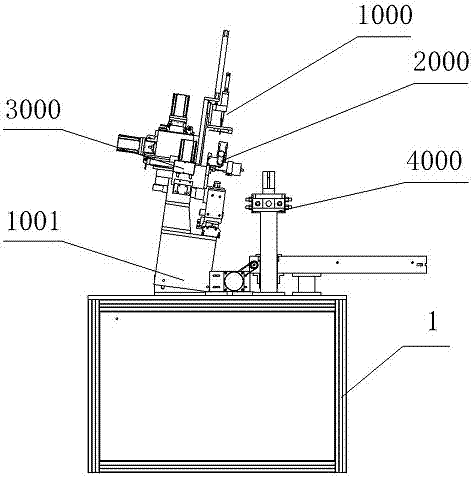

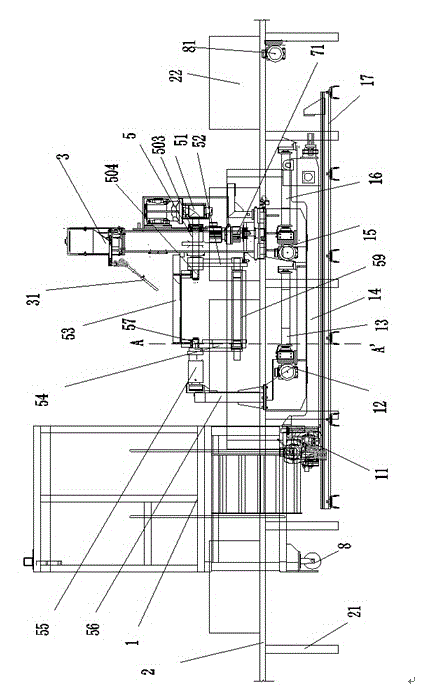

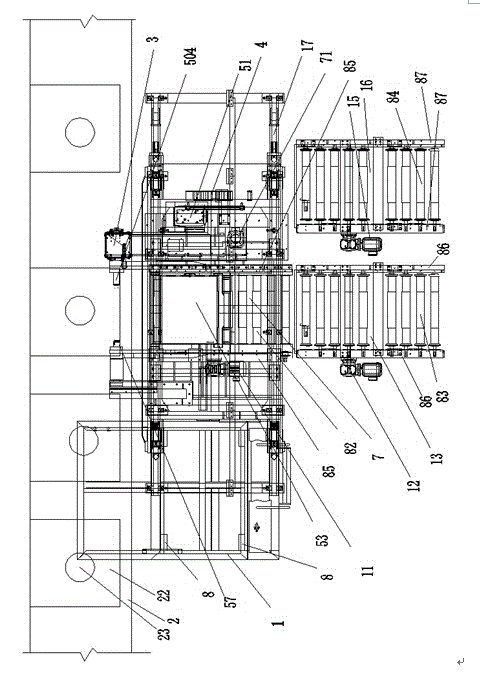

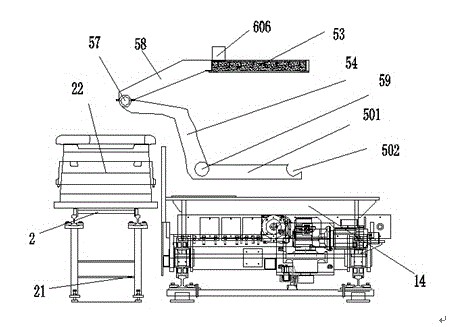

Fully automatic light control resin lens casting machine

ActiveCN107399037AImprove pouring qualityMaintain internal and external air pressure balanceOptical articlesProgrammable logic controllerColloid

The invention discloses a fully automatic light control resin lens casting machine, and belongs to the technical field of lens manufacturing. The fully automatic light control resin lens casting machine comprises a machine frame (1) and a PLC (programmable logic controller) control unit, wherein an automatic mold feeding device (4000), an automatic recovery device (5000), an automatic casting device (1000) and an adhesive tape tearing device (2000) are arranged on the machine frame (1); the automatic casting device (1000) comprises a colloid injection mechanism (1200), a puncture mechanism (1300), a first sensing mechanism (1400) for sensing the colloid overflow condition on the top of a mold, and a second sensing mechanism (1500) for sensing the colloid casting degree in the mold. The fully automatic light control resin lens casting machine has the advantages that the colloid injection by an injection needle (1203) is facilitated; the colloid overflowing is prevented; air bubbles existing in the mold is prevented; the resin lens casting quality can be improved; the production efficiency is improved.

Owner:LINHAI JINZHENG MACHINERY

Construction technology of one-time molding of concrete pouring on top of construction column and construction device thereof

InactiveCN108612260AImprove construction qualityEasy to operateStrutsForms/shuttering/falseworksConcrete beamsArchitectural engineering

Owner:JIANGSU SUZHONG CONSTR GROUP

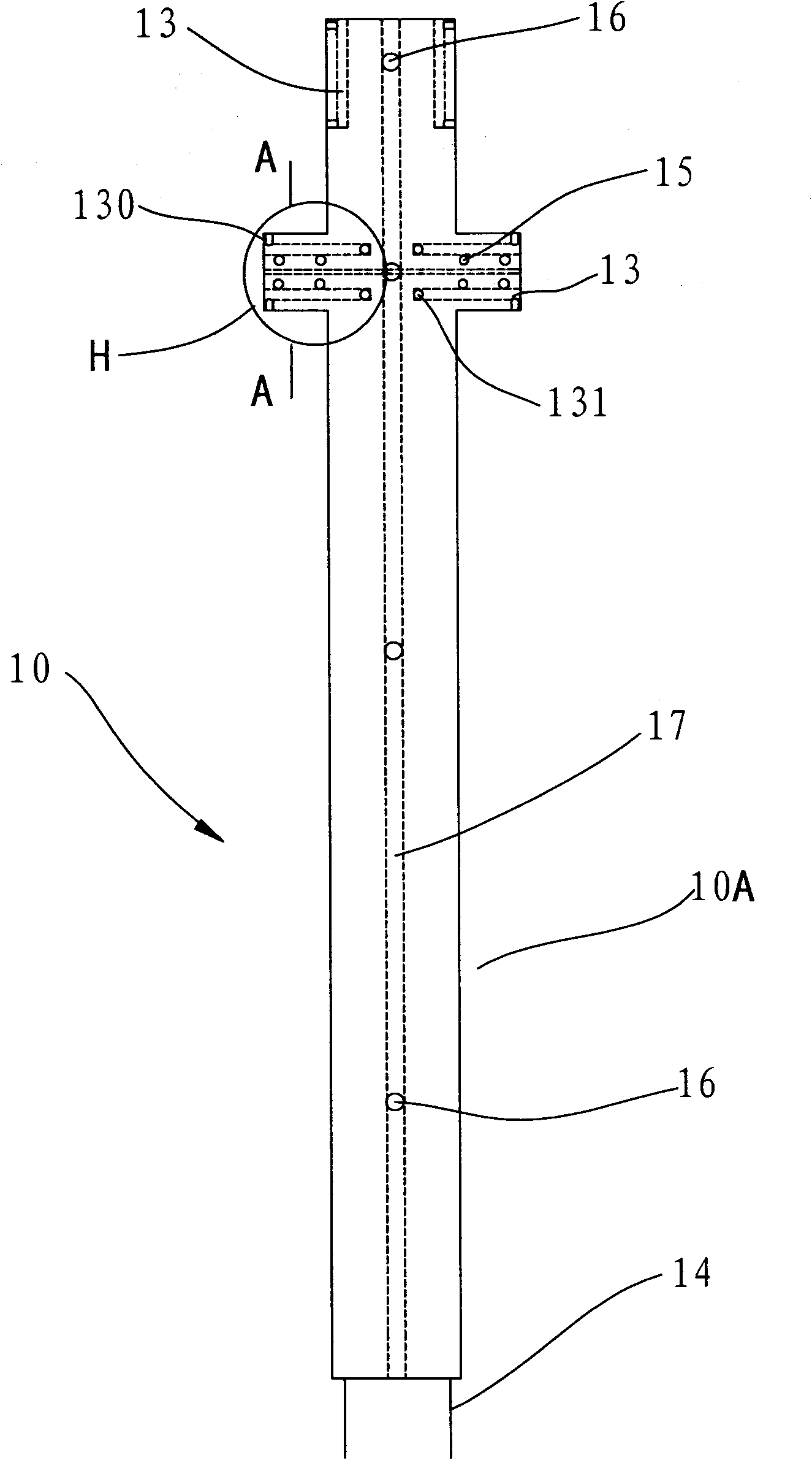

Fabricated frame strip steel bracket long column and construction method thereof

ActiveCN103556781AEasy to processEasy to installStrutsPillarsReinforced concrete columnEarthquake resistance

The invention discloses a fabricated frame strip steel bracket long column and a construction method of the fabricated frame strip steel bracket long column. The column body is a composite column consisting of three parts, namely steel pipe outer reinforced concrete, a steel pipe and steel pipe inner concrete; the steel pipe and the steel pipe inner concrete penetrate through the whole long column; the steel pipe inner concrete is subjected to primary prefabrication to form a steel pipe concrete column; concrete at a steel pipe outer joint or total concrete is poured in advance at the second time; a steel bracket is welded with the steel pipe. The long column has the advantages that 1, a multi-layer frame column is manufactured into a long column, the manufacture is simple, and the installation is convenient; 2, the column body is a composite column, the compression bearing capacity and shear capacity of the column are 2-4 times that of a reinforced concrete column with the same section, and the bearing capacity and anti-seismic property of the frame column are obviously improved; 3, the steel bracket is arranged and can be connected with a steel beam or a cast-in-place reinforcedconcrete beam, and the connection is convenient and reliable; and 4, high-strength concrete in the steel pipe is prefabricated in a factory, and the construction cost of the column is greatly reducedcompared with that of a conventional composite column. Therefore, the long column is suitable for various multi-story and high-rise prefabricated buildings and is wide in market prospects.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

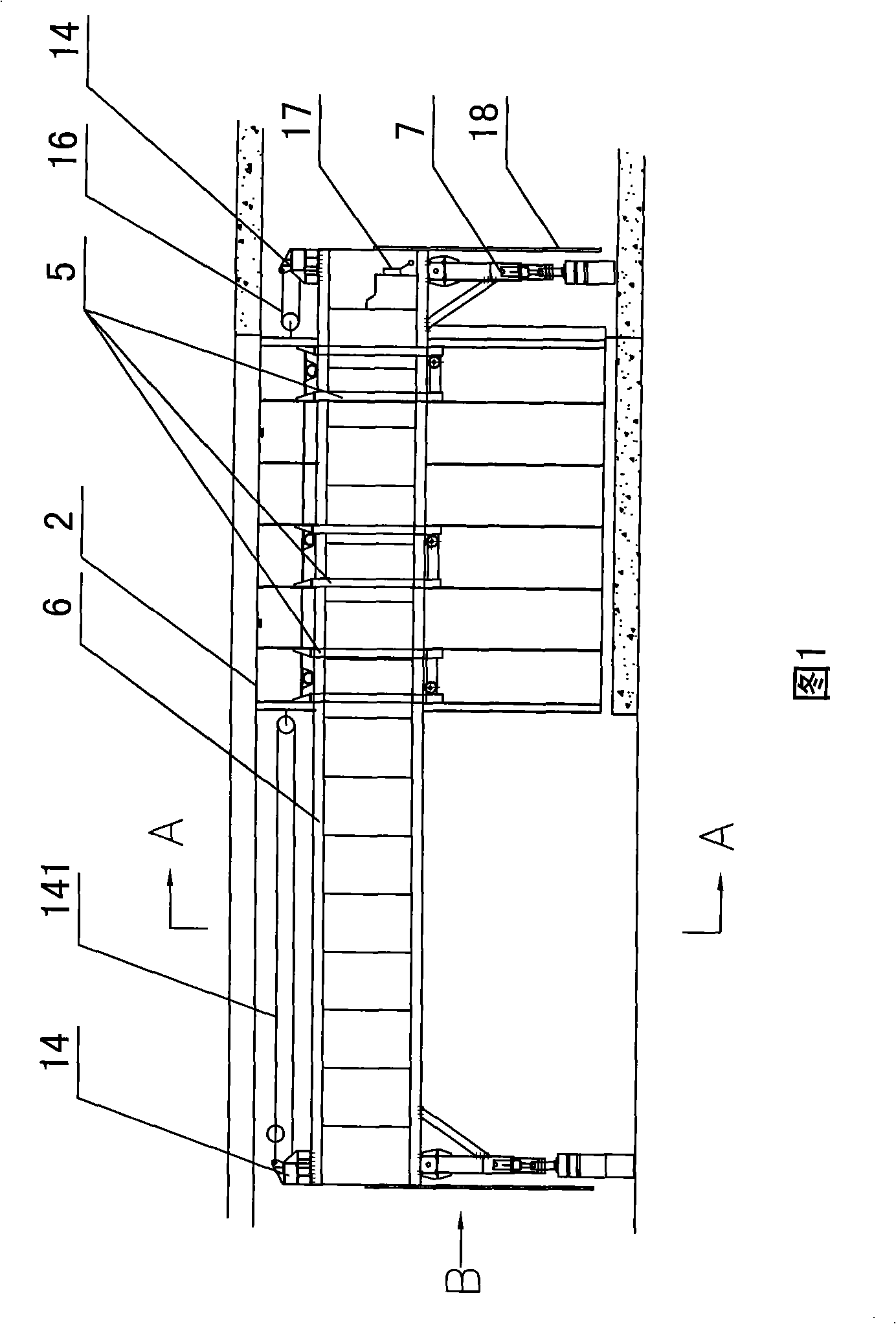

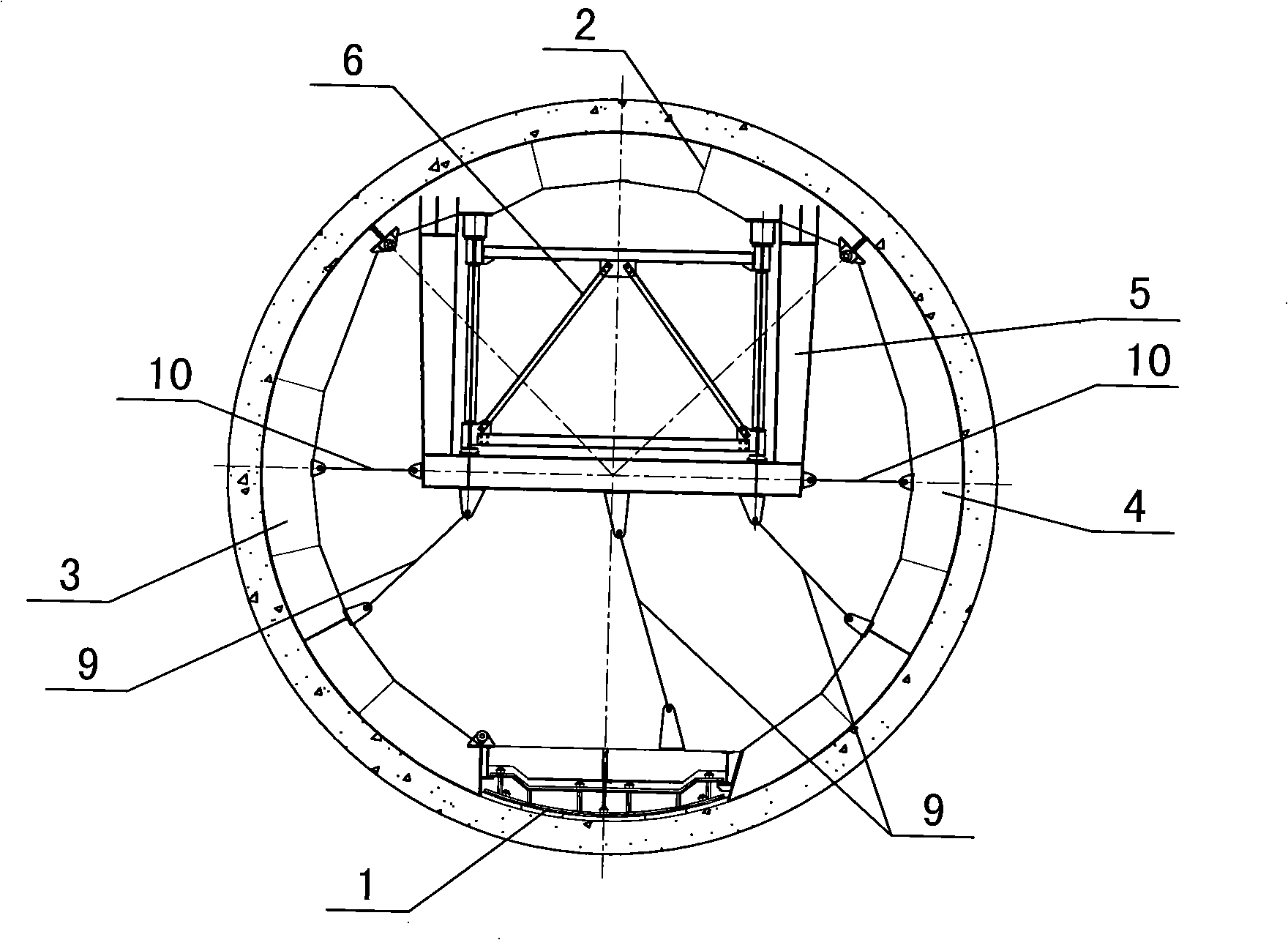

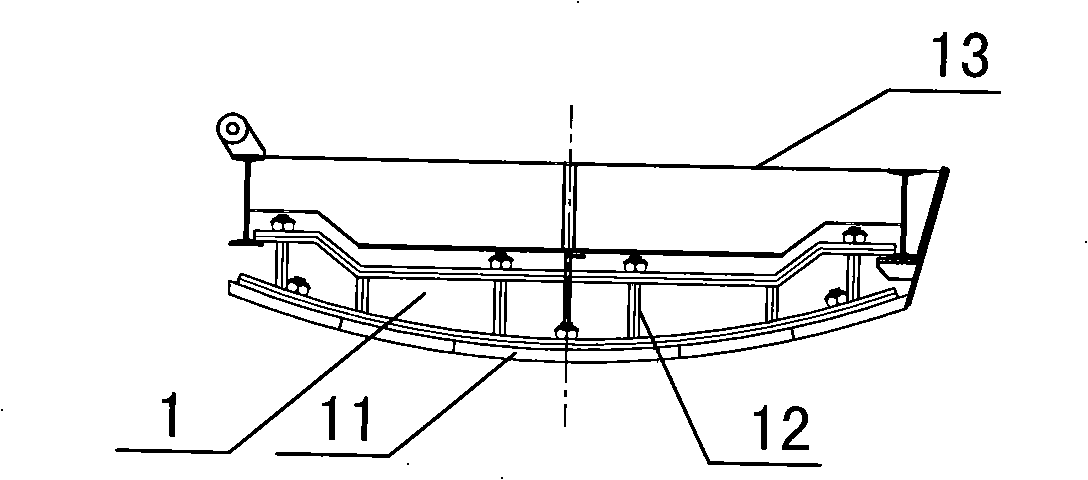

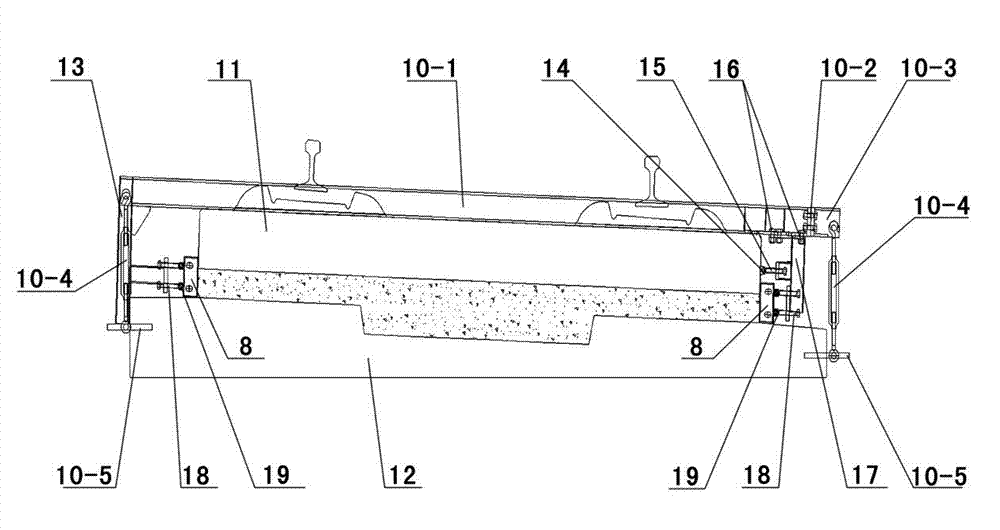

Tunnel concrete lining formwork apparatus

InactiveCN101298839AGood tunnel forming qualityImprove pouring qualityUnderground chambersTunnel liningEngineeringSliding contact

The present invention discloses a tunnel concrete lining template device comprising a template system and needle beam system for bearing; the template system comprises template assembly and template pylon; the template assembly comprises arced left die, right die, top die and bottom die; the left die, right die, top die and bottom die are correspondingly connected to form template assembly with round section; the template pylon is hung on the top die; and bottom of the template pylon is respectively installed with left die, right die and telescopic standing demoulding device connected by the bottom die; the needle beam system comprises bearing needle beam placed in the upper part of the tunnel and pre and post supporting leg device for supporting the bearing needle beam; upper end face of the bearing needle beam is in slide contact with the top die and the needle beam is placed on the template pylon; and the bottom die is in the detachable structure; the bottom die in the detachable structure is installed with opening part which is able to execute trowel-finishing on the surface of the tunnel bottom arch concrete after detaching or turning over when the concrete is initially set. The template device effectively removes the problem of foam of the traditional whole section template bottom arc foam and improves the internal appearance molding quality of the bottom arc concrete.

Owner:SINOHYDRO BUREAU 14 CO LTD

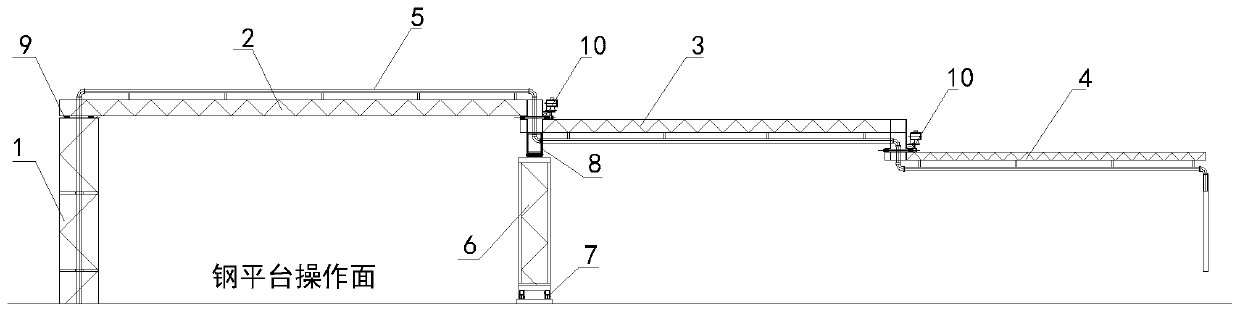

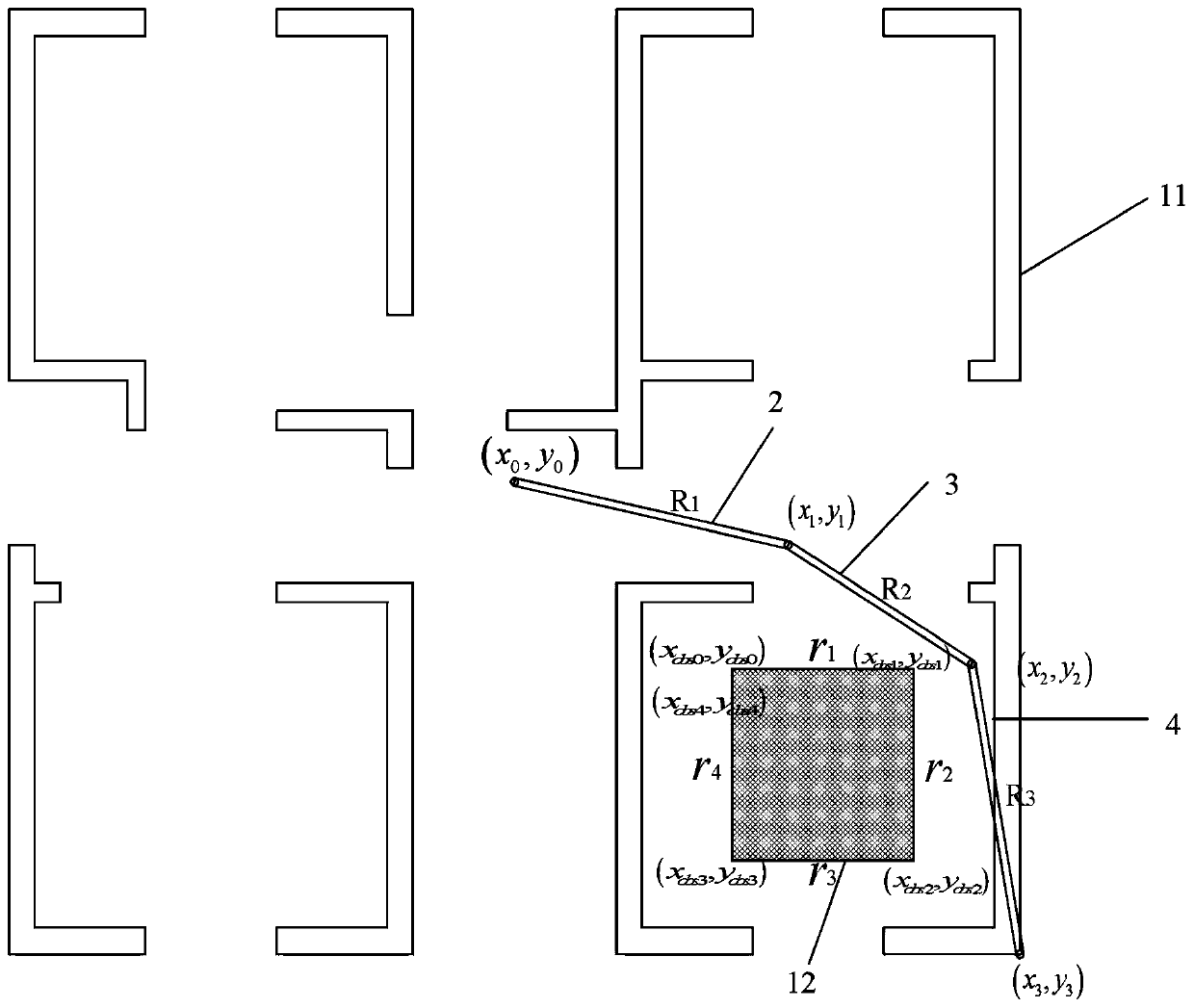

Intelligent concrete distribution control system and method for transverse folding arm concrete spreader

ActiveCN111058637AImprove cloth efficiencyImprove pouring qualityBuilding material handlingDistribution controlControl system

The invention discloses an intelligent concrete distribution control system and method for a transverse folding arm concrete spreader, and belongs to the field of construction engineering machinery. The intelligent concrete distribution system comprises an intelligent terminal, a PLC, a first driver, a second driver, a flow valve, an angle sensor and a flow sensor. According to the system and method, control parameters are sent to the PLC through the intelligent terminal, the first driver and the second driver are controlled by the PLC, and angle control over a rotary mechanism and opening degree control over the flow valve are realized, so that automatic intelligent concrete distribution can be realized through the horizontal folding arm concrete spreader, the concrete distribution position and flow can be precisely controlled, the labor cost is reduced, the concrete distribution efficiency is improved, and the industrialization level of the construction concrete spreader is improved.Meanwhile, the rotation angle of an arm frame, the concrete pouring flow, the position of a discharging port of a pump pipe and the concrete pouring progress can be monitored, precise concrete pouring is achieved, and the concrete pouring quality is improved.

Owner:SHANGHAI CONSTRUCTION GROUP

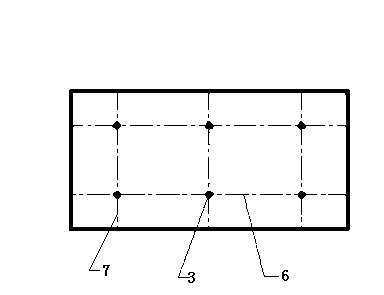

Raft plate post-cast strip pouring template and construction method thereof

ActiveCN104806011AImprove pouring qualitySimple structureForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksEngineeringRebar

The invention provides a raft plate post-cast strip pouring template and a construction method thereof, which belong to the field of building construction equipment. The pouring template comprises a template and a support for supporting the template, wherein the support comprises a vertical beam arranged vertically, and a lower layer reinforcing mesh and an upper layer reinforcing mesh arranged horizontally; the template and the vertical beam are respectively located between the lower layer reinforcing mesh and the upper layer reinforcing mesh; the vertical beam is connected with the upper layer reinforcing mesh and the lower layer reinforcing mesh; the template is attached to the vertical beam; the support also comprises a support beam; one end of the support beam is connected with the vertical beam; the other end of the support beam is connected with the lower layer reinforcing mesh. The construction method is used for manufacturing the raft plate post-cast strip pouring template. The raft plate post-cast strip pouring template can be built in a less space and is convenient to construct in a time and labor saving way, and the cost is saved.

Owner:CHINA MCC5 GROUP CORP

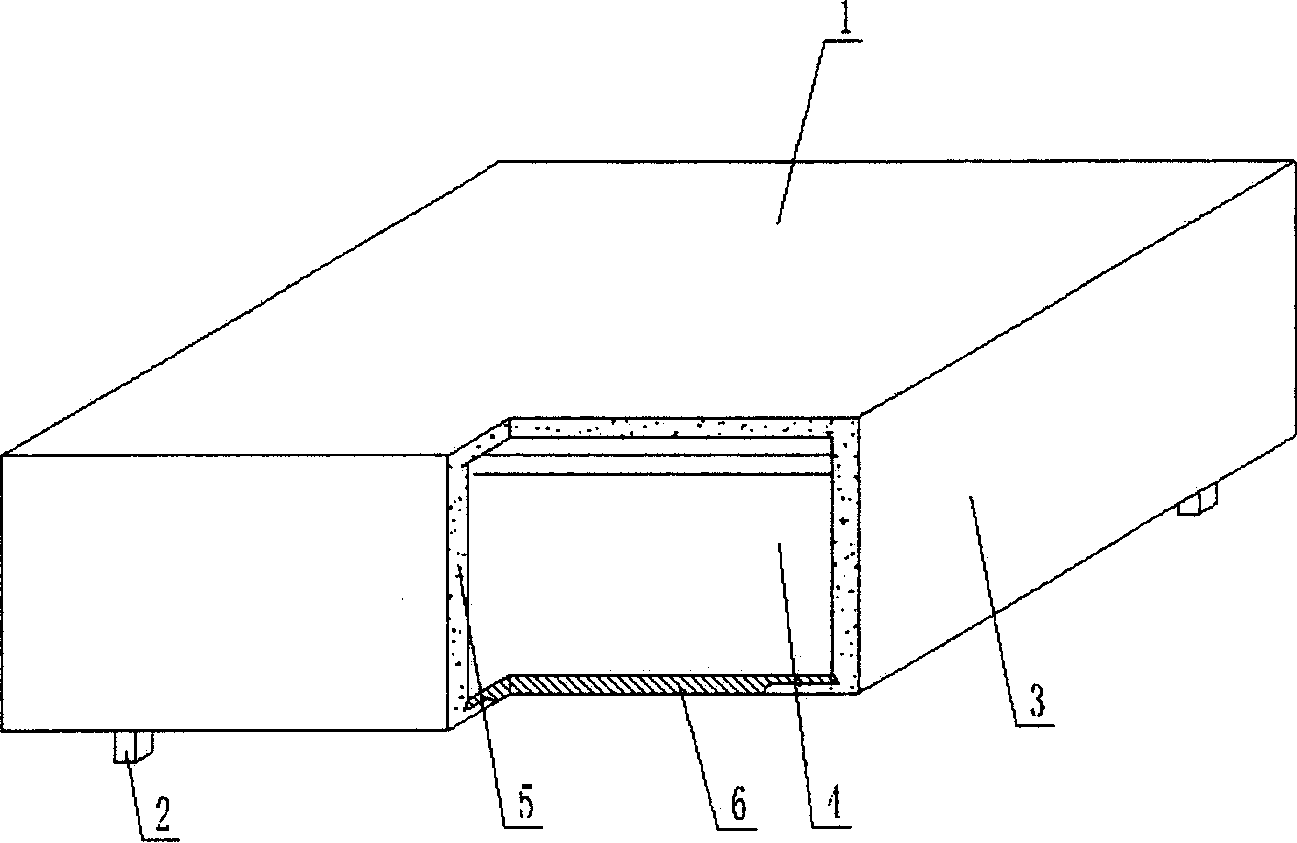

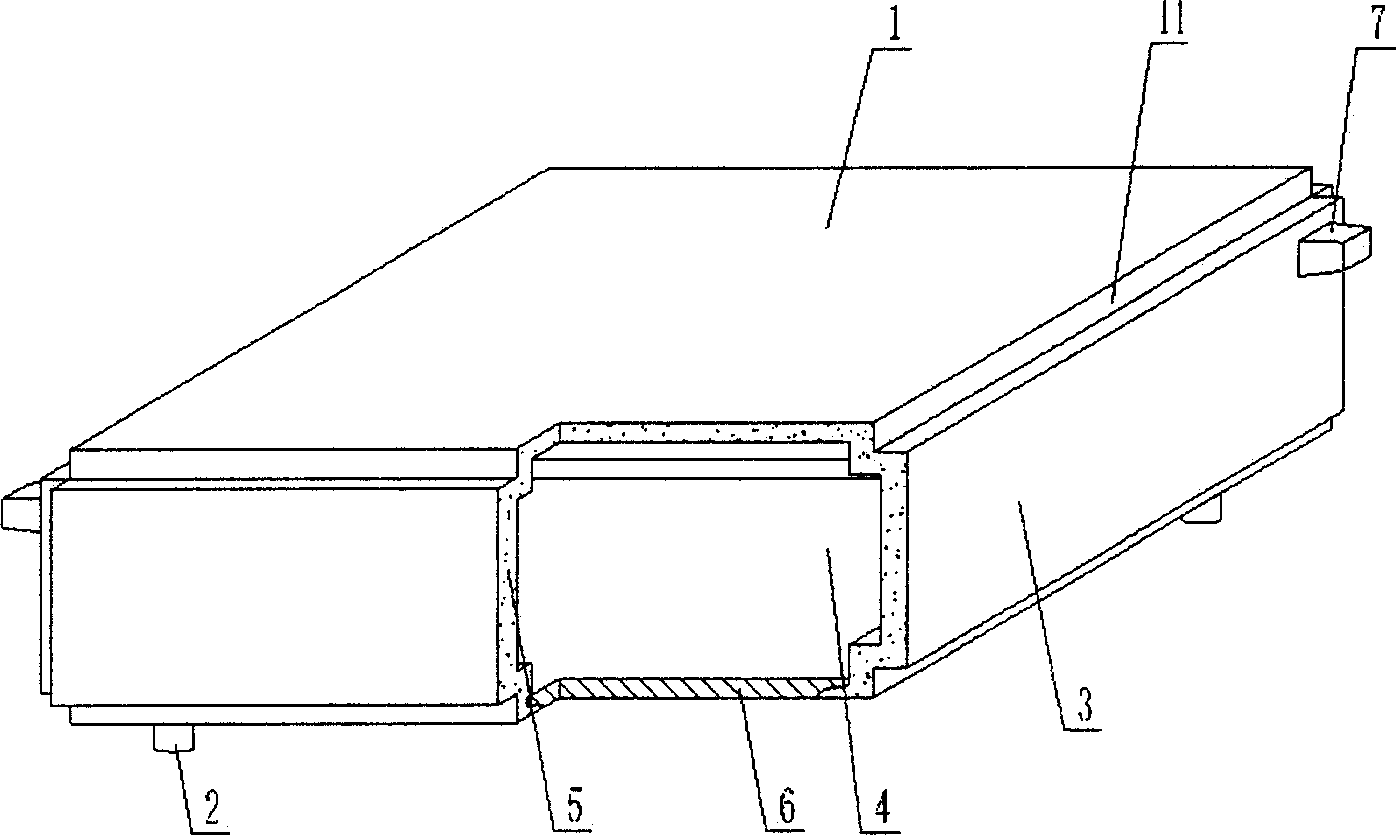

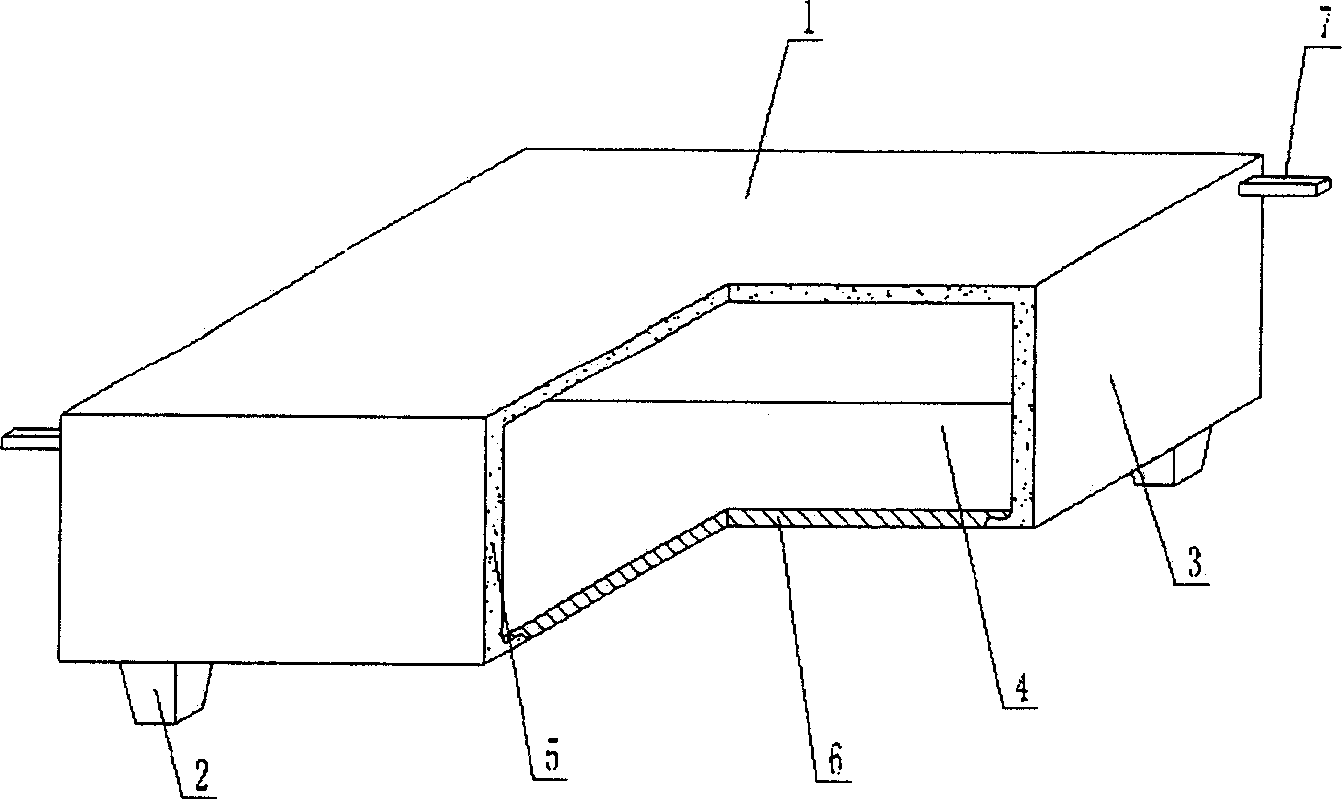

Integral casting process for reinforced concrete wastewater tank in predrilling engineering

ActiveCN103015719AShorten construction timeShorten the construction periodBuilding material handlingReinforced concreteWastewater

The invention discloses an integral casting process for a reinforced concrete wastewater tank in predrilling engineering. The integral casting process comprises the following steps of a, construction of a foundation and a bedding layer, digging a foundation pit, and casting the concrete bedding layer after determining that the foundation bearing force meets the design requirements; b, manufacturing and installation of reinforced bars, manufacturing and installing on site, wherein the overlapping length of the reinforced bars should not be less than 40 times of the diameter (mm) of each reinforced bar, and the overlapping area of the reinforced bars same in cross section should not be more than 50% of the total area; c, supporting of die plates, binding the die plates into the shapes of the bottom and the wall of a concrete tank; d, casting of concrete, after completing the construction of the reinforced bars and the die plates, carrying out the casting construction of concrete, firstly casting the bottom of the concrete tank and the wall with the height less than 1m, leveling the top of the wall of the concrete tank, and reserving no step to complete the first time of casing; casting the residual wall of the concrete tank in at least one hour after completing the first time of casting; and e, removal of the die plates, removing the die plates when the strength of the cast concrete being more than 1.2MPa. The integral casting process has the advantages that the construction time of the wastewater tank in the predrilling engineering is reduced, the construction period of the whole predrilling engineering is shortened, the condition of drilling machines not waiting for well fields is ensured, the construction seams are not reserved in the construction, and the leakage problem caused by the construction seams is avoided.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Casting production technology of valve body

InactiveCN101890477AStrong shrinkageHigh strengthFoundry mouldsFoundry coresVolumetric Mass DensityCasting

The invention relates to a casting production technology of a valve body. The production technology comprises the following steps in turn: preparing a mould, preparing a sand mould, performing core setting, smelting, pouring and performing subsequent operations, wherein the preparation of the sand mould comprises the following steps: firstly filling moulding sands in the mould, secondly ramming moulding sands to complete modeling and installing a charging hole on the completed model; smelting comprises the following steps: firstly selecting material according to the demand of the casting, secondly adding alloy element in molten iron and thirdly performing inoculation when molten iron is discharged; and pouring comprises the following steps: firstly injecting molten iron in an impression, wherein the pouring temperature is 1380-1440 DEG C and the pouring time is 8-20 seconds; and secondly keeping temperature for 40-80 minutes, wherein the production yield is 40%-60%. The casting production technology of the invention has better pouring quality, the density of the casting is uniform; and the sand mould is not easy to crack and has wider application range.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

Fast building earthquake-resisting reinforcing method and device

InactiveCN101936074AGuarantee product qualityShorten the on-site construction periodBuilding repairsShock proofingHalf fieldEngineering

The invention provides fast building earthquake-resisting reinforcing method and device. The fast building earthquake-resisting reinforcing device is a prefabricated part, the inner side of the prefabricated part is provided with a grout groove, and the grout groove is communicated with the outer side of the prefabricated part through more than one grout hole. The reinforcing method comprises the following steps of: removing the skin of the junction surface at the junction part between a wall of the reinforced building and the prefabricated part, and drilling anchoring holes in the wall, wherein the position of each anchoring hole is corresponding to the junction hole in the prefabricated part; installing the prefabricated part on the wall of the reinforced building through anchoring bolts, anchoring adjacent prefabricated parts, and fixedly bonding the prefabricated parts to the surface of the wall together. The technical scheme of field assembly of the prefabricated parts is adopted to reinforce the building, more than half field construction period can be shortened, the prefabricated parts can be produced in factories during school time, and enough time for ensuring production quality is guaranteed.

Owner:BEIJING TEXIDA TECH CO LTD

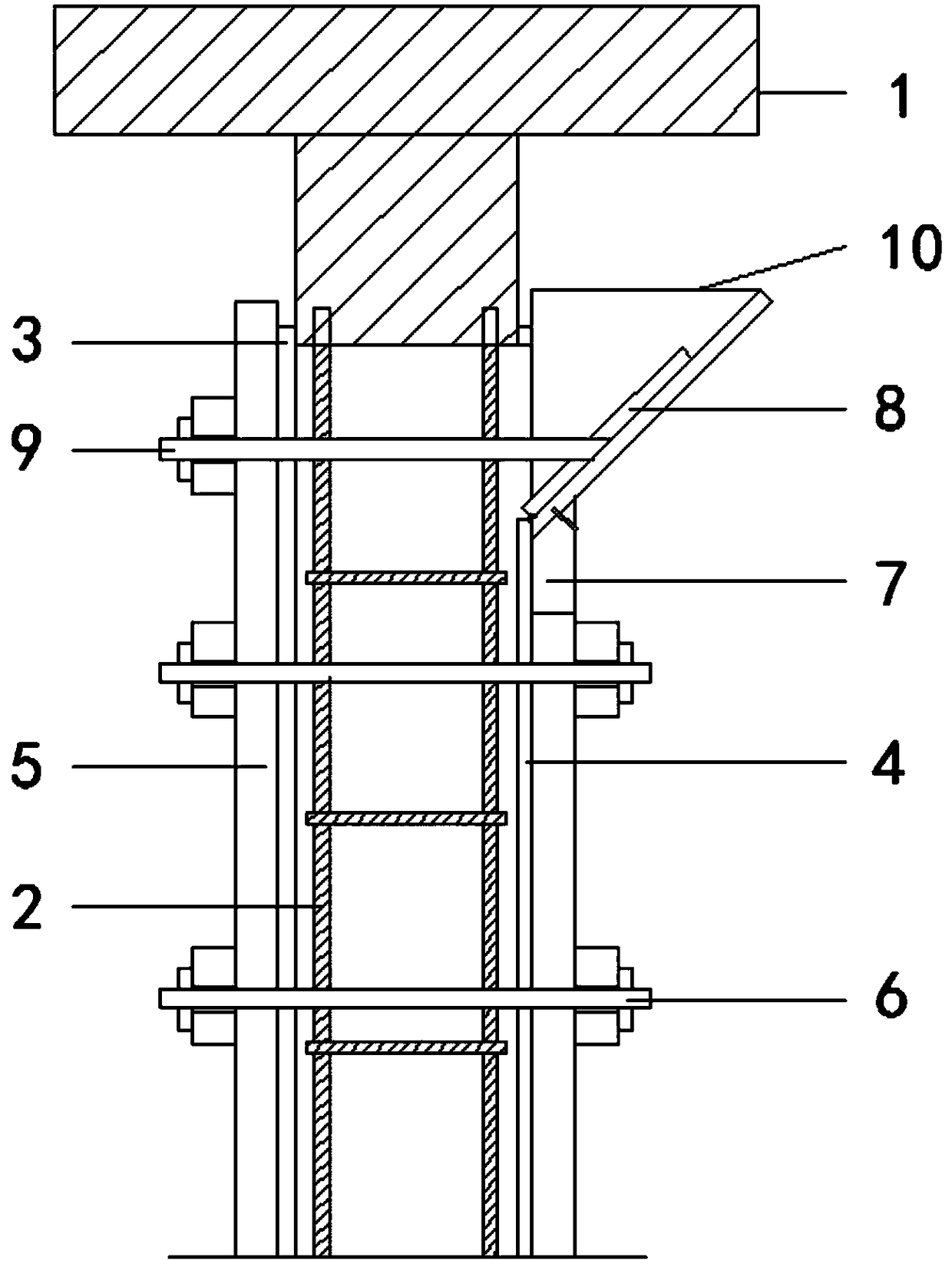

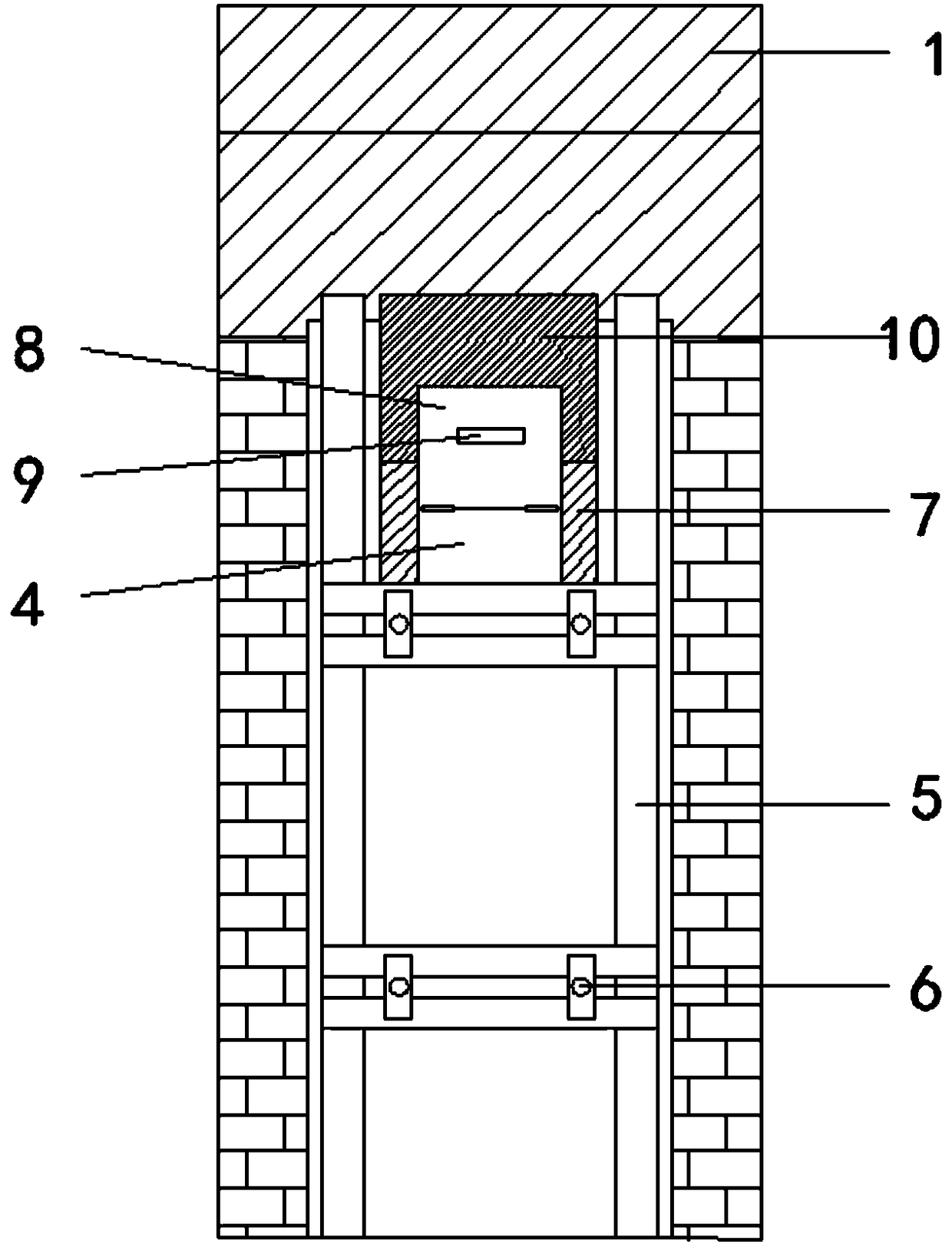

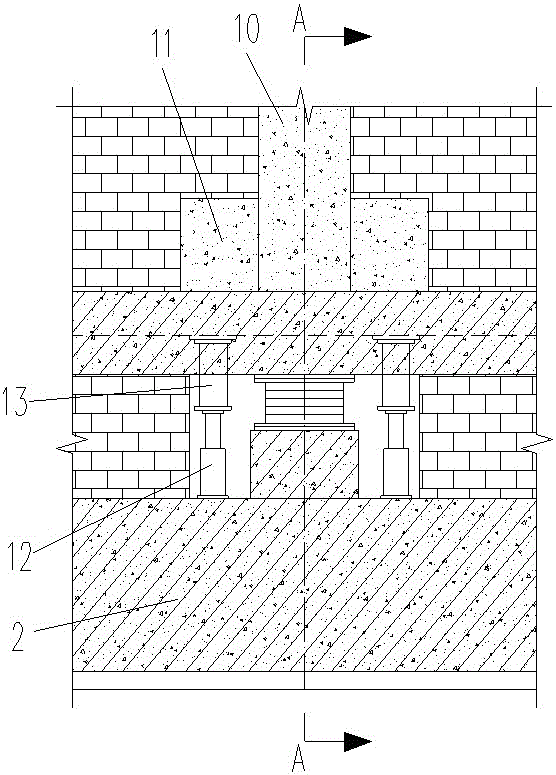

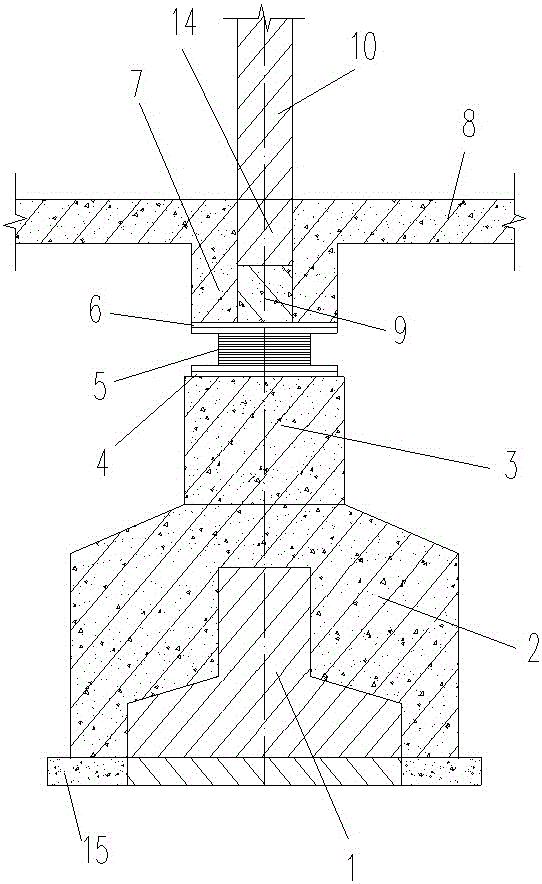

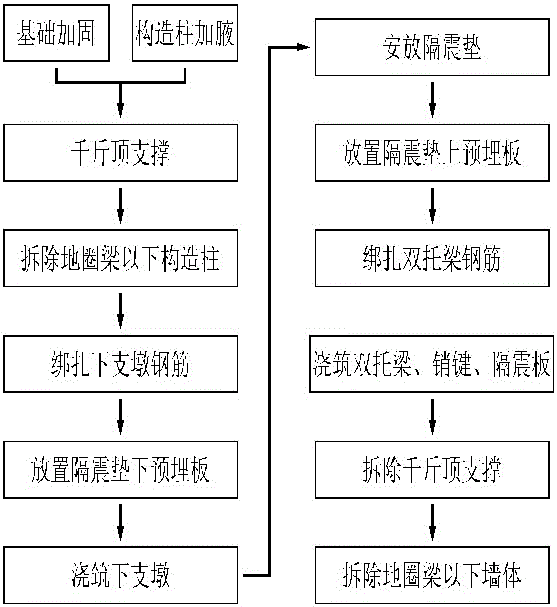

Underpinning and reinforcing structure for seismic isolation bearing of existing brick-concrete structure and construction method for underpinning and reinforcing structure

The invention discloses an underpinning and reinforcing structure for a seismic isolation bearing of an existing brick-concrete structure. The underpinning and reinforcing structure comprises an enlarged foundation arranged on the original foundation, a lower supporting pier arranged on the upper part of the enlarged foundation, a seismic isolation pad lower embedded board arranged on the upper part of the lower supporting pier, a seismic isolation pad arranged on the upper part of the seismic isolation pad lower embedded board, a seismic isolation pad upper embedded board arranged on the upper part of the seismic isolation pad, double supporting beams arranged on the upper part of the seismic isolation pad upper embedded board and a seismic isolation board arranged on the upper parts of the double supporting beams; pin keys are further arranged inside the double supporting beams; and the double supporting beams, the pin keys and the seismic isolation board are of an integrated type poured and molded structure. The invention further provides a construction method for the underpinning and reinforcing structure for the seismic isolation bearing of the existing brick-concrete structure. In this way, the underpinning and reinforcing structure is stable in structure, is high in safety, and has relatively good seismic resistance; besides, the mounting and constructing are relatively convenient, and the efficiency is high.

Owner:JIANGSU DINGDA BUILDING NEW TECH +1

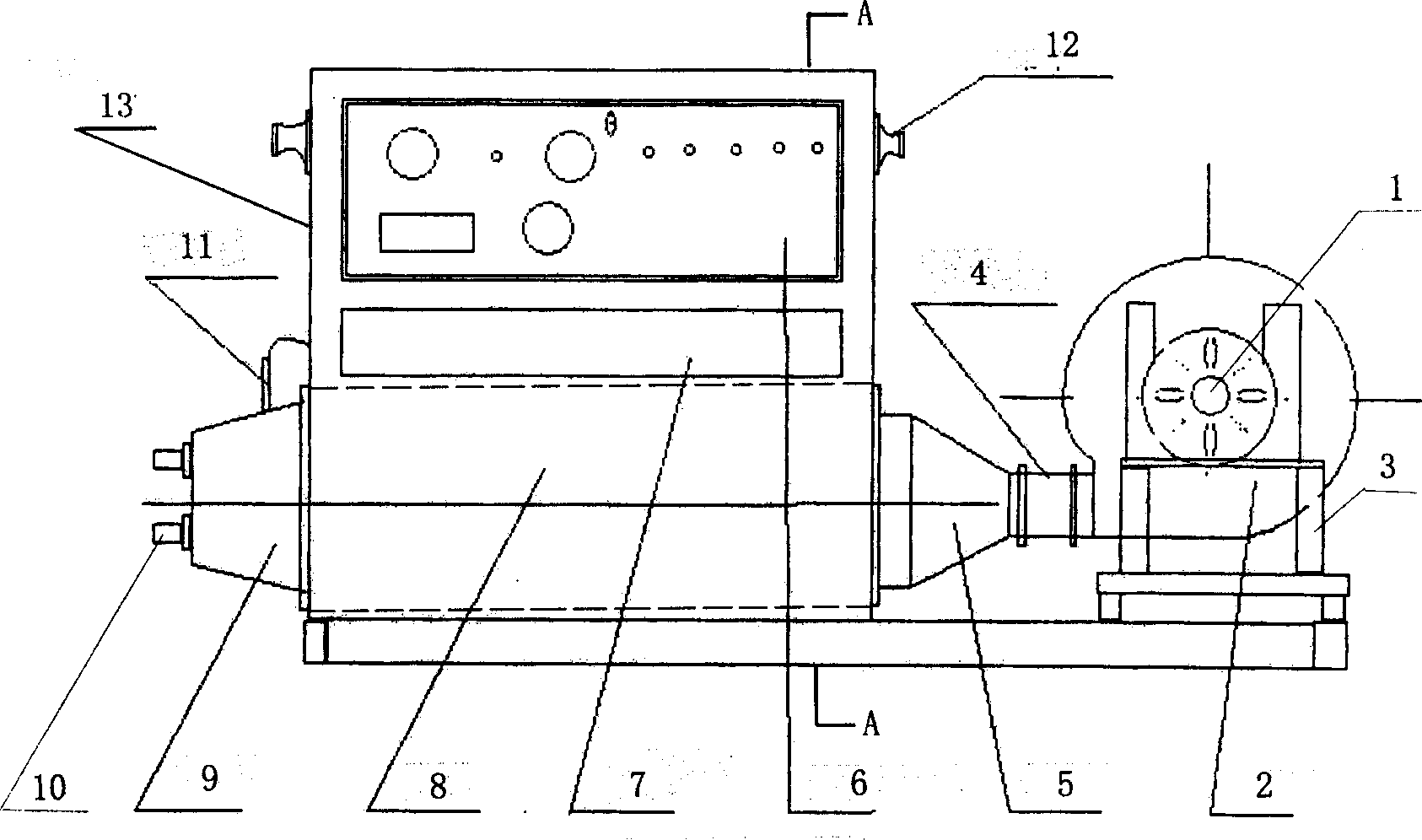

High-precision full-automatic casting machine

ActiveCN104439222AGuaranteed continuityImprove pouring qualityMolten metal supplying equipmentsMetallurgyThermal insulation

The invention discloses a high-precision full-automatic casting machine. The high-precision full-automatic casting machine comprises a casting ladle system, a casting ladle transverse moving and longitudinal moving system, a servo tilt-rotating mechanism, a detection unit and a control unit. The casting ladle system comprises a casting ladle made of thermal insulation materials and a casting ladle moving device. The casting ladle transverse moving and longitudinal moving system comprises a track system and a casting vehicle. The detection unit comprises a load sensor. The load sensor is used for detecting the weight of molten metal in the casting ladle of the casting machine and generating a signal representing the detected weight. The control unit is provided with a first arithmetic unit, a second arithmetic unit and a driving indication unit. The casting machine can effectively shorten the casting time and improve the casting stability.

Owner:山东时风(集团)有限责任公司

Steel plate combined shear wall capable of achieving connection through crossed bending type partition board and preparing method

PendingCN110469043AImprove stabilityEasy to moveConstruction materialWallsEngineeringSteel plate shear wall

The invention discloses a steel plate combined shear wall capable of achieving connection through a crossed bending type partition board and a preparing method. The wall comprises two parallel external package steel plates, the crossed bending type partition board is arranged between the two external package steel plates, and a first opening and a second opening which are alternatively distributedup and down are formed between the crossed bending type partition board and the external package steel plates. According to the steel plate combined shear wall, the quality of the steel plate combined shear wall can be effectively improved, and the whole stress property of the steel plate shear wall is improved.

Owner:THE ARCHITECTURAL DESIGN & RES INST OF ZHEJIANG UNIV

Cast production technology for shell

InactiveCN101875092AImprove mechanical propertiesImprove shrinkageFoundry mouldsFoundry coresCooling effectVolumetric Mass Density

The invention discloses cast production technology for a shell. The technology sequentially comprises the steps of: manufacturing a mould, namely manufacturing an external metal mould, wherein the lower part of the external metal mould is provided with a molten iron inlet; manufacturing a sand mould, namely manufacturing a foaming mould, coating cast steel paint on the surface of the foaming mould, filling resin sands into the mould and hardening the sand mould by air blowing; setting a core, namely assembling the sand mould and the external metal mould, wherein a high temperature resistant material is coated on the core; pouring at the temperature of between 1,380 and 1,420 DEG C for 4 to 8 seconds and preserving the heat for 100 to 150 minutes, wherein a product yield reaches 50 to 70 percent; and performing subsequent operation, namely opening the mould to take the cast out, and cleaning and grinding the cast to obtain the required shell. The technology has the advantages of high sand mould quality, difficult cracking, good cooling effect and uniform internal density of the cast.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

Hot-blast furnace for casting mold and its baking method

InactiveCN1748902AAvoid poor exhaustSatisfy process requirements that require maintenance of optimum temperatureFoundry mouldsFoundry coresMotor driveElectric machinery

The present invention relates to casting technology, and is especially one hot blast furnace with high pressure blower to generate continuous airflow and electric heating element to heat so as to form output hot airflow. The present invention also relates to the stoving method of using the hot blast furnace in stoving casting mold, maintaining hot state of casting mold and eliminating humidity. The technological scheme of the hot blast furnace includes using one motor driven high pressure blower to output continuous airflow, pressurizing the airflow through pipeline to heating chamber and heating the airflow with the electric heating element inside the heating chamber, so as to generate 50-350 deg c high temperature and high pressure airflow. Through metal hose, the hot airflow is forced into the casting mold to stove casting mold, maintain hot state of casting mold and eliminate humidity.

Owner:长兴中建耐火材料科技有限公司

Hollow casing for in-situ concrete casting

ActiveCN1740484AAvoid mobilityPrevent floatingFloorsForms/shuttering/falseworksReinforced concreteFloor slab

The hollow casing for in-situ concrete casting includes hollow casing, and arm braces set on outer bottom wall, and the outer walls enclose to form the hollow casing with cavity. The present invention features that the hollow casing is one hexahedron comprising one integral five-sided open-mouthed body and one prefabricated outer wall to close the opened mouth so as to form one completely closed hollow casing. The hollow casing has easy fabrication, high production efficiency, high integrity, low cost, simple structure, high strength, high rigidity and other features. The present invention is suitable for hollow slab, floor slab, roof, wall, base bottom and bridge of in-situ cast reinforced concrete or pre-stressed reinforced concrete, especially hollow flat floor slab.

Owner:湖南邱则有专利战略策划有限公司

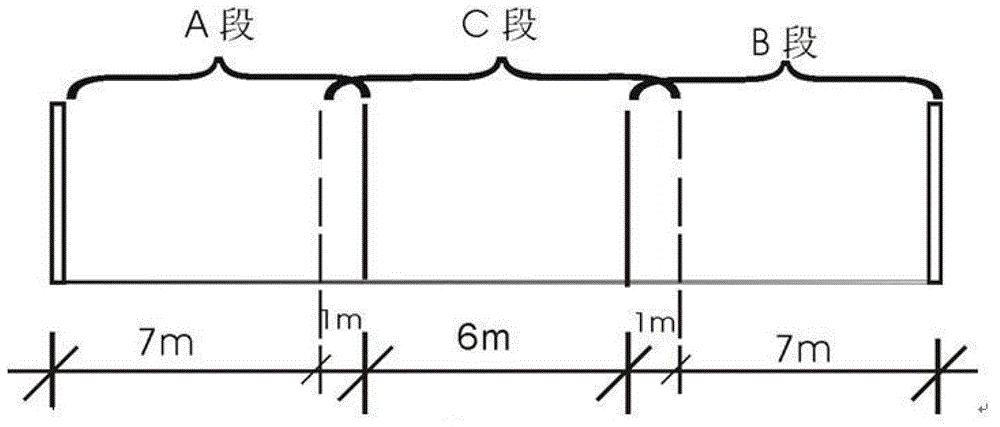

Underground engineering mixed construction method

ActiveCN103334452AShorten the construction periodSave formwork and support systemArtificial islandsUnderwater structuresRebarReinforced concrete

The invention discloses an underground engineering mixed construction method which comprises the following steps that (1) the surface of a road is transversely divided into a section A, a section B and a section C, the section A is sealed, reinforced concrete construction is carried out on the section A, and an underground continuous wall is obtained; (2) the surface layer earthwork is excavated to obtain a basement top slab of the section A; (3) earth is backfilled to recover the traffic of the road face of the section A; (4) the section B is sealed, and reinforced concrete construction is carried out on the section B to obtain an underground continuous wall; (5) the surface earthwork is excavated to obtain a basement top slab of the section B; (6) earth is backfilled to recover the traffic of the road face of the section B; (7) the section C is sealed, the surface earthwork is excavated, and basement bottom slabs of the section A, the section B and the section C are obtained; (8) a basement top slab of the section C is obtained and connected with the top slab of the section A and the top slab of the section B; (9) earth is backfilled, and the road face traffic is recovered. By means of the underground engineering mixed construction method, efficient and safe construction on the road face is achieved, bi-directional traffic is achieved, and the problems that a cover and cut-top down method is limited by excavation depth and is low in excavation speed are solved.

Owner:李涛 +2

Method for constructing combined steel and concrete column of large metallurgy industrial factory building

ActiveCN102102443AEasy to installGuaranteed installation qualityBuilding material handlingSteel columnsRebar

The invention discloses a method for constructing a combined steel and concrete column of a large metallurgy industrial factory building, belongs to the technical field of factory building construction and production, and provides a method for constructing the combined steel and concrete column of the large metallurgy industrial factory building, which can guarantee the manufacturing quality of the combined steel and concrete column. The method for constructing the combined steel and concrete column of the large metallurgy industrial factory building comprises the following steps of: firstly, arranging a steel framework which consists of a steel column and a steel beam on the basis of arrangement, and regulating the arrangement quality of the steel column by arranging a regulation base plate and a cable wind rope; secondly, arranging the outer side of the steel column and the outer side of the steel beam on the steel framework sequentially; then arranging concrete reinforcement on the connection part between the steel column and the steel beam sequentially, and supporting a concrete casting template of the steel column on the outer side of the concrete reinforcement of the steel column, wherein the concrete on the inner side and the outer side of the steel column box body are cast by a high toss and vibrating casting method and a fixed point positioning vibrating casting method; and finally, removing casting template curing concrete after the concrete strength meets the design requirement.

Owner:CHINA 19TH METALLURGICAL CORP

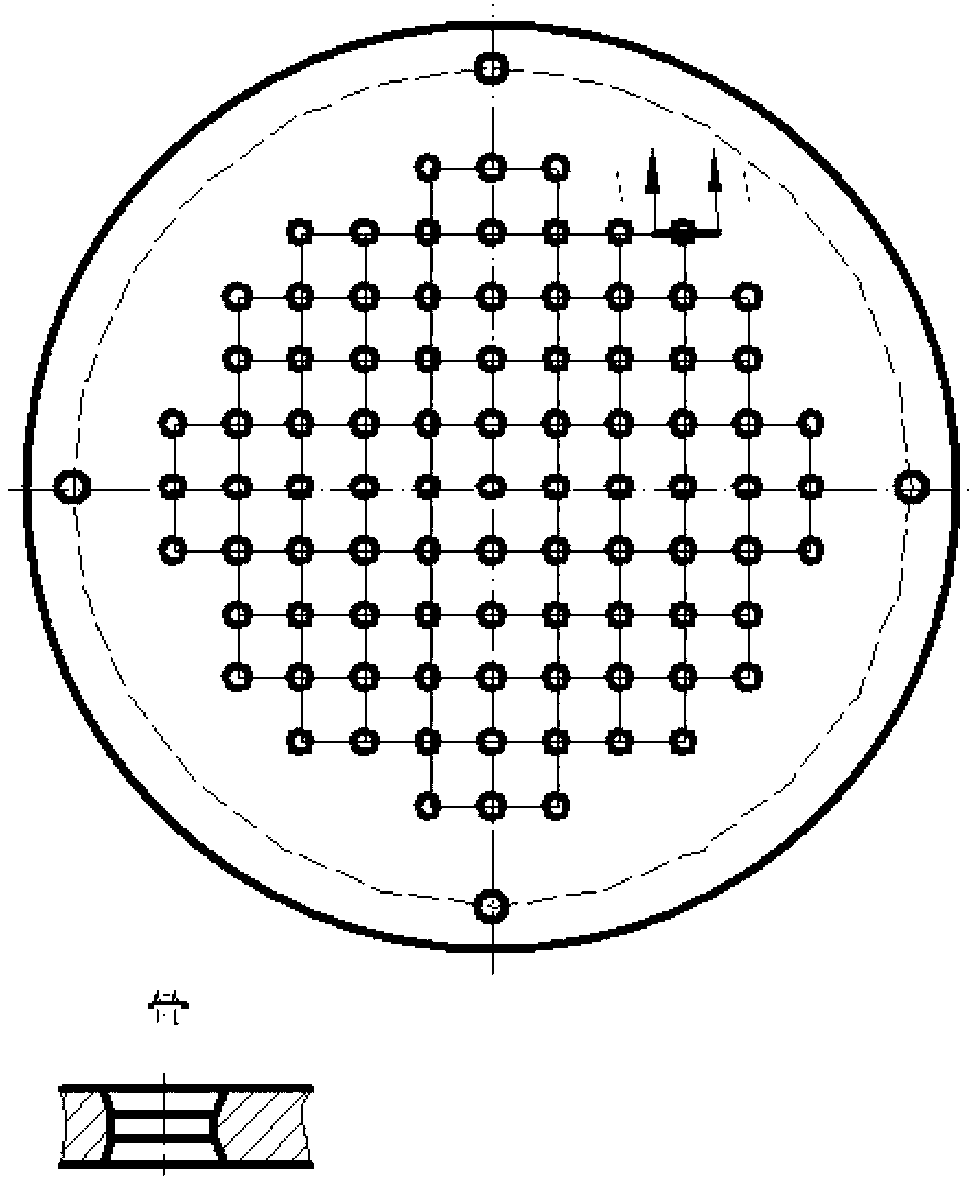

Vacuum skull furnace and working process thereof

The invention provides a vacuum skull furnace. The vacuum skull furnace comprises a smelting chamber, a pouring chamber, a pouring funnel and a pouring valve; the smelting chamber is provided with a graphite crucible, a sensing coil, a crucible tipping mechanism, a first gas exhausting pipe, a first vacuum degree detecting device, an argon inflating pipe and a first gas pressure detecting device; the pouring chamber is provided with a mould shell, a centrifugal turntable, a lifting table, a second gas exhausting pipe, a second vacuum degree detecting device, an inflating pipe and a second gas pressure detecting device; the pouring funnel serves as a channel for the graphite crucible to pour a molten metal to the mould shell; the upper opening of the funnel is arranged in the smelting chamber and is matched with the graphite crucible; and the lower opening of the funnel is arranged in the pouring chamber and is matched with the mould shell. The invention also provides a working process of the vacuum skull furnace. The vacuum skull furnace can realize pressure pouring and centrifugal pouring simultaneously; and the pouring quality is greatly improved.

Owner:SUZHOU ZHENHU ELECTRIC FURNACE

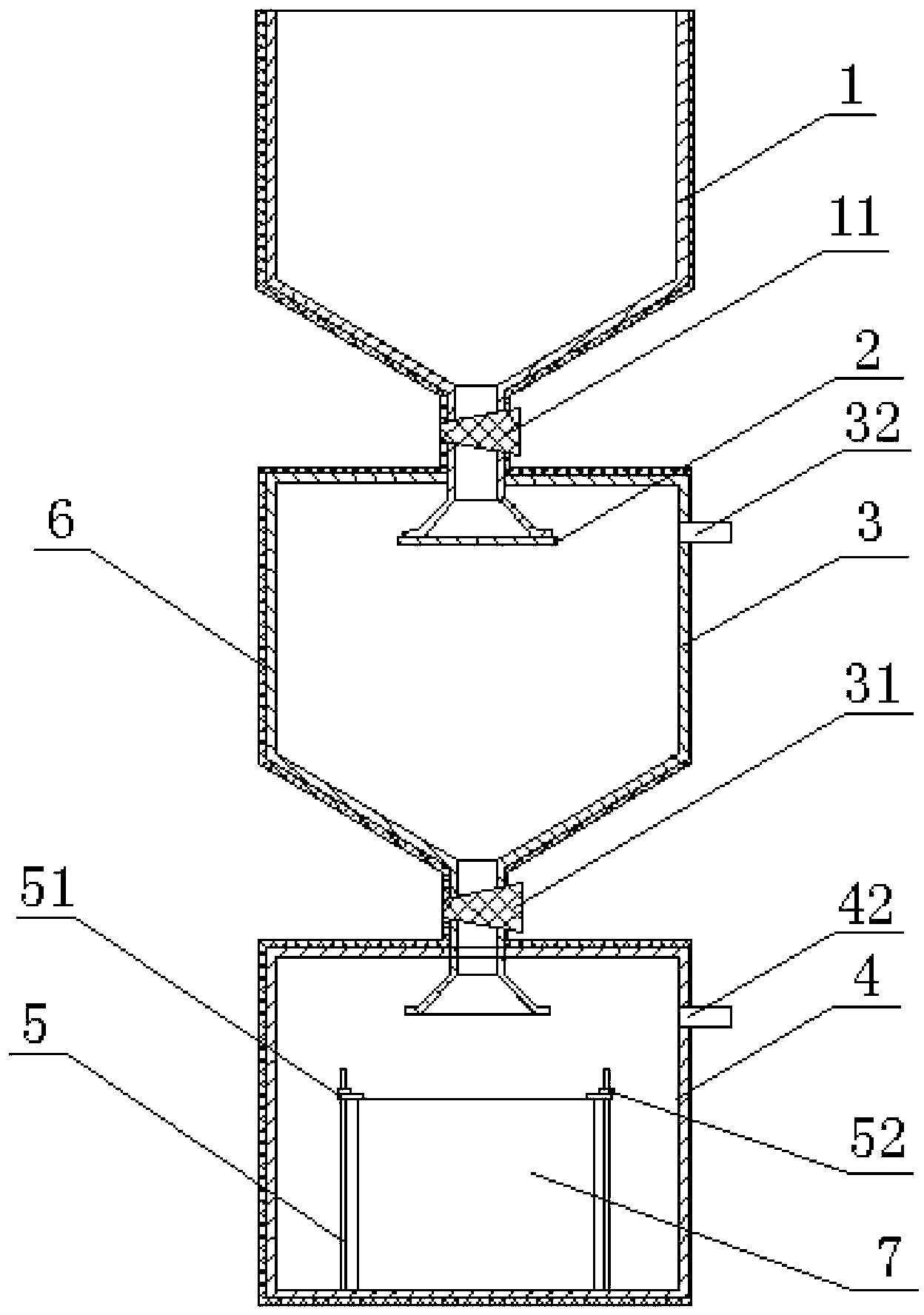

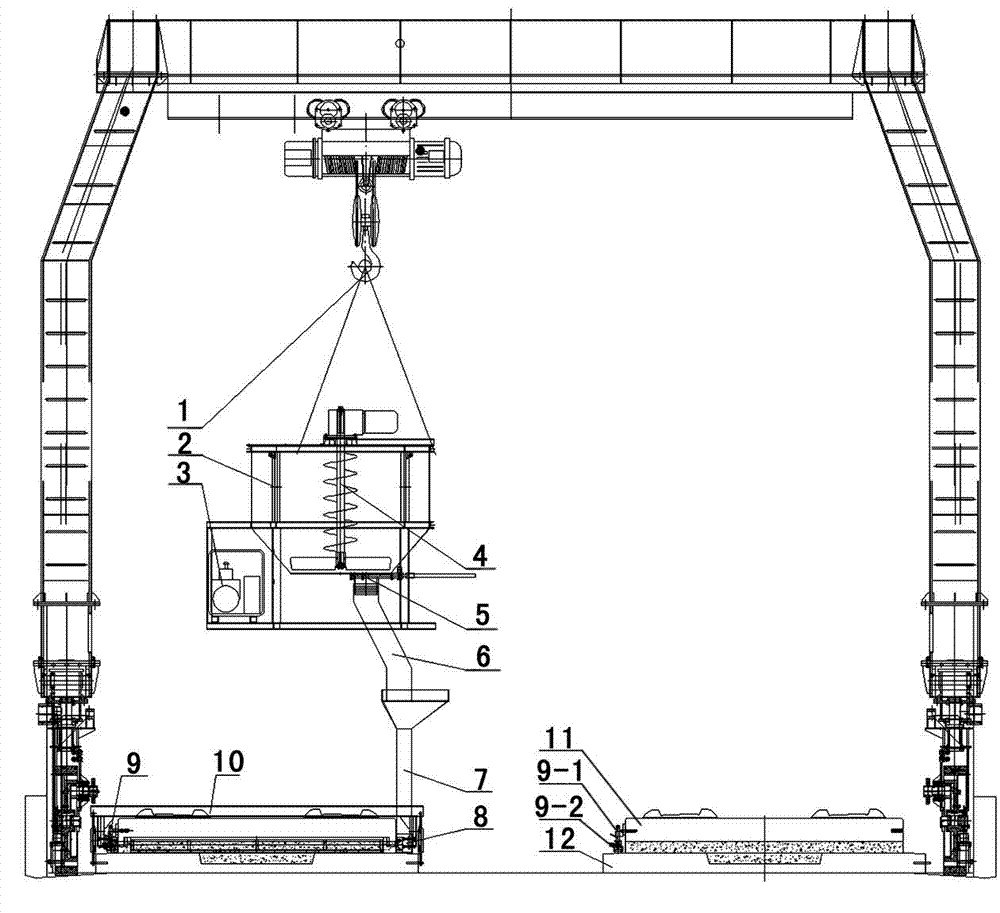

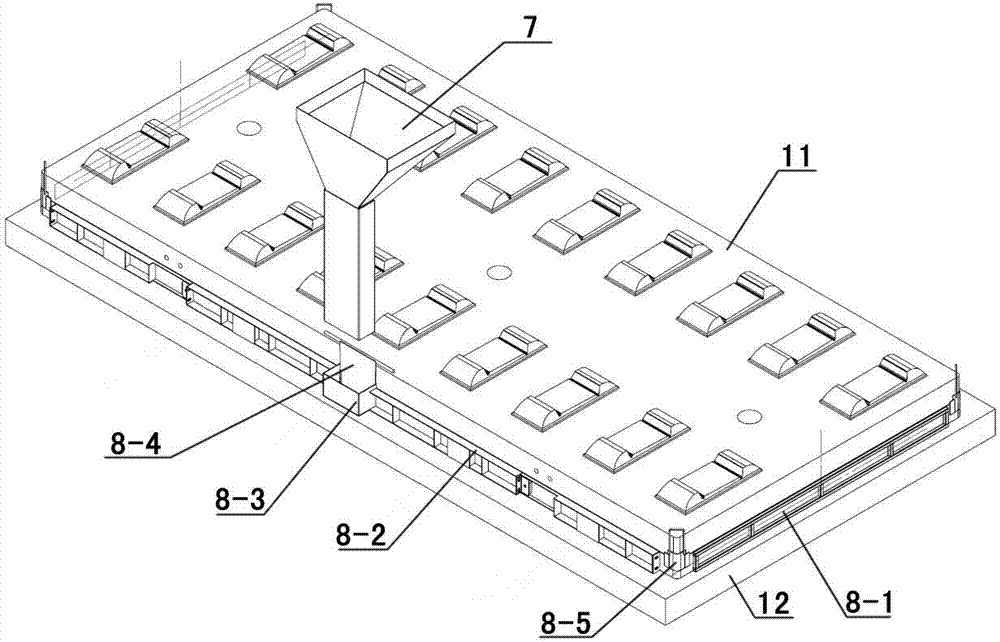

CRTS III type slab ballastless track self-compacting concrete casting tooling and method

The invention provides a CRTS III type slab ballastless track self-compacting concrete casting tooling and method. The casting tooling comprises a base slab, a track slab, a transferring hopper, a casting funnel, a slurry blocking template, a three-dimensional fine regulator, a track slab pressing device, a track slab lateral sliding preventing device and a slurry blocking template pressing device. The middle casting mode is changed into the lateral surface casting, and the problems of casting efficiency and air exhaust in the CRTS III type slab ballastless track construction are solved. The track slab lateral sliding preventing device, the track slab pressing device and the slurry blocking template pressing device effectively solve the problems of upward floating, lateral sliding and slurry leakage of the track slab in the casting process, so the fine regulation and the casting construction of the CRTS III type slab ballastless track are more convenient and fast, and the casting quality is better. The construction process has the advantages that in the use process, the weight is light, the rigidity is high, the efficiency is high, the operation is simple and convenient, the work intensity is low, and the construction process can adapt to the construction of road segments such as bridges, tunnels and roadbeds.

Owner:LANGFANG HELI TIANYI MACHINERY & EQUIP

Flange casting production process

InactiveCN101875090AImprove work efficiencyImprove yieldFoundry mouldsFoundry coresProduction rateThermal insulation

The invention discloses a flange casting production process, which comprises the steps of casting mould making, pouring and subsequent operations sequentially, and the casting mould making comprises the steps of making a flange mould and a flange hole mould respectively, then making a flange core and a flange hole core, then assembling the flange core and the flange hole core, and carrying out core baking to obtain the flange casting mould; then the pouring operation is carried out, which comprises the steps of preheating the flange casting mould at first, then painting a thermal insulation material on the inner surface of the preheated flange casting mould, insulating, and then pouring casting solution to a mould cavity along a pouring port of the flange casting mould, wherein the pouring port is internally provided with a honeycomb filter screen, the pouring temperature is 1330-1400 DEG C, the pouring time is 8-15 seconds; and then insulating the casting, wherein the casting insulation time is 15-25 minutes, and the production rate of the process is 40 percent to 60 percent. The process not only has few processing operations and improves the utilization rate of pouring solution but also is beneficial to formation of high-quality castings.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com