Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1532 results about "Waterstop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A waterstop is an element of a concrete structure, intended to prevent the passages of fluids (such as water) when embedded in and running continuously through concrete joints. Waterstops are grouped in two distinct categories. Waterstops for joints without any movement of the adjoint concrete sections (construction cold joints) and waterstops for joints with movement of the adjoint concrete sections (dilation joints).

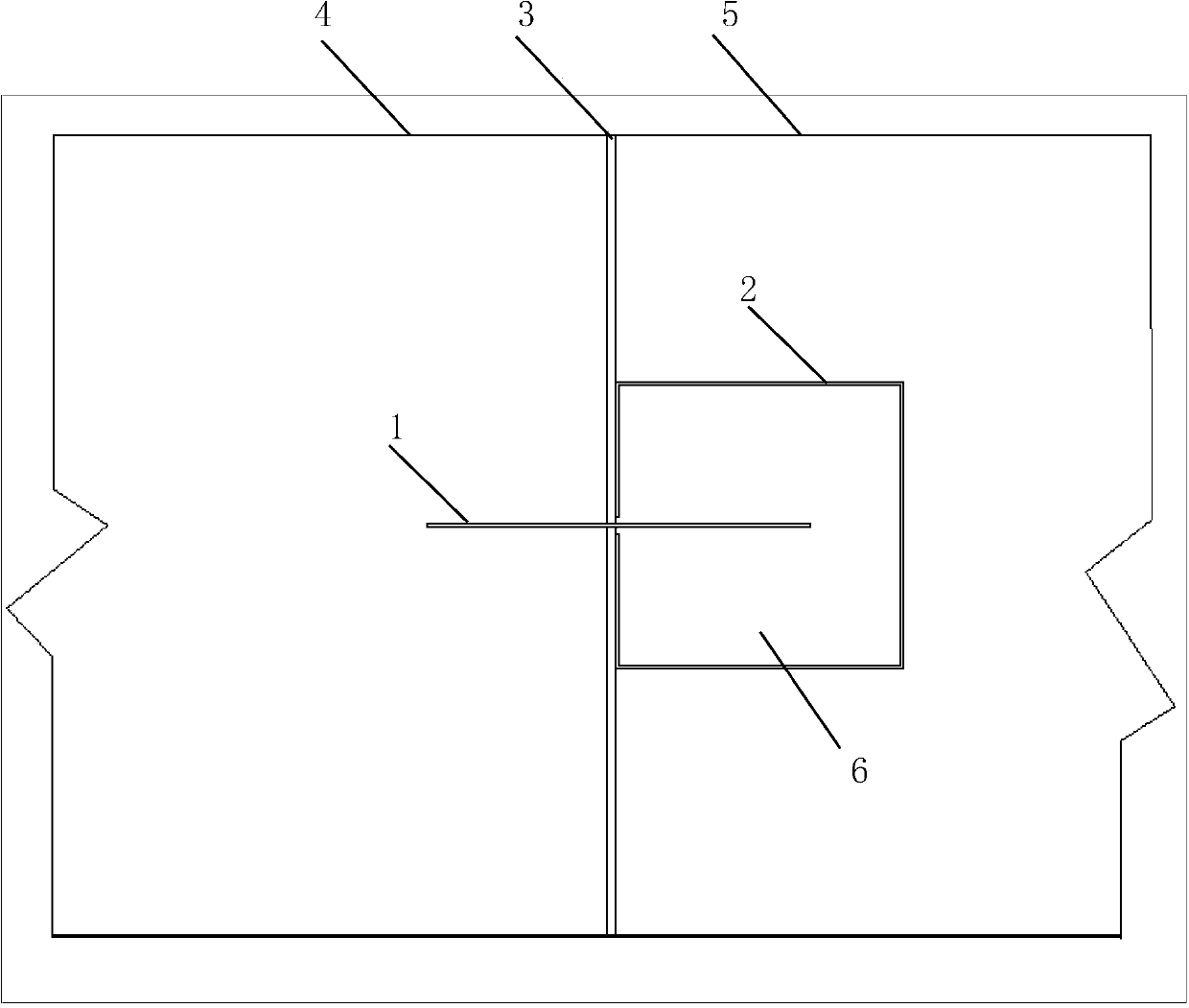

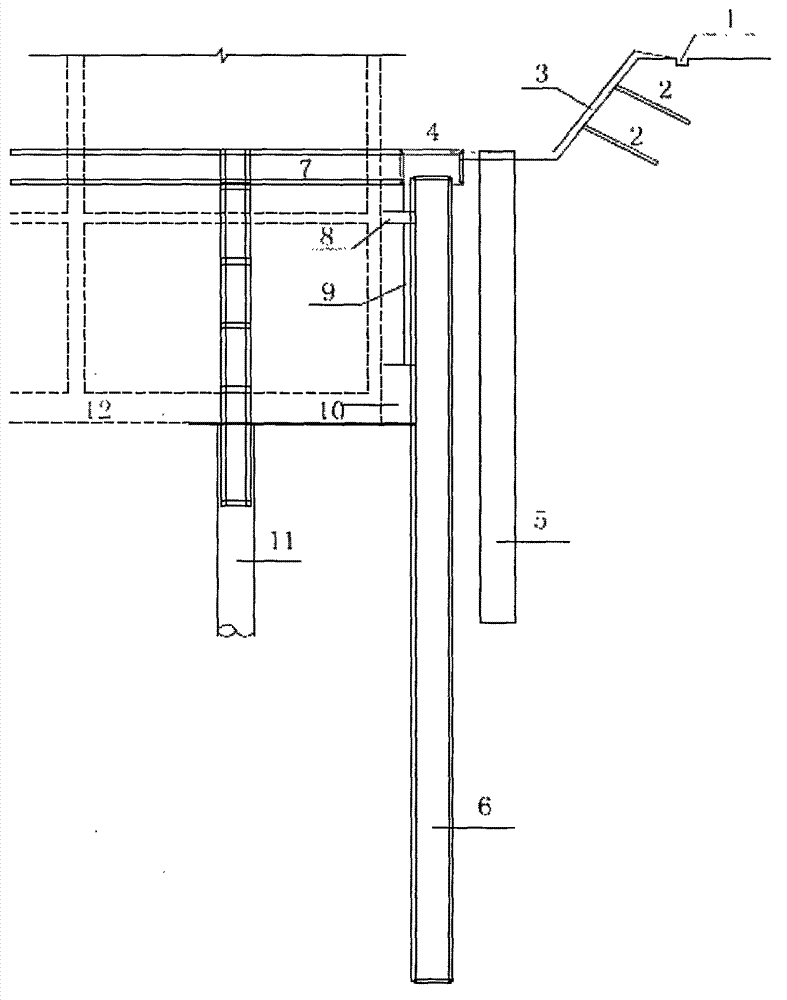

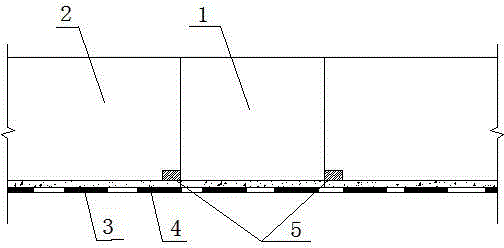

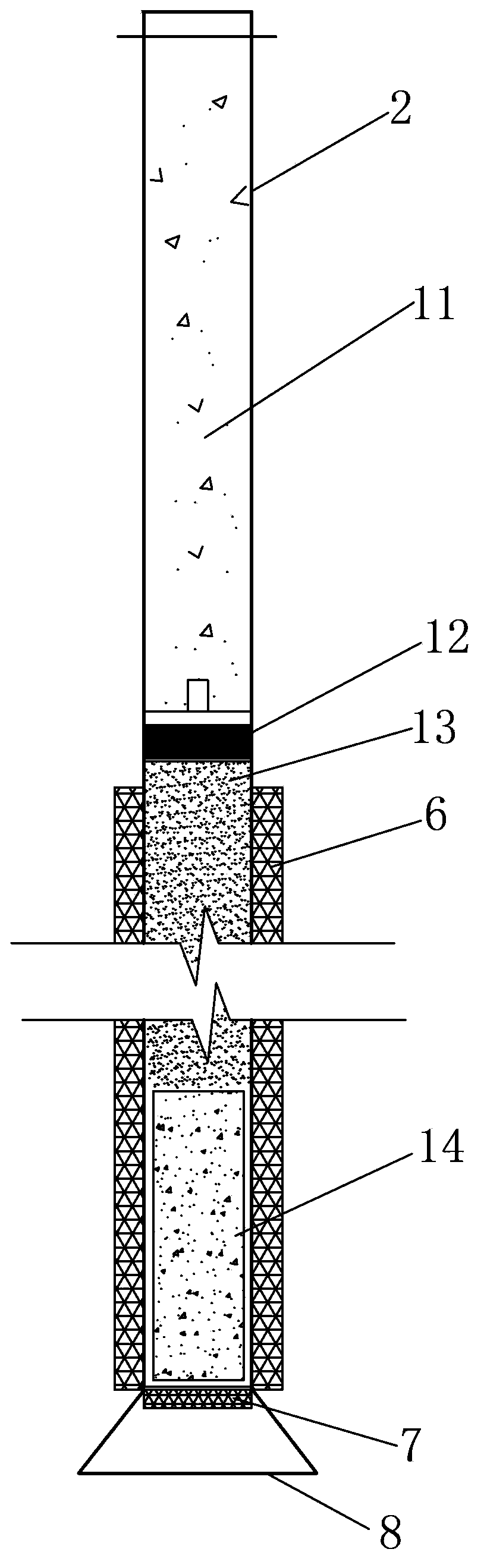

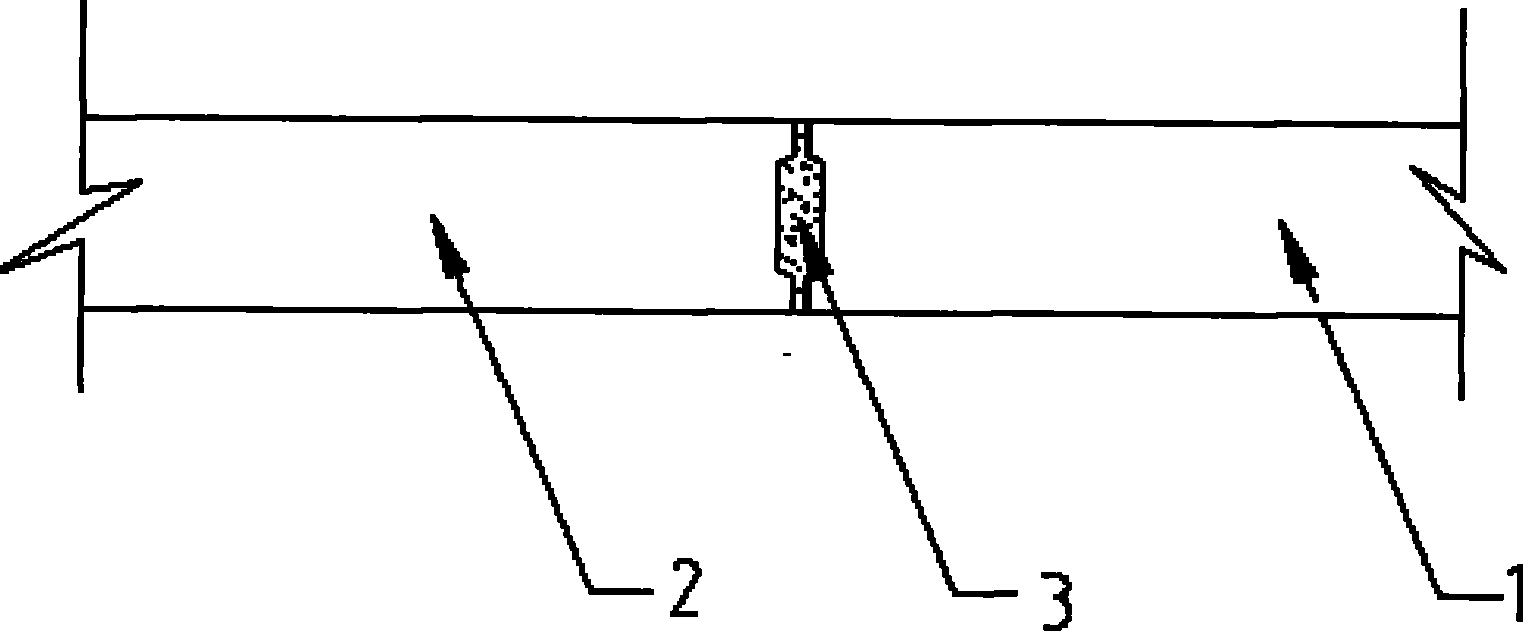

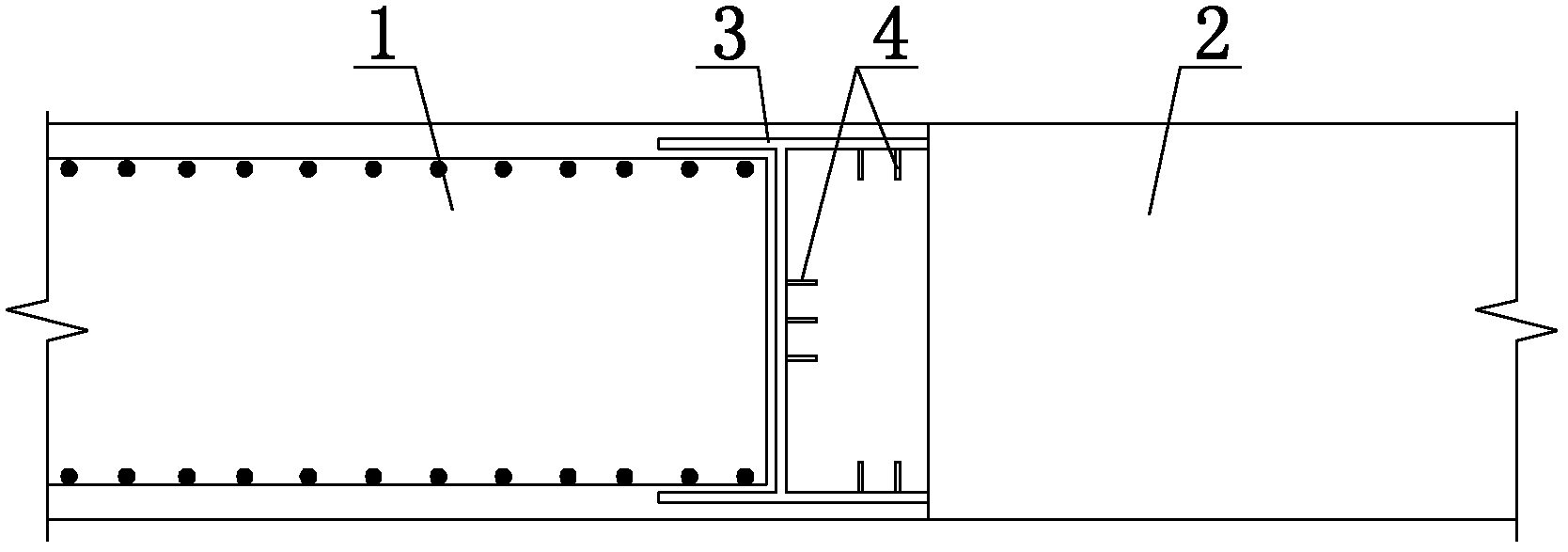

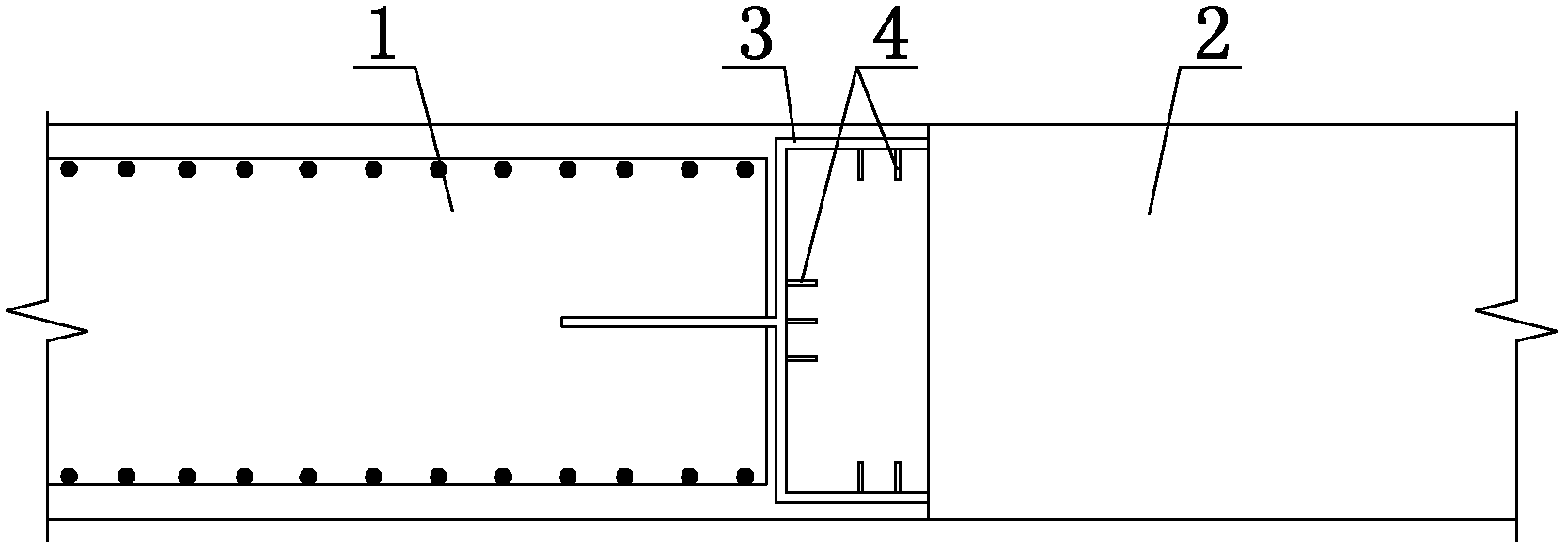

Vertical water-stop structure for concrete engineering expansion joint as well as manufacturing and construction methods for same

InactiveCN103774699ASolve the leakLow costArtificial islandsUnderground chambersUnderwaterEngineering

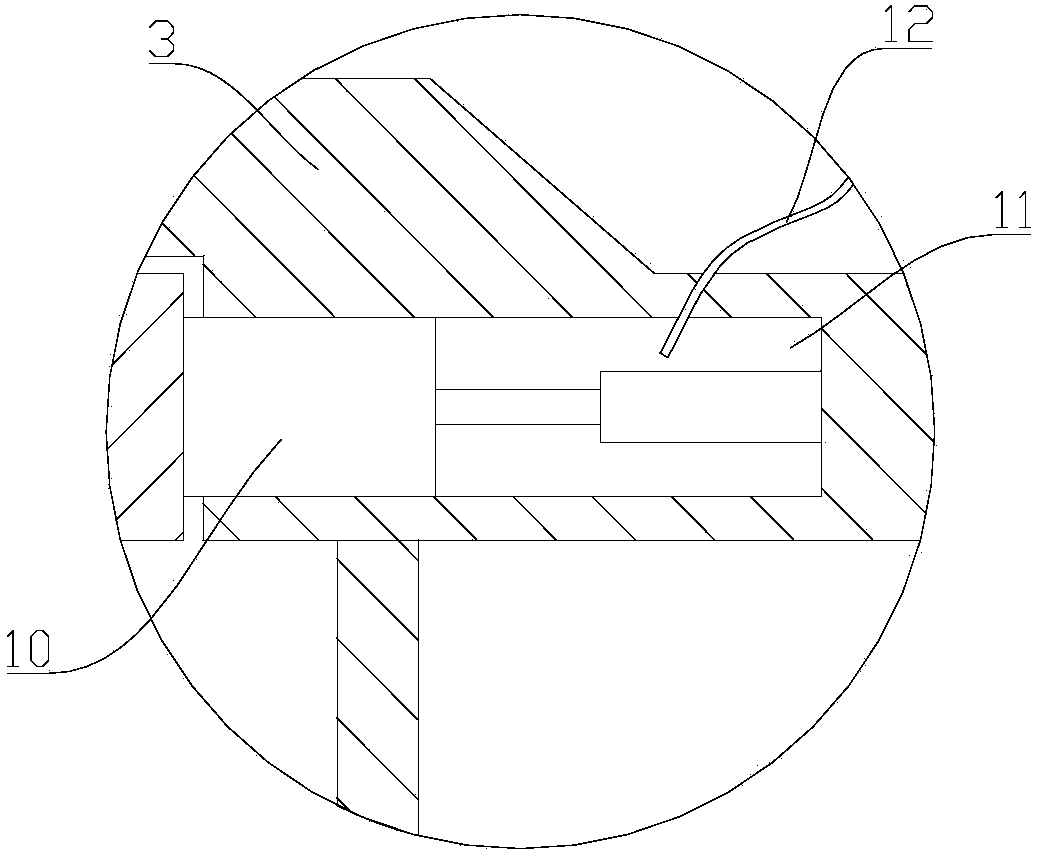

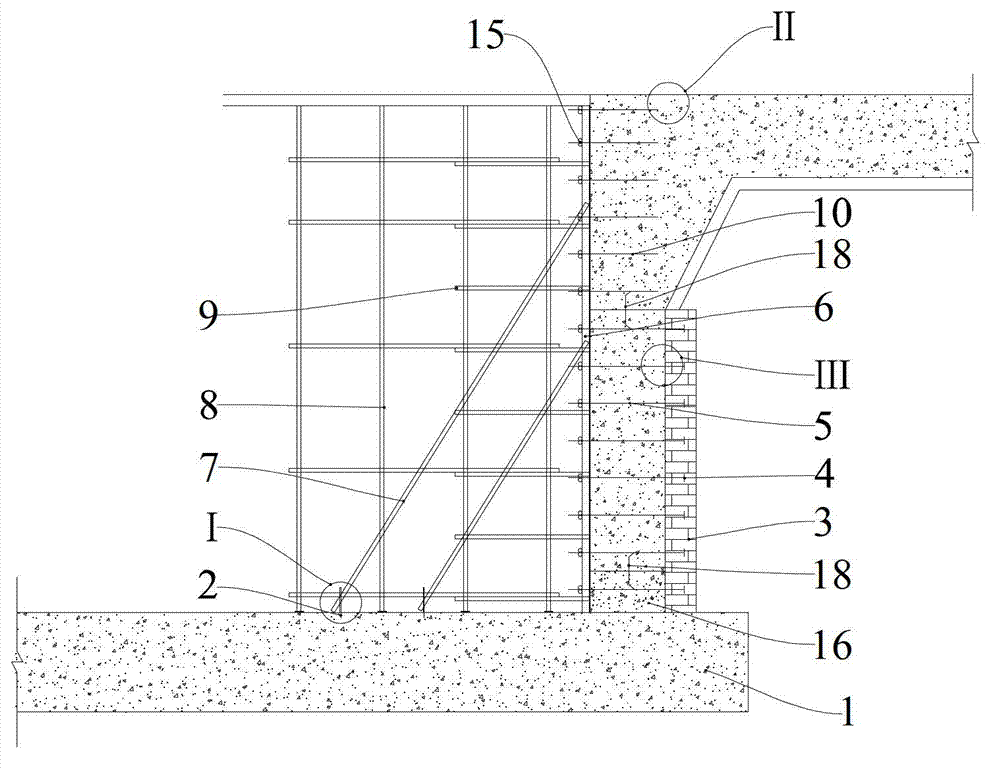

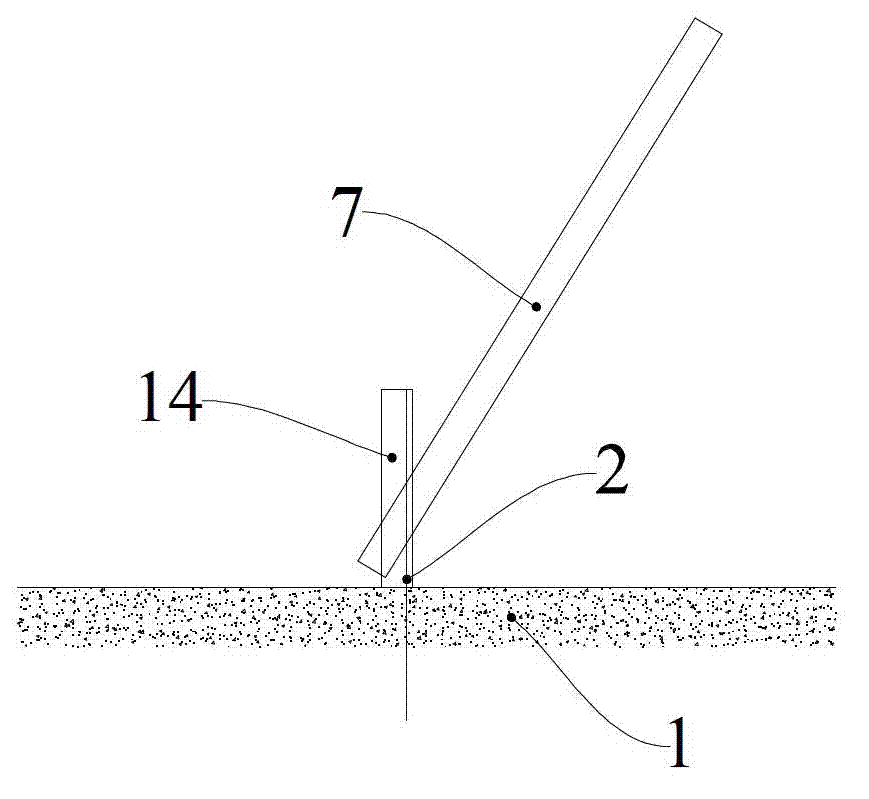

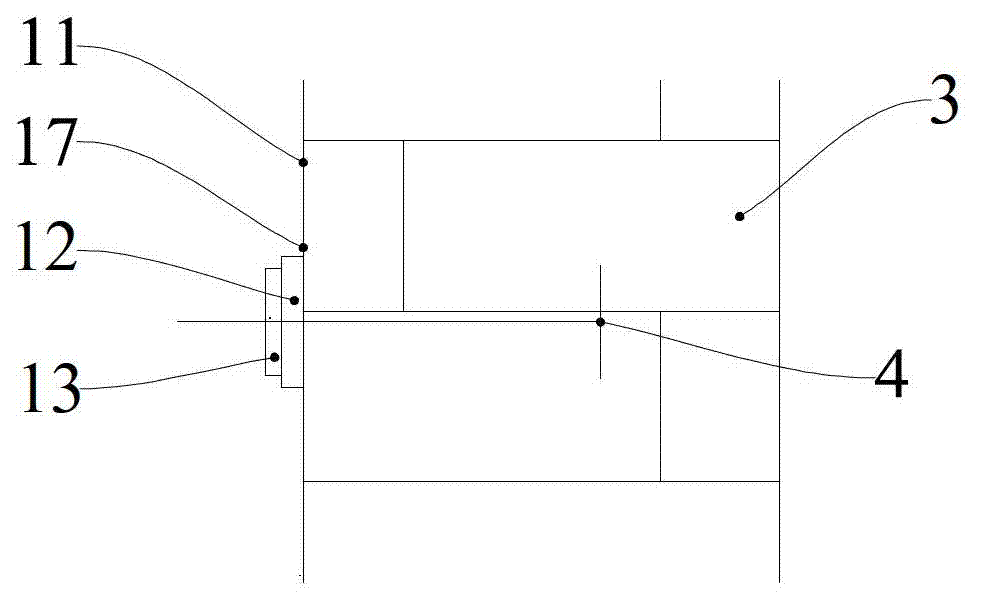

The invention relates to an underground (underwater) building waterproof device, and in particular to a vertical water-stop structure for a concrete engineering expansion joint as well as a manufacturing and construction methods for the same. The vertical water-stop structure comprises a deformation sheet and channel steel, and is characterized in that the deformation sheet is longitudinally arranged, one half is pre-buried in first-stage concrete, the other half is bulged out of a concrete section and externally arranged in a rectangular channel steel opening, and the channel steel is provided with a fixing element and filled with maltha; the surface of the channel steel opening and the section of the first-stage concrete are provided with asphalt felts at the both sides of the deformation sheet, the exposed fixing element is detached after asphalt is cooled, and then second-stage concrete is arranged. According to the vertical water-stop structure disclosed by the invention, the problem of water seepage of a water conservancy project due to the differential settlement or diastrophism of a stratum can be solved, and moreover, labour can be saved and construction period can be shortened.

Owner:福建九鼎建设集团有限公司

Karst grouting reinforcement water-stop constructing method

The invention discloses a karst grouting reinforcement water-stop constructing method, which is to construct according to sizes of karst caves by adopting a principle of from big to small regarding a certain area, construct by adopting a principle of from outside to inside for the karst caves with the same size, and construct by adopting a principle of from the bottom to the top in a vertical direction. On the basis of the construction principles, the method comprises the following steps of: (1) forming grouting holes by adopting a core drill; (2) forming construction exhaust and drainage pressure relief holes; (3) inserting grouting pipes into the grouting holes, wherein the grouting pipes comprise steel pipes, grouting shock pipes and sleeve valve pipes; (4) cleaning the holes, wherein when the step (3) is completed, the grouting pipes are cleaned with clean water; (5) grouting; and (6) drawing out the grouting pipes after the grouting is completed, and blocking the grouting holes with cement mortar or concrete. By adopting the constructing method, the pertinence to karst caves is strong, the grouting quantity is small, the engineering work amount is small, the cost is low, and the effect of filling and reinforcing is good.

Owner:GUANGZHOU URBAN PLANNING & DESIGN SURVEY RES INST

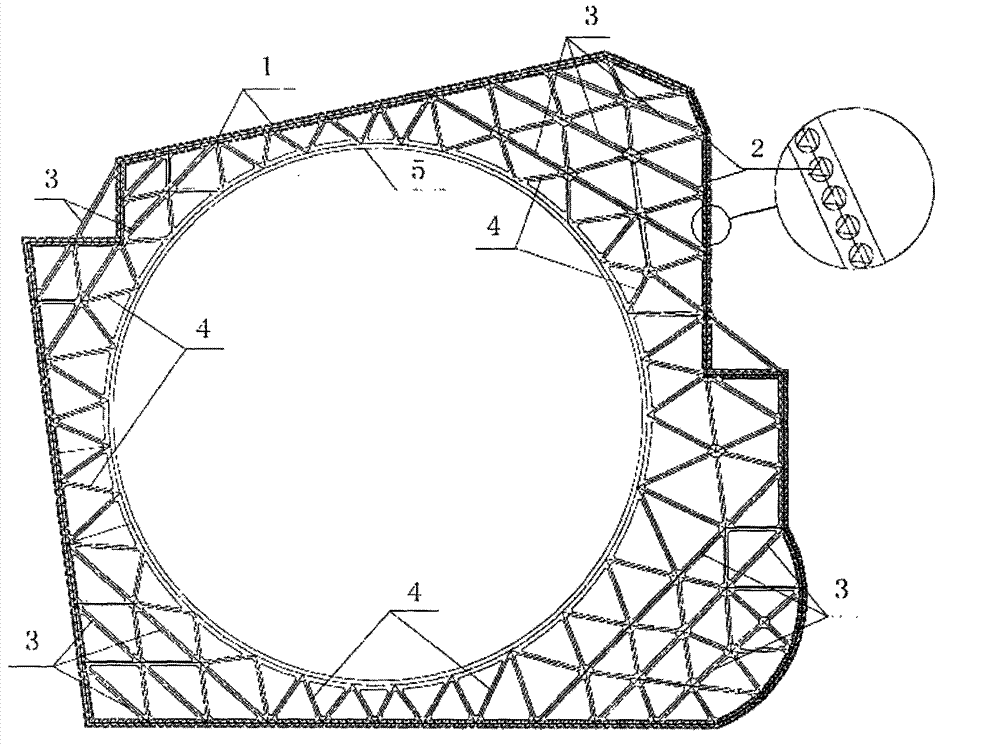

Ring-shaped inner supporting structure used in deep peat soil deep foundation pit

The invention relates to a ring-shaped inner supporting structure used in a deep peat soil deep foundation pit. The ring-shaped inner supporting structure comprises a supporting system, a waterproof curtain, a slope unloading system and a support replacement system and is characterized in that the supporting system is divided into a support pile, a top beam, a ring beam, an angle brace and a communication beam, the top of the support pile is provided with the reinforced concrete top beam; the top beam forms an external structure of the foundation pot; the ring-shaped inner supporting structure is formed in a way of combining the ring beam, the angle brace and the communication in the middle; and the overall plan for the support of the foundation pit engineering is formed by using the combined support and the pit wall waterproof curtain together with the means of large-area soil-discharge de-loading and the like. With the adoption of the ring-shaped inner supporting structure, the problems of small anchor tensile force, easily-happened creep deformation, large deformation as well as invasion and harassment to the adjacent property of an anchor rope in the common design in peat soil are solved generally, and the disadvantages that common inner supporting types such as lattices, trusses and beams seriously affect the earthworks digging and transporting as well as the construction of an underground structure are overcome; and furthermore, the engineering cost is reduced furthest, and the earthworks digging and transporting as well as foundation construction periods are shortened.

Owner:WUHAN DESIGN & RES INST OF CHINA COALTECH & ENG GROUP

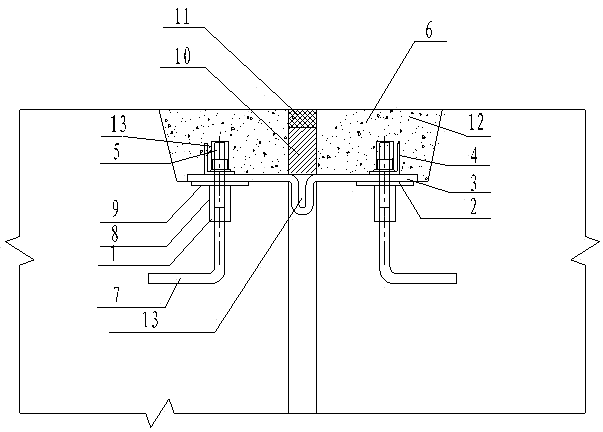

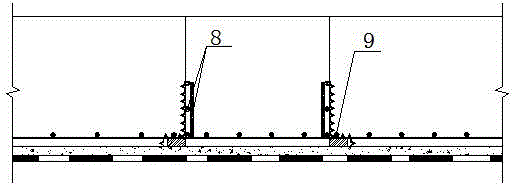

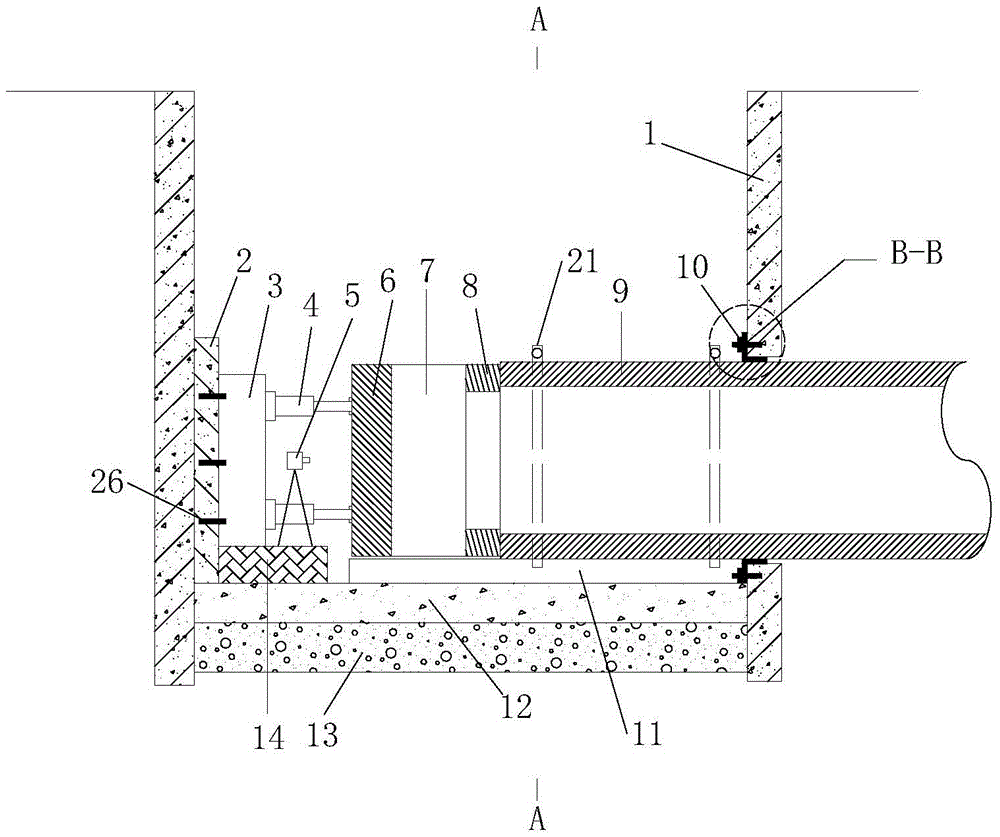

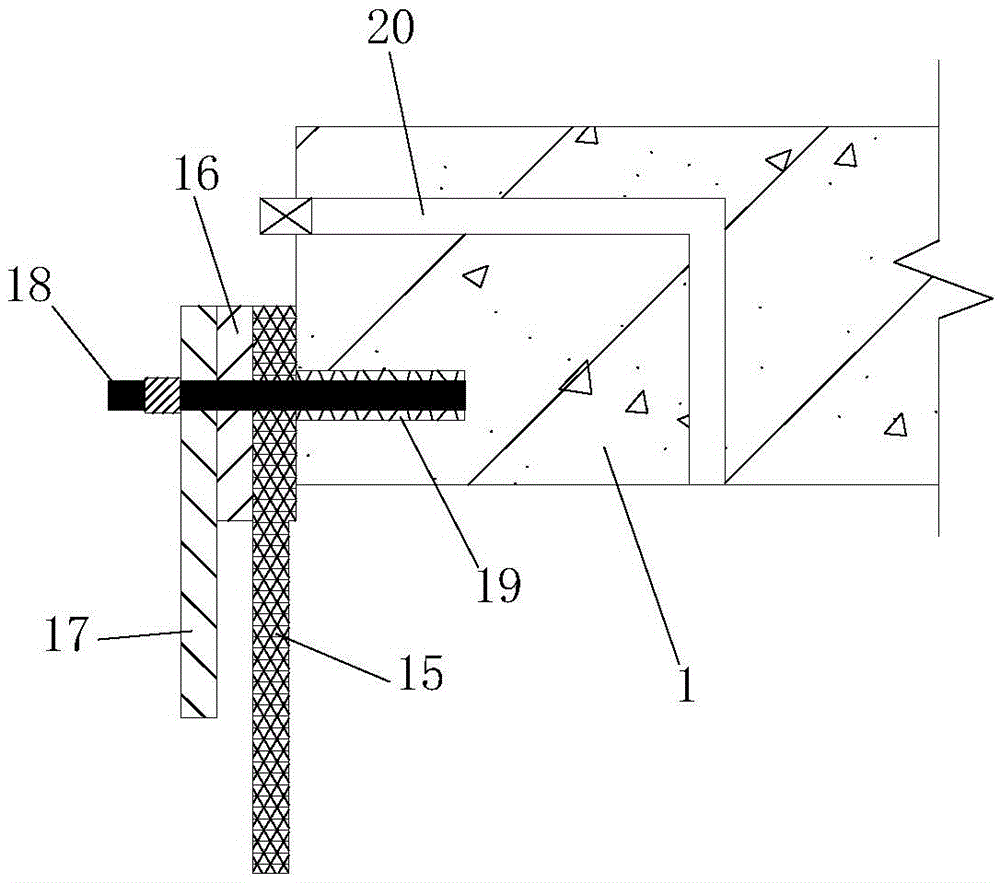

Concrete joint water stop structure and construction method thereof

InactiveCN103669292APrevent water leakageAffect the installationMarine site engineeringAdhesiveEngineering

The invention discloses a concrete joint water stop structure, and belongs to the field of waterproof technologies of concrete buildings. The water stop structure comprises pre-buried anchor holes, adhesives, rubber waterstop, a section steel pressing plate, bolts and a sealing structure; wherein the pre-buried anchor holes are preburied in a concrete structure, the rubber waterstop adheres to the surface of a concrete joint water stop channel through the adhesives, the section steel pressing plate adheres to the upper surface of the rubber waterstop through the adhesives, the bolts penetrates through the section steel pressing plate and the rubber waterstop and are fastened with the pre-buried anchor holes, and the sealing structure is arranged between the rubber waterstop and the concrete joint water stop channel. The invention further discloses a construction method of the concrete joint water stop structure. Compared with the prior art, the concrete joint water stop structure has the advantages of being simple in construction, good in water stop effect and the like.

Owner:河南省水利勘测设计研究有限公司 +1

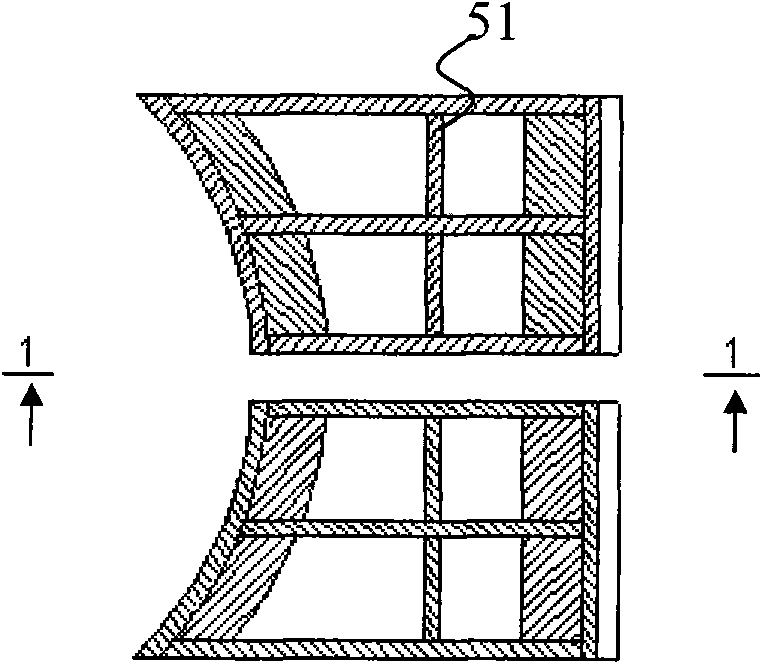

Cross steel plate water-stopping joint continuous concrete wall and joint construction method thereof

InactiveCN101608447AIncreased shear strengthImprove integrityArtificial islandsUnderwater structuresSlurry wallCement slurry

The invention provides a cross steel plate water-stopping joint of a continuous concrete wall and a joint construction method thereof. The cross steel plate joint comprises a longitudinal water-stopping steel plate and a horizontal head steel plate, wherein the longitudinal water-stopping steel plate is about 35-50 cm long, a detouring flow line of cement slurry is lengthened, the impermeability of the joint of the continuous concrete wall is enhanced, the bottom of the horizontal head steel plate extends to the tank bottom level or is inserted into the soil by 20 cm, and the detouring flow line of concrete and sand pulp along the bottom of the head steel plate is blocked; during constructing, a cross steel plate and a steel reinforcement cage are welded into a whole which is then deposited into a tank section so that the joint and a wall body have better integrity; a counterforce box is deposited at the back of the cross steel plate and is impacted to enter soil by over + / -30 cm, and then carpolite or clay are backfilled at the back for sealing; the concrete is cast in the tank section; the counterforce box is pulled out, then a flushing or shoveling tool corresponding to the cross steel plate in structure is adopted to remove the attachment at the part so as to ensure the water-stopping effect and the joint intensity of the cross steel plate.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

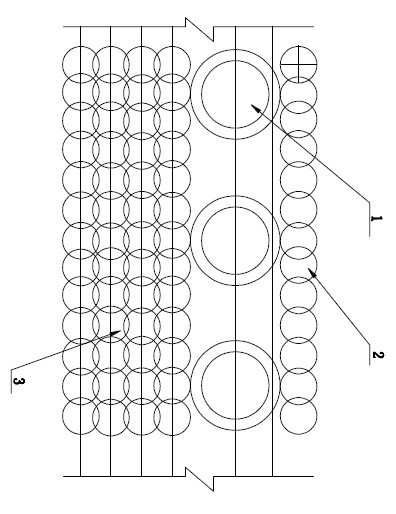

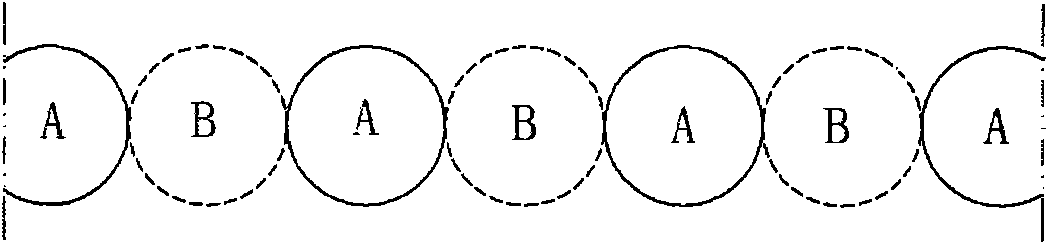

Pit supporting structure and construction method thereof

ActiveCN102011404AEasy constructionShorten the construction periodExcavationsBulkheads/pilesBasementThin walled

The invention relates to a pit supporting structure and a construction method thereof. The pit supporting structure comprises pit supporting row piles, water and soil stopping curtains and lateral row piles, wherein the pit supporting row piles are long and short cast-in-place concrete thin-wall pipe piles at intervals; the water and soil stopping curtains and the lateral row piles are cement mixing piles; the water and soil stopping curtains are a row of mutually engaged cement mixing piles; the lateral row piles are a plurality of rows of bidirectionally engaged cement mixing piles; the water and soil stopping curtains are arranged on one side of pit supporting row piles corresponding to the periphery of the pit; and the lateral row piles are arranged at the bottom of the pit on one side of the pit supporting row piles corresponding to the pit. The technical scheme has the effects that a basement structure is convenient to construct, the pit construction period is shortened and the construction cost is saved.

Owner:温州城建集团股份有限公司

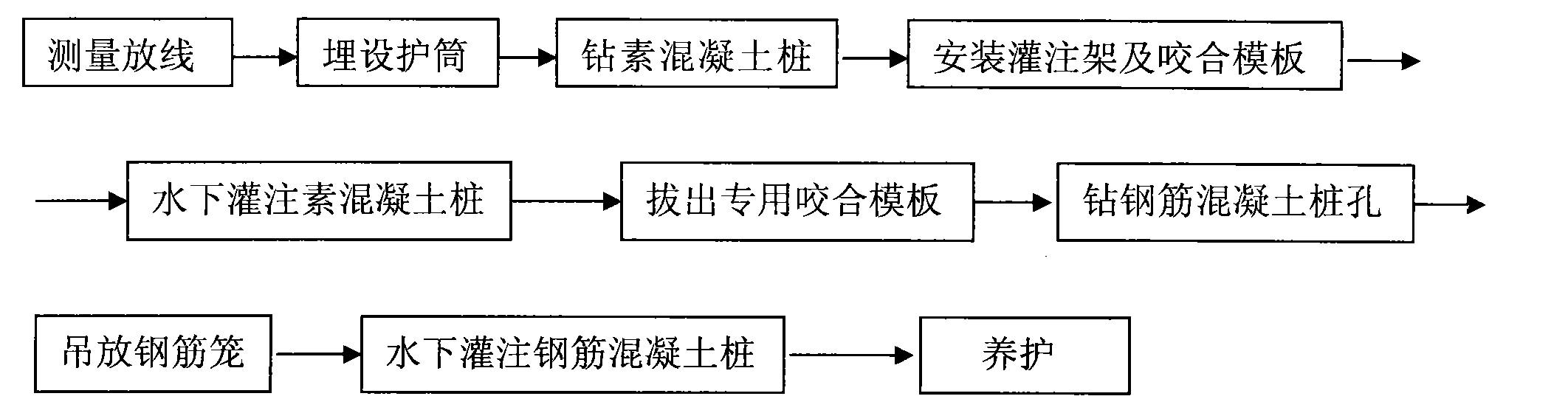

Construction process of concrete form water-stopping occlusion pile

InactiveCN102011397AReduce construction costsShorten the construction periodBulkheads/pilesOcclusion effectReinforced concrete

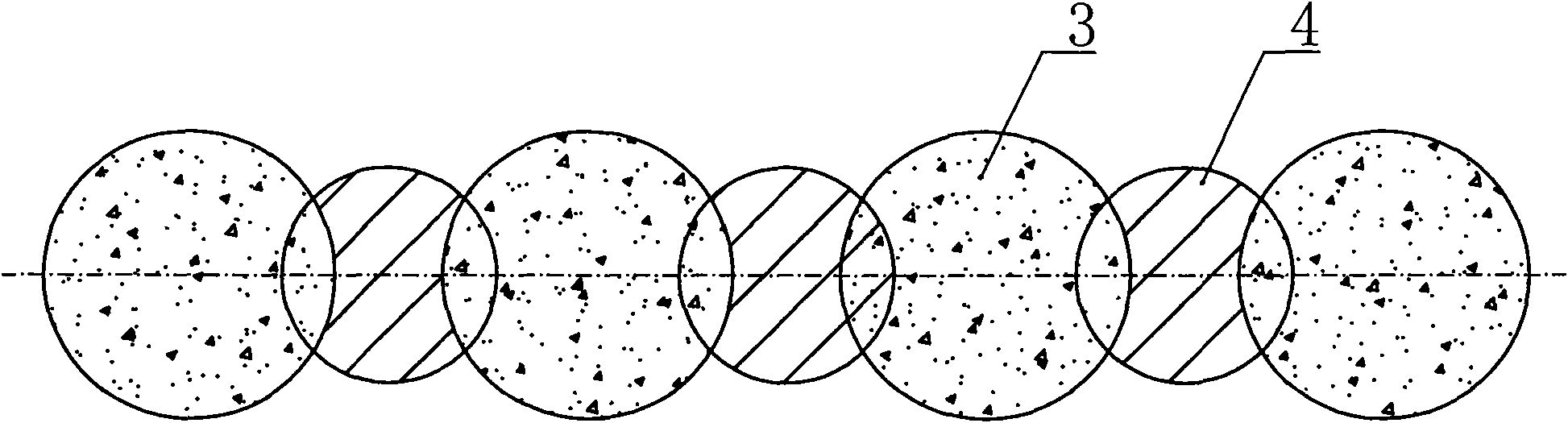

The invention relates to a construction process of a concrete form water-stopping occlusion pile. The construction process comprises the following steps: constructing a plain concrete pile, and using a special occlusion form to form cambered grooves; and constructing a reinforced concrete pile, wherein concrete automatically flows into the cambered grooves of the plain concrete pile at the moment, thereby realizing the occlusion of the plain concrete pile and the reinforced concrete pile to form a curtain so as to achieve the purposes of water stopping and water retaining. Compared with the prior art, the invention has the advantages that the construction cost is greatly saved, the construction cycle is shortened and the water retaining quality is improved because the reinforced concrete pile and the plain concrete pile are matched for use; based on the occlusion effect of the cambered surfaces of the concrete, good occlusion and water-stopping effects between new and old concrete surfaces are achieved, and the construction quality is easy to control; and in addition, the application range is wide, different drilling machines can be used for forming pores in different water-bearing strata, and the predetermined water-stopping effect can be achieved as long as the pore forming quality meets the requirements of the specification.

Owner:ZHONGAN TAIDA CONSTR DEV BEIJING

Tunnel waterproof and water-draining system and construction method thereof

ActiveCN106194255AEliminate frost heaving forceEasy to findUnderground chambersDrainageShotcreteDraining tube

The invention discloses a tunnel waterproof and water-draining system and a construction method thereof. The tunnel waterproof and water-draining system comprises a water draining layer, a transition layer, a waterproof layer, a transverse water draining pipe, a central water draining pipe and the like, and the water draining layer, the transition layer and the waterproof layer are located between a tunnel primary support and a secondary lining. The water draining layer comprises water-permeable shotcrete, a longitudinal water draining pipe, an annular water draining pipe and a waterstop strip, the longitudinal water draining pipe, the annular water draining pipe and the waterstop strip are fixed to the outer surface of the primary support to carry out water draining partitioning on the primary support, and the water-permeable shotcrete is sprayed in each water draining area. The annular water draining pipe and the central water draining pipe are connected through the transverse water draining pipe, and finally the tunnel water draining system is formed. The transition layer and the waterproof layer are formed by shotcrete with different grades and used for waterproofness of a tunnel. According to the tunnel waterproof and water-draining system and the construction method thereof, the water draining pipes and the water-permeable shotcrete form a tunnel stereoscopic water draining passage, the water draining effect of the tunnel is good, the tunnel waterproof and water-draining system and the structure of the tunnel are integrated, and the long-term service performance is good.

Owner:SOUTHEAST UNIV

Foundation post-pouring belt template constructing method

InactiveCN102720216AReduce labor intensityReduce engineering costsArtificial islandsUnderwater structuresEngineeringConstruction management

The invention relates to building construction methods, particularly to a foundation post-pouring belt template constructing method, which includes the following steps: a) pouring concrete stripes on the two sides of the post-pouring belt along the position line of the post-pouring belt after the completion of the foundation waterproof protective layer construction; b) supporting a waterstop steel plate quick and easy closing-up mesh along the side line of the post-pouring belt after the lower layer reinforcing bars of the foundation base plate are bound; c) fixing the reinforcing bar mesh pieces at the lower part of the waterstop steel plate; d) mounting the waterstop steel plate; e) welding the upper part reinforcing bar mesh pieces on the waterstop steel plate and placing the waterstop steel plate upper part quick and easy closing-up mesh; f) binding the upper layer reinforcing bars of the foundation base plate, fixing the waterstop steel plate upper part quick and easy closing-up mesh and mounting the upper part guard of the post-pouring belt; and g) pouring foundation concrete. By adopting the quick and easy closing-up meshes for the post-pouring belt construction joint, the surface poured with the concrete is uneven, so that the complicated conventional procedures for dismounting template and surface dabbing are avoided, the project quality and the construction progress are ensured, the construction wastes are reduced, and the civilized construction management is facilitated.

Owner:NANTONG DAXIN ENG

Steel pipe roof jacking construction method

InactiveCN1800513AReduce settlementEngineering construction safetyArtificial islandsUnderwater structuresEnvironment effectEarth surface

The invention relates to a method for constructing steel tube screen feeding, belonging underground construction technique. It is characterized in the sequence of feeding steel tube screen: mounting device, operation training, stopping water, selecting the type of steel tube screen clamp. The first one fed into steel tubes is hinged steel tube, whose end face has three-section transition steel tube with steel draw rod; the steel tubes are connected via clamp to form square section; in the process, the sedimentation condition of earth surface should be detected and controlled all the time. The invention can significantly reduce the sedimentation, with little effect on the environment and safe operation. The invention can apply the construction on the soft ground near-surface large-section subway.

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD

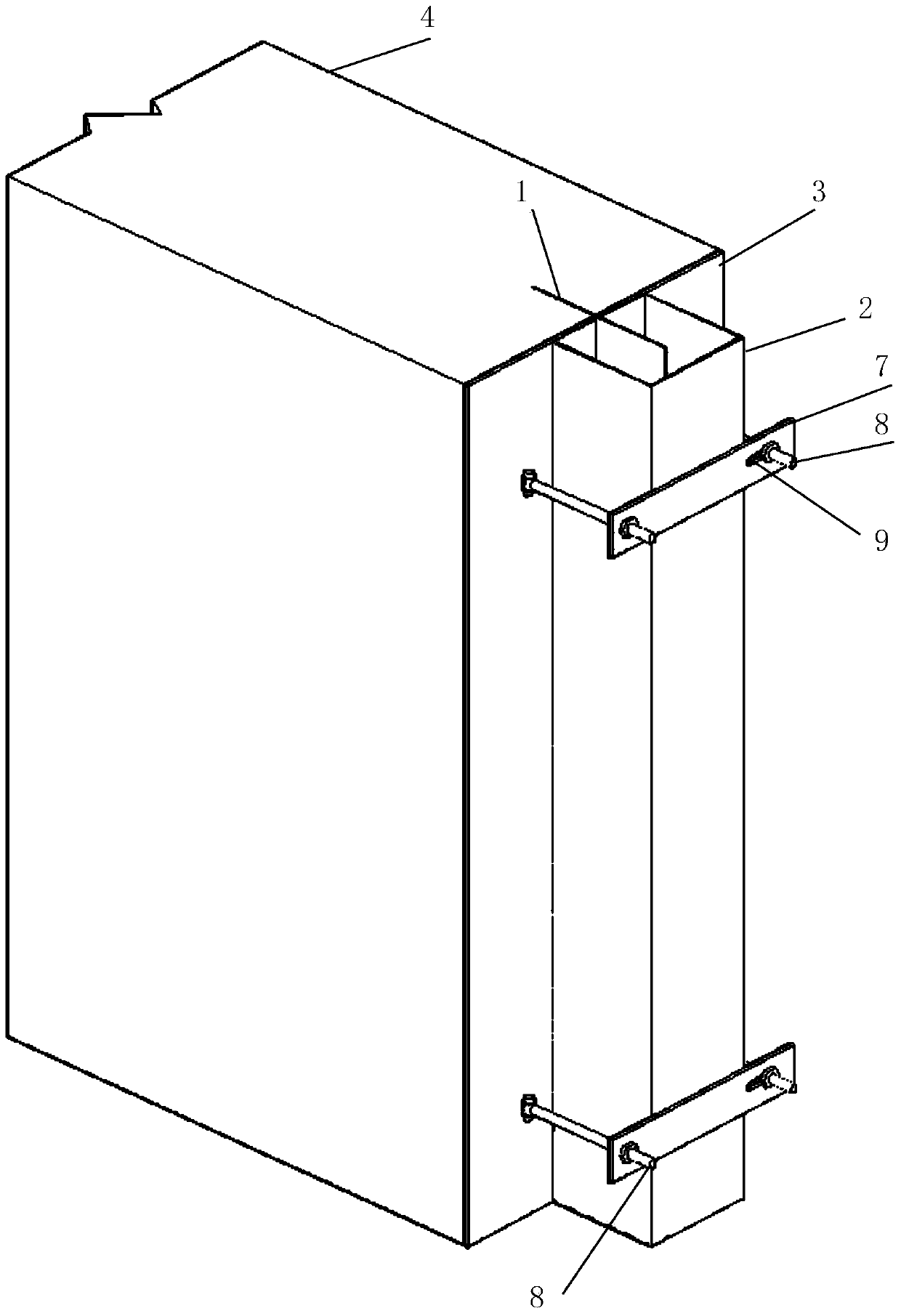

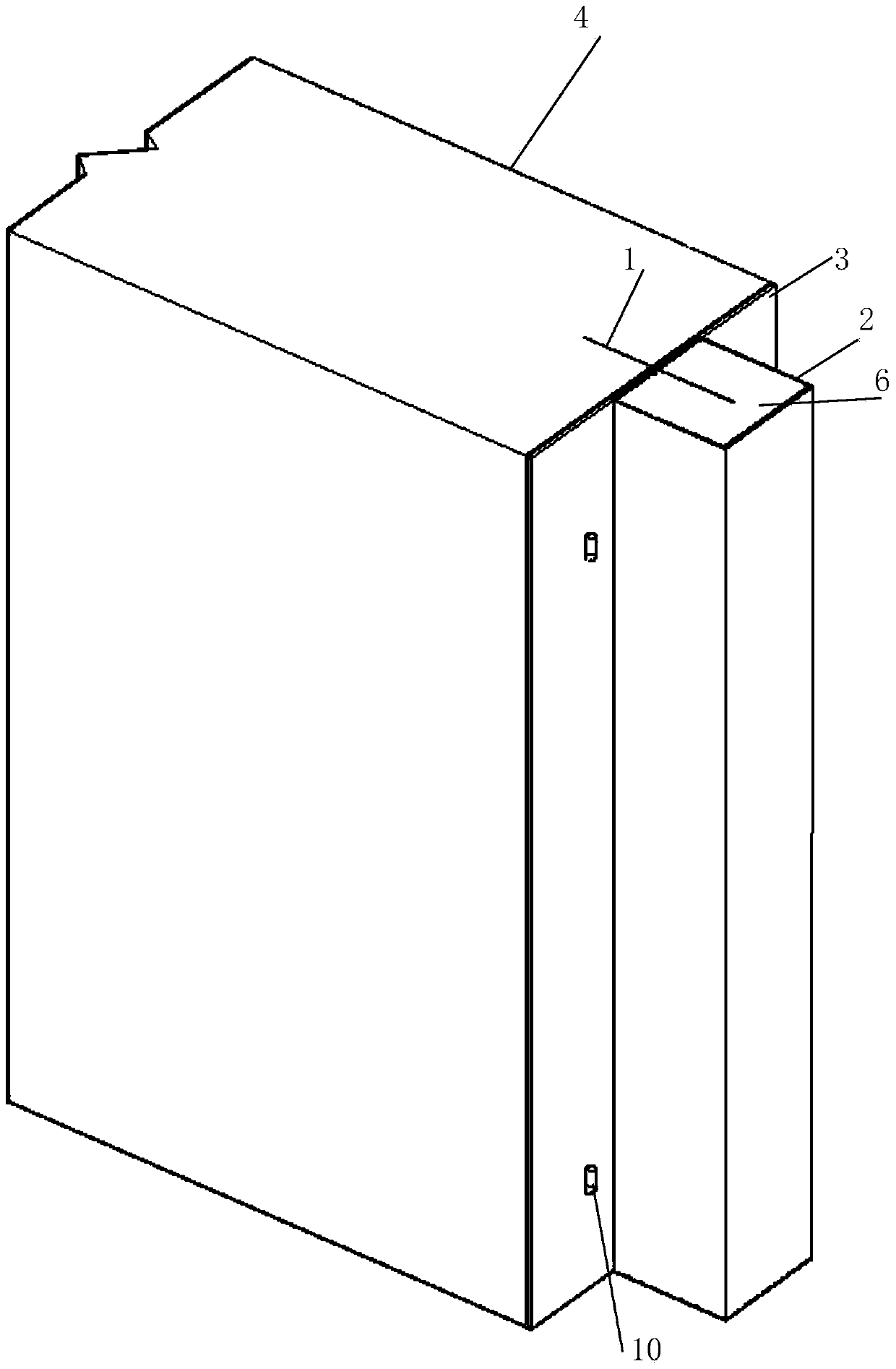

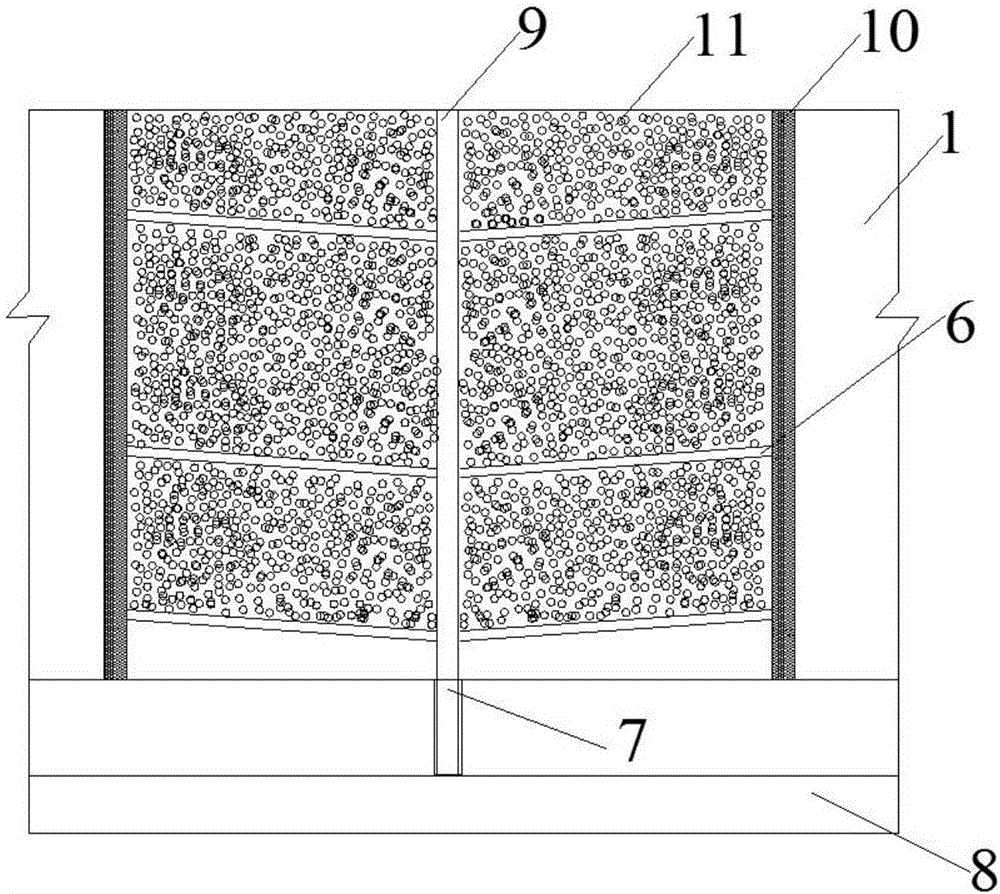

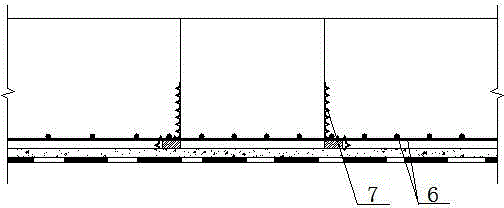

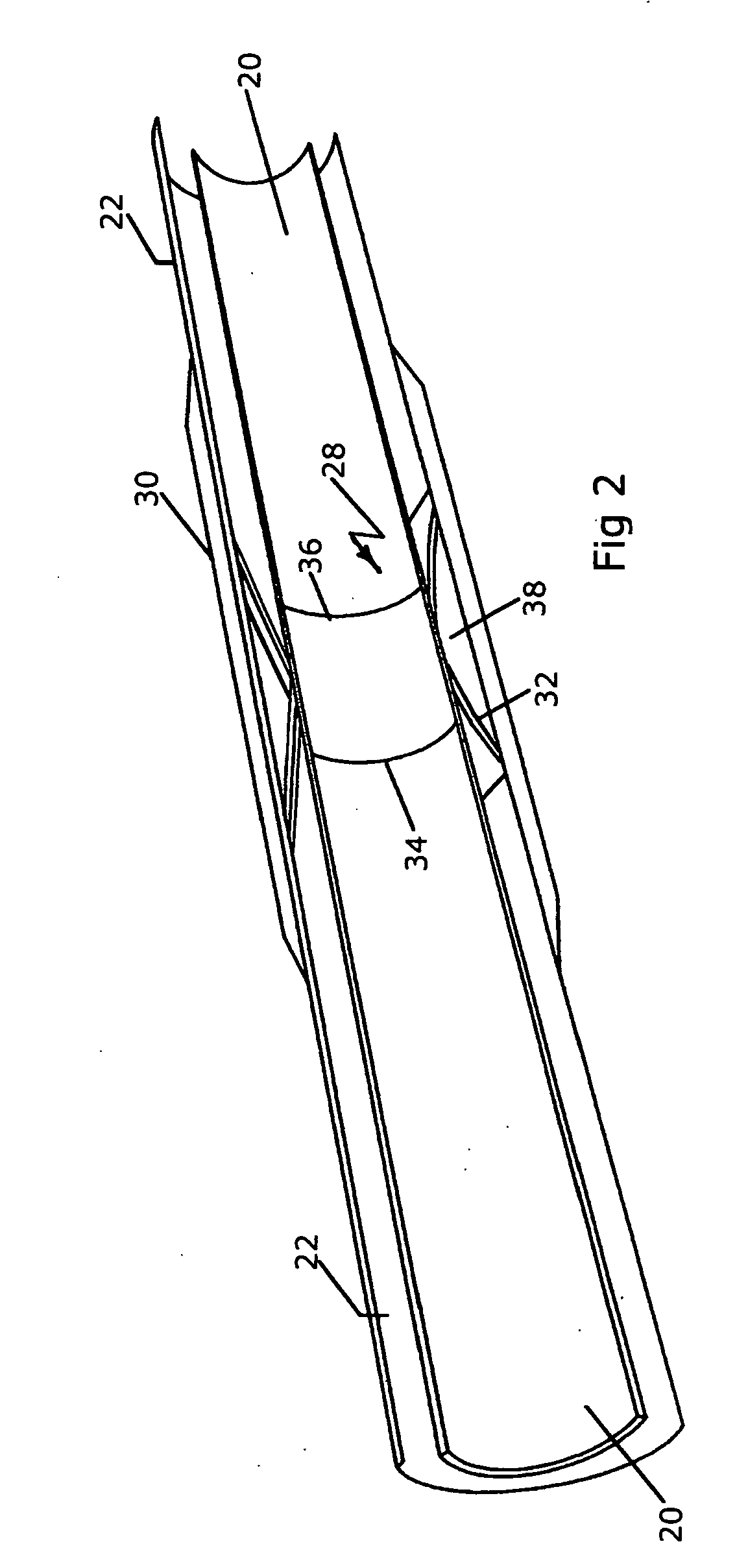

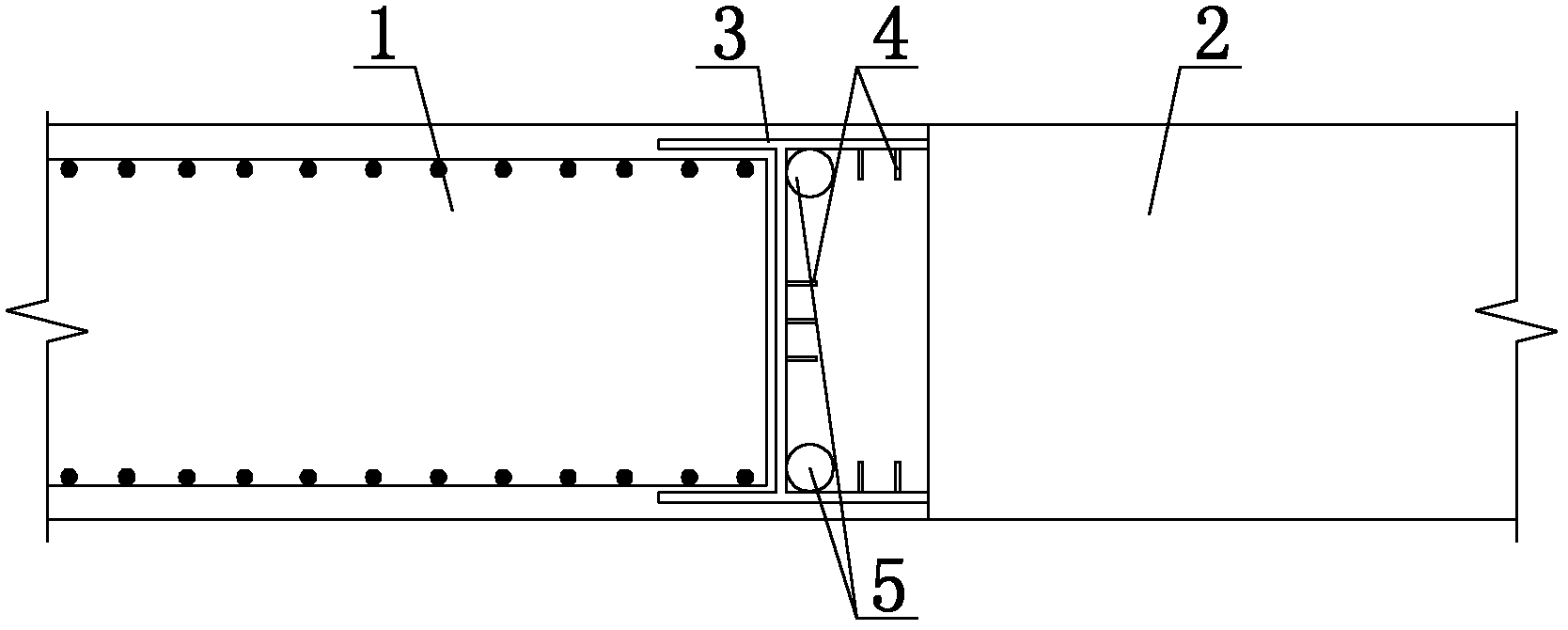

Double-water stop structure for concrete expansion joint and manufacturing and construction method for double-water stop structure

InactiveCN103821180ASolve the leakLow costArtificial islandsUnderground chambersStructure of the EarthUnderwater

The invention relates to an underground (underwater) building waterproof device, in particular to a double-water stop structure for a concrete expansion joint and a manufacturing and construction method for the double-water stop structure. The double-water stop structure comprises two deformation sheets and channel beams. The double-water stop structure is characterized in that a concrete section is provided with the two deformation sheets; the two deformation sheets are longitudinally arranged at a set distance; half of each deformation sheet is embedded in primary concrete, and the other half of each deformation sheet protrudes out of the concrete section, and the other halves of the two deformation sheets are respectively arranged in the corresponding channel beams; asphalt fills each channel beam; an asphaltic felt is arranged on open surfaces of the channel beams and a primary concrete section; exposed fixed parts are removed after the asphalt is cooled, and then, secondary concrete is set. According to the double-water stop structure disclosed by the invention, the water seepage problem caused by differential settlement or faulting of a stratum in hydraulic engineering can be solved; the labor can also be reduced, and the construction period can also be shortened.

Owner:SHANDONG JIAOTONG UNIV

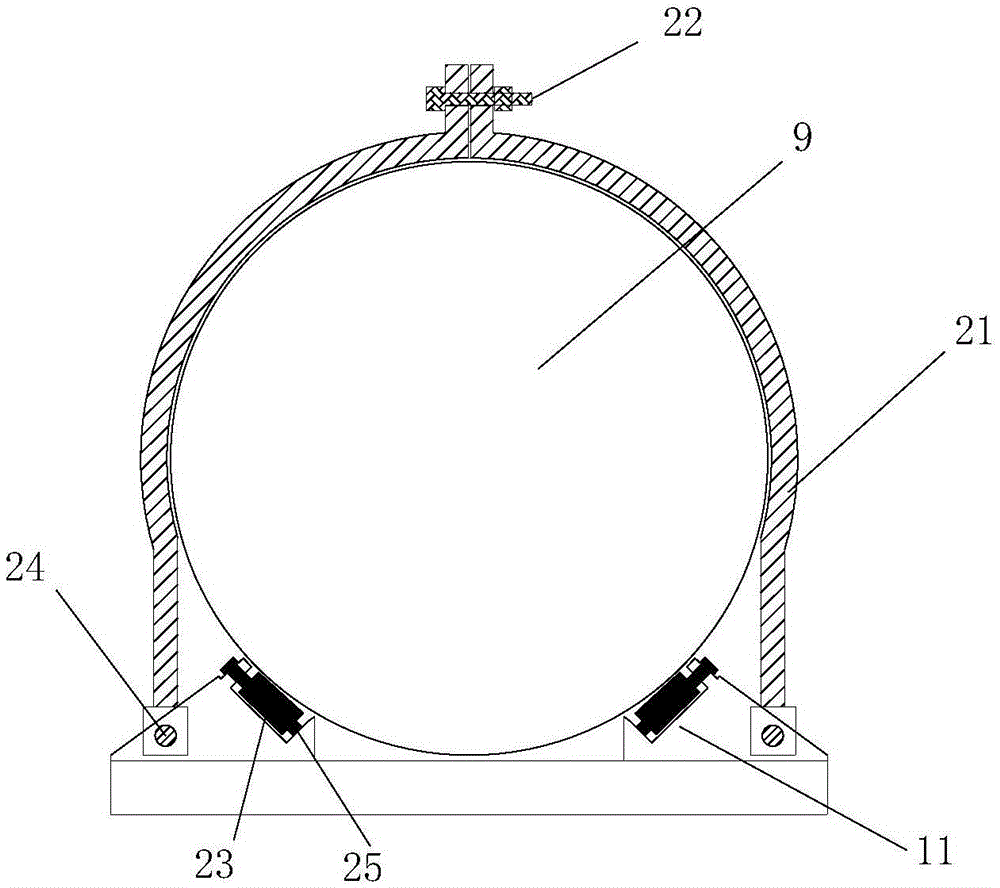

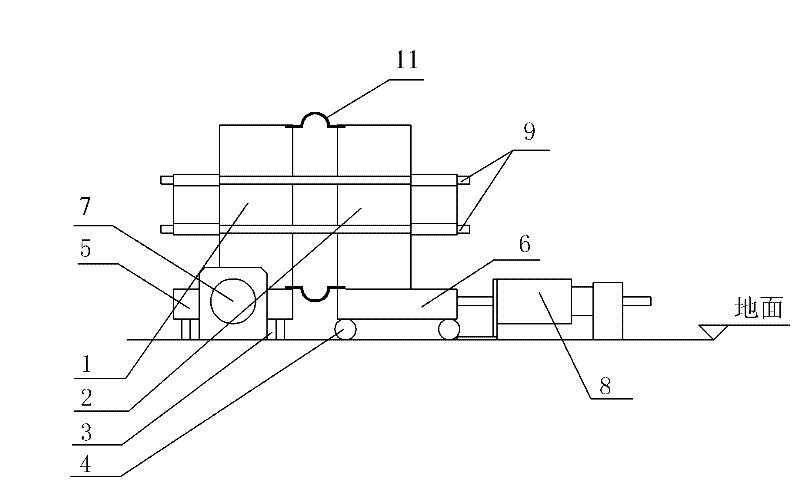

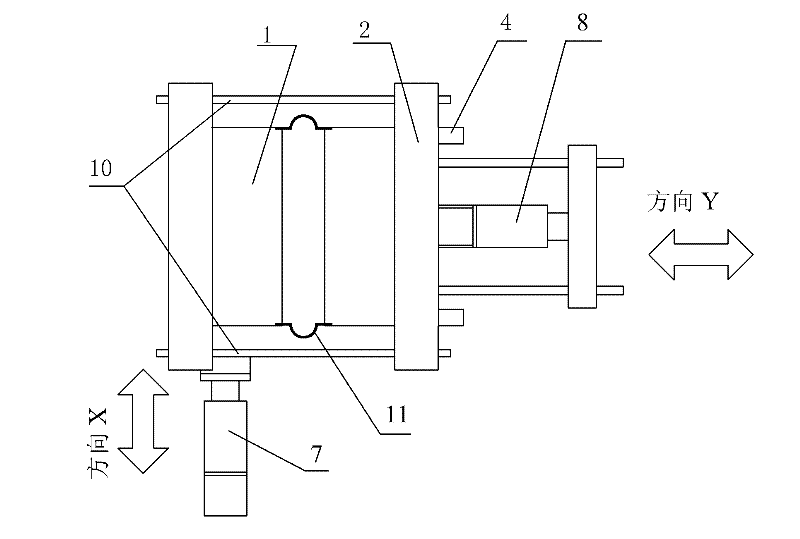

Construction method for jacking structure of pipe jacking work well

InactiveCN105465481AReduce frictionConducive to jacking constructionPipe laying and repairEngineeringCushion

The invention relates to a construction method for a jacking structure of a pipe jacking work well. The construction method mainly comprises the construction steps of 1 cushion layer and back base wall constructing; 2 rail installing; 3 jack installing; 4 hole water stopping system installing; 5 pipe joint and jacking iron hoisting. The construction method has the advantages that disassembly and assembly are convenient, the construction efficiency is high, friction between a rail and a pipe joint can be reduced, auxiliary guide positioning can be supplied to the pipe joint and has the better economic and technical benefit.

Owner:HANGZHOU JIANGRUN TECH LIMITED

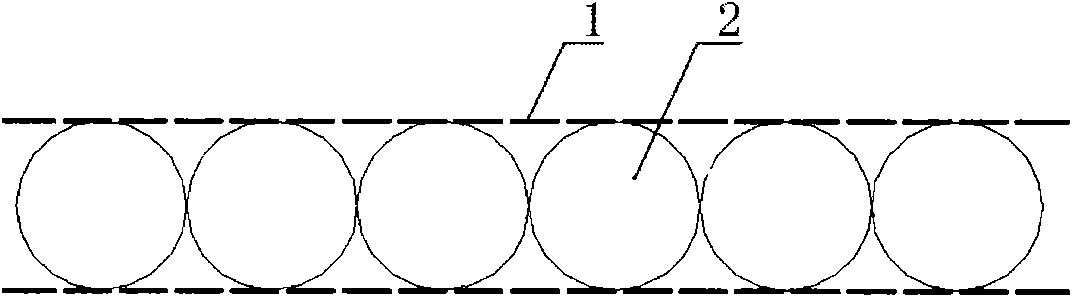

Prestressed concrete precast pile

ActiveCN103572755ANot easy to tiltImprove bending abilityBulkheads/pilesSquare cross sectionPre stress

The invention discloses a prestressed concrete precast pile. The prestressed concrete precast pile comprises a precast pile body with a square cross section, wherein the precast pile body comprises two end plates, a pile body and prestressed reinforcements, the pile body is arranged between the two end plates, and the prestressed reinforcements are arranged in the pipe body and connected with the two end plates; bulge rib which longitudinally extends to an end and a first groove which longitudinally extends and penetrates through the end are arranged on an outer side surface of the precast pile body; and a second groove and a third groove which are corresponding to positions of the bulge rib and the first groove respectively, matched in shape and size and longitudinally extend and penetrate through an end of the precast pile body are formed in one outer side surface which is not adjacent to the outer side surface. According to the prestressed concrete precast pile, the construction is convenient, the engineering cost can be reduced, the water stopping effect is enhanced, and the prestressed concrete precast pile has good bending and shearing resistance.

Owner:宁波中淳高科股份有限公司

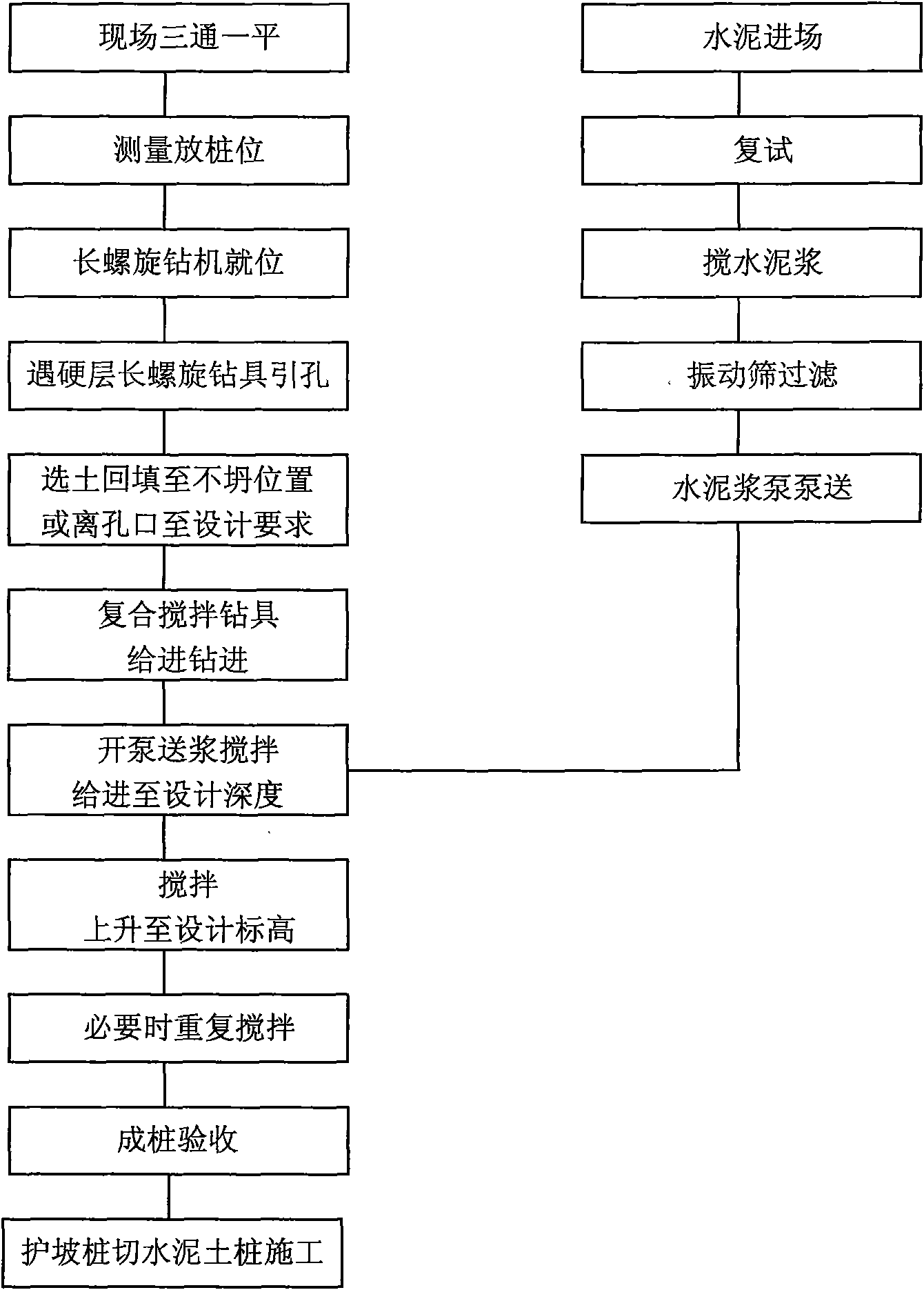

Occlusive pile of long spiral stirring water-stop curtain and construction process thereof

InactiveCN101603309AOvercome drillingPlay a supporting roleDrill bitsRotary drillingEngineeringHardpan

The invention relates to a novel pile-forming method of a cement-soil stirring pile. The method comprises the following steps: measuring and putting lines to determine pile position; putting a long spiral drill in place, and adopting the long spiral drill to drill a hole to determine the accurate position of a pile, loosen a hardpan and eliminate underground barrier; backfilling to the opening of the hole, or reversing and lifting the drill; drilling by a long spiral stirring pile drill while pumping and stirring serum to a designed hole bottom elevation; during returning upwards, guniting while stirring to the designed elevation, and then stirring repeatedly and guniting to form a pile; after finishing stirring pile construction, making use of the long spiral stirring pile drill to drill the stirring pile to form holes; and finally, inserting slope-protection piles used in steel reinforcement cage construction after concrete grouting to form an entire curtain. The novel pile-forming method has the advantages that a long spiral stirring pile is adopted to lay a foundation for the smooth construction of slope-protection piles; the renovated long spiral drill can drill in harder soil stratum, sand stratum and gravel stratum, thereby reaching the designed depth and diameter; and the integral curtain with occlusive slope-protection piles and cement-soil piles not only supports foundation pits, but also realizes effective water stopping.

Owner:深圳市南华岩土工程有限公司

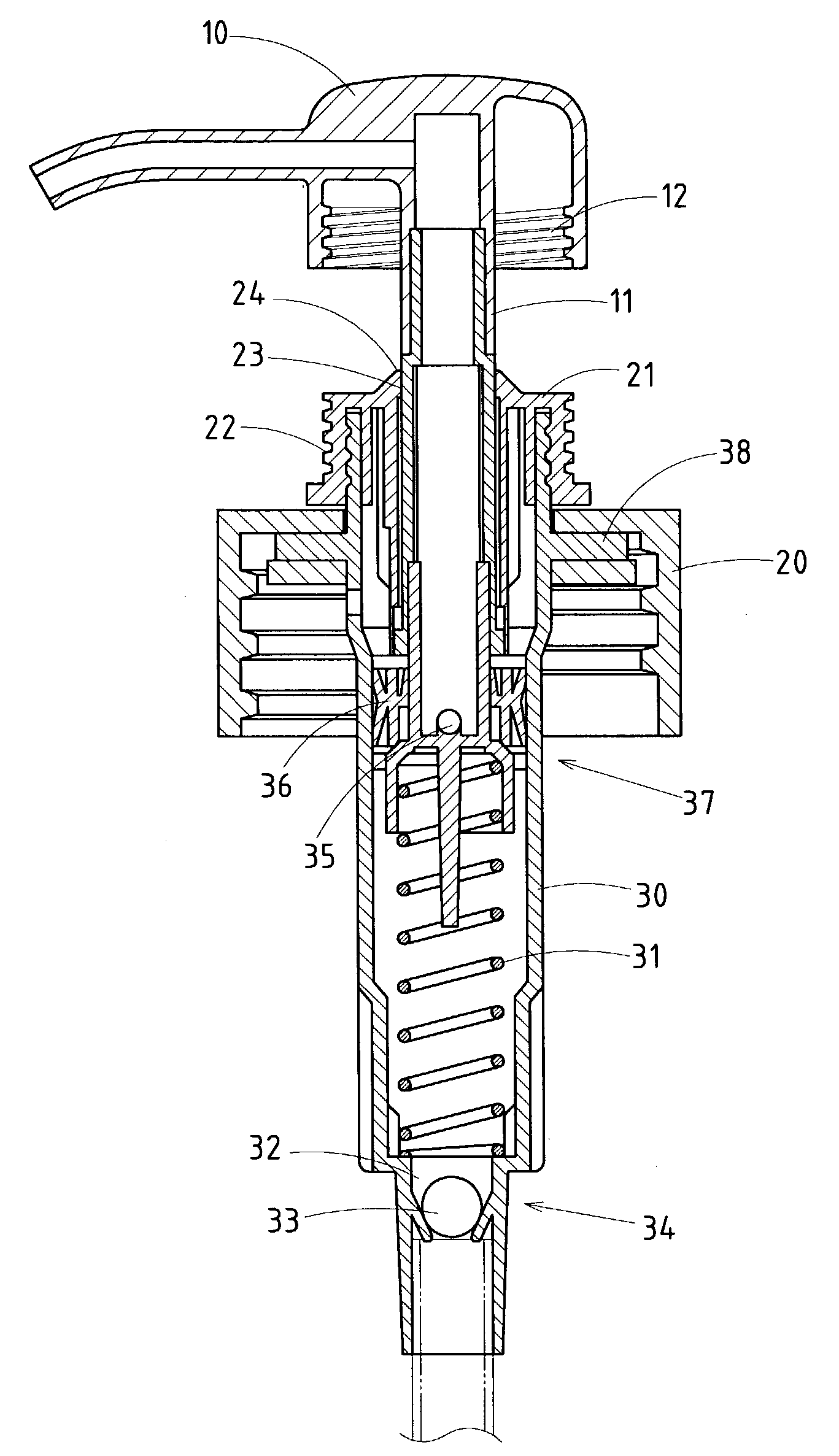

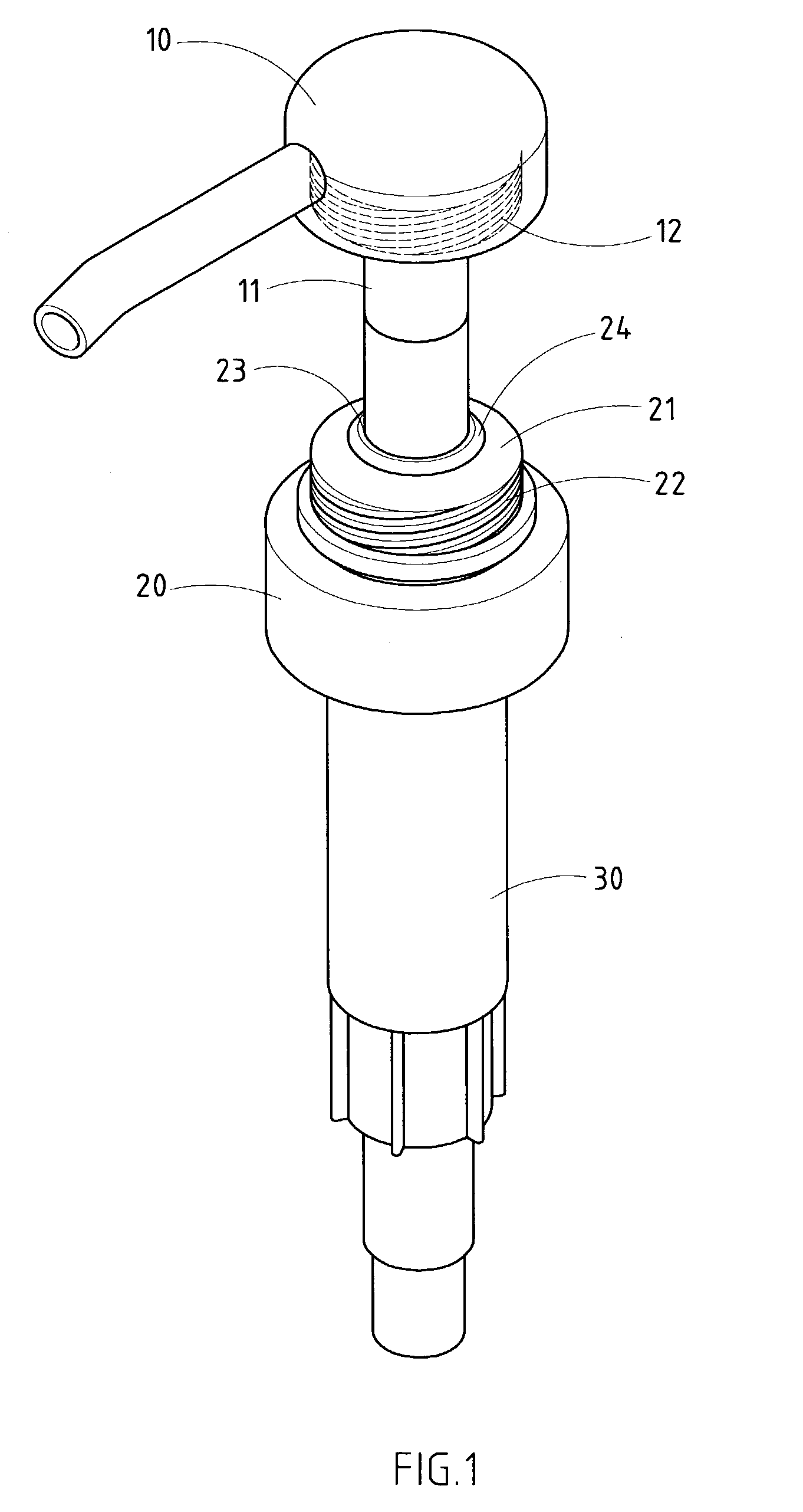

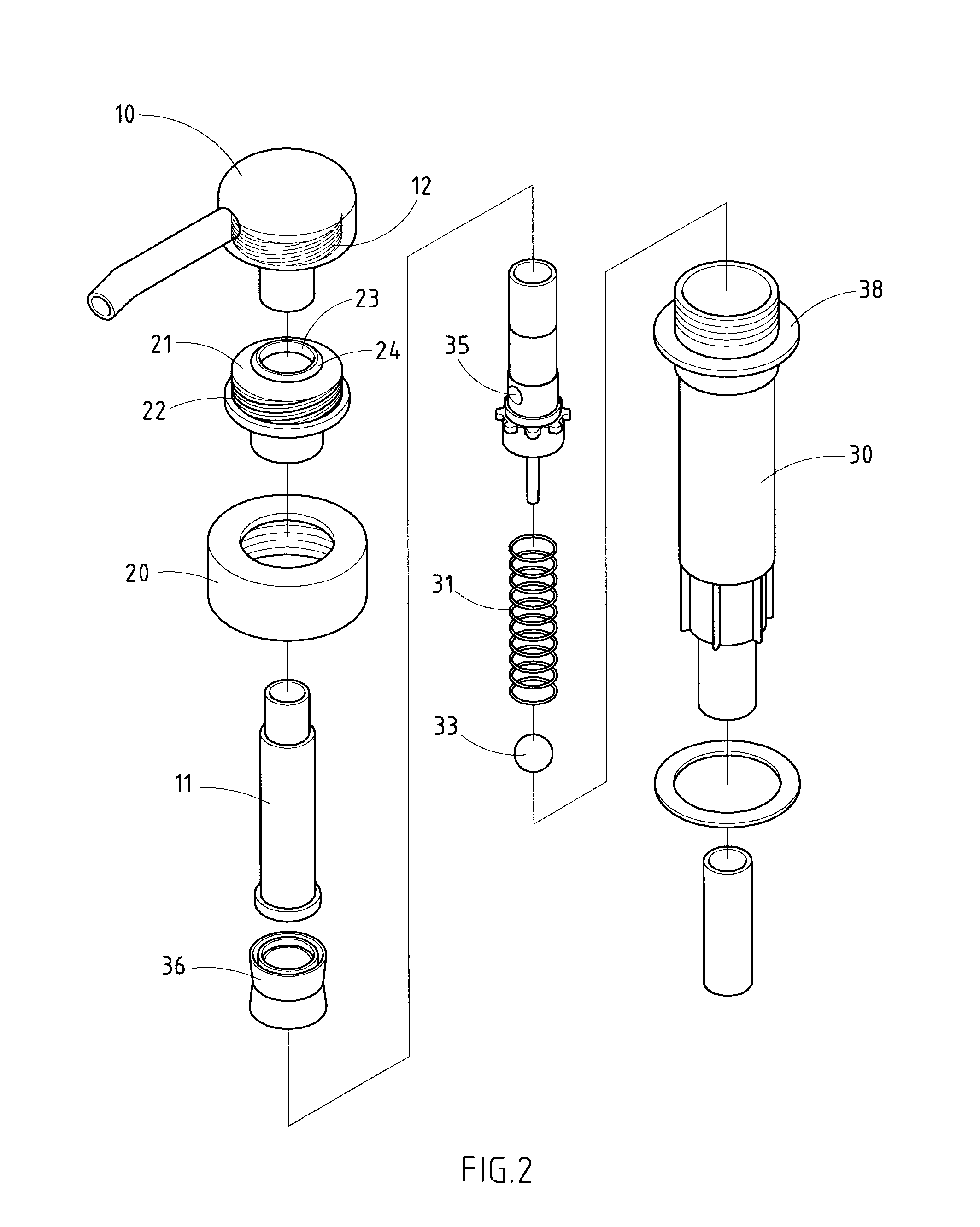

Water infiltration-proof structure

ActiveUS6966459B1Prevent penetrationDecorative coversClosure decorative/protective coversSpray nozzleLotion

A water stopping and infiltration-proof structure for a lotion spray nozzle, which is accomplished by adopting a water-stopping flange that is integrated with the cover top and is expanded from the top of the straight shaft tube, together with female and mate threading that are moved outwards along with the spray nozzle's bottom rim and the integrated cover's rim. This will enable the water-stopping flange to wipe off water drops on the piston shaft surface, and prevent water on the integrated cover top from infiltrating into the shaft tube.

Owner:LIVING FOUNTAIN PLASTIC IND CO LTD

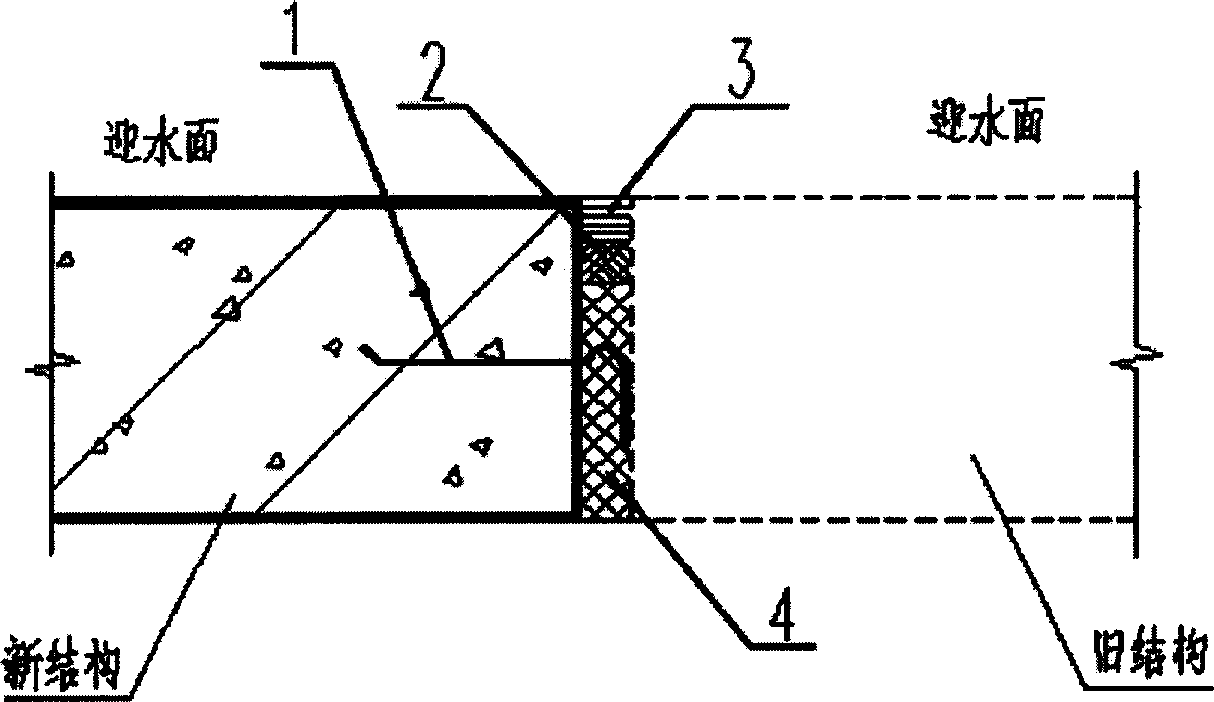

Method for constructing water-proof telescopic seam between new and old concrete building joints and structure thereof

InactiveCN1837528AOvercome positionOvercome immobilityBuilding insulationsArchitectural engineeringEngineering

Owner:GUIYANG AL-MG DESIGN & RES INST

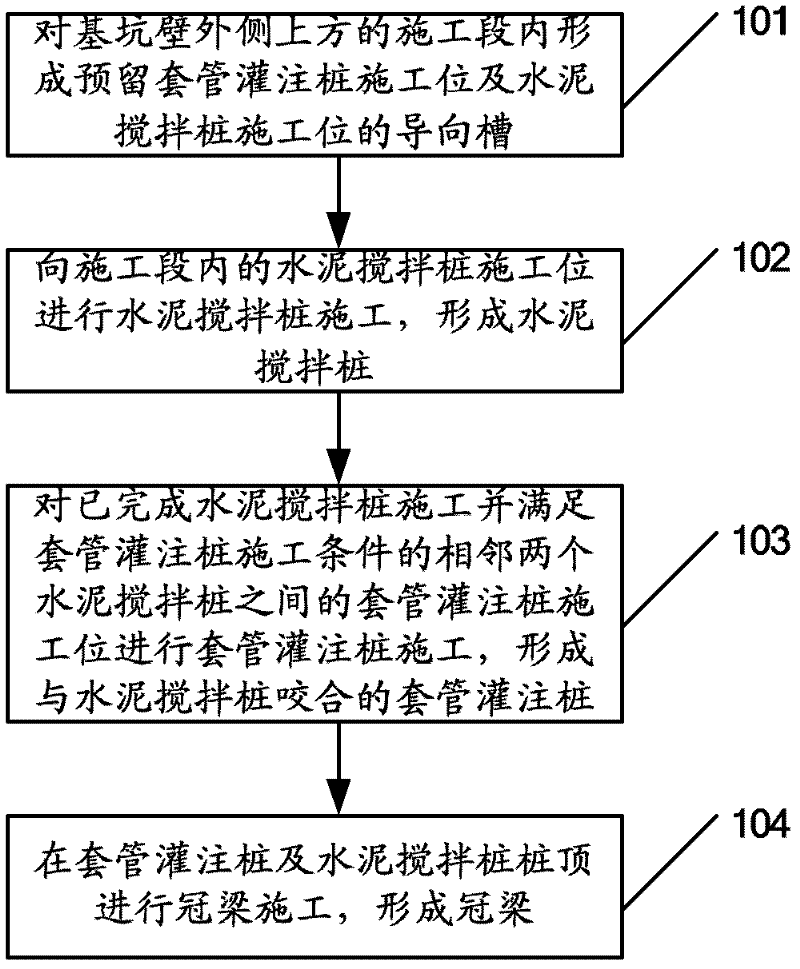

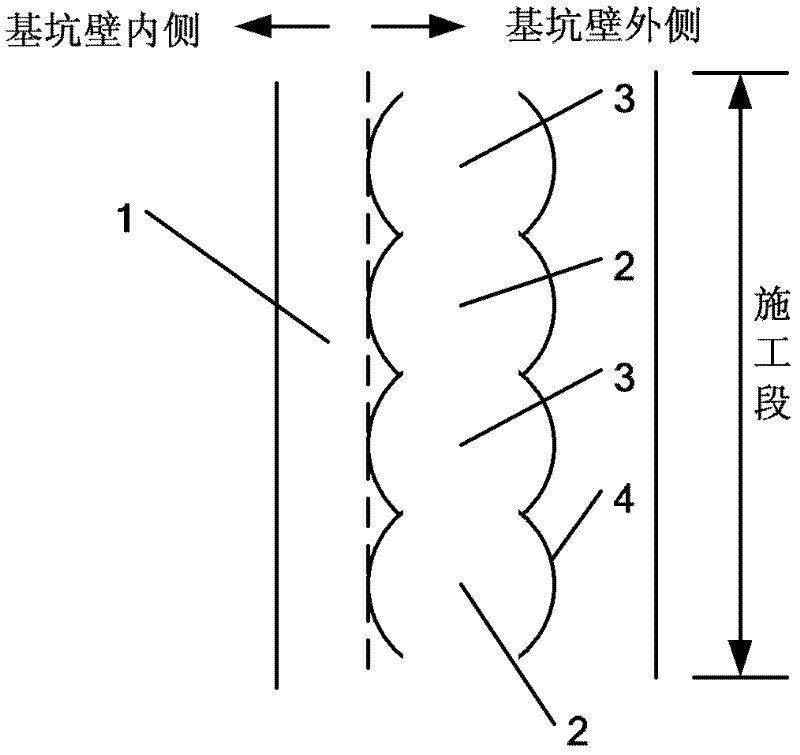

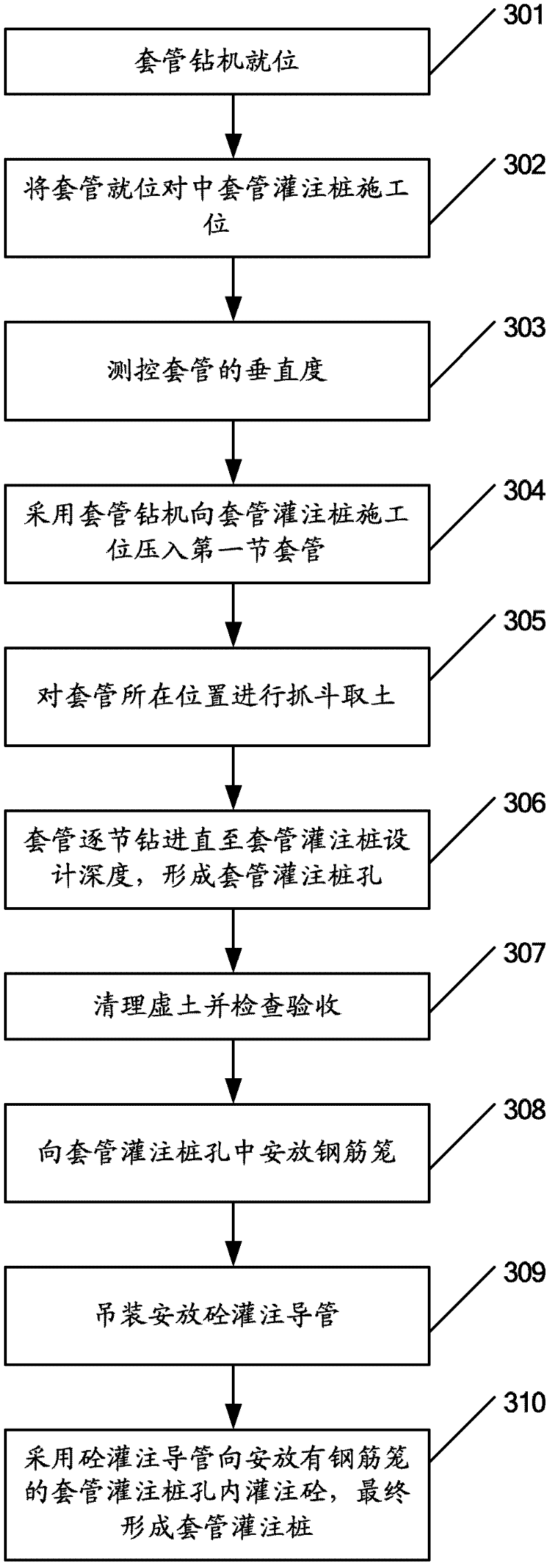

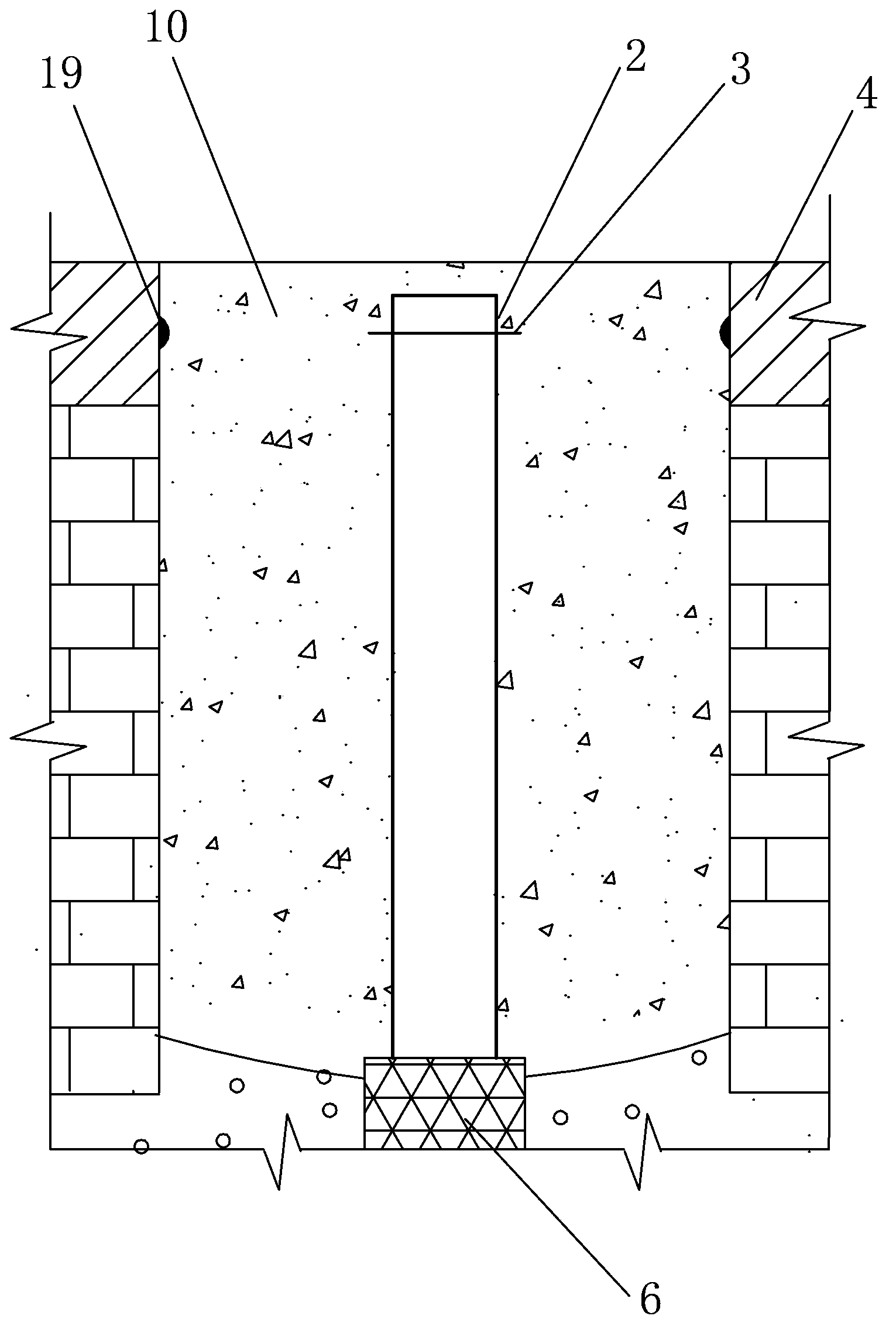

Waterproof curtain and construction method thereof

InactiveCN102286981APrevent water seepagePrevent water leakageExcavationsBulkheads/pilesSlurry wallWater leakage

In the embodiment of the present invention, the water-stop curtain is formed on the outside of the foundation pit wall by the cement mixing pile and the cast-in-place pile being occluded, making full use of the bending resistance performance of the cast-in-place pile and the water-stop performance of the cement mixing pile, so that the operation is safe and the water-forming Reinforced concrete piles are neat and regular; cement mixing piles are used to occlude casing piles to form a water-stop curtain, which can effectively prevent water seepage, water leakage and quicksand in traditional foundation pits, and can effectively prevent collapse, necking and other types of punching and drilling The quality of piles is a common problem; compared with traditional underground diaphragm walls and bored occlusal piles, the construction speed is faster, the cost is lower, and the economic benefits are obvious; the cement mixing piles are constructed first to form the constraints of casing piles and avoid the casing piles. The problem of diameter expansion in soft soil layers; the use of casing piles for support, and the use of cement mixing piles to consolidate and harden the soil, reduce the excavation of earthwork and the impact on the surrounding geology, and reduce the impact of construction on the surrounding environment Impact and environmental pollution, green construction.

Owner:深圳市鸿荣轩建设工程有限公司 +1

Concrete foundation slab restoring method for preformed water collecting well for higher underground hydraulic pressure

ActiveCN103382722ASolve construction difficultiesSolve quality problemsFoundation engineeringWater wellUltimate tensile strength

The invention discloses a concrete foundation slab restoring method for a preformed water collecting well for higher underground hydraulic pressure, and relates to the technical field of building construction. The method comprises the following construction steps: (1) fabricating a water lowering pipe, wherein the lower section of the water lowering pipe is coated with a filter screen and a bottom filter screen is arranged at the bottom end of the water lowering pipe; (2) placing the water lowering pipe into the water collecting well, placing a water pumping pipe into the water lowering pipe for water pumping, pumping out the water lowering pipe filled with underground water, and performing flash set concrete pouring to the foundation slab in the water collecting well except the water lowering pipe, and performing continuous water lowering during pouring; (3) when the poured concrete achieves certain strength, stopping water lowering, withdrawing the water pumping pipe of the pump, and plugging the water lowering pipe by adopting a concrete cylinder, a coarse sand packing layer and a rubber water-seal piston from up to down; (4) performing flash set concrete pouring to the upper section of the rubber water-seal piston in the water lowering pipe. During concrete foundation slab restoring process for the preformed water collecting well, the method can efficiently solve the problems of construction difficulty and incapability of ensuring the restoring quality caused by over high underground hydraulic pressure.

Owner:THE ELEVENTH METALLURGICAL CONSTR GRP

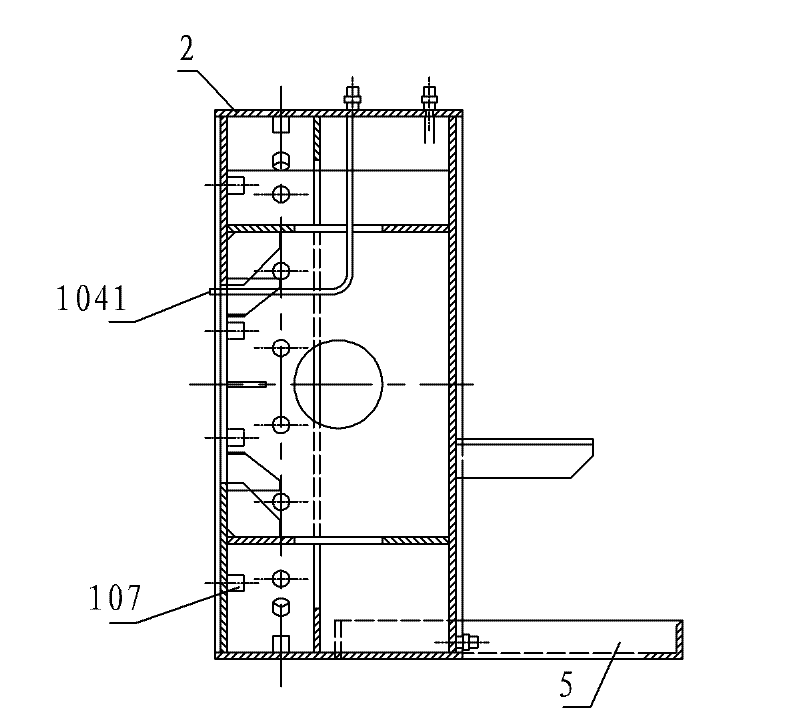

Test system and test method for water tightness test of tunnel deformation joint waterstop

InactiveCN102175406AEnsure safetyConvenient inspectionMeasurement of fluid loss/gain rateEngineeringOmega

The invention discloses a test system for the water tightness test of a tunnel deformation joint waterstop, which comprises two steel tanks mounted, in a sealed manner, at two sides of a waterstop to be tested, a steel structured test bench, an atmospheric pressure test bench, a hydraulic pressure test bench, an air compressor, a remote-distance full-automatic observing and reading apparatus and a safety protection device. The test device of the invention can be used for the water tightness test of a plurality of waterstops, realize random opening displacement and shear displacement accurately, and simulate the stress condition of deformation joint waterstop structure under different working conditions by applying atmospheric pressure in balloon to a tested object through the atmospheric pressure test bench and applying hydraulic pressure to the steel tanks through the hydraulic pressure test bench to simulate seawater pressure. The system and the method are suitable for the test of OMEGA and GINA waterstops as well as expandable waterstop.

Owner:CCCC FOURTH HARBOR ENG INST +2

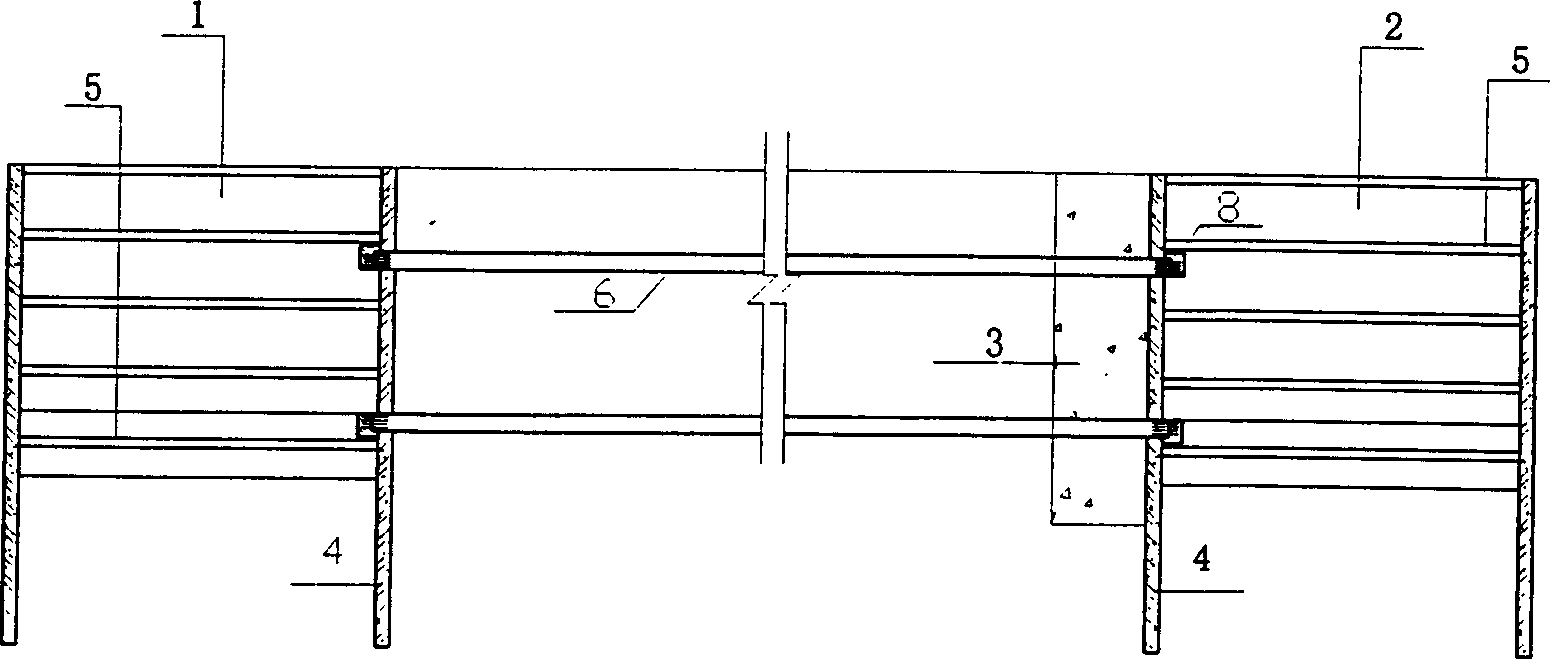

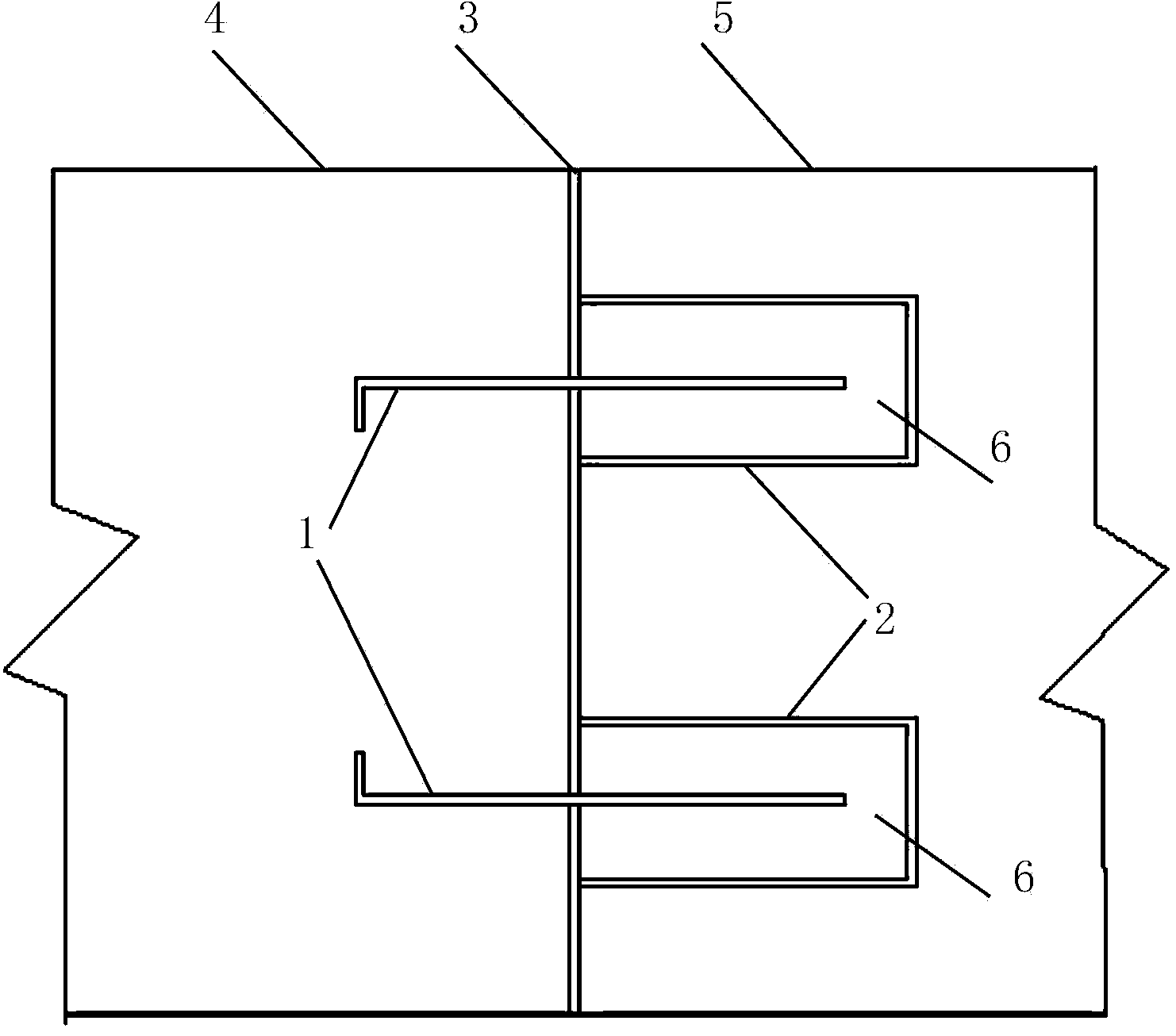

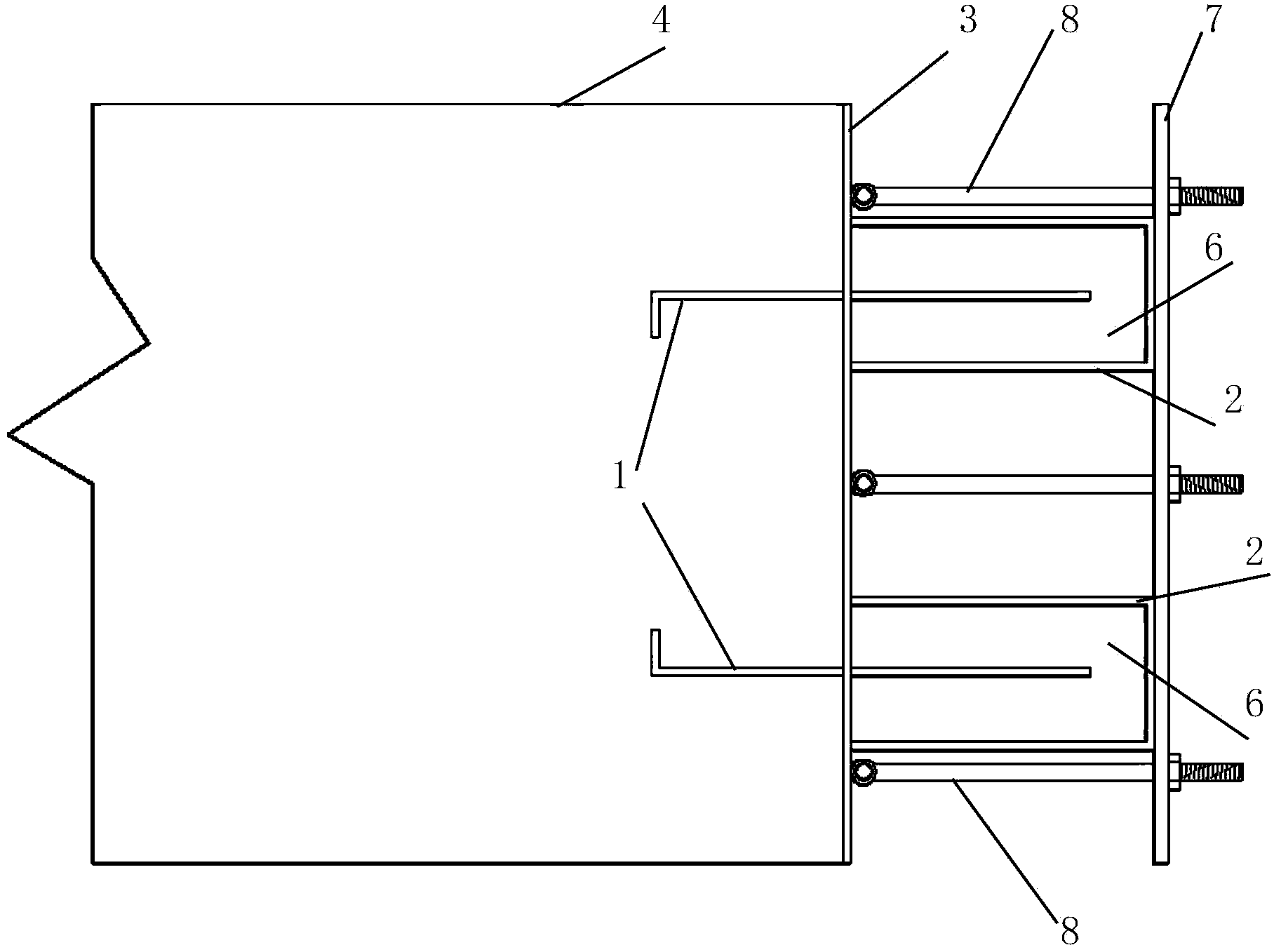

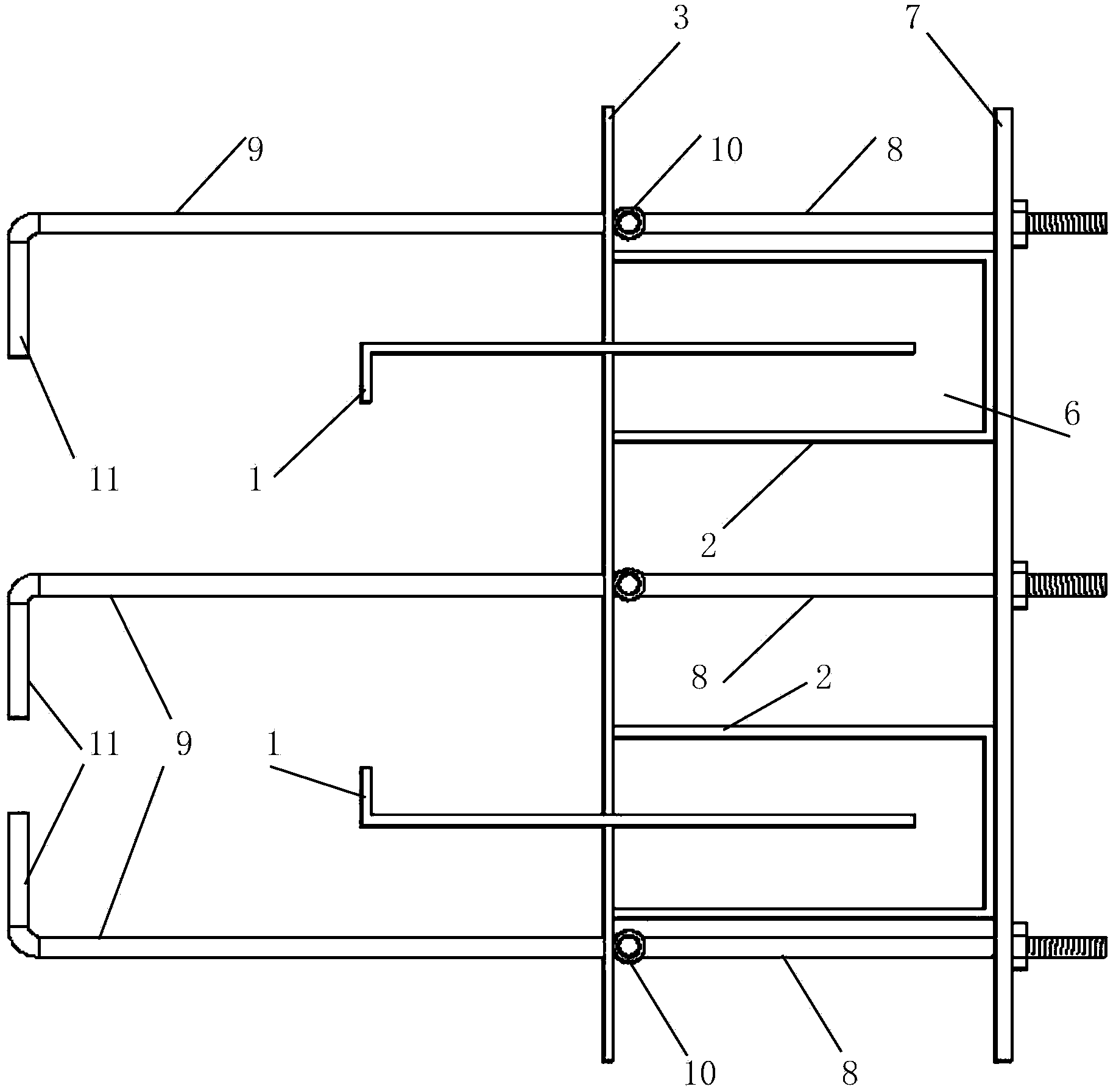

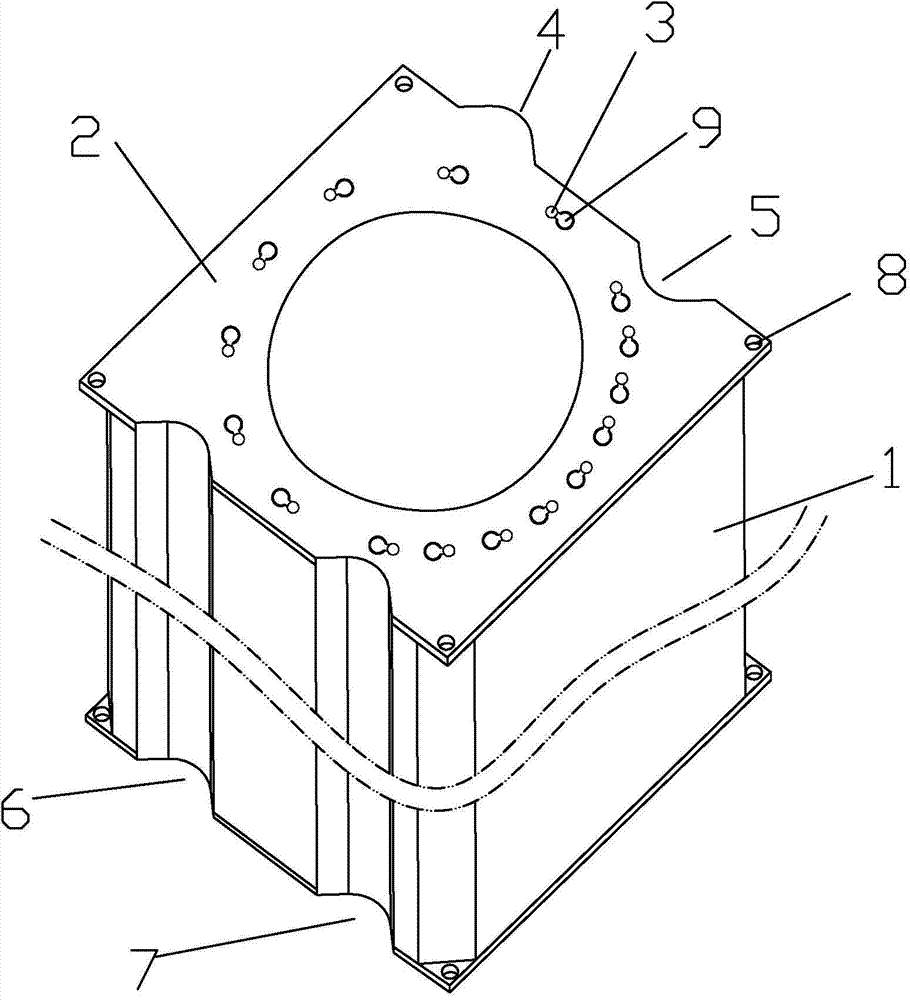

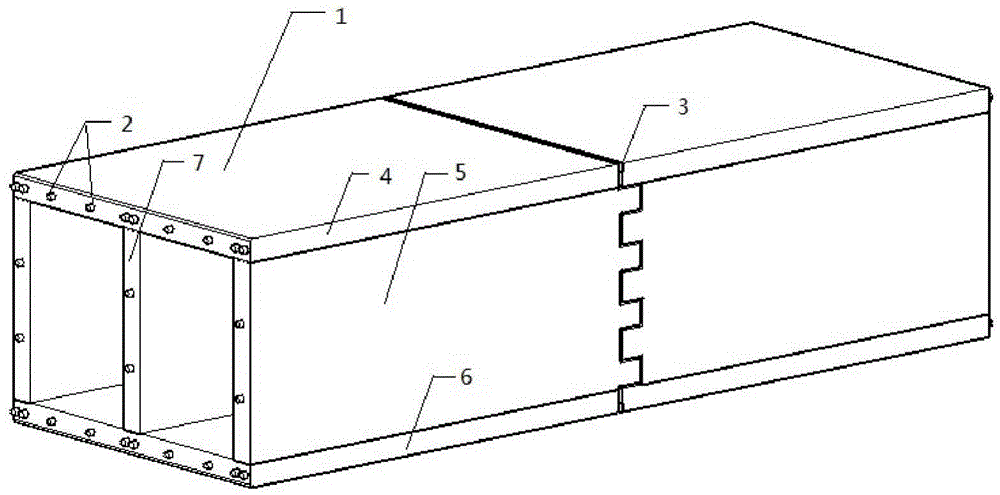

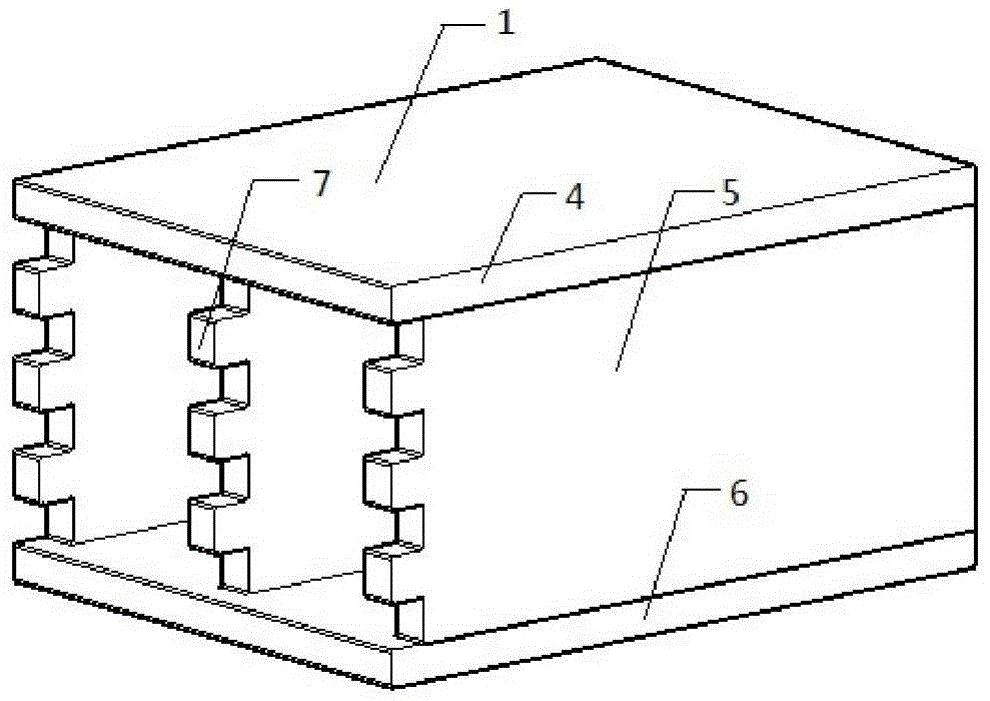

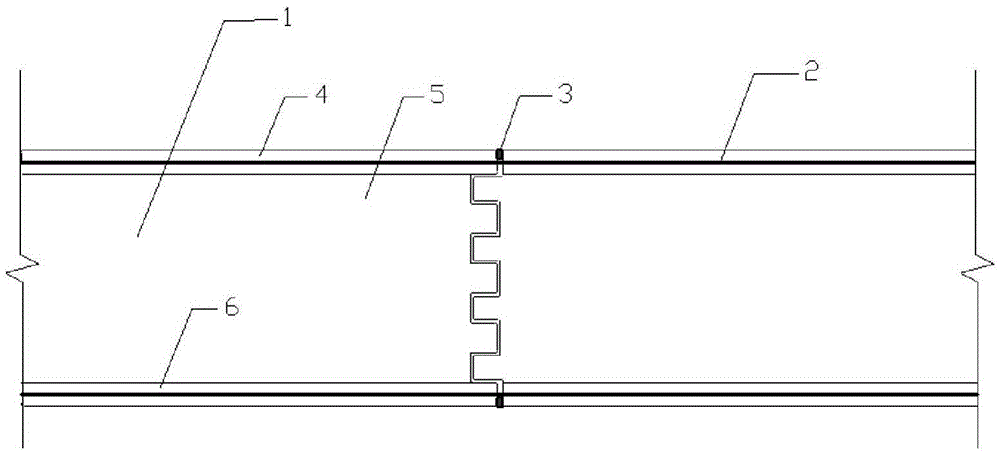

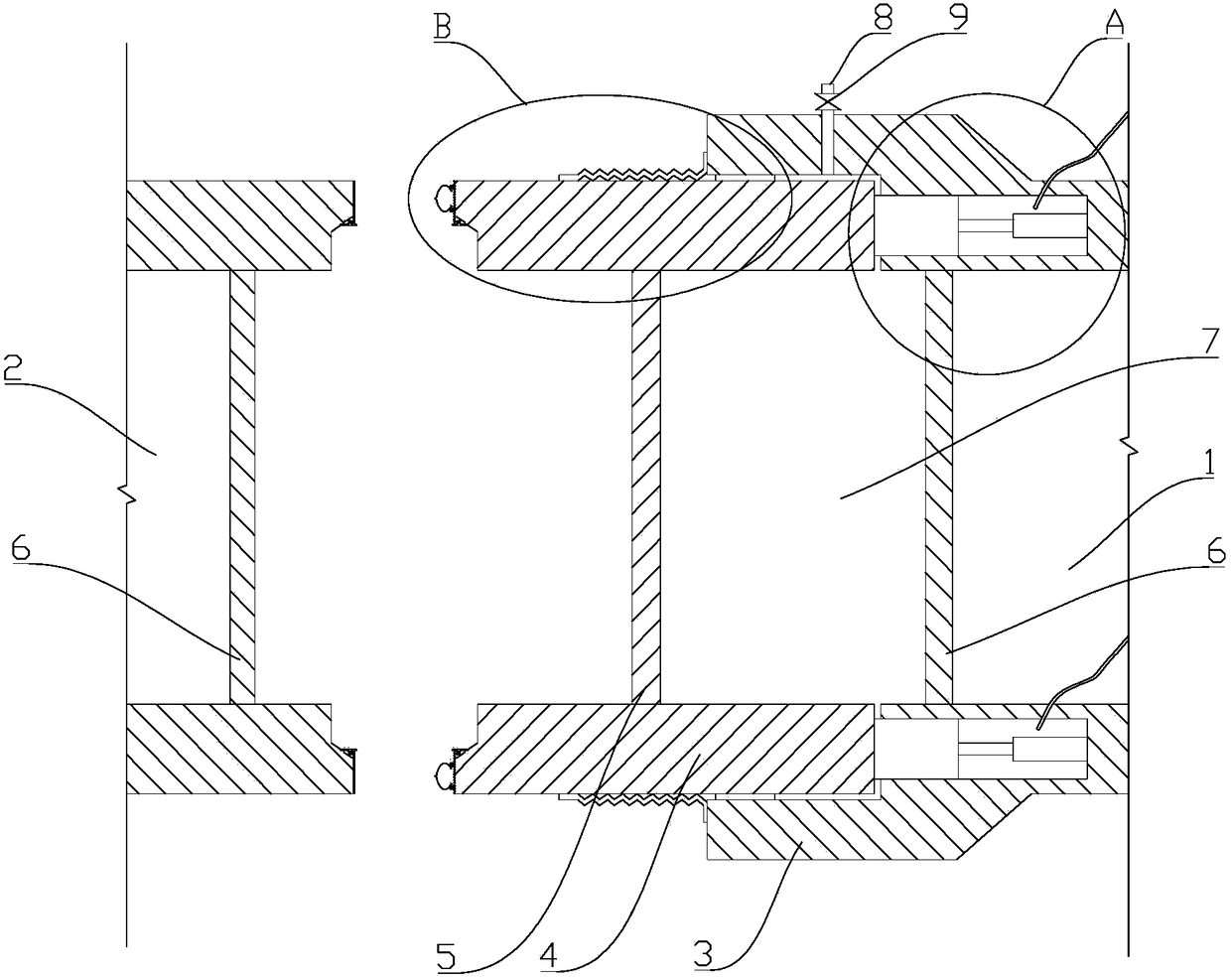

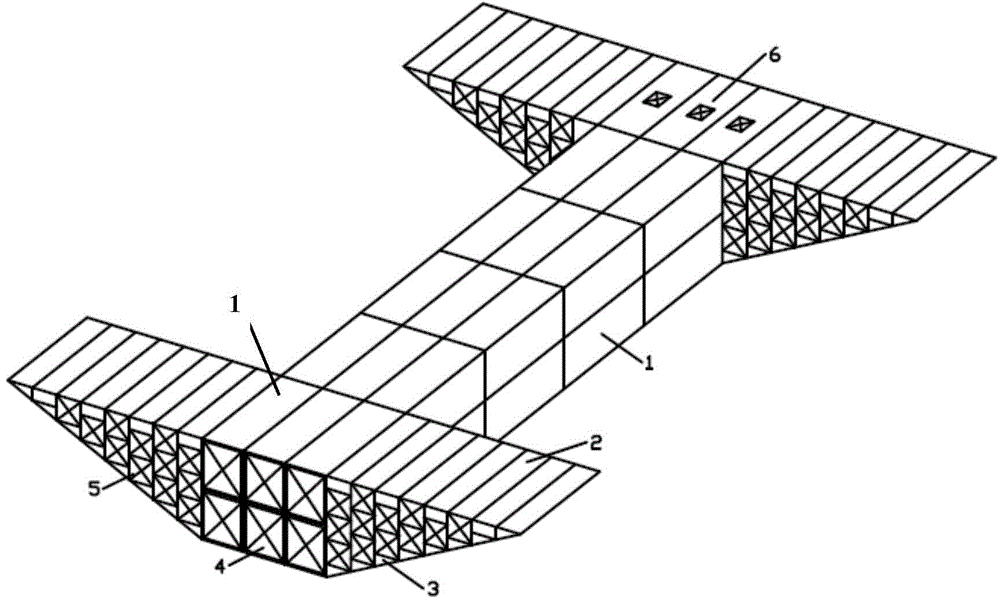

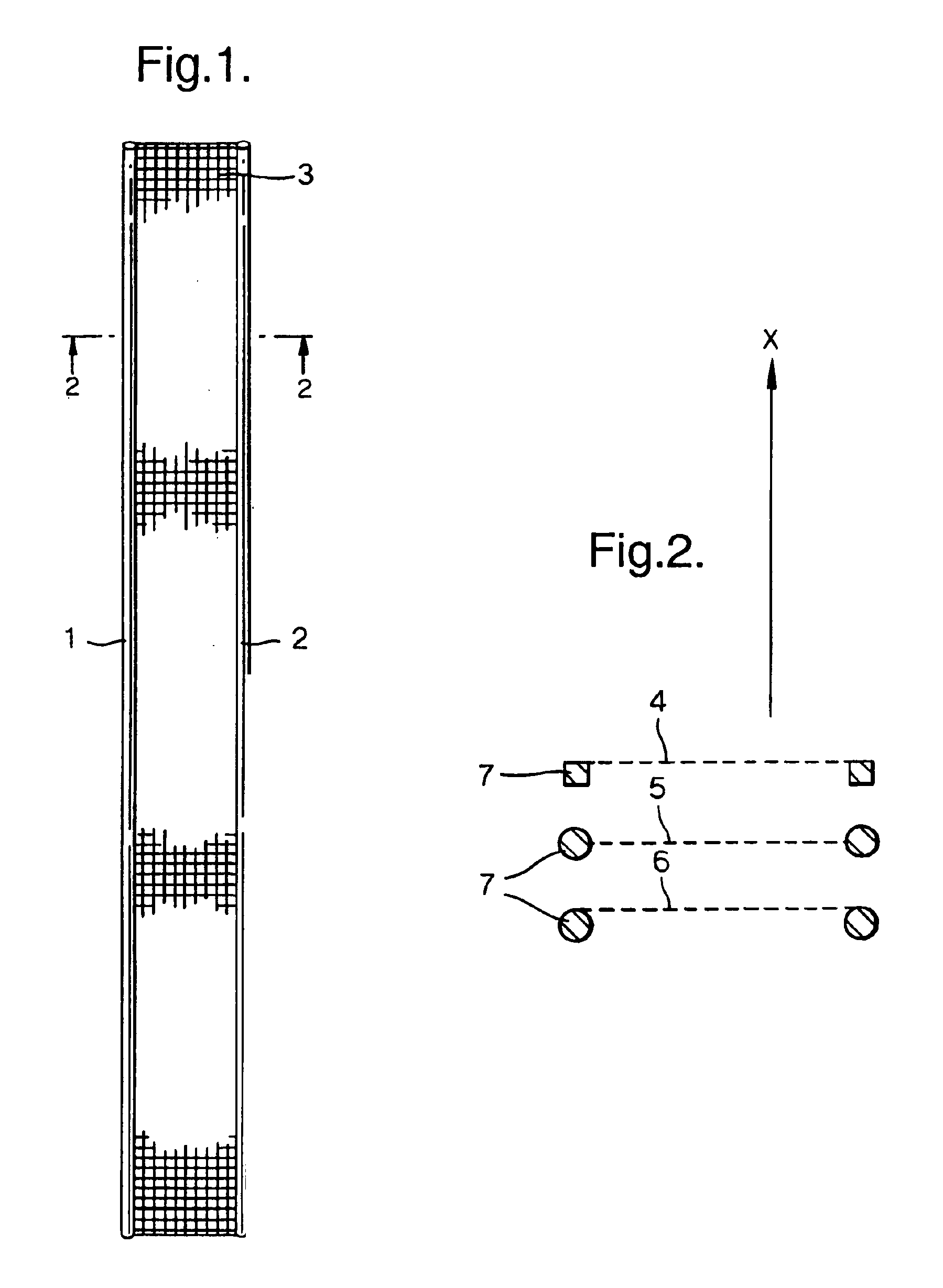

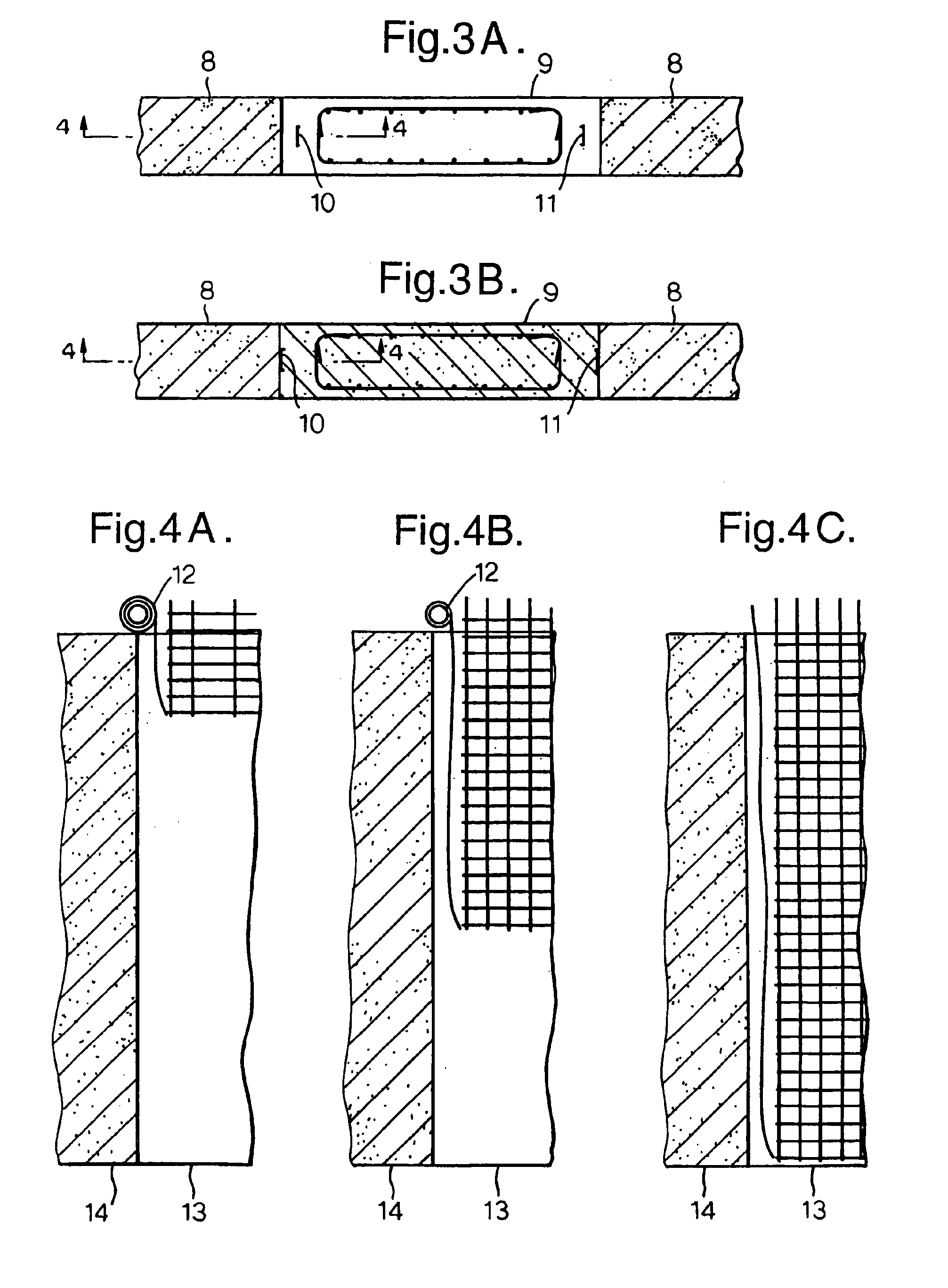

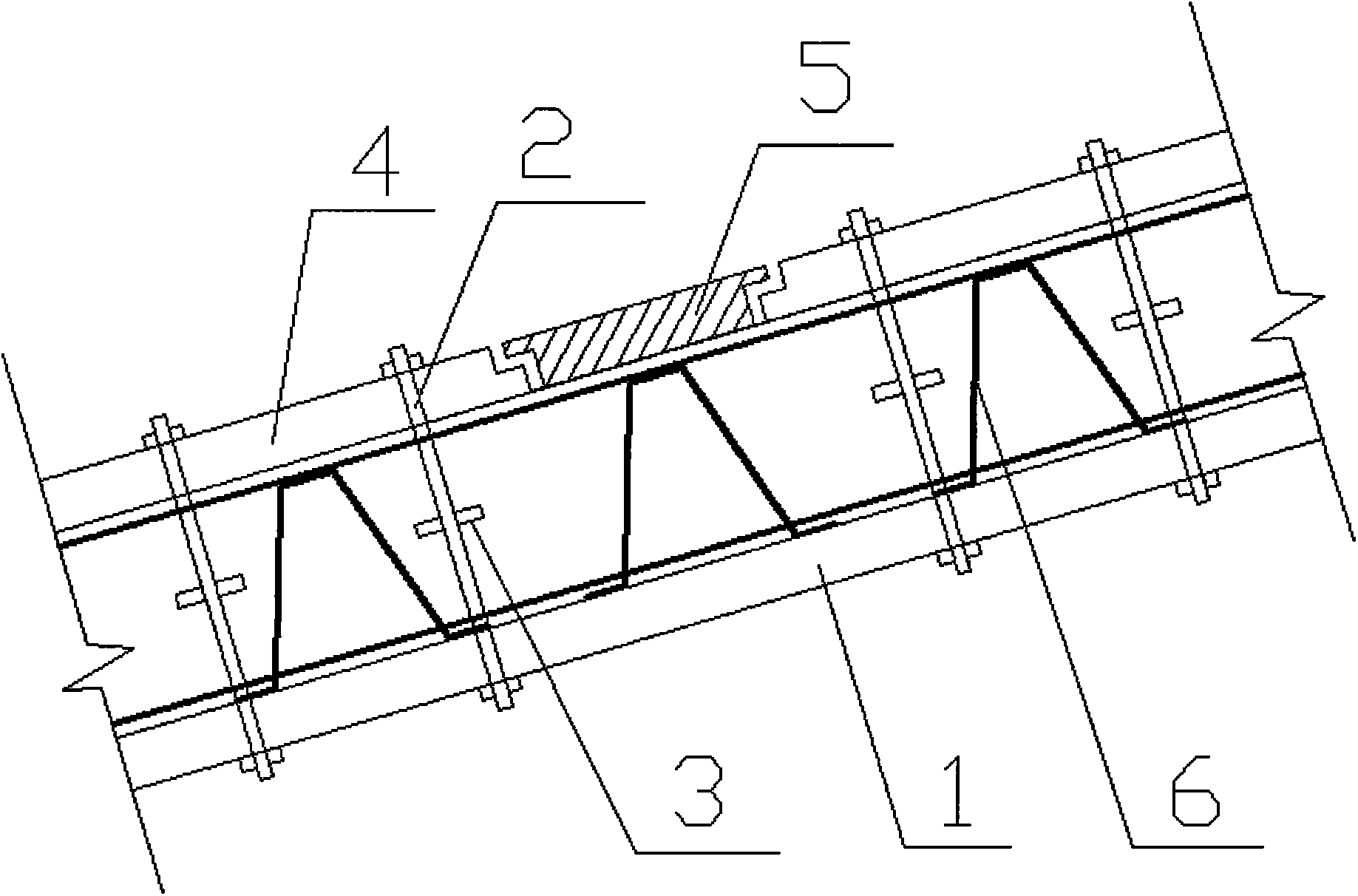

Mortise type prefabricated comprehensive pipe gallery longitudinal connector

InactiveCN105421489AClosely connectedImprove mechanical propertiesArtificial islandsUnderwater structuresMortise and tenonEngineering

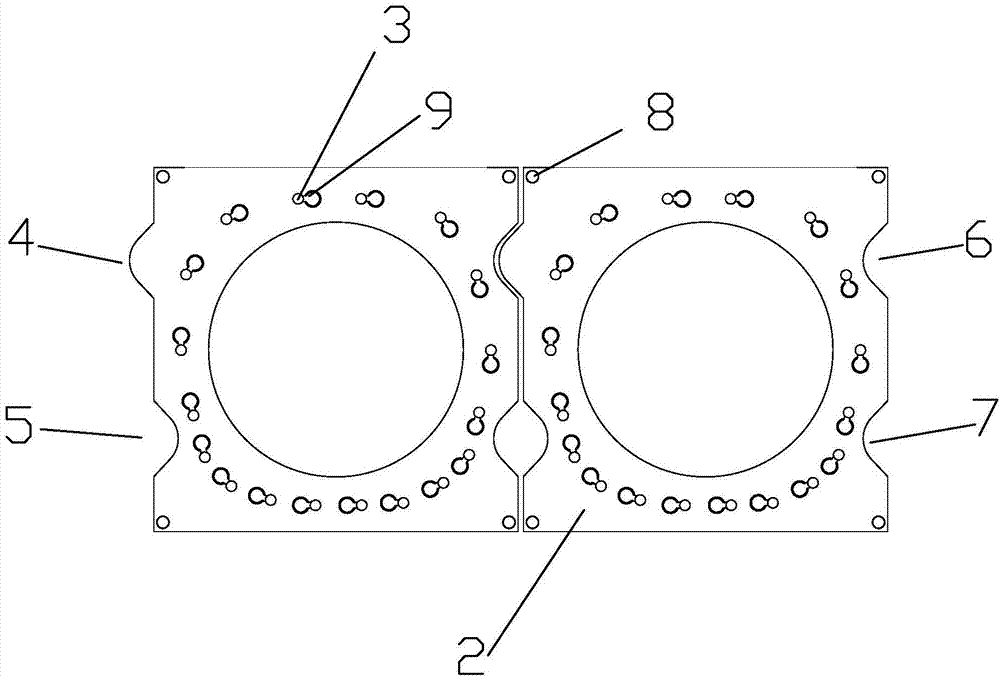

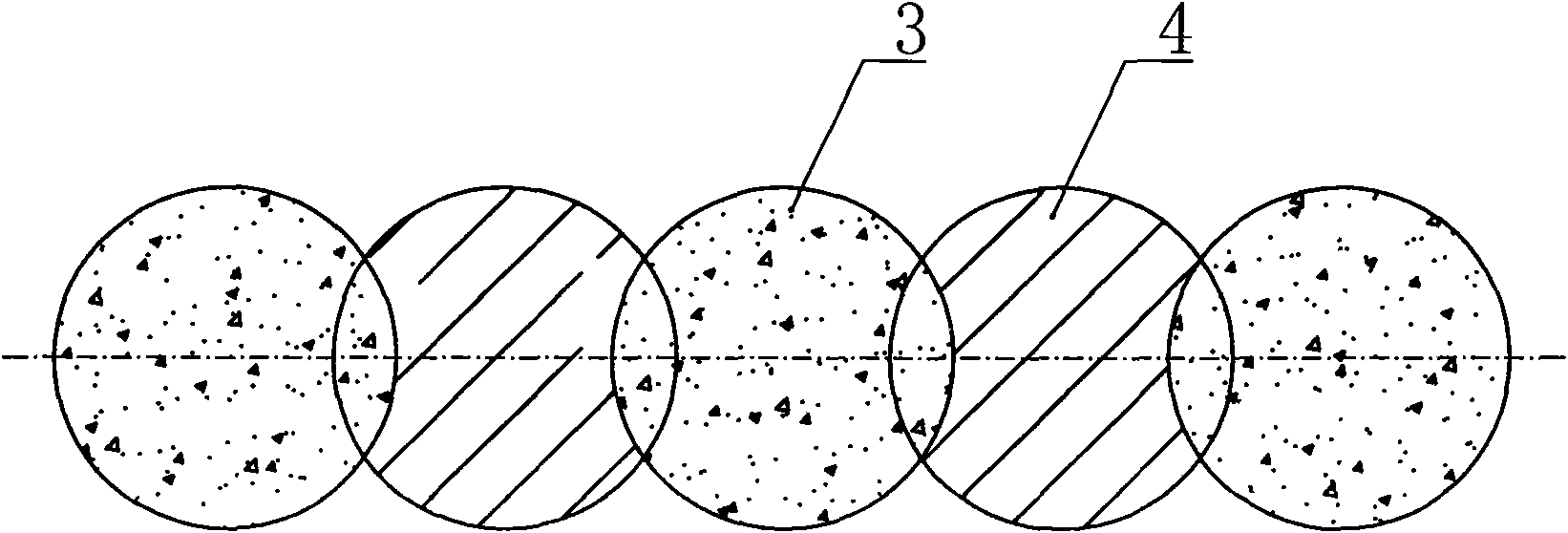

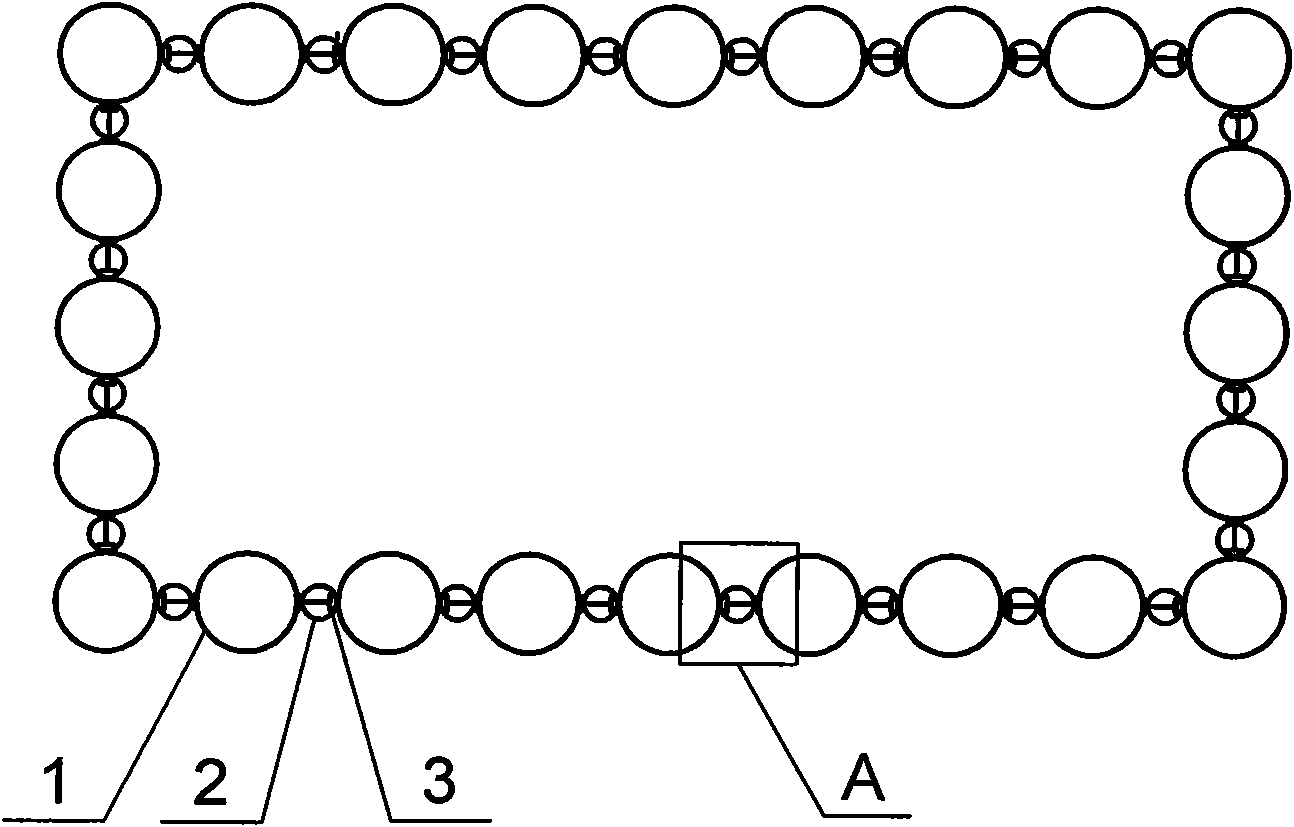

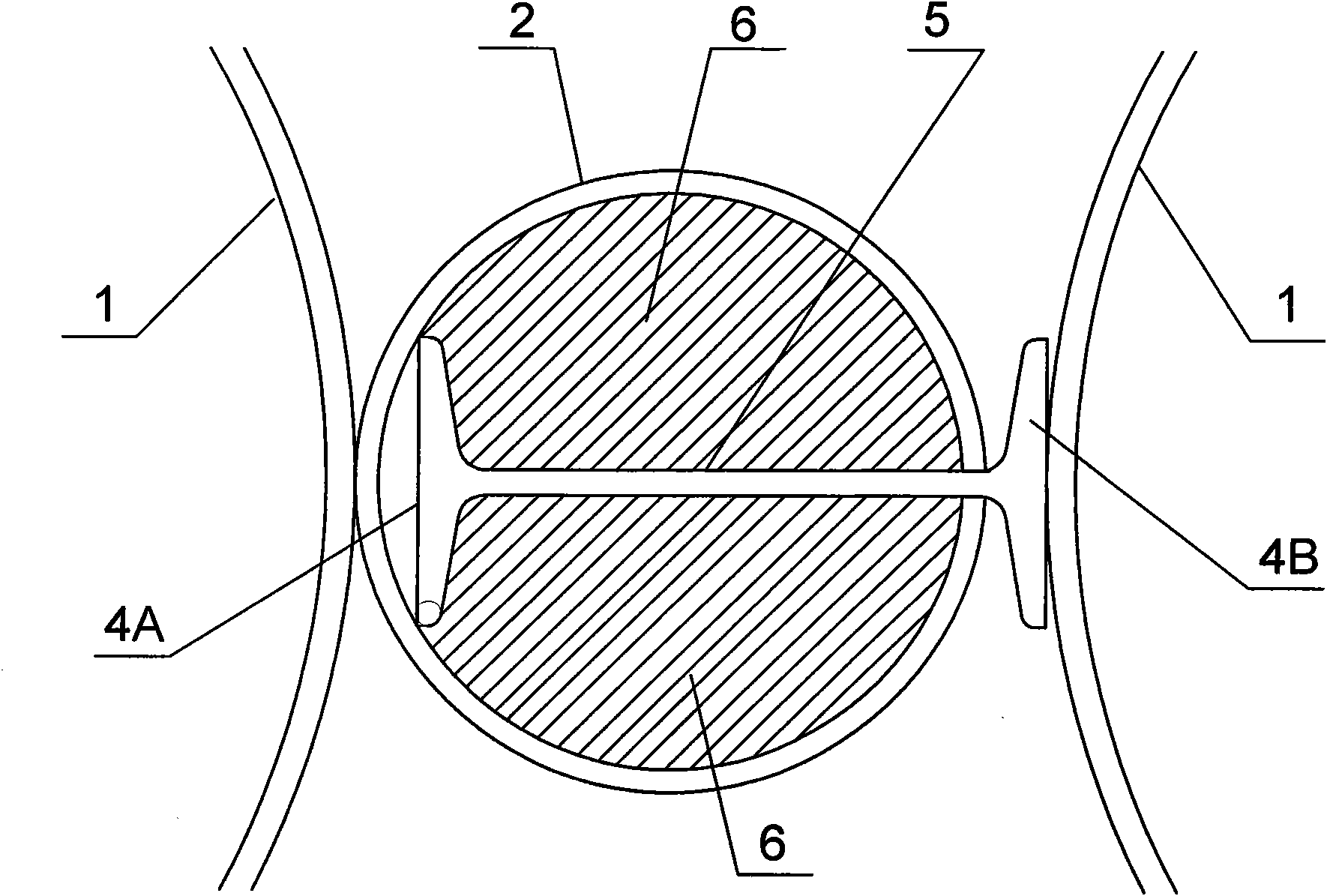

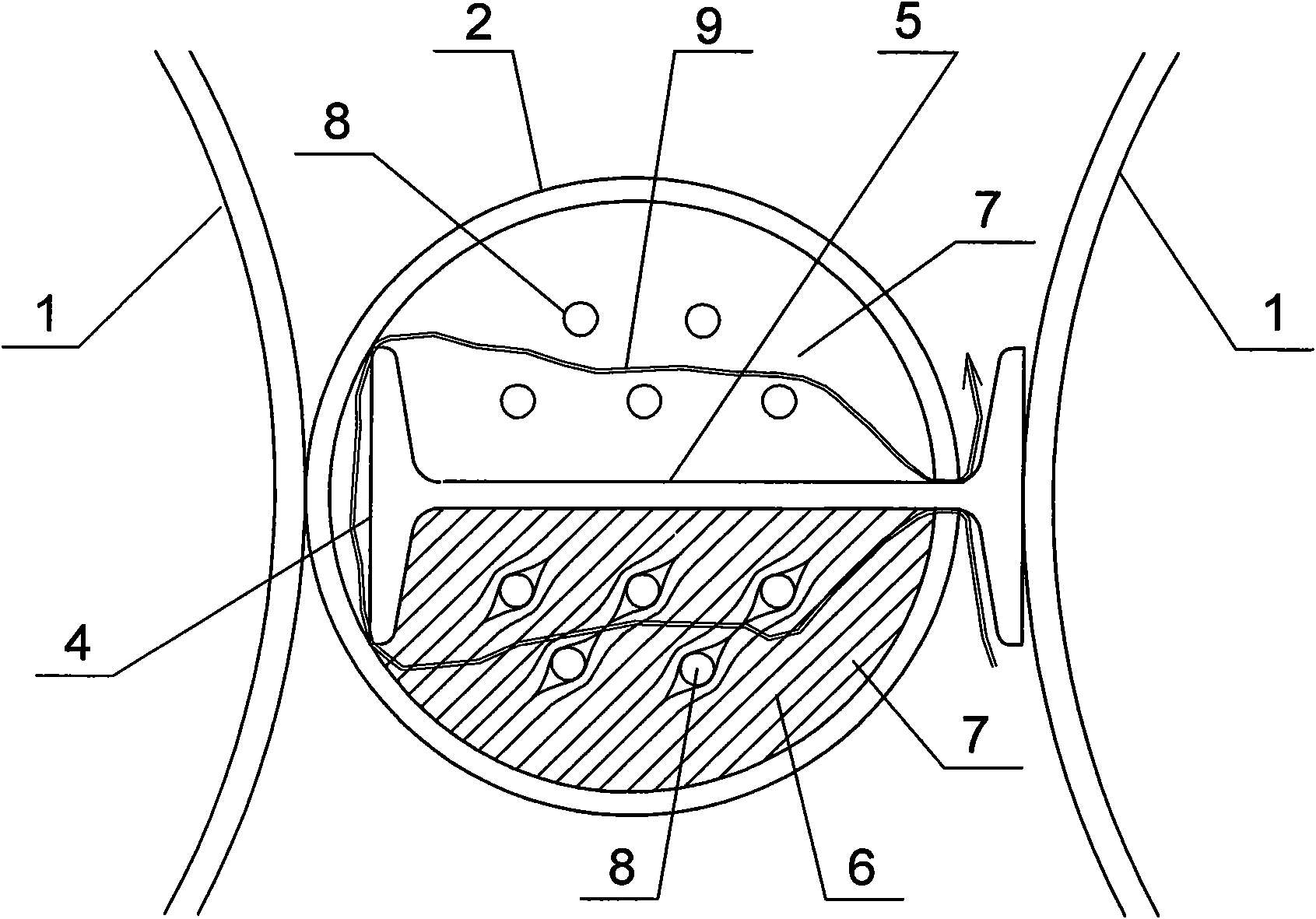

The invention discloses a mortise type prefabricated comprehensive pipe gallery longitudinal connector. The mortise type prefabricated comprehensive pipe gallery longitudinal connector comprises prefabricated pipe gallery sections (1), longitudinal prestress ribs (2) and waterstop rubber belts (3), wherein each prefabricated pipe gallery section (1) comprises a top plate (4), side plates (5) and a bottom plate (6). Tenon-and-mortise components which are matched with each other are arranged at the two ends of each pipe gallery section. During on-site construction and splicing, every two adjacent pipe gallery sections are matched with each other according to the tenon-and-mortise relationship, the waterstop rubber belts are reasonably arranged on joints, then prestress is applied through the longitudinal prestress ribs for tensioning, and thus an integral structure is formed by a prefabricated pipe gallery. According to the mortise type prefabricated comprehensive pipe gallery longitudinal connector, the good mechanical property and waterproof performance of the mortise type connector are utilized, the prestress ribs are used for tensioning, the waterstop rubber belts are used for preventing water, and thus the structural integrity of the prefabricated pipe gallery is improved. Abundant structural forms of the prefabricated comprehensive pipe gallery longitudinal connector are provided, and convenience is provided for further development of the structure of the prefabricated comprehensive pipe gallery.

Owner:SOUTHEAST UNIV

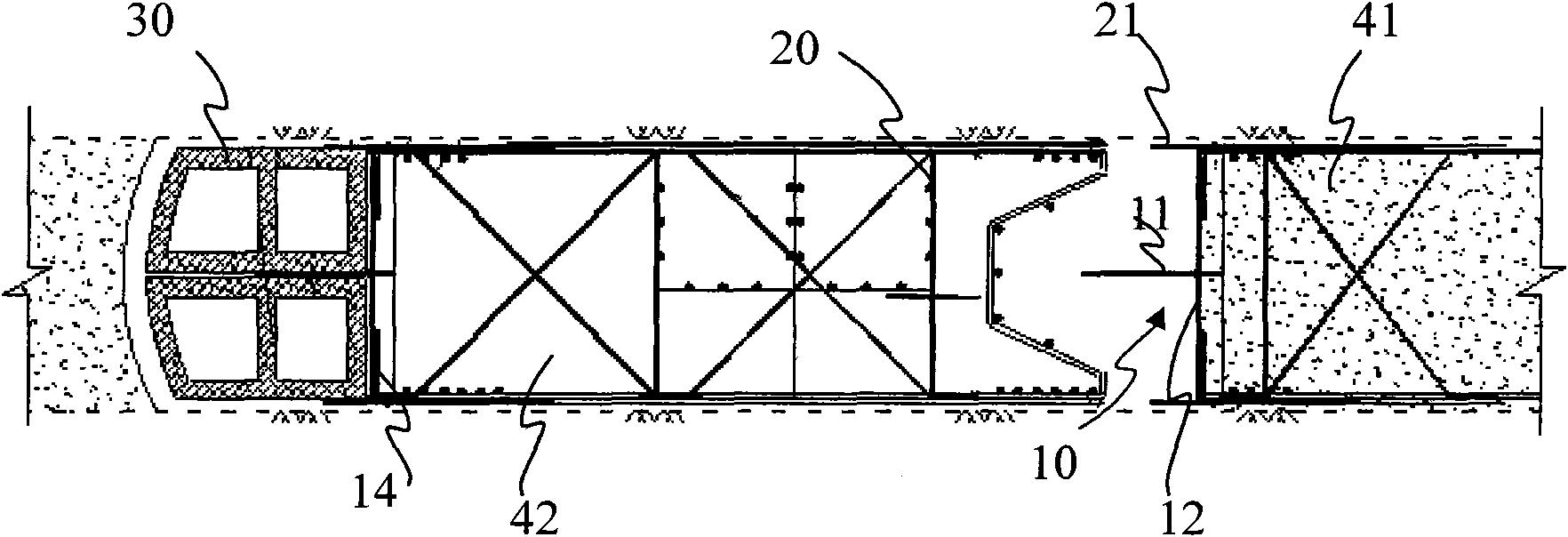

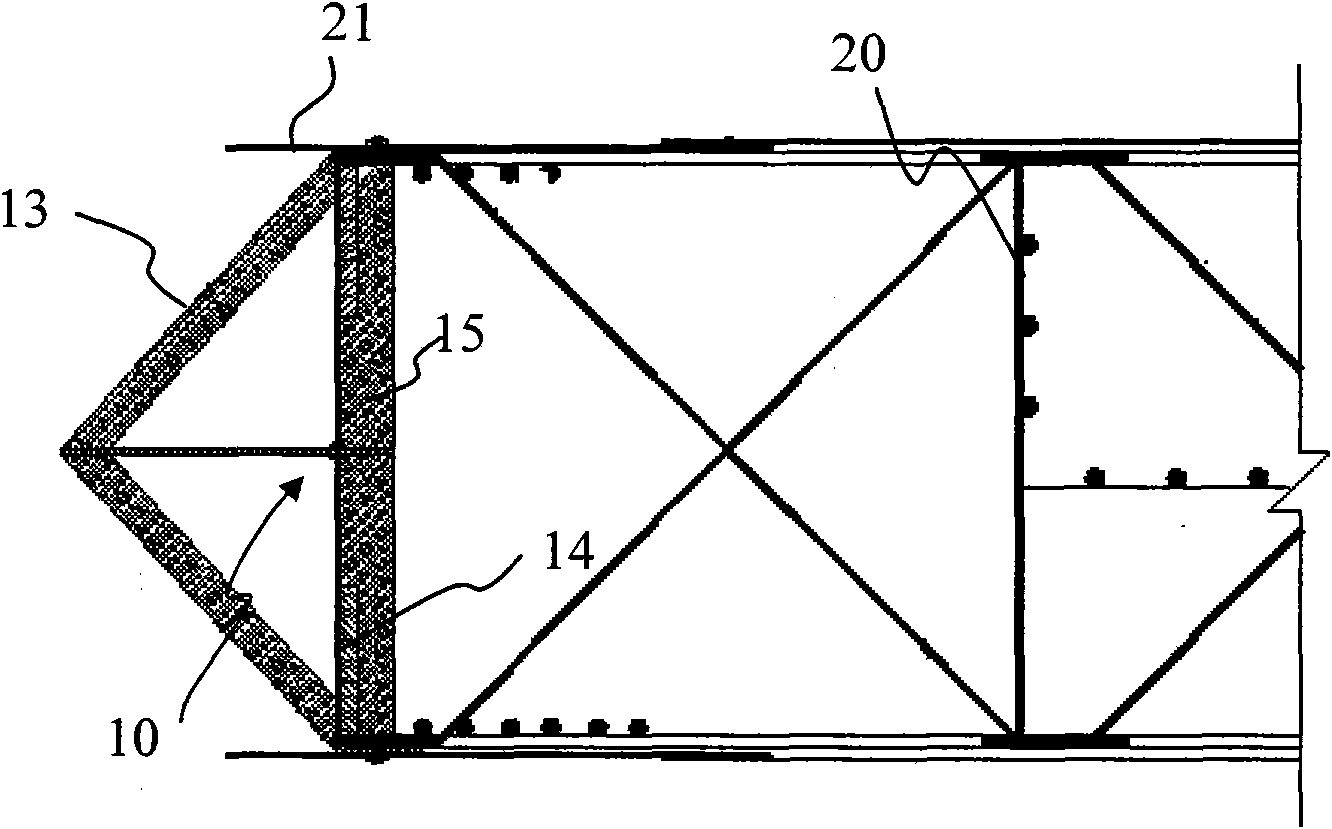

Jacking-pushing-type final joint for immersed tunnel and butt-joint construction method thereof

ActiveCN108385728AThrust achievedEnsure safetyArtificial islandsHydro energy generationButt jointEngineering

The invention provides a jacking-pushing-type final joint for an immersed tunnel and a butt-joint construction method thereof, and belongs to the technical field of immersed tunnel construction. Underwater water stop and push stop of the final joint after jacking pushing can be quickly and effectively achieved, the water stop and push stop effects are good, and the safety is high. The jacking-pushing-type final joint comprises a connecting bearing opening formed in a to-be-mounted pipe segment, further comprises a jacking pushing piece, and further comprises a water stop assembly. A jacking pipe section is sleeved with the connecting bearing opening, a cavity capable of containing the jacking pushing piece is formed in the connecting bearing opening, and a grouting pipe is pre-embedded inthe cavity. The water stop assembly comprises three water stop belts; the first water stop belt is arranged at the end face of the pushed-out end of the jacking pipe section; the second water stop belt and the third water stop belt are both arranged on the periphery of the jacking pipe section; the second water stop belt can extend along with pushing out of the jacking pipe section; one end of thesecond water stop belt is fixedly connected to the jacking pipe section, and the other end of the second water stop belt is fixedly connected to the connecting bearing opening; and the third water stop belt is connected between the jacking pipe section and the connecting bearing opening in a sleeved mode.

Owner:CCCC FIRST HARBOR ENG +2

Mould support method of foundation pit basement haunch shearing wall

ActiveCN103195087AEasy to operateLess space for constructionArtificial islandsUnderwater structuresBasementBrick

The invention provides a mould support method of a foundation pit basement haunch shearing wall. The method includes the following steps: S1 integrally molding a basement base plate and an upper turning shearing wall arranged on the upper surface of the basement base plate in pouring mode and embedding reinforcing bar heads on the basement base plate; S2 building a brick base film on the outer side of the upper turning shearing wall and embedding a plurality of connection pieces in the brick base film; S4 welding a plurality of water stopping screws on the stretching ends of a plurality of connection pieces; S6 fixing a single side mould plate on the extending ends of the plurality of water stopping screws; and S8 building a plurality of inclined supports used for supporting the single side mould plate from the inside of the single side mould plate between the steel bar heads and the single side mould plate. Compared with the existing double side mould support method, the mould support method is simple to operate. Due to the fact that only the single side mould plate is supported on the inner side of the haunch shearing wall, the method is less is required construction space, low in construction cost, small in construction difficulty and short in construction period.

Owner:CCFEB CIVIL ENG

Steel pipe pile locking notch structure and water-stopping method of steel pipe pile cofferdam

The invention discloses a steel pipe pile locking notch structure and a water-stopping method of a steel pipe pile cofferdam by using the structure. The notch-locking structure comprises steel pipe piles and locking notches, wherein the steel pipe piles are arranged at intervals, each locking notch is arranged between two adjacent steel pipe piles, each locking notch comprises a female locking notch and a male locking notch, the male locking notch is I-shaped steel, the female locking notch is a steel pipe which is provided with a slit along the axial direction, and an I-shaped steel web plate is inserted into the slit. When the locking notch structure is used for leak stoppage, clay is pounded into the cavities of the locking notches, and reinforcing steel bars are inserted to carry out compaction processing for the clay. The invention relates to an effective locking notch structure and the water-stopping method thereof which are disclosed specially for solving the problem of difficult water prevention and leak stoppage of the locking notches in the steel pipe pile cofferdam.

Owner:1ST ENG OF CHINA ZHONGTIE MAJORBRIDGE GROUP

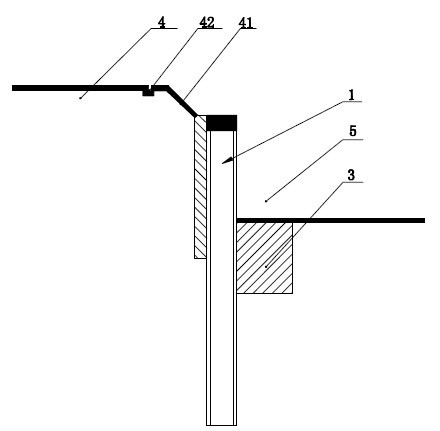

Vertical joint waterproofing node of exterior wall

InactiveCN101806099AShorten the construction periodPlay a waterproof effectWallsWaterstopBuilding construction

The invention discloses a vertical joint waterproofing node of an exterior wall, which belongs to a building structure. Particularly, the invention aims to provide the vertical joint waterproofing node of the exterior wall which has the advantages that the construction speed is high, water retaining grooves are left in the abutted seam of two prefabricated exterior walls, and the waterproofing performance is good. The vertical joint waterproofing node of the exterior wall comprises a first prefabricated exterior wall (1) and a second prefabricated exterior wall (2), and is characterized in that an abutted seam between the side joint of the first prefabricated exterior wall (1) and the side joint of the second prefabricated exterior wall (2) is a micro expansion mortar layer (3). In addition, the abutted seam between the side joint of the first prefabricated exterior wall and the side joint of the second prefabricated exterior wall is 14-16mm.

Owner:NANTONG CONSTR PROJECT GENERAL CONTRACTING +1

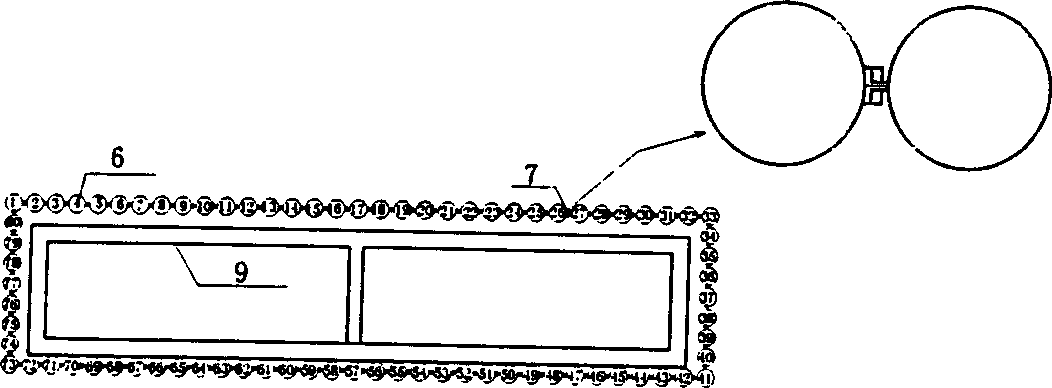

Spliced chamber cofferdam for repair of canal lining projects

The invention discloses a spliced chamber cofferdam for repair of canal lining projects. The cofferdam is in an I shape can comprises top end cofferdams and a middle cofferdam, wherein the top end cofferdams are matched with the cross section of a canal in shapes and located at the two ends of the upstream and the downstream, and the middle cofferdam is arranged between the two top end cofferdams and located in the center of the canal. The cofferdams are formed by splicing a plurality of chamber bodies in the direction of water flow, every two chamber bodies connected in the direction of the water flow are communicated with each other, hydraulic doors used for opening or closing a water flow channel is arranged on the chamber bodies located at the top ends, the adjacent chamber bodies are connected with each other through lock catches and are provided with waterstops, bottom plates of the chamber bodies which are located at the center of the canal and are in contact with the bottom of the cannel can be disassembled, and a pedestrian path leading to the bottom of the canal is arranged at the tops of the chamber bodies of the middle cofferdam. The spliced chamber cofferdam for canal lining repair does not need a pile foundation, is stable without a root, and cannot damage canal lining concrete and water-stopping materials under the canal lining concrete. The spliced chamber cofferdam is convenient to assemble, disassemble, store, transport and construct, good in safety, capable of being repeatedly utilized, and particularly suitable for repair and replacement of the canal lining concrete of large water conveyance projects and the water-stopping materials under the canal lining concrete.

Owner:CHINA WATER RESOURCES BEIFANG INVESTIGATION DESIGN & RES

Advance instrumentation methods for pipes and conduits transporting cryogenic materials

A cryogenic material transfer system incorporates a pipe-in-pipe configuration with a nanoporous or microporous insulating layer filling the annulus between the inner and outer pipe. The insulating layer is of sufficient flexibility to absorb and expansion or contraction of the inner pipe due to the flow of cryogenic material therethrough. For longer transfer systems a bulkhead is provided between adjacent pipe joints. Intermediately of the pipe joints an additional bulkhead may be employed to provide additional sealing or water stops and for providing provide additional load transfer. A fiber optic sensor system is installed in the annuals between the inner and outer pipe.

Owner:ASTRO TECH GRP LLC

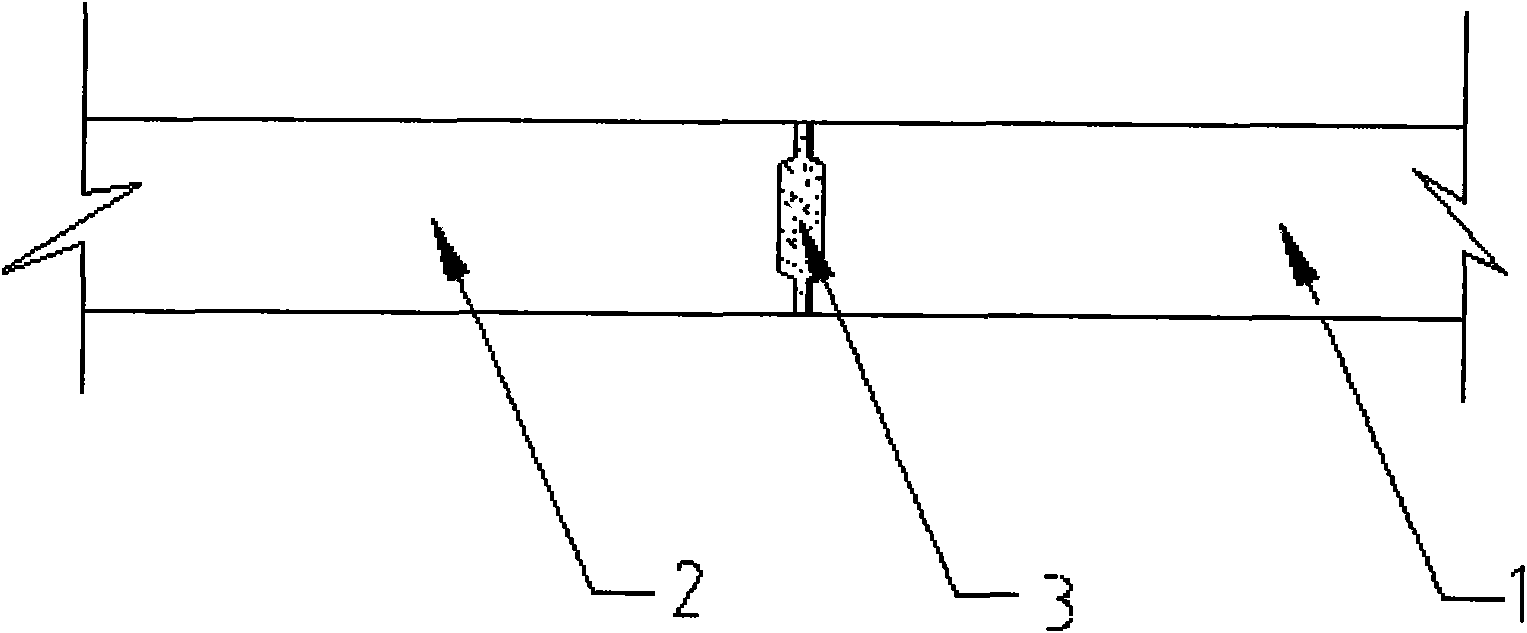

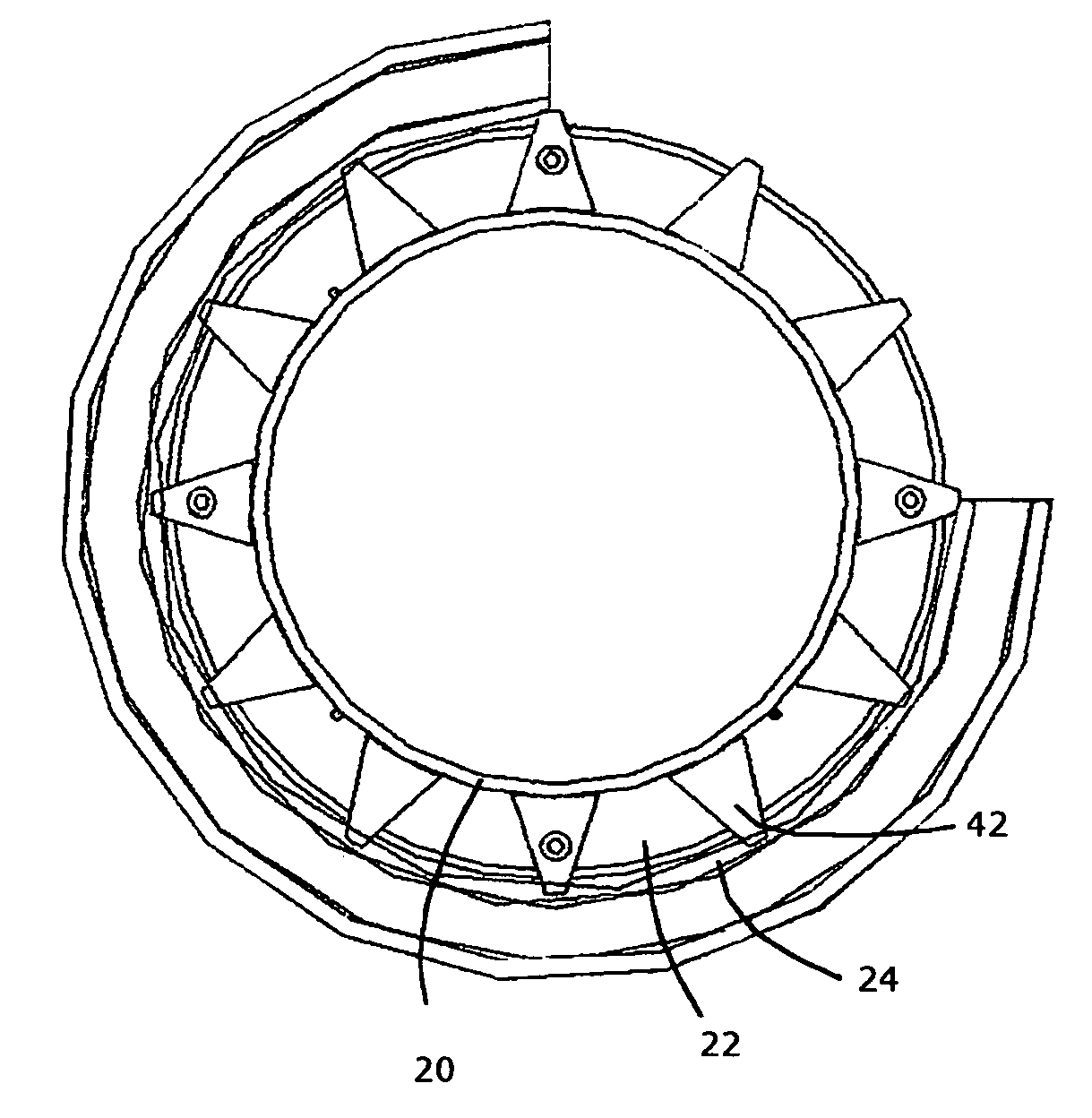

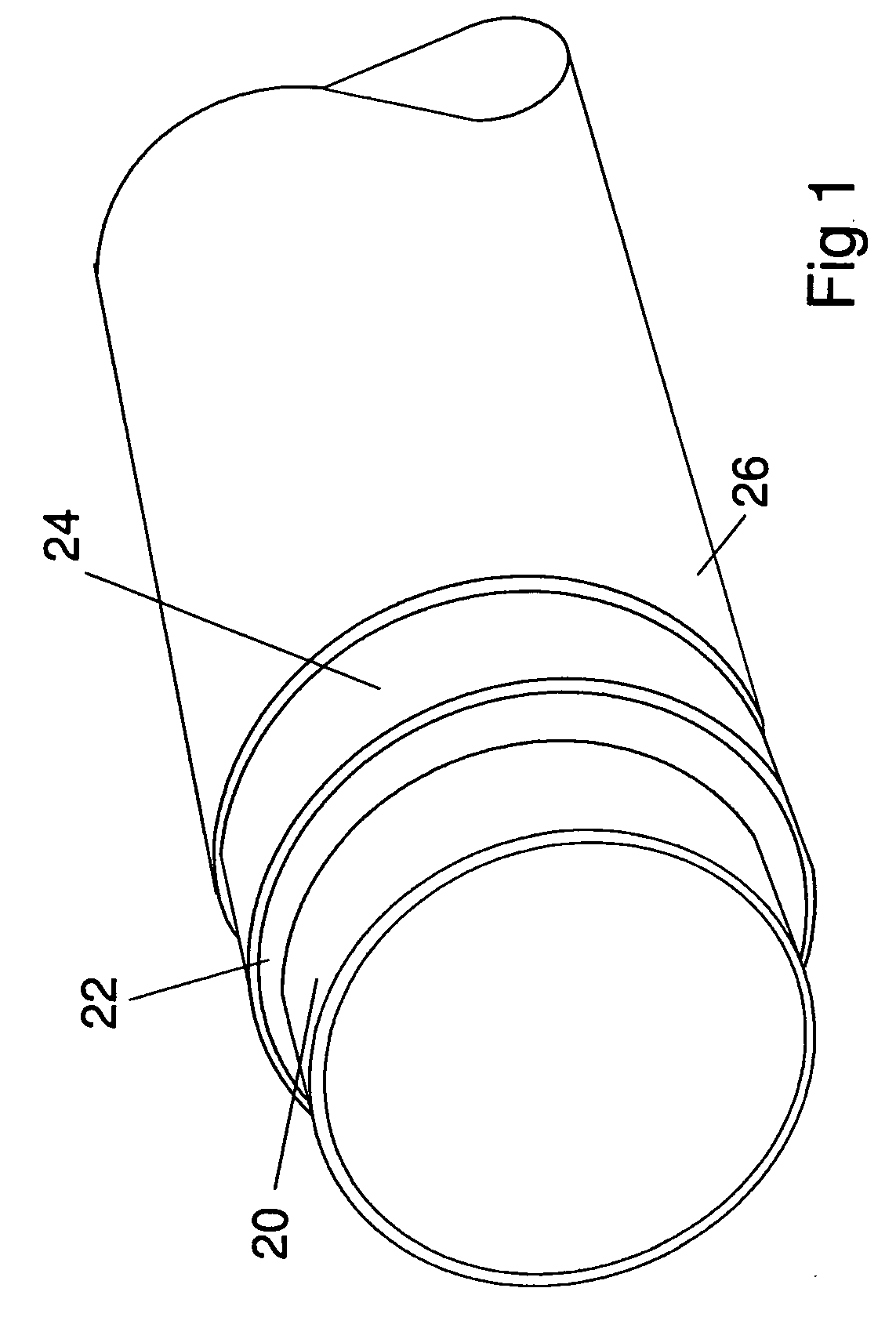

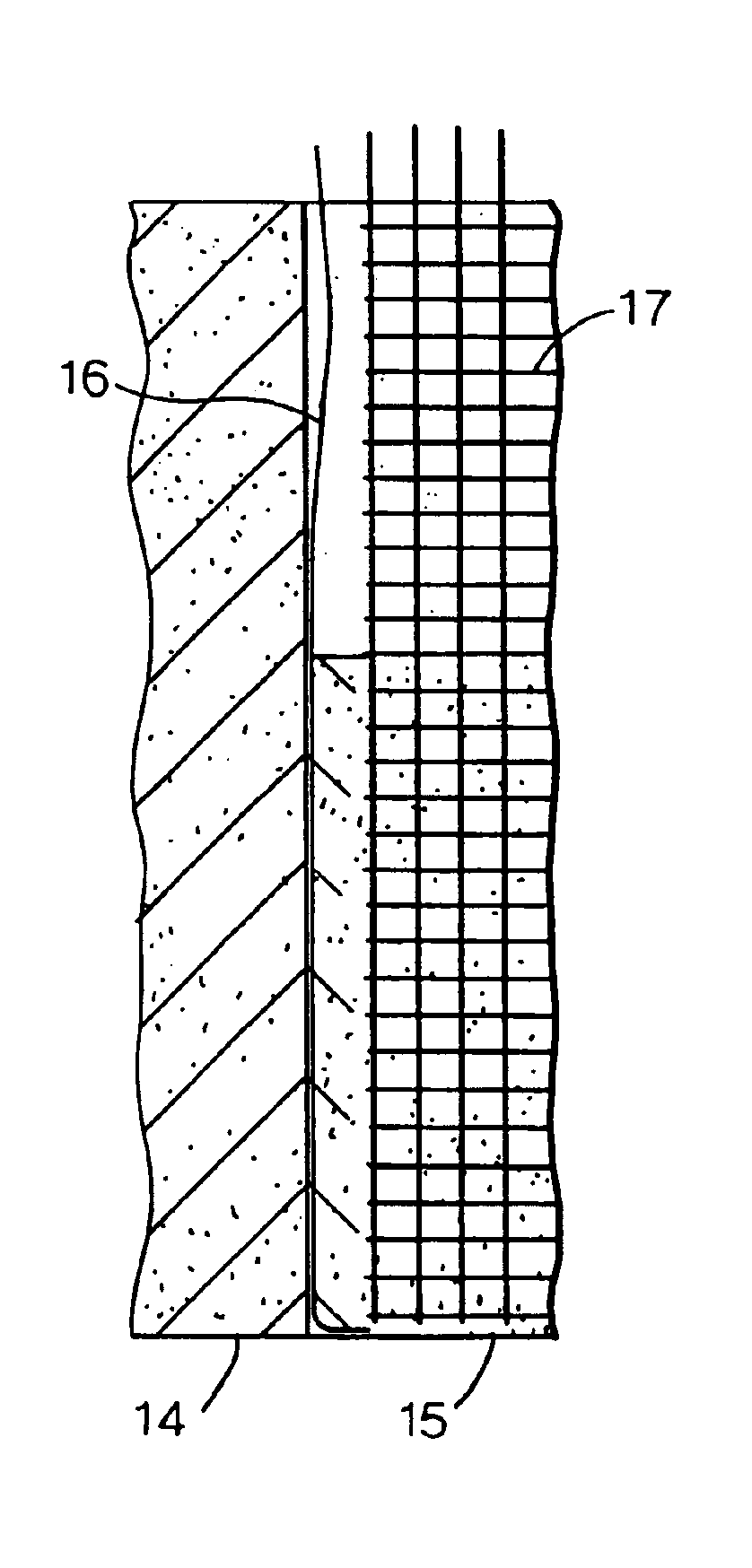

Waterstop for foundation elements and method of installation

InactiveUS6739805B2Conveniently installedProtective foundationPaving detailsWater flowStructural engineering

A waterstop, 10 or 11, for restricting or preventing the flow of water across the joints of foundation elements 8, such as between or along individual diaphragm wall panels or between or along individual secant wall piles. The present invention also relates to a method of installing a waterstop at or near the joints between adjacent foundation elements. The waterstop consists of one or more longitudinal strips, 1 or 2, of hydrophilic material, wherein the or each hydrophilic strip extends vertically along the interface between adjacent foundation elements, from a position at or near the top of the foundation elements, to a position at or near the base of the elements.

Owner:KVAERNER CEMENTATION FOUND LTD

Treatment method for grouting sand-layer foundation on the condition of flowing water

The invention discloses a treatment method for grouting a sand-layer foundation on the condition of flowing water, comprising the following steps: 1. adopting a spindle swing rig to process a plurality of grouting holes which are partially overlapped on the strengthened sand-layer foundation; 2. inserting a grouting pipe into the grouting holes and injecting grouting slurry which is formed by the mixing of mud or two materials of cement and mud to the sand-layer foundation on the condition of flowing water from the grouting pipe; 3. directly injecting pure cement slurry into the same one drilling hole or re-adopting the spindle swing rig to process a plurality of grouting holes which are partially overlapped at the position where a first batch of slurry is grouted after the slurry is precipitated and cured, and then inserting the grouting pipe and injecting the pure cement slurry; and 4. using a waterstop to block the grouting holes after the slurry is injected to each grouting hole. Compared with the pure cement slurry, the treatment method for the grouting of a sand-layer foundation on the condition of flowing water has low cost, good flowability and permeability, high concretion rate, simple technology equipment, and convenient operation.

Owner:GUANGDONG FOUND ENG GRP CO LTD

I-shaped steel joint structure for underground continuous wall and construction method for I-shaped steel joint structure

InactiveCN102535519AGood anti-seepageOvercoming the problem of seam leakageArtificial islandsUnderwater structuresSlurry wallCasting mold

The invention discloses a steel joint structure for an underground continuous wall and a construction method for the steel joint structure, belongs to the technical field of underground continuous walls and aims to provide a steel joint structure for the underground continuous wall which is simple and has a good water stopping effect. According to technical key points, the steel joint structure comprises a front terrae spacing, a rear adjacent terrae spacing and I-shaped steel which is connected between the front terrae spacing and the rear adjacent terrae spacing, wherein anchor bars are distributed among connecting parts between the I-shaped steel and the rear adjacent terrae spacing. The construction method mainly comprises the following steps of: (1) excavating a ground groove of the front terrae spacing; (2) manufacturing a reinforcement cage of the front terrae spacing, and arranging an I-shaped steel joint on the end part of the reinforcement cage of the front terrae spacing; (3) arranging the anchor bars; (4) hoisting and placing the reinforcement cage, and arranging a mud blocking joint pipe on the outer sides of the anchor bars; (5) performing cast molding on concrete; (6) excavating a ground groove of the rear adjacent terrae spacing, manufacturing a reinforcement cage, hoisting a joint pipe, hoisting and placing the reinforcement cage, and cleaning the anchor bars; (7) performing cast molding on the concrete; and (8) circulating the steps from (2) to (7) to form the continuous wall.

Owner:中煤江南建设发展集团有限公司

Pitched roof concrete construction method

InactiveCN103452221AImprove compactnessPrevent leakageBuilding roofsForms/shuttering/falseworksWhole bodyRebar

The invention discloses a pitched roof concrete construction method which is characterized in that a double-sided die sealing method is adopted to carry out construction on a pitched roof of which the slope is greater than or equal to 20 degrees; by bracing a bottom die and a top die of the pitched roof, concrete is poured to form a constraint under the slope condition; a short reinforcement is used as a bracket between the bottom die and the top die of the pitched roof; the short reinforcement has a diameter of 22 to 25 mm; the top die and the bottom die are connected into one whole body by split bolts; the split bolts have diameters of 14 to 16 mm; the split bolts are arranged at intervals of 250 to 300 mm; water stop rings are arranged in the middles of the split bolts; the water stop rings have diameters of 40 to 50 mm; reinforcement split heads are arranged on the upper surface of the bottom die for placing an upper negative reinforcement skeleton; sectional pouring and tamping are adopted in the pouring process of concrete, and a die plate at the upper part of the pitched roof is sealed step by step from bottom to top along the pouring progress of concrete.

Owner:嘉兴市利富通新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com