Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3585 results about "Shield machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

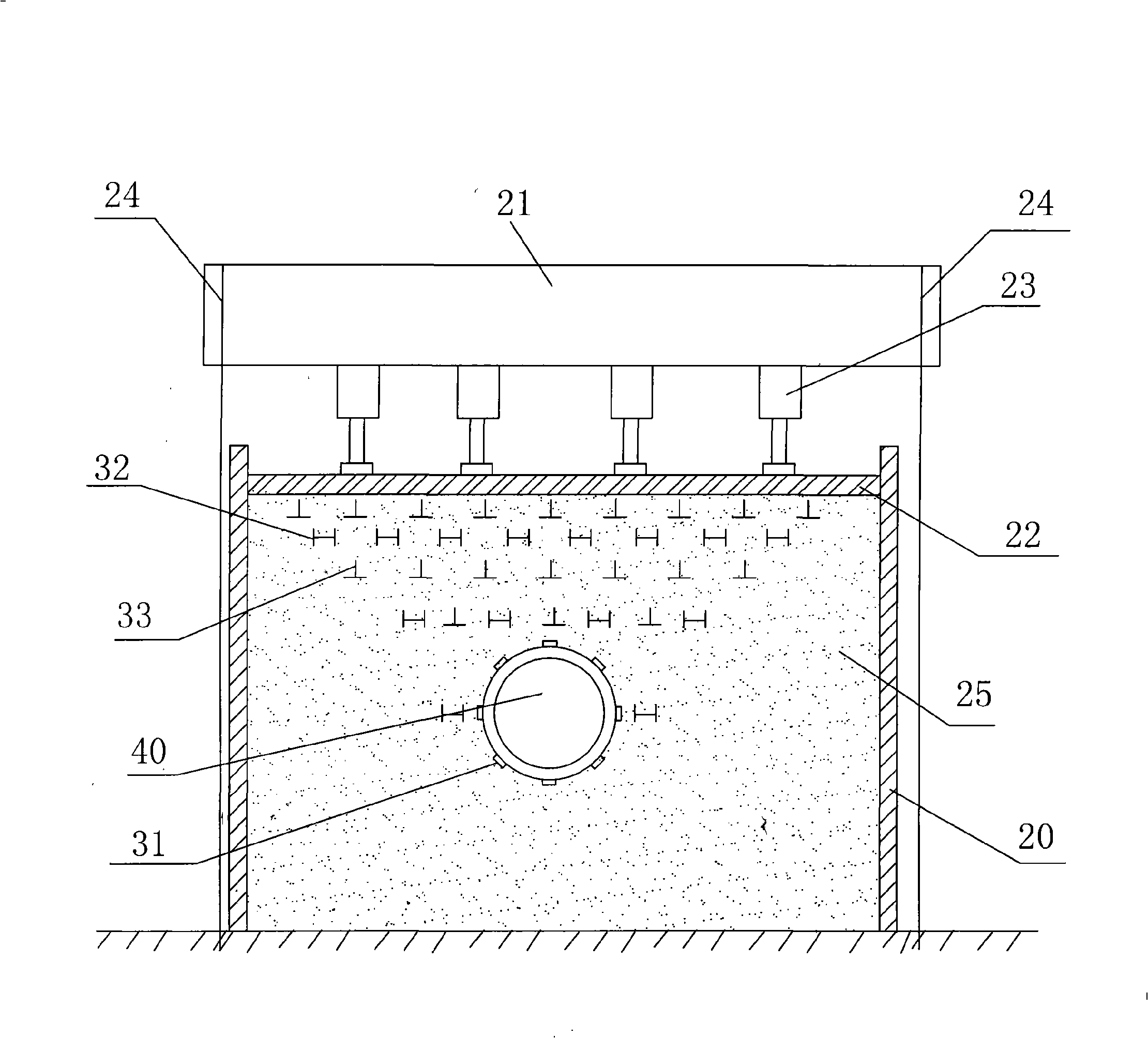

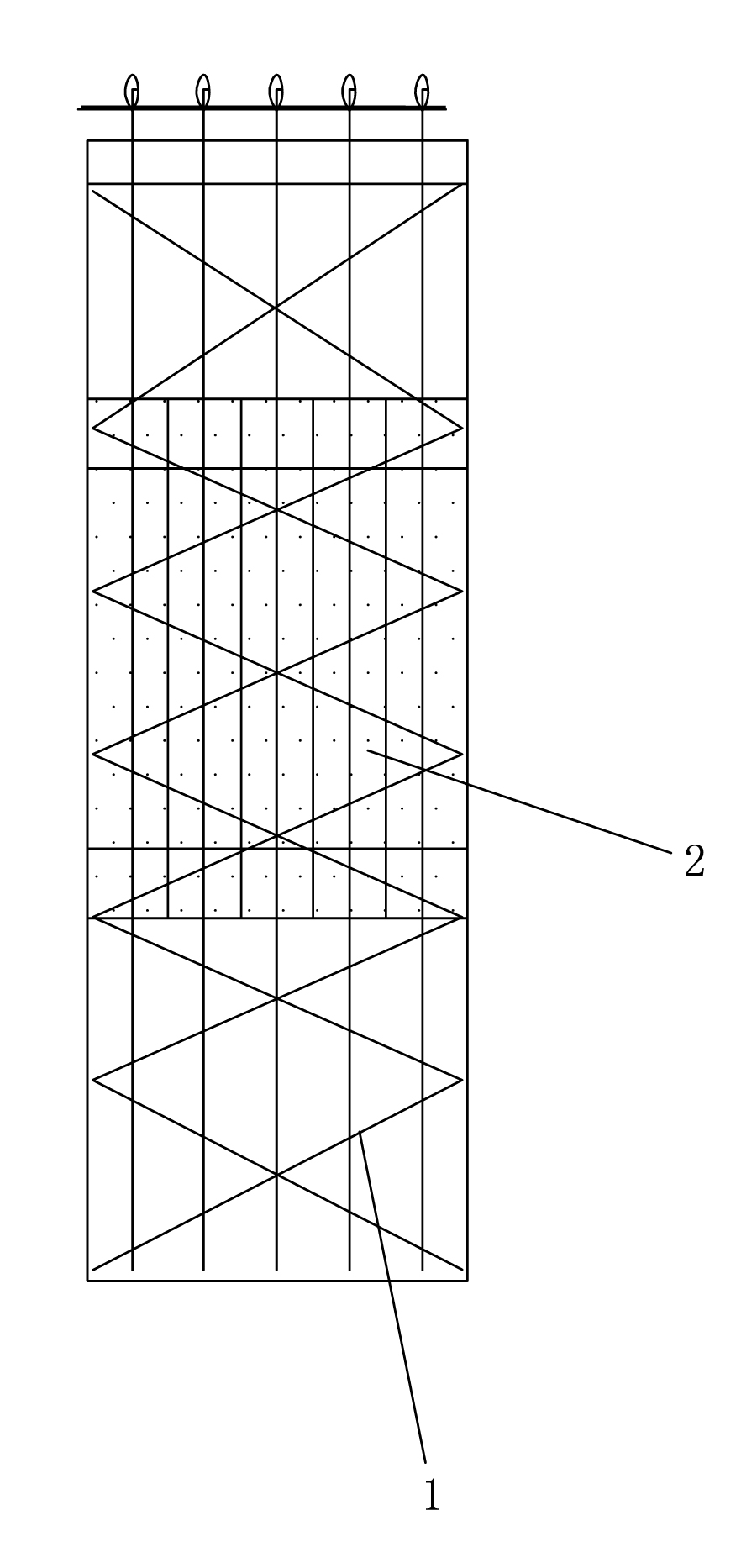

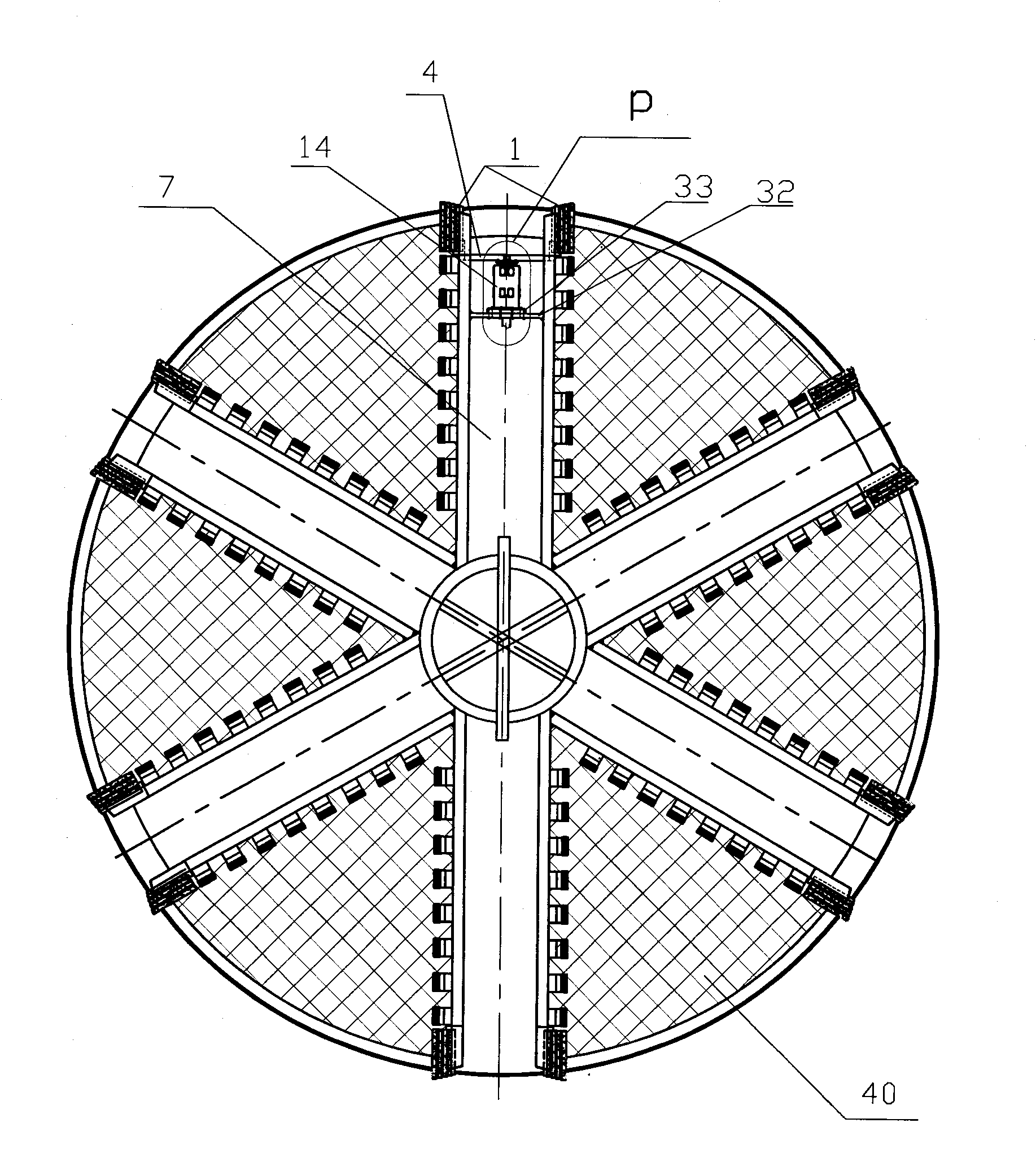

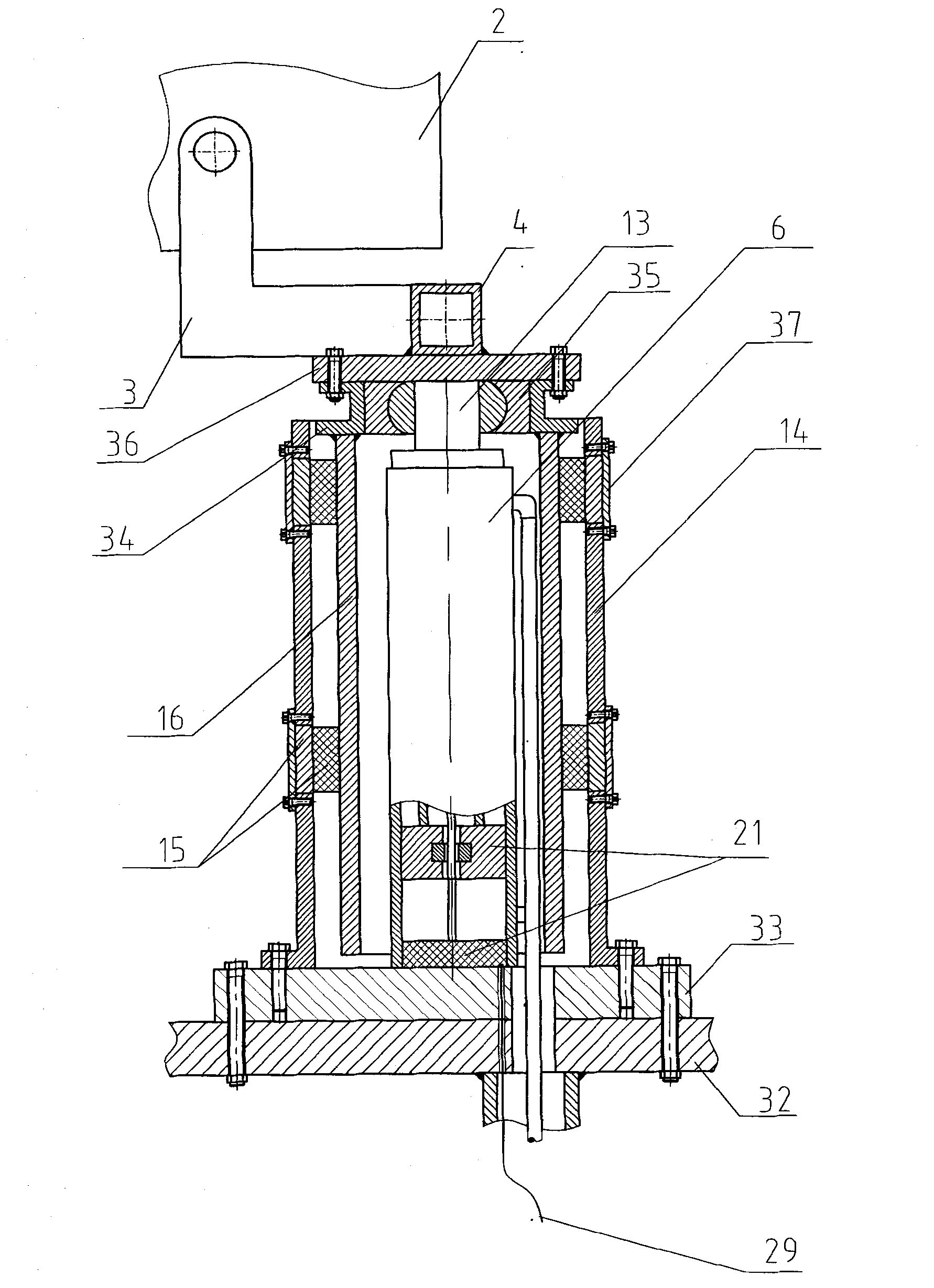

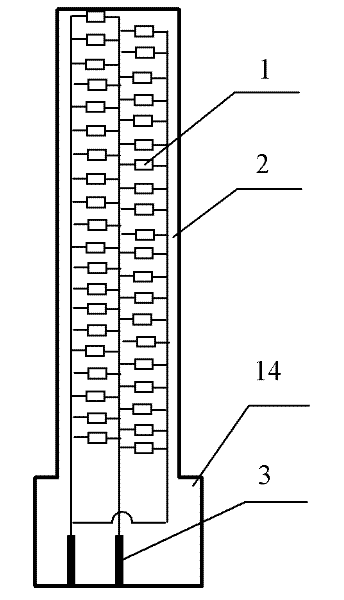

Soil pressure balancing type tunnel shielding simulation experiment system

ActiveCN101403306AEfficient constructionConstruction safetyEducational modelsTunnelsElectricityGrating

The invention relates to a soil pressure balance type tunnel shield analog experiment system, a rectangular soil coelom with the upper part provided with an opening is internally provided with a shield machine model and filled with a simulated soil body, the axle wire of the shield machine model is overlapped with that of the soil coelom; the upper surface of the simulated soil body is covered with a layer of concrete cushion the upper surface of which is connected with a horizontal loading beam by more than two soil pressure jacks, the horizontal loading beam is connected with the bottom of the soil coelom by an anchor rope; and the simulated soil body is also internally embedded with a soil pressure box, a grating fiber optical sensor and a displacement meter, wherein, the soil pressure box, the grating fiber optical sensor and the displacement meter are all electrically connected with a data acquisition and processing device. The system can simulate the influence of shield tunnel construction between subways of cities on the stratum and surrounding environment more conveniently, actually and effectively, and provide more actual and accurate experimental data for tunnel construction and design so as to guarantee the high-efficiency and safety of the shield tunnel construction of cities.

Owner:SOUTHWEST JIAOTONG UNIV

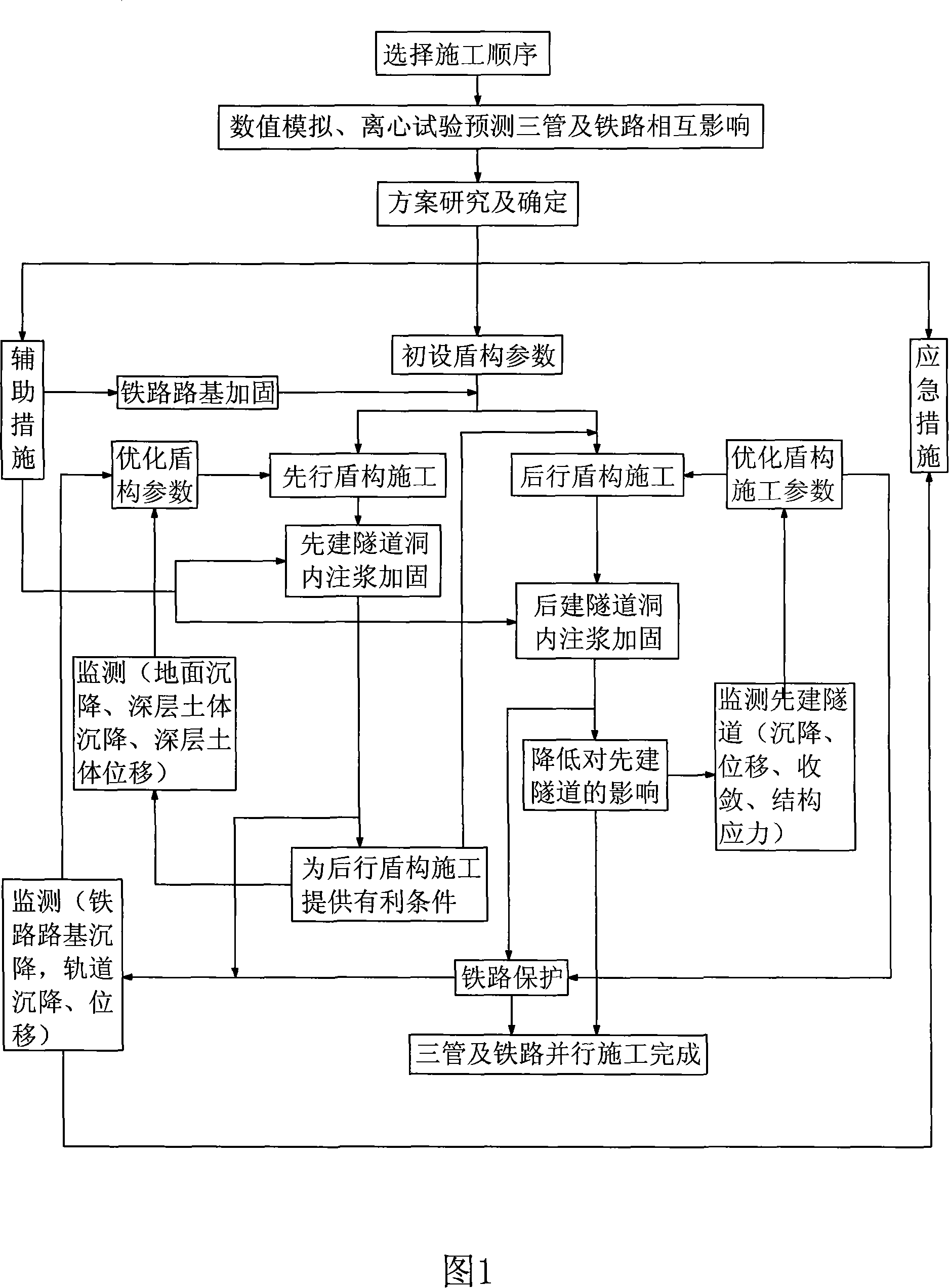

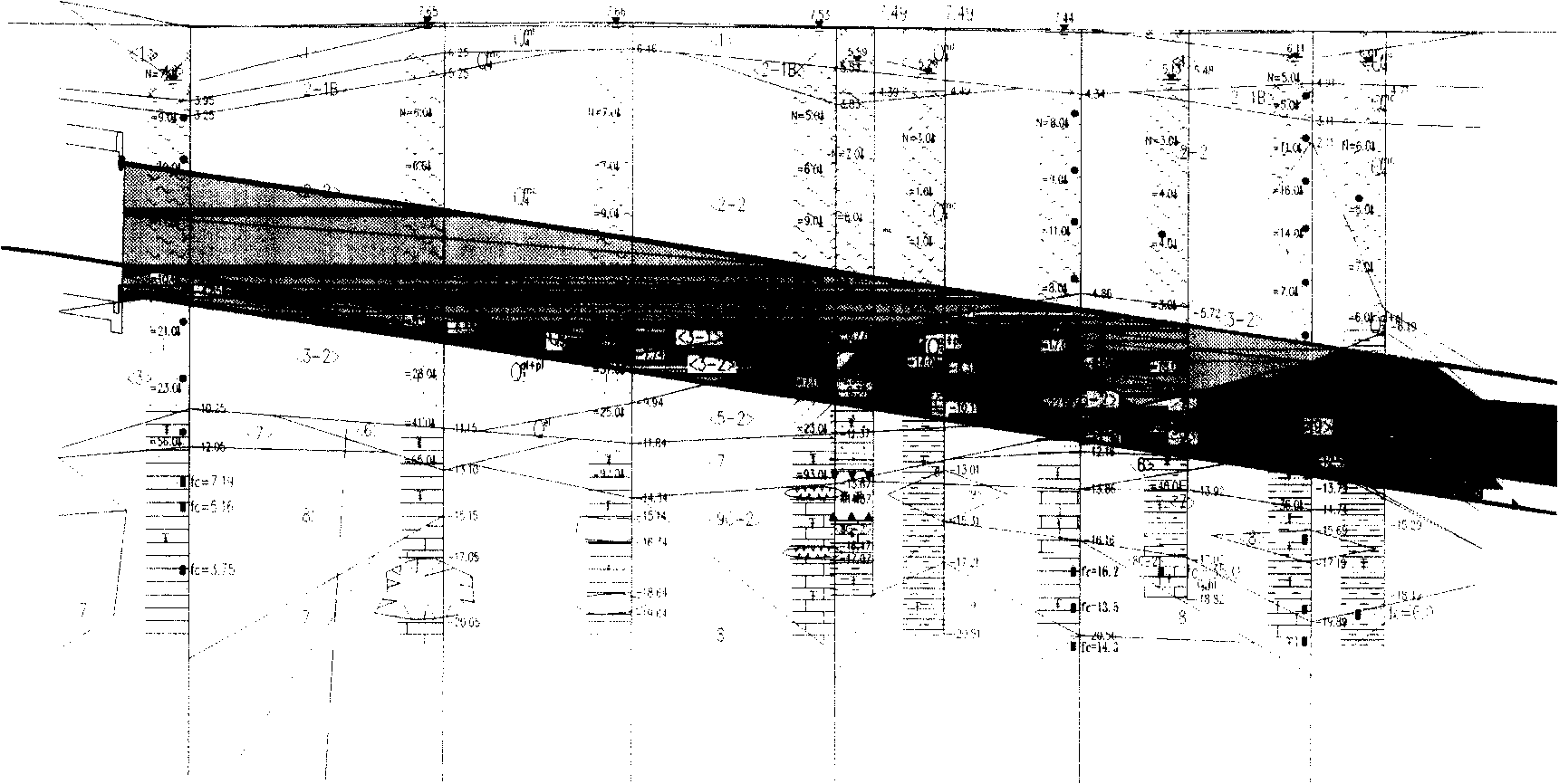

Shield construction method for three-line parallel under-passing trunk railway tunnel

ActiveCN101126318AEffective control of deformationEffective control of displacementUnderground chambersTunnel liningRailway tunnelEconomic benefits

The invention discloses a shield construction method of digging three parallel tunnels under a trunk railway, which belongs to the field of tunnel construction technology. The construction method of the invention comprises the procedure that: the model analysis on each construction sequence and method is made by a three-dimensional finite element and the shield construction sequence is selected; to select the reinforcement project of the railway bed is selected according to the influence degree of the dynamic stress, the load-carrying structural model is adopted to calculate and decide the shield area reinforcing bars enhancement project under the dynamic load of the railway train; the construction parameters are selected according to the test results and the performance of the shield machine, the front earth pressure is reasonably set , the synchronizing mortar injection is enhanced, the forward digging speed and the axis deviation are strictly controlled, the secondary mortar injection is made, the foam or mud is filled by utilizing a pre-embedded injection hole; the strict monitoring measures to monitor the shield construction process is adopted so that the construction unit can adjust the construction parameters in time and guarantee the construction safety. The invention not only guarantees the construction quality and the construction safety of the project but also creates good economic benefit.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

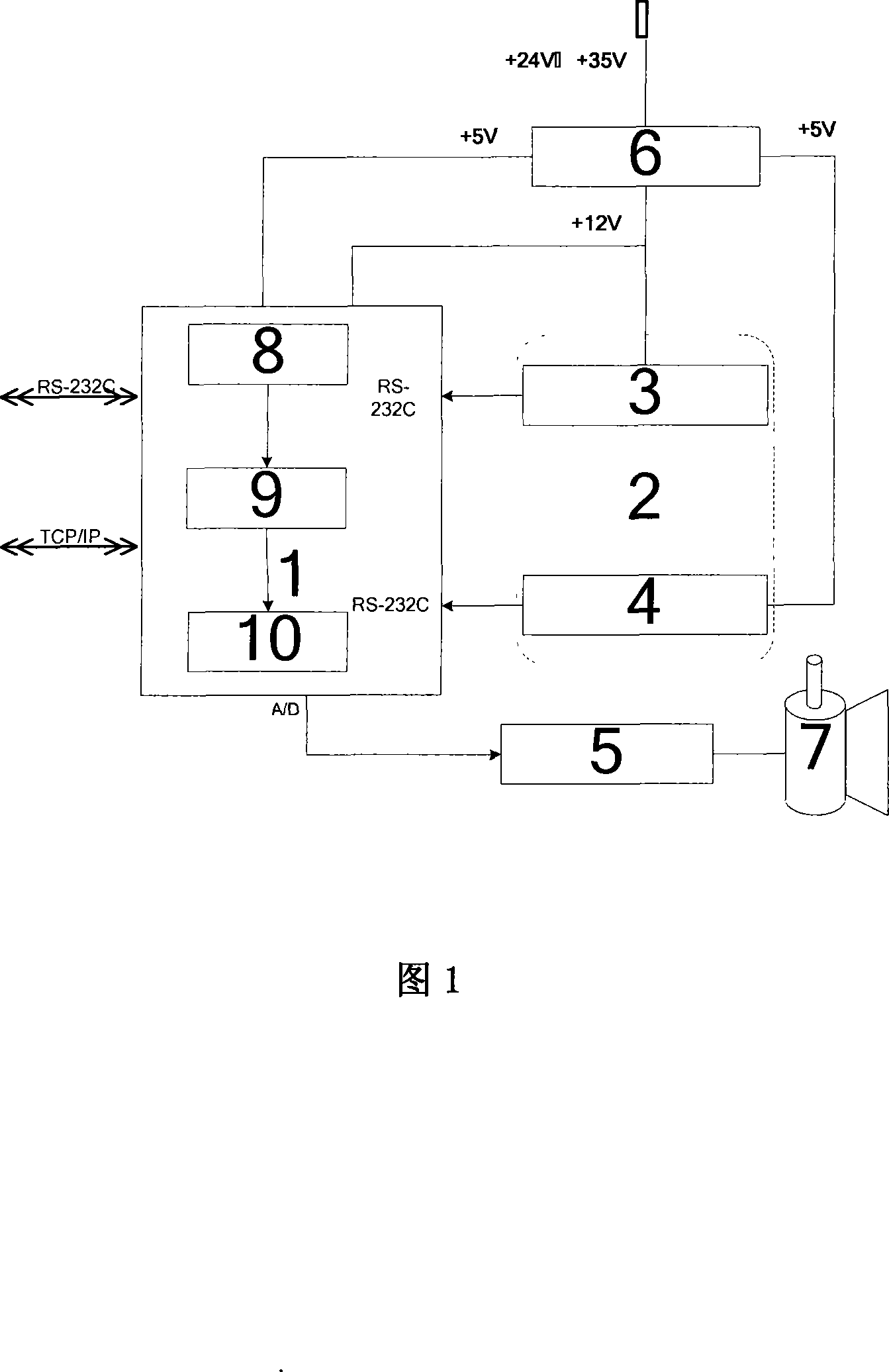

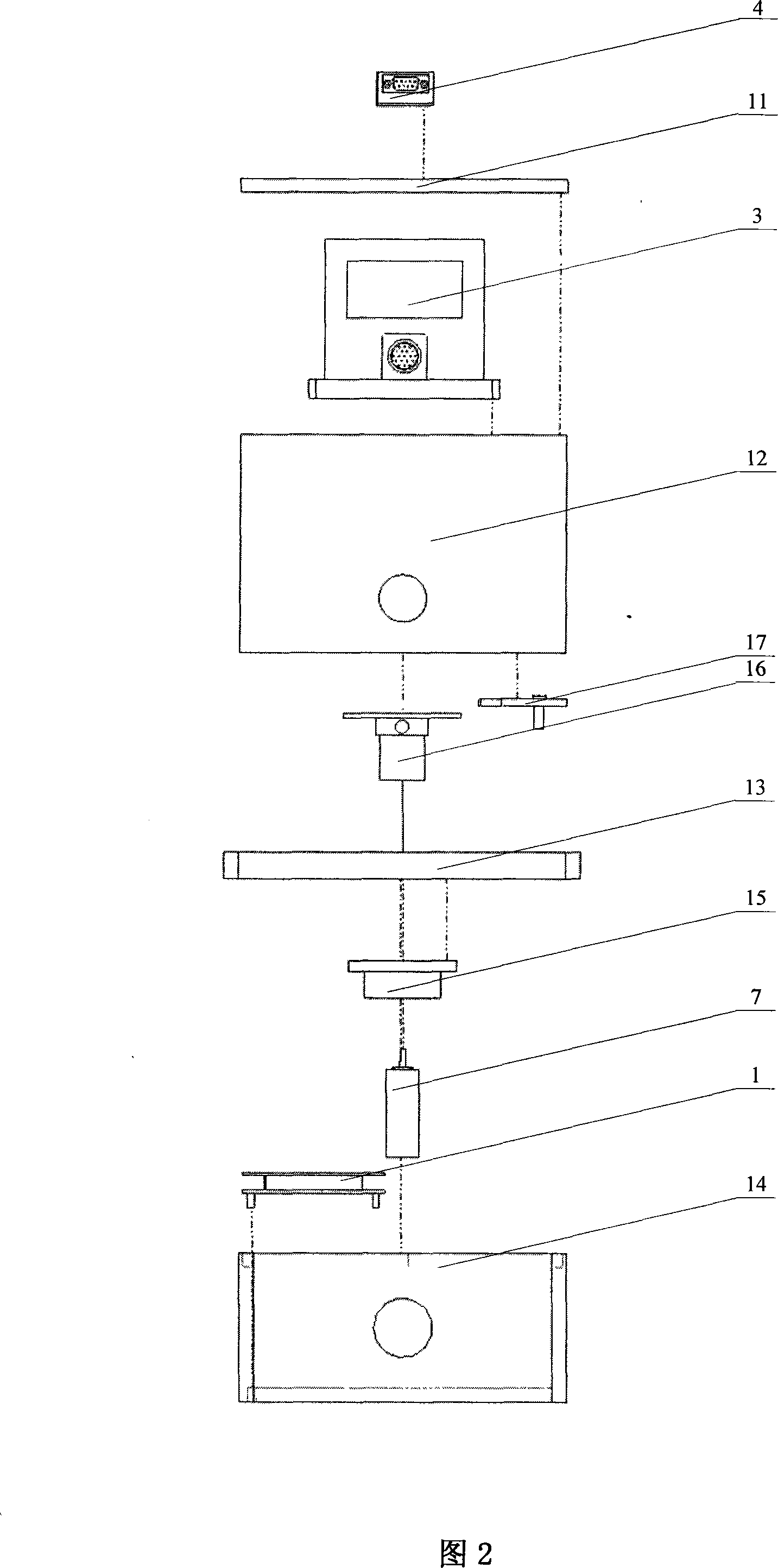

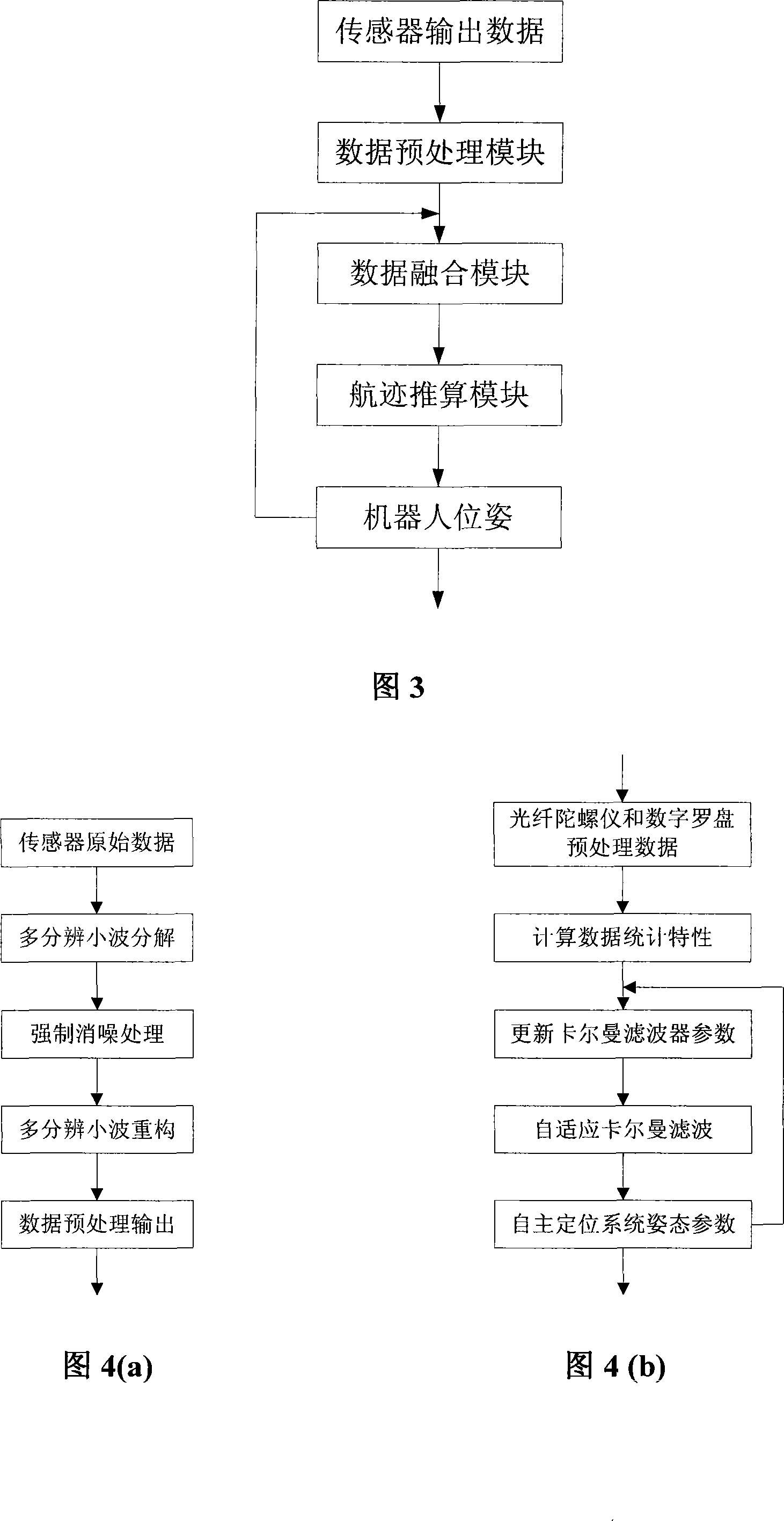

Freedom positioning system for robot

InactiveCN101201626ASolve the self-positioning problemEffective pose informationInstruments for road network navigationPosition fixationEngineeringCoal

The invention provides a robot independent positioning system and belongs to a robot intelligent control device. The invention solves the high-precision and independent positioning problem of the robot in the underground operation. The invention comprises an installation platform, a sensor subsystem, a data processing subsystem and a voltage conversion module; the sensor subsystem, the data processing subsystem and the voltage conversion module are arranged on the installation platform; the upper part of the installation platform is a turntable carrying the sensor subsystem; a fixed base on the lower part of the installation platform has a structure of a sealed cavity; the inside of the fixed base is provided with the data processing subsystem and the voltage conversion module; the sensor subsystem comprises an inertial sensor module and a three-dimensional digital compass; the data processing subsystem comprises a central controller, a data preprocessing module, a data integration module and a dead reckoning module; the data preprocessing module, the data integration module and the dead reckoning module are arranged in the central controller. The invention can be used for the intelligent robot working in the underground environment such as coal mines, tunnels, caverns and so on; the invention can be used for the independent positioning of robots, shield machines, underground locomotives and so on; the invention provides effective pose information for intelligent robots to finish such tasks as reconnaissance, exploration and search in the underground environment.

Owner:湖北鹰特飞智能科技有限公司

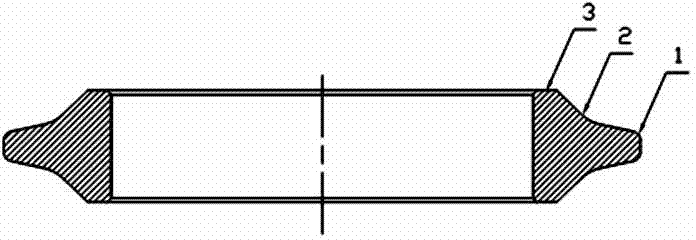

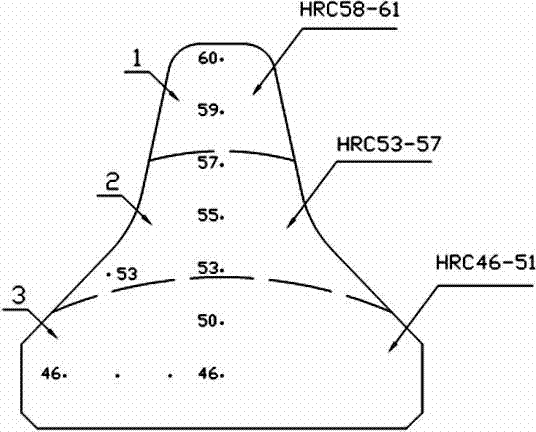

Disk-shaped roller cutter ring and manufacture method thereof

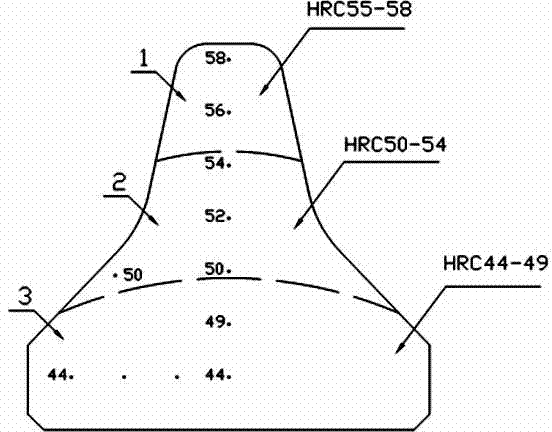

ActiveCN102517502AGuaranteed hardenabilityImprove toughnessFurnace typesHeat treatment furnacesMedium frequencyHardness

The invention discloses a disk-shaped roller cutter ring with high hardness, good toughness and excellent comprehensive performance. The disk-shaped roller cutter ring comprises the following ingredients of: 0.46-0.56% of C, 0.80-1.20% of Si, 0.20-0.65% of Mn, 5.00-5.80% of Cr, 1.15%-1.55% of Mo, 0.85-1.40% of V and the balance Fe and impurities, wherein the content of P is no more than 0.02%, and the content of S is no more than 0.01%; and the overall hardness of the cutter ring is HRC55-61 (Rockwell Hardness C55-61), or the hardness is of graded distribution, i.e. the hardness of a working edge area is HRC55-61, the hardness of a transition surface area is HRC50-57, and the hardness of a step assembly surface area and an inner ring is HRC44-51. A preparation method of the disk-shaped roller cutter ring comprises the following steps of: smelting the raw materials in an electric furnace; carrying out electroslag remelting; preforging; carrying out die forging; carrying out slow cooling; annealing; carrying out rough machining to obtain a disk-shaped roller cutter ring rough blank; carrying out high-temperature vacuum hardening and two-time high-temperature tempering on the cutter ring rough blank; carrying out low-temperature destressing treatment; carrying out fine finishing to obtain the cutter ring with the overall hardness of HRC55-61, wherein the cutter ring with the overall hardness of HRC55-61 is applicable to the tunneling of a hard rock formation by a shield tunneling machine; or carrying out medium-frequency induction tempering treatment prior to the low-temperature destressing treatment to obtain the cutter ring with graded-distribution hardness, wherein the cutter ring with the graded-distribution hardness is applicable to the tunneling of a rock formation with an upper soft part and a lower hard part.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Method for exchanging tool of shield machine for tunnel construction

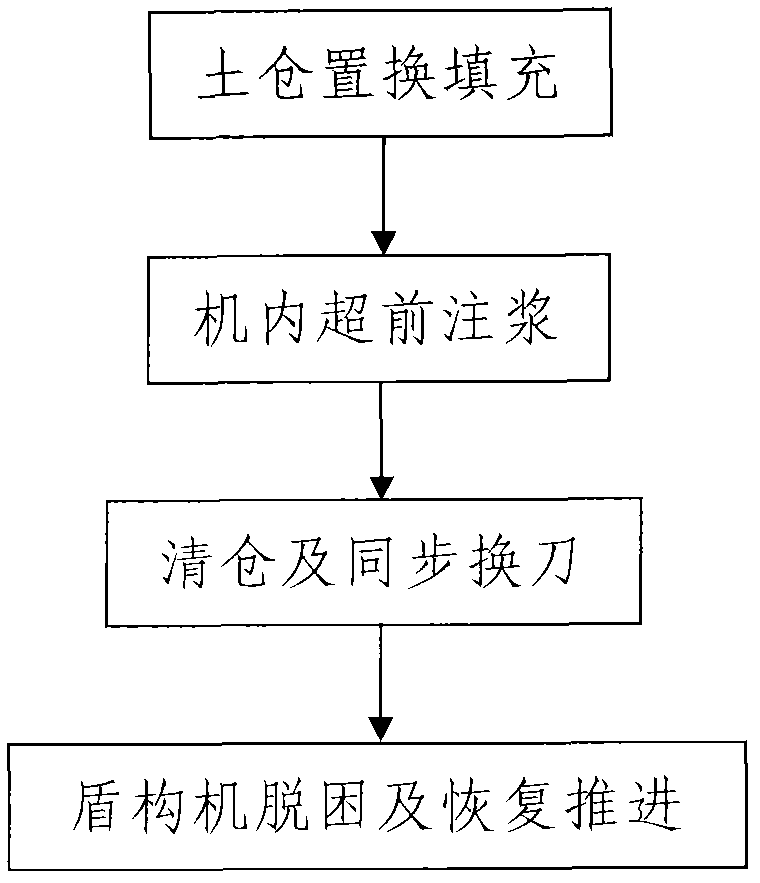

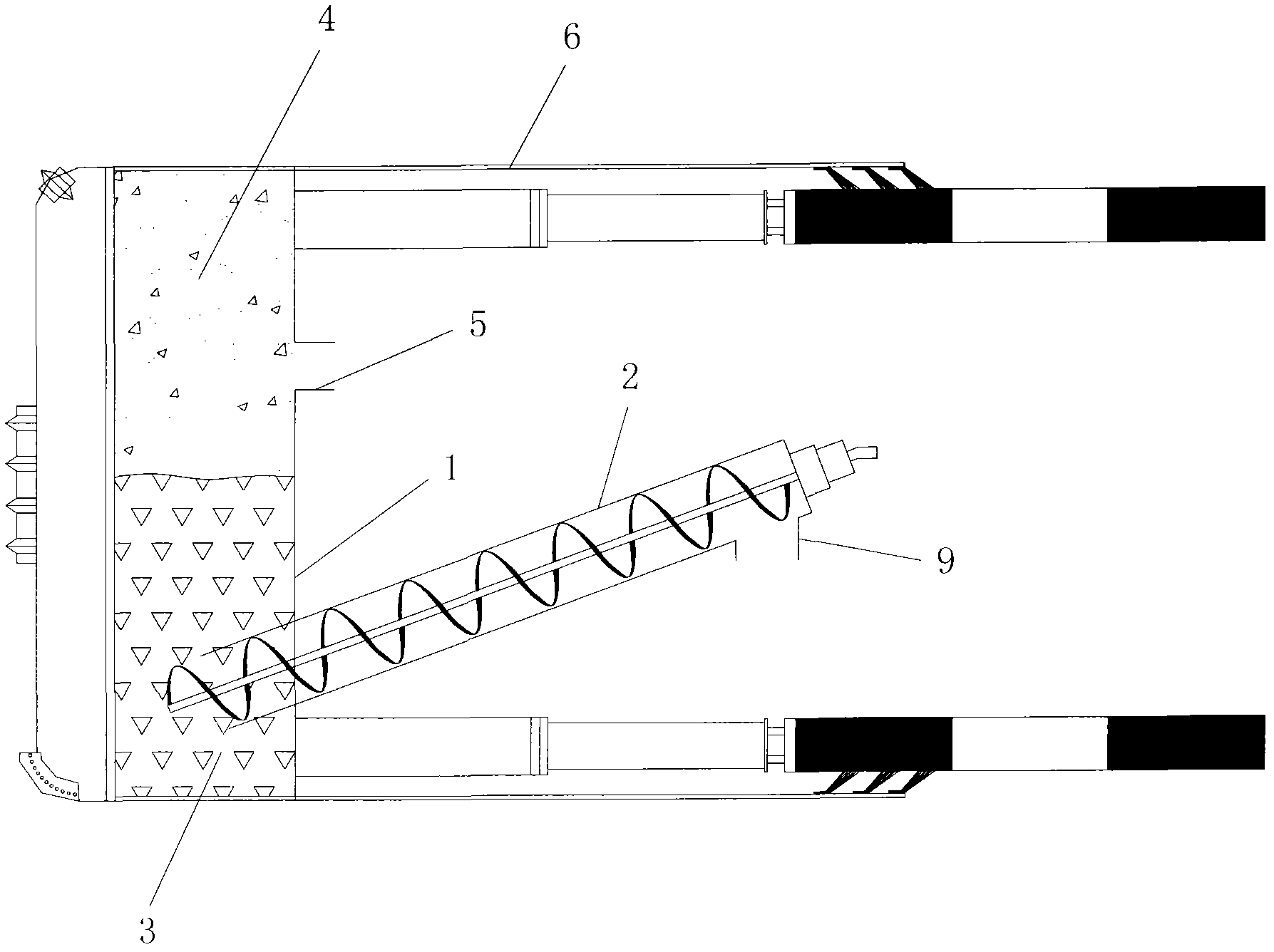

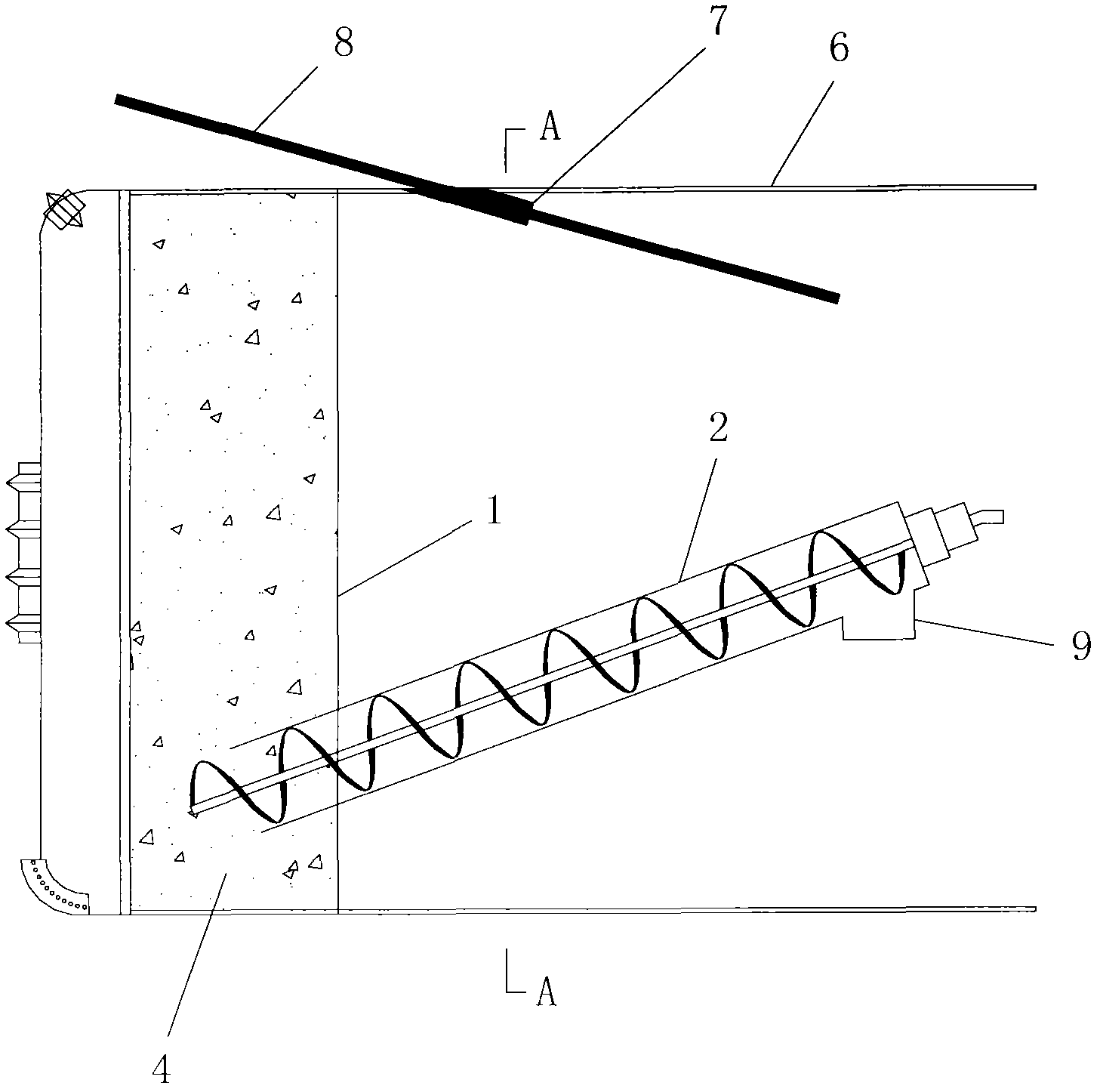

The invention discloses a method for exchanging a tool of a shield machine for tunnel construction, which comprises the steps of: (1) soil cabin replacement filling: performing the process of soil cabin replacement filling by using a spiral excavating machine and a slip casting system synchronously working with the spiral excavating machine; (2) advanced slip casting inside the machine: beating a plurality of slip casting pipes into the soil on the upper part of the shield machine from inner to outer inside the shield machine by respectively passing through a plurality of advanced geologic holes and then synchronously injecting cement paste into the soil on the upper part of the shield machine through the slip casting pipes by using a slip casting device till the cement paste cannot be injected any more; (3) cleaning cabin and exchanging tool synchronously: manually cleaning the cement plaster solidified inside the soil cabin and synchronously exchanging the tool mounted on the shield machine; and (4) getting rid of the difficult position of the shield machine and recovering the process. The method provided by the invention has the advantages of reasonable design, convenience for operation, low cost, high safety factor, good use effect and capable of solving the problem that the tool cannot be exchanged in the traditional tool exchanging mode under severe tool exchanging conditions.

Owner:URBAN RAIL TRANSIT ENG CO LTD OF CHINA RAILWAY FIRST GRP CO LTD +1

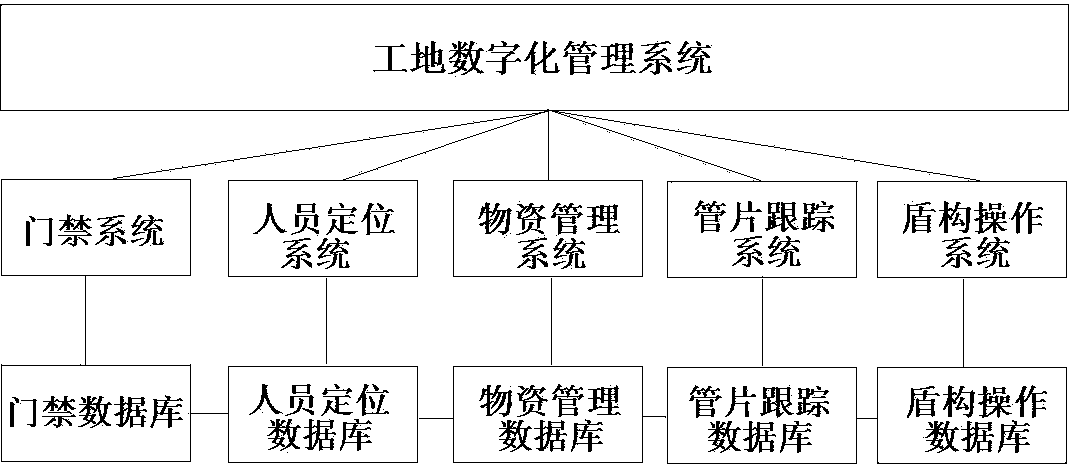

Construction site digital management system and application method thereof

ActiveCN103390255AGuarantee quality and safetyGuarantee authenticityData processing applicationsSensing record carriersOperational systemDigital rights management

The invention belongs to the technical field of construction site digital management and particularly relates to a construction site digital management system and an application method thereof. The management system comprises five sub systems, namely, a PLS (personnel location system), an access control system, a material management system, a shield operating system and a duct piece tracking system, wherein all the sub systems are connected with a remote database server, five sub database corresponding to the five sub systems are established in the remote database server, all the sub systems perform read-write operation on a main management object in a construction site range by using an RFID (radio frequency identification) technology, read data are uploaded to all corresponding sub databases in real time, and the operating authorization of a handheld RFID read head and the operating authorization of a shield machine are obtained through cross verification of data among all main sub databases. The management system and the application method have the advantages as follows: conventional extensive management is improved, the management responsibility is cleared, the management level is improved, and engineering information management, digital management and visual management are realized.

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD

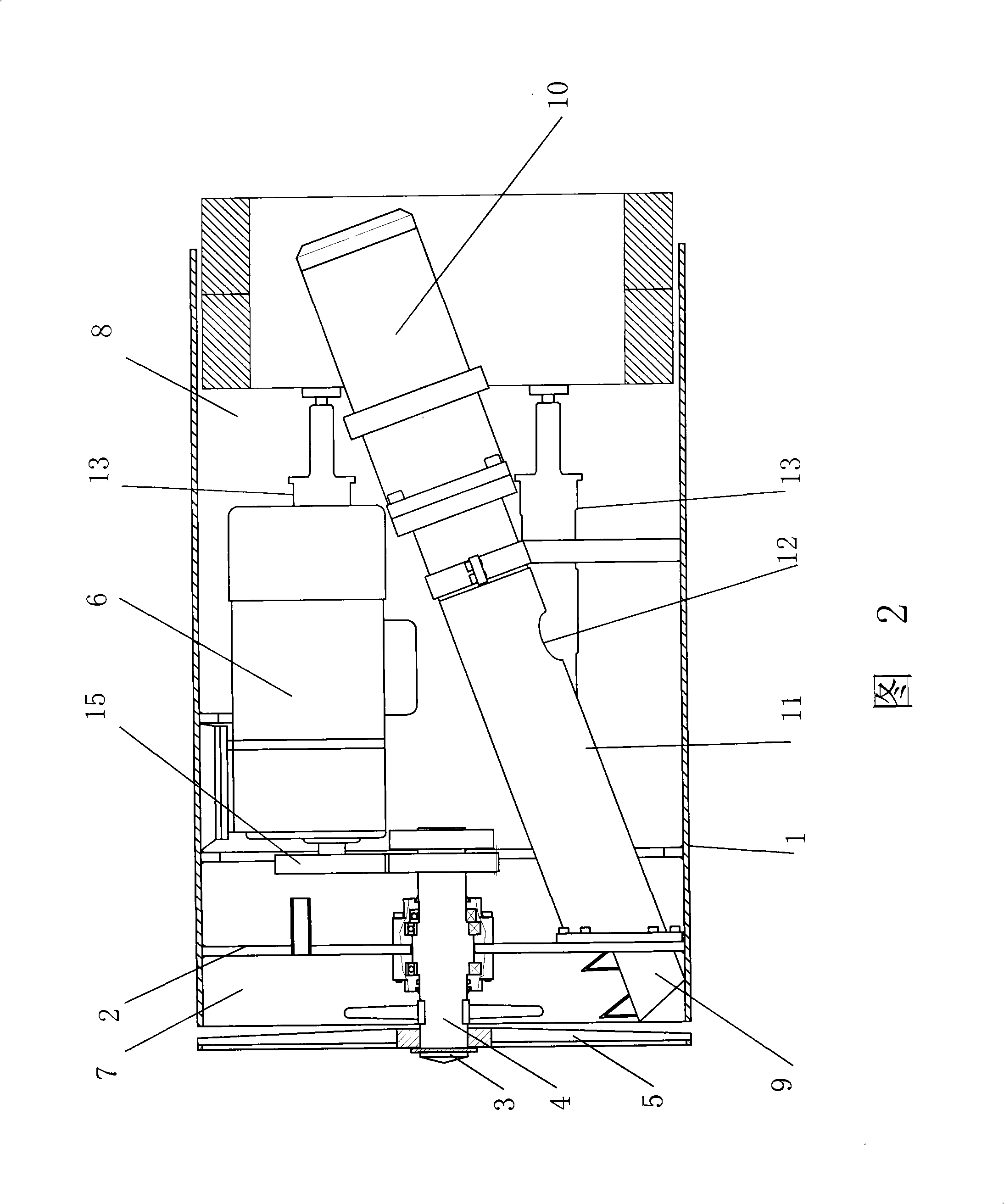

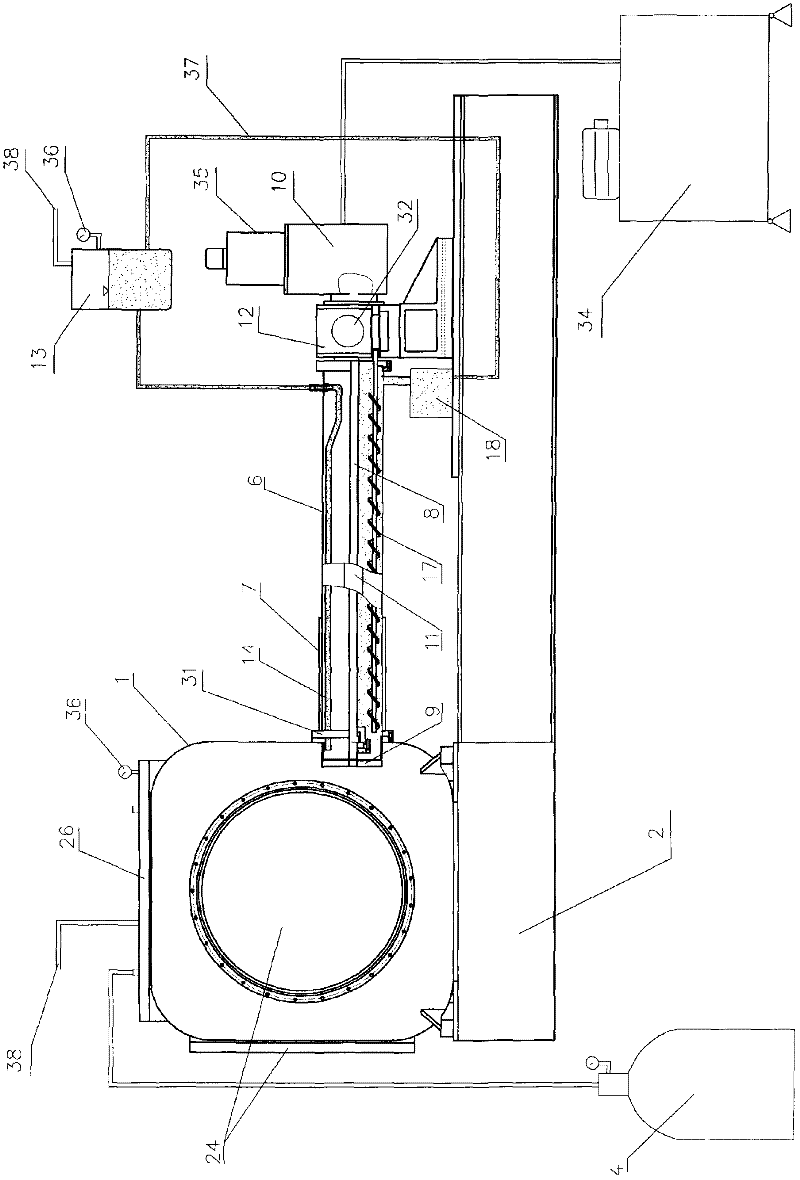

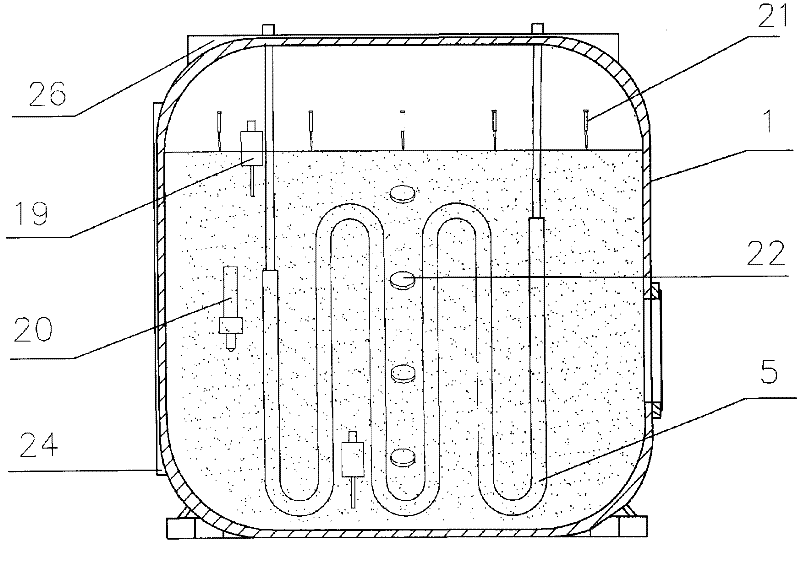

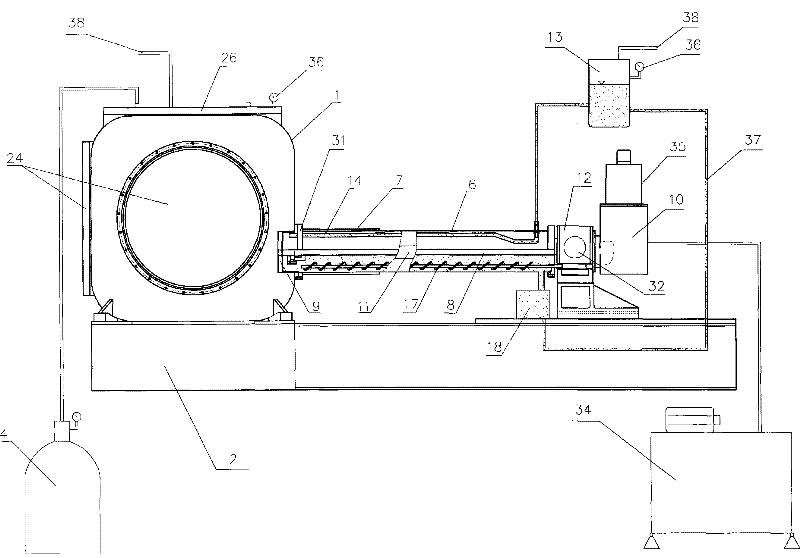

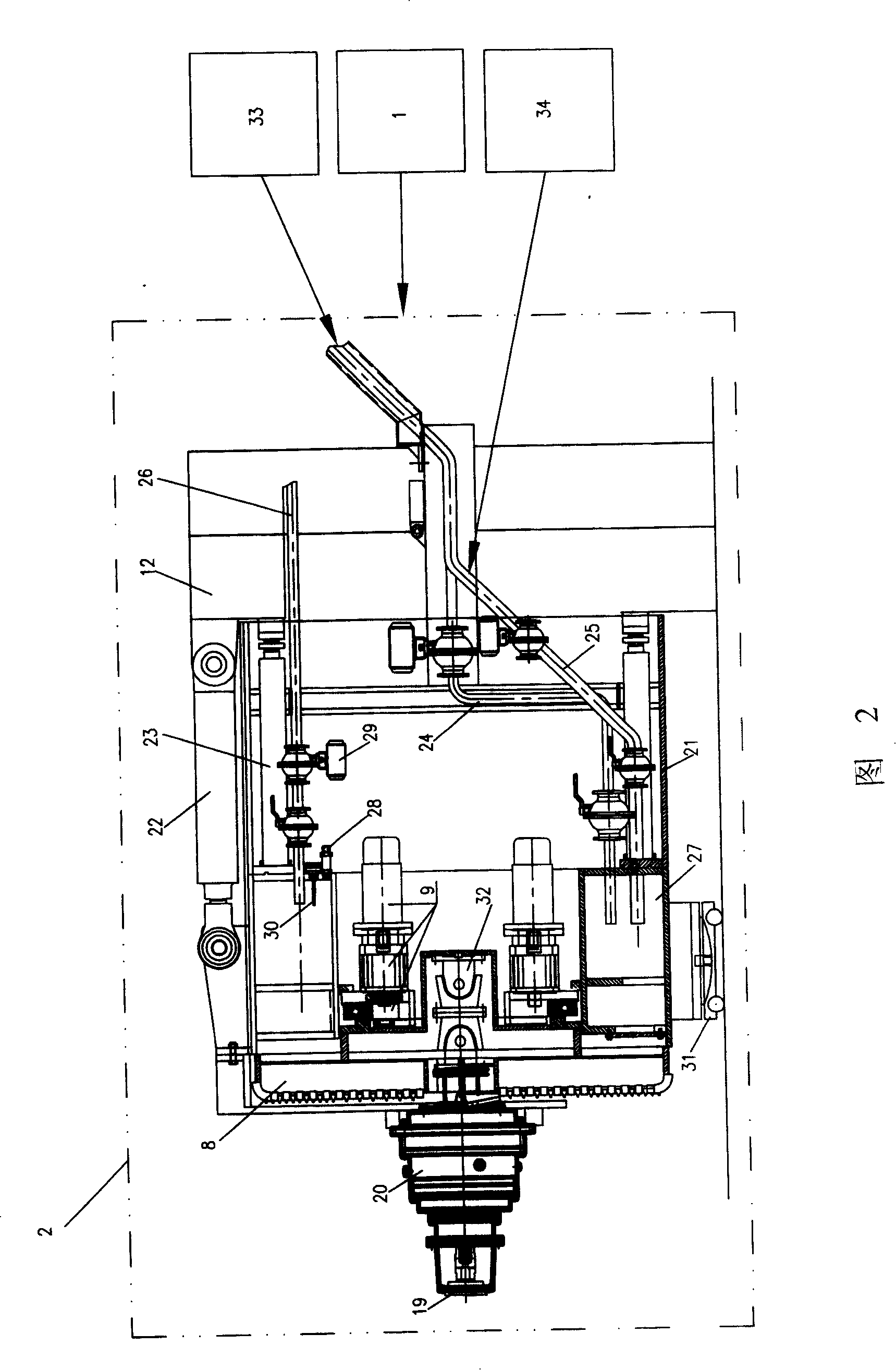

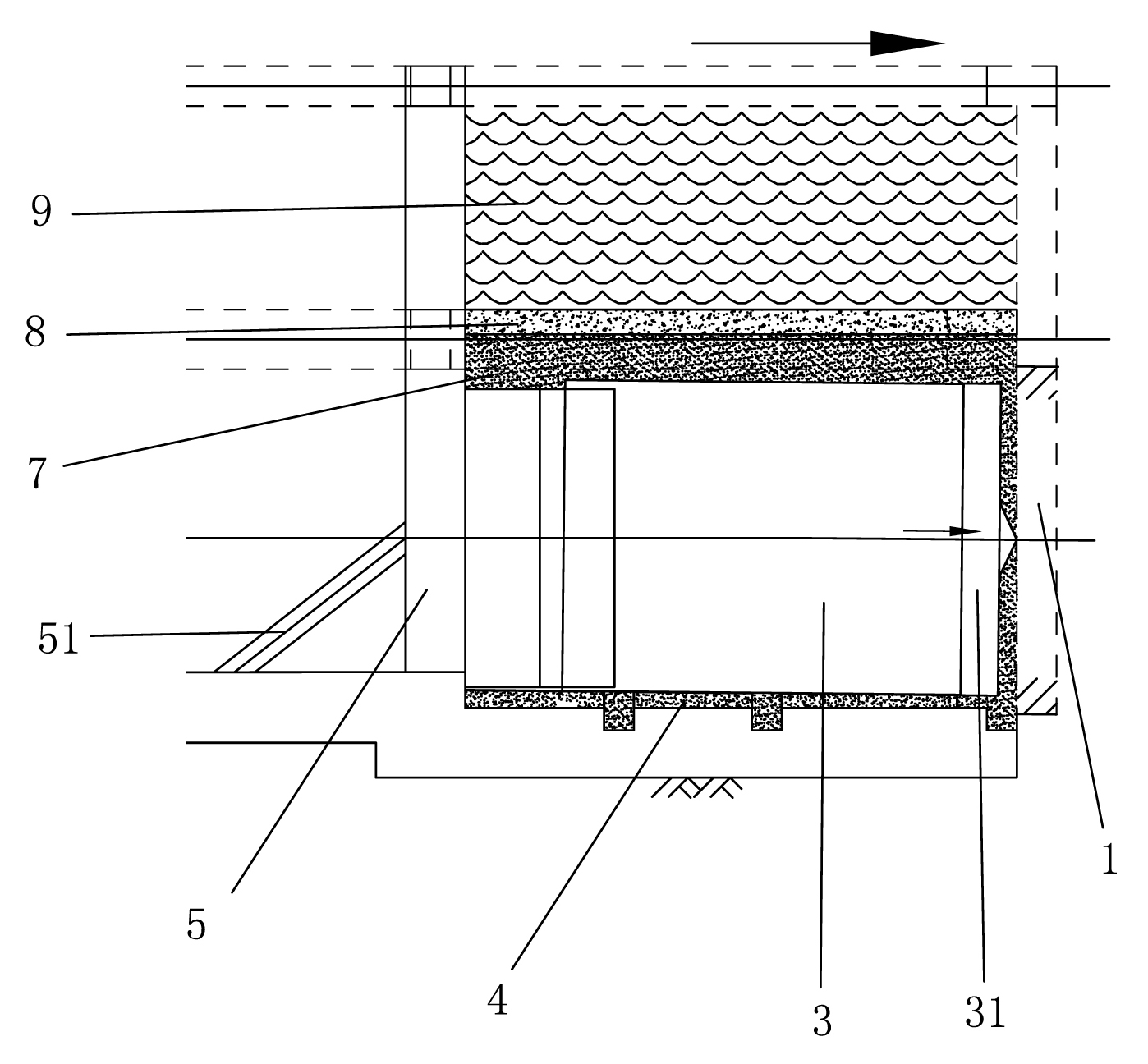

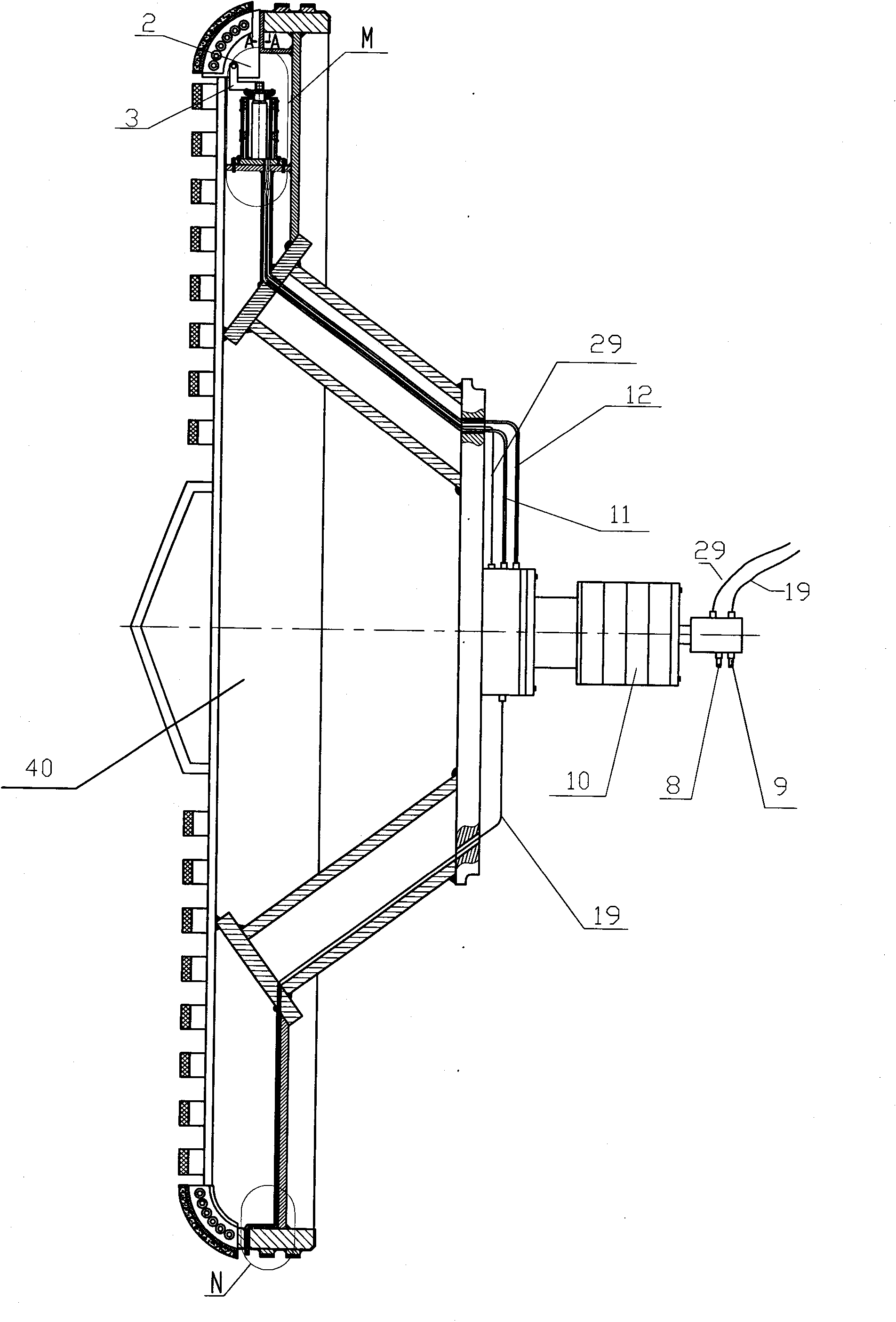

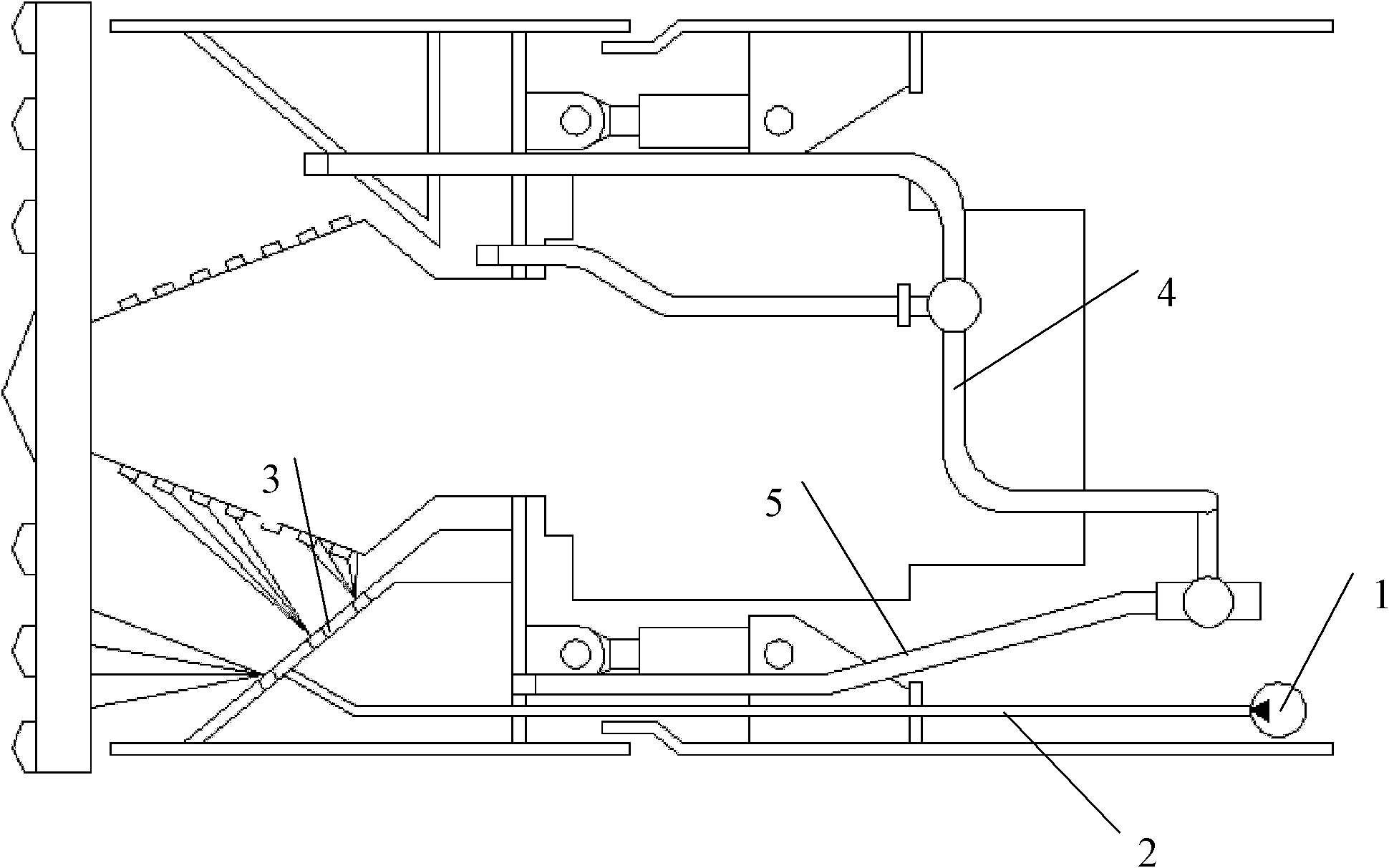

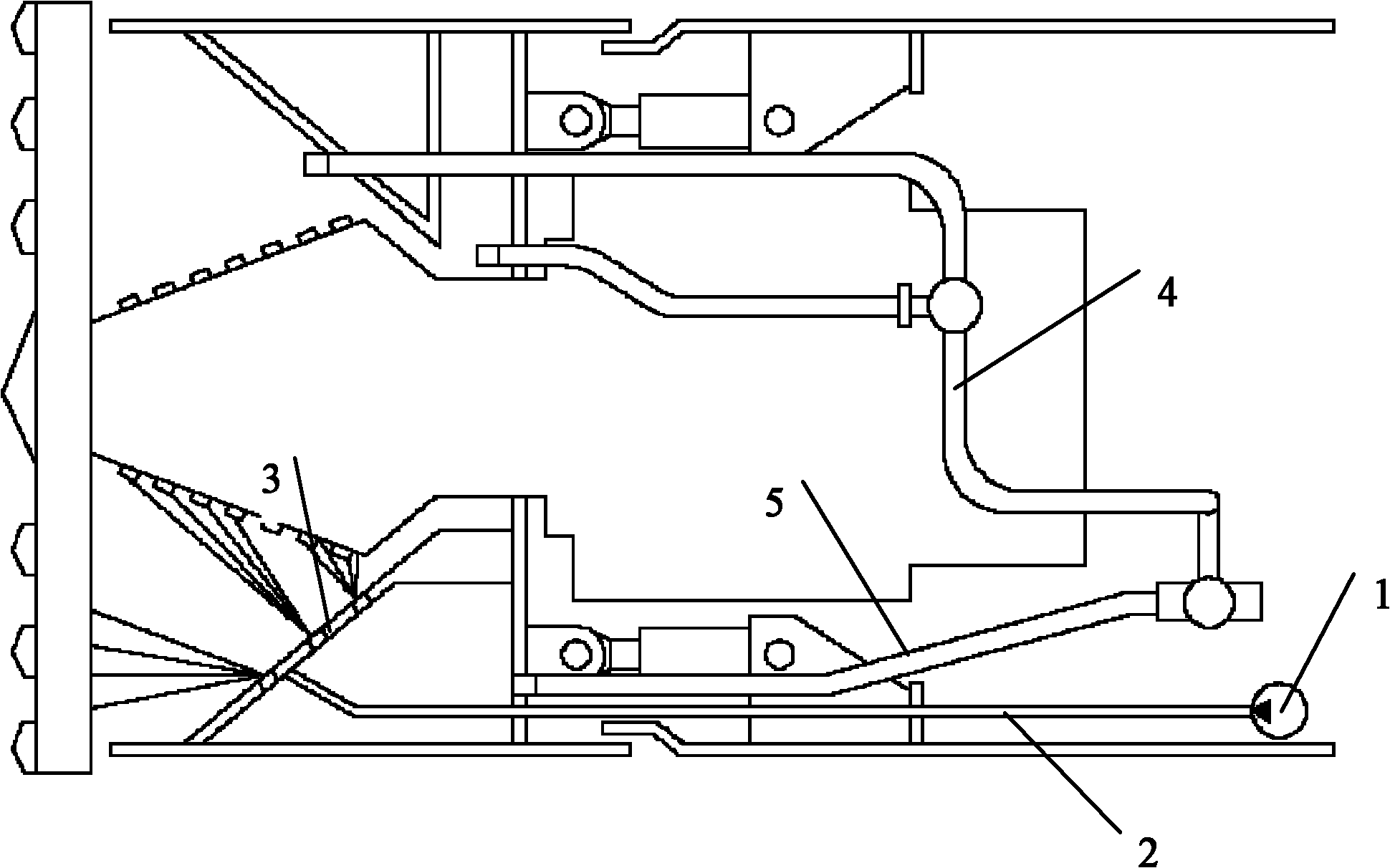

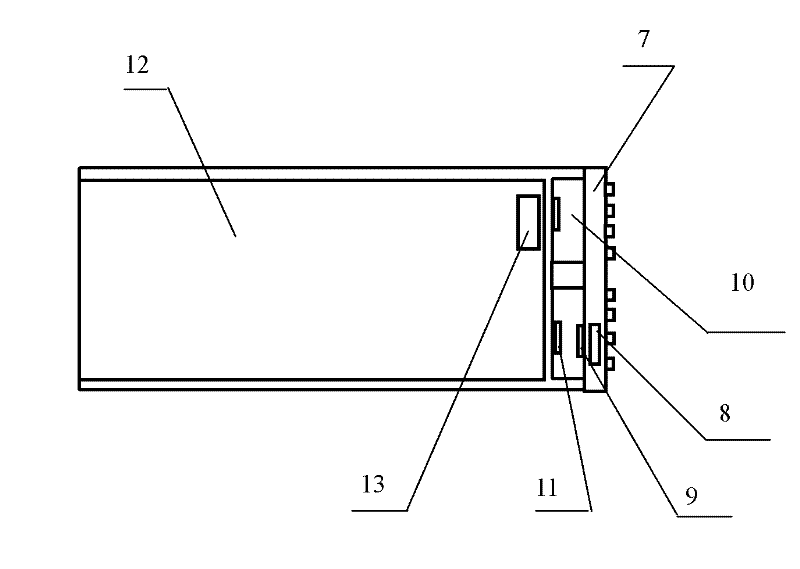

Muddy water balance type shield simulation testing system

ActiveCN102221474AAppropriate tunneling parametersReliable experimental basisStructural/machines measurementPore water pressureEngineering

The invention relates to a muddy water balance type shield simulation testing system. In the structure of the system, a model box for holding soil is fixed on a base; a refrigeration freezing device is communicated with a freezing pipe in the model box; the front part of a shield machine enters the model box through a guide sleeve on the side of the model box; a cutter disk at the front part of the shield machine is connected with the output shaft of a gearbox of a hydraulic power system through a main shaft; jacks at the left and right sides of the shield machine are connected between the model box and the gearbox; a space between a partition plate behind the cutter disk of the shield machine and the cutter disk forms a muddy water cabin; and an injection pipe of a muddy water pot, whichis connected with an air pressure boosting device, penetrates into the shield machine from the tail part of the shell of the shield machine. The system provided by the invention can simulate the tunneling process of the muddy water shield machine in a submerged tunnel construction with high water pressure and can synchronously record soil pressure, water pressure, displacement and the tunneling parameters of the shield machine, thereby finding out and analyzing the mechanism and conditions of muddy water pressure balance country rock and providing more reliable experiment basis for submerged tunnel construction and the design of a muddy water shield machine.

Owner:SOUTHWEST JIAOTONG UNIV

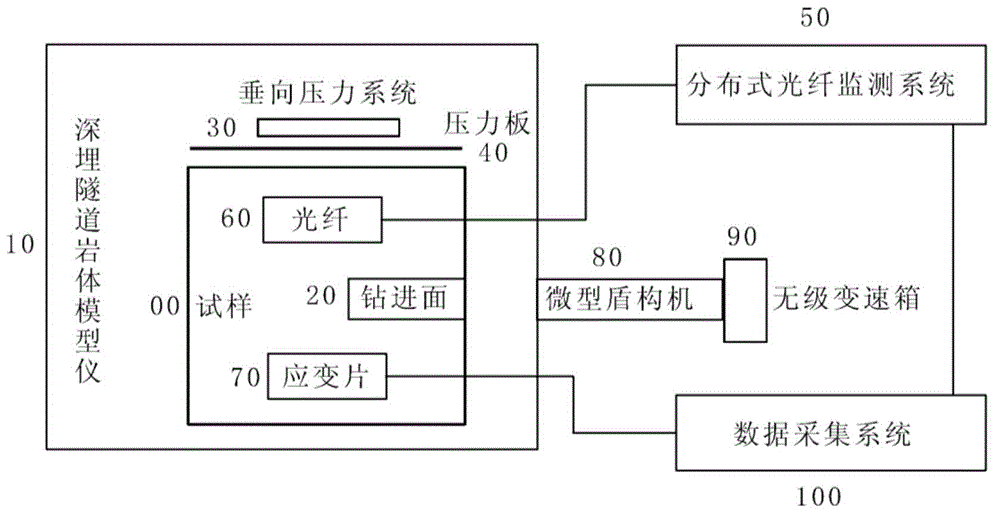

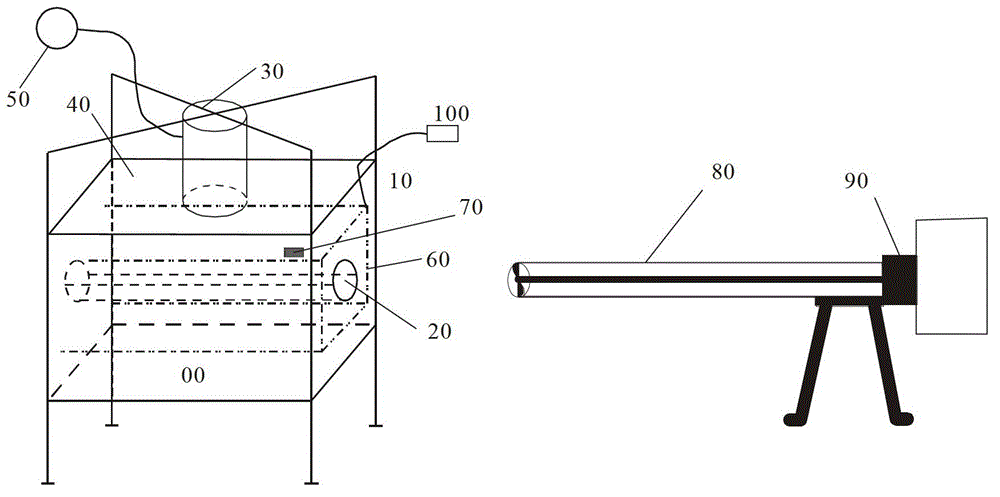

Device and method for physical simulation test of stability of deep tunnel surrounding rock

InactiveCN102721604ASafe Tunnel Construction SpeedEfficient tunnel construction speedStrength propertiesSoil mechanicsData acquisition

The invention discloses a device and a method for a physical simulation test of the stability of a deep tunnel surrounding rock and relates to a rock-soil mechanic technology. A structure of the device is that a pressure plate is covered on a sample in a deep tunnel rock body model instrument, and a vertical pressure system is arranged on the pressure plate and used for loading so as to simulate and exert gravity stress. A miniature shield machine drills into the sample from a drilling surface, and the miniature shield machine, a stepless speed changing box and a motor are sequentially connected to achieve drilling. Eight optical fibers and six strain gauges are distributed in the sample, the optical fibers are connected with a distributed optical fiber monitoring system, and the distributed optical fiber monitoring system and the strain gauges are respectively connected with a data acquiring system so as to achieve detection and recording. By means of the device and the method for the physical simulation test of the stability of the deep tunnel surrounding rock, a development and change law of stress strain when a deep tunnel rock body is excavated in tunnel construction can reappear accurately, and a novel solving path for researching the stability of the grotto surrounding rock and forming mechanism of rock burst in the tunnel construction.

Owner:INST OF GEOMECHANICS

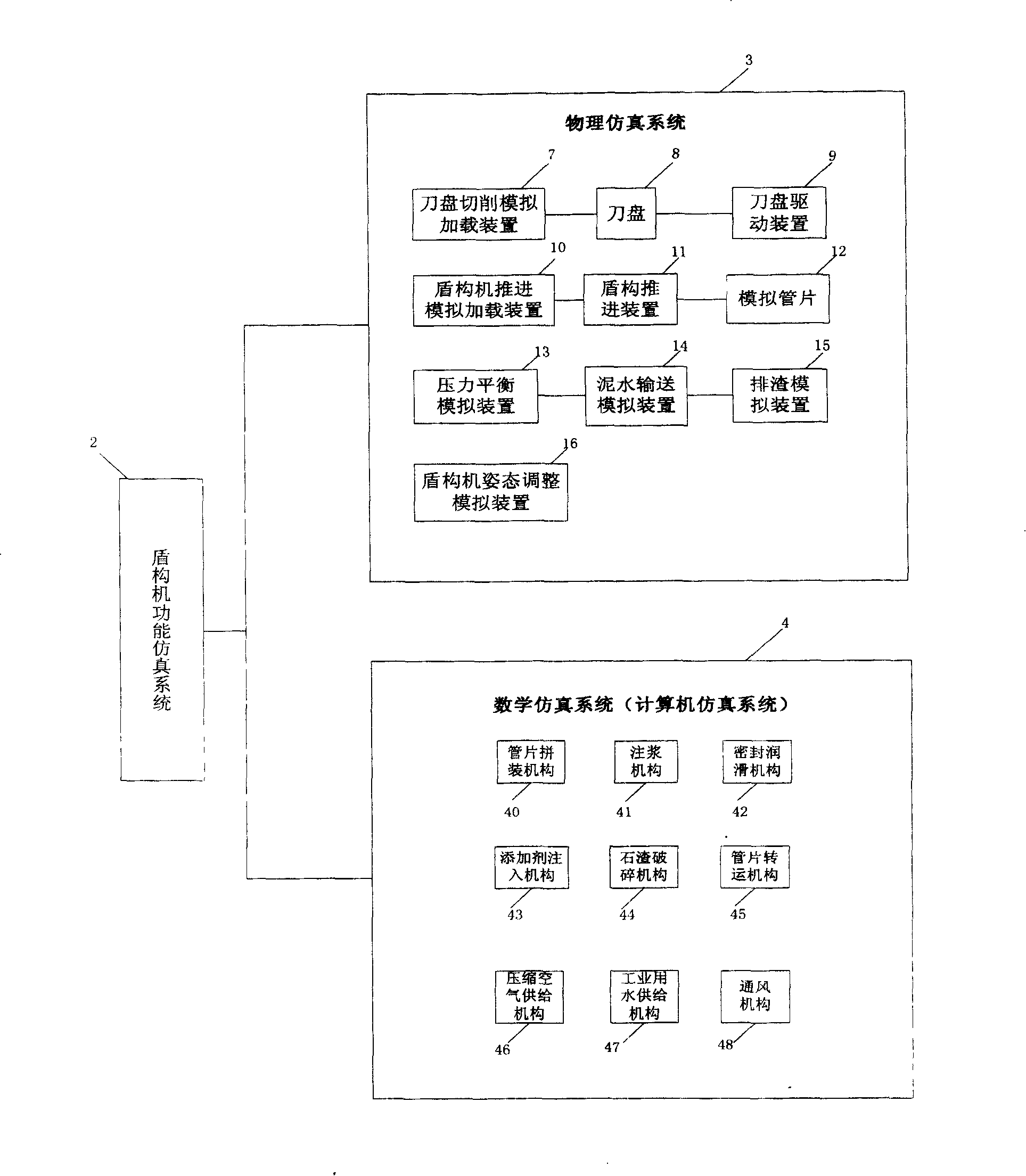

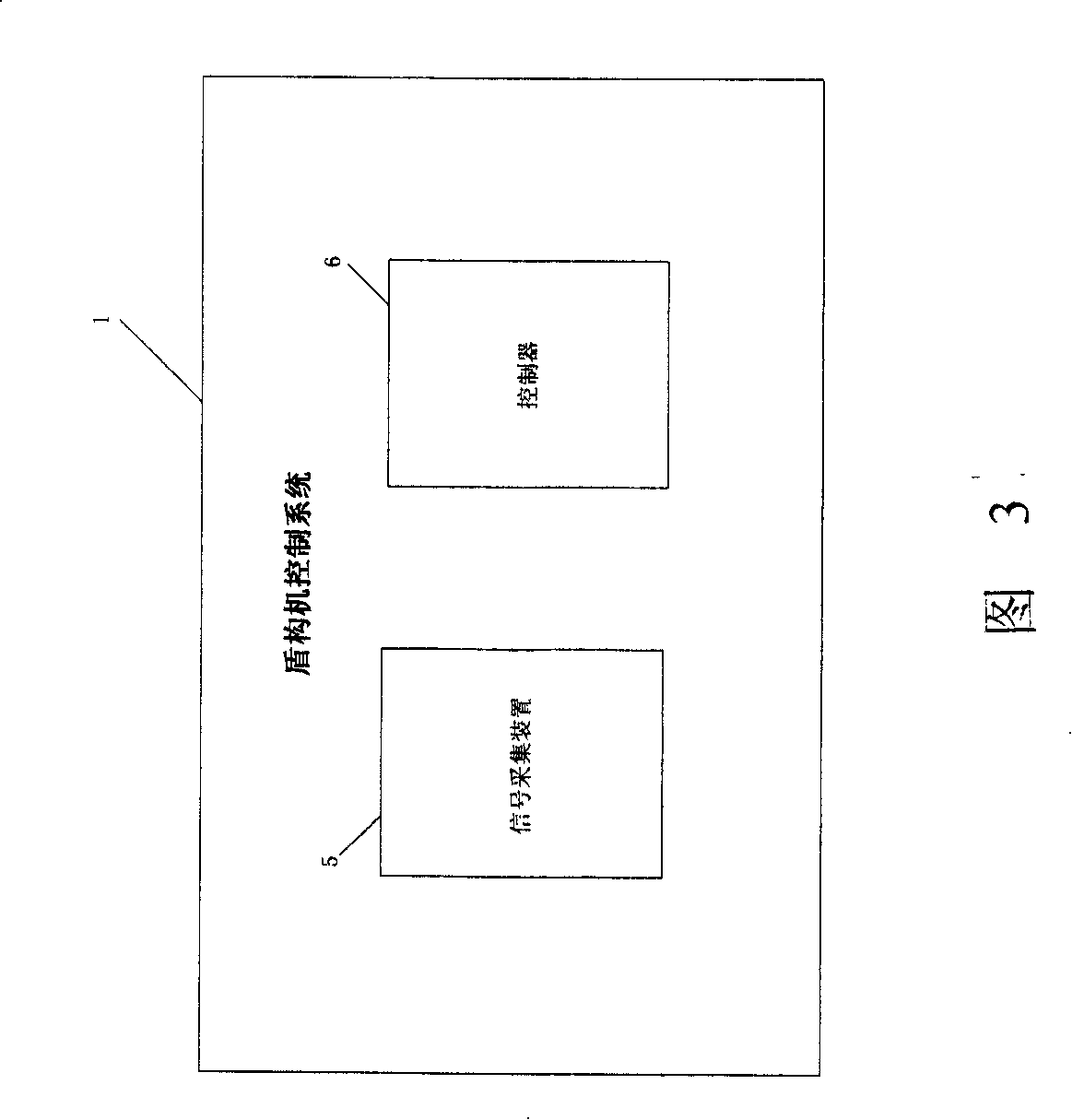

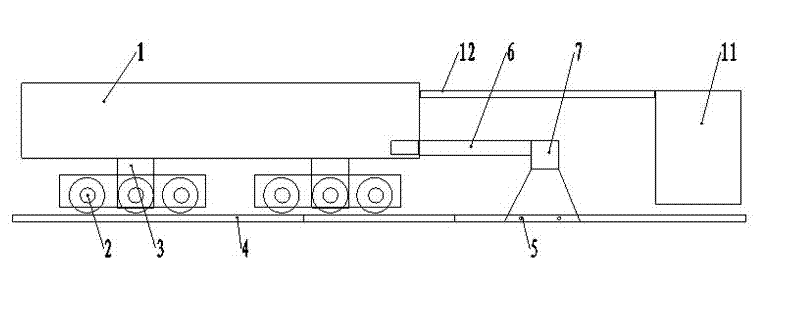

Tunnelling machine control system detection test platform

InactiveCN101211185AVersatileHigh degree of simulationSimulator controlElectric testing/monitoringMachine controlMathematical simulation

A test bench for testing a shield machine control system comprises a shield machine function simulation system and a sensing device arranged in the function simulation system, wherein the sensing device is communicated with the shield machine control system to be tested, and the function simulation system can be a physical simulation system, a mathematical simulation system or a combination of the physical simulation system and the mathematical simulation system. The test bench for testing the shield machine control system can completely simulate various functions of various types of shield machines, so as to test the correctness of the shield machine control system in design, assembly and debugging, avoid the risk arising from direct communication with the shield machine when the design of the control system is faulty, and shorten the circle of developing a new machine. Meanwhile, the invention is helpful for optimization and modification of the shield machine control system and remote fault diagnosis on the shield machine operated in a tunnel.

Owner:CHINA RAILWAY TUNNEL

Closed origin and arrival construction method of shield machine

ActiveCN101608551ASafety tightnessSafe wayUnderground chambersTunnel liningArrival processFilling materials

The invention discloses a closed origin and arrival construction method of a shield machine, comprising the following steps: (1) using a tight continuous wall enclosure structure as a plain concrete continuous wall; (2) opening slanting periphery observation holes on a cavity door to observe the stable and leak conditions of soil bodies; (3) chiseling concrete and steel bars on the cavity door sectionally, and using plain concrete to replace the original continuous wall synchronously; (4) installing a receiving device of the shield machine, and applying pre-applied force; (5) filling materials in a steel sleeve barrel of the receiving device to a request height; (6) testing the pressure resistance of the steel sleeve barrel; (7) carrying out the digging construction of the shield machine until a shield tail of the shield machine enters or separates the cavity door; and (8) decompressing and disassembling the steel sleeve barrel of the receiving device. The closed origin and arrival construction method of the shield machine is safe, economical, efficient and simple, changes uncontrollable factors into controllable factors in a shield origin and arrival process, greatly reduces risks in a construction process, better controls land subsidence and provides the effectively ensured closed origin and arrival construction method of the shield machine.

Owner:CHINA TUNNEL CONSTR GUANGDONG

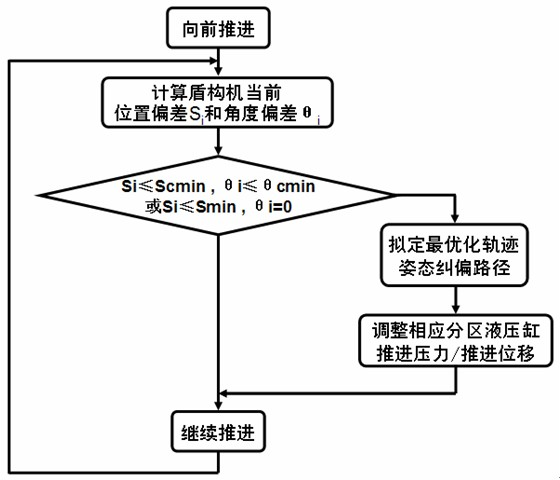

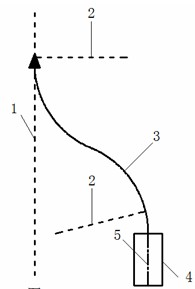

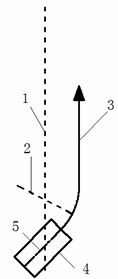

Track and posture composite control method in shield tunneling process

ActiveCN102102522AEliminate positional deviationEliminate Angle DeviationTunnelsHydraulic cylinderAngular deviation

The invention discloses a track and posture composite control method in a shield tunneling process. The method comprises the following steps of: performing control by setting threshold values for a posture and a track; immediately adjusting the posture as long as the posture deviates to exceed the limit even though the track does not reach a deviation correction threshold; solving current positional deviation Si and angular deviation theta I of a shield machine through measurement and calculation when a shield works; continuously propelling the shield machine when the Si is less than or equal to a positional deviation threshold value Scmin of a track and posture composite controller and theta i is less than or equal to an angular deviation threshold value theta cmin of the track and posture composite controller or when the Si is less than or equal to positional allowable deviation Smin of actual tunnel construction and theta i is equal to 0; contrarily, automatically adjusting propelling pressure of a hydraulic cylinder of each sub-region and propelling displacement to simultaneously eliminate the positional deviation and the angular deviation generated in a tunneling process. Thus, an actual tunneling route of the shield machine is controlled within a design axial range of a tunnel, unnecessary overbreak and underbreak are avoided, and the forming quality of the tunnel is improved.

Owner:ZHEJIANG UNIV

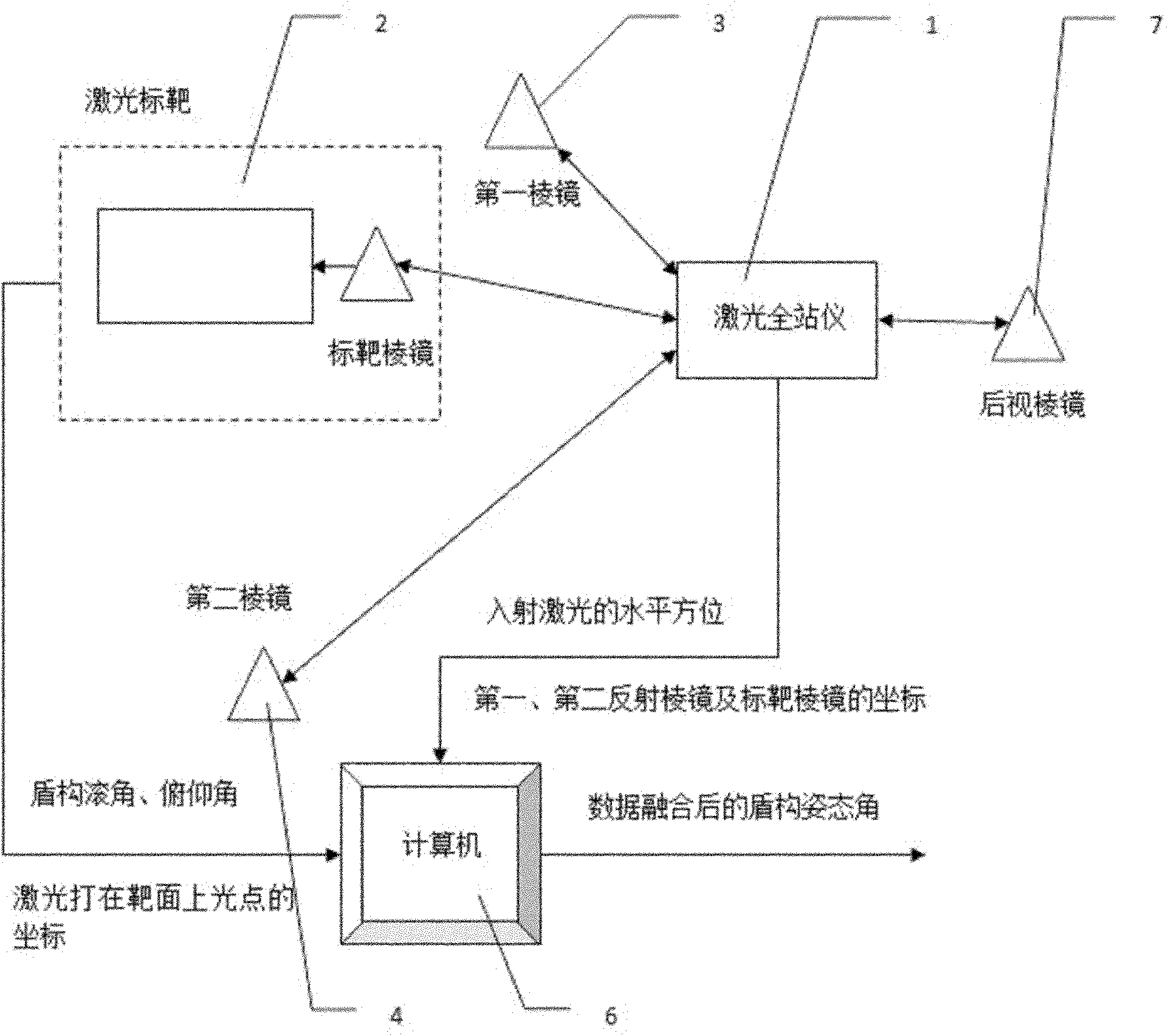

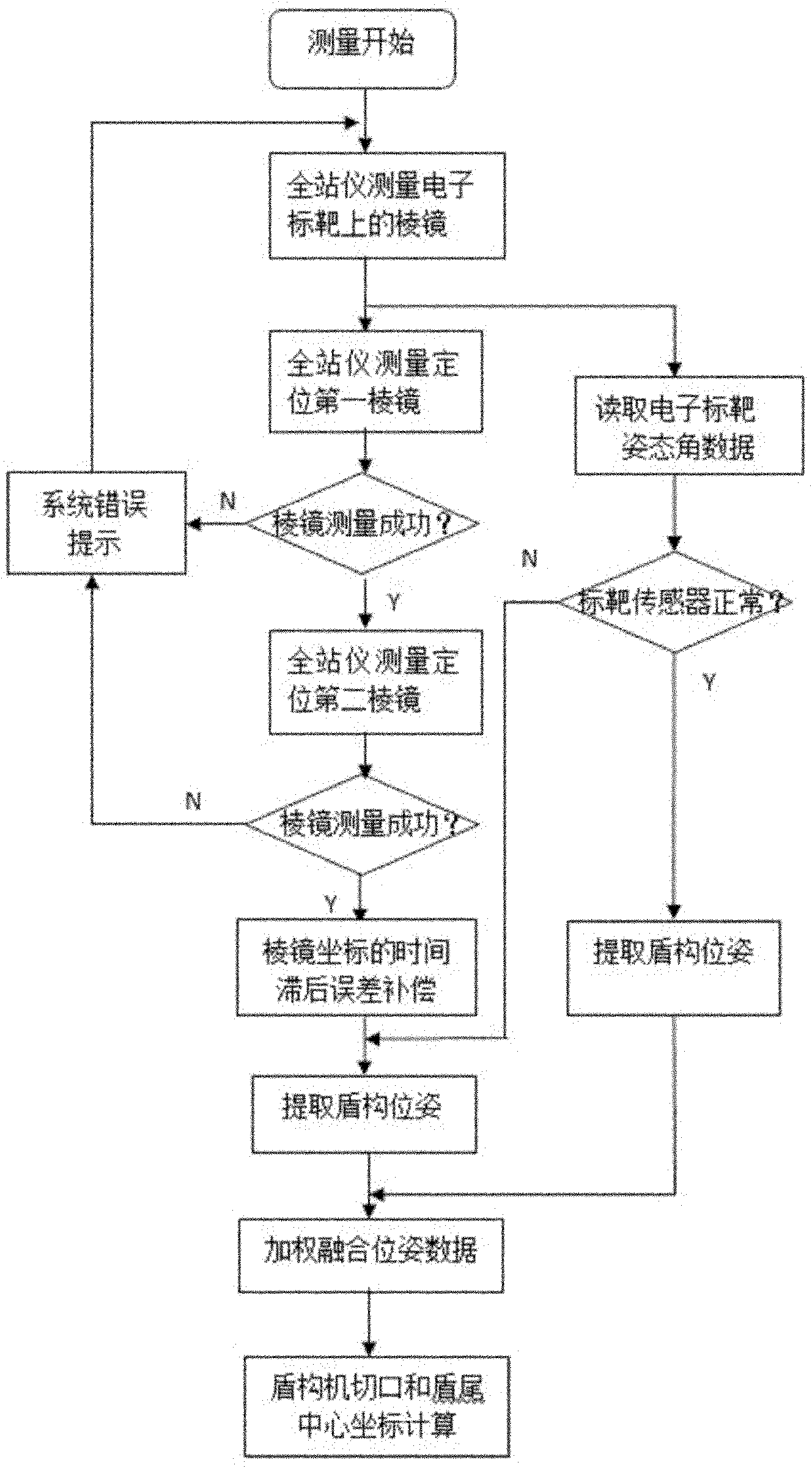

Real-time guide system of multi-sensor data fusion shield machine

ActiveCN102052078AImproving pose measurement accuracyImprove reliabilityAngle measurementTunnelsContinuous measurementLaser target

The invention relates to a real-time guide system of a multi-sensor data fusion shield machine, comprising a laser overall meter, a laser target, a first prism, a second prism, a rear-view prism and a computer, wherein the rear-view prism is used for detecting whether the position of the laser overall meter is changed or not in the measuring process; the laser target is used for measuring an attitude angle of the shield machine in real time; the first prism and the second prism are respectively arranged at both ends of the shield machine; the laser overall meter measures coordinates of the first prism, the second prism and a laser target prism under a geodetic coordinate system by emitting lasers; and the computer computes to obtain multigroup attitude angles by combining with attitude angle data measured by the laser target and carries out fusion processing so as to obtain optimized shield machine attitude angles for implementing the real-time guide of the shield machine. The invention can still obtain the shield machine attitude angles when sensors inside the laser target are faulty or positioning prisms are shielded, ensures the continuous measurement and has high measurement accuracy, strong work stability, and the like.

Owner:WUHAN INTELLIGENT EQUIP IND INST CO LTD

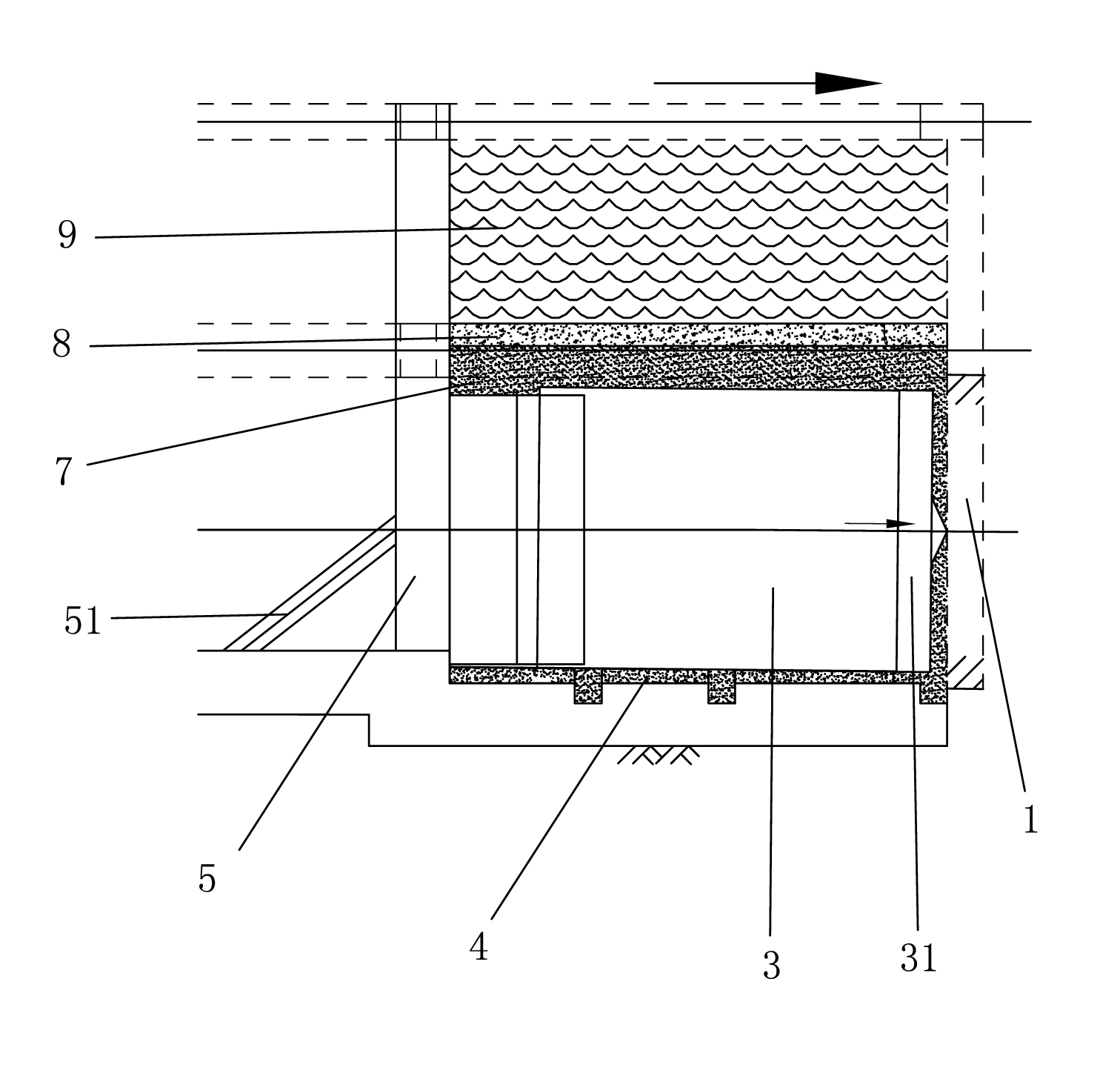

Shield machine balance originating method

ActiveCN102022119AEnsure safetyThere will be no water gushing and sand gushingTunnelsEngineeringCounterforce

The invention discloses a shield machine balance originating method, which comprises the following steps of: constructing a continuous wall envelope structure in a foundation pit; pouring a guide table in an originating well of the foundation pit; pouring a concrete counterforce wall in the originating well; assembling and debugging a shield machine in the originating well; arranging a first negative ring duct piece in the debugged shield machine, pushing the duct piece out of a shield tail to connect the counterforce wall, and sealing the duct piece; jacking a cutter head of the shield machine to the continuous wall, and backfilling the originating well with a sand layer, a concrete layer and a water layer from bottom to top; grouting in back of the duct piece wall; and performing advancement by the shield machine. Because the shield is backfilled in the well before the shield machine originates advancement, the pressure of water and soil inside and outside the foundation pit is balanced, water and sand are not burst when the shield machine originates advancement, and the safety of the foundation pit and the shield machine can be effectively ensured.

Owner:CHINA TUNNEL CONSTR GUANGDONG

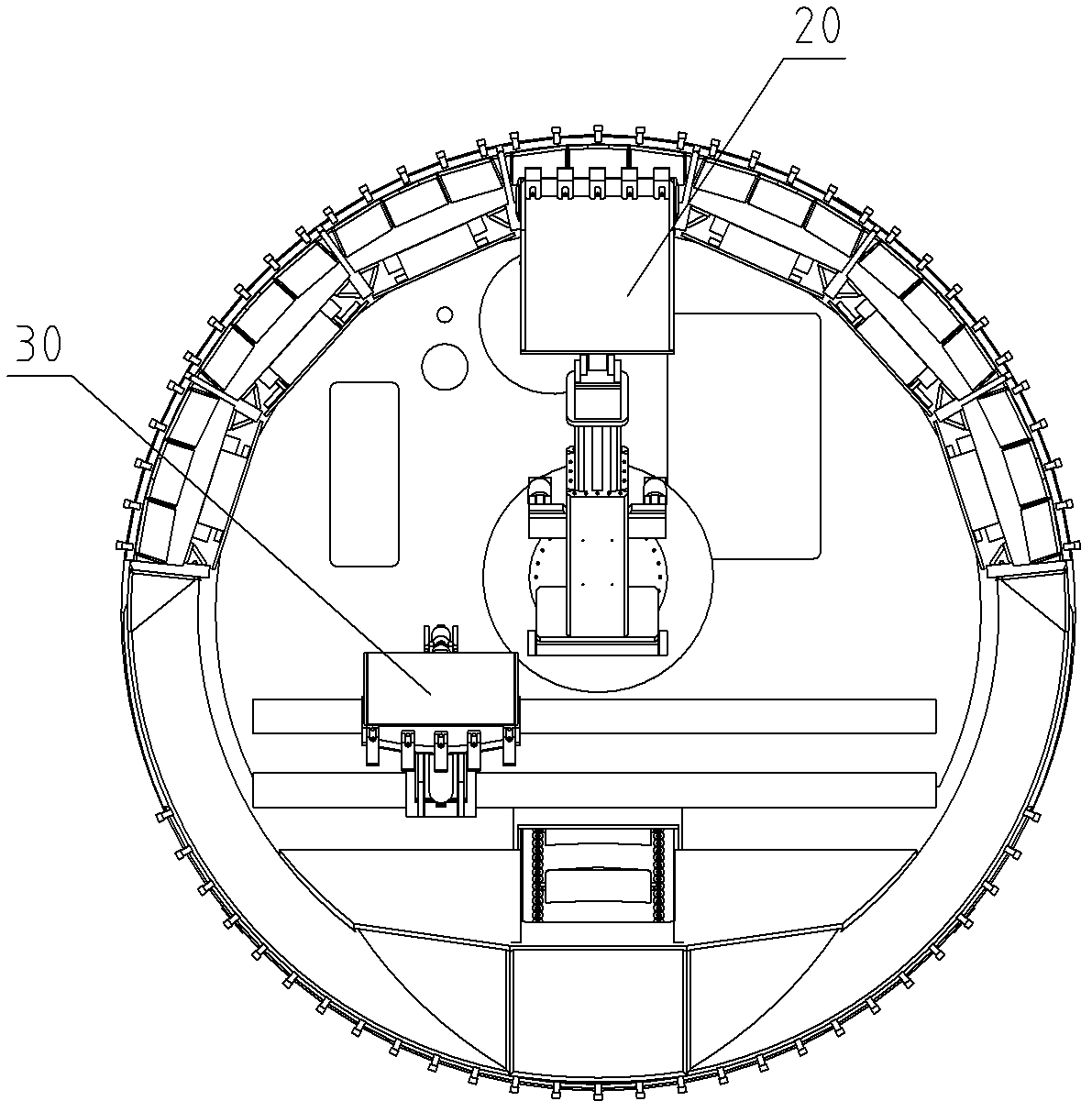

Multistage-separation progressive shield cutter head

InactiveCN102536254ASpeed up the flowEasy control of earth pressure balanceTunnelsEngineeringShield tunneling

The invention discloses a multistage-separation progressive shield cutter head which comprises a plurality of flexible shield cutter heads. During the work, a central shield cutter head primary rotation shaft clutch is closed; a power main shaft drives a primary cutter head to rotate to cut rocks; and at the same time, a rear hydraulic device pushes a central cutter head to tunnel ahead. When a certain distance is tunneled, a primary clutch is separated; after partial components are reassembled, a secondary clutch is closed and a secondary cutter head starts to tunnel ahead; and repeatedly, the multistage cutter head progressive excavation is realized. Cutter heads of a shield tunneling machine of a multistage-separation progressive structure share the same power main shaft and are respectively provided with a central stirring device and an auger delivery chip removal device; and material bulks cut by the cutter heads are crushed and conveyed into a chip removal guiderail at the center of the shield machine.

Owner:XIAN RUITE RAPID MFG ENG +1

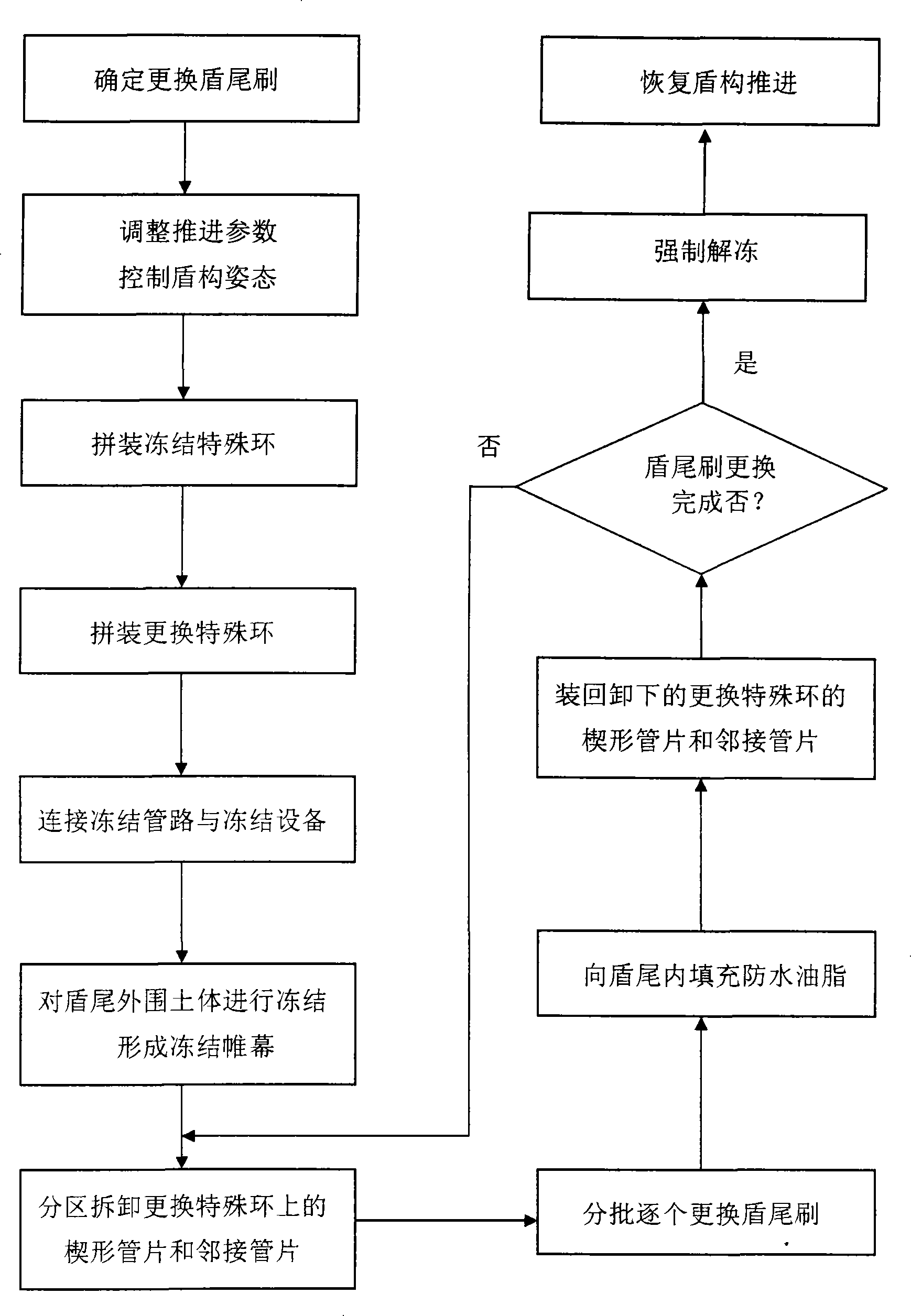

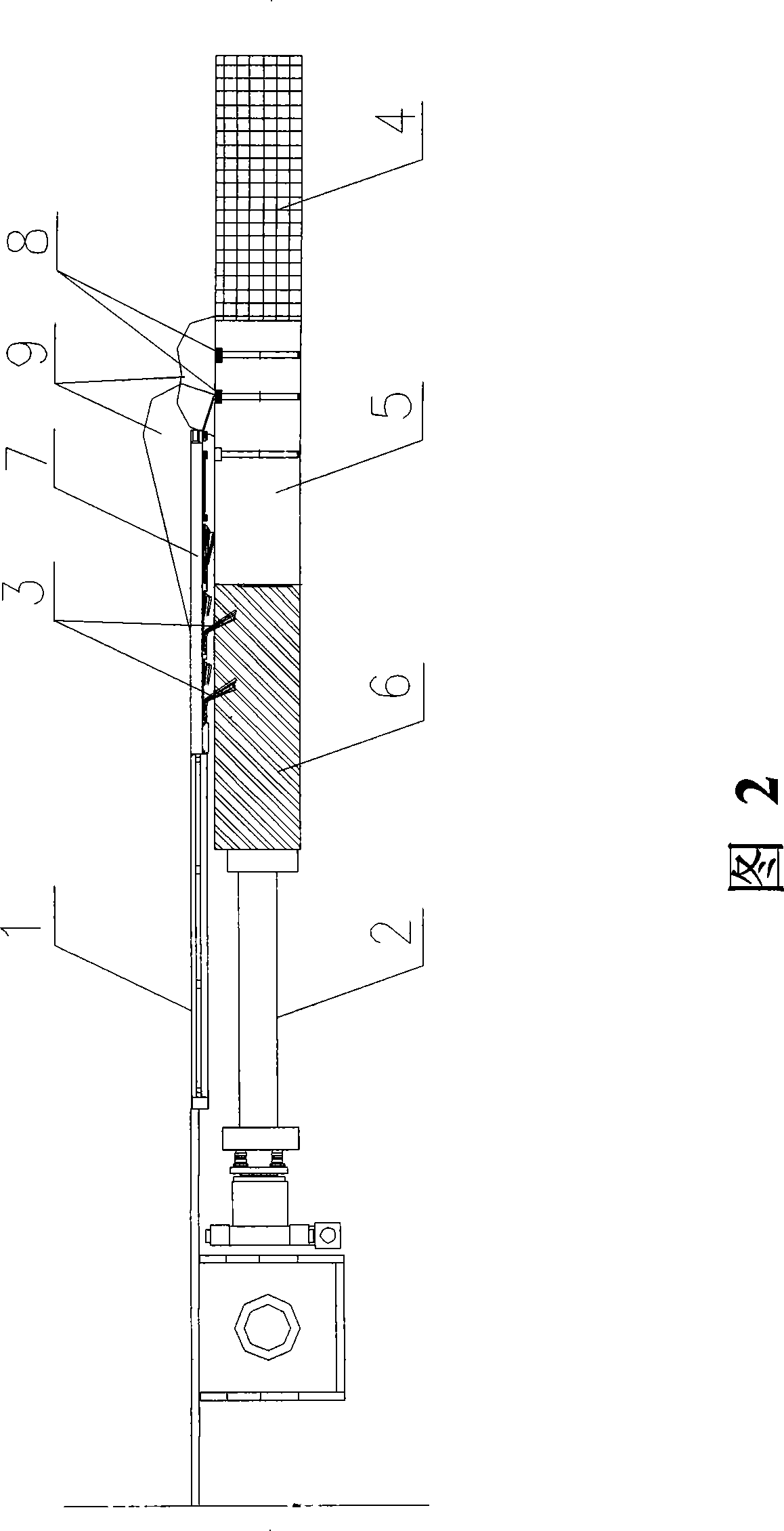

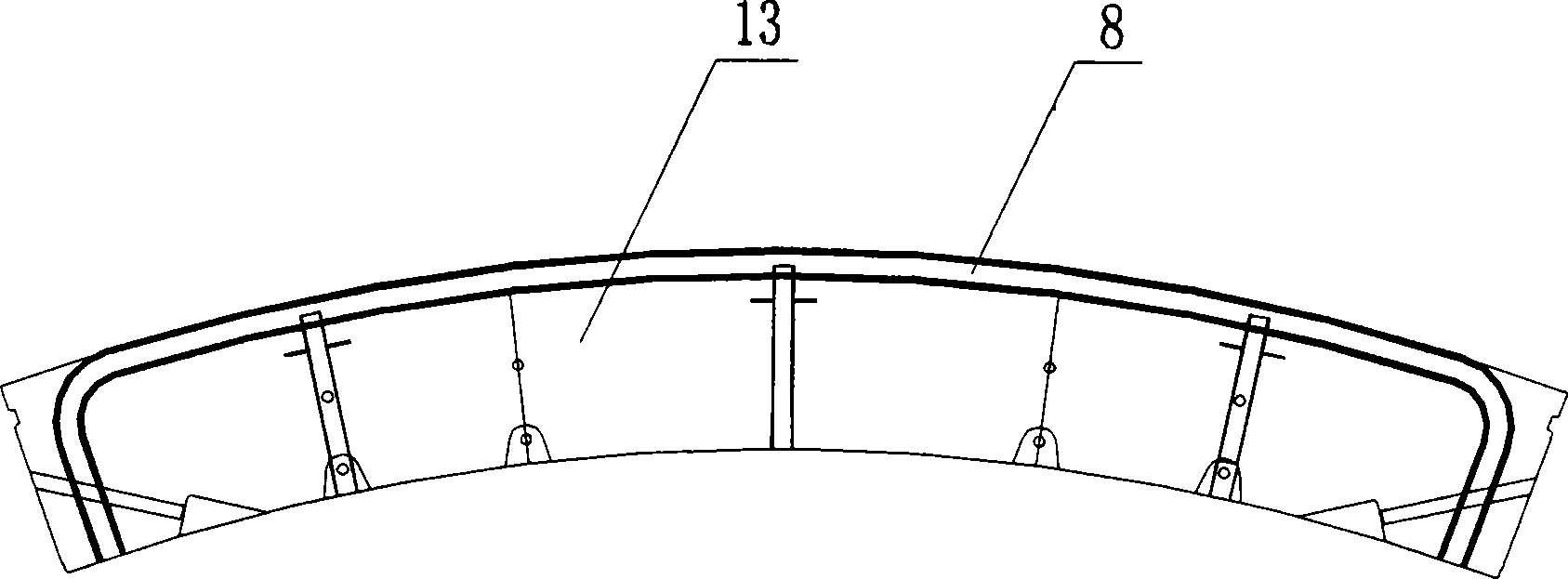

Construction method for exchanging shield ventral brush

The invention relates to a construction method for replacement of tail brushes of a shield, wherein, a tail device of a shield machine is provided with preset freezing pipes. The invention comprises the following operation steps that: replacement of the tail brushes is determined; a propulsion parameter of the shield is adjusted, and the shield posture is controlled; a special freezing ring is assembled in front of a common ring by utilization of freezing segments; the freezing pipes and temperature tubes are buried into the freezing segments in advance; a special replacement ring which is used for replacement of the tail brushes is assembled in front of the special freezing ring; the freezing pipes and freezing equipment are connected; the peripheral soil mass of a shield tail is frozen, and a freezing purdah for waterstop is formed on the rear of the tail brushes; the tail brushes are replaced one by one under the protection of the freezing purdah, and waterproof greases are infused into the tail brushes; the freezing purdah is forced to be unfrozen after replacement of the tail brushes is finished; normal propulsion of the shield is restored. The construction method for replacement of the tail brushes of the shield has the advantages of good waterstop effect, safety and reliability, simple and convenient operation and strong environmental suitability, is widely suitable for various complex special geological conditions and is particularly suitable for construction of a large-scale large-diameter bridge tunnel.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

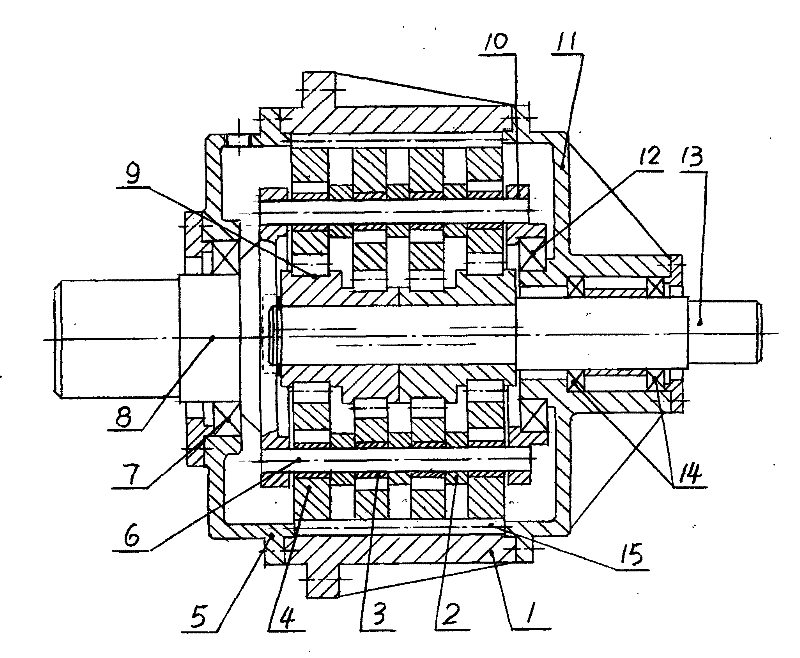

Soil pressure balance shield machine cycloid speed reducer

ActiveCN102192279AIncreased bending stressReduce axial sizeToothed gearingsPhase differenceReduction drive

The invention relates to the technical field of shield machine speed reduction, and discloses a soil pressure balance shield machine cycloid speed reducer. The soil pressure balance shield machine cycloid speed reducer is characterized in that: a cycloid driving part is arranged in a cavity formed by connecting a front end cover with a back end cover by using a pin wheel housing, wherein a half-buried hole of the pin wheel housing is in movable fit with a sleeveless needle pin; four cycloidal wheels are arranged on a double-eccentric bearing, wherein the phase difference between a first cycloidal wheel and a second cycloidal wheel and between a third cycloidal wheel and a fourth cycloidal wheel is 180 degrees, and the second cycloidal wheel and the third cycloidal wheel have the same phase; and a W output mechanism consists of an output shaft, a pin and a uniform loading plate, the pin is provided with three circular ring plates to form a four-section freely supported structure, and the W output mechanism is supported in an inner hole of a front end cover and an inner flange outer circle of a back end cover through a bearing respectively. The soil pressure balance shield machine cycloid speed reducer has the following advantages that: (1) the axial size is 45 to 55 percent shorter than that of a third-class planetary reduction gear of the background art; (2) the cycloidal wheels can be assembled in a reversed mode to double the service life; (3) the manufacturing cost is 40 to 50 percent of that of the third-class planetary reduction gear of the background art; and (4) the inertia force and the inertia moment in operation are theoretically completely balanced.

Owner:国茂精密传动(常州)有限公司

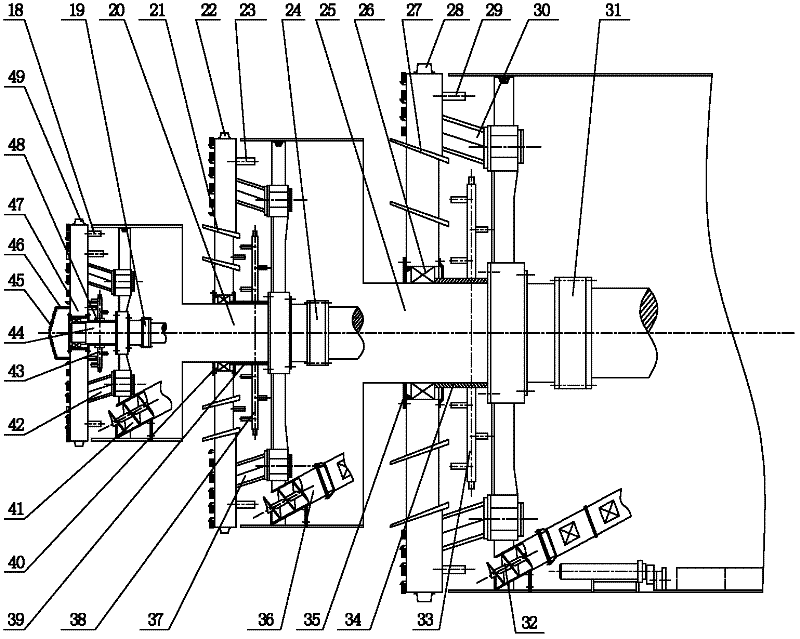

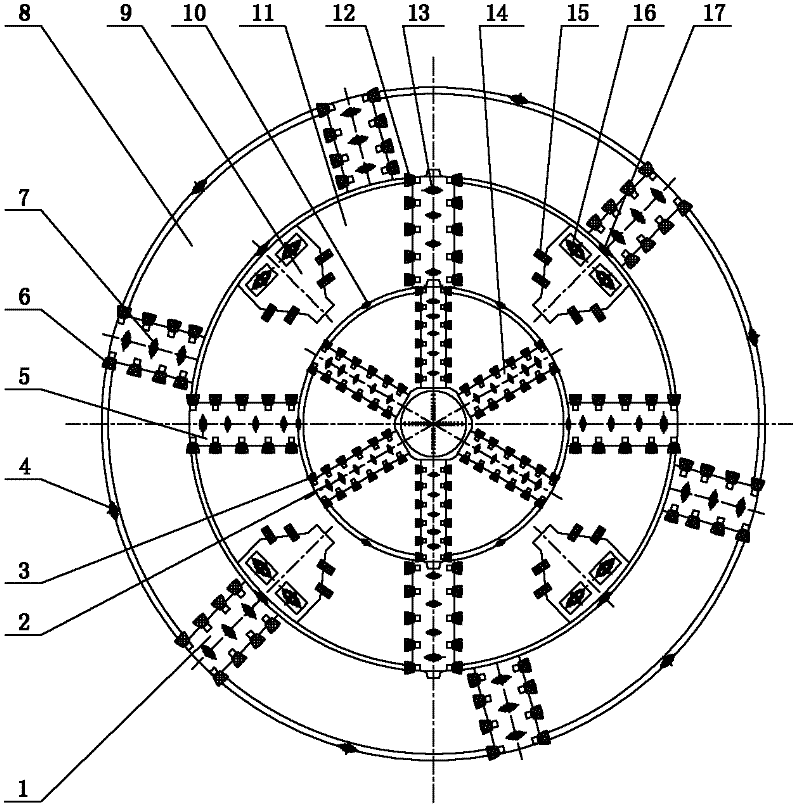

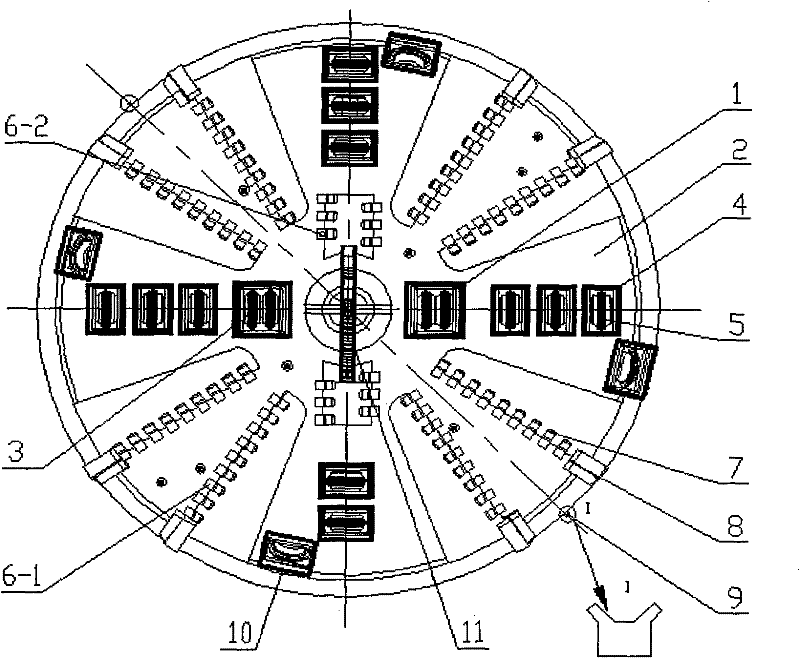

Multi-adaptive cutter head for shield machine

The invention discloses a multi-adaptive cutter head for a shield machine. The cutter head is provided with four cutter seats, three cutters directly fixed with the cutter head and movable cutters. Each cutter seat comprises a central double-edge hob seat, an exchangeable cutter seat, an inner and outer ring side-mounted cutter seat and a peripheral hob seat. The cutters include a peripheral scraper, an over cutter and a fishtail cutter. A main cutting surface of the cutter head is composed of a single-edge hob inlaid in the peripheral hob seat, a cutting blade in the inner and outer ring side-mounted cutter seat and the fishtail cutter; and a full section cutting cutter assembly is composed of a double-edge hob, a single-edge hob, a cutting blade, a peripheral scraper, an over cutter and a fishtail cutter. The multi-adaptive cutter head solves the problem that cutter replacement wastes time and labor, changes the traditional mounting mode to effectively prolong the service life of the cutter because the whole cutter works under a relatively smaller force, and can properly adjust the kind and the number of the cutters according to different geological conditions to effectively improve the adaptability of the cutter head of the shield machine and increase the efficiency and the quality of the tunnel shield.

Owner:TIANJIN UNIV

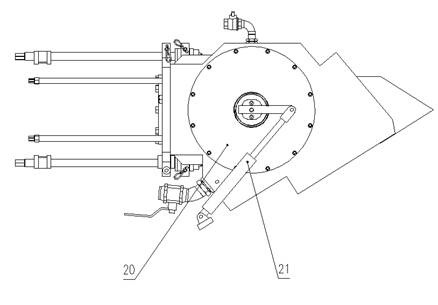

Cutting device with small-range diameter-variable function of soft rock shield machine

A cutting device with of small-range diameter-variable function of a soft rock shield machine comprises a cutter head, a cutter mounted on the cutter head, a side scraper telescoping mechanism, a hydraulic control device and a wearing limit detecting device, wherein two sides of end parts of at least one slag outlet groove of the cutter head are provided with a scraper respectively; the two side scrapers are left-and-right symmetrical according to the radial centerline of the slag outlet groove and are connected with a telescoping mechanism; the telescoping mechanism is mounted in the slag outlet groove of the cutter head and is driven by a driving cylinder in the hydraulic control device; a displacement sensor is arranged in the driving cylinder; and a wearing limit detecting head of the wearing limit detecting device is arranged on a sleeve protruding along the radius of the cutter head. Compared with the existing cutting device, the cutting device can adjust cutting diameter in a certain range, therefore, the cutting device can improve working efficiency, confirm cutting quality and confirm operator safety.

Owner:CREG TUNNEL BORING MFG CO LTD

Processing method for protecting excavation place of shield machine from mudlining

The invention discloses a processing method for protecting the excavation place of a shield machine from mudlining, which is applied in the shield machine industry. Residue soil cut along with the rotation of a cutter enters a tapered breaking cabin from an orifice on the cutter and is mixed with seriflux injected via a seriflux inlet pipeline to form high-density mud; when the shield machine passes through a clay stratum, a great quantity of hard-plastic clay is attached to the cutter and a tapered breaking body; because the clay content is high, more clay is attached on the cutter and the tapered breaking body, and the shield construction is in trouble; when the shield machine meets the super clay stratum, high-pressure water is injected to an excavation cabin by a high-pressure nozzle installed on a front shield; a high-pressure water pump adopts a plunger water pump; a high-pressure water pipe is composed of a seamless steel pipe and a high-pressure hose; the high-pressure nozzle is installed on the lower part of the breaking wall of the front shield of the shield machine to shunt and inject high-pressure water into different positions of the shield machine; and certain high-pressure water is injected to the back of the cutter to clean clay attached on the cutter. The device effectively solves the construction difficulties that clay is attached on the cutter, the torsion of the cutter is added and the like when the shield machine meets the geological condition of super clay, and the processing method has low cost.

Owner:SHENYANG HEAVY MACHINERY GROUP

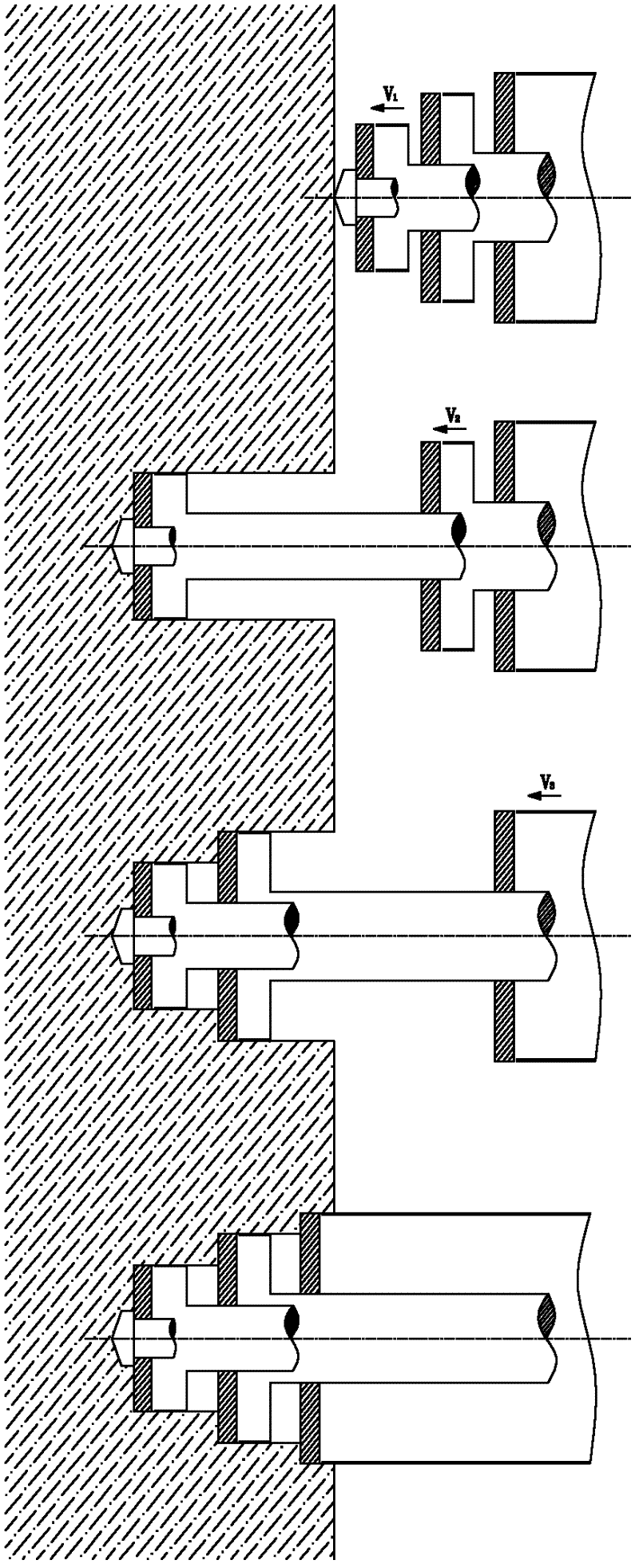

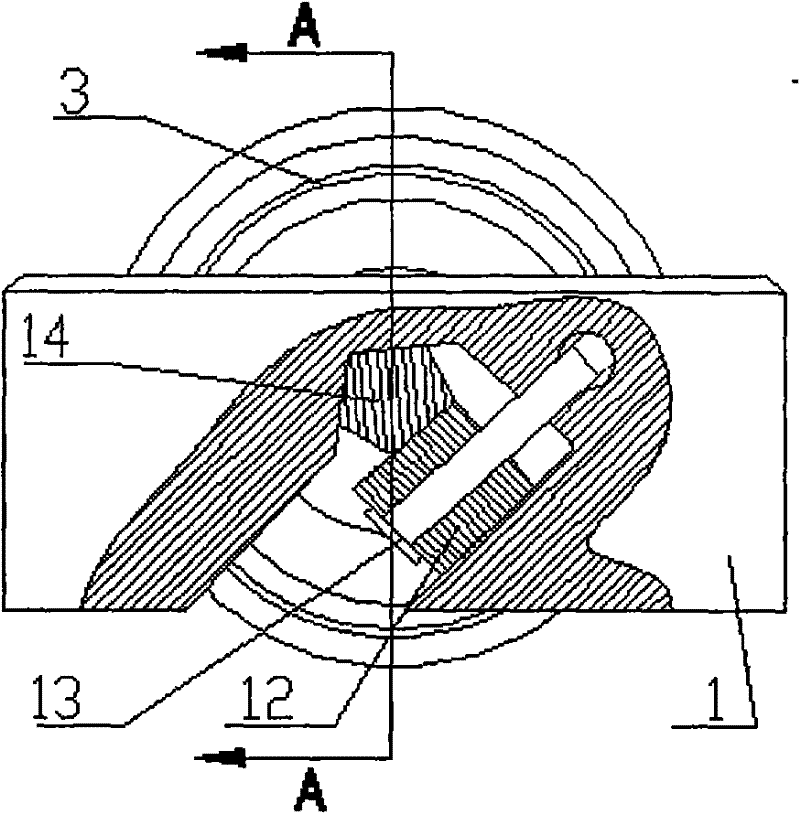

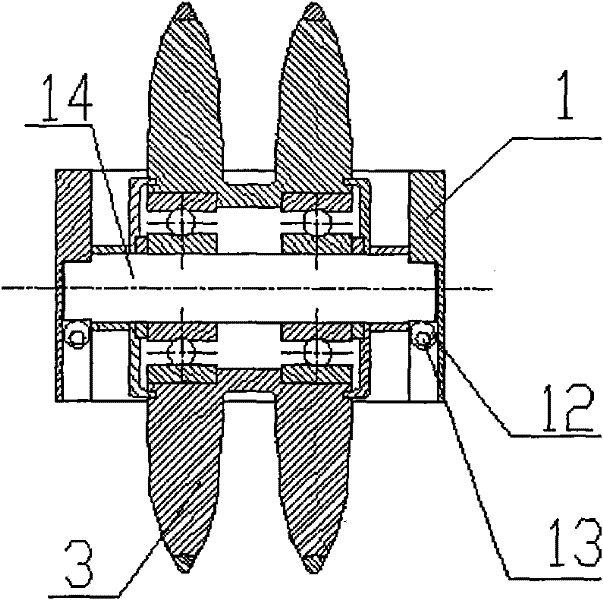

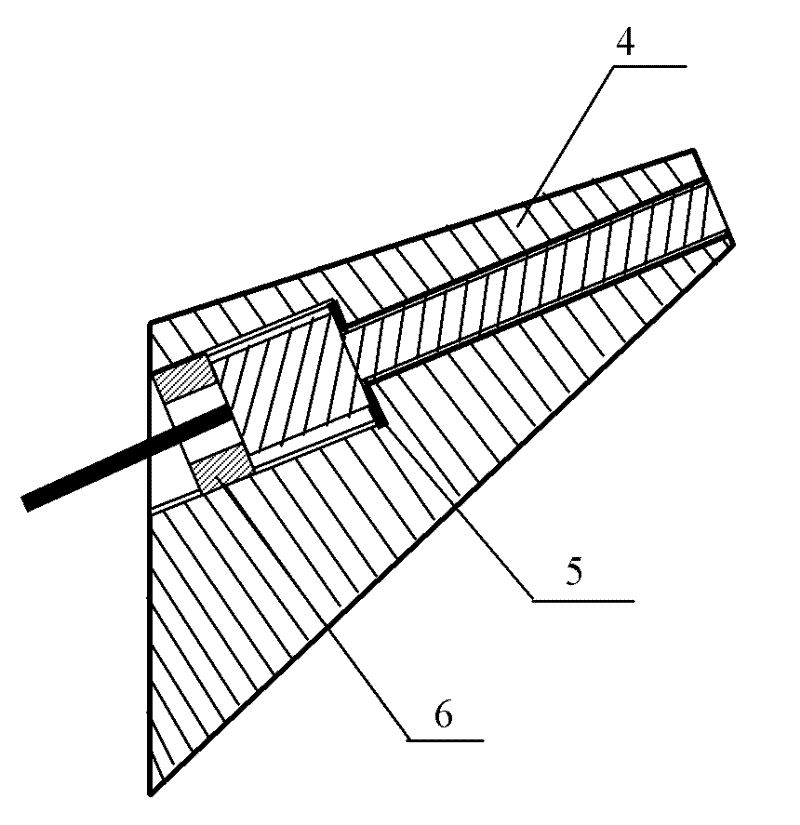

Tool pan back-loading type device for changing tool of slurry-balanced shield machine under normal pressure

The invention relates to a tool pan back-loading type device for changing a tool of a slurry-balanced shield machine under normal pressure, which is applied to the technical field of shield machine engineering machinery. The tool pan back-loading type device for changing the tool of the slurry-balanced shield machine under normal pressure comprises a tool bit, a first seal ring, a tool post, a tool bit fixing sleeve, a tool bit fixing bolt, a tool bar, a cylindrical gate, a grease injection valve, a flushing valve, a third seal ring, a fourth seal ring, a bearing, a large end cover, an oil cylinder and the like; when the tool is in the working state, the tool bit is fixed on the tool bar through the tool bit fixing sleeve and the tool bit fixing bolt; the first seal ring is mounted at thefront end of the tool bar, and the tool bar is matched with the front end of the tool post and is sealed through the first seal ring; the tool bar is fixed on the tool post by the rear end of the tool bar and the tool post through a first fixing screw; the cylindrical gate is fixed on the tool post through the bearing and the large end cover; the grease injection valve and the flushing valve are installed on the tool post; and a serial number is arranged between the cylindrical gate and the tool post. The tool pan back-loading type device for changing the tool of the slurry-balanced shield machine under normal pressure has the advantages of simple structure, reliable working, and capability of conveniently and quickly changing a worn tool under normal pressure (atmospheric pressure) in the shield construction process.

Owner:SHENYANG HEAVY MACHINERY GROUP

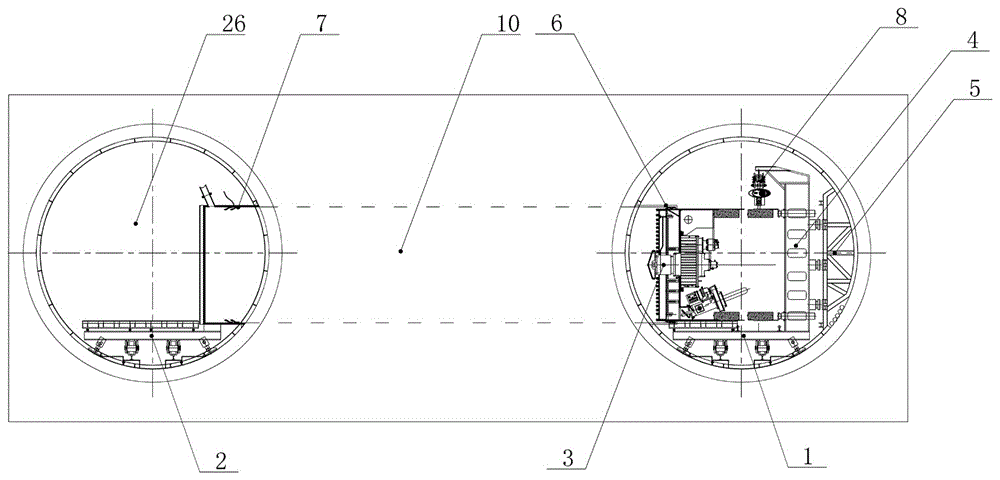

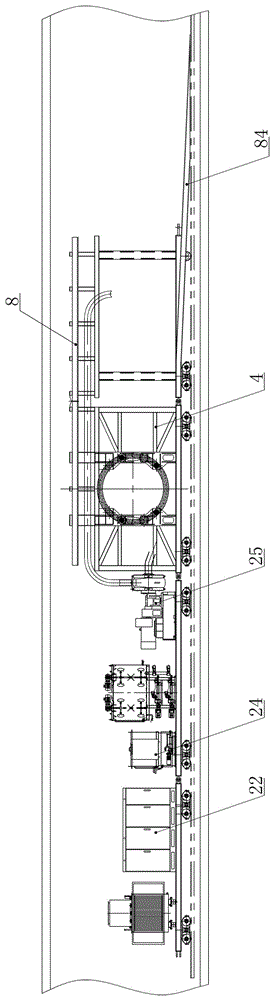

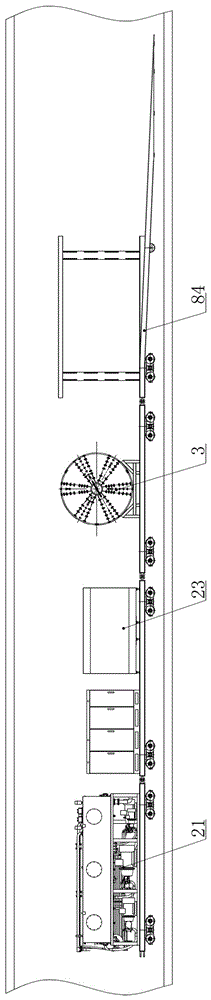

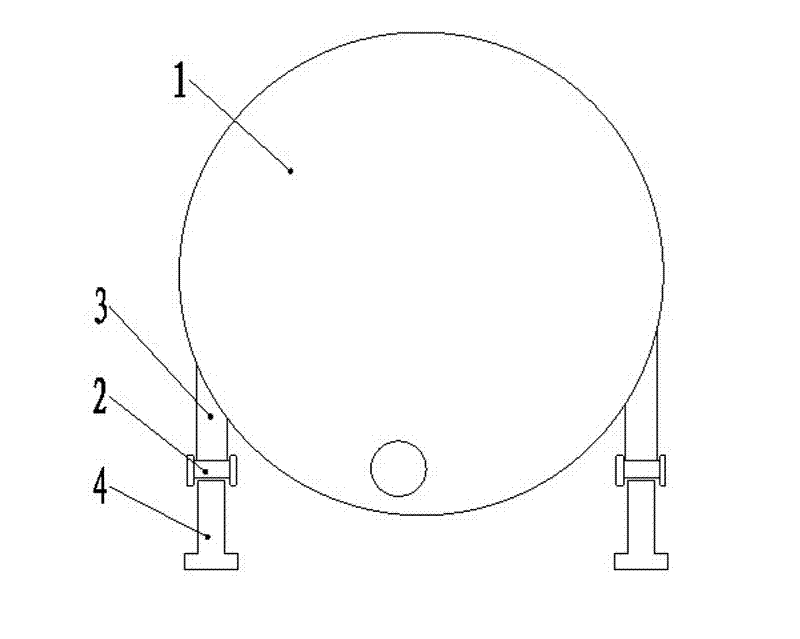

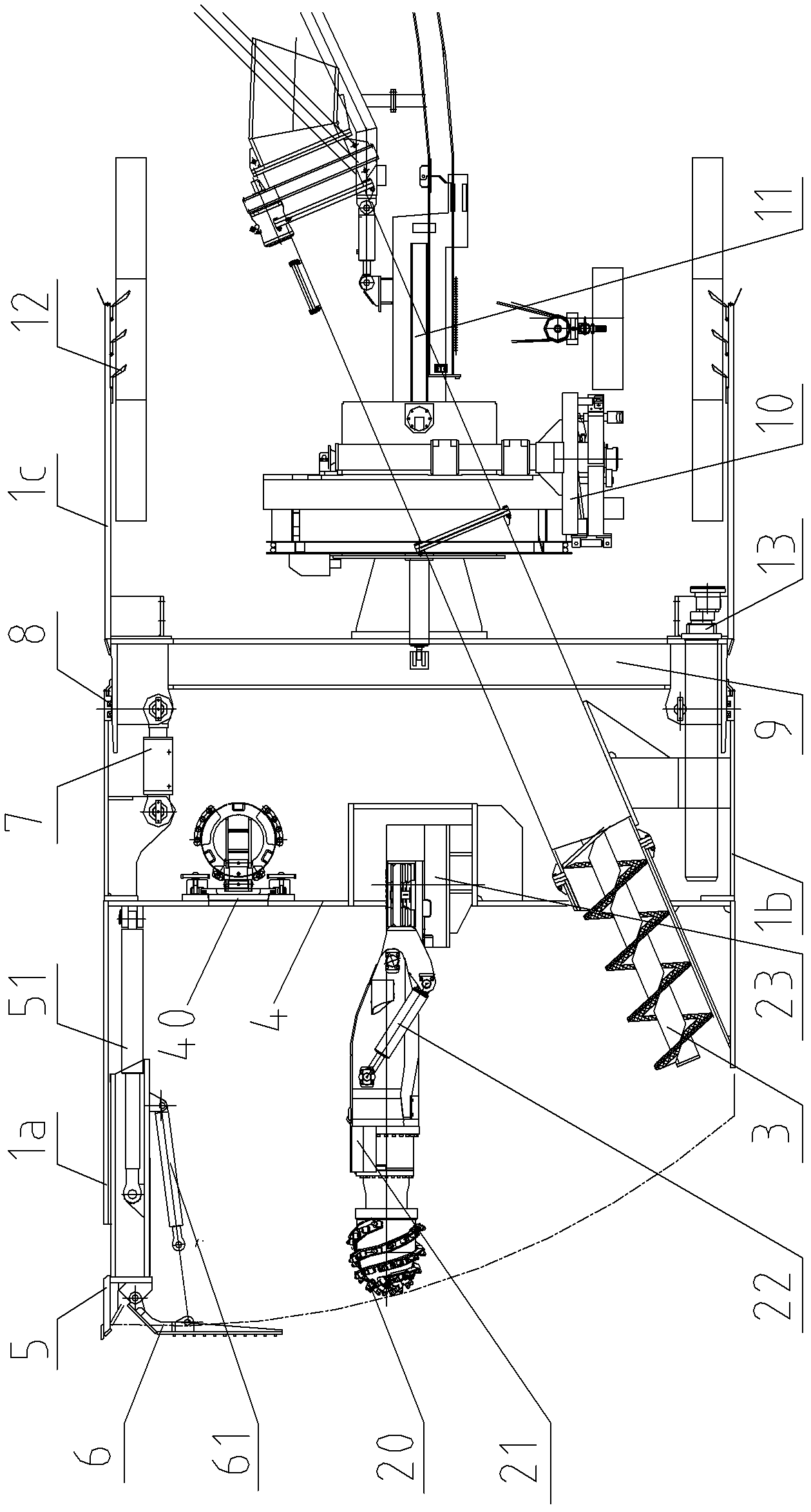

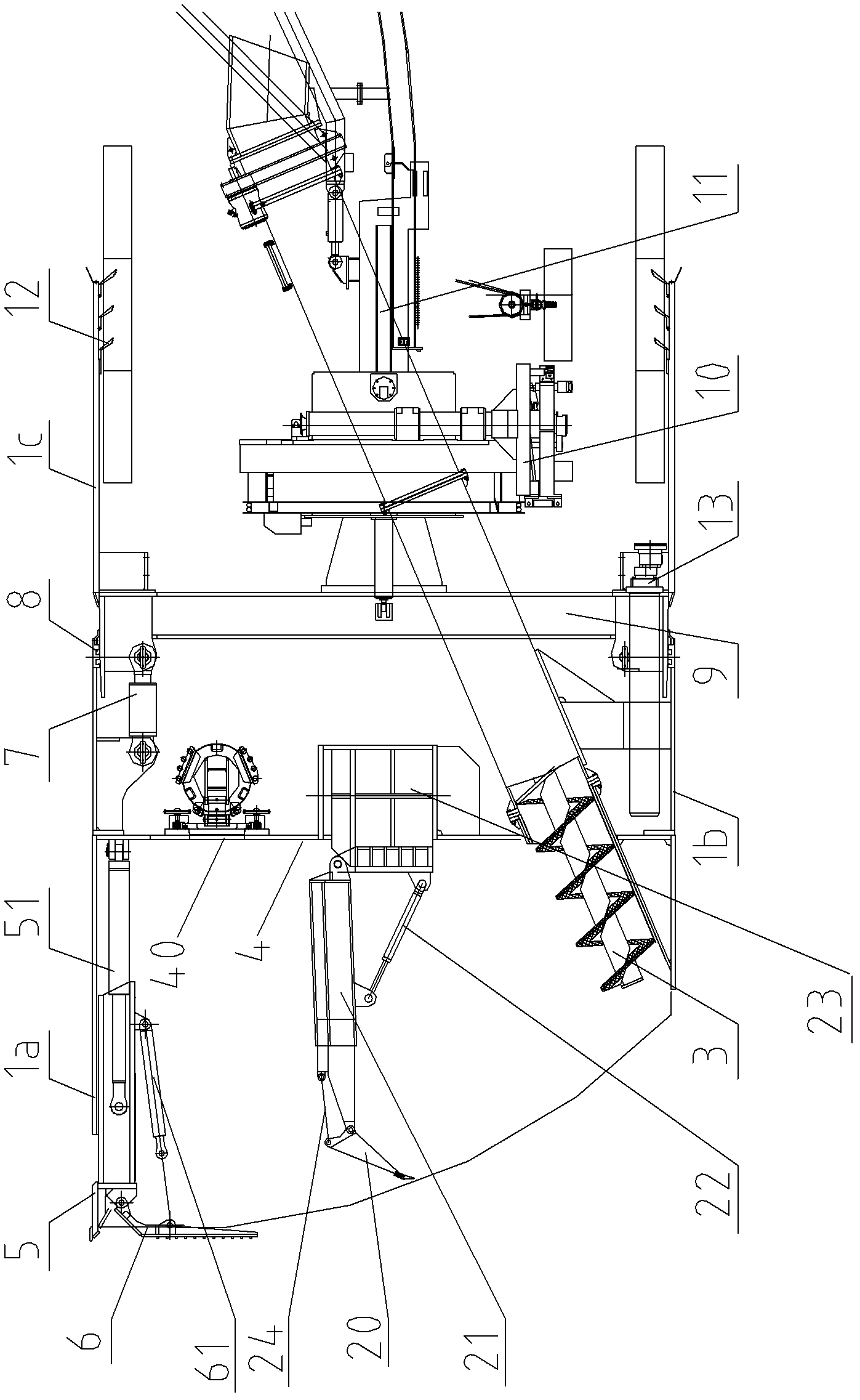

Shield tunneling machine for tunnel connecting passageway and connecting passageway tunneling method of shield tunneling machine

ActiveCN106437735AReaction support enoughCompact and reasonable structure designTunnelsShield tunnelingUltimate tensile strength

The invention belongs to the technical field of tunnel construction equipment, and relates to a shield tunneling machine for a tunnel connecting passageway and a connecting passageway tunneling method of the shield tunneling machine. The shield tunneling machine comprises a start end supporting walking platform and a receiving end supporting walking platform which are respectively arranged on material transportation rails in two main tunnels, a shield tunneling machine main unit, a counterforce supporting frame and a main tunnel supporting assembly which are respectively arranged on the start end supporting walking platform and a corresponding main tunnel duct piece, and a start end socket sealing assembly and a receiving end socket sealing assembly which are respectively arranged at the start end and the receiving end of the connecting passageway, wherein a duct piece hanging assembly is arranged on the start end supporting walking platform; a jacking tunneling assembly is arranged between the counterforce supporting frame and the shield tunneling machine main unit. The shield tunneling machine can realize automatically mechanical excavation; the labor intensity is greatly reduced, the energy consumption is reduced, and the cost is reduced; meanwhile, equipment construction is stable, and the efficiency is high; settling of the ground is effectively controlled, and the construction risk is reduced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

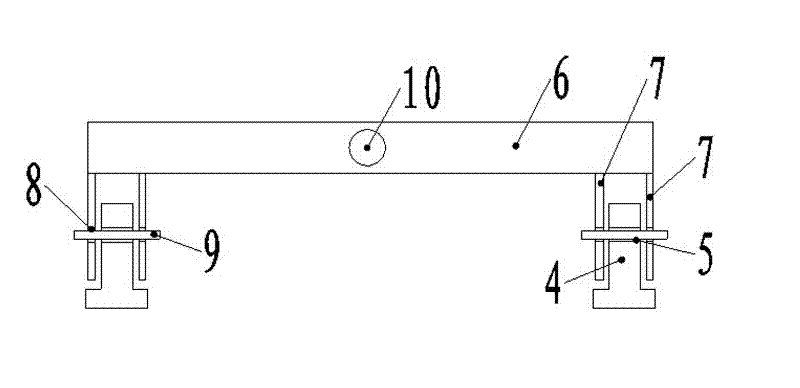

Roller guide rail station-passing construction method of whole shield machine

The invention relates to the field of tunneling shield construction, in particular to a roller guide rail station-passing construction method of a whole shield machine and solving the problems of high difficulty, high cost, long construction peroid and the like of the traditional method. The roller guide rail station-passing construction method comprises the following steps of: machining a shieldforward-moving roller, a forward-moving guide rail, a counter-force device and a rear matched track section; determining whether water stop fabric is arranged in a hole, carrying out shield receivingand welding the forward-moving roller while receiving; moving the whole shield machine forwards, cutting a U-shaped groove plate at a shield connecting bridge off, paving the shield forward-moving guide rail, installing the counter-force device, and enabling the shield to move continuously forwards under the actions of the counter-force device and an oil cylinder; cutting the forward-moving roller off in the process of moving the shield to an originated base forwards, arranging the oil cylinder to the originated base and the side wall of an originated wall, starting the oil cylinder so that the shield body and the originated base translate together along the articulation part of the connecting bridge and the shield body and subsequent associated equipment are in the same straight line, and carrying out second originating. The roller guide rail station-passing construction method has the advantages of simple process, short construction peroid, low cost, risk controllability and the like and has favorable economic and social benefits and wide application range.

Owner:2ND ENG CO LTD OF CHINA RAILWAY 12TH BUREAU GRP +1

Construction method of composite soil pressure balance tunnel shielding machine for traversing shallow-buried water-rich sand layer

ActiveCN101403307AScientific and reasonable technical solutionsEasy to implementTunnelsEngineeringPressure balance

The invention discloses a construction method that a composite soil pressure balanced shield machine passes through a shallow sand layer rich in water, pertaining to the technical field of tunnel construction. When the composite soil pressure balanced shield machine passes through the shallow sand layer rich in water, an injecting system is arranged at the position of a pressure plate and a cutter head of the shield machine so as to inject a matter-a foaming agent, or bentonite, or a macromoleclar polymer, or the mixture of the three, which has the performances of rapid volume expansion and viscosity increase after absorbing water, into the front shallow sand layer rich in water; the shallow sand layer rich in water is rapidly expanded, soil entering an integral pressure cabin is caused to form plastic flow state, and the soil is caused to reach the permeability coefficient of lower than the magnitude of 10<-5>cm / s which is needed by the construction and the caving degree of 10 to 15cm. The technical proposal is scientific and reasonable, simple and easy to implement, can acquire obvious technique effect, adopts the composite soil pressure balanced shield machine for passing through the shallow sand layer rich in water successfully and acquires satisfactory construction quality as well as guarantees the construction period.

Owner:URBAN MASS TRANSIT ENG CO LTD OF CHINA RAILWAY 11TH BUREAU GRP

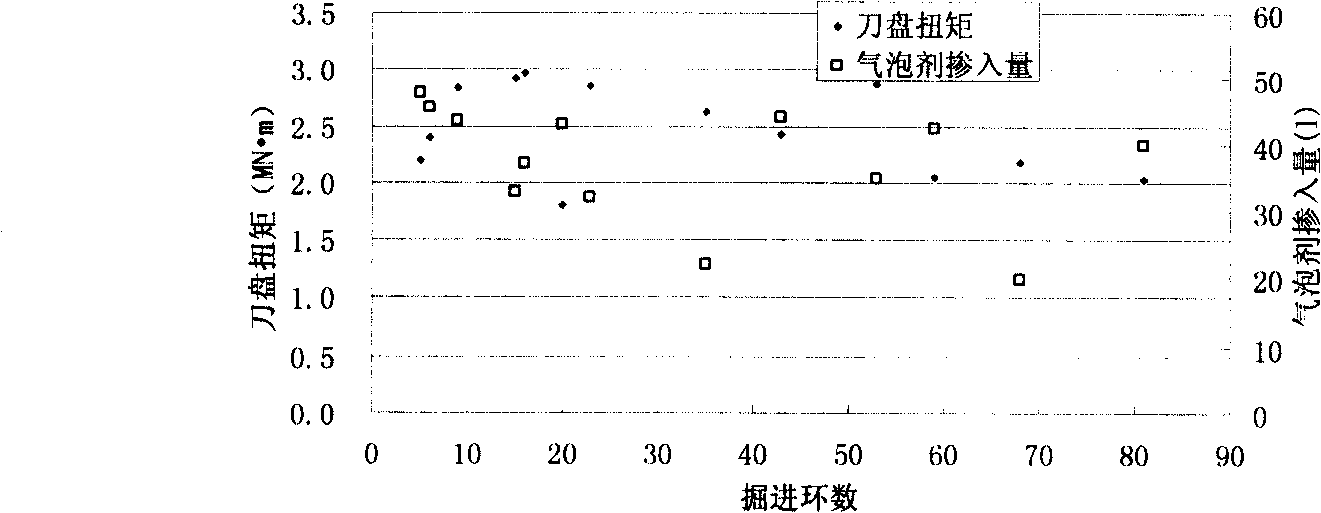

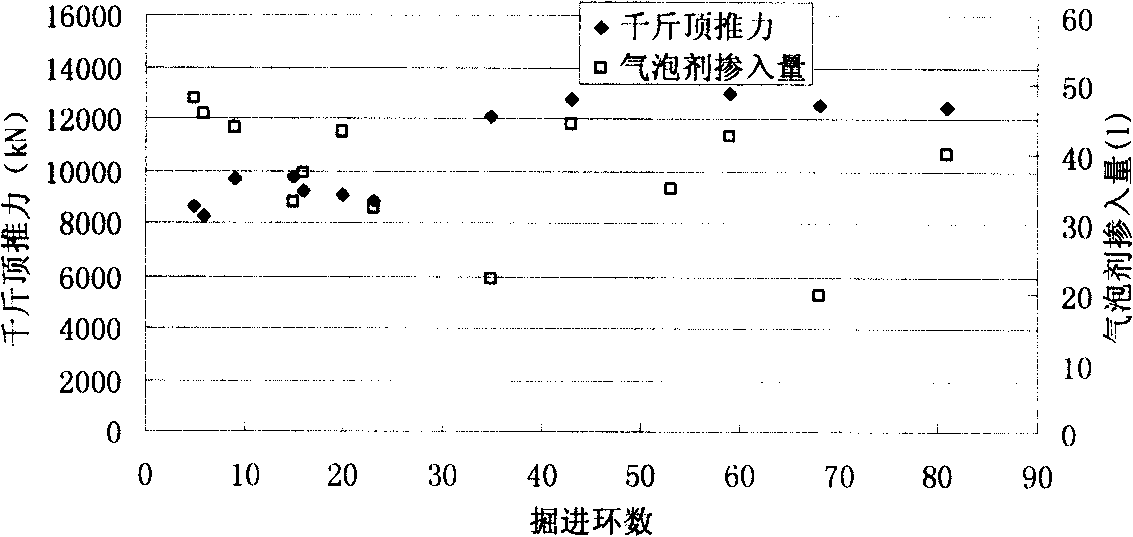

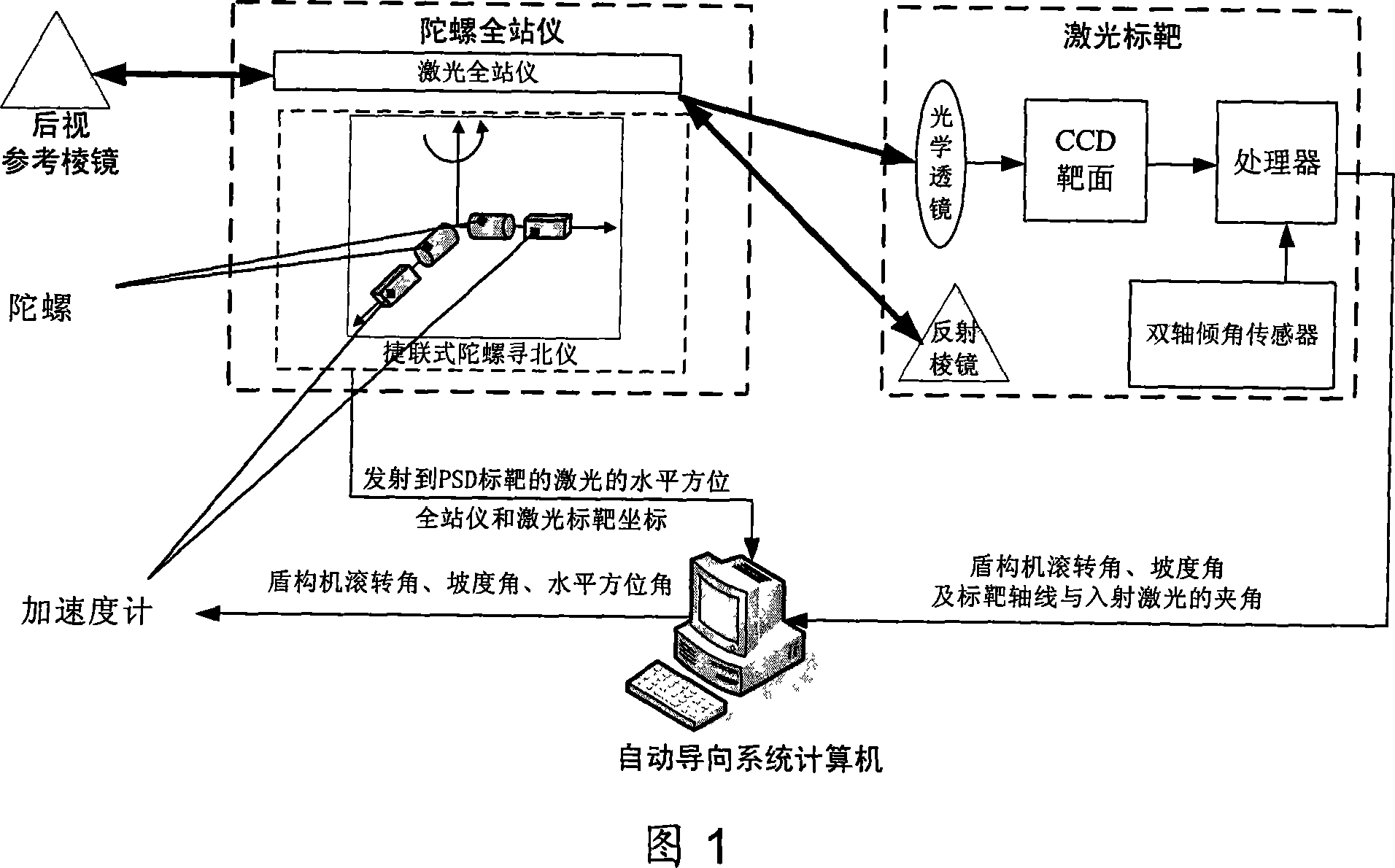

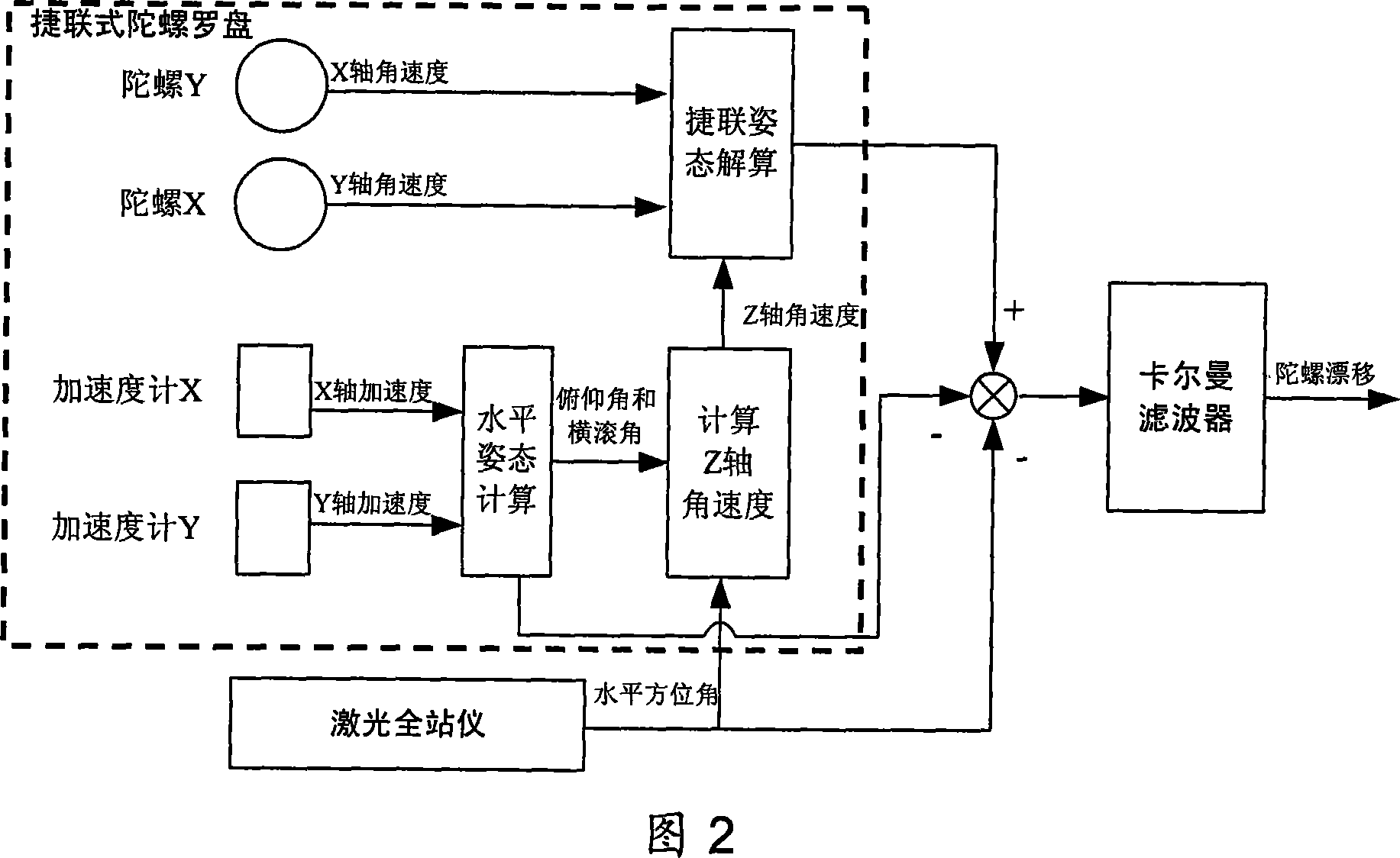

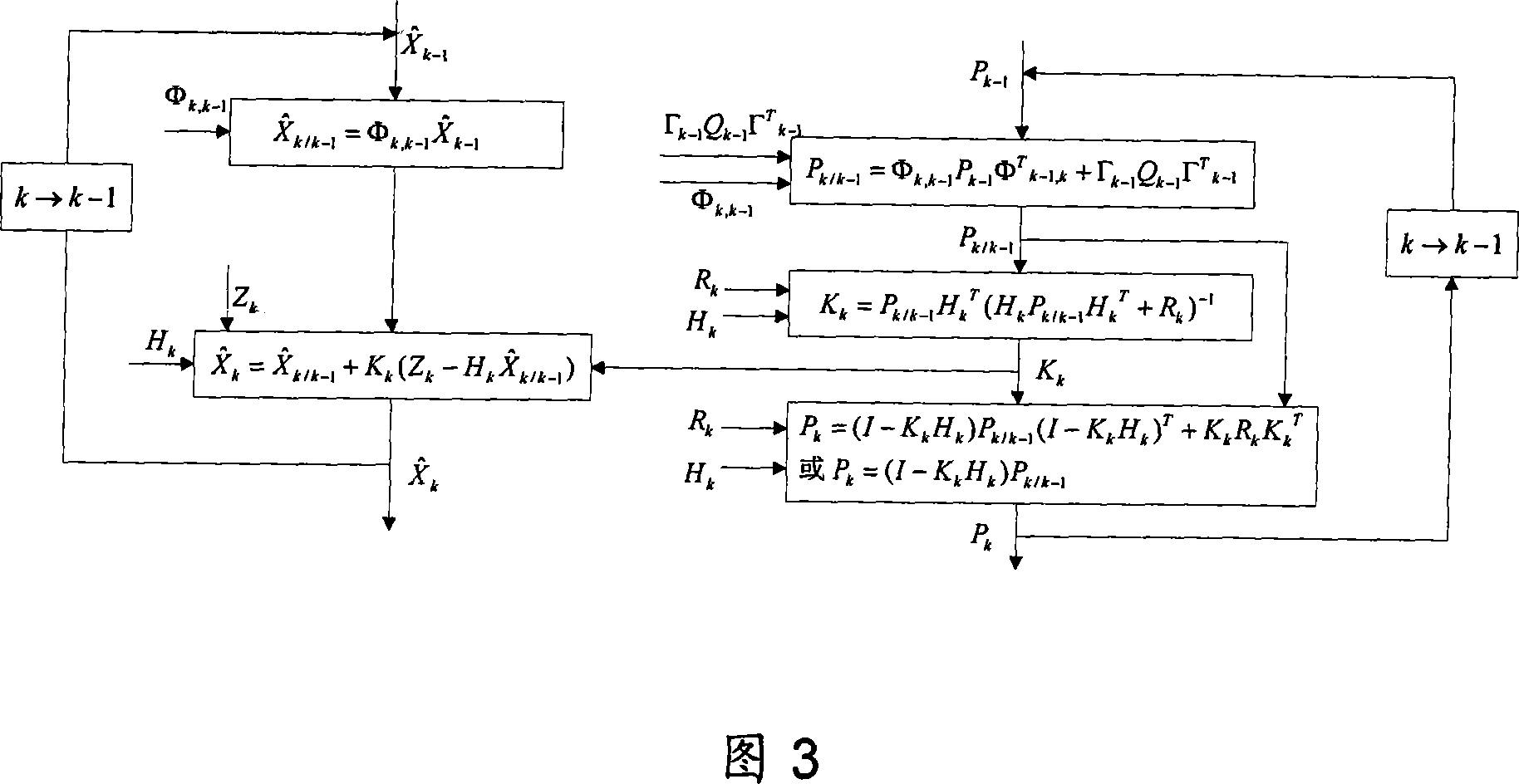

On-line calibration method for shield machine automatic guiding system based on optical fiber gyro and PSD laser target

InactiveCN101078627ARealize online calibrationHigh precisionNavigation by speed/acceleration measurementsKaiman filterElevation angle

The invention relates to an on-line calibration method for automatic guiding system of shield machine based on gyro total station and laser target, characterized in that in digging process of shield machine, laser total station is used to track prism at the lower part of laser target and the change of horizontal azimuth angle of strap-down gyro north finder while by two accumulators in gyro north finder elevation angle and roll angle of gyro north finder are calculated; then by three altitude angles measured accurately angle speed of Z axis, which can not be measured by strap-down gyro north finder, is calculated; and then it is combined with angle speeds of X and Y axes measured by gyro to carry out strap-down altitude algorithm; finally three angles measured accurately are used as observing values and kalman filter is used to evaluate gyro excursion while it is compensated in system. The invention is provided with the merit that the error of gyro excursion can be eliminated on line and can be used to improve accuracy of automatic guiding system.

Owner:BEIHANG UNIV

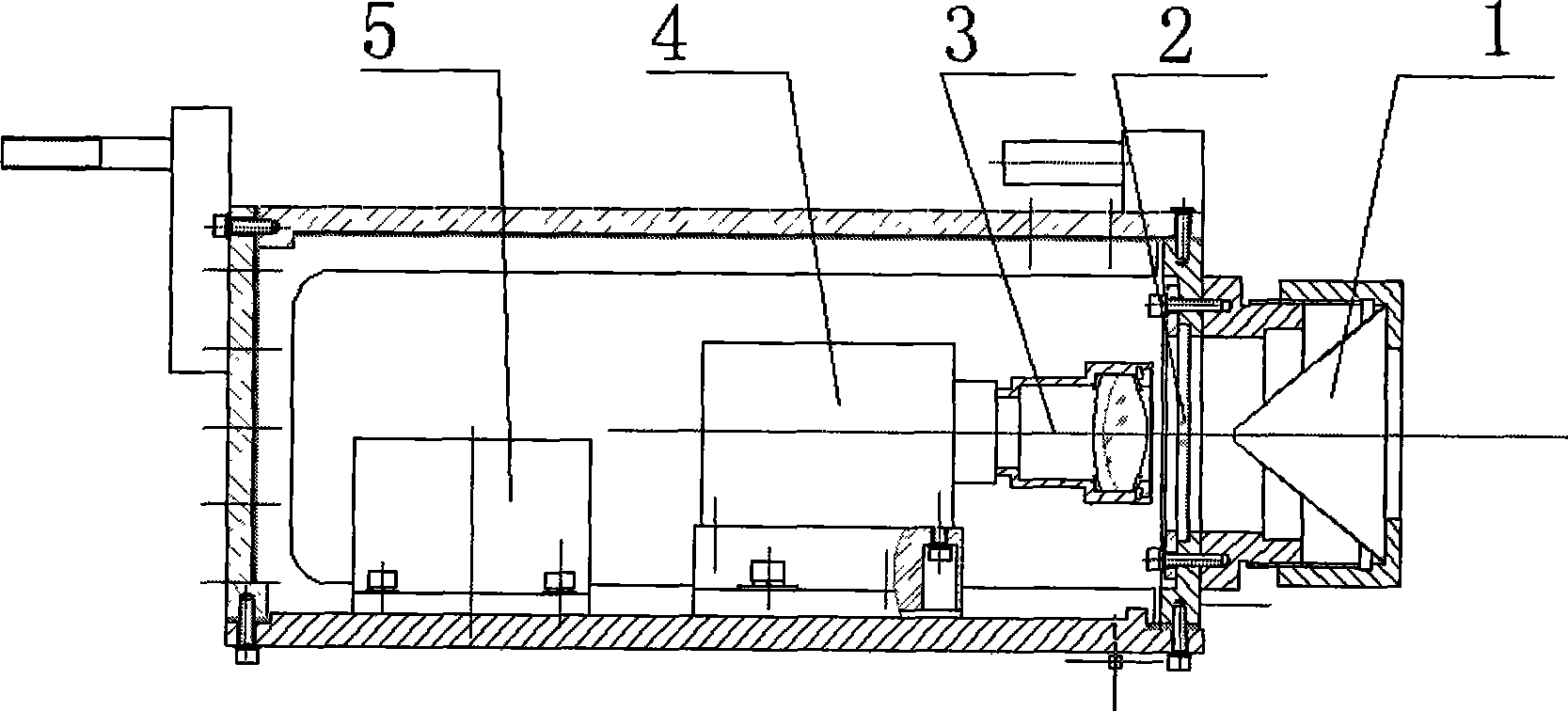

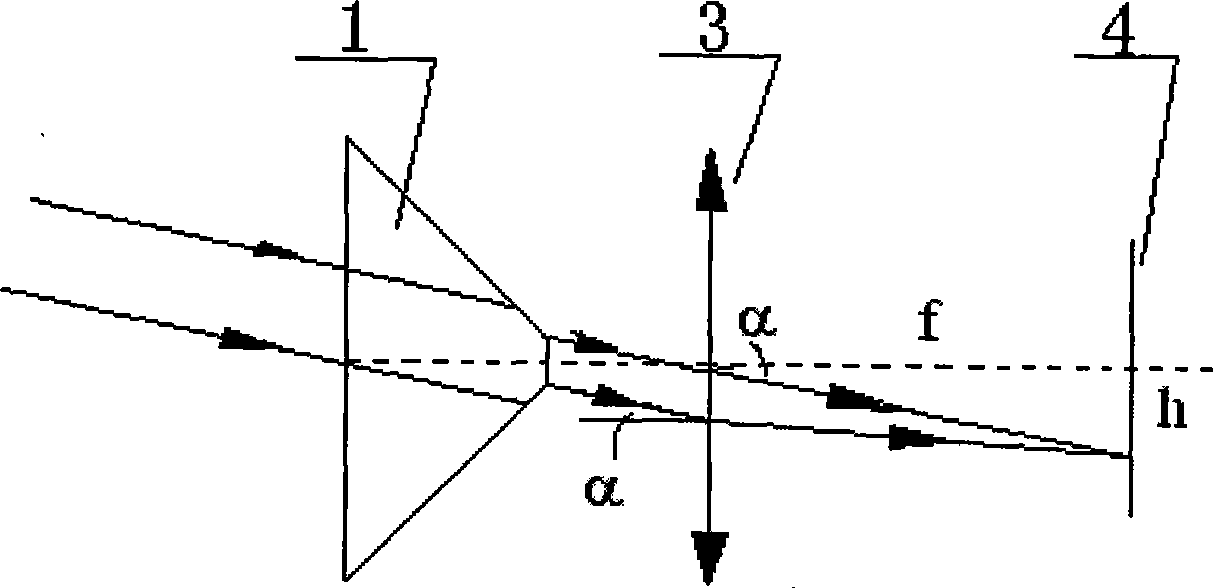

Three-dimensional attitude measuring set of tunneling construction guidance system

The invention discloses a three-dimensional attitude measurement device for a tunneling construction guidance system, which belongs to a positioning measurement device and aims to solve the problems that the prior three-dimensional attitude measurement device has higher requirement on the light intensity and is not accurate to the processing of pulsed light signals so as to simplify the installation and use of equipment. A prism, a lens, a CCD camera and an inclinometer are sequentially arranged on a light path along the axial direction in a machine case of the device, and output signals of the CCD camera are sent to a computer through a gigabit network cable; and output signals of the inclinometer are sent to the computer through an asynchronous serial communication interface. The device has small volume, simplifies the operation, and directly utilizes infrared rays of a total station instrument to focus through the lens to project on the photosensitive surface of the CCD camera to produce a photosensitive signal, the photosensitive signal is processed to obtain deflection angle data of incident light, and the deflection angle data are output to an external computer along with inclination angle data measured by the inclinometer. The device is mainly used for attitude measurement during the construction process of a shield machine and obtains a pitching angle, a rolling direction angle and a horizontal deflection angle of a shield in a real-time mode.

Owner:HUAZHONG UNIV OF SCI & TECH

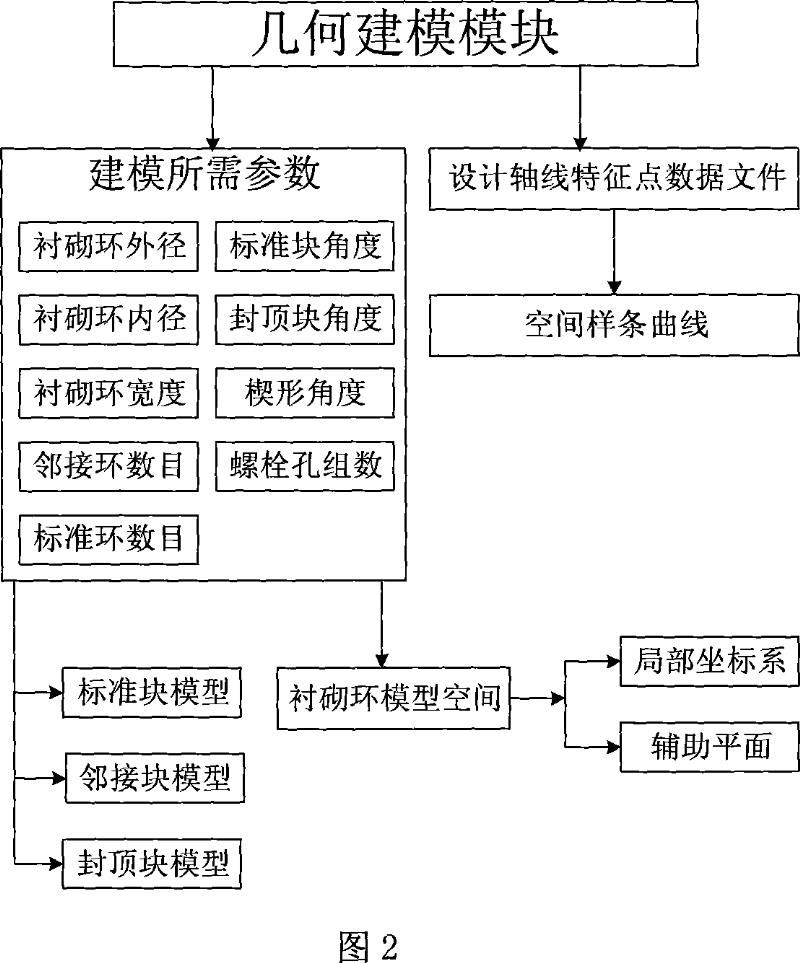

Shield tunnel universal segment dynamic virtual assembling system

InactiveCN101038605APrevent deviationSpecial data processing applications3D modellingDatabase interfaceGraphics

A tunnel shield universal segment dynamic 3D virtual assembling system applied in the tunnel technology field comprising a geometry modeling module for setting up the geometry model of the segments and the tunnel axis by parameter design and storing the model into a database, a universal segment selection module for obtaining the geometry model data from the database and processing them to obtain the segment point sequence of the tunnel axis and storing them into an assembling database, a core module namely the universal segment 3D virtual assembling and deviation detection module for extracting the virtual assembly required data from the assembling database interface, displaying the assembling process on the terminal and displaying the deviation between the virtual assembled segment center with the tunnel theoretical axis in the text and graph mode, a universal segment assembling data processing module for executing the data maintenance and communication with the database. The invention realizes the dynamic function of the universal segment in the tunnel shield construction to facilitate the on-time regulation of the tunnel machine posture.

Owner:SHANGHAI JIAO TONG UNIV

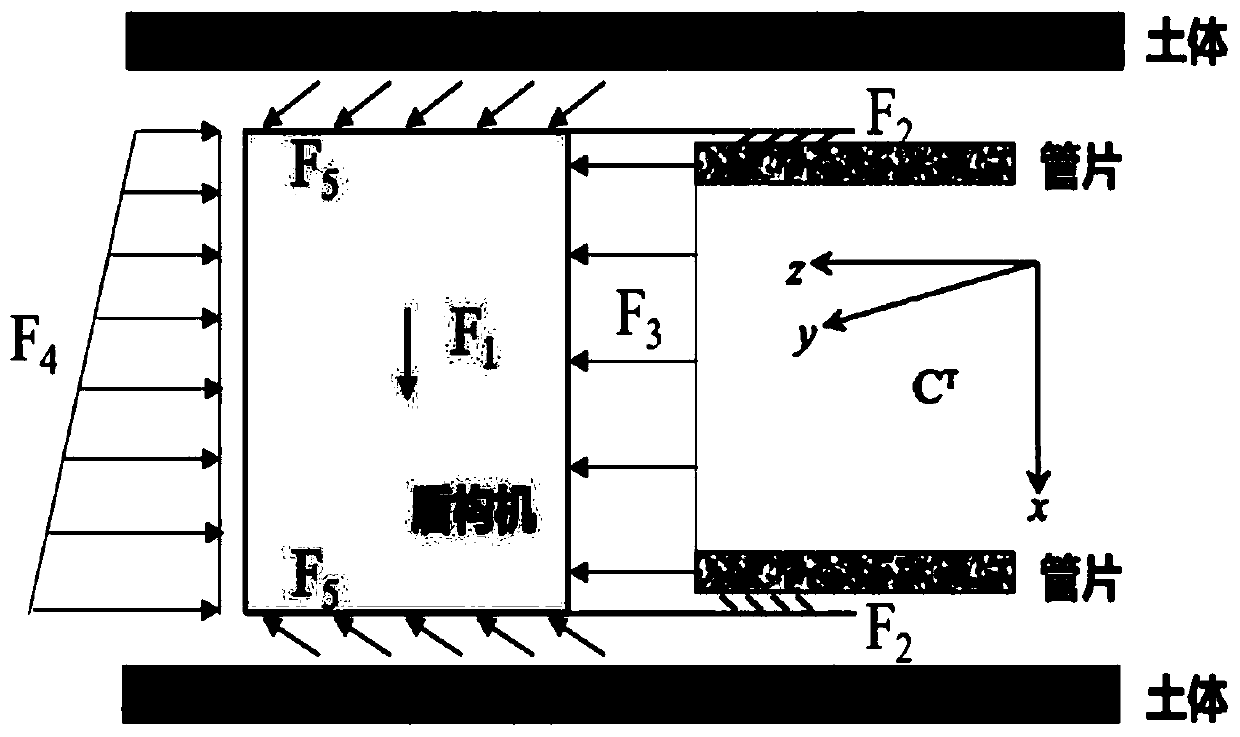

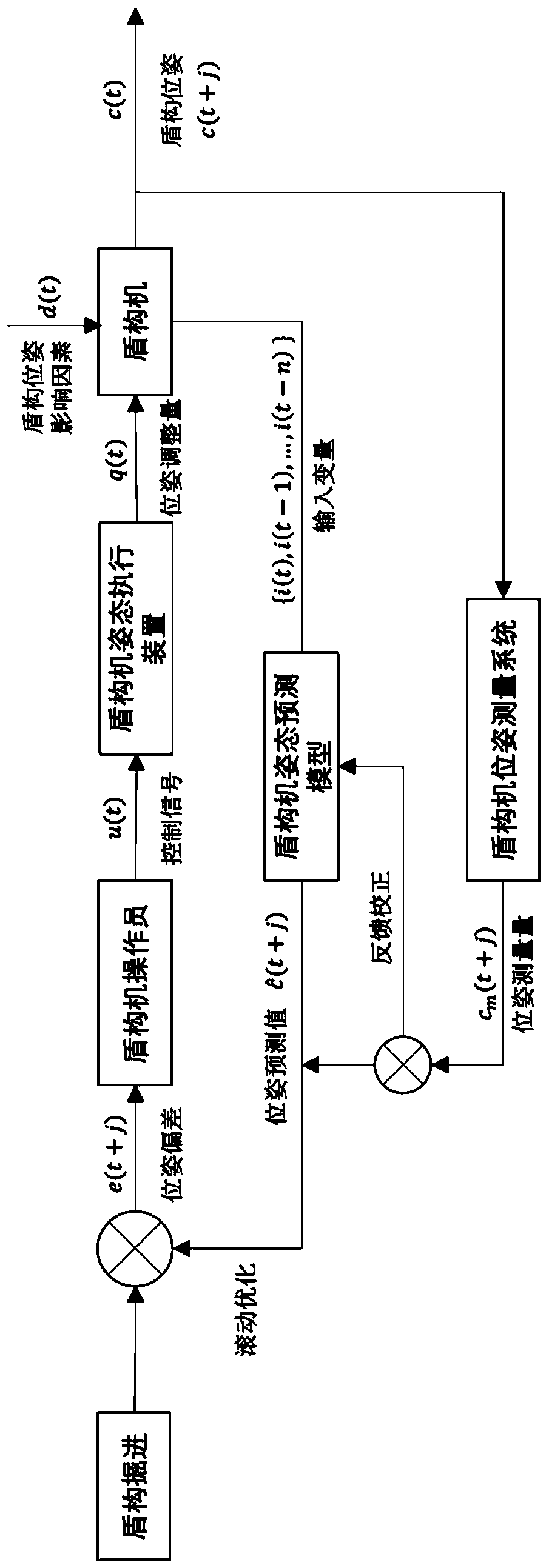

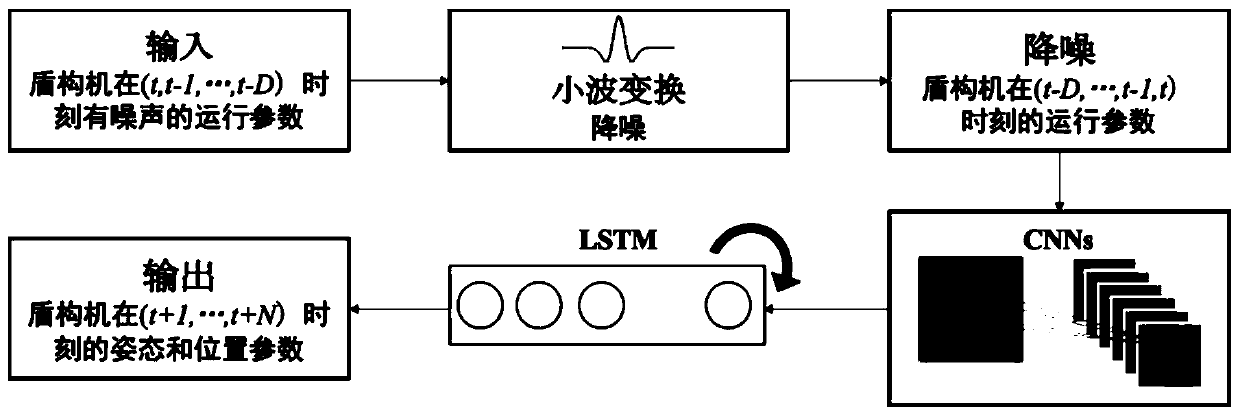

Shield tunneling position and pose intelligent prediction method and system based on hybrid depth learning

ActiveCN110195592AFacilitates early interventionEasy to controlMining devicesTunnelsControl engineeringShield tunneling

The invention discloses a shield tunneling position and pose intelligent prediction method and system based on hybrid depth learning, and belongs to the field of construction of subway shields. According to the method, a prediction control principle and an artificial intelligence technology are adopted based on a shield misalignment mechanism, positions and poses in a shield tunneling stage are predicted according to a built hybrid depth learning model WCNN-LSTM, an adjustment strategy of the shield positions and poses is formulated, and pre-adjustment and prior control of operation parametersare realized so that the problem of shield misalignment is improved. The method is used for performing intelligent prediction of subsequent change of the positions and poses in a tunneling process ofa shield machine, supports a shield machine driver to adjust the shield positions and poses in advance, solves the snake-shaped motion difficulty of the shield machine, alleviates the modulation control hysteretic effect of the shield positions and poses, realizes accurate control of a tunneling axis of the shield machine, can effective promote formation quality of the tunnels and has higher engineering practical values.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Process for grouting on back of shield segment

The invention discloses a process for grouting on the back of a shield segment to control stratum settlement in shield tunnel construction. The process comprises steps of synchronous grouting, secondary grouting and a special treatment process; during synchronous grouting, when a shield advances and a shield tail is formed, a grouting pump of a shield tunneling machine is used for symmetrical grouting through a synchronous grouting system of the shield tunneling machine; during secondary grouting, double grout is injected to the back of the segment through a shield segment secondary grouting hole, and a gap on the back of the segment is subjected to secondary filling and compression; and the special treatment process comprises steps of adding a triallyl cyanurate (TAC) high-molecular polymer material solution and pressing and injecting epoxy resin seal reinforcing rings. By the process, particularly the TAC high-molecular polymer is added to improve a soil layer and the epoxy resin reinforcing rings are pressed and injected to reinforce the stratum in the special treatment process, the grouting effect is good in a safe and convenient way, the flow and loss of the grout are prevented, the grouting plumpness is ensured, the soil body can be well improved, the stratum is reinforced, the settlement amount is effectively controlled, and the shield tunneling construction is safely and smoothly carried out.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Shield machine and anterior shield system thereof

InactiveCN102305083AImprove balanceEstablish balanceUnderground chambersSoil-shifting machines/dredgersEngineeringOperation point

The invention provides a shield machine and an anterior shield system thereof. The system comprises an anterior shield body, an excavation device, a conveyor, and a partition plate, wherein the anterior shield body has a cylindrical structure; the excavation device is arranged on fixing components of the shield machine and a head of the excavation device is used for performing multi action excavation operation on different operation points on an excavation surface; and the conveyor is used for discharging dregs excavated by the head of the excavation device, a first end of the conveyor is arranged below the excavation device and a second end of the conveyor is arranged on the rear part of the first end; and the head of the excavation device and the first end of the conveyor are positioned in front of the partition plate, the second end of the conveyor is positioned on the rear part of the partition plate, and the partition plate is provided with a sealing door which can be opened and closed. The invention can avoid the mud cake agglomeration of a cutter, rolling of the shield body, improved treatment of dregs and pressurized cabin entering operation and has the advantages of quick construction progress, high stability and adaptability and the like.

Owner:BEIJING SANY HEAVY MASCH CO LTD

On-line monitoring device for tool wear of shield machine based on resistance row

InactiveCN102288099AReal-time prediction of wear statusExtended service lifeUsing electrical meansEpoxyElectrical resistance and conductance

The invention discloses an on-line monitoring device for tool wear of a shield tunneling machine based on a resistance row type. inside the tool of the machine. The part where the resistor row contacts the cutter is filled with epoxy resin to ensure the insulation between the resistor row and the cutter. There is a rubber pad at the contact part between the resistance row base and the cutter, and the rubber pad also has a sealing effect, and the resistance row base is fixed with the cutter as a whole with a lock nut. There are three signal amplifiers on the cutterhead, three transmitting antennas are installed on the back of the cutterhead corresponding to the signal amplifiers, receiving antennas are installed on the inner wall of the soil pressure chamber opposite to the transmitting antennas, and signal receiving antennas are installed in the main cabin of the shield tunneling machine. device. The invention can predict the wear state of the excavating tool on-line, effectively reducing or avoiding the occurrence of huge economic losses, personal casualties and other dangerous accidents caused by tool accident shutdown.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com