Prestressed concrete precast pile

A technology of concrete prefabricated piles and prefabricated piles, which is applied in sheet pile walls, buildings, and foundation structure engineering, etc., which can solve the problems of mud pollution from mud transportation, road cracks, and high engineering costs, and achieve enhanced overall bending resistance and anti-corrosion. Shear ability, enhanced waterproof effect, and the effect of ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

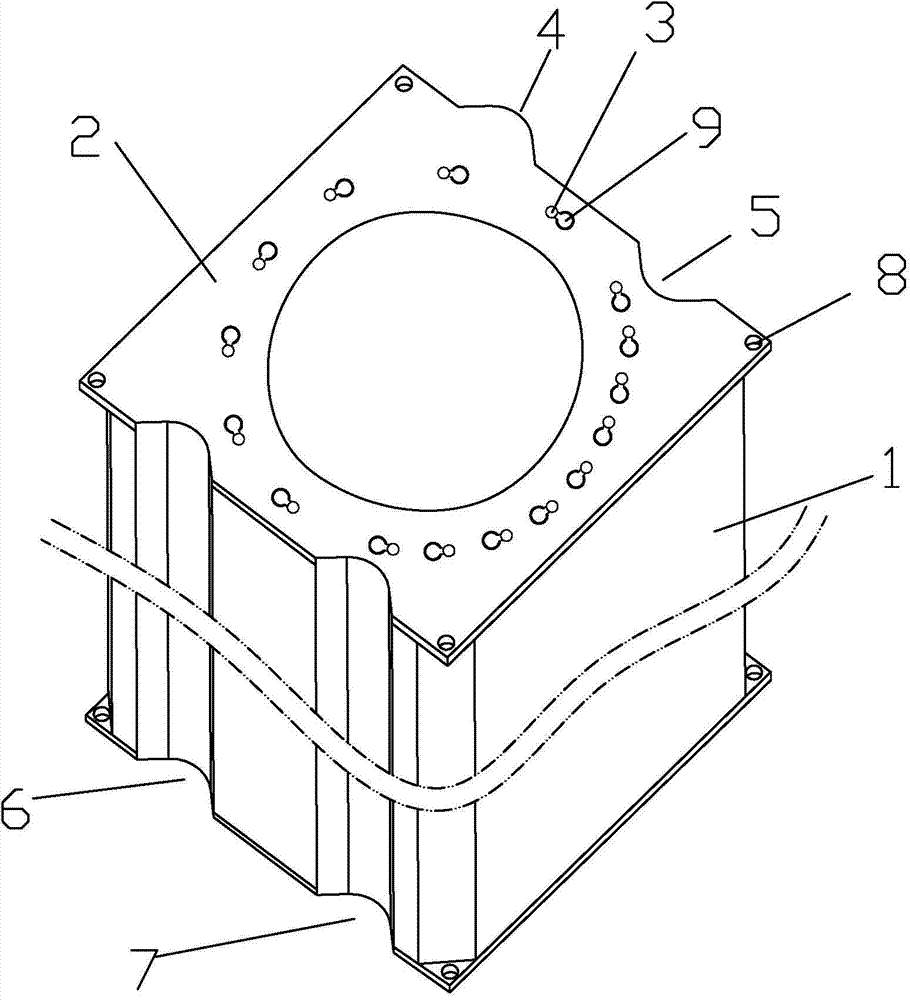

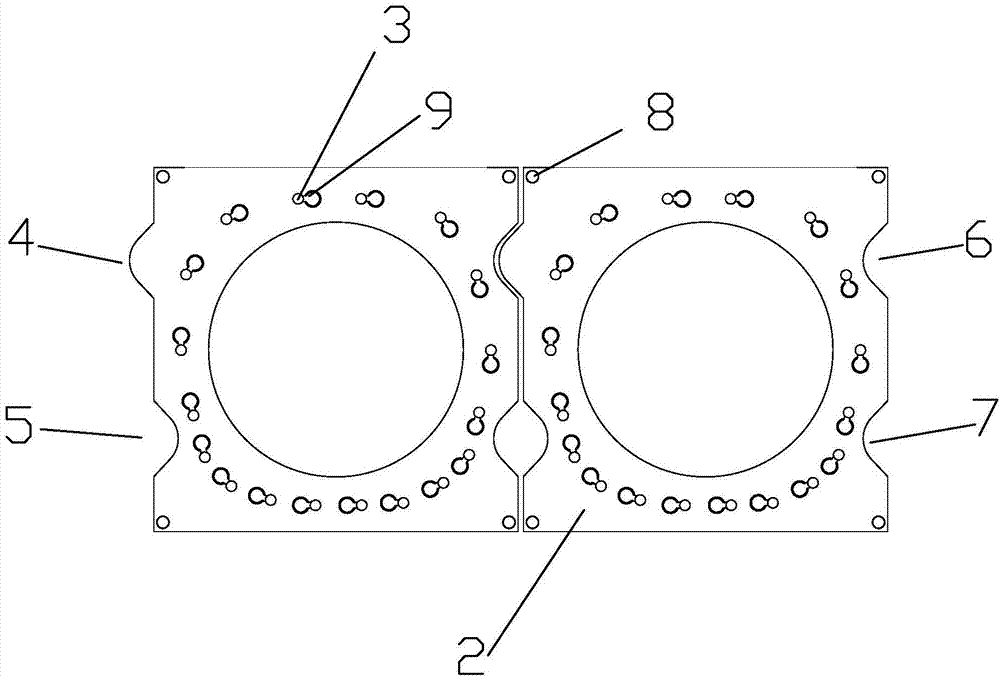

[0020] Such as figure 1 As shown, a prestressed concrete prefabricated pile includes a prefabricated pile body with a square cross section, and the prefabricated pile body includes two end plates 2 and a pile body 1 arranged between the two end plates 2 and a pile body 1 The prestressed steel bars 3 inside and connected to the end plates 2; the end plates 2 are provided with prestressed steel anchor holes 9, and the two ends of the prestressed steel bars 3 are respectively anchored to the end plates 2 through the anchor holes 9 or welding; one outer surface of the prefabricated pile body is provided with a rib 4 extending longitudinally to the end and a first groove 5 extending longitudinally and penetrating the end, and on an outer surface not adjacent to the outer surface That is to say, the opposite outer surface is provided with the second groove 6 and the second groove 6 corresponding to the position of the rib 4 and the first groove 5, matching in shape and size, extendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com