Prefabricated tunnel lining segment

A lining segment and prefabricated technology is applied in the field of tunnel construction and lining of circular cross-section tunnels, which can solve the problem of reducing the durability and strength of fastening bolts, restricting the construction efficiency of shield tunneling methods, and easy corrosion of bolt steel. problems, to reduce the difficulty, improve the pouring quality and overall strength, and shorten the sealing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

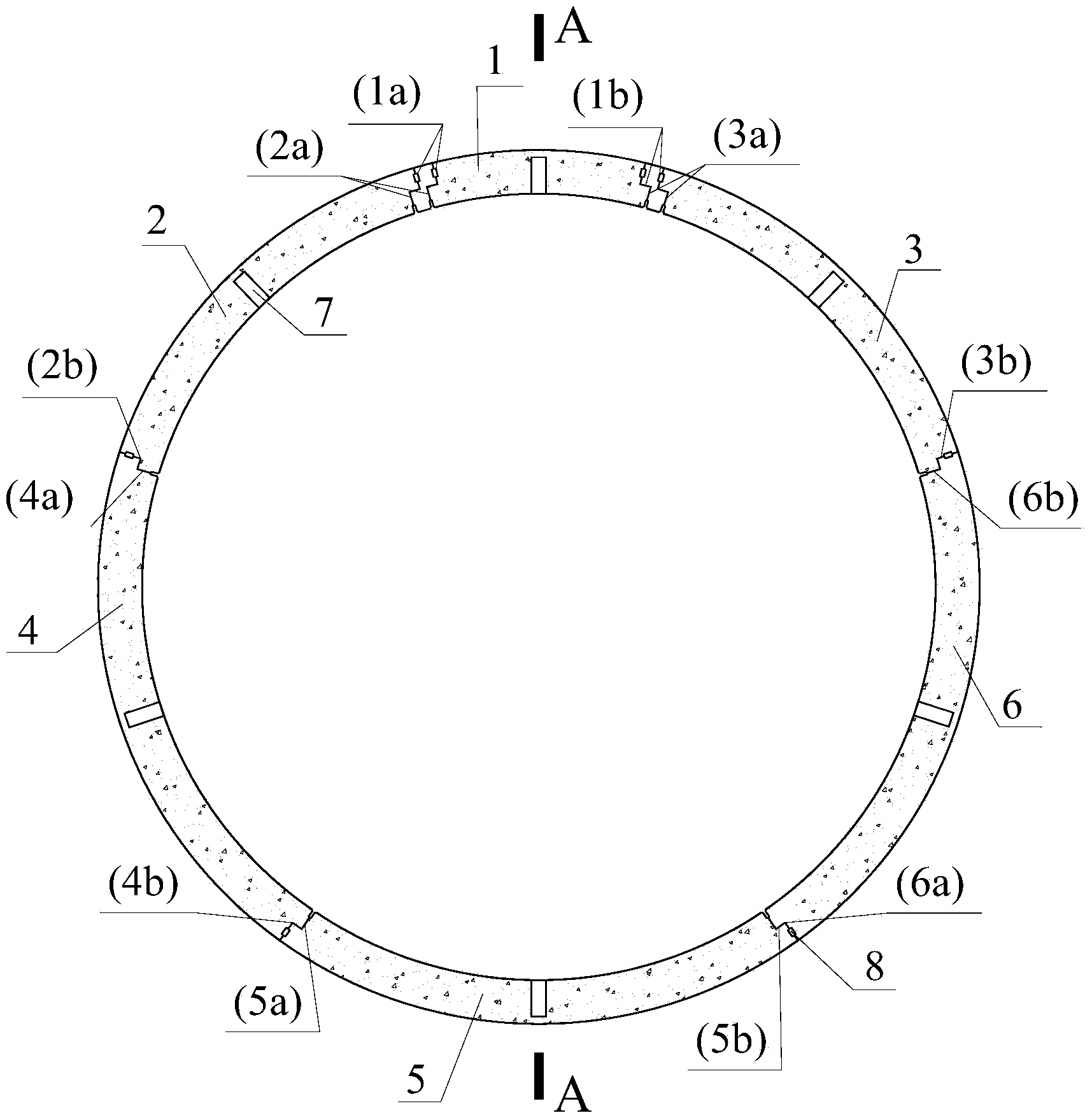

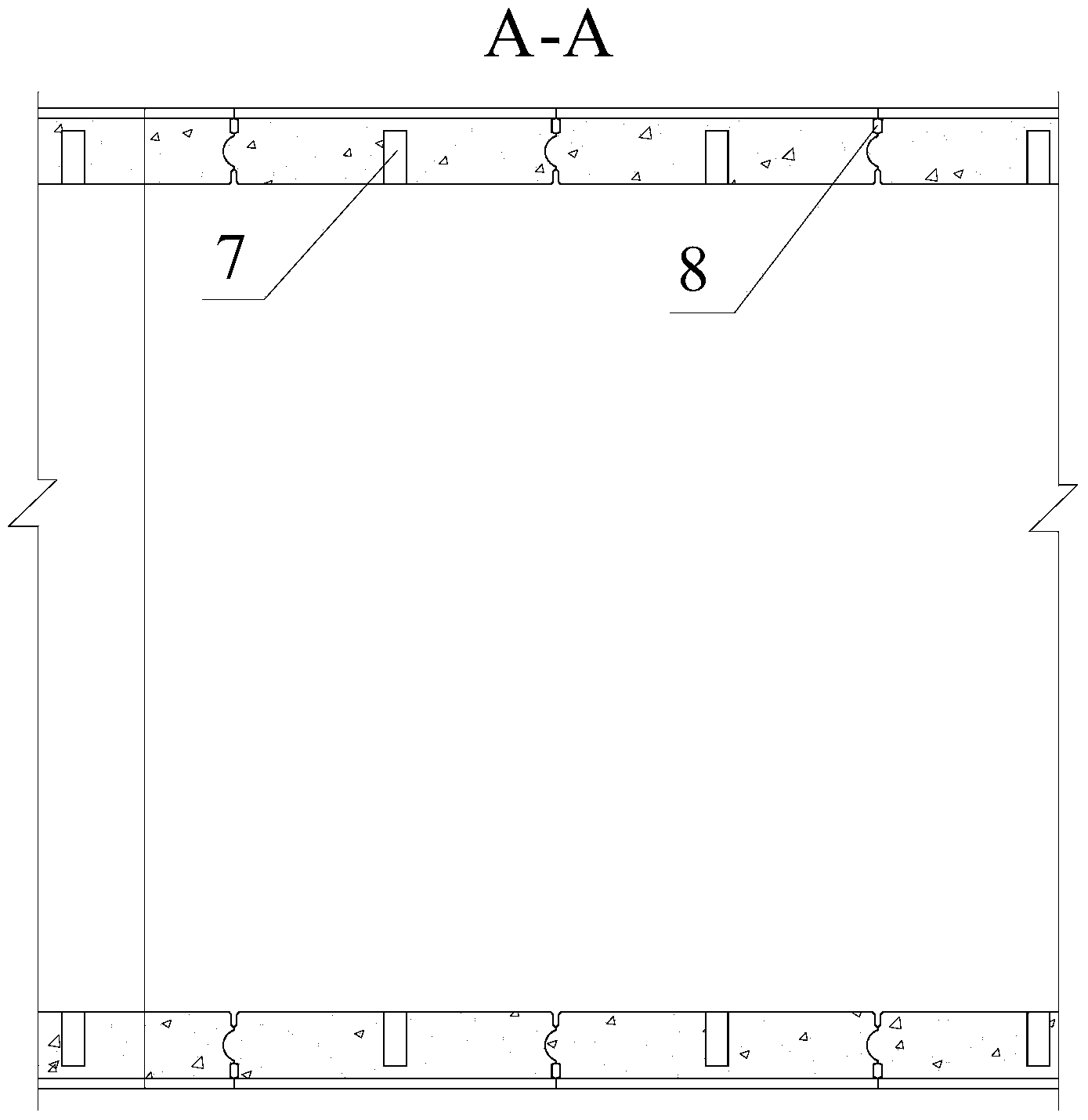

[0043]A specific embodiment of the present invention is an assembled tunnel lining segment, which is suitable for tunnel lining with a circular cross section excavated by mechanical methods such as shield machine method or manual excavation method,

[0044] A fabricated tunnel lining segment, the method of which is:

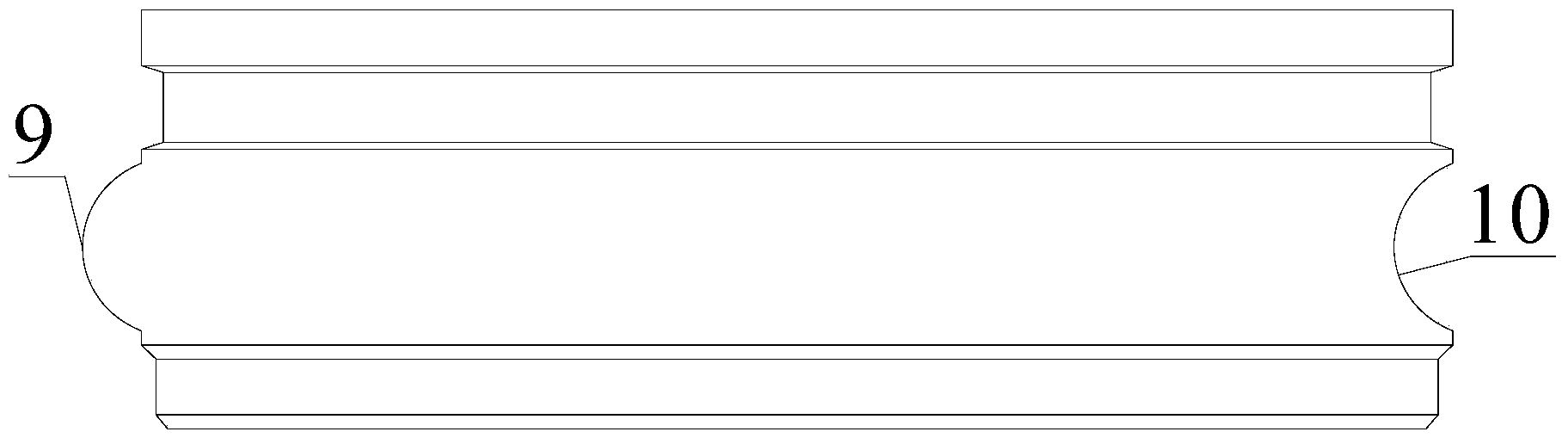

[0045] A. Divide the concrete lining in the circular tunnel cross-section into six concrete prefabricated segments, each of which has a circular arc in the cross-section, which are: capping block 1, two adjacent blocks 2, 3 and Three standard blocks 4, 5, 6, their two end faces are provided with structurally symmetrical or opposite concave-convex steps; the shape of the capping block 1 is positive wedge shape, the structure is symmetrical, the adjacent block 2 and the adjacent block 3 are both partial wedge-shaped, The structure of the two is opposite; the structure of standard block 4 and standard block 6 is opposite, and the structure of standard block 5 is sym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com