Cutting device with small-range diameter-variable function of soft rock shield machine

一种切削装置、盾构机的技术,应用在采矿设备、土方钻采、隧道等方向,能够解决影响工程质量、费工、不能保持不变等问题,达到保证工程质量、确保人身安全、提高工作效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

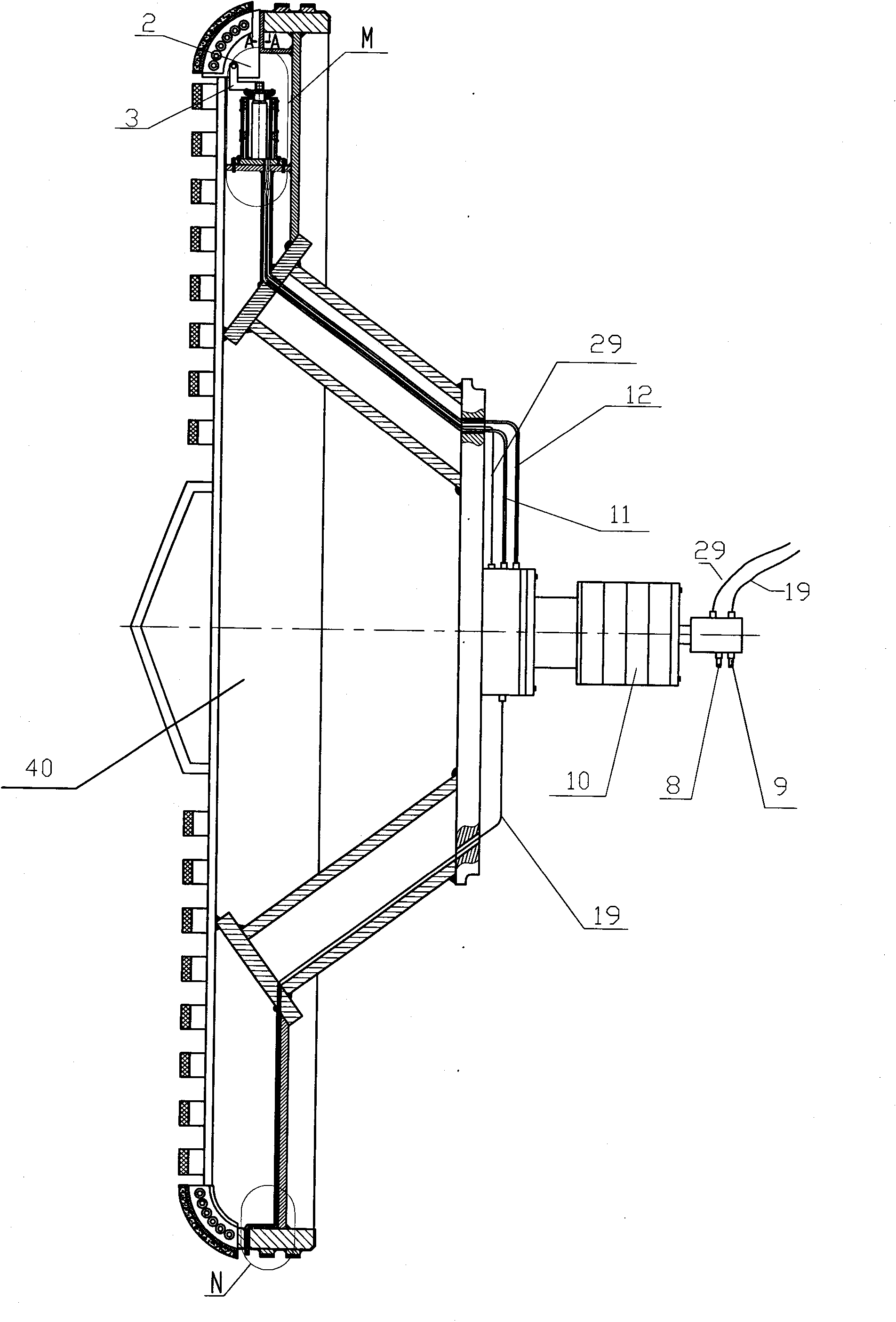

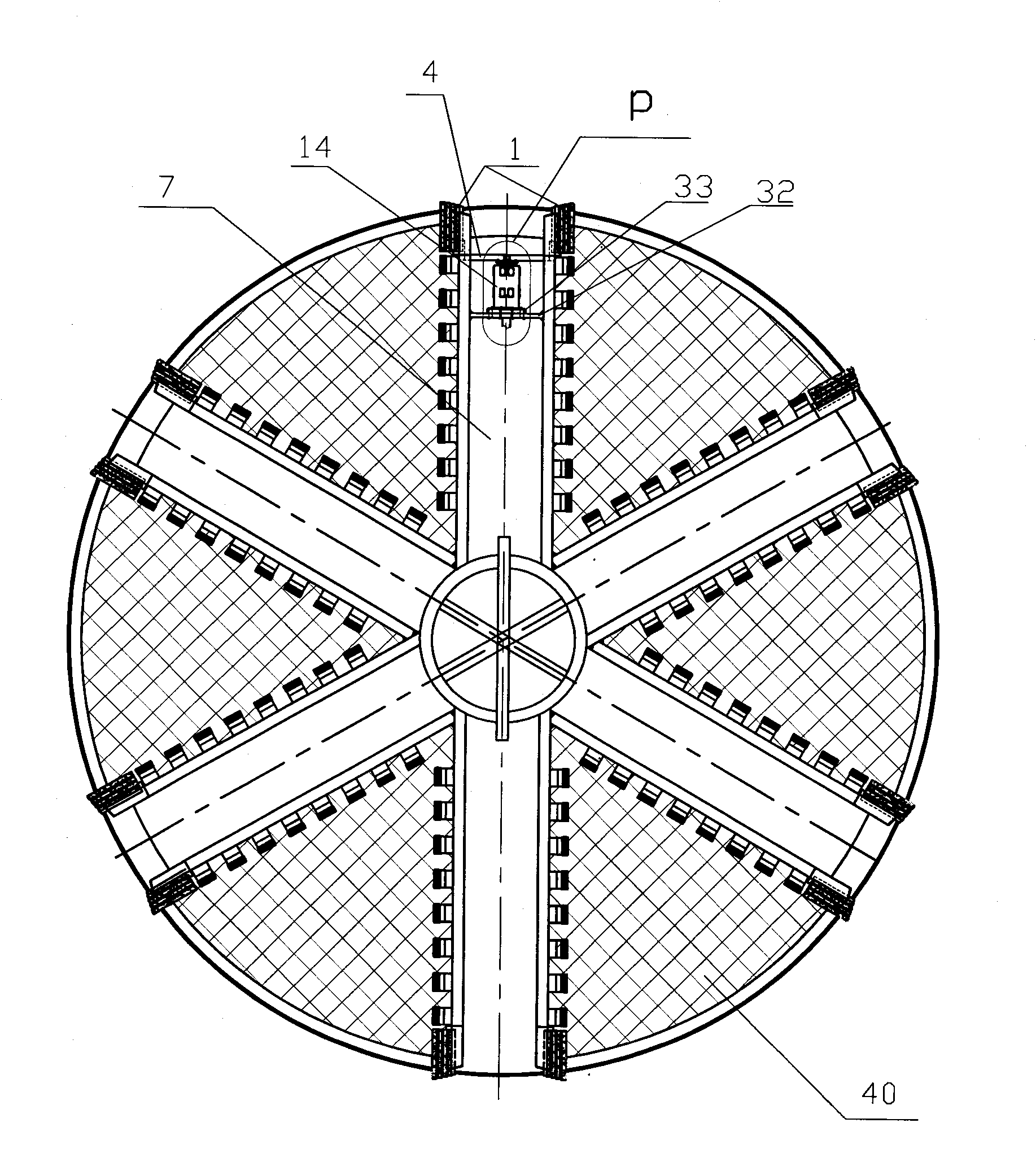

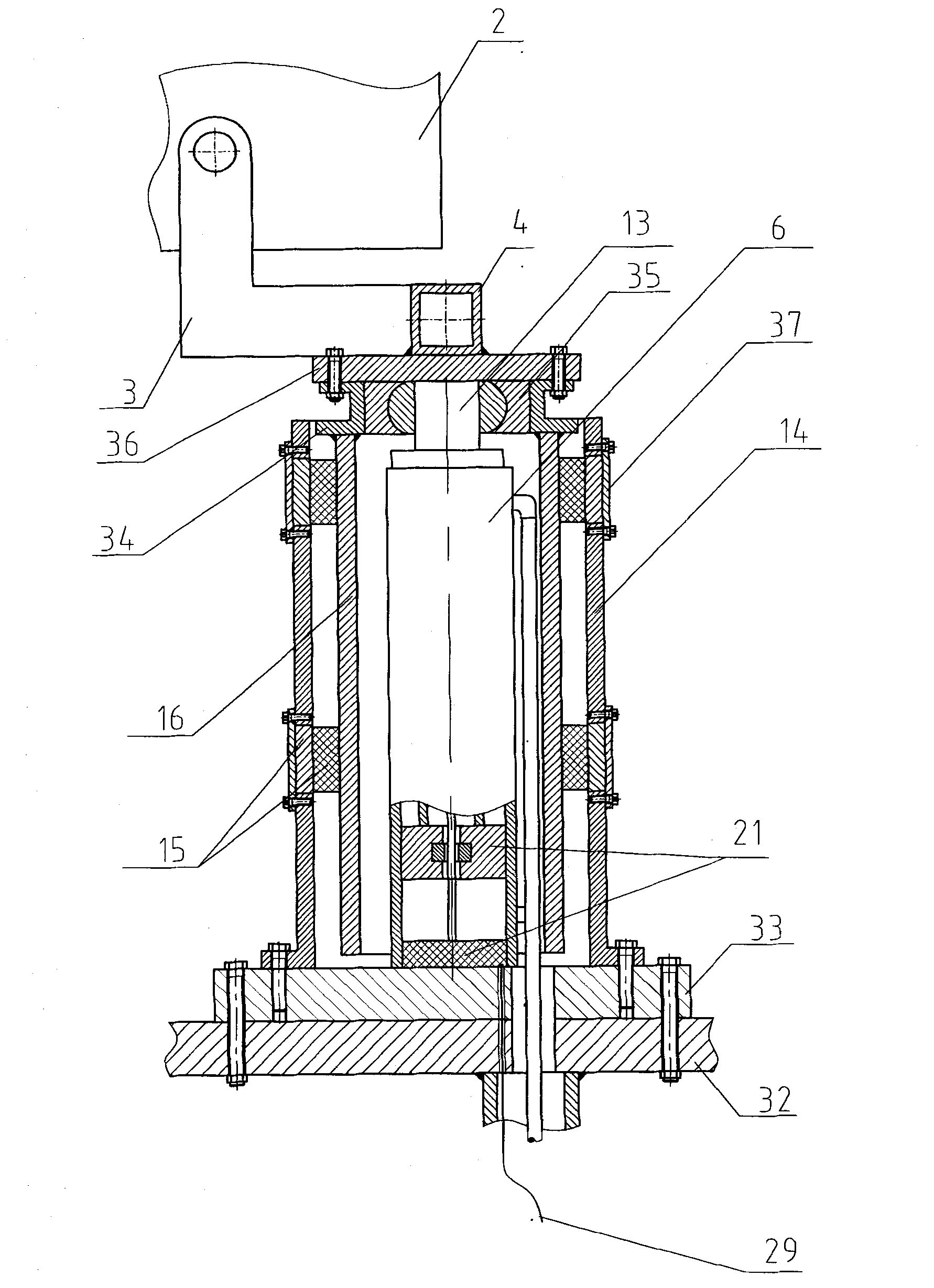

[0016] A cutting device with a small-scale diameter reducing function in a soft rock shield machine. It is composed of a cutter head, a cutter assembled on the cutter head, a side scraper and its side scraper telescopic mechanism, a hydraulic control device and a wear limit detection device. composition.

[0017] A side scraper 1 is installed on both sides of the end of a slag tapping groove 7 of the cutter head 40, and the two side scrapers are symmetrical about the radial center line of the slag tapping groove. The two side scrapers 1 are connected to a telescopic mechanism, and the telescopic mechanism is installed in the slag tap 7 of the cutter head 40. The telescopic mechanism consists of a set of left and right side scraper seat plates 2, a set of left and right connecting rods 3 connected with a set of left and right side scraper seat plates 2, and a support beam 4 connected with these two sets of connecting rods 3 . In this embodiment, a set of side scraper seat plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com