Tool pan back-loading type device for changing tool of slurry-balanced shield machine under normal pressure

A mud-water balance and shield machine technology, which is applied in mining equipment, earth-moving drilling, tunnels, etc., can solve the problems of high risk, high cost, and unfavorable health of operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

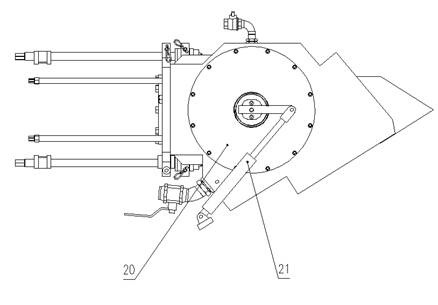

[0013]Referring to the accompanying drawings, a back-mounted normal-pressure tool changing device for a mud-water balance shield machine cutter head consists of a cutter head 1, a first sealing ring 2, a cutter seat 3, a cutter head fixing sleeve 4, a cutter head fixing bolt 5, and a cutter bar 6. Cylindrical gate 7, grease injection valve 8, second sealing ring 9, screw rod 10, first fixing screw 11, small end cover 12, screw nut 13, guide rod 14, nut 15, flushing valve 16, third seal Ring 17, fourth sealing ring 18, bearing 19, large end cover 20, oil cylinder 21, fifth sealing ring 22, second fixing screw 23, sixth sealing ring 24, when the cutter is in working state, the cutter head 1 passes through the cutter head The fixed sleeve 4 and the cutter head fixing bolt 5 are fixed on the cutter bar 6, the front end of the cutter bar is equipped with a sealing ring 2, the cutter bar 6 cooperates with the front end of the cutter seat 3, and is sealed by the sealing ring 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com